Patents

Literature

1491 results about "Grain storage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

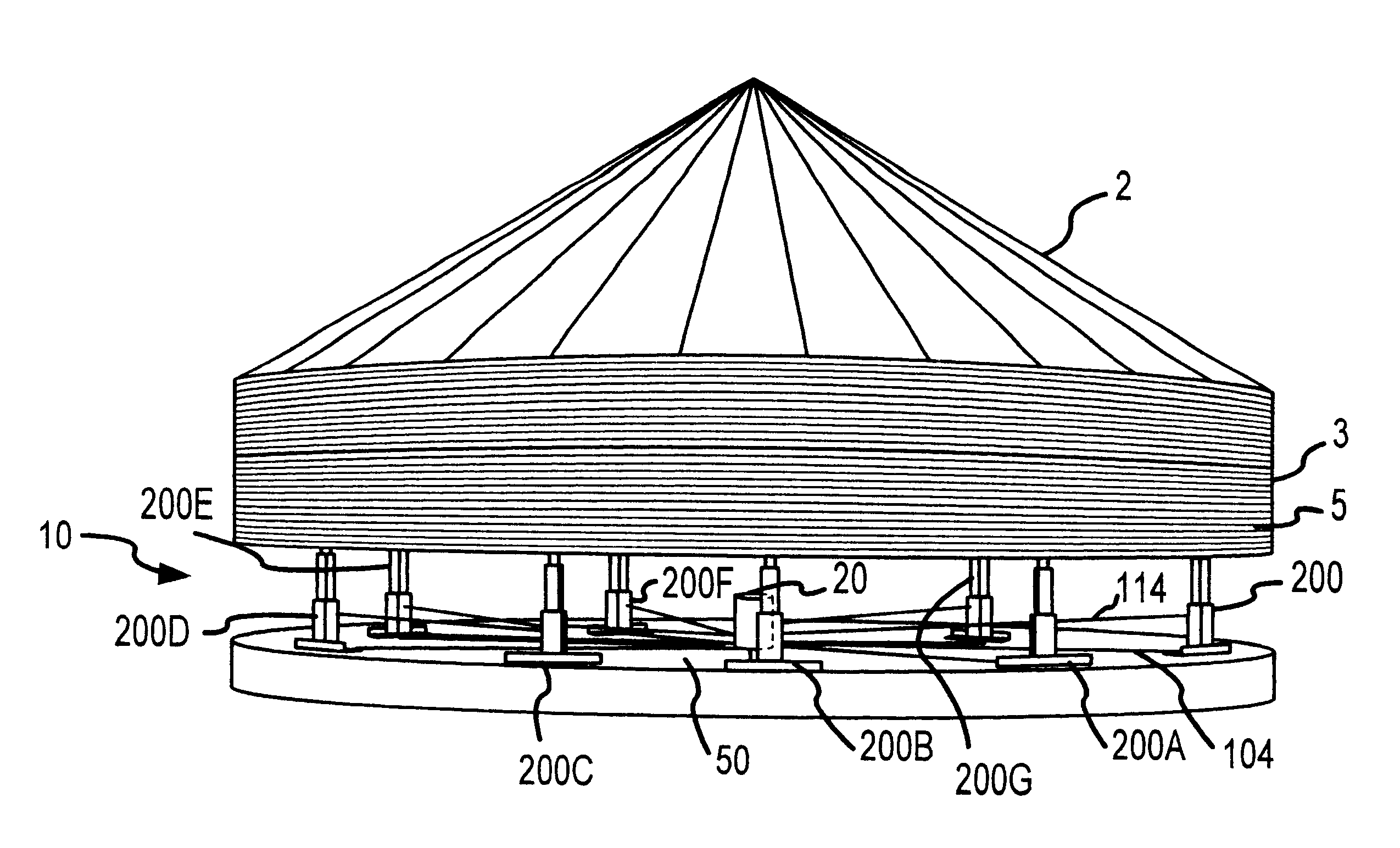

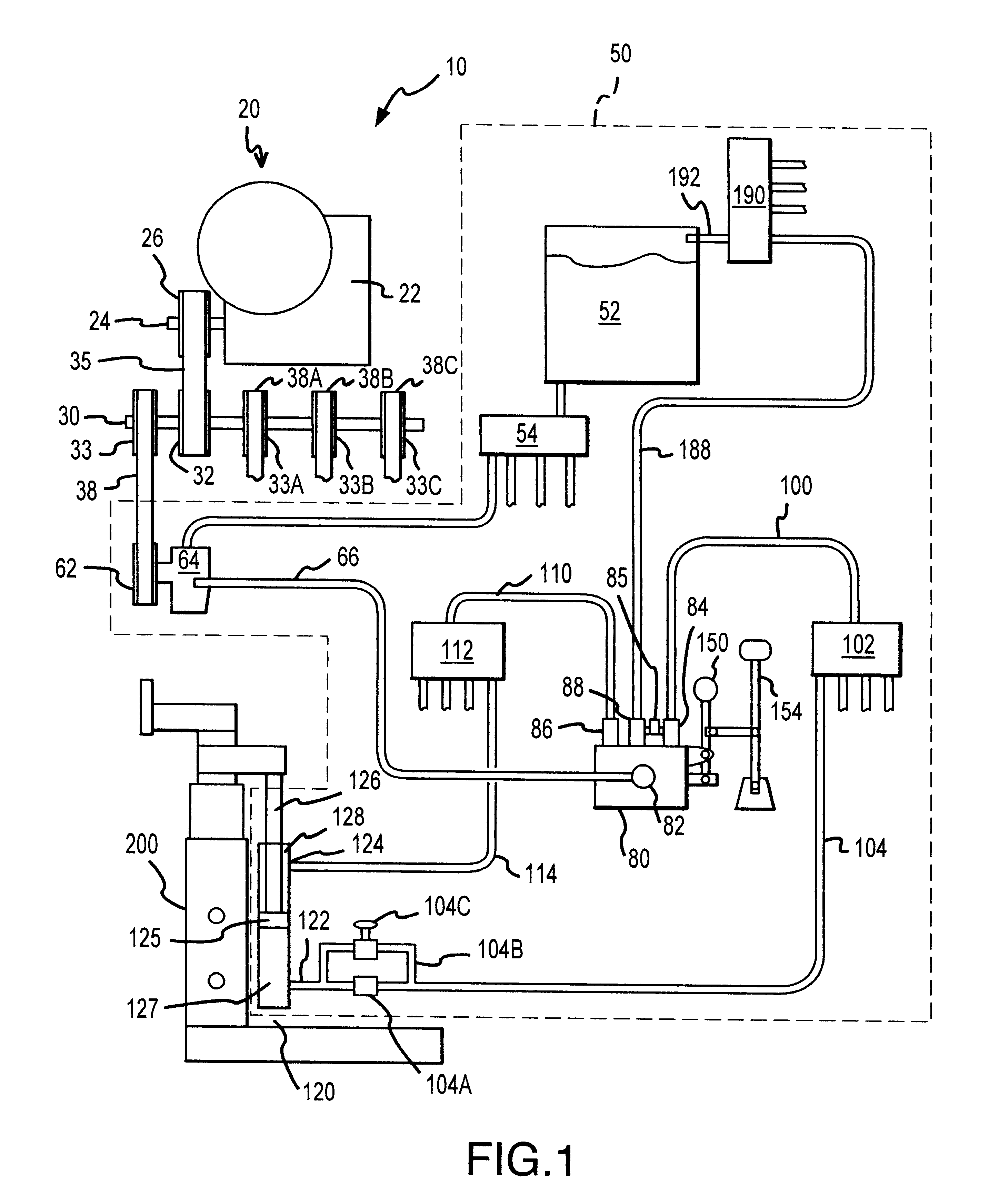

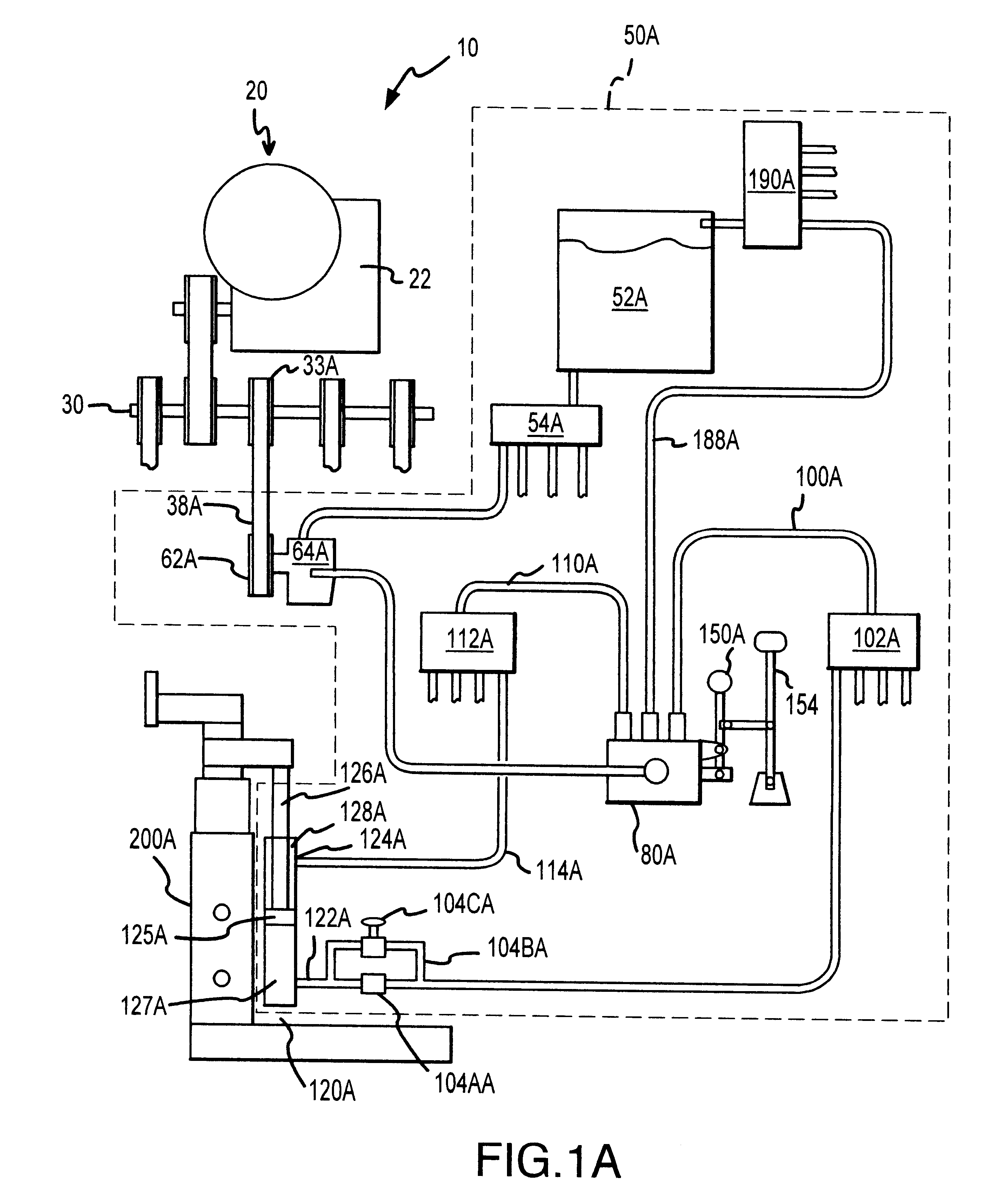

Hydraulic grain storage bin lifting system and method

The present invention is a method for constructing cylindrical grain bins. The method employs a sets of identical, telescoping jacks actuated by hydraulic cylinders and an hydraulic system having separate hydraulic circuits that serve each set of jacks. Using the set of identical, hydraulic, telescoping jacks, successive rings of a grain bin structure made up of connected panels are lifted. After a first ring is lifted, a second ring can be attached to the lower edge of the first ring. The second ring is then lifted and the process is repeated until the grain bin is completed.

Owner:BAINTER WESLEY ALLEN

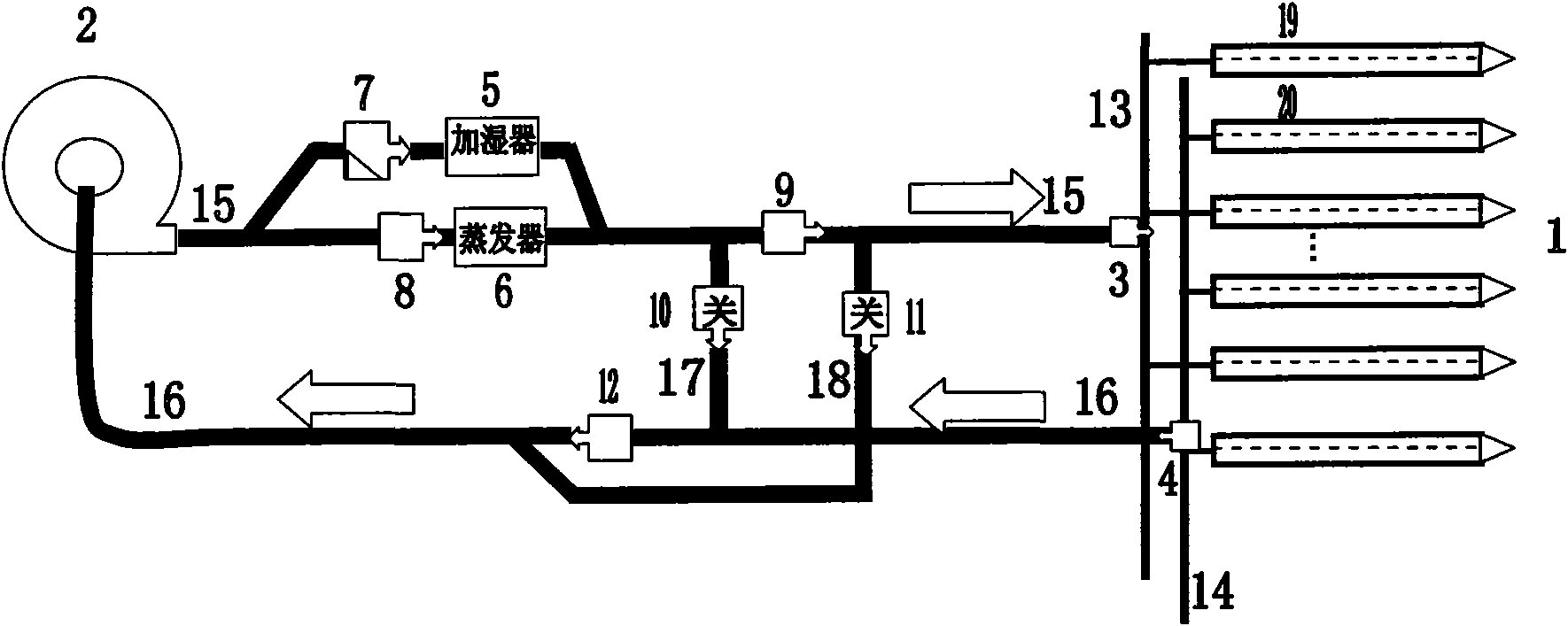

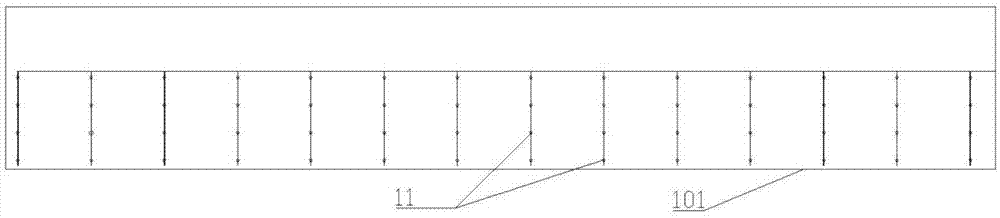

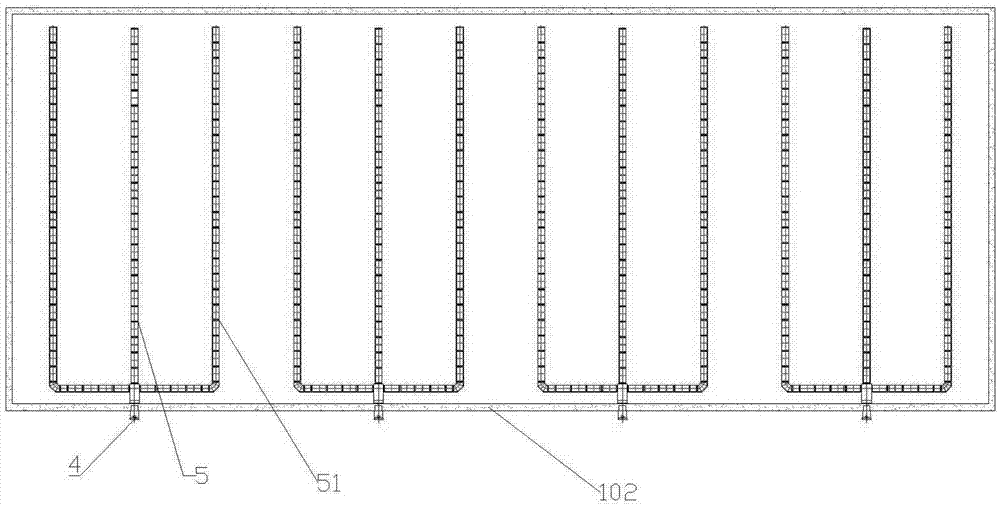

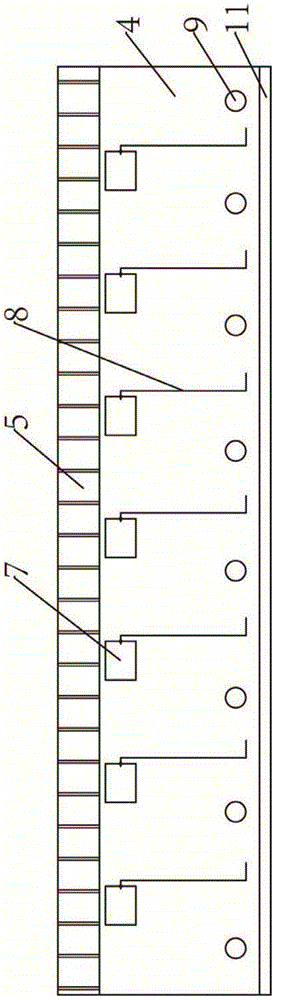

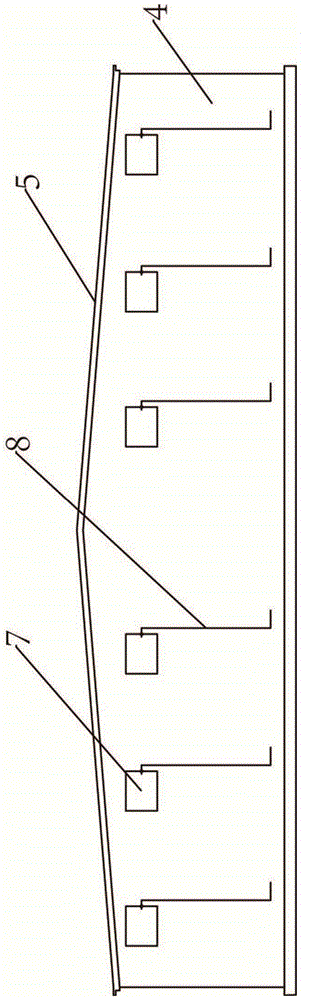

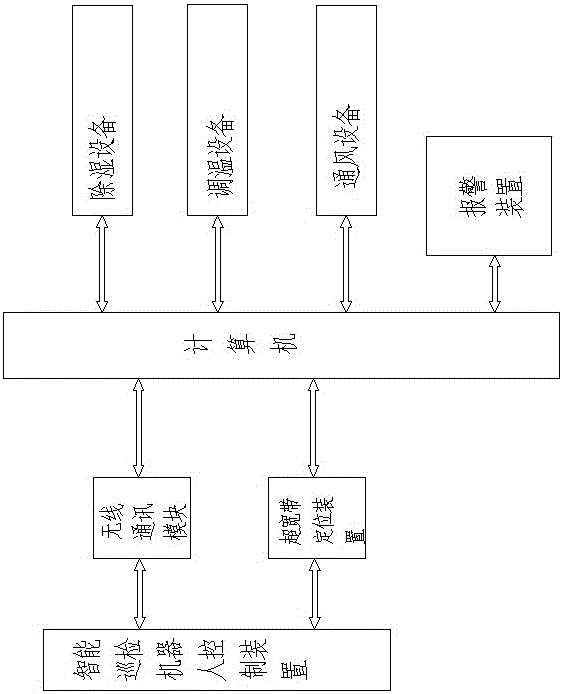

Automatic control system of intelligent low-temperature grain storage and control method thereof

InactiveCN101919330AReduce storage lossIncrease freshnessAgriculture tools and machinesHarvested fruit hanging devicesAutomatic controlMotor drive

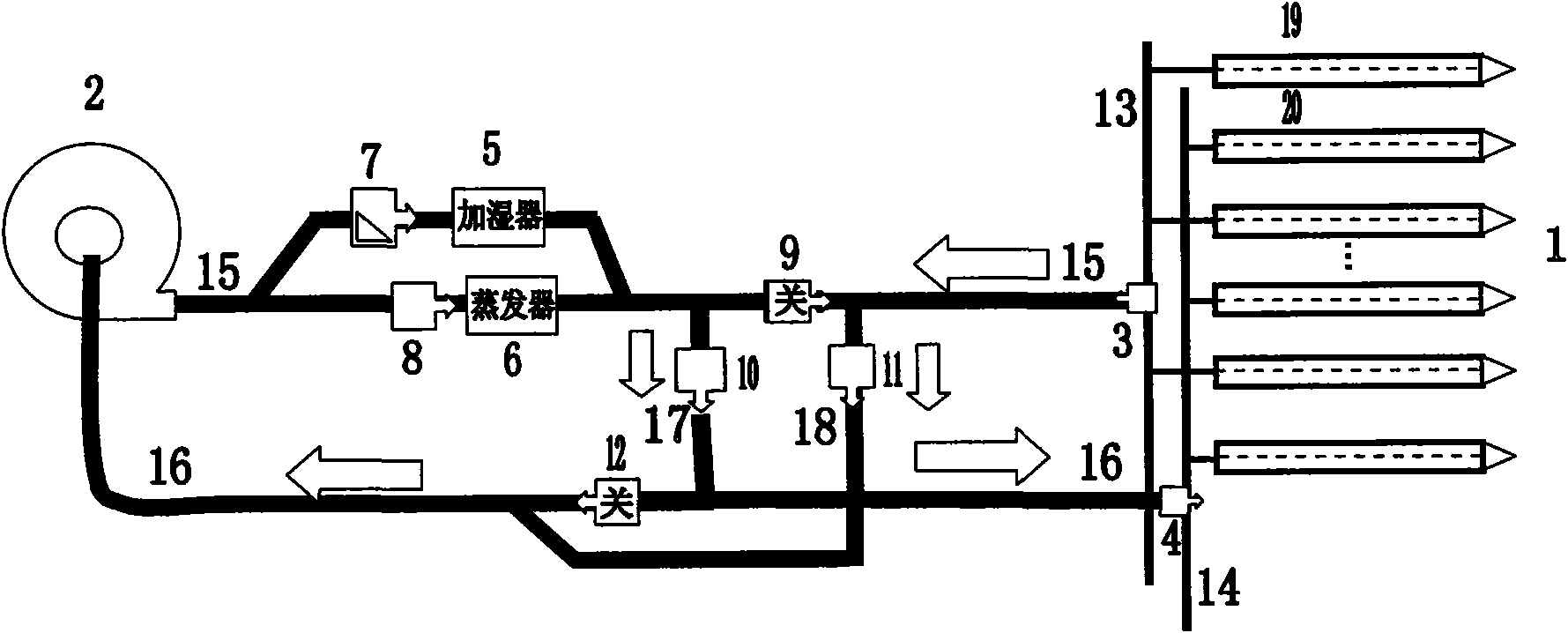

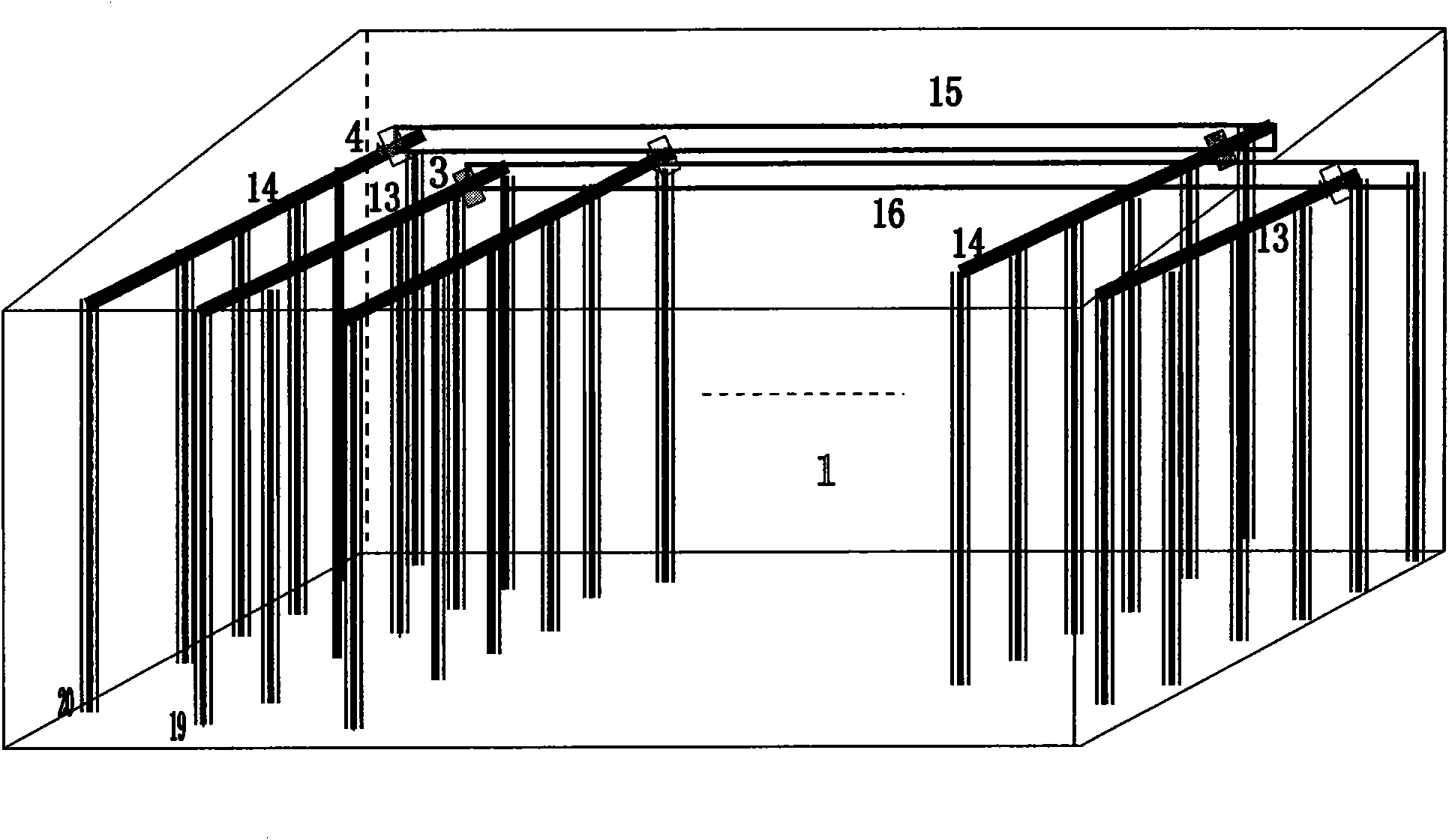

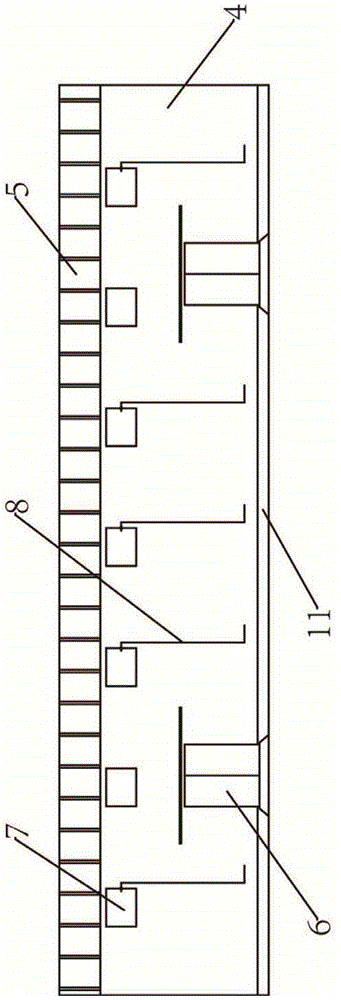

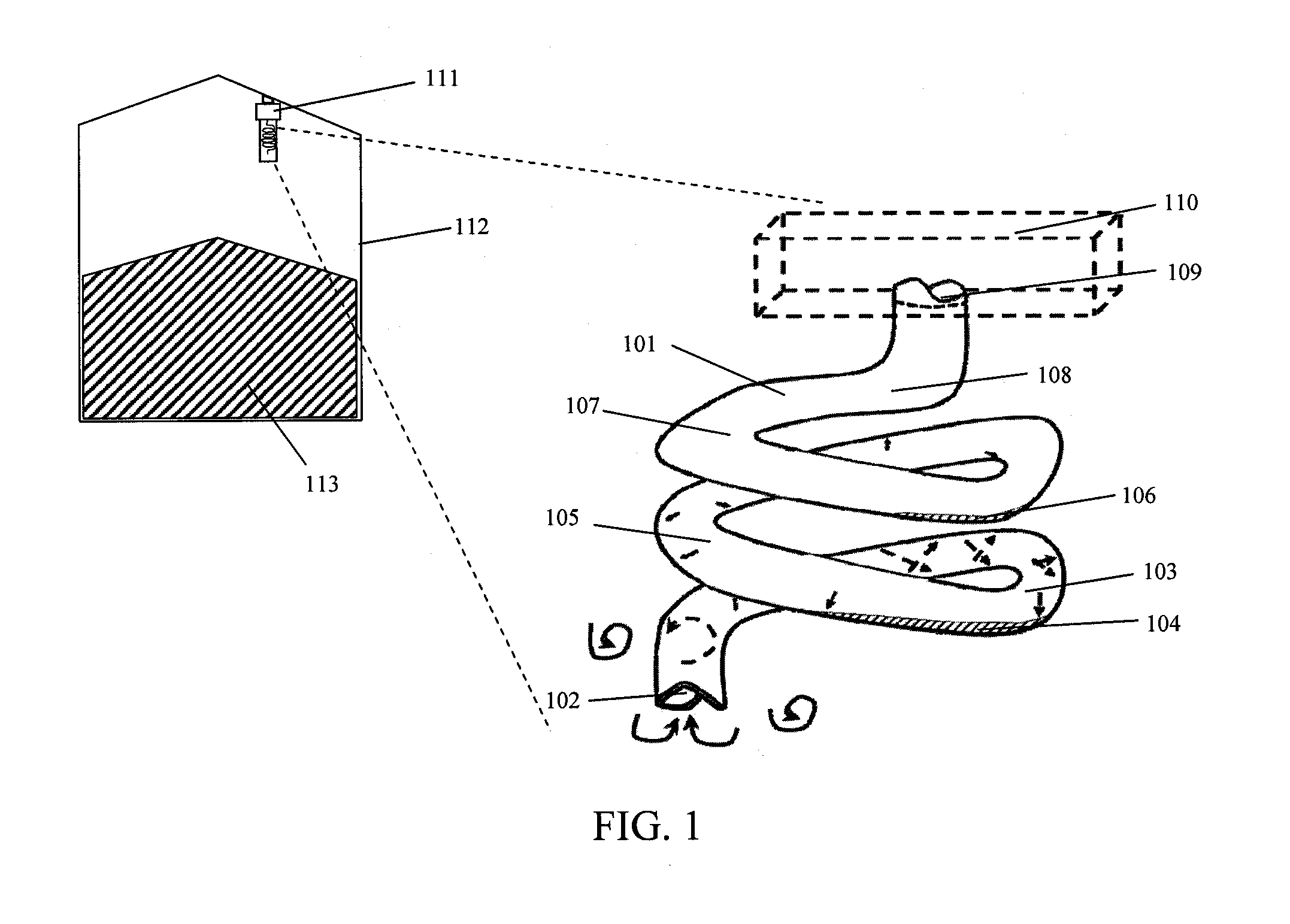

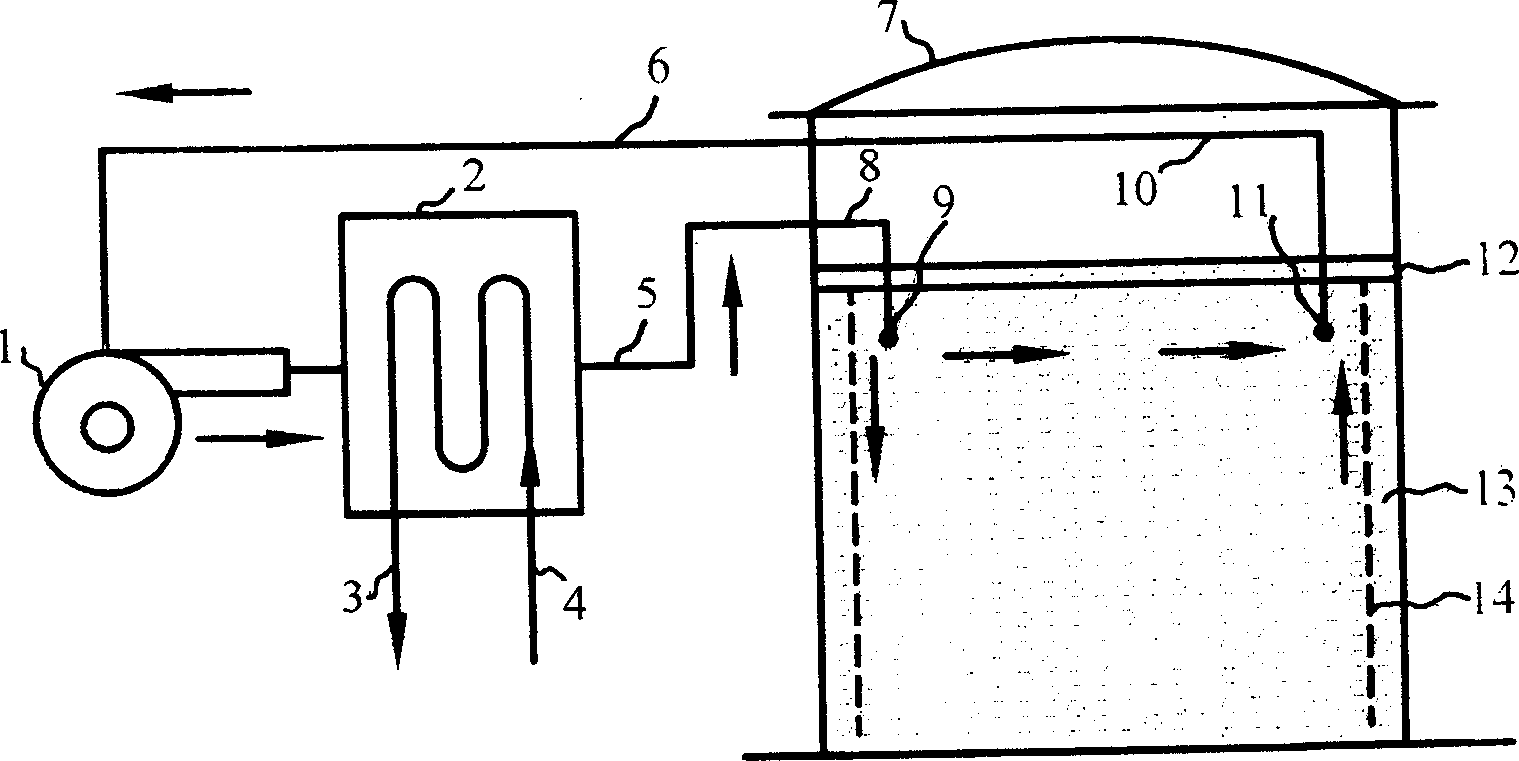

The invention relates to an automatic control system of intelligent low-temperature grain storage and a control method thereof. The automatic control system is provided with a plurality of three-dimensional vent pipes which are vertically arranged in storage space in a grain store; a three-dimensional branch vent is divided into multiple groups of first branches and second branches for which air blast and indraft are exchanged, wherein the first branch is connected with the air outlet of a circulating fan respectively through a first divided manifold and a first header pipe, and the second branch is connected with the air inlet of the circulating fan respectively by a second divided manifold and a second header pipe; a first branch pipe and a second branch pipe which carry out wind direction commutation control to the first branch and the second branch by an air valve are arranged between a blast main and an air suction header pipe; and the first branch, the second branch, the first divided manifold, the second divided manifold, the first header pipe and the second header pipe are all provided with a motor-driven air valve connected with the control device. The system and the method of the invention assure grain storage quality, save fund and energy, obtain the purpose of environmentally-friendly storage, can assure the safety and health of prevention personnel, reduce larbor intensity and have simple operation.

Owner:AGRI SCI & TECH DEV CO LTD JILIN BOTAI

Grain storage quantity detection method for horizontal warehouse and shallow silo

InactiveCN102706417ALow costReduce workloadWeighing apparatus for materials with special property/formGrain storageSurface pressure

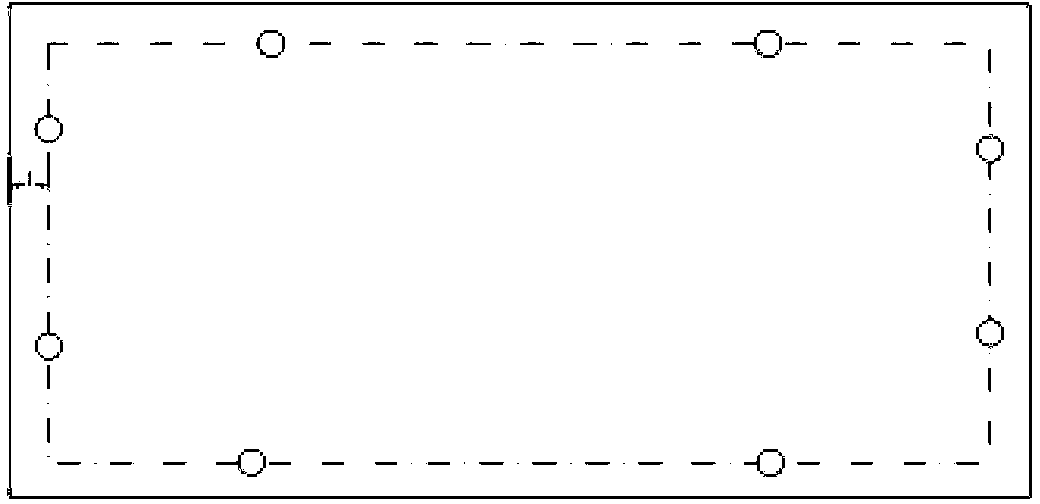

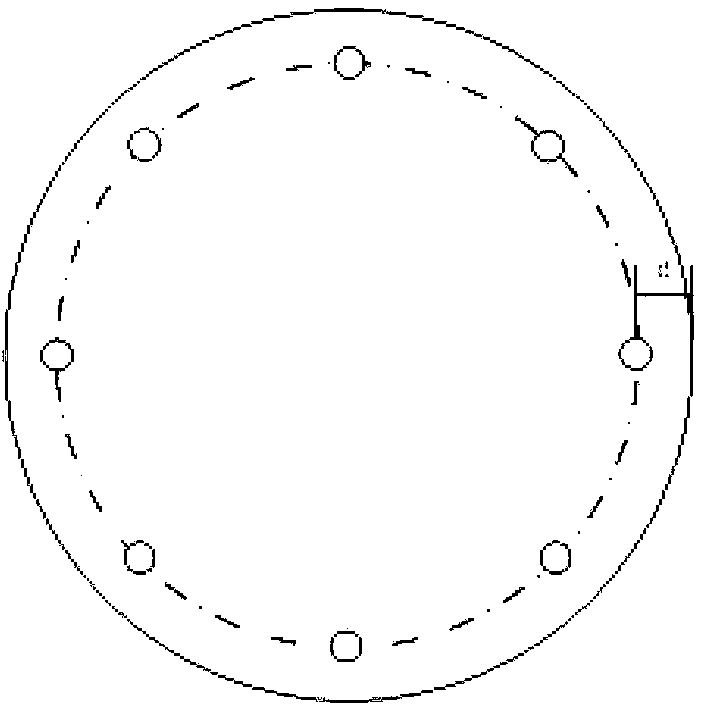

The invention relates to a grain storage quantity detection method for horizontal warehouses and shallow silos. The grain storage quantity detection method comprises the following steps of: firstly selecting specific pressure sensors to lay a grain warehouse pressure sensor detection network; distributing the pressure sensors along the side wall of the grain warehouse in the mode that all the pressure sensors are evenly-spaced laid at d meter distance from the side wall; and determining whether a grain warehouse is calibrated or not so as to obtain a calibration parameter and a grain warehouse weight prediction model, spreading the top surface of a grain pile in the grain warehouse after the grain warehouse is fully filled with the grain, detecting the average output valve of the pressure sensor at the bottom of the grain warehouse, and detecting the grain storage quantity of the grain warehouse according to an actually-tested bottom surface area of the grain warehouse, a bottom surface area of the calibrated grain warehouse and calibrated parameters by using a model so as to obtain an estimated value of the weight of the grain warehouse. According to the grain storage quantity detection method provided by the invention, the pressure sensors are required to be arranged on the bottom surface of the grain warehouse, and a compensating item of a side grain warehouse friction action is added into a bottom surface pressure estimating model in order to avoid using the side pressure sensor and accurately obtain the estimated value of the pressure of the bottom surface of the grain warehouse, so that the quantity of the sensors is obviously reduced, and the device detection cost and the installation and maintenance cost are reduced.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

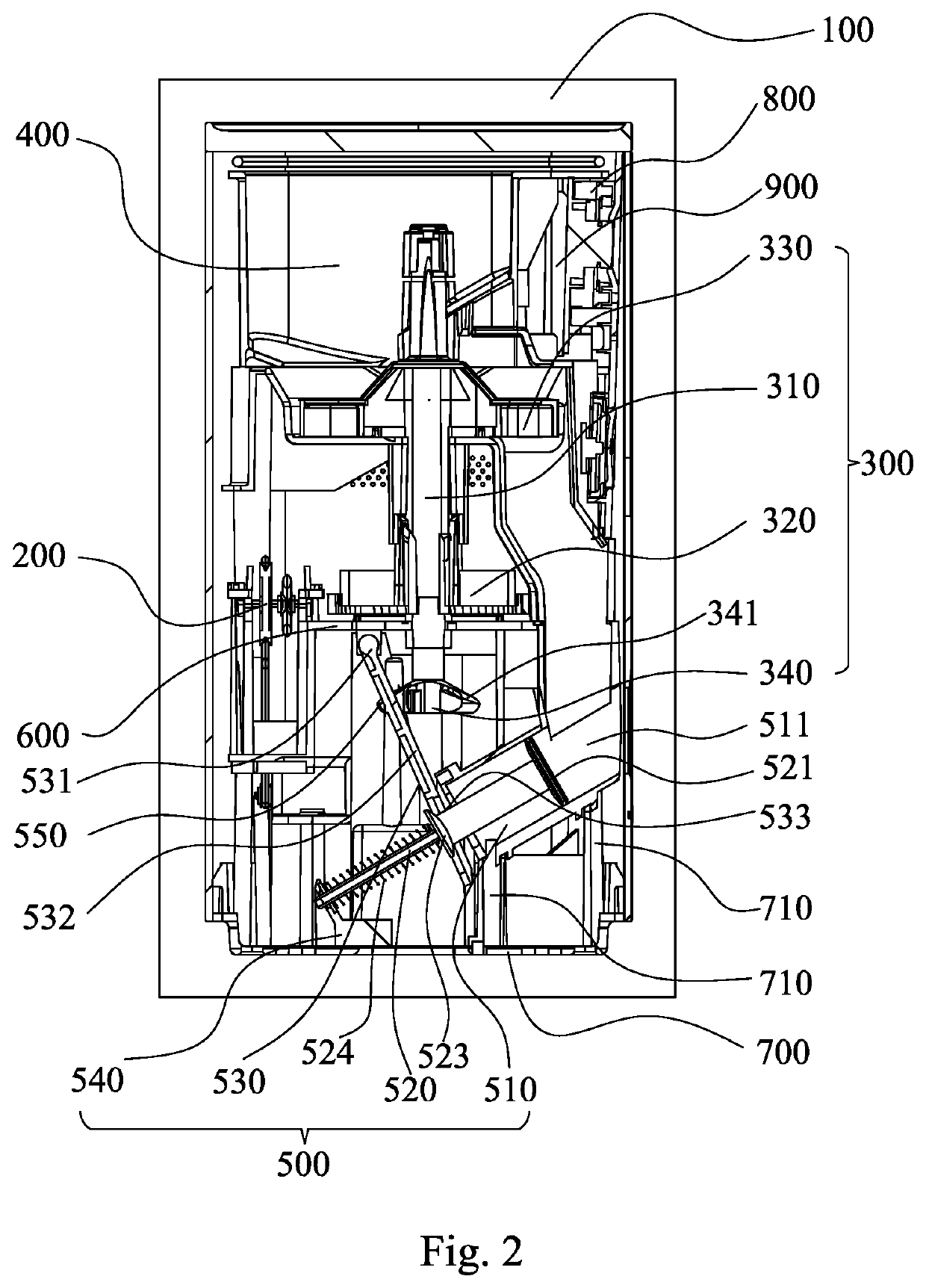

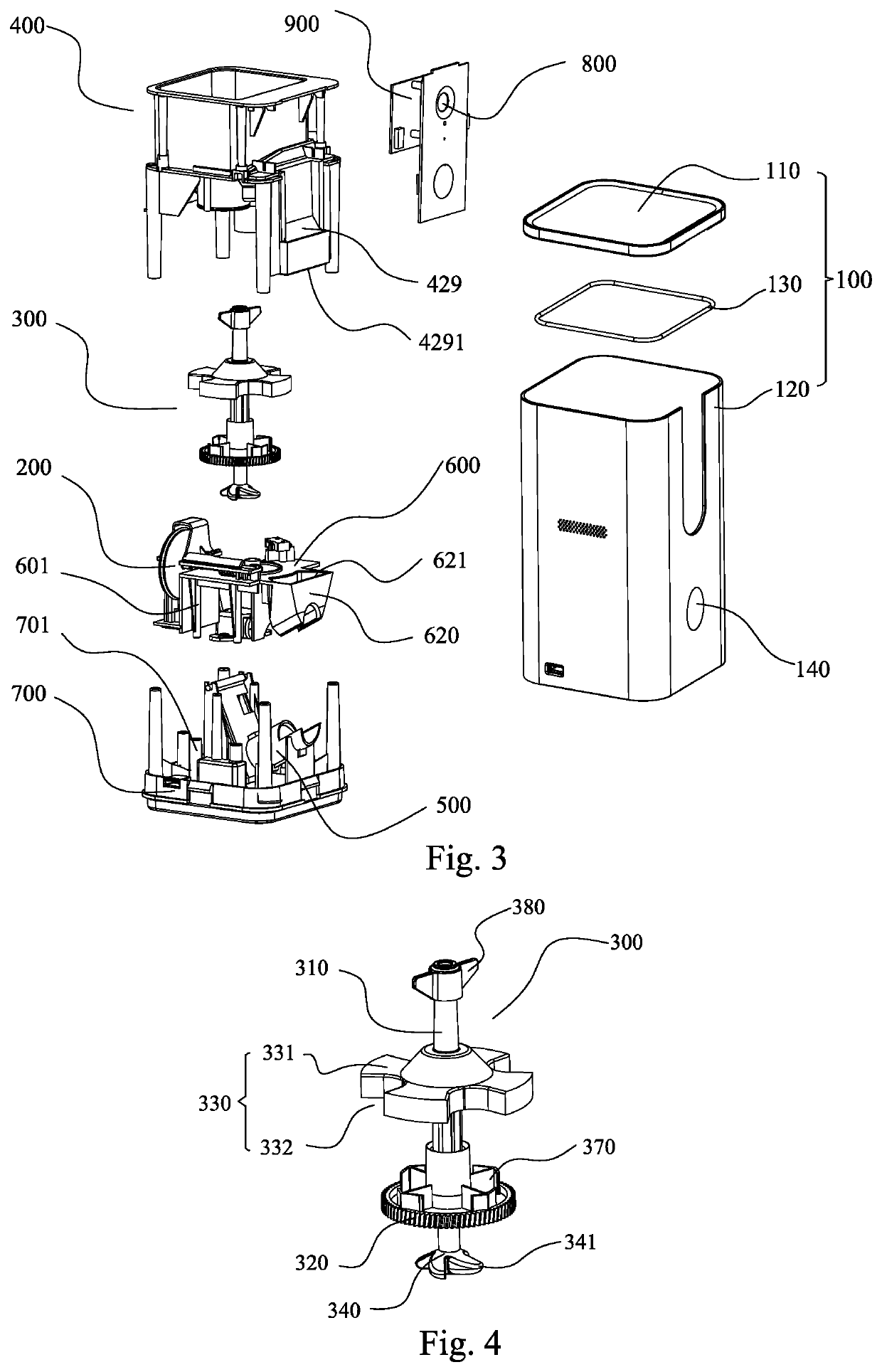

Smart pet feeder

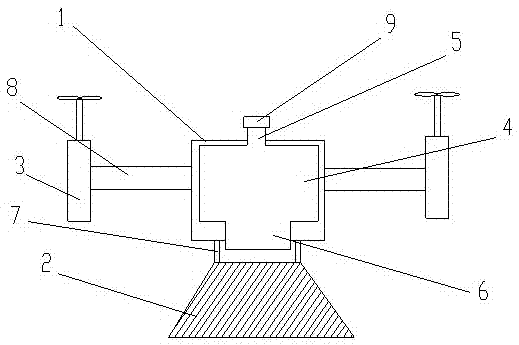

ActiveUS20200100460A1Improve feeding effectAnimal feeding devicesOther apparatusGear wheelGrain storage

The smart pet feeder includes a housing, and a grain storage component, a driving component and a rotating component, arranged therefor in the upper part, the middle part and the lower part of the housing; a rotating component is arranged in the housing, and the rotating component has a supporting column, the upper part, of it is provided with a wheel, the lower part of it is provided with a driving gear, the bottom end of it is provided with a cam; the upper part is extended into the grain storage component, and the wheel is contained in the grain storage component; the driving gear is rotatably connected with the driving component, the cam is connected with the throwing component.

Owner:DOGNESS GRP LLC

Sowing unmanned aerial vehicle with anti-scattering protective cover base

InactiveCN105438472AImprove protectionAvoid flying aroundAlighting gearBroadcast seedersPropellerGrain storage

The invention discloses a sowing unmanned aerial vehicle with an anti-scattering protective cover base. The sowing unmanned aerial vehicle comprises an unmanned aerial vehicle body and the protective cover base, wherein a plurality of propeller wings are arranged at the outside end of the unmanned aerial vehicle body; a grain storage bin is arranged in the unmanned aerial vehicle body; the upper end of the grain storage bin is connected with a charge pipe, and the lower end of the grain storage bin is connected with a discharge pipe; the discharge pipe leads to the outer part of the unmanned aerial vehicle body; the two ends of the charge pipe and the two ends of the discharge pipe are opened and communicated; a clamping ring is arranged on the end surface of the bottom of the unmanned aerial vehicle body at the outer side of the discharge pipe; the protective cover base is connected with the clamping ring to cover the bottom of the unmanned aerial vehicle body; and the protective cover base is of a cavity structure of which the two ends are communicated. Through the way, the protection of the bottom of the unmanned aerial vehicle body can be strengthened, and the protective cover base not only can be used as a bottom support frame of the unmanned aerial vehicle but also can be used as a sowing protective cover to prevent seeds from scattering all round during sowing, thereby improving the sowing efficiency and ensuring that the seeds are sown in the designated position.

Owner:WUXI MIRACLE SCI & TECH CO LTD

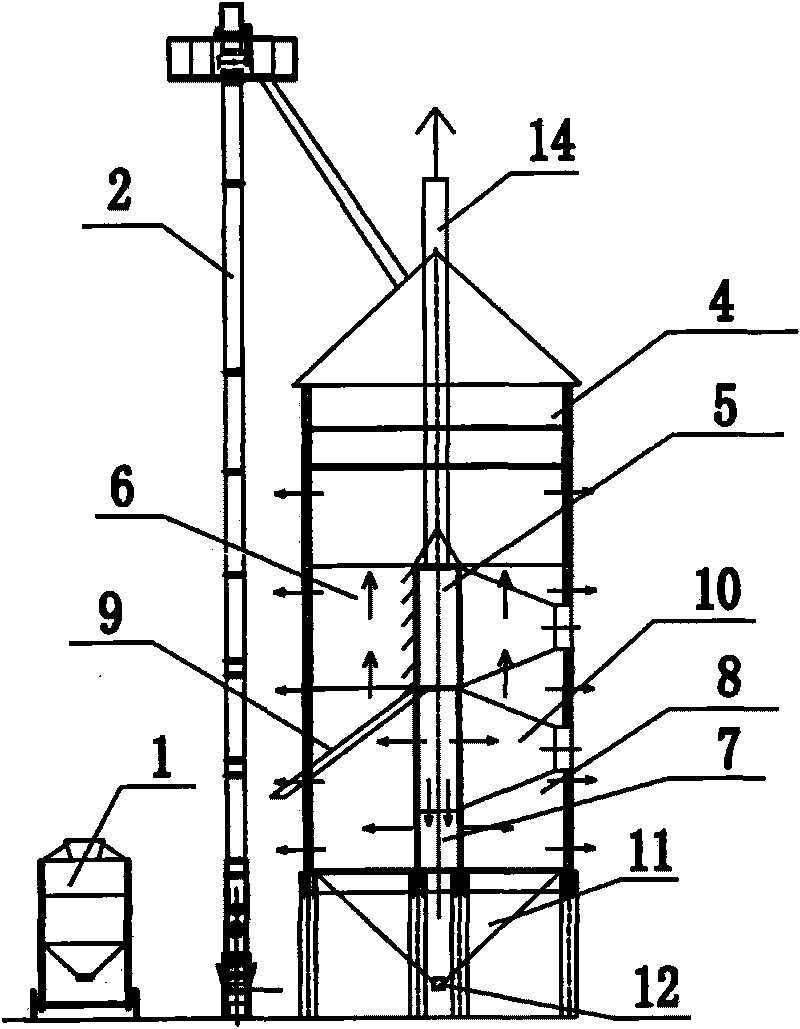

Centralized drying system of high-humidity grain and drying method thereof

InactiveCN101731327AImprove drying efficiencyReduce consumptionFood processingClimate change adaptationLiquid wasteEngineering

The invention relates to a centralized drying system of high-humidity grain and a drying method thereof. According to the grain deliver direction, the centralized drying system comprises a preliminary cleaning machine, a wet grain hoister, a wet grain dryer, a conveyor, a middle hoister, a main drying tower, a dry grain conveyor, a dry grain hoister and a dry grain storage silo which are successively connected, wherein the main drying tower successively comprises a high-temperature drying section, a low-temperature drying section and a cooling section; the system also comprises a hot-blast stove, a heat exchanger, a dust remover and a smoke draught fan which are successively connected, wherein the smoke draught fan is connected with the wet grain drier; the heat exchanger is connected to the main high-temperature drying section by an air heater, and the air heater is connected to the low-temperature drying section by a thermosistor; the heat exchanger is connected with the wet grain drier by a wind stopping device and an air cooler; and ambient air is communicated with the air cooler by the cooling section. The drying system can fully utilize natural air and recycle the waste heatand waste gas of the drying system to efficiently dry in an energy saving mode and reduce drying waste gas, waste liquid and dust emission; the drying system has favourable drying effect and is especially suitable for drying a great quantity of high-wet grain in a centralized mode.

Owner:SOUTH CHINA AGRI UNIV

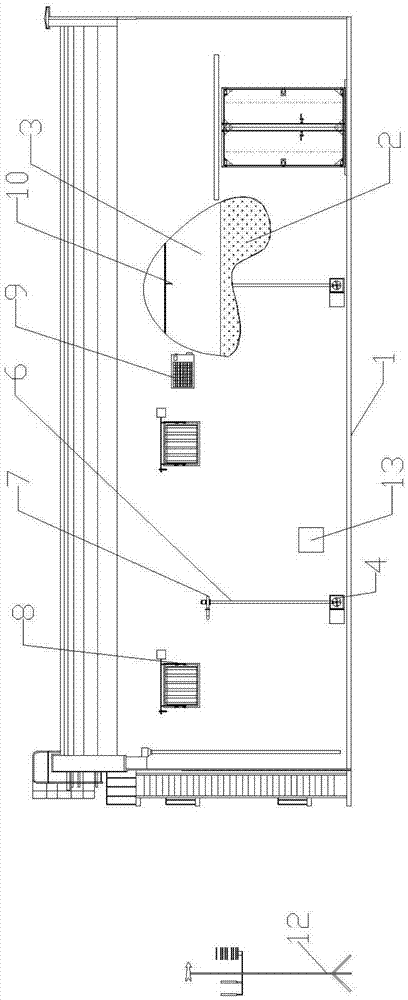

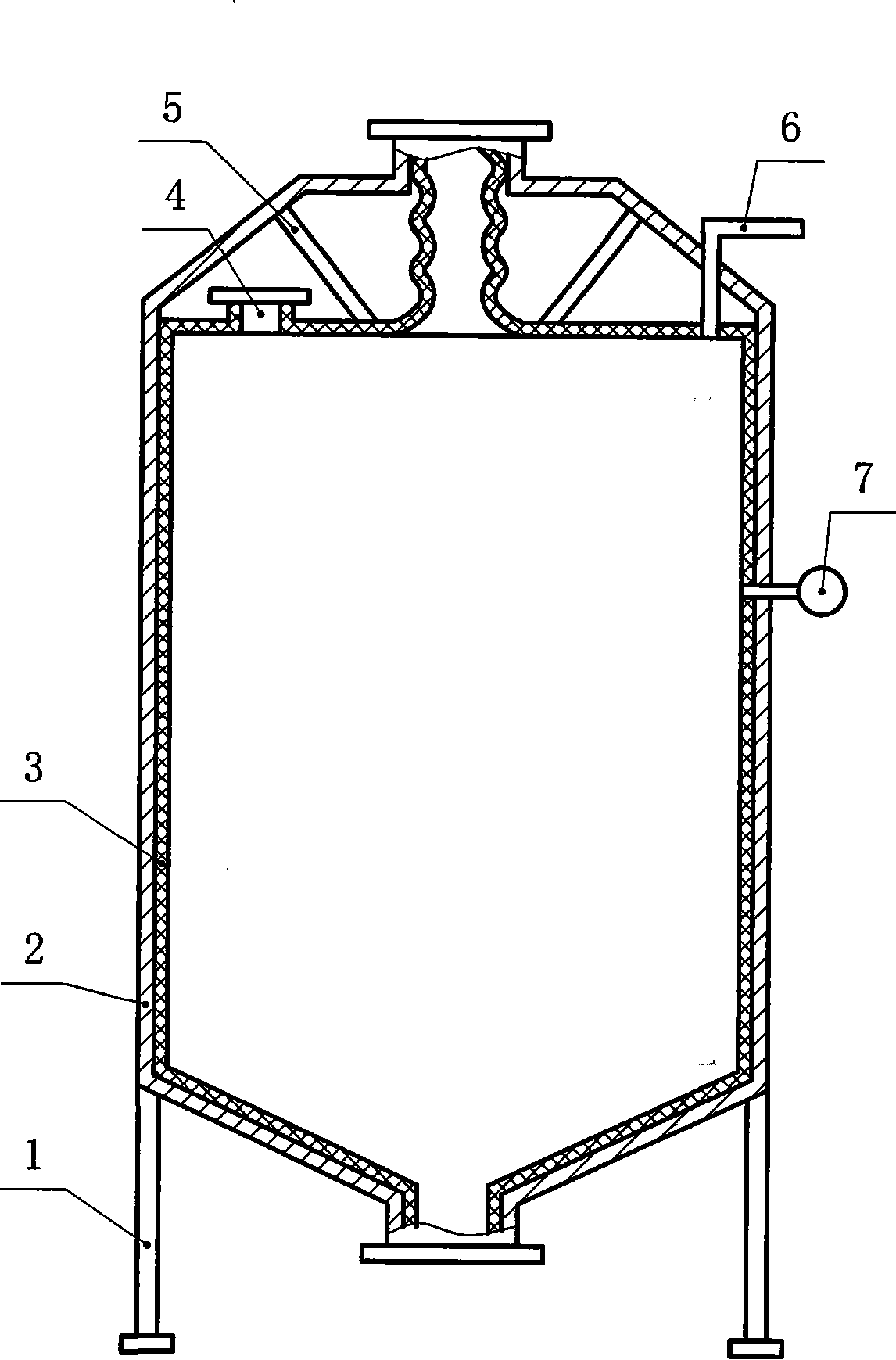

Natural low-temperature barn and grain storage method thereof

ActiveCN105432262ALow costReduce the temperatureAgriculture tools and machinesHarvested fruit hanging devicesGrain storageEngineering

The invention discloses a natural low-temperature barn. The barn comprises a barn body, a ventilation window, an air inlet, ventilation pipelines, a circulating pipeline, a third fan, refrigeration equipment, multiple first temperature sensors, multiple humidity sensors, multiple second temperature sensors and meteorological monitoring equipment. The ventilation window is formed in the upper surface of the barn body, the air inlet is formed in the lower surface of the barn body, the ventilation pipelines are buried inside grain stacks, and the first ends of the ventilation pipelines are communicated with the air inlet, wherein a first fan is arranged inside the ventilation window and used for exhausting air inside space above the grain stacks to the external environment and / or a second fan is arranged inside the air inlet and used for introducing air in the external environment into the grain stacks; the air inlet end of the circulating pipeline is also communicated with the first ends of the ventilation pipelines, and the third fan is arranged inside the circulating pipeline. The invention further discloses a grain storage method of the natural low-temperature barn. Energy is saved, the refrigeration effect is good, and temperature distribution is even.

Owner:HUBEI YE WEI INTELLIGENT TECH +1

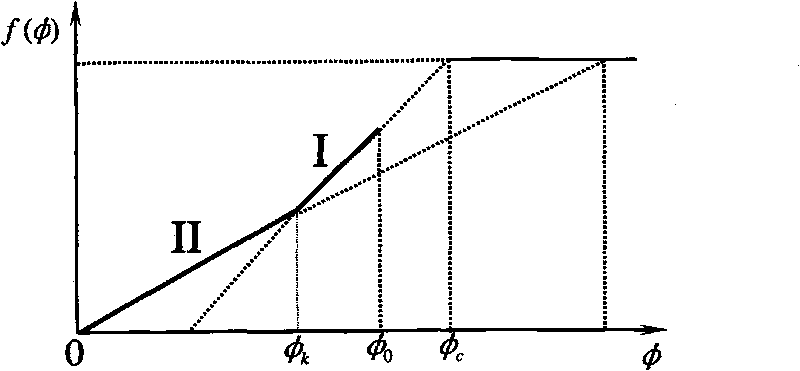

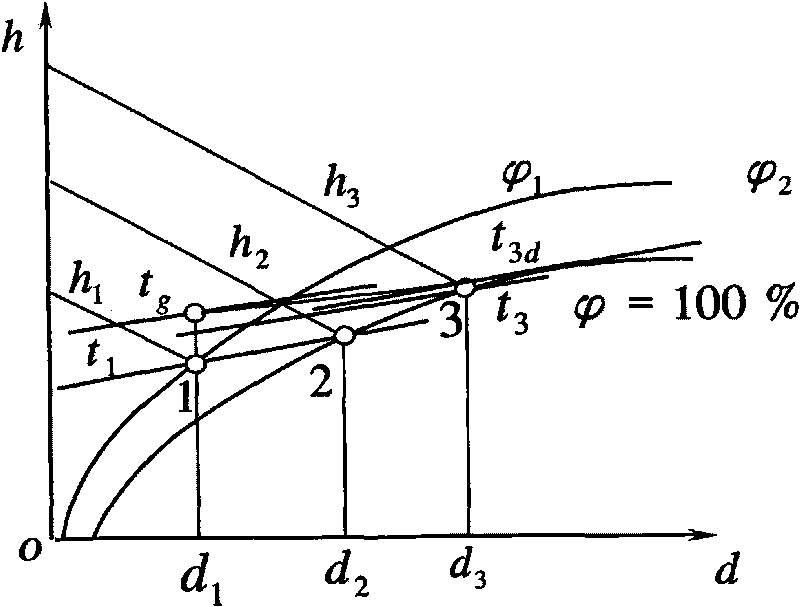

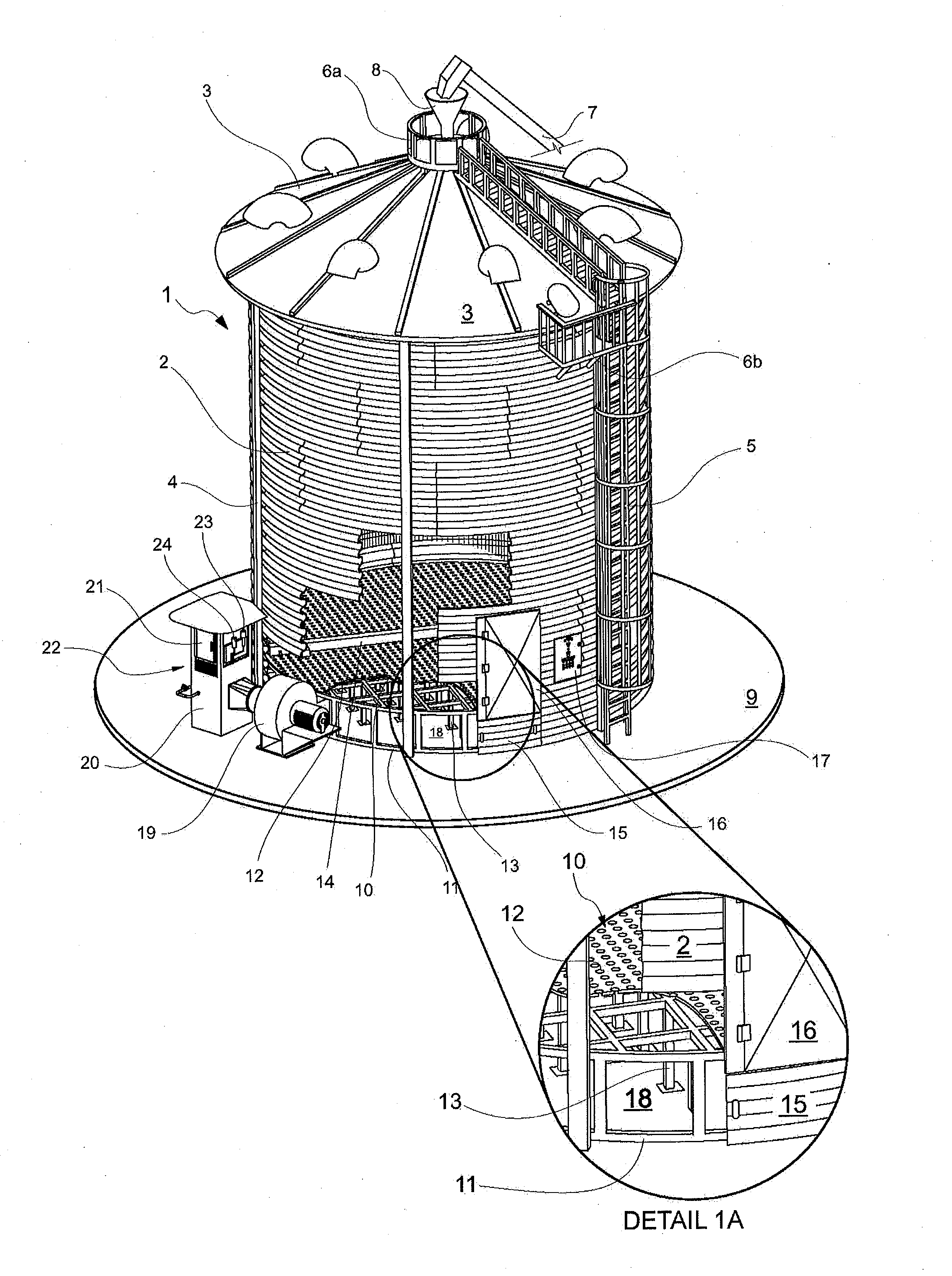

Procedure and facility for grain moisture control

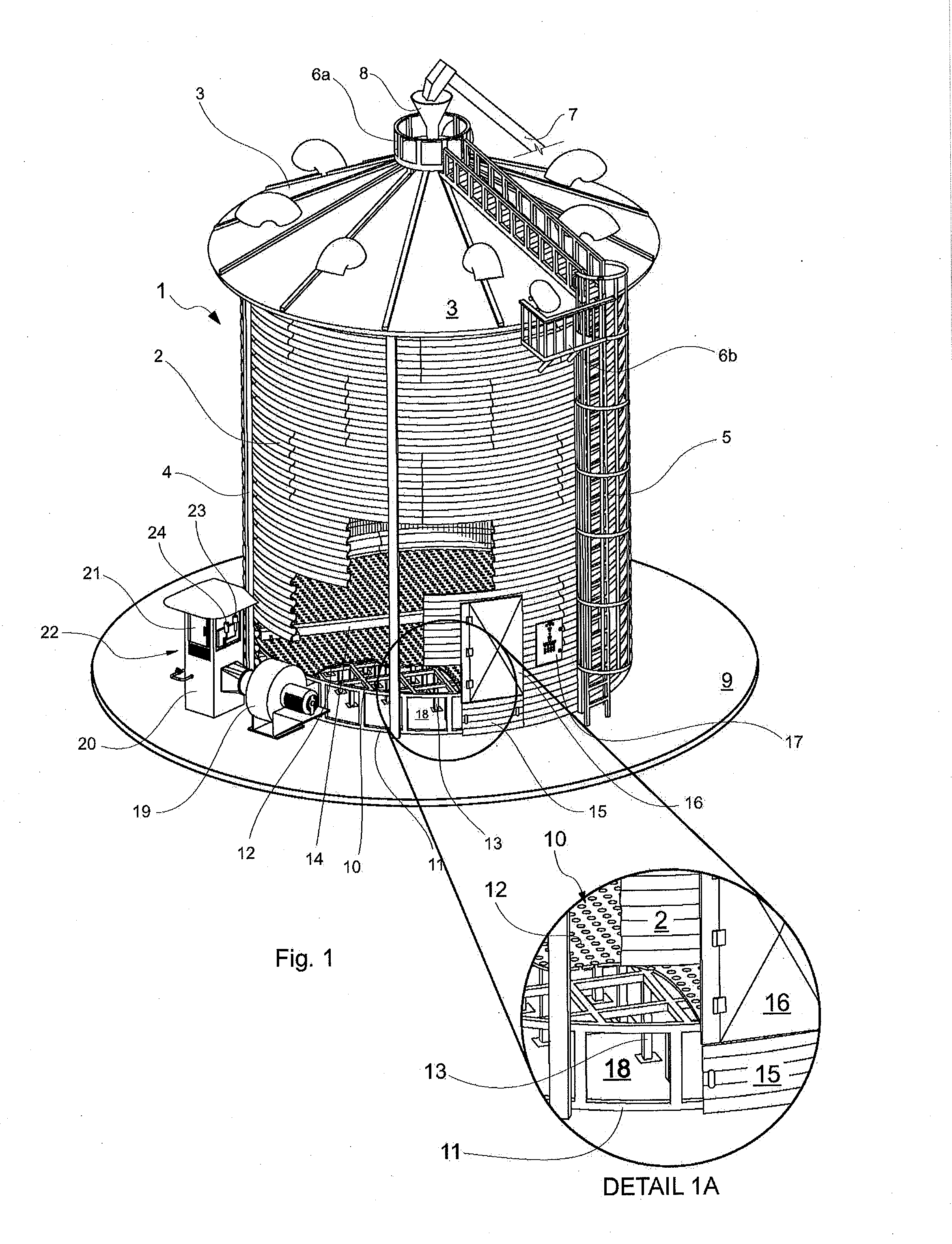

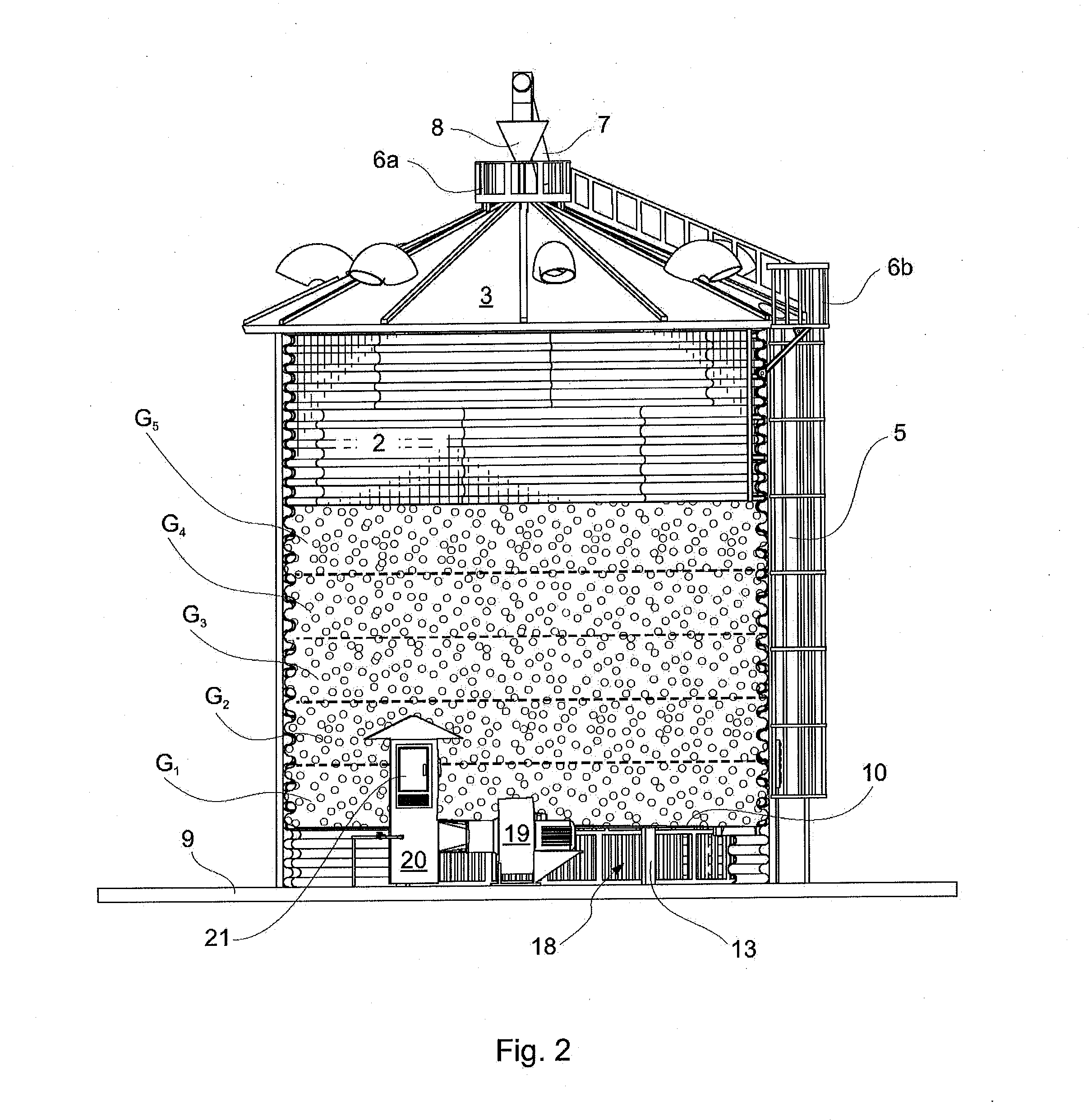

ActiveUS20140360045A1The process is simple and effectiveEasy to set upAgriculture tools and machinesDrying solid materials with heatGrain storageEngineering

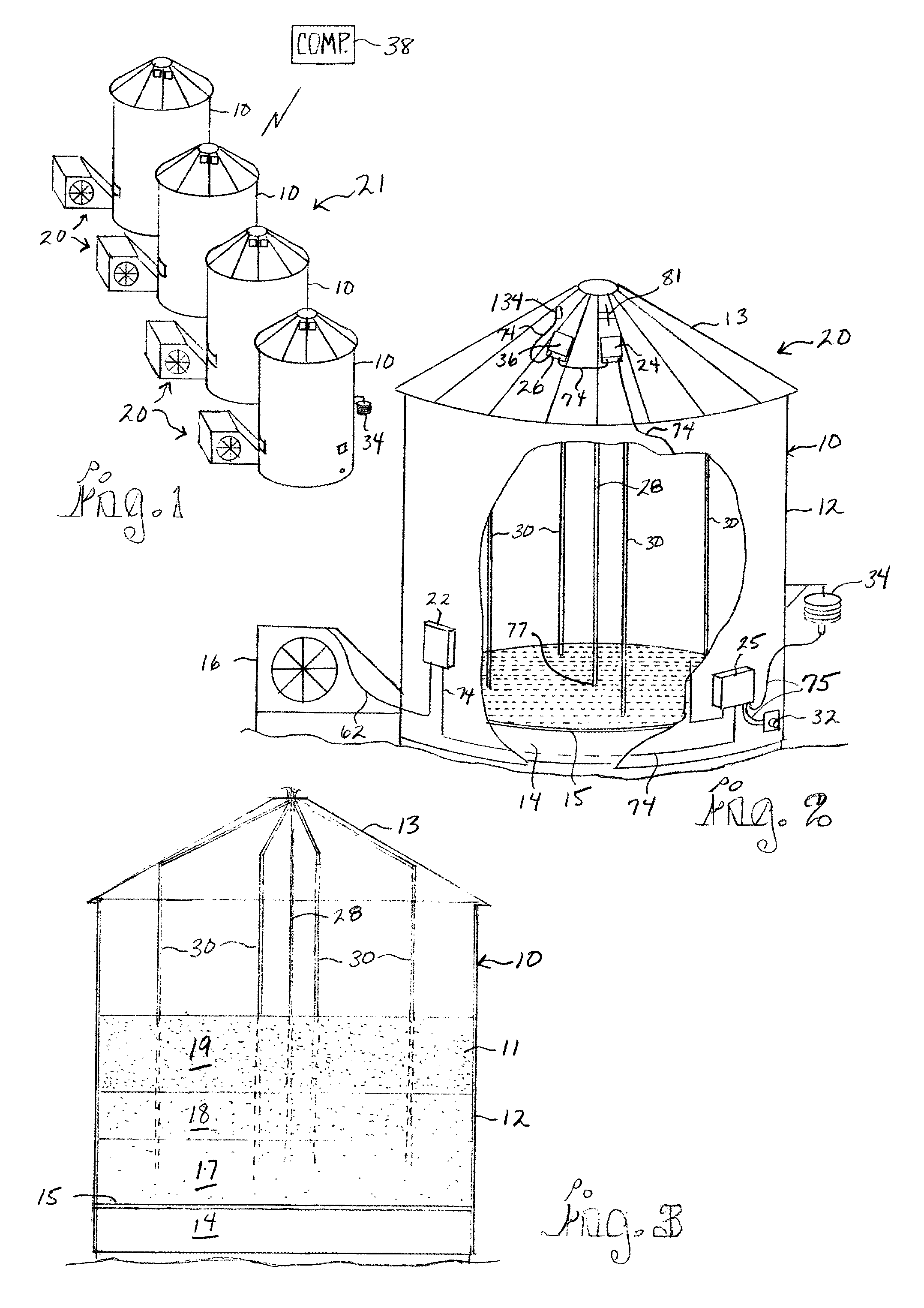

A facility for controlling the grain moisture provided with a grain storage silo conveniently installed on a hard flat floor and inside of which an elevated floor comprising air passageways is provided, determining an air chamber inside the silo and below the perforated floor, into which previously conditioned air is blown by an air heater, wherein the control of hot air blowing times is determined based on means of modeling and calculating on and off times applied through an electronic control means, with the ability to read and record manual input data entered by an operator and reading data from a temperature sensor in the air chamber, below the perforated floor, further aided with an ambient temperature and moisture sensor, thereby causing the application of different stages of drying, re-humidification and maintenance of the grain moisture.

Owner:INST NACIONAL DE TECNOLOGIA AGROPECUARIA

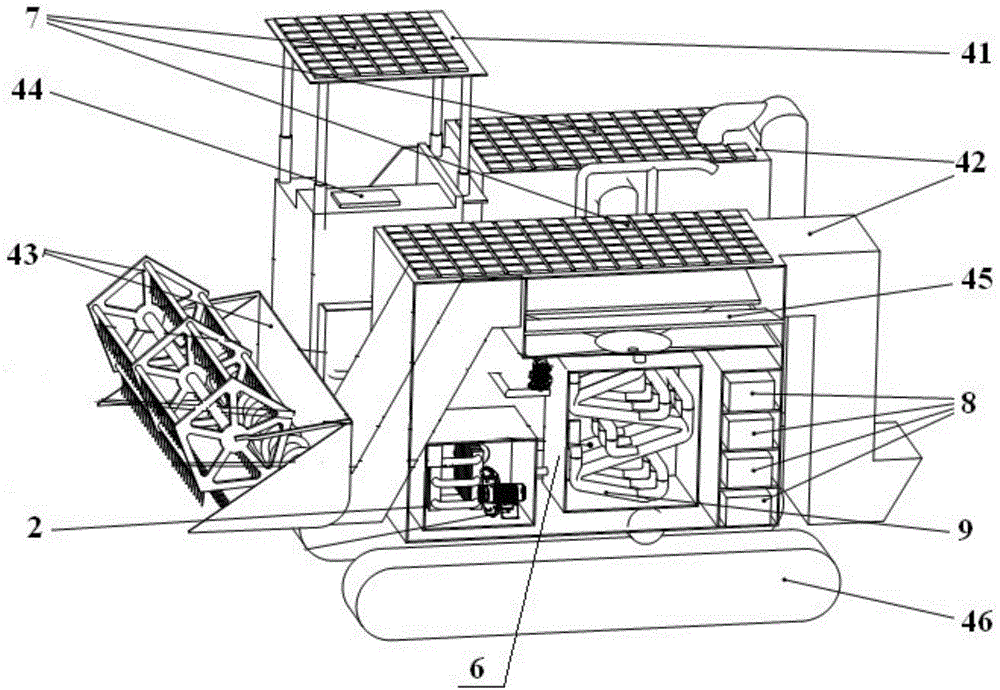

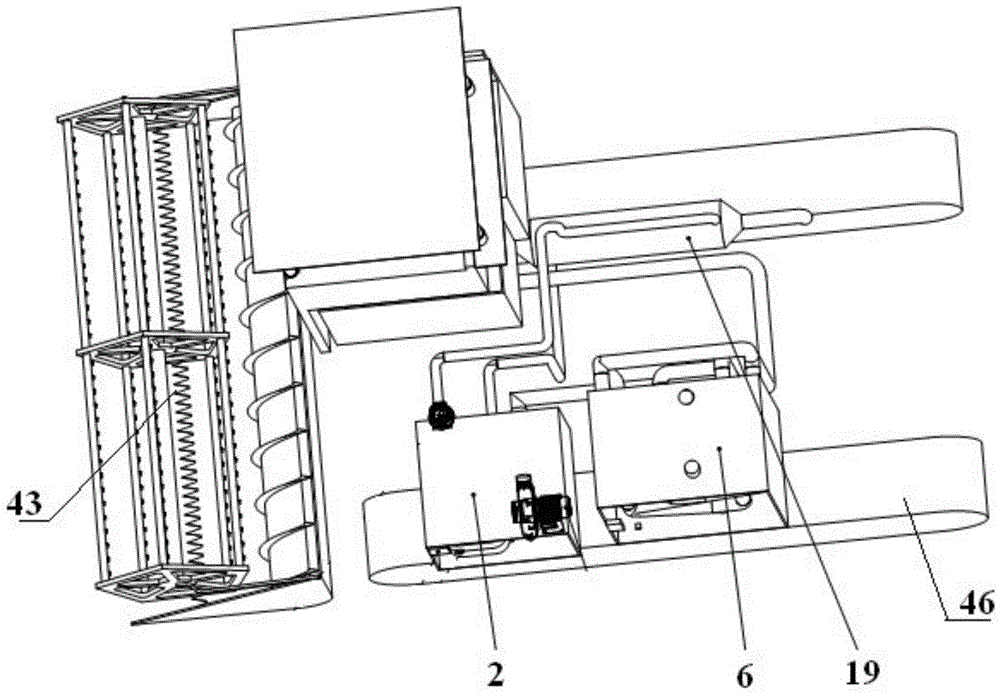

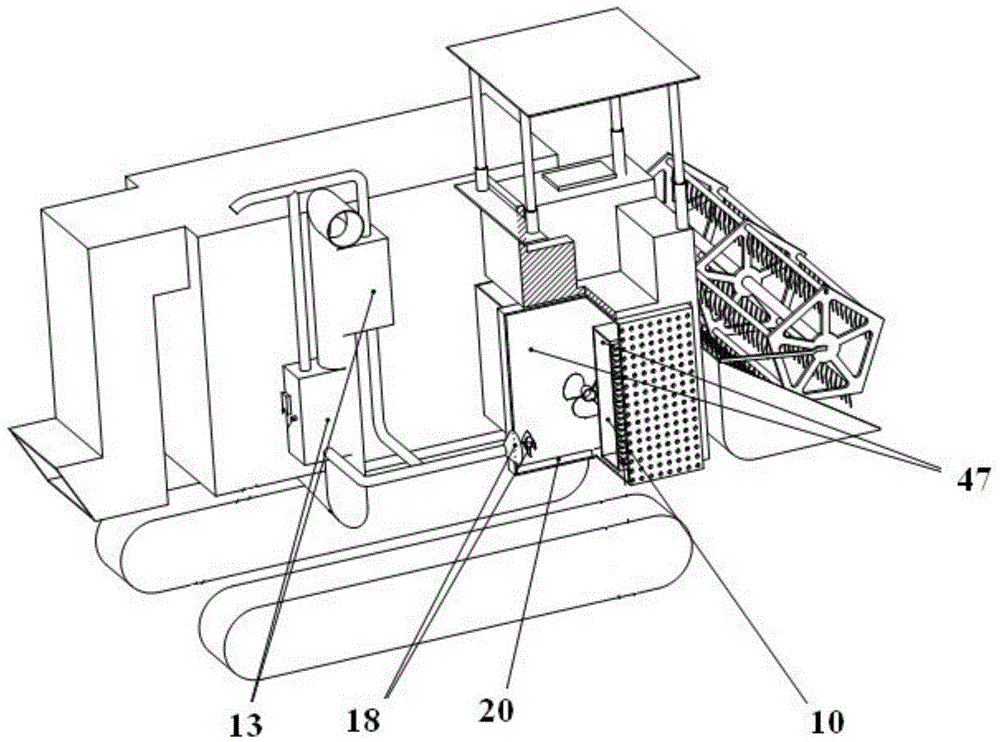

Environmental-friendly and energy-saving harvester with drying function

ActiveCN104429327AReduce energy consumptionReduce manufacturing costMowersGrain storageProcess engineering

The invention discloses an environmental-friendly and energy-saving harvester with the drying function. The environmental-friendly and energy-saving harvester comprises a harvester shell (42), a harvesting system (43) mounted on the harvester shell (42), a threshing system (45) connected with the harvesting system (43), a grain conveying pipeline (9) connected with the threshing system (45), a grain storage box (14) connected with the grain conveying pipeline (9), an internal combustion engine power system (47) mounted on a harvester chassis and a walking system (46) mounted at the bottom of the harvester chassis. The harvester provided by the invention is reasonable in structural design, convenient to operate, high in working efficiency, capable of greatly saving labor time, and especially, is excellent in energy conservation and environmental protection properties, low in energy consumption, low in production cost and high in applicability, the harvester has various functions of harvesting, threshing and drying and can instantly dry and pack grains. The harvester can overcome the defects in the prior art of high labor cost, long drying time, constraint by weather and low working efficiency, thereby having important popularization and application values.

Owner:徐州天骋智能科技有限公司

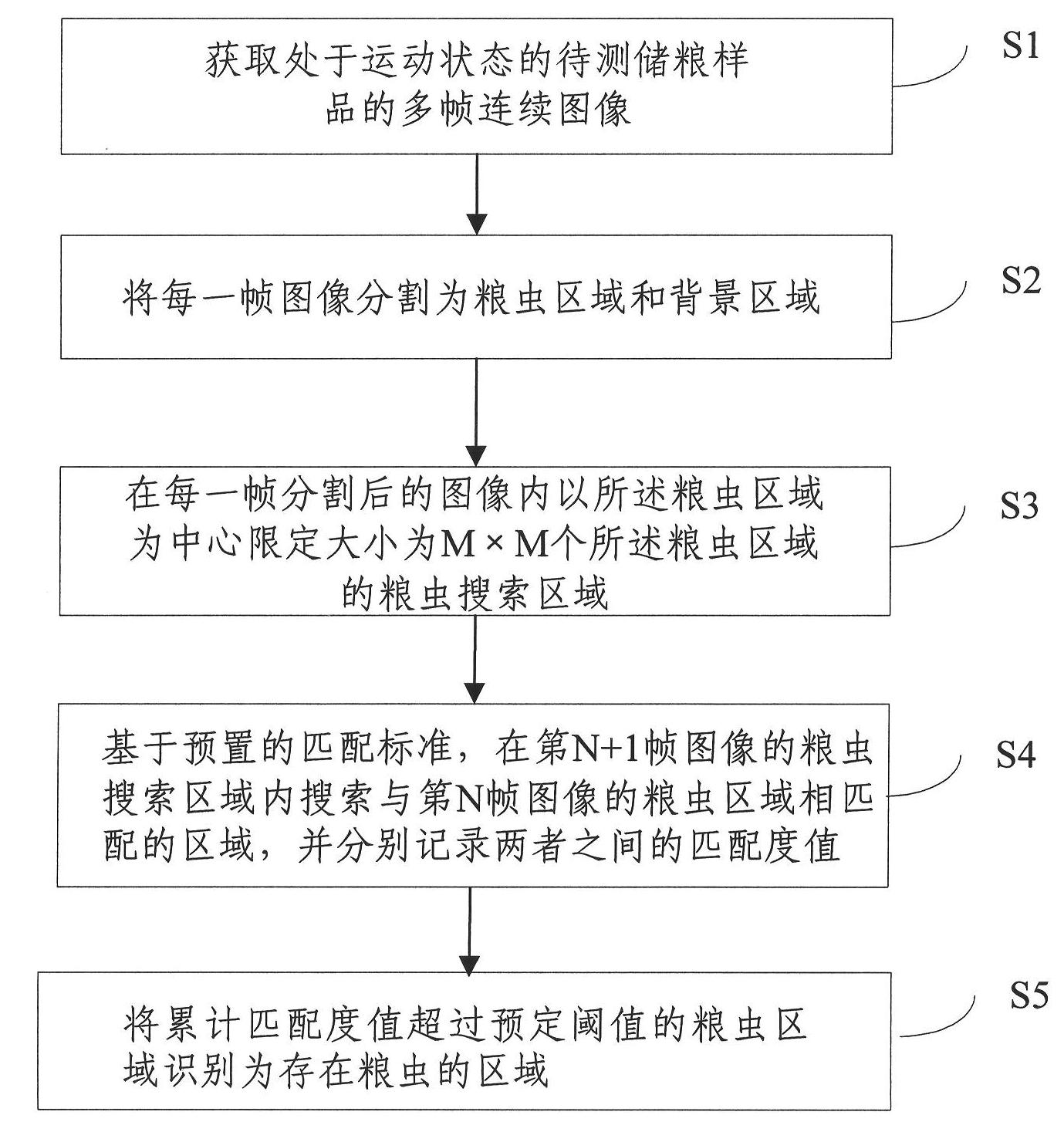

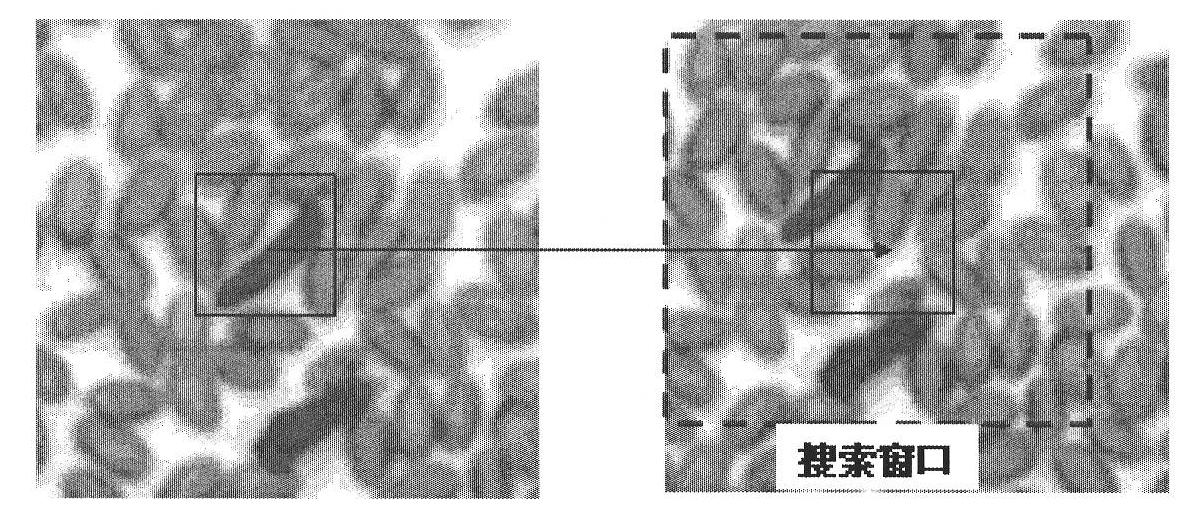

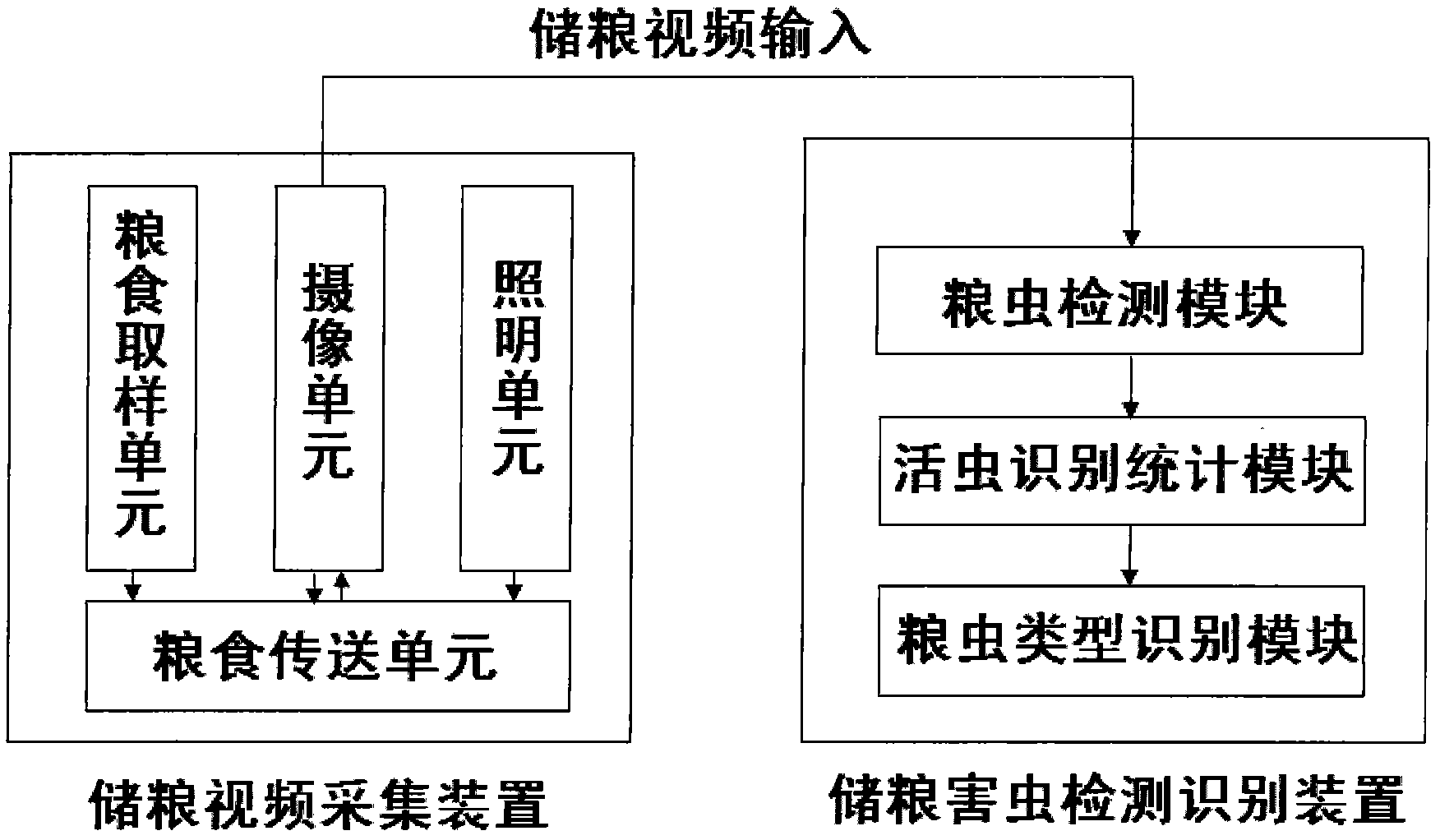

Grain storage pest detection and identification method based on video analytics and system thereof

InactiveCN101976350AImprove accuracyAvoid missing detectionCharacter and pattern recognitionMultiple frameGrain storage

The invention provides a grain storage pest detection and identification method based on video analytics and a corresponding detection and identification device. The method of the invention comprises the following steps: S1. obtaining the multiple frames of continuous images of a moving grain storage sample to be detected; S2. cutting each frame of image into a grain pest area and a background area; S3. in each frame of cut image, defining a grain pest searching area by taking the grain pest as the center, wherein the grain pest searching area is composed of M*M grain pest areas; S4. based on a preset match criteria, searching an area matched with the pest area of the Nth frame of image in the grain pest searching area of the (N+1)th frame of image, and recording the matching degree value between areas; and S5. identifying the grain pest area of which the accumulated matching degree value exceeds a preset threshold value as the area with grain pests. The method can overcome the defects of false detection and missed detection existing in the existing detection and identification method and can judge grain pest survival and types.

Owner:CHINA AGRI UNIV

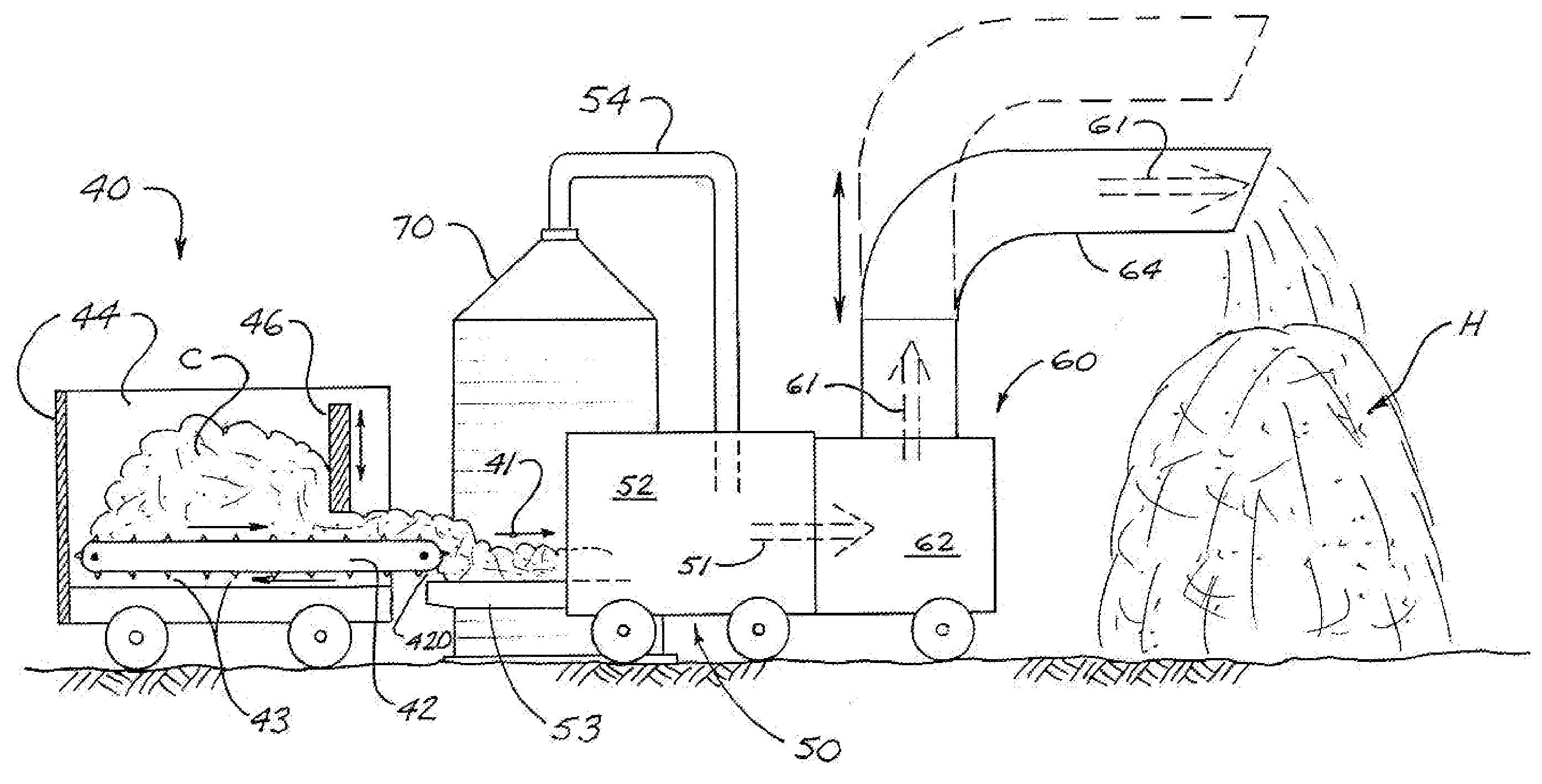

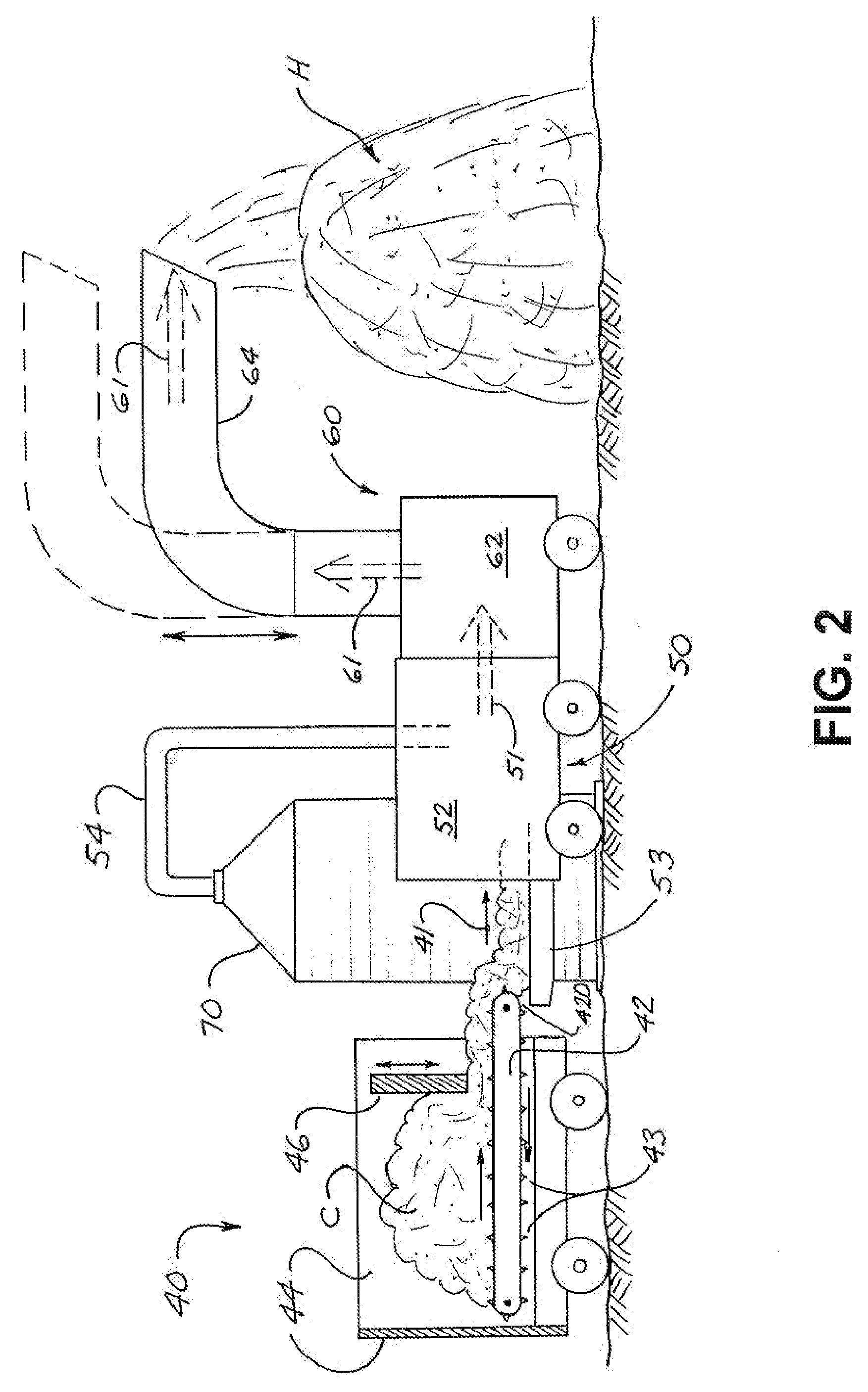

Crop processing method and apparatus

InactiveUS20090017885A1Easy constructionLower requirementHarvestersThreshersMass storageGrain storage

In a method for processing swathed crops, the entire cut crop is picked from the field and transported to a processing facility located away from the field. The processing facility has a threshing apparatus which separates grain from the cut crop, leaving a crop residue comprising plant stalks, chaff, and other constituents of the cut crop. The separated grain is conveyed from the threshing apparatus to a grain storage bin or directly to a transport truck for delivery to a grain terminal. The processing facility also includes crop residue handling means for conveying crop residue to a bulk storage pile, to a baling machine, or to some other selected location. The method makes field baling operations unnecessary, thus expediting the total removal of the crop from the field.

Owner:HALLS FLOYD W

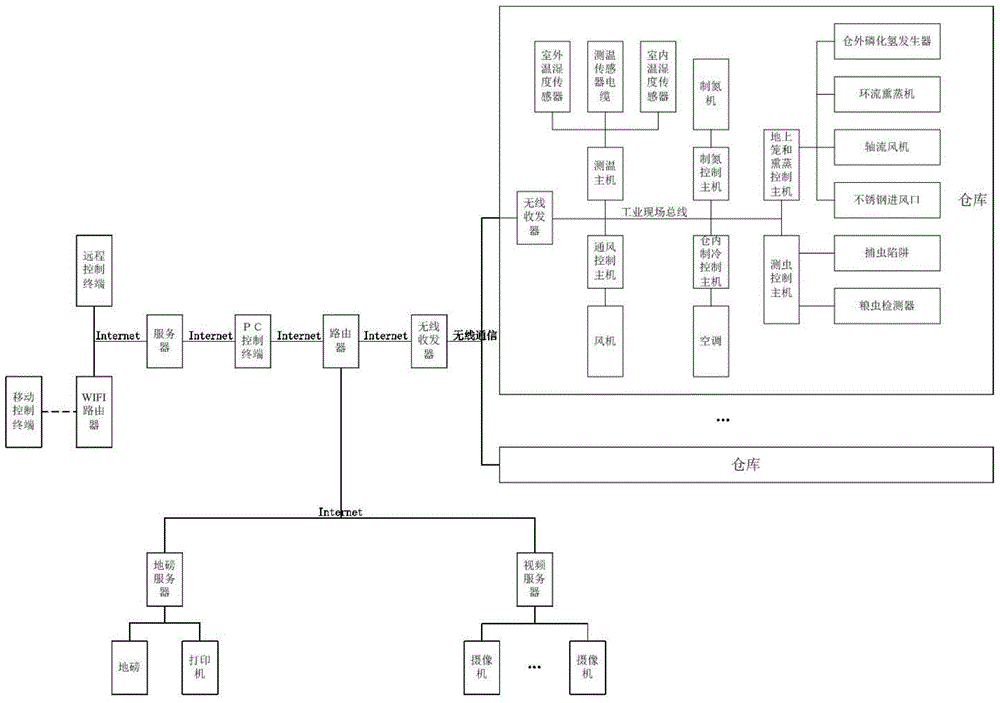

Intelligent digitalized grain depot grain situation monitoring system

InactiveCN104656624AArrange neatlyOptimize layoutSimultaneous control of multiple variablesProgramme total factory controlVideo monitoringWireless transceiver

The invention discloses an intelligent digitalized grain depot grain situation monitoring system. The intelligent digitalized grain depot grain situation monitoring system is characterized by comprising a grain situation measuring and controlling system arranged in the depot, an intelligent ventilation system, a depot grain refrigerating system, an out-depot insect measuring system, a nitrogen charging grain storage system, a ground cage and circulating fumigation system, a wagon balance weight-checking and weighing networking system and a video monitoring system, wherein the wagon balance weight-checking and weighing networking system and the video monitoring system are connected to a PC control terminal through Internet and a router; the grain situation measuring and controlling system, the intelligent ventilation system, the depot grain refrigerating system, the out-depot insect measuring system, the nitrogen charging grain storage system, and the ground cage and circulating fumigation system are all connected to a wireless transceiver through an industrial field bus; the wireless transceiver is connected to the PC control terminal through the router; the PC control terminal is connected with a remote control terminal through a server; the PC control terminal is further connected to a mobile control terminal through a WiFi router.

Owner:ANHUI YINING GRAIN STORAGE EQUIP

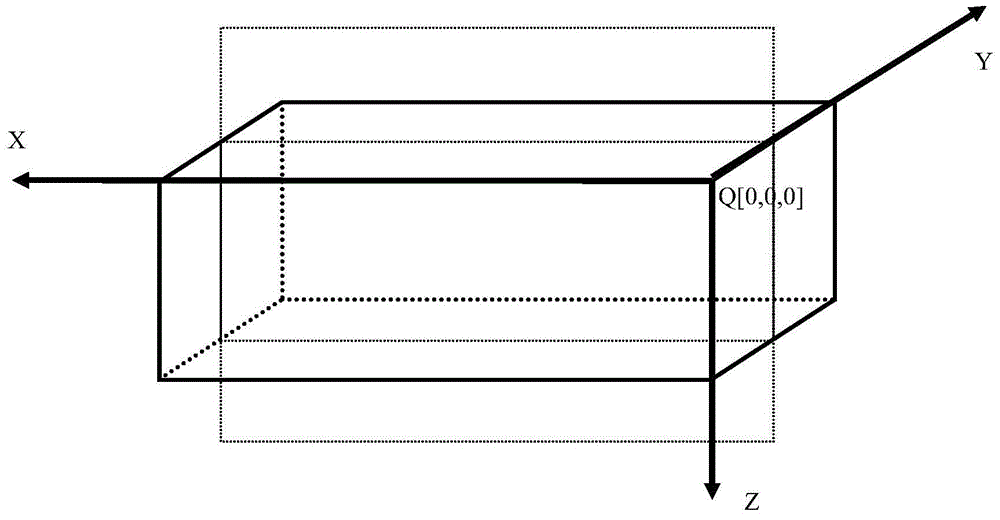

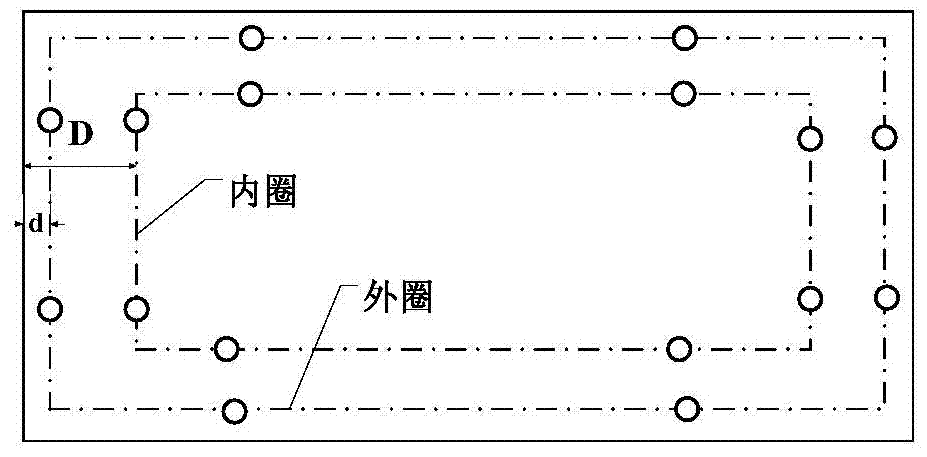

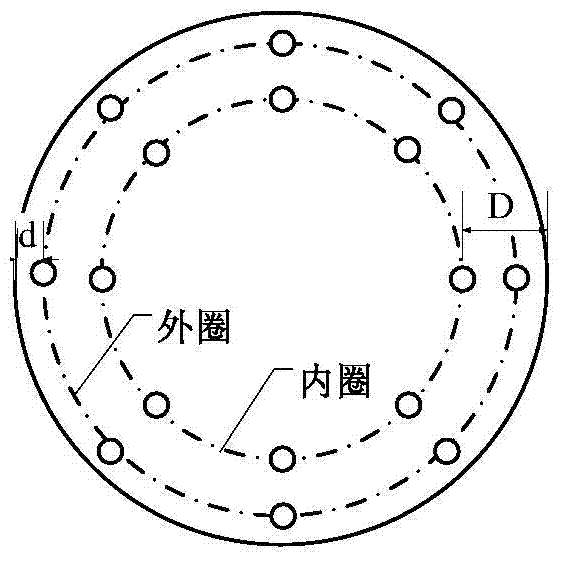

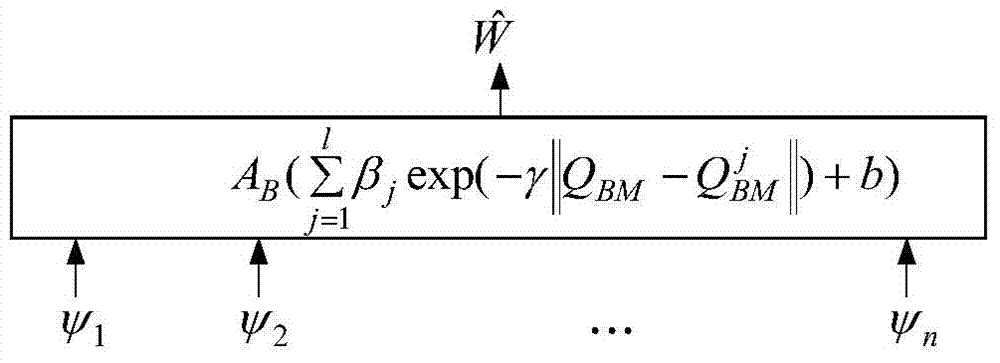

Granary grain storage quantity detection method based on support vector regression

ActiveCN104331591AWeighing apparatus for materials with special property/formSpecial data processing applicationsGrain storageSurface pressure

The invention relates to a granary grain storage quantity detection method based on support vector regression. The method comprises the following steps: arranging two circles of pressure sensors on the bottom surface of a granary, detecting an output value of each sensor, and computing granary grain storage weight estimation (FOMRULA) according to a detection model (FOMRULA). Aiming at urgent need of the nation to national grain storage online quantity detection and specific requirement of the detection, the invention provides the granary grain storage quantity detection method based on the support vector regression according to the granary bottom surface pressure intensity distribution and pressure intensity measured value change characteristics; the provided method is high in detection precision, and suitable for the grain storage quantity detection in various granary structure types.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

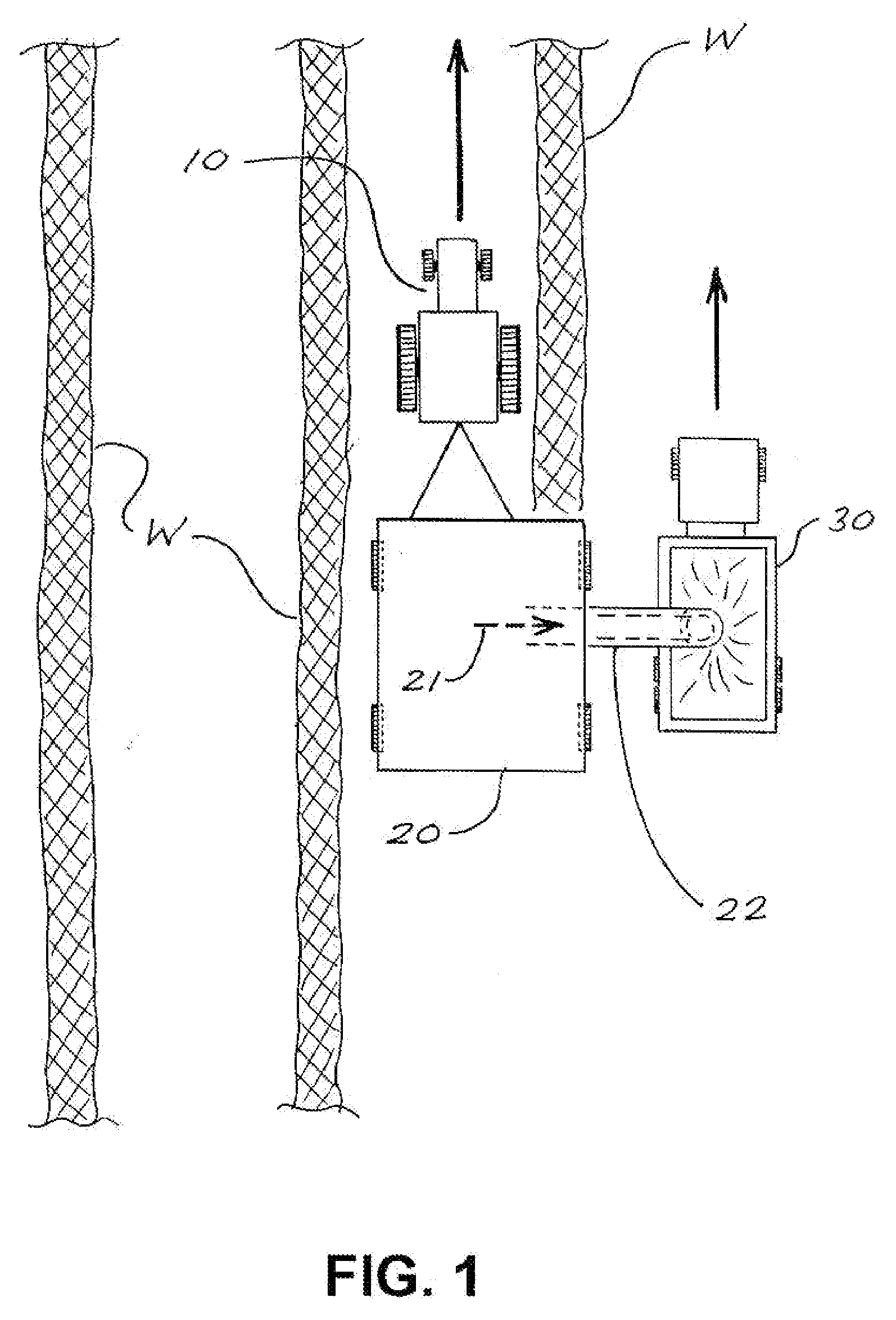

Grain drying system

ActiveUS8806772B1Accurately determinedEasy to determineDrying solid materials with heatDrying gas arrangementsModem deviceGrain storage

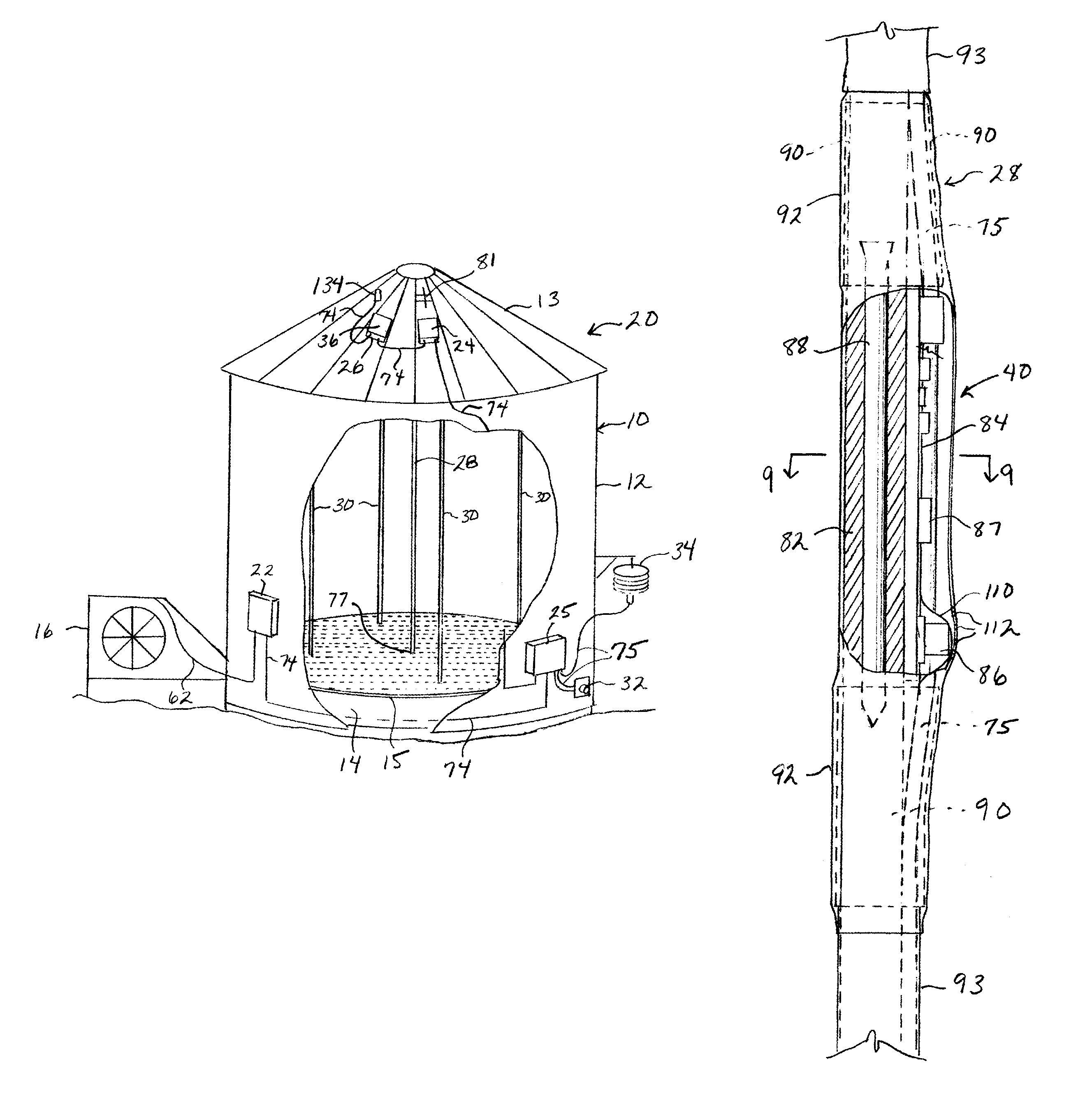

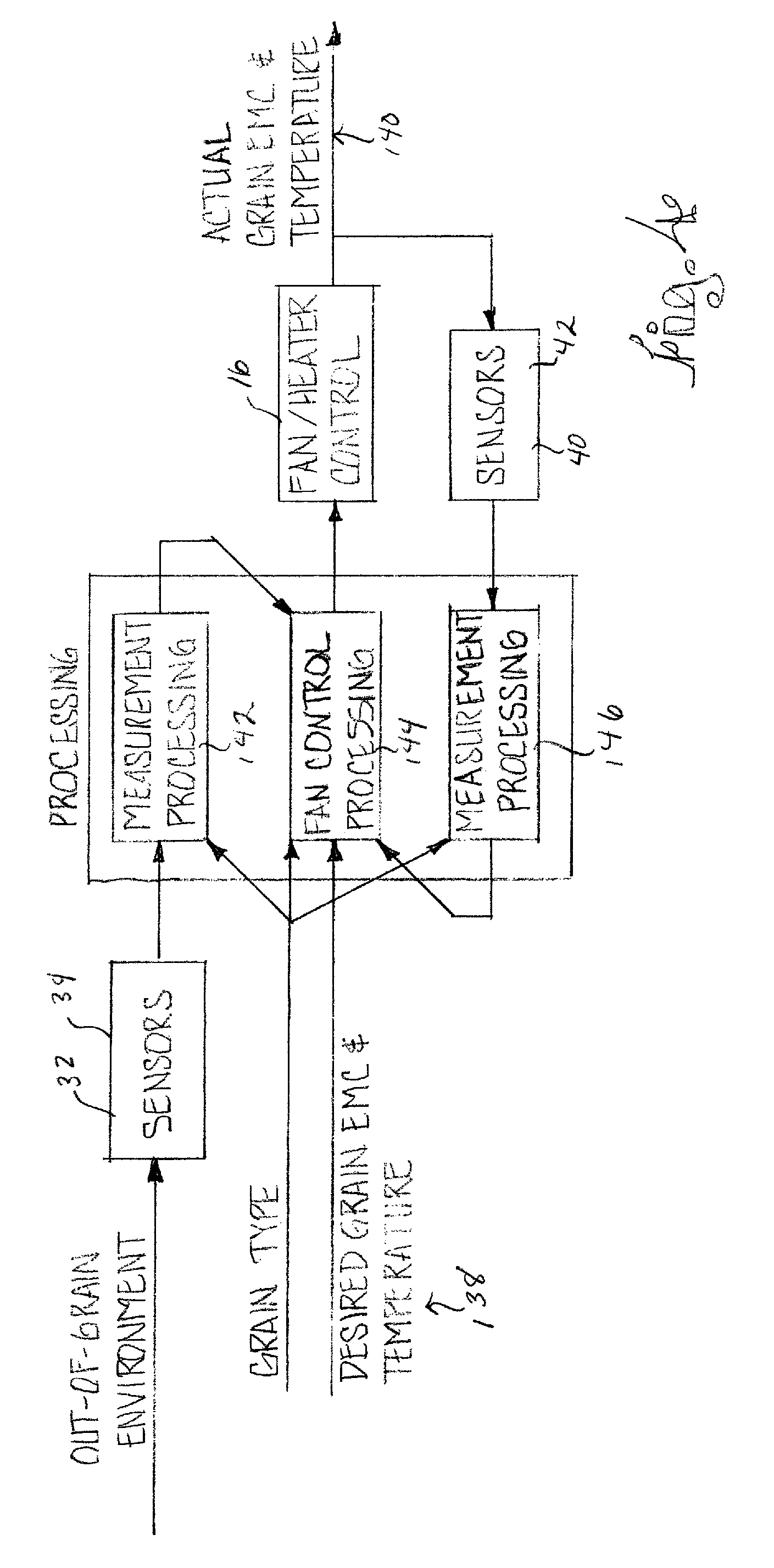

A grain drying system includes a master control unit external to the grain storage bin which is preprogrammed with a desirable grain moisture content or EMC. Condition sensor assemblies mounted within the grain bin determine the relative humidity and the temperature of the grain within the grain bin. Also, sensors mounted in the bin's plenum determine temperature, relative humidity and air pressure. A weather station mounted externally of the grain bin determines the outside air temperature and relative humidity. Depending on the conditions determined by the sensor assemblies and the weather station, the master control unit selectively activates the grain bin's drying fan when needed and when it is efficient and effective to do so. A radio or cellular modem allows for communication of the grain's condition. The internal sensor assemblies are preferably secured to flexible cables hung within the grain bin. The cable and rigid rod-like members support the sensors. The sensors may be secured in a spaced relationship along the cable so that the grain condition can be determined throughout the grain bin.

Owner:AGI SURETRACK LLC

Steel structure grain bin and mounting method thereof

ActiveCN104612448AShorten the construction periodLow costWallsClimate change adaptationGrain storageSteel columns

The invention provides a steel structure grain bin and a mounting method thereof, and belongs to the technical field of grain storage equipment. The steel structure grain bin comprises a floor, a steel structure frame, walls and a roof, and the floor is a composite layer floor and is provided with sill anchors in an embedded mode. The steel structure frame is fixedly connected with the sill anchors and comprises steel columns, steel beams, wall purlines, roof purlines, wall bracing bars and roof bracing bars. The steel columns and the steel beams are connected through bolts to form a door type frame in even distribution, and the wall purlines are arranged on the outer sides of the steel columns and are perpendicular to the steel columns. The wall bracing bars are fixedly arranged between the wall purlines through bolts, and the roof bracing bars are fixedly arranged between the roof purlines through bolts. The walls are waterproof walls and are fixedly arranged on the outer side of the steel structure frame, and wash aprons are arranged at the bottoms of the outer sides of the walls. A plurality of windows are arranged on the walls, and each window is provided with a window transfer bar. A double-layer bin gate is arranged on the wall on one side, and ventilation holes are evenly formed in the lower portion of the wall on the opposite side. The roof is a waterproof roof and is arranged on the top of the steel structure frame. The steel structure is firm and is good in waterproof performance and heat insulation performance.

Owner:辽宁福瑞达建筑科技有限公司

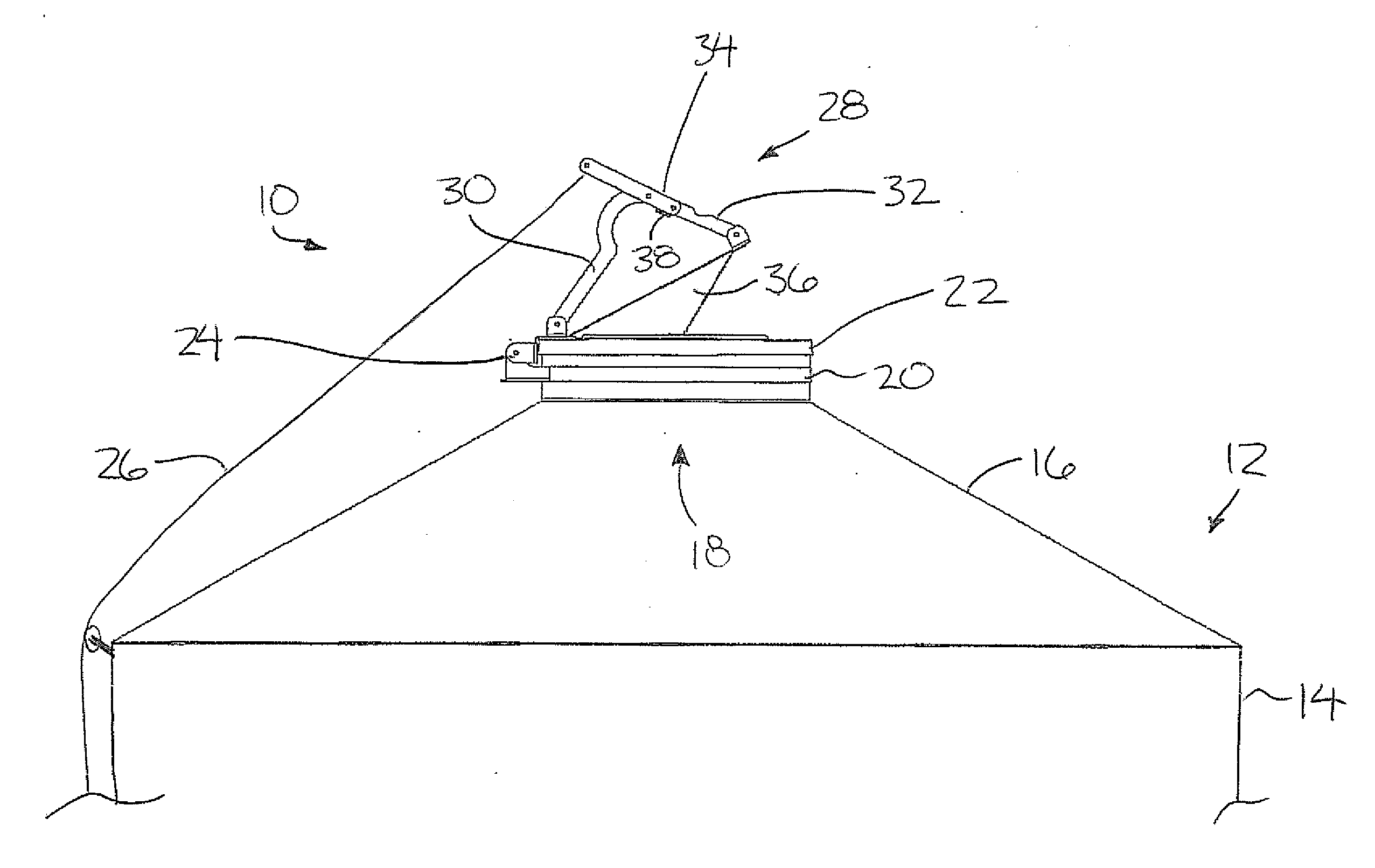

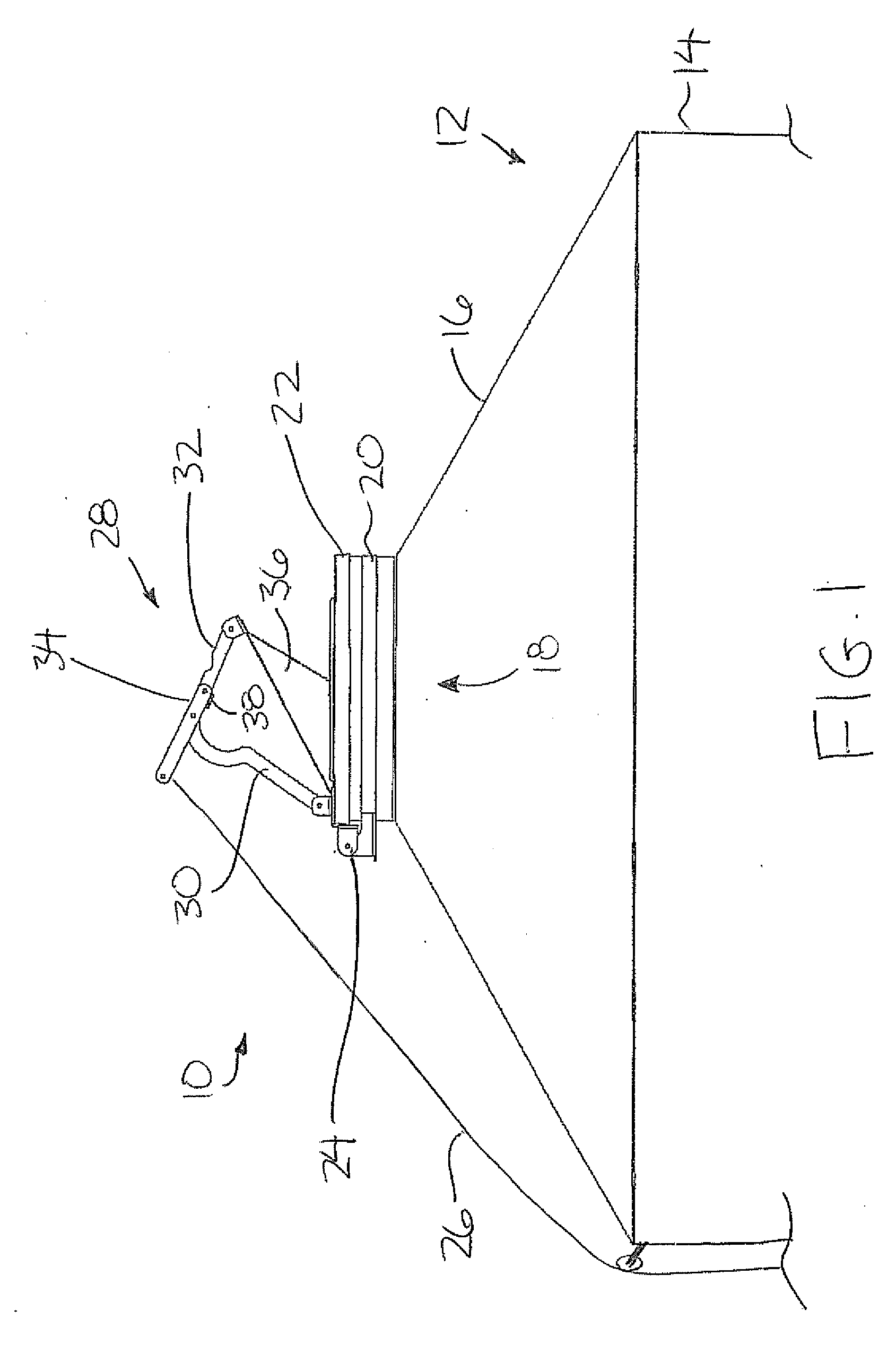

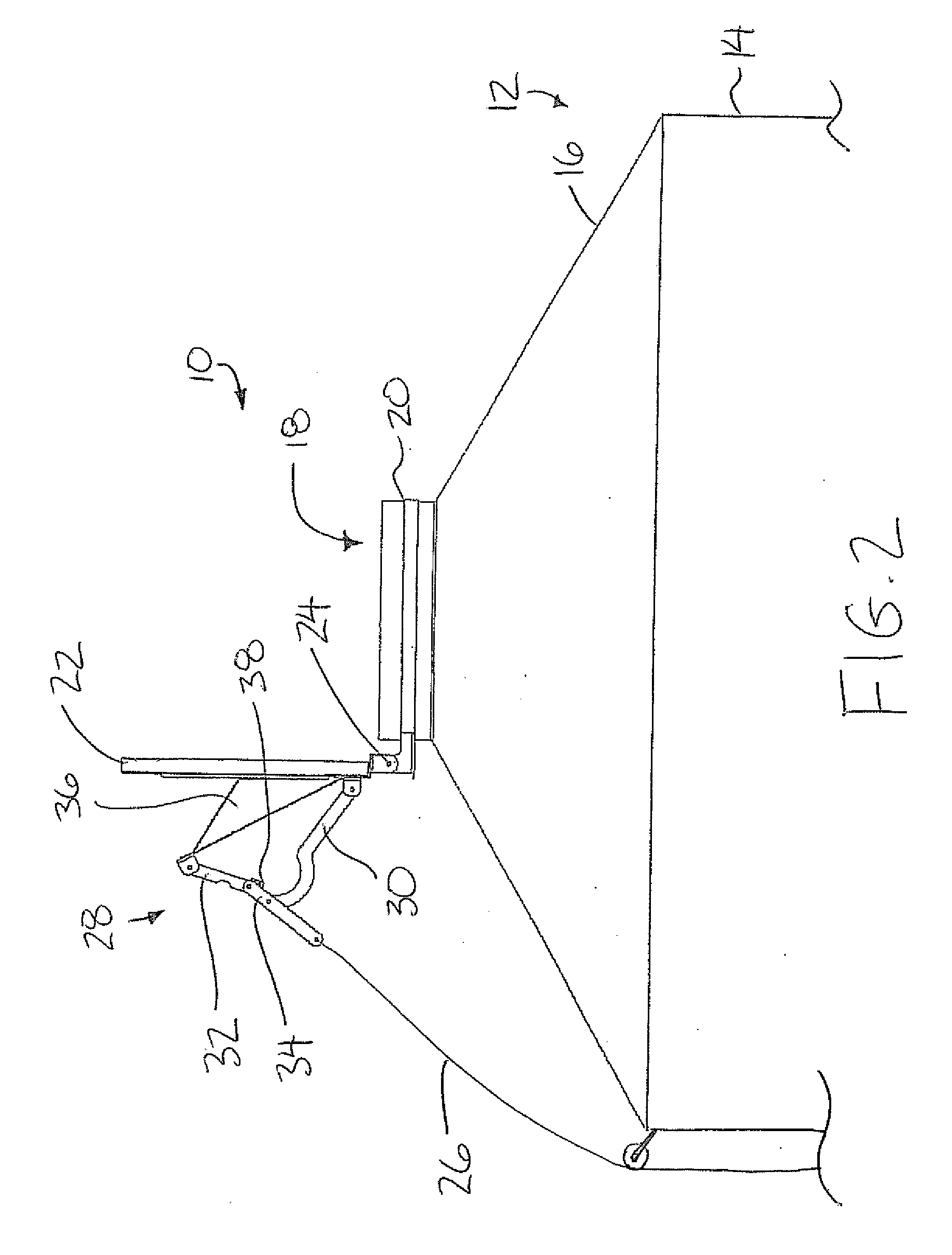

Grain Bin Lid Assembly

A bin lid assembly includes a lid member arranged to span across an opening in the roof of a grain storage bin. The lid member is supported by a hinge which is biased towards a closed position extending forwardly across the bin opening from an open position extending rearwardly. An operating linkage is pivotally connected to the lid member and includes a opening arm which is folded relative to the lid member from a first position extending upwardly in the closed position of the lid member to a second position extending rearwardly in the open position of the lid member to allow the lid member to be opened 180 degrees. The linkage also allows a mechanical advantage to be maintained when pulling the lid open using an actuator tether alongside the bin which is connected at an upper end to the opening arm.

Owner:MERIDIAN MFG

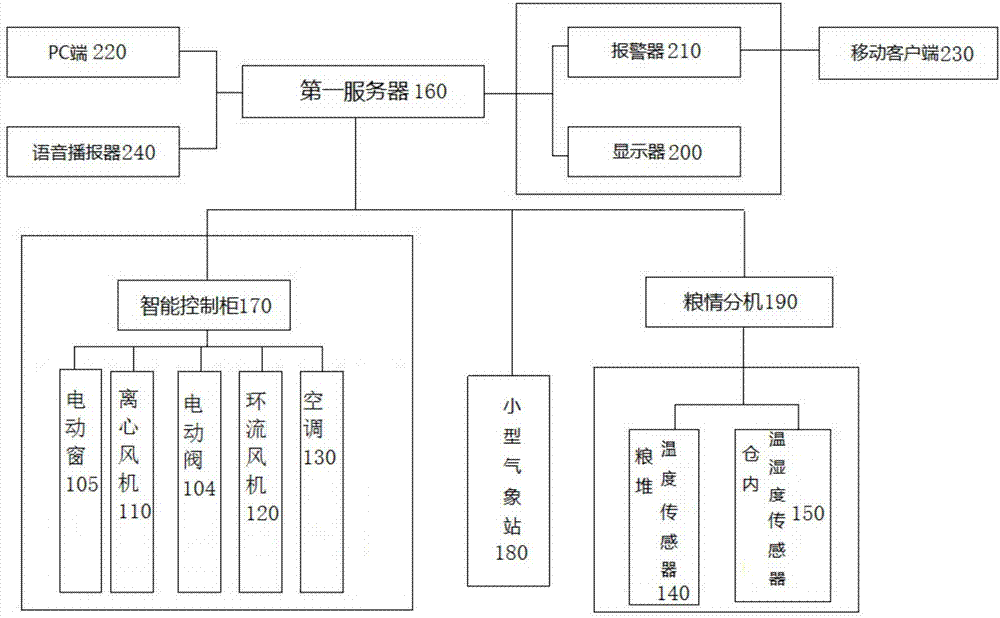

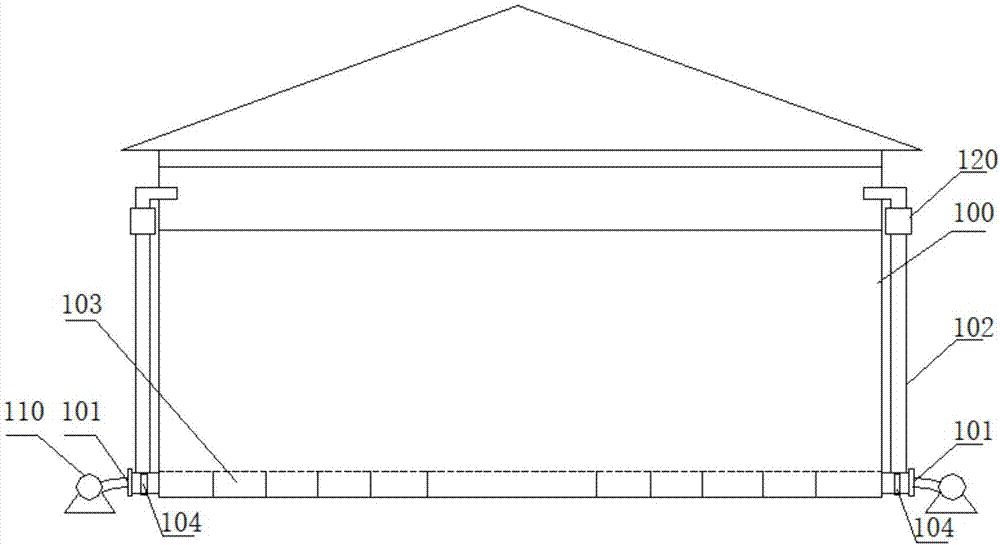

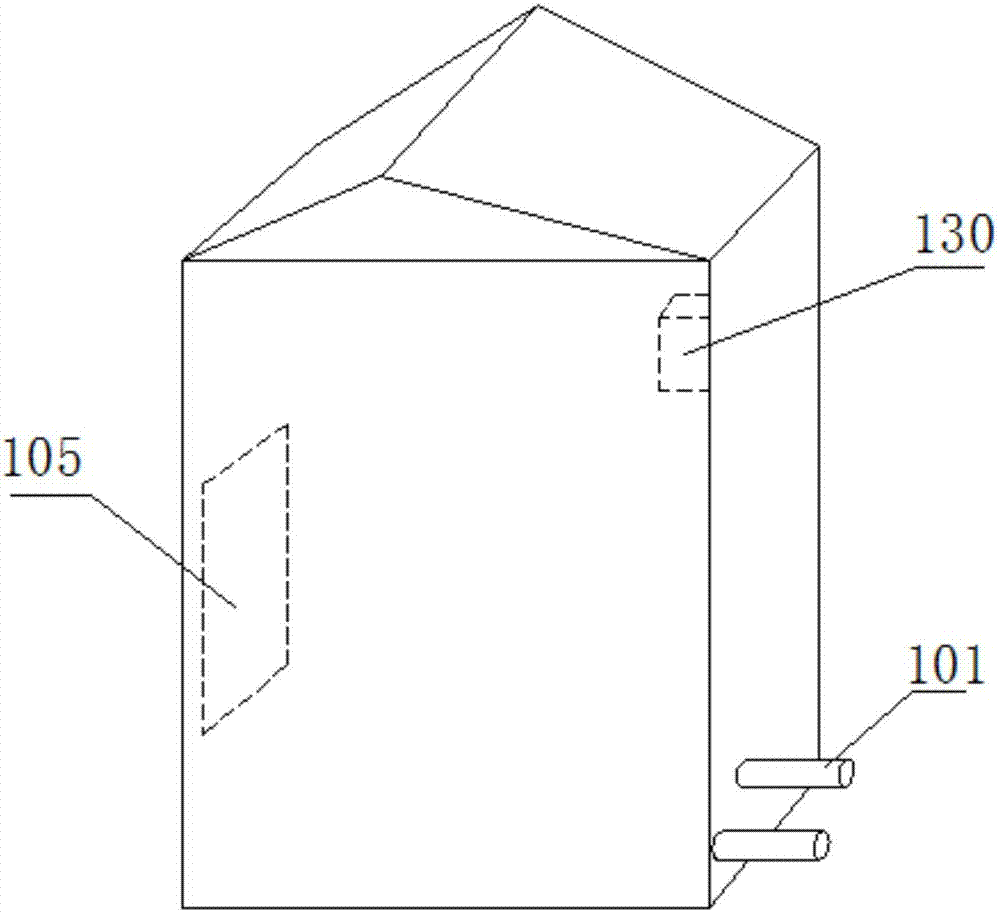

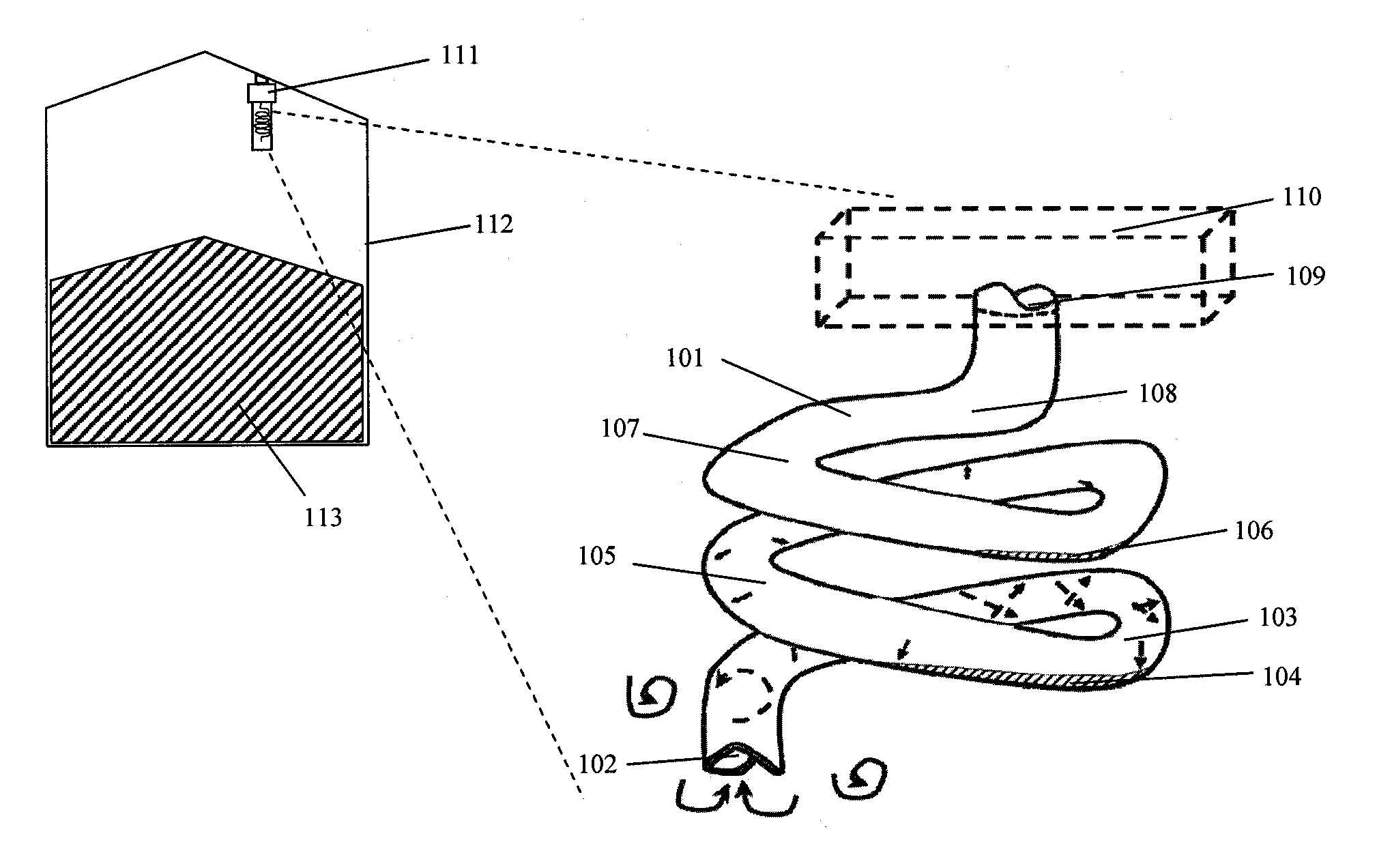

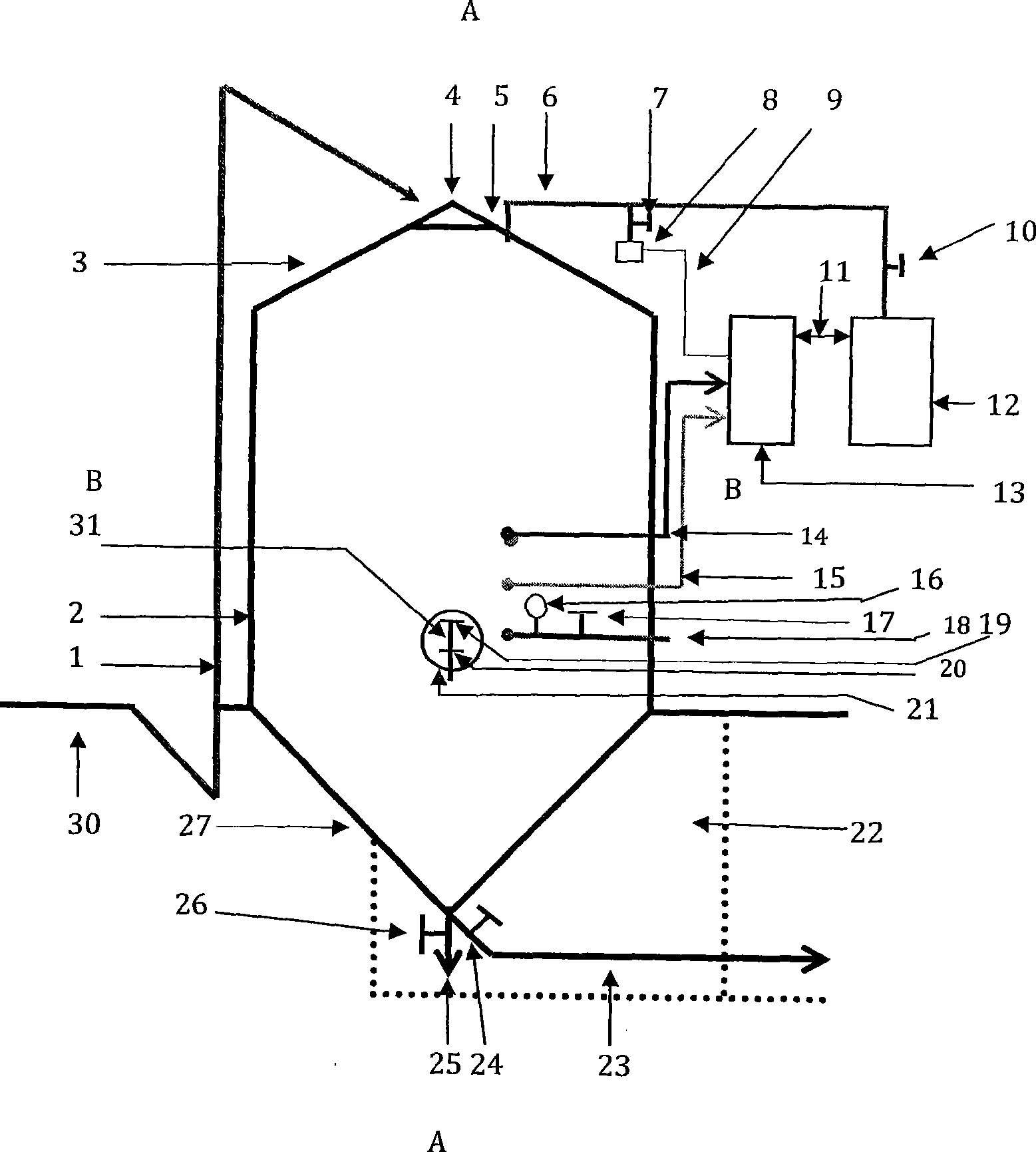

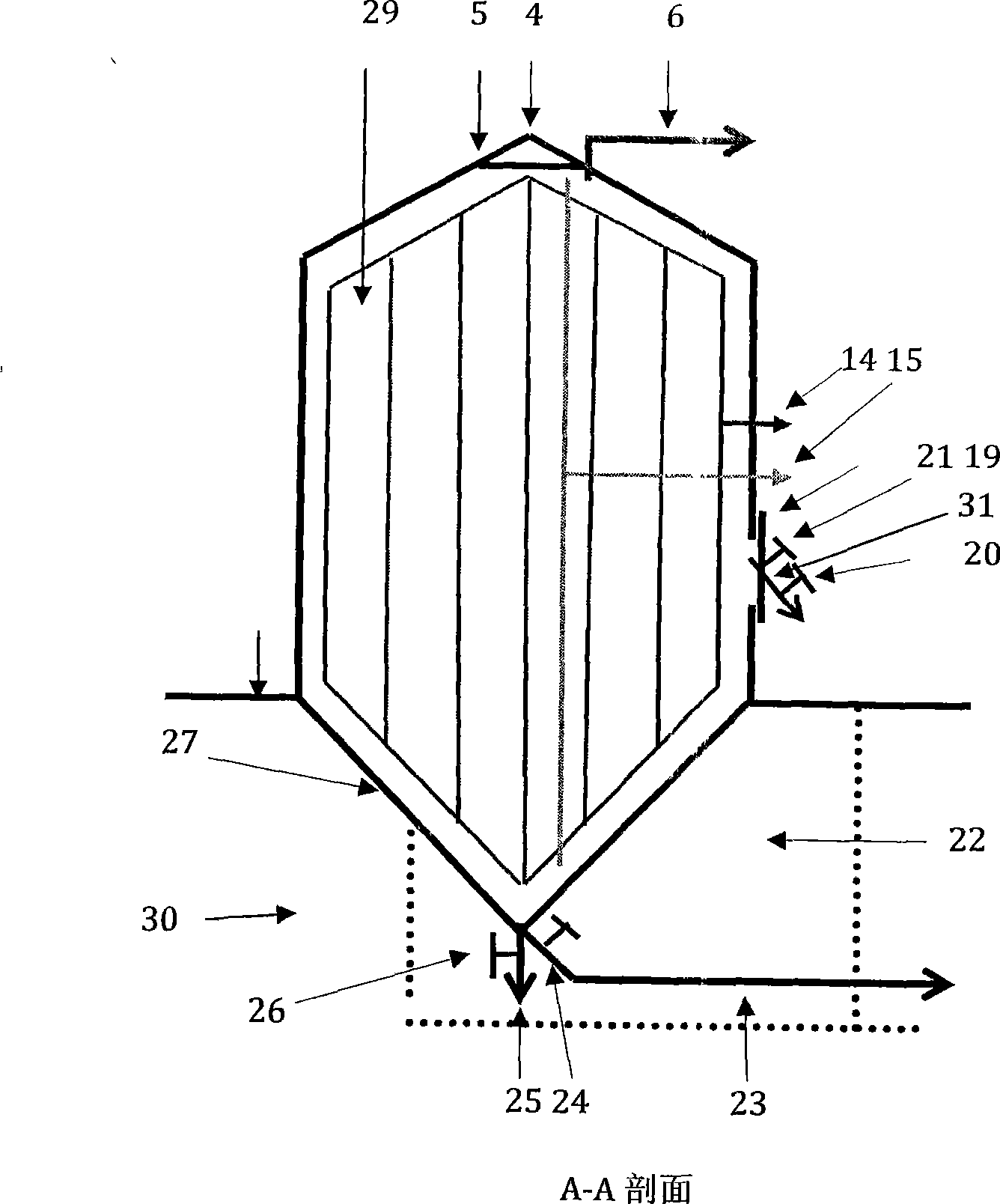

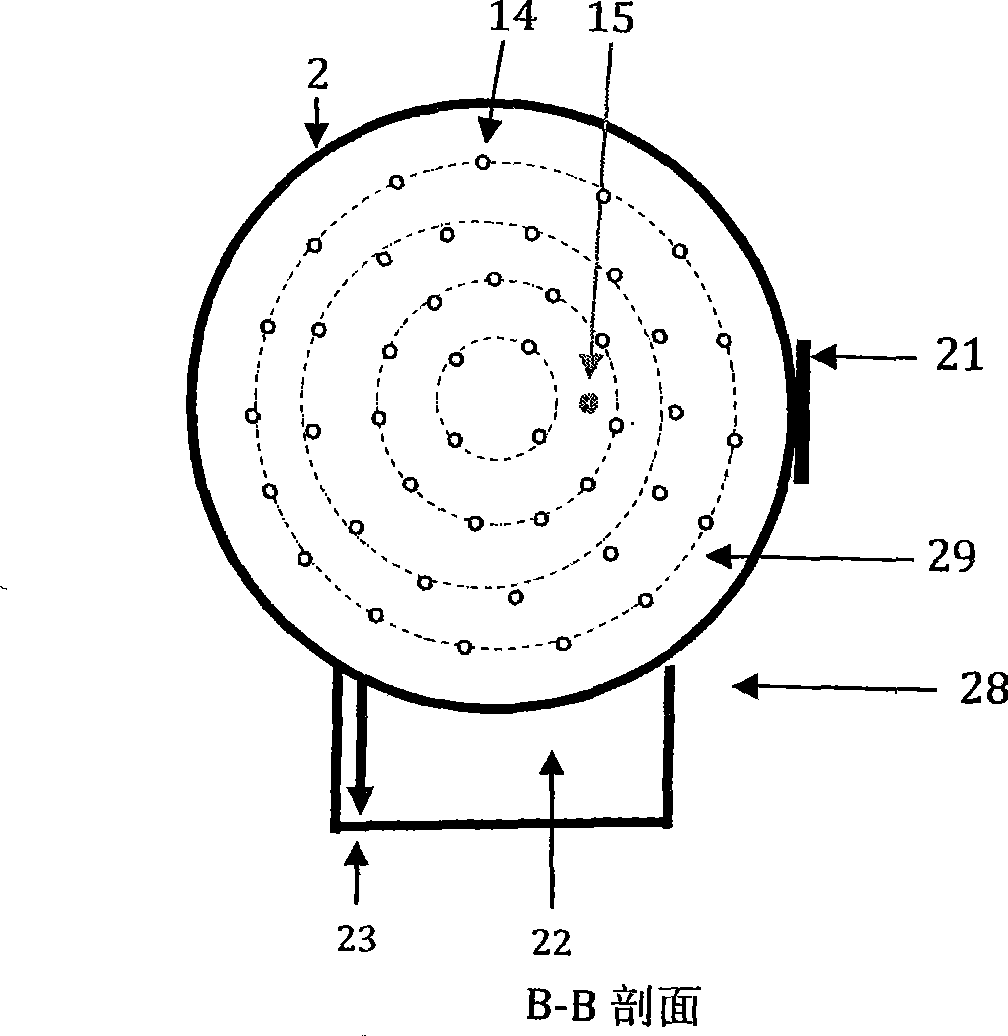

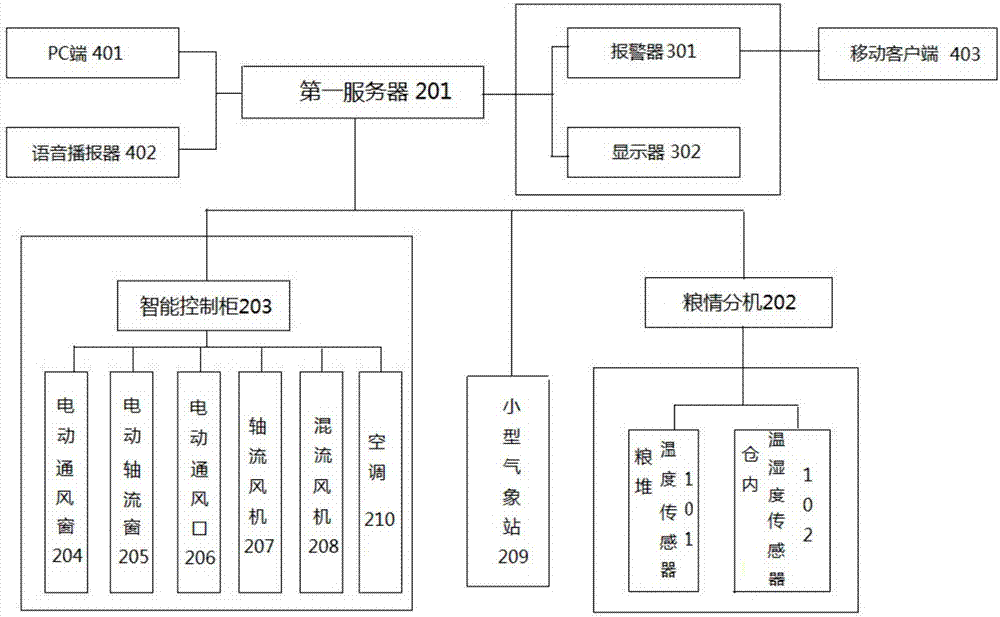

Internal-circulation low temperature grain storage system and method

ActiveCN107246715AEffective temperature monitoringAvoid inaccurate temperature monitoringAgriculture tools and machinesSpace heating and ventilation safety systemsAutomatic controlThermal insulation

The invention discloses an internal-circulation low temperature grain storage system and method. The internal-circulation low temperature grain storage system comprises a grain bin, ventilation equipment, a grain condition detection unit and an intelligent ventilation unit, wherein at least one ventilation opening is formed in the bottom of the grain bin; an electric window is arranged on one wall surface; an electrically operated valve is arranged at each of the ventilation openings; each of the ventilation openings communicates with one end of a thermal insulation pipe; the other end of each of the thermal insulation pipes is connected with a circulating fan; a ground ventilation cage is arranged on the ground surface in the grain bin; the ventilation equipment comprises at least one centrifugal fan, the at least one circulating fan and at least one air conditioner; the grain condition detection unit comprises a plurality of grain pile temperature sensors and a bin inner temperature and humidity sensor; the intelligent ventilation unit comprises a first server and an intelligent control cabinet; the first server is in communication connection with a small-sized meteorological station outside the bin; and the operation of the ventilation equipment and the opening and closing of the electrically operated valves are automatically controlled by the intelligent control cabinet. According to the internal-circulation low temperature grain storage system and method, the intelligent regulation and control can be carried out timely when the grain pile temperature and the bin inner temperature and humidity deviate from the safe grain storage range, the labor intensity of grain bin keepers is reduced, and the grain bin management cost is greatly reduced.

Owner:HUBEI YE WEI INTELLIGENT TECH +1

Grain storage quantity monitoring method and device based on vision

ActiveCN107036687AAchieve online monitoringWill not affect daily granary operationsWeighing apparatus for materials with special property/formFunctional diversityGrain storage

The invention discloses a grain storage quantity monitoring method based on vision. The method comprises steps that binocular vision snapshot equipment is arranged at a top portion of an inner warehouse at a gate of a grain storage enterprise granary, the binocular vision snapshot equipment is made to face a grain surface of the grain storage enterprise granary, multiple characteristic points are randomly arranged at the grain surface in a shooting scope of the binocular vision snapshot equipment, height of the characteristic points is monitored at each time interval, if height change of any characteristic point surpasses a set first scope threshold, whether a state of the granary within a certain time scope is in warehouse incoming / outgoing states is checked, if not, the first-level alarm information is emitted. The invention further discloses a grain storage quantity monitoring device. The method is advantaged in that height of the multiple characteristic points of the grain surface is analyzed through utilizing a video analysis method, and functional diversity, operation convenience, low cost and low network requirement are realized.

Owner:HUBEI YE WEI INTELLIGENT TECH +1

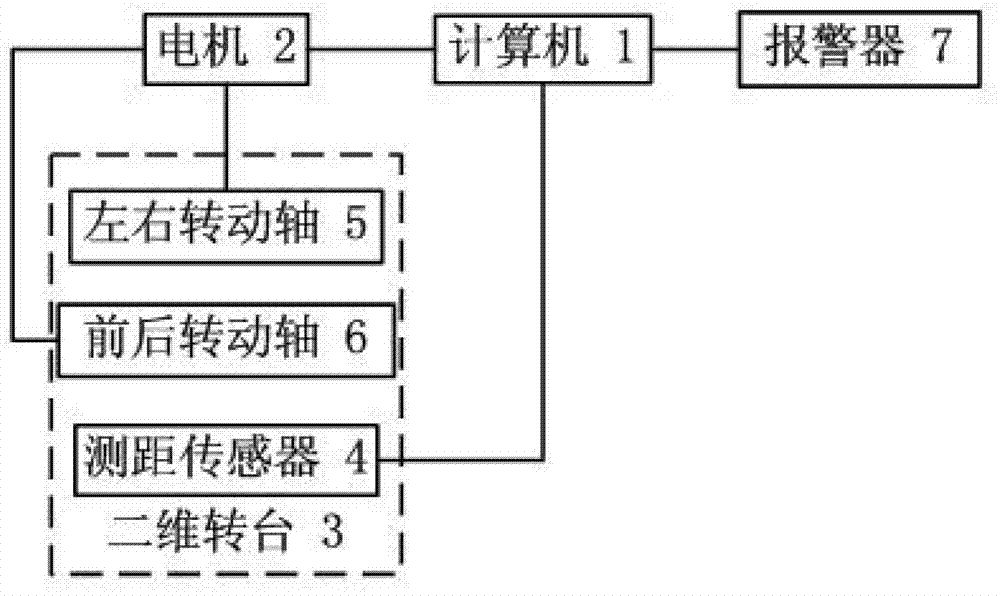

Grain bin grain condition intelligent detection and monitoring system based on mobile robot technology

InactiveCN105739579AReduce lossesReduce reserve lossesSimultaneous control of multiple variablesUltra-widebandAutomatic control

The invention provides a grain bin grain condition intelligent detection and monitoring system based on a mobile robot technology. The system comprises a grain bin intelligent tour inspection robot, a grain bin intelligent tour inspection robot control device, a wireless communication module, an ultra-wideband positioning device, environmental adjustment equipment, a computer and an alarm device. The grain bin intelligent tour inspection robot comprises a crawler type walking system, a grain bulk automatic detection system, a grain bulk grain surface leveling system, a power supply, an image photographing monitoring system, a wireless signal transmission system and a control system. The system can perform autonomous movement, accurate positioning and grain bulk temperature and humidity real-time detection and automatic control and adjustment in the grain bulk, and can realize real-time dynamic omnibearing grain condition monitoring and grain storage environment full-automatic adjustment.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

Bulk grain storage spoilage detection apparatus

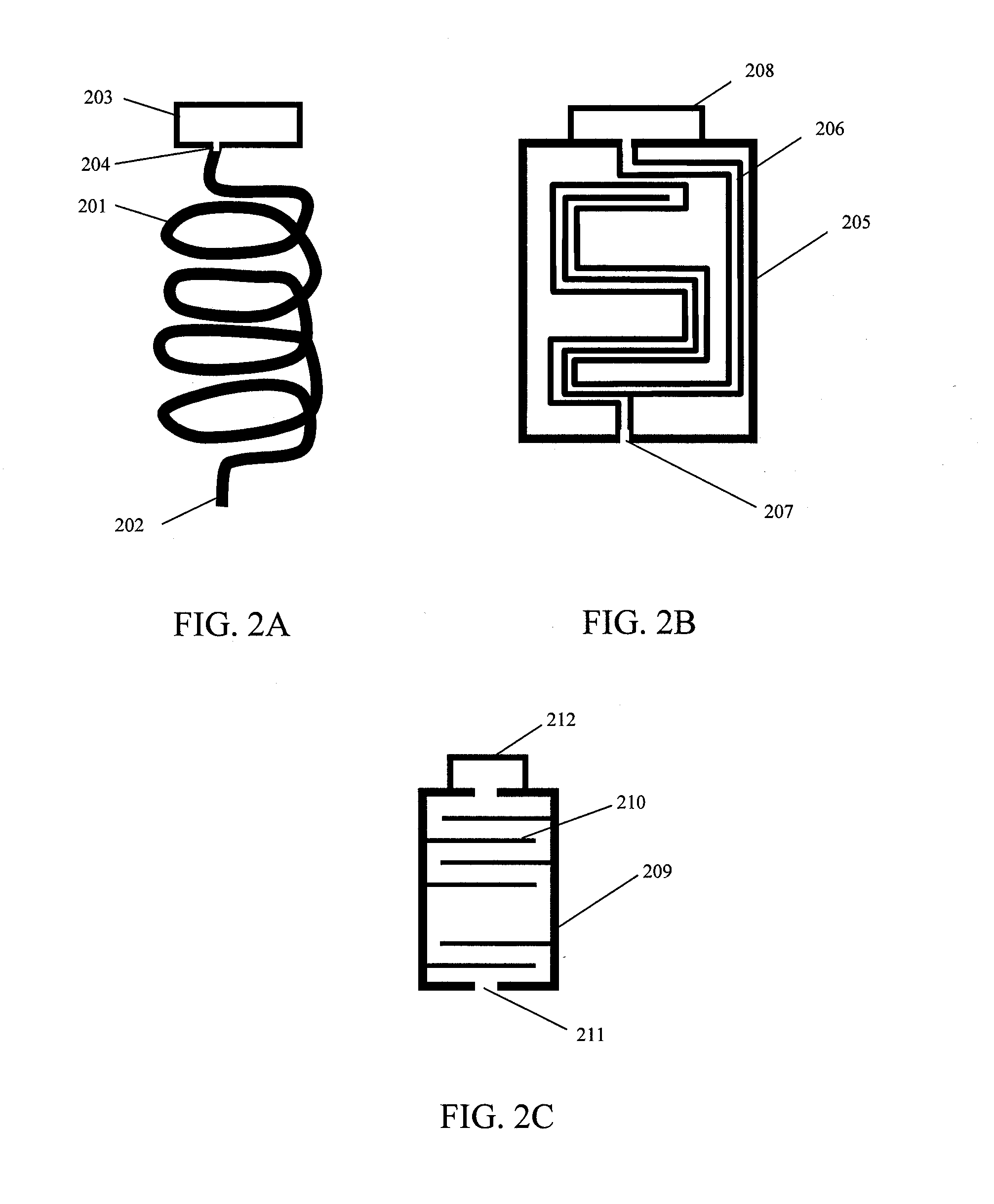

ActiveUS20110241889A1Reduce personnel safety hazardsIncreasing overall workforce safetySamplingMaterial analysis by electric/magnetic meansGas detectorEngineering

An apparatus is disclosed for facilitating spoilage detection in bulk grain storage bins via dust-free or substantially dust-free air sampling. Dust particles are passively removed from sampled air without the use of barrier filters or electrostatic screens, but instead through the use of a non-linear pathway that is open at one end and closed at the other end. A system is disclosed that incorporates a coiled pathway as an air inlet element combined with a carbon dioxide or other gas detector element to provide an integrated detector module suitable for permanent installation in a dusty bulk grain storage bin environment to provide spoilage gas measurements over time. The system may communicate data to a central data storage system via cellular telephone or long range radio frequency data transmission. Alerts and alarms are generated and transmitted electronically to users via email, SMS text, automated phone messages and other means.

Owner:BIN TECH L

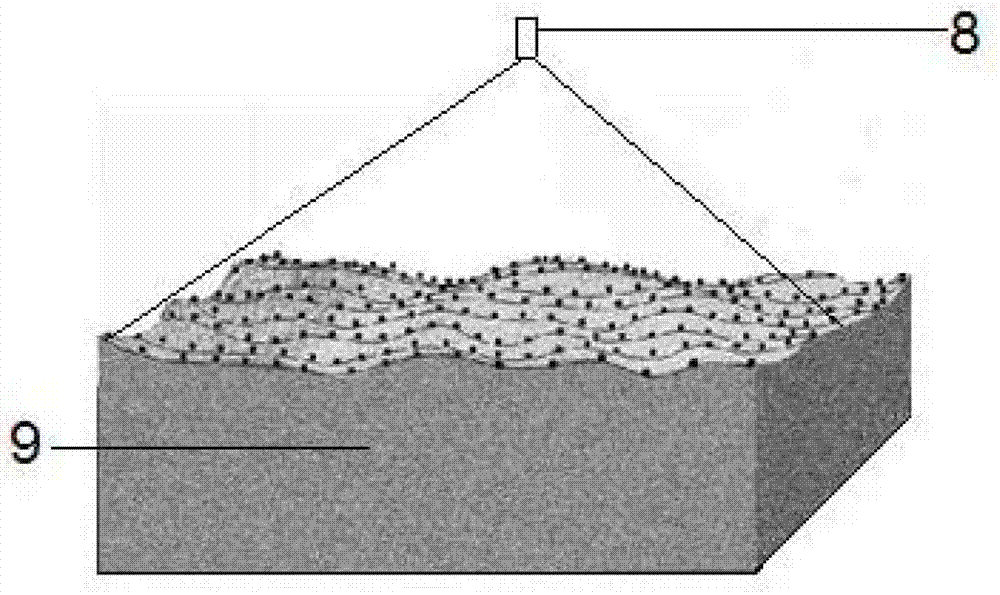

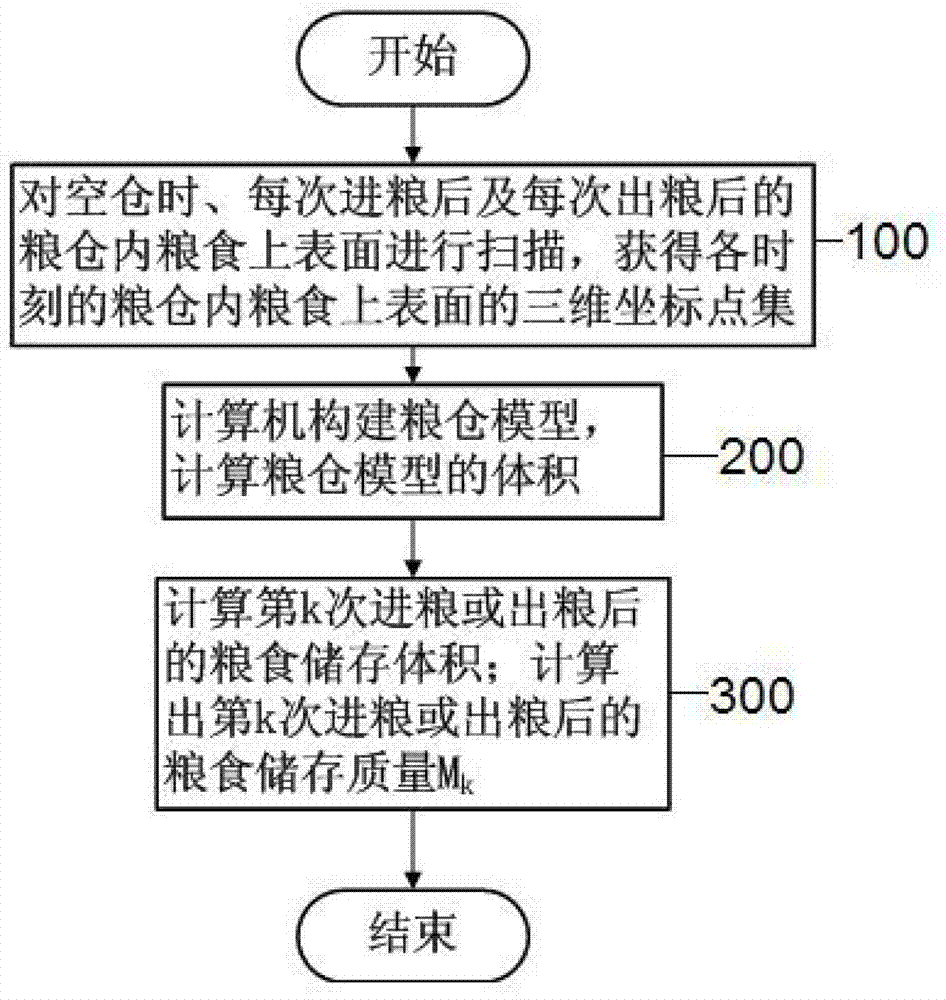

Monitoring method for grain stock in barn

ActiveCN103307976ADetect abnormalities in timeReal-time monitoring of storage capacityUsing optical meansGrain storageComputer science

The invention discloses a monitoring method for grain stock in a barn. The monitoring method can be used for scanning the upper surface of grains in the barn when the barn is empty and after the grains are put in and got out of the barn; a three-dimensional coordinate point set of the surface of the grains stored in the barn at the moments when the barn is empty and after the grains are put in and got out of the barn is obtained respectively; a barn model corresponding to each moment is constructed by software in a computer according to the three-dimensional coordinate point set at each moment respectively; and the size of the barn model is calculated, the grain stock size after ith grain inlet or outlet is calculated, the grain stock after ith grain inlet or outlet is calculated according to the density of the grains and the grain storage size, and Mi is stored in the computer. The monitoring method has the characteristics of capabilities of monitoring the grain stock and the grain variation during each gain inlet and outlet in real time, timely discovering the abnormal condition of the grains in the barn and reducing the loss to the minimum, high measuring precision, simple, convenient and quick monitoring process and capability of reducing the manual cost.

Owner:SHINING 3D TECH CO LTD

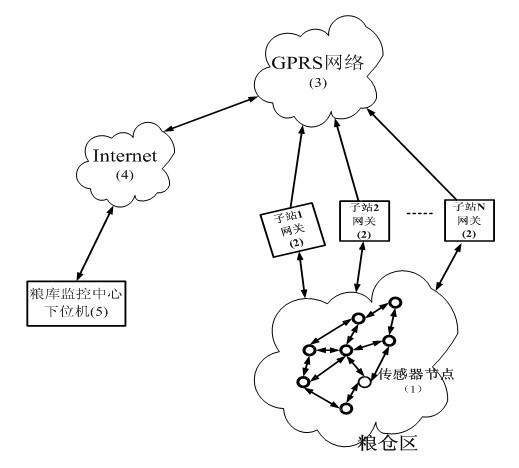

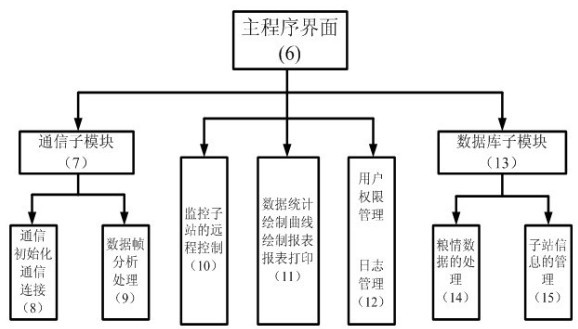

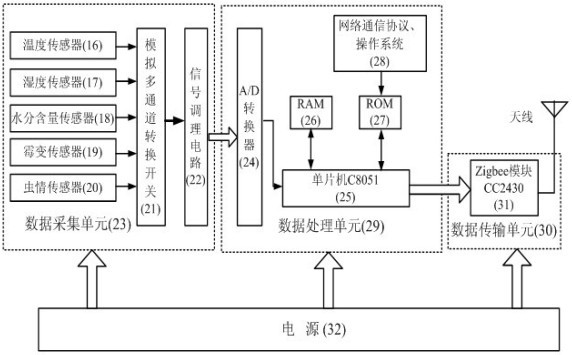

Wireless sensor network monitoring system for grain situation of grain depot

InactiveCN102004479AMonitor temperature in real timeHumidity real-time monitoringNetwork topologiesTotal factory controlGeneral Packet Radio ServiceThe Internet

The invention discloses a wireless sensor network monitoring system for the grain situation of a grain depot. The system comprises wireless sensor nodes, gateway nodes, a general packet radio service (GPRS) network, Internet and a monitoring center lower computer, wherein a group of wireless sensor nodes for acquiring grain situation parameters of the grain depot are connected with the GPRS network by a group of gateway nods; and the GPRS network is connected with the monitoring center lower computer by the Internet. The wireless sensor network monitoring system based on a ZigBee protocol can realize multi-parameter monitoring and monitor grain situation information such as temperature, humidity, grain moisture, mildew, insect pests and the like inside the grain depot in real time; and the GPRS network is connected with the Internet network, so the wireless sensor network monitoring system has low cost and high reliability, and is suitable for various grain storage depots.

Owner:NANJING UNIV OF FINANCE & ECONOMICS +1

Method for long term storage of grain without deterioration and equipment thereof

InactiveCN101485356ALong shelf lifeThe solution will not deteriorateSeed preservation by dryingEngineeringNitrogen gas

The invention relates to a method for prolonging storage tenure of grains and bean grains to prevent deterioration, and equipment thereof. The equipment comprises a grain store, wherein the grain store can ensure vacuum degree and can be sealed; a vacuum pump assembly is arranged outside and communicated with the grain store; a pipeline and a valve are arranged on the store wall to fill nitrogen into the grain store; the store wall is provided with an entry inspection door; an air lock store is arranged on a cover board of the entry inspection door, is communicated with the grain store through an air lock valve and the outside through a sampling valve; a discharge valve, a discharge pipeline and a conveying pipeline with a turnover valve are arranged in the center of the bottom of the store; and an electroheat low-temperature drying system, a temperature sensor and a humidity sensor are arranged in the grain store, and the temperature sensor and the humidity sensor can detect temperature and humidity in the grain store respectively, so that oxygen and humidity during the period of grain storage can be controlled by the vacuum technology, and the grains are enforced to be in natural dormancy. Therefore, speed of natural exhaustion of the grains can be controlled to achieve the aim of prolonging the tenure of storage of the grains to prevent deterioration, and the grain store has low cost, easy construction and wide application range.

Owner:胡屹博 +2

Intelligent grain storage ventilation system

ActiveCN107166663ATimely automatic regulationEffective temperature monitoringSpace heating and ventilation safety systemsLighting and heating apparatusExtension setAir volume

The invention discloses an intelligent grain storage ventilation system. The intelligent grain storage ventilation system comprises a grain situation detection unit, an intelligent ventilation unit and a grain situation monitoring and alarming unit. The grain situation detection unit comprises a grain pile temperature sensor arranged in a grain pile and a bin interior temperature and humidity sensor arranged above the bin interior grain pile, and the grain pile temperature and bin interior temperature and humidity data are output. The intelligent ventilation unit comprises a first server receiving the grain pile temperature and the bin interior temperature and humidity through a grain situation extension set, the first server compares the obtained real-time temperature and humidity of a small meteorological station outside a bin with the grain pile temperature and bin interior temperature and humidity, and ventilation equipment is controlled for running at different air volumes. Grain pile temperature alarming range threshold values of different grain varieties are further preset in the first server, and an alarm instruction is output if the value is not in the range of the alarming range threshold values. The grain situation monitoring and alarming unit comprises a display and an alarm device which are in communication with the first server. By means of the intelligent grain storage ventilation system, timely intelligent regulation and control can be conducted when the grain pile temperature and bin interior temperature and humidity deviate from control, the labor intensity of warehouse keepers is relieved, and the warehouse management cost is greatly reduced.

Owner:HUBEI YE WEI INTELLIGENT TECH +1

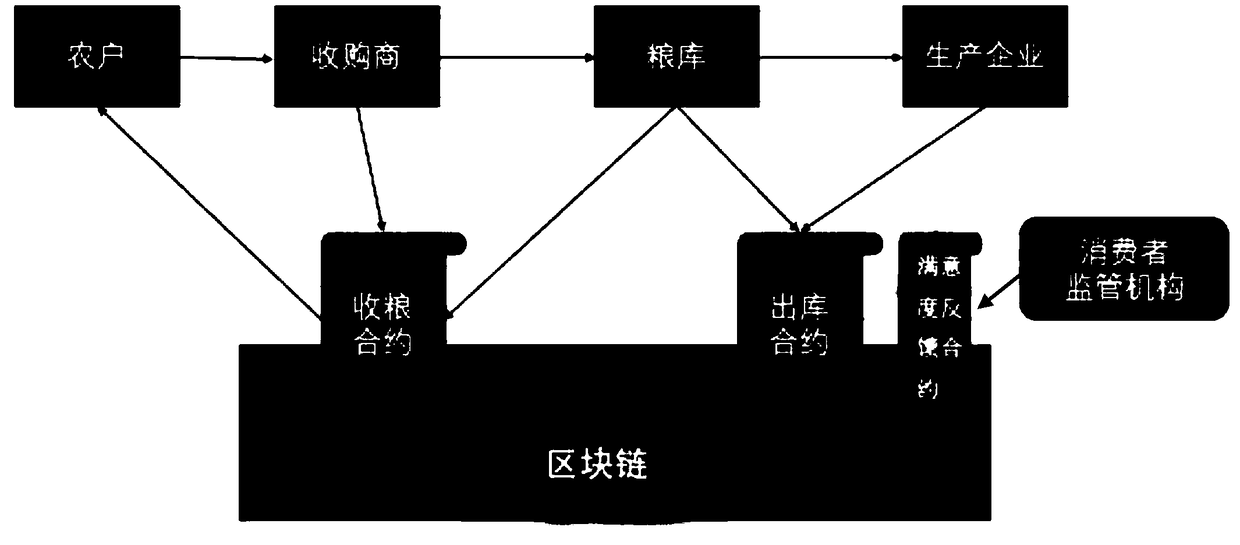

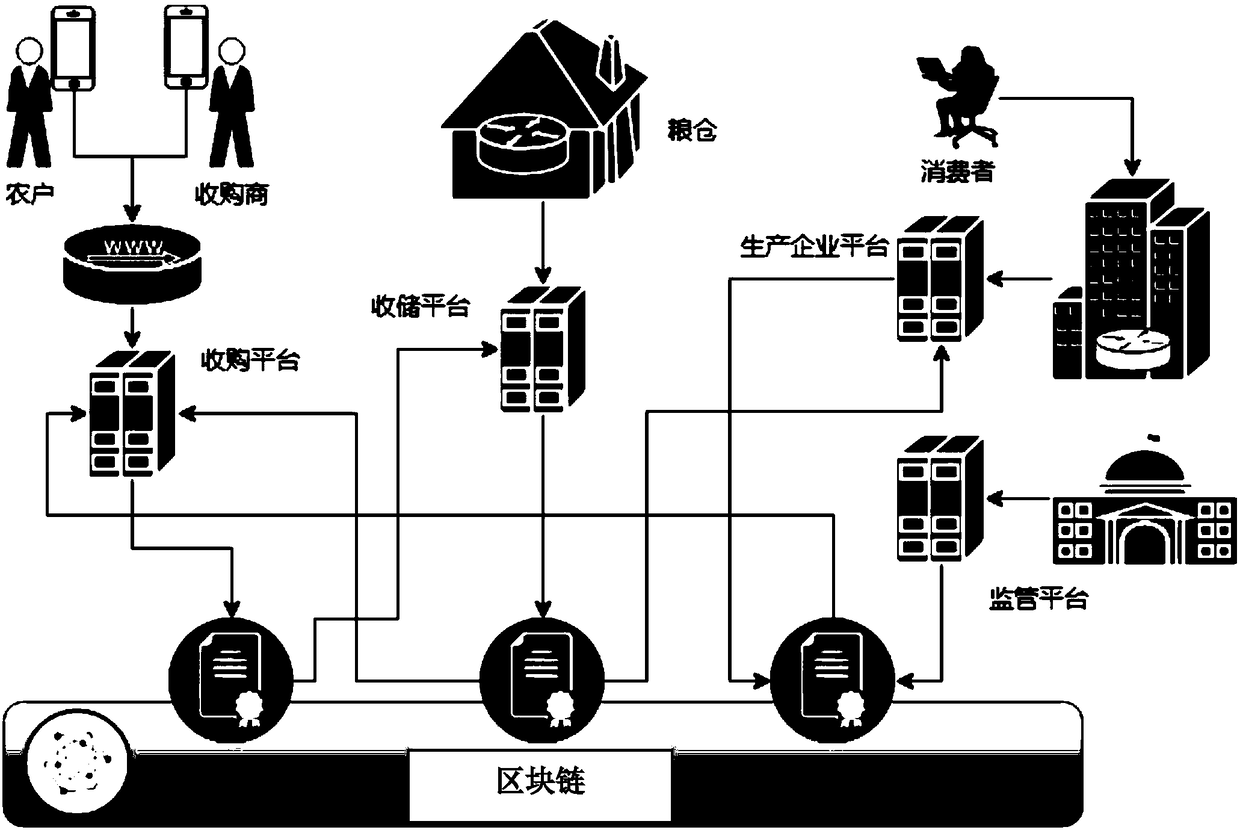

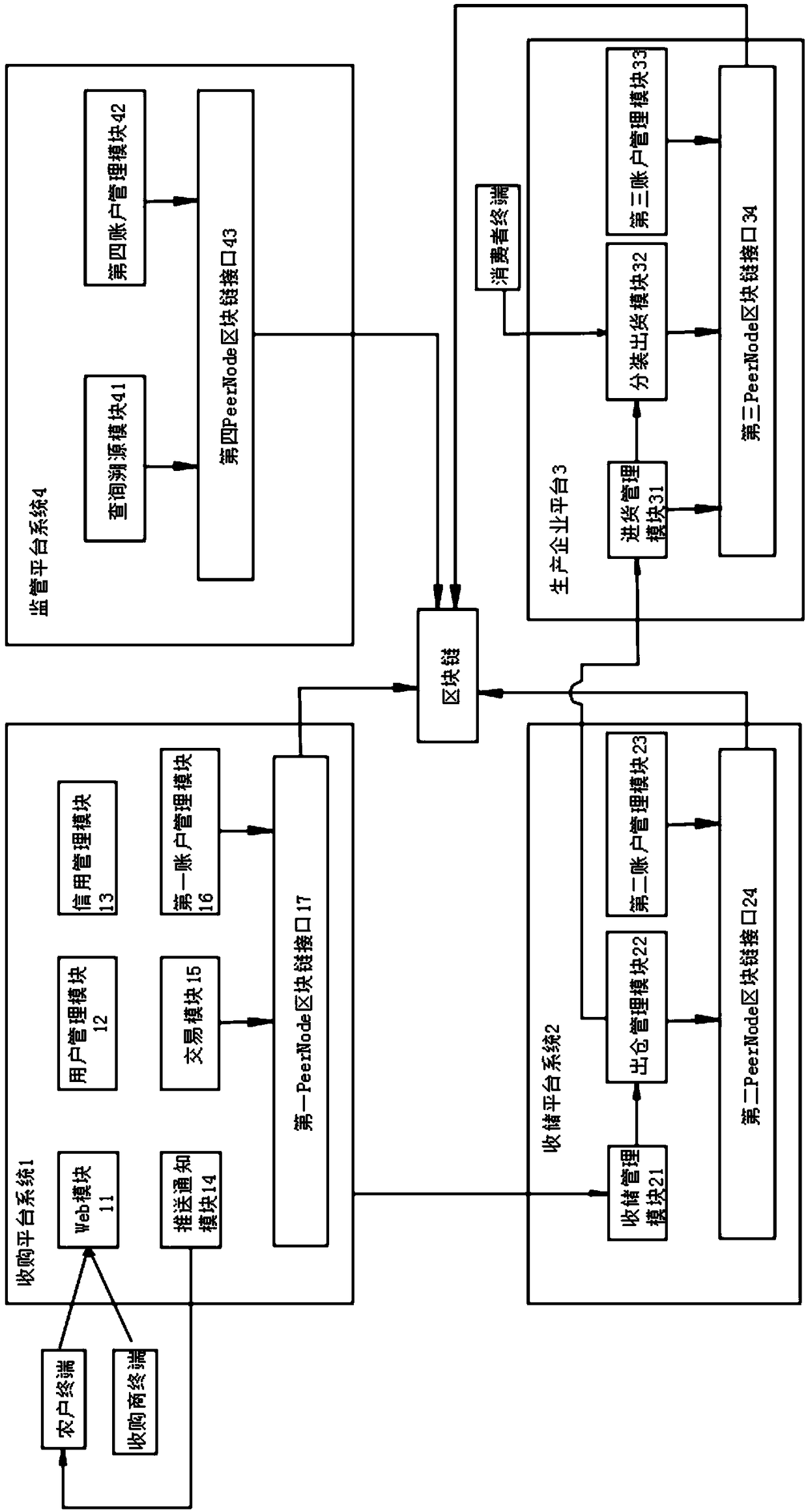

Grain security source-tracing and motivating method and system based on block chain

ActiveCN108694584AAccurate source of food originEasy to harvestDiscounts/incentivesFinanceAgricultural engineeringGrain storage

The invention relates to a grain security source-tracing and motivating method and system based on a block chain. A grain storage enterprise which collects grains can accurately know the grain originsource; purchasers can be motivated by honest operation, and can get the credit rating recognized by all parties, so as to receive better grains; farmers can get certain market feedback and bonuses tobe encouraged to hand in grains quickly and well, find reputable purchasers to sell grains, constantly improve planting technology, and select better varieties; regulators and end users can use the product source-tracing function to query the specific collection, storage and transfer process of grain raw materials; grain production enterprises can obtain complete grain circulation data to improvemarket competitiveness; and for the food sector, tokens can be rewarded to maximize the economic benefits of the subsidies by doubling the effectiveness of the relevant food subsidies.

Owner:湖北大学知行学院

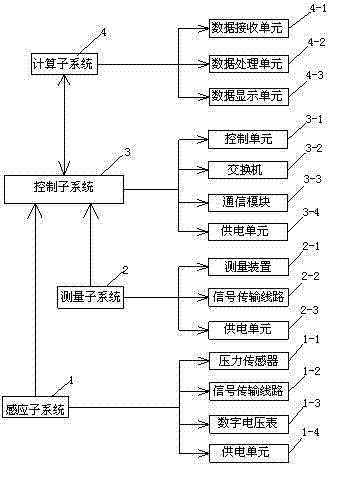

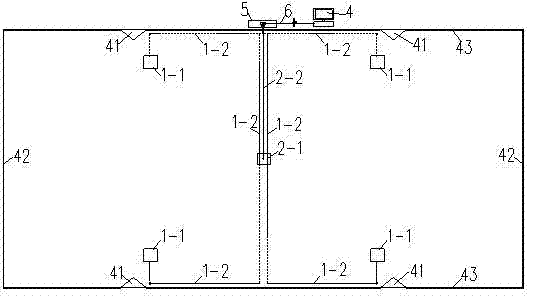

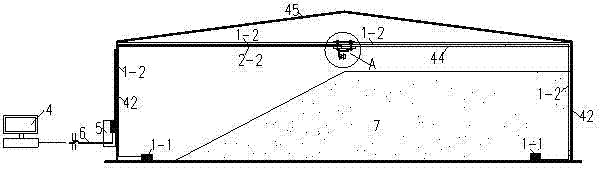

Granary capacity real-time monitoring system

ActiveCN103292693AEasy remote intelligent controlWith remote intelligent controlElectric signal transmission systemsForce measurementEngineeringAccuracy and precision

The invention relates to a granary capacity real-time monitoring system, and belongs to field of grain storage amount monitoring. According to the technical scheme, the granary capacity real-time monitoring system comprises a sensing sub-system, a measuring sub-system, a controlling sub-system and a computing sub-system. The sensing sub-system comprises a pressure sensor, a signal transmission line, a digital voltmeter and a power supplying unit. The measuring sub-system comprises a measuring device, a signal transmission line and a power supplying unit. The controlling sub-system comprises a controlling unit, a switchboard, a communication module and a power supplying unit. The computing sub-system comprises a data receiving unit, a data processing unit and a data displaying unit. The sensing sub-system senses change of grain stack states in real time, the measuring sub-system collects grain face information in a granary, the controlling sub-system controls the sensing sub-system and the measuring sub-system and conducts storage and management on the data collected by the sensing sub-system and the measuring sub-system, and the computing sub-system conducts processing on the storage data of the controlling sub-system and then obtains real-time granary capacity. The granary capacity real-time monitoring system has the advantages of being capable of conducting remote intelligent control, high in measuring precision, high in reliability, good in stability and durability, resistant to dust and corrosion and the like. Furthermore, the granary capacity real-time monitoring system is convenient to popularize and apply.

Owner:郑州工大粮安科技有限公司

Lower ventilating method and apparatus for low-temperature grain storage film in bungalow barn

InactiveCN1840974AReduce the temperatureReduce cooling capacityAgriculture tools and machinesLighting and heating apparatusPresent methodGrain storage

The invention discloses a low-temperature crop-reserving film ventilating method and device of flat warehouse, which comprises the following parts: transverse ventilating cooling method, transverse inlet pipe, return air pipe and vertical probe pipe ventilating cooling device. The invention overcomes the deficiency of present method, which forms the cooling air loop to save the power.

Owner:中央储备粮扬州直属库有限公司

Cereal vacuum storage device

ActiveCN101185462AQuality is not affectedDoes not reduce moistureEdible seed preservationVacuum pumpingSocial benefits

The invention discloses a set of vacuum storage equipment of a grain: an inner cavity of a hollow grain storage silo body is sleeved with a flexible bag body, the size and shape of which are matched with the inner cavity of the hollow grain storage silo body. A bag inlet and a bag outlet arranged on the flexible bag body are corresponding to a silo inlet and a silo outlet arranged on the hollow silo. The bag inlet and the bag outlet are respectively provided with a sealing mechanism. The upper part at the outer surface of the flexible bag body is connected with the upper part of the inner cavity of the hollow grain storage silo body by a flexible cable; furthermore, a flexible vacuum-pumping pipe is arranged on the flexible bag body and the inner end of the vacuum-pumping pipe is communicated with the flexible bag body and the outer end thereof is communicated with a set of vacuum-pumping equipment. The invention has simple structure, novel design, convenient use and wide application range, can effectively keep the quality of the grain stored in a long term, reaches environment friendly standard as well and is beneficial to the health of eaters, thus having good economic and social benefits.

Owner:郑州中粮科研设计院有限公司 +1

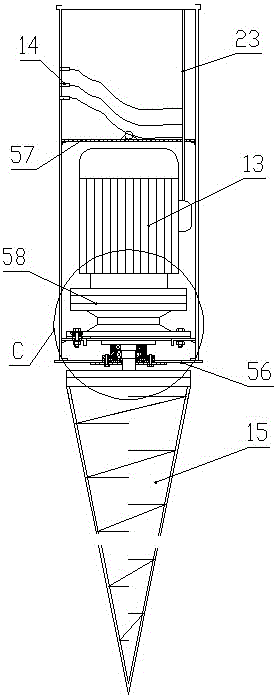

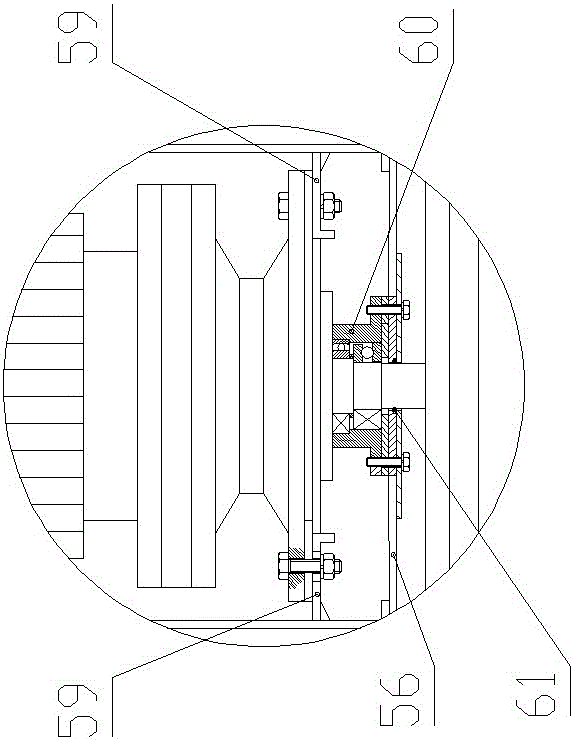

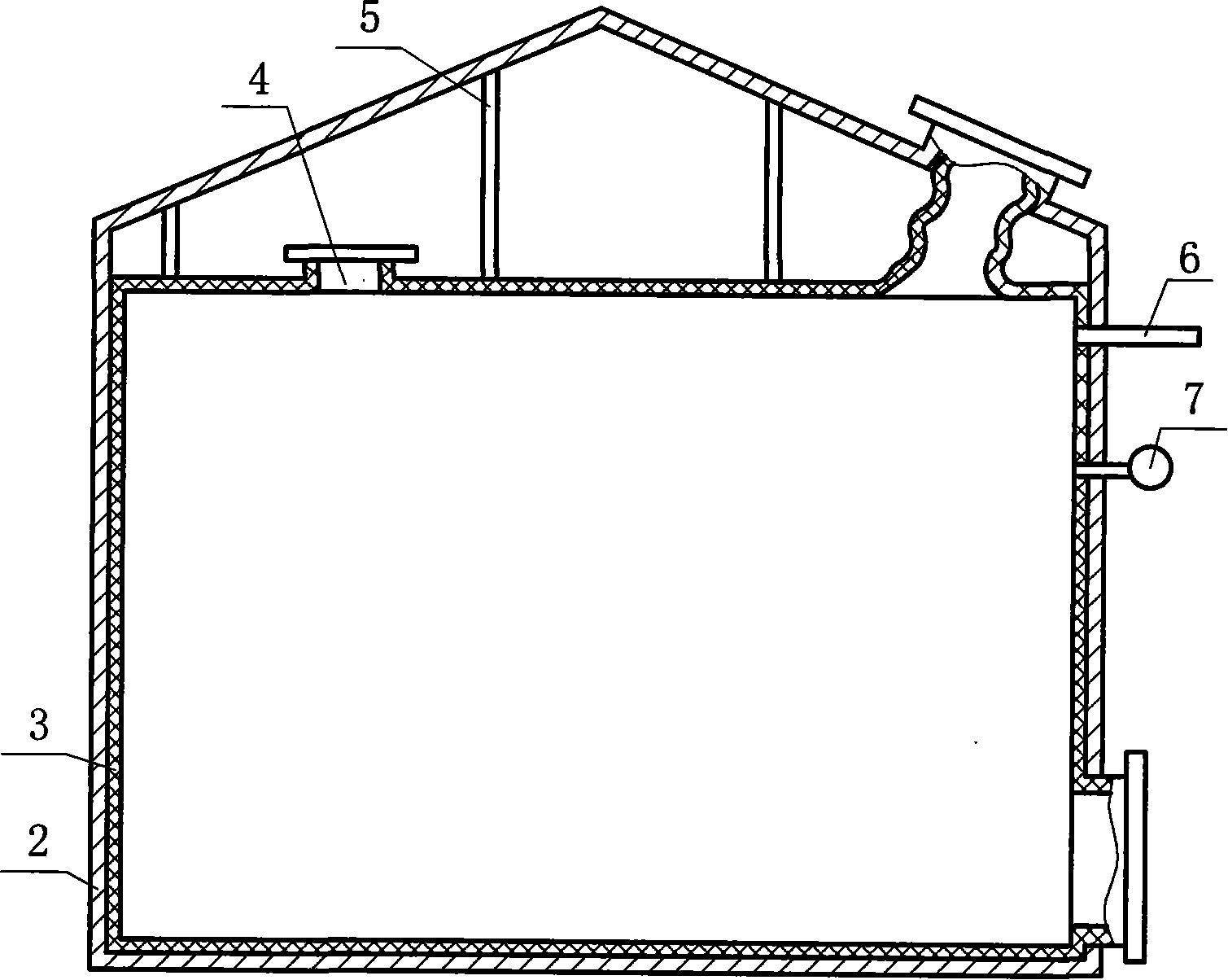

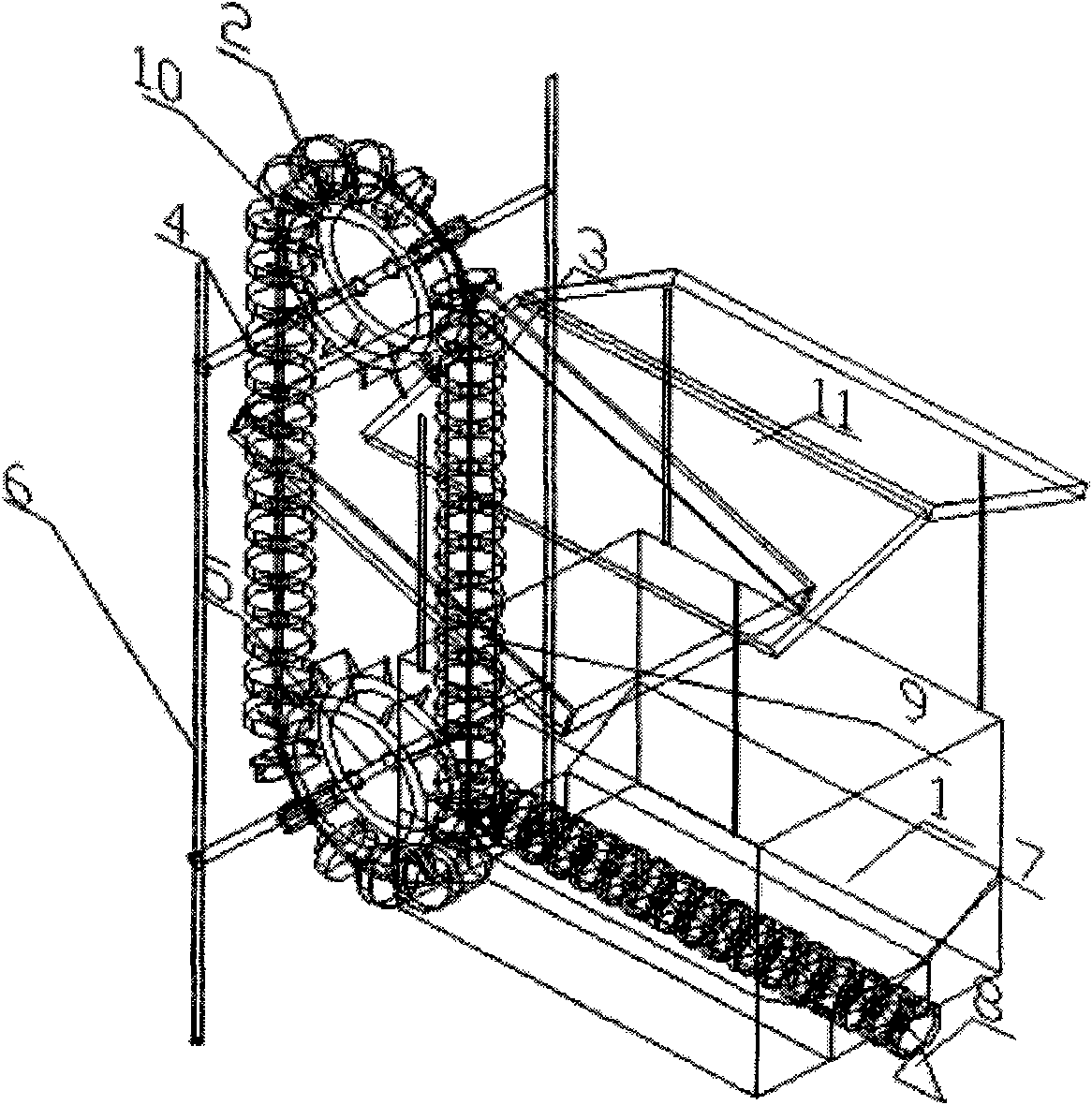

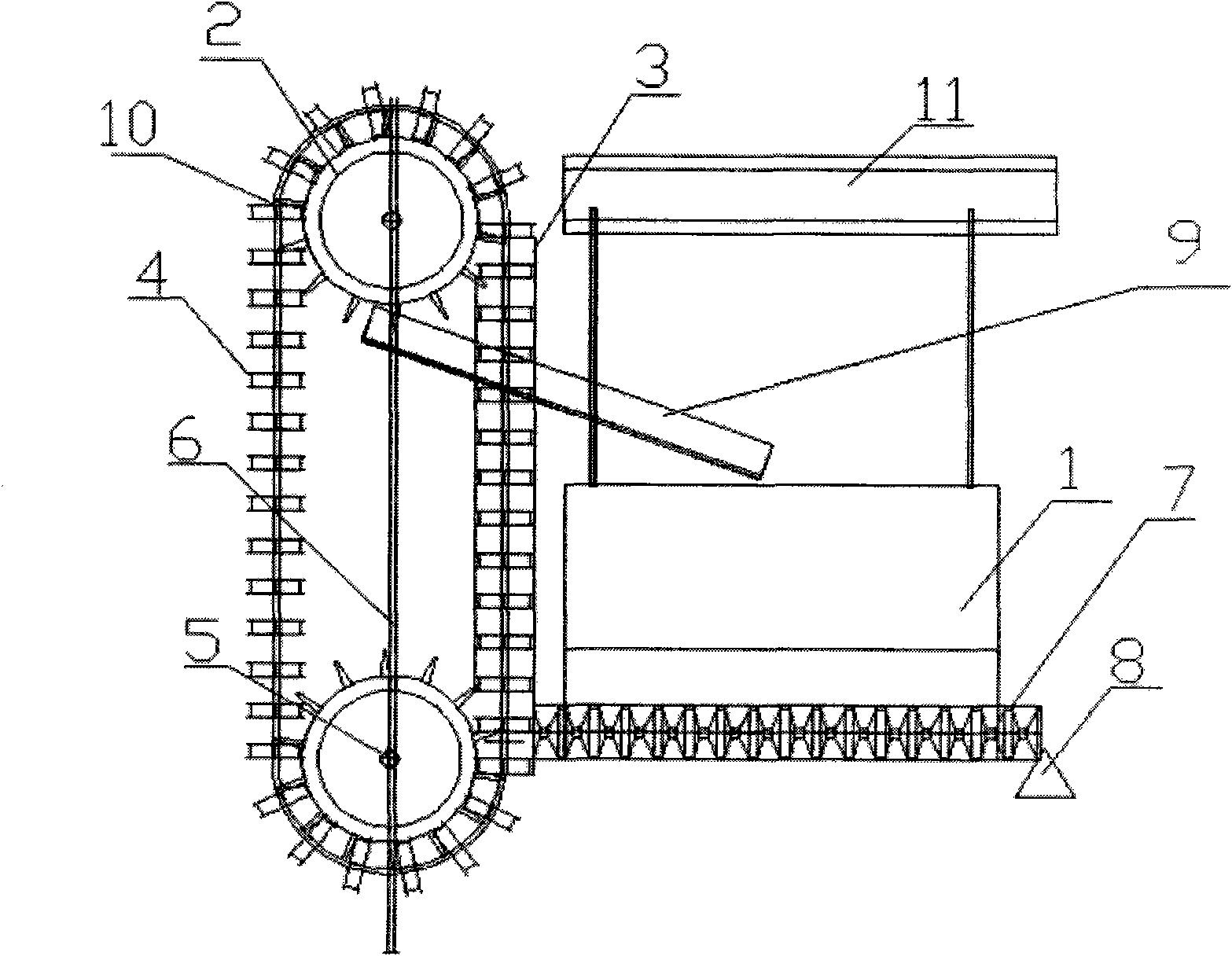

Ventilation and air-drying system for grain store of grain depot

InactiveCN102090227ASimple structureEasy to operateAgriculture tools and machinesConveyorsGrain storageSocial effects

The invention relates to a grain air-drying and ventilation system for a grain store of a grain depot in the grain storage security industry, which aims to solve the problems of high cost of grain storage, air-drying, ventilation and the like, difficulties in the gathering and warehousing of grains in cloudy and rainy days, high labor intensity and waste of time. The scheme is that: a cylindrical hoisting device is arranged on the outer wall of the grain store of the grain depot; the lower part of the grain store of the grain depot forms an inverted prismatoid; an axial screw is arranged on the lowest part of the inverted prismatoid; an inclined air-drying surface is formed on the grain store of the grain depot; the upper part of the grain store of the grain depot realizes the ventilation and air-drying of the grains by utilizing natural wind and sunshine; and the axial screw is arranged at the wall bottom of the grain store of the grain depot to convey the grains of the inverted prismatoid to the cylindrical hoisting device, and the hoisting device hoists the grains at the bottom onto the inclined air-drying surface on the grain store, so the grains are air-dried on the inclined air-drying surface, slide down by self weight and are ventilated for mould prevention, corrosion prevention and temperature reduction by the natural wind. The system has a simple, novel and unique structure, is simple and convenient to use and operate, ensures low labor intensity and remarkable economic efficiency and social effects, can realize the mechanization and automation of a grain air-drying system and greatly improve the labor efficiency, and is a great innovation in the grain storage industry.

Owner:HENAN POLYTECHNIC UNIV

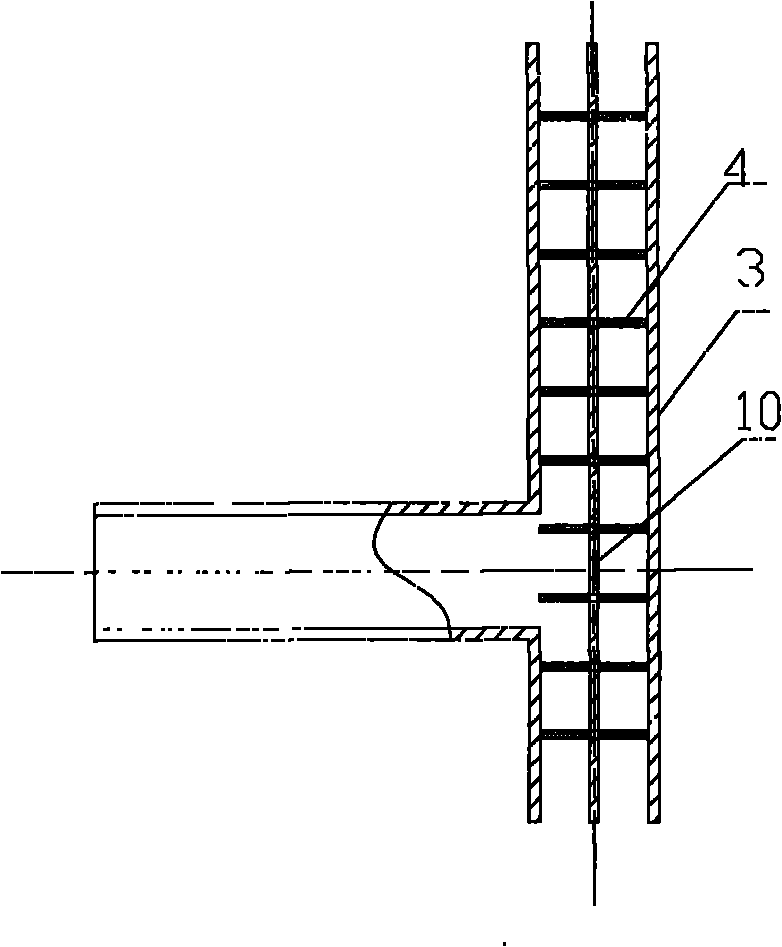

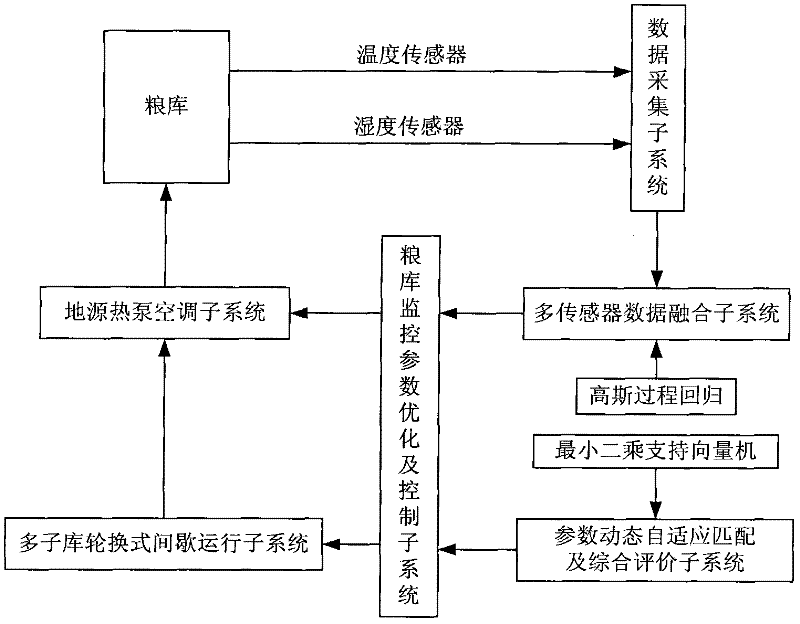

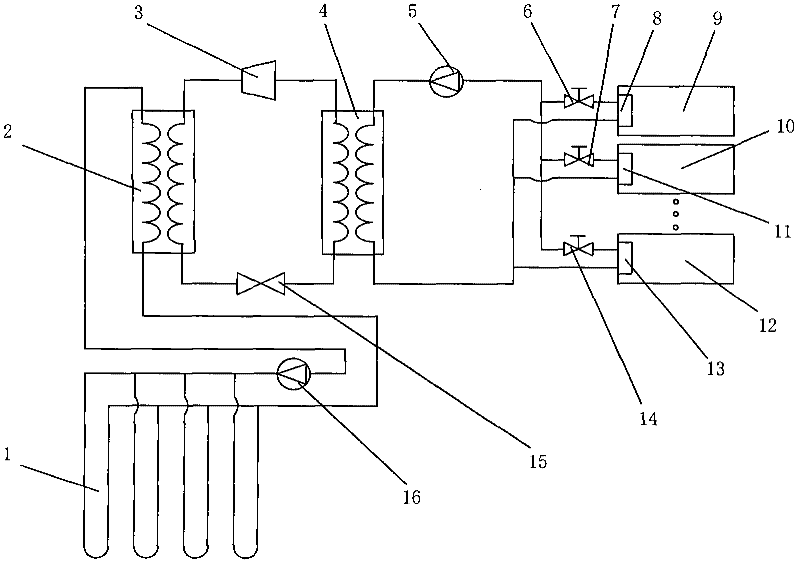

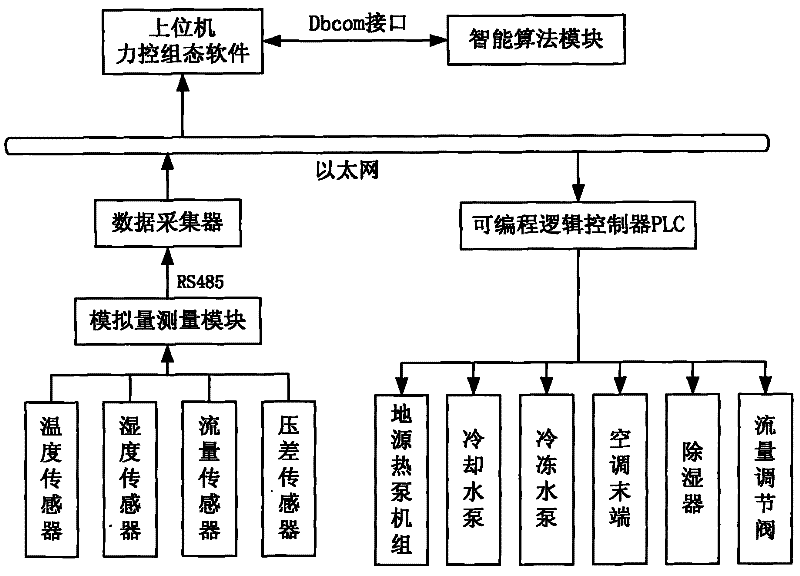

Intelligent shallow ground energy low temperature grain storage system

InactiveCN102283283AGuaranteed temperature and humiditySave moneyFood processingClimate change adaptationData acquisitionLeast squares support vector machine

The invention discloses an intelligentized superficial geothermal energy low-temperature grain storage system which comprises a ground source heat pump air conditioner subsystem, a data acquisition subsystem, a multi-sensor data fusion subsystem, a grain bin monitoring parameter optimization and control subsystem, a parameter dynamic adaptive matching and comprehensive evaluating subsystem and a multi-subbin rotational intermittent operation subsystem, wherein the ground source heat pump air conditioner subsystem is used as a cold energy source of a grain bin in the intelligentized superficial geothermal energy low-temperature grain storage system, and an automatic grain-condition monitoring center of the grain bin is established by combining with a Gaussian process regression-based data fusion technology; and a least square support vector machine optimized by using an optimal-worst particle swarm algorithm is applied to the prediction and control of grain storage environmental parameters of the grain bin so that dynamic adaptive matching of cold energy supply and cold energy demand is realized. The intelligentized superficial geothermal energy low-temperature grain storage systemhas the characteristics of high efficiency, intellectualization, man-machine interaction, energy saving, environmental friendliness and the like.

Owner:GUANGXI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com