Patents

Literature

9204 results about "Pulverised fuel ash" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

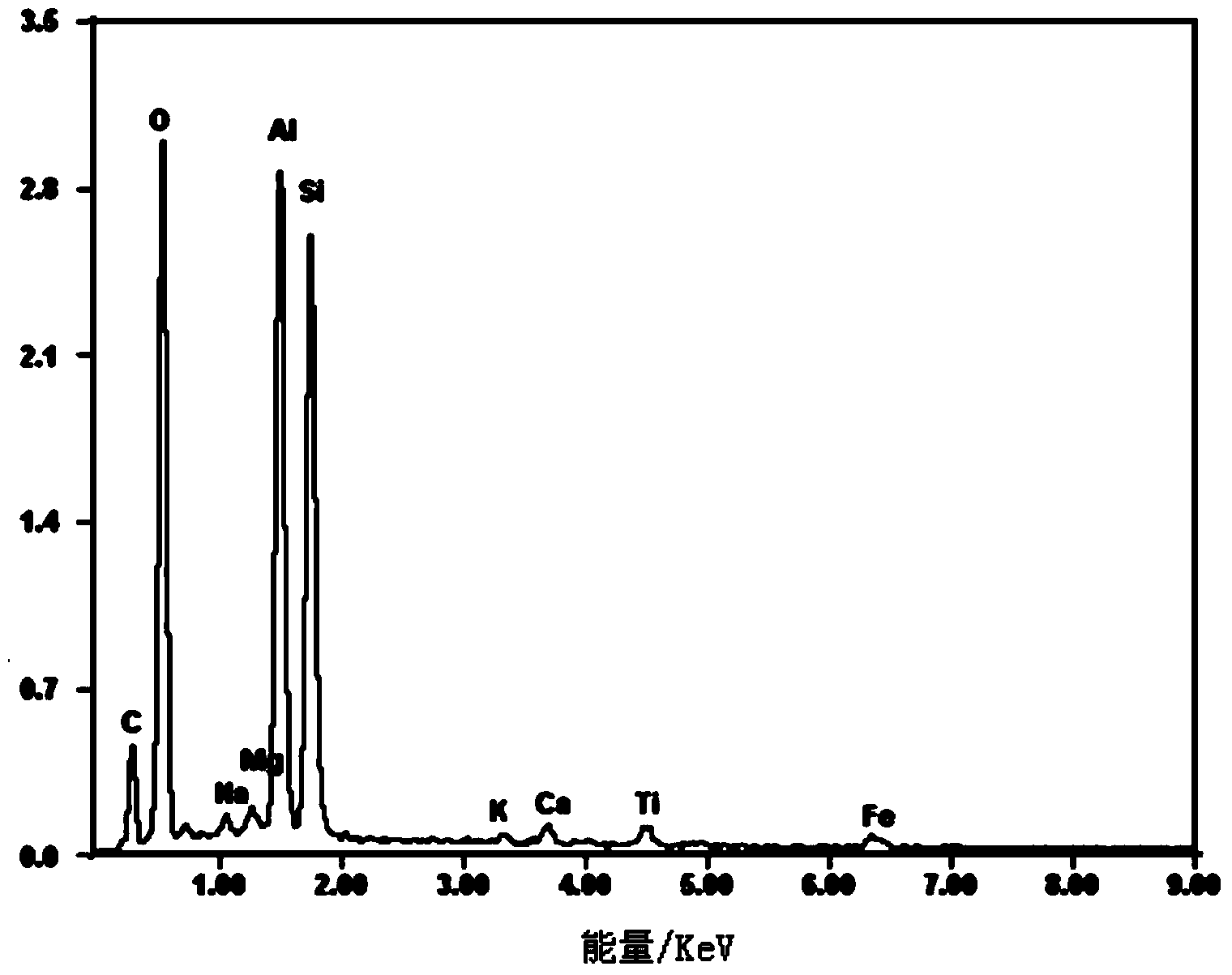

Pulverised fuel ash, is a waste product of pulverised fuel fired power stations. The fuel is pulverised into a fine powder, mixed with heated air and burned. Approximately 18% of the fuel forms fine glass spheres, the lighter of which are borne aloft by the combustion process. They are extracted from the flue gasses by cyclones and electrostatic precipitation. The resultant material is used as engineering fill and as a component for concrete. It has been widely used, particularly in the UK, for concrete block production. The blocks are lightweight and have excellent thermal insulation properties. PFA can undergo a pozzolanic reaction and become brittle over time. PFA has a fine dust texture and is grey in colour. When newly produced the dust is strongly alkaline; a pH as high as 11 is known, and >9 is normal. It leaches a solution dominated by sodium and sulfate, with enough boron to kill most plants, though coastal species often tolerate the salinity and boron to grow on young ash lagoons. In dry conditions these solutes rise to the surface to form a hard salt crust, impeding all plant growth, though hardy grass species such as Vulpia myuros can later colonise it.

Road dust suppressant

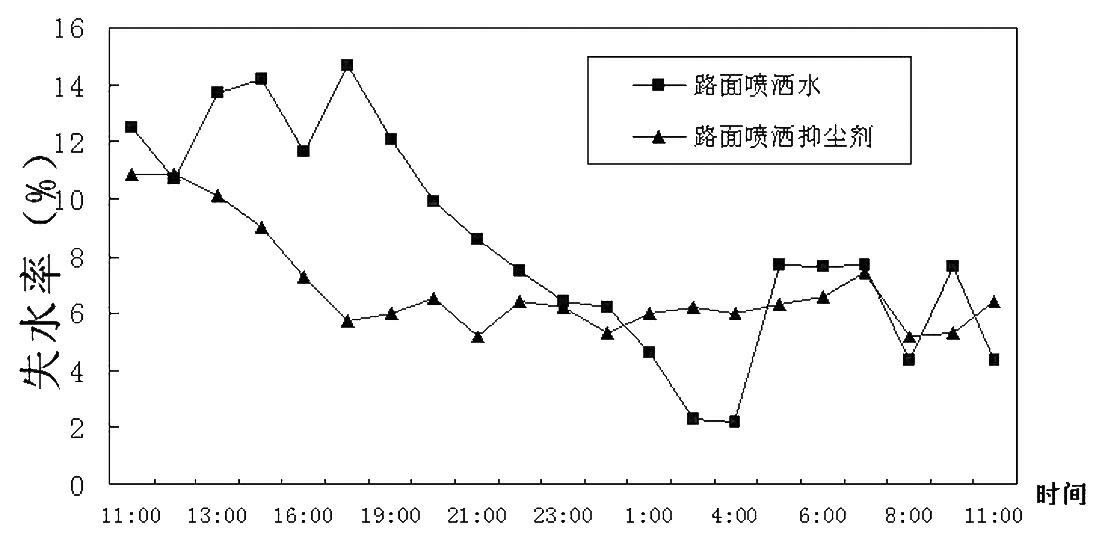

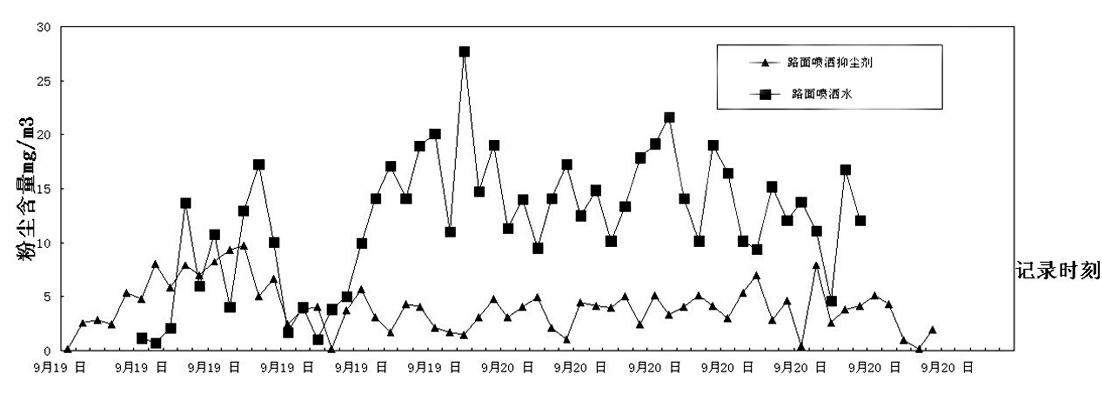

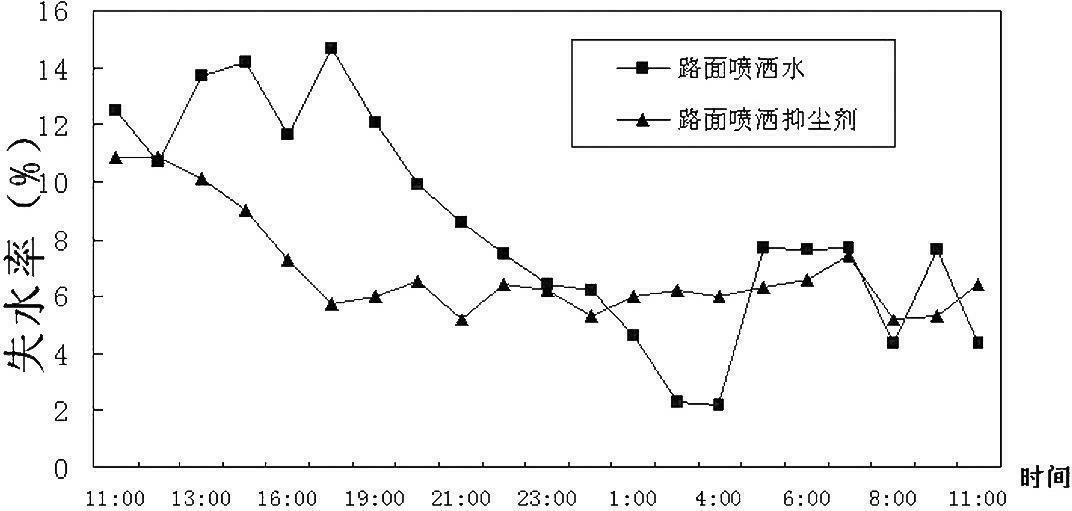

ActiveCN102660227AStrong anti-pressure functionLarge particle sizeOther chemical processesLiquid productEvaporation

The invention discloses a road dust suppressant, which is prepared by mixing and blending 0.1-2.0% of water-soluble high molecular polymer, 20-50% of moisture absorption humectant, 1.0-5.0% of preservative, 0.5-5.0% of penetrating agent and the balance water. The road dust suppressant is a dynamic dust-proof and dust-suppressing liquid product which combines functions of wetting, bonding, permeating, adsorbing moisture and the like into a whole and has extremely strong pressurization-resistant function. The road dust suppressant has the advantages of obvious anti-evaporation performance and good water retention hygroscopicity, and dust on the road surface can be coagulated and is unlikely to fly. The road dust suppressant disclosed by the invention not only can be applied to road dust suppressing but also can be simultaneously used for the aspects, such as the mine exploration and transportation environment, storage yards of coal ash, coal and other ores, and the treatments of municipal construction earthwork dust raise.

Owner:山西兴源盛科技有限公司

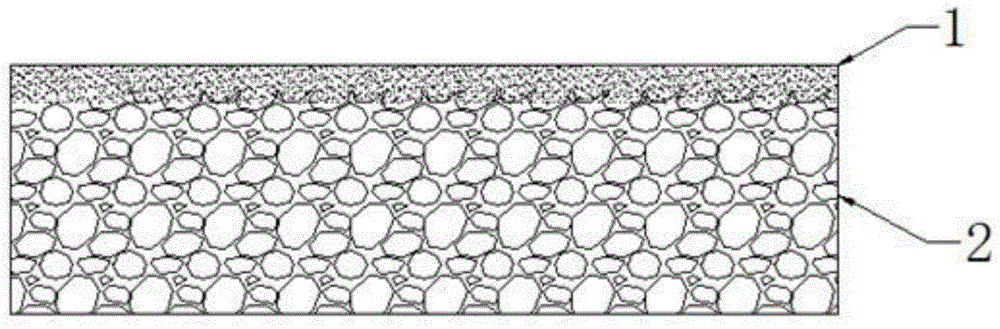

Water permeable brick and preparation method thereof

ActiveCN104452525AHigh porosityHigh strengthSolid waste managementSidewalk pavingsSolid componentBrick

The invention discloses a water permeable brick and a preparation method thereof. The water permeable brick comprises two parts, namely a surface layer and a base layer, wherein the material of the surface layer is prepared from the following components in percentage by mass: 60-70% of ceramic sand, 15-20% of sand and 15-20% of cement, and in addition to the solid components with the sum of 100% in percentage by mass, water accounting for 50-60% by mass of cement is further added; and the material of the base layer is prepared from the following components in percentage by mass: 45-65% of building silt unburned ceramsite, 10-15% of cement, 5-10% of fly ash, 10-15% of melon seed-shaped drug slices and 10-15% of sand, and in addition to the solid components with the sum of 100% in percentage by mass, the water accounting for 30-40% and a water reducer accounting for 1-1.5% relative to total mass of the cement and the fly ash are further added. The water permeable brick disclosed by the invention is prepared by using the building silt unburned ceramsite to replace natural aggregate or calcined ceramsite, on one hand, the using ways of the building silt unburned ceramsite can be expanded, the utilization rate of solid wastes is improved, and negative effects on an environment are reduced, and on the other hand, the obtained water permeable brick has excellent performance.

Owner:浙江合泽环境科技有限公司

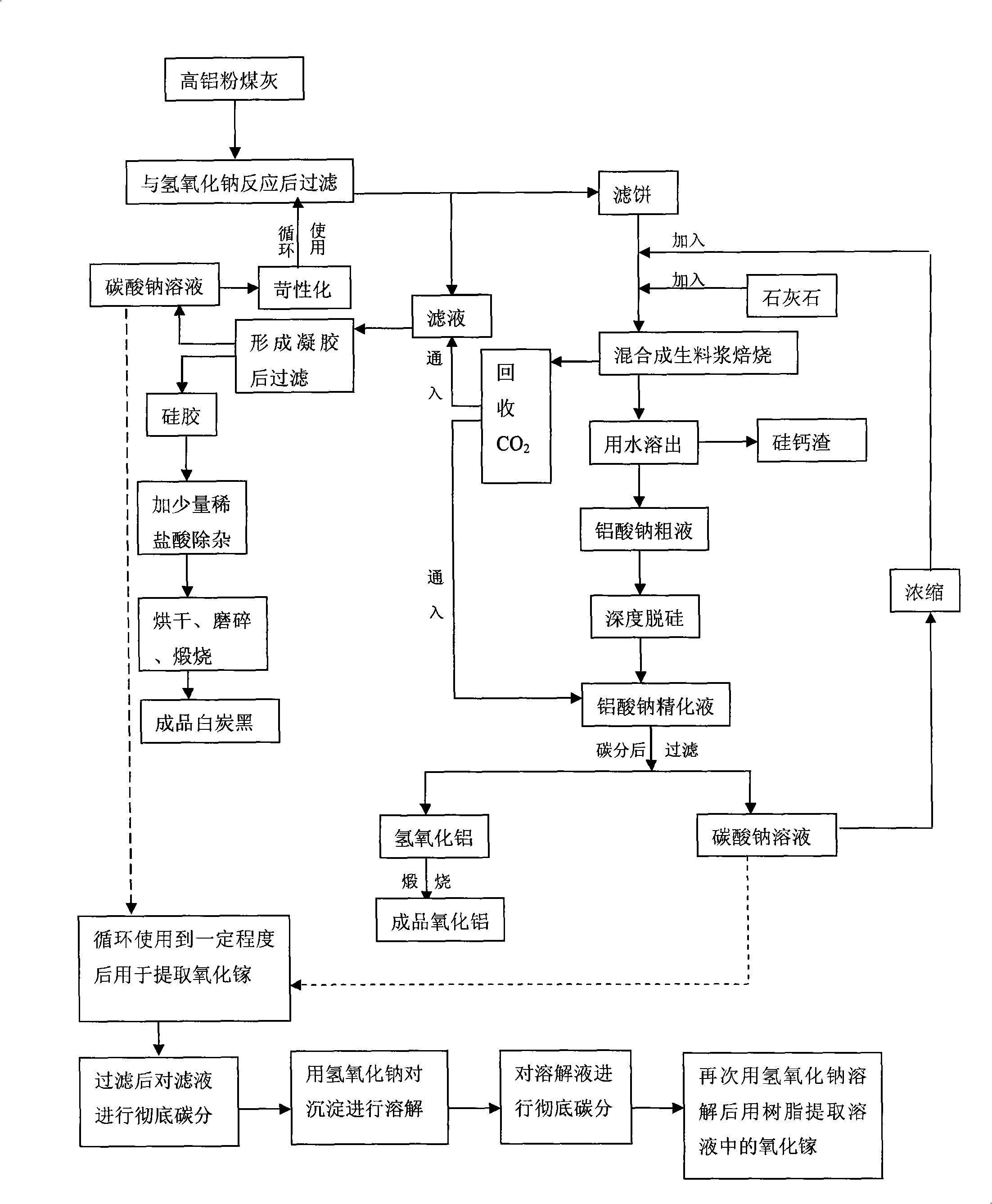

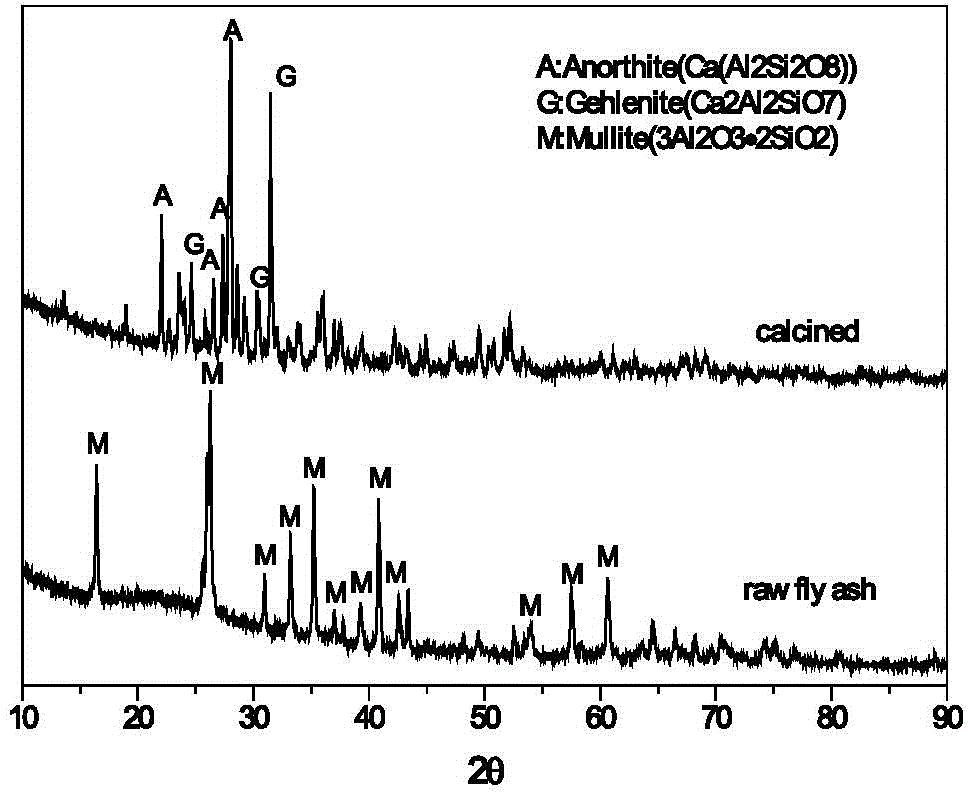

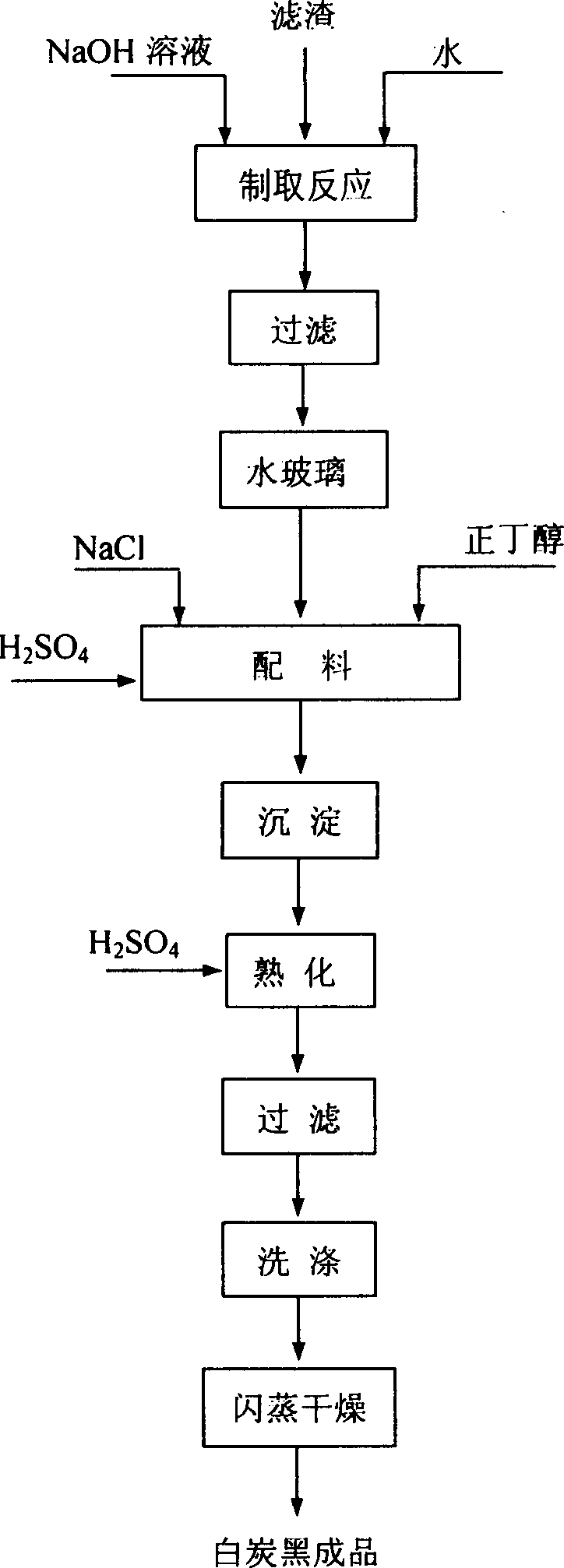

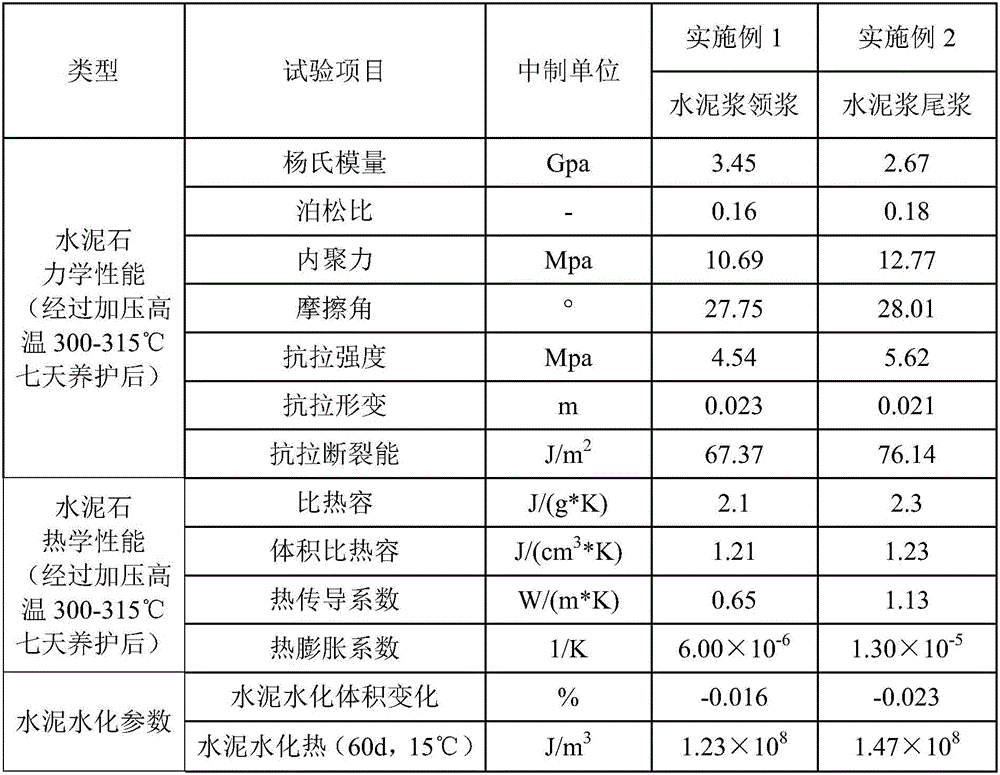

Process for abstracting earth silicon, oxide of alumina and gallium oxide from high-alumina flying ash

ActiveCN101284668AReduce the total massLow firing temperatureGallium/indium/thallium compoundsSilicon oxidesChemical industryFiltration

A method for extracting silicon dioxide, alumina and gallium oxide from high-alumina fly ash relates to the technology fields of environmental mineralogy and material, chemical industry and metallurgy. The method comprises the main steps as follows: causing the high-alumina fly ash to react with sodium hydroxide solution; filtering the solution; introducing CO2 to the filtrate for full gelation; cleaning, purifying, drying, grinding and calcining the silica gel after gel filtration to obtain finished white carbon black; adding limestone and a sodium carbonate solution into the filter mass after the reaction and filtration of the high-alumina fly ash and the sodium hydroxide solution; ball grinding the mixture into raw slurry; dissolving out the clinker obtained by baking the raw slurry; subjecting the filtrate to deep desiliconization to obtain sodium aluminate extraction liquid; filtrating the sodium aluminate extraction liquid after subjecting the sodium aluminate extraction liquid to carbon dioxide decomposition; baking the aluminum hydroxide after washing the filter mass to form the aluminum hydroxide product; and extracting the gallium oxide from the carbon dioxide decomposition mother solution and desiliconized solution. The method has the advantages of low material price, simple operating procedures, low investment, low production cost, low energy consumption and less slag.

Owner:TSINGHUA UNIV +1

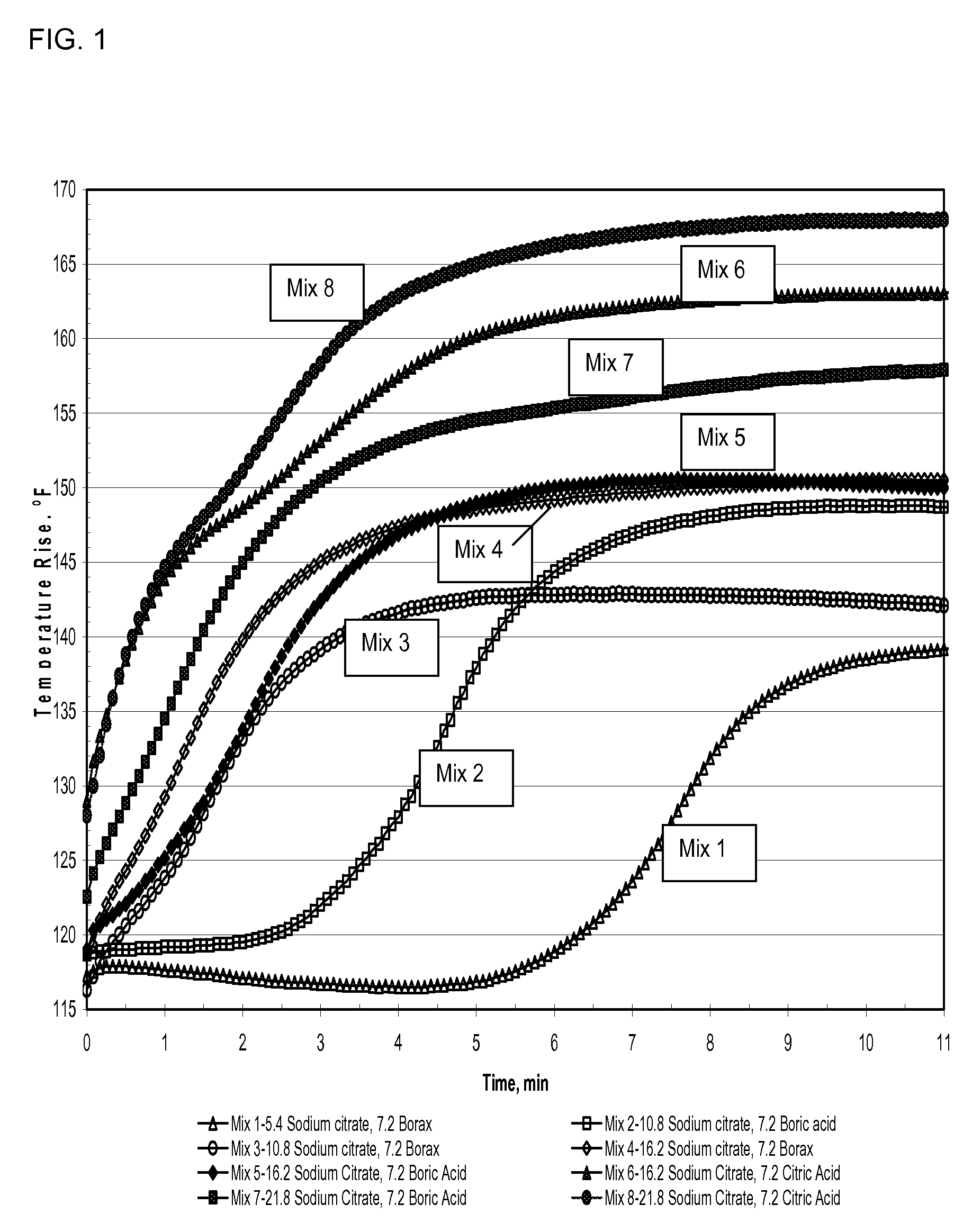

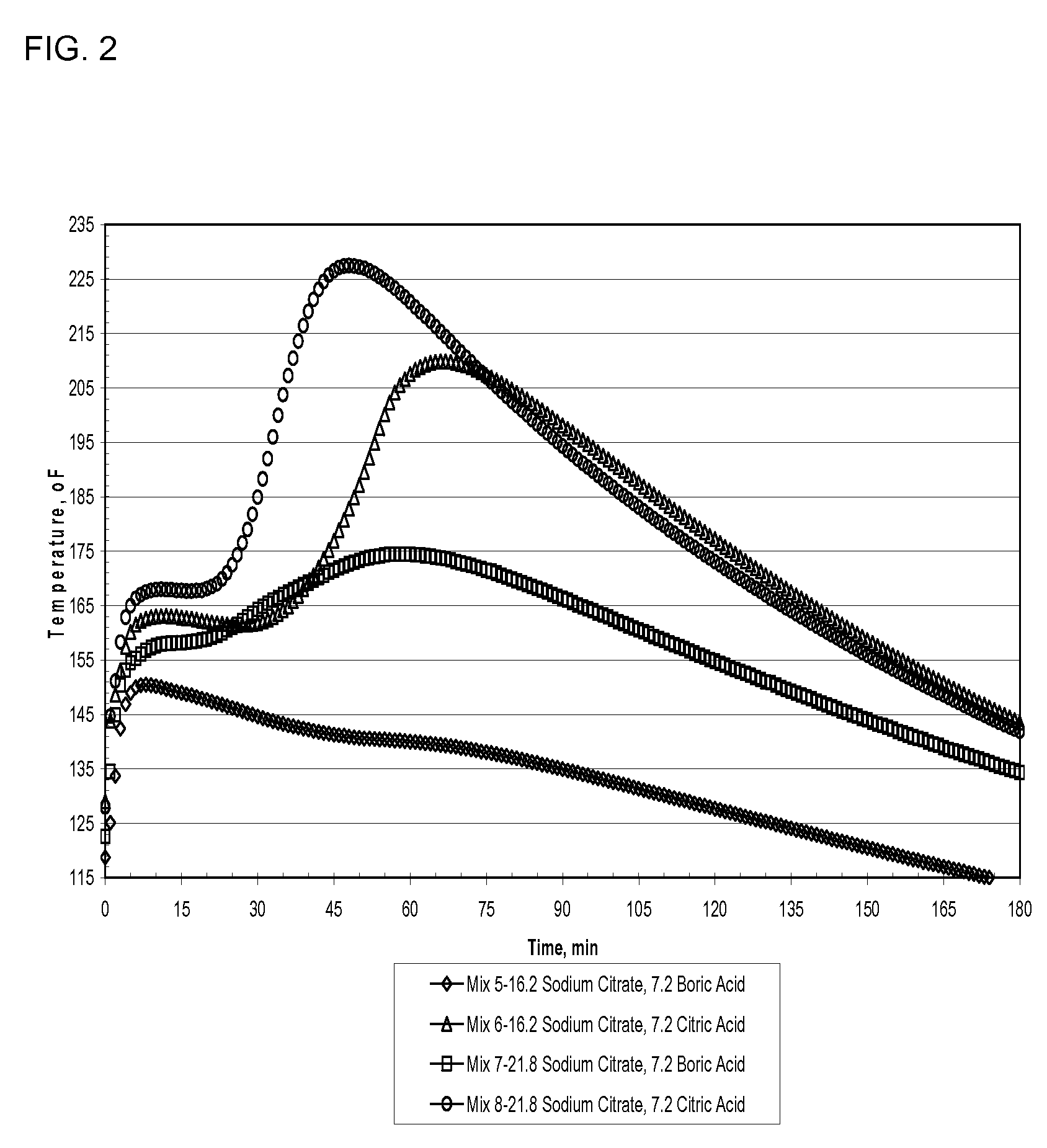

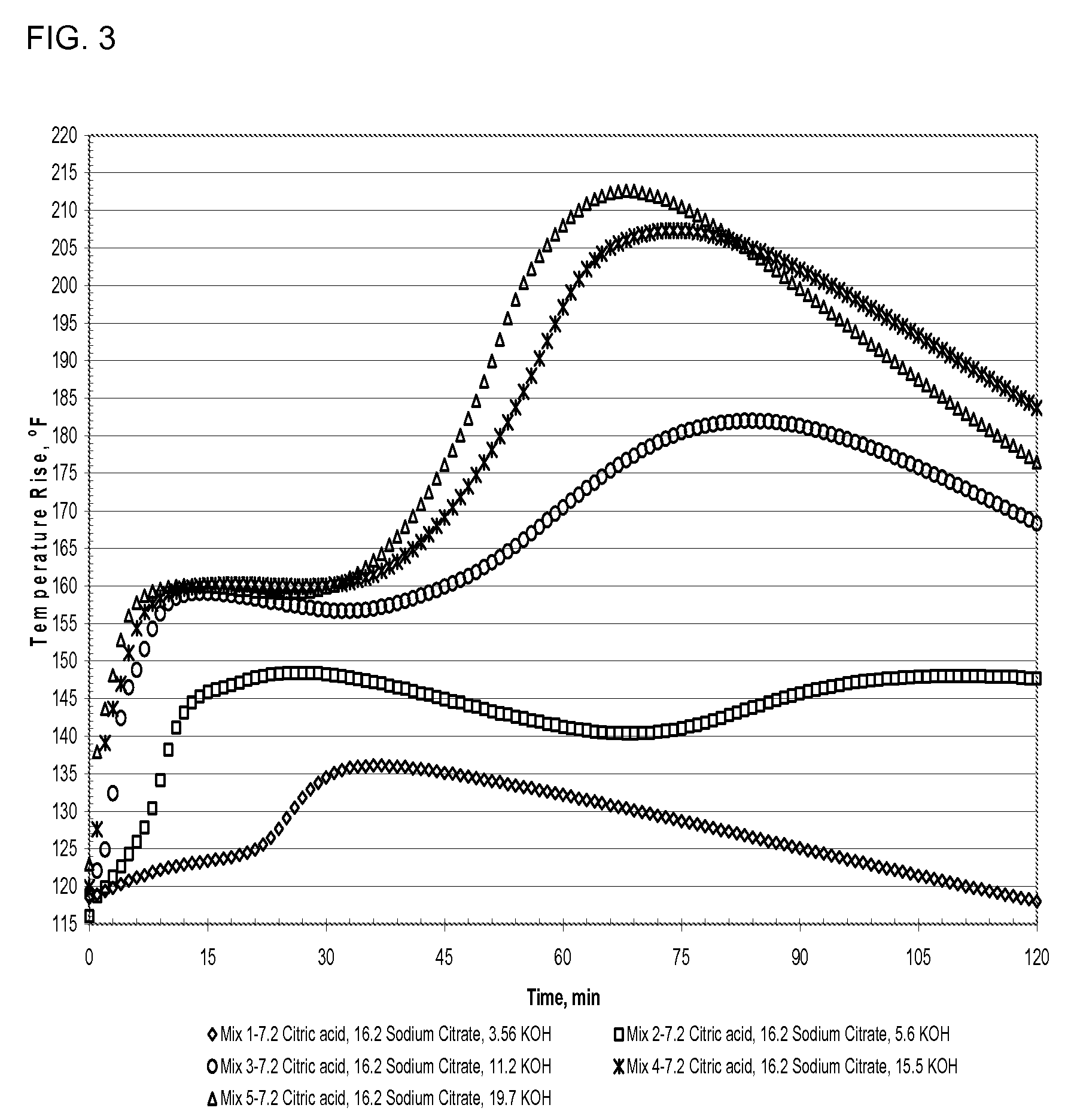

Fly ash based lightweight cementitious composition with high compressive strength and fast set

InactiveUS20100071597A1Quick SetupEnhanced early and final compressive strengthSolid waste managementPolymer scienceCompressive strength

A method of making a rapid setting lightweight cementitious composition with improved compressive strength for products such as boards is disclosed. The method mixes fly ash, alkali metal salt of citric acid and lightweight aggregate with water. Compositions which include fly ash, alkali metal salts of citric acid and lightweight aggregate are also disclosed.

Owner:UNITED STATES GYPSUM CO

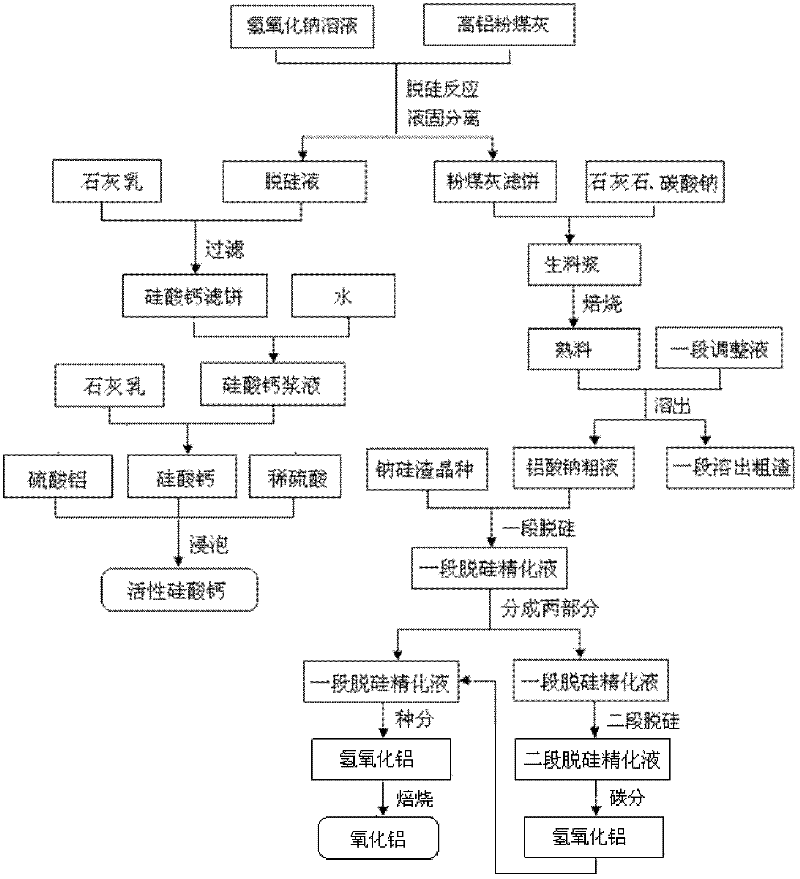

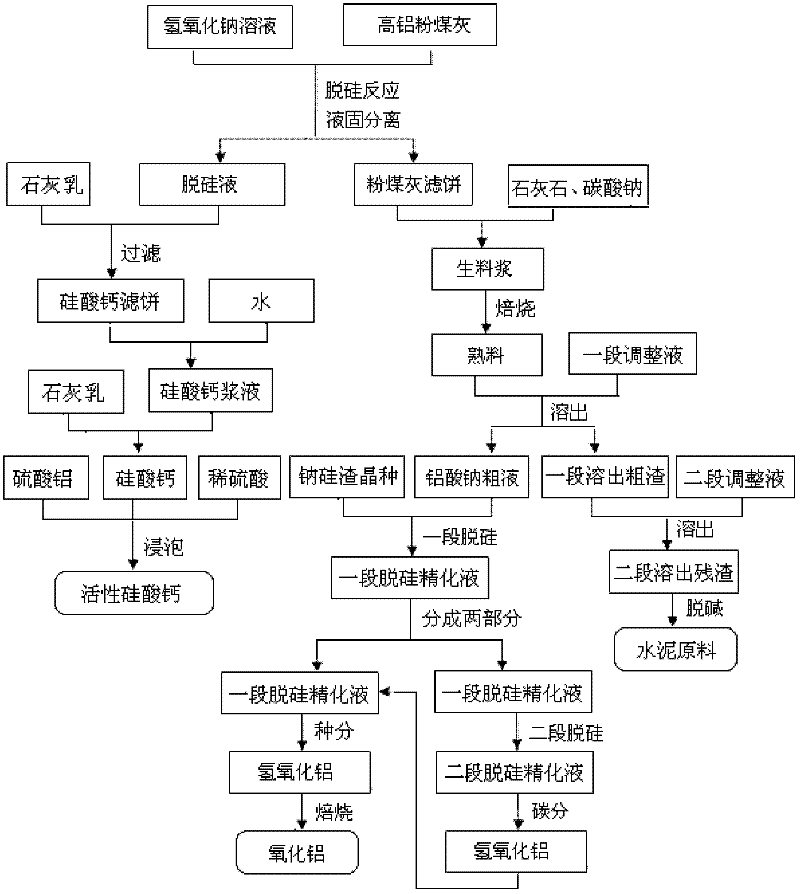

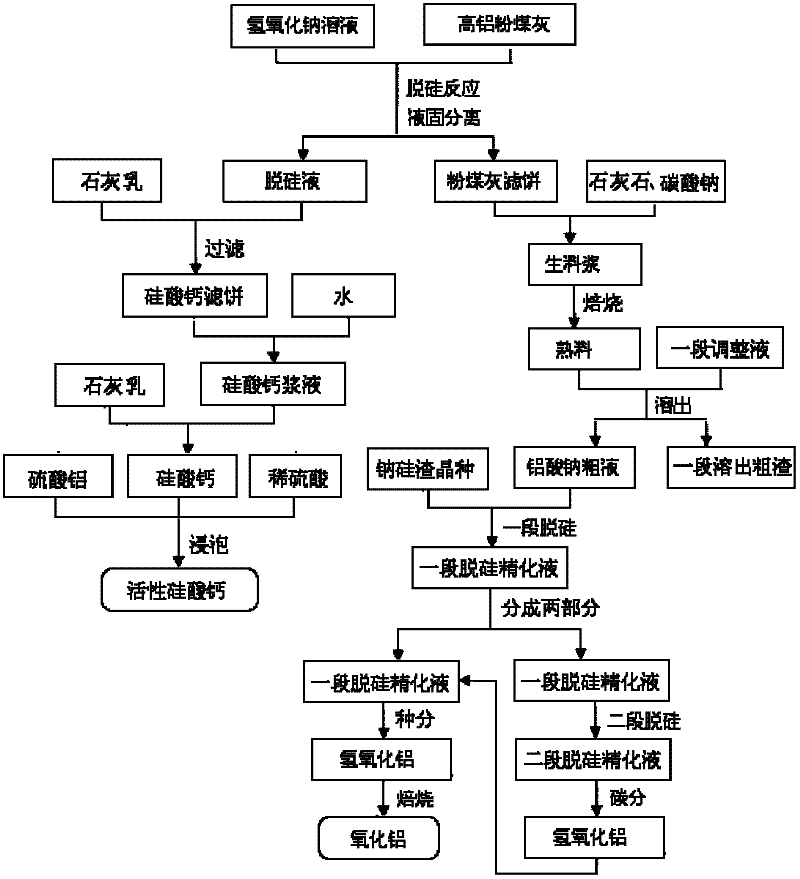

Method for producing aluminum oxide and co-producing active calcium silicate through high-alumina fly ash

ActiveCN102249253AExtraction is effective and cheapIncrease Al-Si RatioAlkaline-earth metal silicatesAluminium oxide/hydroxide preparationCalcium silicateSodium aluminate

The invention provides a method for producing aluminum oxide and co-producing active calcium silicate through high-alumina fly ash. The method comprises the following steps that: the high-alumina fly ash firstly reacts with a sodium hydroxide solution to carry out pre-desilication to obtain a liquid-phase desiliconized solution and a solid-phase desiliconized fly ash; lime cream is added to the liquid-phase desiliconized solution to carry out a causticization reaction, the resulting solid phase is active calcium silicate which is prepared through carrying out filter pressing, flash evaporation and drying to obtain the finished product; limestone and a sodium carbonate solution are added to the desiliconized fly ash to blend qualified raw slurry, then the blend qualified raw slurry is subjected to baking into the clinker, the liquid phase generated from dissolution of the clinker is a crude solution of sodium aluminate; the crude solution of the sodium aluminate is subjected to processes of first-stage deep desilication, second-stage deep desilication, carbonation, seed precipitation, baking and the like to obtain the metallurgical grade aluminum oxide meeting requirements. According to the present invention, the defects in the prior art are overcome; purposes of less material flow and small amount of slaggling are achieved; energy consumption, material consumption and production cost are relative low; extraction rate of the aluminum oxide is high; the calcium silicate with high added value is co-produced; the method provided by the present invention can be widely applicable for the field of chemical engineering.

Owner:INNER MONGOLIA DATANG INT RENEWABLE RESOURCES DEV

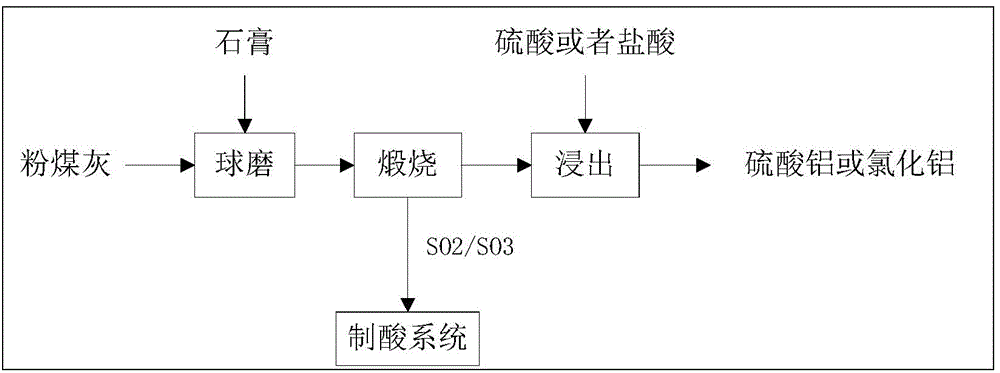

Method for cooperative activation of fly ash and decomposition of gypsum for recovery of sulfur resource

The invention provides a method for cooperative activation of fly ash and decomposition of gypsum for recovery of a sulfur resource. According to the method, solid waste, i.e., fly ash, discharged by a coal-fired power plant or coal-fired boiler is used as a raw material, a certain proportion of desulfurized gypsum discharged by the coal-fired power plant or waste phosphogypsum produced in the phosphorus chemical industry is added and mixed with the fly ash, then the obtained mixture is subjected to ball milling, and activation and calcination at a temperature of 950 to 1450 DEG C are carried out for 5 to 180 min; calcium sulfate in the gypsum are almost totally decomposed after calcination, and produced gas contains sulfur dioxide or sulfur trioxide which can be used as feed gas for preparation of sulfuric acid; and calcination enables solid fly ash to be activated, leaching with a sulfuric acid or hydrochloric acid solution is carried out at a temperature of 50 to 100 DEG C, and the leaching rate of alumina is greater than 80%. The method provided by the invention has the advantages that since all the raw materials are solid waste, the purpose of treating the waste by using the waste is achieved; elemental sulphur in the gypsum can be recovered; and the fly ash can be activated and activity of the fly ash can be improved, so a high alumina recovery rate at a low temperature can be realized. With the method, high-efficiency extraction of alumina in the fly ash is realized; the sulfur resource in the gypsum is recovered; shortage in industrial sulphur in the sulfuric acid industry in China is compensated; and the method has good economic benefits and wide industrial application prospects.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

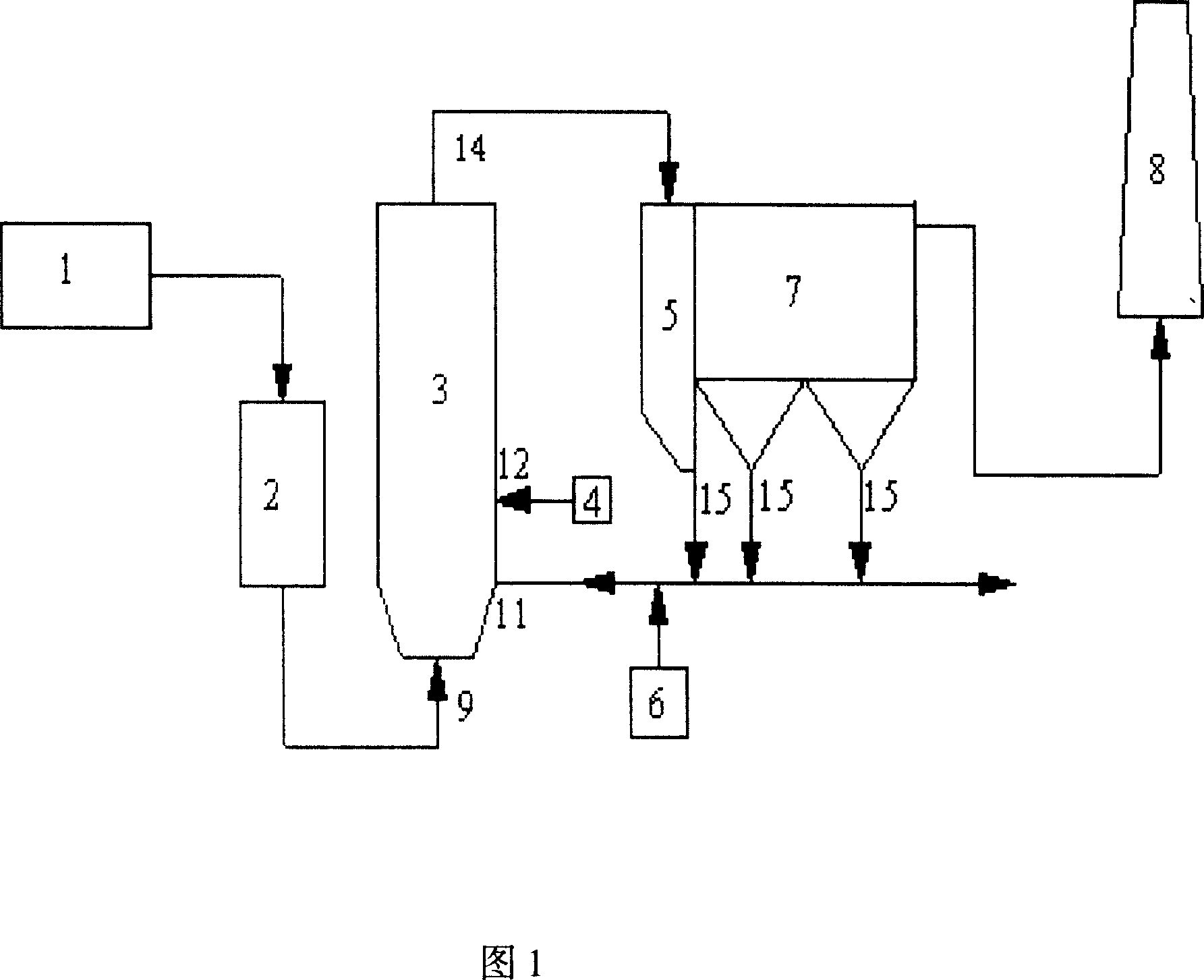

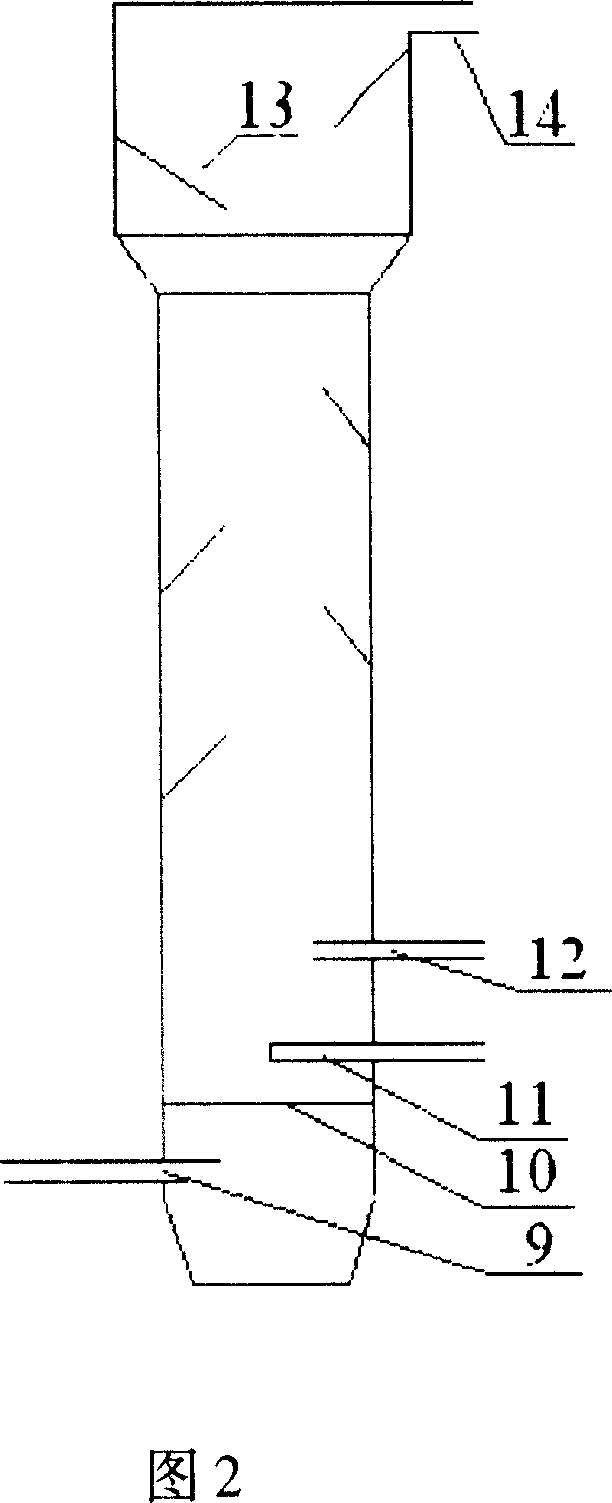

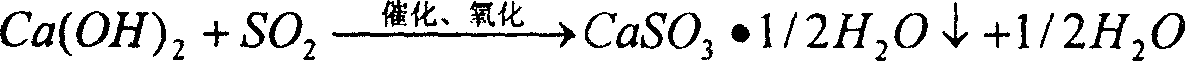

Method and apparatus for removing sulfur, nitrate and mercury simultaneously from boiler flue gas

InactiveCN1962034AExtended stayIncrease profitDispersed particle separationOxygenCalcium hypochlorite

The invention relates to a method for realizing desulfuration, denitration and demercuration of boiler smoke synchronously, wherein it comprises feeding smoke into cycle fluidize bed reactor, and injecting oxygen-enriched active absorber; said absorber is formed by coal ash at 20-70, lime hydrate at 27-80, additive at 0.5- 3 as kalii permangana KMnO4, sodium chlorite NaClO2, natrii chloridum NaCl, calcium hypochlorite Ca(ClO)2 or acetic hyctro peroxide CH3COOH. The invention's desulfuration efficiency can reach 90%, the denitration efficiency can reach 60%, and the demercuration can reach 50%, with low cost and non pollution.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Composite tailing non-fired and non-steamed building block brick and preparation method thereof

InactiveCN102093004AHigh waste rateSolve the problem of excessive dosageSolid waste managementBrickSlag

The invention discloses a composite tailing non-fired and non-steamed building block brick and a preparation method thereof. The brick comprises the following raw materials in parts by weight or volume: 50-300 parts of tailing and 3-30 parts of cement; and at least two components are selected from the active wastes such as fly ash, coal gangue, shale slag, alkaline residue, carbide slag, chemical gypsum and the waste residue of metallurgical industry to be mixed with the raw materials. The preparation method comprises the following steps: mixing to stir, compressing and shaping, performing natural curing or utilizing the solar heaing hydrating maintenance to prepare the composite tailing building block brick. By adopting the preparation method of the invention, the single performances of the tailings and slags can be changed, thus the product can have higher strength and quality owning to the interaction of materials; the technology does not adopt firing and steaming, the cost is low; different sizes of solid bricks, perforated bricks, hollow blocks, floor tiles, grass planting bricks, roadside bricks and artistic rails can be prepared by changing the mould; and various harmful slags such as tailings can become good, the Chinese development direction of the comprehensive utilization of resources is satisfied and the brick of the invention has development and application prospect.

Owner:郭东京 +2

Burning-free block brick prepared from bulky industrial waste residues

The invention relates to a burning-free block brick prepared from bulky industrial waste residues. The burning-free block brick is characterized in that the block brick comprises the following raw materials in parts by weight or volume: 10-80 parts of at least one of tailing, magnesium slag, basic slag, mountain flour, cinder, fly ash, coal gangue, oil shale waste and sulfuric acid slag, 0-80 parts of at least one of gravel, waste sand, construction waste, garbage to be burnt, steel slag, mineral slag, copper slag, iron slag with gold, ardealite, phosphorous slag and carbide slag, 0-50 parts of active cementing material, 0-30 parts of cement clinker, 2-15 parts of cement and a defined amount of water. The preparation method of all types of burning-free and steaming-free standard bricks, perforated bricks, hollow blocks, paving tiles, road edge bricks and fence railings which have low cost and high strength, is as follows: proportioning, stirring for 1-6 minutes, adding a defined amount of water to stir, placing in moulds to form in a machine and performing natural curing for 7-28 days. The burning-free block brick has high raw material selectability, simple technology and wide development and application prospects, and is environmental-friendly.

Owner:司密花 +2

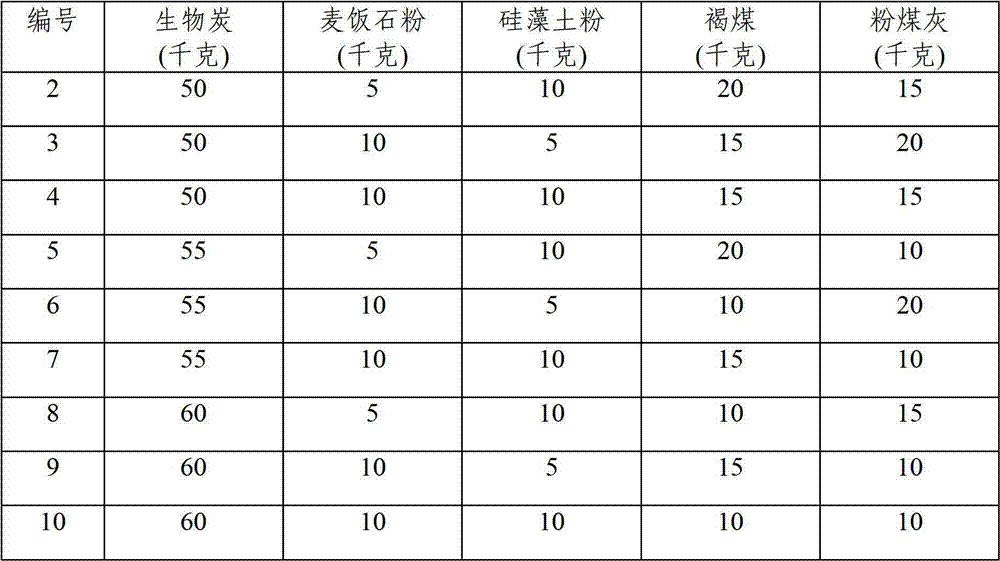

Biochar mixing type protected horticultural vegetable field soil heavy metal passivant and preparation method thereof

InactiveCN102807872ASimple processNo pollution in the processAgriculture tools and machinesOrganic fertilisersSoil heavy metalsBiochar

The invention relates to a soil improvement technology and an environment protection technology and particularly discloses a biochar mixing type protected horticultural vegetable field soil heavy metal passivant and a preparation method thereof. The soil heavy metal passivant comprises the following components in percentage by weight: 50 to 60 percent of biochar, 5 to 10 percent of medical stone powder, 5 to 10 percent of diatomite powder, 10 to 20 percent of lignite and 10 to 20 percent of coal ash. The preparation method for the soil heavy metal passivant comprises the following steps of: mixing the medical stone powder which is screened by an 80-mesh sieve, the diatomite powder which is screened by an 80-mesh sieve, the lignite, and the coal ash which is screened by an 80-mesh sieve, uniformly stirring, mixing with biochar which is screened by a 20-mesh sieve, fully stirring, and mixing uniformly to prepare the soil heavy metal passivant. The soil heavy metal passivant is easy to prepare; and the effects of passivating the protected horticultural vegetable field soil heavy metal, and reducing the content of recyclable heavy metal of plant in soil can be achieved under the synergistic effects of all components.

Owner:SHENYANG INST OF APPL ECOLOGY CHINESE ACAD OF SCI

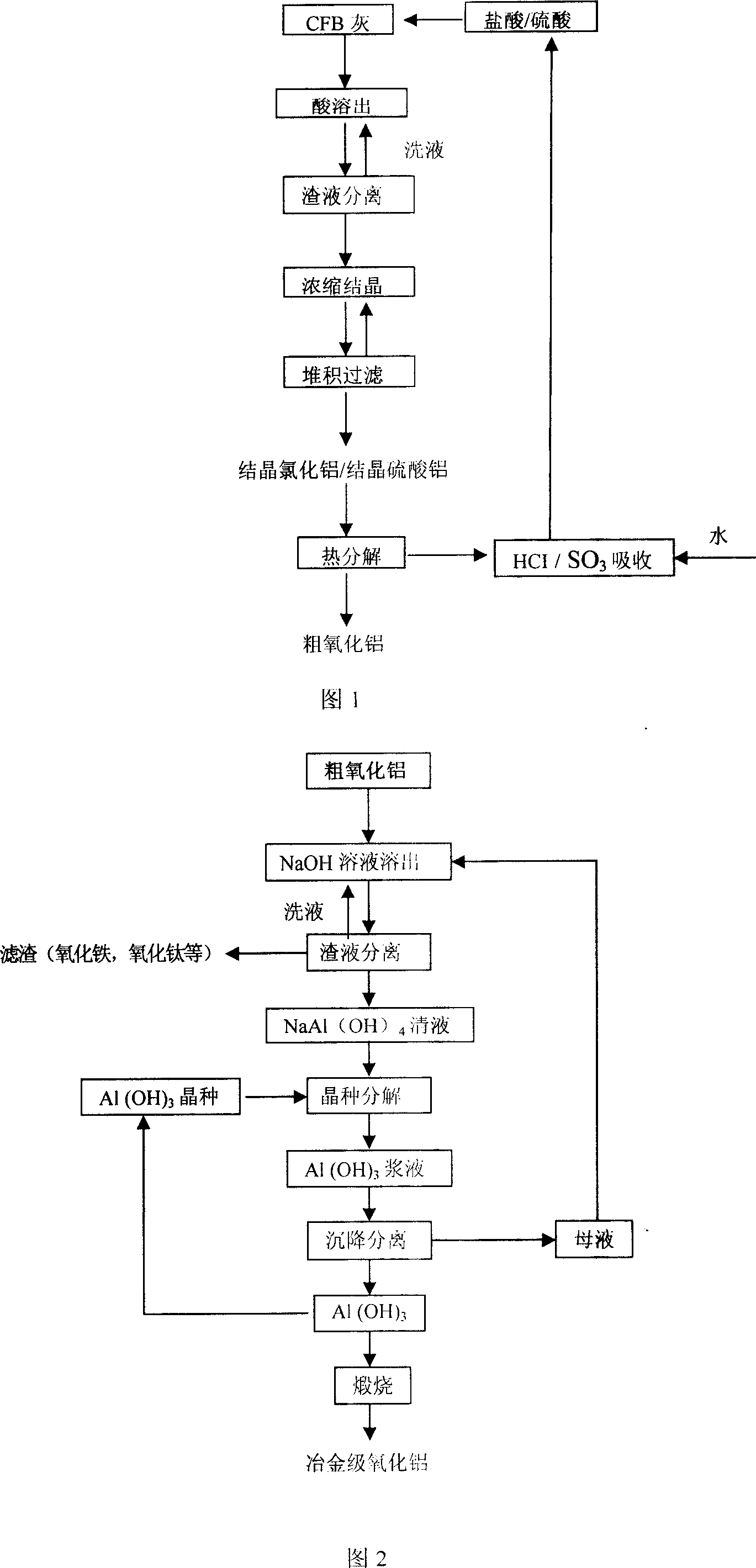

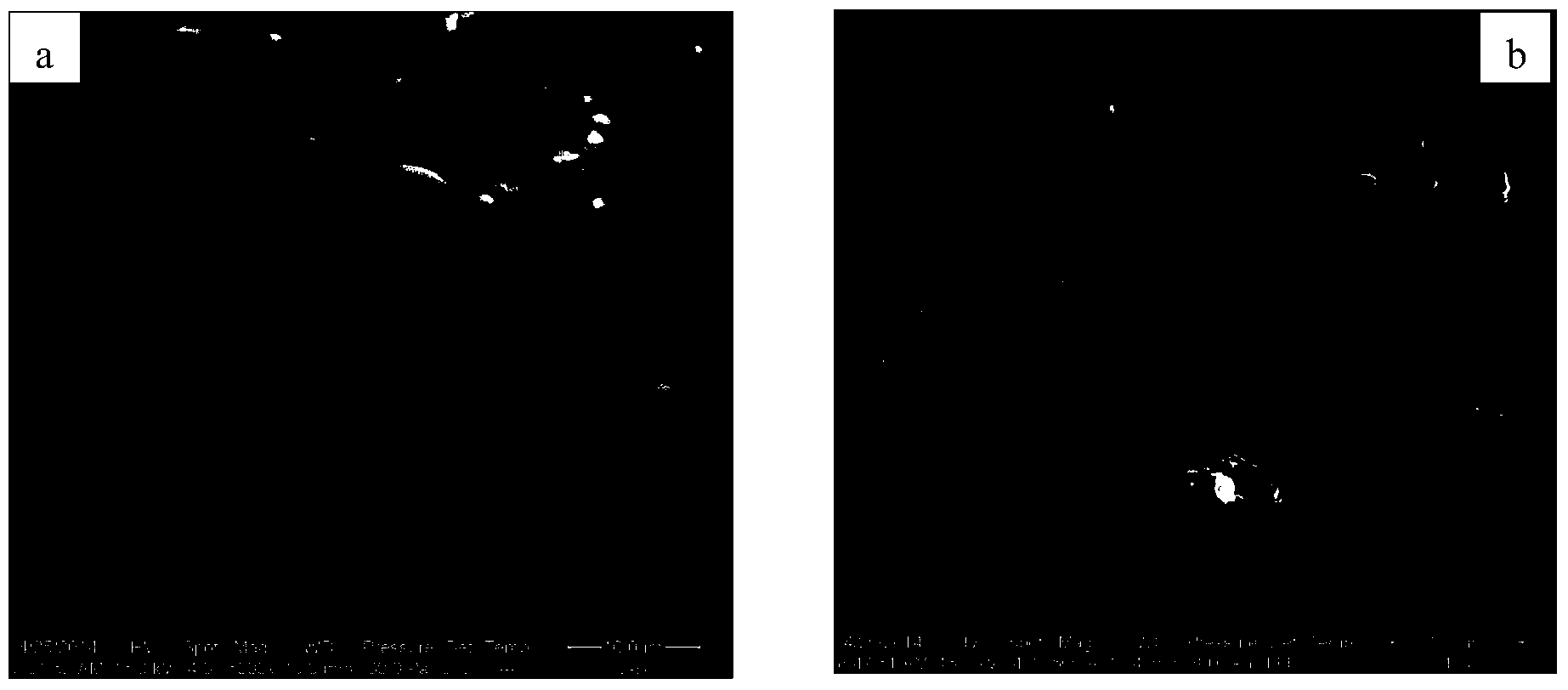

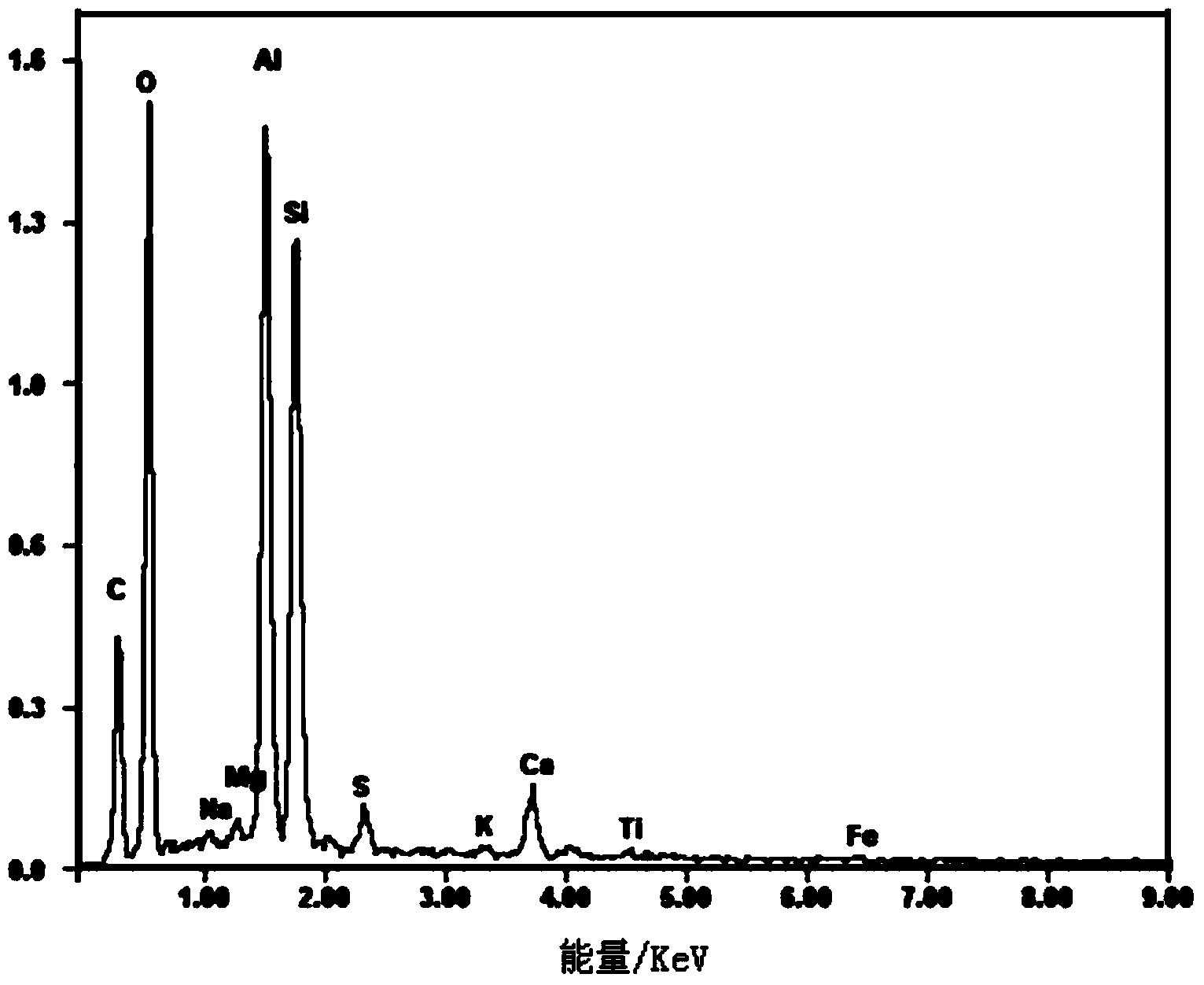

Preparation method of alumina

ActiveCN1927716AReduce pollutionReduce consumptionAluminium oxide/hydroxide preparationAluminium oxides/hydroxidesAluminium hydroxideDecomposition

The process of preparing alumina includes: the reaction of flyash from circular fluidizing bed and acid to obtain aluminum chloride solution, eliminating silicon impurity, concentrating to crystallize and heating to decompose and to obtain crude alumina product; reaction of crude alumina product and hot alkali solution to obtain sodium aluminate solution; eliminating iron, titanium and other impurity, adding aluminum hydroxide crystal seed into sodium aluminate solution for seed separating decomposition to obtain aluminum hydroxide precipitate; and final calcining aluminum hydroxide to obtain metallurgical alumina. The normal pressure process has no any cosolvent added, and the alumina product has Al2O3 content up to 98 %. The process has small sodium hydroxide consumption, reuse of most of sodium hydroxide, simple operation, low cost, low power consumption, capacity of reducing flyash pollution and other advantages.

Owner:SHENHUA ZHUNGER ENERGY

Spherical porous light haydite for treating waste water and its production method

InactiveCN1380137AHigh economic valueSolve the way outOther chemical processesSustainable biological treatmentPorosityEnvironmental resistance

The present invention relates to a kind of spherical porous loight-ceramsite produced by using industrial waste slag, steel-smelting rod mud and flyash as main raw material, using clay as binding agent, adding proper quantity of pore-forming agent and adopting high-temp., sintering process. Said invention also provides its production method, and said product can be specially used as filtration material for water treatment. Its product quality is as follows: specific surface area is 4-10 sq.m / g, average pore size is 50-250 micrometers, apparent density is 1.40-1.80 g / cu.cm and its voidage is 30-40%.

Owner:HUAQI ENVIRONMENT PROTECTION SCI & TECH

Granular filtering material for adsorbing and removing heavy metals in water and preparation method thereof

ActiveCN104289185AWide variety of sourcesRealize resource utilizationOther chemical processesWater contaminantsIndustrial waste waterSorbent

The invention discloses a granular filtering material for adsorbing and removing heavy metals in water and a preparation method thereof. The granular material consists of the following components in part by mass: 80-120 parts of an adsorbent, 7-14 pats of an additive and 0.5-3 parts of a binding agent, wherein the adsorbent consists of the following components in part by mass: 50-70 parts of coal ash and 30-50 parts of zeolite powder or sea-foam stone powder; the additive consists of the following components in part by mass: 5-7 parts of Mg-Al hydrotalcite, 2-6 parts of biochar and 0.5-1 part of magnesium Lignosulfonate; the binding agent is bentonite. The granular filtering material is prepared through the steps of adsorbent acid modification, biochar preparation, granulation and heat treatment process. According to the invention, the prepared granular filtering material is 3-6 mm in granule size, is large in adsorption capacity and excellent in adsorption effect and can effectively remove heavy metals in water, and no secondary pollutants are dissolved out, so that the granular filtering material can be applied to the treatment on heavy metal micro-polluted water and industrial waste water containing heavy metals, and has good economic and social benefits.

Owner:BEIJING FORESTRY UNIVERSITY

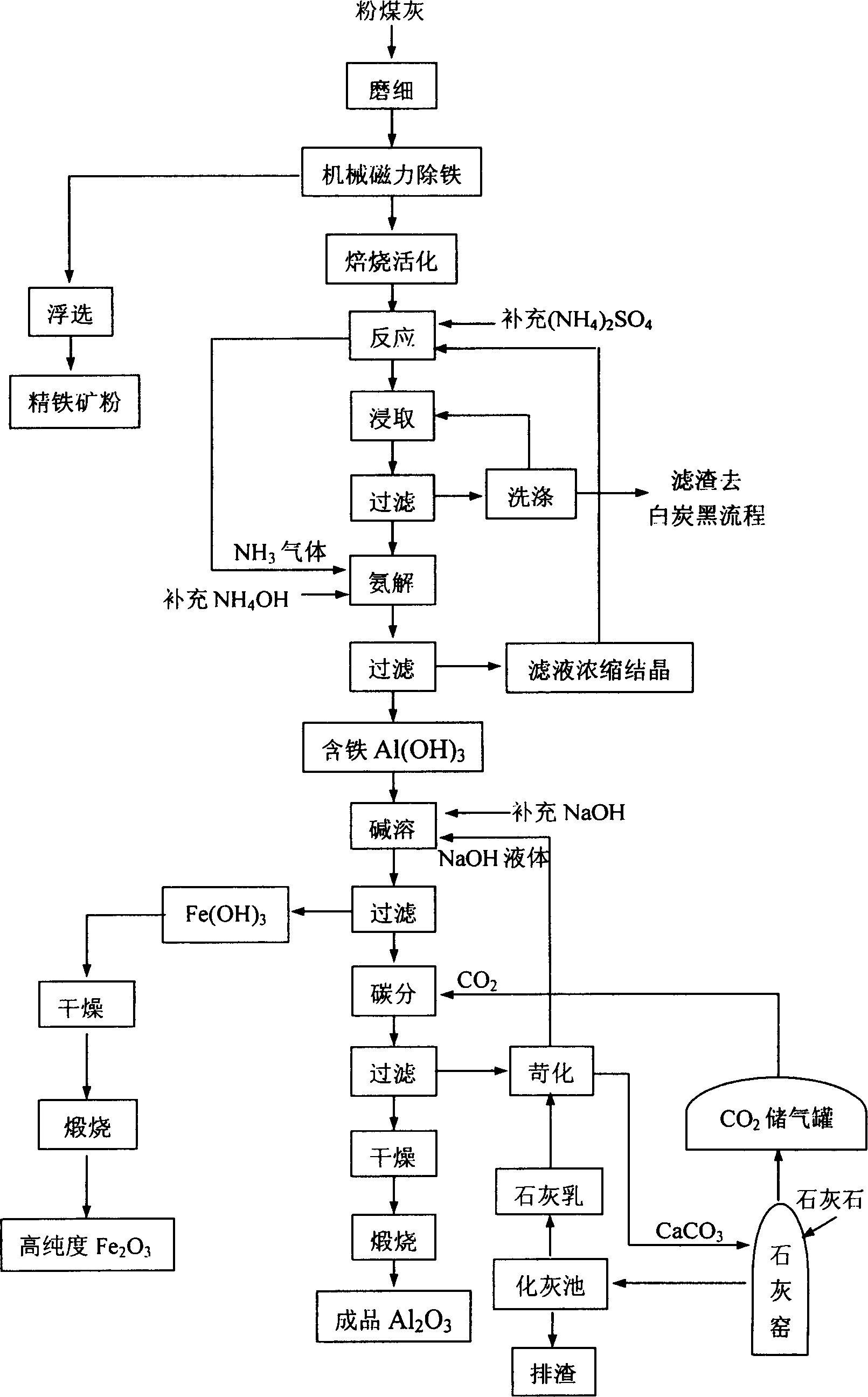

Method of extracting aluminium oxide from fly ash and simultaneously producing white carbon black

InactiveCN1868884AHigh activityUniform particle sizeSilicaAluminium oxides/hydroxidesAluminium hydroxideCoal

A process for extracting alumina from powdered coal ash while generating white carbon black includes such steps as grinding powdered coal ash, activating, adding ammonium sulfate, reacting, adding water, filtering, filling ammonia gas into the filtered liquid to obtain the deposited mixture of aluminum hydroxide and iron hydroxide, adding the solution of sodium hydroxide to dissolve the aluminum hydroxide deposit, adding carbon to obtain pure aluminum hydroxide, and calcining to obtain Al2O3.

Owner:NORTH UNITED POWER CO LTD

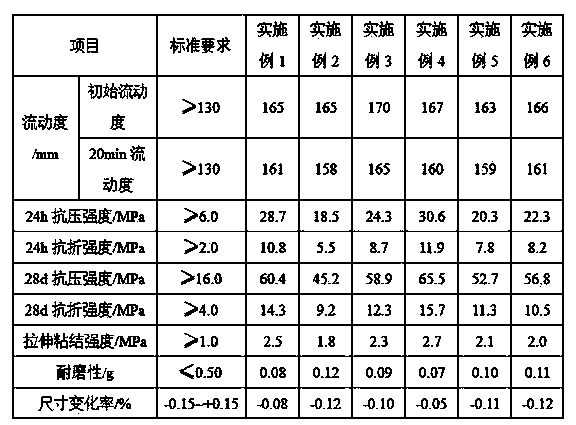

Cement-base dual-liquid slip-casting material

The invention relates to a kind of pair-slurry affusing material prepared with cement as basic raw material. It is comprised of two kinds of dry powdery mixed materials A and B of affusing slurry pair-liquid formed after adding water. Their weight percents are respectively: mixed material A: sulfur aluminate cement 30% - 98.1%, retarder citric acid 0.1% - 0.5%, flocculant polyacrylamide 0% - 0.8%, water-reducing agent FDN 0.6% - 1.5% and inorganic padding pulverized coal ash 0% - 69.1%; mixed material B: Portland cement 20% - 88%, land plaster 6% - 15%, flocculant UWN 0% - 0.7%, accelerator lithium carbonate 0.4% - 1.0%, water-reducing agent FDN 0.5% - 1.3%, calcareousness 2.0% - 5.0% and inorganic padding pulverized coal ash 0% - 70.8%.

Owner:张振秋

Fire proofing and extinguishing agent composite for mine and preparation and use method thereof

The invention belongs to the technical field of mine waste treatment and fire prevention, relating to a fire proofing and extinguishing agent composite for a mine and a preparation and use method thereof. The fire proofing and extinguishing agent composite comprises the following components in percentage by weight: 1.0-6.0wt% of glass fibre substance, 3.0-6.0wt% of lime, 3.5-6.0wt% of loess, 3.1-6.2wt% of coal ash, 0.01-0.03wt% of binding agent, 0.01-0.03wt% of water-retaining agent, 0.002-0.013wt% of dispersing agent and 80-90wt% of water. The fire proofing and extinguishing agent is non-toxic, harmless and safe to use and has the advantages of adjustable proportion, high inhibition rate and better inhibition performance. The slurry is easy to flow under the wet state and is in solid net body state after being dried, and the slurry has stronger impermeable plugging function; grouting equipment has strong adaptability, professional grouting equipment is adopted, and spraying and planting equipment can be used for construction. The slurry has big adjustable range of activity period and can be adjusted within 1-30 hours.

Owner:北京丰林源生态园林设计研究院有限公司

Single-component high-performance mortar for repairing and reinforcing concrete

InactiveCN101935201AShrinkage controlImprove bindingSolid waste managementFlexural strengthPollution

The invention provides single-component t high-performance mortar for repairing and reinforcing concrete, which comprises the following components in part by mass: 200g of sand, 55 to 75 parts of ordinary portland cement, 10 to 30 parts of sulphate aluminium cement, 3 to 7 parts of siliceous dust, 8 to 12 parts of flyash, 0.18 to 0.22 part of water reducing agent, 2 to 4 parts of flexibilizer, 0.04 to 0.06 part of water-retaining agent, 1.0 to 2.0 parts of swelling agent and 0.1 to 0.2 part of polymer synthetic fiber. The single-component t high-performance mortar has the advantages of high initial strength, good adhesion, excellent cracking resistance, low ratio of compressive strength to flexural strength, excellent toughness, simple and convenient construction, single component, no toxin or smell, no harm to human bodies, and environmental protection without pollution.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP

High performance cement-base self-leveling mortar

The invention discloses a high performance cement-base self-leveling mortar. The mortar is characterized by comprising cement, an auxiliary gel material, fine aggregate, a filling material, an additive, and water; wherein the cement is common silicate cement and sulphoaluminate-silicate cement, the auxiliary gel material comprises mineral slag, fly ash, silica fume, and gypsum, and the ratio of common silicate cement to sulphoaluminate-silicate cement to gypsum is equal to 1:0.2-0.6:0.1-0.4. The mortar has a self-leveling function without vibration, so the surface flatness is very high. The curing speed of the mortar is very quick, and after two hours, the strength of the mortar can meet the requirements of subsequent construction. Moreover the mortar has the advantages of low contraction rate, good volume stability, good surface wear resistance, and high compression strength.

Owner:广东省建筑工程监理有限公司

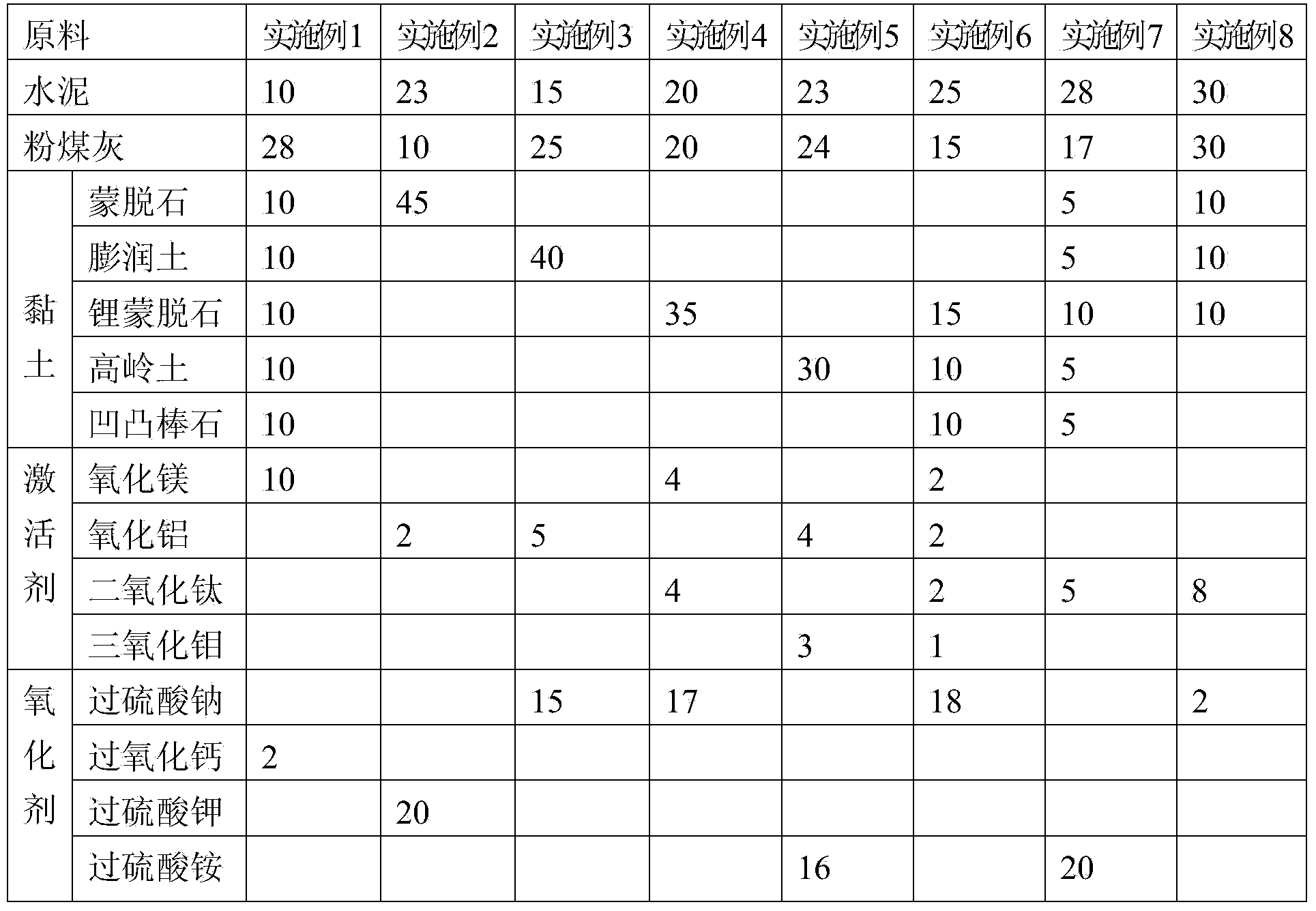

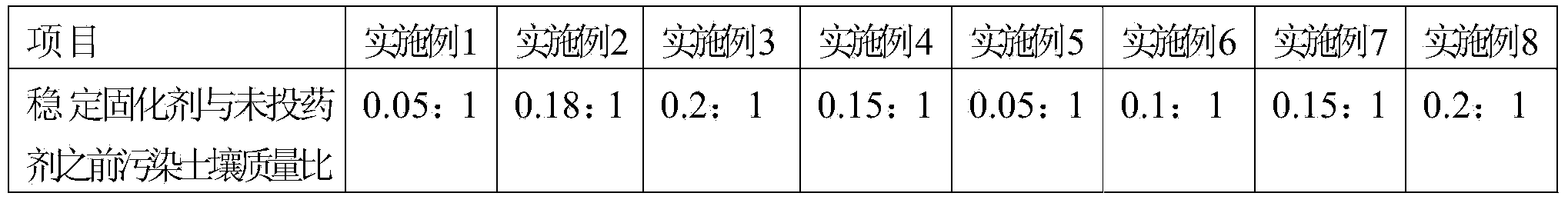

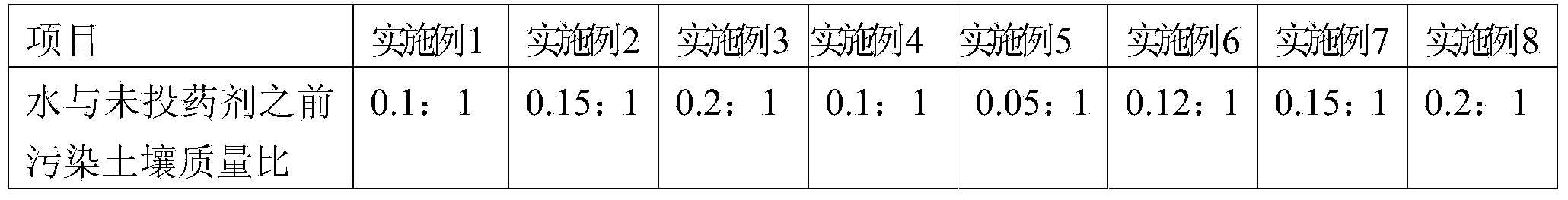

Stable curing agent of repairing heavy metal and toxic organic matter combined polluted soil and using method of curing agent

ActiveCN103881727AImprove repair effectBioeffectiveAgriculture tools and machinesContaminated soil reclamationPotassium persulfateCoal

The invention relates to a stable curing agent of repairing heavy metal and toxic organic matter combined polluted soil. The stable curing agent comprises the following raw materials in percentage by weight: 10-30% of cement, 10-30% of coal ash, 20-50% of clays, 2-10% of an activating agent and 2-20% of an oxidizing agent, wherein the activating agent is a composition of one or more than two of magnesium oxide, aluminum oxide, titanium dioxide or molybdenum trioxide, and the oxidizing agent is a composition of one or more than two of sodium persulfate, calcium peroxide, potassium persulfate and ammonium persulfate. The raw materials are put into a grinder to be uniformly grinded and mixed to prepare the stable curing agent with the specific surface area of 400-800 / kg. The stable curing agent provided by the invention has the characteristics of low cost, good soil repairing effect and simplicity in construction.

Owner:WELLE ENVIRONMENTAL GRP CO LTD

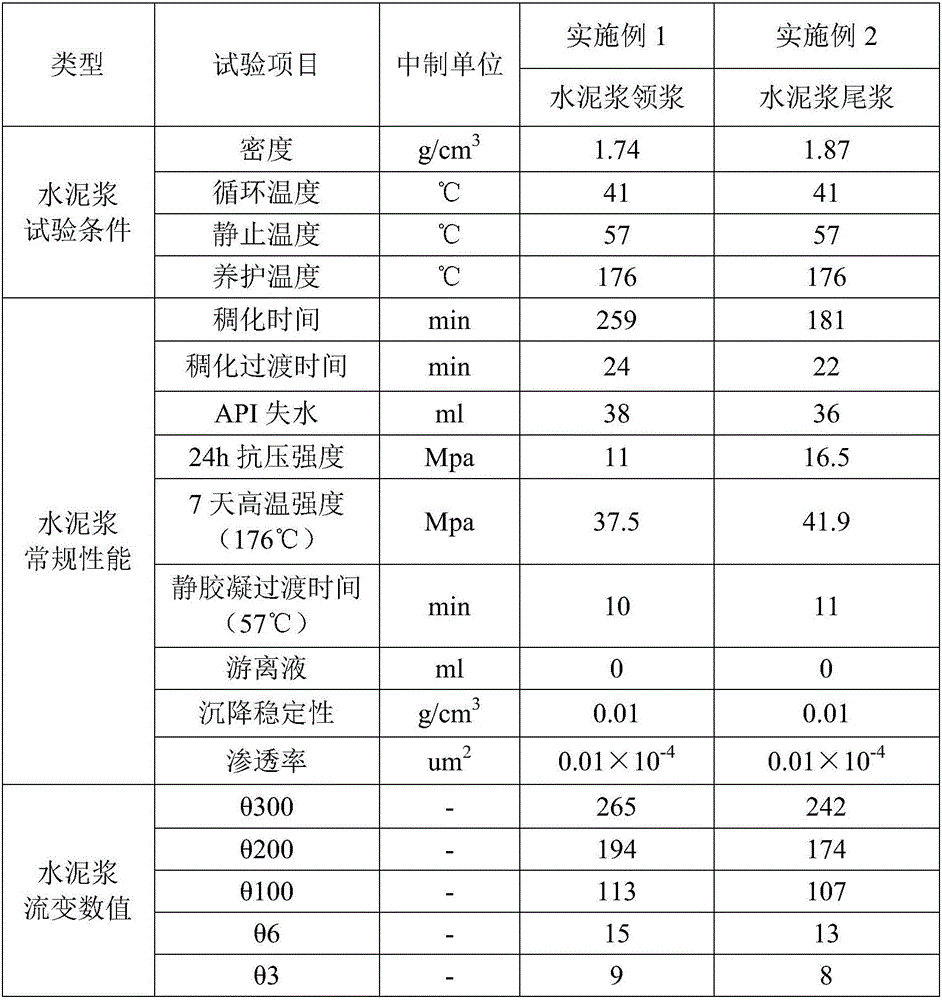

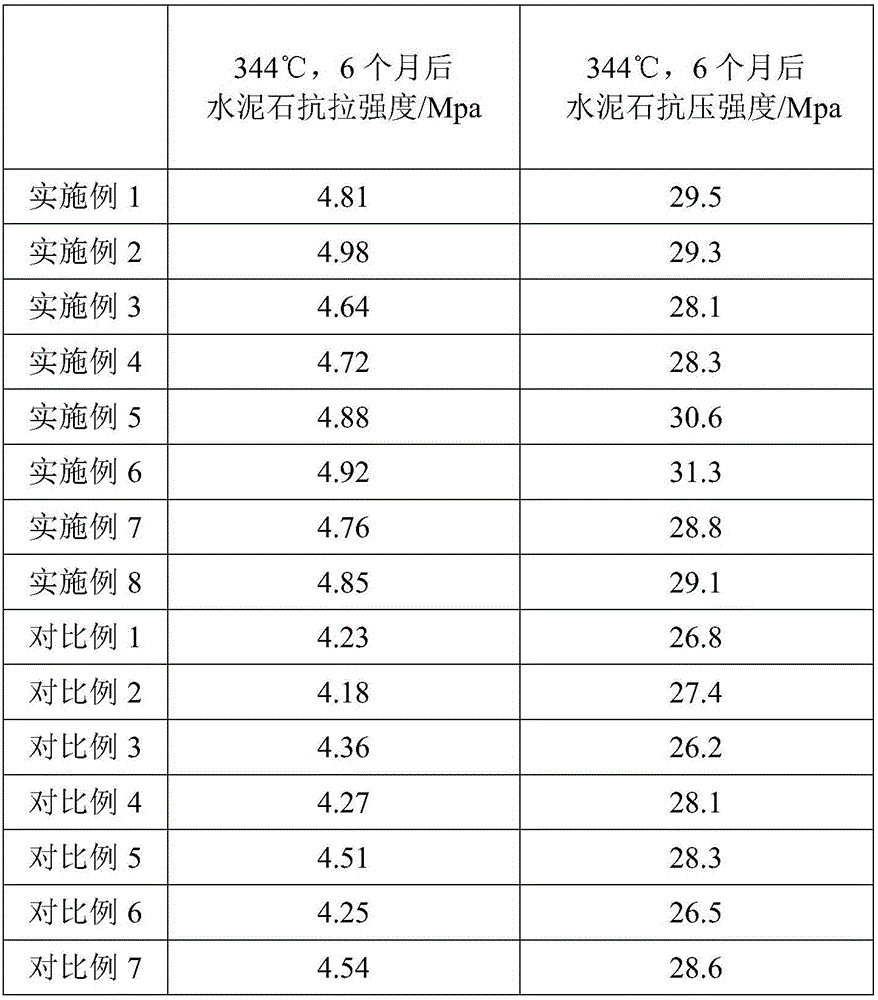

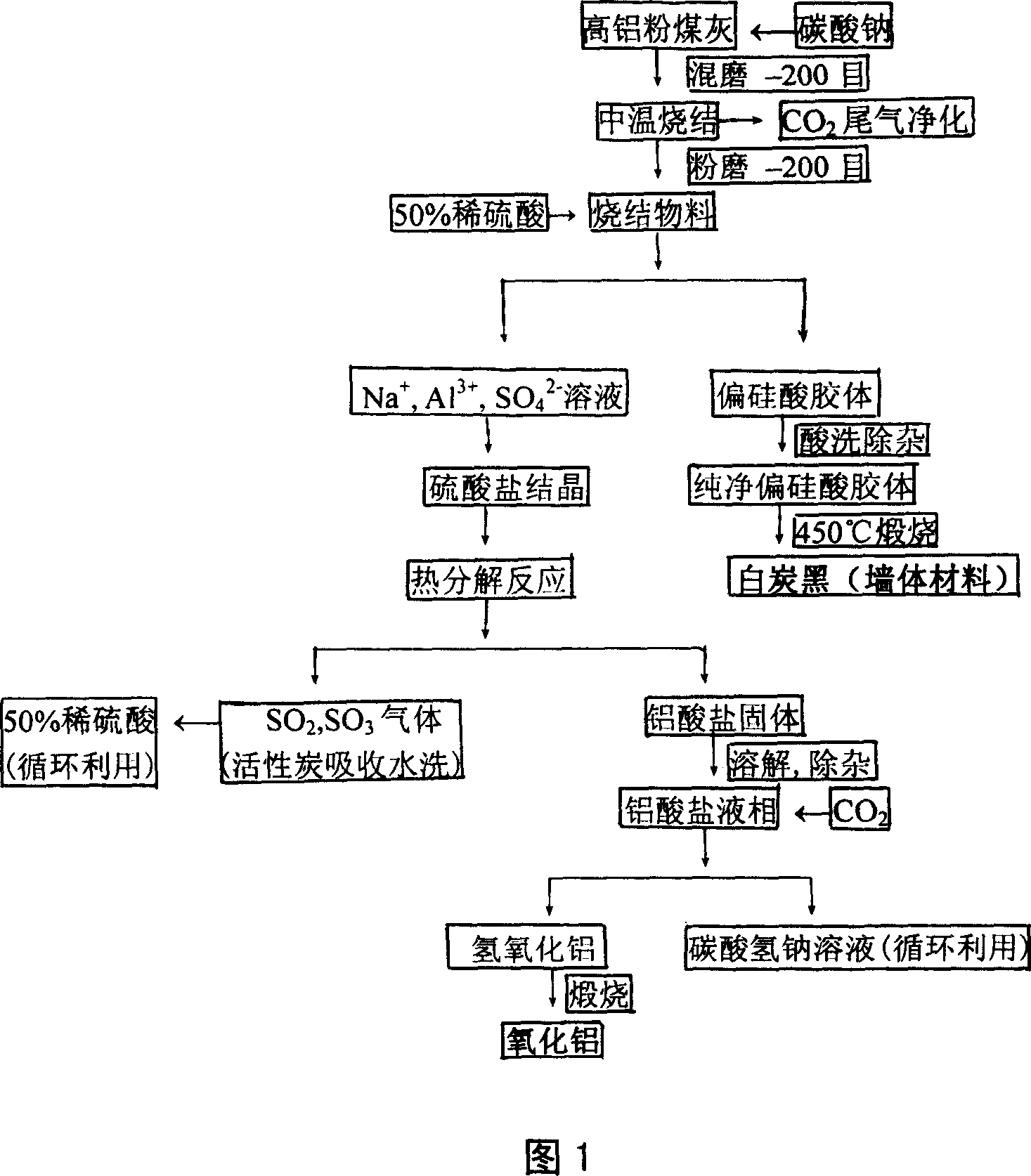

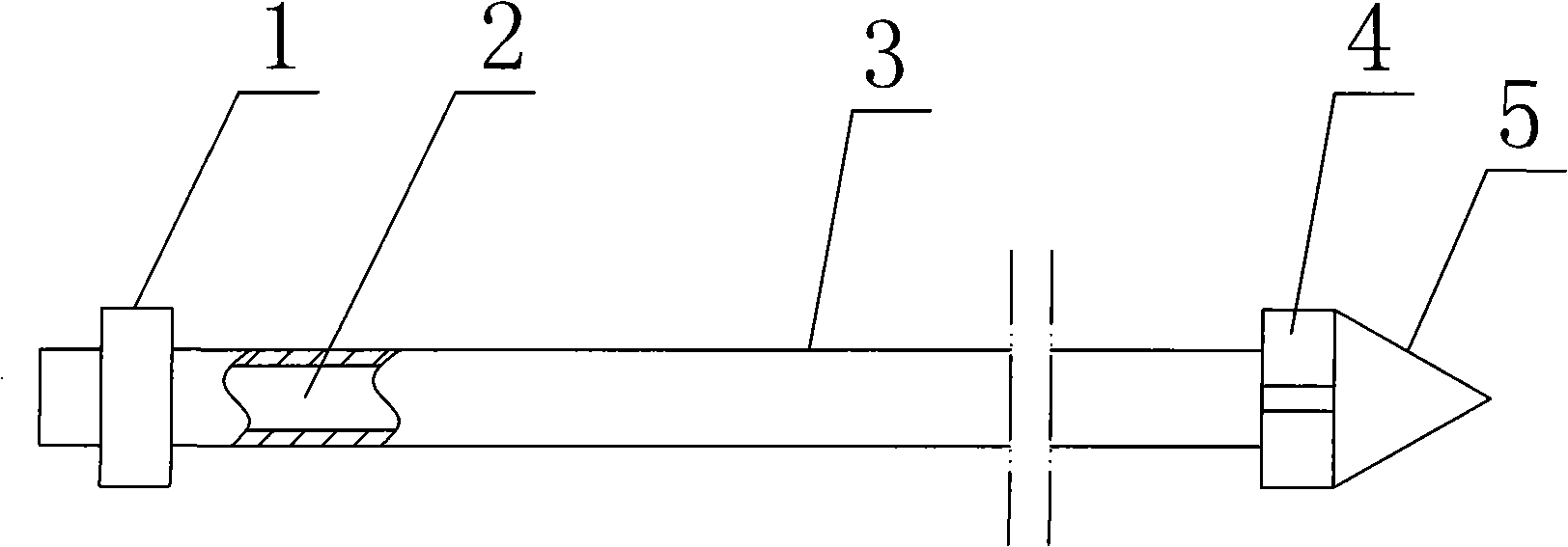

Cement slurry with long-term-integrity cement sheath for heavy-oil thermal-recovery well and preparation method thereof

ActiveCN106007545AGuaranteed general performanceEnsure that the cement slurry system has conventional comprehensive performanceDrilling compositionFiberClay minerals

The invention provides a cement slurry with long-term-integrity cement sheath for a heavy-oil thermal-recovery well. The cement slurry comprises, by weight, 100 parts of thermally responsive cement, 25 to 65 parts of water and 0.2 to 8 parts of a cement slurry aid. The thermally responsive cement comprises 30 to 60 parts of oil well cement, 10 to 20 parts of active silicon powder, 0 to 10 parts of hollow glass beads and 10 to 50 parts of a thermally responsive composite material. The thermally responsive composite material comprises 20 to 30 parts of clay mineral, 10 to 20 parts of fly ash and / or vulcanic ash, 5 to 20 parts of rubber powder and / or latex powder, 3 to 10 parts of carbon fiber, 10 to 15 parts of nanometer silicon dioxide, 5 to 10 parts of calcined magnesia, 10 to 20 parts of ultrafine superfine slag powder and 5 to 10 parts of inorganic whiskers. The cement slurry provided by the invention can solidify at normal temperature; and set cement can resist long-term high temperature, and the mechanical properties and thermal properties of the set cement in a high temperature environment are integrally adaptive to strata and casing pipes.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Clean production technique for preparation of aluminium oxide and white carbon black by using high-alumina coal ash

InactiveCN101041450ATake advantage ofWide variety of sourcesSilicon oxidesAluminium oxides/hydroxidesSodium bicarbonateSilica gel

The invention discloses a clean producing craft of aluminum oxide and white carbon black comprehensively with high-alumina coal ash, which comprises the following steps: making sodium carbonate as raw material; disintegrating high-alumina coal ash under medium-temperature; generating acid dissoluble aluminosilicate materials; using dilute sulphuric acid to acid dip; separating aluminum oxide and silica in the high-alumina coal ash; further treating aluminous liquid part; generating hydrated alumina deposition; finishing gamma-alumina or alpha- alumina product through calcining; washing, purifying, drying; calcining the silica gel part; getting white carbon black, silica aerogel, ultra-fine silica, porous silica and so on inorganic silicide.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

Drifting sand layer and gravel stratum water-moving double-liquid high pressure slip-casting water-blocking construction method

InactiveCN101255698AHigh strengthImprove water stabilitySolid waste managementUnderground chambersWater blockCement slurry

The present invention discloses a running sand layer and sandy gravel layer dynamic-water double-liquid high-pressure slurry-injecting water-shutoff construction method which comprises the following construction steps: drilling a hole, flushing the hole, executing double-liquid high-pressure slurry-injecting operation and sealing the hole. The running sand layer and sandy gravel layer slurry-injecting liquid adopts an ordinary portland cement (P.O.42.5) and 40''Be sodium silicate as material for preparing the slurry, according to the weight proportion of water: cement, namely the cement slurry is prepared with the water cement ratio for 0.5-1.2:1. Then the slurry-injecting liquid is prepared with the volume ratio of cement slurry: sodium silicate for 1:0.08-0.15. The sodium silicate is taken as additive for regulating the initial setting time of the slurry-injecting liquid. The cement slurry can also be doped with fly-ash with cement consumption (weight proportion) for 10%-15%. The invention executes water-insulating construction aiming at the characteristics of large pressure of the underground dynamic water and high flowing velocity in the running sand layer and sandy gravel layer, and can obtain the maximal application sphere and optimum water-shutoff effect.

Owner:HUNAN CONSTR ENG GRP COR

Method for firstly extracting silicon and secondly extracting aluminum from fly ash

ActiveCN101125656AImprove resource utilization valueIncrease Al-Si RatioAluminium oxide/hydroxide preparationSilicon oxidesSODIUM SILICATE SOLNCarbonation

Owner:PINGSHUO INDAL

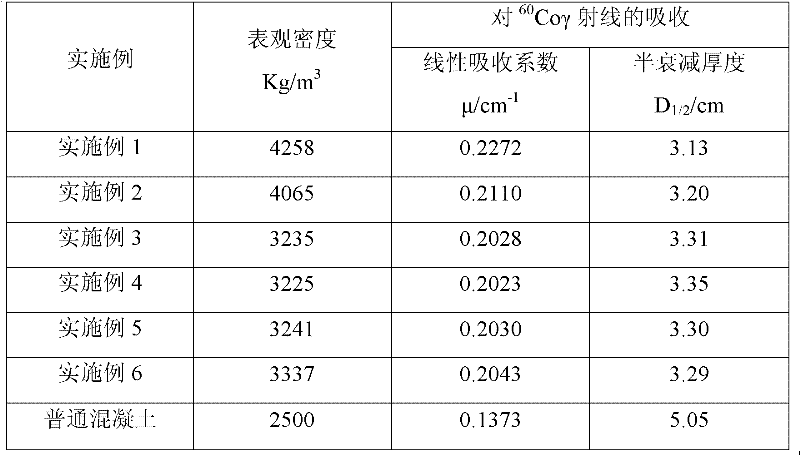

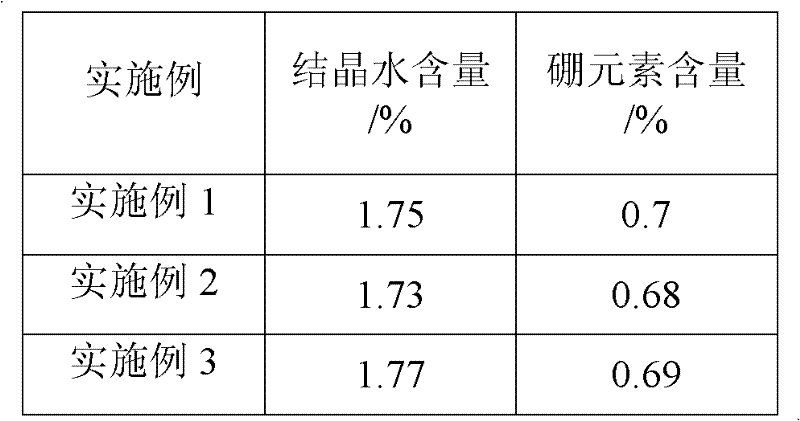

Radiation shield concrete and preparation method thereof

InactiveCN102219459AReduce water-cement ratioLow shrinkageSolid waste managementShieldingSlagSuperplasticizer

The invention relates to radiation shield concrete and a preparation method thereof. The radiation shield concrete is characterized by comprising a cementing material, coarse aggregates, fine aggregates, steel fibre, a high-efficiency slushing agent and water; the cementing material is composed of ordinary portland cement and inorganic mineral admixtures; the inorganic mineral admixtures are siliceous dust and coal ash; the fine aggregates are natural sand, boron glass powder and steel slag powder; the coarse aggregates are steel sections or a mixture of the steel sections and steel slag; the proportions of various types of components are as follows: 500 kg / m<3> of cementing material, 1400-2215 kg / m<3> of coarse aggregates, 750-950 kg / m<3> of fine aggregates, and 155-200 kg / m<3> of water; the high-efficiency slushing agent is 0.5-1.0% of the total weight of the cementing material by weight; and the steel fibre is 1.0-1.5% of the total volume of the concrete by volume. The radiation shield concrete has good mechanical property and lasting quality, good shielding effect on gamma rays, good effect on shielding neutron rays, can be used or comprehensively recycling wastes and has low cost.

Owner:WUHAN UNIV OF TECH

Nano-composite environment-friendly water permeable brick and production method thereof

InactiveCN103290753AGuaranteed compression performanceGood water permeabilitySingle unit pavingsCeramic shaping apparatusEnvironmental resistanceBrick

The invention discloses a nano-composite environment-friendly water permeable brick and a production method thereof. The nano-composite environment-friendly water permeable brick comprises a concrete bottom layer and a mortar surface layer arranged on the concrete bottom layer, wherein the concrete bottom layer and the mortar surface layer are compounded to form an integrated structure; the concrete bottom layer is prepared from the following raw materials in parts by weight: 20-40 parts of cement, 10-20 parts of water, 5-15 parts of fly ash, 50-65 parts of recycled aggregate, 50-65 parts of natural coarse aggregate, 65-85 parts of sand and 0.05-0.2 part of water-reducing agent; and the mortar surface layer is prepared from the following raw materials in parts by weight: 70-100 parts of cement, 5-20 parts of nano-TiO2, 30-60 parts of water, 200-400 parts of sand and 0.1-1.0 part of water-reducing agent. The nano-composite environment-friendly water permeable brick disclosed by the invention is integrally formed and has the advantages of high compressive strength, high flexural strength, good water permeability and good water retention, and a ground surface laid by the nano-composite environment-friendly water permeable bricks can timely dredge and drain rainwater, is conductive to growth of surrounding vegetation and can effectively supplement groundwater, reduce the pressure of a municipal drainage system and reduce the influence of surface gathered water on the traffic; and the nano-composite environment-friendly water permeable brick has a photocatalytic self-cleaning function and can decompose and remove organic stains on the surface of the brick and beautify the urban environment.

Owner:CHINA STATE CONSTR HAILONG TECH CO LTD

Method for preparing alumina by using fly ash

InactiveCN101397146AEffective leachingPromote leachingAluminium oxide/hydroxide preparationAluminium oxides/hydroxidesAluminium hydroxideSodium aluminate

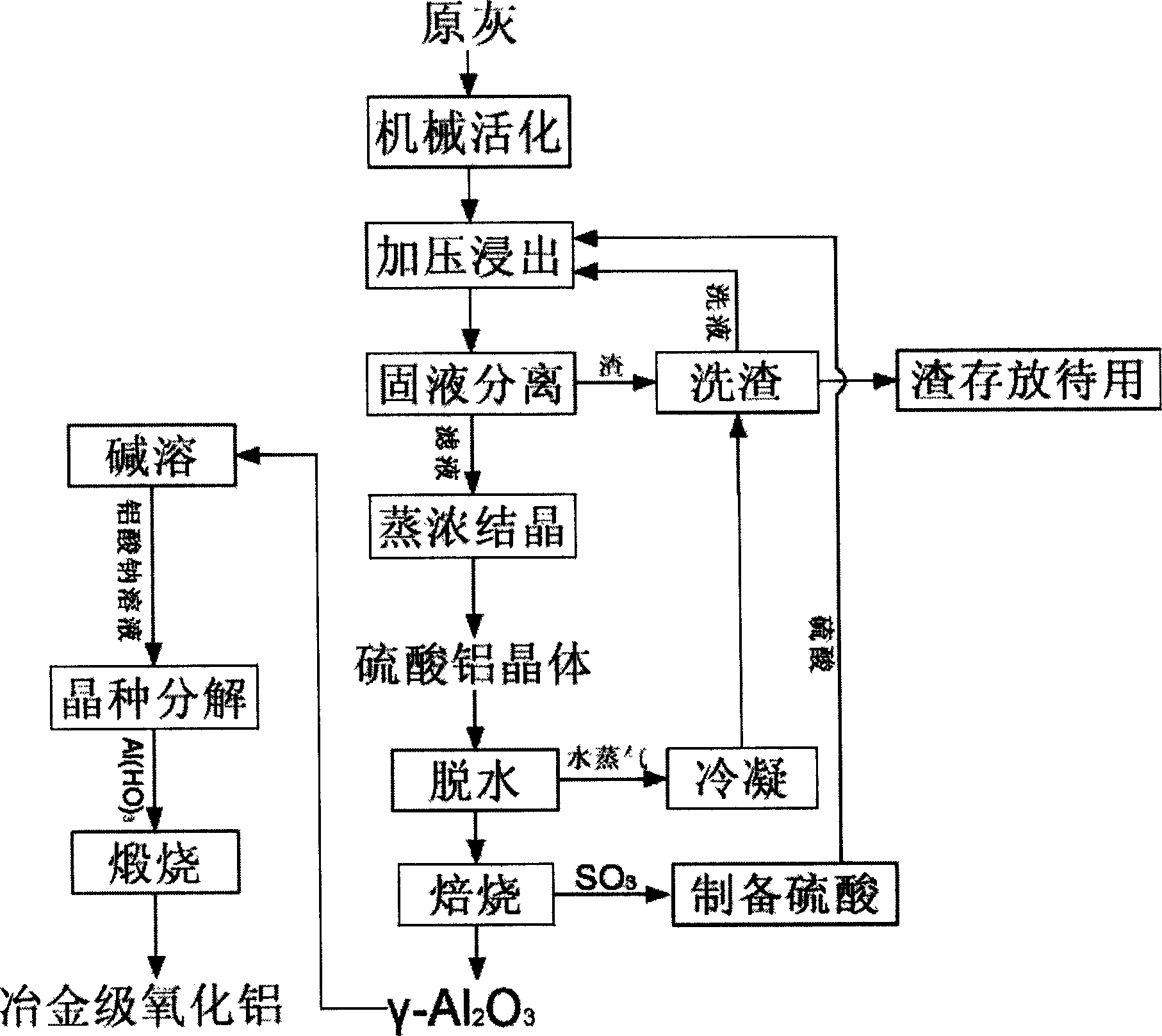

The invention discloses a method for producing alumina by disposing and utilizing industrial solid wastes, in particular to a method for preparing alumina by fly ash, comprising the steps as follows: the fly ash is mechanically activated; the activated fly ash, water and concentrated sulfuric acid react in a reaction kettle under the conditions of heating and pressurizing; the solid is separated from the liquid after the temperature of the reaction is reduced so as to gain aluminium sulfate liquid; the aluminium sulfate liquid is evaporated, concentrated and cooled so as to precipitate aluminium sulphate crystals; the aluminium sulphate crystals are dehydrated and decomposed to gain gama-Al2O3 and SO3; coarse gama-Al2O3 is dissolved in alkaline solution; after the solid is separated from the liquid, the pure sodium aluminate solution is gained; aluminum hydroxide crystal seed is added to the sodium aluminate solution so as to precipitate the aluminum hydroxide; the coarse gama-Al2O3 can be prepared by circularly dissolving the seed-precipitated alkaline solution after vaporization-concentration; the metallurgical alumina can be gained by baking the prepared aluminum hydroxide. The method adds no additive, can lead the alumina in the fly ash to be effectively leached out with the leaching rate more than 90% and saves the energy resource.

Owner:SHENYANG ALUMINIUM MAGNESIUM INSTITUTE

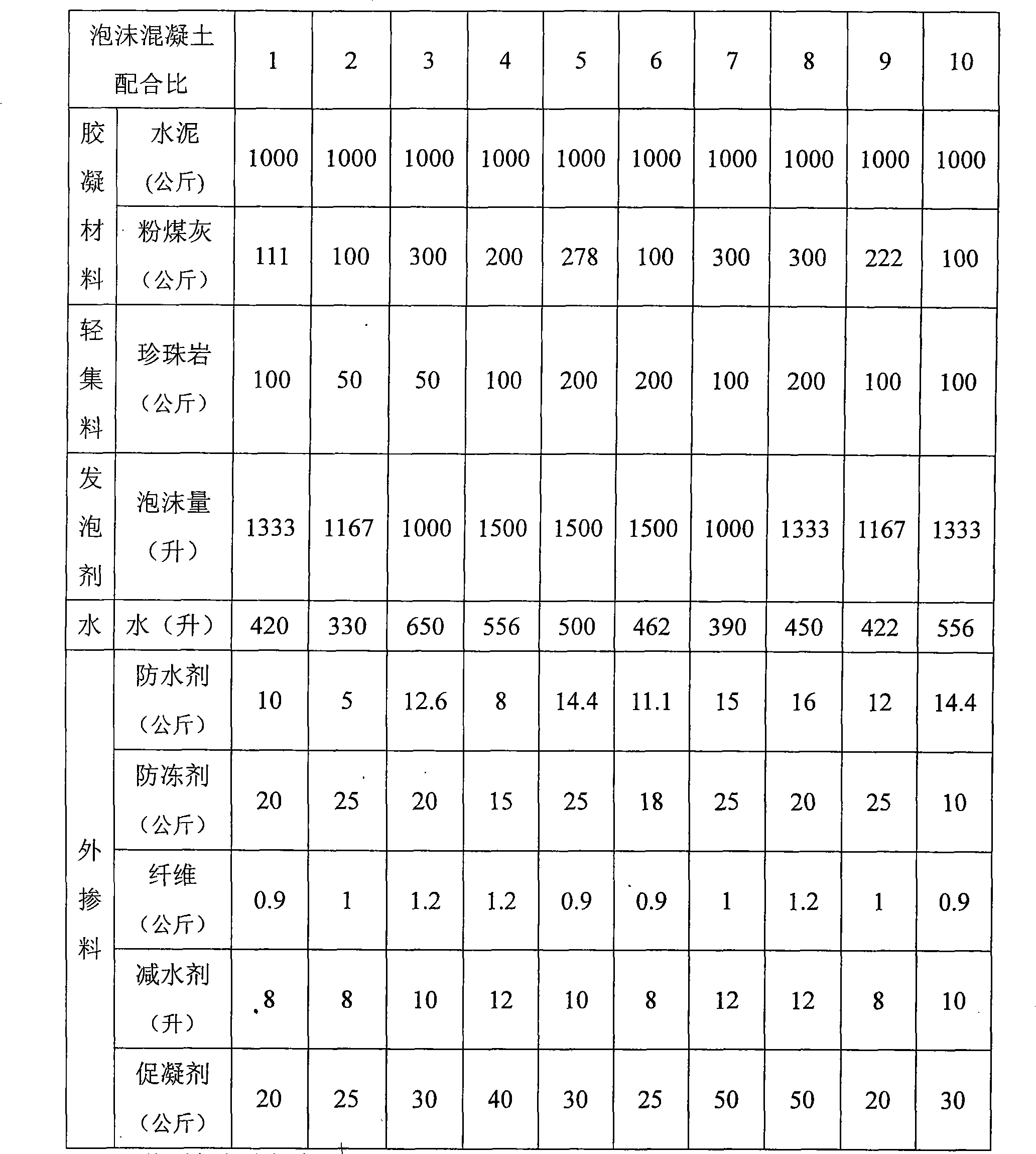

Foam concrete and preparing process thereof

InactiveCN101497533AHigh strengthLight weightCeramic shaping apparatusCement mixing apparatusFoam concreteFiber

The invention discloses foam concrete and a preparation method thereof. The foam concrete comprises a gelling material, light aggregate, water, admixture and foaming agent. The preparation method comprises the following steps: (1) pre-treating raw materials to prevent hard lumps and hard grains in the raw materials from depositing in foam slurry; (2) weighing each component according to a proportion; (3) preparing and adding foaming solution; (4) loading and stirring, namely, adding water into a stirrer, starting the stirrer, and adding cement, coal ash, perlite, waterproof agent, anti-freezing agent, water reducing agent and fiber into the stirrer in turn; (5) foaming, namely, foaming at the same time of stirring the slurry, sealing a valve firstly and then pressurizing the valve by an air compressor; (6) adding foam, namely, after the gelling slurry is well prepared, adding the foam into the gelling slurry under the state of stirring without stopping the stirrer; and (7) casting and molding, namely, when the slurry surface has no floating foam, finishing the preparation of the foam slurry. The foam concrete has the functions of light weight, water proofing, fire resistance, heat insulation, freezing resistance, cracking resistance, shock resistance and the like, and is particularly suitable for engineering insulating layers in cold areas and water-blocking and shock-resistant layers of underground engineering.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI

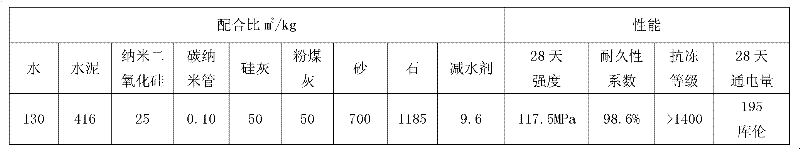

Nano-material composite concrete with super high performance

InactiveCN102199021AImprove mechanical propertiesIncreased durabilitySolid waste managementCarbon nanotubeAmmonium bromide

The invention relates to a preparation technology for concrete with super high performance, and belongs to the field of concrete technology in civil engineering. The invention is characterized in that: 1 m<3> of concrete contains 380 to 420 kg of cement, 680 to 740 kg of fine aggregate, 1120 to 1190 kg of coarse aggregate, 130 to 160 kg of water, 50 to 75 kg of fly ash, 25 to 64 kg of silica fume, 6.1 to 10.4 kg of a high performance water reducer, 0.05 to 0.25 kg of multi-walled carbon nanotubes and 15 to 25 kg of nanometer silica. The preparation technology is to carry out mechanical stirring for 180 to 240 seconds. The carbon nanotubes are added in the form of dispersion liquid, and a dispersant is cetyl trimethyl ammonium bromide (C16TAB), wherein the dispersion liquid is prepared according to the following portion MWNRs : C16TAB : water = 0.48 g : 4.1 g : 40 ml. The invention enables the super high performance concrete to have an enhanced mechanical property and lasting quality, a drastically increased service life, and capacity of being used in projects where requirements for the performance of concrete are high, for example, large-scale cross-sea bridges, super high buildings, and the like. The invention has a high utility value.

Owner:DALIAN UNIV OF TECH

Nitrobacteria growth promoter

The nitrobacteria growth promoter consists of molasses 100 weight portions, metal salt 0.2-2.5 weight portions and adsorbent 1-8 weight portions. The metal salt includes component A of FeSO4 or FeCl2, and component B of MgSO4 and / or CaCl2, in the molar ratio of 10 to (0.5-5). The adsorbent is zeolite powder, diatomite, powdered active carbon, fly ash or their mixture. The nitrobacteria growth promoter is used in biological nitrification process of eliminating ammonia nitrogen and thrown into sewage directly to promote the propagation and growth of nitrobacteria in sewage. It has raised ammonia nitrogen eliminating rate and low cost.

Owner:SINOPEC SHANGHAI PETROCHEMICAL CO LTD

Nano foamed concrete, reinforced insulation wallboard and preparation method of reinforced insulation wallboard

ActiveCN103359997AAvoid interferenceAvoid pollutionBuilding componentsFoam concreteAdditive ingredient

The invention belongs to the field of building materials and construction technologies and relates to nano foamed concrete, a reinforced insulation wallboard and a preparation method of the reinforced insulation wallboard. The nano foamed concrete disclosed by the invention is prepared from the following ingredients in parts by weight: 100 parts of cement, 0.1-5 parts of desulfurized oil coke ash residue, 0.012 part of waterproofing agent, 10-30 parts of fly ash, 0.1-6 parts of superplasticizer, 50-200 parts of water, 1-20 parts of foamer and 0.01-5 parts of nano wave absorbing agent. Thus, when a wallboard product, prepared by embedding steel wire meshes in the nano foamed concrete disclosed by the invention, is applied nearby airports, docks, navigation marks, television stations and receiving stations or applied to concrete-based retaining walls of electromagnetic wave interference preventing scientific research departments, precise instrument plants and information leakage prevention high-grade buildings of national confidential units and the like, the most basic physical, mechanical, heat preservation and heat insulation properties are guaranteed on one hand, and the wallboard product has the capabilities of lowering noise and insulating sound on the other hand.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com