Patents

Literature

150 results about "Aluminium sulphate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Alkali-free liquid accelerating agent and preparation method thereof

The invention belongs to the technical field of tunnel construction, and relates to an alkali-free liquid accelerating agent for tunnel wet jet concrete and a preparation method thereof. The alkali-free liquid accelerating agent is characterized in that aluminium sulphate is adopted to serve as a main accelerating component; aluminium is added to an aluminium sulphate solution to be polymerized in a form of aluminium fluoride; aluminium ions are introduced to the greatest extent so as to reduce other ion introduction; and the accelerating effect is ensured. The alkali-free liquid acceleratingagent comprises the following components in percentage by mass: 30-55% of aluminium sulphate, 5-15% of aluminium hydroxide, 10-30% of hydrofluoric acid, 0.5-5% of water glass, 0-0.2% of stabilizing agent, and the balance of water. For jetting concrete, the alkali-free liquid accelerating agent disclosed by the invention has the positive effects that: ordinary cement can be initially solidified within 2 min in lower doping quantity and finally solidified within 4 min; the 1d strength of cement plaster can achieve above 15 MPa; the 28d compressive strength ratio is more than 100%; and the alkali-free liquid accelerating agent has good adaptability to different types of cements.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD

Precipitated silicic acid

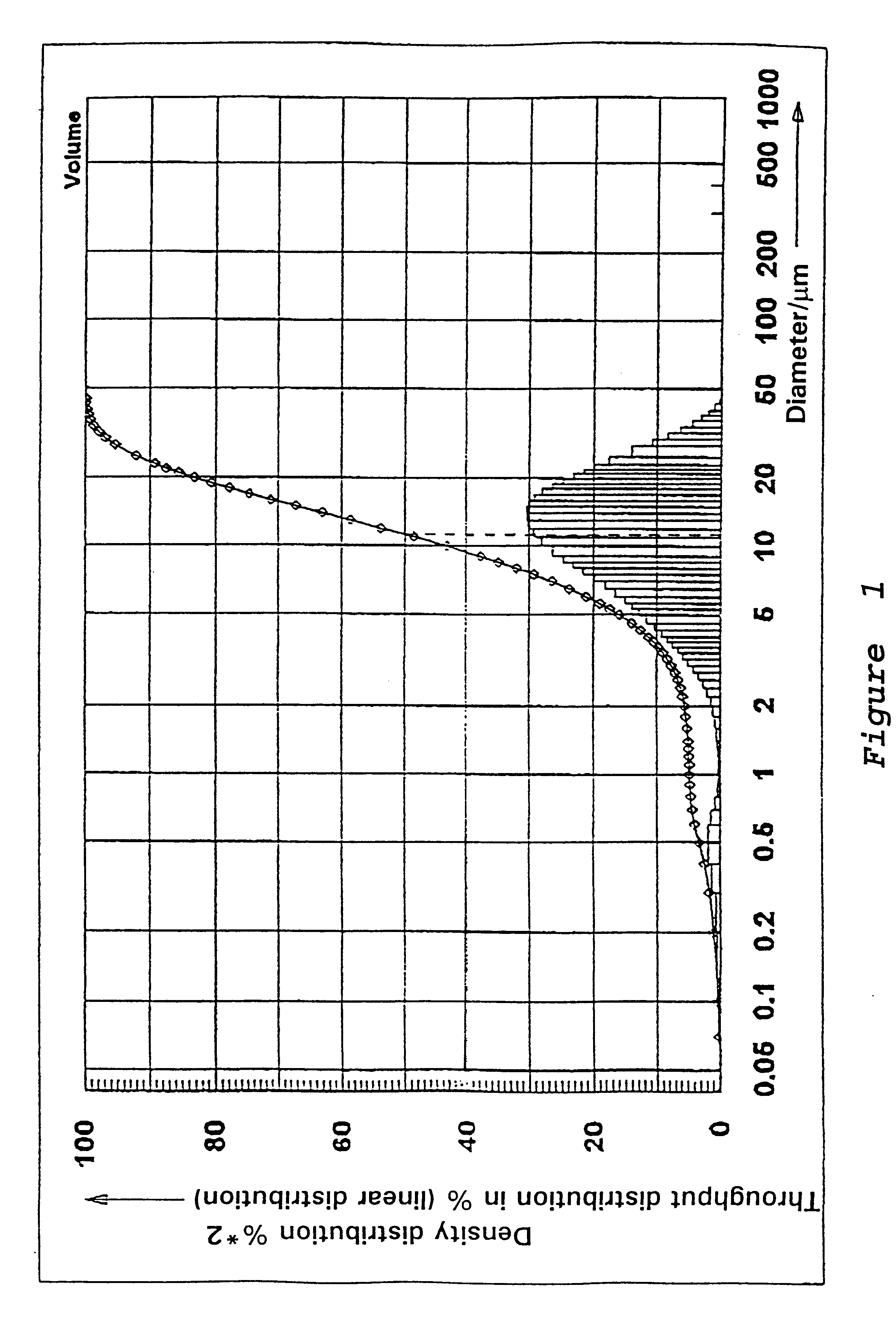

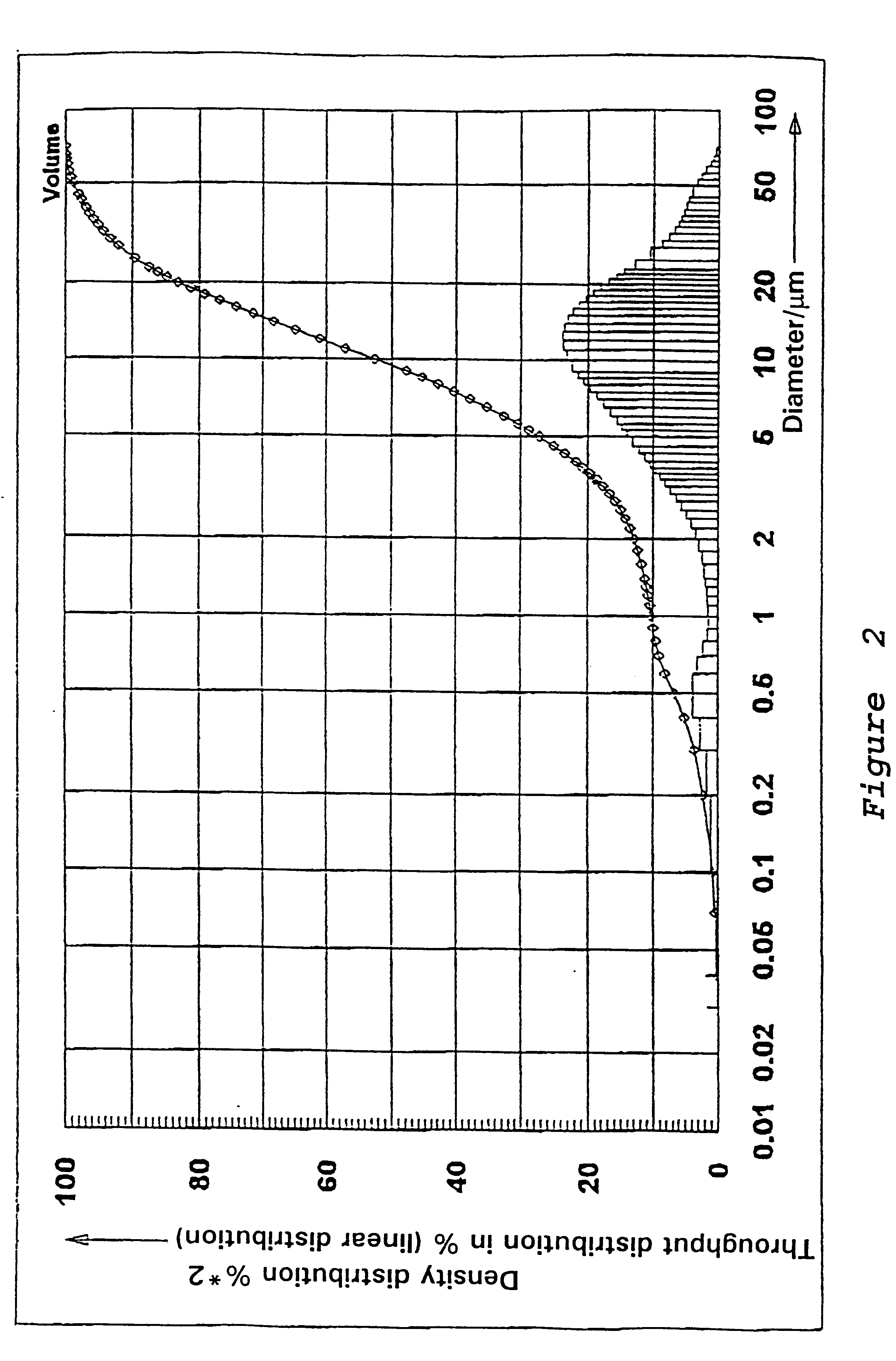

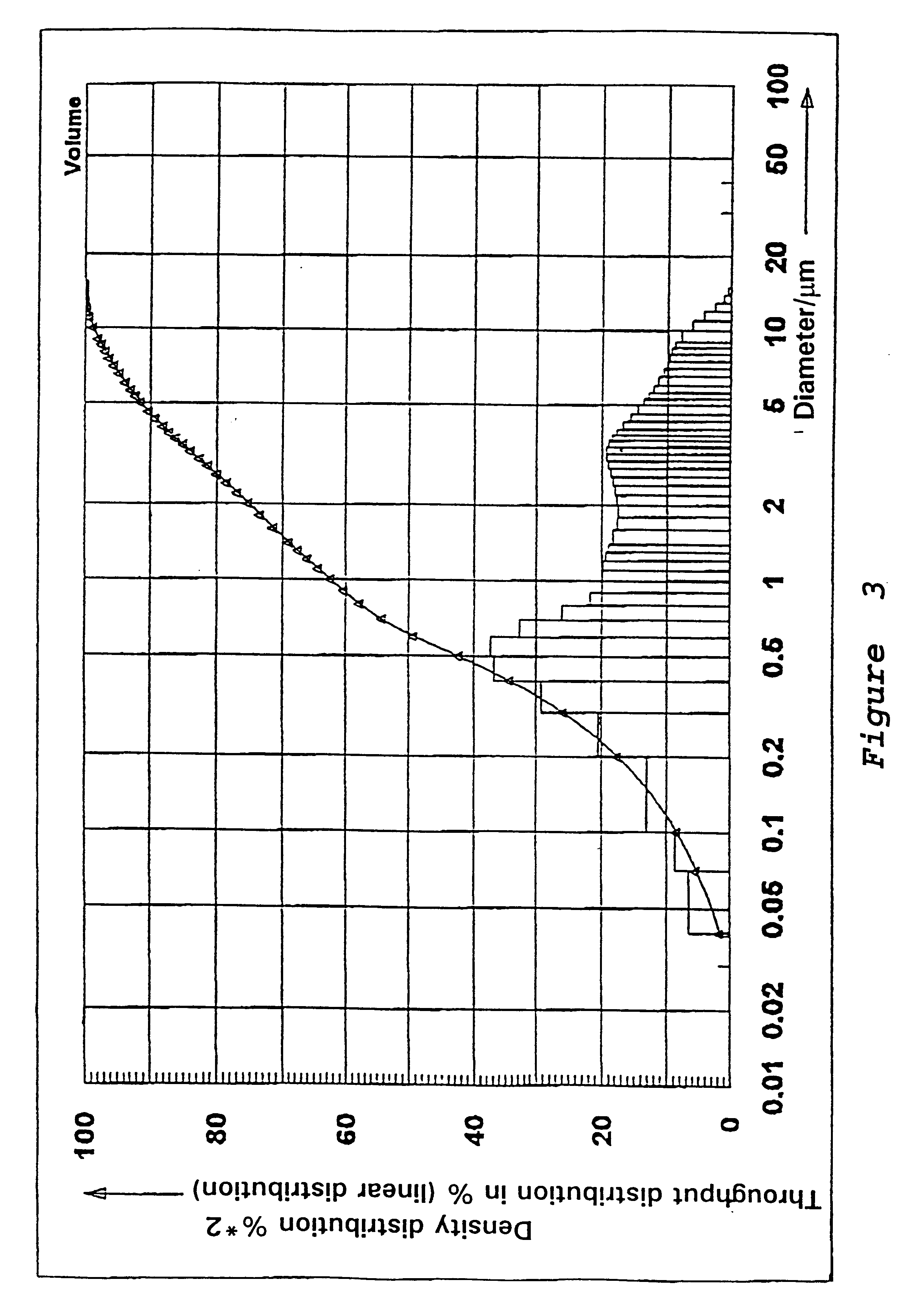

InactiveUS6268424B1Easily dispersible in tire carcassExtended service lifePigmenting treatmentSilicaSilicic acidPhysical chemistry

Precipitated silica having the following parameters:is prepared by reacting alkali silicate with mineral acids and aluminum sulfate solution at temperatures of 60-95° C. at a pH of 7.0-10.0 while stirring constantly, wherein the reaction is continued to a solids concentration of 40-110 g / l, the pH is adjusted to a value between 3 and 5, and the precipitated silica is filtered off, washed and then dried, and optionally ground or granulated.

Owner:EVONIK DEGUSSA GMBH

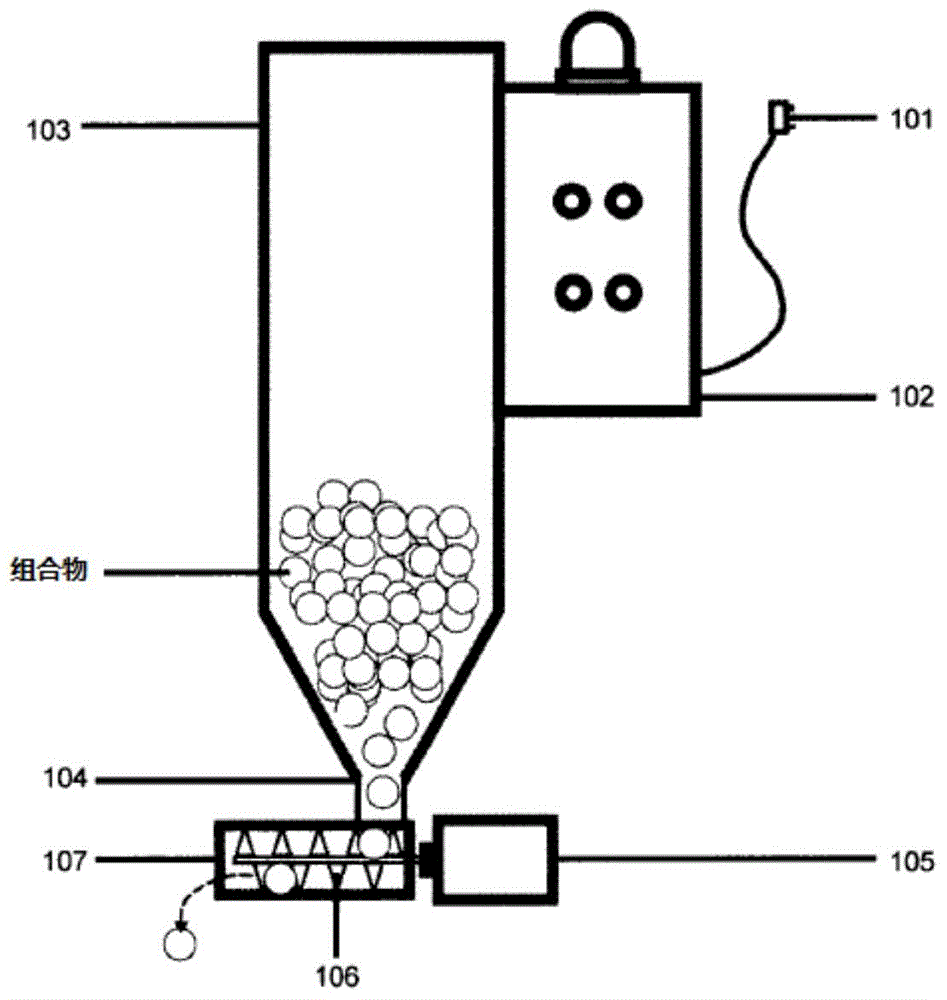

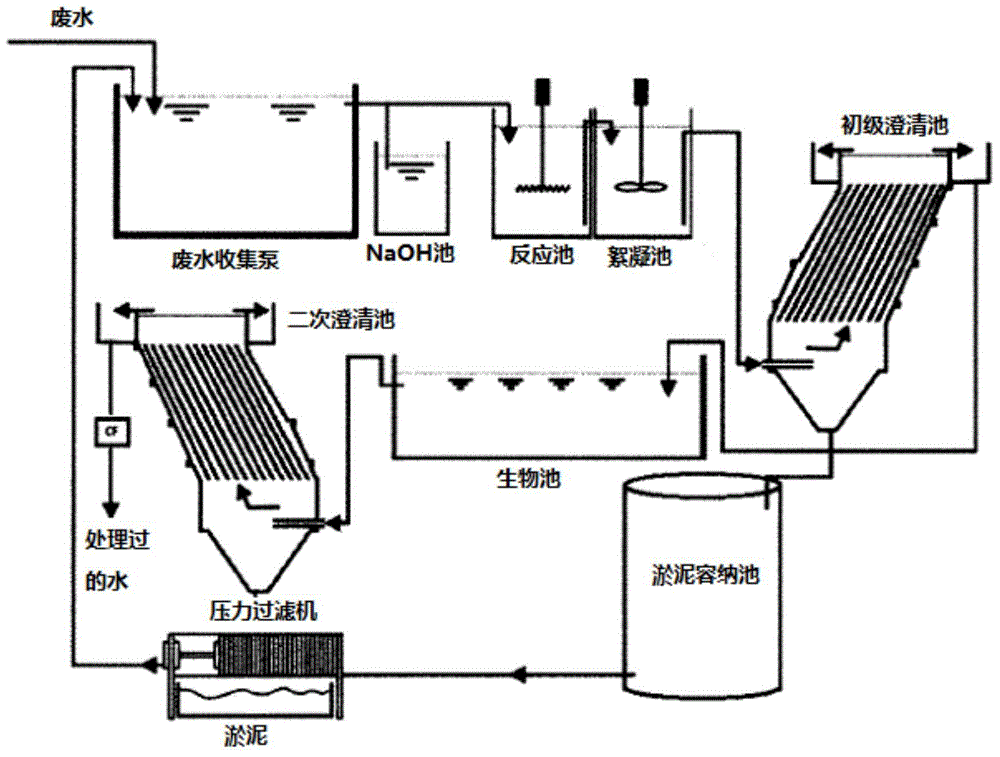

A composition for treating waste water

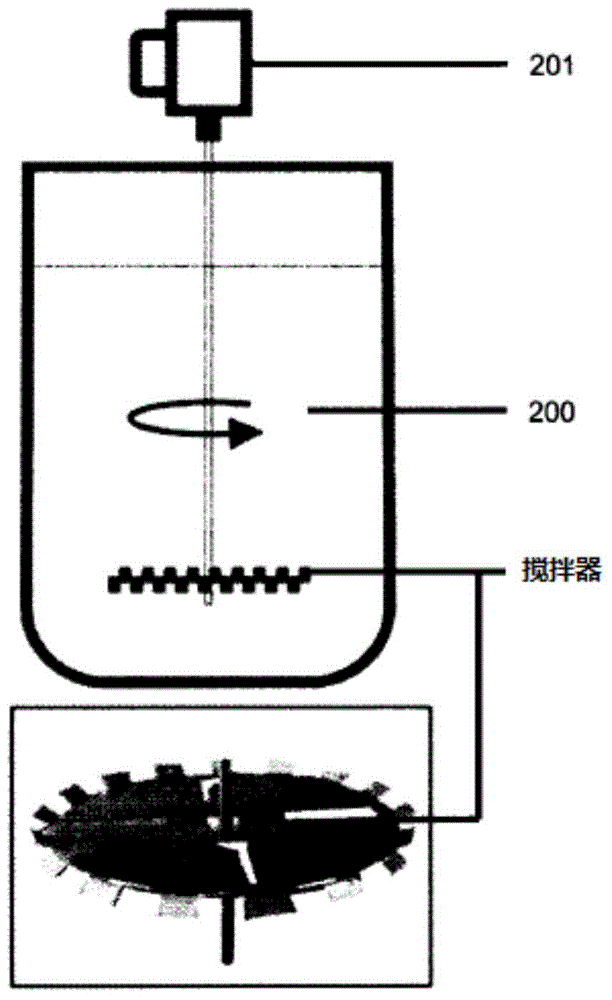

ActiveCN104903252AEasy to encapsulateEasy to separateSludge treatment by de-watering/drying/thickeningTreatment using aerobic processesAluminium sulphateMaterials science

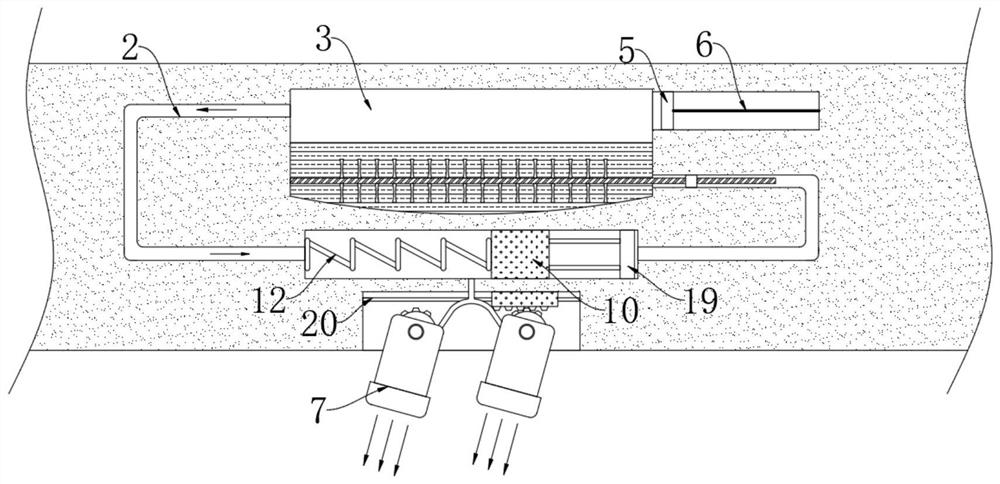

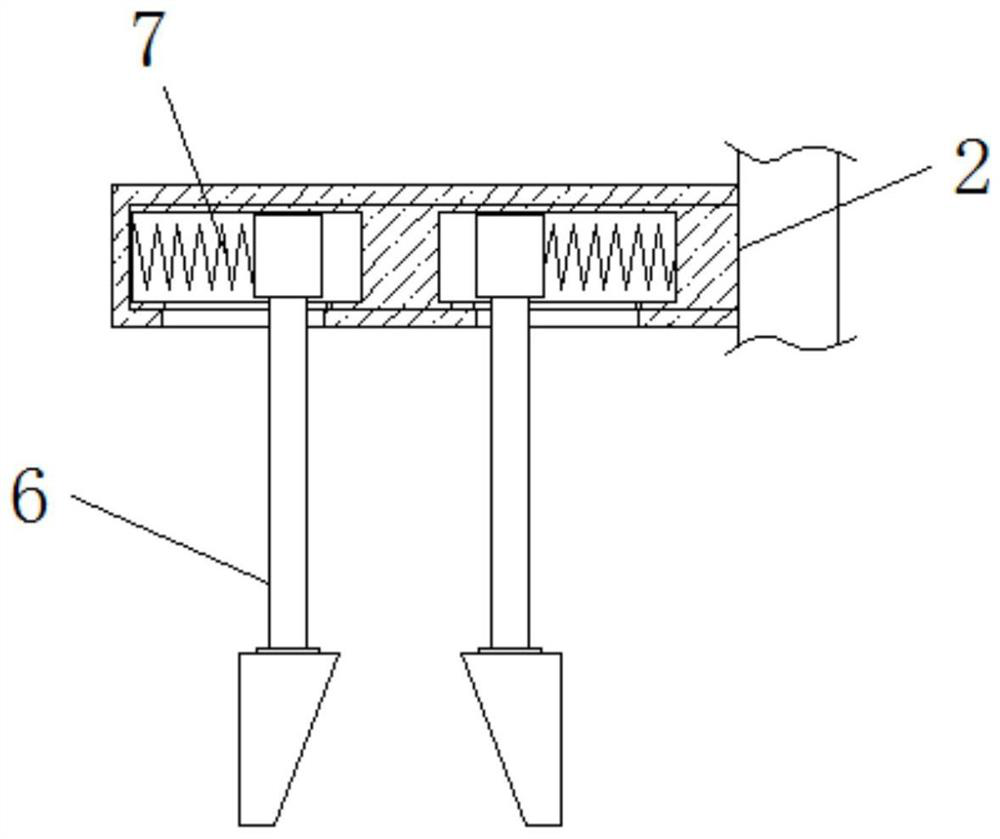

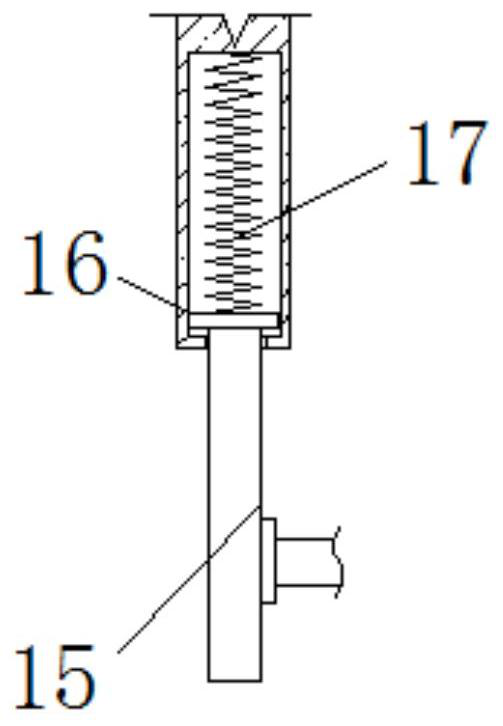

The present invention relates to a composition for treating waste water comprises, by weight percentage,: 43.7 - 46.2% bentonite; 24.1 - 25.9% aluminium sulphate (AI2(SO4)3), wherein the particle size of the AI2(SO4)3 is 18 - 74pm; 19.2 - 20.8% ceramic powder; 4.8 - 5.2% chitosan, wherein the particle size of the chitosan is 44μm; and 4.8 - 5.2% calcium carbonate (CaCO3). Further disclosed is a method of using the composition for treating waste water. In another further disclosure, there is introduced an apparatus for dispensing the composition into the waste water.

Owner:周朝晖

Method for preparing aluminium sulphate, sodium silicate, and derivative products from coal slack

This invention relates to a method for producing aluminum sulfate, sodium silicate and their derivatives from gangue. The method comprises: crushing the gangue by a jaw crusher, torrefying to remove organic substances, pulverizing by a ball mill till 80% powder are 200 mesh or finer, placing the gangue powder in a reaction kettle, adding 46-60% sulfuric acid and reacting to obtain aluminum sulfate solution, filtering, sending into a refinery tank, adding BaS to remove iron, adding silicon dioxide residue and liquid alkali into a reaction kettle, reacting at 120-160 deg.C under 0.7-0.8 MPa for 3-5 h, and filtering to obtain liquid sodium silicate. The method does not produce harmful substances, thus is not pollutive to the environment.

Owner:刘希林

Sorbent for processing transformer waste oil and method for producing the same

InactiveCN101406824ANon-flammable and explosiveImprove adsorption capacityTransformers/inductances coolingOther chemical processesHazardous substanceSorbent

The invention relates to an absorbent for treating and reclaiming waste liquid oil, in particular for treating and reclaiming waste transformer oil and a production method thereof. The absorbent is characterized in that the absorbent is prepared from the following raw materials according to the weight ratio: sulphuric acid solution, aluminium sulphate solution, sodium silicate solution and ammonia water are mixed, aged, roasted and dried, cleaned and re-roasted; and the finished product of the absorbent is obtained. The absorbent for treating the waste oil has the characteristics of innocuity, noninflammability, nonexplosiveness and so on, and higher capability of adsorbing substances in the waste oil such as acid, carbon microsphere, metal, water content, gel, and the like. The absorbent is sufficiently contacted with the waste oil so as to remove harmful substances in the oil. The absorbent not only has a simple production process, wide raw material sources, low production cost and no environmental pollution, but also has good effect of waste oil treatment, and high yield. The absorbent can save mass production cost for enterprises and energy for the country.

Owner:STATE GRID CORP OF CHINA

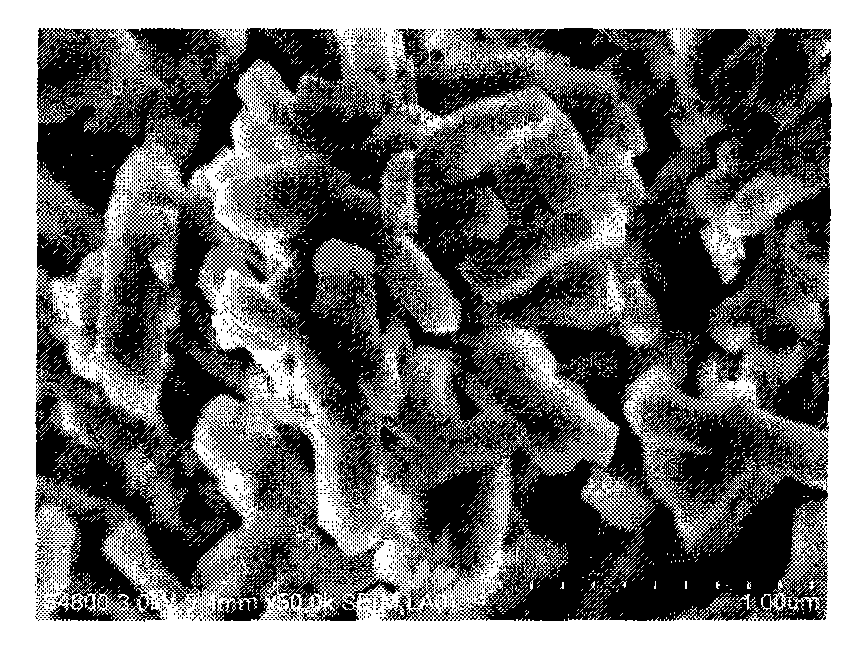

Synthesis of nano-ZSM-5 molecular sieve

InactiveCN101428818ALarge specific surface areaShort production processPentasil aluminosilicate zeoliteInorganic ChemicalIsopropylamine

The invention discloses a method for synthesizing nanometer ZSM-5 molecular sieve, which belongs to the technical field of inorganic chemosynthesis. The method comprises steps as follows: sodium metaaluminate or aluminium sulphate, silica sol or water glass, sodium hydroxide and isopropylamine are prepared into reaction mixer; the reaction mixer is subjected to hydrothermal crystallization; and the reaction mixer after the hydrothermal crystallization is filtered, washed, dried and baked conventionally to obtain nanometer ZSM-5 molecular sieve. The synthesized ZSM-5 molecular sieve has the advantages of higher specific surface, short production flow and low cost, and the section of the synthesized ZSM-5 molecular sieve crystal grain has an average diameter not larger than 100 nm, thereby facilitating industrialization production and application.

Owner:EAST CHINA NORMAL UNIVERSITY

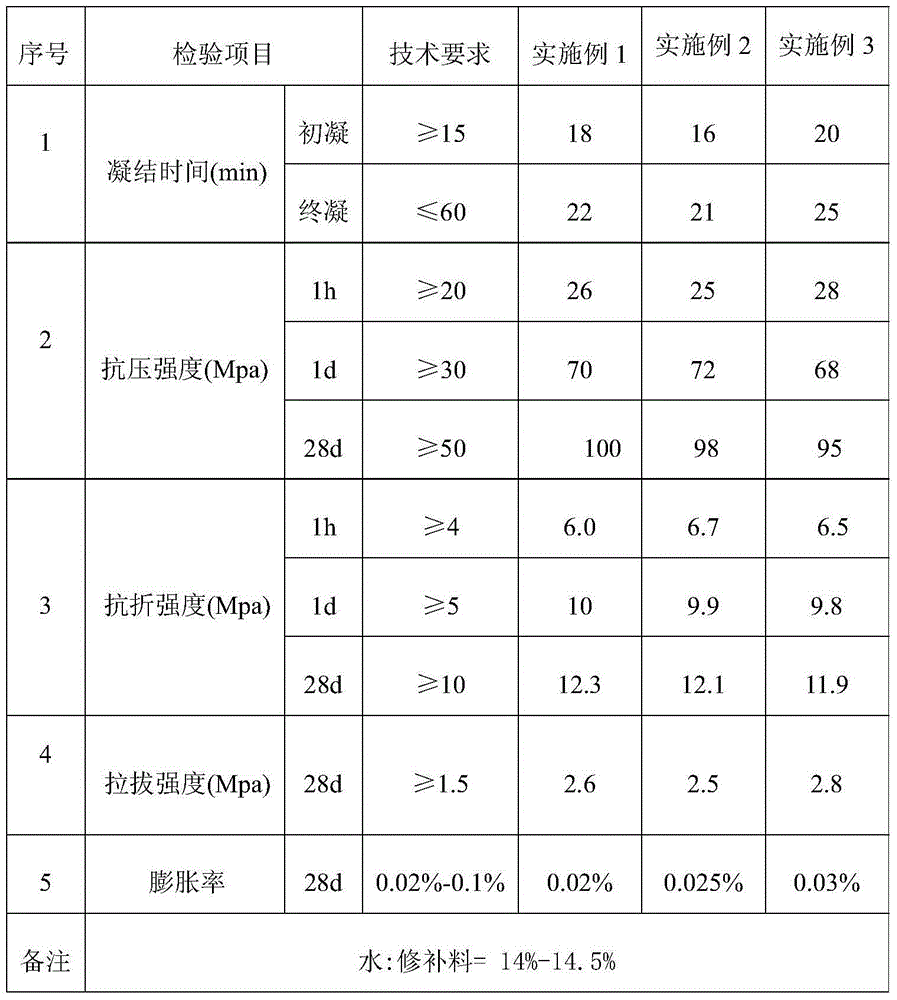

Pavement/bridge deck concrete fast mending material and application thereof

The invention relates to a pavement / bridge deck concrete fast mending material and application thereof. The mending material comprises the following raw materials by weight: 20 to 30 parts of sulphoaluminate cement, 8 to 10 parts of ordinary Portland cement 52.5, 5 to 10 parts of polymer powder, 0.5 to 1.5 parts of aluminium sulphate, 1 to 2 parts of water glass, 0.1 to 1 part of organic silicon, 1 to 2 parts of gypsum, 2 to 3 parts of slag, 0.1 to 0.5 part of silica micropowder, 0.5 to 1 part of an HPCA high-performance concrete expansive material, 3 to 5 parts of fly ash, 20 to 30 parts of washed-out and dried sand, 25 to 30 parts of corundum, 3 to 5 parts of composite fiber, 1 to 3 parts of a polycarboxylate superplasticizer, 0.1 to 0.5 part of boric acid, 0.1 to 0.3 part of sodium gluconate, and 0.2 to 1 part of lithium carbonate. The mending material is high in early strength, and has the advantages that traffic can be opened fast only 1 to 2 hours after mending is completed, so as to reduce traffic jams, and effectively reduce the generation of traffic accidents.

Owner:HENAN HUINENG ROAD & BRIDGE TECH CO LTD

Synthesis of nano-ZSM-5 molecular sieve

InactiveCN101428818BLarge specific surface areaShort production processPentasil aluminosilicate zeoliteInorganic ChemicalIsopropylamine

The invention discloses a method for synthesizing nanometer ZSM-5 molecular sieve, which belongs to the technical field of inorganic chemosynthesis. The method comprises steps as follows: sodium metaaluminate or aluminium sulphate, silica sol or water glass, sodium hydroxide and isopropylamine are prepared into reaction mixer; the reaction mixer is subjected to hydrothermal crystallization; and the reaction mixer after the hydrothermal crystallization is filtered, washed, dried and baked conventionally to obtain nanometer ZSM-5 molecular sieve. The synthesized ZSM-5 molecular sieve has the advantages of higher specific surface, short production flow and low cost, and the section of the synthesized ZSM-5 molecular sieve crystal grain has an average diameter not larger than 100 nm, thereby facilitating industrialization production and application.

Owner:EAST CHINA NORMAL UNIV

Novel wall lightweight heat-insulating material and method for preparing same

InactiveCN101139200AImprove insulation effectLow thermal conductivitySolid waste managementFiberOXALIC ACID DIHYDRATE

The present invention discloses a new type wall body light heat-preservation material, which is characterized in that: the present invention comprises the following raw materials according to the weight ratio: 10-15 percent of magnesia or magnesium hydrate, 3- 7 percent of magnesium chloride, 4-8 percent of perlite, 1-5 percent of alkali resisting fibre, 6-12 percent of powder coal ash or calcium carbonate and 0.3-1 percent of modifier, wherein, the modifier is made of the following components according to weight ratio: 6-10 percent of ferrous sulfate, 1-3 percent of oxalic acid, 1-3 percent of tertiary sodium phosphate, 0.5-2 percent of hexametaphosphate and 12-18 percent of aluminium sulphate. Compared with the original heat-preservation system, the material is with much better heat-preservation performance, much lower heat-conductivity coefficient, much lower density, and much lower water content and water absorption ability. The present invention is with much better performance in heat-preservation, heat-insulation as well as sound absorption and sound insulation and so on. The present is able to bear or endure acid, alkali and corrupted. The manufacturing cost is much lower and the construction process is much more convenient. The present is easy to be popularized.

Owner:成都市圣欧实业有限公司

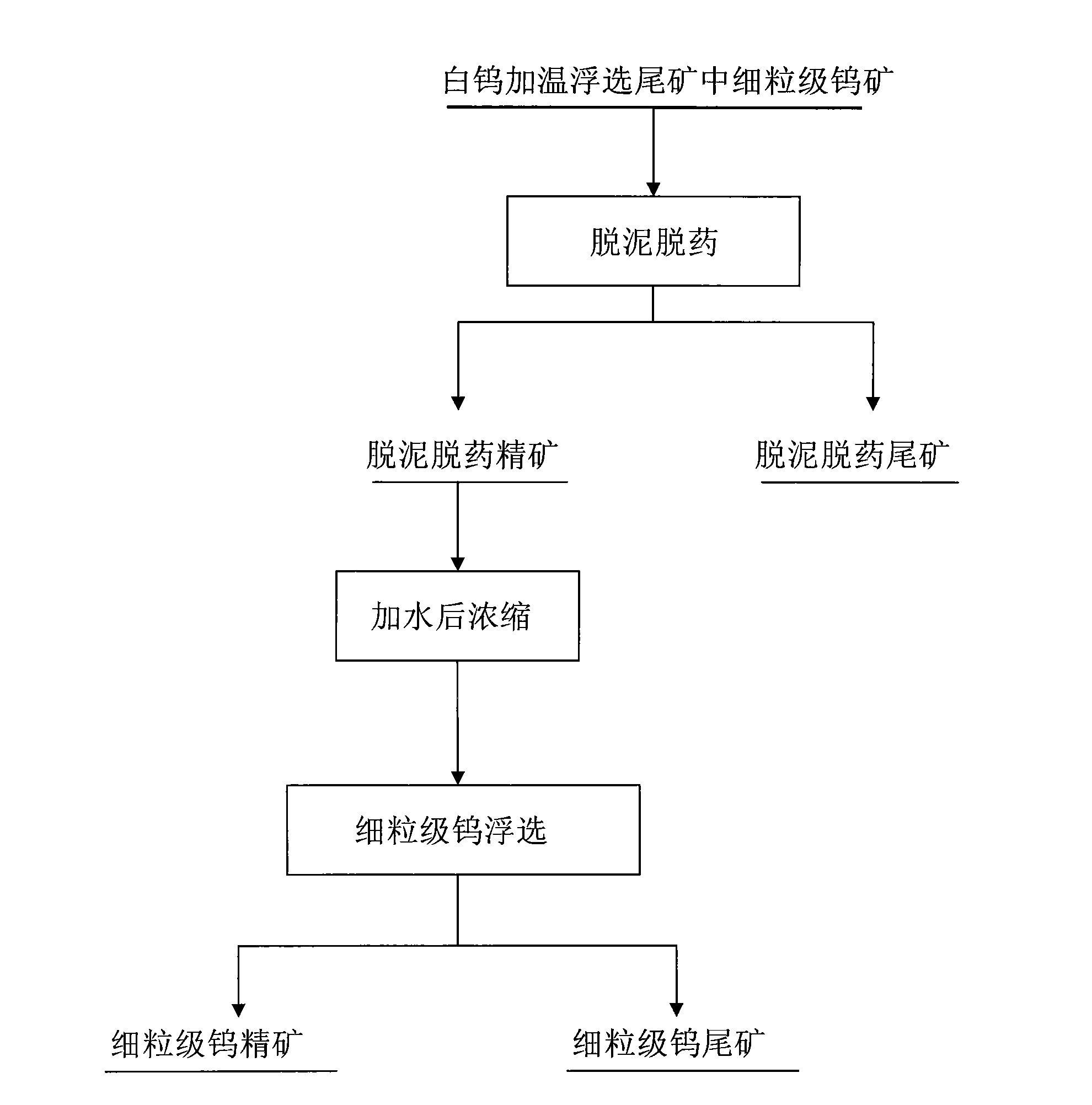

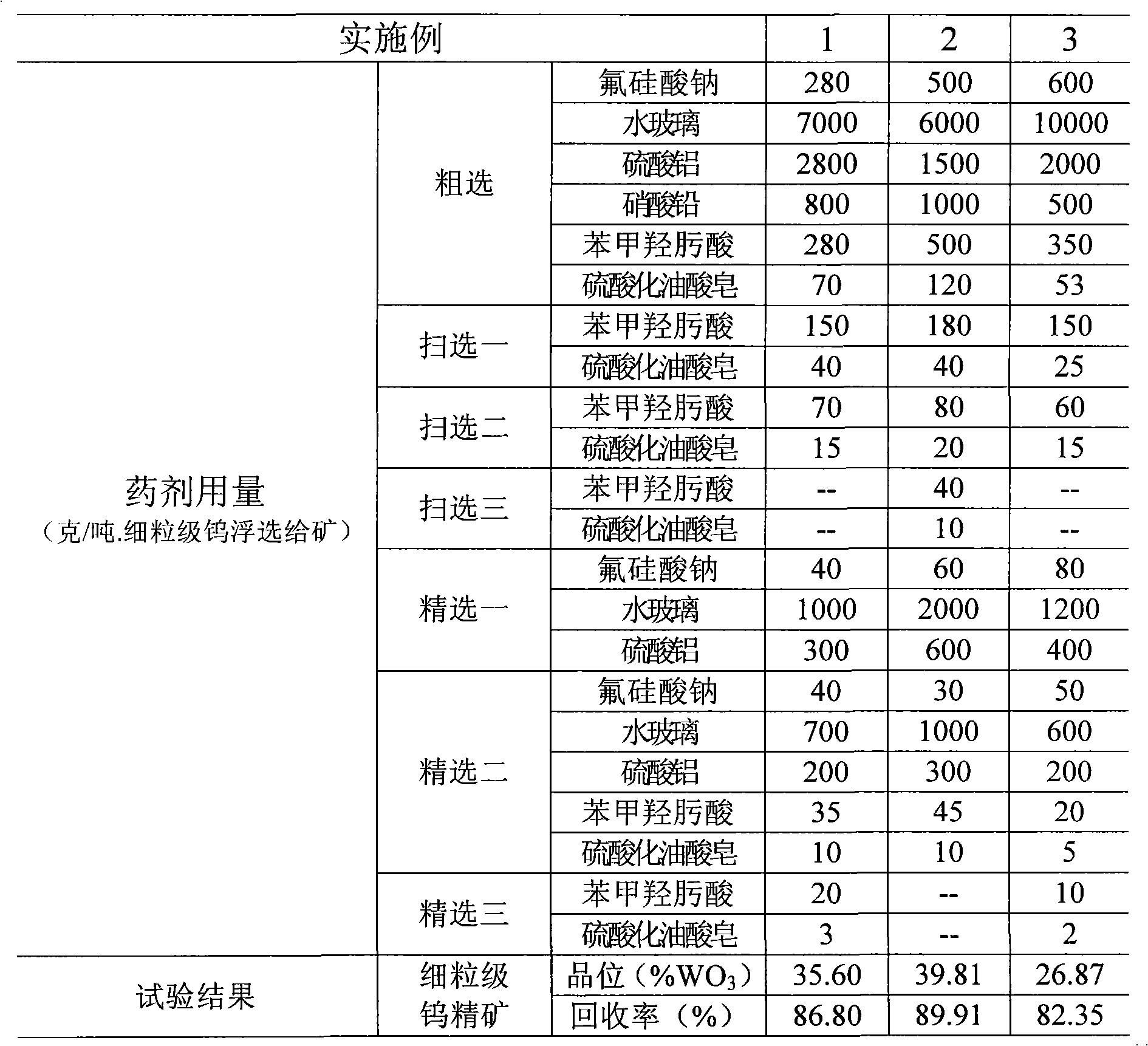

Benefication method for concentrating fine tungsten ore in tailings by warming scheelite

InactiveCN101579653ASimple recycling processThe beneficiation process is stableFlotationWet separationLead nitrateSoluble glass

The invention discloses a benefication method for concentrating fine tungsten ore in tailings by warming scheelite, which is characterized by comprising the following steps in turn: performing desliming and reagent removal; condensing concentrate after desliming and reagent removal, which is added with water, into 26 to 44 percent of pulp density, and controlling the pH of pulp at about 8.5; performing floatation on the fine tungsten ore; adding regulators of sodium fluosilicate, soluble glass, aluminium sulphate and lead nitrate; and adding collecting agents of benzohydroxamic acid and sulfated oleate soap, and performing rough concentration, concentration and scavenging to obtain the fine tungsten ore concentration and fine tungsten tailings. The method has simple recovery process flow, stable benefication process, high tungsten recovery rate, and low cost of reagents; the used benefication reagents do not pollute environment; and tailing water can meet the emission requirement. The method is suitable for the fine tungsten ore, of which the WO3 content is 0.95 to 5.10 percent, the ratio of peanut ore to the scheelite is between 1:9 to 9:1, and the occupancy rate of WO3 metal smaller than 30 microns is more than or equal to 60 percent, and which is subjected to concentration of the tailings by warming the scheelite and then reconcentration of the tailings by a shaker.

Owner:GUANGZHOU RES INST OF NON FERROUS METALS

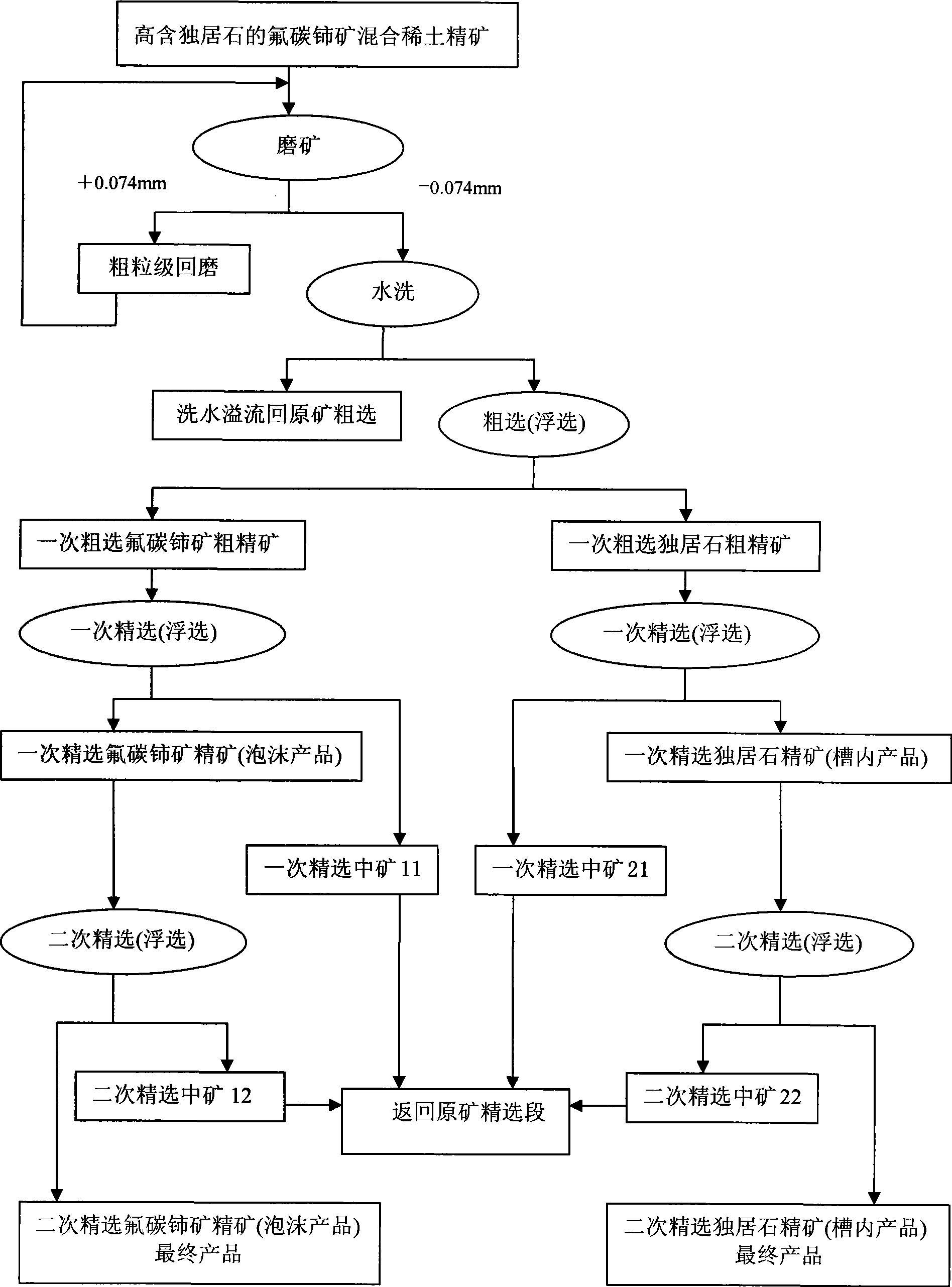

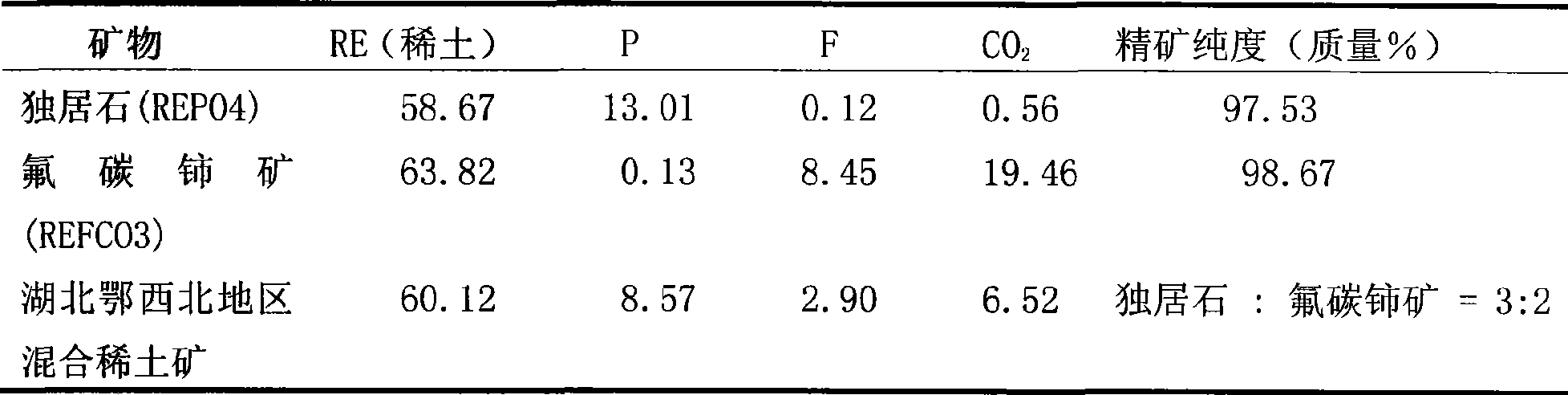

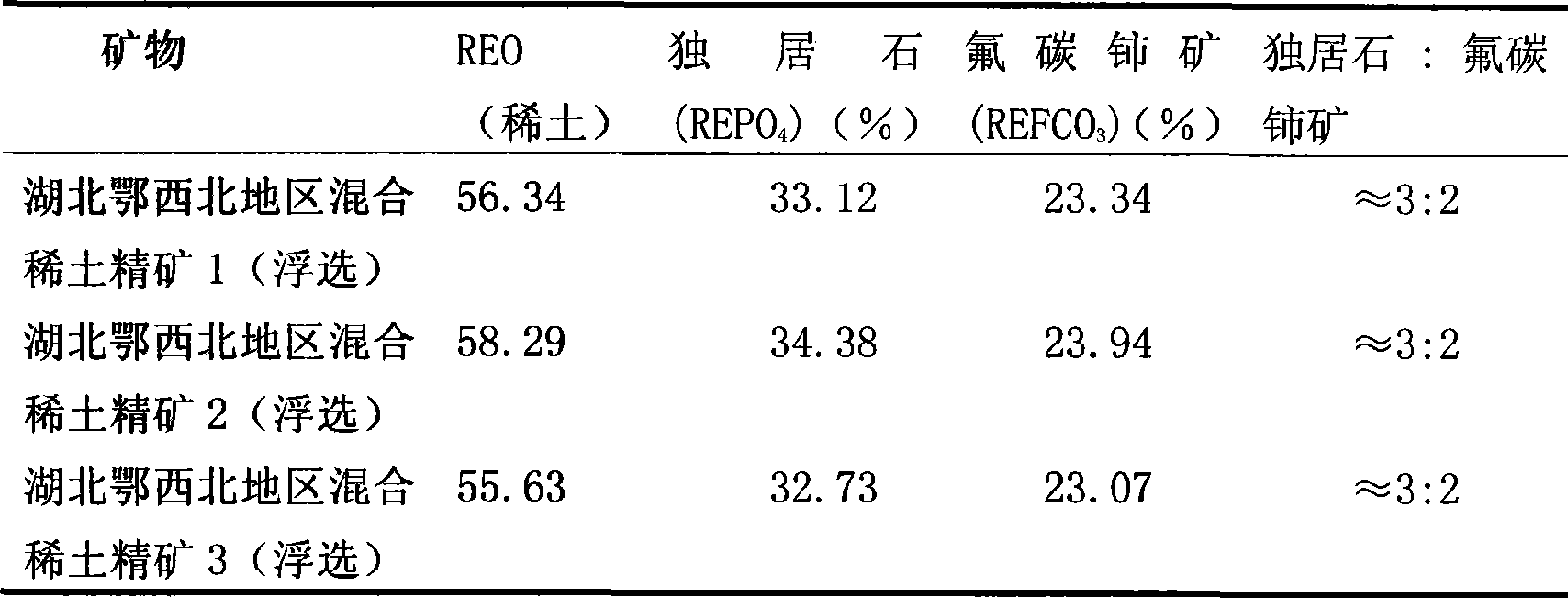

Floatation separation method for mengite and hamartite in misch metal ore concentrate

The invention relates to a method for the flotation separation of a collective rare earth ore, in particular to a method for the flotation separation of monazite and bastnaesite of a collective rare earth ore concentrate. The method is characterized by comprising the following steps: an aluminium sulphate inhibitor, a hydroximic acid collecting agent and a frothing agent are used as floating agents, and bastnaesite collective rare earth ore concentrate with the high content of monazite is processed at a temperature ranging from 18 to 30 DEG C; first-stage roughing parisite rough concentrate and first-stage roughing monazite rough concentrate are obtained by first-stage separation and rougher flotation; the first-stage roughing parisite rough concentrate is processed by the operation of second-stage close sizing to obtain second-stage close sizing bastnaesite concentrate; the first-stage roughing monazite rough concentrate is also processed by the operations of size mixing and second-stage close sizing to obtain second-stage close sizing parisite concentrate; and the first-stage roughing monazite rough concentrate is processed by the operations of size mixing and second-stage close sizing to obtain second-stage close sizing monazite concentrate. High grade single monazite concentrate and single bastnaesite concentrate can be produced by the separation roughing and the flotation operation of the respective close sizing of the first-stage roughing parisite rough concentrate and the first-stage roughing monazite rough concentrate. The method has the advantages of simple process and low production cost, and can produce the high grade single monazite and the single bastnaesite.

Owner:武汉工大科技园发展有限公司

Electrolyte of lead-acid battery and preparation method thereof

ActiveCN101685884AGood dispersionImprove stabilityFinal product manufactureLead-acid accumulators constructionDispersityActive agent

The invention relates to an electrolyte of lead-acid battery and preparation method thereof. The electrolyte comprises the following raw materials by parts by weight: 20-40 parts of deionized water, 62-68 parts of dilute sulphuric acid, 1.5-2.5 parts of nano aerosol and 2-2.5 parts of electrolyte active agent; wherein the electrolyte active agent is formed by analytically pure potassium sulphate,zinc sulphate, ammonium sulphate, magnesium sulphate, aluminium sulphate, sodium sulphate, cobalt sulphate, aluminium phosphate and lithium iodide in certain ratio; and multiple micro elements are added into the electrolyte, so that the nano silicon oxide particles have favourable dispersity, the prepared electrolyte has no sedimentation, flocculation or layering for a long time, and meantime service life and environmental performance of battery can be effectively improved.

Owner:深圳市夺标环保技术有限公司

Metal alloy electroplating liquid

The invention discloses a metal alloy electroplating liquid. The metal alloy electroplating liquid is composed of the following raw material components in parts: 30-40 parts of copper sulphate, 30-50 parts of aluminium sulphate, 50-60 parts of copper chloride, 50-60 parts of nickel hydroxide, 20-30 parts of cobalt sulphate, 30-40 parts of cobalt chloride, 10-15 parts of iron sulphate, 30-35 parts of ferrous chloride, 50-58 parts of cuprous oxide, 16-18 parts of hydrochloric acid, 15-20 parts of acetic acid, 3-4 parts of Tween-60, 4-5 parts of sodium hydroxyethyl sulfonate, 5-6 parts of allyl polyethenoxy ether, 6-7 parts of polyethylene glycol, 3-4 parts of ammonium lauryl sulphate, 5-8 parts of sodium lauryl sulphate and 200-300 parts of deionized water. The metal alloy electroplating liquid is good in stability, the surface of a plated film is high in brightness and smoothness, the flexibility of a plated layer is obviously improved, and the defects of burrs, roughness and the like on the outer surface of a plated part are basically eliminated.

Owner:梁胜光

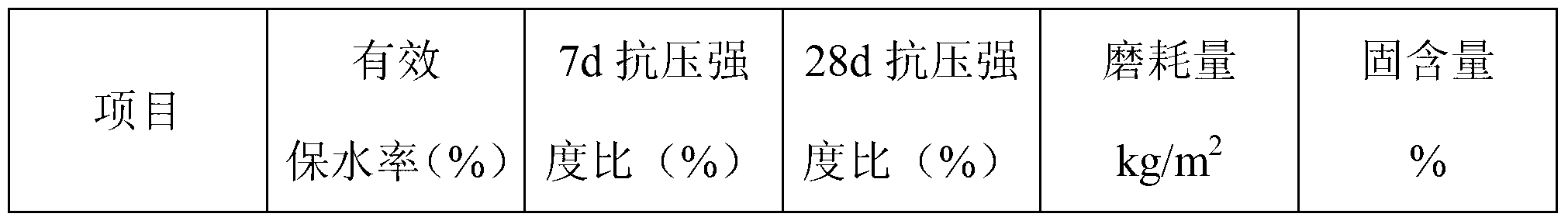

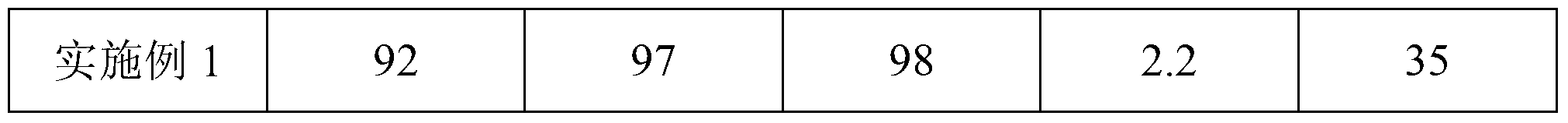

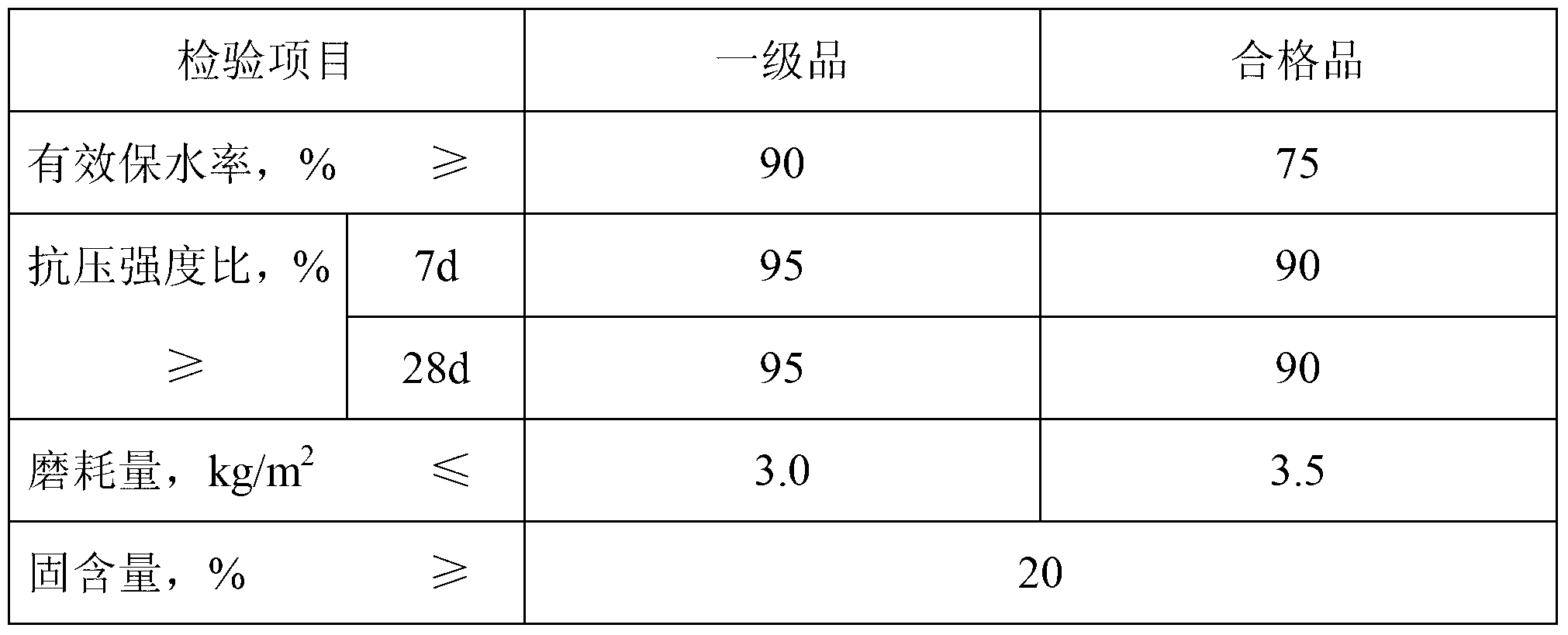

Composite-type cement concrete curing agent and preparation method thereof

The invention relates to a cement concrete curing technology, and discloses a composite-type cement concrete curing agent and a preparation method thereof. The composite-type cement concrete curing agent is characterized by comprising the following components in percentage by mass: 35-45% of water-borne epoxy resin emulsion, 50-60% of an aluminium sulphate-modified sodium silicate solution, 3-6% of a film-forming auxiliary, 1-2.5% of a coupling agent, 0.5-3% of a defoaming agent, and 1-2.5% of a levelling agent. The preparation method comprises the step of effectively compounding the water-borne epoxy resin emulsion with the aluminium sulphate-modified sodium silicate solution to form an organic / inorganic double-component system, so that the prepared curing agent has the excellent film-forming property of the organic component, and the high permeability and chemical activity of the inorganic component, and is sprayed on the surface of cement concrete to form a compact curing film, thus greatly reducing the evaporation of water on the surface of cement concrete, and achieving the purpose of efficient water retention.

Owner:CHANGAN UNIV

Red schorl type titanium dioxide coating method and preparation of used reagent

InactiveCN101463195AHigh whitenessHigh glossPigment treatment with non-polymer organic compoundsAluminateWeather resistance

The invention relates to a rutile type titanium dioxide coating method and a preparation method of reagent used thereby. A layer of ZrO2 is firstly coated on a TiO2 particle, thus improving the white content, lustrousness and weather resistance of the product; four layers of pellumina are coated in batches to further improve the performances such as weather resistance, dispersivity (dry powder fluidness), hiding power, lustrousness and the like of the product; finally, the main function of organic coating is to improve the dry powder fluidness of the product and the dispersivity in the application media; meanwhile, the lustrousness of the product is improved, and the aggregation resistant performance of the product in storage and transportation can be enhanced. Sodium aluminate or aluminium sulphate is added at the different stages of the coating process, so that the pH value the sizing agent can be regulated by utilizing the different pH values of the two aluminates, and the complicated operation that the pH value the sizing agent is regulated after coating agent is added every time is omitted. The titanium dioxide which coated and finally obtained has the advantages of high lustrousness, dispersivity, dry powder fluidness and weather resistance.

Owner:HENGYANG TIANYOU CHEM

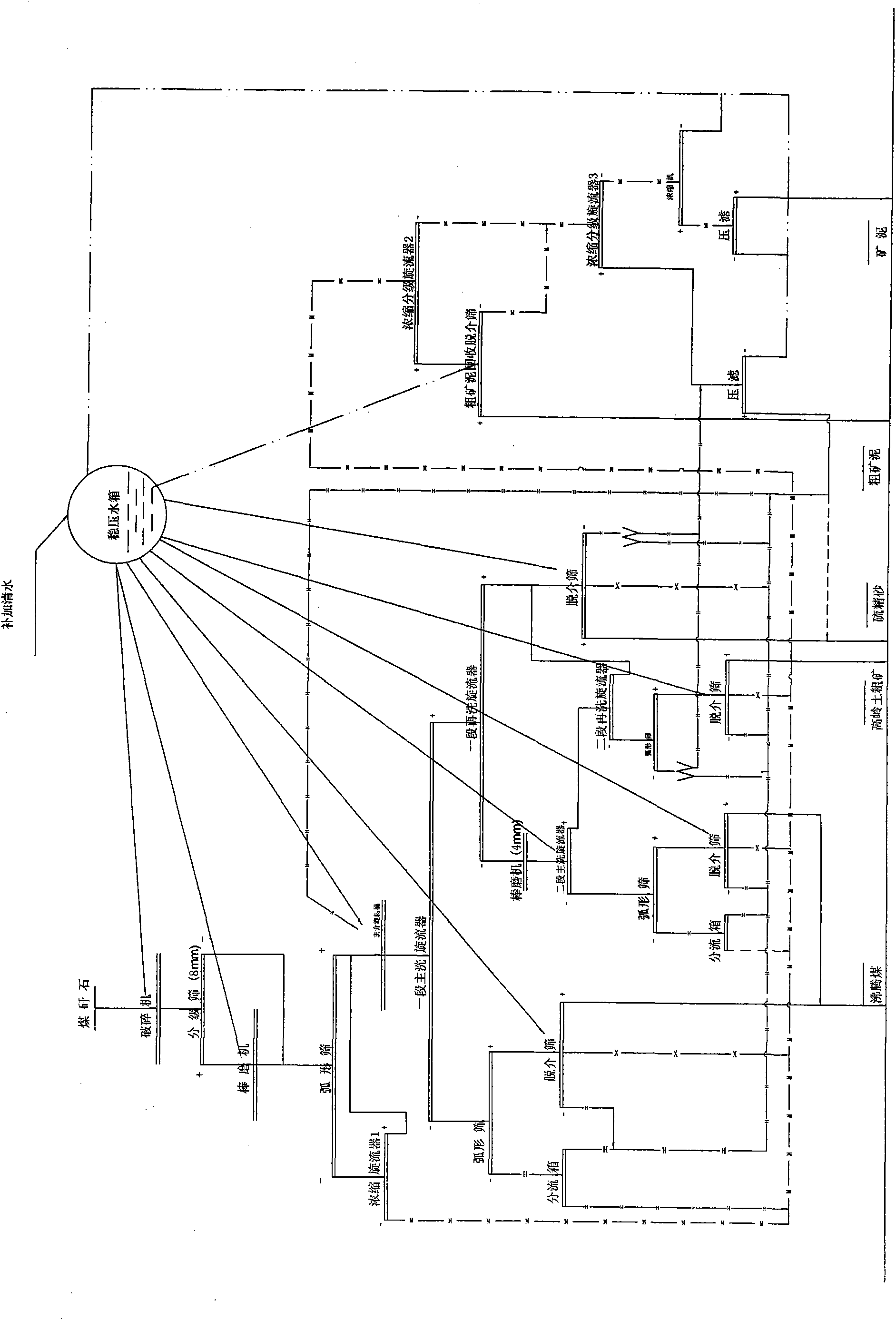

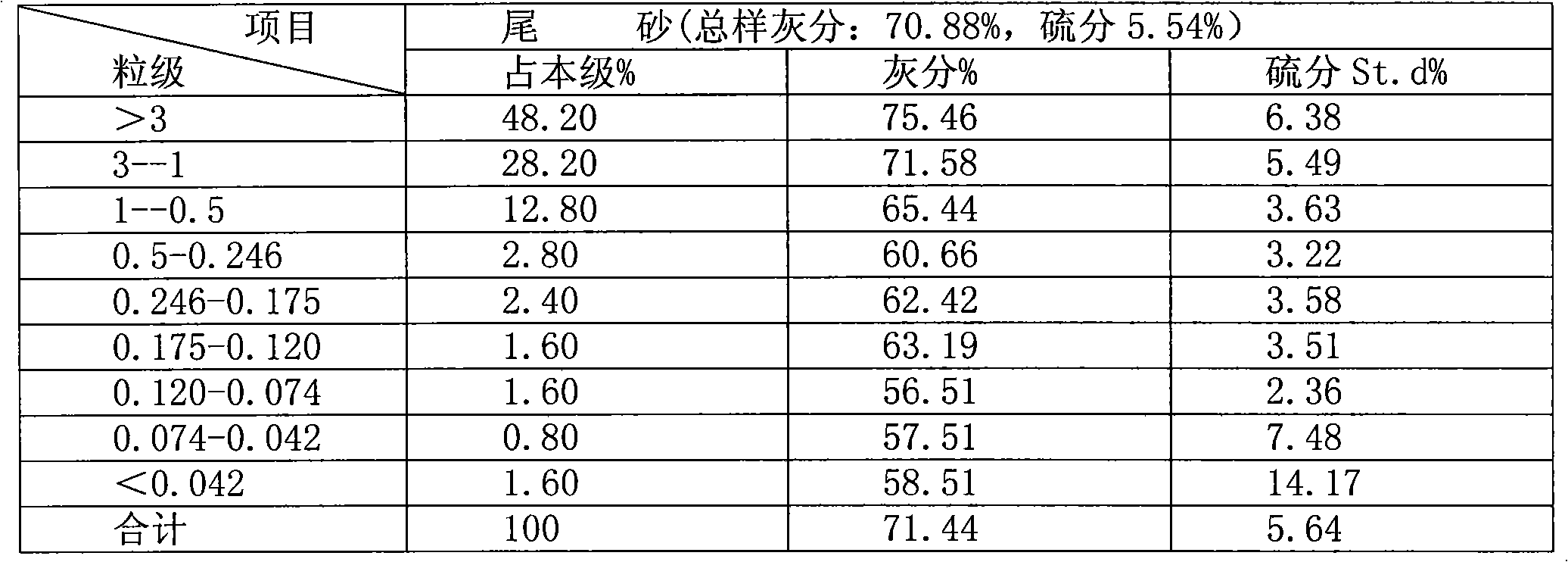

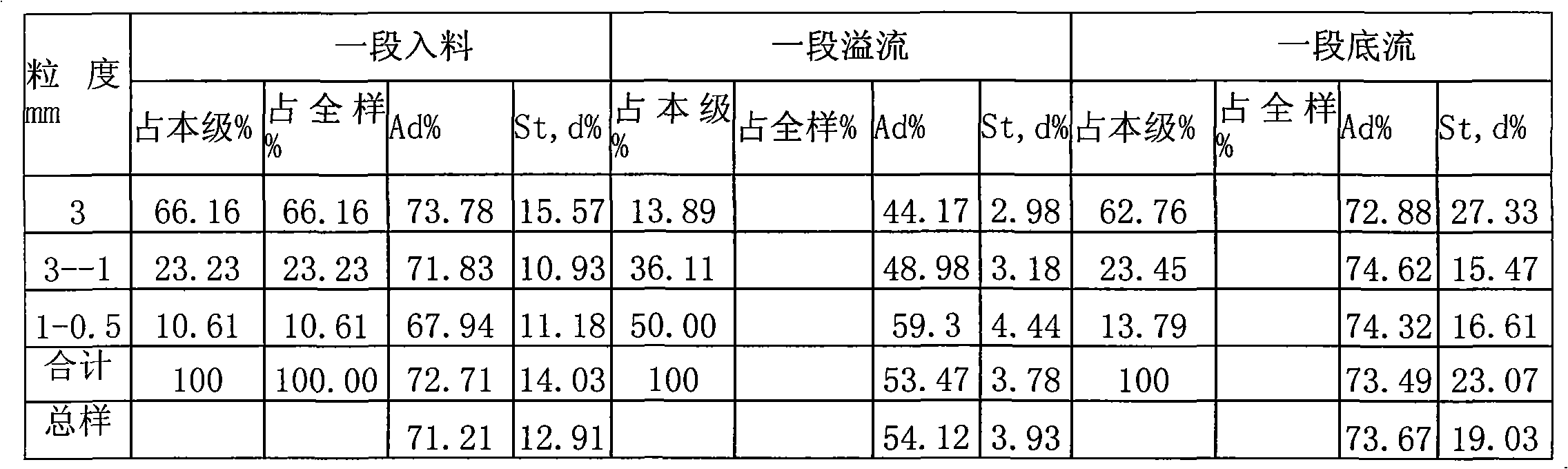

Coal gangue sorting process

InactiveCN101869877ASmall footprintEasy to handleReversed direction vortexPulverized fuel ashChloride

The invention discloses a coal gangue sorting process. The coal gangue is separated through the steps including the steps of making the coal gangue enter a sulfur recovery sorting system after crushing and graded milling and the like. The invention is characterized in that the sulfur recovery sorting system adopts a cyclone device for separating the coal gangue in the sorting step, and the conical angle of the cyclone device is between 70 and 90 DEG C. The sulfur ore concentrate products produced by the invention are between 4 and 0 mm, the sulfur content is more than or equal to 28.40 percent, the sulfur ore concentrate products are mainly used for chemical plants, the produced boiling ash coal content can be lower than 70 percent, the sulfur content is lower than 4.0 percent, the products are mainly used for power plants (to be merged with electric coal and coal discharged from a dense medium system), and the system full sulfur recovery rate is more than or equal to 70 percent. The produced kaolin coarse ore ash content is more than 80 percent, and products can be used as raw materials for producing aluminium oxide, aluminium sulphate or basic aluminum chloride. The percentage is metered by mass percent.

Owner:重庆南桐矿业有限责任公司选煤厂

Method for preparing nanometer cobalt blue dye

InactiveCN1831047ASmall particle sizeSimple production processPigmenting treatmentTitanium tetrachlorideSodium hydroxide

This invention discloses a preparation method of nm cobalt blue, and it belongs to synthetic technique of nm spinel style colorant. This method includes following procedures cobaltous sulfate and aluminium sulphate, chromic chloride and titanium tetrachloride are mixed with water and agitated to solve, there mol ratio is that 1:(0.5-2): (0-3): (0-3), then they are heated and sodium hydrate solution is added to adjust pH value to 8-10. They are agitated, aging and water flushed, the precipitate stuff is hydrothermal cultivated at 160-260 degrees centigrade, then the hydrothermal cultivated stuff is filtrated, dried and crashed, finally it is solid phase high temperature crystallized at 900-1200 deg.C to get nm cobalt blue product. The advantage of this invention is that two step ways synthetic technique are used, so the particles can reach nm grade after high temperature crystallization, the particle diameter of cobalt blue particles made is small, the average particle diameter is 30-80nm, and its production technique is simple, energy consumption is relatively low.

Owner:TIANJIN UNIV

Decolorizing coagulant as well as preparation method and uses thereof

InactiveCN101254970AImprove decolorizationImprove the ability to remove CODcrSedimentation separationWaste water treatment from textile industryAluminium chlorideProcess equipment

The invention relates to an industrial waste treatment technology, in particular to a method for preparing an efficient decolorizing flocculant. Under the effect of a catalyzer, preliminary condensation polymerization is performed among lignin, dicyandiamide and a part of formaldehyde under a certain condition, a part of formaldehyde is mixed after the heat release of the reaction is stable, the temperature is controlled between 65 to 95 DEG C, and a product can be obtained after heat preservation is performed for 2 to 6 h. The catalyzer of the invention can be one or more of ammonium chloride, aluminium chloride, aluminium sulphate and alum. The process equipment of the invention is simple, the operation is secure and the cost is low. The product can be applied to the advanced treatment of the wastewater in dye, printing and dyeing, pulp and paper engineering industries, and the decolorization ratio can reach more than 95 percent.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

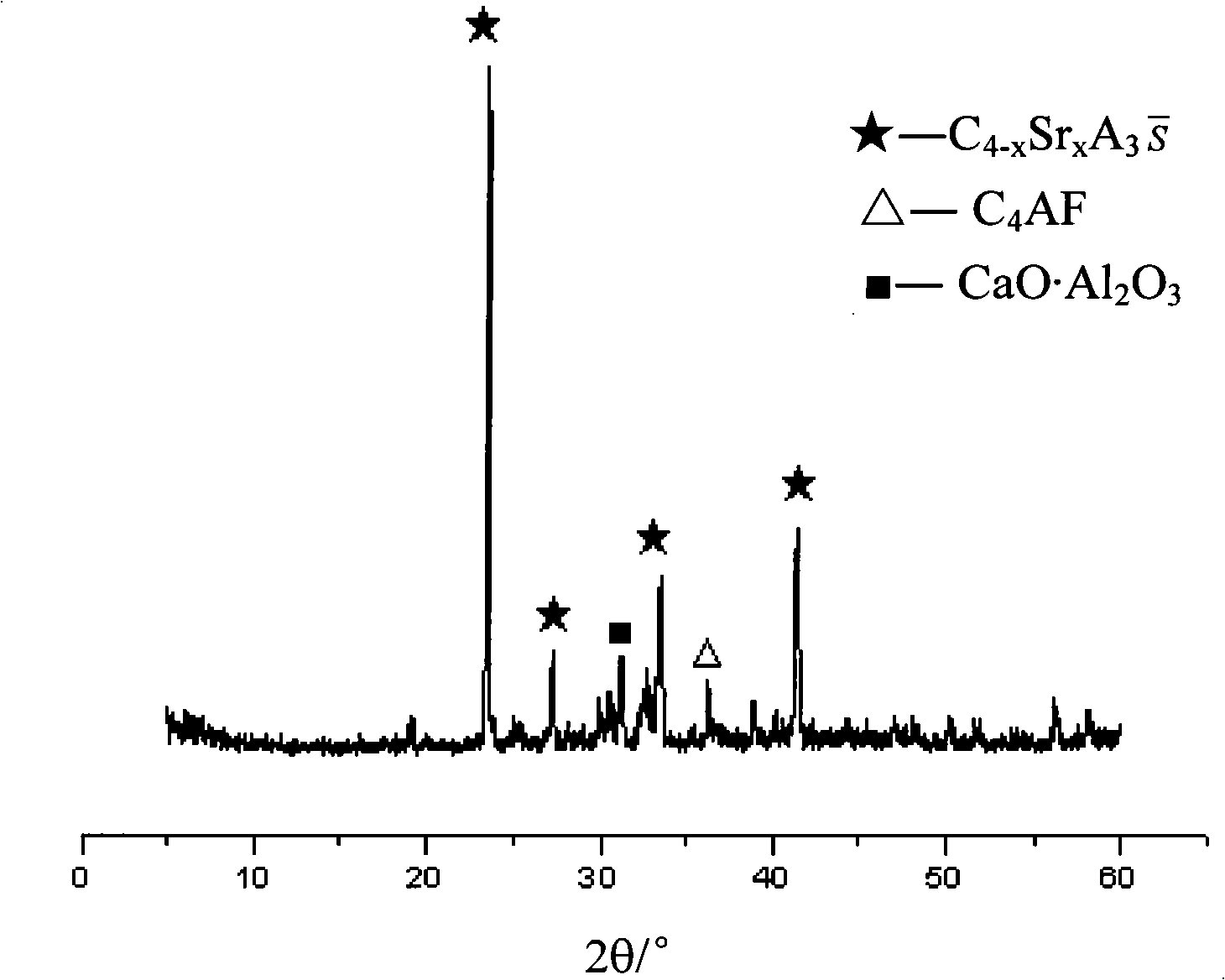

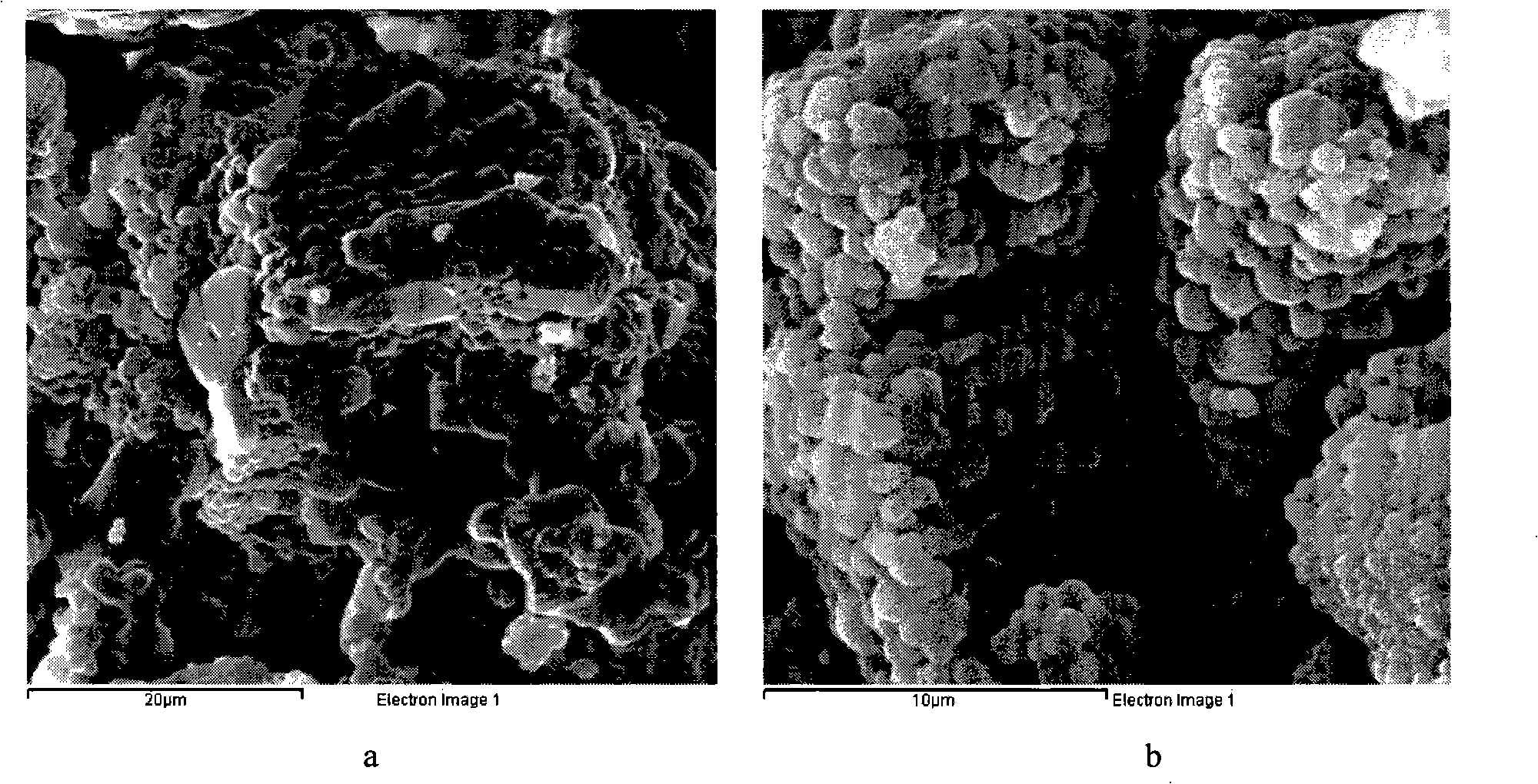

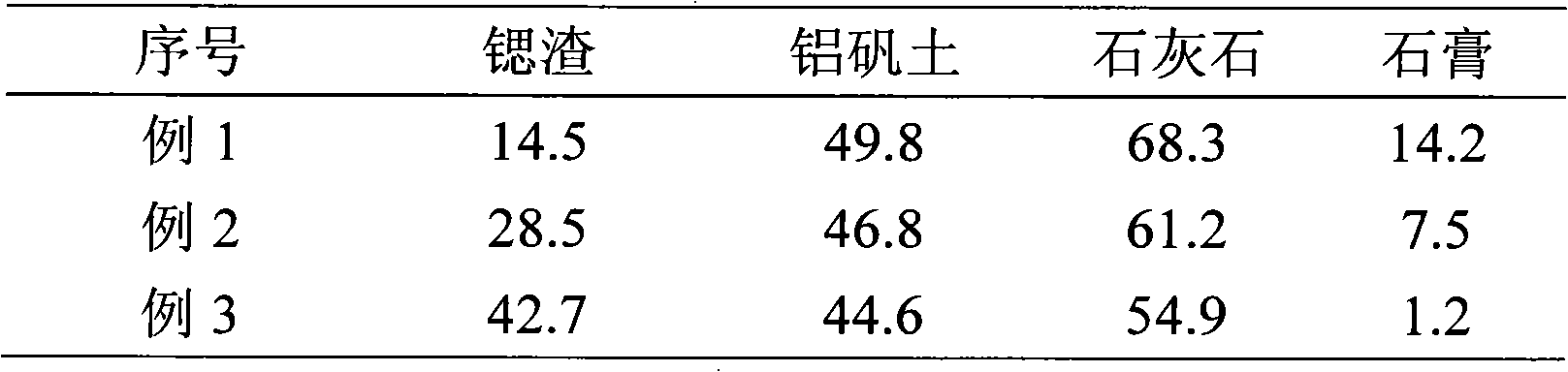

Strontium calcium aluminium sulphate cement

InactiveCN101343152AImprove corrosion resistanceImprove radiation resistanceNatural mineralToxic industrial waste

The invention relates to a new variety of cement taking strontium calcium sulphoaluminate and dicalcium silicate as main mineral phases, which belongs to the cement technique field. The invention discloses a strontium calcium sulphoaluminate cement, a cement clinker is a mineral phase system composed of strontium calcium sulphoaluminate mineral, dicalcium silicate and calcium ferroalumnate, and all minerals include, in weight percentage: 40 to 80 percent of strontium calcium sulphoaluminate mineral, 15 to 40 percent of dicalcium silicate, and 2 to 25 percent of calcium ferroalumnate. The cement has advantages of low sintering temperature, fast coagulation time, high initial and later strength and good corrosion resistance. The cement uses industrial strontium-containing waste residues when producing the cement clinker, reduces the environmental pollution by strontium residues, finds an effective way for treating industrial waste residues, reduces the usage of natural mineral resources, and has rather high social benefit and economic benefit.

Owner:UNIV OF JINAN

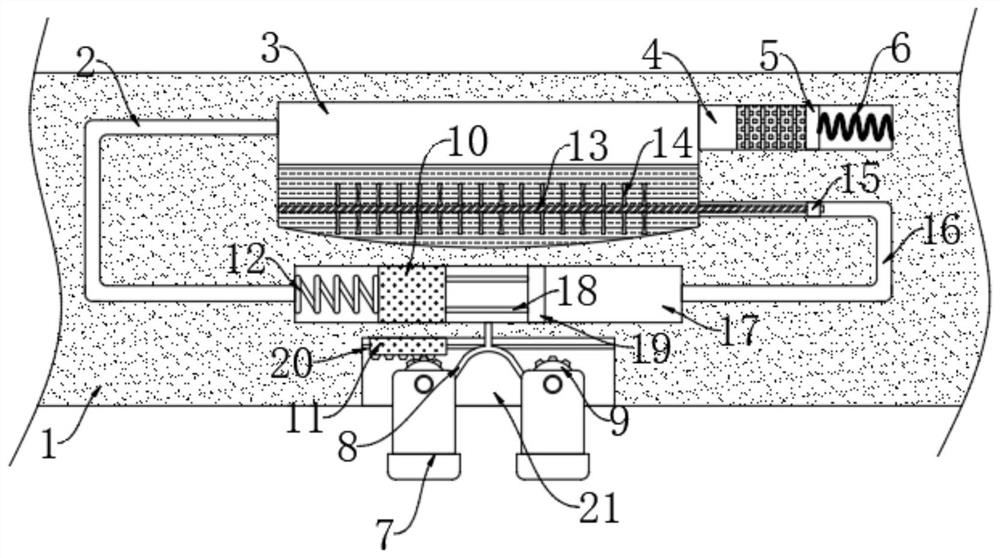

Efficient fireproof system for office building office

ActiveCN111888700AImprove fire extinguishing effectAvoid casualtiesFire rescueMetal filamentFire - disasters

The invention discloses an efficient fireproof system for an office building office. The efficient fireproof system comprises a top plate, a carbon dioxide generation mechanism and a spraying mechanism, the top plate is sequentially provided with a reaction chamber, a transverse cavity and a mounting groove from top to bottom, and a containing groove communicating with the reaction chamber is formed in one side of the reaction chamber; the carbon dioxide generation mechanism comprises an aluminum sulfate solution arranged at the bottom in the reaction chamber, a push plate used for sliding left and right is arranged in the containing groove, the right side of the push plate is connected with the inner wall of one side of the containing groove through a memory metal wire, and sodium bicarbonate powder is placed in the containing groove and located in the left side space of the push plate; and the spraying mechanism comprises a magnetic piston and a piston block which are arranged in thetransverse cavity, the magnetic piston is fixedly connected with the piston block through two connecting rods, and the magnetic piston is located on the left side of the piston block. The fire prevention system does not need to be manually controlled, and can extinguish fire in time when a fire disaster occurs, so that the fire disaster is killed in a cradle, and casualties and capital loss caused by the fire disaster are avoided.

Owner:AMP TECHNOLOGIES

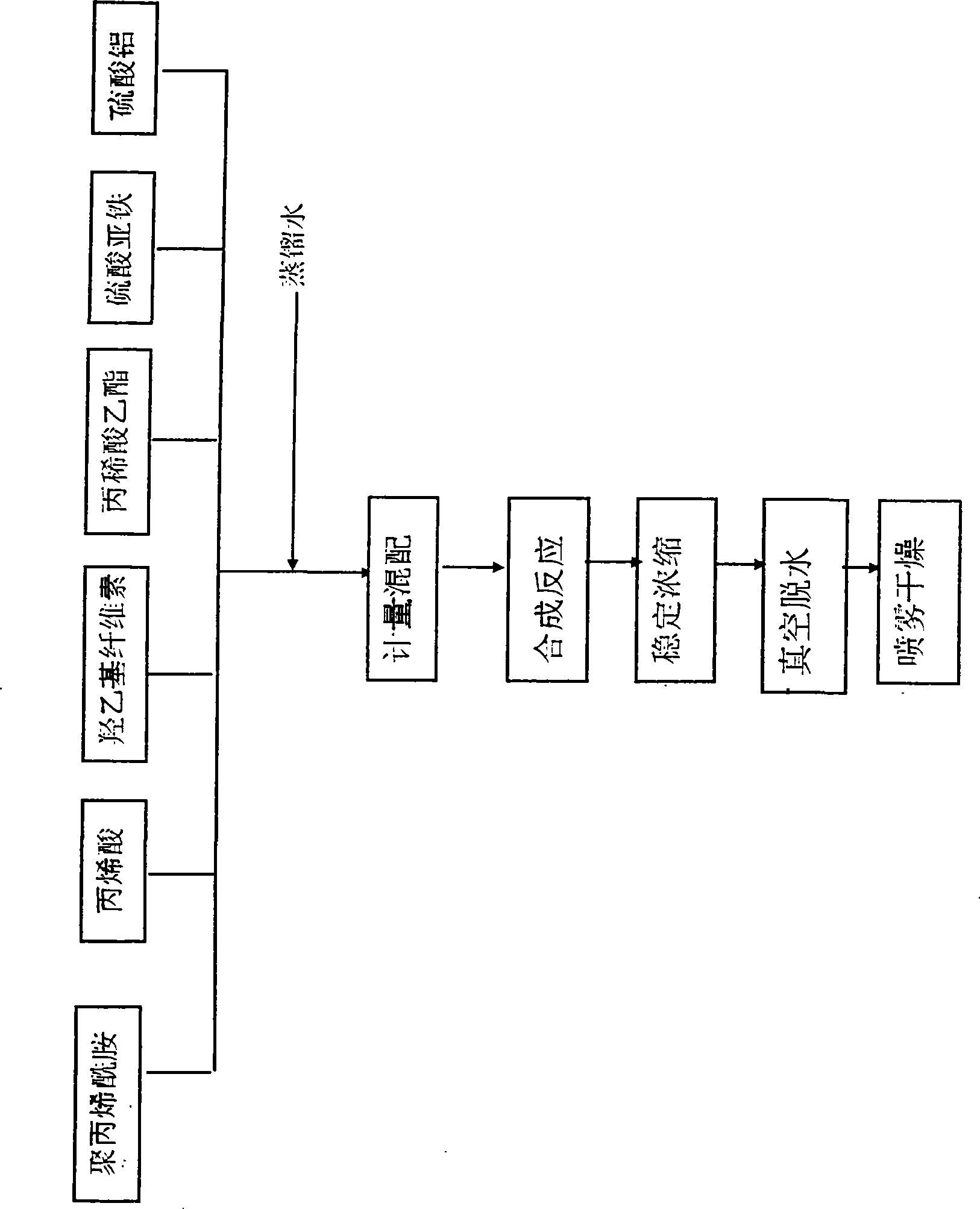

Compound high-efficiency flocculating agent

InactiveCN101519237AAdsorptiveWith flocculation abilityWater/sewage treatment by flocculation/precipitationWater qualityHydrolysis

The invention relates to a compound high-efficiency flocculating agent used for seriously polluted water. The flocculating agent takes water soluble polymer polyacrylamide as main materials, takes water soluble polymer acrylic acid, hydroxyethyl cellulose and ethyl acrylate as active coagulant aid, takes ferrous sulphate and aluminium sulphate of inorganic salts as catalyzing flocculating agent, uses the configured universal chemical industrial production equipment and adopts the technique processing technologies of metering blending, synthetic reaction, stabile concentration, vacuum hydrolysis and spray drying and the like; and a compound high-efficiency flocculating agent with high polymerization degree, high relative molecular quality, low use amount and simple use method is developed. Due to the unique molecular structure and chemical function, the compound high-efficiency flocculating agent has stronger absorption and flocculating effect to fine particles in seriously polluted water, can absorb the fine particles containing various inorganic substances and difficult degradable organic substances in the seriously polluted water and flocculate the fine particles into floccules, and can realize the purpose of improving and purifying the water quality after the flocculating groups are removed. The flocculating agent is especially applicable to the industrial wastewater treatment of seriously polluted enterprises of paper-making, printing and dyeing, leather-making, electroplating, food and chemical engineering and the like.

Owner:SIPING HAITE ENVIRONMENT PROTECTION EQUIP

Oil-water well chemical resin type sand consolidating agent and sand prevention technology

The invention relates to an oil-water well chemical resin type sand consolidating agent and a sand prevention technology. The technology formula includes: 5 percent to 10 percent of organic silicon resin, 15 percent to 20 percent of dispersant (furfural), 10 percent to 15 percent of mutual solvent (acetaldehyde), 10 percent to 15 percent of curing agent (metaphosphoric acid), 15 percent to 20 percent of emulsion splitter, 15 percent to 20 percent of aniline modified phenol formaldehyde resin, 25 percent to 30 percent of hydrochloric acid, 5 percent to 10 percent of trolamine, 5 percent to 10 percent of aluminium sulphate, and 5 percent to 10 percent of OP10. The technology includes: washing sand to the required position of design, putting sand in an operating tool string according to design requirements, pre-processing the oil layer, then selecting a positive-substitute resin type sand consolidating agent for squeezing the resin type sand consolidating agent and displacing liquid, lifting the sand out from the operating tool string after pressure naturally diffuses, and finally coming to well completion after 72 hours of coagulation.

Owner:覃忠校

Modified polyurethane/epoxy resin composite grouting cement mortar and preparation method thereof

The invention relates to modified polyurethane / epoxy resin composite grouting cement mortar and a preparation method thereof, belonging to the field of building materials. The mortar is prepared from the following components in parts by weight: 80 to 100 parts of cement, 120 to 180 parts of fine sand of 50 to 200 meshes, 20 to 50 parts of water, 4 to 7 parts of sodium silicate, 2 to 3 parts of aluminum sulfate, 1 to 2 parts of calcium chloride, 1 to 2 parts of sodium hydroxide, 10 to 15 parts of polyurethane modified epoxy resin toughening emulsion containing modified wood fiber, 1.5 to 6 parts of early strength agent and 0.9 to 2.4 parts of water reducing agent. On the basis of a modified polyurethane / epoxy resin composite material, the modified wood fiber is further compounded to facilitate the crack resistance of the grouting mortar, improve the toughness and reduce the later maintenance cost of engineering.

Owner:FUJIAN JIANGXIA UNIV

Power distribution cabinet automatic fire extinguishing warning mechanism based on water conservancy project power transmission

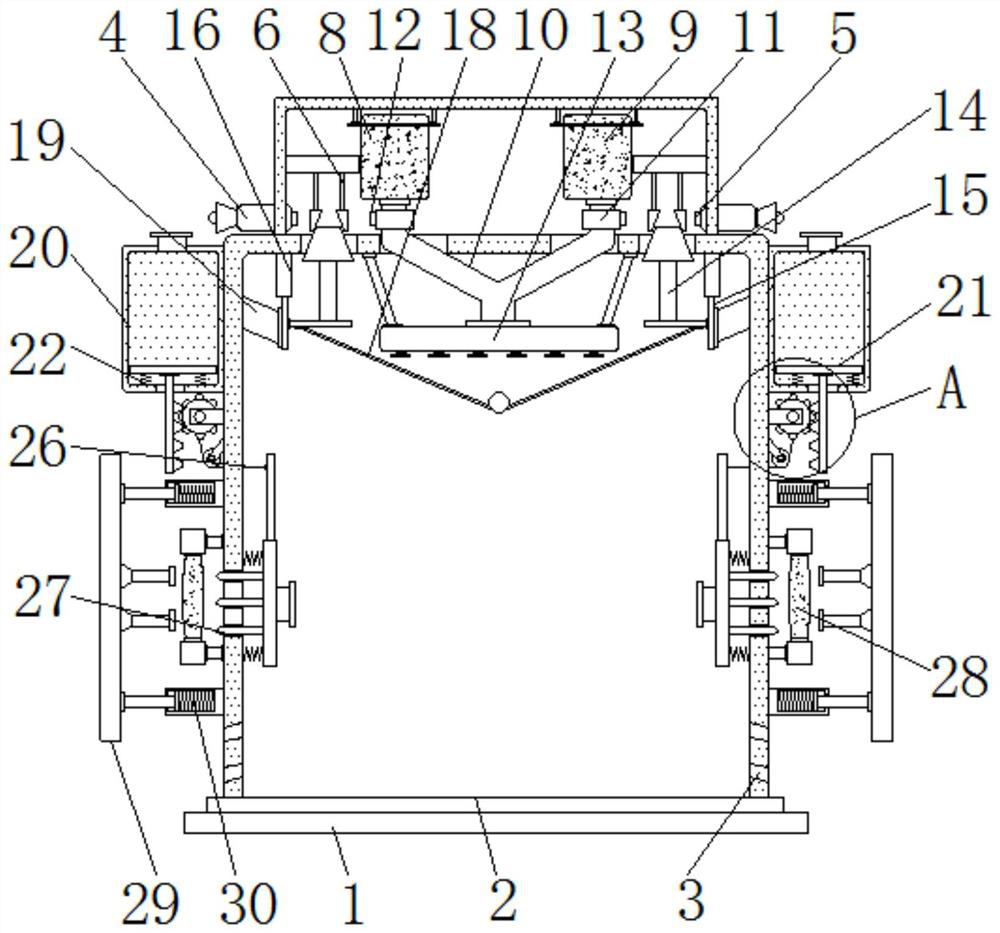

ActiveCN112003157AGood fire fighting practicesReduce lossesSubstation/switching arrangement cooling/ventilationFire rescueAutomatic fire suppressionStructural engineering

The invention discloses a power distribution cabinet automatic fire extinguishing warning mechanism based on water conservancy project power transmission. The warning mechanism comprises a base, a power distribution cabinet body and radiating holes, wherein the power distribution cabinet body is fixedly mounted in the middle of the upper end of the base; the outer side of a start-stop switch is connected with an extrusion block; an aluminum sulfate storage tank is mounted on the inner side of an extrusion block; the lower end of a flowing pipe is mounted in the middle of the upper end of an air outlet plate; the side of the air outlet plate is fixedly installed in the power distribution cabinet body; a discharge port is installed on the outer side of a baffle; the outer end of the discharge port is fixedly installed on the inner side of a dry powder storage chamber; a transmission rod is installed in the middle of a circular gear; and the buffer is installed on the outer side of a lateral air bag. According to the power distribution cabinet automatic fire extinguishing warning mechanism for water conservancy project power transmission, a good fire extinguishing measure can be achieved, losses caused by a fire behavior are reduced to the maximum extent, and meanwhile alarm reminding can be conducted on surrounding people in time when the fire behavior occurs.

Owner:广东海彬线槽有限公司

Sodium bentonite ore composite water disposal agent and its preparation method and uses

InactiveCN1765804AIncrease concentrationImproved activation processWater/sewage treatment by flocculation/precipitationWater/sewage treatment by sorptionAluminium sulphateMagnesium

The invention discloses a treating agent for sodium bentonite mineral complex water, which comprises: sodium bentonite, ferric sulfate, aluminium sulphate and magnesium sulphate. This product has obvious dirt-removal effect for COD and heavy metal, and can be used in wide range, such as paper-making, dyeing and electroplating sewage.

Owner:上海申丰地质新技术应用研究所有限公司 +1

Coal energy-saving clean proliferating agent

The invention relates to a coal energy-saving clean proliferating agent; by being weighed according to weight percentage of component materials, the proliferating agent comprises the following materials: oil shale, humic acid, acidified coal gangue, sodium nitrate, potassium permanganate, aluminium sulphate, sodium chloride, calcium carbonate, sodium carbonate, manganese dioxide, sodium phosphate and light magnesium oxide; the component materials are mixed and crushed according to percentage weight with powder fineness of 20 meshes to 40 meshes, stirred in a stirrer for 5 to 10 minutes, inspected and packed into finished products. The proliferating agent has rich materials, simple production technique, little investment, fast effect and convenient use; the rate of sulfur fixation and desulfurization is up to 80 percent by inspection of relevant environmental protection and energy-saving departments; the boiler efficiency is improved by 16.8 percent; the carbon content of slag is reduced by 56.7 percent; in addition, by practices, using units prove that the proliferating agent has the advantages and effects of decoking, eliminating smoke and inhibiting corrosion by more than 95 percent.

Owner:HUNAN XINWANG ENERGY SAVING ENVIRONMENTAL PROTECTION TECH

Method for reducing and controlling hexafluorosilicate concentration during the polishing of glass objects in a polishing bath containing sulphuric acid and hydrofluoric acid

The invention relates to a method for reducing and controlling the concentration of hexafluorosilicate ions arising when glass objects are polished in a polishing bath containing sulphuric acid and hydrofluoric acid. Potassium floride, potassium sulphate, sodium fluoride, sodium sulphate or aluminium sulphate is added to the polishing bath or sulphuric acid rinsing bath in quantities such that a drop in the concentration of fluoride ions below the optimum working range is avoided.

Owner:埃里希・扎尔茨勒 +1

Color cement made from copper-smelting slag

InactiveCN101434460AColorful and brightUniform colorSolid waste managementAnhydrous Calcium SulfateSlag

Colored cement produced by copper-smelting slag is characterized by comprising portland cement clinker 525<#>, copper-smelting slag, lime, fly ash, plaster, composite excitant, paint and cement intensifier, wherein, the composite excitant consists of dead plaster and active aluminium silicon; cement intensifier consists of aluminium sulphate, silicon dioxide, alumina and common salt. The invention mixes a little amount of low-active copper-smelting slag in the cement composite material, and then adds additives such as the lime, the fly ash, the composite excitant, the cement intensifier and the like to excite the activity of the copper-smelting slag, thus preparing the bright, even and various colored cement which has the characteristics of saving energy, reducing discharge, having simple technique, reducing the cement cost, and the like.

Owner:苏艳杰

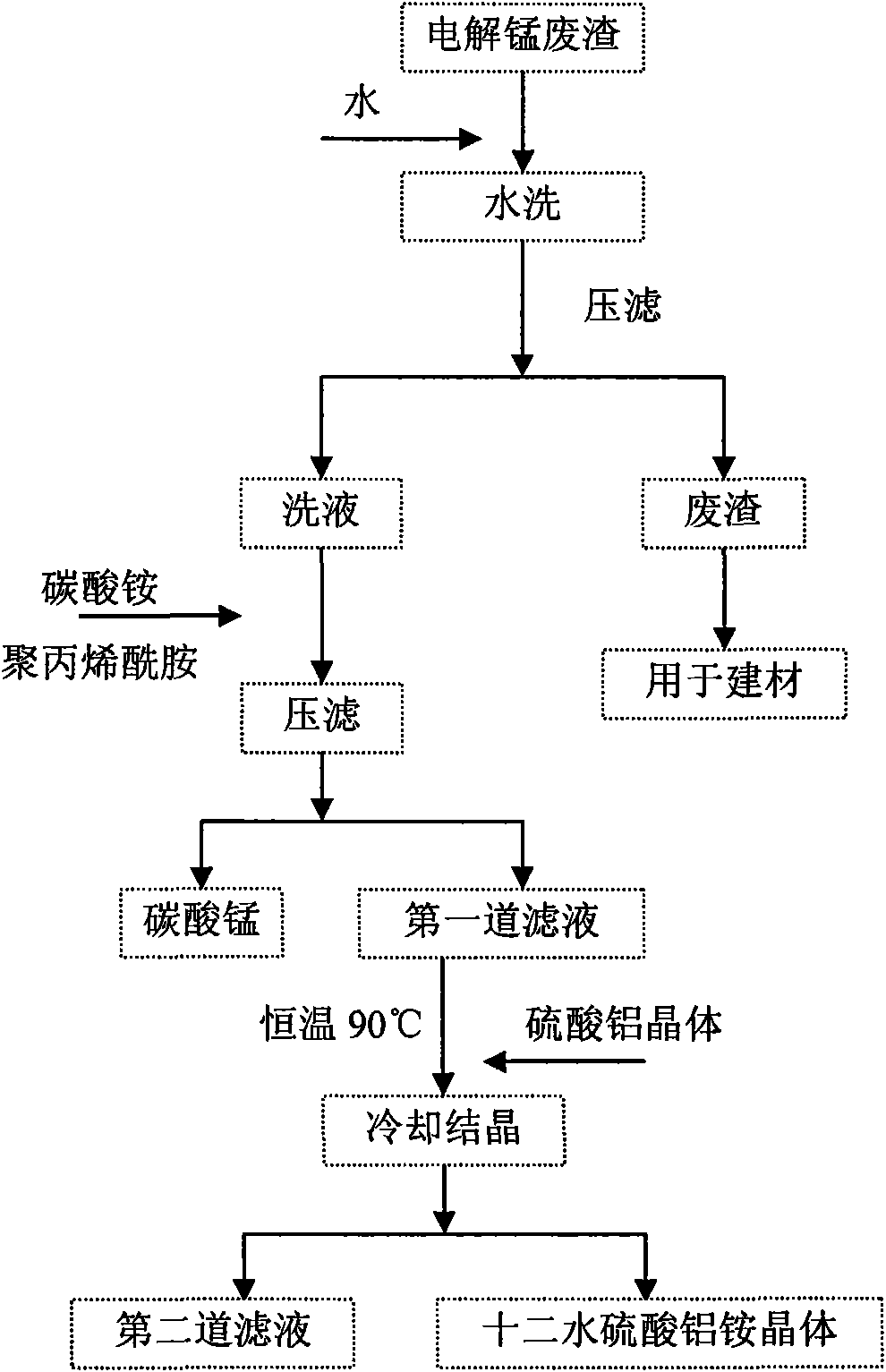

Method for processing and utilizing electrolytic manganese waste residue

The invention relates to a method for processing and utilizing electrolytic manganese waste residue, which comprises the following steps of: the electrolytic manganese waste residue is washed so as to a water washing liquid; salvolatile and flocculating agent and polyacrylamide are added so as to obtain a manganous carbonate precipitation and a first filtrate; aluminium sulphate crystal and crystal modifier borax are added into the first filtrate so as to separate out dodecahydrate aluminium ammonium sulfate crystal. The method can convert manganous sulfate in the electrolytic manganese waste residue which is difficult to isolate a manganese element into the manganous sulfate which is convenient to isolate the manganese element, can convert the manganous sulfate which is difficult to isolate a nitrogen element into the dodecahydrate aluminium ammonium sulfate crystal which is convenient to isolate the nitrogen element. The method has the low manufacturing cost, is easy to operate and convenient for realizing the commercial process.

Owner:CHONGQING UNIV

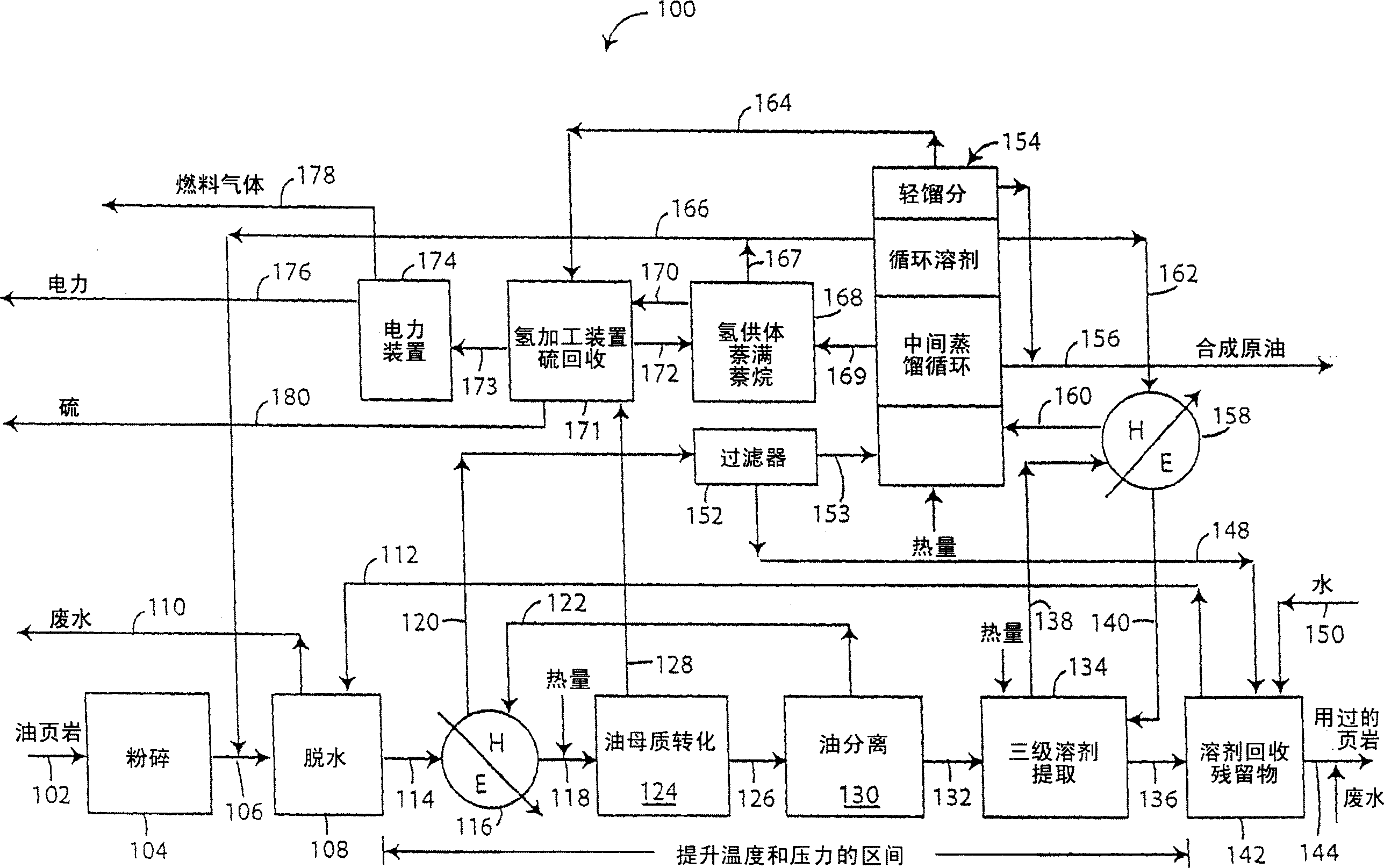

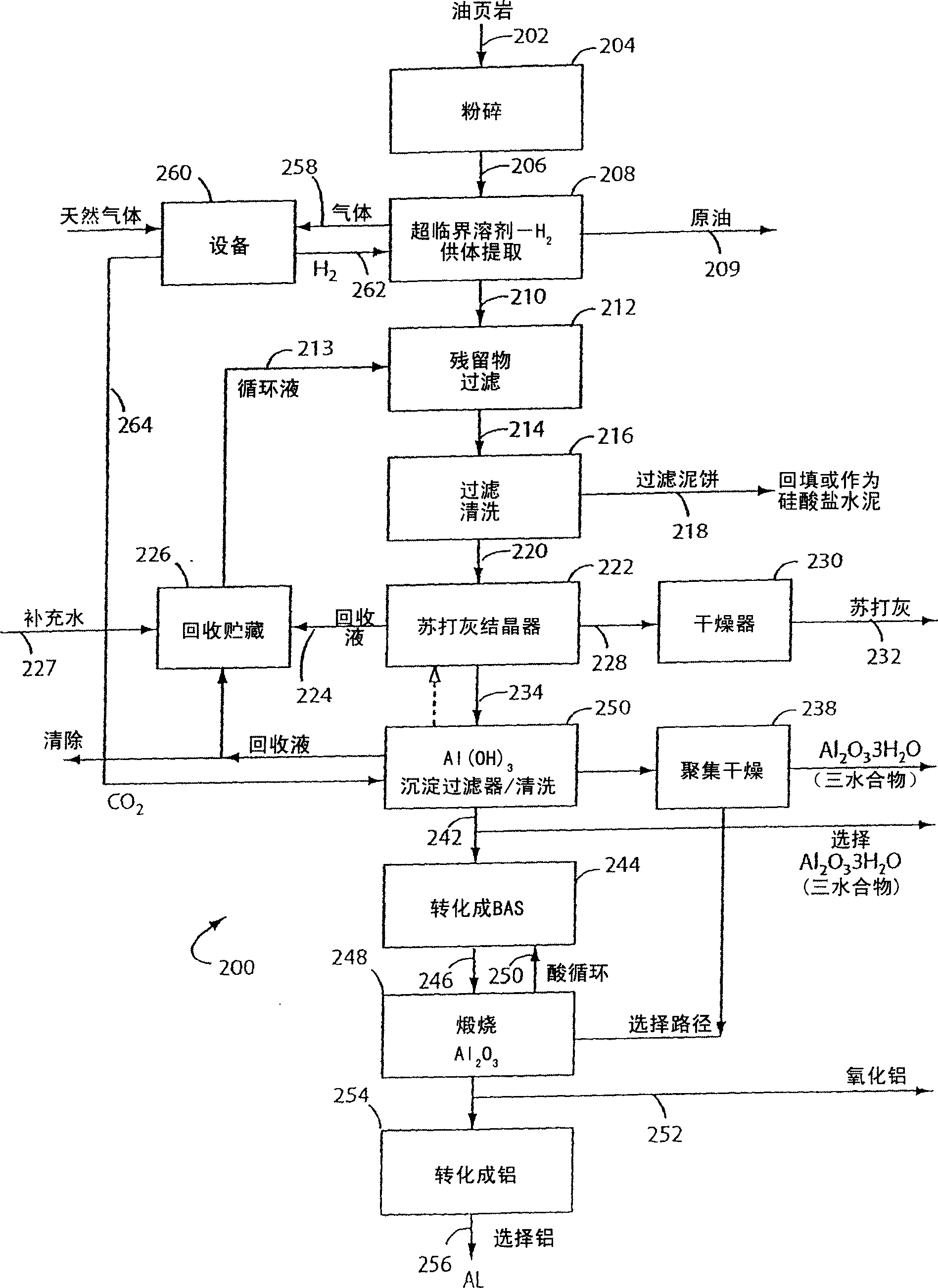

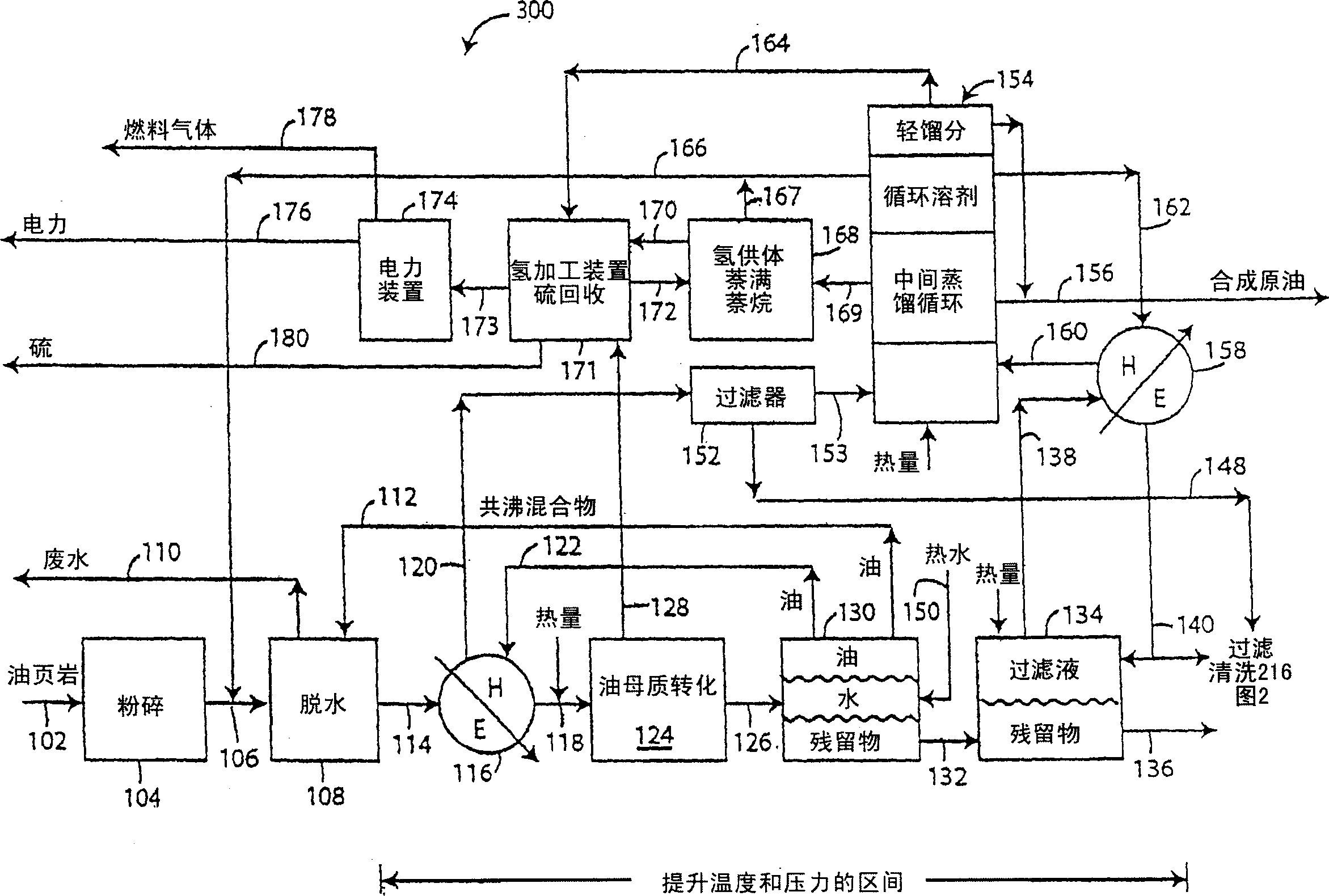

Supercritical hydro extraction of kerogen and aqueous extraction of alumina and soda ash with a residue for portland cement production

InactiveCN1688672AReduce pollutionLiquid hydrocarbon mixture productionParticulatesAluminium hydroxide

The present invention discloses a method and a device for extracting a hydrocarbon product, alumina and barilla from oil shale, and the oil shale contains the chemical substances with various contents, all of which are extracted by most of the hydrocarbon solvents under the temperature of approximate 400 DEG C. The oil shale residue is filtered by sodium carbonate aqueous solution under a decreased temperature of 150 DEG C and a corresponding decreased pressure to obtain useful alumina and barilla ingredients. Under a temperature of 100 DEG C, the useful hydrate ingredient of the barilla is deposited from filtering medium along with the useful alumina ingredient settled by CO2. Under a temperature of 65 DEG C, the circulated particulate aluminum trihydrate is selected to produce the alumina. By resolving the circulated acid steam of the alumina, aluminium hydroxide is converted into acidic alumina in order to filter out any silica impurities. Under a temperature of approximate 200 DEG C and a pressure of 250 PSIG, alkaline aluminium sulphate is deposited, and under a temperature of approximate 900 DEG C, the subsequent calcination is carried out. Consequently, the alumina is produced, and sulfur oxide gas is recycled by a sulphuric acid device.

Owner:约翰·S·伦德尔

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com