Patents

Literature

7629results about "Soldering apparatus" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

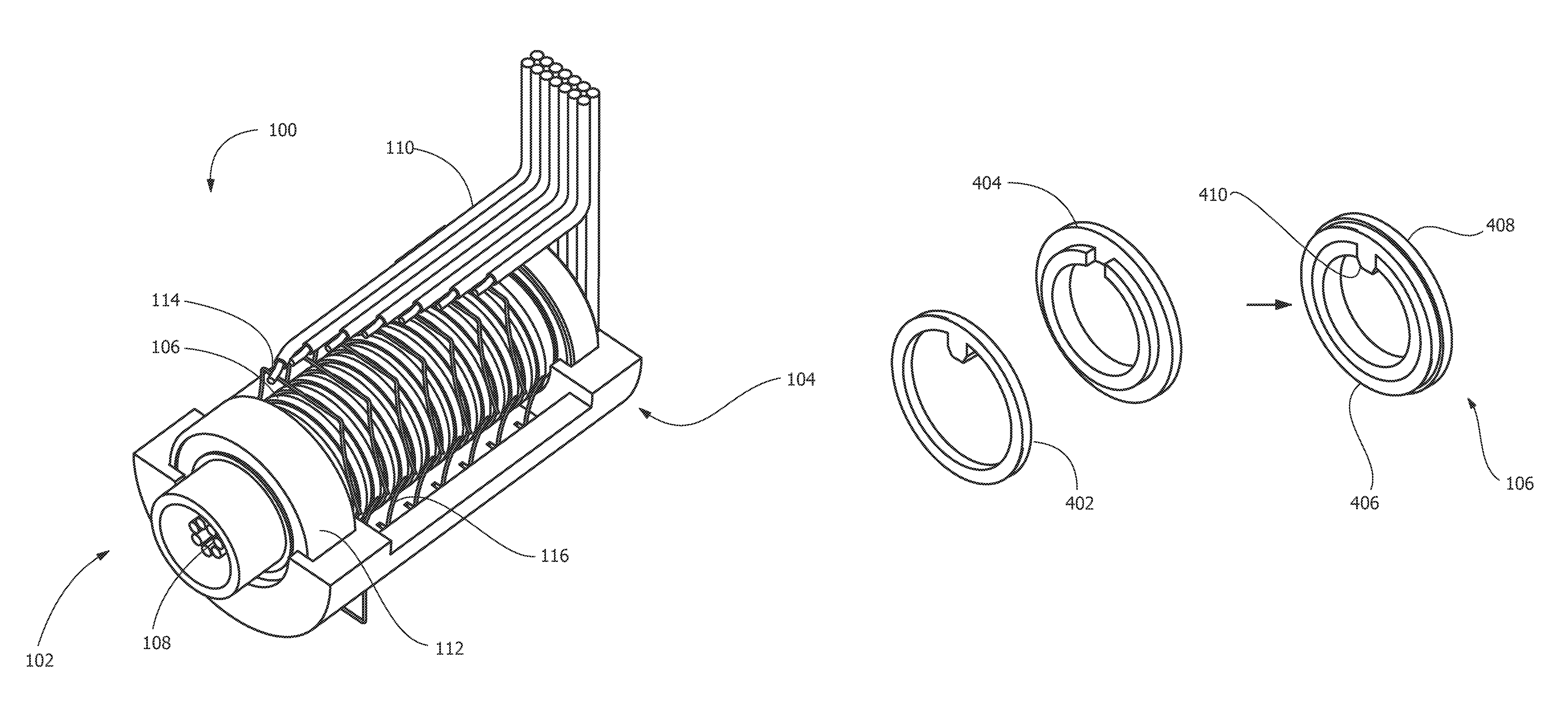

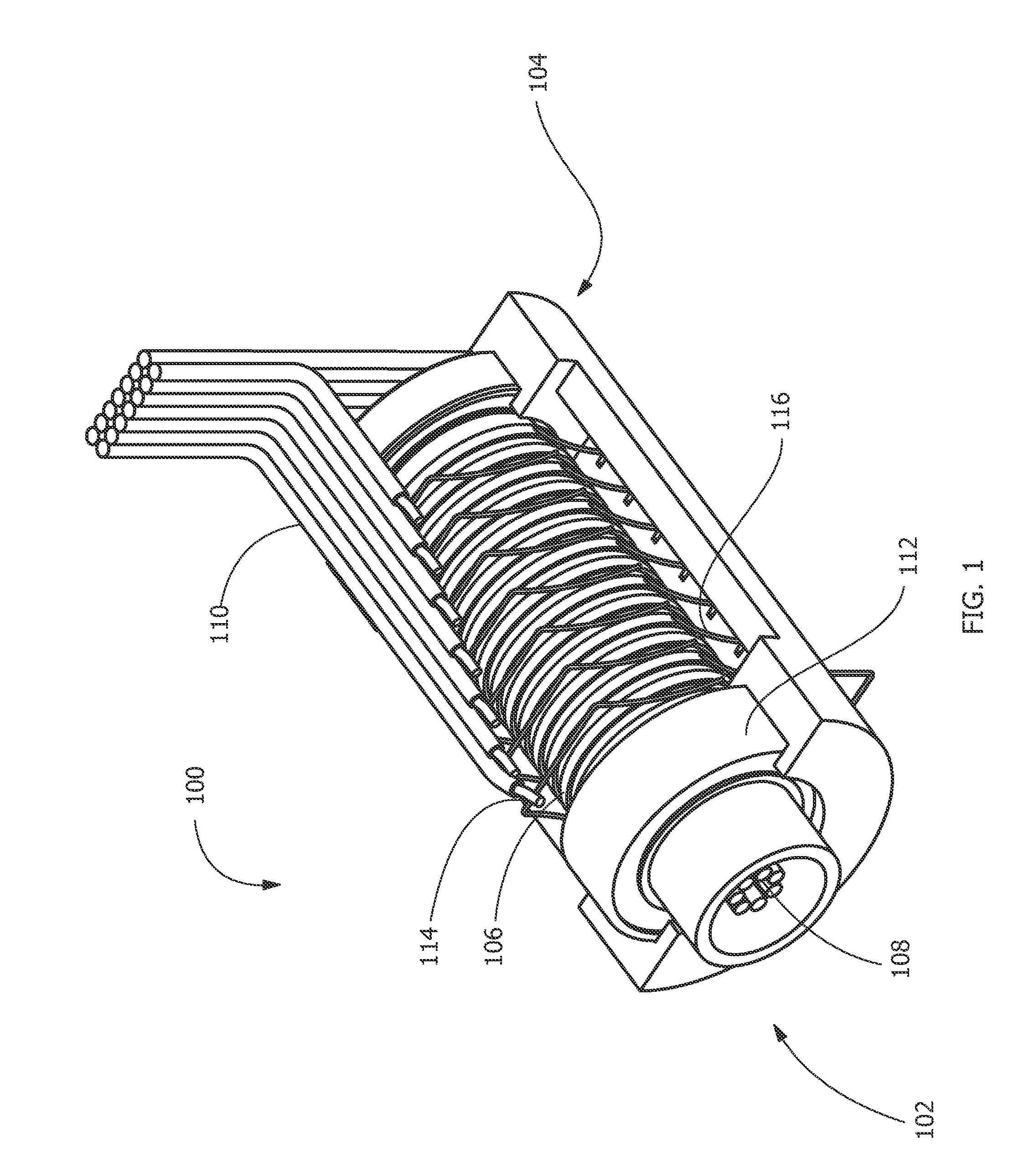

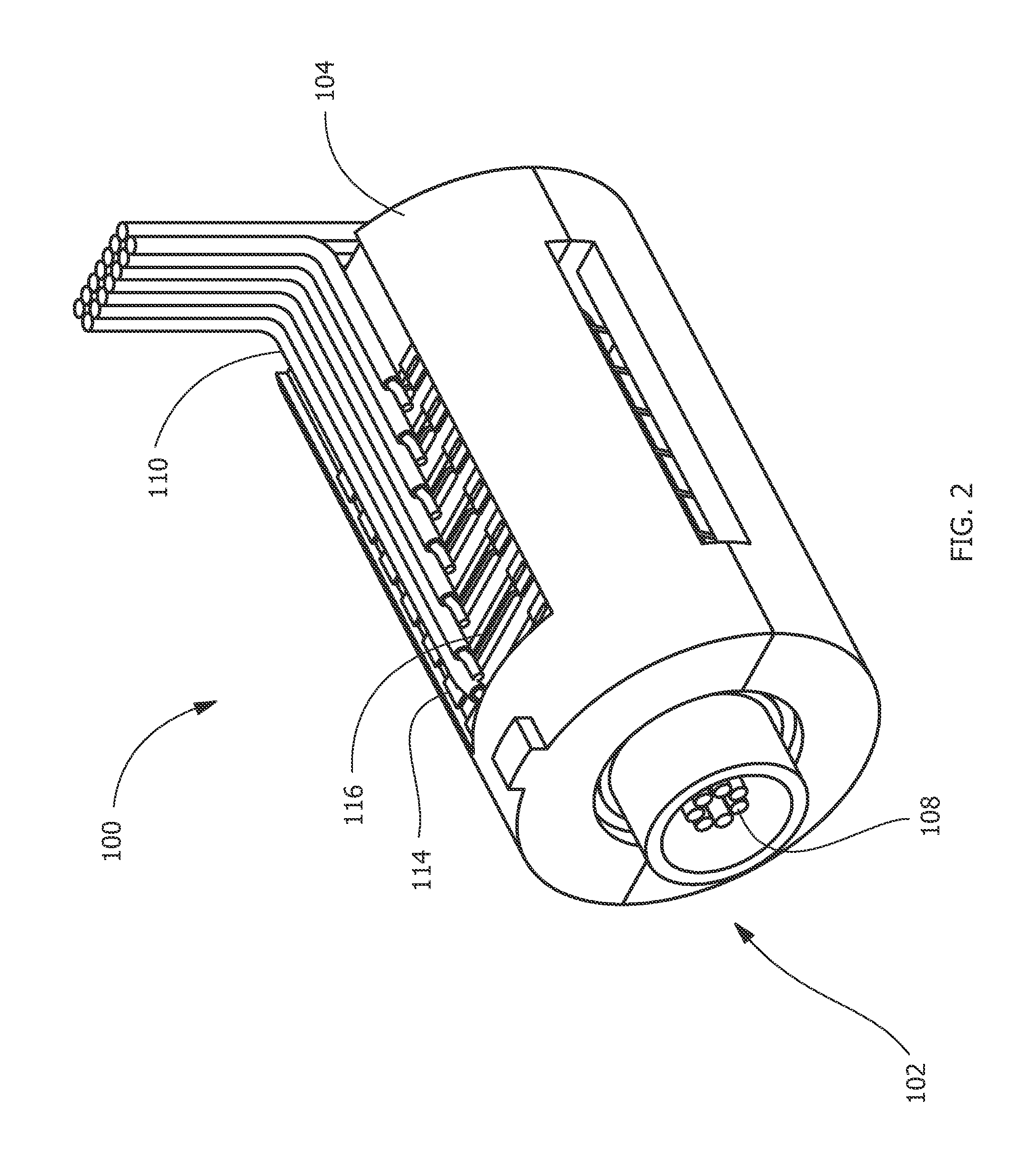

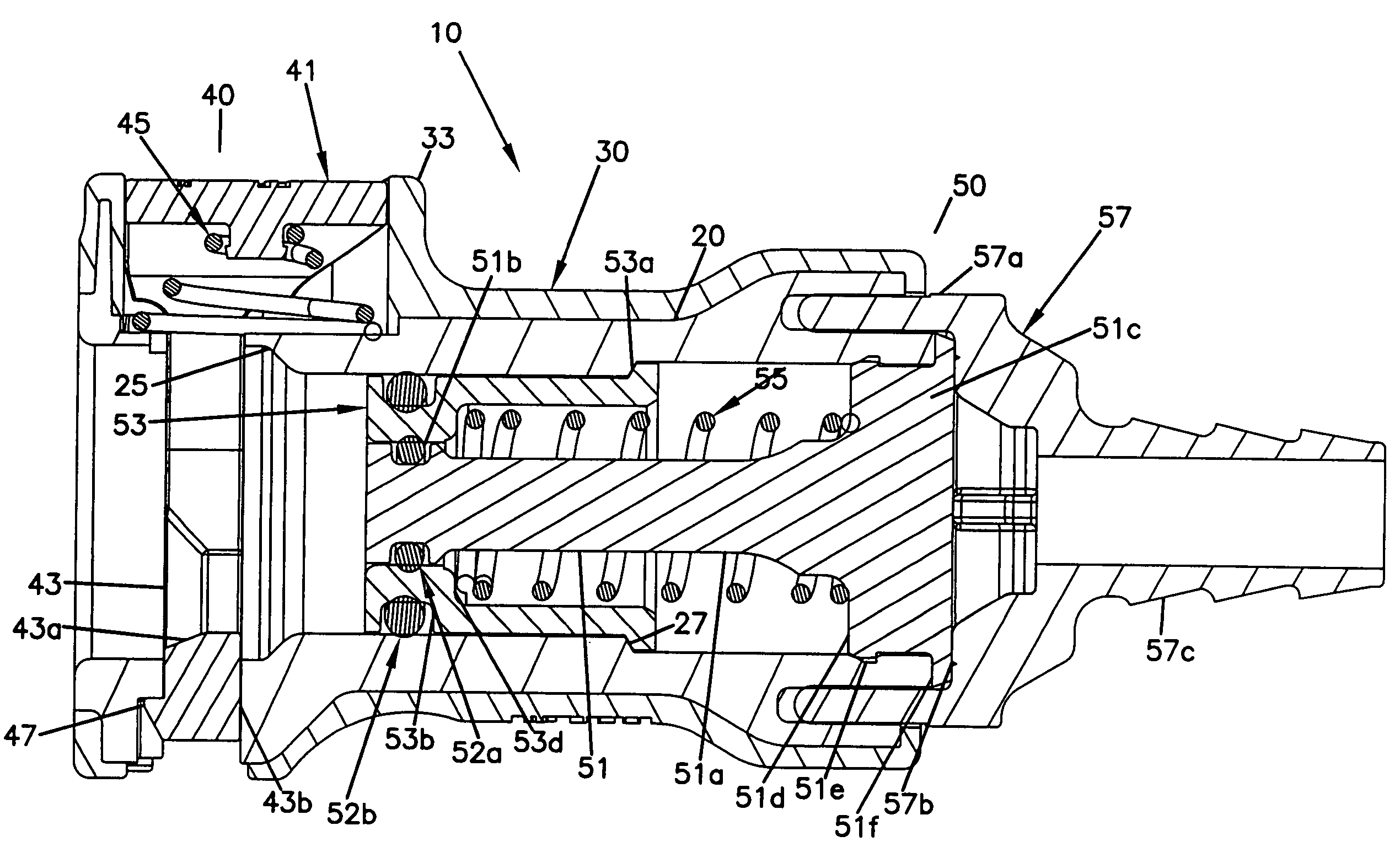

Method of fabricating a slip ring component

A process of fabricating a slip ring component, a slip ring component, and a slip ring assembly are disclosed. The process includes forming a first shot, forming a second shot, and immersion bathing the first shot and the second shot. The immersion bathing applies an electrically conductive plating to exposed surfaces of the second shot.

Owner:TYCO ELECTRONICS LOGISTICS AG (CH)

Hermetically sealed microchip reservoir devices

InactiveUS20050077584A1Fixed microstructural devicesVolume/mass flow measurementGlucose sensorsHermetic seal

Devices are provided for the controlled exposure or release of contents stored in hermetically sealed reservoirs. The devices comprise a primary substrate having a front side and a back side, and including one or more hermetic sealing materials; a plurality of reservoirs in the primary substrate positioned between the front side and the back side; reservoir contents, which comprise chemical molecules (such as drugs) or a secondary device (such as a glucose sensor), located inside the reservoirs; a hermetic sealing substrate having a surface composed of one or more hermetic sealing materials; and a hermetic seal formed between and joining the primary substrate and the hermetic sealing substrate, wherein the hermetic seal independently seals the reservoirs.

Owner:MICROCHIPS BIOTECH INC

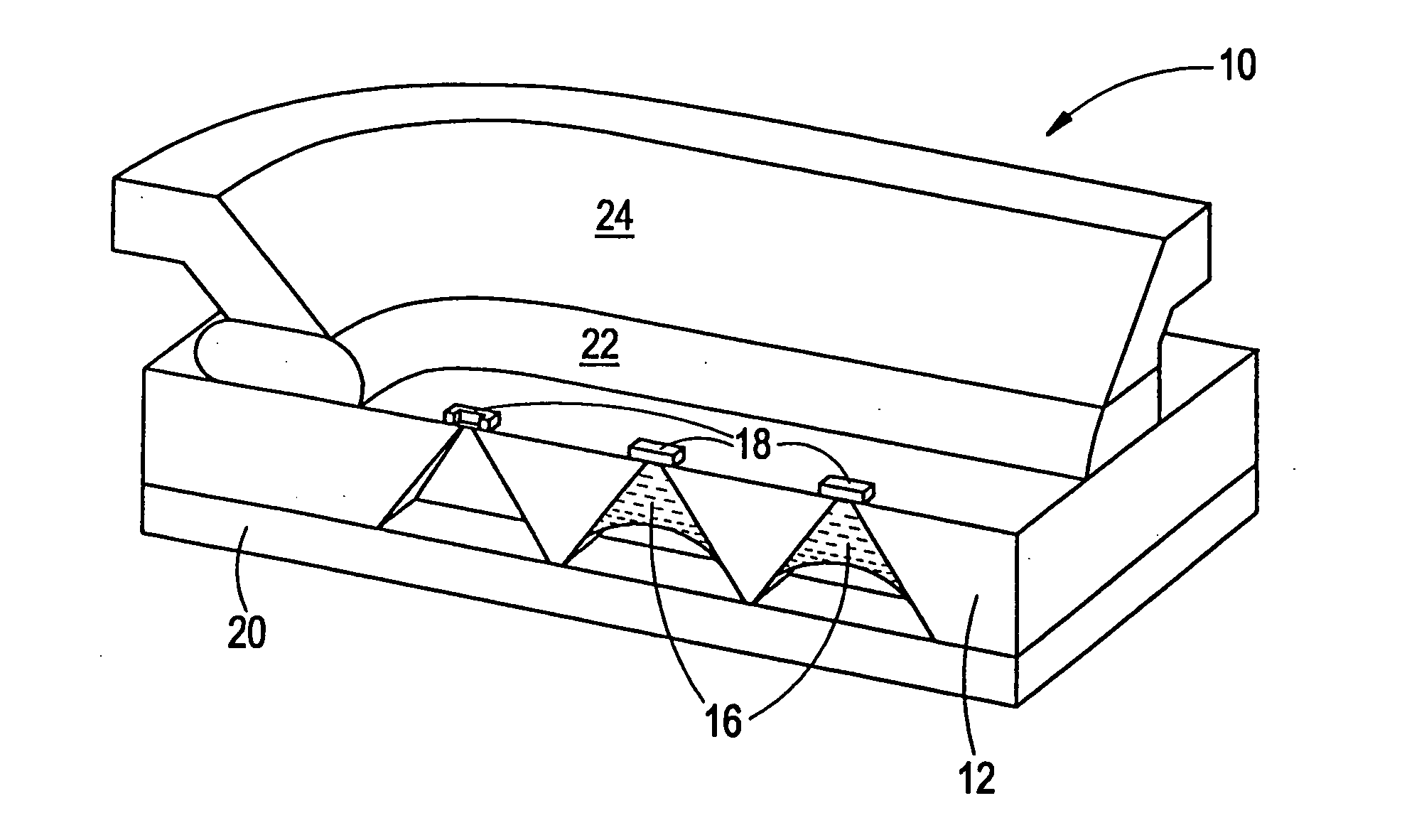

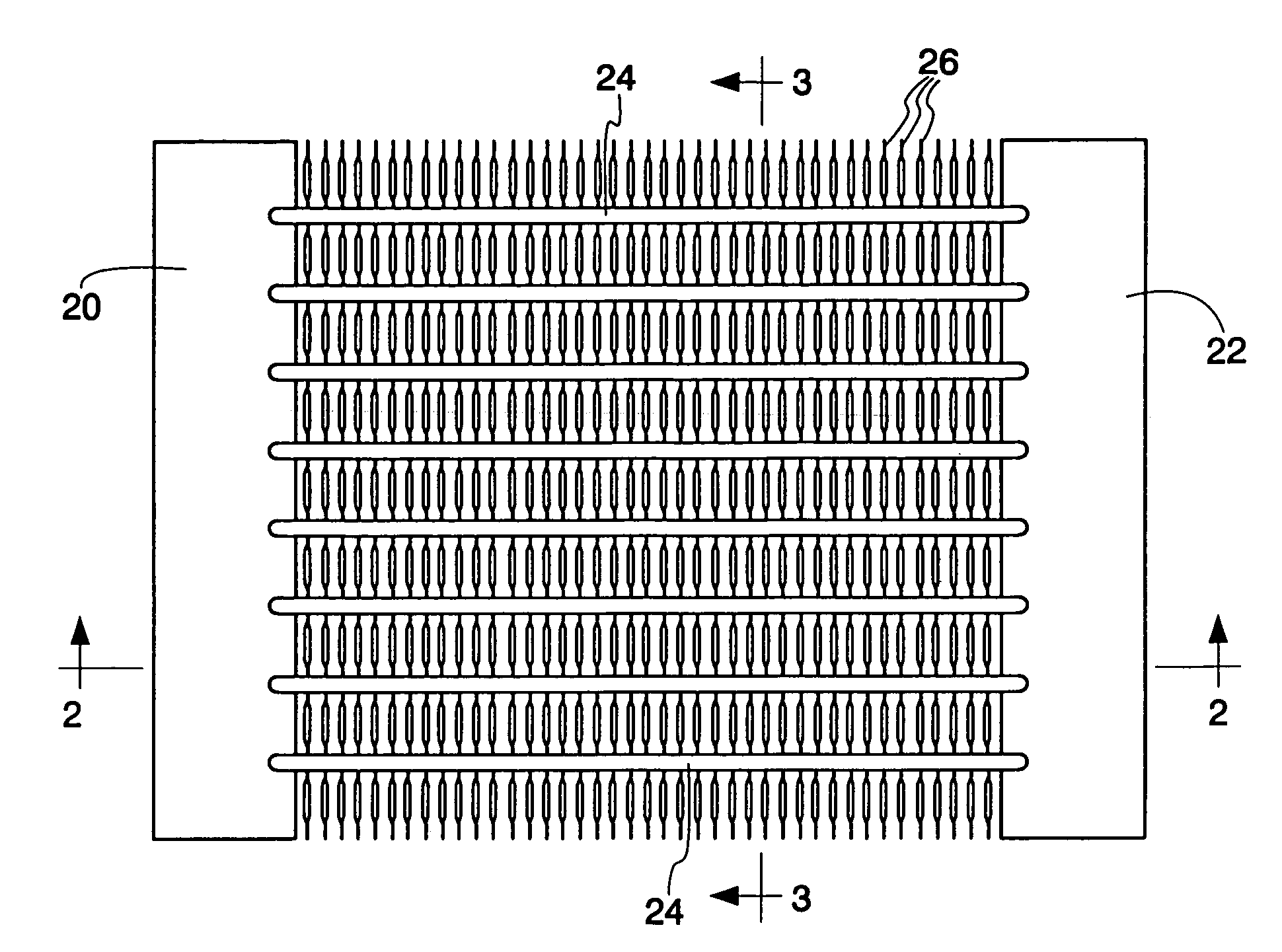

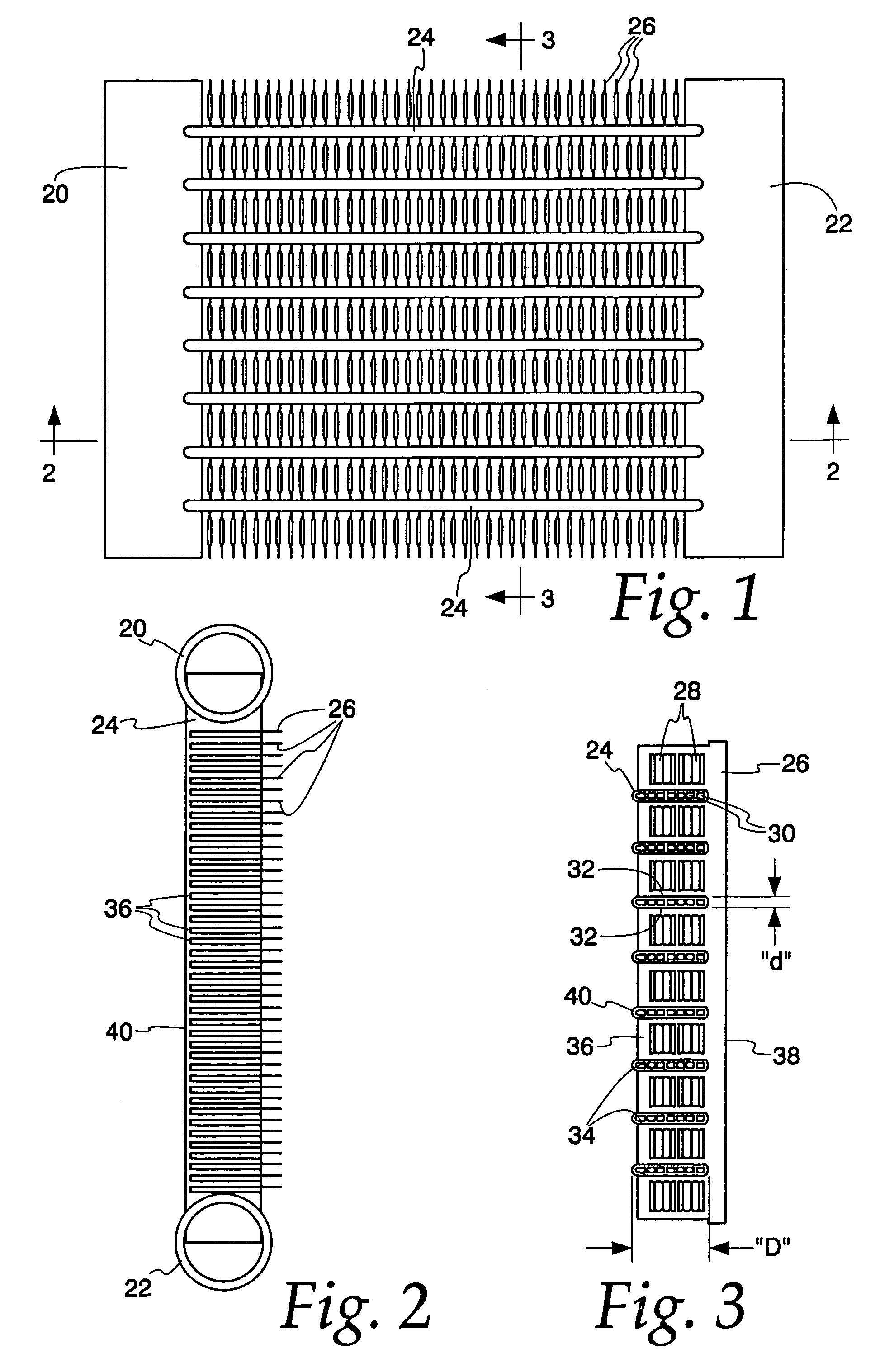

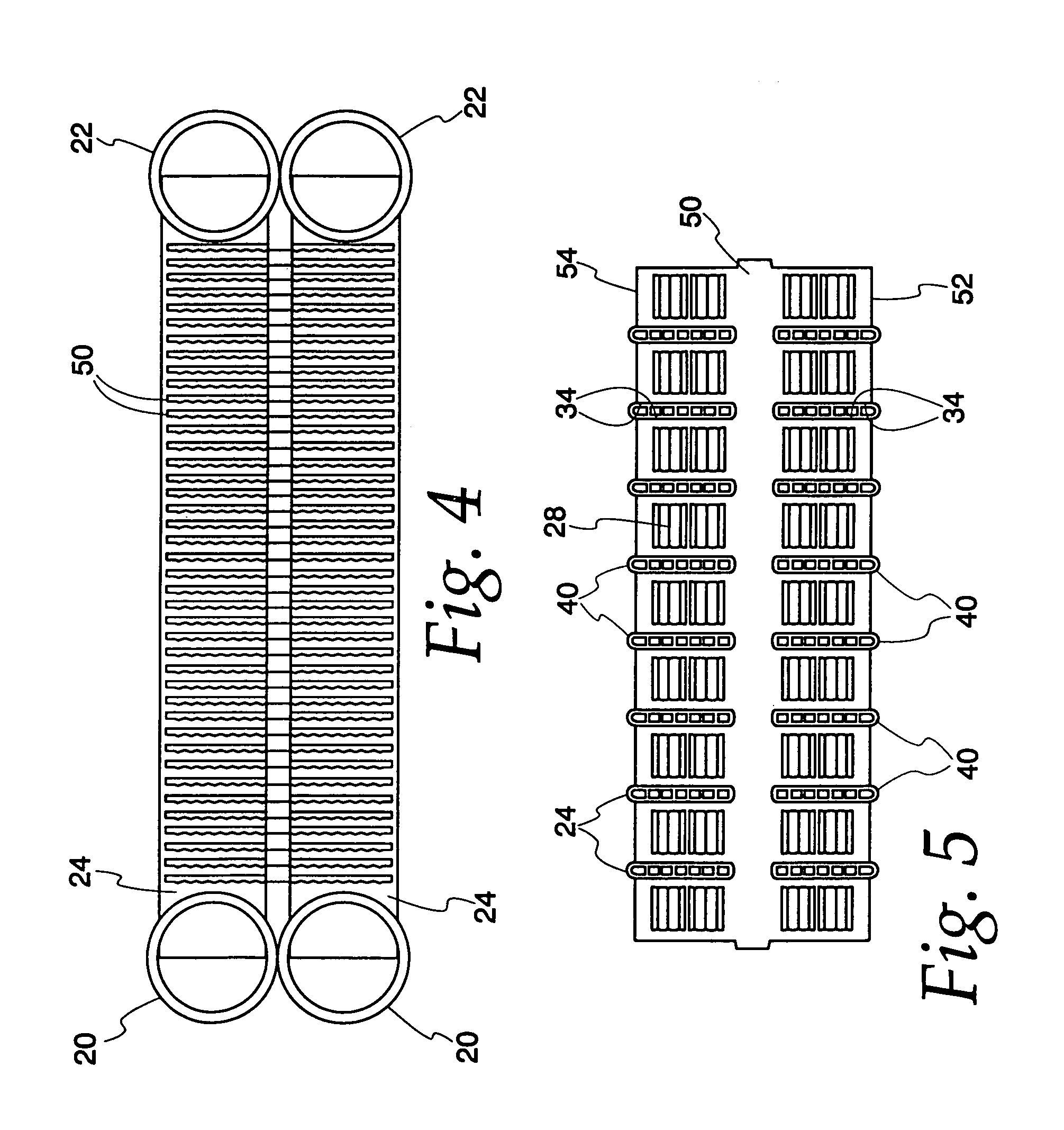

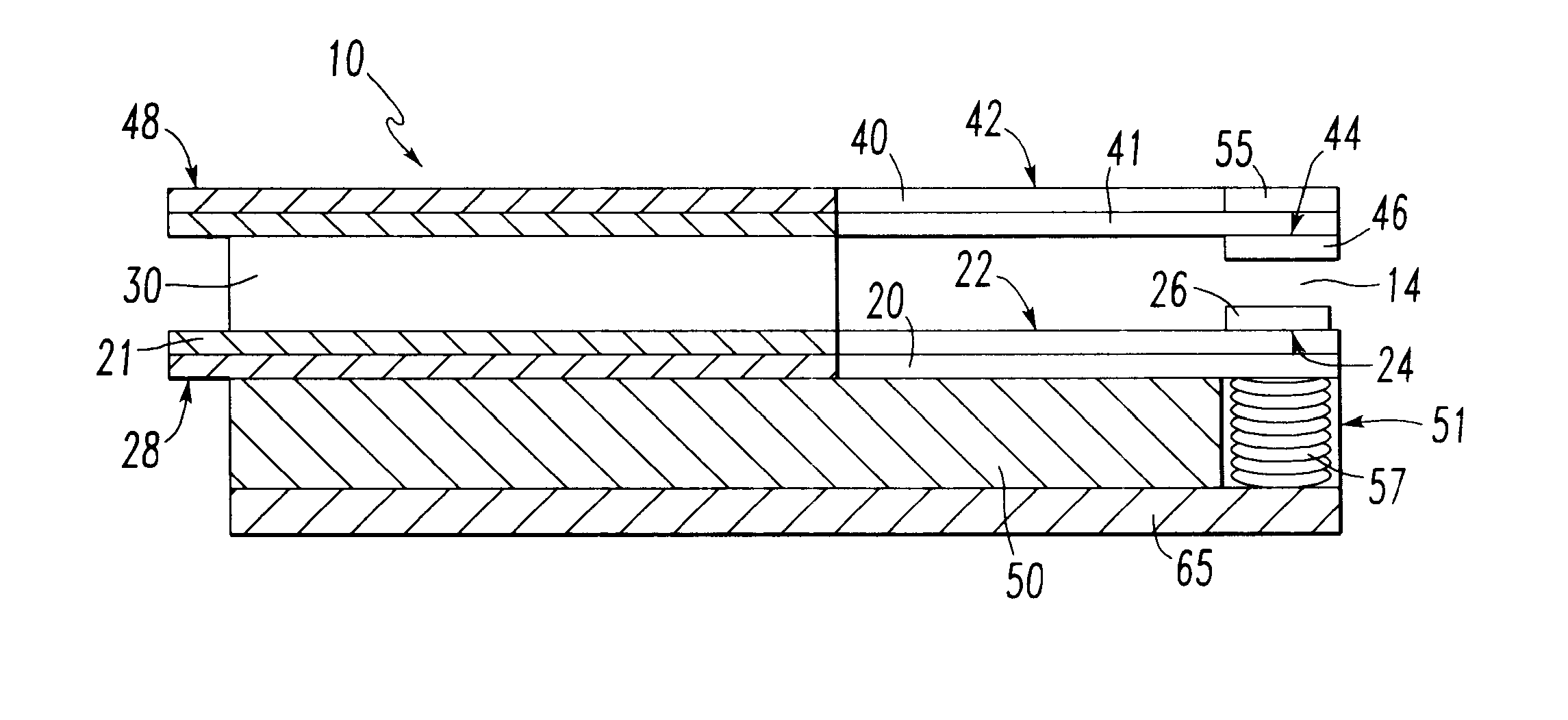

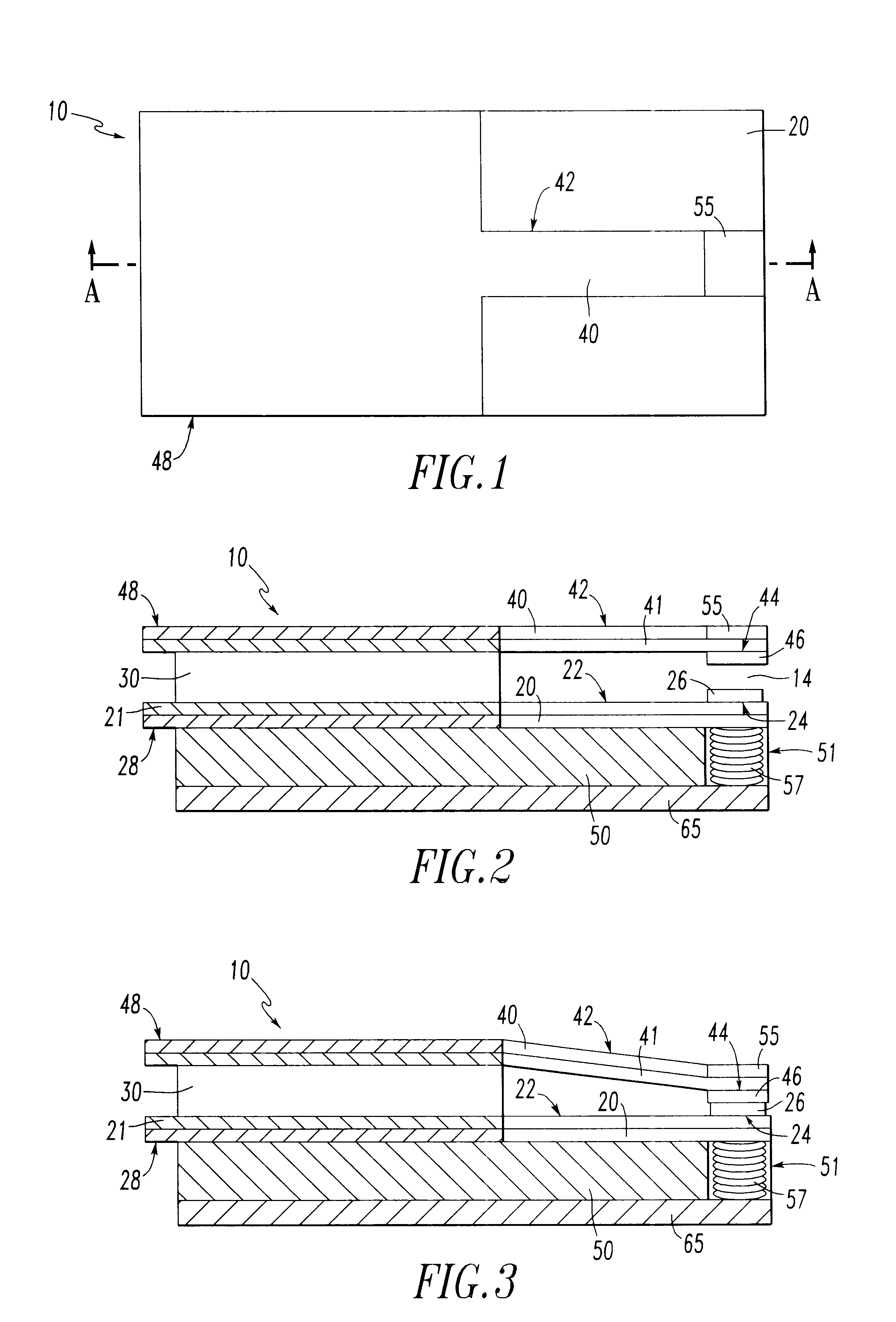

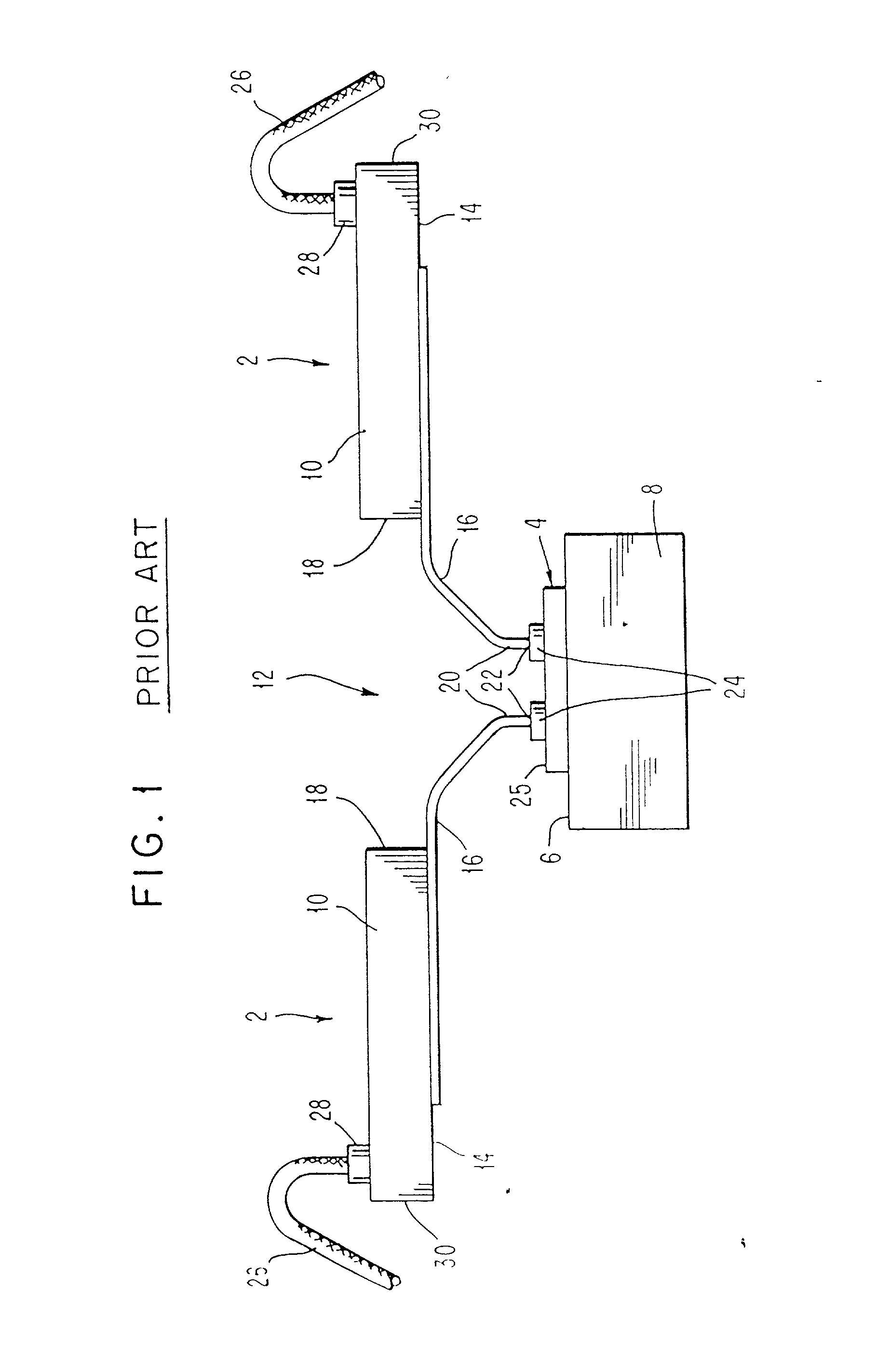

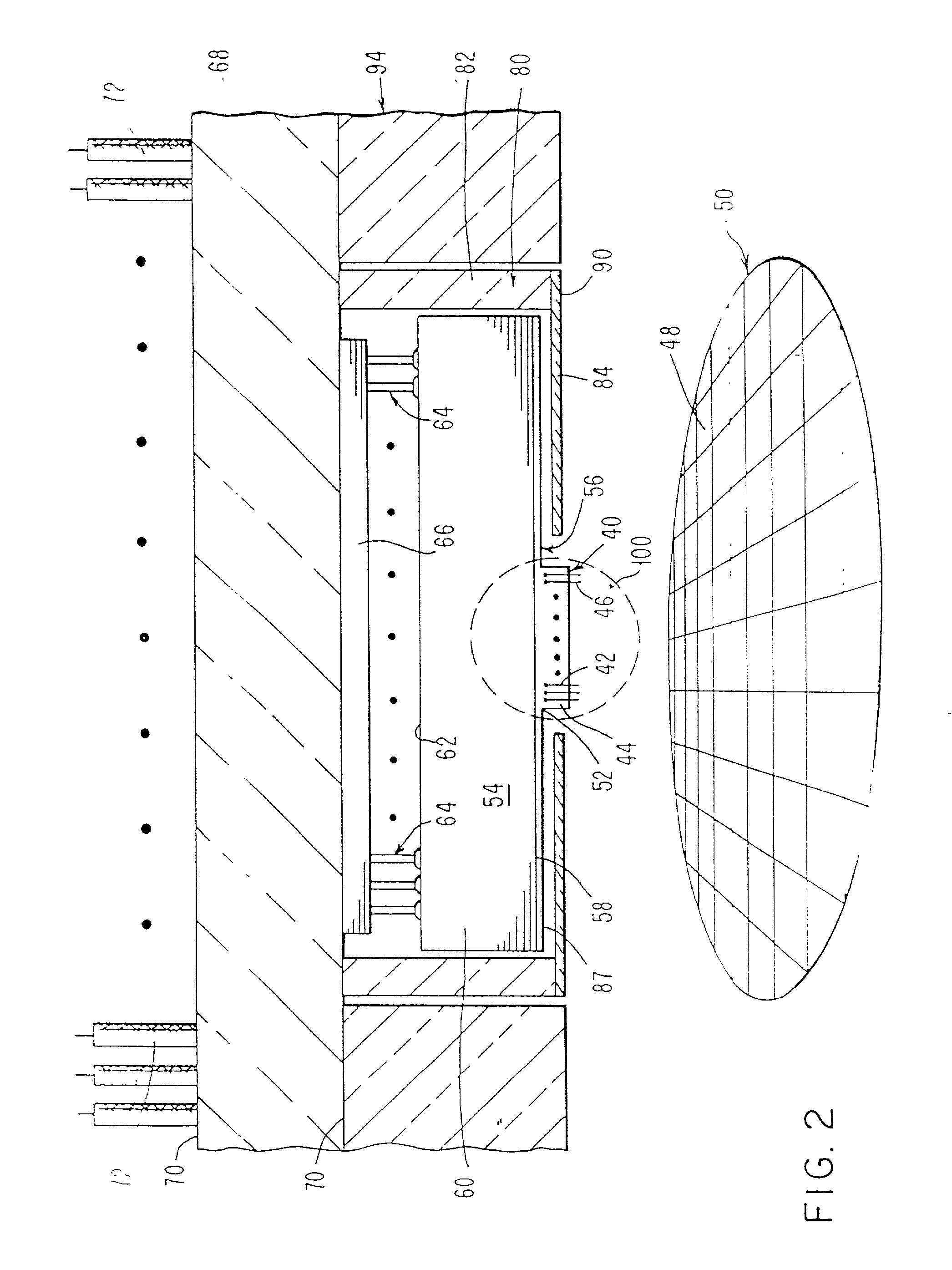

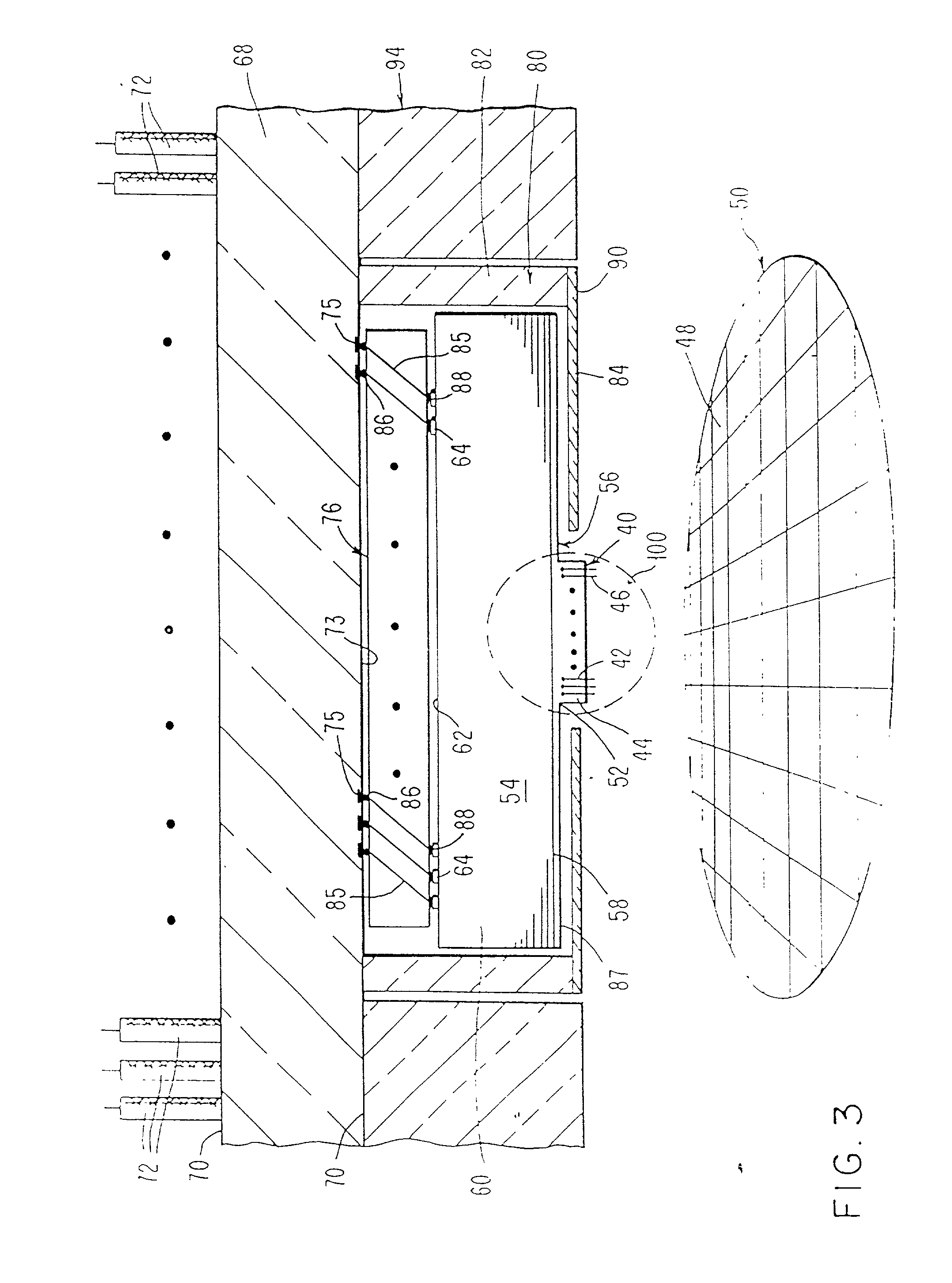

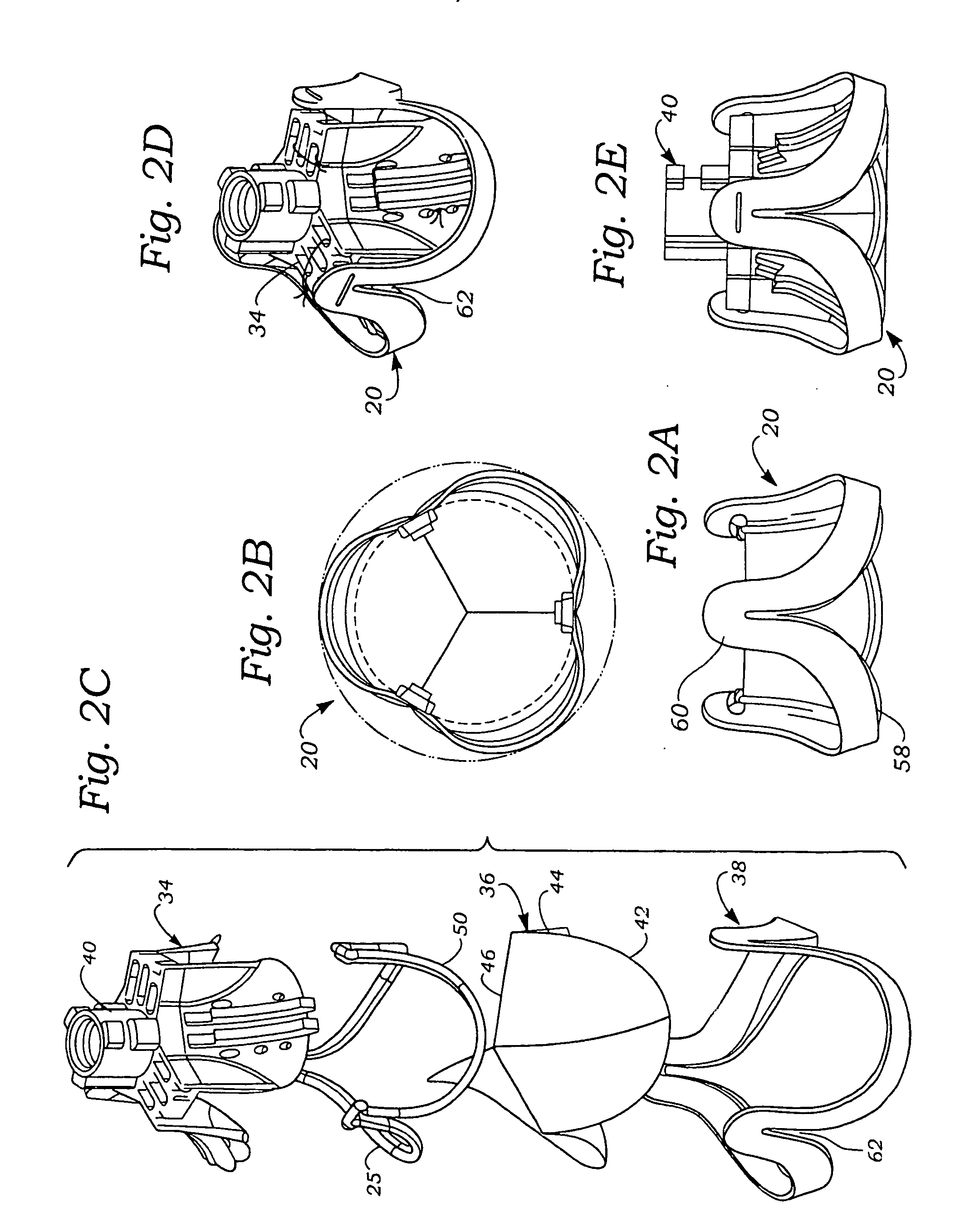

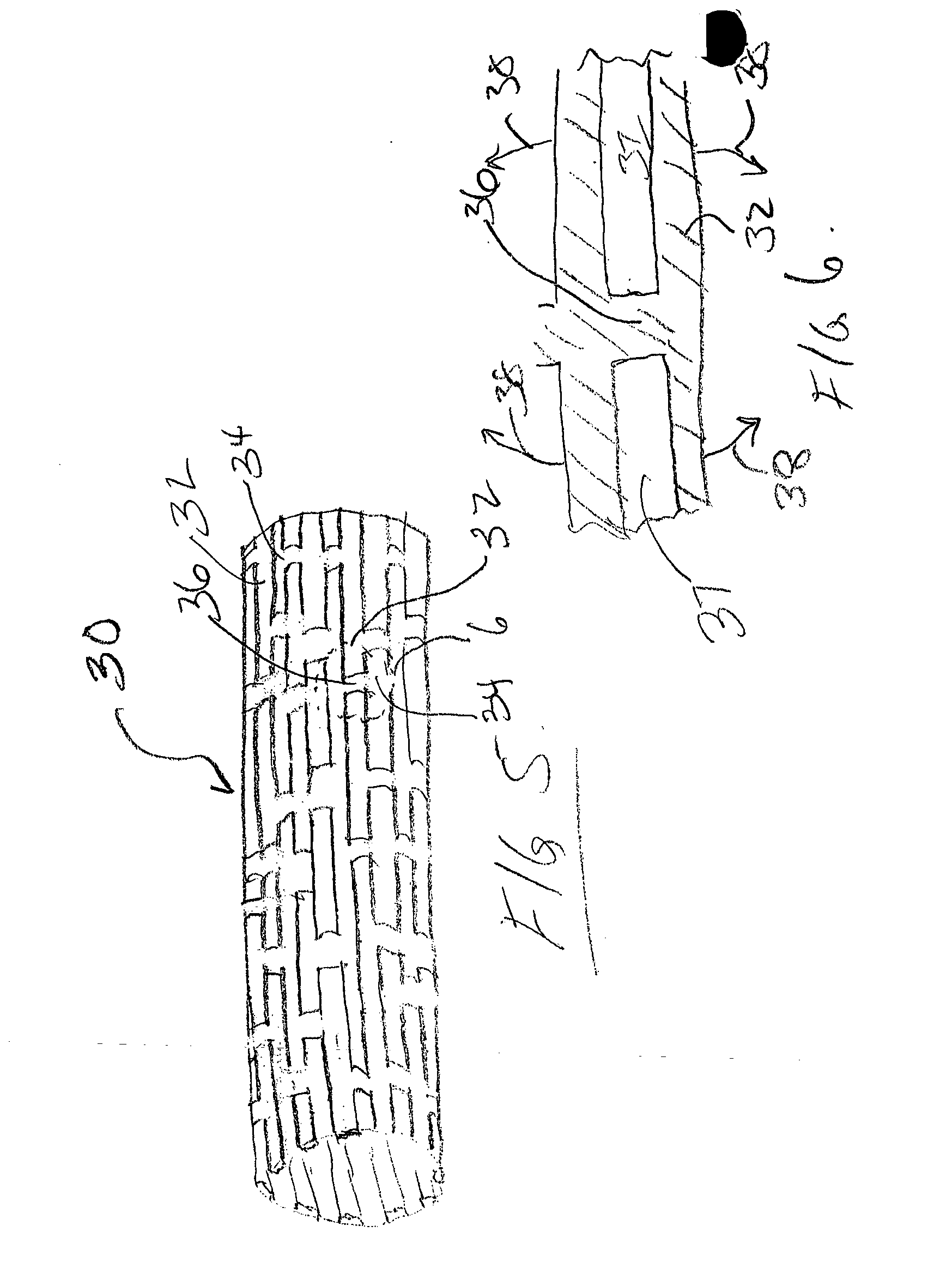

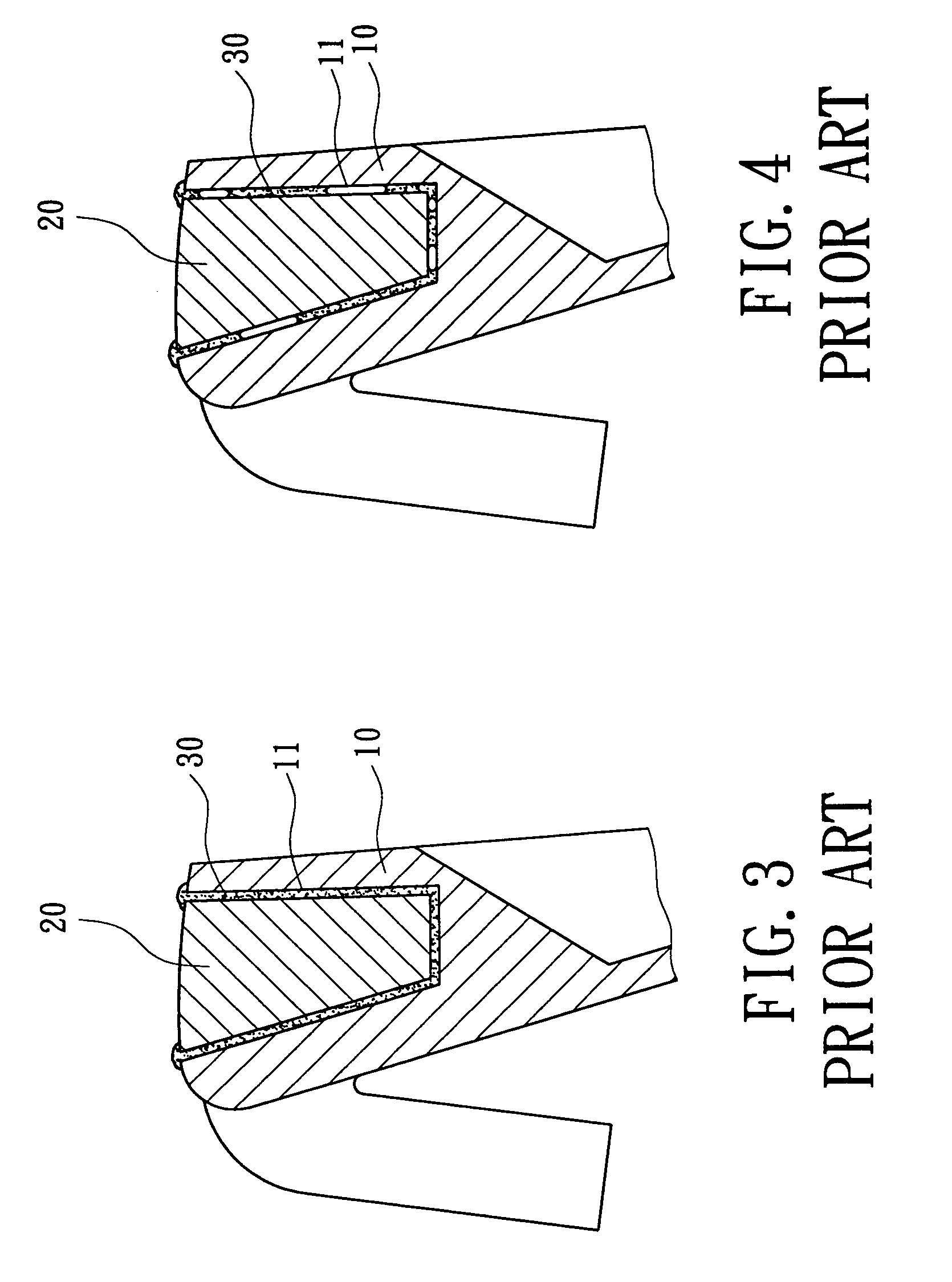

Heat exchanger

InactiveUS6964296B2Eliminate requirementsImprove relationshipSoldering apparatusHeat exhanger finsEngineeringMechanical engineering

Heat exchange inefficiencies found in round tube plate fin heat exchangers are eliminated in an aluminum heat exchanger that includes first and second headers (20), (22) and at least one flattened tube (24), (70) extending between the headers (20), (22). A plurality of generally parallel tube runs are defined and each has opposite edges. A plurality of plate fins (26), (50) are arranged in a stack and each has a plurality of open ended slots (34), one for each run of the tubes (24), (70). Each of the tube runs (24), (70) is nested within corresponding slots (26) and the fins (26), (50) with one of the edges (40) of the tube runs extending outwardly of the corresponding fin (34). The assembly is brazed together.

Owner:MODINE MFG CO

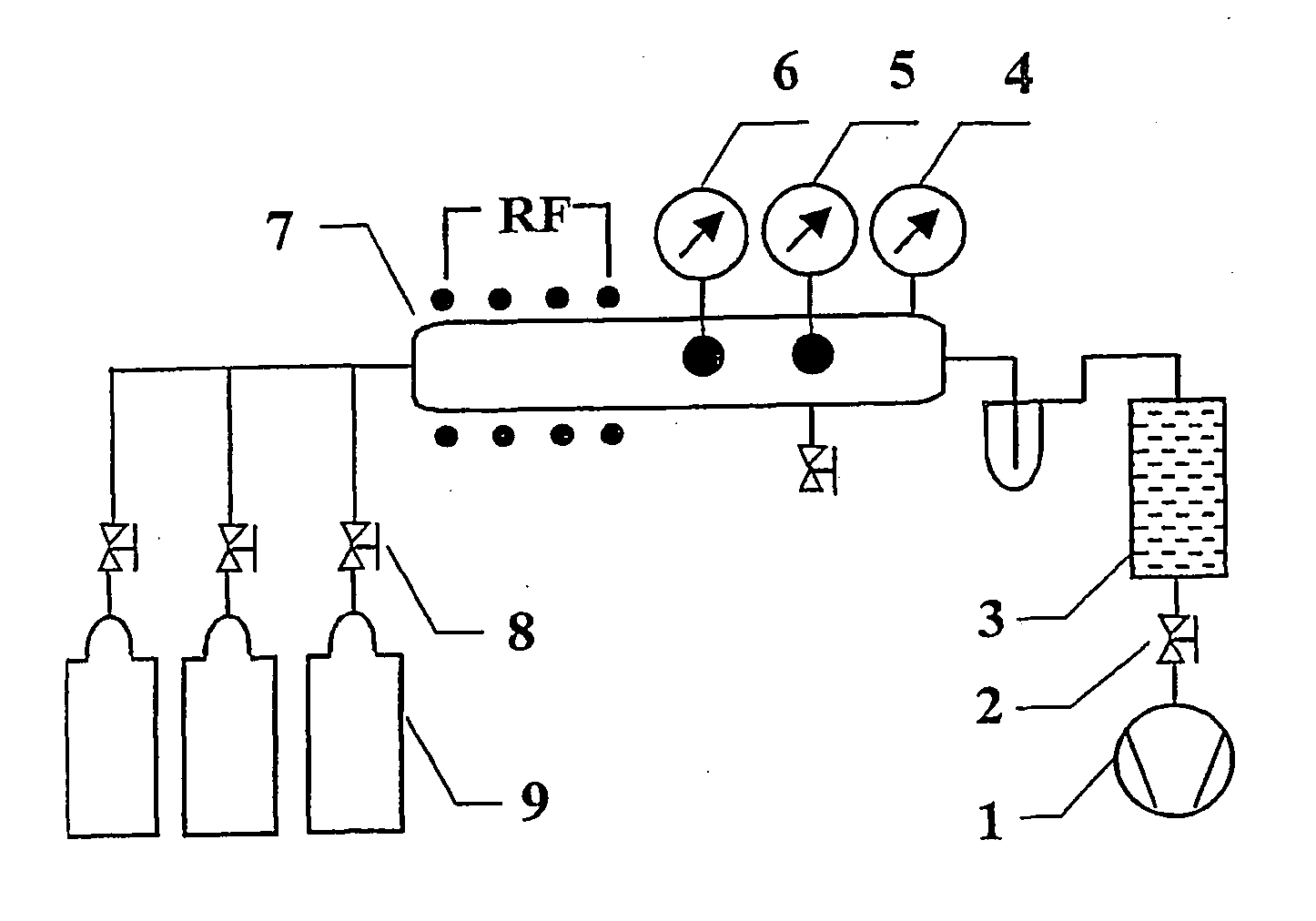

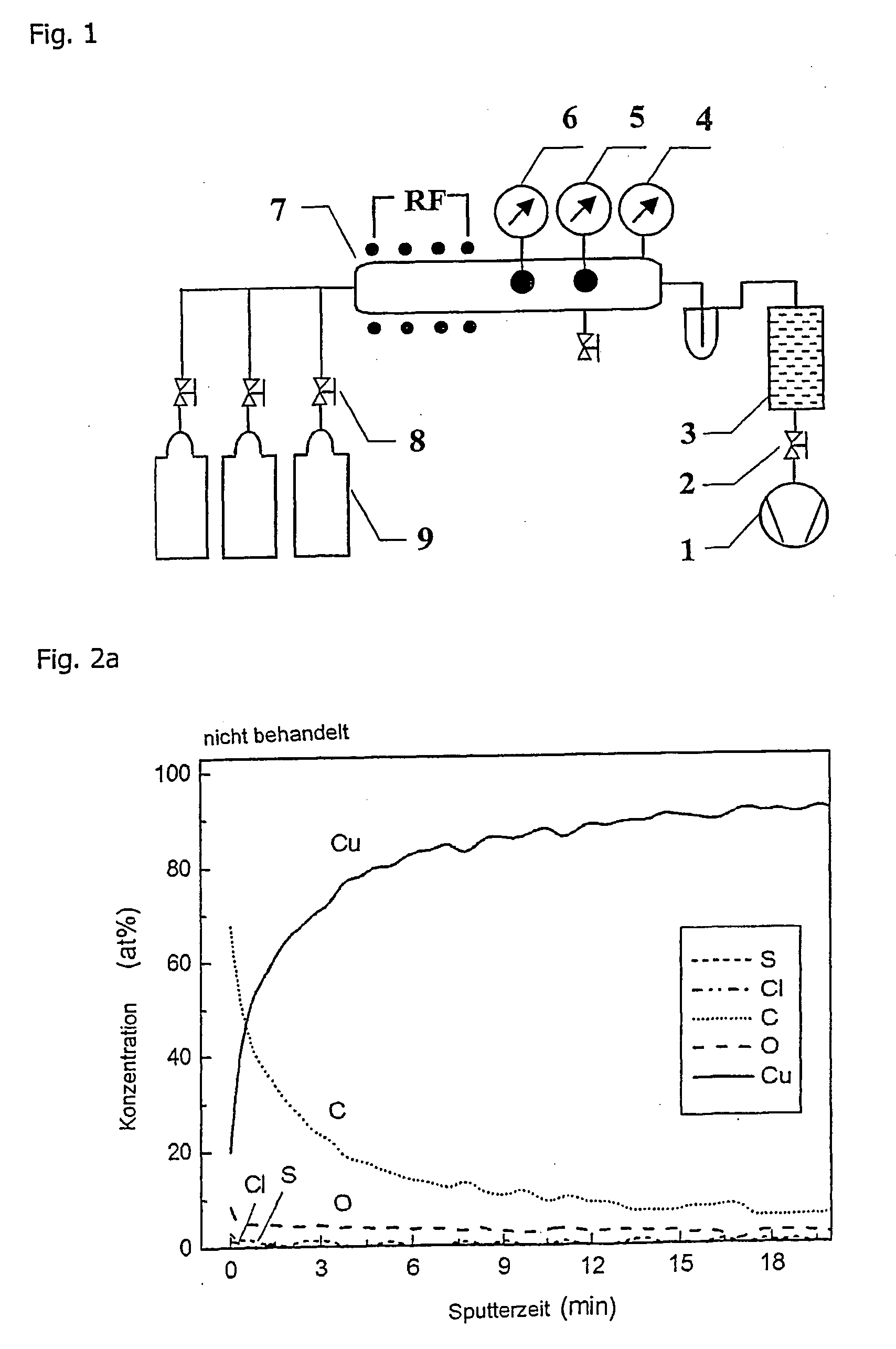

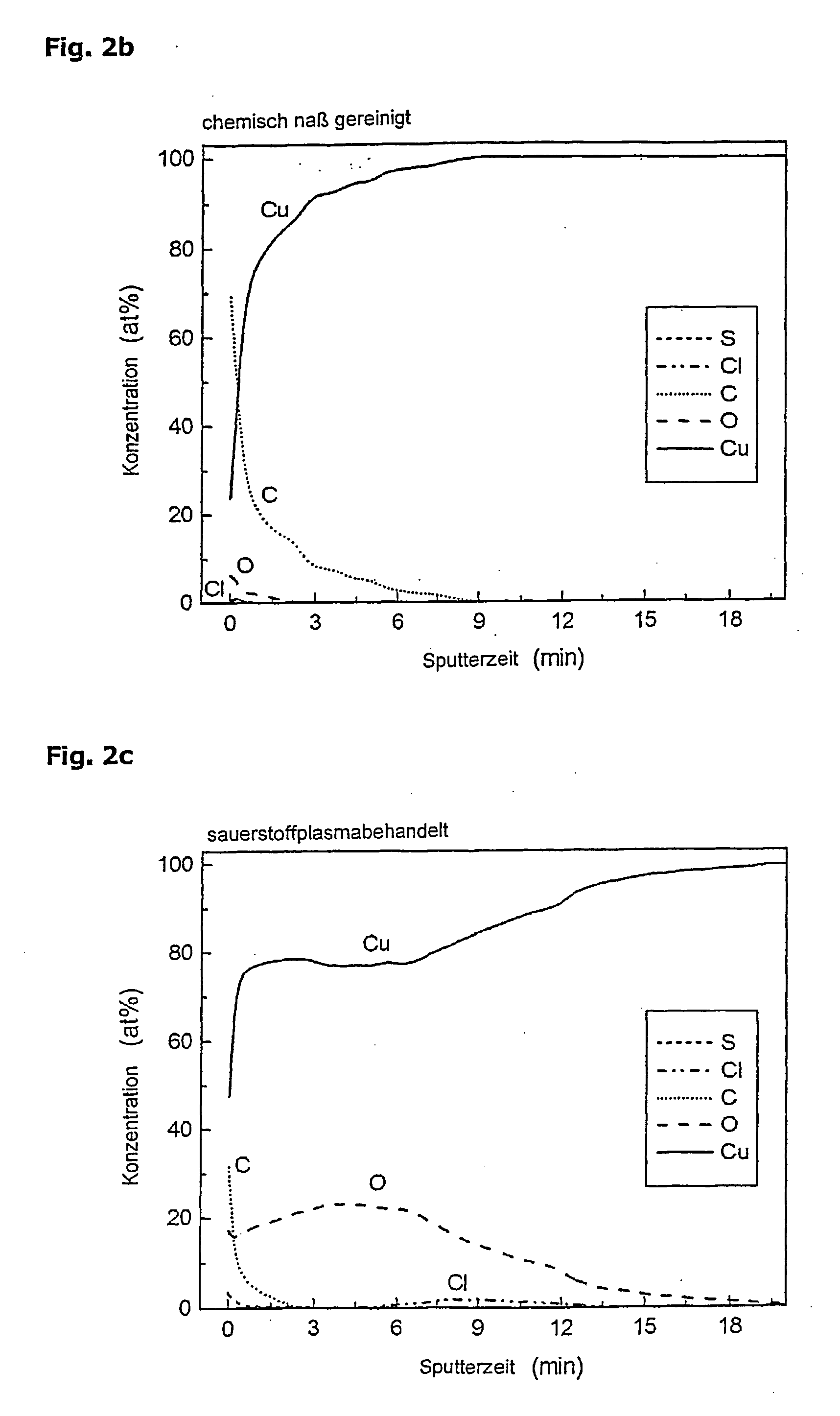

Plasma treatment for purifying copper or nickel

InactiveUS20060054184A1Reduce connection resistanceReduce impuritySoldering apparatusElectrostatic cleaningAlloyOxygen

A method for treating electronic components made of copper, nickel or alloys thereof or with materials such as brass or plated therewith and includes the steps of arranging the components in a treatment chamber, generating a vacuum in the treatment chamber, introducing oxygen into the treatment chamber, providing a pressure ranging between 10−1 and 50 mbar in the treatment chamber and exciting a plasma in the chamber, allowing the oxygen radicals to act on the components, generating a vacuum in the treatment chamber, introducing hydrogen into the treatment chamber, providing a pressure ranging between 10−1 and 50 mbar in the treatment chamber and exciting a plasma in the chamber and allowing the hydrogen radicals to act on the components.

Owner:KOLEKTOR GRP D O O

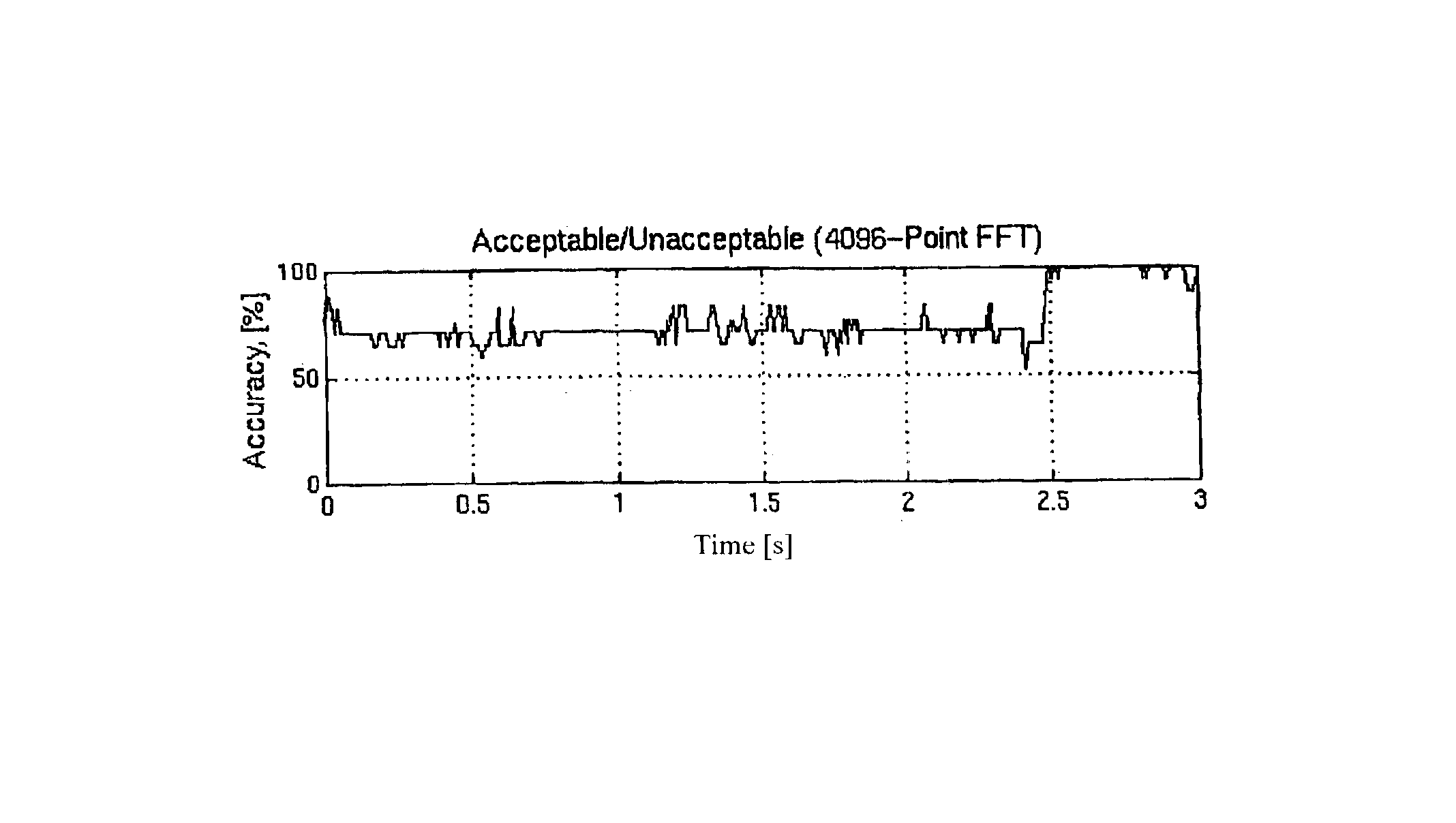

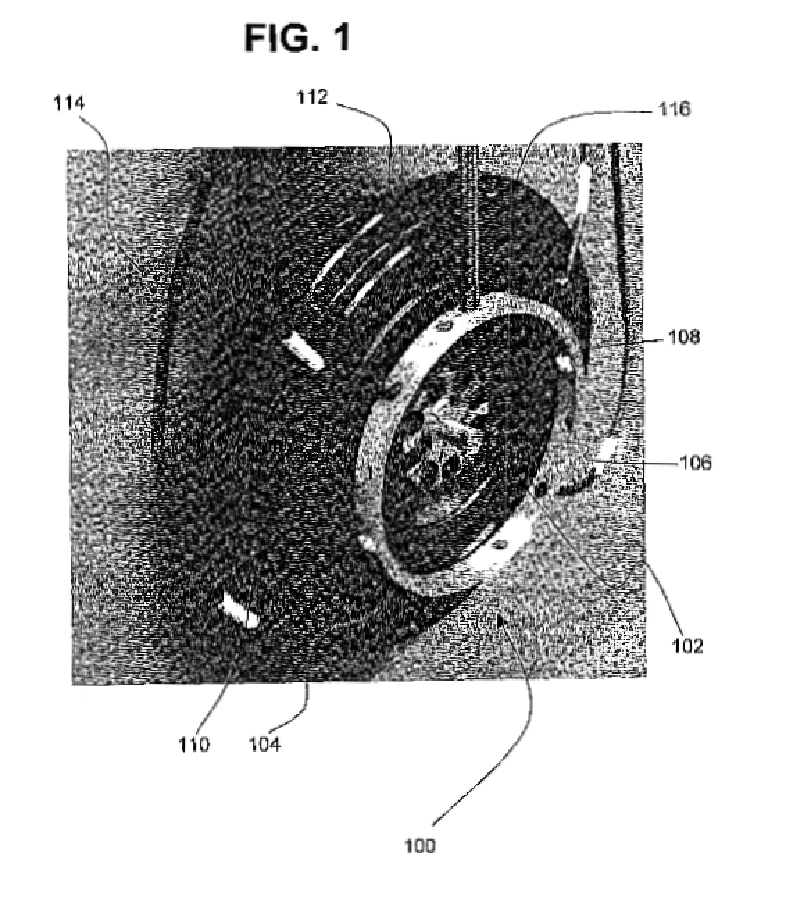

Method and apparatus for in-process sensing of manufacturing quality

InactiveUS6857553B1Low costShorten the timeAnalysing solids using sonic/ultrasonic/infrasonic wavesResonant frequencyFriction weldingAcoustics

A method for determining the quality of an examined weld joint comprising the steps of providing acoustical data from the examined weld joint, and performing a neural network operation on the acoustical data determine the quality of the examined weld joint produced by a friction weld process. The neural network may be trained by the steps of providing acoustical data and observable data from at least one test weld joint, and training the neural network based on the acoustical data and observable data to form a trained neural network so that the trained neural network is capable of determining the quality of a examined weld joint based on acoustical data from the examined weld joint. In addition, an apparatus having a housing, acoustical sensors mounted therein, and means for mounting the housing on a friction weld device so that the acoustical sensors do not contact the weld joint. The apparatus may sample the acoustical data necessary for the neural network to determine the quality of a weld joint.

Owner:THE UNITED STATES AS REPRESENTED BY THE DEPARTMENT OF ENERGY

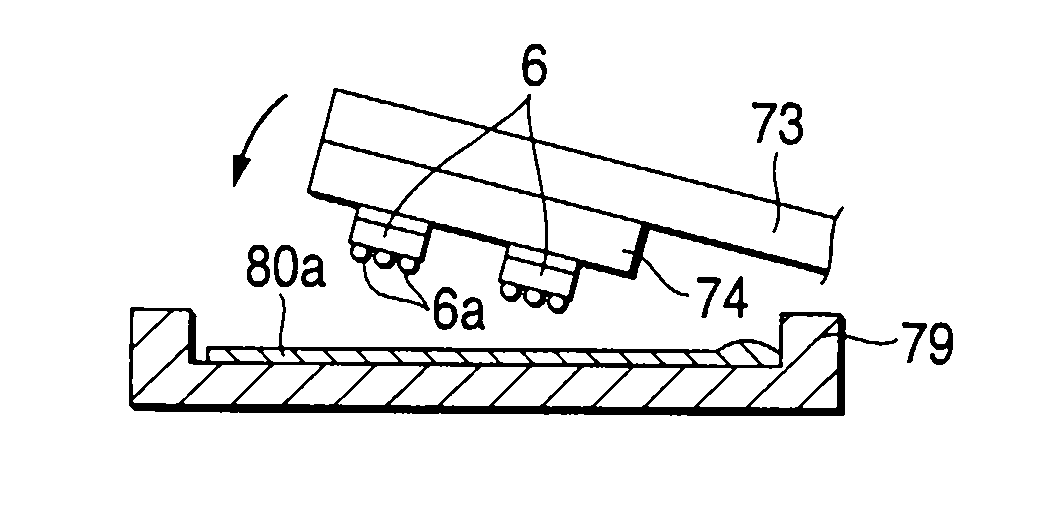

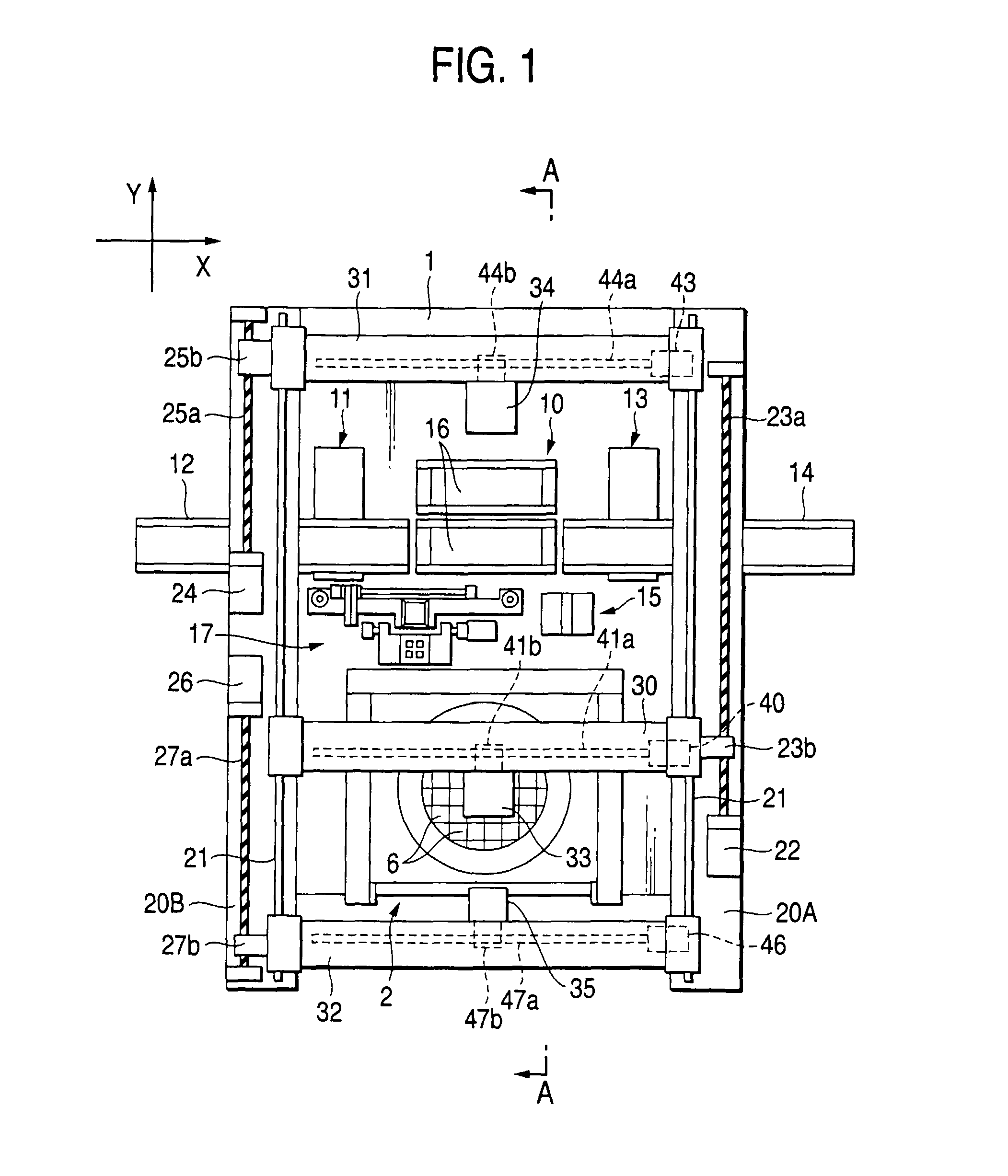

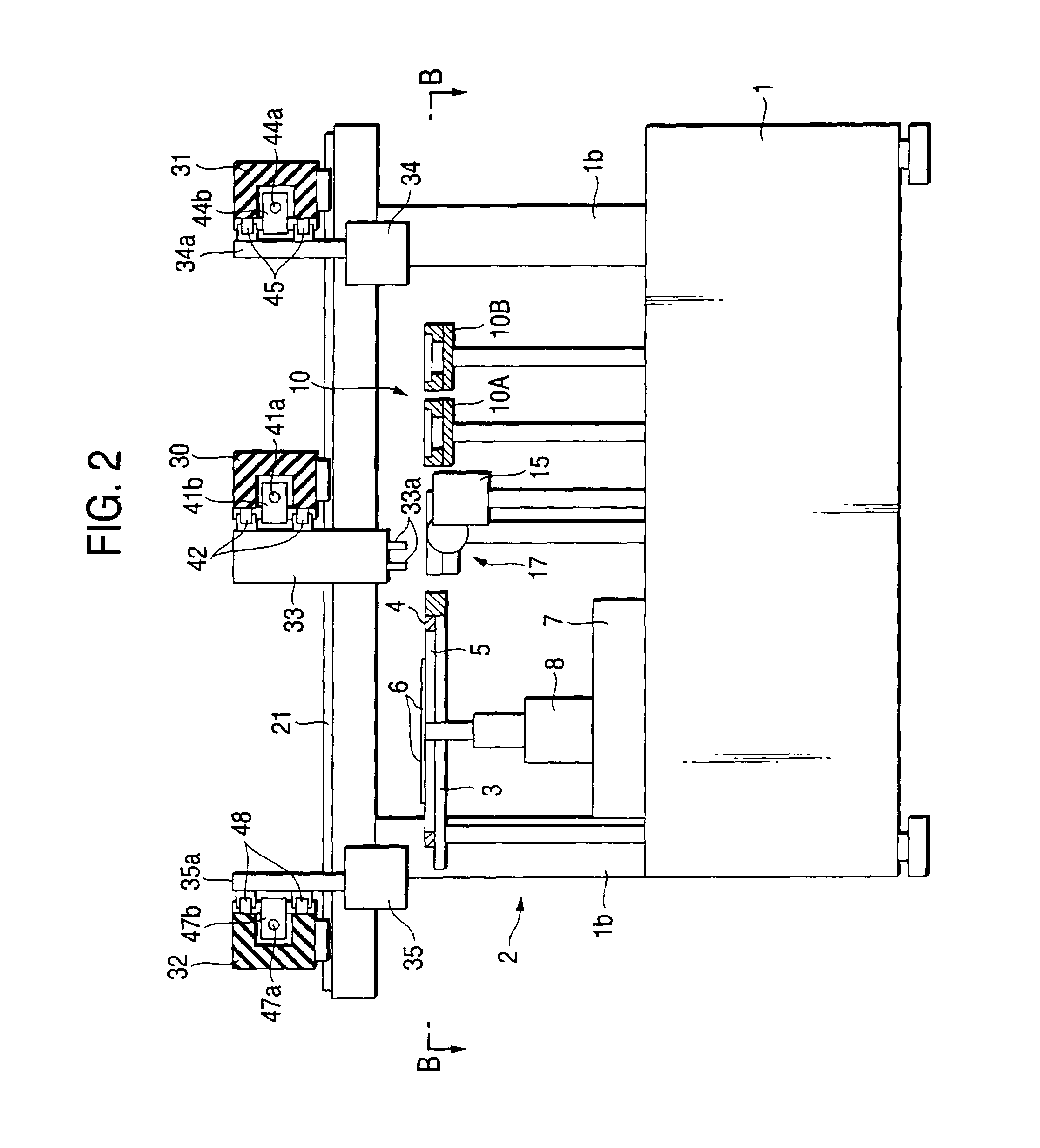

Electronic component mounting apparatus and electronic component mounting method

InactiveUS7033842B2Eliminate processingImprove efficiencySolid-state devicesSoldering apparatusElectronic componentCoating

The present invention provides an electronic component mounting apparatus, wherein a high speed operation can be provided by simplifying the structure of a mounting head and wherein the working efficiency can be improved by eliminating the use of the mounting head for a coating process. In the electronic component mounting apparatus, a flux is coated on chips supplied to an electronic component feeding unit while bump formation faces are directed upward. The chips are mounted on a substrate. A holding head receives the chips extracted from an adhesive sheet by a mounting head and is inverted relative to a stage on which a flux is spread. As a result, the bumps of the chips are covered with the flux and are flattened, and after the holding head is returned to the original stage, the chips on the stage are extracted and mounted on the substrate by the mounting head.

Owner:PANASONIC CORP

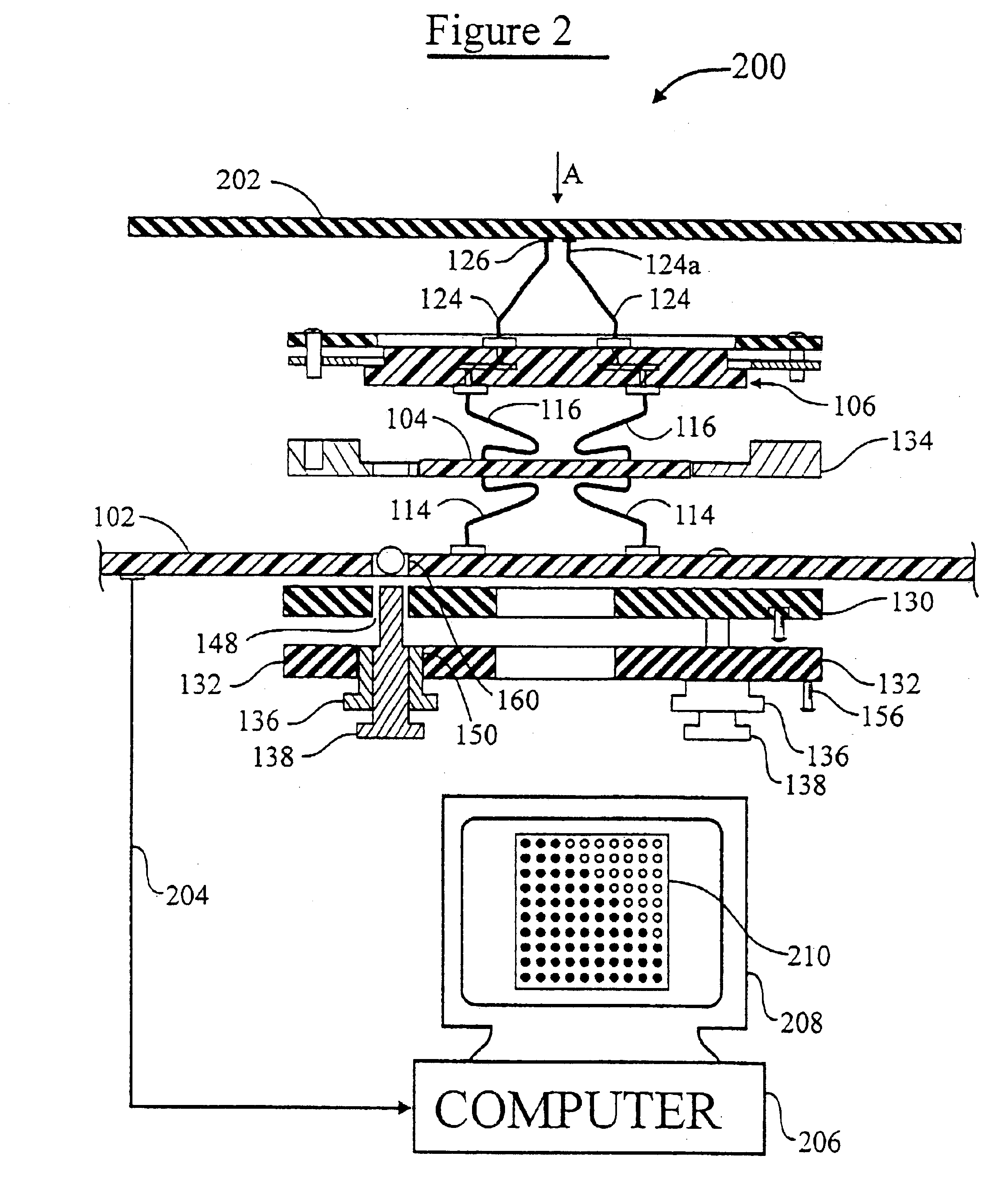

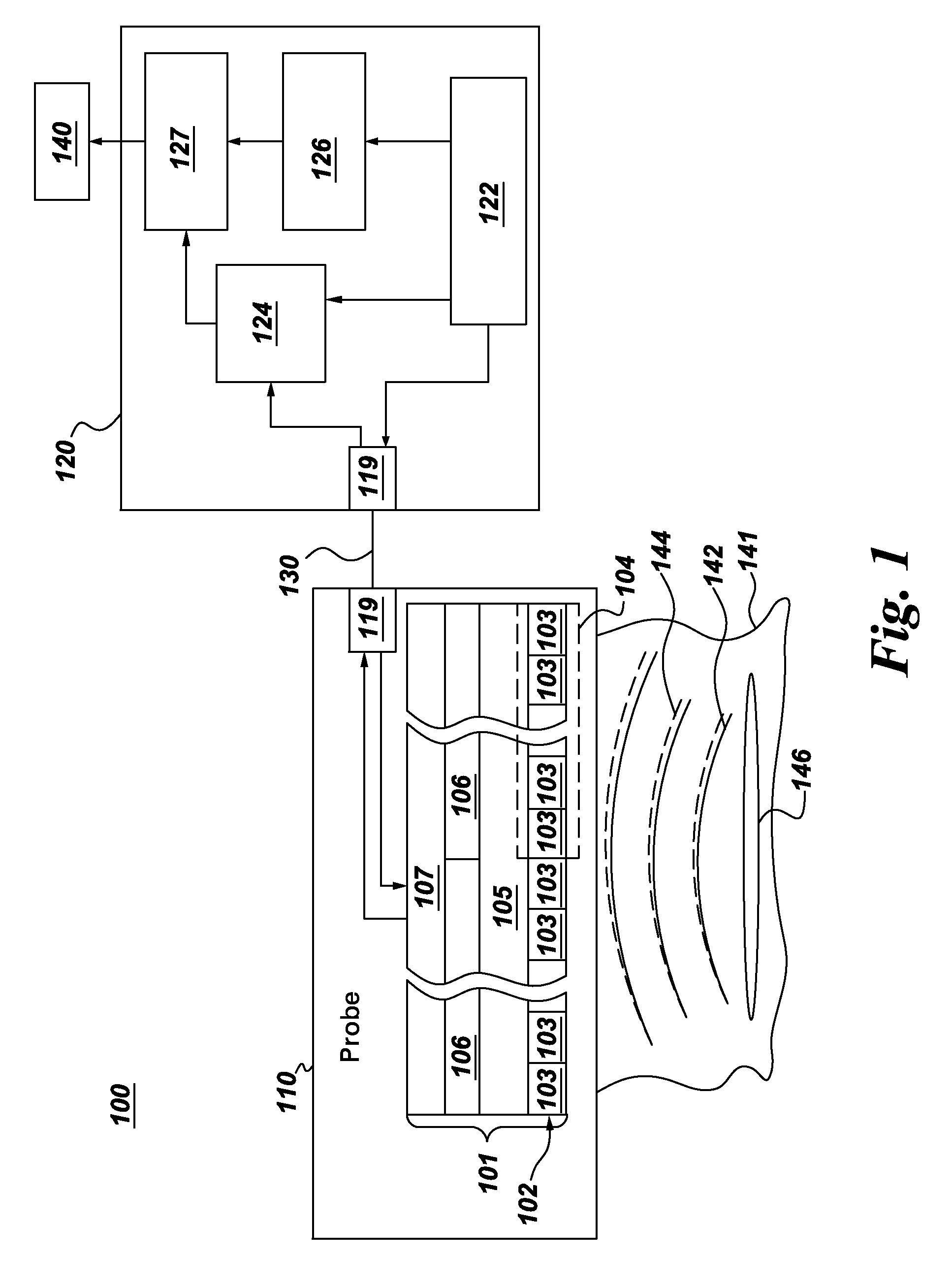

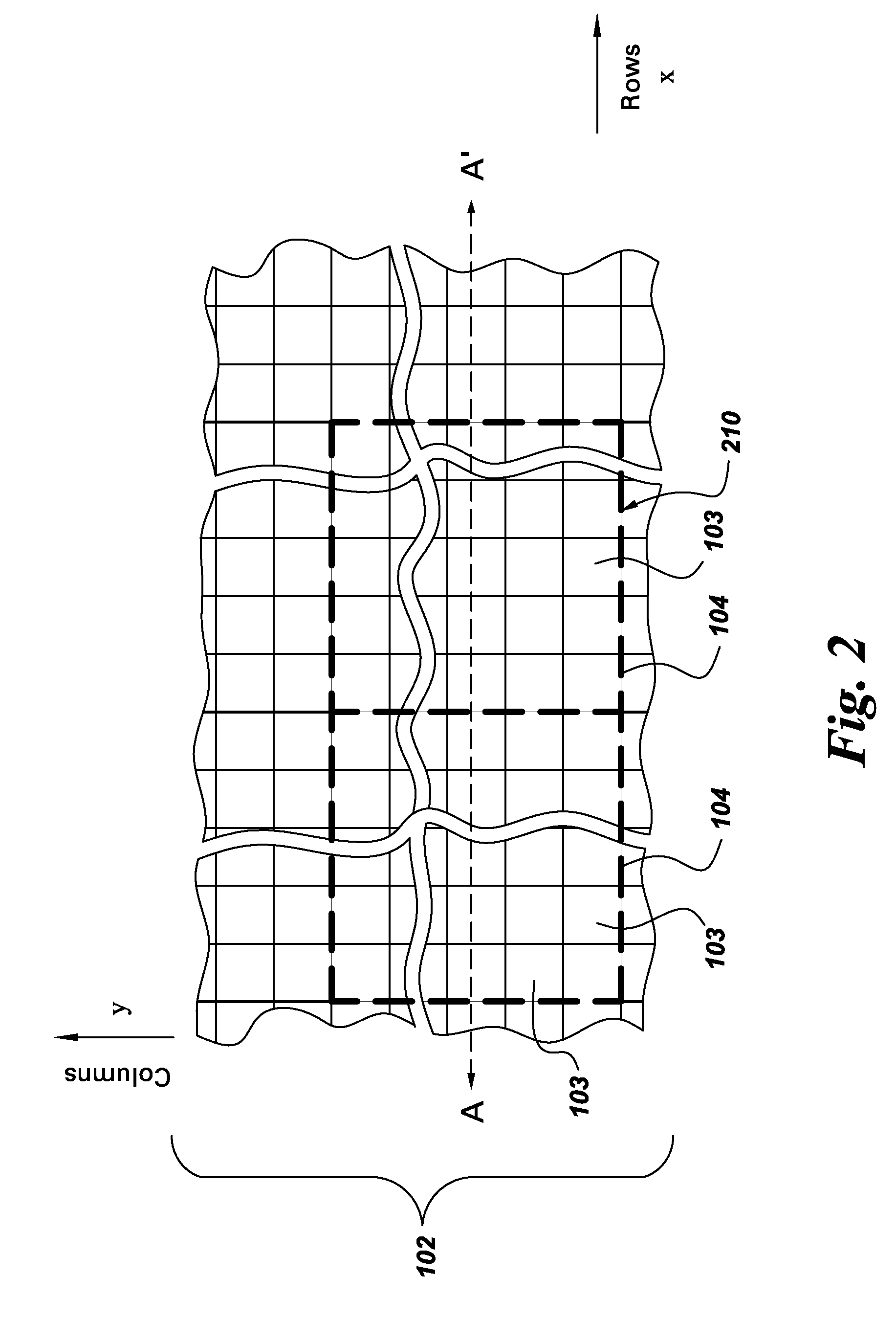

Probe card assembly

InactiveUS6838893B2Easy to disassembleEffective shieldingSemiconductor/solid-state device testing/measurementFinal product manufactureProbe cardTransformer

In a probe card assembly, a series of probe elements can be arrayed on a silicon space transformer. The silicon space transformer can be fabricated with an array of primary contacts in a very tight pitch, comparable to the pitch of a semiconductor device. One preferred primary contact is a resilient spring contact. Conductive elements in the space transformer are routed to second contacts at a more relaxed pitch. In one preferred embodiment, the second contacts are suitable for directly attaching a ribbon cable, which in turn can be connected to provide selective connection to each primary contact. The silicon space transformer is mounted in a fixture that provides for resilient connection to a wafer or device to be tested. This fixture can be adjusted to planarize the primary contacts with the plane of a support probe card board.

Owner:FORMFACTOR INC

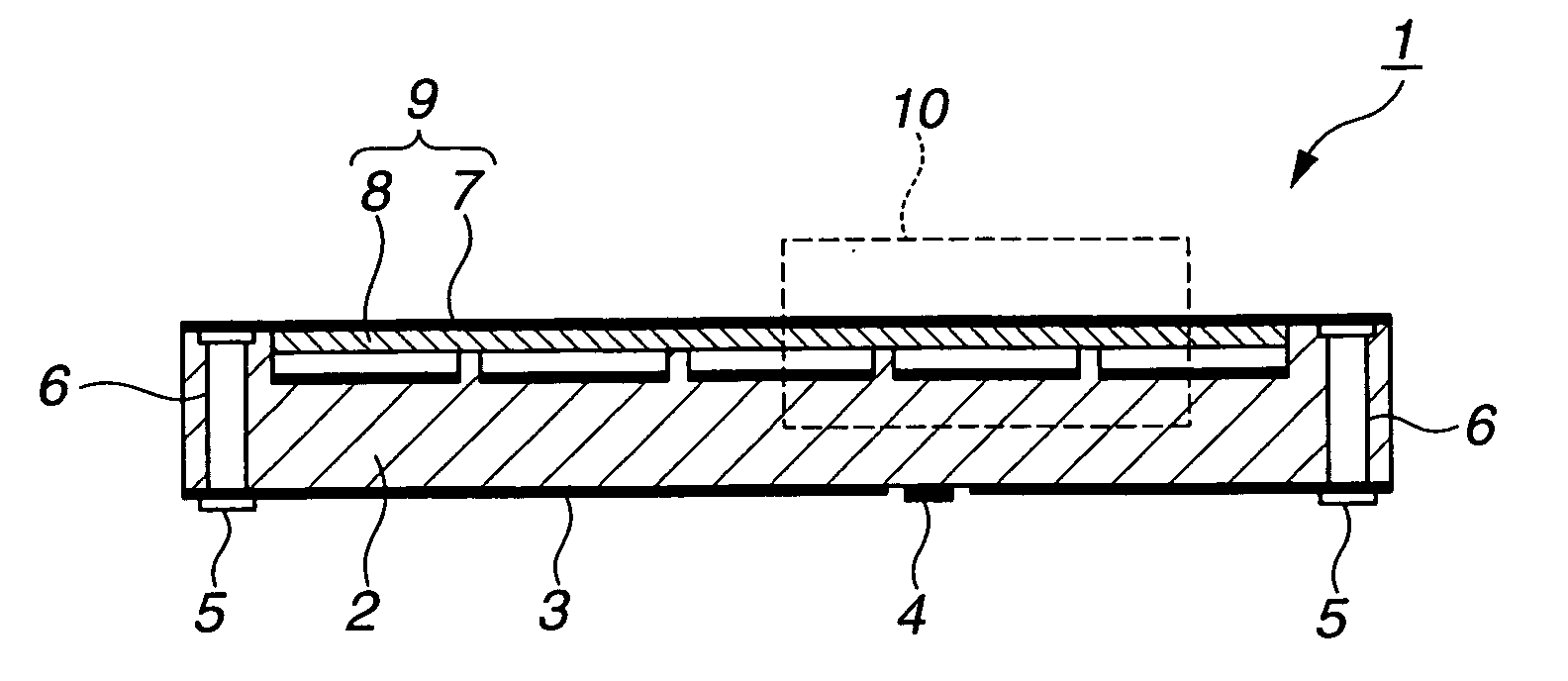

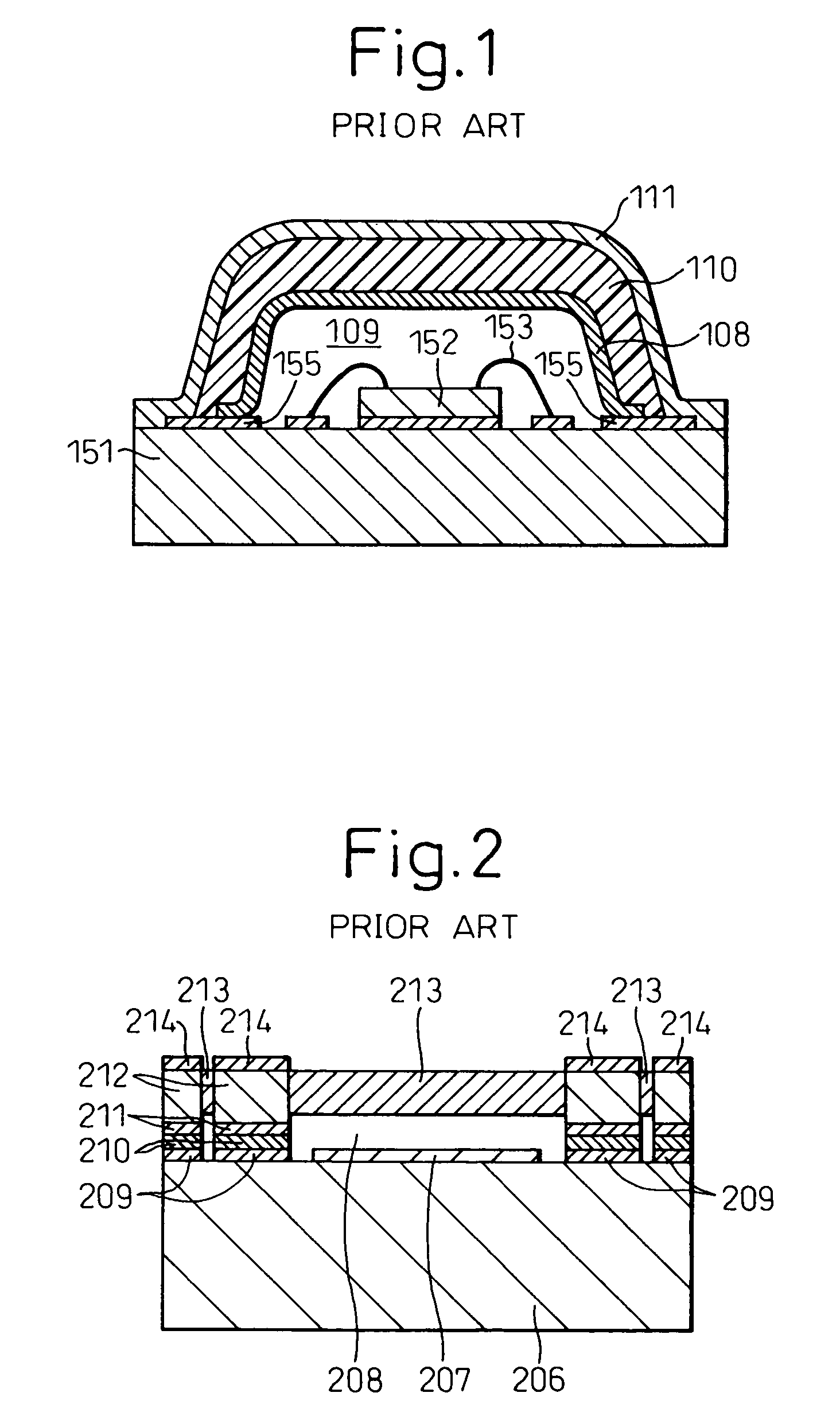

Capacitive ultrasonic transducer, production method thereof, and capacitive ultrasonic probe

InactiveUS20070164632A1Increase sound pressureSimple methodUltrasonic/sonic/infrasonic diagnosticsTransducer detailsSound pressureUltrasonic transmission

It becomes possible to obtain high sound pressure in a high frequency domain by a capacitive ultrasonic transducer which comprises a membrane on which one electrode is formed, a cavity constructed in its backface, and a substrate on which these are mounted and supported and on whose surface an electrode is provided, on a surface in an ultrasonic transmission and reception side, characterized in that the membrane comprises two or more layers, and at least one layer of them comprises a high dielectric constant film.

Owner:OLYMPUS CORP

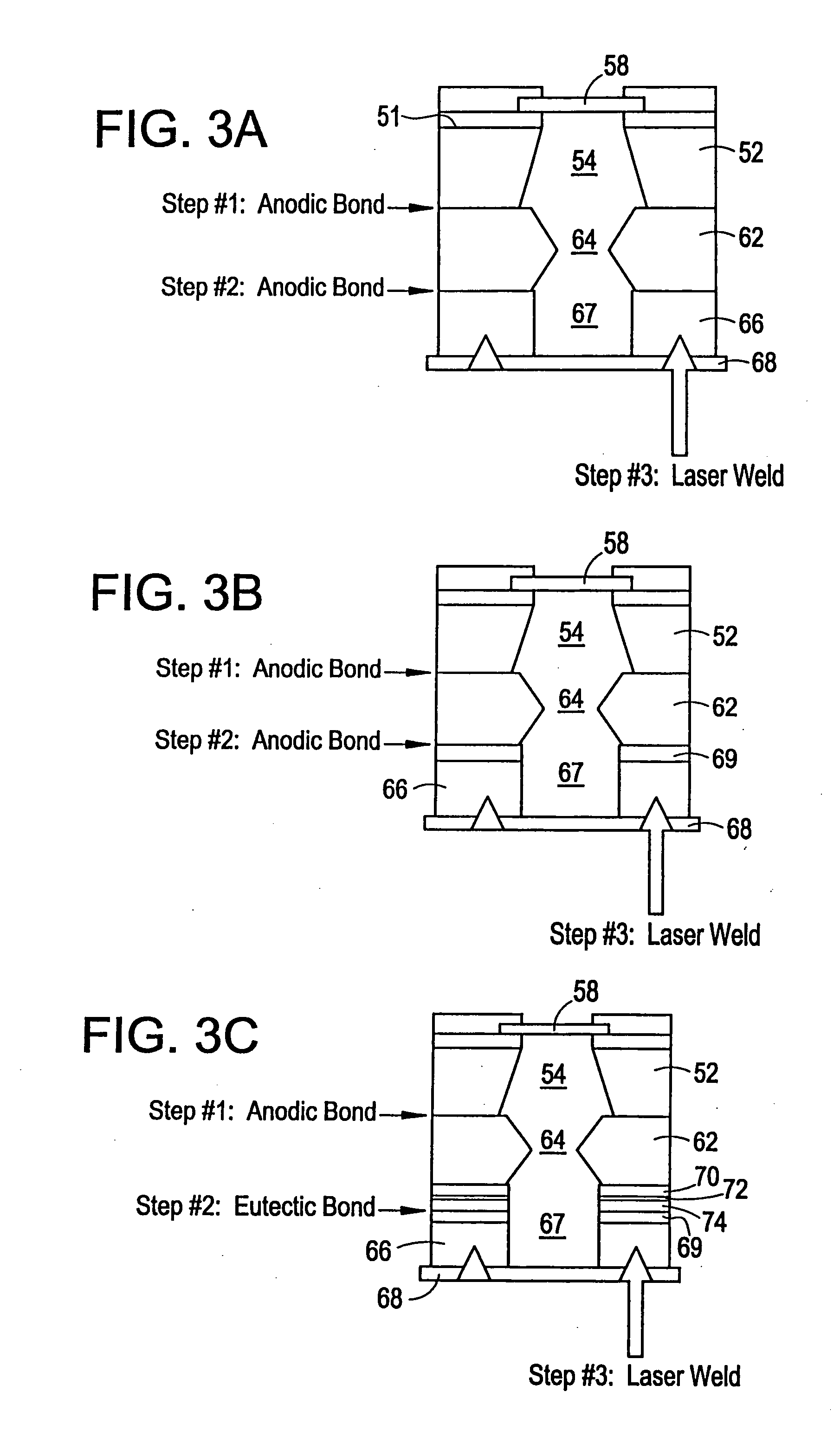

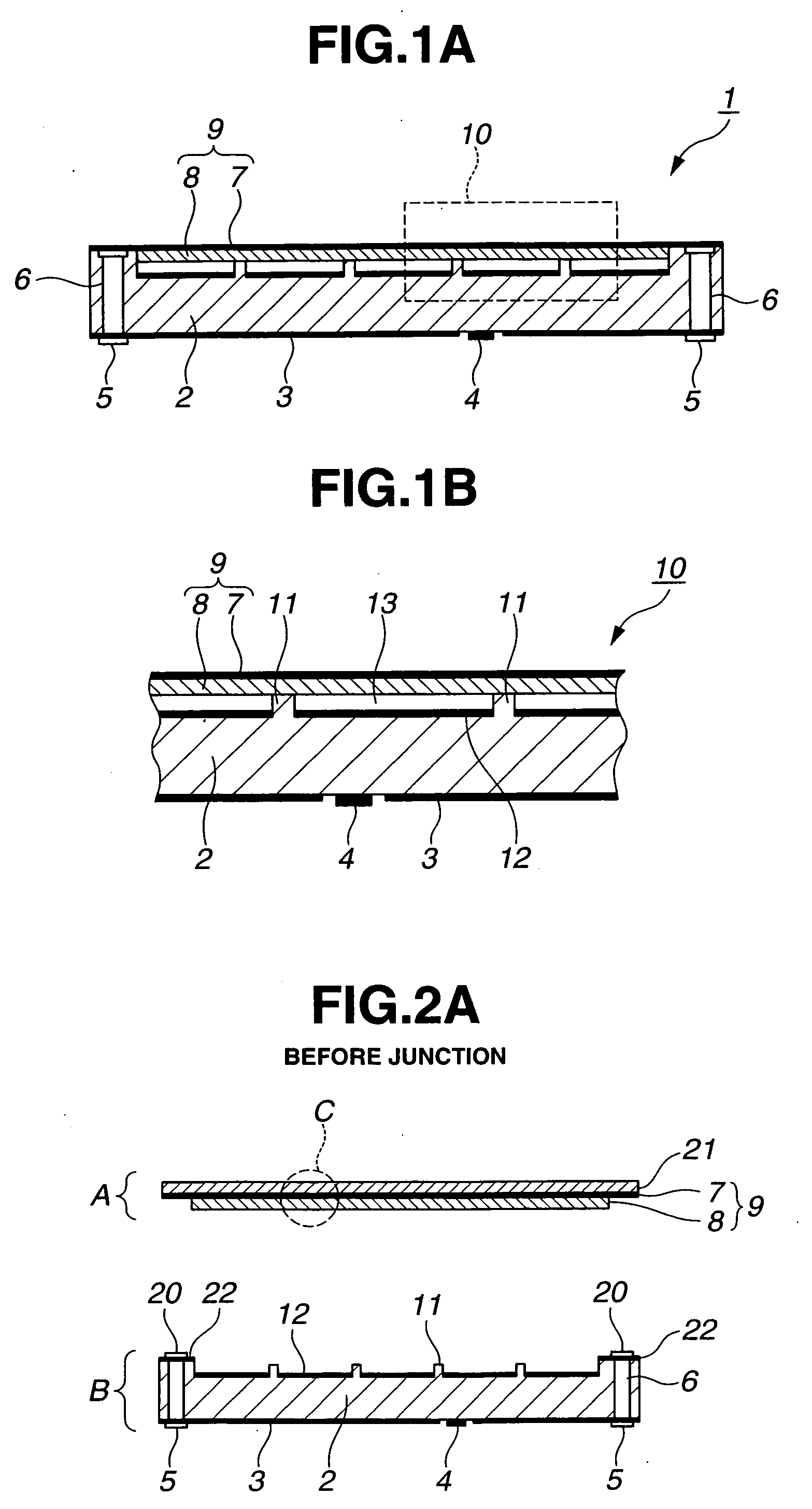

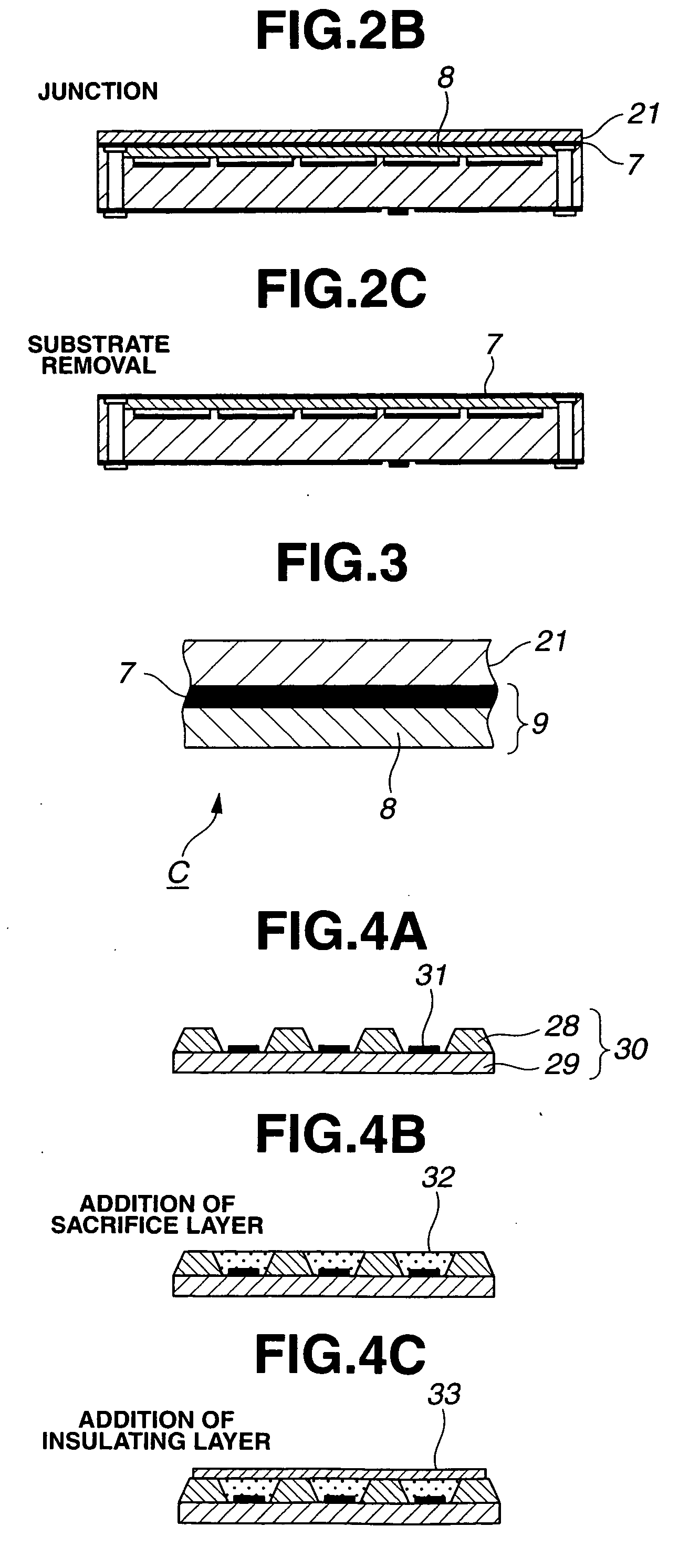

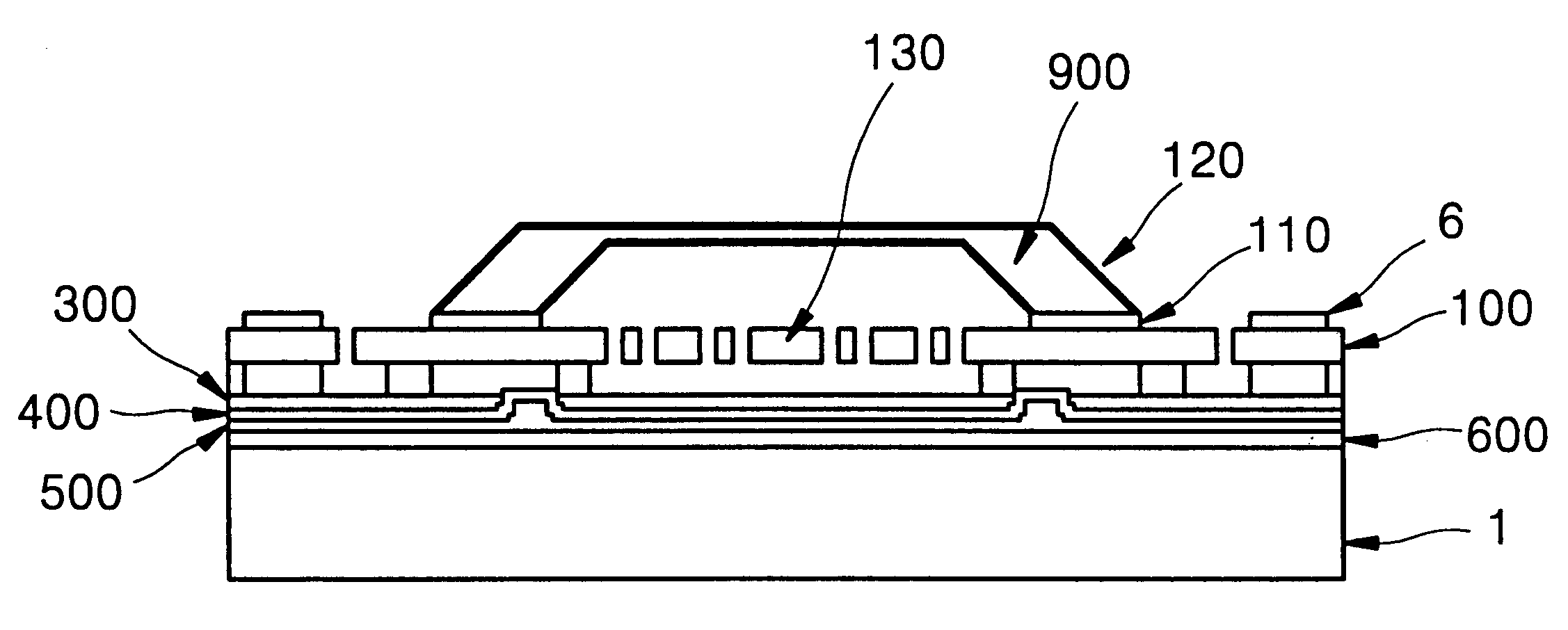

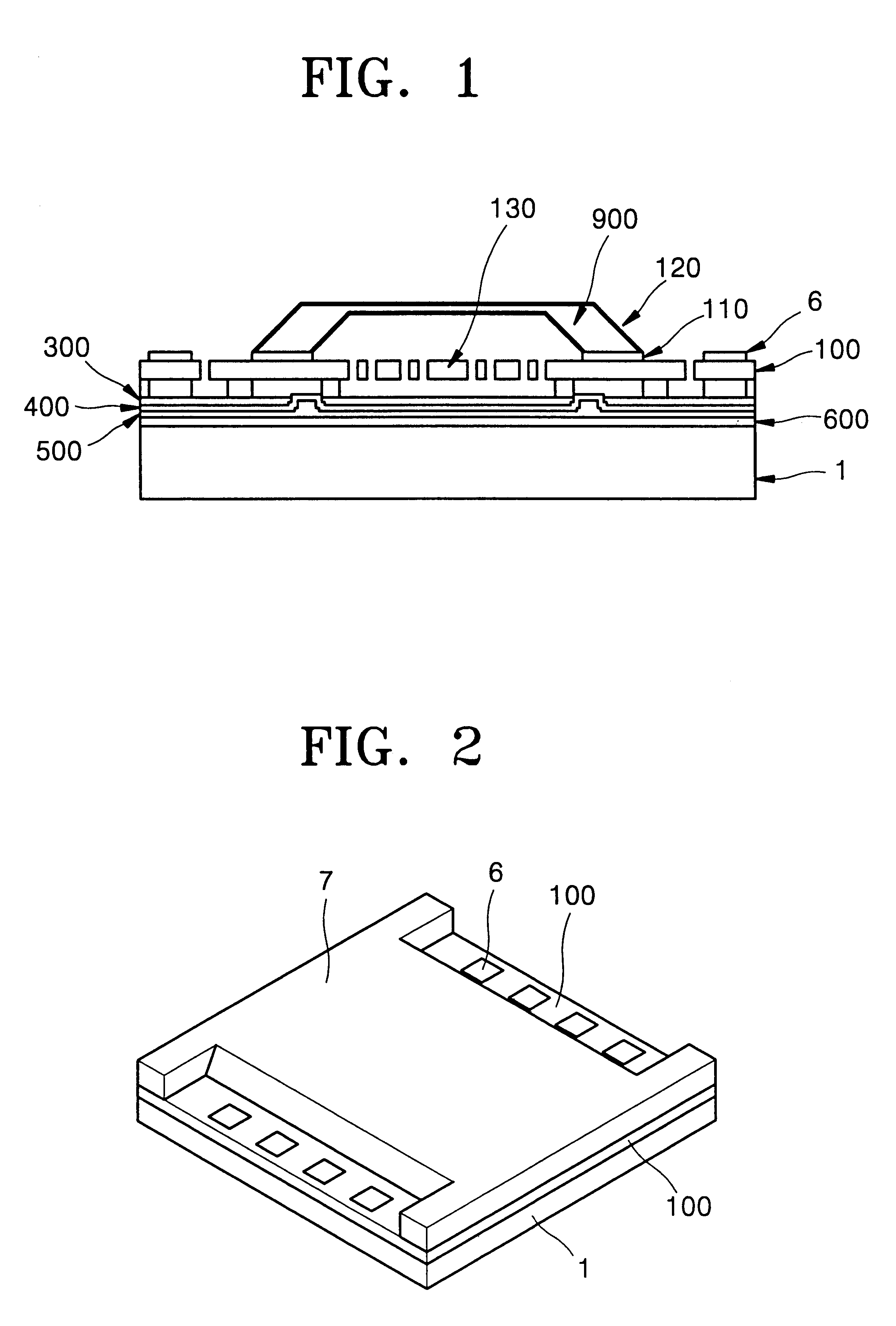

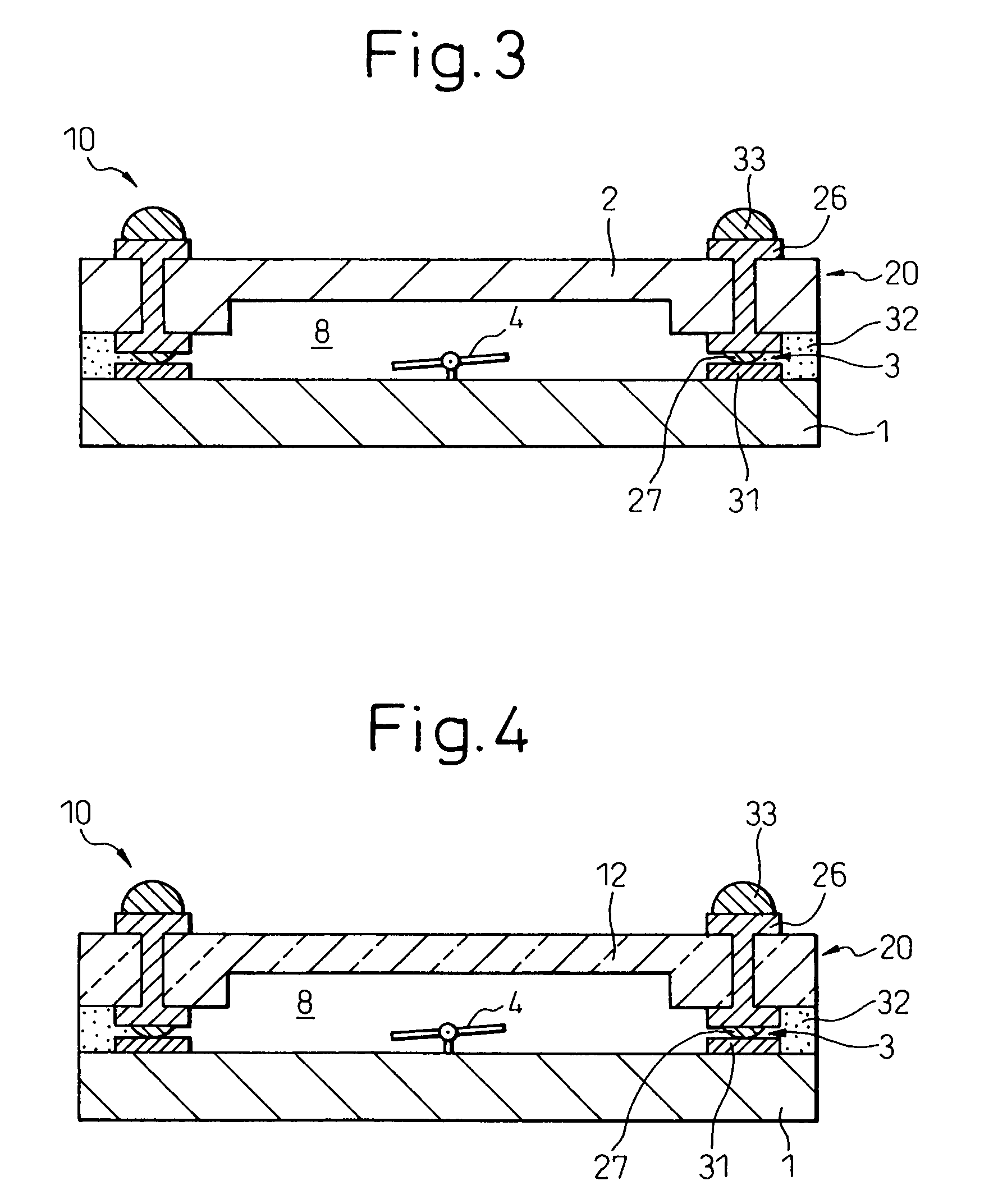

Method of fabricating micro electro mechanical system structure which can be vacuum-packed at wafer level

InactiveUS6391673B1Acceleration measurement using interia forcesSemiconductor/solid-state device detailsVacuum packVacuum level

A method of fabricating a micro electromechanical system (MEMS) structure which can be vacuum-packaged at the wafer level is provided. The method includes the steps of forming a multilayered stack including a signal line on a first wafer; bonding a second wafer to the multilayered stack; polishing the first wafer to a predetermined thickness; forming a MEMS structure in a vacuum area of the first wafer and a pad outside the vacuum area, the MEMS structure and the pad being connected to the signal line; forming a structure in a third wafer to have space corresponding to the vacuum area of the MEMS structure; and bonding the third wafer to the polished surface of the first wafer in a vacuum state. For protection of the structure and maintaining a vacuum level required for operation, the fabricated structure is vacuum-packaged at the wafer level, thereby improving the yield of fabrication. In addition, since a special vacuum packaging process is not necessary, the fabrication can be simplified.

Owner:SAMSUNG ELECTRONICS CO LTD

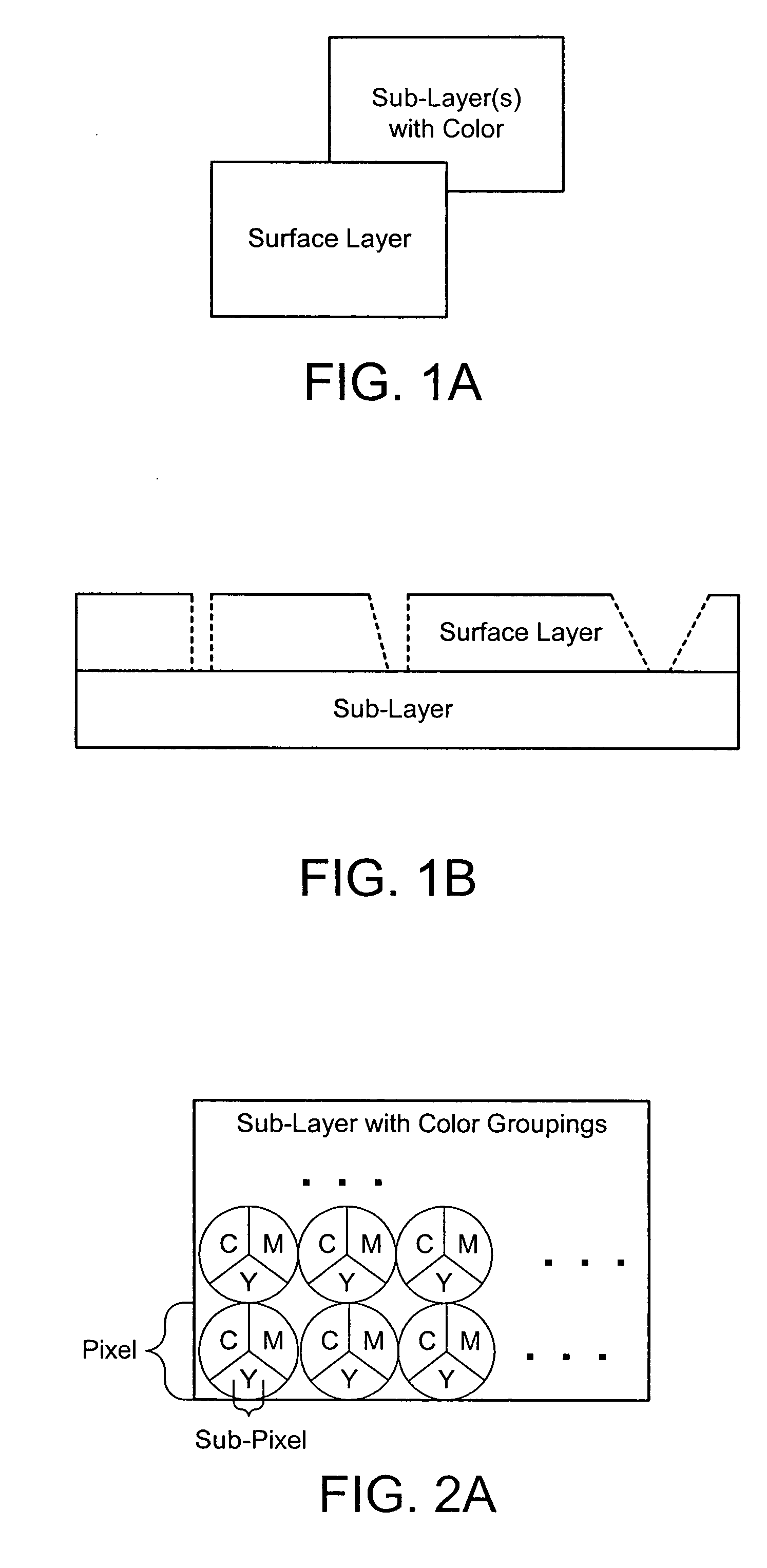

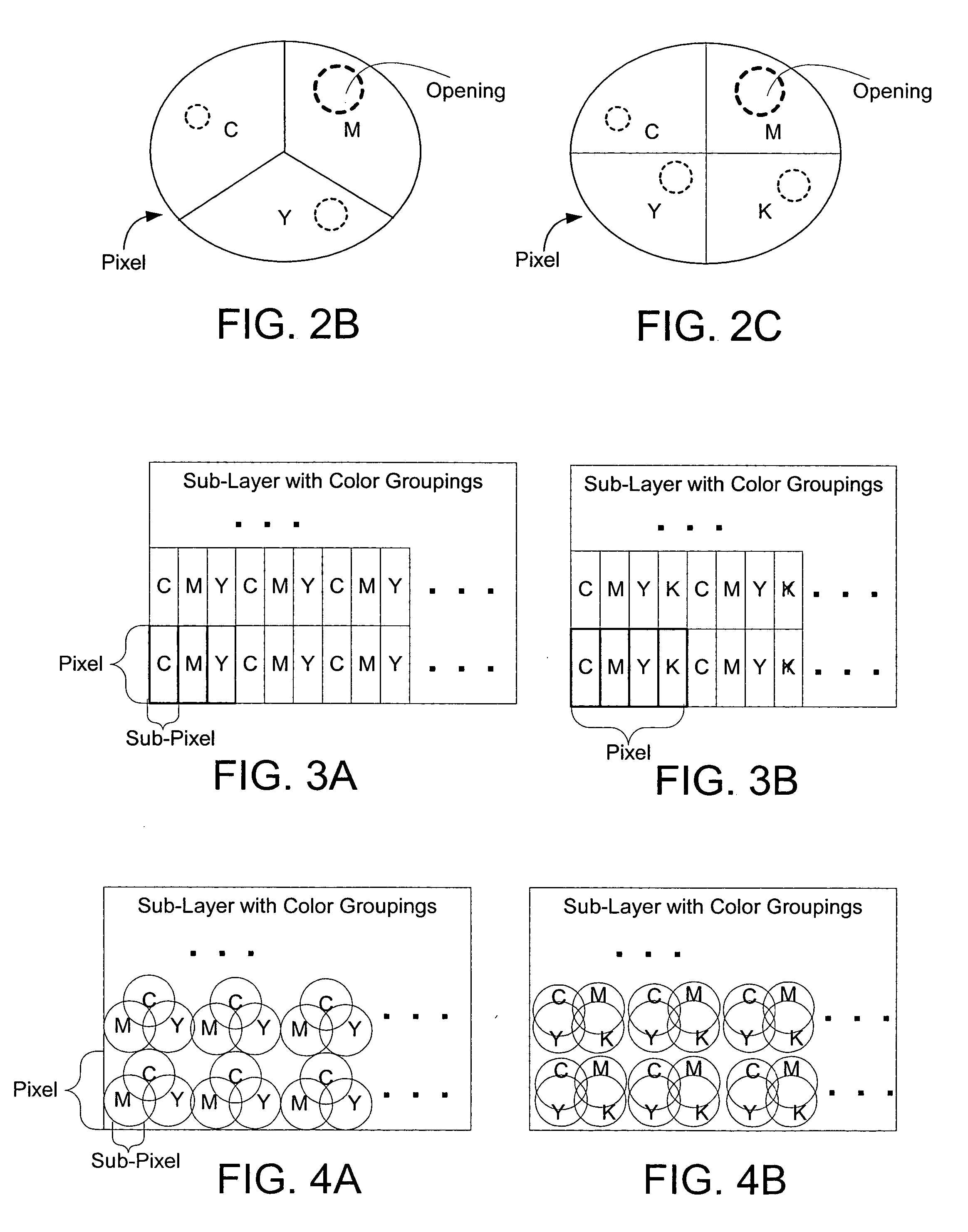

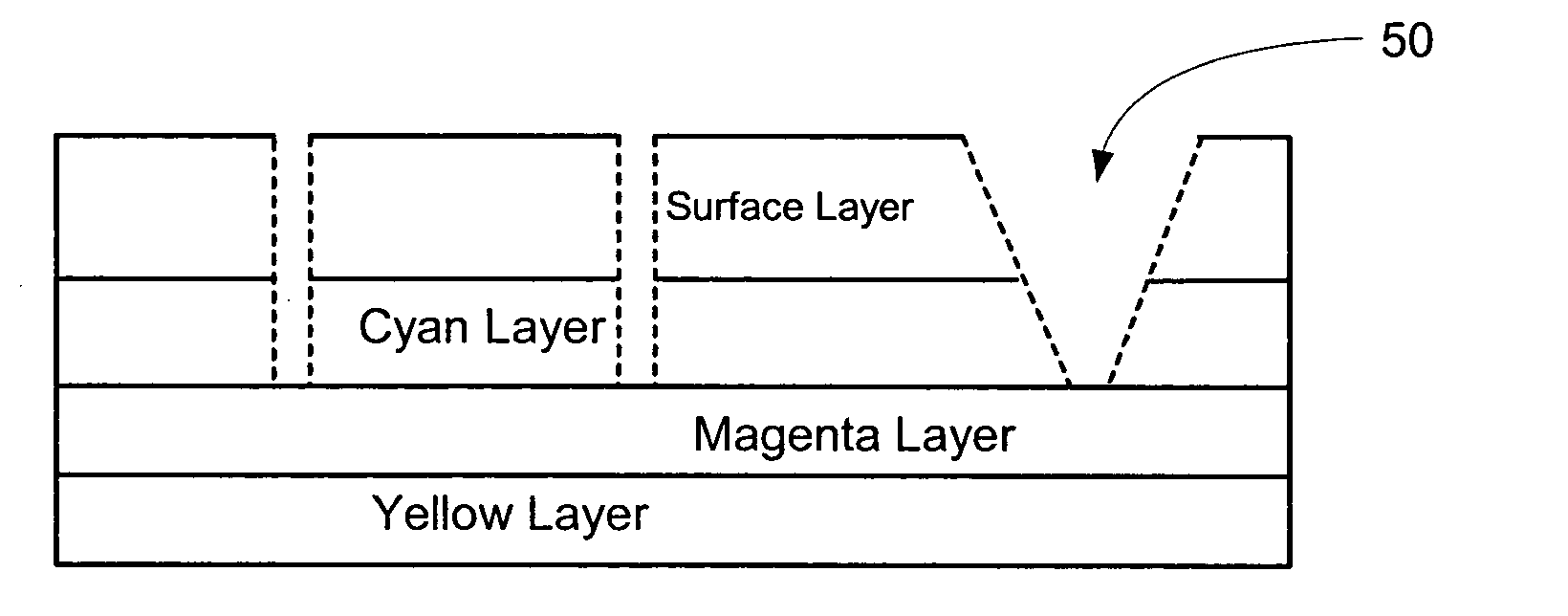

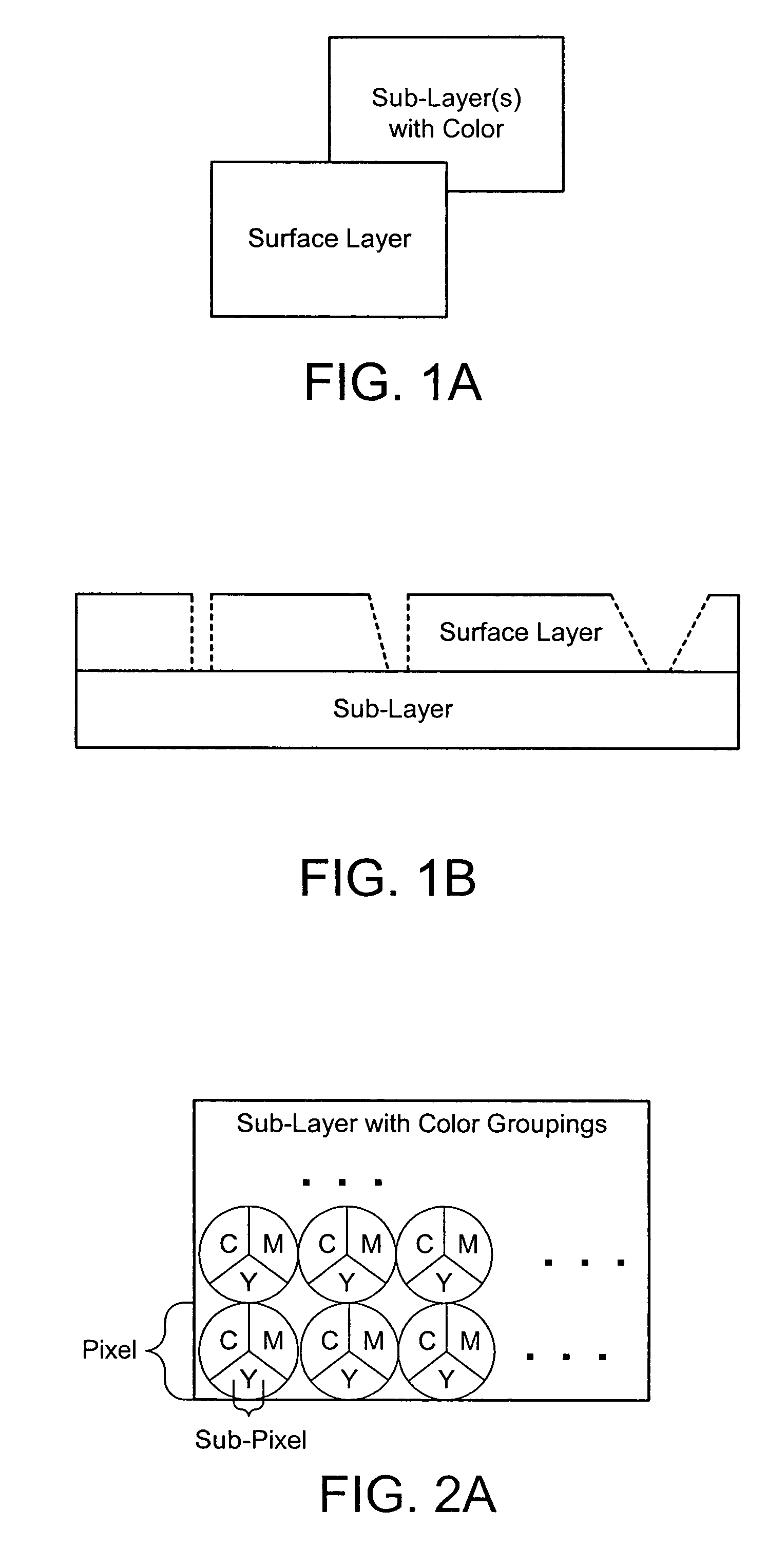

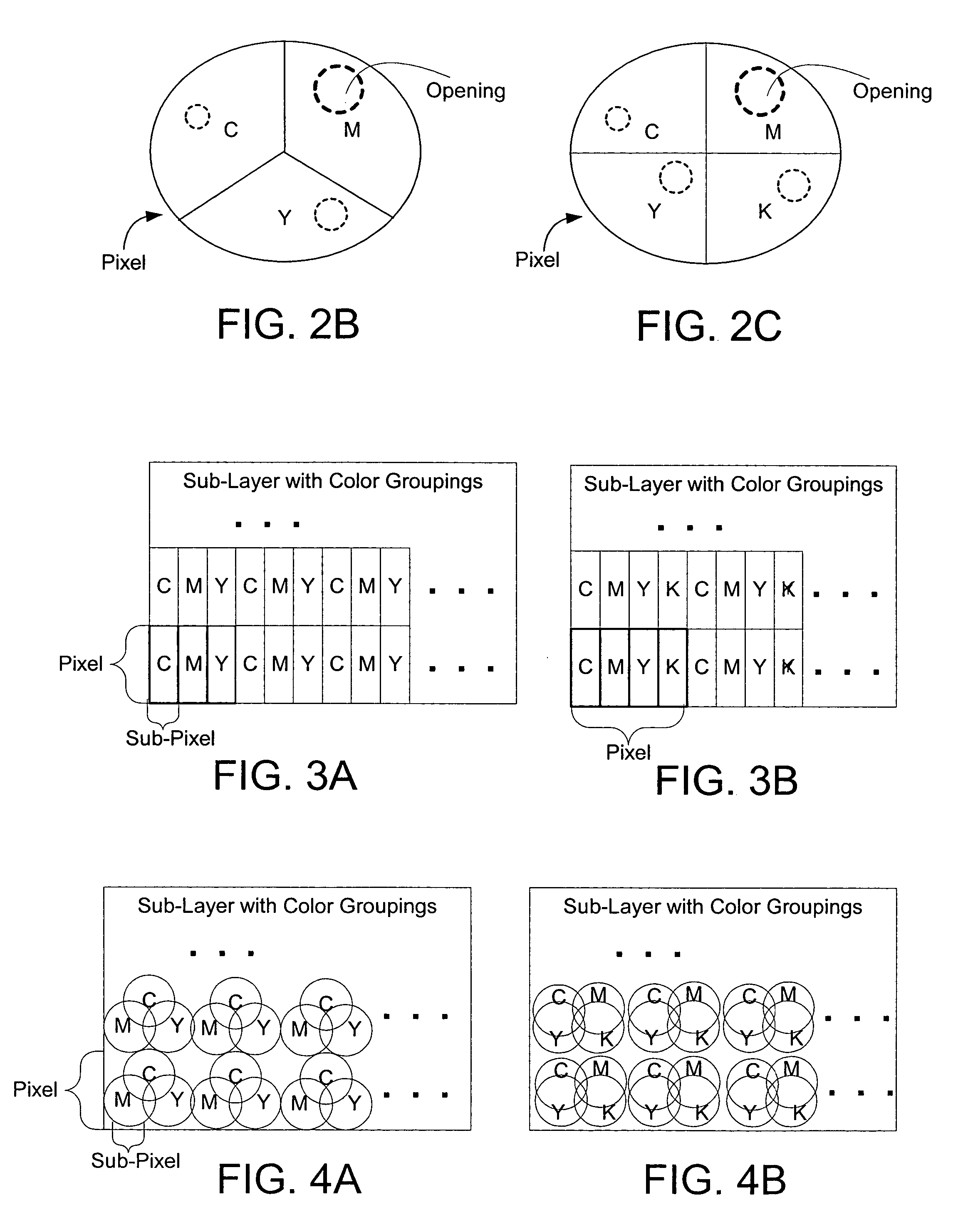

Color laser engraving and digital watermarking

A color laser engraving method engraves a document including a surface layer and one or more sub-layers. The sub-layer includes different colors and orientations of ink. A laser provides openings in the surface layer—to expose color ink in the sub-layer—to create color images and / or text. The different orientations of the colored inks include, e.g., circular, linear and overlapped groupings of ink. A sub-layer preferably includes many repeated instances of the grouping. A digital watermark is embedded in a document via transfer of the digital watermark in an embedded image or text, or by pre-embedding the document via altering intensity of colored inks on the original document card stock. A digital watermark can be carried via modulation with a pseudo-random noise sequence.

Owner:DIGIMARC CORP

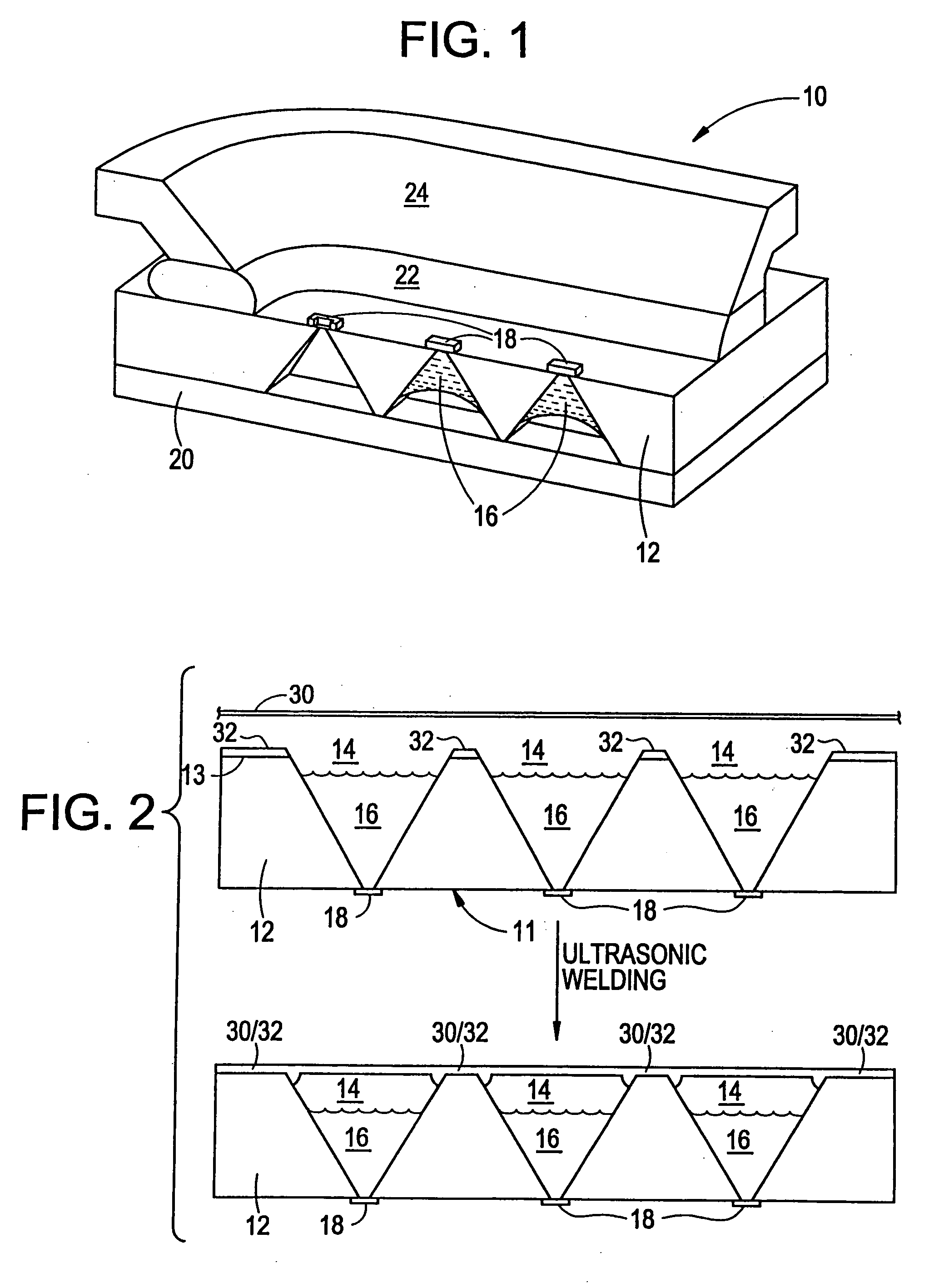

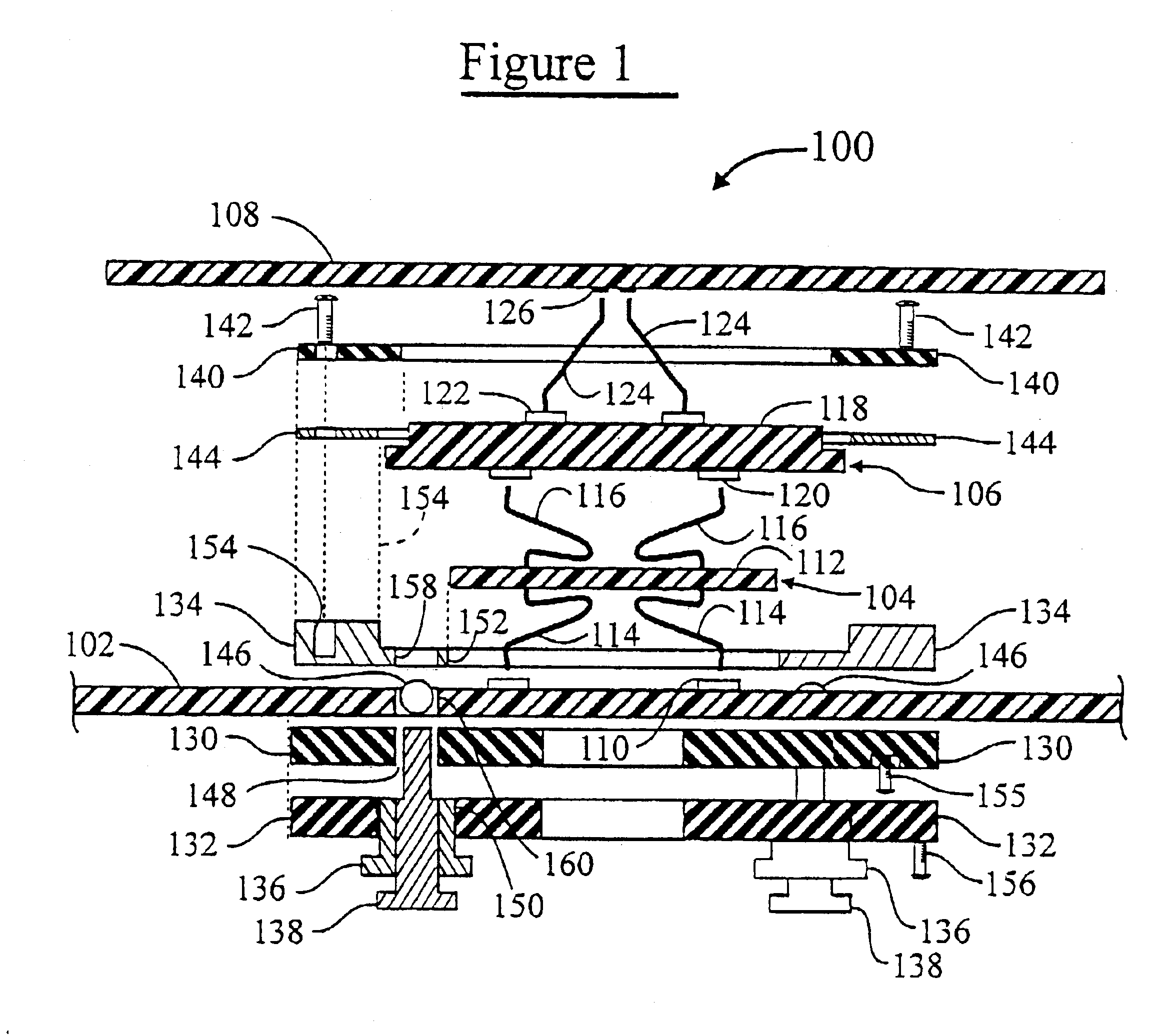

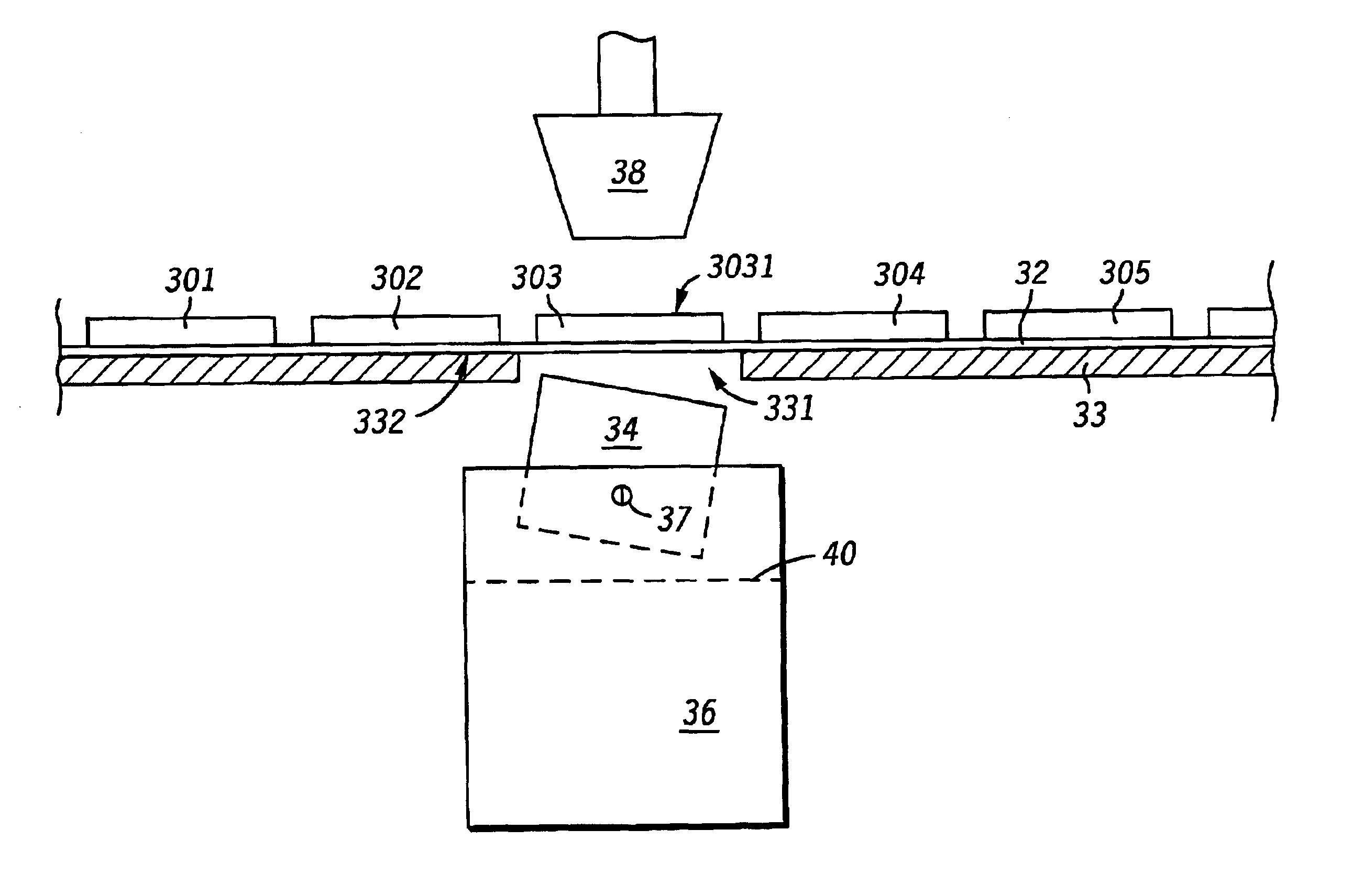

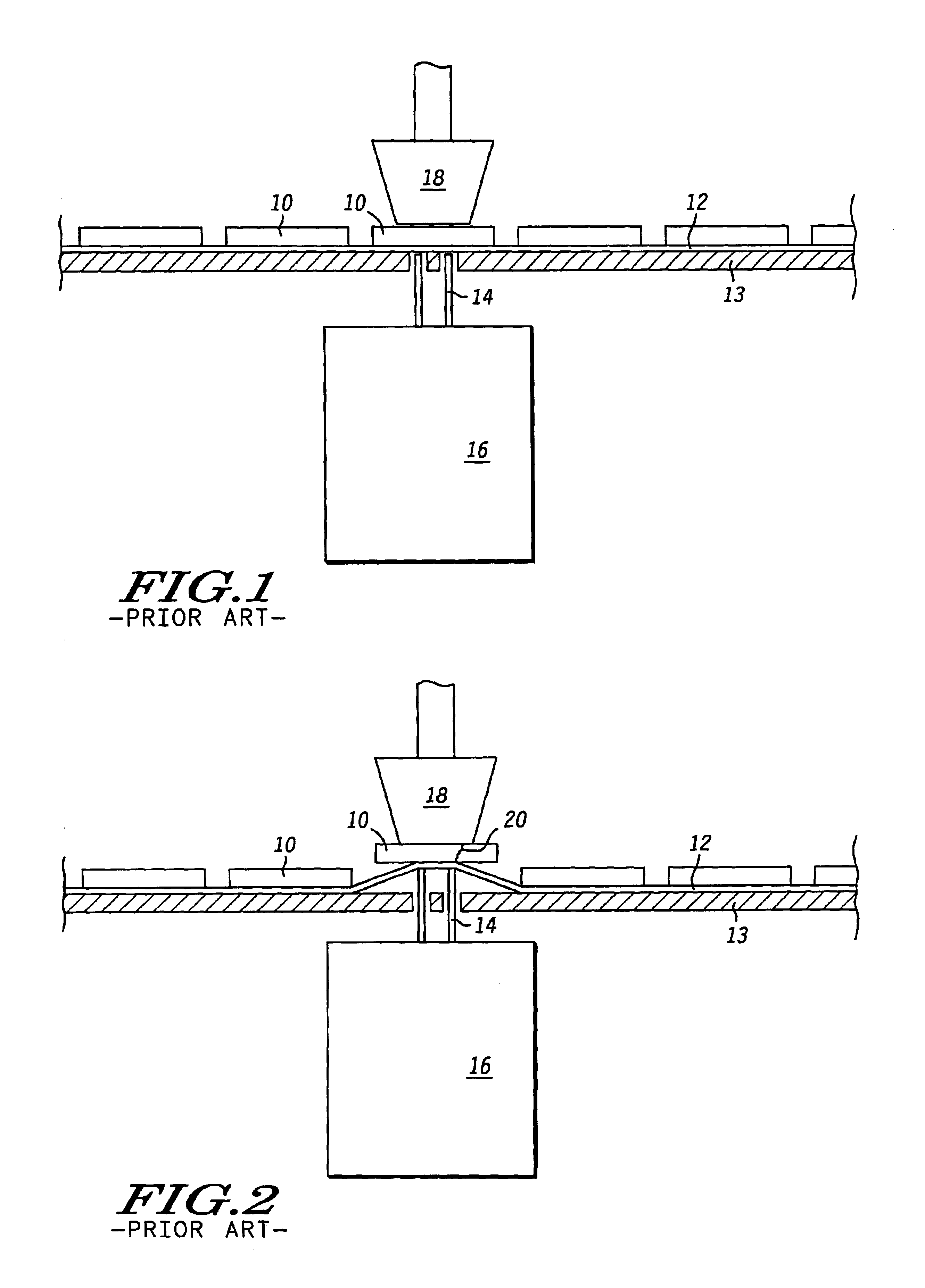

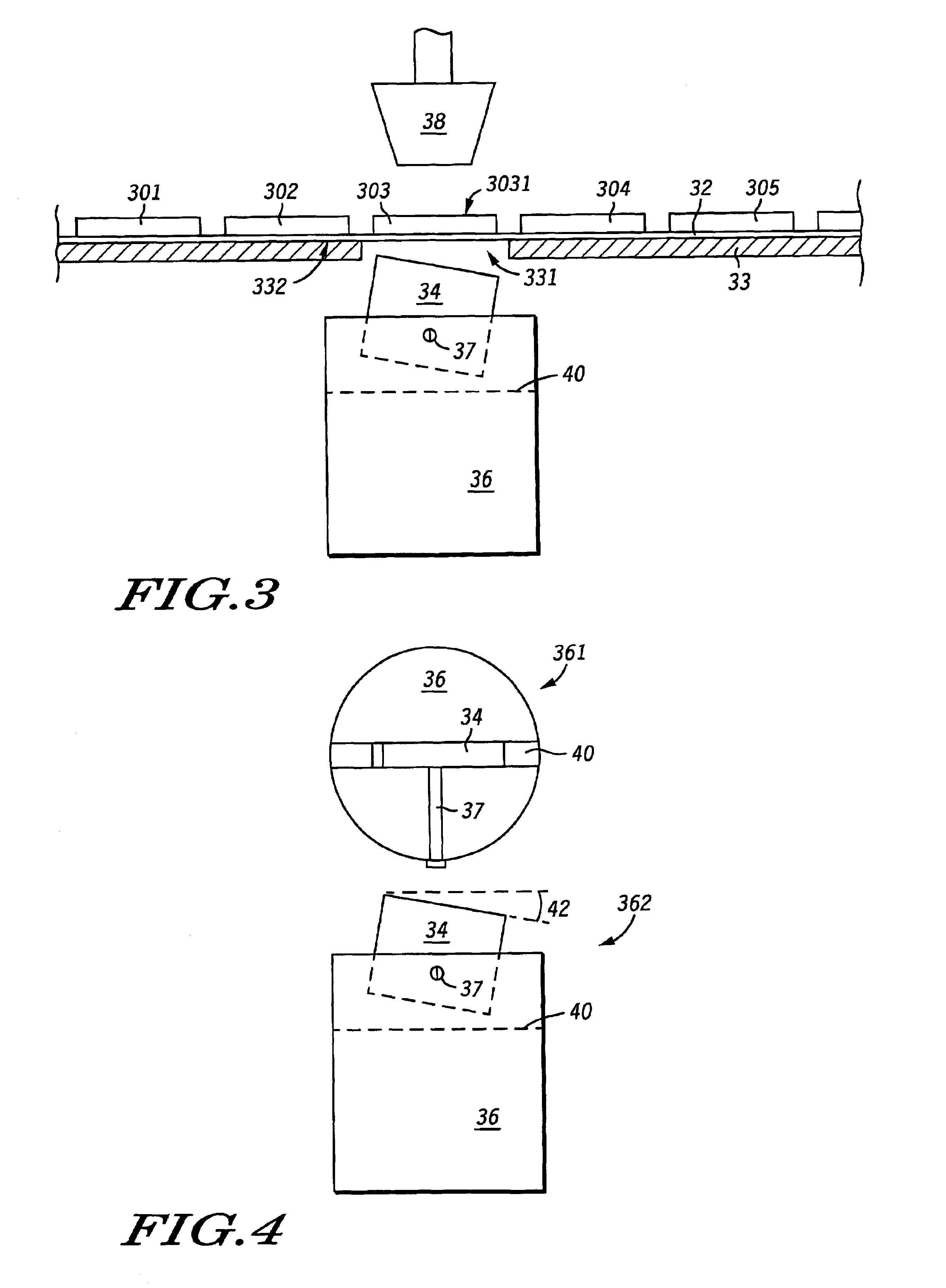

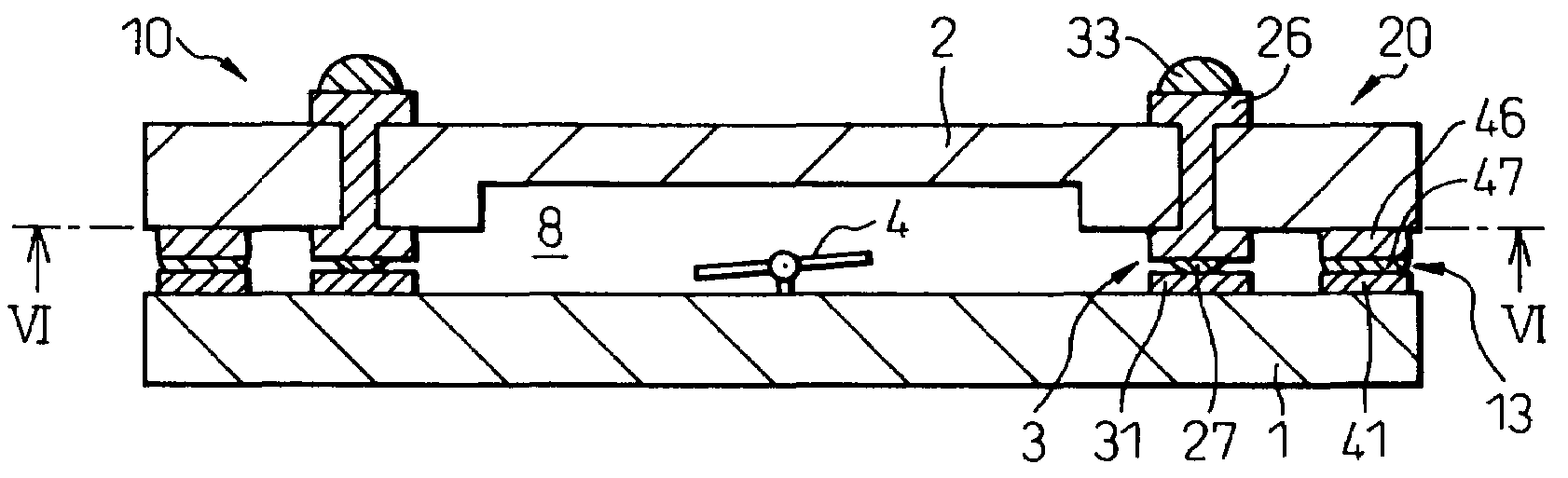

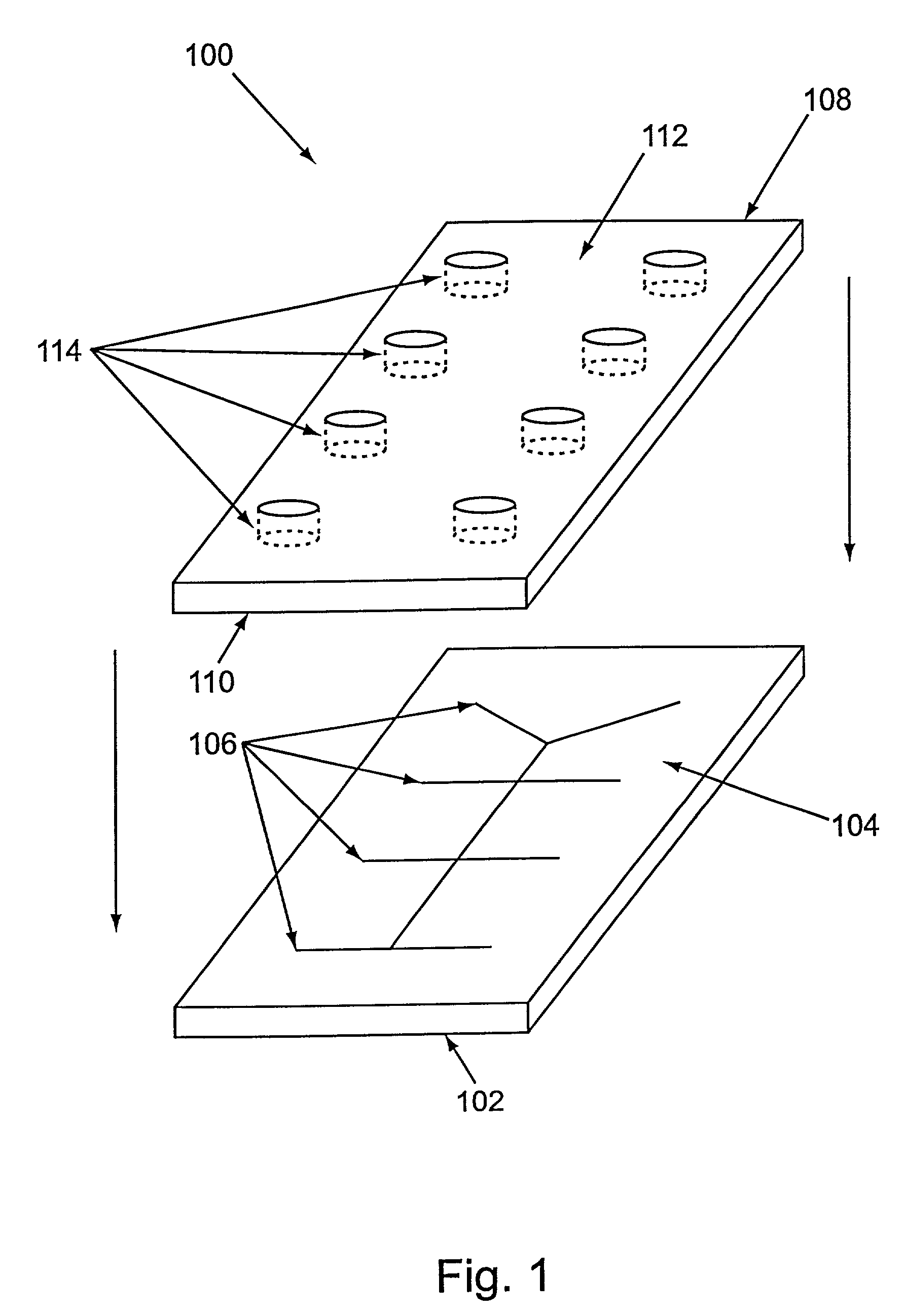

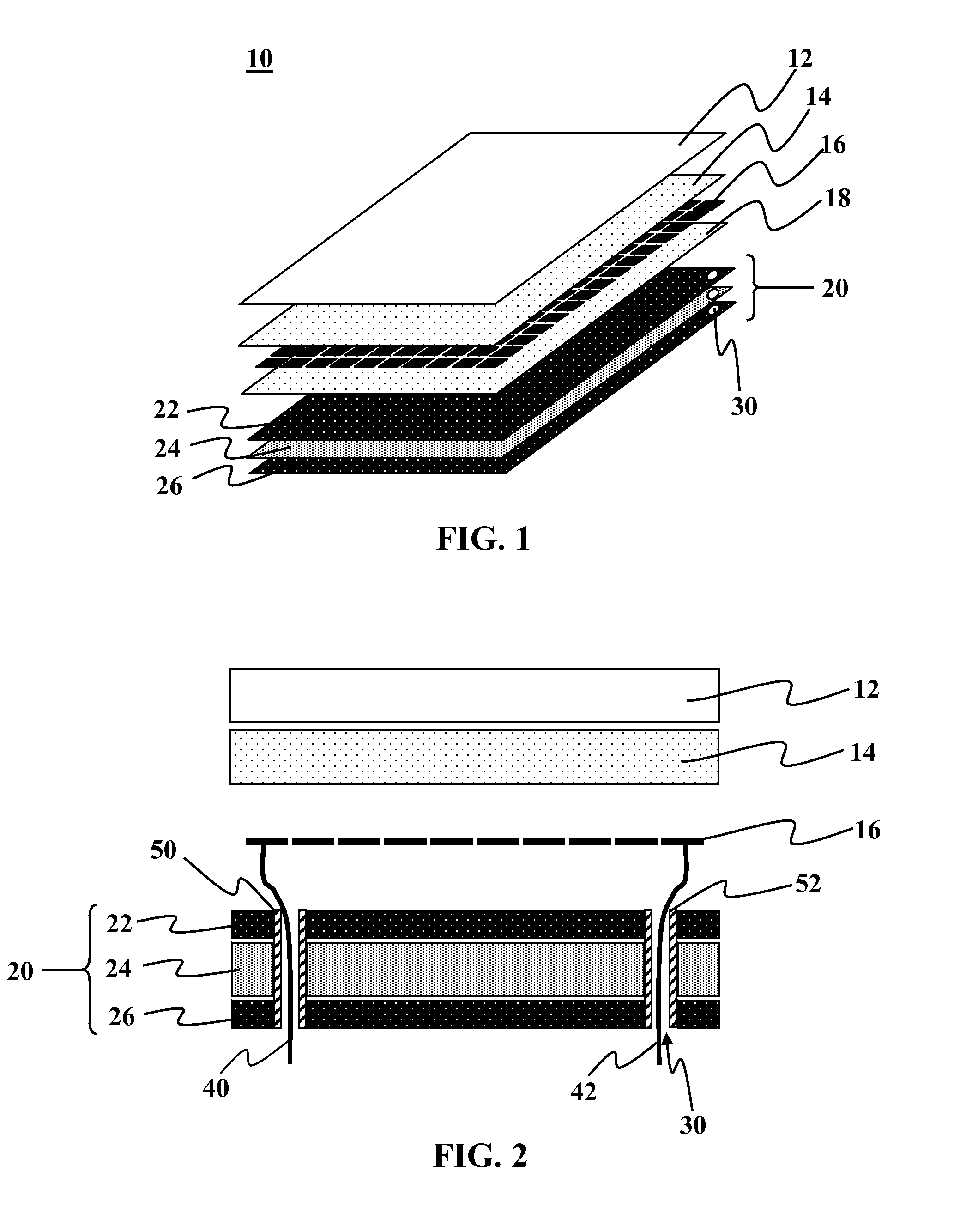

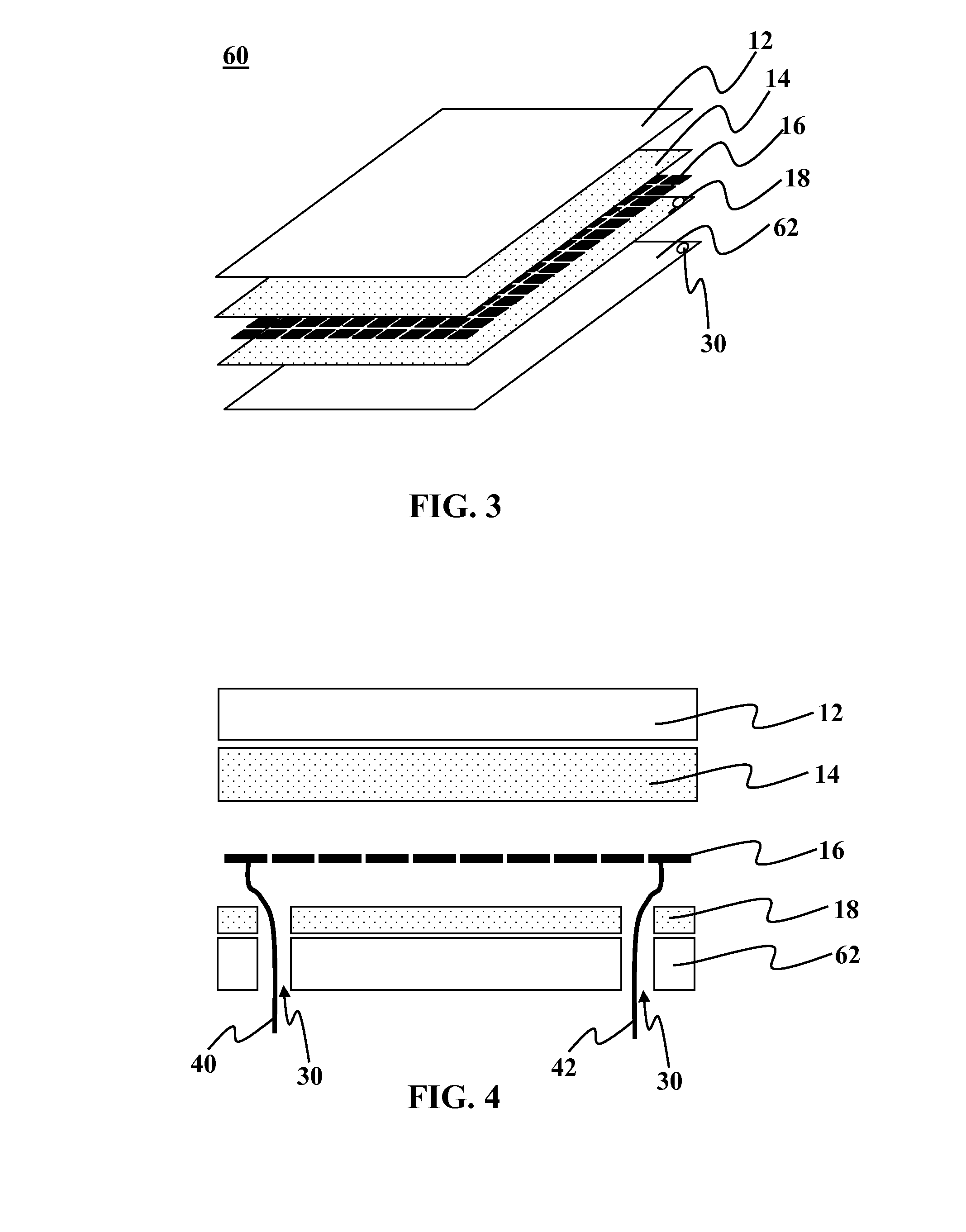

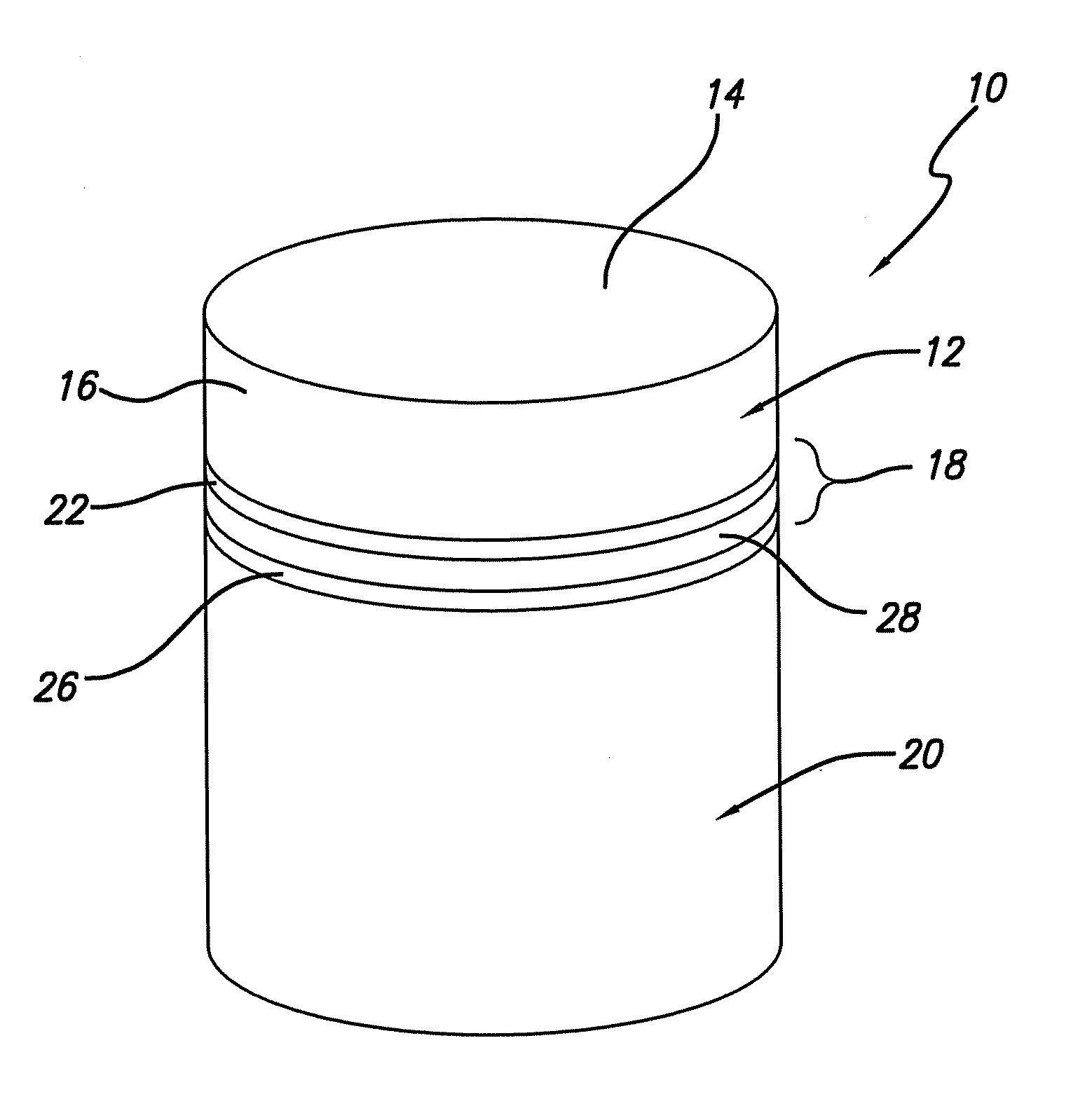

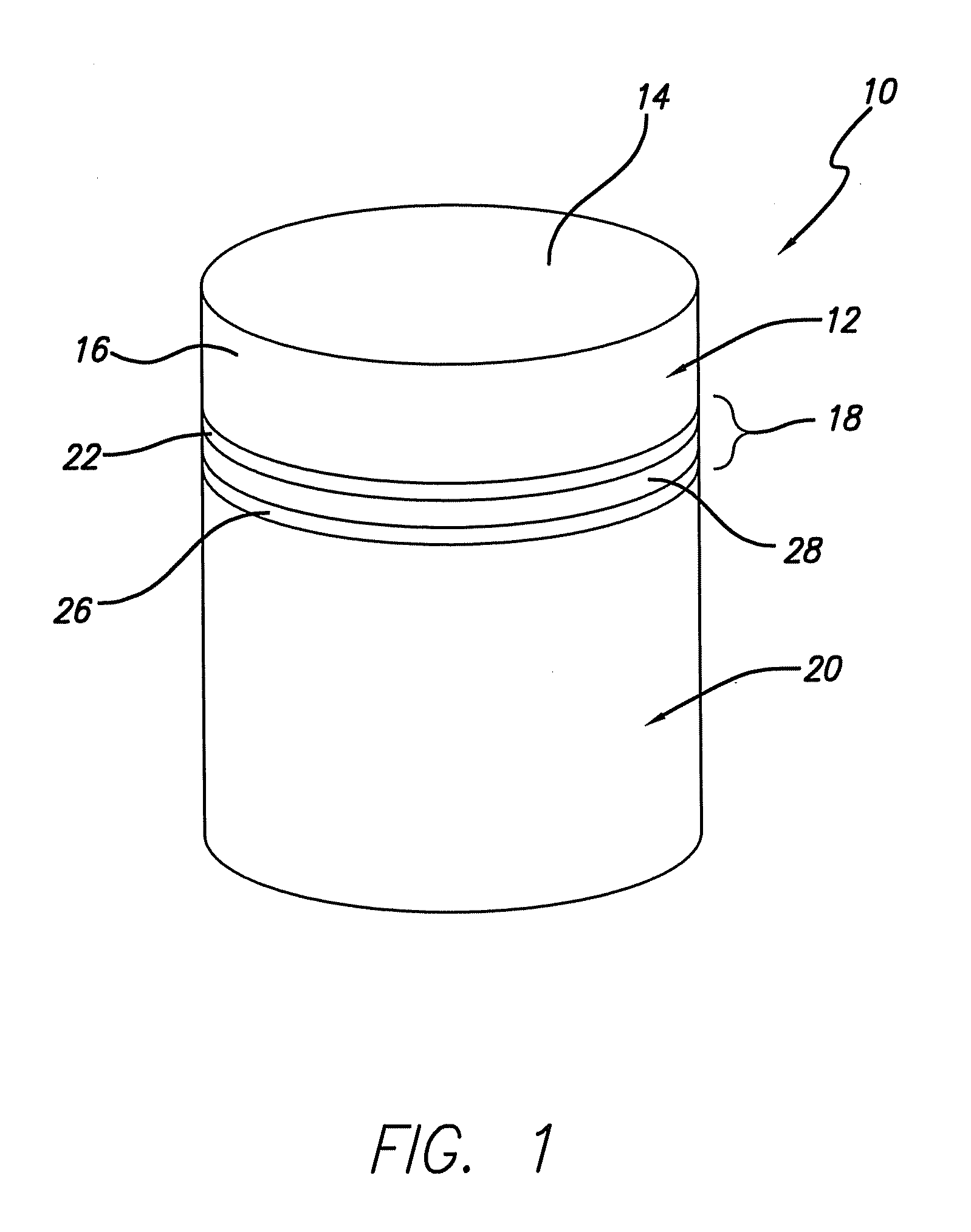

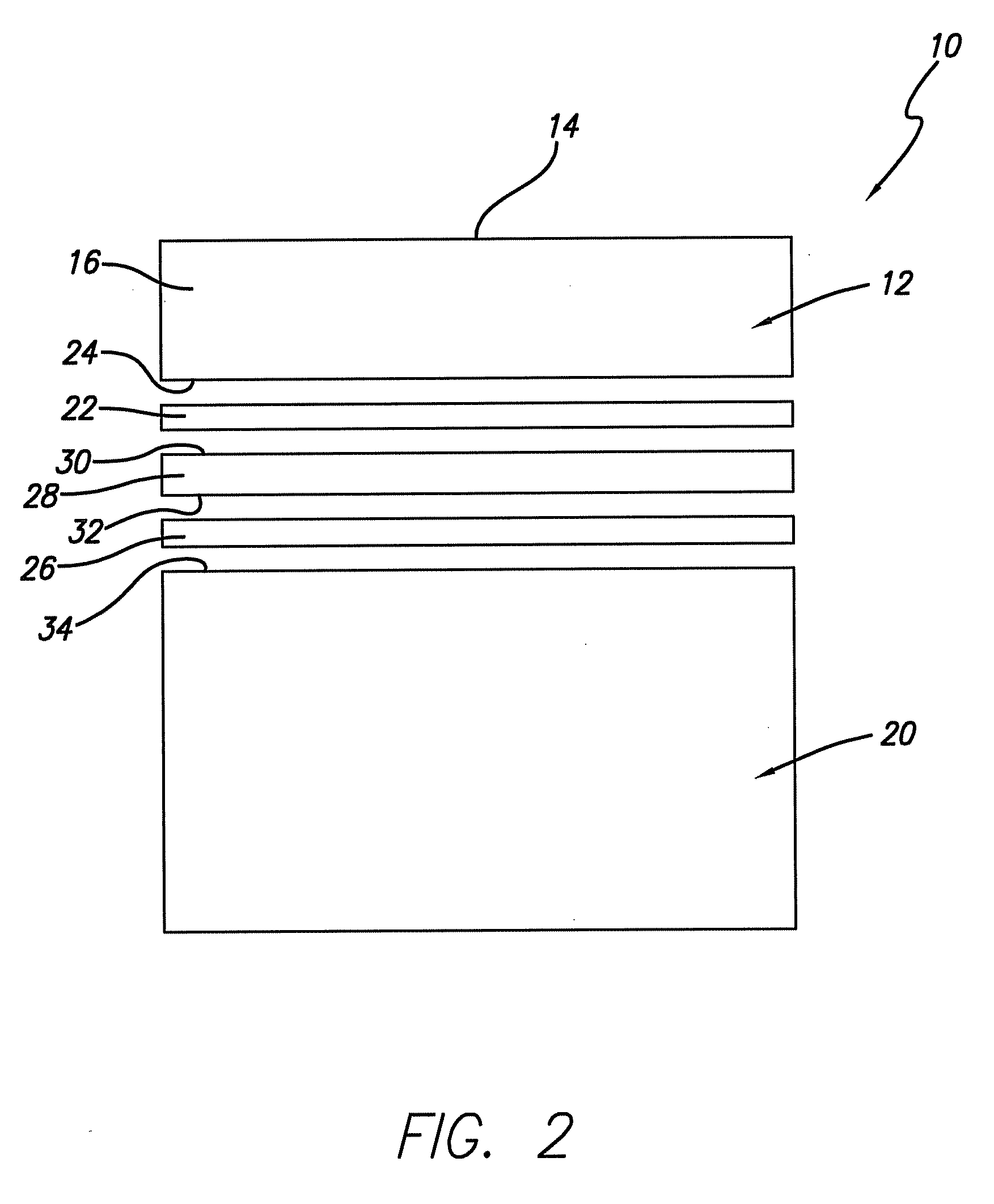

Laminate-based apparatus and method of fabrication

InactiveUS6410360B1CostDesigned withContact member manufacturingPrecision positioning equipmentDielectricManufacturing technology

The present invention discloses a laminate-based electromechanical device and a method of fabricating laminate-based electromechanical devices. The device includes two or more layers of laminate bonded together to form a unitary laminate structure. The layers of laminate include a layer of organic dielectric material that may have at least a portion of one layer of electrically conductive material adherent thereto. The layers of organic dielectric material are bonded to form a unitary laminate structure through a process of lamination. The structures that make up the electromechanical device may be formed either before or after bonding. In particular, the various electromechanical structures that make up the electromechanical device are formed from the layers of organic dielectric material and the layers of electrically conductive material adherent thereto using a predetermined sequence of additive and subtractive fabrication techniques.

Owner:TELEDYNE

Process for disengaging semiconductor die from an adhesive film

Owner:NXP USA INC

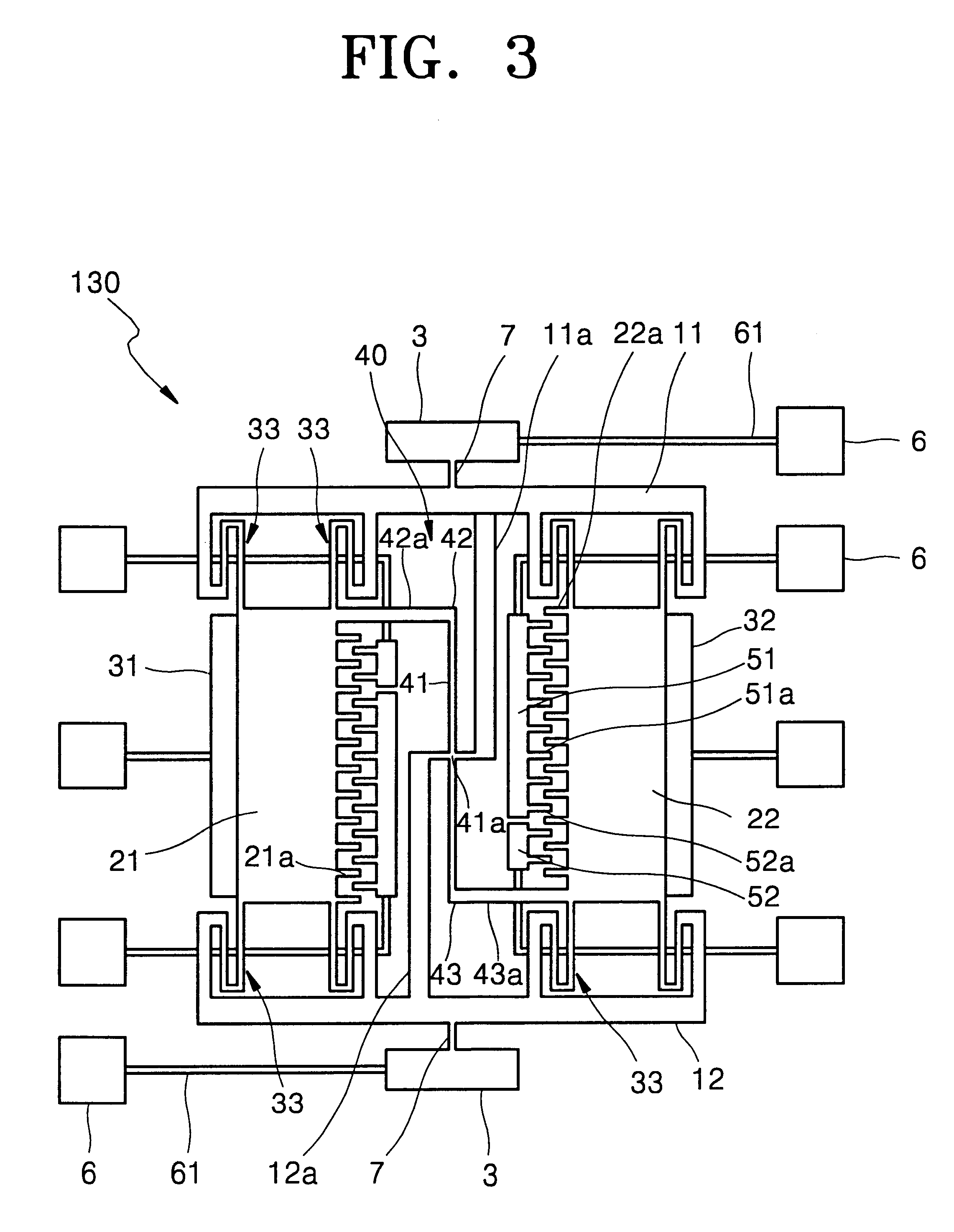

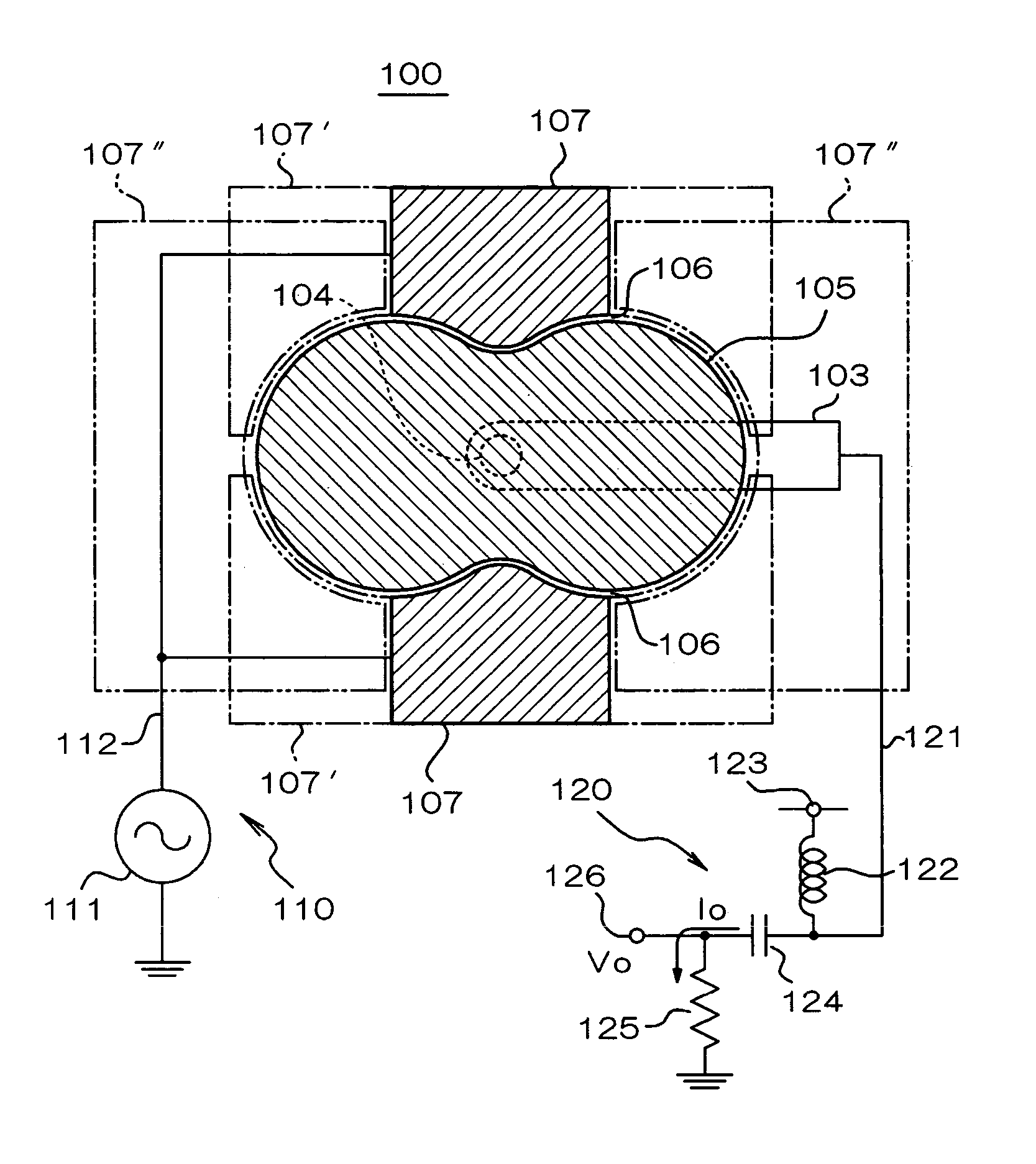

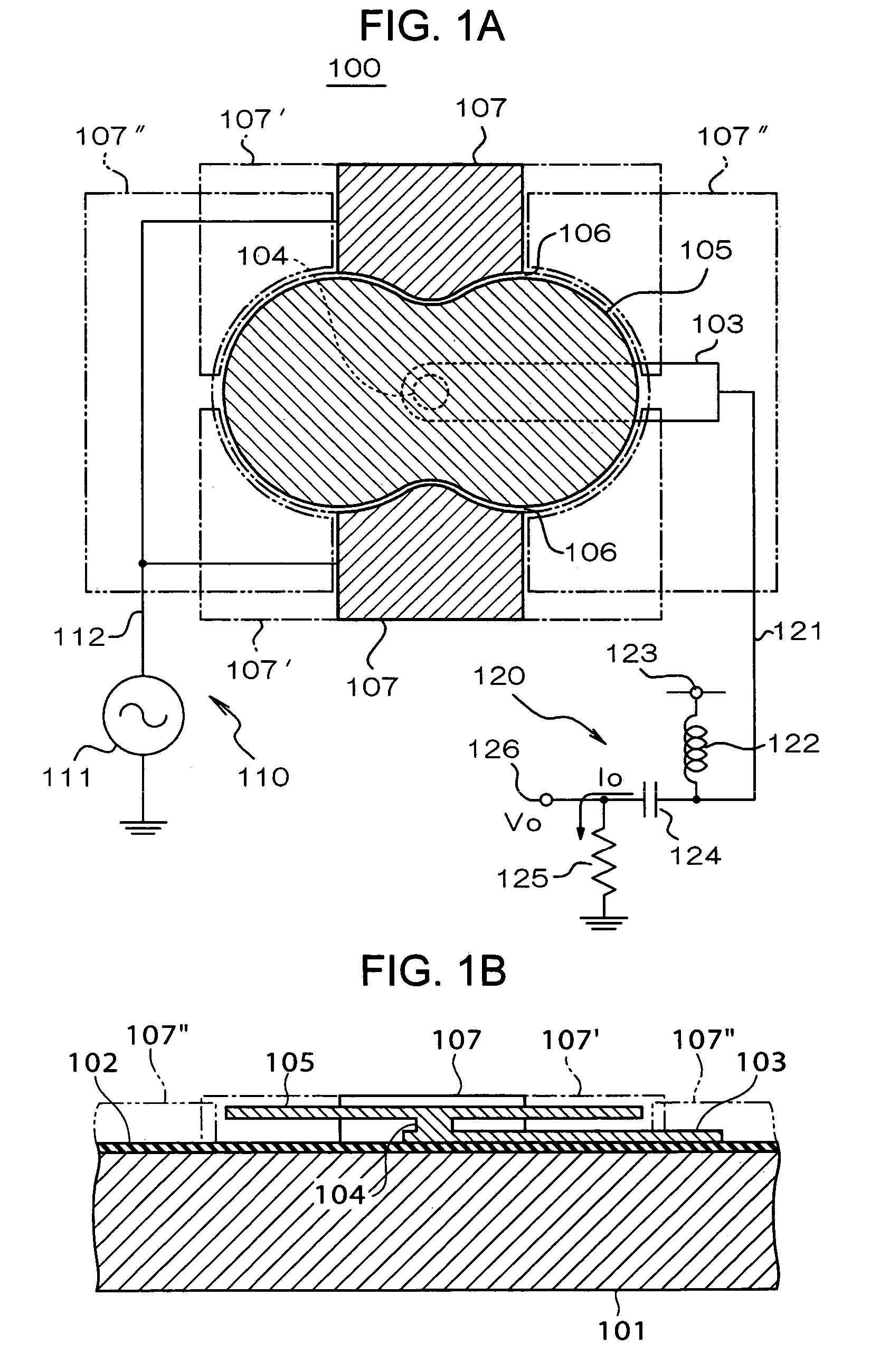

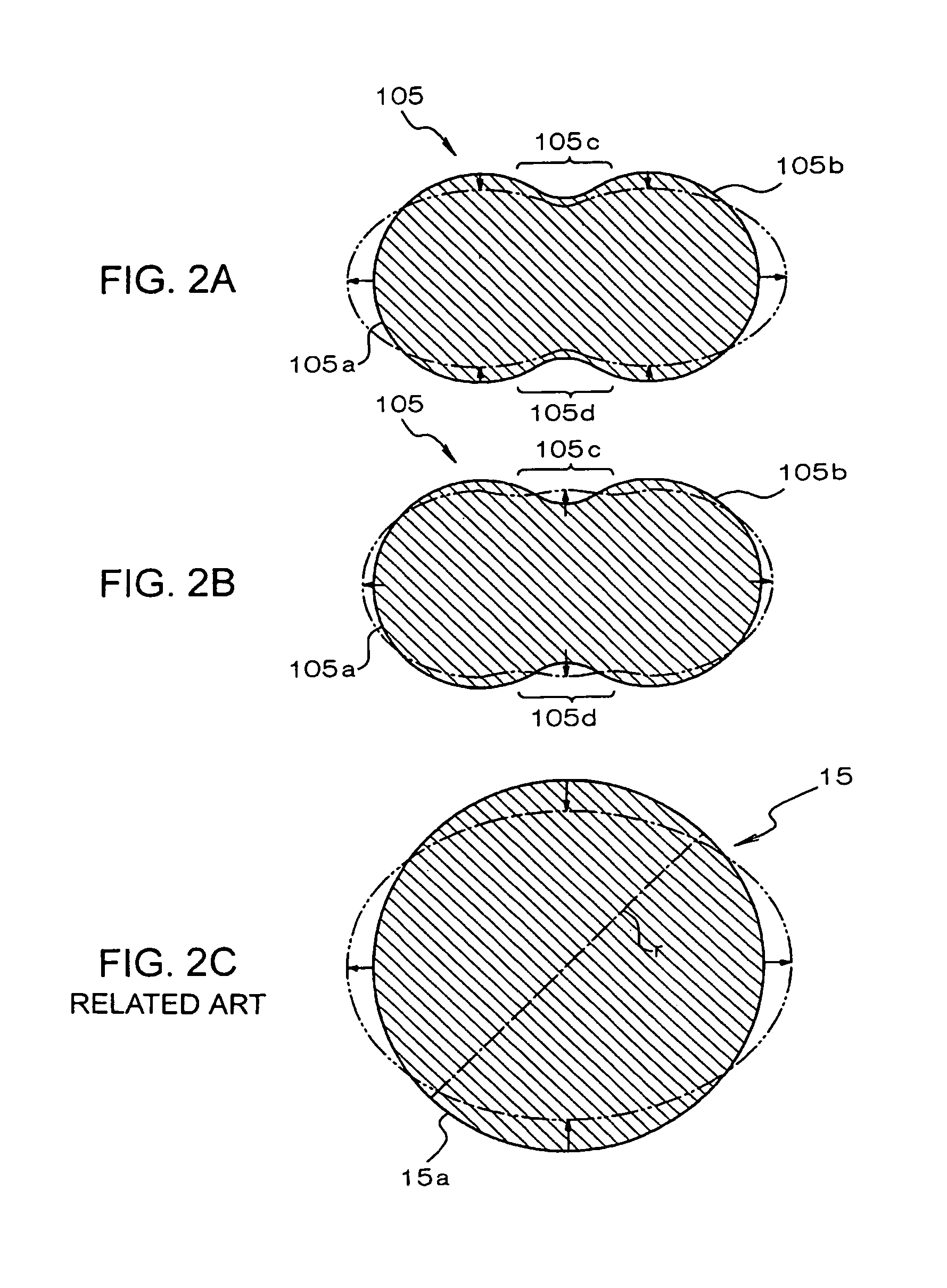

Micromechanical electrostatic resonator

InactiveUS7215061B2CapacitanceLarge capacitancePiezoelectric/electrostriction/magnetostriction machinesDecorative surface effectsCapacitanceAlternating current

Owner:SEIKO EPSON CORP

Electronic devices and its production methods

ActiveUS7456497B2Deterioration of characteristicSmall and compactFixed microstructural devicesVolume/mass flow by thermal effectsHermetic sealEngineering

An electronic device having mounted thereon an MEMS element or other functional elements, in which a device body and lid define an element-carrying space, the element-carrying space is sealed air-tight by an ultrasonic bonded part bonding the device body and the lid, and the element-carrying space having arranged inside it a system element secured to the device body and / or the lid by flip-chip connection.

Owner:SHINKO ELECTRIC IND CO LTD

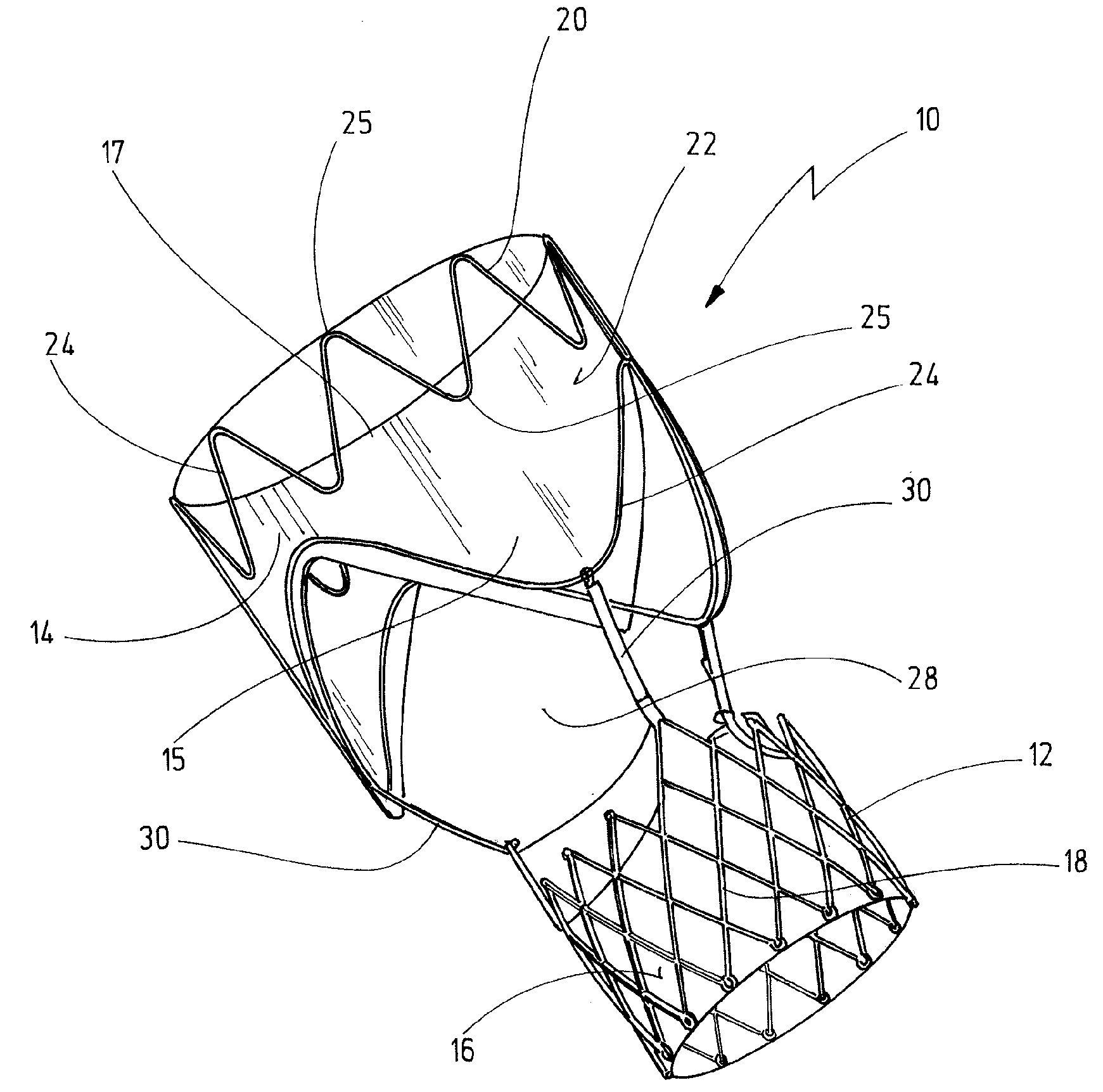

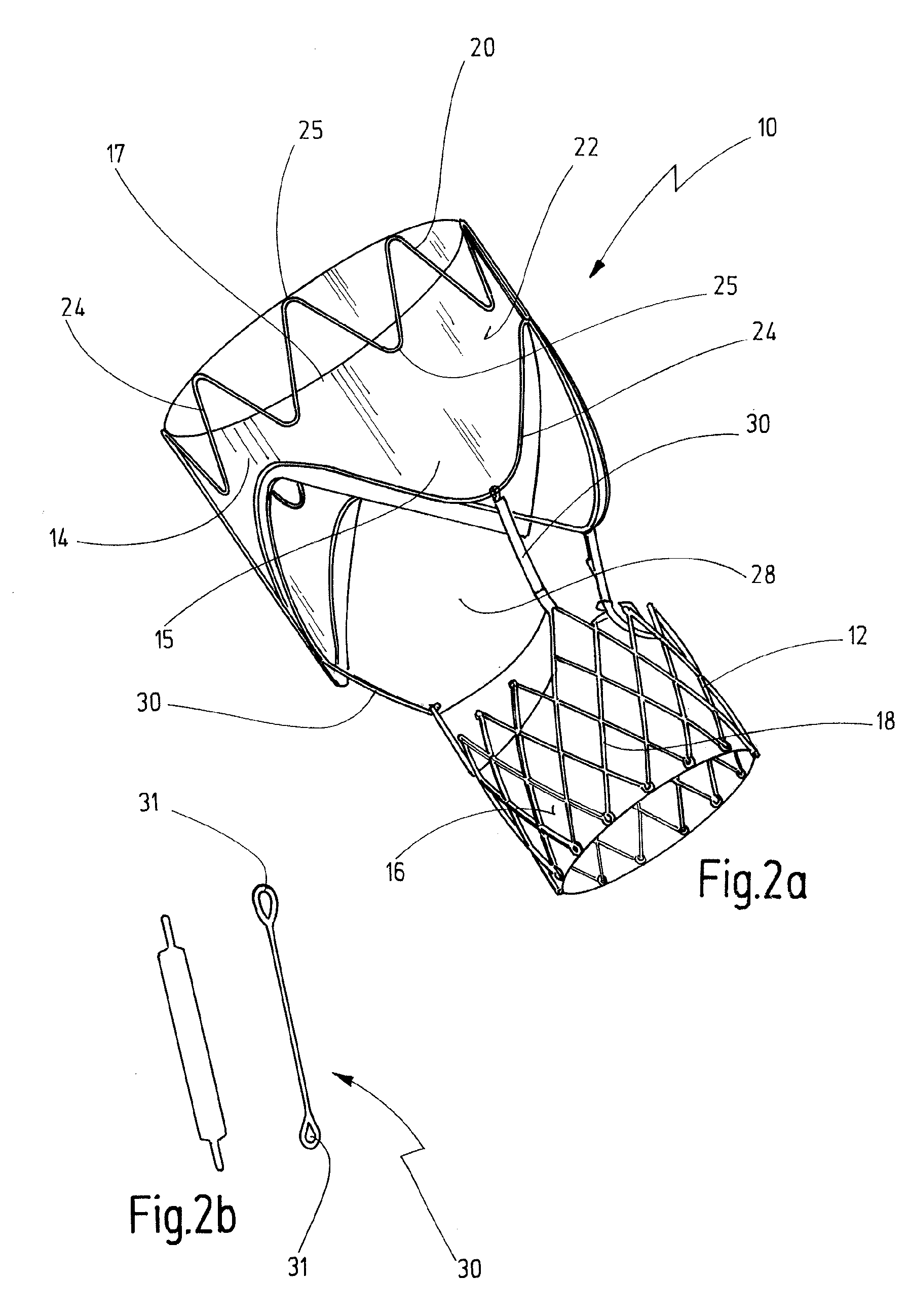

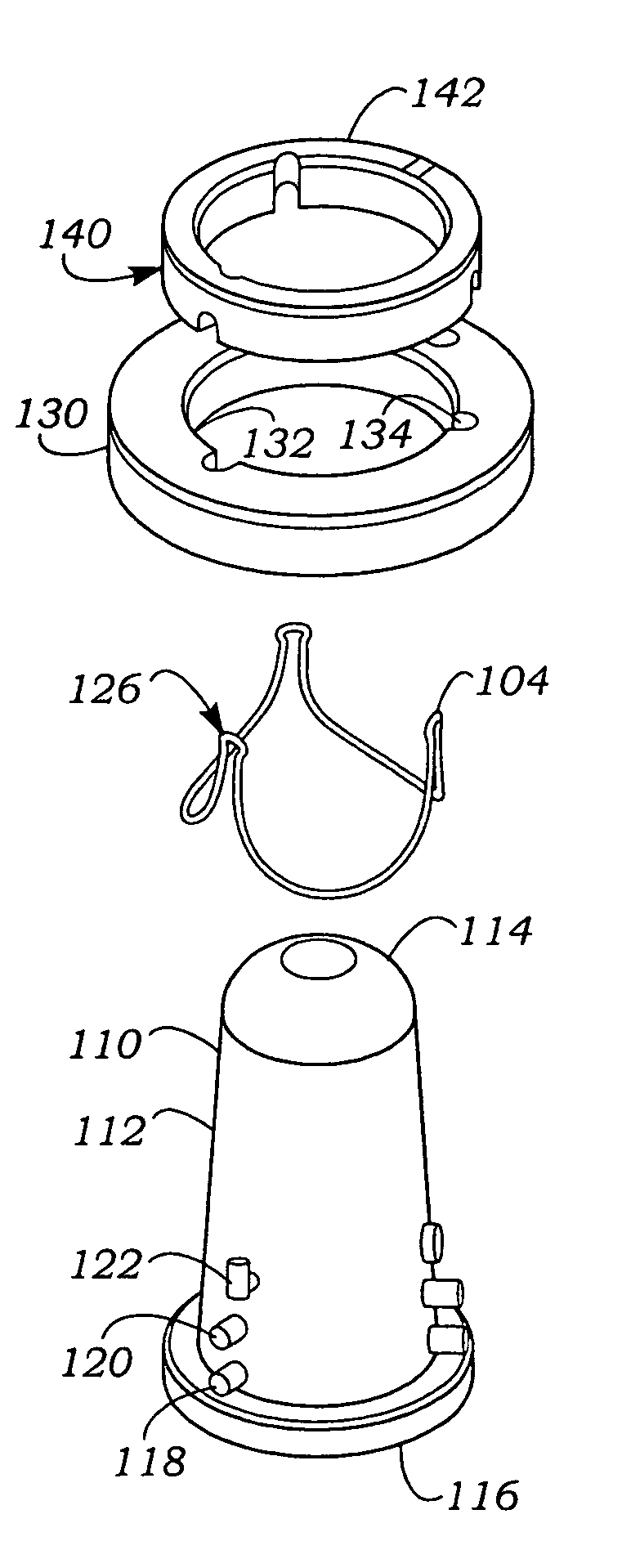

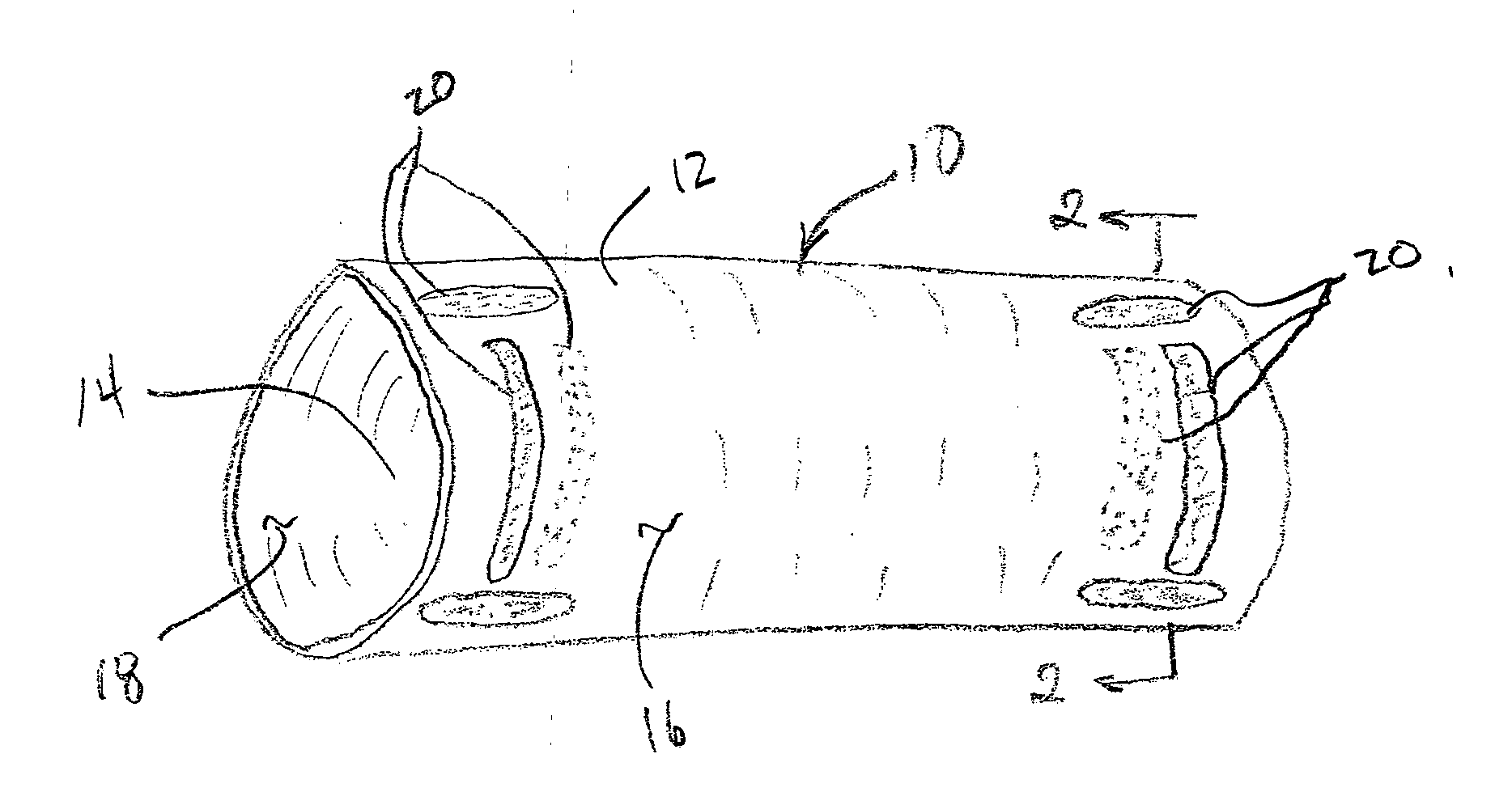

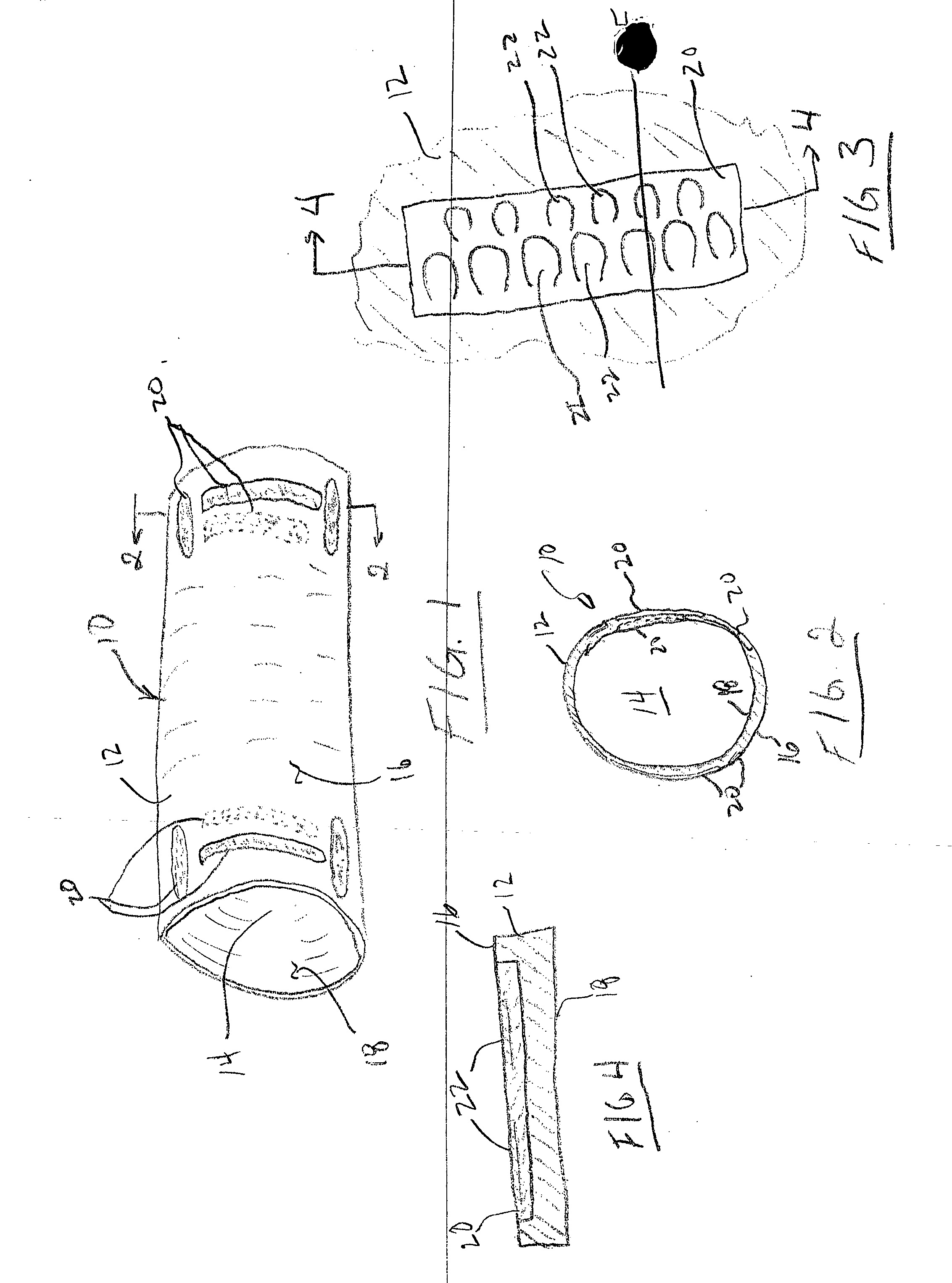

Cardiac valve prosthesis system

The present invention concerns a cardiac valve prosthesis system (10; 40) for implantation into the body of a mammal. The prosthesis system (19; 40) comprises a valve (16) mounted on an stent element (18) to form a stented valve element (12), and an anchoring element (14) to be arranged within the aorta of the mammal to be treated with the prosthesis and spaced-apart form the stented valve element (12). Further, the anchoring element (14) comprises a cylindrical tube element composed of fabric (22) supported by a metal mesh, and the stented valve element (12) and the anchoring element (14) represent two constructional distinctive elements being associated by ligament-like connecting means (30; 50), such, that the connecting region (28) between the stented valve element (12) and the anchoring element (14) is generally free from foreign material.

Owner:NVT

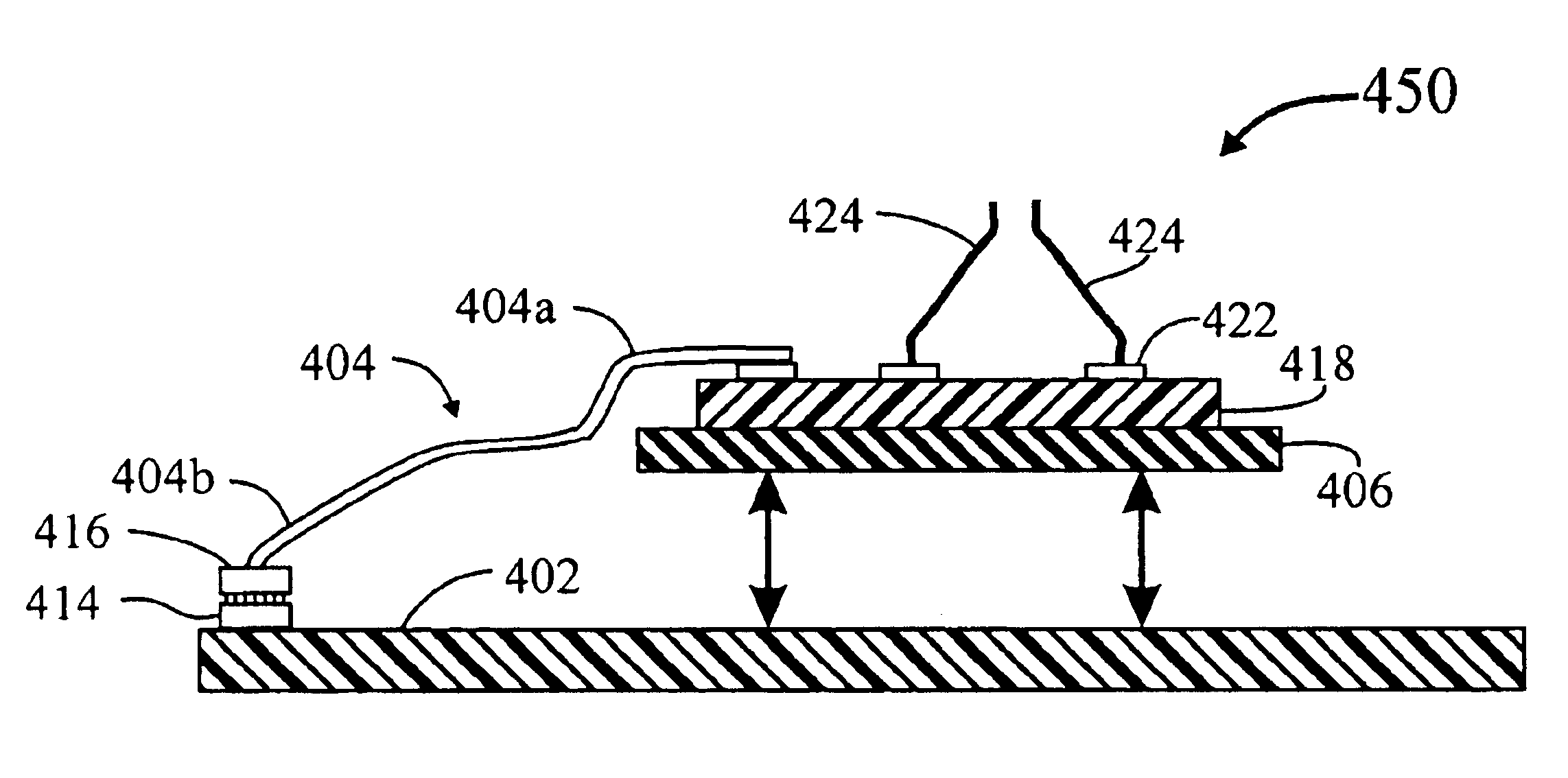

High density integrated circuit apparatus, test probe and methods of use thereof

InactiveUS20070271781A9High performance functional testingHigh-temperature burnElectrically conductive connectionsElectronic circuit testingElastomerElectricity

The present invention is directed to a high density test probe which provides a means for testing a high density and high performance integrated circuits in wafer form or as discrete chips. The test probe is formed from a dense array of elongated electrical conductors which are embedded in an compliant or high modulus elastomeric material. A standard packaging substrate, such as a ceramic integrated circuit chip packaging substrate is used to provide a space transformer. Wires are bonded to an array of contact pads on the surface of the space transformer. The space transformer formed from a multilayer integrated circuit chip packaging substrate. The wires are as dense as the contact location array. A mold is disposed surrounding the array of outwardly projecting wires. A liquid elastomer is disposed ion the mold to fill the spaces between the wires. The elastomer is cured and the mold is removed, leaving an array of wires disposed in the elastomer and in electrical contact with the space transformer The space transformer can have an array of pins which are on the opposite surface of the space transformer opposite to that on which the elongated conductors are bonded. The pins are inserted into a socket on a second space transformer, such as a printed circuit board to form a probe assembly. Alternatively, an interposer electrical connector can be disposed between the first and second space transformer.

Owner:GLOBALFOUNDRIES INC

Methods and devices for enhancing bonded substrate yields and regulating temperature

InactiveUS7351377B2Reduce thermal couplingReduce transportationSludge treatmentHeating or cooling apparatusBonding processEngineering

Owner:CAPLIPER LIFE SCI INC

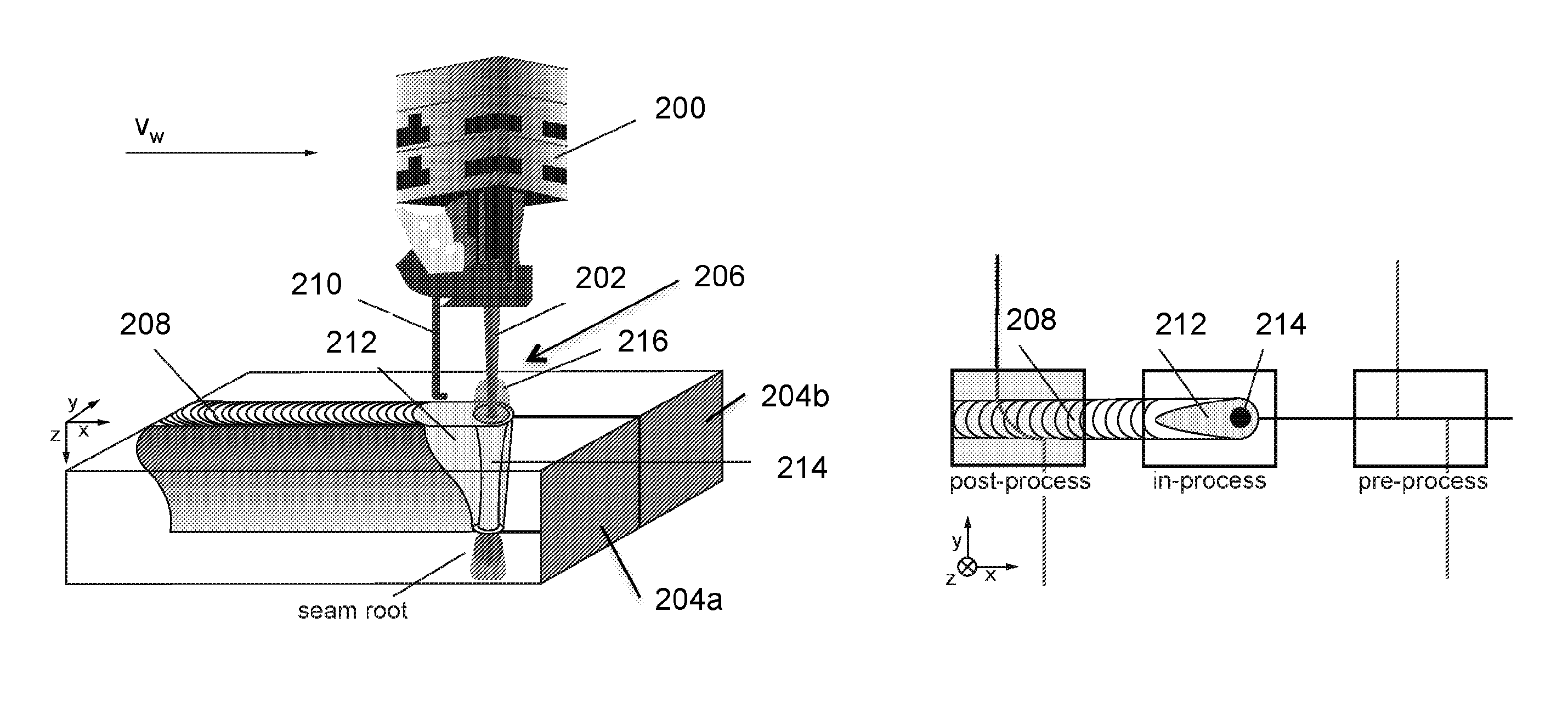

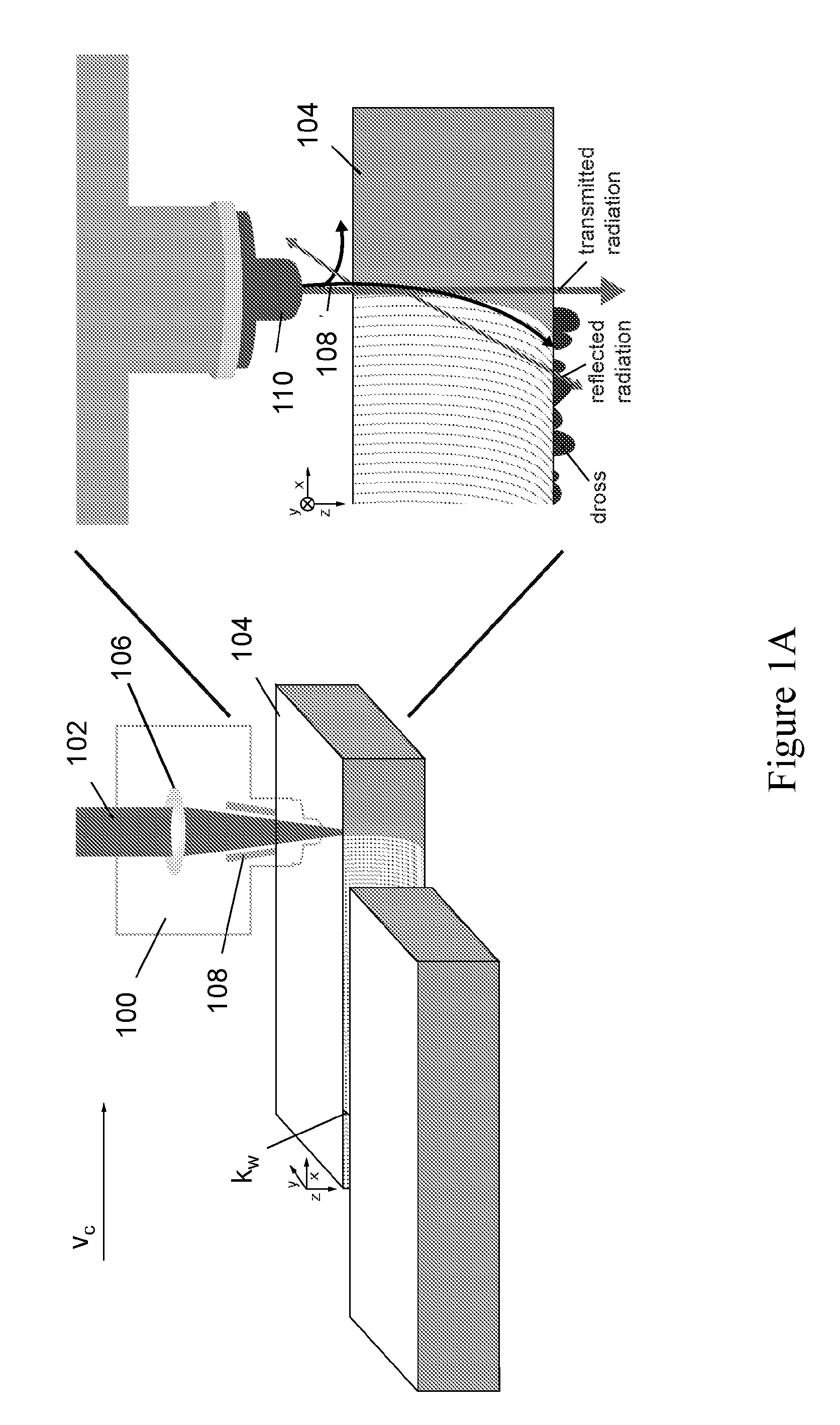

Method for closed-loop controlling a laser processing operation and laser material processing head using the same

ActiveUS20130178952A1Reliable detectionSimilar levelImage analysisSoldering apparatusLaser processingAlgorithm

The present invention relates to a method for closed-loop controlling a processing operation of a workpiece, comprising the steps of: (a) recording a pixel image at an initial time point of an interaction zone by means of a camera, wherein the workpiece is processed using an actuator having an initial actuator value; (b) converting the pixel image into a pixel vector; (c) representing the pixel vector by a sum of predetermined pixel mappings each multiplied by a corresponding feature value; (d) classifying the set of feature values on the basis of learned feature values into at least two classes of a group of classes comprising a first class of a too high actuator value, a second class of a sufficient actuator value and a third class of a too low actuator value at the initial time point; (e) performing a control step for adapting the actuator value by minimizing the error et between a quality indicator ye and a desired value; and (f) repeating the steps (a) to (e) for further time points to perform a closed-loop controlled processing operation.

Owner:PRECITEC GMBH +1

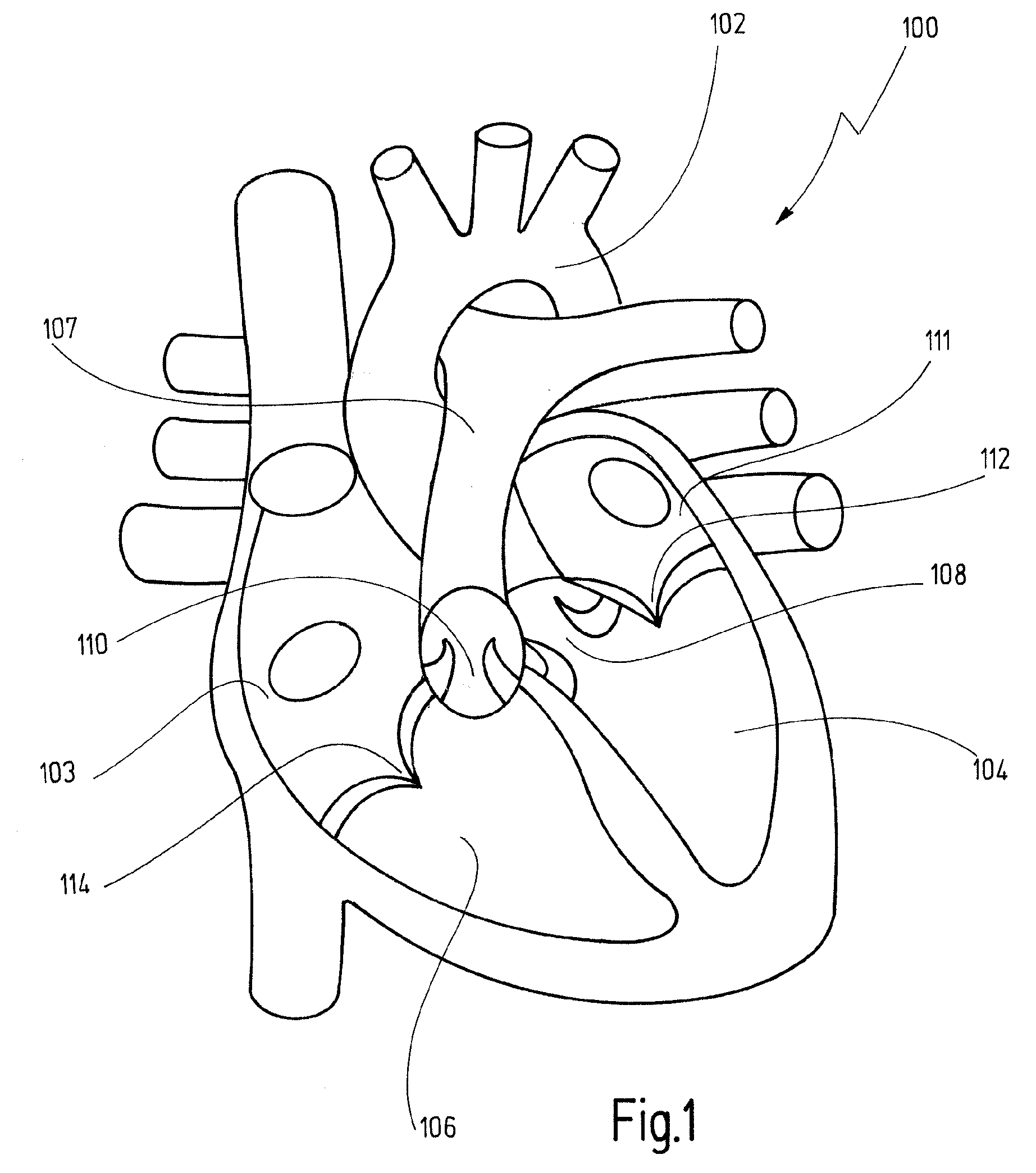

Method of manufacture of a heart valve support frame

InactiveUS20050150775A1Eliminate unevennessIncrease flexibilityElectrolysis componentsFrom normal temperature solutionsEngineeringReady to use

Methods for forming a support frame for flexible leaflet heart valves from a starting blank include converting a two-dimensional starting blank into the three-dimensional support frame. The material may be superelastic, such as NITINOL, and the method may include bending the 2-D blank into the 3-D form and shape setting it. A merely elastic material such as ELGILOY may be used and plastically deformed in stages, possibly accompanied by annealing, to obtain the 3-D shape. Alternatively, a tubular blank could be formed to define a non-tubular shape, typically conical. A method for calculating the precise 2-D blank shape is also disclosed. A mandrel assembly includes a mandrel and ring elements for pressing the blank against the external surface of the mandrel prior to shape setting.

Owner:EDWARDS LIFESCIENCES CORP

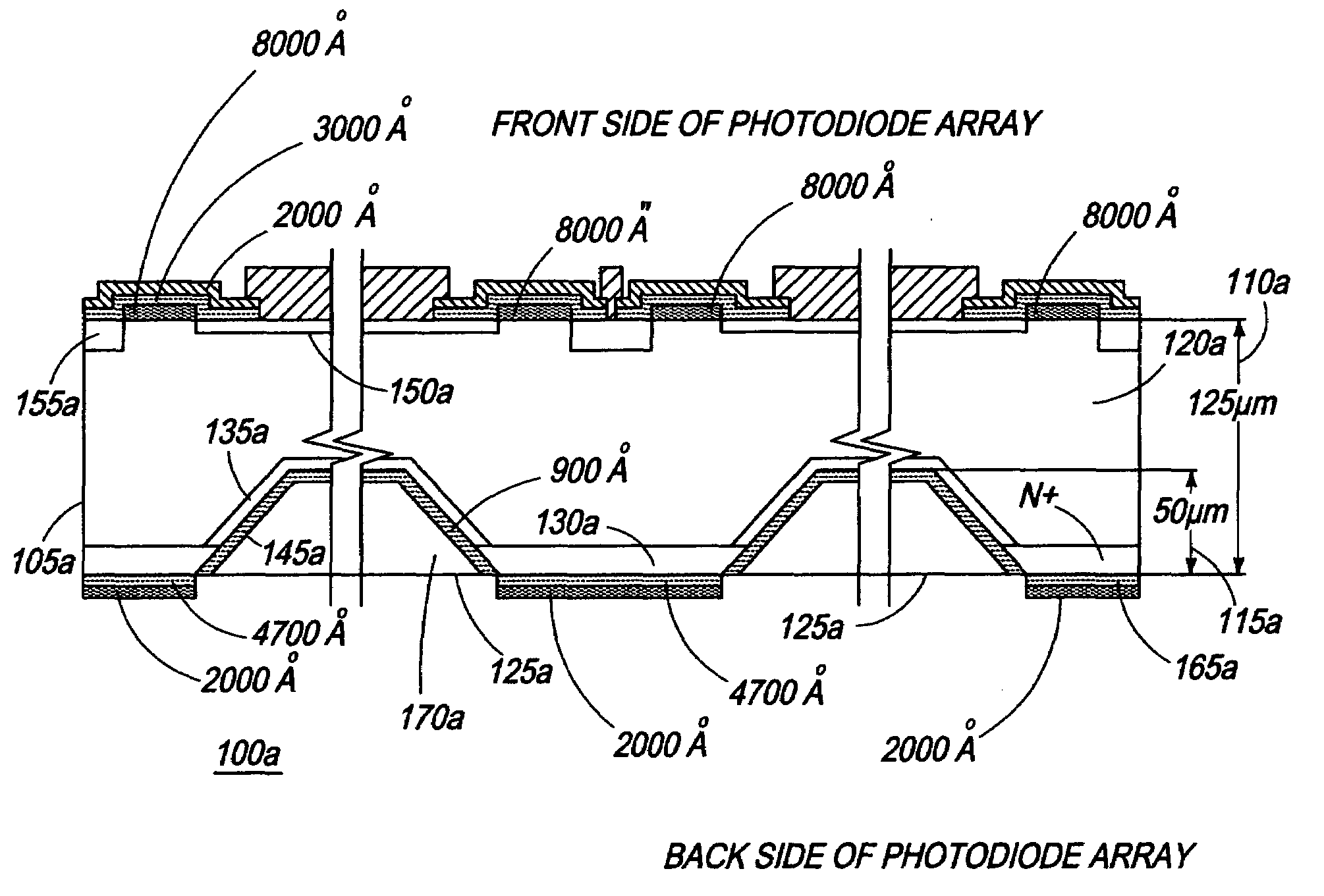

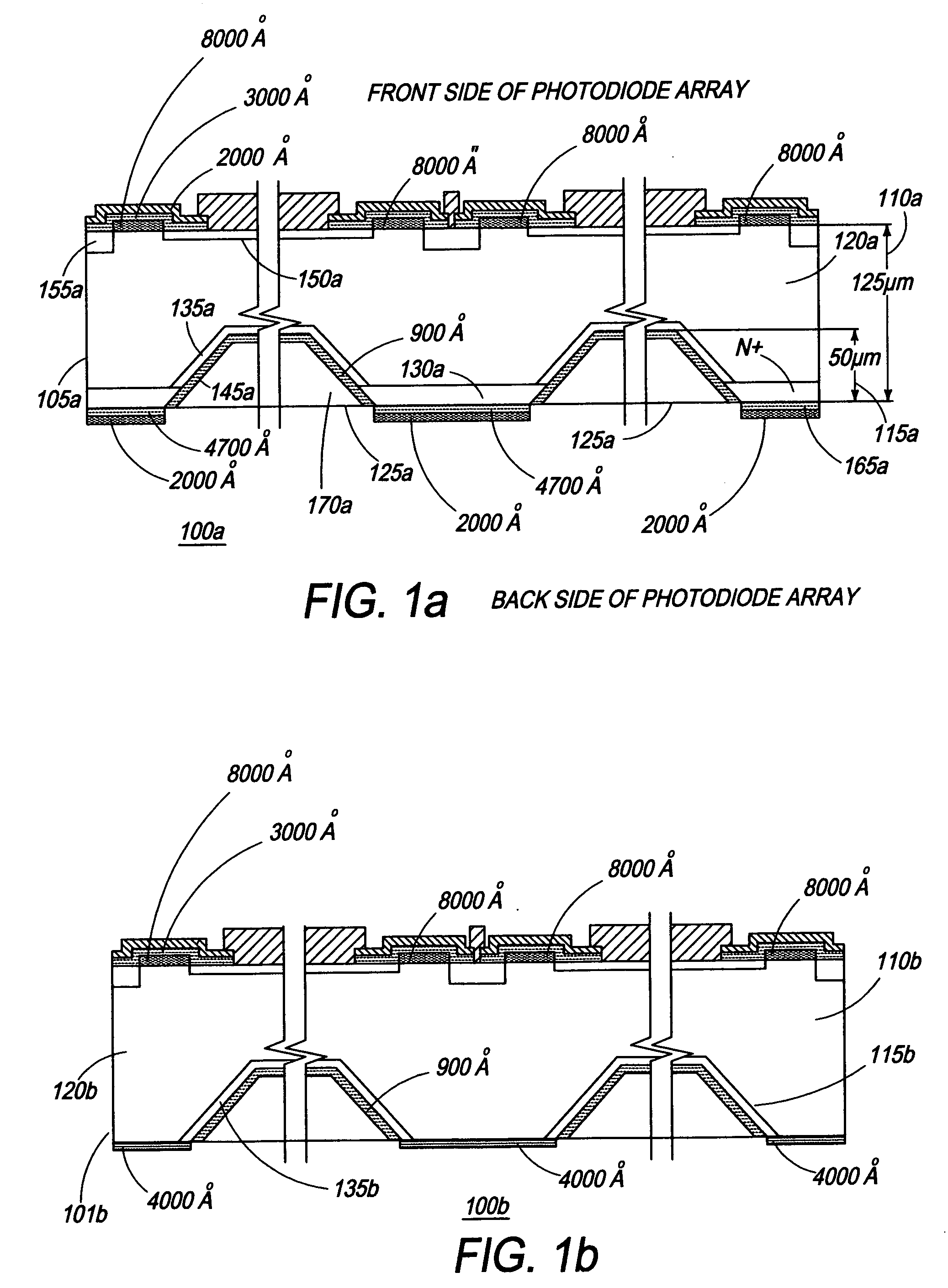

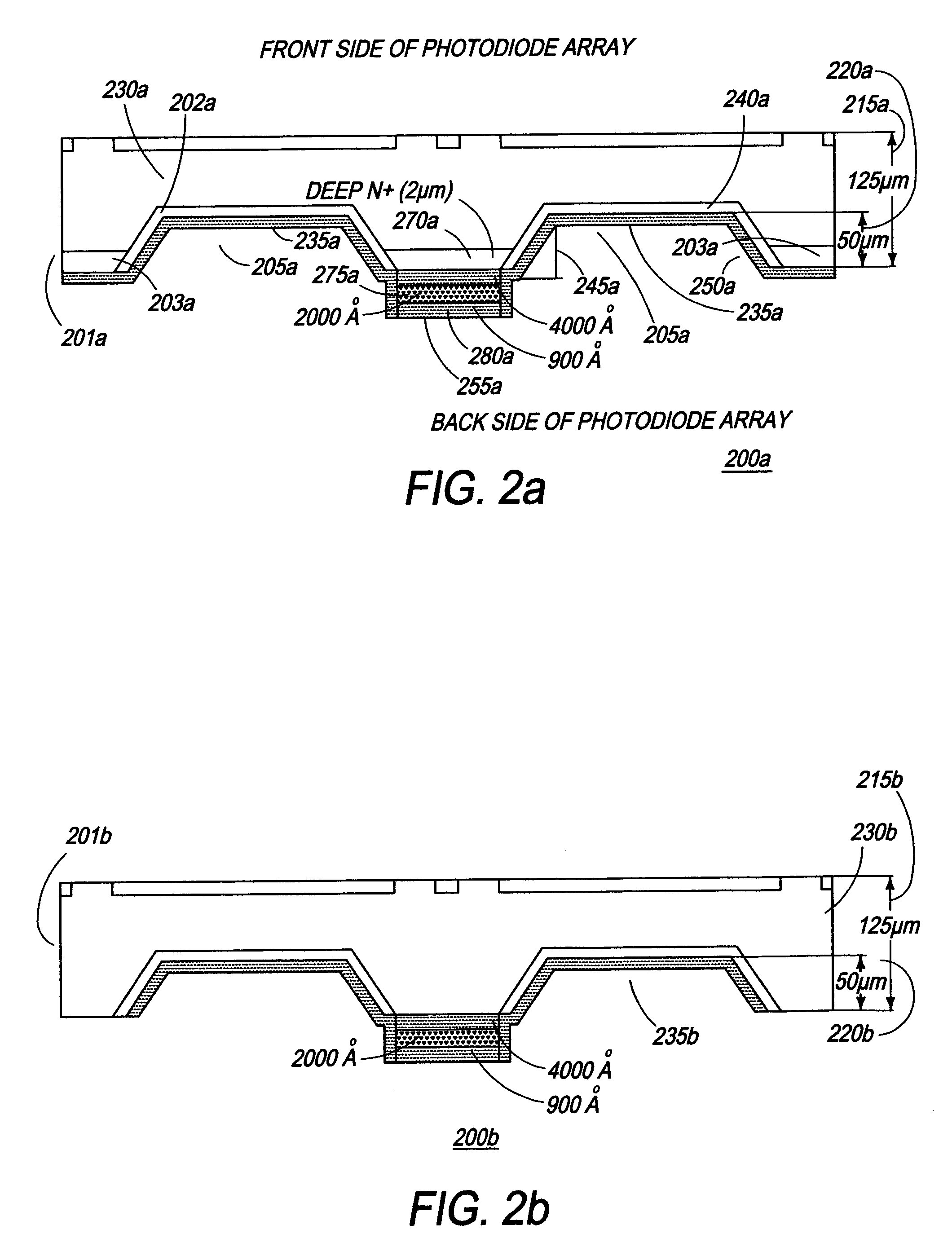

Thin wafer detectors with improved radiation damage and crosstalk characteristics

ActiveUS20080128846A1Reduces its damage susceptibilityImprove application flexibilityPrinted circuit aspectsSoldering apparatusCapacitanceDetector array

The present invention is directed toward a detector structure, detector arrays, and a method of detecting incident radiation. The present invention comprises several embodiments that provide for reduced radiation damage susceptibility, decreased affects of crosstalk, reduced dark current (current leakage) and increased flexibility in application. In one embodiment, a photodiode array comprises a substrate having at least a front side and a back side, a plurality of diode elements integrally formed in the substrate forming the array, wherein each diode element has a p+ fishbone pattern on the front side, and wherein the p+ fishbone pattern substantially reduces capacitance and crosstalk between adjacent photodiodes, a plurality of front surface cathode and anode contacts, and wire interconnects between diode elements made through a plurality of back surface contacts.

Owner:OSI OPTOELECTRONICS

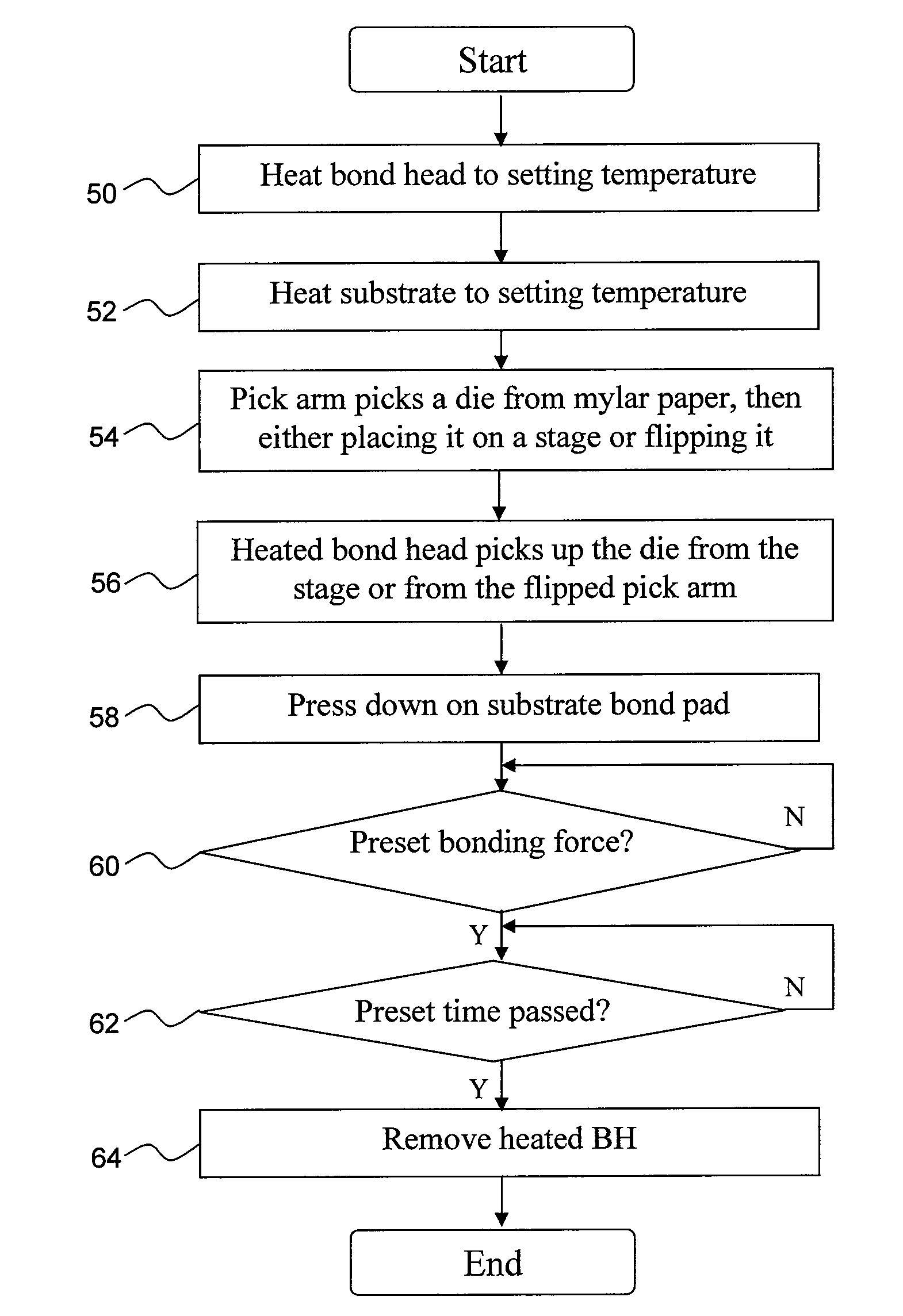

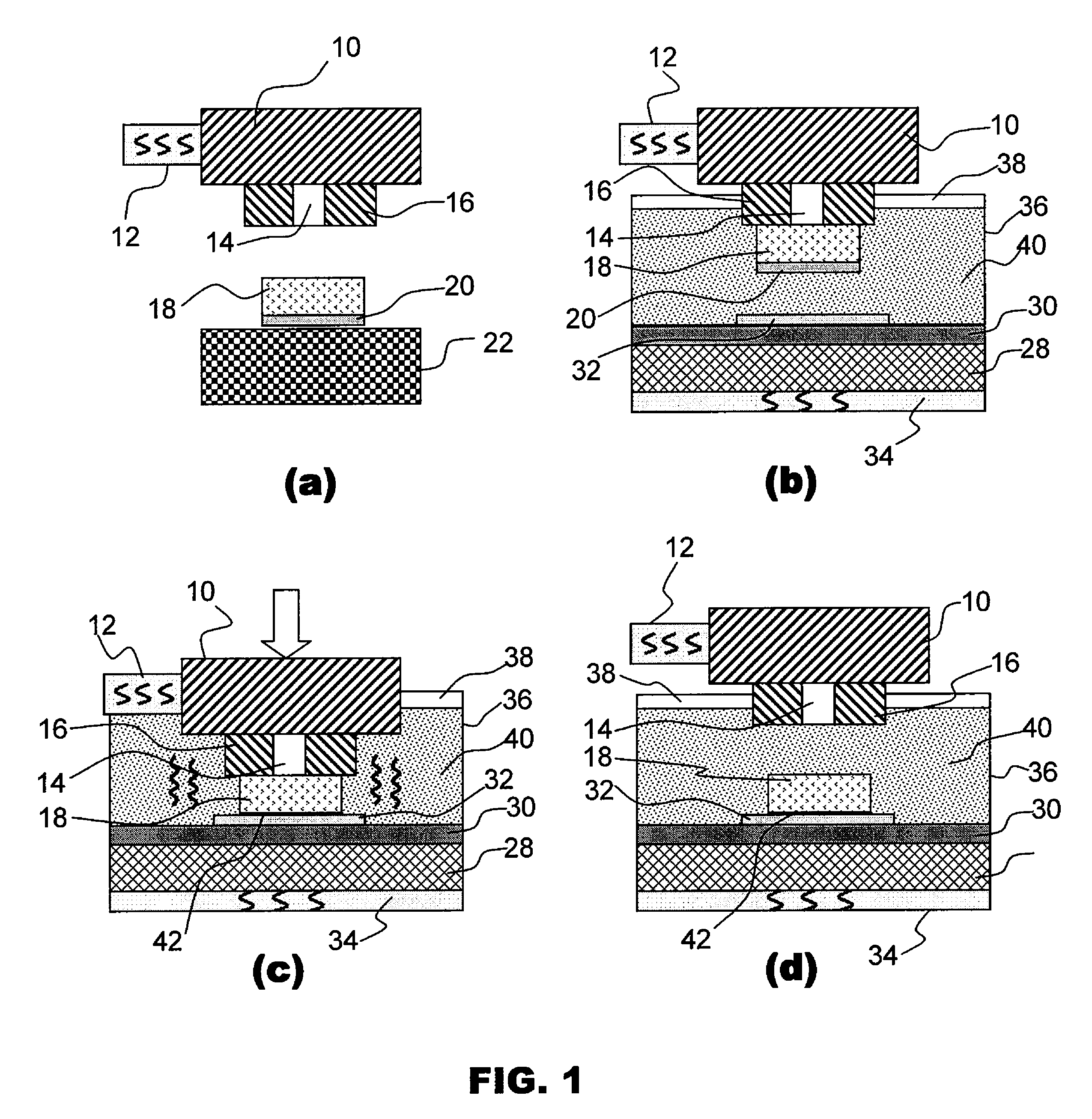

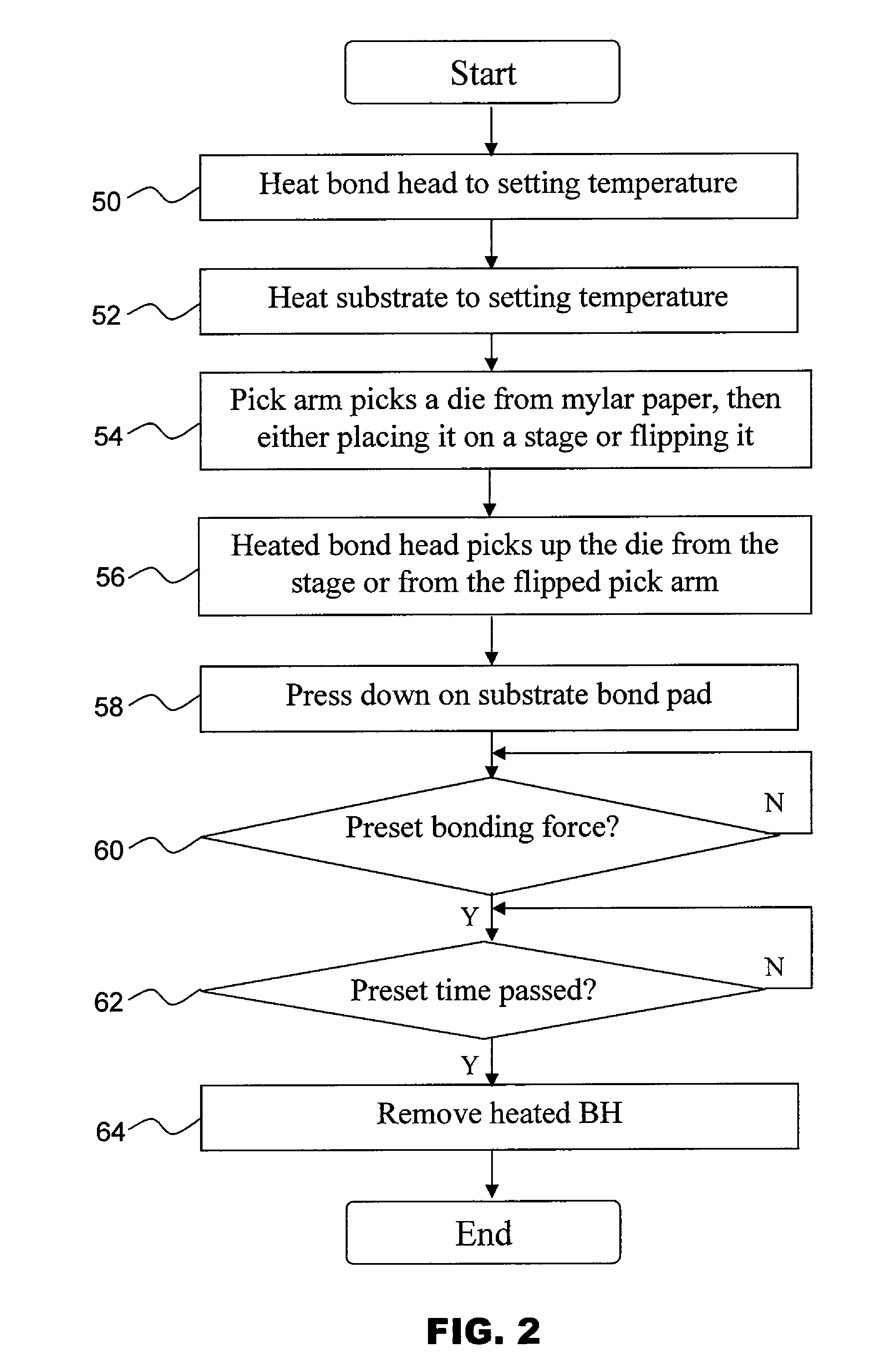

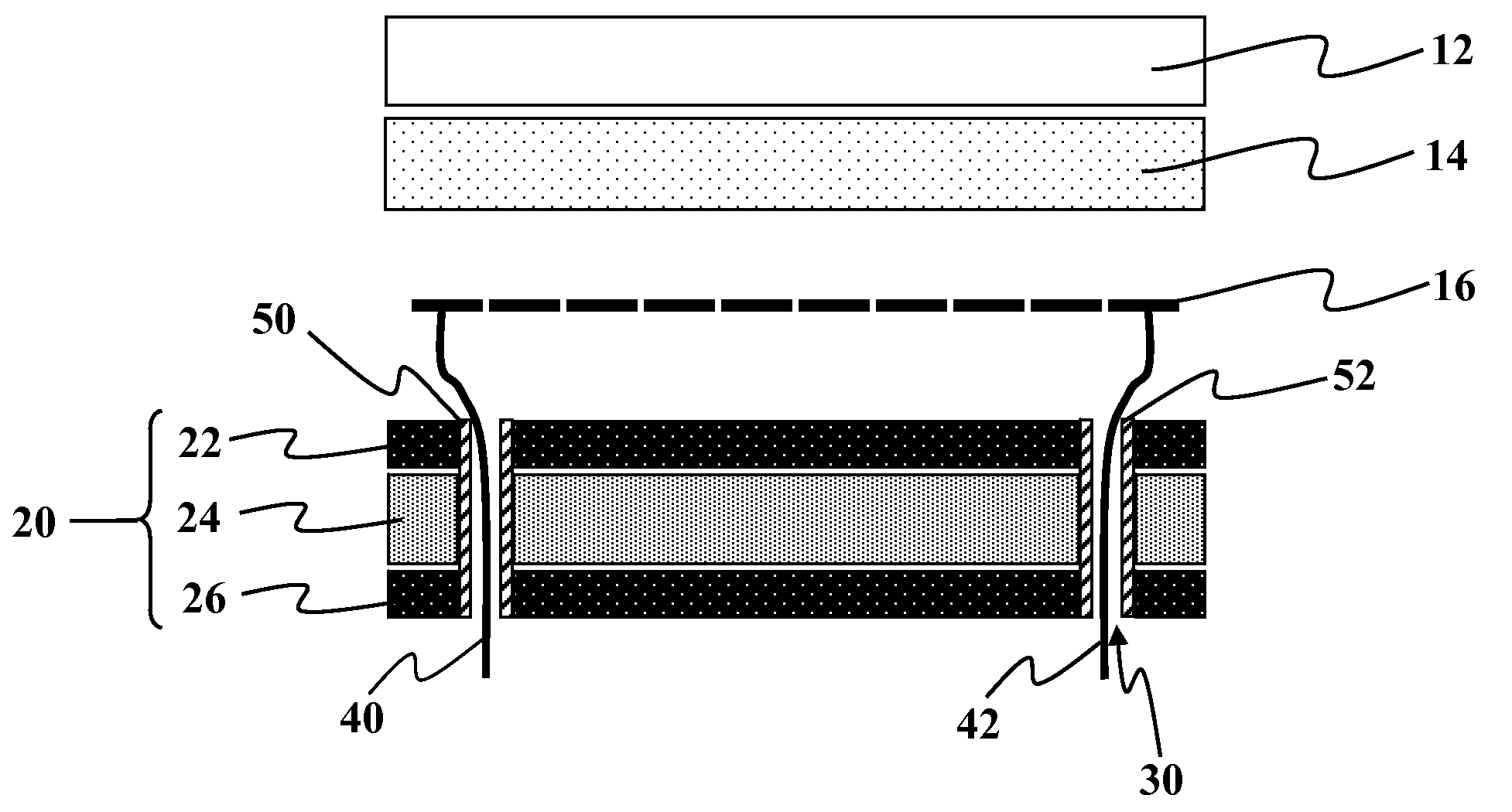

Direct die attach utilizing heated bond head

A method is provided for bonding a die comprising a solder layer which has a melting point Tm. A bond head is heated to a bond head setting temperature T1, which is higher than Tm, and a substrate is heated to a substrate setting temperature T2, which is lower than Tm. The bond head then picks up the die and heats the die towards temperature T1 so as to melt the solder layer. The solder layer of the die is pressed onto the substrate so as to bond the die to the substrate, and thereafter the bond head is separated from the die so that the solder layer is cooled towards T2 and solidifies.

Owner:ASMPT SINGAPORE PTE LTD

Methods and devices for large-scale solar installations

InactiveUS20080041434A1Reduce manufacturing costReduce redundant partsPV power plantsSoldering apparatusJunction boxSolar energy

Methods and devices are provided for improved large-scale solar installations. In one embodiment, a junction-box free photovoltaic module is used comprising of a plurality of photovoltaic cells and a module support layer providing a mounting surface for the cells. The module has a first electrical lead extending outward from one of the photovoltaic cells, the lead coupled to an adjacent module without passing the lead through a junction box. The module may have a second electrical lead extending outward from one of the photovoltaic cells, the lead coupled to another adjacent module without passing the lead through a junction box. Without junction boxes, the module may use connectors along the edges of the modules which can substantially reduce the amount of wire or connector ribbon used for such connections.

Owner:NANOSOLAR

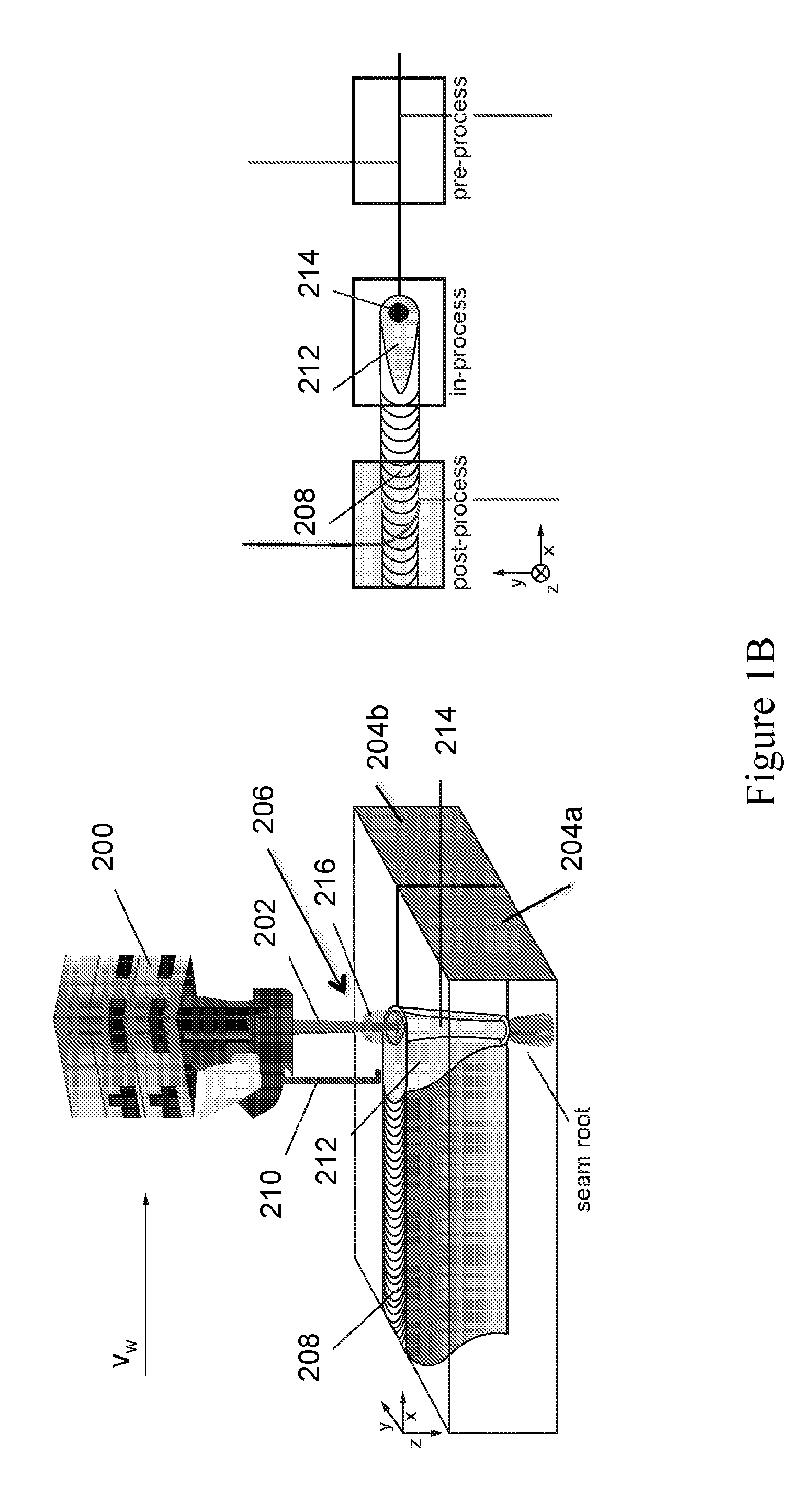

In VIVO sensor and method of making same

InactiveUS20060074479A1Easy to detectUltrasonic/sonic/infrasonic diagnosticsSurgeryIn vivoRadio frequency

Implantable in vivo sensors used to monitor physical, chemical or electrical parameters within a body. The in vivo sensors are integral with an implantable medical device and are responsive to externally or internally applied energy. Upon application of energy, the sensors undergo a phase change in at least part of the material of the device which is then detected external to the body by conventional techniques such as radiography, ultrasound imaging, magnetic resonance imaging, radio frequency imaging or the like. The in vivo sensors of the present invention may be employed to provide volumetric measurements, flow rate measurements, pressure measurements, electrical measurements, biochemical measurements, temperature, measurements, or measure the degree and type of deposits within the lumen of an endoluminal implant, such as a stent or other type of endoluminal conduit. The in vivo sensors may also be used therapeutically to modulate mechanical and / or physical properties of the endoluminal implant in response to the sensed or monitored parameter.

Owner:VACTRONIX SCI LLC

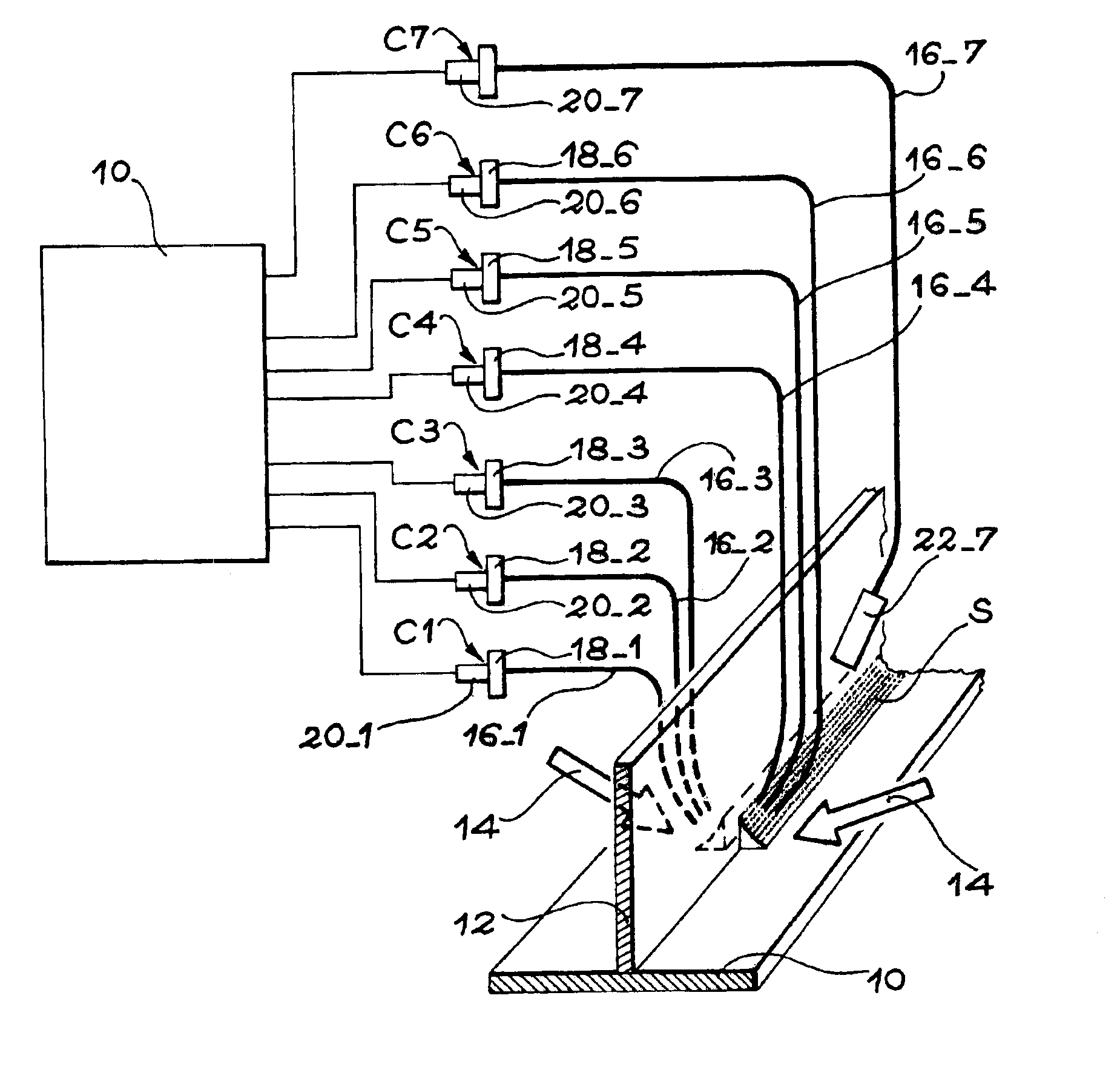

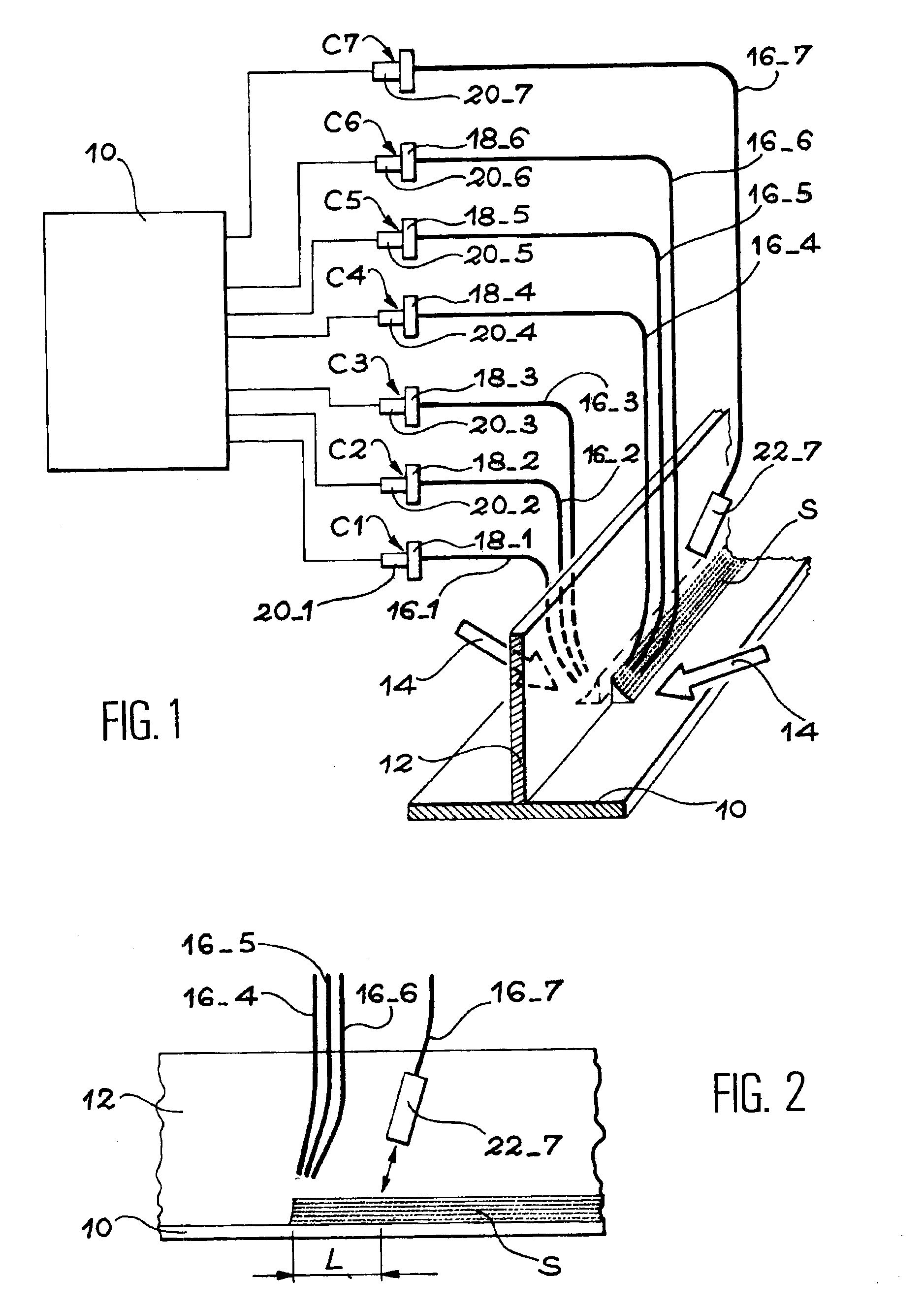

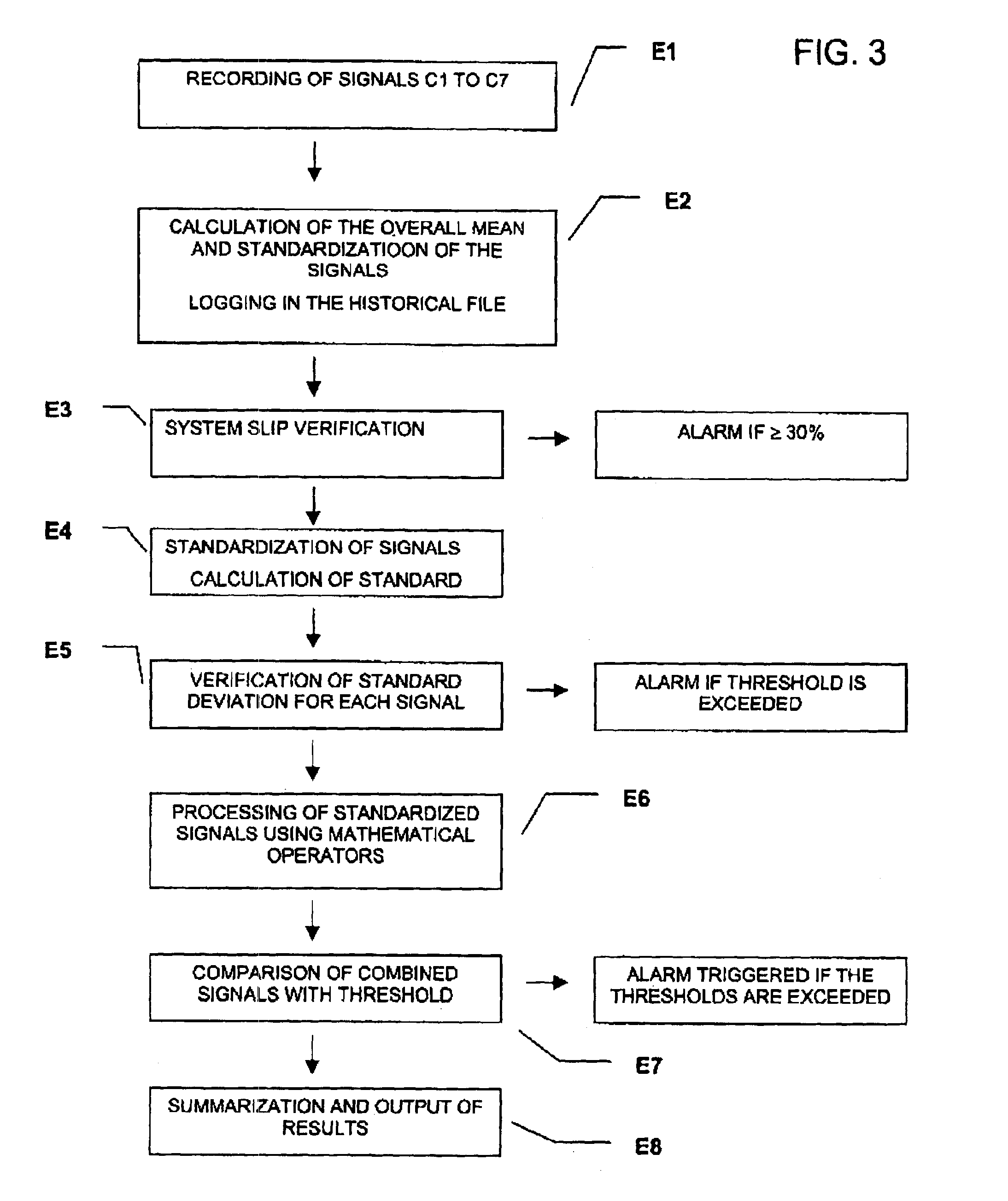

Method for detecting and identifying defects in a laser beam weld seam

A method for detection and identification of defects in a weld seam created using a laser beam.According to this method, at least two measurement signals are acquired in real time delivered by optical sensors (C1 to C6) detecting variations in luminous intensity of the plasma formed by the laser beam (14). These signals are then combined by applying a mathematical operation. The combined signal obtained is then compared to a predetermined threshold. Depending on the result of this comparison, a determination is made of the presence or absence of a defect corresponding to the operator used.

Owner:AEROSPATIALE MATRA

Ultra-hard and metallic constructions comprising improved braze joint

An ultra-hard and metallic construction comprises an ultra-hard component that is attached to a metallic component via a braze joint. The braze joint is interposed between the ultra-hard component and the metallic component, and comprises a first braze material bonded to a surface of the ultra-hard component. The braze joint includes an intervening layer in direct contact with the first braze material, and that is formed from a rigid material. The braze joint further comprises a second braze material that is interposed between the intervening layer and the metallic component, and that is different from the first braze material. Configured in this manner, the use of the braze joint operates to provide an optimum level of bond strength within the construction to enable its use in certain demanding wear and / or cutting applications.

Owner:SMITH INT INC

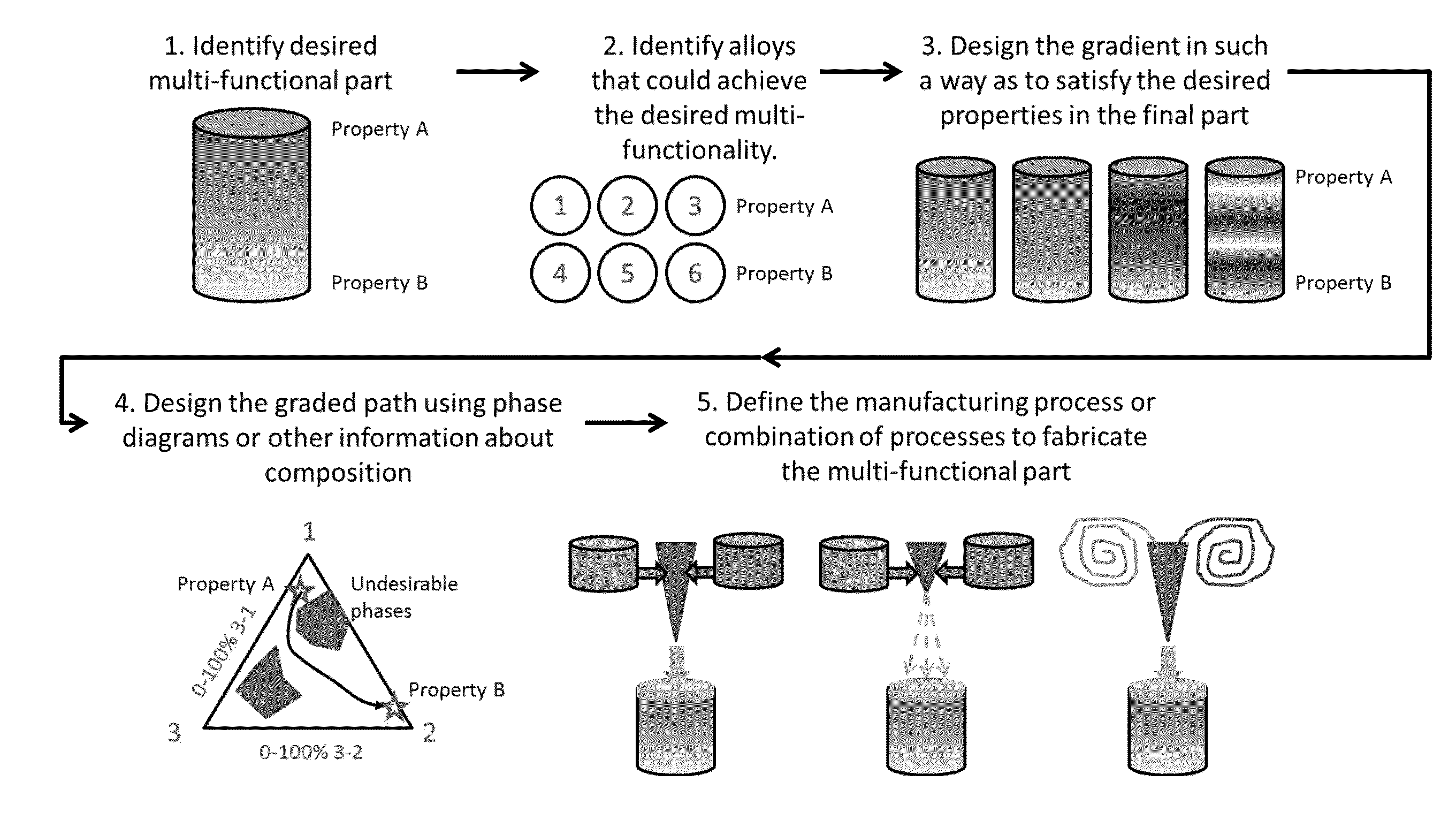

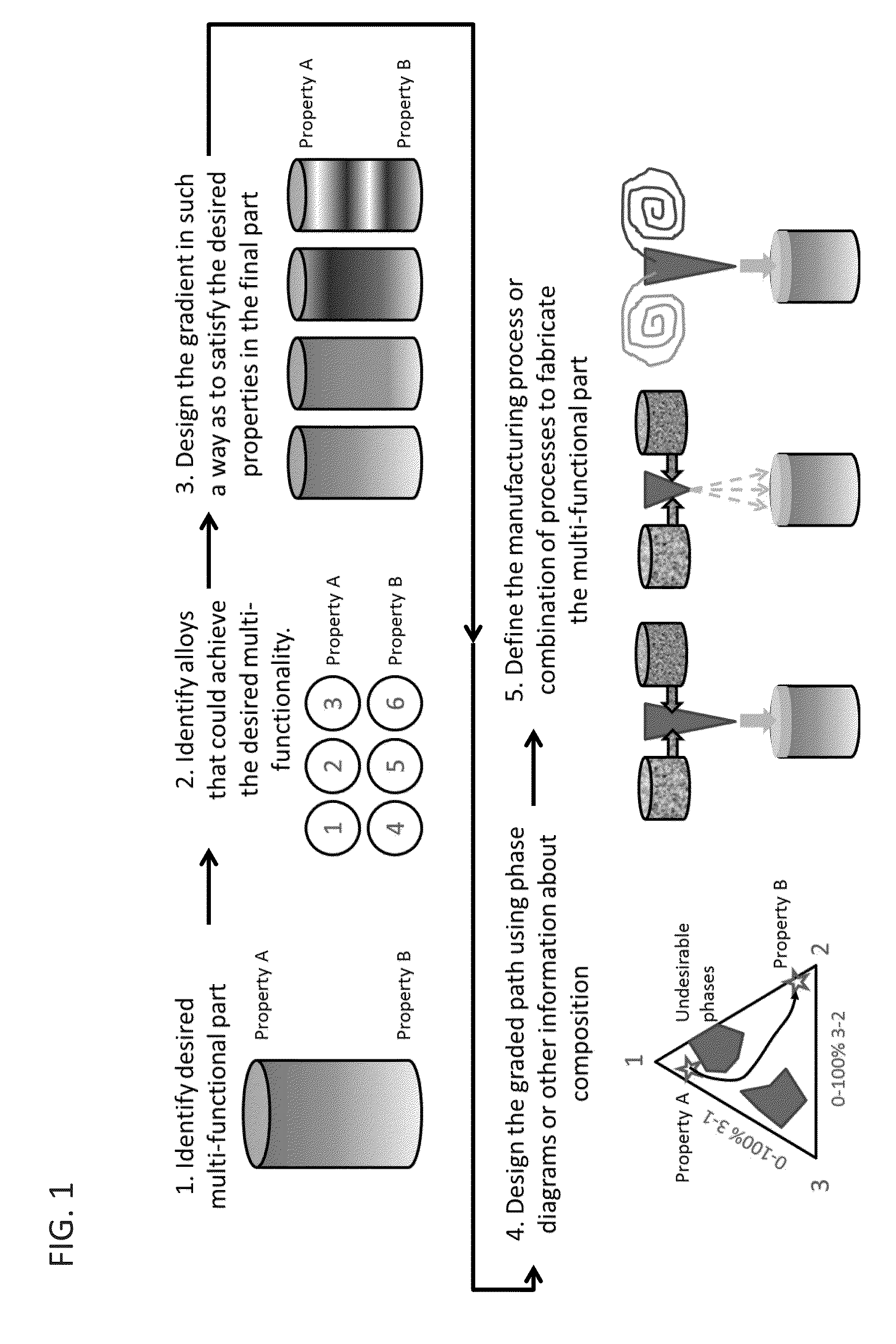

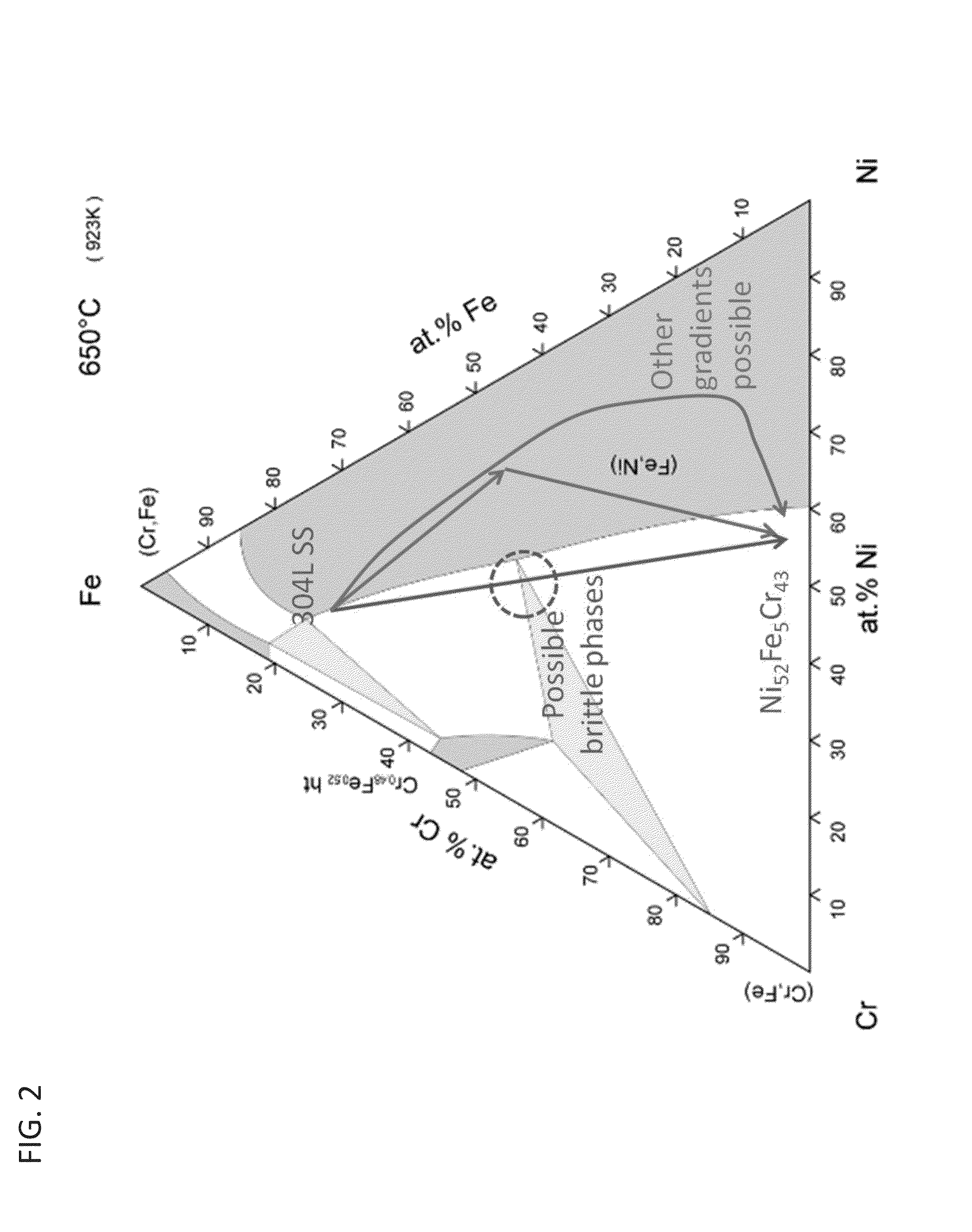

Methods for fabricating gradient alloy articles with multi-functional properties

ActiveUS20150044084A1High speedSufficient cooling rateAdditive manufacturingMolten spray coatingMetal alloyGradient material

Systems and methods for fabricating multi-functional articles comprised of additively formed gradient materials are provided. The fabrication of multi-functional articles using the additive deposition of gradient alloys represents a paradigm shift from the traditional way that metal alloys and metal / metal alloy parts are fabricated. Since a gradient alloy that transitions from one metal to a different metal cannot be fabricated through any conventional metallurgy techniques, the technique presents many applications. Moreover, the embodiments described identify a broad range of properties and applications.

Owner:CALIFORNIA INST OF TECH

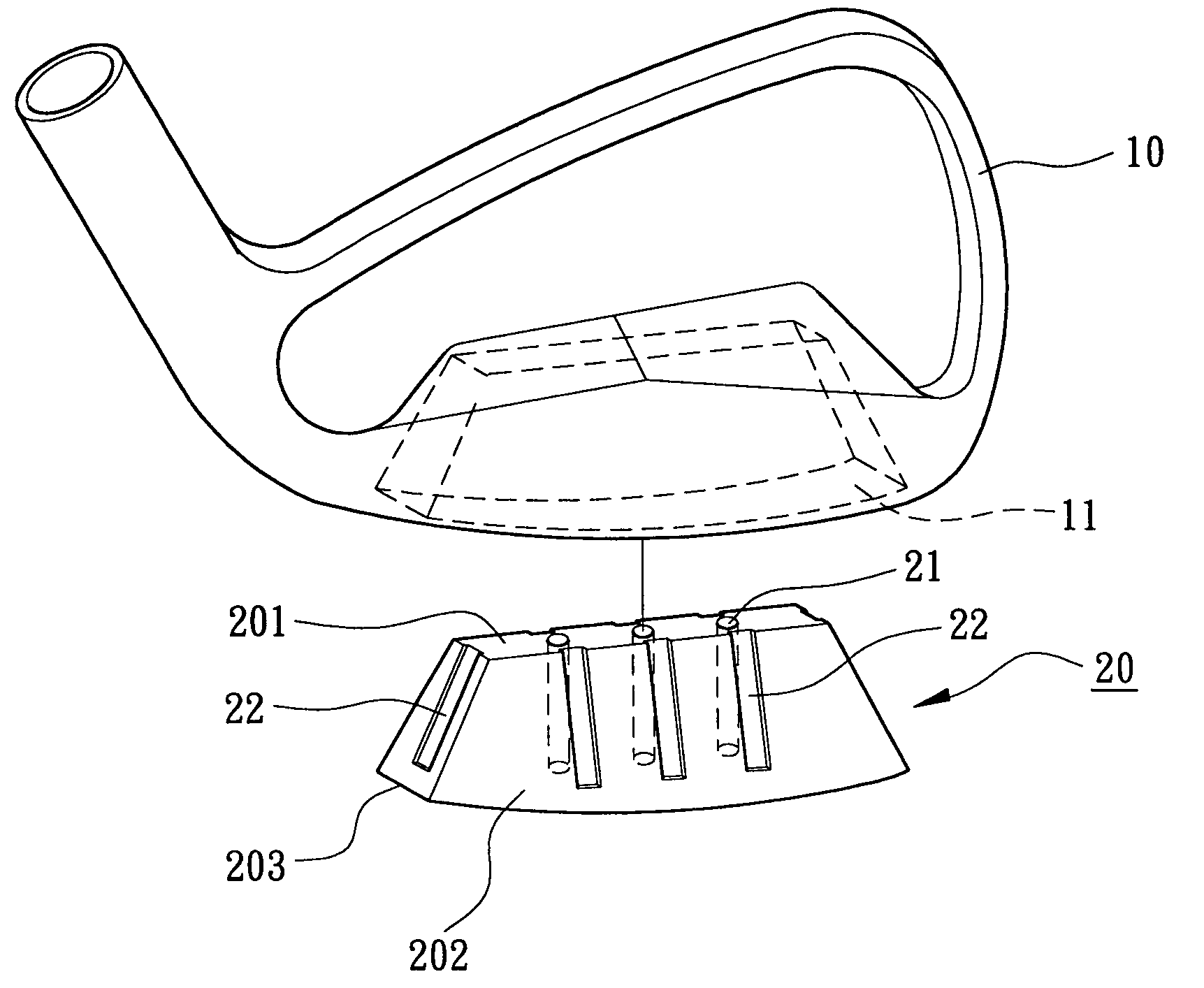

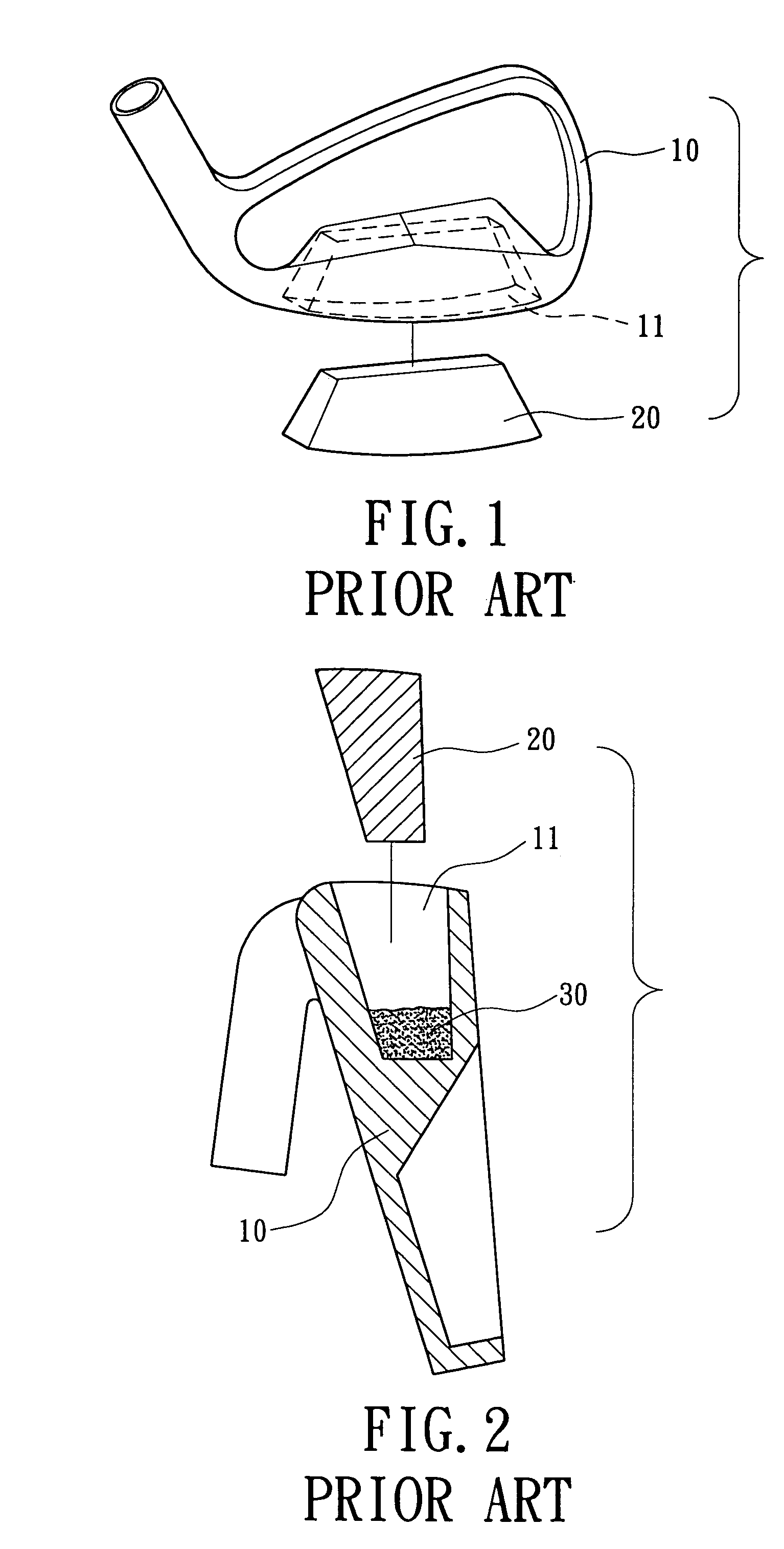

Weight member for a golf club head

InactiveUS7086964B2Improve reliabilityRaise the ratioSoldering apparatusGolf clubsFilling materialsEngineering

A golf club head includes a golf club head body and a weight member mounted in a recession of the golf club head body. The weight member includes at least one compartment for receiving a filling material. The weight member is mounted in the recession of the golf club head body before a brazing process for bonding the weight member with the golf club head body. During the brazing process, the filling material is melted and fills a gap between the weight member and walls delimiting the recession of the golf club head body to thereby increasing bonding strength between the weight member and the walls delimiting the recession of the golf club head body.

Owner:FUSHENG IND CO LTD

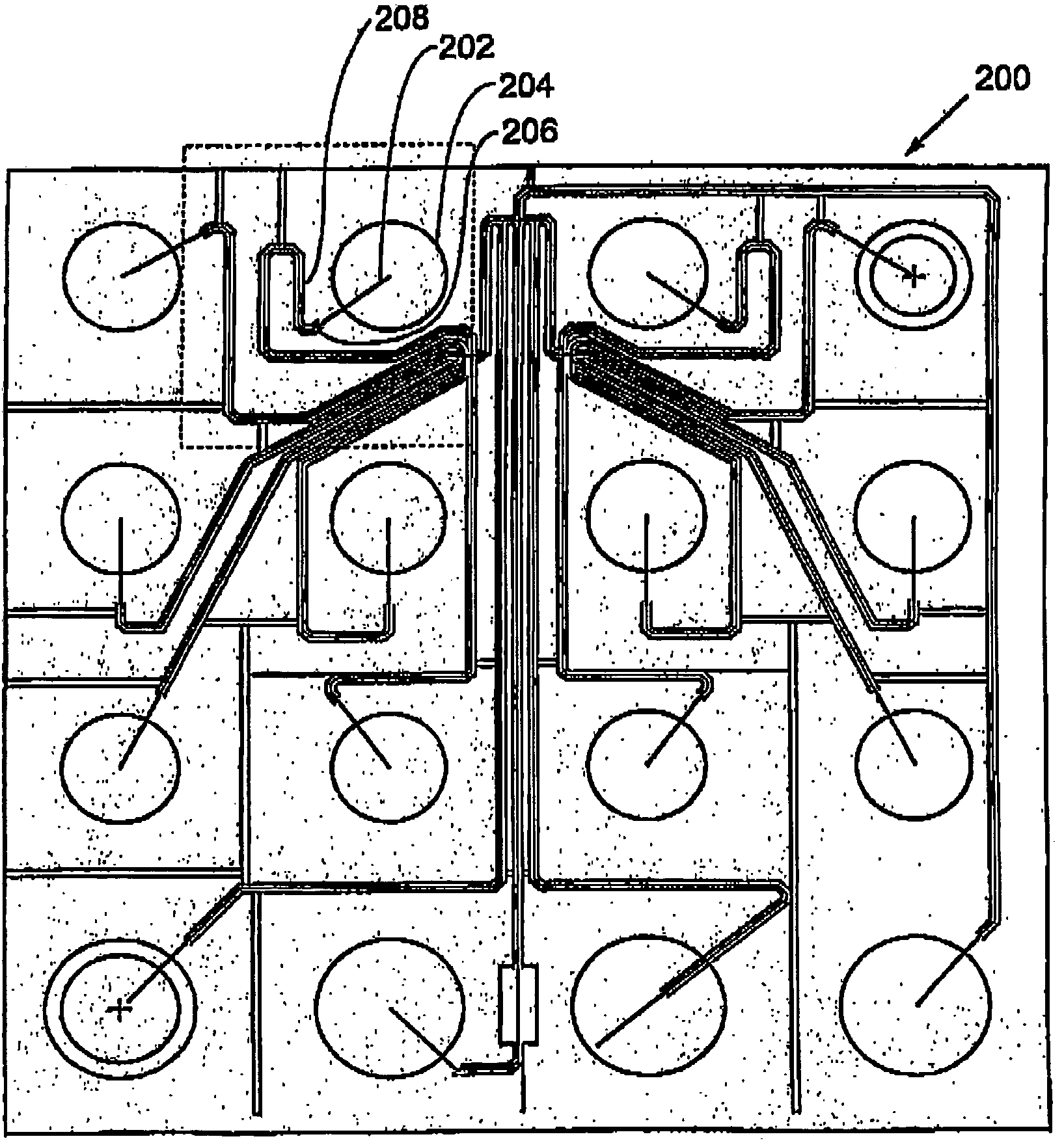

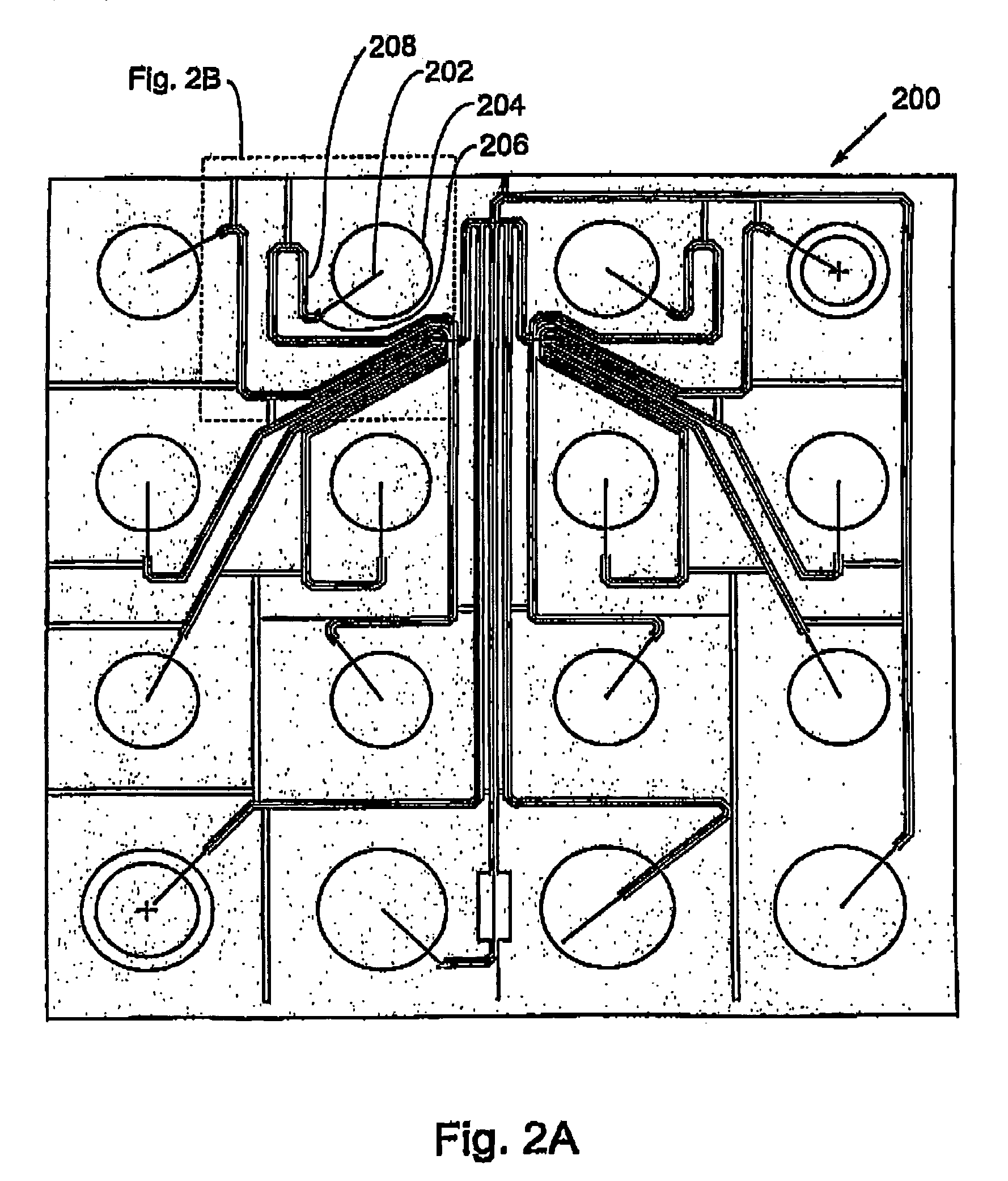

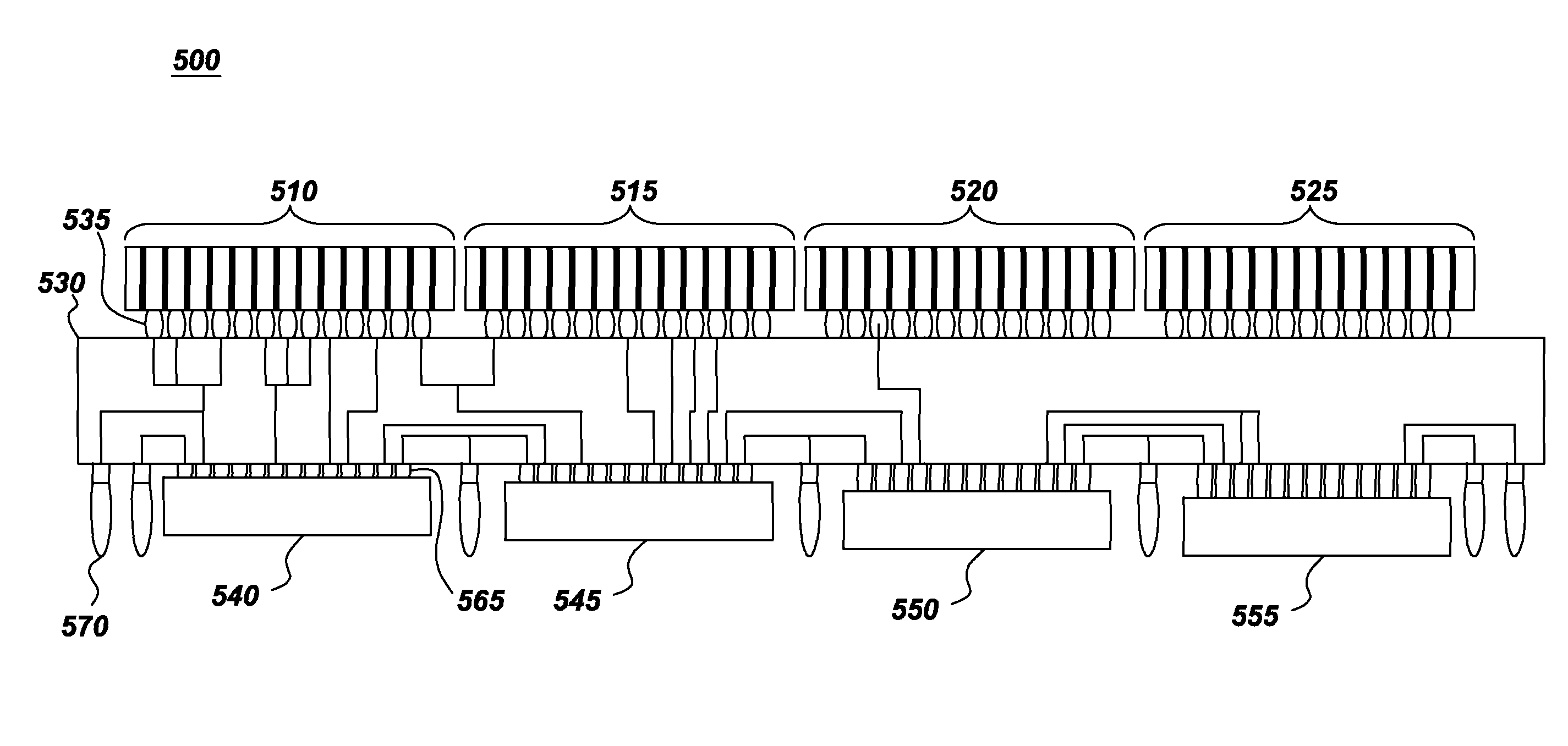

Large area modular sensor array assembly and method for making the same

ActiveUS20110071397A1Ultrasonic/sonic/infrasonic diagnosticsMaterial analysis using sonic/ultrasonic/infrasonic wavesSensor arrayTransducer

A modular and tileable sensor array with routing in the interposer carrying the signals from the sensors to the integrated circuits. In one embodiment a large area modular sensor array assembly includes one or more tileable modules coupled together. The tileable modules have a plurality of transducer cells forming a sensor, an interposer coupled on a first side to the plurality of transducer cells by a plurality, one or more integrated circuits coupled to a second side of the interposer, wherein the interposer is configured to form the connection of at least some of the transducer cells to the integrated circuits, and one or more input / output connectors coupled to the interposer and providing an external interface.

Owner:GENERAL ELECTRIC CO

Color laser engraving and digital watermarking

A color laser engraving method engraves a document including a surface layer and one or more sub-layers. The sub-layer includes different colors and orientations of ink. A laser provides openings in the surface layer—to expose color ink in the sub-layer—to create color images and / or text. The different orientations of the colored inks include, e.g., circular, linear and overlapped groupings of ink. A sub-layer preferably includes many repeated instances of the grouping. A digital watermark is embedded in a document via transfer of the digital watermark in an embedded image or text, or by pre-embedding the document via altering intensity of colored inks on the original document card stock. A digital watermark can be carried via modulation with a pseudo-random noise sequence.

Owner:DIGIMARC CORP

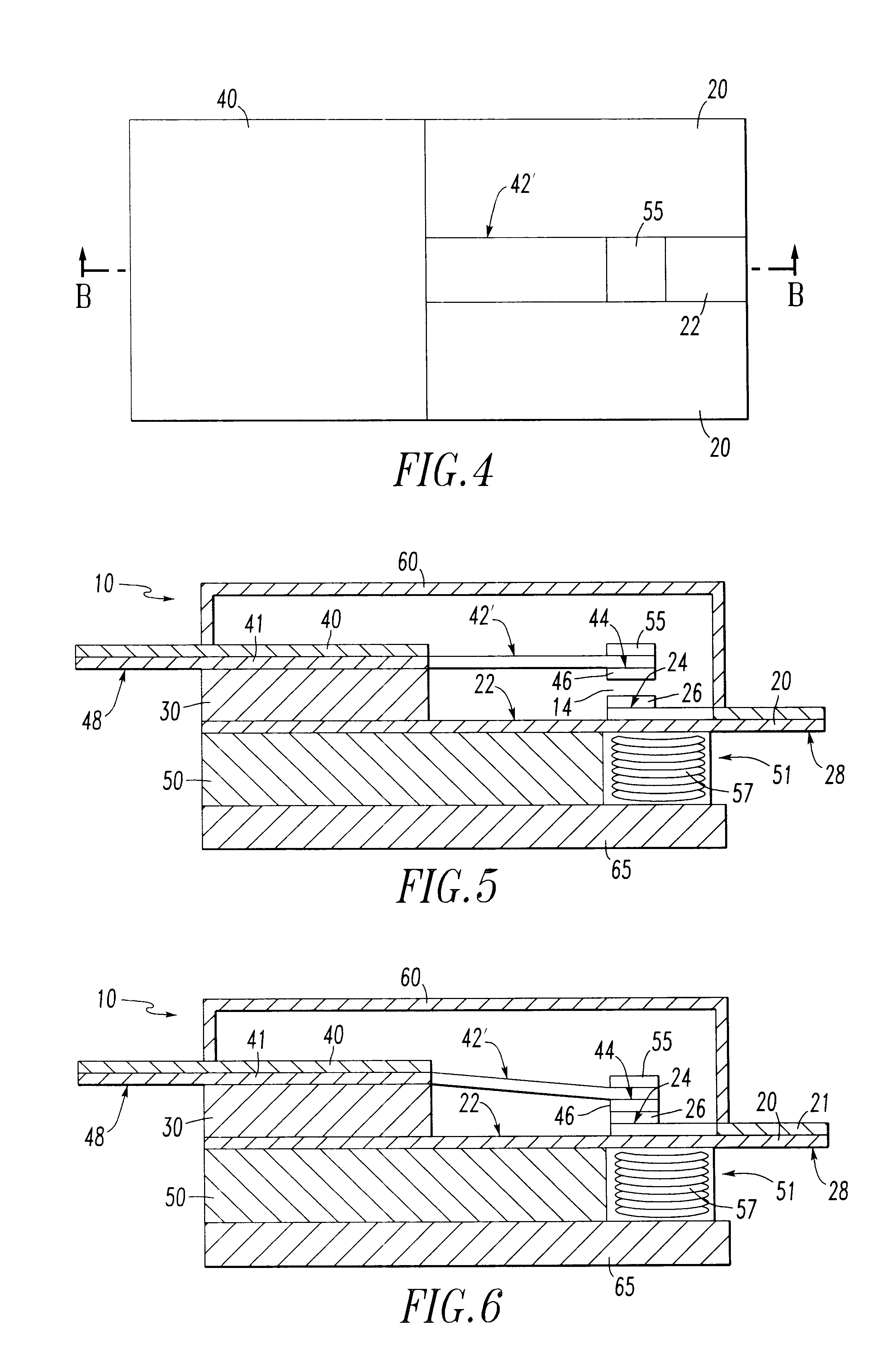

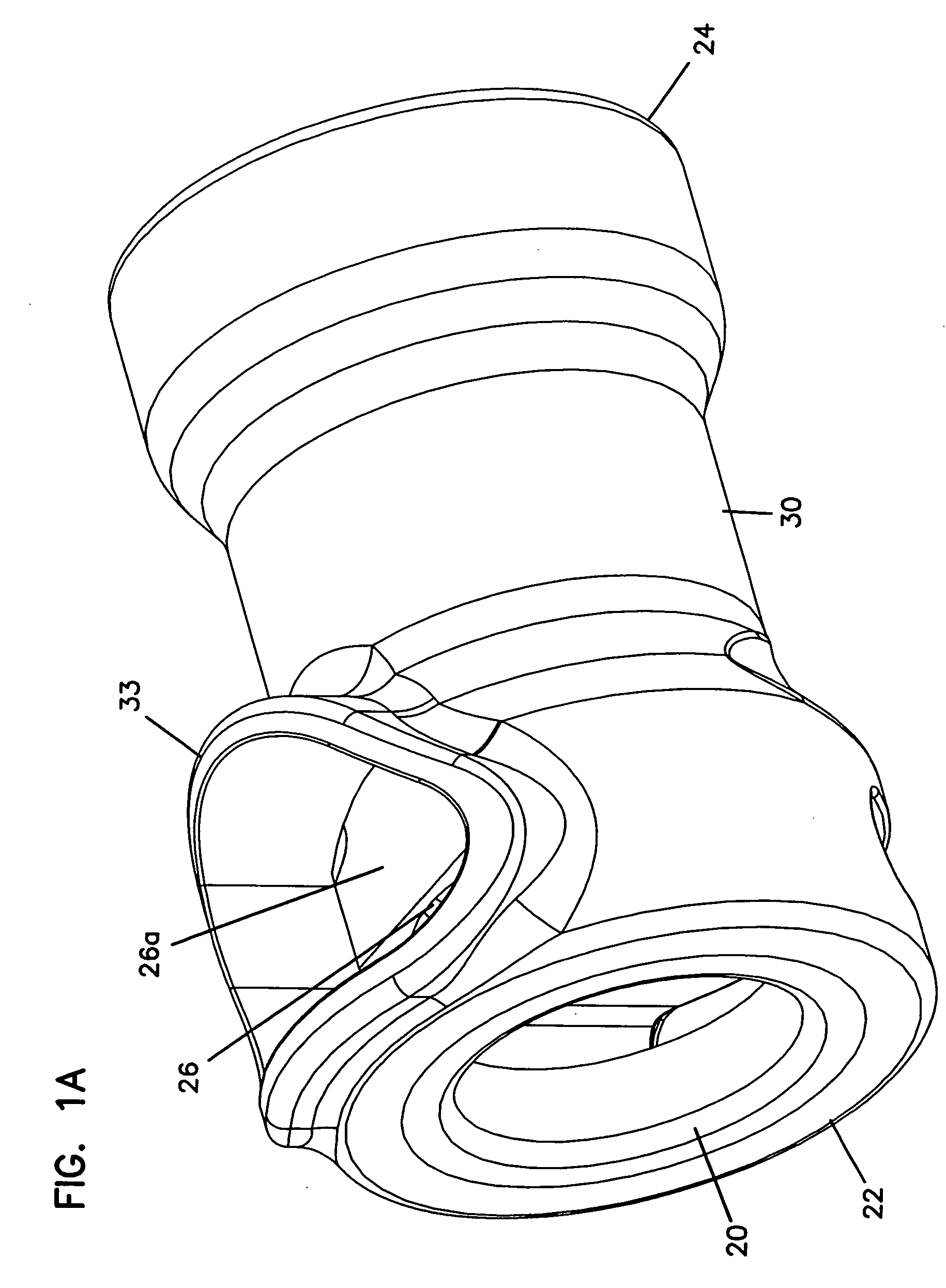

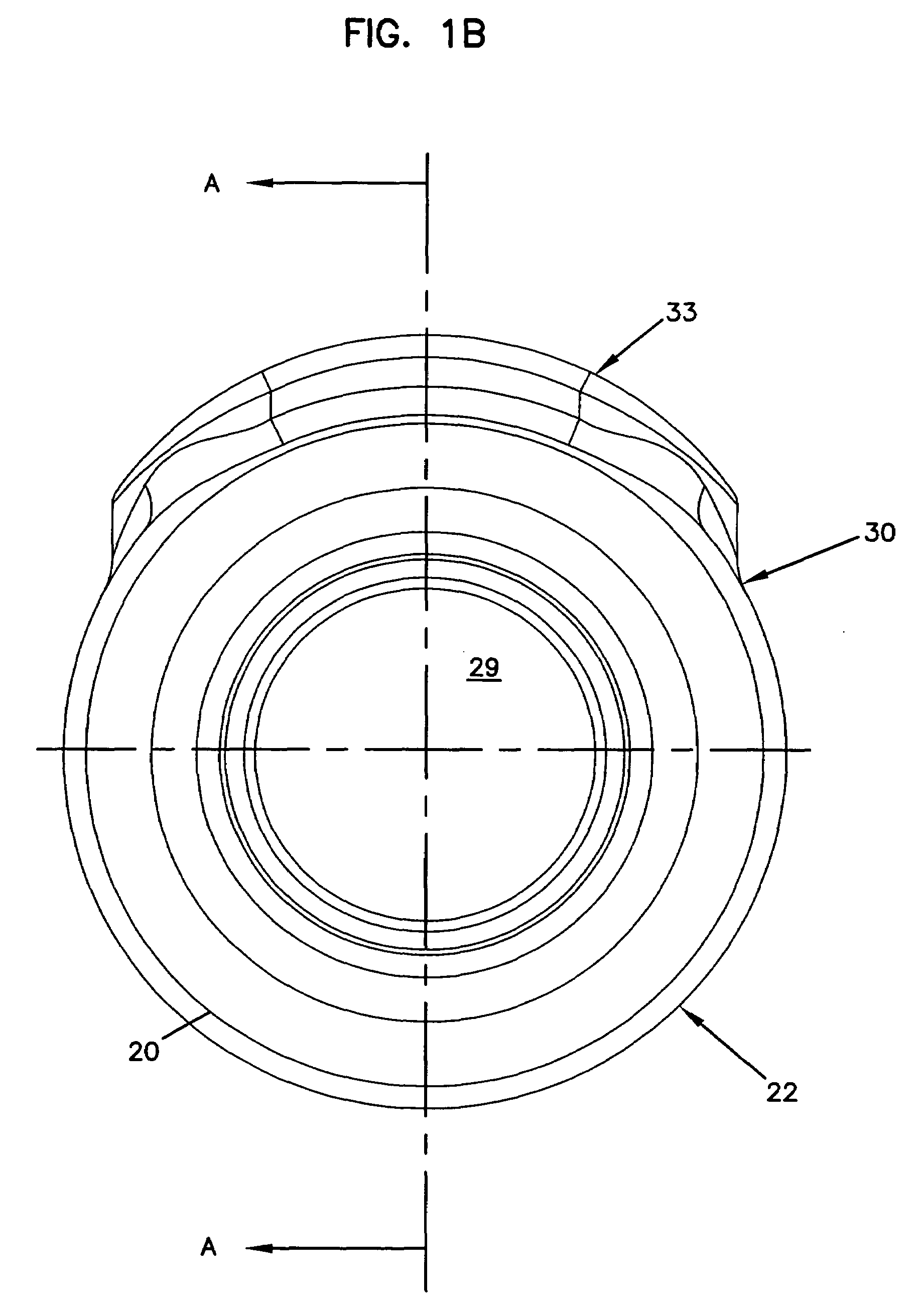

Method of making molded coupler

Owner:COLDER PRODS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com