Patents

Literature

84results about How to "Solve cohesion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

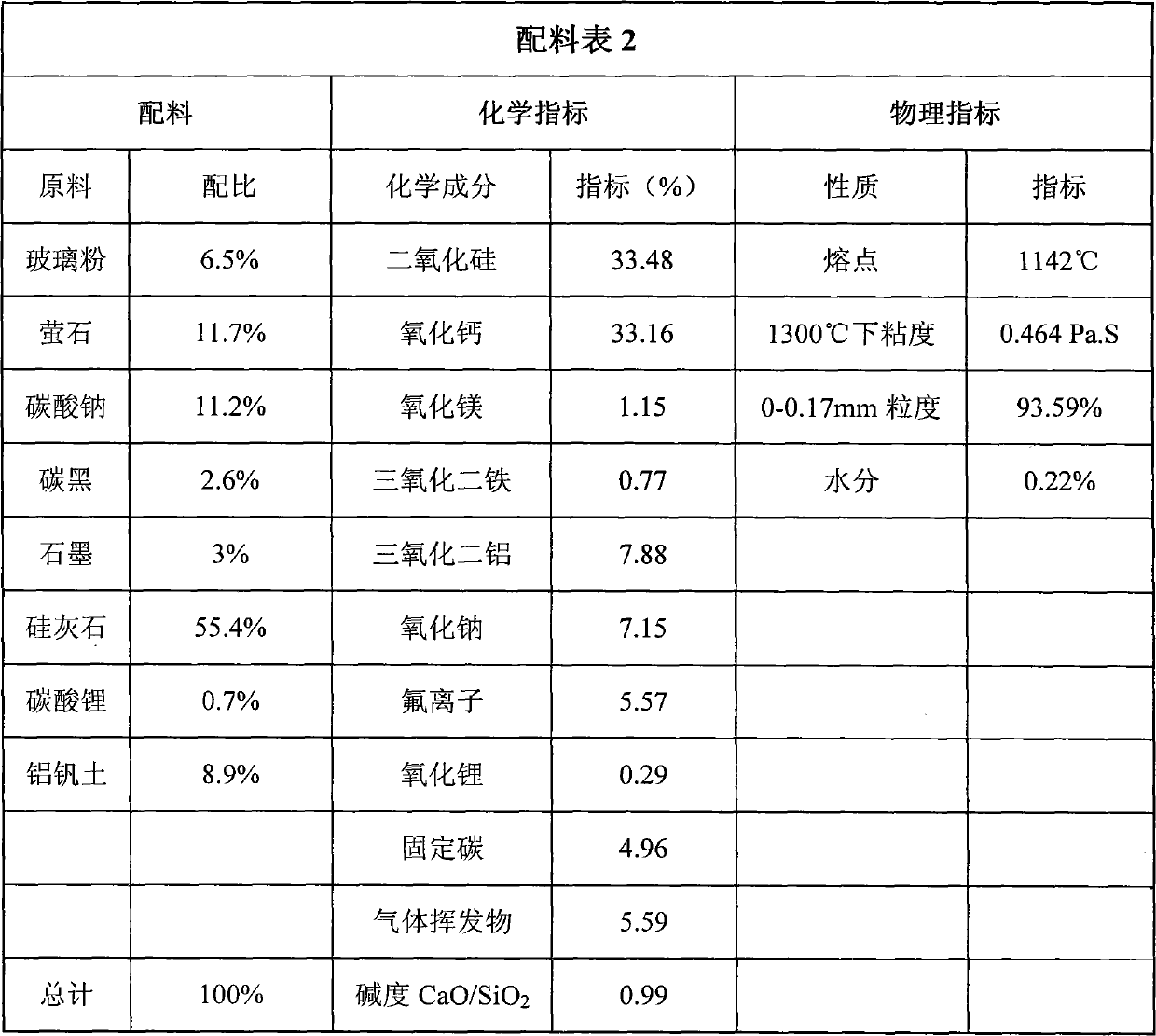

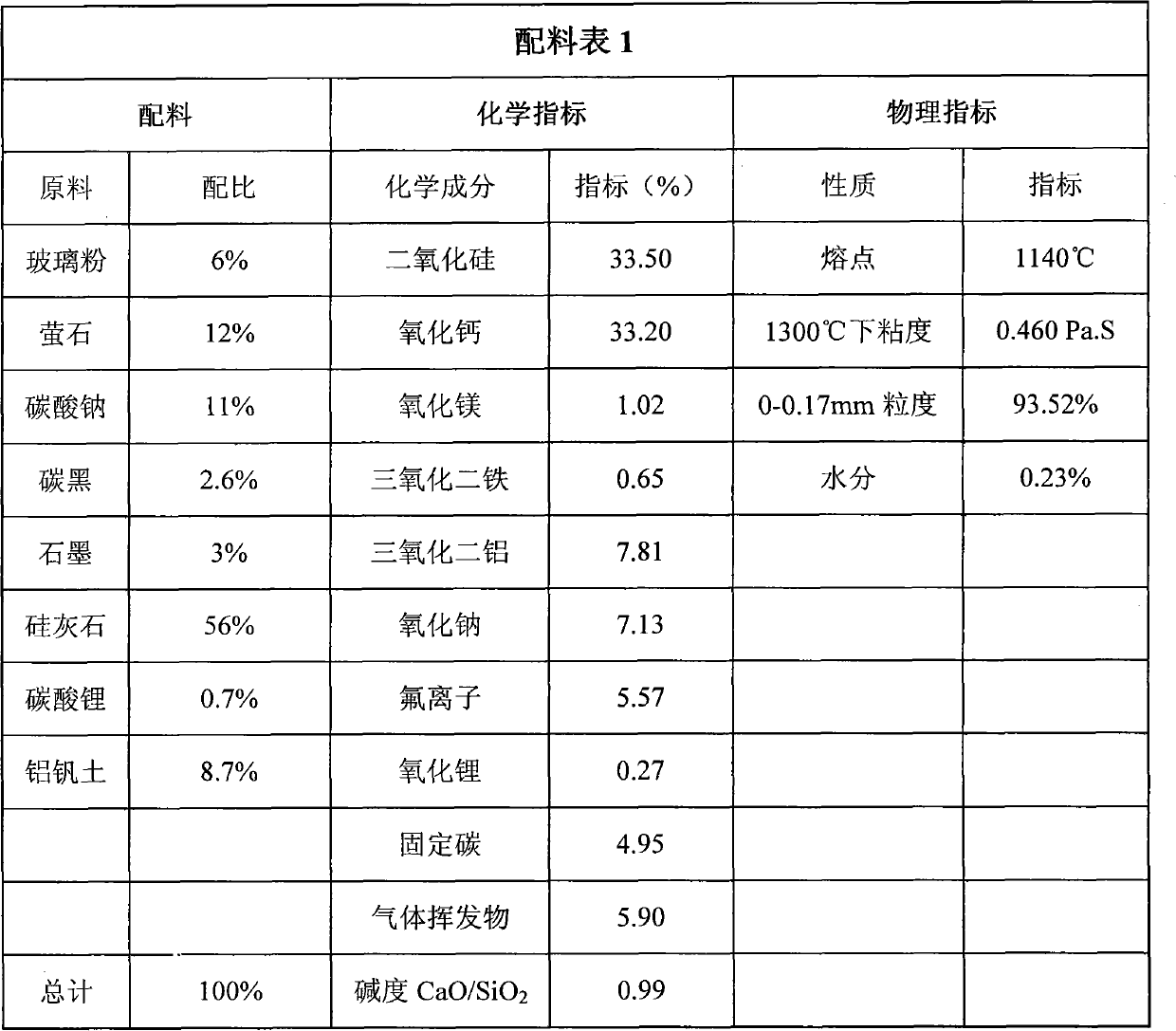

High-manganese high-nitrogen low-nickel stainless steel plate blank continuous casting crystallizer covering slag and preparation method thereof

The invention discloses high-manganese high-nitrogen low-nickel stainless steel plate blank continuous casting crystallizer covering slag which comprises the following components in percentage by weight: 54-57% of wollastonite, 9-13% of fluorite, 9-13% of sodium carbonate, 0-1% of lithium carbonate, 5-7% of glass dust, 8-12% of vanadine soil, 2.5-2.7% of soot carbon and 3-3.5% of graphite, and comprises the chemical components in percentage by weight: 31.9-34.9% of calcium oxide, 32.1-35.1% of silicon dioxide, 7.3-8.3% of aluminium oxide, 0.5-1.5% of magnesium oxide, 0.5-1.4% of iron sesquioxide, 4.4-6.4% of fluorion, 6.5-7.5% of sodium oxide, 0-0.39% of lithium oxide, 4.5-6.0% of fixed carbon and 4-7% of gas volatile matters. The alkalinity of the covering slag, namely the ratio of CaO to SiO2, is 0.91 to 1.00, the melting point of the covering slag is 1100 DEG C to 1160 DEG C, and the viscosity of the covering slag is 0.3 to 0.6 Pa.s at 1300 DEG C. The invention can solve the problems of easy crusting, slag entrainment, slag inclusion, slag sticking on casting blank surfaces, bubbles under skins, cracks, deep chatter mark, felting, bleed-out, and the like of the covering slag in the crystallizer during high-manganese high-nitrogen low-nickel stainless steel plate blank continuous casting, and has the advantages of uniform and stable slagging in the crystallizer, good casting blank quality, difficult felting and bleed-out, and the like.

Owner:XIXIA LONGCHENG METALLURGICAL MATERIALS CO LTD

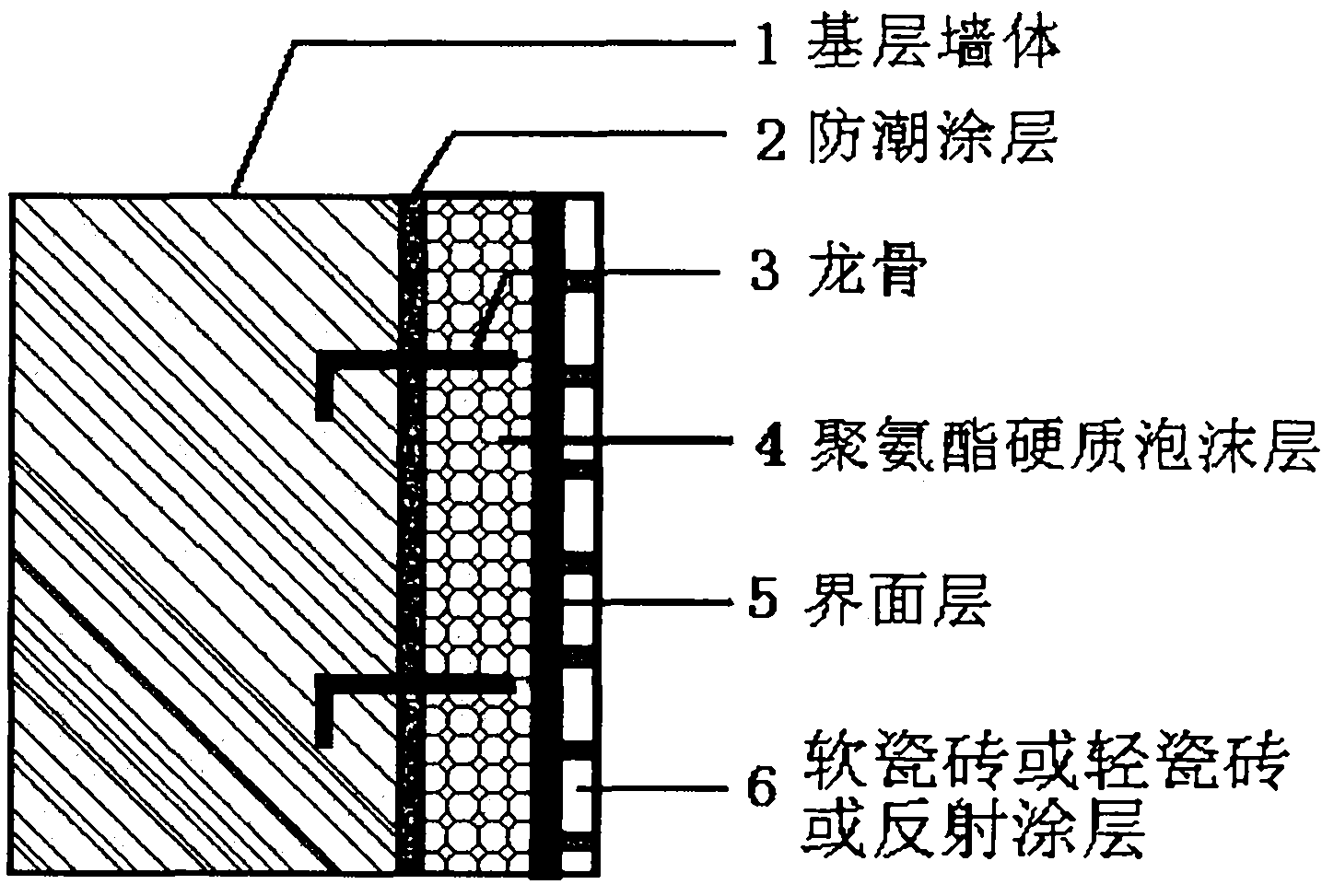

High flame retardant polyurethane rigid foam outer wall thermal insulation system

ActiveCN101956429AMeet the needs of beautificationImprove the problem of shrinkage and collapseHeat proofingBuilding material handlingWet bondingKeel

The invention discloses a high flame retardant polyurethane rigid foam outer wall thermal insulation system. From a basic unit wall provided with a keel and connecting pieces, a prime coat thickening layer, a polyurethane rigid foam layer, an interface layer, and soft tiles, light tiles or a reflective coating are arranged in turn. In the system, the prime coat thickening layer has high adhesion and good wet bonding strength for the basic unit wall and the polyurethane rigid foam; and the high flame retardant polyurethane rigid foam outer wall thermal insulation system is foamed by pure water, and is halogen-free, flame retardant, safe and environment-friendly. The vertical face of the wall is successfully foamed on site, and the polyurethane rigid foam can be directly sprayed and foamed on the basic unit wall which is treated by the prime coat thickening layer, can reach high adhesion to the basic unit wall after 24 to 48 hours, and has the coefficient of thermal conductivity of less than 0.03W / (m.K), the vertical burning reaching V-0 level, and the water absorption of less than 2.5 percent.

Owner:海聚高分子材料科技(广州)有限公司

Preparation method of preserved rice noodles

InactiveCN102178179ASolve the problem of resurrectionSolve cohesionFood preparationWater bathsFiltration

The invention relates to a preparation method of preserved rice noodles. The preparation method includes the steps of rice machining and sand filtration, smashing, humidity adjustment, extrusion for gelatinization, extrusion for emerging of silk noodles, cutting off, checking and packaging. The preparation method is characterized by taking the rice noodles before extrusion for emerging of silk noodle and drying as materials, wherein the water content of the rice noodles at the moment is 25wt%-30wt% and the temperature is 40-60 DEG C; cutting the rice noodles to 17-19cm; soaking the rice noodles for 60-100min in Didazuril bactericide solution with concentration of 50%-60% and temperature of 35-45 DEG C, wherein the ratio of material to liquid is 1wt%:5wt%; conducting vacuum packaging, wherein the vacuum degree is 0.09MPa-0.092Mpa; thermally sterilizing the rice noodles for 0.5h-1h in a water bath maintained at the temperature of 90-95 DEG C; cooling packaging bags with circulating cold water so as to fast reduce the temperature in the center of the packaged material to 30-35 5 DEG C; blowing the water at the outer surfaces of the packaging bags to dry; checking whether the packaging bags bulge and break and conducing metal detection; putting the rice noodles together with auxiliary materials such as matched sauce bags in a packaging box; and sealing the packaging box, thus obtaining a finished product. For the preserved rice noodles produced according to the preparation method, the water content is higher than 60% and the quality guarantee period is longer than 6 months; the infusing and dispersing performance is good; caking does not happen and undesirable odor does not emerge; the dissolving starch rate of the rice noodles is low; after culture for 1 month at the temperature of 37 DEG C, the rice noodles achieve 1426g of hardness, 26.14gs of crisp performance, 512 of viscosity, 0.513s of viscoelasticity.

Owner:江西华达昌食品有限公司

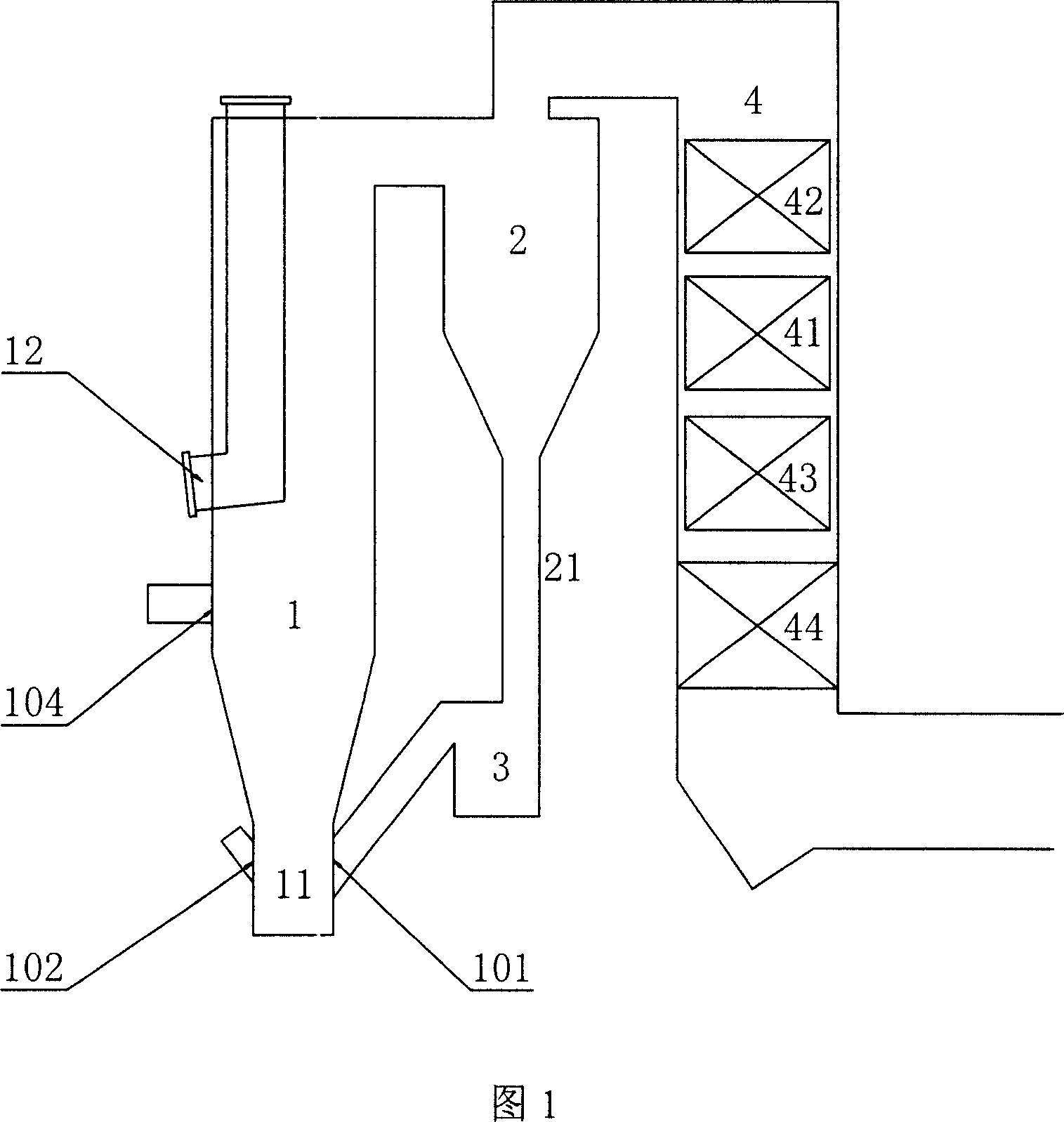

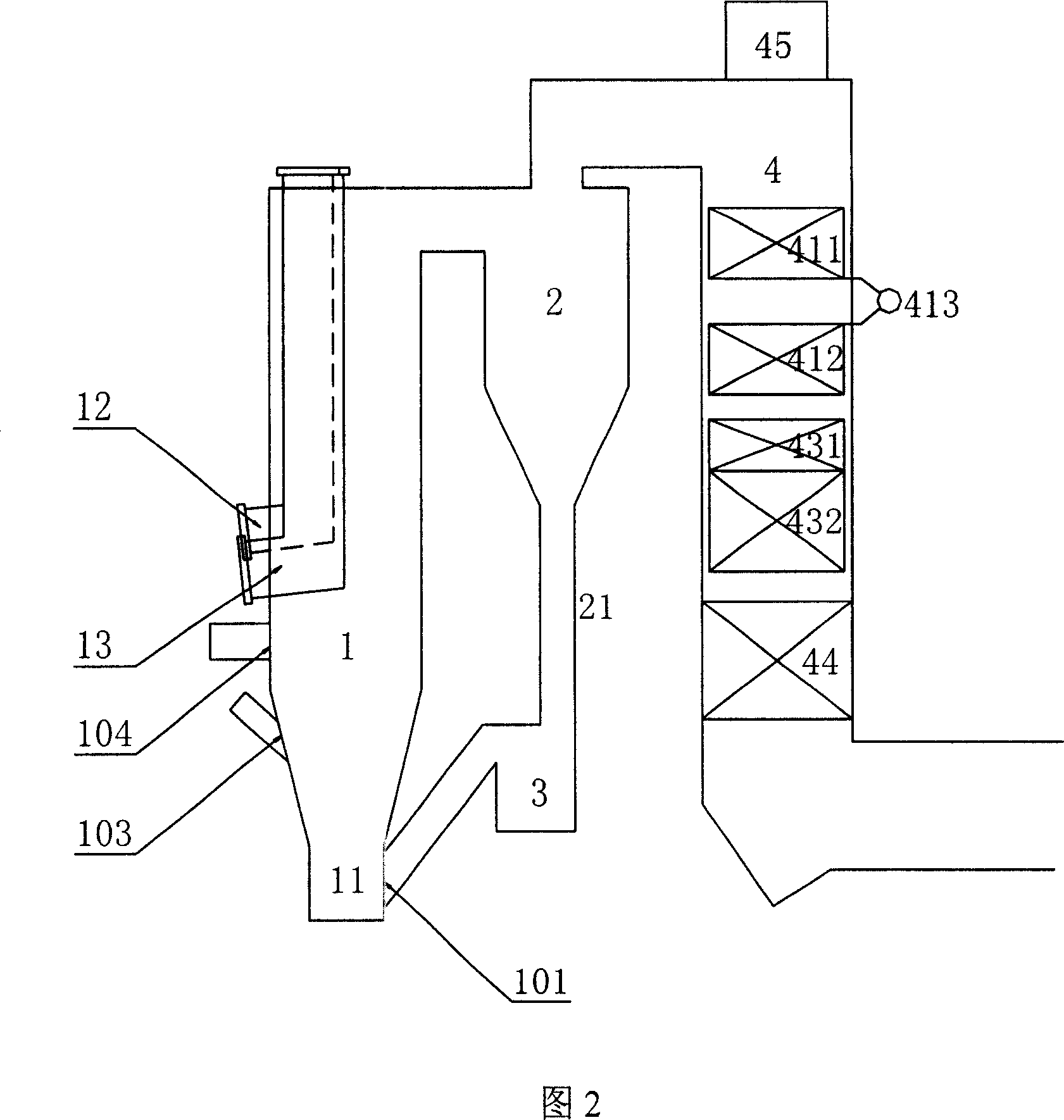

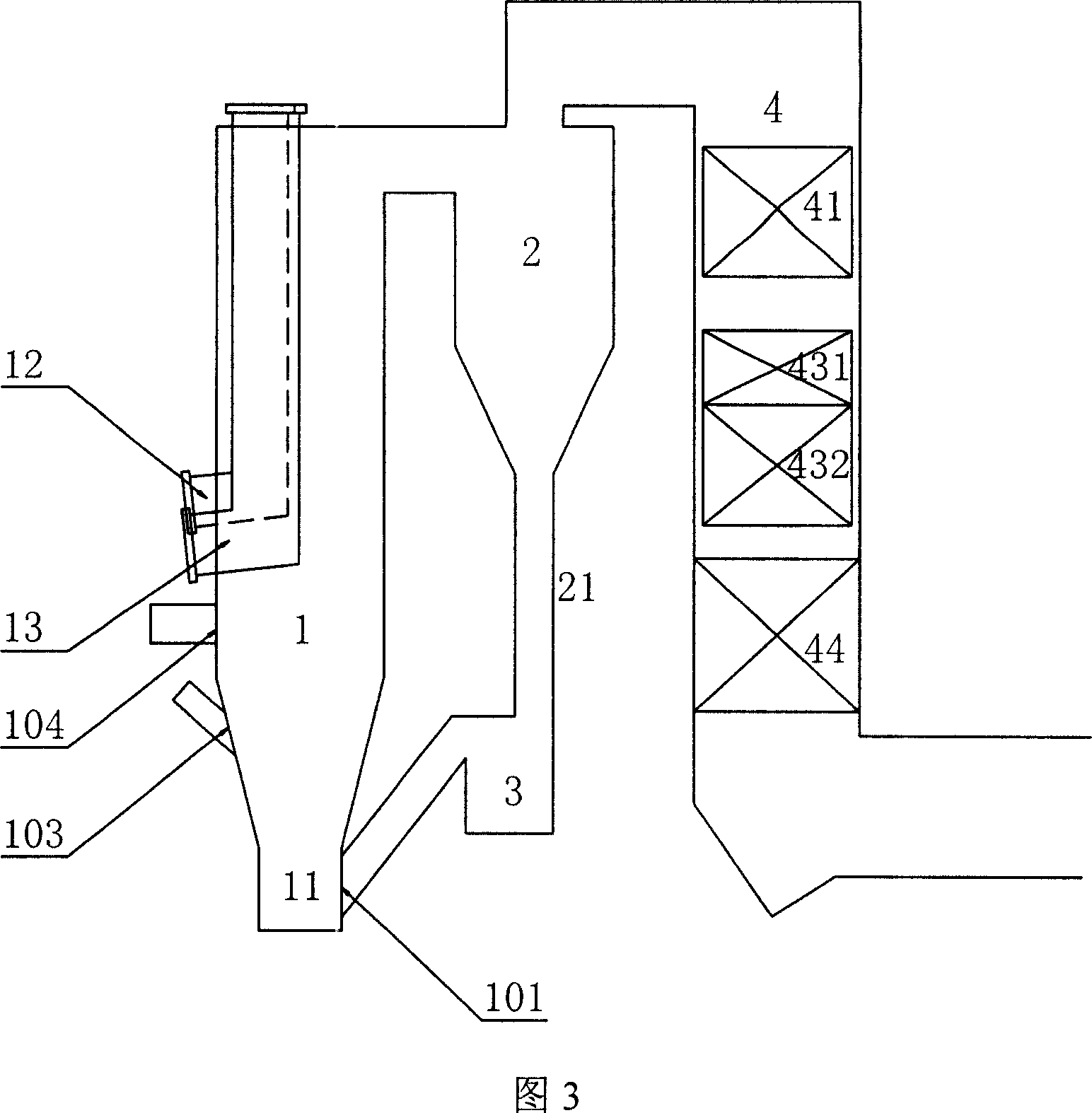

Biomass circulating fluid bed burning method and biomass circulating fluid bed boiler

ActiveCN101113816AReduce the temperatureImprove working environmentFluidized bed combustionApparatus for fluidised bed combustionTemperature controlSuperheater

The invention discloses a biological circulation fluidized bed combustion method and a biological fueled circulation fluidized bed boiler; the fluidized bed boiler comprises a boiler cavity, a clutch, a material refeeder, a tail chimney, wherein, the boiler cavity is provided with a superheater high temperature section, and the tail chimney is provided with a superheater low temperature section. Through the arrangement of heating surfaces of the boiler cavity and the tail chimney and other auxiliary measures, the temperature of the upper part of the boiler cavity is controlled at 550 to 800 DEG C, the outlet steam temperature of the tail heating surface is controlled at 350 to 400 DEG C, so as to solve the problem that: the temperature distribution of the boiler cavity is unreasonable, and the material concentration of the lower part of the boiler cavity is too low when the biological fuels are combusted in the circulation fluidized bed based on the stable fire, complete consumption of biological fuels , so that the temperature distribution in the boiler cavity tends to be equalized and the boiler cavity can be prevented from clinkering, and the accumulated ashes on the heating surfaces can also be prevented from being clinkered, furthermore, the boiler output capacity can be ensured, and a high steam parameter can also be achieved to ensure the generation efficiency.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

Three-layer lithium battery diaphragm and preparation method thereof

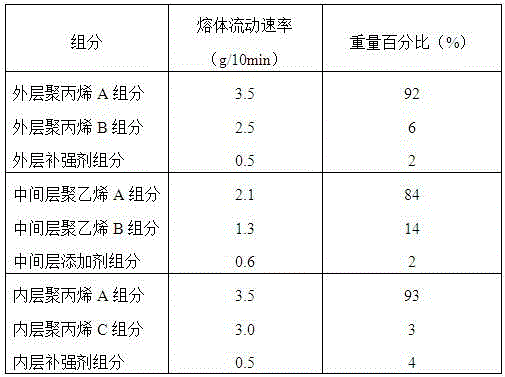

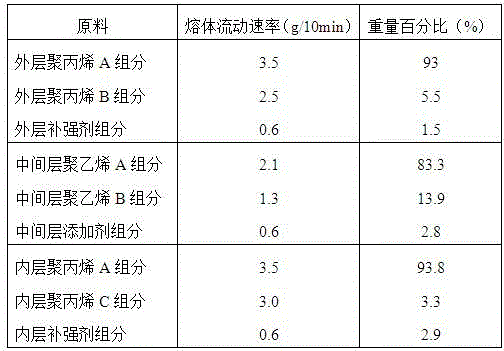

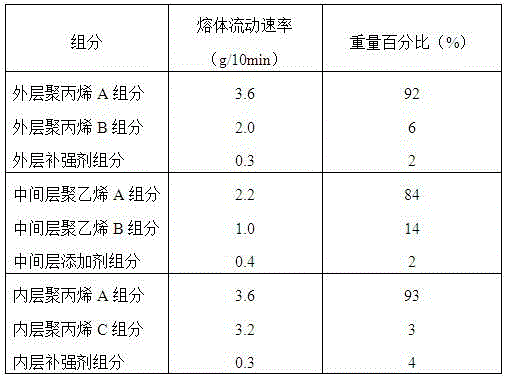

ActiveCN104022249ALow closed cell temperatureResolve Longitudinal WrinklesSynthetic resin layered productsCell component detailsPolymer sciencePolypropylene

The invention discloses a three-layer lithium battery diaphragm and a preparation method thereof. The diaphragm is prepared by adopting a three-layer coextrusion technology, and comprises an outer layer, a middle layer and an inner layer, wherein the outer layer is prepared from 92-93% of polypropylene A, 5-6% of polypropylene B and 1-3% of a reinforcing agent which are taken as raw materials; the middle layer is prepared from 83-86% of polypropylene A, 13-14% of polypropylene B and 1-4% of an additive which are taken as raw materials; the inner layer is prepared from 93-95% of polypropylene A, 3-4% of polypropylene C and 1-4% of a reinforcing agent which are taken as raw materials. The preparation method comprises the following steps of a) mixing and absorbing materials; b) extruding and stretching; c) baking; and d) stretching. The middle layer of the three-layer lithium battery diaphragm provided by the invention is a polypropylene layer, and the three-layer lithium battery diaphragm is prepared from the polypropylene layers of the outer layer and the inner layer in a three-layer coextrusion mode. The obturator temperature decreases greatly and reaches 138 DEG C minimally.

Owner:FOSHAN YINGBOLAI TECH

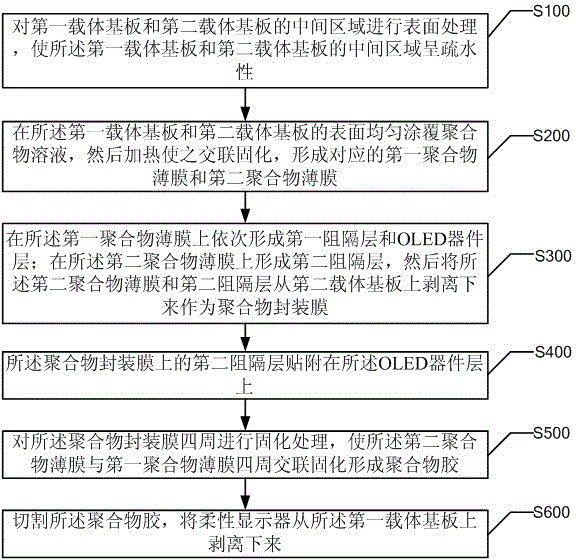

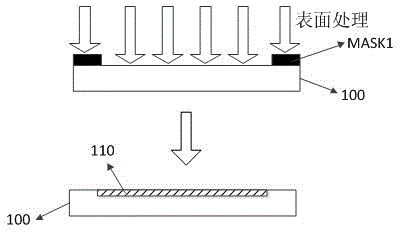

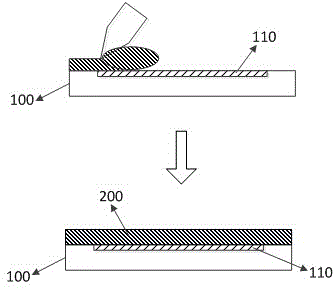

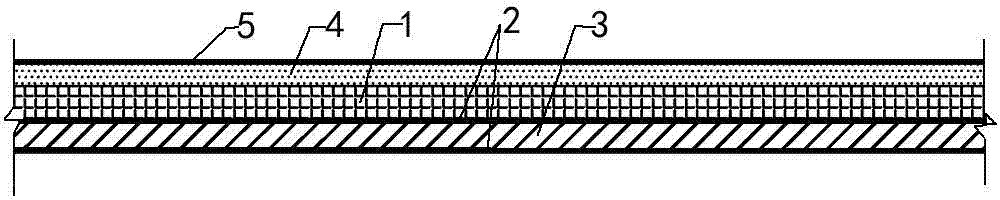

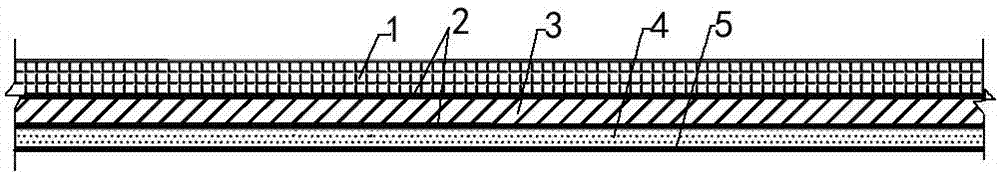

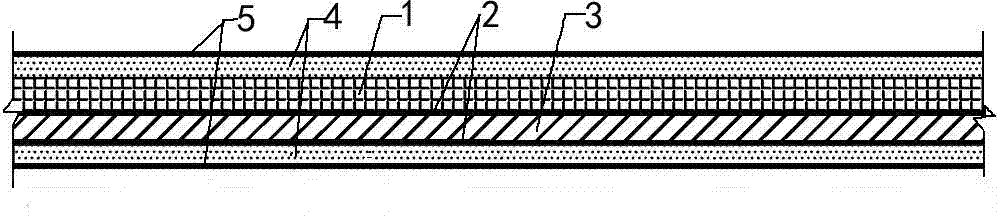

Flexible display and thin film packaging method thereof

ActiveCN105098088ASolve complexitySolve quality problemsSolid-state devicesSemiconductor/solid-state device manufacturingPolymer scienceDisplay device

The invention discloses a flexible display and a thin film packaging method thereof. The thin film packaging method comprises steps: after surface processing is carried out on a middle region between a first carrier substrate and a second carrier substrate, a polymer solution is applied uniformly, and a corresponding first polymer thin film and a second polymer thin film are formed through heating, crosslinking and curing; on the first polymer thin film, a first blocking layer and an OLED device layer are sequentially formed; a second blocking layer is formed on the second polymer thin film, the second polymer thin film and the second blocking layer are separated from the second carrier substrate to serve as a polymer packaging film; curing processing is carried out around the polymer packaging film, and thus the second polymer thin film and the first polymer thin film are crosslinked and cured around to form polymer gel; and the polymer gel is cut, and the flexible display is separated from the first carrier substrate. The thin film packaging technology is simplified, the display device can be separated from the carrier substrate easily, and a bonding agent does not need to be used.

Owner:TCL CORPORATION

Construction method for installing plastic sounding pipe

ActiveCN1755016ASimple construction processImprove construction qualityFoundation testingBulkheads/pilesEngineeringRebar

The invention discloses a construction method of plastic acoustic pipe fixation, which comprises the following steps: first, connecting the plastic acoustic pipe as long as reinforcement cage with the major steel of reinforcement cage; second, connecting the roll end with the last acoustic pipe end and one end of joining member with the other end of acoustic pipe by binder; then, dragging the drilling; putting down the reinforcement cage; injecting water in the acoustic pipe; putting down the second reinforcement cage in connection with the former cage; connecting the acoustic pipe with the inner acoustic pipe of previous reinforcement cage by joining member and binder; filling the acoustic pipe with clean water until the last pipe according to the analogy; binding the roll end and the top of acoustic pipe by binder; finally, casting concrete. This method has the following characteristics: simple construction process; low strength construction for workers; low cost and so on, which can be set in the filling plastic acoustic pipe.

Owner:SHANGHAI CONSTR NO 5 GRP CO LTD

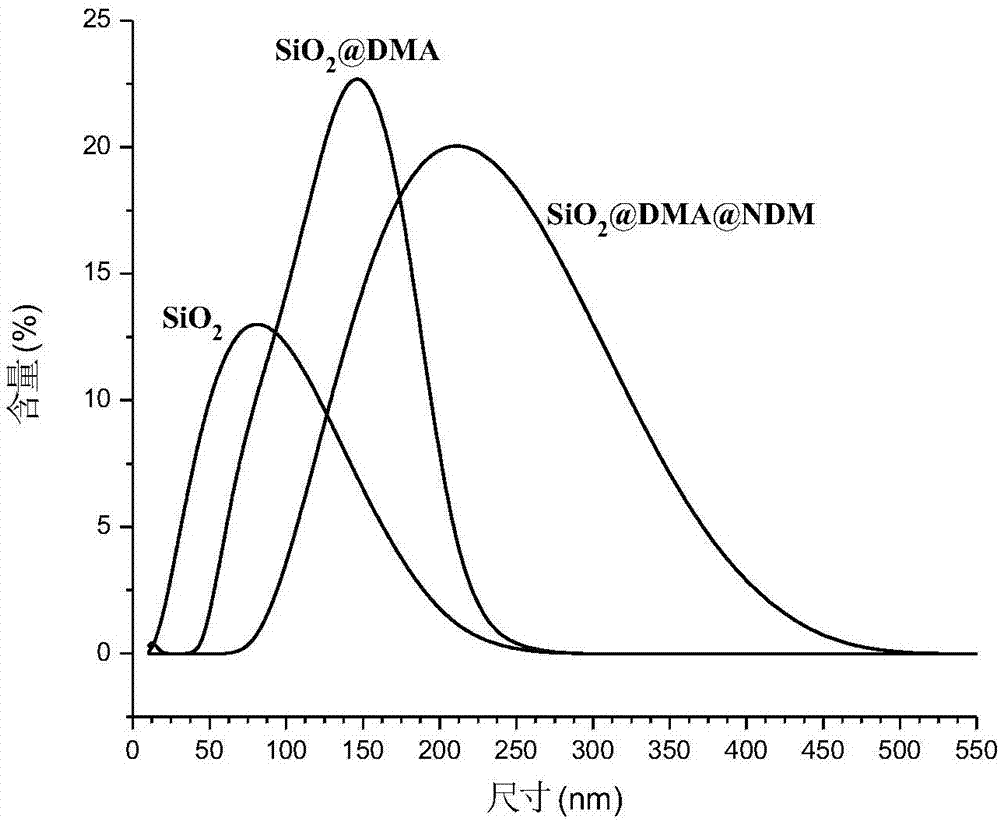

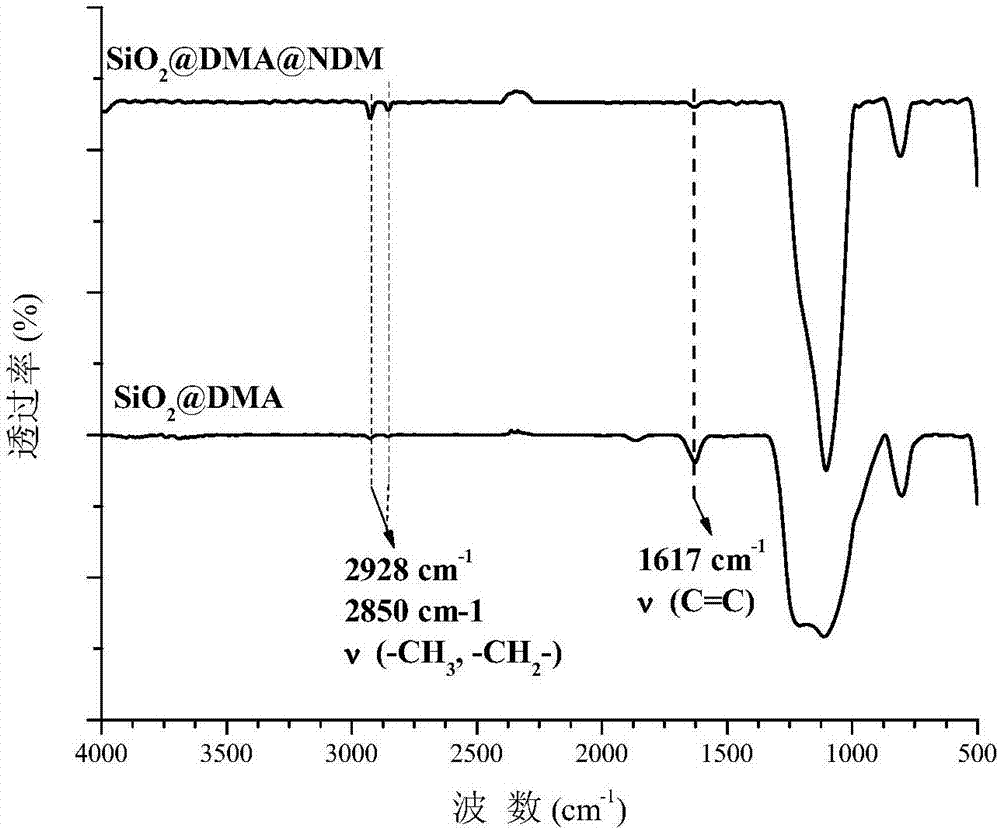

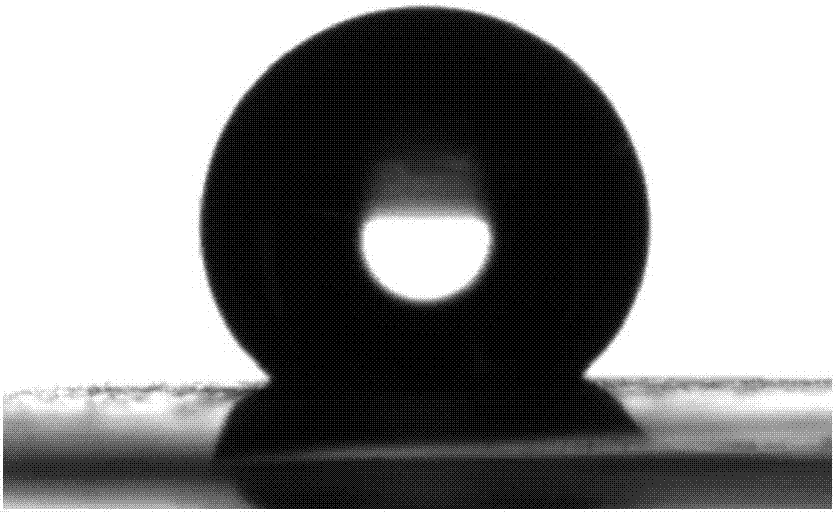

High-hydrophobicity antibacterial adhesion surface taking dopamine as anchor molecule and preparation method thereof

ActiveCN107446401ASolve limitedSolve complexityLiquid surface applicatorsAntifouling/underwater paintsDouble bondDopamine

The invention discloses a high-hydrophobicity antibacterial adhesion surface taking dopamine as anchor molecule and a preparation method thereof. The preparation method comprises the following steps: firstly, preparing hydrophobic modified SiO2 nanometer particle by utilizing dopa derivative containing double bond and alkyl sulfhydryl modified SiO2 nanometer particle, and then modifying the dopamine and the hydrophobic modified SiO2 nanometer particle to the base material surface under an alkaline condition, thereby acquiring the high-hydrophobicity antibacterial adhesion surface taking dopamine as anchor molecule. According to the invention, an antibacterial adhesion surface material with high hydrophobicity is prepared in the manner of taking the dopamine and derivative molecule thereof with reaction activity as the anchor molecule, taking the hydrophobic SiO2 nanometer particle as an interface material and utilizing the super-strong adhesion characteristic of catechol group in the anchor molecule structure to link the substrate and the hydrophobic SiO2 nanometer particle. According to the invention, the problems of limited modification substrate and complex modifying method are solved, the implementation process and condition are simple and the operation is convenient and feasible.

Owner:SOUTH CHINA UNIV OF TECH

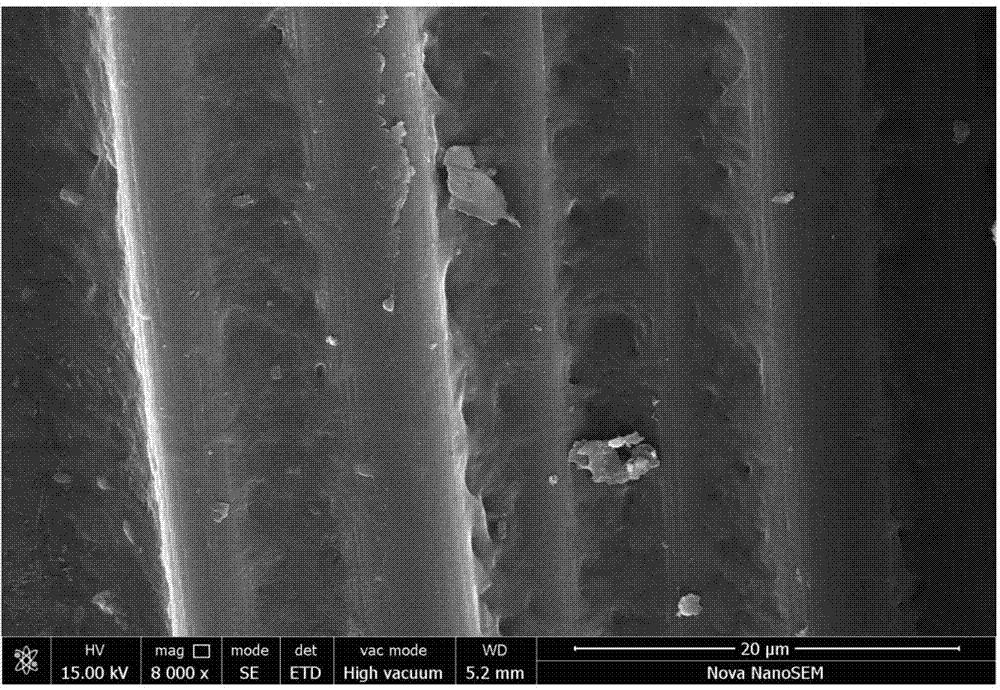

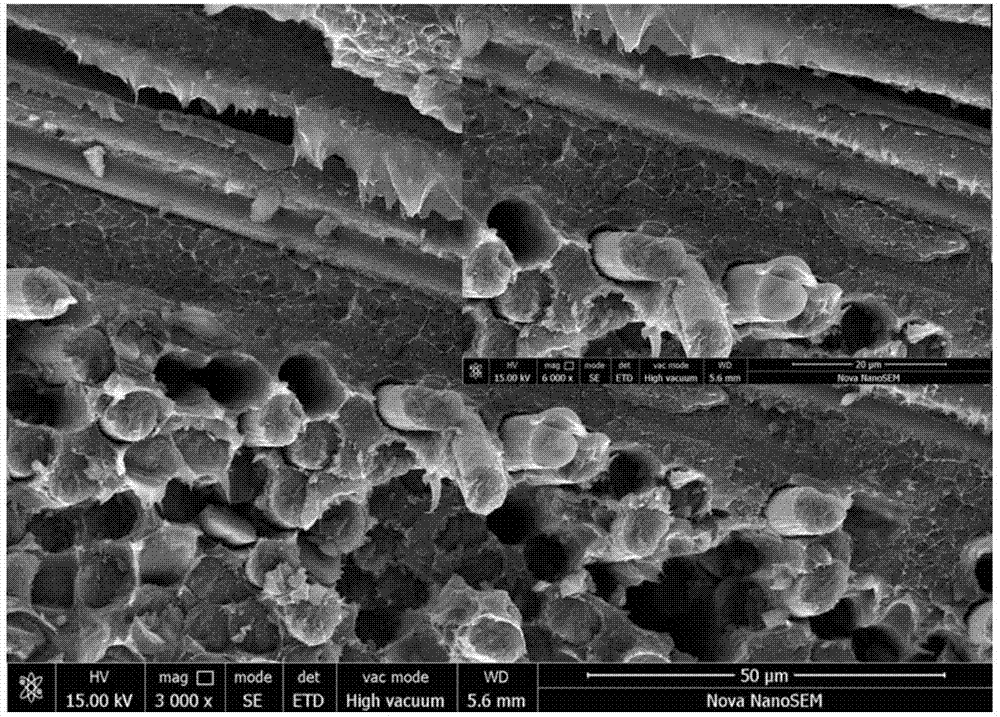

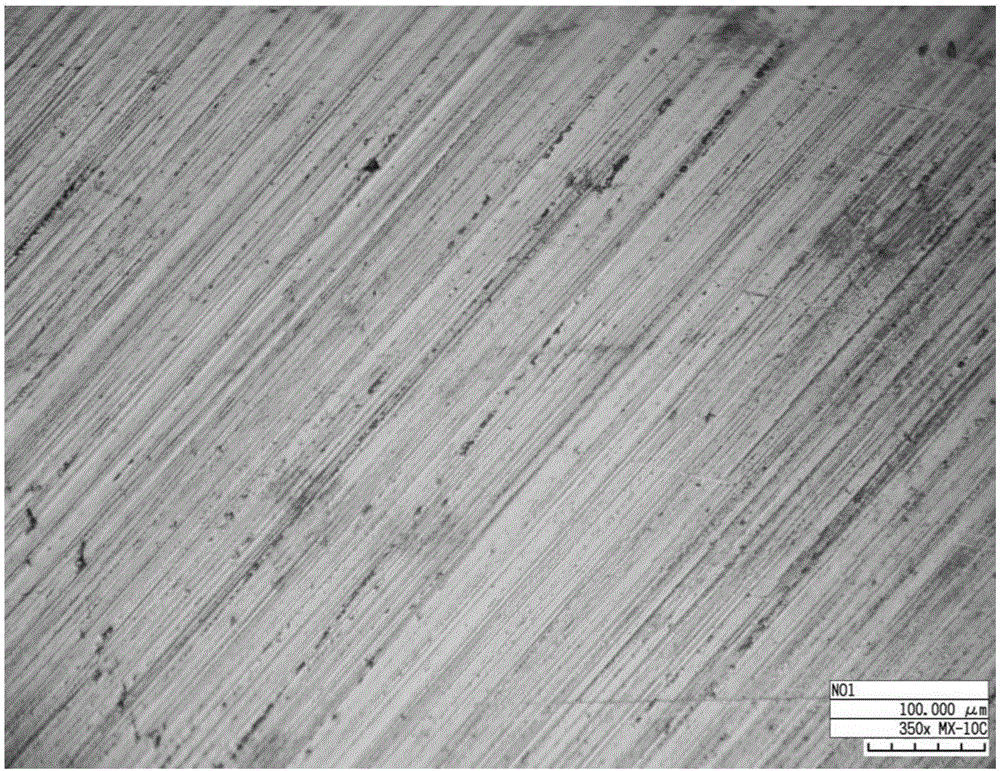

Preparation method of acrylic polymer grafted carbon fiber multi-scale reinforcement

InactiveCN103275282AThe surface is inertSmall specific surface areaPhysical treatmentInterlaminar shearResin matrix

The invention discloses a preparation method of an acrylic polymer grafted carbon fiber multi-scale reinforcement, relating to a carbon fiber reinforcement and a preparation method thereof. The preparation method comprises the following steps of: 1) performing oxidation treatment on a carbon fiber surface; 2) grafting a silane coupling agent to the carbon fiber surface after the oxidation treatment; 3) obtaining chain transfer agent grafted carbon fiber through a reaction between the carbon fiber surface grafted silane coupling agent and a chain transfer agent; and 4) initiating acrylic monomer grafting polymerization on the surface of the chain transfer agent grafted carbon fiber to finally obtain an acrylic polymer grafted carbon fiber multi-scale reinforcement. The method disclosed by the invention has the advantages that the roughness of the carbon fiber surface can be greatly improved, a great quantity of active functional groups can be introduced, the reaction activity of the carbon fiber surface is improved, the wettability and cohesiveness between the carbon fiber and a resin matrix are improved, and the interlaminar shear strength of an epoxy composite material is enhanced by 40-50%.

Owner:NANCHANG HANGKONG UNIVERSITY

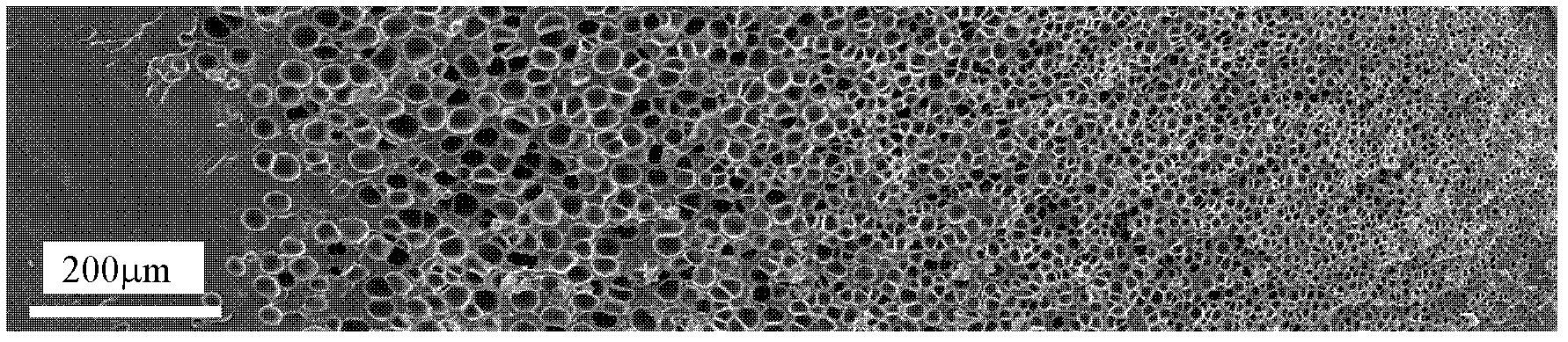

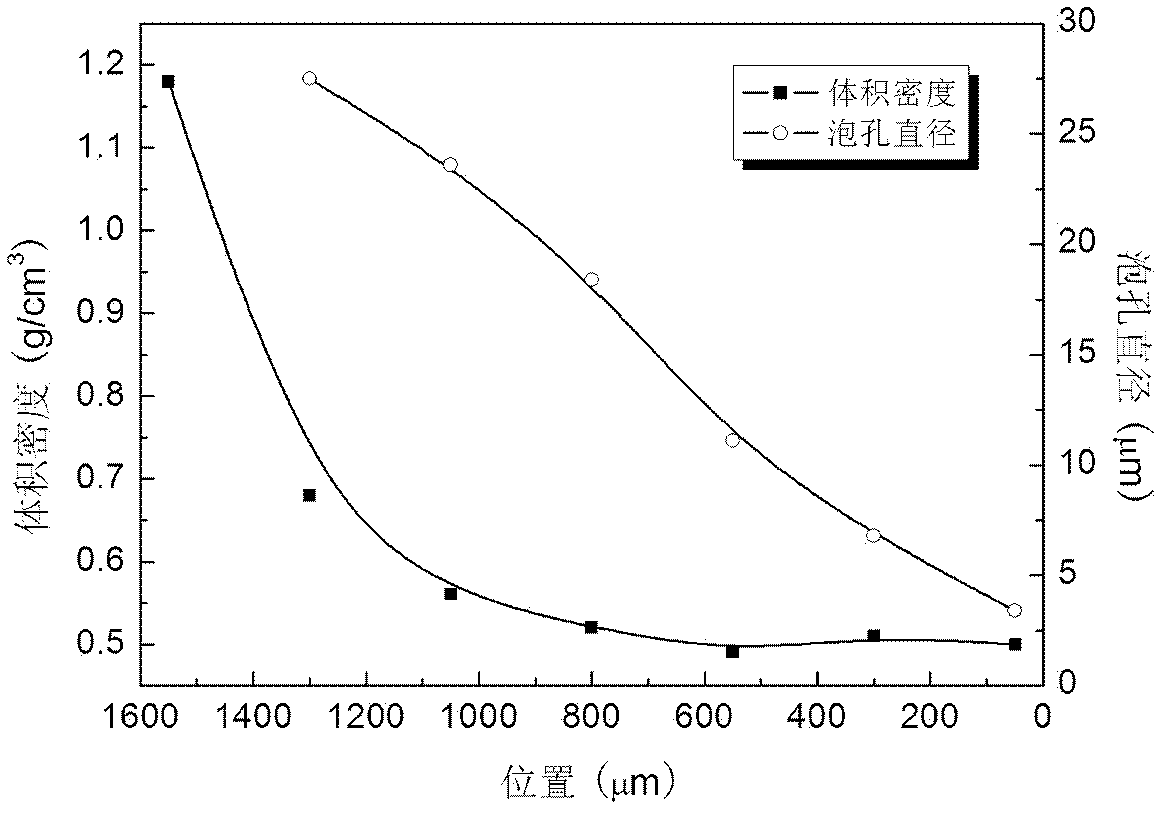

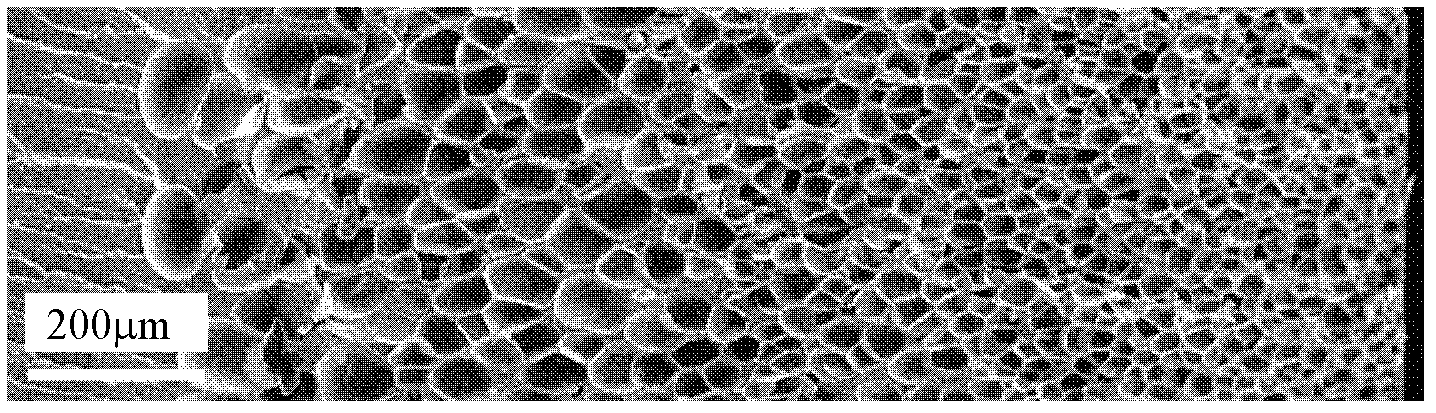

Preparation method of polymethyl methacrylate (PMMA) cellular gradient material

The invention relates to a preparation method of a polymethyl methacrylate (PMMA) cellular gradient material. The method specifically comprises: placing a unidirectionally opened die loaded with PMMA into an autoclave, controlling the oriented adsorption of highpressure carbon dioxide in PMMA to form a concentration gradient, with the pressure of the carbon dioxide controlled at 10-30MPa and the temperature maintained at 50-150DEG C, preserving the heat and pressure for 1-60min, then conducting pressure releasing, and finally cooling a sample to room temperature with an ice-water mixture, thus obtaining the cellular gradient material. A cellular structure with a small cell diameter and a thin cell wall forms in a high concentration carbon dioxide diffusion area on the surface layer, a cellular structure with a large cell diameter and a thick cell wall forms in a low concentration area of the central section, and the innermost layer is compact PMMA matrixes. The porosity of the sample changes from high to low continuously from the surface layer to the inner layer. With a cell diameter controlled at micron magnitude, the gradient material provided in the invention has good dimensional stability, wide porosity variation range and high mechanical strength.

Owner:WUHAN UNIV OF TECH

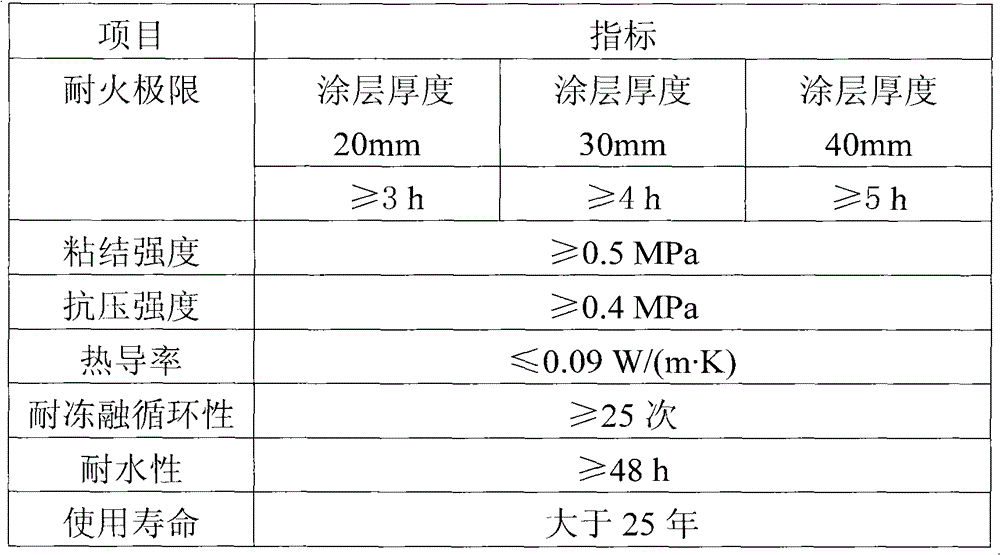

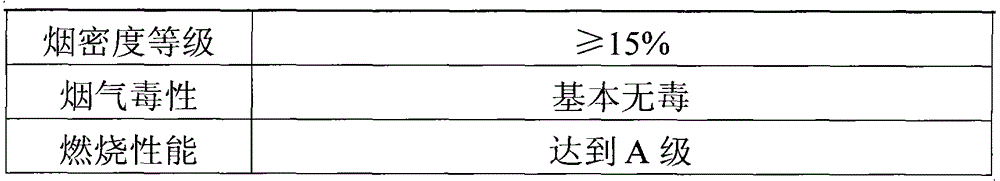

Steel structure fireproof paint by taking expanded and vitrified small ball as base material

The invention provides a preparation method of a steel structure fireproof paint by taking expanded and vitrified small ball as a base material, which is characterized in that on the basis of a traditional organic inorganic clad steel structure fireproof paint, and expanded and vitrified small ball and phenolic resin are used for obtaining the steel structure fireproof paint with excellent performance. According to the invention, expanded and vitrified small ball in the inorganic component replace a traditional lightweight aggregate, thereby the paint has the advantages of low density, high strength, stable physical and chemical performance, and has excellent performances of aging resistance and weatherability, heat insulation, fire resistance, sound insulation and insulation; phenolic resins can replace a traditional film forming agent in the organic component, no fire retardant is applied, so that the coating has the advantages of difficult combustion, good heat stability, low smoke, low toxicity, high mechanical strength, and strong anti-corrosion capability and weather resistance. The paint overcomes the disadvantages of poor flame resistance and toxic flue gas release due to thermal decomposition of the common organic resin.

Owner:BEIJING BUILDING TECH DEV

Silicon dioxide nanometer aerogel hollow-core glass bead composite fireproof insulation board material and preparation method thereof

ActiveCN106567474APromote sheddingReduce thermal bridge effectClimate change adaptationInsulation improvementThermal insulationCarbon nanotube

The invention relates to the technical field of insulation building materials and particularly discloses a silicon dioxide nanometer aerogel hollow-core glass bead composite fireproof insulation board material and a preparation method thereof. The silicon dioxide nanometer aerogel hollow-core glass bead composite fireproof insulation board material is characterized by comprising an upper inorganic fiber layer and a lower inorganic fiber layer. A composite insulation sandwich layer is bonded between the upper inorganic fiber layer and the lower inorganic fiber layer and is formed by mixing modified silica sol emulsion, melamine aerogel powder or water-soluble powder phenolic resin, a dispersant, a water repellent, silicon dioxide nanometer aerogel, hollow-core glass beads, a carbon nano tube, wollastonite powder, mica powder, a fine foamer, a curing agent and a hydrosolvent according to a certain weight ratio. According to the silicon dioxide nanometer aerogel hollow-core glass bead composite fireproof insulation board material and the preparation method thereof, innovative composite technology and fine foaming technology are adopted, high-tech space thermal insulation materials are changed for industrial and civil use, and the fireproof insulation board material is prepared and becomes an important way for technological development of fireproof insulation materials in the future.

Owner:王贵然

Preparation method for carbon fibre fabric-reinforced polyetheretherketone polymer composite material

The invention discloses a preparation method for a carbon fibre fabric-reinforced polyetheretherketone polymer composite material, and belongs to the technical field of composite material preparation. The preparation method comprises the following steps: carrying out slurry remover treatment on the surface of a carbon fibre fabric; dissolving polyarylsulfone powder in chloroform or N,N-dimethyl formamide to prepare polymer solution with a certain concentration, then adding polyetheretherketone ultrafine powder, and stirring to obtain a suspension; flatly paving the treated carbon fibre fabric in a cloth-type funnel, pouring the suspension on the carbon fibre fabric, and carrying out low-pressure suction filtration; melting, pressurizing and maintaining a pressure in a hot press; then cooling to a room temperature and demoulding. The preparation method disclosed by the invention solves the problems of high process control difficulty, too high equipment and energy consumption costs, poor adhesive property of polyetheretherketone and carbon fibres, and the like of the existing polyetheretherketone resin during a carbon fibre soaking process, so that preparation for the large fibre fabric-reinforced polyetheretherketone composite material is realized by using simple equipment and a simple and convenient process method.

Owner:JILIN UNIV

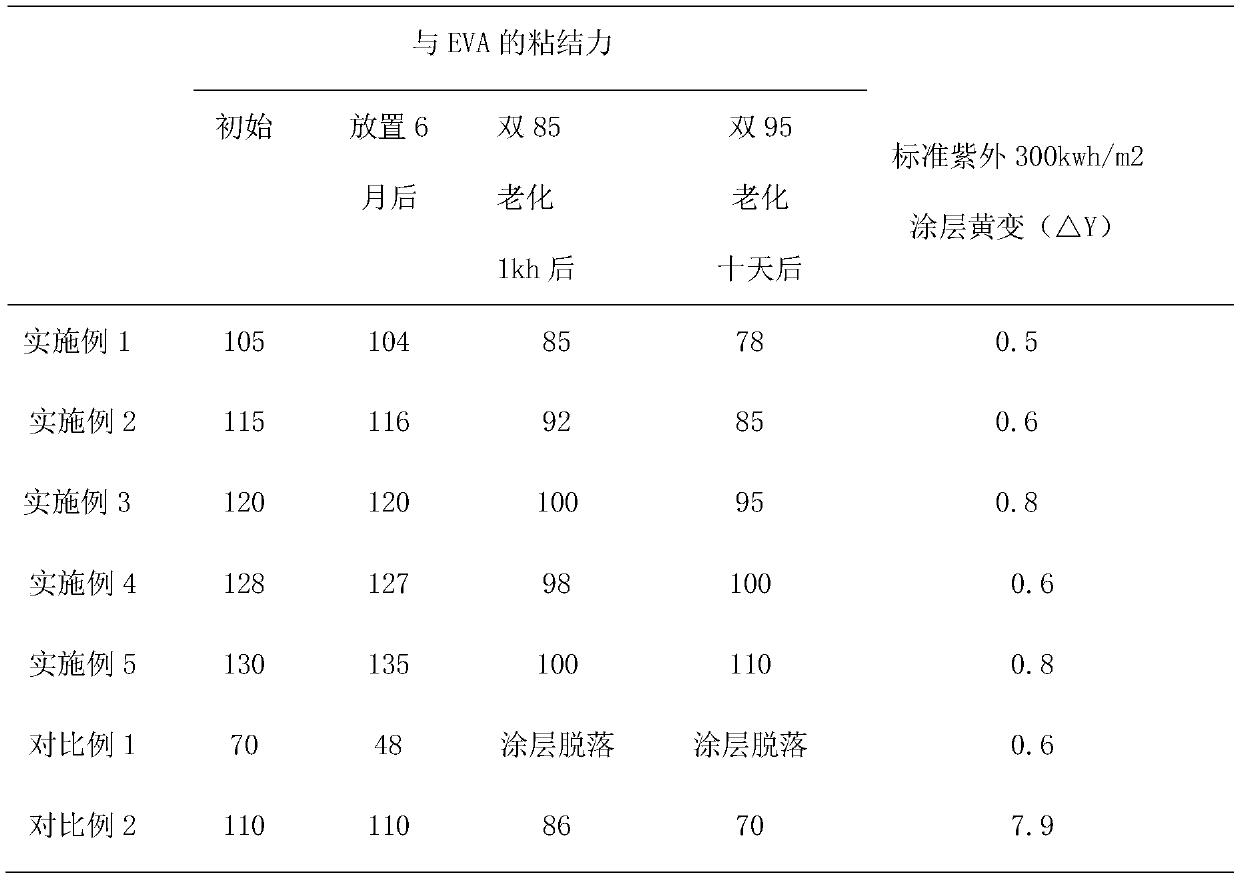

Coating for solar cell back plates

ActiveCN109735177AGood interlayer forceEasy to degradeCoatingsPhotovoltaic energy generationWeather resistanceAcrylic resin

The invention relates to coating for solar cell back plates. The coating comprises, by mass percentage, 9.2-14.4% of fluorocarbon resin, 3.6-9.2% of acrylic resin, 20.5-25.3% of pigment, 37.6-48.1% ofsolvent, 0.6-1% of auxiliaries and an isocyanate curing agent, wherein the mole ratio of hydroxyl in the fluorocarbon resin and the acrylic resin to the isocyanate in the curing agent is 0.8-1.6, andthe total mass percentage of the components is 100%. The coating has the advantages that the coating is good in interlayer performance, a coating layer after hydrothermal aging is good in bonding force with EVA, and the problem that fluorocoating cannot give consideration to both weather resistance and cohesiveness is solved.

Owner:乐凯胶片股份有限公司

High efficiency lime powder product and production process thereof

The invention discloses a high efficiency lime powder product and a production process thereof and particularly relates to a surface-modified lime powder product used in molten iron desulfurization pretreatment process and a production process thereof. According to the production process, silicone oil is firstly selected as surface modifier to be sprayed on crushed active lime; the adding amount of the surface modifier is 0.1-0.3% in percentage by weight. The surface-modified lime powder product disclosed by the invention has the advantages that the powder product is high in hydrophobicity and flowability and low in cost and is suitable for molten iron desulfurization pretreatment; the problems that a gun is blocked by lime powder and the lime powder is bonded on the material tank wall in the molten iron pretreatment process can be well solved, the lime powder can effectively penetrate through a gas-liquid interface and enter the interior of molten iron, so that the use ratio of calcium oxide is increased by a large margin and the molten iron pretreatment cost can be remarkably reduced; in addition, the production process of the powder product is simple, can be carried out at room temperature and is relatively simple in equipment, so that the powder product is small in investment, low in cost and high in efficiency.

Owner:TAIYUAN IRON & STEEL GROUP

Low-temperature heat-seal high-separating coating thin film and production method thereof

ActiveCN102848671AIncreased sealing temperatureThe sealing temperature is 80-85℃, and the heat sealing strength is improvedFlexible coversWrappersChewing gumHigh heat

The invention relates to a low-temperature heat-seal high-separating coating thin film. The low-temperature heat-seal high-separating coating thin film comprises a base material, an upper coating layer and a lower coating layer arranged on the upper and lower surfaces of the base material, an upper bottom glue layer arranged between the base material and the upper coating layer and a lower bottom glue layer arranged between the base material thin film and the lower coating layer, wherein the upper coating layer is an acrylic acid coating layer; the lower coating layer is a polyvinylidene chloride (short for PVDC as below) coating layer; the acrylic acid coating layer is a low-temperature heat-seal layer; the PVDC coating layer is a high-separating layer; and during sealing, the acrylic acid coating layer and the PVDC coating layer are sealed in a heating manner, namely sealed in a lapping manner from inside and outside, and the heat-seal strength can reach 3.6N / 15mm. The coating thin film has the advantages of low heat-seal temperature, high heat-seal strength and high separating performance, and is particularly suitable for packaging chewing gum and chocolates sensitive to temperature at high speed.

Owner:HAINAN SHINER IND

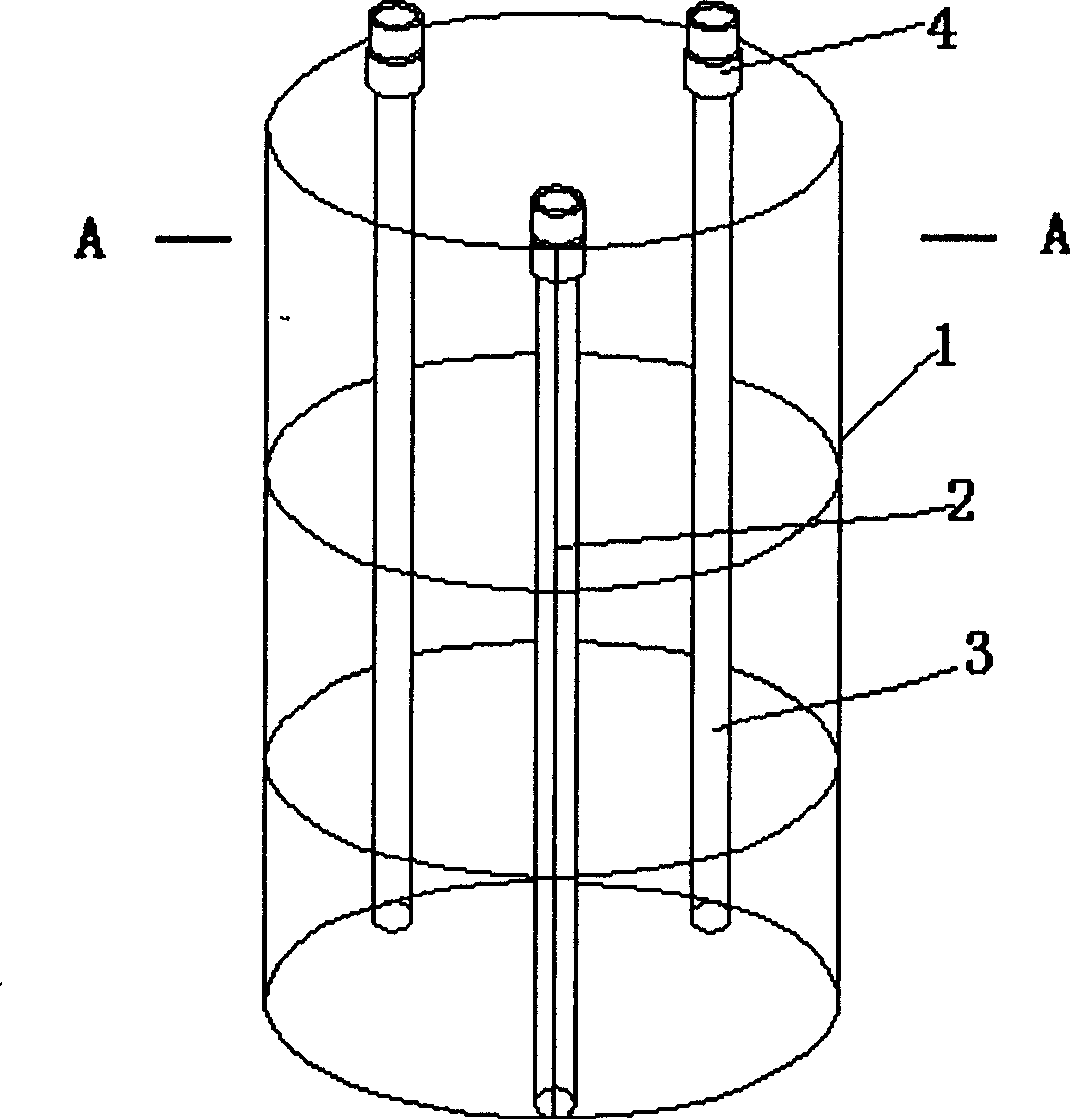

Rotary calcining furnace

The invention provides a rotary calcining furnace. The rotary calcining furnace comprises a furnace tube, a heating part and a liquid feeding liquid mixing device, wherein the liquid feeding liquid mixing device comprises a liquid mixing container, a turbulence plateand a fixing piece; and the liquid mixing container is provided with a feeding portand a material supplying port,the turbulence plateis fixed inside the liquid mixing container through the fixing part. The rotary calcining furnace is perfect in design, good in performance and convenient to operate, and can well solve the problemsthat materials are not uniform, the inner wall of the furnace tube is bonded, blocked and the like in a radioactive waste liquid rotary calcining process, industrial production is easy to realize, andtechnical support is provided for development and improvement of the two-step cold crucible glass curing technology in China.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

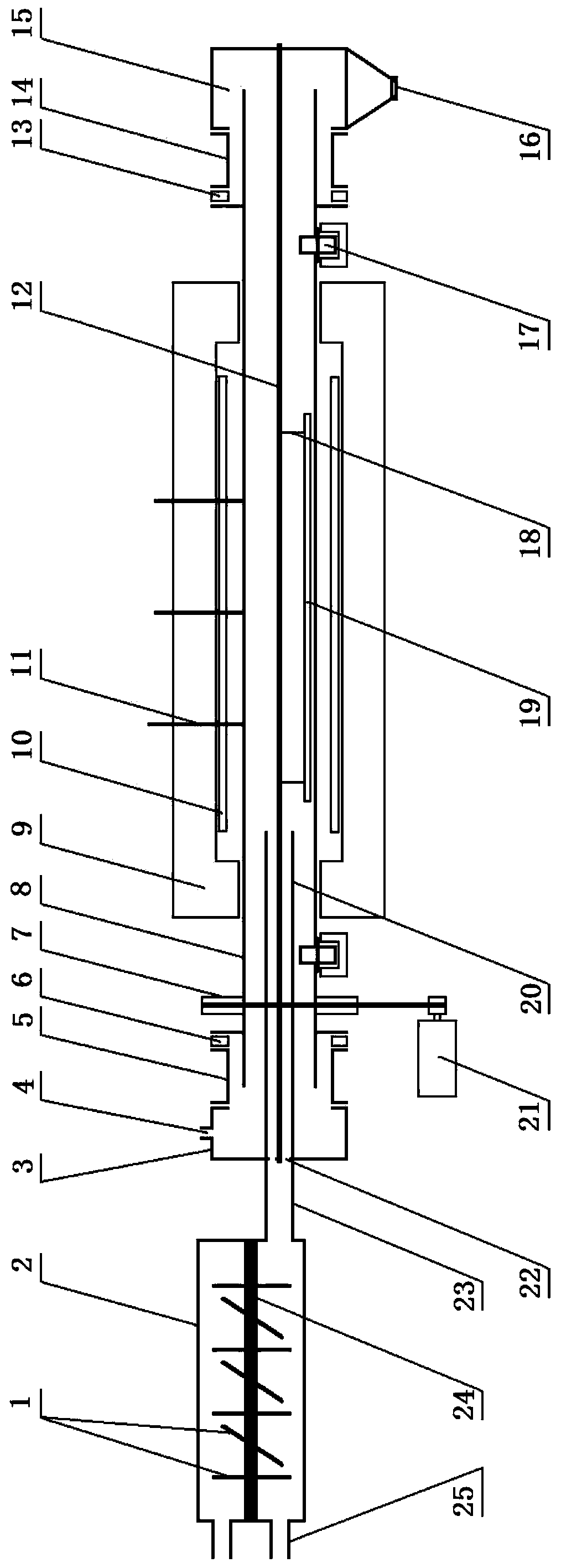

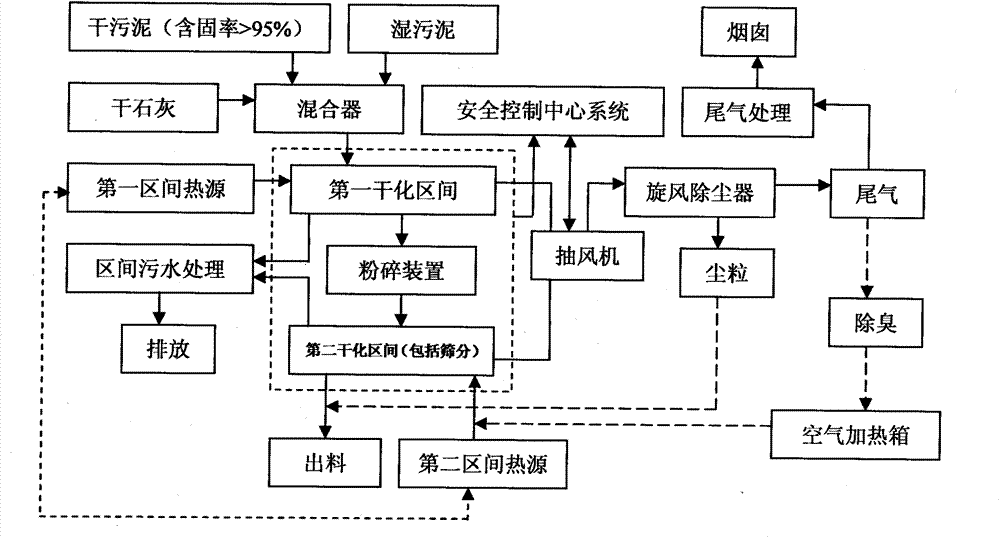

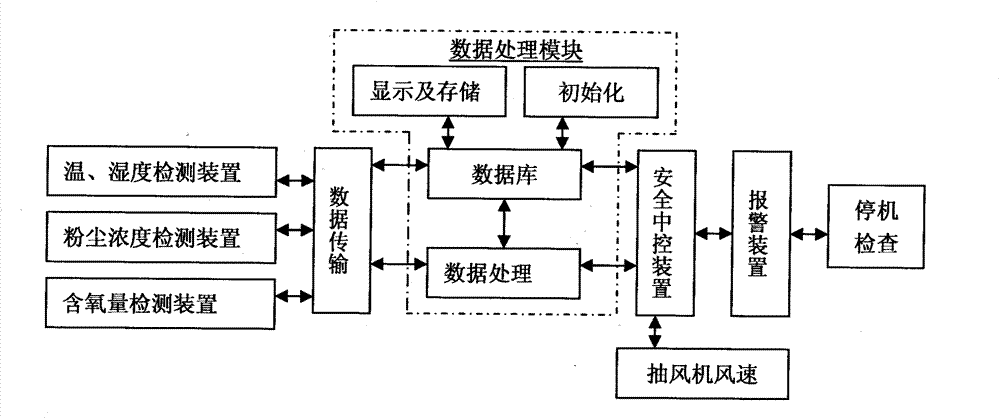

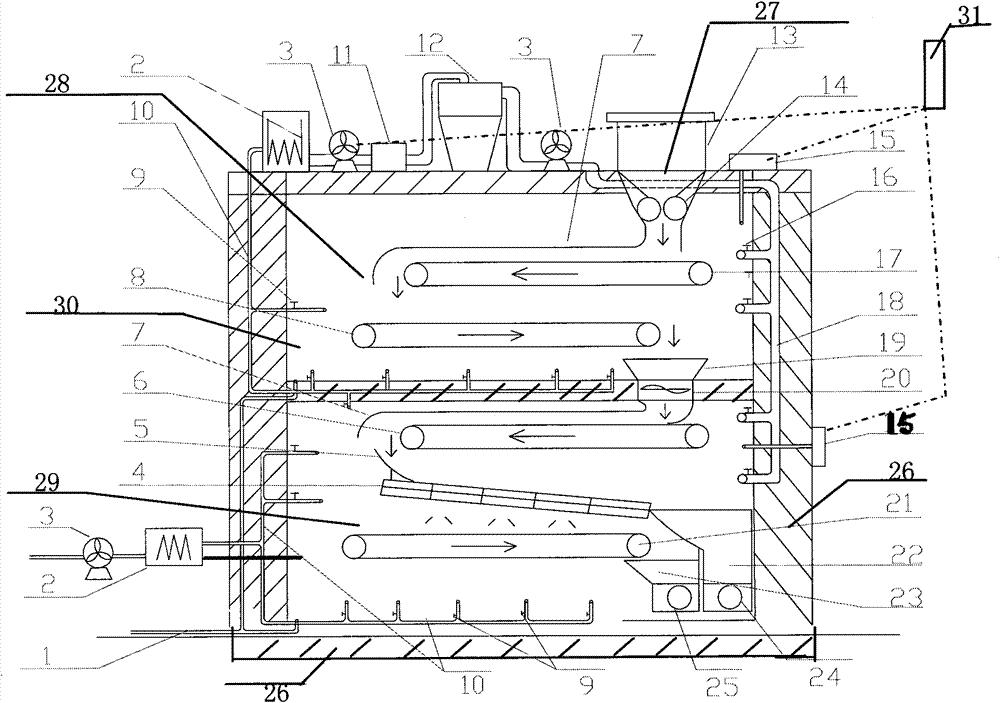

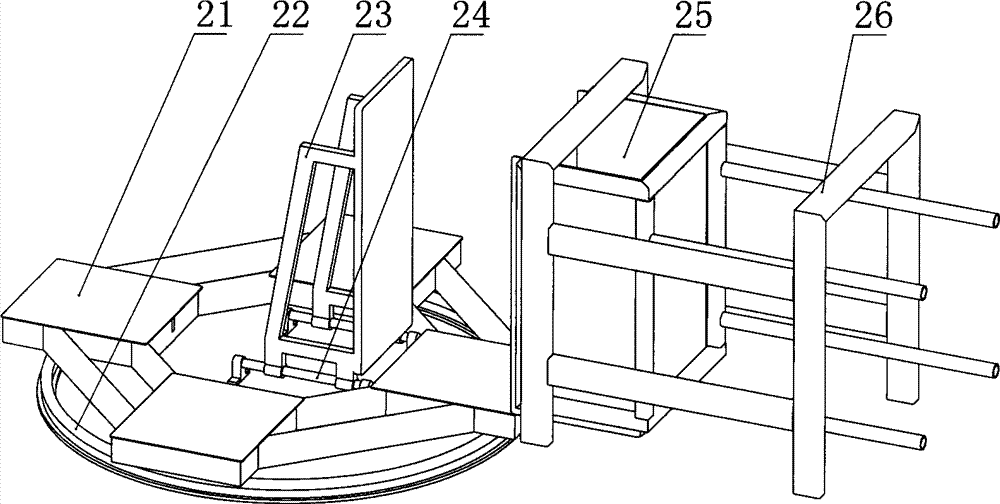

Vertical inter-partition sludge drying method and equipment with crushing and safety monitoring functions

InactiveCN103803769ASolve the costSolve cohesionSludge treatment by de-watering/drying/thickeningRefluxThermal insulation

The invention discloses a vertical inter-partition sludge drying method and equipment with crushing and safety monitoring functions. The method comprises the following steps: dividing a sludge drying process into a dried material back-mixing stage, a first drying stage, a crushing treatment stage, a second drying stage and a final screening and discharging stage, wherein the sludge drying operation is performed under monitoring of a safety monitoring system. The equipment comprises a heating box provided with multiple energy interfaces, a rolling plodder, a drying box (a crusher, a metallic screen and a conveyer belt are arranged in the drying box, and the interior of the drying box is partitioned into two intervals by a thermal insulation material and the crusher position in the middle), an exhaust fan, a dust remover, a deodorization device, a water vapor reflux pipe and is also equipped with a safety control center system. According to the sludge drying equipment, the drying method can be effectively performed. The problems of cost, adhesion and safety during sludge drying are appropriately solved, the drying efficiency is high, the discharging uniformity is high, and the sludge resource recycling value is high.

Owner:CHONGQING JIAOTONG UNIVERSITY

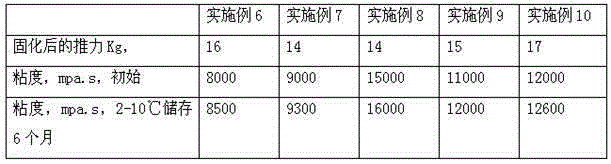

Ultraviolet/heating-curing epoxy resin adhesive and preparation method thereof

InactiveCN105111986AFix compatibility issuesSolve cohesionNon-macromolecular adhesive additivesMacromolecular adhesive additivesEpoxyUltraviolet

The invention relates to a preparation method of an ultraviolet / heating-curing epoxy resin adhesive. The ultraviolet / heating-curing epoxy resin adhesive is prepared from the following raw materials in percentage by mass: 50-70% of epoxy resin, 1-5% of ultraviolet initiator, 1-5% of thermal initiator, 5-20% of diluter, 5-20% of toughener, 1-10% of thixotropic agent and 1-2% of colorant. The ultraviolet / heating-curing epoxy resin adhesive only adopts the epoxy resin system; and the single resin system can better solve the problems in storage stability, compatibility and binding force. The epoxy resin system is utilized to simultaneously implement ultraviolet curing and heat curing, thereby avoiding the problems in compatibility and stability caused by different resin systems. By adopting hexafluoroantimonate as the thermal initiator, the ultraviolet / heating-curing epoxy resin adhesive has high stability, and can implement storage at 2-10 DEG C without stratification, thereby lowering the storage cost.

Owner:连云港华海诚科电子材料有限公司

Polymer alloy waterproof coiled material and production method thereof

InactiveCN104260479AHigh tensile strengthGood high and low temperature resistanceNon-macromolecular adhesive additivesSynthetic resin layered productsPolymer alloyAcrylic resin

The invention relates to a polymer alloy waterproof coiled material and a production method thereof. The coiled material comprises an alloy plate layer and a polymer material layer, which are integrated together. Two side surfaces of the alloy plate layer are both painted by an anti-oxidant material. At least one side of the waterproof coiled material is provided with a waterproof anticorrosion self-adhesive rubber layer, whose external side is covered by a silicone oil membrane. The waterproof anticorrosion self-adhesive rubber is composed of the following components in percentage by weight: 20 to 45% of thermoplastic butadiene styrene rubber, 10 to 35% of aromatic hydrocarbon oil, 3 to 25% of thermoplastic solid acrylic resin, 3 to 5% of antirust antiseptic, and 8 to 19% of talcum powder. The coiled material has the advantages of good waterproofness, good corrosion resistance, UV resistance, low temperature resistance, aging resistance, puncture resistance, and quickness for construction, is a novel waterproof material that can be perfectly bound and integrated with buildings, is suitable for various construction projects such as subways, tunnels, bridges, roads, underground projects, roofs, and the like, and is especially suitable for waterproof projects on the surface layer of plant roots.

Owner:中联天盛建材集团有限公司

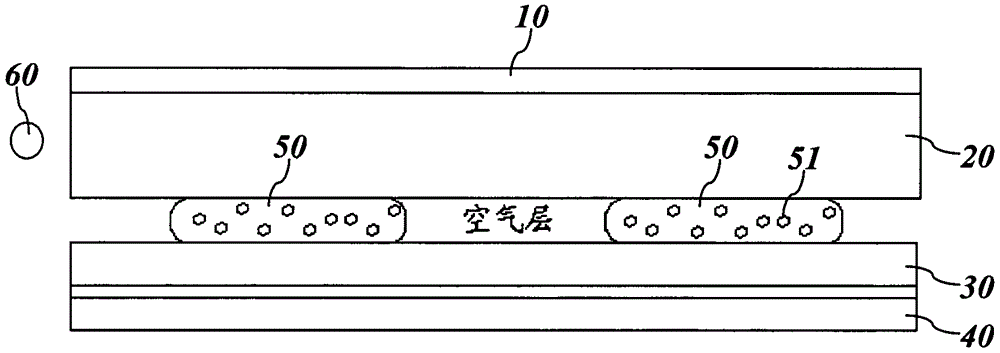

Novel liquid crystal display module and novel liquid crystal displayer

The invention provides a novel liquid crystal display module and a novel liquid crystal displayer.The novel liquid crystal display module comprises an optical membrane, a light guide plate, a reflective sheet and a protection layer thin film.The optical membrane is arranged on the light outlet surface of the light guide plate, the reflective sheet is arranged on the shady face of the light guide plate through light guide cement which is distributed on printing dots of the light guide plate or the reflective sheet, a gap exists between the light guide plate and the reflective sheet and is filled with air, reflection particles are mixed in the light guide cement, and the protection layer thin film is attached to the surface, back to the light guide plate, of the reflective sheet.According to the novel liquid crystal display module and the novel liquid crystal displayer, under the premise that the performance of the module is not lowered, the thickness of the module can be reduced by omitting a metal backboard and a plastic rear cover, and thus the thickness of a liquid crystal television is reduced.In addition, by omitting the metal backboard and the plastic rear cover, cost can be reduced besides reduction of the thickness.Furthermore, printing of the light guide cement can be completed through one printing process, efficiency is high, and the purposes of light guiding and bonding are achieved.

Owner:方继恒

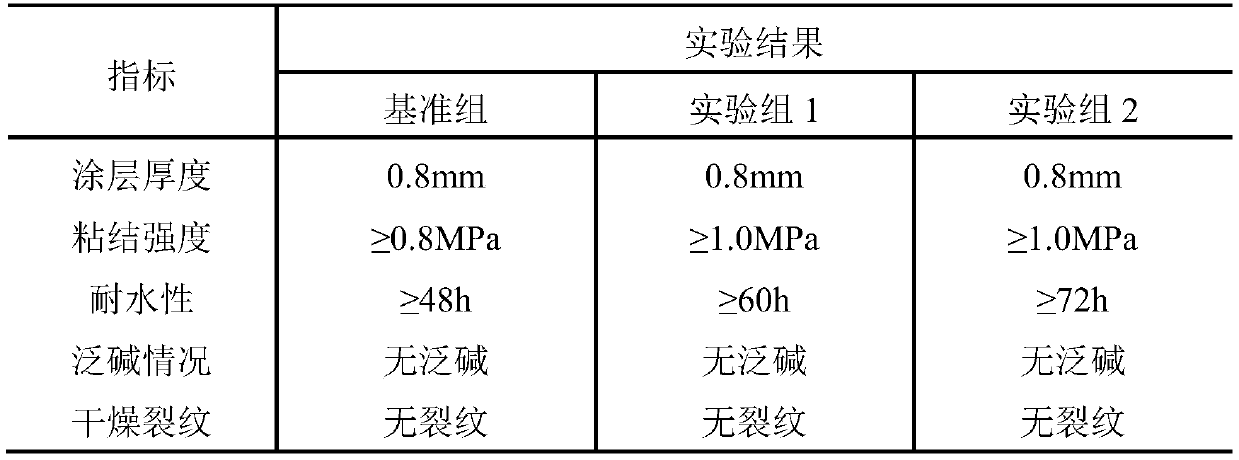

Pulverized-fuel-ash-based geopolymer steel structure non-shrinking anti-corrosive coating

InactiveCN110117424AImprove performanceIncreased humidity sensitivityAlkali metal silicate coatingsAnti-corrosive paintsCrack resistanceCarbonization

The invention provides a non-shrinking pulverized-fuel-ash-based geopolymer steel structure anti-corrosive coating. Surface coatings of steel structures can obstruct direct contact of corrosive mediums such as chloride ions with reinforcing steel bars, and the anti-corrosive performance of the reinforcing steel bars is effectively improved; however, currently, surface coatings of the reinforcing steel bars have shortcomings that the interface bonding performance of the reinforcing steel bars and the concrete is lowered, pitting corrosion is triggered due to the defects of the coatings, and application of the coatings in practical engineering is seriously restricted accordingly. According to the non-shrinking pulverized-fuel-ash-based geopolymer steel structure anti-corrosive coating, by conducting blending to obtain a proper alkali excitation matching proportion, the cracking resistance and saltpetering resistance of the pulverized-fuel-ash-based geopolymer inorganic anti-corrosive coating are improved; meanwhile, the compactness, carbonization resistance and ion infiltration resistance of the coating are improved, the bonding strength between the coating and the reinforcing steelbars is improved, and the cost is reduced.

Owner:CHONGQING UNIV

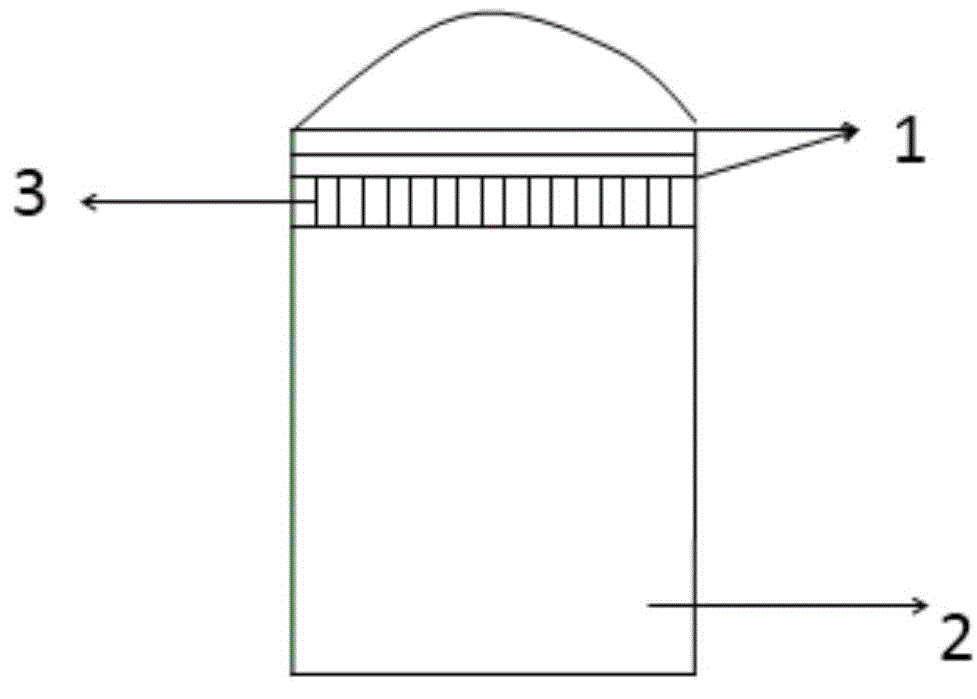

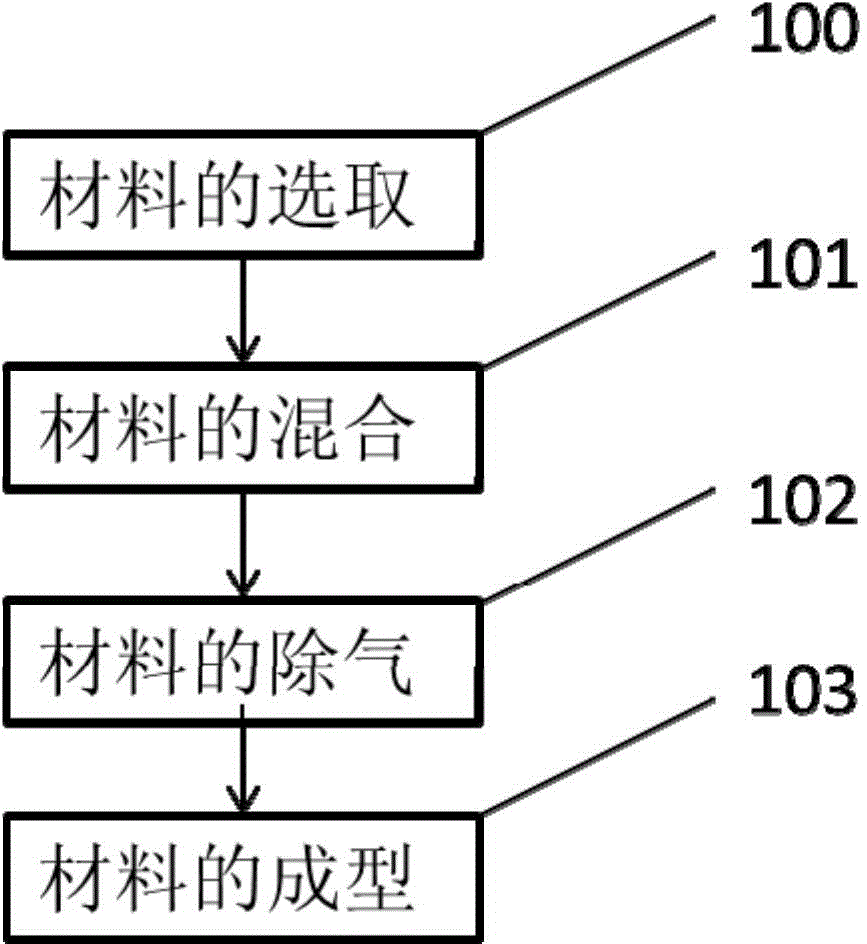

Preparation method of high-attenuation backing material

ActiveCN104552718ASmaller size than limitedIncrease volume percentageUltrasound attenuationImage resolution

The invention provides a preparation method of a high-attenuation backing material and the high-attenuation backing material obtained through the preparation method. The method comprises the following steps: (100) selecting materials; (101) mixing the materials; (102) degassing the materials; and (103) carrying out hot press molding on the materials. The backing material has high voice attenuation performance and high coefficient of heat conduction. By utilizing the backing material, imaging resolution ratio is improved, heat generated in the use process of an ultrasonic probe can be conducted quickly, and the service life of the ultrasonic probe can be correspondingly prolonged.

Owner:EDAN INSTR

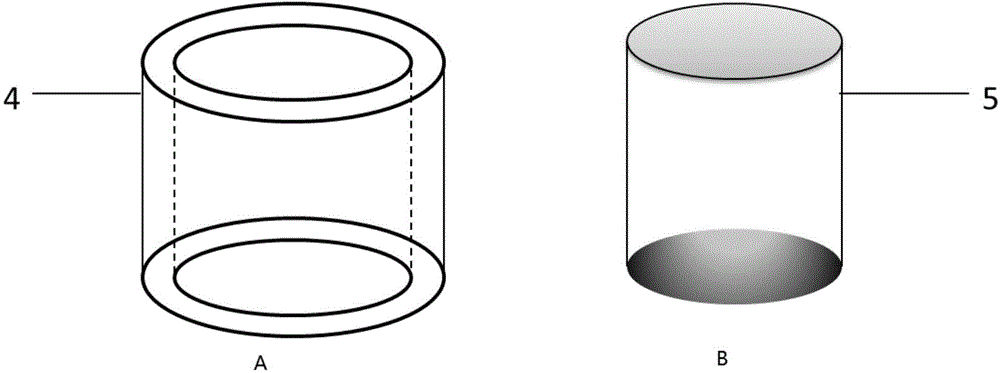

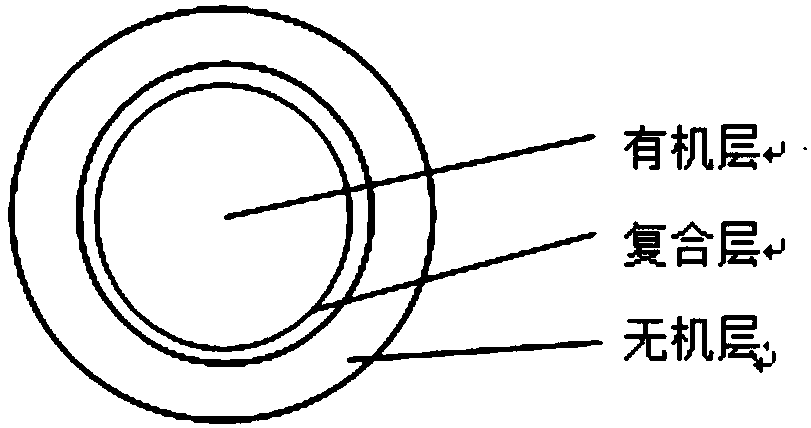

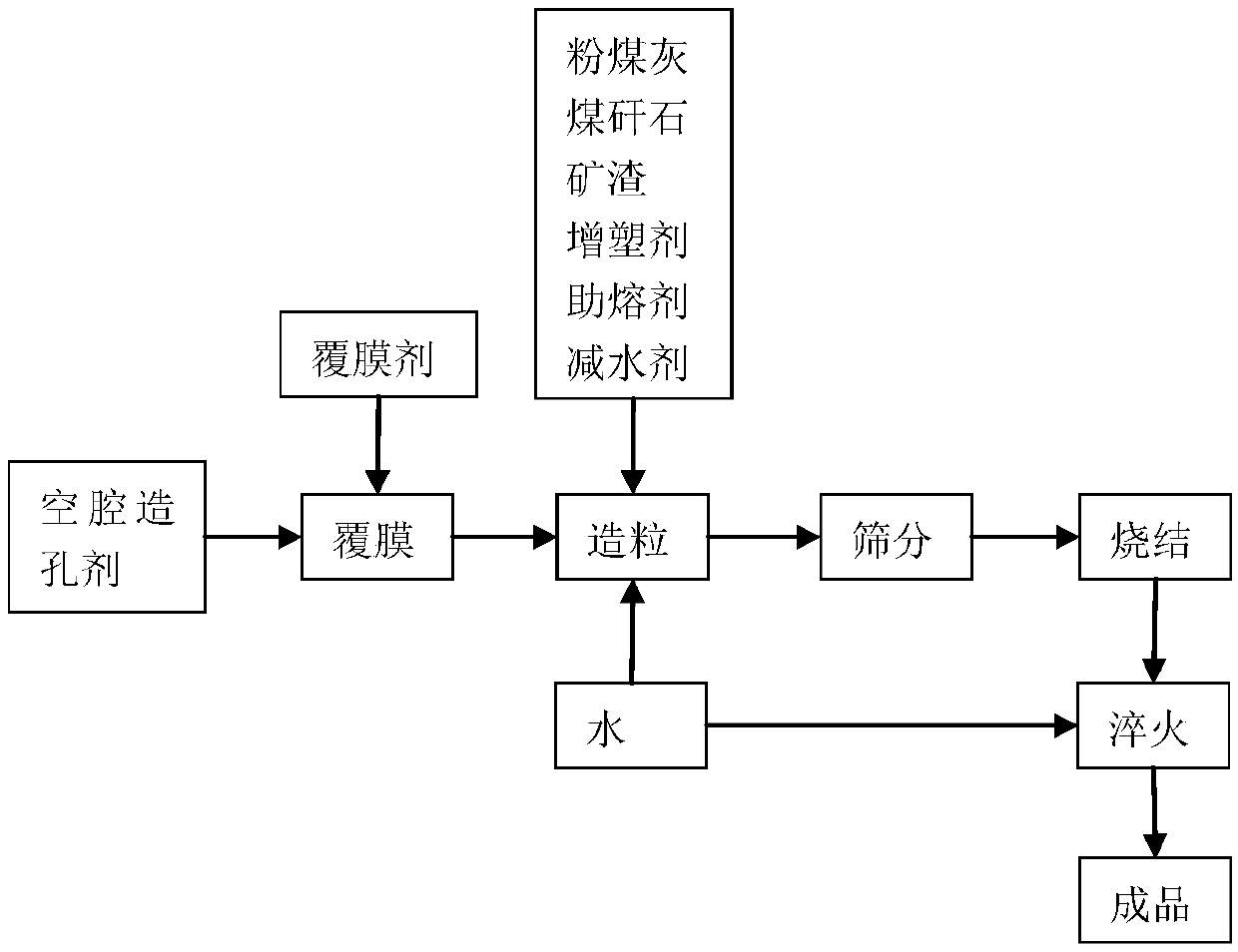

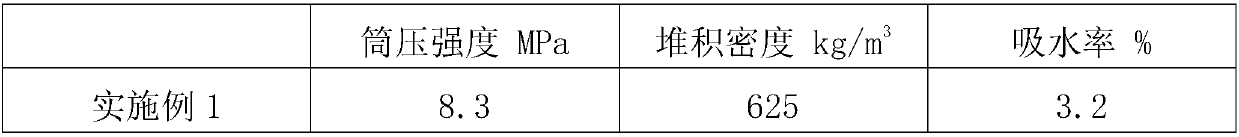

High-strength hollow ceramsite and preparation method thereof

ActiveCN110759745ALow water absorptionSmall bulk densityCeramic materials productionCeramicwareSlagExpanded clay aggregate

The invention relates to the field of solid waste recycle and in particular to a high-strength hollow ceramsite and a preparation method thereof. For solving the problems such as high stacking densityand high sintering energy consumption of existing sintered ceramsites, the invention provides a high-strength hollow ceramsite and a preparation method thereof, and meanwhile, the recycle of solid wastes such as coal ash is realized. The high-strength hollow ceramsite disclosed by the invention takes a film covering agent as a composite layer, so that the problem that a hollow pore forming agenton an organic layer cannot be bonded with a mineral material on an inorganic layer to result in pelletizing difficulty is solved; and meanwhile, the film covering agent is attached to the inner side of the inorganic layer after being melted in a high-temperature state, so that a cavity inside the hollow ceramsite is stopped from absorbing water, and the water absorption rate of the hollow ceramsite is greatly reduced. Due to the adoption of the internal cavity structure , the sintering temperature and the stacking density of the ceramsite are also reduced. The ceramsite is prepared by taking the solid wastes such as coal ash, gangue and mineral slag as raw materials, so that an effective approach is provided for the recycle of the solid wastes; in addition, the raw materials of the ceramsite are available, so that the preparation cost of the ceramsite is reduced.

Owner:GUANGDONG TSINGDA TONGKE ENVIRONMENTAL PROTECTION TECH CO LTD

Inorganic adhesive for bamboo-wood structures and preparation method thereof

ActiveCN111423820ASolve cohesionSolve the durability problemNon-macromolecular adhesive additivesInorganic adhesivesAdhesiveSilicic acid

The invention relates to the technical field of adhesive for bamboo and wood materials, in particular to inorganic adhesive for bamboo-wood structures and a preparation method of the inorganic adhesive. The inorganic adhesive comprises the following components: magnesium oxide, magnesium sulfate heptahydrate, silica fume, silica sol, lithium silicate, sodium silicate, citric acid and water. The bonding performance between the inorganic adhesive and the bamboo-wood material is good, and the fire resistance, strength and durability of an obtained bonded bamboo-wood composite material are improved.

Owner:SHANDONG JIANZHU UNIV +2

High strength debris aerated brick

InactiveCN105130317ASolve cohesionSolve water retentionSolid waste managementButadiene-styrene rubberAluminium

The invention discloses a high strength debris aerated brick. The high strength debris aerated brick is made from, by weight, 18-28 parts of cement, 5-7 parts of mineral powder, 5-8 parts of fly ash, 70-75 parts of debris, 1-2 parts of calcium lignin sulphonate, 1.8-2.5 parts of a CTF concrete synergist, 0.3-0.5 parts of aluminum powder, 1-2 parts of carboxylic styrene butadiene latex, 1-2 parts of calcium sulphoaluminate, 0.2-0.3 parts of chlorinated paraffin, 20-30 parts of diatomite, 10-20 parts of bentonite, 3.5-4.8 parts of sodium gluconate and 5-13 parts of compound modified concrete particles.

Owner:安徽阜阳富龙建筑材料有限责任公司

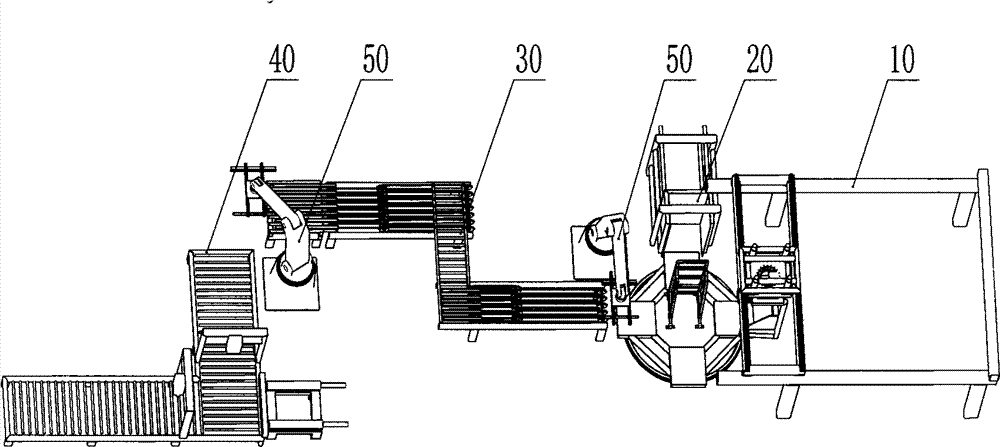

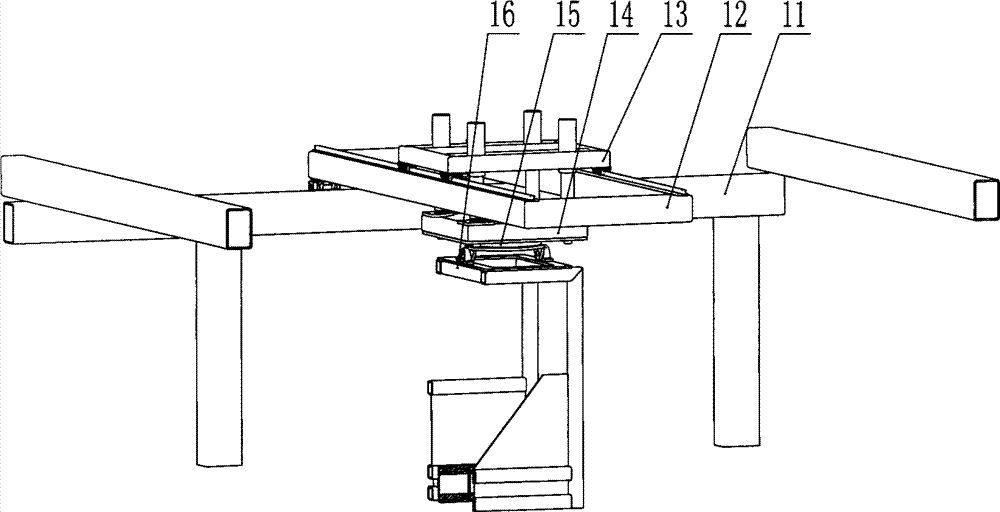

Full-automatic unloaded brick packer

ActiveCN104843224ASolve cohesionSolve the deformation of brick stacksShock-sensitive articlesBrickMechanical engineering

The invention discloses a full-automatic unloaded brick packer. The full-automatic unloaded brick packer is formed by connecting an unpiler, a piler, a robot, a braider, another robot and a packer end to end in sequence, and has a working process as follows: one pile of burnt bricks is unloaded from a kiln car by the unpiler each time, and is put on the piler for shaping; the robot takes down one layer of bricks from the brick piles shaped by the piler each time to put on the braider; the braider transversely gathers and longitudinally tightens the bricks; the bricks are divided into a stated strip number according to the requirement of the packer; the another robot grabs up the brick sets divided by the braider to put on the packer; after the brick piles on the packer reaches a preset layer number, a lower roller of the packer forwards moves to drive the brick piles to advance, the head of the packer transversely packs the brick piles in sequence; then, the brick pile moving direction is changed by 90 degrees; and another head of the packer longitudinally packs the brick piles.

Owner:SHANDONG KAILIN ENVIRONMENTAL PROTECTION EQUIP

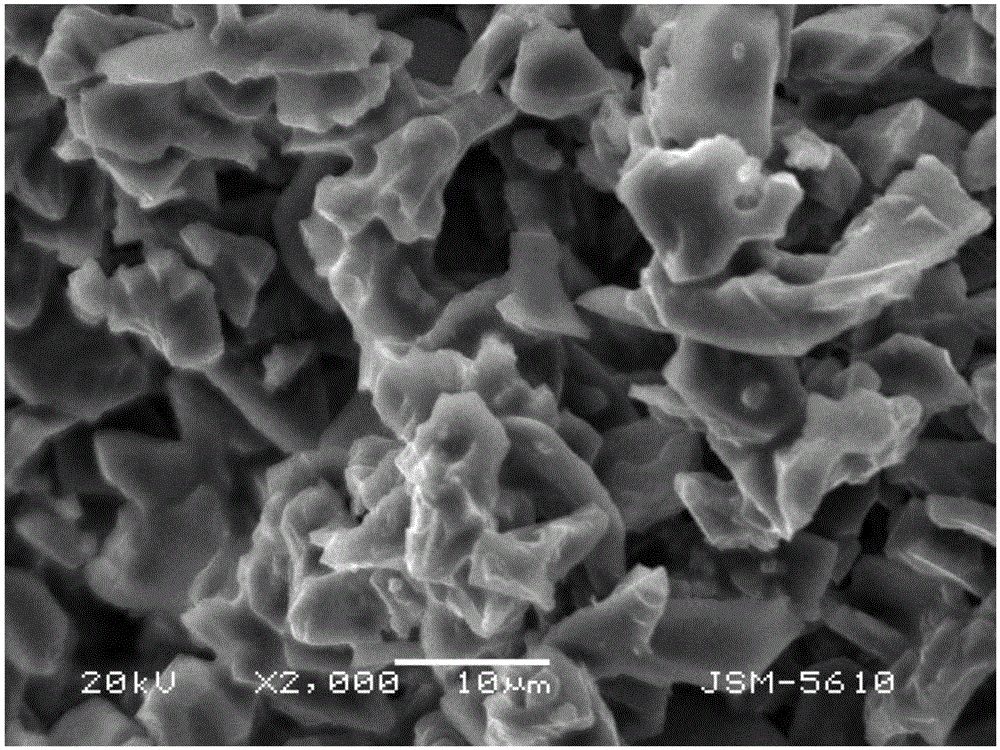

Preparation technology of cubic boron nitride accumulation abrasive material

ActiveCN106541339AHigh strengthSolve the problem of difficult wetting CBN abrasiveAbrasion apparatusGrinding devicesAdhesiveSingle crystal

The invention discloses a preparation technology of cubic boron nitride accumulation abrasive material. The preparation technology comprises the following steps: preparing an adhesive from titanium dioxide sol, water glass solution and boric acid; compounding the adhesive with yellow dextrin powder and cubic boron nitride abrasive material, carrying out ball-milling and sieving, and drying the sieved material to obtain dry pressing material of the cubic boron nitride accumulation abrasive material; carrying out compression moulding, drying, sintering and cooling on the dry pressing material of the cubic boron nitride accumulation abrasive material to obtain block of the cubic boron nitride accumulation abrasive material, and levigating the block to obtain the cubic boron nitride accumulation abrasive material. Compared with cubic boron nitride single crystal abrasive material, the cubic boron nitride accumulation abrasive material has more excellent grinding property.

Owner:HUNAN UNIV

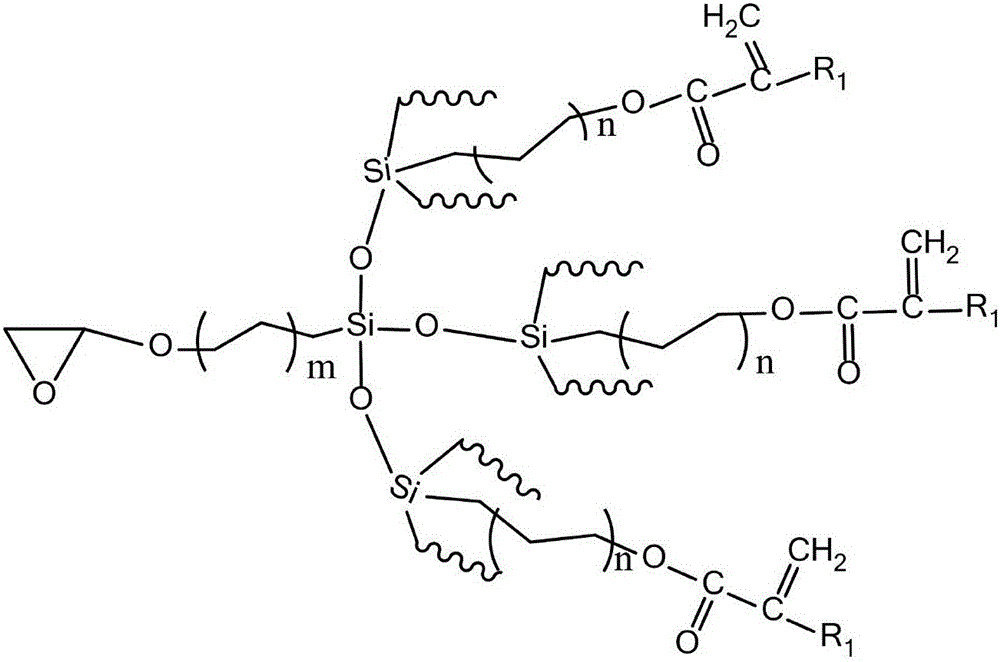

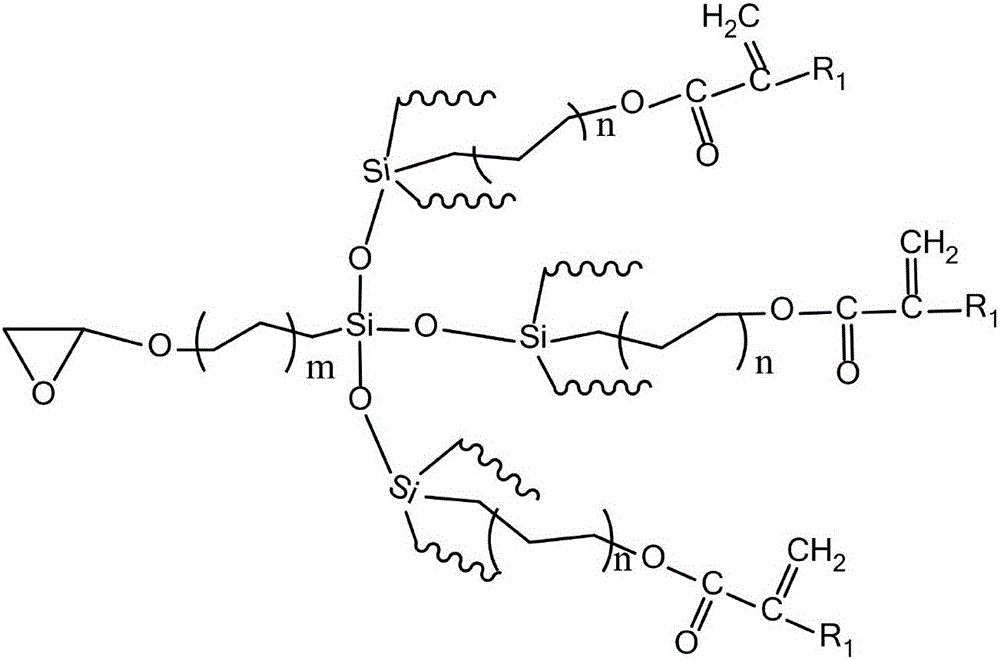

Epoxy based silicon tackifier and organosilicon conductive insulating gel prepared from same

The invention discloses an epoxy based silicon tackifier and organosilicon conductive insulating gel prepared from the same. The tackifier is formed by hydrolytic condensation of vinyl siloxane and expoxy-based siloxane under the acidic condition, and the organosilicon conductive insulating gel is obtained by mixing the tackifier with vinyl silicone oil, a catalyst, hydrogen contained silicon oil and a thermal conductive filler and subjecting the mixture to stirring, vacuum defoaming, warming and curing. Epoxy groups are introduced to a hydrogen silicon oil contained side chain through hydrosilylation, the problem about poor compatibility of the former tackifier and matrix resin is solved, shortcomings that a traditional epoxy resin based material is poor in thermal resistance and prone to yellowing and aging are overcome by applying the tackifier to preparation of the organosilicon conductive insulating gel, and the prepared organosilicon conductive insulating gel has the advantages of good thermal resistance, high mechanical strength and good adhesiveness.

Owner:FOSHAN CENT FOR FUNCTIONAL POLYMER MATERIALS & FINE CHEM

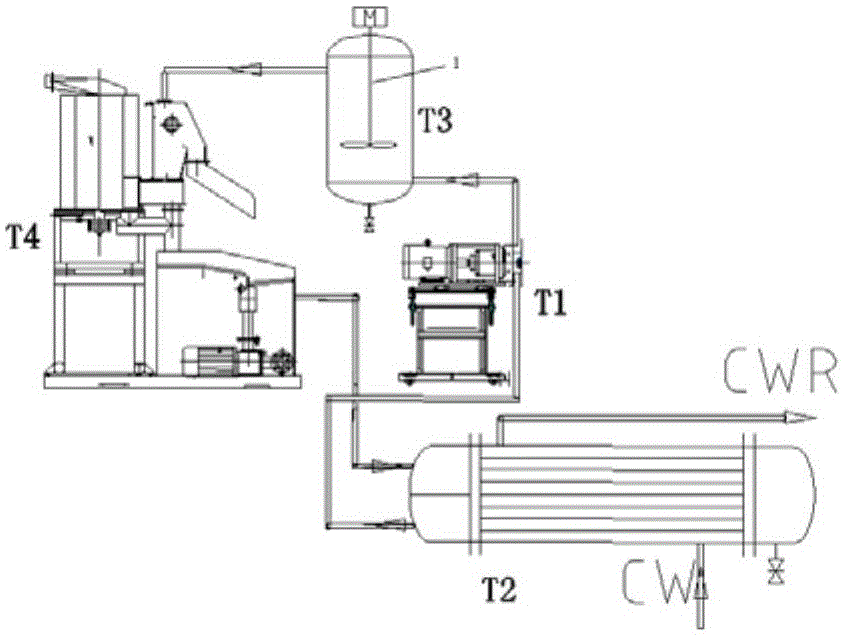

Thermoplastic elastomer prilling process

ActiveCN105034195ASolve cohesionSolve the problem of caking after product packagingCoatingsColloidal particlePolymer chemistry

The invention discloses a thermoplastic elastomer prilling process. According to the thermoplastic elastomer prilling process, a double-screw extruder is used for melting and extruding thermoplastic elastomer; a granulator is used for granulation and forming under the effect of water-phase atmosphere, and colloidal particles and colloidal particle water are dispersed in a dispersion still after granulation; meanwhile, the water phase pushes materials to enter a centrifugal dehydrator to be dehydrated and then enter a vibration classifier to be classified; and the water phase is filtered, enters a cooler to be subjected to heat exchange and cooling, and can be reused. Granulated particles obtained through the process are round and full. Adhesion and deformation of products are effectively avoided. Production stability and product quality are improved.

Owner:HUNAN BORUIKANG NEW MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com