Patents

Literature

1240results about How to "Improve feeding effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Birds feed additive

InactiveCN1471836ANo cross resistanceImprove immunityAnimal feeding stuffAccessory food factorsFowlFishery

An additive for fowl's feed is prepared from more Chinese-medicinal materials, and can serve to improve immunity, promote appetite and absorption, and relieve inflammation. Its advantages are high effect and low cost.

Owner:FEED RESEARCH INSTITUTE CHINESE ACADEMY OF AGRICULTURAL SCIENCES

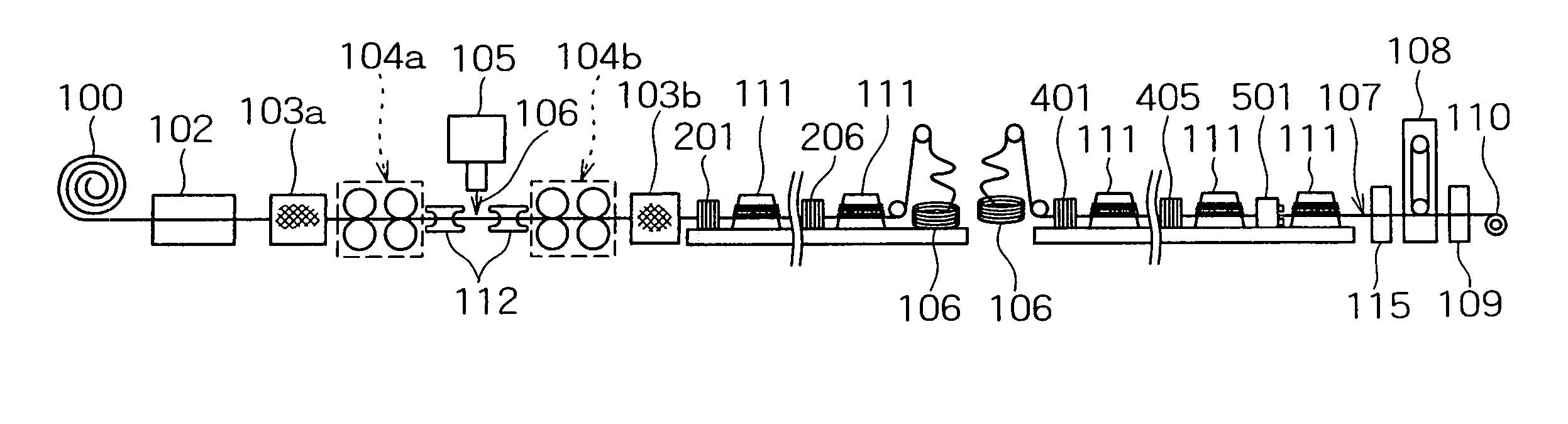

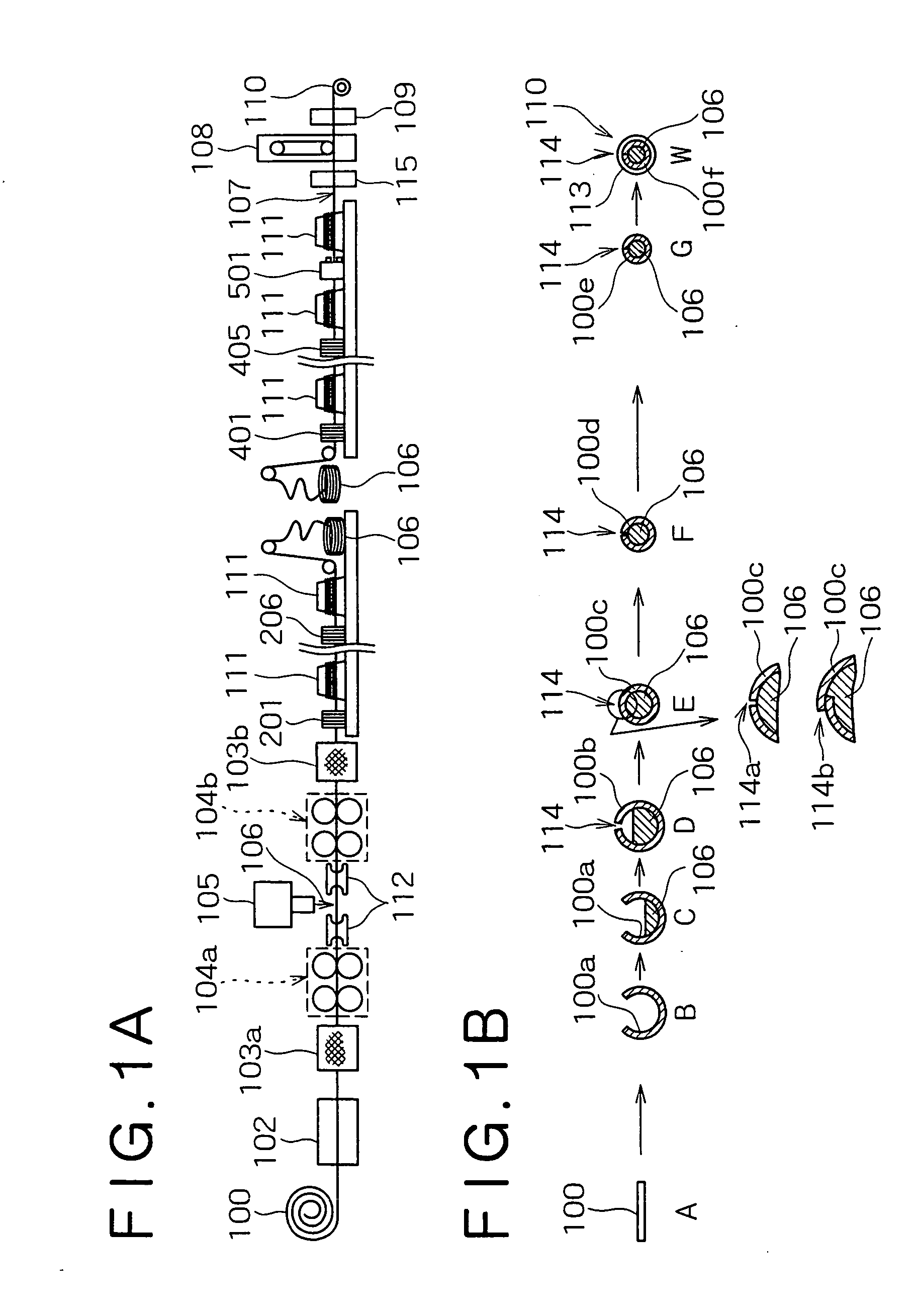

Method for manufacturing seamed flux-cored welding wire

ActiveUS20050044687A1Improve feeding effectReduce contentDrawing diesWelding/cutting media/materialsWire rodSulfur

Disclosed herein is a manufacturing method, excellent in wire drawability, of a seamed flux-cored welding wire having both favorable feedability and low hydrogen content characteristic. The method for manufacturing a seamed flux-cored wire, comprises the steps of: drawing a tube-like formed wire including a flux filled therein using a lubricant; removing the lubricant from the drawn wire by a physical means; and coating a lubricant (coating an oil) for wire feeding on the wire surface. The respective steps are carried out in an in-line manner. In the wire drawing step, a wire drawing lubricant containing a sulfur-bearing high-pressure lubricant is used, and the overall wire drawing from the tube-like formed wire to a roughly product-diameter wire is carried out by means of a roller die.

Owner:KOBE STEEL LTD

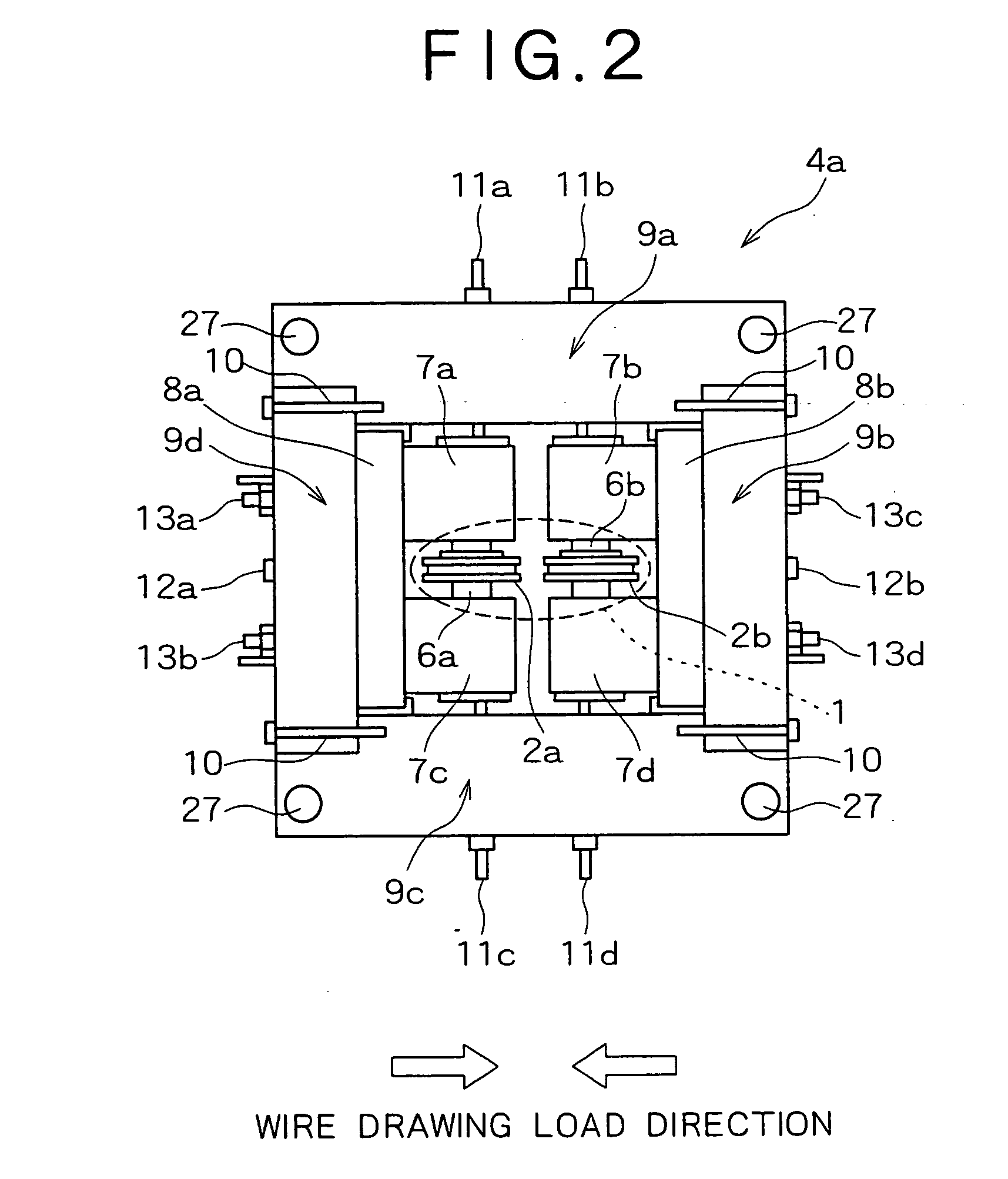

Multicolumn strip packing machine

ActiveCN102730214AIncrease productivitySimple structureWrapping material feeding apparatusWrapper twisting/gatheringReciprocating motionEngineering

The invention relates to a multicolumn strip packing machine, in particular to a multicolumn strip packing machine capable of carrying out continuous bag-making and packing through automatic operation, comprising a frame, and a film feeding mechanism, a slitting cutter mechanism, a feeding mechanism, a bag molding mechanism, a longitudinal sealing mechanism, a transverse sealing mechanism and a cut-off mechanism arranged on the frame respectively, wherein the transverse sealing mechanism comprises a transverse sealing device which comprises a transverse sealing floating device, two transverse sealing holders, and transverse sealing seats arranged on the two transverse sealing holders respectively; a plurality of transverse sealing guide shafts are together sleeved to transverse beam sliders on the same side; at least one transverse sealing seat is connected to a transverse sealing cylinder for driving the transverse sealing seat to do reciprocating motion; and the axial direction of the transverse sealing guide shaft is consistent with the motion direction of the transverse sealing seat. The transverse sealing mechanism of the multicolumn strip packing machine is capable of providing a buffering force for an object to be packed so that the impact on the object to be packed can be reduced and the object to be packed can be protected against damage; and a plurality of combined components are arranged in a multi-row parallel manner, so that the production of a plurality of packing bags can be completed at the same time; as a result, the production efficiency is greatly improved.

Owner:SHANGHAI SOONTRUE MACHINERY EQUIP

Multiple microorganism straw fermented fodder and leaven and its preparing method

InactiveCN1425317AImprove disease resistanceHigh nutritional valueBacteriaFood processingMicroorganismBiotechnology

The microbe fermented feed is produced through preparing fermenting agent with several kinds of microbial strains, mixing supplementary material, straw and activated fermenting agent, fermentation inside one container of fermenting pond. The fermenting agent has wide application range of fermentation conditions and various straw and vine, green or dry, of different crops may be used as the main material for producing the fermented feed. The fermented feed has good feeding effect, and is delicious and easy to digest and absorb.

Owner:TIANJIN DAMEI SCI & TECH

Artificial feed for antlered larvae, its preparing method and use

InactiveCN1653937ANutritional diversityLow priceAnimal feeding stuffAccessory food factorsYeastVitamin C

The present invention relates to one kind of artificial feed for raising larvae of lepidopterous insect, and the recipe consists of beer yeast powder, wheat plumule powder, tomato, food preservative, vitamin C, edible oil, agar and water. The present invention also relates to the preparation process of the feed. The feed of the present invention has low cost, easy compounding, stable feeding effect and powerful practicability.

Owner:INST OF ZOOLOGY CHINESE ACAD OF SCI

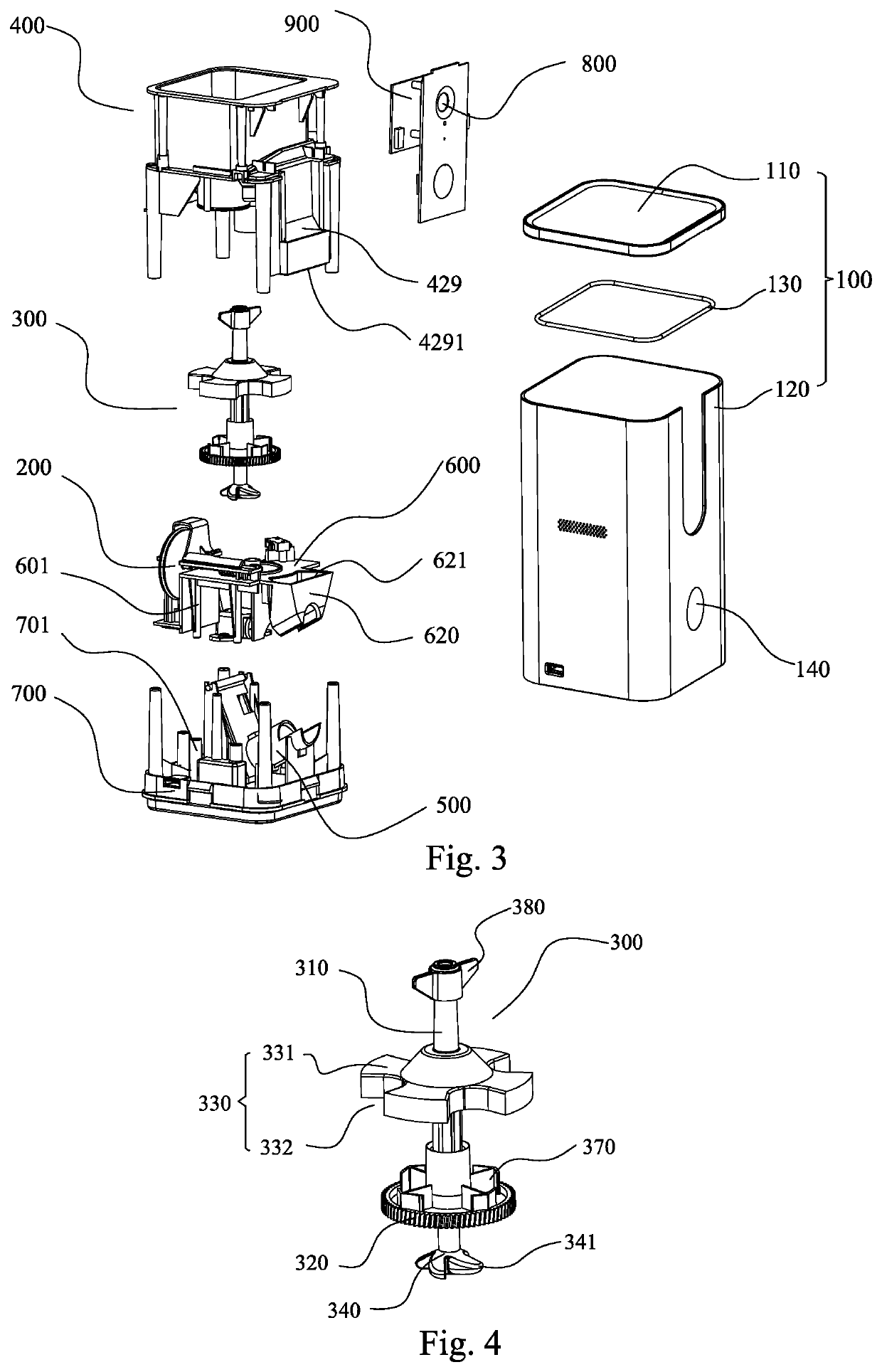

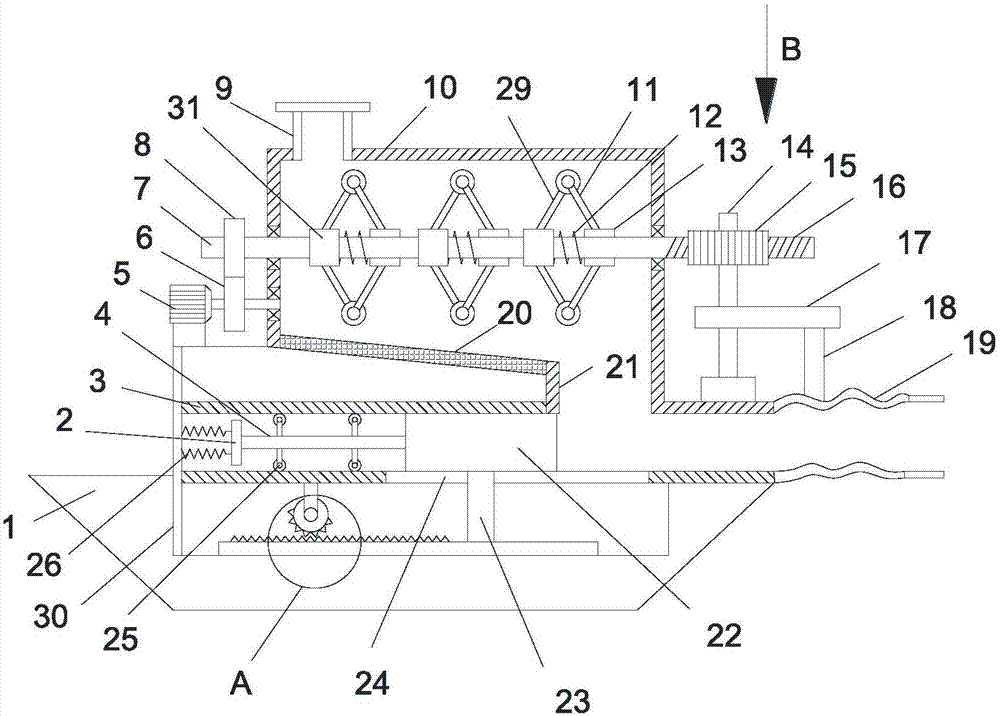

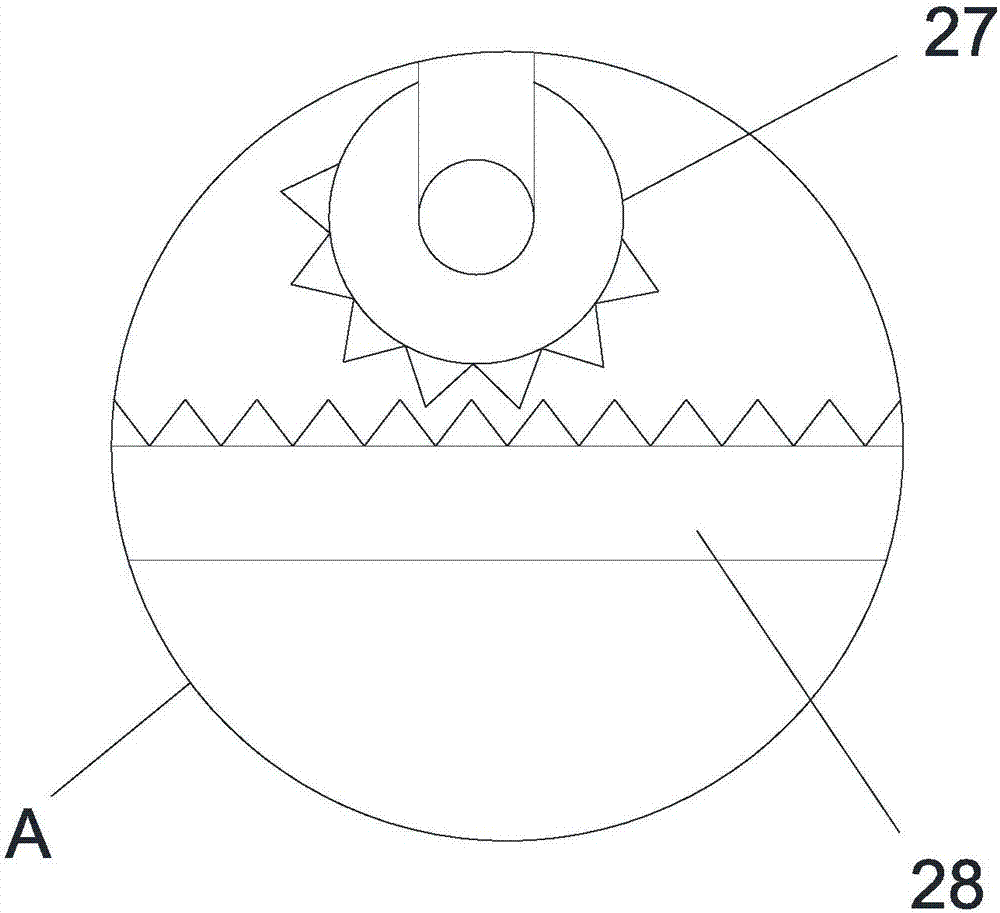

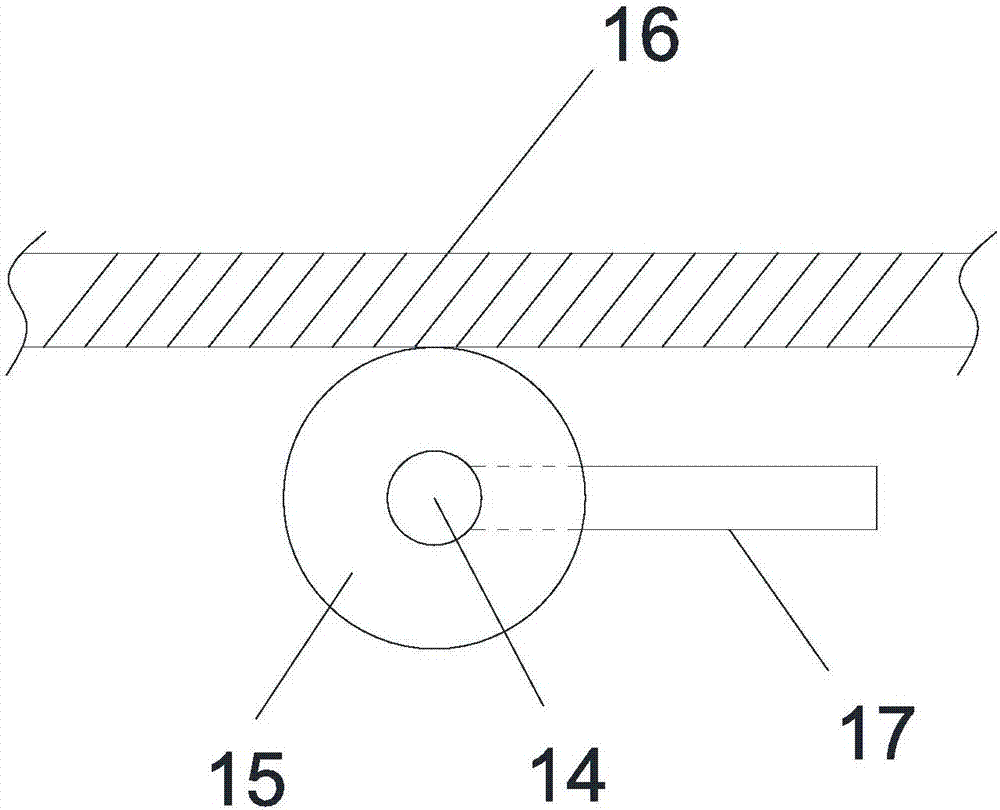

Smart pet feeder

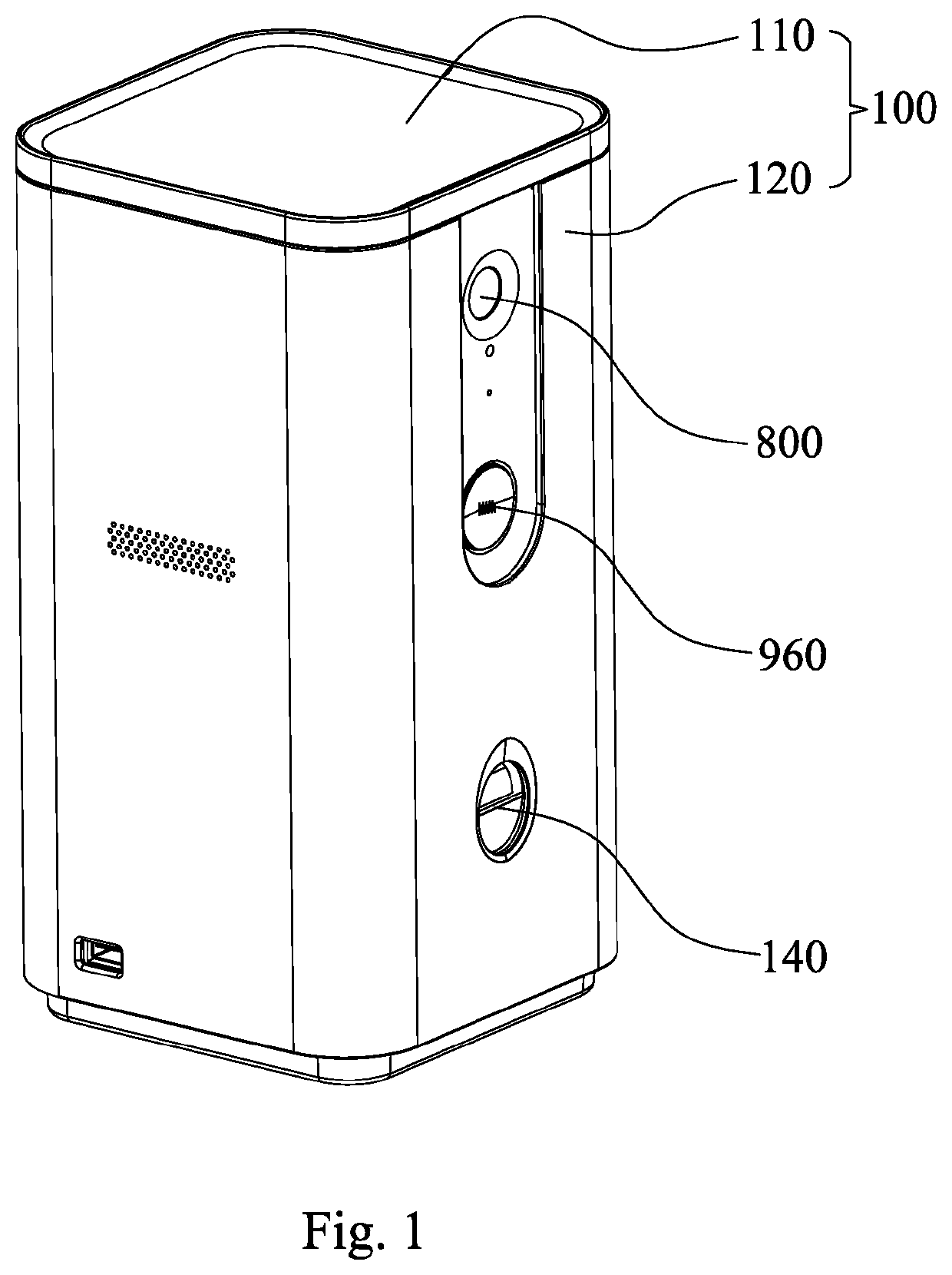

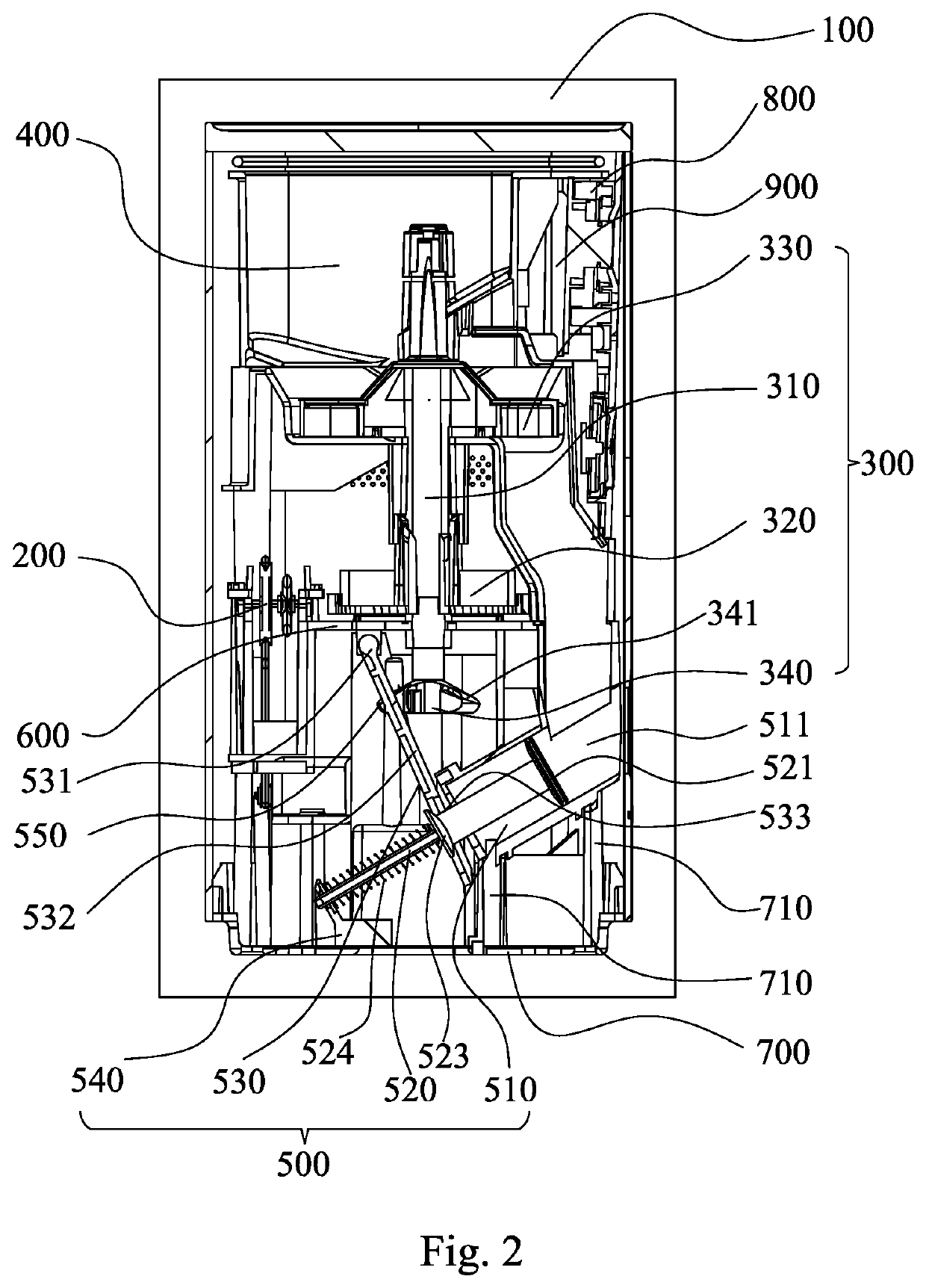

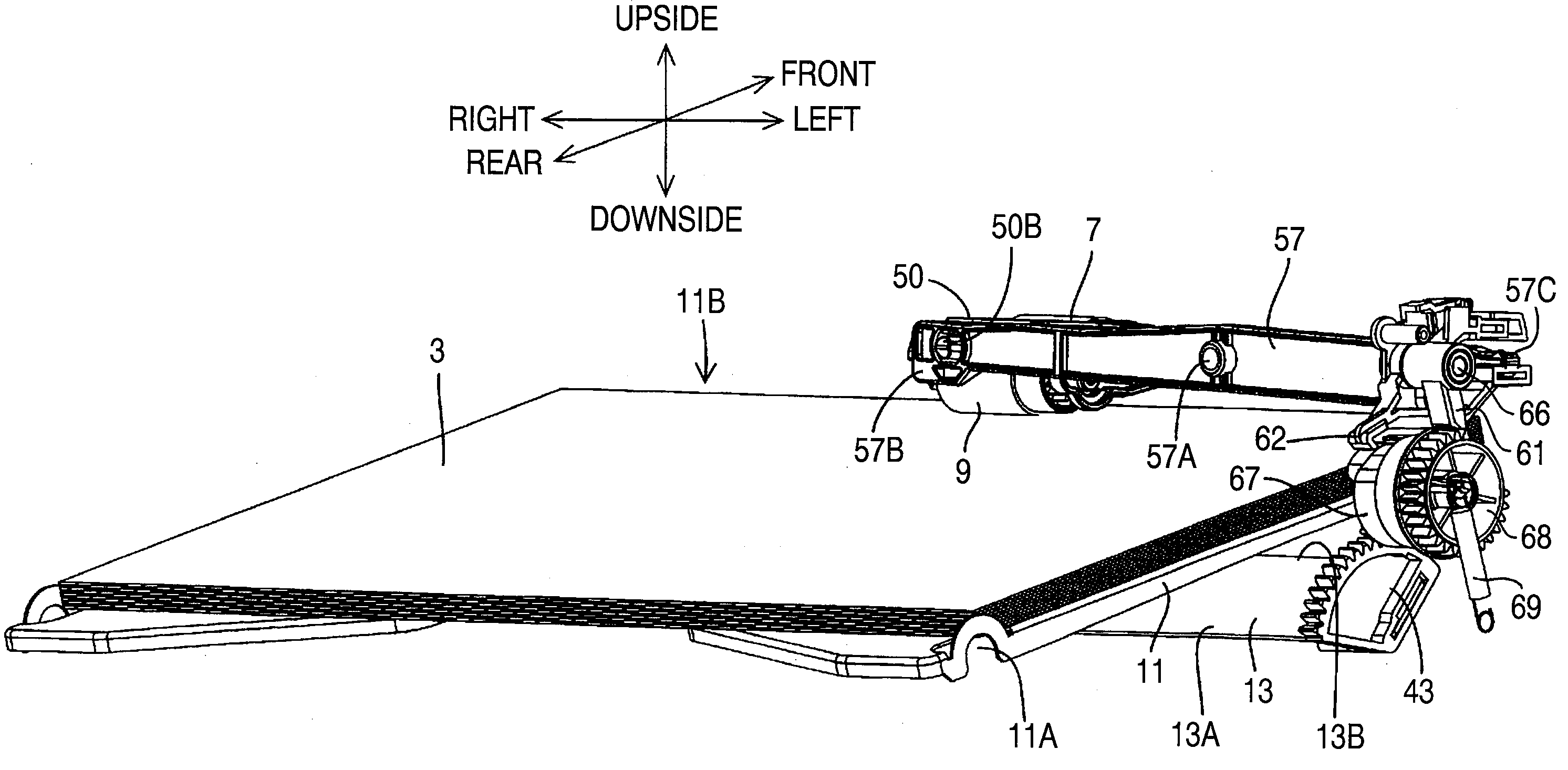

ActiveUS20200100460A1Improve feeding effectAnimal feeding devicesOther apparatusGear wheelGrain storage

The smart pet feeder includes a housing, and a grain storage component, a driving component and a rotating component, arranged therefor in the upper part, the middle part and the lower part of the housing; a rotating component is arranged in the housing, and the rotating component has a supporting column, the upper part, of it is provided with a wheel, the lower part of it is provided with a driving gear, the bottom end of it is provided with a cam; the upper part is extended into the grain storage component, and the wheel is contained in the grain storage component; the driving gear is rotatably connected with the driving component, the cam is connected with the throwing component.

Owner:DOGNESS GRP LLC

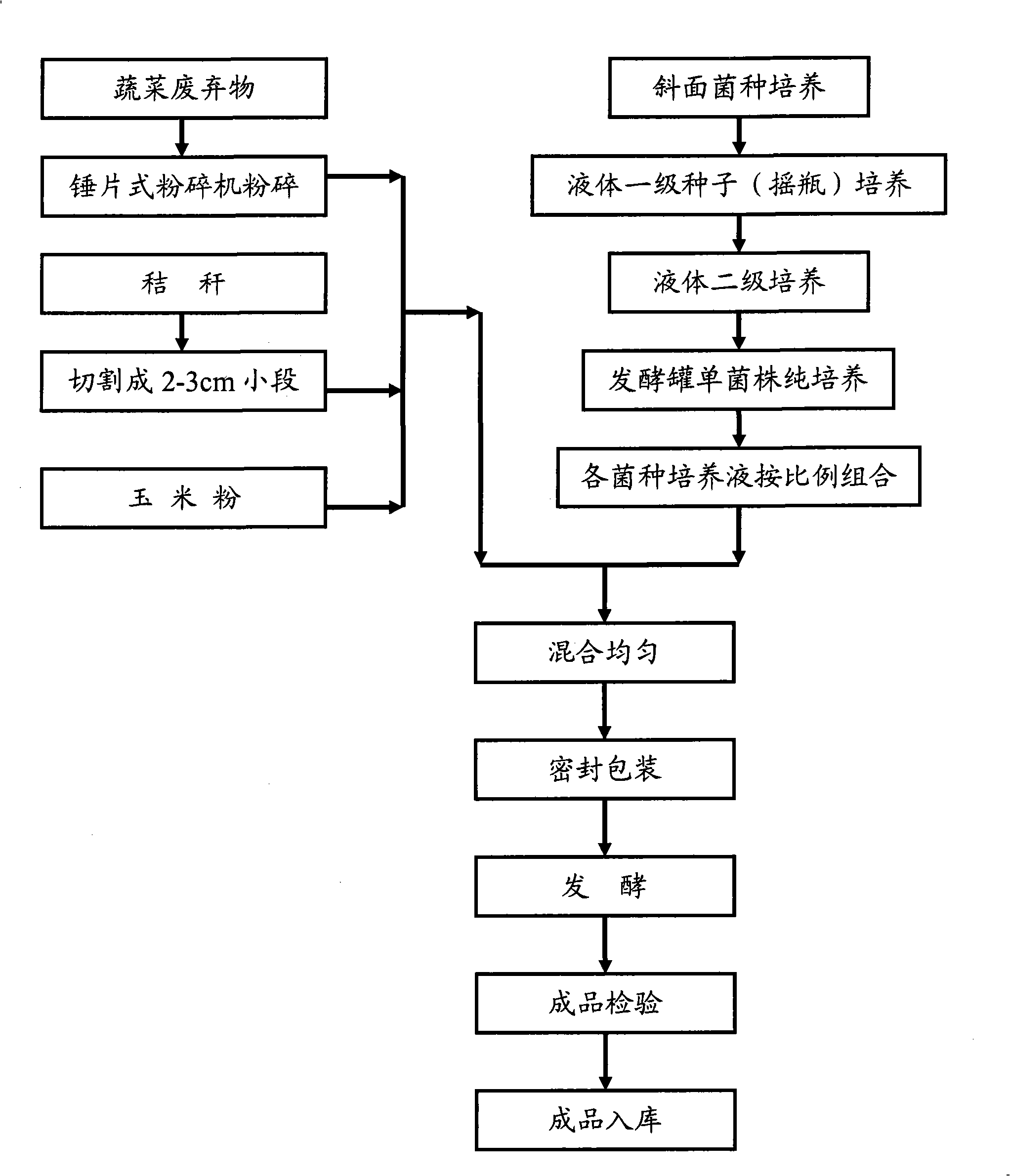

Fermented abandoned vegetable feedstuff and preparation method thereof

InactiveCN101401616AAdaptableSuitable for a wide range of raw materialsFood processingAnimal feeding stuffBiotechnologyMicroorganism

The invention relates to fermentation waste vegetables feed and a preparation method. The fermentation waste vegetables feed consists of mixed raw materials and microorganism living bacteria liquid, wherein the mixed raw materials consist of vegetable waste materials, straw and corn powder; and each ton of the mixed raw materials are formed according to the weight ratio (w / w): 70 to 80 percent of waste vegetables, 20 to 25 percent of straw, and 4 to 6 percent of corn powder. Each ton of the mixed raw materials are added with 30 to 40 milliliters of the microorganism living bacteria liquid, and the content of living bacteria for the microorganism living bacteria liquid is between 1.0x10<9>cfu / mL and 1.0x10<11>cfu / mL. The fermentation waste vegetables feed and the preparation method have the advantages of reasonable formulation, scientific production method, wide applicable areas, simple operation, easy master, low cost, reasonable formula design, convenient production, suitability for broad peasant households and livestock breeding plants, safe and no toxity, and great adaptability to fermentation conditions, and can be used as feed of cows, sheep, geese, and so on, make full use of side products in agriculture industry, realize reasonable use of the resources, and provide new techniques for clean and sustainable agricultural industry.

Owner:北京阔利达生物技术开发有限公司 +1

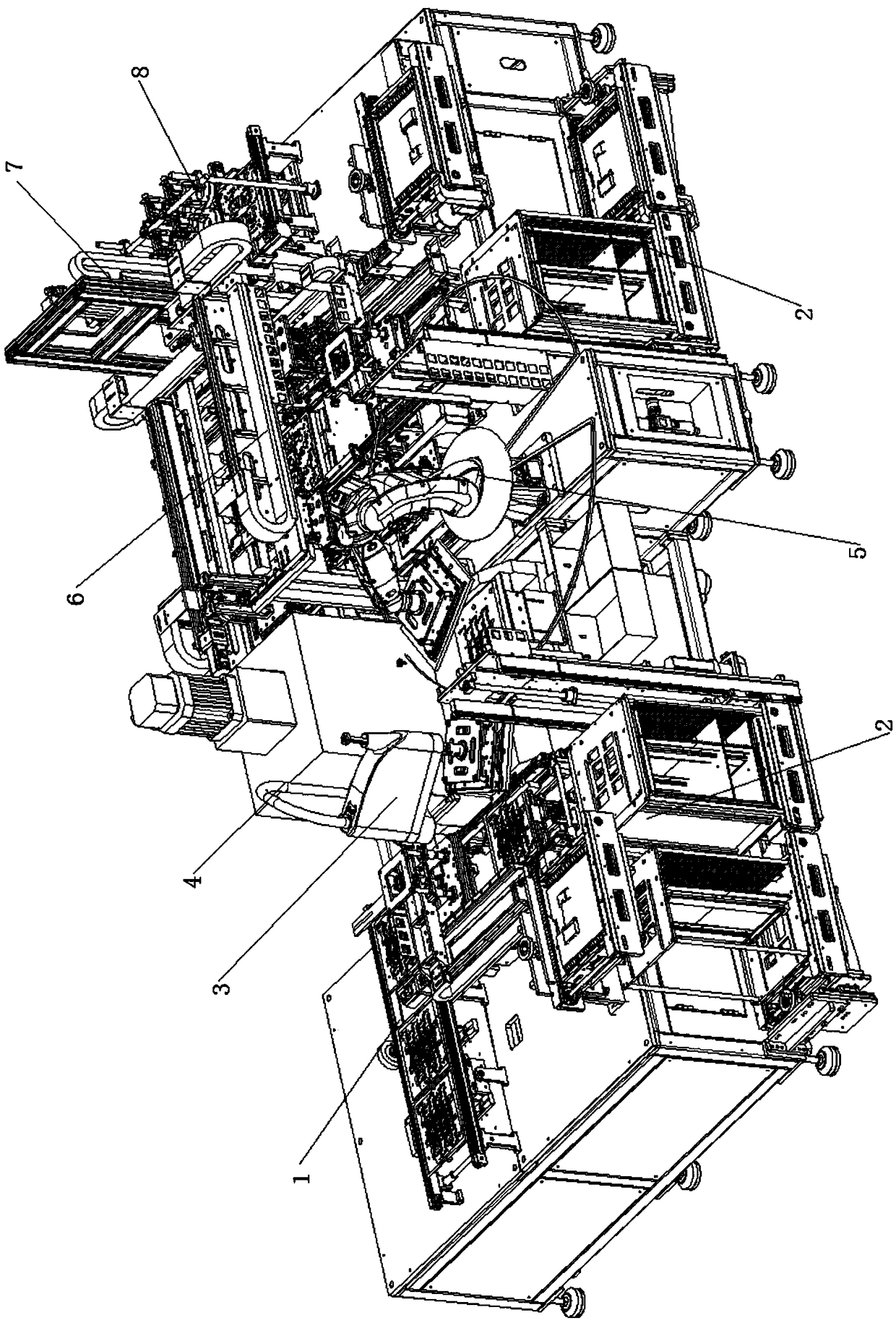

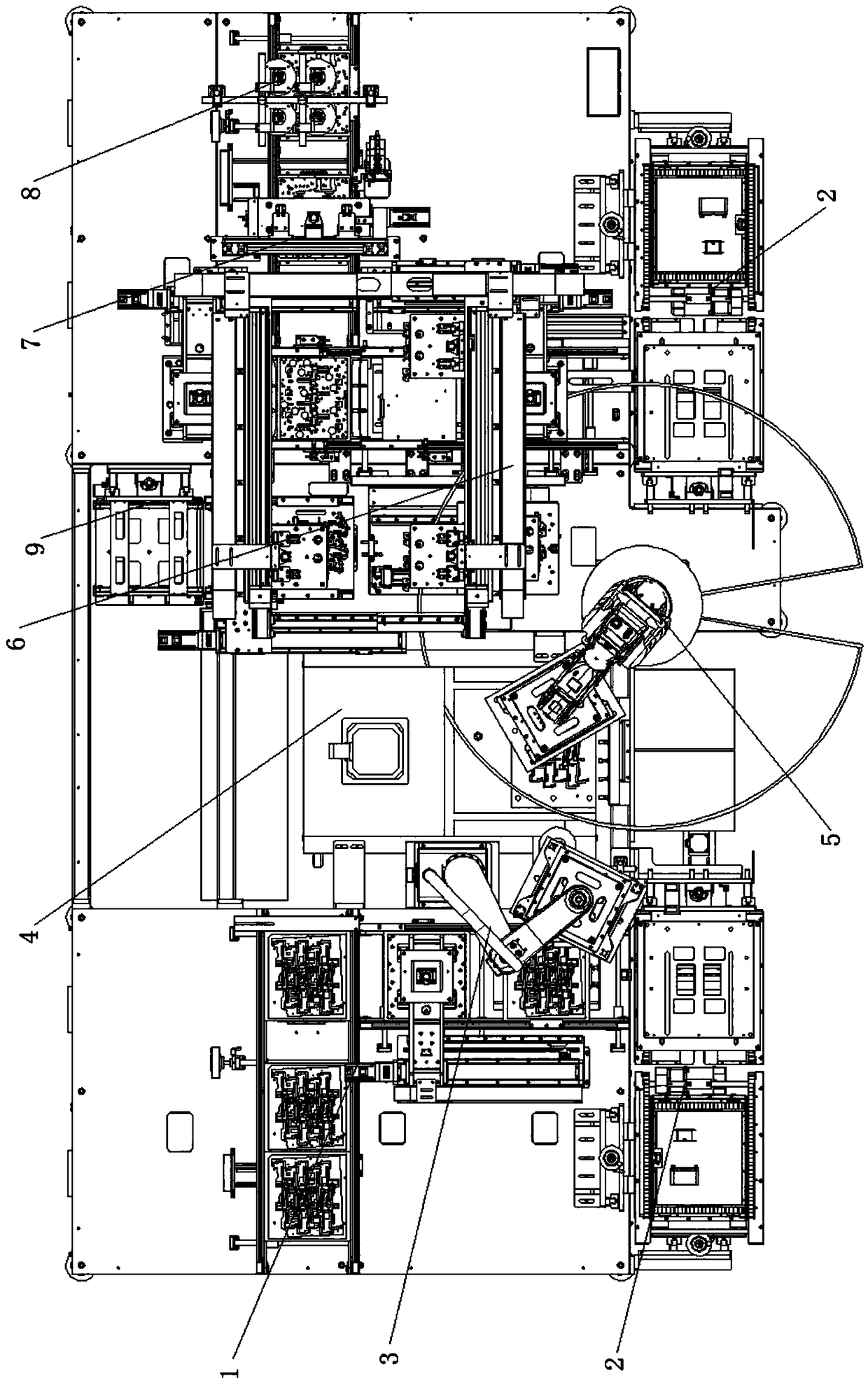

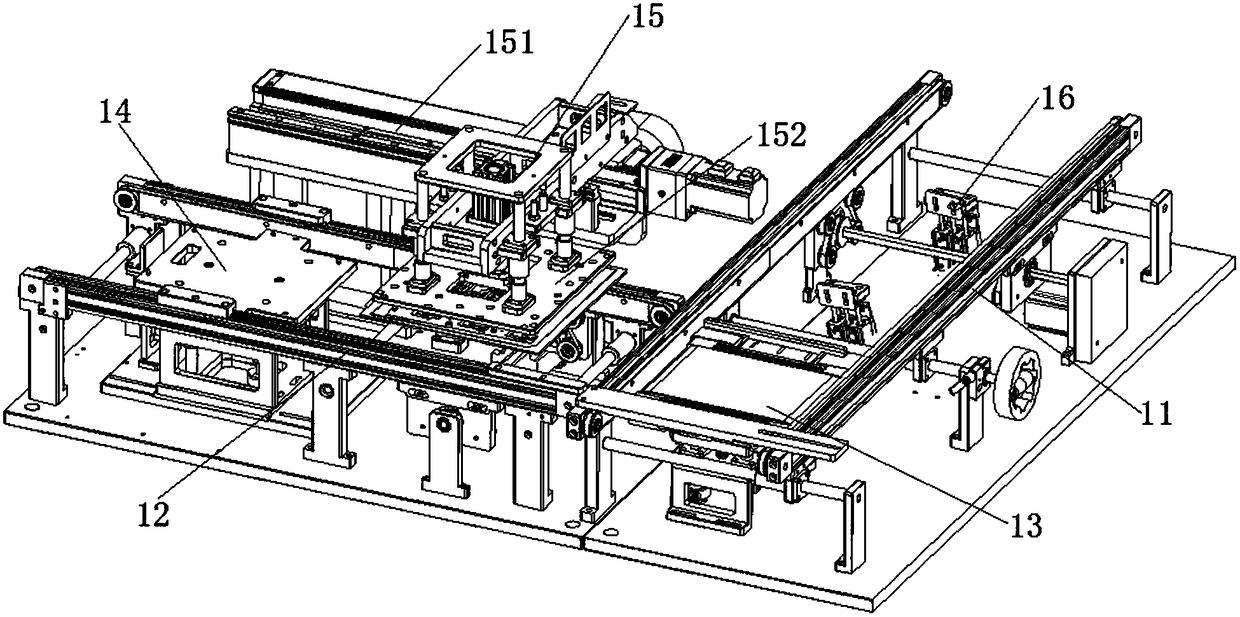

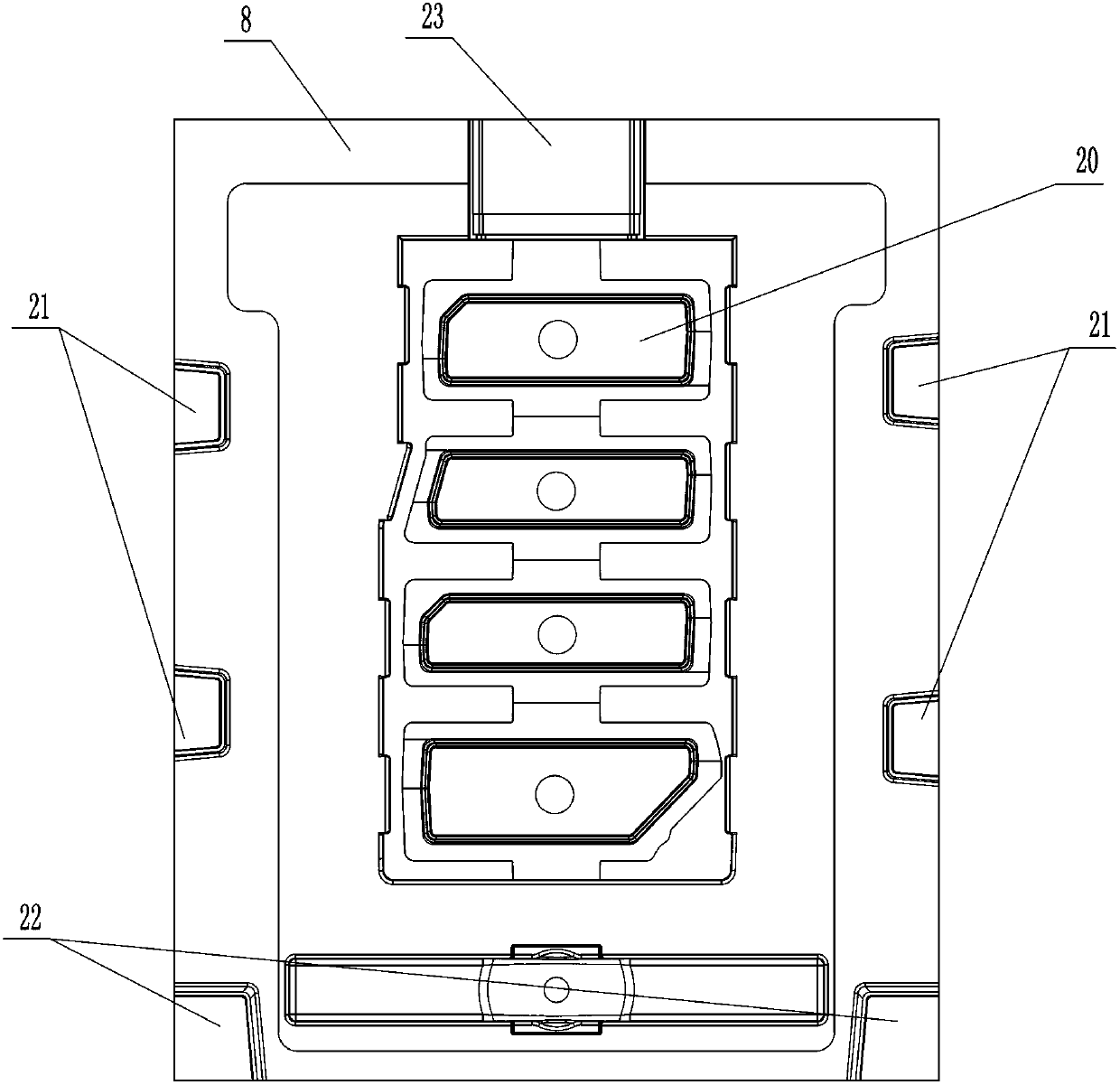

FPC flexible printed circuit board automatic processing equipment

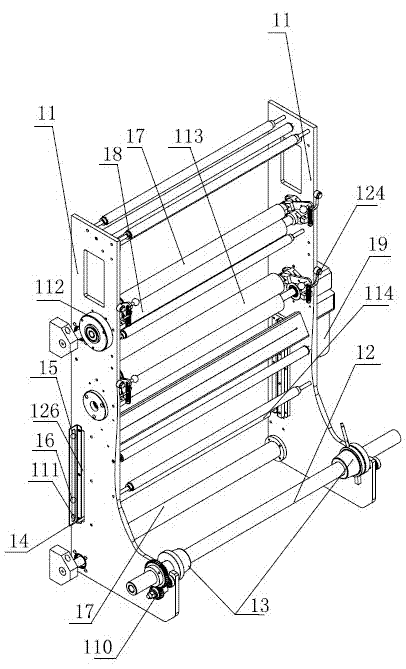

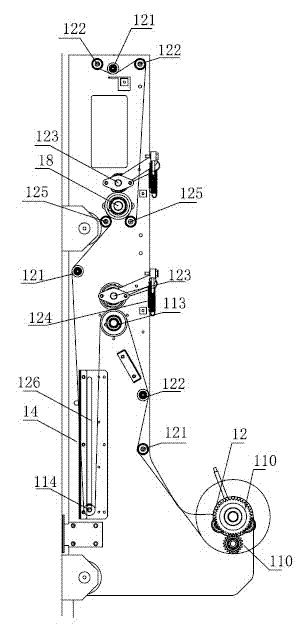

PendingCN108323016AImprove feeding effectImprove work efficiencyLaminating printed circuit boardsPunchingAutomatic test equipment

The invention relates to the automation equipment field, and especially relates to FPC flexible printed circuit board automatic processing equipment; a convey structure transports a carrier carrying acircuit board to a first transplant unit; the first transplant unit conveys the circuit board to a punching structure for punching; a second transplant unit conveys the punched circuit board to a positioning feed structure for secondary positioning discharge; a turning structure turns the discharged circuit board; a detection structure detects the turned circuit board to realize precise feeding and blanking; the circuit board is processed by the automatic processing equipment; the positions between the convey structures can be automatically placed; each station can simultaneously realize feeding and blanking functions, thus greatly improving the material piece conveying speed; in addition, instead of using CCD, the automatic processing equipment uses a machinery structure to position, thus improving the positioning efficiency, greatly improving the attaching efficiency, and effectively preventing oxidation influence and non-uniform working strength problems caused by using fingers topaste chips.

Owner:SUZHOU JIERUISI INTELLIGENT TECH CO LTD

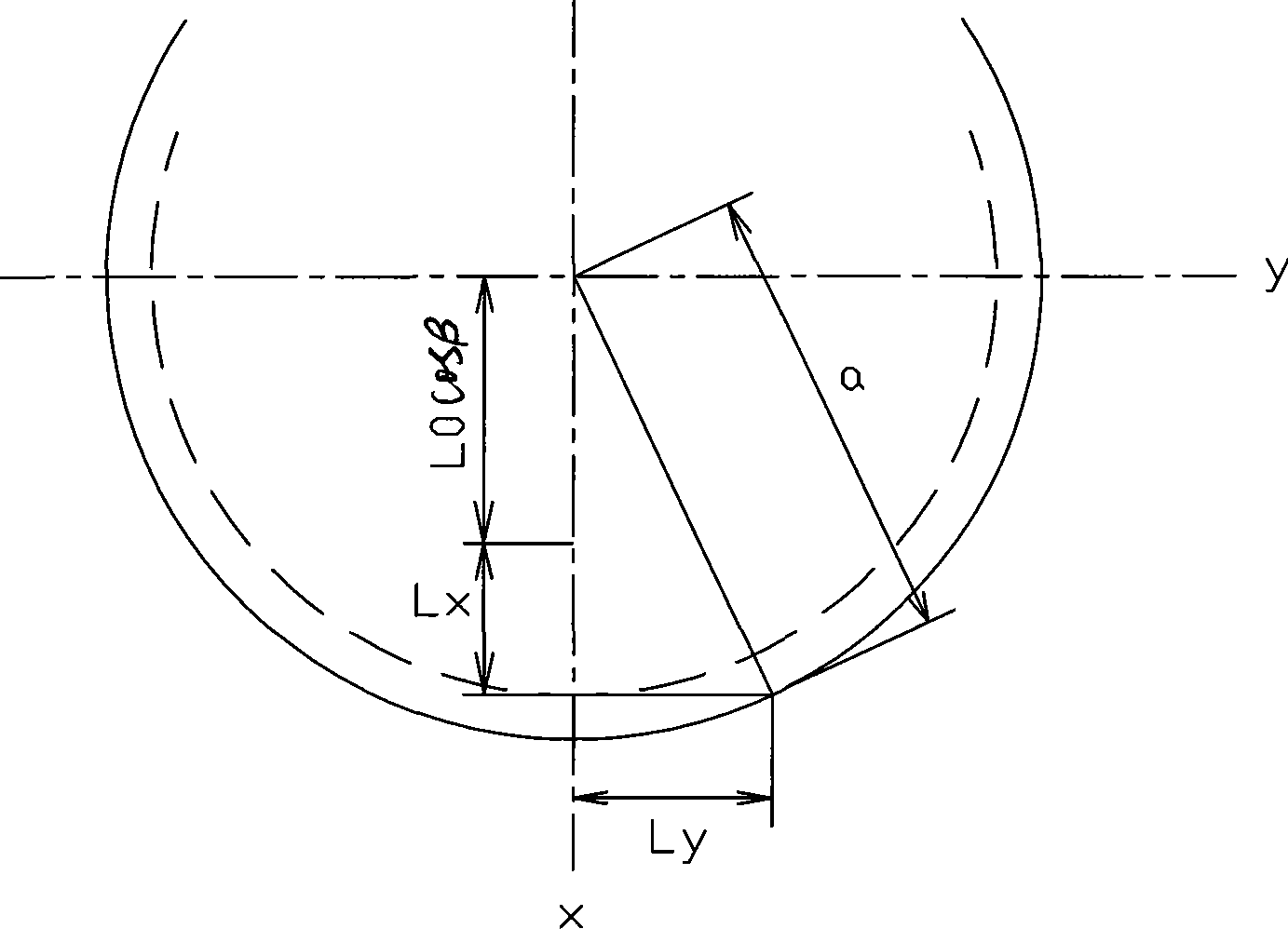

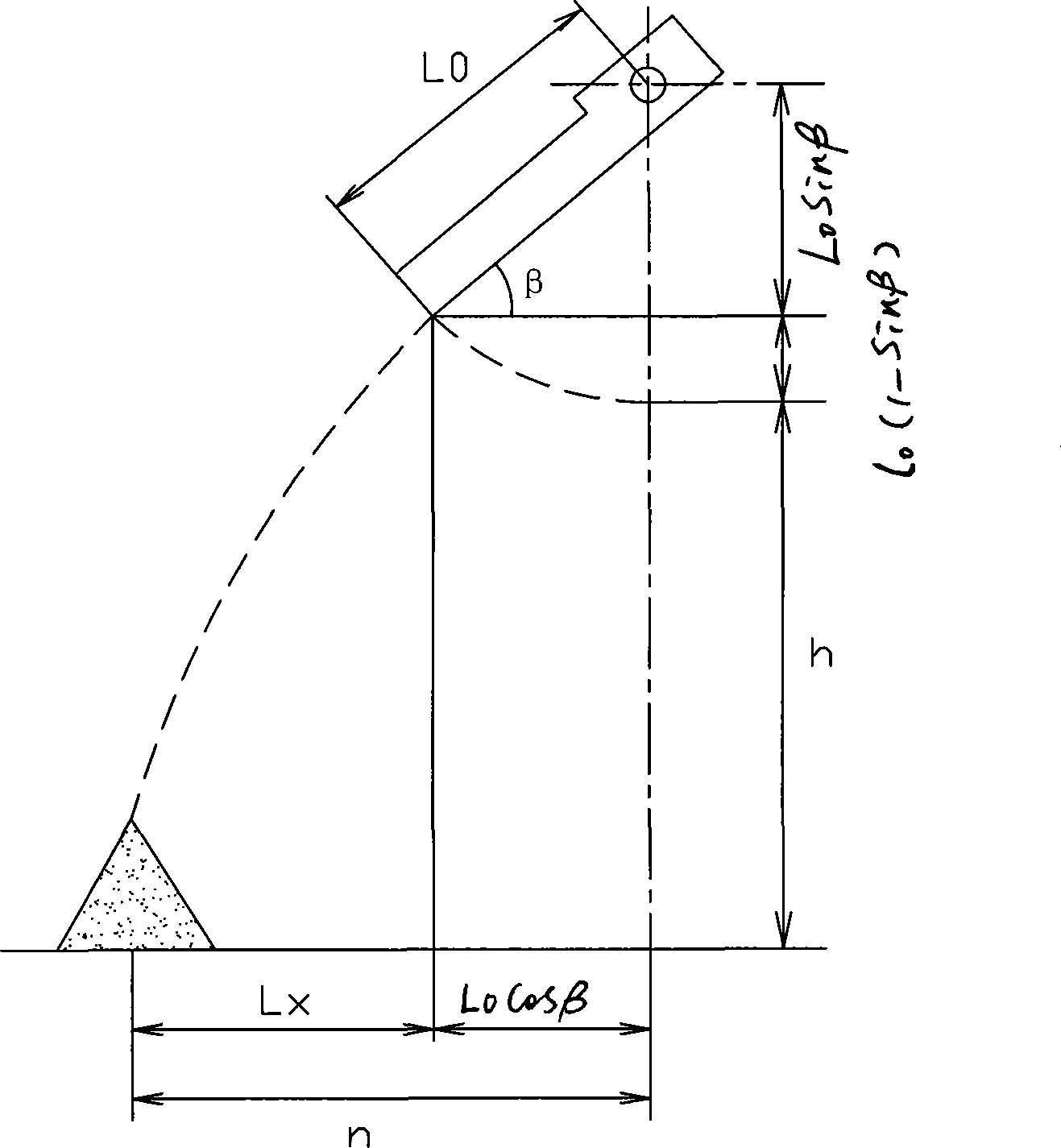

Blast furnace chute polycyclic distributing method

InactiveCN101250602AIncrease production capacityUniform material layerBell-and-hopper arrangementBlast furnace detailsRing numberGravitation

The invention discloses a blast furnace chute multi-ring burden distribution, which comprises firstly calculating the distance from the center of furnace burden from the center of a blast furnace after furnace burden fell into an xy plane, secondly deciding largest and smallest burden distribution angles in theory, thirdly deciding the actual burden distribution angles of outer ring and inner ring of ores and coke, fourthly deciding the burden distribution ring number of ores and coke, determining the burden distribution angle of middle ring of ores and coke and the angel difference of adjacent rings, and sixthly determining the burden distribution rings of each ring in ores and coke. The process largely enriches the regulating method on the upper portion of the blast furnace, changes coal gas distribution, effectively increases the coal gas usage of the blast furnace, reduces coke ratio, realizes the stable and long term operation of the blast furnace, has strong loading material capacity, can eliminate furnace burden gravity segregation and the existing of pile top, much reasonably distributes furnace burden, is beneficial for strengthening smelting, and improves the press amount relationship and further increases the air quantity of the blast furnace.

Owner:CHONGQING IRON & STEEL (GRP) CO LTD

Wire for welding

InactiveUS6841246B2Improve feeding effectStable and smooth feedElectric discharge heatingWelding/cutting media/materialsMetal filamentUnsaturated hydrocarbon

Owner:KOBE STEEL LTD

Method for producing biological particle grain-saving straw feed

InactiveCN102113623ATake advantage ofSimple methodFood processingAnimal feeding stuffSocial benefitsCorn meal

The invention relates to a method for producing a biological particle grain-saving straw feed, effectively solving the problem of grain waste in the production of a biological particle straw feed so as to meet the need of stockbreeding on feeds. The method comprises the following steps of: firstly, mixing the raw materials in percentage by weight: 70-80 percent of straws, 17-27 percent of corn meal, 0.5-1 percent of ammonium bicarbonate, 0.2-0.4 percent of brown sugar, 0.5-1 percent of active biochemical bacterium and 0.4-0.6 percent of common salt; adding 45-55 percent by the raw material weight of water at 24-30 DEG C and uniformly stirring and mixing; and then, putting in a sterile workshop at 40-44 DEG C, carrying out anaerobic fermentation for 6-8 days, extruding to remove 30-40 percent of water content to form a fermented raw material and then granulating and air-drying. The method provided by the invention is simple, rich in raw materials and easy to produce, can fully utilize biological straws and save grains, has good feeding effect and remarkable economic and social benefits and therefore is a great innovation on the biological feed.

Owner:曹孟

Livestock feed addictive composition as well as preparation method and application thereof

InactiveCN101480225ATo promote metabolismImprove immunityFood processingAnimal feeding stuffDiseasePolygonum fagopyrum

The invention discloses a livestock feed additive composition and the preparation method and the application thereof. The livestock feed additive composition comprises following ingredients by weight percentages: 70 to 90 percent of medicated leaven, 70 to 90 percent of sweetflag, 35 to 45 percent of tangerine peel, 35 to 45 percent of dyers woad leaves, 35 to 45 percent of isatis root, 25 to 35 percent of white peony, 25 to 35 percent of divaricate saposhnikovia root, 25 to 35 percent of fennel, 25 to 35 percent of liquorice and 90 to 110 percent of lack tartary buckwheat. The invention adopts natural Chinese herbal medicine, can fully avoid damaging human bodies by added chemical synthetic drugs and toxic chemical substances, does not generate the cross drug resistance of the drugs shared by human beings and livestock, is favorable to the enhancement of the organism immunity of livestock and improves the metabolism capability of the livestock so as to achieve the aims of resisting diseases and promoting the growth of the livestock .

Owner:FEED RESEARCH INSTITUTE CHINESE ACADEMY OF AGRICULTURAL SCIENCES +1

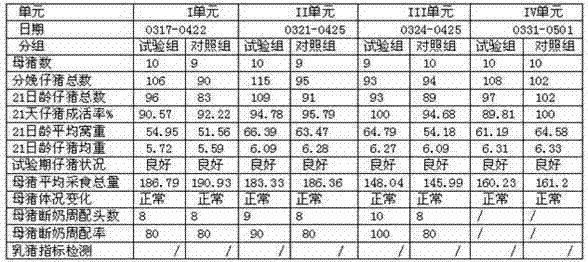

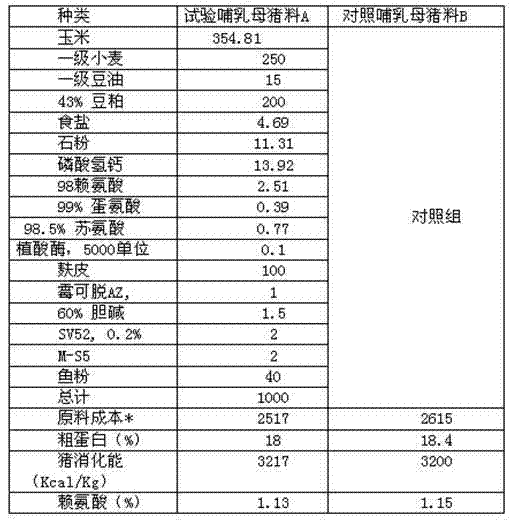

Feed for lactating sow and preparation method thereof

The invention discloses a feed for lactating sows and a preparation method thereof. The feed comprises the following components in parts by weight: 300-400 parts of corn with caloric value being 3250kcal / kg, 100-120 parts of bran, 10-15 parts of first grade bean oil, 200-250 parts of wheat, 200-230 parts of 43% of bean pulp, 2-5 parts of salt, 10-12 parts of stone powder, 12-14 parts of calcium hydrophosphate, 0.3-1 part of 99% of methionine, 0.5-1 part of 98% threonine, 2-5 parts of 98% lysine, 0.1-0.5 part of phytase, 0.5-2 parts of MYCO-AD, 1.5-2 parts of 60% choline chloride, 20-50 parts of Peruvian fish meal, 2-4 parts of SV52 and 2-4 parts of M-S5. The feed has scientific mixture ratio, is convenient to prepare, reduces the use amount of the antibiotics, can improve the weaning weight of the sows, improve the weight of the weaned pigs and shorten the weaning time and simultaneously can positively influence the health conditions of the suckling pigs, improve the survival rate andincrease the economic benefits.

Owner:潍坊新希望六和饲料科技有限公司

Low-tryptophan feed for hybrid chicken and preparation method of the low-tryptophan feed

ActiveCN102178100APromote growthImprove survival rateFood processingAnimal feeding stuffSalvia miltiorrhizaSide effect

The invention discloses low-tryptophan feed for hybrid chicken. The low-tryptophan feed includes the components as follows: tryptophan, stone powder, Maxus, wheat bran, crushed maize, fish meal, rice bran and traditional Chinese medicine additive. The bulk pharmaceutical chemicals of the traditional Chinese medicine additive further includes: ligusticum wallichii, astragalus, dried tangerine peel, haw, scutellaria baicalensis, medical stone, folium isatidis, turmeric, wolfberry, dodder, white atractylodes rhizome, hedyotis diffusa, angelica, salvia miltiorrhiza and white paeony root. The technical benefits are as follows: concretely, the content of tryptophan meets the normal demand of the hybrid chicken by the optimization on the structure of feed materials, and the waste of tryptophan is reduced to minimum simultaneously when the demand of the hybrid chicken for tryptophan is met; and simultaneously the growth performance can be influenced negatively. The low-tryptophan feed for hybrid chicken greatly improves the survival rate of the chicken, accelerates the growth of the chicken, eliminates the injury of chemical agents to the chicken as well as the side effect of indirectly influencing food safety, adopts fully-new traditional Chinese medicine feed additive and can greatly enhance the slaughtering rate.

Owner:SHANDONG NEW HOPE LIUHE GROUP

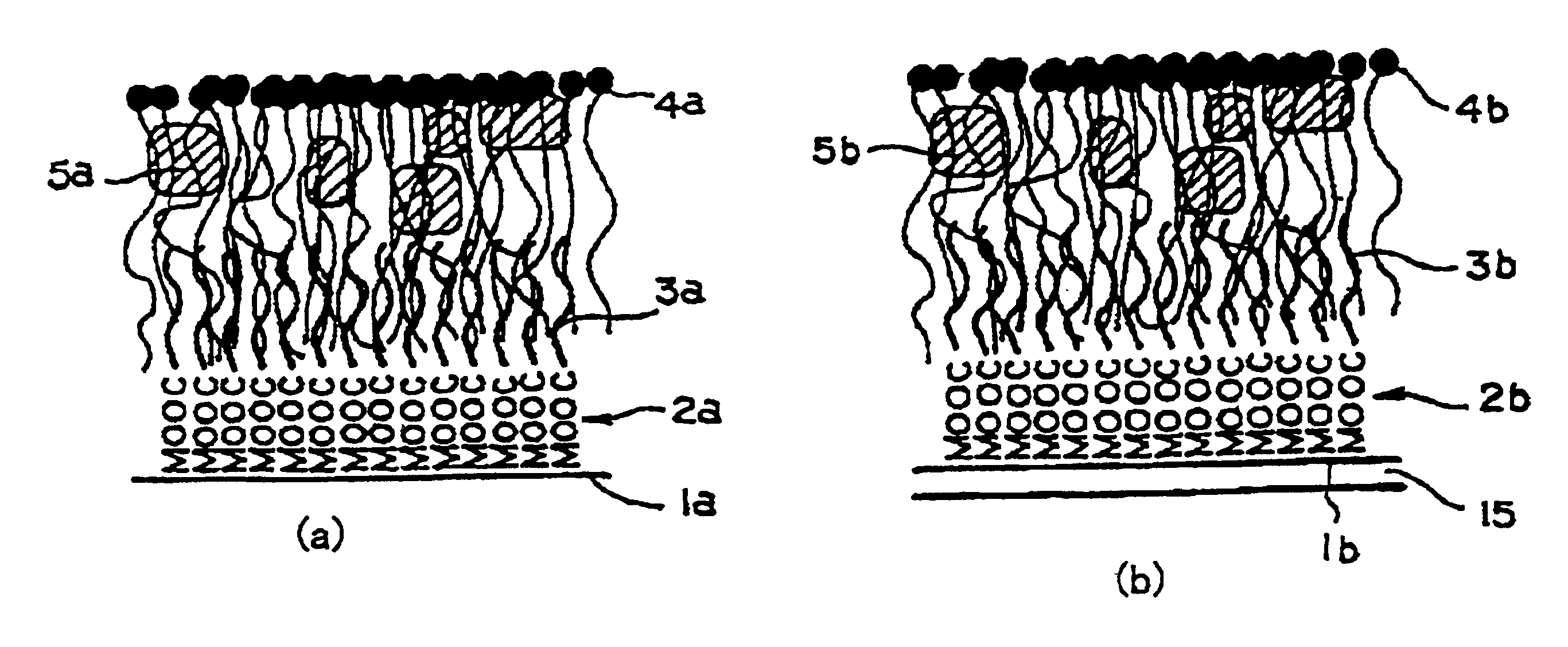

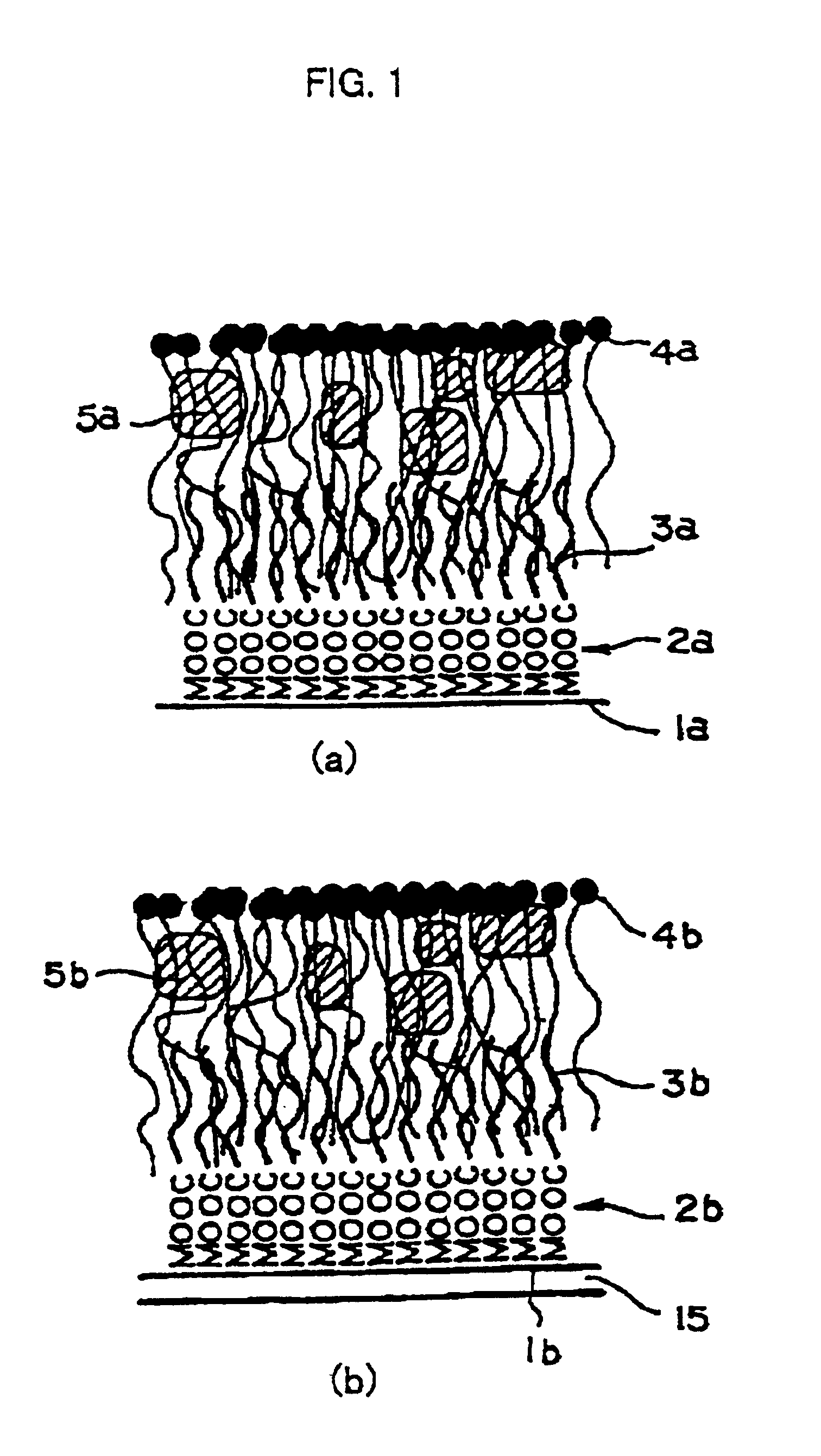

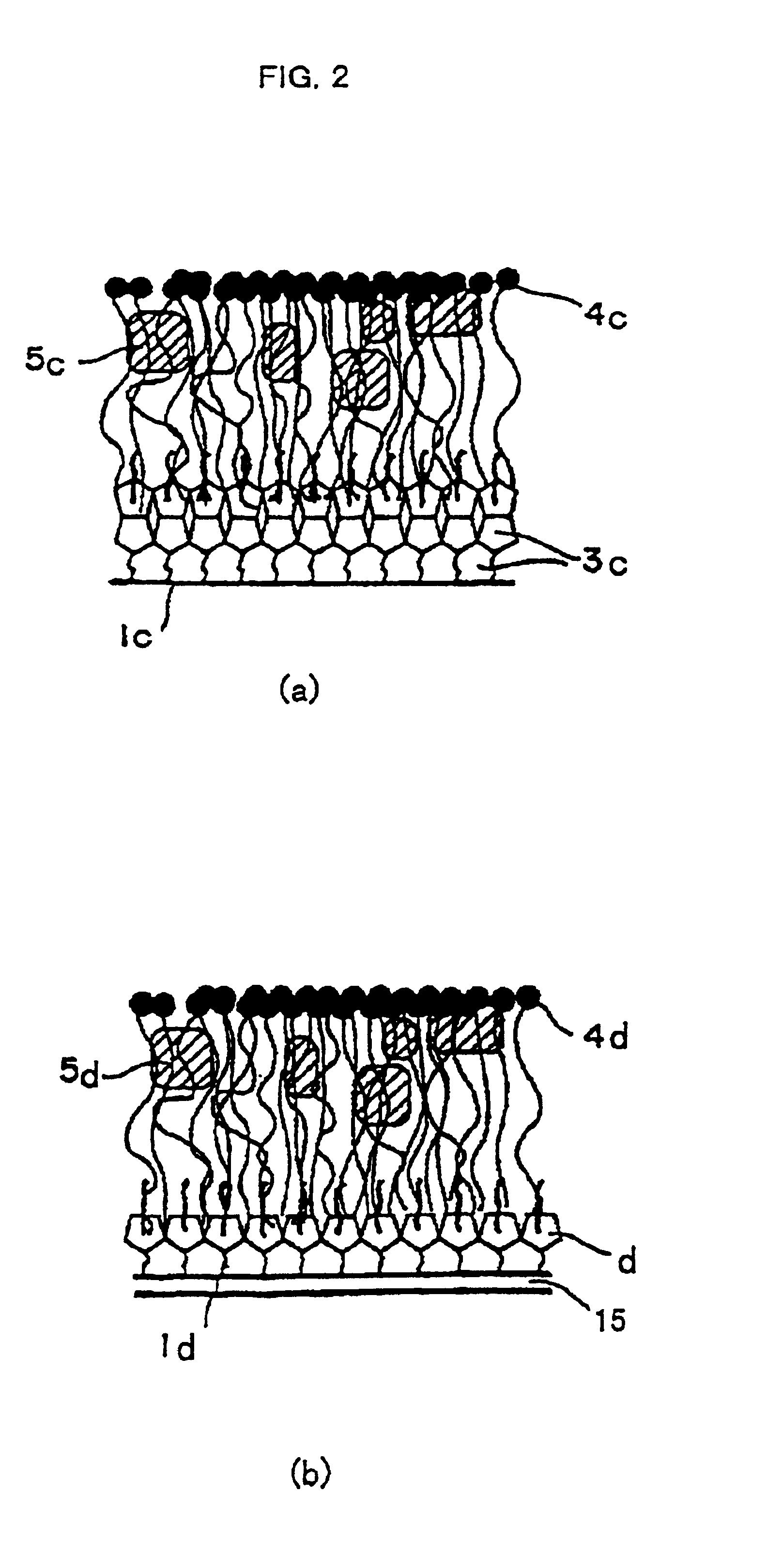

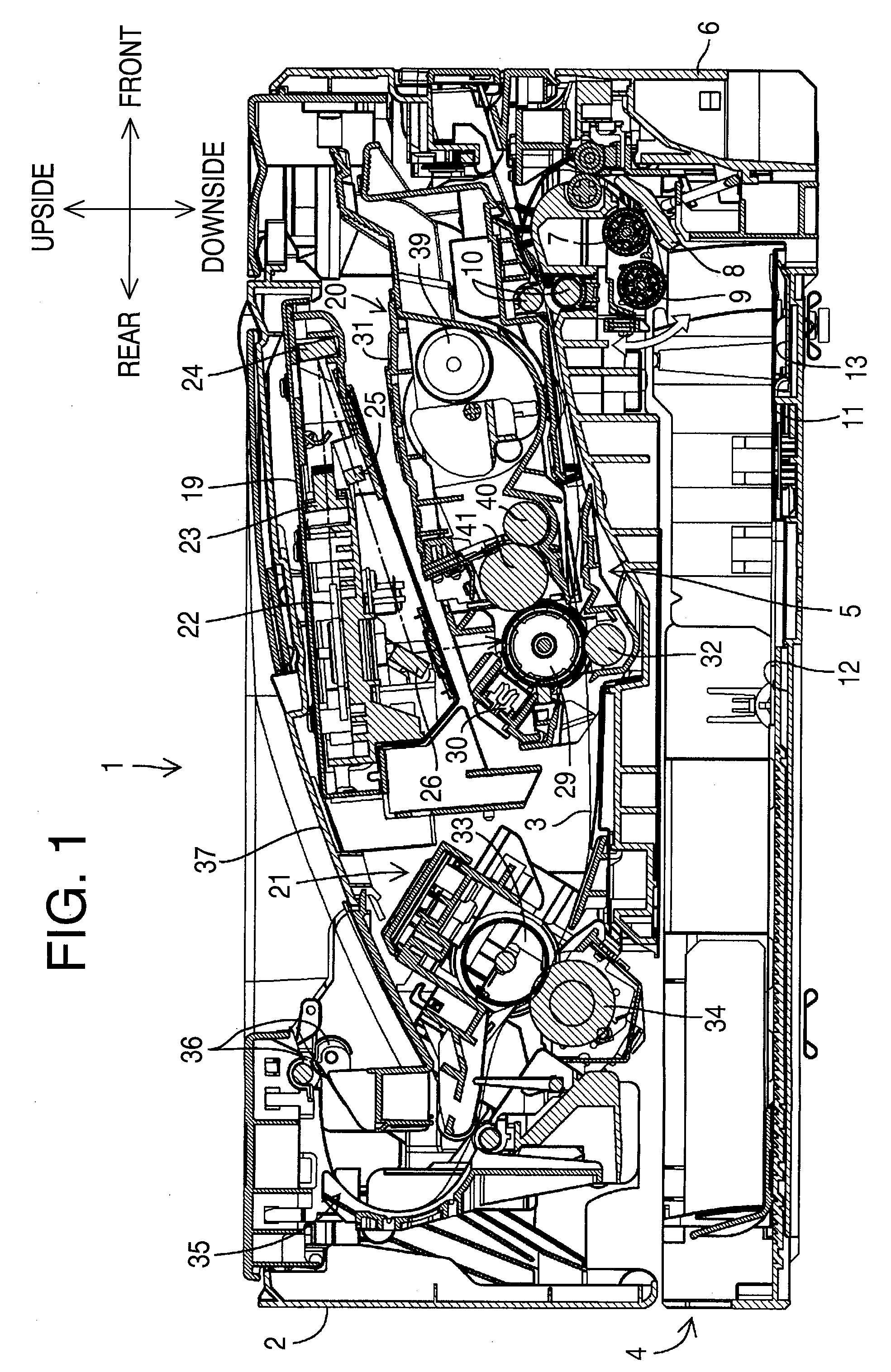

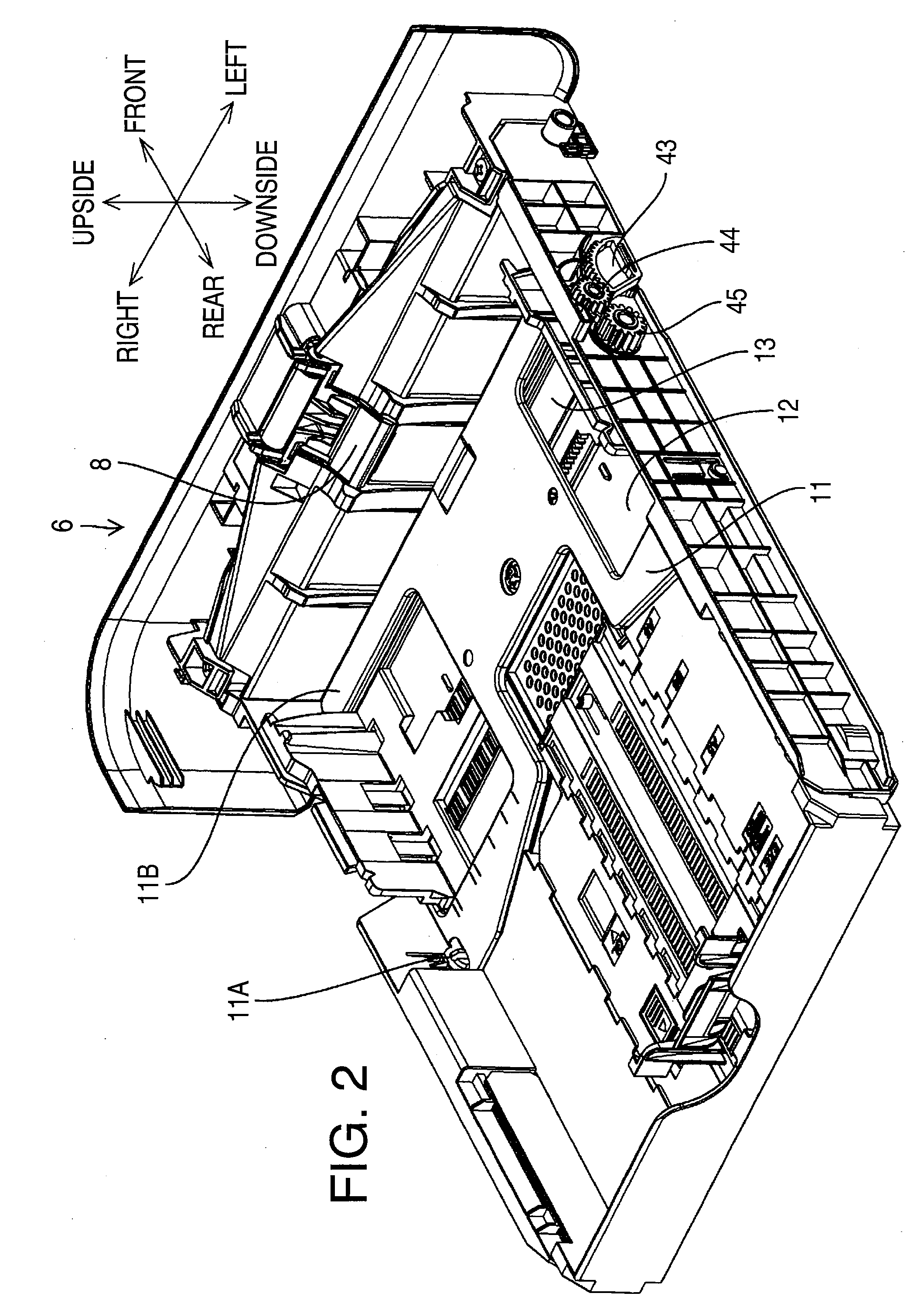

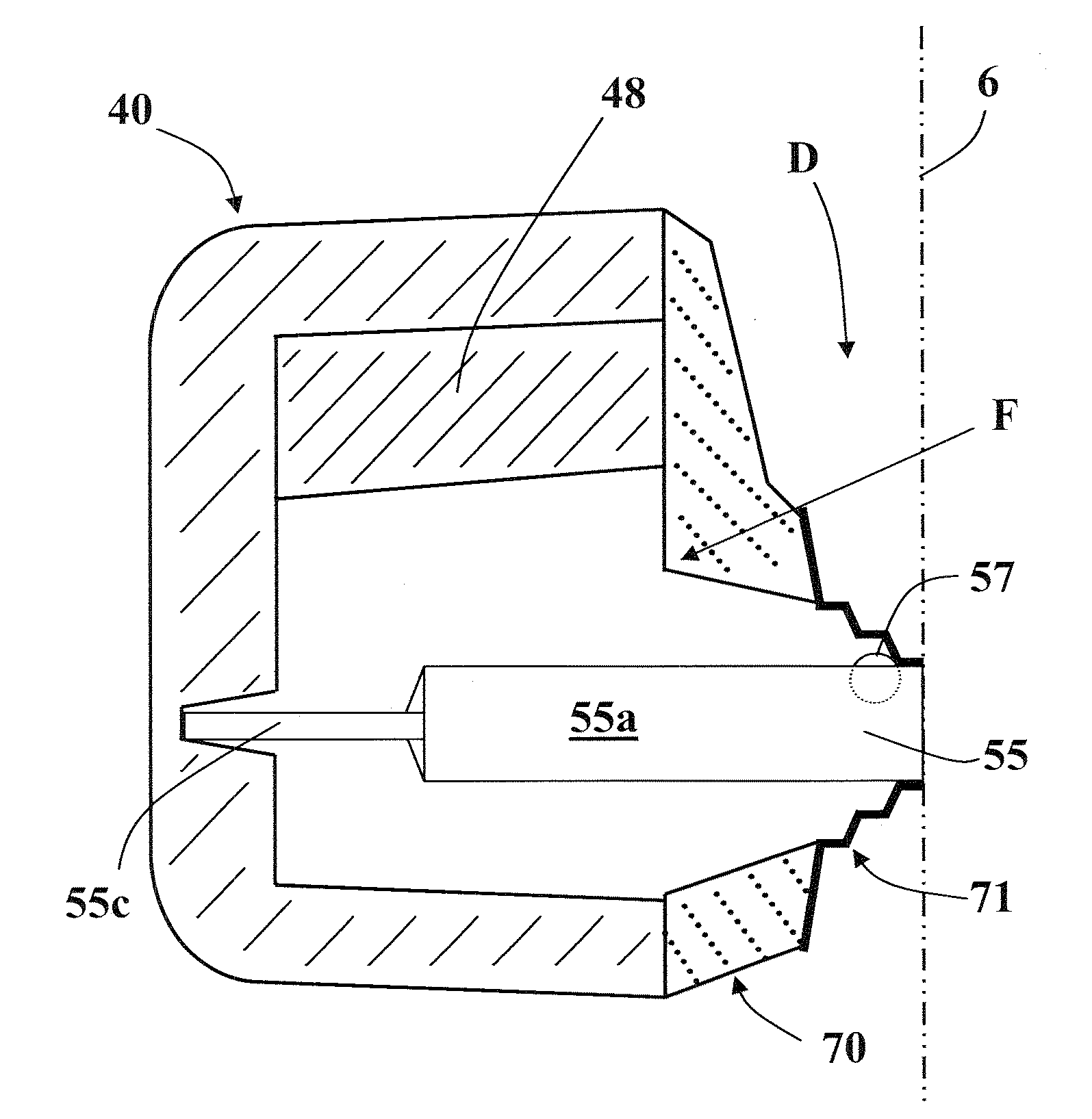

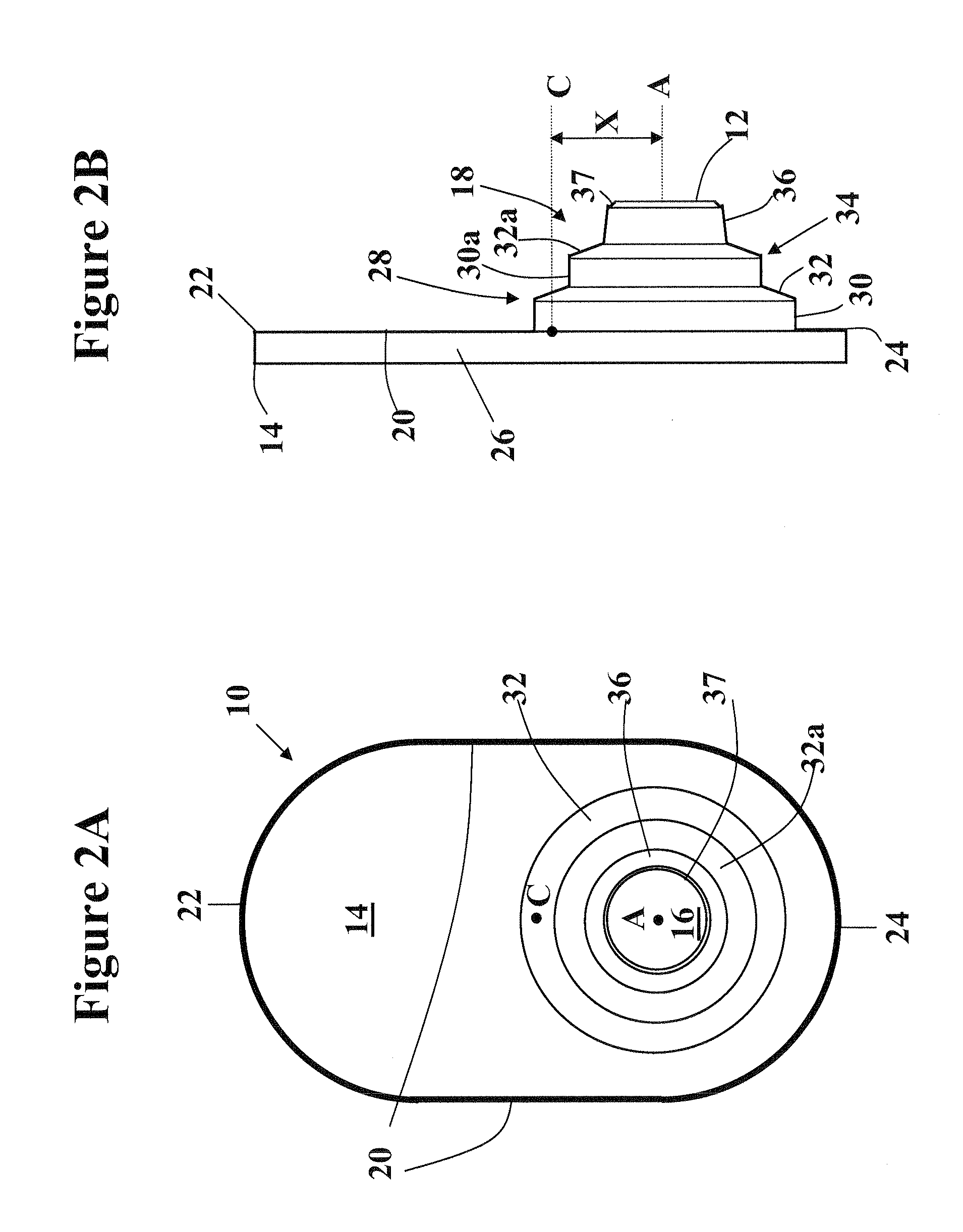

Sheet Feeding Device and Image Forming Apparatus

ActiveUS20090008868A1Improve feeding effectRestrain worsening of sheet feeding performanceArticle separationEngineeringPaper sheet

A sheet feeding device includes a loading portion configured to be loaded with a sheet, a lifting mechanism that lifts the loading portion in an operating state and stops the loading portion in an stopped state, a cam configured to be rotated alternately to a first rotational position for setting the lifting mechanism to the operating state and to a second rotational position for setting the lifting mechanism to the stopped state, a detecting unit having a contact portion movable up and down while contacting the sheet on the loading portion, which detects whether the sheet reaches a first height based upon the movement of the contact portion thereof, and a control unit configured to rotate the cam before the detecting unit detects that the sheet reaches the first height and to stop the cam in the second rotational position in response to the detection by the detecting unit.

Owner:BROTHER KOGYO KK

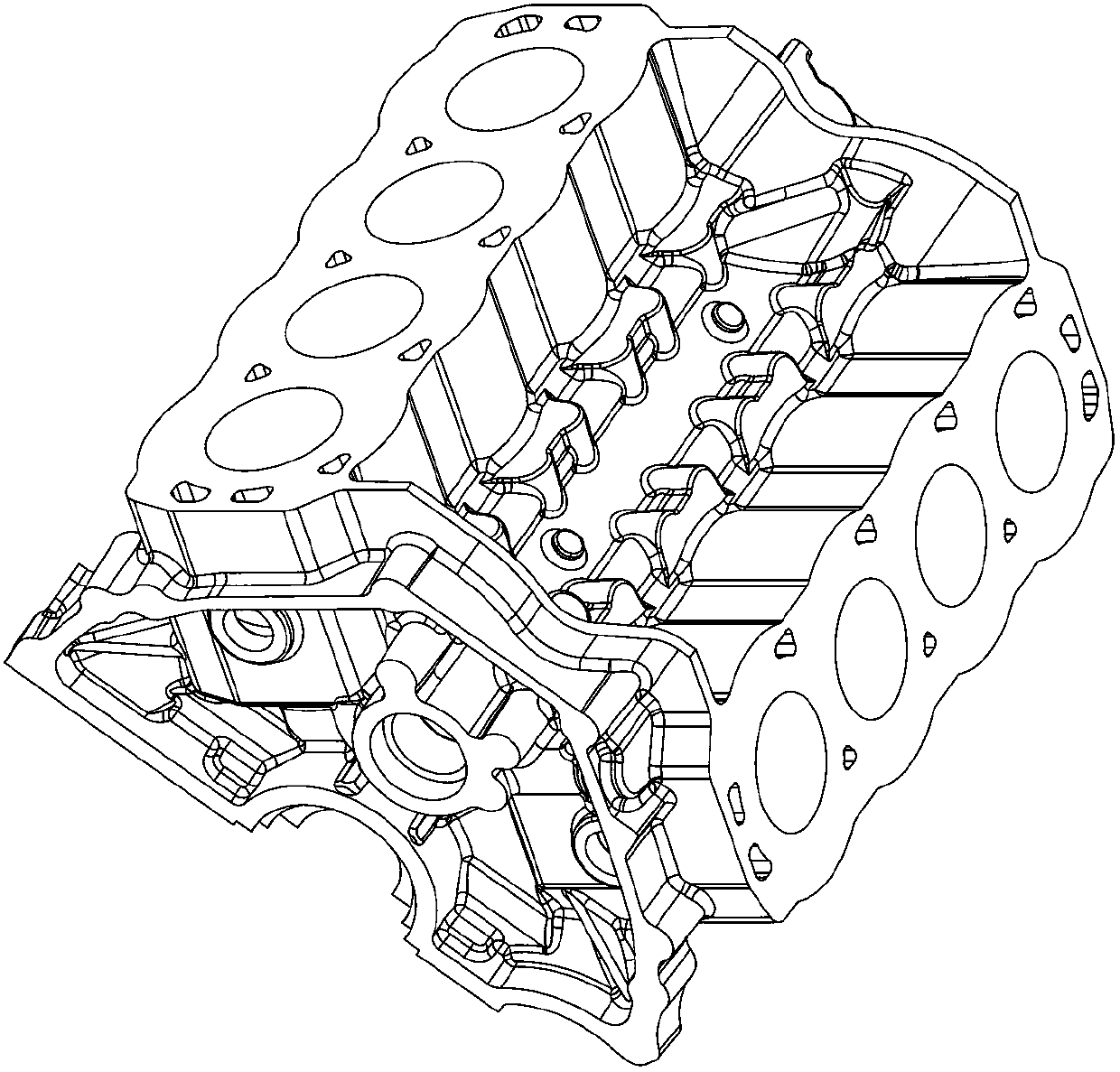

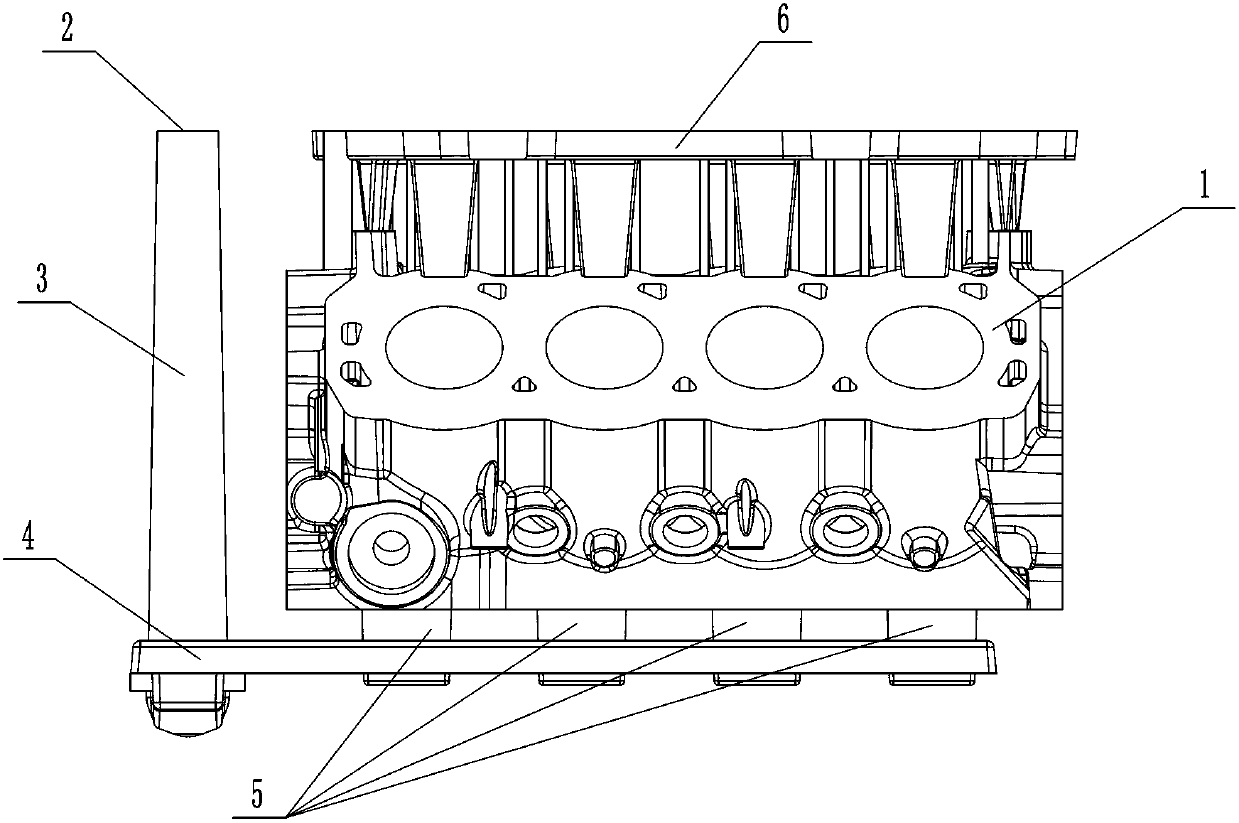

V8 type gray cast iron cylinder body casting pouring method

ActiveCN103121082AStable flow rateSmall structureFoundry mouldsFoundry coresAssembly structureMaterials science

The invention discloses a V8 type gray cast iron cylinder body casting pouring method which is carried out by adopting a core assembly pouring mode. The V8 type gray cast iron cylinder body casting pouring method comprises the following steps of: 1, setting a pouring position of a casting; 2, arranging a pouring system; 3, assembling a core assembly; and 4 pouring. Compared with the prior art, the V8 type gray cast iron cylinder body casting pouring method has the characteristics of relatively simple core assembly structure, high yield and low production cost.

Owner:宁波亿泰来模具有限公司

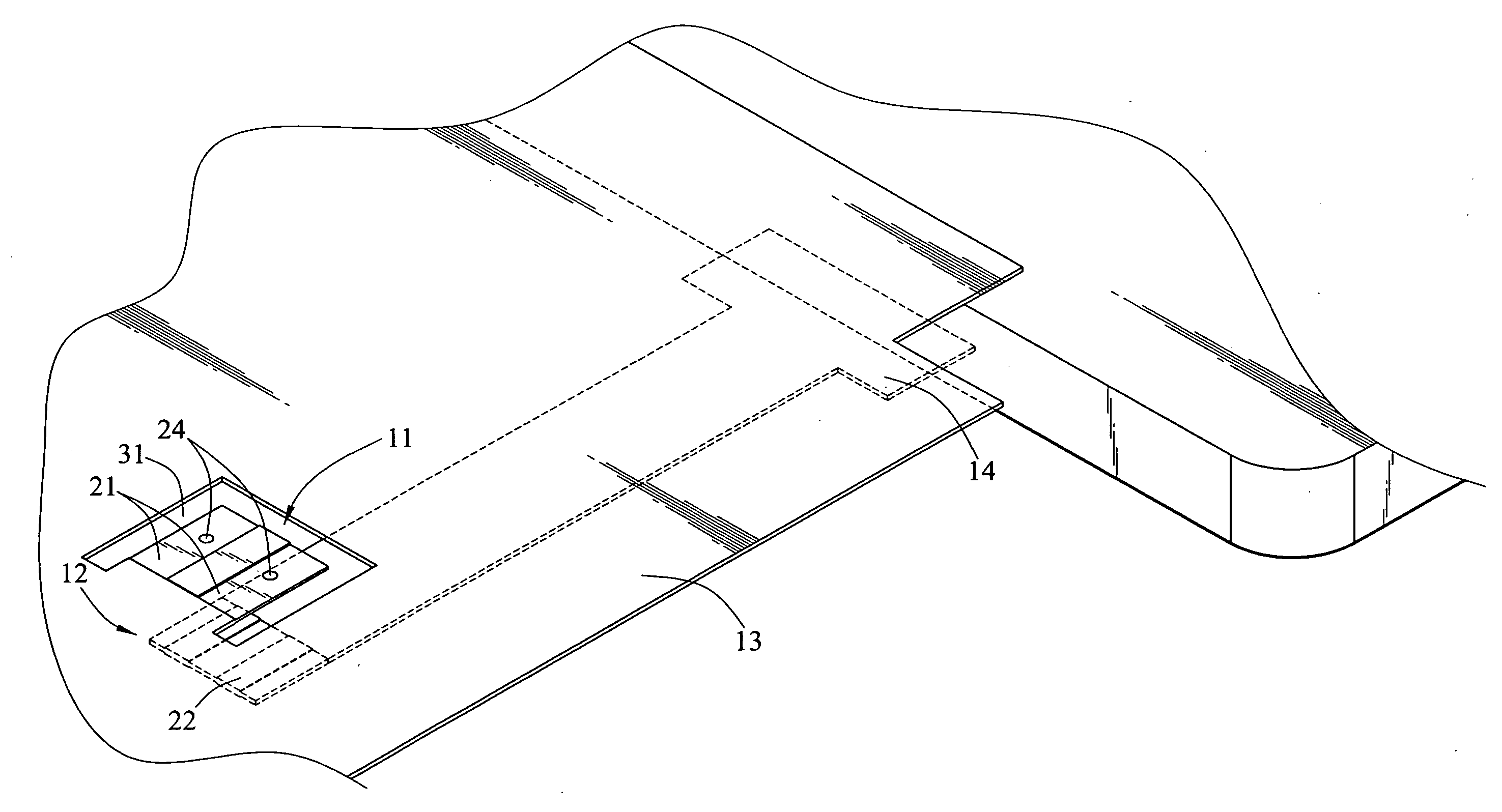

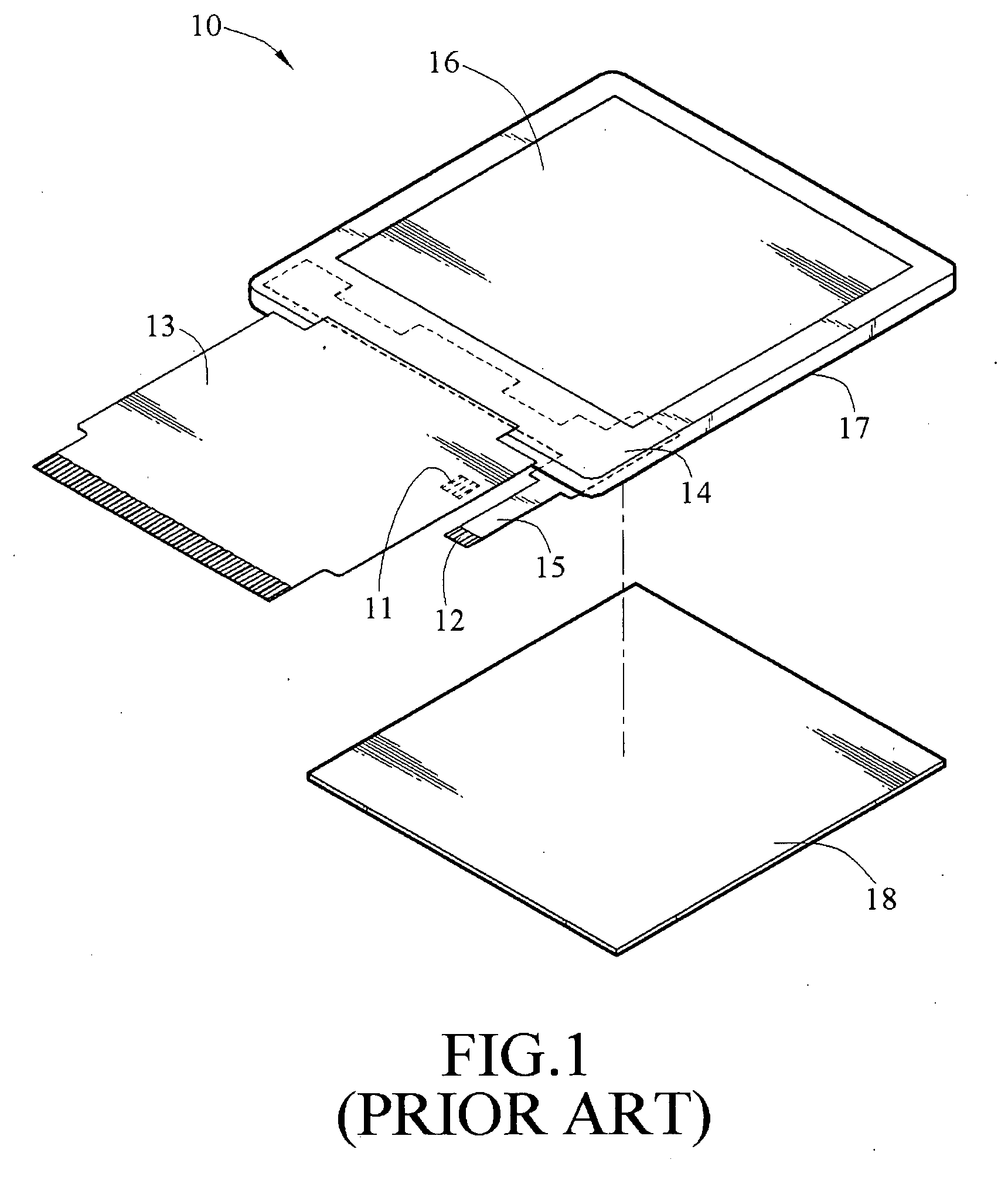

Connecting structure of printed circuit board of liquid crystal display module

ActiveUS20080045077A1Low costImprove production yieldElectrically conductive connectionsPrinted circuit aspectsLiquid-crystal displayEngineering

A connecting structure of a printed circuit board of a liquid crystal display (LCD) module includes a double side printed circuit board and a single side printed circuit board. With the design of the double side printed circuit board having a solder element with two solder surfaces with a plurality of plated through holes (PTHs), and the design of the opening neighboring the solder element, the conducting surface of the single side printed circuit board may easily accord with the structural requirements to select the corresponding solder surface for performing welding.

Owner:WINTEK CORP

Formula of livestock-poultry grain-saving feed using biological fermentation straw to partially replace corn

ActiveCN102204630AHigh nutritional valueIncrease profitFood processingAnimal feeding stuffNutritive valuesAnimal science

The invention relates to a formula of livestock-poultry grain-saving feed using biological fermentation straw to partially replace corn. In the formula, the biological fermentation straw partially replaces the corn in the common livestock-poultry feed, and the biological fermentation straw accounts for 5 to 20 percent of the total weight of the common livestock-poultry feed. In particular, the livestock-poultry feed consists of the following ingredients in percentage by weight: 45 to 65 percent of corn, 20 to 35 percent of bean pulp, 4 to 15 percent of biological fermentation straw, 1 to 3 percent of fish meal, 3 to 8 percent of bean oil, 0.5 to 2 percent of rock flour, 1 to 2 percent of calcium hydrogen phosphate, 0.05 to 0.2 percent of methionine, 0.3 to 0.4 percent of common salt and 1percent of premixing material. Due to the combination of steam explosion of straw and microorganism fermentation treatment, the method has the advantages of improving nutritive value and utilization rate of the corn straw, making changing the waste crop straw into the valuables possible, partially replacing the corn in the pig and chicken feed, improving the daily gain of livestock and poultry, having good feeding effect and bringing huge economic benefits.

Owner:HENAN PUAI FEED GRP CO LTD +1

Method for casting air sucking valve steel casting part

ActiveCN103056325AGuaranteed surface qualityGuaranteed compactnessFoundry mouldsFoundry coresMetal moldZircon

The invention relates to a method for casting an air sucking valve steel casting part. The method comprises the steps (1) using central cross sections of flange holes on two sides of the casting part as parting surfaces, manufacturing a metal mold, using water glass quartz sand to manufacture an upper portion and a lower portion, using water glass limestone sand as back sand, using the water glass quartz sand as facing sand to manufacture sand cores and brushing zircon power coatings on the surfaces of the upper portion, the lower portion and the sand cores; (2) placing the sand cores into a cavity of the lower portion, placing outer cold irons on flange end faces of the lower portion, placing open risers and riser pads on the upper portion, placing second outer cold irons on two end faces of an inner flange of the lower portion, correspondingly placing blind risers and riser pads on the upper portion, placing inner cold irons at the valve rod hole positions of a second sand core and a fourth sand core and leading a straight pouring channel and a horizontal pouring channel of a pouring system into flange edges on two sides at the parting surface positions; (3) assembling the mold after the cores fall; (4) smelting furnace burden and pouring the casting part; and (5) performing cooling, mold opening and core falling to clean the casting part. By means of the method for casting the air sucking valve steel casting part, casting part cracks can be decreased, an internal structural of the casting part is compact, and the rate of finished products is high.

Owner:CRRC QISHUYAN INSTITUTE CO LTD +1

High-frequency vibration casting mold of conical sand maker rolling mortar wall and casting process

ActiveCN102962398AImprove wear resistanceReduce the cost of sand makingFoundry mouldsFoundry coresChromiumCast iron

The invention relates to a high-frequency vibration casting mold of a conical sand maker rolling mortar wall and a casting process capable of achieving the effect of no shrinkage cavity and effectively improving the cast density during casting feeding of the conical sand maker rolling mortar wall. The high-frequency vibration casting mold is characterized in that a sand box is located on a high-frequency vibration platform; the height of a rolling mortar wall forming mold cavity in the sand box is smaller than the height of a casting riser or the volume of the forming mold cavity is smaller than the volume of the casting riser. The casting process comprises the following steps: casting high chromium cast iron into the rolling mortar wall forming mold cavity and the casting riser, then carrying out high-frequency vibration on the high-frequency vibration platform, and cooling to obtain the high chromium cast iron rolling mortar wall with a high density. The high-frequency casting mold and the casting process have the advantages that firstly, the wear resistance of the high chromium cast iron rolling mortar wall is effectively improved, and the sand making cost is greatly reduced; secondly, the feeding effect is good, the cast is high in density, and the occurrence of damage phenomenon is avoided; and thirdly, the wear resistance, the shock resistance and the service life are increased by nearly 5 times, and unexpected technical effects are achieved.

Owner:ZHEJIANG SHUANGJIN MACHINERY HLDG

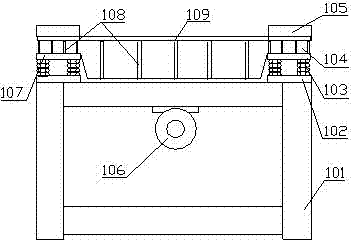

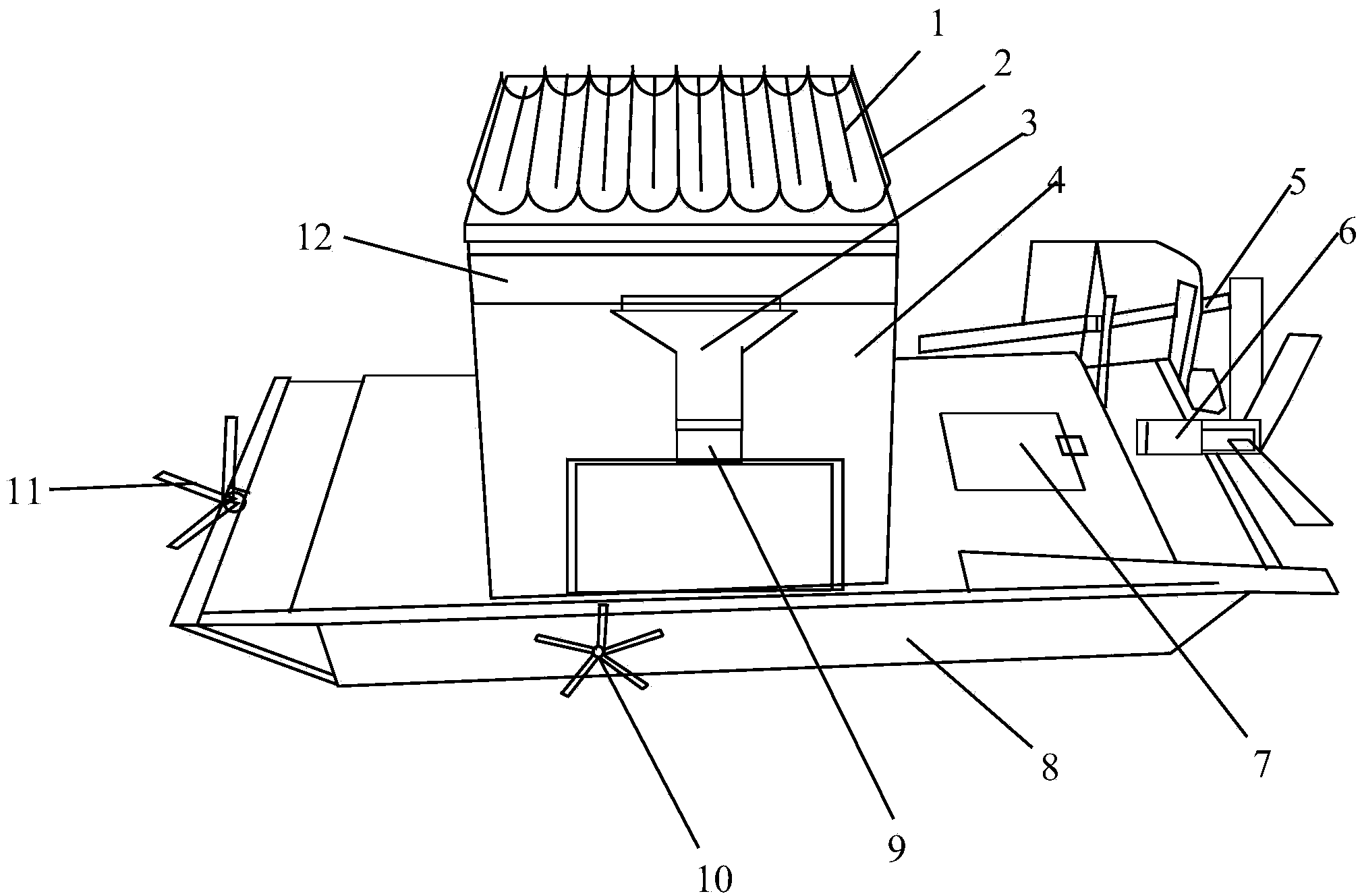

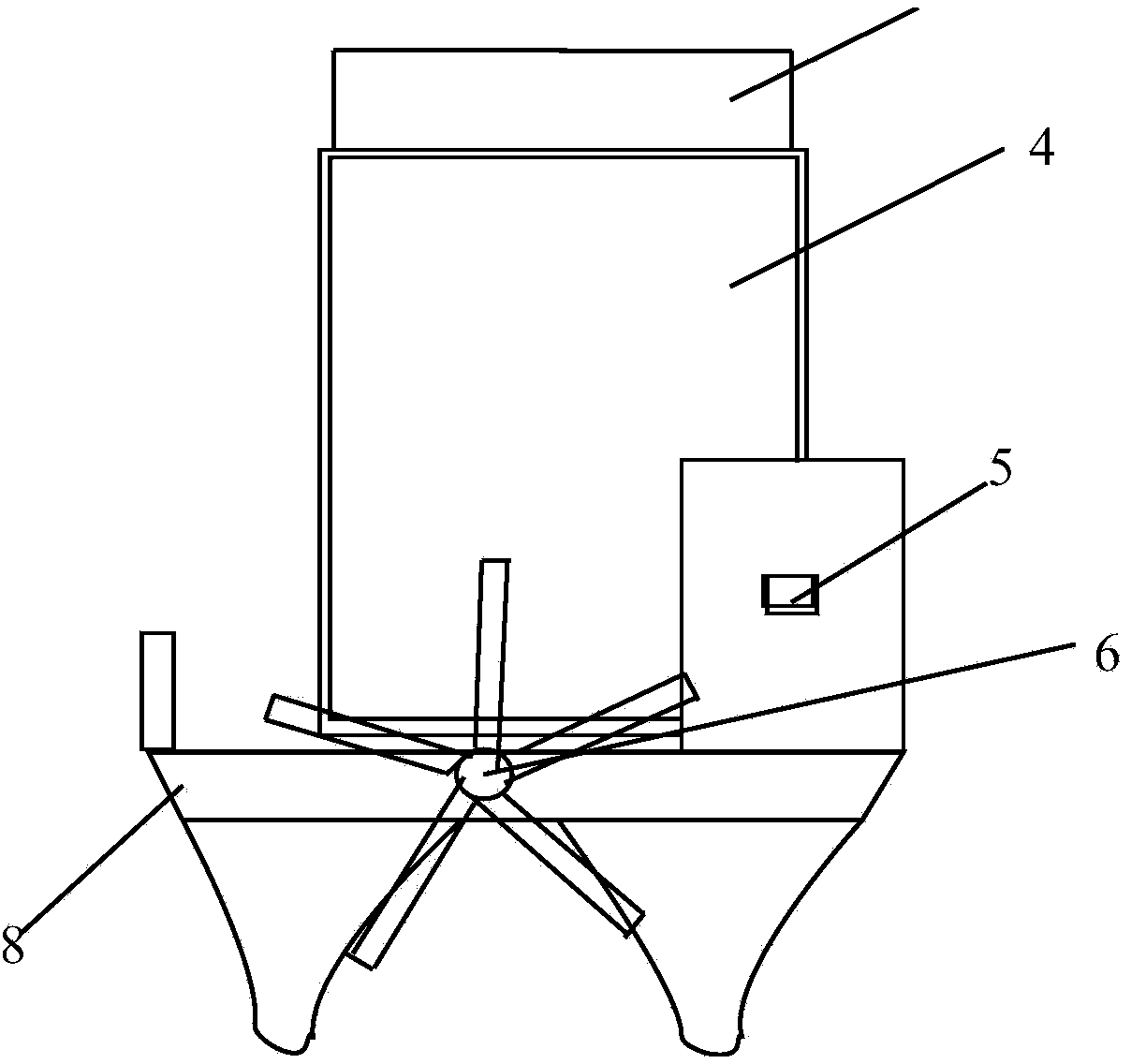

Feed feeding fishing boat for aquaculture

InactiveCN107494370AImprove feeding effectFull mixing effectClimate change adaptationPisciculture and aquariaAquatic productEngineering

The invention discloses a feed feeding fishing boat for aquaculture. The feed feeding fishing boat comprises a boat body, a stand plate is vertically and fixedly installed on the boat body, a limiting sleeve is horizontally and fixedly installed at the right side of the stand plate, a feed storage bin is arranged at the upper portion of the limiting sleeve, a feeding pipe is arranged at the top of the feed storage bin, a driving gear is coaxially and fixedly installed on an output shaft of a forward and backward rotation motor, a rotary shaft is provided with a worm gear connected with a worm in a matching mode, a vertical rod which penetrates through a slide hole is vertically and fixedly installed at the lower bottom face of an impact slide block, and a straight rack is fixedly and horizontally installed at the lower end of the vertical rod. The feed feeding fishing boat for the aquaculture is simple in structure, reasonable in design and good in feed feeding effect, feed inside the feed storage bin is rotated and stirred through a stirring component, and the sufficient mixing effect of the feed is achieved; a connecting rod can drive a feed discharging hose to rotate around the rotary shaft, feeding of the feed at different angles is achieved, the feed is uniformly spread in a fish pond, and the situation that food intake of fish is influenced since the feed is too centralized is avoided.

Owner:储成立

Method for artificially feeding Bemisia tabaci Gennadius

InactiveCN101411321AGuaranteed standardizationWide variety of sourcesAnimal feeding stuffAccessory food factorsExperimental researchBiological property

The invention discloses a method for artificial feeding of tobacco whiteflies, which belongs to the technical field of insect feeding. The method provides a feed formula for the artificial feeding of the tobacco whiteflies and a method for feeding by applying the feed, and the method comprises the steps of the acquisition and disinfection of tobacco whitefly eggs, the preparation of an artificial all-nutrition feed liquid, the preparation of a feeding container, the feeding and so on. The method has the advantages that the method realizes the aim of the indoor artificial feeding of the tobacco whiteflies all the year around, can obtain various instar insects with relatively consistent biological type, instar stage, state and so on, overcome the defect that easy influence by different host plants, biological types, growth states, instar stages and so on, caused by acquiring insect sources from natural birthplaces leads to the defect that the difference exists in experimental results, and ensure the standardization of test insects for experiments. The method can be used for experimental research on biological characteristics and a high-efficiency prevention and control technology of the tobacco whiteflies.

Owner:ZHEJIANG ACADEMY OF AGRICULTURE SCIENCES

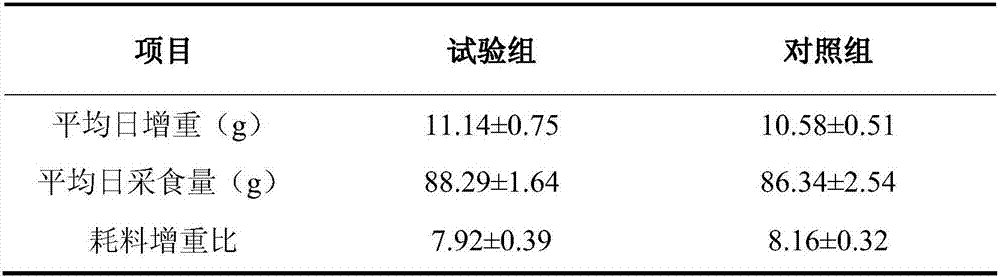

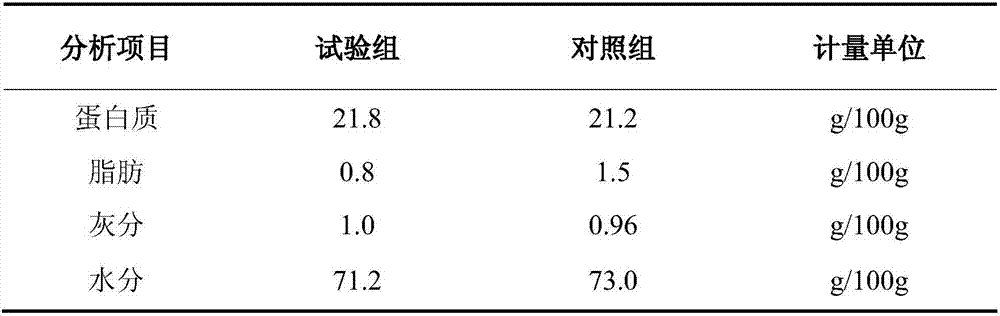

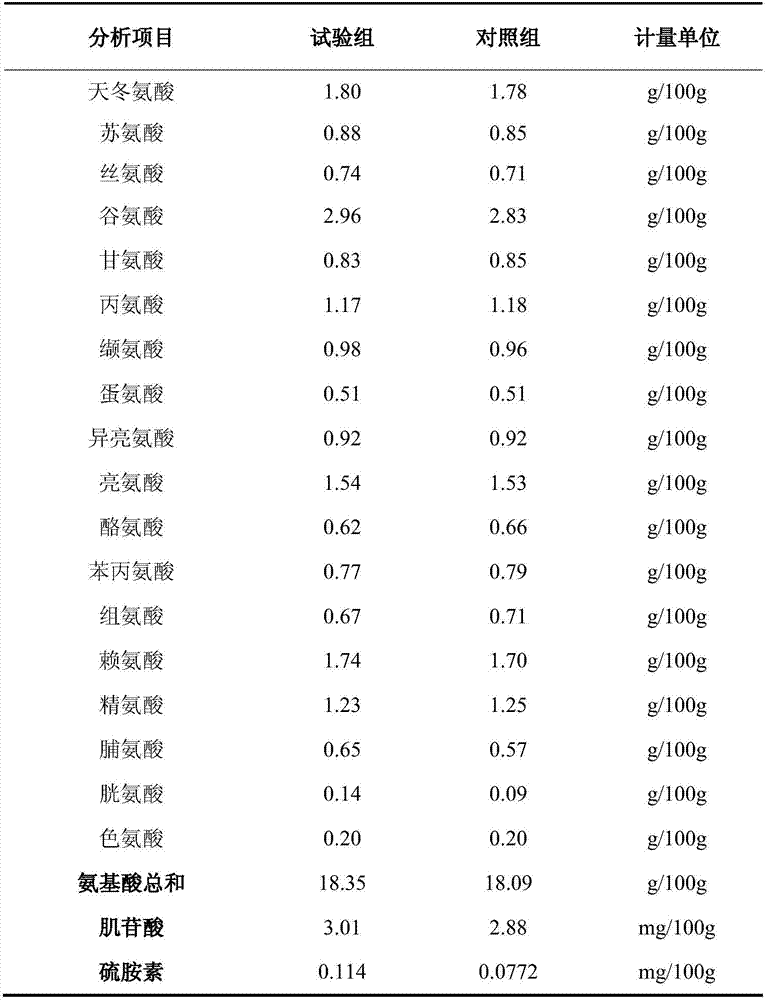

Broiler feed added with fermented hybrid paper mulberry powder and application thereof

InactiveCN106954756ANutritional balanceIncrease feed intakeAnimal feeding stuffBiotechnologyInorganic salts

The invention discloses a broiler feed added with fermented hybrid paper mulberry powder and an application thereof. The broiler feed contains 10-20% of fermented paper mulberry powder; the fermented paper mulberry powder is prepared by the following steps: when the stalk of the paper mulberry grows to 1-1.2m high, cutting the stalk from the last leaf, and carrying out airing in the shade for 2 days; grinding fresh paper mulberry leaves and stalk; polishing the paper mulberry leaves and stalk into rice grain size; inoculating the paper mulberry powder with microorganisms and adding a carbon source and inorganic salt; carrying out sub-packaging, compacting and storing in a sealed plastic film bag; and carrying out fermentation and culture for 5-8 days at room temperature. The paper mulberry is preferentially hybrid paper mulberry. In the broiler feed disclosed by the invention, the fermented hybrid paper mulberry powder contained has double functions of nutrition and pharmacological activity as well as high digestibility and can meet the nutrition need for broiler growth and remarkably improve the chicken quality and flavor and is of great significance to the promotion and efficient development of the national poverty alleviation industry adopting paper mulberry and to the healthy breeding of broilers.

Owner:广东禾欣构树产业发展有限公司 +1

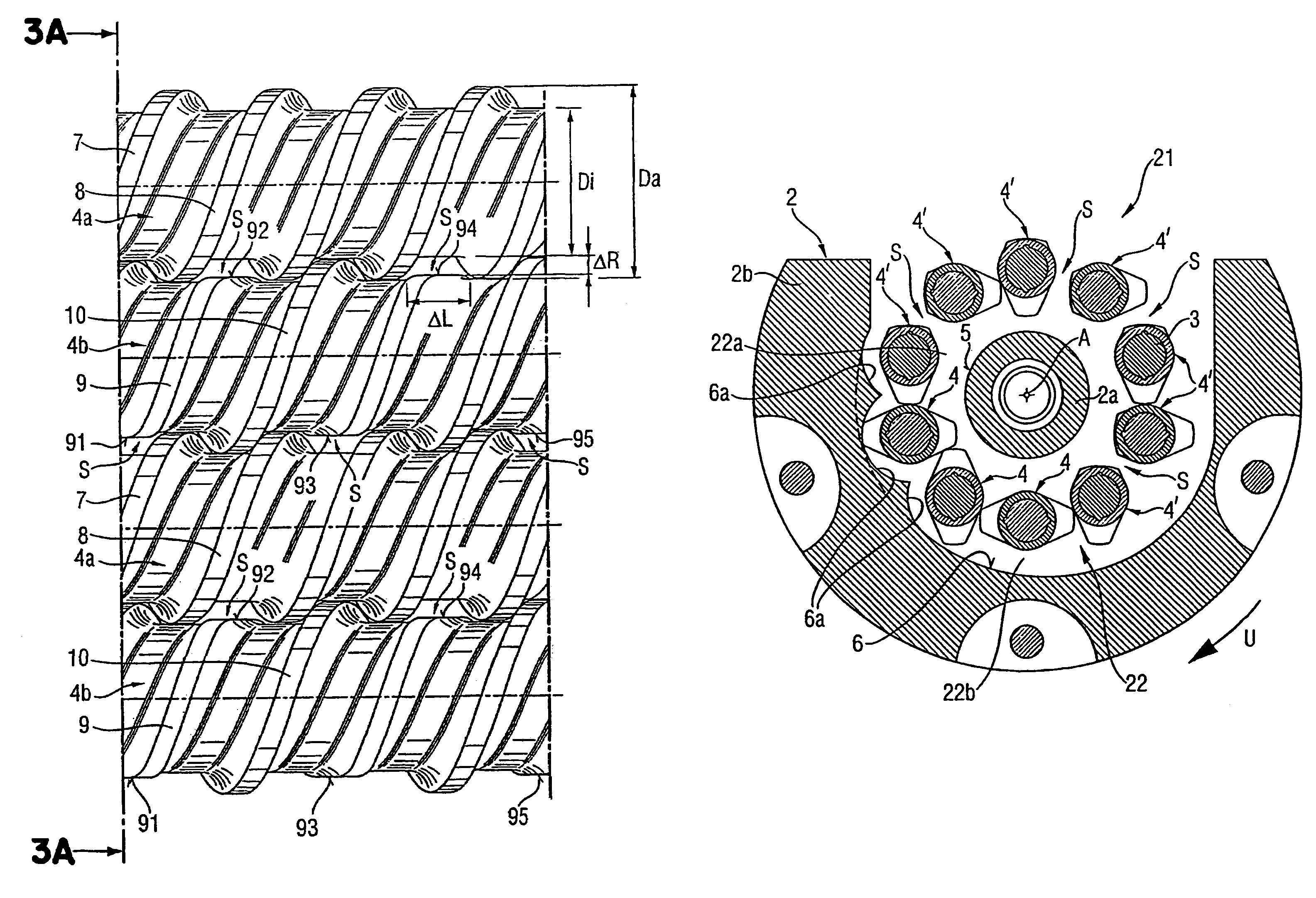

Multi-screw extruder

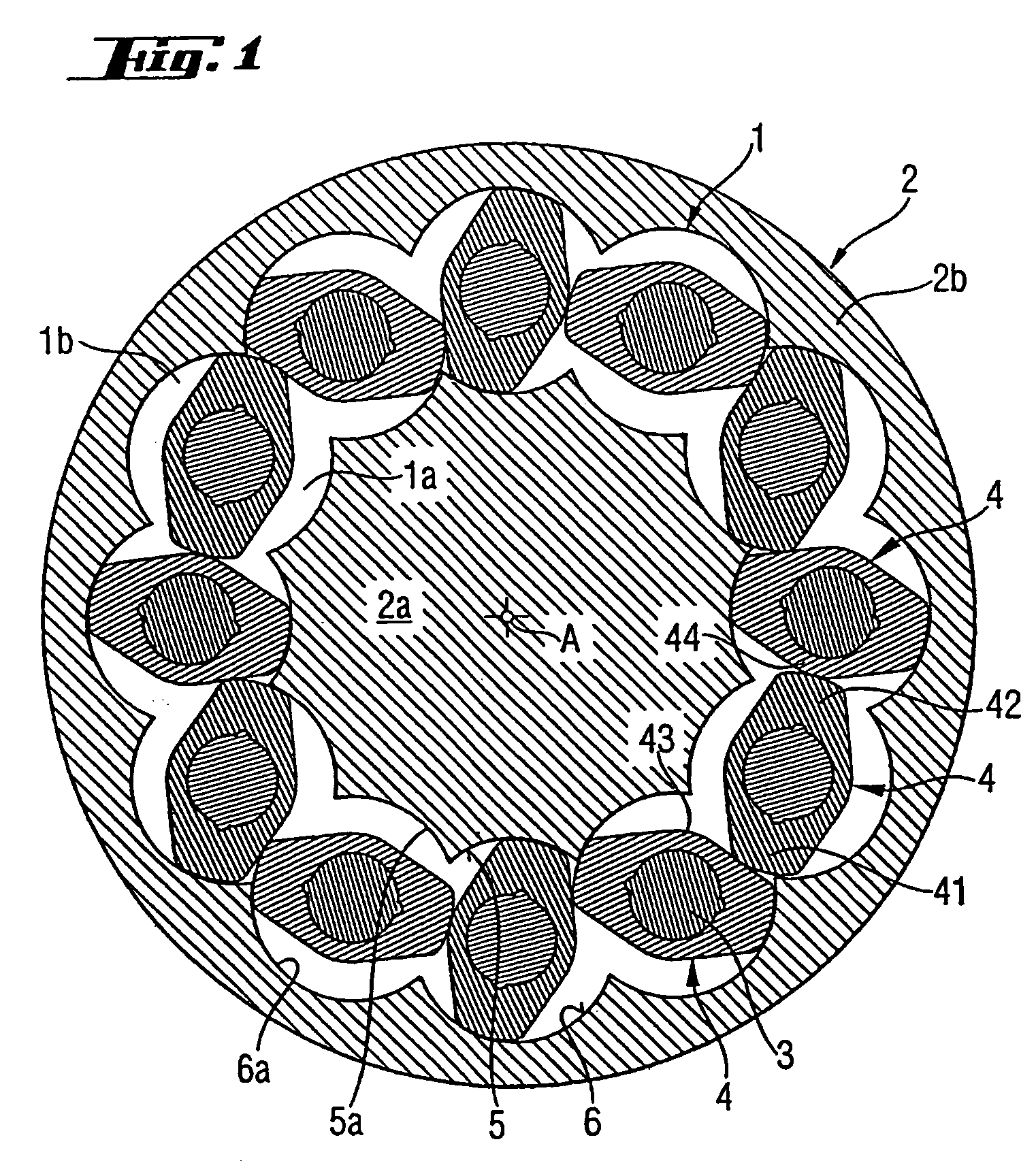

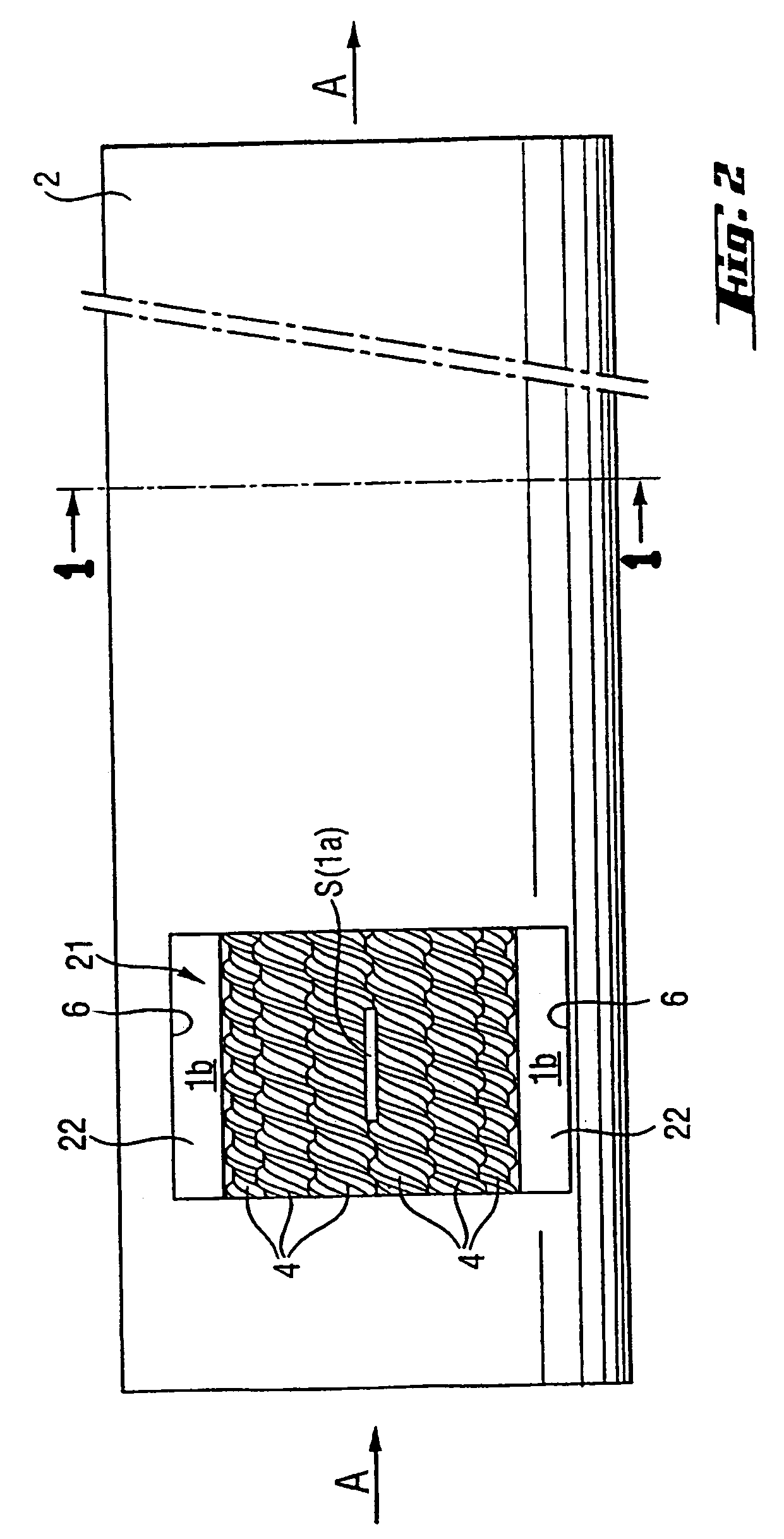

InactiveUS7080935B2Improve the delivery effectImprove carrying capacityRotary stirring mixersFrozen sweetsEngineeringProcessing element

The invention relates to a multi-shaft extruder for the continuous treatment and / or processing of bulk material, especially a powdery, granular or flocculent product, comprising a plurality of shafts (3) which are arranged in a crown-like manner in a cavity (1) of an extruder housing (2), said shafts extending parallel to the axial direction (A) of the extruder and forming an inner processing chamber (1a) inside the crown, and an outer processing chamber (1b) outside the crown. Each shaft carries a number of axially successive processing elements (4), at least part of the same being elements (4a; 4c; 4e) having a transporting effect, and with which adjacent shafts engage in a sealed manner at least in partial regions. At least one transporting endless screw element (4b; 4d; 4f) comprising at least one transporting screw thread (9, 10; 14, 15, 16; 19, 20) is placed in the region of the supply opening (21) in the extruder housing (2), and does not engage in a sealing manner in at least one partial region along the axial direction (A).

Owner:BUHLER THERMAL PROCESSES

Full-automatic cruising batch feeding ship for prawn pond

InactiveCN104012440APrevent yawSpread evenlyWaterborne vesselsAgricultural fishingPrawnEngineering plastic

The invention provides a full-automatic cruising batch feeding ship for a prawn pond. The ship comprises a ship body, a fodder box, a batch feeding controller, a distance detector and a solar cell panel. The ship body is of a double-body three-propeller structure. An engineering plastic mould is used for injection moulding. Good corrosion resistance, stability and wind wave resistance are achieved. A GPS locating instrument is arranged in the ship body and can effectively prevent the ship from yawing during traveling. A wind turbine and a feeding locking device are arranged in the batch feeding device, feeding amount can be controlled according to needs, and prawn fodder is evenly and accurately thrown to feeding points of prawns. The ship is suitable for carrying out batch feeding in ponds with different shapes and different sizes, batch feeding effect is good, the solar cell panel is used as a driving energy source, environment pollution is lowered, and energy is saved. The ship has the advantages that batch feeding is automatic, manual operation is of no need, energy loss is reduced, and labor cost is lowered.

Owner:TIANJIN HEZHENGMEI SCI & TECH DEV

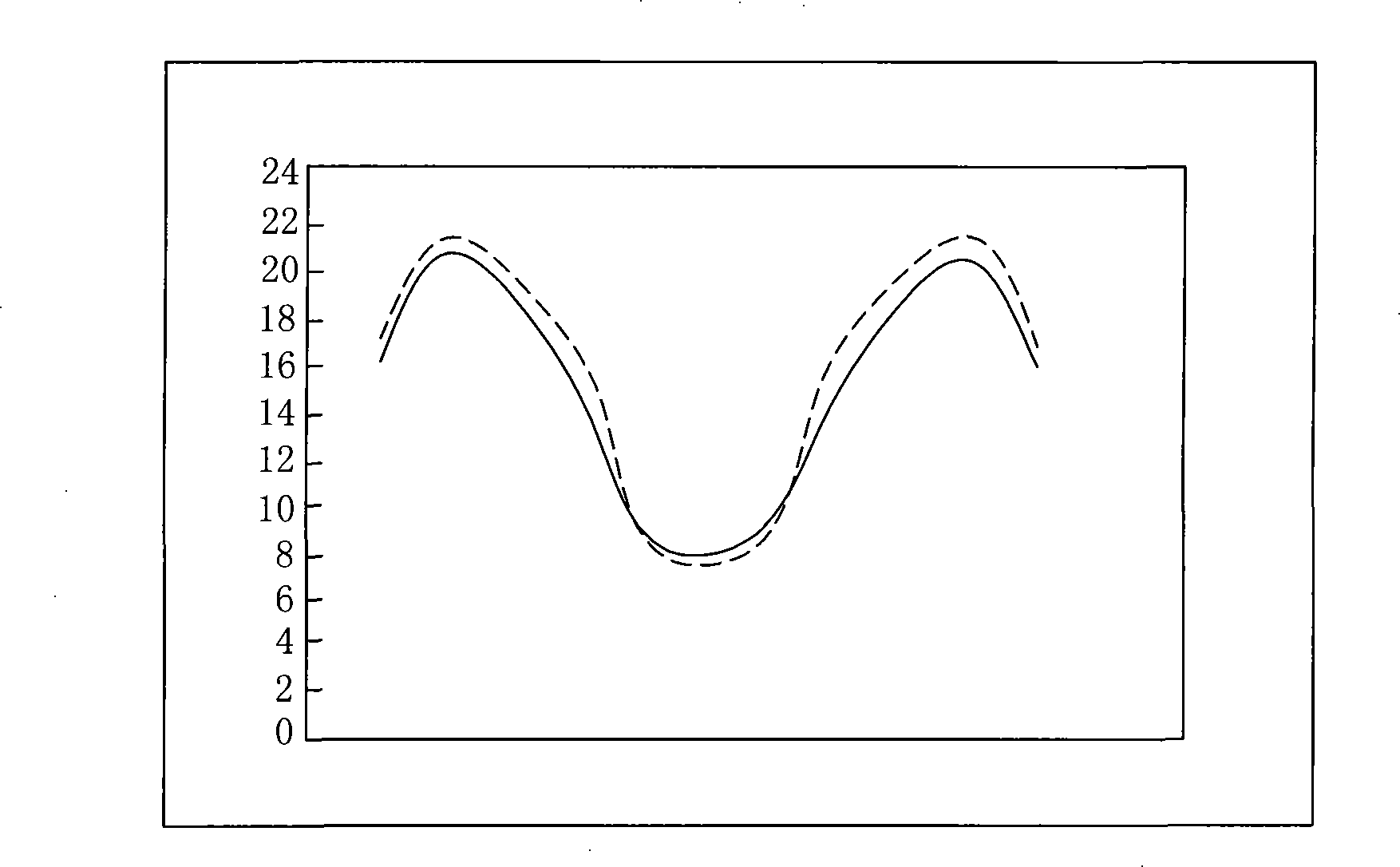

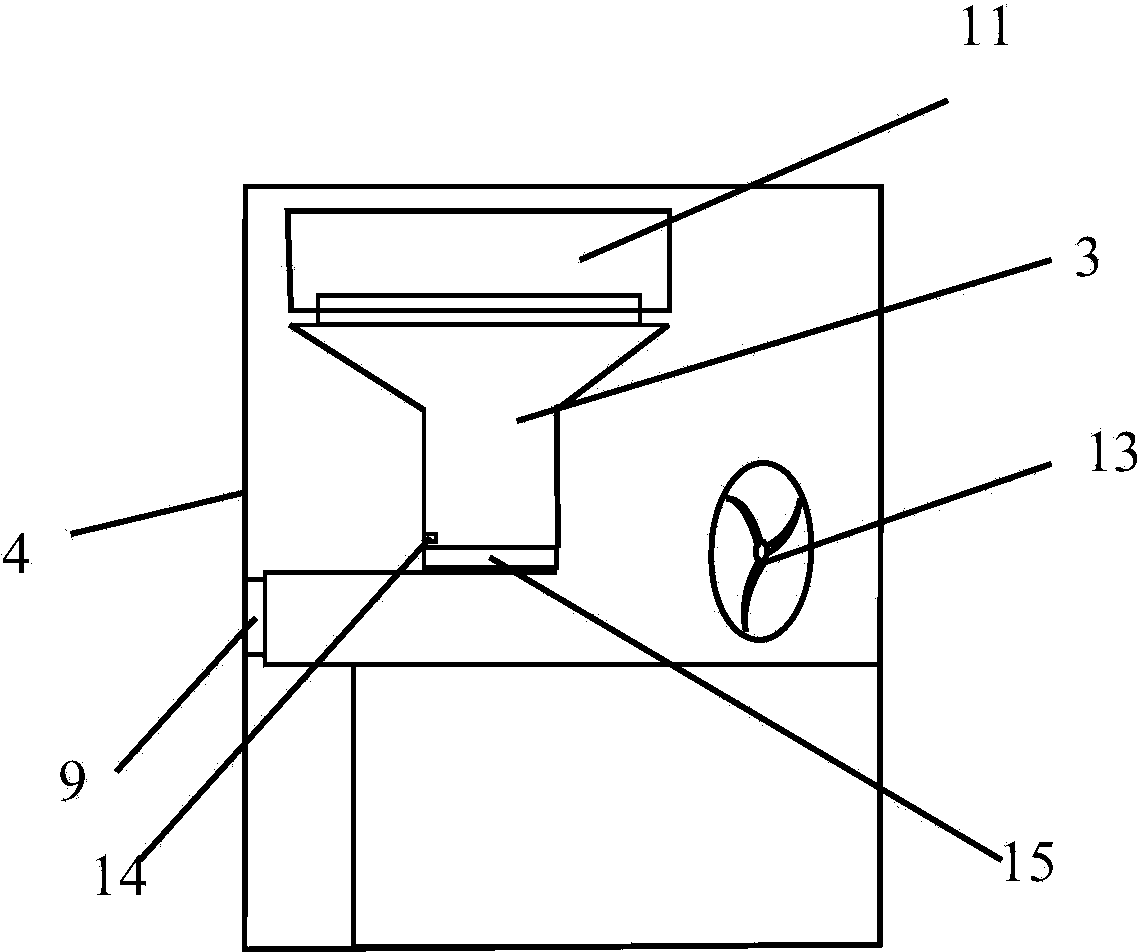

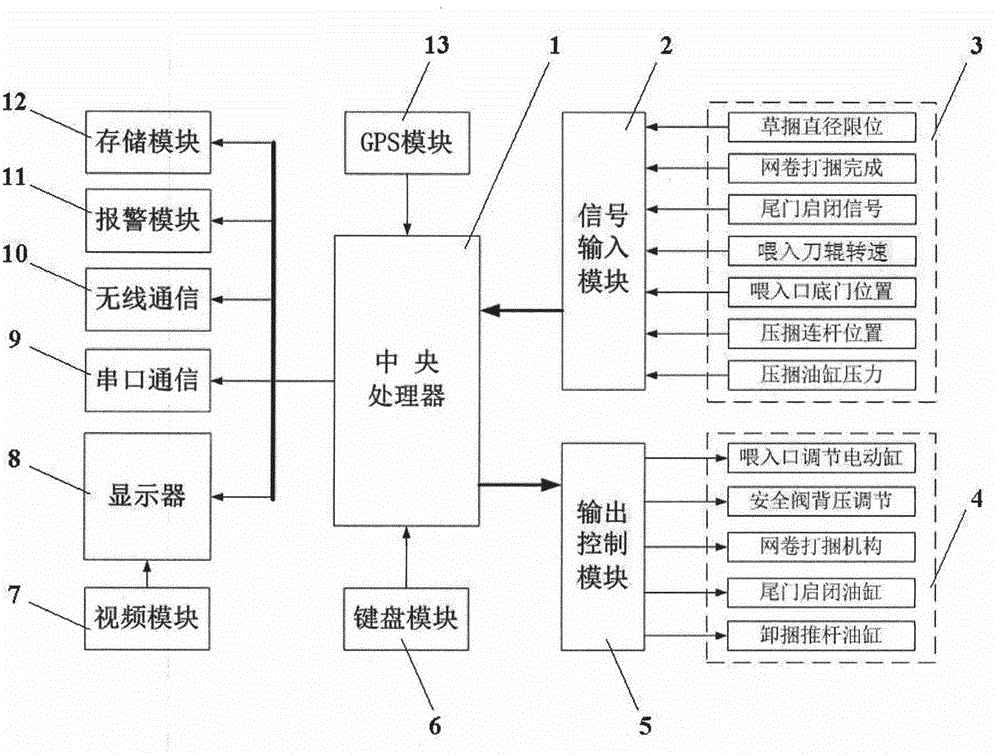

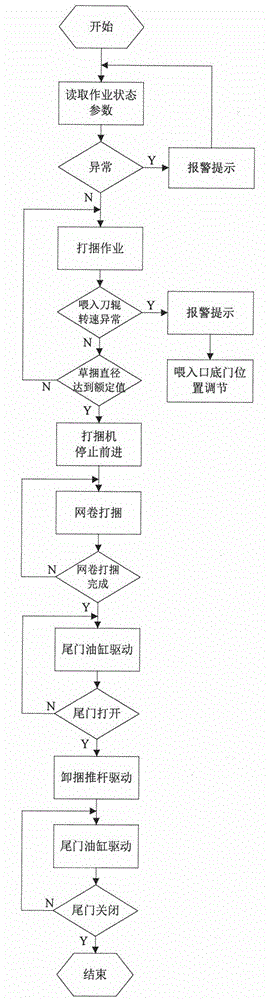

Vehicle-mounted terminal of round bander and control system and method

InactiveCN104635582AImprove feeding effectIncrease the level of automationProgramme controlComputer controlVolumetric Mass DensityEngineering

The invention discloses a vehicle-mounted terminal of a round bander and a control system and a method. A central processor is used for acquiring parameters such as the rotating speed of a feeding knife roll of the bander, the position of a feeding hole bottom door, the position of a baling connecting rod and the pressure of a baling oil cylinder in real time through a signal input module in real time, and the back pressure of a safety valve is changed through an output control module, so that density regulation of bales is realized; the opening of a feeding hole can be adjusted according to the rotating speed change characteristic of the feeding knife roll by changing the position of the feeding hole bottom door, so that straw blockage is avoided, and logical control of picking, bundling, parking, winding and unloading is realized. The operation state and parameters, geographic position information and the like of the bander can be displayed and stored in real time, and output and remote monitoring can be performed through serial communication and wireless communication. The operation state and parameters of the bander are monitored in real time, so that the overall operation performance, efficiency and reliability are improved.

Owner:JIANGSU UNIV

Forage for artificial breeding of Monochamus alternatus Hope and method for preparing the same

InactiveCN101983580AWide variety of sourcesEasy to manufactureAnimal feeding stuffAccessory food factorsSucroseArtificial rearing

The invention discloses the forage for artificial breeding of Monochamus alternatus Hope and method for preparing the same. The forage comprises 90-110 g of pine wood chip, 18-22 g of cane sugar, 10-15 g of yeast powder, 35-45 g of agar, 1.8-2.1 g of sodium benzoate, 0.9-1.2 g of mythyl p-hydroxybenzoate, 10 mL of H2SO4 (0.5 mol / L), 15-25 g of wheat germ powder, 1.2-1.5 g of cholesterol, 3-4.5 g of ascorbic acid, 18-21 g of casein, 0.7-1.1 g of choline and 750-850 mL of water. The forage provided by the invention has the advantages of abundance in resources, convenient manufacture and low cost, and the method for preparing the same is simple and workable. The development time of larvae fed with the above forage is significantly shortened, compared with that of larvae under natural circumstance in the forest. The development period of larvae that develop from egg development to adult emergence lasts for about 100 days. The forage is applicable to the large-scale breeding of Monochamus alternatus Hope larvae. Reproduction and breeding of Monochamus alternatus Hope at controlled temperatures can be realized to ensure the supplies of experimental populations of different stages, different instars and stable activities.

Owner:NANJING FORESTRY UNIV

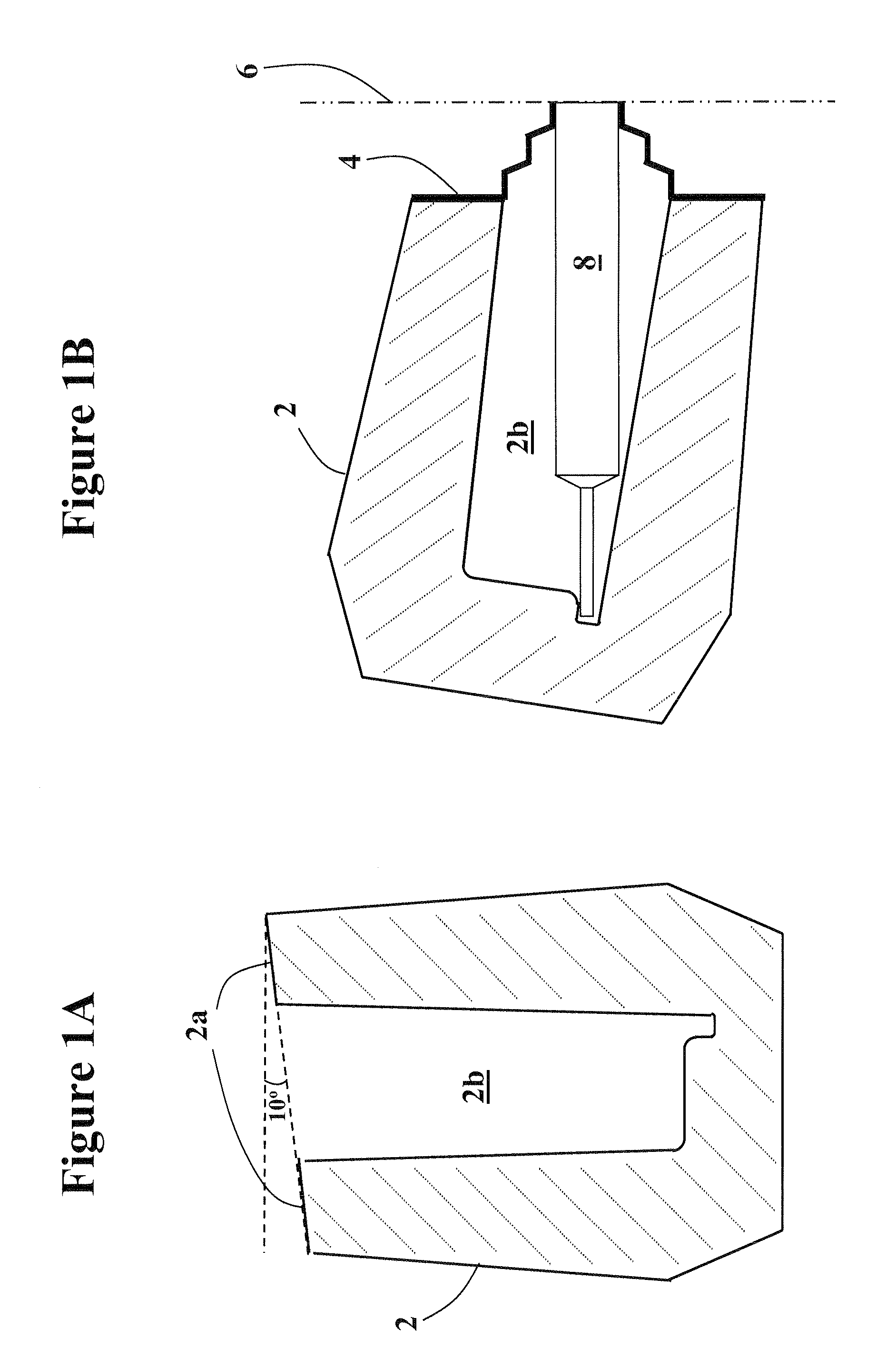

Feeder element

ActiveUS20120211192A1Great and efficient flowAffects efficiencyFoundry mouldsFoundry coresEngineeringHigh pressure

The present invention relates to a feeder element for use in metal casting. The feeder element comprises a first end for mounting on a mould pattern or swing plate, an opposite second end comprising a mounting plate for mounting on a feeder sleeve and a bore between the first and second ends defined by a sidewall. The feeder element is compressible in use whereby to reduce the distance between the first and second ends. The bore has an axis that is offset from the centre of the mounting plate and an integrally formed rim extends from a periphery of said mounting plate.The feeder element of the invention finds particular utility in high pressure vertically parted sand moulding systems.

Owner:FOSECO INT LTD

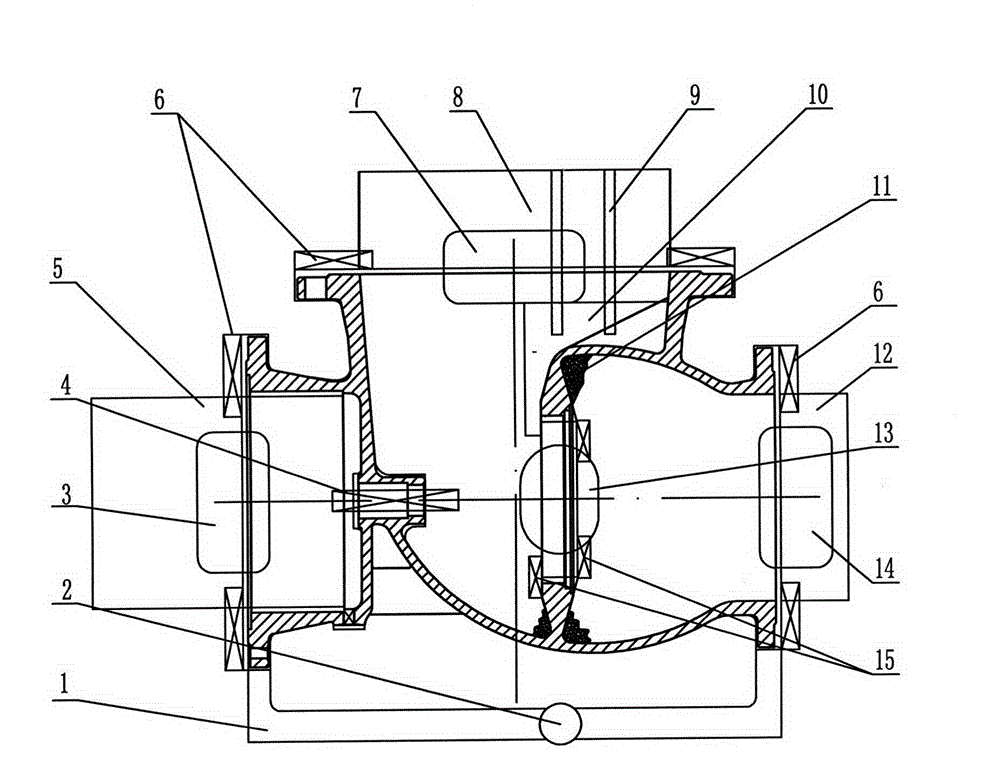

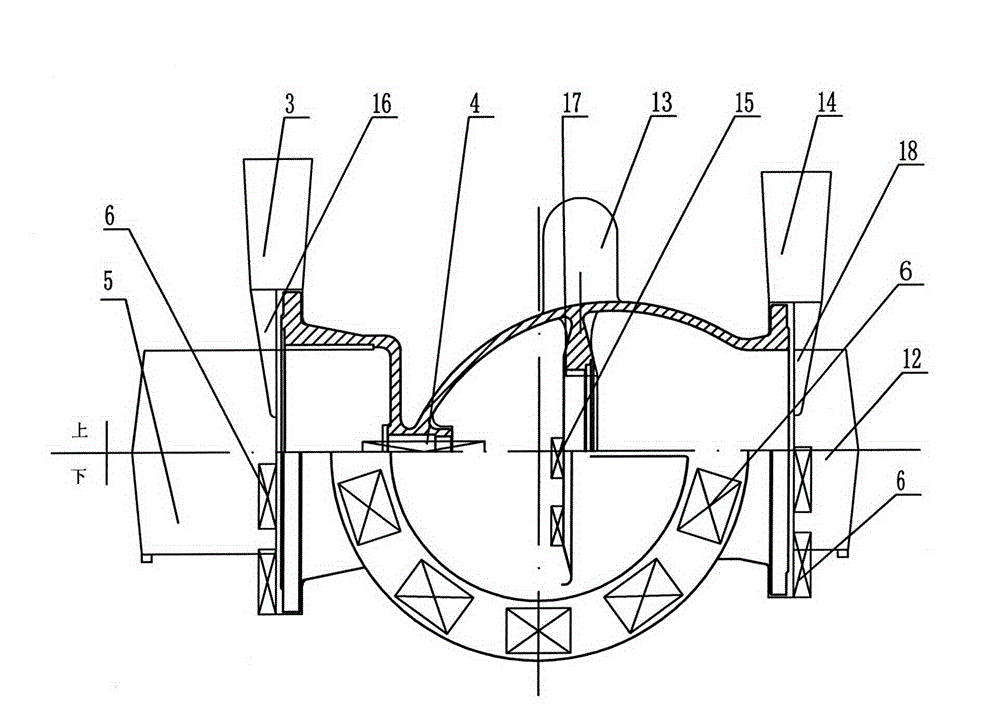

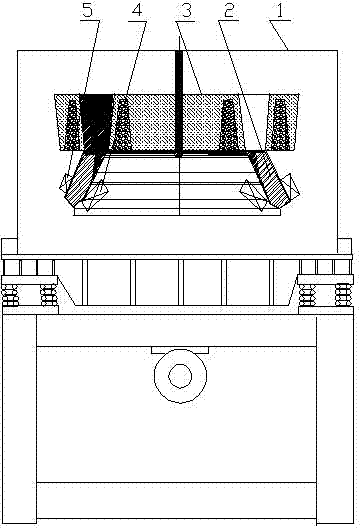

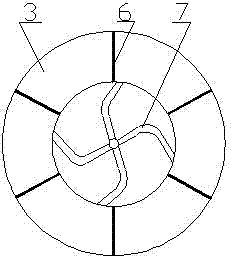

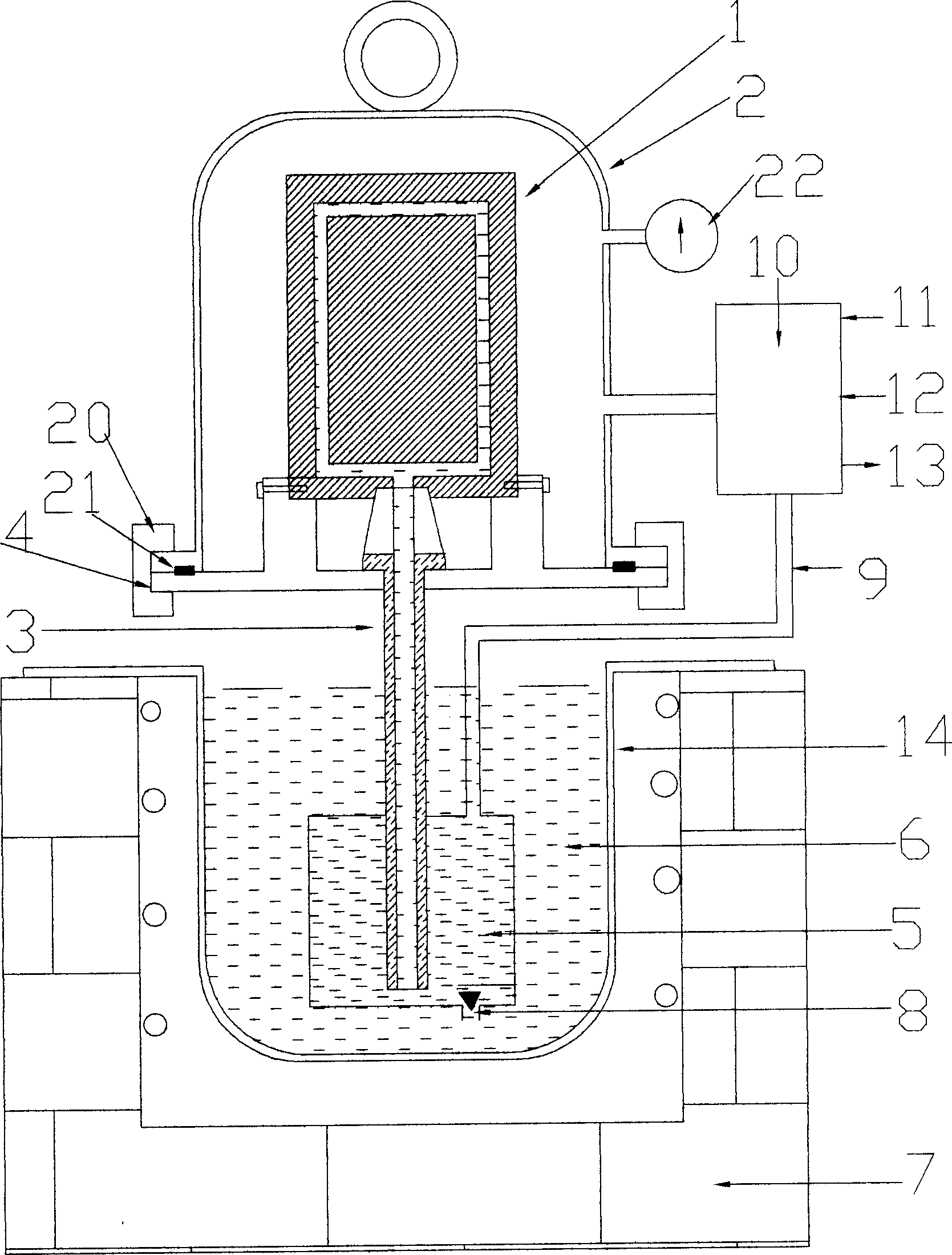

Vacuum pressure casting machine for magnesium alloy

The invention belongs to metal casting device. The magnesium alloy cast is complex, and the performance is bad. The invention is a magnesium alloy casting device which fills shape in vacuum state and solidifies them in various pressure state. It can realize the optimized casting process condition, it can be applied to produce each kind of large, complex, thin magnesium alloy casting piece with precise size and high thickness.

Owner:李书伟 +2

Microbial fermented feed, microbe mother liquor for fermented feed and its production process

InactiveCN1608486AImprove disease resistanceLow costFood processingAnimal feeding stuffBiotechnologyMicroorganism

The present invention is microbial fermented feeds, microbe mother liquor for fermented feeds and their production process. Several microbe strains may be used in anaerobic fermentation of various crop stalk powder, husk, bran, bean residue, etc. to produce various kinds of fermented feed. The present invention has reasonable composition, scientific production process, wide application range and other advantages, and the fermented feed has low cost high feeding efficiency and capability of raising animal's resistance.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com