Patents

Literature

497 results about "Gradient material" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Methods for fabricating gradient alloy articles with multi-functional properties

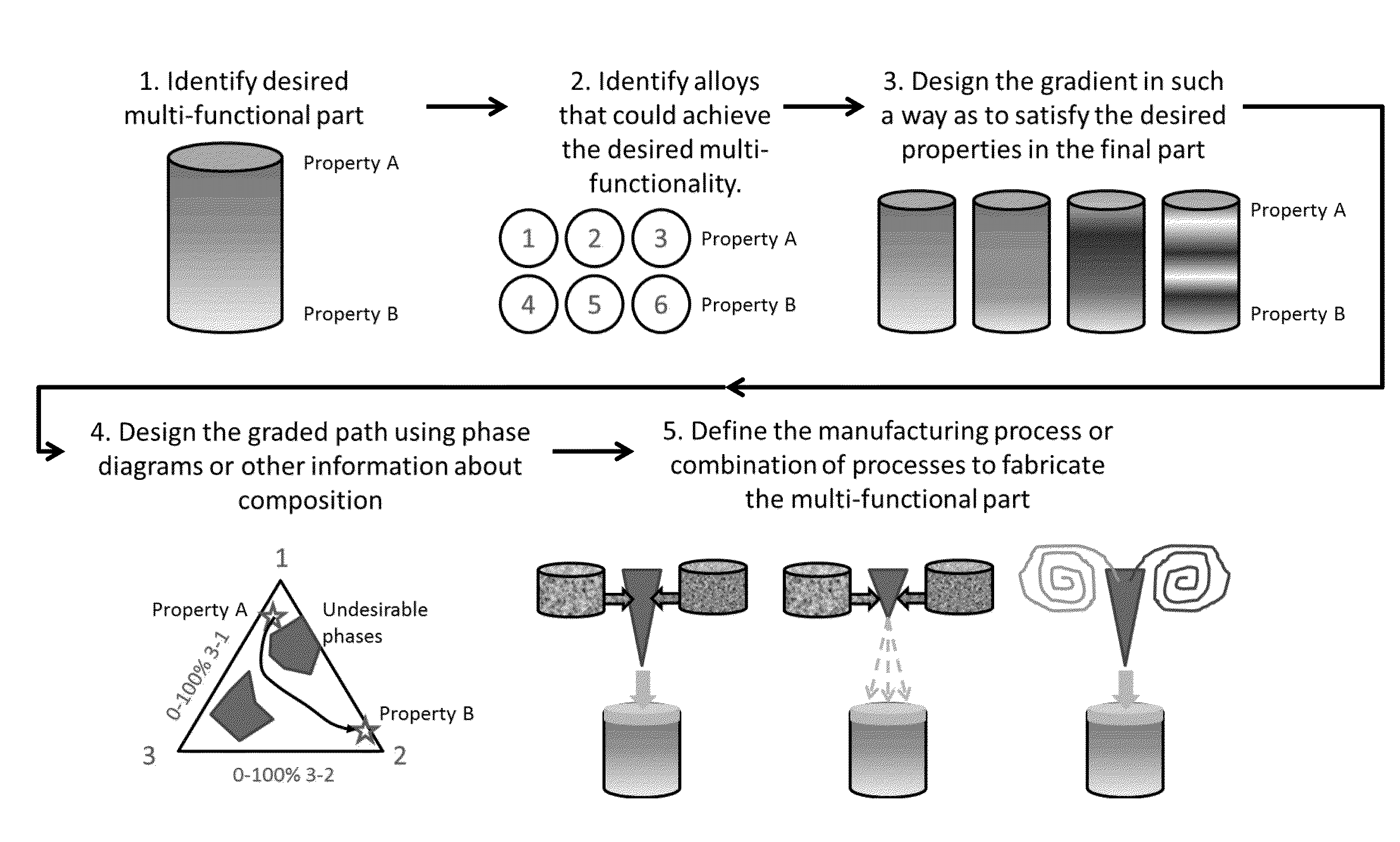

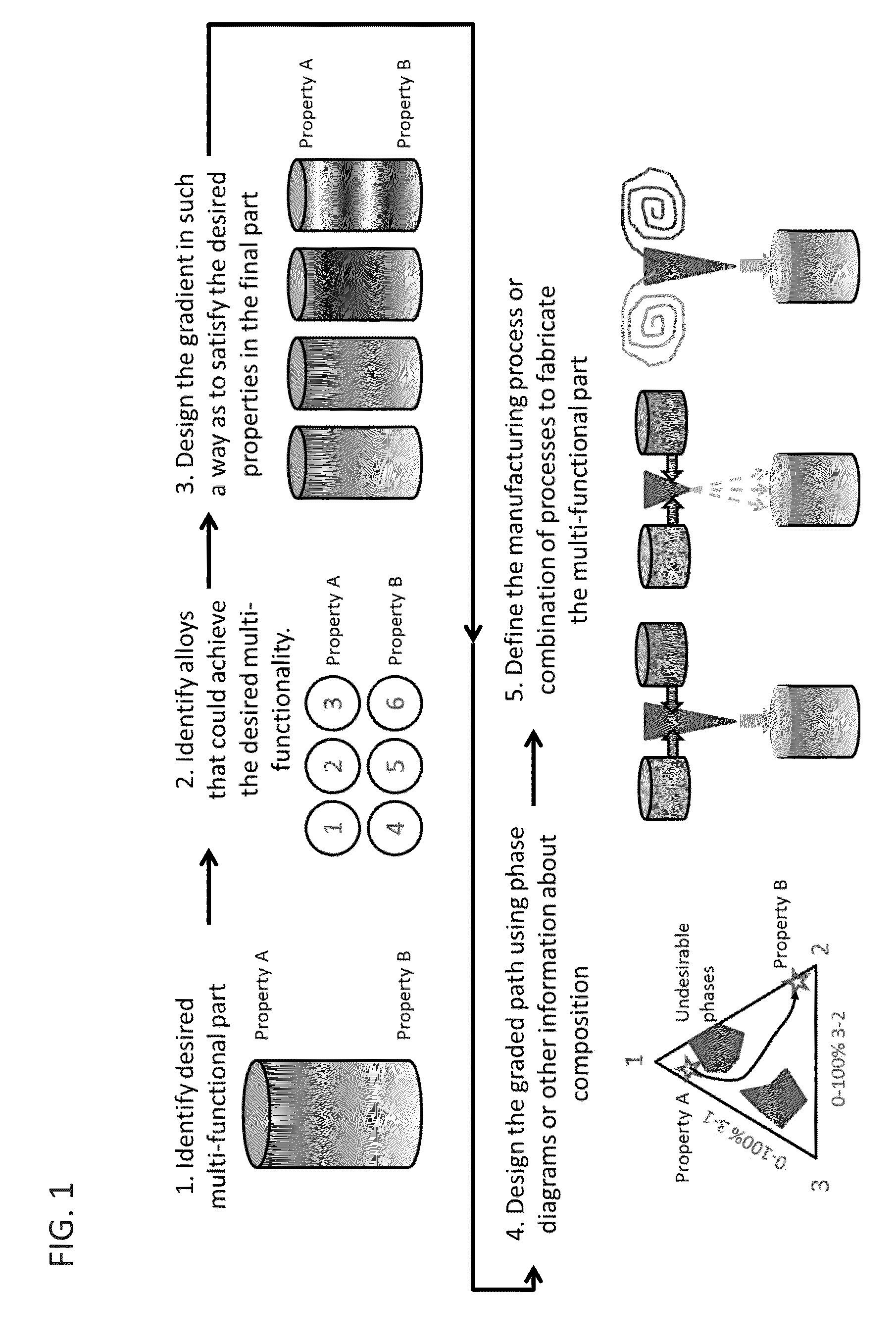

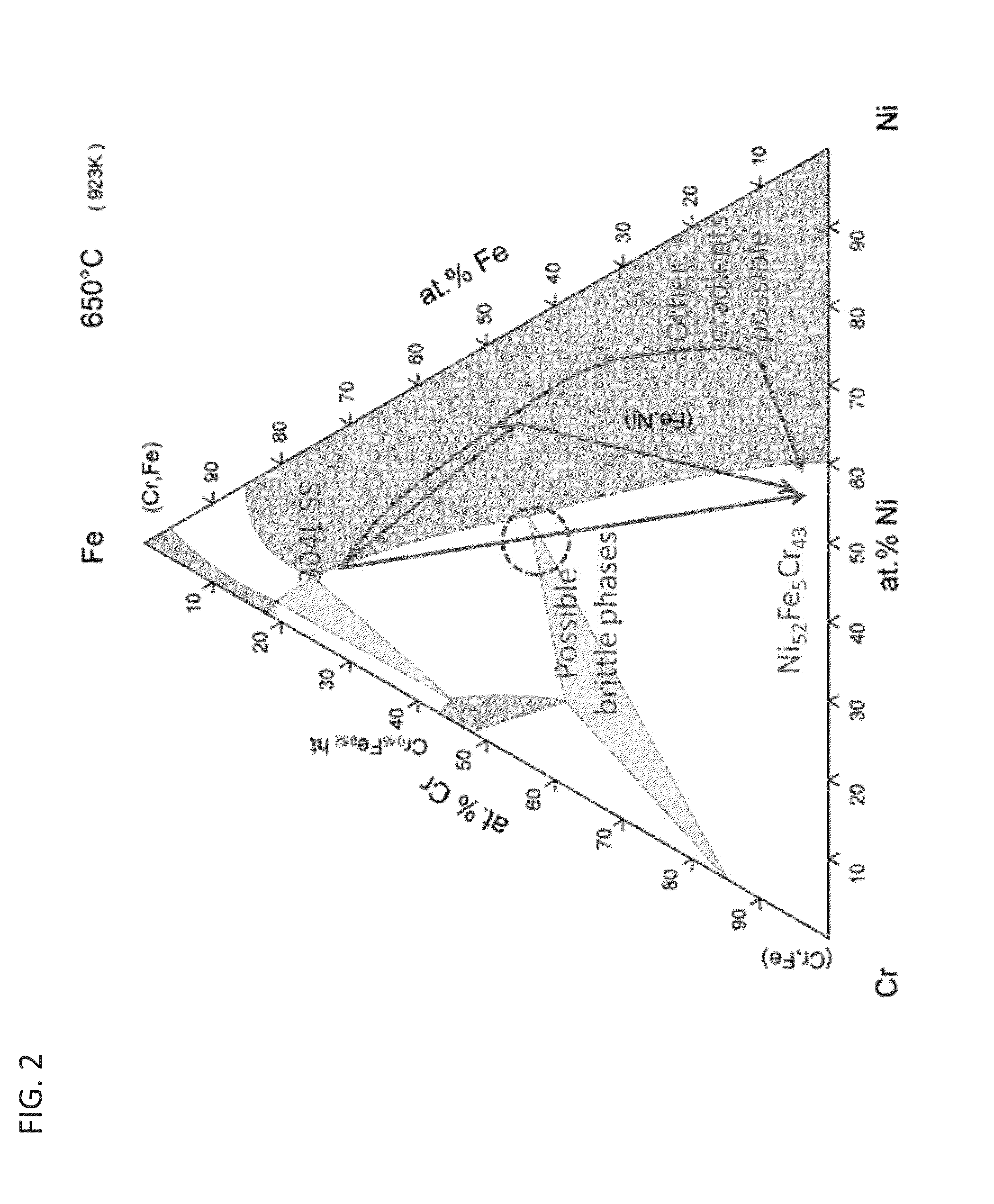

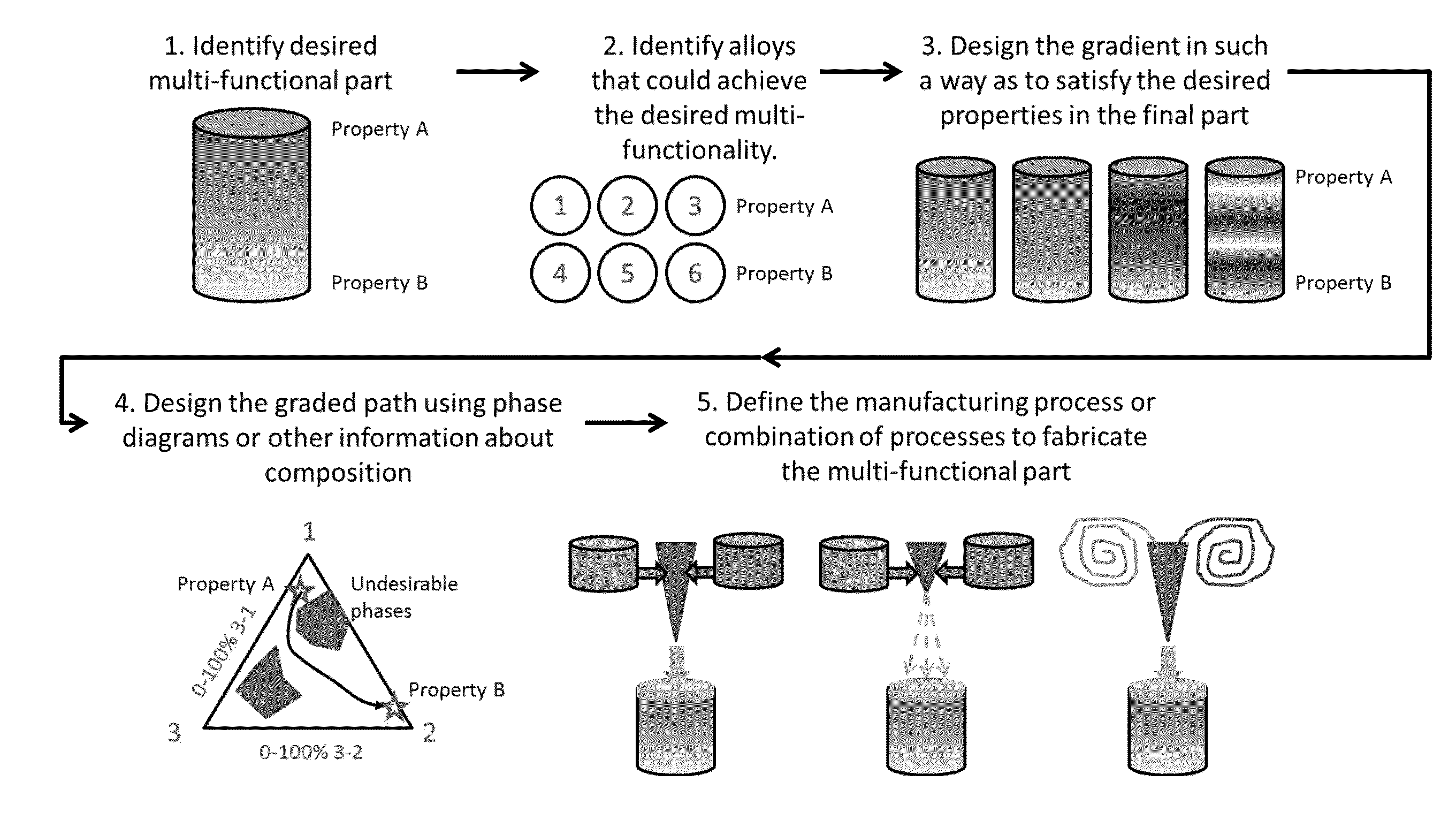

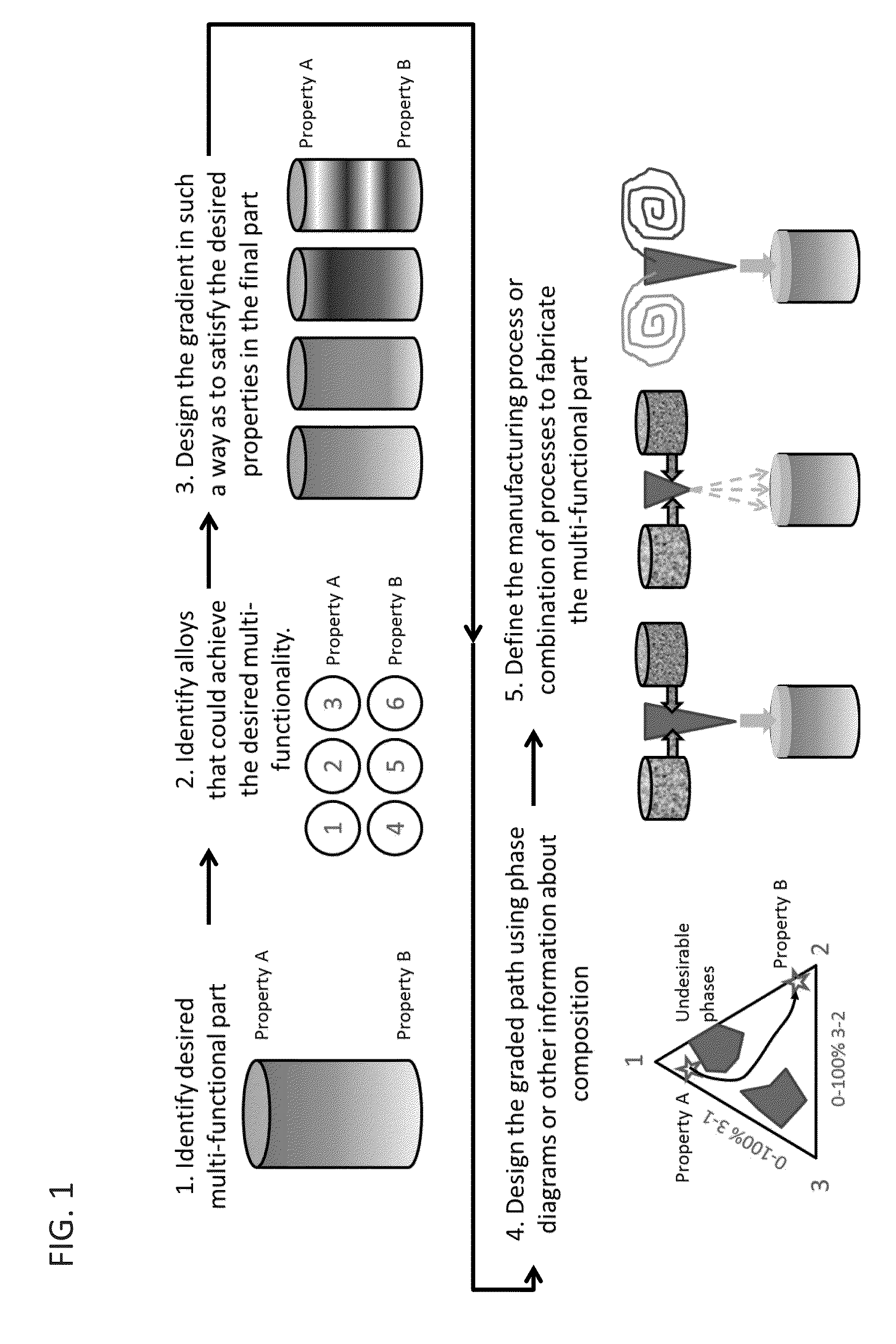

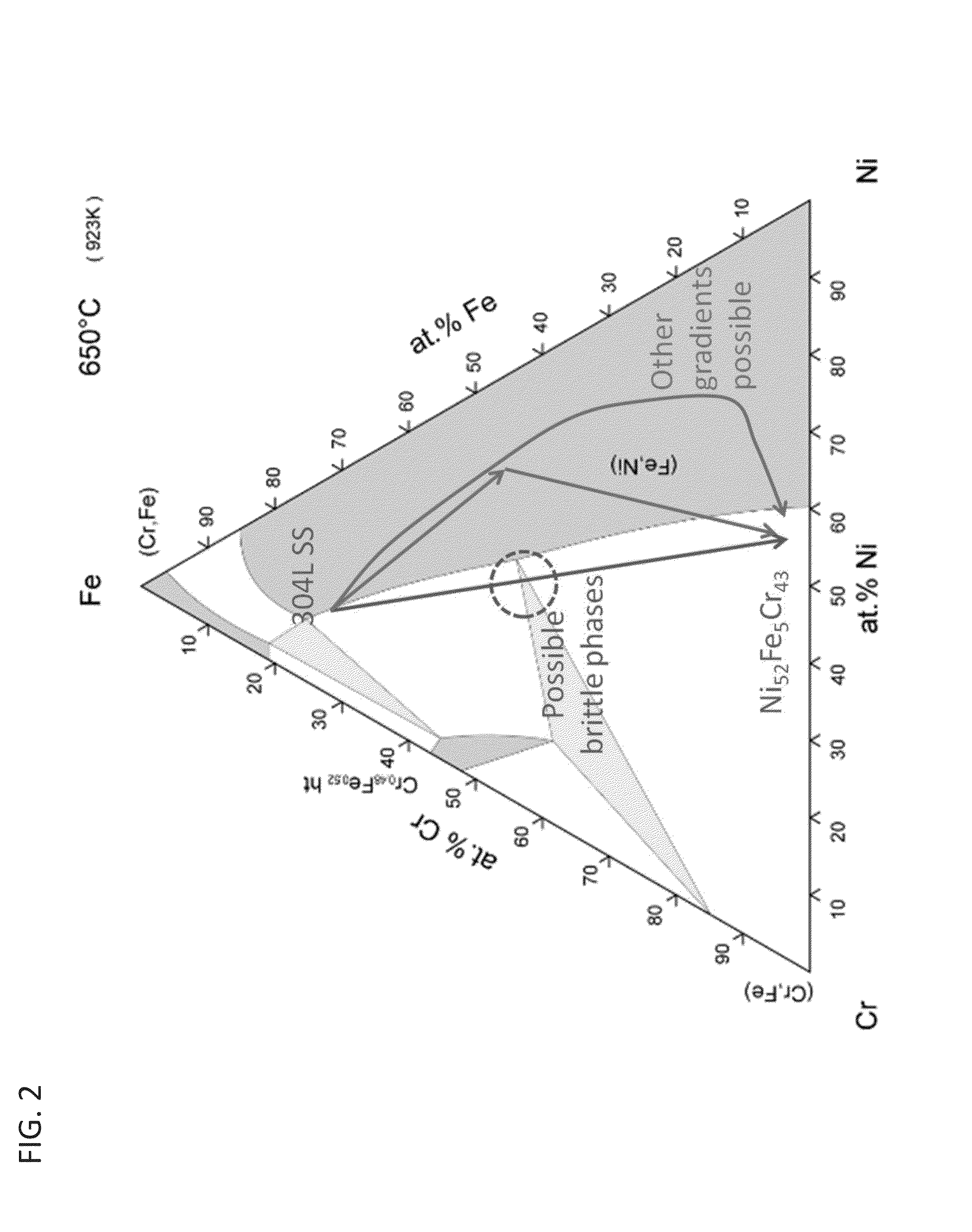

Systems and methods for fabricating multi-functional articles comprised of additively formed gradient materials are provided. The fabrication of multi-functional articles using the additive deposition of gradient alloys represents a paradigm shift from the traditional way that metal alloys and metal / metal alloy parts are fabricated. Since a gradient alloy that transitions from one metal to a different metal cannot be fabricated through any conventional metallurgy techniques, the technique presents many applications. Moreover, the embodiments described identify a broad range of properties and applications.

Owner:CALIFORNIA INST OF TECH

Methods for fabricating gradient alloy articles with multi-functional properties

ActiveUS20150044084A1High speedSufficient cooling rateAdditive manufacturingMolten spray coatingMetal alloyGradient material

Systems and methods for fabricating multi-functional articles comprised of additively formed gradient materials are provided. The fabrication of multi-functional articles using the additive deposition of gradient alloys represents a paradigm shift from the traditional way that metal alloys and metal / metal alloy parts are fabricated. Since a gradient alloy that transitions from one metal to a different metal cannot be fabricated through any conventional metallurgy techniques, the technique presents many applications. Moreover, the embodiments described identify a broad range of properties and applications.

Owner:CALIFORNIA INST OF TECH

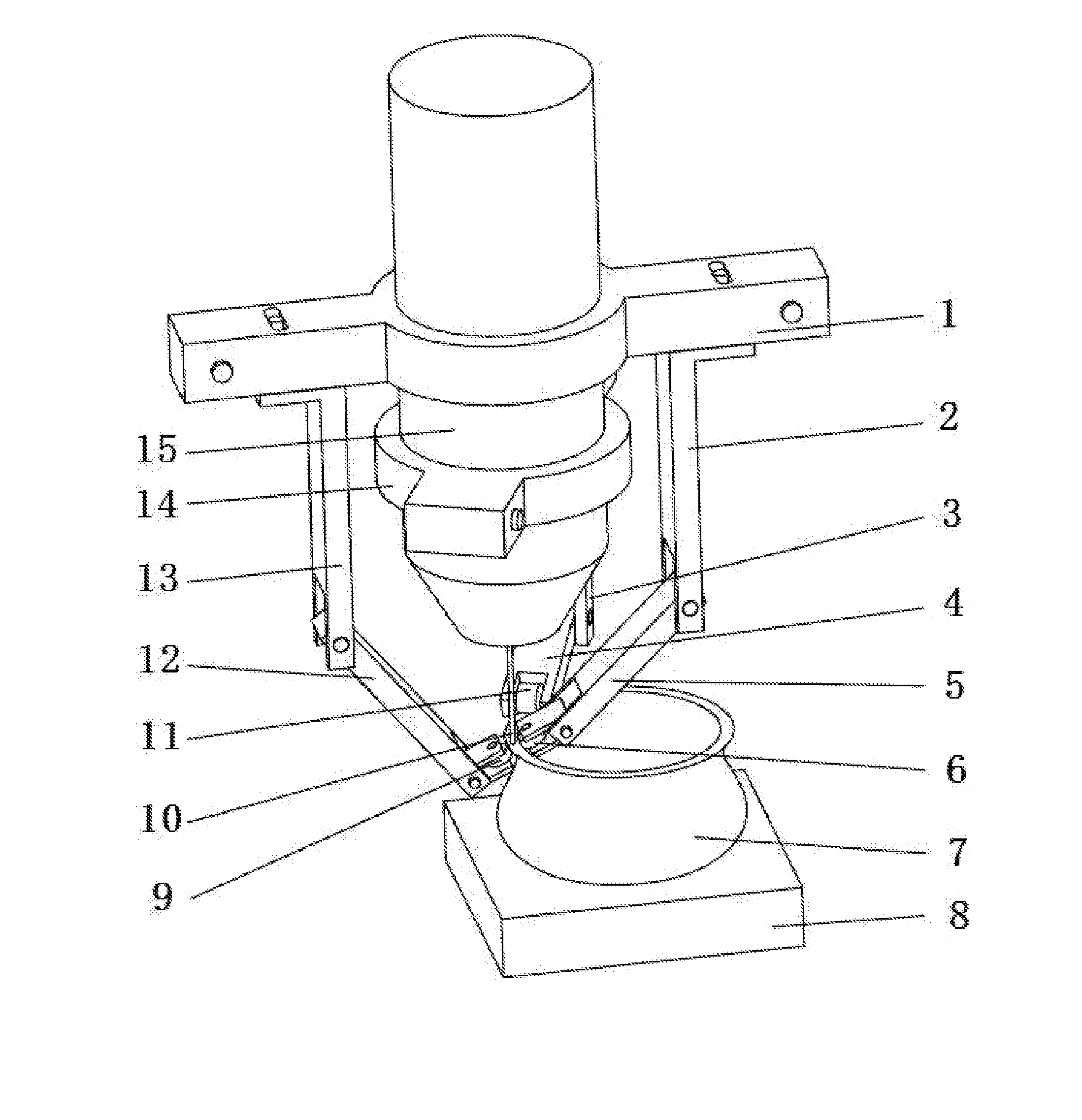

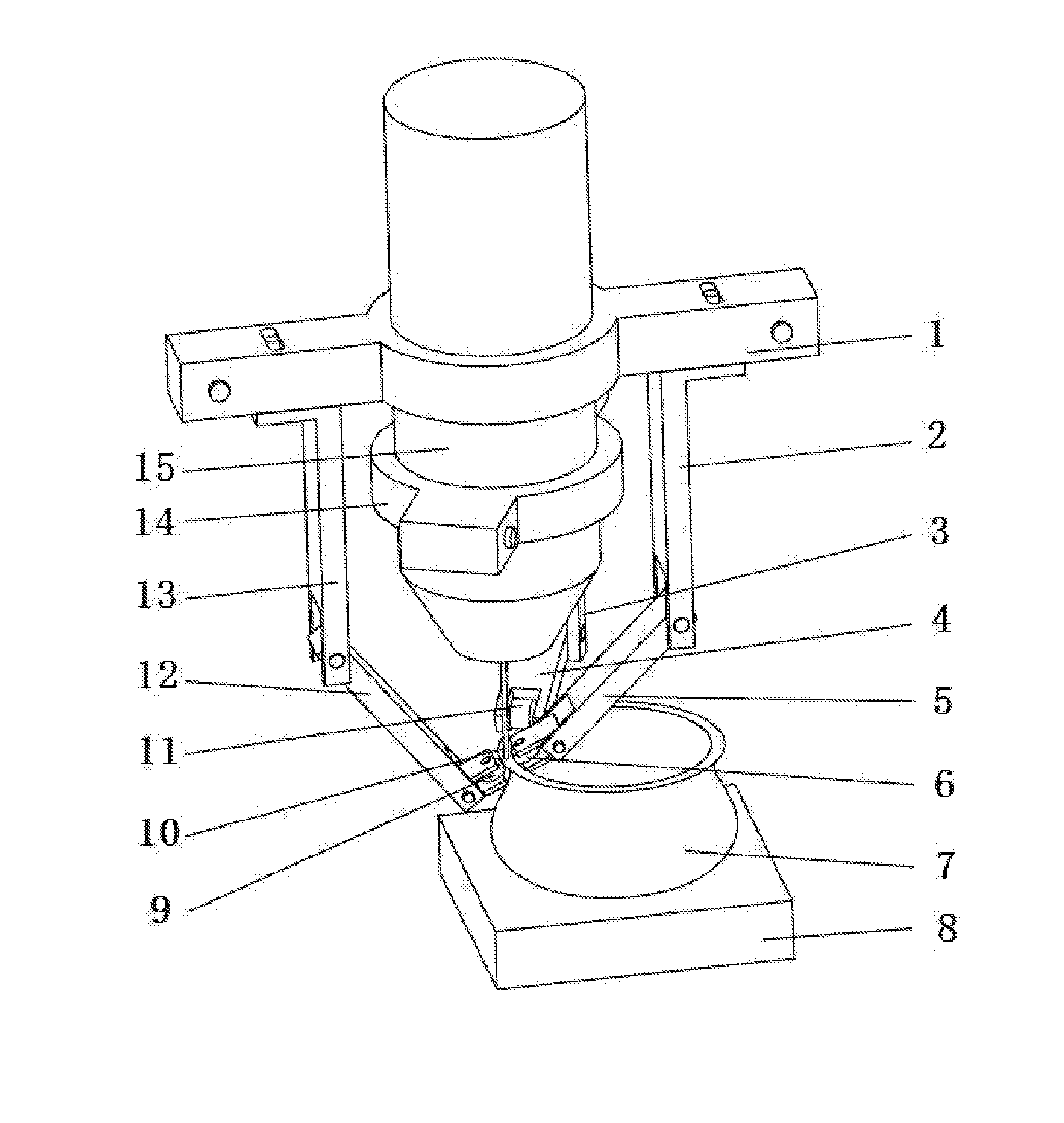

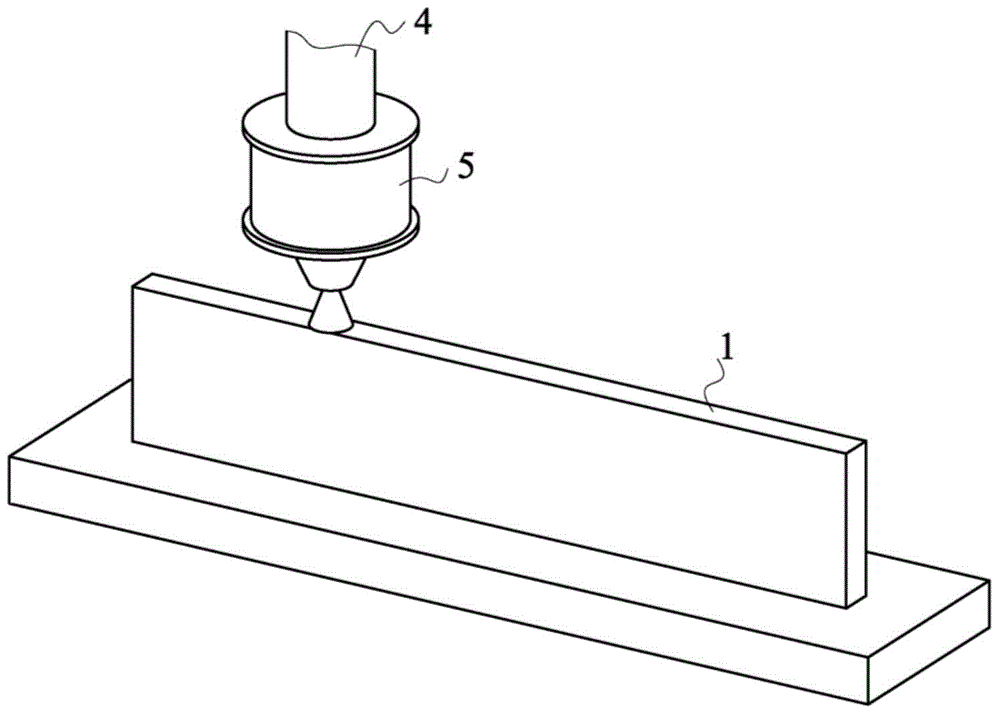

Method for manufacturing metal parts and molds and micro-roller used therefor

ActiveUS20130197683A1Formability of complexImprove accuracyArc welding apparatusAdditive manufacturing with liquidsNumerical controlWire rod

A method for manufacturing parts and molds by: 1) slicing a three-dimensional CAD model of a part or mold; 2) planning a modeling path according to slicing data of the three-dimensional CAD model, whereby generating numerical control codes for modeling processing; and 3) performing fused deposition modeling of powders or wire material of metal, intermetallic compounds, ceramic and composite functional gradient materials by layer using a welding gun on a substrate layer via a numerical control gas shielded welding beam or laser beam according to a track specified by the numerical control code for each layer. A micro-roller or a micro-extrusion unit is installed at a contact area between melted and softened areas. The micro-roller or the micro-extrusion unit synchronously moves along with fused deposition area, which results in compressing and processing of the fused deposition area during the fused deposition modeling.

Owner:HUAZHONG UNIV OF SCI & TECH

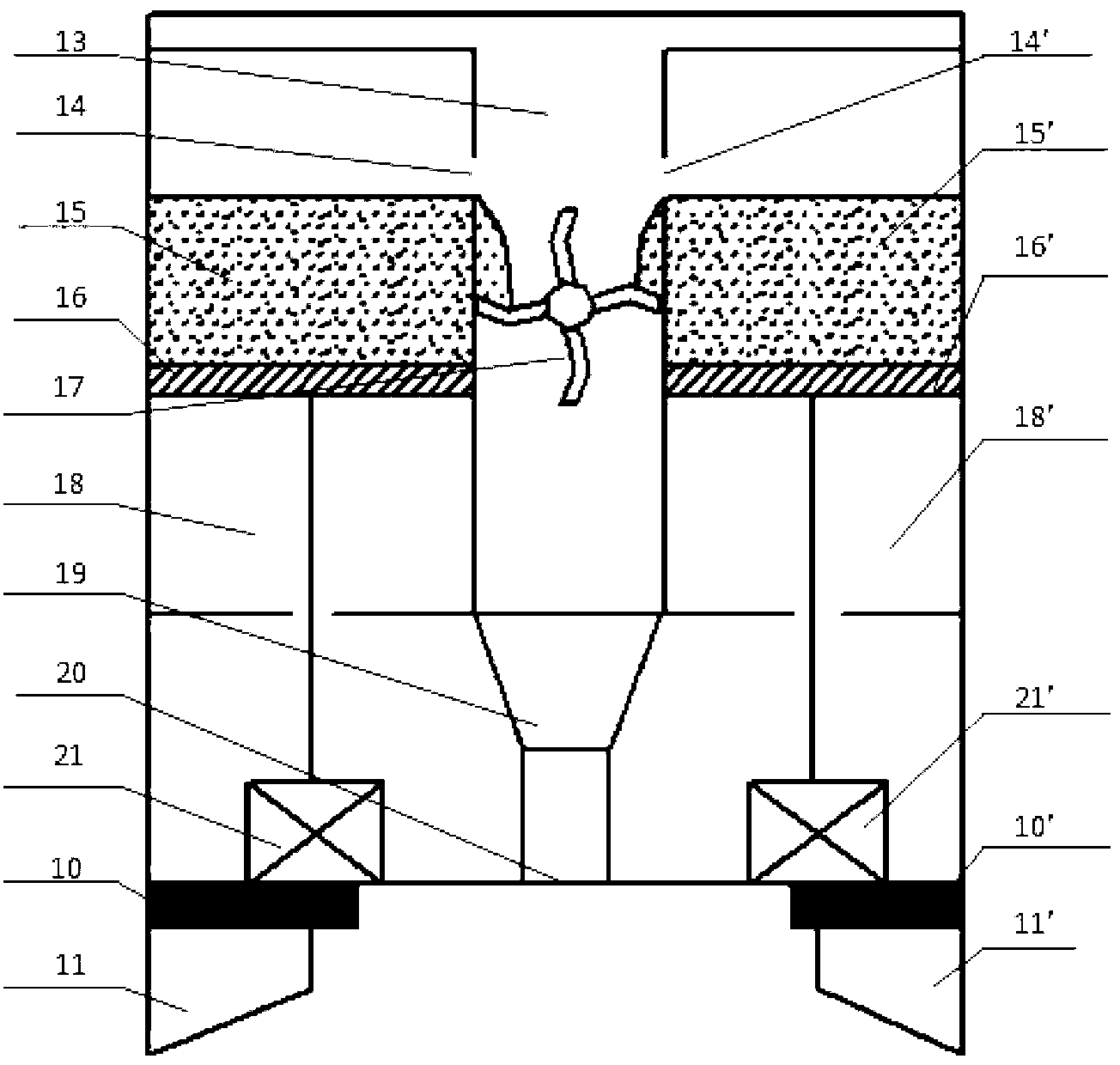

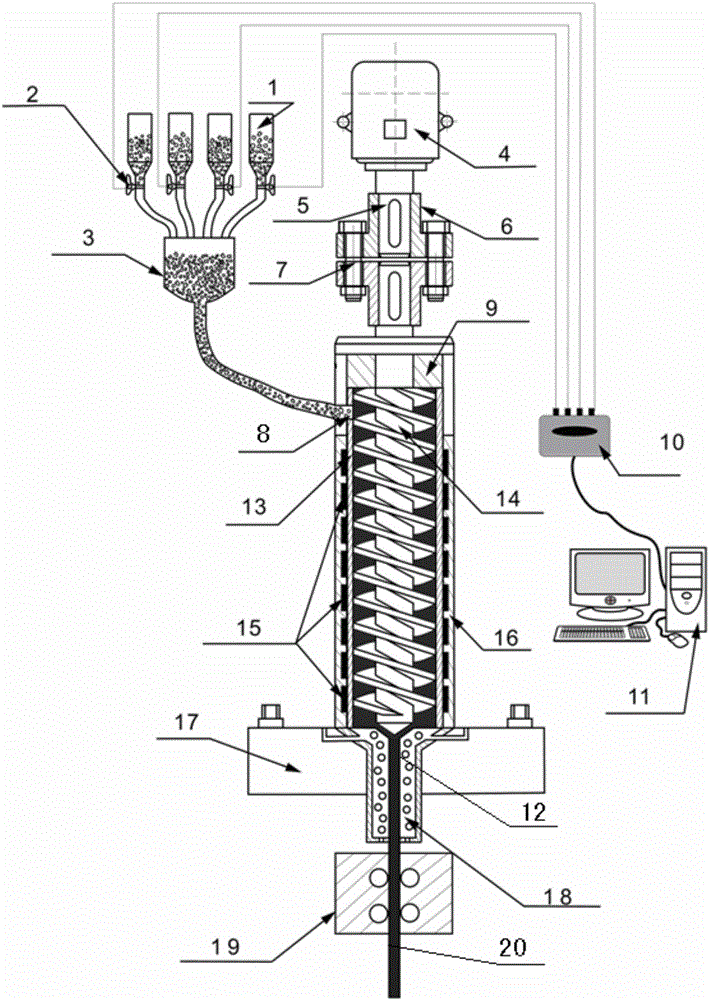

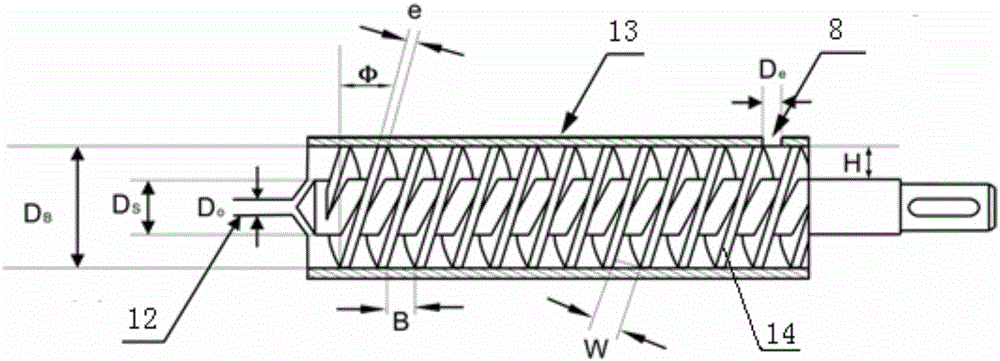

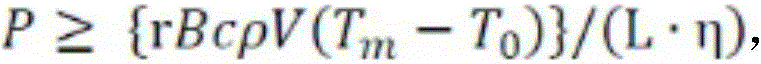

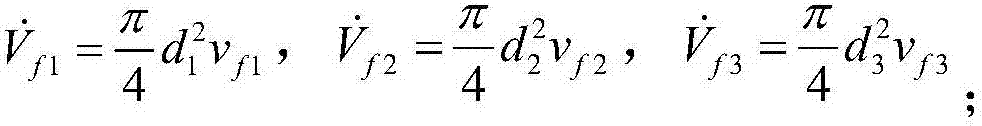

3D printing dispensing extruding device capable of realizing online alloying

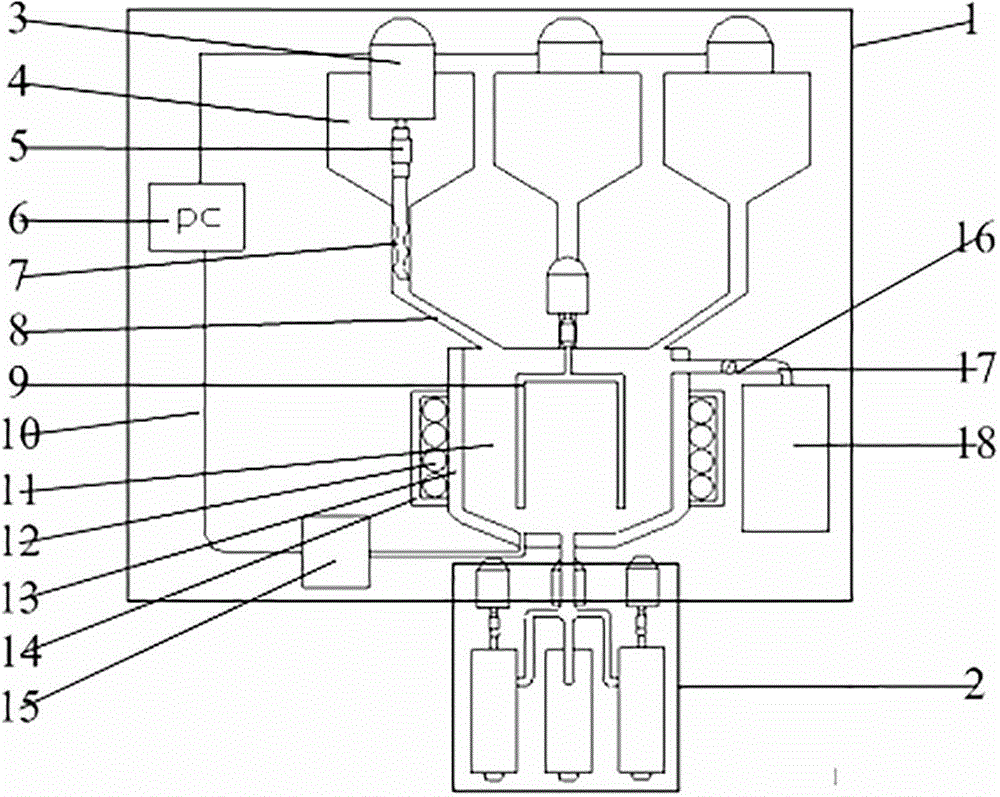

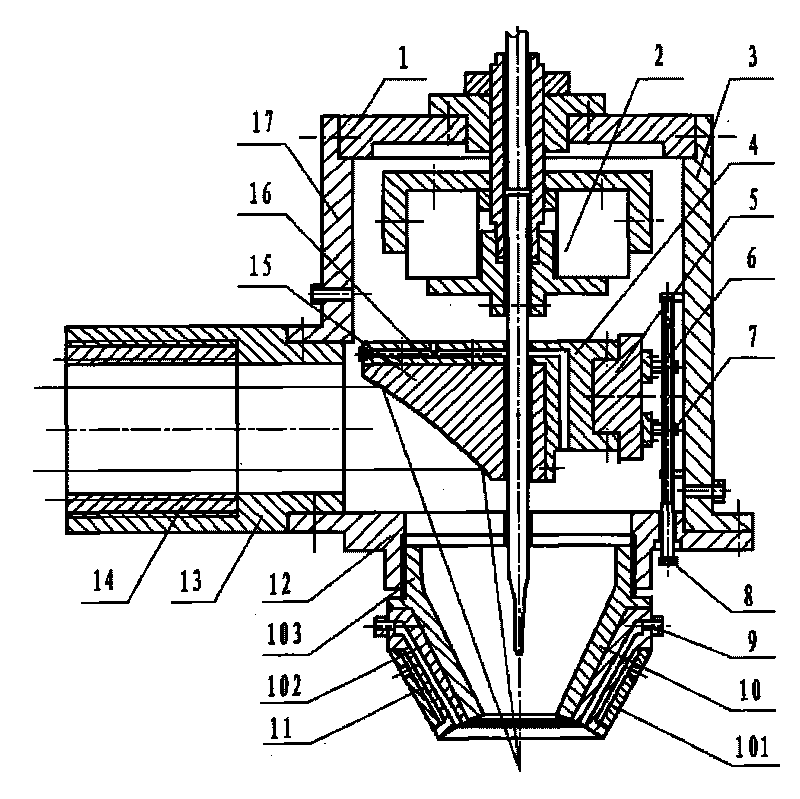

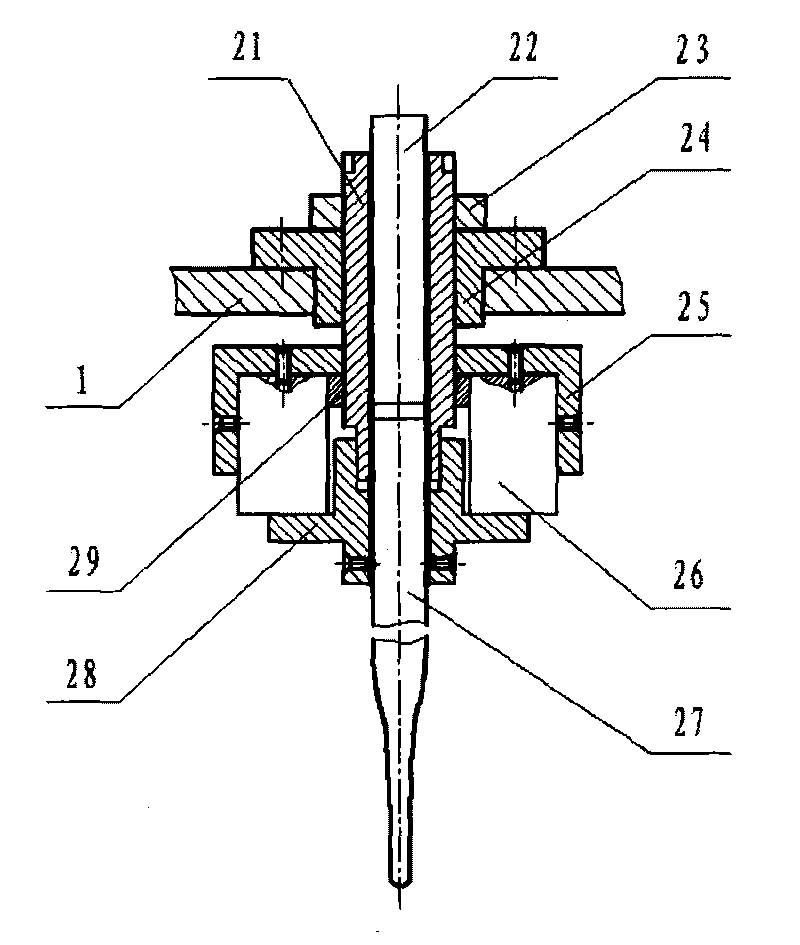

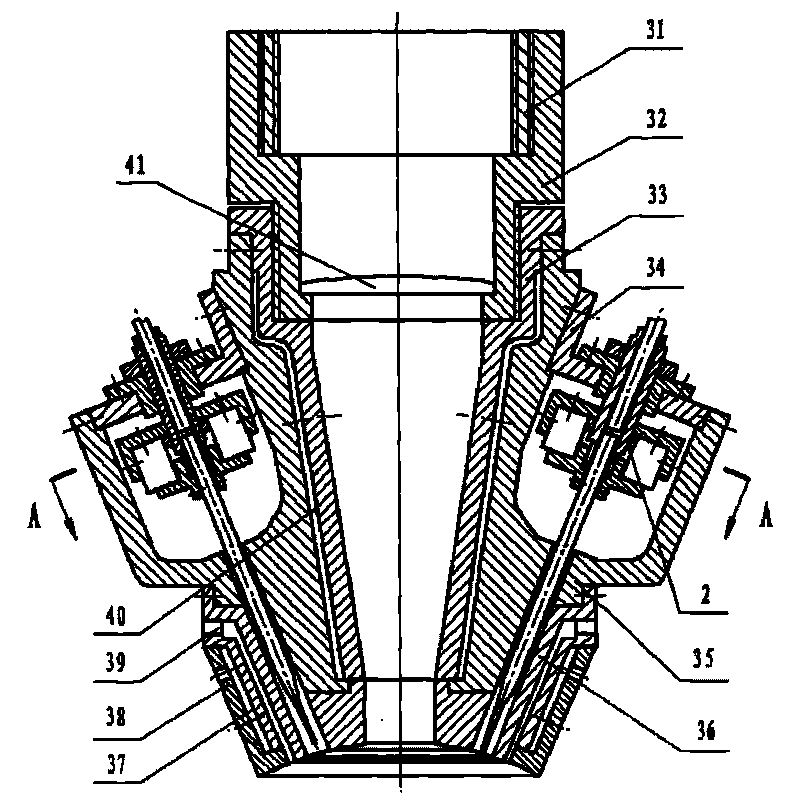

The invention discloses a 3D printing dispensing extruding device capable of realizing online alloying. The 3D printing dispensing extruding device comprises an online dispensing mechanism and a plurality of molten metal extruding spray heads. The online dispensing mechanism comprises more than one storage compartment, a feeding device, a mixing compartment, an air supply device, an online molten metal component detection device and a PC. The six molten metal extruding spray heads are communicated to the bottom of the mixing compartment through conveying pipes, and a screw extruding mechanism is arranged inside each extruding spray head, so that the real-time controllable extrusion of the molten metal can be realized. In the working process, the current layer material information is firstly printed according to 3D, the preparation, mixing, melting and online detection of a metal raw material are carried out by the online dispensing mechanism, when the molten metal component meets the requirement, the molten metal is led into the extruding spray heads through conveying pipes on the lower end of the mixing compartment, and then the molten metal component is extruded by the screw extruding mechanism in each spray head to be scanned, printed and formed layer by layer. The 3D printing dispensing extruding device is reasonable in design and precise in dispensing and is suitable for online mixing and detection of multiple metal powder / particles, and the online alloying of 3D printer and the integrated formation of gradient material structural parts can be effectively achieved.

Owner:ADVANCED MFG TECH CENT CHINA ACAD OF MASCH SCI & TECH

Preparation method for quick preparing functional gradient material

ActiveCN1803348ASimple processImprove productivityProgramme controlComputer controlProduction rateGradient material

The invention discloses a rapid making method of functional gradient material, which comprises the following steps: grading the dosage according to the component ratio; affirming the laser manufacturing technological parameter for each layer; preheating each layer of powder to do thermal-insulating disposal; paving the powder on the working bench through powder feeding device; scanning layer by layer to realize the preparation of functional gradient material.

Owner:HUAZHONG UNIV OF SCI & TECH

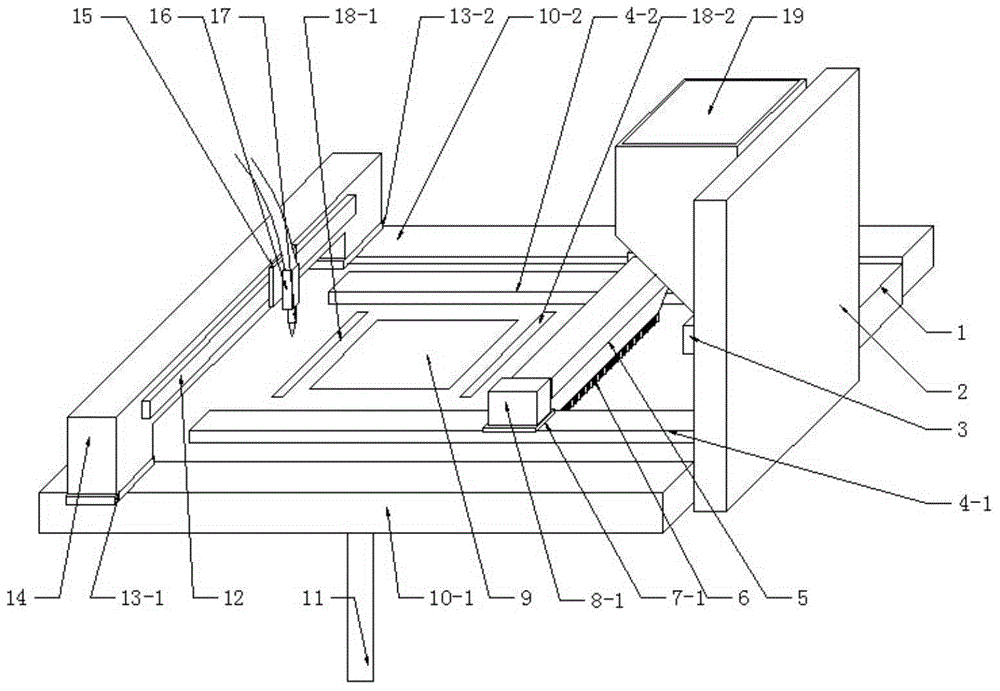

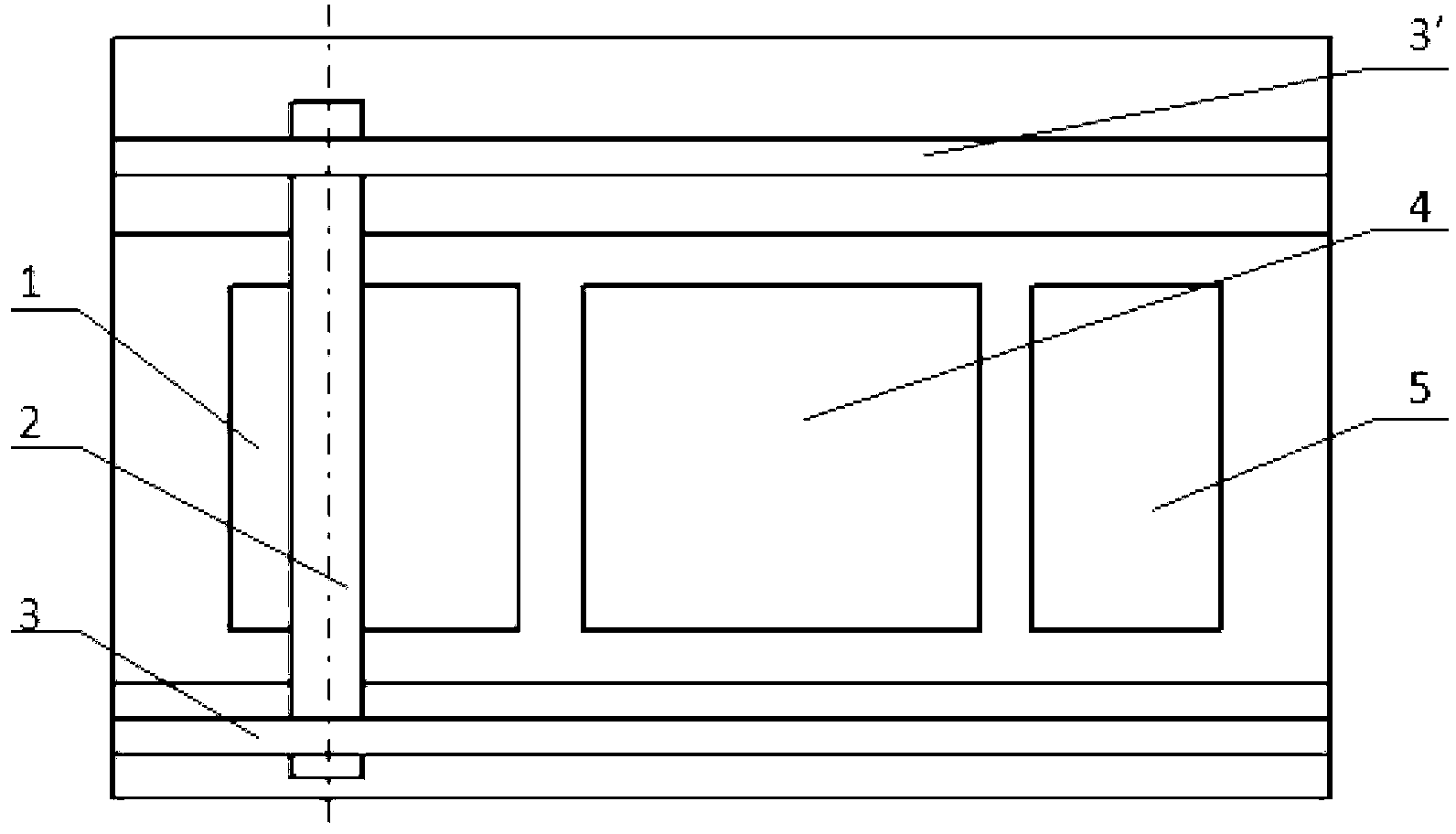

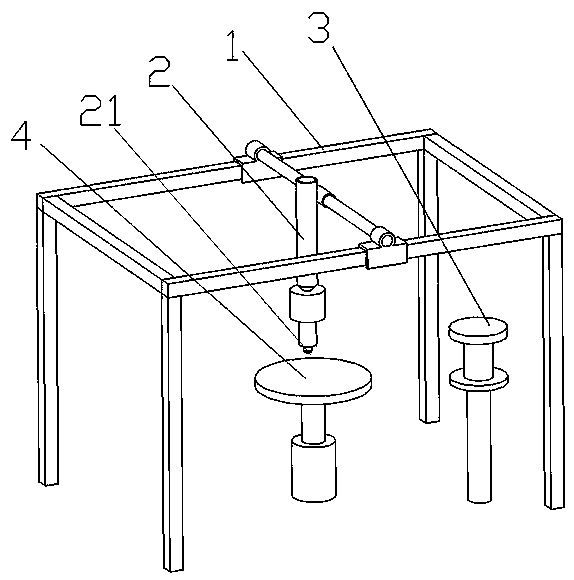

Selective laser melting powder sending and laying device used for compounding of different types of powder

ActiveCN105562687ASolve recycling difficultiesReduce consumptionIncreasing energy efficiencySelective laser meltingMetallurgy

The invention discloses a selective laser melting powder sending and laying device used for compounding of different types of powder. The selective laser melting powder sending and laying device comprises a worktable, a forming cylinder, a powder spraying device and a powder laying device. The upper surface of the forming cylinder is arranged on the worktable. The powder spraying device and the powder laying device are arranged on the two sides of the forming cylinder. The powder spraying device is characterized in that powder spraying electric guide rails, a support, a nozzle electric guide rail and a nozzle are included; the nozzle is arranged on the nozzle electric guide rail; the nozzle electric guide rail is arranged on the powder spraying electric guide rails through the support; and the powder spraying electric guide rails are fixed to the worktable. The powder laying device comprises a powder hopper, a powder scraping electric guide rail and a supporting frame; the powder hopper is arranged on the powder scraping electric guide rail through the supporting frame; and the powder scraping electric guide rail is fixed to the worktable. According to the selective laser melting powder sending and laying device used for compounding of different types of powder, the selective laser melting technology and the laser cladding coaxial powder sending technology are combined, and the purposes of effectively recovering powder during compound additive manufacturing of gradient materials and forming parts with complex gradients in any direction are achieved.

Owner:NANJING UNIV OF SCI & TECH

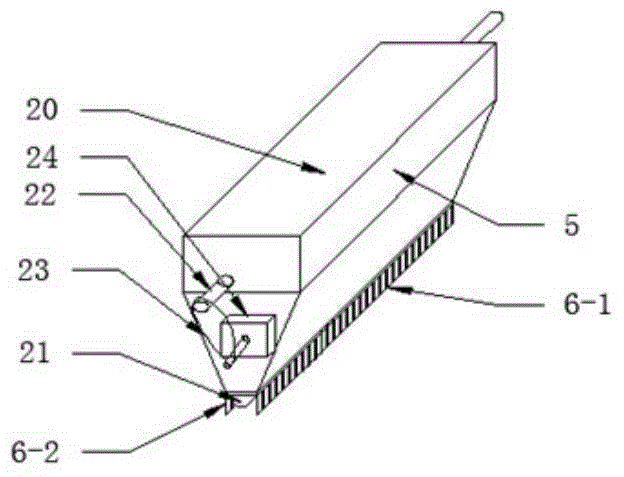

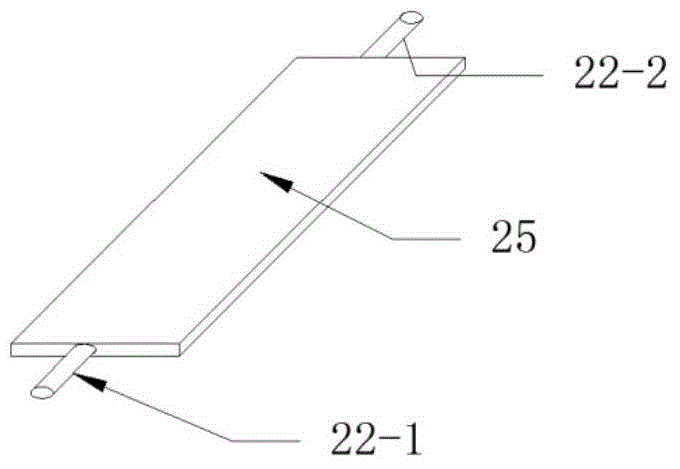

Powder conveying and paving mechanism linked with power bed

ActiveCN103173759AReduce volumeRealize formingAdditive manufacturing apparatusIncreasing energy efficiencyGradient materialEngineering

The invention discloses a powder conveying and paving mechanism for enhanced material manufacturing equipment. The powder conveying and paving mechanism comprises a powder conveying mechanism, a powder paving mechanism and a transmission mechanism, wherein a powder conveying box body performs a side-to-side movement on a forming workbench along a guide rail mounted on the side wall of a forming cavity under the driving of a motor; by mounting scraper plates on the two sides of a lower powder opening, the powder is paved left and right when the powder is conveyed; by filling different powder into a hopper, the conveying quantity of the different powder is controlled accurately by controlling the displacement speed of a piston, so that the proportioning of the different material powder can be adjusted; by utilizing the high-speed rotation of a stirrer, the different powder can be mixed evenly; and the proportioning of the powder can be changed for multiple times during the one-step forming process, so that a gradient material component formed by compounding the multiple materials arbitrarily can be prepared. According to the powder conveying and paving mechanism, the volume of the forming cavity is reduced greatly, so that the powder consumption is saved. In addition, the powder conveying and paving mechanism is simple to operate and convenient to adjust.

Owner:HUAZHONG UNIV OF SCI & TECH

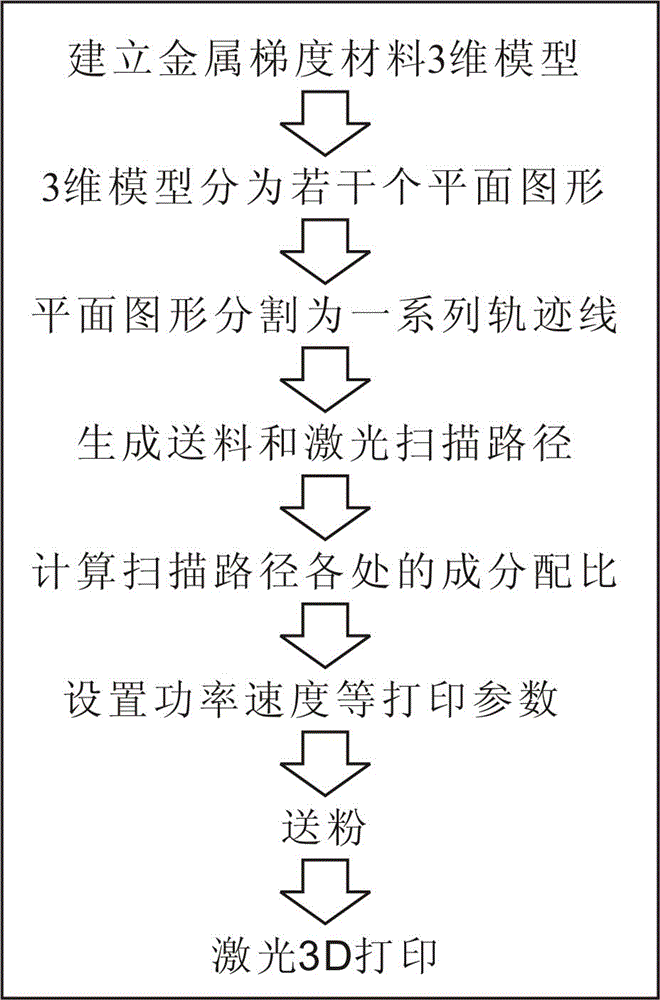

Laser 3D printing manufacturing method of metal gradient material

InactiveCN104439243AImplement gradient distributionImprove work efficiencyIncreasing energy efficiencyGradient materialOptoelectronics

The invention provides an efficient, easy and convenient laser 3D printing manufacturing method of a metal gradient material. The laser 3D printing manufacturing method comprises the steps that (1) a computer three-dimensional diagrammatic sketch of the metal gradient material is built, and a scanning path is built; (2) component ratios of different positions are calculated; (3) corresponding printing parameters are set; (4) raw material powder is fed into a powder conveying barrel; (5) printing equipment is started to carry out laser 3D printing, a feeder carries out feeding according to the set track, the component ratios and speed, meanwhile, a laser device caries out laser cladding on the metal powder, the metal powder forms a whole through melting and solidification, printing is carried out row by row to form a face according to a trace, and printing is carried out layer by layer to form the three-dimensional metal gradient material. The laser 3D printing manufacturing method has the advantages that the raw material component ratios of different positions are strictly controlled through a computer, and therefore gradient distribution of components is achieved in a real sense; powder feeding and melting and solidification are completed at the same time through laser 3D printing, and work efficiency is improved; the 3D printing technology is a material increasing manufacturing method, and compared with a traditional process, raw materials are saved.

Owner:彭晓领

3D printing method of gradient material structure

InactiveCN104923787AFast preparationFast processingIncreasing energy efficiencyComputer control systemGradient material

The invention discloses a 3D printing method of a gradient material structure. Mixed printing of multiple materials can be achieved, and the structure having gradient gradually-changing mechanical property and physical property is processed. The device adopted in the 3D printing method mainly comprises a computer-control system, a powder spreading mechanism, a laser printing system and a printing worktable. When the 3D printing method is used for 3D printing, a gradient gradually-changing layer and a composite layer in a printing layer piece are needed to be further subdivided, and the material component information of layer pieces, selection information of the powder spreading device, powder spreading path information and printing path information are recorded. The information is utilized to control the powder spreading process and printing process in the printing forming process in real time. The 3D printing method is a novel method for quick processing and manufacture of functional gradient material structures and composite material structures and quick manufacture of complicated-shaped functional gradient material structures and composite material structures.

Owner:TONGJI UNIV

Method for preparing tungsten/copper functional gradient material by infiltration - weld method

InactiveCN1593818AEasy to prepare and effectiveSolve thermal stressMetal layered productsFritGradient material

The invention relates to a new method of making tungsten-copper functional gradient material, which consists of pure tungsten layer and tungsten-copper gradient transit layer. First, make the gradient hole-framework with boring fluid of percent 5~80 volume ratio and tungsten powder of 1~20 micron. Infiltrate copper fluid to make the tungsten-copper gradient transit layer. Weld the W / Cu gradient layer and the pure tungsten by hot pressure. The process is following: mix the material and mould them, then frit framework, Infiltrate copper, weld and check. The method has both the advantage of melt-casting technique and jointing technique. The tungsten-copper functional gradient material made by this method is better heatproof and suited to electric sealing material, heat sinking material, and anti-high temperature plasma scouring unit such as the first layer material in nuclear fusion.

Owner:UNIV OF SCI & TECH BEIJING

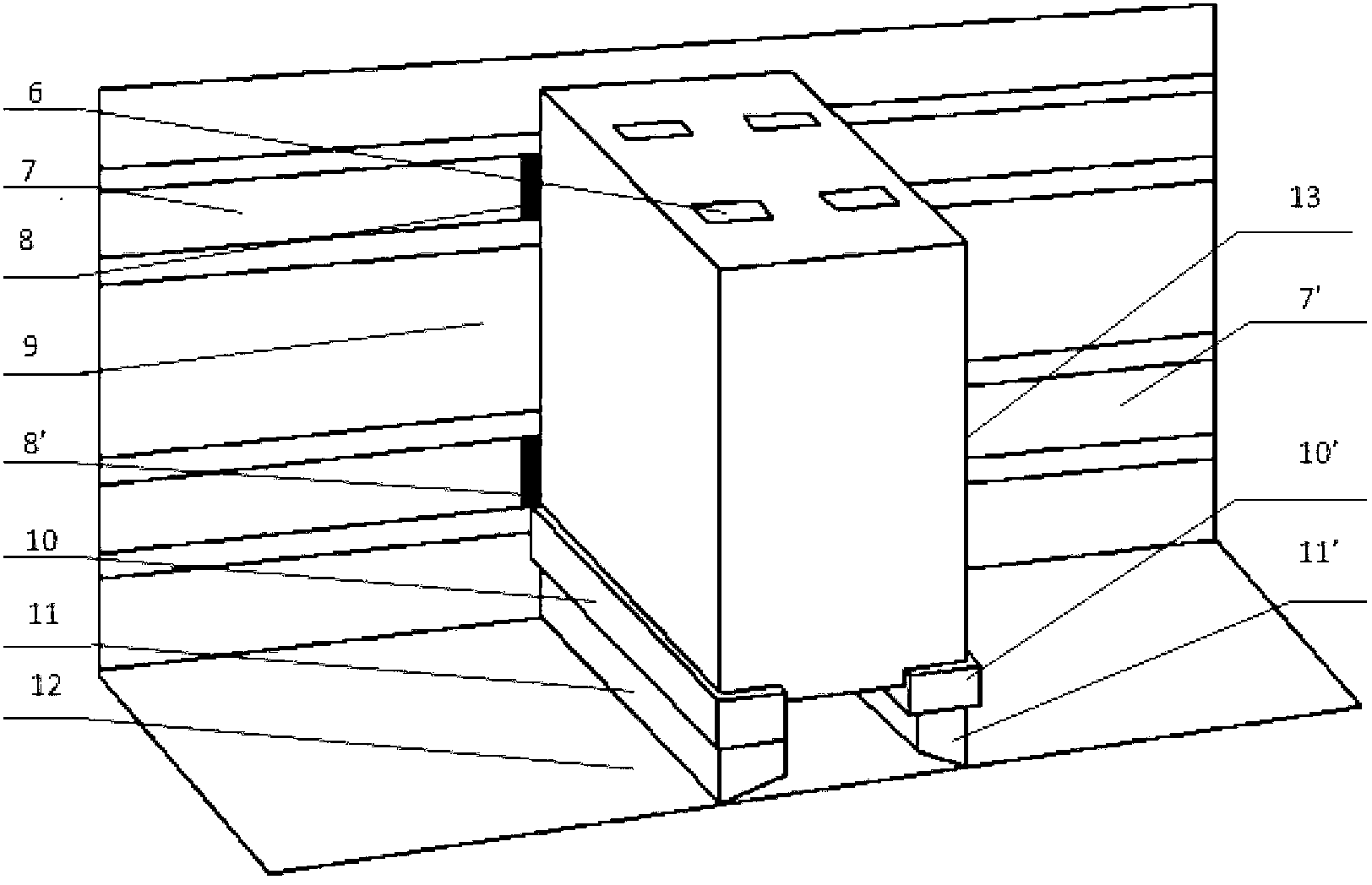

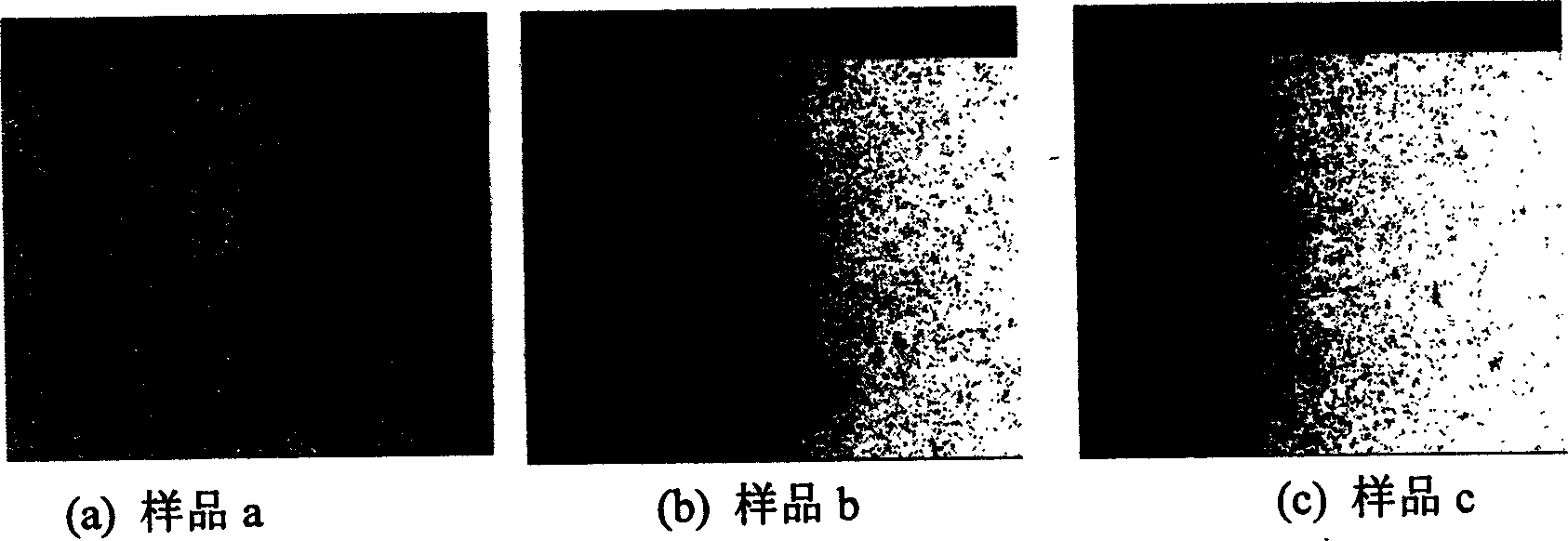

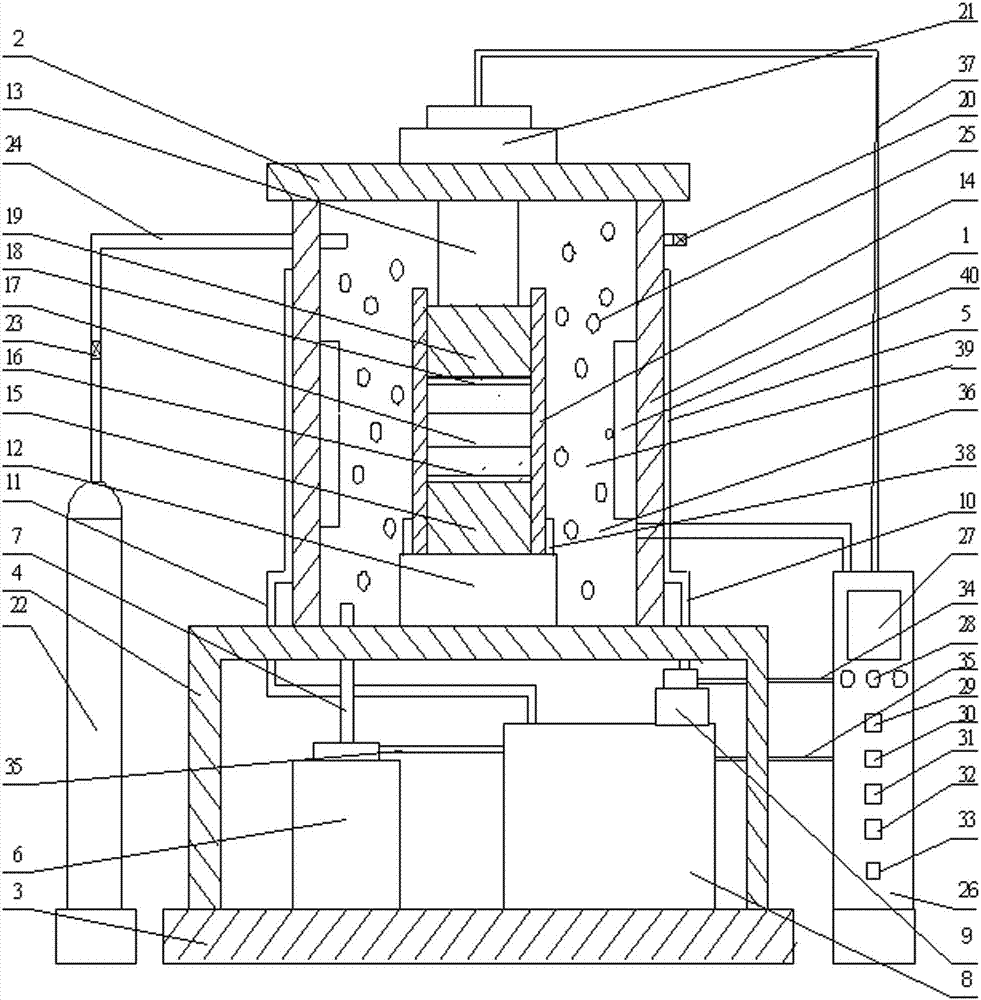

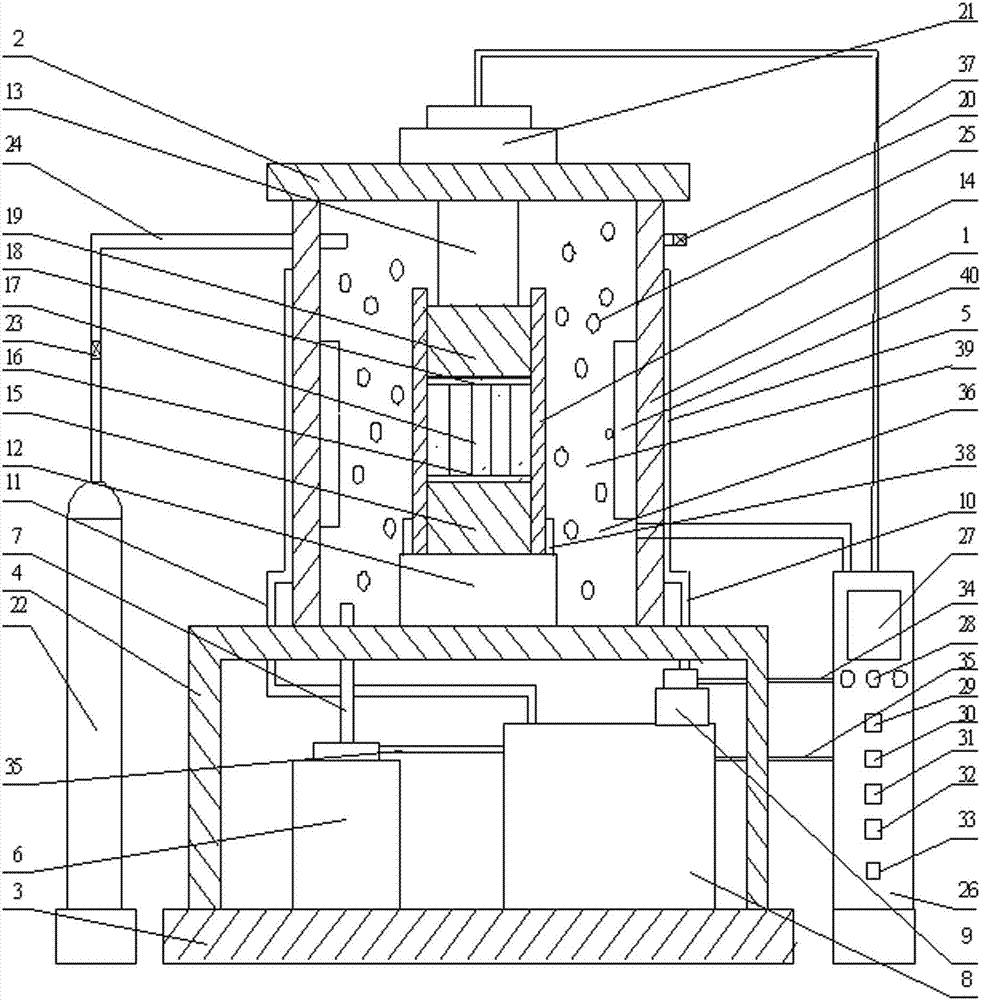

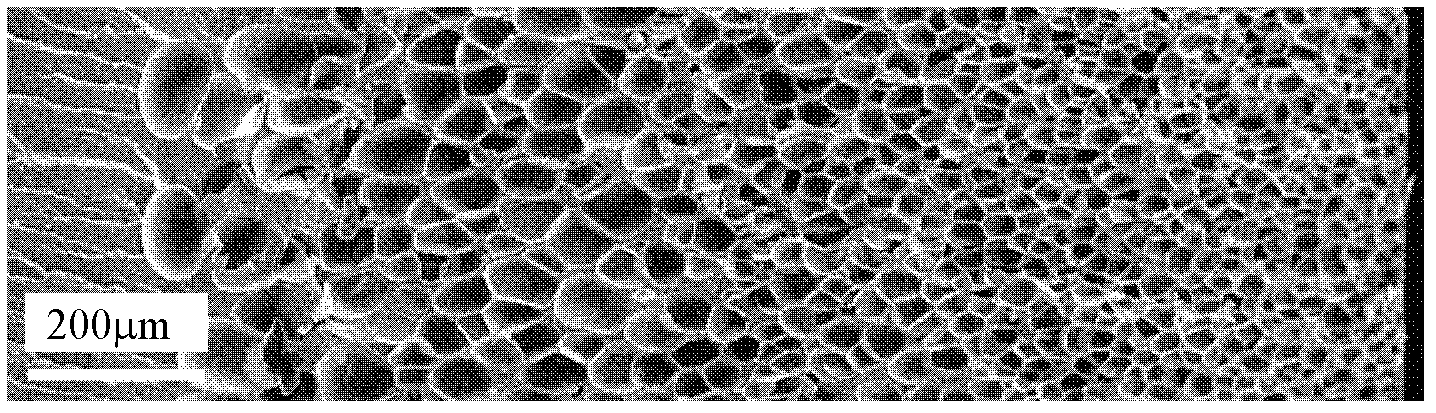

Device for high-throughput preparation of multi-component gradient metal materials

ActiveCN105954074ASimple structureEasy to useAdditive manufacturing apparatusPreparing sample for investigationGradient materialMetallic materials

The invention belongs to the field of metal processing preparation, and in particular, relates to a method for high-throughput preparation of multi-component gradient metal materials for multi-component alloy tubes, rods, sectional materials and other long materials with continuous gradient distribution of chemical components in the length direction. The device comprises a powder flow velocity on-line regulating system, a rotary feeding system, a heating system, a heat preservation system, a motor drive system, a blank forming system and a control system. By adopting the technical scheme, the device has the advantages of simple structure, convenient use and easy control; the device achieves preparation of high-throughput preparation of the multi-component gradient metal materials through controlling of molten metal components and a continuous casting process, shortens the time course of the materials in composition design, melting, performance preparation and application preparation, reduces the metallurgical energy consumption of multi-furnace smelting of the alloys, reduces development costs, and improves the preparation quality and efficiency of the new metal gradient materials.

Owner:UNIV OF SCI & TECH BEIJING

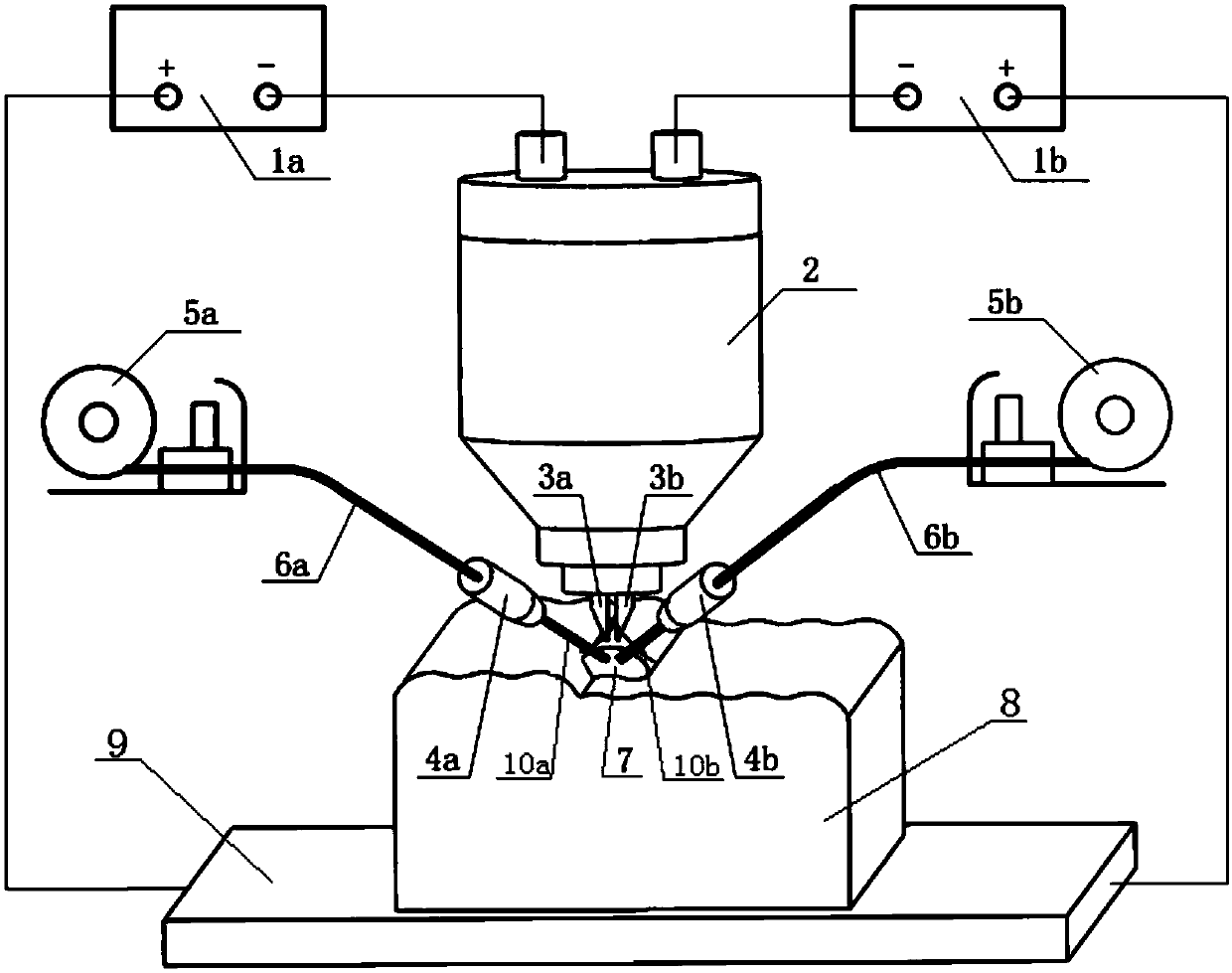

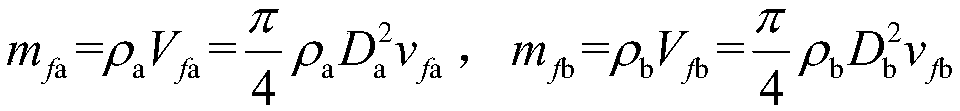

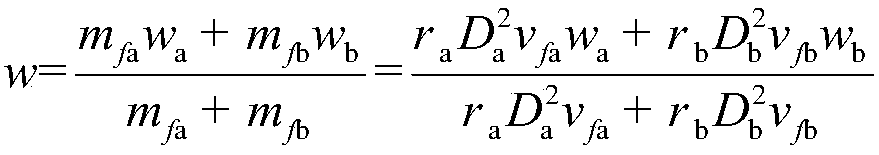

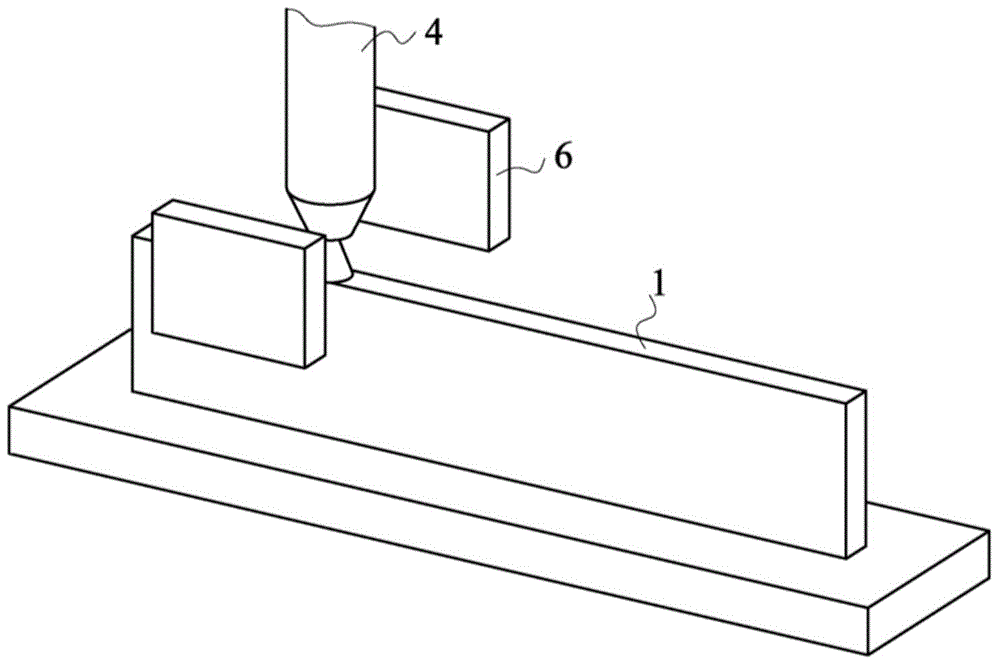

Device and method for gradient materials additive manufacturing by using two-wire twin-electrode tungsten inert gas arc

InactiveCN108788389ABroaden process specification windowImprove deposition efficiencyAdditive manufacturing apparatusArc welding apparatusMelting tankPower flow

The invention provides a device and method for gradient materials additive manufacturing by using two-wire twin-electrode tungsten inert gas arc. A first partial tungsten electrode and a second partial tungsten electrode are installed below a two-tungsten-electrode argon arc additional material manufacturing gun of the device, and are vertically arranged above a base plate. A first wire guide nozzle and a second wire guide nozzle are arranged in front of the two-tungsten-electrode argon arc additional material manufacturing gun. In the deposition process, two metal wires of dissimilar compositions are conveyed to a melting bath at the same time, the composition and performance of a deposition bead are controlled by adjusting the feeding proportion of the metal wires, and thus manufacturingof the gradient material arc additional material is achieved. It is ensured that excellent forming can still be achieved in the deposition process with large current and high wire feeding speed, thecomposition of the prepared gradient material formed part can be continuously transited from the composition of one metal wire to the composition of the other metal wire without replacement of the welding wires, and the deposition efficiency is up to 330 cm<3> / h; and in addition, the deposition bead is more uniform in composition, and the relative error between the components of the deposition bead and target set compositions is smaller than 10%.

Owner:HARBIN INST OF TECH

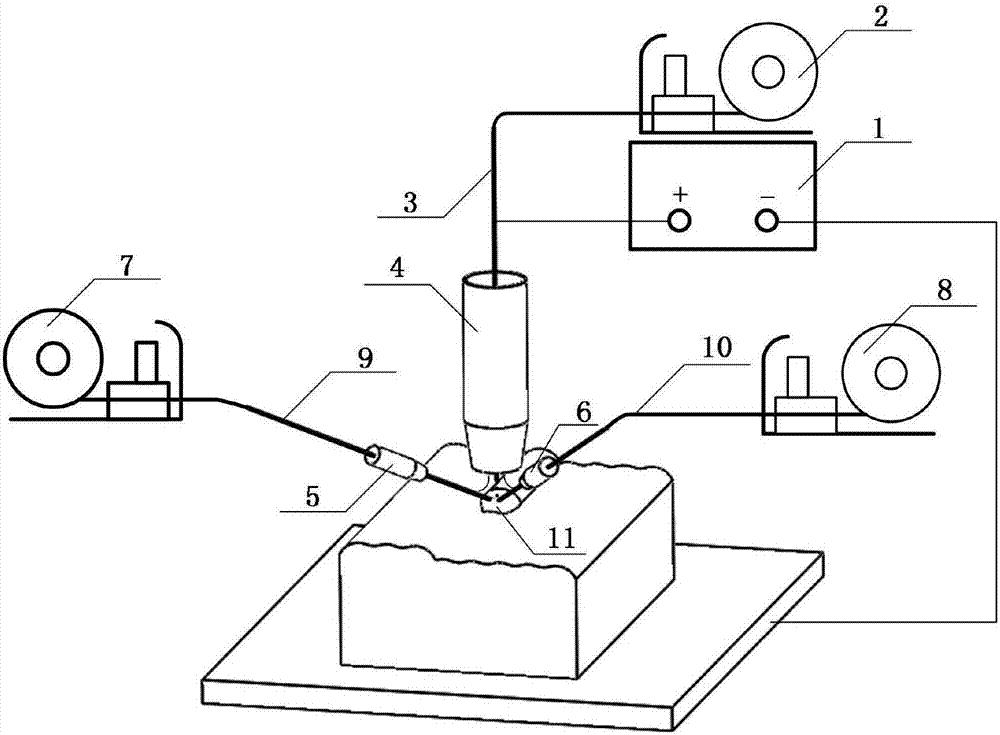

Auxiliary wire filling GMA additive manufacturing device and method for gradient material manufacturing

ActiveCN107414259AImprove energy utilizationSimple structureWelding accessoriesMelting tankGradient material

The invention discloses an auxiliary wire filling GMA additive manufacturing device and method for gradient material manufacturing. The device comprises a GMAW arc welding power source, a wire feeder, a GMAW welding gun, two wire guiding nozzles and two auxiliary wire filling wire feeders. The wire feeder is used for conveying a consumable electrode welding wire, and a feeding hose of the wire feeder is connected with the GMAW welding gun. The GMAW welding gun is vertically arranged over a molten bath and used for guiding the consumable electrode welding wire into the molten bath, and the generated arc is located between the consumable electrode welding wire and the molten bath. The two auxiliary wire filling wire feeders are used for conveying homogenous filling welding wires and heterogeneous filling welding wires, and feeding hoses of the two auxiliary filling wire feeders are connected with the two wire guiding nozzles correspondingly. The two wire guiding nozzles are fixed to the front end of the GMAW welding gun and used for guiding the homogenous filling welding wires and the heterogeneous filling welding wires to be fed into the molten bath. The auxiliary wire filling GMA additive manufacturing device and method solve the problem that in the traditional GMA additive manufacturing process, heat accumulation of a formed part is serious, and continuous component adjustment cannot be achieved.

Owner:HARBIN INST OF TECH

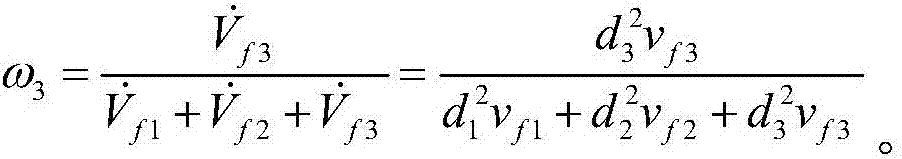

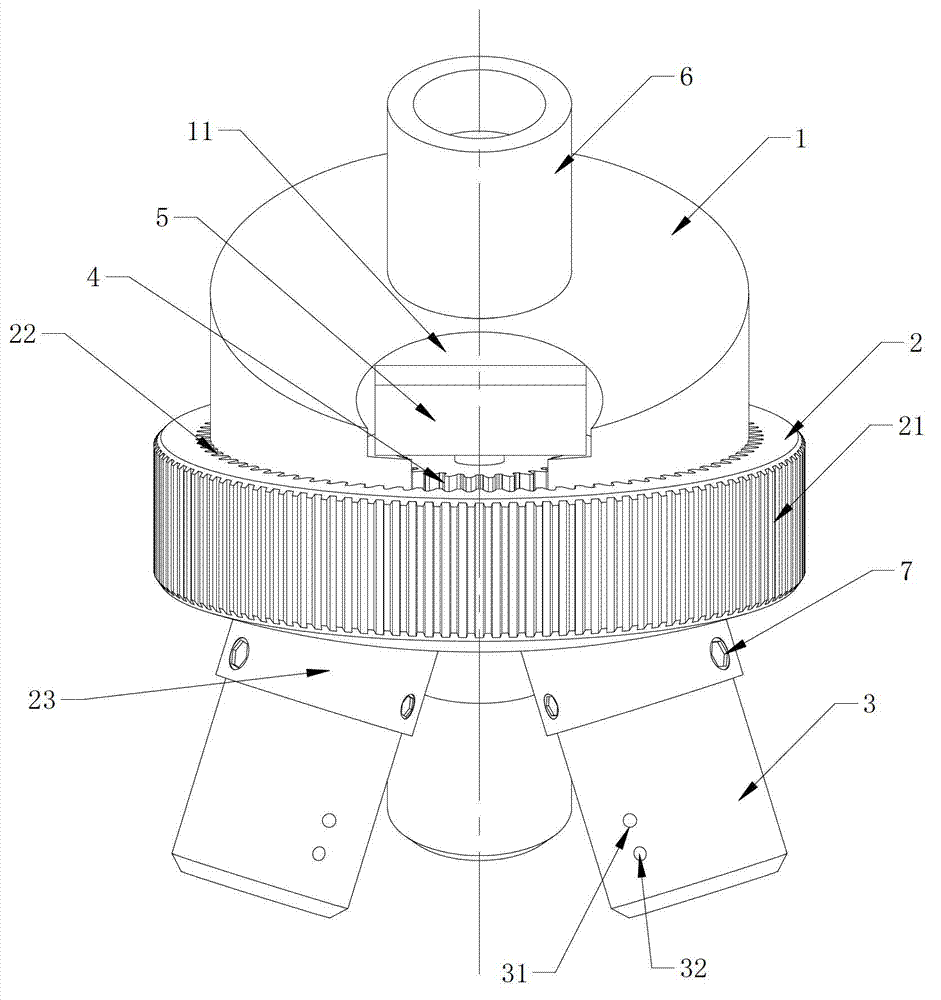

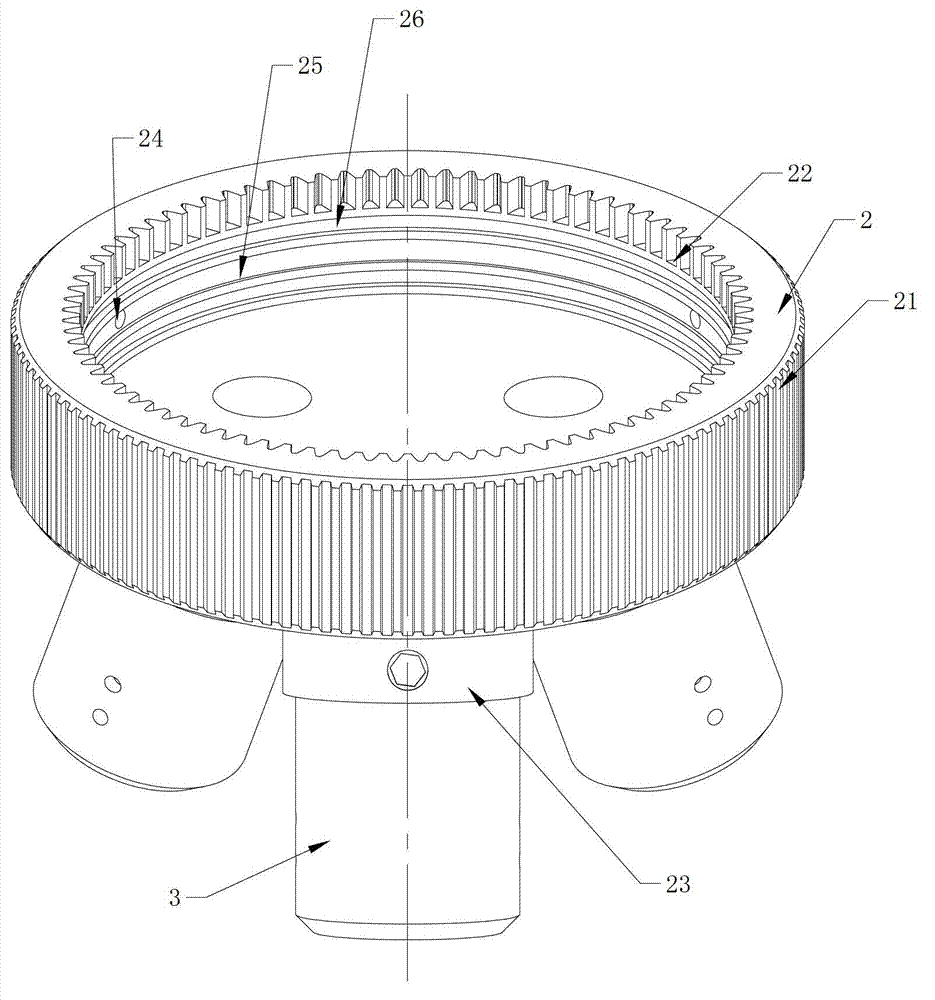

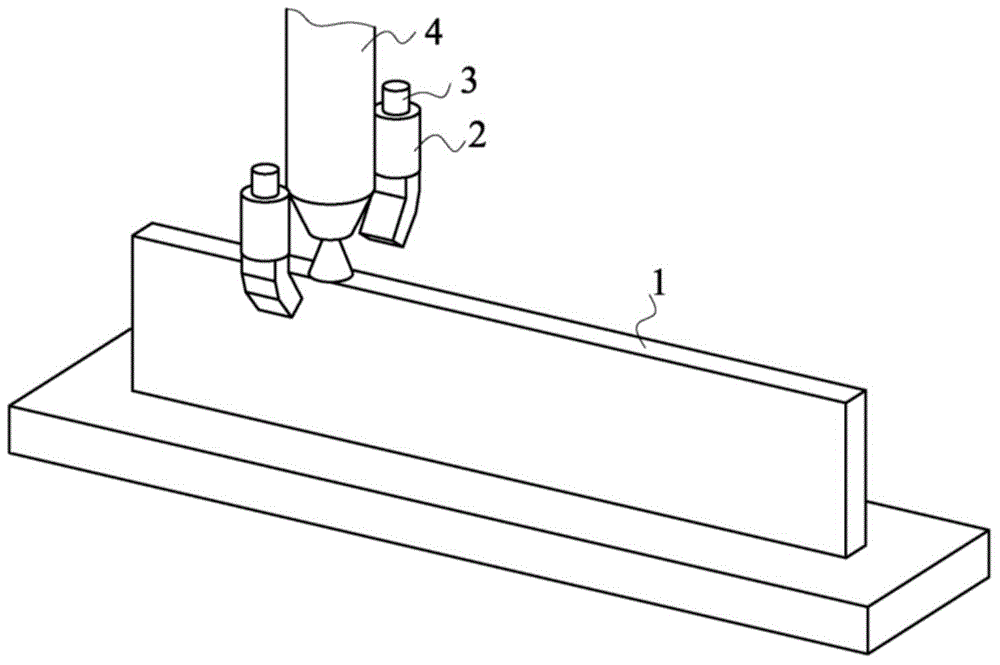

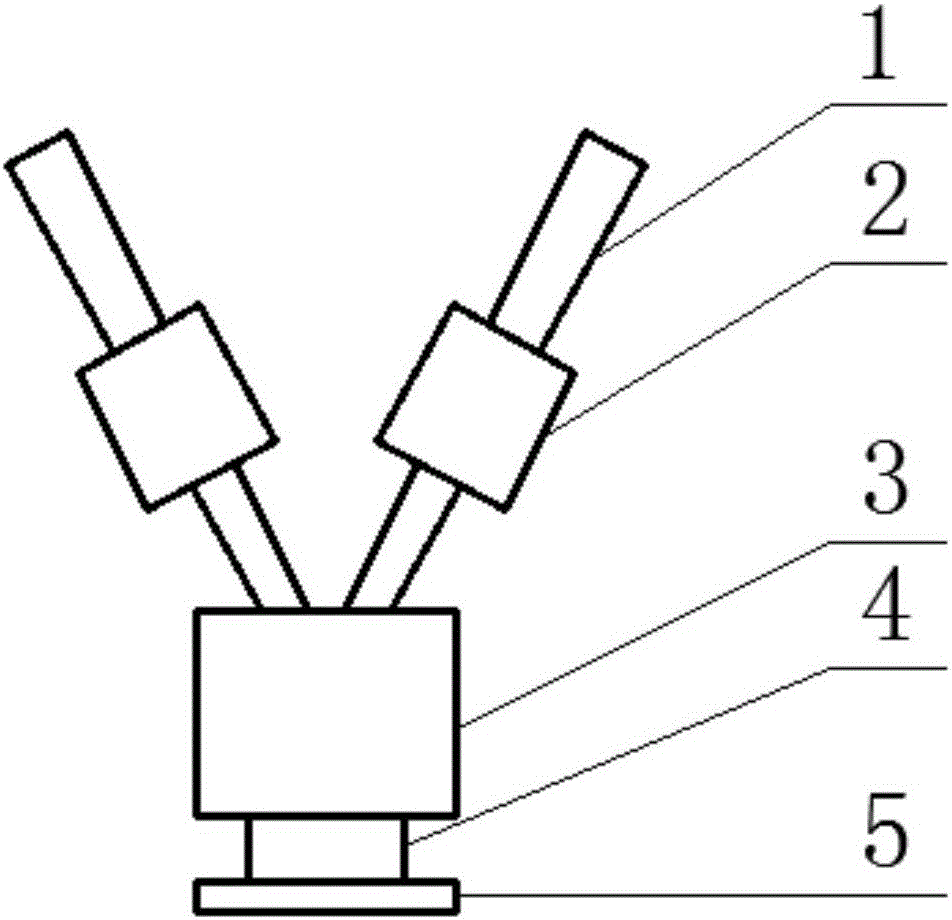

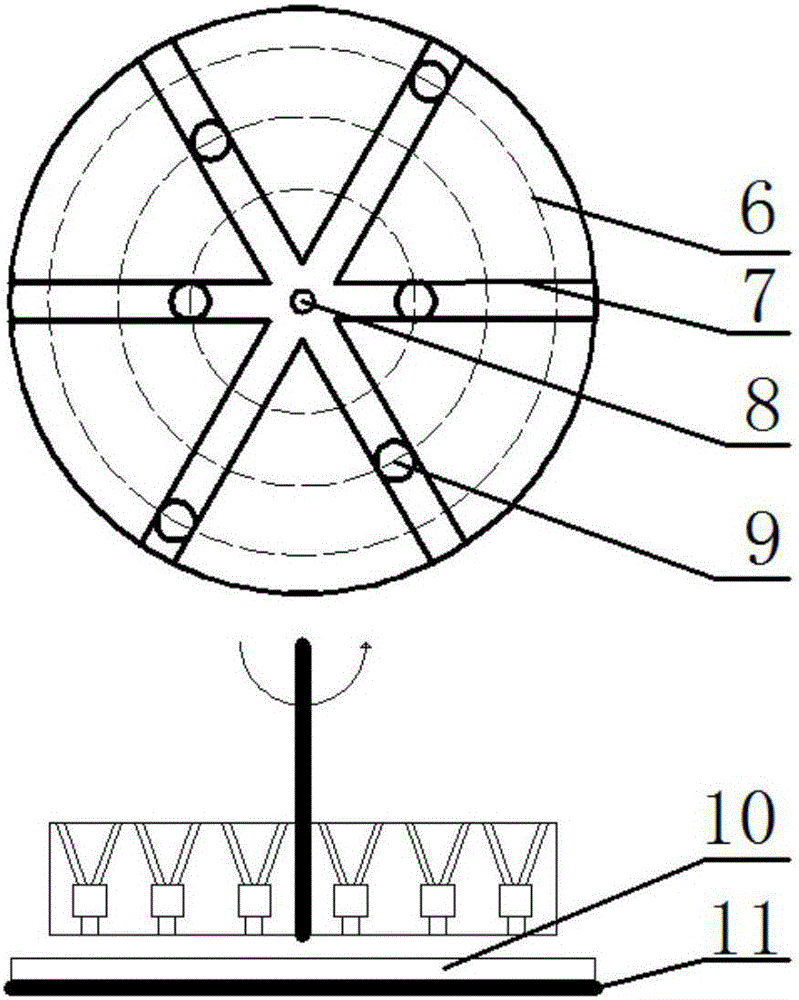

Laser 3D (three-dimensional) printing device with multiple inkjet heads

The invention discloses a laser 3D printing device with multiple inkjet heads. The laser 3D printing device with multiple inkjet heads includes a laser generator, a laser inkjet head, a mechanical arm and a working table, wherein the laser inkjet head includes a laser head and a power inkjet head assembly, the power inkjet head assembly comprises a connecting base, a rotating disc and at least two power inkjet heads, the rotating disc is sleeved outside the periphery of the connecting base, the connecting base is provided with a laser through hole which is coaxially communicated with a laser jet hole of the laser head, the at least two power inkjet heads are detachably arranged on the rotating disc and are distributed relative to the periphery of the rotating center of the rotating disc, any power inkjet head is coaxially communicated with the laser jet hole when rotating to a working station, and a fixing unit is arranged between the rotating plate and the connecting base. The laser inkjet head of the laser 3D printing device with the multiple inkjet heads is provided with a plurality of powder inkjet heads and the plurality of powder inkjet heads can be used alternately so that the laser 3D printing device can use a plurality of metal powers to print under the condition that the laser inkjet head is not changed, and the laser 3D printing device meets the 3D printing requirements of FGM (Functionary Gradient Materials) metal pieces.

Owner:CHANGZHOU TIANZHENG IND DEV CO LTD

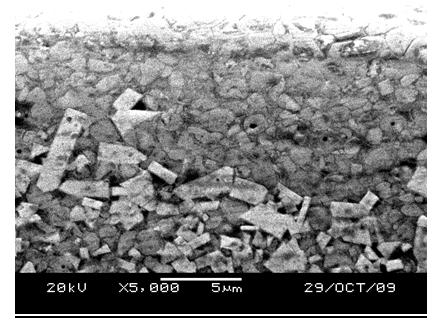

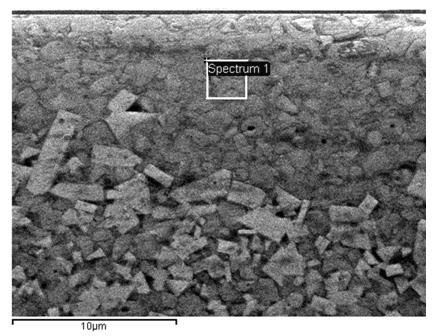

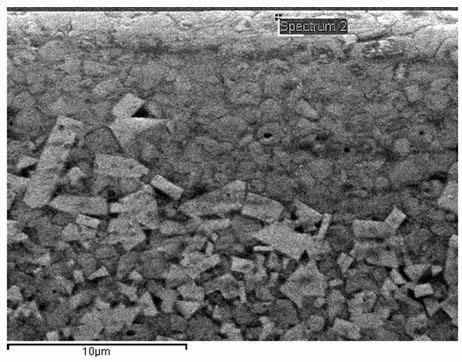

Functionally gradient hard alloy with cubic phase-rich surface and preparation method thereof

InactiveCN102134660AHigh value-added productsEasy to realize technology transformationSolid state diffusion coatingGradient materialAlloy

The invention discloses a functionally gradient hard alloy with a cubic phase-rich surface and a preparation method thereof, and belongs to the technical field of preparation of gradient materials through surface nitriding treatment. A gradient layer of the hard alloy comprises a surface layer rich in cubic phases, and a transition layer rich in binding phases under the surface layer; and the wear resistance and toughness of the alloy can be improved simultaneously, and the alloy can be used for machining metals. In the preparation method, the functionally gradient hard alloy is prepared by a nitriding and sintering process; and by controlling the sintering temperature, sintering time and a nitrogen pressure parameter, the components and thickness of the gradient layer of the alloy are controlled. The invention has the advantages that: the conventional equipment and process are not changed greatly, and the functionally gradient hard alloy can be produced; and the invention is suitable for industrial production.

Owner:CHONGQING UNIV OF ARTS & SCI +1

Method for preparing functional gradient material by adopting doctor-blade casting process

InactiveCN1460661AIncrease the areaChange the strength of the magnetic fieldOrganic solventGradient material

The method for preparing functional gradient material by adopting doctor-blade casting process includes the following steps: 1). mixing ceramic powder, strong-magnetic metal powder, organic solvent and additive according to a certain proportion, stirring them in ball-grinding machine to obtain uniform dispersed slurry material; 2) in the static magnetic field with magnetic field intensity of 0.1-5.0 Tesla making the slurry material into film by means of doctor-blade casting process; and (3) drying and sintering, and forming.

Owner:ZHEJIANG UNIV +1

Gel-casting 3D printing preparation method for ceramic gradient material

InactiveCN104493952AImplement gradient distributionImprove work efficiencyCeramic shaping apparatusGradient materialAdditive ingredient

The invention discloses a gel-casting 3D printing preparation method for ceramic gradient material. The gel-casting 3D printing preparation method for the ceramic gradient material includes steps that 1) building a computer three-dimensional sketch map of the ceramic gradient material, slicing, and building a scanning route; 2) calculating ingredient proportions of different positions; 3) setting corresponding printing parameters; 4) preparing ceramic ingredient, organic monomer, cross-linking agent, initiator, catalyst and the like; 5) starting printing equipment to perform sol-gel 3D printing, pouring the ceramic ingredient, organic premixed liquid, initiator and catalyst to a printing head, and printing to form according to a set track and a set speed after mixing; 6) sintering the green body to prepare the ceramic gradient material. The gel-casting 3D printing preparation method for the ceramic gradient material has advantages that the gradient distribution for the ingredients is really realized through using a computer to control the ingredient proportions at different positions; the 3D printing technology belongs to a material increase preparing method, compared with a traditional technique, raw material is saved.

Owner:HARBIN UNIV OF SCI & TECH

Tape casting preparation for gradient material in rotating magnetic field

InactiveCN101503297AChange the strength of the magnetic fieldChange the magnetic field speedCombustionOrganic solvent

The invention relates to a preparation method for tape casting of a gradient material in a revolving magnetic field. The existing method has complicated process and high requirement on equipment. The method comprises the following steps: mixing ferromagnetic particles and non-magnetic particles into mixed powder; adding an organic solvent, a dispersing agent, a plasticizing agent and a cementing agent into the mixed powder; adding the plasticizing agent and the cementing agent into the mixed powder after ball milling; and obtaining dispersed slurry through ball milling, ultrasonic dispersion treatment and vacuum degassing; pouring the dispersed slurry into a casting machine to apply revolving magnetic field on the substrate which is made of high temperature resistant ceramic; and carrying out dry combustion to obtain a finished product. The method can prepare thin and flat gradient material with large area in a large ingredient range, and the mature tape casting process is used to ensure that the process for producing the gradient functional material is simplified and cost is reduced.

Owner:CHINA JILIANG UNIV

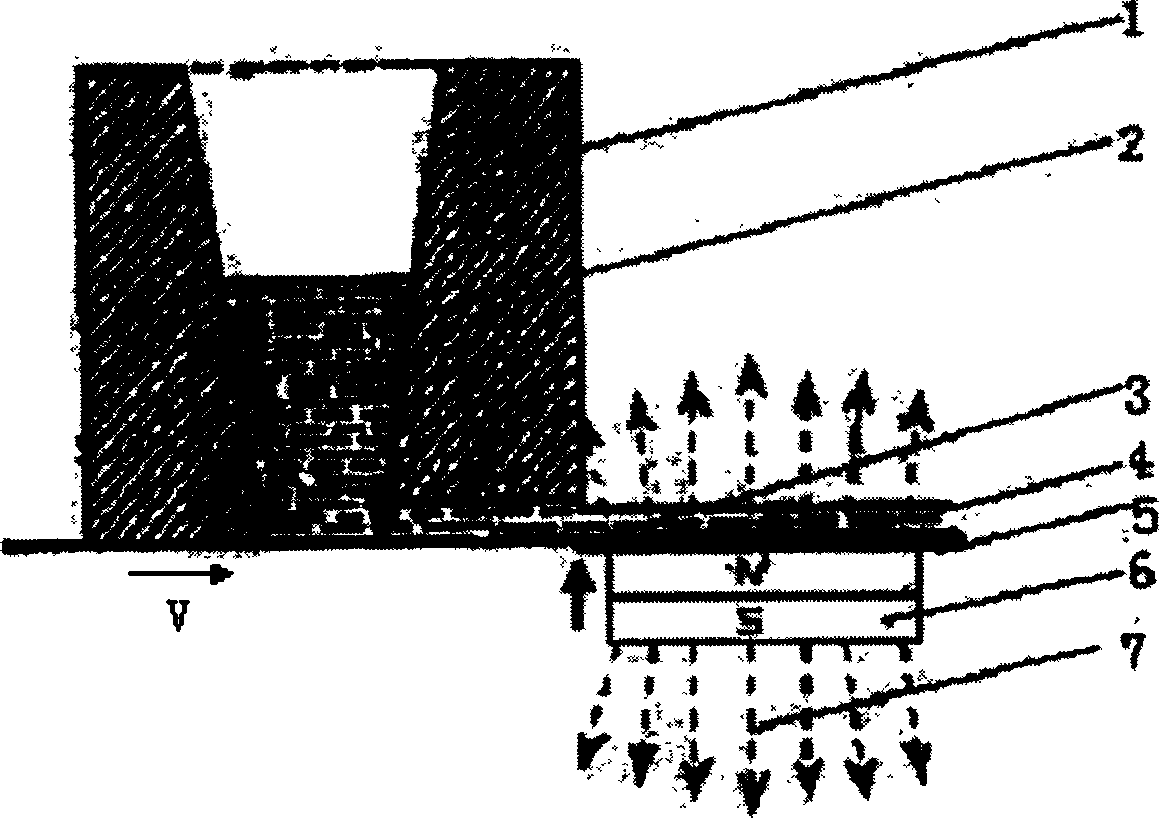

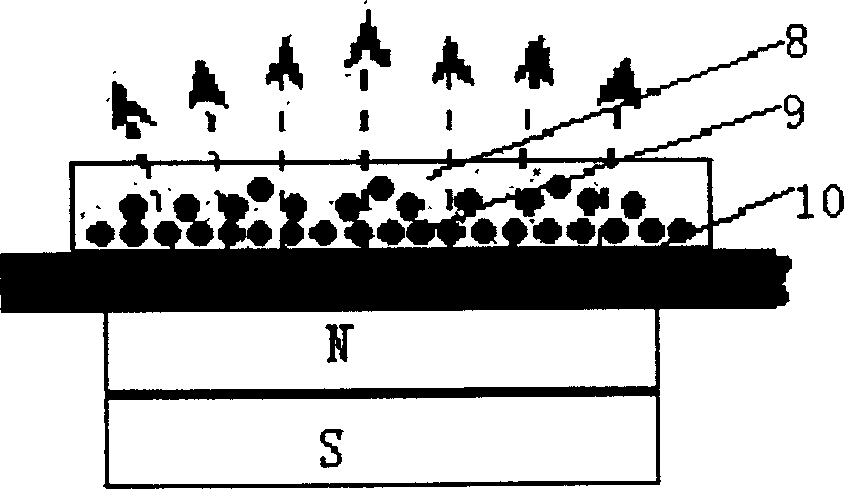

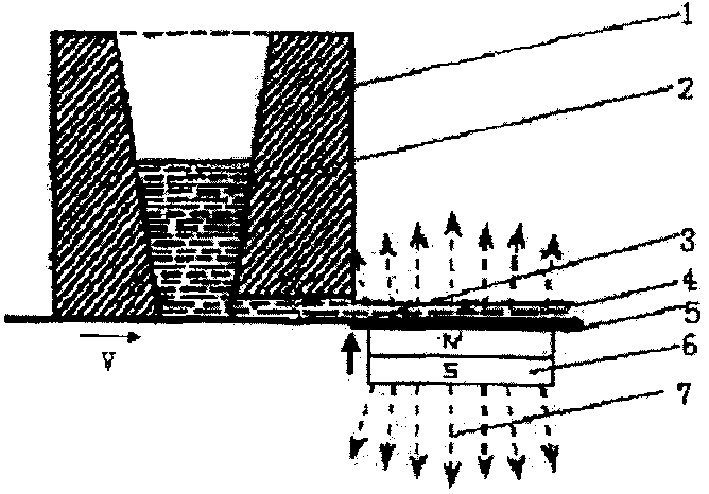

Electromagnetic flexible composite fused deposition direct preparation forming method for gradient part

ActiveCN104959601ARealize integrated manufacturingReduce pollutionAdditive manufacturing apparatusArc welding apparatusNumerical controlPhysical field

Owner:武汉昱峰科技产业发展有限公司

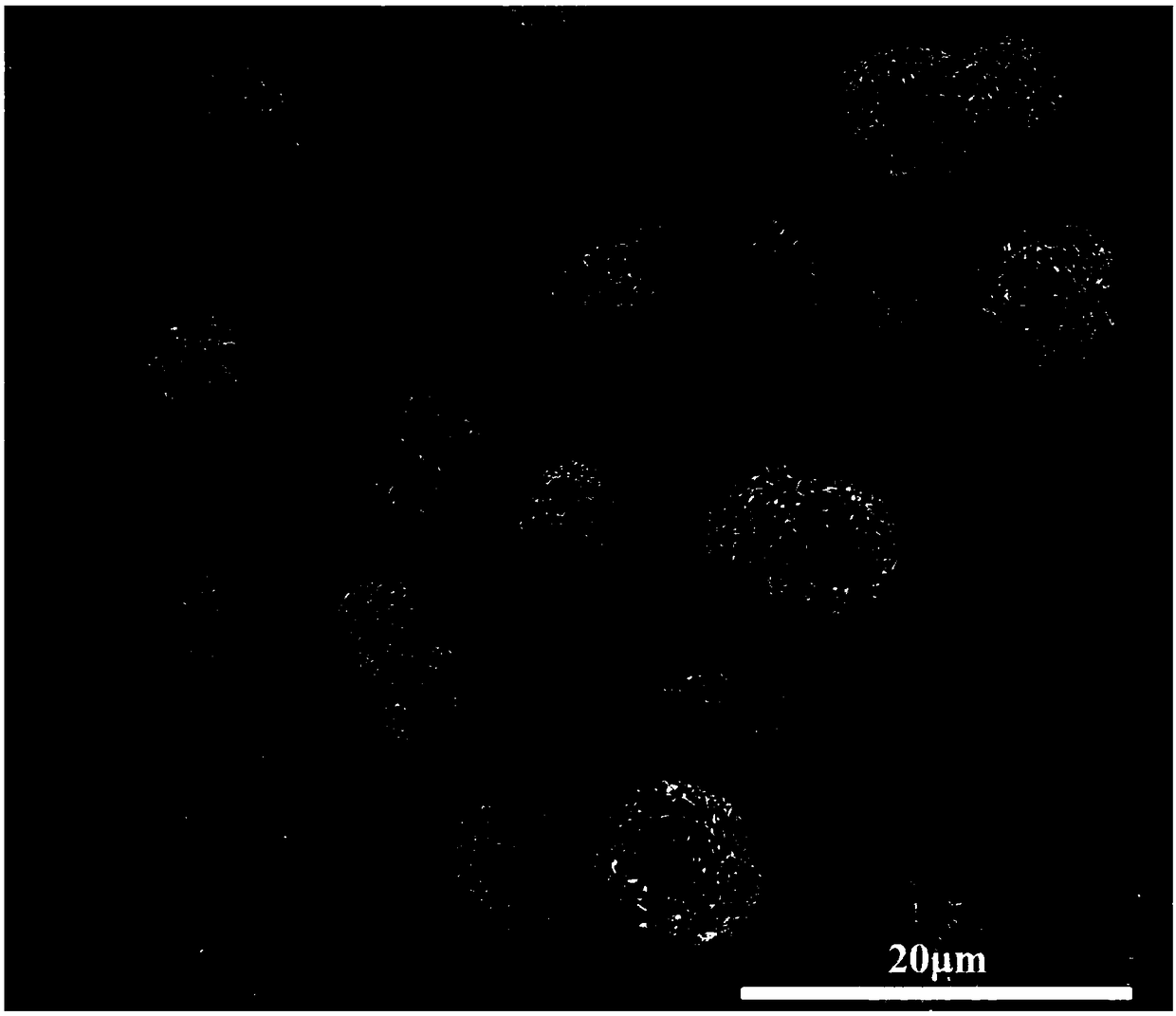

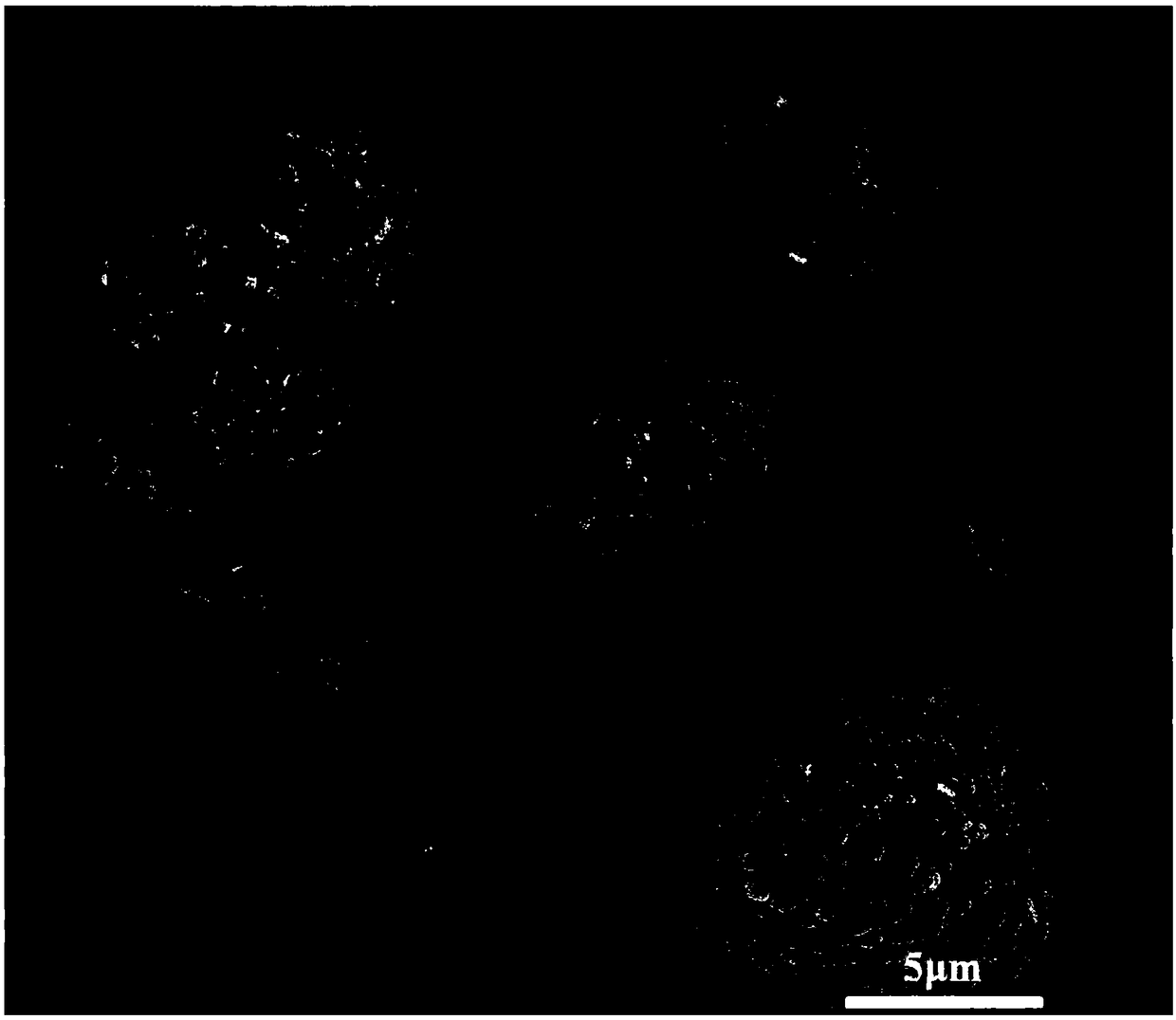

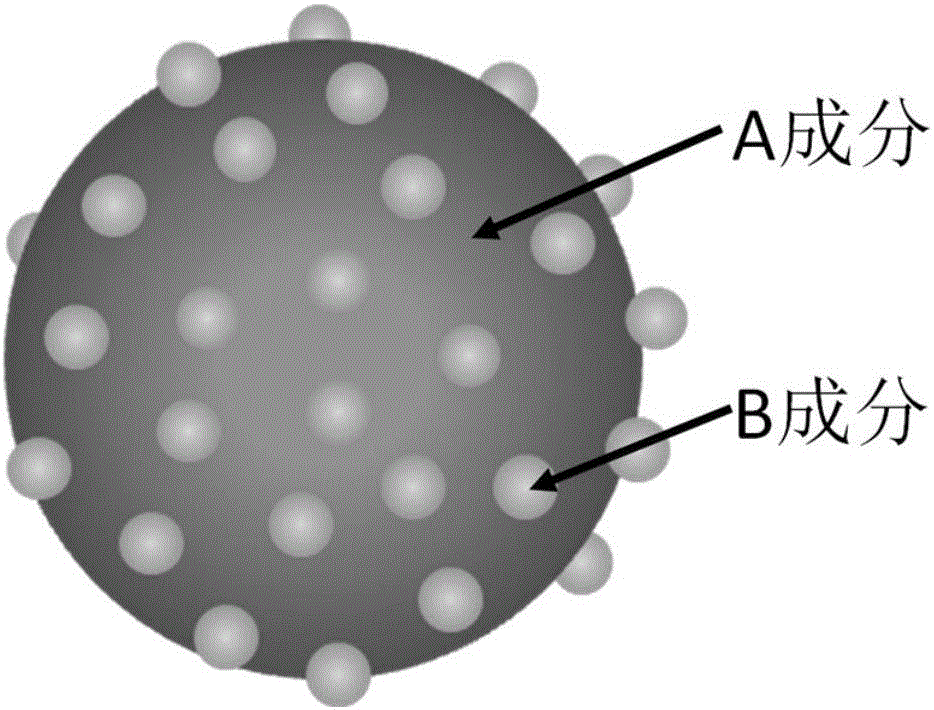

Cation-doped gradient high-nickel multi-material precursor and preparation method and application thereof

InactiveCN109301240ALower Phase Boundary ResistanceImprove performanceCell electrodesMulti materialControl system

The invention discloses a cation-doped gradient high-nickel multi-material precursor and a preparation method and application thereof. An automatic program control system is combined with a special-designed U-shaped reactor; material component ratio and a preparation process are controlled; therefore, a high-nickel multi-material precursor with nano-spherical microstructure is prepared in controllable manner. The precursor herein comprises a core and a multilayer shell portion attached to the same. A cathode material prepared with the precursor herein has continuously gradient changes in composition and structure; no evident boundary occurs in the cathode material. A core portion of the cathode material has high nickel content, so that the specific capacity is very high; a shell portion has more stable structure and better electrochemical properties; doping components help improve conductivity and battery rate performance; therefore, a gradient material with excellent comprehensive performance is attained. The preparation method herein is highly operable, easy to control and suitable for large-scale industrial production.

Owner:圣戈莱(北京)科技有限公司

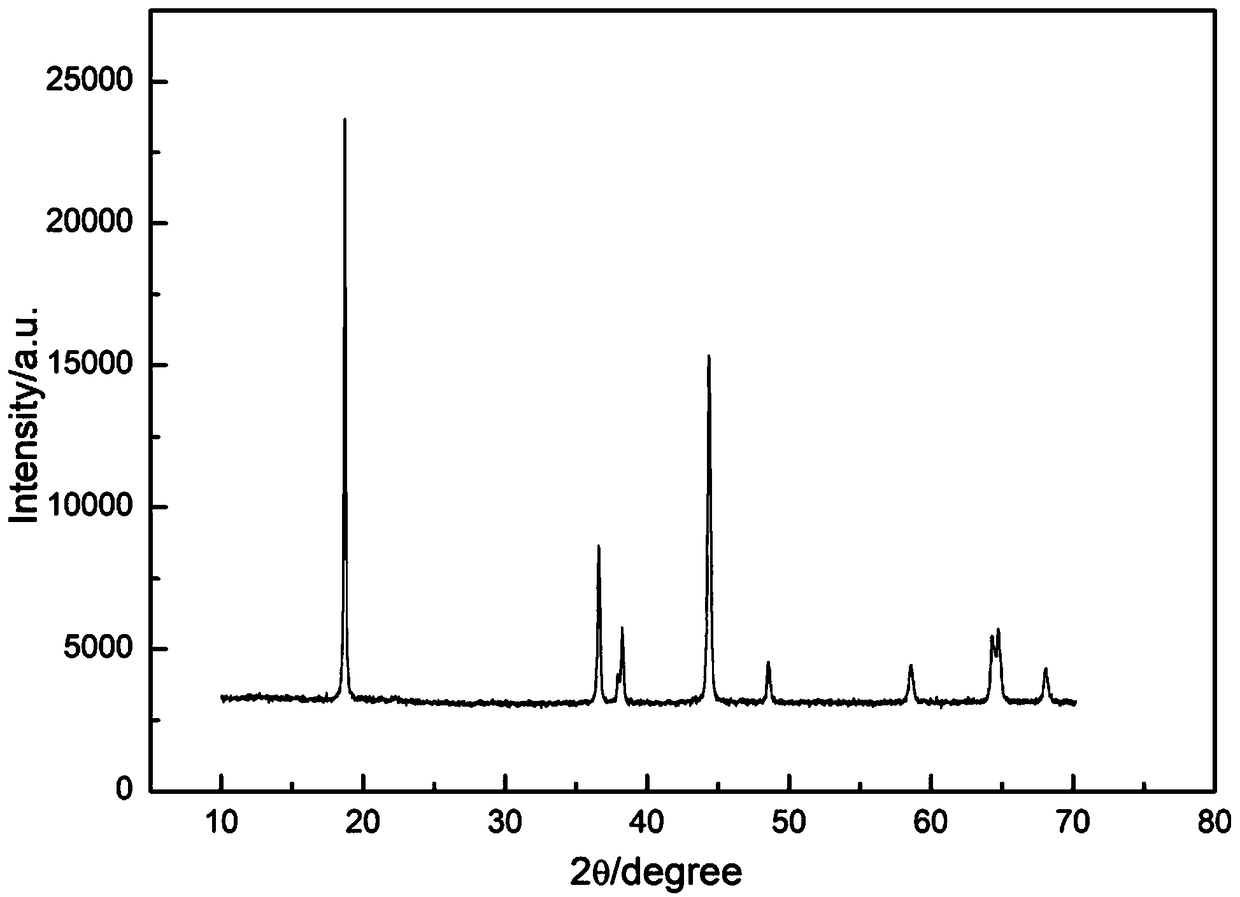

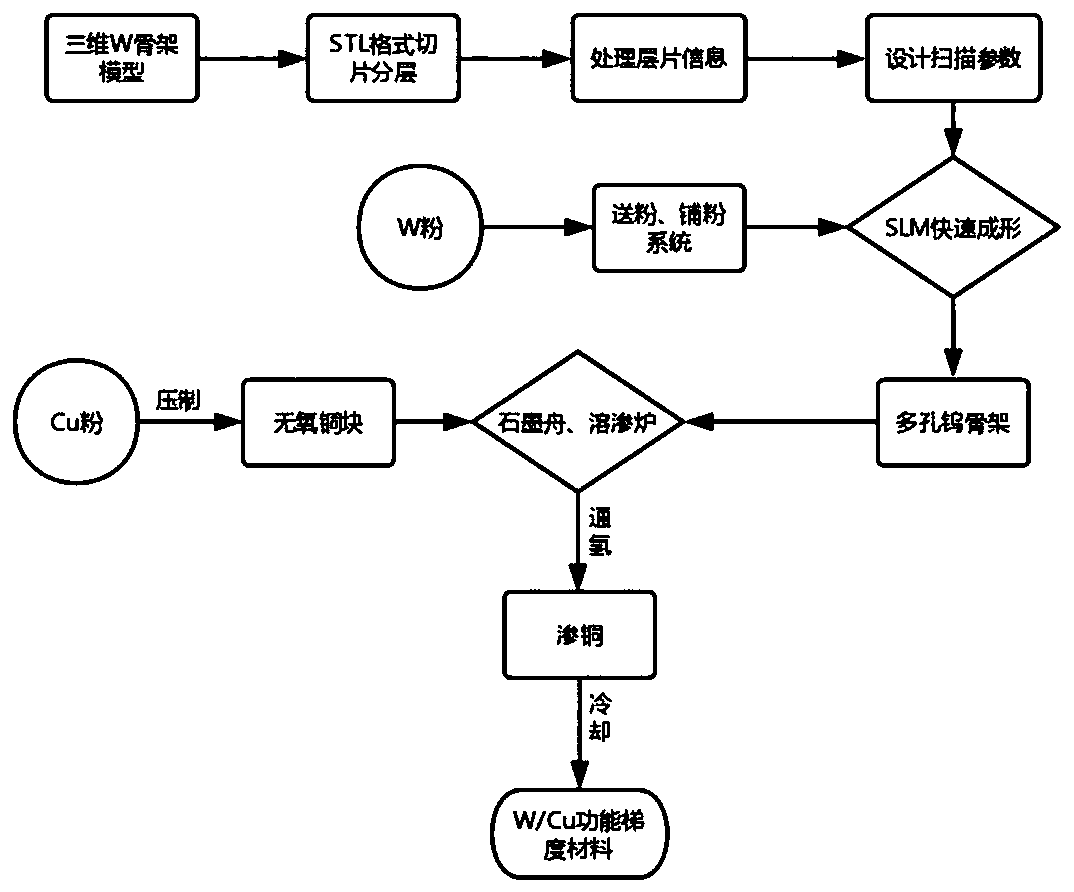

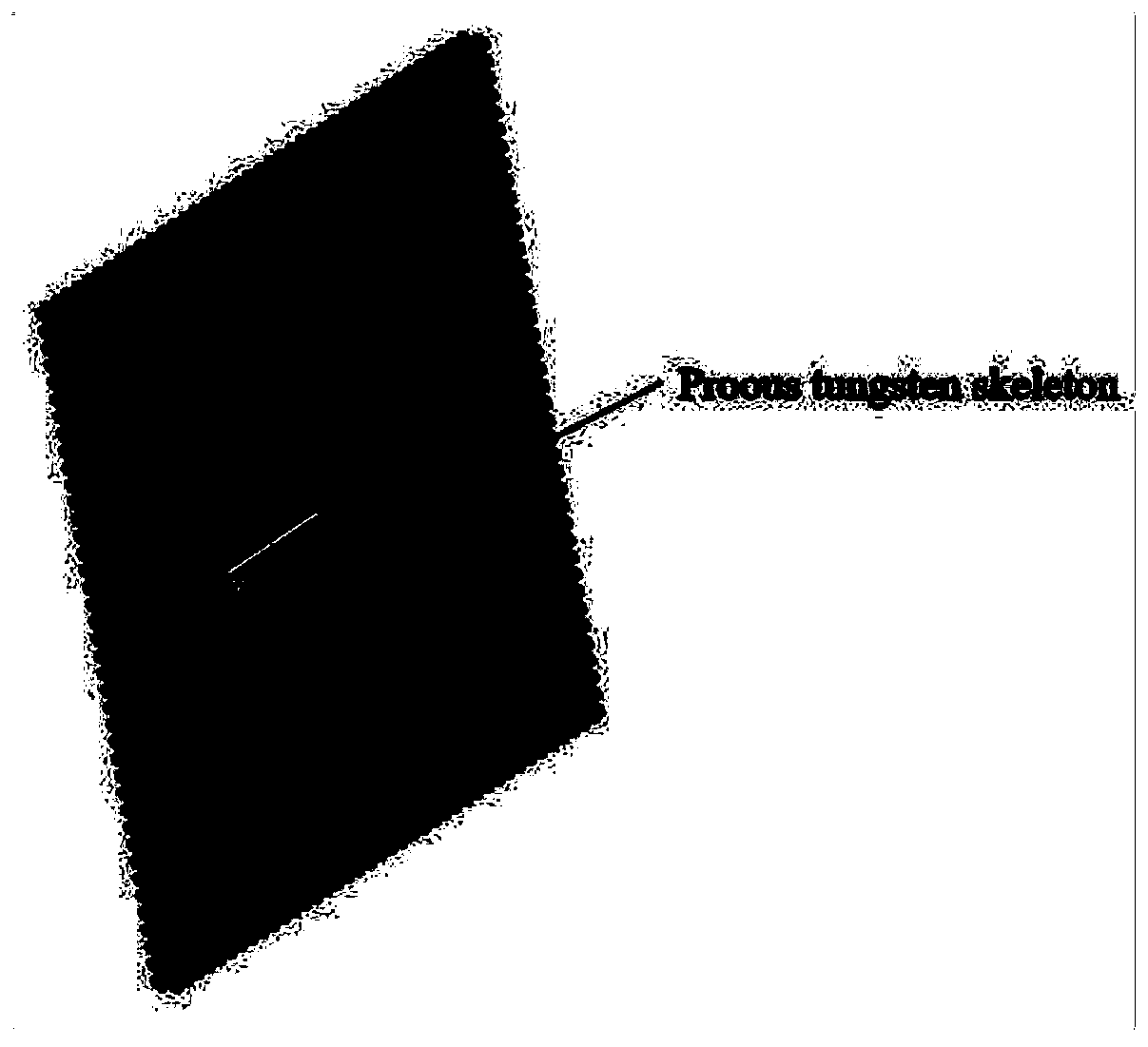

W/Cu functionally gradient material and preparation method thereof

InactiveCN109702200AOvercome various defects in processingImprove efficiencyManufacturing technologyGradient material

The invention discloses a W / Cu functionally gradient material and a preparation method thereof, and belongs to the fields of additive manufacturing technology and powder metallurgy. In terms of structure, the W / Cu functionally gradient material comprises a pure tungsten substrate on one side and a pure copper substrate on the other side, a gradient material is formed through copper infiltration ofa porous tungsten skeleton to connect the two substrates, wherein the porous tungsten skeleton is prepared by 3D printing, and then the porous tungsten skeleton copper infiltrated gradient material is prepared by a copper infiltration method; and the gradient material is prepared from the elements in percentage by mass: 50% of W and 50% of Cu. The W / Cu functionally gradient material adopts a digitalized additive manufacturing technology, a porous tungsten skeleton complex structure can be quickly formed, uniform distribution and mass gradient distribution of tungsten skeleton pores can be accurately controlled, and thus a novel technology means for preparing a properW / Cu functionally gradient material is provided.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN) +1

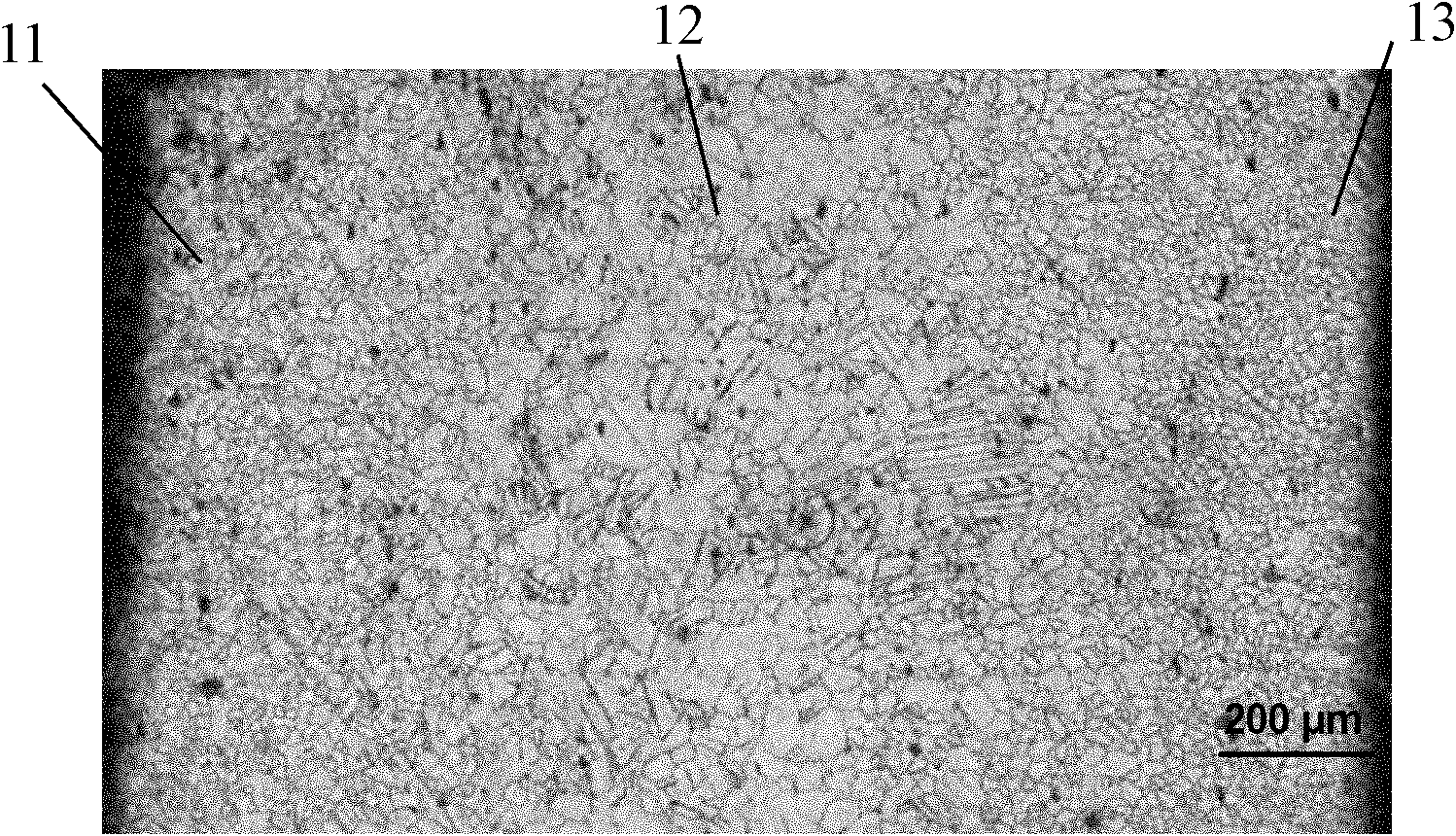

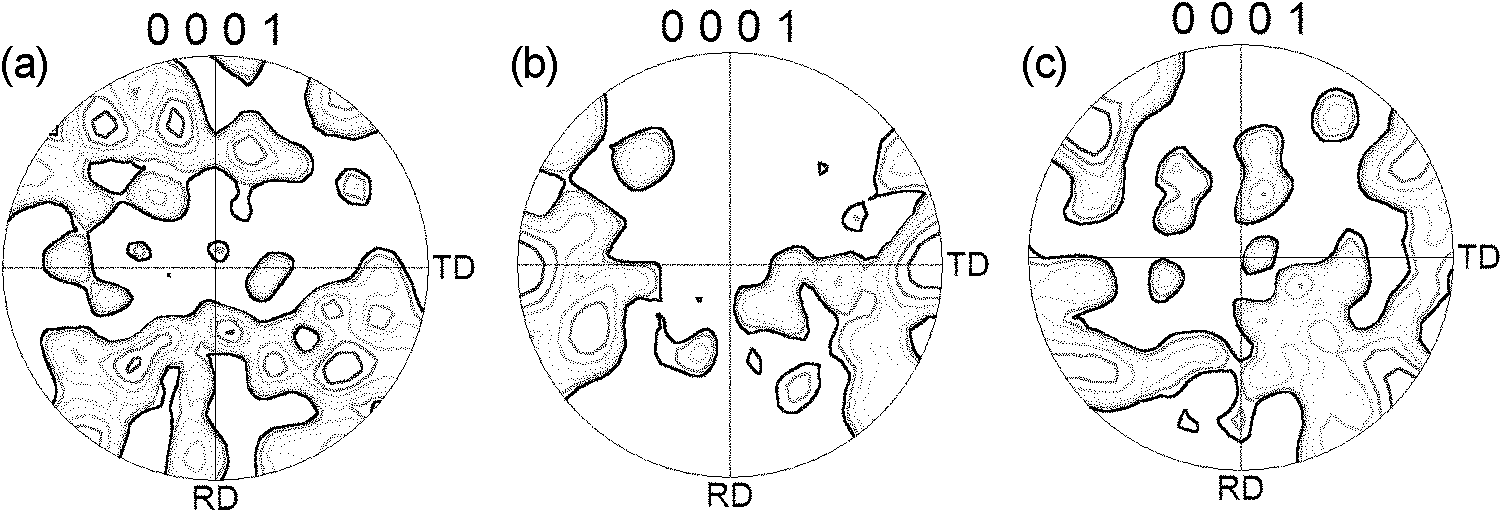

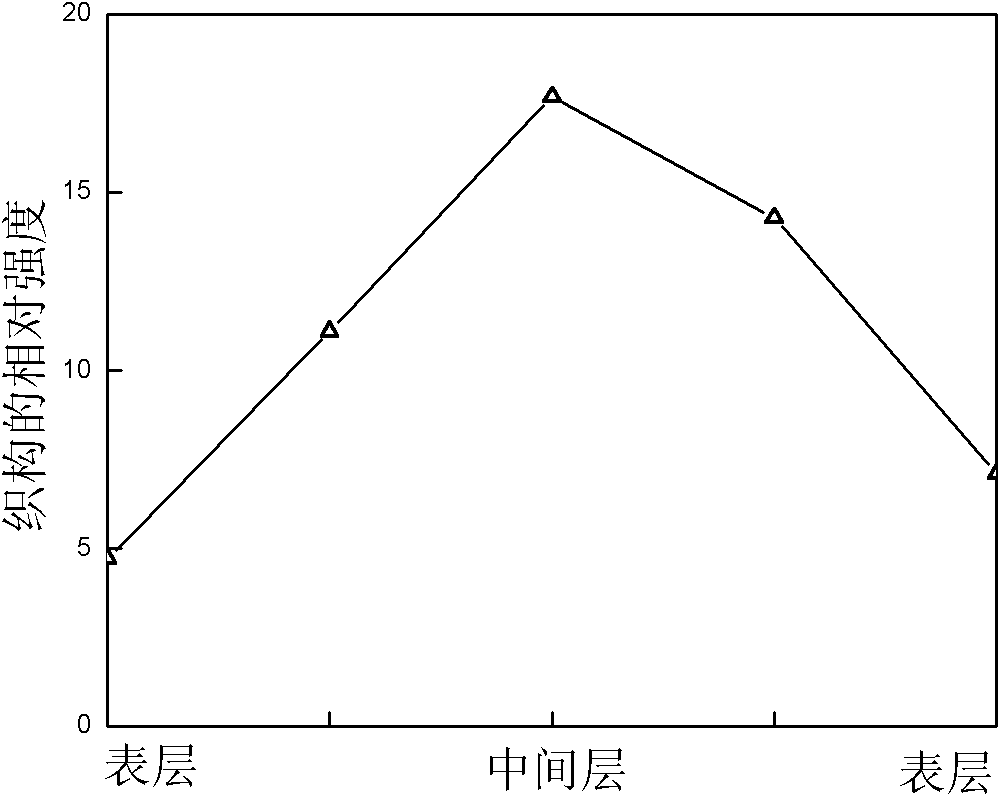

Method for preparing magnesium alloy plate strip with grain size in symmetric gradient distribution along plate thickness direction

The invention relates to a method for preparing a magnesium alloy plate strip with a grain size in symmetric gradient distribution along a plate thickness direction. In the method, the magnesium alloy plate strip is subjected to bidirectional continuous bending deformation and then recrystallization annealing; during deformation, a surface layer is subjected to large twinning deformation, and shear stress applied to the surface layer makes a base surface texture deflected and weakens the original texture; during annealing, the surface layer with large deformation is subjected to static recrystallization so as to refine grains and randomize the texture; and when the deformation is less than or equal to 0.03, the grains on the surface layer are quickly recrystallized and grown to be coarsened due to a low recrystallization nucleation rate. By the method, two gradient materials with refined or coarsened grains on the surface layer can be prepared. The process is reasonable in design and easy to operate, required equipment is realized by modifying and upgrading the conventional straightener, the gradient structure along the plate thickness direction is obtained by coordinating repeated bending with recrystallization annealing, the texture of the magnesium alloy plate strip is weakened, the strength and the ductility of the magnesium alloy plate strip are improved, and the subsequent processability of a magnesium alloy plate is improved.

Owner:CENT SOUTH UNIV

3D printing preparation method of polymeric gradient material

InactiveCN104552951AImplement gradient distributionImprove work efficiencyAdditive manufacturing apparatusPolymer scienceInorganic particle

The invention provides a 3D printing preparation method of a polymeric gradient material. The method comprises the following steps: (1) preparing inorganic components, polymers and other raw materials; (2) establishing a three-dimensional computer sketch map of the polymeric gradient material, performing slicing processing, and establishing a scanning path; (3) calculating the component ratios at different positions; (4) setting the corresponding printing parameters; and (5) starting printing equipment for performing 3D printing, simultaneously injecting the inorganic particles and polymers into the printing head, heating, mixing, and printing and forming according to the set track and speed. The method disclosed by the invention has the advantages that the raw material component ratios at different positions are controlled by the computer, so that gradient distribution of the components is really realized. The 3D printing technology is a material increase manufacturing method, and compared with the traditional process, the method disclosed by the invention has the advantage that the raw materials are saved.

Owner:彭晓领

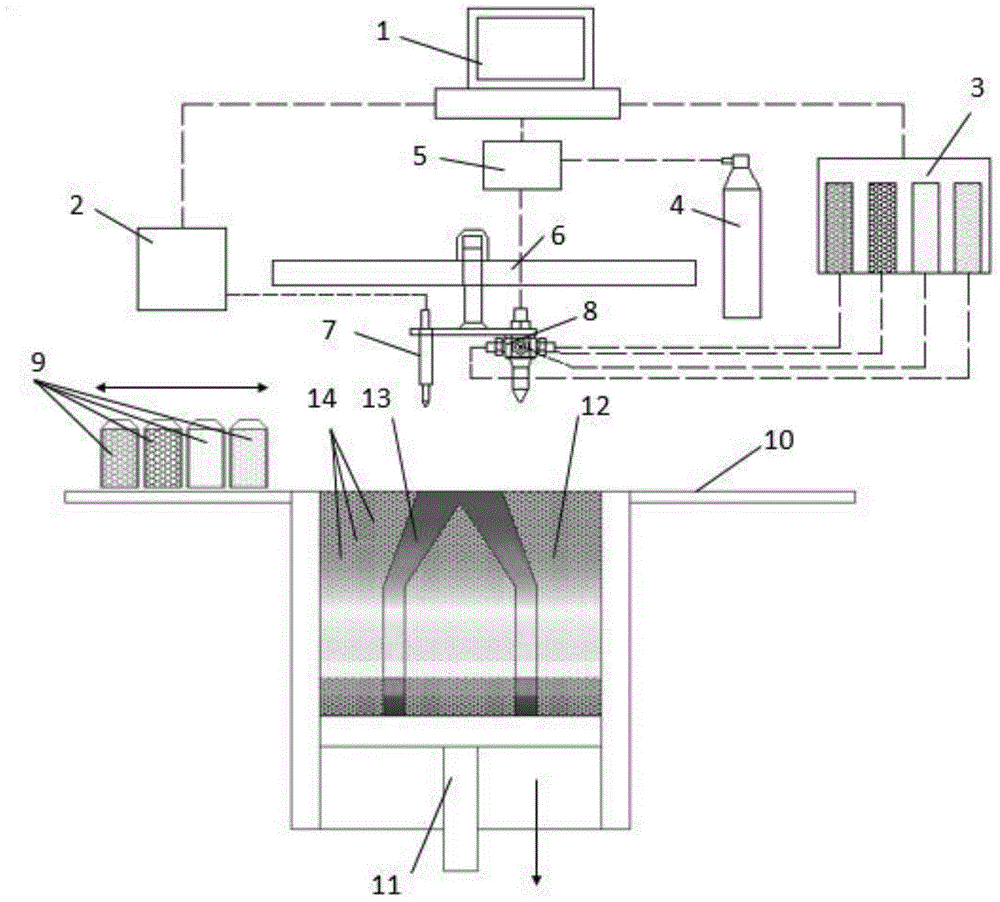

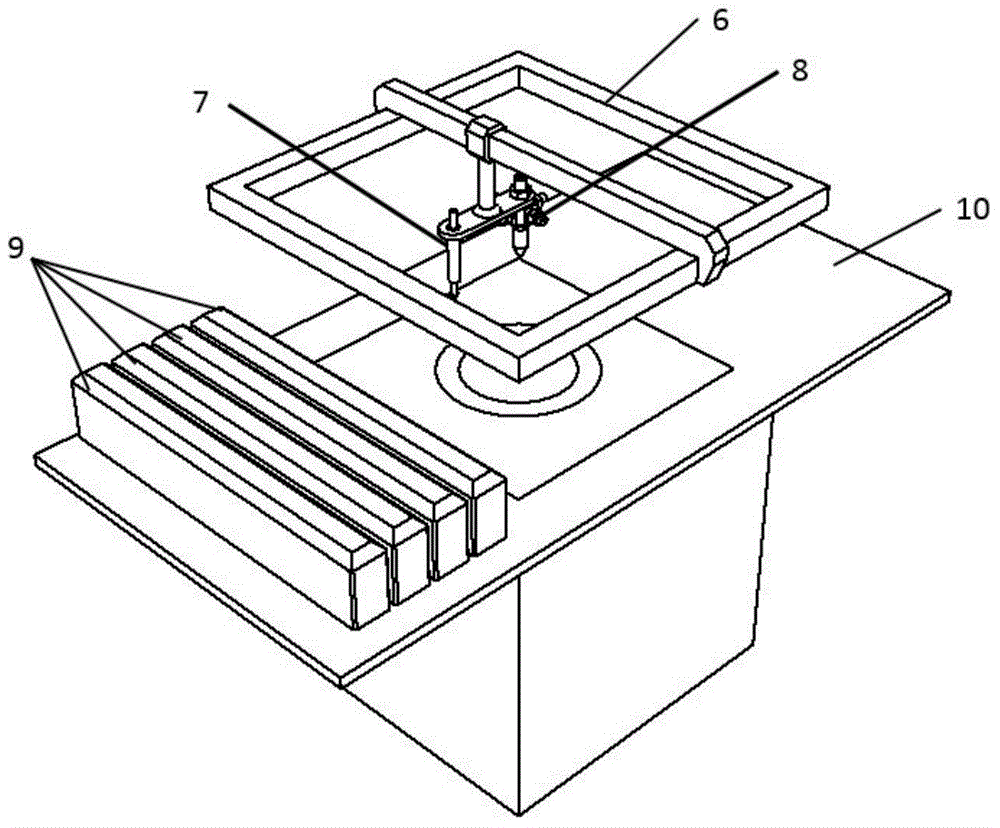

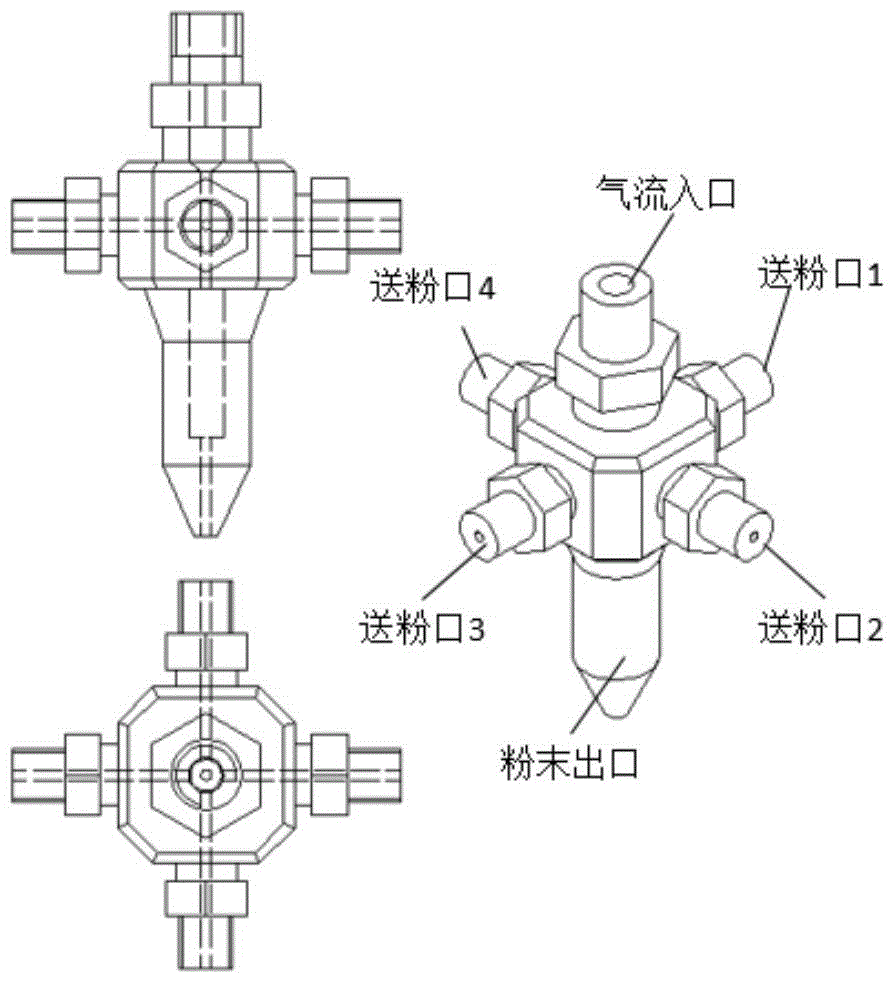

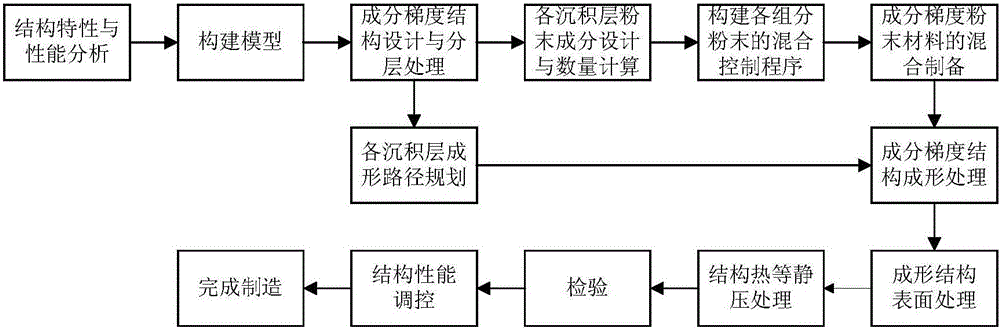

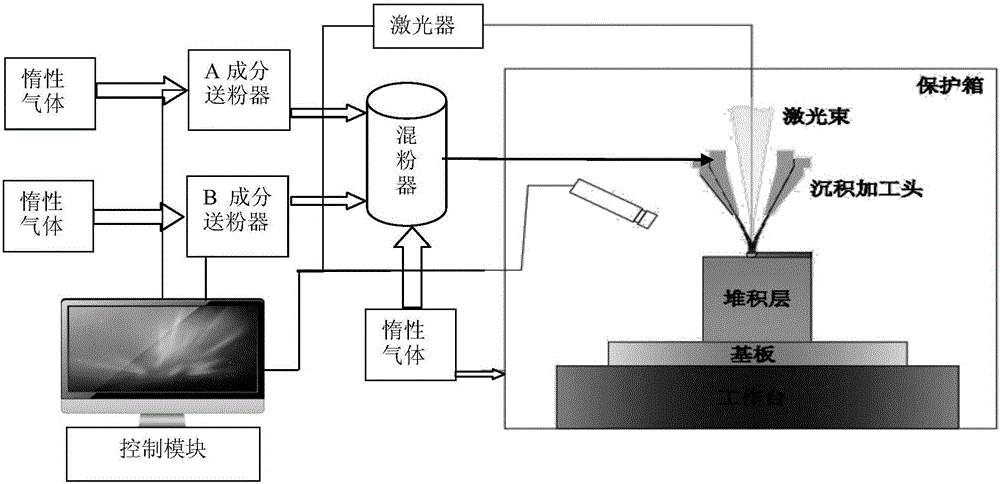

Rapid prototyping system and method of gradient material structure

ActiveCN105772723AEasy to prepareIncrease profitAdditive manufacturing apparatusIncreasing energy efficiencyGradient materialRapid prototyping

The invention relates to the field of rapid prototyping manufacturing, particularly to a rapid prototyping system of a gradient material structure. The rapid prototyping system comprises a control module, a powder feeding module and a processing module, wherein the powder feeding module comprises a power mixing device and at least two powder feeding devices; the powder components in the powder feeding devices are different; the powder feeding devices are connected with the powder mixing device; the processing module comprises a laser and a deposition processing head; and the control module is used for performing analysis according to the performances and characteristics of the gradient material structure required to be shaped and controllin the operation of the powder feeding module and the processing module according to the analysis result. According to the rapid prototyping system, the materials and the structure components are continuously and transitionally regulated, the problem that in a dissimilar material connection structure, the structural performance mutates due to the material interface factor is solved, the manufacturing of a compositional gradient structure is easy to implement, the requirement of the utilization performance of an integral structure is better met, the powder utilization rate is high, the prototyping speed is high, and the device is simple in structure.

Owner:XIAN ZHIRONG METAL PRINTING SYST CO LTD

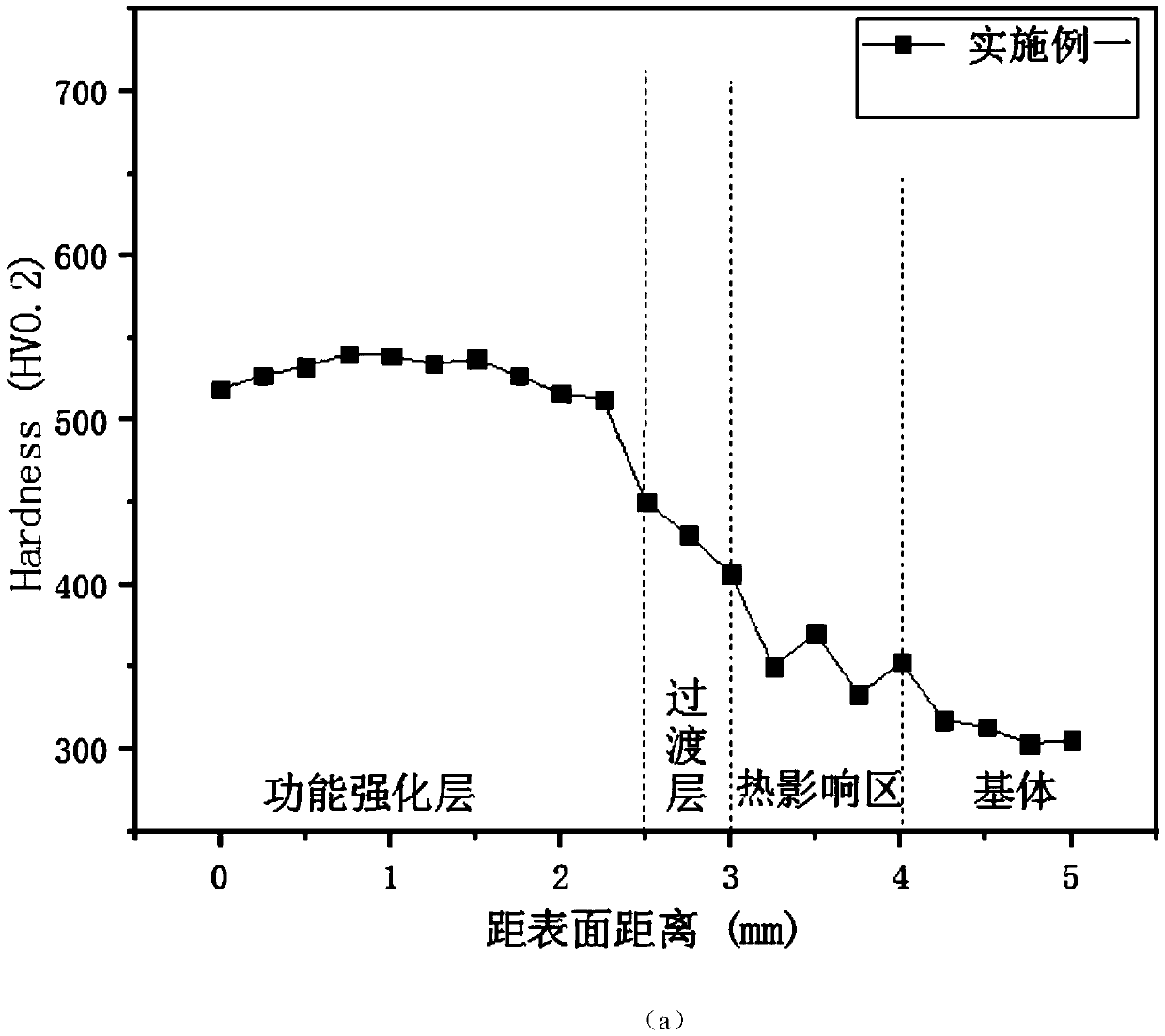

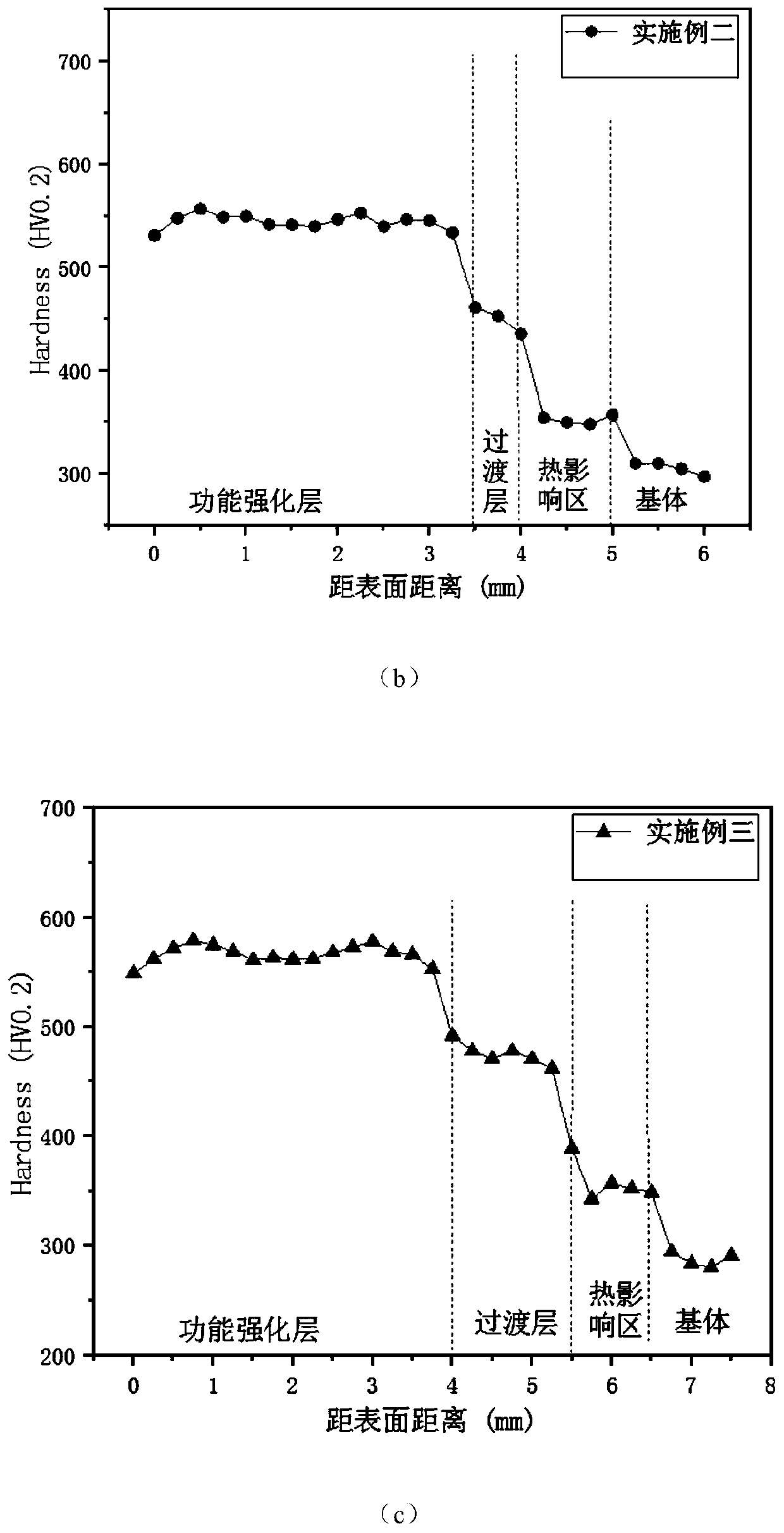

Gradient material steel rail frog prepared by laser cladding

ActiveCN110129674AImprove wear resistanceImprove carrying capacityMetallic material coating processesHeat-affected zoneGradient material

The invention provides a gradient composite material steel rail turnout coating prepared by laser cladding. The composite material is characterized in that a transition layer adopts a Fe-based alloy material, wherein the Fe-based alloy material comprises the following components of, in percentage by weight, 13wt%-17wt% of Cr, 3wt%-6wt% of Ni, 1wt%-1.5wt% of Si, 0.5wt%-1wt% of Mn, 0.3wt%-1.2wt% ofNb, 1wt%-1.5wt% of B, 0.05wt%-0.7wt% of C, 0.5wt%-1.2wt% of V, and the balance Fe; a strengthening layer is arranged above the transition layer, and the strengthening layer adopts a Fe-based metal nano-phase composite material. The preparation method comprises the following steps of preparing the Fe-based metal powder and the Fe-based metal nano-phase composite material coating; preheating a steelrail by using laser scanning heating so as to reduce the temperature gradient; preparing the gradient composite material coating on the surface of the steel rail by utilizing a laser cladding technology, and performing laser scanning heat treatment; and reducing the cooling rate after laser cladding, so that the martensite of the heat affected zone is prevented from being generated, and the cracking property of the coating is reduced. The prepared steel rail frog has the advantages that the hardness curve is smooth, the overall toughness and bearing performance are good, the strength and hardness is higher than a common heavy-load railway frog, the service life is longer, and manufacturing integration is relatively strong.

Owner:BEIJING UNIV OF TECH +2

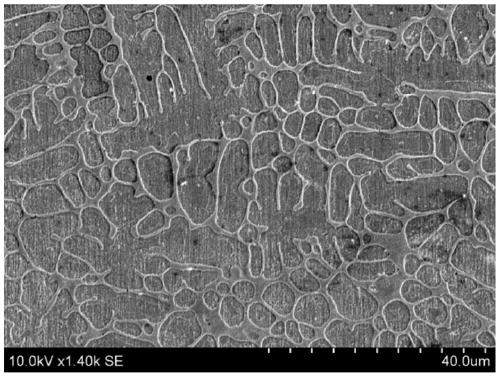

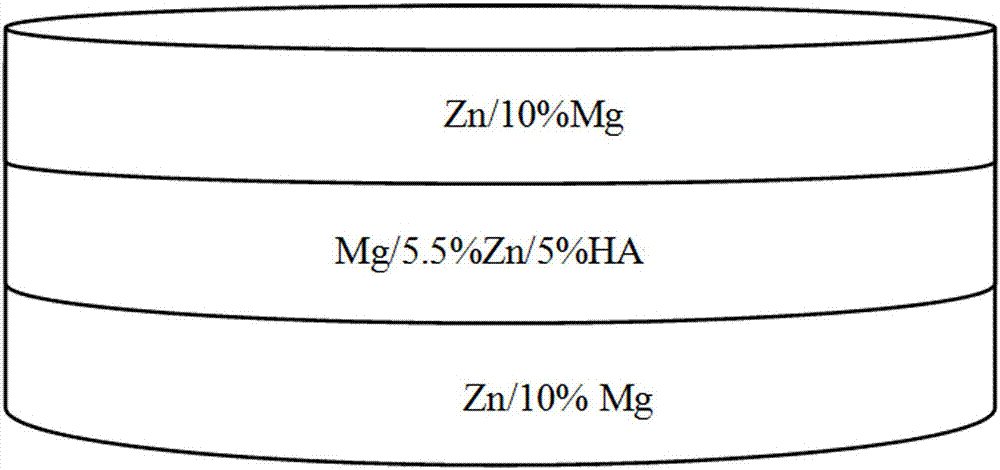

Preparing method of zinc magnesium function gradient biological composite

ActiveCN107385251AImprove the bonding strength of the interfaceNo debondingGradient materialStress shielding

The invention relates to a preparing method of a zinc magnesium function gradient biological composite. Magnesium powder, zinc powder and HA powder are adopted to serve as raw materials, ball milling powder mixing, die filling and vacuum discharge plasma sintering are carried out, and a zinc magnesium composite of two gradient structures is prepared. The preparing method is advanced in technology, data are full and accurate, a prepared zinc magnesium gradient material is high in combination strength on the interface, the debinding phenomenon is avoided, wear resistance and mechanical properties(the crush resistance strength is 293.66MPa, the elasticity modulus is 8.0 GPa, and breaking tenacity is 9.327 MPa.mm<1 / 2>) of all gradient layers are matched with the natural bone, the stress shielding effect is effectively avoided, and the preparing method is an ideal preparing method for a degradable biomedical metal gradient material.

Owner:TAIYUAN UNIV OF TECH

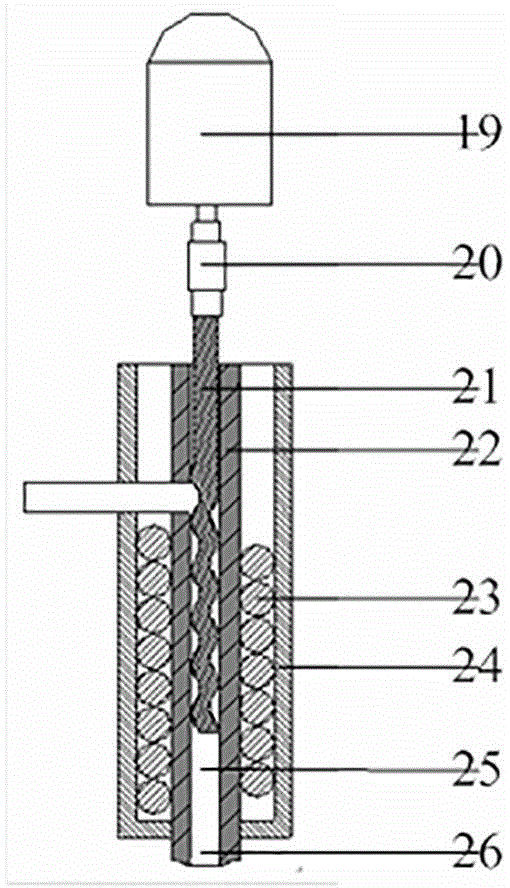

Precise laser micro-forming and powder feed method and coaxial laser powder device thereof

InactiveCN101695752AHigh resolutionContinuously adjustable amplitudeMetallic material coating processesPiezoelectric actuatorsGradient material

The invention discloses a precise laser micro-forming and powder feed method and a coaxial laser powder device thereof. The precise laser micro-forming and powder feed method of the invention adopts a powder feed device to perform piezoelectricity actuated powder feed; after a piezoelectric cermic in a piezoelectric actuator in the power feed device is electrified, the pulse inertial force generated by a converse piezoelectric effect thereof is conducted to a quartz micro-nozzle to actuate metal powder to overcome a resistance to spout to a former pulse continuously; and the piezoelectric cermic of the piezoelectric actuator is controlled to work by a computer. When micro-forming or micro-cladding a metal component of a uniform material, a central single-powder pipe powder feed method is adopted; and when micro-forming or micro-cladding a metal component of a gradient material or a multilayer compound layer, a lateral multi-path powder feed method is adopted. The invention also discloses a coaxial laser powder device thereof for realizing the laser precisely micro-forming and powder feed method, which has the advantages that: the defocusing distance and powder feed speckle thereof are convenient and adjustable; the powder feed resolution is high; the single pulse discharge is accurate to the magnitude of microgramme; the powder feed is uniform, stable and continuous; and the powder feed density meets the requirement of micro-forming.

Owner:HUAIHAI INST OF TECH

3D printing method of metal ceramic functional gradient part in alternating magnetic field

ActiveCN105499570AAdditive manufacturing apparatusIncreasing energy efficiencyElectricityGradient material

The invention discloses a 3D printing method of a metal ceramic functional gradient part in an alternating magnetic field. A metal material with excellent electric conductivity in the alternating magnetic field generates induction current inside due to continuous change of a magnetic field; based on different responses of the metal material with excellent electric conductivity and ceramic not easy to conducting electricity to the alternating magnetic field, the directional distribution of the metal materials is controlled through the alternating magnetic field in the printing process; the magnitude of driving force is changed through changing alternating current intensity and current frequency; the metal ceramic functional gradient part is prepared; the 3D printing of the metal ceramic gradient part in the alternating magnetic field is realized; the gradient material distribution can be realized in any space position; the material and the equipment cost are saved; and the 3D printing method is suitable for wide popularization and application.

Owner:JILIN UNIV

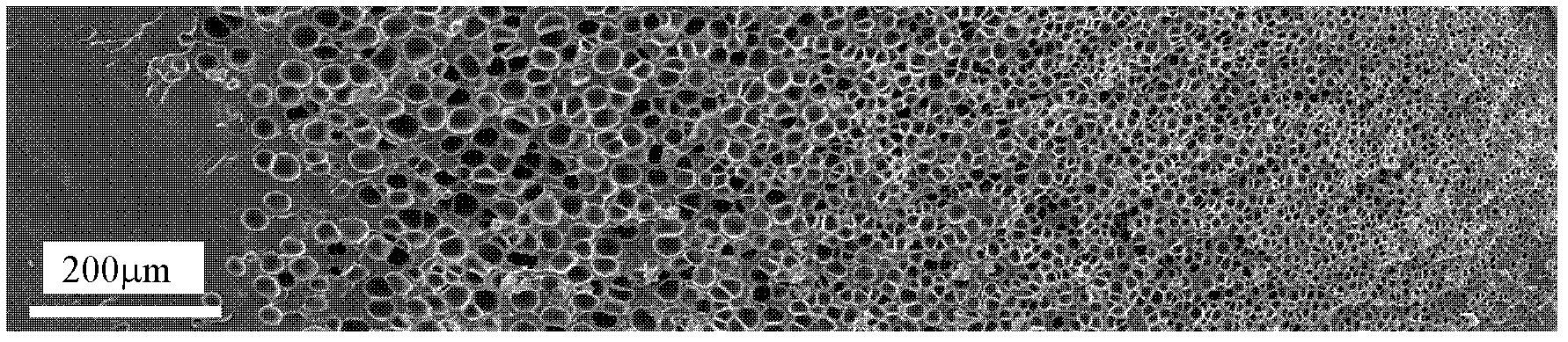

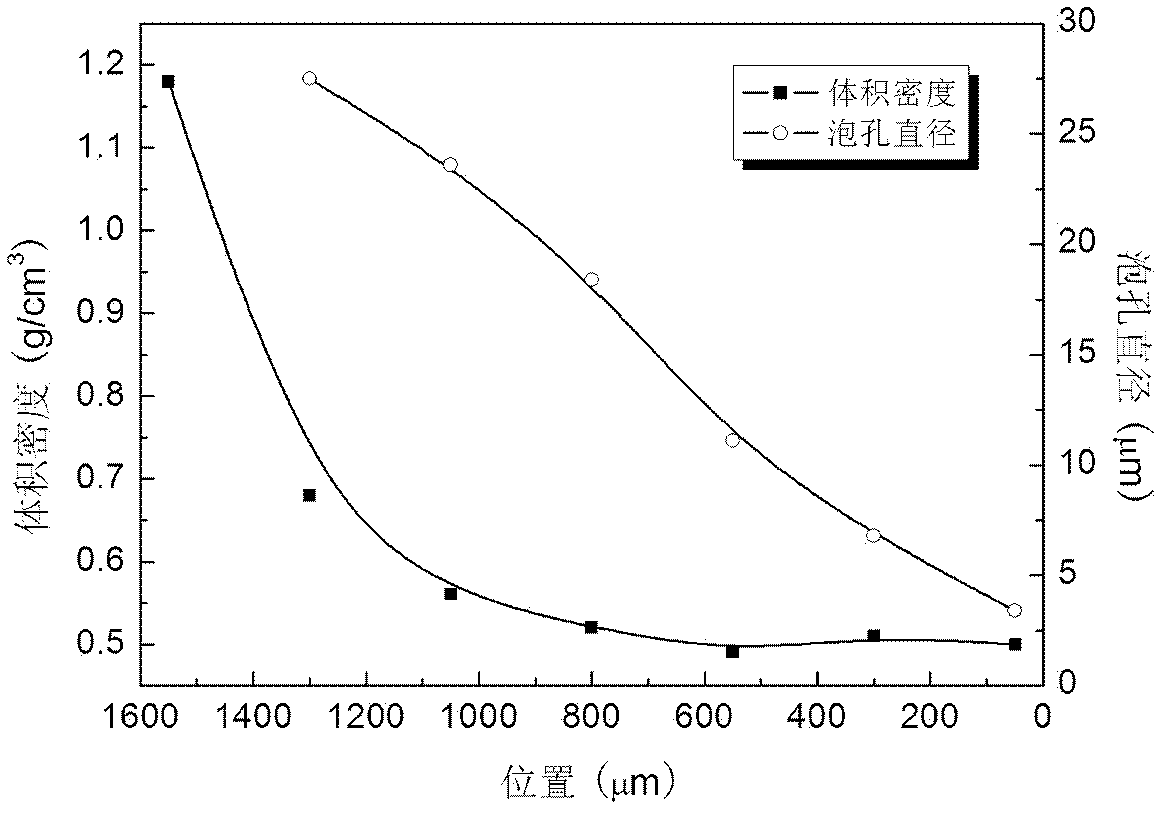

Preparation method of polymethyl methacrylate (PMMA) cellular gradient material

The invention relates to a preparation method of a polymethyl methacrylate (PMMA) cellular gradient material. The method specifically comprises: placing a unidirectionally opened die loaded with PMMA into an autoclave, controlling the oriented adsorption of highpressure carbon dioxide in PMMA to form a concentration gradient, with the pressure of the carbon dioxide controlled at 10-30MPa and the temperature maintained at 50-150DEG C, preserving the heat and pressure for 1-60min, then conducting pressure releasing, and finally cooling a sample to room temperature with an ice-water mixture, thus obtaining the cellular gradient material. A cellular structure with a small cell diameter and a thin cell wall forms in a high concentration carbon dioxide diffusion area on the surface layer, a cellular structure with a large cell diameter and a thick cell wall forms in a low concentration area of the central section, and the innermost layer is compact PMMA matrixes. The porosity of the sample changes from high to low continuously from the surface layer to the inner layer. With a cell diameter controlled at micron magnitude, the gradient material provided in the invention has good dimensional stability, wide porosity variation range and high mechanical strength.

Owner:WUHAN UNIV OF TECH

Powder-material-oriented SLM/SLS powder laying technology

ActiveCN106180711AImprove work efficiencyAdjust the ratioAdditive manufacturing apparatusIncreasing energy efficiencySelective laser meltingSelective laser sintering

The invention discloses a powder-material-oriented SLM (selective laser melting) / SLS (selective laser sintering) powder laying technology. Manufacturing through selective powder laying and selective laser melting individual gradient material is achieved. According to the main function, powder of different material components can be precisely laid on a powder bed in a fixed-point manner through a plurality of spraying heads, and then, through SLM / SLS manufacturing, continuous gradient changes of materials between different portions can be achieved. Along the material proportioning line, powder laying is carried out, through cooperation of all flow controllers, mixed powder with different proportions can be obtained, the proportion of different kinds of powder can be adjusted in advance, and then powder laying is carried out; in the powder laying process, the proportion of different kinds of powder can be dynamically adjusted, and continuous gradient changes of the materials between the different portions can be achieved.

Owner:XI AN JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com