Method for improving programming speed and precision of soldering robot by using computer-aided design (CAD) file

A technology of soldering robot and programming speed, which is applied in metal processing and other directions, can solve problems such as low programming efficiency, low position accuracy, and limited proficiency of programmers, and achieve the effect of reducing programming time and improving welding accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

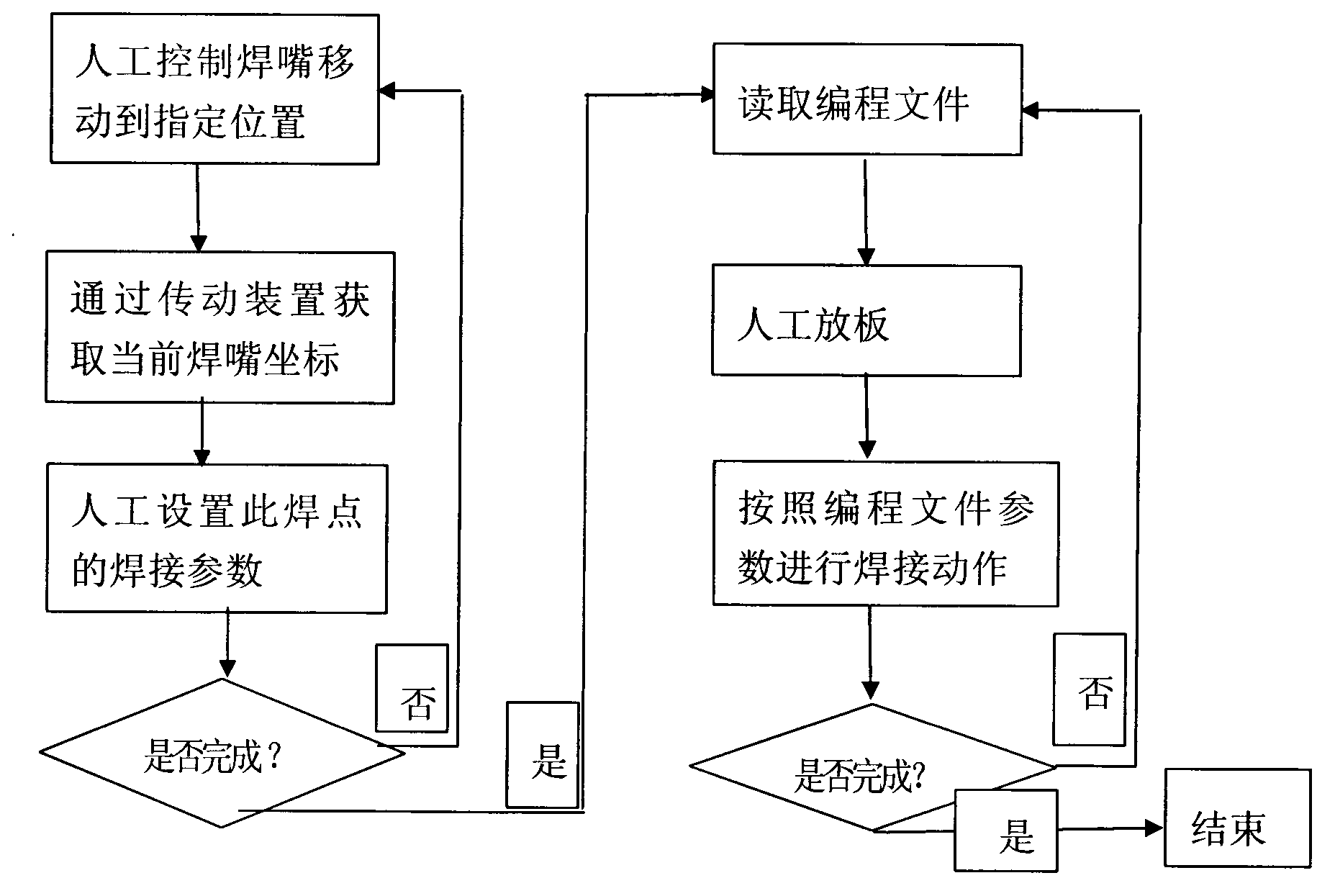

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

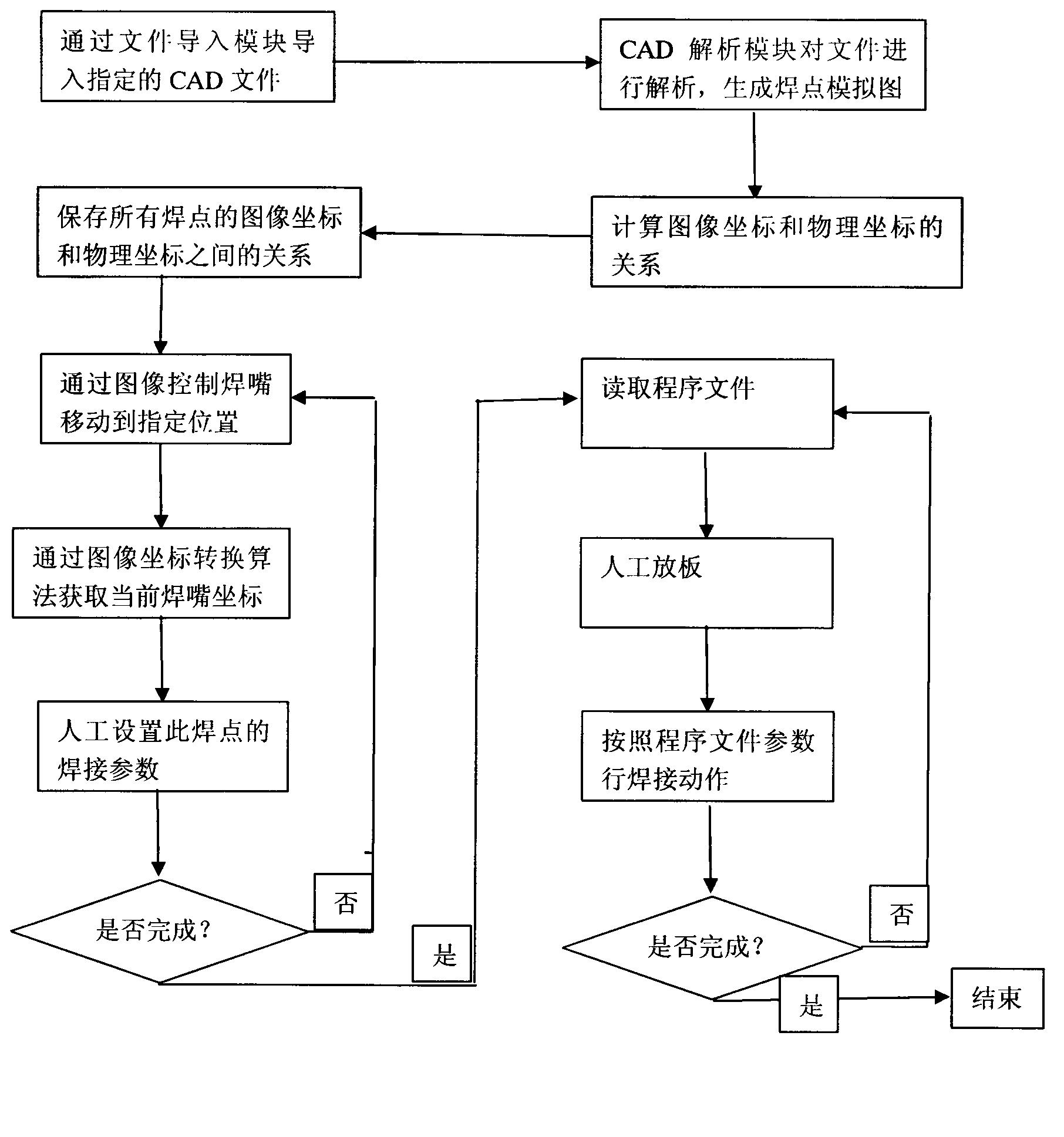

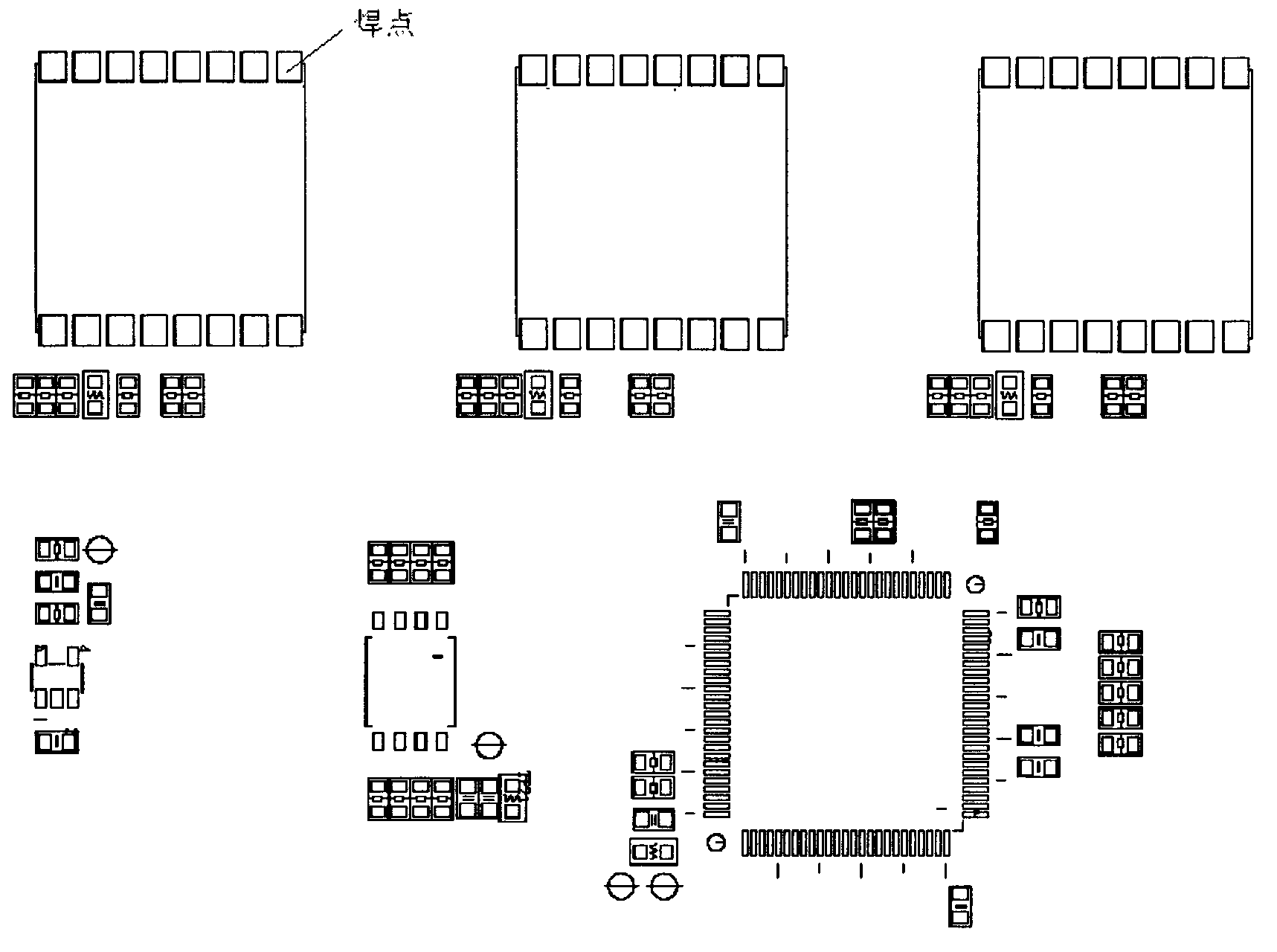

[0032] The technical idea of the present invention is: in the programming process, the CAD file of the PCB board is imported into the programming file. CAD files refer to: files containing CAD graphics information, CAD graphics are converted and generated by CAD files through software code processing; programming files can convert CAD graphics information contained in CAD files through software code processing into a file format supported by the program file, and then import it. The import method is: start the soldering robot programming software, and select the corresponding CAD file, then the CAD file analysis function module inside the soldering robot will analyze the CAD file line by line according to the standard CAD file format, and convert it It is a standard image file (such as bmp, jpg, etc.).

[0033] By importing CAD files, the included CAD graphic information can generate corresponding CAD graphics and display them in the program file. The graphics are further ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com