Patents

Literature

1381results about How to "Improve welding precision" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

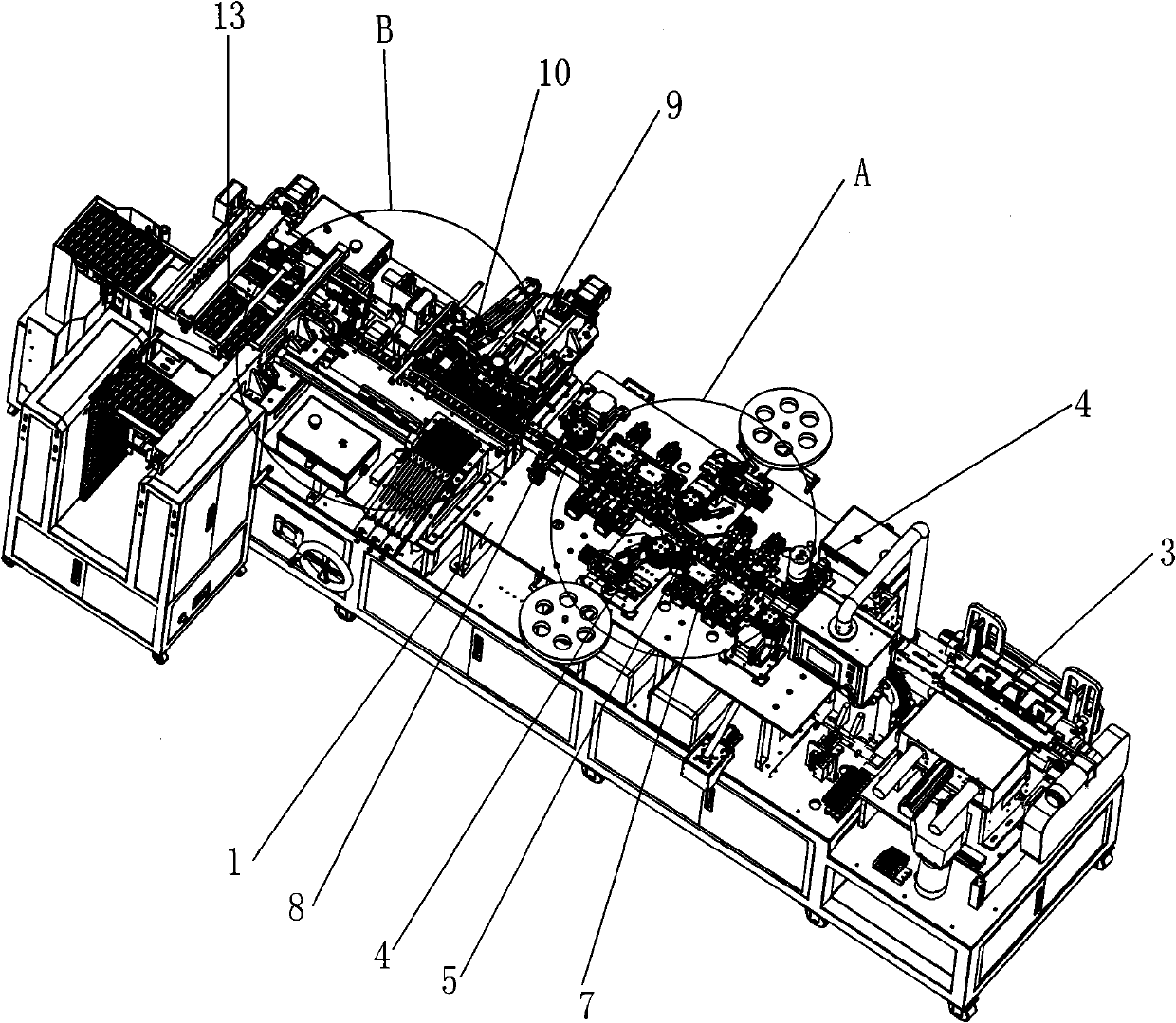

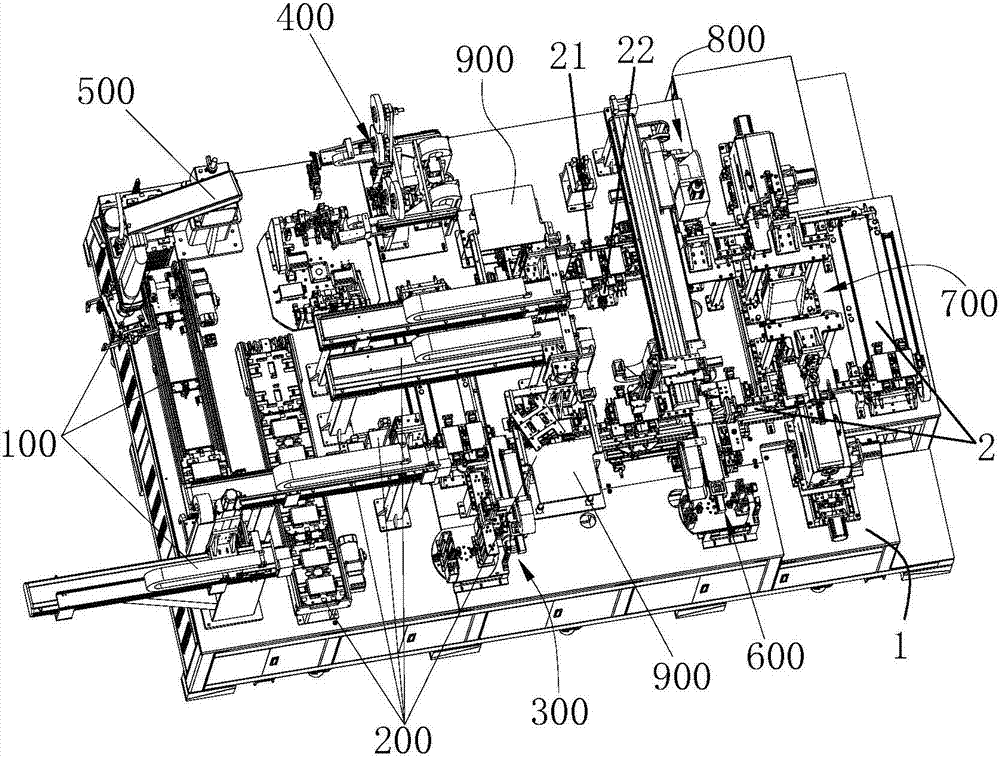

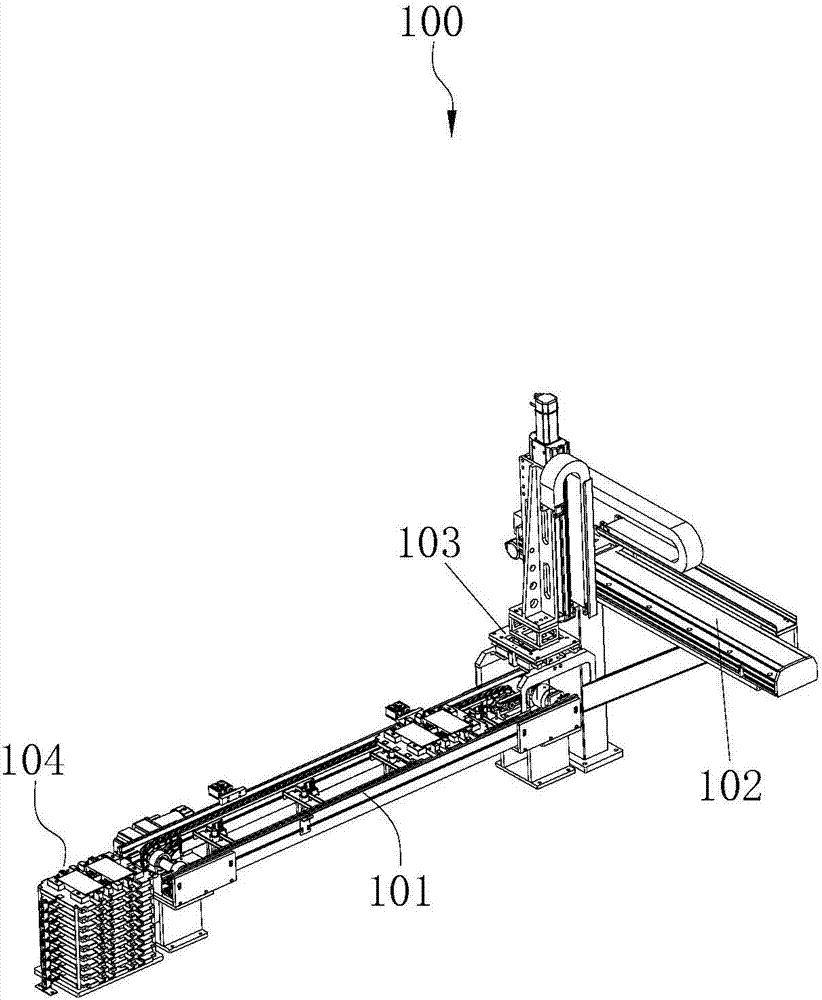

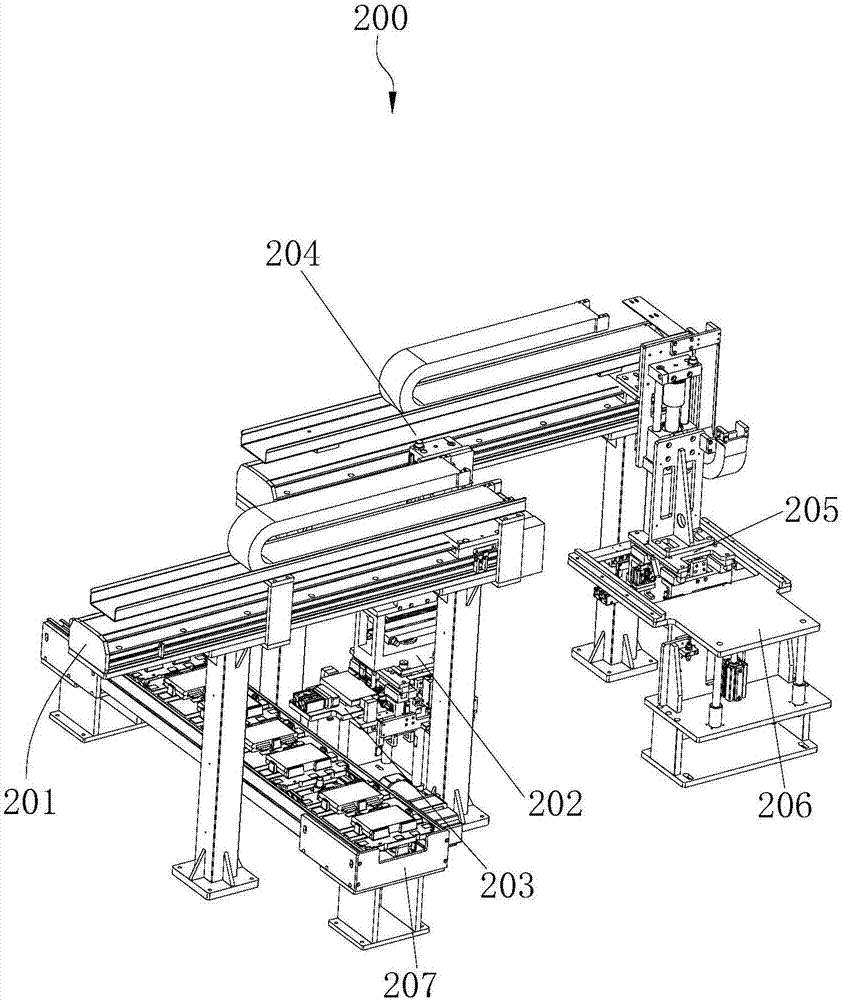

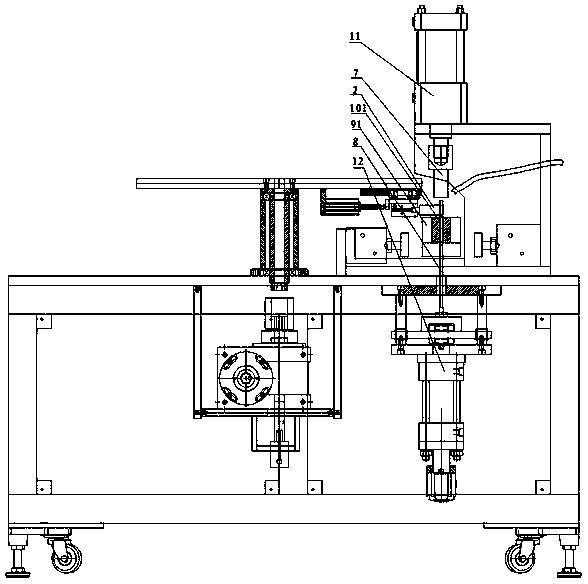

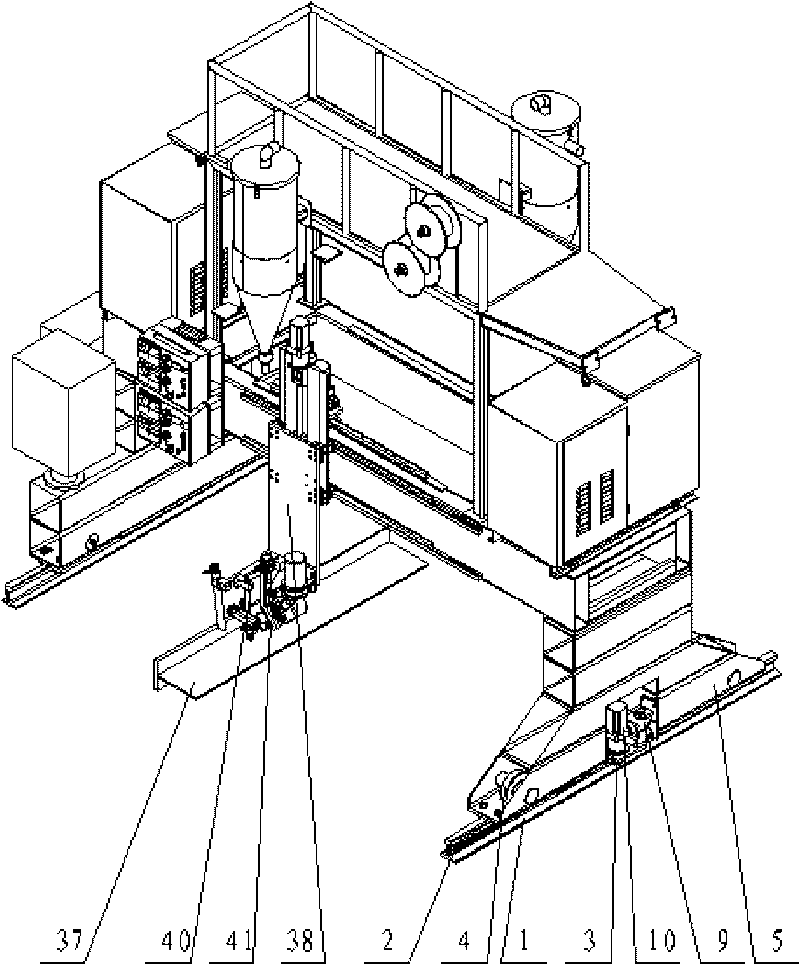

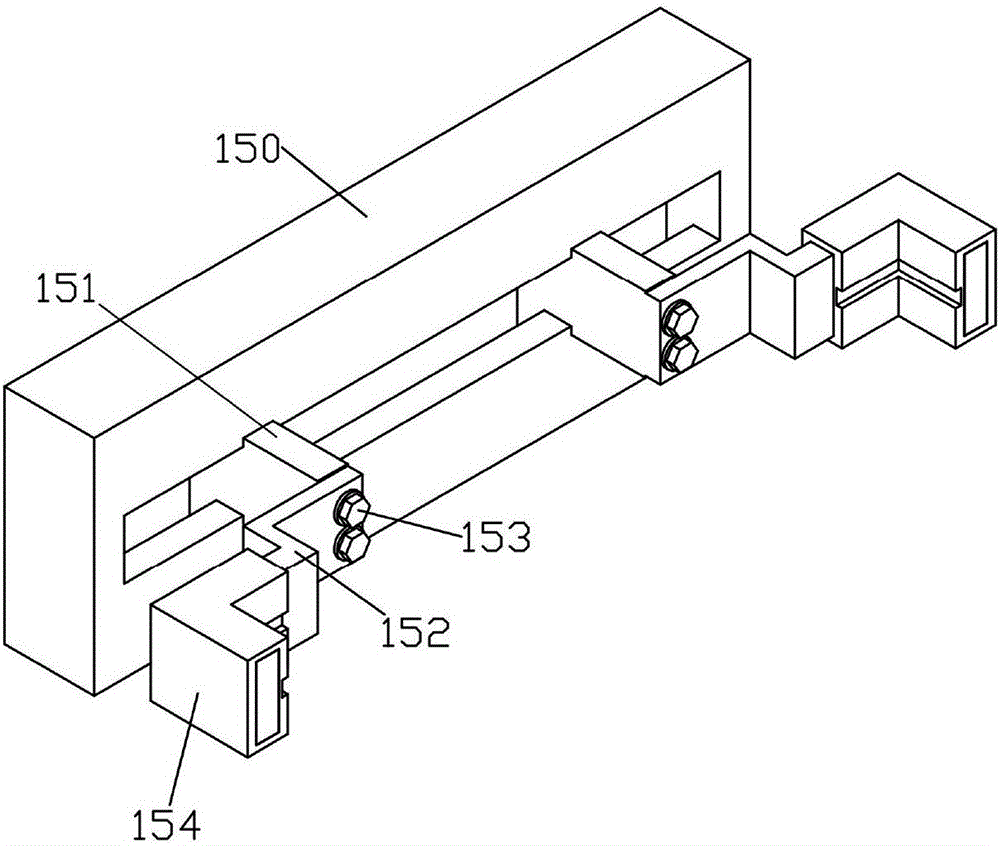

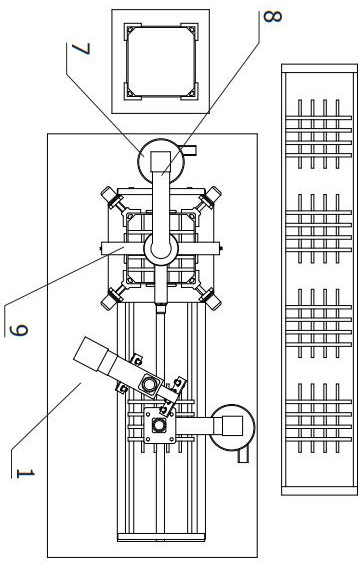

Automatic spot welding equipment

ActiveCN101992341AQuality improvementImprove quality and efficiencyResistance welding apparatusHigh volume manufacturingElectrical control

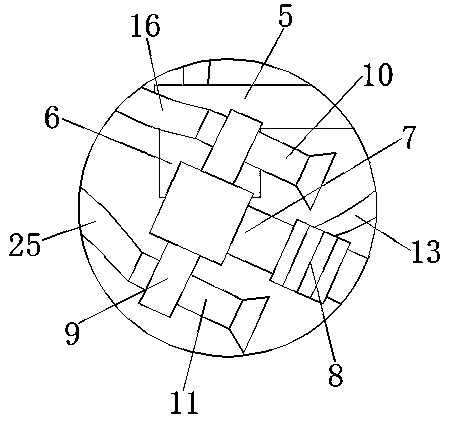

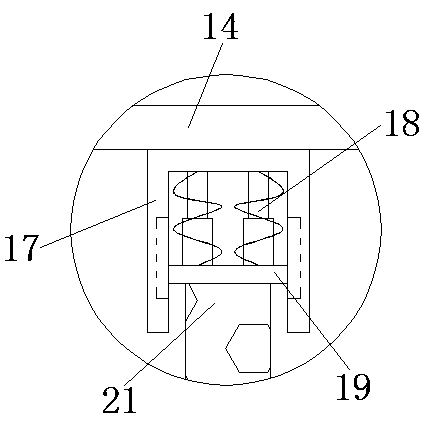

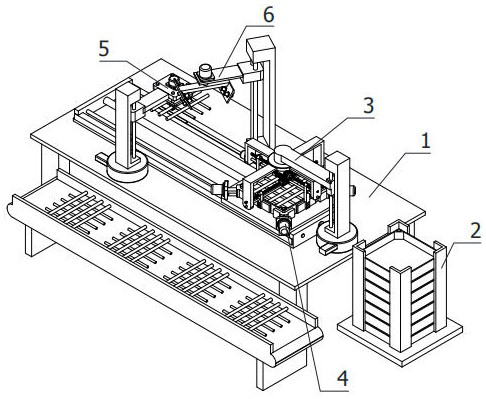

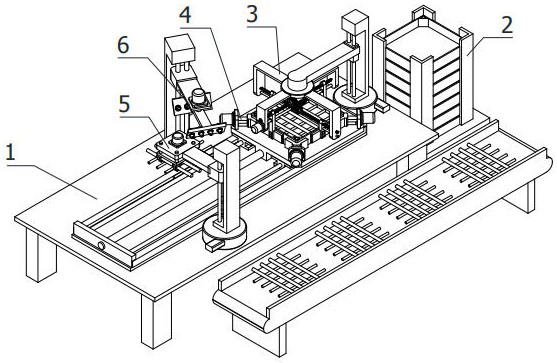

The invention relates to automatic spot welding equipment which comprises a stand and a workbench arranged on the stand, wherein the workbench is provided with a battery feed mechanism, a steel band feed mechanism, a transfer mechanism, a welding tab cut-off mechanism, a welding mechanism and a good product blanking mechanism, wherein the battery feed mechanism and the steel band feed mechanism are respectively used for feeding a battery and a steel band connected with a welding tab into a welding station; the transfer mechanism is used for bearing and transferring the battery; the welding tab cut-off mechanism is used for cutting off the welding tab on the steel band; the welding mechanism is used for welding the welding tab to the anode end and the cathode end of the battery; the transfer mechanism is provided with a battery clamping seat used for clamping the battery, and an elastic piece inwards pressing the battery is arranged on the battery clamping seat; and the mechanisms are connected with a master control circuit. In the invention, the structural design of the equipment is reasonable, and the automatic feeding, the welding and the property detecting of the battery and the steel band are realized by adopting electrical control, thus the equipment has the advantages of high feed speed, high welding precision and good welded product quality, improves the quality and the production efficiency of the welded product, reduces the labor intensity of workers, saves the production cost and is particularly suitable for producing batteries welded with welding tabs in batches, thereby improving market competitive force of enterprises.

Owner:GUANGDONG LYRIC ROBOT INTELLIGENT AUTOMATION CO LTD

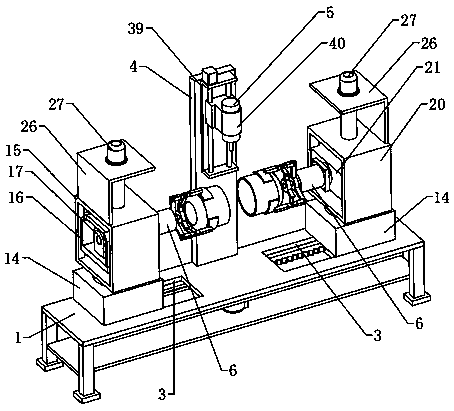

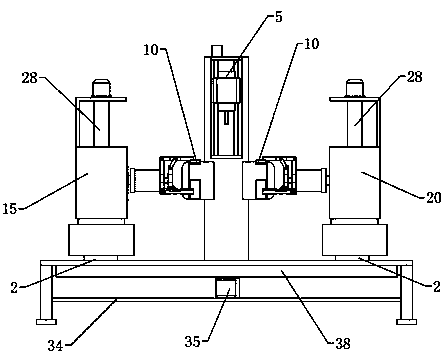

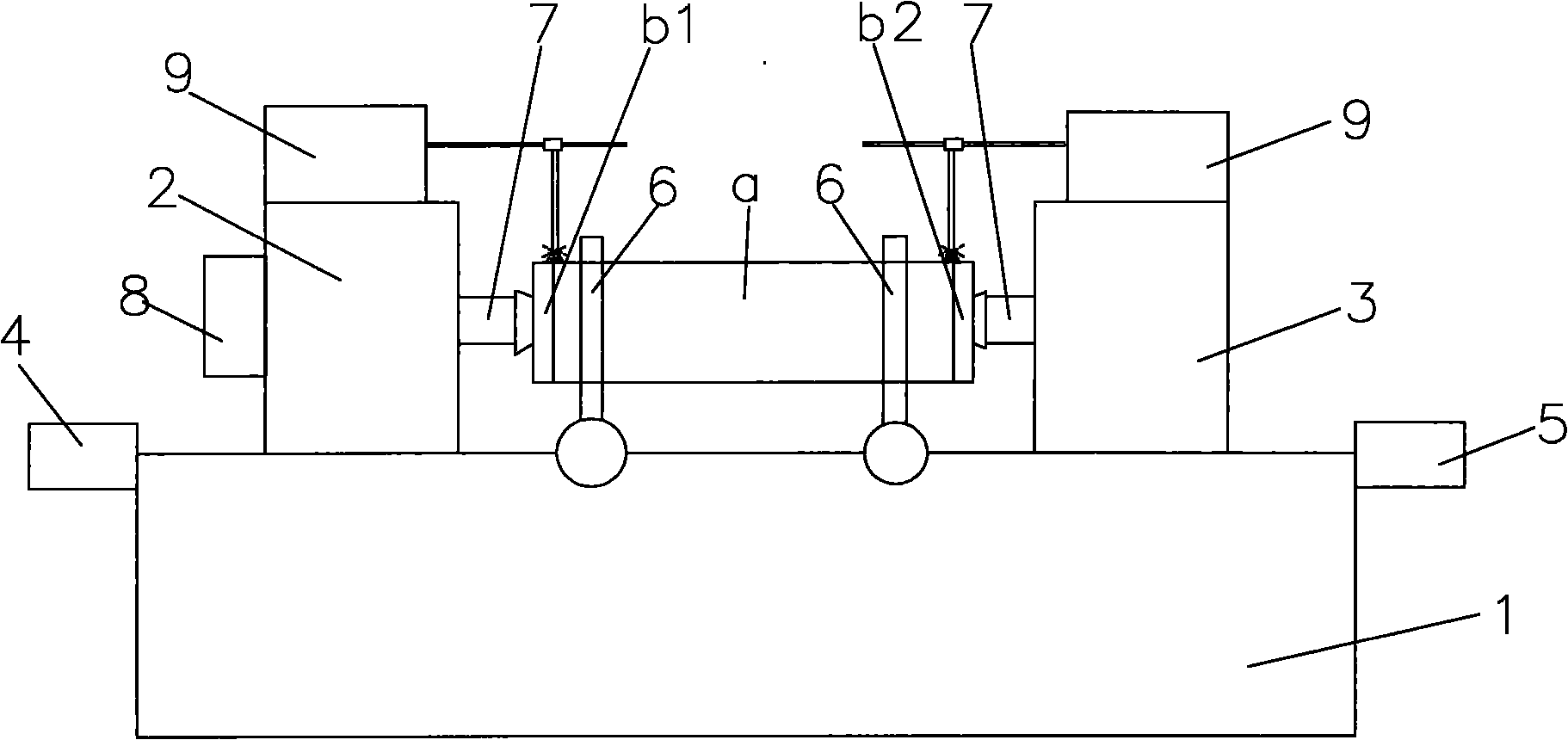

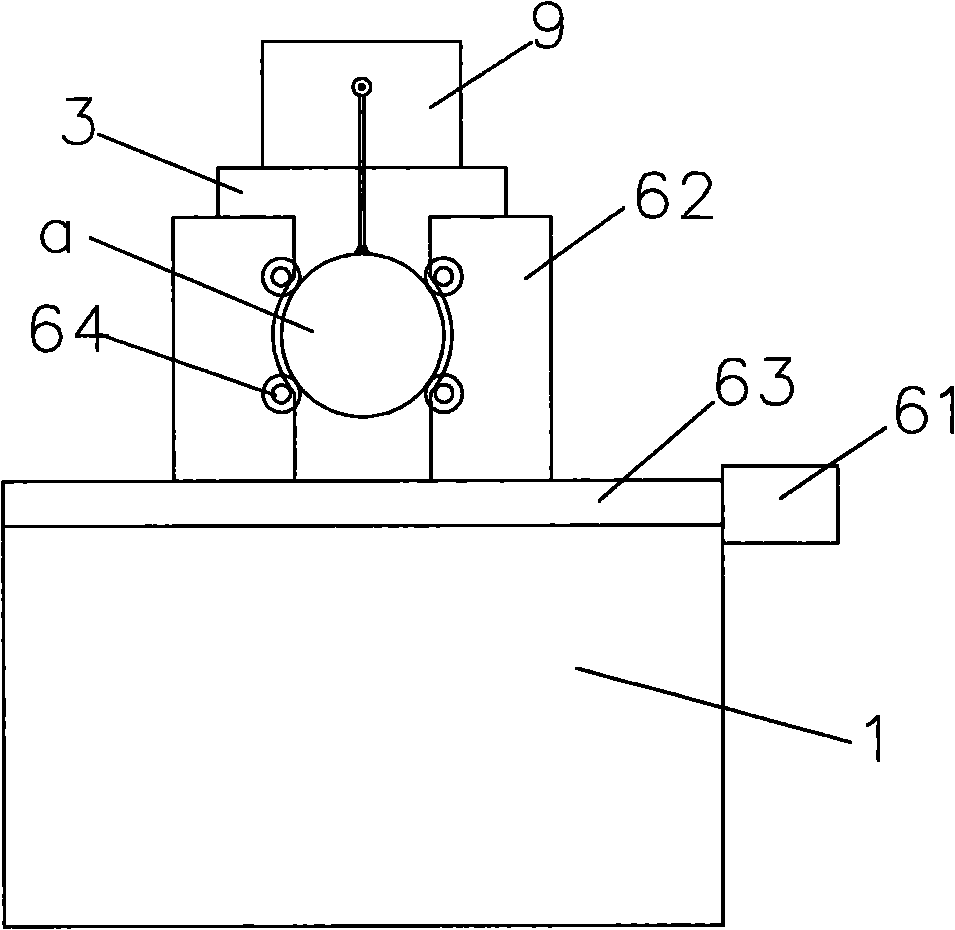

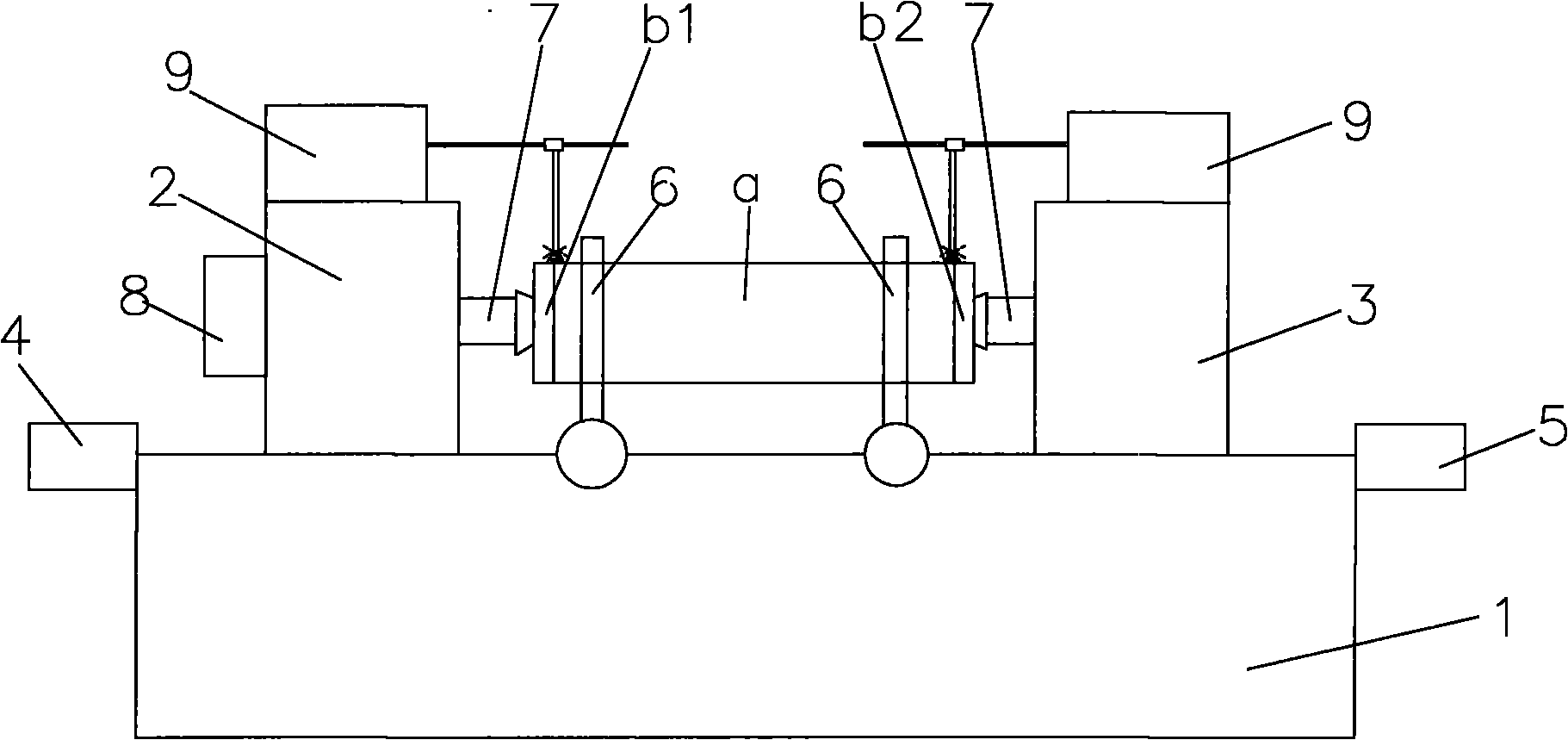

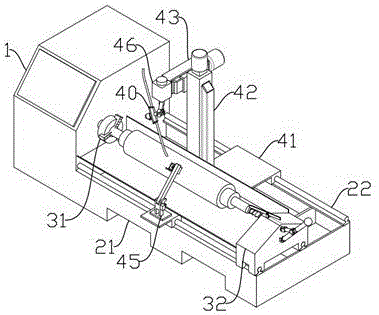

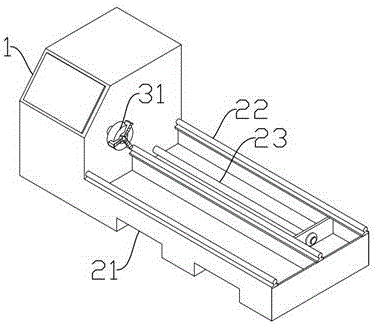

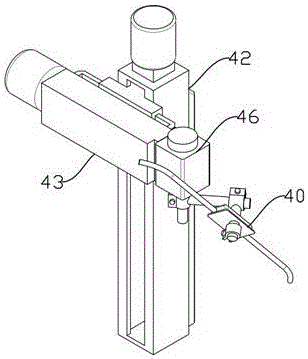

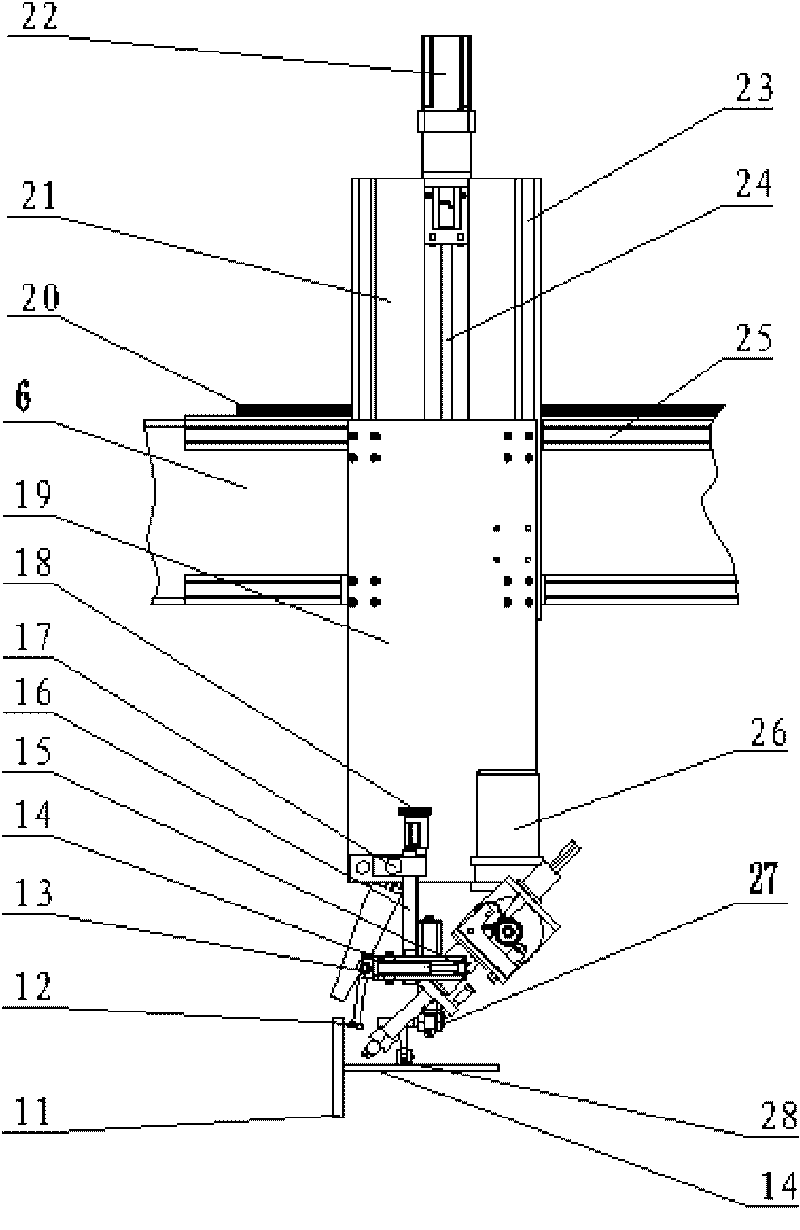

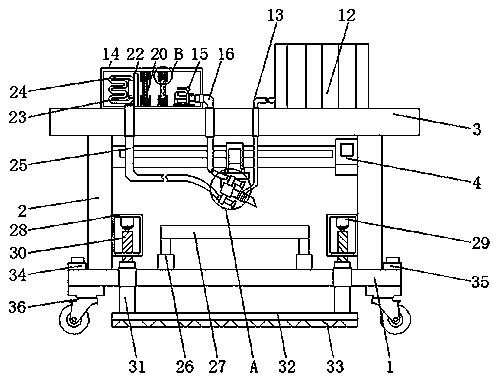

Automatic steel cylinder girth welding device

InactiveCN110666385AAutomatic height adjustmentImprove welding precisionWelding/cutting auxillary devicesAuxillary welding devicesButt jointSteel cylinder

The invention relates to the technical field of steel cylinder girth welding, and specifically relates to an automatic steel cylinder girth welding device. The automatic steel cylinder girth welding device comprises an operation table, wherein an opposite driving assembly is arranged at the bottom of the operation table; the opposite driving assembly comprises two movable bottom plates; a movablenotch used for allowing each movable bottom plate to move is formed in the operation table; a rotary table is arranged at the top of each movable bottom plate; a left side rotating assembly and a right side auxiliary rotating assembly are arranged on the two rotary tables correspondingly; clamping jaw assemblies are arranged at the adjacent ends of the left side positioning rotating assembly and the right side rotating assembly correspondingly; lifting adjusting assemblies are arranged above the left side rotating assembly and the right side auxiliary rotating assembly correspondingly; a vertical support is arranged between the two clamping jaw assemblies; and a welding gun capable of lifting is arranged on the vertical support. According to the device, the height of each steel cylinder needing to be welded can be adjusted correspondingly, butt joint is automatically carried out, the height of the welding gun can be automatically adjusted, and the welding precision is improved.

Owner:温金建

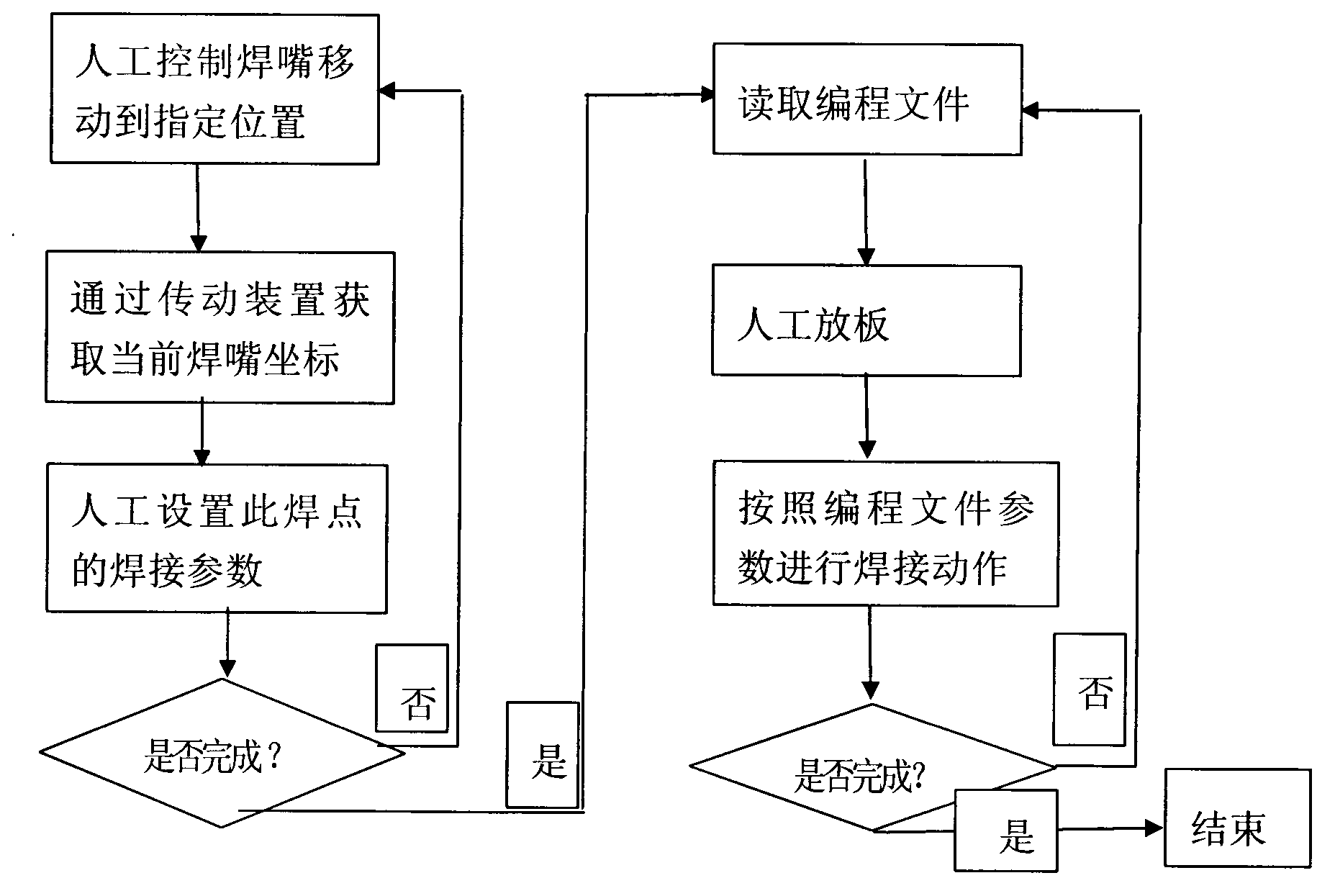

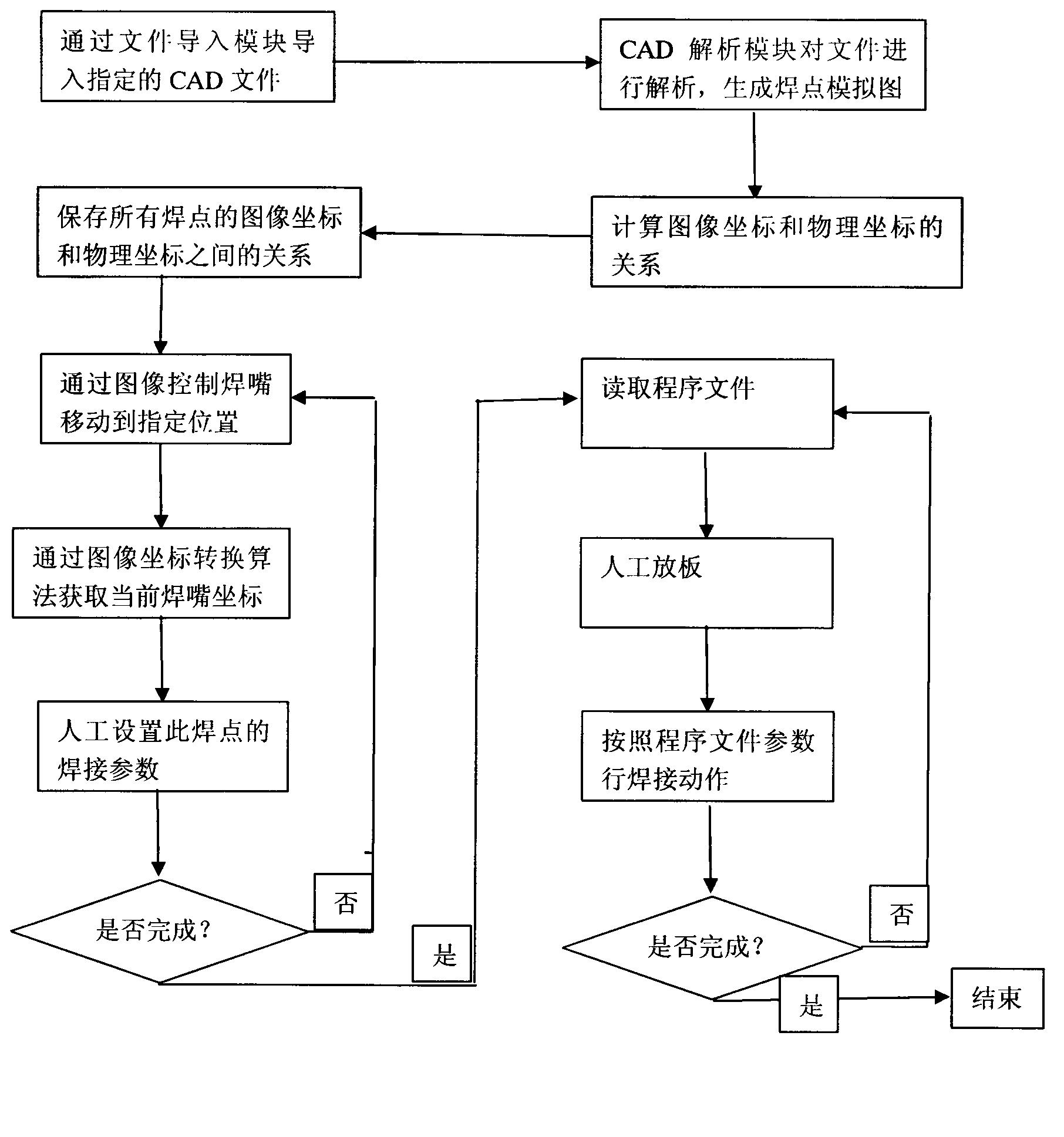

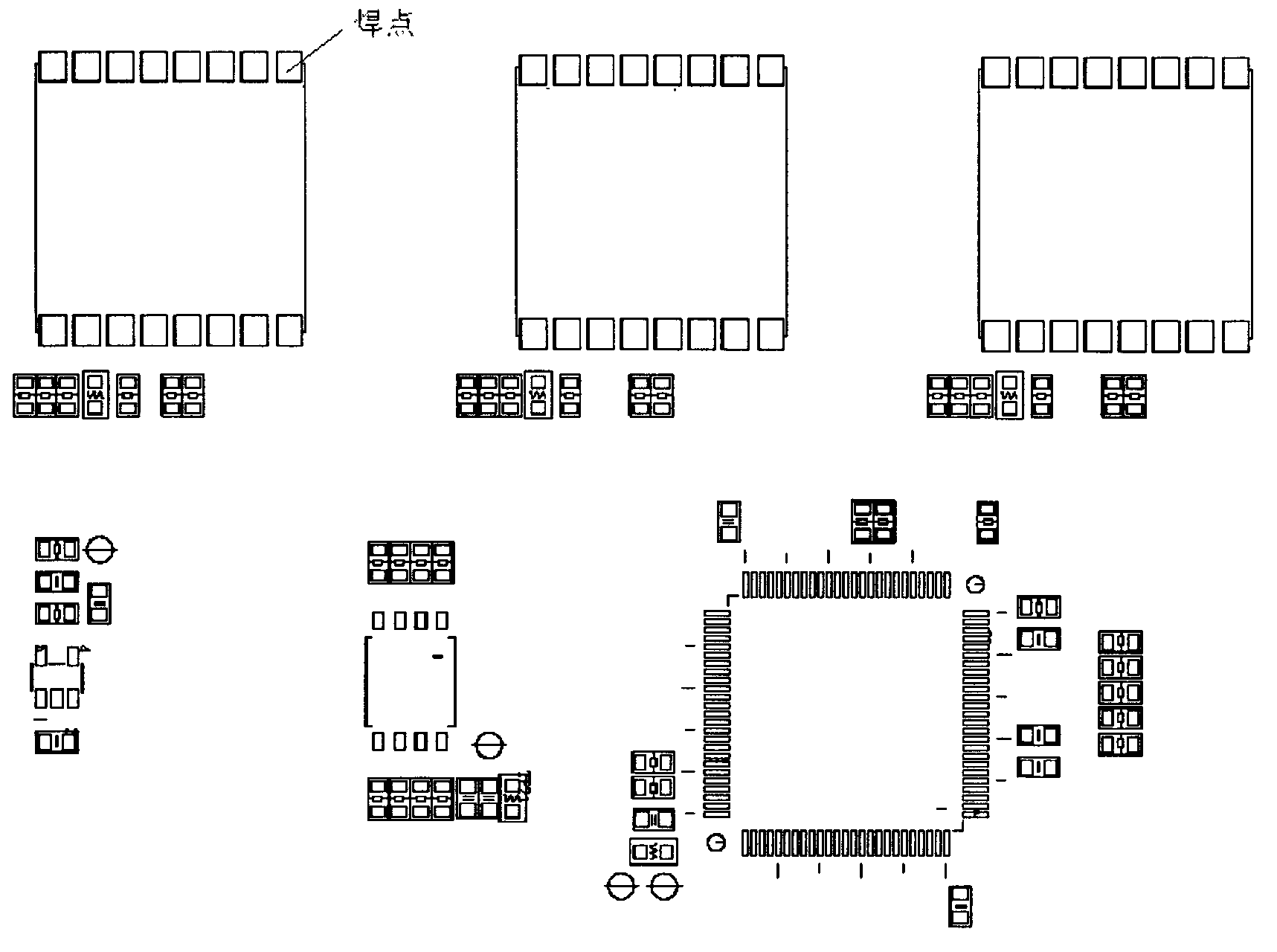

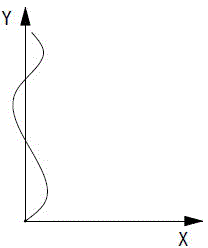

Method for improving programming speed and precision of soldering robot by using computer-aided design (CAD) file

ActiveCN102990179APrecise angle of rotationAccurate compensationMetal working apparatusGraphicsComputer Aided Design

The invention discloses a method for improving programming speed and precision of a soldering robot by using a computer-aided design (CAD) file. The method comprises the following steps of: (1) introducing the CAD file comprising a printed circuit board (PCB) into a programming file; (2) analyzing the CAD file, and converting the programming file into a supportable file format; (3) generating a corresponding CAD graph in the programming file, wherein the graph comprises precise position information of all the welding disks; (4) processing the generated CAD graph, and constructing a relation between graph coordinates and object coordinates; (5) selecting a welding point to be welded on the processed CAD graph, obtaining actual physical coordinates according to the coordinate conversion relation obtained in step (4), and moving a welding nozzle to a position with the actual physical coordinates so as to perform parameter setting and welding; and (6) finding other welding points by the method in step (5), and welding. By adopting the method, a camera is not required to shoot a thumbnail, and the programming time is shortened; the rotating angle of the PCB can be accurately calculated and can be compensated; and the welding precision is improved.

Owner:廖怀宝

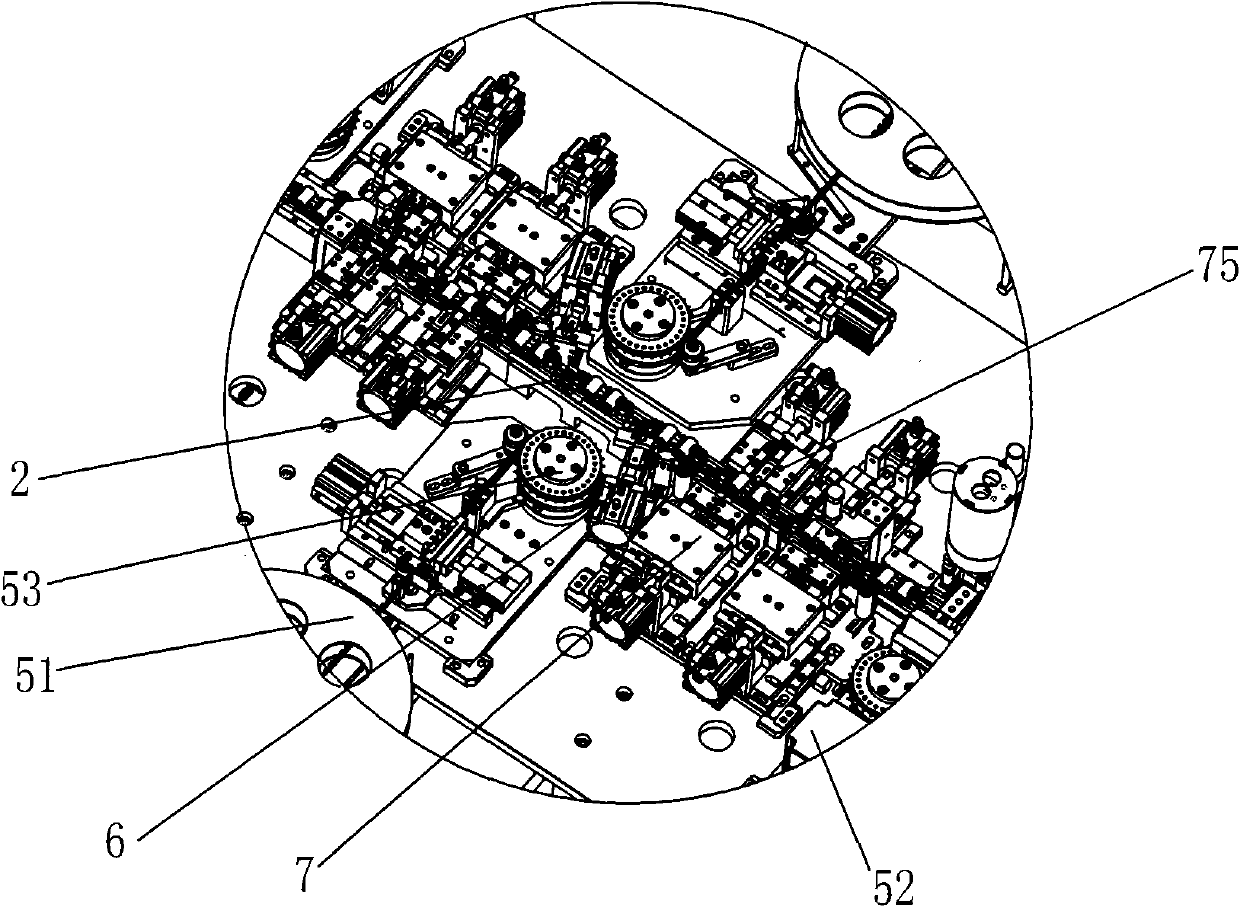

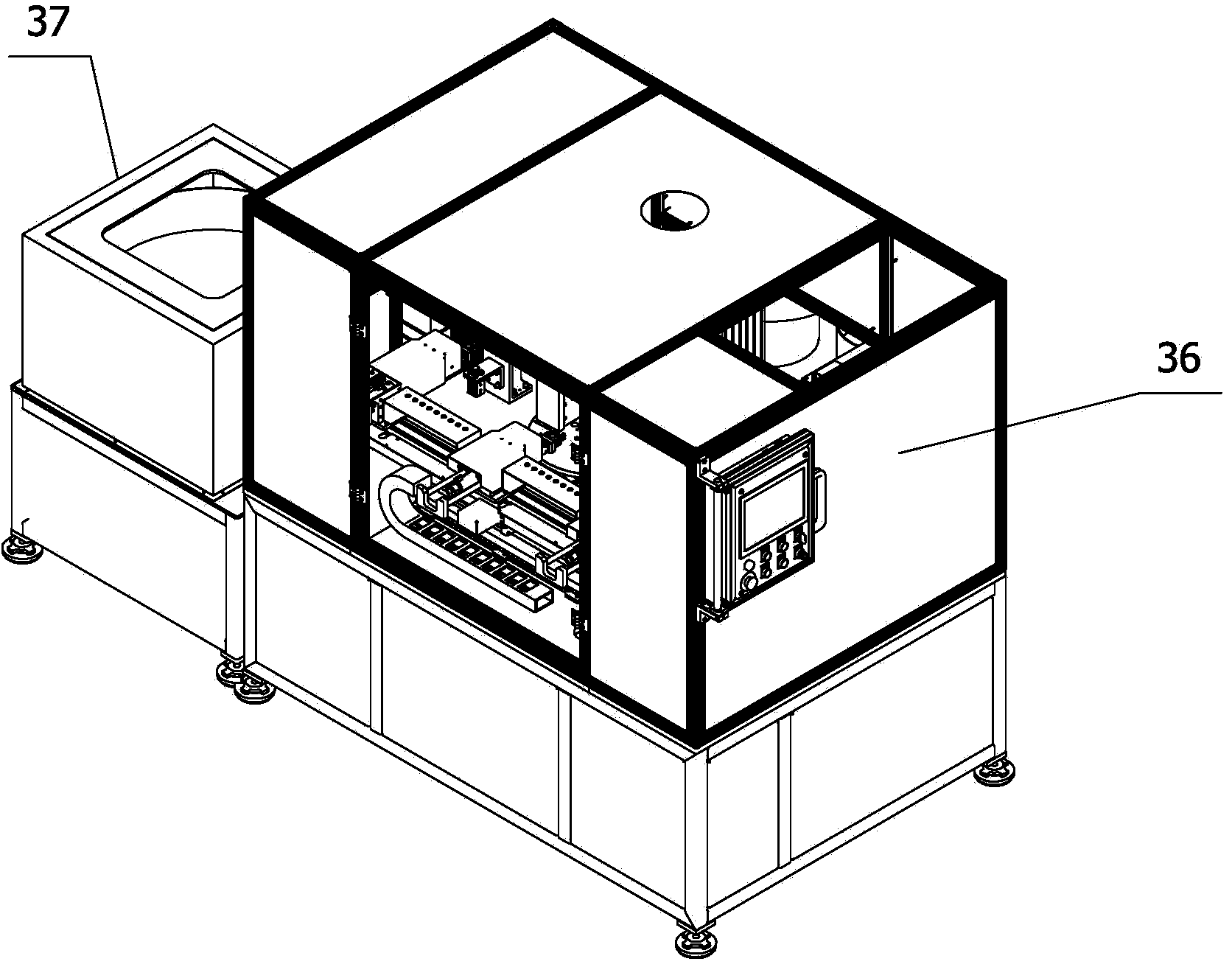

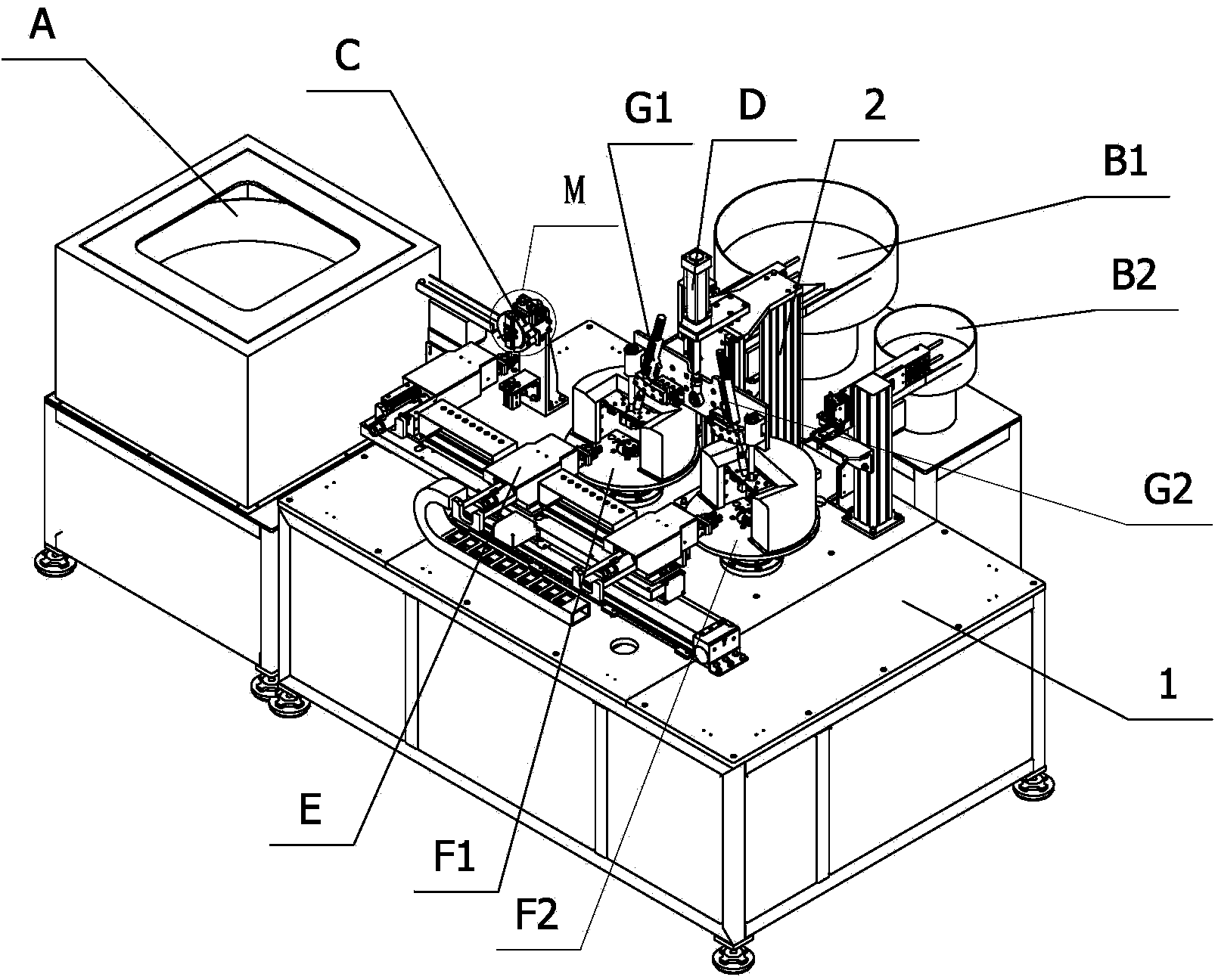

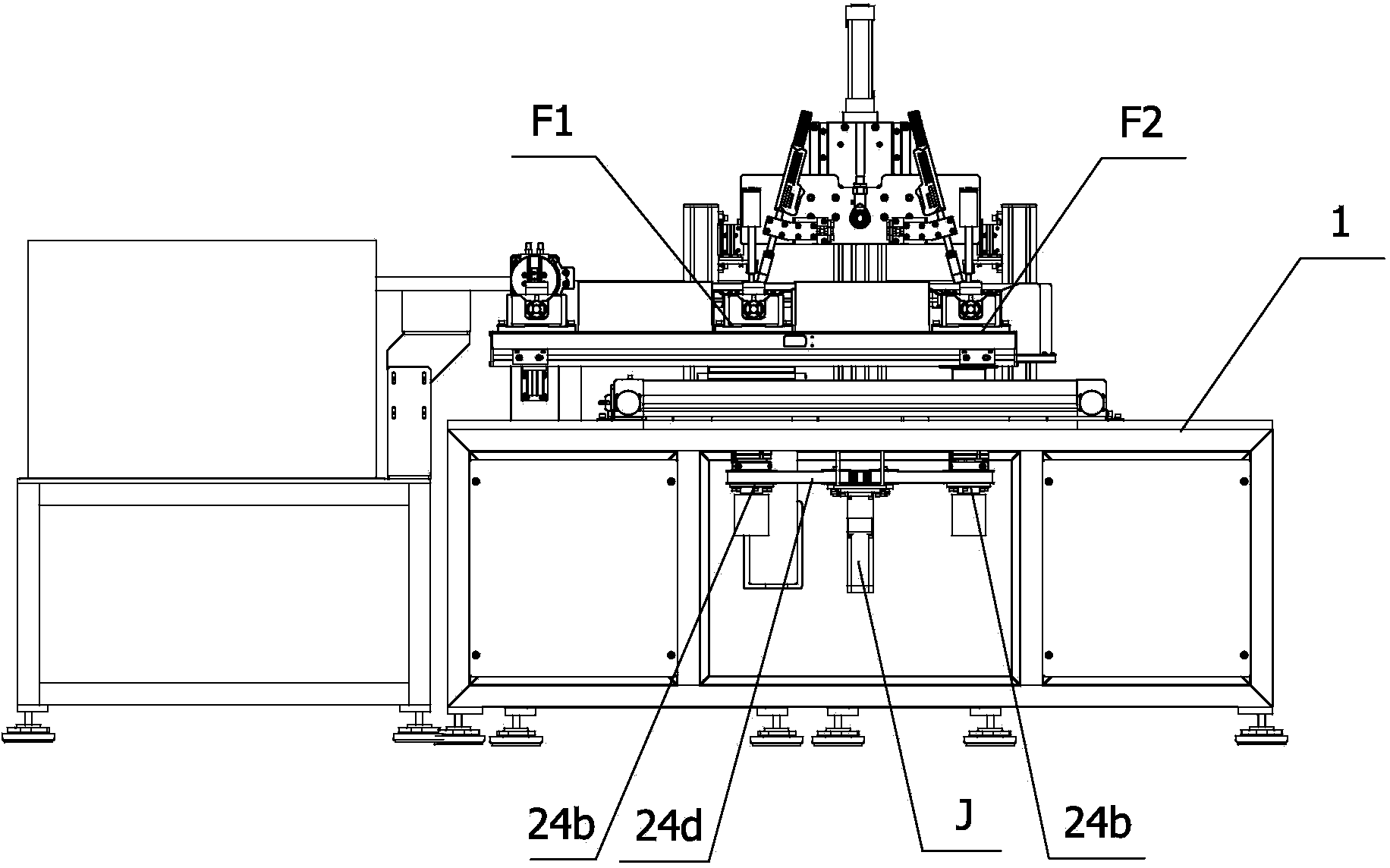

Power battery ultrasonic welding equipment

ActiveCN107096990AHigh degree of automationImprove welding efficiencyNon-electric welding apparatusPower batteryFailure rate

The invention discloses power battery ultrasonic welding equipment. The power battery ultrasonic welding equipment comprises a working table, a tray feeding assembly, a cell feeding assembly, a connecting link feeding assembly, a film-pasting assembly, a cell discharging assembly, a protecting plate feeding assembly, an ultrasonic welding assembly, an electric resistance welding assembly and pressing plate pick-and-place assemblies, wherein the tray feeding assembly, the cell feeding assembly, the connecting link feeding assembly and the film-pasting assembly are arranged on the working table, the tray feeding assembly is used for feeding trays, and the cell feeding assembly is used for positioning cells; the connecting link feeding assembly is used for feeding copper and aluminum connecting links into fixtures, the film-pasting assembly is used for pasting blue glue on the welding area, and the cell discharging assembly is used for outputting the cells pasted with the film; and the protecting plate feeding assembly used for feeding protecting plates, the ultrasonic welding assembly used for compressing and welding positioned lugs, connecting links and protecting plates, the electric resistance welding assembly used for carrying out repair-welding on ultrasonically welded copper poles, and the pressing plate pick-and-place assemblies which are symmetrically arranged on the two sides of a return line body, and are used for transferring pressing plates into the fixtures or disassembling the pressing plates are arranged on the periphery of the return line body. According to the power battery ultrasonic welding equipment, the technical problems that the degree of welding automation of an existing power battery is not high, the manufacturing efficiency, the welding precision and the yield are low, and the manufacturing cost and the failure rate are high are solved; and the power battery ultrasonic welding equipment has the characteristics that the implementation is easy and the stability is high.

Owner:CONTEMPORARY AMPEREX TECH CO +1

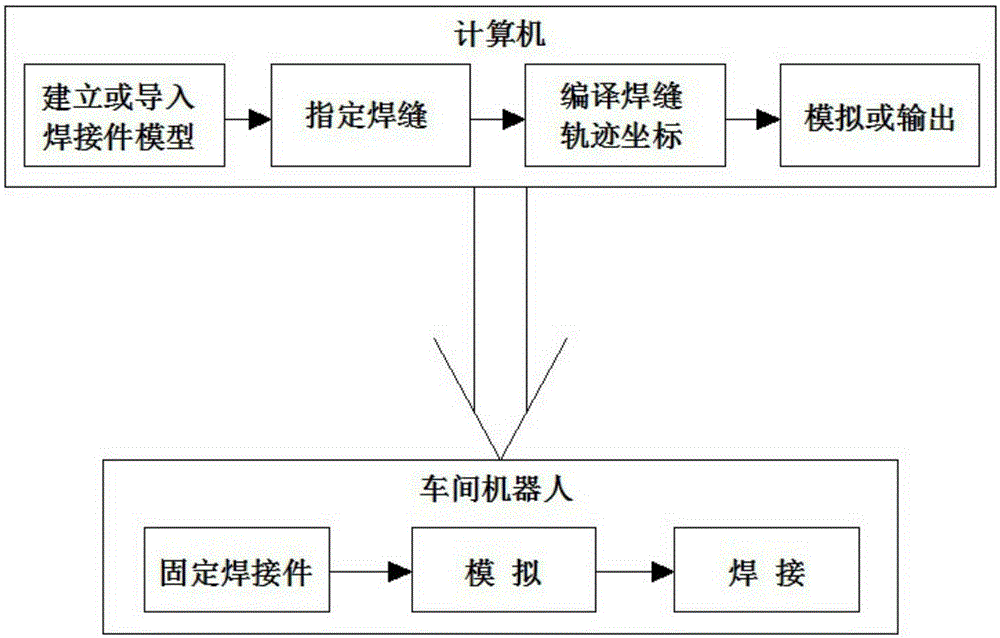

3D printing welding method using multi-degree-of-freedom robot

InactiveCN105171742AAvoid Poor Weld Quality SituationsLow costProgramme-controlled manipulatorArc welding apparatusGraphicsImaging processing

The invention discloses a 3D printing welding method using a multi-degree-of-freedom robot. A computer and a workshop welding robot are included, and the computer controls a welding arm of the workshop welding robot; by means of the novel 3D printing technology, a welding part 3D model is built in the computer, and then a welding line required to be welded in the model is assigned, the computer will extract welding line trajectory coordinates, and the trajectory coordinates are compiled into execution stage robot language commands which are output to the workshop welding robot; and after simulation is free of errors, 3D printing welding is achieved. Through the method, the condition that according to a modern automatic welding robot, due to problems of welding line tracing, image processing and the like, the welding quality is poor is avoided, welding is stable, operation is convenient, a large number of sensors are not needed, and the cost is low.

Owner:NANJING UNIV OF TECH +1

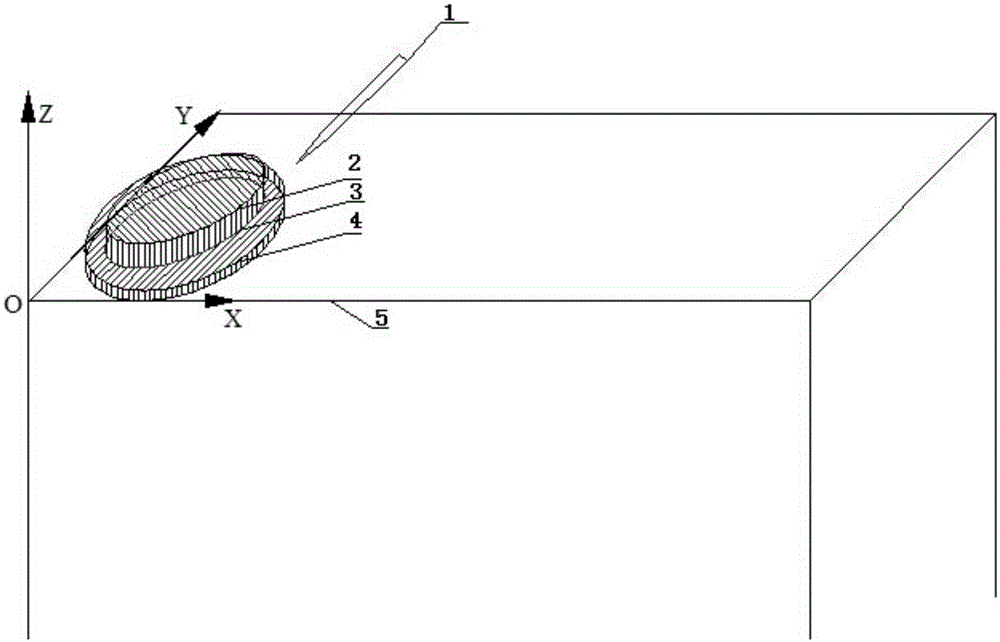

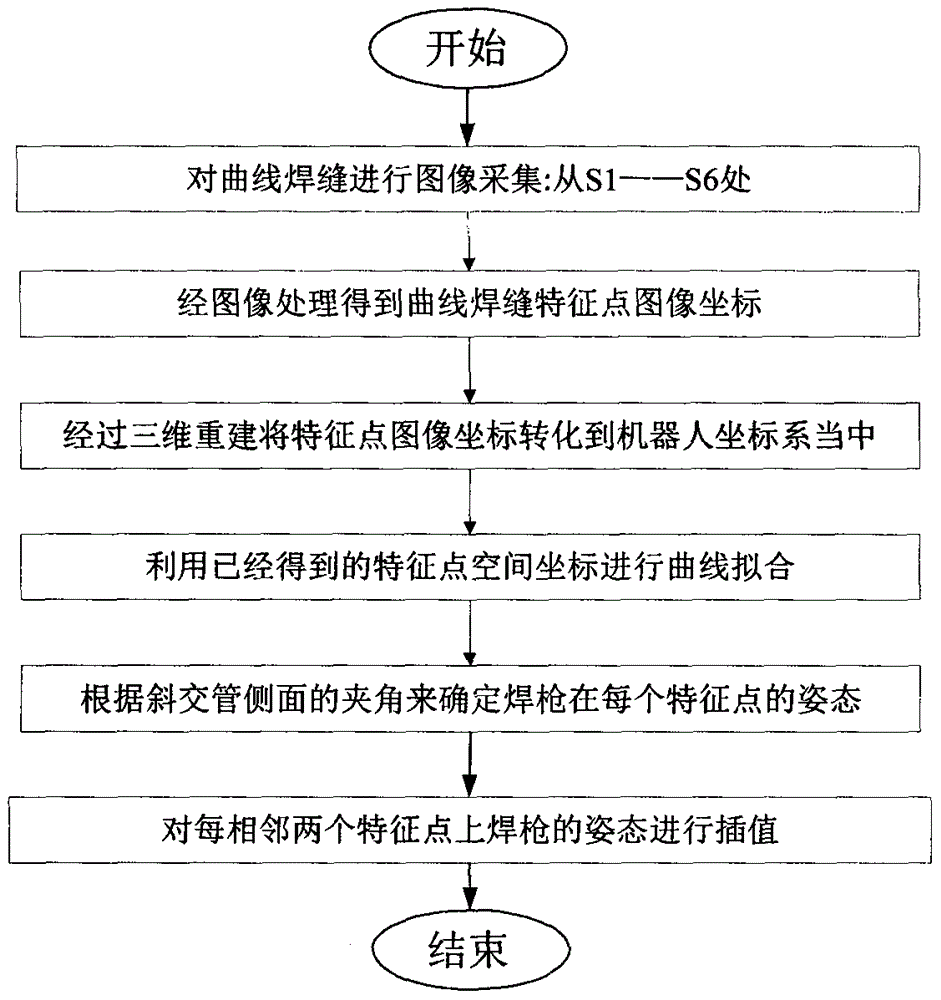

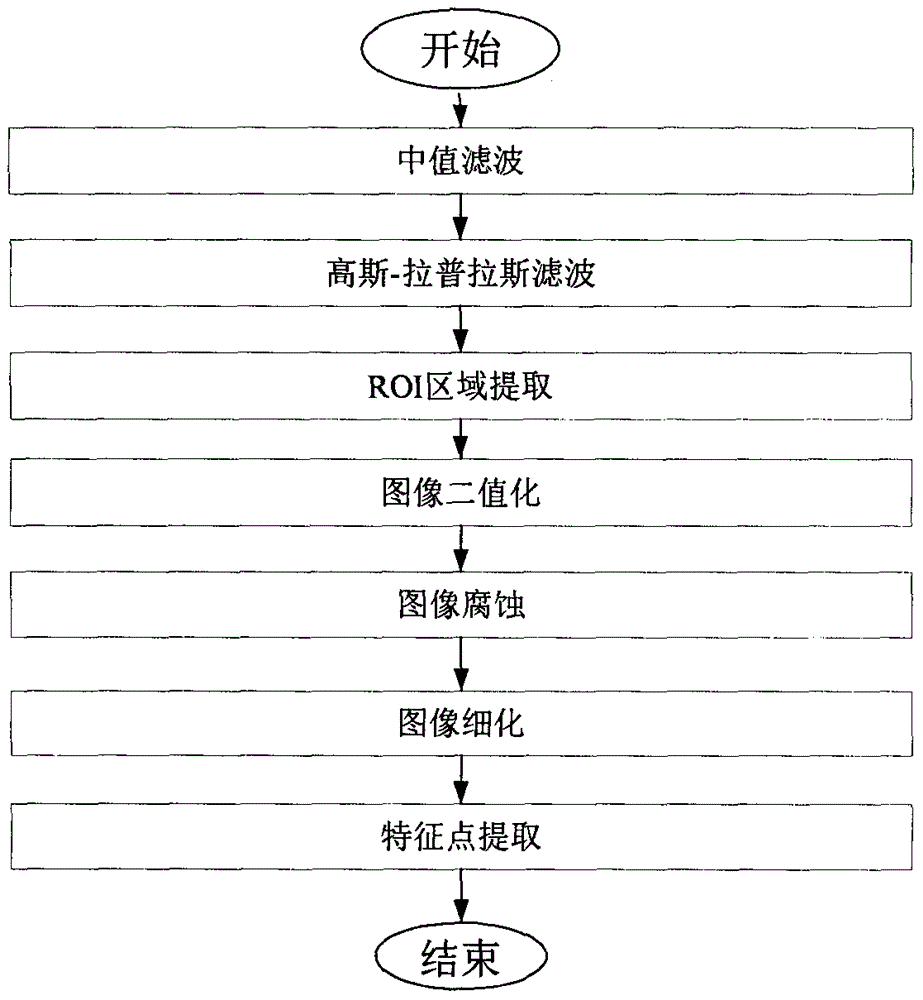

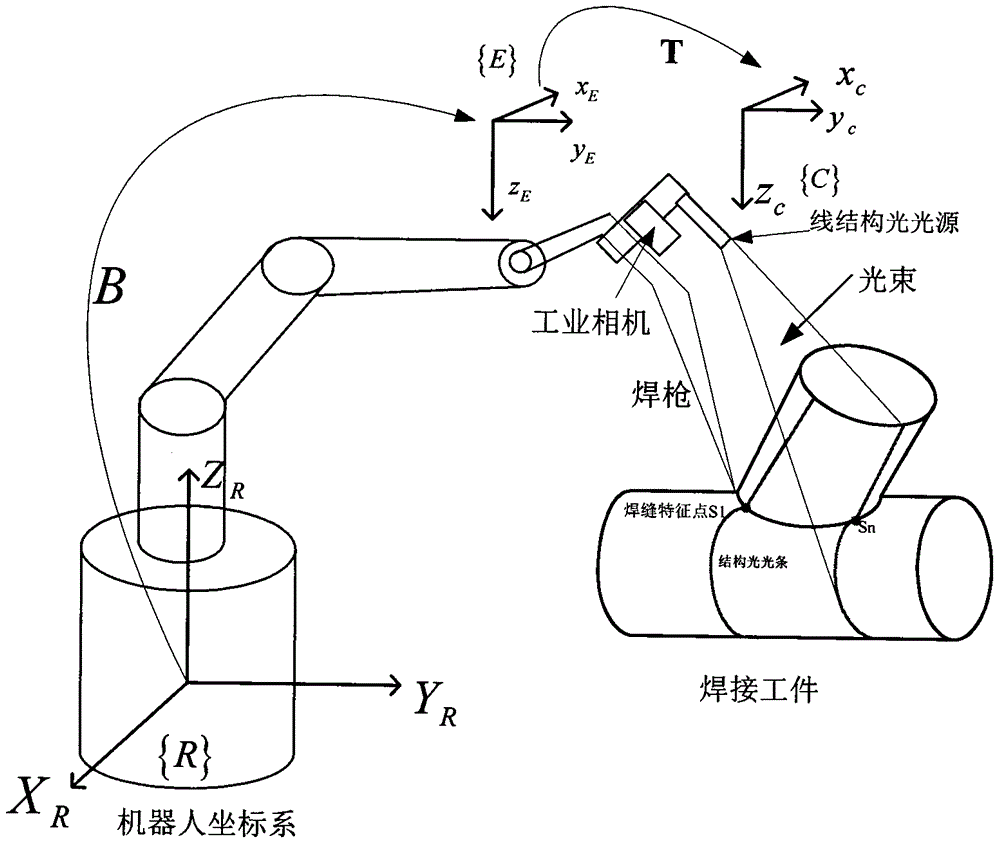

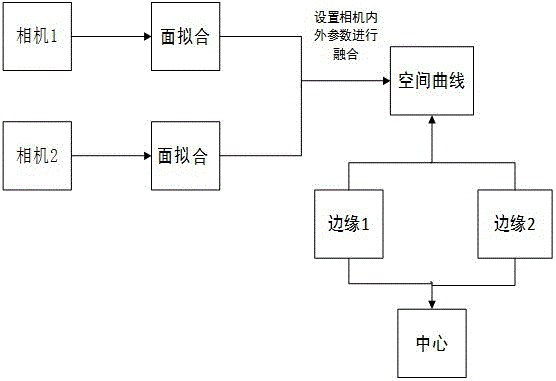

Curve welding seam welding technology based on line structured light

InactiveCN106425181AAchieving identifiabilityAchieve weldingWelding/cutting auxillary devicesAuxillary welding devicesTracking modelEngineering

The invention discloses a curve welding seam welding technology based on line structured light and oriented to an oblique crossed tube. According to the method, machine version and robot kinematics are combined very well, so that the problems that the process of obtaining curve welding seam feature points is not flexible, and a curve track model are difficult to establish are solved. The curve welding seam welding technology comprises the following steps of: firstly, controlling a six-degree-of-freedom robot, enabling a robot end to drive an industrial camera to shoot a curve welding seam image with the line structured light; and then, carrying out a series of image pre-treatment and feature point extraction work to obtain space coordinates of all feature points of a curve welding seam, and fitting through a B sample curve, and finally obtaining a smooth space curve. Besides, the gesture of a welding gun can be changed in real time according to included angles at the two sides of a workpiece when the welding gun is used for welding a curve, so that the welding process and welding requirements are improved better.

Owner:NANJING UNIV OF TECH

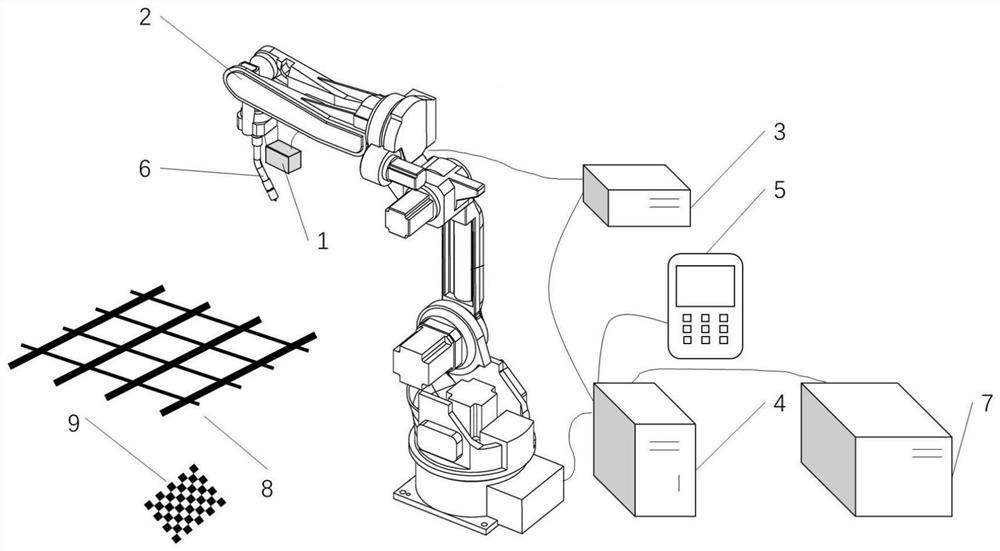

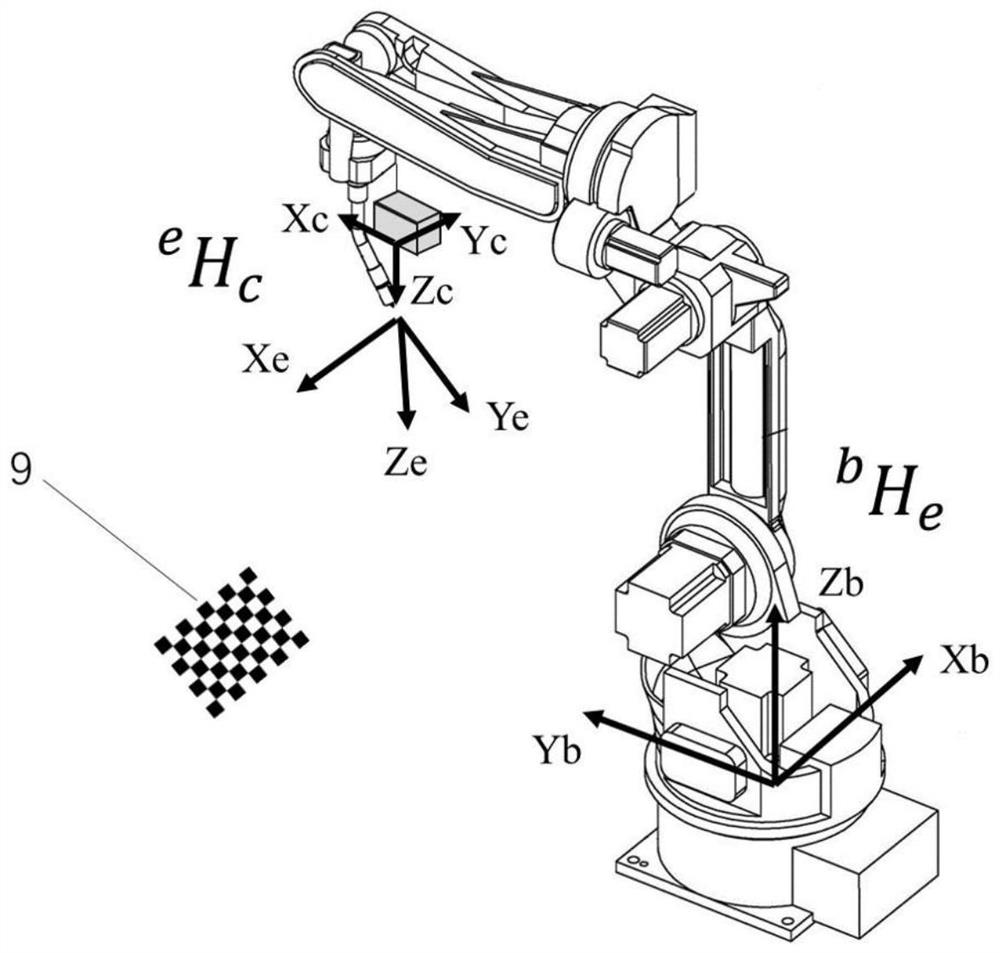

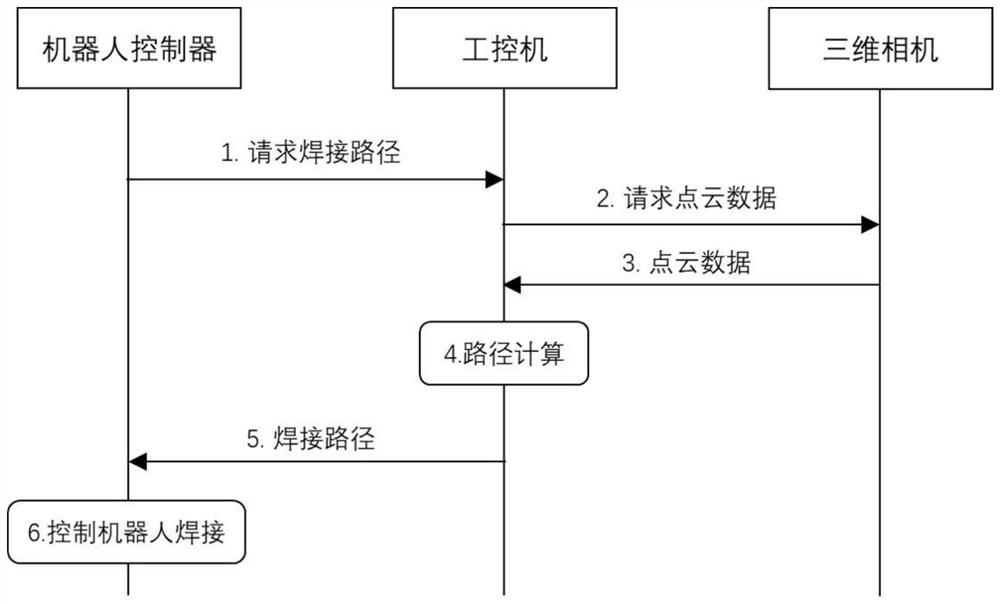

Visual location welding system and method based on robot welding

ActiveCN112122840ASimplify the teaching processFully automatedWelding/cutting auxillary devicesAuxillary welding devicesPoint cloudEngineering

The invention provides a visual location welding system and method based on robot welding. The visual location welding system is composed of a hand-eye calibration module, a photographing point location recording module and a welding execution module. The hand-eye calibration module is used for calculating a position and pose conversion relationship between a camera coordinate system and a robot coordinate system; three-dimensional information of crossed steel bars is acquired through the photographing point location recording module, and welding paths of the crossed steel bars are calculatedthrough a steel bar point cloud welding line extraction algorithm; and the welding paths are sent to the welding execution module, and the welding operation of steel bar crossing points is completed through the welding execution module . Through visual location of the crossed steel bars, the problem of poor precision of a workpiece and a clamp is solved, flexible and accurate welding is achieved,and the welding quality is guaranteed. According to the welding system, automatic calculation of the welding paths is achieved, and the demonstration of the welding paths is omitted; the robot demonstration process is simplified, and the requirement for operators is reduced; and the welding automation of the steel bars is achieved, and the welding effect and the production efficiency are improved.

Owner:XIAN CHISHINE OPTOELECTRONICS TECH CO LTD

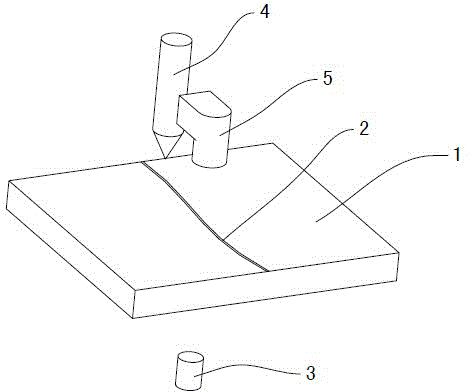

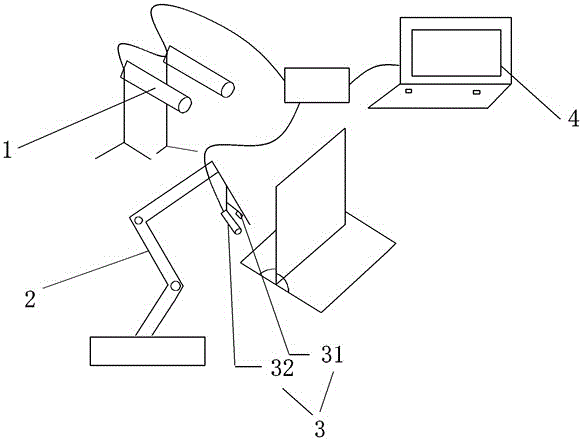

Method for automatically detecting and tracking weld seam

ActiveCN104014907AFind quickly and without errorAvoid collectingWelding/cutting auxillary devicesArc welding apparatusWeld seamLight source

The invention belongs to the technical field of automatic welding and discloses a method for automatically detecting and tracking a weld seam. The method includes the following steps that workpieces (1) to be welded are spliced in advance, the gap between the workpieces (1) is formed, the width of the gap is 1.5 mm-3 mm, a bottom light source (3) is arranged underneath the workpieces (1), and an image collecting unit is used for extracting pre-calibrated trails of light transmitting the gap in an actual weld space coordinate system; then the workpieces (1) are tightly spliced to form the weld seam (2) of which the width is smaller than 1 mm; the image collecting unit is used for collecting images of the surfaces of the multiple workpieces (1), a search area containing the pre-calibrated trails is determined in each image, the weld seam (2) is searched for, and a welding gun (4) is guided to perform welding. The weld seam (2) can be found accurately through the bottom light source, the search range of the weld seam is greatly narrowed through determining one search area in each image, in this way, workloads of searching for the weld seam are reduced, working efficiency is improved, and welding by mistake is avoided.

Owner:北京创想智控科技有限公司

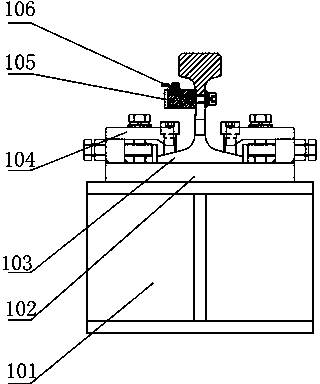

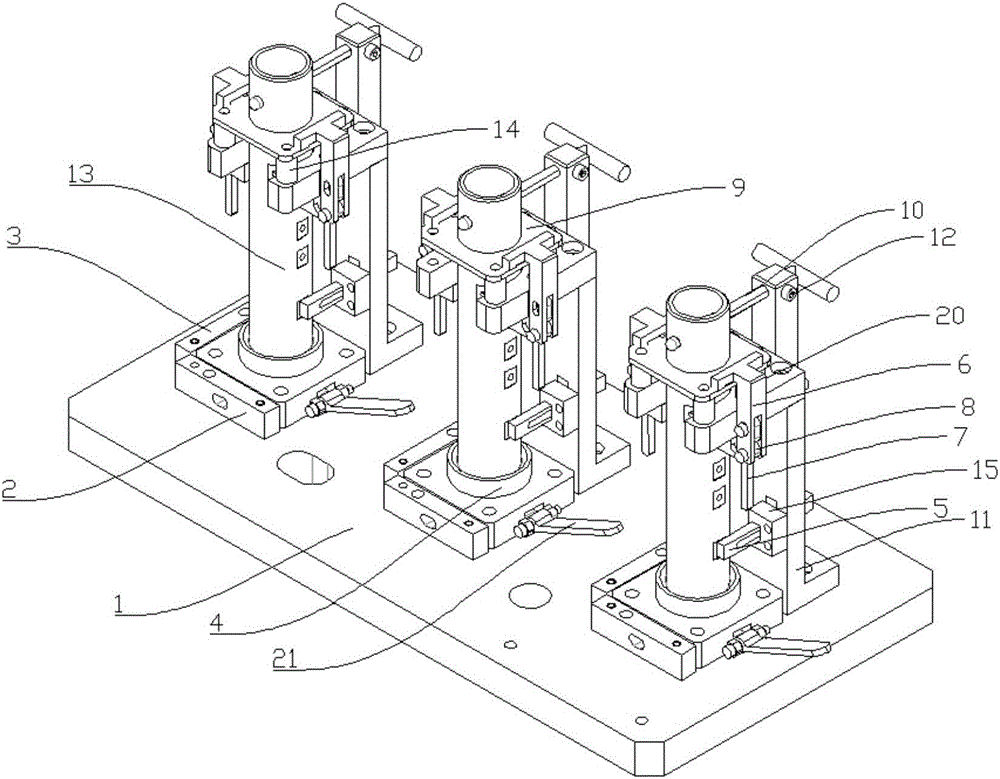

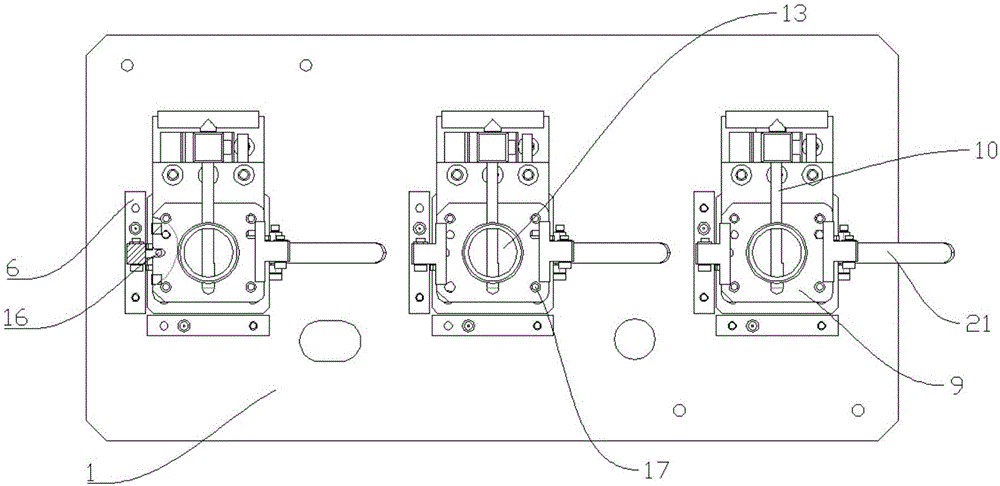

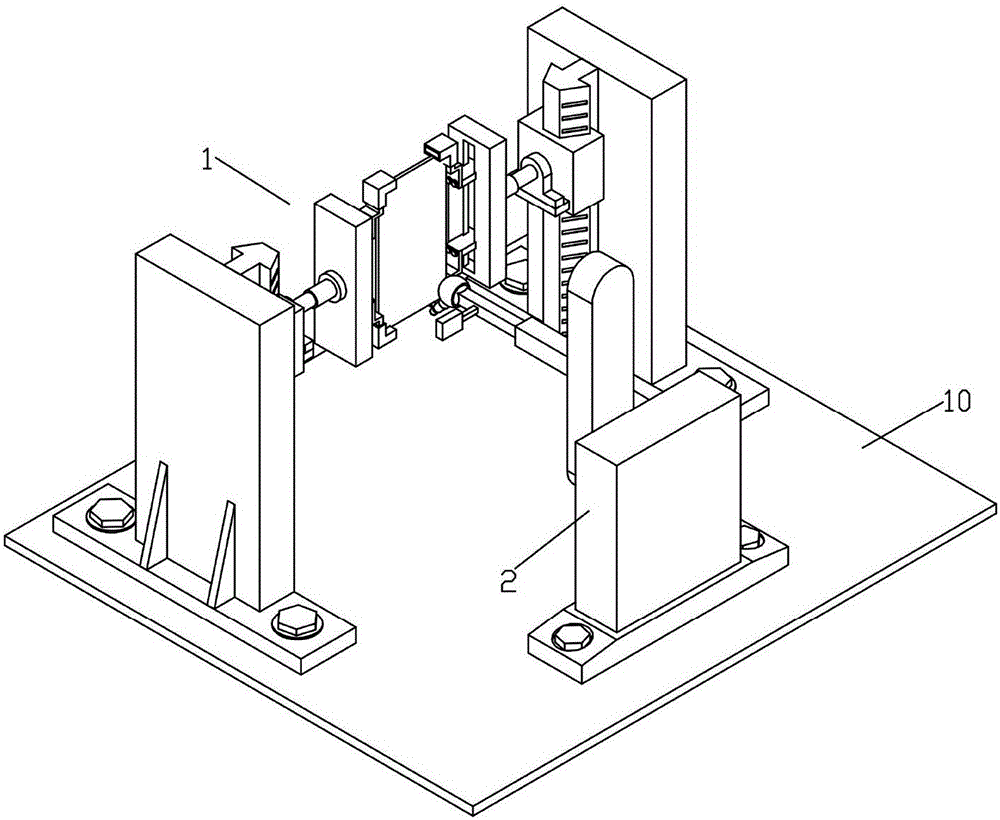

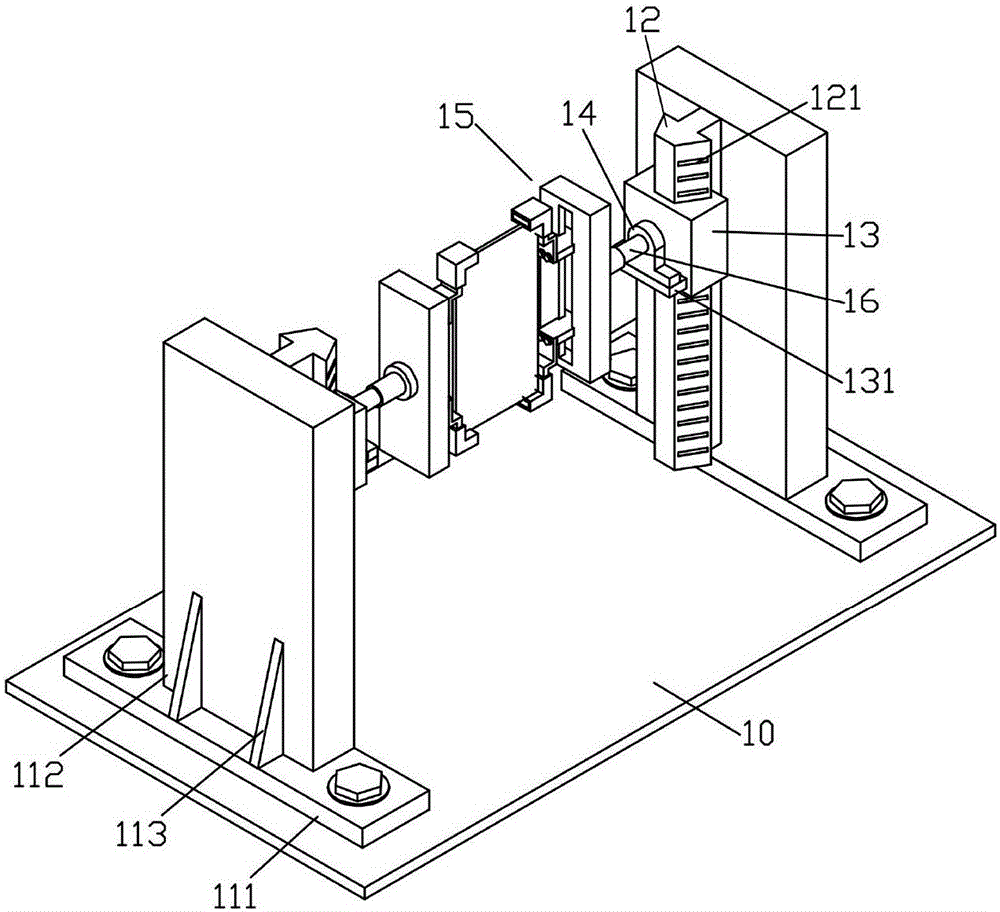

Thin-wall three-way pipe clamping device

PendingCN108000047AImprove stabilityAvoid pinchingWelding/cutting auxillary devicesAuxillary welding devicesEngineeringThin walled

The invention discloses a thin-wall three-way pipe clamping device. The thin-wall three-way pipe clamping device comprises a base plate. A thin-wall three-way pipe vertical segment clamping module anda thin-wall three-way pipe horizontal segment clamping module are mounted on the base plate. The thin-wall three-way pipe vertical segment clamping module comprises vertical sliding rods which are movably mounted on the base plate. Vertical segment V-shaped clamping mechanisms are movably mounted on the vertical sliding rods. A trapezoids support frame for locating is mounted between each vertical sliding rod and each vertical segment V-shaped clamping mechanism. The thin-wall three-way pipe horizontal segment clamping module comprises a horizontal sliding rod support frame which is movably mounted on the base plate. A horizontal sliding rod is mounted on the horizontal sliding rod support frame. Horizontal segment V-shaped clamping mechanisms are movably mounted on the horizontal slidingrod. The thin-wall three-way pipe clamping device has universality and is precise in locating and capable of improving welding precision and operation efficiency.

Owner:ZHEJIANG COLLEGE OF ZHEJIANG UNIV OF TECHOLOGY

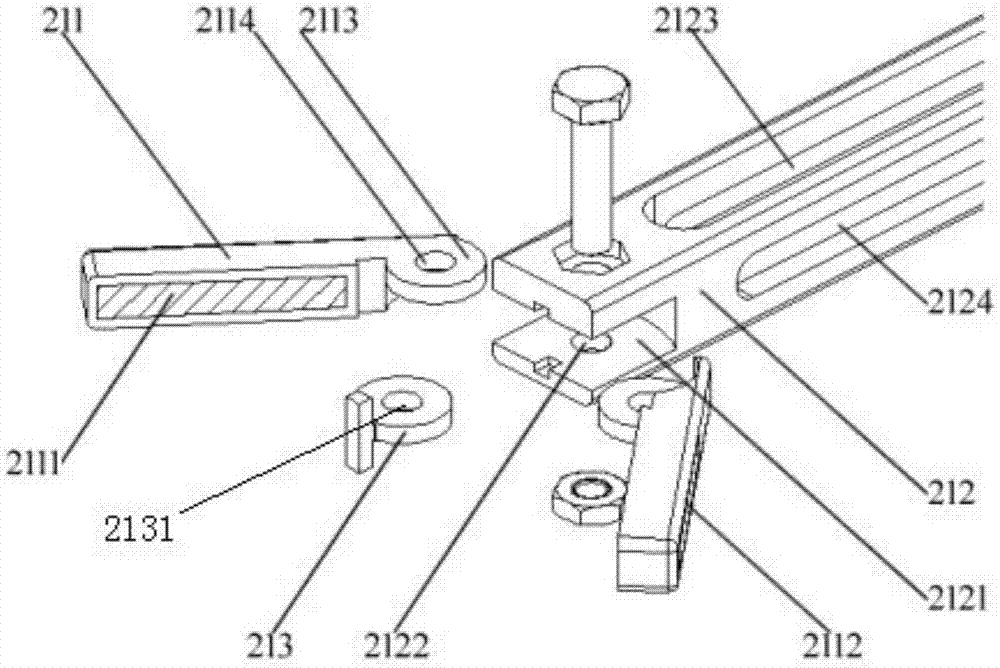

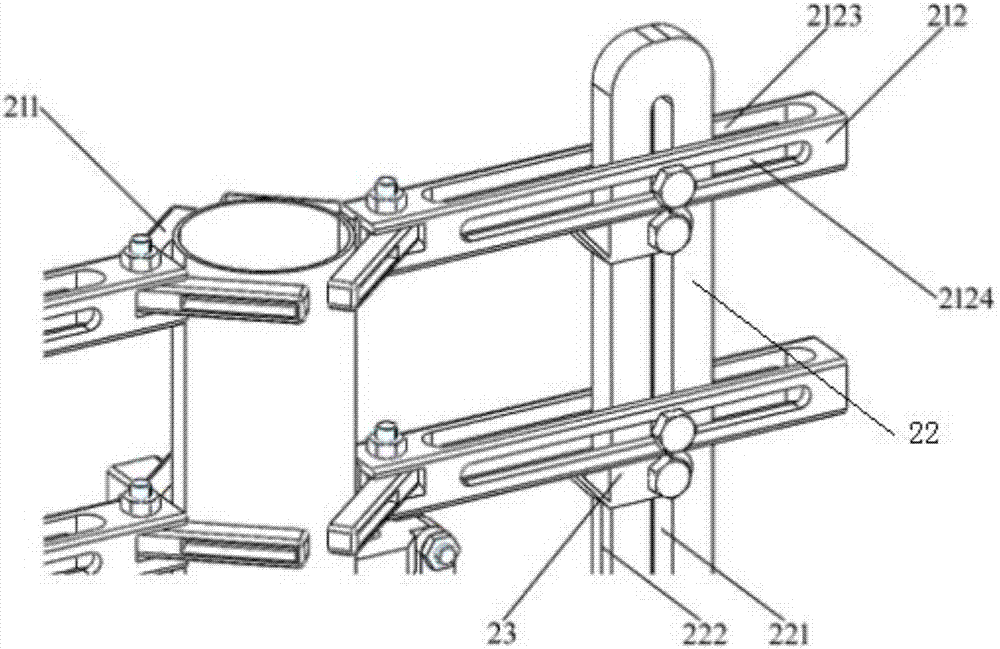

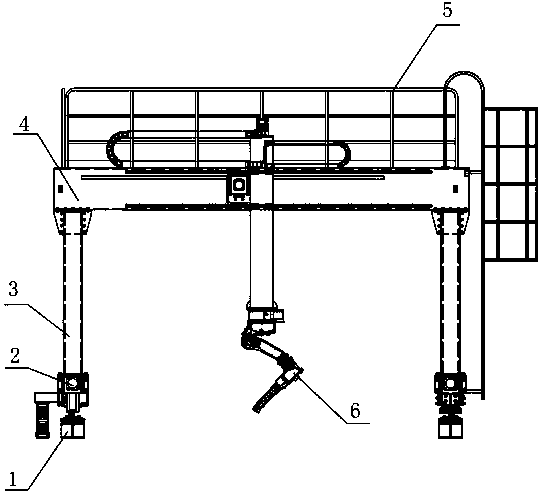

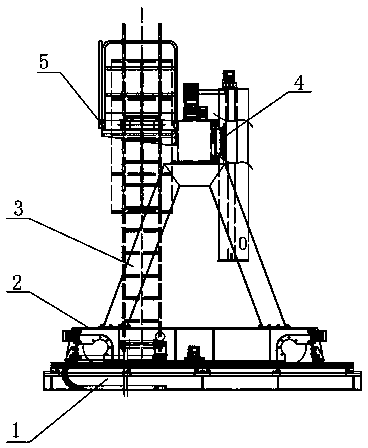

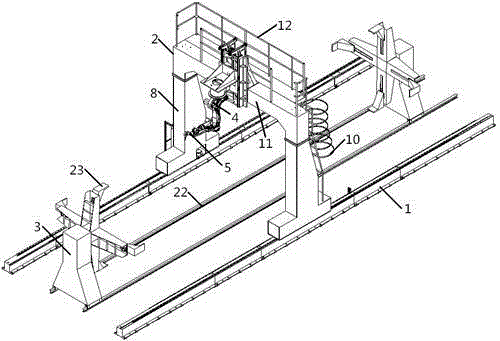

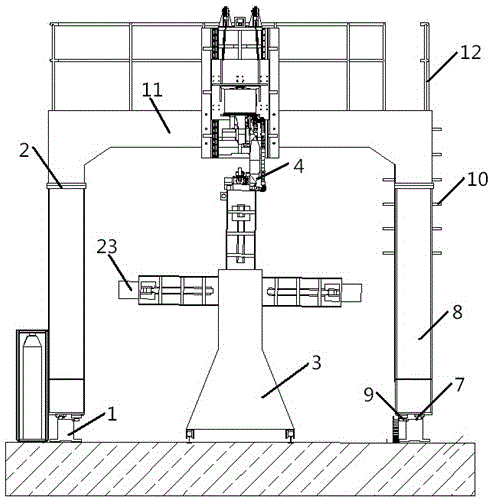

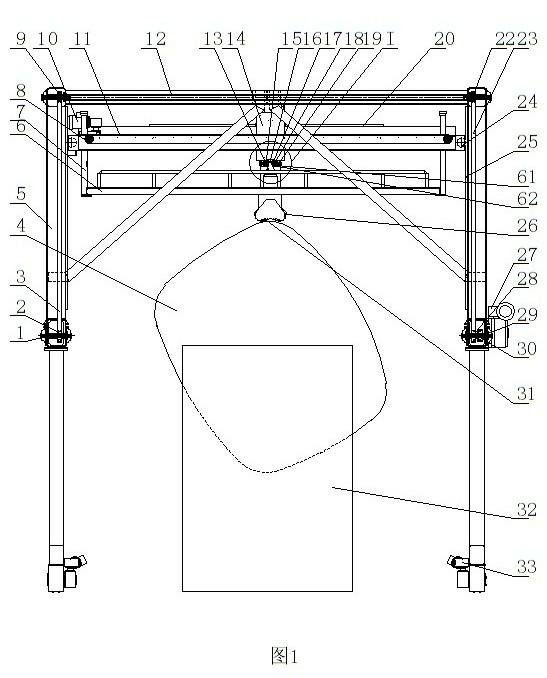

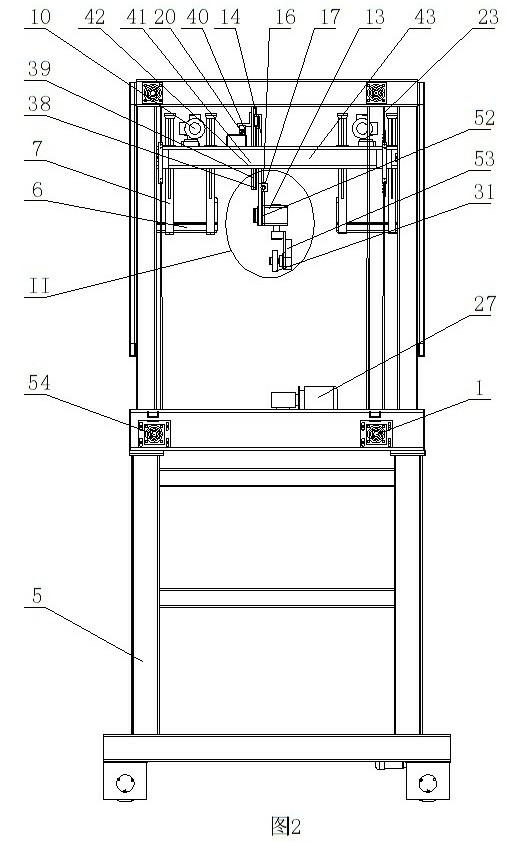

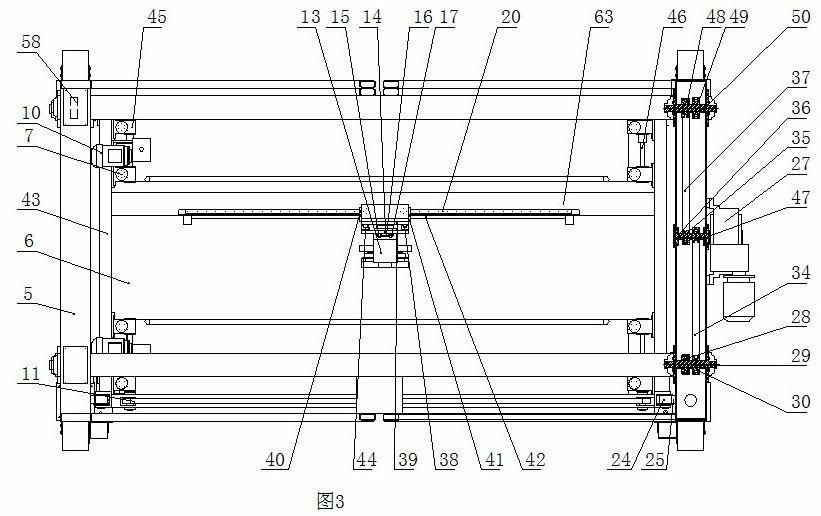

Portal robot welding machine

ActiveCN104384766AEasy to clean and maintainReduce labor intensityWelding/cutting auxillary devicesAuxillary welding devicesRobotic systemsThree-dimensional space

The invention relates to a portal robot welding machine. The portal robot welding machine comprises guide rail assemblies arranged on the ground at a certain interval, wherein driving mechanisms are arranged at the upper ends of the guide rail assemblies; inverted V-shaped upright posts are fixed at the upper ends of the driving mechanisms; a welding arm cross-shaped moving mechanism is arranged above the upright posts; a carrying platform is fixed at the back end of the welding arm cross-shaped moving mechanism; a robot system is arranged at the bottom of the welding arm cross-shaped moving mechanism. Welding work of workpieces of irregular shapes or a large quantity can be finished rapidly and accurately in a three-dimensional space by using the motion of the guide rail assemblies, a longitudinal guide rail and a transverse guide rail; the labor intensity of workers is lowered, the automatic degree is high, the welding accuracy is high.

Owner:WUXI HUALIAN SCI & TECH GROUP

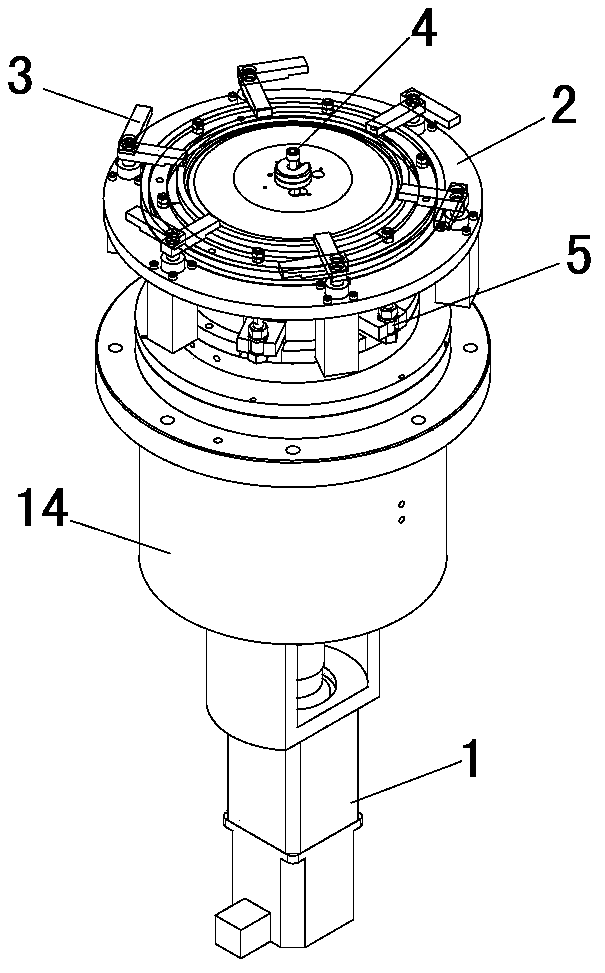

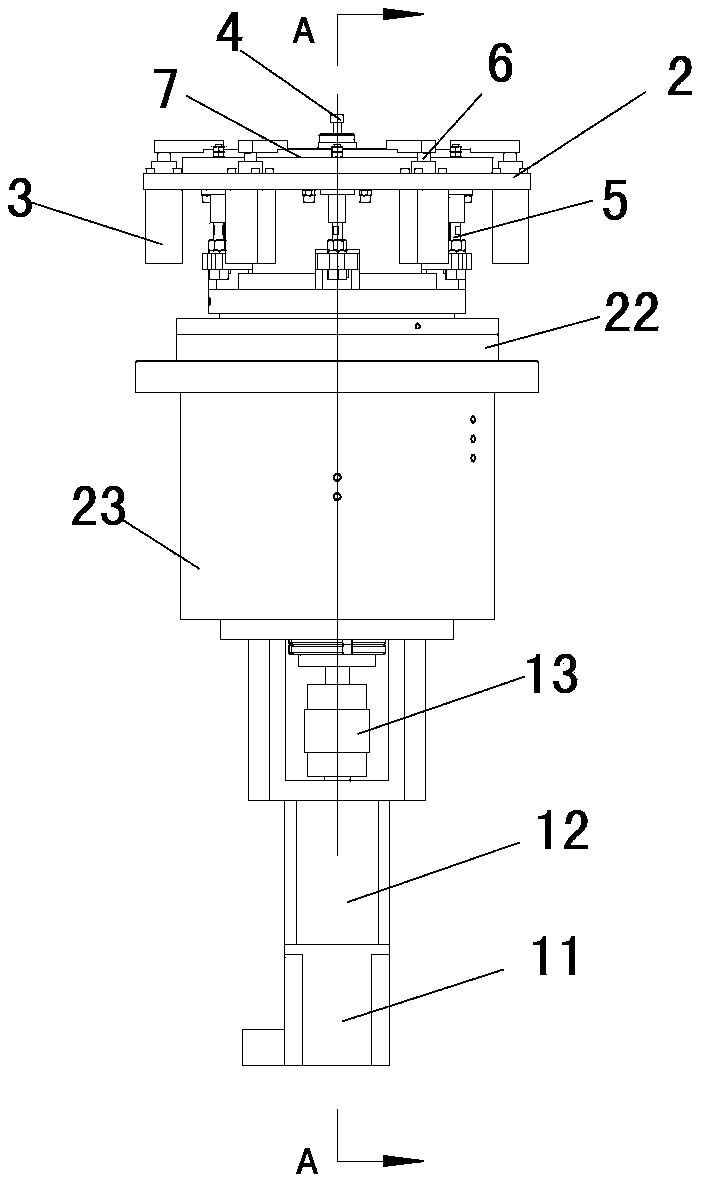

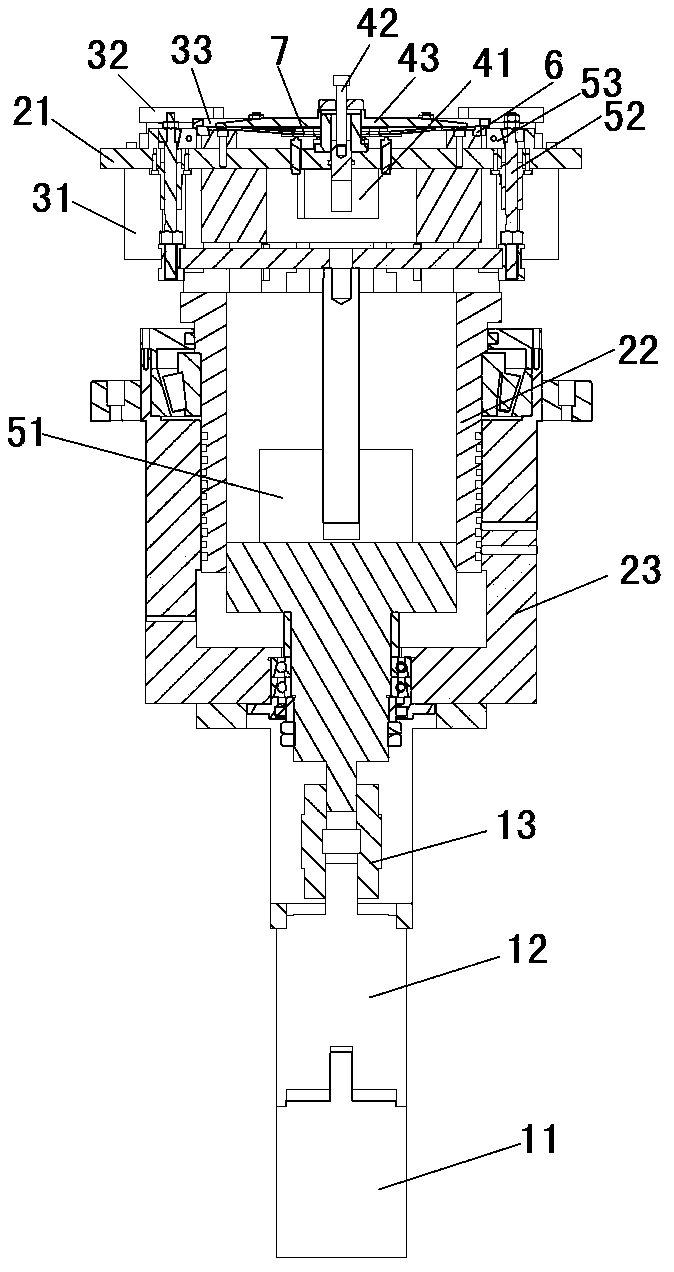

Full-automatic production equipment for compressor copper pipes

ActiveCN103801937AReduce processing timeFully automaticOther manufacturing equipments/toolsMetal working apparatusPipe fittingEngineering

The invention relates to full-automatic production equipment for compressor copper pipes, and belongs to the technical field of machining devices for compressor parts. The full-automatic production equipment for the compressor copper pipes comprises a feeding station, a flaring station, a connector binding station, a discharging station and a turntable, wherein the feeding station, the flaring station, the connector binding station and the discharging station are arranged on the side edge of the turntable in sequence, and a mechanical arm is arranged on the bottom of the turntable and is used for moving a pipe fitting to be machined from a previous station to a next station. After the pipe fitting enters through the feeding station, the pipe fitting is moved to the flaring station by the mechanical arm, flaring machining is carried out on the pipe fitting to be machined at the flaring station, the mechanical arm moves the flared pipe fitting to the connector binding station to carry out connector binding machining, then the mechanical arm moves the flared and connector bound pipe fitting to the discharging station, and thus a finished product is obtained. Through the adoption of the production equipment, full-automatic consecutive production of the feeding, the flaring, the connector binding and the discharging of the compressor copper pipes can be achieved.

Owner:绍兴汉立工业自动化科技有限公司

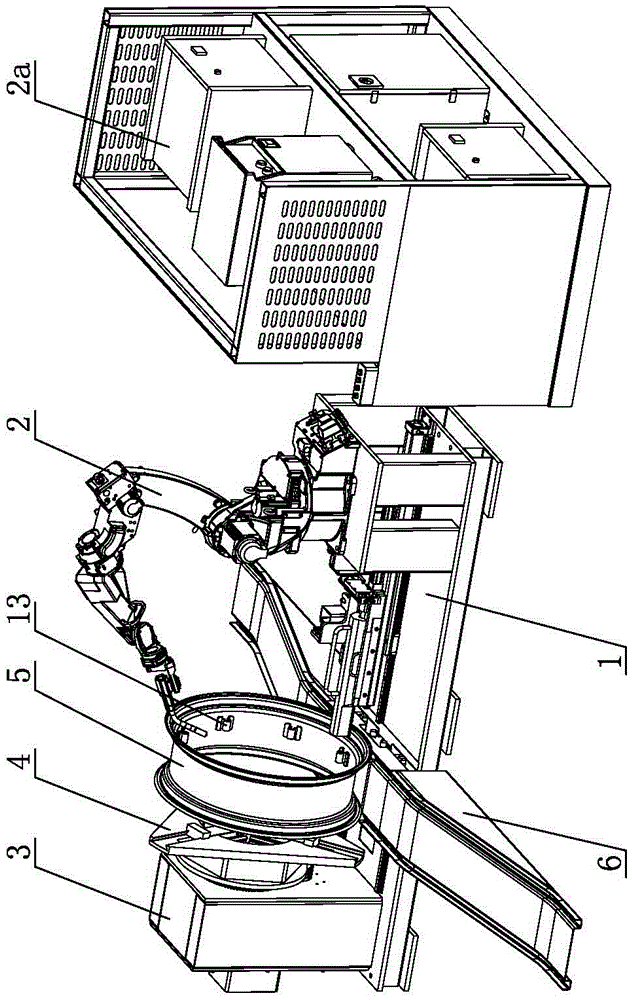

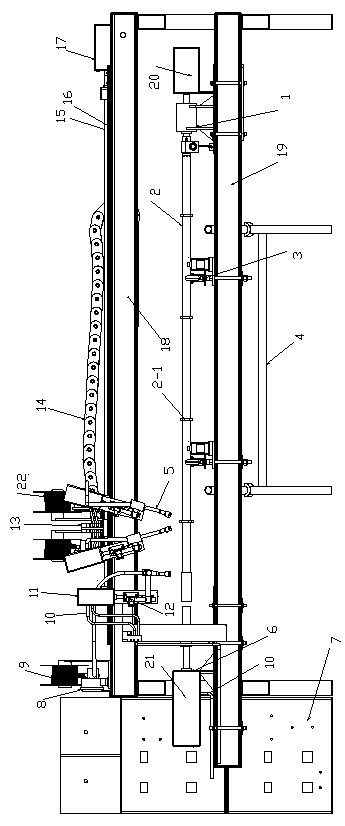

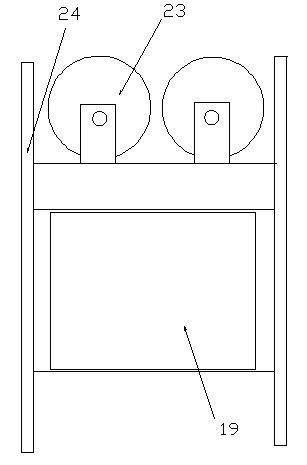

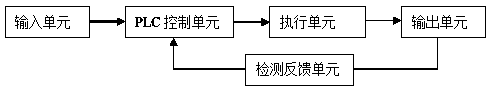

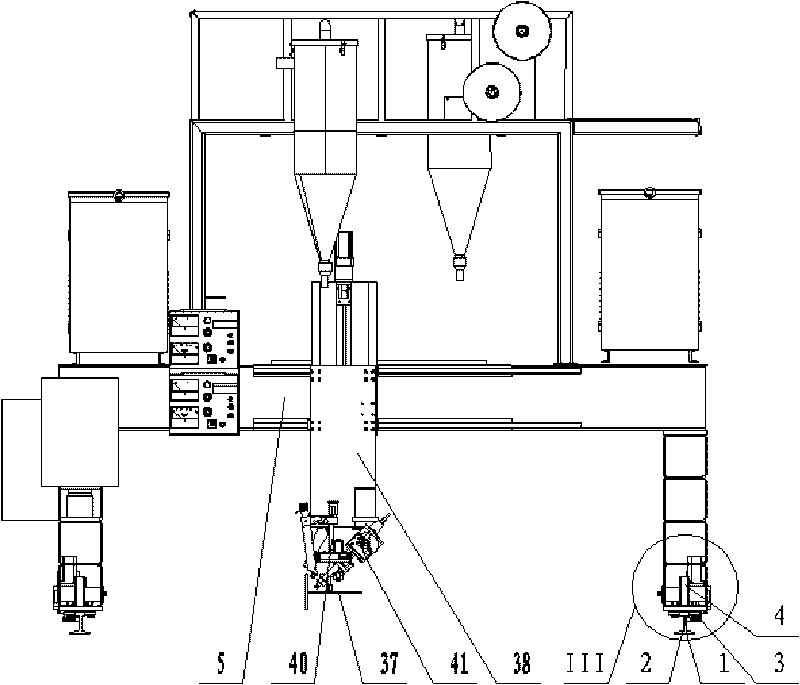

Robot automatic welding workstation for large tank and welding method using robot automatic welding workstation for large tank

InactiveCN104999188AFree and flexible space movementImprove welding precisionWelding/cutting auxillary devicesAuxillary welding devicesAutomatic controlControl system

The invention discloses a robot automatic welding workstation for a large tank and a welding method using the robot automatic welding workstation for the large tank. The robot automatic welding workstation for the large tank comprises a welding system and a PLC automatic control system which is connected with the welding system through a network bus. The robot automatic welding workstation for the large tank is characterized in that the welding system comprises sliding rails, positioners and a rack; the rack is installed on the sliding rails in a sleeved mode; the positioners are located on the center line of the two sliding rails; the rack is provided with a six-axis linkage robot fixedly provided with a welding gun. The PLC automatic control system controls the welding route of the welding system through a driver. By the adoption of the robot automatic welding workstation for the large tank and the welding method using the robot automatic welding workstation for the large tank, full automation of the welding system can be achieved; welding joints are more smooth and flatter; the welding precision is high; the space positioning accuracy can reach 0.1 mm; the welding quality is good; deformation is small; as the space actions of the six-axis linkage robot are flexible, the welding gun can be moved to each portion of the tank and can weld welding joints of various forms.

Owner:HUBEI QIXING TRUCK & CABIN MFG

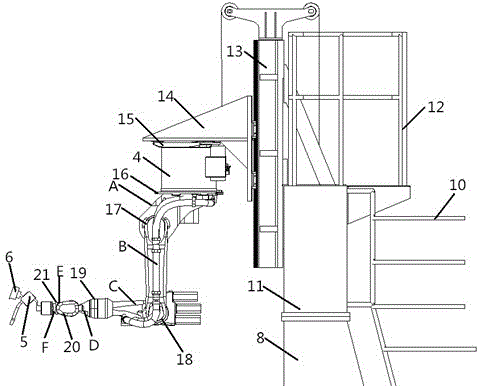

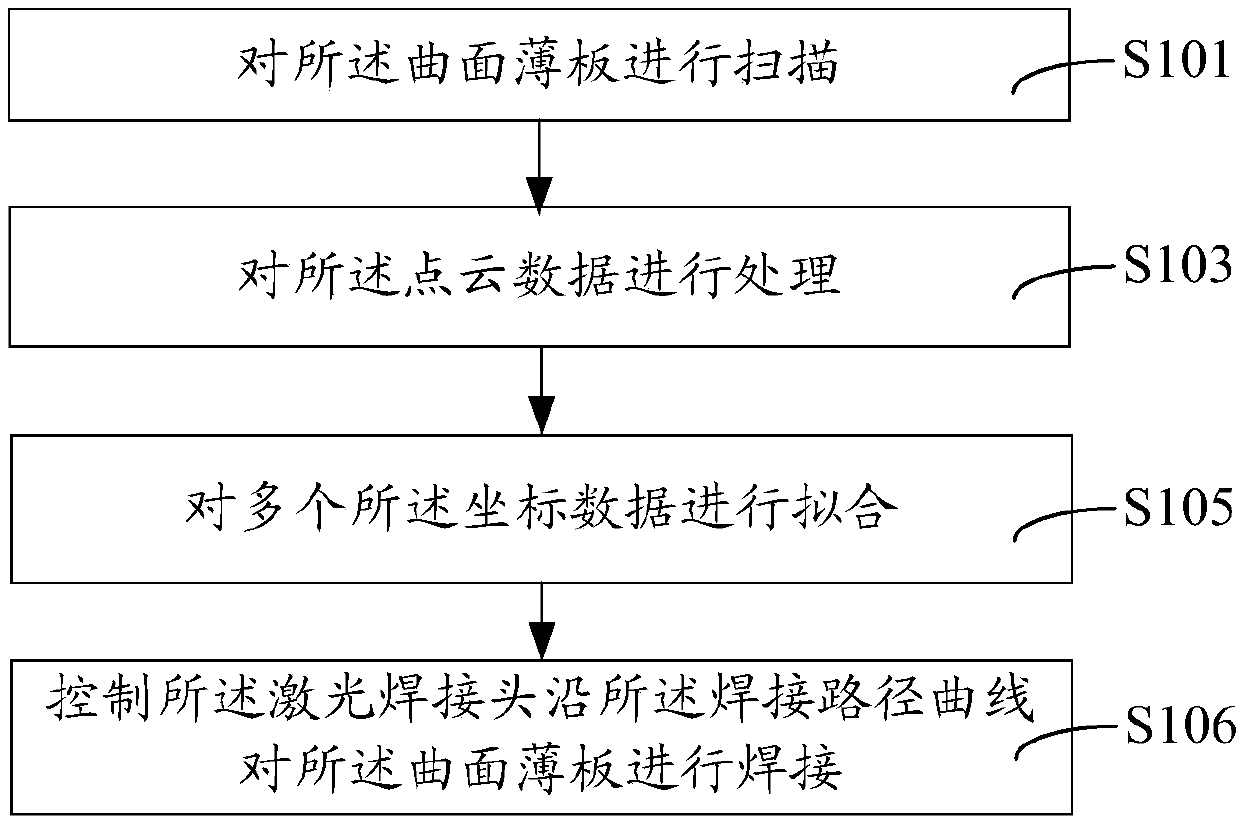

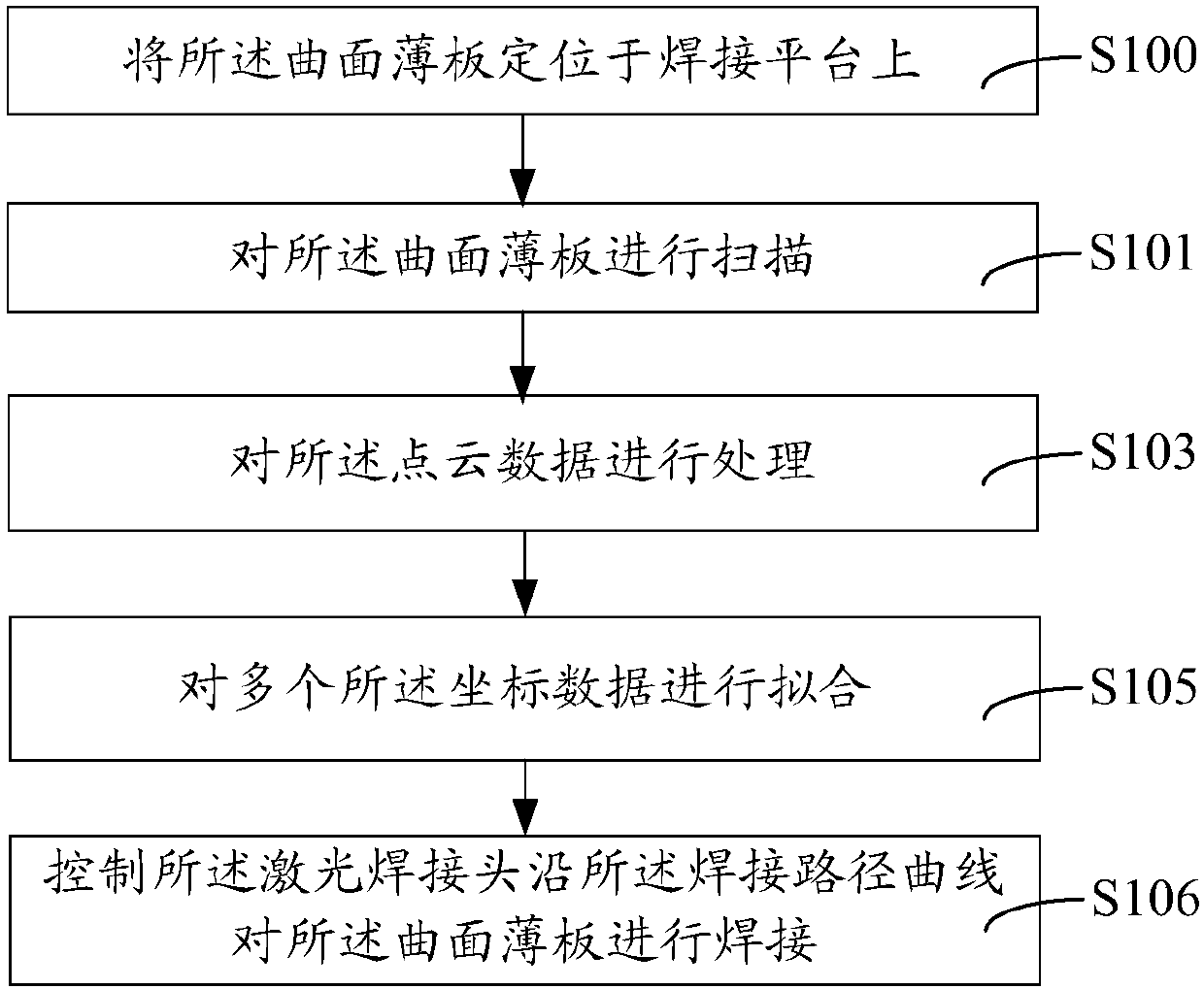

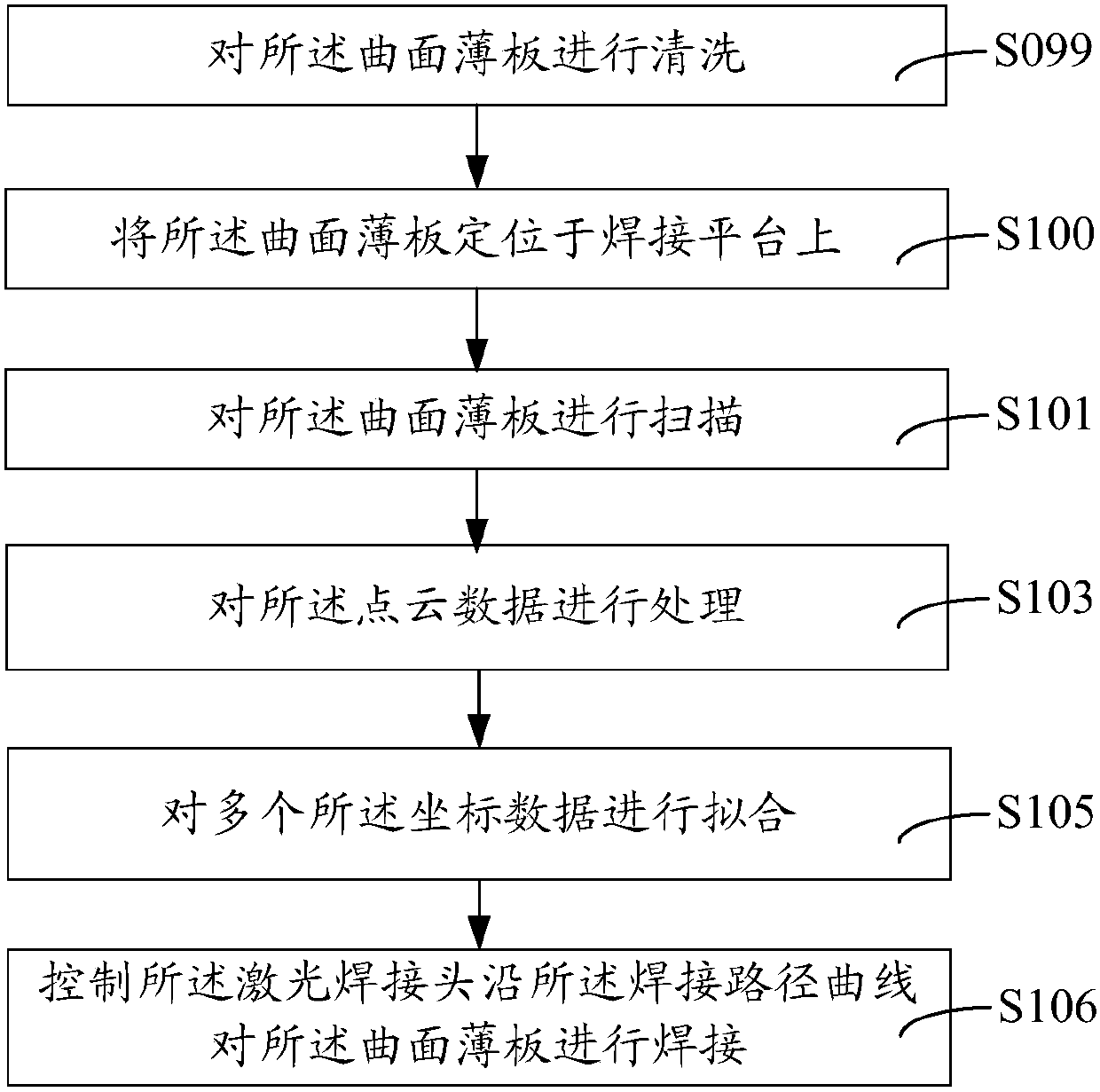

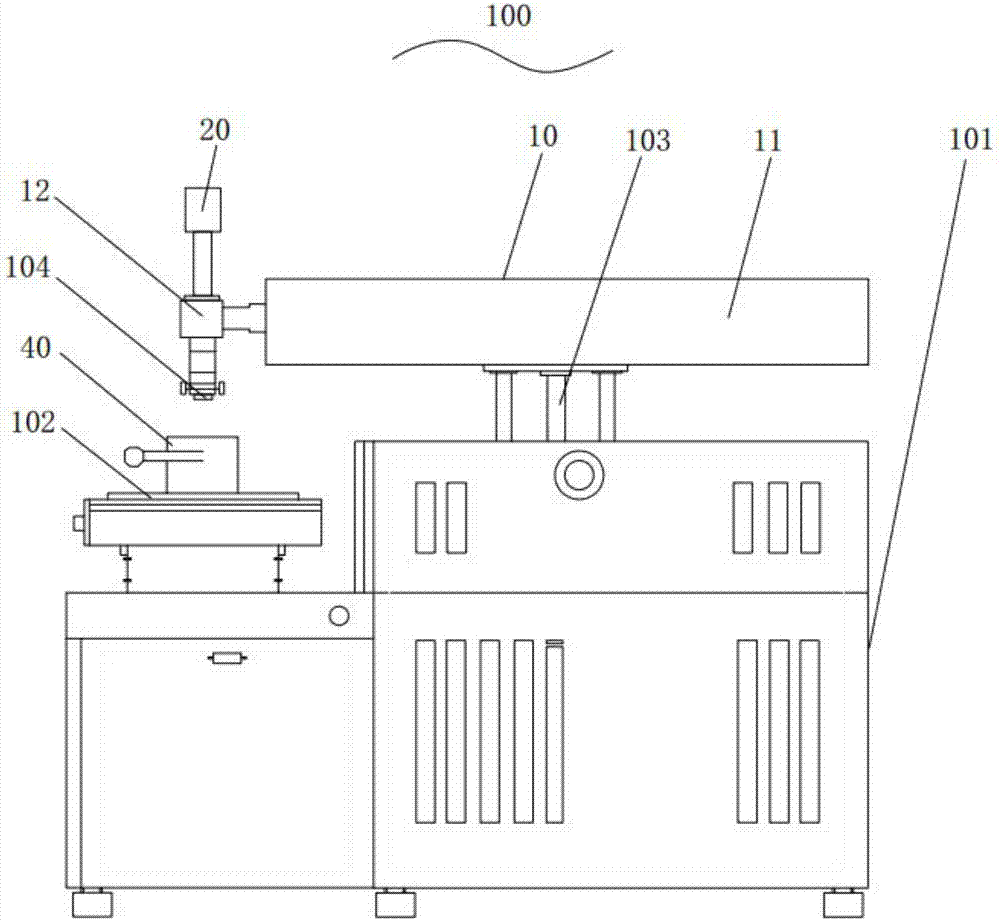

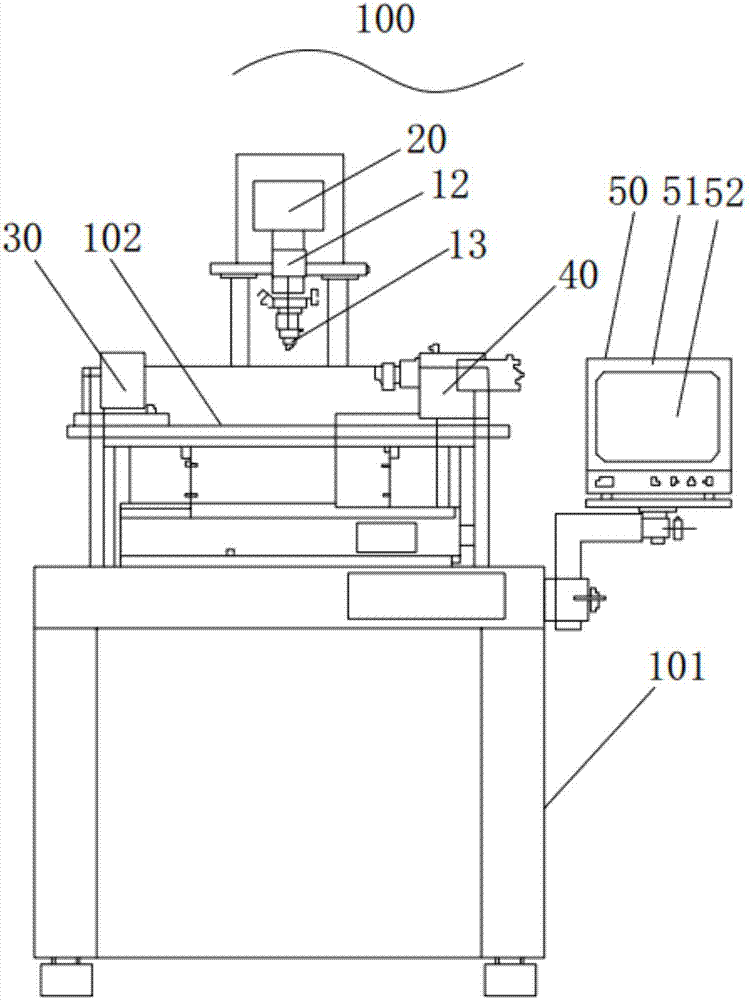

Curve thin board and laser welding method and laser welding system thereof

InactiveCN107914084AImprove welding accuracyImprove welding precisionWelding/soldering/cutting articlesMetal working apparatusPoint cloudEngineering

The invention relates to a curve thin board and a laser welding method and laser welding system thereof. The laser welding method of the curve thin board comprises the steps of scanning the curve thinboard, and obtaining curve point cloud data of the curve thin board; treating the point cloud data, and obtaining multiple coordinate data of the curve welding path; fitting the multiple coordinate data, and obtaining the curve welding path curve; controlling a laser welding head to weld the curve thin board along the welding path curve. According to the curve thin board and the laser welding method and laser welding system thereof, the distance between the laser welding head and the curve thin board can be adjusted, the laser welding head adapts to the welding line of the curve thin board, the welding precision of the welding line of the curve thin board is higher, and the problem that the welding precision of the curve thin board is poor is solved.

Owner:惠州市顺步科技有限公司

Laser welding equipment and laser welding method

ActiveCN107052571AImprove welding efficiencyImprove welding precisionLaser beam welding apparatusControl systemLaser scanning

The invention provides laser welding equipment and a laser welding method. The laser welding equipment comprises a welding equipment body, a welding table, a support, a dynamic focusing galvanometer welding system, a vision detection system, a workpiece positioning mechanism, a welding head adjusting driving mechanism and a control system. Image data of a workpiece are obtained through the vision detection system so that accurate positioning can be conducted on a welding line on the workpiece, the welding head is controlled to rapidly move to the welding line position through the control system, and the dynamic focusing galvanometer welding system transmits laser pulses to conduct rapid and accurate laser scanning welding on the workpiece. Meanwhile, in the laser scanning welding process, the dynamic focusing galvanometer welding system is used for conducting dynamic compensation on the out-of-focus error of the laser pulses emitted by the dynamic focusing galvanometer welding system, accordingly, dynamic focusing of the laser pulses is achieved, the welding efficiency and precision of laser welding can be greatly improved, and the labor cost is reduced.

Owner:深圳市佳康捷科技有限公司

Tank body circular seam welding machine

ActiveCN102133696AConvenient welding workImprove welding qualityWelding/cutting auxillary devicesAuxillary welding devicesSlide plateSeam welding

The invention discloses a tank body circular seam welding machine comprising a rack. A lifting mechanism is arranged on the rack, and a lifting platform is arranged on the lifting mechanism and is movably matched with the rack; a working platform lifting mechanism is arranged on the lifting platform, and an operating platform is arranged on the working platform lifting mechanism; a first horizontal guide rail is horizontally arranged on the lifting platform, a first sliding block is arranged on the first horizontal guide rail, a fixed sliding plate is arranged on the first sliding block, a vertical guide rail is arranged on the fixed sliding plate, a vertical sliding block is arranged on the vertical guide rail, a vertical sliding plate is arranged on the vertical sliding block, a welding mechanism is arranged on the vertical sliding plate, a shaft is arranged on the vertical sliding plate, a welding trolley is arranged on the shaft, a profiling mechanism is arranged on the welding trolley, two profiling wheels and a profiling wheel driving mechanism are arranged on the welding trolley, and the profiling wheel driving mechanism is connected with the two profiling wheels. In the tank body circular seam welding machine, the liftable operating platform is arranged, so that more convenience is provided for welding operation of operators, the accurate welding control can be realized, and the efficiency and the accuracy of welding are improved.

Owner:SHANDONG SHUIBO WELDING & CUTTING EQUIP MFG CO LTD

Laser welding fixture for gear

InactiveCN103506761AReduce complexityAvoid welding deformationWelding/cutting auxillary devicesAuxillary welding devicesGear wheelEngineering

A laser welding fixture for a gear comprises a power rotating mechanism, a welding platform, a gear ring clamping mechanism, a wheel disc clamping mechanism and a gear ring tightening mechanism. The welding platform is in fixed transmission connection with the power rotating mechanism, the gear ring clamping mechanism is installed on the welding platform and used for clamping a gear ring axially, the wheel disc clamping mechanism is installed on the welding platform and used for clamping a wheel disc axially, and the gear ring tightening mechanism is arranged on the welding platform and used for clamping the gear ring radially. According to the laser welding fixture for the gear, the gear ring contracts and is clamped through the gear ring tightening mechanism in the radial direction, and therefore the concentricity of the gear ring can be guaranteed; the gear ring is clamped through the gear ring clamping mechanism in the axial direction, so that the end face accuracy of the gear ring is guaranteed, and the anti-splash protection effect is achieved at the same time; the wheel disc is clamped through the wheel disc clamping mechanism in the axial direction, so that welding deformation of the wheel disc is prevented, and welding accuracy is improved. The whole laser welding fixture for the gear can effectively prevent welding deformation, protect the gear, and improve welding accuracy and welding efficiency.

Owner:上海团结普瑞玛激光设备有限公司

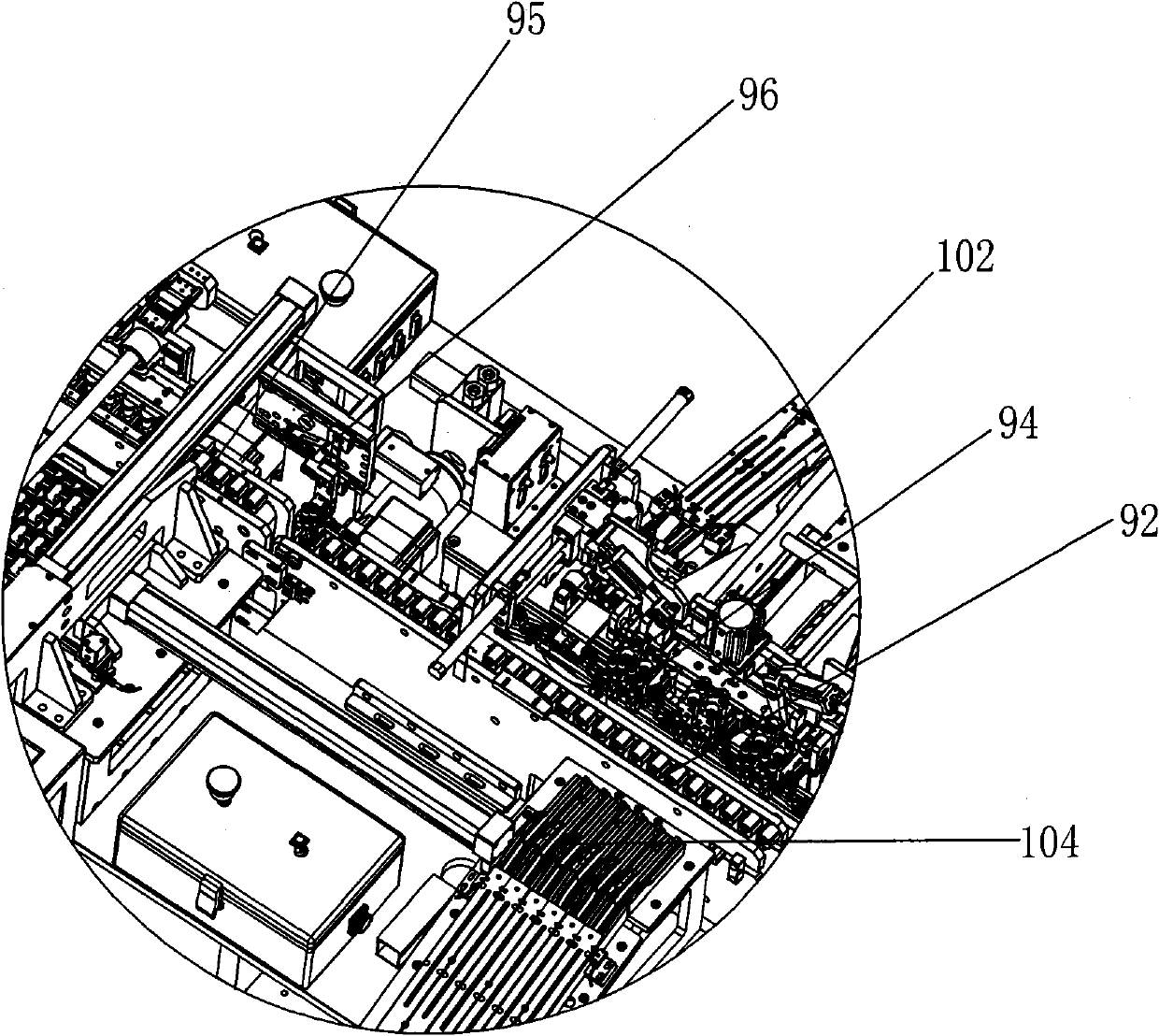

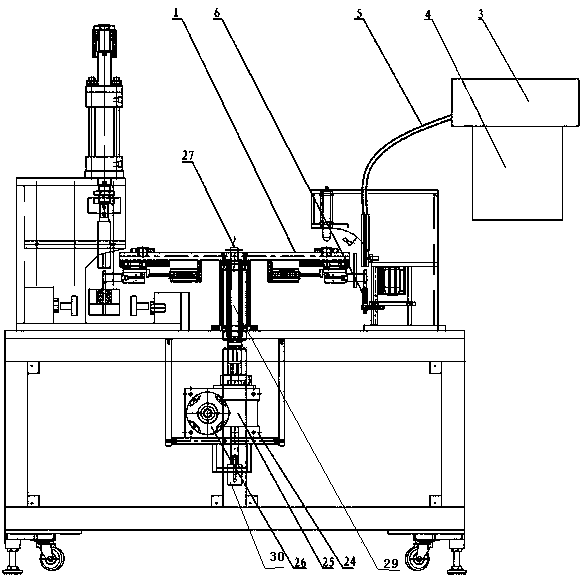

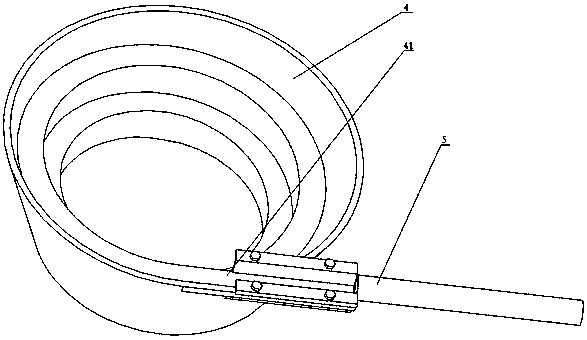

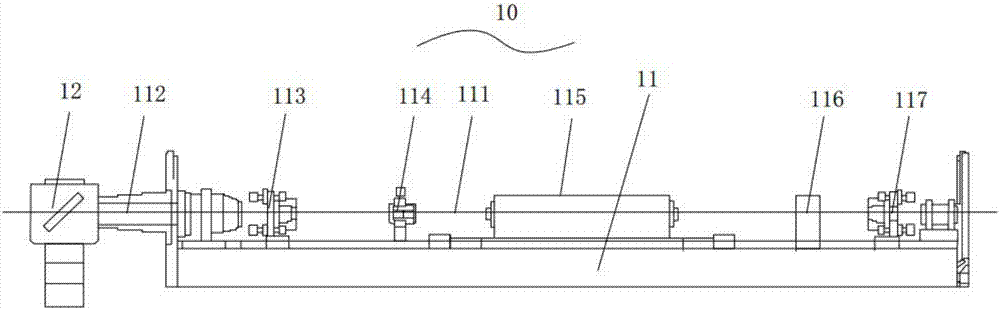

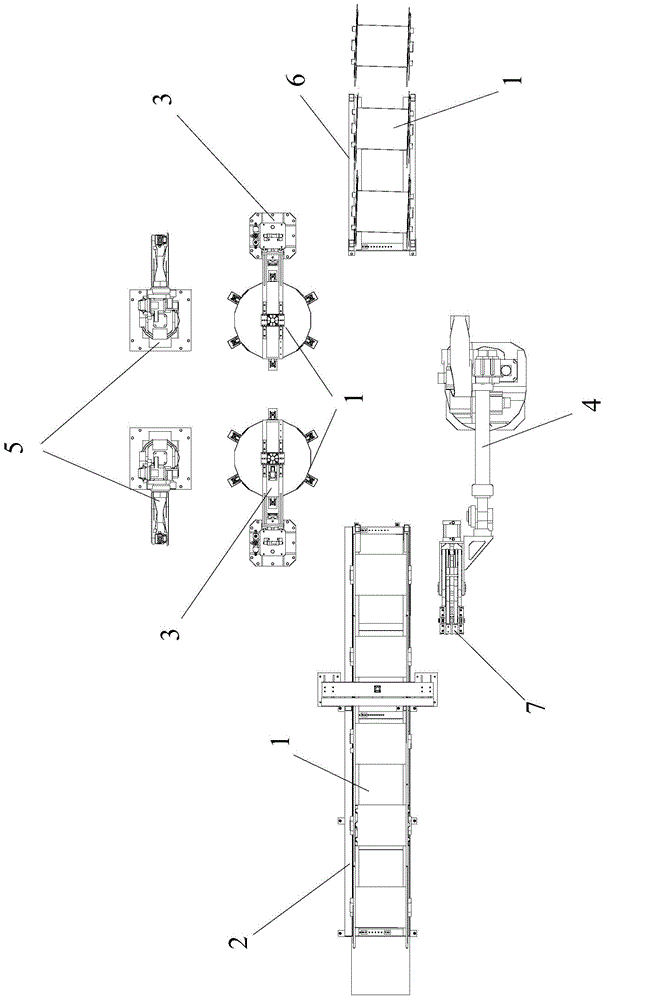

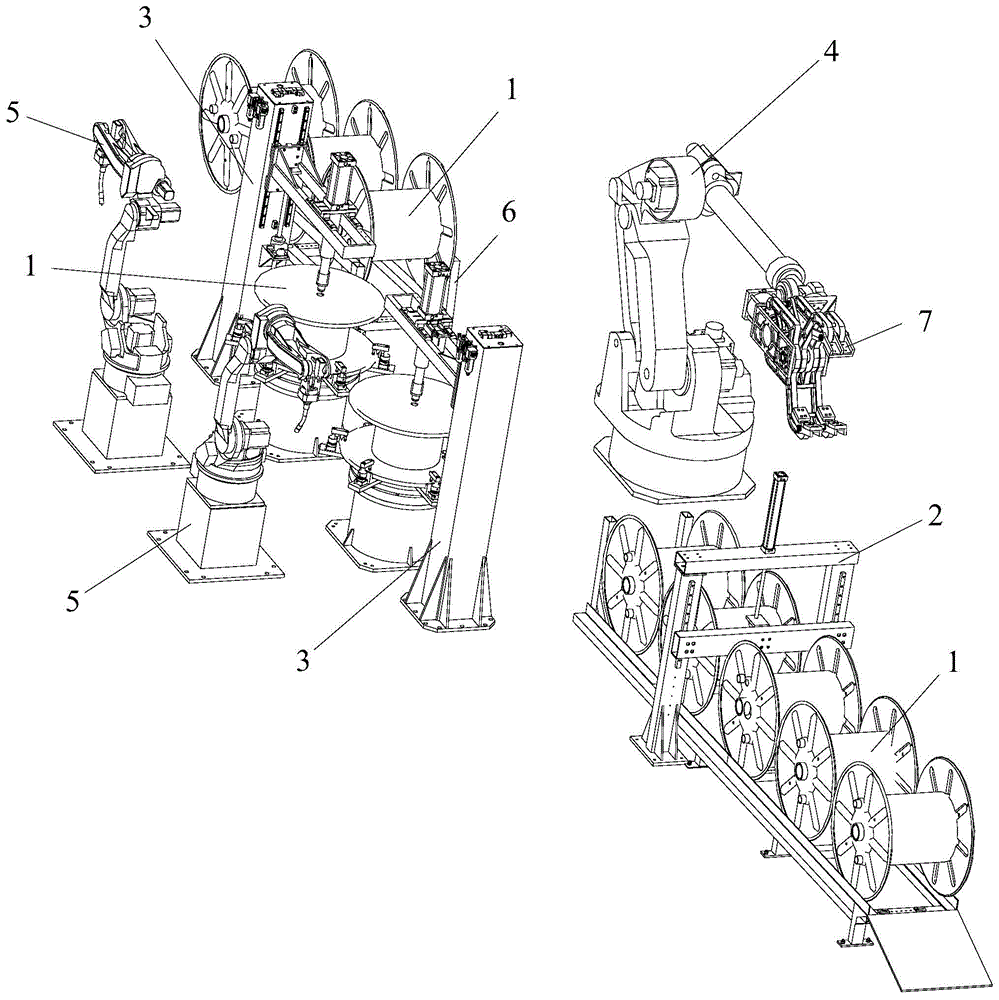

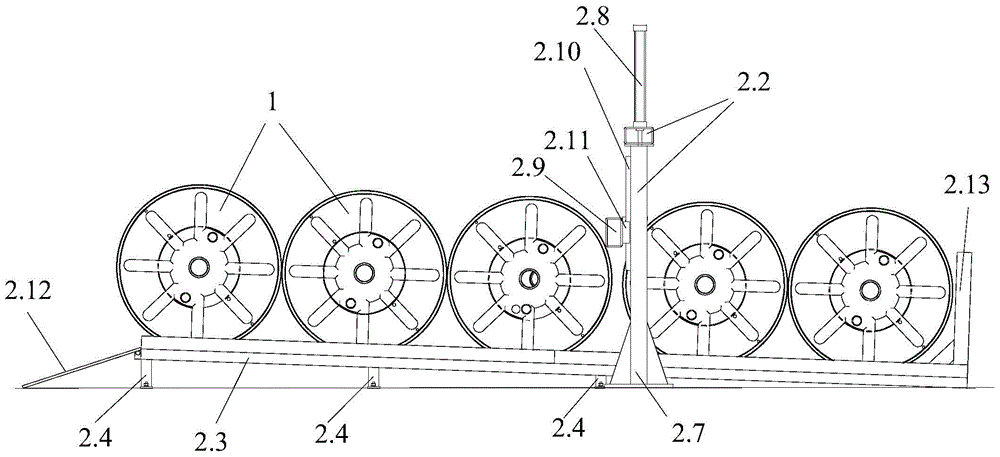

Automatic welding production line and automatic welding method for wire coils

ActiveCN104625454AHigh precisionHigh speedWelding/cutting auxillary devicesAuxillary welding devicesProduction lineEngineering

The invention provides an automatic welding production line for wire coils. The production line comprises a feeding and conveying mechanism, a pressing and positioning mechanism, a transferring manipulator, a welding manipulator, a discharging and conveying mechanism and a control mechanism in signal connection with the feeding and conveying mechanism, the pressing and positioning mechanism, the transferring manipulator and the welding manipulator. The production line is simple in structure, high in welding speed and high in welding quality stability, the phenomenon that welding of welded junctions is not uniform because of manual welding can be effectively avoided, and therefore welding efficiency, welding precision and welding quality of the wire coils can be improved. The invention further provides an automatic welding method for the wire coils. The method includes a feeding procedure, a transferring and positioning procedure, a welding procedure and a discharging procedure which are all performed in sequence, wherein in the transferring and positioning procedure, the transferring manipulator is controlled to clamp, move and overturn the wire coils, meanwhile, the pressing and positioning mechanism is used for pressing, positioning and rotating the wire coils, and the welding procedure starts. The method can be used for solving the problem that the automation degree in the current welding industry is low.

Owner:佛山市慧智智能装备有限公司

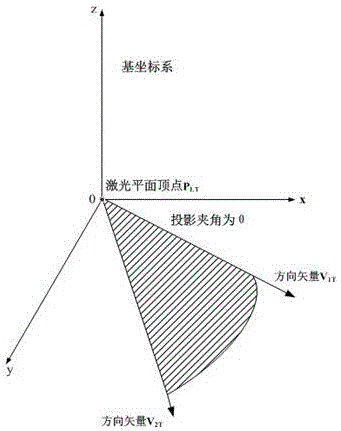

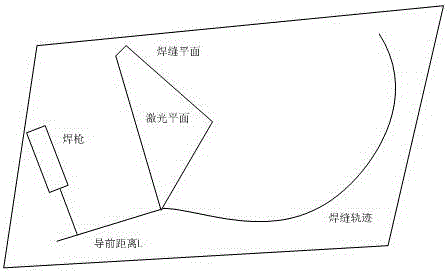

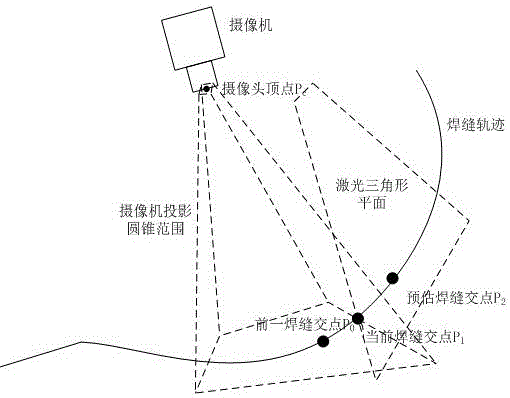

Robot welding motion control method based on laser seam tracking sensor

InactiveCN106346129AImprove welding precisionImprove execution efficiencyLaser beam welding apparatusGenetic algorithmEngineering

The invention discloses a robot welding motion control method based on a laser seam tracking sensor. The method includes the steps that the world coordinate system of an initial welding robot, a robot tail end tool coordinate system, the welding gun initial point, laser triangular plane parameters, welding speed and motion time are set first; then the welding gun top end position point in the next control period is searched for from data points in a centralized mode according to measurement data of the laser seam tracking sensor; finally the optimal posture of the welding gun is searched for through a genetic algorithm. The robot welding motion control method has the advantages of being high in welding accuracy, high in execution efficiency, high in generality and capable of being widely applied to welding of various space unknown straight line or curve welding seams.

Owner:CHINA JILIANG UNIV

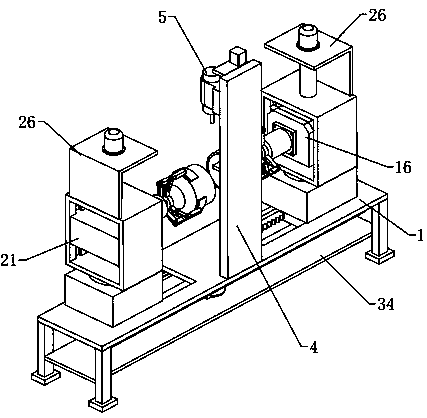

Automatic circular welding machine for plate roller plug

InactiveCN102049648AReduce production auxiliary facilitiesIncrease productivityWelding/cutting auxillary devicesAuxillary welding devicesTailstockEngineering

The invention provides an automatic circular welding machine for a plate roller plug. The circular welding machine comprises a lathe bed, a head stock and a tail seat, wherein a machine head is provided with a first speed-reducing motor; and a tail stock is provided with a second speed-reducing motor. The circular welding machine further comprises two four-wheel positioning centre frames, two finals, a third speed-reducing motor and two welding machines, wherein the two four-wheel positioning centre frames are arranged in the middle of the lathe bed at intervals; the two finals are rotationally arranged on the head stock and the tail seat respectively and oppositely; the third speed-reducing motor is installed on the head stock and connected with the finals arranged on the head stock in atransmission mode; and the two welding machines are respectively arranged above the head stock and the tail seat. In the invention, the excircle of a pipe and the centre hole of the plug are taken aspositioning references, the excircle of the pipe is centered by the four-wheel positioning centre frames, the centre hole of the plug is centered by the finals, and the centers of the four-wheel positioning frames and the two finals are in the same horizontal line. Thus, the concentricity of the centre hole of the plug and the excircle of the pipe is ensured, thereby ensuring the welding quality.

Owner:SHANGHAI YUNCHENG PLATE MAKING

Automatic welding device for rotary tillage cutter shaft

InactiveCN106216901AHigh precisionSimple structureWelding/cutting auxillary devicesAuxillary welding devicesBall screwDynamic balance

The invention relates to the technical field of agricultural machine machining, in particular to an automatic welding device for a rotary tillage cutter shaft. The automatic welding device comprises a numerical control part, a base part, a fixing part and a welding gun part. The numerical control part comprises a numerical control system and a transmission mechanism. The base part comprises a base shell, a sliding rail and a ball screw. The fixing part comprises a three-jaw clamping disc and a clamping seat. The welding gun part comprises a welding gun and a displacement adjusting mechanism. The automatic welding device is controlled through numerical control, the automation degree is high, the welding quality is high, a mechanical structure is simple, operation is stable, maintenance is easy and convenient, and the cost is low; and according to the rotary tillage cutter shaft welded through the automatic welding device, a rotary tillage cutter seat is more uniform in distribution, and the dynamic balance of the rotary tillage cutter shaft is better.

Owner:河北耕耘农业机械制造有限公司

Pipe welding jig and welding method

ActiveCN106493501APrevent rotationWon't rotateWelding/cutting auxillary devicesAuxillary welding devicesRelative displacementEngineering

The invention discloses a pipe welding jig which is used for welding of a pipe and sheet metal. The welding jig comprises a jig bottom plate and further comprises at least one set of pipe welding unit connected with the jig bottom plate. Each pipe welding unit comprises a pipe positioning mechanism which is used for positioning the pipe, a pipe rotation preventing mechanism which is used for preventing rotation during pipe welding, a sheet metal positioning mechanism which is used for positioning the sheet metal, and a sheet metal pressing mechanism which is used for tightly pressing the sheet metal. The pipe welding jig has the beneficial effects that the pipe positioning mechanism is arranged and used for positioning the pipe; the pipe rotation preventing mechanism is used for preventing rotation during pipe welding; the sheet metal positioning mechanism is used for positioning the sheet metal; the sheet metal pressing mechanism is used for tightly pressing the sheet metal; in the welding process, the pipe and the sheet metal can be positioned simultaneously, relative displacement between the pipe and the sheet metal is avoided, and the welding precision is high; and meanwhile, rotation is avoided during welding, and the welding efficiency is greatly improved.

Owner:YIHE PRECISION IND SUZHOU

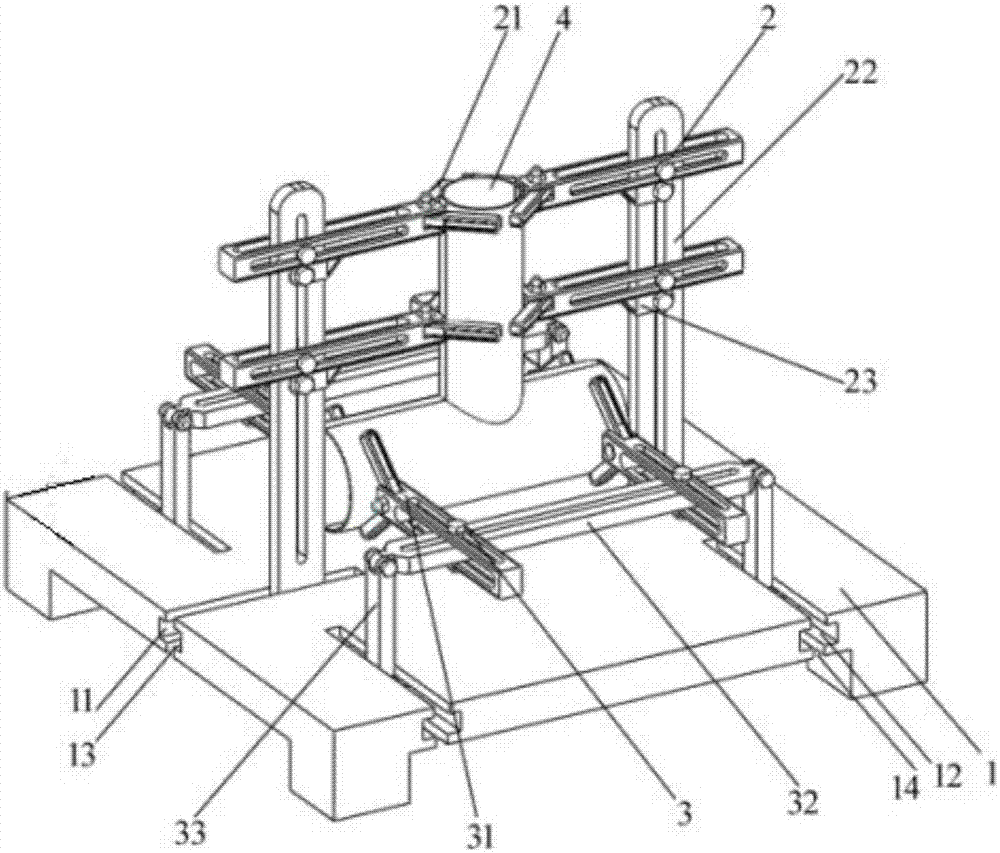

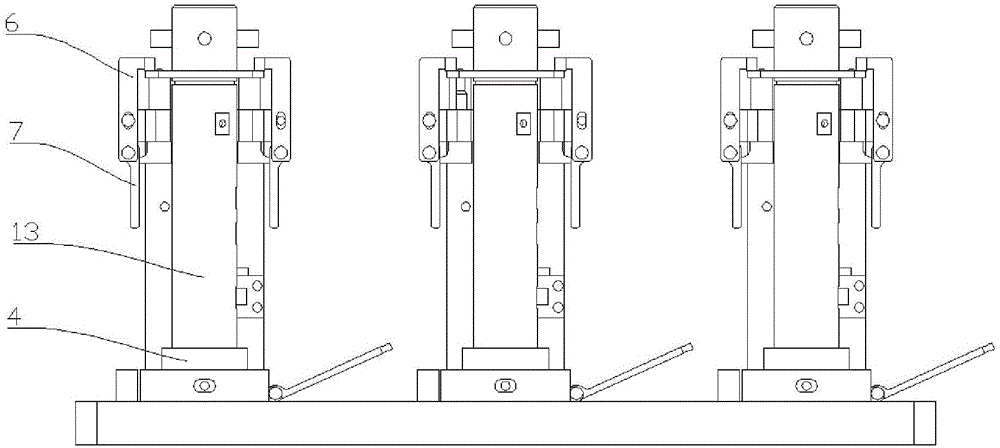

Automatic welding system of hub small parts

ActiveCN106077987AEliminate secondary positioning errorsImprove welding precisionWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWelding

The invention discloses an automatic welding system of hub small parts in the field of automatic welding equipment. The system comprises a base provided with a welding robot; a welding revolving mechanism is arranged on the base, and is connected with a flowing centered clamping mechanism; a hub loading / unloading guide rail is arranged below a hub; a small part loading mechanism is arranged on the base, and includes a horizontal slide base and a vertical slide base; the horizontal slide base is slidingly connected with the base; the vertical slide base is slidingly connected with the horizontal slide base; a support table is arranged on the vertical slide base; a lower support plate is mounted on the support table; a center shaft pipe is arranged on the lower support plate, and is coated with small parts to be welded; a stopper is arranged at one end of the center shaft pipe, and the other end of the center shaft pipe is connected with a swing rod; an upper gland is embedded above the lower support plate; positioning pin shafts are arranged on two sides of the upper gland; a positioning groove is formed in the lower support plate; and two sides of the lower support plate are connected with locking glands. The system can automatically weld the small parts to be welded on the hub, eliminates secondary positioning errors, and improves the welding precision and efficiency.

Owner:YANGZHOU JINYUAN ROBOTICS AUTOMATION

Automatic welder of wheel buckle type scaffold vertical rods

InactiveCN104084728AReduce labor intensityReduce failureWelding/cutting auxillary devicesAuxillary welding devicesSolenoid valveBall screw

The invention discloses an automatic welder of wheel buckle type scaffold vertical rods. The welder comprises a bracket and a control cabinet, wherein the bracket comprise a bracket upper part and a bracket lower part; the welder is characterized in that an electric bracket assembly, a pneumatic clamping assembly and a steel tube bracket assembly are arranged at the bracket lower part; a pneumatic cylinder, a welding gun adjusting mechanism, a solenoid valve, a welding gun, a wire feeder, a wire reel, a ball screw, a stepping motor, a linear guide rail and a drag chain are arranged at the bracket upper part; the solenoid valve is connected with the pneumatic cylinder through the drag chain; the solenoid valve controls the welding gun to move longitudinally; the stepping motor is connected with the ball screw; the ball screw is connected with the welding gun; the welding gun moves laterally on the linear guide rail through the ball screw; the welding gun adjusting mechanism adjusts the angle of the welding gun. The welder can completely replace manual welding, controls the rotation of steel tubes through a rotating motor, reduces the labor intensity, controls the longitudinal, lateral and angle motions of two welding guns through the control cabinet, and has the advantages of high welding precision, high efficiency, low fault rate and low cost.

Owner:JIAOZUO HAOFENG METAL PROD

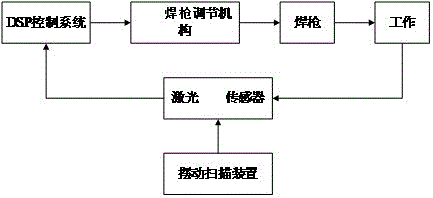

Laser-assisted intelligent trailing system and method for welding line

ActiveCN106392304ARealize secondary detectionHigh precisionLaser beam welding apparatusControl systemLaser assisted

The invention discloses a laser-assisted intelligent trailing system for a welding line. The laser-assisted intelligent trailing system for the welding line is used for welding the welding line and comprises a binocular stereoscopic vision orientation module, a welding robot module and a laser assisted feedback module, wherein the binocular stereoscopic vision orientation module is arranged and fixed to be able to shoot the welding line; the welding robot module comprises a DSP control system, a welding gun adjusting device and a welding gun, the welding robot module is in signal communication with the binocular stereoscopic vision orientation module, and the welding robot module acts in response to parameter actions collected by the binocular stereoscopic vision orientation module; the laser-assisted feedback module comprises a laser sensor and a monocular camera, the laser-assisted feedback module is in signal connection with the binocular stereoscopic vision orientation module and the welding robot module respectively, and the laser-assisted feedback module feeds the detected parameters back to the binocular stereoscopic vision orientation module and the welding robot module. The invention also discloses a laser-assisted intelligent trailing method for the welding line.

Owner:河北省自动化研究所有限公司

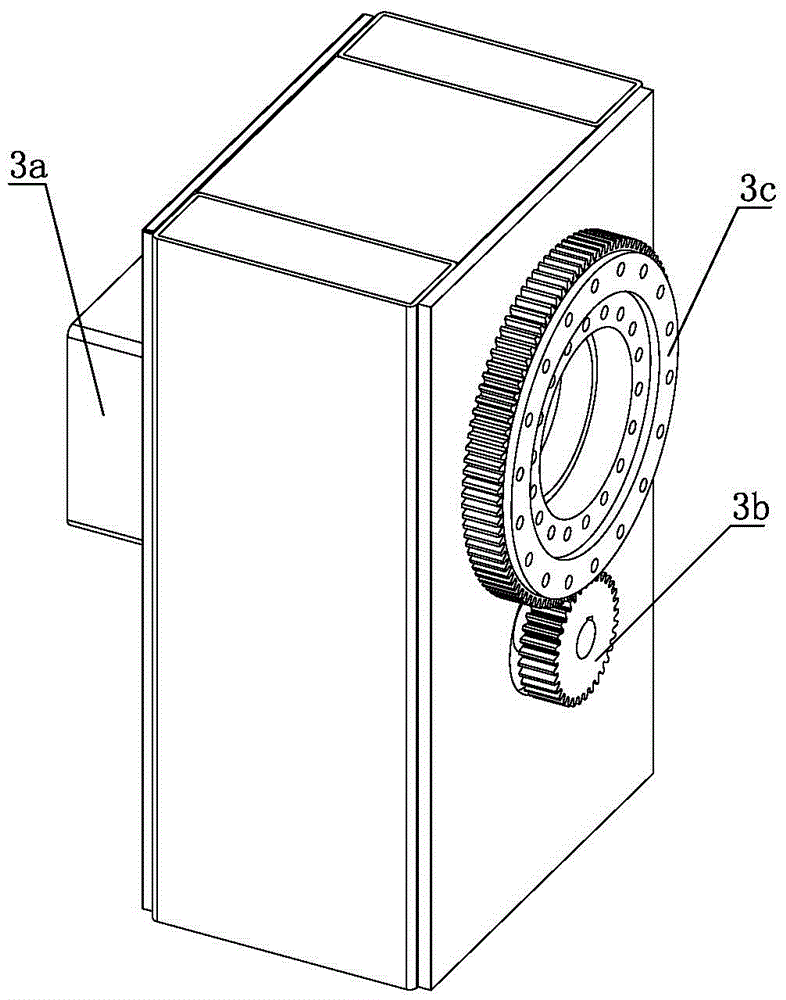

Profiling device and numerical-control gate-type stringer welding machine using same

InactiveCN101716710AAccurate trackingImprove welding precisionWelding/cutting auxillary devicesArc welding apparatusStringerEngineering

The invention provides a profiling device comprising a shell. A rotating shaft is mounted on the shell and provided with a contact and a rocker; a resetting device is mounted on the rocker and connected with the shell which is provided with two sensors; and the free end of the rocker is arranged between the two sensors. The numerical-control gate-type stringer welding machine using the profiling device comprises a walking frame on which a walking power mechanism is mounted; a welding gun-moving mechanism is mounted on the beam of the walking frame and provided with a welding gun, a second profiler and a first profiler; the first profiler is the profiling device and comprises a first shell which is connected with the welding gun-moving mechanism and provided with a first rotating shaft; the first rotating shaft is provided with the first contact and the first rocket which is provided with the first resetting device; the first shell is connected with the first resetting device and provided with the second sensor and the first sensor; and the first rocket is arranged between the second sensor and the first sensor.

Owner:SHANDONG SHUIBO WELDING & CUTTING EQUIP MFG CO LTD

Welding device of electronic elements on integrated circuit board

InactiveCN106270913AImprove welding efficiencyImprove welding precisionPrinted circuit assemblingMetal working apparatusCcd cameraElectricity

The invention discloses a welding device of electronic elements on an integrated circuit board. The welding device comprises a base, a positioning clamping mechanism is fixedly arranged on the upper portion of the base, a welding mechanism is arranged on the side face of the positioning clamping mechanism, a control box is arranged on the upper portion of the base, and is electrically connected with the positioning clamping mechanism and the welding mechanism, and the positioning clamping mechanism comprises two opposite supporting frames of the same structure; each supporting frame comprises a bottom plate, a vertical plate is fixedly connected to the upper portion of each bottom plate, a reinforcing plate is arranged between each bottom plate and the corresponding vertical plate, a lifting sliding rail is arranged on the inner side of each vertical plate, the end of each lifting sliding rail is in an isosceles trapezoid, and racks are arranged on the two outer side inclined sides. The welding mechanism is adopted to weld the electronic elements, the welding efficiency is improved, the welding precision is improved, meanwhile, a CCD camera on the welding mechanism can detect the welded integrated circuit board, and whether the welding is good or not can be distinguished.

Owner:DONGGUAN LIANZHOU INTPROP OPERATION MANAGEMENT CO LTD

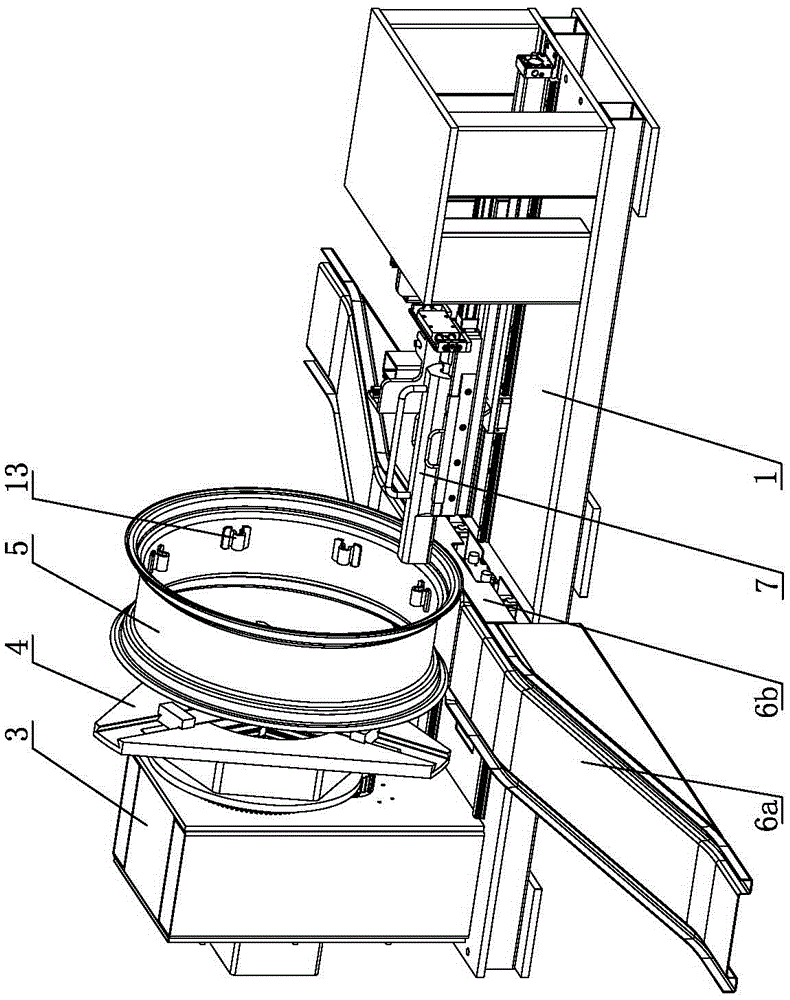

Flange type sleeve welding station

InactiveCN104289834AImprove productivity and welding accuracyCompact structureWelding/cutting auxillary devicesAuxillary welding devicesManipulatorNozzle

The invention discloses a flange type sleeve welding station. The flange type sleeve welding station comprises a pipe vibration feeding machine, a first flange vibration feeding machine, a second flange vibration feeding machine, a turnover feeding mechanism, a welding gun supporting assembly, a workpiece clamping manipulator mechanism, a first workpiece welding rotary assembly and a second workpiece welding rotary assembly; the pipe vibration feeding machine, the turnover feeding mechanism and the welding gun supporting assembly are sequentially arranged from left to right; the welding gun supporting assembly comprises a welding gun head stand column, a first welding nozzle assembly and a second welding nozzle assembly, and the first welding nozzle assembly and the second welding nozzle assembly are in symmetry left and right; the first workpiece welding rotary assembly is arranged under the first welding nozzle assembly; the second workpiece welding rotary assembly is arranged under the second welding nozzle assembly; the first flange vibration feeding machine is arranged right ahead of the first welding nozzle assembly; the second flange vibration feeding machine is arranged right ahead of the second welding nozzle assembly; the workpiece clamping manipulator mechanism is located behind the welding gun supporting assembly. Full-automatic welding of a flange type sleeve can be achieved, and production efficiency is improved.

Owner:重庆东创机械有限责任公司

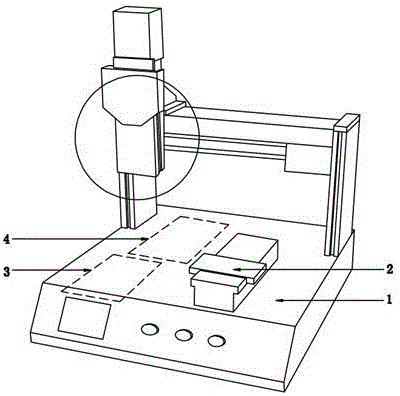

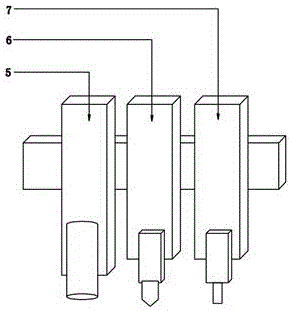

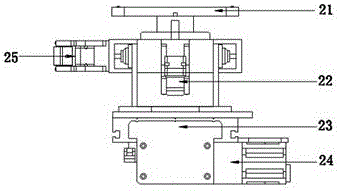

High-precision multi-axis motion three-dimensional micro-welding robot

ActiveCN106392238AImprove welding qualityHigh precisionMetal working apparatusSoldering auxillary devicesRotary stageMachine vision

The invention discloses a high-precision multi-axis motion three-dimensional micro-welding robot, and relates to the technical field of robots. The whole robot is of a standard table type robot structure, a high-precision machine vision positioning system, a high-performance graphite material superconducting welding system and a high-precision ultramicro dispensing system are arranged on a support, a three-dimensional rotating table is arranged on a work table board, and a high-precision direct drive transmission system and a central control system are connected and are arranged in the robot and are connected to an operation panel. Multiple frontier technologies of the high-performance graphite material superconducting welding system technology, the high-precision ultramicro dispensing system technology, the three-dimensional rotating table technology, the high-precision machine vision positioning system technology, the high-precision direct drive transmission system technology and the like are integrated, the robot can comprehensively replace the manual welding technology under a microscope, and the robot has the beneficial effects of being high in welding quality, welding speed, welding precision and welding efficiency.

Owner:WUXI VOCATIONAL & TECHN COLLEGE

Welding machine with welding smoke treatment function

InactiveCN108971808AImprove securityReduce CooldownDispersed particle filtrationWelding/cutting auxillary devicesEngineeringCooling time

The invention relates to the technical field of welding machines and discloses a welding machine with a welding smoke treatment function. The welding machine comprises a bottom plate, supporting plates are fixedly connected with two sides of the top of the bottom plate, a top plate is fixedly connected to tops of the supporting plates, an electric slide rail is fixedly connected between tops of opposite sides of the two supporting plates, a slider is in slide connection with the surface of the electric slide rail, and a first air cylinder is fixedly connected to the left side of the bottom ofthe slider through a supporting block. The welding machine with the welding smoke treatment function has advantages that particles and harmful gases in welding smoke can be filtered and adsorbed, harms caused by dizziness, headache, cough, chest distress, shortness of breath, smoke poisoning and the like to bodies of operating personnel inhaling a great quantity of welding smoke are prevented, andaccordingly safety in operation is improved for the operating personnel; primary cooling of welds can be realized, so that subsequent weld cooling time is shortened, operating efficiency is improved,and extensive popularization is benefited.

Owner:WUHU RUITAI PRECISION MACHINERY

Welding equipment for automatically and efficiently welding reinforcing steel bars to invisible well lid

InactiveCN112192103APrecise positioning functionReduce manual labor intensityWelding/cutting auxillary devicesAuxillary welding devicesMesh reinforcementRebar

The invention relates to the technical field of welding machining of invisible well lids, in particular to welding equipment for automatically and efficiently welding reinforcing steel bars to an invisible well lid. The welding equipment comprises a rack, a storage frame, a clamping and feeding assembly, a material moving and bearing assembly, a reinforcing steel bar feeding assembly and a weldingassembly; the clamping and feeding assembly comprises a first rotary table arranged on the side, close to the storage frame, of the rack, a first lifting mechanism vertically mounted at the output end of the first rotary table, a first mounting support horizontally mounted at the output end of the first lifting mechanism, a clamping and driving mechanism arranged on the first mounting support anda positioning and clamping mechanism arranged at the output end of the clamping and driving mechanism; and the clamping and driving mechanism is in transmission connection with the positioning and clamping mechanism. According to the welding equipment for automatically and efficiently welding the reinforcing steel bars to the invisible well lid, the reinforcing steel bars of the invisible well lid can be automatically welded, the labor intensity is reduced, the working efficiency is improved, the welding precision is improved, and the multiple ends of a reinforcing steel bar net can be weldedat the same time.

Owner:傅迪生

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com