Triaxial MEMS gyroscope rotation integral calibration method based on uniaxial turntable

A single-axis turntable and calibration method technology, which is applied in the field of MEMS gyroscopes, can solve the problems of low precision, time-consuming and fast calibration methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

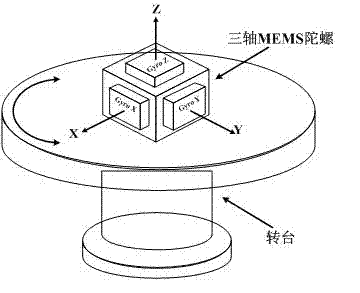

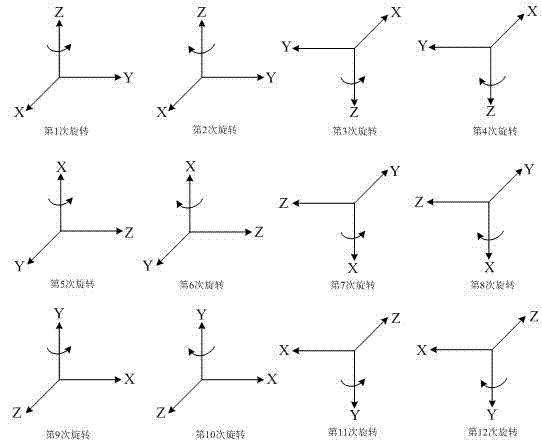

[0034] Technical solution of the present invention: the three-axis MEMS gyroscope is fixed on the single-axis turntable, such as figure 1 , first let the input sensitive axis of the Z-axis gyro point to the sky (+Z direction), the position function of the turntable controls the turntable to turn counterclockwise 360°, record data, then let the turntable turn clockwise 360°, record data; then the Z-axis The input sensitive axis of the gyro points to the ground (-Z direction), test and record the data in the same way. Then, place the gyroscope in ±X and ±Y directions respectively, repeat the above steps and methods, and record the data.

[0035] Through the 12 rotations of the above 6 positions,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com