Patents

Literature

1341 results about "Length measurement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Length measurement is implemented in practice in many ways. The most commonly used approaches are the transit-time methods and the interferometer methods based upon the speed of light. For objects such as crystals and diffraction gratings, diffraction is used with X-rays and electron beams. Measurement techniques for three-dimensional structures very small in every dimension use specialized instruments such as ion microscopy coupled with intensive computer modeling.

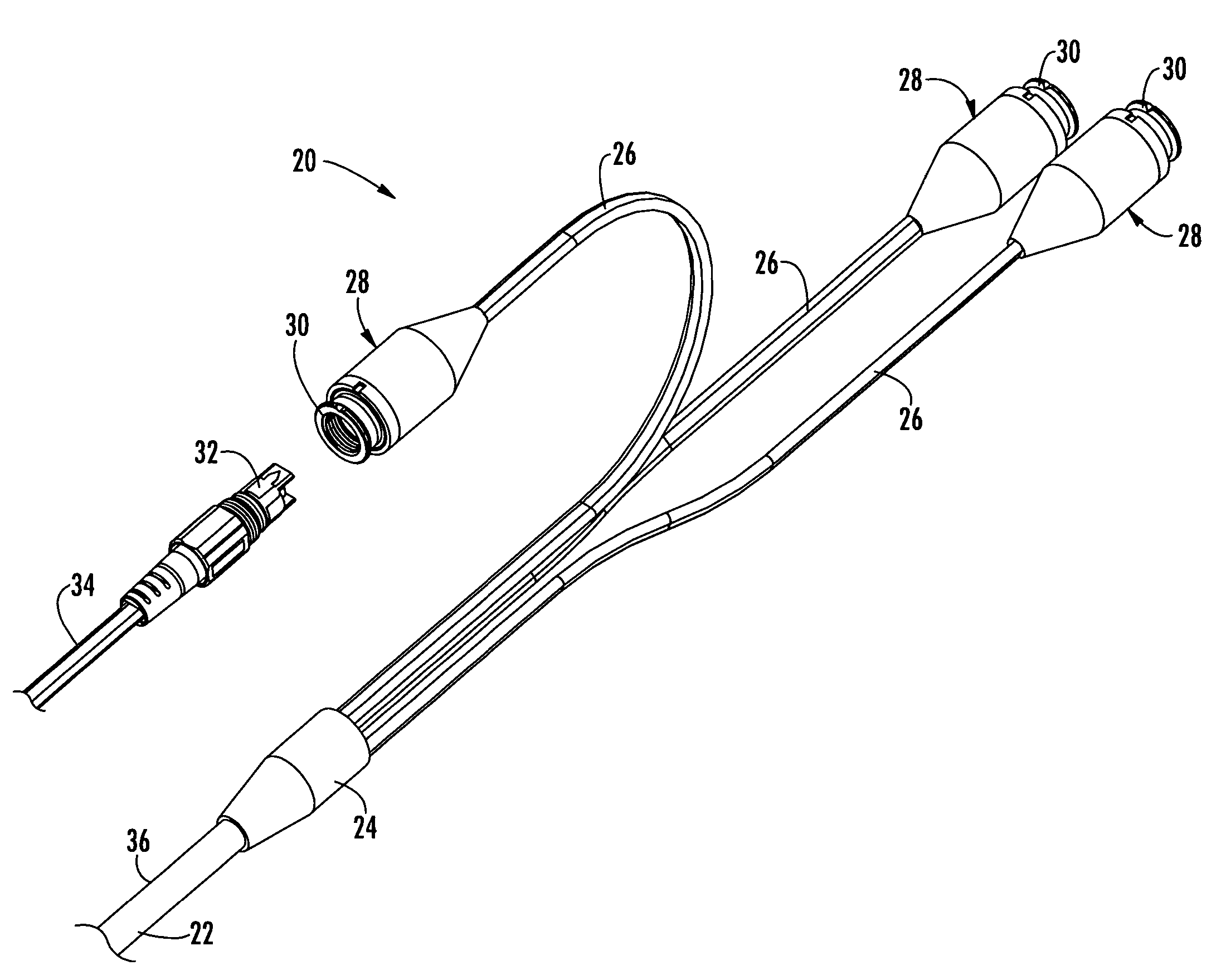

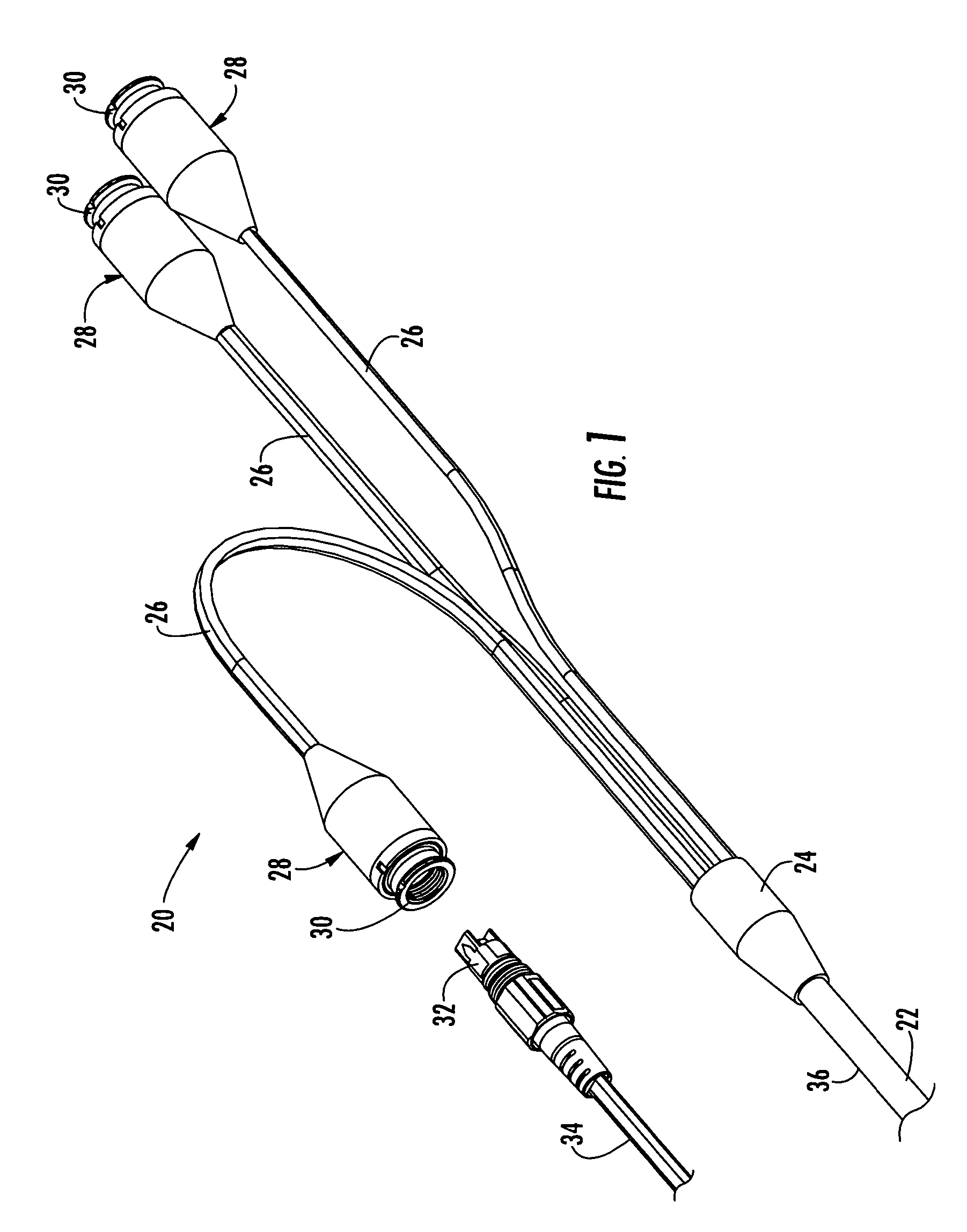

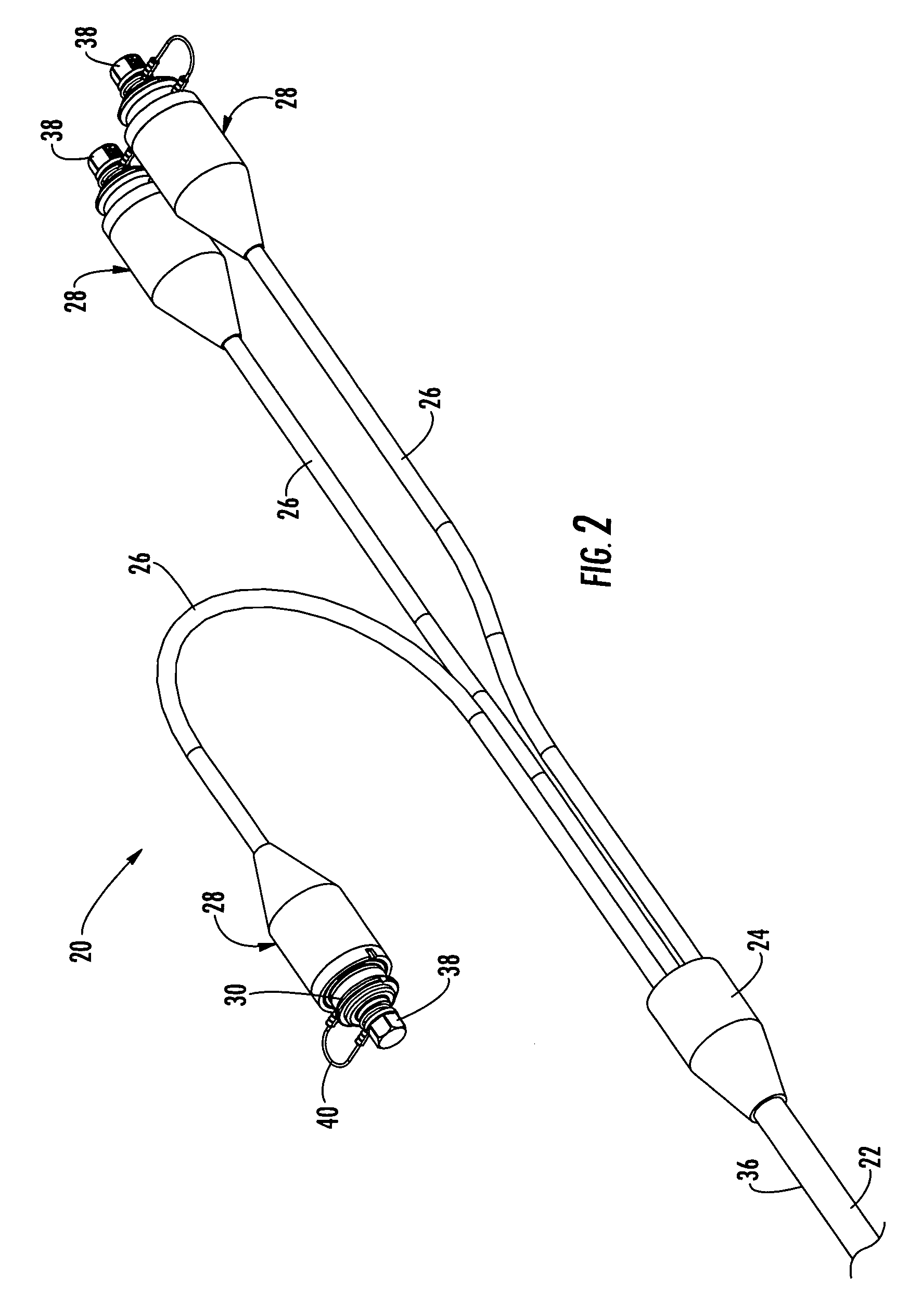

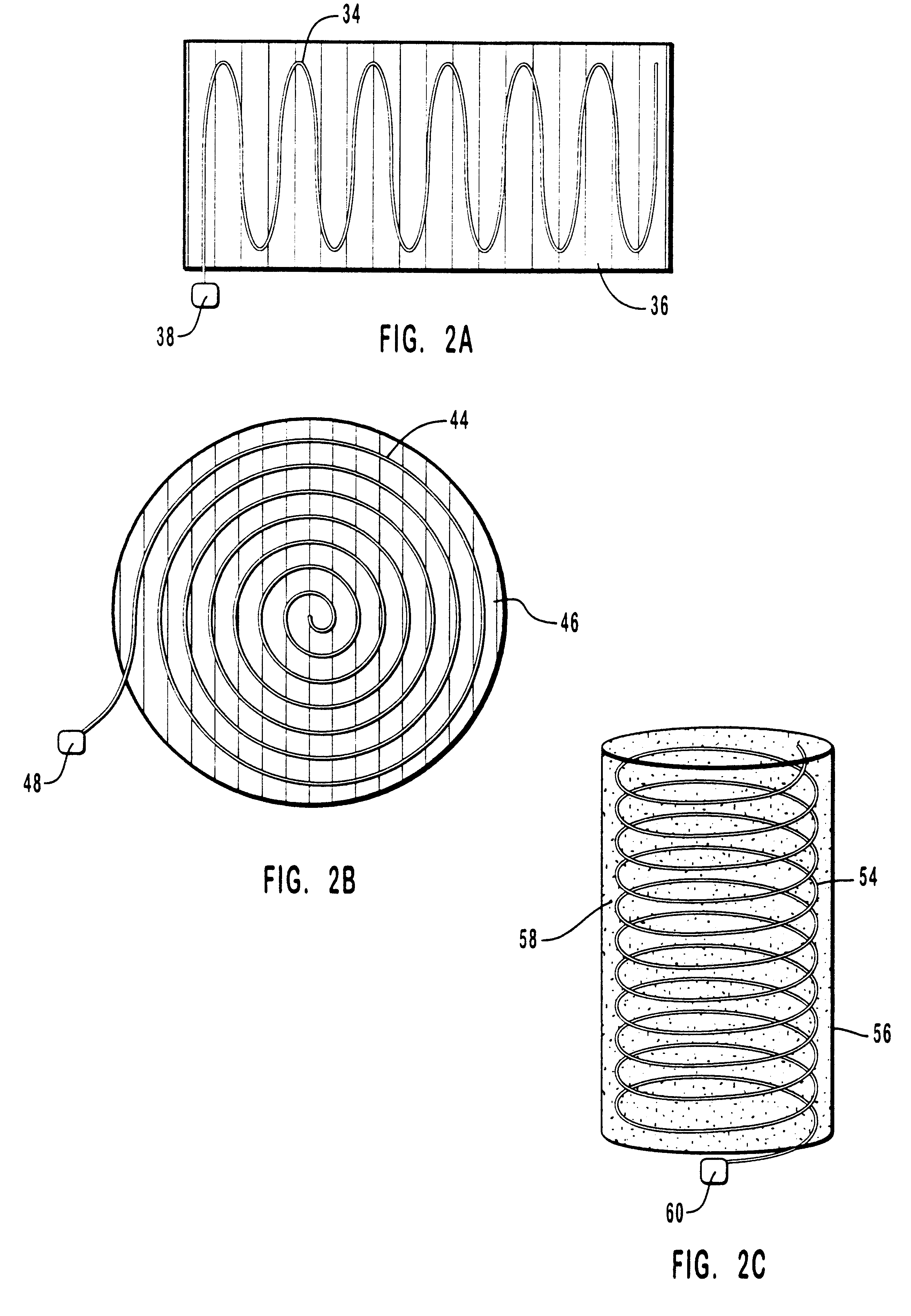

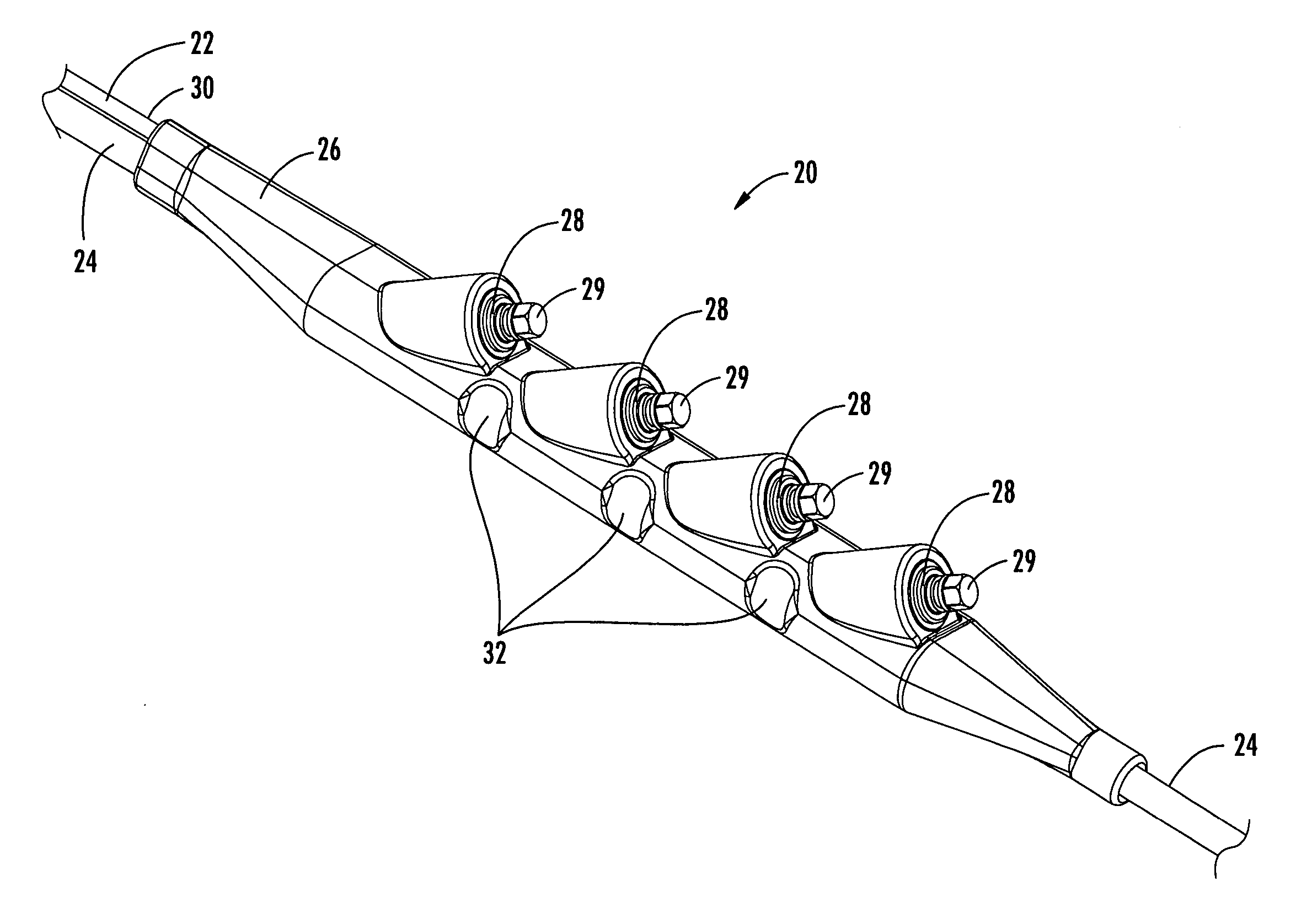

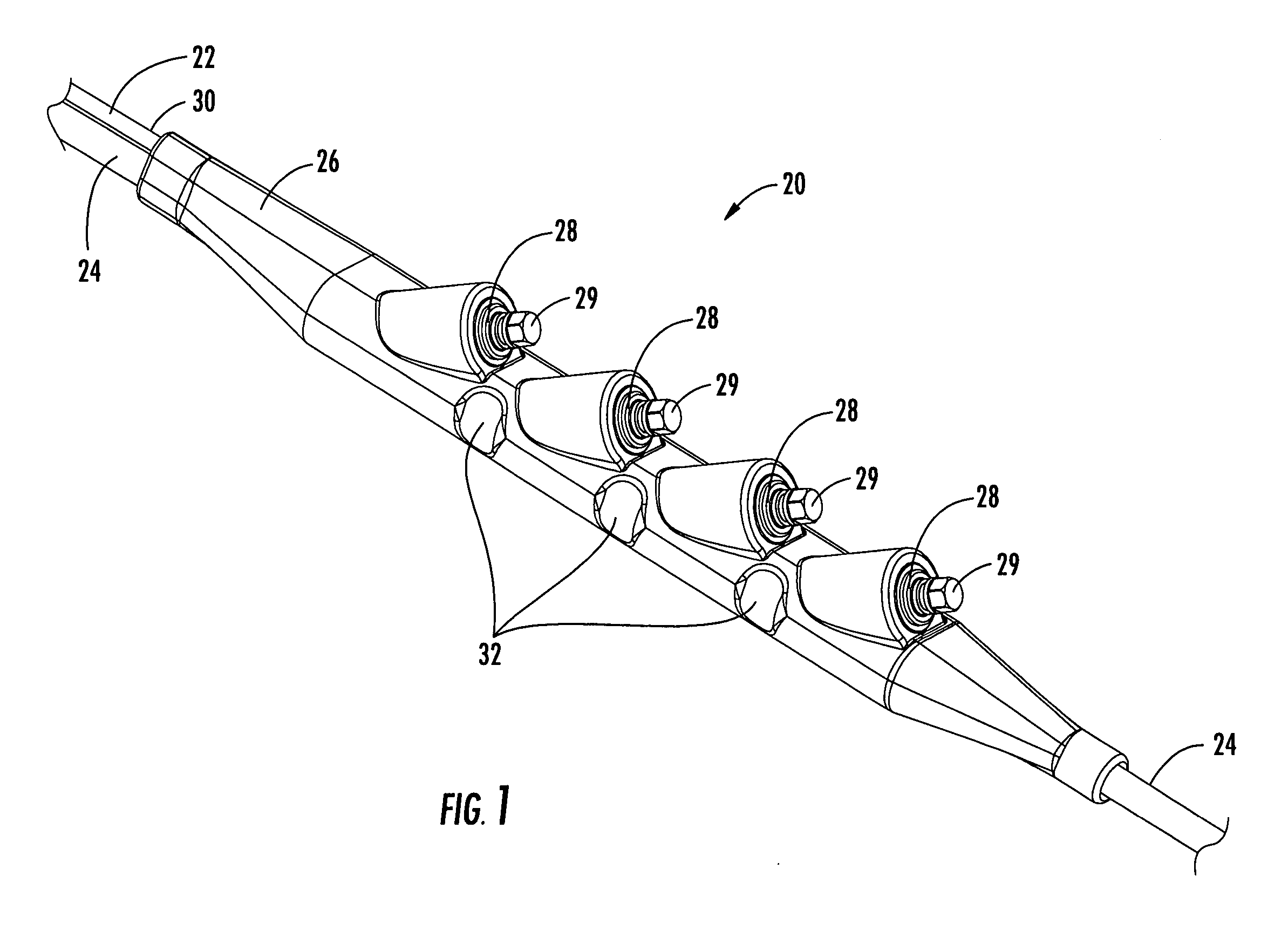

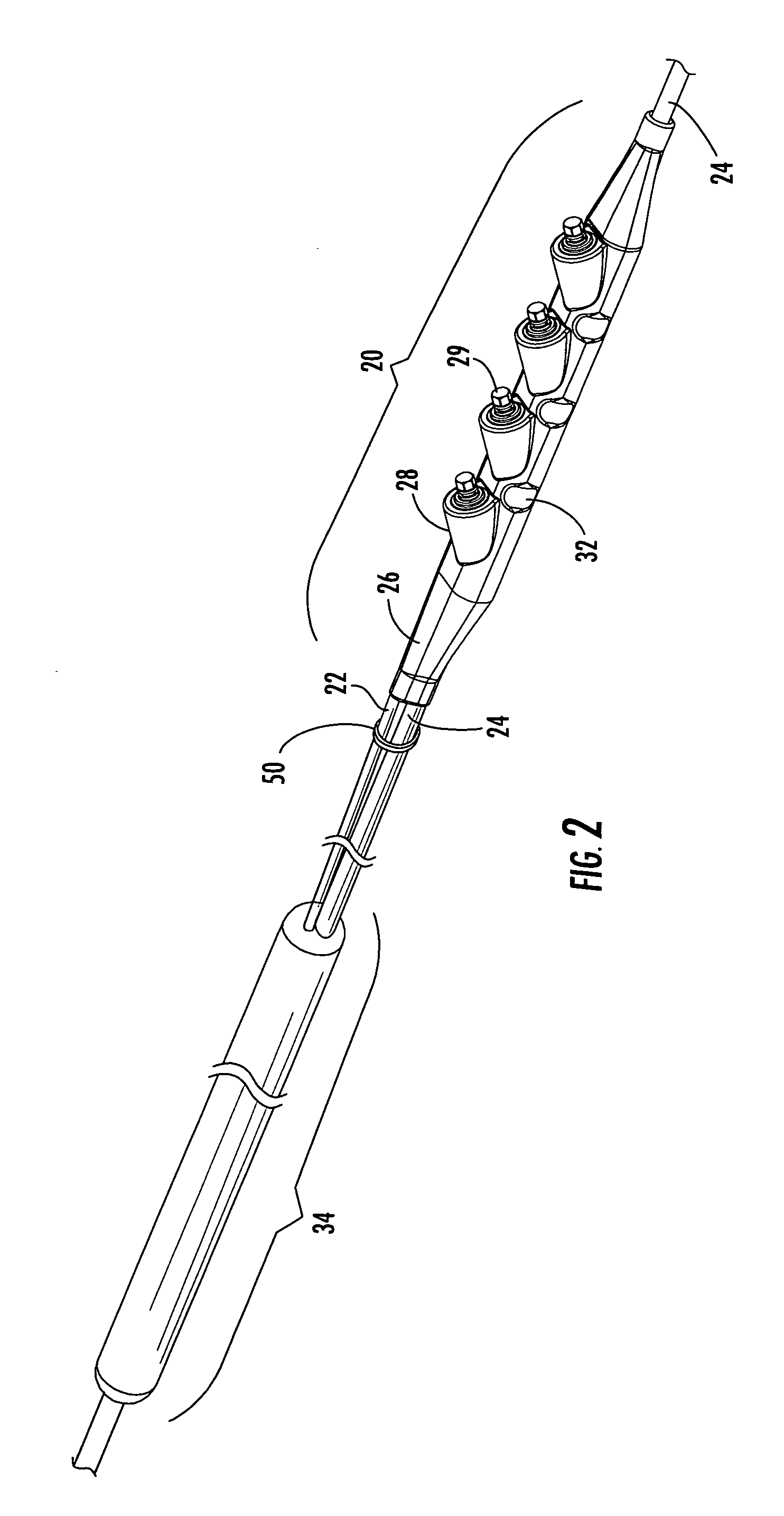

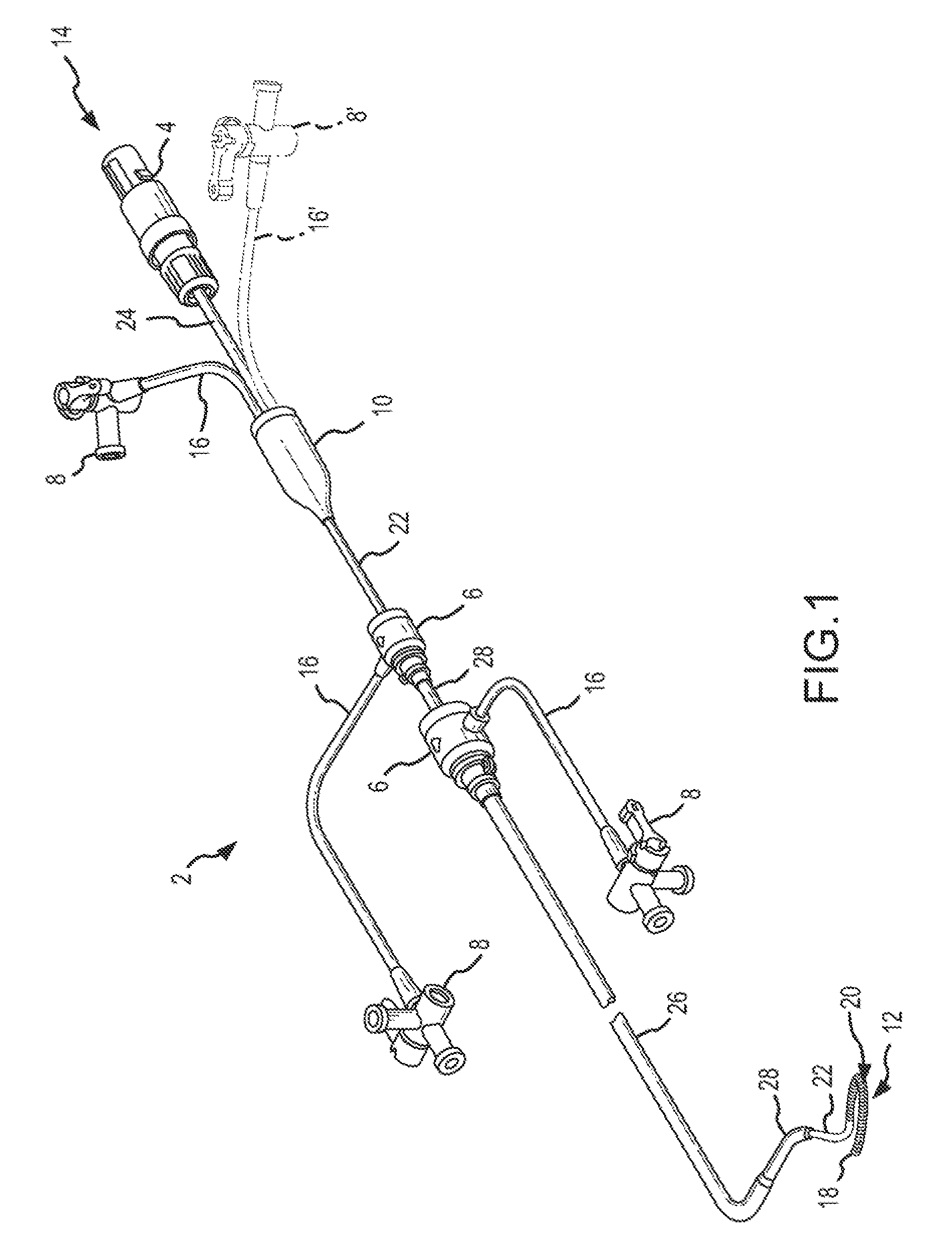

Tether assembly having individual connector ports

ActiveUS7277614B2Reduce the differenceSmall sizeCoupling light guidesFibre mechanical structuresFiberMating connection

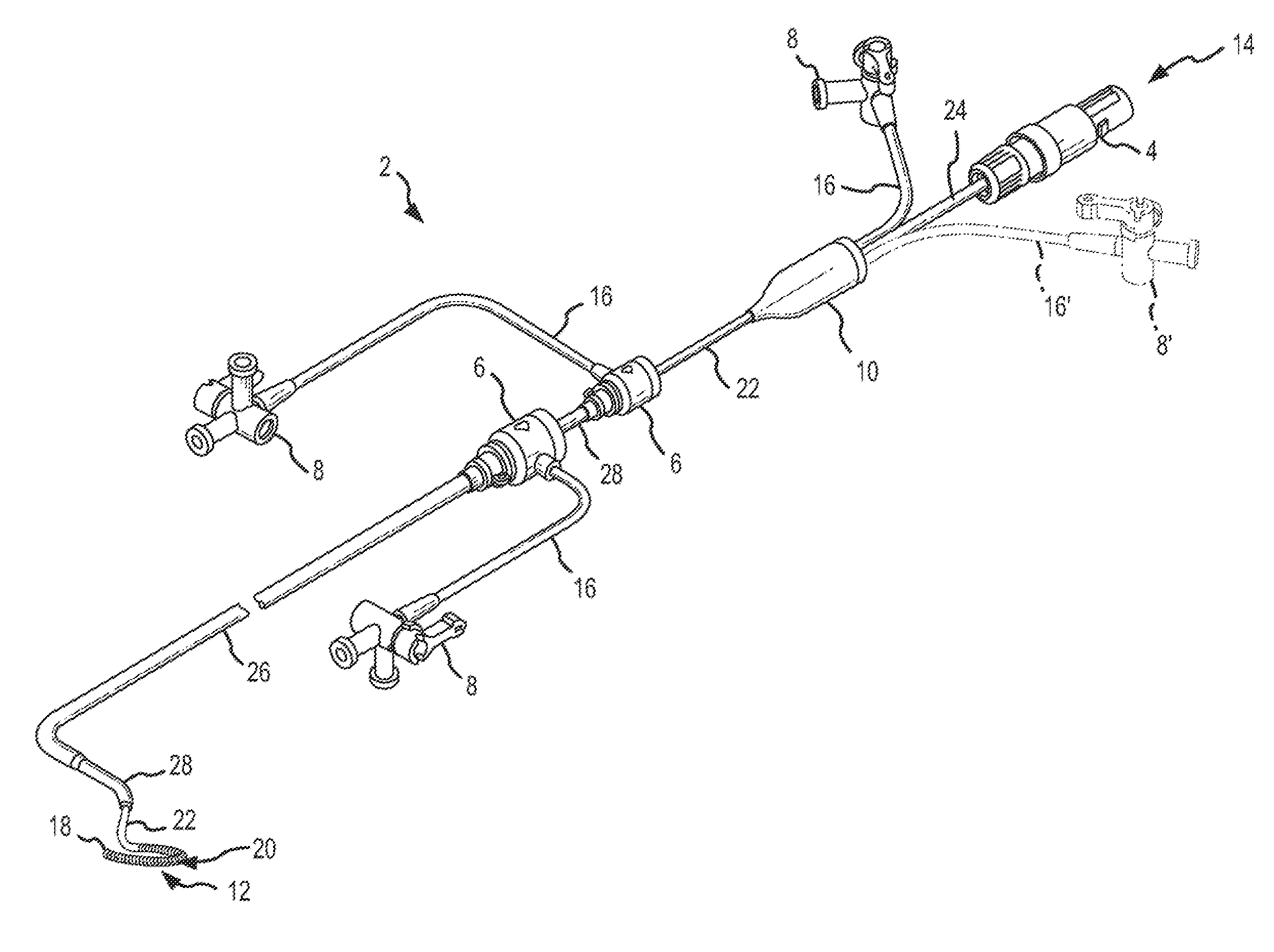

A tether assembly includes a tether cable containing optical fibers and adapted to be attached to a fiber optic distribution cable at a mid-span access location. A furcation at the end of the tether cable separates and transitions the optical fibers into furcation legs terminating in individual connector ports. Each connector port may be a receptacle for receiving a connector mounted upon one of the optical fibers and a mating connector of a drop cable, a plug mounted upon one of the optical fibers that is received within a plug alignment member operable to align the plug with a mating plug of a drop cable, or a connector that is routed to a receptacle disposed within an external wall of a network connection terminal from within the enclosure. The tether assembly provides a distribution cable assembly and method for mitigating a span length measurement difference in a pre-engineered communications network.

Owner:CORNING OPTICAL COMM LLC

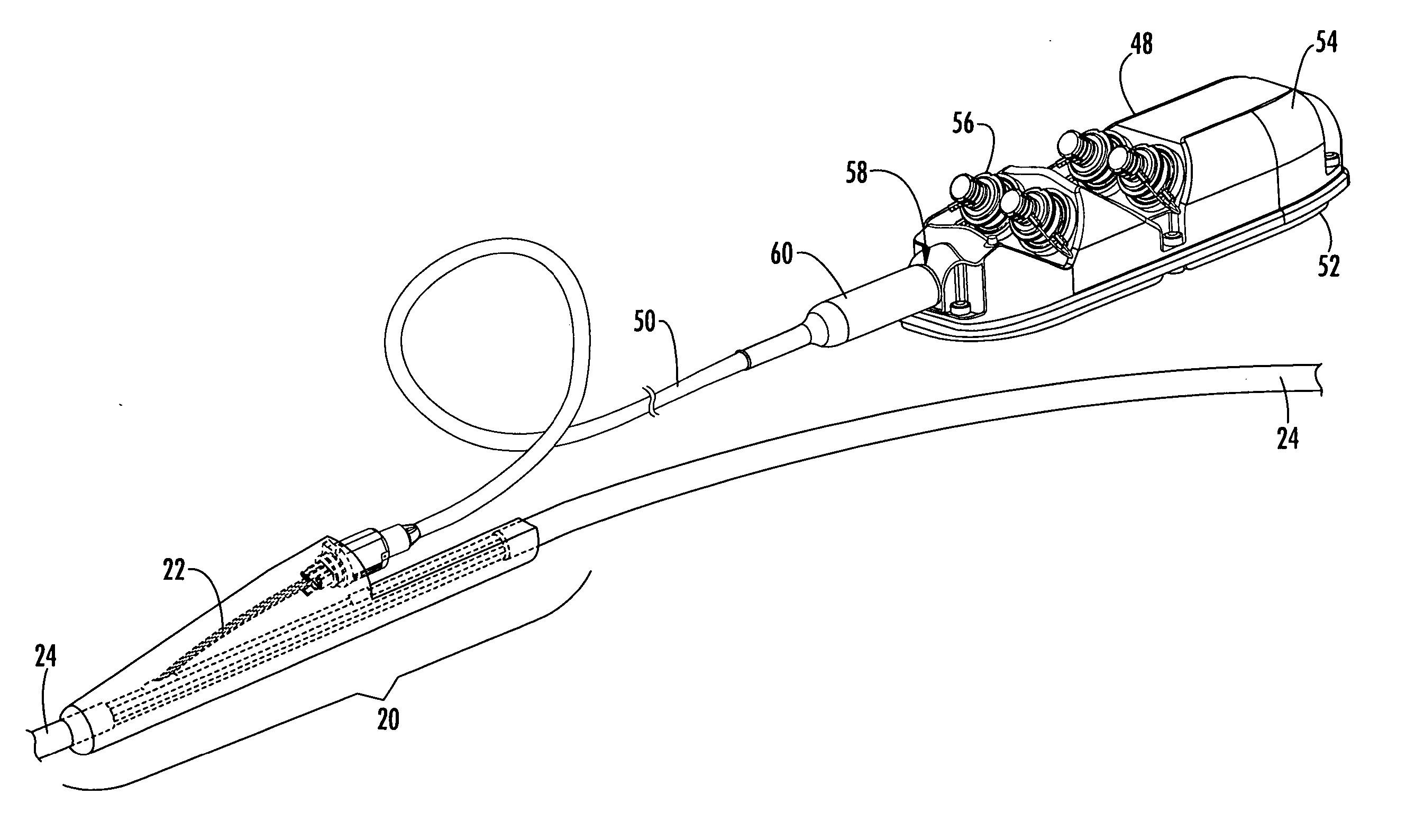

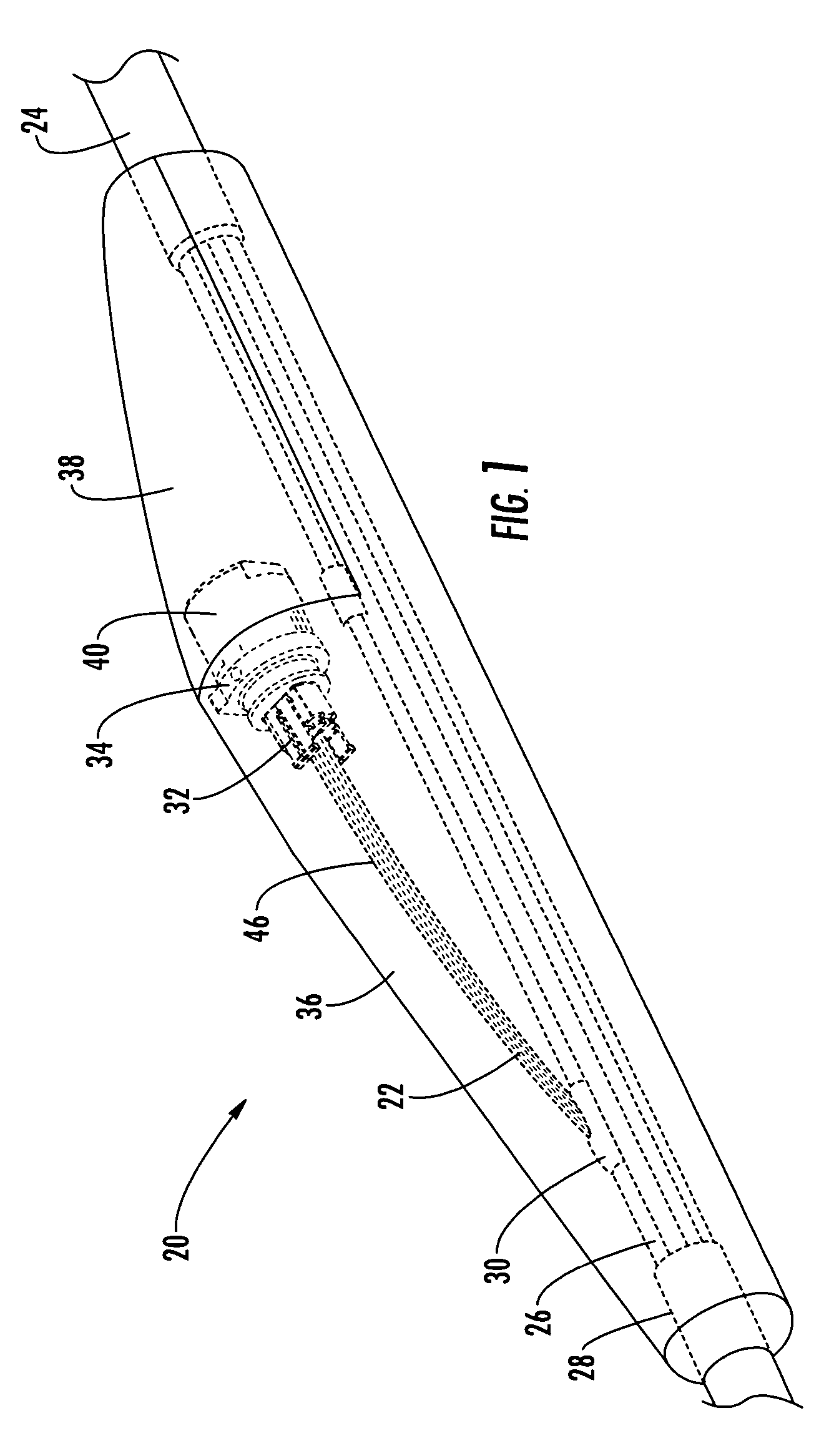

Pre-connectorized fiber optic distribution cable having overmolded access location

A pre-connectorized fiber optic distribution cable assembly includes a plurality of optical fibers and at least one mid-span access location along the length of the distribution cable. At least one of the optical fibers is accessed, terminated and then connectorized at the mid-span access location to an optical connector disposed within a receptacle. The mid-span access location, the accessed, terminated and connectorized optical fiber, the optical connector and at least a portion of the receptacle are encapsulated with a protective overmolded shell. A tether including at least one optical fiber connectorized at a first end of the tether is optically connected to the optical connector through the receptacle. A second end of the tether opposite the first end terminates in a network optical connection terminal, thereby compensating for a span length measurement difference between the actual location of the mid-span access and the desired location of the optical connection terminal.

Owner:CORNING CABLE SYST LLC +1

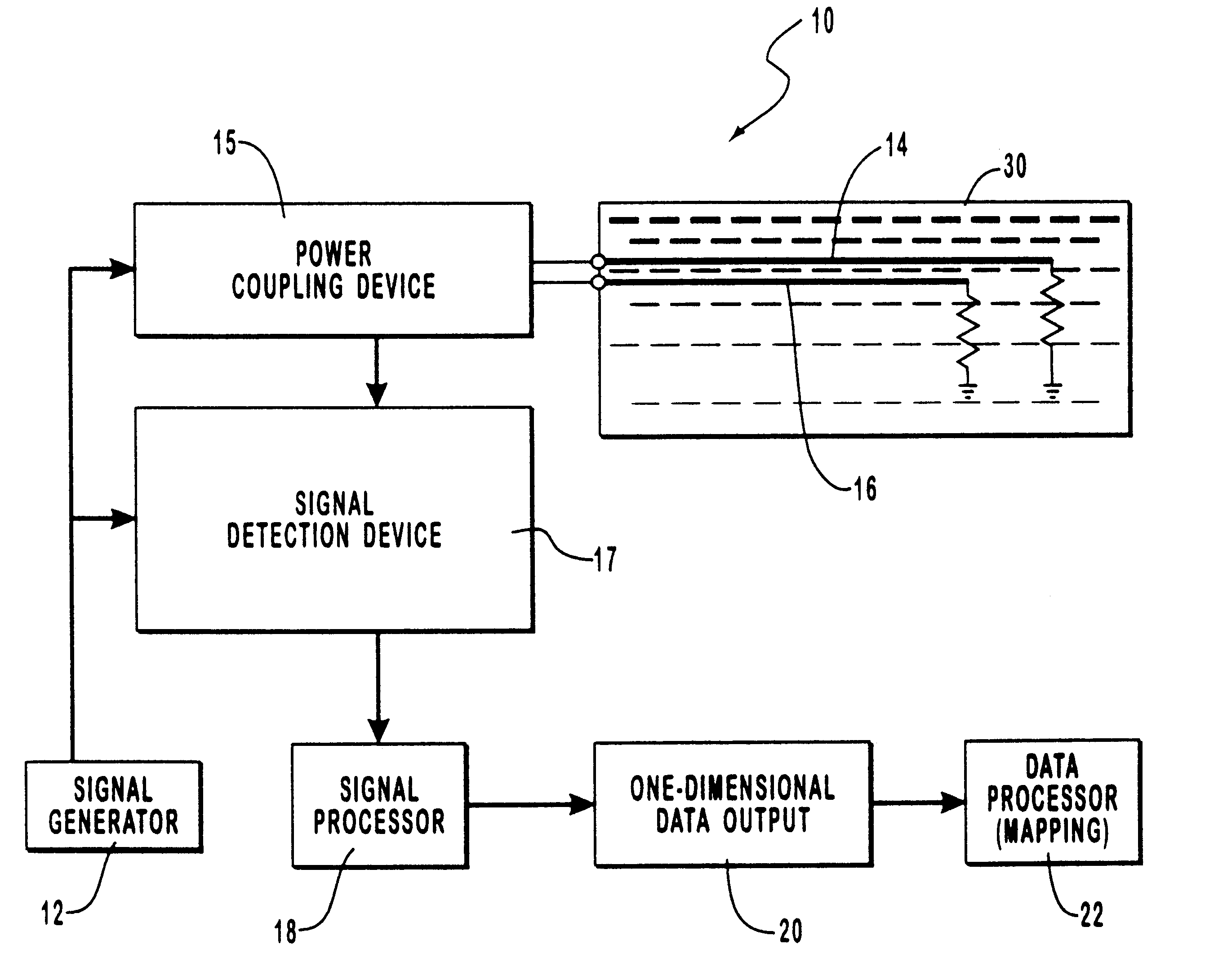

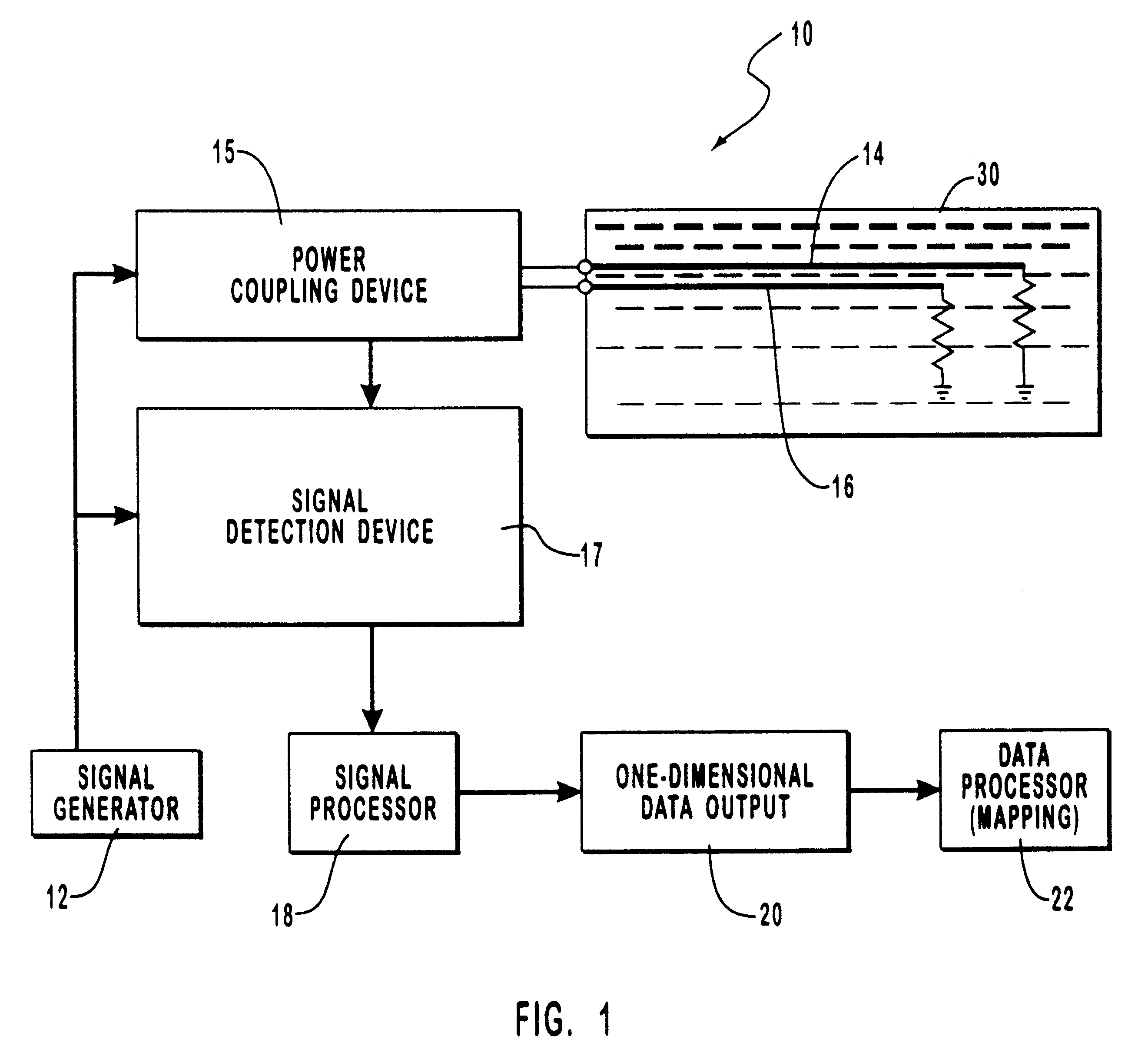

System and method for monitoring water content or other dielectric influences in a medium

Owner:BATTELLE ENERGY ALLIANCE LLC +1

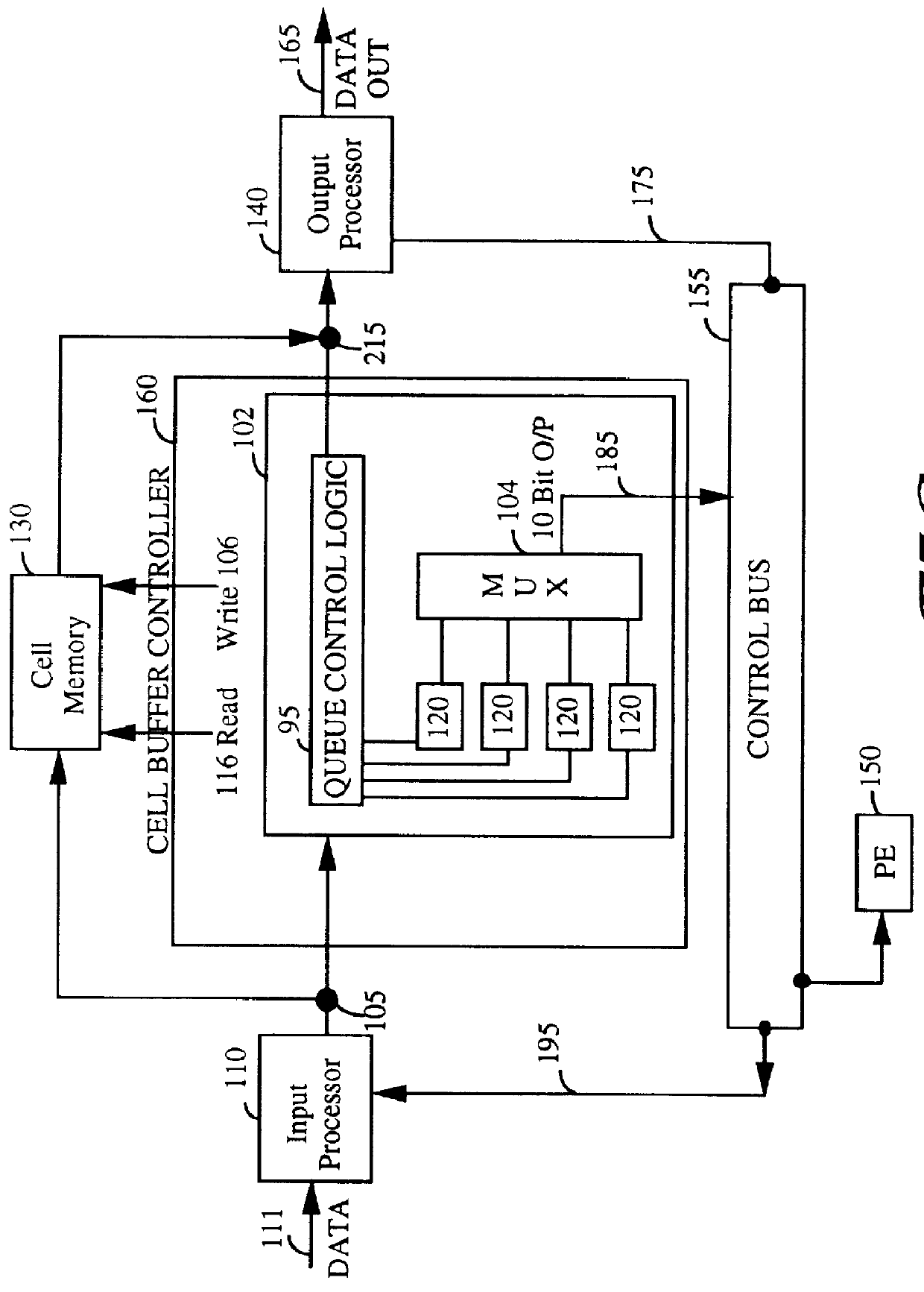

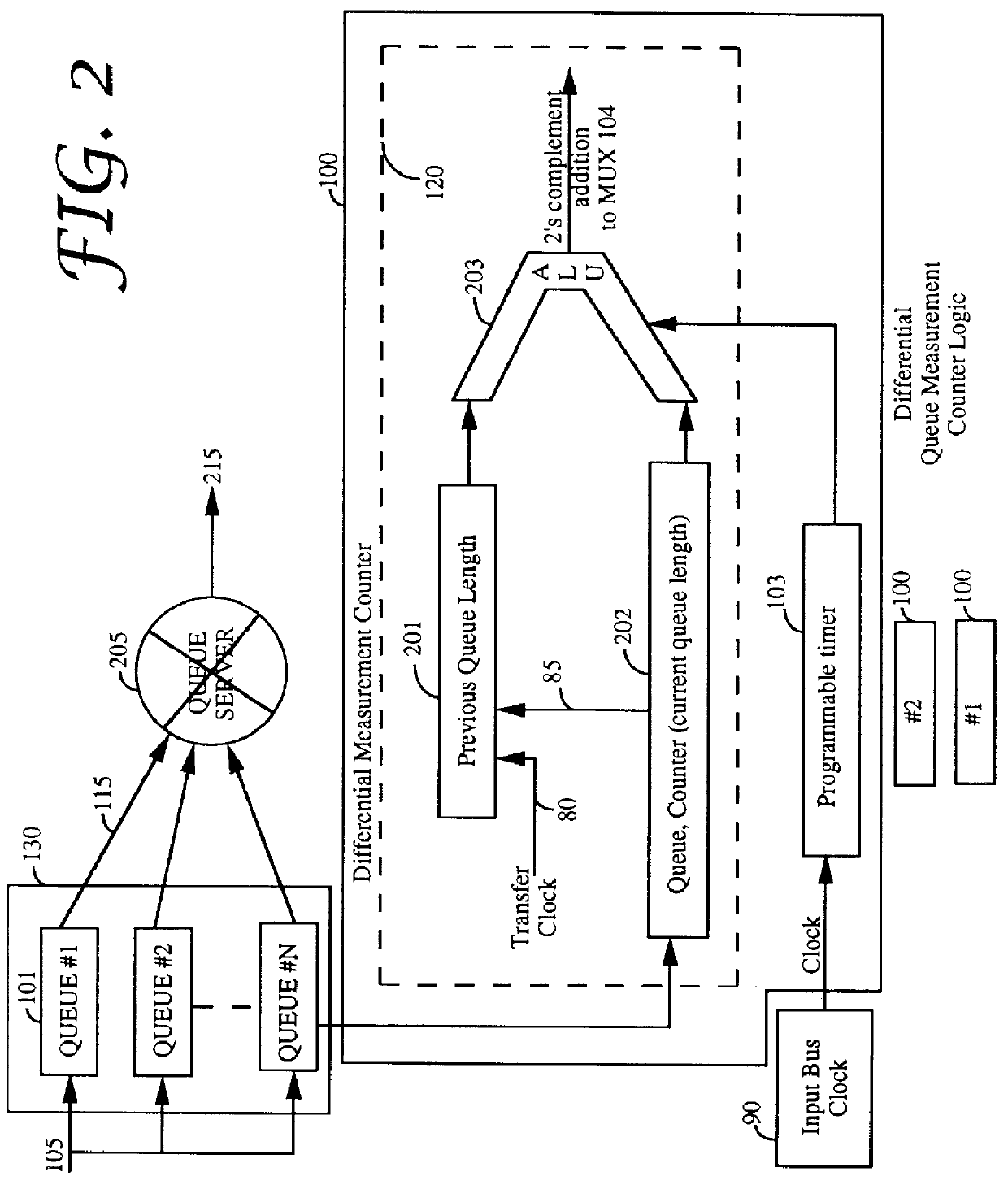

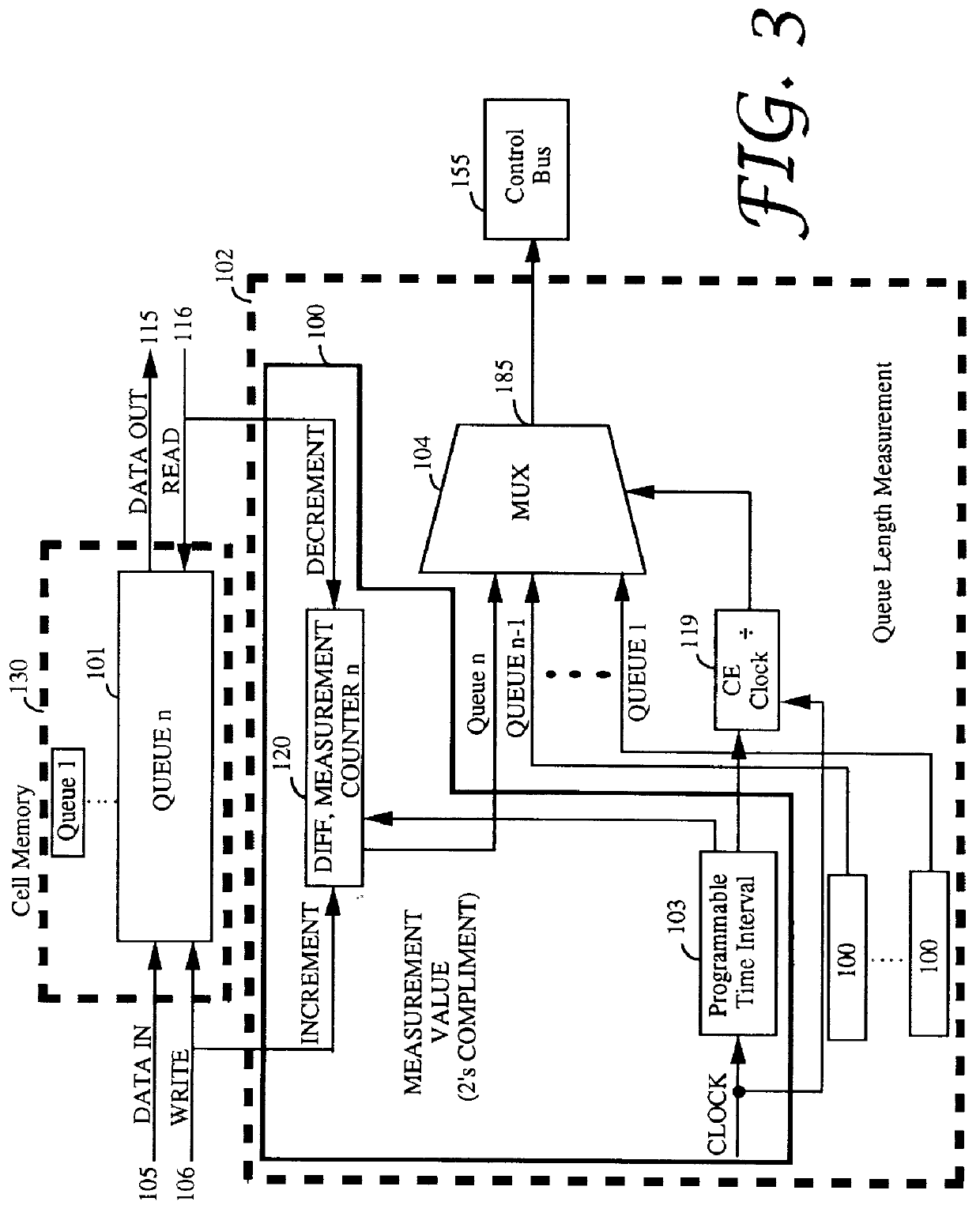

Closed loop congestion control using a queue measurement system

A queue length measurement device that is comprised of a number of queues that are capable of holding data cells. A differential counter is coupled to each queue. The counter is incremented when a cell is written into the queue and decremented when a cell is read from the queue. An interval measurement device, coupled to the differential counter, generates a pulse to reset the counter at fixed intervals equivalent to n cells time (where n is the maximum number of cells the queue counter can measure). A multiplexer is coupled to the multiple differential counters. A transfer control circuit coupled to the interval measurement device selects the appropriate queue measurement to be output from the multiplexer to the other switch elements. A system and methodology provide for queue flow statistics and closed loop control of cell flow into the queue. A congestion control system is provided comprising a queue (having an input and an output, and capable of storing and outputting a plurality of data cells), an input processor (for coupling a plurality of data cells to the queue input), an output processor, an interval measurement device (generating a pulse at predetermined intervals), and differential queue length generation logic. The output processor, couples to the queue output, for receiving a plurality of data cells from the queue, which generates a queue change in size signal in response to determining for each of the predefined intervals of the difference between a present and a previous queue length.

Owner:WHITTAKER COMM

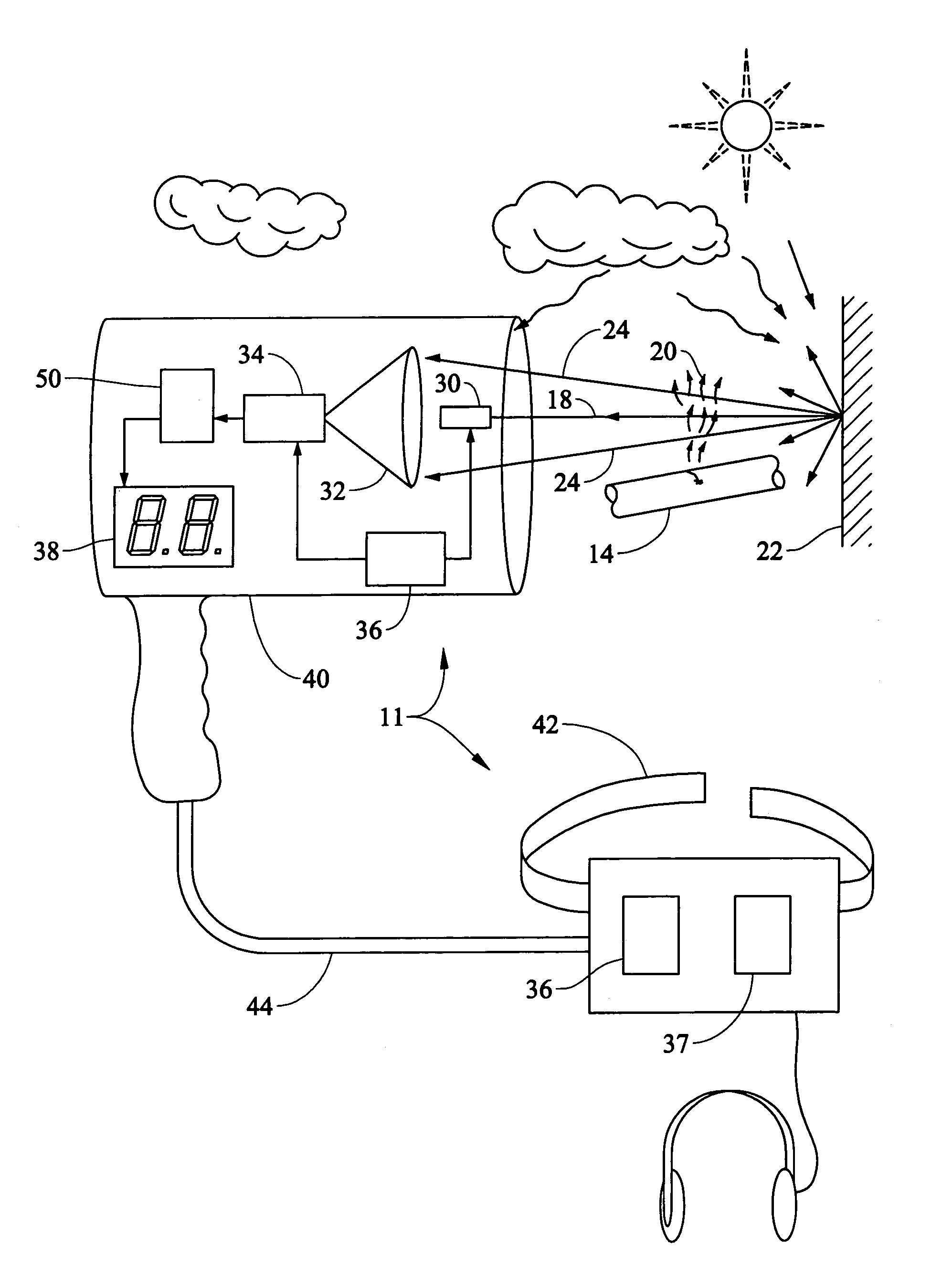

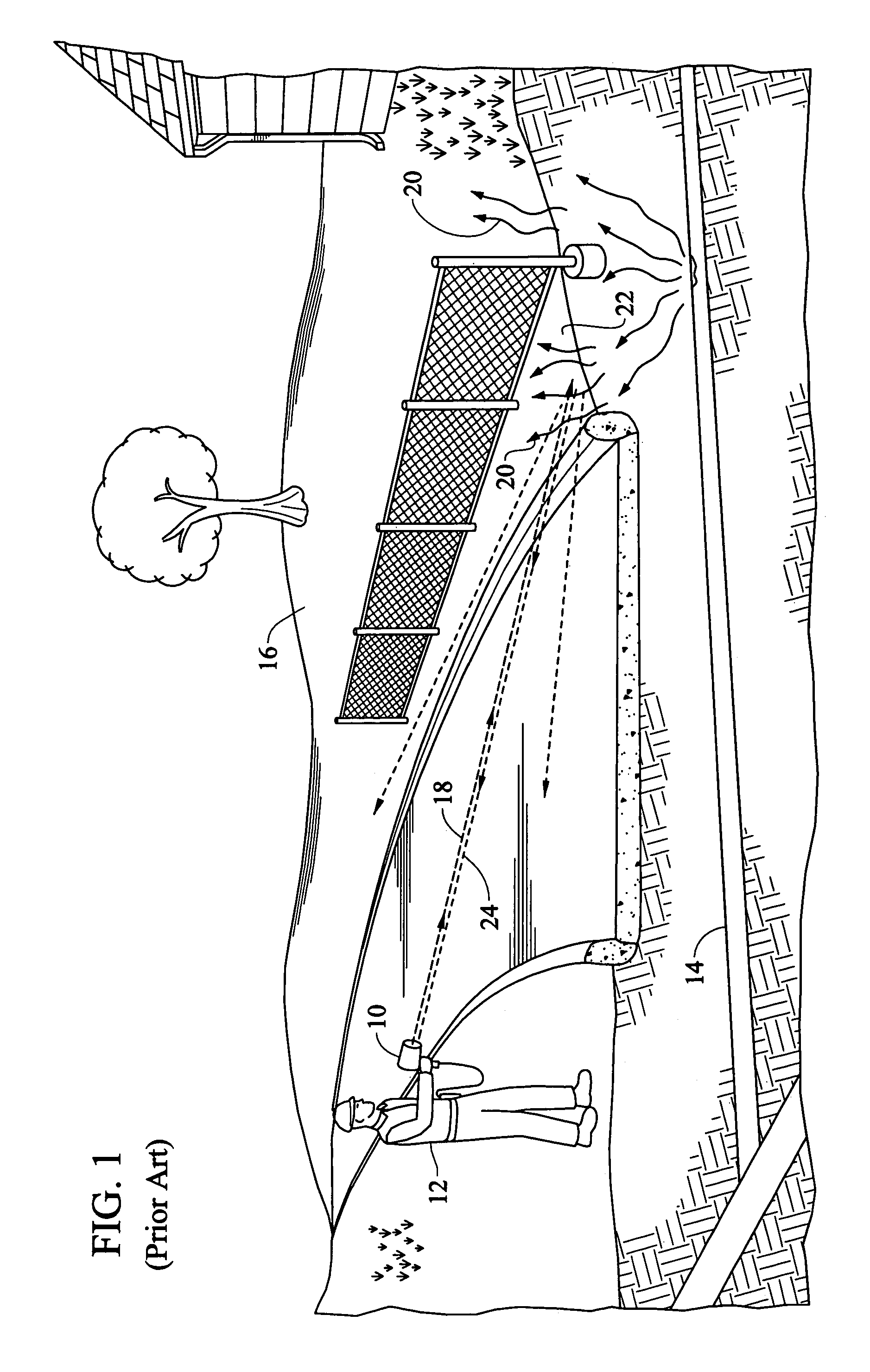

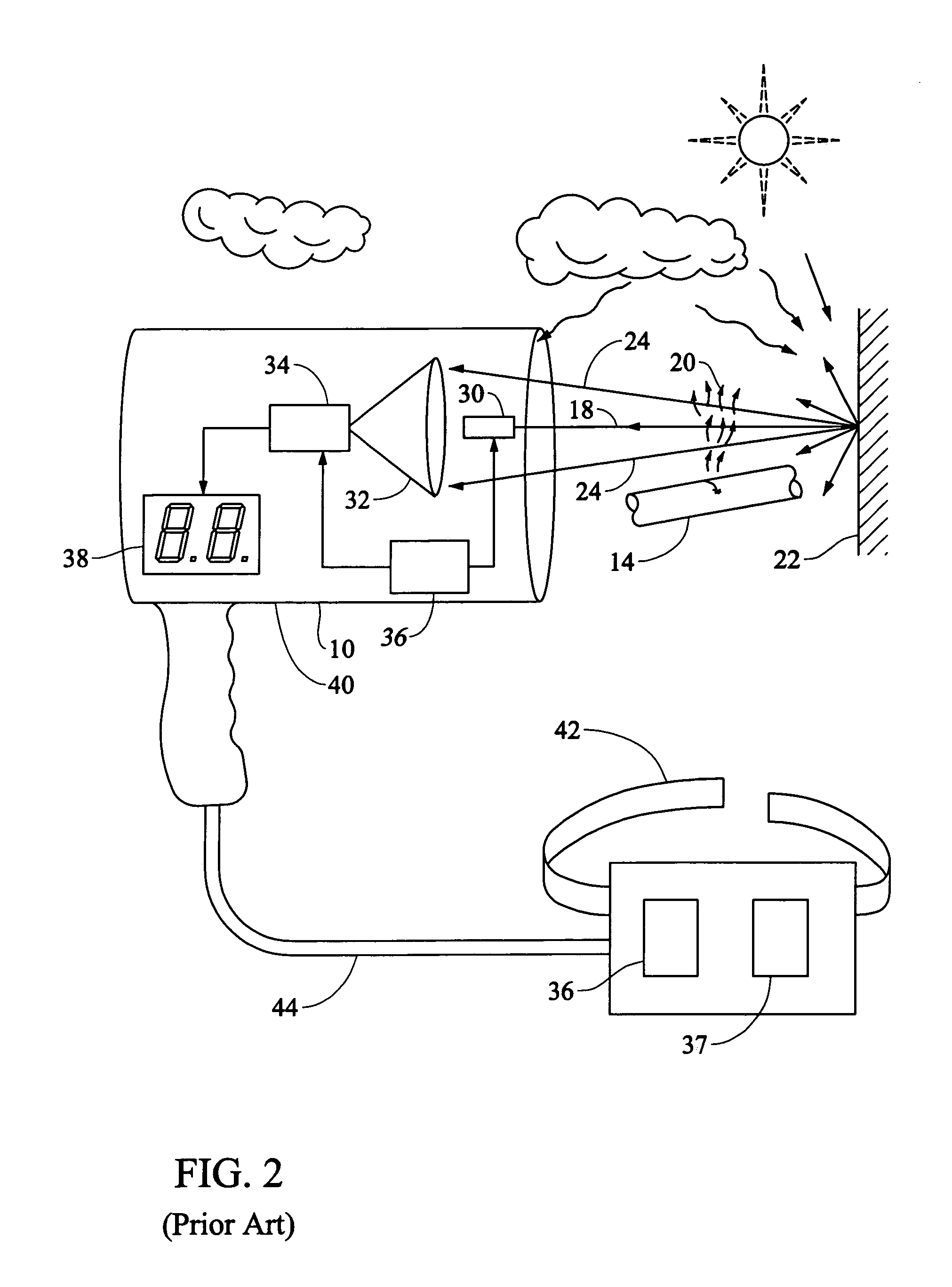

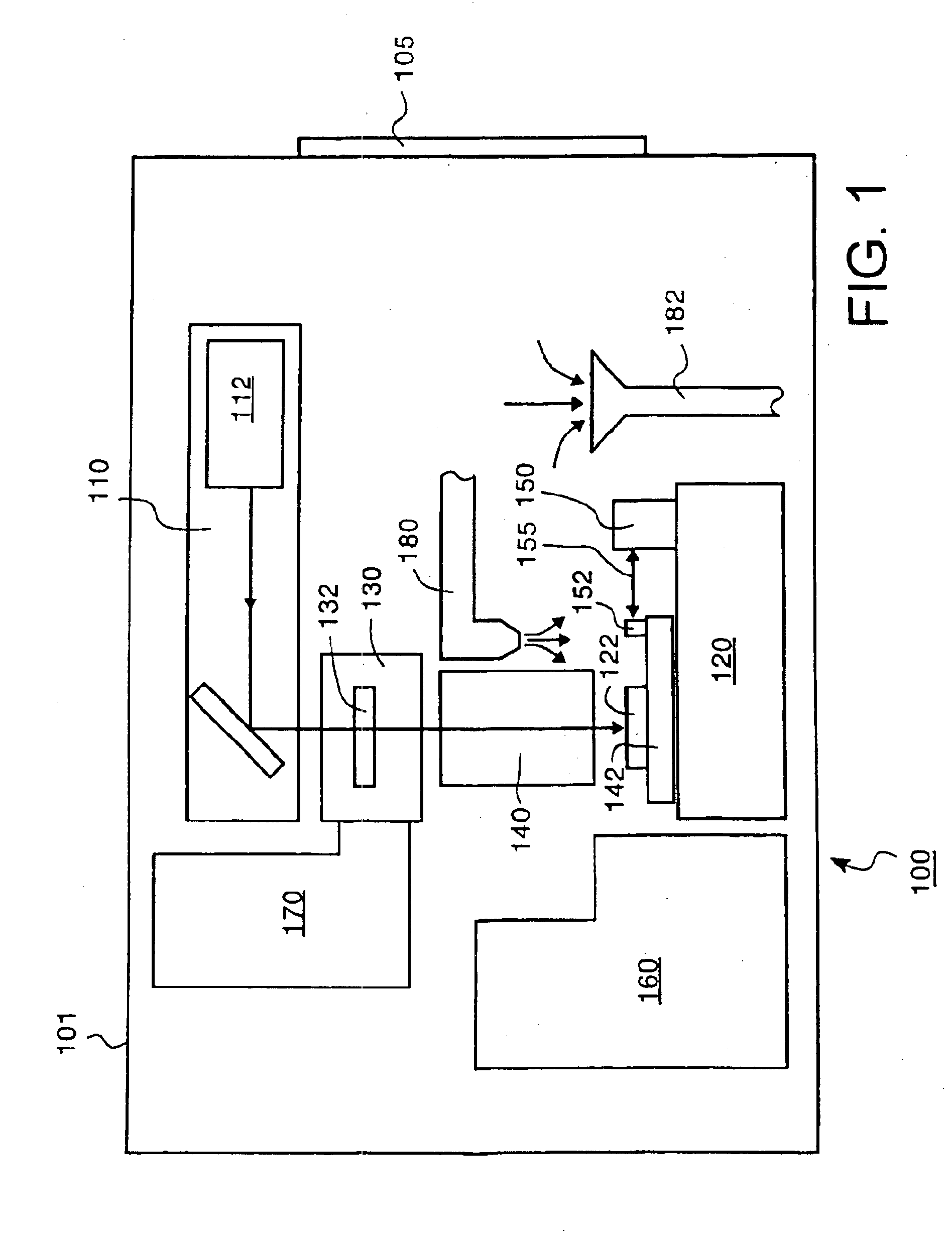

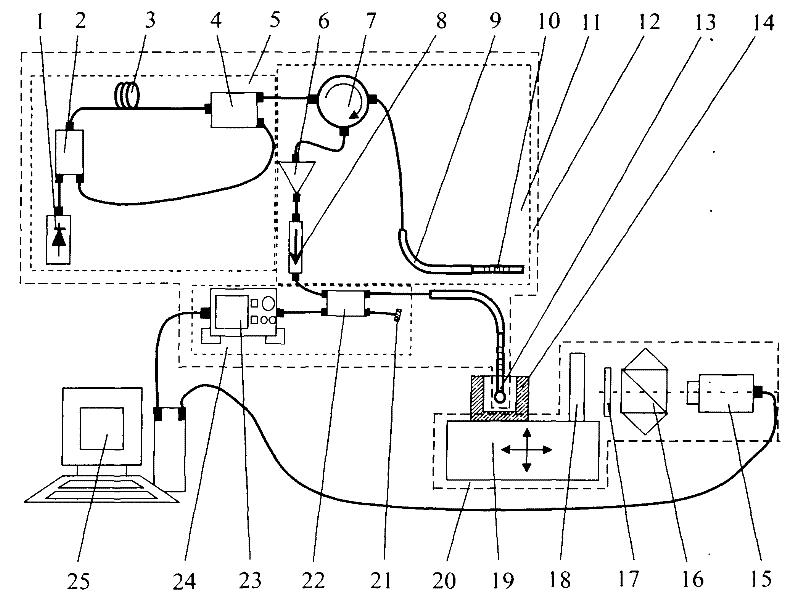

Method and apparatus for laser-based remote methane leak detection

ActiveUS7075653B1Promotes user comfortEasy to identifyDetection of fluid at leakage pointRadiation pyrometryMoving averageSpectroscopy

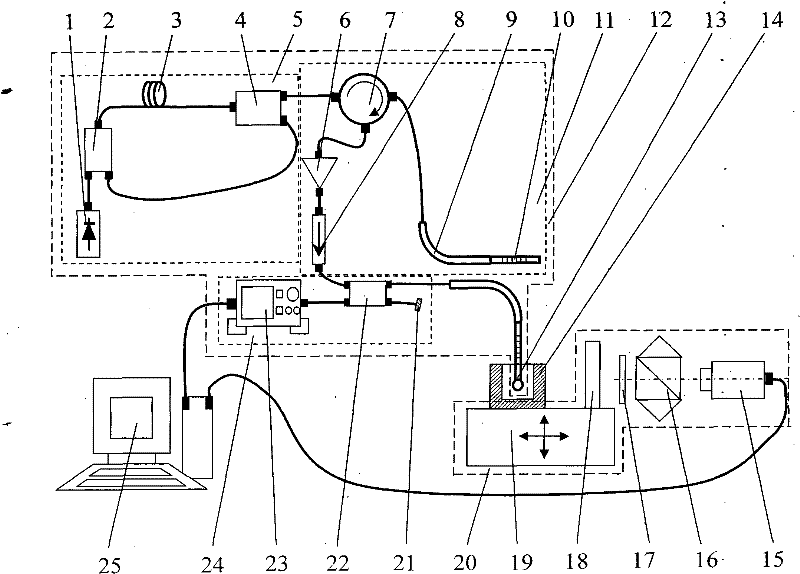

A method and apparatus for remote laser-based detection of gas at levels exceeding natural background levels preferably utilizing wavelength modulated tunable diode laser absorption spectroscopy. In a preferred embodiment, background gas and noise are estimated using statistical moving average and variance calculations. Gas concentration length measurements resulting from the spectroscopy are preferably compared in real-time or near-real-time to the sum of the background and noise estimates and an alarm limit to detect gas presence of concern. Gas levels exceeding this detection threshold are preferably indicated by a prolonged output tone with a pitch indicative of the magnitude of the gas measurement, and gas levels below the detection threshold are preferably indicated by silence.

Owner:HEATH CONSULTANTS

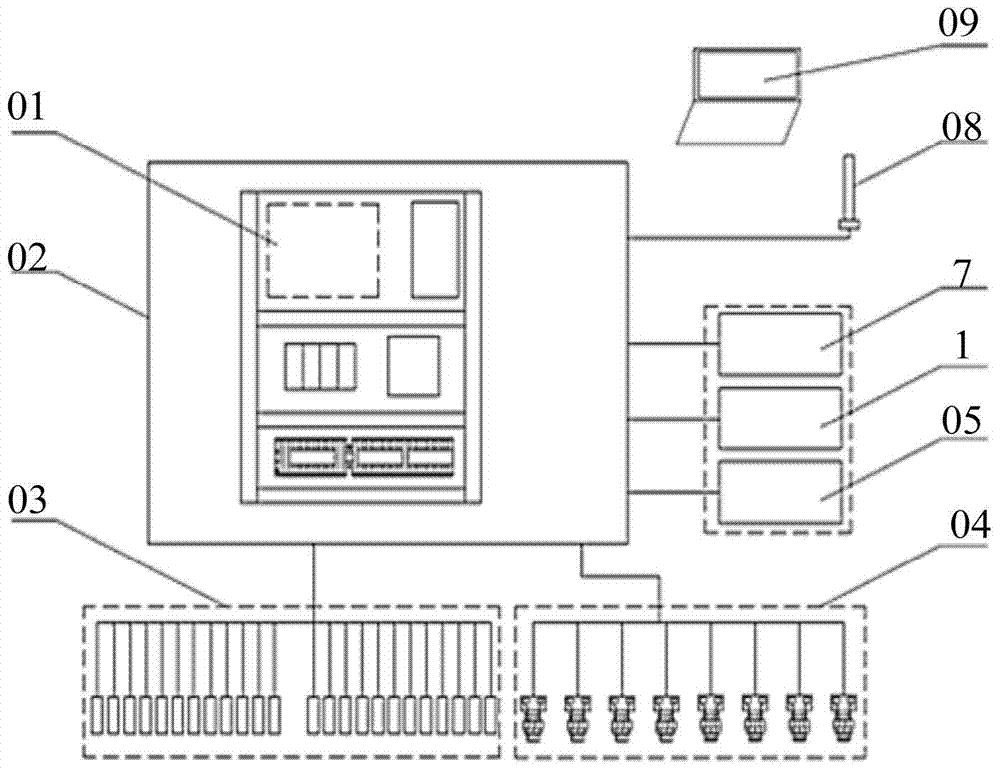

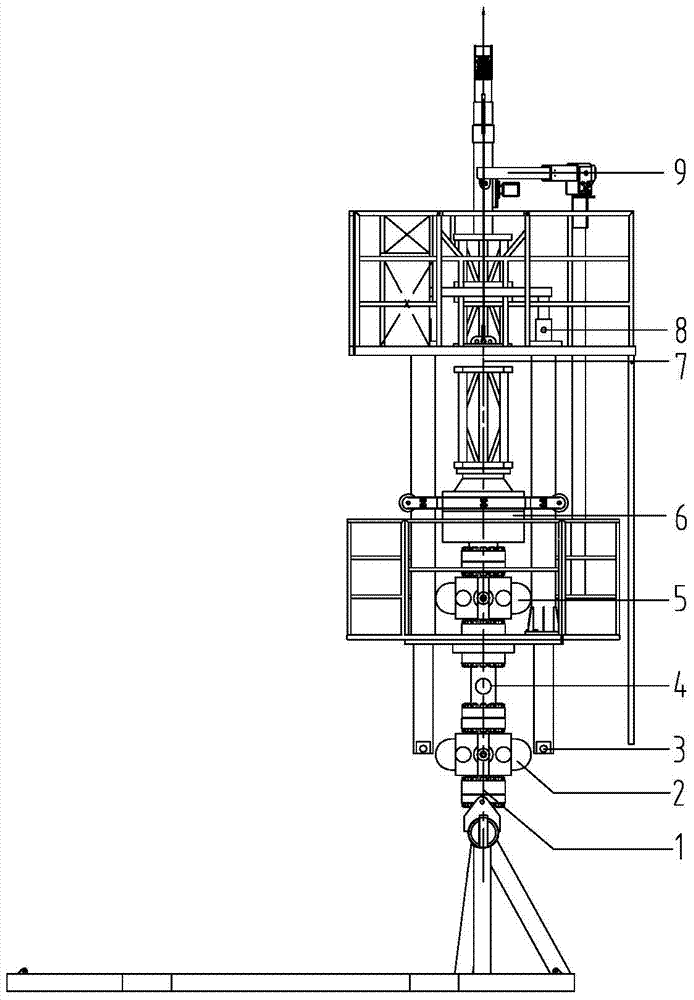

A kind of snubbing equipment and its real-time monitoring system

ActiveCN104820372BImprove securityReduce labor intensitySimulator controlDisplay deviceMonitoring system

The invention relates to a real-time monitoring system for snubbing equipment, comprising: an oil cylinder stroke sensor, which is used to detect the stroke of the driving oil cylinder that drives the swimming load-bearing slips and the swimming anti-top slips to move up and down; The controller is connected with the stroke sensor, and when the pipe is being lifted, the controller only records the lifting stroke of the driving cylinder; when the pipe is being lowered, the controller only records the pressing stroke of the driving cylinder; it is used to display the lifting stroke and pressing trip display. The real-time monitoring system effectively reduces the labor intensity of operators, and at the same time improves the accuracy and efficiency of oil pipe length measurement. The invention also discloses a snubbing device with the above-mentioned real-time monitoring system.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD +1

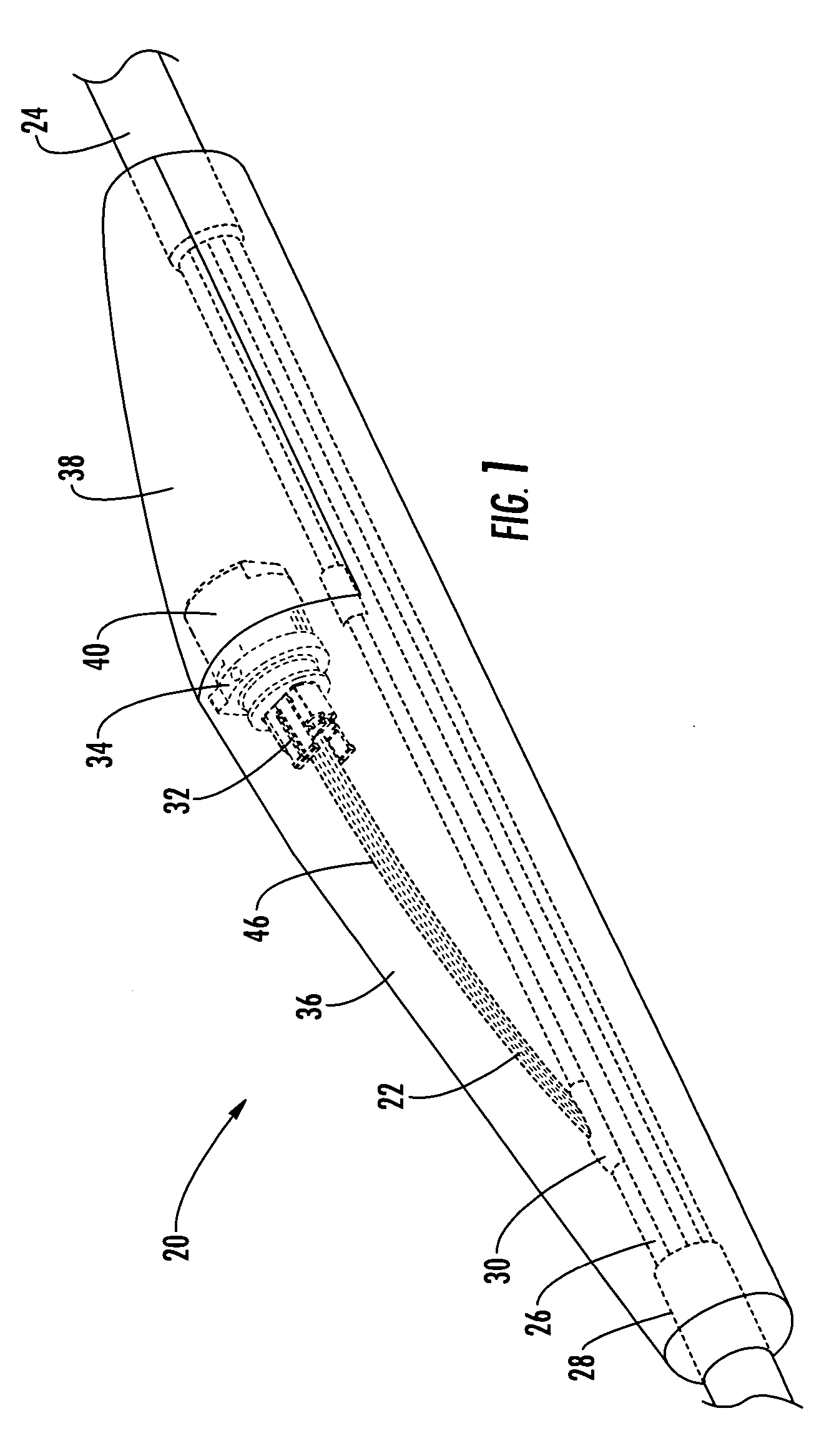

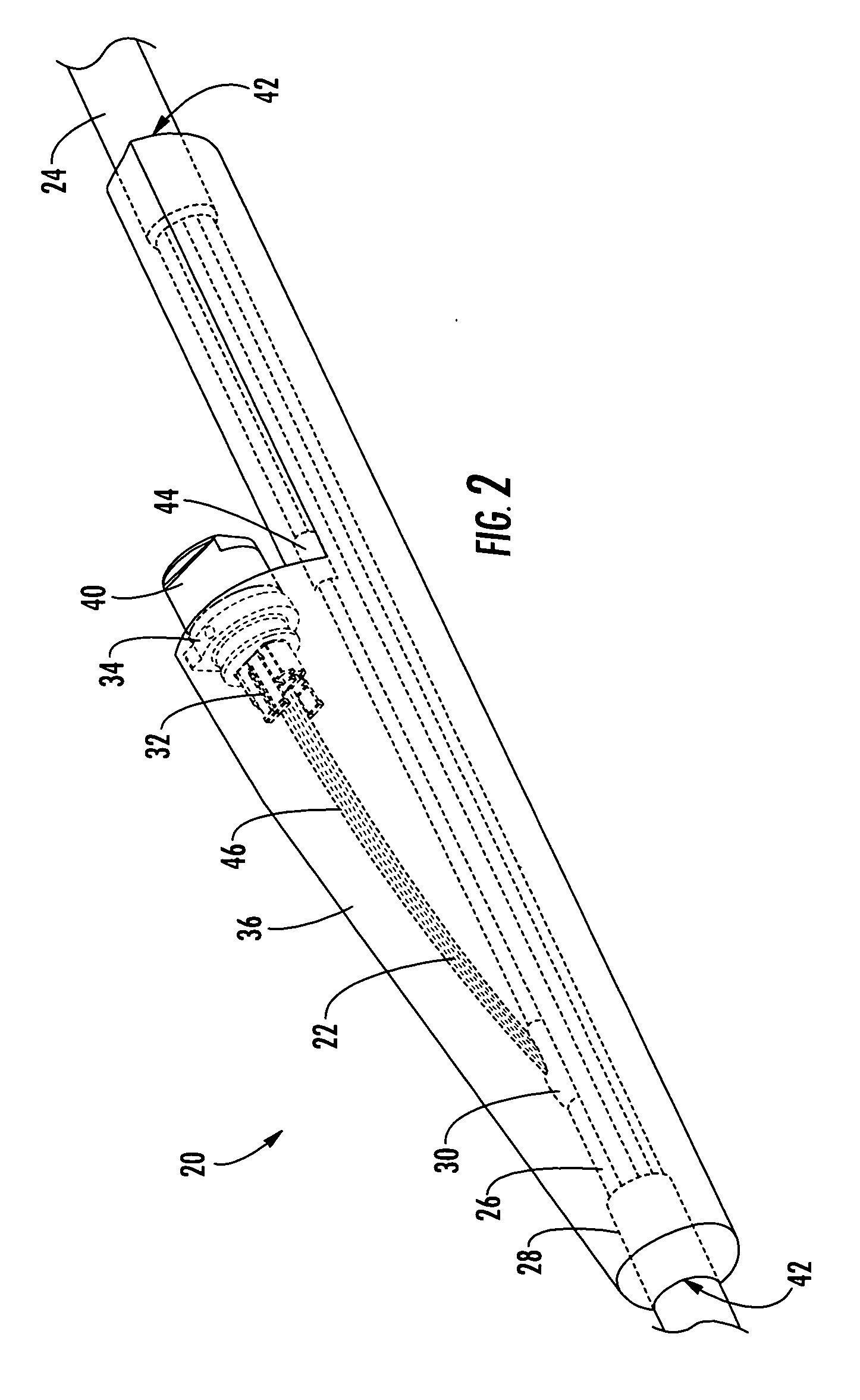

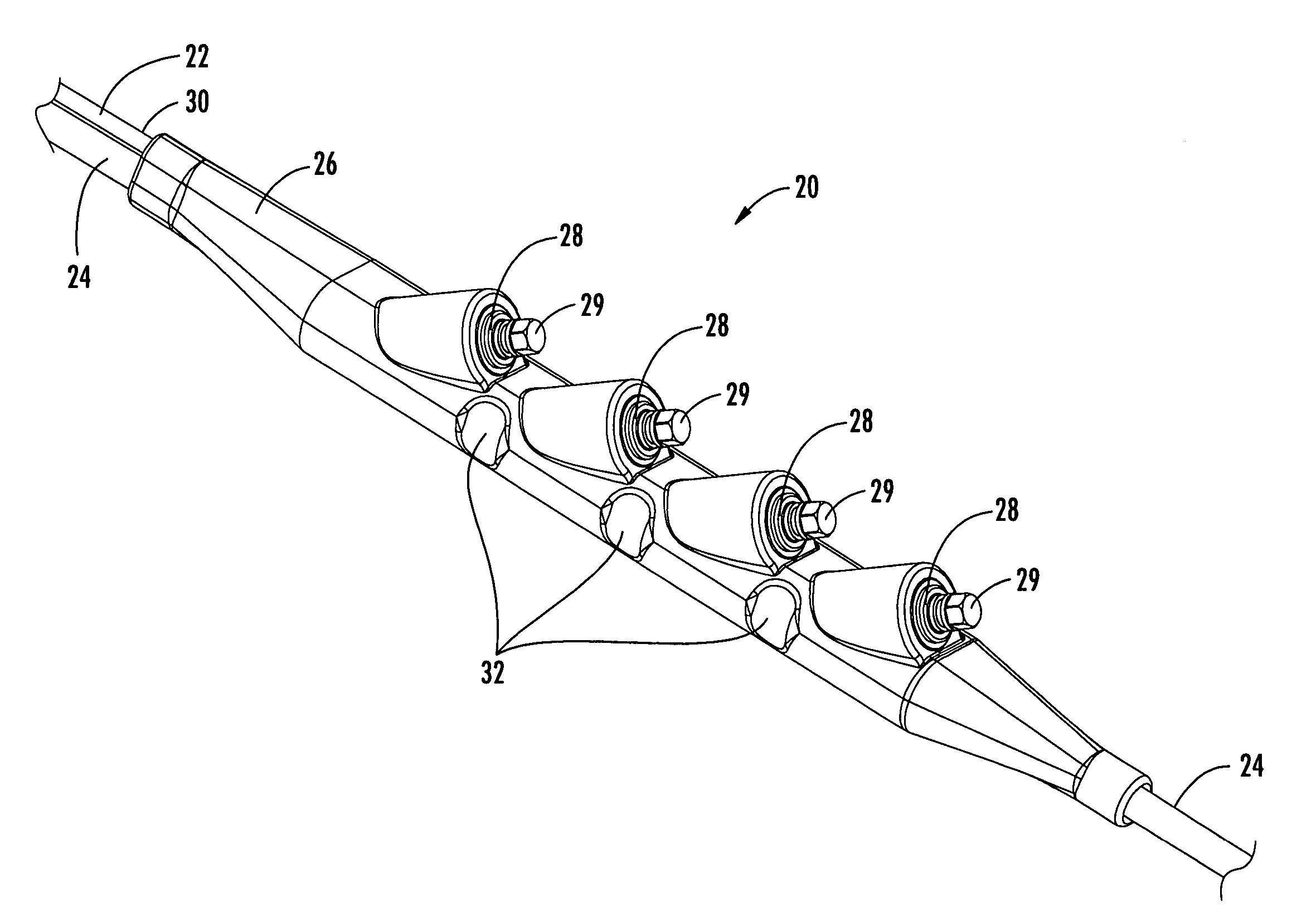

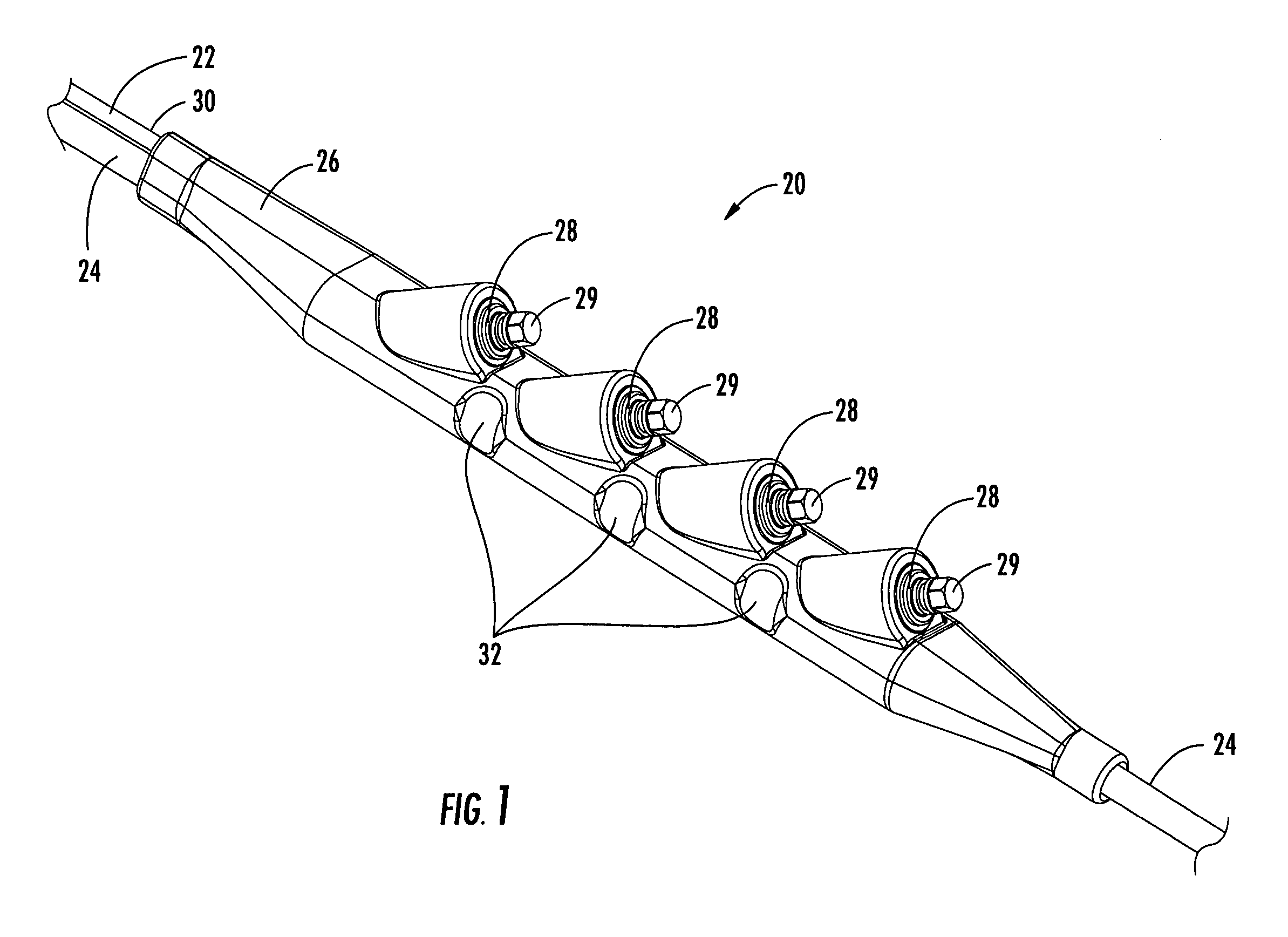

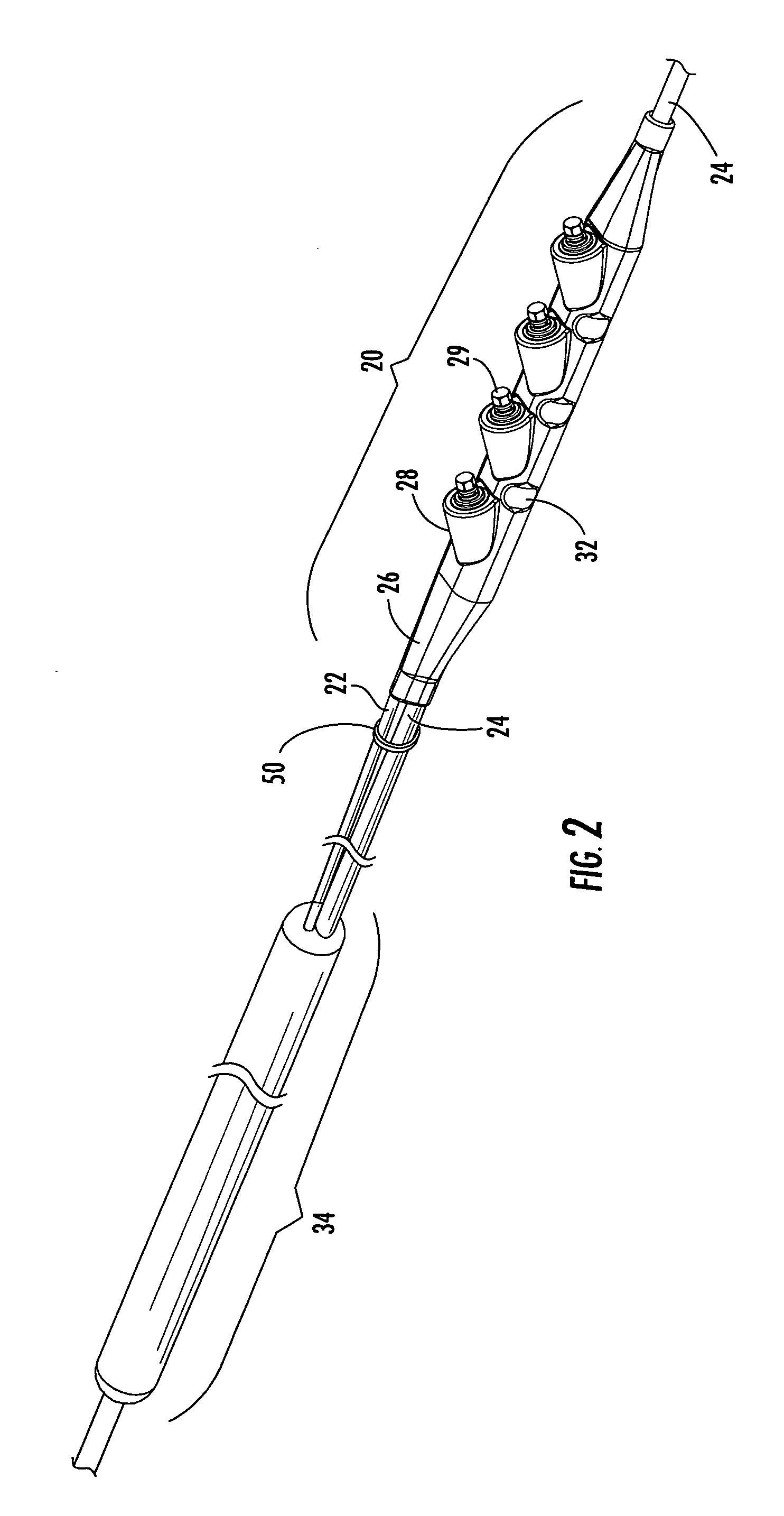

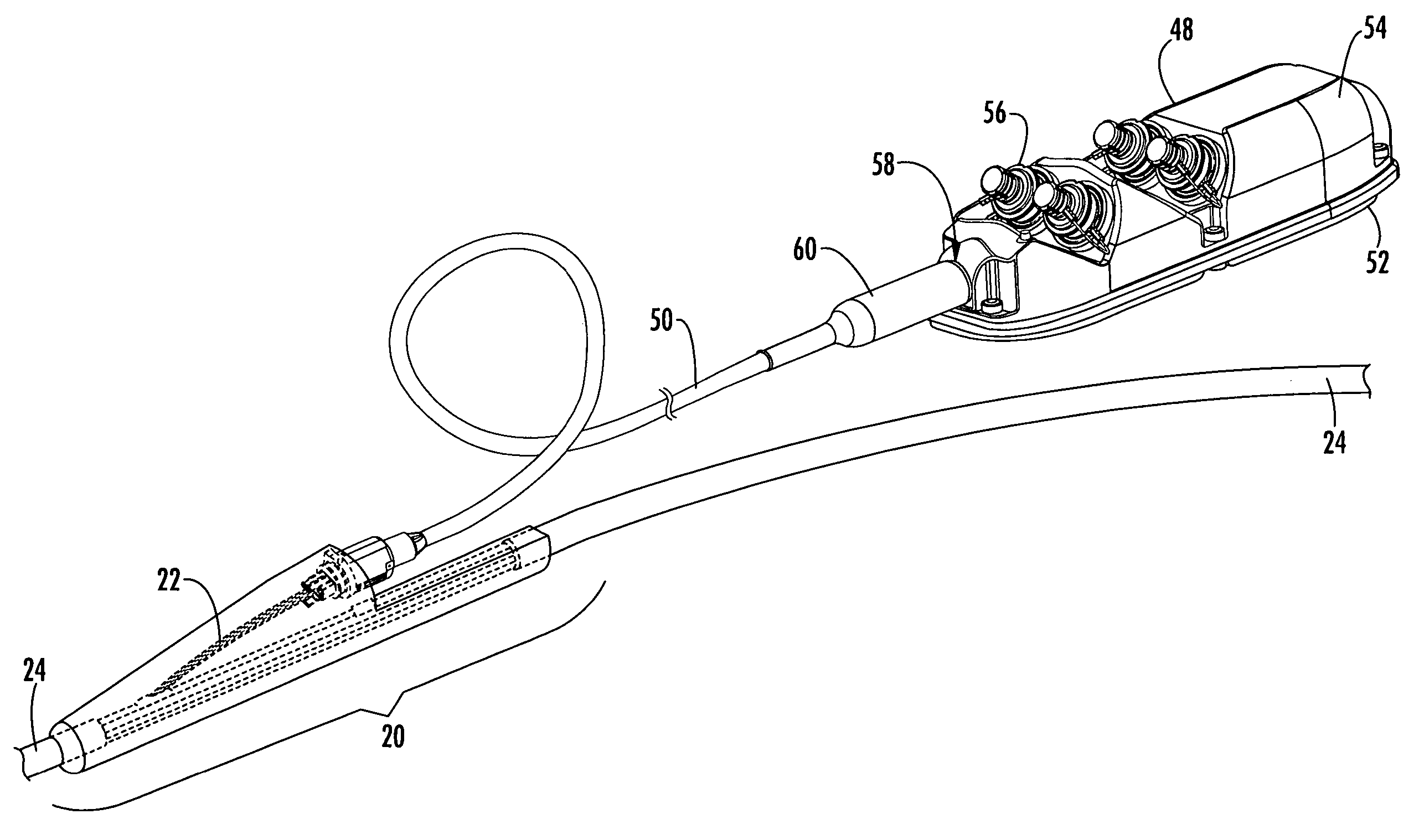

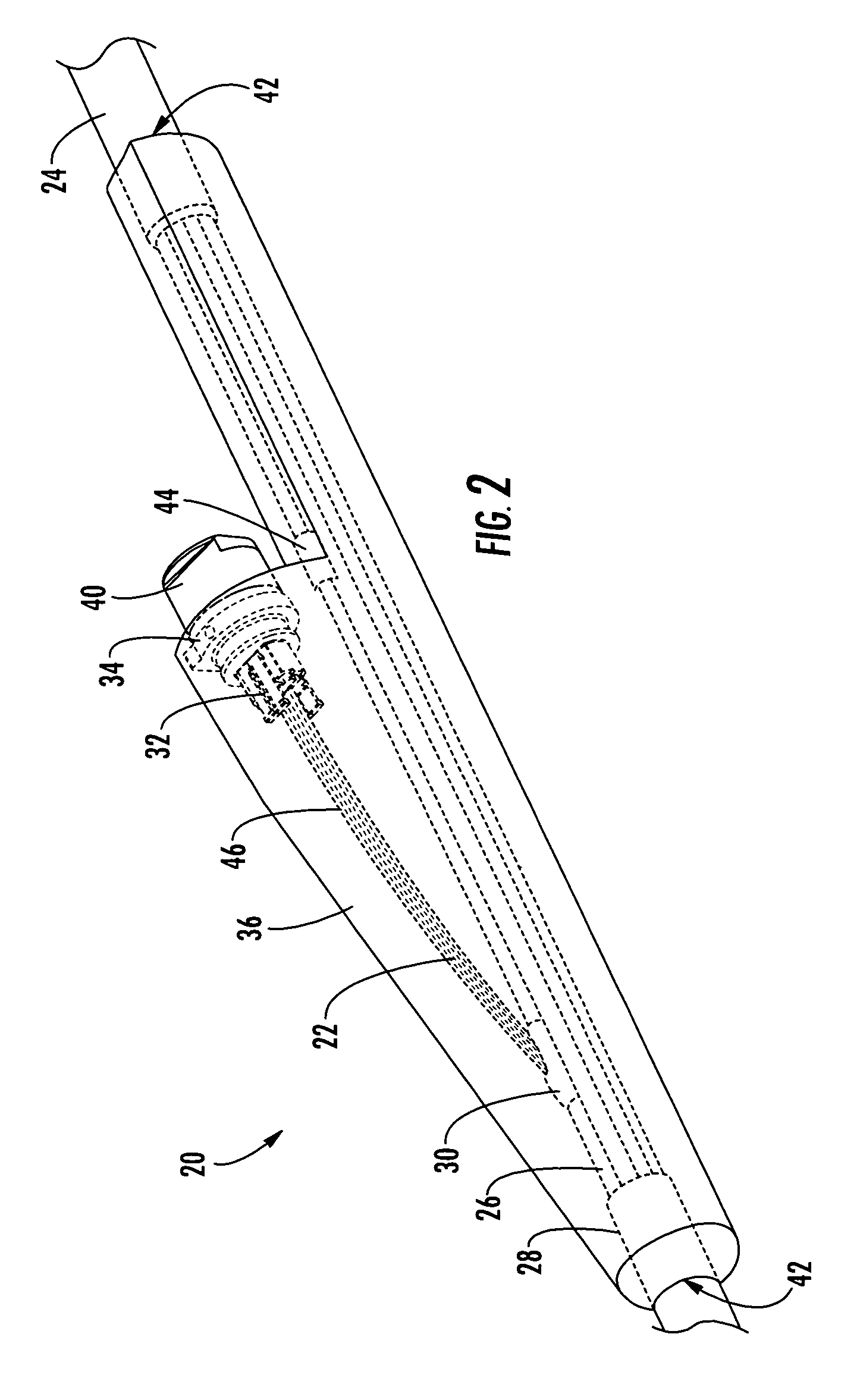

Adjustable tether assembly for fiber optic distribution cable

InactiveUS20060115220A1Wrong cable lengthPrecise positioningCoupling light guidesFibre mechanical structuresFiberEngineering

An adjustable tether assembly for a fiber optic distribution cable includes a tether cable and an overmolded housing secured at the end of the tether cable having at least one connector port. The tether assembly is attached to the distribution cable such that the position of the connector port is adjustable along the length of the distribution cable for mitigating differences between the pre-engineered span length distance and the actual span length distance following installation of the distribution cable. A method for mitigating a span length measurement difference in a pre-engineered fiber optic communications network is provided that includes optically connecting an adjustable tether assembly at a mid-span access location of a fiber optic distribution cable and positioning a housing secured at the free end of a tether cable having at least one connector port at a desired location in the network to compensate for the span length measurement difference.

Owner:CORNING OPTICAL COMM LLC

Adjustable tether assembly for fiber optic distribution cable

InactiveUS7228036B2Precise positioningReduce the differenceCoupling light guidesFibre mechanical structuresFiberLength measurement

Owner:CORNING OPTICAL COMM LLC

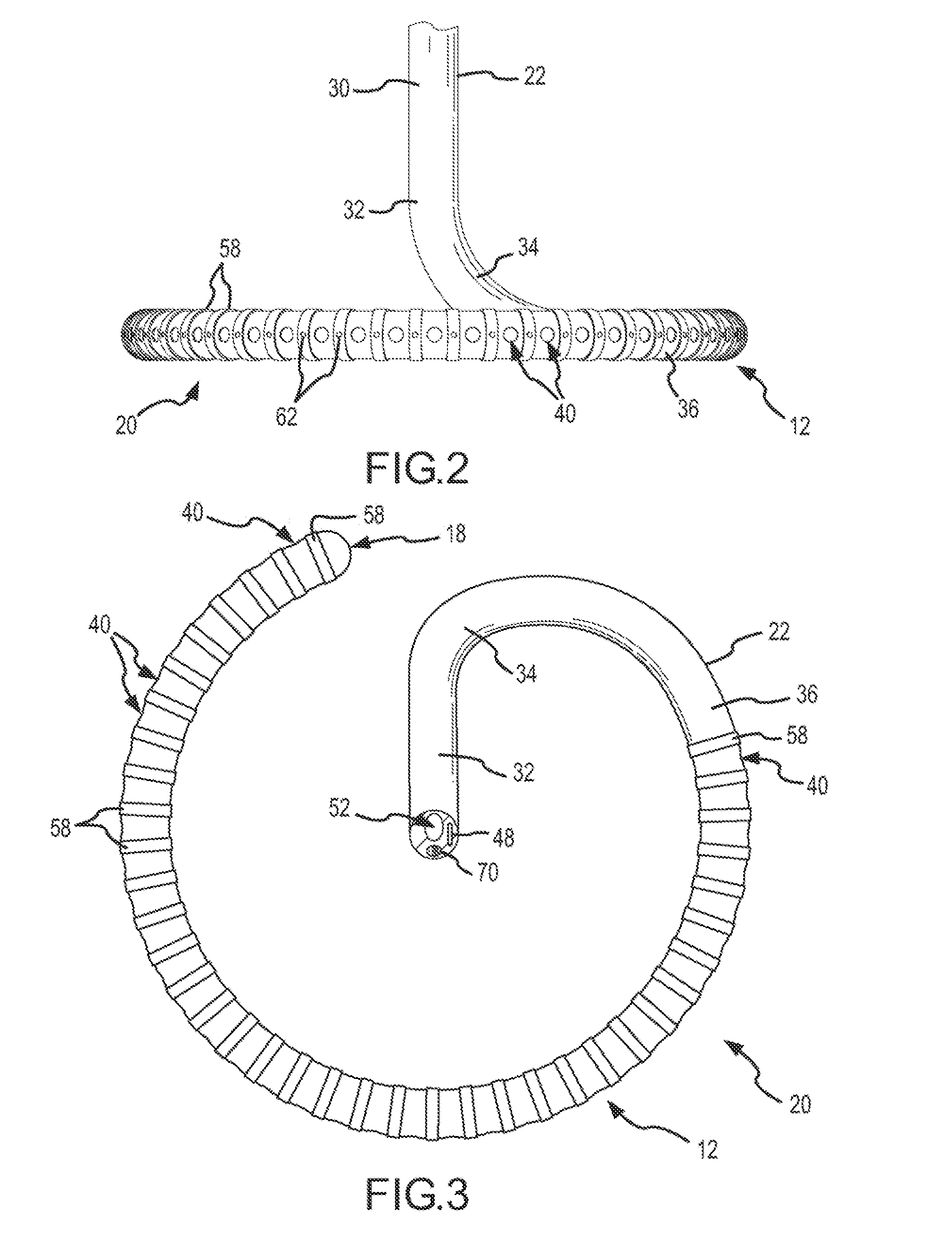

Ablation Catheter With Sensor Array And Discrimination Circuit To Minimize Variation In Power Density

InactiveUS20080161788A1Reduce connectionsReduce the numberThermometers using electric/magnetic elementsUsing electrical meansSensor arrayEngineering

A catheter is designed with a virtual electrode structure for creating a linear lesion. The catheter includes a sensor array that measures temperatures of adjacent tissue along the length of the virtual electrode section. The sensors in the sensor array include a conductive material that is substantially coated with an electrically and thermally insulating material. An aperture is formed in the insulating coating to expose an area of the conductive material. Leads are coupled with each sensor and are connected at their opposite, proximal ends with a discrimination circuit. The circuit processes the signals induced in the sensors to output a single temperature measurement, for example, the highest temperature, the lowest temperature, or the average temperature. The sensors also measure cardiac electrical activity and the leads are further connected to an electrocardiograph monitor to determine the efficacy of treatment.

Owner:ST JUDE MEDICAL ATRIAL FIBRILLATION DIV

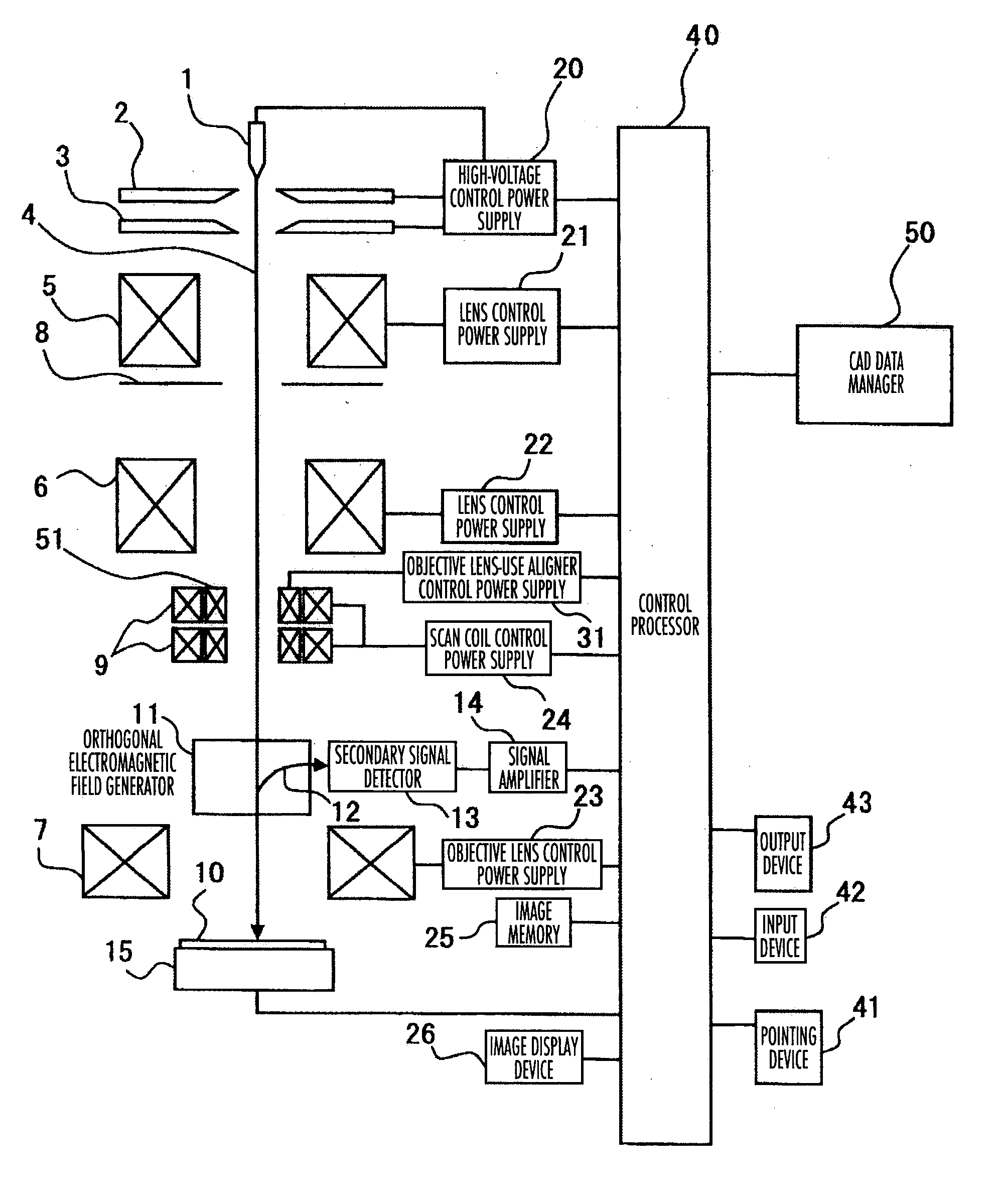

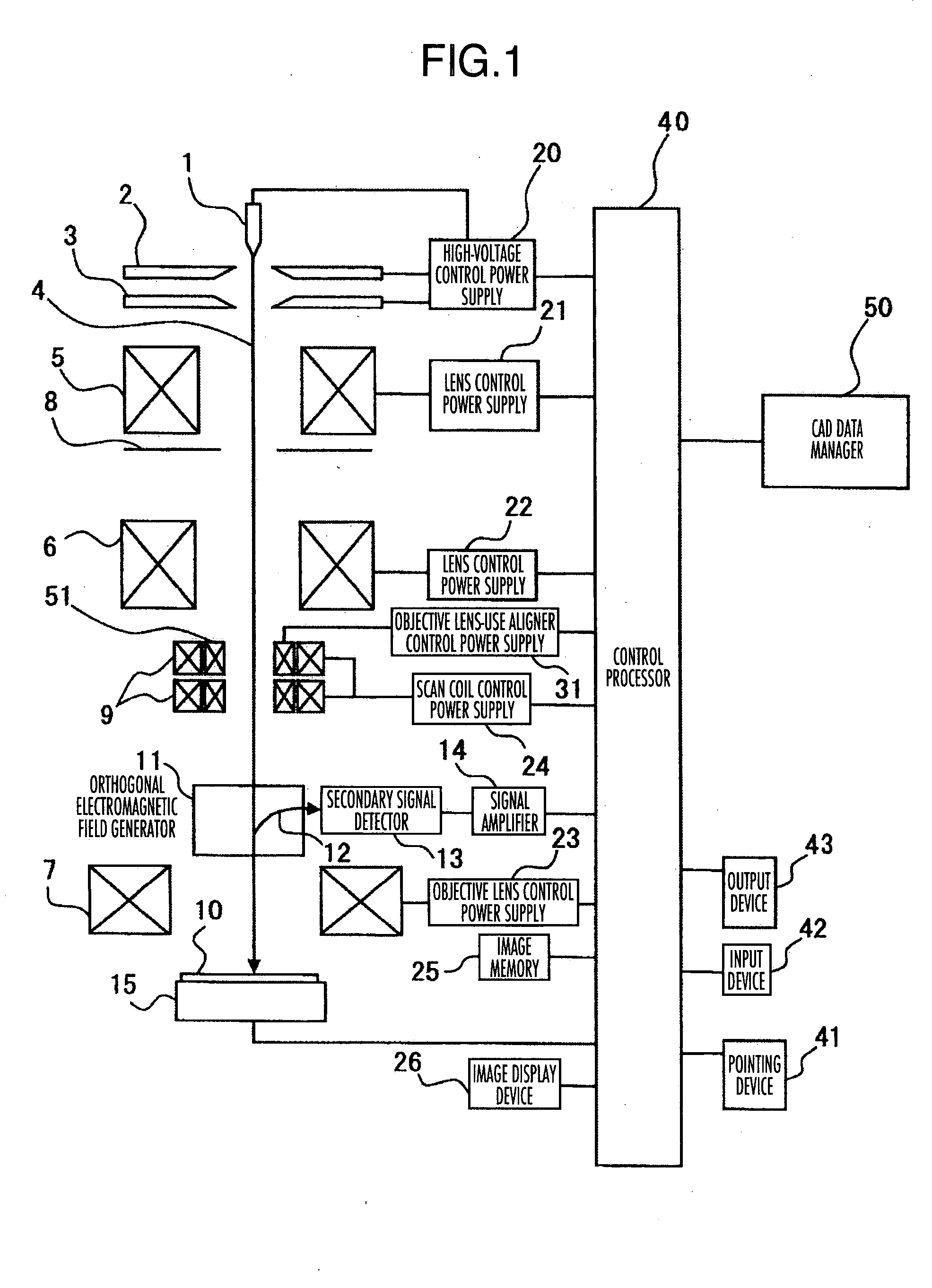

Workpiece size measurement method and apparatus

ActiveUS20070221842A1Increased complexityImprove measurement efficiencyMaterial analysis using wave/particle radiationCharacter and pattern recognitionSize measurementEngineering

A workpiece size measurement method suitable for length measurement of multilayered circuit elements with increased complexities is disclosed. This method employs a technique for changing measurement conditions in a way pursuant to either an image of workpiece or the situation of a target semiconductor circuit element to be measured when measuring pattern sizes on the workpiece image using design data of the semiconductor circuit element. With such an arrangement, adequate measurement conditions are selectable in accordance with the state of workpiece image and / or the state of a circuit element formed on the workpiece, thereby making it possible to improve the measurement efficiency. A workpiece size measurement apparatus using the technique is also disclosed.

Owner:HITACHI HIGH-TECH CORP

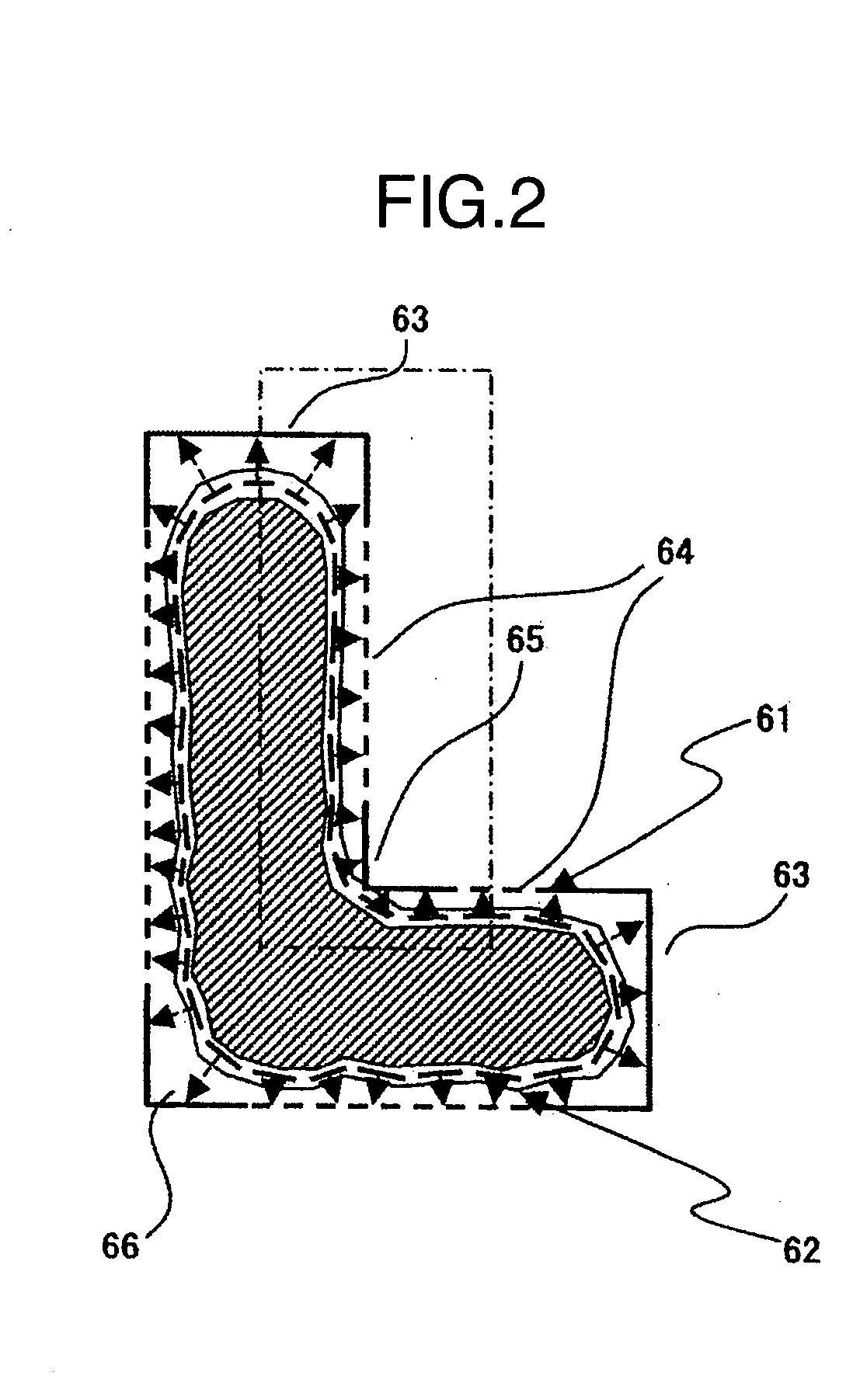

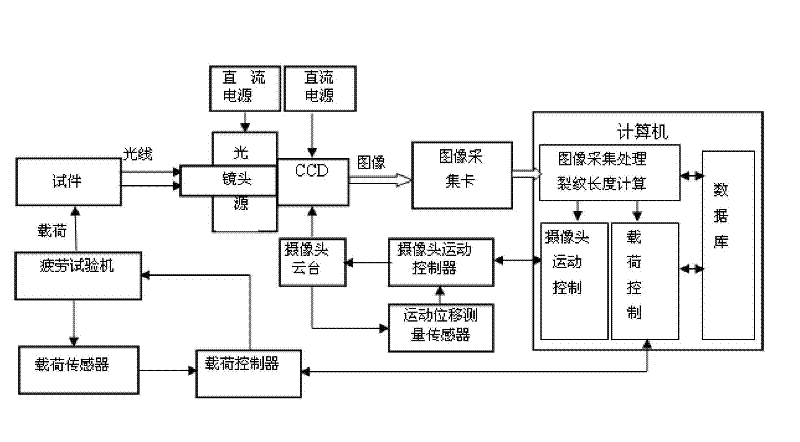

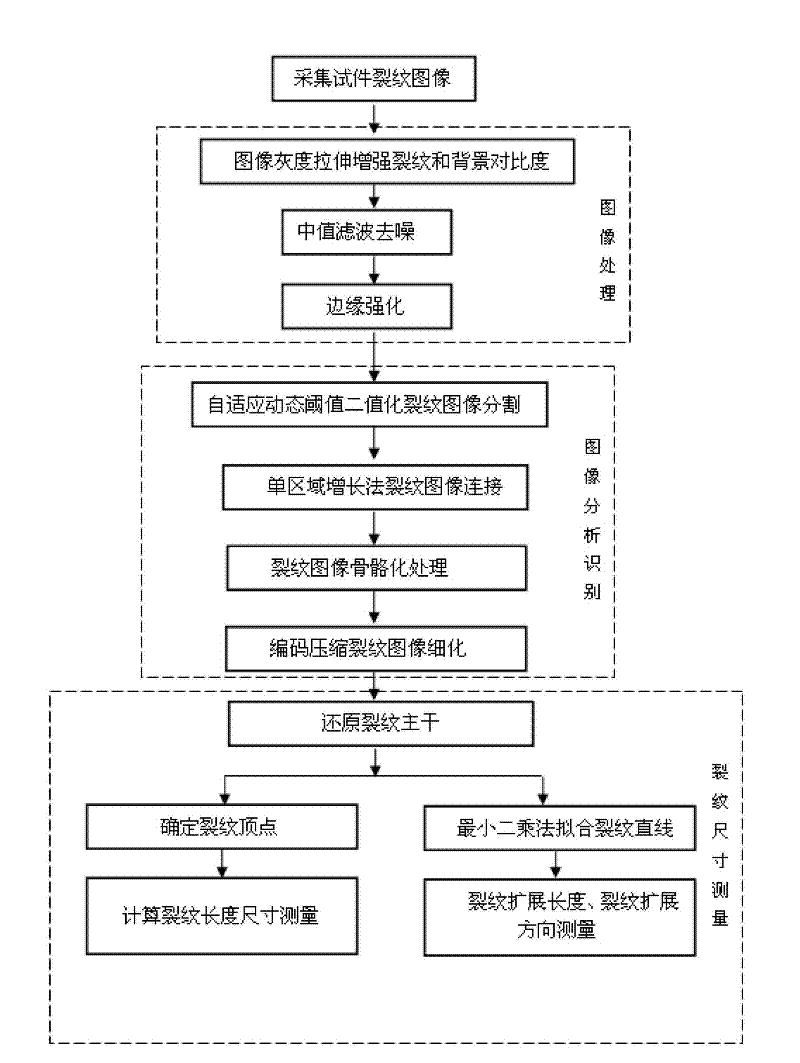

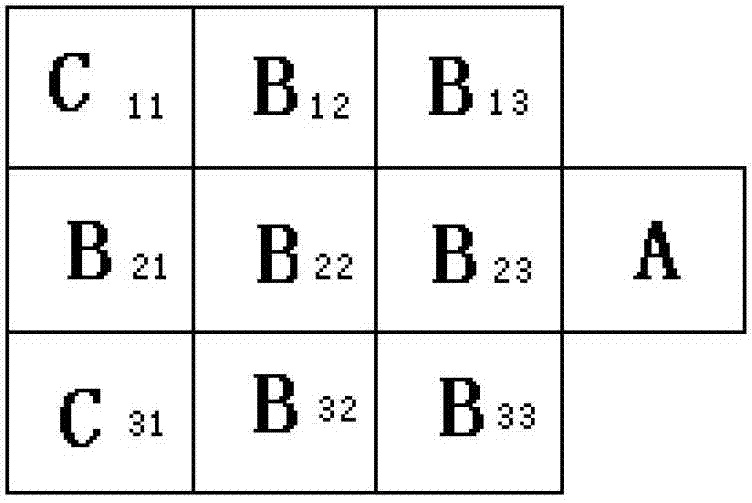

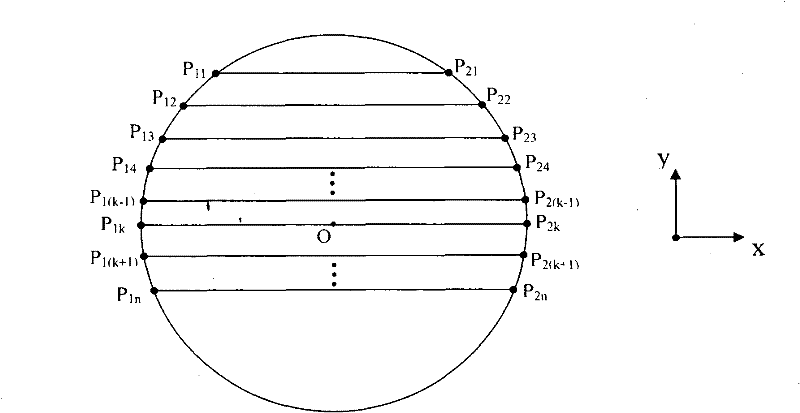

Dynamic crack length measurement method for machine vision fatigue crack propagation test

ActiveCN102692188AHigh measurement accuracyIntuitive visualization of the expansion processUsing optical meansMaterial strength using repeated/pulsating forcesAnti jammingInternational standard

The invention provides a dynamic crack length measurement method for a fatigue crack propagation test based on the machine vision technology. The method comprises the following steps: 1, performing machine vision crack measurement system calibration; 2, performing fatigue test, wherein a test piece with precracks begins to generate fatigue cracks along the direction of the precracks, and the fatigue cracks extend; 3, collecting crack images, wherein a mode of collecting single-face images of the test piece and a mode of collecting two-side images of the test piece are used in the fatigue crack propagation test; 4, reinforcing the collected images; 5, identifying the position of the trunk of cracks, as well as peaks and identifying directions of cracks by using the method of image analysis and crack identification; and 6, calculating the actual crack identifying length and crack length. The method has the advantages of simplifying the process and reducing work load; and by the method, the crack identifying process can be visually and accurately observed and recorded, the calculated crack length specified by the international standard can be measured accurately. The method also has the advantages of high measurement accuracy and good system anti-jamming performance.

Owner:平邑经济开发区投资发展有限公司

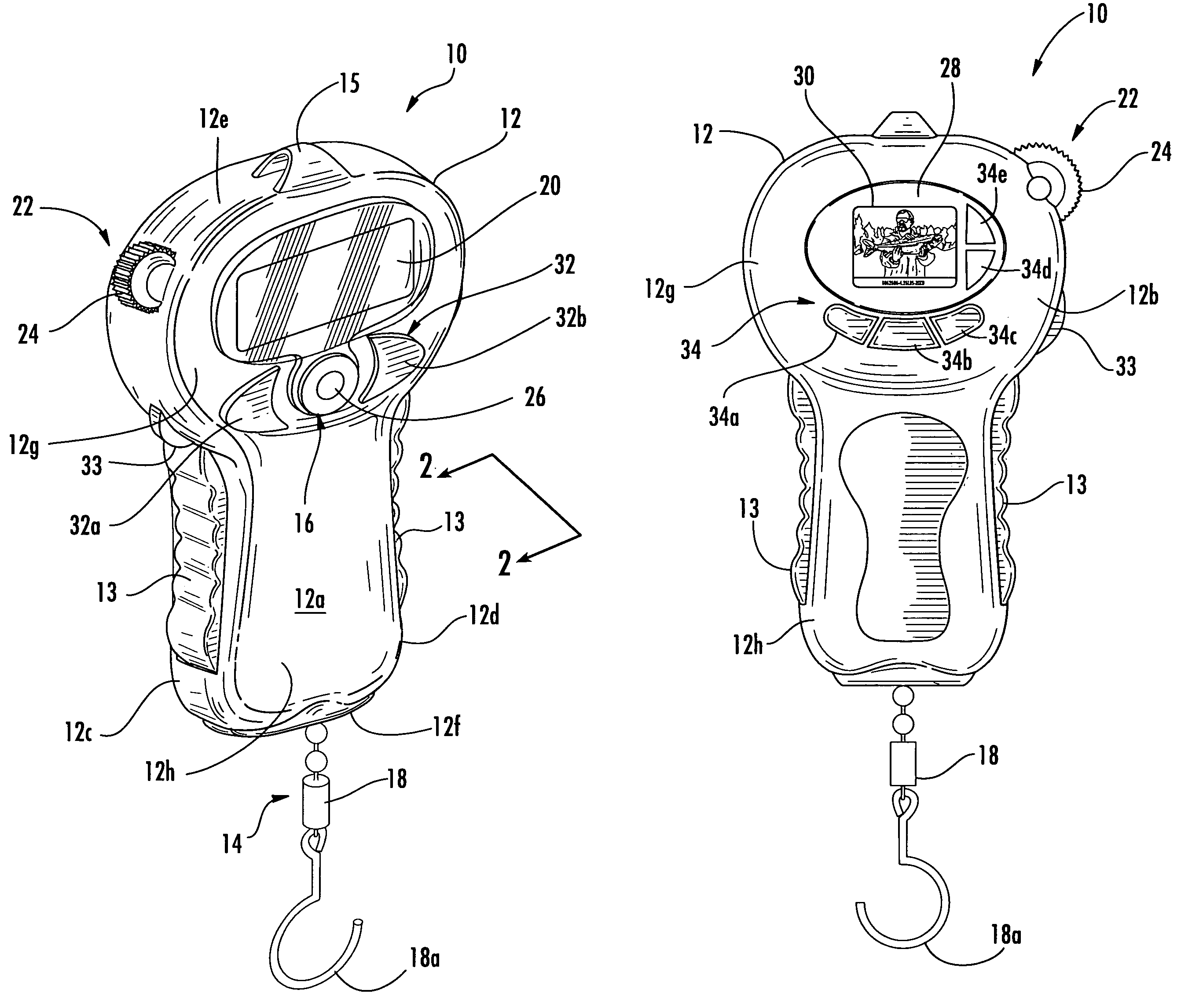

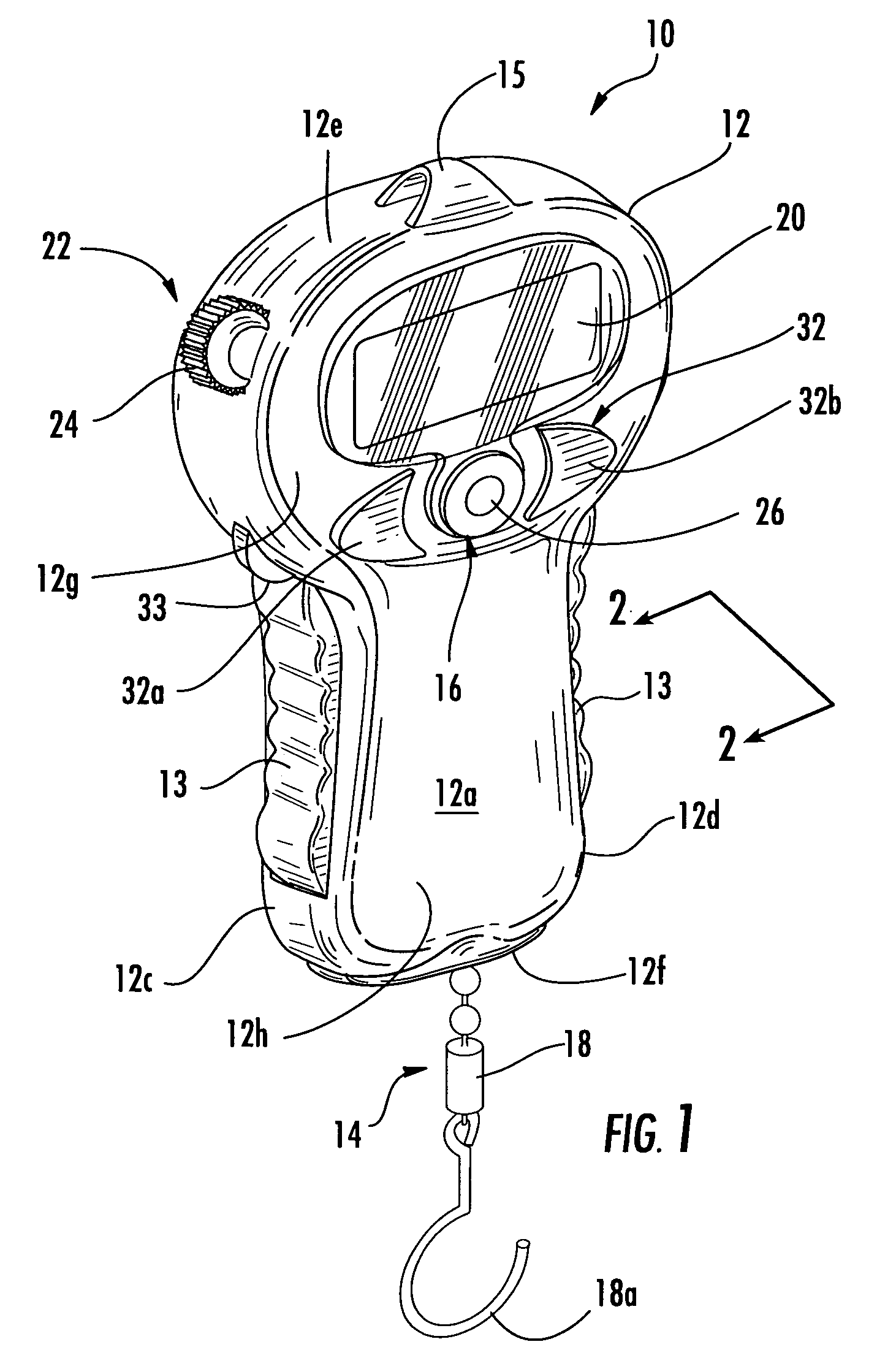

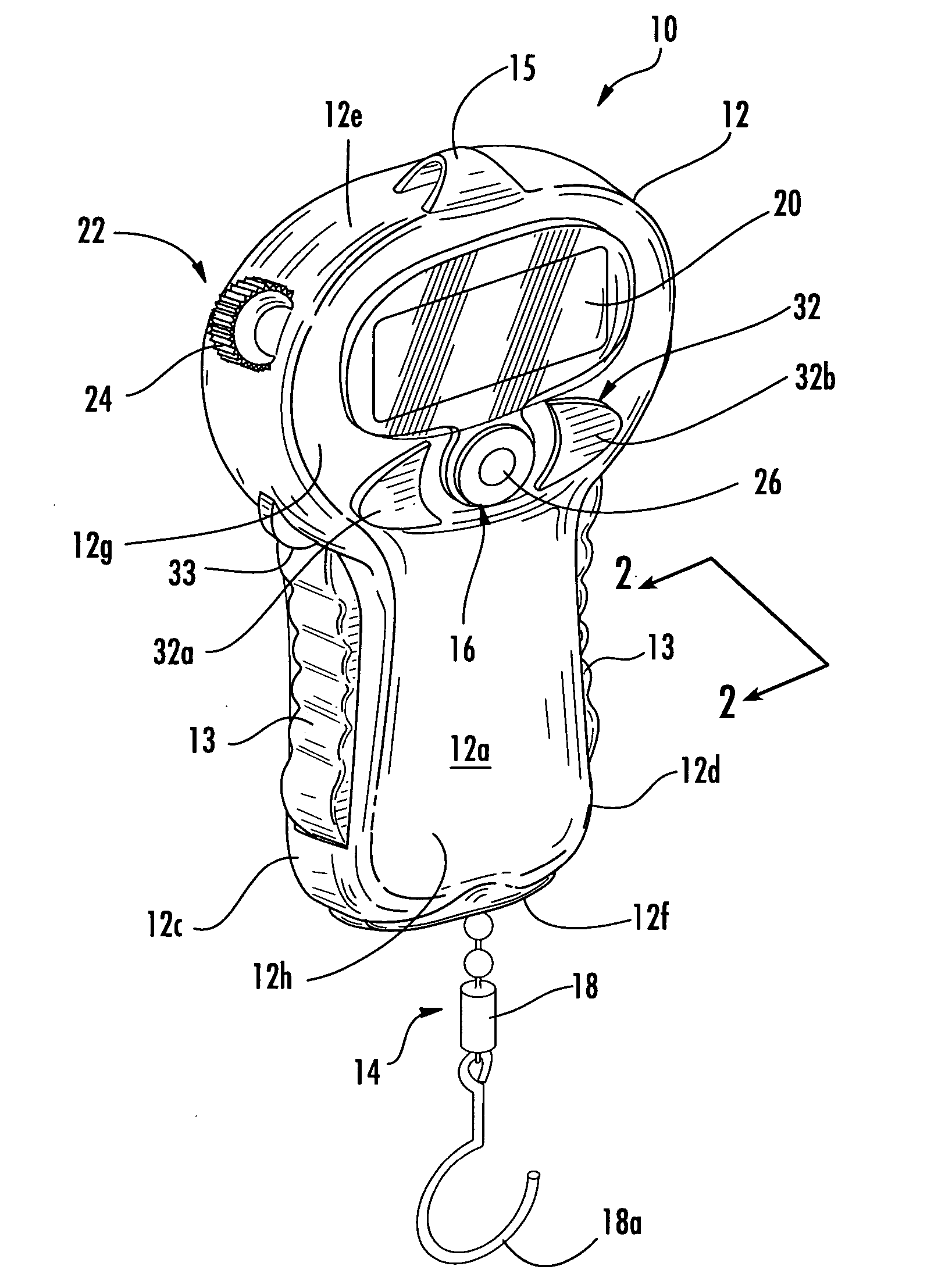

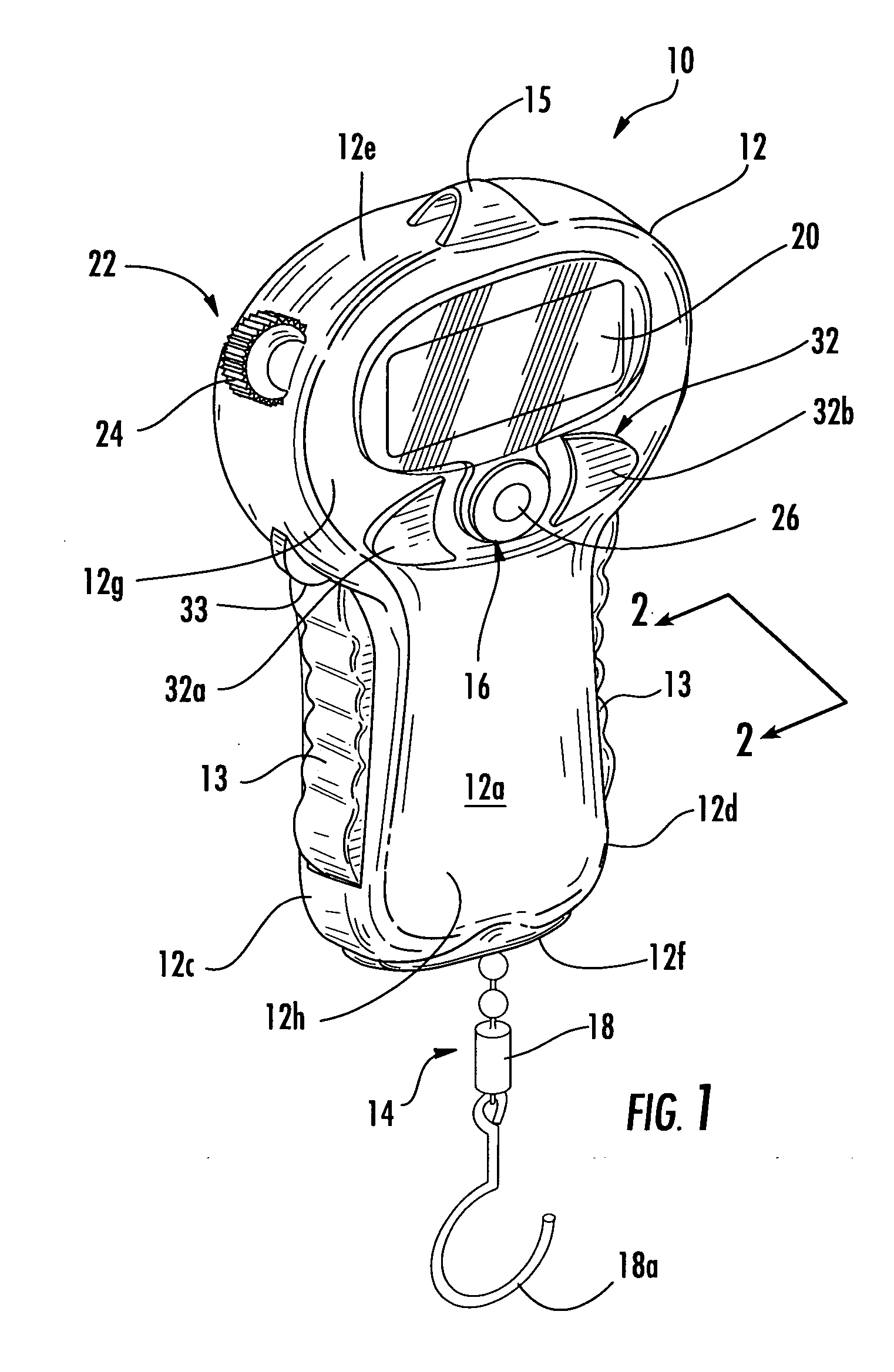

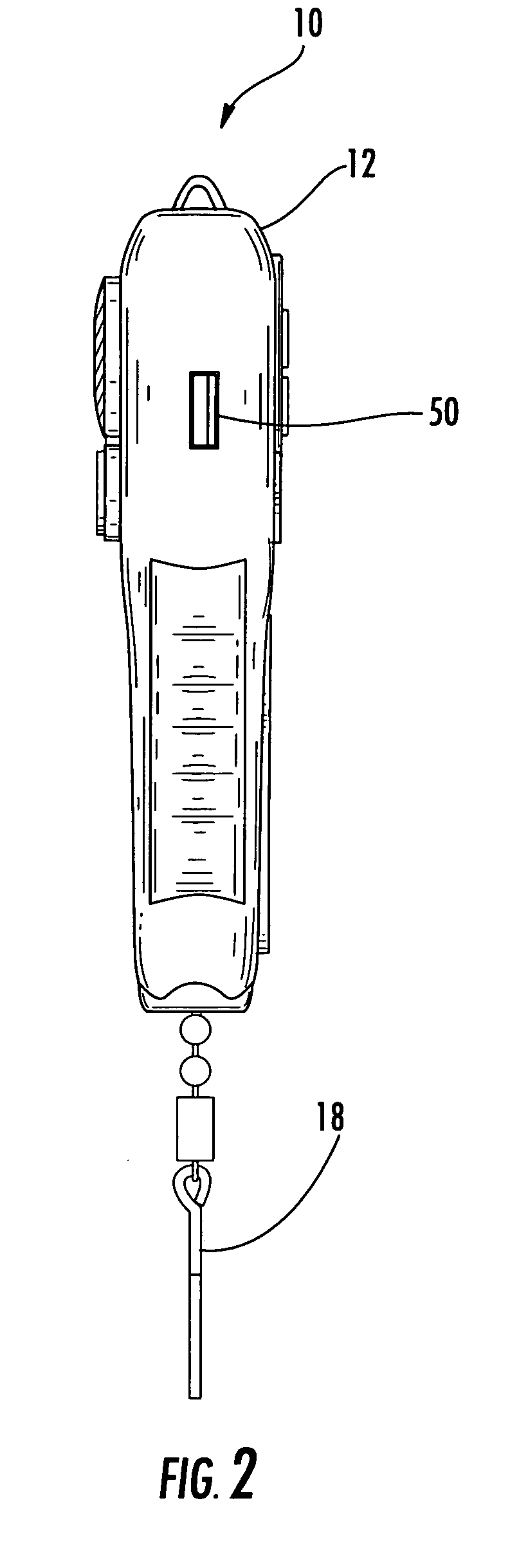

Handheld fish measuring apparatus with integral camera

A handheld apparatus for measuring fish, game, and the like is provided and includes a scale, a camera, and a length measuring device. The scale includes a support member that extends outwardly from the apparatus housing, and a display that is visible through the housing. The support member is configured to suspend an object therefrom for weighing via the scale, and the display is configured to display the weight of an object suspended from the support member. The length measurement device is configured to measure the length of an object and the display is configured to display the length of an object measured by the length measurement device. The camera includes a lens, an image sensor configured to capture images obtained via the lens, and a camera display. The camera display displays an image of an object taken by the camera with weight and / or length information for the object.

Owner:PROPEL IP

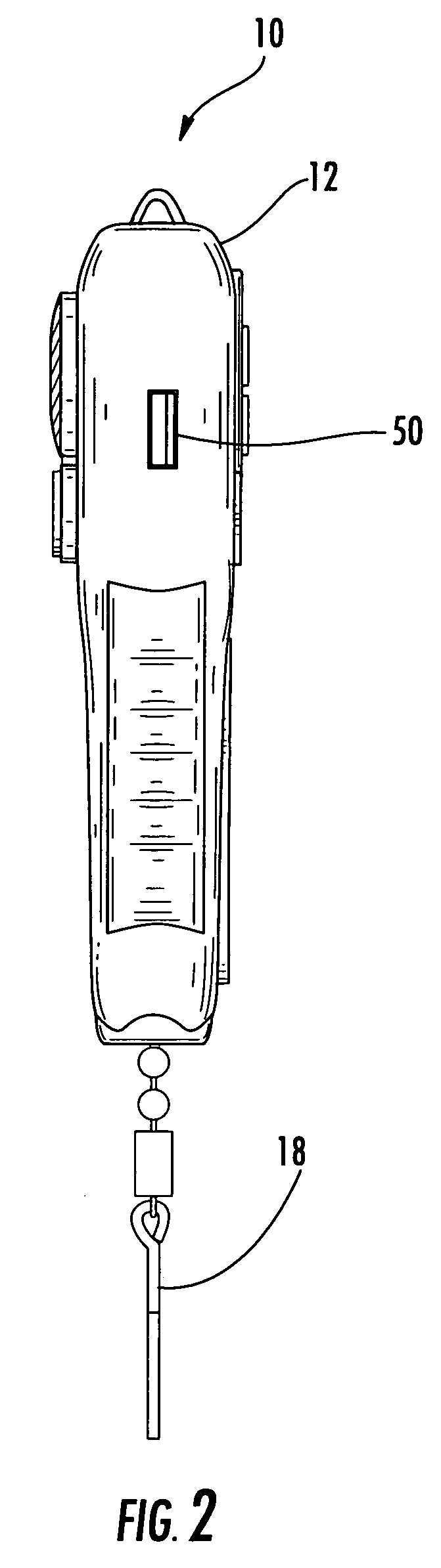

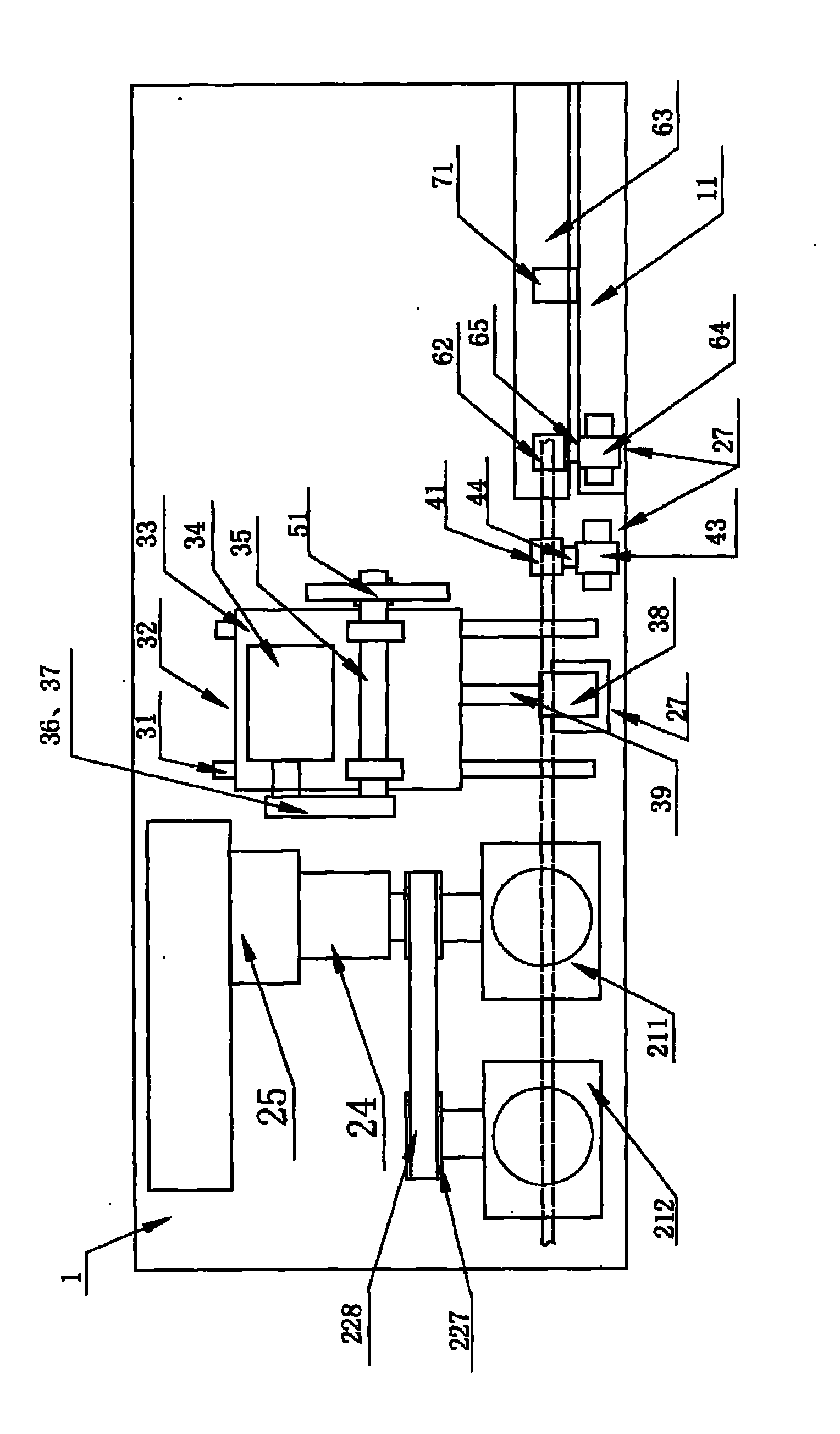

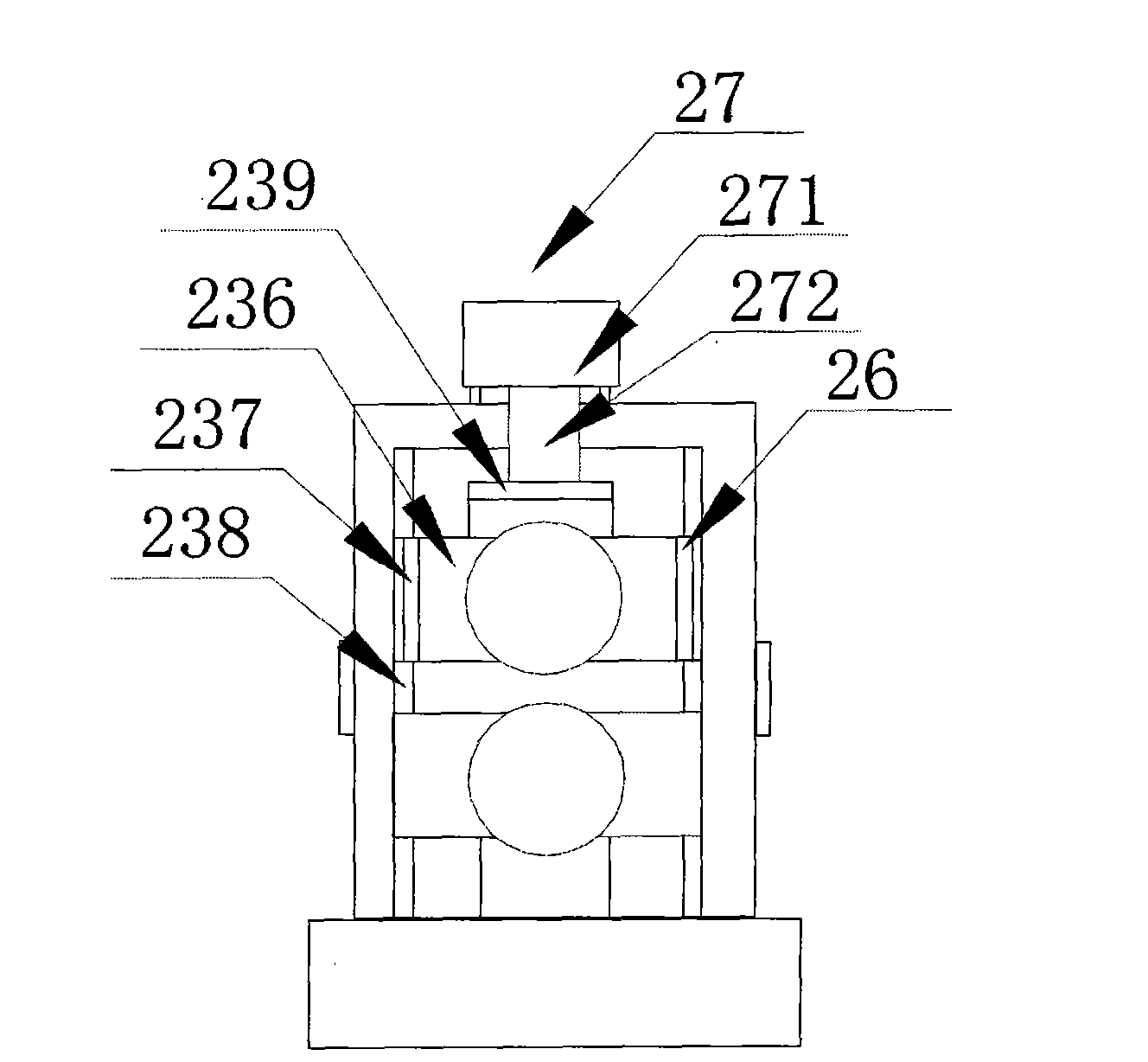

Full automatic pipe cutting machine

InactiveCN102179562AHigh degree of automationImprove cutting efficiencyTube shearing machinesShearing machine accessoriesEngineeringLength measurement

The invention discloses a full automatic pipe cutting machine. The pipe cutting machine comprises a feeding drive part, a cutting drive part, a pipe clamping part, a cutting part, an unloading part and a cutting measurement part which are sequentially arranged on an operating platform, wherein the feeding drive part conveys pipes to the cutting part by a driving wheel and a rolling wheel, then the pipes are cut off by a cutting tool driven by the cutting drive part; the driving wheel of the pipe cutting machine is driven by a stepping motor, and the lengths of the cut pipes can be accurately detected and controlled according to the electrical signals of stepping quantity of the stepping motor and the data of radius of the driving wheel; and in addition, the operating platform is also provided with an infrared distance measurement sensor, and the length accuracy of the cut pipe is jointly ensured by the electrical distance measurement signals and the movement detection signals of the stepping motor. By adopting the clamping feeding structure, the automatic cutting structure, the automatic clamping structure, the automatic unloading structure and the automatic cut pipe-length measurement and control mechanism, the degree of automation of the pipe cutting machine is improved.

Owner:中臻工业有限公司

Pre-connectorized fiber optic distribution cable having overmolded access location

A pre-connectorized fiber optic distribution cable assembly includes a plurality of optical fibers and at least one mid-span access location along the length of the distribution cable. At least one of the optical fibers is accessed, terminated and then connectorized at the mid-span access location to an optical connector disposed within a receptacle. The mid-span access location, the accessed, terminated and connectorized optical fiber, the optical connector and at least a portion of the receptacle are encapsulated with a protective overmolded shell. A tether including at least one optical fiber connectorized at a first end of the tether is optically connected to the optical connector through the receptacle. A second end of the tether opposite the first end terminates in a network optical connection terminal, thereby compensating for a span length measurement difference between the actual location of the mid-span access and the desired location of the optical connection terminal.

Owner:CORNING CABLE SYST LLC +1

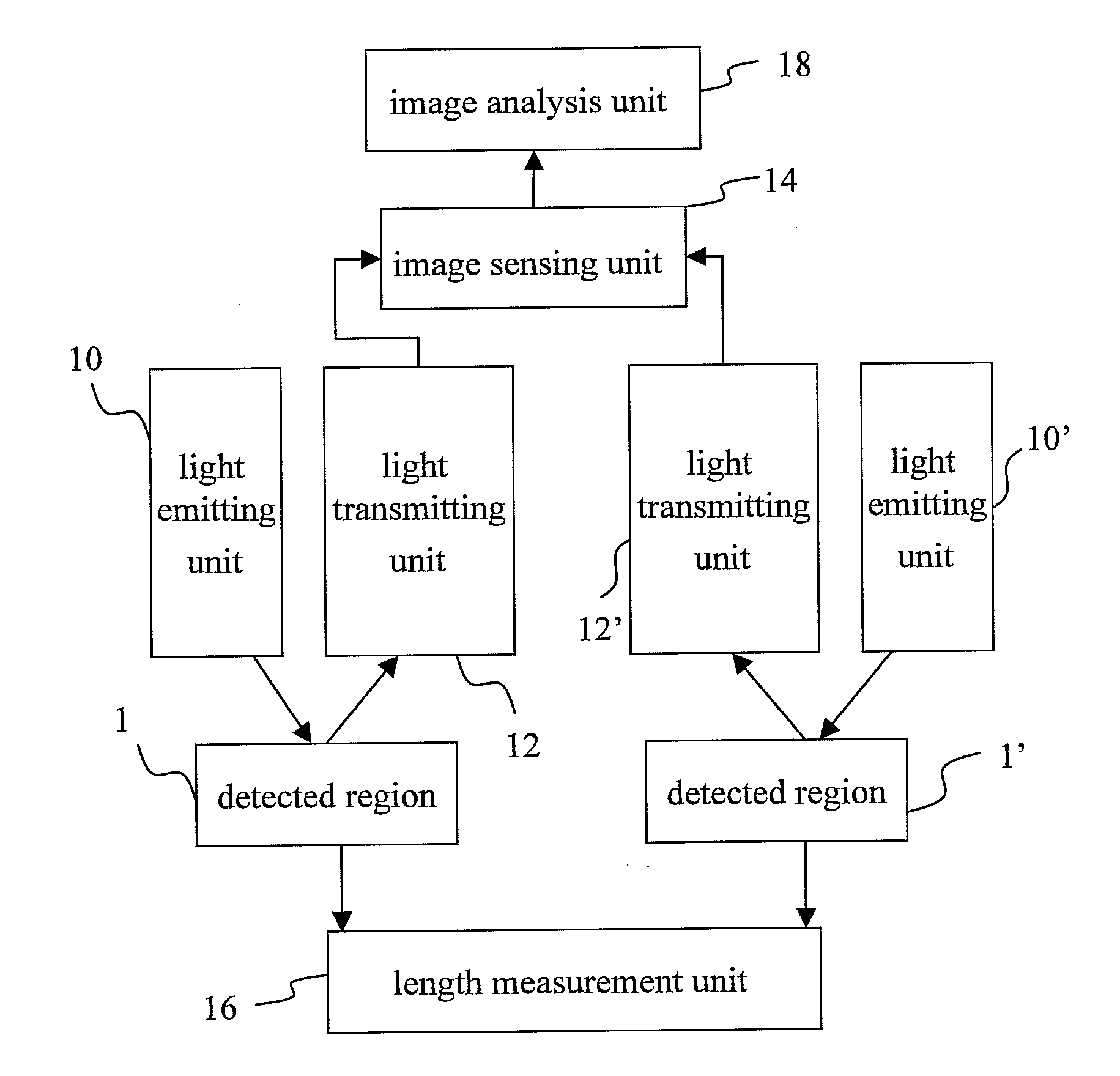

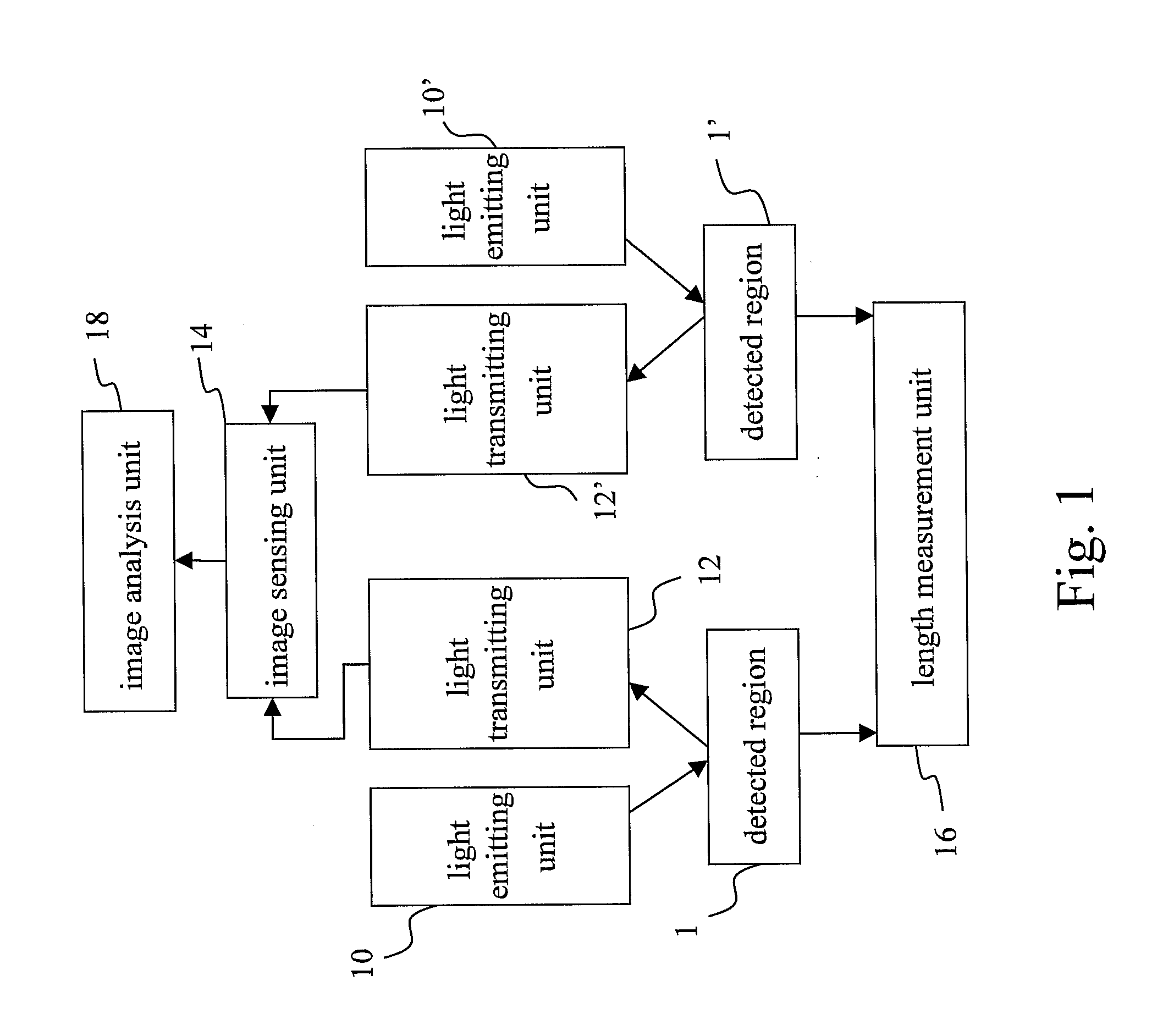

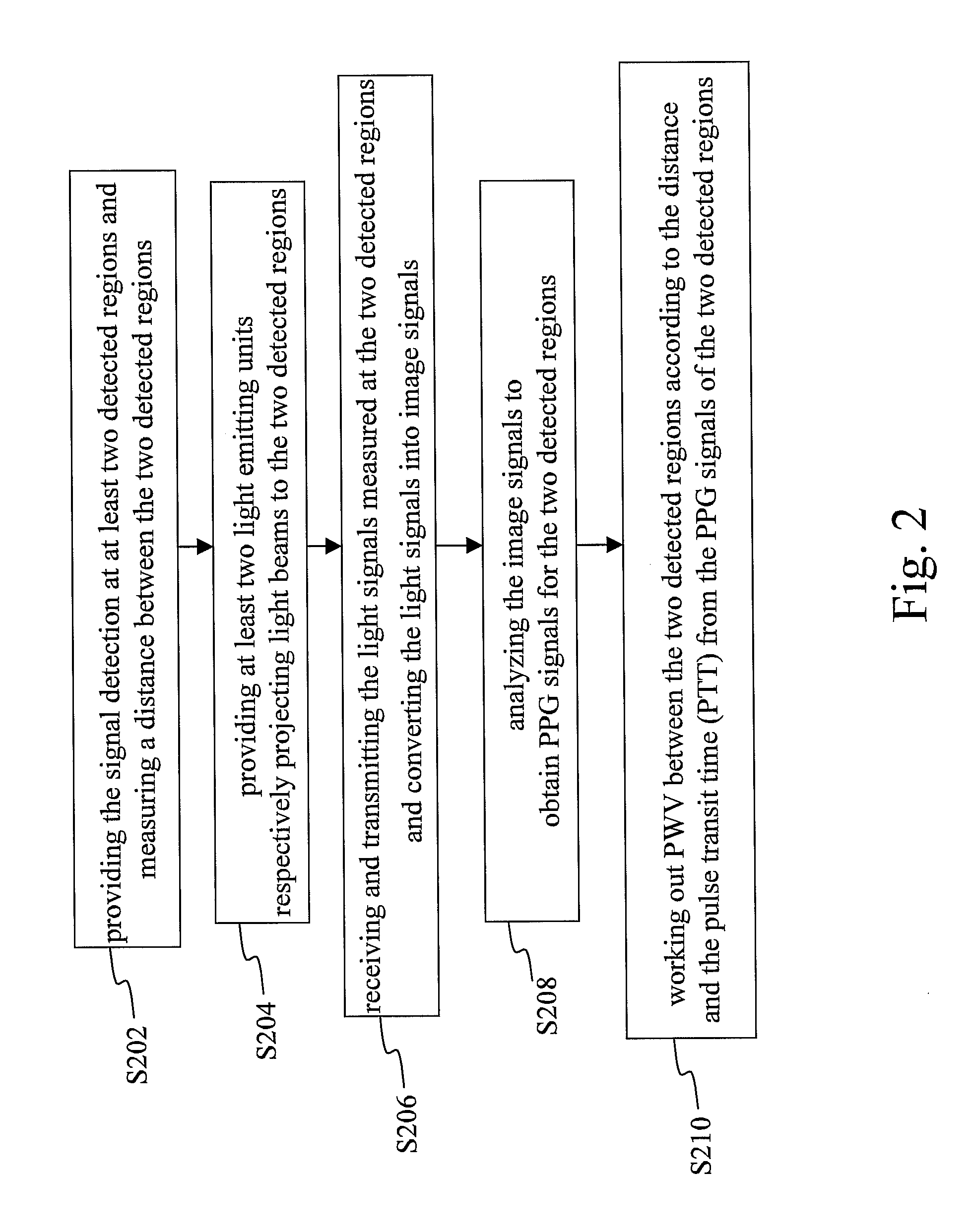

Image-based pwv measurement device and method

InactiveUS20130046192A1Flexibility in measurementCatheterDiagnostic recording/measuringMeasurement deviceLength measurement

An image-based PWV measurement device and method are provided. The measurement device comprises at least two light emitting units respectively projecting light beams to at least two detected regions on body surface; at least two light transmitting units respectively receiving and transmitting light signals measured at the different detected regions; an image sensing unit converting the light signals measured at the detected regions into image signals; a length measurement unit used to measure the distance between the detected regions; and an image analysis unit analyzing the image signals to obtain PPG signals for the detected regions. According to the PPG signals, the image analysis unit calculates the physiological parameters, including the perfusion index, respiration rate, pulse rate, stiffness index, reflection index, and PWV between the detected regions, which is derived according to the distance and the pulse transit time from the PPG signals of the two detected regions.

Owner:CHUNG YUAN CHRISTIAN UNIVERSITY

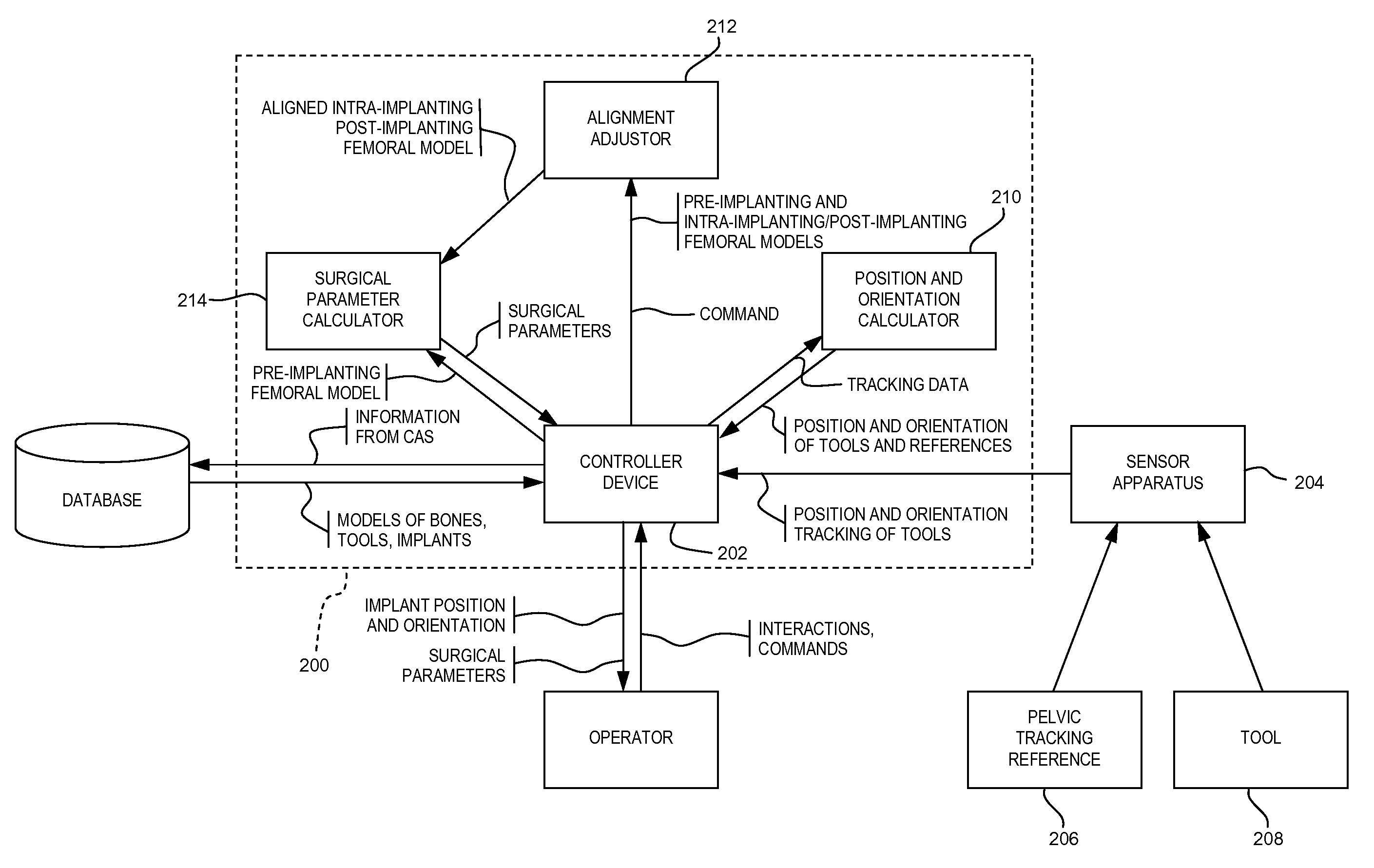

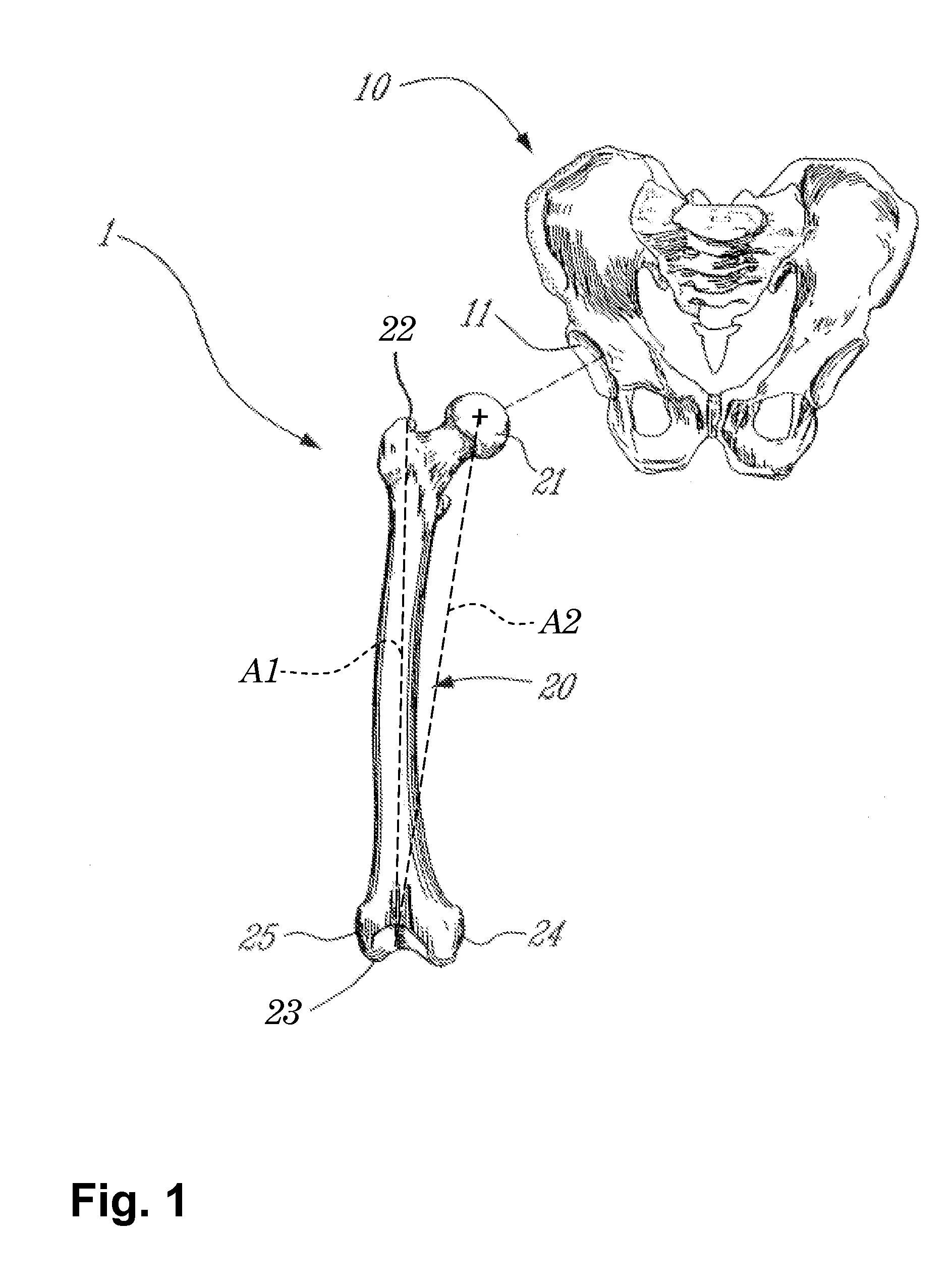

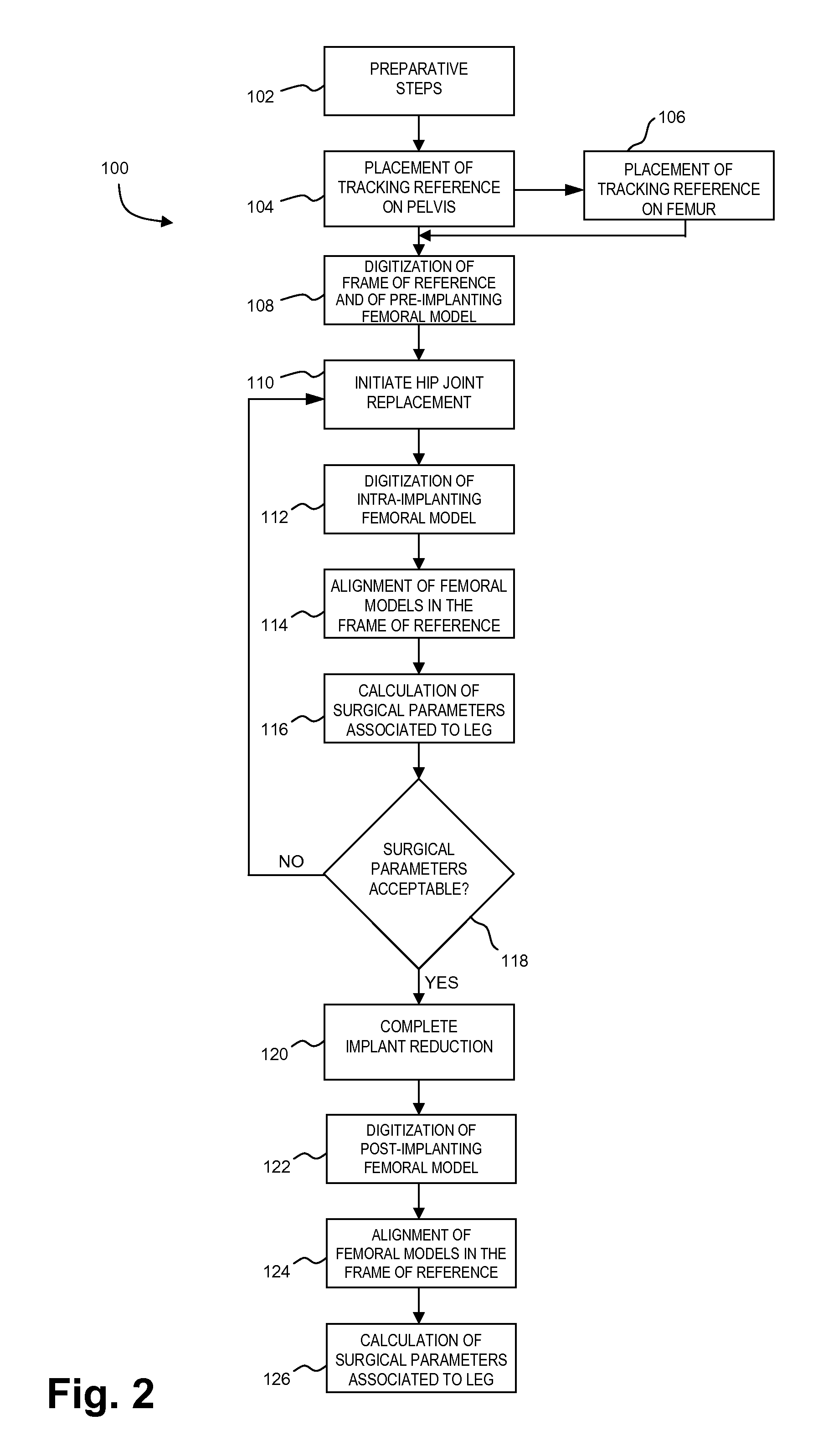

Leg alignment and length measurement in hip replacement surgery

InactiveUS20090125117A1Surgical navigation systemsJoint implantsHip joint replacement operationPelvic fixation

A CAS system for measuring surgical parameters during hip replacement surgery comprises a first tracking reference in fixed relation with the pelvis to form a frame of reference. A registration tool is trackable. A sensor apparatus tracks the first tracking reference and the registration tool. A controller unit receives tracking data for the first trackable reference and the registration tool. The controller unit has a position and orientation calculator for calculating from the tracking data a position and orientation of the pelvic tracking reference to track the frame of reference, and of the registration tool to produce femoral models at a first and a second sequential operative steps. An alignment adjustor aligns the femoral models with the frame of reference. A surgical parameter calculator calculates surgical parameters as a function of the femoral models as aligned by the alignment adjustor.

Owner:ORTHOSOFT

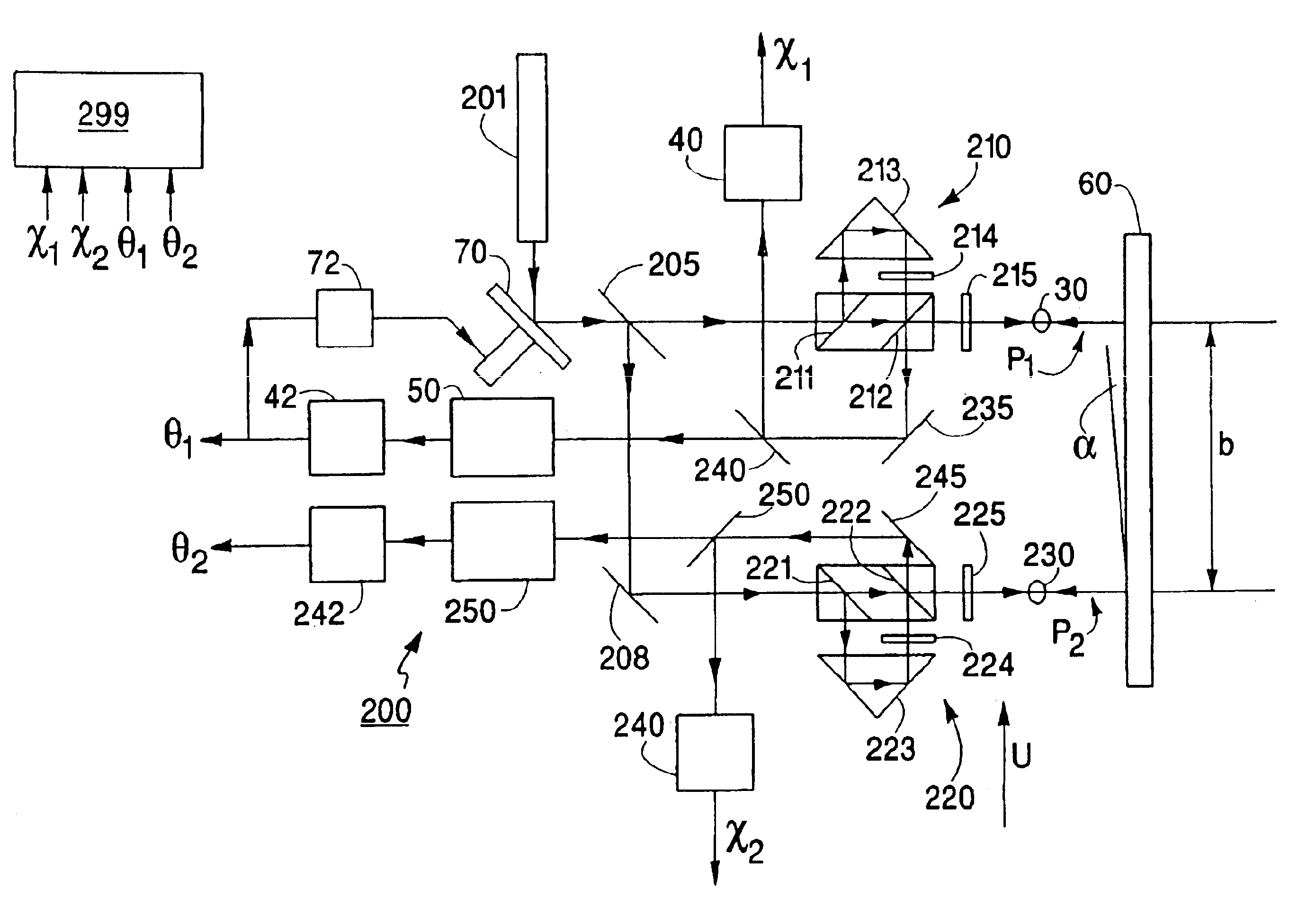

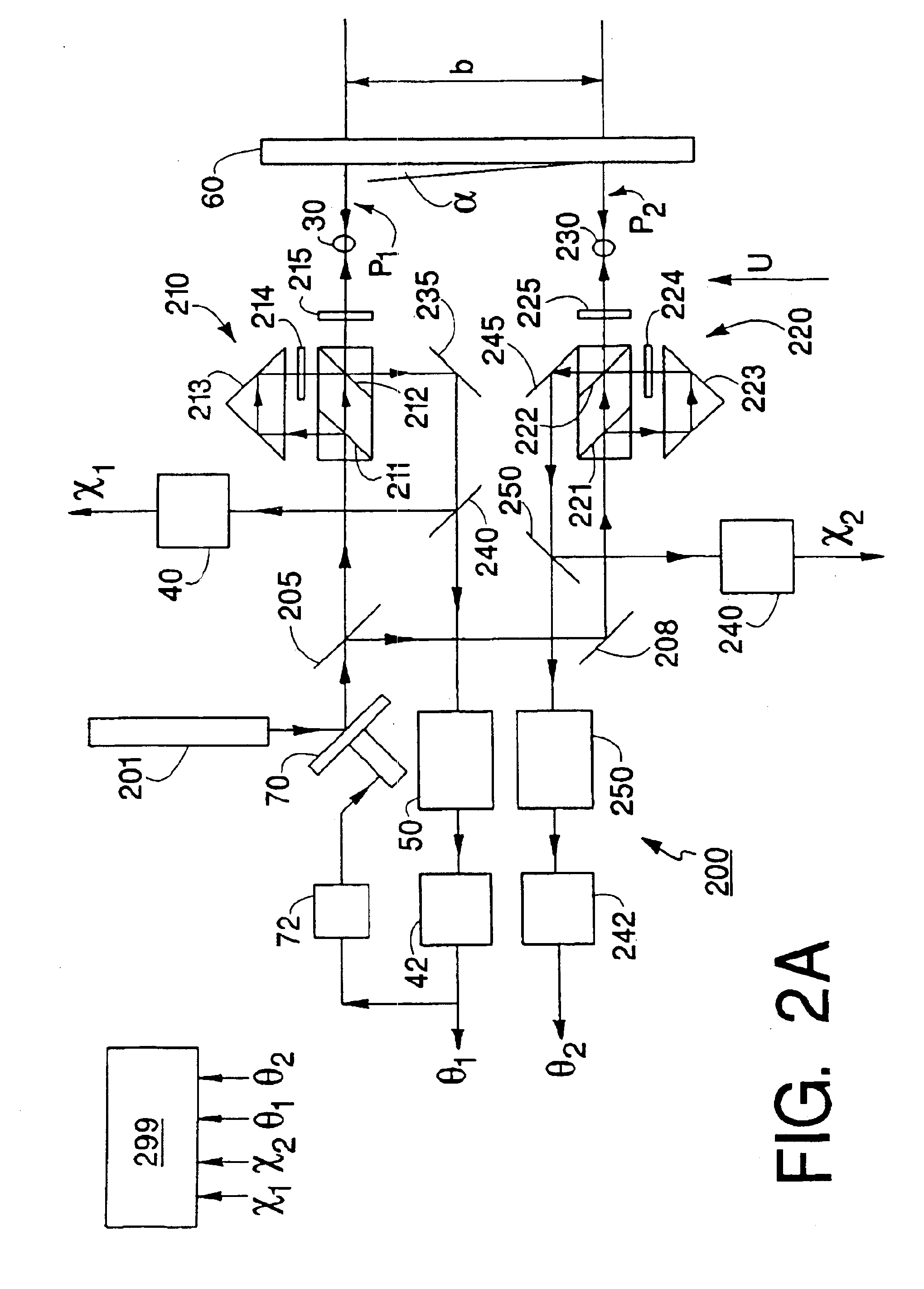

Method and apparatus for compensation of time-varying optical properties of gas in interferometry

InactiveUS6839141B2Accurate measurementElectric discharge tubesInterferometersOptical propertyLight beam

In general, in one aspect, the invention features a method, including interferometrically measuring first and second optical path lengths to a measurement object along respective first and second paths, wherein the measurement of the optical path lengths includes directing first and second measurement beams to reflect from the measurement object, measuring propagation directions of the first and second measurement beams, compensating the first measured optical path length for time-varying optical properties of gas in the first path based on the first and second measured optical path lengths and the first and second measured propagation directions.

Owner:ZYGO CORPORATION

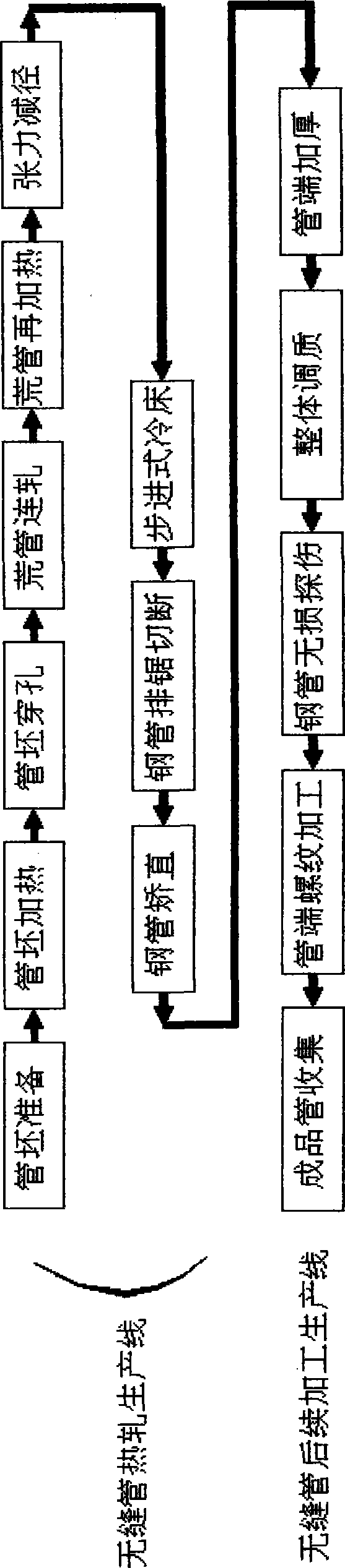

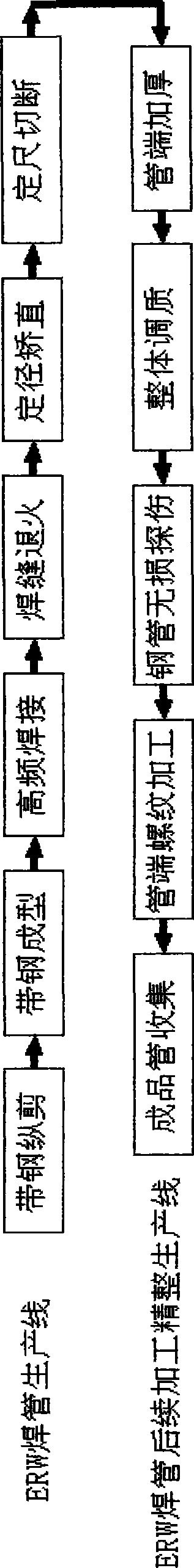

High steel level petroleum casing pipe and oil pipe manufacturing process

InactiveCN101481995AUniform wall thicknessSmooth wallDrilling rodsFurnace typesIntermediate frequencyLength measurement

The invention discloses a preparation method of high-grade steel petroleum casing pipes and oil pipes, and relates to a manufacturing method of petroleum casing pipes and oil pipes; hot rolled steel coils are taken as raw material for manufacturing the steel pipes, and ERW welded pipe material is firstly manufactured by the processes such as longitudinal-shearing striping, band steel formation, high-frequency welding, burr cleaning inside and outside of the welding seams, welding seam detection, intermediate-frequency welding seam annealing, sizing, cutting off, straightening and the like; and the processes such as post-welding finishing, end upsetting (heavy wall tubing needs the process), integral hardening and tempering, medium-temperature straightening, pipe end detection, pipe threading processing, collar screw coupling, hydraulic pressure test, path test, pipe body detection, length measurement, weighting, oiling and the like are carried out, thus producing the high-grade steel petroleum casing pipes and oil pipes. The steel grade of the steel pipe can reach the steel grade specified in API 5CT standard for manufacturing N80Q, L80, C95, P110 and Q125 with a welding method. The high-grade steel petroleum casing pipes and oil pipes manufactured by the invention has the advantages of high production efficiency, low production cost, high lumber recovery, and high product quality.

Owner:江苏嘉宝科技制管有限公司

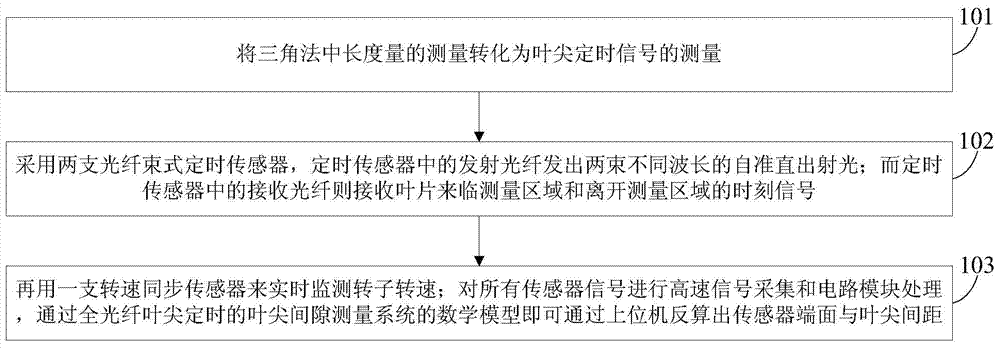

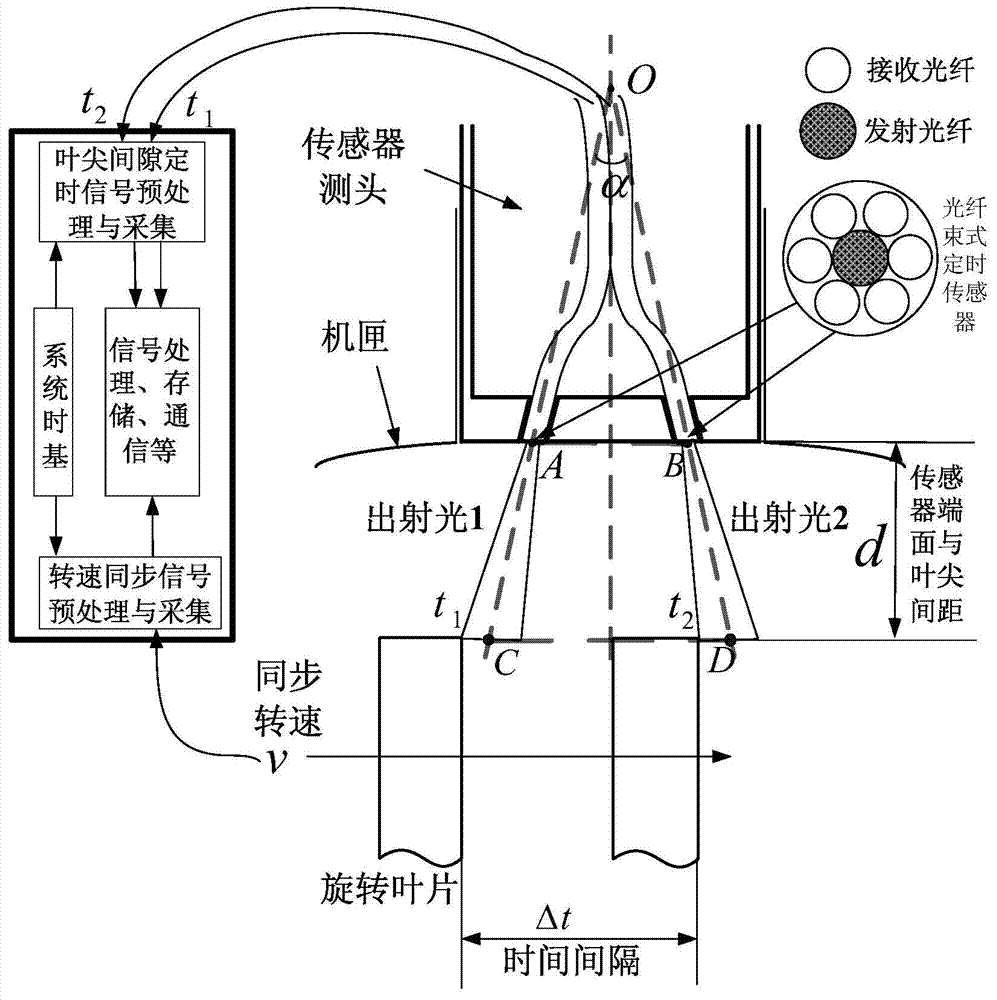

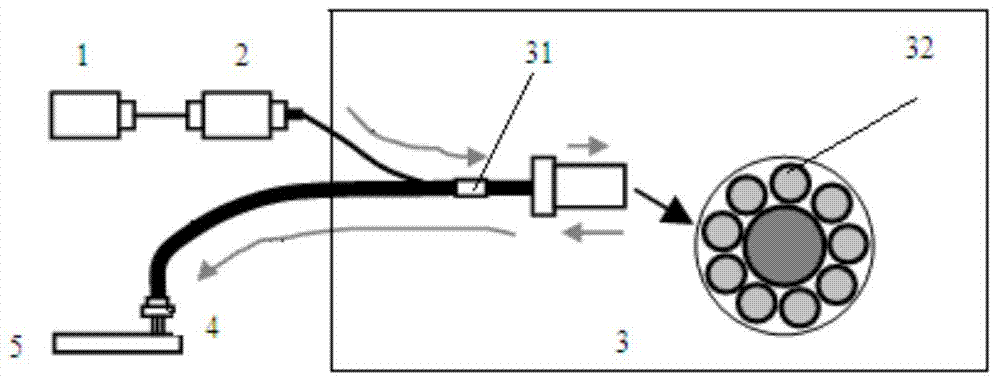

Tip clearance measurement method based on all-fiber tip timing

InactiveCN104501728AImprove anti-electromagnetic interference performanceFast dynamic responseUsing optical meansMathematical modelLength measurement

The invention discloses a tip clearance measurement method based on all-fiber tip timing. The method comprises the following steps: converting measurement on length measurement in a triangle method into measurement on a tip timing signal; adopting two fiber bundle type timing sensors, and enabling emission fibers in the timing sensors to emit two beams of auto-collimation emergent light with different wavelengths; enabling receiving fibers in the timing sensors to receive moment signals when leaves approach and leave a measurement region; monitoring the rotating speed of a rotor in real time by a rotating speed synchronization sensor; performing high-speed signal acquisition and circuit module processing on all the sensor signals, and reversely calculating a distance between the end face of each sensor and each leaf tip by an upper computer through a math model. According to the tip clearance measurement method, a clearance value is ingeniously converted into a tip timing signal relevant to the clearance value, so that a measurement system is irrelative to most environmental factors such as the leaf and electromagnetic interference, and the interference resistance and the clearance measurement precision of the system are improved.

Owner:TIANJIN UNIV

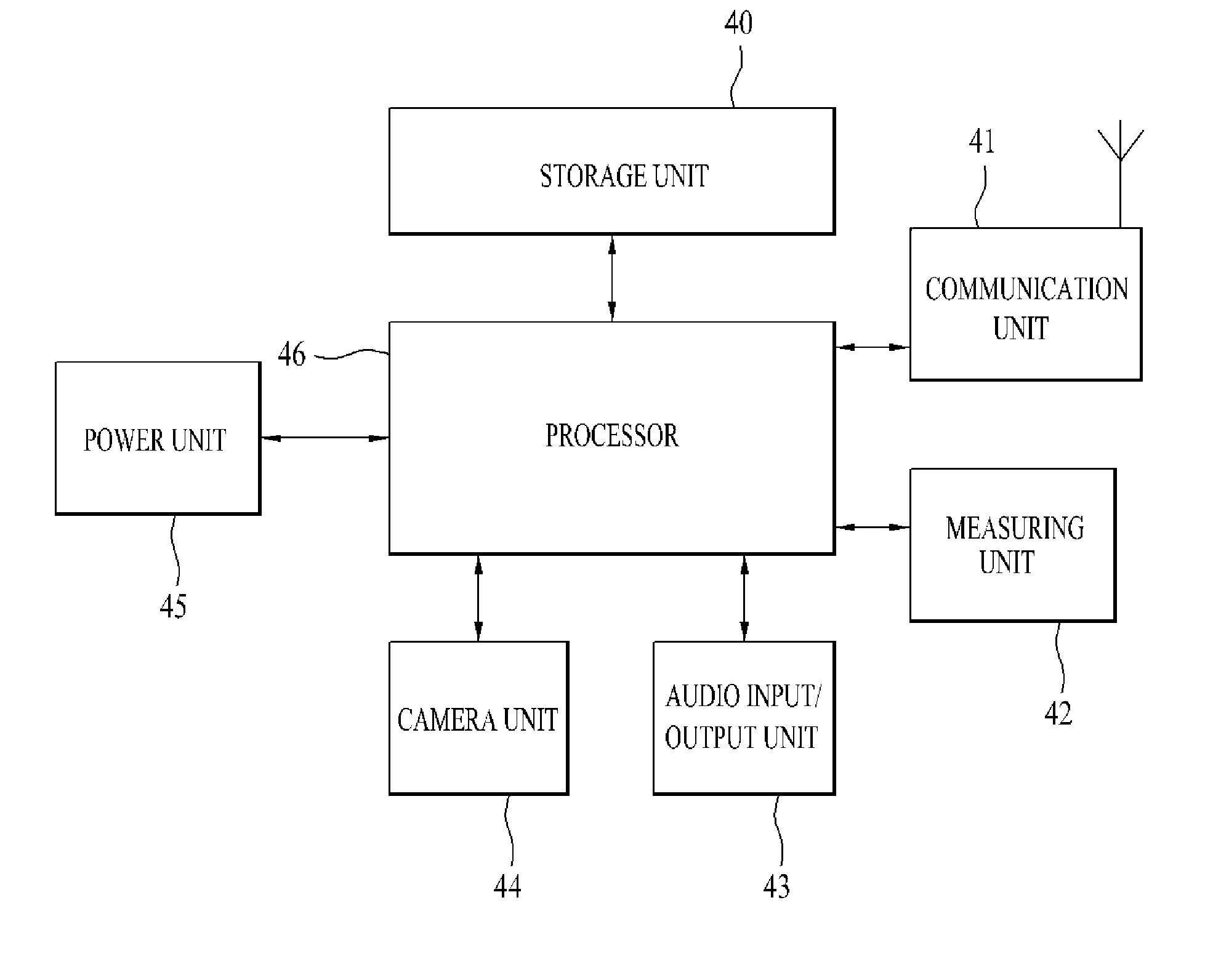

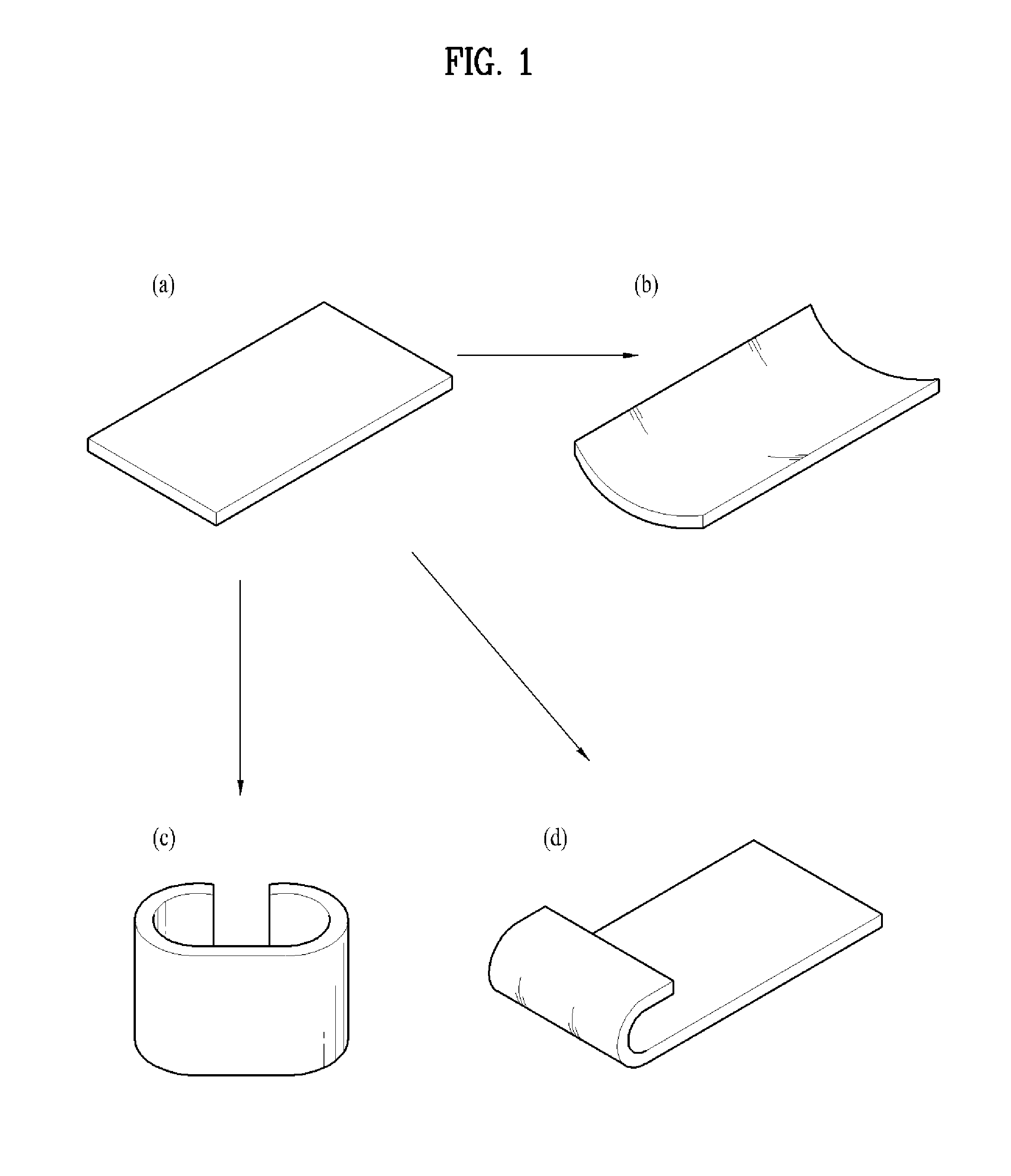

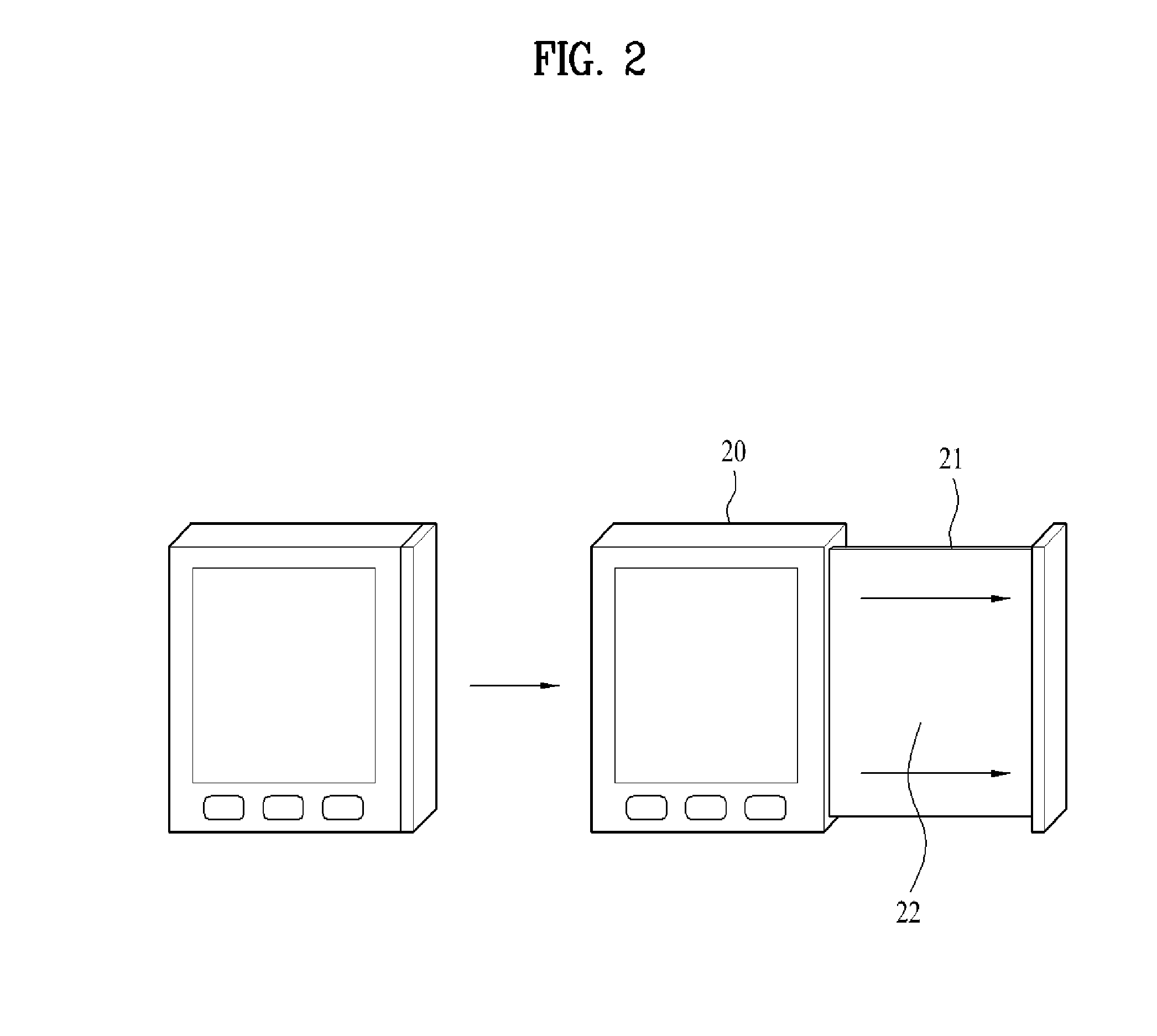

Device equipped with flexible display and controlling method thereof

ActiveUS20140218375A1Easy to controlAvoid energy wasteDigital data processing detailsDigital computer detailsDisplay deviceEngineering

A device enabling for a user to control a flexible display more convenient and precise and a controlling method therefor, are discussed. According to one embodiment disclosed for this, the device includes a flexible display, a length measuring unit configured to measure an expanded length of the flexible display expanded from the device, a speed measuring unit configured to measure a speed of which the flexible display expanded from the device and a processor configured to control the flexible display, the length measuring unit, and the speed measuring unit, wherein if the flexible display is expanded to a unit length, the processor displays an application execution screen corresponding to the unit length in the flexible display.

Owner:LG ELECTRONICS INC

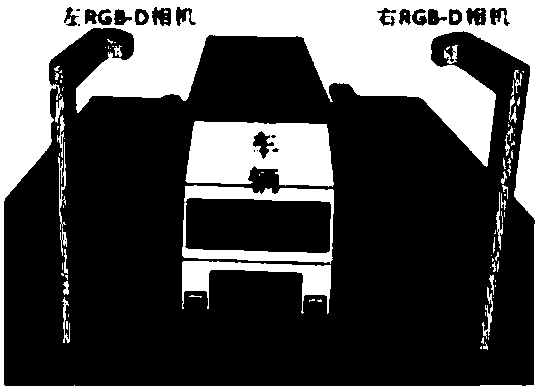

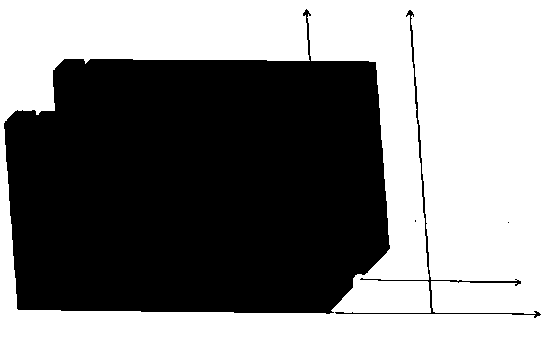

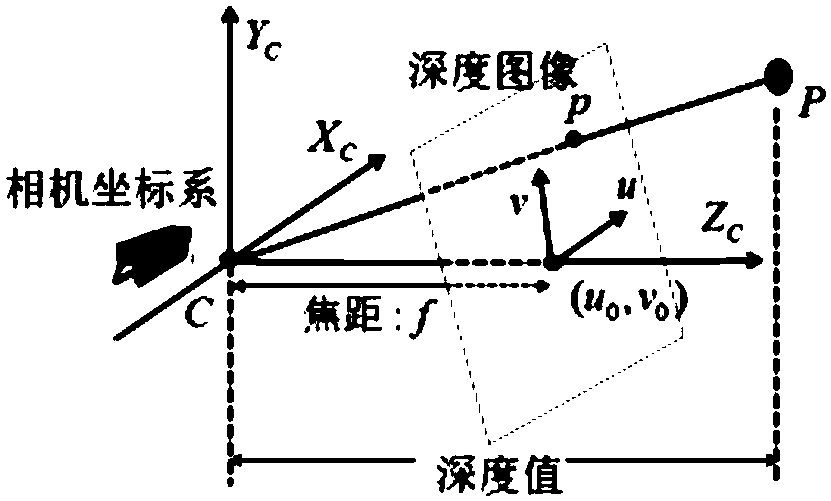

Measuring method for length, width and height of vehicle based on RGB-D camera

InactiveCN108550143ARealize 3D measurementRealize the solutionImage enhancementImage analysisGraphicsPoint cloud

The invention discloses a measuring method for length, width and height of a vehicle based on an RGB-D camera. The method comprises the steps of acquiring a clear vehicle image in a camera short-distance mounting manner, calibrating the camera according to a calibrating method based on a disappearing point, obtaining an internal parameter and an external parameter of the camera, realizing three-dimensional point cloud conversion of a vehicle target in a world coordinate system through a camera depth image solution, and acquiring three-dimensional coordinate information of the external surfaceof the vehicle; acquiring the three-dimensional coordinate of the external surface of the vehicle by means of prior knowledge and an image processing method, splicing a vehicle image according to sequence patterns in a vehicle motion process through a registering method, and realizing three-dimensional measurement to the profile of the vehicle. The measuring method overcomes defects of high equipment requirement and tedious operation in a traditional method and realizes high calibration precision. The actual displacement of the vehicle is comprehensively analyzed through a matching relation ofpoints which correspond with the same position of the vehicle in the image sequence, thereby realizing relatively high registering precision. The measuring method further has advantages of realizingaccurate splicing of the vehicle side surfaces, reducing vehicle length measurement error and improving accuracy in splicing the vehicle side surfaces.

Owner:CHANGAN UNIV

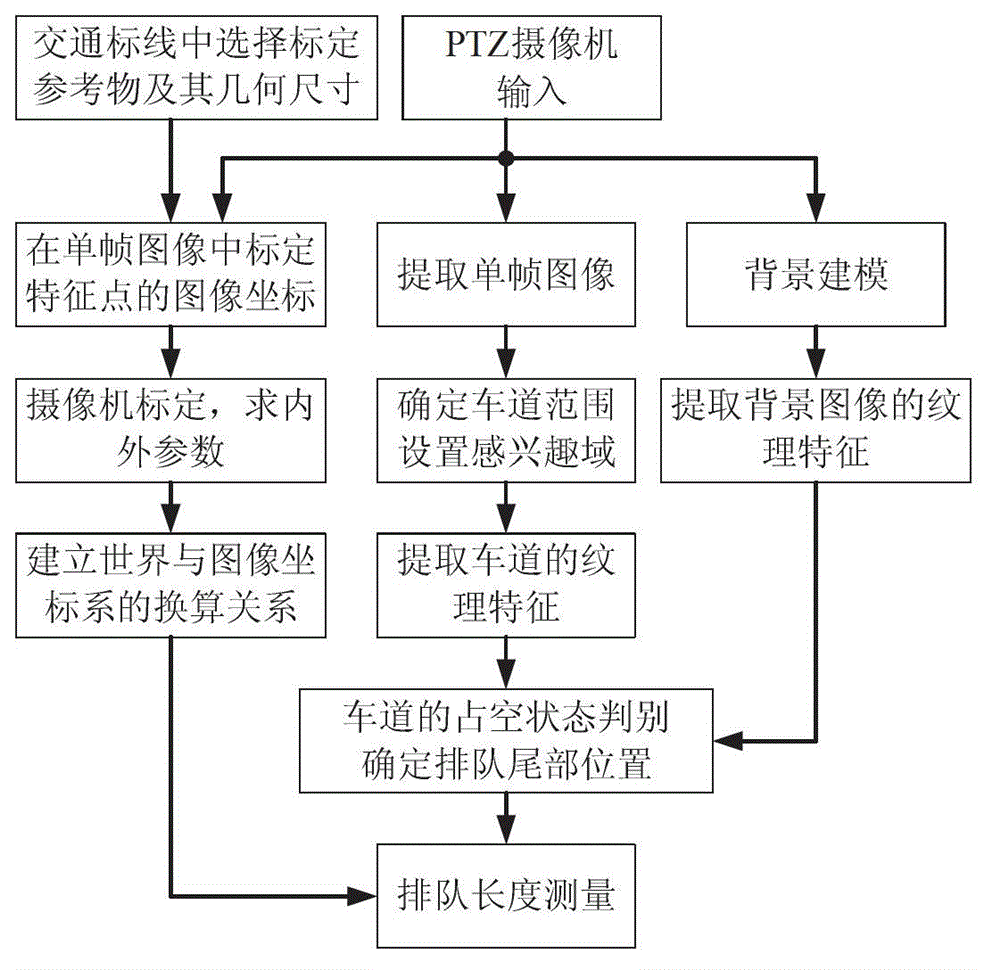

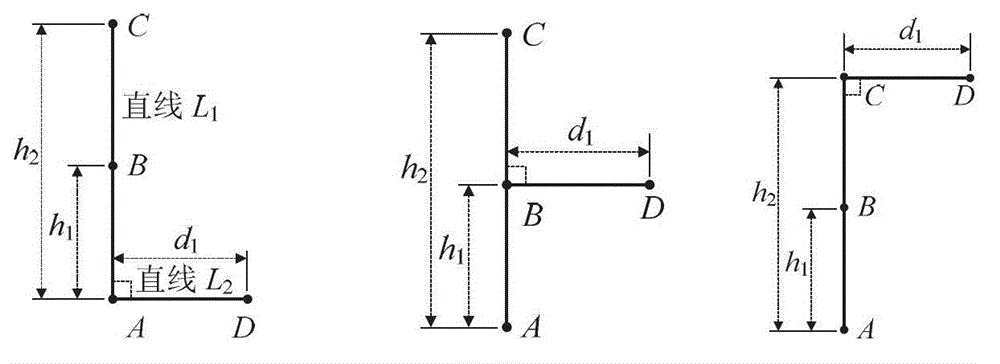

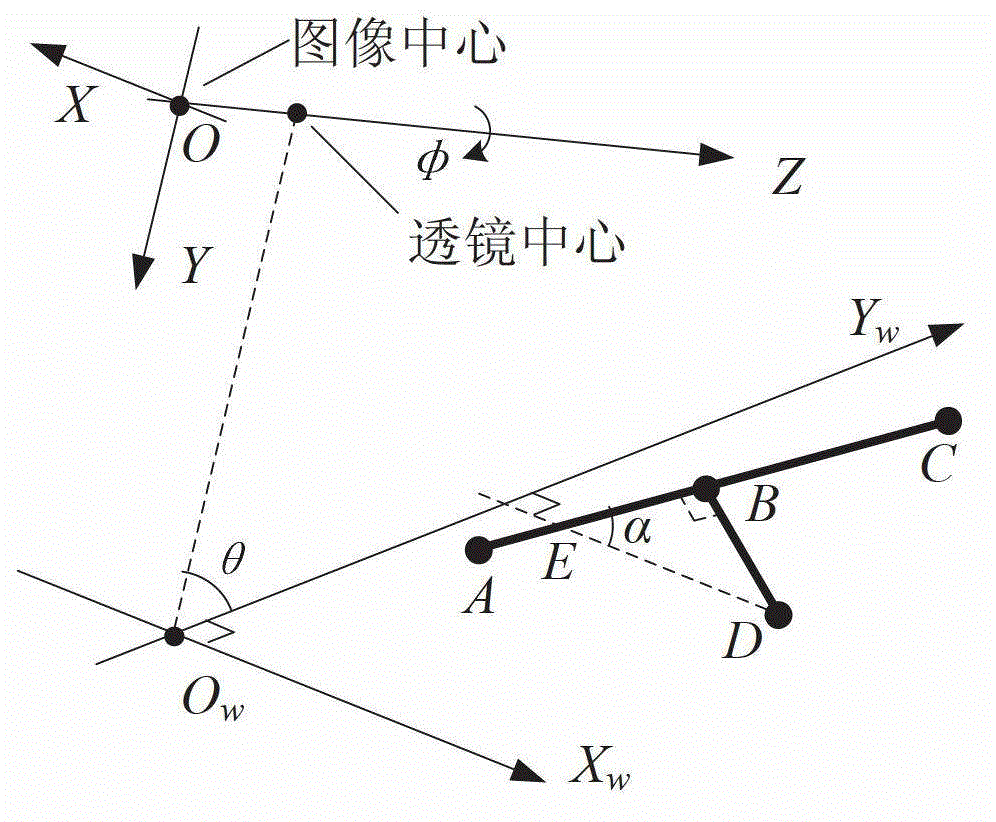

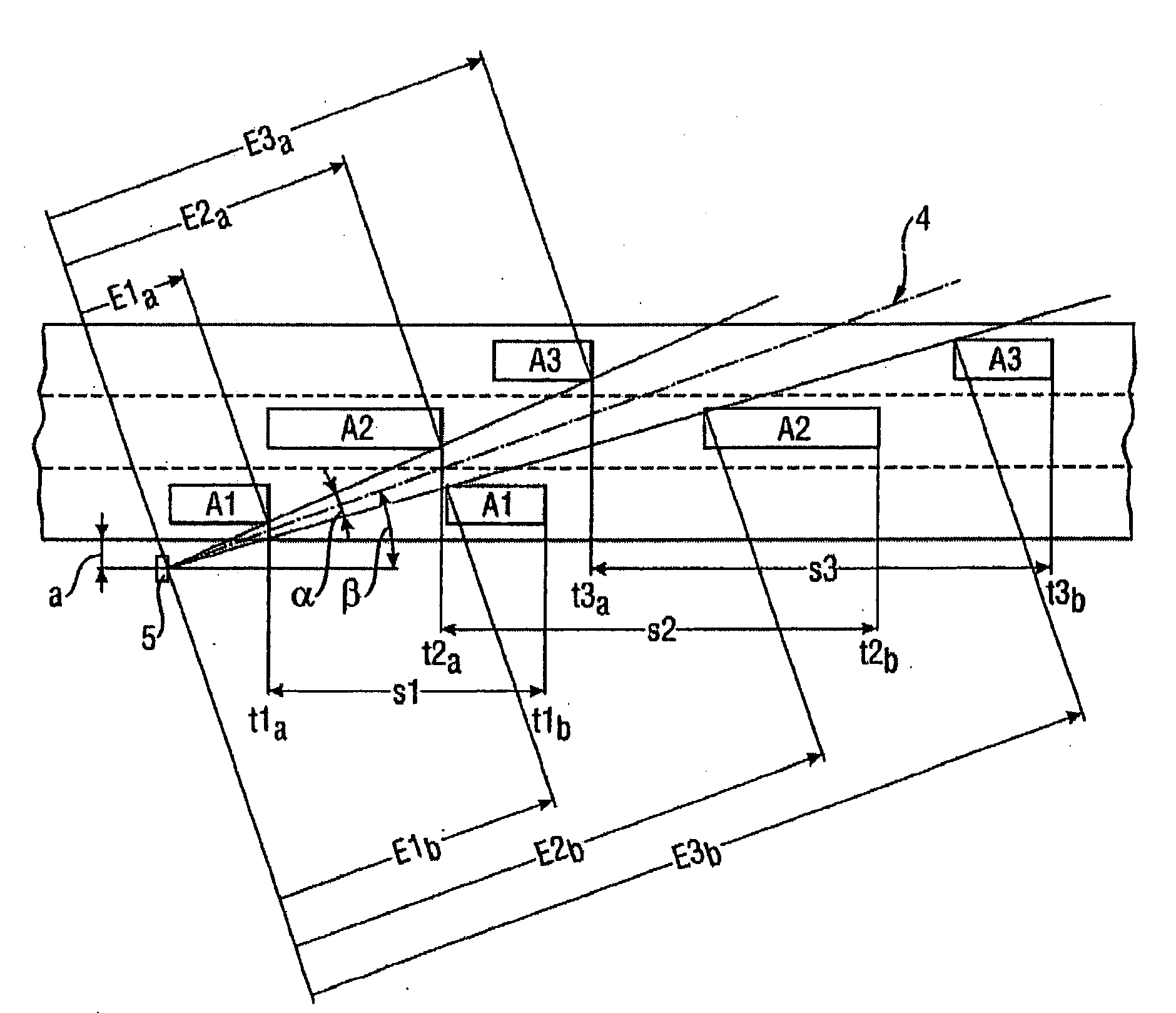

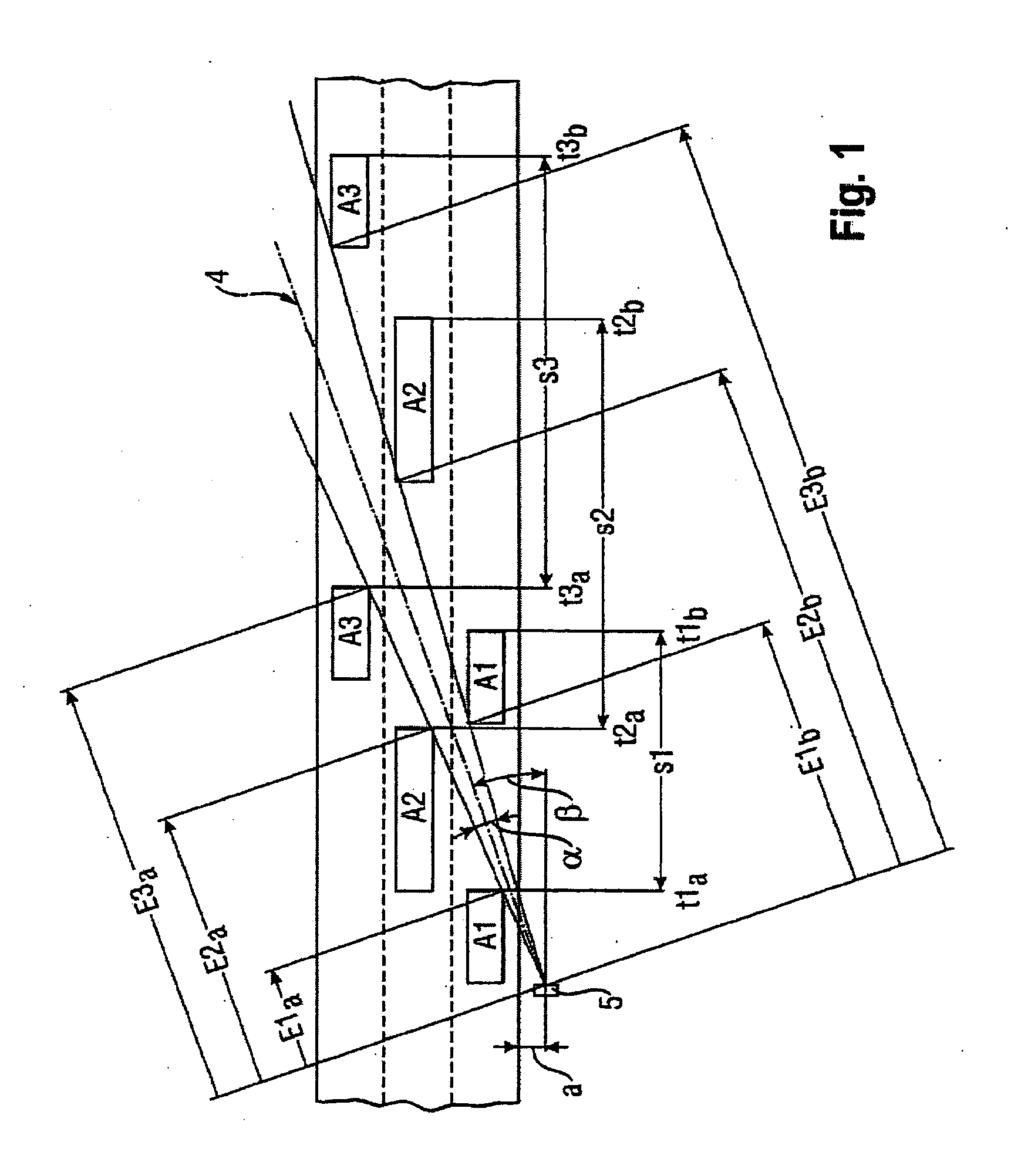

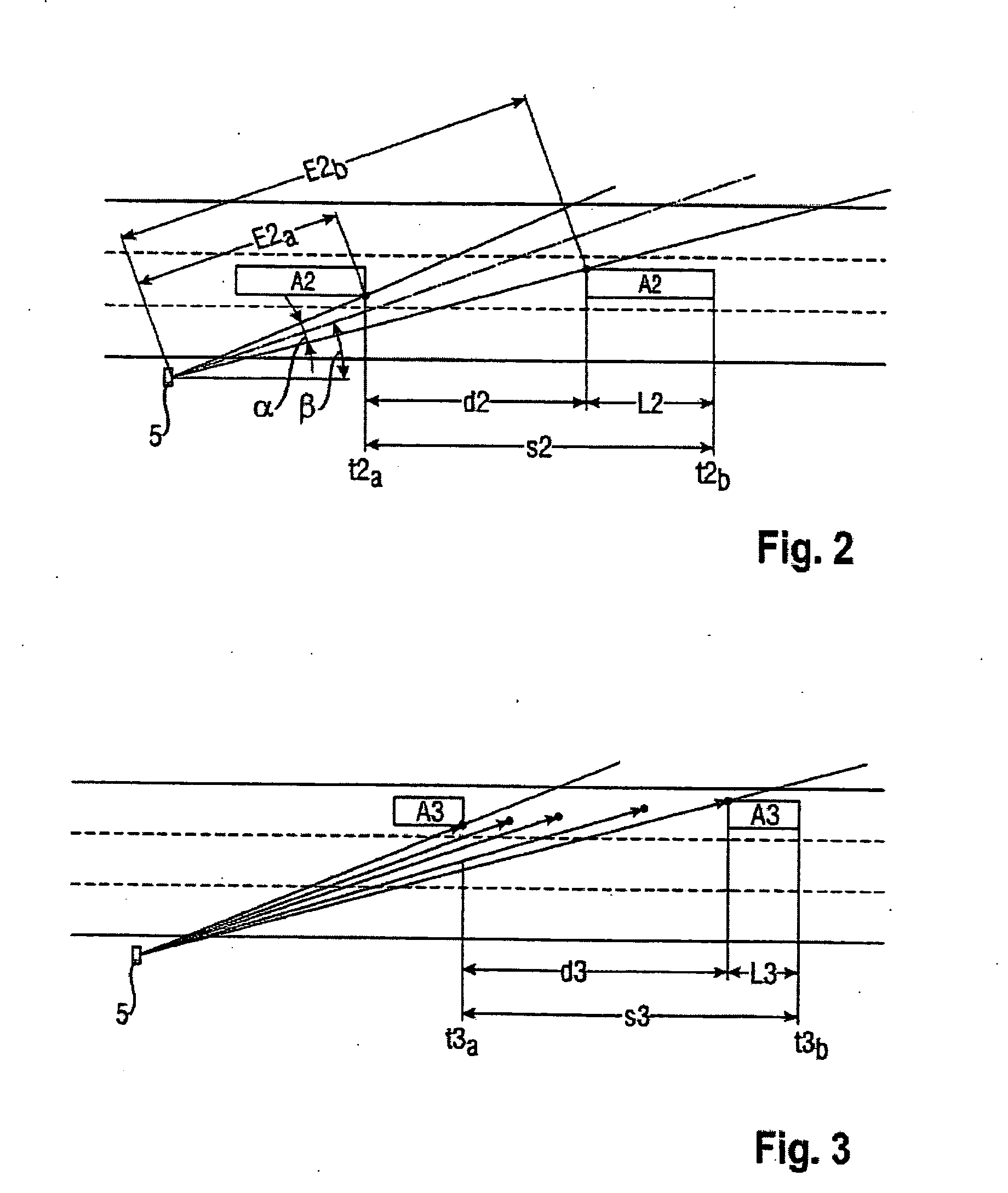

Vehicle queue length measurement method based on PTZ (Pan/Tilt/Zoom) camera fast calibration

InactiveCN102867414ARealize visual measurementEasy to chooseImage analysisDetection of traffic movementCamera auto-calibrationLength measurement

The invention discloses a vehicle queue length measurement method based on PTZ (Pan / Tilt / Zoom) camera fast calibration. The vehicle queue length measurement method based on the PTZ camera fast calibration comprises the following steps of choosing two vertically-crossed traffic markings to form a T-shaped scaling reference and establishing a conversion relation between coordinates of pixels in an image and coordinates of roadway corresponding points in a world coordinate system according to the defined models of the image coordinate system and the world coordinate system; acquiring video images of a traffic monitoring scene by adopting a PTZ camera, setting an ROI (Region Of Interests) of a lane, detecting the vehicle queue state in the ROI by the adoption of an adaptive background update algorithm and textural features, and acquiring the pixels and pixel coordinates of the tails of the vehicle queues; converting the detected pixel coordinates of the tails of the vehicle queues into the world coordinate and finally computing the length of the vehicle queues. The tail position of the vehicle queues is judged according to the textural features, and the measurement of length of the vehicle queues is finished by the combination of the camera, so that the vehicle queue length measurement method based on the PTZ camera fast calibration, disclosed by the invention, has the advantages of low cost, strong embedded type, and the like.

Owner:HUNAN UNIV +1

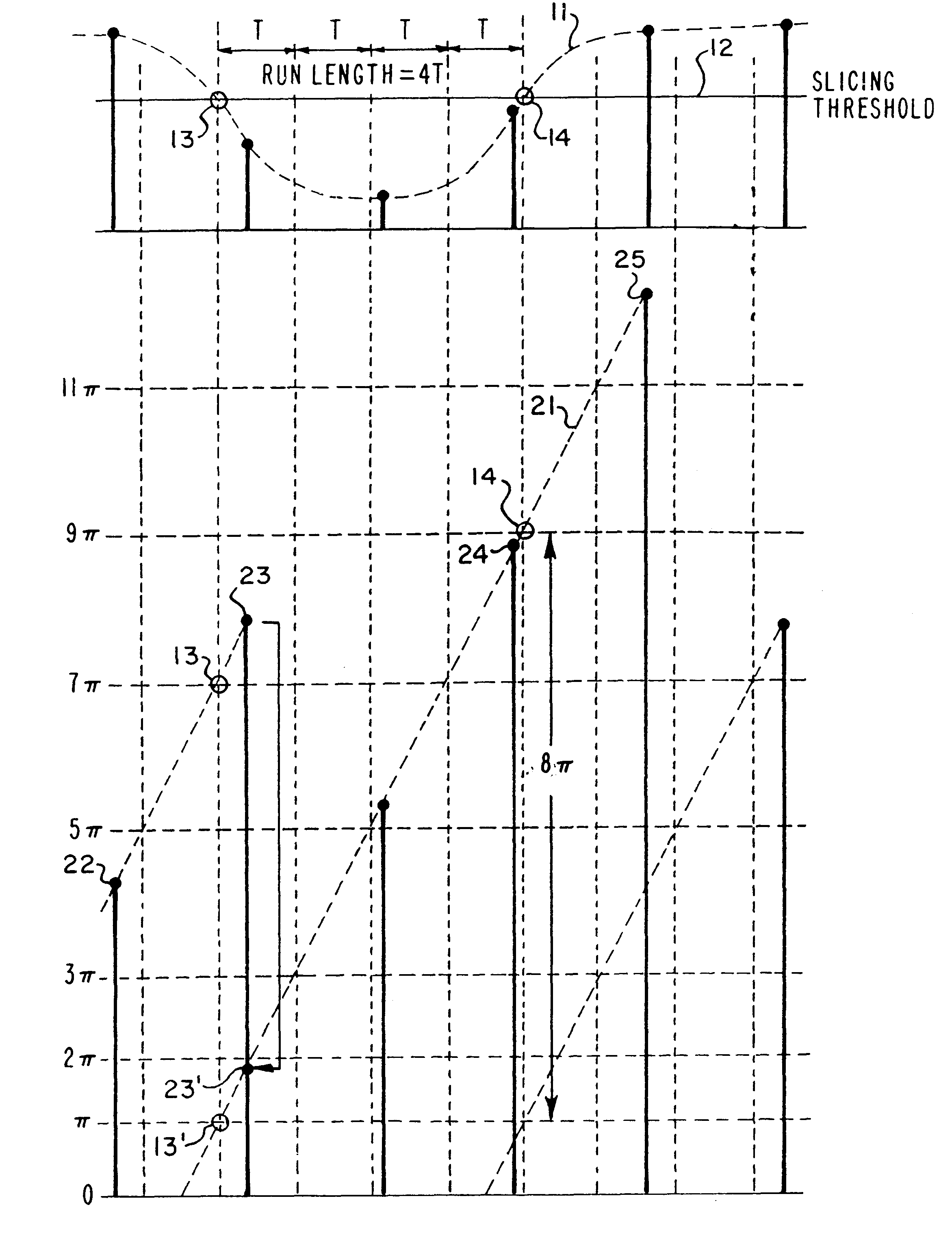

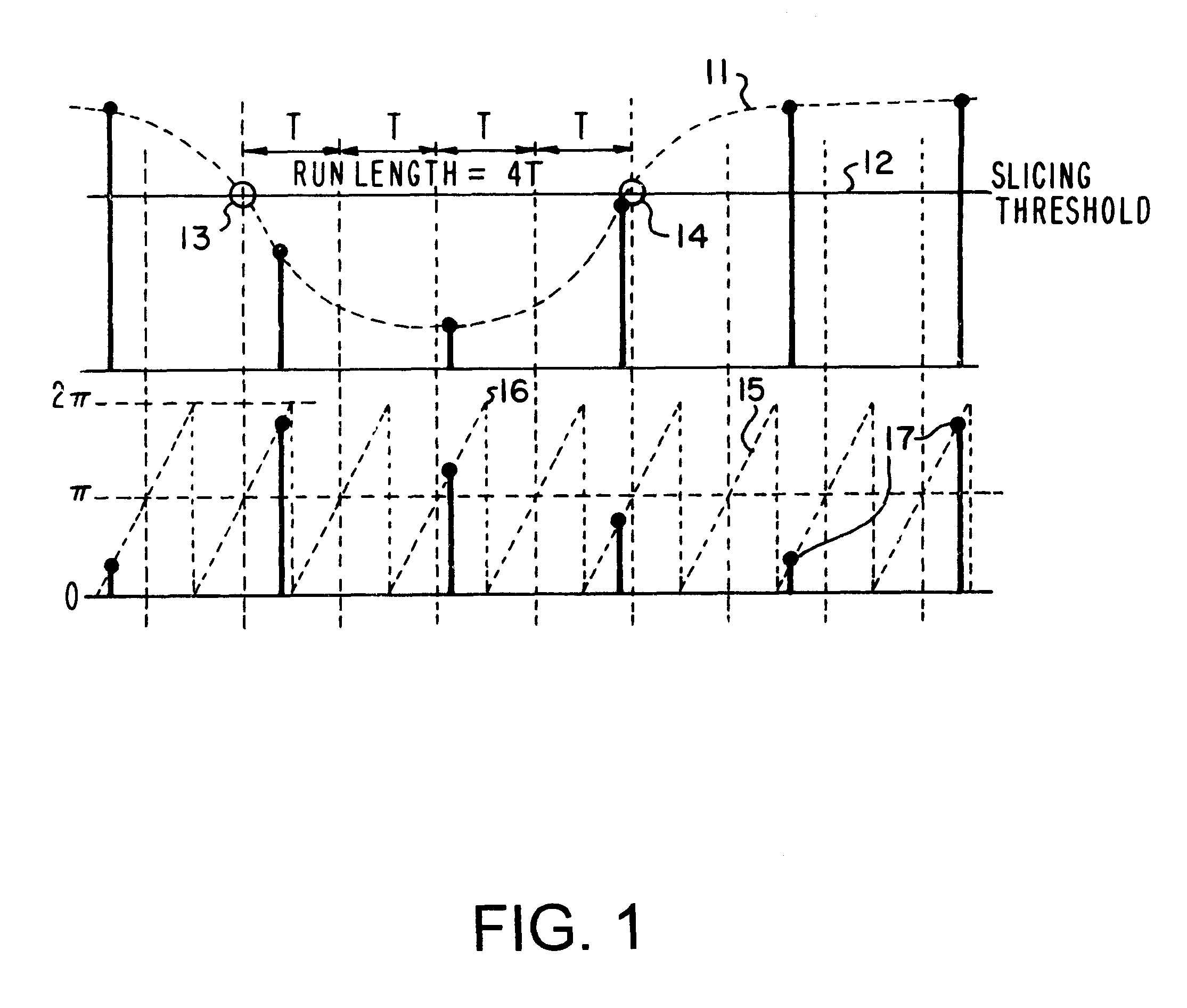

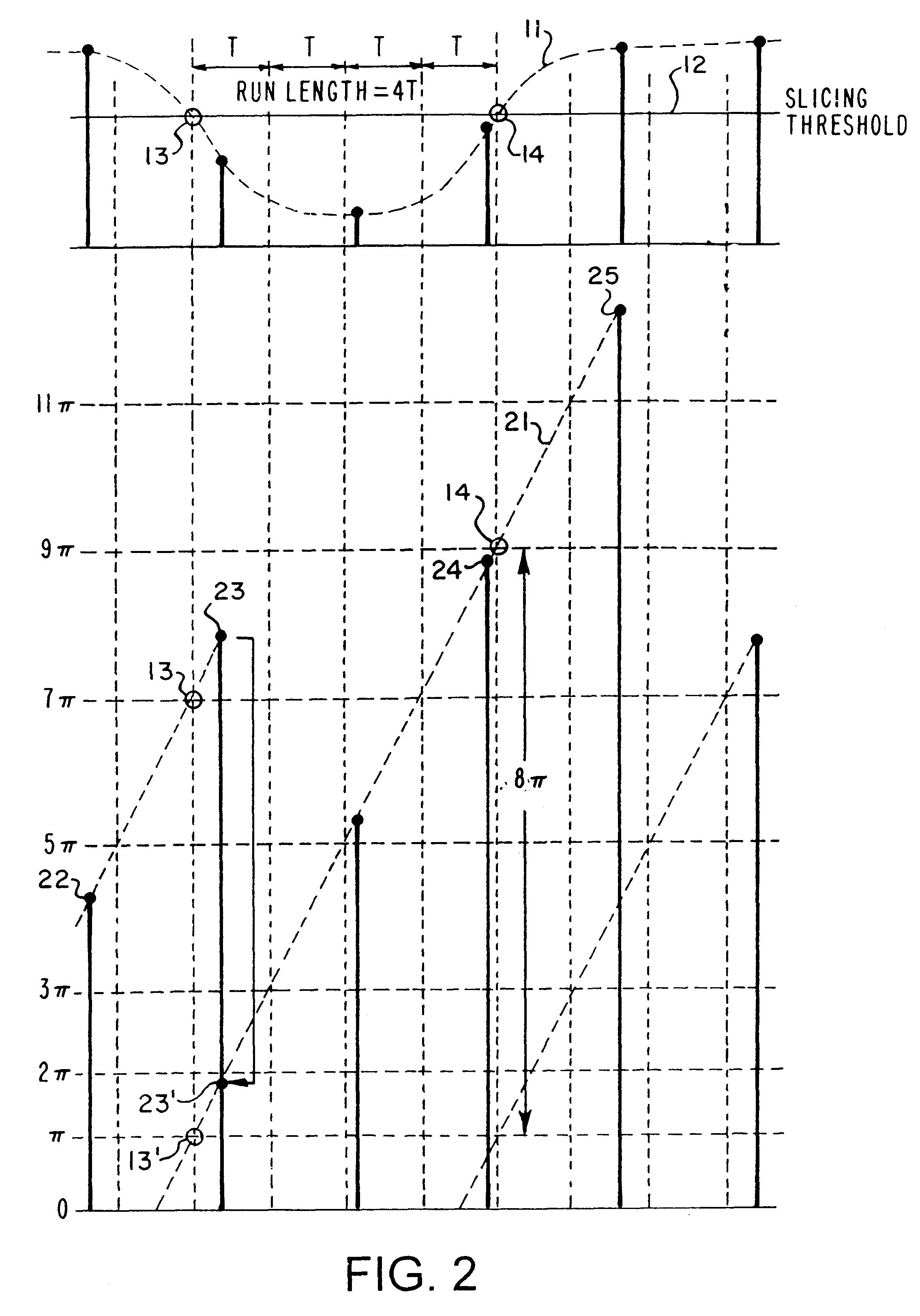

Pulse run-length measurement for HF data signal by dividing accumulated phase difference between first and second zero-crossings by single-cycle range using multiple cycle range sawtooth waveform

InactiveUS6389548B1Modulated-carrier systemsDigital data processing detailsPhase differenceLength measurement

A system and method for accurately measuring a pulse run length in a high frequency (HF) data signal while utilizing a low analog-to-digital conversion (ADC) sampling rate. Four bits are added to the most significant end of an oscillator's accumulator register so that the oscillator generates a sawtooth clock waveform ranging in phase from zero (0) to 32pi radians. An interpolator detects a first zero-crossing transition of the HF data signal at the leading edge of the pulse run length, and a phase detector measures a first phase increment at that time. The MSBs of the accumulator register is then initialized to place the measured first phase increment in a range between zero (0) and 2pi radians. The accumulator register then accumulates phase increments until the interpolator detects a second zero-crossing transition of the HF data signal at the trailing edge of the pulse run length, and the phase detector measures a second phase increment when the second zero-crossing transition is detected. An accumulated phase difference is calculated by subtracting the initialized first phase increment from the measured second phase increment. The pulse run length is then obtained by dividing the accumulated phase difference by 2pi.

Owner:CEVA IRELAND +1

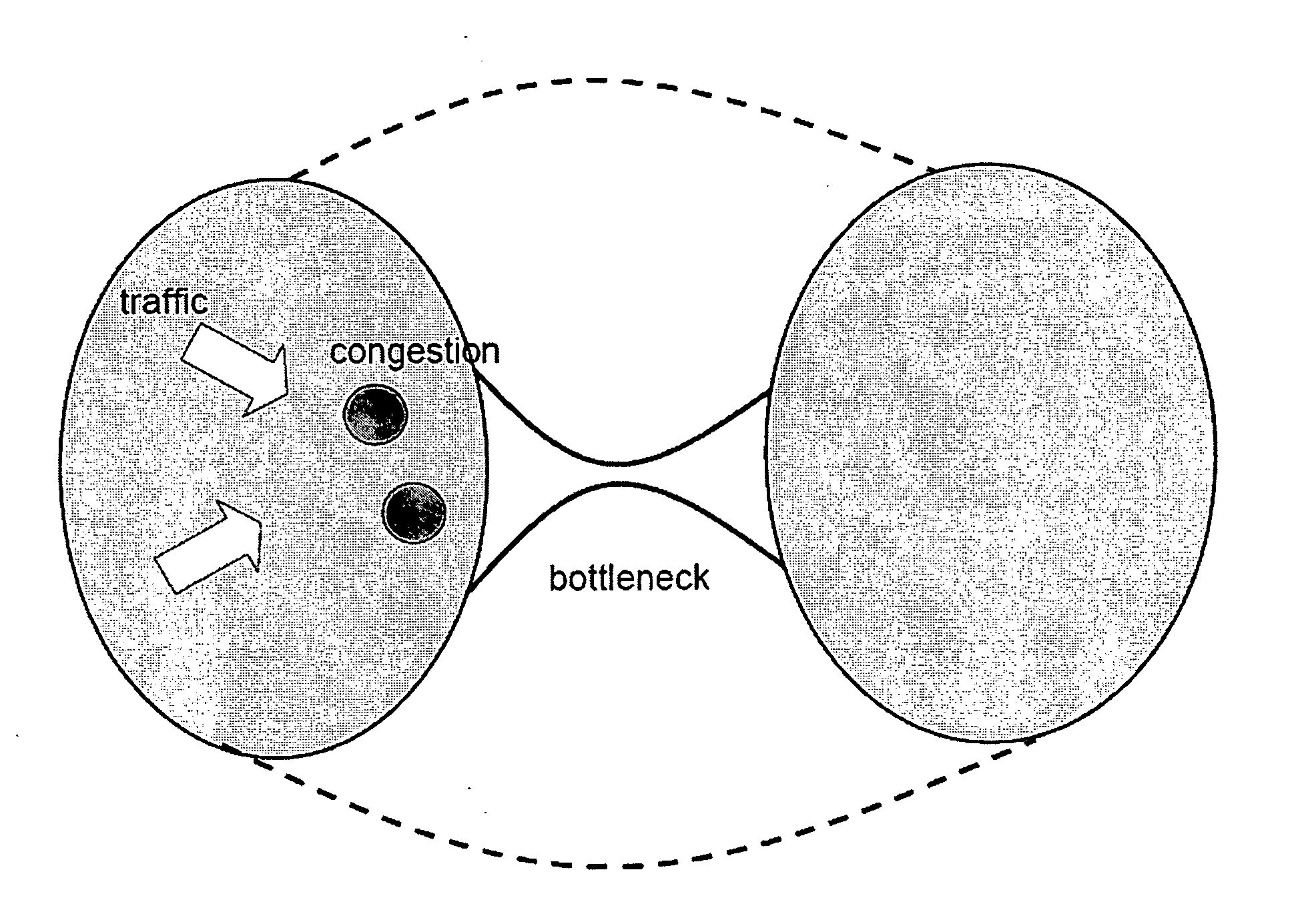

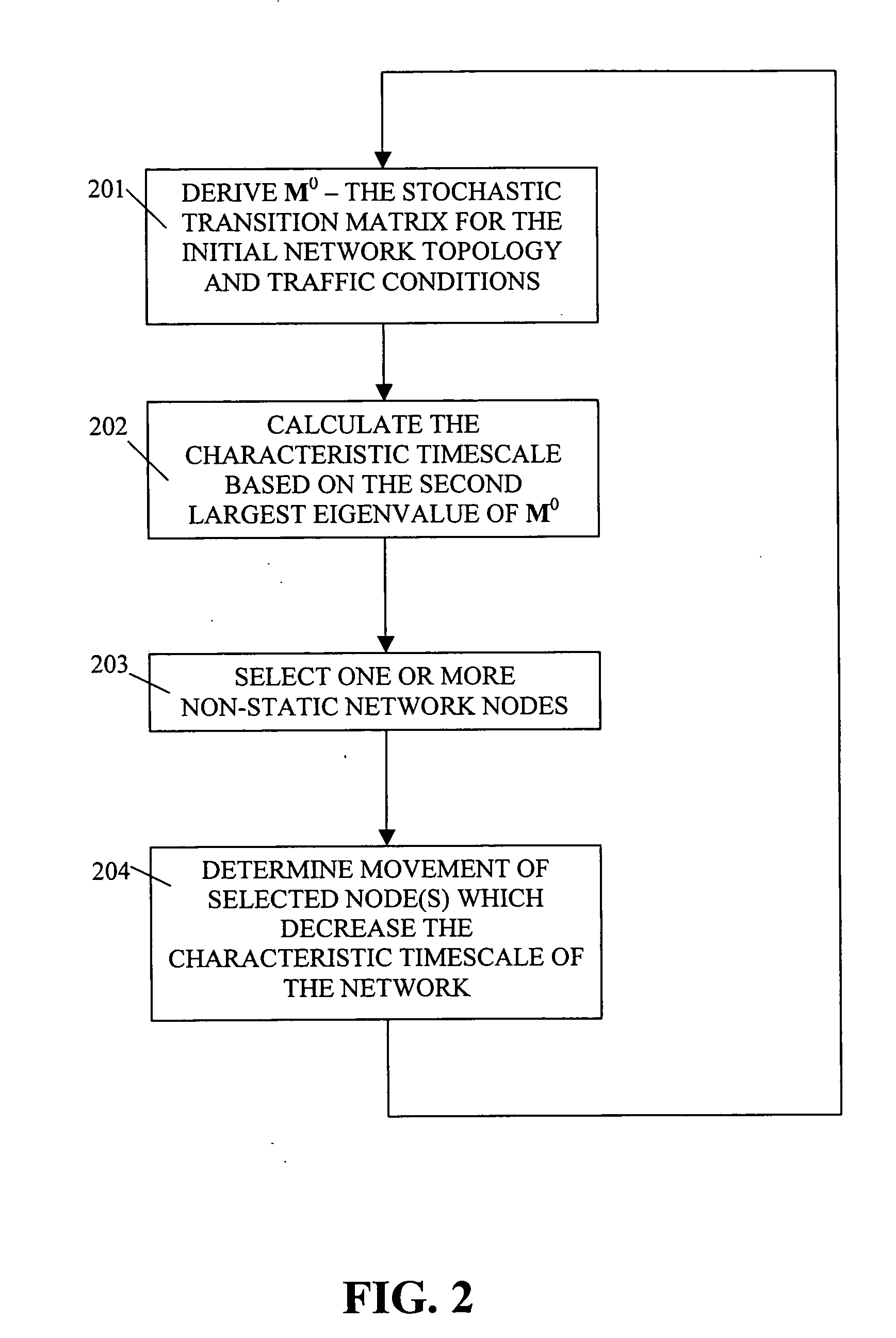

Method and apparatus for dynamically reducing end-to-end delay in multi-hop wireless networks in response to changing traffic conditions

InactiveUS20060039286A1Reduces mean end-to-end network transmission delayReduce transmission delayError preventionTransmission systemsLength measurementTraffic conditions

A method and apparatus for deforming the network topology of a multi-hop wireless network dynamically (i.e., in real time), in response to changing network traffic conditions and in order to advantageously reduce mean end-to-end network (transmission) delay. Two illustrative embodiments of the invention deform the network topology dynamically in response to traffic conditions (i) by changing the network connectivity between the existing network nodes and (ii) by adding one or more new nodes (and associated connections thereto and therefrom) to the network. In both cases, the traffic conditions may be fed into the algorithm in real time as, for example, a set of queue length measurements. Then, in response, the network is advantageously reorganized into a configuration that reduces the mean end-to-end network transmission delay.

Owner:LUCENT TECH INC

Handheld fish measuring apparatus with integral camera

A handheld apparatus for measuring fish, game, and the like is provided and includes a scale, a camera, and a length measuring device. The scale includes a support member that extends outwardly from the apparatus housing, and a display that is visible through the housing. The support member is configured to suspend an object therefrom for weighing via the scale, and the display is configured to display the weight of an object suspended from the support member. The length measurement device is configured to measure the length of an object and the display is configured to display the length of an object measured by the length measurement device. The camera includes a lens, an image sensor configured to capture images obtained via the lens, and a camera display. The camera display displays an image of an object taken by the camera with weight and / or length information for the object.

Owner:PROPEL IP

Method and Device for Determining the Vehicle Class of Vehicles

InactiveUS20080278366A1Criterion be improvedAccurately derivedRoad vehicles traffic controlRadio wave reradiation/reflectionLength measurementRadar beam

The invention relates to a method and device with which a vehicle traveling through a radar cone is classified by means of length criteria. The length criteria are formed by the difference of the driven distance that the vehicle covers, during which it reflects the radar beam, and the passage distance of the vehicle through the radar cone, which gives a more or less precise measurement for the vehicle length according to the accuracy of the determined passage distance. For determining the passage distance, range values are derived from the radar signals.

Owner:ROBOT VISUAL SYST

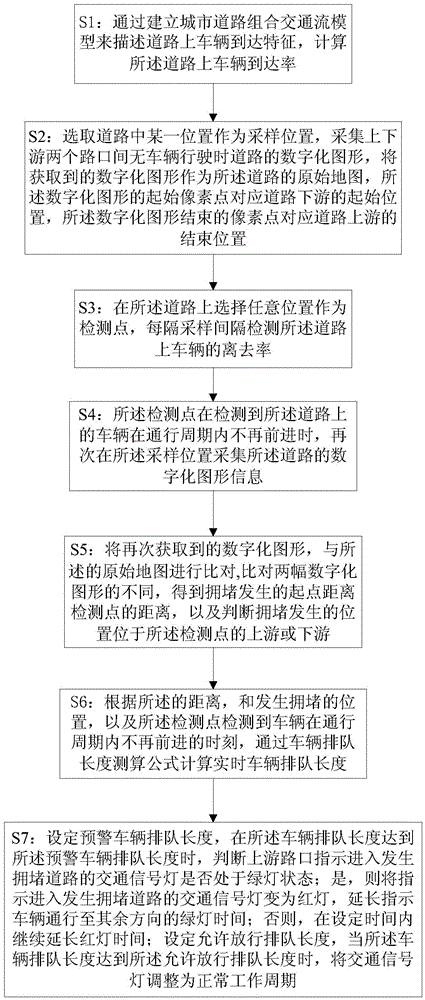

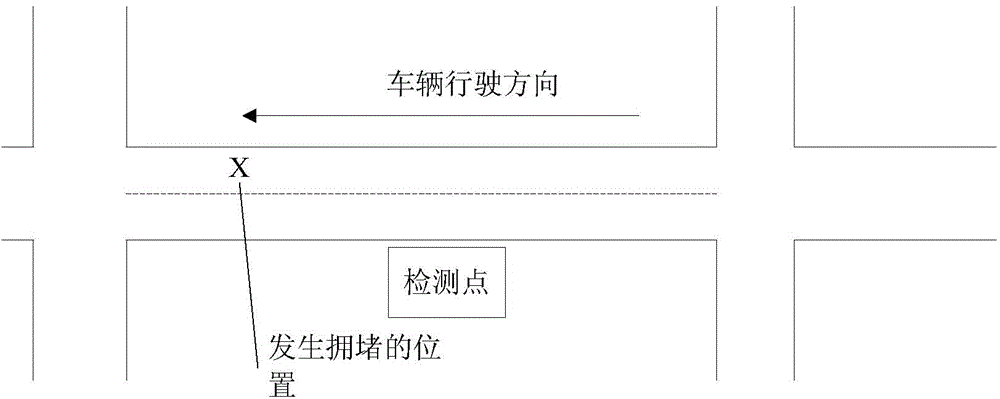

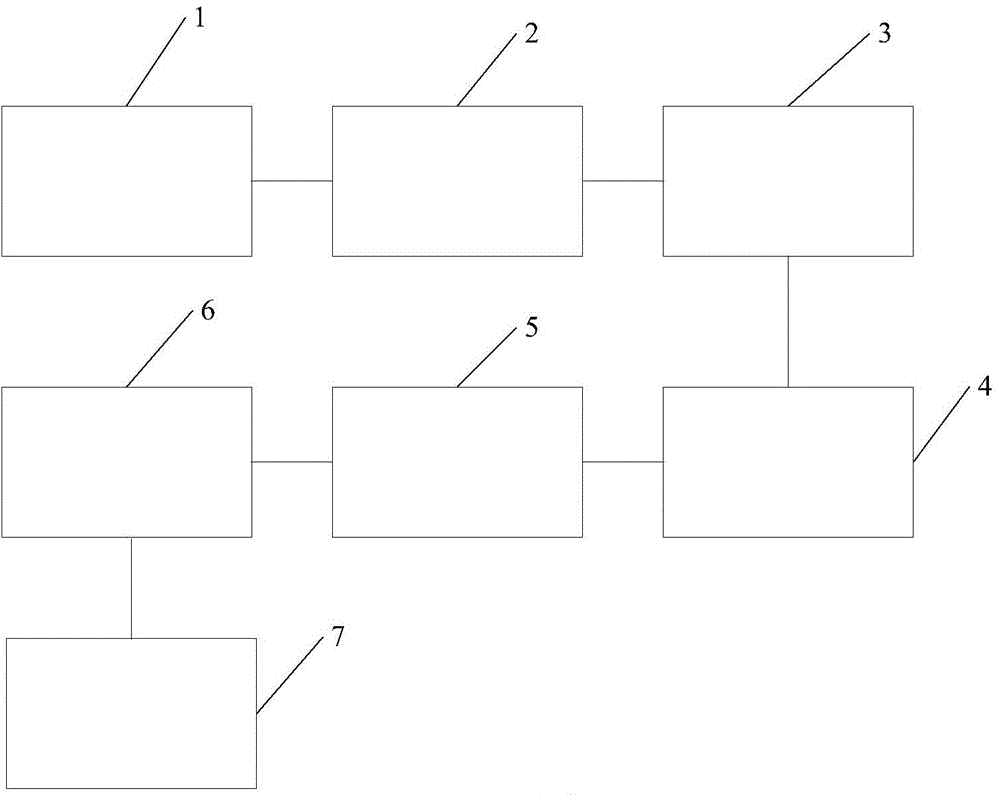

Traffic signal light control method and system based on vehicle queuing length measurement

InactiveCN103985261ASimulation is accurateAvoid traffic jamsControlling traffic signalsTraffic flow modelingGraphics

The invention provides a traffic signal light control method and system based on vehicle queuing length measurement. Vehicle flow information is divided into steady flow and combined flow by building a city road combined traffic flow model, and actual vehicle flow information can be accurately simulated. Pixel points in an original map of a digital graph can serve as road coordinates by carrying out digital graph collecting on a road, a sampling time interval is set, digital graph information of the road is collected on a sampling position again when it is detected that a vehicle on the road does not move forward any more in a road go-through cycle, a congestion starting position is obtained, a real-time vehicle queuing length can be calculated according to the distance from the congestion starting point to a detection point by means of a vehicle queuing length computational formula, the operation state of an upstream intersection signal light is controlled according to the real-time vehicle queuing length, and accordingly upstream intersection traffic congestion caused due to the fact that the upstream intersection vehicle enters the congested road is avoided.

Owner:SOUTHEAST UNIV +1

Device and method for measuring micro-pore size based on fiber Bragg grating

InactiveCN102564309AMeet the measurement requirementsImprove adaptabilityUsing optical meansMeasurement deviceGrating

The invention provides a device and method for measuring a micro-pore size based on a fiber Bragg grating and belongs to the technical fields of precision instrument manufacture and precision test metering. The device consists of an aiming and signaling device for generating aiming signals, a length measuring device for measuring the movement distance of a micro-pore to be measured within a time interval of measuring measurement starting and stopping signals which are sent by the aiming and signaling device, and a computer for controlling a measurement process of the entire measuring device. The method comprises the following steps of: continuously moving a working table along a direction vertical to a length measurement direction, and moving the working table along a measurement line to obtain a maximum displacement, relative to the micro-pore to be measured, of a probe, so as to obtain the diameter of the micro-pore to be measured. According to the device and method disclosed by the invention, the adaptability of the aiming and signaling device to the environment is greatly improved. The device disclosed by the invention has the characteristics of simple structure, good real-time capability and easiness for actual application, and has obvious advantage of carrying out rapid and ultra-precise measurement and aiming on the size of the micro-pore.

Owner:HARBIN INST OF TECH

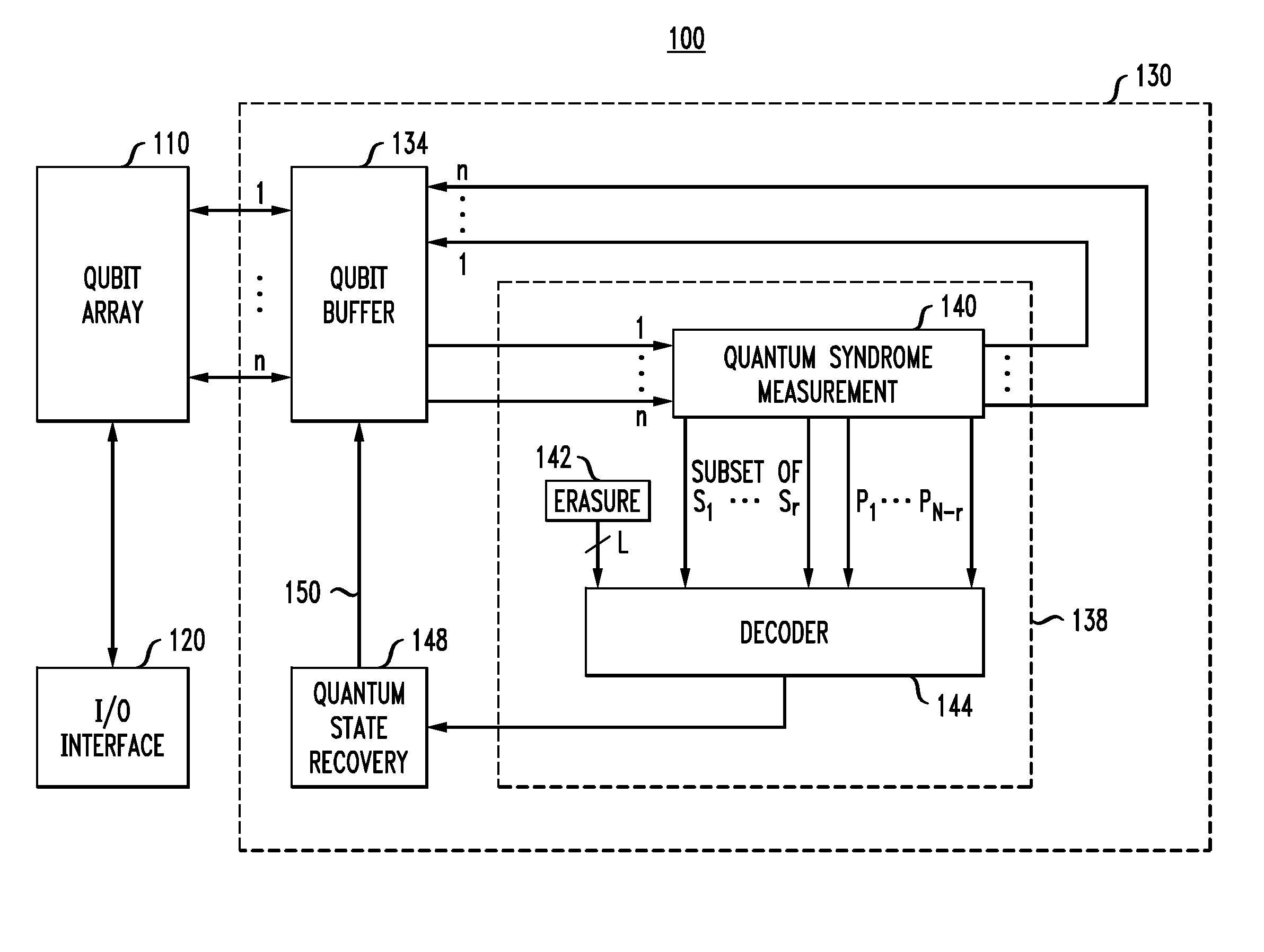

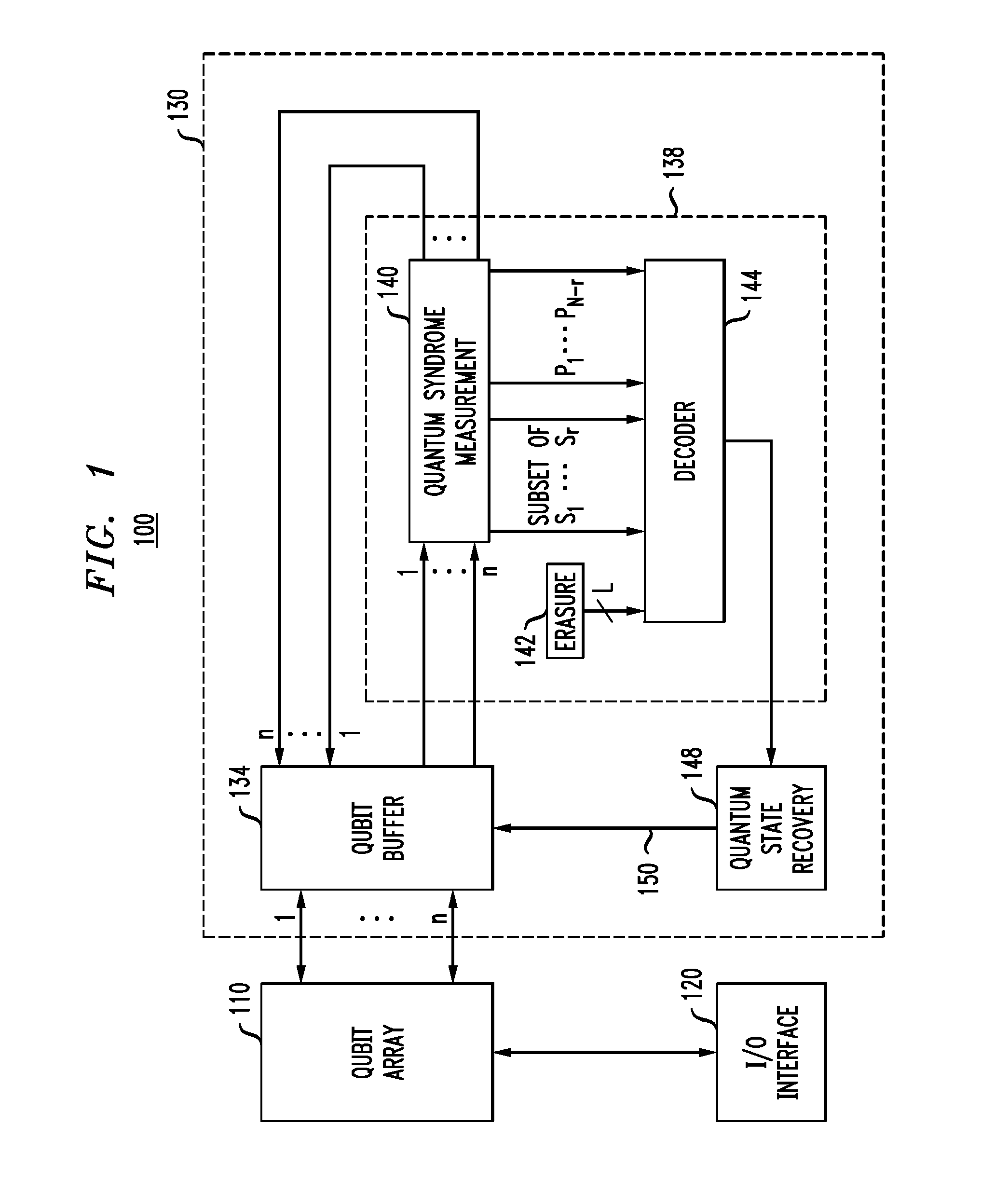

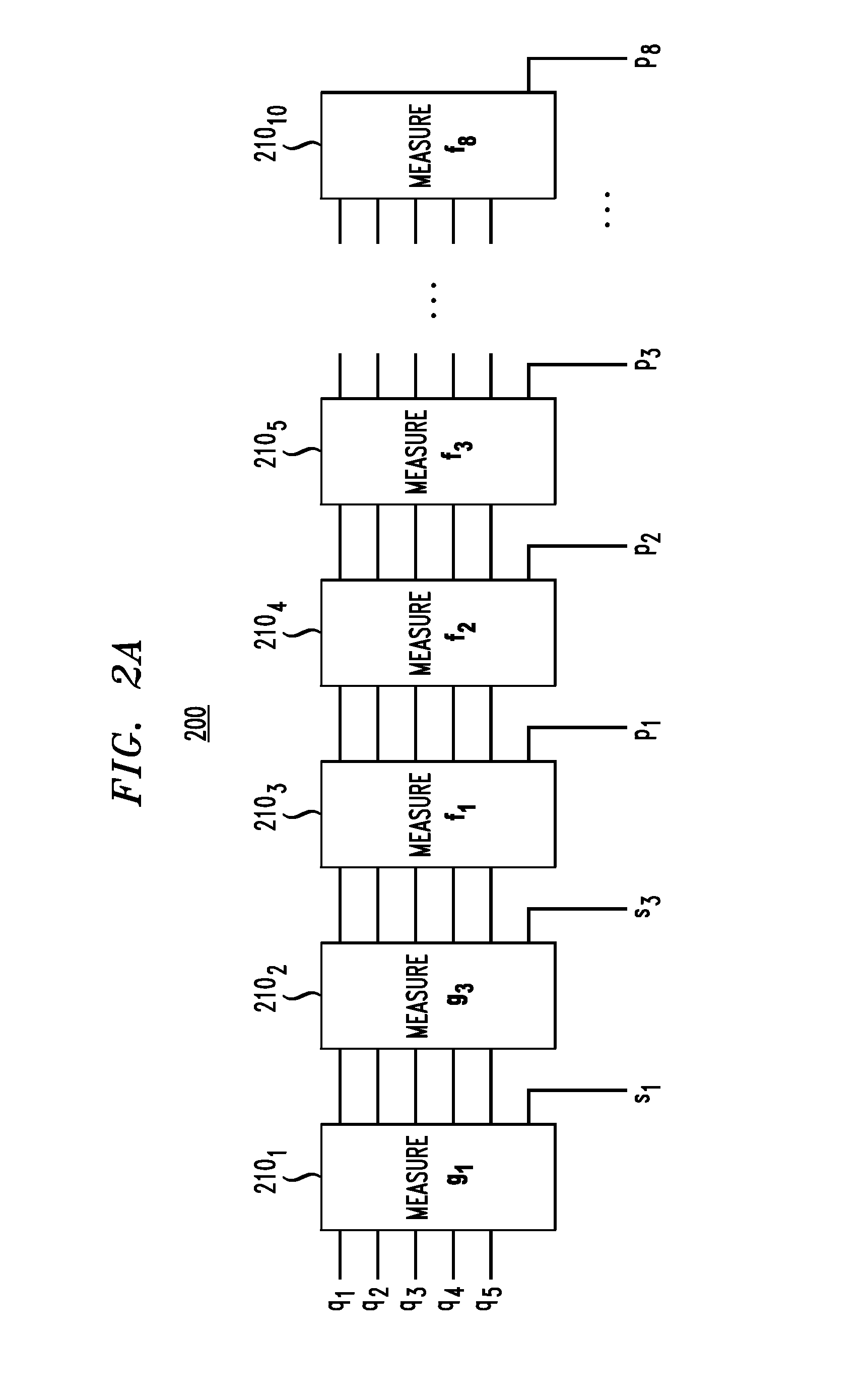

Hardware-efficient syndrome extraction for entangled quantum states

ActiveUS20160112066A1Reduction in fidelityQuantum computersCode conversionLength measurementQuantum gate

A quantum-state-refresh module of a memory system is configured to detect an error in an entangled qubit state stored therein by performing a redundant measurement of syndrome values corresponding to a quantum stabilizer code, with the redundant measurement being based on a block error-correction code. The quantum-state-refresh module includes a plurality of measurement sub-modules, each configured to measure a respective syndrome value or a respective parity value corresponding to the entangled qubit state. The total number of the measurement sub-modules is smaller than the codeword length of the block error-correction code, and the initial approximation of the punctured syndrome values is replaced in the decoding process by erasure values. With the block error-correction code appropriately constructed for the use of erasure values, the quantum-state-refresh module is advantageously capable of providing reliable error detection with fewer quantum gates than that used for the full-length measurement of the codeword.

Owner:ALCATEL LUCENT SAS

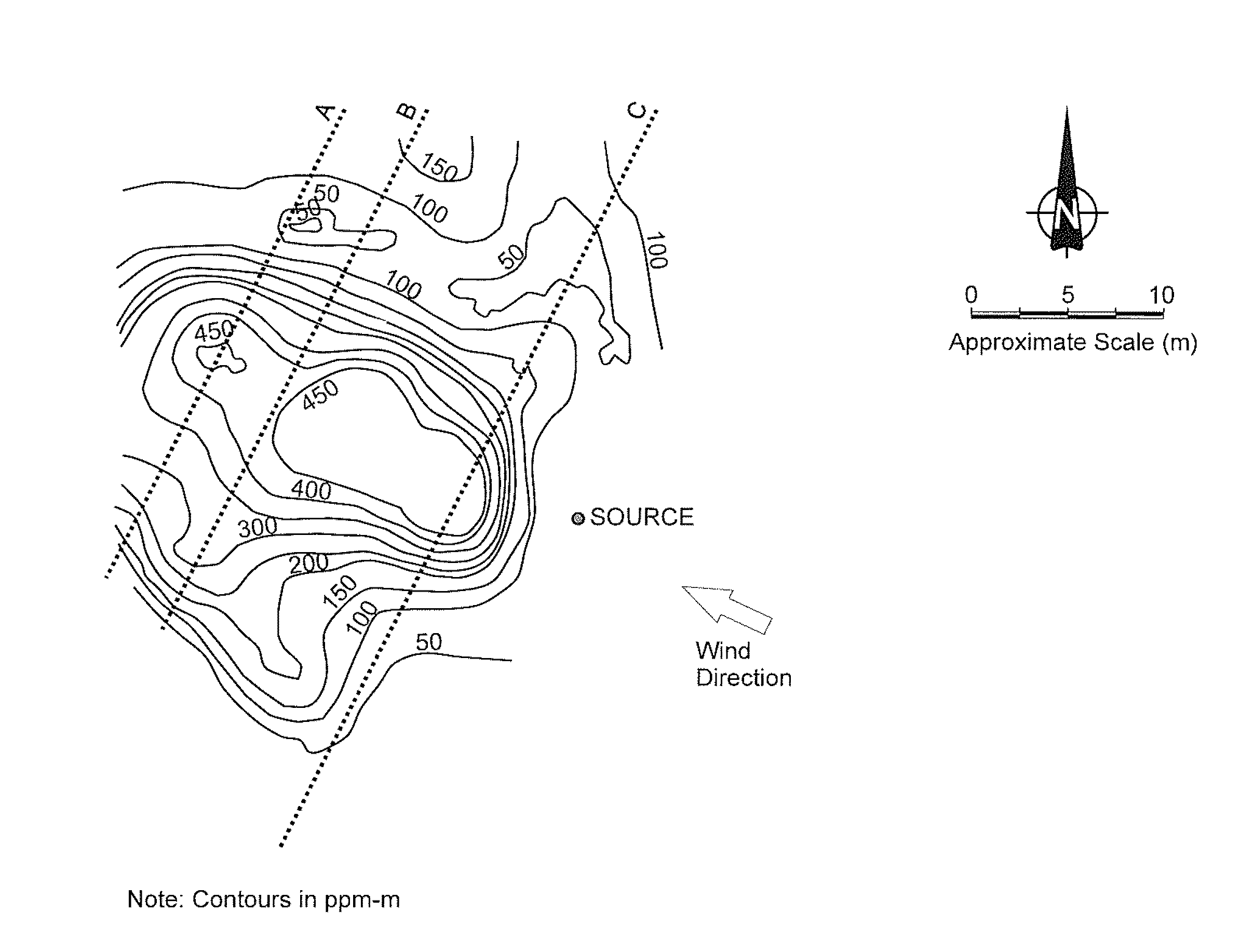

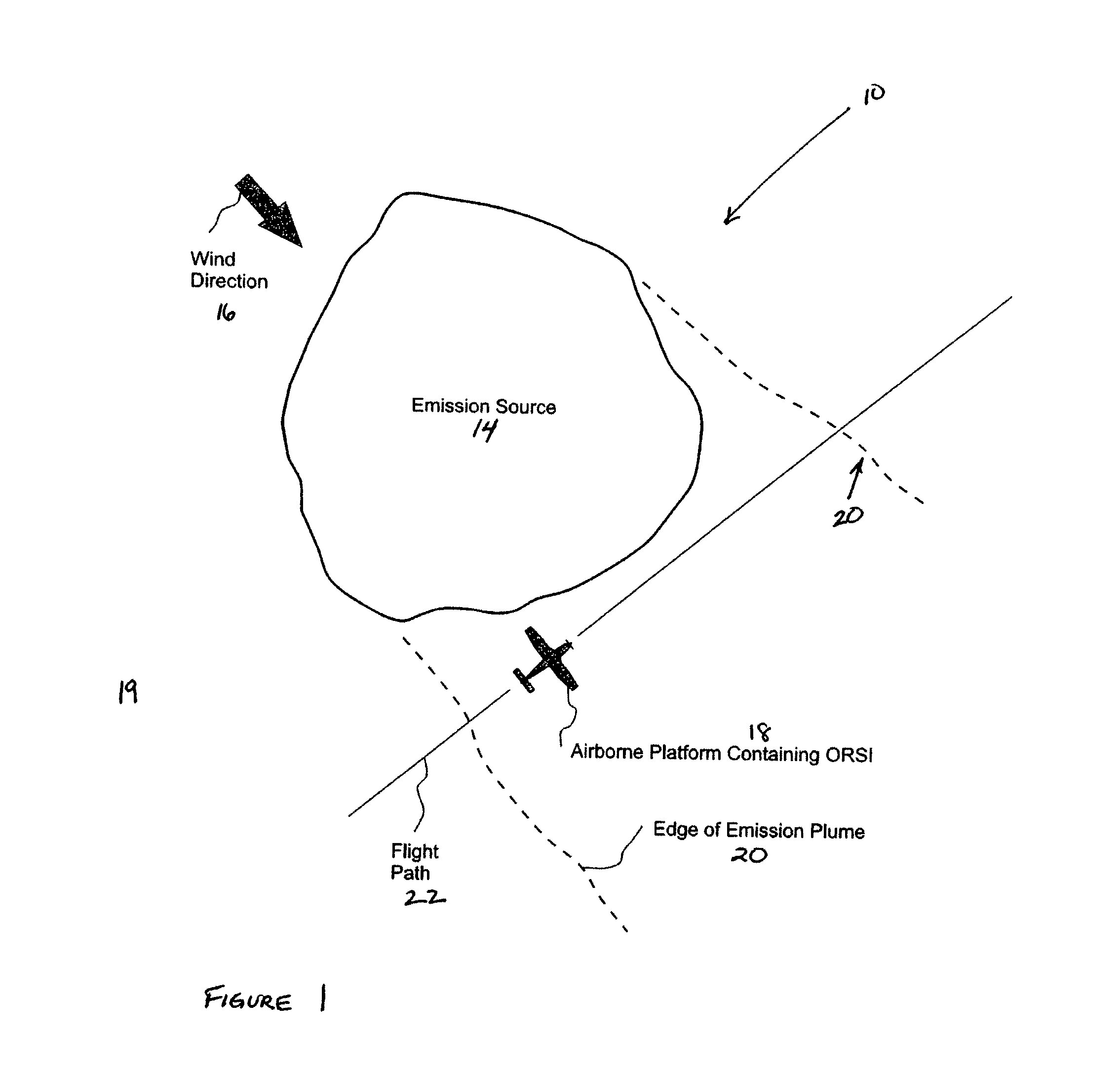

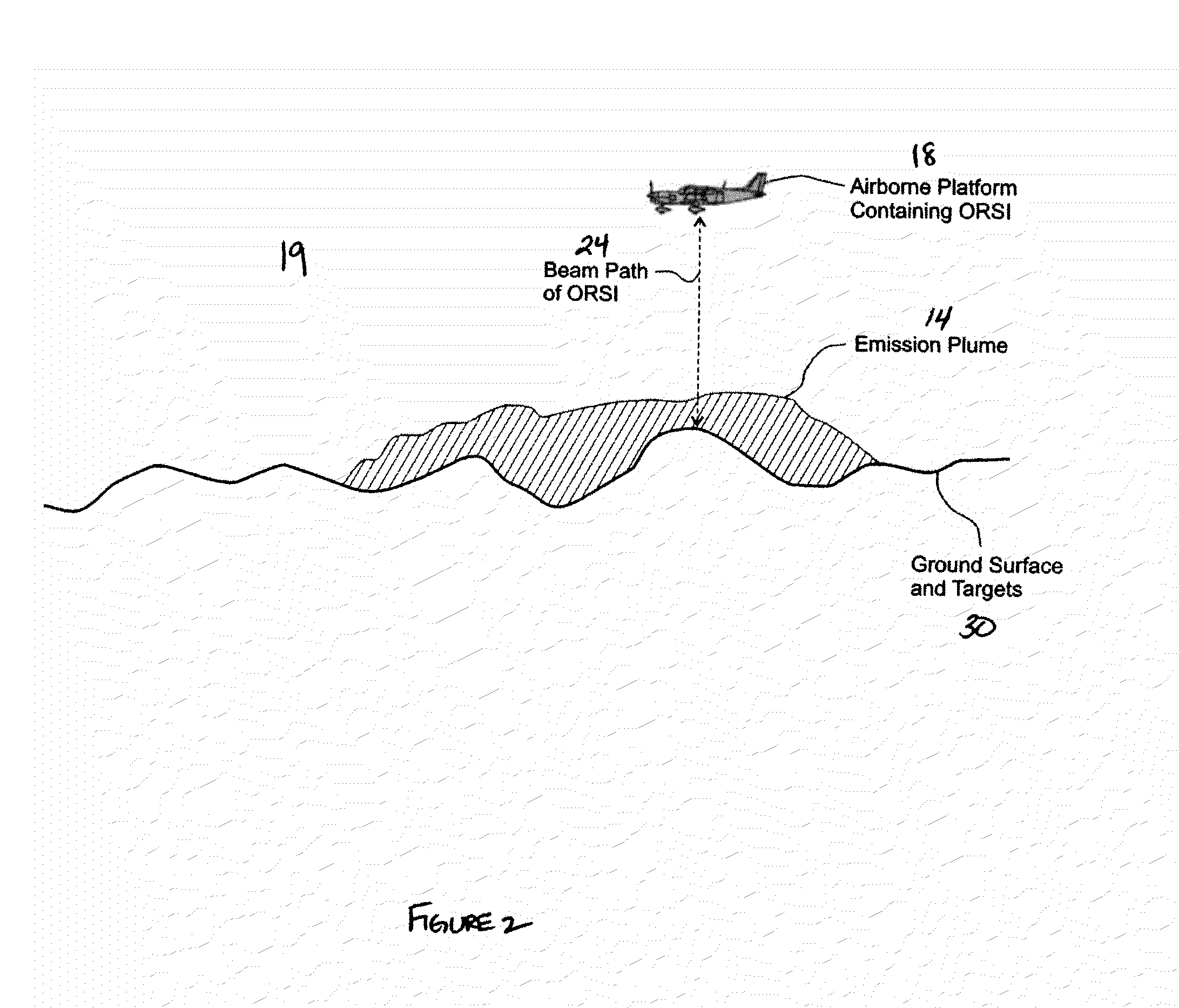

Fugitive emission flux measurement

A method of obtaining a fugitive emission flux measurement of airborne matter is provided. The method involves measuring the airborne matter along one or more than one measurement plane that spans the fugitive emission using two or more than two measurement beam paths where each of the two or more than two measurement beam paths are parallel to each other, or substantially parallel to each other, and determining a mass per unit length measurement for the measurement plane, determining a representative wind velocity at or near the one or more than one measurement plane, and calculating the fugitive emission flux of the airborne matter in mass per unit time using the mass per unit length determination and representative wind velocity.

Owner:GOLDER ASSOCIATES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com