Grain storage quantity detection method for horizontal warehouse and shallow silo

A detection method and shallow warehouse technology, applied in the field of granary detection, can solve the problems of too many pressure sensors and high cost of the detection system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

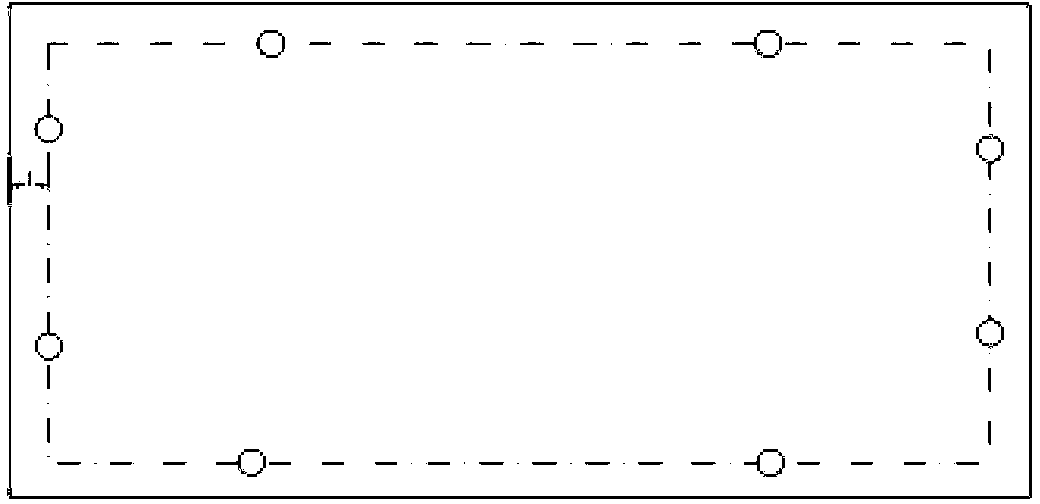

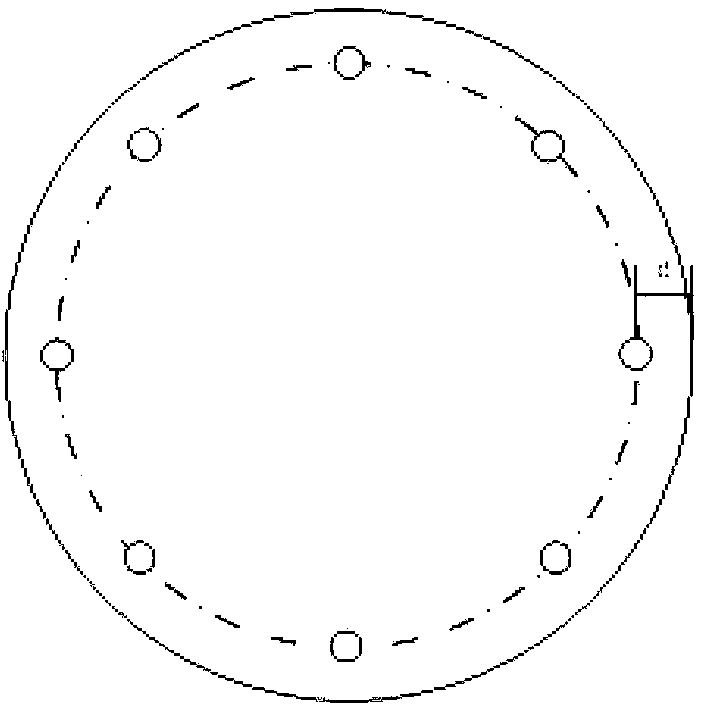

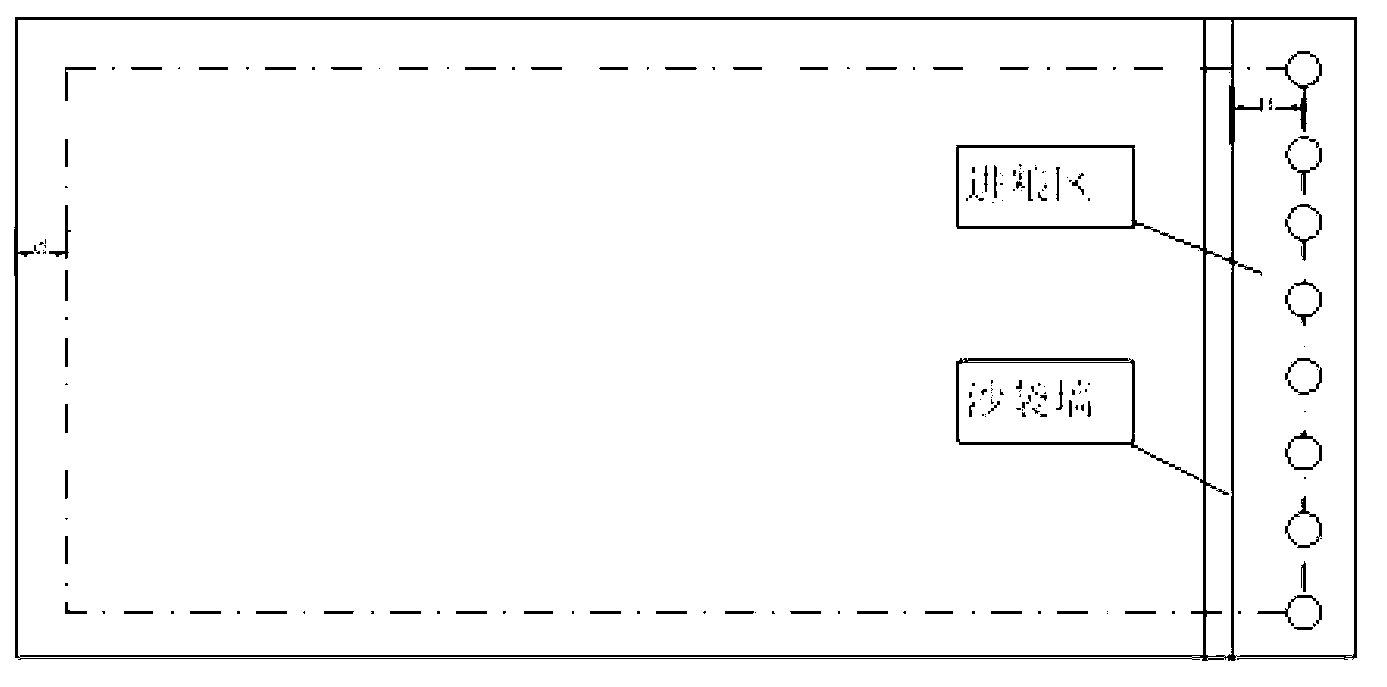

[0027] In view of the characteristics of flat warehouses and shallow round warehouses, in order to further reduce the number of pressure sensors and reduce the cost of detection equipment and installation and maintenance under the condition of ensuring detection accuracy, an estimation based on the uniform pressure of the bottom surface of the granary is proposed. Method for predicting the weight of the granary.

[0028] In theory, assuming that the top surface of the granary pile is flat, the friction between the side of the granary and the grain is zero, and the pressure on the bottom surface is evenly distributed, then the weight of the grain pile W is

[0029] W=A B q B (1)

[0030] Among them, W is the weight of the grain pile; q B Is the pressure on the bottom of the granary; A B Is the area of the bottom of the granary. For a granary with a rectangular bottom, A B =L L L W , Where L L ,L W They are the length and width of the bottom of the granary. For circular silo, A ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com