Patents

Literature

2209results about How to "Improve calibration efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Communication device

InactiveUS6934541B2Improve calibration accuracyImprove reception qualitySpatial transmit diversityCode division multiplexSignal cancellationEngineering

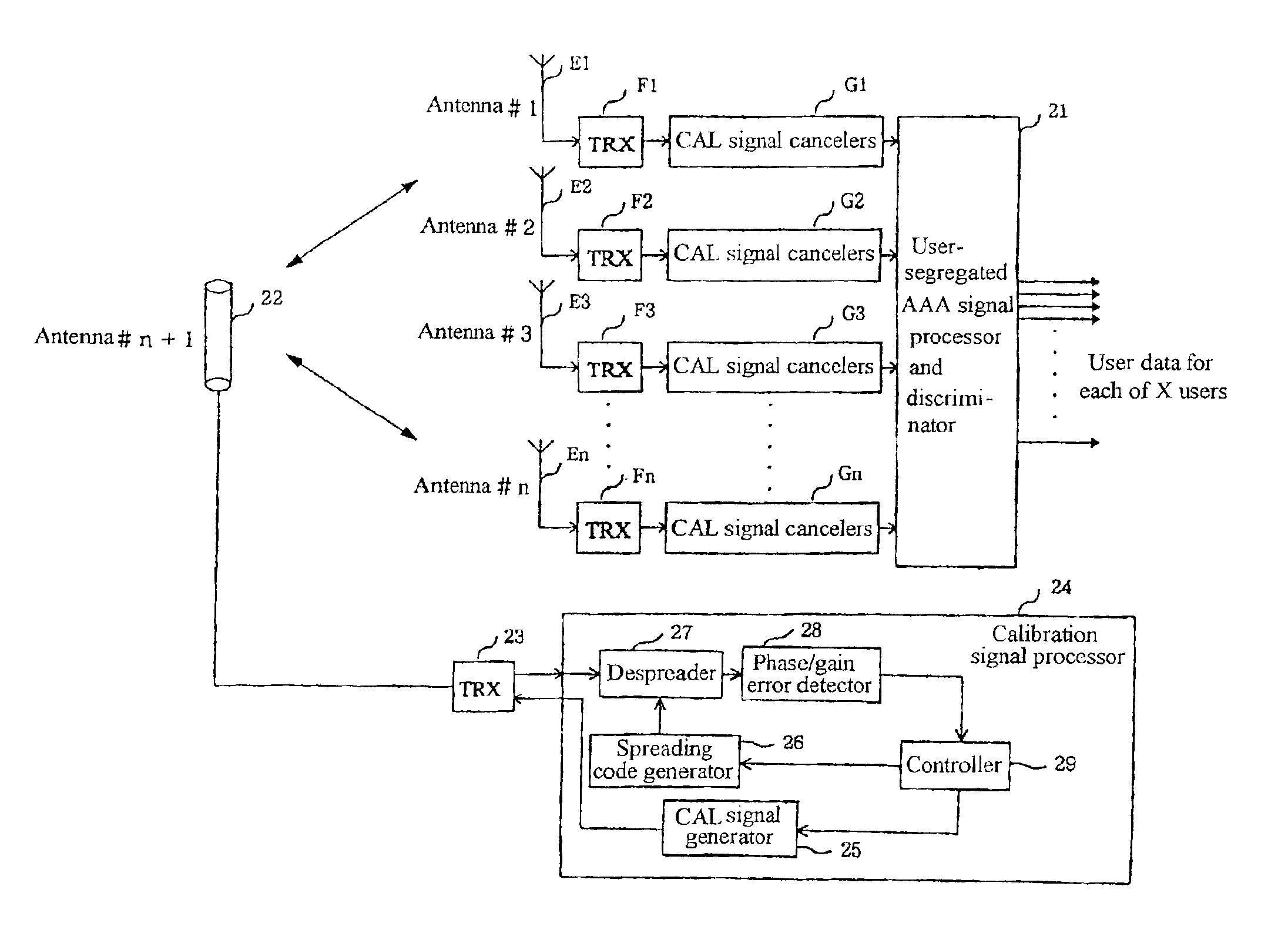

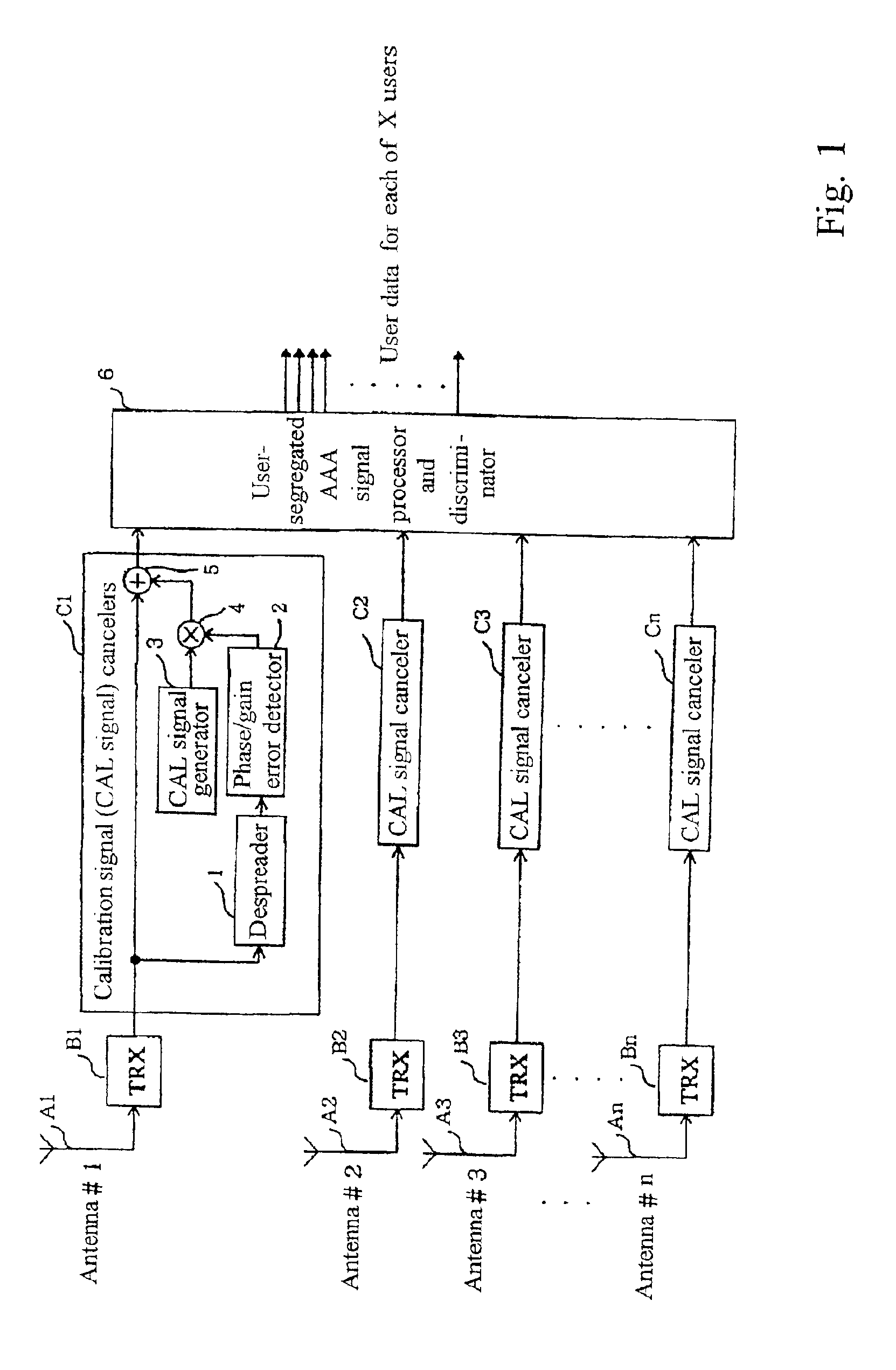

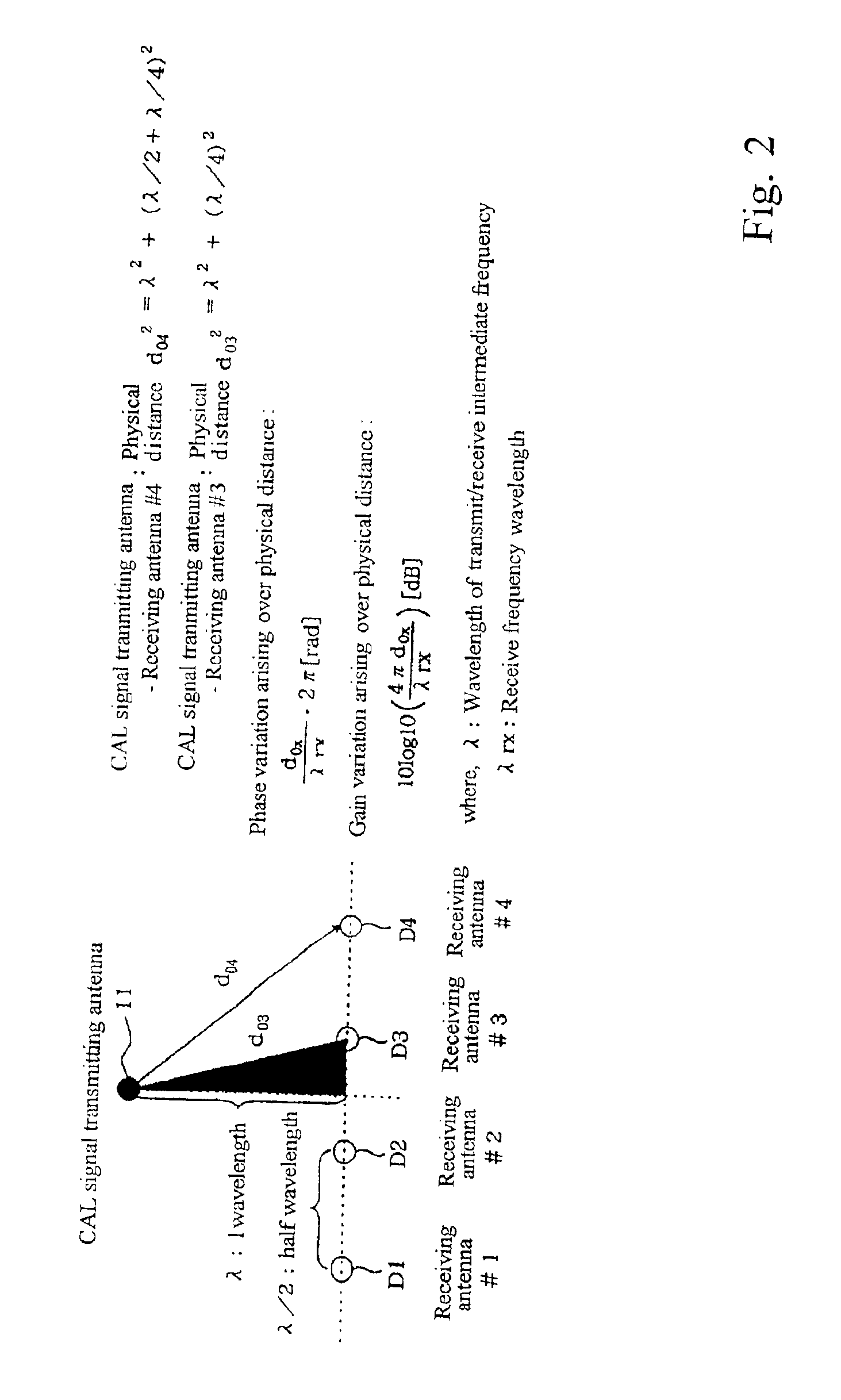

A communication device for transmitting and / or receiving signals by using a communication antenna includes signal characteristic information detection means for detecting information regarding signal characteristics of a calibration signal which are contained in a signal received by the communication antenna, calibration means for calibrating a communication antenna chain based on the detected signal characteristic information, and cancellation signal generating means for generating a cancellation signal corresponding to a calibration signal contained in the signal received by the communication antenna based on the calibration signal. The device also includes signal cancellation-by-subtraction means for subtracting the generated cancellation signal from the signal received by the communication antenna, and receive signal processing means for processing the received signal that is diminished by the cancellation signal.

Owner:KOKUSA ELECTRIC CO LTD

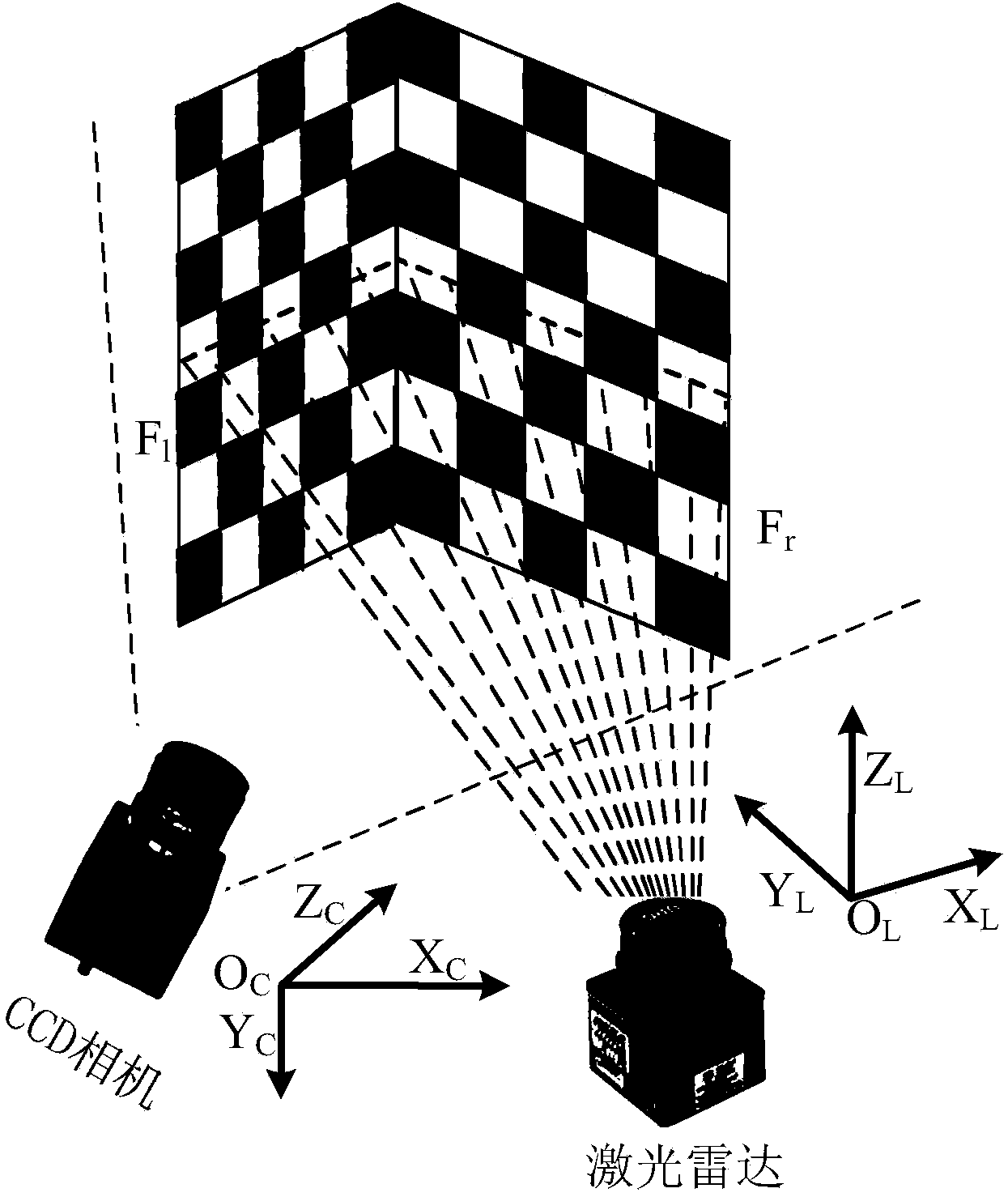

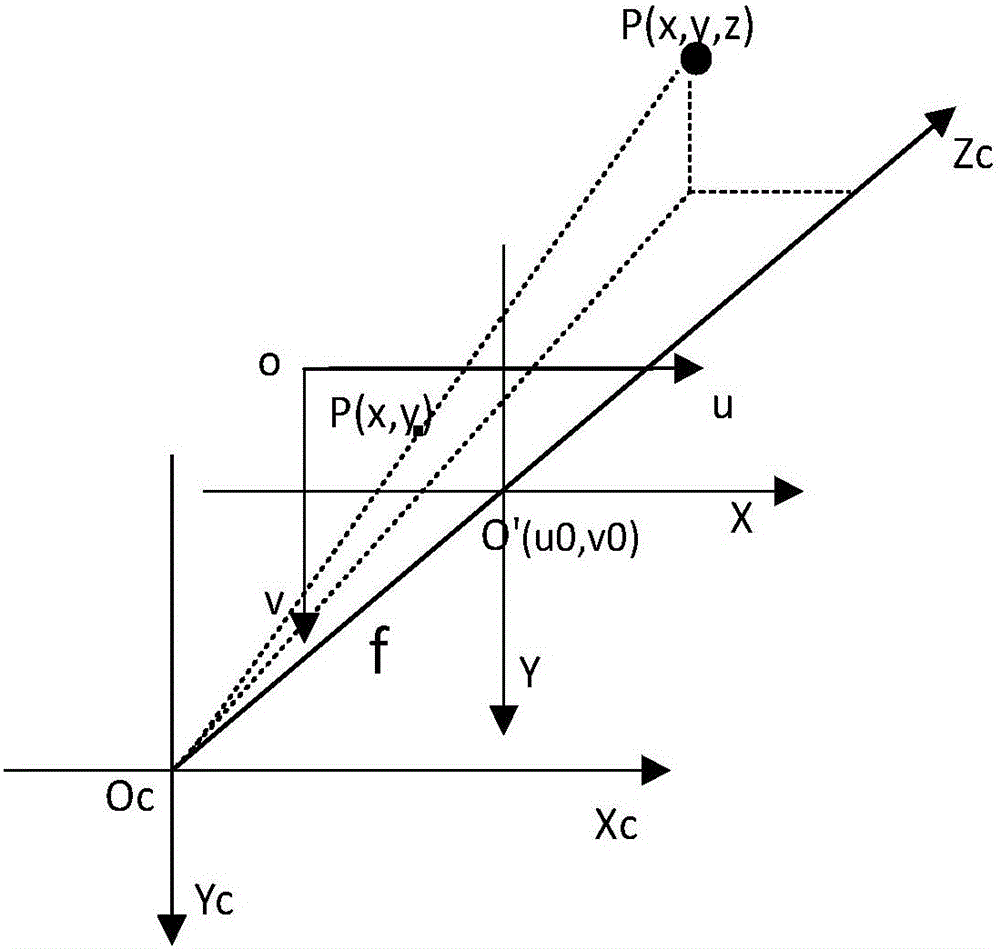

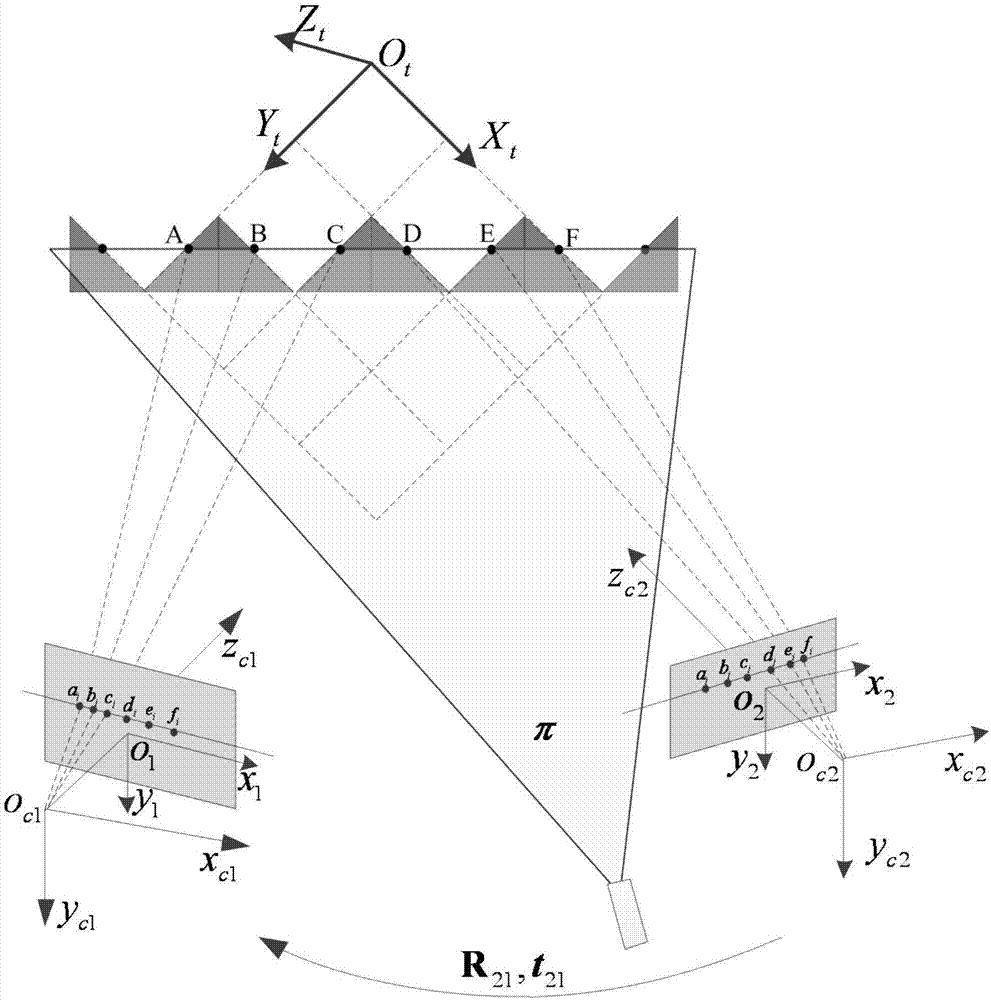

Vector-relation-based method for calibrating single-line laser radar and CCD camera

InactiveCN103837869AEasy to operateImprove calibration efficiencyImage analysisWave based measurement systemsRadarLaser scanning

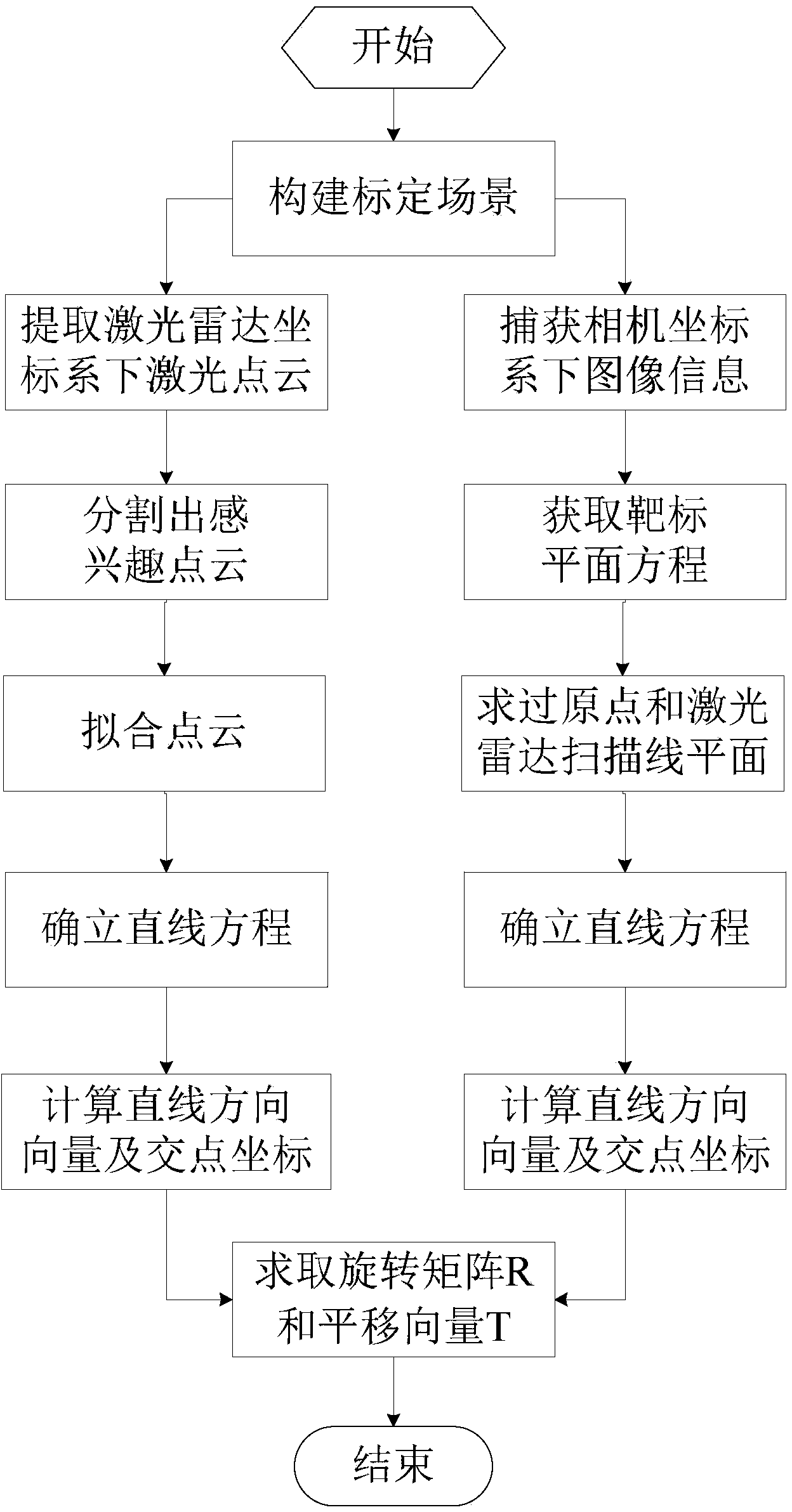

The invention relates to a vector-relation-based method for calibrating single-line laser radar and a CCD camera. Point set information of the laser radar for scanning a V-shaped target is extracted in a laser coordinate system, and direction vectors and intersection coordinates of straight lines in two different planes of the target are obtained by means of straight line fitting; the CCD camera is used for capturing images in a camera coordinate system, target plane equations and an equation of a plane passing through an original point and laser radar scanning lines are obtained by processing image information, a straight-line equation of laser radar scanning is built, and furthermore, the direction vectors and the intersection coordinates of the straight lines are obtained; finally, calibration is finished according to the relations between direction vectors and the intersection coordinates of the straight lines corresponding to the different coordinate systems. According to the method, no object in a calibration scene needs to be moved, collection of all calibration data can be completed at a time, and calibration efficiency is improved greatly. According to the method, the direction vectors of the straight lines of the laser scanning target planes under the coordinate systems of sensors to be calibrated are obtained directly, calibration precision is guaranteed, and meanwhile the calibration algorithm is simplified.

Owner:BEIJING UNIV OF TECH

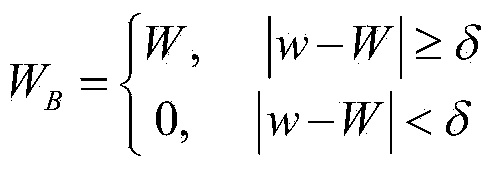

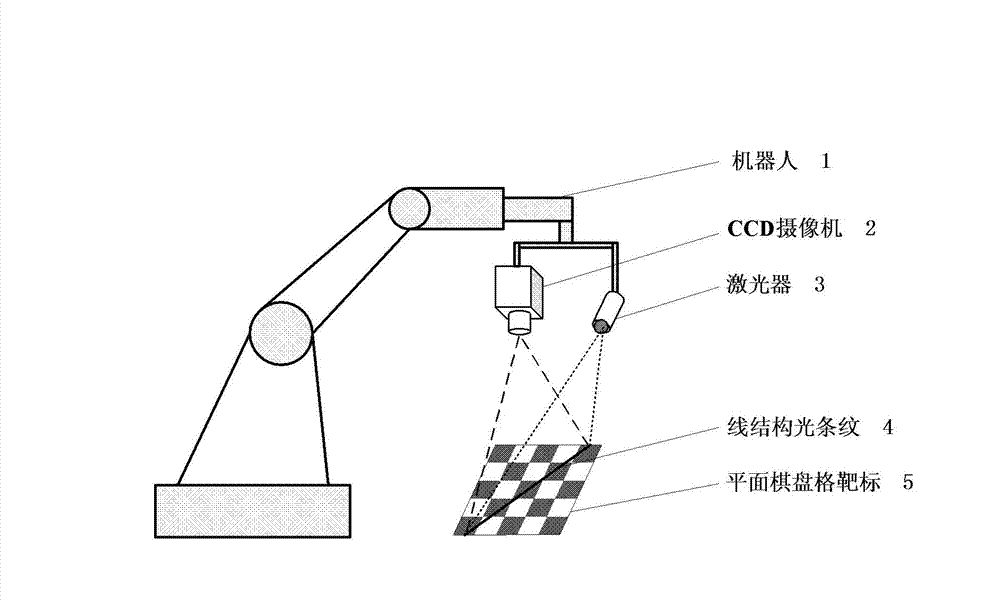

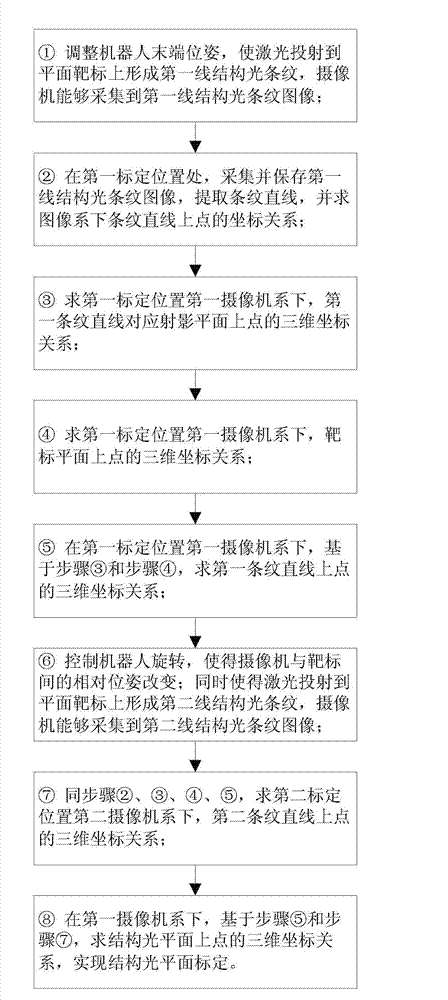

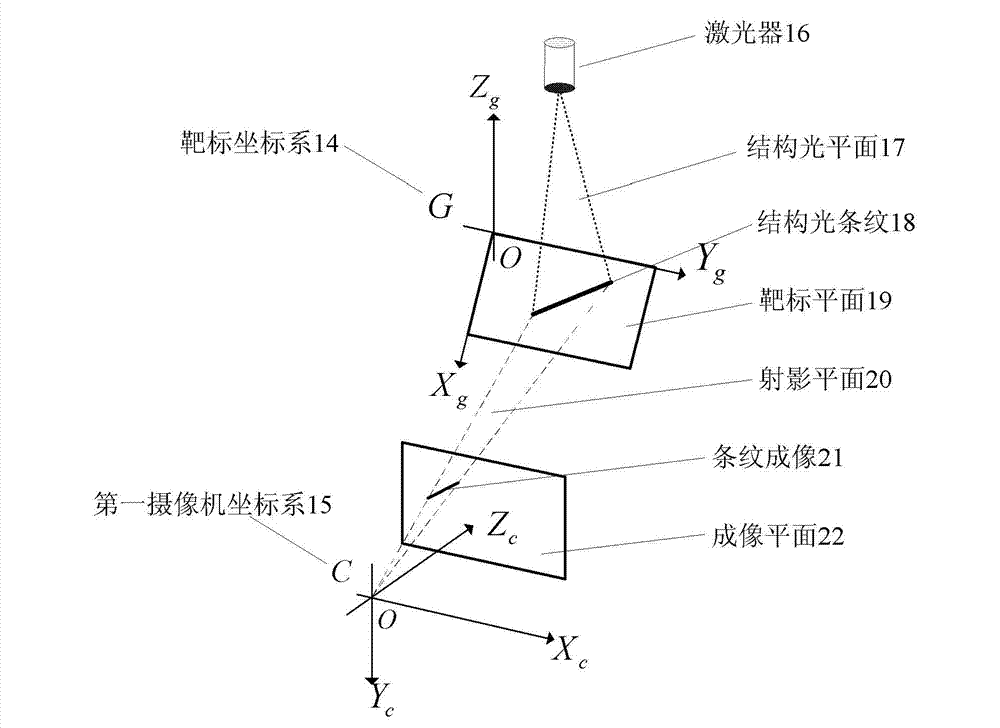

Robot eye-on-hand system structured light plane parameter calibration device and method

The invention discloses a robot eye-on-hand system structured light plane parameter calibration device and a method. According to the device, a camera and a laser device are installed at the tail end of a robot to form a robot eye-on-hand system, and on the premise of obtaining camera intrinsic parameters, plane parameters of structured light projected by the laser device are calibrated, and thereby structured light three-dimensional vision measurement can be achieved. The robot eye-on-hand system structured light plane parameter calibration method includes that a plane checkerboard target is placed in a calibration area, laser lights are projected on the target to form a first line structured light stripe, the robot is controlled to move in a constraint mode so as to project the laser lights to another position of the target to form a second line structured light stripe, the camera respectively acquires images of two structured light stripes at two calibration positions, the relation of three-dimensional coordinate of points on stripe straight lines under a camera coordinate system at the two calibration positions is calculated, and thereby the structured light plane parameter calibration with the structured light stripe straight lines serving as calibration elements can be achieved.

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI +1

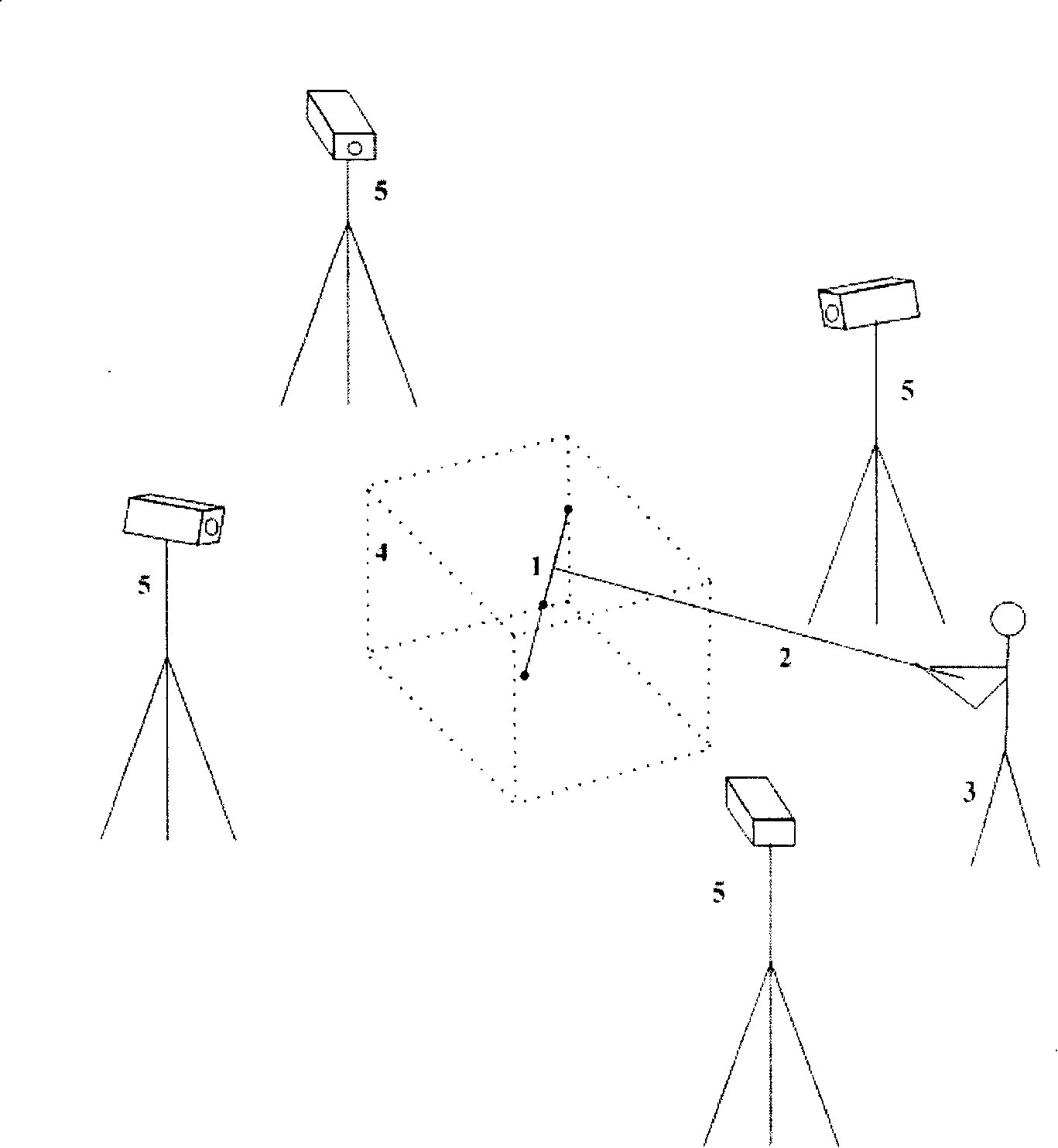

Method and apparatus for standardization of multiple camera system

InactiveCN101226638AOvercoming the DifficultImprove calibration accuracyImage analysisTelevision systemsTransformation matrixRigid motion

The invention discloses a polyphaser system calibration method, comprising a calibration component which is formed by three or more signalized points with known geometry in rigid motion at the work area of the polyphaser system, obtaining a plurality of images of calibration and inputting the images to a computer, extracting image coordinate of the signalized points and regarding the image point which is shot by different cameras on the same signalized points on the calibration component at certain position as a group of corresponding points, linearly recovering the projection transformation matrix of every camera in the polyphaser system according to the geometry contained in the image corresponding points and the signalized points and utilizing nonlinearity arithmetic to optimize. The device disclosed by the invention comprises a calibration part, a handle, an operation system, a work area and a polyphaser system. The invention overcomes the shortages of low efficiency, having relatively large accumulated errors and the like in the existing calibration method which needs to calibrate the cameras in the polyphaser system one by one or step by step. Further, the invention realizes calibrating the whole polyphaser system at one-time, thereby having important practical engineering value.

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI

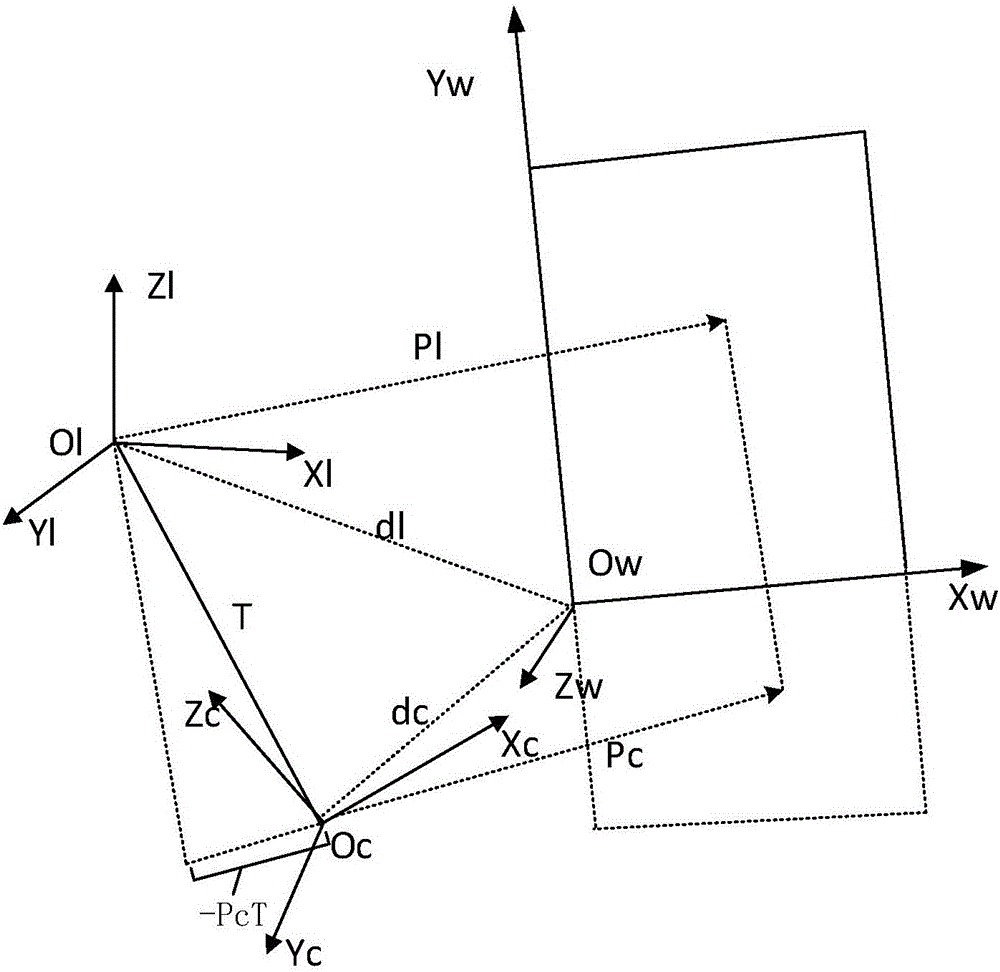

A joint calibration method of a 3D lidar and a monocular camera

InactiveCN106228537ASimplify the calibration processFast calibrationImage analysisCalibration resultCorrespondence principle

The invention relates to a joint calibration method of a 3D lidar and a monocular camera, and belongs to the field of information fusion. The invention aims at improving the calibration efficiency under the requirement of ensuring the joint calibration accuracy of multi-sensor information fusion. Firstly, the monocular camera is calibrated, and then a normal vector of a target calibration plate in a monocular camera coordinate system, the distance from the target calibration plate to the origin in the monocular camera coordinate system, a normal vector of a fitting plane in a 3D lidar coordinate system and the distance from the origin to the fitting plane in the 3D lidar coordinate system are respectively solved at each position. Then, the results of the joint calibration are solved by using the distance correspondence principle. Finally, the result of the joint calibration is taken as the initial value into an optimization objective function to obtain the optimal joint calibration result. The joint calibration method of the invention greatly reduces human participation, reduces random errors caused by complicated man-made operation, simplifies the process of multi-sensor joint calibration and improves the precision of the calibration.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

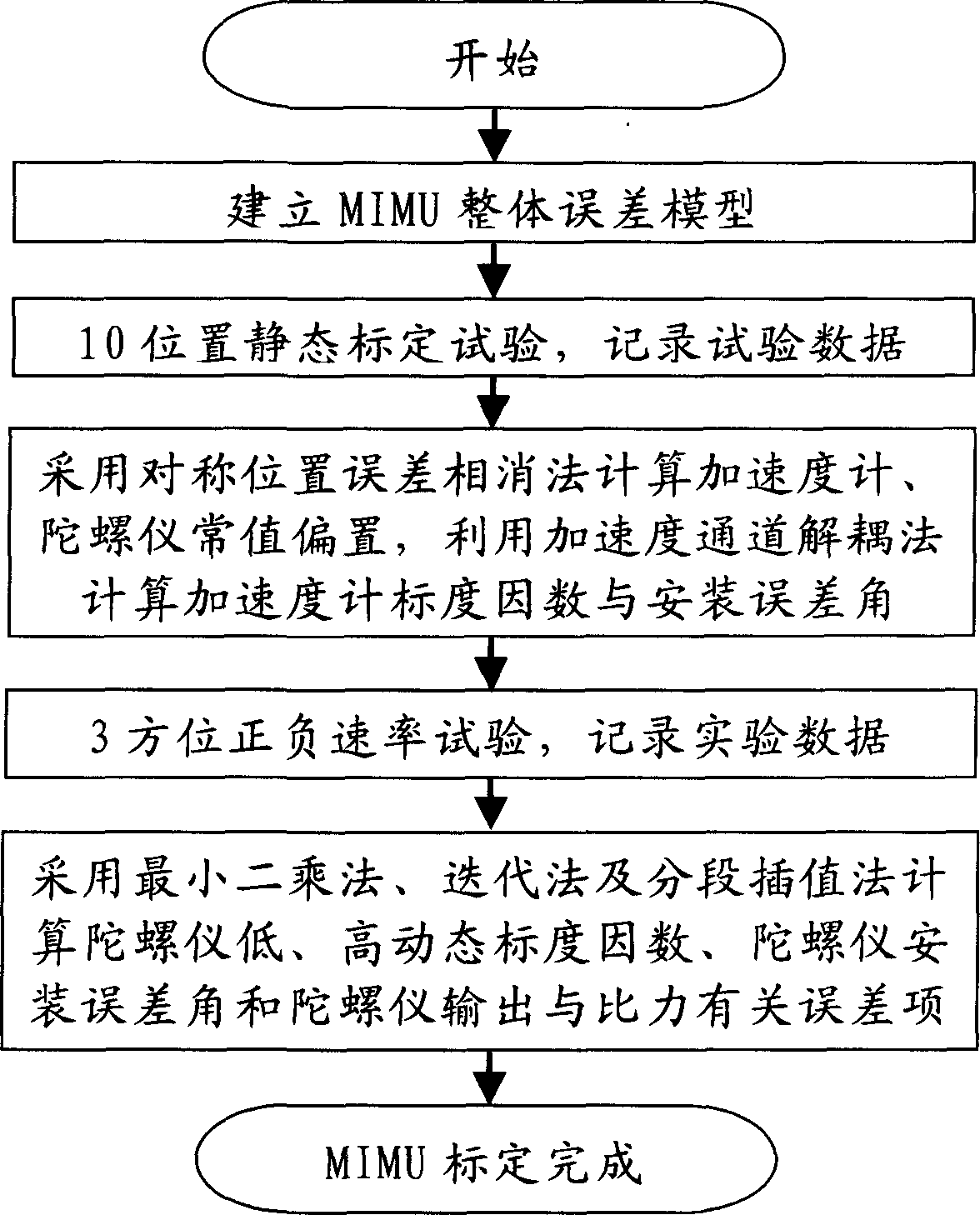

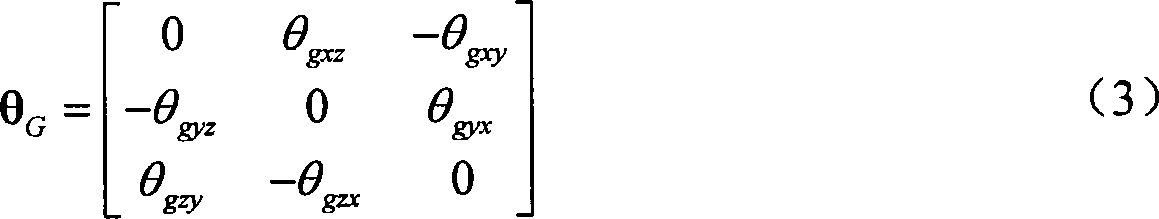

Microinertia measuring unit precisive calibration for installation fault angle and rating factor decoupling

InactiveCN1818555ASolve the errorSolving Scale Factor Coupling IssuesNavigation by speed/acceleration measurementsAccelerometerGyroscope

An accurate calibration method of micro inertia measuring unit by decoupling erection error angle (EEA)with scale factor includes setting up MIMU integral error model and separating couple between EEA of accelerometer and gyroscope and scale factor ,using position error canceling method to calculate out and to separate out scale factor and EEA of accelerometer as well as using least square method and iteration method to calculate out EEA of gyroscope and its relative error items in 10 position static calibration test and in 3 direction positive and negative rate test ,then using interpolation method to calculate out scale factor of gyroscope .

Owner:BEIHANG UNIV

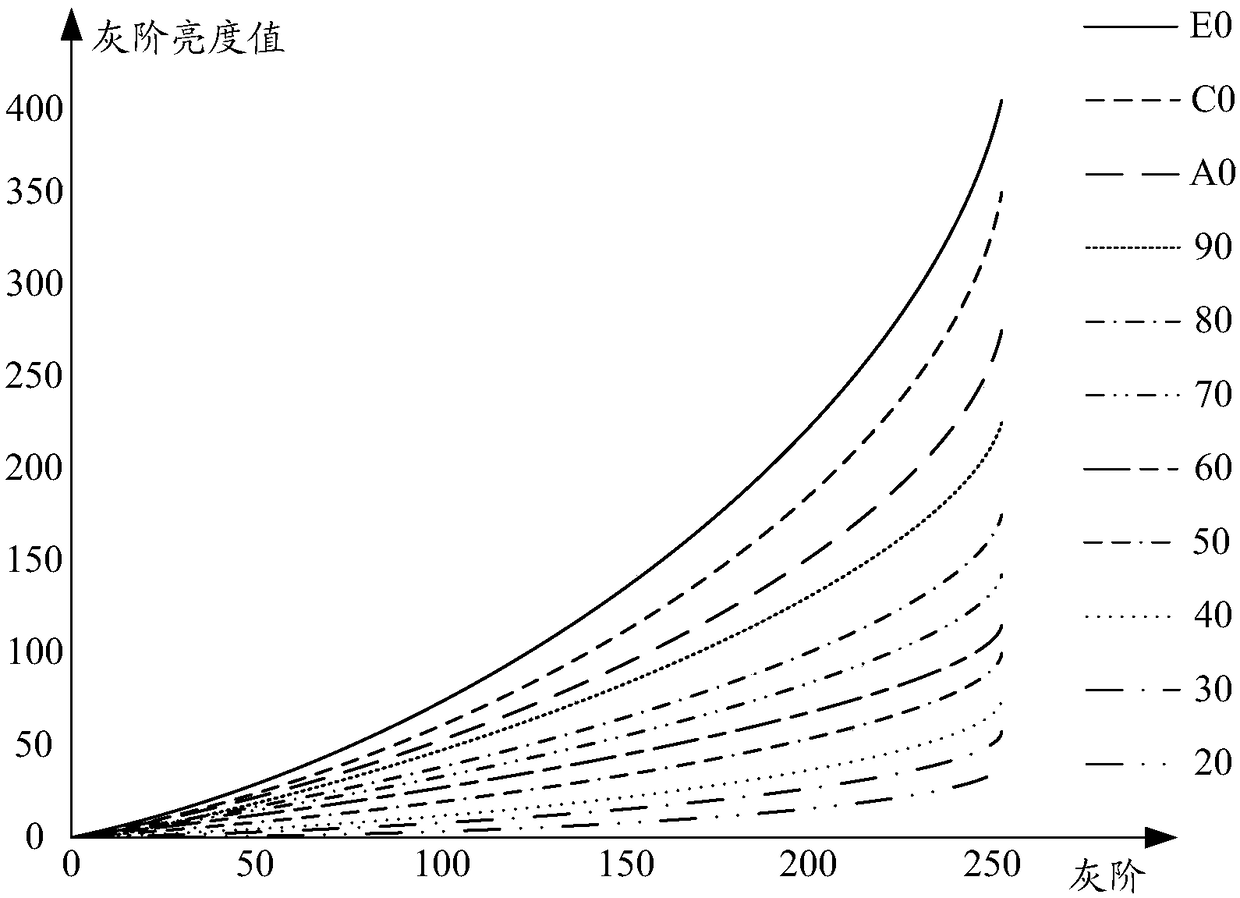

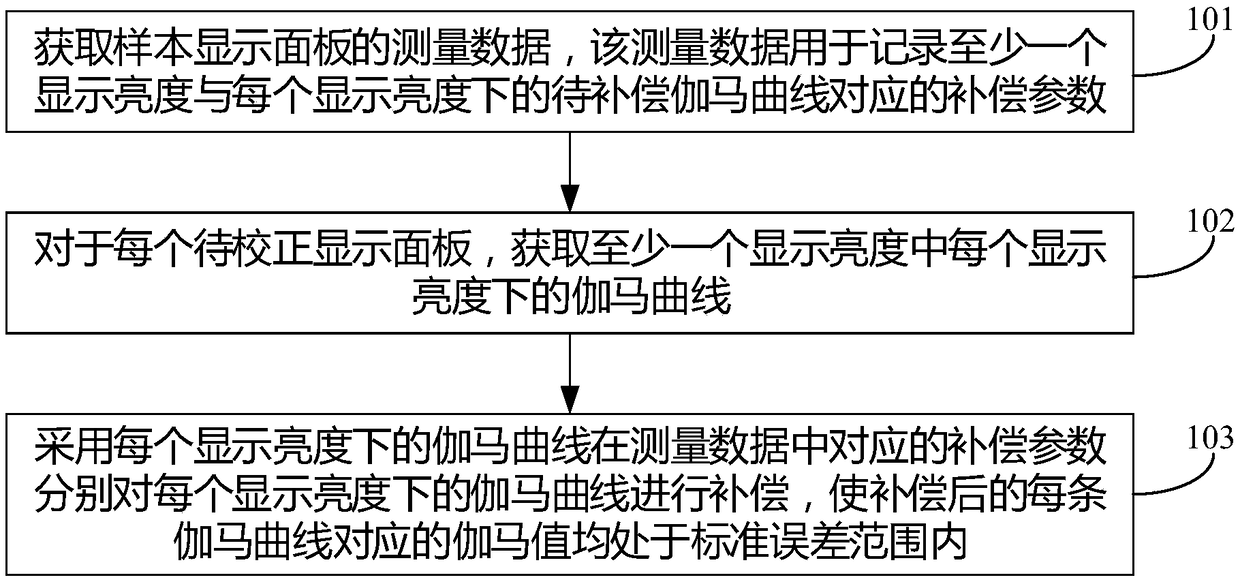

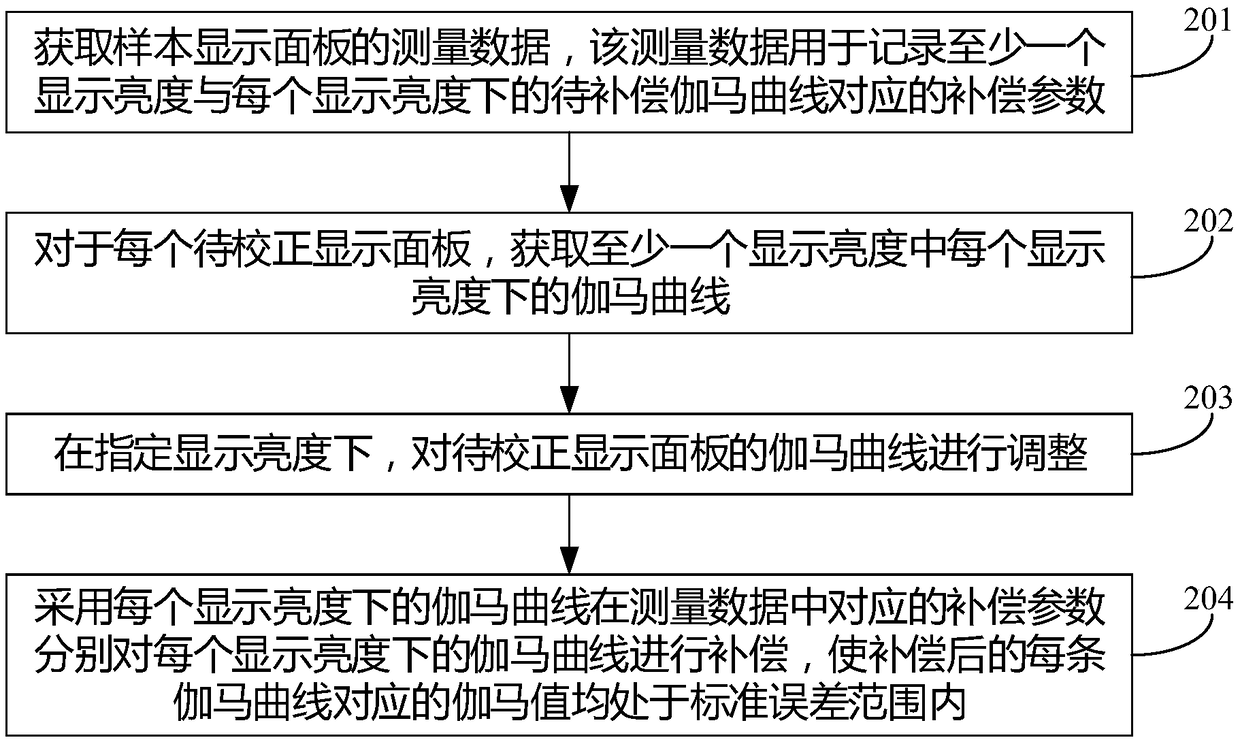

Gamma correction method and device, display device and computer storage medium

ActiveCN108550345AShorten the timeImprove calibration efficiencyStatic indicating devicesDisplay deviceBrightness perception

The invention discloses a gamma correction method and device, a display device and a computer storage medium, belonging to the technical field of display. The method comprises the following steps: acquiring measurement data of a sample display panel, wherein the measurement data is used for recording at least one display brightness and compensating parameters corresponding to a to-be-compensated gamma curve under each display brightness; acquiring a gamma curve under each display brightness in at least one display brightness of each to-be-corrected display panel; and respectively compensatingthe gamma curve under each display brightness by virtue of the corresponding compensating parameters of the gamma curve under each display brightness in the measurement data until a gamma value corresponding to each compensated gamma curve is in a standard error range, wherein the to-be-corrected display panels and the sample display panel are produced in the same batch. The gamma correction method can solve the problems that the consumed time of a gamma correction process is relatively long, and the gamma correction efficiency is relatively low in relevant techniques.

Owner:CHENGDU BOE OPTOELECTRONICS TECH CO LTD +1

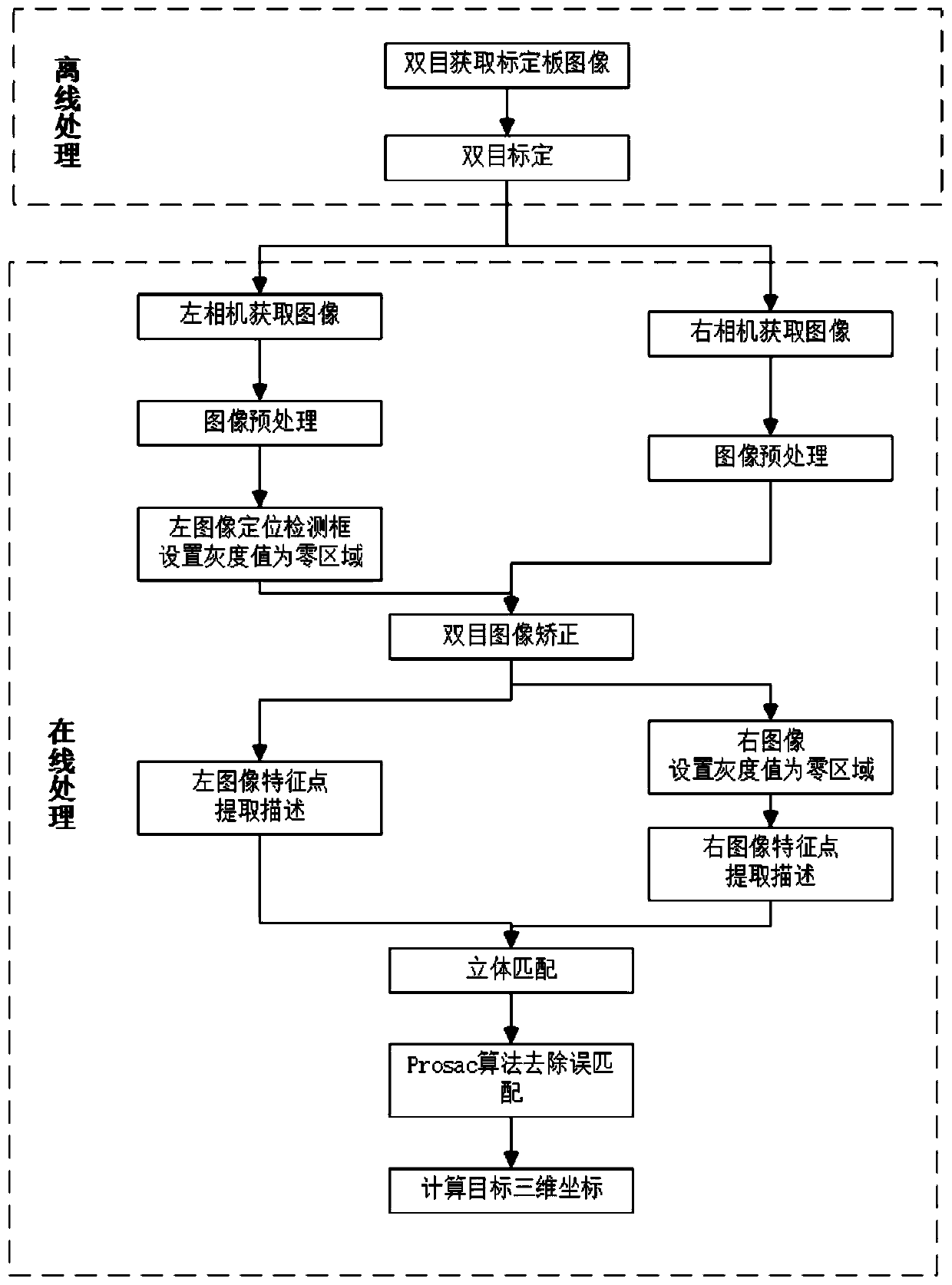

Binocular vision positioning method for target grabbing of underwater robot

ActiveCN111062990AMeet real-time requirementsReduce random errorImage enhancementImage analysisImage correctionBinocular stereo

The invention relates to a binocular vision positioning method for target grabbing of an underwater robot, and belongs to the field of computer vision. The method is mainly used for accurately acquiring three-dimensional information of a grabbed target when an underwater robot works. The method comprises the following steps: double-target positioning: calculating internal and external parameters of left and right cameras; target detection: positioning a target object detection frame; binocular image correction: carrying out distortion correction and stereo correction, and determining a right image target area; binocular image stereo matching: extracting image feature points, describing the feature points, performing stereo matching, and removing mismatching; and calculating the three-dimensional information of the target in the image under the left camera coordinate. According to the method, the accurate parallax value is obtained by extracting feature points, removing unstable featurepoints through non-maximum suppression, constructing a binary descriptor, matching the feature points and removing mismatching. Through the scheme, the binocular stereo matching robustness can be improved, and meanwhile, the three-dimensional information of the detection target can be accurately obtained, so that the real-time positioning requirement on the target when the underwater robot grabsthe target is met.

Owner:HARBIN ENG UNIV

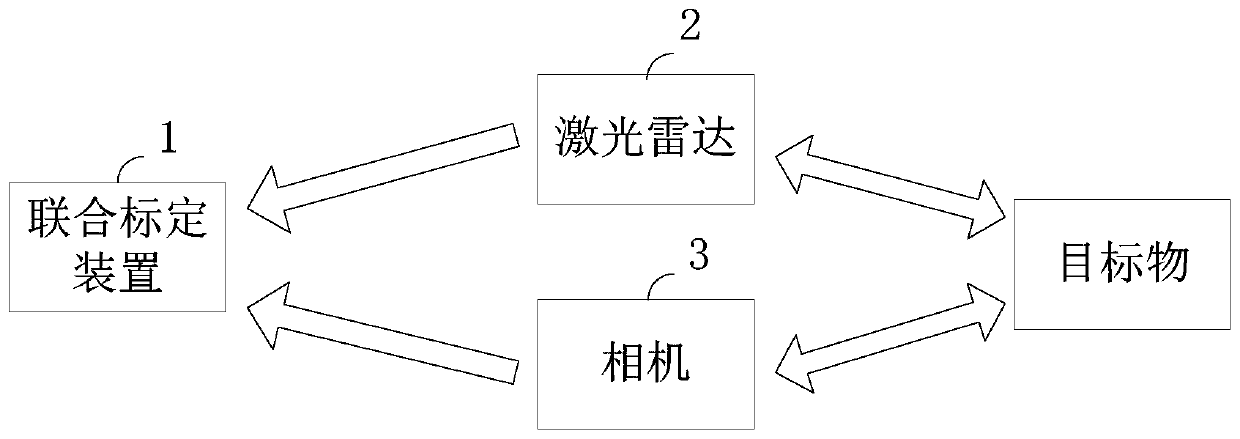

Joint calibration method and device, electronic equipment and storage medium

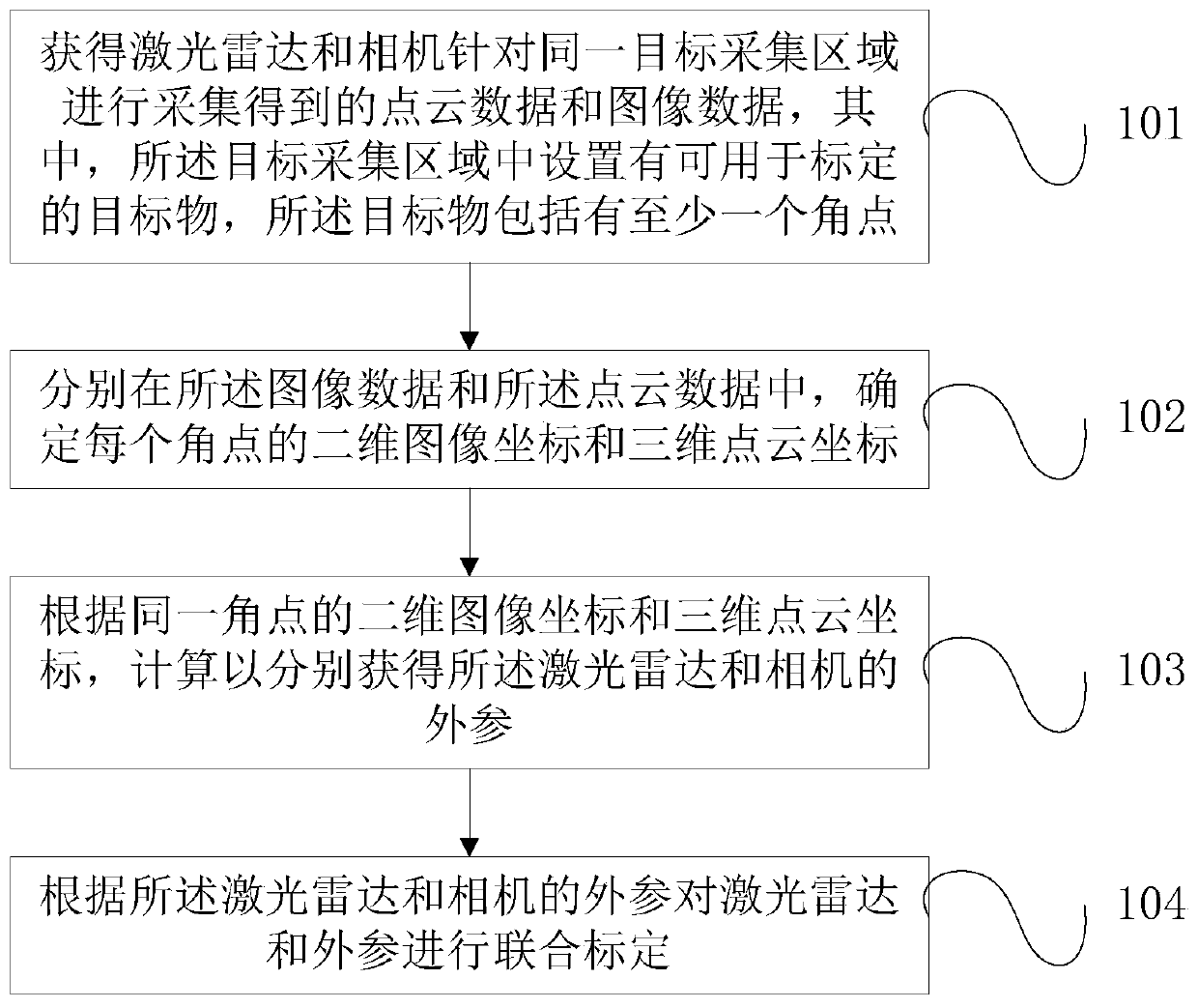

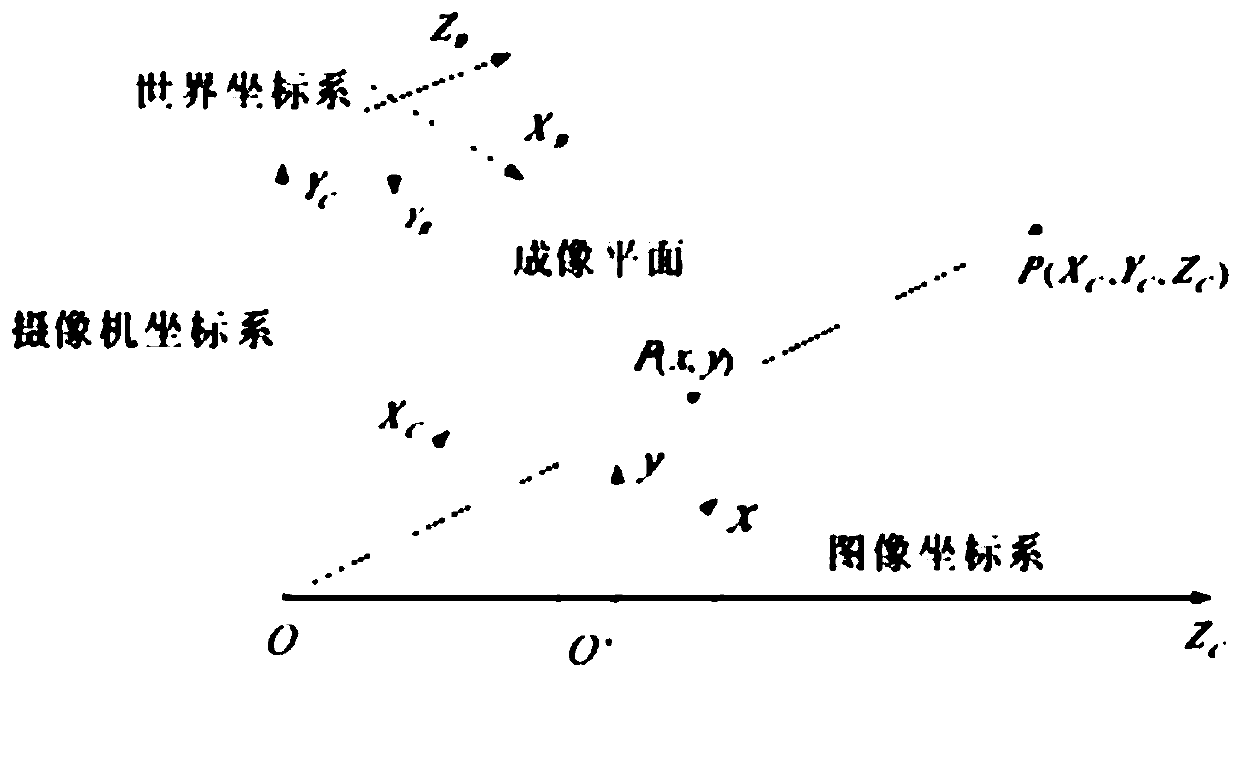

PendingCN111127563AGood for repeated calibrationImprove calibration efficiencyImage enhancementImage analysisPoint cloudEngineering

According to the joint calibration method and device, the electronic equipment and the storage medium provided by the invention, the method includes: acquiring the point cloud data and the image dataacquired by the laser radar and the camera for the same target acquisition area, wherein the target acquisition area is internally provided with the target object capable of being used for calibration, and the target object comprises at least one corner point; determining a two-dimensional image coordinate and a three-dimensional point cloud coordinate of each corner point in the image data and the point cloud data respectively; according to the two-dimensional image coordinates and the three-dimensional point cloud coordinates of the same angular point, performing calculating to respectivelyobtain external parameters of the laser radar and the camera; performing joint calibration on the laser radar and the external parameters according to the external parameters of the laser radar and the camera. Therefore, the calibration of the laser radar and the camera is not carried out by using a calibration plate; insteadly, the point cloud data and the image data acquired by the laser radar and the camera aiming at the target object in the same target acquisition area are directly calibrated, so that the calibration efficiency is improved, the calibration process is simplified, and repeated calibration of the laser radar and the camera is facilitated.

Owner:BEIJING WANJI TECH

Robust lens distortion correction method

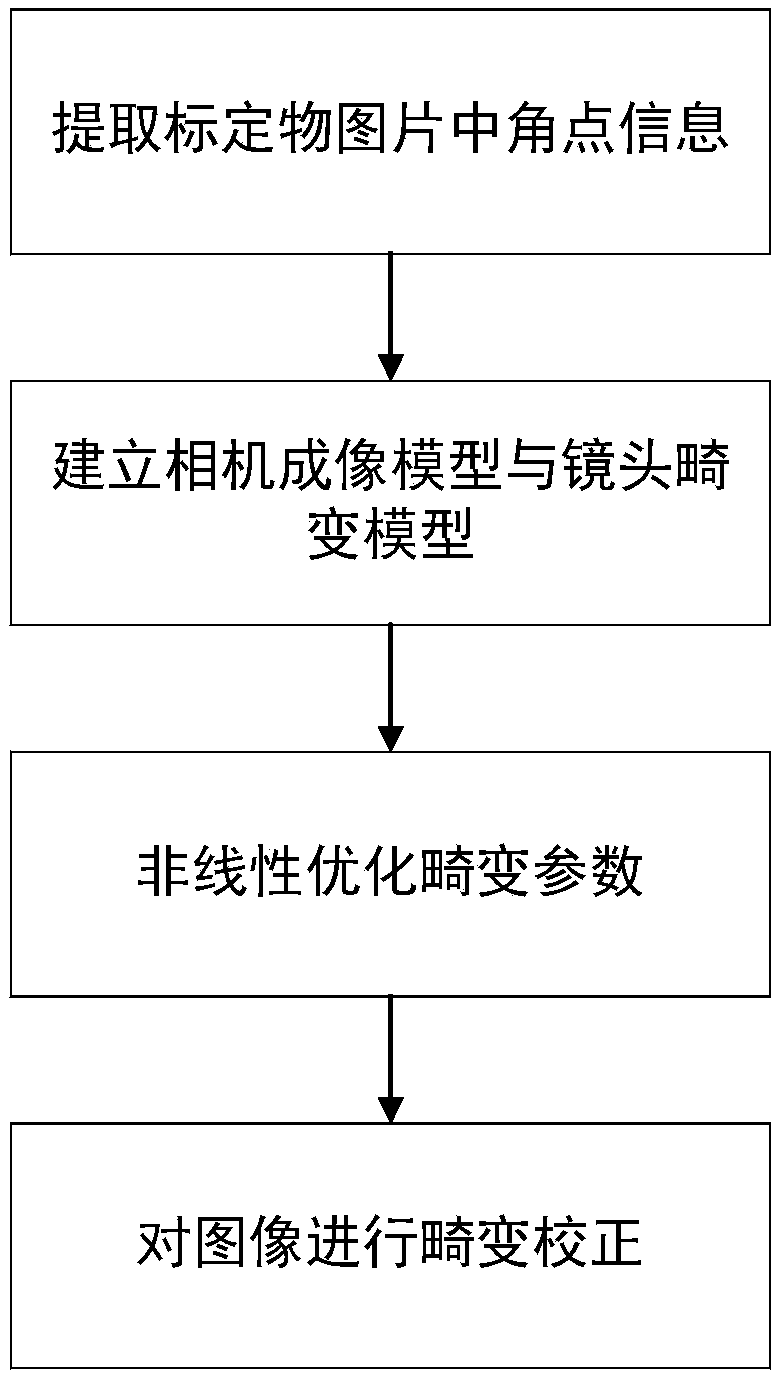

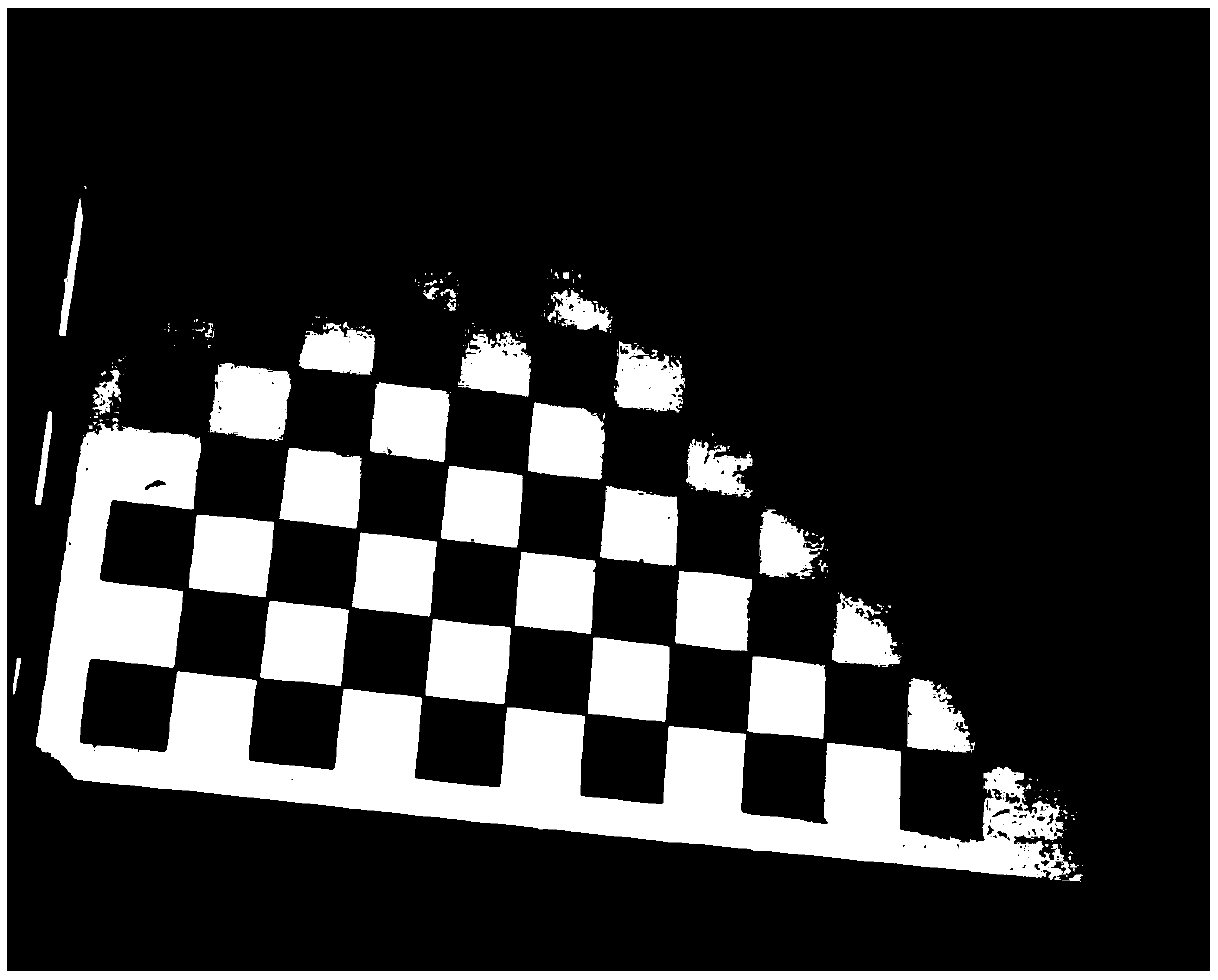

InactiveCN108876749ASolve complexitySolve the large amount of calculationImage enhancementImage analysisFeature extractionAngular point

The invention discloses a robust lens distortion correction method. The invention provides a method for separating lens distortion from camera parameters to be solved separately. The method comprisesthe following steps of: performing a feature extraction from a checkerboard calibration object by firstly performing angular point detection utilizing a Shi-Tomasi operator, then performing screeningaccording to the specific characteristics of symmetry and large variance of the checkerboard angular point, and finally obtaining an sub-pixel coordinate with accurate checkerboard angular point by utilizing a sub-pixel optimization algorithm; establishing a camera imaging model and a lens distortion model to obtain an optimized objective function with respect to a distortion parameter; and solving the distortion parameter by utilizing a nonlinear optimization algorithm for distortion correction. According to the robust lens distortion correction method, a calculation of all main distortion parameters can be accomplished with only one calibration object image containing the checkerboard, the model is simple, the calculation efficiency and stability are high, the application adaptability isgood in an industrial field, and the calculation accuracy is comparable to a traditional method.

Owner:NANJING HUICHUAN IND VISUAL TECH DEV +1

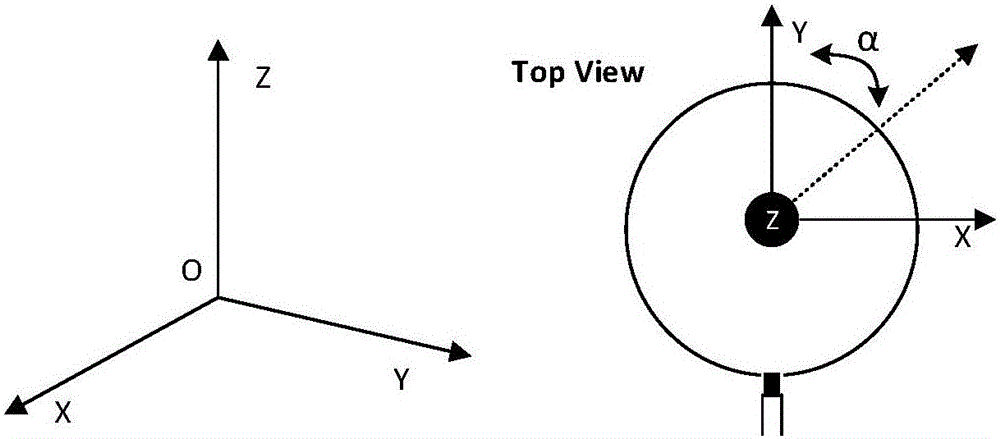

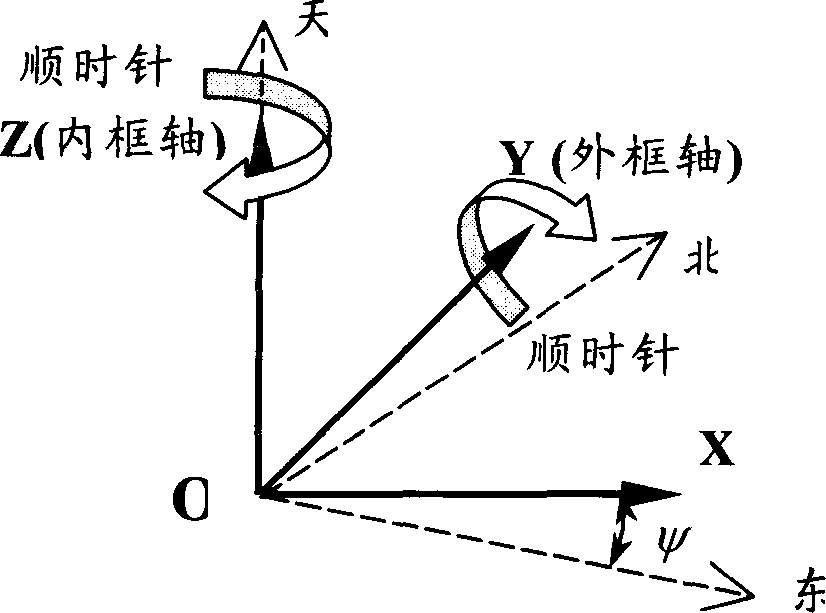

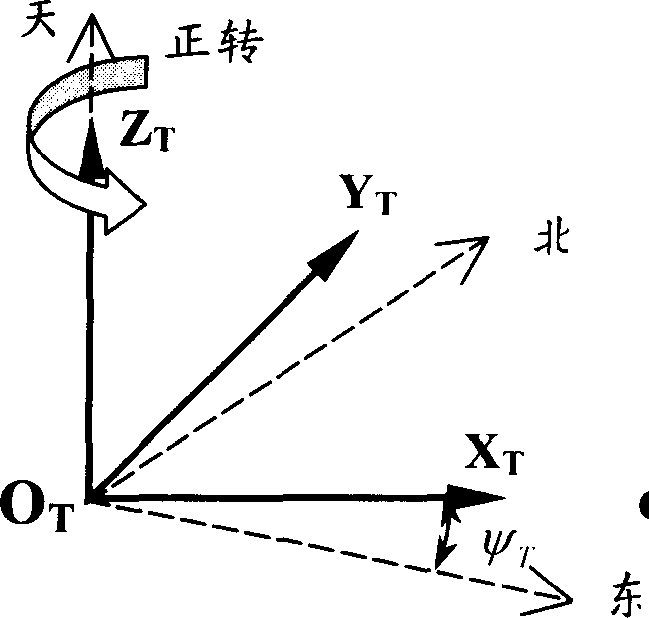

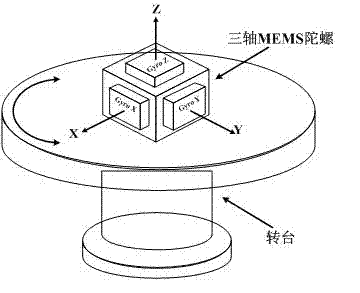

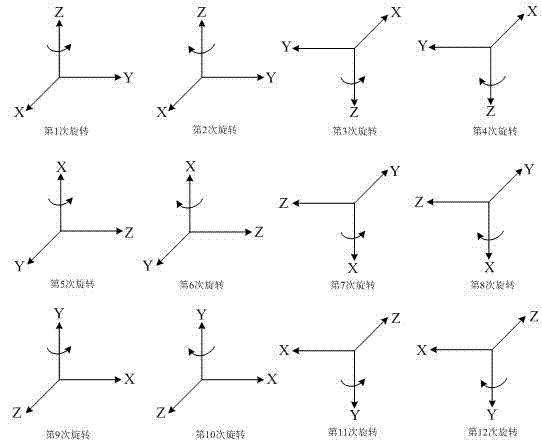

Triaxial MEMS gyroscope rotation integral calibration method based on uniaxial turntable

The invention discloses a triaxial MEMS gyroscope rotation integral calibration method based on a uniaxial turntable. According to the invention, first, a triaxial MEMS gyroscope error model is established; the triaxial MEMS gyroscope is fixed on the uniaxial turntable; MEMS gyroscope six-position rotary calibration is carried out; test data and sampling time of 12 times of rotation of the MEMS gyroscope at the 6 positions are tested and recorded; through the 12 times of rotation of the MEMS gyroscope at the 6 positions, a MEMS gyroscope error model is simplified, and an error model after gyroscope rotation is obtained; integral calculations are carried out upon two sides of the equation of the error model after gyroscope rotation, an error equation set is established, and MEMS gyroscope error coefficient is obtained by calculation. With the method provided by the invention, calibration precision is ensured; and fixed zero bias, scale factor, cross-coupling error coefficient, and acceleration sensitivity coefficient of the MEMS gyroscope can be solved rapidly, such that calibration efficiency is improved.

Owner:EAST CHINA INST OF OPTOELECTRONICS INTEGRATEDDEVICE

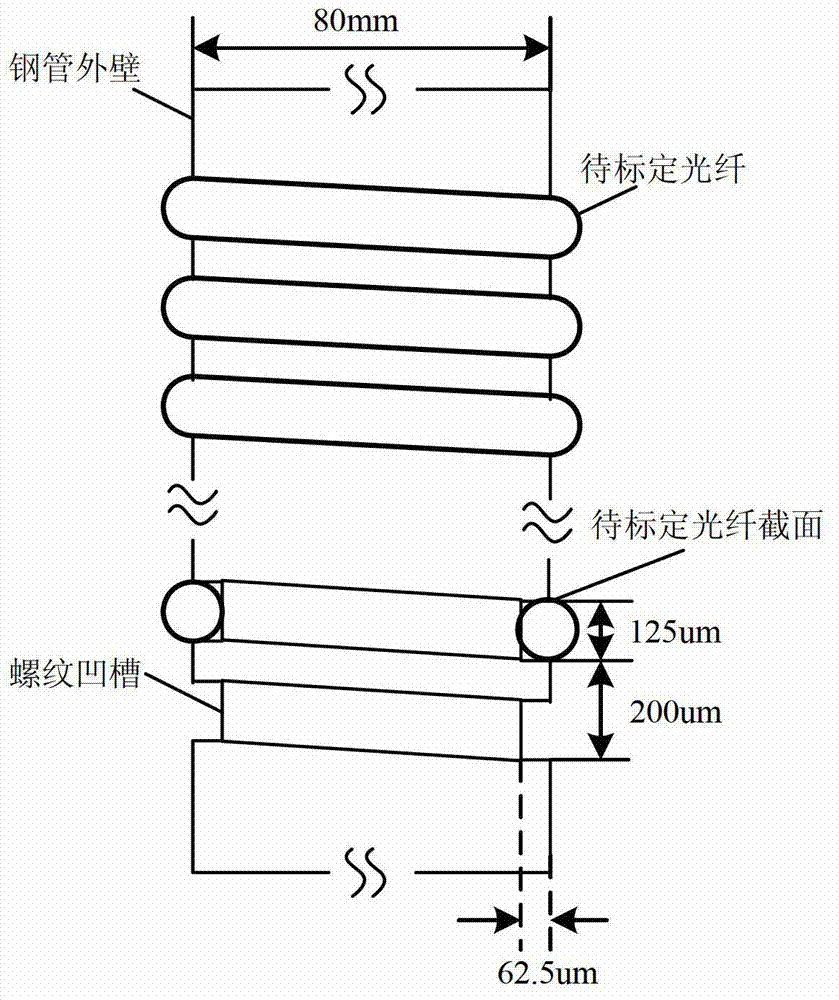

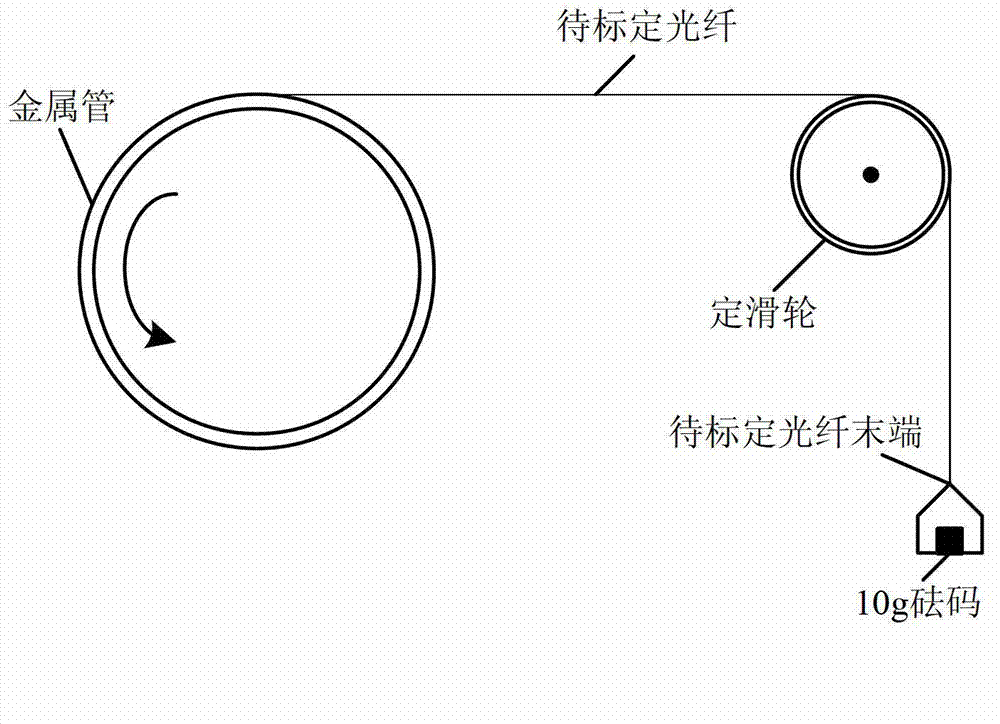

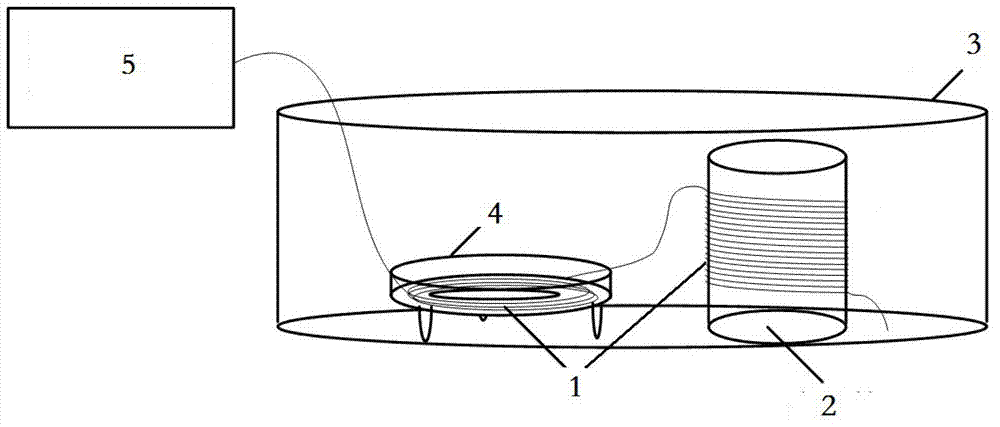

Optical fiber strain and temperature simultaneous calibration device and method based on Brillouin scattering

InactiveCN103115642AControl lengthEnsure consistencyMeasurement devicesPlastic optical fiberHigh strain

The invention belongs to the technical field of distribution-type optical fiber sensing measurement, in particular to an optical fiber strain and temperature simultaneous calibration device and a method based on Brillouin scattering. The optical fiber strain and temperature simultaneous calibration device comprises optical fiber Brillouin sensing measurement equipment, a shockproof support frame, a metal pipe and constant-temperature equipment. According to the method, the metal pipe with large and stable linear expansion coefficient is adopted to manufacture the strain calibration device, and the position of an optical fiber is accurately controlled by curving a thread on the outer wall of the metal pipe. Due to the characteristic that the optical fiber on the metal pipe bears strain and temperature at the same time, and the loose optical fiber only bears temperature, the temperature and the strain are calibrated simultaneously. The constant-temperature equipment is used for applying accurate and controllable strain and temperature on the optical fiber and the loose optical fiber on the metal pipe, and calibration of the strain of the optical fiber and temperature coefficient is carried out by means of detailed calibration steps. By means of the strain and temperature high-accuracy simultaneous calibration device and the method of the optical fiber Brillouin sensor, the problems of high strain calibration error and low efficiency of strain and temperature calibration are resolved.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

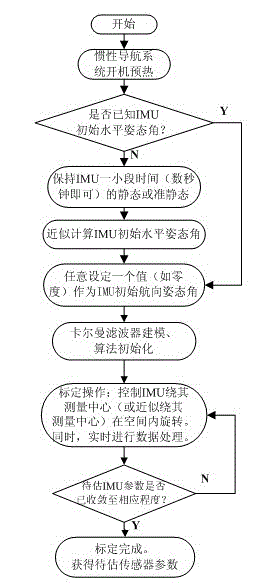

Quick calibration method for inertial measurement unit

ActiveCN102865881AImprove calibration efficiencyImprove calibration accuracyTesting/calibration of speed/acceleration/shock measurement devicesAccelerometerError coefficient

The invention relates to a quick calibration method for an inertial measurement unit (IMU). According to the method, twelve error coefficients such as gyro zero bias, scale factor, accelerometer zero bias and scale factor can be calibrated precisely within a short time just by holding and rotating the IMU to traverse directions by a user without using any external devices. The quick calibration method for the IMU provided by the invention has the characteristics of no hardware cost, high efficiency and simpleness and practicability, and a certain calibrating precision can be ensured. The quick calibration method for the IMU is in particular suitable for quick calibration in the field of middle-precision and low-precision IMUs, the environment sensitive problems of parameters of micro-mechanical IMUs are effectively solved, and popularization and application of MEMS (Micro-electromechanical Systems) inertial components are promoted.

Owner:WUHAN YIDELU POSITION TECH CO LTD

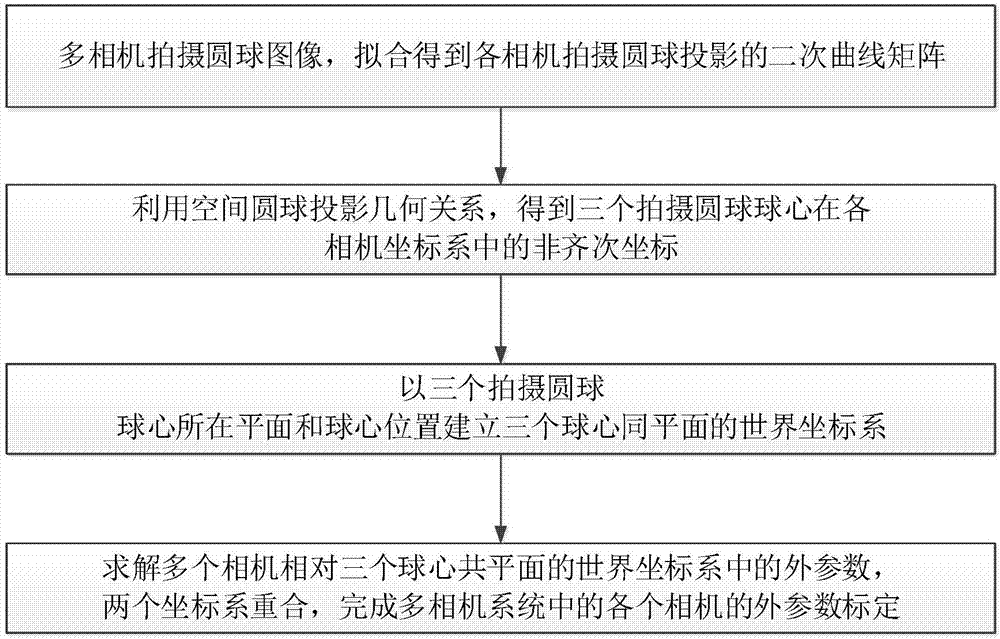

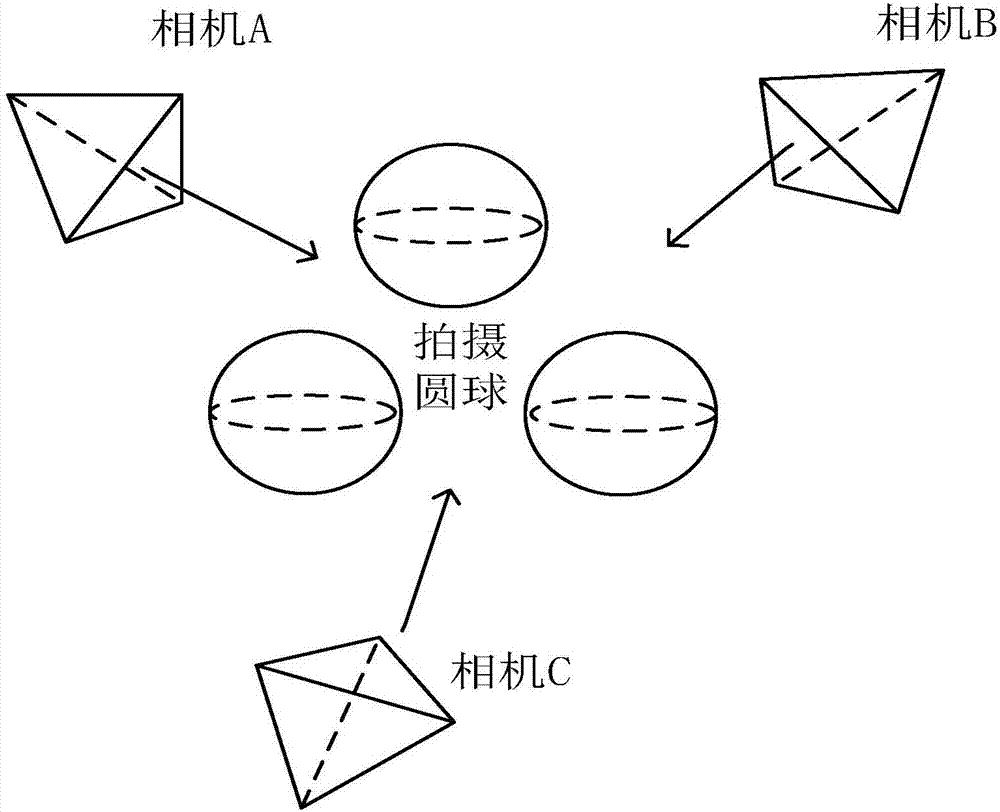

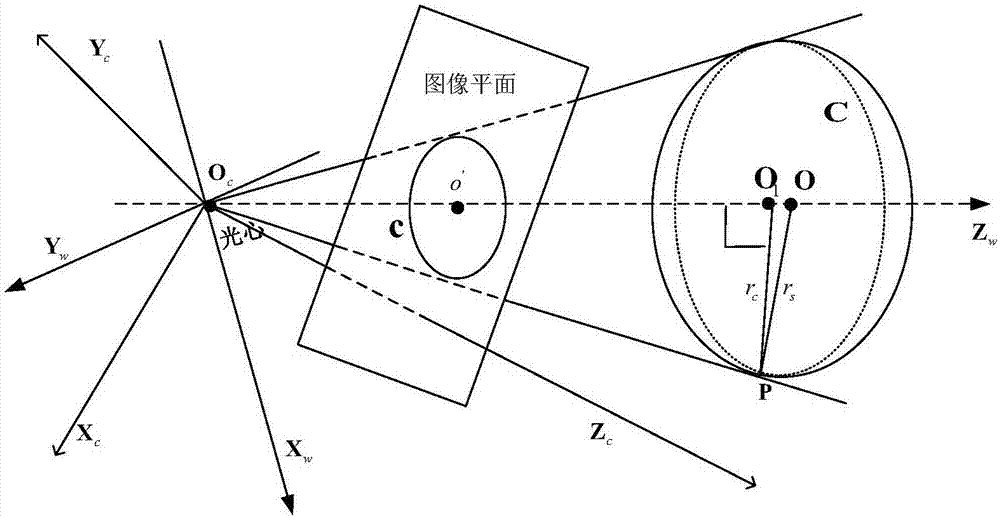

Camera external parameter calibration method of multi-camera system

InactiveCN107146254ASimple Calibration Facility RequirementsImprove calibration accuracyImage enhancementImage analysisMulti cameraMarine navigation

The invention discloses a camera external parameter calibration method of a multi-camera system for solving the problems that a three-dimensional precise calibration object is difficult to manufacture, the efficiency of a multi-camera external parameter calibration process is low, and that accumulative errors are generated in the existing method. The method comprises the following steps: performing fitting to obtain quadratic curve matrixes of shooting ball projections of cameras; solving inhomogeneous coordinates of three spherical centers in a camera coordinate system; establishing a world coordinate system in which the three spherical centers are located on the same plane through the plane where the three spherical centers are located and the positions of the spherical centers; solving external parameters of a plurality of cameras in the world coordinate system in which the three spherical centers are located on the same plane, and accomplishing the external parameter calibration of the cameras in the multi-camera system, wherein the two coordinate systems are overlapped. By adoption of the camera external parameter calibration method disclosed by the invention, the external parameters of the plurality of cameras in the same world coordinate system are calculated quickly, conveniently and accurately without requiring more conversion, no accumulative error is generated, and the camera external parameter calibration precision is high. The camera external parameter calibration method is applied to the fields of image measurement, three-dimensional reconstruction, unmanned aerial vehicle navigation, etc.

Owner:XIDIAN UNIV

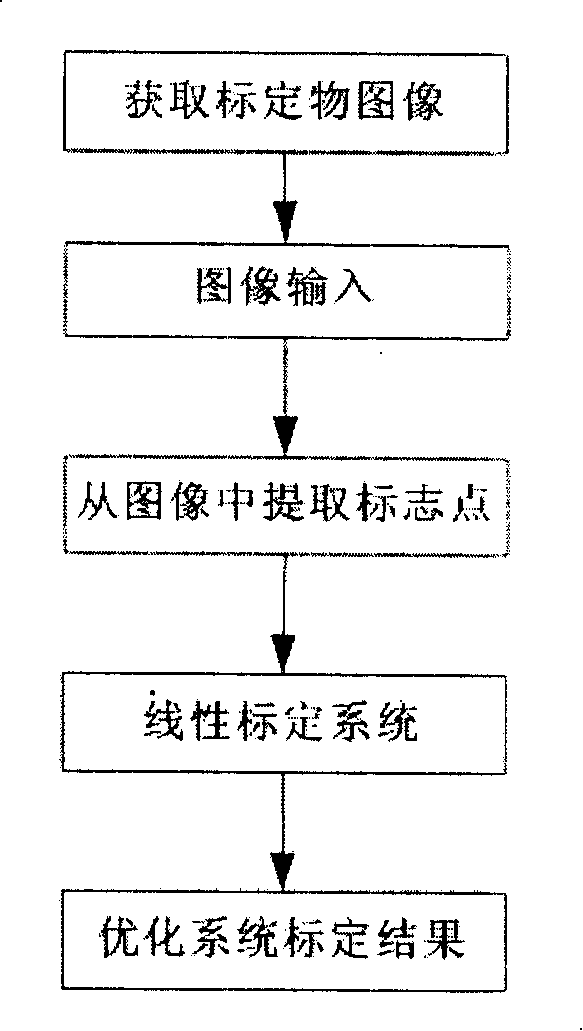

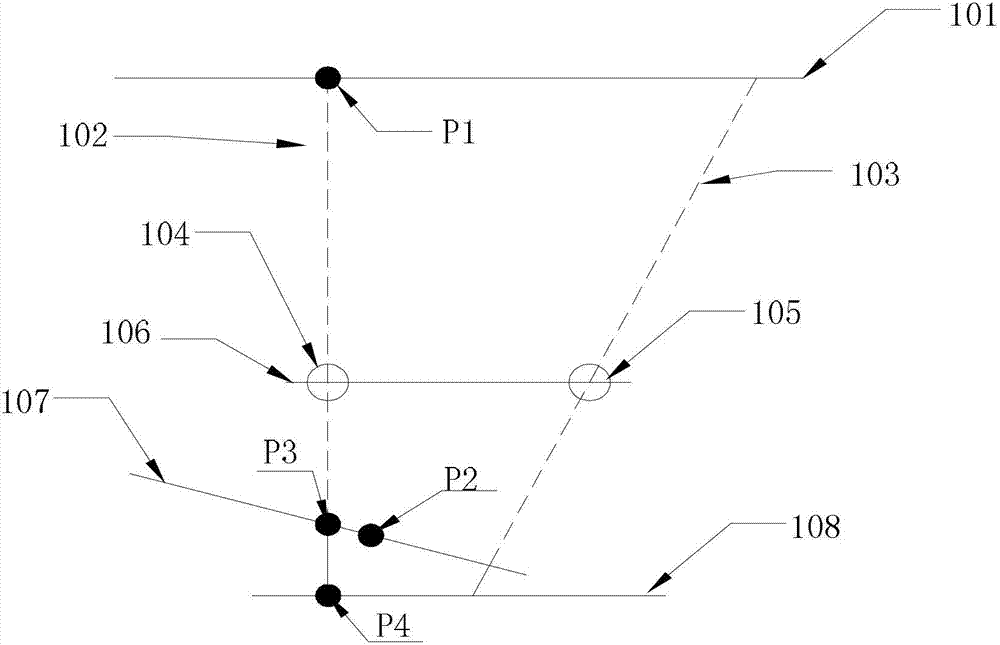

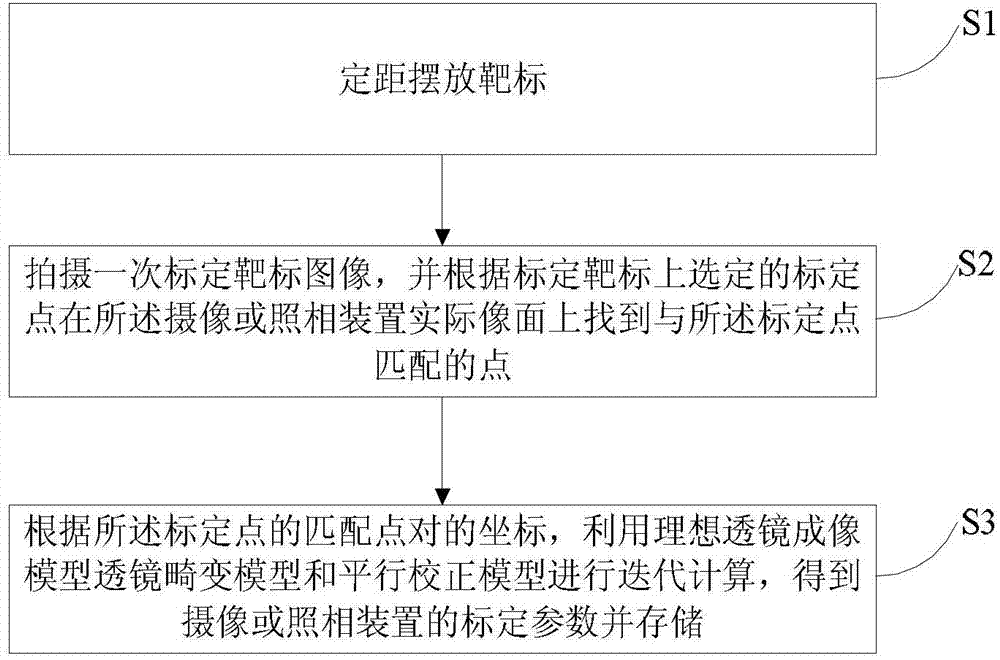

Method for calibrating camera shooting or photographing device

The invention discloses a method for calibrating a camera shooting or photographing device, and belongs to the technical field of measurements. The method comprises the following steps of: presetting a position relationship between a calibration target and the camera shooting or photographing device; performing iterative computations according to coordinates of a preselected calibration point on the calibration target and a matching point of the calibration point on an actual image plane of the camera shooting or photographing device by utilizing an ideal lens imaging model, a lens distortion model and a collimation model; and calibrating the parameters of the camera shooting or photographing device. By the method, the position relationship between the calibration target and the camera shooting or photographing device is preset, the displacement calculation process of the optical center of the lens of the camera shooting or photographing device relative to the origin of coordinates of the plane of the calibration target is simplified, so that the whole calibration process is high-efficiency; and moreover, by the method, the problem that the parameters of the device are calibrated when the focusing is inaccurate can be effectively solved, the target pattern is only required to be photographed at one time, and the calibration efficiency is improved. In addition, the three-dimensional distance under the out-of-focus condition can be effectively measured.

Owner:SHENZHEN TAISHAN SPORTS TECH CO LTD

Portable multifunctional vacuum calibration system and method

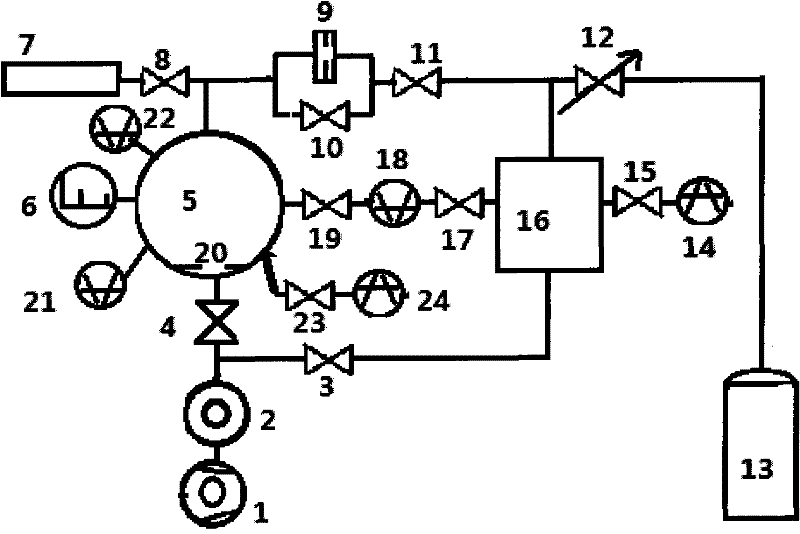

InactiveCN102589803ASimple structureHigh precisionMeasurement of fluid loss/gain rateTesting/calibration apparatusEngineeringSmall hole

The invention relates to a portable multifunctional vacuum calibration system and a method, belonging to the field of measurement technologies. The calibration system comprises a mechanical pump 1, a molecular pump 2, a first vacuum valve 3, a second vacuum valve 4, a third vacuum valve 8, a fourth vacuum valve 10, a fifth vacuum valve 11, a sixth vacuum valve 17, a seventh vacuum valve 19, an eighth vacuum valve 23, a ninth vacuum valve 15, a calibration chamber 5, a quadrupole mass spectrometer 6, a first small hole 9, a second small hole 20, a fine-adjustment valve 12, a gas source 13, a first vacuum gauge 14, a second vacuum gauge 18, a third vacuum gauge 21, a fifth vacuum gauge 24 and a pressure-stabilizing chamber 16; and the method comprises a vacuum leak calibration method and a vacuum gauge calibration method. According to the system, the vacuum gauges and a gas micro-flow calibration function are combined, and the vacuum gauges, vacuum leaks, leak detectors and gas micro-flowmeters can be calibrated in an on-site or on-line manner, so that the system has the characteristics of multifunction, high accuracy, little weight, small volume, portability and the like.

Owner:江苏东方航天校准检测有限公司

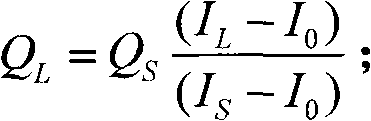

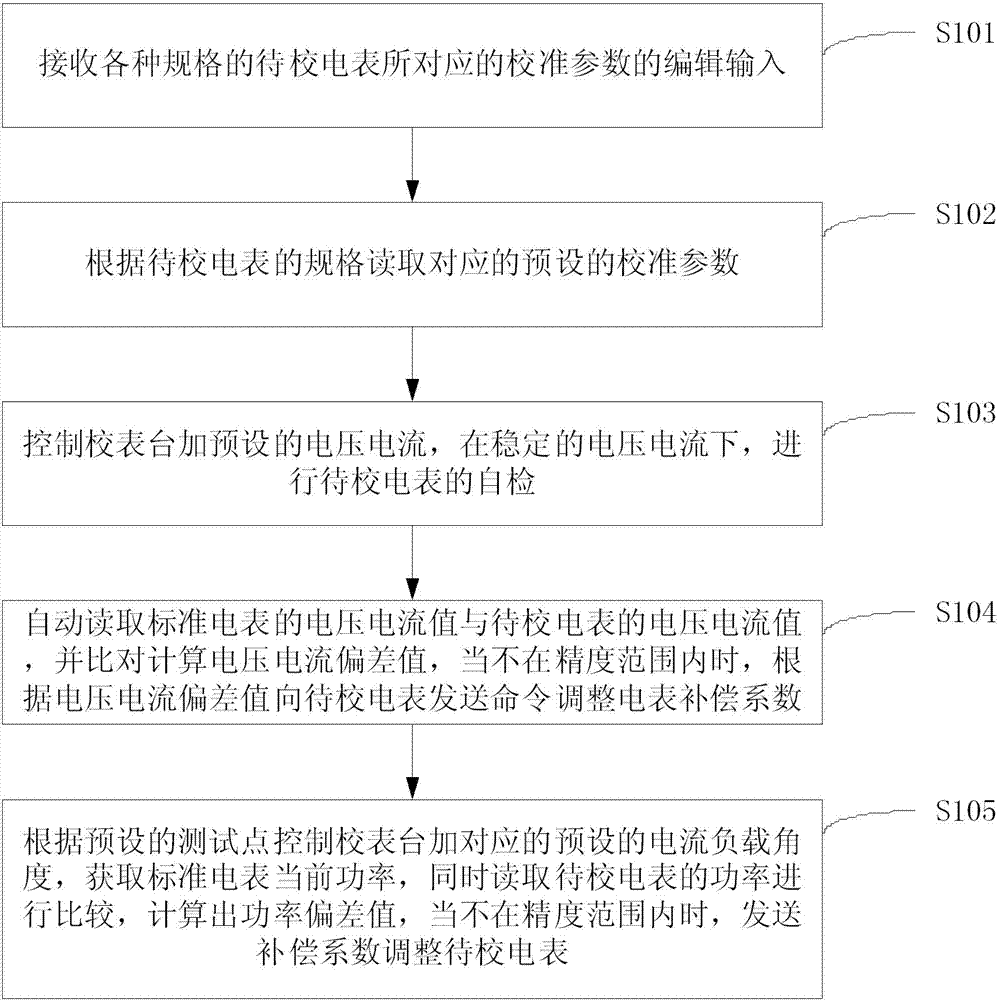

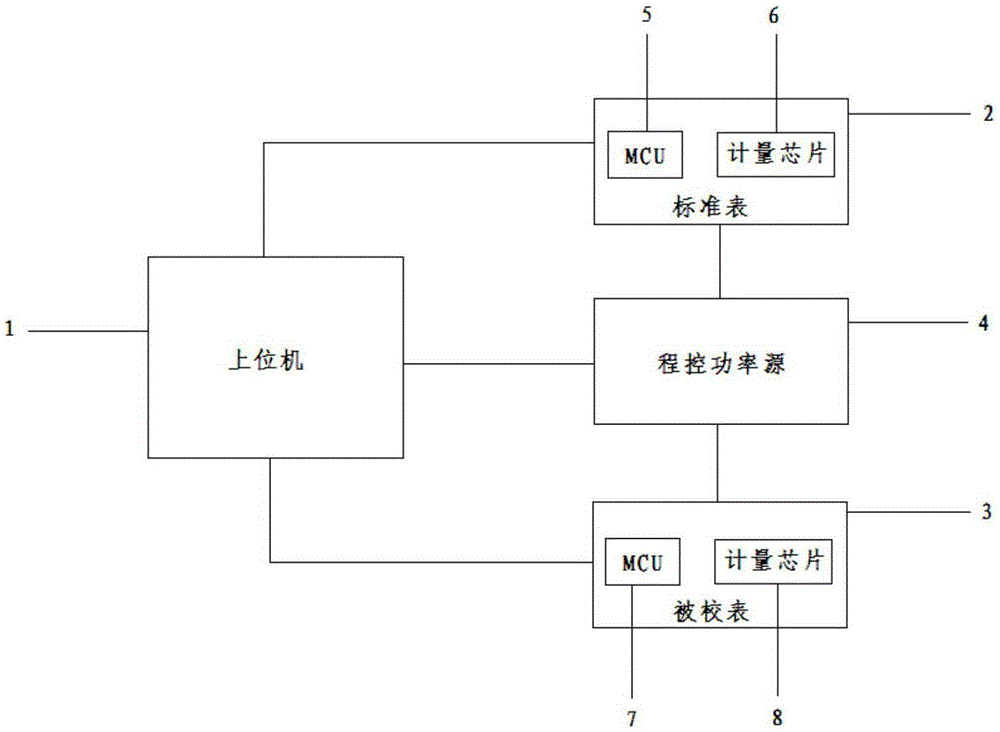

Electric meter calibrating method and automatic calibrating system

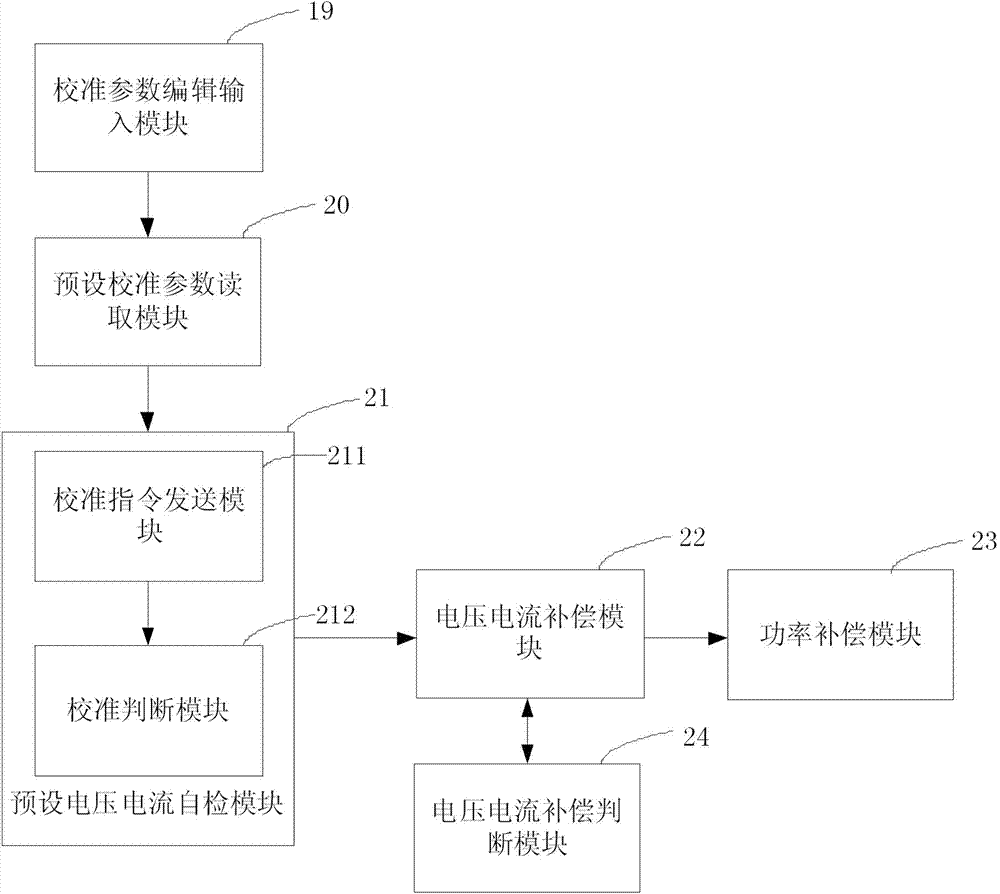

ActiveCN103487782AReduce human inputImprove calibration efficiencyElectrical measurementsCurrent loadEngineering

The invention is applicable to the electric power field and provides an electric meter calibrating method and an automatic calibrating system. The method comprises the steps that preset voltages and currents are controlled to be exerted on an electric meter calibrating station, and self-inspection of an electric meter to be calibrated is carried out under the stable voltages and currents; voltage values and current values of a standard electric meter and voltage values and current values of the electric meter to be calibrated are automatically read, and voltage deviation values and current deviation values are compared and calculated, and a command is sent to the electric meter to be calibrated for adjusting an electric meter compensation factor according to the voltage deviation values and the current deviation values when the voltage deviation values and the current deviation values are not within accuracy ranges; a corresponding preset current load angle is controlled to be exerted on the electric meter calibrating station according to a preset test point, the current power of the standard electric meter is obtained, meanwhile, the power of the electric meter to be calibrated is read for comparison, power deviation values are figured out, and a compensation factor is sent for adjusting the electric meter to be calibrated when the power deviation values are not within an accuracy range. Thus, the calibration of multiple electric meters can be automatically completed at a time through the electric meter calibrating station, extra manual intervention is not required, and efficiency is improved.

Owner:SHENZHEN TECHRISE ELECTRONICS

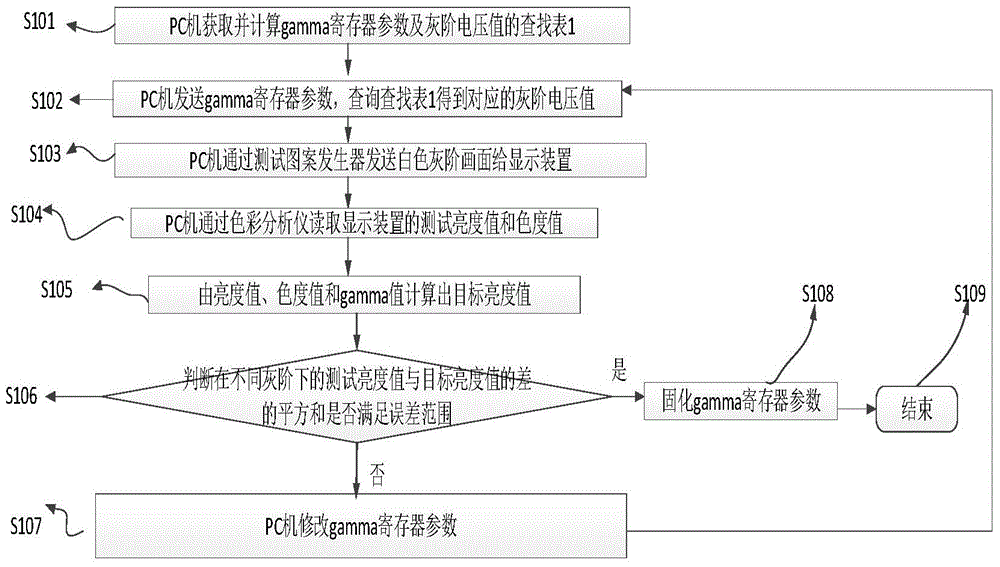

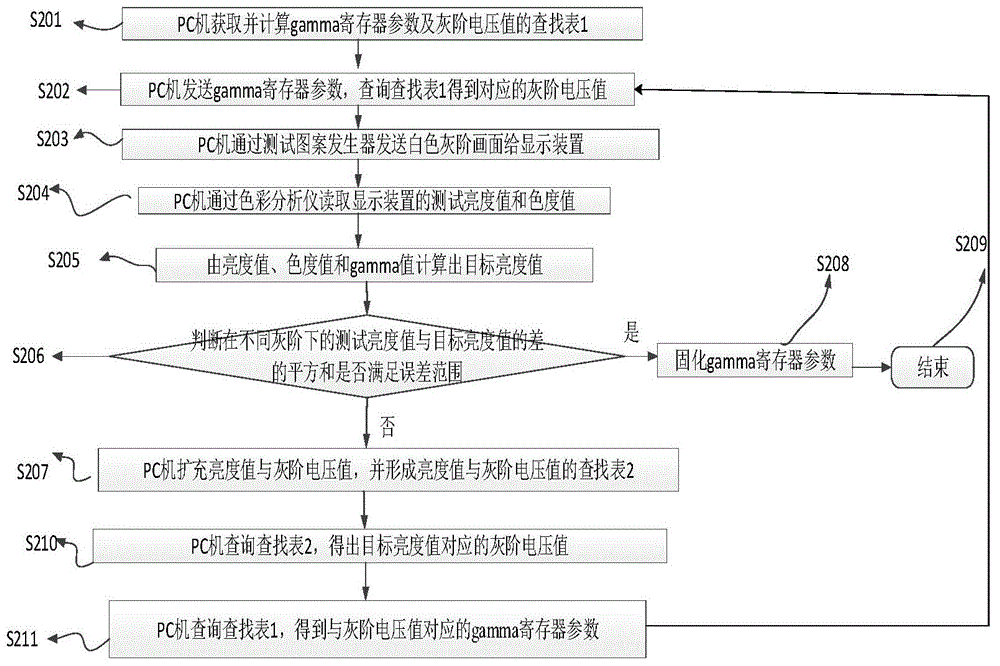

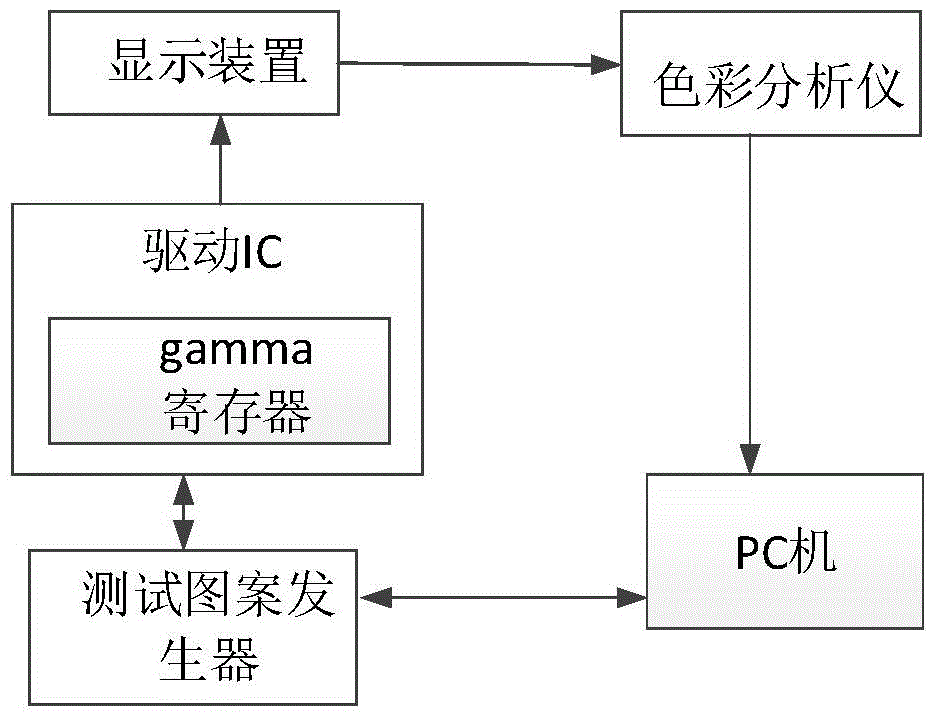

Automatic gamma and white balance correction method and device for display device

ActiveCN104809974AWill not be affected by subjective judgmentImprove Calibration AccuracyCathode-ray tube indicatorsElectricityGray level

The invention relates to a correction method and device, in particular to an automatic gamma and white balance correction method and a device for a display device. The automatic gamma and white balance correction device comprises a display device, a color analysis meter, a PC (Personal Computer) and a test pattern generator which are sequentially connected electrically; the test pattern generator is electrically connected with the display device through a driving IC (Integrated Circuit). According to the automatic gamma and white balance correction device, whether the quadratic sum of difference between luminance values under different gray levels and target luminance values satisfies an error range or not is judged, correction is finished after solidification of gamma register parameters in a gamma register of the driving IC, the gamma register parameters are modified if not, and recalibration is performed until the quadratic sum of the difference between the luminance values and the targeted luminance values satisfies the error range; a calibration result is automatically judged after calibration of gamma and white balance and the calibration result is not influenced by subjective judgment of tested person.

Owner:TRULY HUIZHOU SMART DISPLAY

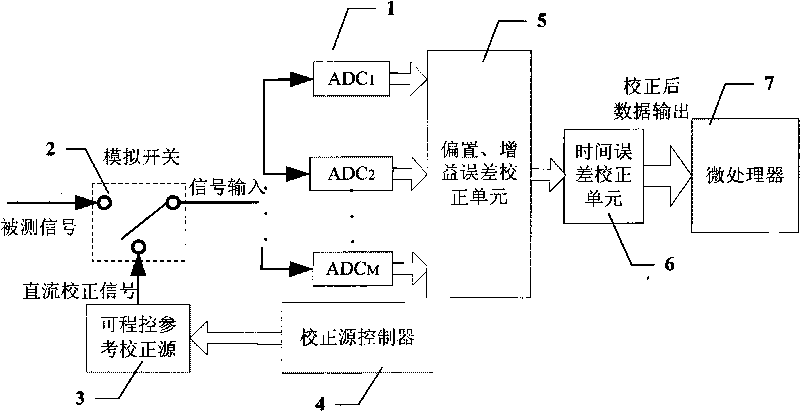

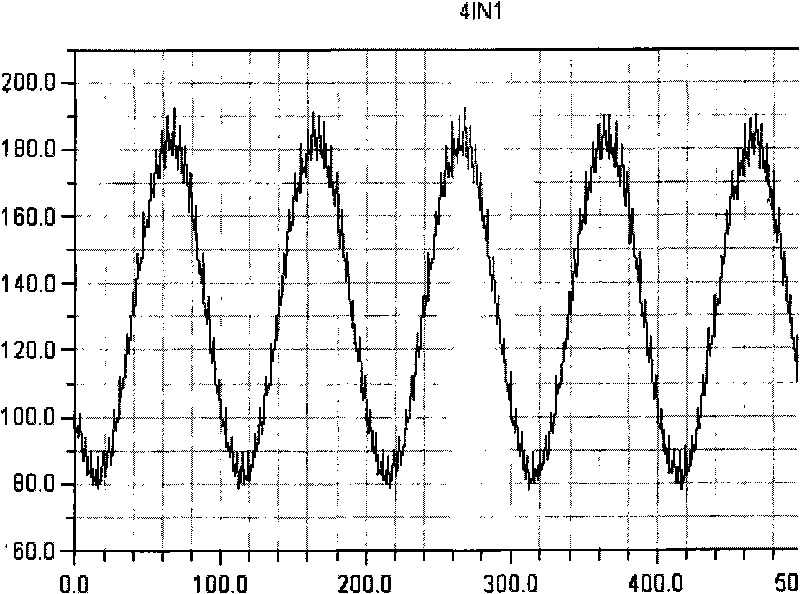

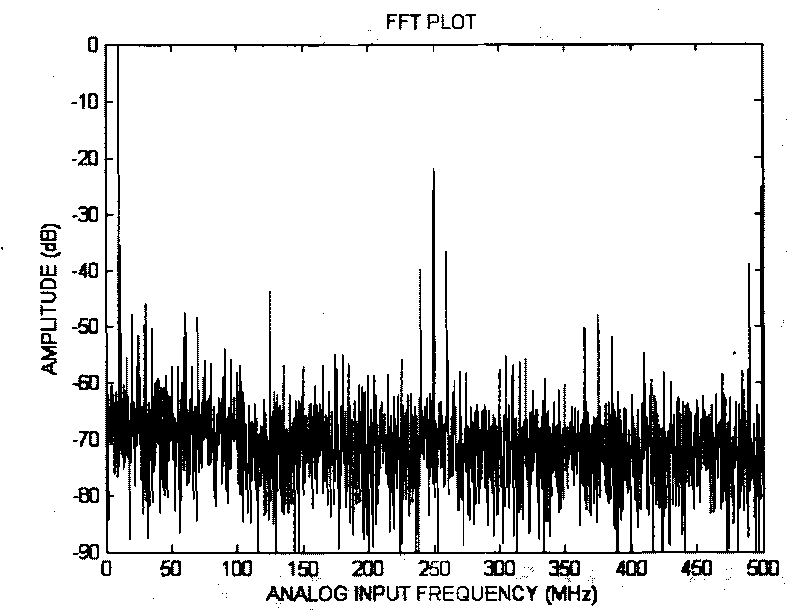

Method for real-time correcting error of multi-channel high-speed parallel alternative acquisition system

InactiveCN101718562ASimple processSmall amount of calculationMitigation of undesired influencesTime errorLow-pass filter

The invention discloses a method for real-time correcting error of a multi-channel high-speed parallel alternative acquisition system, which comprises the following steps: in correction, inputting direct current correction signals of different voltages, acquiring a quantization value of each ADC and performing correction point by point to obtain errors point by point and form an error matrix; in measurement, inputting a signal to be measured and performing sampling at time alternating, acquiring quantization values and searching a table in the error matrix, deducting corresponding error value from the quantization values respectively to obtain corrected actual quantization values; and then, rearranging the corrected quantization values according a time phase relationship; converting the rearranged and corrected quantization values into acquisition data for output; and performing low-pass filter; and filtering time-base deviation error spectral line so as to finish the correction of a time error. Compared with the prior art, the method has the advantages that: the deviation and a gain error can be corrected at the same time; and a table searching operation is a corresponding relationship operation of which the process is simple and the calculation amount is small. A low-pass digital filter is very easy to be implemented in a DSP processor and the operation rate is fast so that the efficiency of the time error correction is improved greatly.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

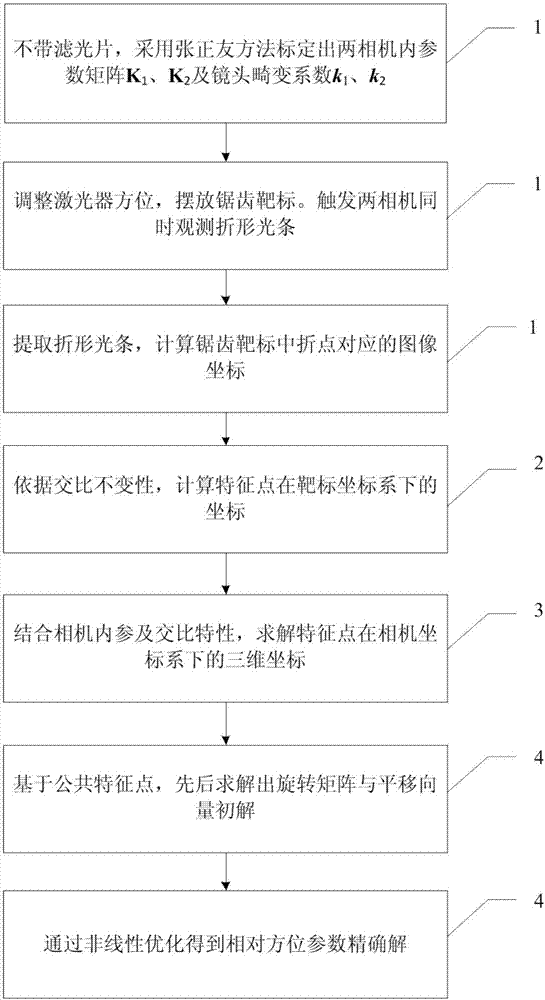

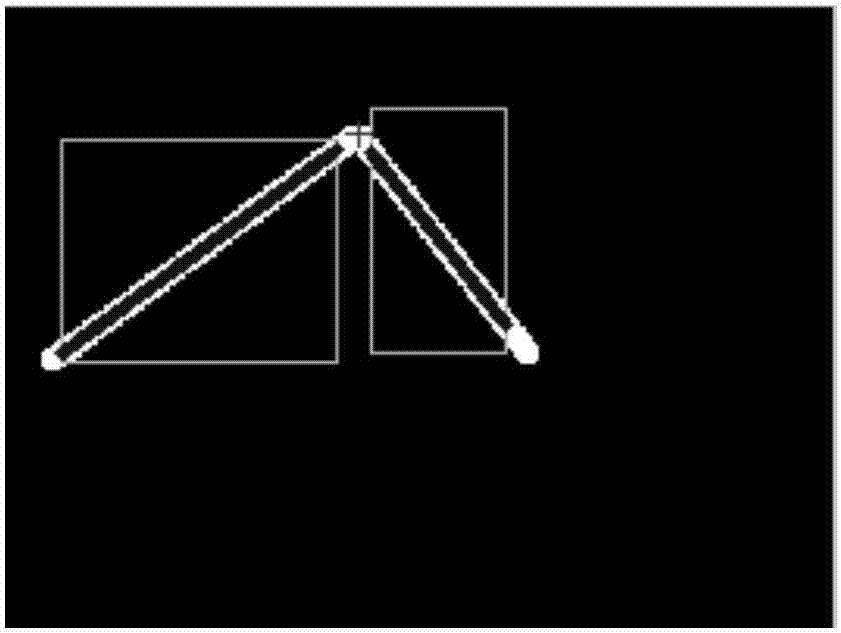

Binocular vision sensor on-site calibration method and binocular vision sensor on-site calibration device in complicated environment

ActiveCN107255443AShielding effectImprove calibration efficiencyUsing optical meansWavelengthVision sensor

The invention discloses a binocular vision sensor on-site calibration method and a binocular vision sensor on-site calibration device in complicated environment. A sawtooth target capable of moving freely is cooperated with a linear laser having a wavelength corresponding to that of an optical filter to complete on-site rapid calibration. According to light strip information irradiated on the target, an image coordinate of a characteristic break point formed by a light strip and the sawtooth target is determined. Based on cross-ratio invariability, the coordinates of all of the break points in a target coordinate system are determined, and by combining with internal parameters of video cameras, the three-dimensional coordinates of all of the target characteristic points in the coordinate systems of the video cameras are calculated, and therefore an external parameter initial value between the two video cameras is calculated. By an integral non-linear optimization, the exact solution of the external parameter between the two video cameras is acquired. An important practical application value is provided for solving a problem of multi-vision sensor global calibration in the complicated environment.

Owner:BEIHANG UNIV

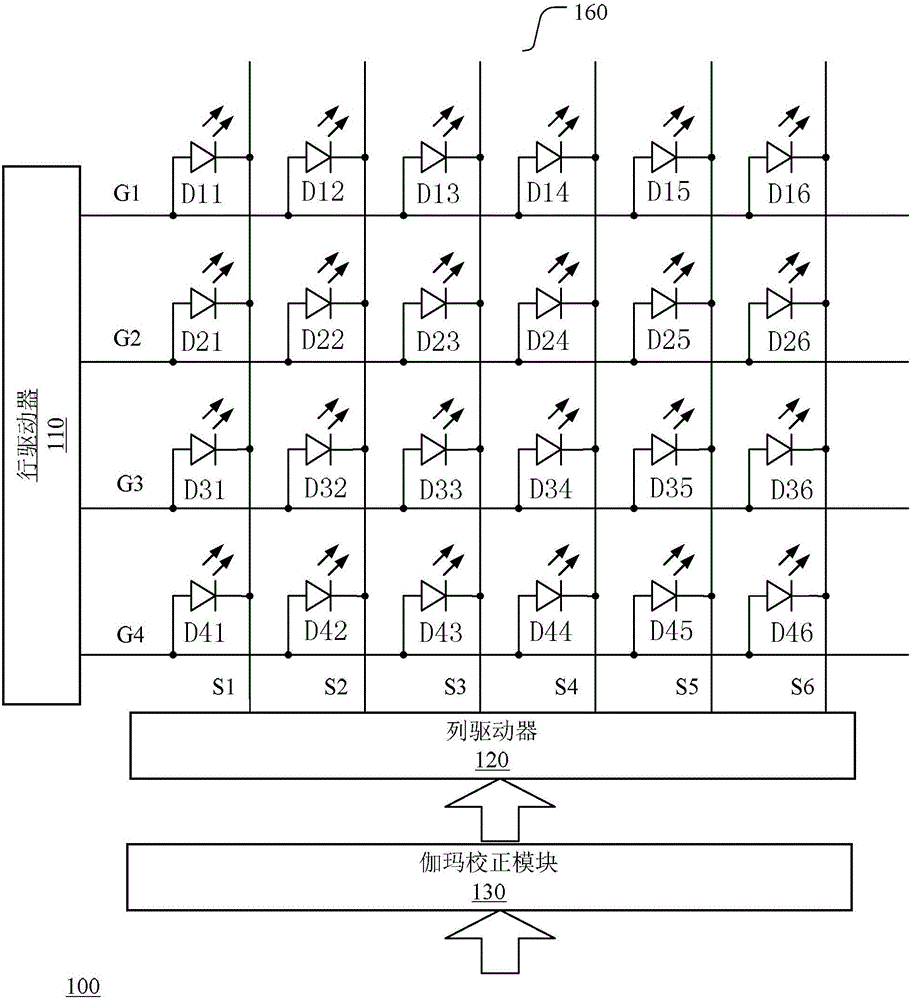

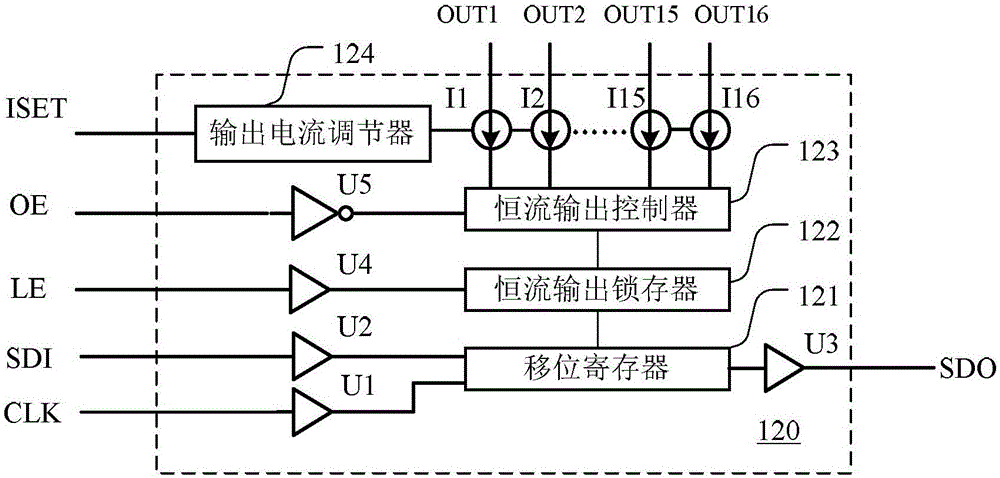

LED display device and driving method thereof

ActiveCN106373516AImprove the correction effectImprove the display effectStatic indicating devicesDriving currentLED display

The application discloses an LED display device and a driving method thereof. The LED display device comprises a plurality of LEDs serving as pixel units. The method includes: gray scale data are generated according to a display image; according to a practical frame rate and a practical refreshing rate, a practical gamma table is generated; on the basis of the practical refreshing rate, gamma correction is carried out on the gray scale data to obtain display data; a PWM signal is generated based on the display data; and a constant-current source is controlled to provide a driving current by using a PWM signal, so that LEDs are lightened to generate brightens corresponding to a gray scale. According to the method, the practical gamma curve is generated based on the practical frame rate and the practical refreshing rate, thereby improving an effect of gamma correction.

Owner:CHIPONE TECH BEIJINGCO LTD

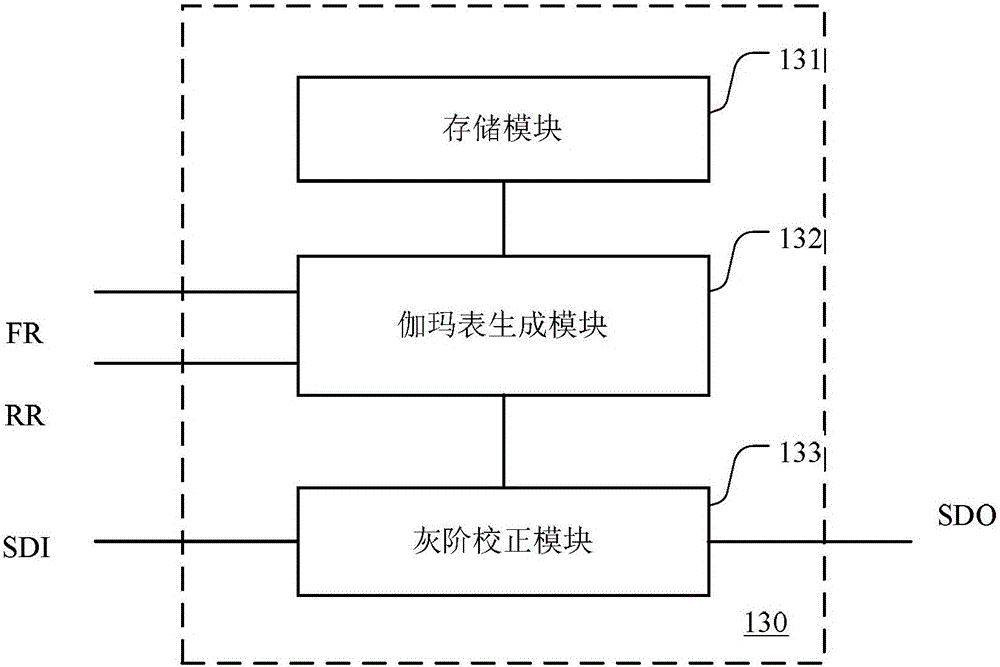

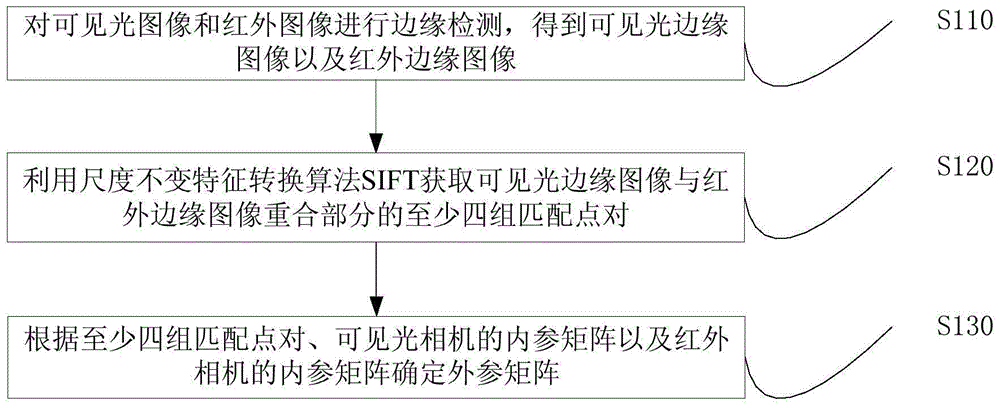

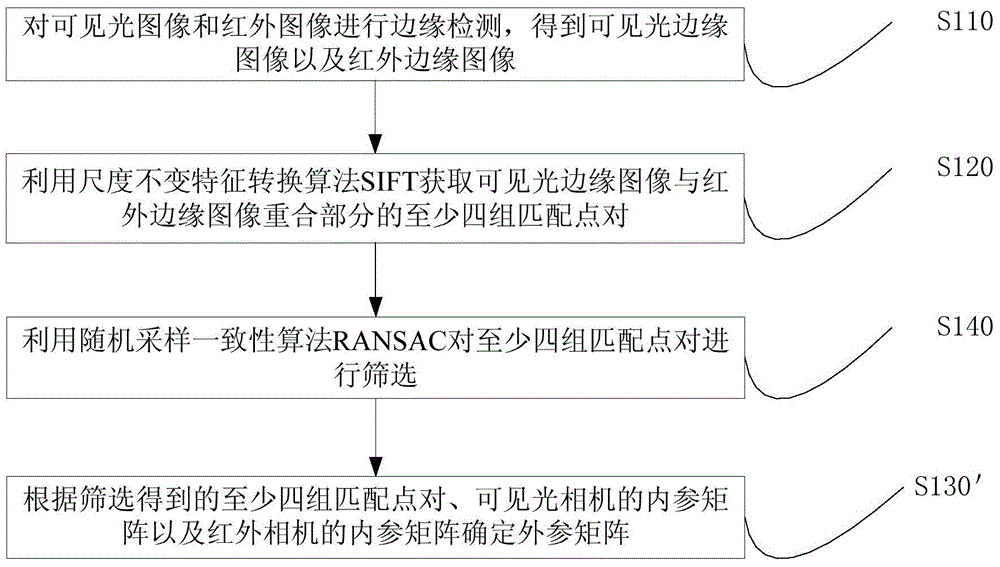

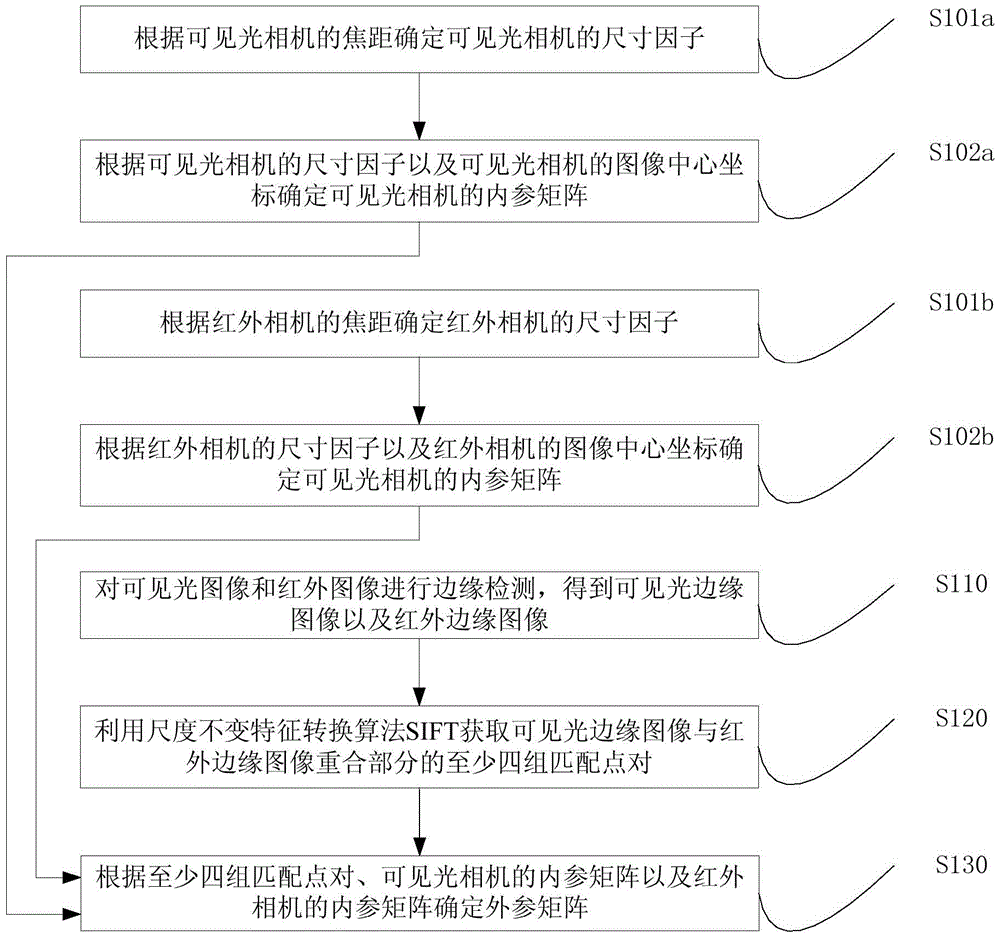

Method and device for jointly calibrating parameters of visible light camera and infrared camera

ActiveCN105701827AReduce calibration costsImprove calibration efficiencyImage enhancementImage analysisScale-invariant feature transformIntrinsics

The invention discloses a method and device for jointly calibrating the parameters of a visible light camera and an infrared camera. The method comprises steps of: detecting the edges of a visible light image and an infrared image to obtain a visible light edge image and an infrared edge image; acquiring at least four groups of matched point pairs of the visible light edge image and the infrared edge image by using a scale invariant feature transform (SIFT) algorithm; and determining an extrinsic parameter matrix according to the at least four groups of matched point pairs, the intrinsic parameter matrix of the visible light camera, and the intrinsic parameter matrix of the infrared camera. The method and the device may acquire the matched point pairs in the visible light edge image and the infrared edge image without a calibration board and determine the extrinsic parameter matrix without the calibration board so as to reduce the calibration cost of camera parameters. Further, when a focal length of the camera is changed, the extrinsic parameter matrix can be determined without camera position adjustment so that parameter calibration efficiency is increased.

Owner:CHINA FORESTRY STAR BEIJING TECH INFORMATION CO LTD

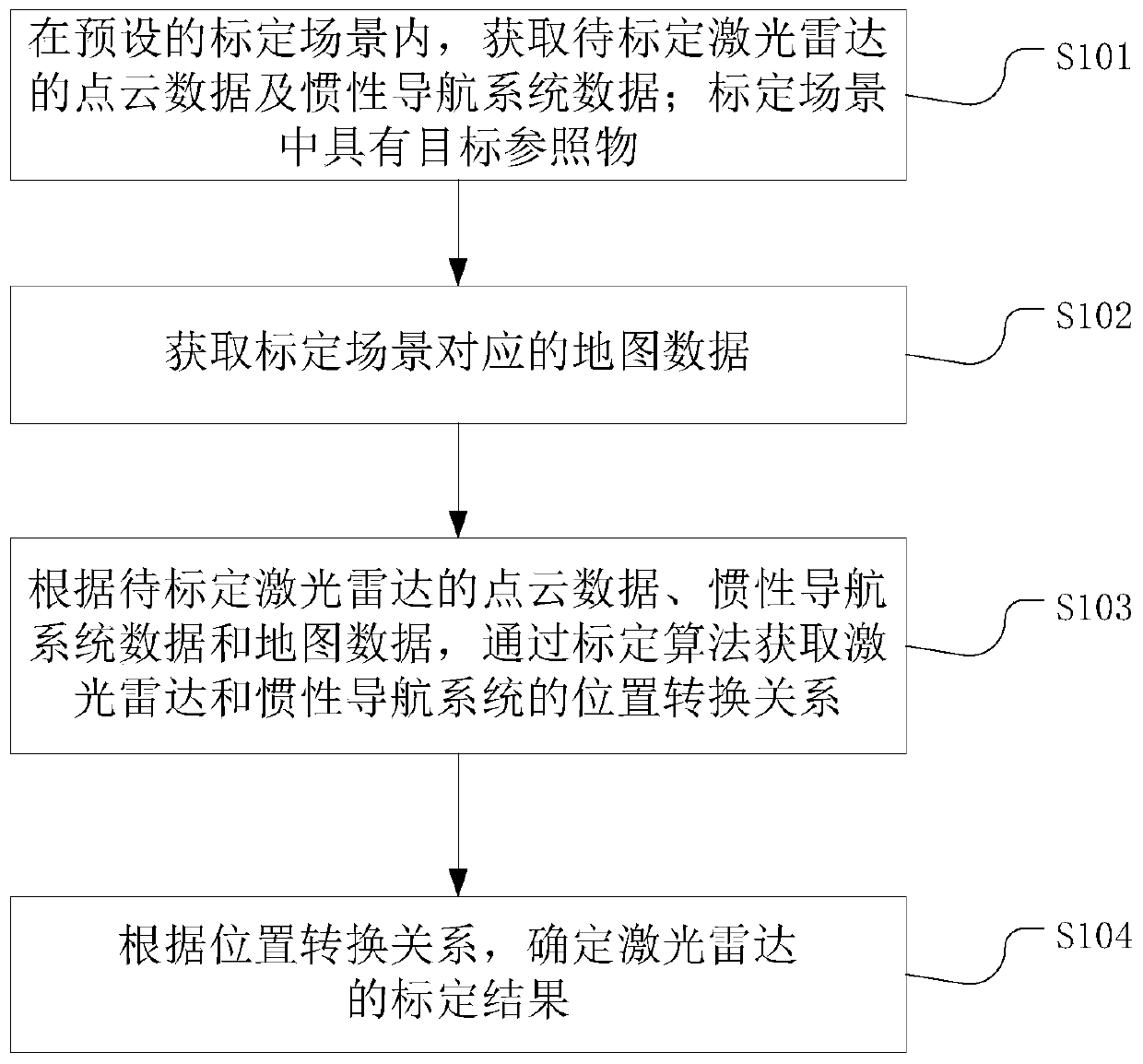

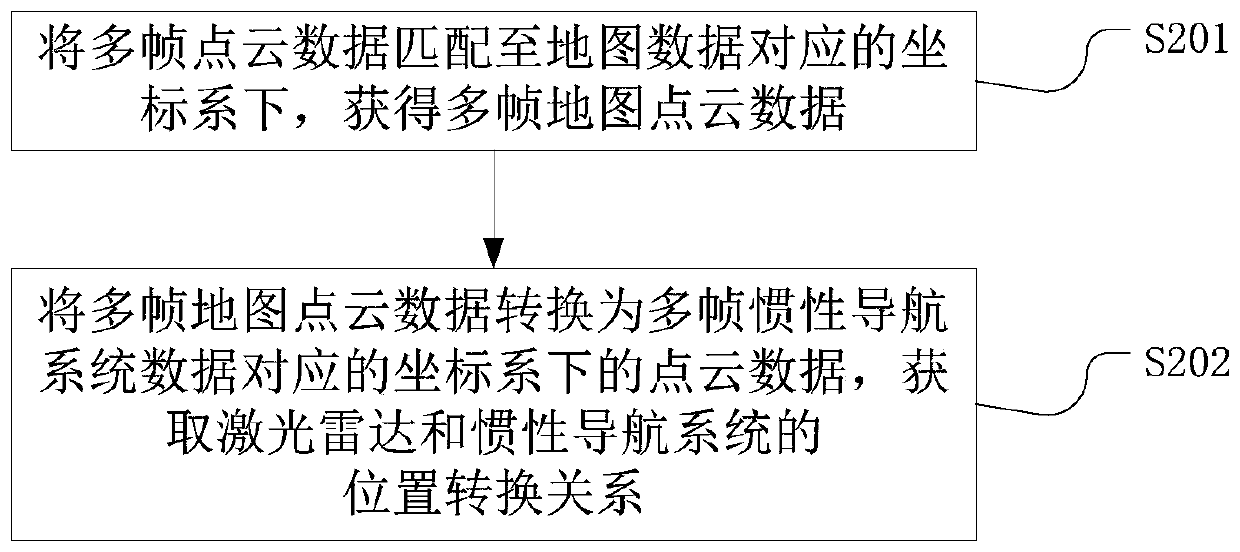

Laser radar calibration method and device, equipment and memory medium

ActiveCN109901139AImprove calibration efficiencyElectromagnetic wave reradiationICT adaptationPoint cloudComputer terminal

The invention relates to a laser radar calibration method and device, equipment and a memory medium. In a preset calibration scene, a terminal obtains point cloud data of a to-be-calibrated laser radar and data of an inertial navigation system, obtains map data corresponding to the calibration scene, further obtains a position conversion relationship through utilization of a calibration algorithmaccording to the point cloud data of the to-be-calibrated laser radar, the data of the inertial navigation system and the map data, and further determines a calibration result of the laser radar according to the position conversion relationship. According to the method, the device, the equipment and the memory medium, the terminal automatically obtains the position conversion relationship of the laser radar and the inertial navigation system through utilization of the calibration algorithm according to the point cloud data of the to-be-calibrated laser radar, the data of the inertial navigation system and the map data and further determines the calibration result according to the position conversion relationship. The obtained calibration result of the laser radar is automatically obtainedthrough utilization of the calibration algorithm, a process of carrying out manual measurement to obtain the calibration result of the laser radar is avoided, and further calibration efficiency of thelaser radar is improved.

Owner:WERIDE CORP

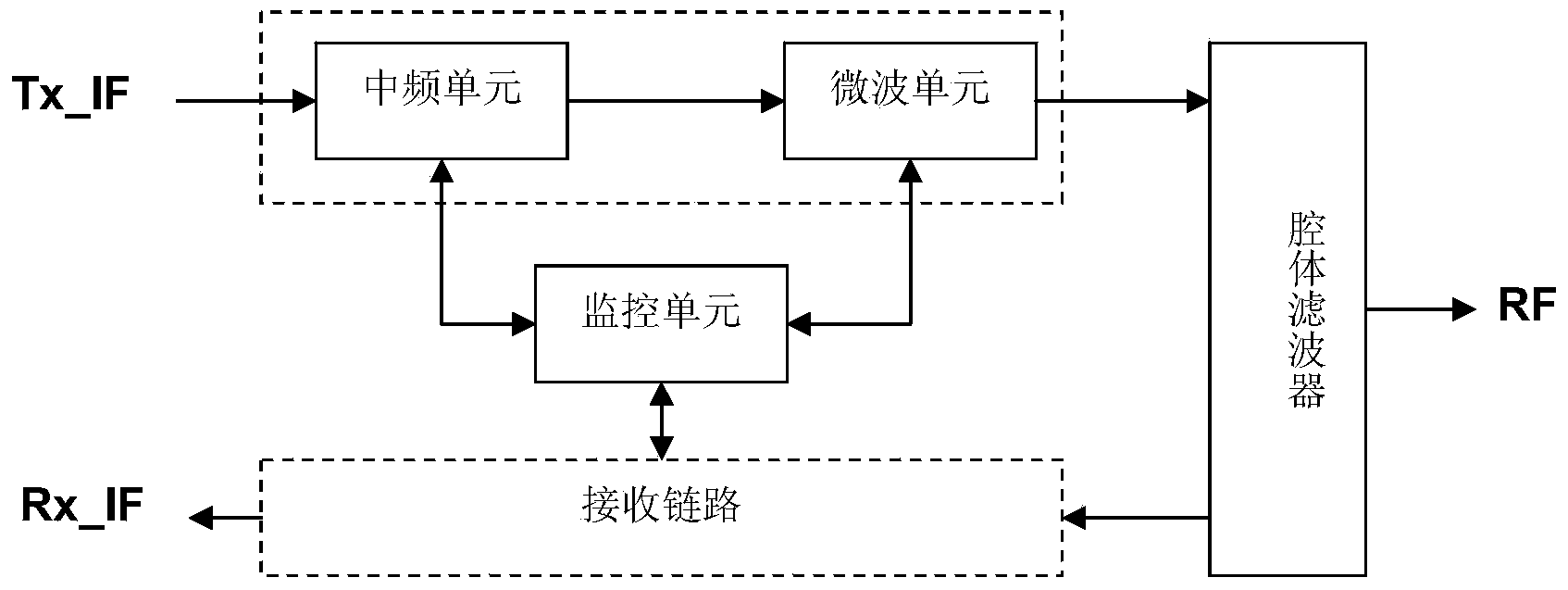

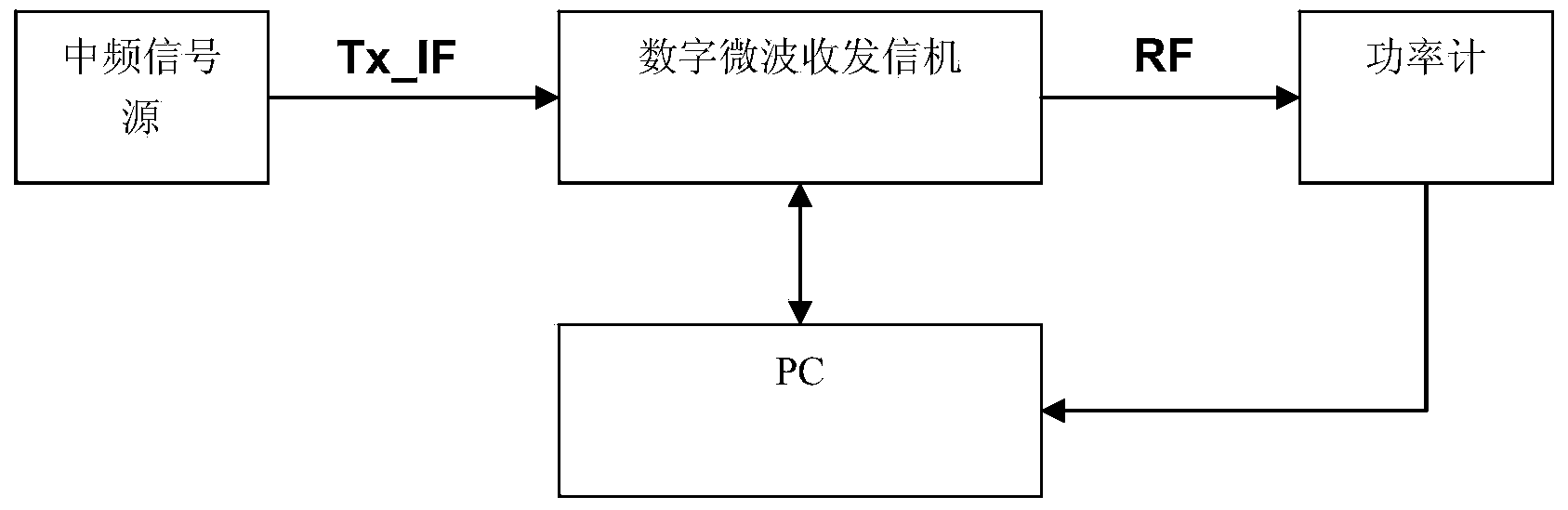

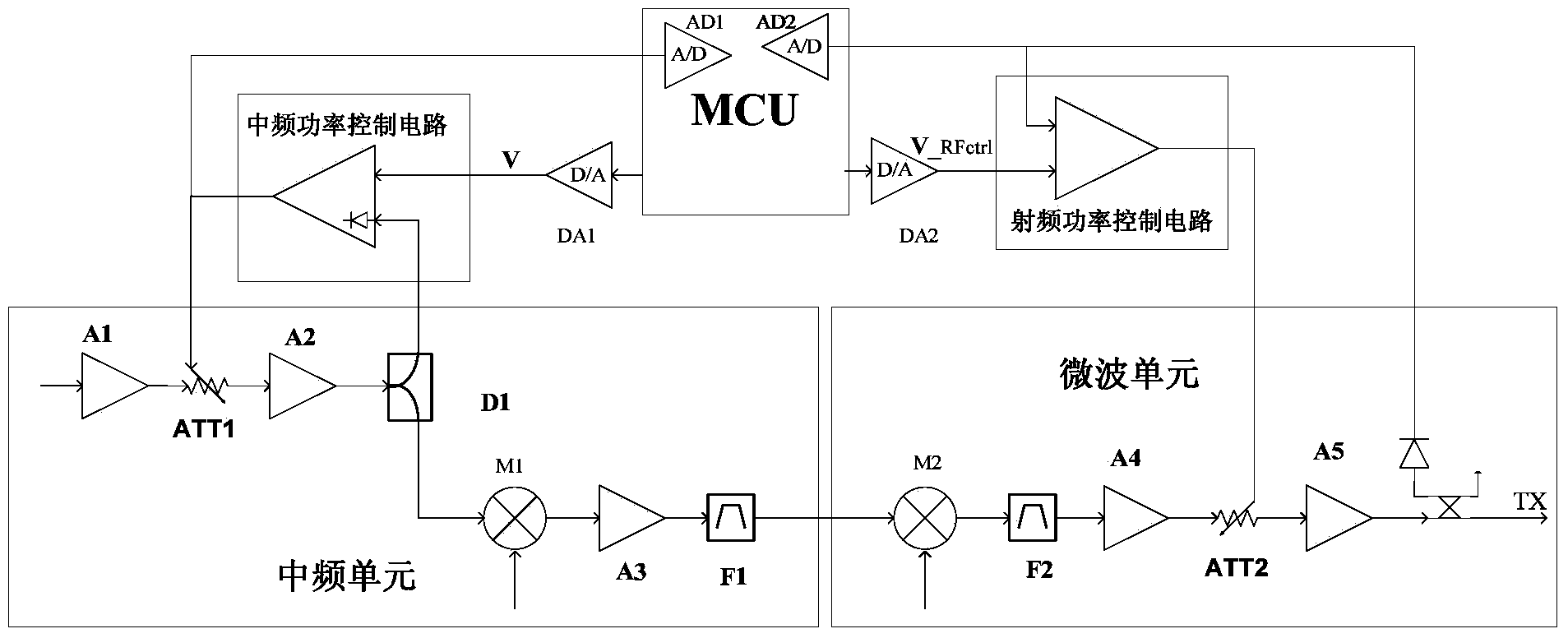

Calibration method and calibration circuit for transmitted power of digital microwave transceiver

ActiveCN103686968ASimple methodImprove mass production efficiencyPower managementTransceiverTransmitted power

The invention discloses a calibration method for the transmitted power of a digital microwave transceiver. The calibration method comprises the following steps of first generating a transmitted power calibration table according to transmitted power control voltages and actual radio frequency transmitted power which corresponds to the transmitted power control voltages and is transmitted by the microwave transceiver, second generating a channel calibration table, and thirdly correcting the transmitted power control voltage value in the transmitted power calibration table by using a channel correcting method. The invention further discloses a calibration circuit for achieving the calibration method for the transmitted power of the digital microwave transceiver. The calibration circuit comprises a microwave unit and a monitoring unit, and the microwave unit comprises a first power detection tube, a second power detection tube, a microwave amplifier and a microwave attenuator. The calibration circuit has the advantages of being high in batch production efficiency, high in calibration rate, high in transmitted power stability, simple in calibration method and the like.

Owner:波达通信设备(广州)有限公司

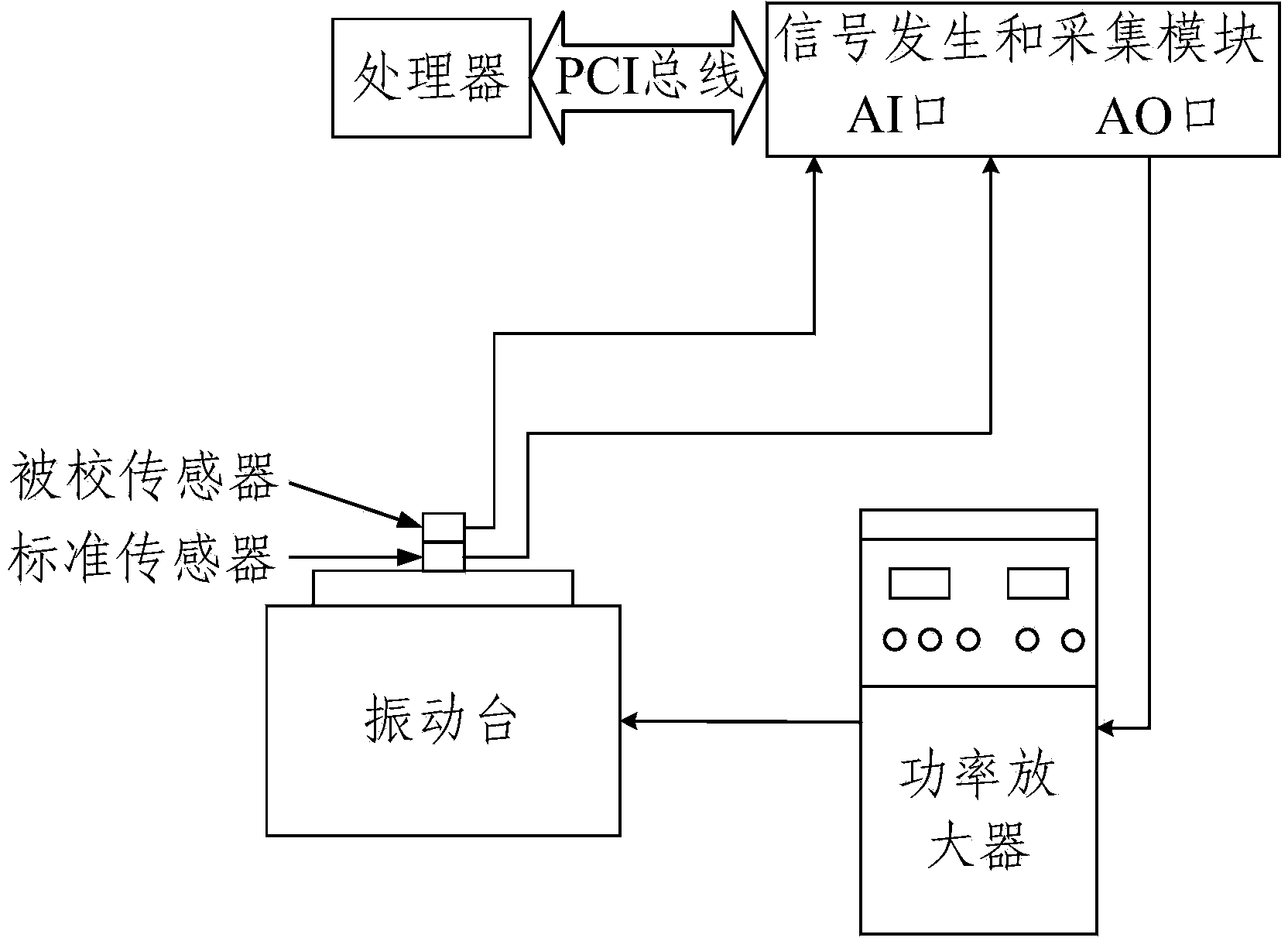

Method for multi-frequency hybrid calibration of vibration measuring sensor

ActiveCN103759814AMulti-frequency calibrationImprove calibration efficiencySubsonic/sonic/ultrasonic wave measurementAcousticsAmplifier

A method for multi-frequency hybrid calibration of a vibration measuring sensor comprises the following steps that a standard sensor and a measured sensor are fixed on a vibration table, and the axial direction of the two sensors is consistent with the main vibration direction of the vibration table; a signal producing module generates multi-frequency signals; the multi-frequency signals pass through a power amplifier and drive the vibration table; output signals of the standard sensor and the corrected sensor are collected, and the output signal of the standard sensor is converted to obtain an amplitude spectrum of the vibration table; the output signal of the corrected sensor is converted to obtain a corresponding amplitude spectrum; the amplitude spectrum of the vibration table is divided by the amplitude spectrum of the corrected sensor, and the obtained set of quotients is the sensitivity of the corrected sensor at frequency points synthesizing the multi-frequency signals. The method has the advantage of being capable of achieving rapid and accurate calibration of the vibration measuring sensor.

Owner:ZHEJIANG UNIV

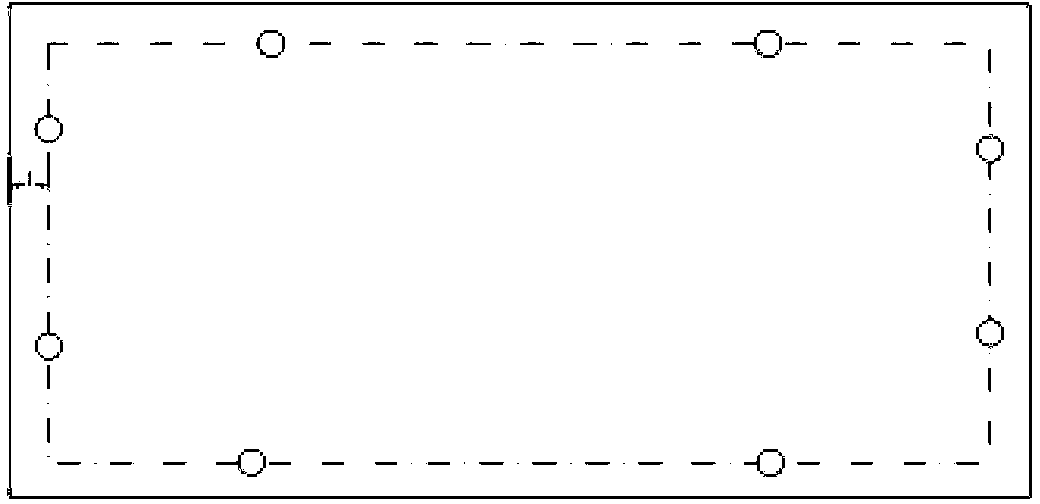

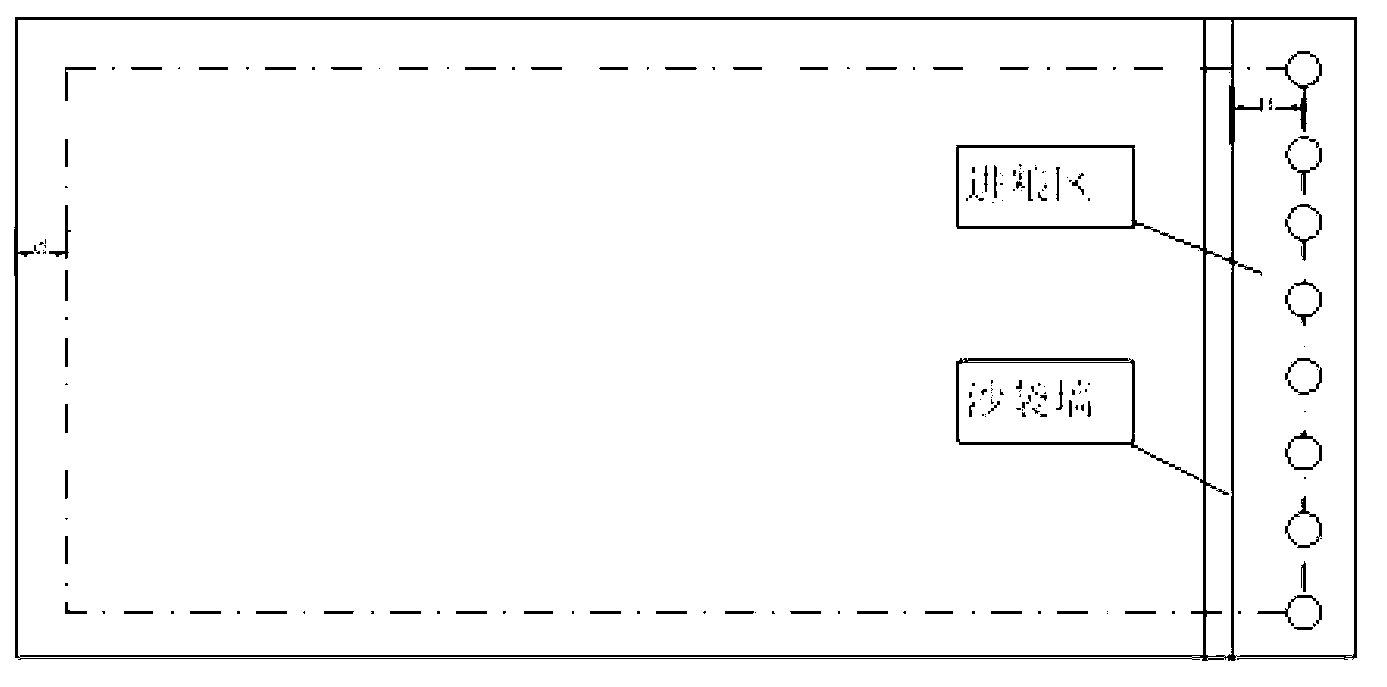

Grain storage quantity detection method for horizontal warehouse and shallow silo

InactiveCN102706417ALow costReduce workloadWeighing apparatus for materials with special property/formGrain storageSurface pressure

The invention relates to a grain storage quantity detection method for horizontal warehouses and shallow silos. The grain storage quantity detection method comprises the following steps of: firstly selecting specific pressure sensors to lay a grain warehouse pressure sensor detection network; distributing the pressure sensors along the side wall of the grain warehouse in the mode that all the pressure sensors are evenly-spaced laid at d meter distance from the side wall; and determining whether a grain warehouse is calibrated or not so as to obtain a calibration parameter and a grain warehouse weight prediction model, spreading the top surface of a grain pile in the grain warehouse after the grain warehouse is fully filled with the grain, detecting the average output valve of the pressure sensor at the bottom of the grain warehouse, and detecting the grain storage quantity of the grain warehouse according to an actually-tested bottom surface area of the grain warehouse, a bottom surface area of the calibrated grain warehouse and calibrated parameters by using a model so as to obtain an estimated value of the weight of the grain warehouse. According to the grain storage quantity detection method provided by the invention, the pressure sensors are required to be arranged on the bottom surface of the grain warehouse, and a compensating item of a side grain warehouse friction action is added into a bottom surface pressure estimating model in order to avoid using the side pressure sensor and accurately obtain the estimated value of the pressure of the bottom surface of the grain warehouse, so that the quantity of the sensors is obviously reduced, and the device detection cost and the installation and maintenance cost are reduced.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

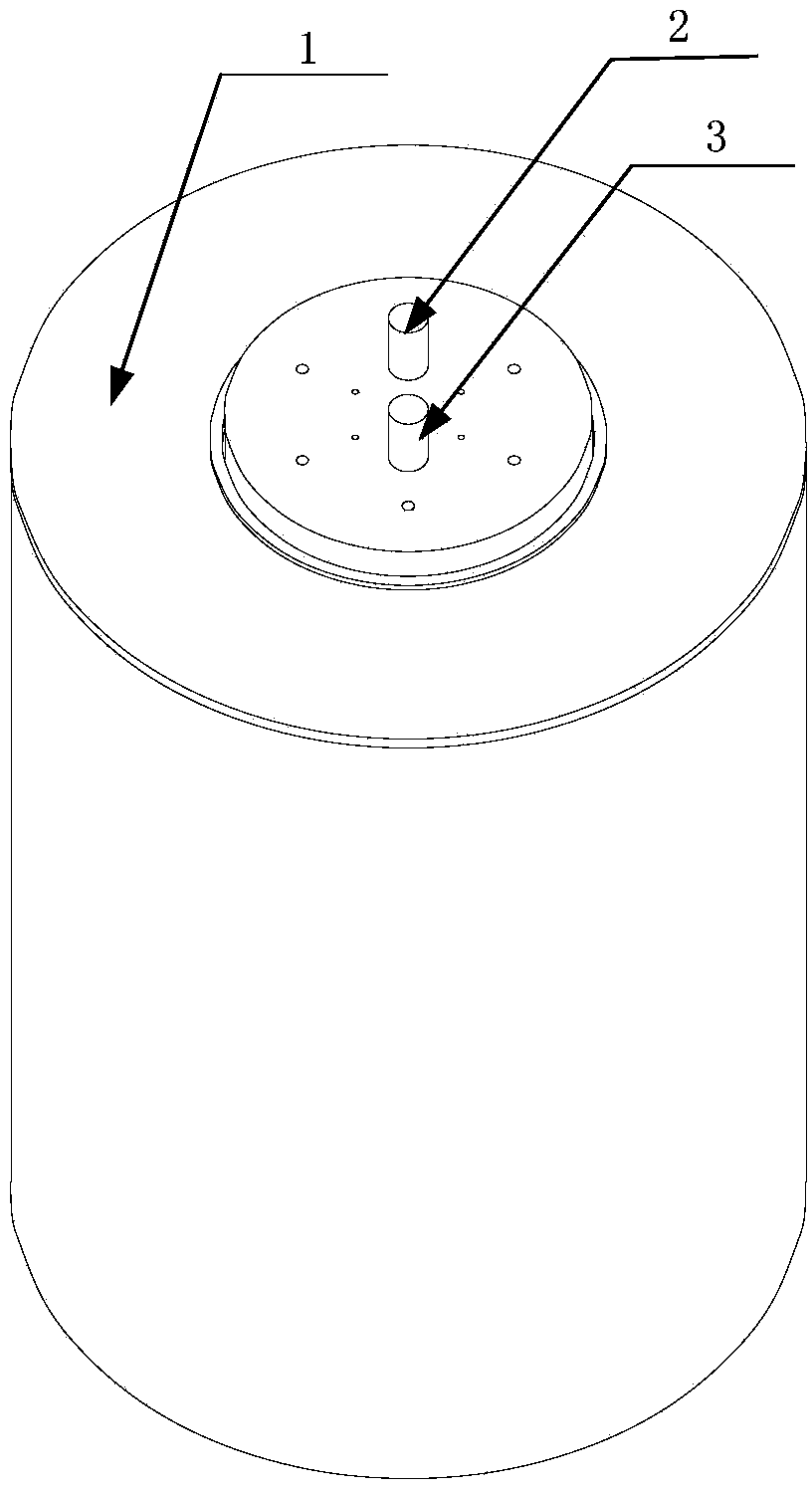

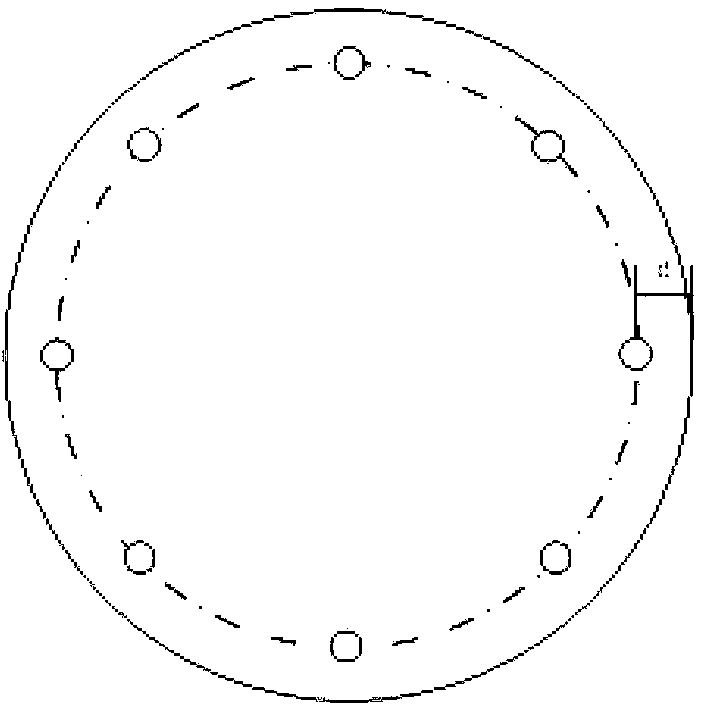

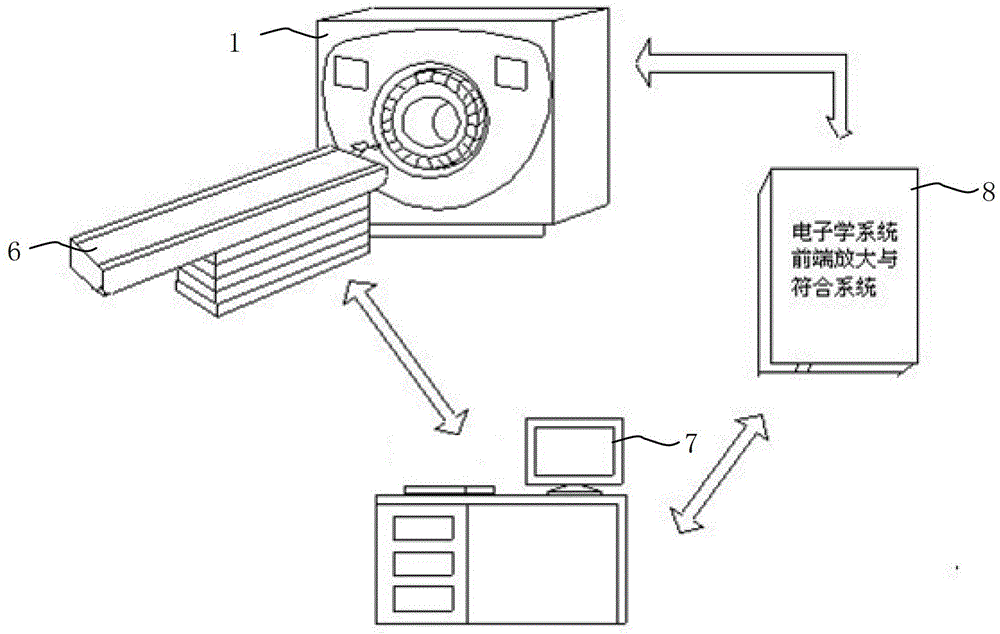

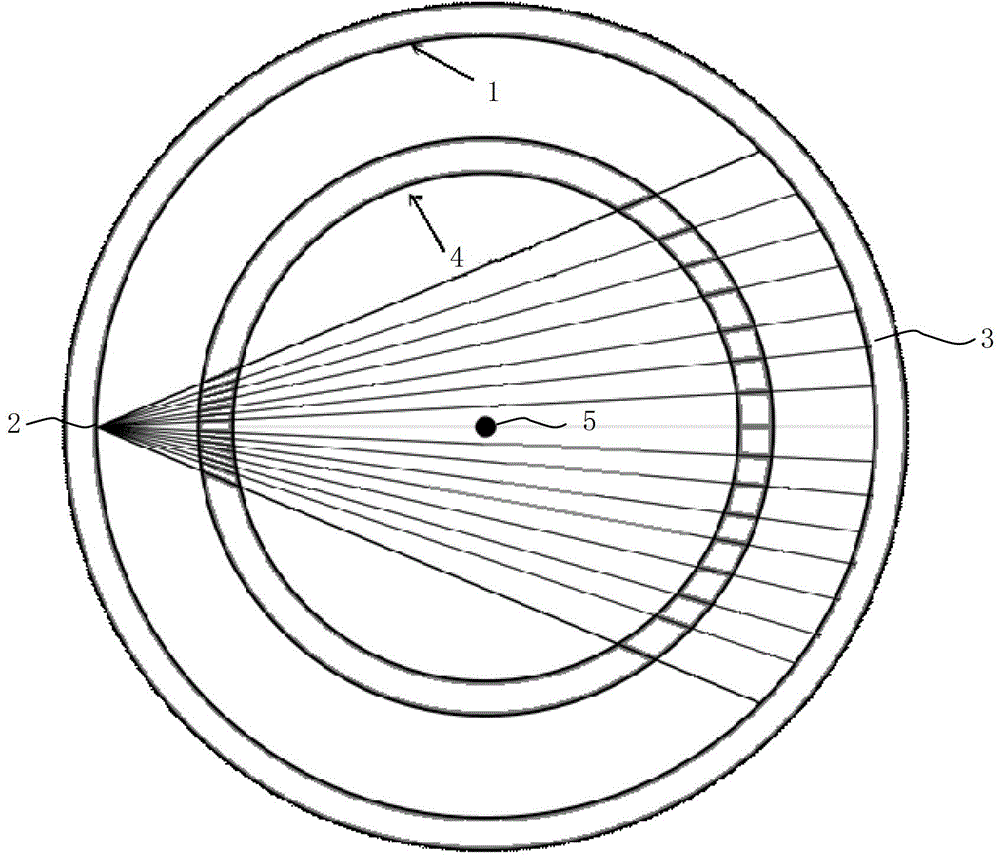

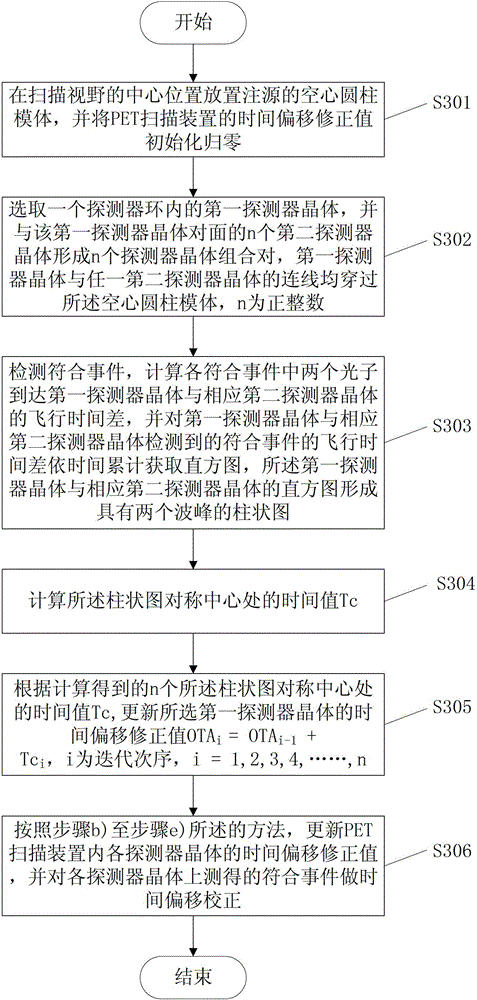

PET scanning device and time migration correcting method thereof

ActiveCN104434160AImprove calibration efficiencyImprove the correction effectComputerised tomographsTomographyBody areaEngineering

The invention discloses a PET scanning device and a time migration correcting method thereof. The PET scanning device comprises a cylindrical rack. A plurality of detector crystals are arranged on the inner side of the cylindrical rack. A hollow cylindrical die body of an injection source capable of being used for PET scanning device time migration correction is arranged in the cylindrical rack. The hollow cylindrical die body is arranged in the mode that the center axis of the hollow cylindrical die body and the center axis of the cylindrical rack are overlapped. According to the PET scanning device and the time migration correcting method of the PET scanning device, the hollow cylindrical die body of the injection source is utilized for calculating the time migration correction value of each detector crystal and carrying out time correction on coincidence events, the die body area which is really effective for time migration correction is sufficiently utilized, and the non-effective area is directly abandoned, so that existing TOF-PET time correction efficiency and effect are effectively improved, and correction is easy, convenient and reliable.

Owner:SHANGHAI UNITED IMAGING HEALTHCARE

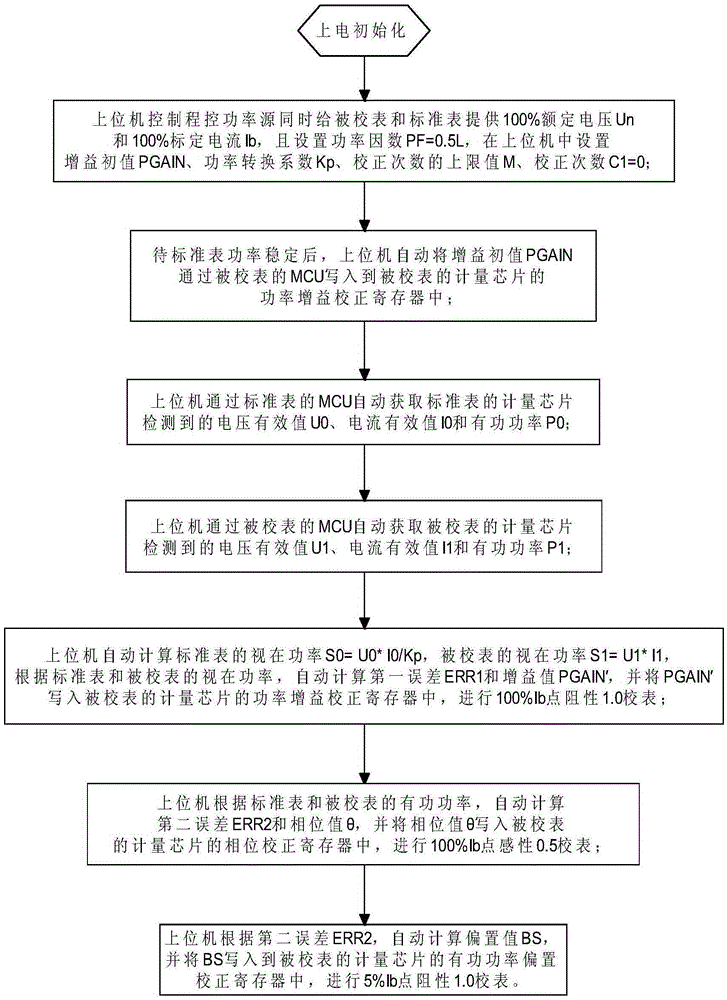

Fast calibration method of single-phase electric energy meter

ActiveCN105242233AFast stabilizationReduce waiting timeElectrical measurementsPhase correctionSignal correction

The invention relates to a fast calibration method of a single-phase electric energy meter. According to the fast calibration method, the gain initial value of a power gain correction register of a metering chip of a calibrated meter is preset so as to be fast positioned to a target error value, only a 100%Ib-point 0.5-induction error point is debugged; apparent power deviation and active power deviation are simultaneously obtained at the error point; 100%Ib-point 1.0-resistance gain correction is performed through utilizing the apparent power deviation; 100%Ib-point 0.5-induction phase correction is performed through utilizing the active power deviation; and a 100%Ib-point 0.5-induction error value which has been obtained through calculation is directly utilized to perform 5%Ib-point 1.0-resistance small signal correction, and therefore, too long debugging time of small signals can be avoided. The fast calibration method has the advantages of fast error target value positioning, high meter calibration efficiency and significantly-improved accuracy.

Owner:NINGBO SANXING MEDICAL & ELECTRIC CO LTD

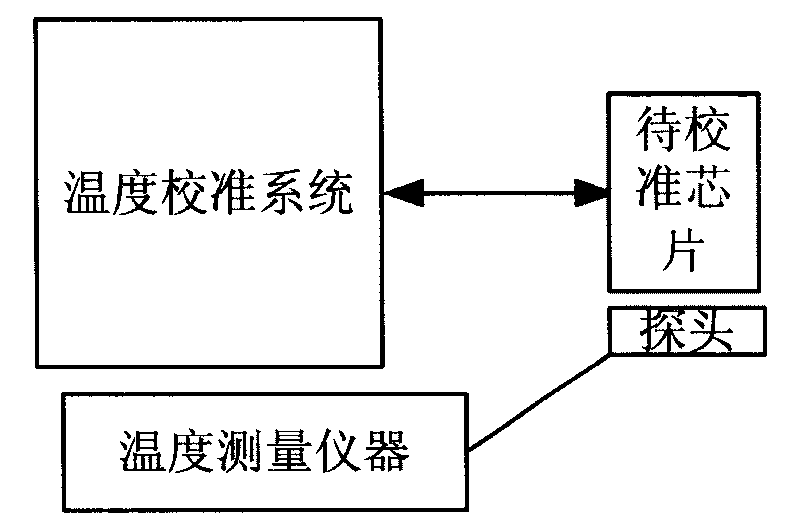

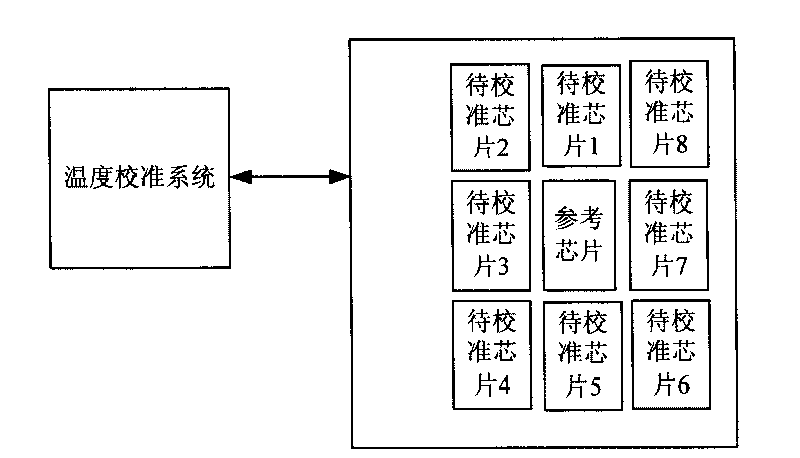

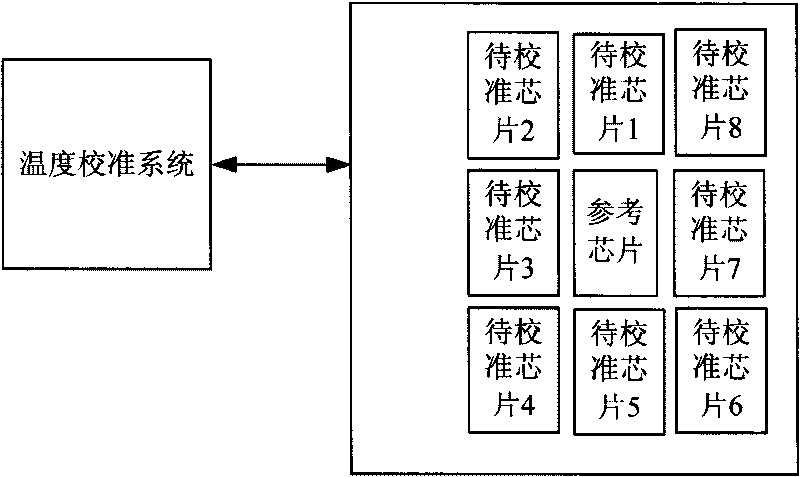

Calibration system and calibration method of temperature sensor chip

ActiveCN101750170ASimple structureEasy to buildThermometer testing/calibrationDigital interfaceEngineering

The invention discloses a calibration system of a temperature sensor chip, which comprises a test board and a temperature calibration system, wherein the test panel is provided with a temperature sensor reference chip and a chip to be calibrated; and each chip is connected and communicates with the temperature calibration system through a unified digital interface. The temperature calibration system reads the temperature values of various calibration chips and reference chips through the unified digital interface; and various chips to be calibrated simultaneously acquire the data, thereby realizing synchronous acquisition and calibration of multichip data, greatly improving the acquisition efficiency of the data and reducing the test and calibration time of the chips and calibration cost. The invention has the advantages of simple structure, easy building, short calibration time, high calibration efficiency, low cost, high degree of automation and the like. The invention also discloses a calibration method of the temperature sensor chip.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

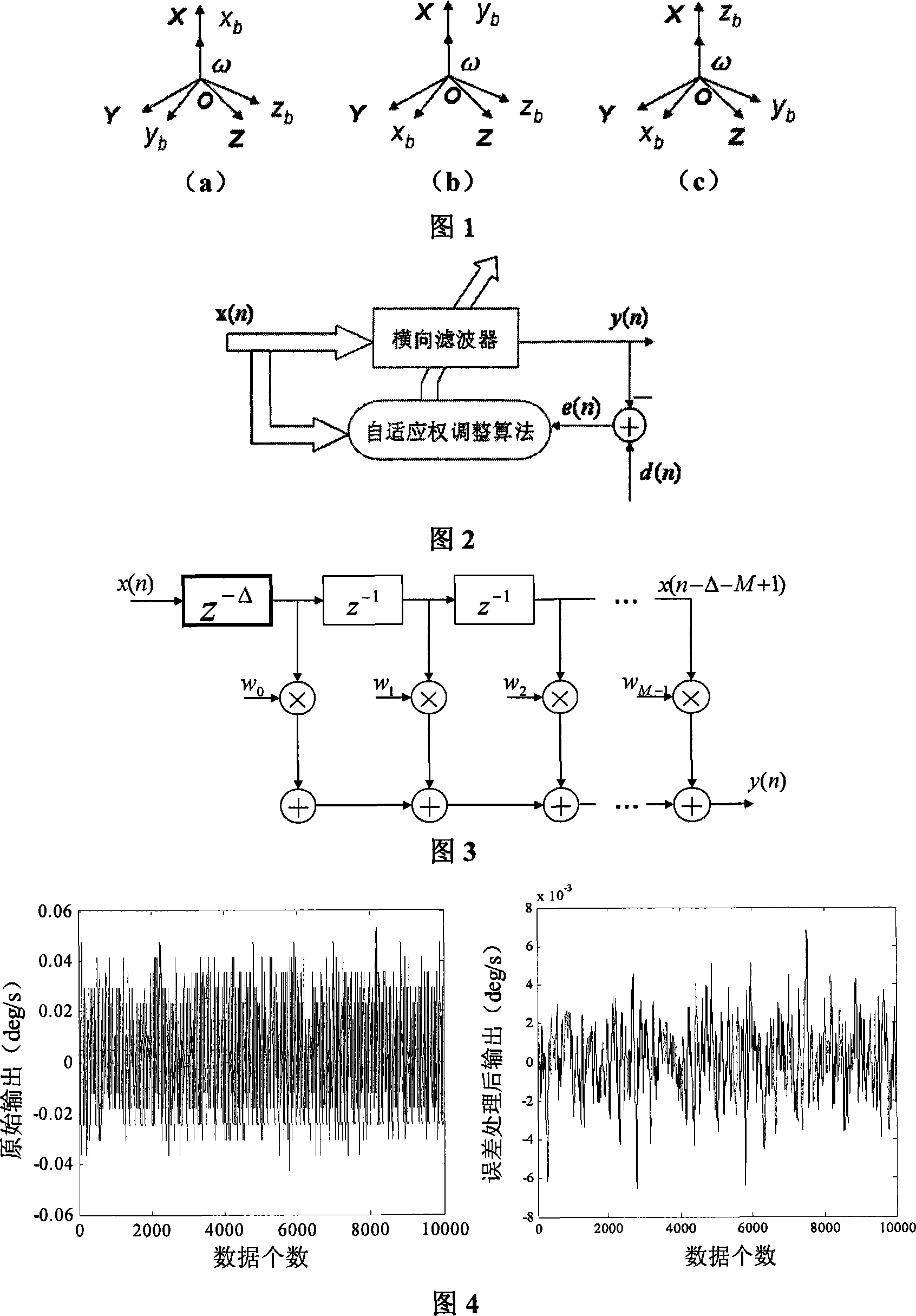

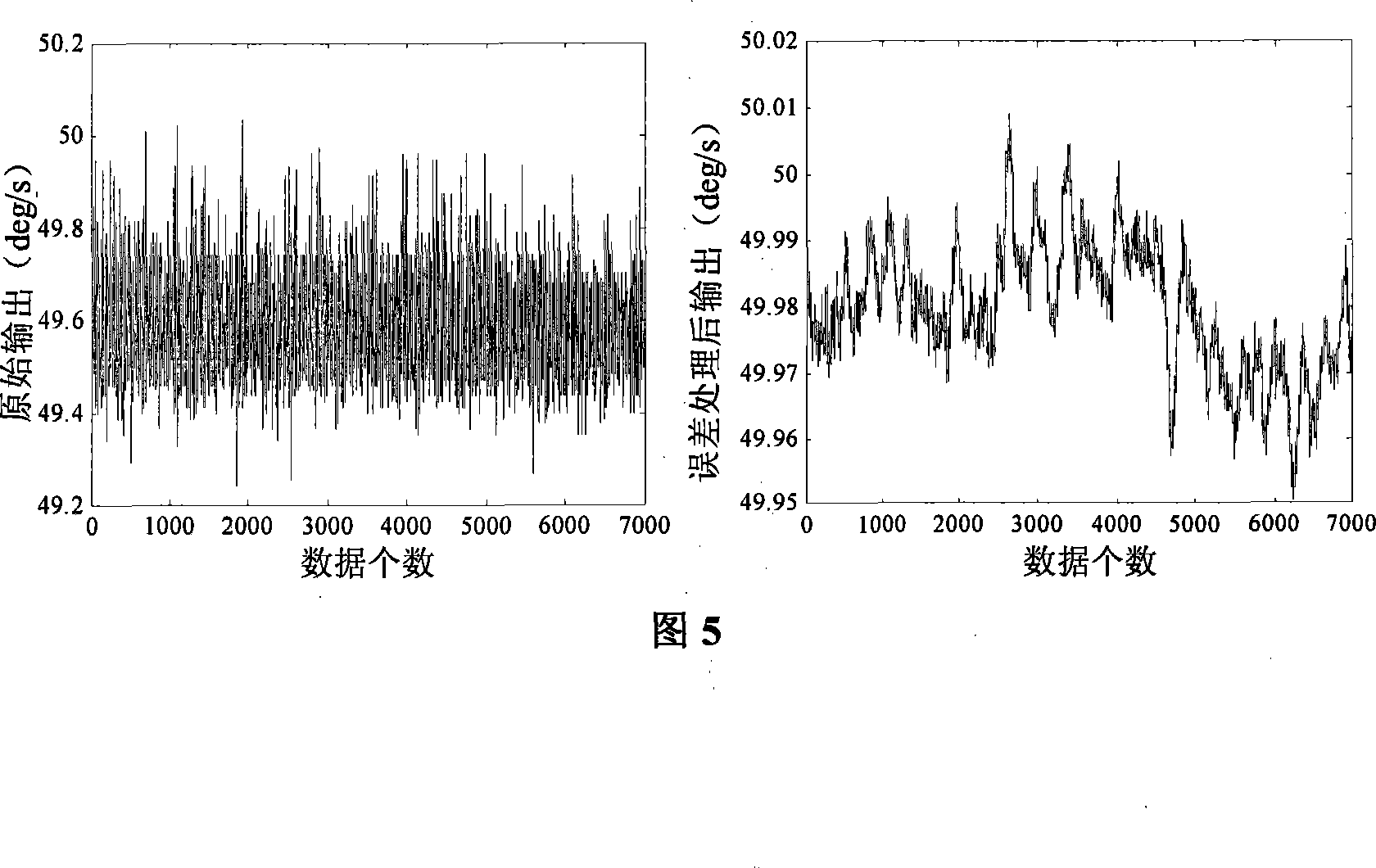

Error processing method for output signal of optic fiber gyroscope component

InactiveCN101221046AReduce random errorReduce zero offset driftAdaptive networkNavigation by speed/acceleration measurementsSelf adaptiveInertial navigation system

The invention discloses an error processing method of the output signal of an optical-fiber scopperil component and belongs to the error processing methods of the output signal of an optical-fiber scopperil component in an inertial navigation system. The concrete steps of the processing method are that: an output signal model of the optical-fiber scopperil component and an error model thereof are built; the marking and the compensation of the fixed error of the optical-fiber scopperil component are implemented; the self-adaptive filtering of the random error of the optical-fiber scopperil component is implemented. The processing method effectively reduces the zero-offset drift of the optical-fiber scopperil component which is caused by temperature changes, has high marking precision of the fixed error, high marking efficiency and good adaptability; furthermore, the processing method effectively reduces the random error of optical-fiber scopperil, has small amount of computation, and is suitable for real industrial applications.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com