Pulverized-fuel-ash-based geopolymer steel structure non-shrinking anti-corrosive coating

A technology of geopolymers and anti-corrosion coatings, applied in anti-corrosion coatings, alkali metal silicate coatings, coatings, etc., can solve problems such as cracking, electrochemical corrosion, and large pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

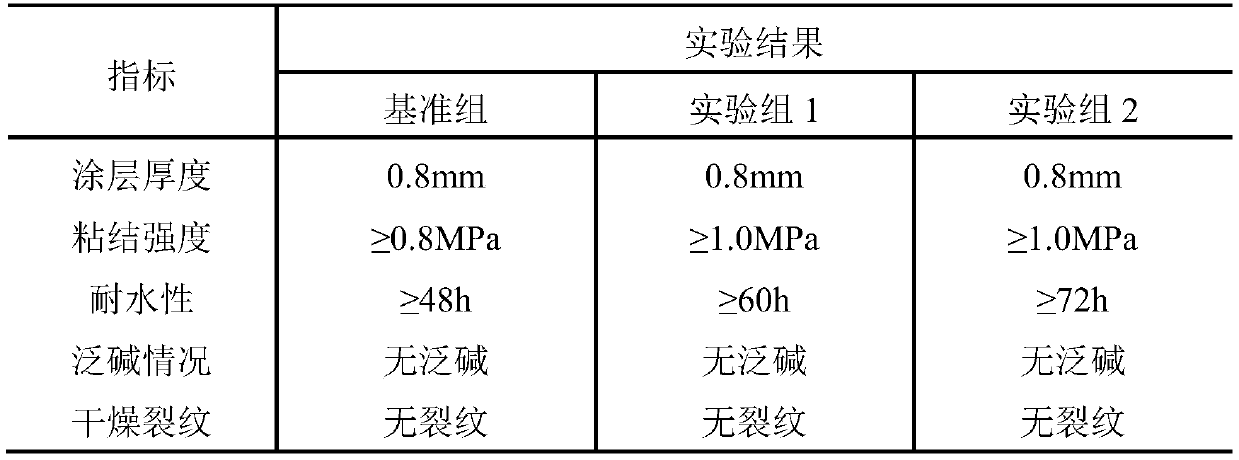

Examples

Embodiment 1

[0025] An anti-cracking and anti-pan-alkaline anti-corrosion and shrinkage coating for geopolymer steel structures excited by fly ash base, its mixing ratio is: 10% water glass, 5.5% sodium hydroxide, 16% water, 53% fly ash, 13.5 % slag, 2% talc;

[0026] (1) Take the above-mentioned mass fraction of sodium hydroxide and water glass and mix uniformly to prepare an alkali solution, stir evenly until the sodium hydroxide is completely dissolved, and seal and age for 24 hours; then mix and stir the above-mentioned low-calcium fly ash and slag Evenly, add the aged alkali activator and an appropriate amount of water (water-cement ratio 0.44) and continue to stir until uniform, and then the alkali-activated gelling material is obtained;

[0027] (2) Weigh the talcum powder according to the above mass fraction, add it to the alkali-activated gelling material in the above step (1), after the feeding is finished, increase the rotating speed to 4000r / min, and fully stir for 4min to obta...

Embodiment 2

[0031] An anti-cracking and anti-pan-alkaline anti-corrosion and shrinkage coating for geopolymer steel structures excited by fly ash base, the mixing ratio of which is: 9-10% water glass, 5% sodium hydroxide, 15% water, 49-50% powder Coal ash, 12-13% slag, 2% talcum powder, 6% titanium tailings.

[0032] (1) Take the above mass fraction of sodium hydroxide and water glass and mix uniformly to prepare an alkali solution, stir evenly until the sodium hydroxide is completely dissolved, and seal and age for 24 hours; then the above mass fraction of low-calcium fly ash, slag and extract Mix and stir the titanium tailings evenly, add the aged alkali activator and an appropriate amount of water (water-cement ratio 0.44) and continue to stir until uniform, and then the alkali-activated gelling material is obtained;

[0033] (2) Weigh the talcum powder according to the above mass fraction, add it to the alkali-activated gelling material in the above step (1), after the feeding is fini...

Embodiment 3

[0037] An anti-cracking and anti-pan-alkaline anti-corrosion and shrinkage coating for geopolymer steel structures excited by fly ash base, the mixing ratio of which is: 9-10% water glass, 5% sodium hydroxide, 15% water, 49-50% powder Coal ash, 12-13% slag, 2% talcum powder, 0.03% graphene oxide.

[0038] (1) Take the above-mentioned mass fraction of sodium hydroxide and water glass and mix uniformly to prepare an alkali solution, stir evenly until the sodium hydroxide is completely dissolved, and seal and age for 24 hours; then mix and stir the above-mentioned low-calcium fly ash and slag Evenly, fully dissolve the graphene oxide with the above mass fraction in an appropriate amount of water (water-cement ratio 0.44), add the aged alkali activator and continue stirring until uniform, that is, the alkali-activated gelling material is obtained;

[0039] (2) Weigh the talcum powder according to the above mass fraction, add it to the alkali-activated gelling material in the above...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bond strength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Water resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com