Patents

Literature

179results about "Measuring wheels" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

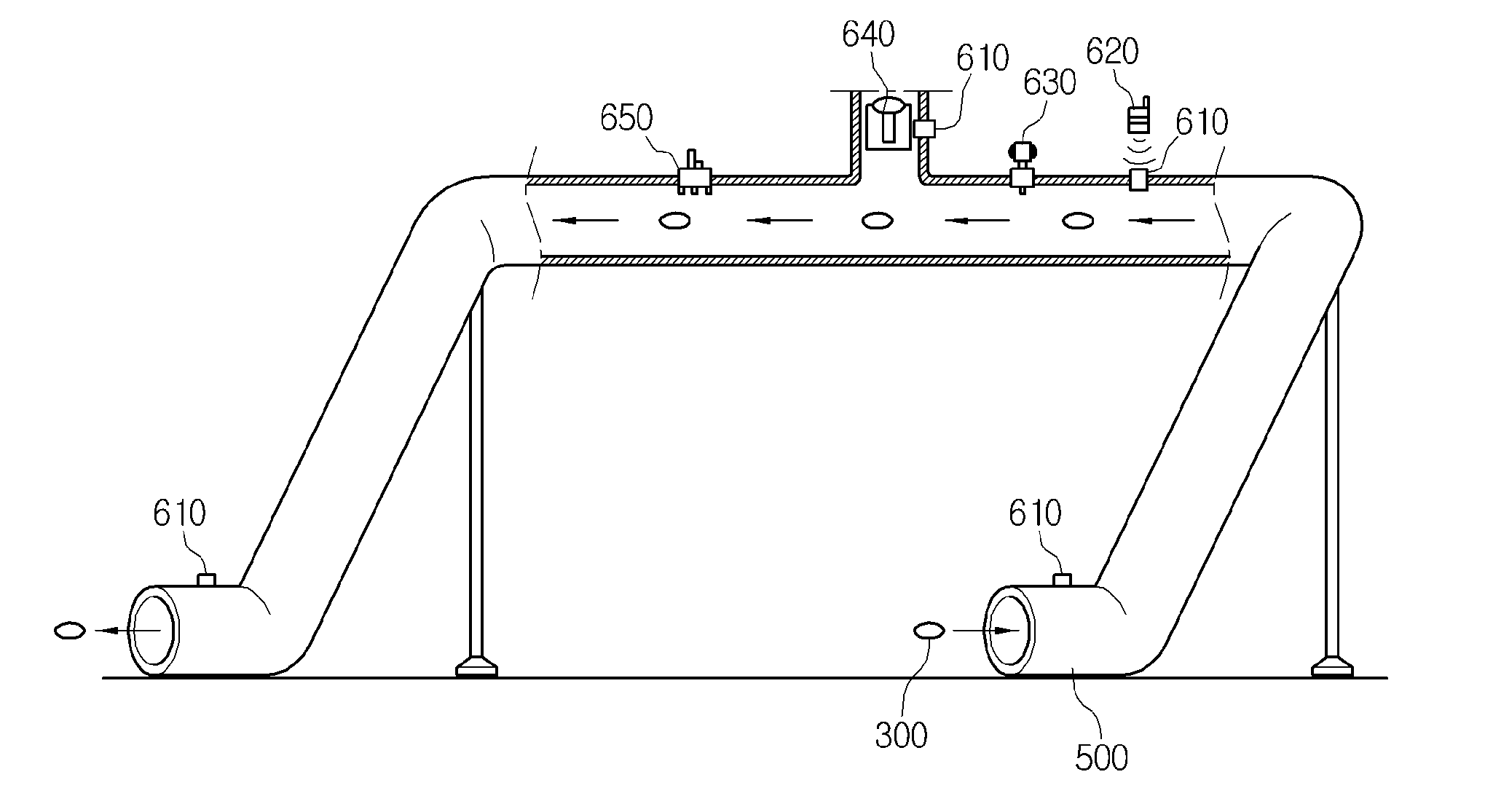

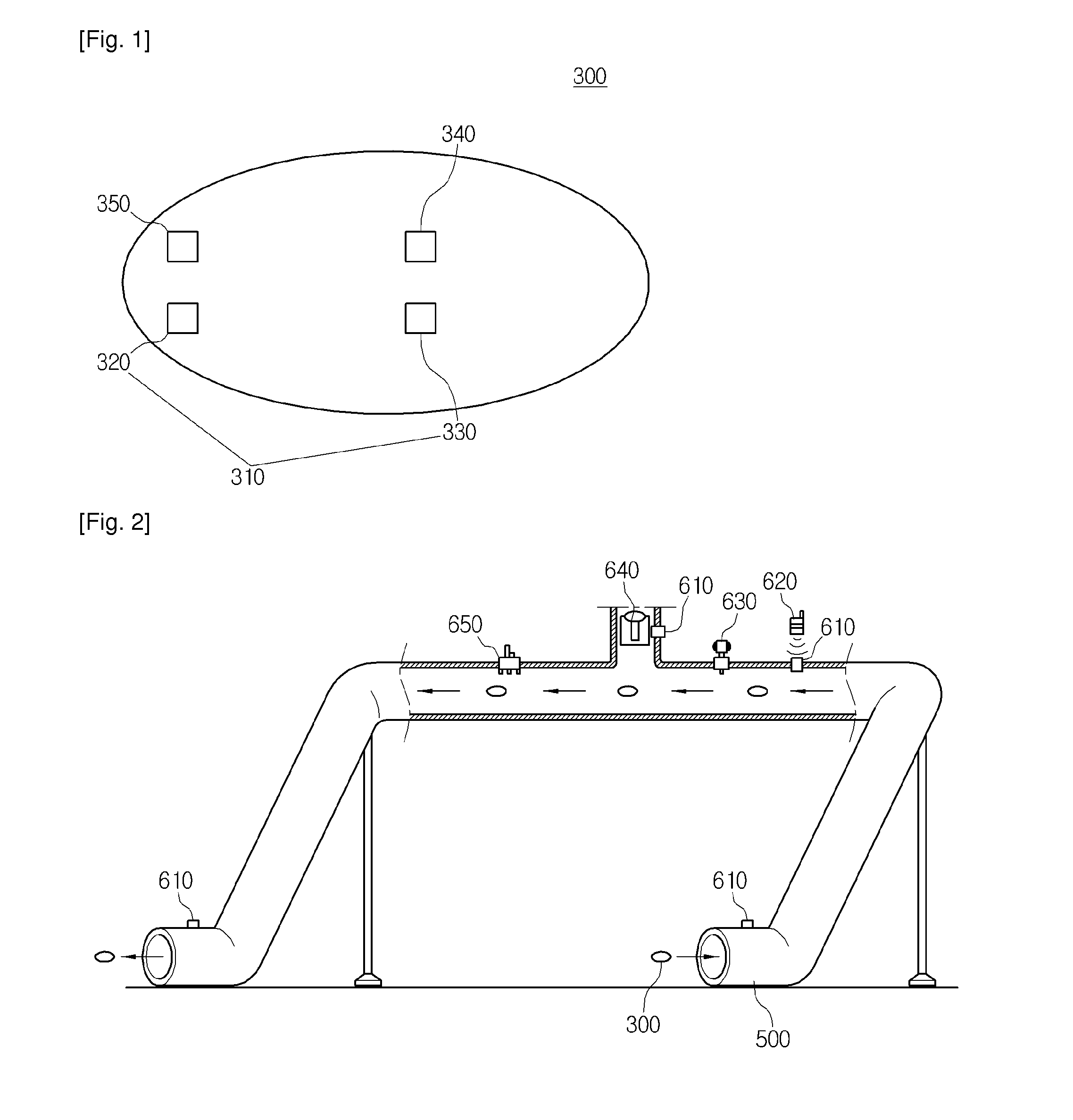

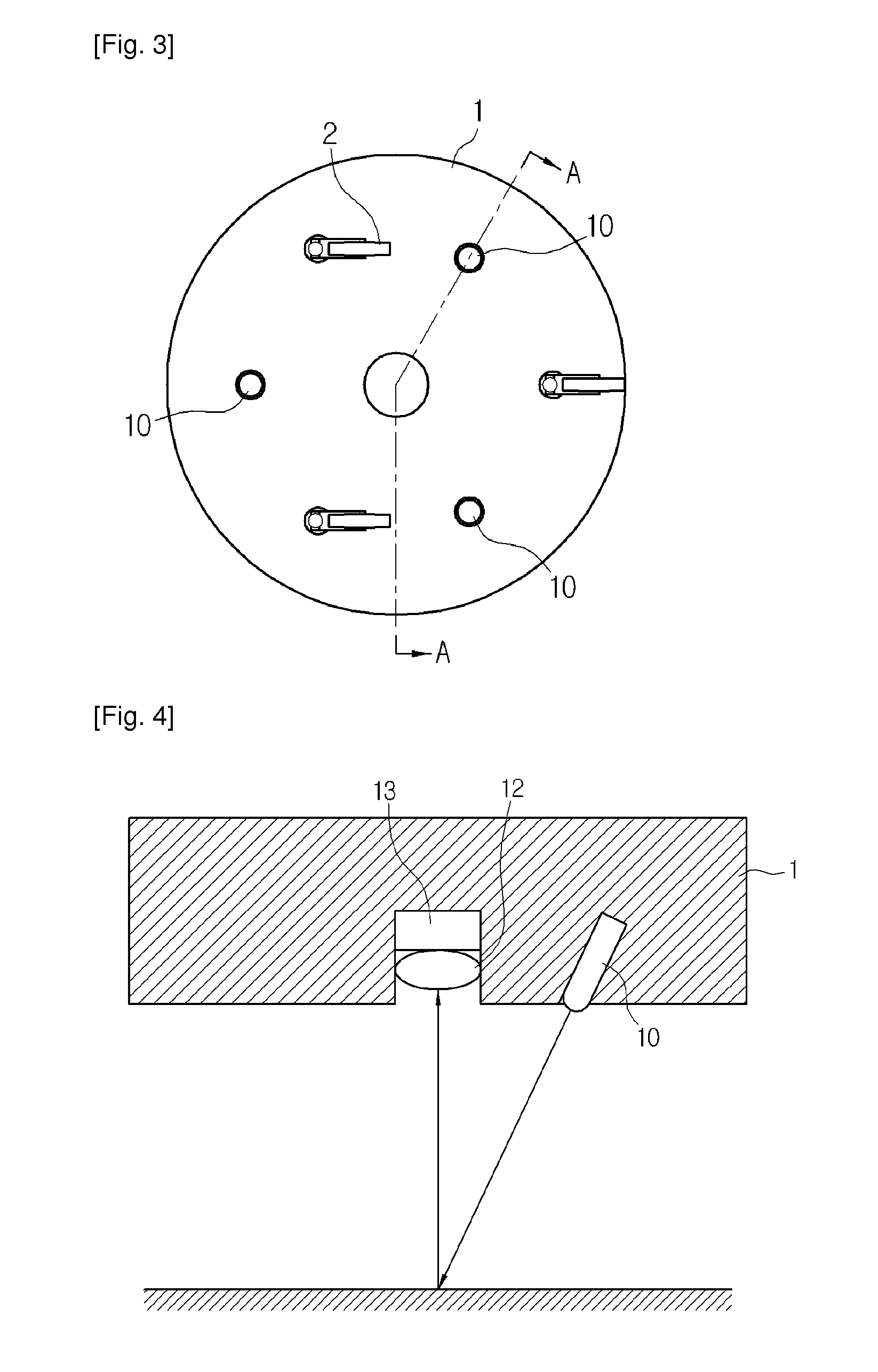

Apparatus for acquiring 3-dimensional geomatical information of underground pipes and noncontact odometer using optical flow sensor and using the same

InactiveUS20100211354A1Effective maintenanceEffective preservationOptical rangefindersMeasuring wheelsOptical flowOdometer

An apparatus to acquire 3-dimensional geographical information of an underground pipe includes an in-pipe transfer unit which moves along the inside of the underground pipe, a sensing unit which senses 3-dimensional location information of the in-pipe transfer unit, and an information storage unit which stores a value measured by the sensing unit. Accordingly, the depth at which the underground pipe is located as well as 2-dimensional location information of the underground pipe is stored in the information storage unit so that maintenance and repair of the underground pipe can be carried out with greater efficiency.

Owner:WATER RESOURCES ENG +1

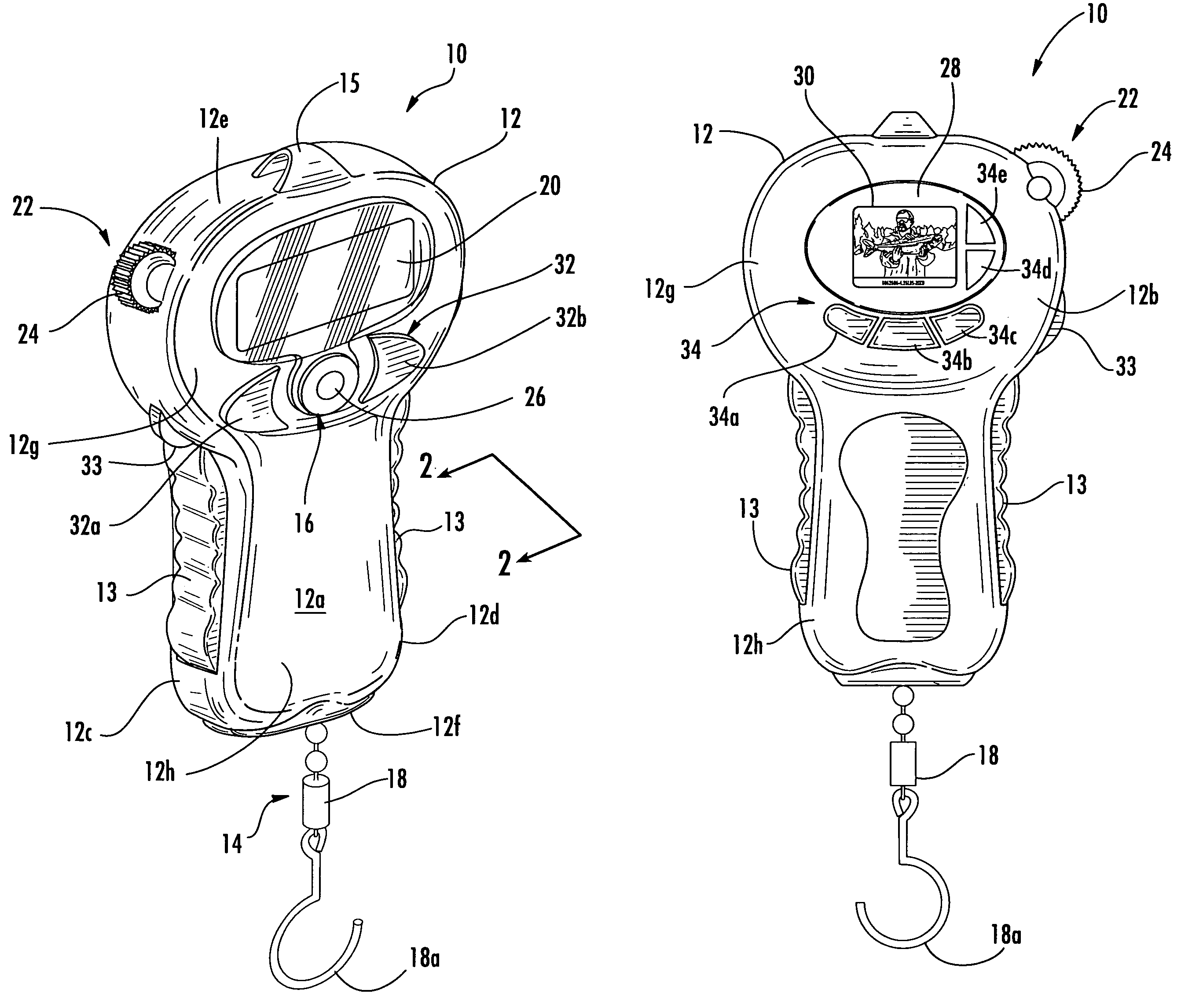

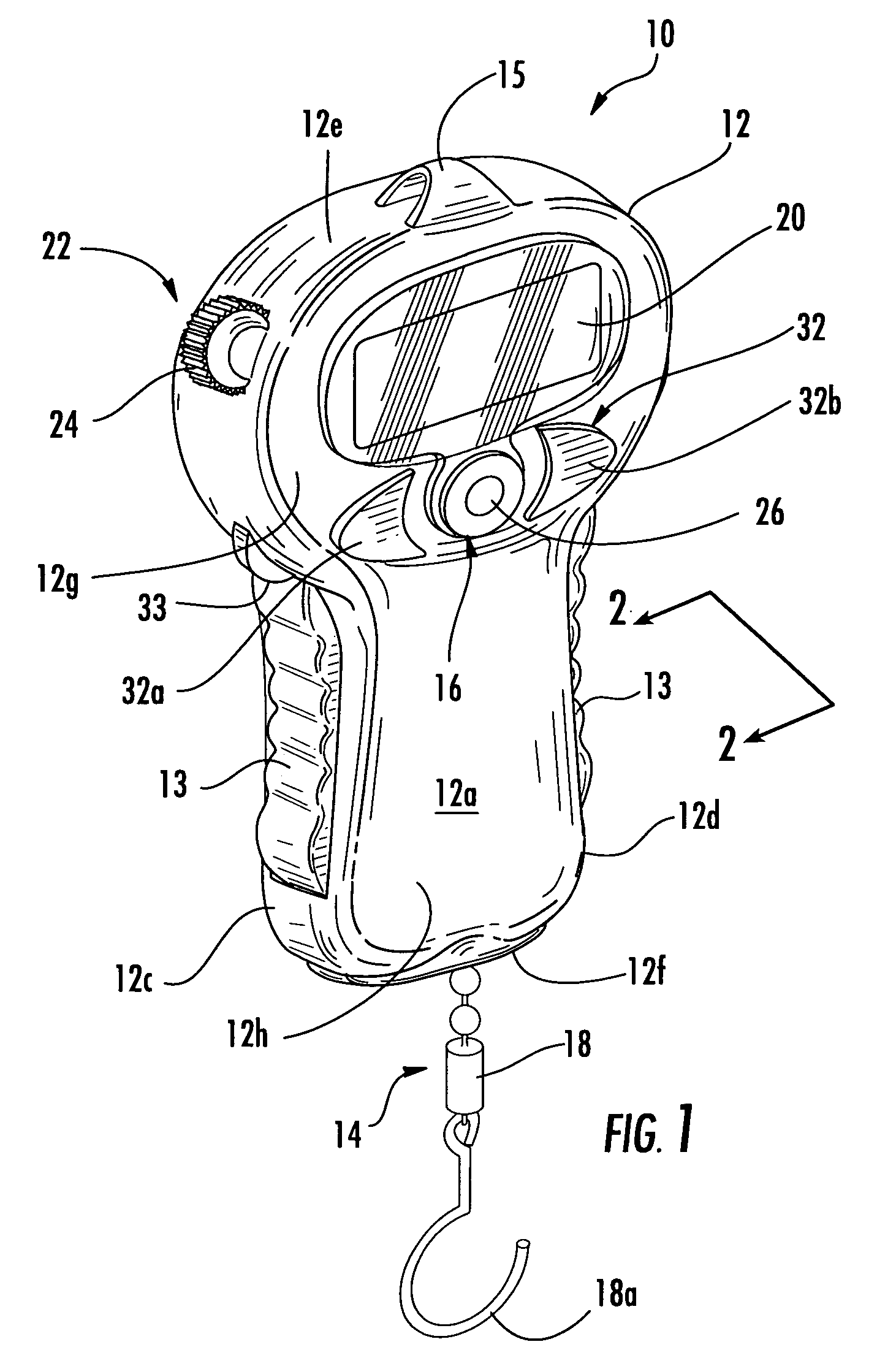

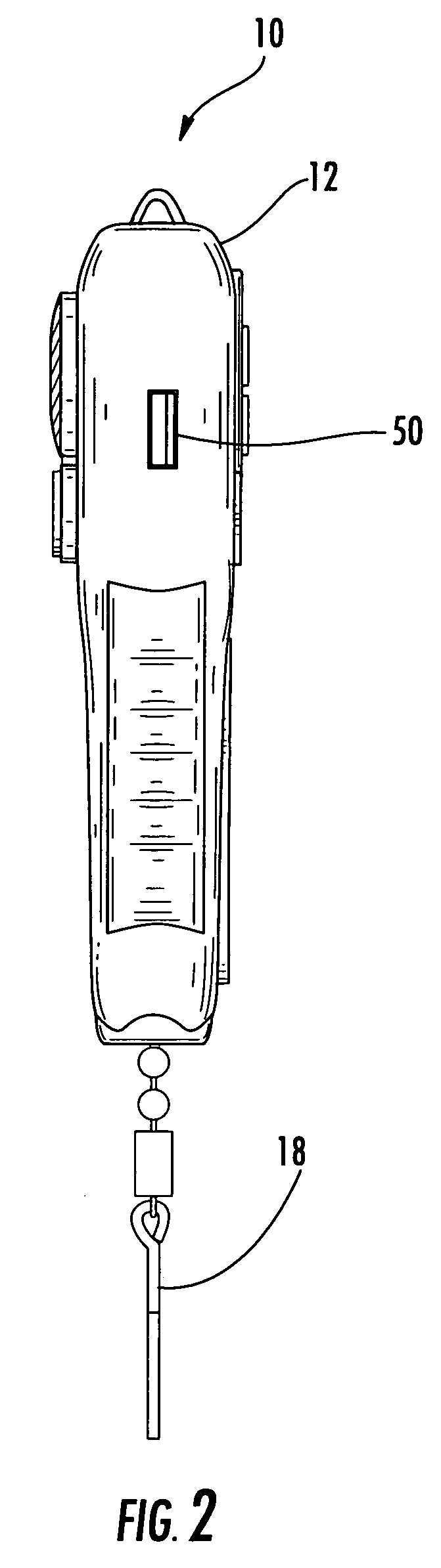

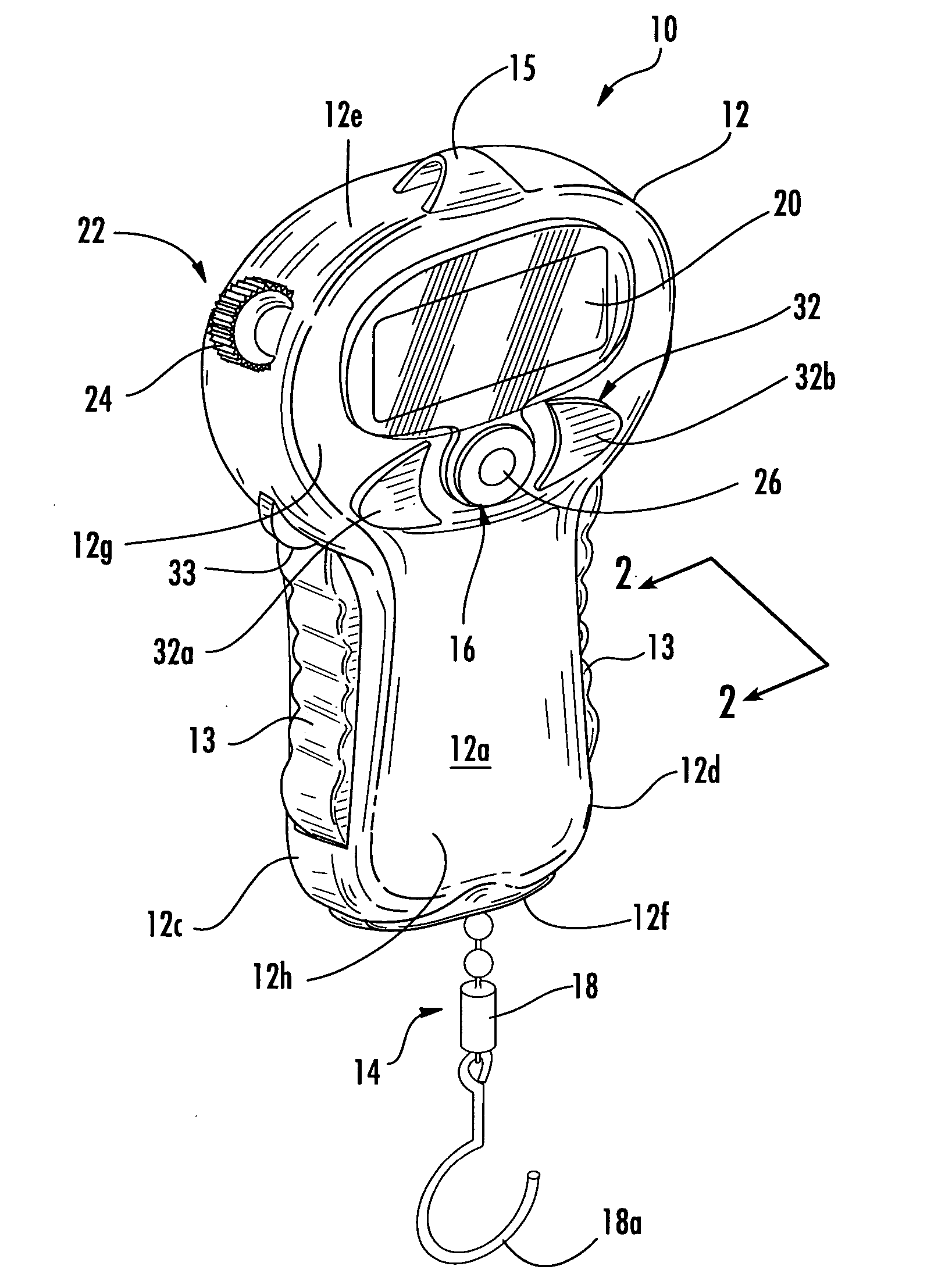

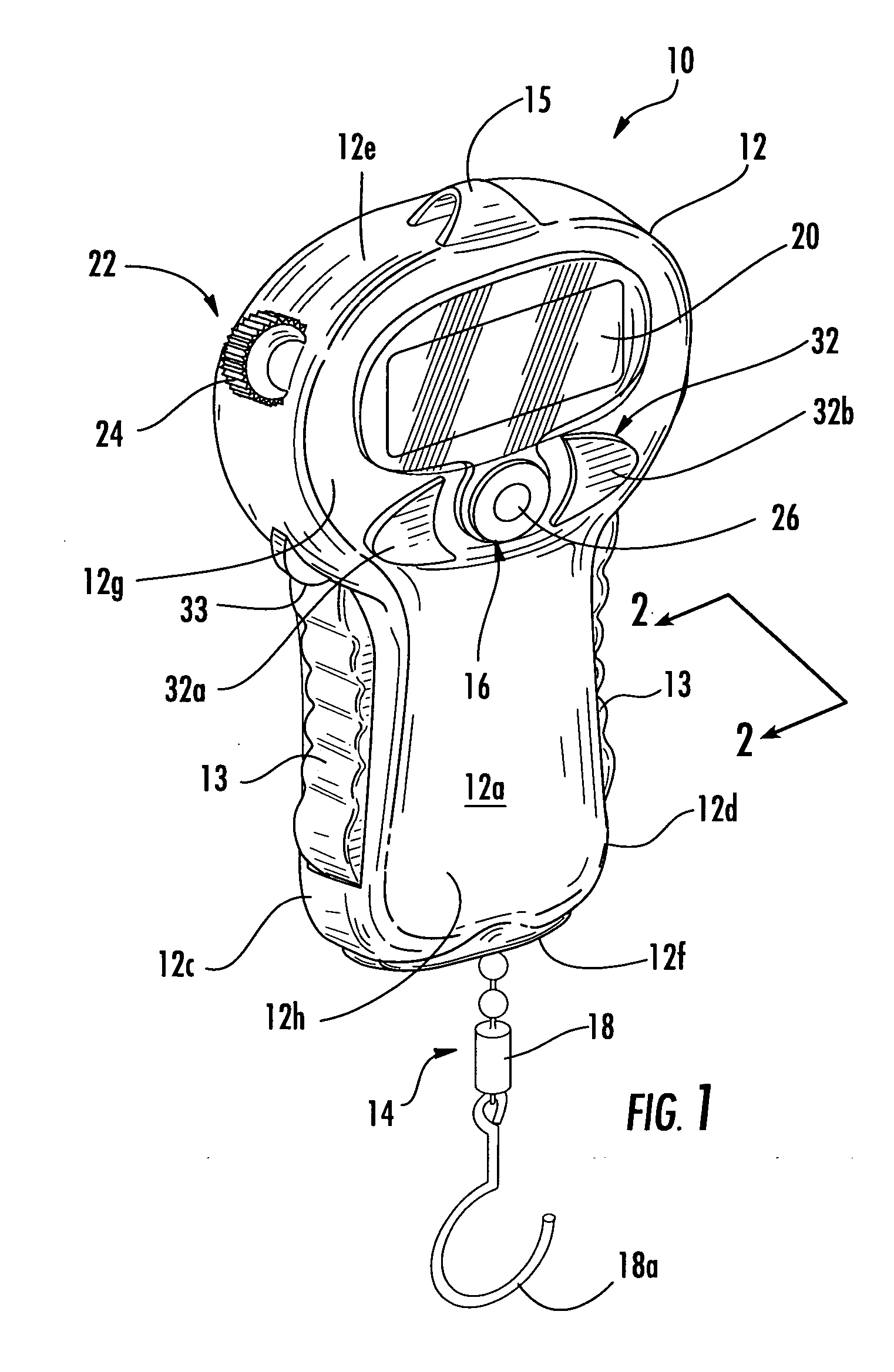

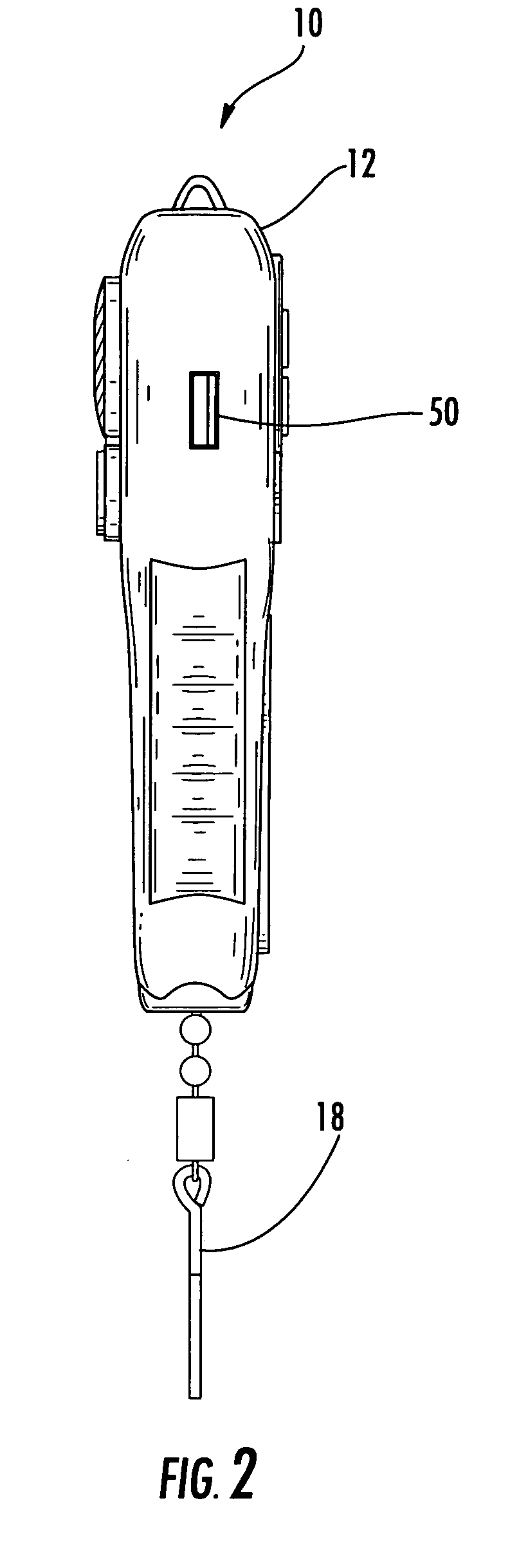

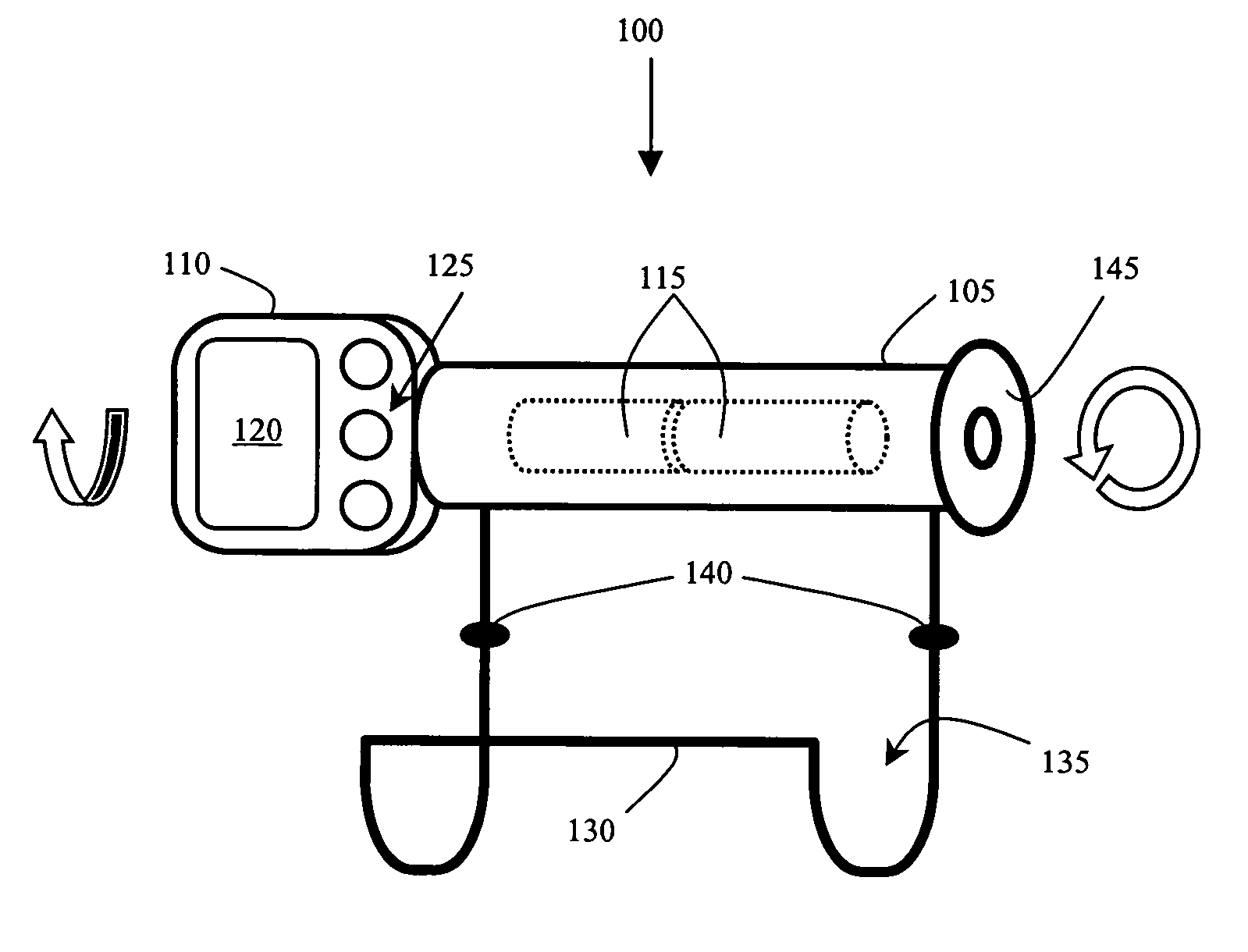

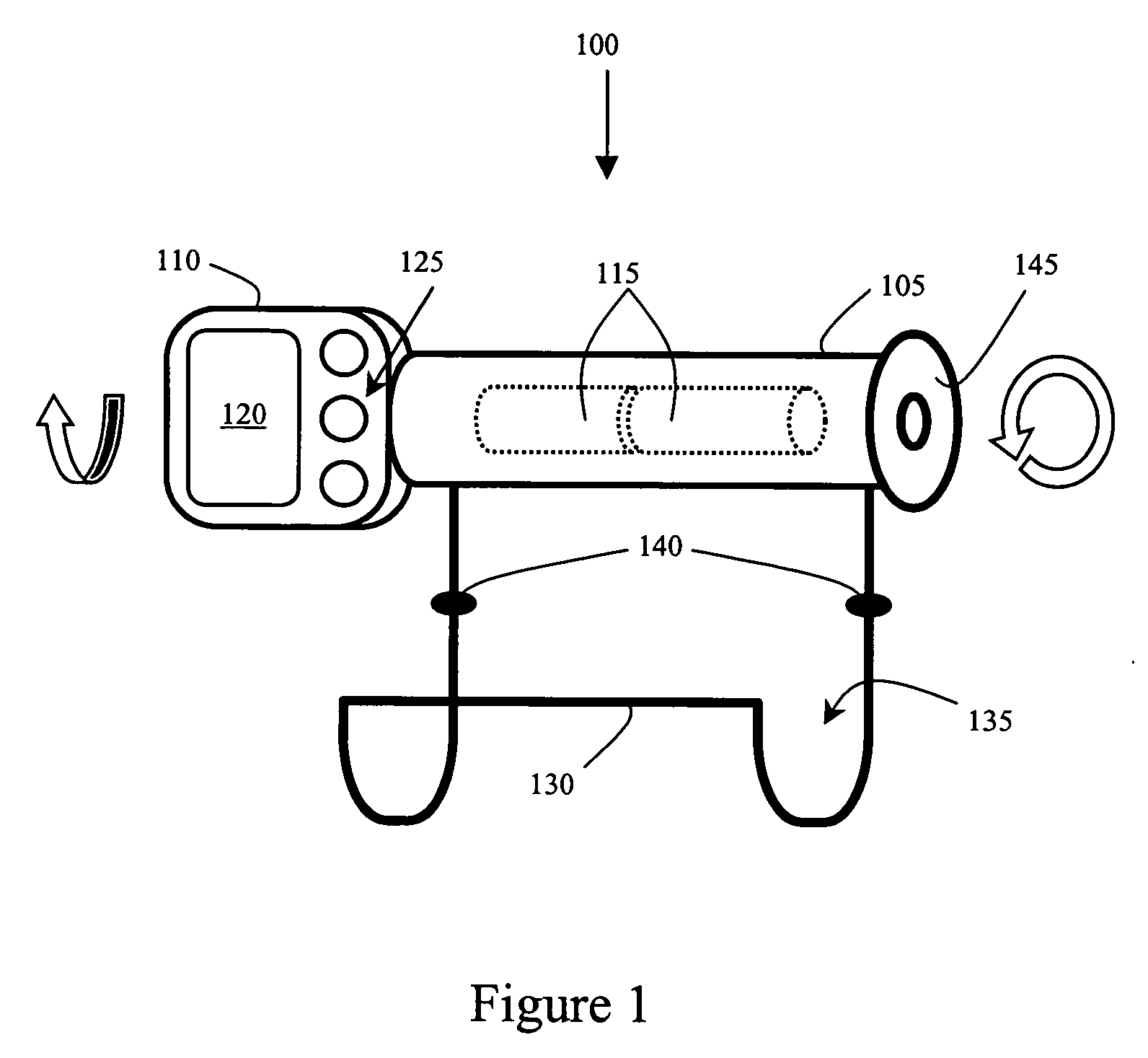

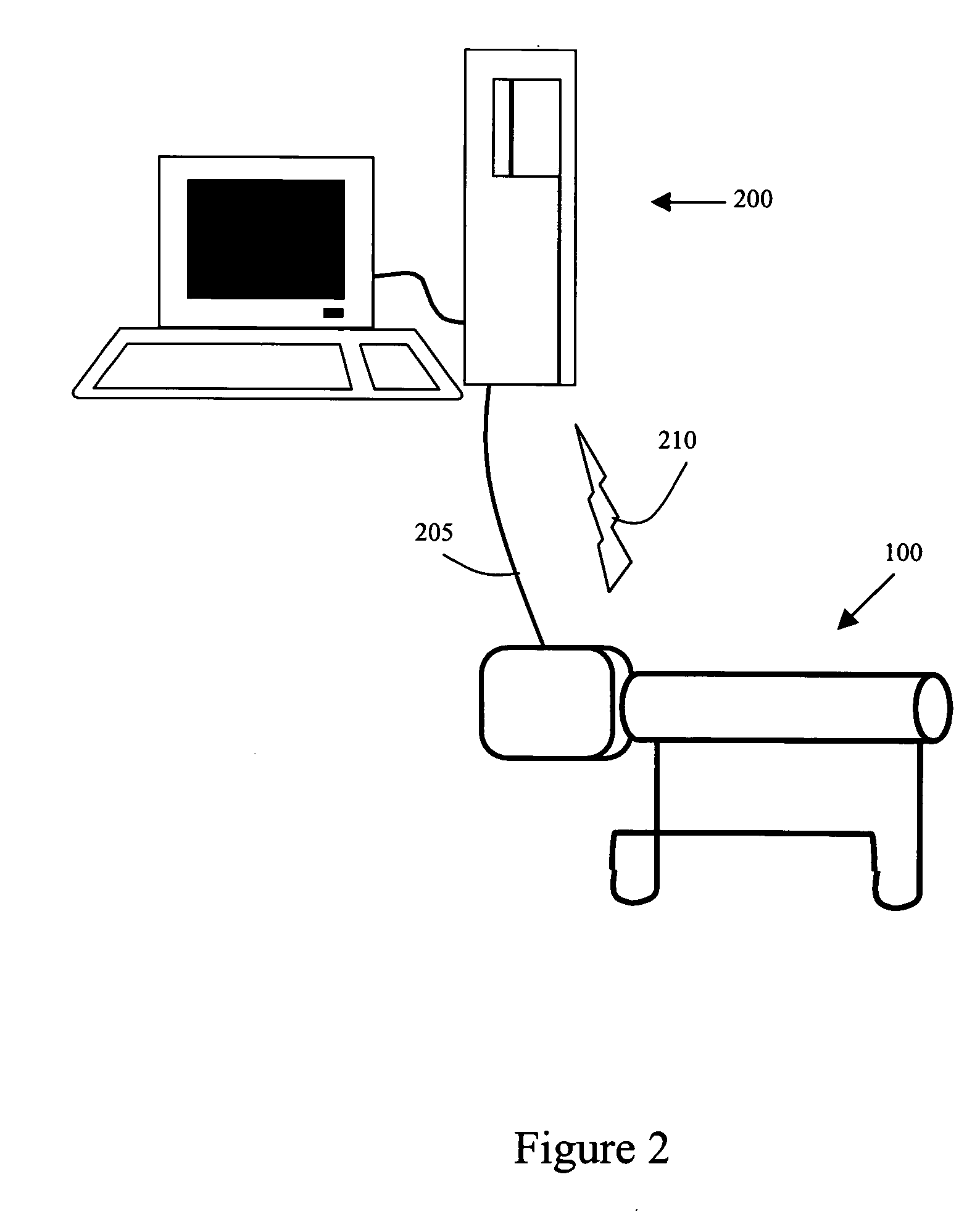

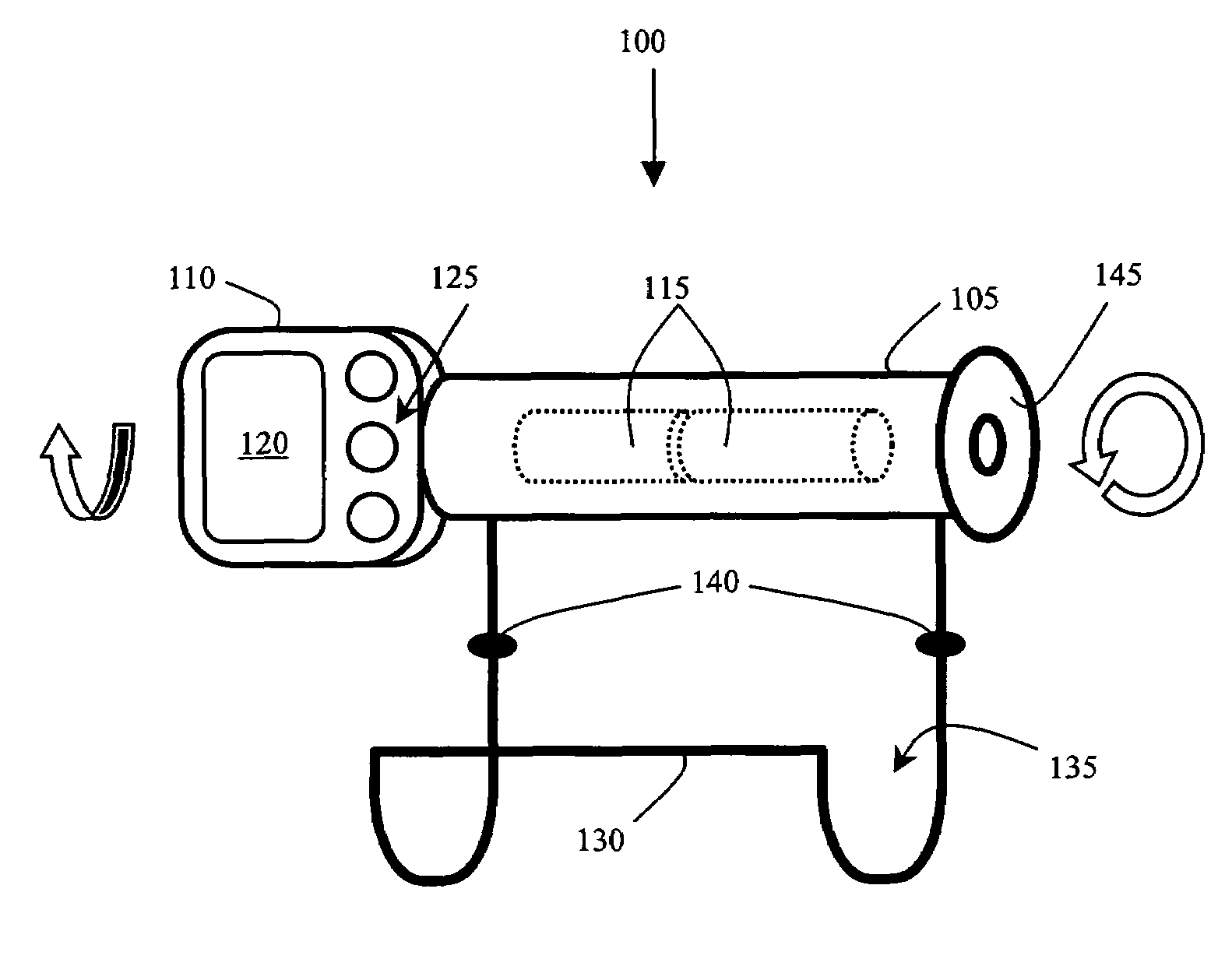

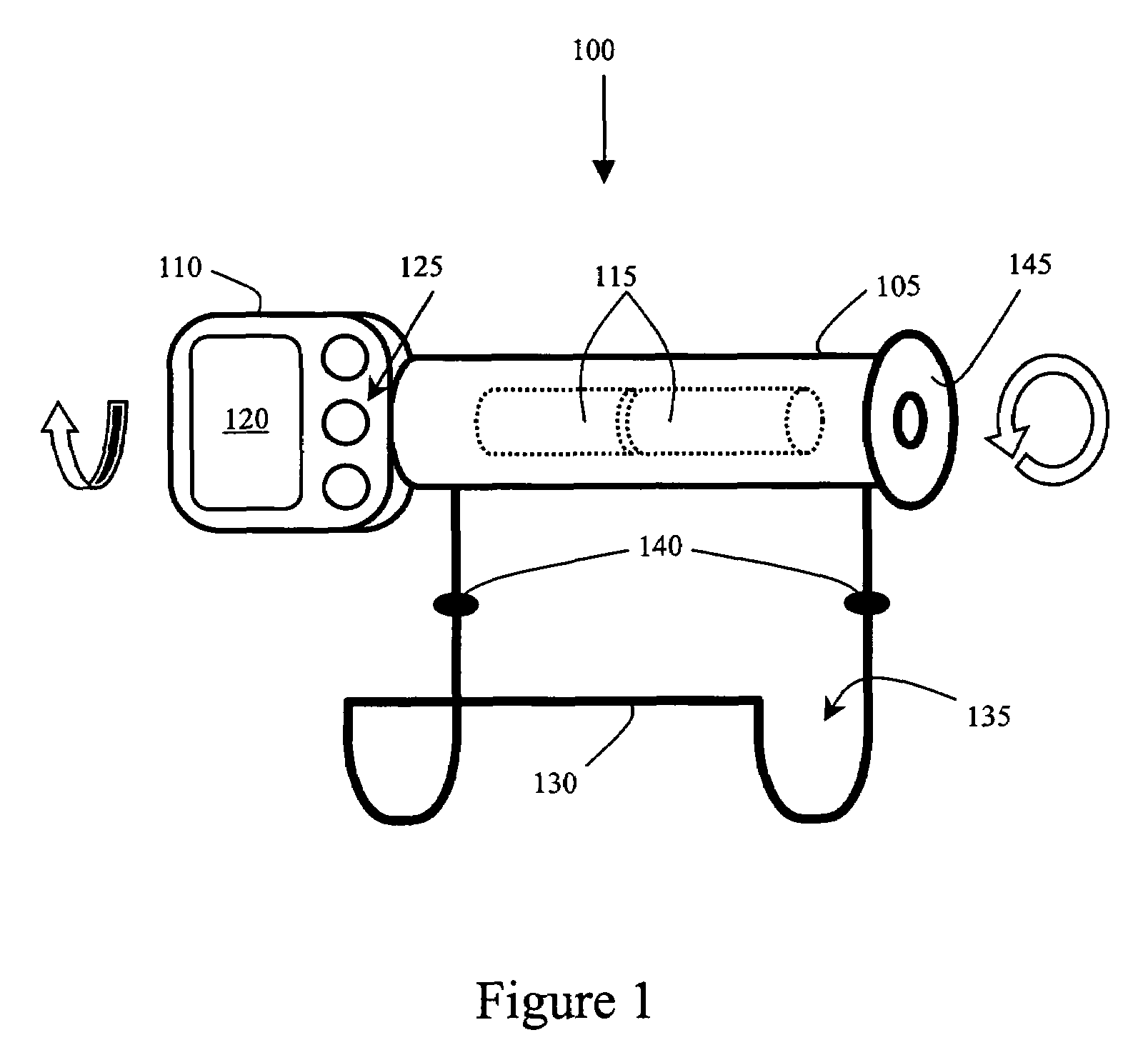

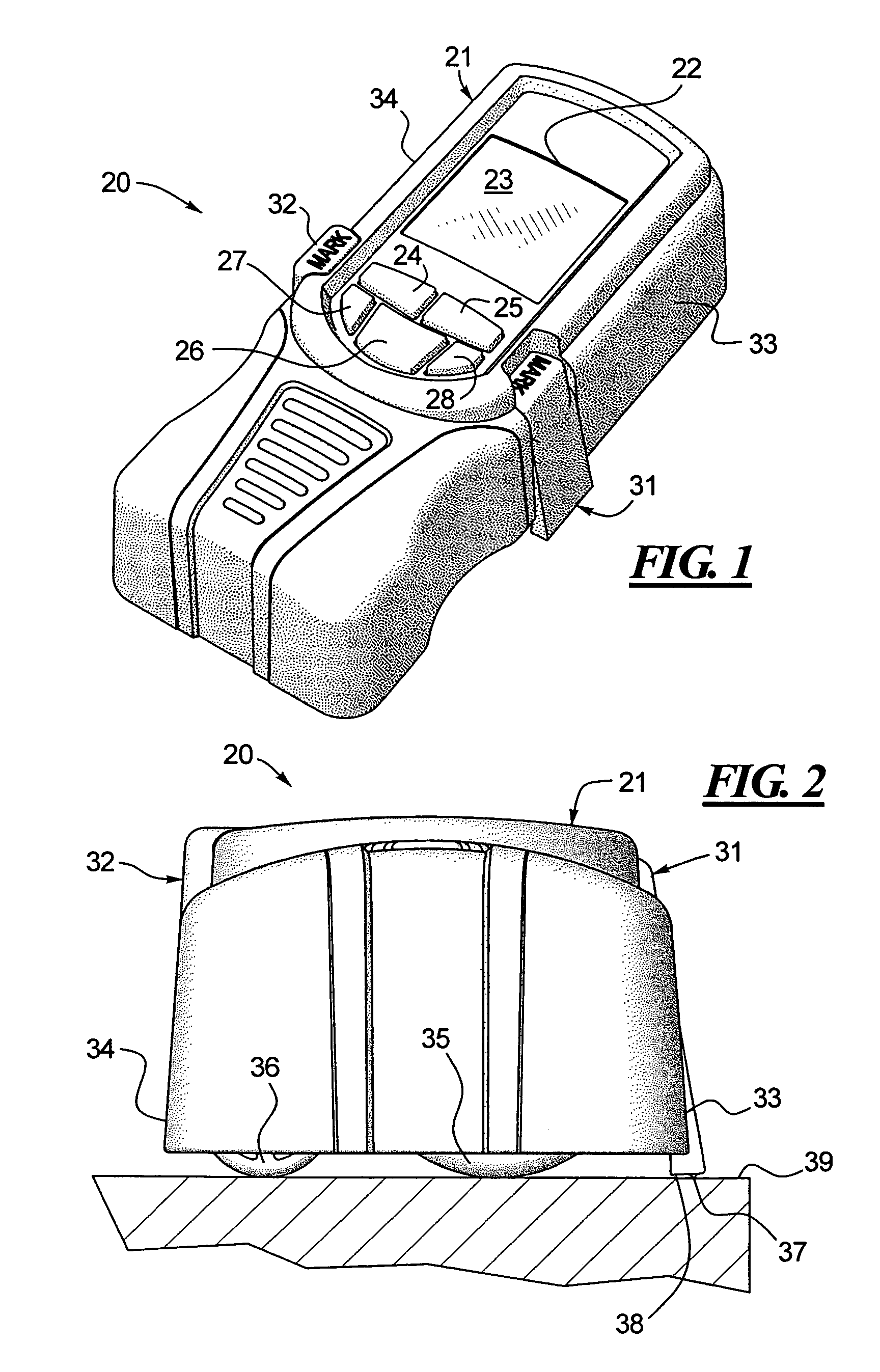

Handheld fish measuring apparatus with integral camera

A handheld apparatus for measuring fish, game, and the like is provided and includes a scale, a camera, and a length measuring device. The scale includes a support member that extends outwardly from the apparatus housing, and a display that is visible through the housing. The support member is configured to suspend an object therefrom for weighing via the scale, and the display is configured to display the weight of an object suspended from the support member. The length measurement device is configured to measure the length of an object and the display is configured to display the length of an object measured by the length measurement device. The camera includes a lens, an image sensor configured to capture images obtained via the lens, and a camera display. The camera display displays an image of an object taken by the camera with weight and / or length information for the object.

Owner:PROPEL IP

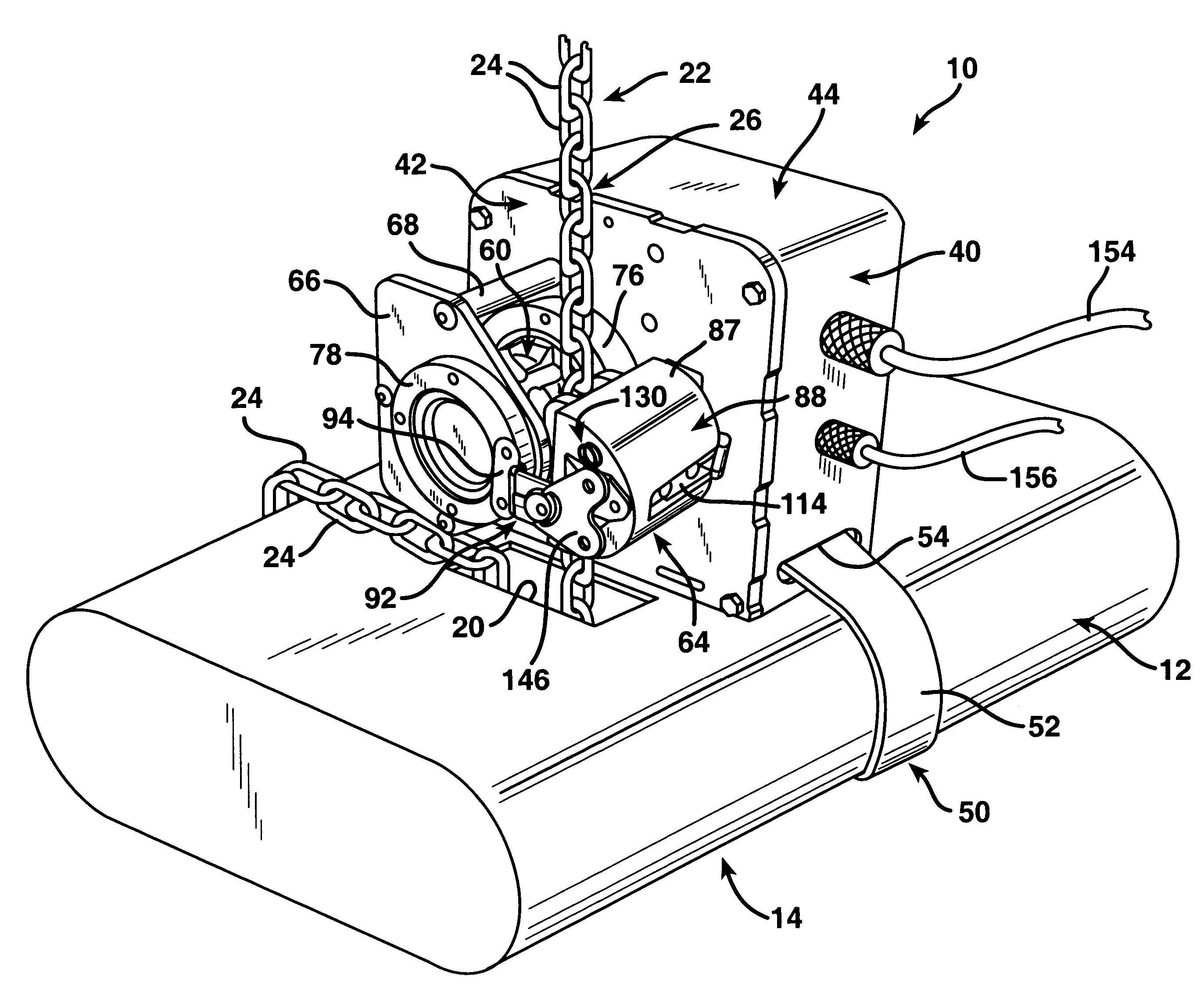

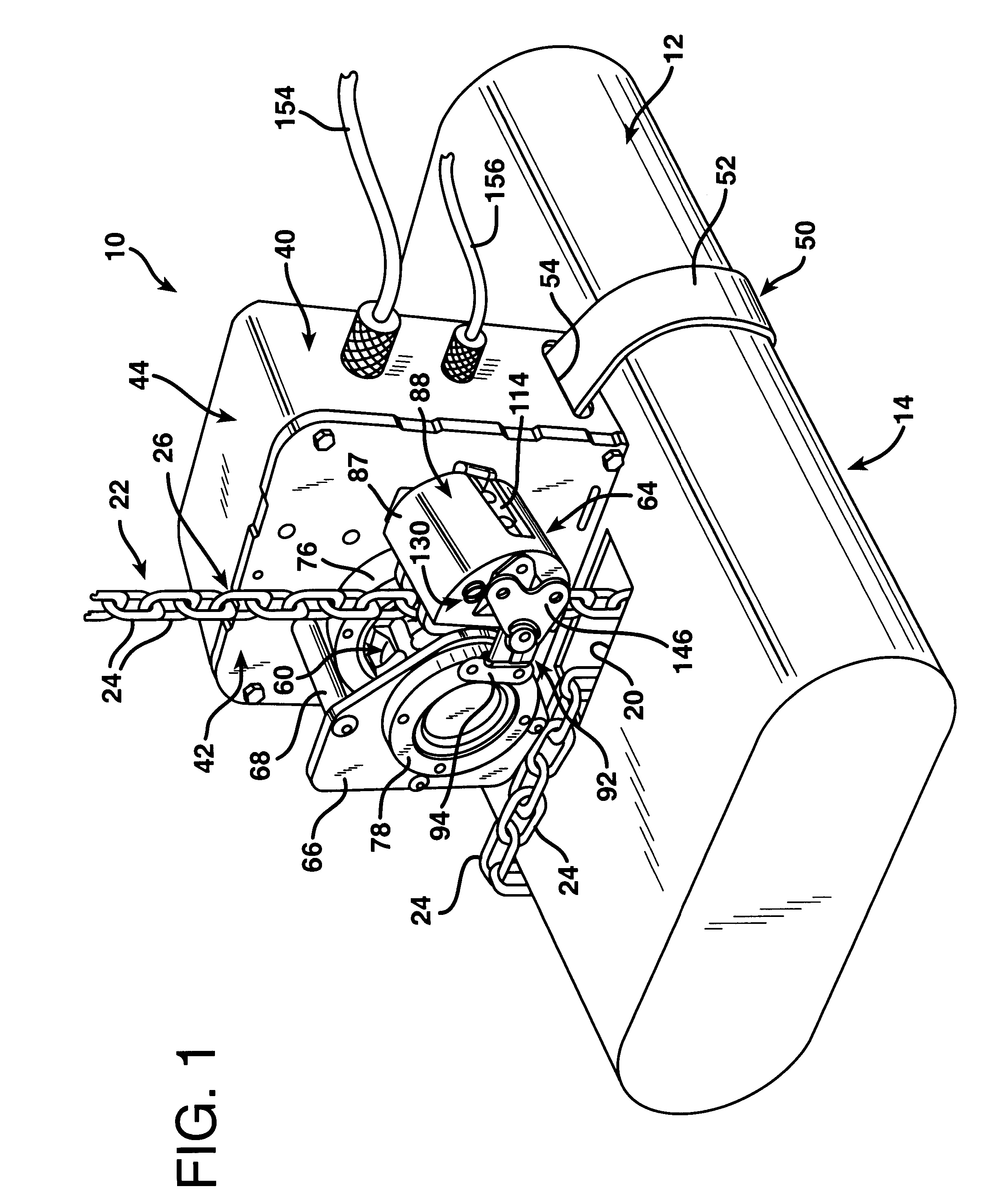

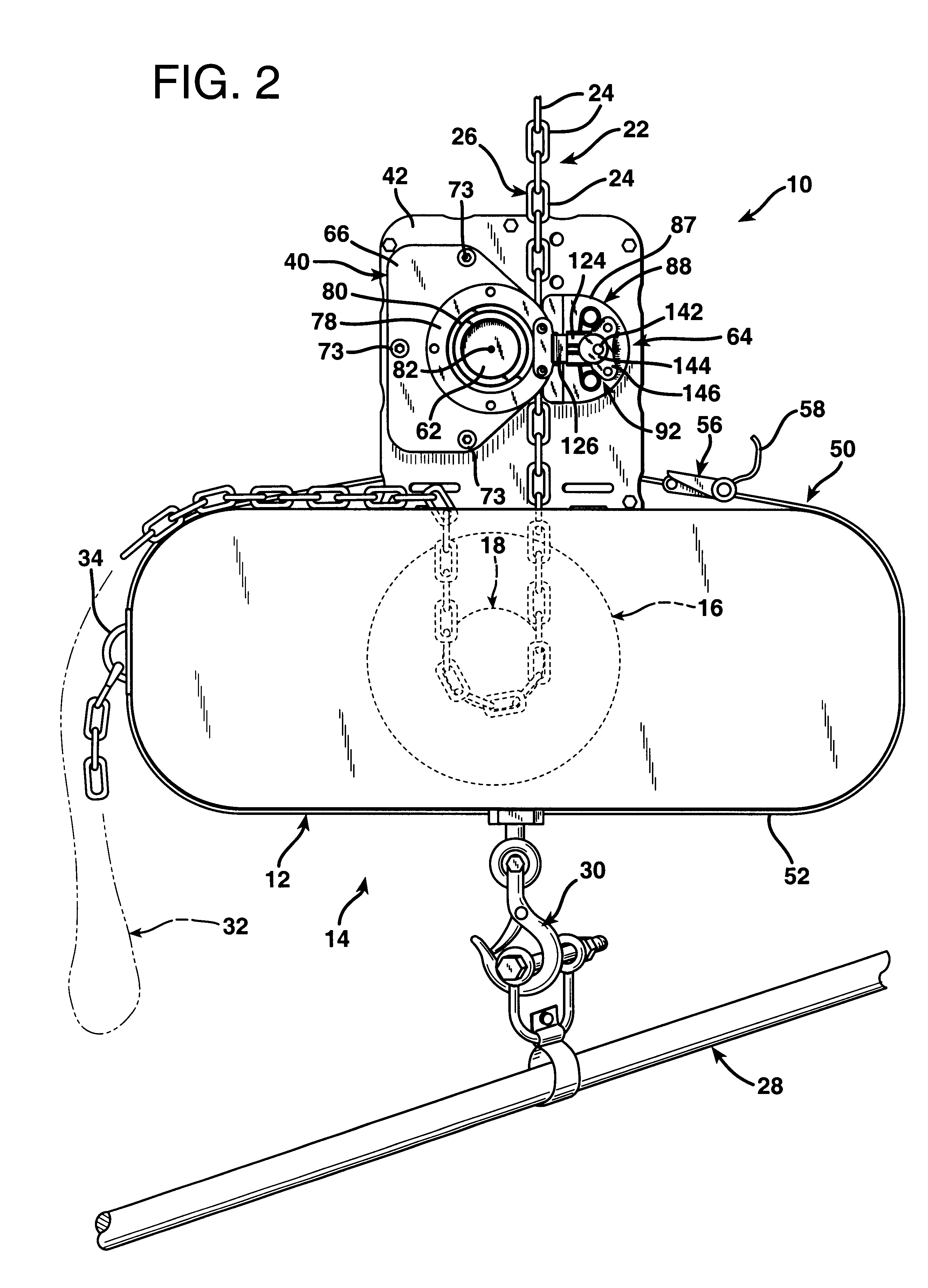

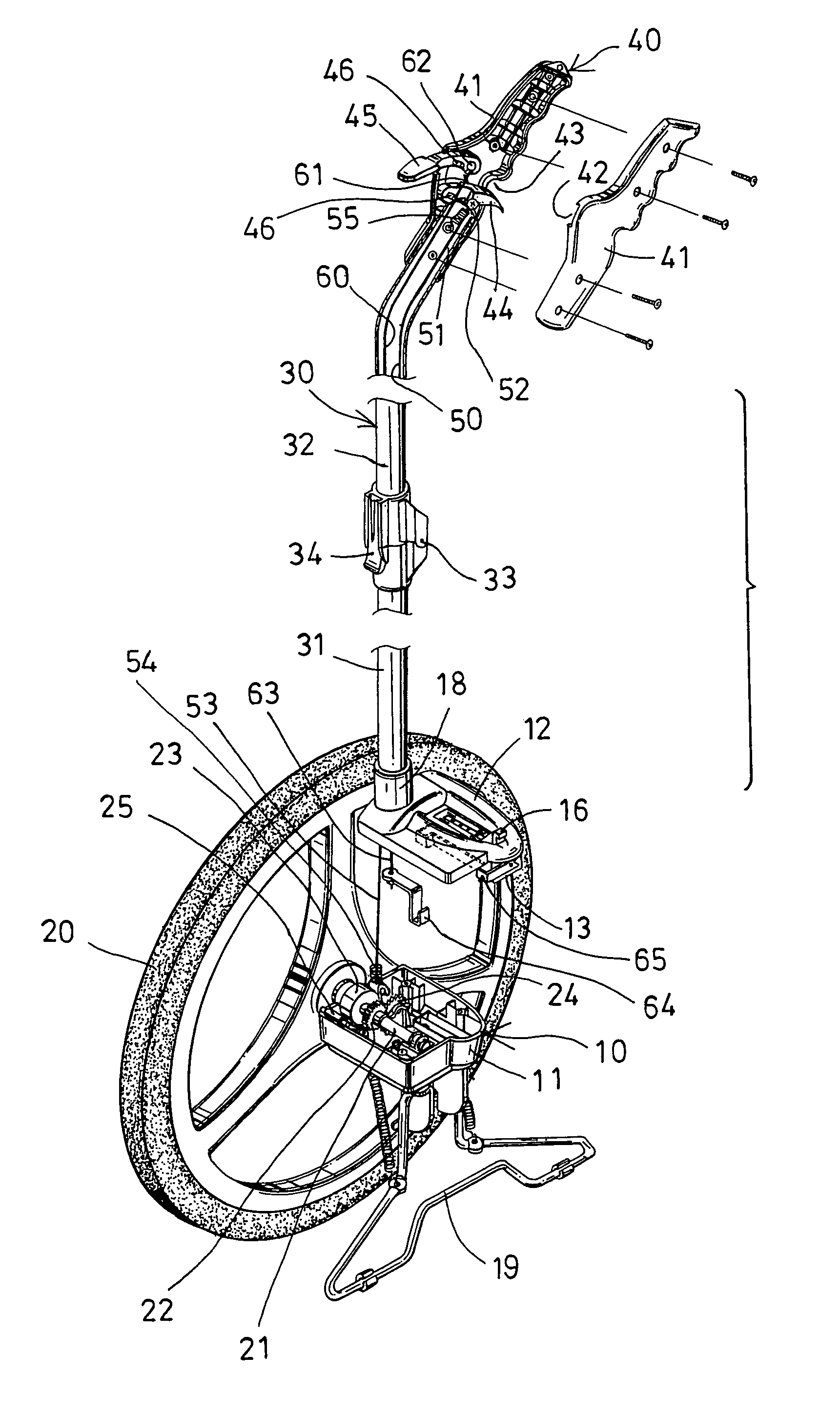

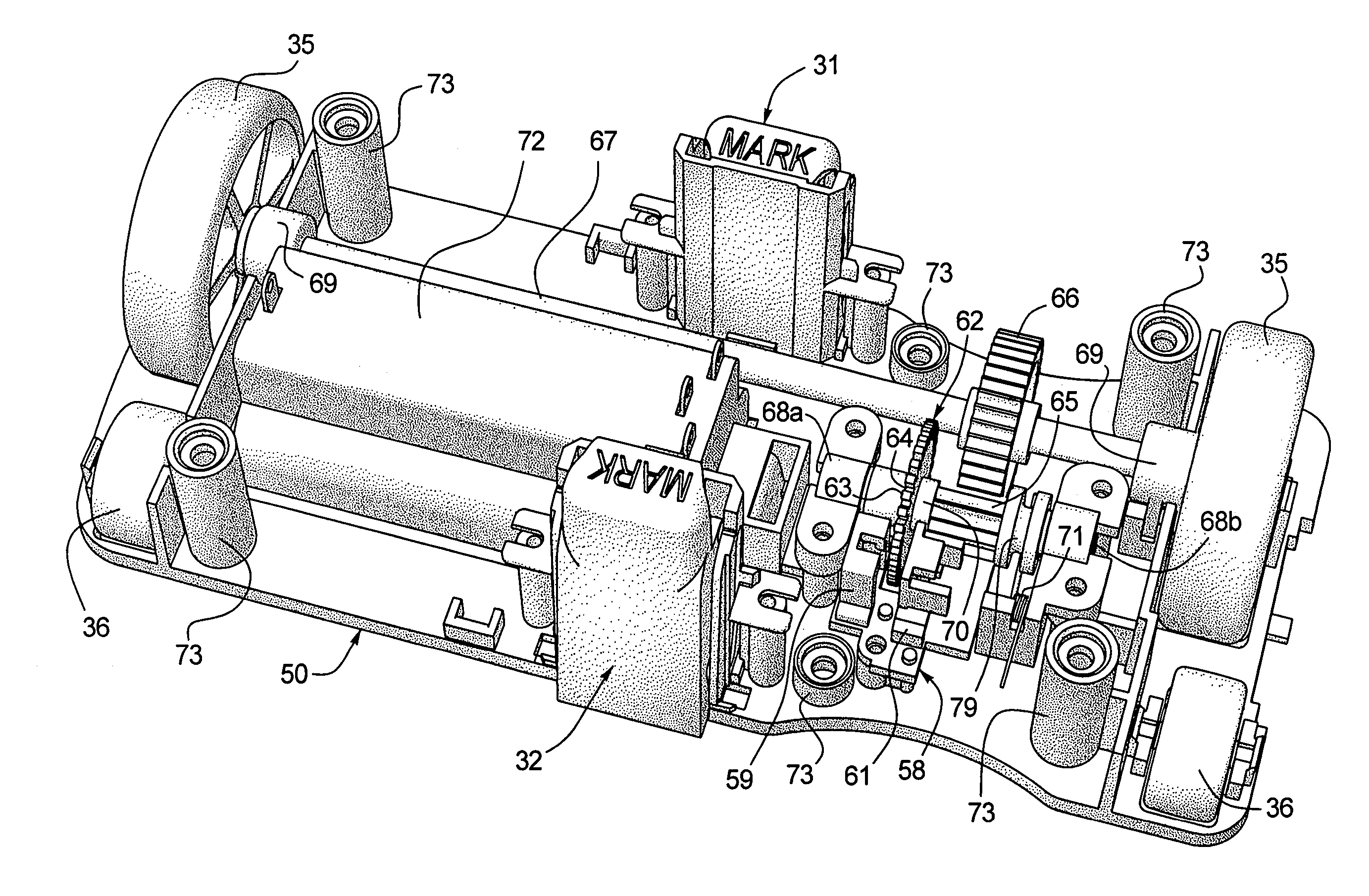

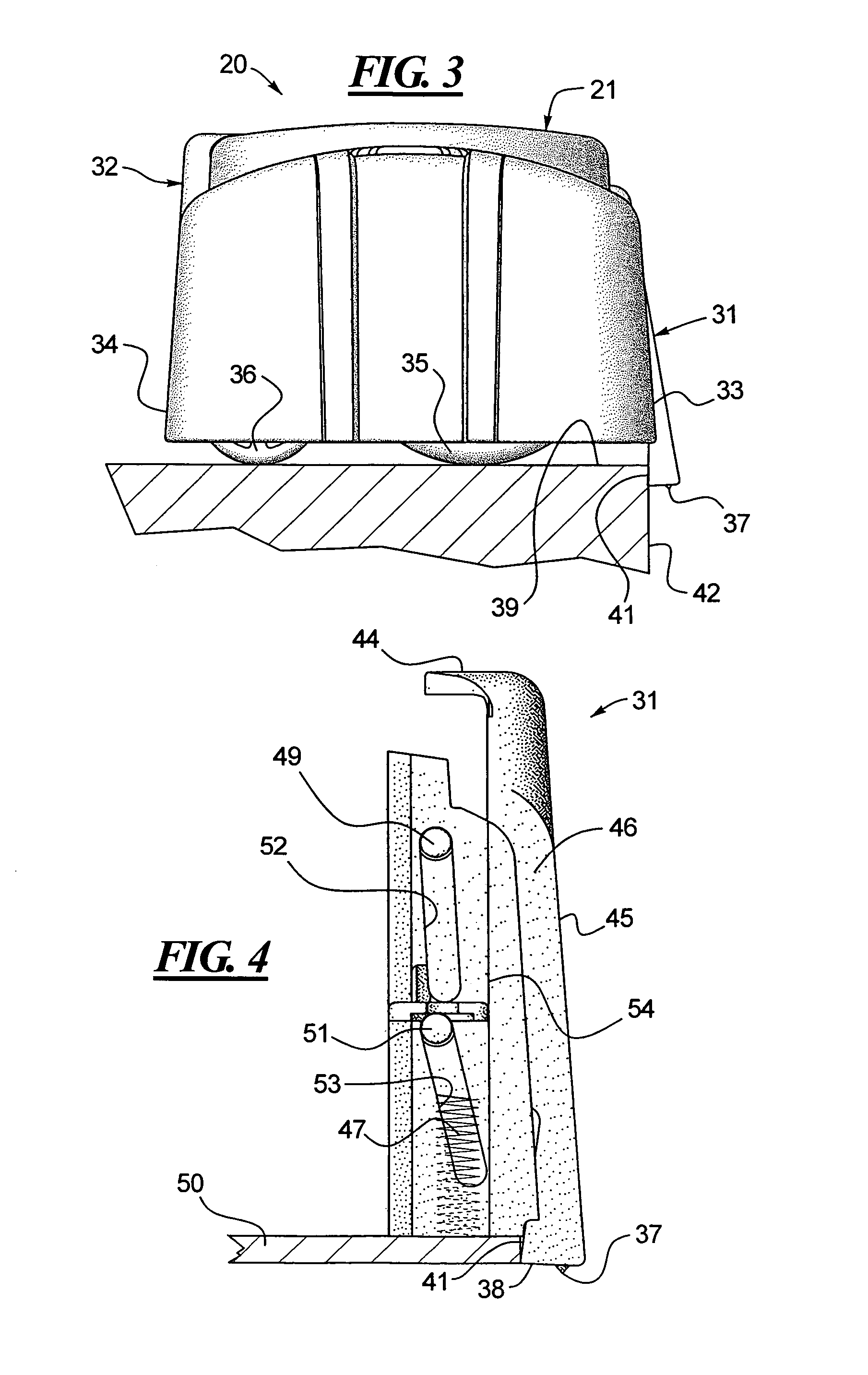

Removable chain hoist position encoder assembly

InactiveUS6209852B1Not easy to damageImprove precision controlMeasuring wheelsPortable liftingEngineeringSprocket

A chain hoist having a casing into which and with respect to which a chain travels is provided with an externally mounted position encoder assembly. A releasable connector, such as a ratchet strap, is employed to firmly but removably couple the position encoder assembly housing externally on the chain hoist casing. The releasable connector holds the position encoder assembly housing in a fixed position relative to the chain hoist casing. The position encoder assembly has a chain gear that is rotatably mounted relative to the position encoder assembly housing proximate to the chain access opening in the chain hoist casing. The precision encoder assembly chain gear engages the portion of the chain that is maintained under tension at a location externally of the chain hoist casing and rotates as the chain travels relative to the chain hoist casing. A releasable clamp is anchored relative to the position encoder assembly housing and is engageable to maintain engagement of the position encoder assembly chain gear with the chain. An encoder is mounted with respect to the position encoder assembly housing and detects rotational movement of the position encoder assembly chain gear. The sensor provides electrical output signals indicative of the extent and direction of rotational movement of the position encoder assembly chain gear. The position encoder assembly provides precise, reliable output signals indicative of the position of the chain relative to the chain hoist. The position encoder assembly may be readily removed from the chain hoist, and just as easily attached thereto.

Owner:GEORGE & GOLDBERG DESIGN ASSOC

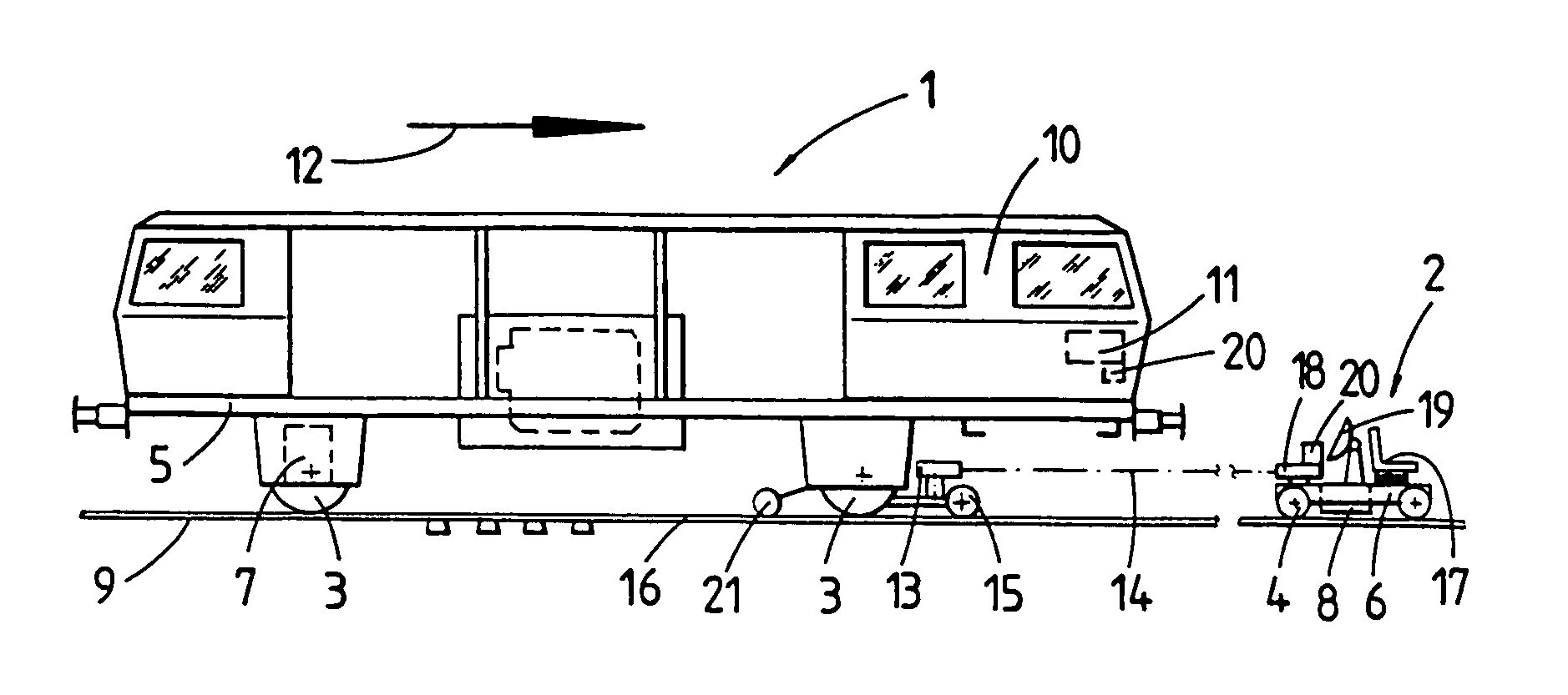

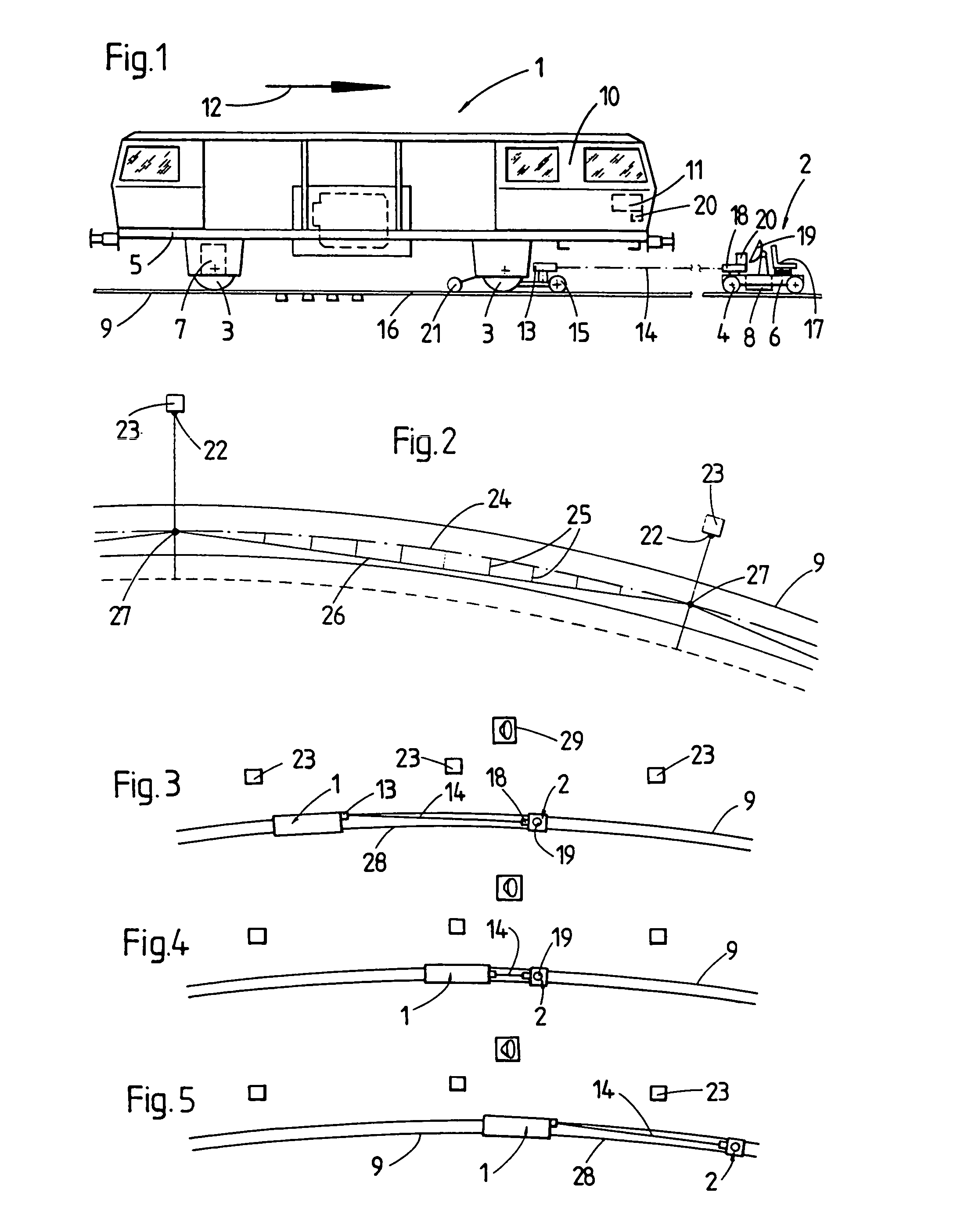

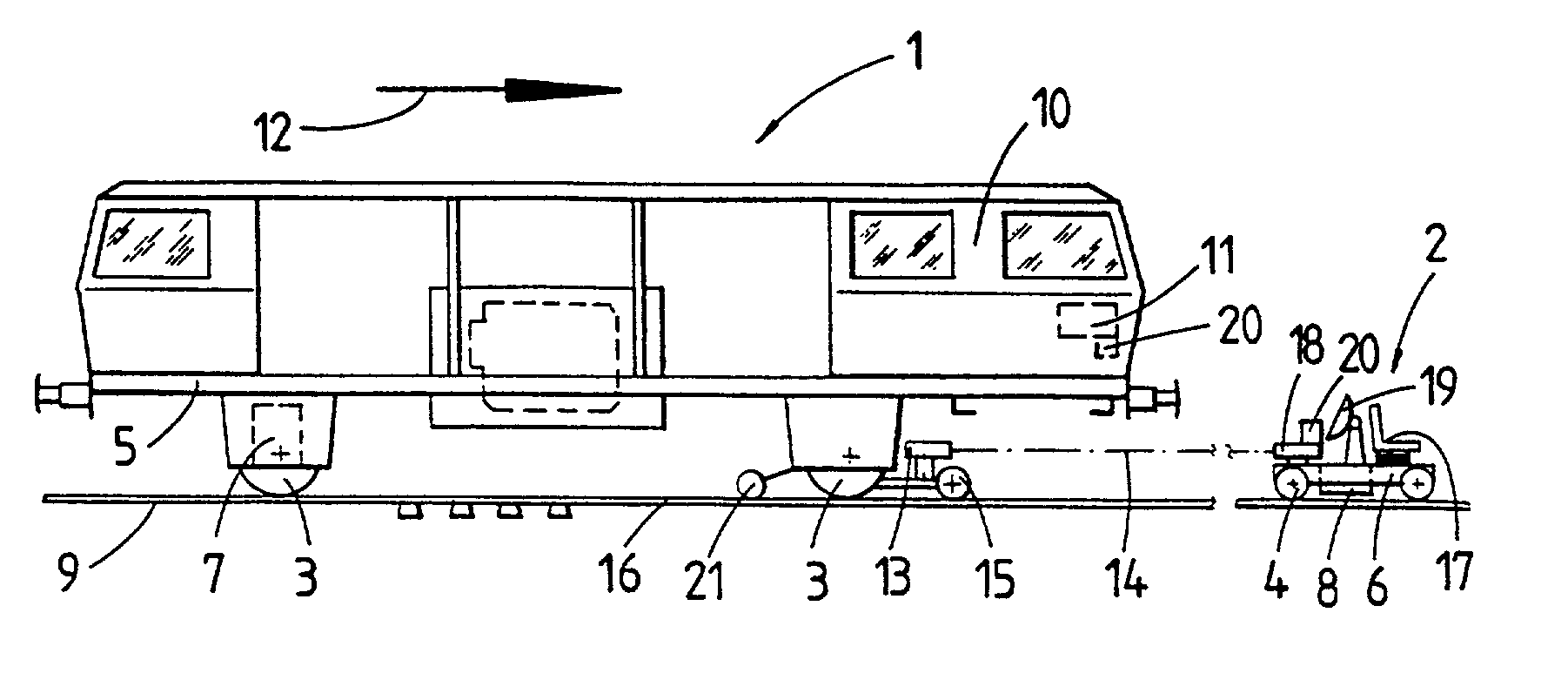

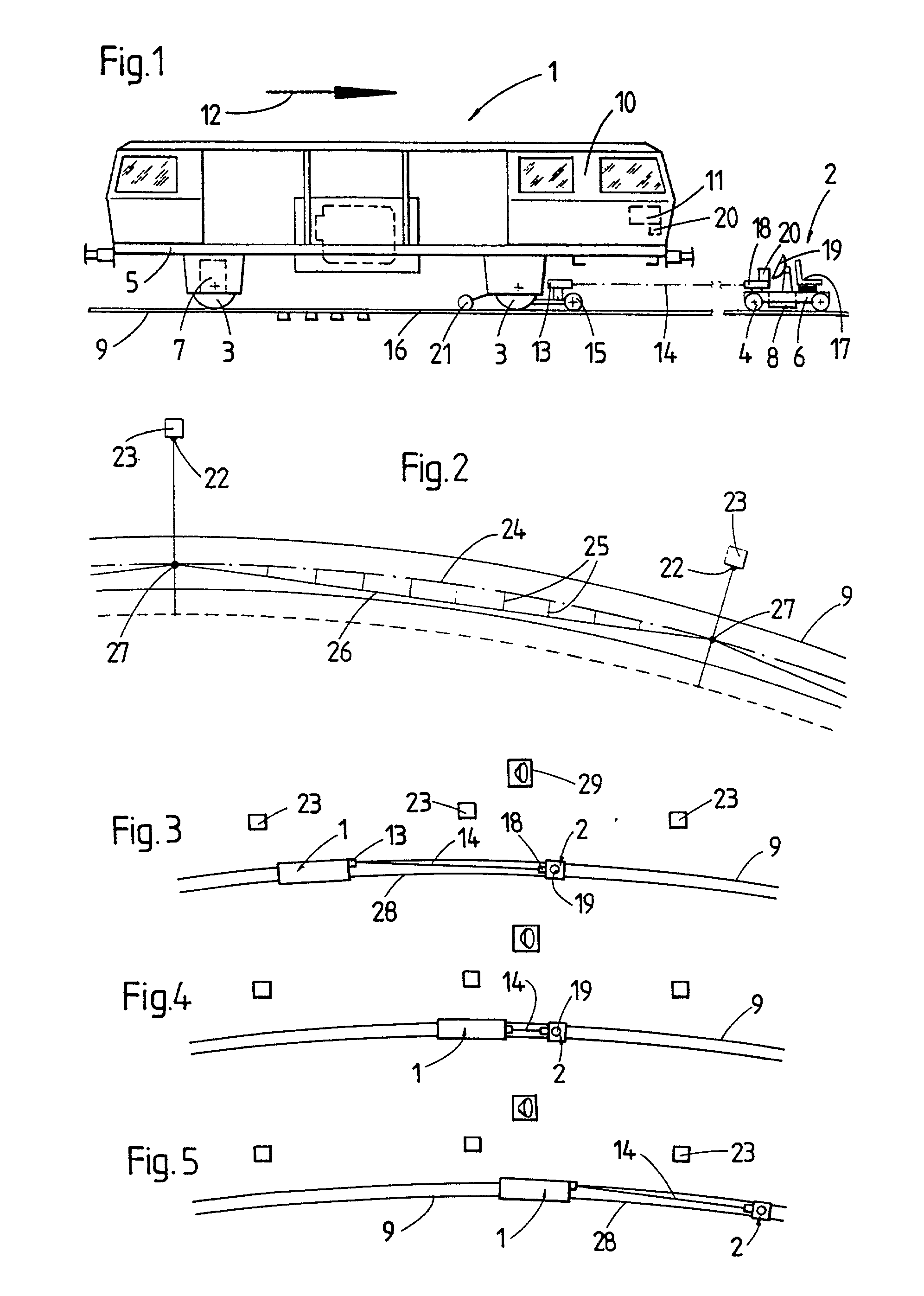

Method of surveying a track

InactiveUS7050926B2Improve accuracyFast progressBallastwayDigital data processing detailsGps receiverEngineering

In a method of surveying a track (9), a first or mobile measuring vehicle (1) and a second or stationary measuring vehicle (2) are placed at a distance apart from one another on a track section to be measured. A reference line (14) is formed by a laser beam emitted from the stationary measuring vehicle (2). At the start of each measuring cycle, by using a GPS receiver (19), the relative position of the stationary measuring vehicle (2) with reference to a fixedly installed GPS reference station (29) located adjacent to the track section is determined, the said GPS reference station being known within a terrestrial coordinate system. The reference line (14) is aligned with the mobile measuring vehicle (1) on the basis of the determined position data, and the track surveying operation is carried out by advancing the mobile measuring vehicle (1) while changes of the actual track position relative to the reference line (14) are registered.

Owner:FRANZ PLASSER BAHNBAUMASCHINEN IND GMBH

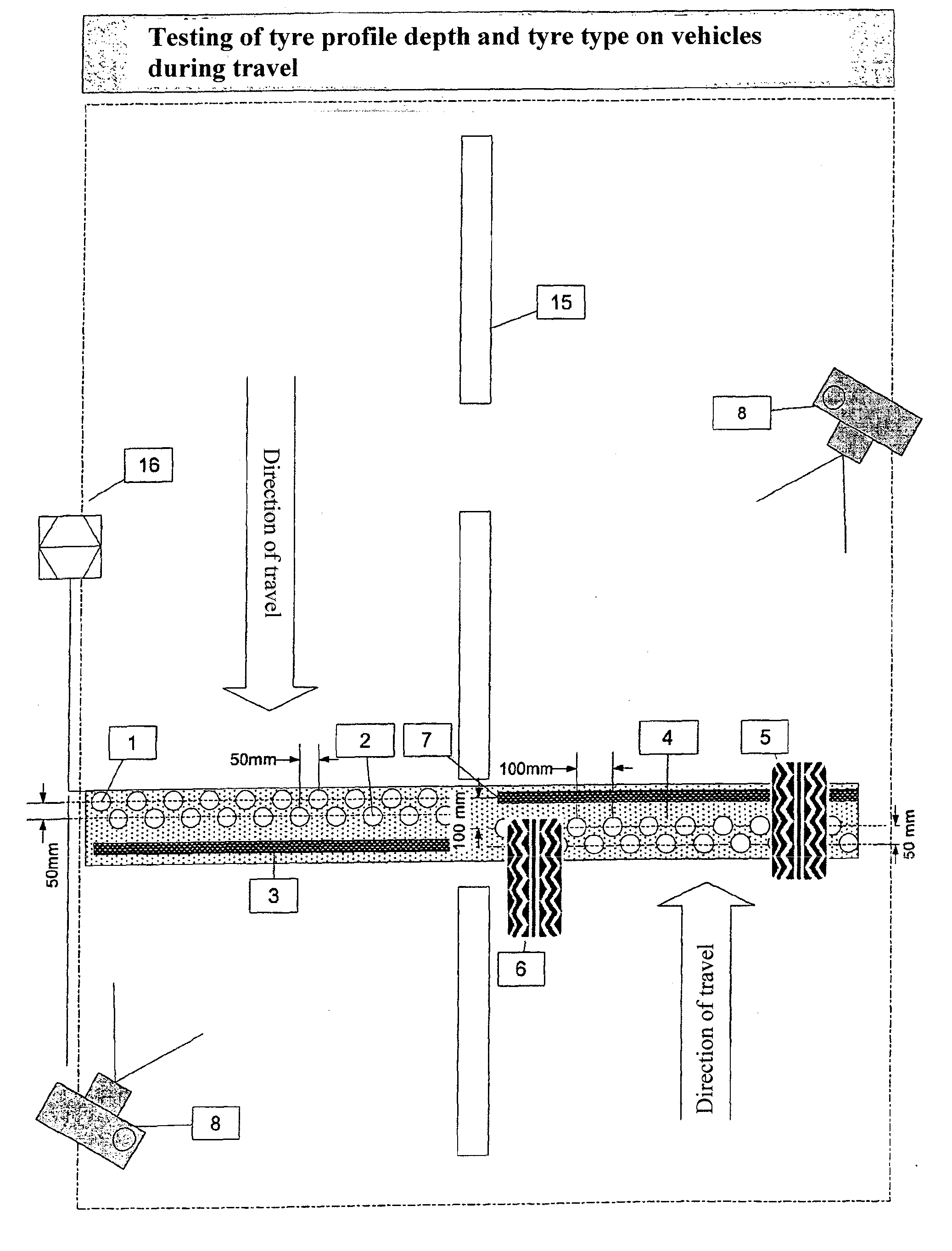

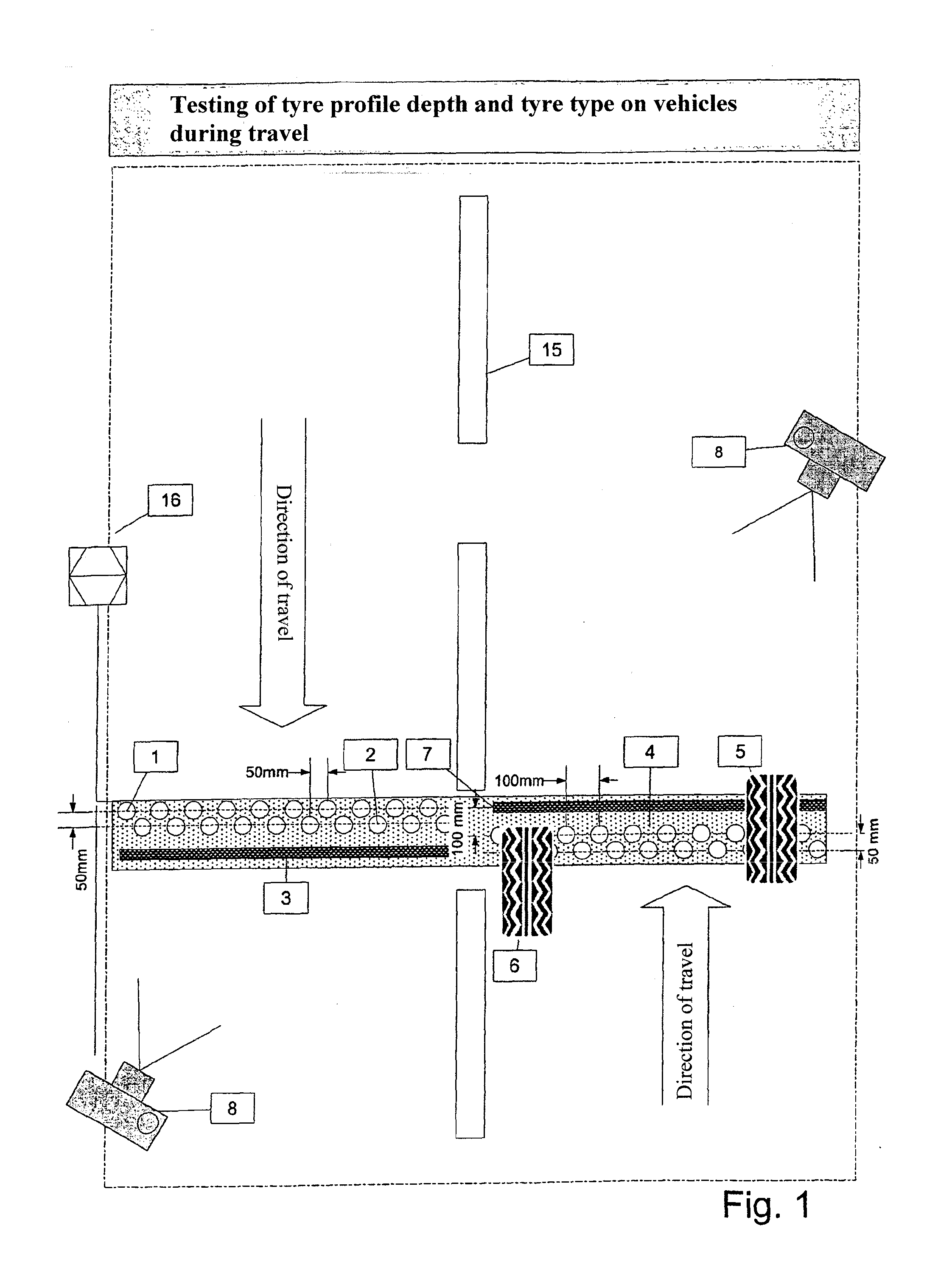

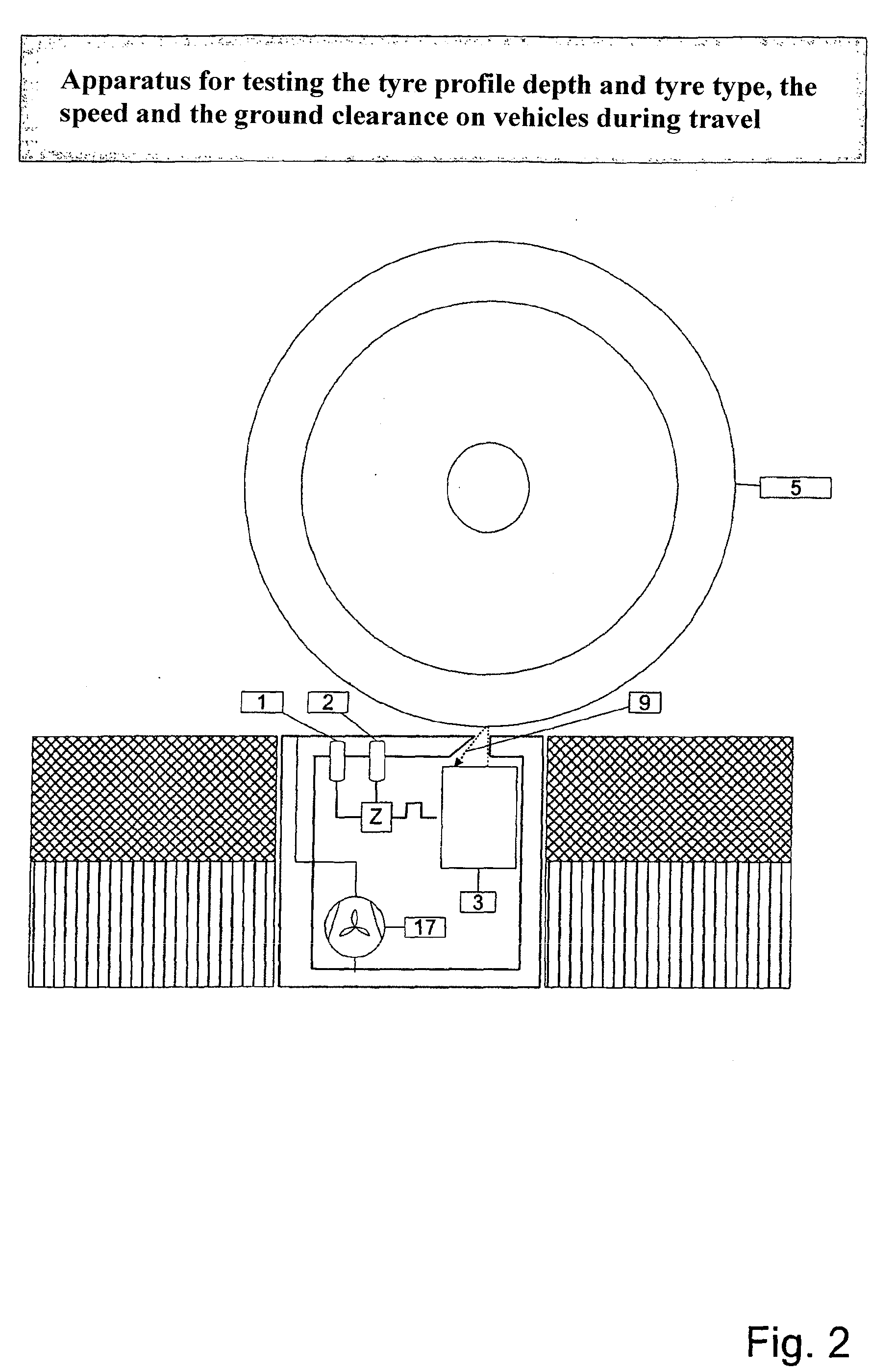

Device for Checking the Tire Profile Depth and Profile Type, and the Speed and Ground Clearance of Vehicles in Motion

InactiveUS20080256815A1Better presentAvoid problemsMeasuring wheelsUsing optical meansAcceleration UnitAutomotive engineering

A device for detecting a profile depth and / or a profile type of a vehicle tire has a profile-measuring device, a camera system for detecting the vehicle, an evaluating unit, which couples the profile-measuring device and the camera system to one another; and further having at least one of the components: a speed-measuring device for detecting the vehicle speed; a direction of travel-measuring device for detecting the steering situation or movement direction of the vehicle, wherein the evaluating unit is designed to produce a measuring signal for the current acceleration of the vehicle and the control is designed to permit an evaluation only when the vehicle is situated in a preset frame at a relatively uniform speed; and wherein a measuring signal for the movement direction of the vehicle can be produced by the evaluating unit and the measuring signal is provided for control of the evaluation of the profile measurement and the control is designed to permit an evaluation only when the vehicle is situated in a preset frame when traveling in a straight line.

Owner:SCHAFER FR H

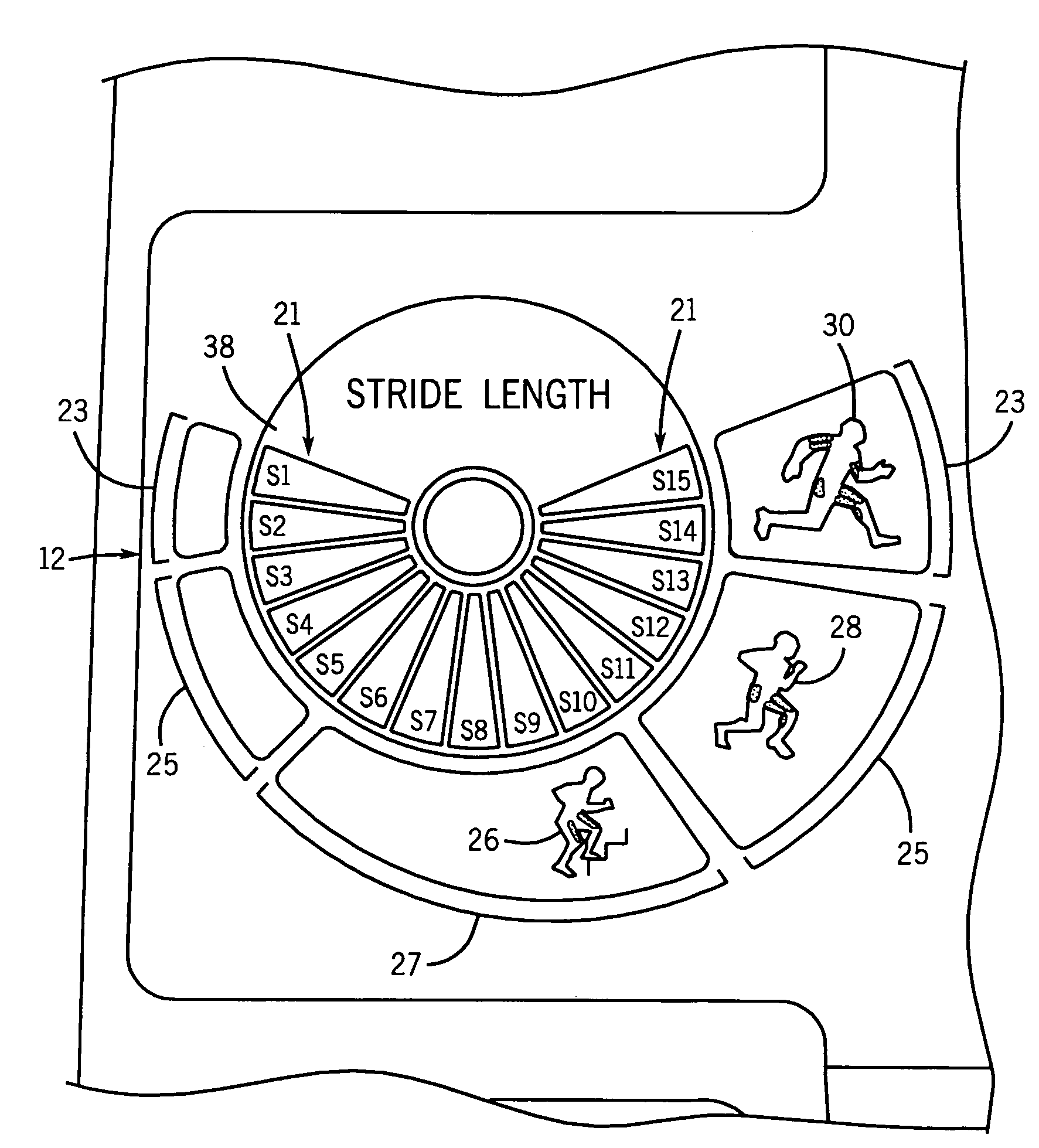

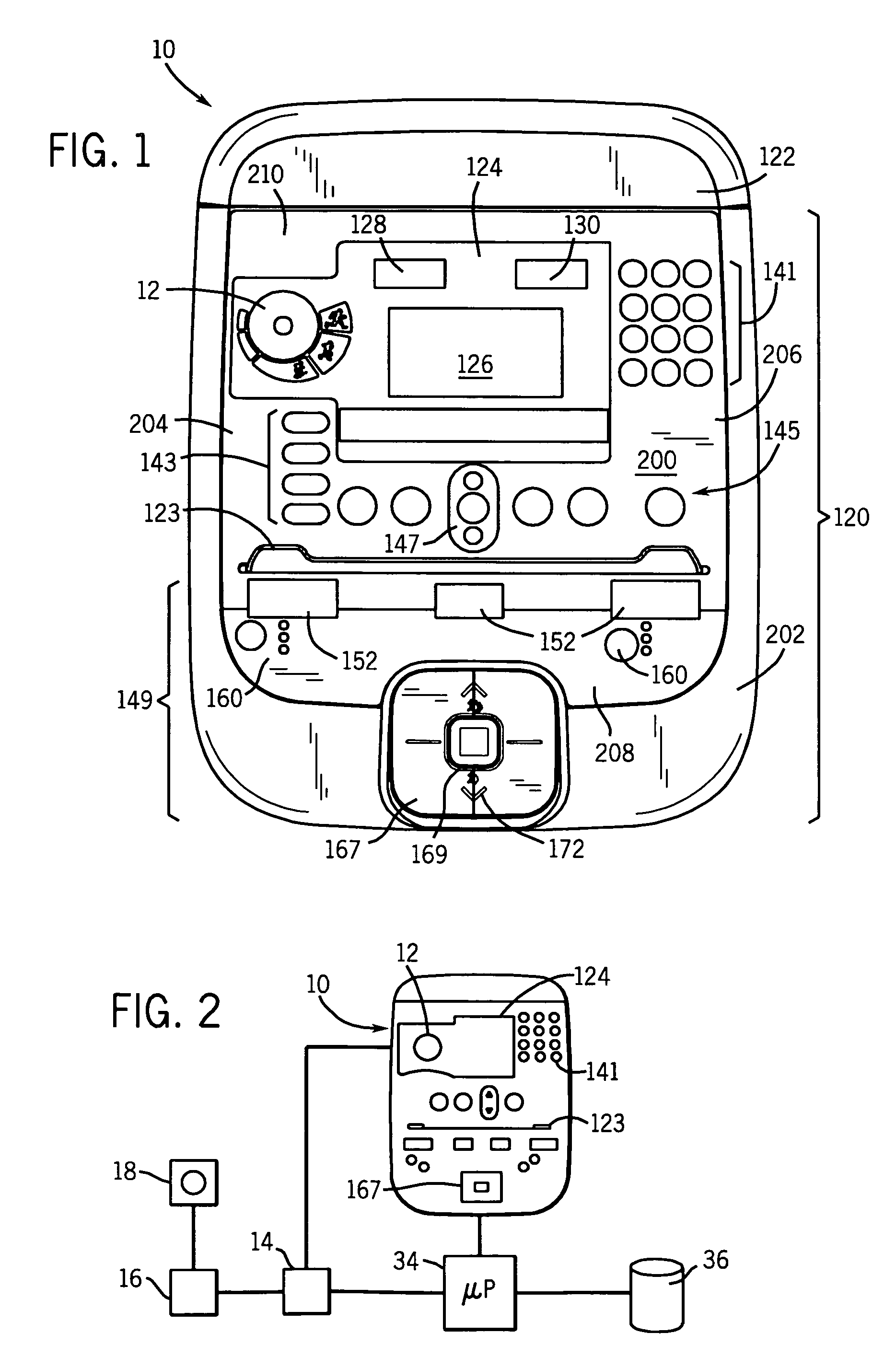

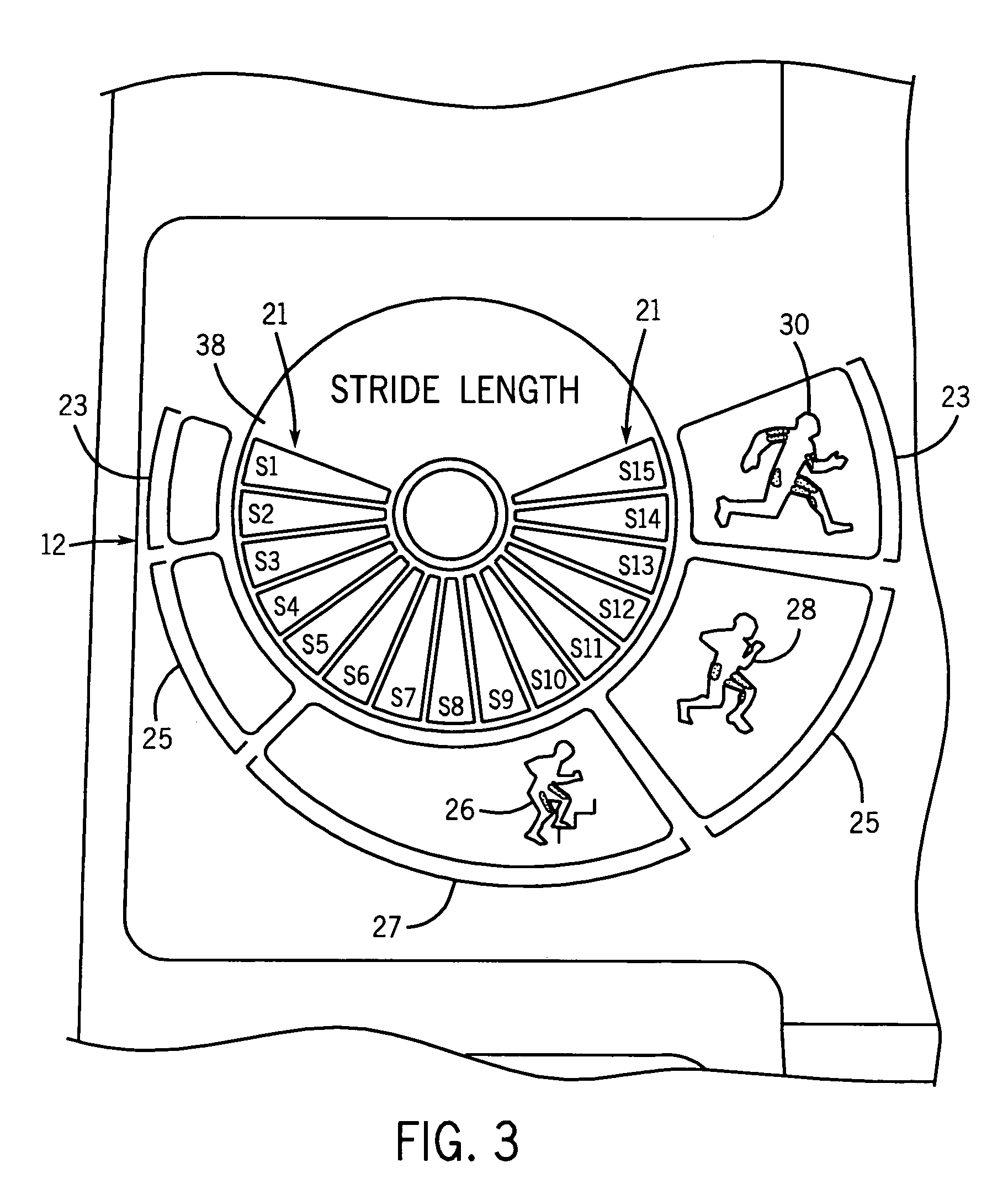

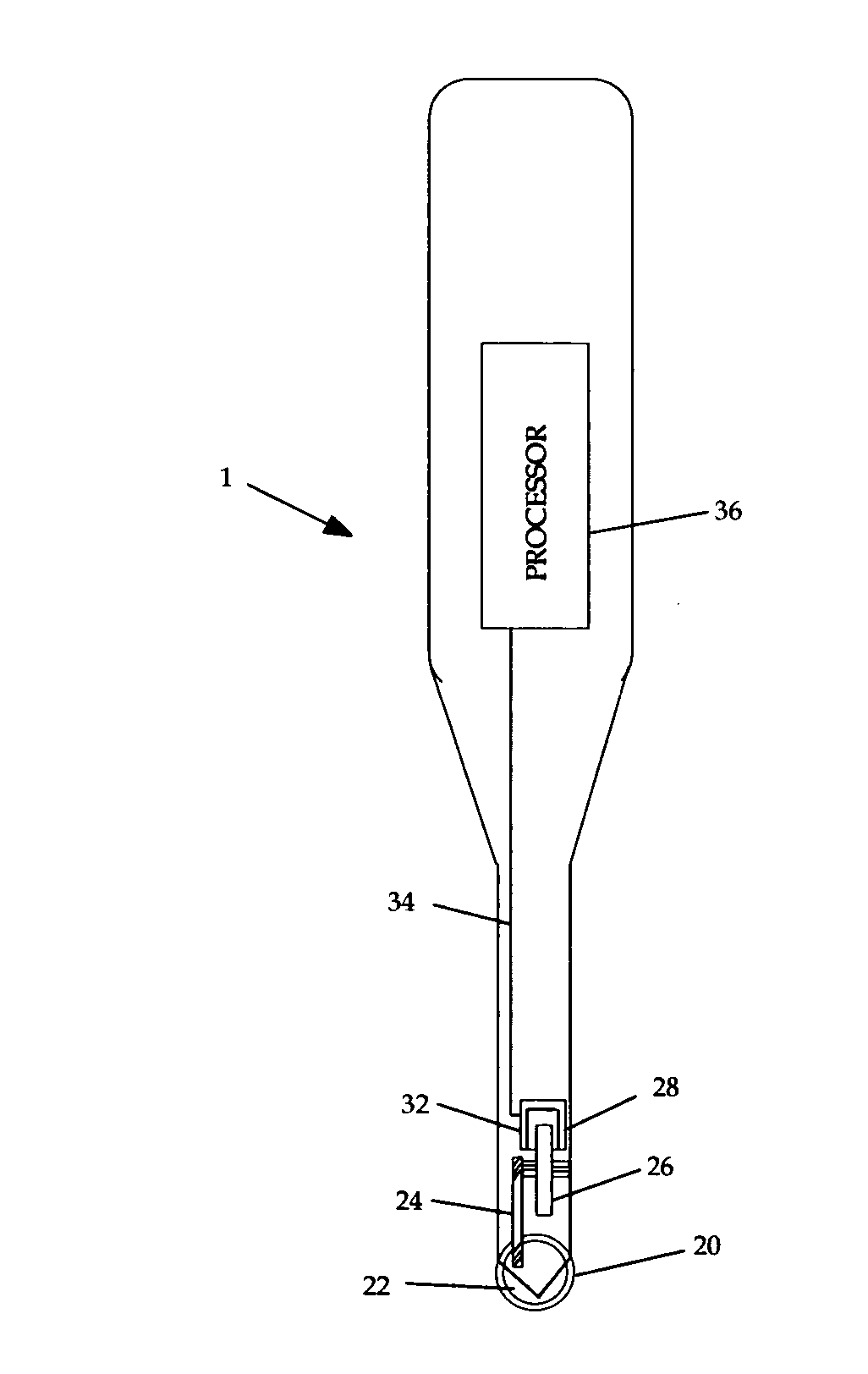

Metric display for exercise equipment

A display system for exercise equipment in accordance with the present invention includes a processor, a memory, a metric sensor and a metric display. The memory in communication with the processor. The metric sensor operably coupled to the processor. The metric sensor senses an extent of a metric of a user of the exercise equipment. The metric display is operably coupled to the metric sensor and displays the user metric in a generally oscillating manner.

Owner:PELOTON INTERACTIVE INC

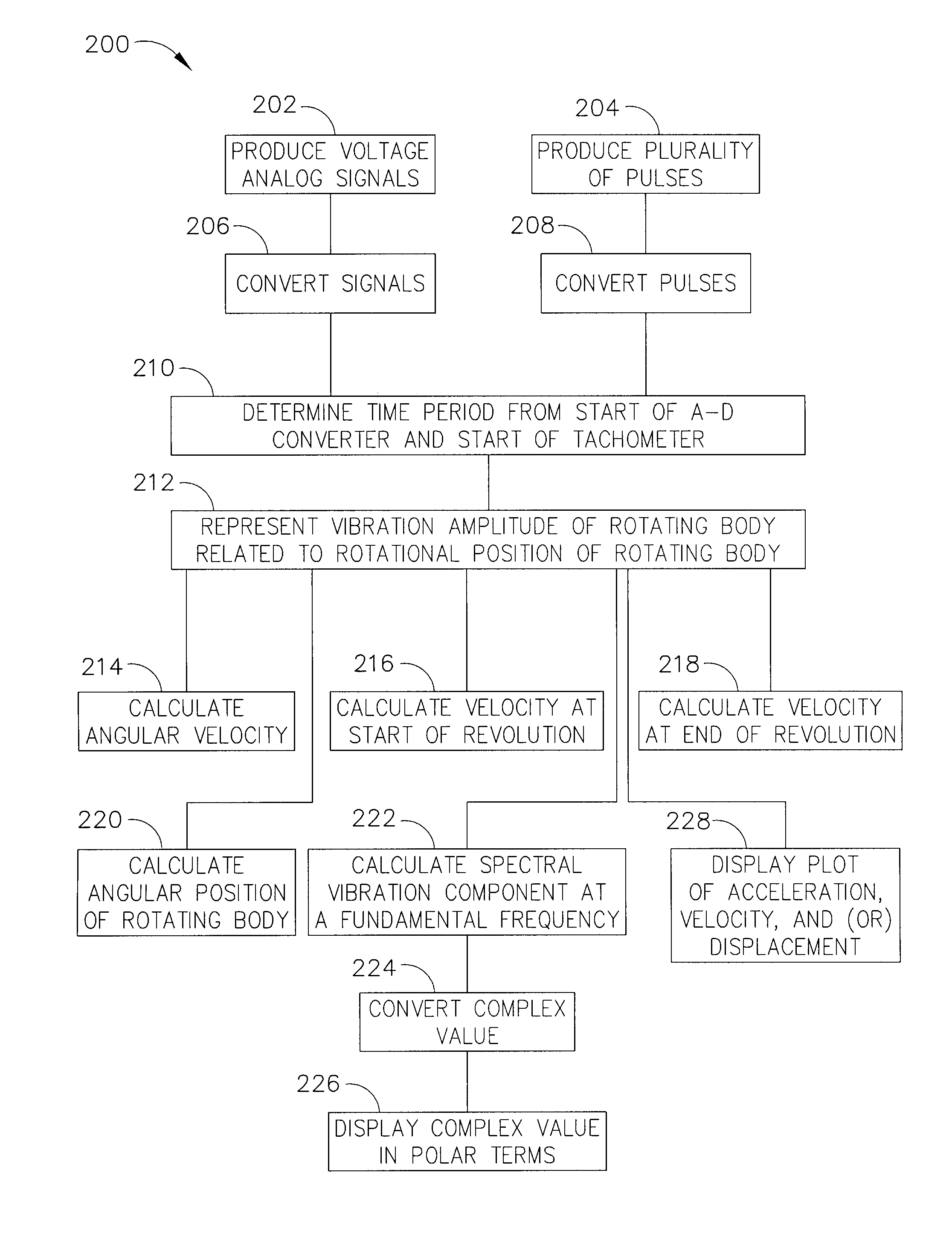

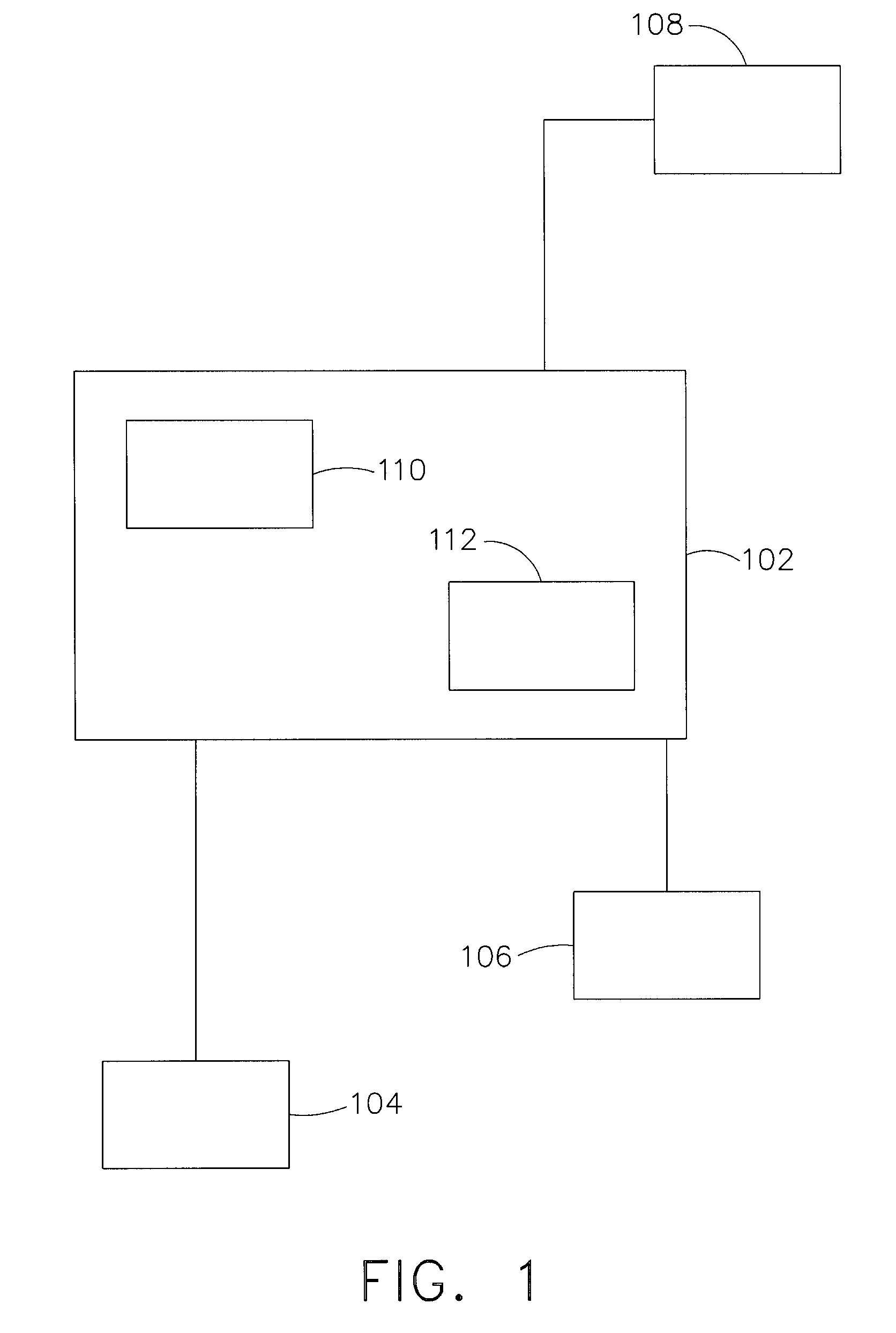

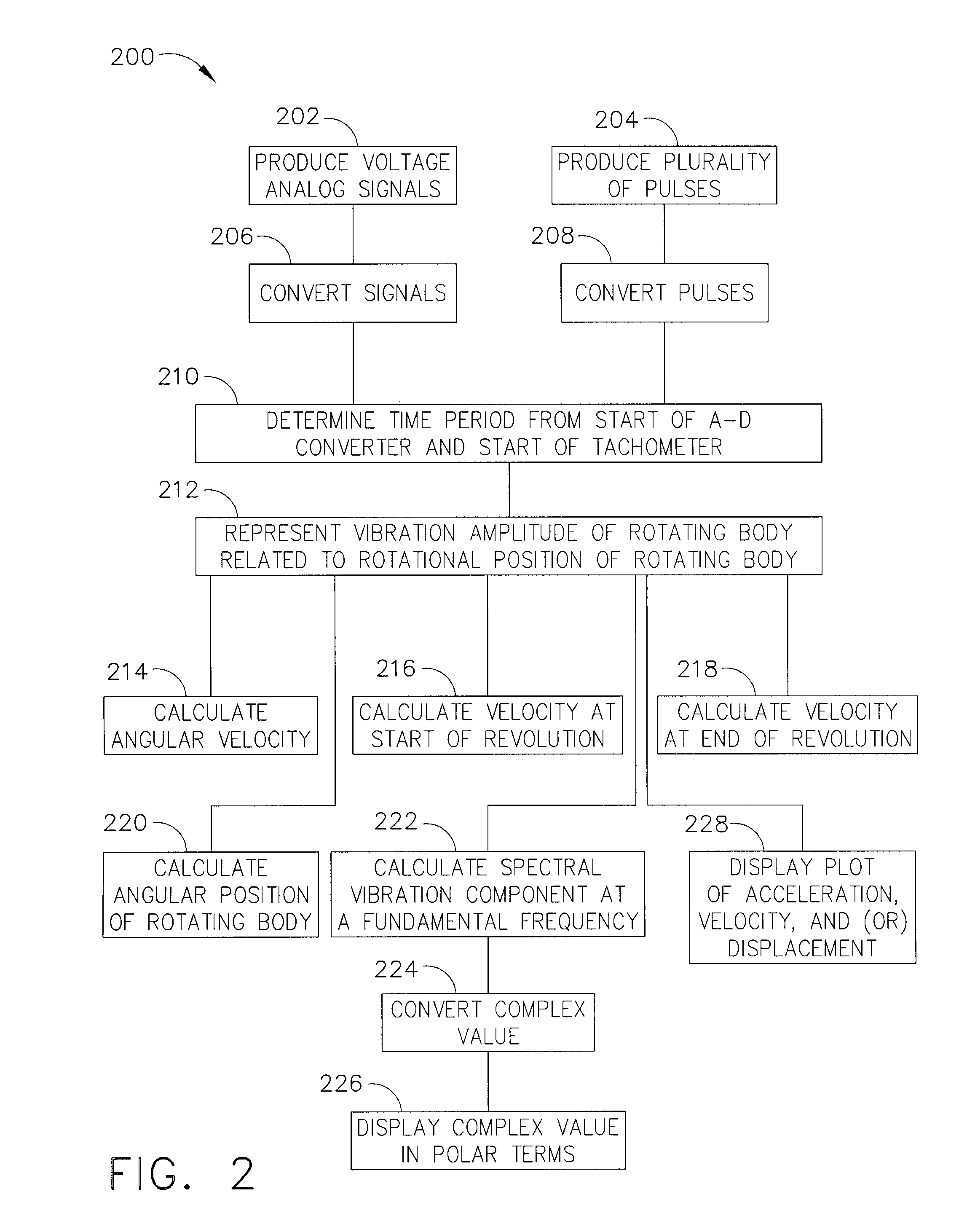

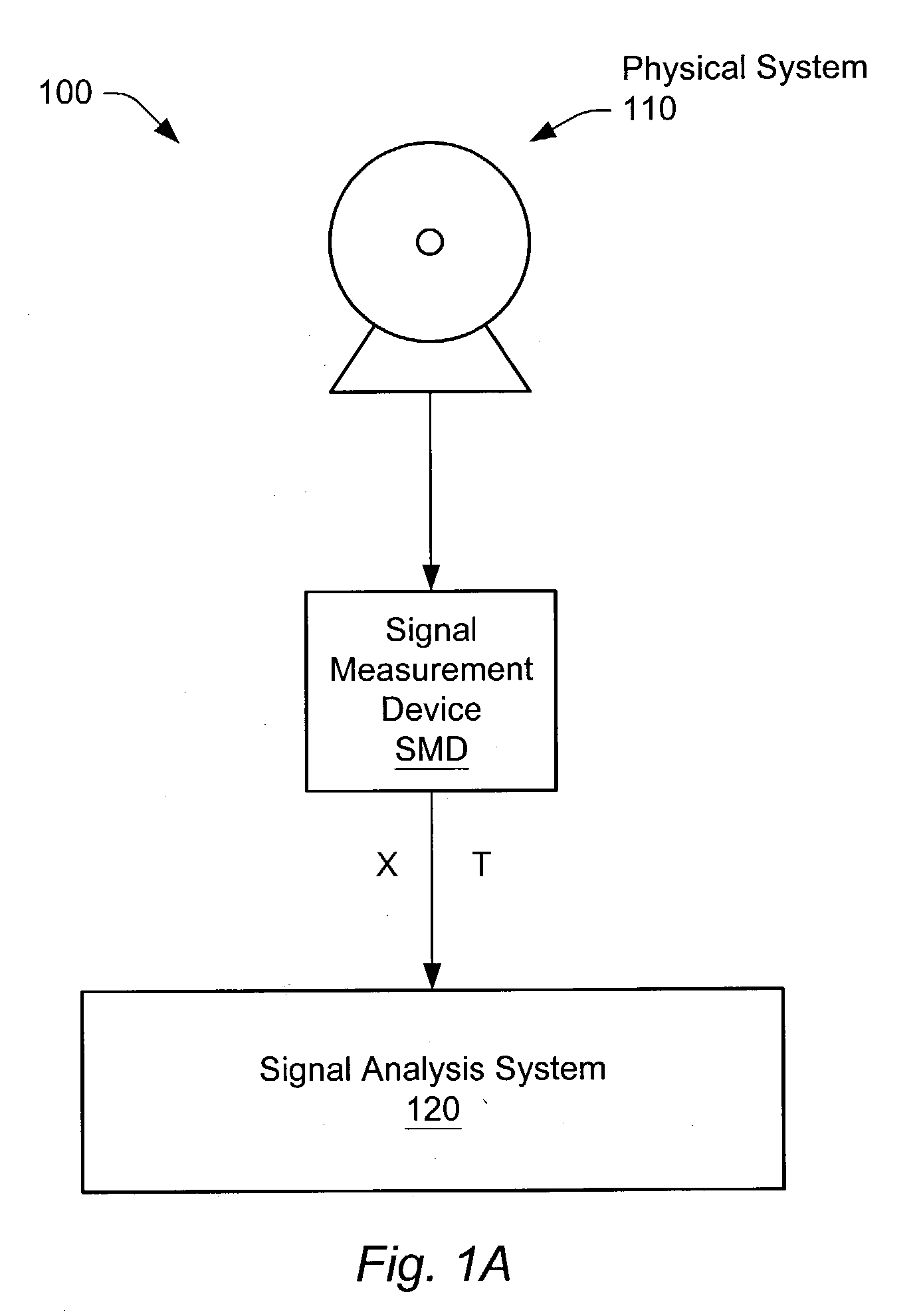

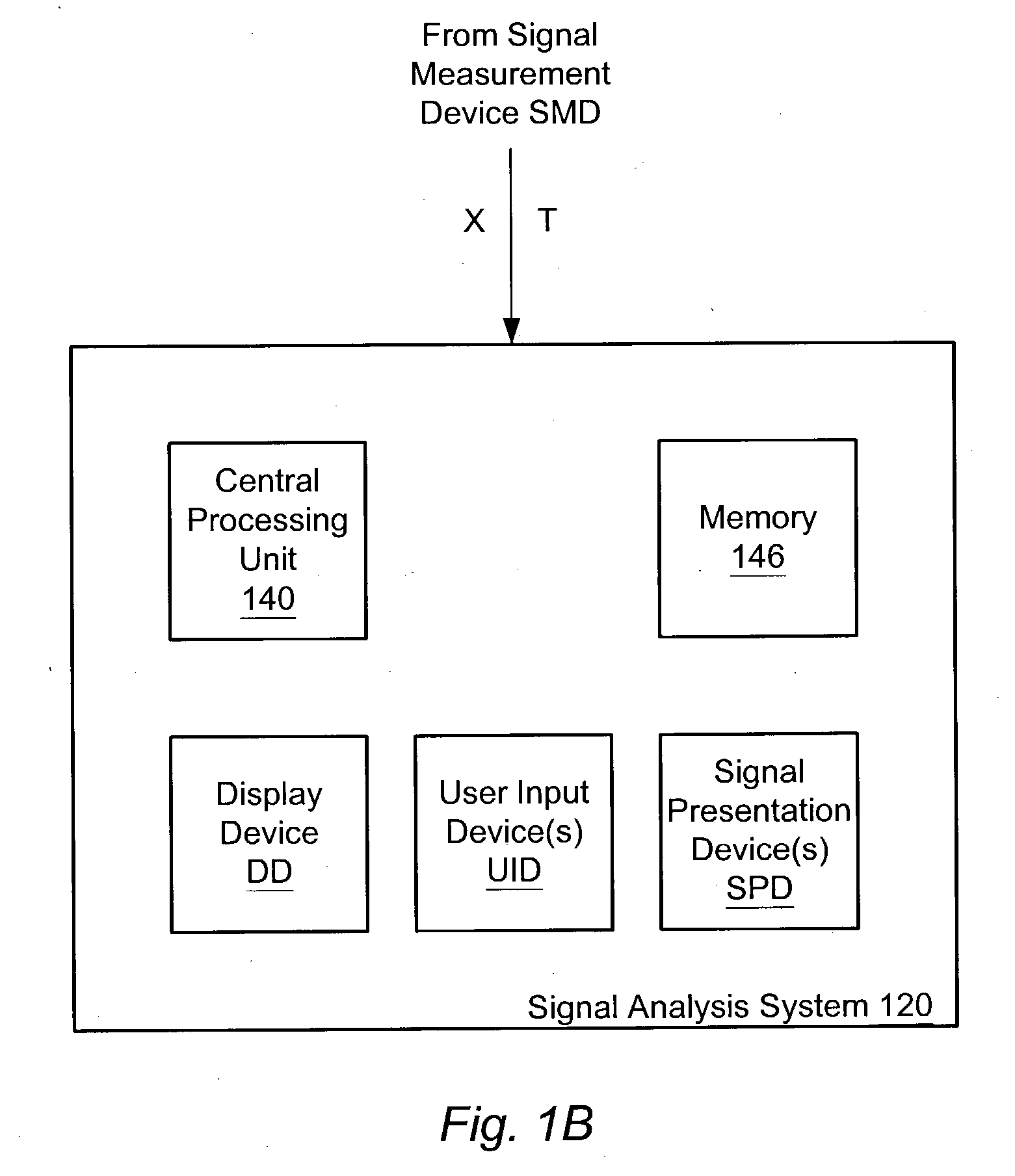

Method and system for use in analyzing vibrations of a variable speed rotating body

A method is provided for analyzing vibrations of a variable speed rotating body. The method includes producing a signal that is proportional to an acceleration of the rotating body and producing a plurality of pulses. Each pulse represents a revolution of the rotating body and is indicative of a vibration sample at a rotational position of the rotating body. The signal is converted to a numeric value that is indicative of a vibrational amplitude of the rotating body. The plurality of pulses are converted to revolution time periods indicative of a rotational rate of the rotating body. The method also includes producing a harmonic vibrational amplitude at a harmonic of the rotational rate of the rotating body, and representing a phase of the harmonic vibrational amplitude relative to the rotational position of the rotating body.

Owner:GENERAL ELECTRIC CO

Handheld fish measuring apparatus with integral camera

A handheld apparatus for measuring fish, game, and the like is provided and includes a scale, a camera, and a length measuring device. The scale includes a support member that extends outwardly from the apparatus housing, and a display that is visible through the housing. The support member is configured to suspend an object therefrom for weighing via the scale, and the display is configured to display the weight of an object suspended from the support member. The length measurement device is configured to measure the length of an object and the display is configured to display the length of an object measured by the length measurement device. The camera includes a lens, an image sensor configured to capture images obtained via the lens, and a camera display. The camera display displays an image of an object taken by the camera with weight and / or length information for the object.

Owner:PROPEL IP

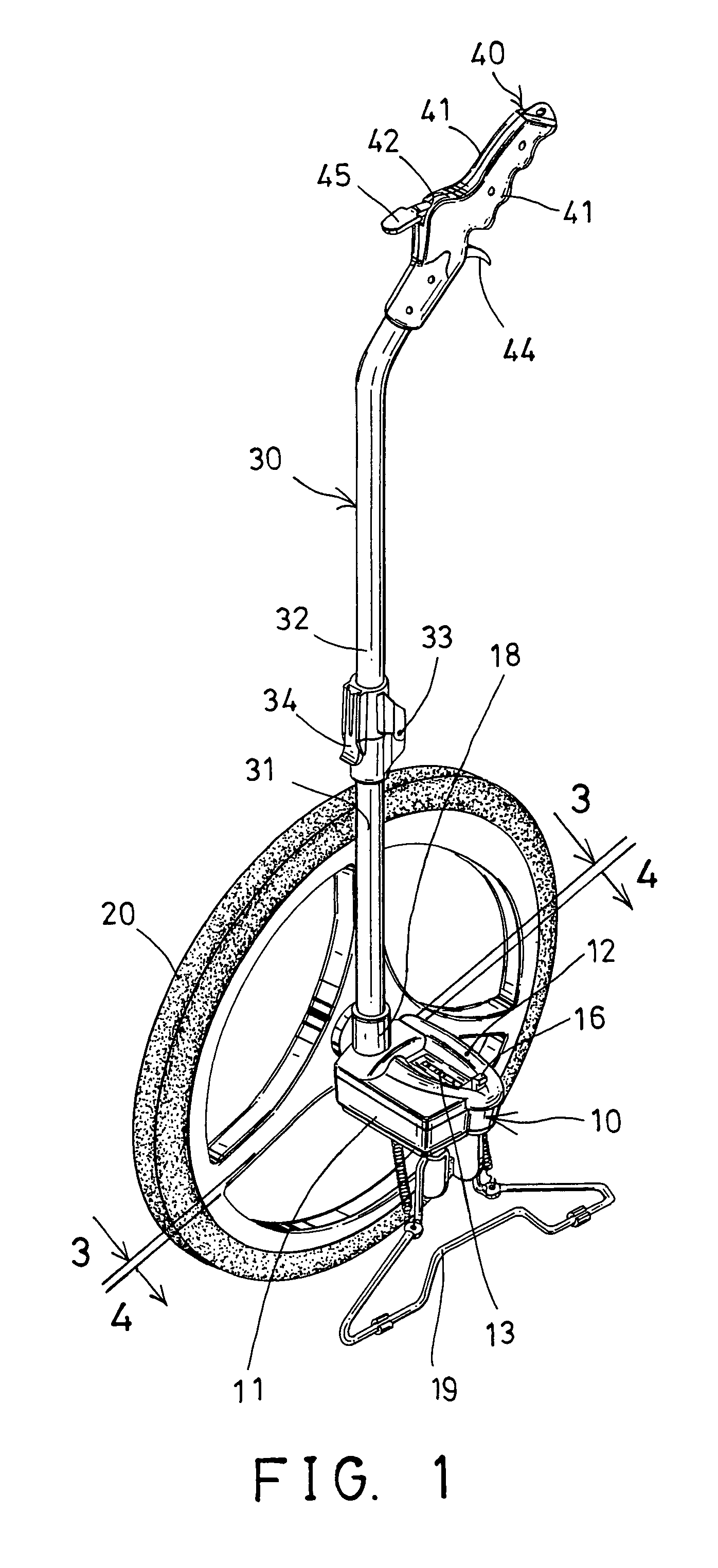

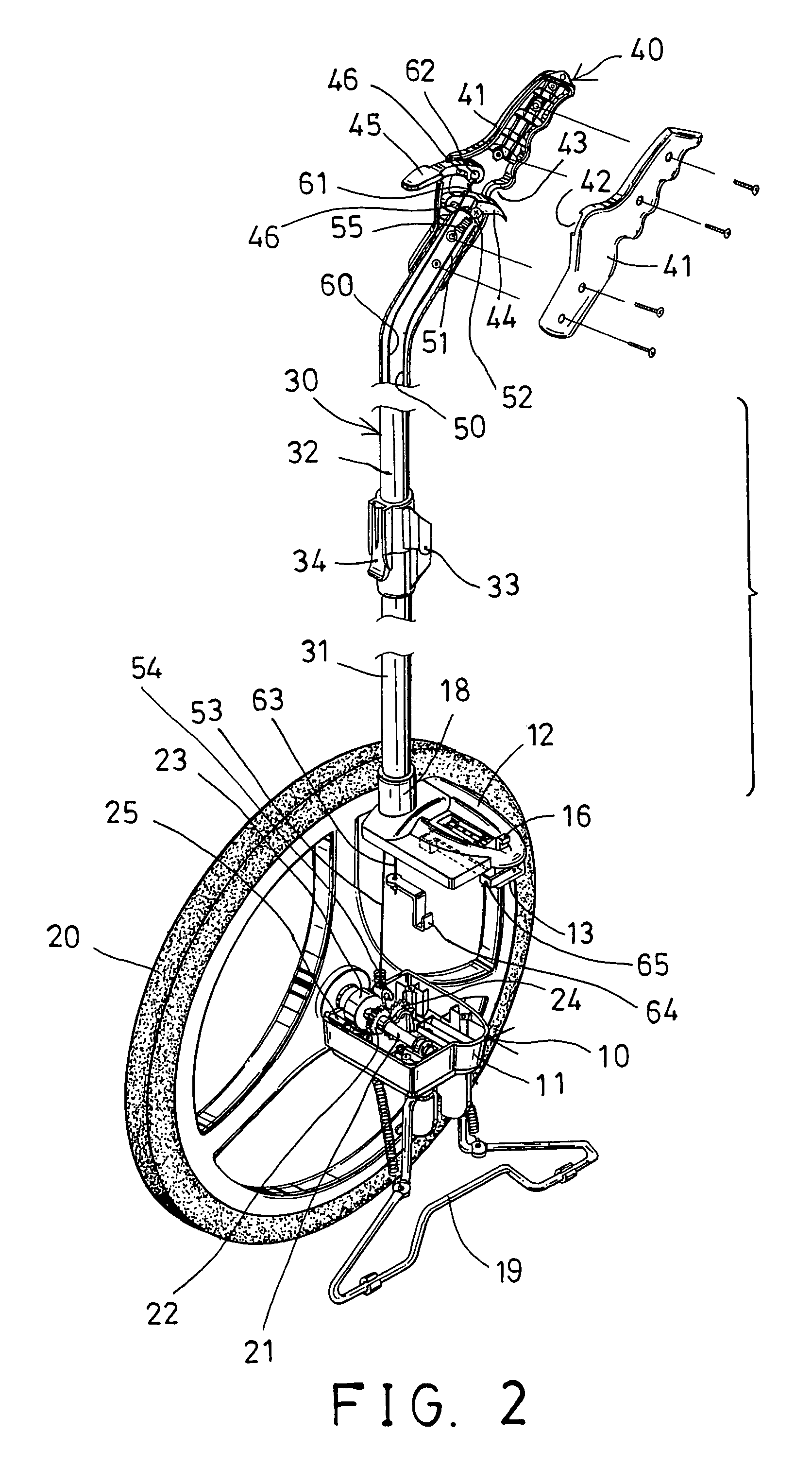

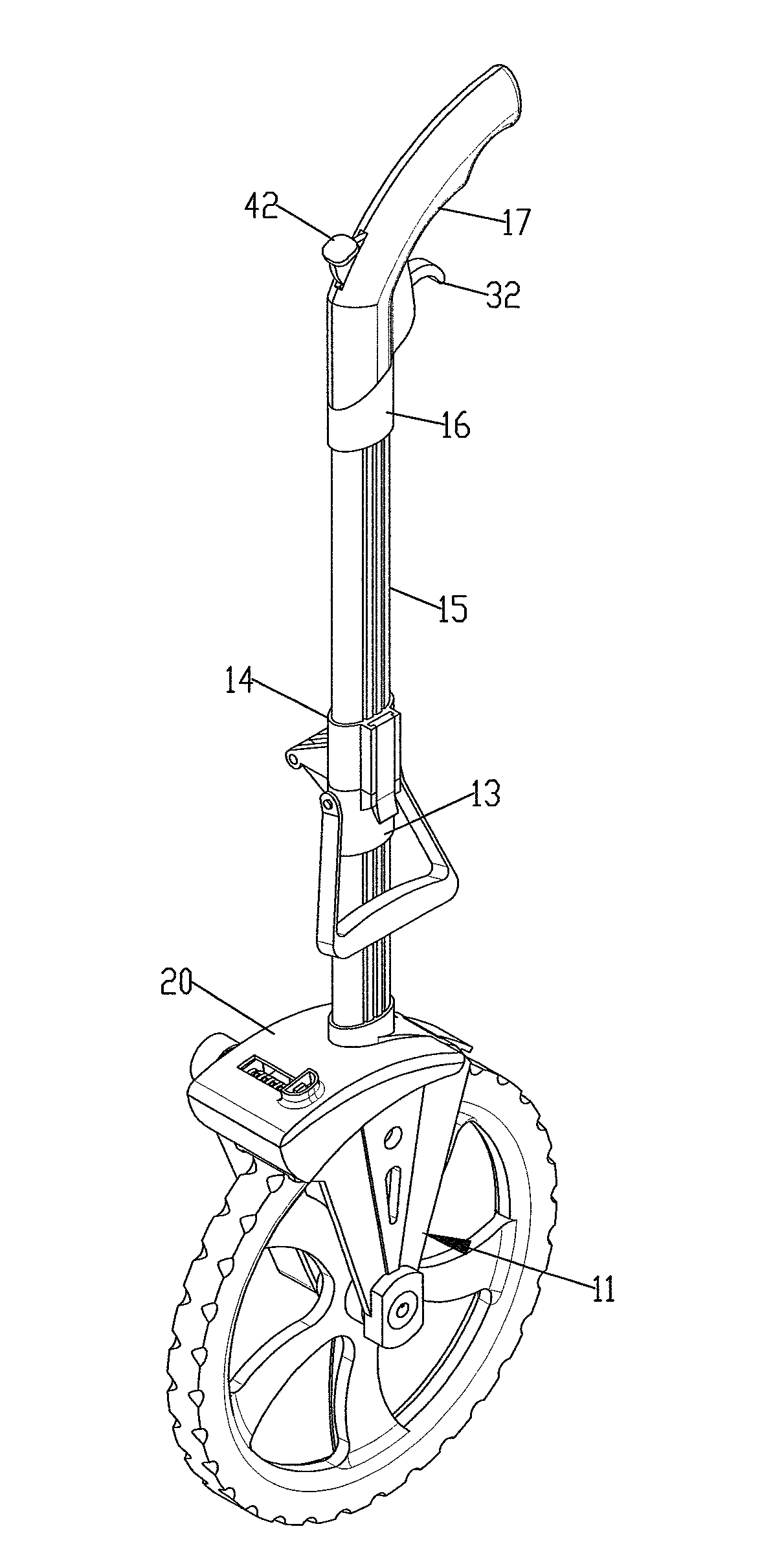

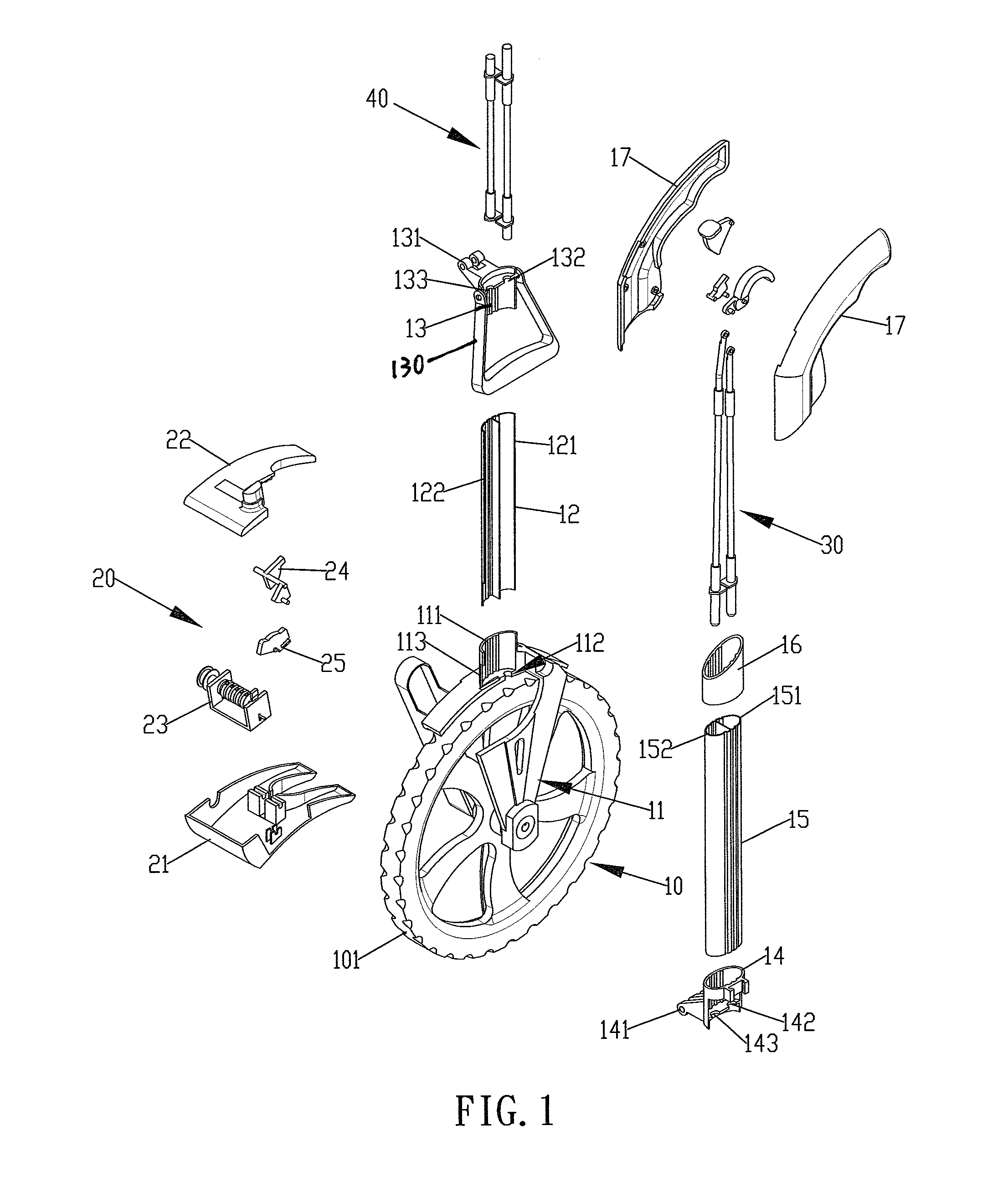

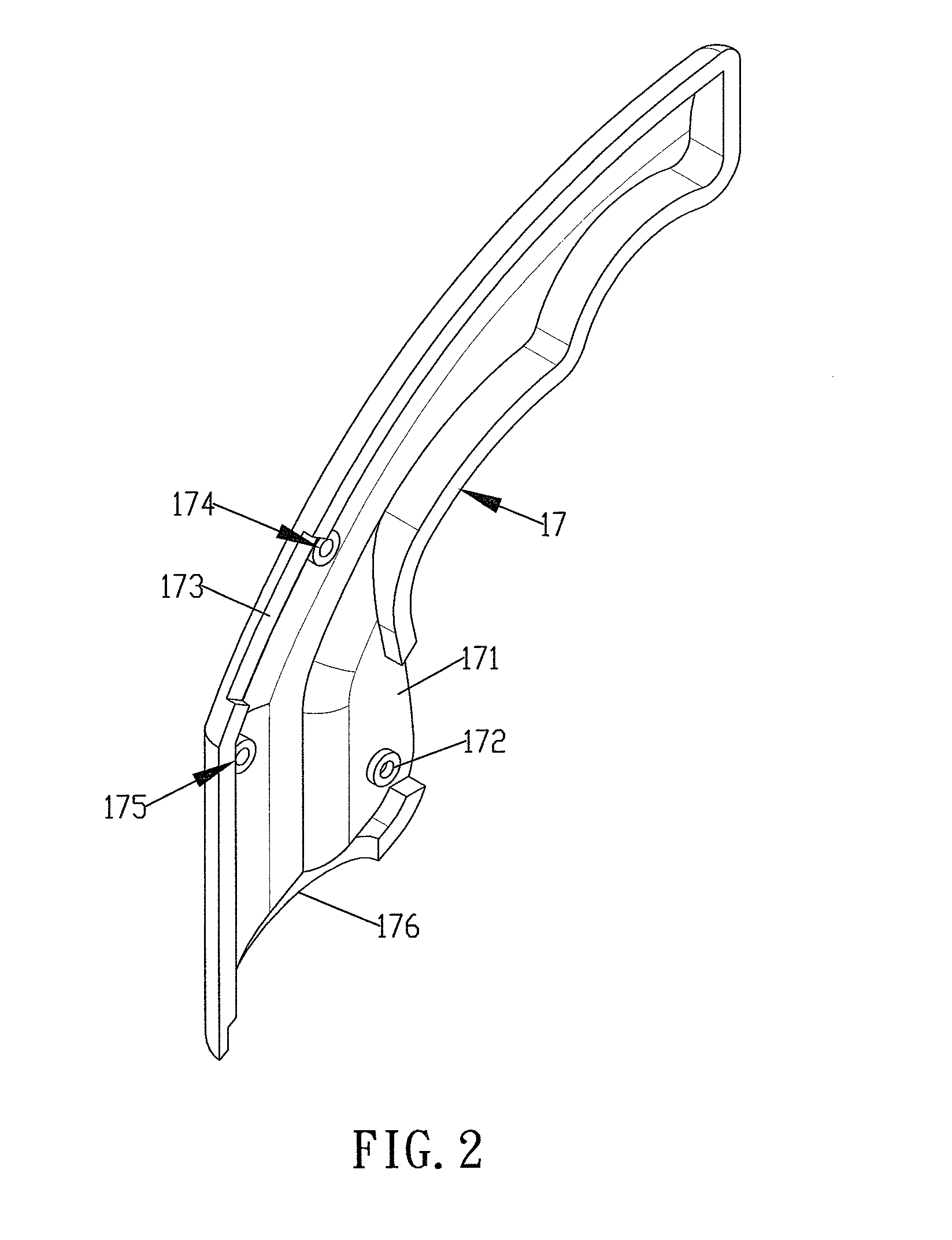

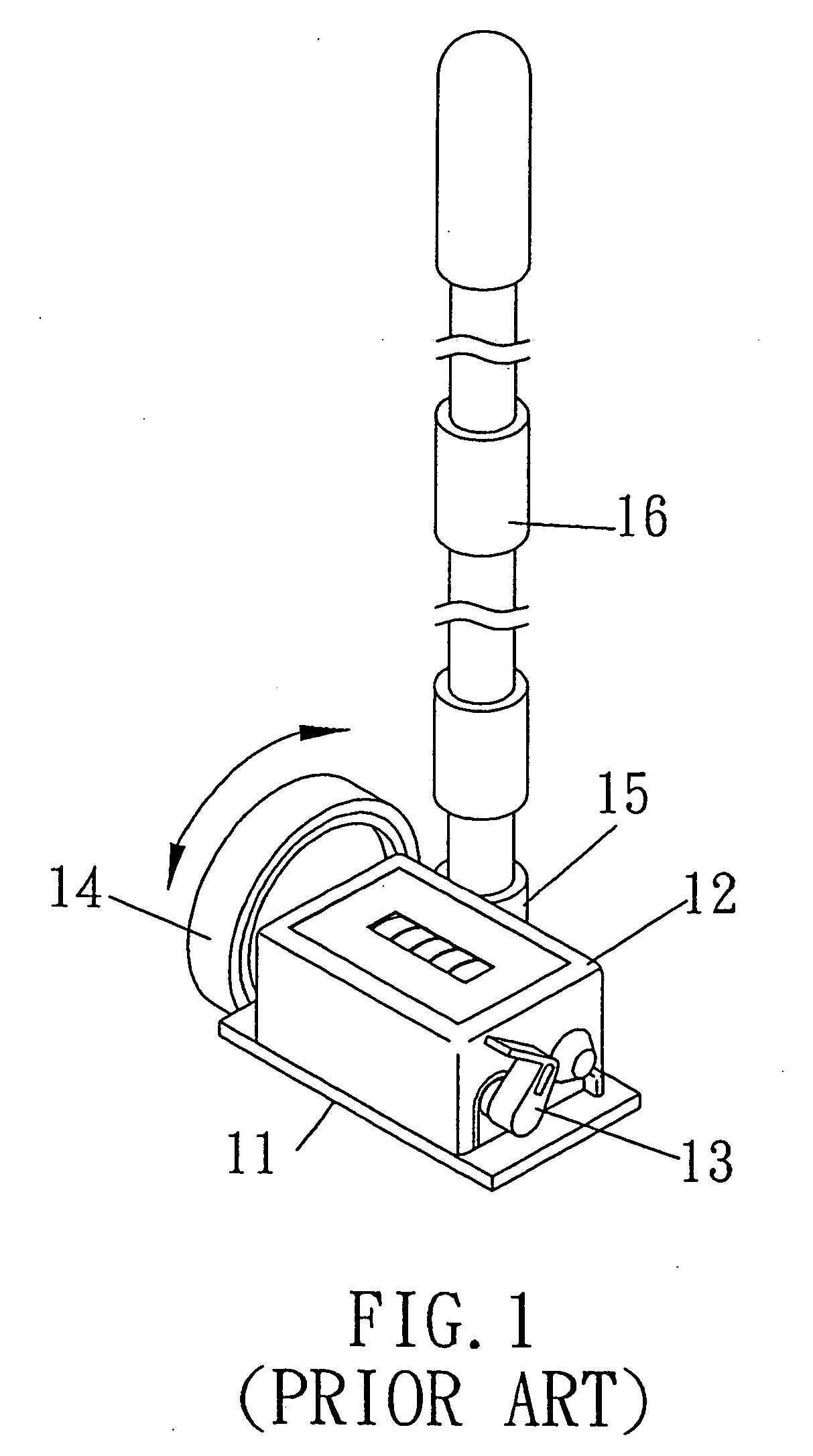

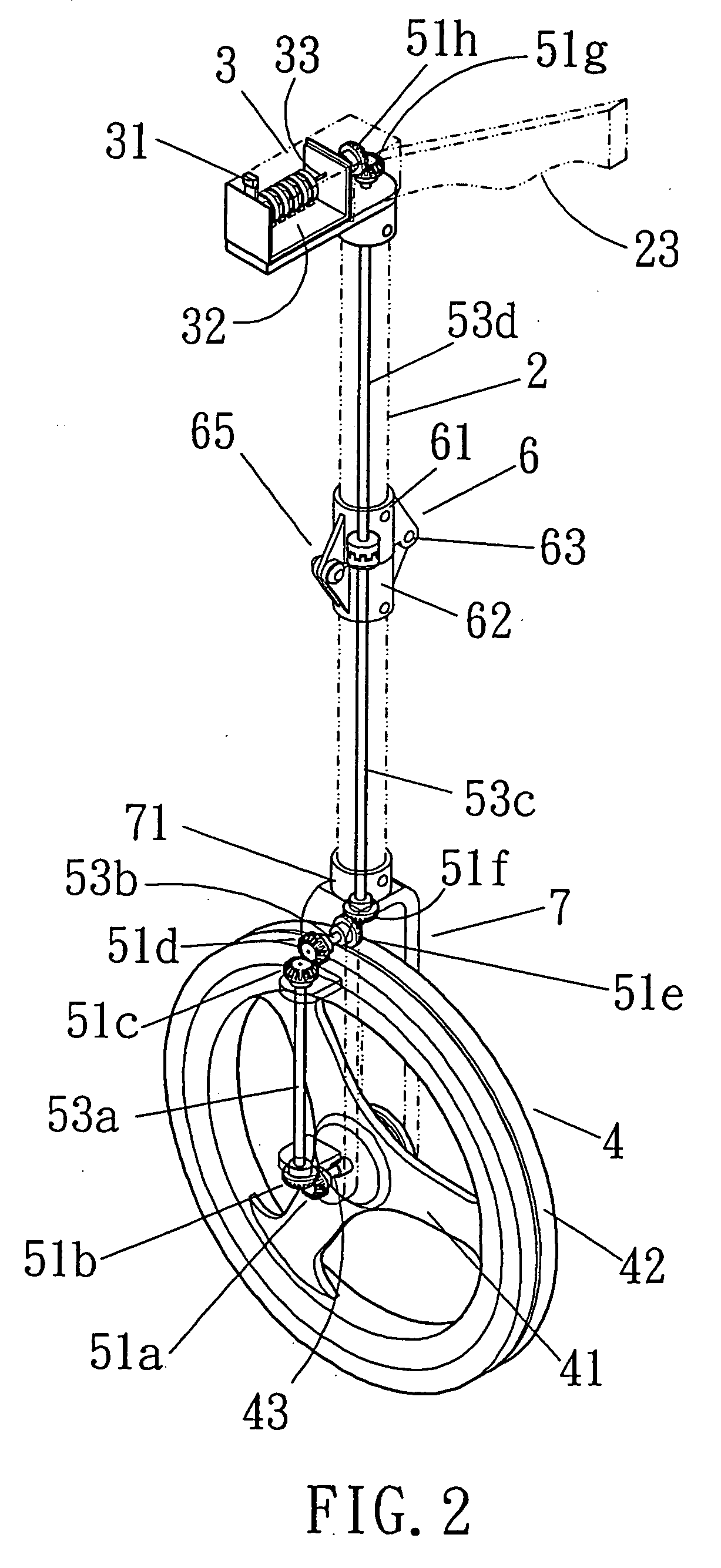

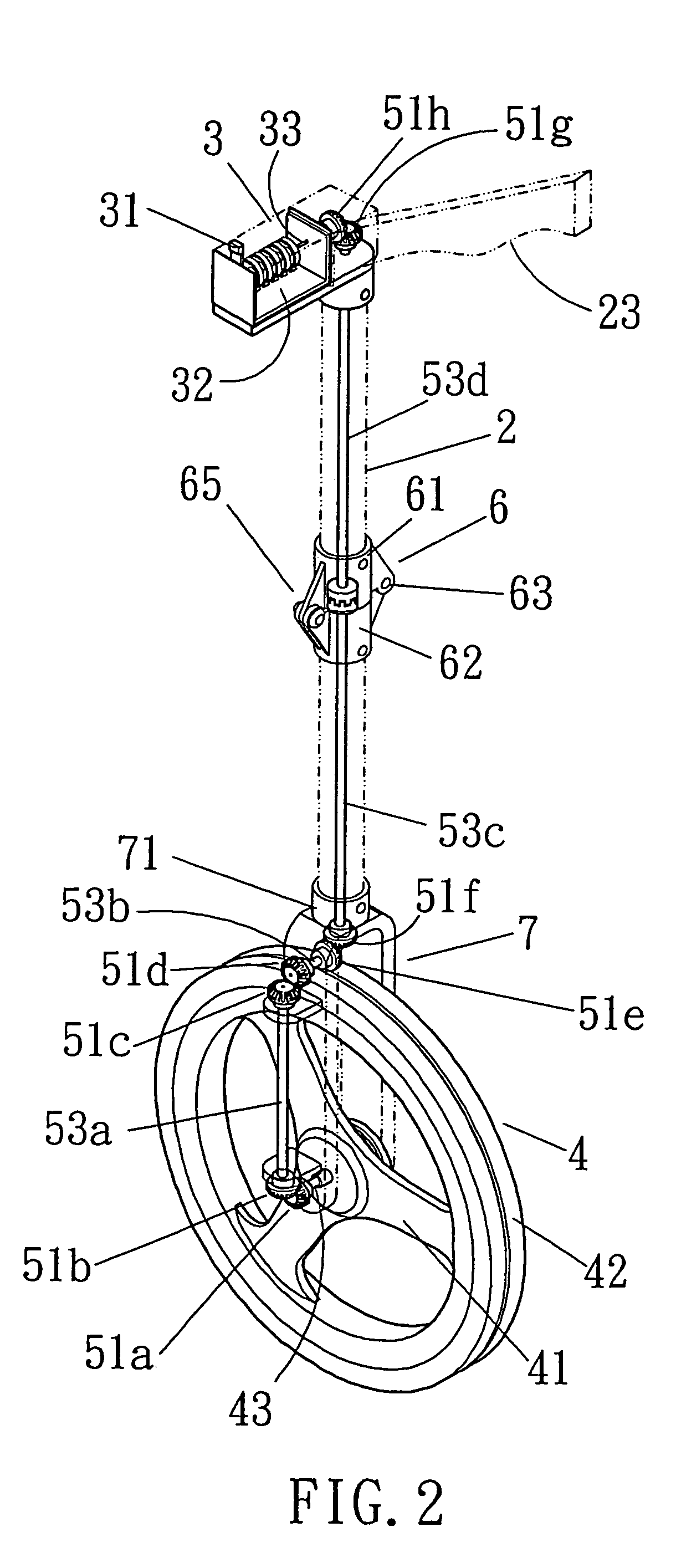

Distance measuring device

A distance measuring device includes a housing having a distance meter, a measuring wheel having a wheel axle rotatably engaged into the housing and coupled to the distance meter. A brake wheel is disposed on the wheel axle. A brake arm is pivotally secured in the housing and movable to engage with the brake wheel for braking the brake wheel. A pole includes a foldable structure, a handle is disposed on top of the pole, a brake lever and a handgrip are pivotally secured to the handle and extended out of the handle for being actuated by users, and coupled to the brake arm and the distance meter with flexible brake cable and a flexible wire, which allow the segments of the pole to be folded relative to each other.

Owner:WANG HUI CHEN

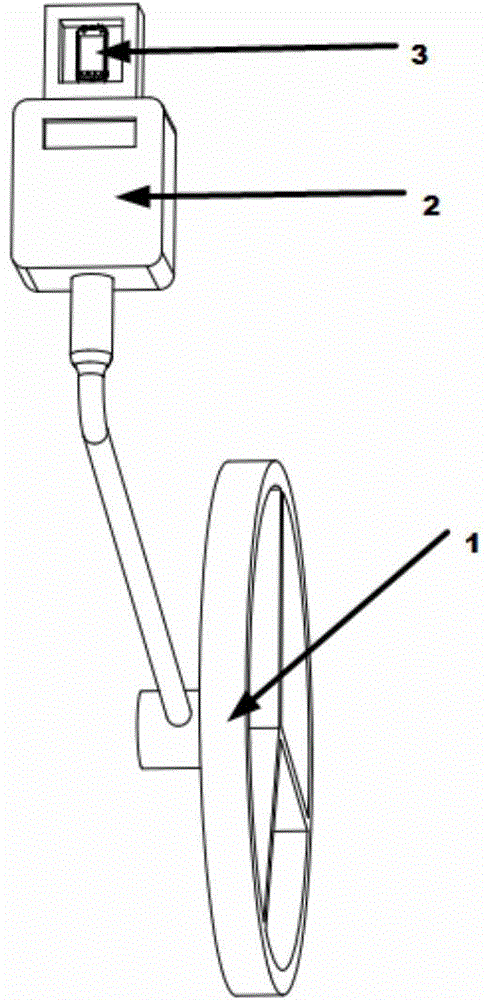

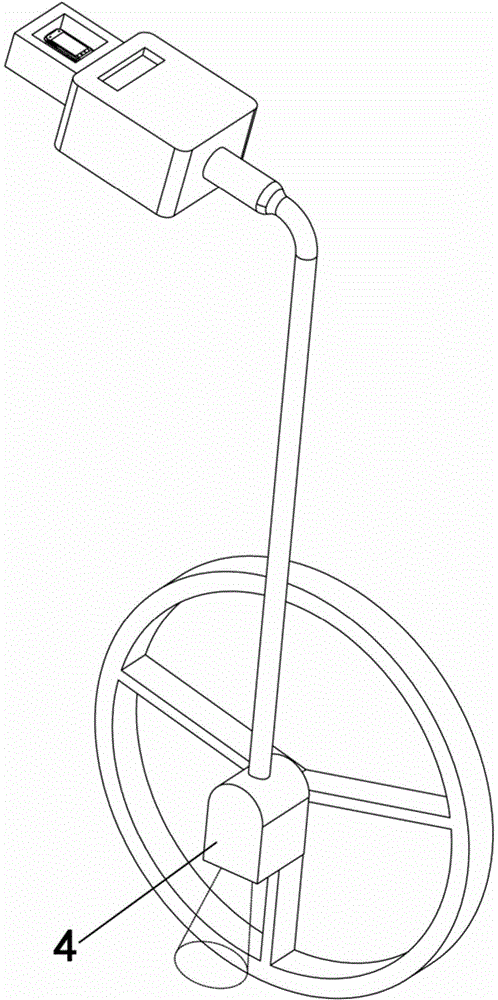

Distance-measuring system and distance-measuring method

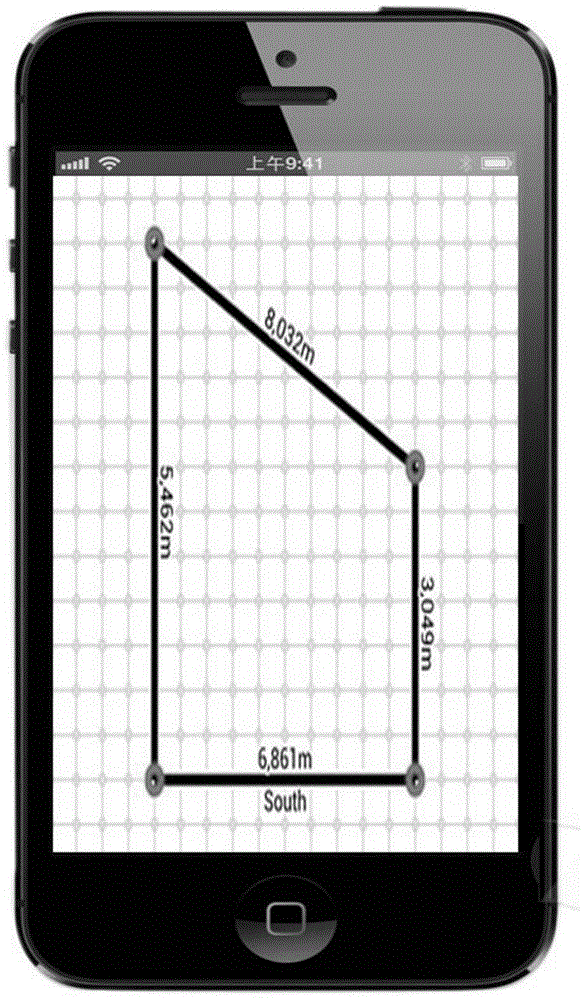

InactiveCN104634222ATo achieve the purpose of measuring distanceImprove work efficiencyMeasuring wheelsNetwork topologiesTerminal equipmentEngineering

The invention discloses a distance-measuring system, which comprises a distance-measuring device and terminal equipment, wherein the distance-measuring device comprises measurement wheels, a rotating shaft and an electronic counter, wherein the rotating shaft is arranged on the measurement wheels; the electronic counter is connected with the rotating shaft and is used for acquiring distance information of the measurement wheels; the distance-measuring device or the terminal equipment also comprises an angle sensor; the terminal equipment and the distance-measuring device are respectively provided with communication modules; the terminal equipment comprises a data processing module which is configured to generate an advancing track diagram of the measurement wheels according to the distance-measurement information from the electronic counter and the angle information of an angle sensor in real time. The invention further discloses a distance-measuring method based on the distance-measuring system. A graph paper of an advancing track can also be generated in real time on the basis of achieving the distance-measuring function, so that the work efficiency is effectively improved; when the distance-measuring system is provided and matched with a line marker, the function of marking a line at the construction site according to the graph paper which is designed in advance can be achieved; the distance-measuring system has the characteristics of being simple in structure, light and handy, and flexible.

Owner:NORTHWEST INSTR SHANGHAI +1

Aweigh we go multi-purpose digital scale

InactiveUS20070045011A1Function increaseEasy to holdMeasuring wheelsUsing electrical meansCommon carrierComputer science

A portable scale that allows travelers to calculate the weight of their luggage and compare the weight against weight limits that are imposed by common carriers. The scale includes circuitry for calculating weight and a memory for storing weight limits. Weight and other information is shown to the user via a display screen. In the preferred embodiment, the scale includes a hook and handle that facilitate weighing suitcases and other objects. The preferred embodiment also includes a digital measuring tape that allows the traveler to check the size of his luggage against size restrictions imposed by common carriers. The scale can also be incorporated into a portable weighing mat, which allows weight to be determined simple by placing the object on the mat. The scale can also be incorporated into the handle of a suitcase wherein the weight of the suitcase is calculated when the suitcase is lifted by its handle.

Owner:DITTRICH JOSEPHINE M +1

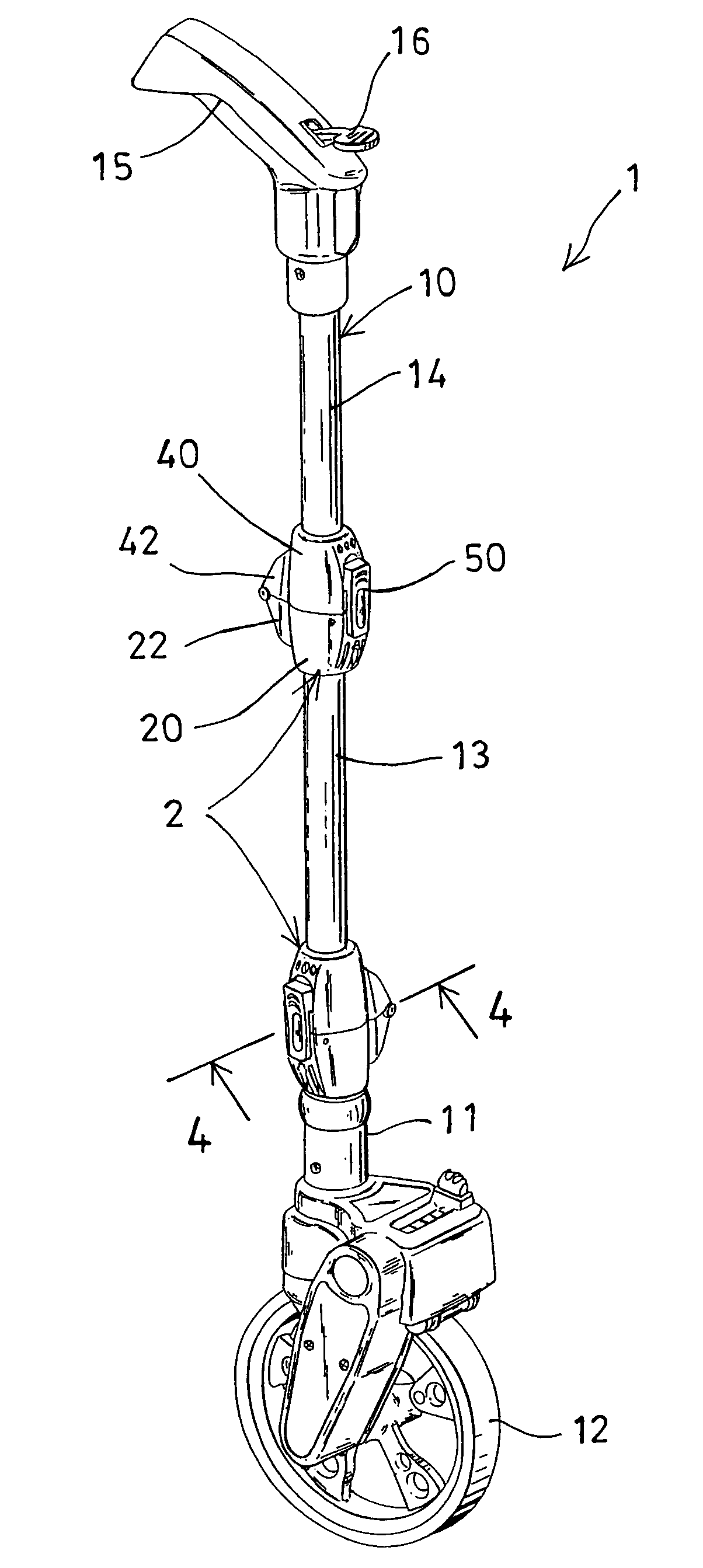

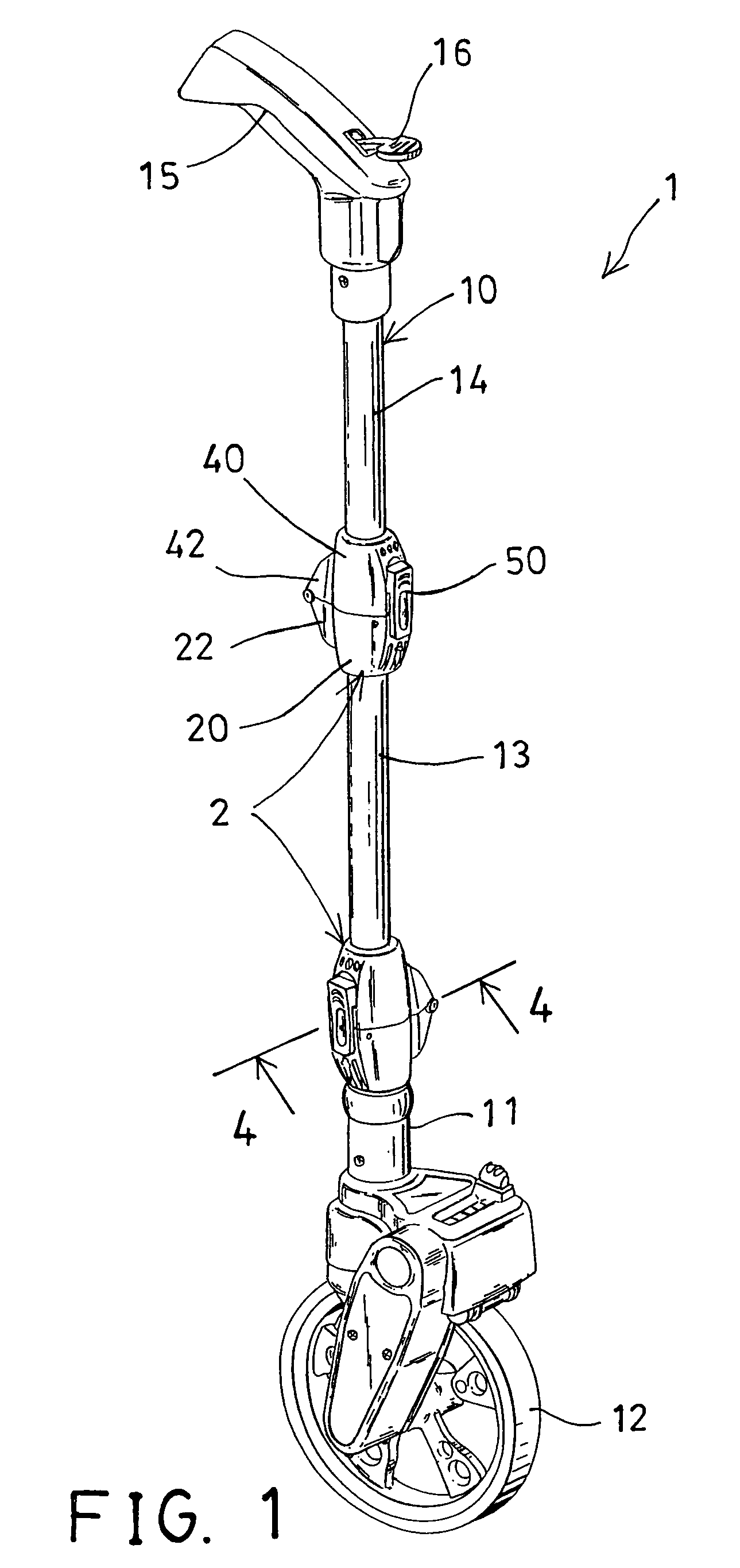

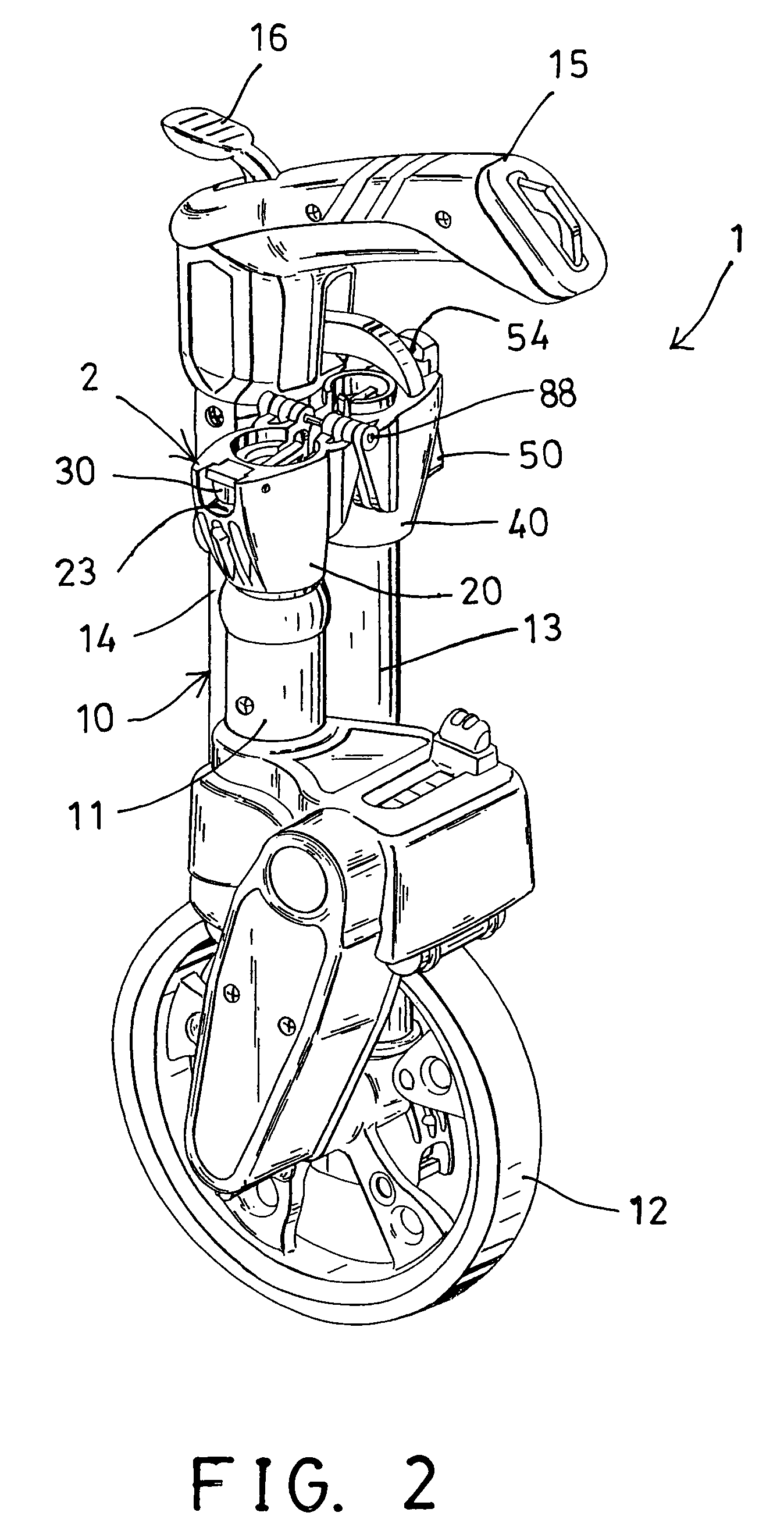

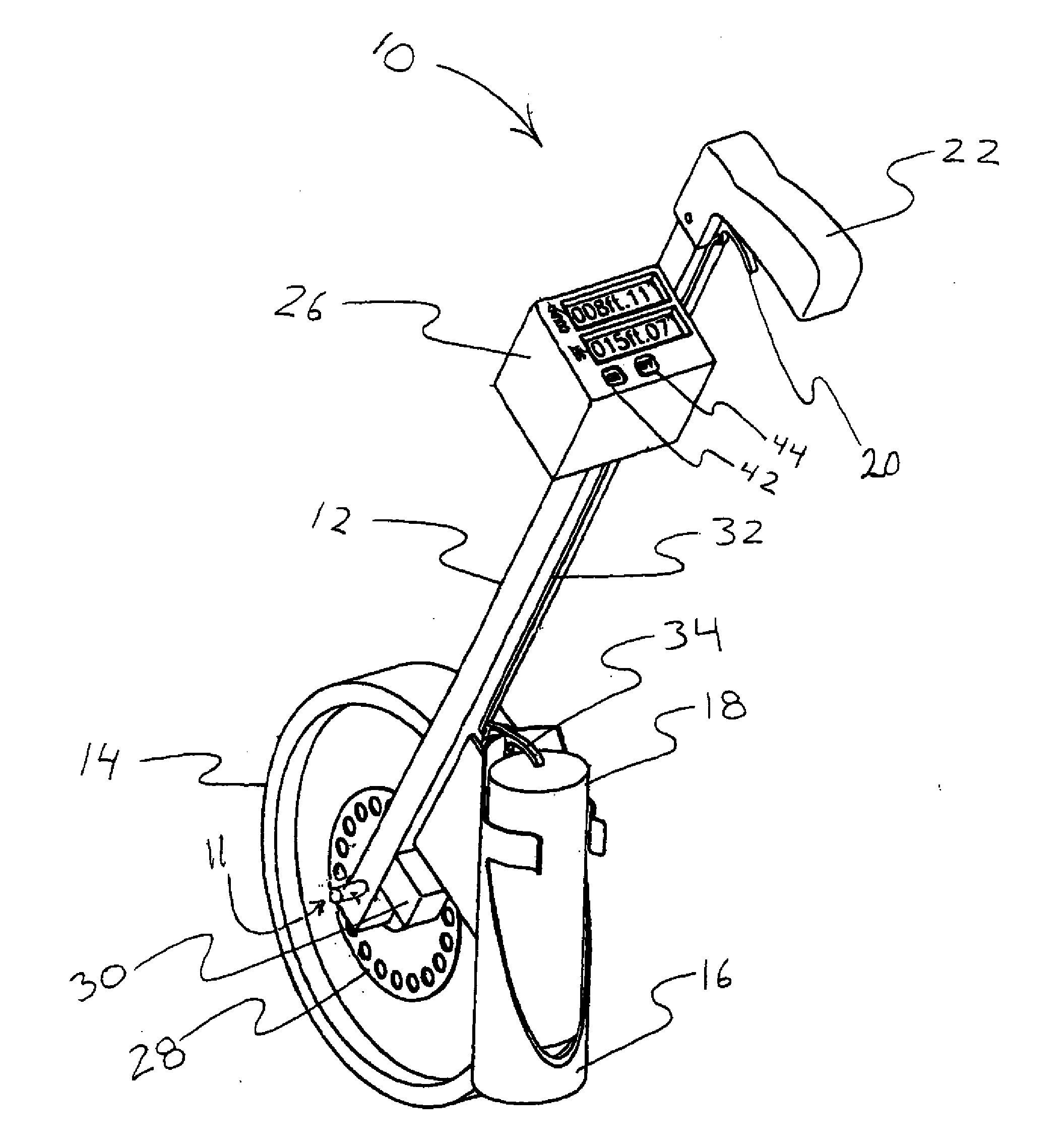

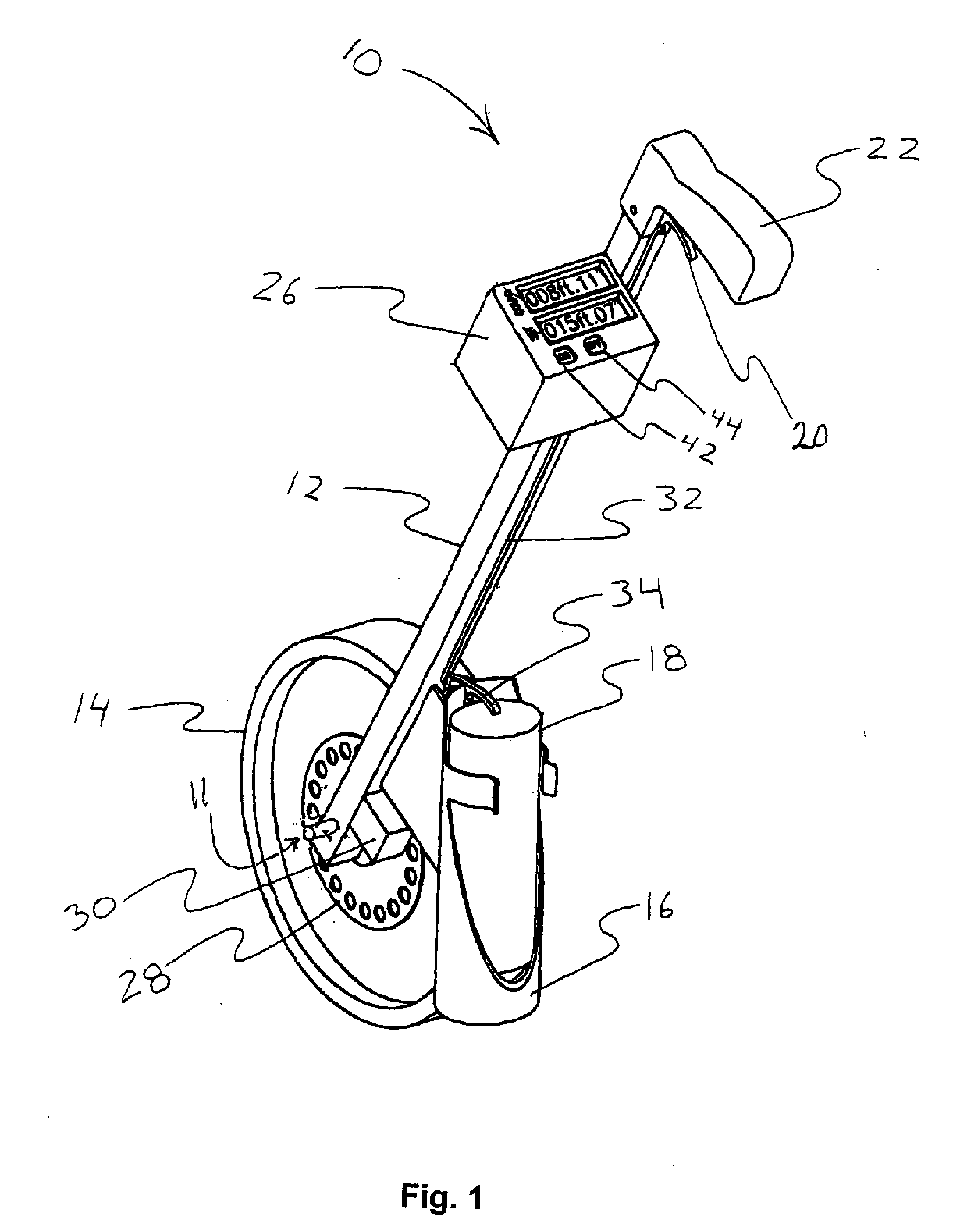

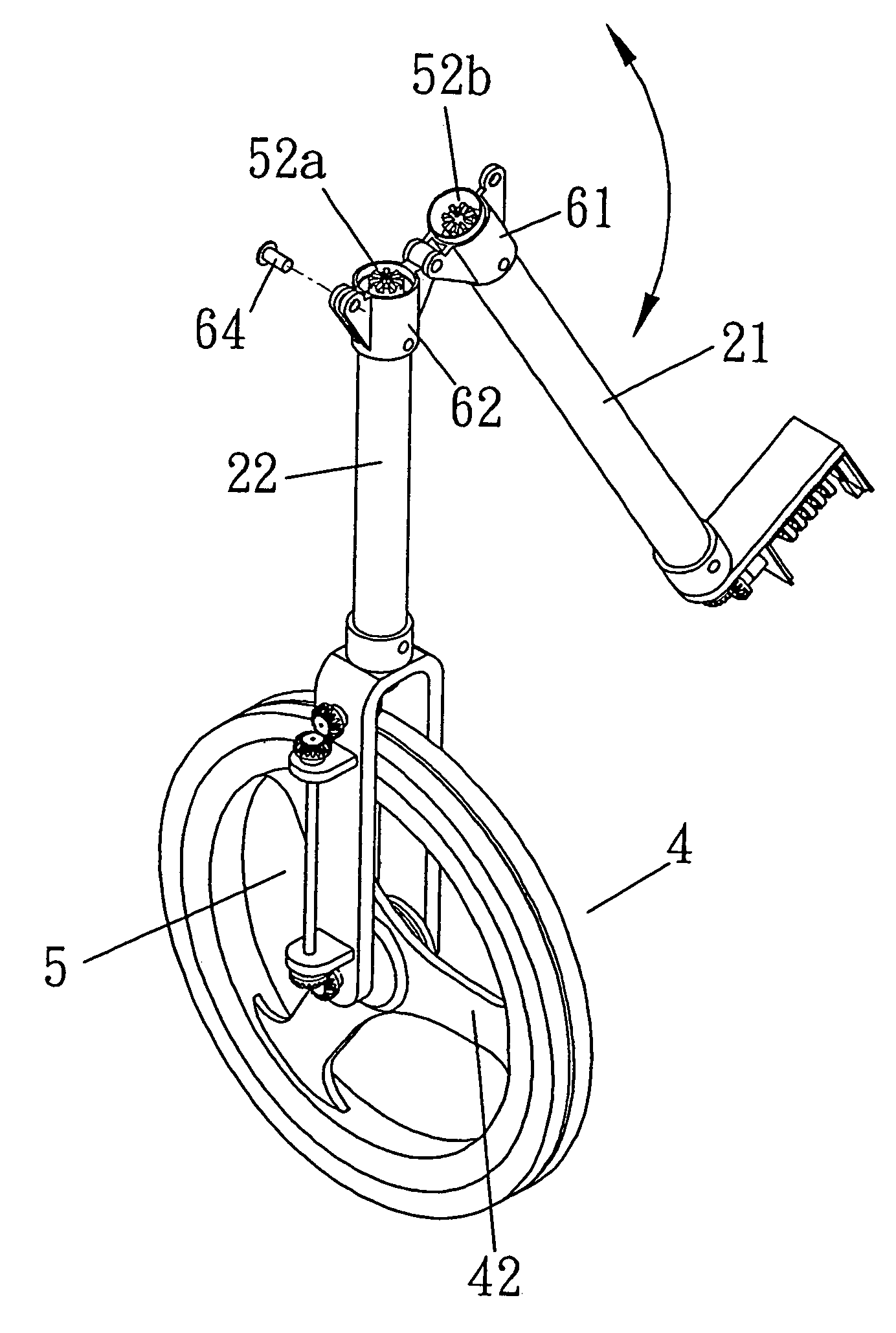

Wheeled distance measuring device

A wheeled distance measuring device includes a wheel unit having a wheel and a front fork with which the wheel is rotatably connected. A pole unit is connected to the front fork and a handle is connected to a top of the pole unit. A measuring unit is connected to a side of the front fork and a brake unit and an initialization unit are connected to the measuring unit. The brake unit and the initialization unit have a brake key and an initialization key received in the handle. Two respective rods are connected to the brake and initialization keys respectively and extend through the pole unit and connected to the measuring unit. By operating the brake key and the initialization key, the wheel can be braked and the measuring unit can be initialized respectively.

Owner:TECHTRONIC POWER TOOLS TECHNOLOGY LTD

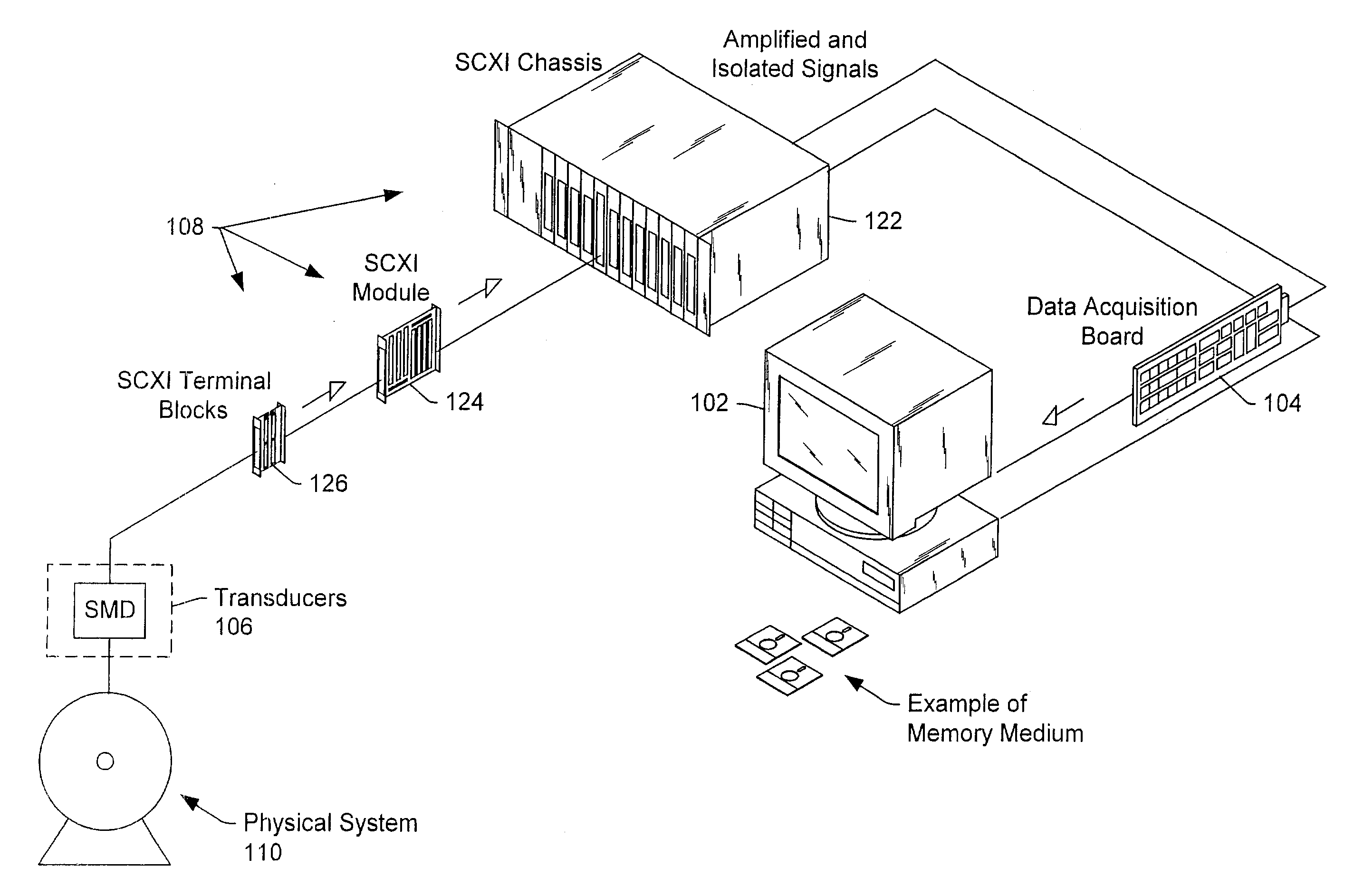

Analysis of rotating machines

System and method for analyzing an input signal acquired from a physical system with a rotating element. A tachometer signal is received comprising rotation speed information for the rotating element. A time sequence is determined using the tachometer signal, comprising time values for the rotating element at substantially equal angle increments, e.g., by edge detection software or timer / counter. A software-based first digital interpolation filter, e.g., a Cascade-Integrator-Comb filter, is applied to the time sequence, generating a modified time sequence. A digitized data signal is received comprising data for the rotating element at substantially equal time increments. A second software-based digital interpolation filter is applied to the data signal, generating a modified data signal which is re-sampled using the modified time sequence to generate an angle domain data signal, comprising data signal values at substantially equal angle increments, where the angle domain data signal is usable to analyze the physical system.

Owner:NATIONAL INSTRUMENTS

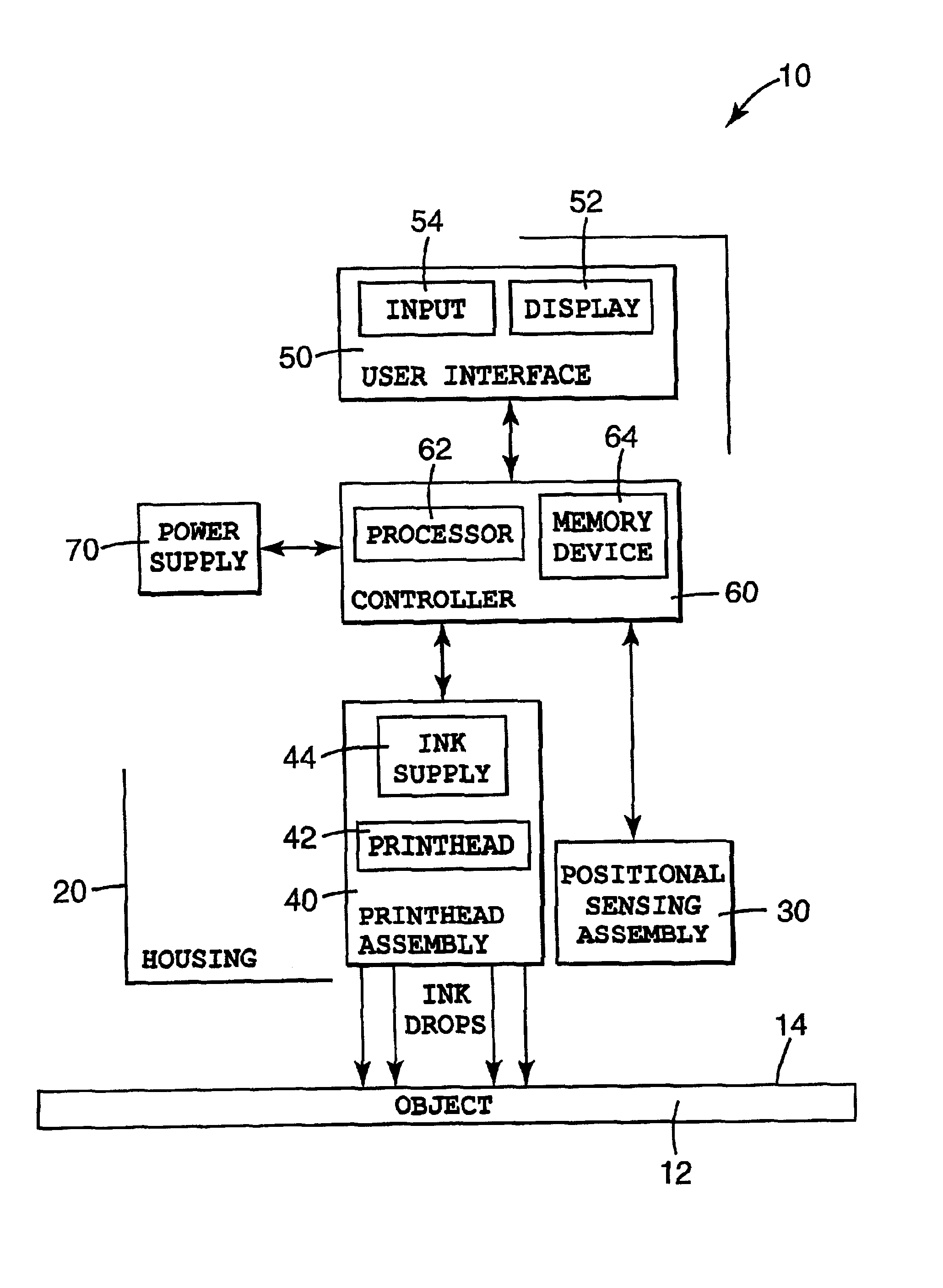

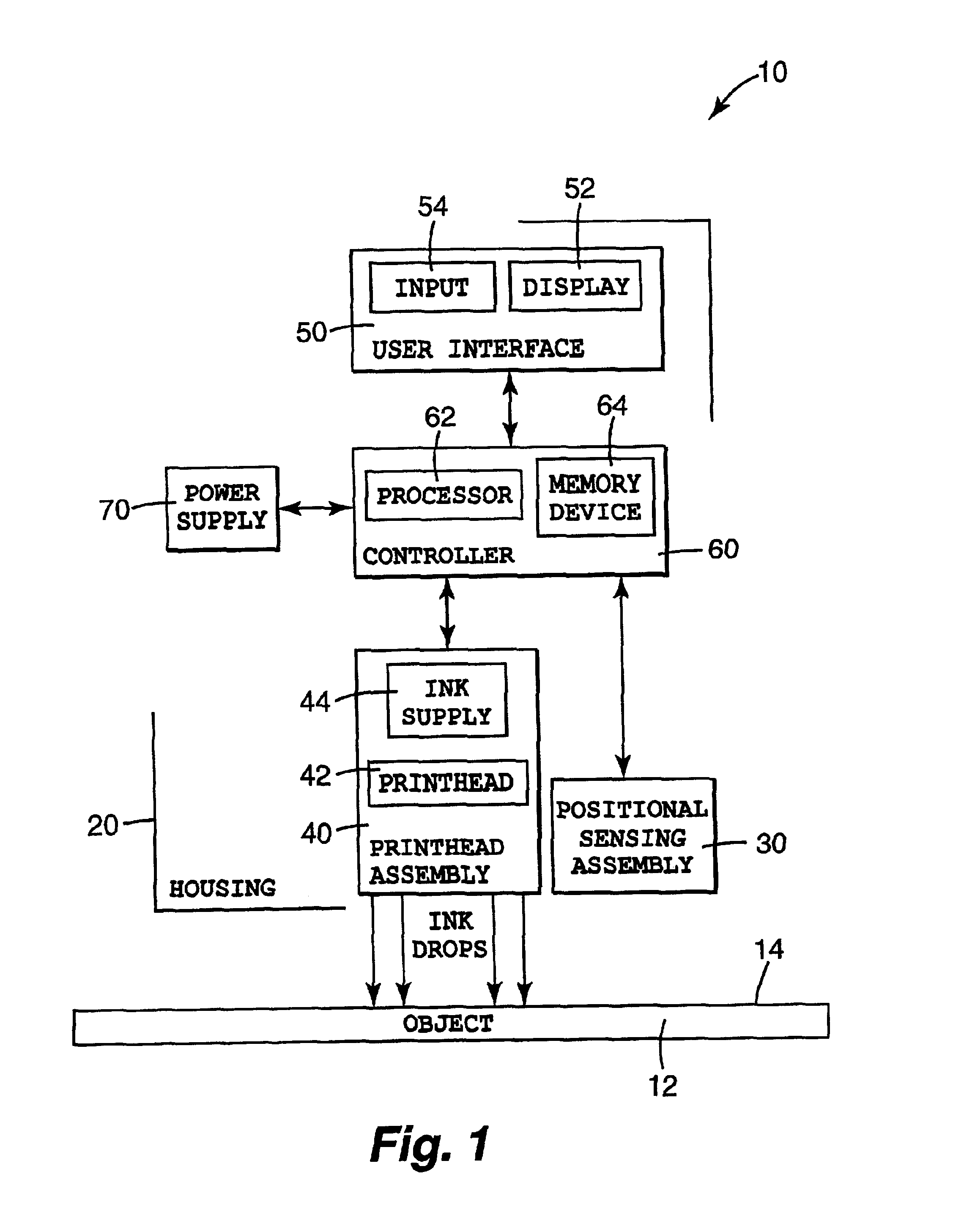

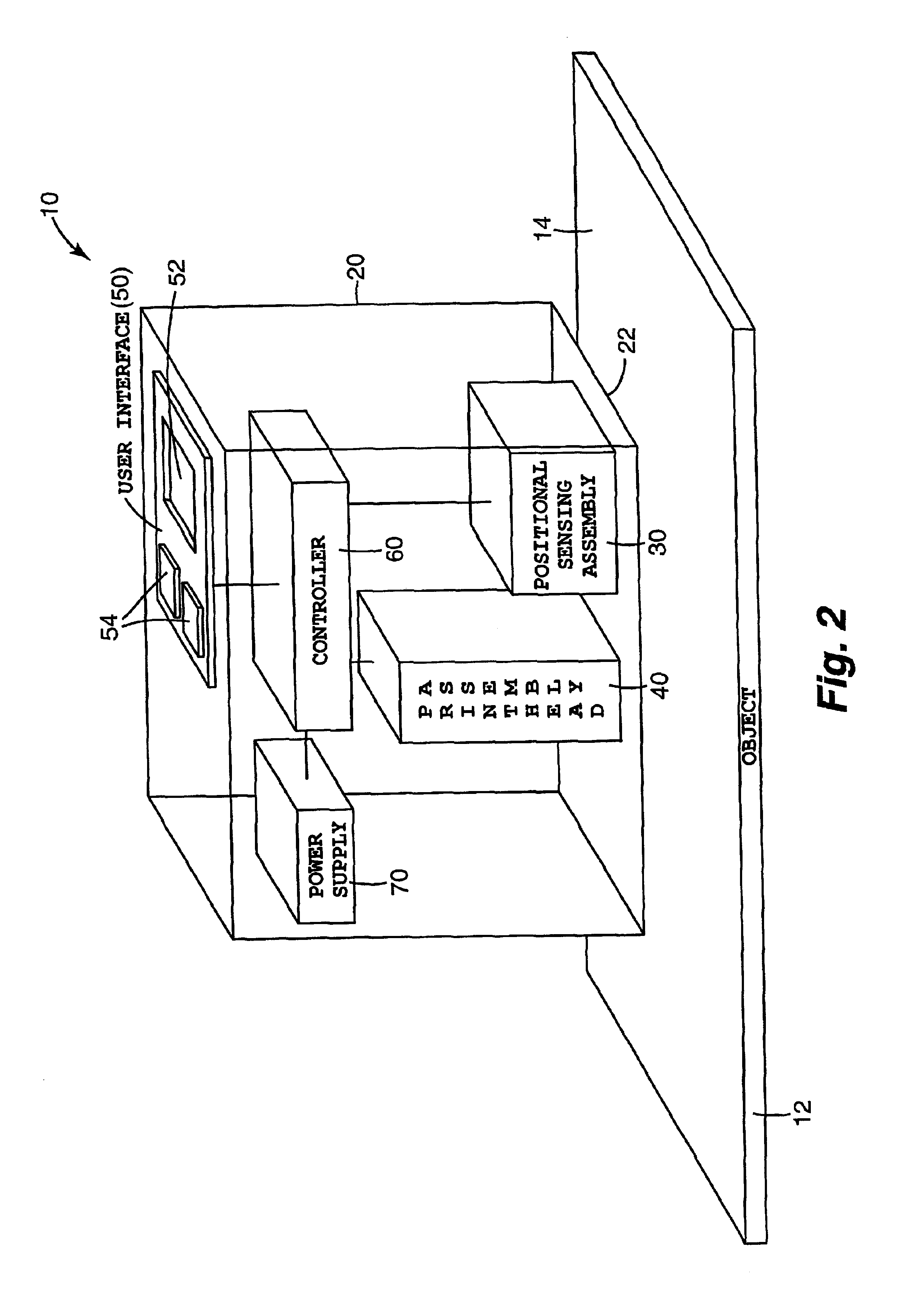

Measurement and marking device

A measurement and marking device includes a housing, a positional sensing assembly mounted in the housing, a printhead assembly mounted in the housing, and a controller mounted in the housing and communicating with the positional sensing assembly and the printhead assembly. The positional sensing assembly is adapted to sense a position of the housing relative to an object as the housing is moved along a surface of the object and the printhead assembly is adapted to print on the surface of the object as the housing is moved along the surface of the object. As such, the controller is adapted to operate the printhead assembly to print a mark on the surface of the object based on the position of the housing relative to the object as the housing is moved along the surface of the object.

Owner:HEWLETT PACKARD DEV CO LP

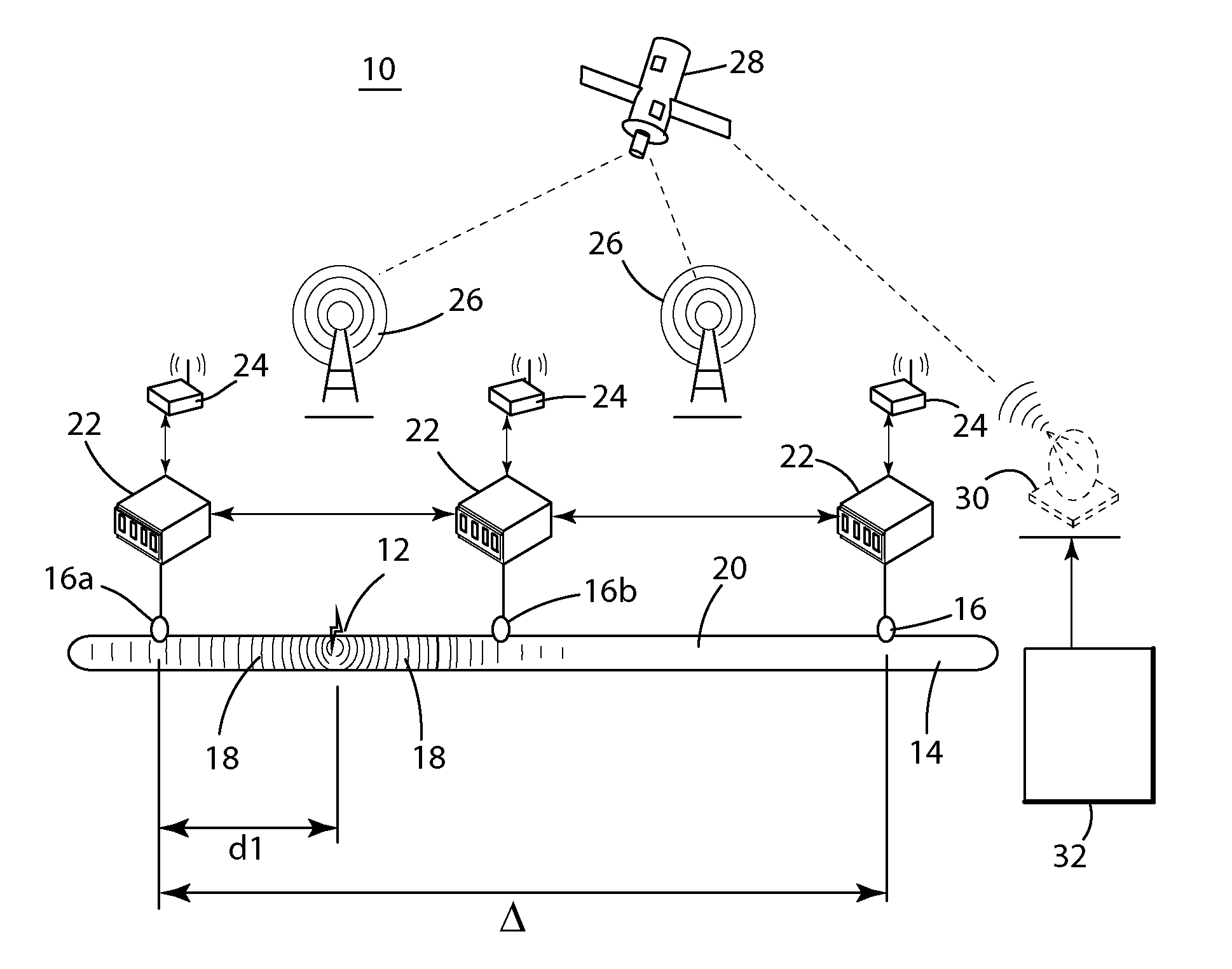

Inline Inspection System and Method for Calibration of Mounted Acoustic Monitoring System

ActiveUS20110161037A1Testing/calibration apparatusStatic/dynamic balance measurementSound sourcesMonitoring system

An inline inspection system and method for calibrating an acoustic monitoring structure installed along a pipe. The system includes a pipe inspection vehicle; a microprocessor configured to attach a time stamp to a measured distance traveled by the pipe inspection vehicle; an acoustic source attached to the pipe inspection vehicle and configured to generate sound waves inside the pipe, the sound waves having predetermined frequencies and predetermined amplitudes; plural sensors disposed along the pipe and configured to record time of arrivals and intensities of the sound waves generated by the acoustic source; and a processing unit configured to communicate with the plural sensors and receive the time of arrivals, intensities and frequencies of the sound waves from the plural sensors. The processing unit calibrates the acoustic monitoring structure by calculating a distance between the acoustic source and a first sensor of the plural sensors.

Owner:PII CANADA

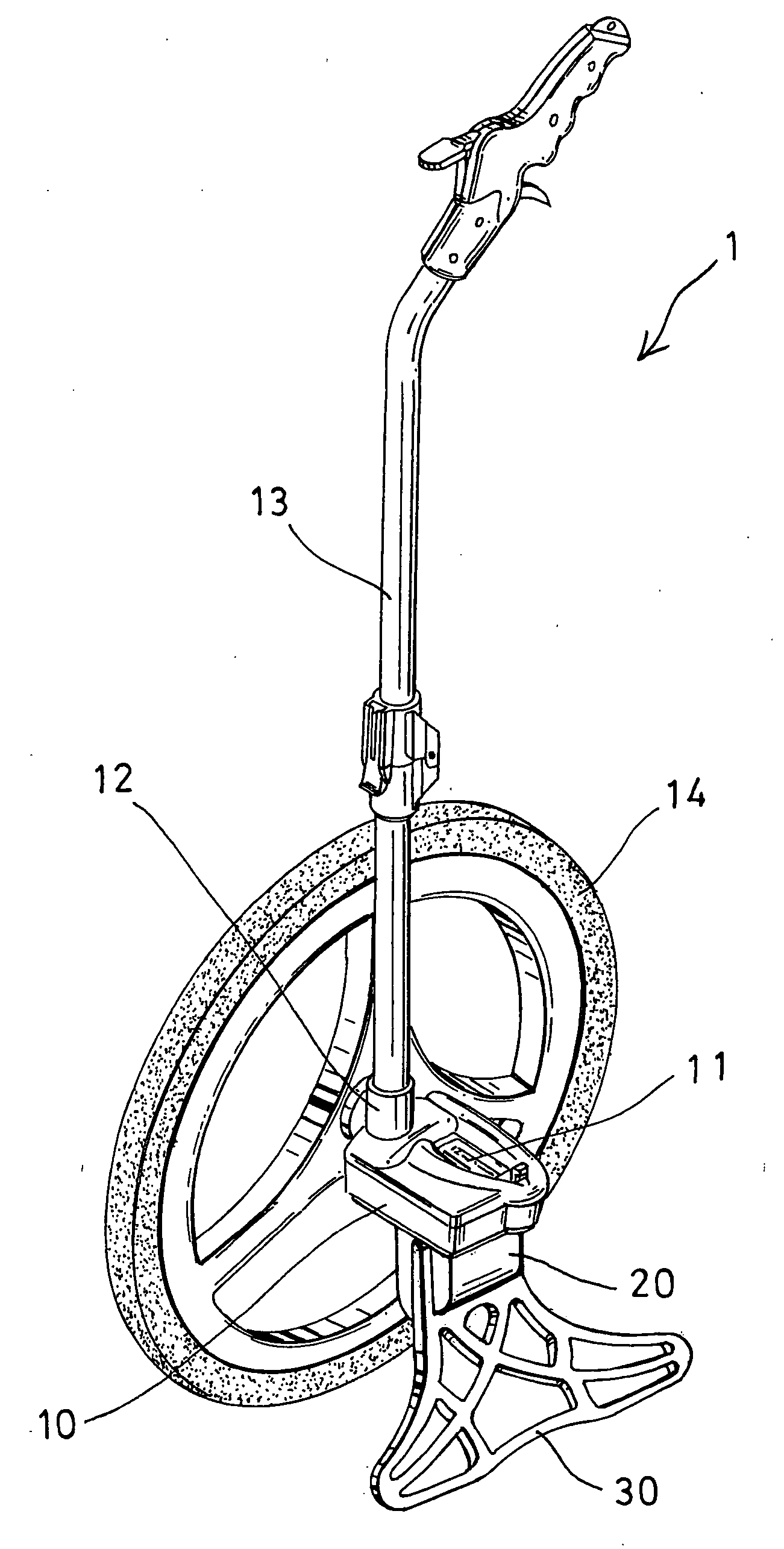

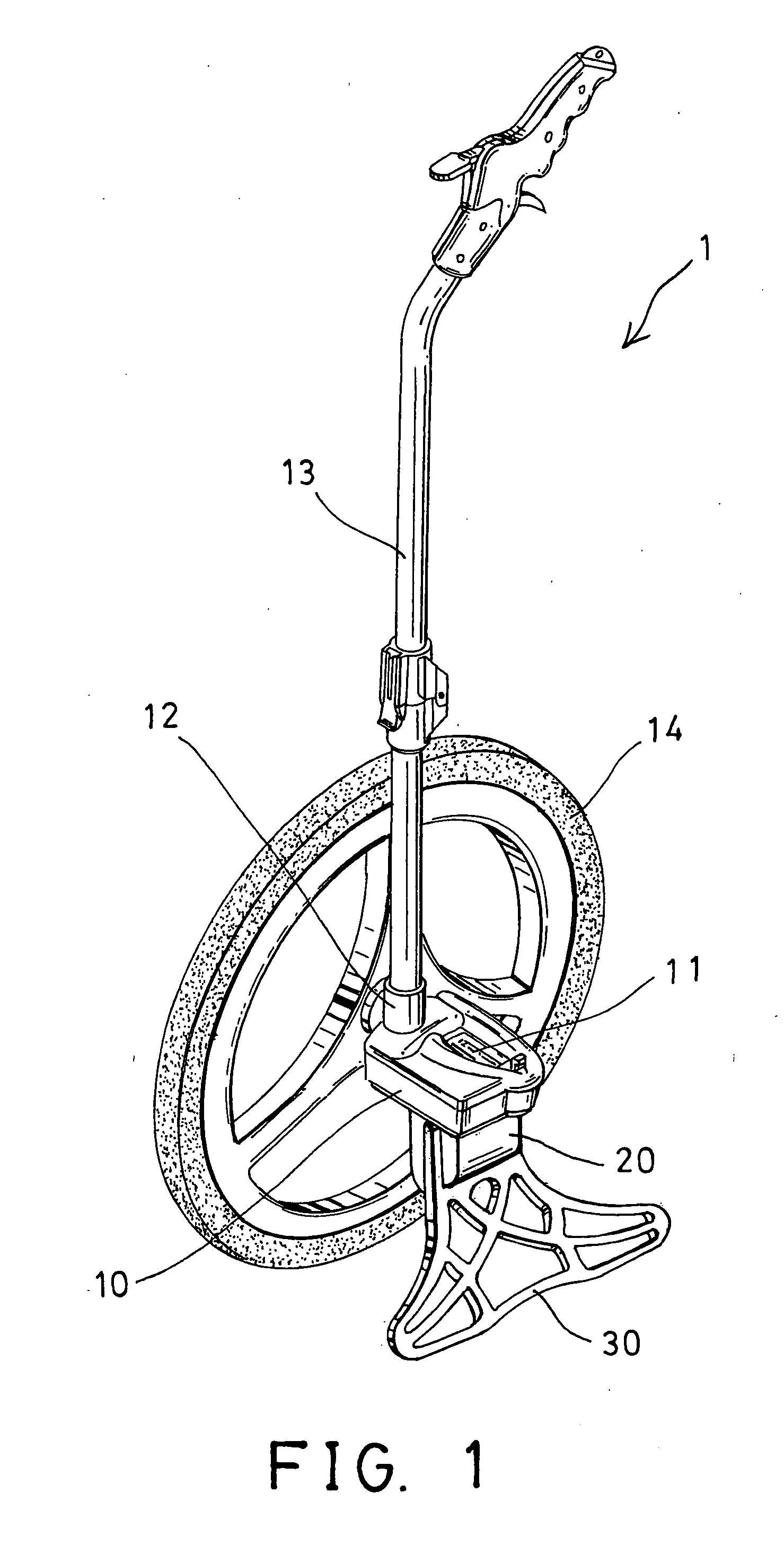

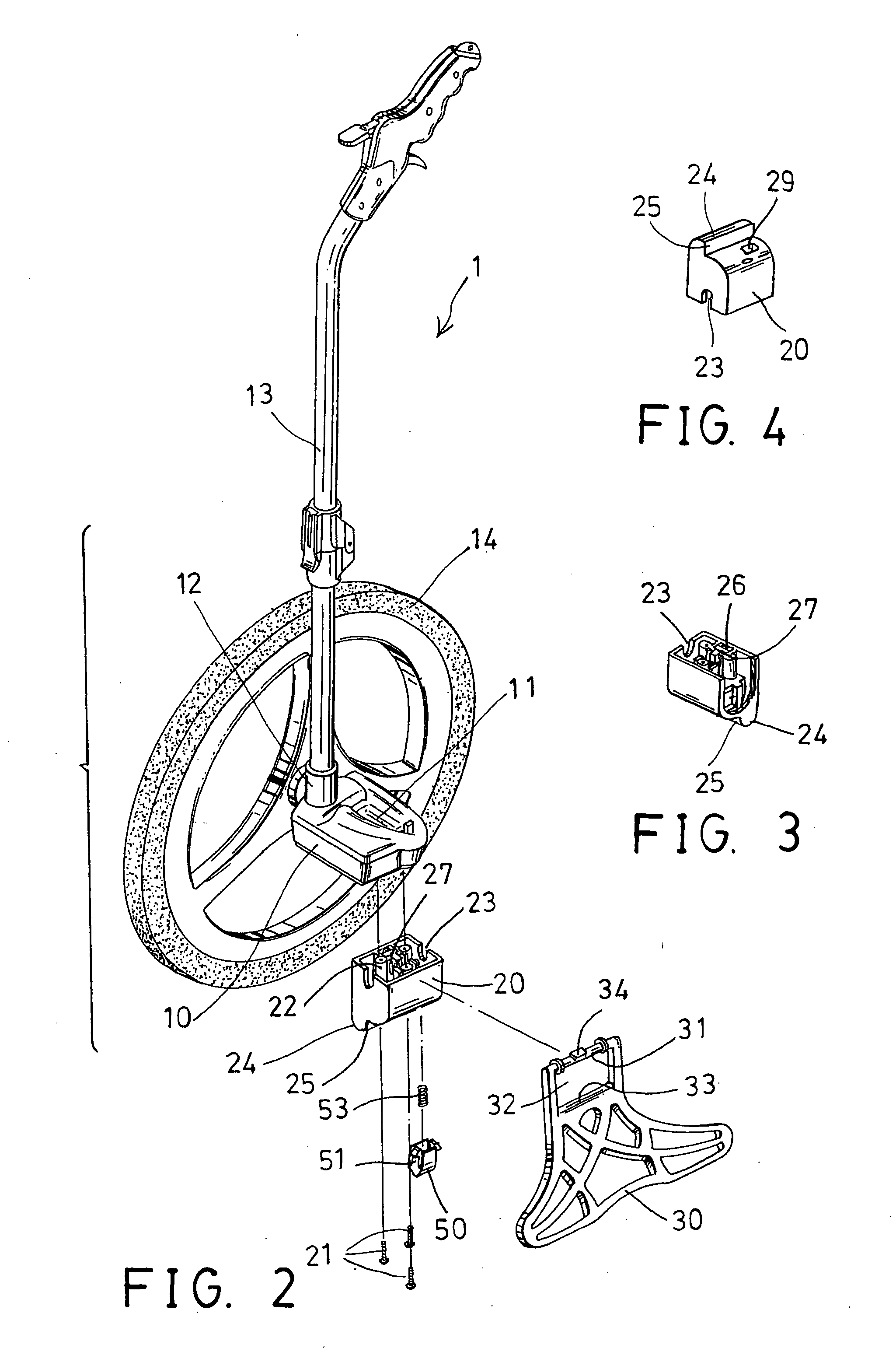

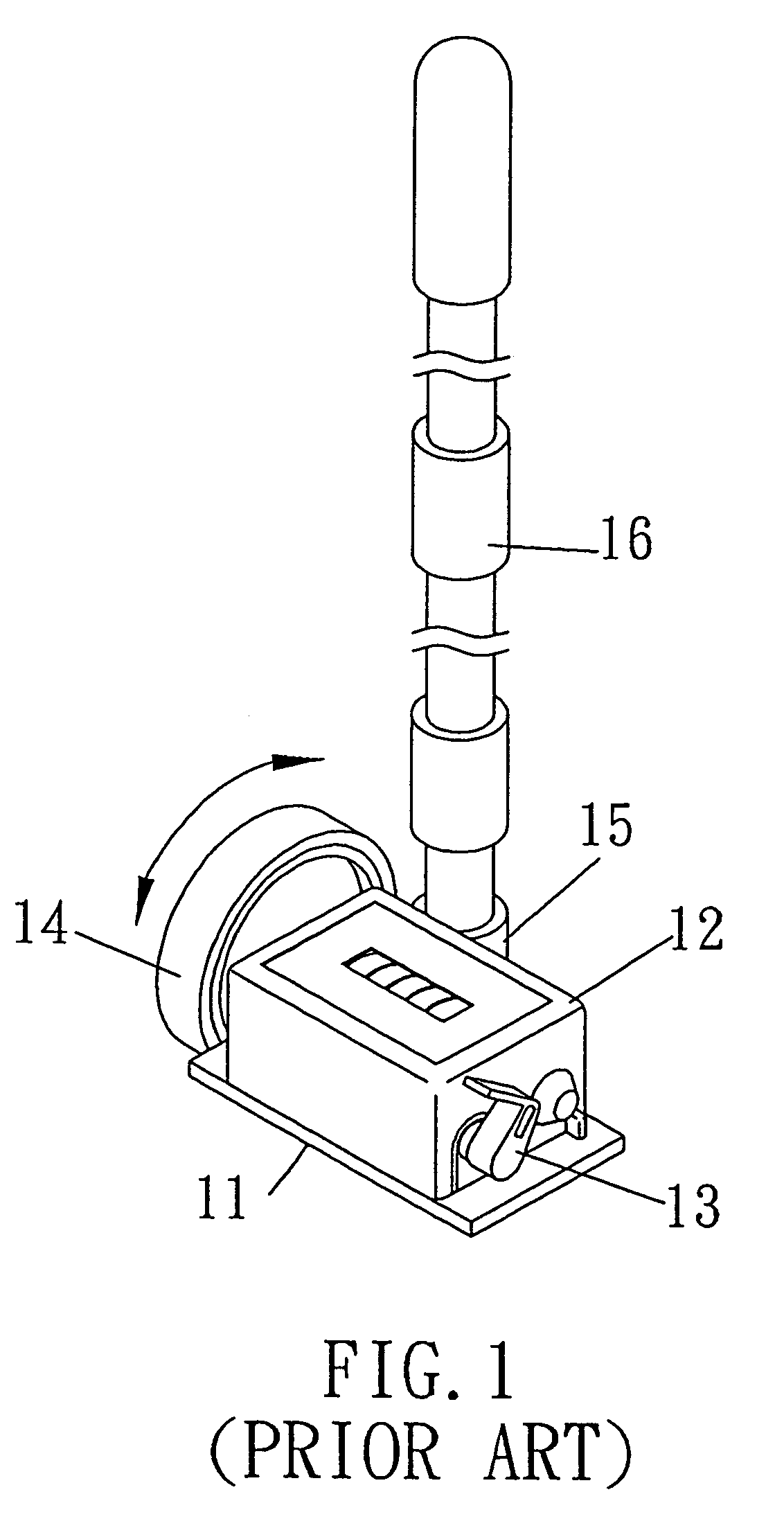

Wheeled distance measuring device

InactiveUS20070084076A1Prevent fallingRestrict movementMeasuring wheelsUsing electrical meansEngineeringCam

A wheeled distance measuring device includes a wheel rotatably attached to a housing, a casing secured to the housing and having a protrusion to form an anchoring shoulder, and a stand having a shaft rotatably attached to the casing and having an anchoring edge for engaging with the protrusion of the casing and for positioning the stand to the casing at a downward working position. The casing includes a spring-biased latch extendible out to selectively engage with the stand, and to further position the stand to the casing at the downward working position. The casing includes an actuator biased to engage with a cam member of the stand, for selectively positioning the stand to the casing.

Owner:WANG HUI CHEN

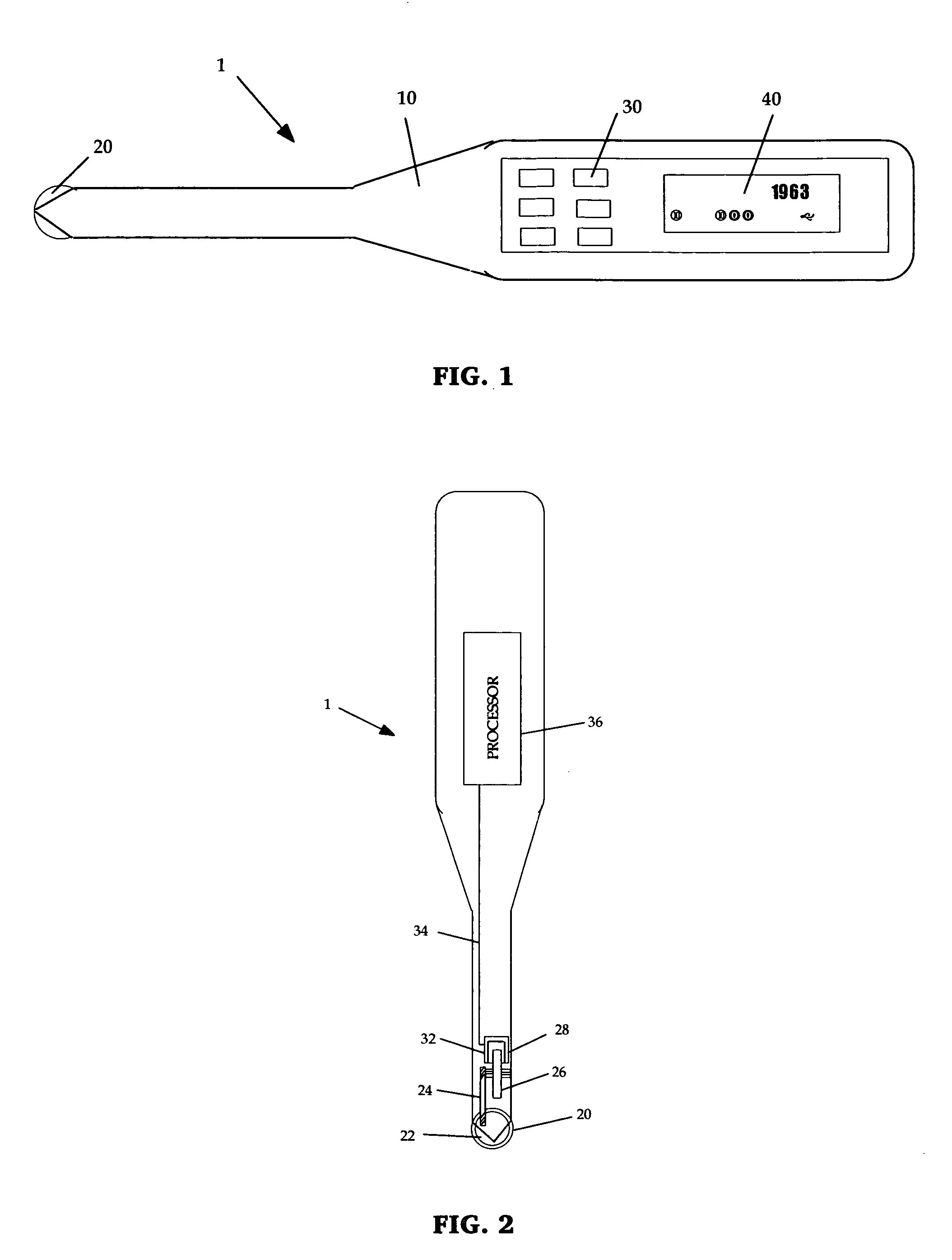

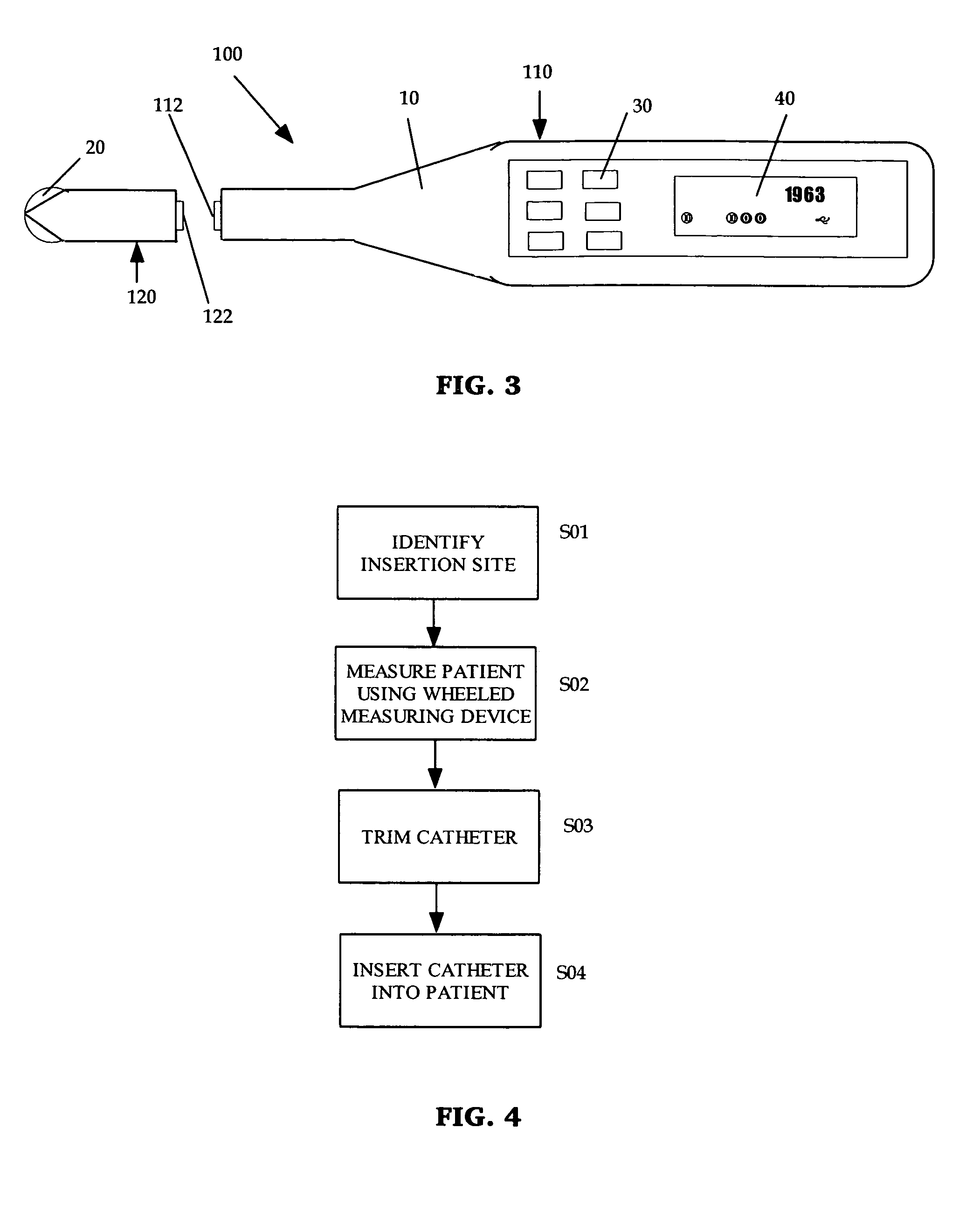

Method of determining an appropriate catheter length

A method of inserting a catheter into a body of a patient includes identifying a catheter insertion site on the patient's body; measuring a length, from the insertion site to another site external to the body of the patient, and along an external path that follows a presumed internal path of the catheter from the insertion site to a target site within the patient's body, using an automatic measuring device; trimming the catheter to an appropriate length based on the length measured by the automatic measuring device; and inserting the trimmed catheter into the body of the patient through the insertion site to the target site.

Owner:TELEFLEX LIFE SCI LTD

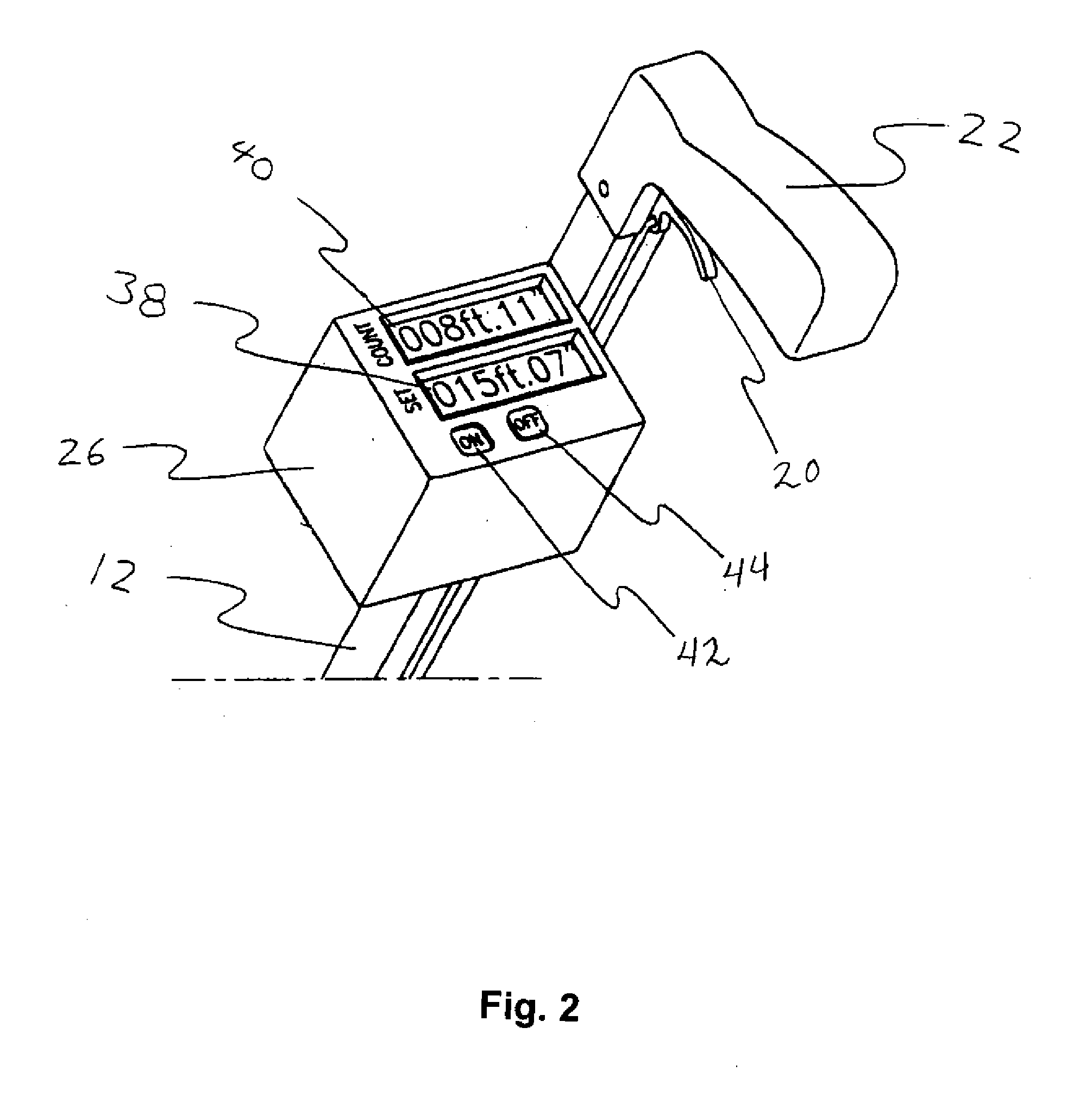

Multi-purpose digital scale for travelers

InactiveUS7238895B2Easy to holdEasy to grip handleMeasuring wheelsUsing electrical meansCommon carrierComputer science

A portable scale that allows travelers to calculate the weight of their luggage and compare the weight against weight limits that are imposed by common carriers. The scale includes circuitry for calculating weight and a memory for storing weight limits. Weight and other information is shown to the user via a display screen. In the preferred embodiment, the scale includes a hook and handle that facilitate weighing suitcases and other objects. The preferred embodiment also includes a digital measuring tape that allows the traveler to check the size of his luggage against size restrictions imposed by common carriers. The scale can also be incorporated into a portable weighing mat, which allows weight to be determined simple by placing the object on the mat. The scale can also be incorporated into the handle of a suitcase wherein the weight of the suitcase is calculated when the suitcase is lifted by its handle.

Owner:DITTRICH JOSEPHINE M +1

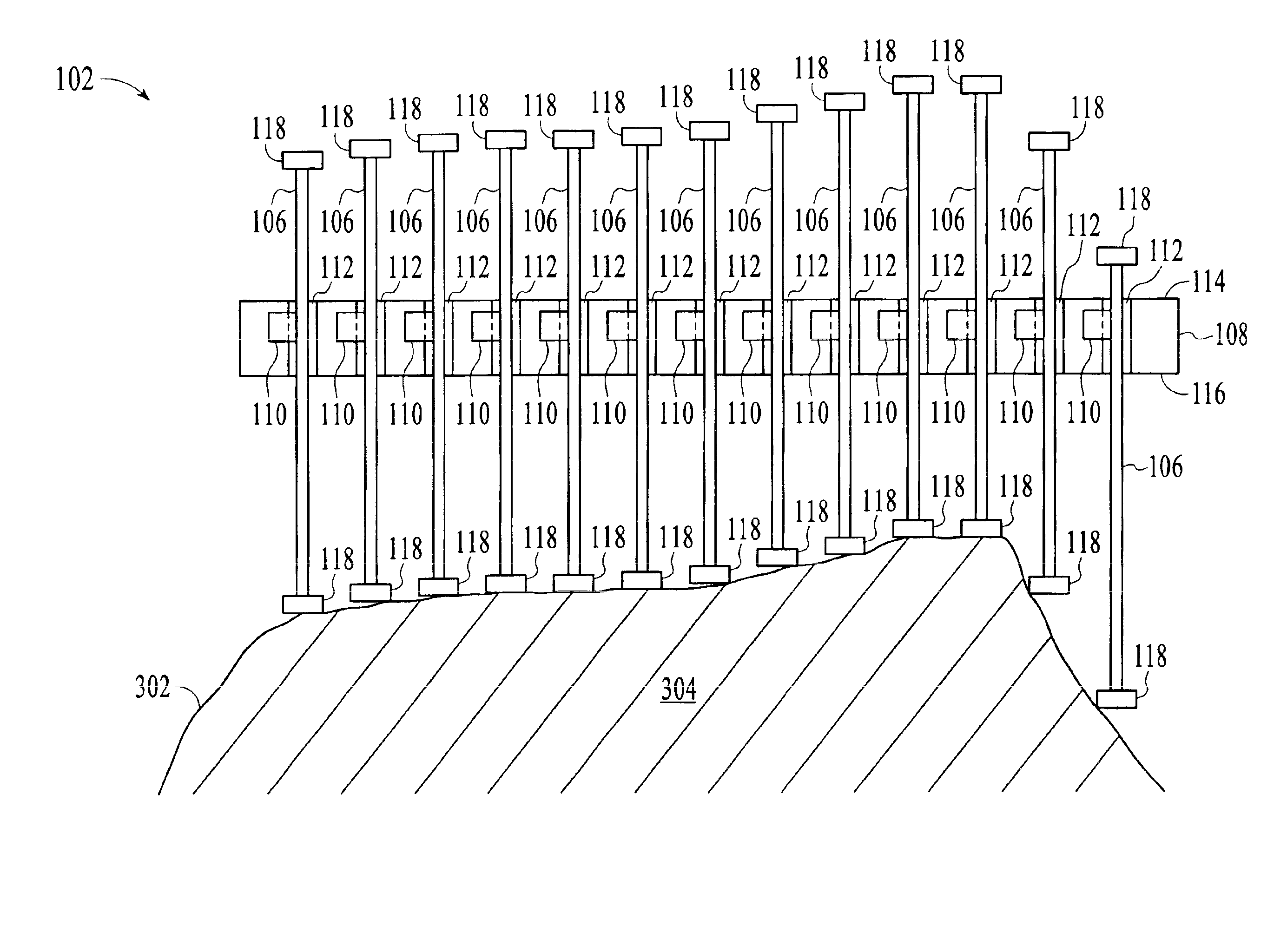

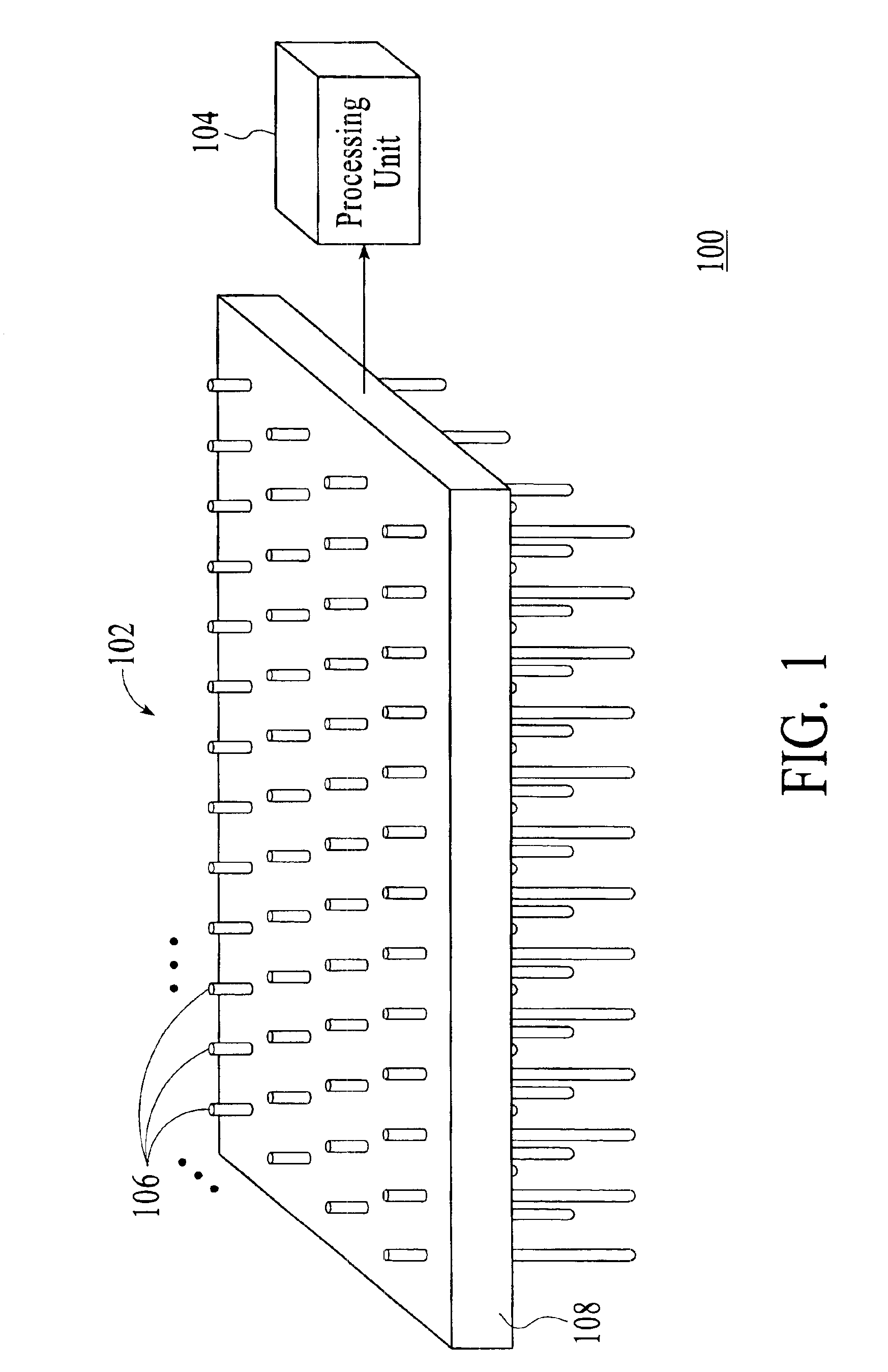

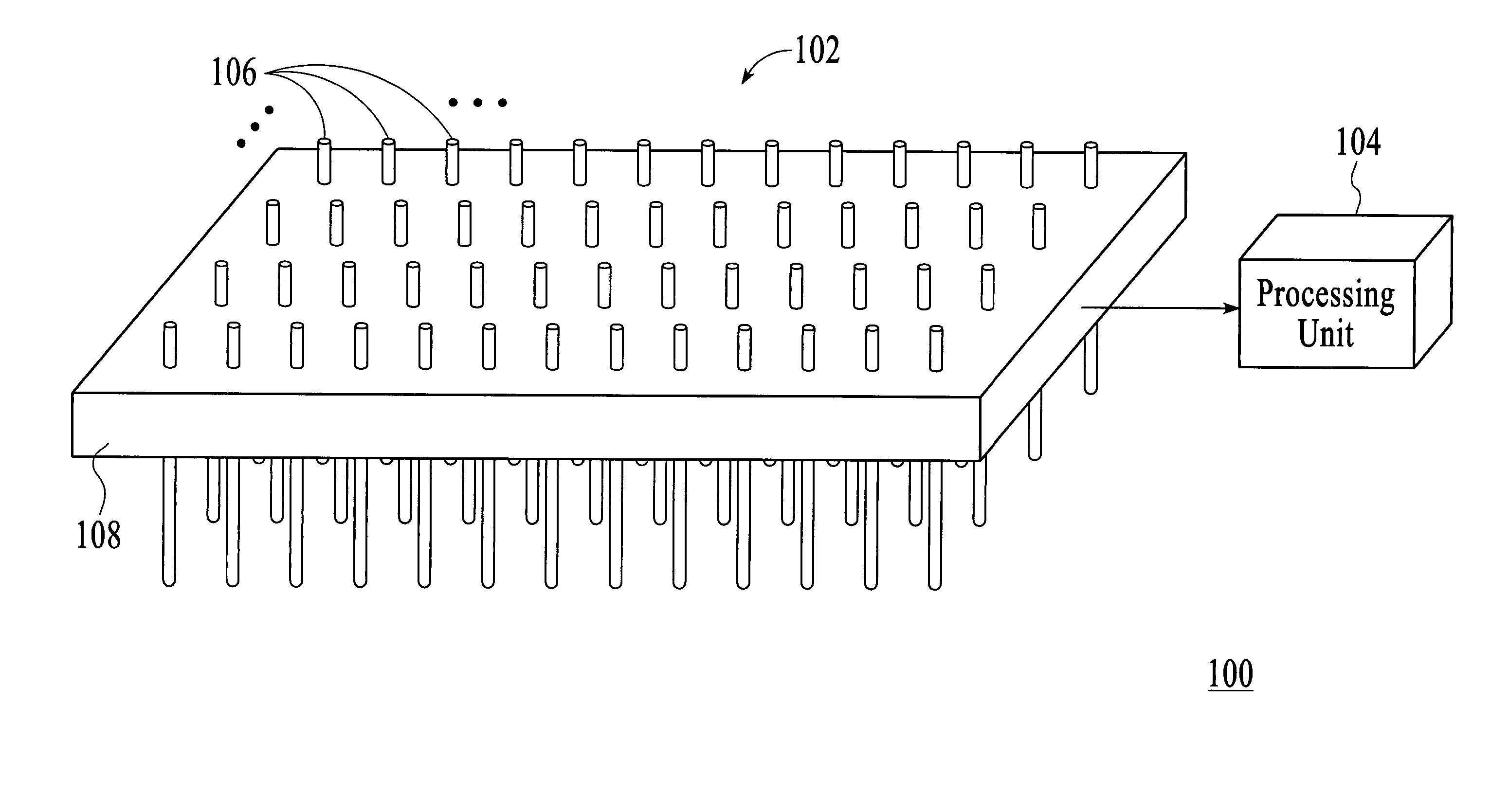

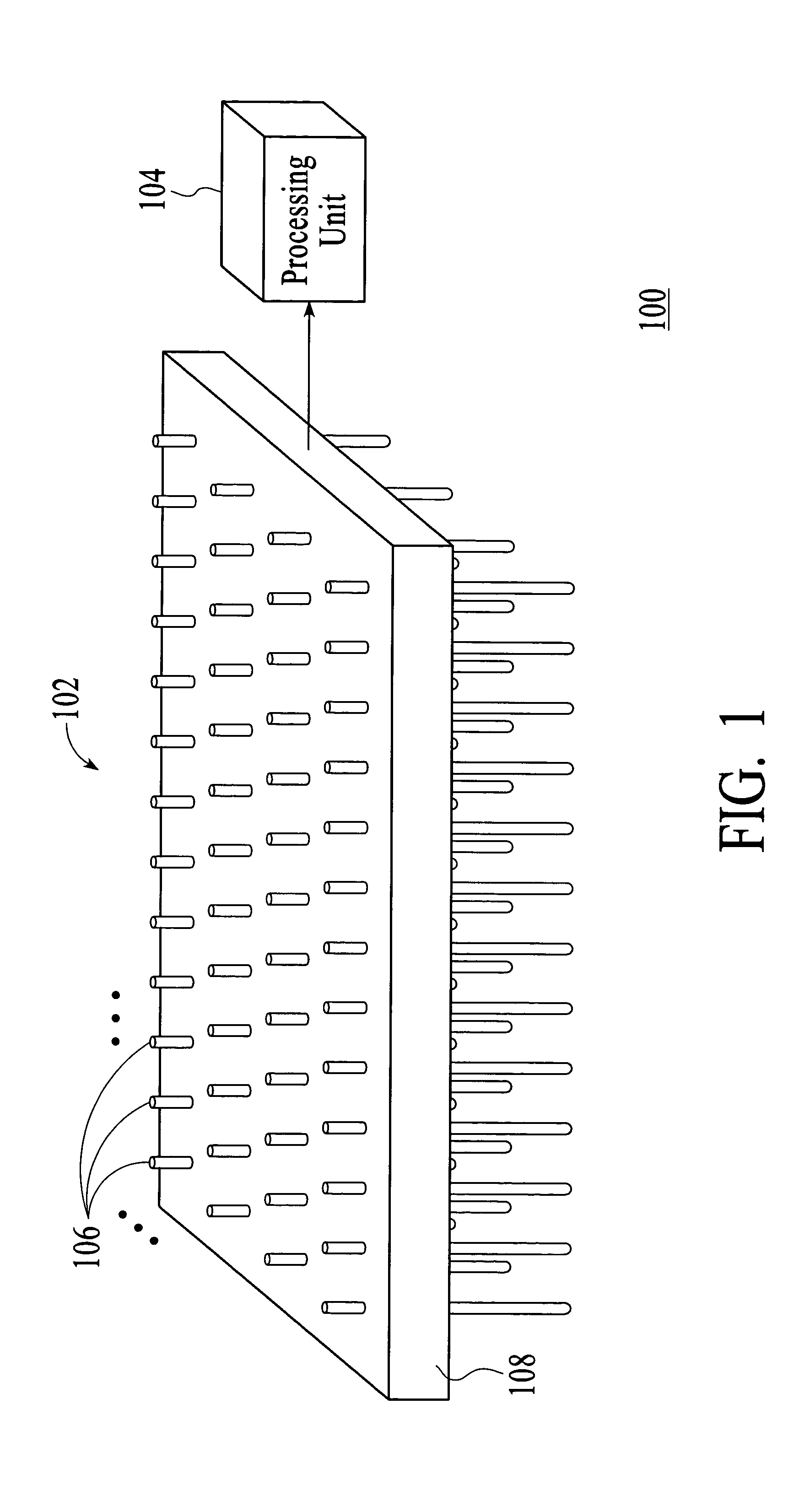

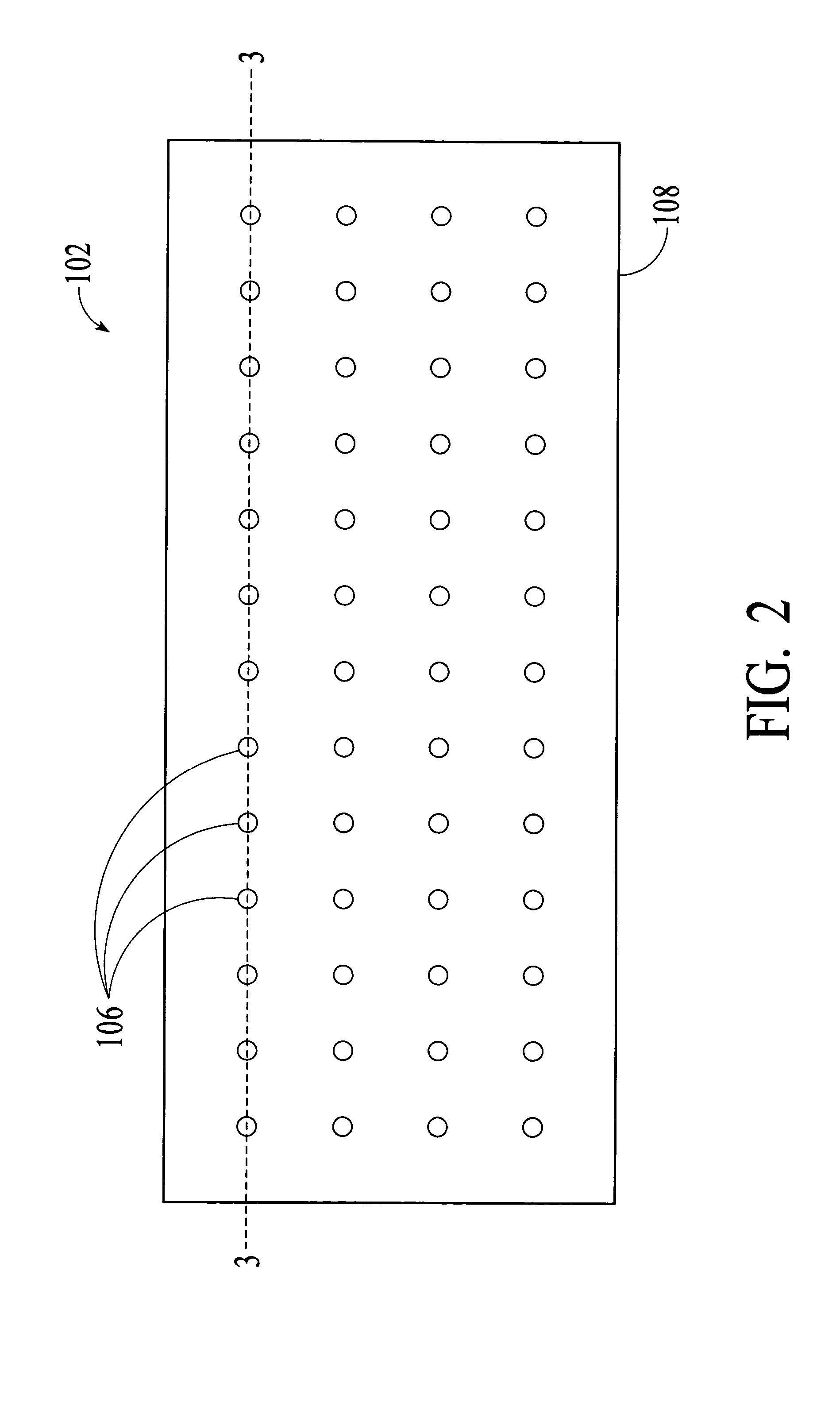

System and method for measuring three-dimensional objects using displacements of elongate measuring members

InactiveUS6907672B2Short processFeeler-pin gaugesUsing subsonic/sonic/ultrasonic vibration meansClassical mechanics

Owner:HEWLETT PACKARD DEV CO LP

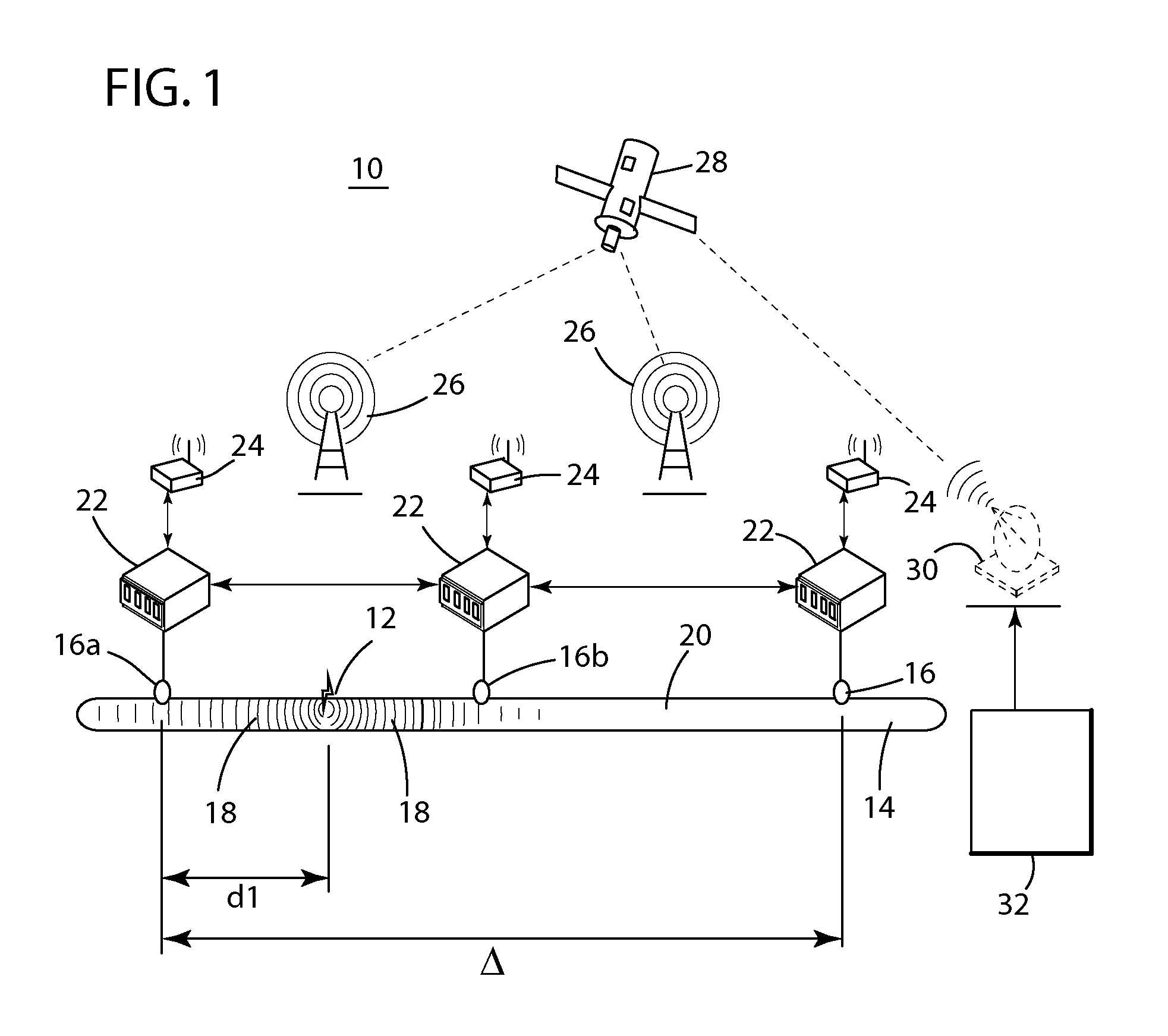

Method of surveying a track

InactiveUS20030097235A1Time-consume taskImprove accuracyBallastwayDigital data processing detailsGps receiverReference line

In a method of surveying a track (9), a first or mobile measuring vehicle (1) and a second or stationary measuring vehicle (2) are placed at a distance apart from one another on a track section to be measured. A reference line (14) is formed by a laser beam emitted from the stationary measuring vehicle (2). At the start of each measuring cycle, by using a GPS receiver (19), the relative position of the stationary measuring vehicle (2) with reference to a fixedly installed GPS reference station (29) located adjacent to the track section is determined, the said GPS reference station being known within a terrestrial coordinate system. The reference line (14) is aligned with the mobile measuring vehicle (1) on the basis of the determined position data, and the track surveying operation is carried out by advancing the mobile measuring vehicle (1) while changes of the actual track position relative to the reference line (14) are registered.

Owner:FRANZ PLASSER BAHNBAUMASCHINEN IND GMBH

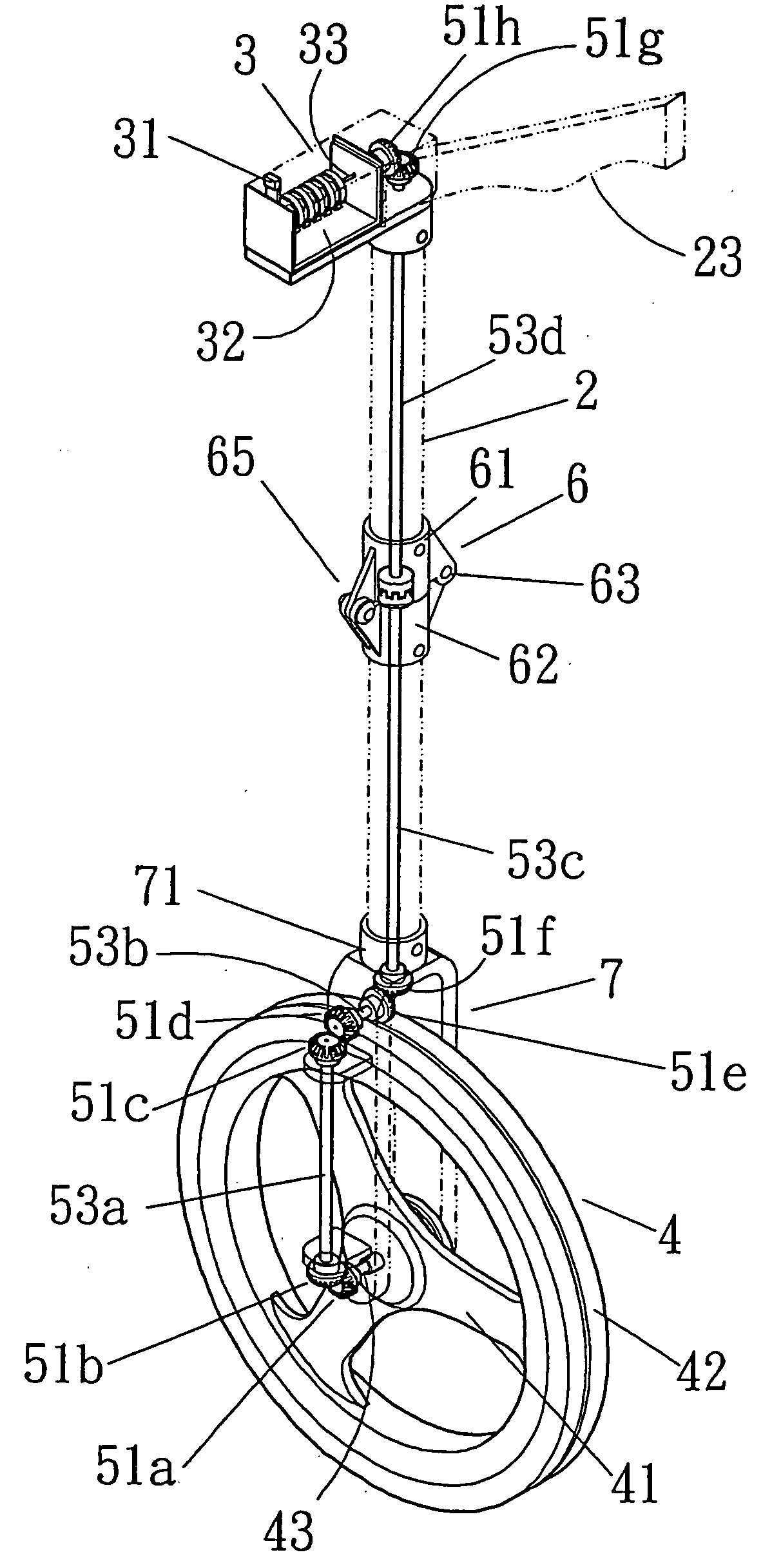

Wheel vehicle measuring apparatus

InactiveUS20060156573A1Accurate measurementImprove ease of useMeasuring wheelsUsing electrical meansMechanical engineeringWheel and axle

Owner:INDEX MEASURING TAPE

Wheeled distance measuring device

ActiveUS7555846B1Efficient foldingSelectively and solidly coupled togetherMeasuring wheelsUsing electrical meansDrop-shapedElectrical and Electronics engineering

A wheeled distance measuring device includes a longitudinal pole having two segments, a housing and a casing attached to the segments and pivotally coupled together, a latch device pivotally attached to the housing and having a latch, and a lock device pivotally attached to the casing and having a catch for engaging with the latch of the latch device and for detachably securing the segments together. The casing includes a chamber formed by a wall for receiving the lock device, and a channel formed in the wall for pivotally engaging with a water-drop-shaped pivot member of the lock device and for pivotally attaching and coupling the lock device to the casing.

Owner:WANG CHENG LIN

System and method for measuring three-dimensional objects using displacements of elongate measuring members

InactiveUS20050076521A1Shorter measuring processShort processFeeler-pin gaugesUsing subsonic/sonic/ultrasonic vibration meansClassical mechanics

A system and method for measuring a three-dimensional object uses a number of elongate measuring members that can be displaced with respect to a base in response to a surface of the object. The displaced distances of the elongate measuring members due to the surface of the object are then determined. The displaced distances are measurements of the object surface.

Owner:HEWLETT PACKARD DEV CO LP

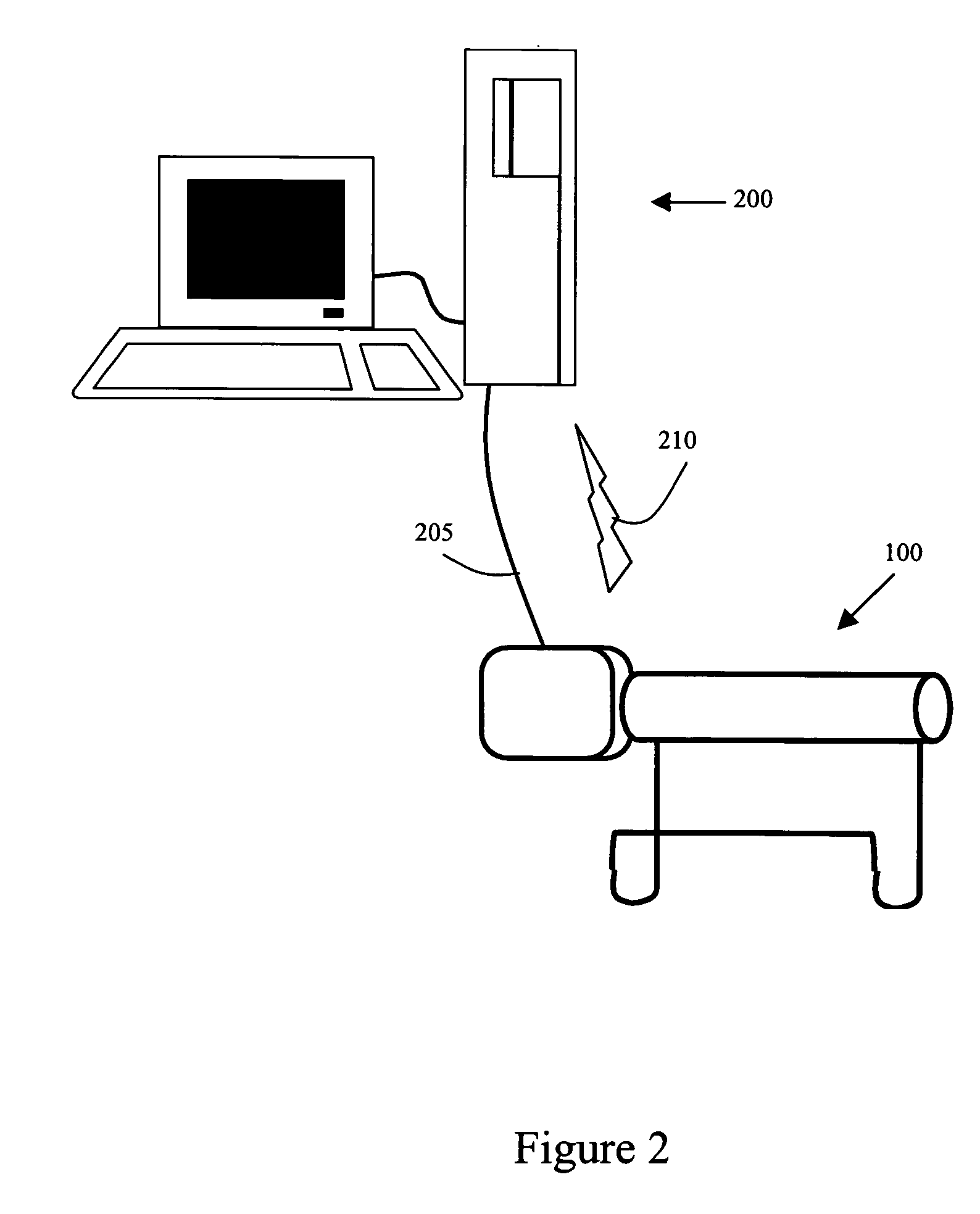

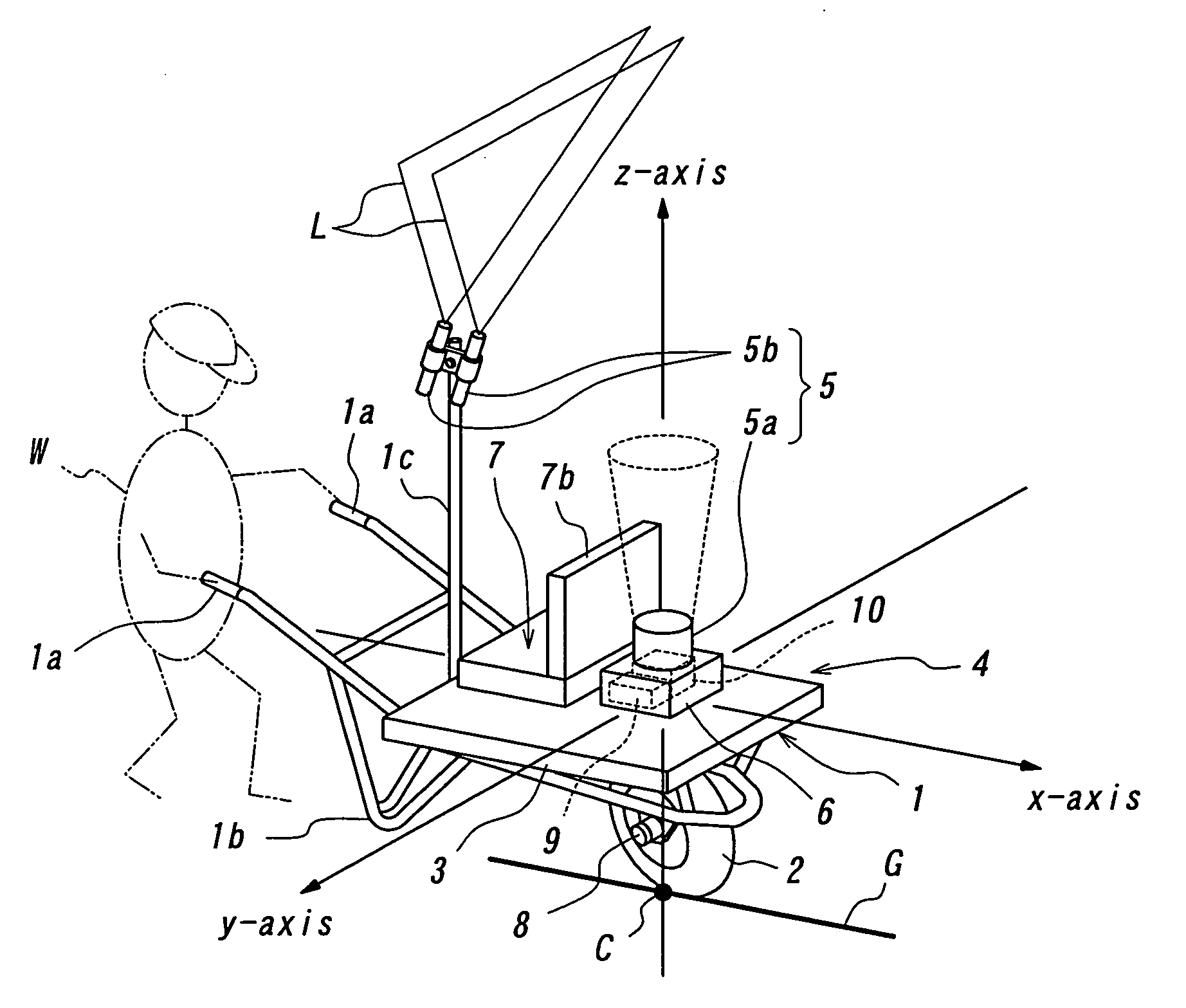

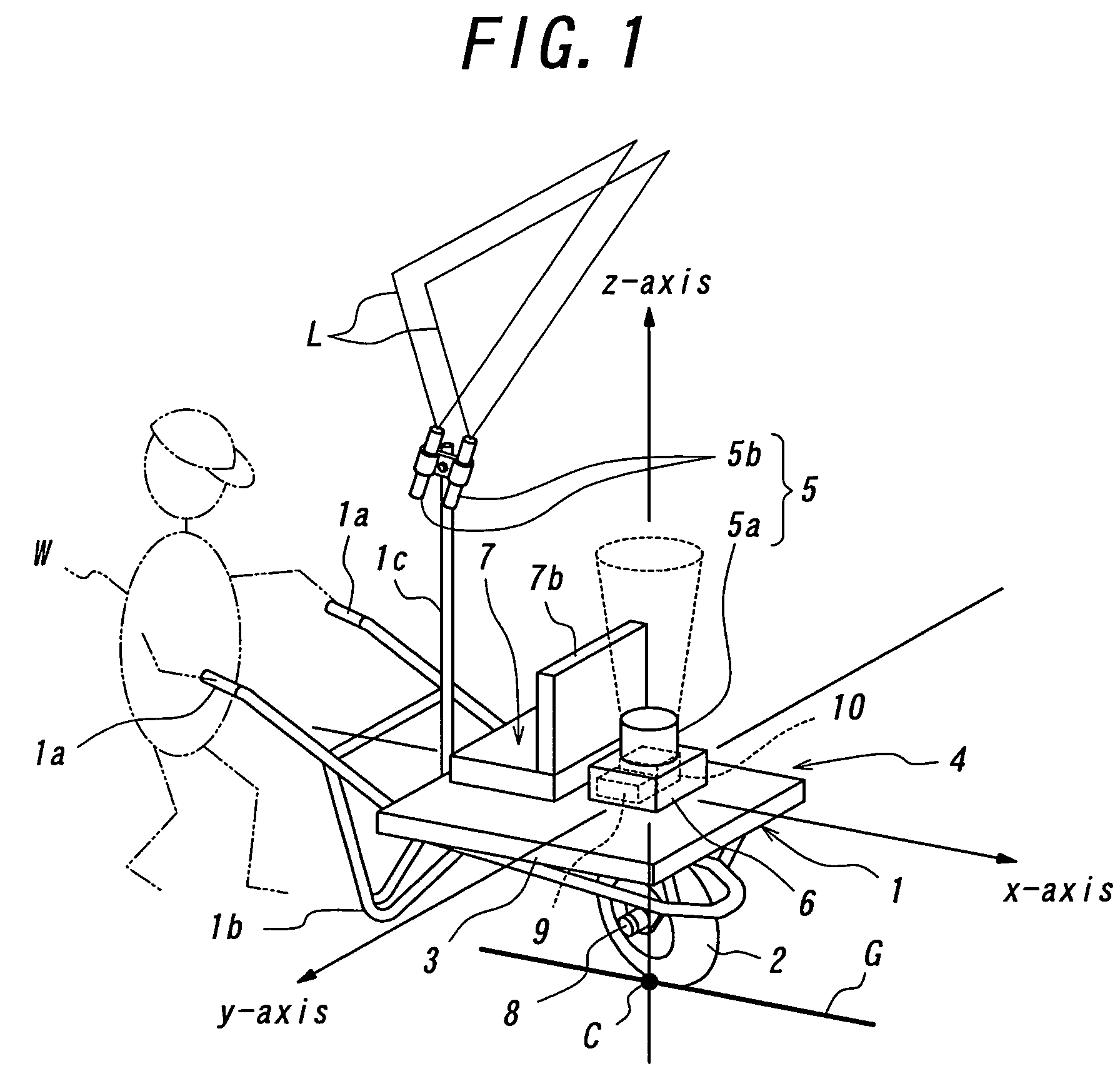

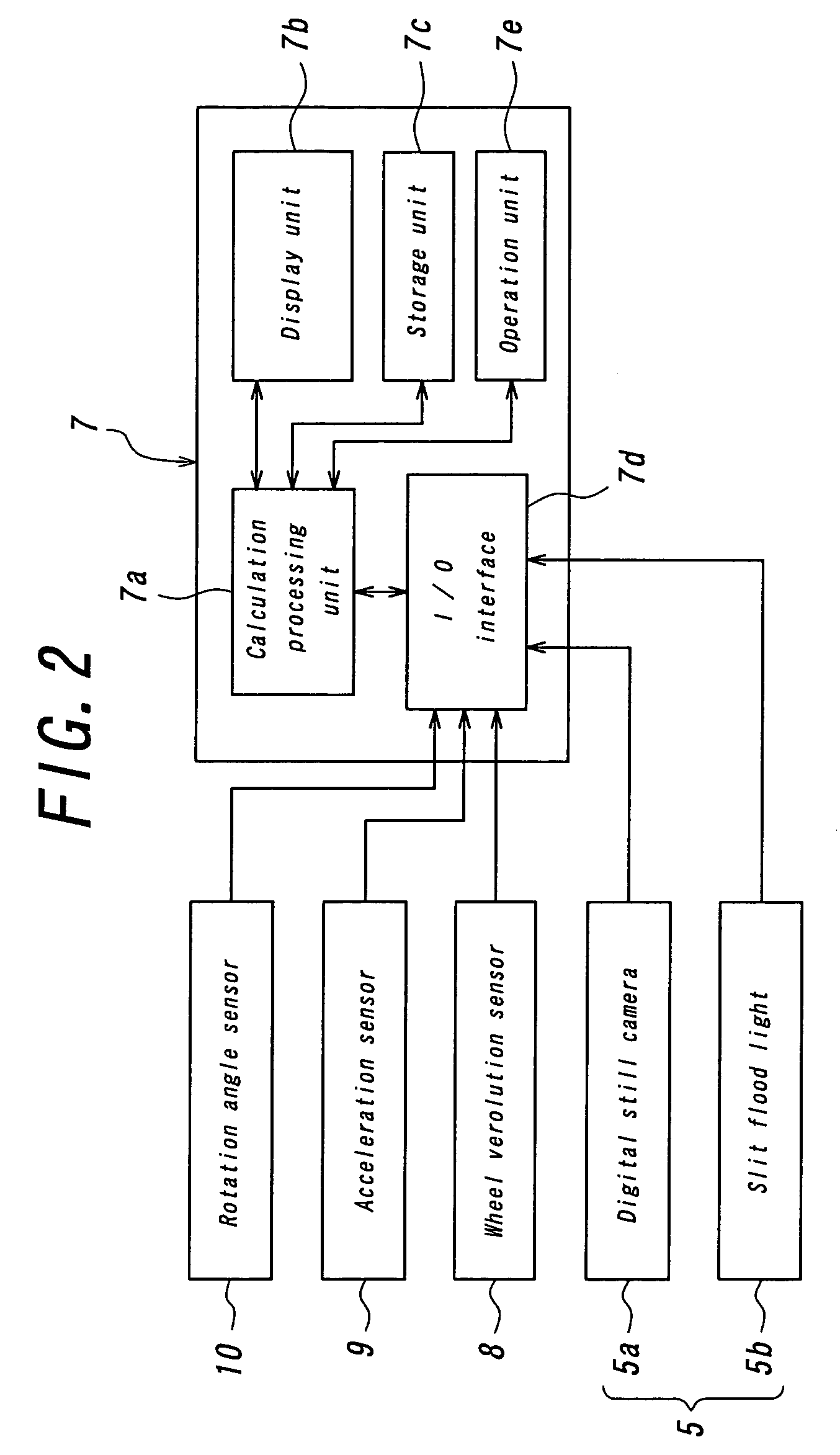

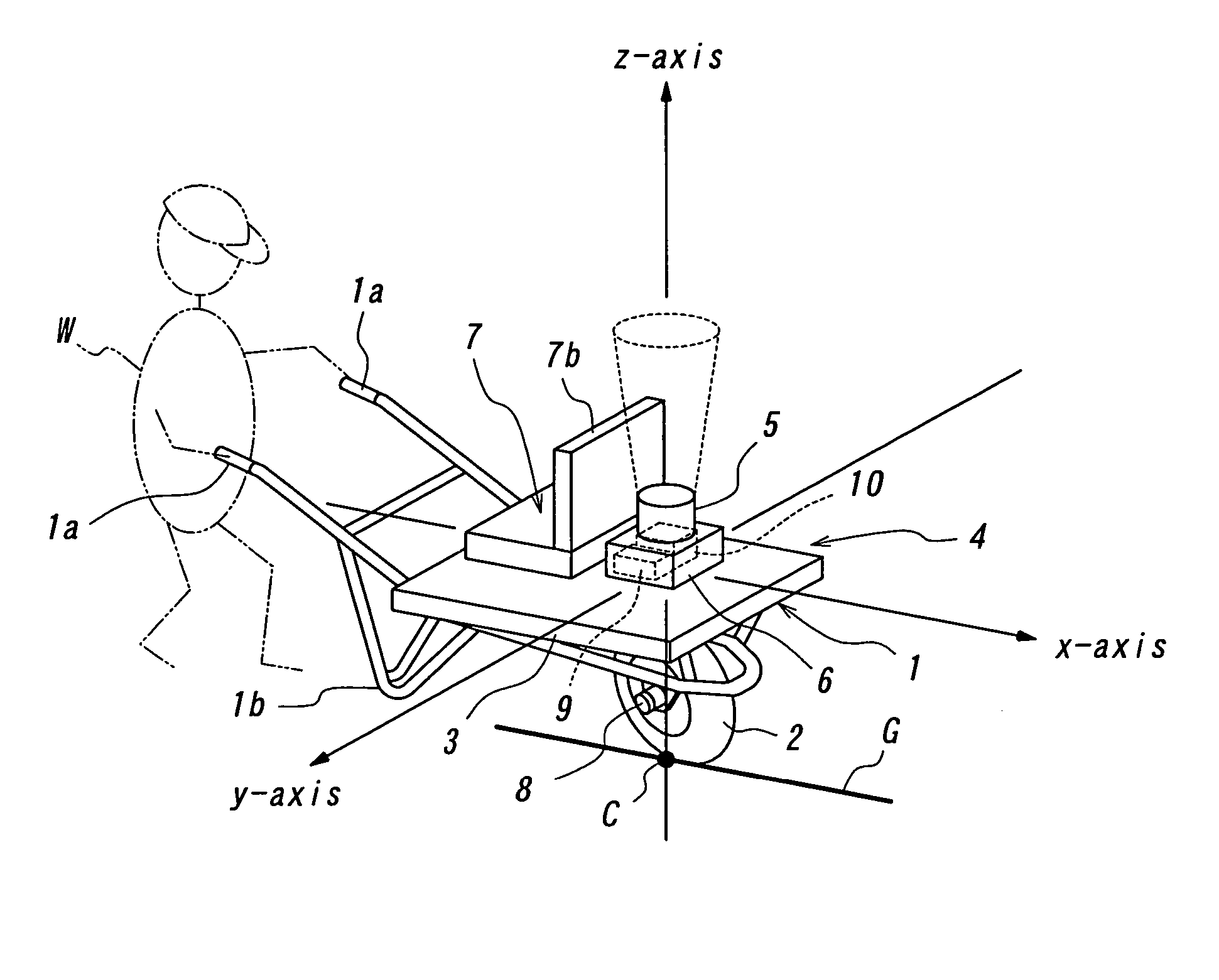

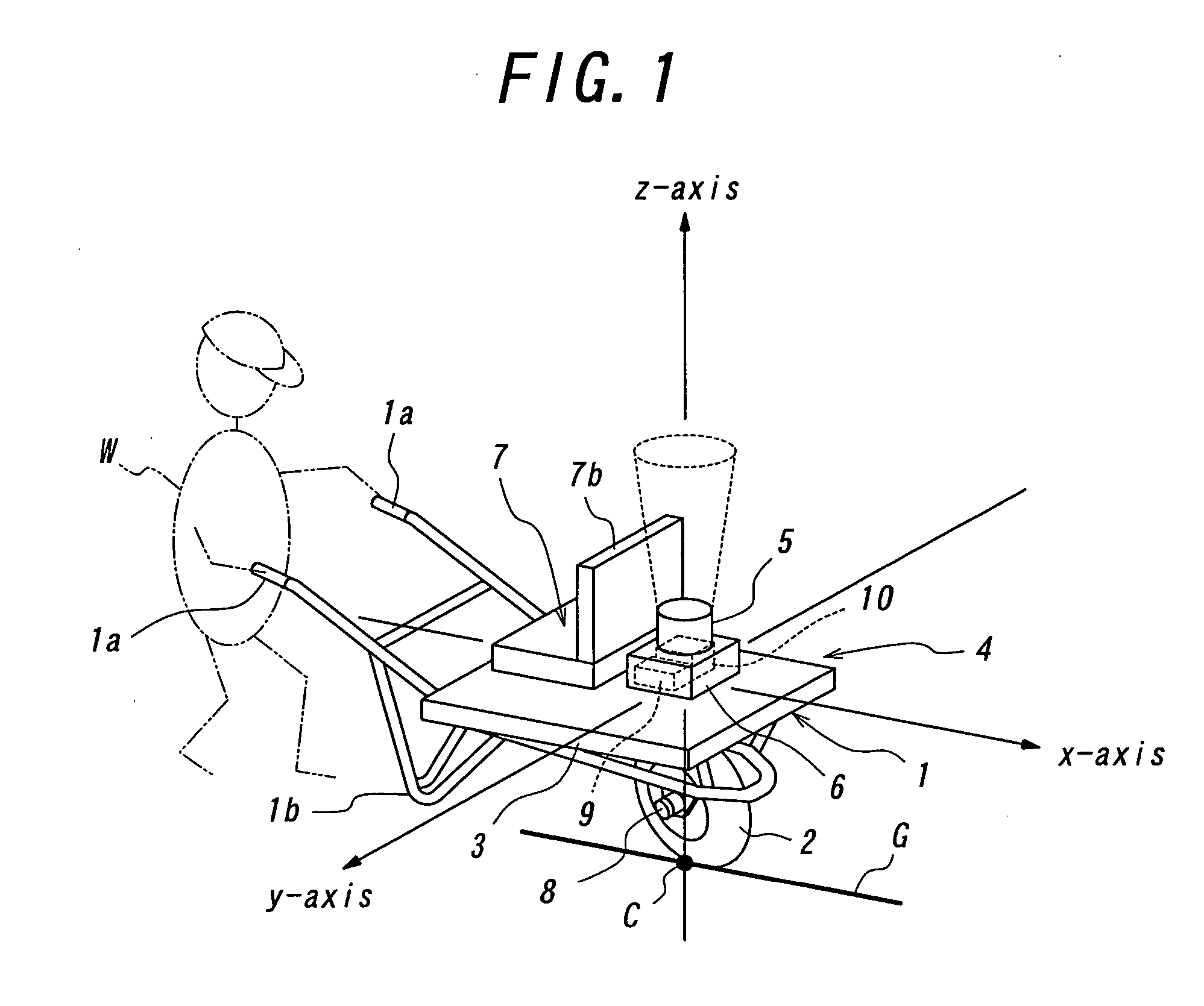

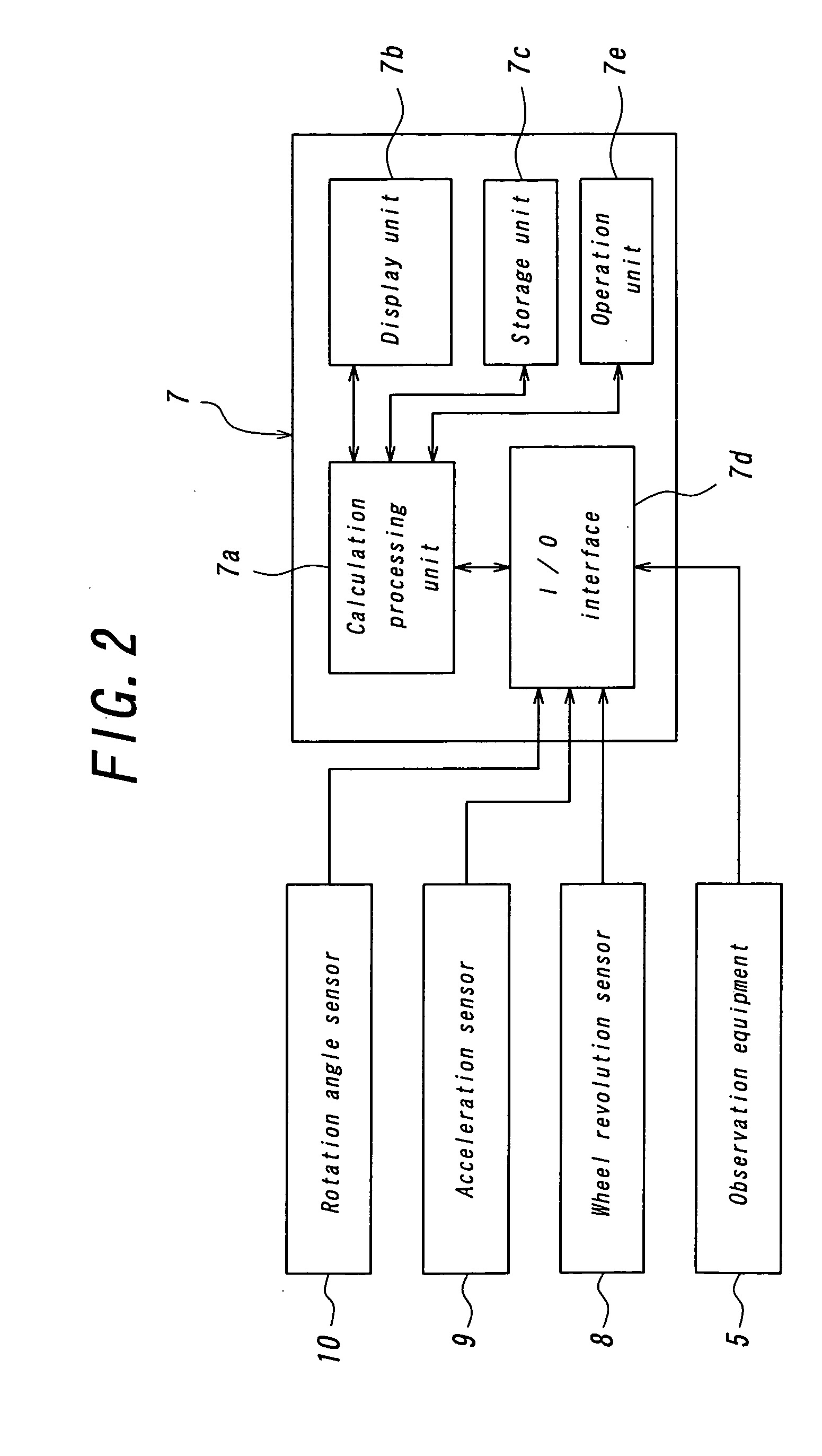

Mobile measurement system of three-dimensional structure

InactiveUS7032458B2Low costNo expenseAngle measurementMeasuring wheelsMarine navigationMeasuring equipment

This invention relates to a mobile measurement system of three-dimensional structure comprises a measuring equipment 5 to measure three-dimensional structure of an object for measurement and a barrow 4 for moving measurement which the equipment 5 is mounted. The measuring equipment 5 has a digital camera 5a, a slit floodlight 5b, and a three-dimensional structure calculating device that calculates and outputs three-dimensional structure of the object by using a light plane range-finding method from the each position and direction of the floodlight and the camera and the picture that is taken by the camera. The barrow has an measurement position and direction calculating device that calculate the each position of the floodlight and the camera, the direction of the floodlight, the direction of the camera at the measurement by the equipment in accordance with an information of self-contained navigation from an acceleration sensor 9 and a rotation angle sensor 10 that detects an acceleration and a rotation angle of the barrow, respectively, and an information of moving distance from the wheel revolution sensor 8 and transmit the result of the calculation to the three-dimensional structure calculating device 7.

Owner:NAGOYA UNIVERSITY

Measuring roller and spray device

A measuring device includes a frame, a rolling wheel carried by the frame, measuring means for determining a distance traveled by the wheel, and signal means responsive to the measuring means for indicating when the wheel has traveled a preselected set distance. The measuring device may also include marking means such as spray paint, a braking mechanism, and a sonar position indicator.

Owner:WATKINS NATHAN P

Wheel vehicle measuring apparatus

InactiveUS7111412B2Accurate measurementImprove ease of useMeasuring wheelsUsing electrical meansEngineeringRotation cycle

Owner:INDEX MEASURING TAPE

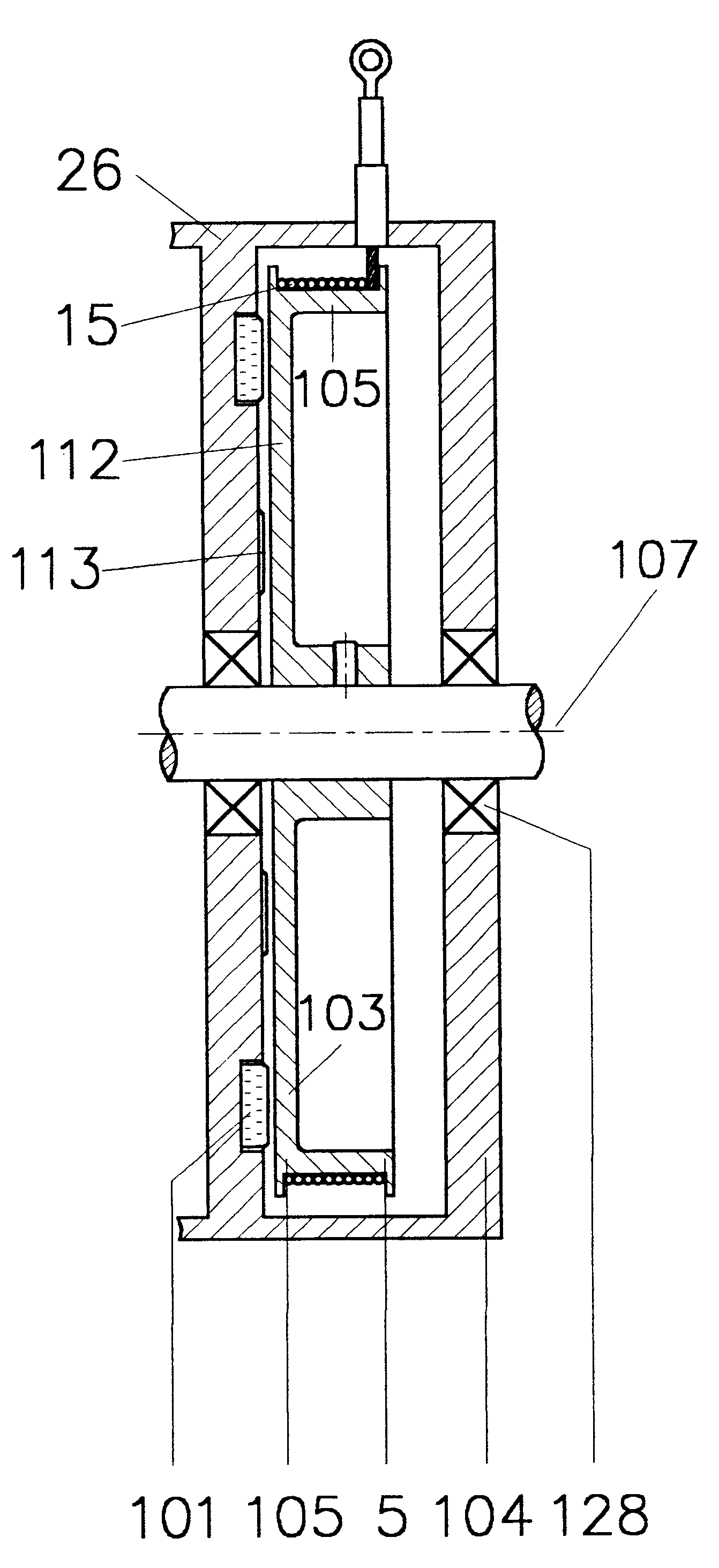

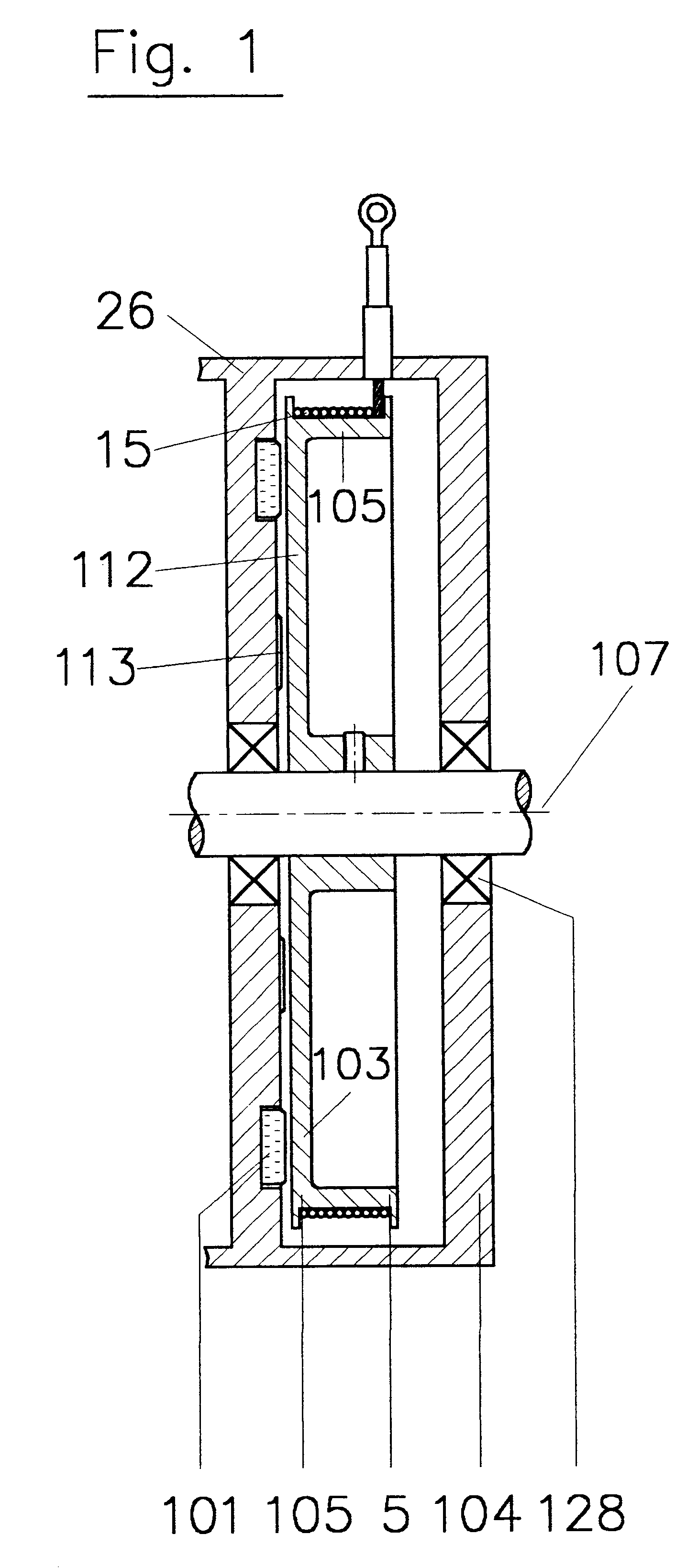

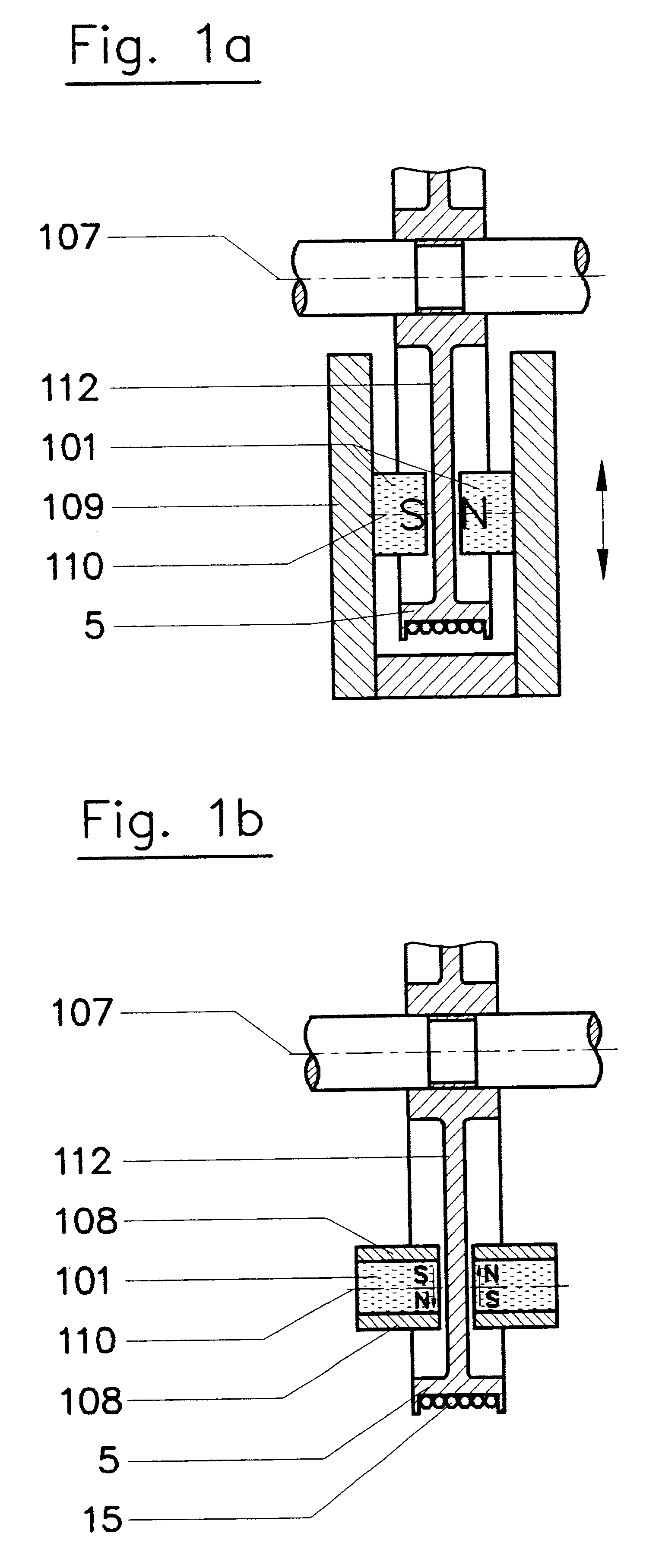

Measuring cable travel sensor

InactiveUS6543152B1Avoid liftingLimit speed of rotary movementMeasuring wheelsFilament handlingConductor CoilMagnet

A measuring cable travel sensor includes a housing accommodating a measuring cable drum and a rotary spring urging the cable drum in the direction of winding of a measuring cable thereon. At least one braking magnet is arranged either on the cable drum or on the housing to provide for magnetic control of the rotary movement of the cable drum at least in the cable winding-on direction. The cable drum may also carry holding magnets for holding the winding cable into close contact with the peripheral surface of the cable drum. The housing may also have a band extending at least in part around the cable drum for correctly positioning the cable thereon as it is being wound on.

Owner:ASM AUTOMATION SENSORIK MESSTECHN GMBH

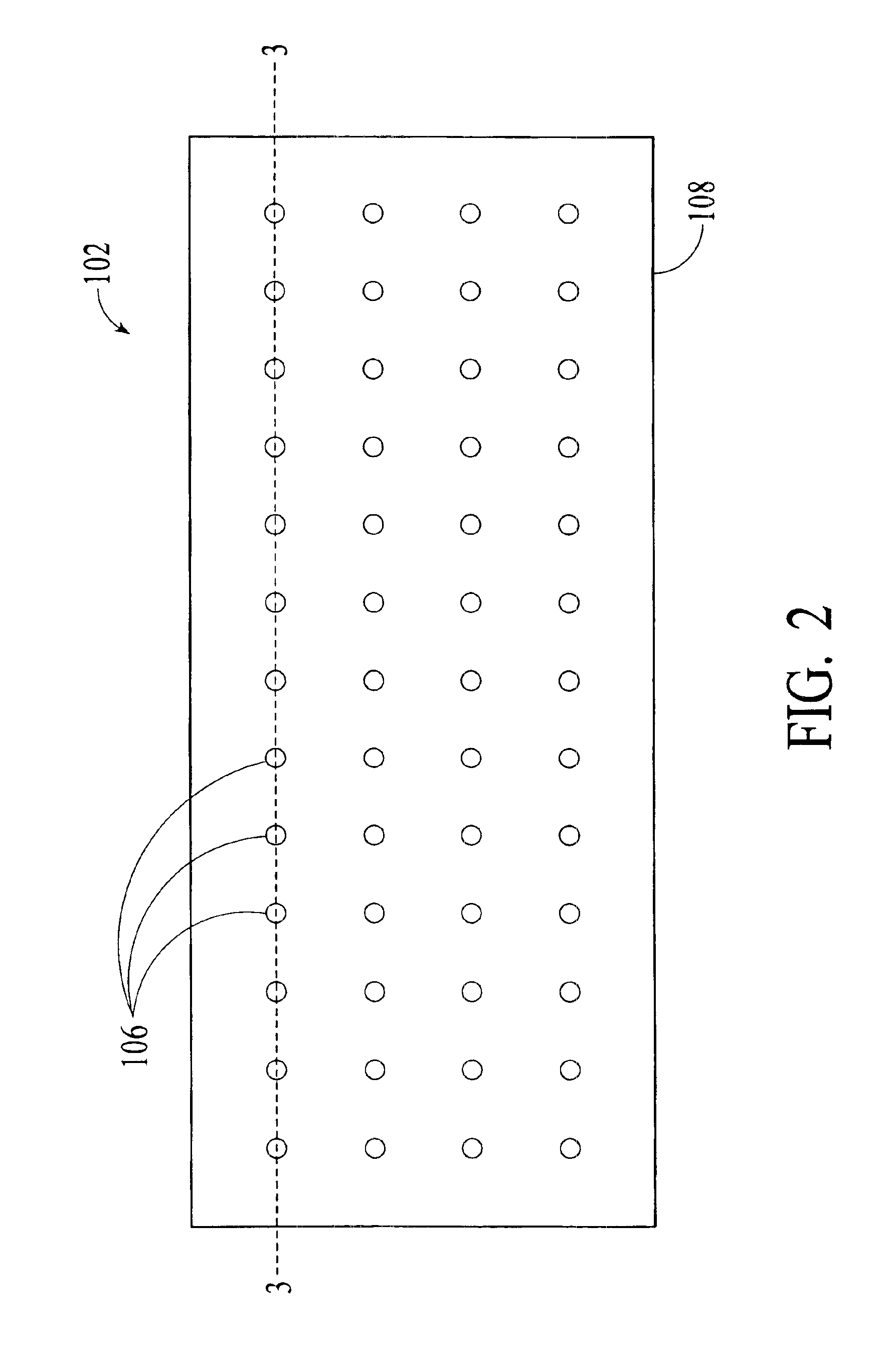

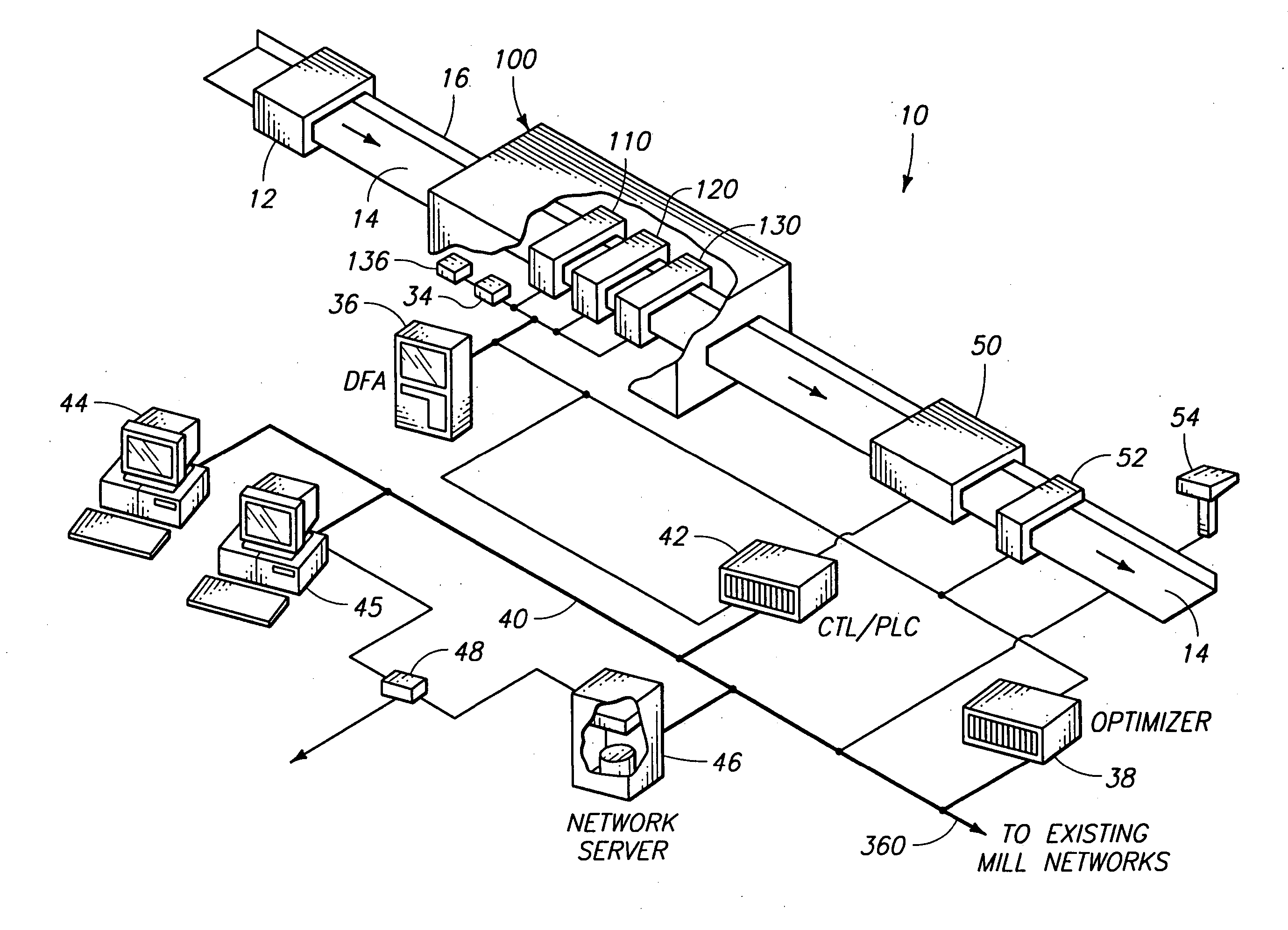

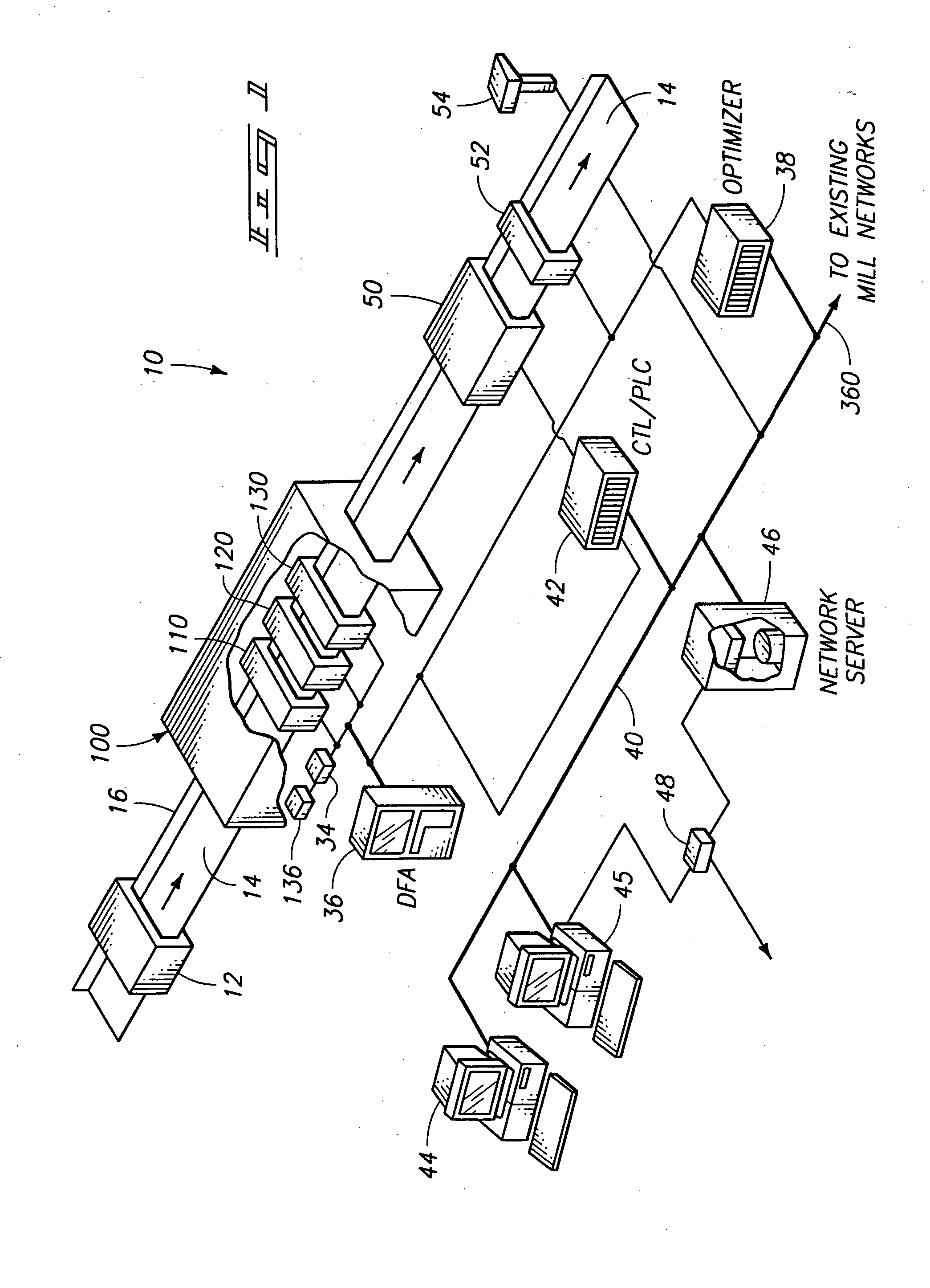

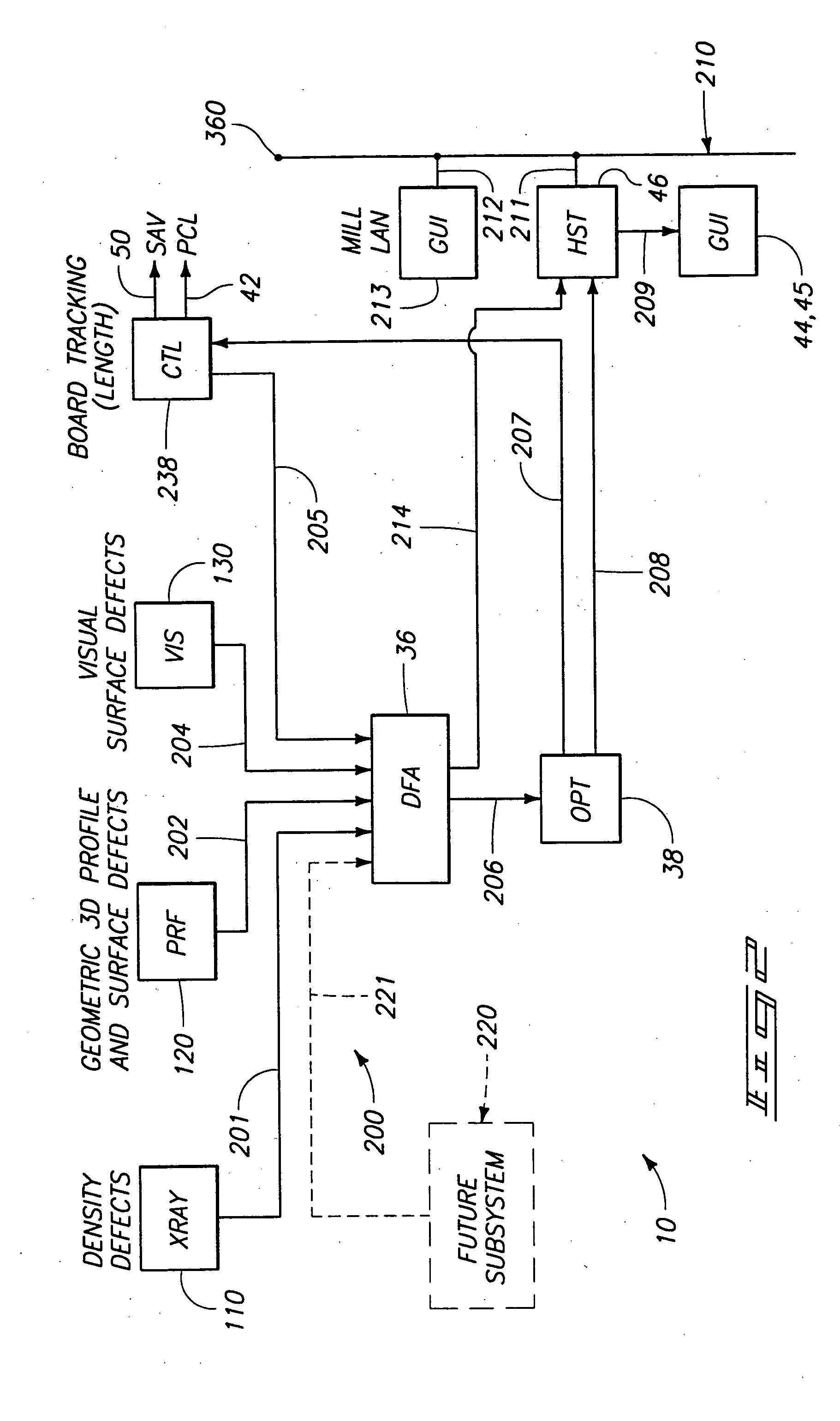

Method and apparatus for improved inspection classification of attributes of a workpiece

InactiveUS20050021280A1Linear/angular speed measurementFluid speed measurementKinematicsAngular velocity

An apparatus for detecting the probable existence, location, and type of defects in a workpiece is described. The apparatus includes a sensor subsystem, an optimizer, a control subsystem, and a computer system having a processor and computer readable memory. Sensor subsystem senses a first section of the workpiece and produces signals corresponding to a physical characteristic of the workpiece. The computer system is configured to generate a workpiece model based on the signals produced by the sensor subsystem. In an alternate embodiment, a defect assembler can be provided to merge signals from a plurality of sensor subsystems. The defect assembler can also be configured to generate the workpiece data model. The optimizer is configured to generate workpiece segmentation recommendations based on the workpiece data model. The processor is configured with a first producer thread program which, in response to the receipt of a first set of signals by the computer system, receives a data subscription request from a subsystem which uses data and transmits the signals from the computer readable memory to the generator of the data subscription request. The processor is further configured to generate a second producer thread in response to storage of a second set of signals in the computer readable memory. The second producer thread is configured to receive one of the data subscription requests and selectively send the second set of signals to the generator of the data subscription request. A tracking device for tracking selective kinematics of a workpiece moving through a plant is also disclosed. The tracking device includes an encoder wheel configured to tangentially contact a workpiece and rotate at an angular velocity coincident with the linear velocity of the workpiece. The tracking apparatus further includes a drive mechanism for driving the encoder wheel at a first angular velocity approaching the angular velocity of the encoder wheel which is coincident with the linear velocity of the workpiece. The tracking device also includes a signal generator configured to interact with the encoder wheel and generate a signal in response to the angular velocity of the encoder wheel. The tracking apparatus can be incorporated into the apparatus for detecting defects within a workpiece by providing the signal from the signal generator to the control subsystem.

Owner:USNRKOCKUMS CANCAR

Rolling electronic length measuring device

InactiveUS7036241B2Prevent reboundGood for scrollingMeasuring wheelsUsing electrical meansMeasurement deviceControl theory

An electronic measuring device is disclosed which includes a pair of wheels connected to an axle that passes through a drive gear. The drive gear is enmeshed to a second gear which, in turn, is coaxially connected to an encoder disk. The encoder disk has spaced-apart fins around its outer periphery. As the wheels turn and the encoder disk rotates, the fins and openings between the fins pass between an emitter and a receiver. The emitter and receiver are linked to a controller which calculates the distance traversed by the wheels based upon the number of fins that pass between the emitter and receiver, or with an active counting system (ACS). The controller also includes functions to establish start and stop points for a measurement and an easy means for dividing a measured distance into equal parts or segments and a means for marking the boundary points that define the segments when the measuring device is rolled back across the measured distance. The device can be used on both planar and non-planar surfaces.

Owner:IRWIN IND TOOL CO

Barrow for moving observation

InactiveUS20050029764A1Quick and accurate moving observationReduce errorsCarriage/perambulator with single axisMeasuring wheelsEngineeringAcceleration Unit

Owner:NAGOYA UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com