Multi-station full-automatic welding equipment for fan impeller machining

A fully automatic welding and fan impeller technology, applied in welding equipment, auxiliary welding equipment, metal processing equipment, etc., can solve the problems of low production efficiency and low degree of automation, and achieve the goal of improving welding efficiency, improving precision and ensuring consistency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

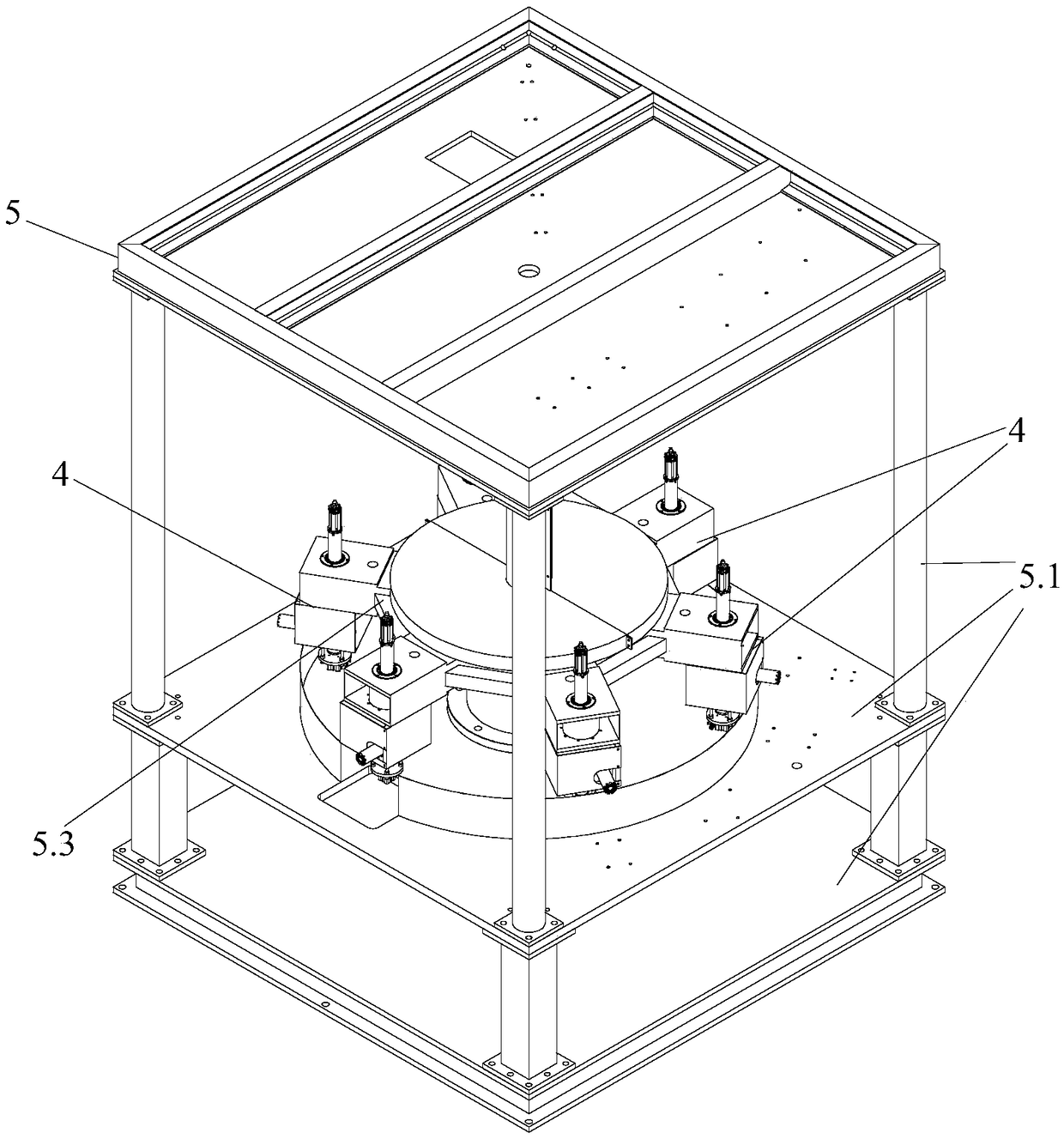

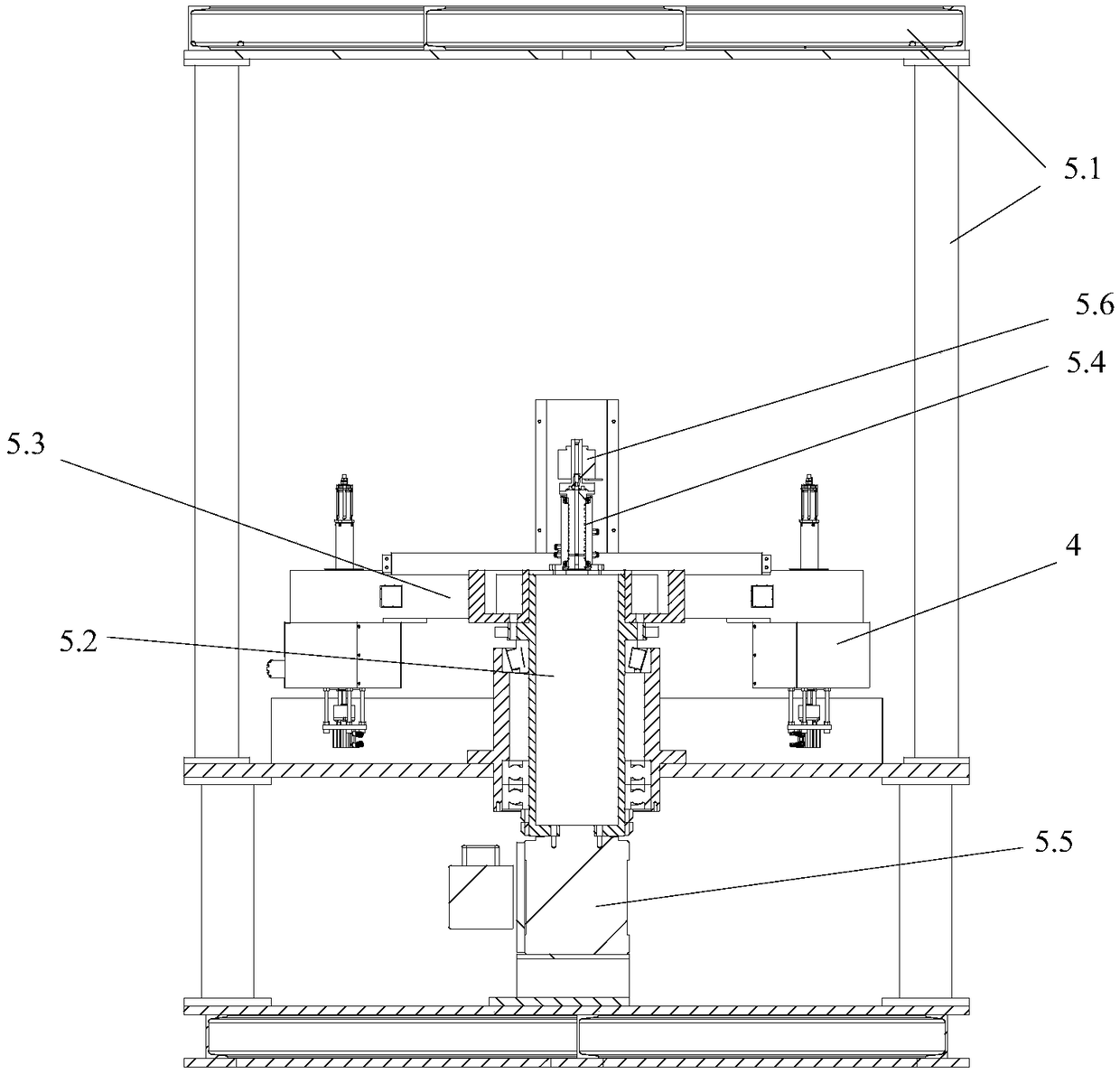

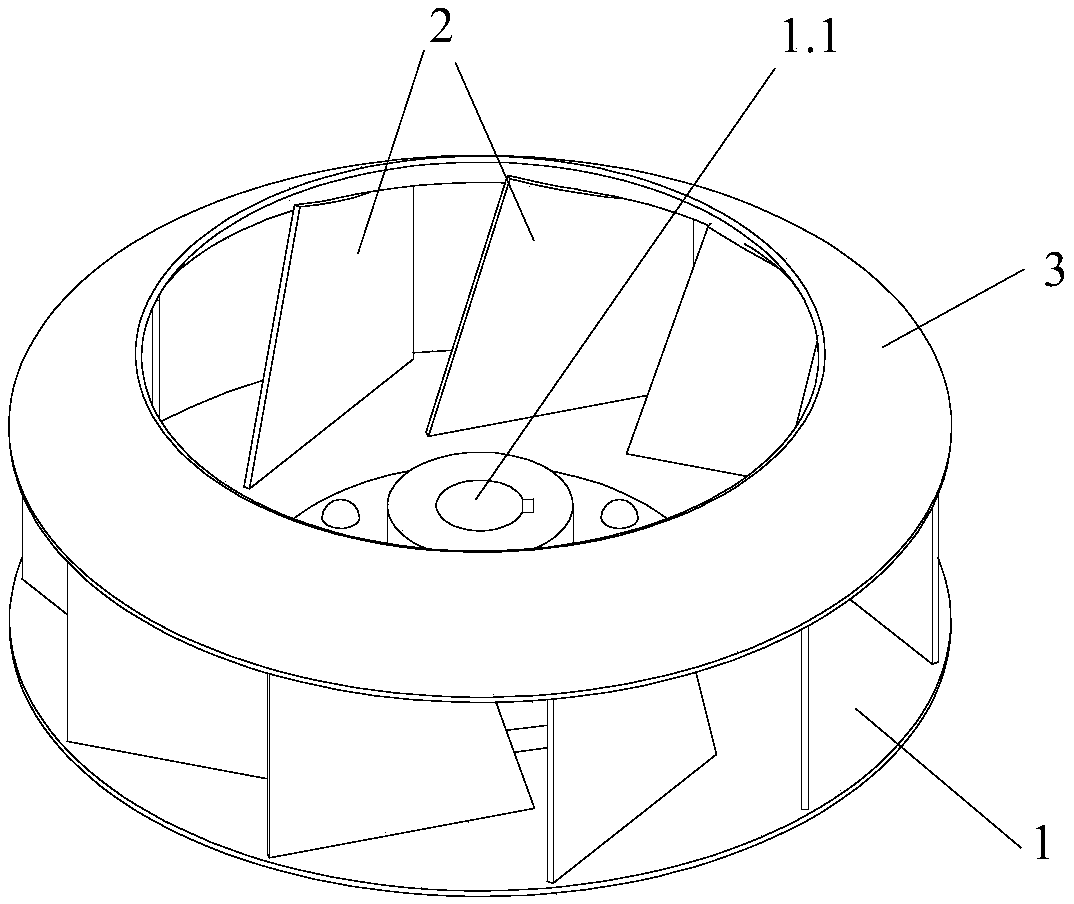

[0085] like Figure 1 to Figure 19 As shown, the multi-station automatic welding equipment for processing the fan impeller of the present invention is provided with six processing stations for processing the fan impeller respectively; comprising:

[0086] A chassis positioning mechanism 4 for positioning each chassis 1 at each processing station;

[0087] The main frame mechanism 5 used to drive the chassis positioning mechanism 4 to rotate alternately at six processing stations and provide total power and signals to each station;

[0088] It is used to press and hold the chassis 1 on the chassis positioning mechanism 4, push the blade 2 and correct the blade and chassis assembly positioning mechanism positioned on the chassis 1, and the blade and chassis assembly positioning mechanism is located at the second processing station;

[0089] A first welding mechanism for welding the blade and chassis on the second processing station;

[0090] A top cover feeding mechanism for a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com