Equipment for preparing bean pulp solid-state fermentation substrate material and use method thereof

A solid-state fermentation and matrix material technology, applied in feed, application, food science and other directions, can solve the problems of power consumption, unable to achieve continuous operation, large number of equipment, and high labor intensity, saving manpower, easy adjustment and control. , the effect of high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

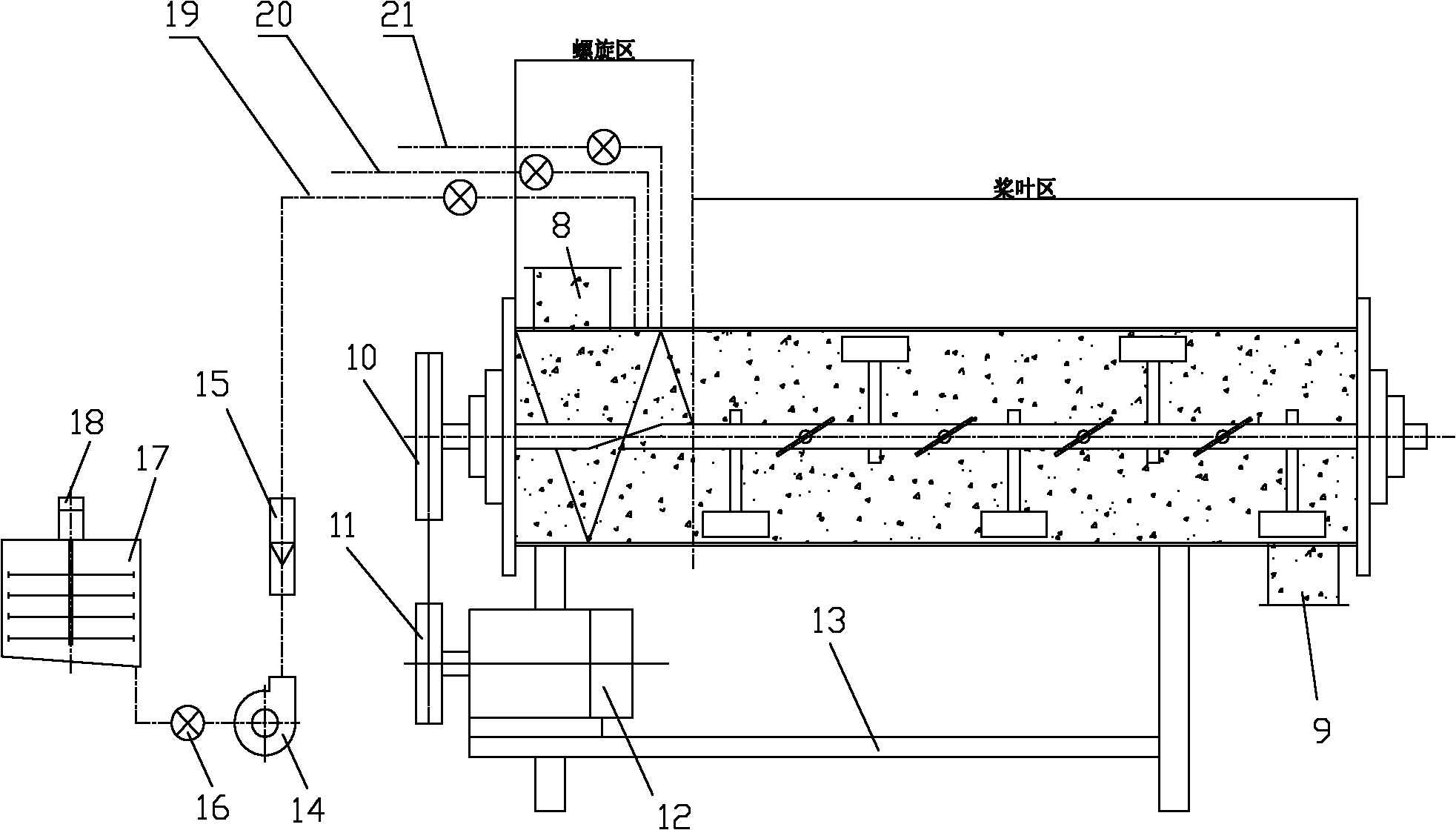

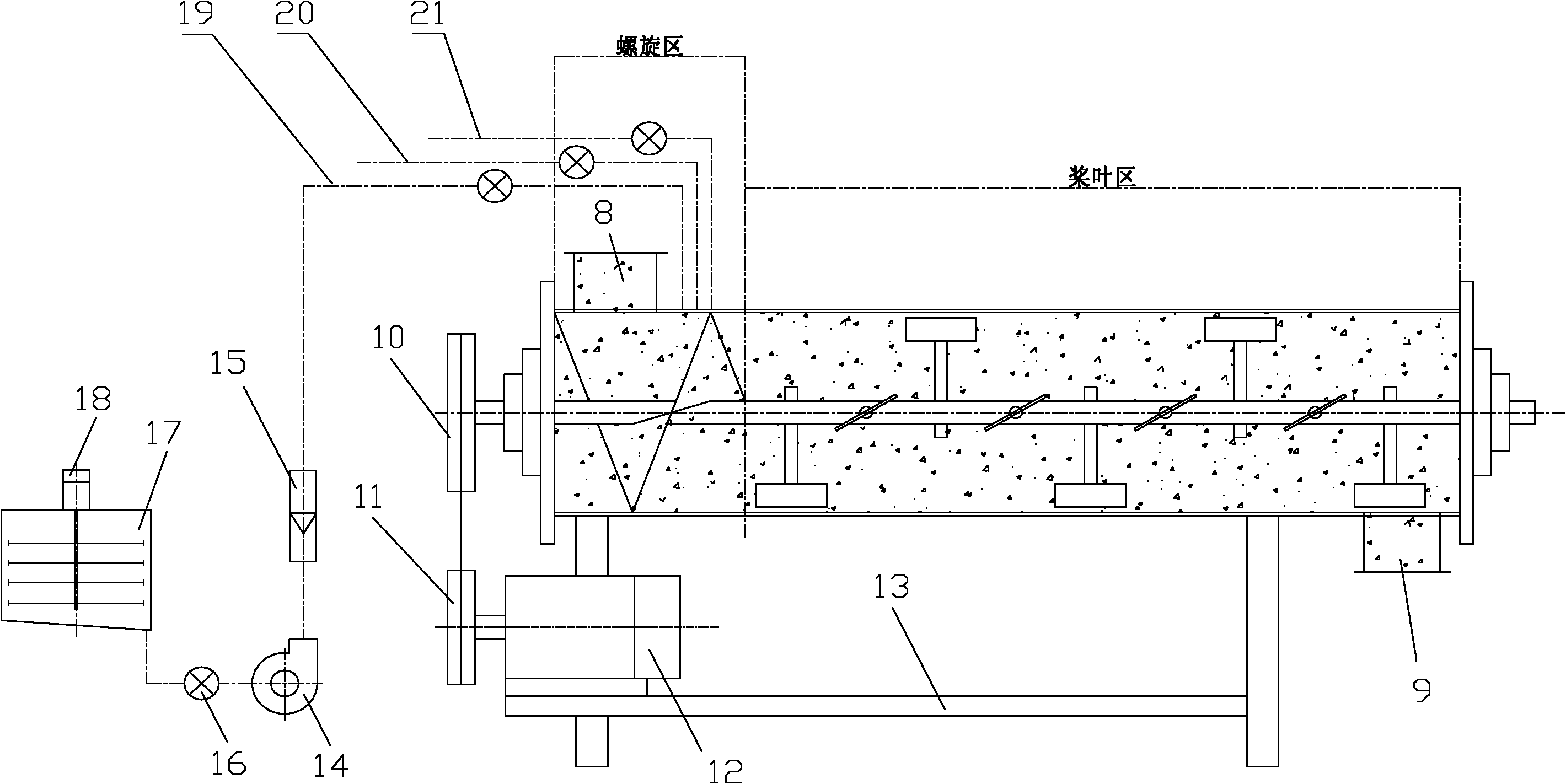

[0029] The details of the present invention will be further described below in conjunction with the accompanying drawings.

[0030] A preparation equipment for soybean meal solid-state fermentation base material,

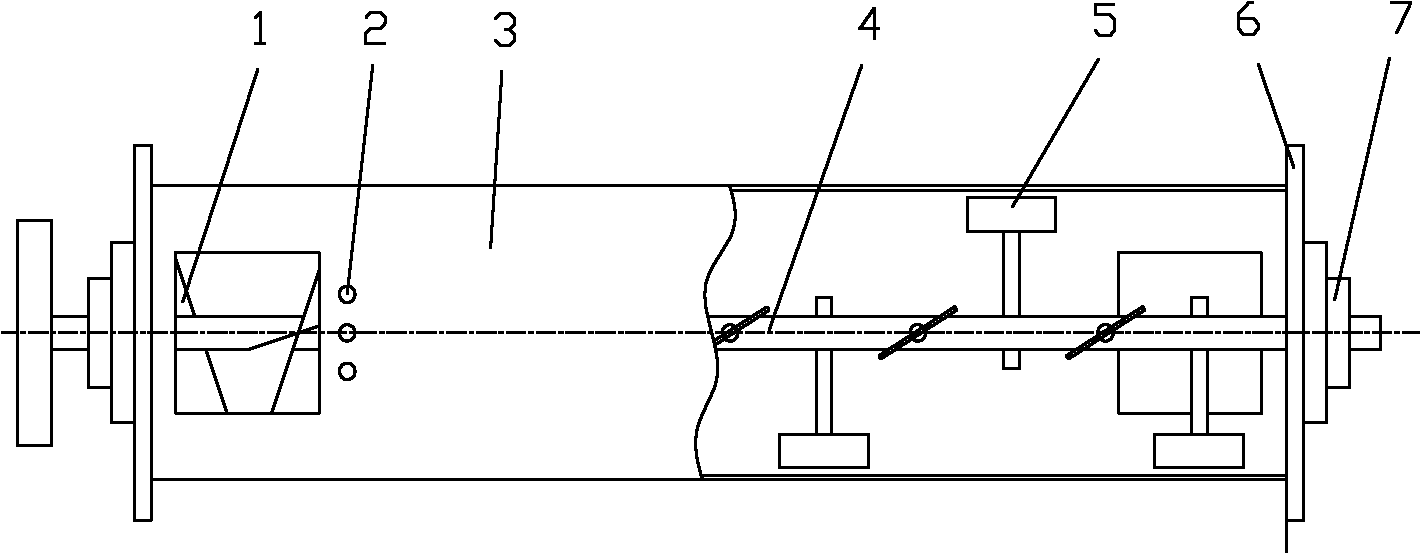

[0031] The flanges 6 are fixedly connected to the two ends of the horizontal cylindrical cylinder 3, the stirring shaft 4 is arranged at the center of the circle through the bearing 7, and the feeding port 8 with an upward opening is set at one end of the cylinder 3, and the corresponding other of the cylinder 3 One end is provided with a discharge port 9 with an opening downward; it is used for feeding in raw materials and outputting finished products.

[0032] The inside of the barrel 3 is divided into a spiral area on the side of the feed inlet and a blade area on the side of the outlet. The screw blade 1 is arranged on the part of the stirring shaft 4 located in the spiral area, and multiple radial blades are arranged on the part of the stirring shaft 4 located ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com