Patents

Literature

658 results about "Metal filament" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Metal filled filaments are made by mixing a fine metal powder into a base material, providing a unique metallic finish and added weight. Overview. Metal filled filaments contain very fine metal powder such as Copper, Bronze, Brass, and Stainless Steel.

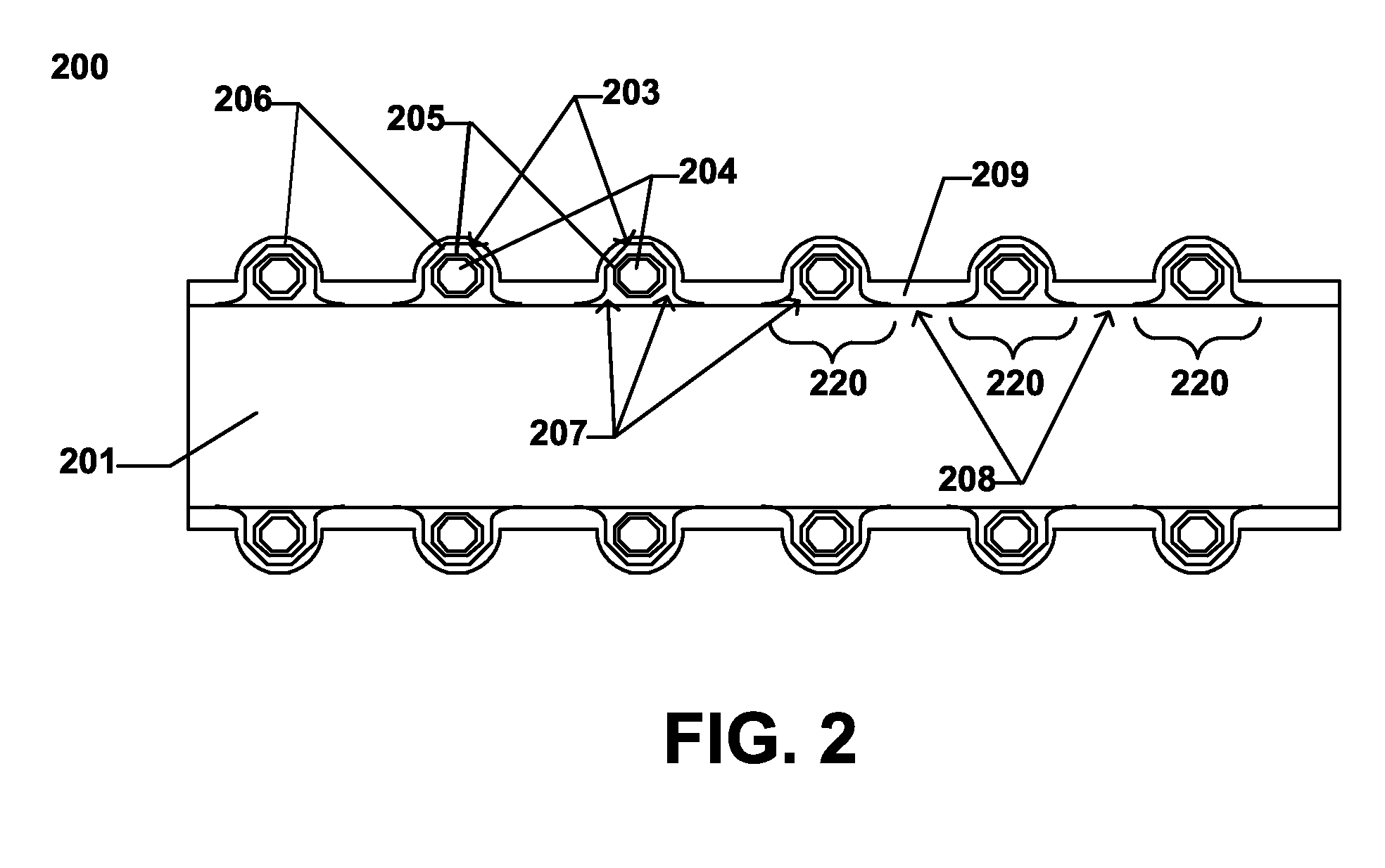

3D printer and printhead unit with multiple filaments

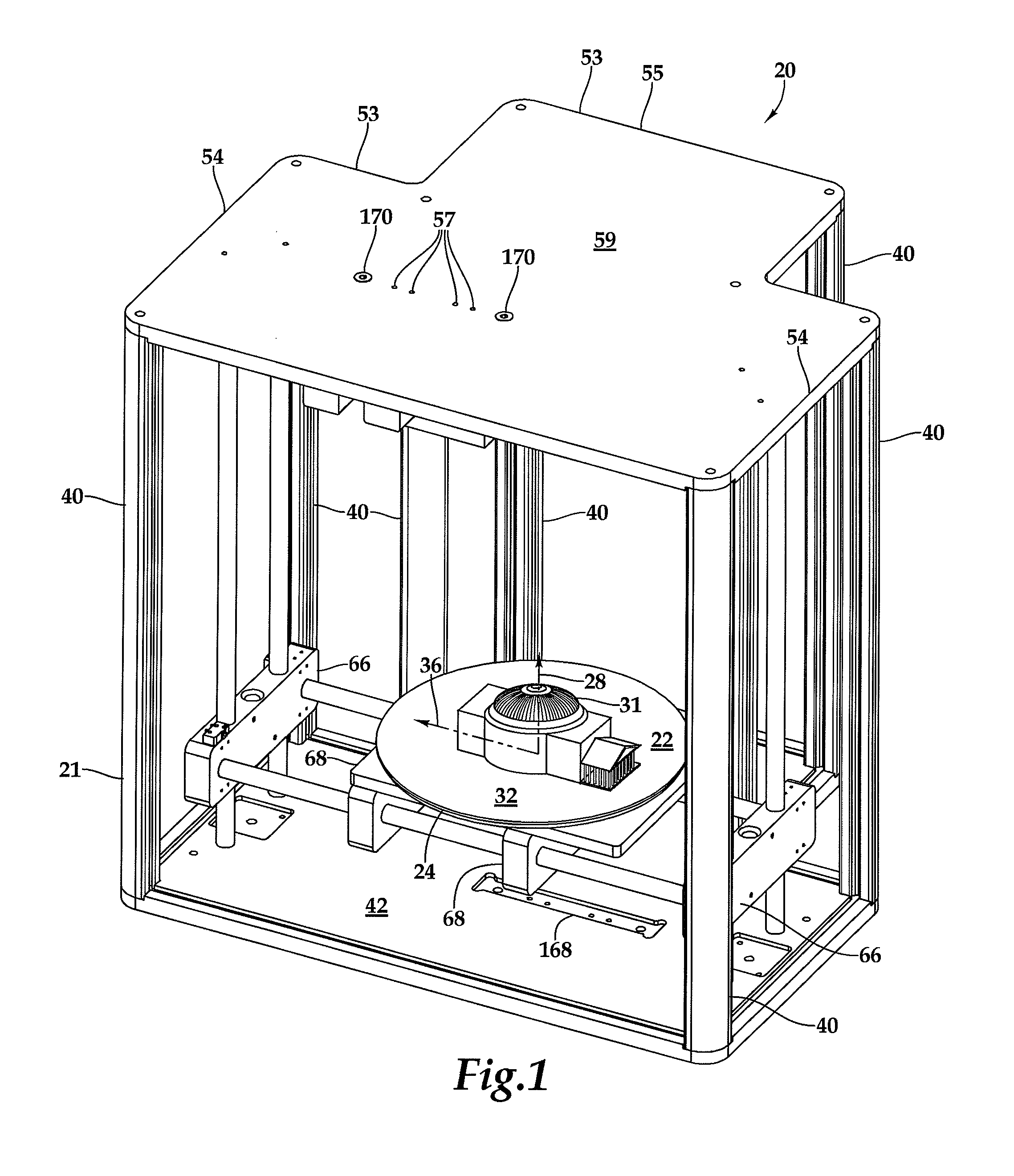

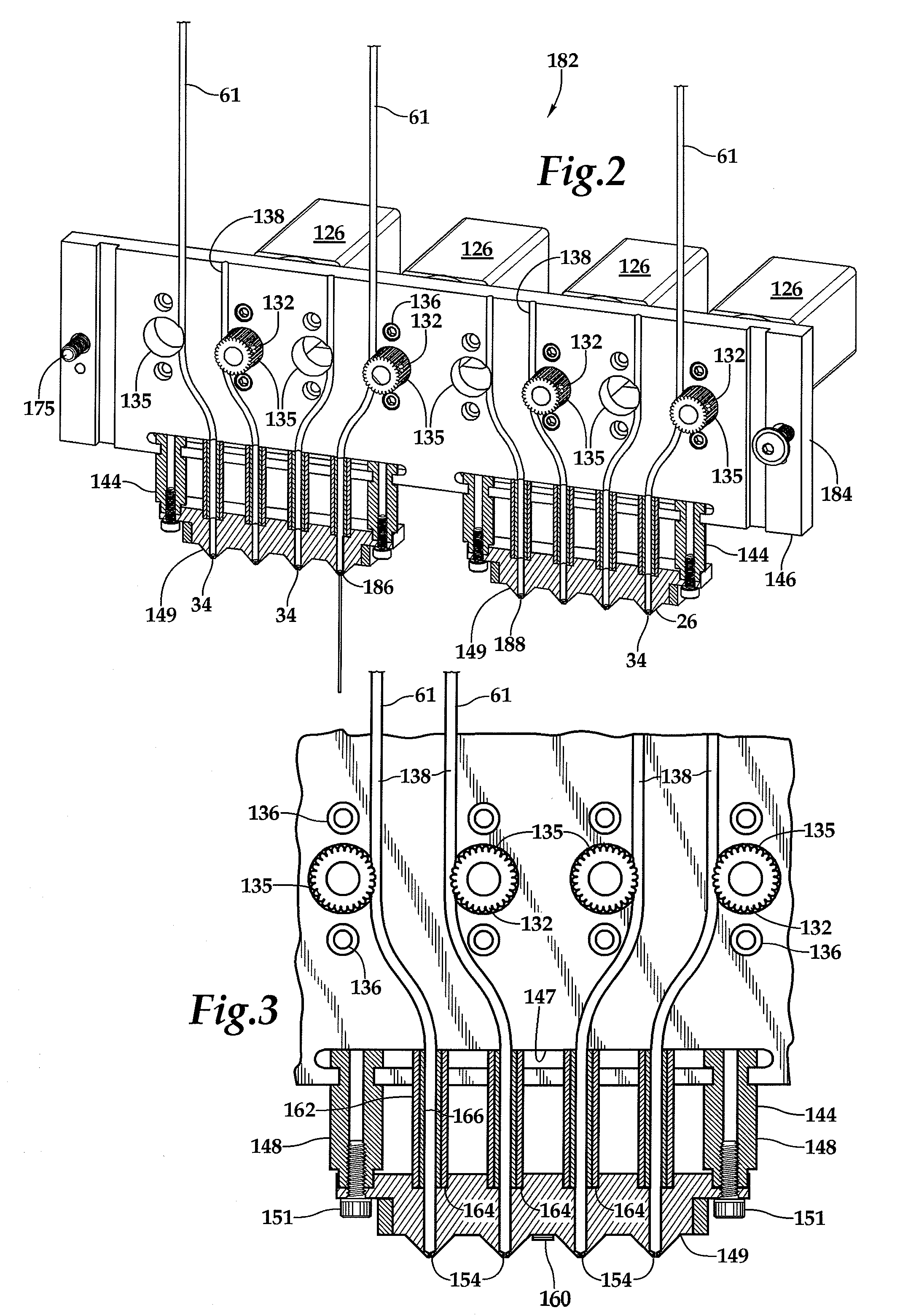

InactiveUS8827684B1Reduce complexityIncrease speedConfectionerySweetmeatsFused filament fabricationMetal filament

A fused filament fabrication printer has a fixed extrusion module having multiple printheads having print tips. The fixed arrangement of the printing heads allows the close spacing of multiple print tips in a printhead unit, and the simple routing of multiple plastic or metal filaments to the individual printing heads. The closely spaced print tips in the printhead unit share common components. An exemplary printhead unit has four printing heads which share a common heating block and heating block temperature sensor. The heating block incorporates a group of four print tips evenly spaced along a line. Each printing head has a separate filament which is controlled and driven by its own stepper motor through the heating block to one of the print tips. Printing of a part is by control of individual stepper motors which drive filaments through the heating block and through one of the printing tips.

Owner:RADIANT FABTION

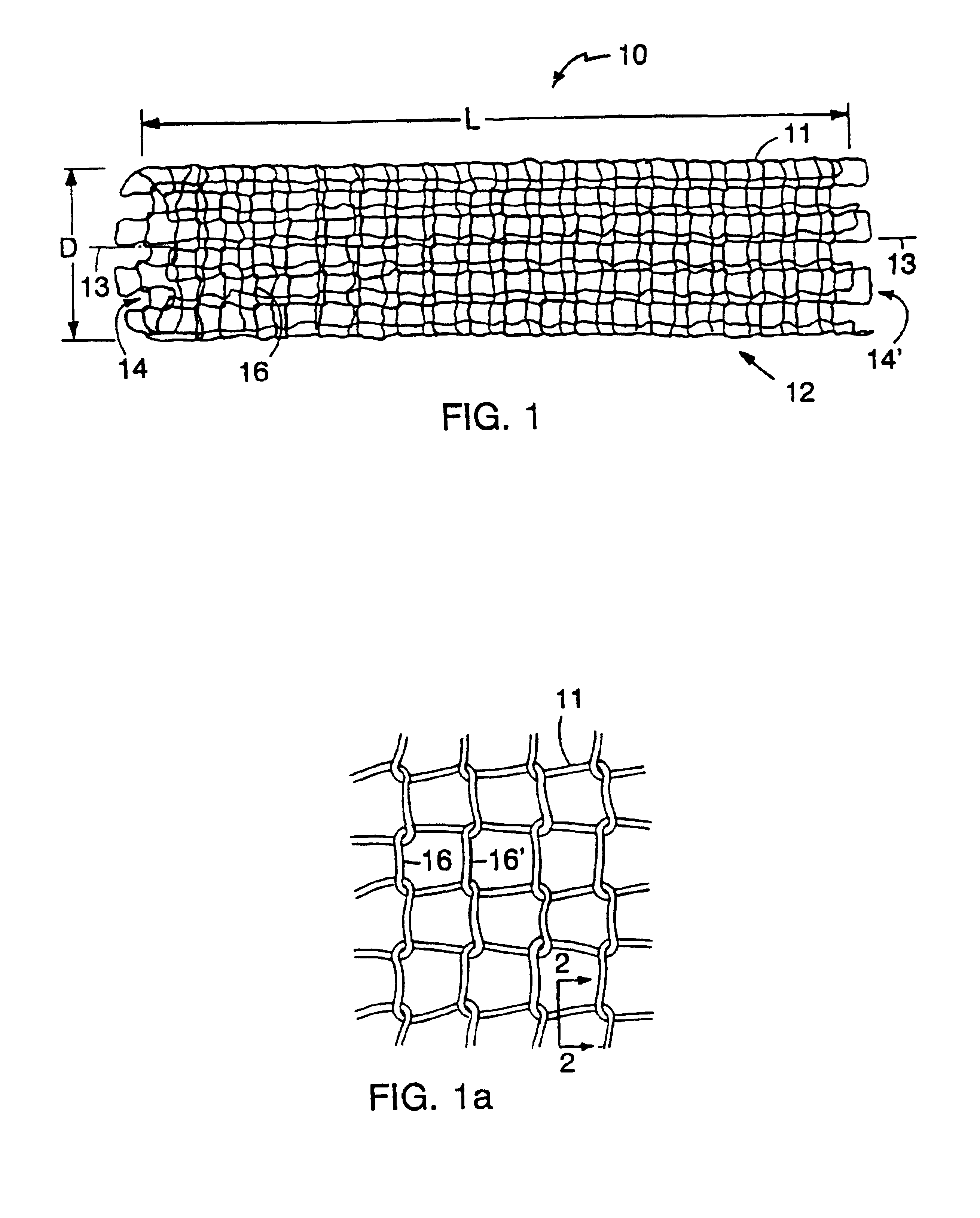

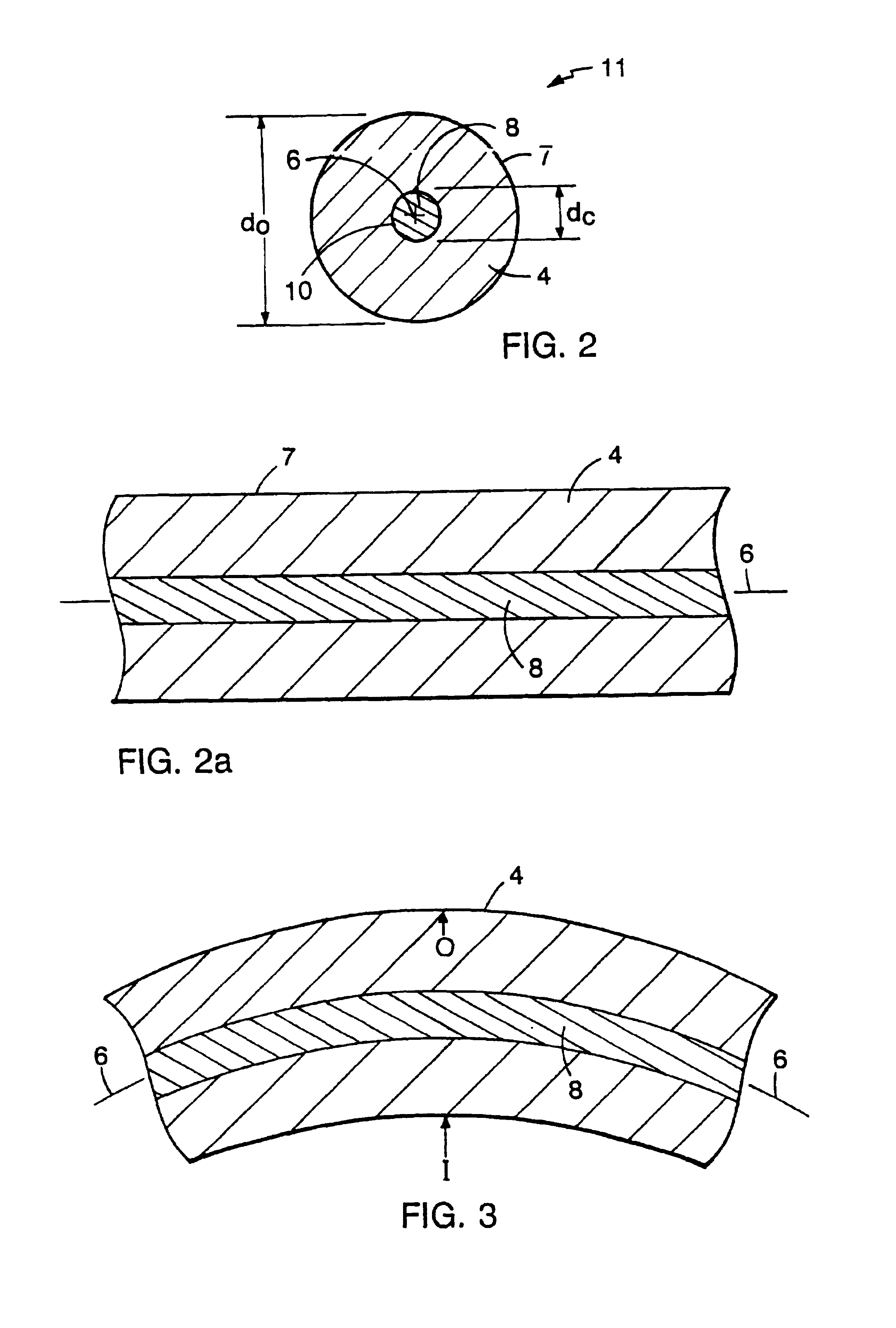

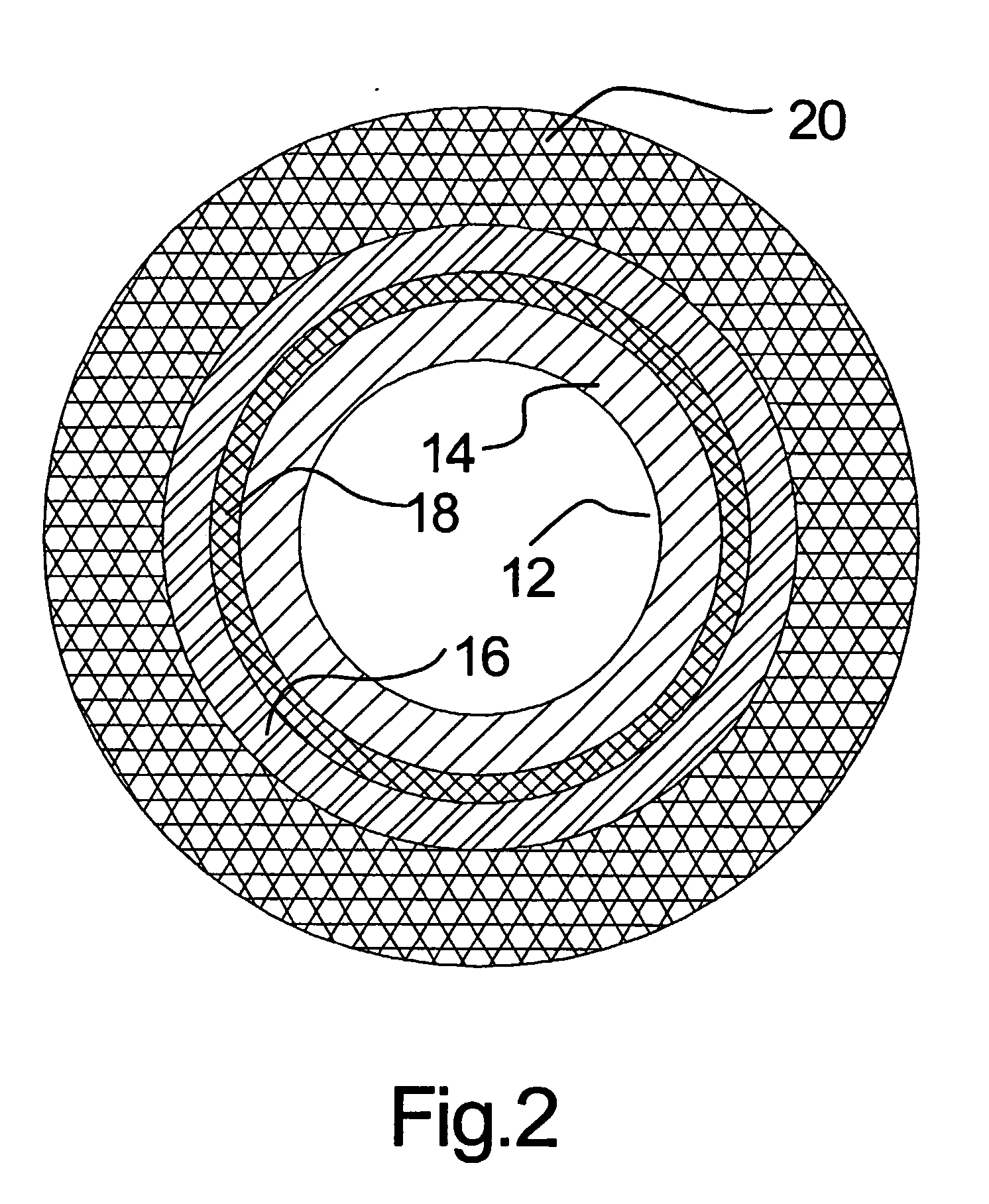

Tubular medical endoprostheses

InactiveUS7101392B2More elasticityImprove radiopacityStentsWeft knittingMetal filamentInsertion stent

A tubular prosthesis device for use within the body. The device includes, a metal filament material formed of metal outer member having an exposed outer surface and a core within the extended outer member formed of a different metal than the outer member. The core is secured within and substantially enclosed by the outer member. The device can be reduced to a small size for introduction into the body lumen and expandable to a sufficiently large size to engage the wall of the body lumen. Stents formed of composite wires are shown.

Owner:BOSTON SCI SCIMED INC

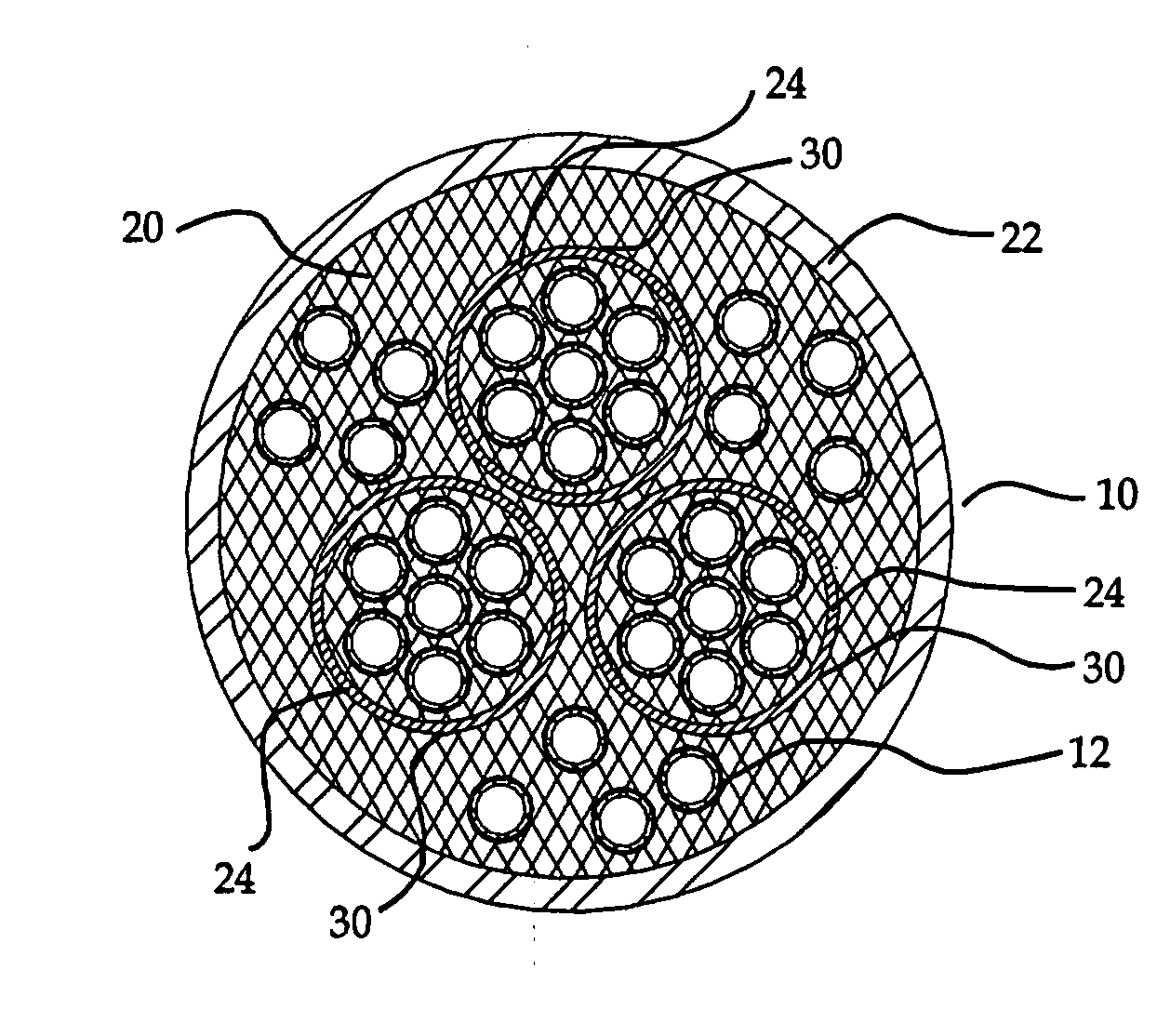

Tubular solid oxide fuel cell stack

This invention relates to a stack comprising a continuous solid-phase matrix and tubular fuel cells embedded in the matrix. Each fuel cell comprises an inner electrode layer, an outer electrode layer, and an electrolyte layer sandwiched between the inner and outer electrode layers. The matrix is sufficiently porous to allow a first reactant to flow through the matrix and to the outer electrode of each fuel cell, and have sufficient mechanical strength to support the fuel cells in the stack. The fuel cells are embedded such that a second reactant may be flowed through the inside of each tubular fuel cell and to the inner electrode thereof. Alternatively, a stack of tubular separation membranes or a stack of tubular membrane reactors may be embedded in the matrix. The matrix material may comprise solid state foam, metal filament, or metal, cermet, or ceramic wool.

Owner:INNOTECH ALBERTA INC

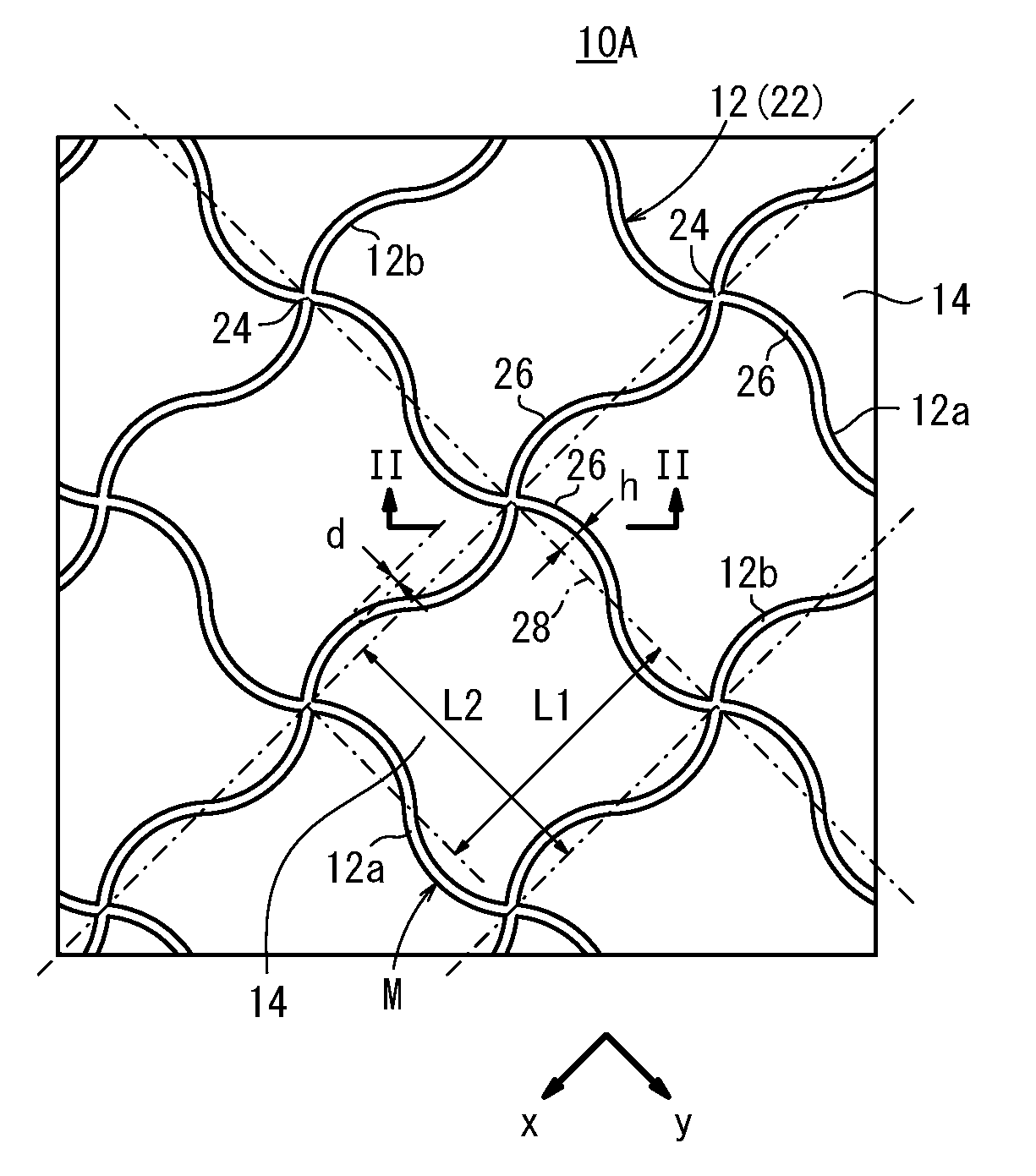

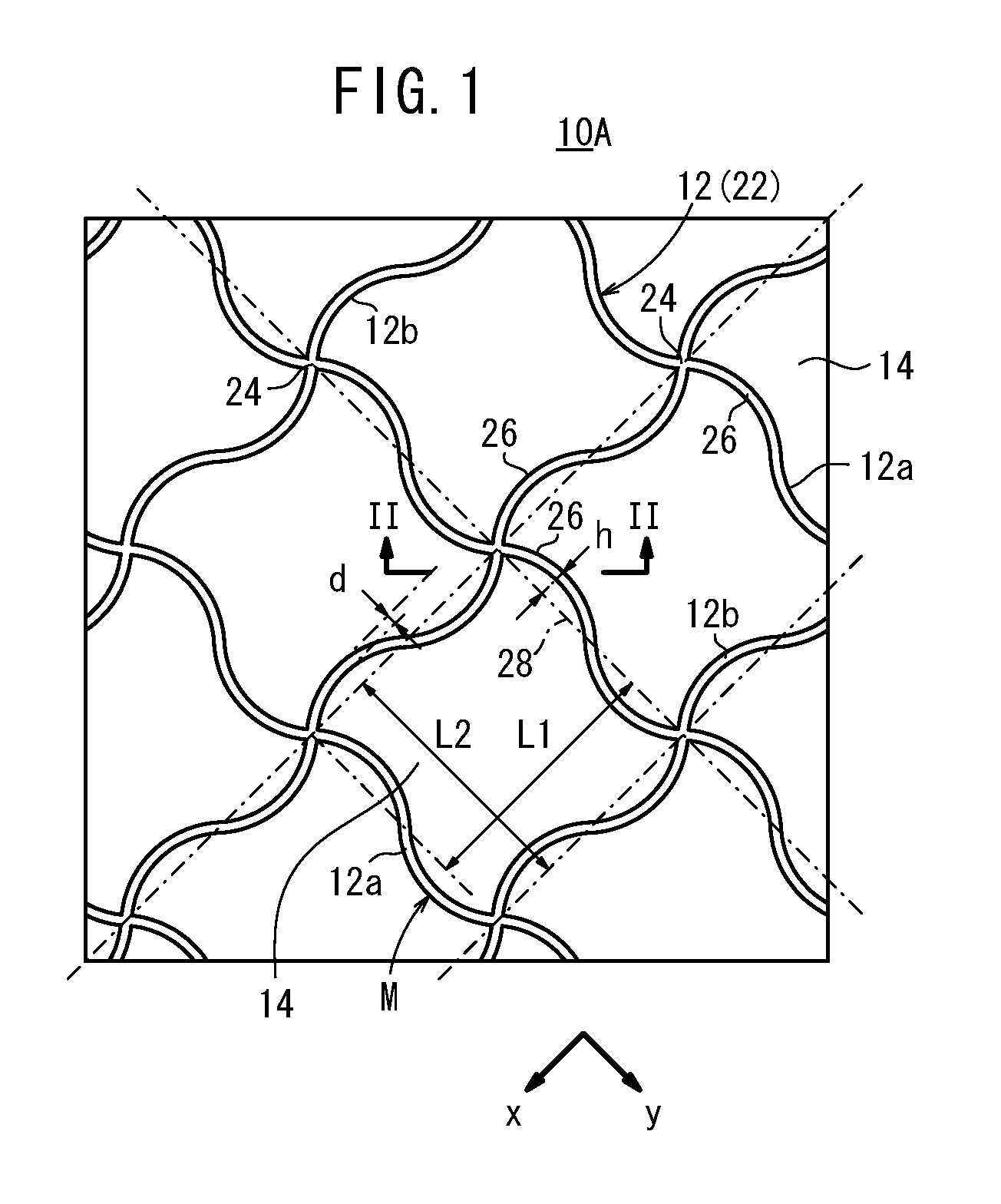

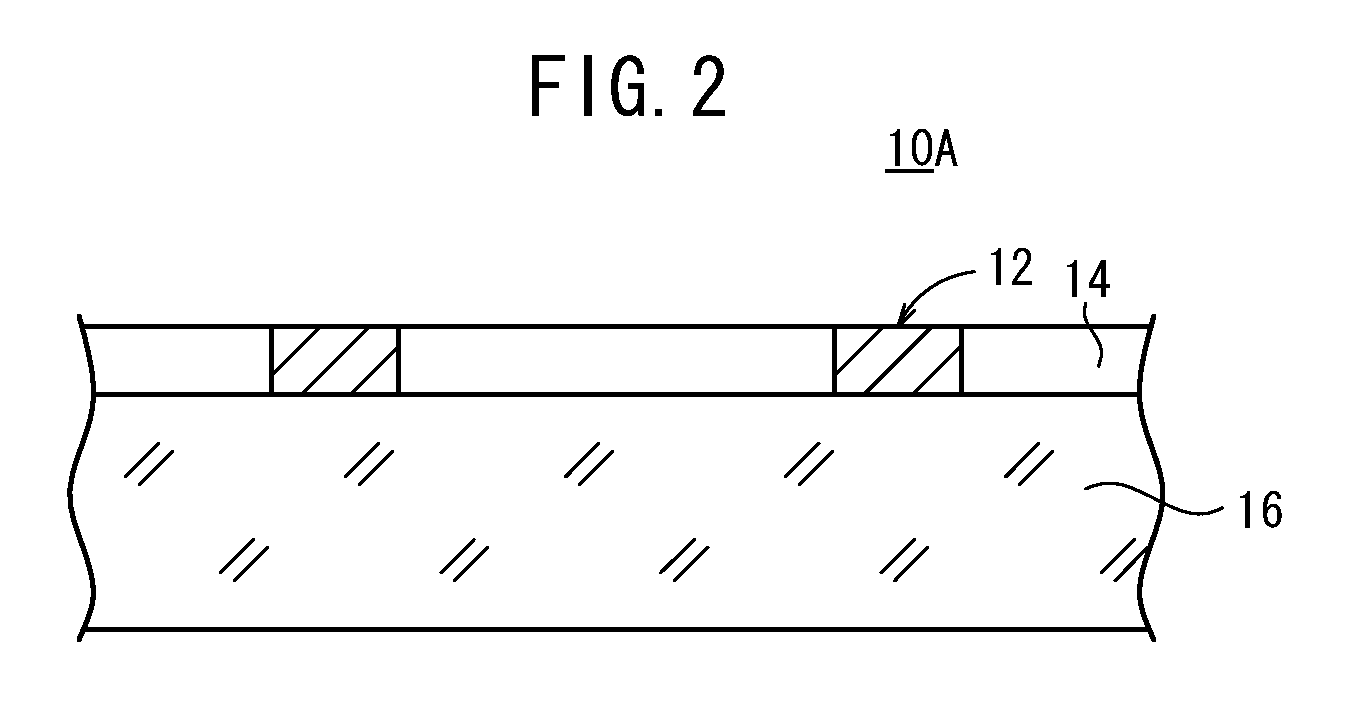

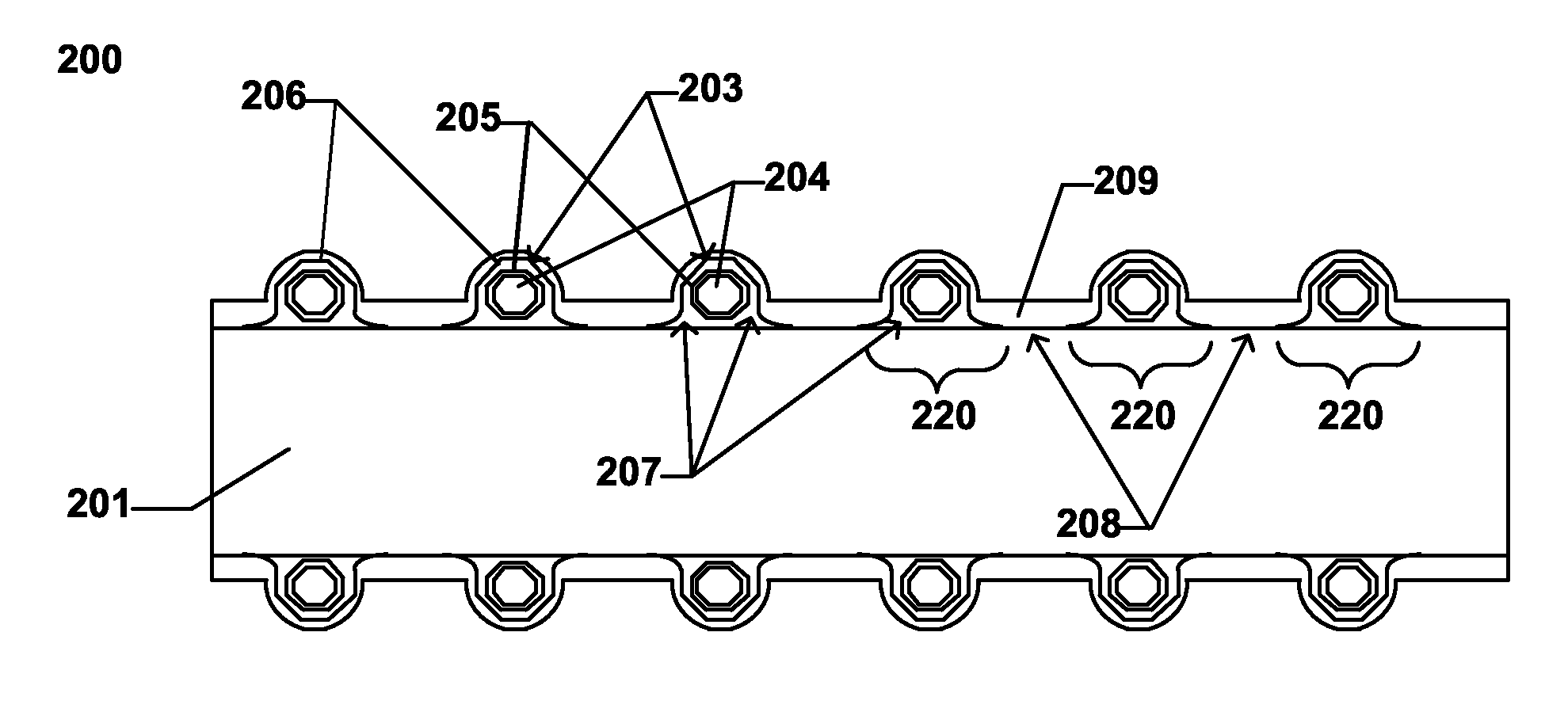

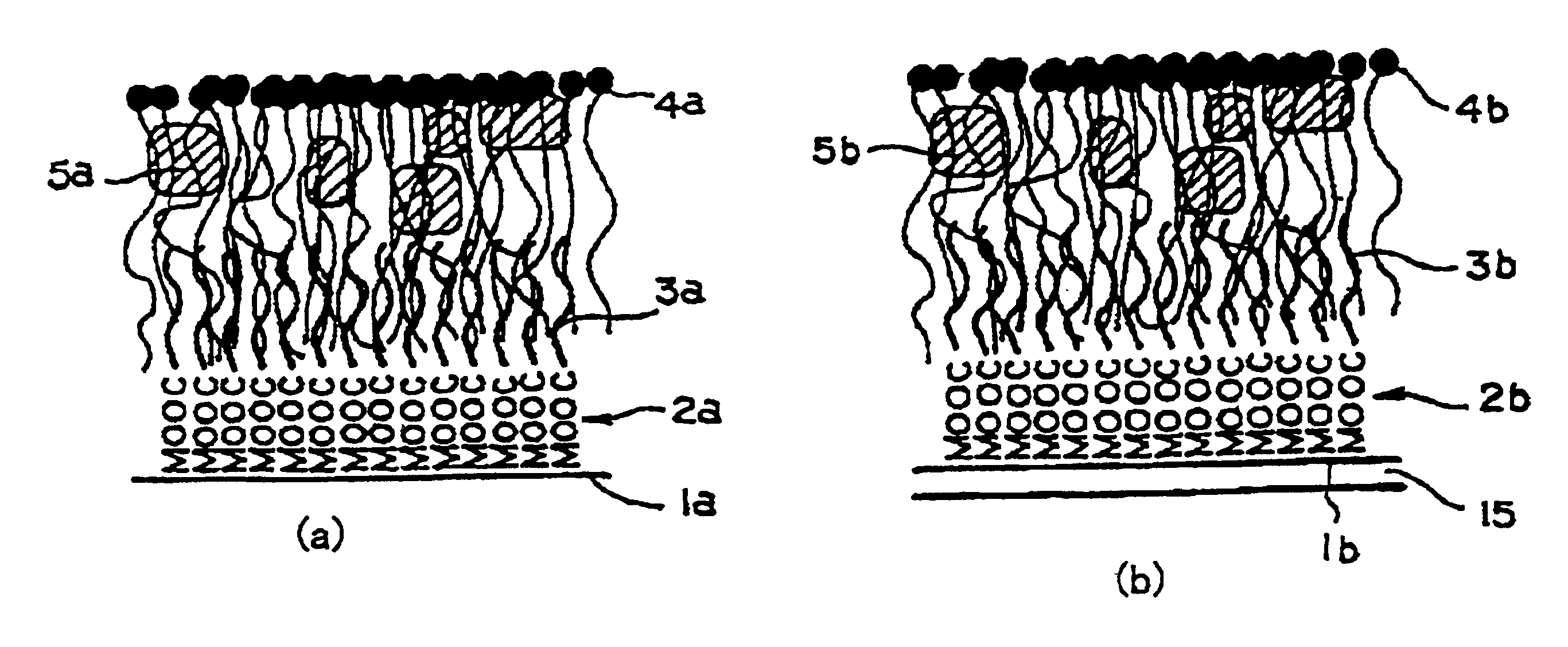

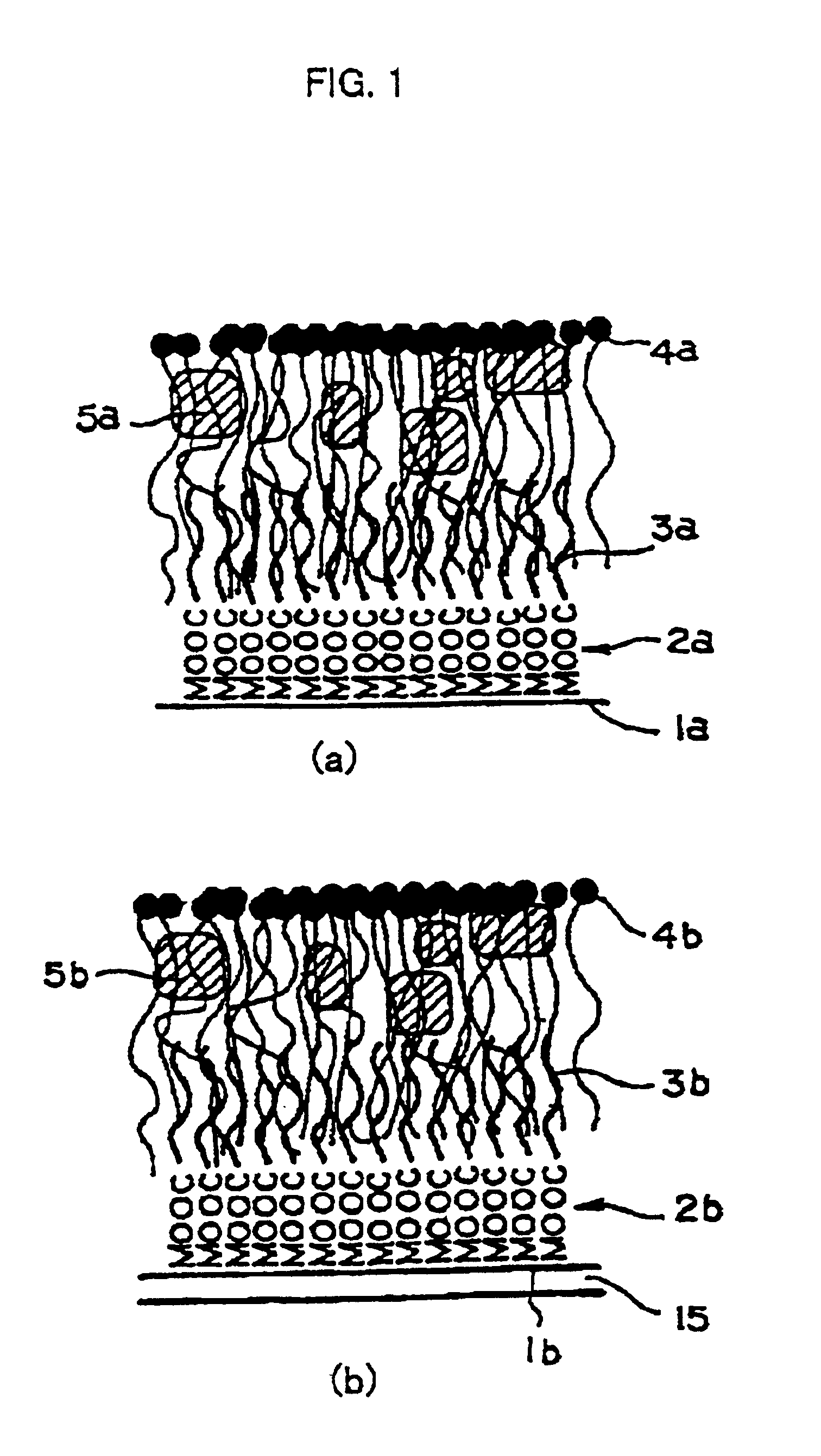

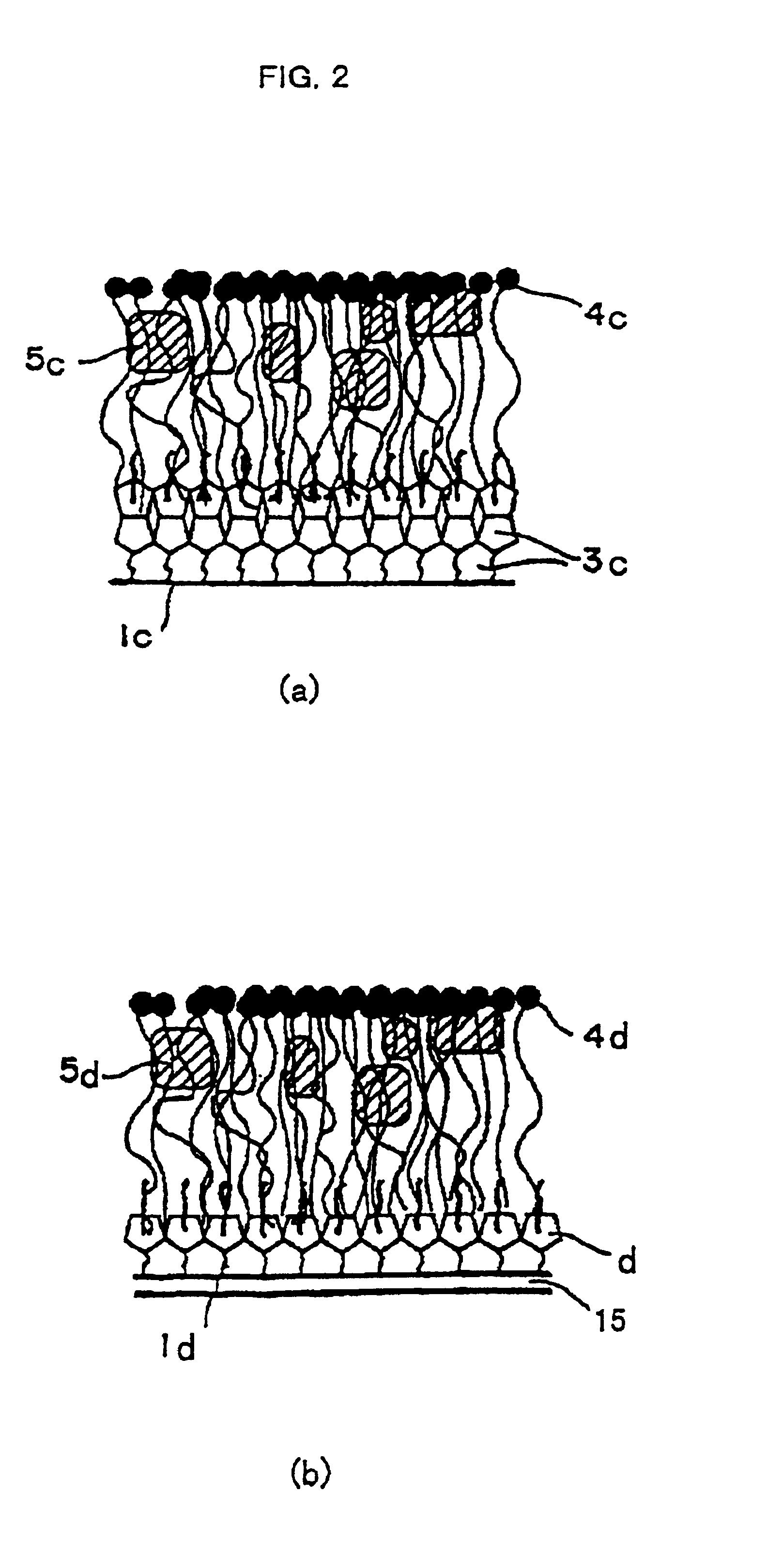

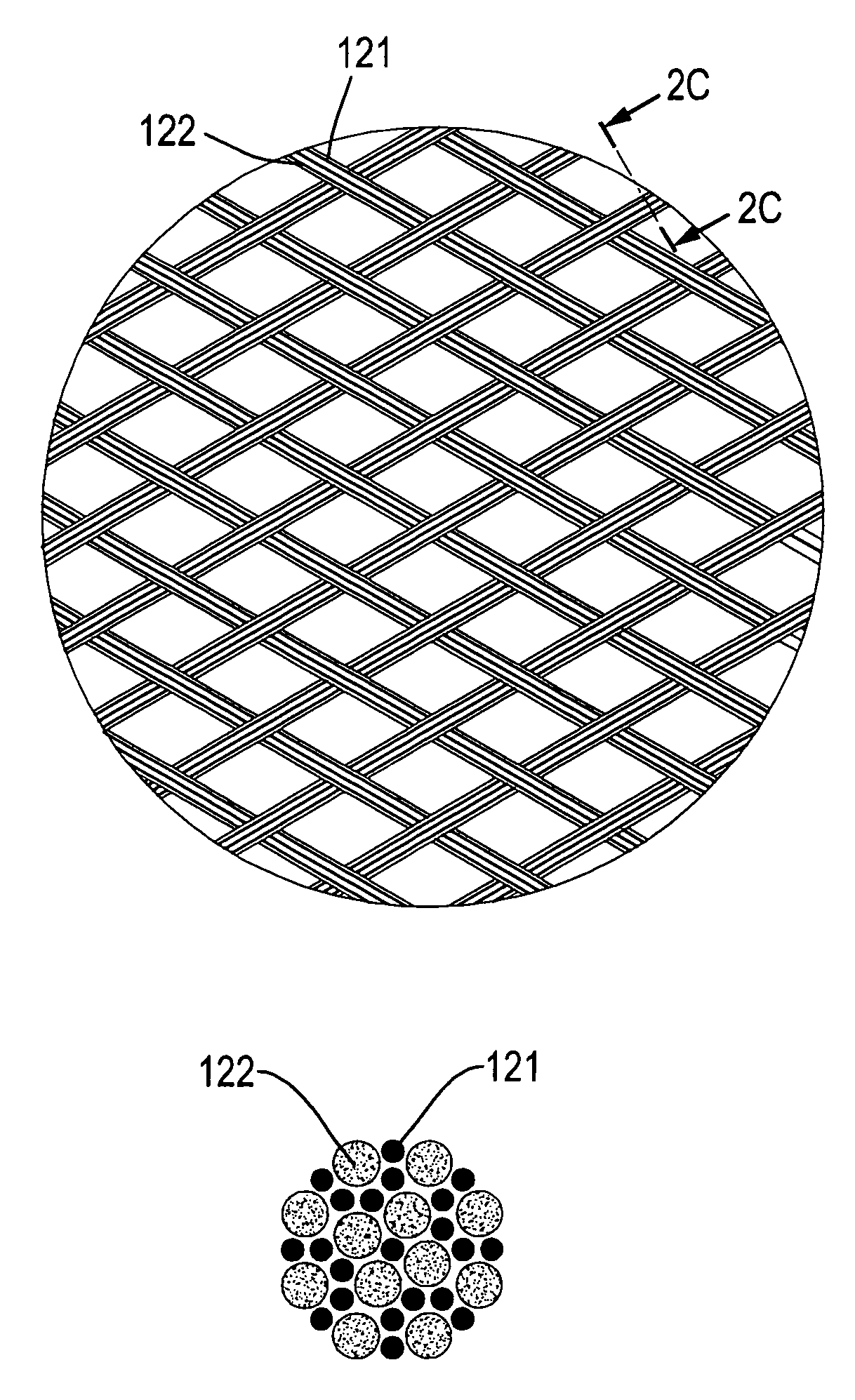

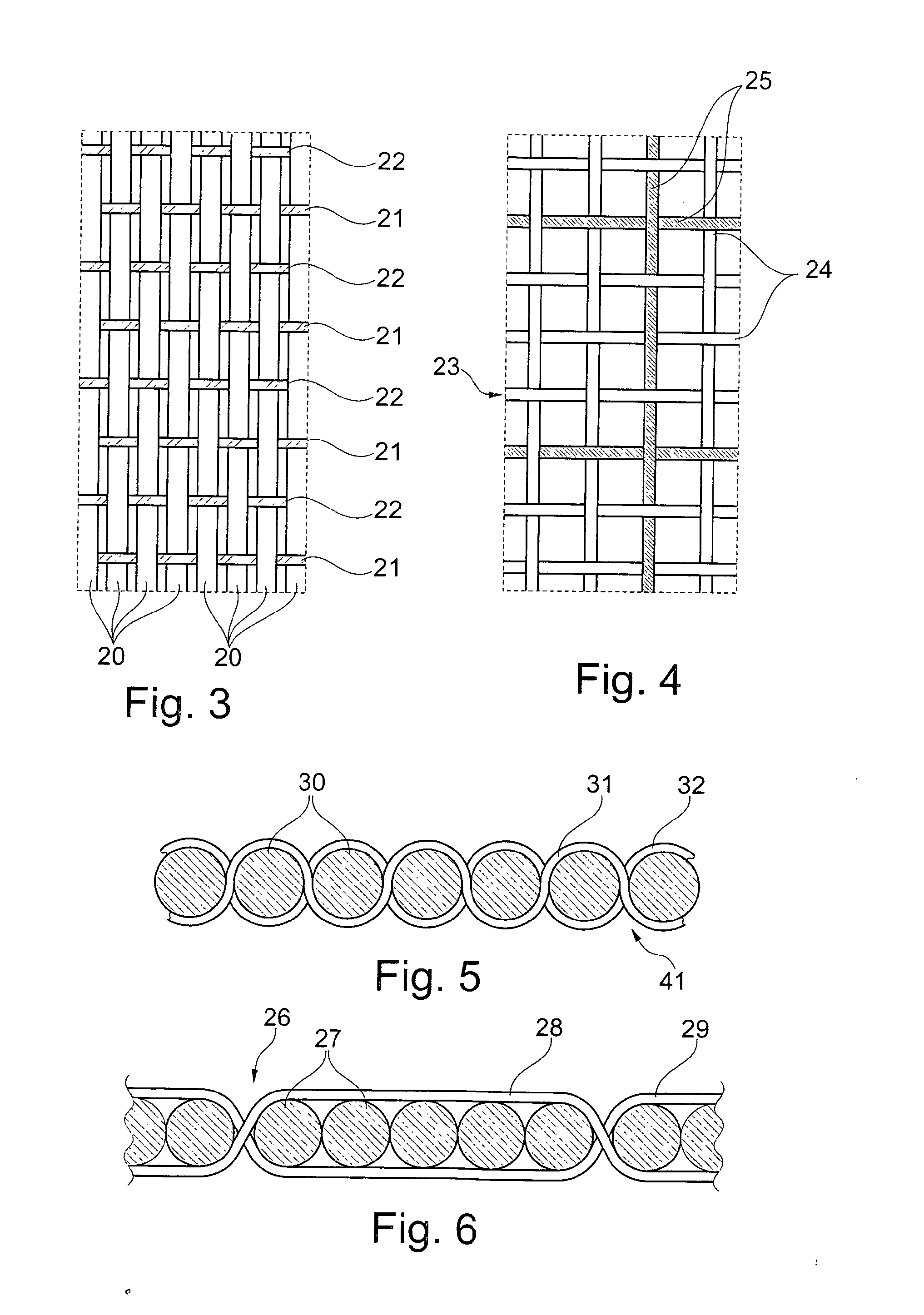

Conductive film, and transparent heating element

ActiveUS20110062146A1High light transmittanceIncrease blockingLayered productsTransparent/reflecting heating arrangementsVisibilityMetal filament

Provided is a conductive film, which is suitably used in a heating element of a transparent property (a transparent heating element) excellent in visibility and a heating power. The conductive portion of a first conductive film includes mesh patterns having multiple intersecting points (intersecting portions), which are constituted of a plurality of first metal filaments and a plurality of second metal filaments, and the conductive portion between the intersecting portions is formed into an undulating shape having at least one curve. The first conductive film is shaped such that the curves are arcuate and two arcs are formed continuously between the intersecting portions, wherein the protrusion-recess directions of the arcs are opposite to each other. Each arc has a center angle of about 90 degrees. Moreover, the conductive portion has a crossing angle of about 90 degrees.

Owner:FUJIFILM CORP

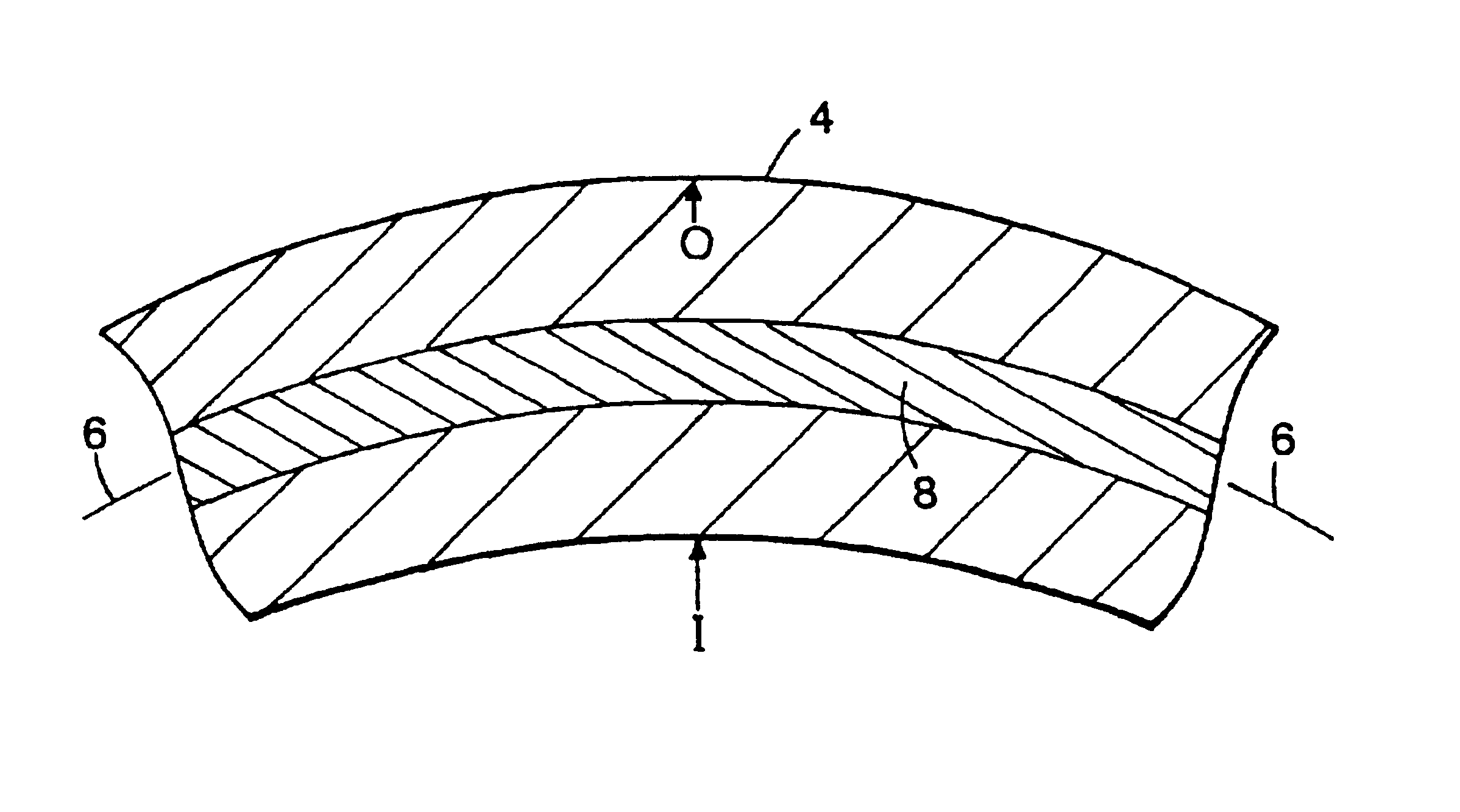

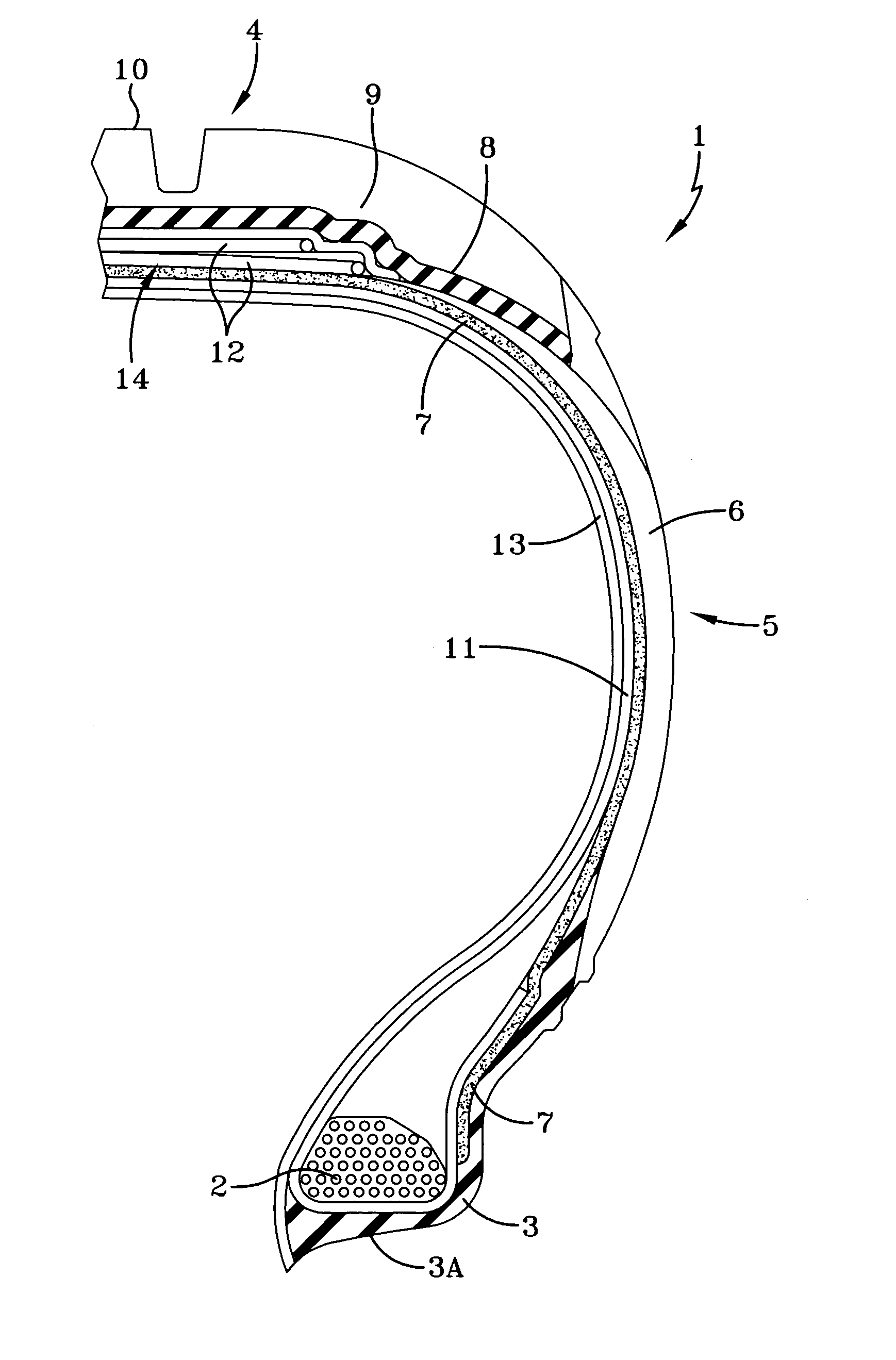

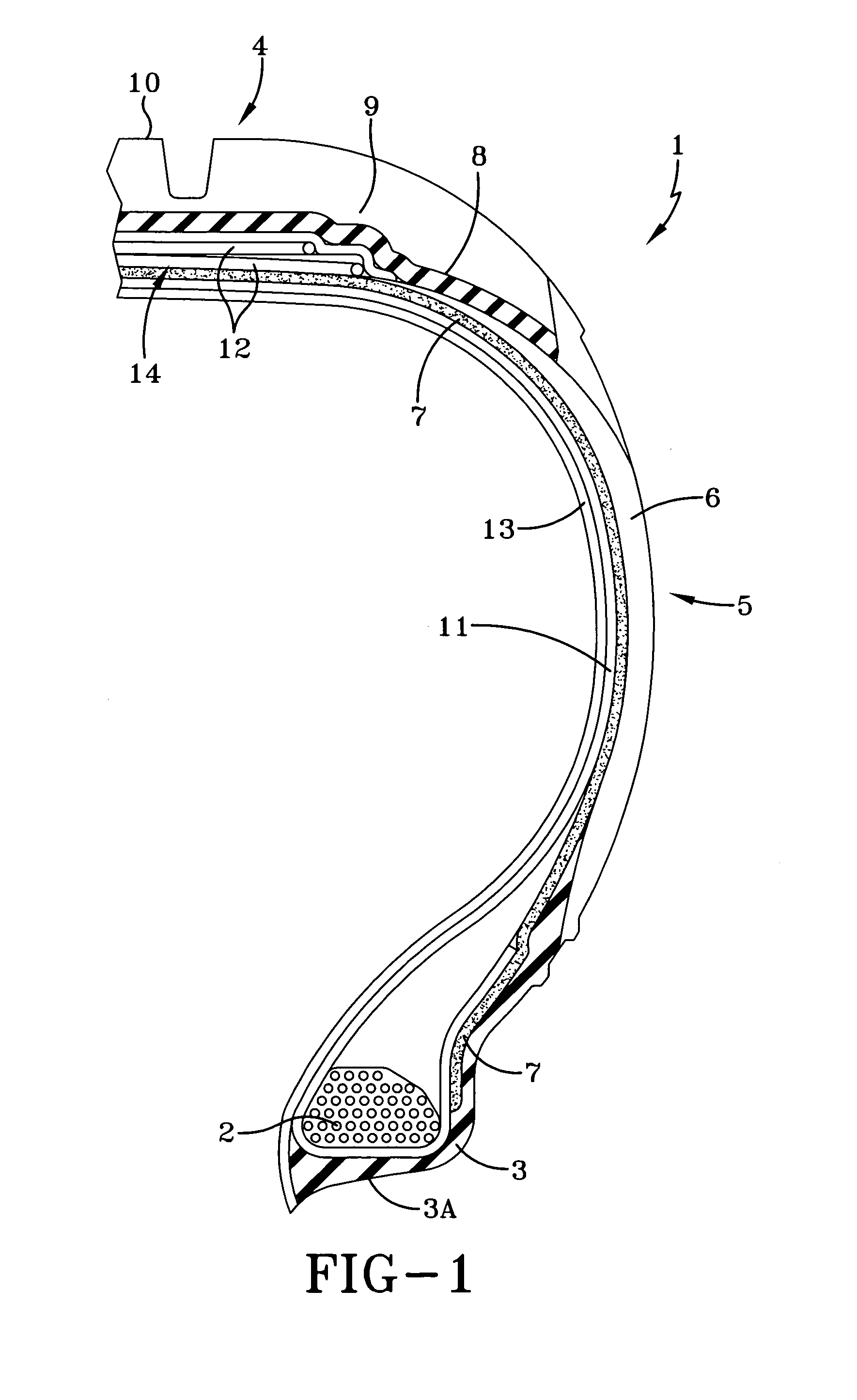

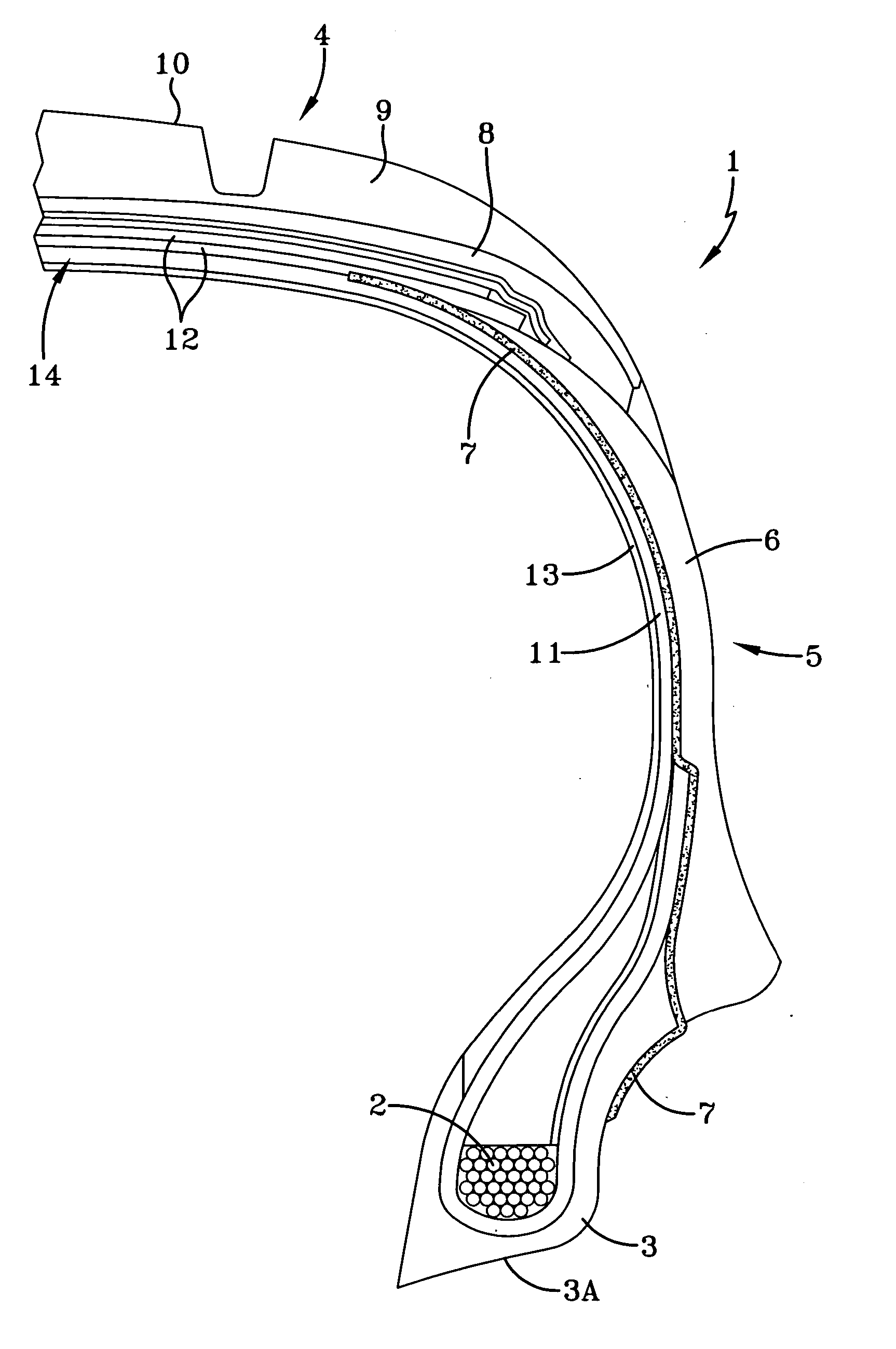

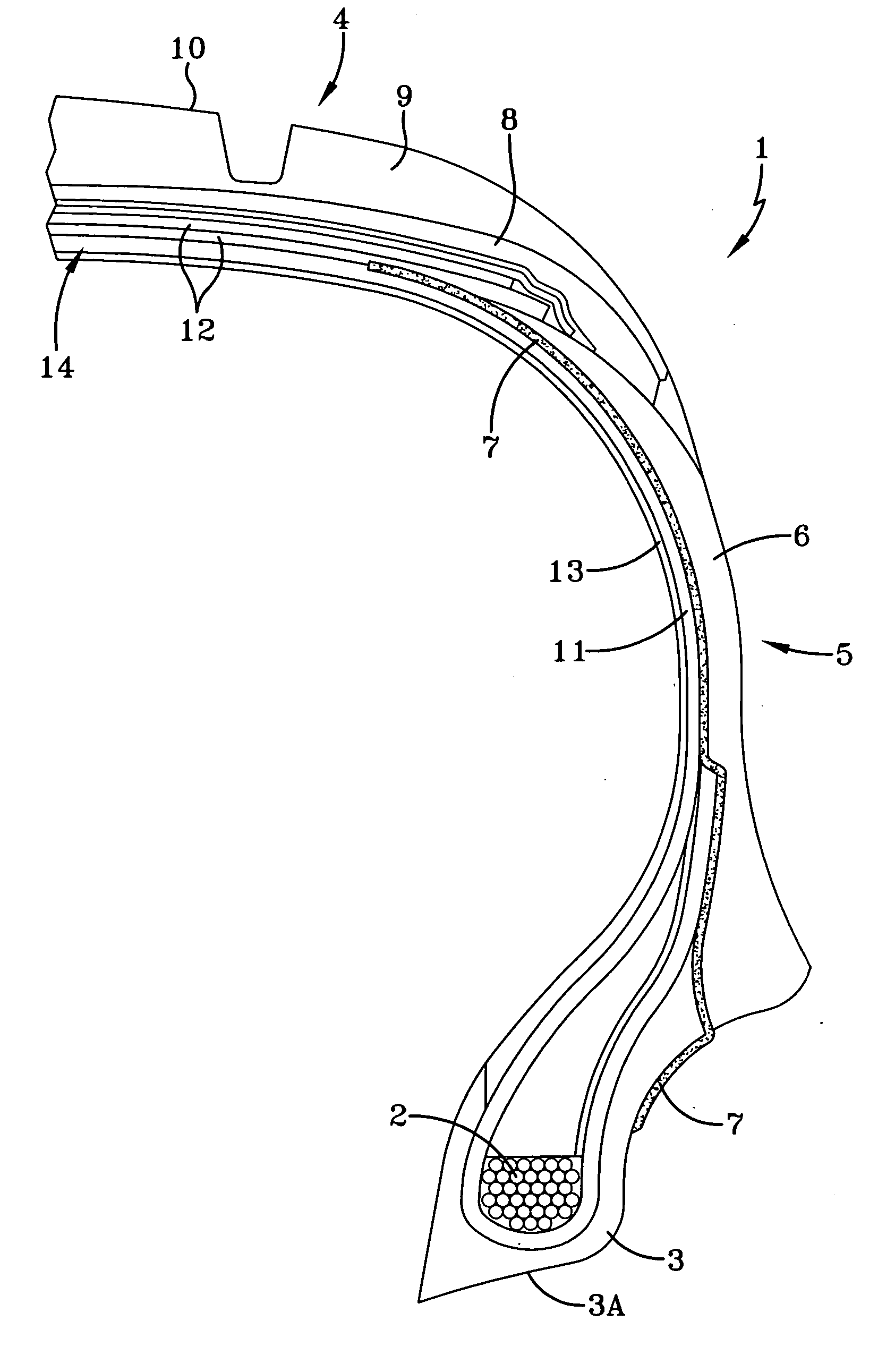

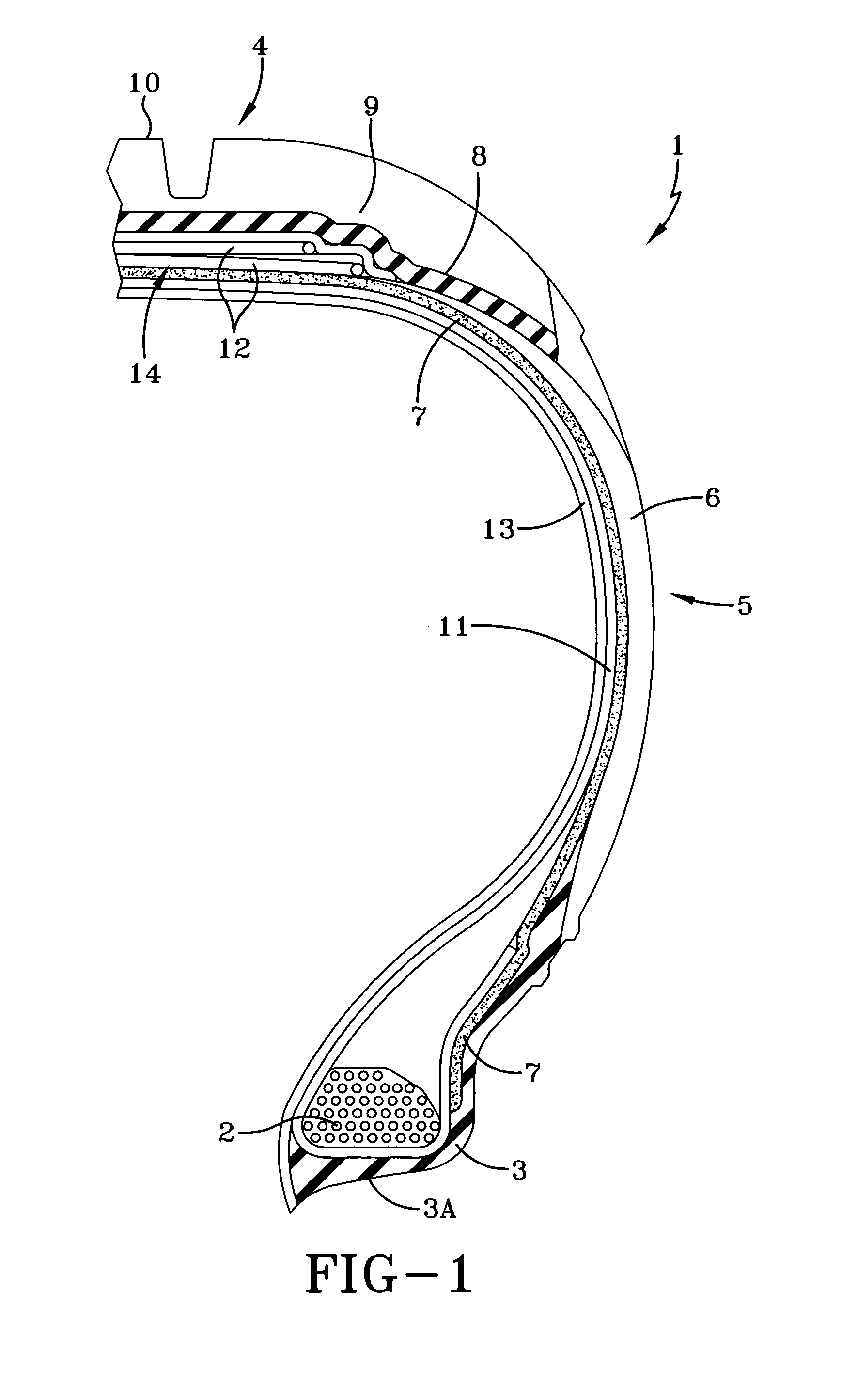

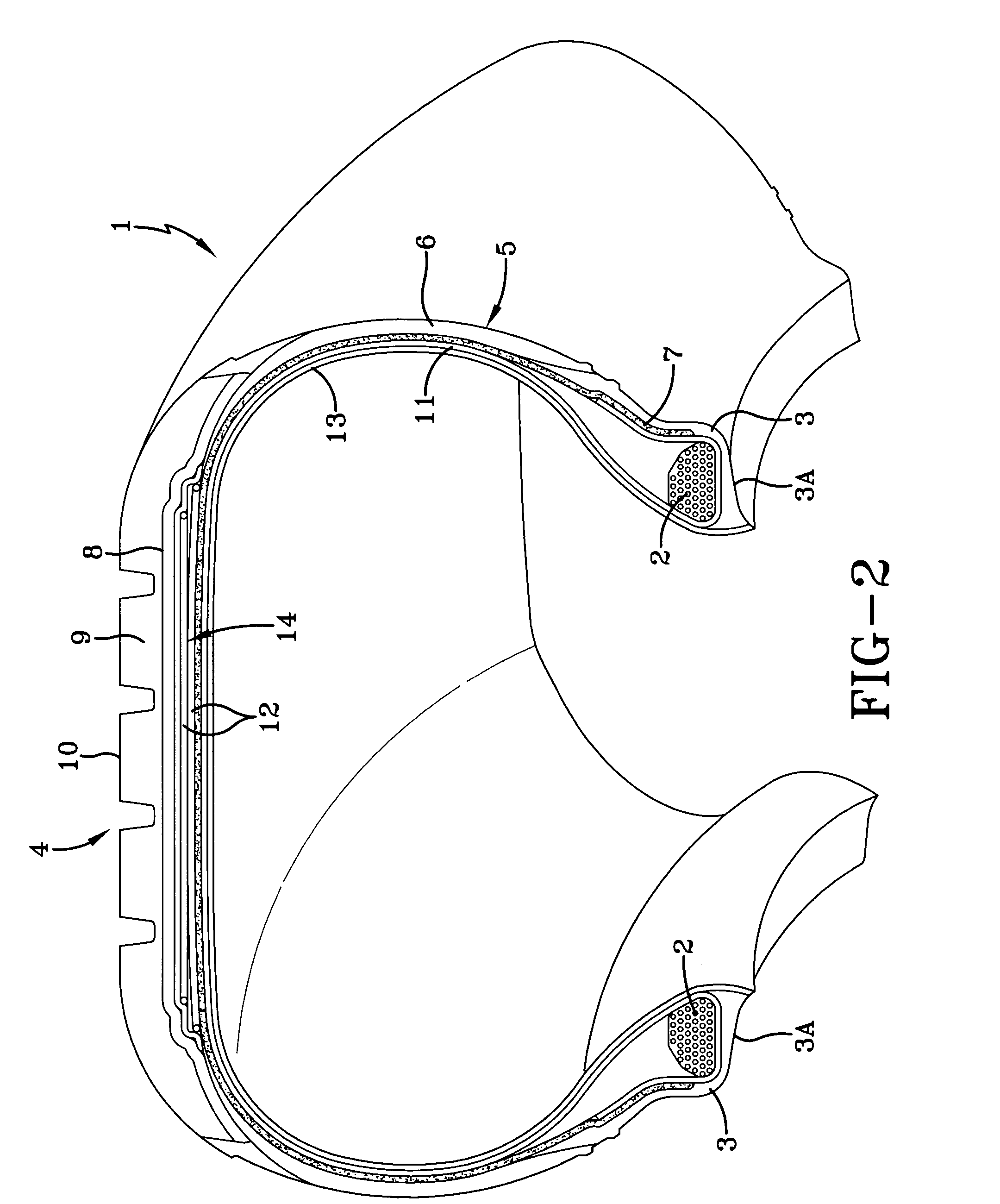

Pneumatic tire with electrically conductive cord extending between a bead portion and a tread portion of the tire

InactiveUS20050087275A1Low resistivitySpecial tyresPneumatic tyre reinforcementsFiberElectrical resistance and conductance

This invention relates to a pneumatic rubber tire which contains at least one electrically conductive cord extending between its bead portion and its tread portion to provide a path of least electrical resistance. The electrically conductive cord is comprised of at least one electrically conductive metal filament spirally wound around a centrally disposed core of at least one organic fiber. The electrically conductive cord extends from a rubber component in a bead portion of the tire which is relatively electrically conductive to a rubber component in the tread portion of the tire which is relatively electrically conductive in a manner that said electrically conductive cord does not extend to, and therefore is exclusive of, an outer surface of the tire. An electrically conductive path is thereby provided between a mounting surface of the tire in its bead region to a running surface of the tire tread. The electrically conductive cord may also be comprised of an electrically conductive metal filament, electrically conductive carbon fiber, or their combination, spirally wound around a core of at least one organic fiber.

Owner:THE GOODYEAR TIRE & RUBBER CO

Diamond/cubic boron nitride saw blade for cutting metal and fabricating method therefor

ActiveCN1669708ANo harmHuman and Environmental HazardsMetal sawing toolsSawing tools dressing arrangementsBoron carbideBoron nitride

This invention relates to a saw bit belonging to mechanical working field, which comprises metal base being alloy steel or carbon steel, with Phi8-Phi10mm radiating holes equispaced on its surface; Carcass including alumina, zircite, quartz, tungsten carbide, zirconium diboride, molybdenum disilicide; common abradant including brown fused alumina, carbofrax, green silicon carbide, cubic carbofrax, boron carbide; superhard abradant including diamond and cubic boron nitride. The produce process includes mixing carcass flour, working layered material batching-mixing process, welding layered material batching-mixing process, koldflo, thermal pressing-sintering formation, arc milling, welding, dressing and making edge. The invention has improved working efficiency, lowered product cost, and is suitable for cutting metal tube, plate such as this materials.

Owner:SF DIAMOND CO LTD

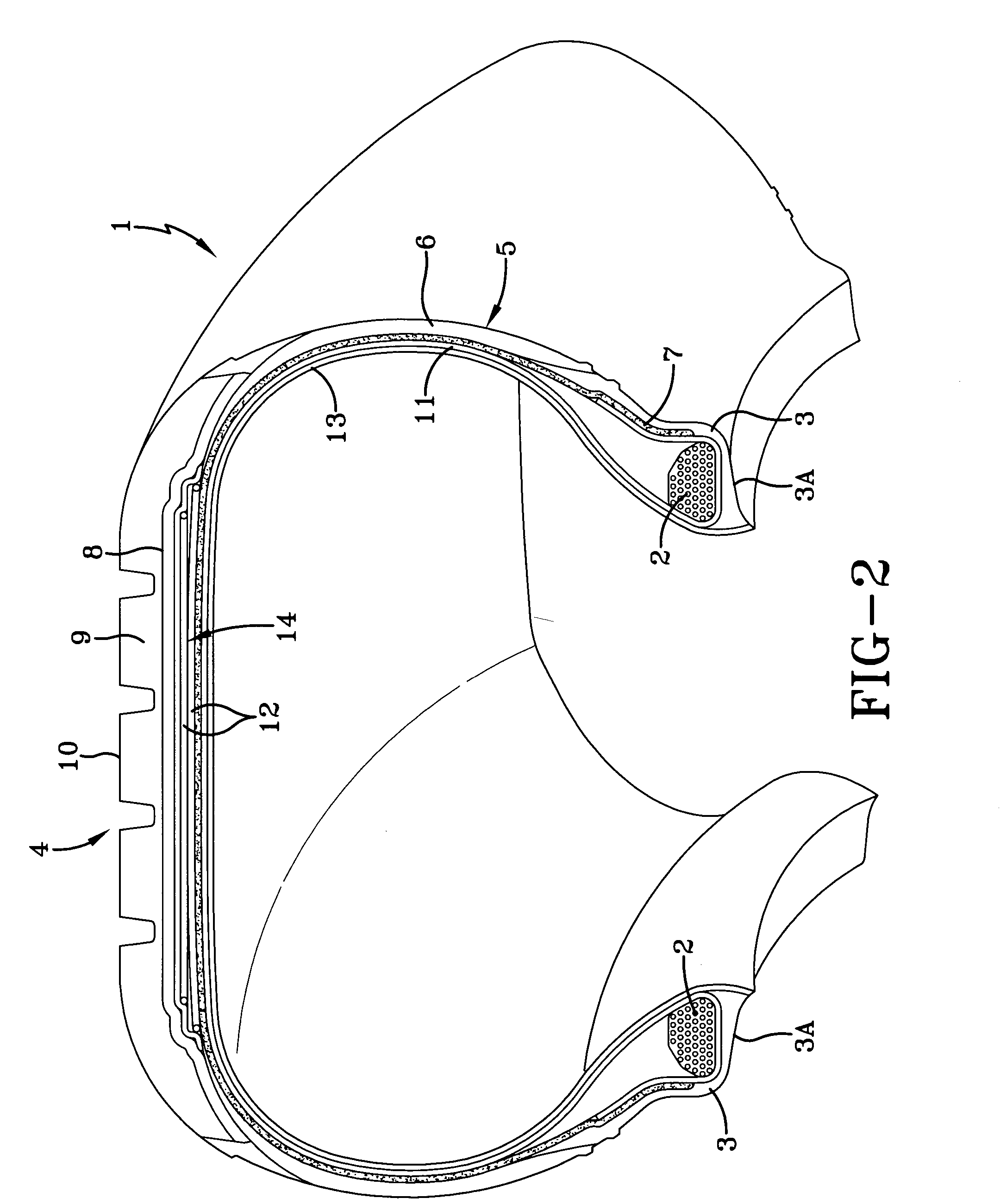

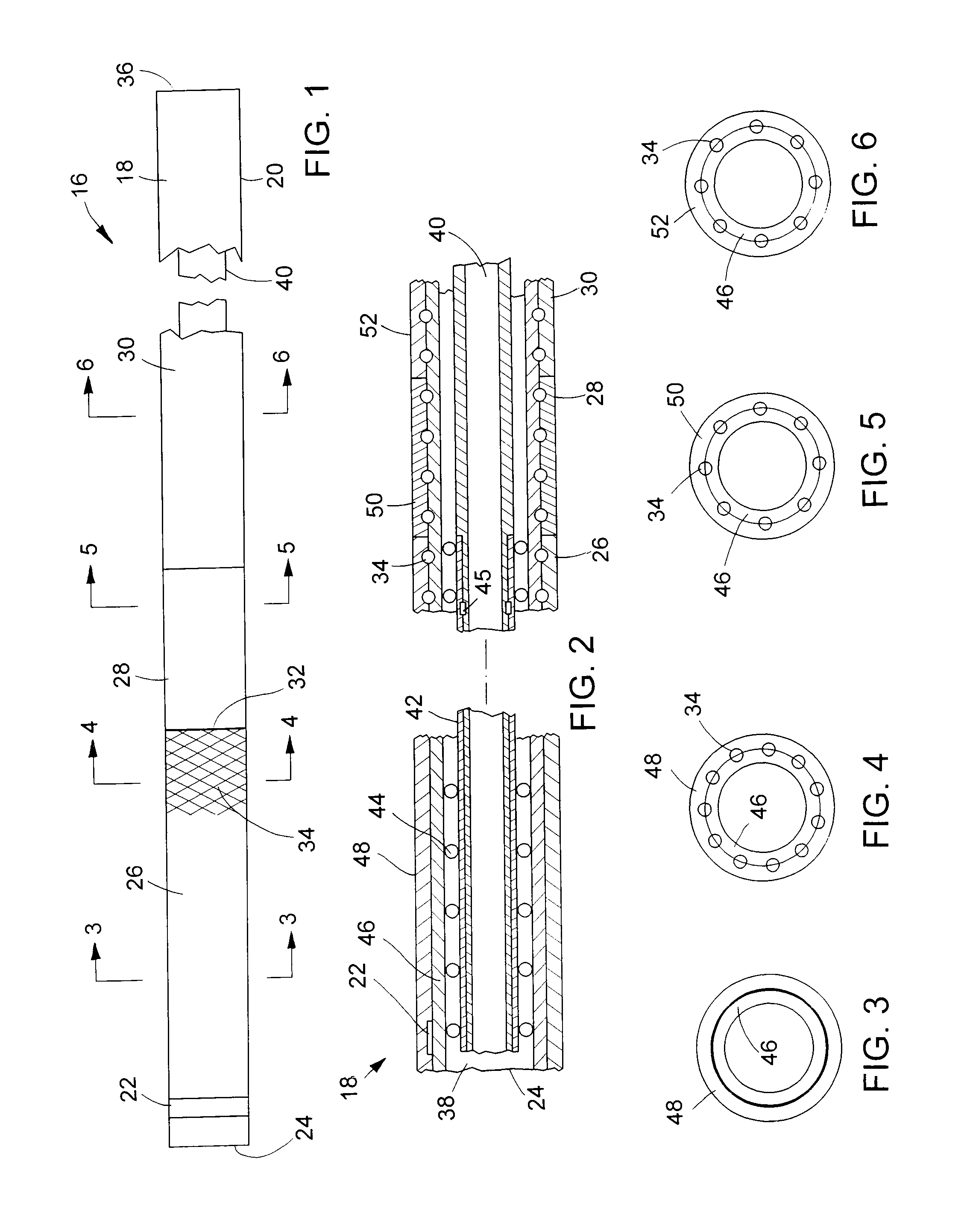

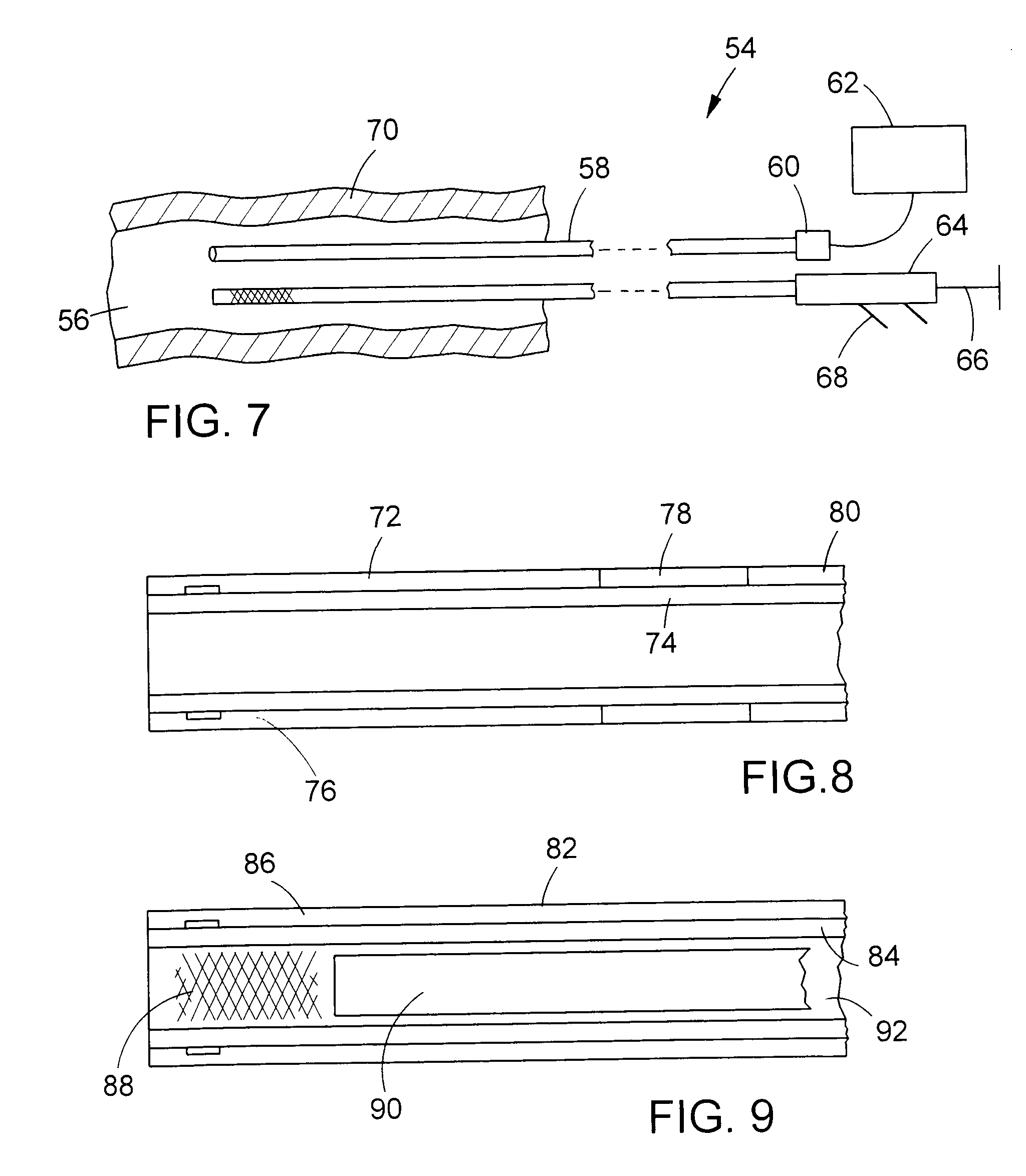

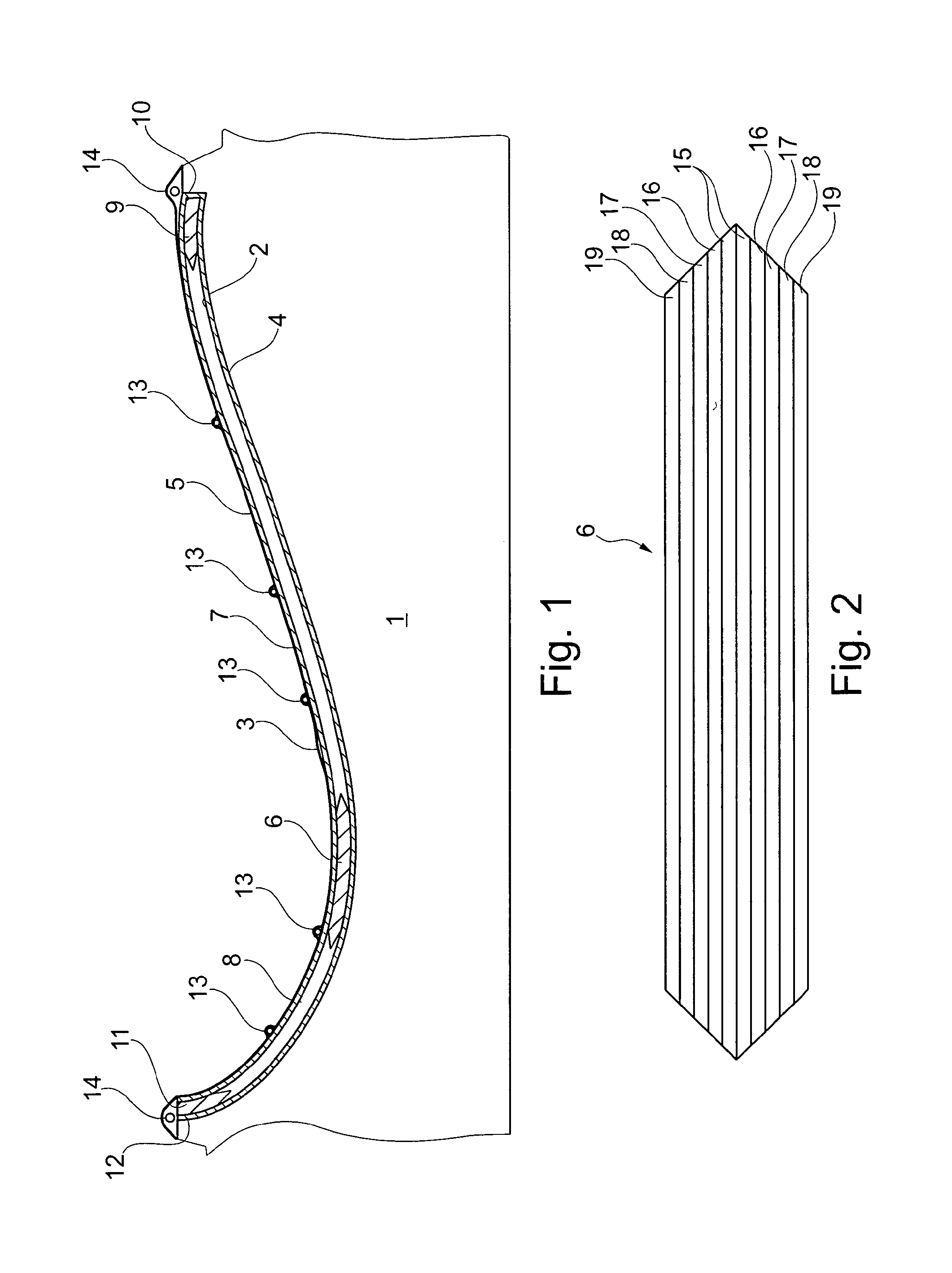

Prosthesis deployment device with translucent distal end

InactiveUS20090228092A1Precise positioningEffective monitoringStentsSynthetic resin layered productsMetal filamentExternal catheter

A prosthesis delivery and deployment device includes an elongate and flexible outer catheter. The outer catheter has a tubular wall of layered construction, including a translucent inner liner running the complete catheter length, and three outer layers including a translucent distal layer, an opaque medial layer and an opaque proximal outer layer. The outer layers are adjacent one another and are bonded to the liner. A braid composed of helically wound metal filaments is disposed between the liner and the proximal and medial outer layers, and includes a distal portion between the liner and a proximal portion of the distal outer layer. The liner and distal outer layer provide a translucent distal region of the catheter that is adapted to constrain a radially self-expanding prosthesis in a radially reduced, axially elongated state. Because the stent constraining region is translucent, an endoscope can be used to visually monitor the stent when so constrained. Radiopaque markers can be mounted to the outer catheter and to an inner catheter used to deploy the prosthesis, to afford a combined visual and fluoroscopic monitoring for enhanced accuracy in positioning the prosthesis, both before and during its deployment.

Owner:BOSTON SCI SCIMED INC

Wire for welding

InactiveUS6337144B1Increase the number ofElectric discharge heatingSynthetic resin layered productsUnsaturated hydrocarbonCarbon steel

A welding wire of the type consists of a plated or uncovered solid wire and a flux-cored wire for carbon steel or stainless steel, wherein one or more of hydrocarbon compounds selected from the group consisting of saturated or unsaturated hydrocarbon compounds, which have from 5 to 12 carbon atoms and a linear or branched structure, and hydrocarbon compounds having a cyclic structure are deposited on a wire surface. A lubricating oil and / or lubricating particles are chemically combined with a wire surface through the one or more hydrocarbon compounds. The total amount of the hydrocarbon compounds, and a lubricating oil and / or lubricating particles deposited on the wire surface is in the range of 0.1 to 5 g per 10 kg of the wire.

Owner:KOBE STEEL LTD

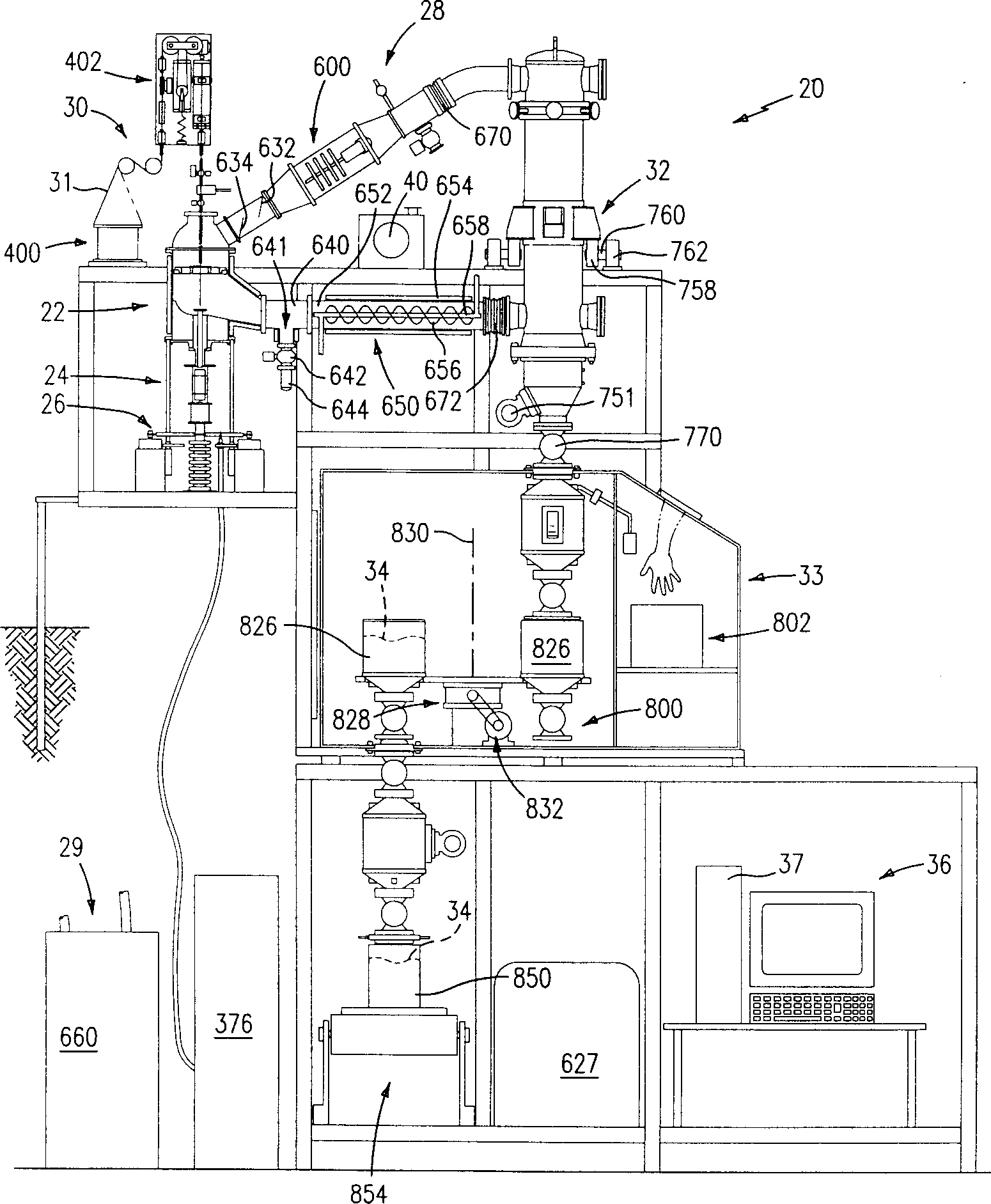

Apparatus and methods for the production of powders

Metal powders are formed by the electro-explosive wire (EEW) method. The device (20) for producing this powder comprises a closed loop gas passage between the reaction chamber (100) and the extractor (32). The wire (31) is transported from the source (400) to the chamber along the wire channel from the ambient conditions outside the reaction chamber. Inside the chamber, a first electrode (200) has a hole defining said wire channel, and a second electrode (202) is near the end of the wire channel. The electric energy source (26) applies a discharge voltage between the electrodes to make this section of metal wire explode to form initial particles. The starting microparticles can optionally be extracted and processed to produce desired powders, especially high energy powders that are passivated so as to be stable under ambient conditions.

Owner:AMERICAN INTER METALLICS

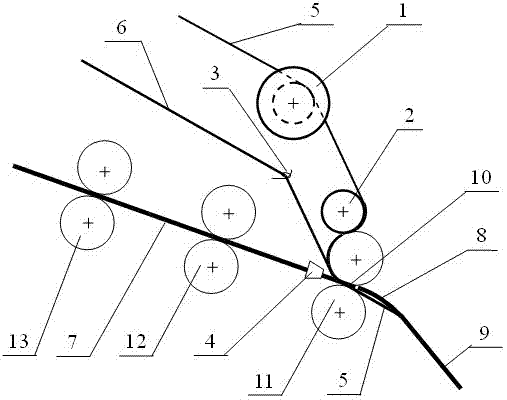

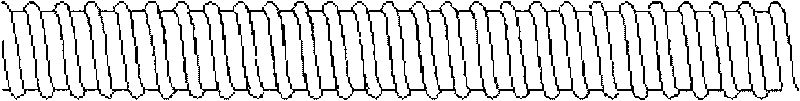

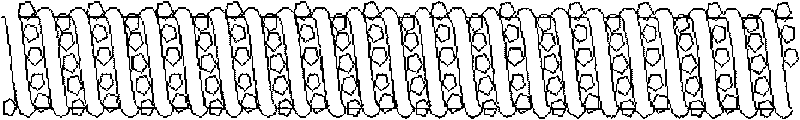

Electromagnetic shielding yarn with metal wire wrapped elastic yarn, production equipment and production method thereof

ActiveCN102296400AComfortable to wearThe method is simple and fastContinuous wound-up machinesYarnYarnFiber

The invention provides an electromagnetic shielding yarn of metal filament-wrapped elastic filaments and production equipment as well as a production method thereof. The electromagnetic shielding yarn is characterized by comprising elastic filaments, wherein wrap yarn sections are wound outside the elastic filaments and comprise metal filaments and chopped fiber strands which wrap the metal filaments. The production equipment comprises a ring spinning frame, and is characterized by also comprising a tension pulley, a holding roller, a yarn guide hook and a bundler. In the invention, the composite yarn with high extensibility and elasticity and electromagnetic shielding function can be prepared. The obtained electromagnetic shielding yarn can be used for producing common clothes and household and industrial textile products.

Owner:DONGHUA UNIV

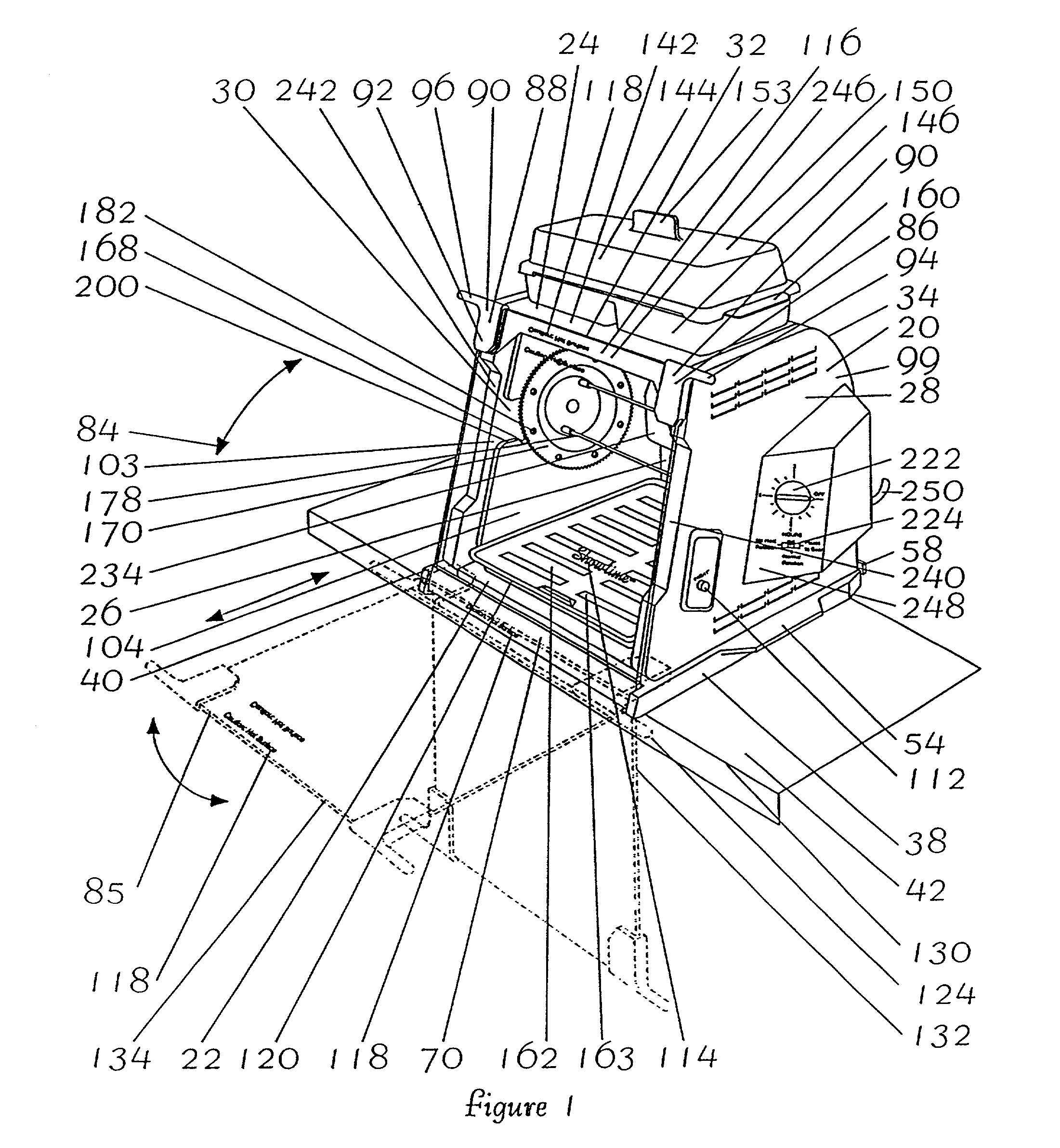

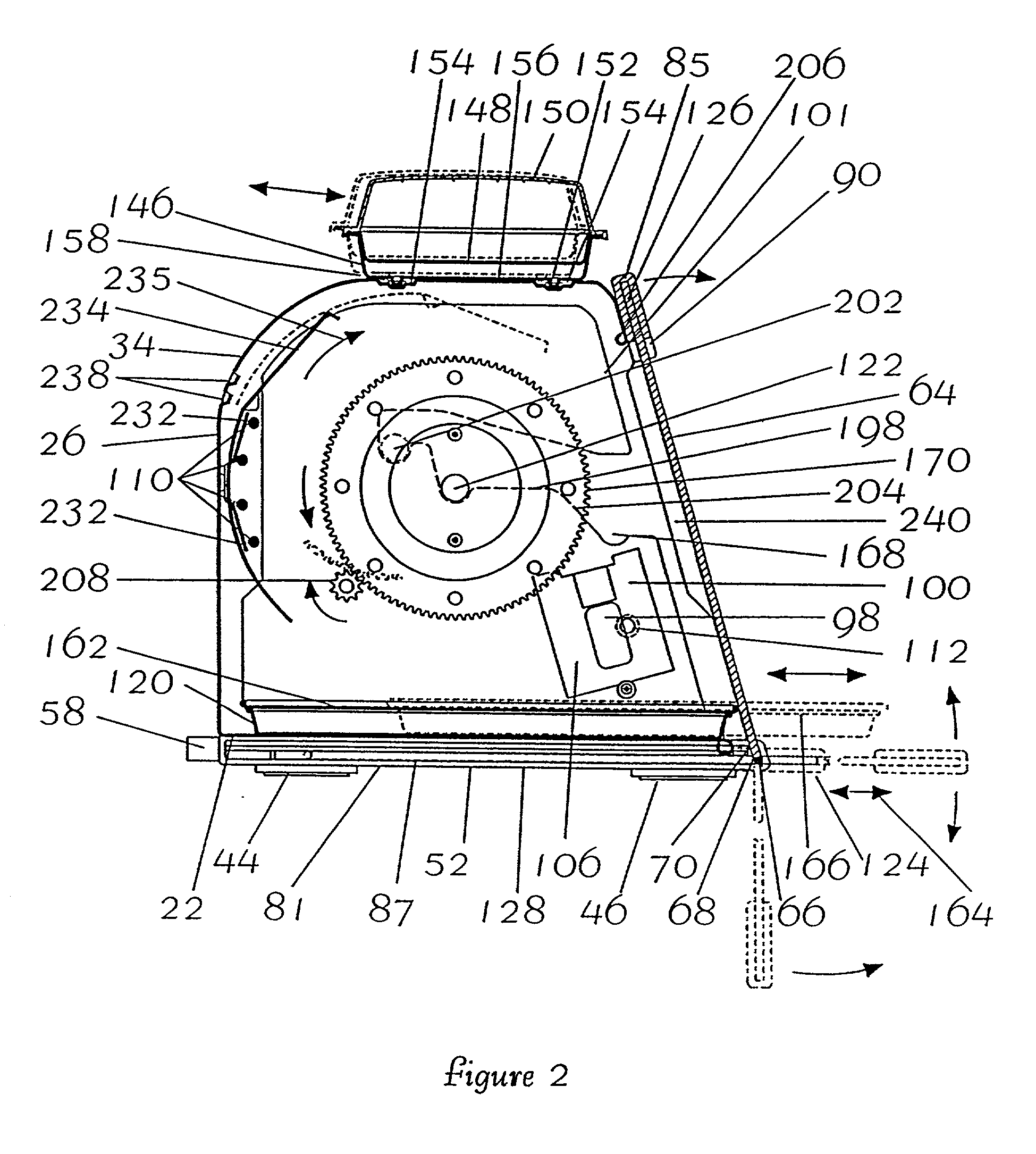

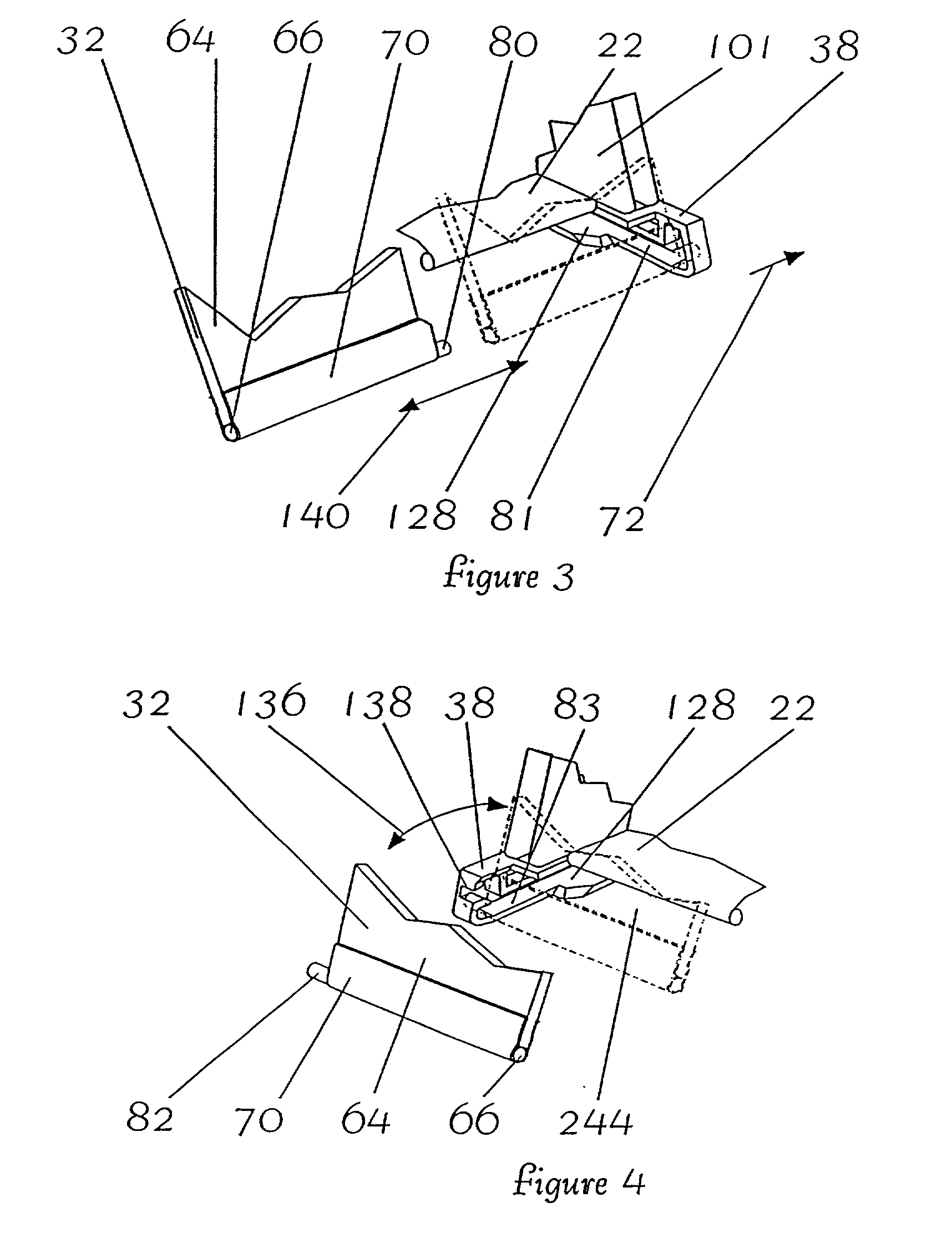

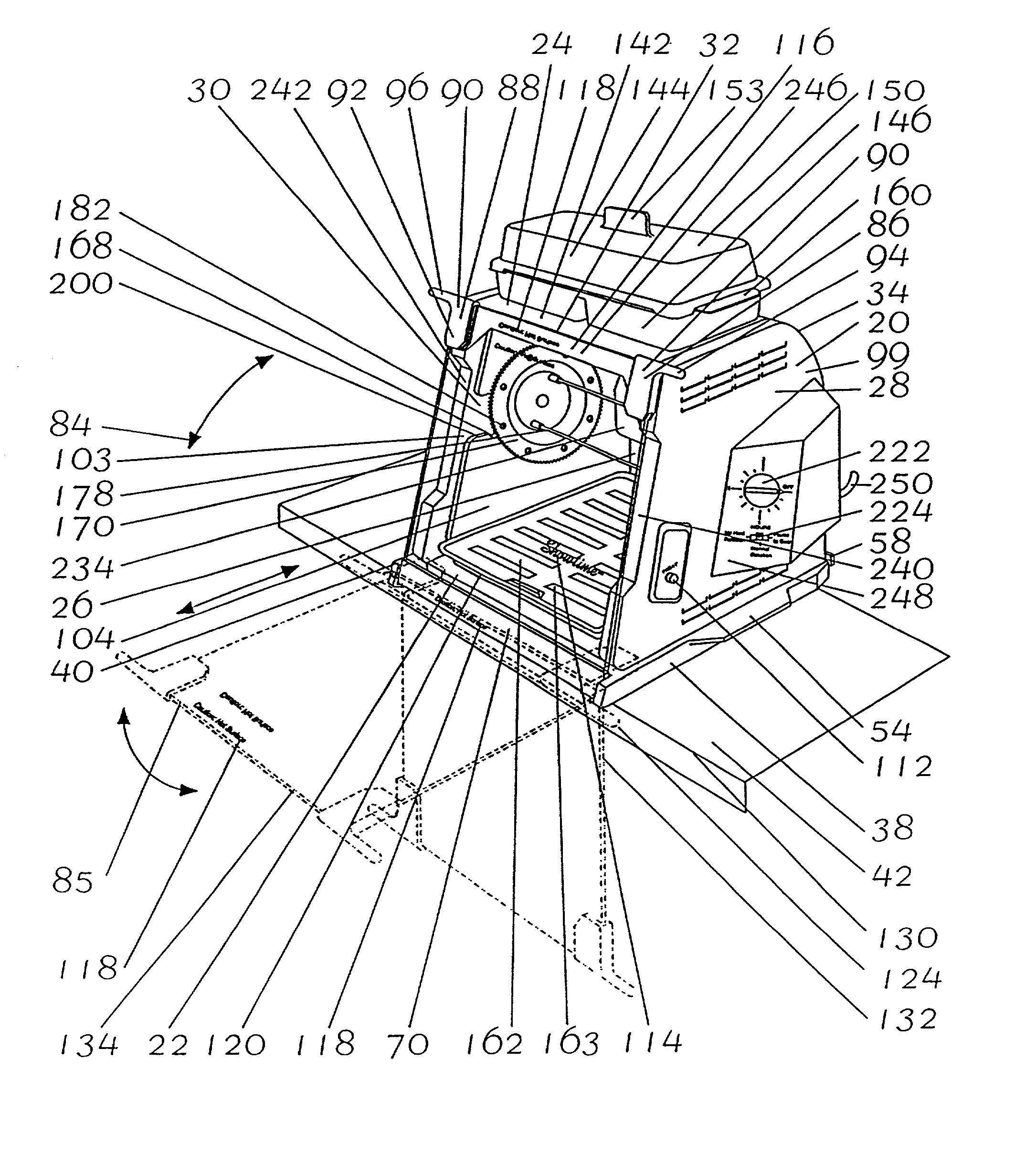

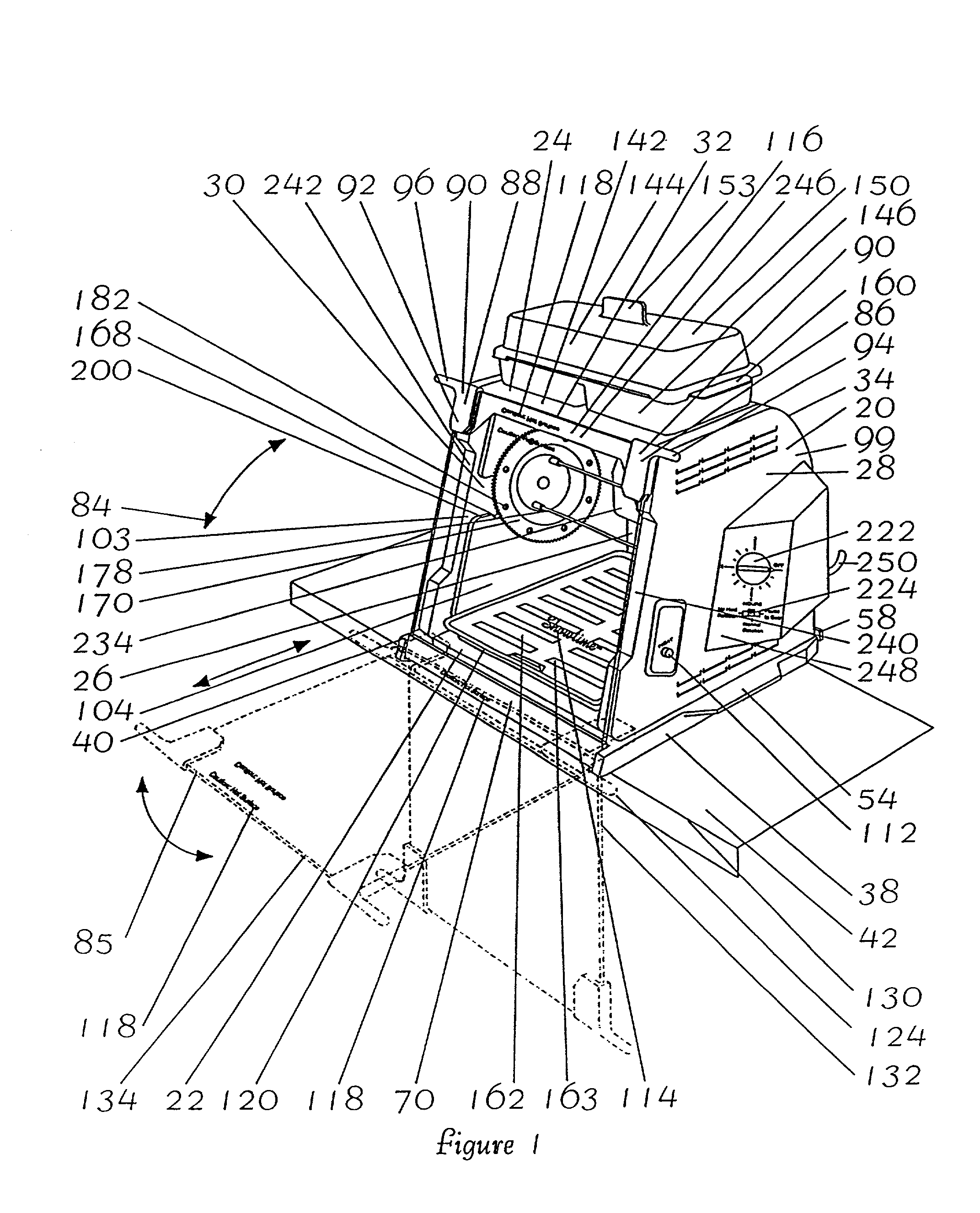

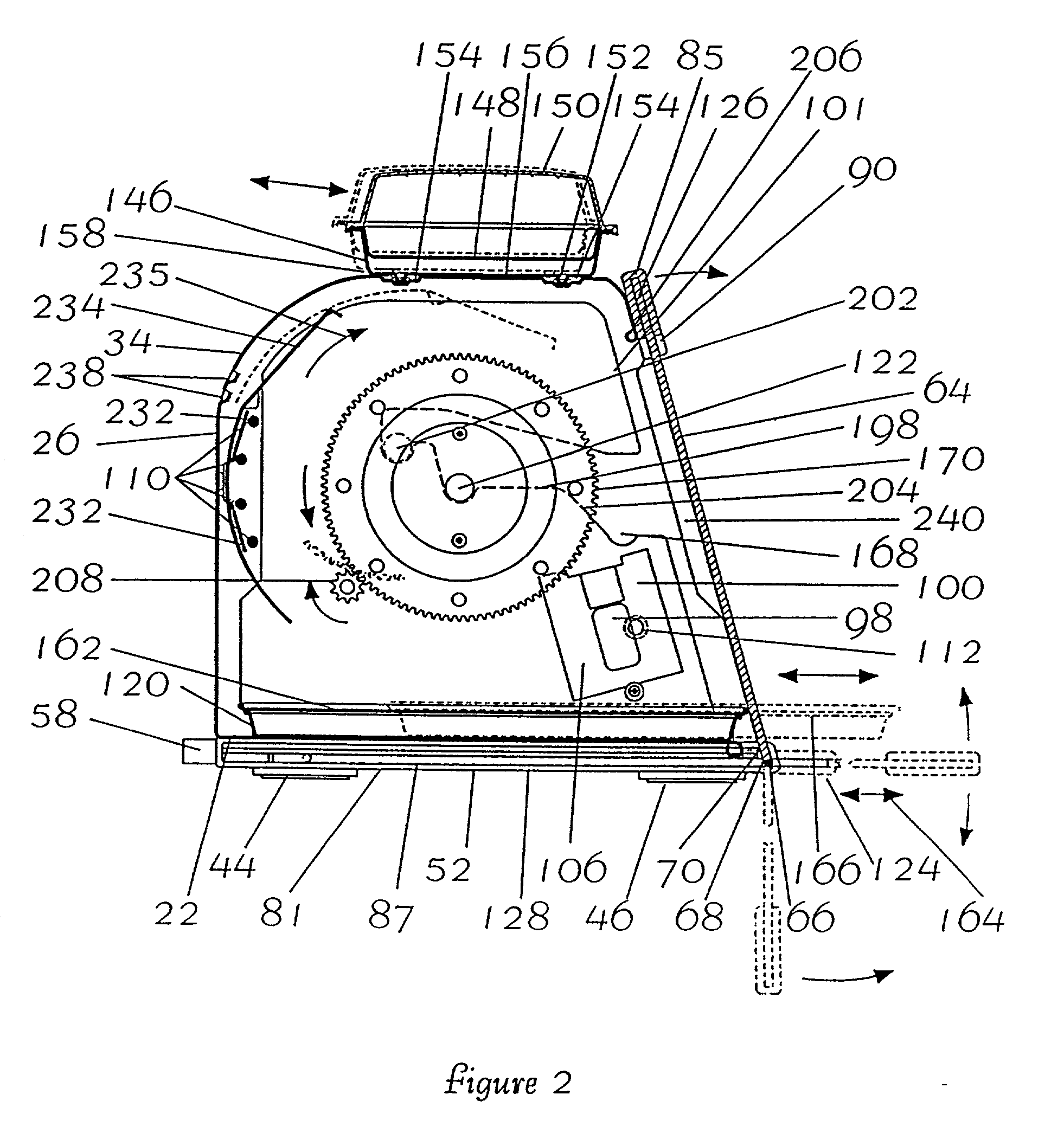

Rotisserie oven having a heat shield

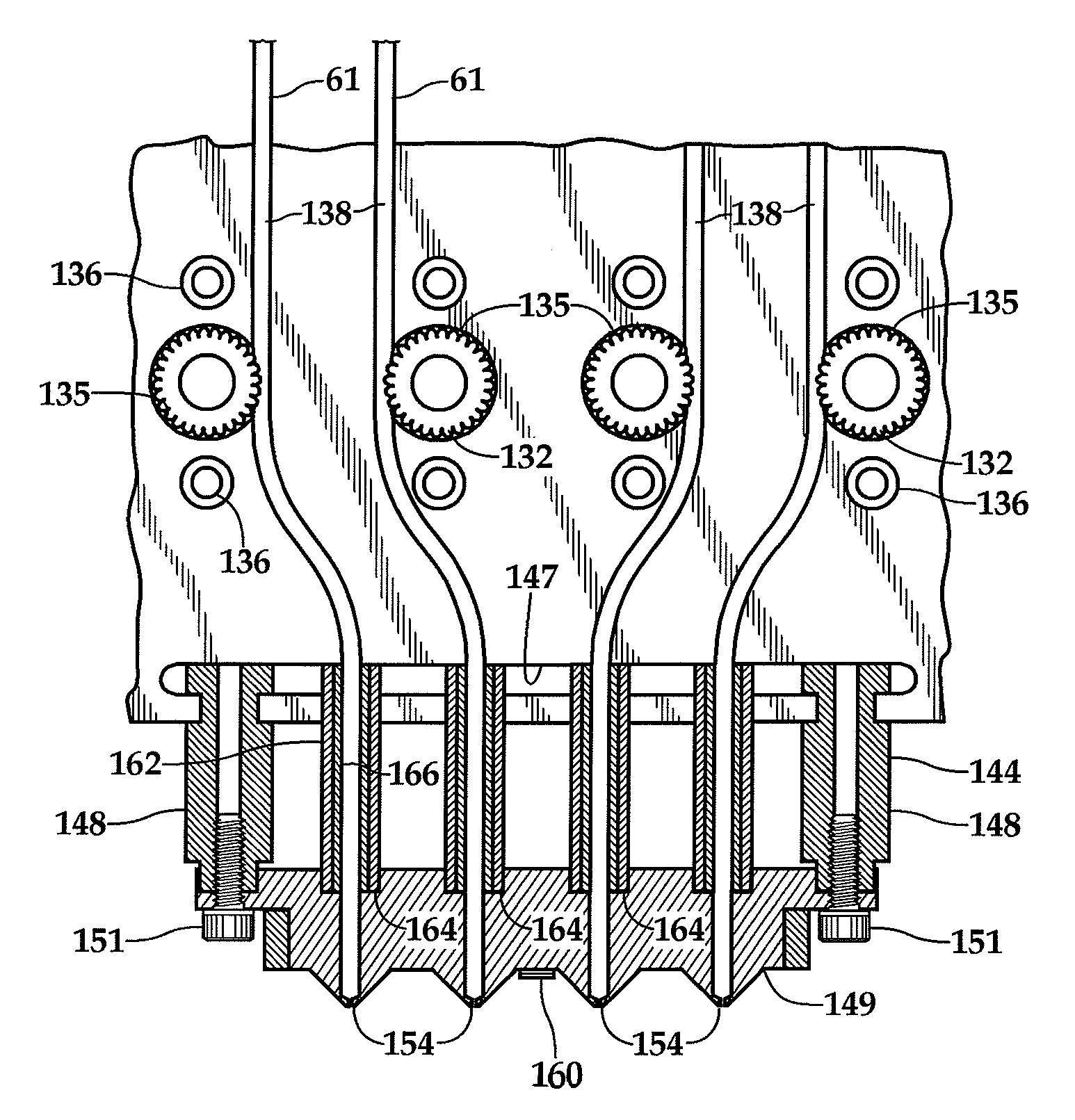

InactiveUS20010009128A1Prevent slippingEasy to handleCooking-vessel lids/coversMeat processingGear driveReady to use

Enclosed rotisserie with added convenience, including a countertop resting box-like enclosure housing a safety rear mounted heating element and a power rotated dual rod spit assembly. The gear driven spit assembly may be easily inserted and removed straight into and out of the enclosure without need for angling or coupling the assembly to a power drive socket. The spit assembly may also be mounted at various distances from the heating element to decrease cooking times. The open front of the enclosure is from time to time covered by an inclined glass panel door which may be opened in various ways to facilitate food insertion into and removal from the enclosure, and which may be easily removed for cleaning or other purposes. The embodiment's design makes efficient use of valuable counter space by recessing back and raising off the countertop its controls. A contained light as well as room light emitted through the inclined glass door illuminate the enclosure's interior to make the rotisserie cooking into a taste tempting show. Two countertop supported sizes for the embodiment are suggested, one for larger families and entertaining, and the other for small families and singles. Cooking times are decreased and manufacture simplified by the embodiment heating element remaining on constantly during the cooking process. Maintenance is minimized by various embodiment parts being removable for cleaning including a cleaning shield located behind the heating element, the glass door, and a drip pan with slotted cover. A variety of foods may be cooked using the spit and accessories that attach to the spit. Such accessories include wire baskets and a rotating stir fryer. Foods may be cooked on top of the embodiment as well using an included warming tray and an inserted steaming tray with cover. Grease-tight rotisserie / barbecue gloves make food handling easier and safer, as can also be said for a spit support platform which supports the spit assembly for food mounting and carving. Self-rotating kabob rods cook kabobs on all sides evenly and allow for increasing rotisserie capacity by increasing the length of rotating rods available for rotisserie food mounting.

Owner:RONCO HLDG +1

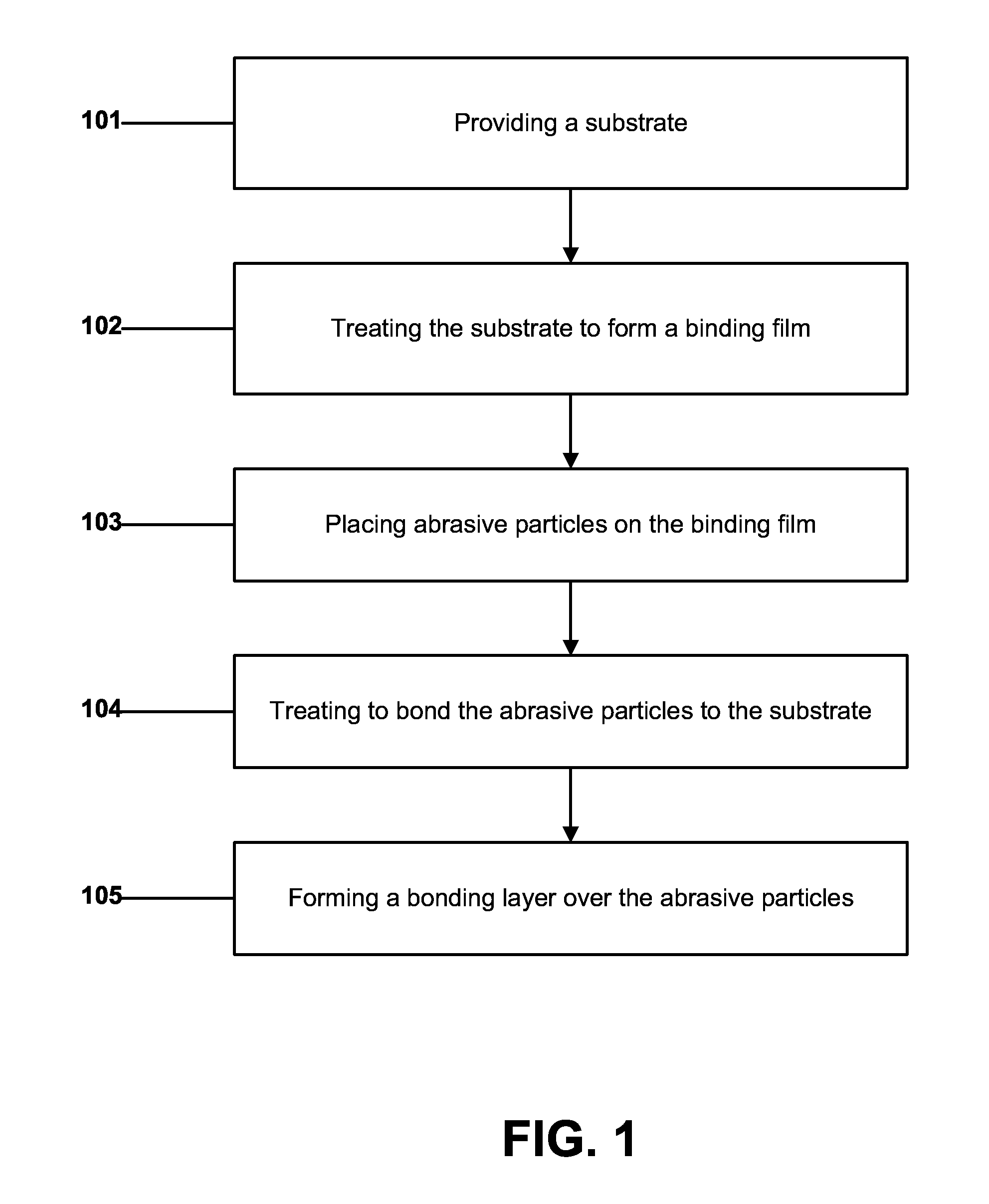

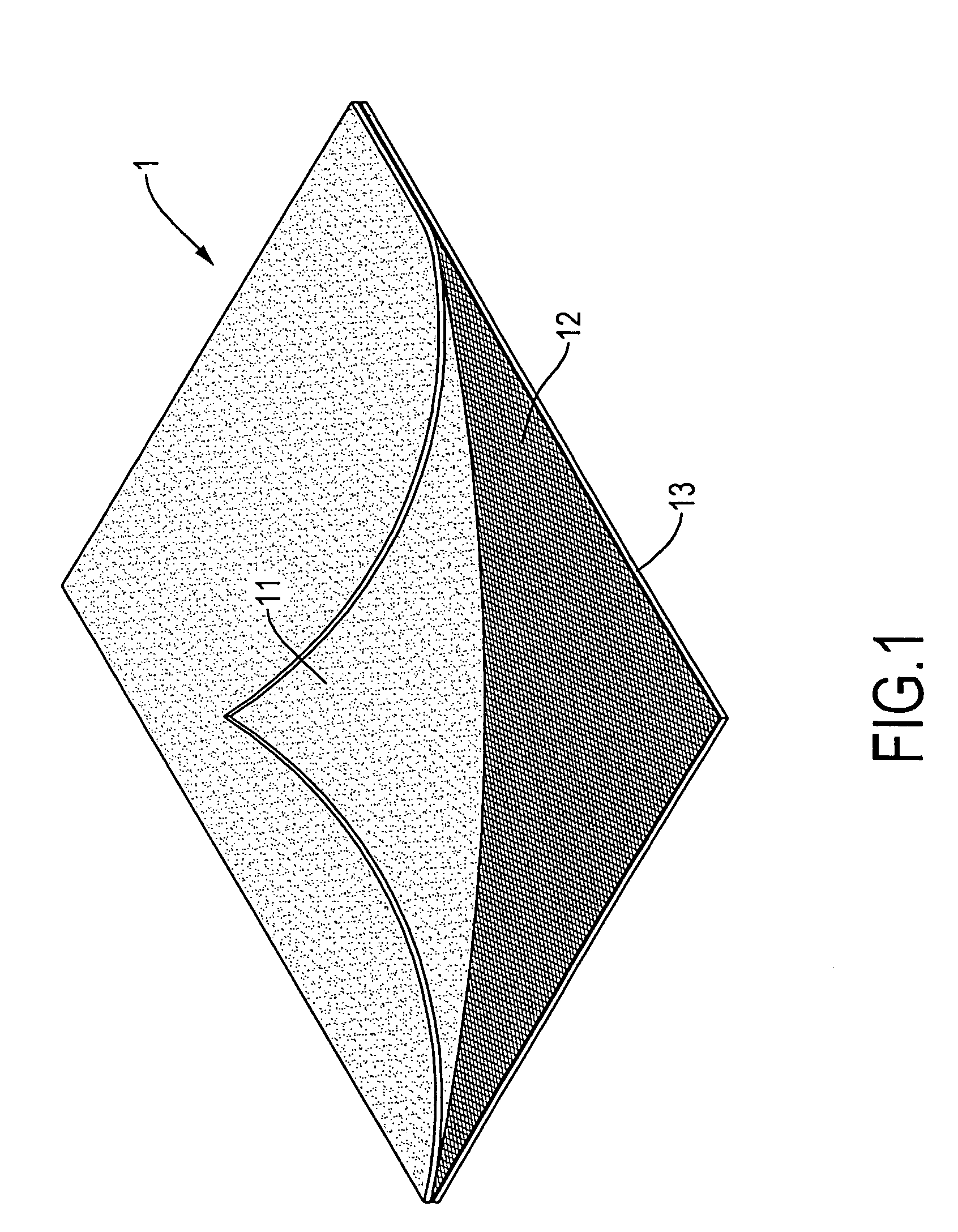

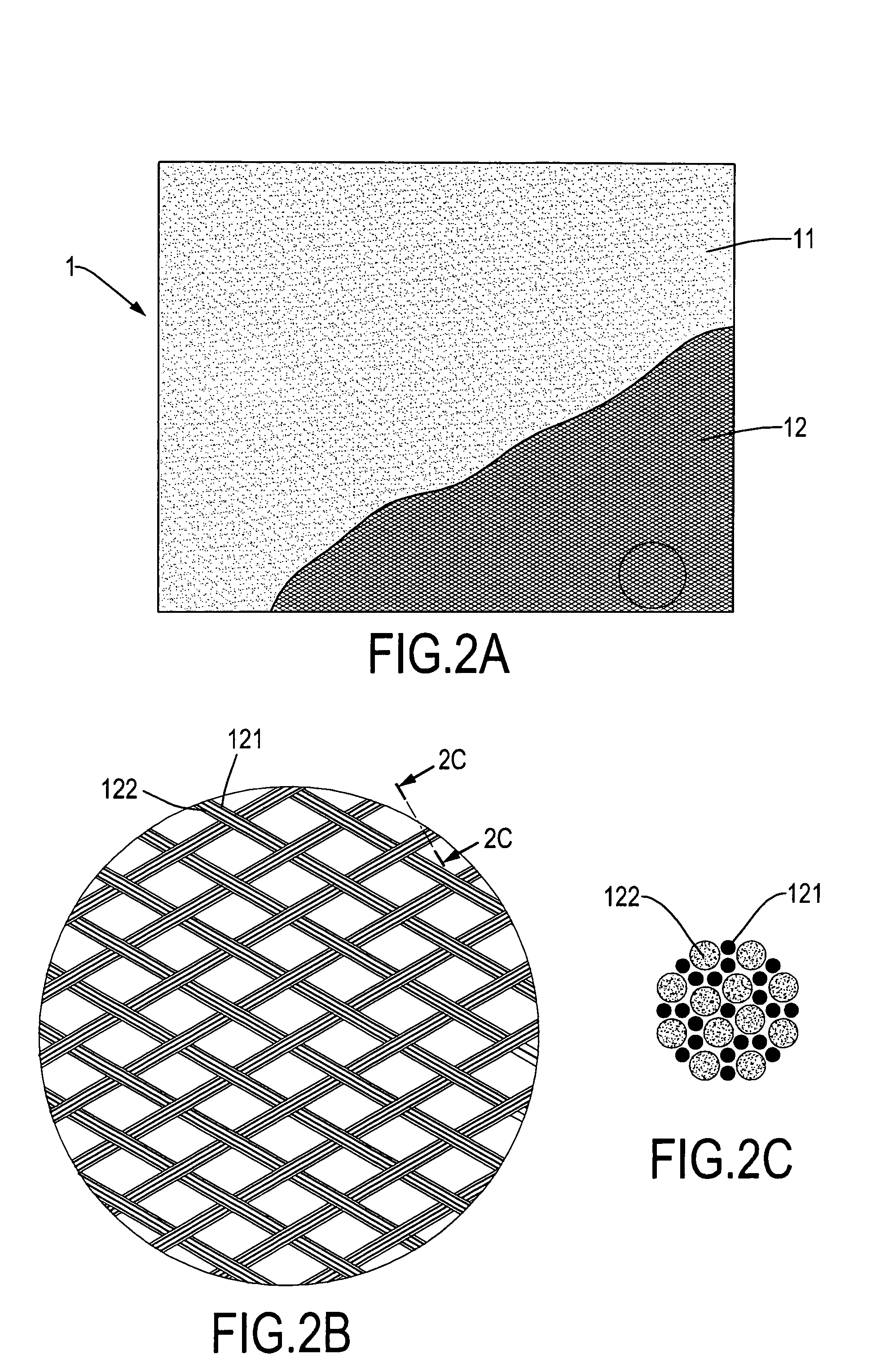

Abrasive article and method of forming

An abrasive article including a substrate made of a wire, abrasive particles affixed to the substrate, the abrasive particles having a first coating layer overlying the abrasive particles, and a second coating layer different than the first coating layer overlying the first coating layer. The abrasive article further including a bonding layer overlying the substrate and abrasive particles.

Owner:SAINT GOBAIN ABRASIVES INC +1

Production method of metal fibrofelt

The invention relates to a production method of a metal fibrofelt, which comprises the steps that: metal wires or metal alloys are made into metal fibers, then the metal fiber is chopped to obtain chopped fiber, according to the requirement of filter fineness, metal fibers with different wire diameters are treated by the felt coating method of a felt coater to obtain a single-layered porous metal fibrofelt; meanwhile, one layer or more layers of the obtained single-layered porous metal fibrofelt is / are overlaid, and then is / are placed into a vacuum sintering furnace or is sintered under protective atmosphere with reducibility, wherein the sintering temperature is 1100-1500 DEG C, and the temperature holding time is 1-5 hours; and after the sintered metal fibrofelt is cooled, the metal fibrofelt with a certain porosity can be obtained, and then the sintered metal fibrofelt is pressed by a rolling mill to adjust the thickness of the fibrofelt to obtain the metal fibrofelt finished product with specified thickness. The metal fibrofelt has good combination property and the method can be widely applied to the industrial fields of chemical industry, medicine, power generation, metallurgy, food and the like.

Owner:王东伟

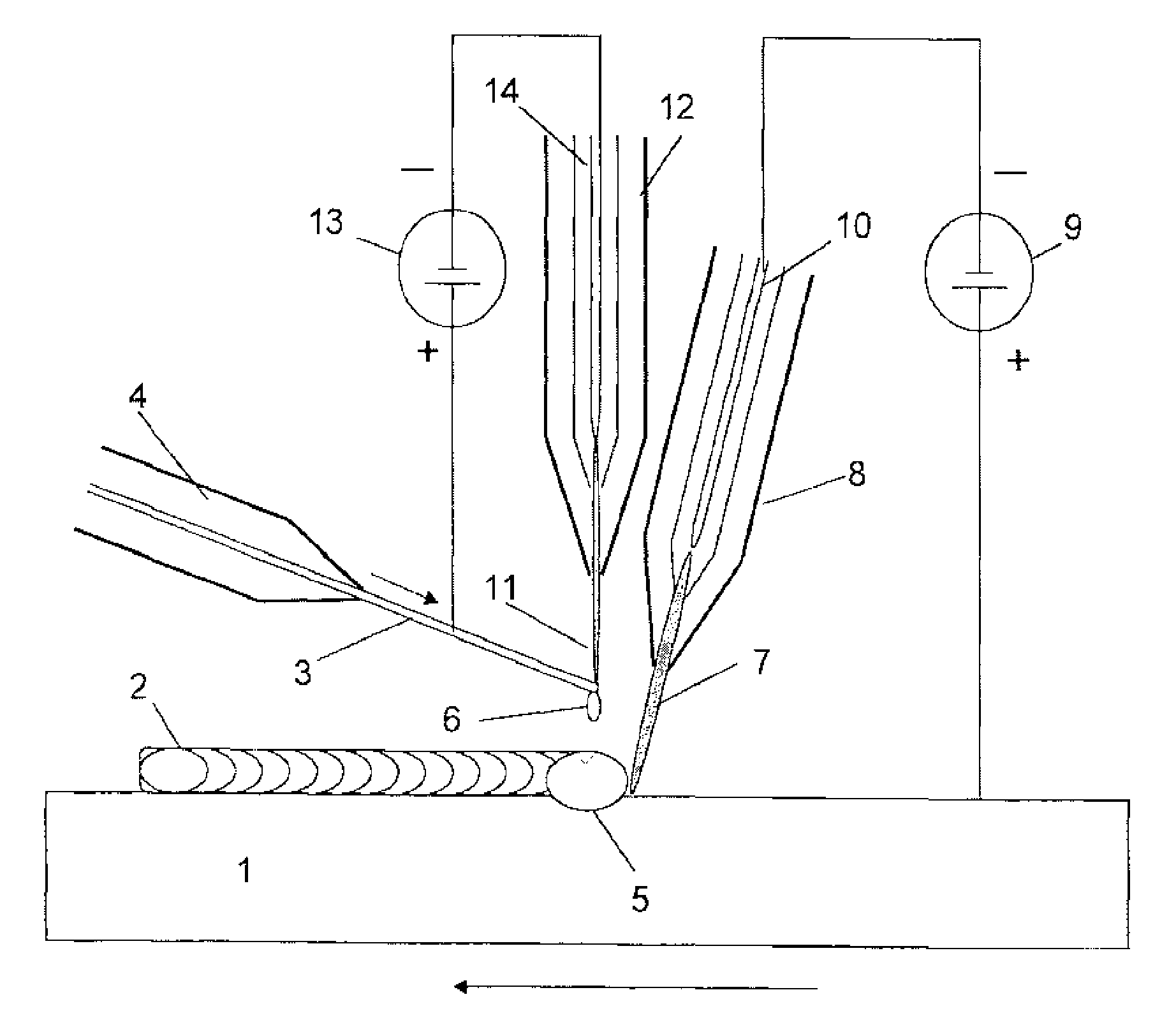

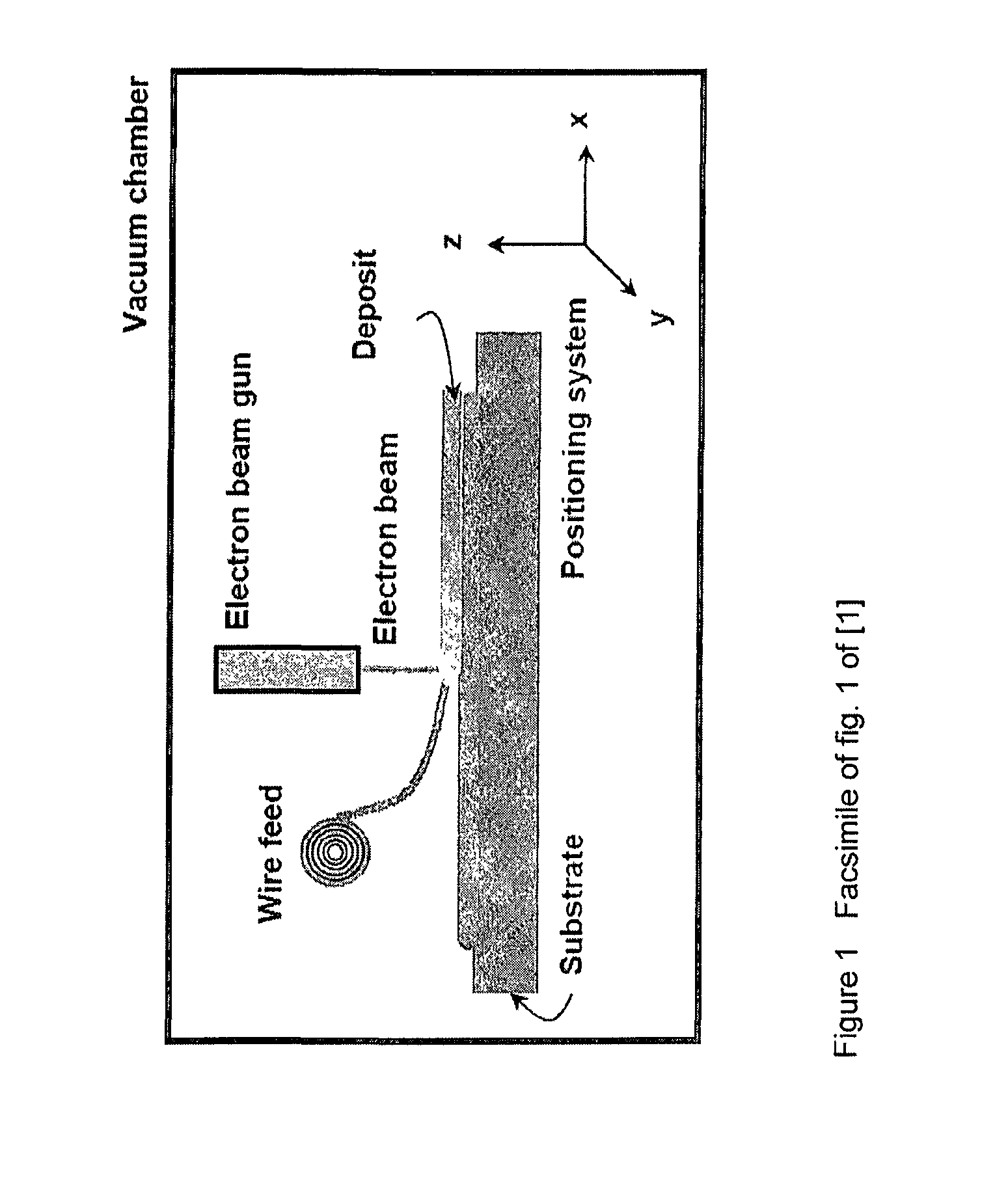

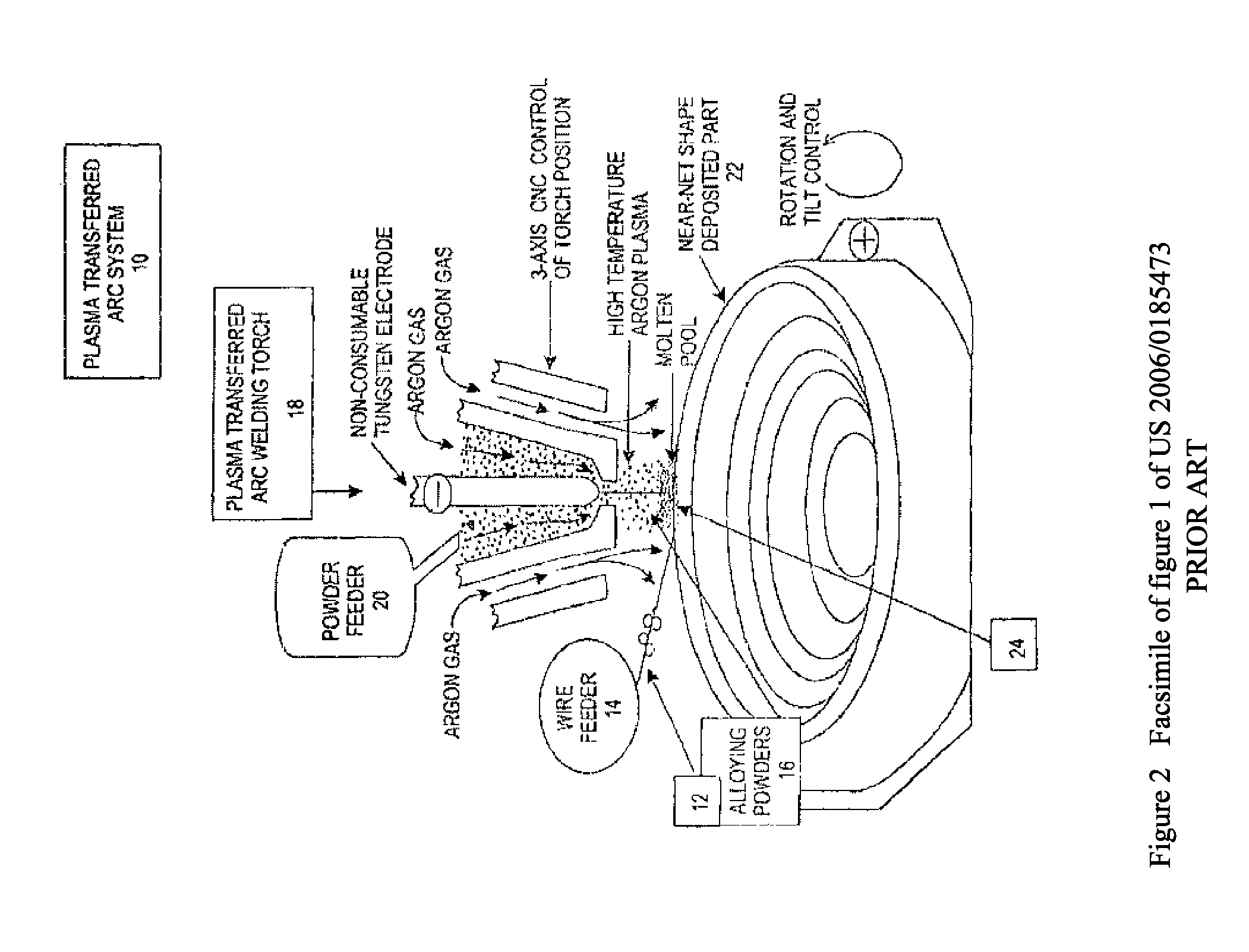

Method and arrangement for building metallic objects by solid freeform fabrication

ActiveUS9481931B2Easy to controlStable and consistent arcProgramme controlAdditive manufacturing apparatusTitaniumTitanium alloy

A method and arrangement for manufacturing objects by solid freeform fabrication, especially titanium and titanium alloy objects, wherein the deposition rate is increased by supplying the metallic feed material in the form of a wire and employing two gas transferred arcs, one plasma transferred arc for heating the deposition area on the base material and one plasma transferred arc for heating and melting the feed wire.

Owner:NORSK TITANIUM

Wire for welding

InactiveUS6841246B2Improve feeding effectStable and smooth feedElectric discharge heatingWelding/cutting media/materialsMetal filamentUnsaturated hydrocarbon

Owner:KOBE STEEL LTD

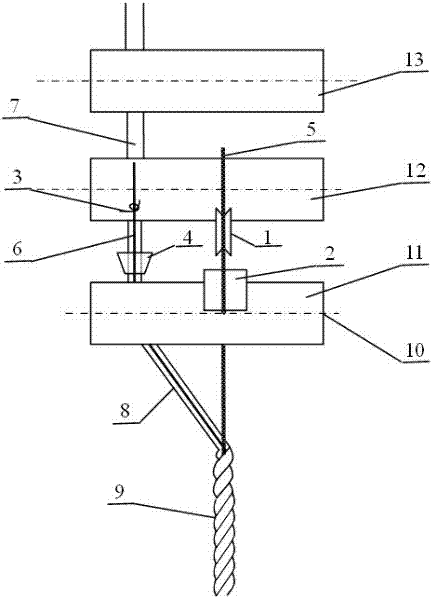

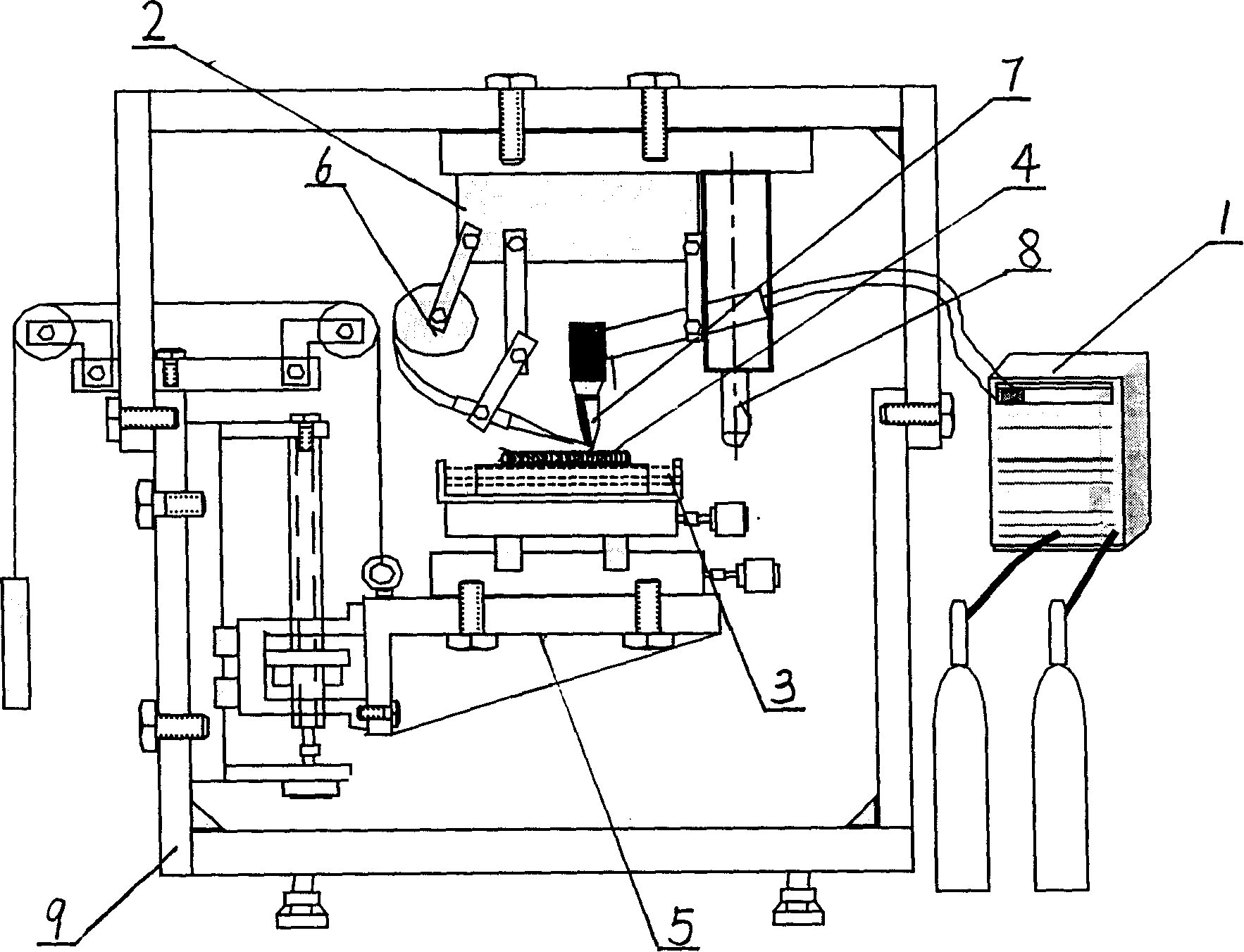

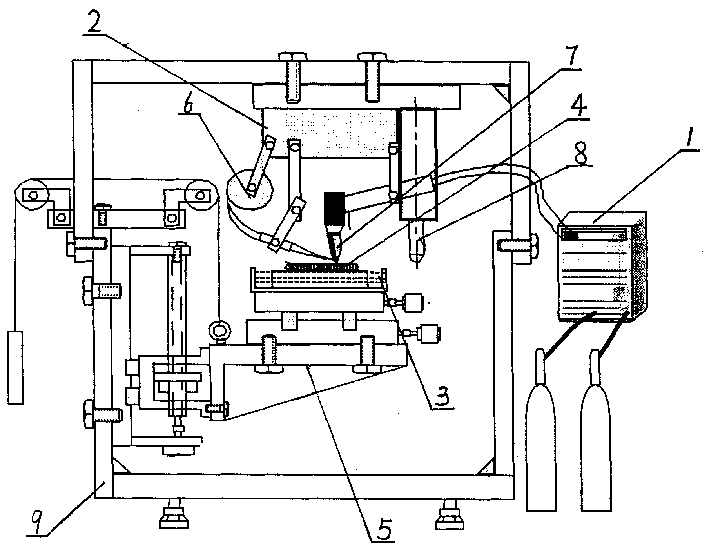

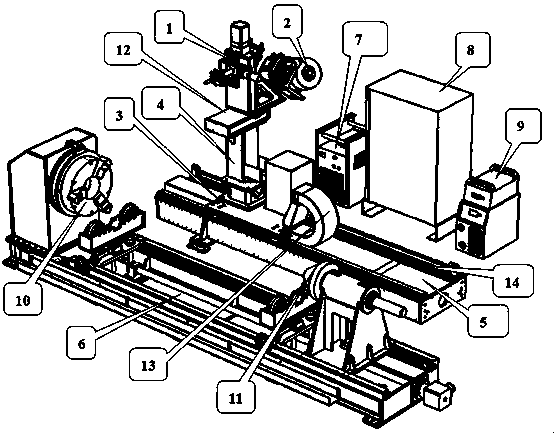

Directly and fast forming method and device for polymetal based on welding amassed

InactiveCN1481972AGuaranteed accuracyArc welding apparatusOther manufacturing equipments/toolsSelf adaptiveEngineering

The present invention is direct fast polymetallic forming method and apparatus based on welding stackup. The method includes material stackup of arc welding source molten metal wire material, high speed milling head machining of laminated plane and contour to ensure precision the machined part, and digitally controlled program control of 3D working bench to obtain required geometric characteristic of the part. During the formation, the filament feeding direction is adaptively regulated and embedded medium is used to improve temperature field so as to raise the formation quality. The present invention has the features of low cost and compact structure of the formed part, and high efficiency, and can realize the fast formation of the metal part with functional gradient.

Owner:XI AN JIAOTONG UNIV

Method for preparing zirconium metal filaments

The invention discloses a method for preparing zirconium metal filaments. The method comprises the steps of firstly, preparing zirconium ingots and forging bar billets; secondly, rolling the bar billets into bars and machining and removing surface scales; thirdly, drawing the bars to obtain wires; fourthly, performing acid cleaning to the wires and then carrying out vacuum annealing; fifthly, carrying out multi-path drawing on the wires after vacuum annealing, and then performing vacuum annealing to the drawn wires; sixthly, carrying out acid pickling, prefilming, electroplating and flushing on the wires subjected to vacuum annealing sequentiall, and then drying; seventhly; seventhly, bundling the dried wires and loading into copper tubes and compounding on a broaching machine so as to obtain composite tubes, and drawing after vacuum annealing; and eighthly, carrying out acid pickling on the drawn composite tubes to remove copper and oxidation films, flushing with deionized water, and naturally drying to obtain the zirconium fiber filaments. According to the method, the bundling and drawing process is adopted to prepare the zirconium fiber filaments, and the zirconium composite tube cannot be fractured during the bundling and drawing process due to selection of proper zirconium-copper cross section ratio.

Owner:西安西部新锆科技股份有限公司

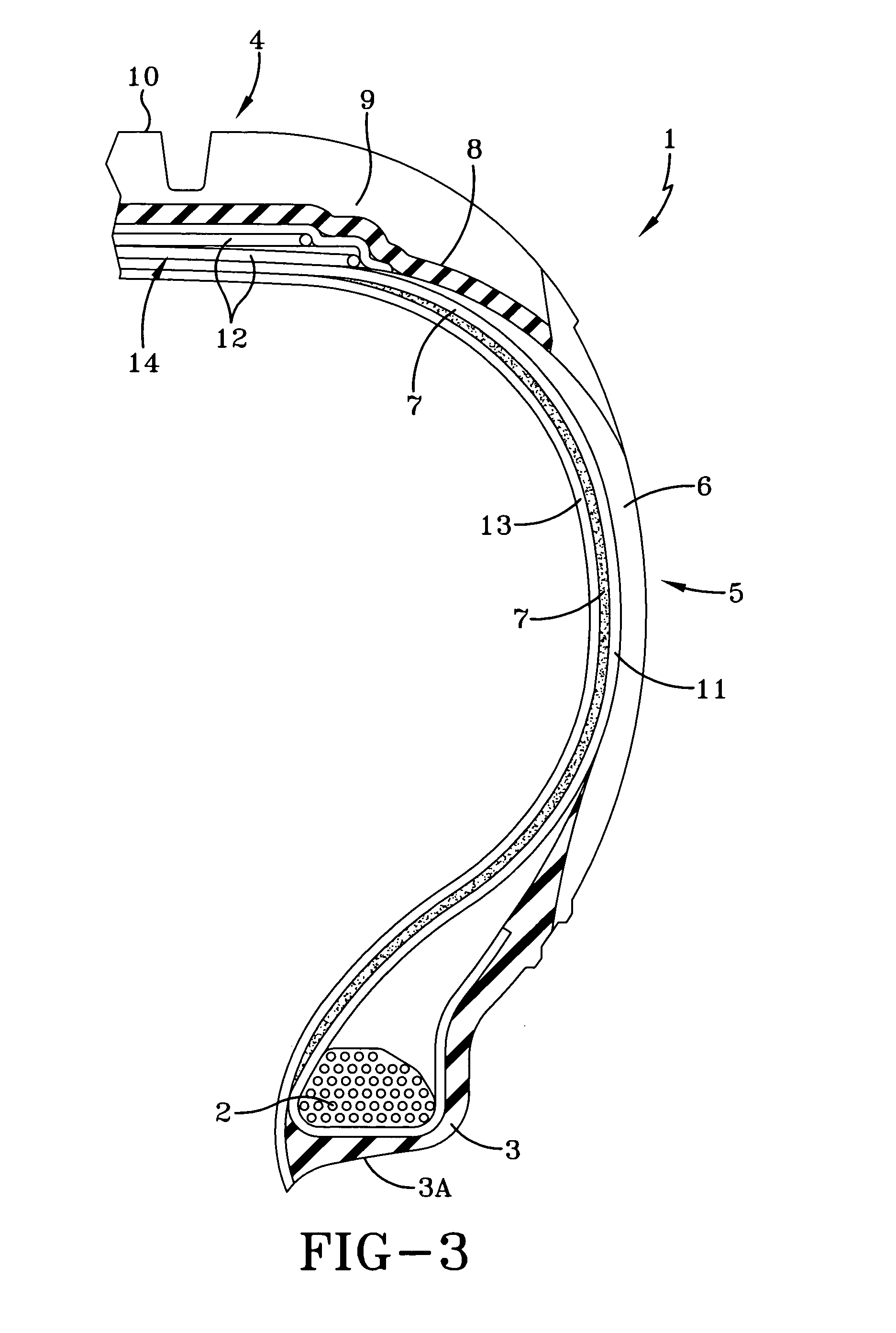

Pneumatic tire with electrically conductive cord extending from its outer wheel-rim mounting surface to its internal tread portion

This invention relates to a pneumatic rubber tire which contains at least one electrically conductive cord extending from an external outer surface of its wheel-rim mounting surface rubber component to an internal electrically conductive tread base layer rubber component to provide a path of least electrical resistance, namely an electrically conductive path, between the outer tire wheel-rim mounting surface and the internal tire tread base layer. The electrically conductive cord is comprised of at least one electrically conductive metal filament (e.g. metal filament, carbon fiber or combination of metal filament and carbon fiber) spirally wound around a centrally disposed core of at least one organic fiber.

Owner:THE GOODYEAR TIRE & RUBBER CO

Electromagnetic shielding device

An electromagnetic shielding device has a bottom layer, a shielding layer and a top layer. The shielding layer is mounted between the bottom layer and the top layer and is made of metal filaments and textile fibers. The metal filaments and the textile fibers of the shielding layer are blended and formed into a mesh. The electromagnetic shielding device in the present invention may be made into patches or forms that can be adhered to electrical and electronic equipment, or adapted for use in clothing.

Owner:KING STAR ENTERPRISE

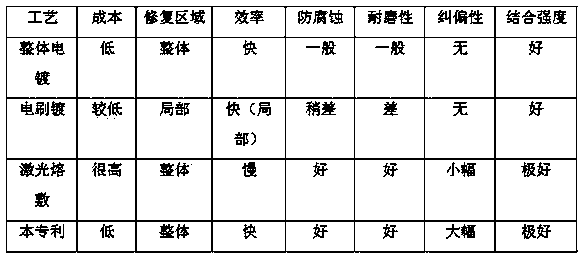

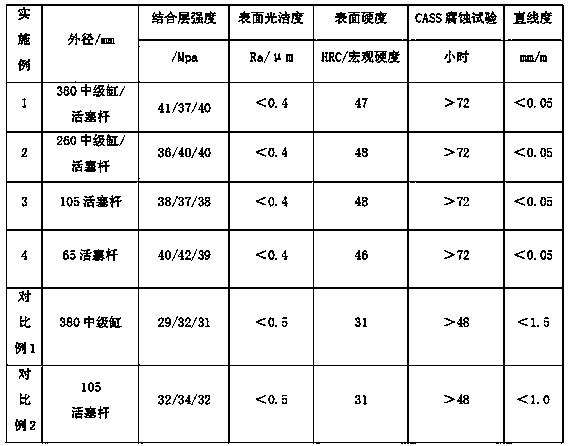

Method for repairing and remanufacturing outer surface of piston rod of hydraulic cylinder or outer surface of intermediate cylinder

ActiveCN104191152AHigh surface macrohardnessImprove wear resistanceArc welding apparatusHydraulic cylinderMetal filament

The invention provides a method for repairing and remanufacturing the surface of a piston rod of a hydraulic cylinder or the outer surface of an intermediate cylinder for coal mines. Aiming at remanufacturing after the surface of the piston rod of the hydraulic cylinder or the outer surface of the intermediate cylinder for the coal mines is damaged and fails, the long-term practice is combined, a metal wire adopting the specific metal powder proportion is creatively designed to serve as a powder core wire, and namely the metal wire is formed by wrapping the metal powder with Cr, Ni and Fe as the main ingredients through a stainless steel foil layer; based on the arc thermal spraying process method, the surface is repaired and remanufactured creatively, and on the premise that the corrosion resistance and the hardness of the repaired layer of the surface are equal to those of the surface treated through the surface laser cladding technology, consideration is given to the good economic applicability and the good practical production efficiency; an existing electroplating technology can be completely replaced, and the method has the wide application and popularization prospects in repairing of the piston rod of the hydraulic support oil cylinder and the intermediate cylinder for the coal mines.

Owner:SHAANXI TIANYUAN MATERIALS PROTECTION TECH

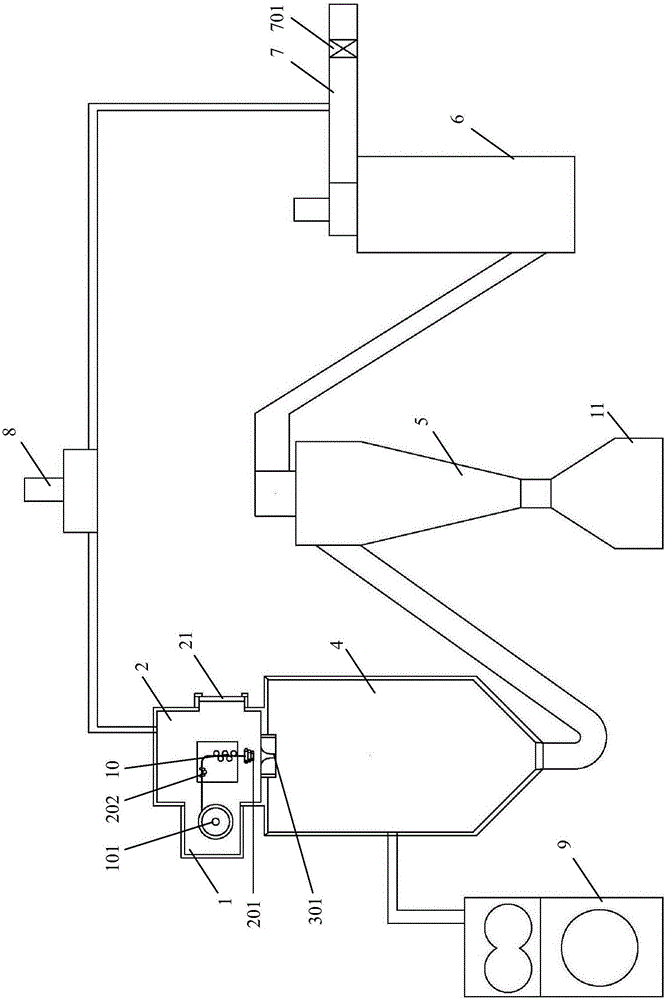

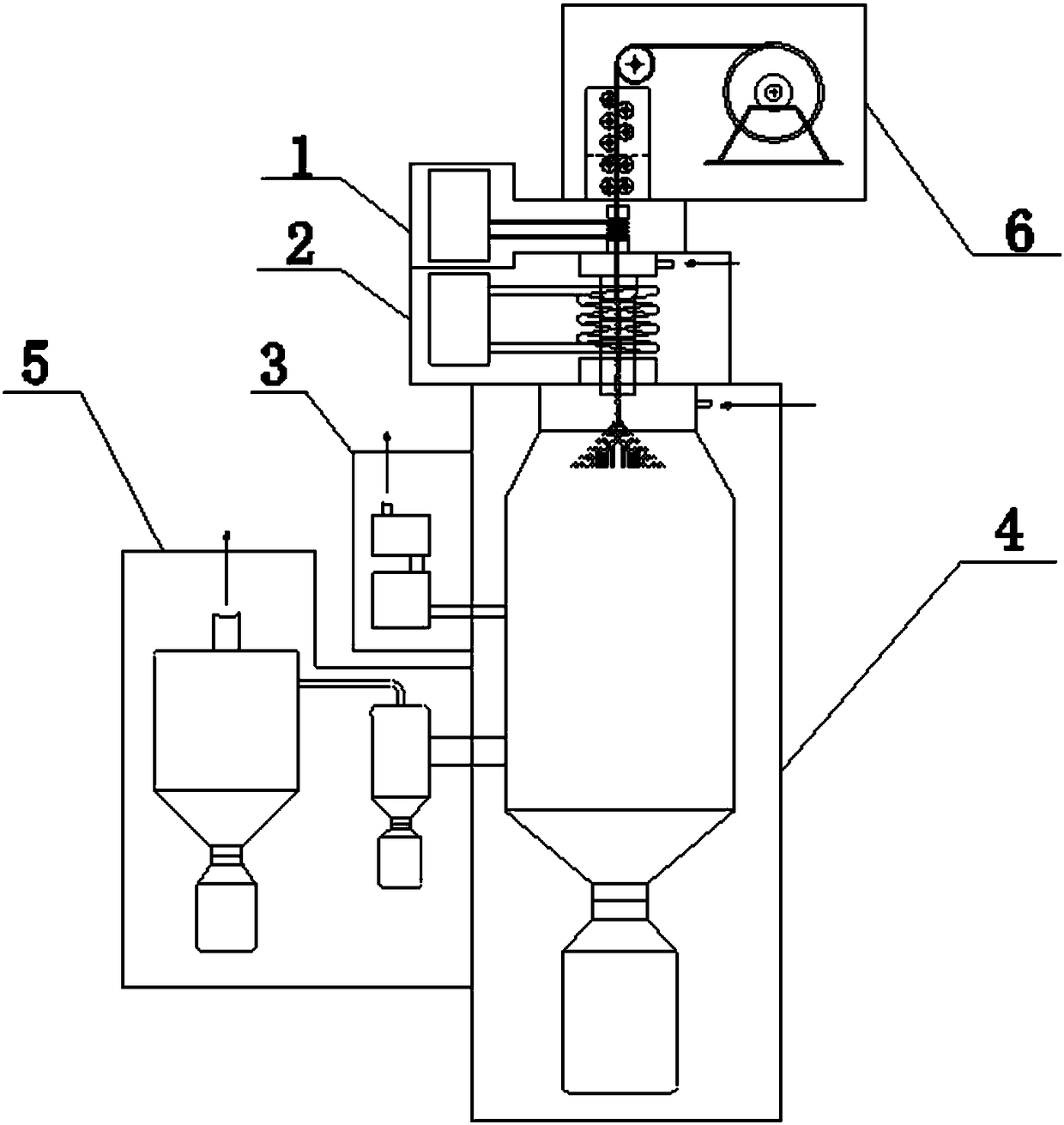

Gas atomization powder production equipment and powder production method thereof

The invention discloses gas atomization powder production equipment and a powder production method thereof and belongs to the technical field of metal powder production. The gas atomization powder production equipment is characterized in that a rotary support rack for placing a metal wire material plate is arranged in the raw material bin of the powder production equipment; a smelting chamber is communicated with the raw material bin and provided with an induction coil and a wire feeder inside, and the wire feeder is used for guiding metal wire on the rotary support rack into a positon above the center of the induction coil; an atomizer is connected with the smelting chamber, and the upper-end opening of the atomizing nozzle of the atomizer faces the induction coil; an atomizing tower is connected with a cyclone separator, and the top of the atomizing tower is connected with the atomizer; a vacuum system is connected with the atomizing tower. The powder production equipment and the powder production method thereof have the advantages that the bar-shaped raw material is replaced by the metal wire, the utilization rate and production efficiency of atomizing gas are increased, and cost of gas atomization powder production is lowered; small liquid drops can obtain high superheat degree favorably, and the fine powder content in the atomized powder is increased.

Owner:浙江天钛增材制造技术有限公司

Horizontal spit rotisserie cooking device

InactiveUS20020023547A1Easy to mountFacilitated releaseBoiling over preventionMeat processingGear driveEngineering

Enclosed rotisserie with added convenience, including a countertop resting box-like enclosure housing a safety rear mounted heating element and a power rotated dual rod spit assembly. The gear driven spit assembly may be easily inserted and removed straight into and out of the enclosure without need for angling or coupling the assembly to a power drive socket. The spit assembly may also be mounted at various distances from the heating element to decrease cooking times. The open front of the enclosure is from time to time covered by an inclined glass panel door which may be opened in various ways to facilitate food insertion into and removal from the enclosure, and which may be easily removed for cleaning or other purposes. The embodiment's design makes efficient use of valuable counter space by recessing back and raising off the countertop its controls. A contained light as well as room light emitted through the inclined glass door illuminate the enclosure's interior to make the rotisserie cooking into a taste tempting show. Two countertop supported sizes for the embodiment are suggested, one for larger families and entertaining, and the other for small families and singles. Cooking times are decreased and manufacture simplified by the embodiment heating element remaining on constantly during the cooking process. Maintenance is minimized by various embodiment parts being removable for cleaning including a cleaning shield located behind the heating element, the glass door, and a drip pan with slotted cover. A variety of foods may be cooked using the spit and accessories that attach to the spit. Such accessories include wire baskets and a rotating stir fryer. Foods may be cooked on top of the embodiment as well using an included warming tray and an inserted steaming tray with cover. Grease-tight rotisserie / barbecue gloves make food handling easier and safer, as can also be said for a spit support platform which supports the spit assembly for food mounting and carving. Self-rotating kabob rods cook kabobs on all sides evenly and allow for increasing rotisserie capacity by increasing the length of rotating rods available for rotisserie food mounting.

Owner:BACKUS ALAN L +1

Brazing diamond fret saw with grinding materials being arranged in order in spiral shape and manufacturing process thereof

InactiveCN101704276AHigh holding strengthImprove cutting lifeFine working devicesStone-like material working toolsDiamond wire sawFiller metal

The invention relates to brazing diamond fret saw with grinding materials being arranged in order in a spiral shape and a manufacturing process thereof, belonging to the field of manufacturing of grinding materials and grinding apparatus. The brazing diamond fret saw is composed of a steel wire substrate, brazing bonding agent and diamond grinding materials which are arranged in a spiral shape. The key steps of the process are as follows: coating pressure sensitive adhesive on the surface of the steel wire substrate; evenly winding a fine metal silk thread or nonmetal silk thread on the steel wire coated with pressure sensitive adhesive in a certain thread pitch; arranging the diamond grinding materials; dismantling the metal silk thread or the nonmetal silk thread; arranging a layer of powdery brazing filler metal; heating to the melting of the brazing filler metal in vacuum or protective atmosphere; and fixing the cooled diamond grinding materials firmly on the surface of the steel wire through brazing bonding agent to form the brazing diamond fret saw with the grinding materials being arranged in order in a spiral shape. The fret saw has the advantages of long cutting service life and high cutting efficiency.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Pneumatic tire with electrically conductive cord extending between a bead portion and a tread portion of the tire

InactiveUS7284582B2Low resistivitySpecial tyresPneumatic tyre reinforcementsElectrical resistance and conductanceFiber

A pneumatic rubber tire containing at least one electrically conductive cord extending between its bead and tread portions to provide a path of least electrical resistance. The electrically conductive cord is comprised of at least one electrically conductive metal filament spirally wound around a centrally disposed core of at least one organic fiber. The electrically conductive cord does not extend to, and is exclusive of, an outer surface of the tire.

Owner:THE GOODYEAR TIRE & RUBBER CO

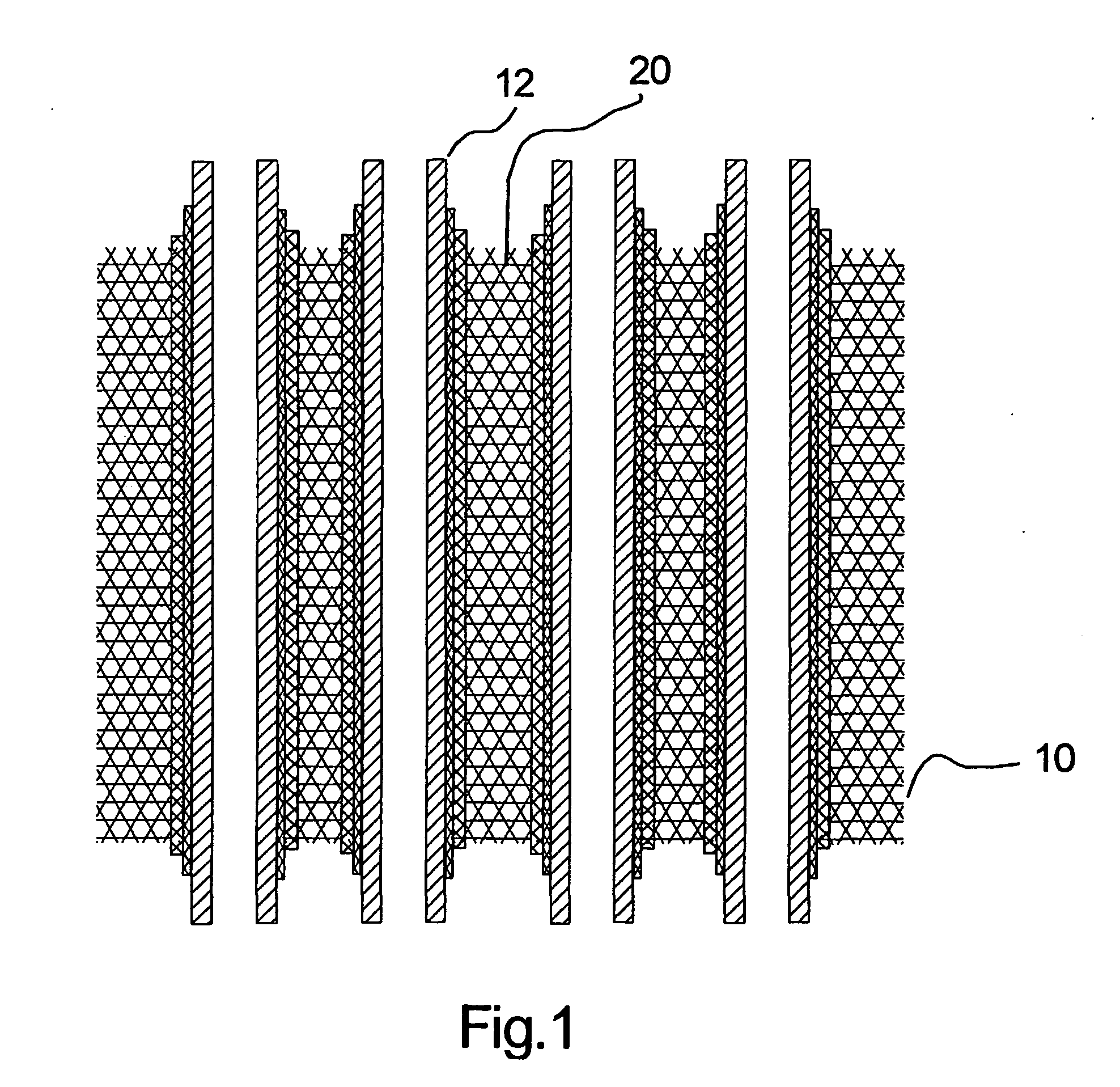

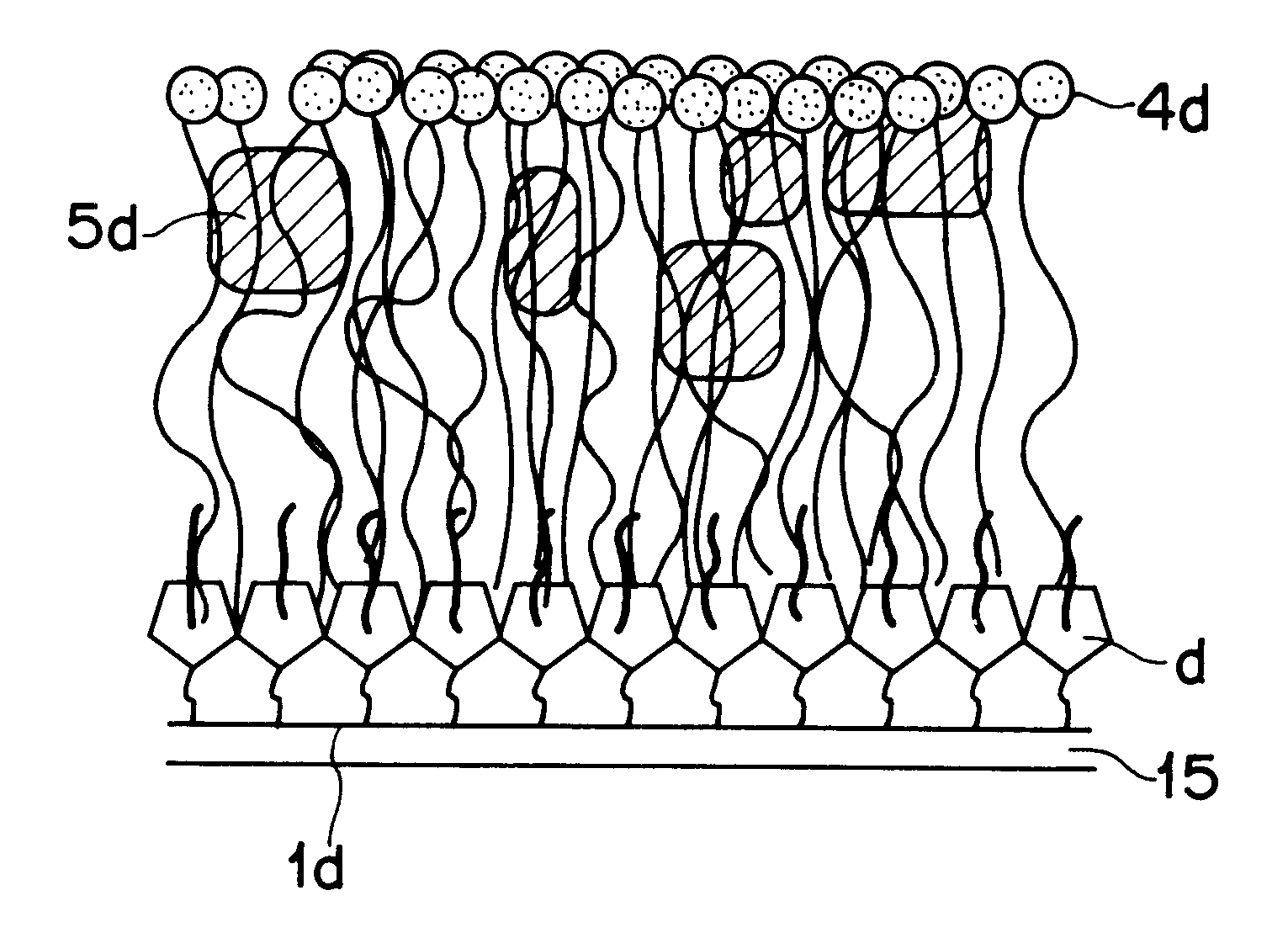

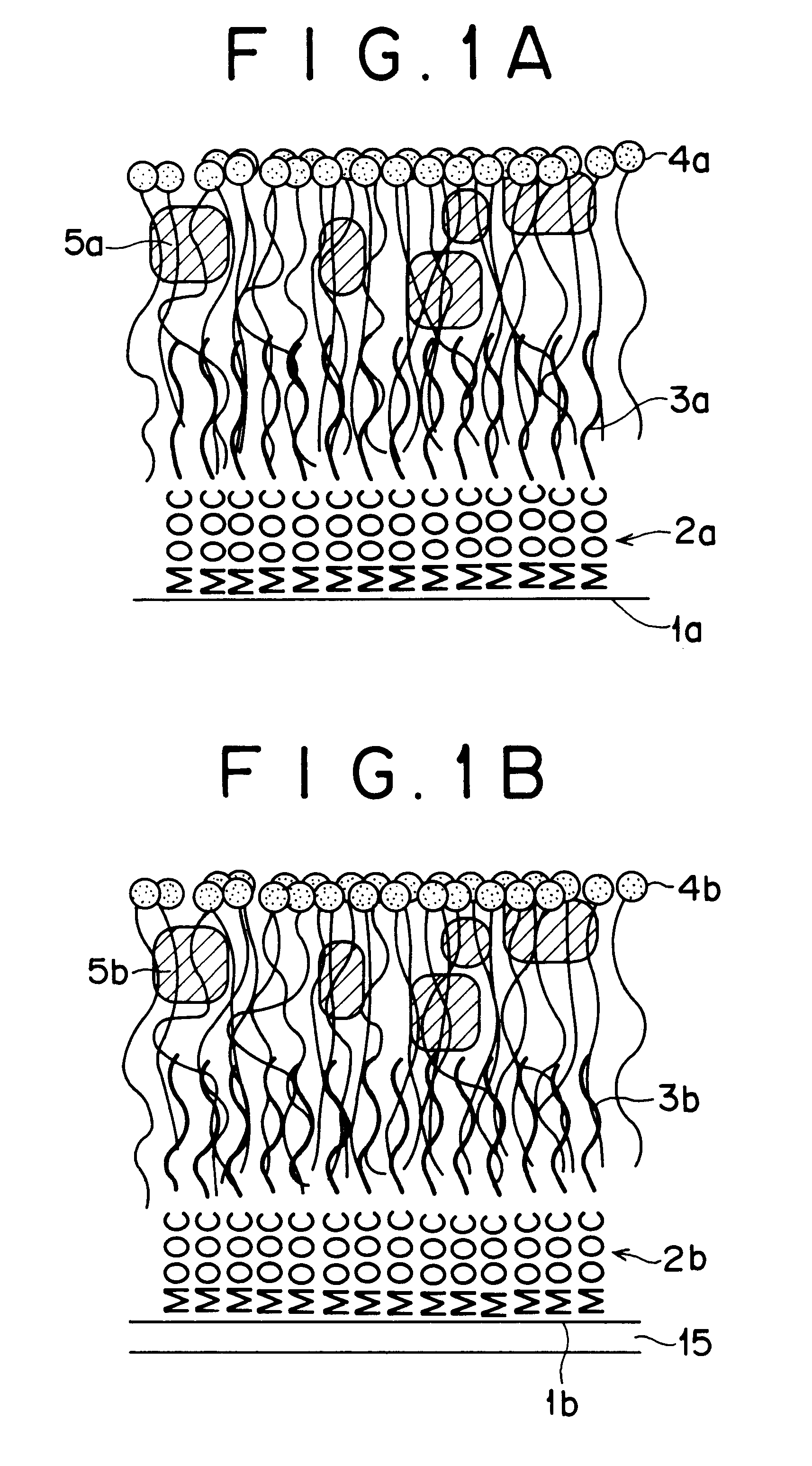

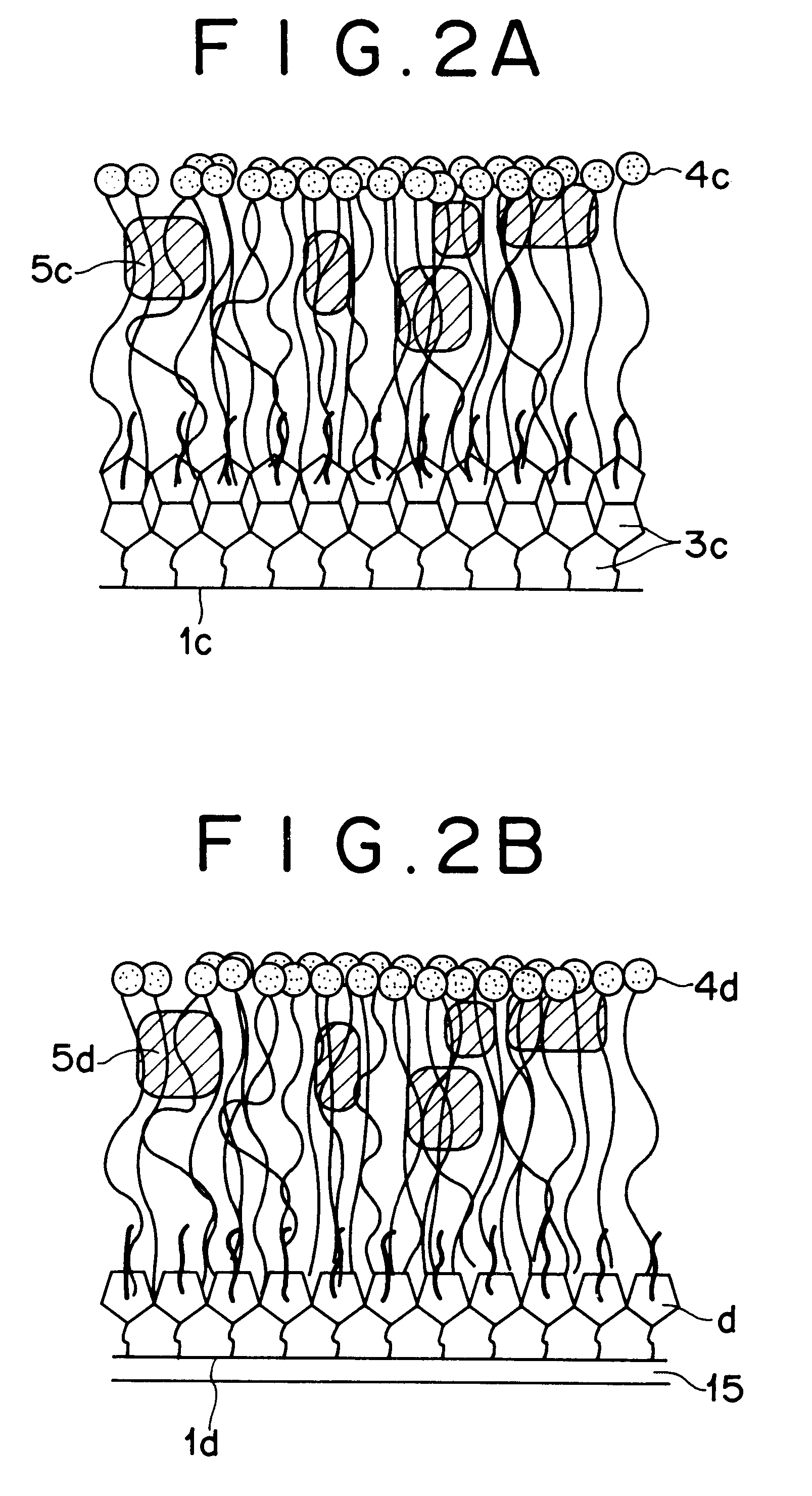

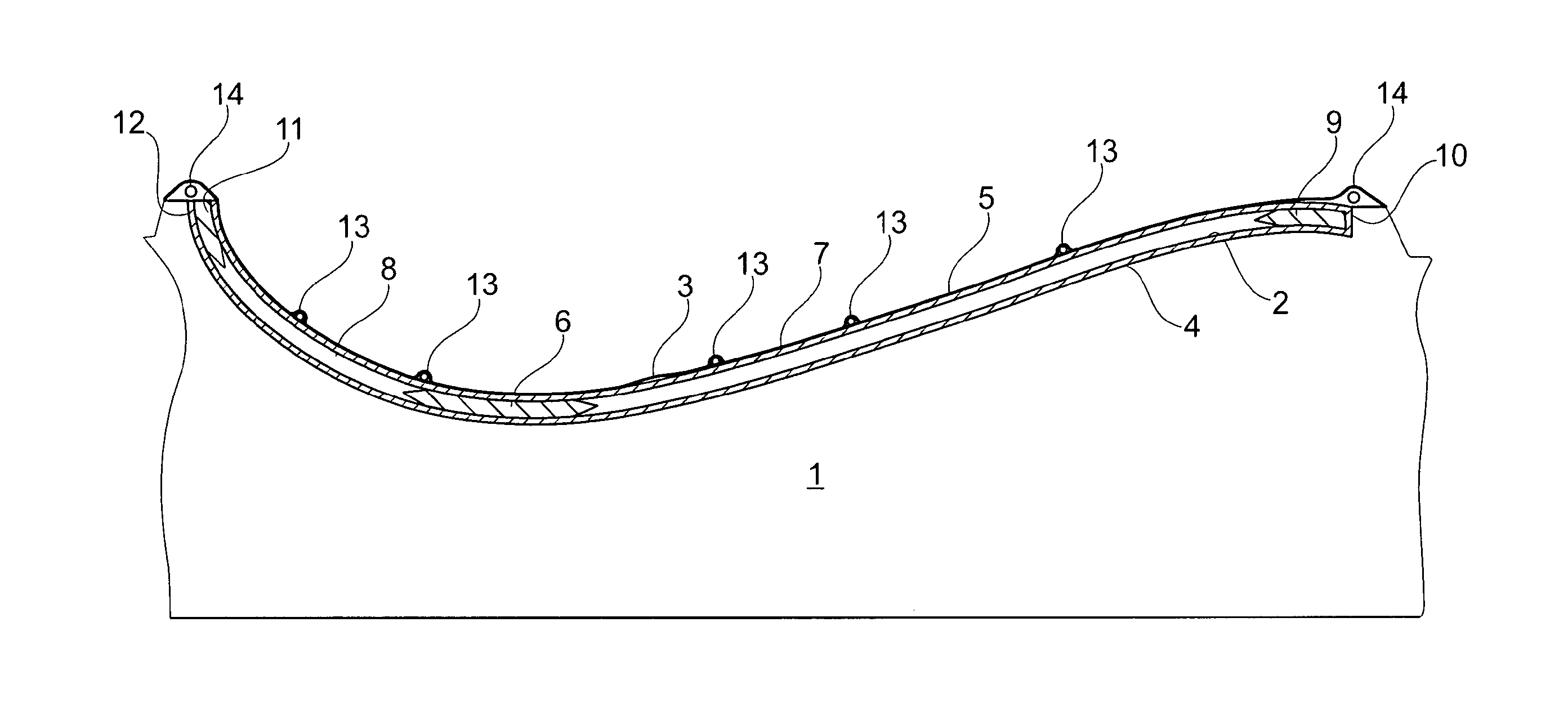

Wind turbine blade comprising metal filaments and carbon fibres and a method of manufacturing thereof

ActiveUS20140119936A1Lower resistanceHigh trafficFinal product manufactureBlade accessoriesFiberCarbon fibers

Wind turbine blade has a longitudinal direction and includes a shell structure made of a fibre-reinforced polymer material including a polymer matrix and reinforcement material comprising a plurality of carbon fibre layers embedded in the polymer matrix. At least a portion of the shell structure is formed of a laminate 6 comprising at least one metal filament layer 15, 18 comprising metal filaments and being sandwiched between two carbon fibre layers 16,16;17,18 comprising carbon fibres only. The carbon fibre layers are arranged contiguously with the metal filament layer.

Owner:LM WIND POWER AS

Method for producing compound filter of multi-layer metal meshes and metal powder

ActiveCN102059340ASmall filter resistanceLarge filtration fluxFiltration separationMetal filamentMetal powder

The invention relates to a method for producing compound filter of multi-layer metal meshes and metal powder, which comprises the steps of weaving metal wires to obtain metal meshes with different mesh numbers; laminating the metal meshes with different mesh numbers to obtain a laminated layer structure, wherein the mesh numbers of the laminated layers from one side to the other side increase continuously and the number of laminated layers is 2-6; then placing the laminated layer structure in a vacuum furnace and sintering at 1000-1600 DEG C to obtain a multiple support layers; then cooling and taking out of the support layers, manufacturing a metal compound layer of 100-600 meshes on one side of the support layer of high mesh by means of electrostatic spraying and curtain coating, controlling the thickness of the compound layer with 0.1-0.5mm and then sintering at 1000-1600 DEG C, cooling and taking out of the compound layer to obtain the compound filter of multi-layer metal meshes and metal powder. The compound filter has the advantages of low filtering resistance, large filter flux and strong bearing capacity and can be widely applied to industrial fields of chemical engineering, medicine, power generation,metallurgy, food and the like.

Owner:王东伟

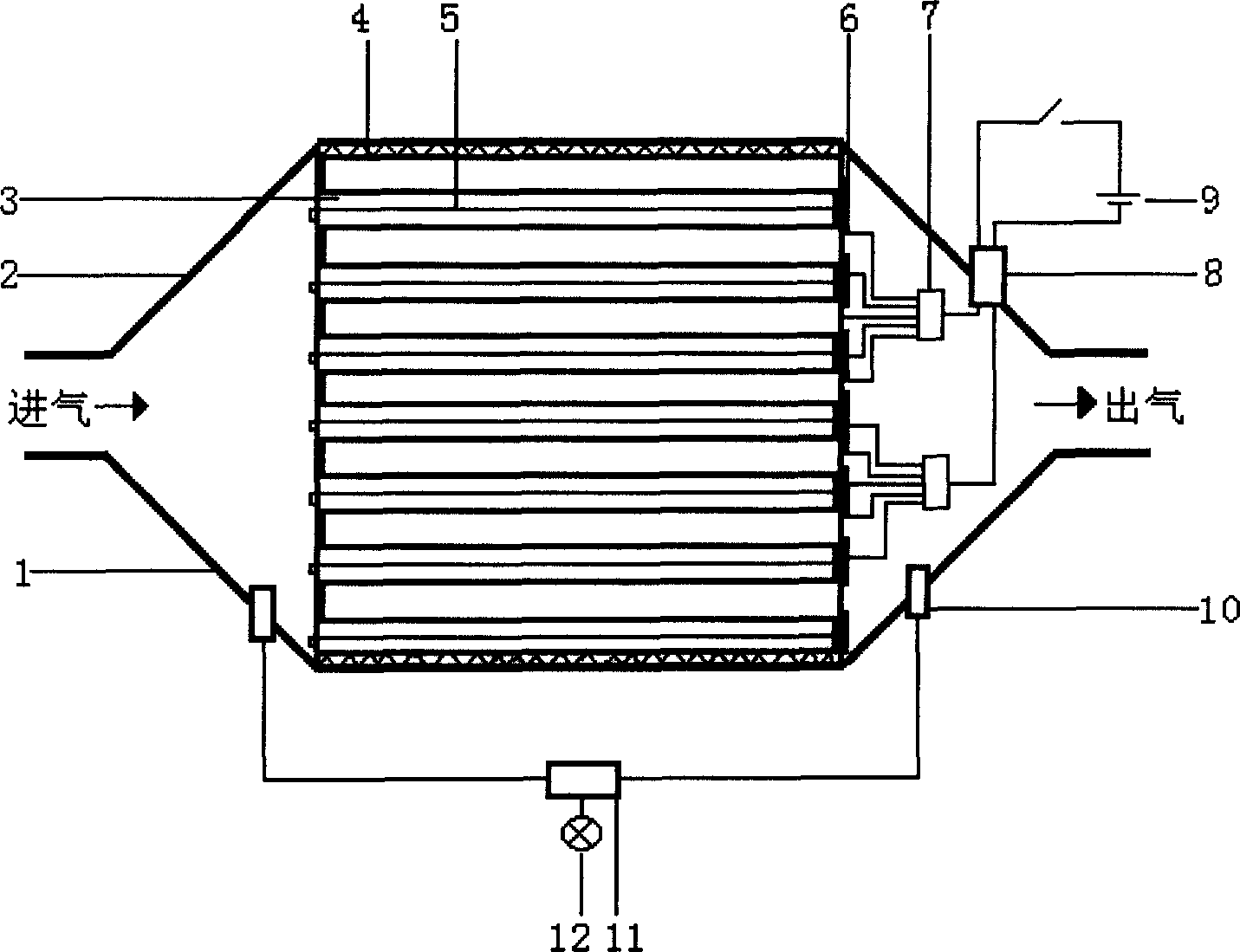

Wall flow exhaust particle filtering and electricalloy heating post-regeneration treating device for diesel engine

InactiveCN1554860AExtend your lifeReduce vibrationExhaust apparatusSilencing apparatusElectrical resistance and conductanceMetal filament

The wall flow type exhaust particle filtering and electrically heating post-regeneration treating device for diesel engine includes mainly lower casing, upper casing, wall flow type honeycombed ceramic, metal filament, heating wire, connecting sheet, canal, power source, pressure sensor, electric controller and warning lamp. The wall flow type honeycombed ceramic is installed inside the post-treating unit casing with one metal wire layer in between. The U-shaped heating wire is inserted into the filtering holes along the wall flow type honeycombed ceramic and connected via the connecting sheet to the wall flow type honeycombed ceramic, with the heating wires in different areas are connected parallelly. Pressure sensors are installed on two ends of the lower casing, and when pressure difference reaches some value, the particle is regenerated. The device has high filtering efficiency, complete regeneration, long ceramic life, high reliability and low cost.

Owner:SHANGHAI JIAO TONG UNIV

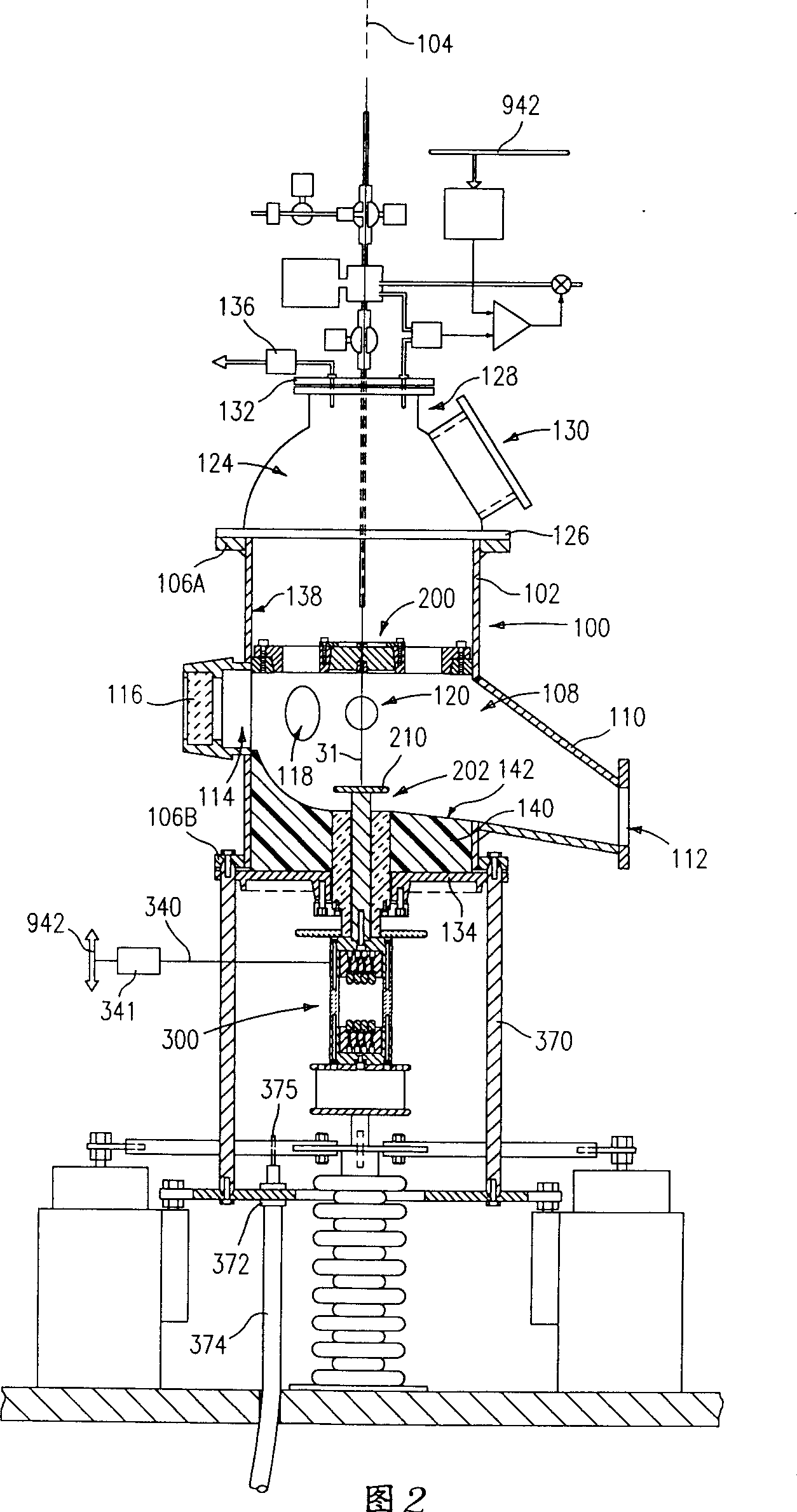

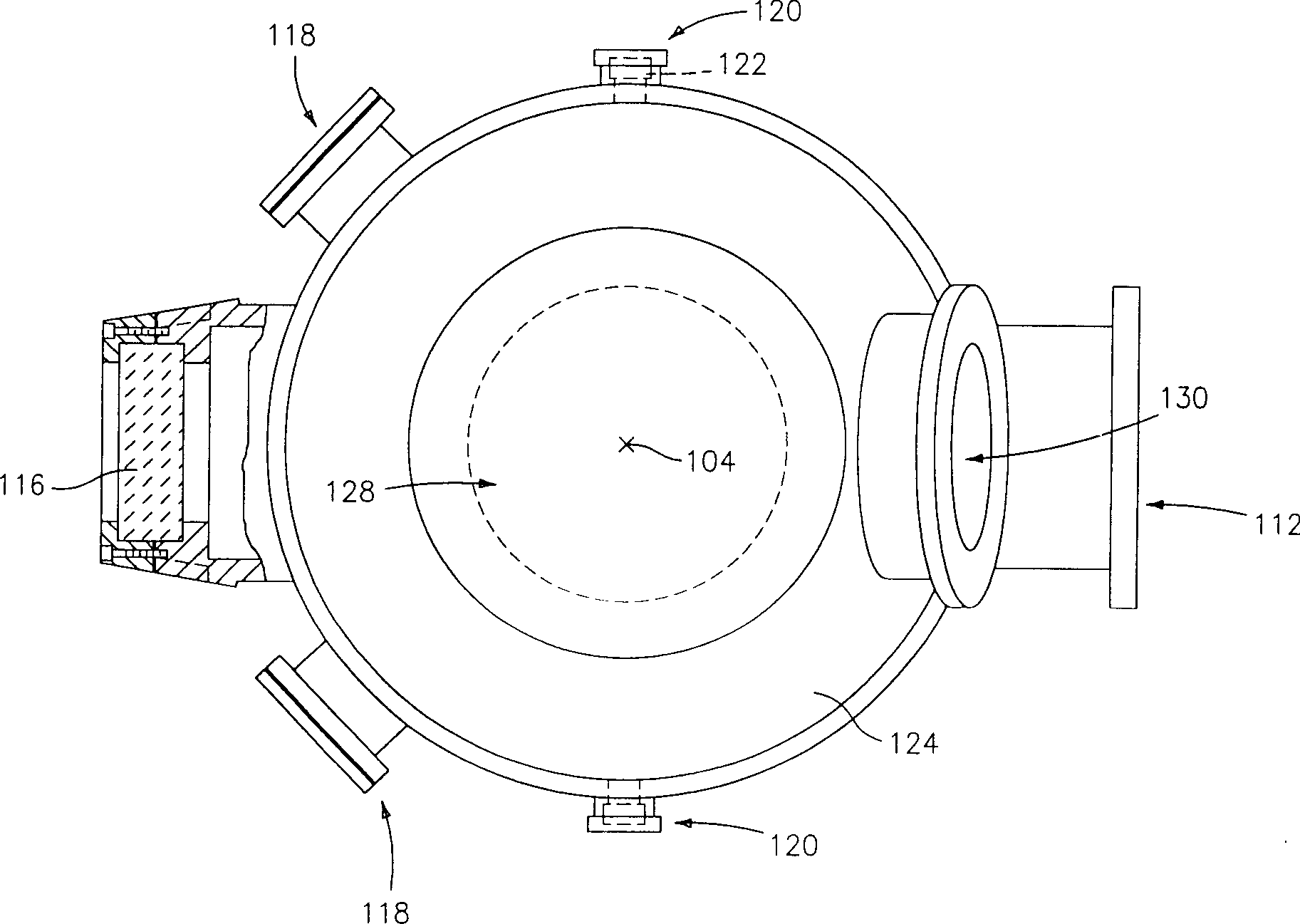

Powder preparation method for induction heating and radio frequency plasma combined atomizing powder system

ActiveCN108161019AHigh purityPrevent purityAdditive manufacturing apparatusHigh pressureRadio frequency

The invention relates to a powder preparation method for an induction heating and radio frequency plasma combined atomizing powder system. The powder preparation method comprises the following steps that (1), raw materials are prepared and processed; (2), the system is pre-vacuumed and a protective atmosphere is established; (3), wire materials are straightened and conveyed; (4), high-frequency induction preheating is carried out; (5), radio frequency plasma melting is carried out; (6), powders are prepared by atomizing; (7), separation and dust removal are carried out; and (8), the powder size is graded. The powder preparation method for the induction heating and radiofrequency plasma combined atomizing powder system uses high purity metal wire material instead of the powders as the raw materials, so that the carrying of raw materials to adsorb gas and water is reduced; a technology of the high frequency induction heating combined with the radio frequency plasma smelting and gas atomization is adopted, during the whole process of heating, melting, and the gas atomization is free of pollution and impurities in the protective atmosphere, and the degree of superheat of liquid flow ordroplets is increased during the process of radio frequency plasma smelting; and high quality spherical powders can be obtained by adopting high pressure atomizing nozzles atomizing, and the yield ofmetal powders per unit time is increased.

Owner:北京金物科技发展有限公司

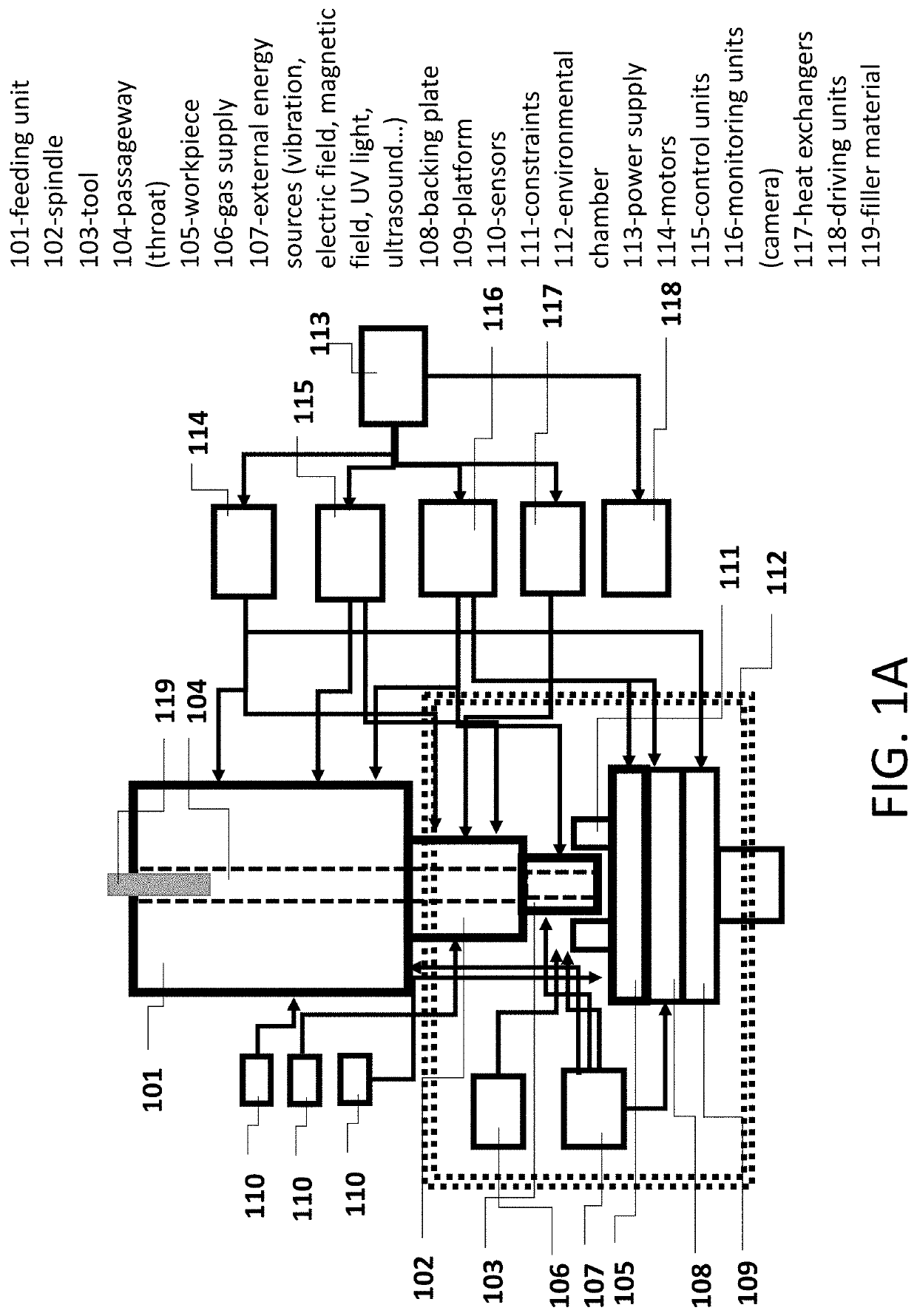

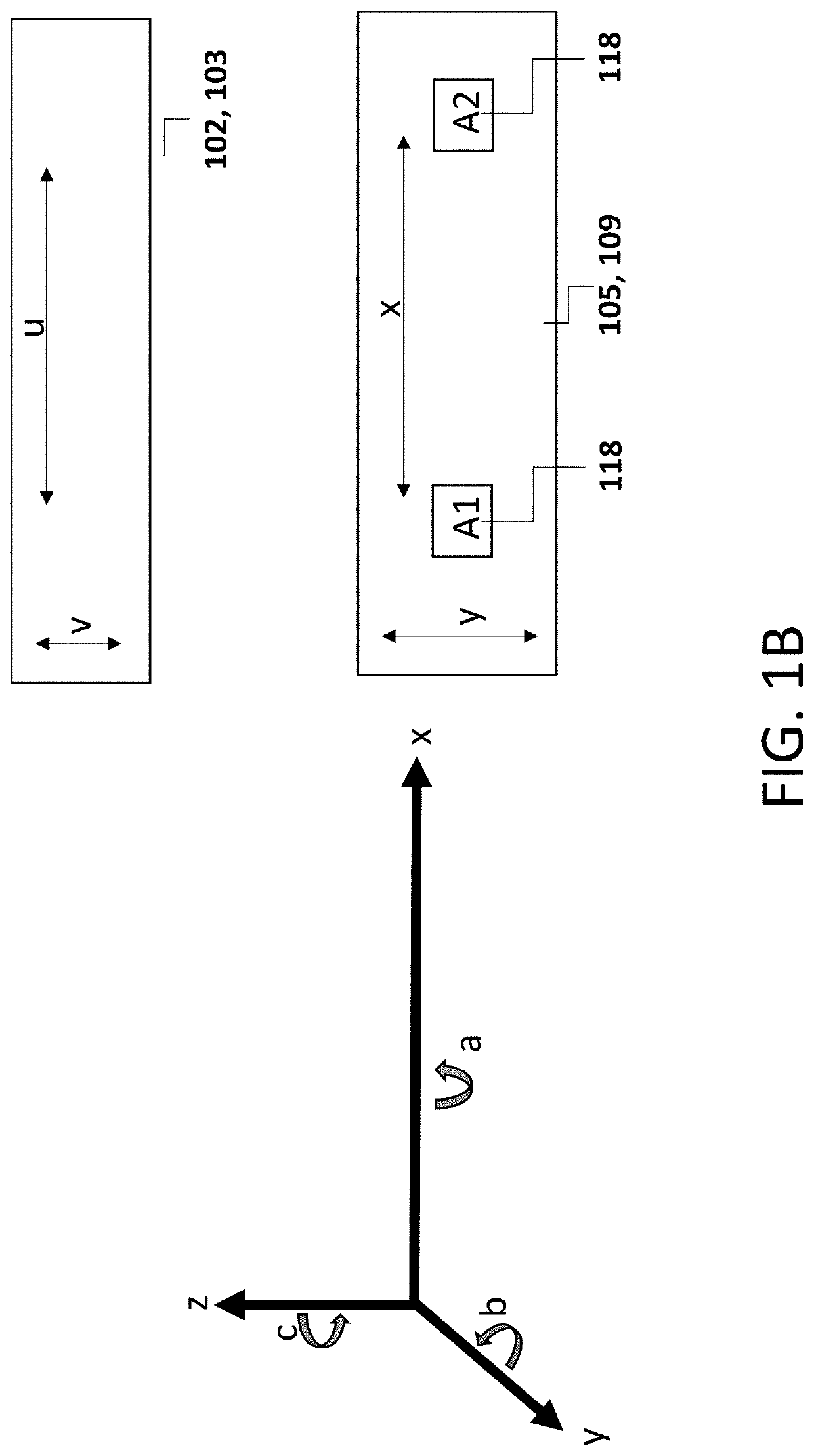

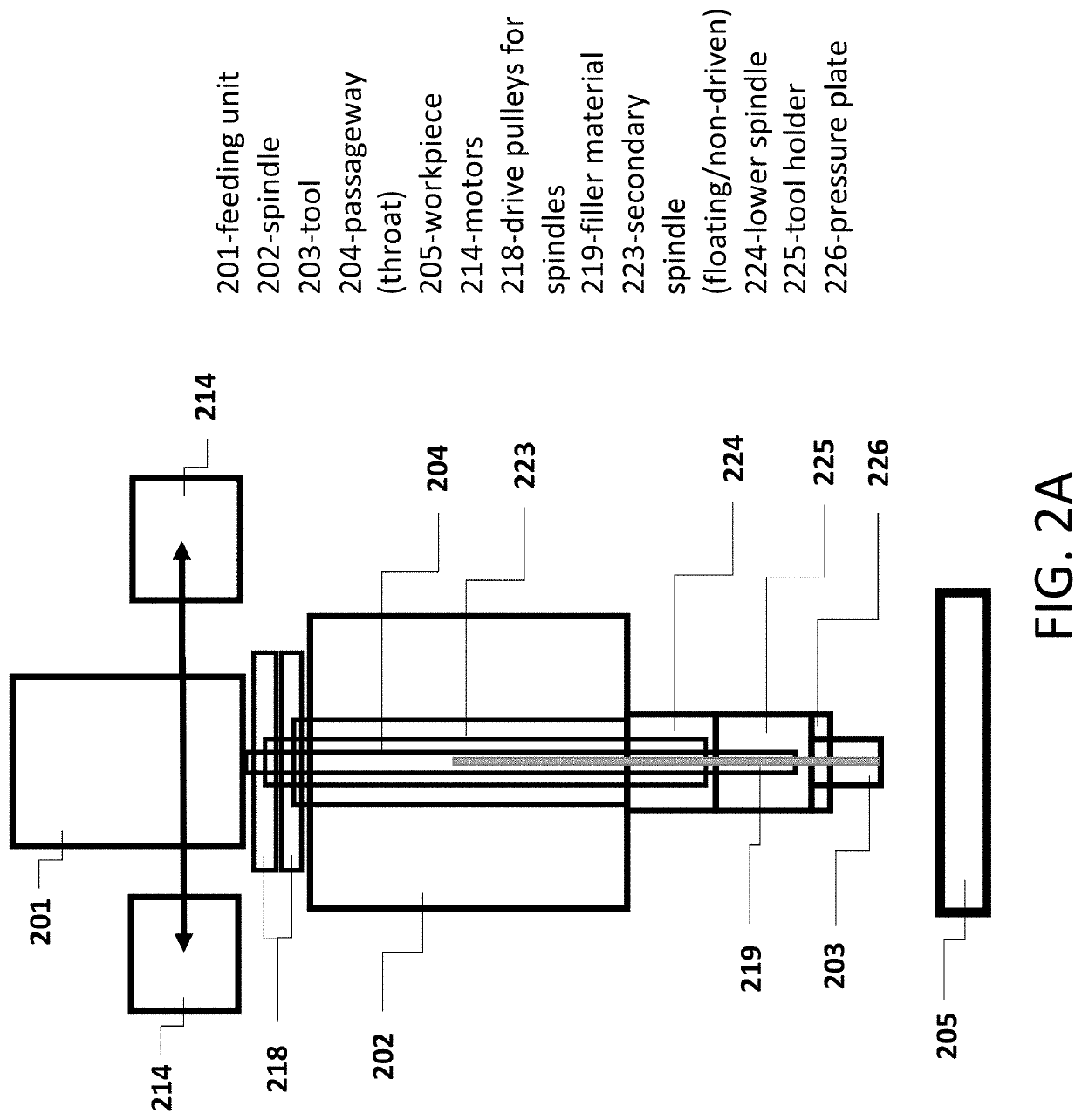

Solid-state additive manufacturing system and material compositions and structures

ActiveUS20200306869A1Grain refinementMaintain good propertiesAdditive manufacturing apparatusComputer controlMetal filamentMetal alloy

A solid-state additive manufacturing additive manufacturing system applicable to building up 3D structures, coating and functionalizing surfaces, joining structures, adding customized features to objects, compounding proprietary compositions and repairing various structures is disclosed. The solid-state additive manufacturing system enables deposition of different fillers, viz. metals, metal alloys, MMCs, polymers, plastics, composites, hybrids and gradient compositions, as well as controls the resulting deposit structures, e.g. specific nano- / micro-, gradient- and porous-material structures. The system accommodates various feeding-, spindle- and tool-designs for depositing different forms of filler materials, viz. rods, wires, granules, powders, powder-filled-tubes, scrap pieces or their combination, and a working platform with multiple access points. One or multiple motors, driving and monitoring units control the movement of the workpiece, spindle and tool and move the filler through the feeding system, which passageway is in communication with the passageways of the spindle and the tool.

Owner:MELD MFG CORP

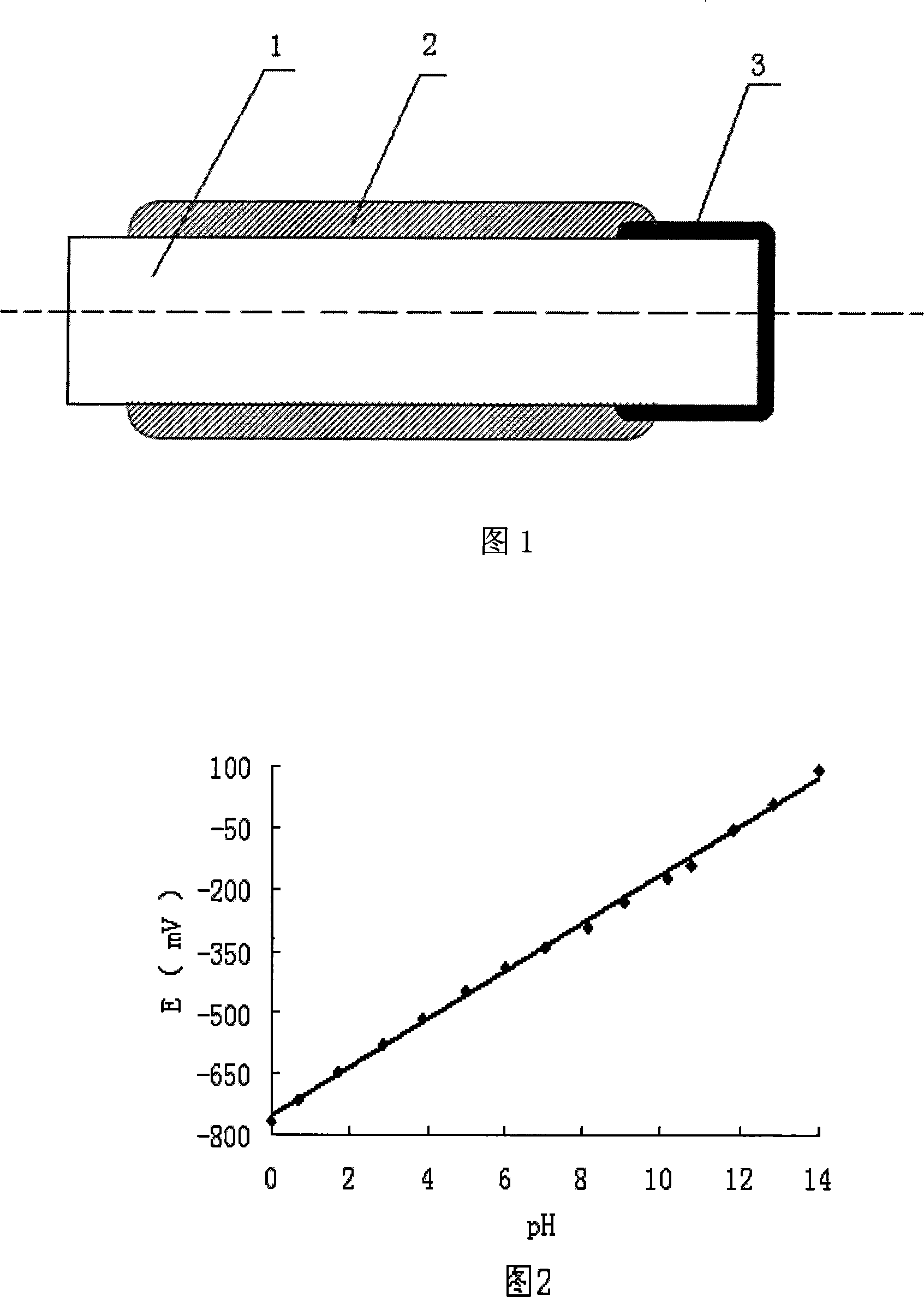

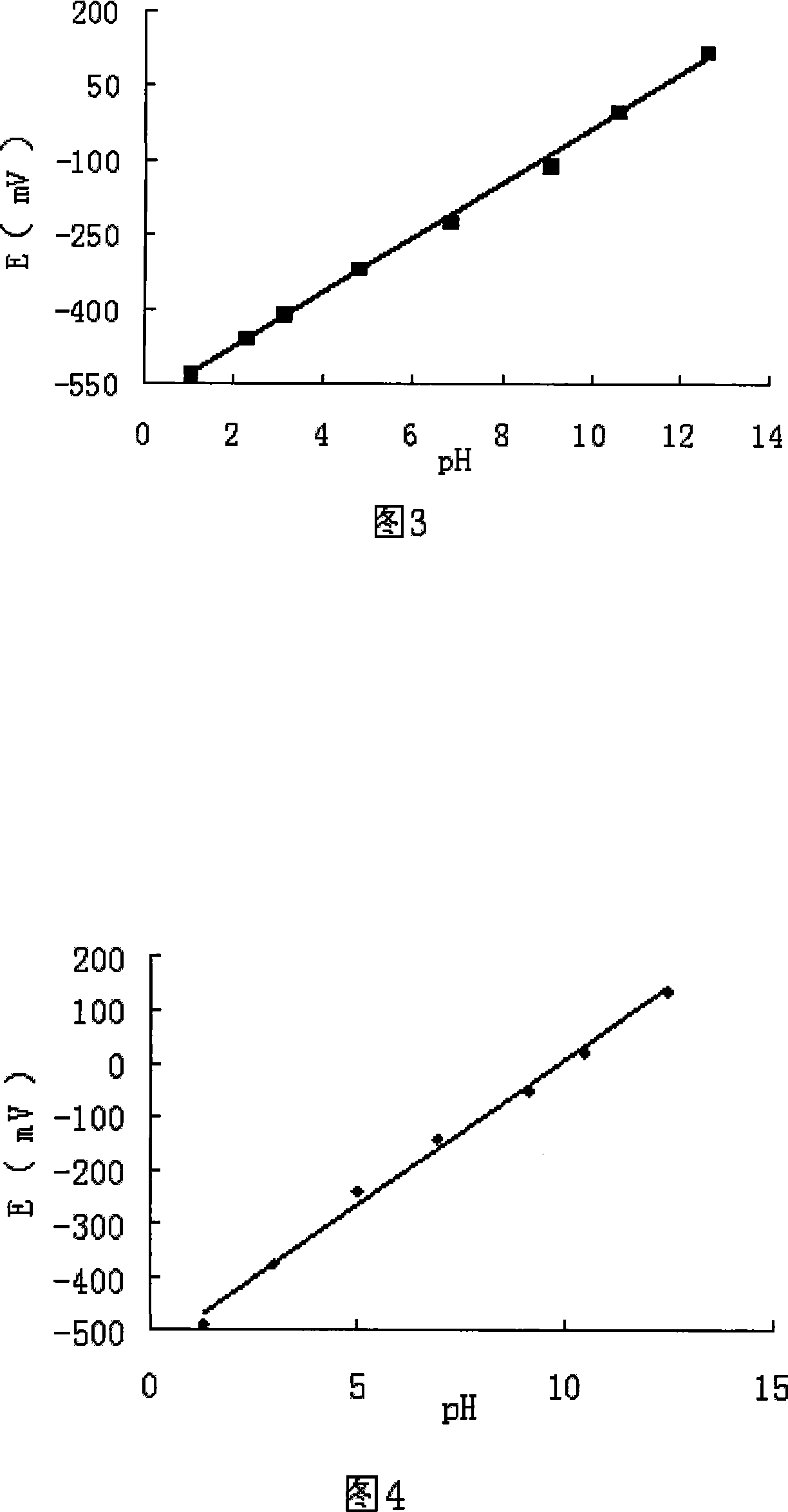

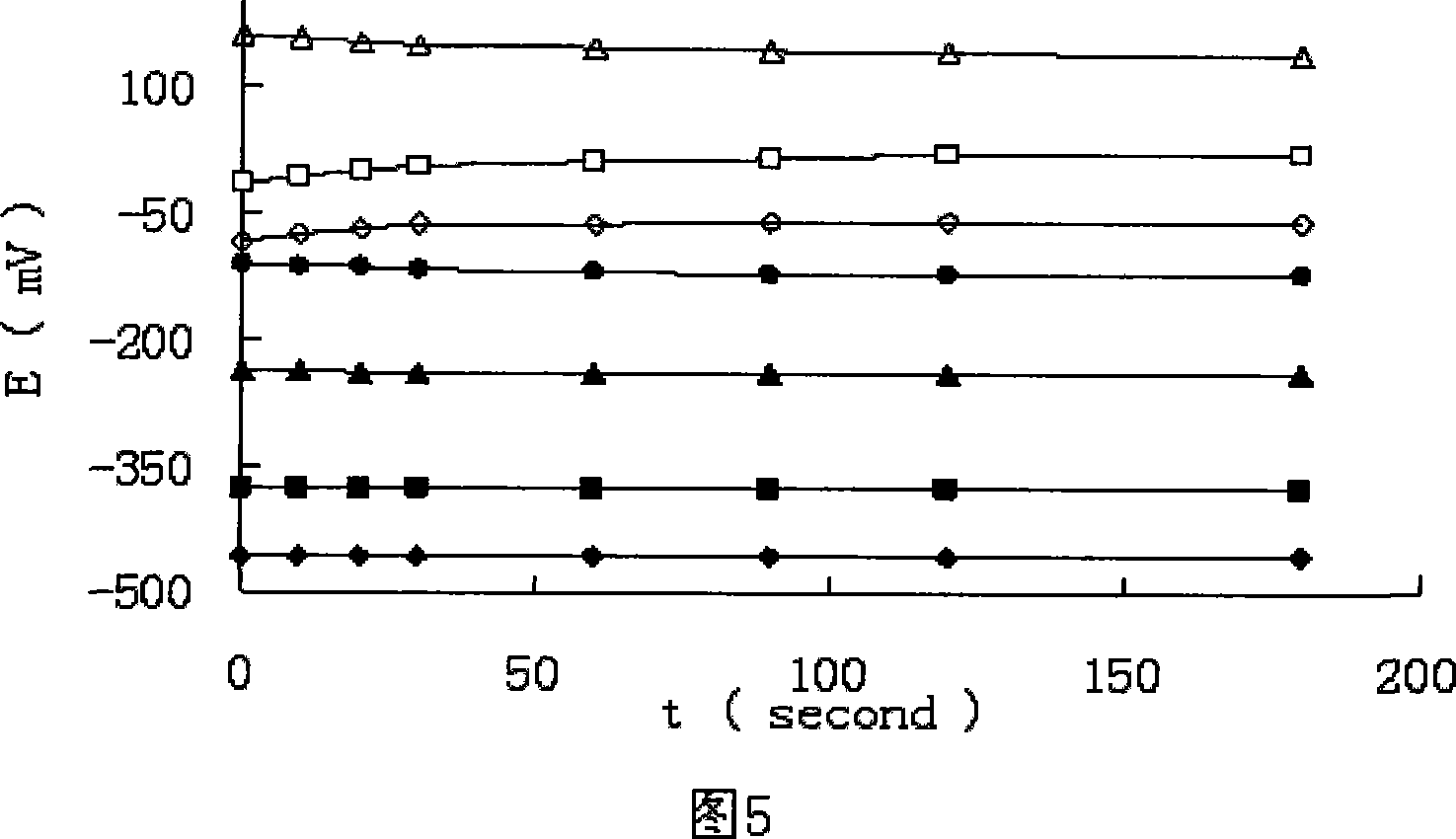

Metal-metallic oxide pH electrode and method for making same

InactiveCN101210902ASimple preparation processLow priceMaterial electrochemical variablesChemical cleaningHydrogen ion

The invention provides a metal-metal oxide pH electrode and a preparation method thereof. The method comprises the following steps of: using a chemically stable metal filament is used as a basal body, removing the original oxide film on the surface of the metal filament by mechanical polishing and chemical cleaning, and forming a IrOx (x=1 to 3) active oxide film sensitive to hydrogen ion on the treated metal filament surface with the thermal decomposition method. Comparing with glass pH electrode and conventional metal-metal oxide pH electrode, the inventive metal-metal oxide pH electrode has the advantages of simples preparation method, low cost, easiness for batch production, high mechanical strength, low fracture liability, small volume, high sensitivity of pH measurement, and rapid response speed, wide response range; and is suitable for pH measurement of low-temperature solution with wide pH range, particularly solution below zero degree (such as anti-freezing fluid and refrigerating fluid).

Owner:FUZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com