Patents

Literature

13815 results about "Wheel and axle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The wheel and axle is a machine consisting of a wheel attached to a smaller axle so that these two parts rotate together in which a force is transferred from one to the other. A hinge or bearing supports the axle, allowing rotation. It can amplify force; a small force applied to the periphery of the large wheel can move a larger load attached to the axle.

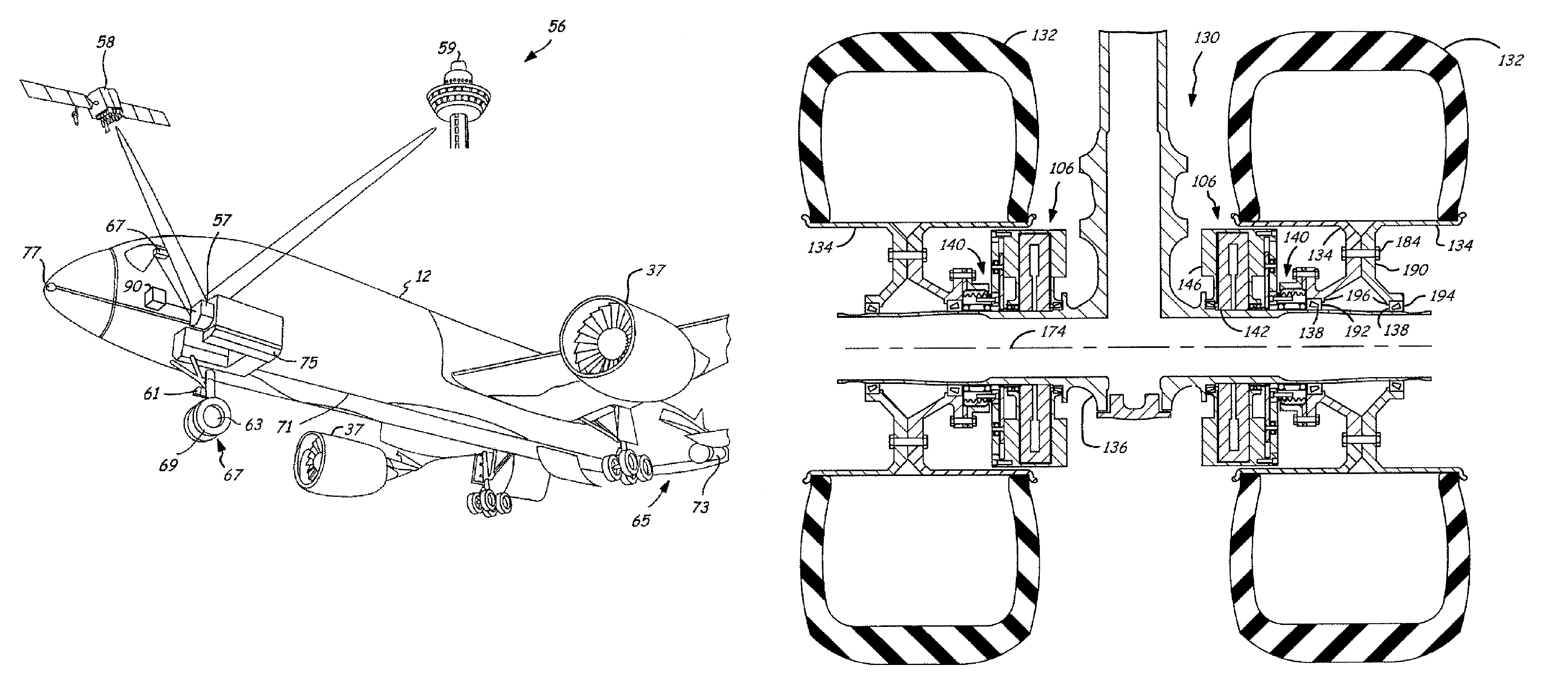

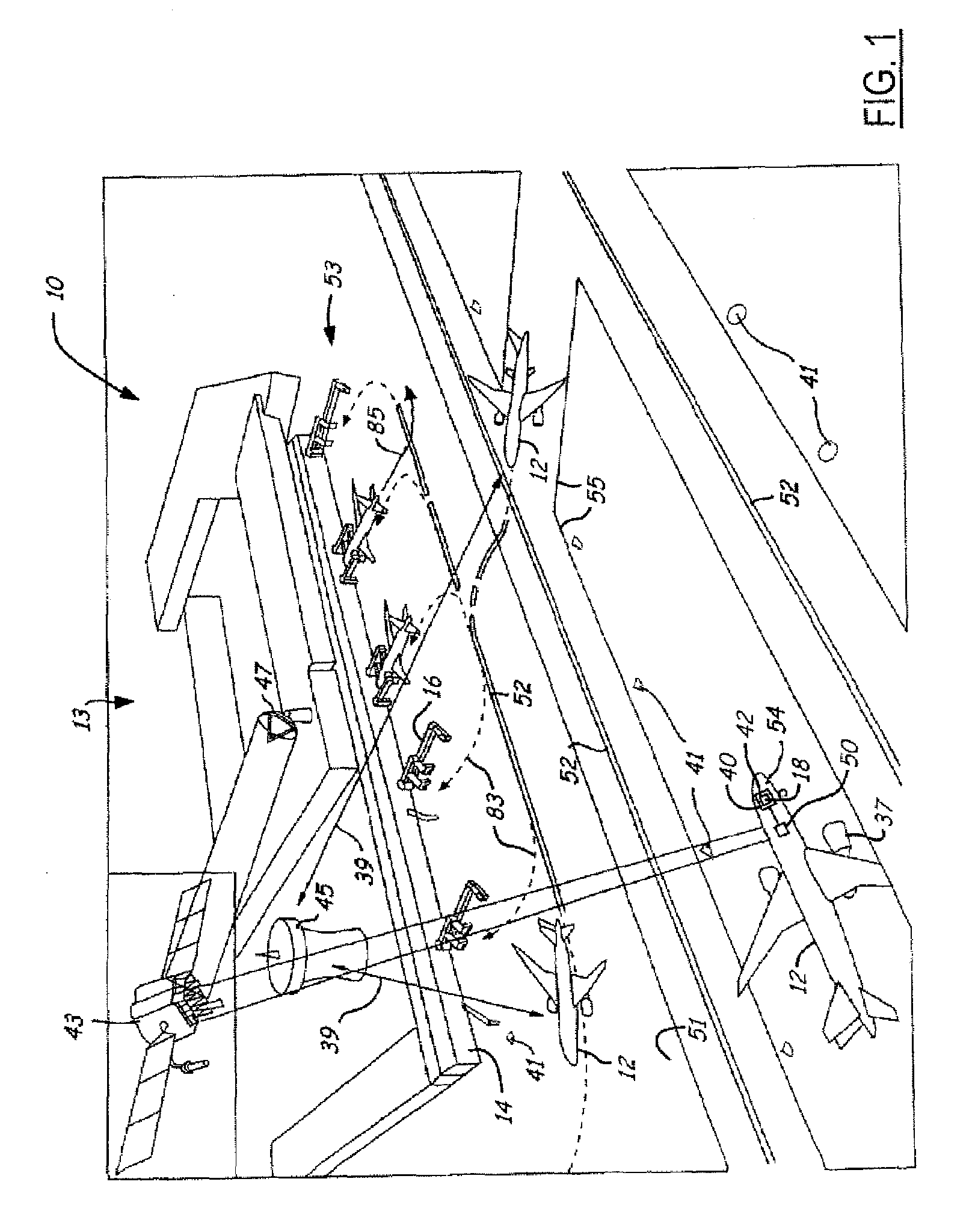

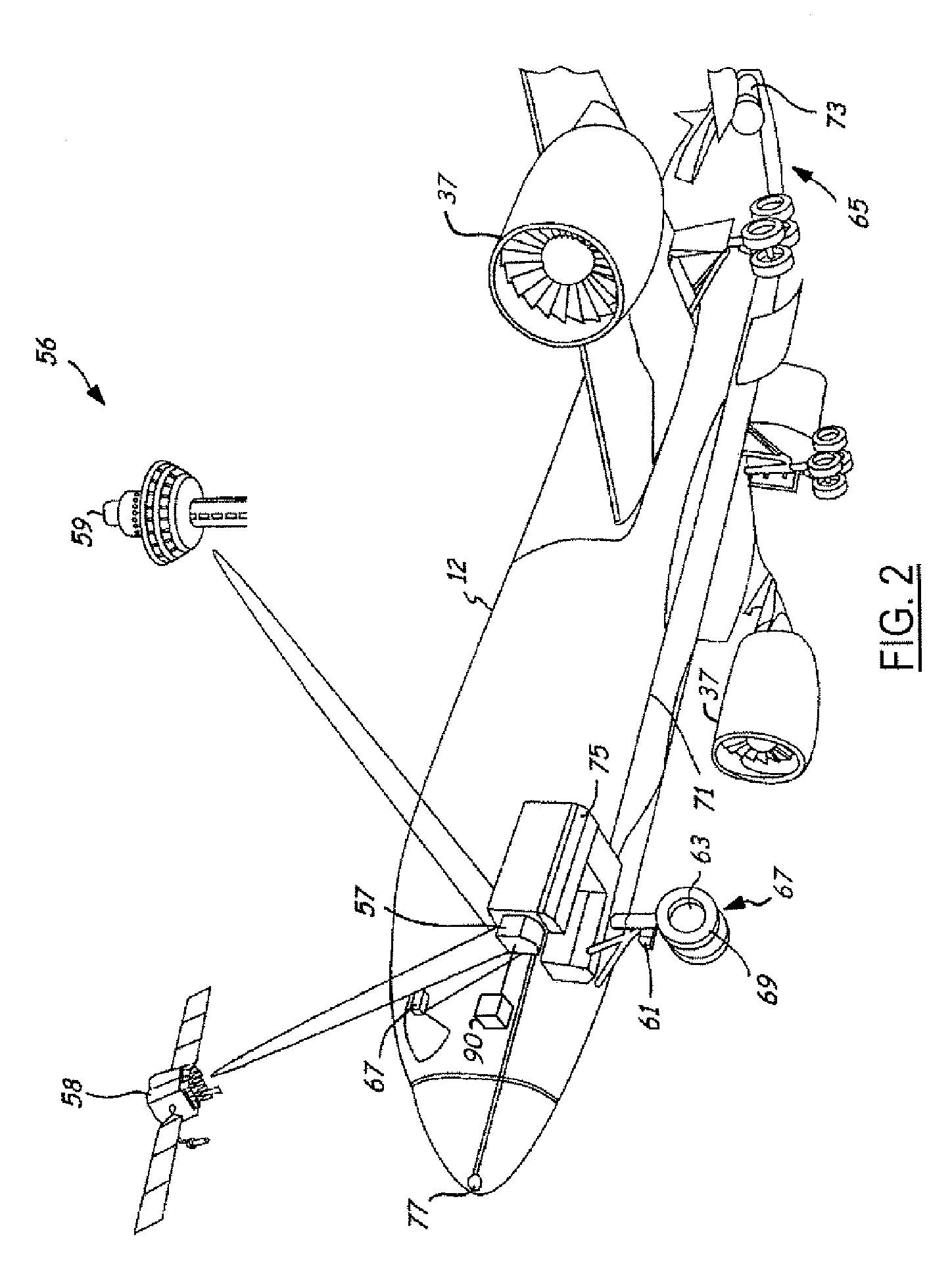

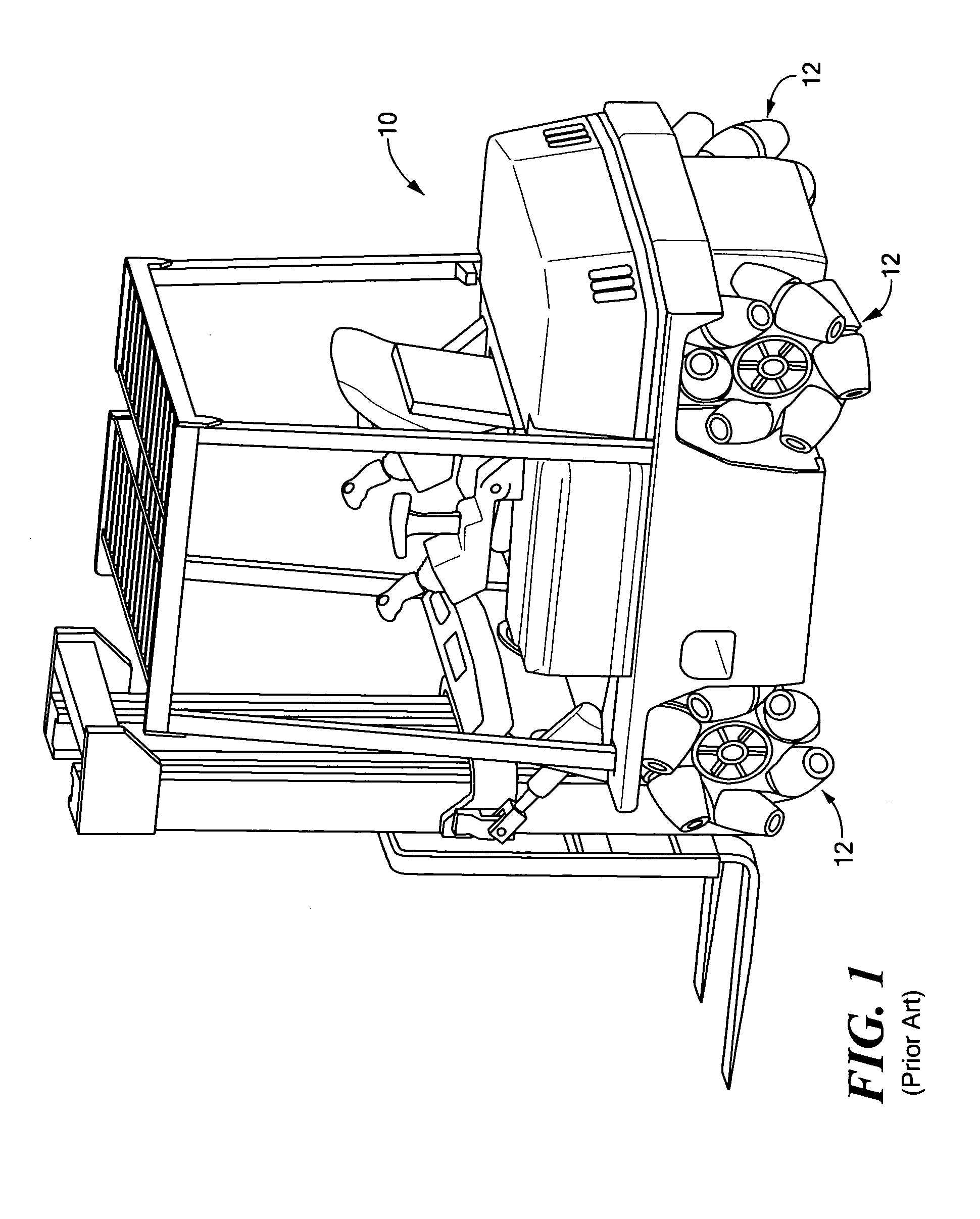

Powered nose aircraft wheel system

InactiveUS7445178B2Improves arrival and departure efficiency and productivityEasy to useLiquid handling installationsEnergy efficient operational measuresNoseAuxiliary power unit

A powered nose aircraft wheel system (130) for an aircraft (12) includes landing gear (104) that extends from the aircraft (12). A wheel axel (136) is coupled to the landing gear (104). A wheel (134) is coupled to the wheel axel (136). A wheel motor (106) is coupled to the wheel axel (136) and the wheel (134). A controller (120) is coupled to the wheel motor (106) and rotates the wheel (134). A method of taxiing an aircraft (12) includes permitting the wheel (134) of the aircraft (12) to freely spin during the landing of the aircraft (12). Power is transferred from an auxiliary power unit (73) of the aircraft (12) to the wheel motor (106). The wheel (134) is rotated via the wheel motor (106). The aircraft (12) is steered and the speed of the wheel (134) is controlled via one or more controllers selected from an onboard controller (18, 118, 120) and an offboard controller (45, 58, 59).

Owner:THE BOEING CO

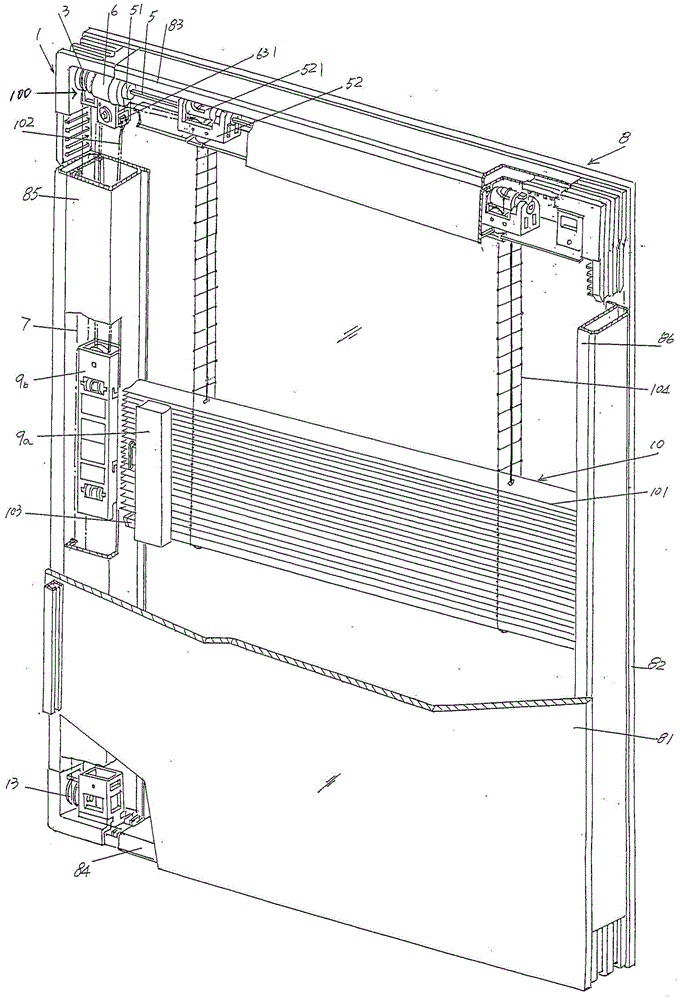

Single-operated double-glazed insulating glass with built-in shutters

ActiveCN105064896BAvoid frictional damageAvoid damageLight protection screensEngineeringVenetian blinds

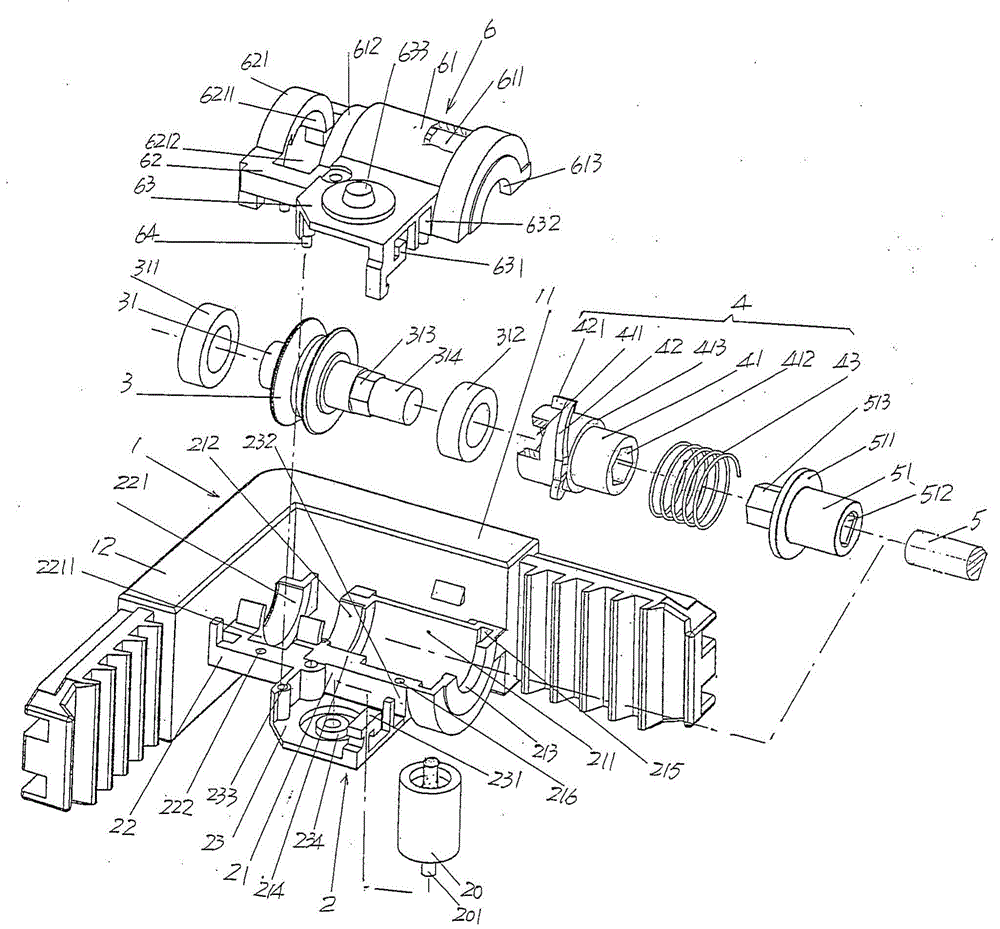

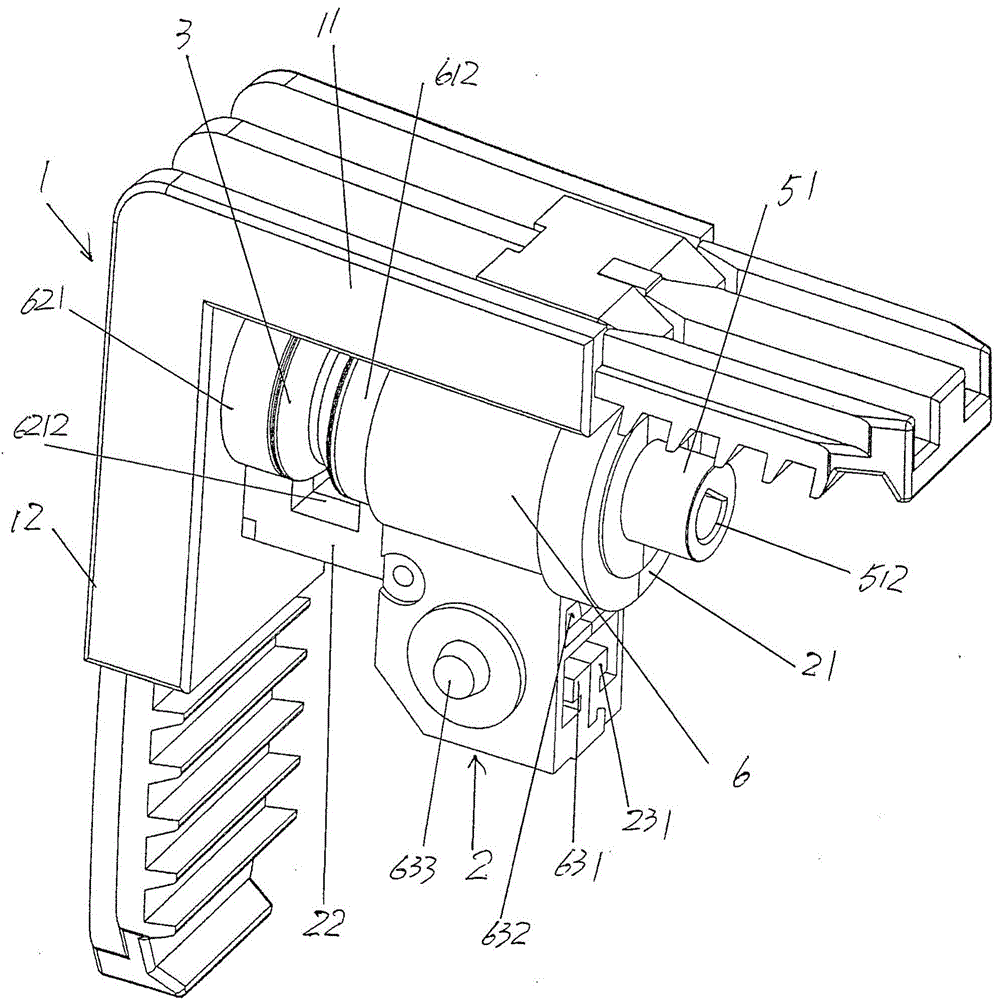

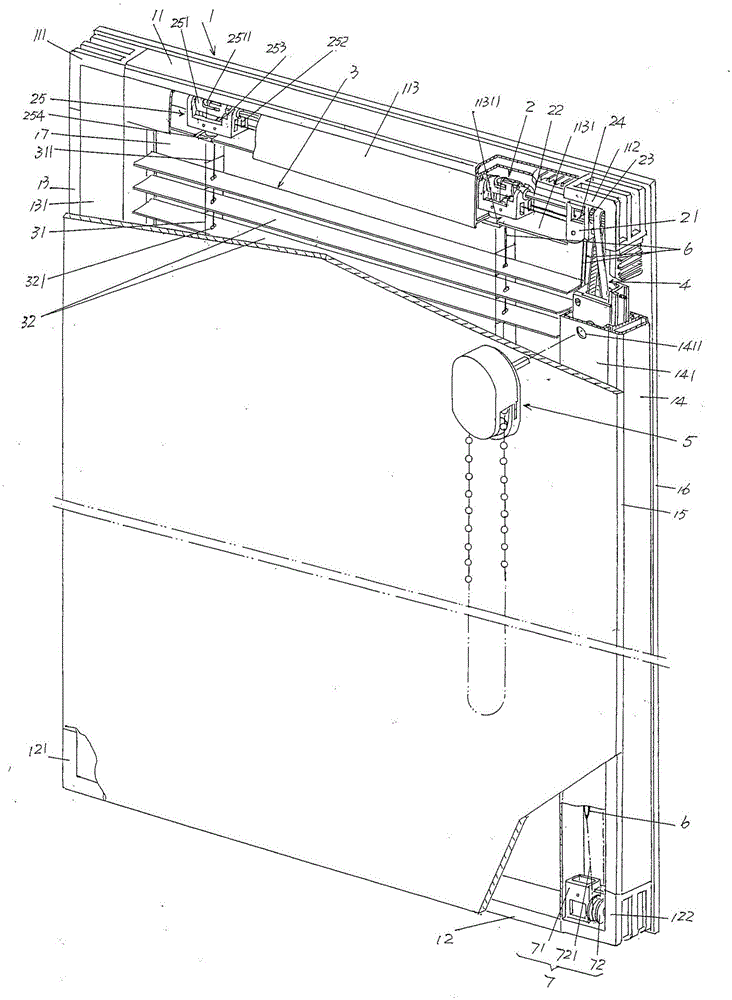

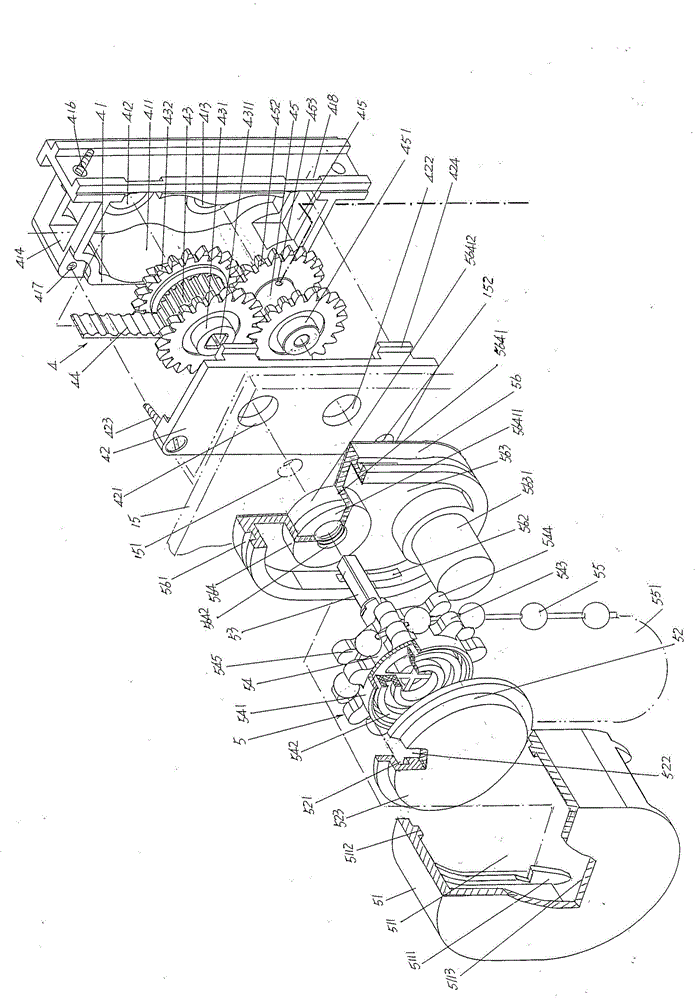

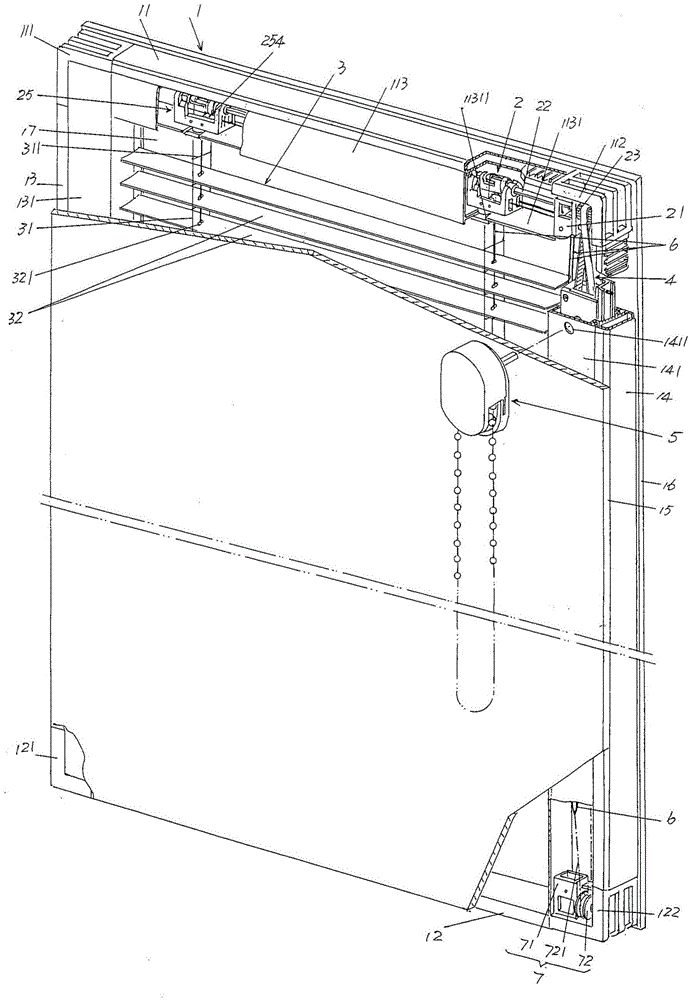

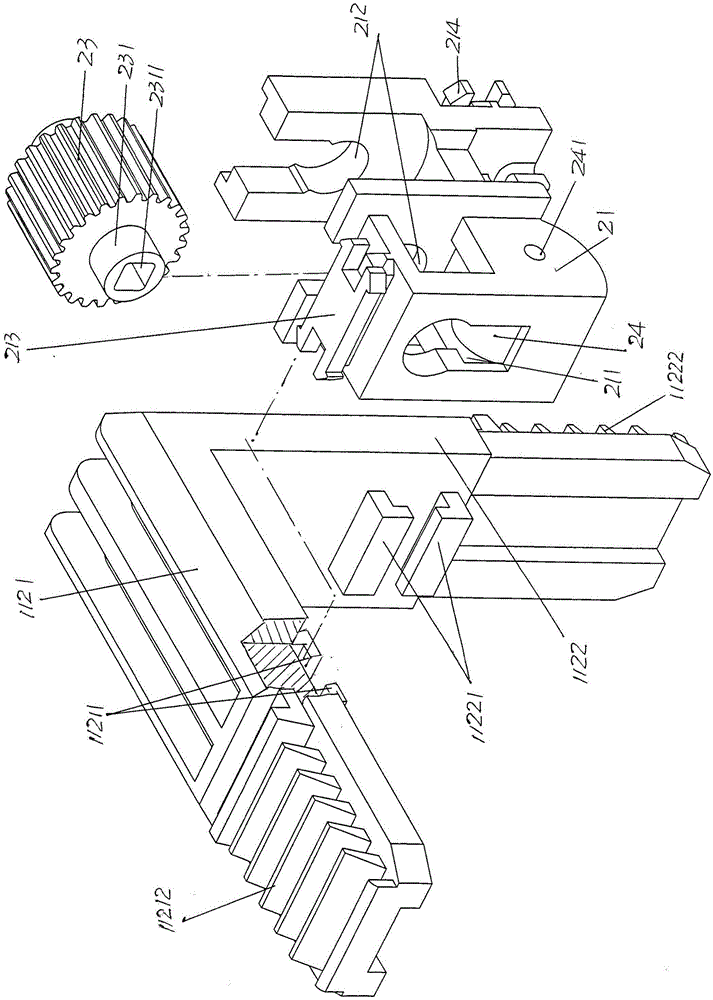

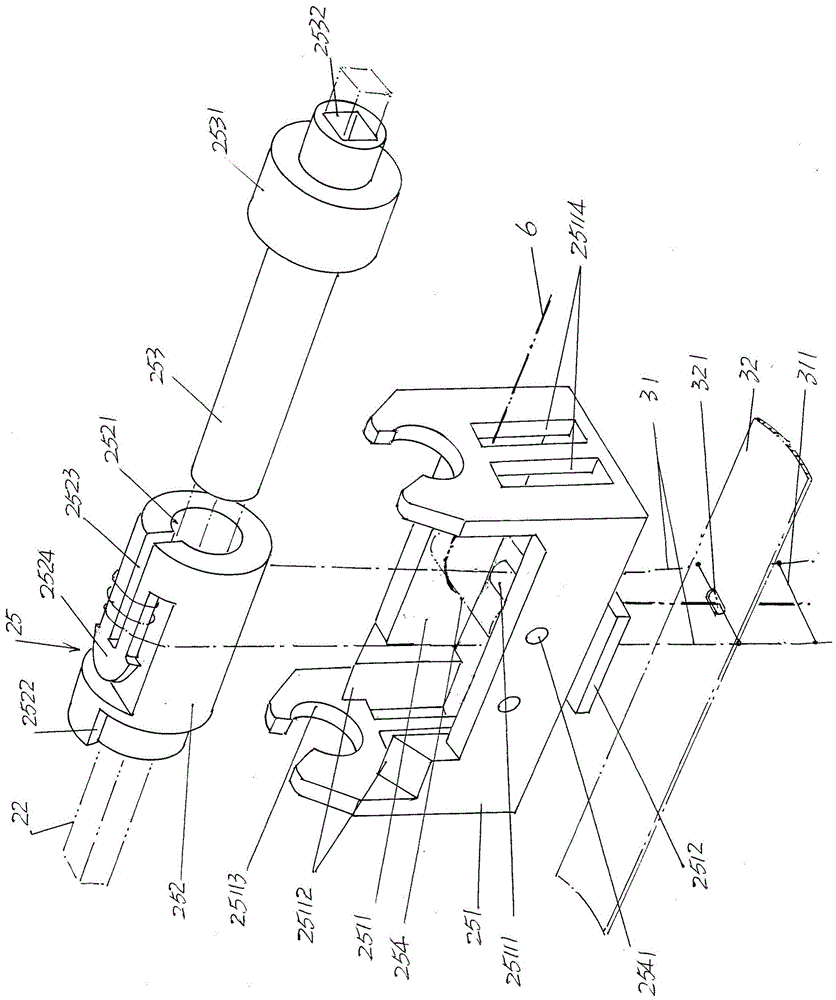

The invention provides a blind window with built-in single-control double-layer hollow glass, and belongs to the technical field of sunshade hollow glass products. The blind window with the built-in single-control double-layer hollow glass comprises a window body and venetian blind blade overturning devices, wherein the window body comprises inner glass, outer glass, an upper transverse frame strip, a lower transverse frame strip, a left longitudinal frame strip and a right longitudinal frame strip; and the venetian blind blade overturning devices are arranged on connectors of corners of a frame of the window body. The blind window with the built-in single-control double-layer hollow glass is characterized in that each venetian blind blade overturning device comprises a supporting mechanism, a blade overturning wheel, a clutch mechanism, a blade overturning shaft and a clutch shielding mechanism; each supporting mechanism is arranged on the connector of the corresponding corner of the frame of the window body; each blade overturning wheel is fixed on a corresponding blade overturning wheel shaft; each clutch mechanism is arranged on the corresponding supporting mechanism; each blade overturning shaft is connected with the right end of a corresponding blade overturning shaft sleeve; and each clutch shielding mechanism is matched with the corresponding supporting mechanism. When each clutch mechanism is connected with the right end of the corresponding blade overturning wheel shaft, each blade overturning wheel drives the corresponding blade overturning wheel shaft; and when blades of a venetian blind are overturned to be closed, the blade overturning wheels rotate independently, movement resistance of a blade overturning traction rope is reduced obviously, the blade overturning traction rope is prevented from being rubbed and damaged, and the blade overturning wheels are prevented from being damaged.

Owner:CHANGSHU ZHONGQIN BUILDING MATERIAL

Non-magnet driven double-glazed built-in shutters

ActiveCN105041170BMeet the use requirementsSave resourcesLight protection screensWindow shutterEngineering

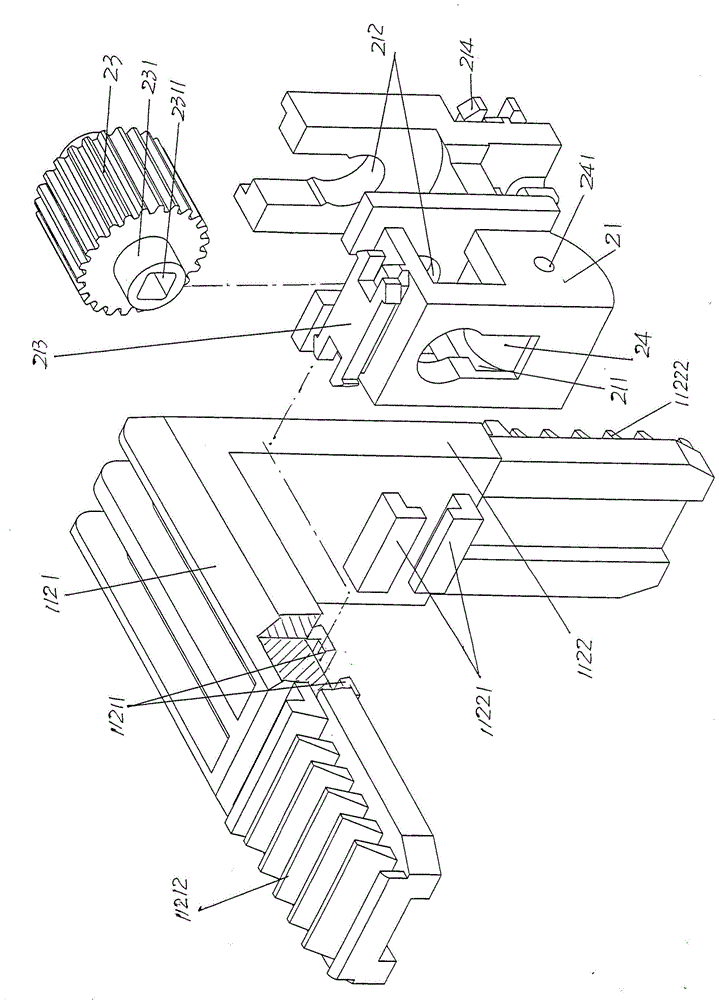

The invention discloses a non-magnetic driven type blind window with internally-installed double-layer hollow glass, and belongs to the technical field of sunshade hollow glass products. The non-magnetic driven type blind window with the internally-installed double-layer hollow glass comprises a window body which comprises inner glass and outer glass, a blind sheet turning mechanism, a venetian blind, an internal manipulation mechanism, an external manipulation mechanism and a venetian blind lifting pulling rope. The non-magnetic driven type blind window with the internally-installed double-layer hollow glass is characterized in that the internal manipulation mechanism comprises a case body, a case cover, a synchronous pulley, a synchronous belt and a lifting pulling rope driving wheel, the case body is arranged in a hollow cavity and fixed with the window body, the synchronous pulley is located above the case body cavity, one end of a synchronous pulley shaft is supported on the case cover, and the other end of the synchronous pulley shaft is supported on the cavity bottom wall of the case body cavity; one end of the synchronous belt is arranged on the blind sheet turning mechanism in a sleeving mode, and the other end of the synchronous belt is arranged on the synchronous pulley in a sleeving mode; the lifting pulling rope driving wheel is arranged in the case body cavity of the case body and located on the lower portion of the case body cavity; the external manipulation mechanism comprises a shield, a friction disc, a bead chain wheel shaft, a bead chain wheel hub, a bead chain and a bead chain wheel shaft seat; one end of the lifting pulling rope of the venetian blind is connected with the lifting pulling rope driving wheel. Therefore, resources are saved, the cost is reduced, and the labor is saved in operation.

Owner:CHANGSHU ZHONGQIN BUILDING MATERIAL

Bead-chain driven double-glazed built-in shutters

ActiveCN105041172BMeet the use requirementsReduce manufacturing costLight protection screensManufacturing cost reductionWindow shutter

The invention discloses a bead chain driving type double-layer hollow glass built-in louver and belongs to the technical field of sunshade hollow glass products. The louver comprises a window body, a curtain piece turning mechanism, a venetian blind, an inner control mechanism, an outer control mechanism and a venetian blind lifting traction rope. The window body comprises an upper window body transverse tube, a lower window body transverse tube, a left window body longitudinal tube, a right window body longitudinal tube, inner glass and outer glass. The louver is characterized in that the inner control mechanism comprises a box body, a box cover, a synchronous belt pulley, a synchronous belt and a lifting traction rope driving wheel. The outer control mechanism comprises a protective cover, a friction plate, a bead chain wheel shaft, a bead chain wheel shaft hub, a bead chain and a bead chain wheel shaft base. The protective cover forms a protective cover cavity. The friction plate is arranged in the protective cover cavity. The bead chain wheel shaft hub is supported by a shaft hub cavity. The bead chain wheel shaft is arranged in the middle of the bead chain wheel shaft hub. One end of the bead chain is arranged on the bead chain wheel shaft hub in a sleeving mode. The other end of the bead chain forms a suspending end. The bead chain wheel shaft base is matched with the protective cover. One end of the venetian blind lifting traction rope is in driving connection with a lifting traction rope driving wheel. Manufacturing cost is reduced; labor is saved during operation; service life is long, and the using effect is good; resource-saving economy is reflected.

Owner:CHANGSHU ZHONGQIN BUILDING MATERIAL

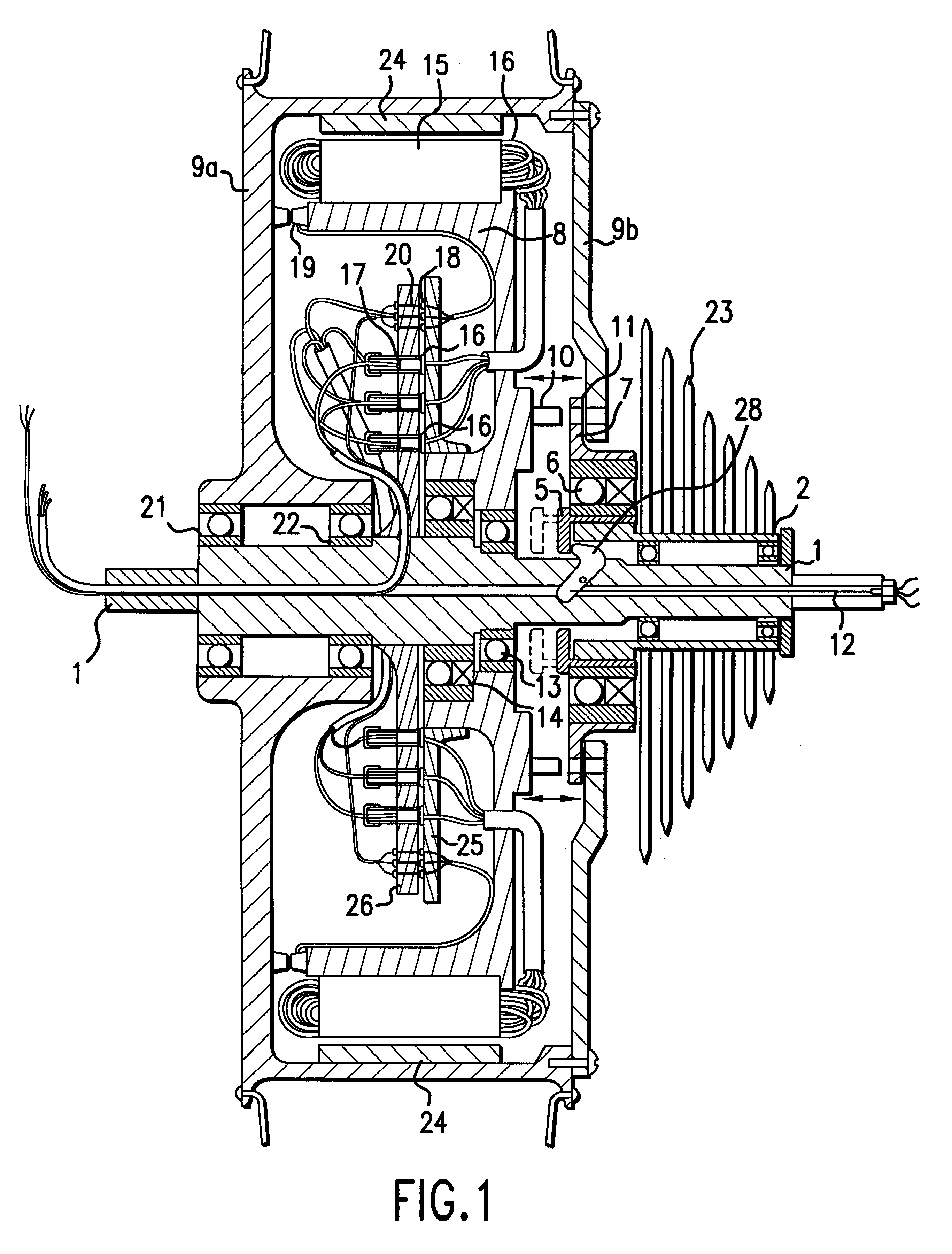

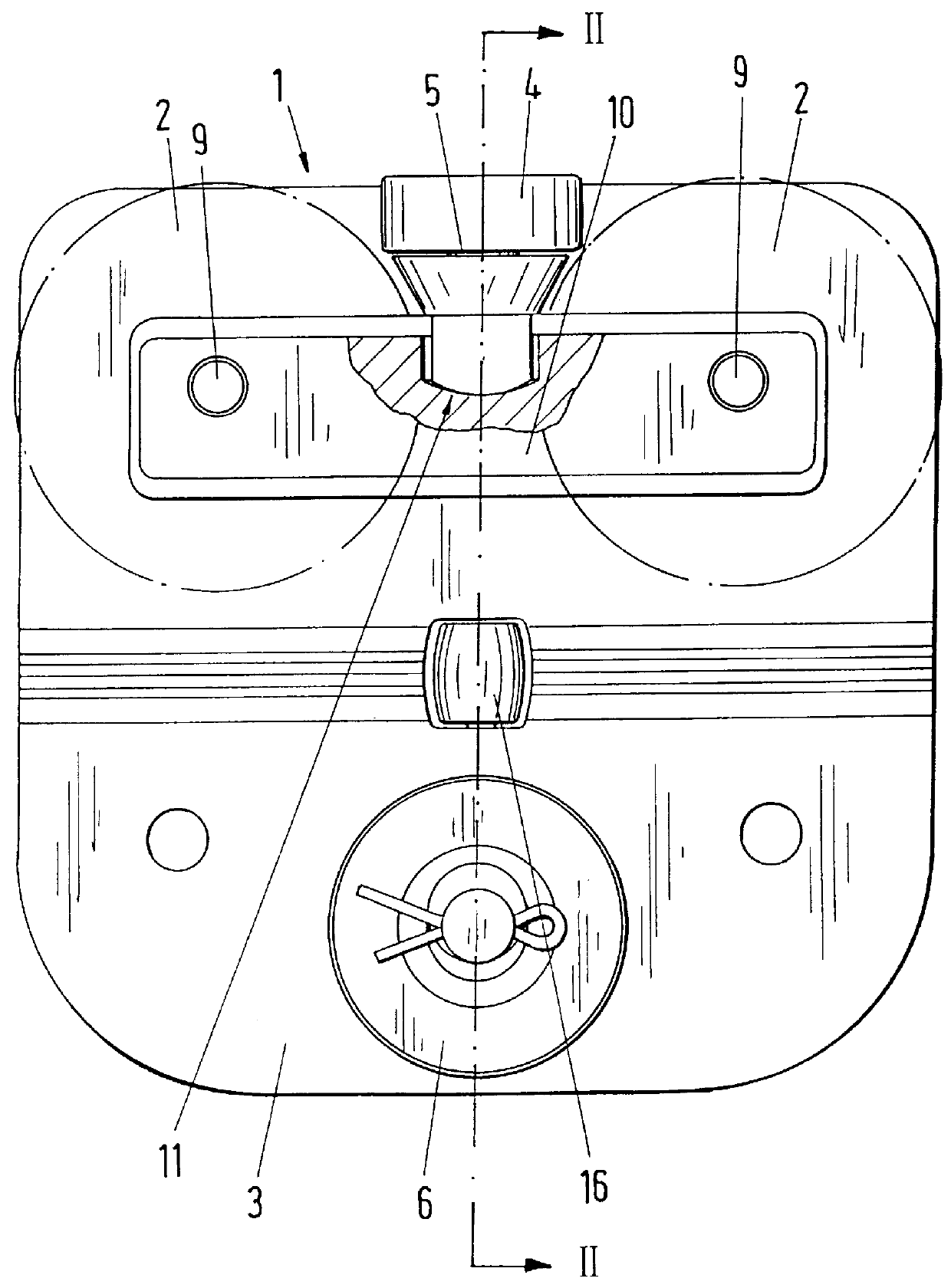

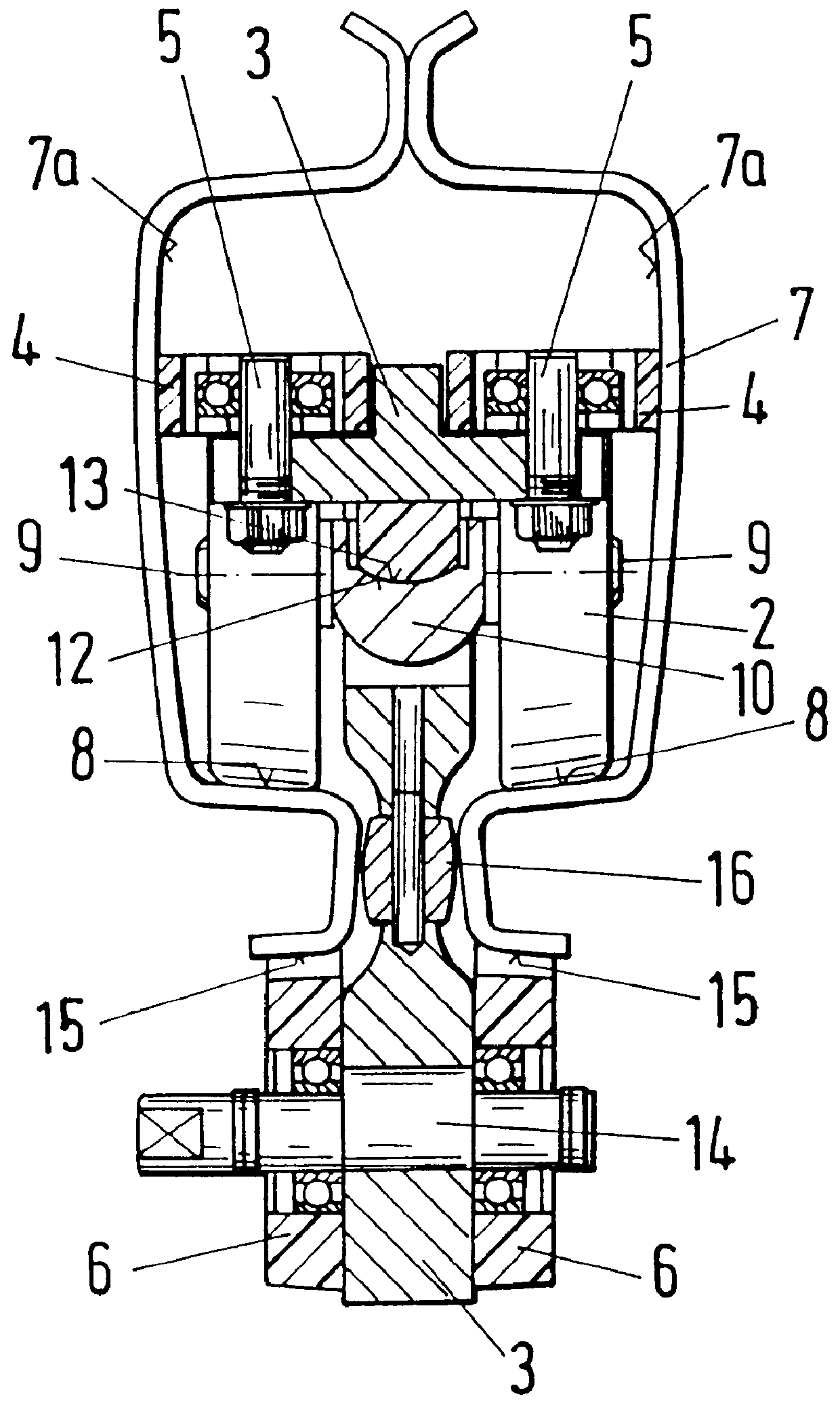

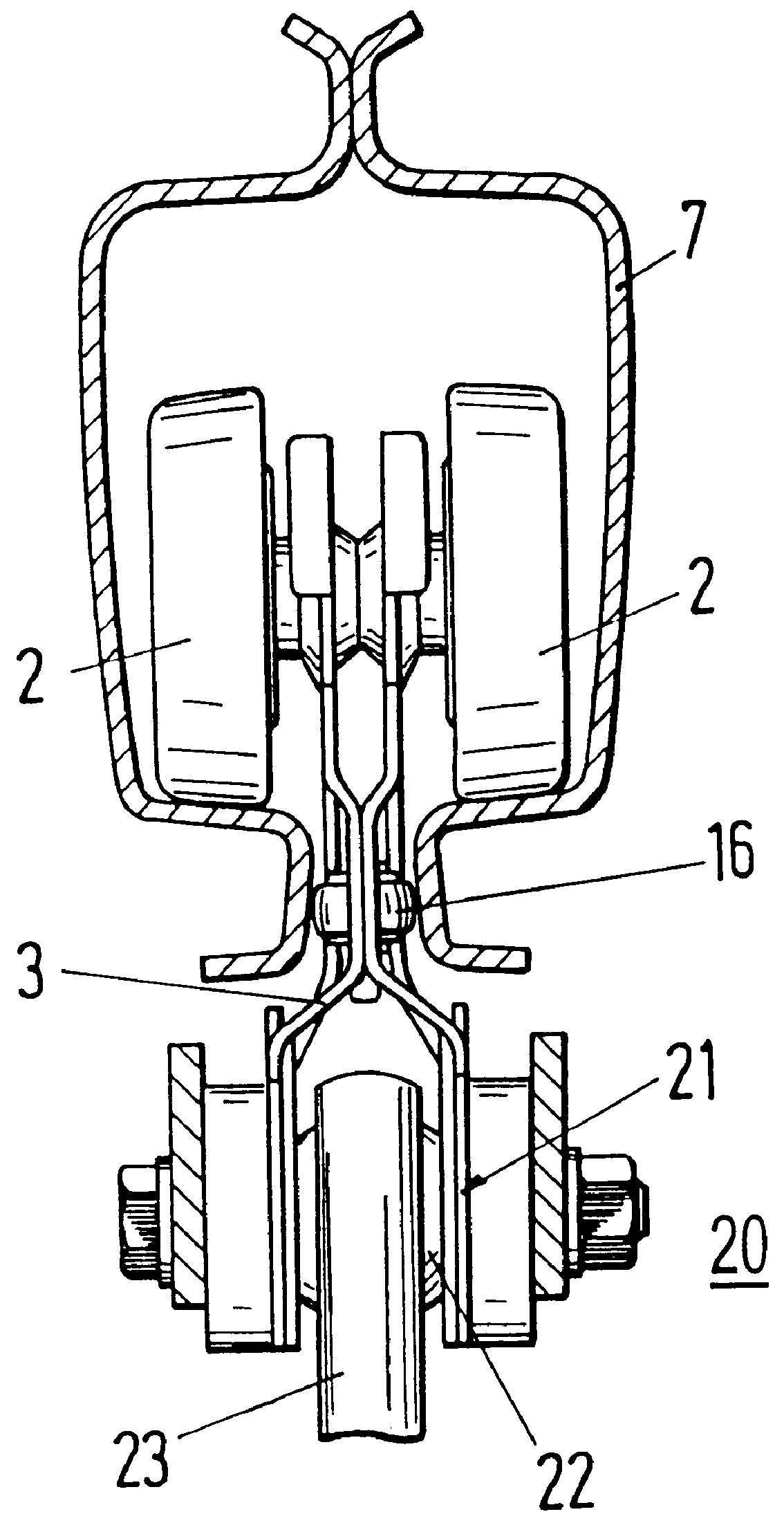

Hybrid drive mechanism for a vehicle driven by muscle power, with an auxiliary electric motor

InactiveUS6286616B1High speedEasy to assembleElectric propulsion mountingVehicle transmissionDrive wheelControl theory

A hybrid drive mechanism for a wheel-driven vehicle. The drive mechanism has an electromotor with a rotor and a stator as a first drive source, with a first speed and a first torque, and a pedal drive as a second drive source, with a second speed and a second torque. The stator of the electromotor is positioned on an axle or shaft of the drive train between the pedal crank and the drive wheel, preferably on a wheel axis, in such a way that it can rotate. The stator can be coupled mechanically with the second drive source so that the stator is driven by the second drive source, and the rotor of the electromotor has a speed which corresponds to the sum of the first speed of the first drive and the second speed of the second drive.

Owner:KUTTER MICHAEL

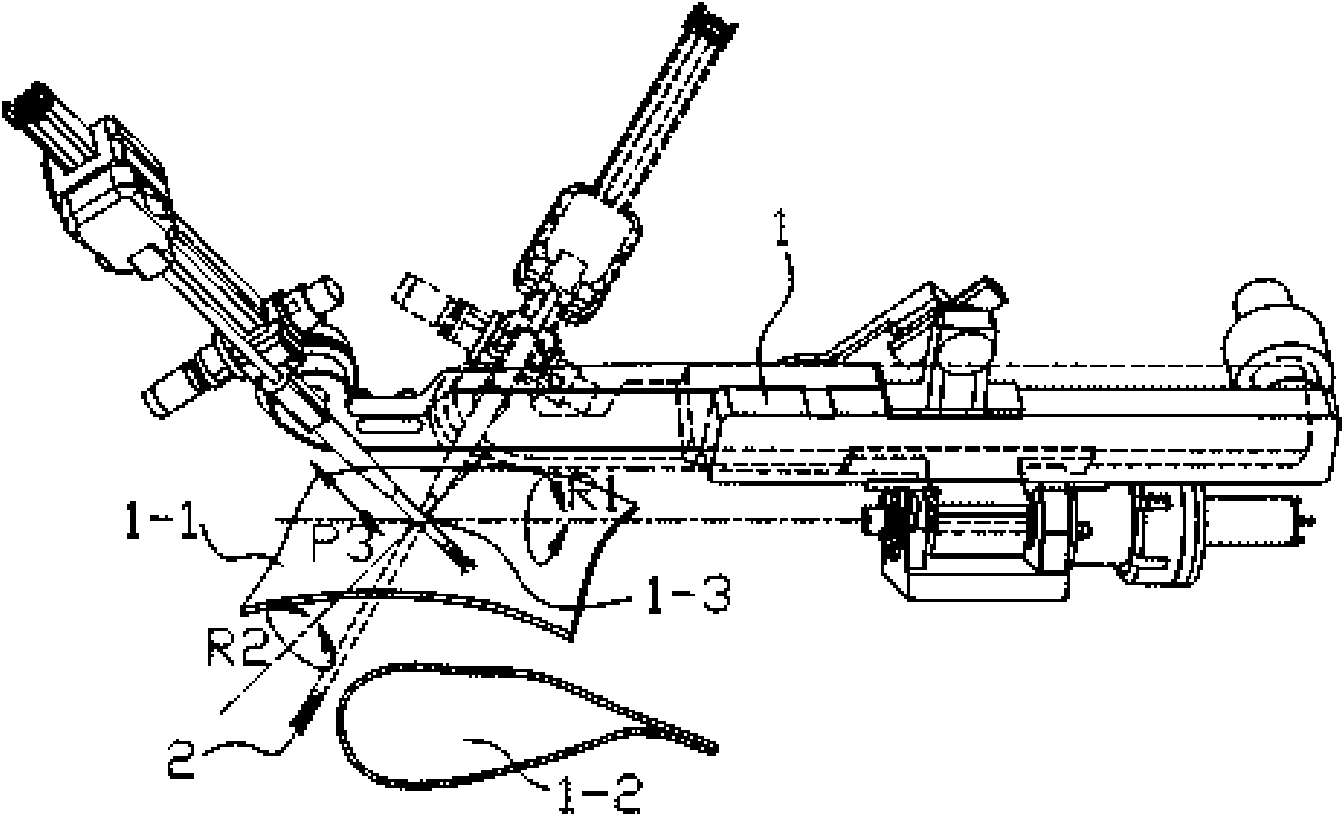

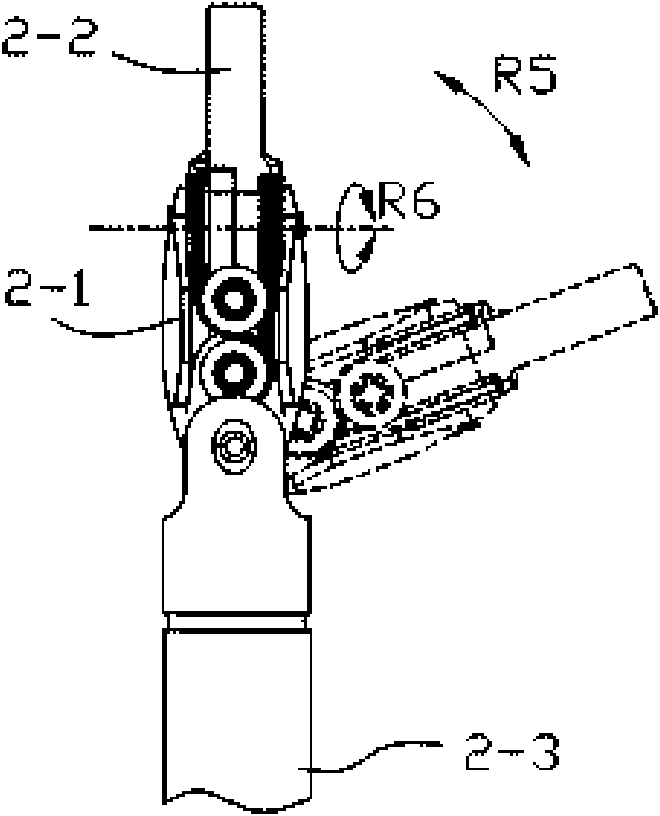

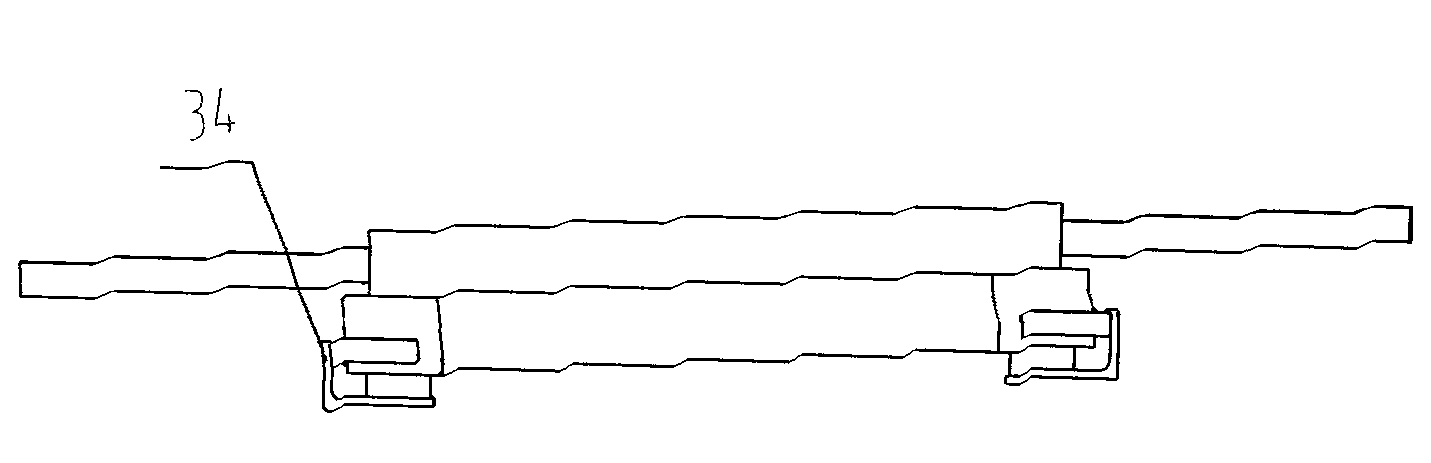

Minimally invasive surgical wire driving and four-freedom surgical tool

ActiveCN101637402ARealize long-distance transmissionEliminate hysteresisSuture equipmentsInternal osteosythesisDrive wheelEngineering

The invention discloses a minimally invasive surgical wire driving and four-freedom surgical tool which comprises a tool connecting rod, wherein one end of the tool connecting rod is connected with the tail end of the tool, and the tail end of the tool comprises a main tool body; the rear end of the main tool body is connected with a main body driving wheel; the front end of the tool connecting rod is provided with a rear shaft pin; both sides of the rear shaft pin are respectively provided with two rear driving wheels which are connected with the main tool body of the tail end of the tool through the main body driving wheel in the middle of the two rear driving wheels; the middle part of the main tool body is provided with two middle driving shafts with middle driving wheels; the front end of the main tool body is provided with a front shaft pin which is connected with a tool pliers body through two pliers body driving wheels arranged on the tool pliers body; each pliers body drivingwheel is fixedly connected with one end of a front wire rope and divides the front wire rope into two parts, and one part is turned for one time, while the other part is turned for two time through the middle wheels. The tool realizes long-distance driving by adopting the wire rope, thereby eliminating return differences and guaranteeing reliable driving.

Owner:SHANDONG WEIGAO SURGICAL ROBOT CO LTD

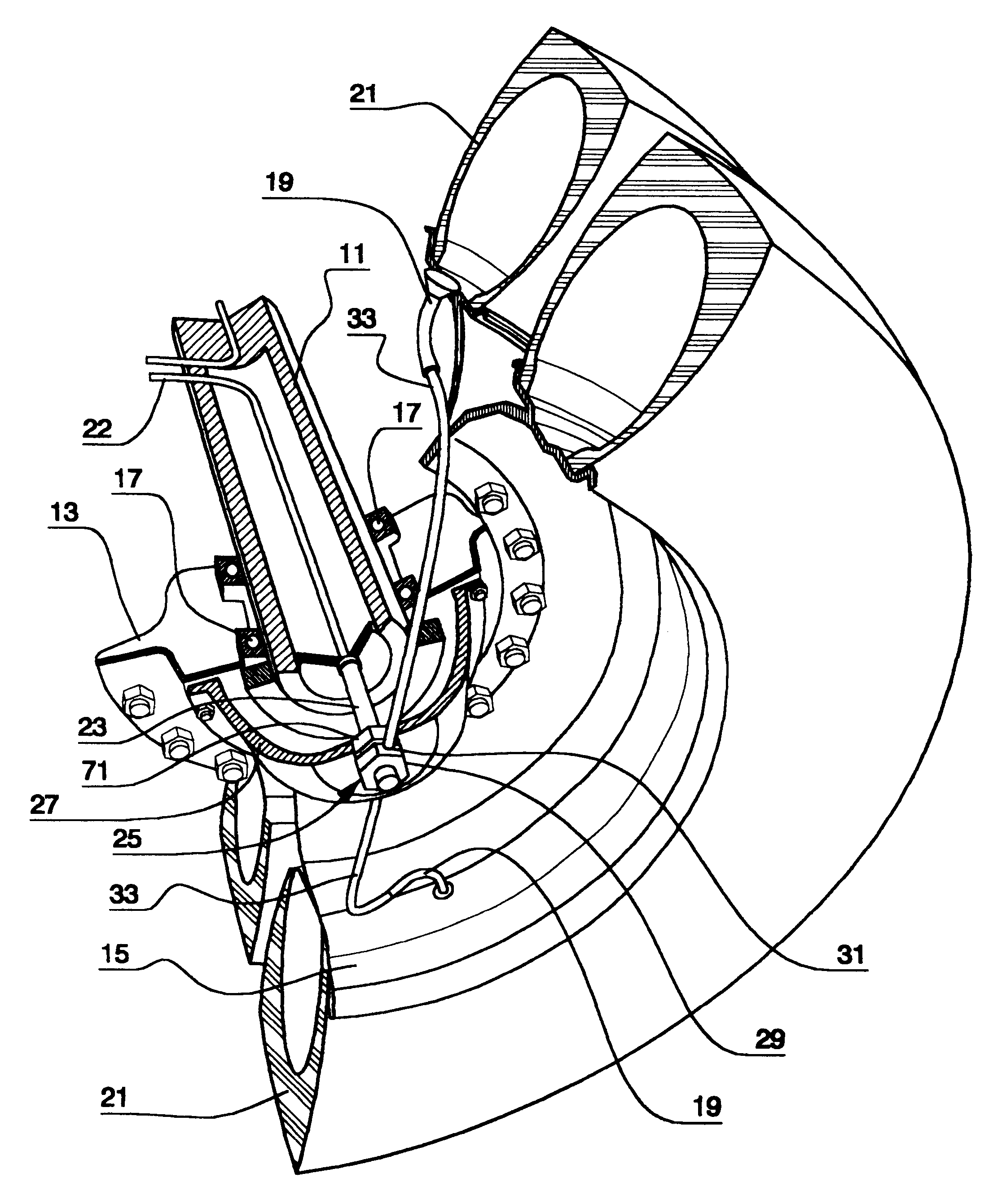

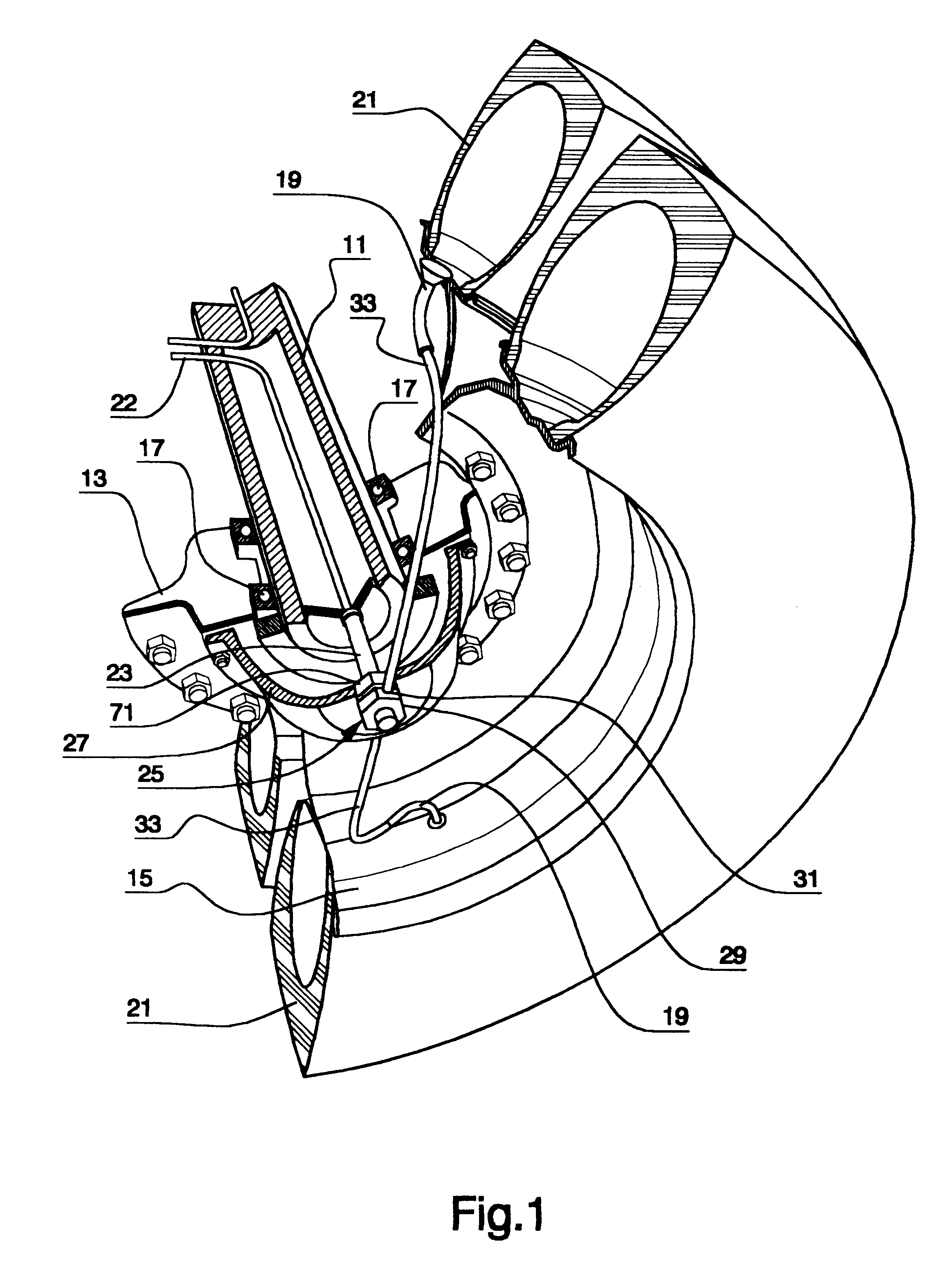

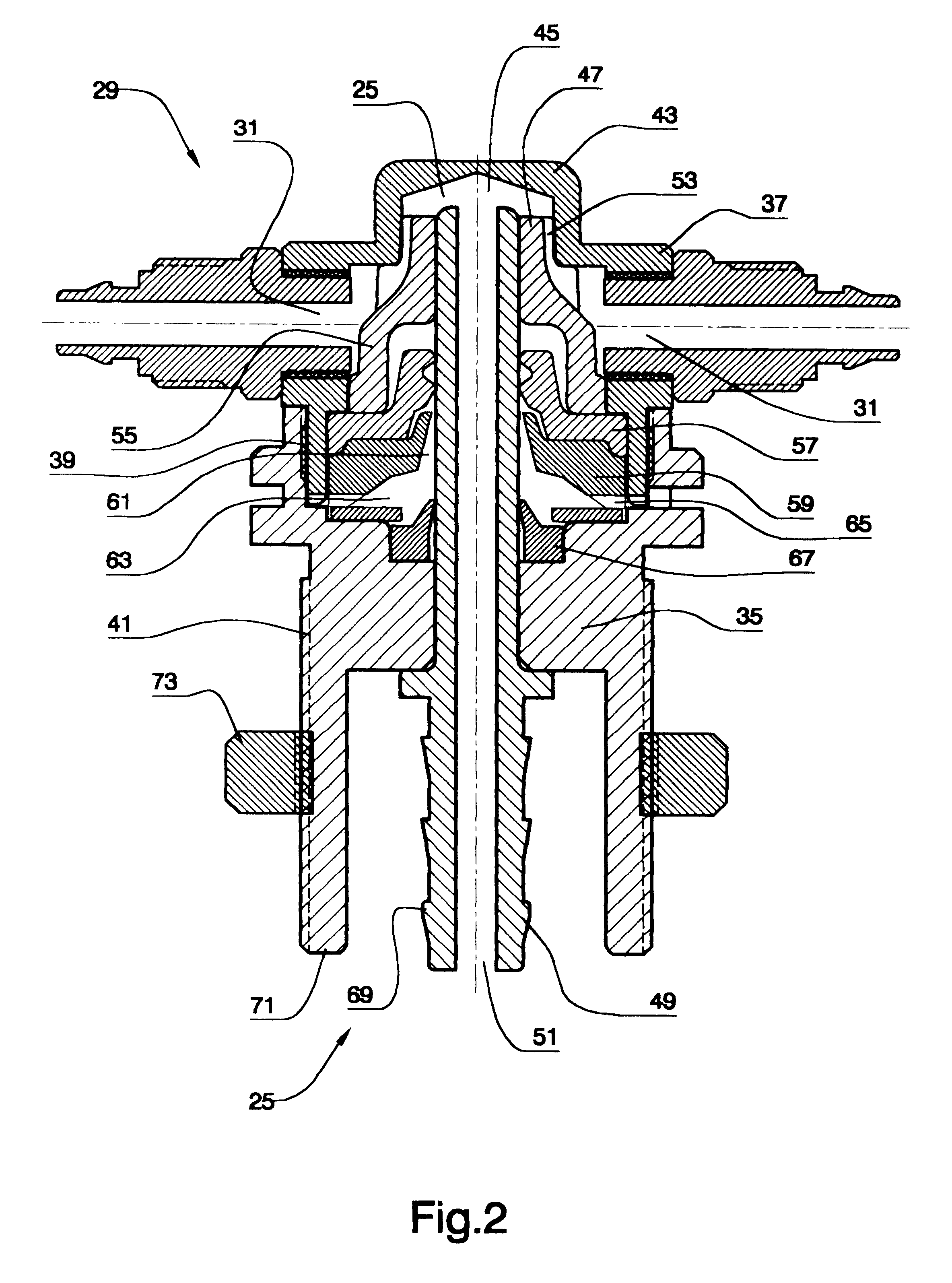

Pneumatic rotary wheel coupling

InactiveUS6325124B1Avoid exposing the wheel's bearingsTyre measurementsTyre-inflating valvesControl theoryWheel and axle

A pneumatic rotary coupling (25) for an air pressure installation for one or more wheels of a vehicle, in which the wheel's axle (11) is used as the section of the pipe of the static installation, in accordance to the system of the coupling used. The coupling's stem (49) has one end formed in the shape of a nozzle which extends in the plane of the wheel, disposed as an axial extension of the wheel's axle end. The stem is located rotatable and slidable inside block (35) which is fixed to the wheel's hub cover. A cover (37) fixed to the block presents a cavity (45) with an edge that defines a seat for a plastic bushing (47) that supports the coupling's stem. The external surface of this bushing is conformed by grooves (53) that communicate the cavity towards the orifices linking with the tires. One method allows for the detection of bearing faults using the same coupling when the axial sliding of the stem is sufficient to vent the pressurized air.

Owner:COL VEN

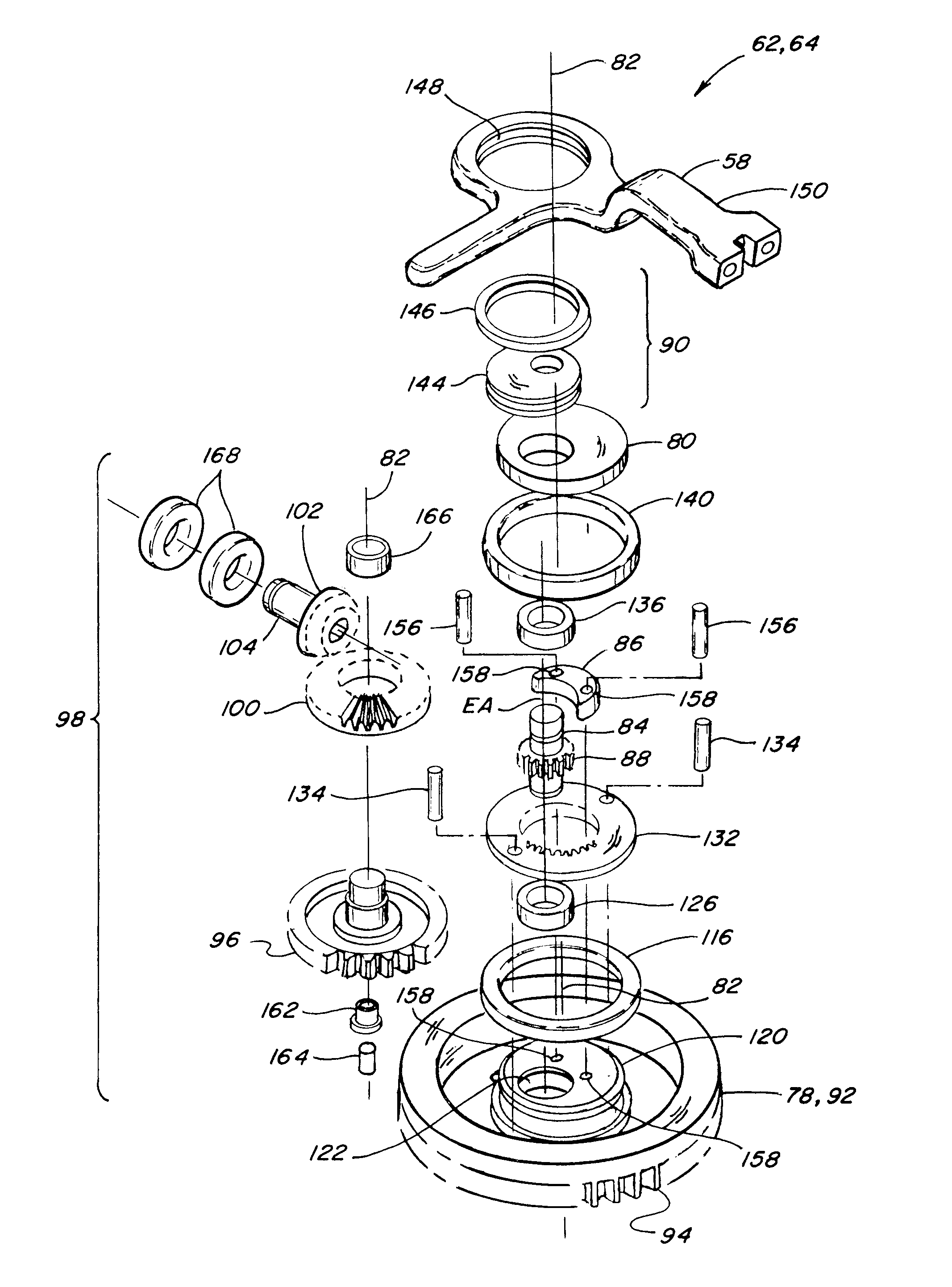

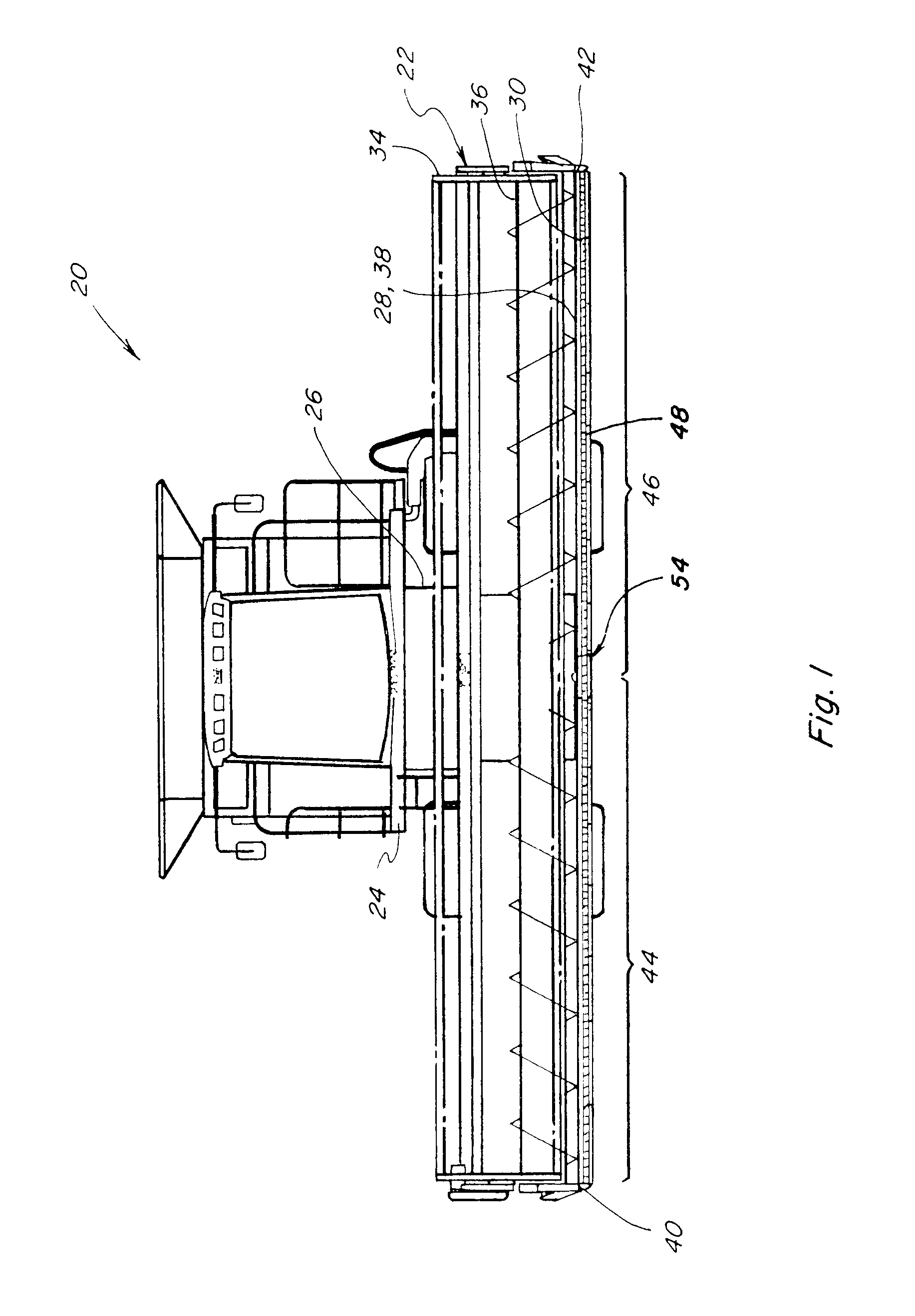

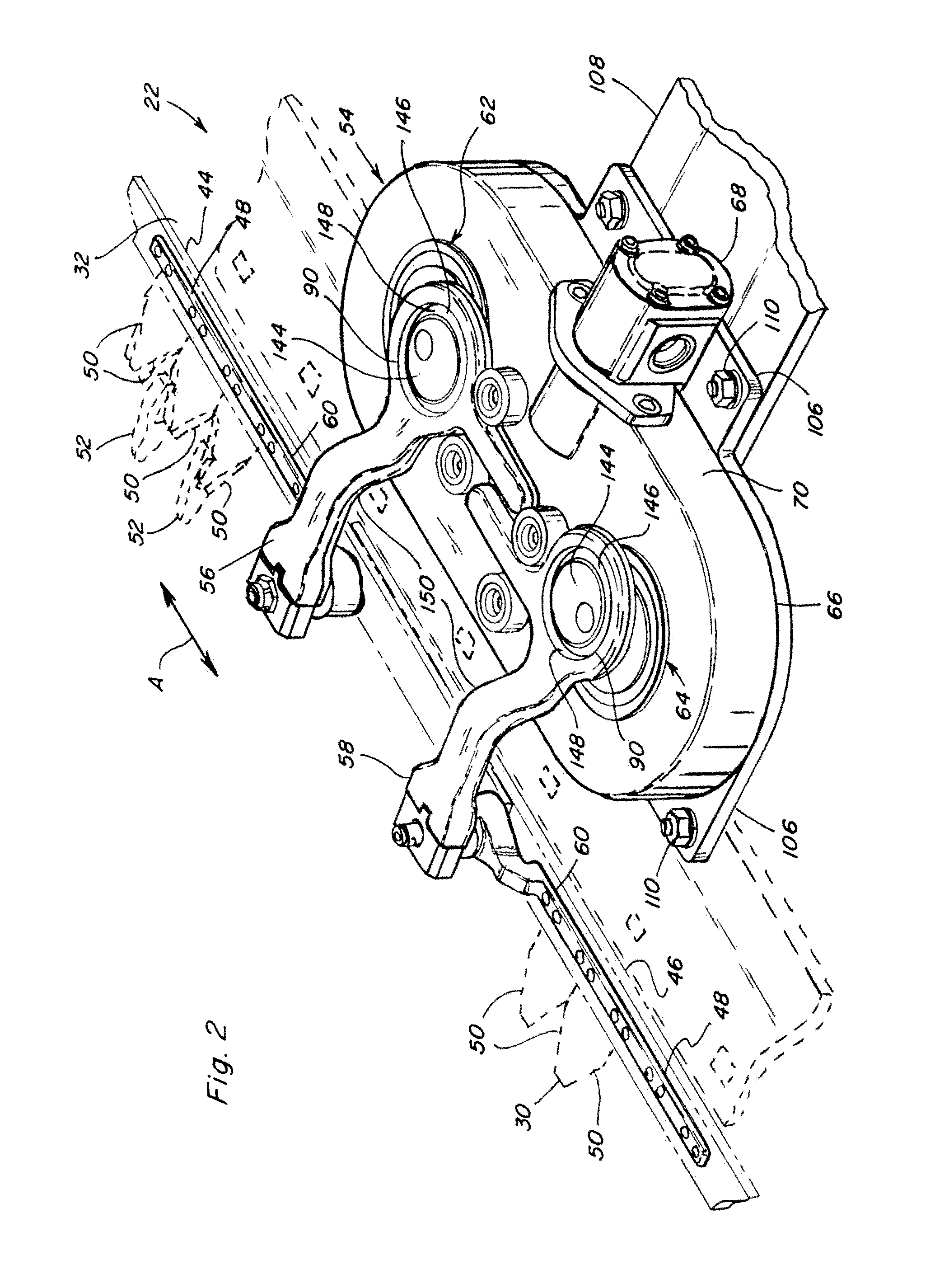

Dual flywheel axially compact epicyclical drive

The epicyclical drive incorporates a dual flywheel carrying a pinion in a balanced axially compact assembly. The assembly includes a counterweight for the pinion nested between the flywheels, which also connects the flywheels and transfers loading conditions therebetween, to reduce and distribute torsional and eccentric loading conditions and reduce vibrations. The use of a second flywheel also provides an improved rotary seal capability for keeping out dust, debris and moisture. The drive is adapted for incorporation into a floor of a header of an agricultural harvesting machine for reciprocatingly driving a sickle thereof, advantageously jointly with a mirror image companion drive in a side by side relationship and timed such that forces generated by the reciprocating actions are cancelled.

Owner:BLUE LEAF I P INC

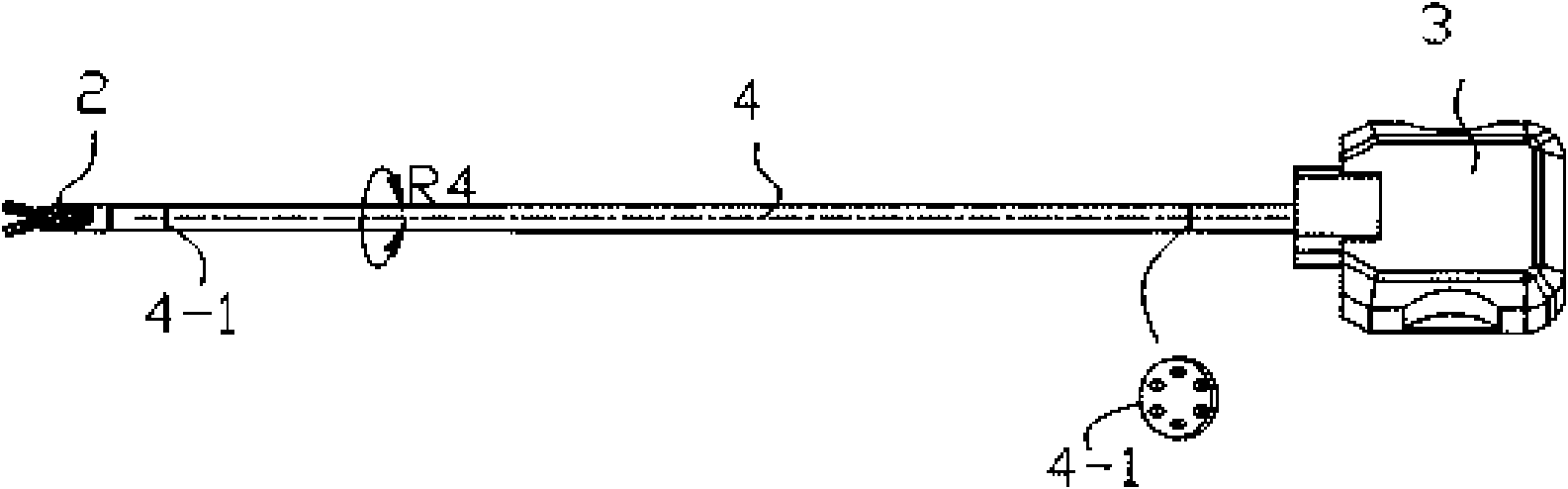

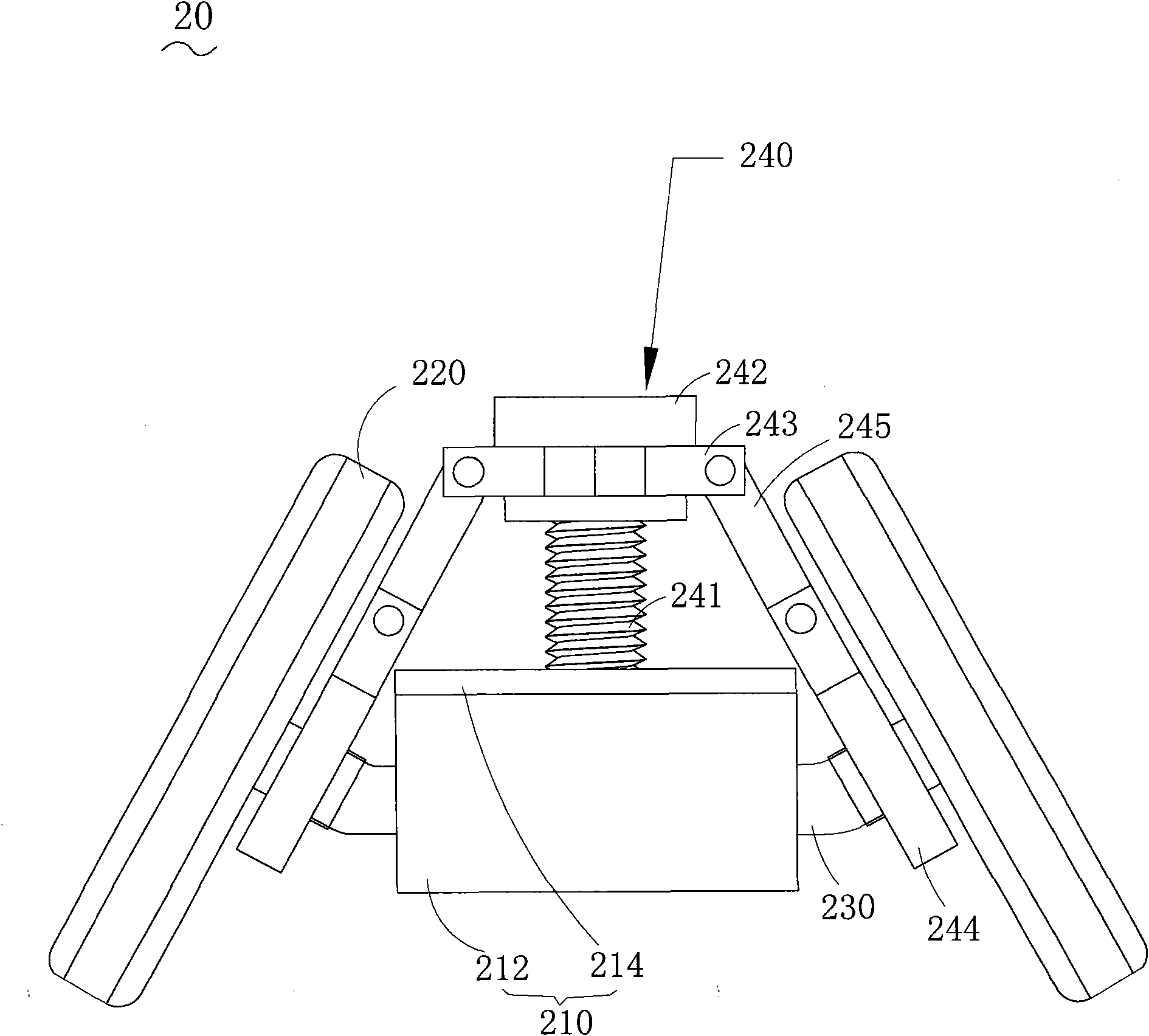

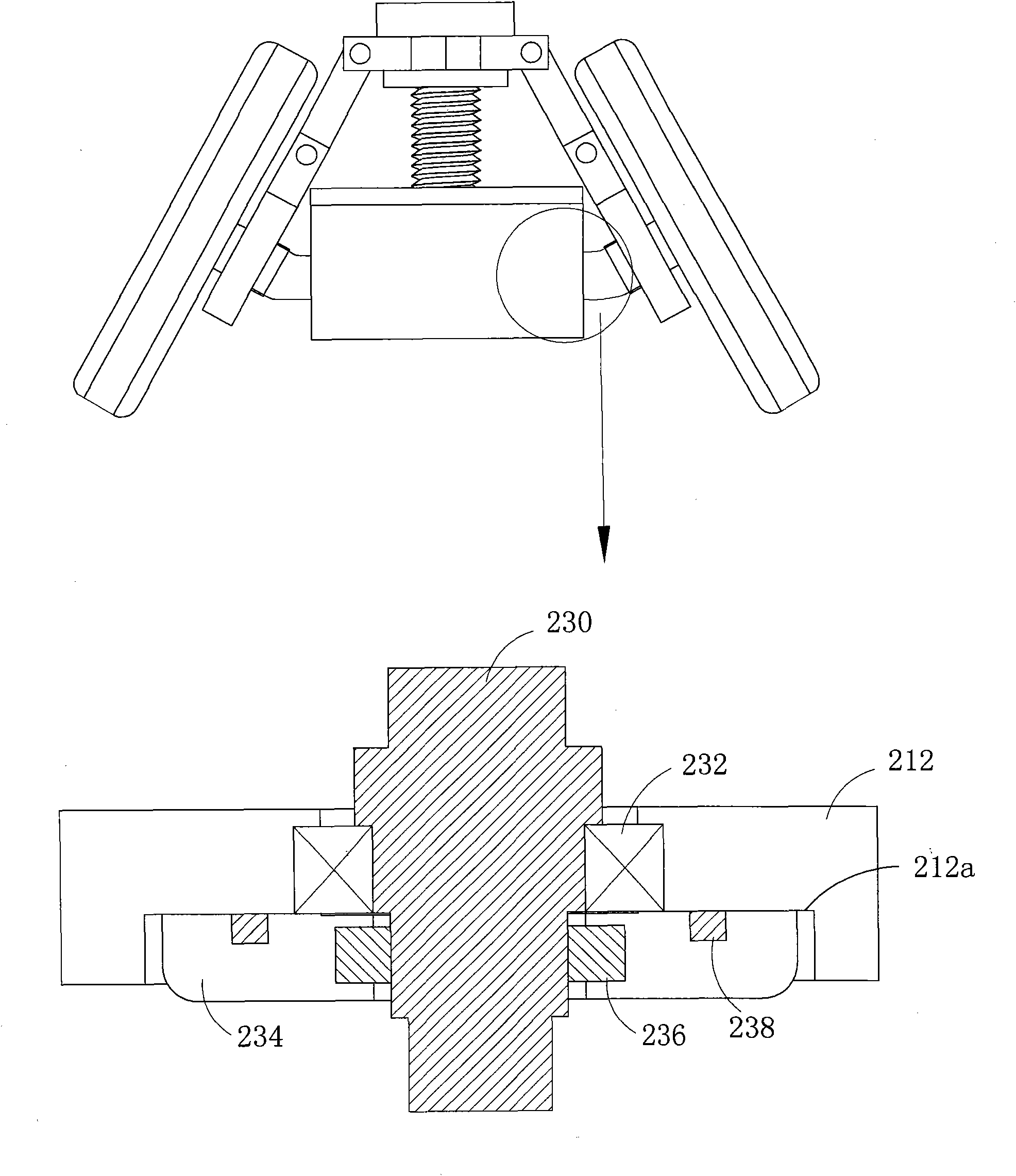

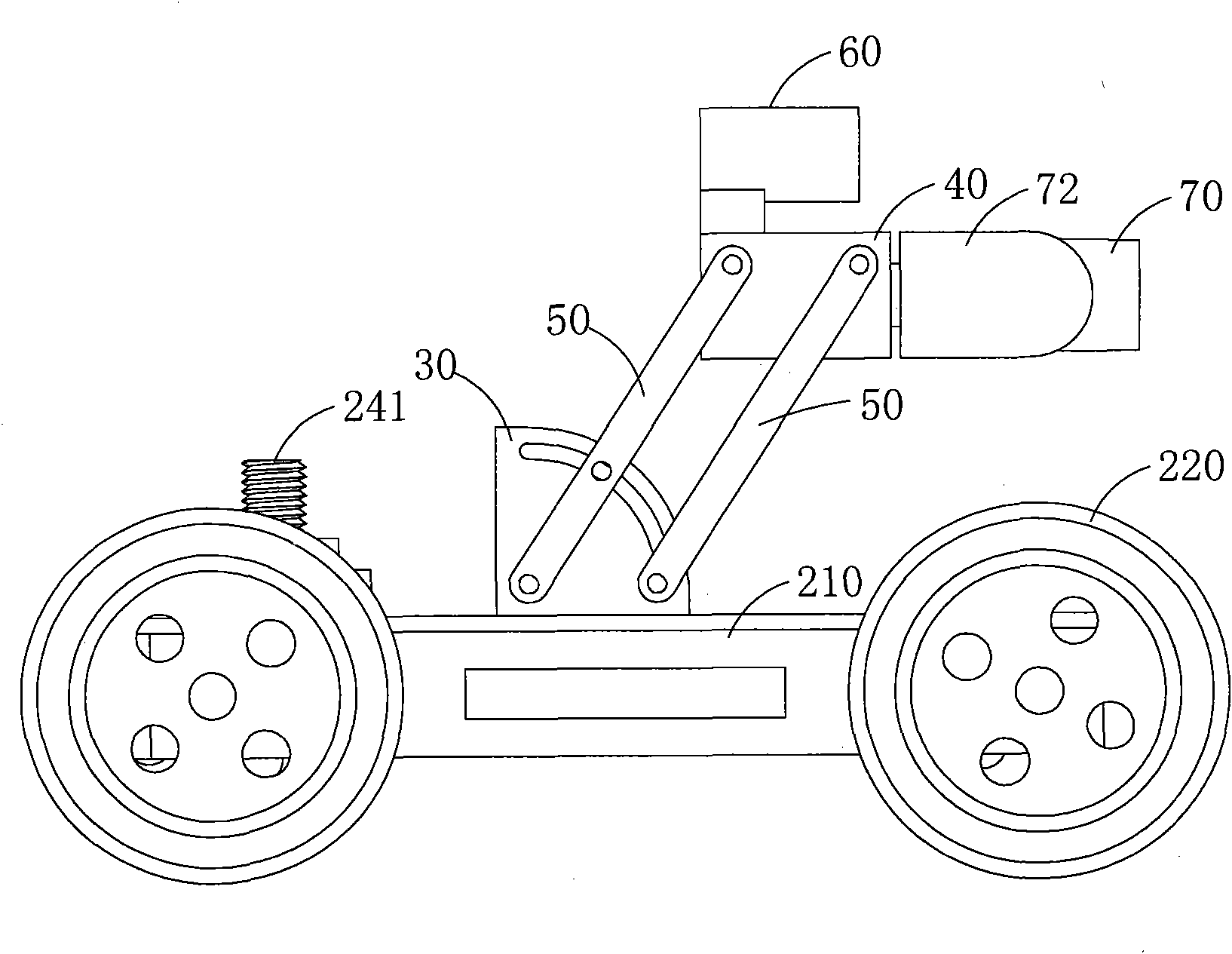

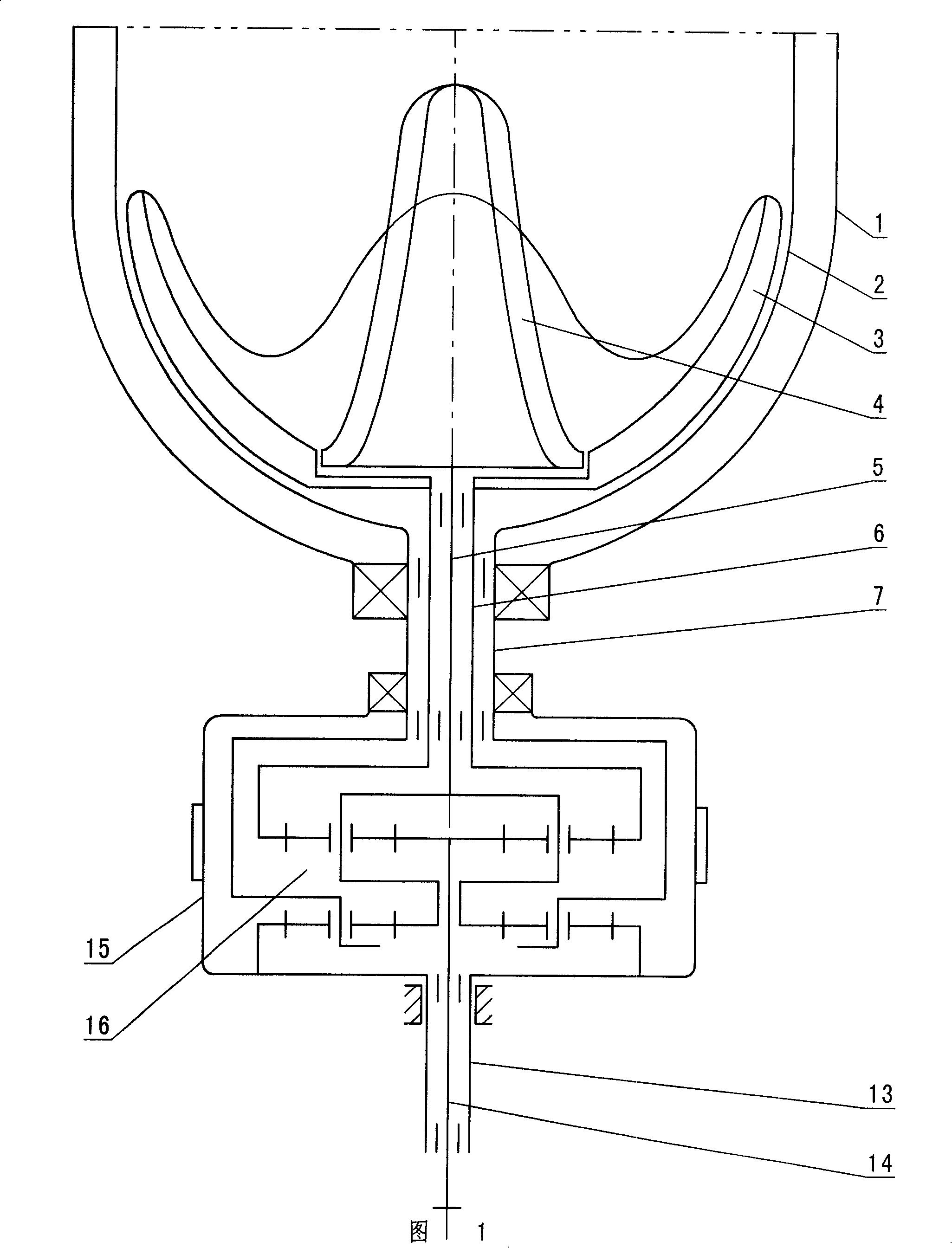

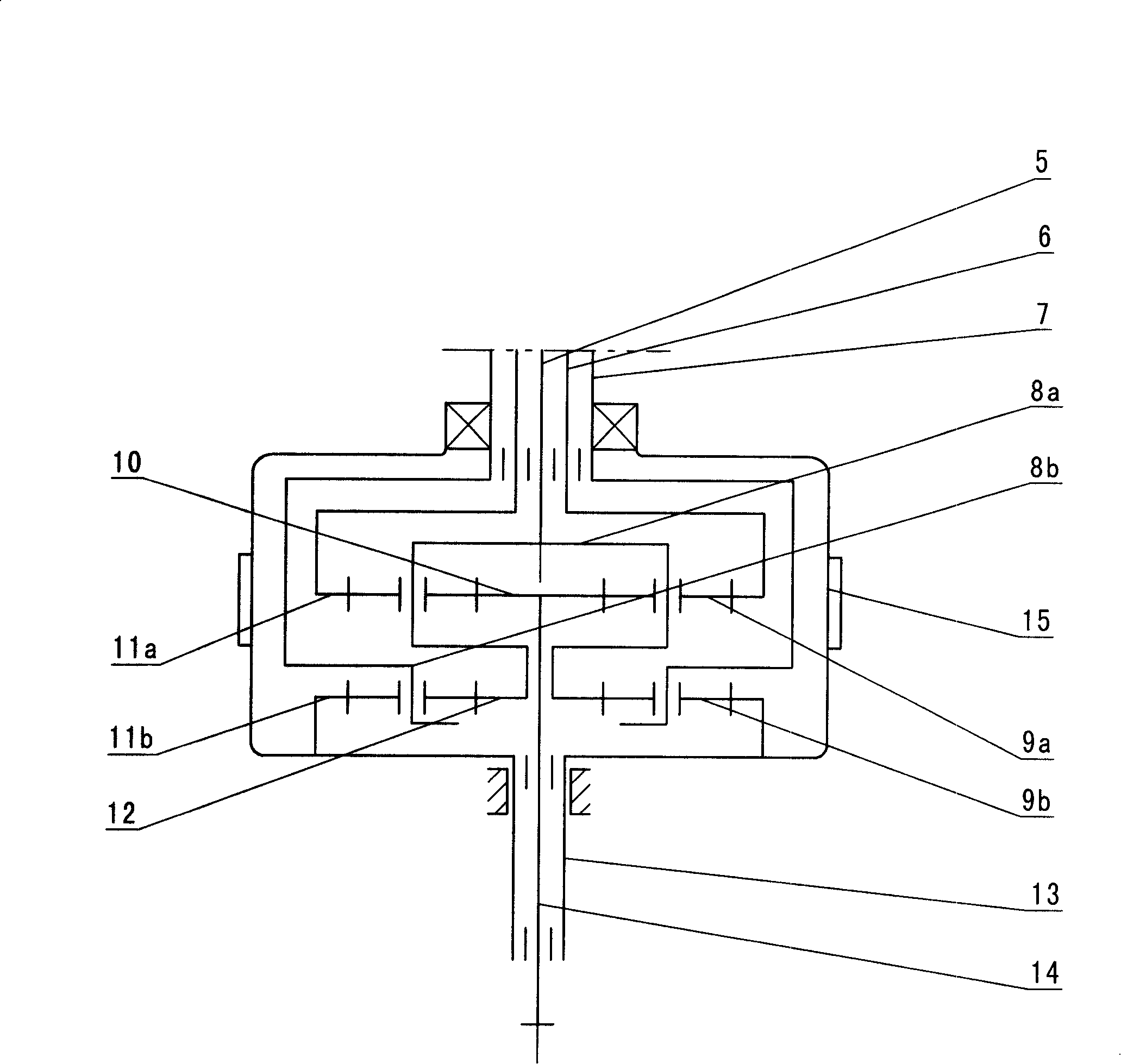

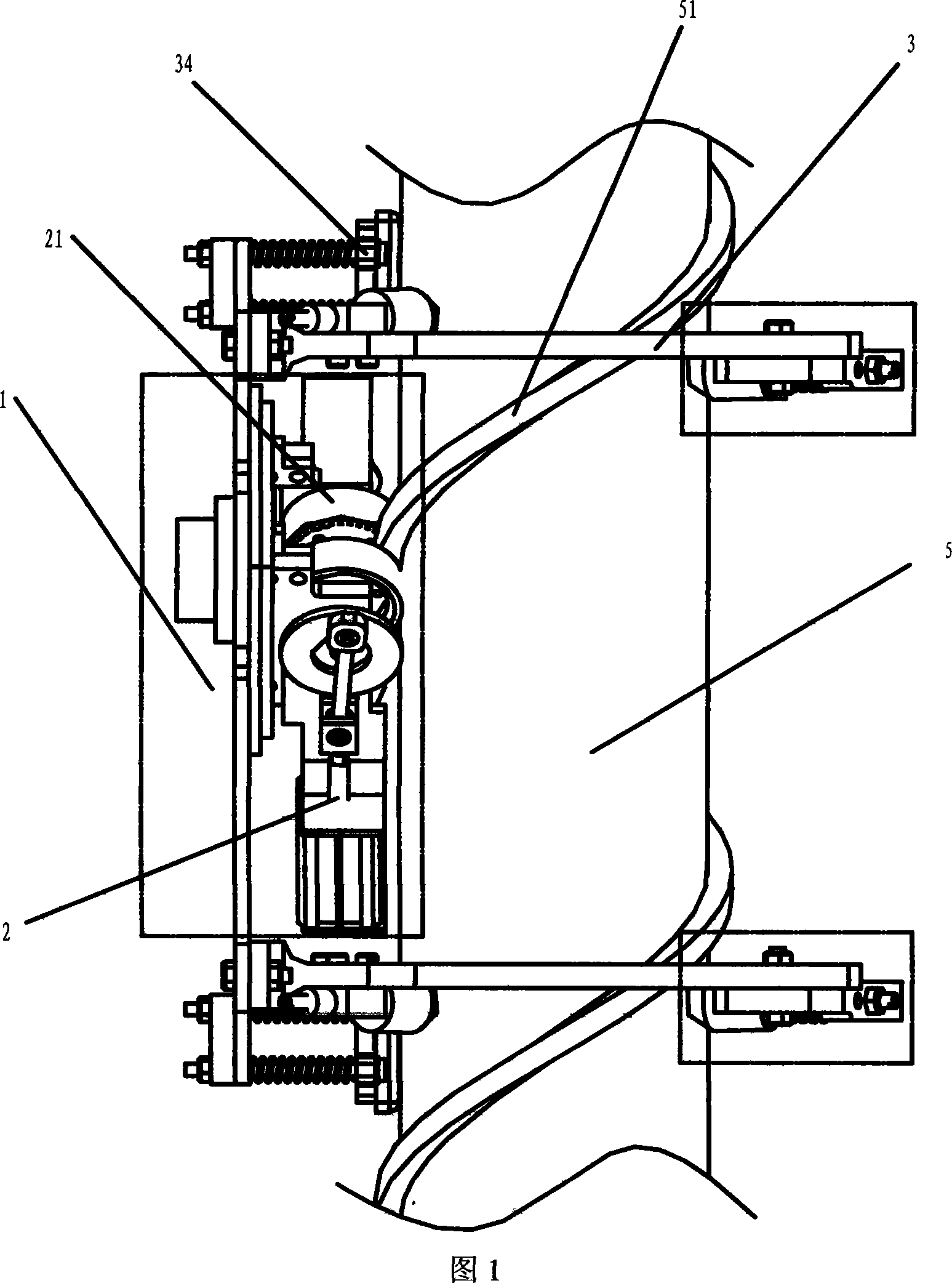

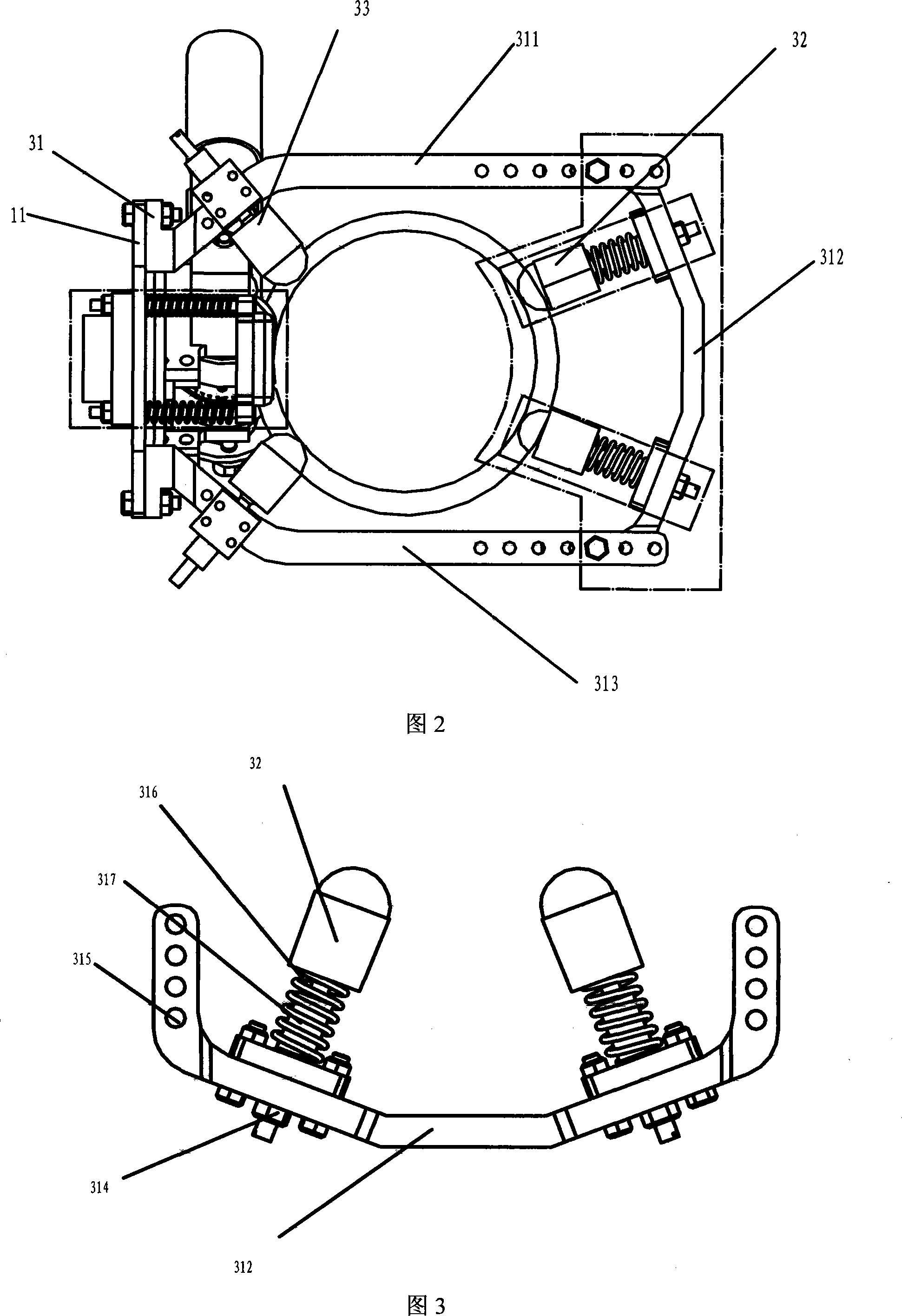

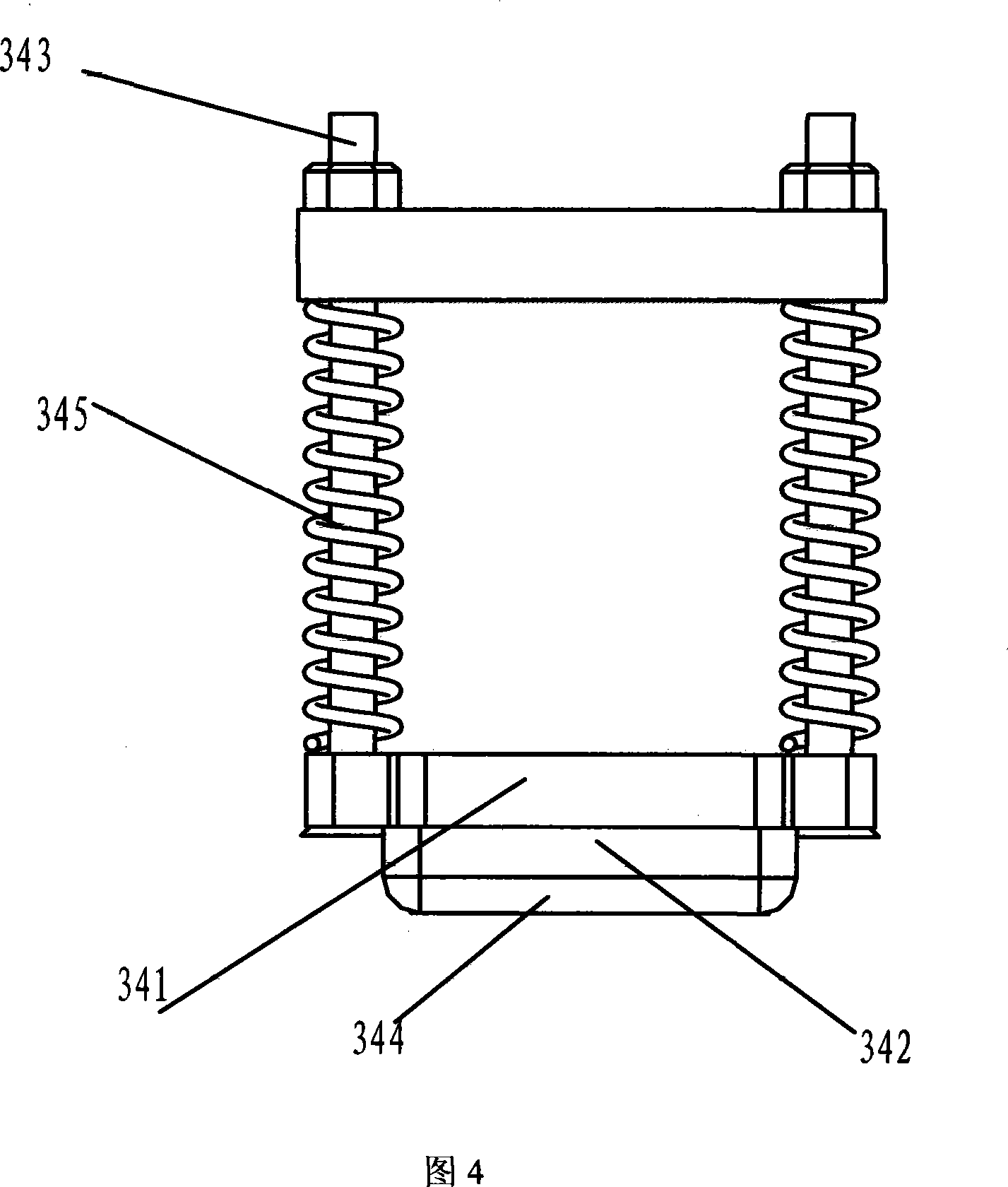

Pipeline robot

The invention relates to a pipeline robot, which comprises a main pipeline robot body. The main pipeline robot body comprises a moving carrier, and the moving carrier comprises a carriage body, wheels, flexible wheel shafts, a rocker and slider mechanism, and also comprises a robot base, a holder, a rod mechanism, a lighting lamp and a camera connected with the holder, wherein the flexible wheel shafts are used for connecting the carriage body and the wheels; the rocker and the slider mechanism is connected with the carriage body and the flexible wheel shafts and used for adjusting included angles between the wheels and the carriage body; the robot base is arranged on the moving carrier; the rod mechanism is used for connecting the holder and the robot base; and the lighting lamp is arranged on the holder. The included angles between the robot wheels and the carriage body are adjustable so as to ensure that when the robot works in pipelines with different diameters, the peripheries of the wheels are still in vertical contact with wall surfaces, therefore, a contact area between the peripheries and the pipeline wall surface is increased, the robot can operate more stably in the pipeline; and moreover, the structure can provide larger driving force. The flexible shafts are adopted for connecting the driving wheels and the carriage body so that the included angles between the wheels and the main pipeline robot body are adjustable and the sufficient driving force can be ensured.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

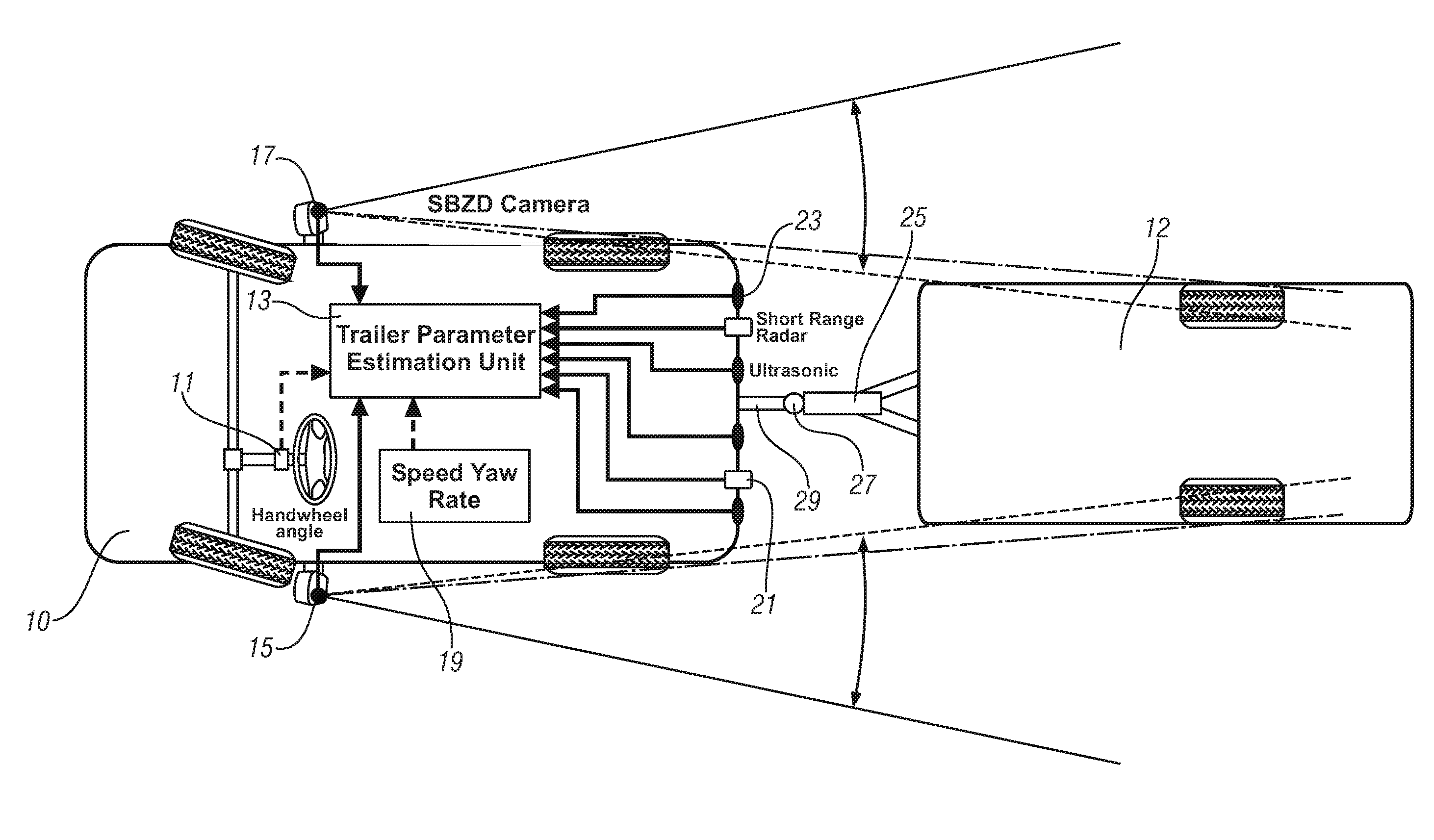

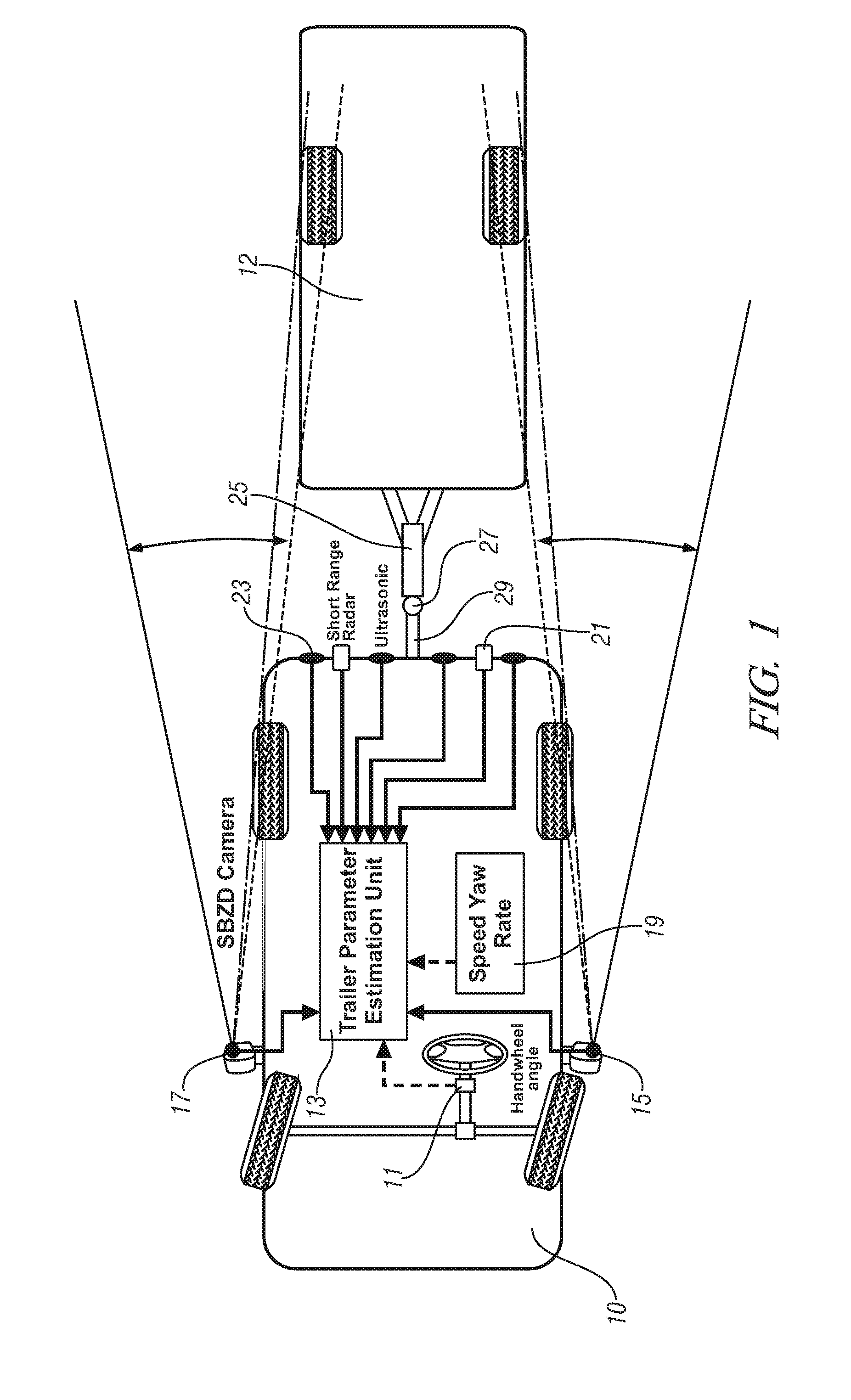

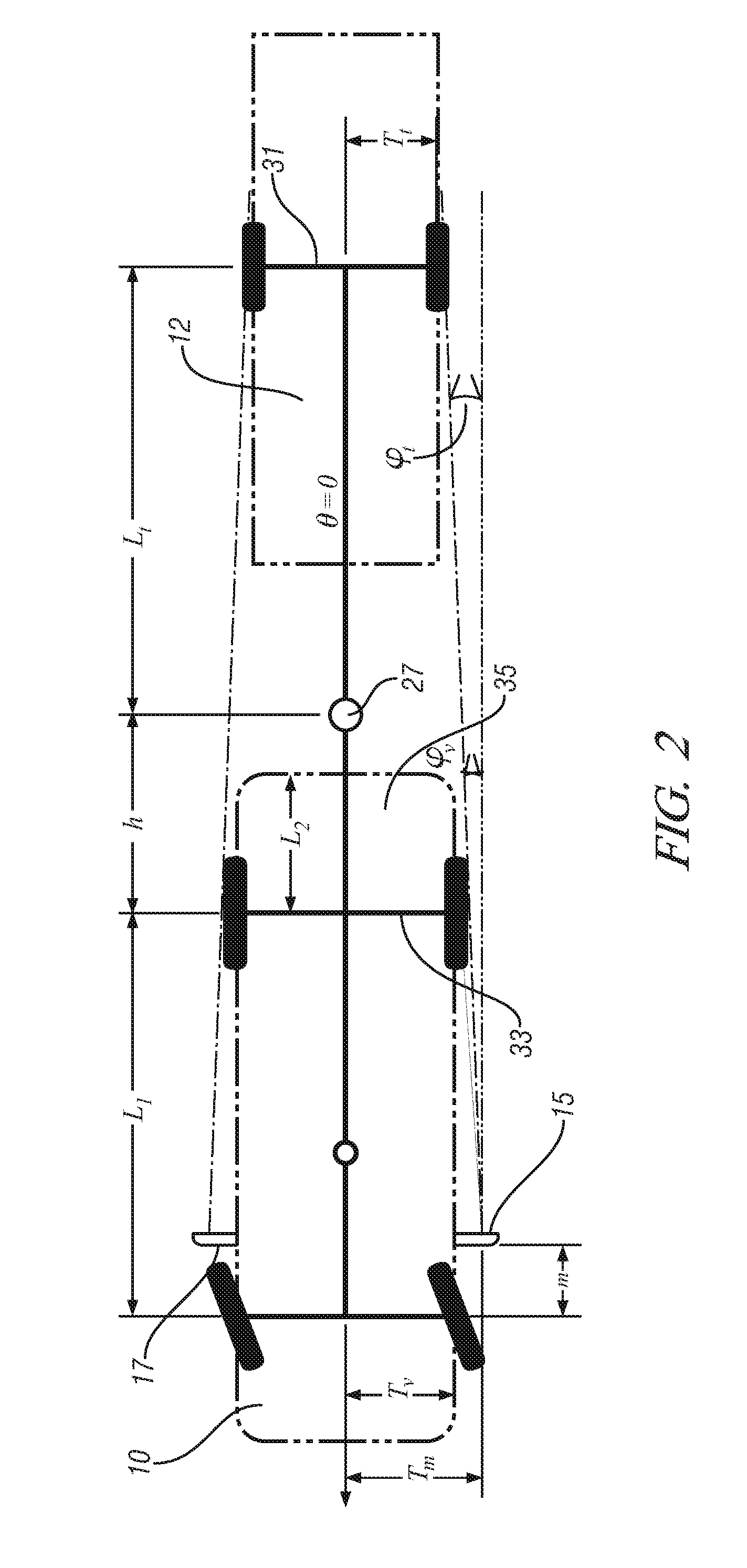

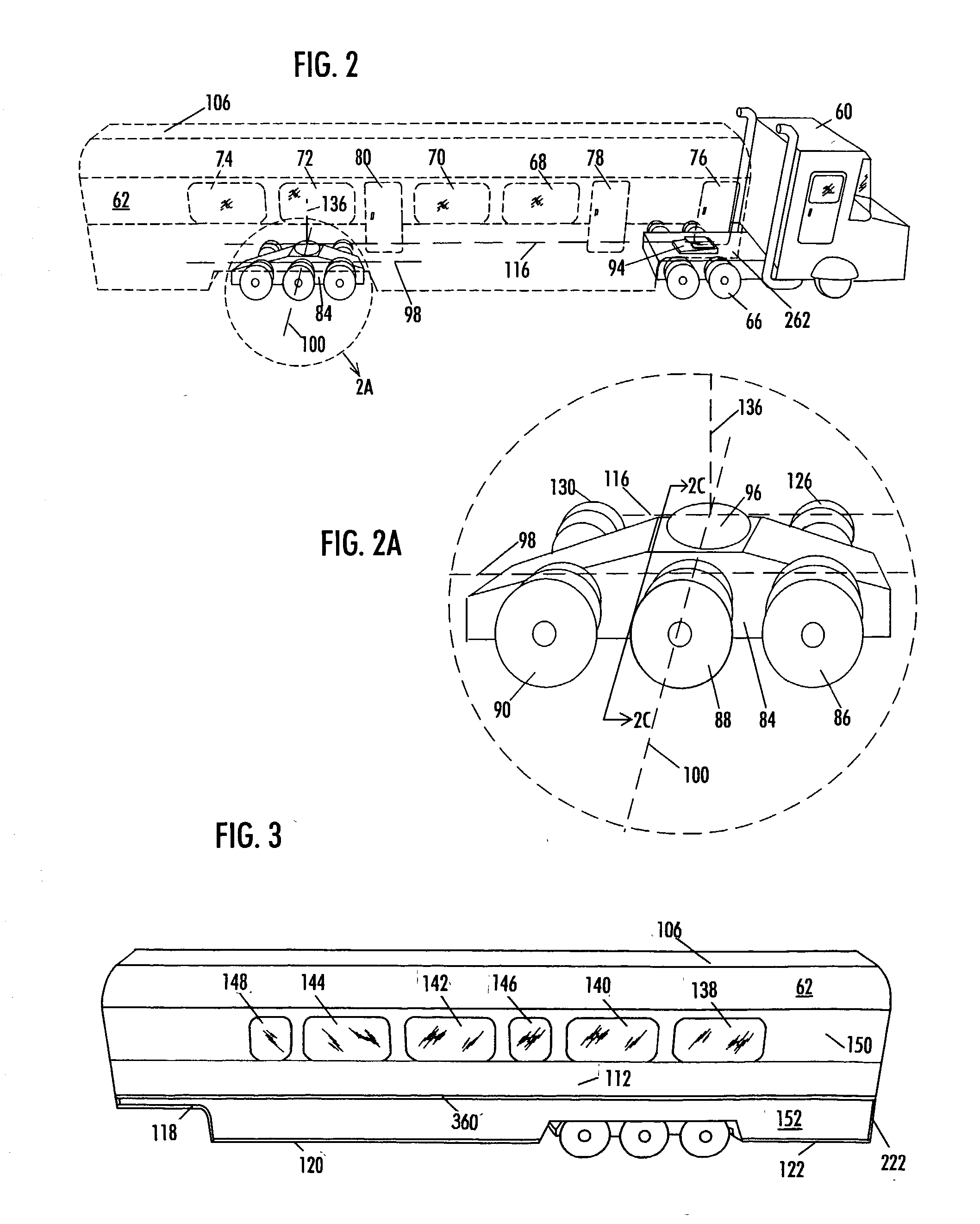

Trailer articulation angle estimation

A method for operating a vehicle includes acquiring position information including an azimuth angle between a non-contacting sensor and a wheeled axle of an attached trailer, determining a trailer tongue length correlated to the position information, determining a track width of the attached trailer correlated to the position information, and calculating a trailer hitch articulation angle corresponding to the trailer tongue length and the track width of the attached trailer.

Owner:GM GLOBAL TECH OPERATIONS LLC

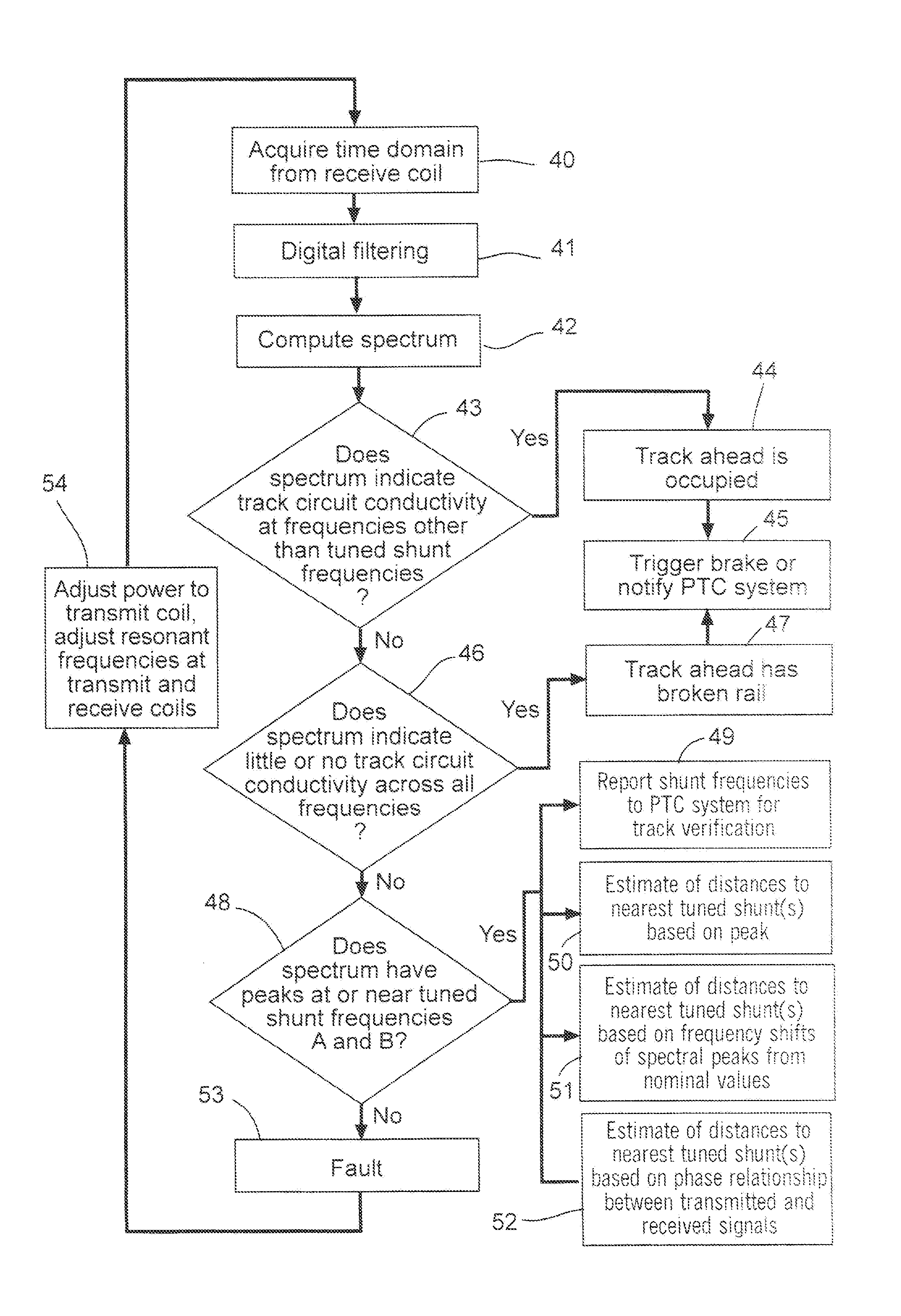

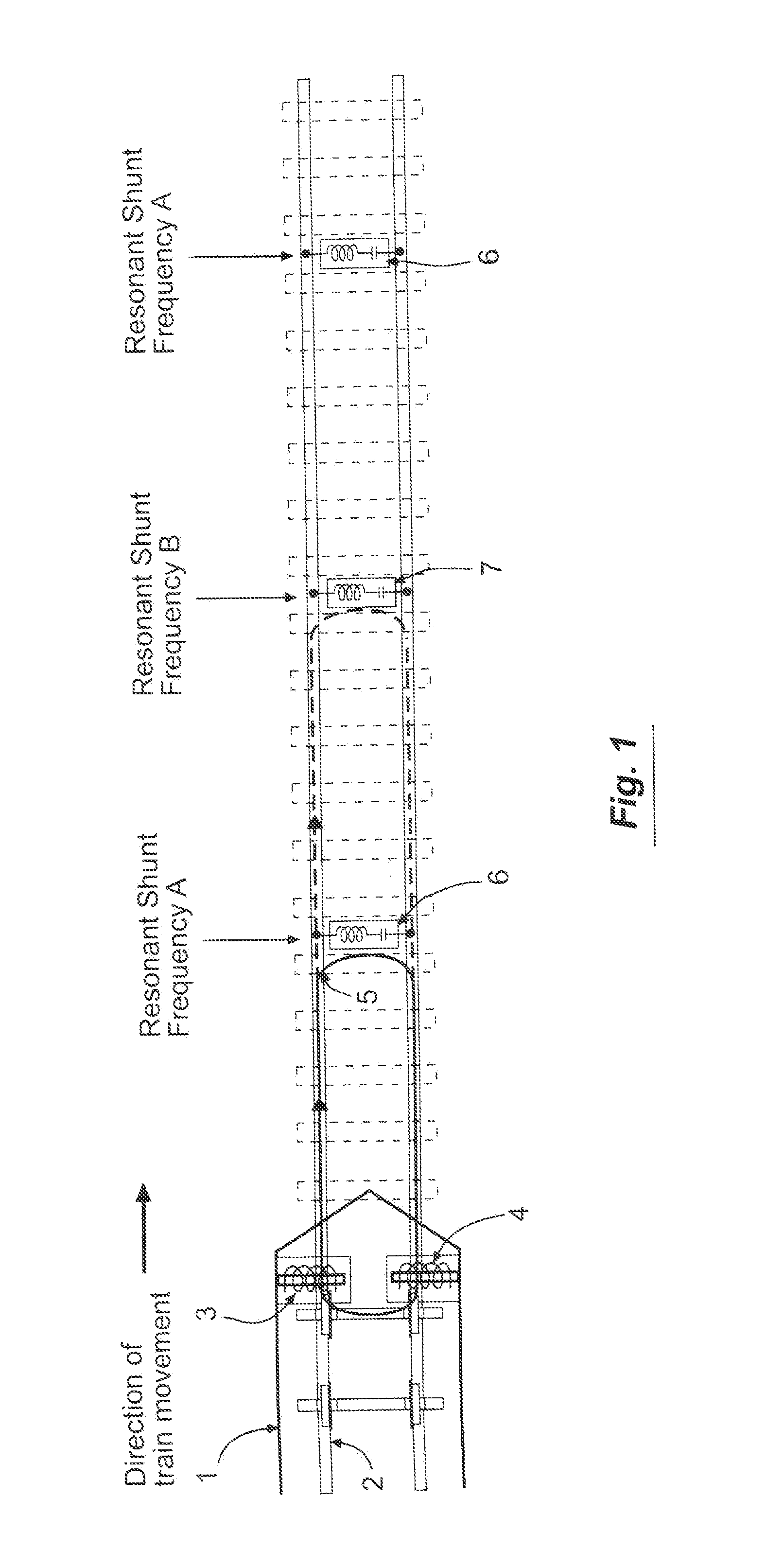

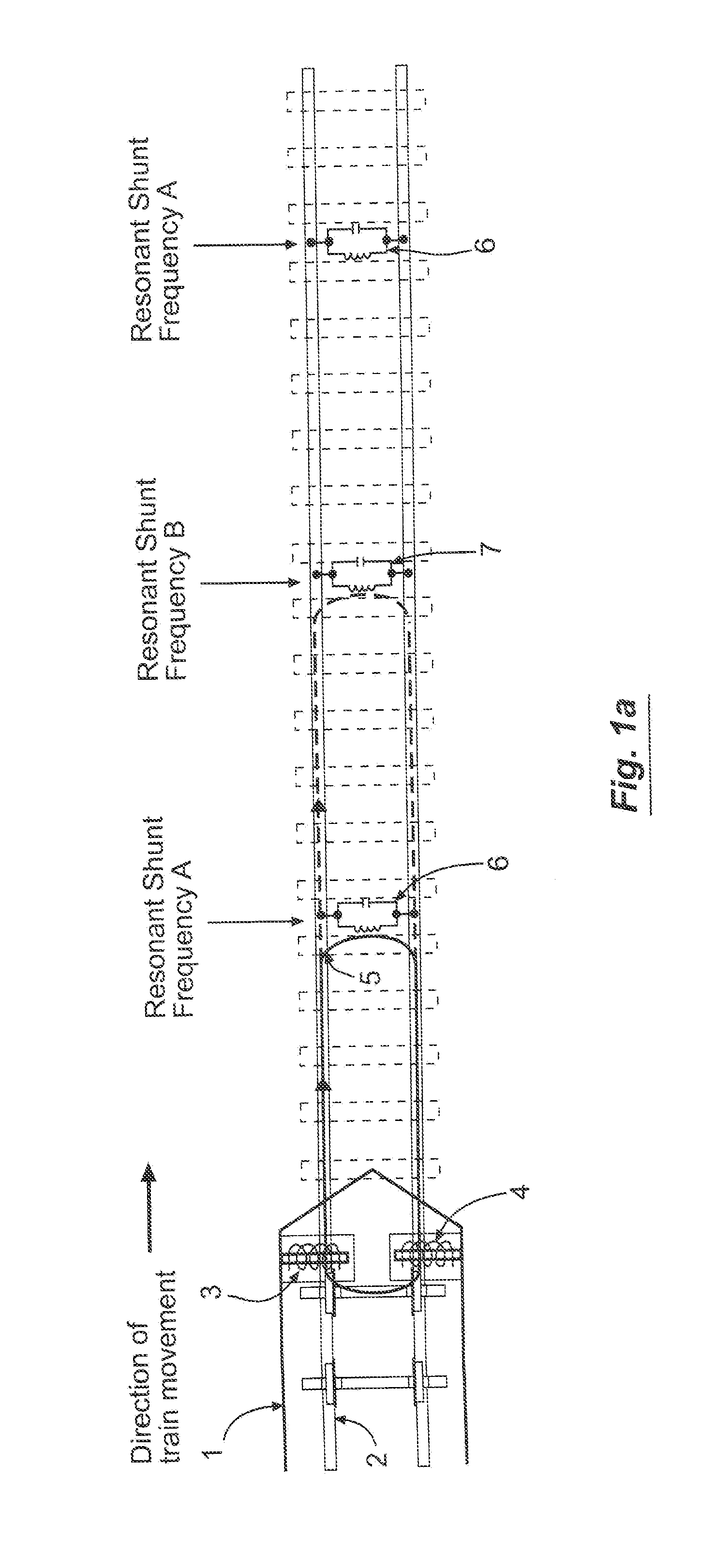

System and method for detecting broken rail and occupied track from a railway vehicle

ActiveUS20130284859A1Operational performance advantageGood estimateRailway traffic control systemsSignal boxes station blockingSignal onOrbit

A method is provided for detecting broken rail, unintentionally misaligned turnouts, and track occupancy ahead of or behind a railway vehicle traveling on a railroad track. Shunts extend between the rails at intervals along the railroad track. Each shunt has electrical signal transmission characteristics differing from those of adjacent shunts. A test unit on the railway vehicle induces a test signal in a first rail to create a track circuit in which the test signal propagates along the first rail, through at least one of the shunts, returns to the railway vehicle along the second rail, and through the wheels and axle of the railway vehicle. The test signal has electrical properties selected to interact with at least one of the shunts. The received test signal on the second rail is analyzed to identify predetermined conditions concerning the status of the railroad track.

Owner:TRANSPORTATION TECH CENT

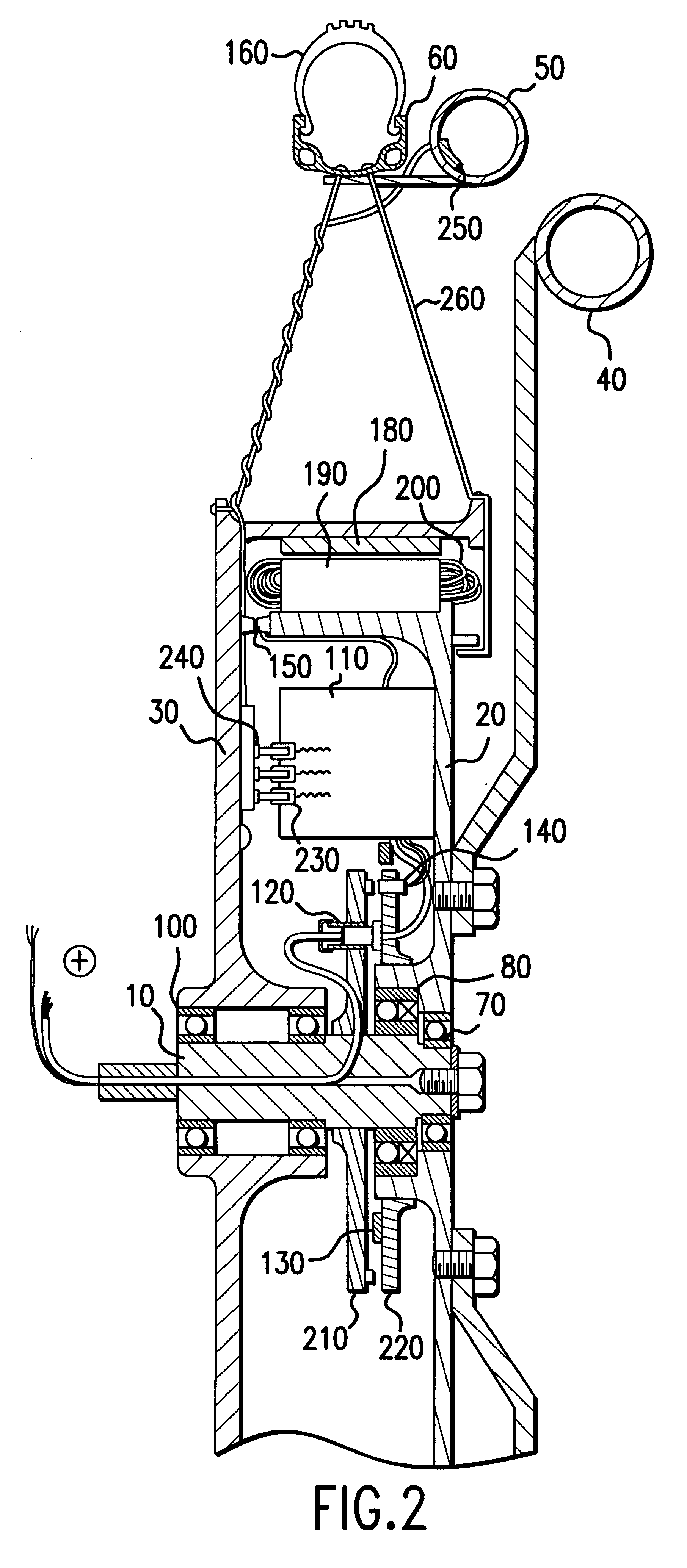

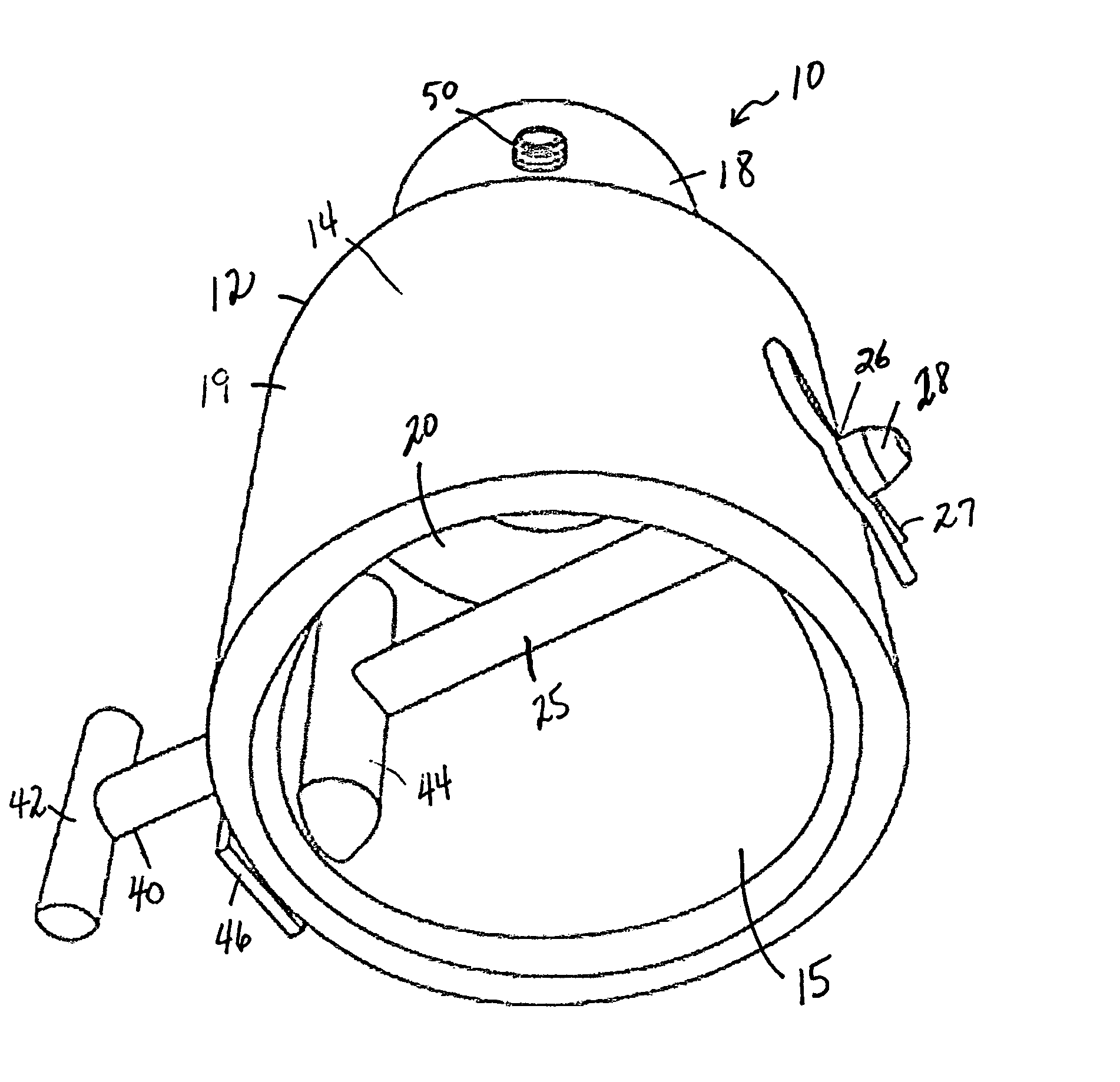

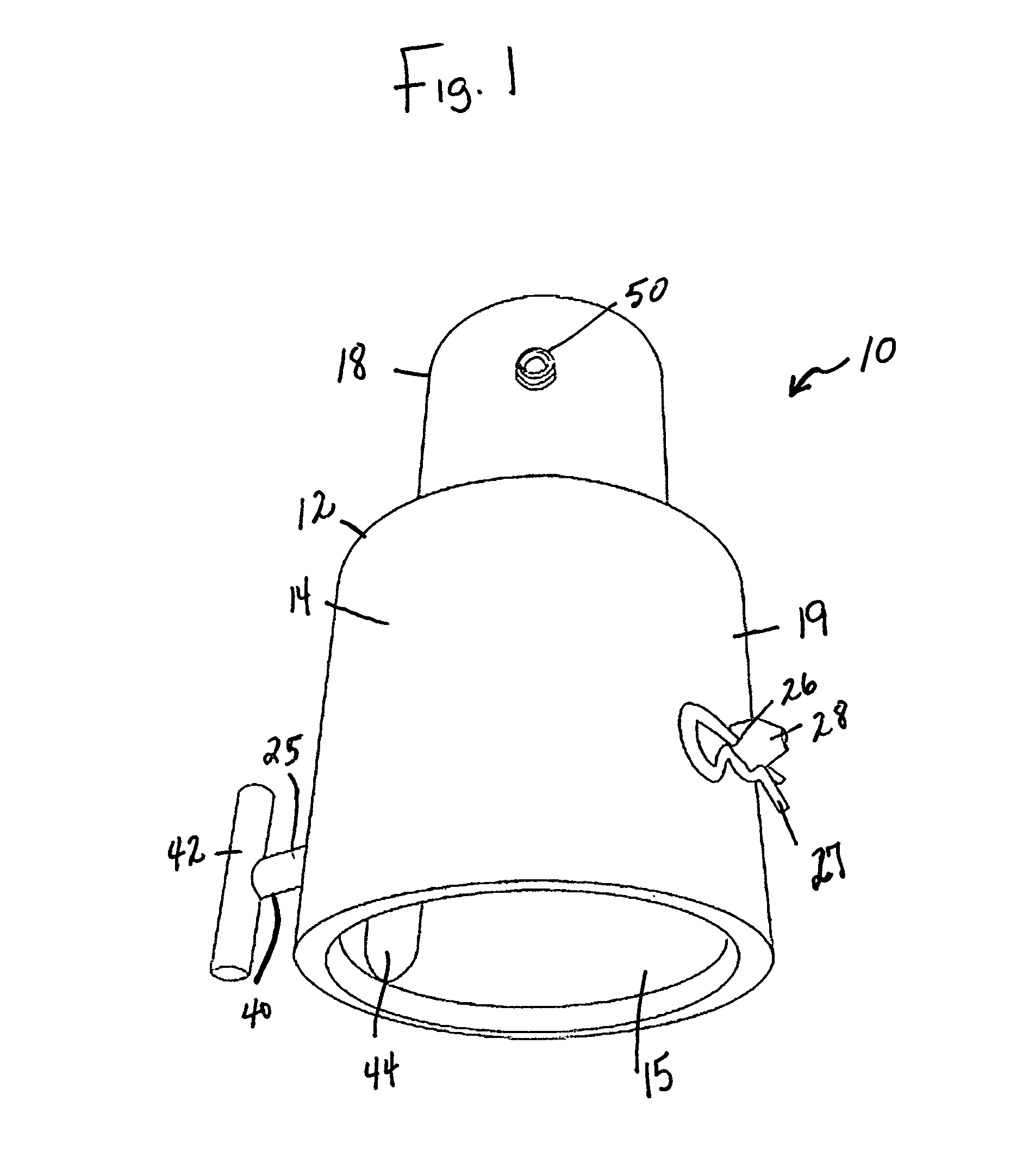

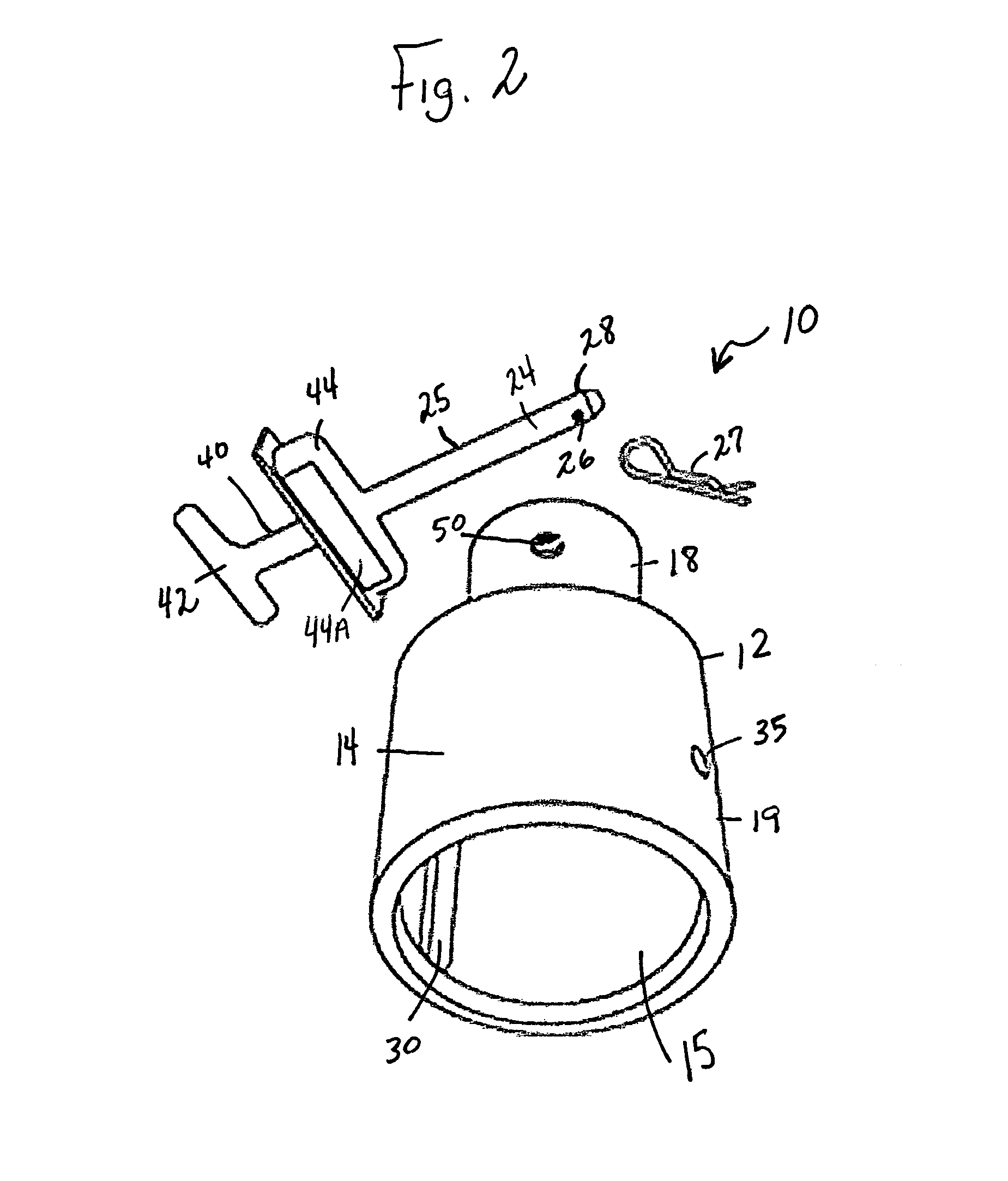

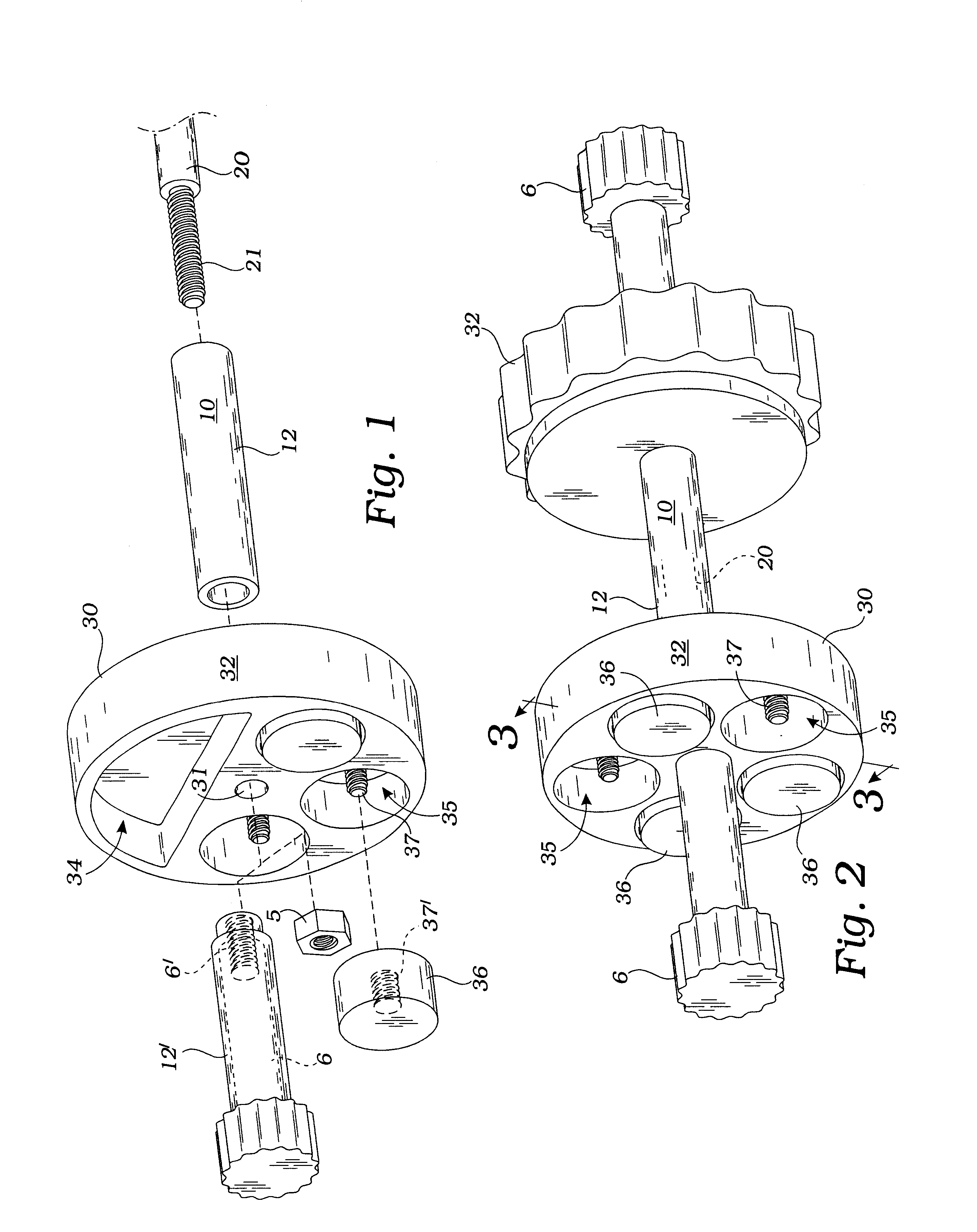

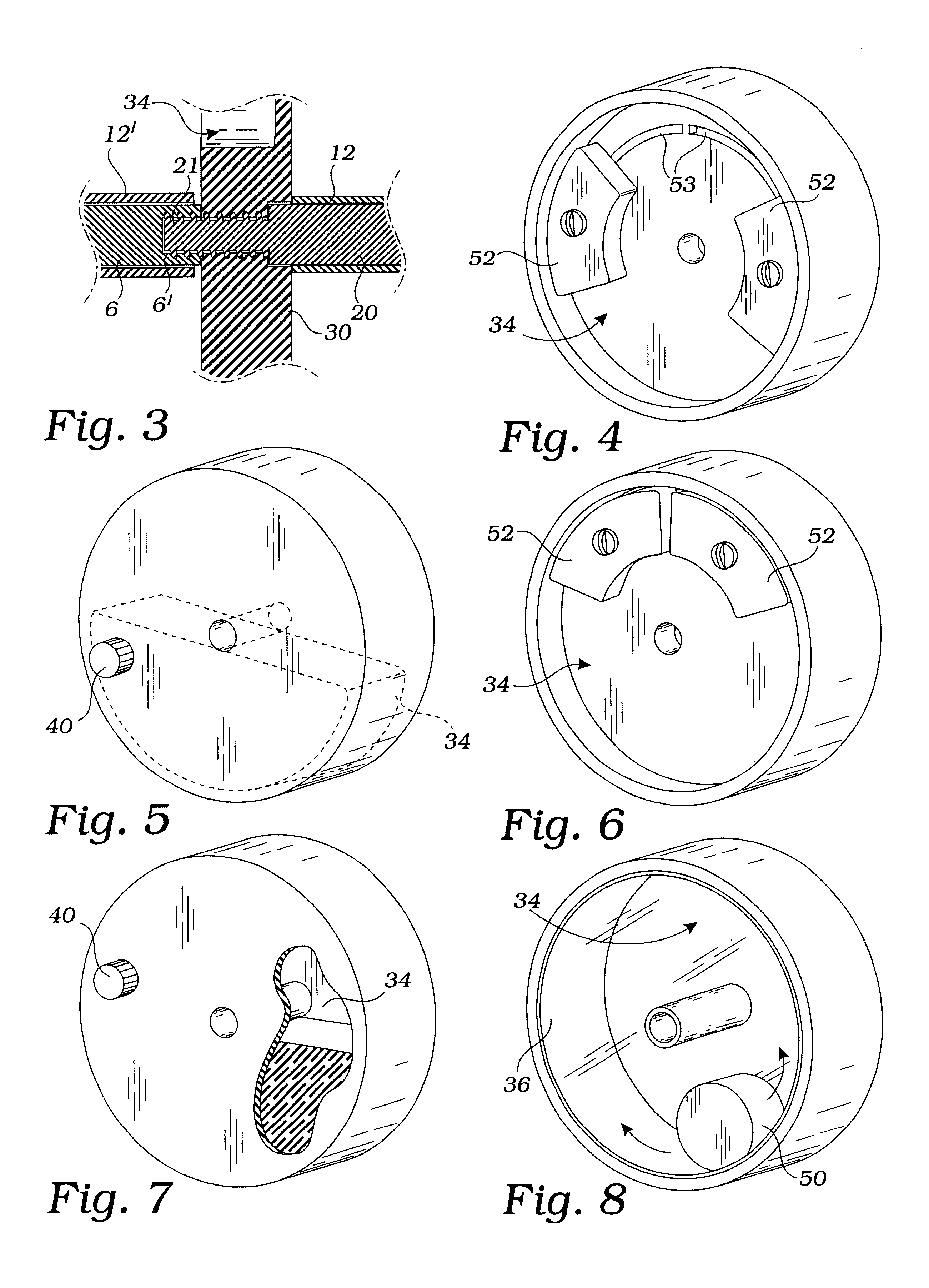

Coupling assembly for molten metal pump

ActiveUS8137023B2Precise positioningAxial position is accuratePump componentsReaction enginesImpellerCoupling

A coupling assembly for connection between a drive shaft and an impeller in a molten metal pump. The coupling assembly includes an upper portion to receive an end of the motor drive shaft and a lower portion to receive an end of the impeller shaft. The impeller shaft is pinned to the lower portion with a pin member which extends through first and second apertures in the lower portion of the coupling body. The pin member includes a handle portion, a driver member, and a stop. The driver member has an elongated configuration sized and shaped to pass through the first aperture of the coupling member. In application, once the impeller shaft is positioned in the coupling body, the pin member is passed through the apertures such that the driver member passes through the second aperture until the stop is in abutting relationship with the coupling member outer surface. Once the pin member and therefore driver member is inserted, the driver member is a contact point between the interior of the coupling member and impeller shaft.

Owner:WM REFRACTORIES S DE R L

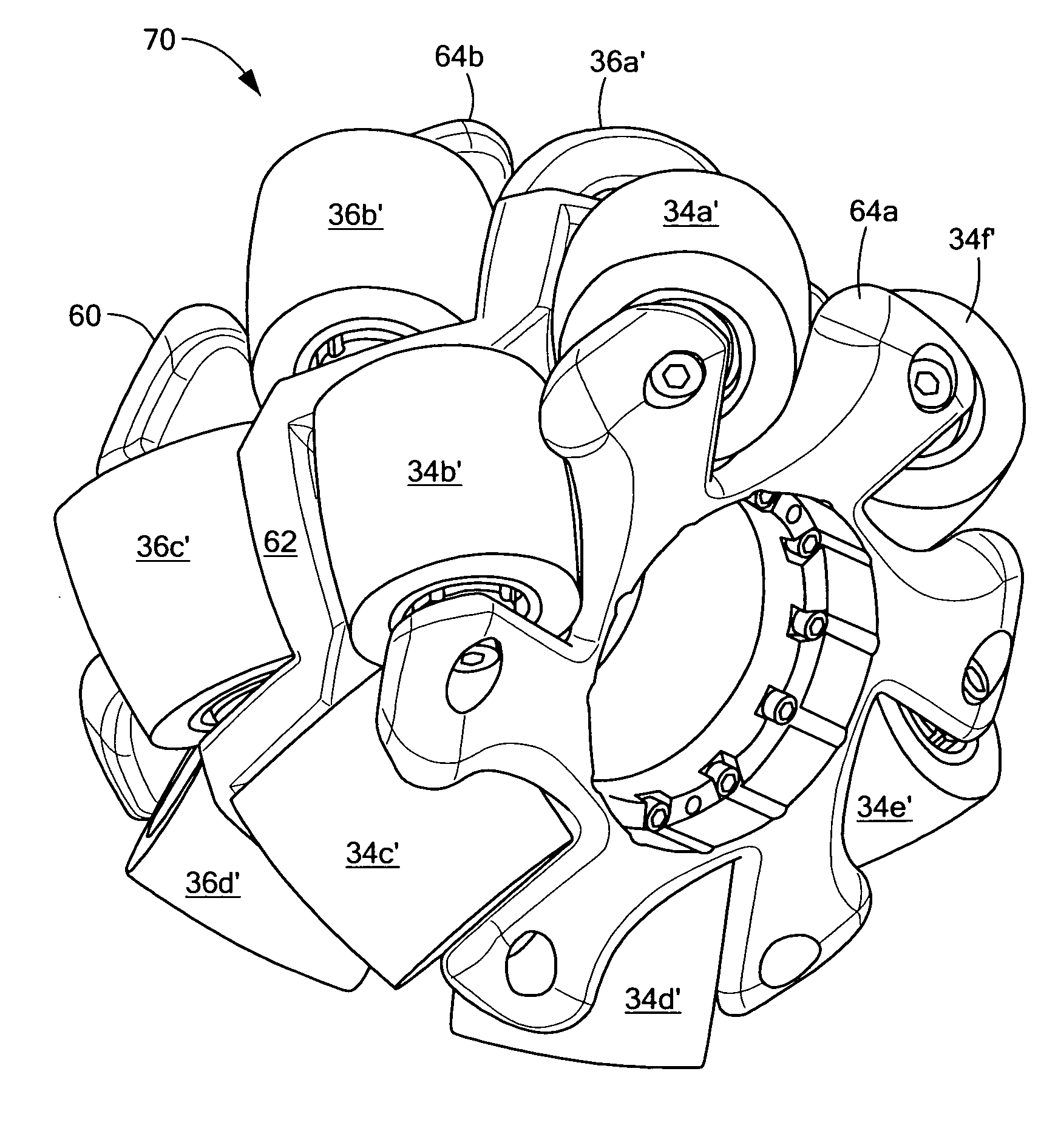

Omni-directional wheel

ActiveUS20100187779A1Vibration minimizationAvoid swingingVehicle body stabilisationHubsEngineeringOmni directional

Owner:FOSTER-MILLER

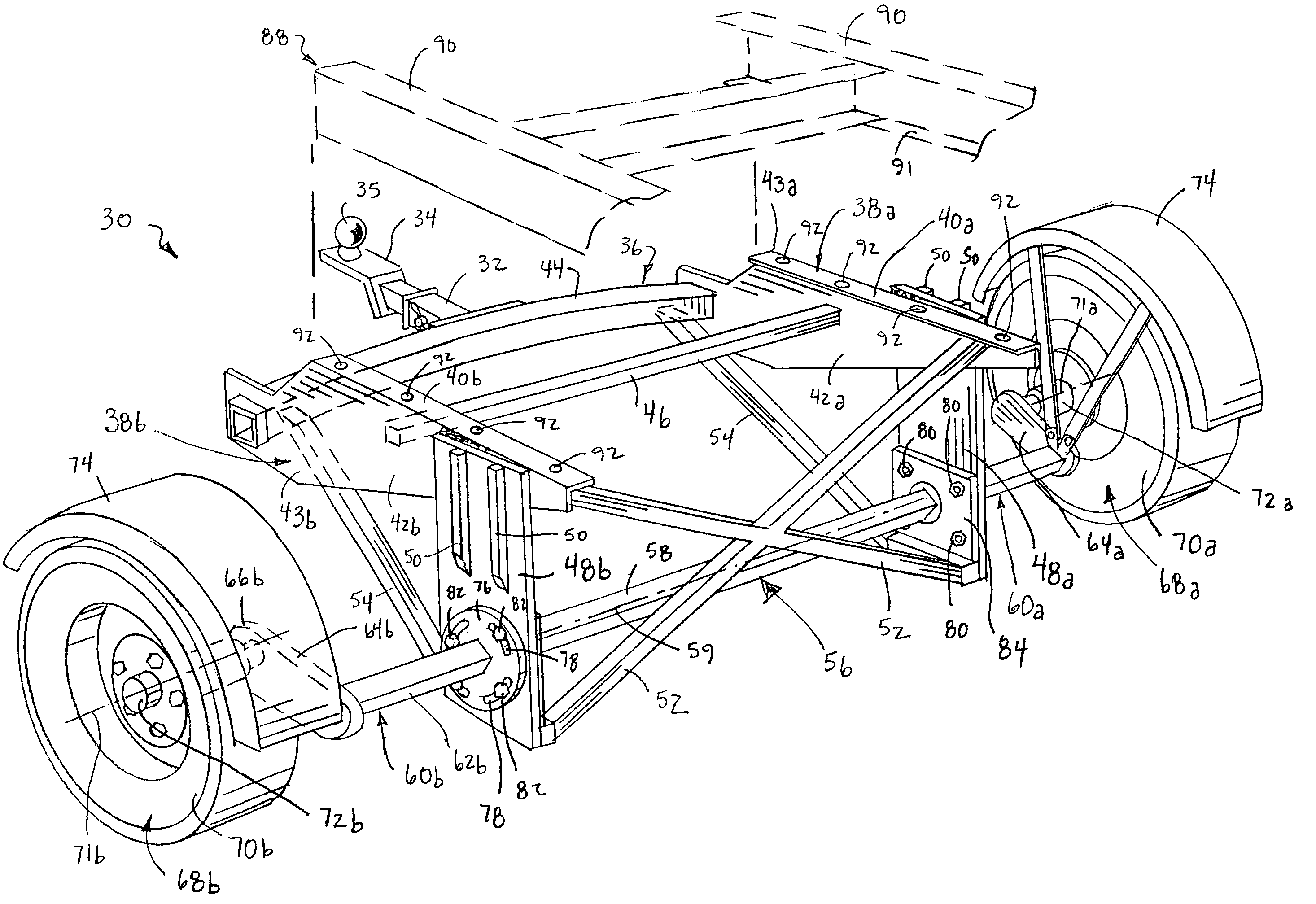

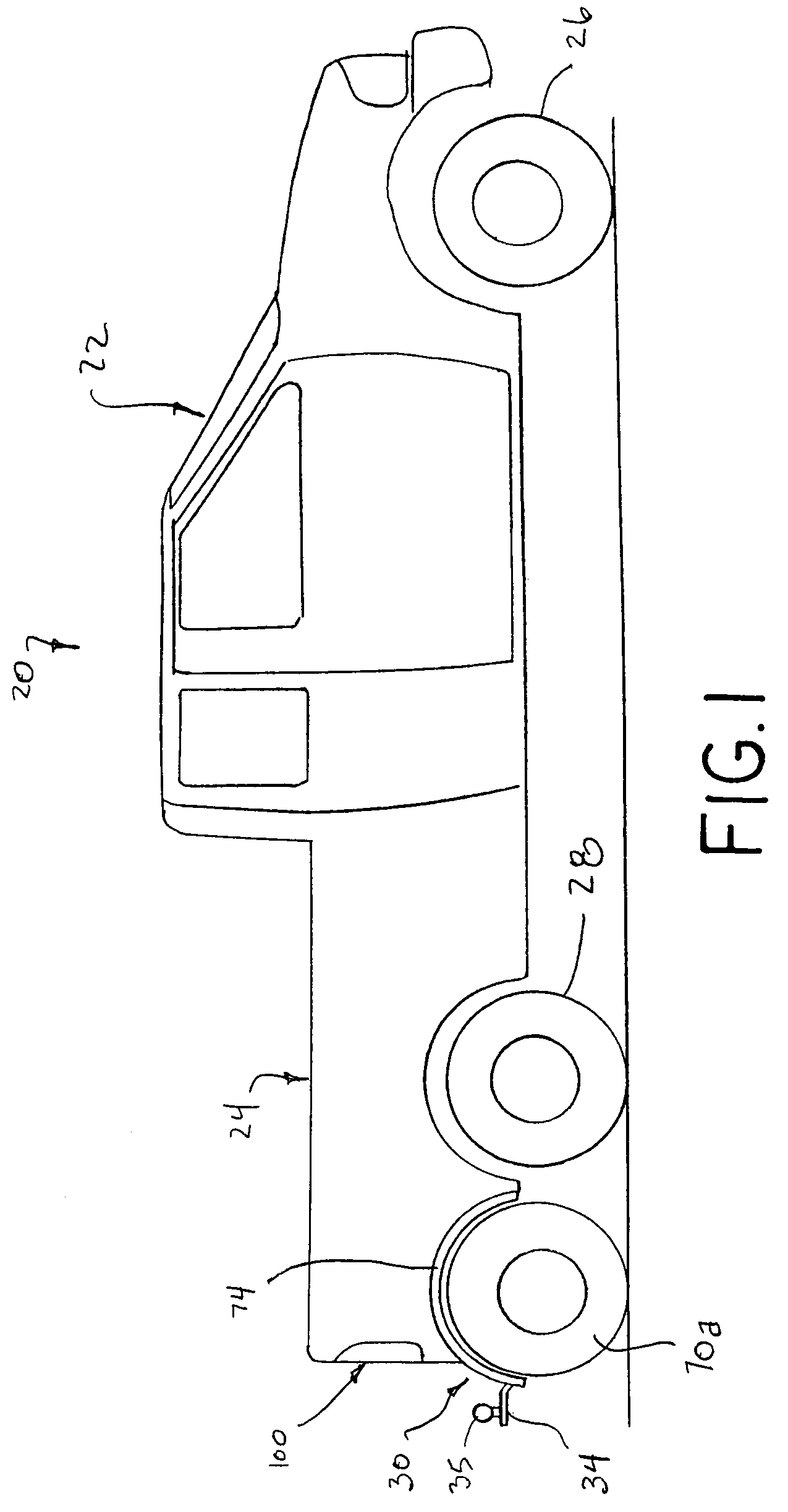

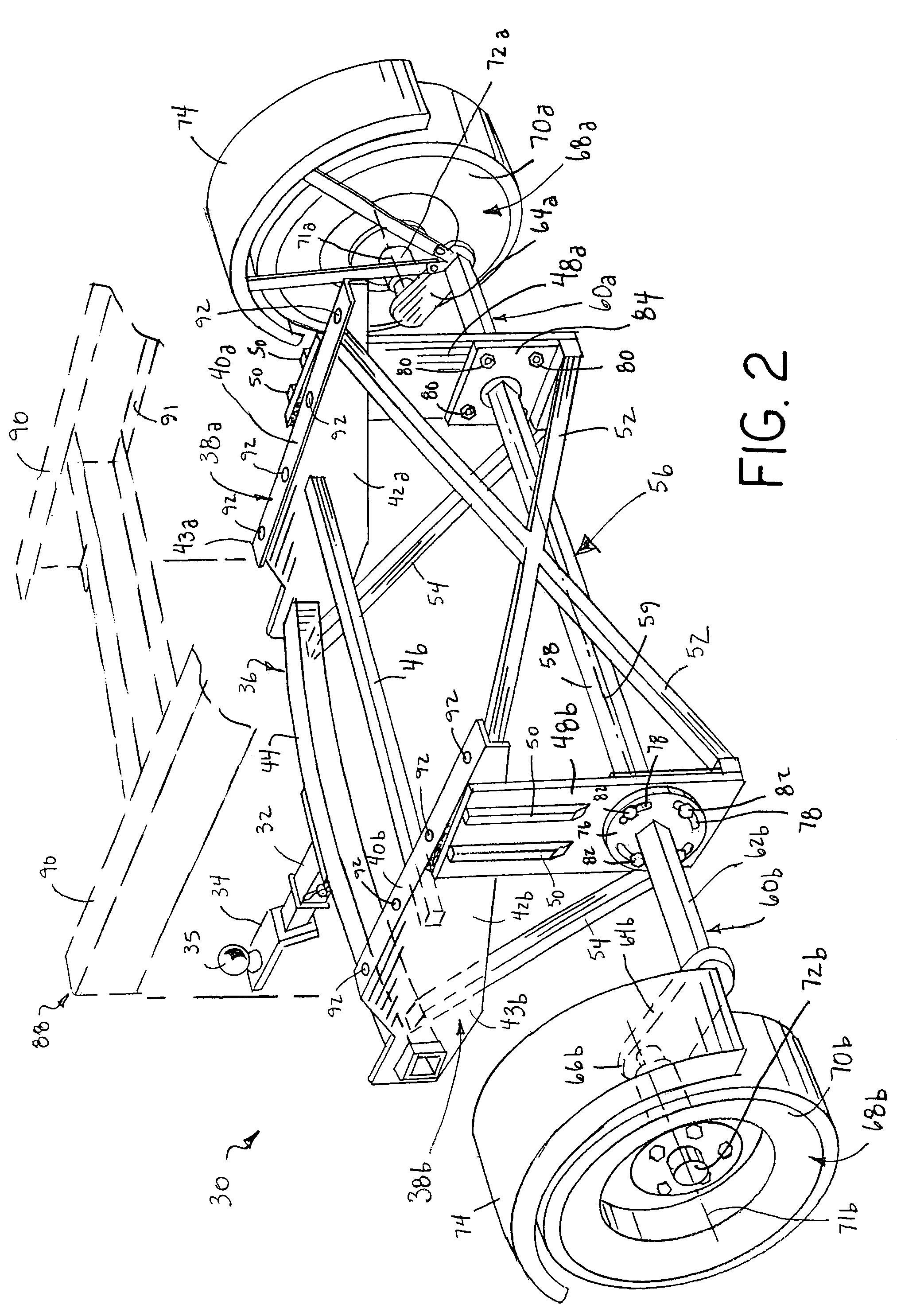

Detachable axle and hitch assembly

InactiveUS7237789B1Easy towingIncrease load capacityTractor-trailer combinationsTowing devicesRotational axisDistal portion

A hitch and axle assembly including a support structure detachably securable to a vehicle and an axle assembly. A hitch is mountable on the support structure. The axle assembly includes a primary axle member defining a primary axis. Torsion beam assemblies are coupled to opposite lateral sides of the primary axle member. The torsion beam assemblies each include a torsion member that extends substantially coincident with the primary axis and a lever arm that extends substantially transversely from the torsion member. Wheel assemblies are mounted on a distal portion of the lever arms wherein the wheel assemblies each define an axis of rotation that is parallel and spaced from the primary axis. The two wheel axes are substantially coincident. The torsion bar assemblies may be rotationally adjustable relative to the primary axle to thereby provide for the vertical adjustment of the wheel assemblies.

Owner:HERMAN ANTHONY

Robot clamping carrier

The invention relates to a robot clamping carrier which comprises two carrying trolleys which are symmetrically distributed, have the same structure and are used for respectively clamping front wheels and rear wheels of a vehicle, wherein each carrying trolley is provided with a synchronous clamper with two pairs of mechanical hands; the two carrying trolleys are connected through a telescopic bending arm; each carrying trolley is internally provided with an electrical positioning system for detecting the positions of the front wheels and the rear wheels of the vehicle and comprises a trolley body, a walking drive motor speed reducer, a chain wheel, a chain, a driving wheel, a driving wheel shaft, a tensioning wheel, a driven wheel and a guide mechanism; each synchronous clamper comprises a clamping framework connected with the trolley body, an upper cover plate, a clamping motor speed reducer fixed on the upper cover plate, a worm shaft I, a worm shaft II, a worm gear I, a worm gear II, a spindle and mechanical hands; and each clamping motor speed reducer is simultaneously connected with the worm shaft I and the worm shaft II to drive respective worm gear pairs and mechanical hands to rotate along the spindles. In the invention, the positions of the rotating spindles of the clamping mechanical hands are fixed without moving; a single motor controls a group of mechanical hands, which ensures that the motions are synchronous, and the structure is simple and reliable; meanwhile, the defects of carriers in a carrier plate type and a comb tooth exchange type are overcome; and the robot clamping carrier has the advantages of high vehicle access speed, good rigidity, low civil engineering cost, and the like.

Owner:北京航天汇信科技有限公司

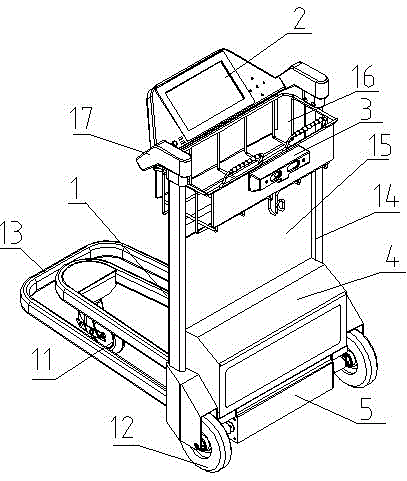

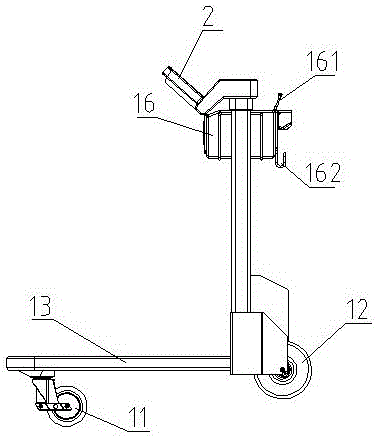

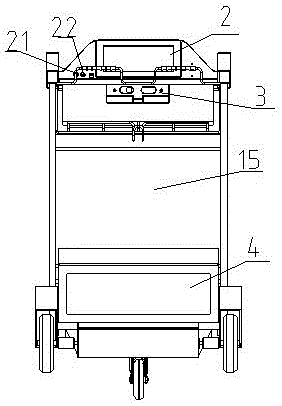

Intelligent luggage barrow of airport

ActiveCN106741028AAchieve positioningSolve charging problemsGround installationsHand carts with multiple axesService experienceControl system

The invention discloses an intelligent luggage barrow of an airport. The intelligent luggage barrow is characterized in comprising a main body frame, a control panel, a deep visual identification device, a control box and a chassis driving device, wherein the main body frame comprises a luggage load bearing device and a functional frame; the functional frame comprises two supporting rods and an advertising space panel arranged between the two supporting rods; a small part luggage frame is arranged between the supporting rods on the top; two sides of the top end of each supporting rod are provided with panel supporting frames; the control panel is embedded into the panel supporting frames on two sides and is fixed by bolts; the deep visual identification device is fixed on a rear plate of the small part luggage frame; the chassis driving device is arranged on a wheel axle, and the supporting rods above the chassis driving device are riveted with the control box; a control system is integrated in the control box. According to the intelligent luggage barrow, functions including autonomous navigation, intelligent following, voice interaction, service consultation, on-line entertainment, convenient shopping, automatic weighting, forbidden article detection, automatic conversation, one-key recovery, kid missing prevention, automatic printing of boarding checks and the like are combined, and the intelligent luggage barrow of the airport can lead intelligent, fashionable, relaxed and convenient brand-new airport service experience.

Owner:四川西部动力机器人科技有限公司

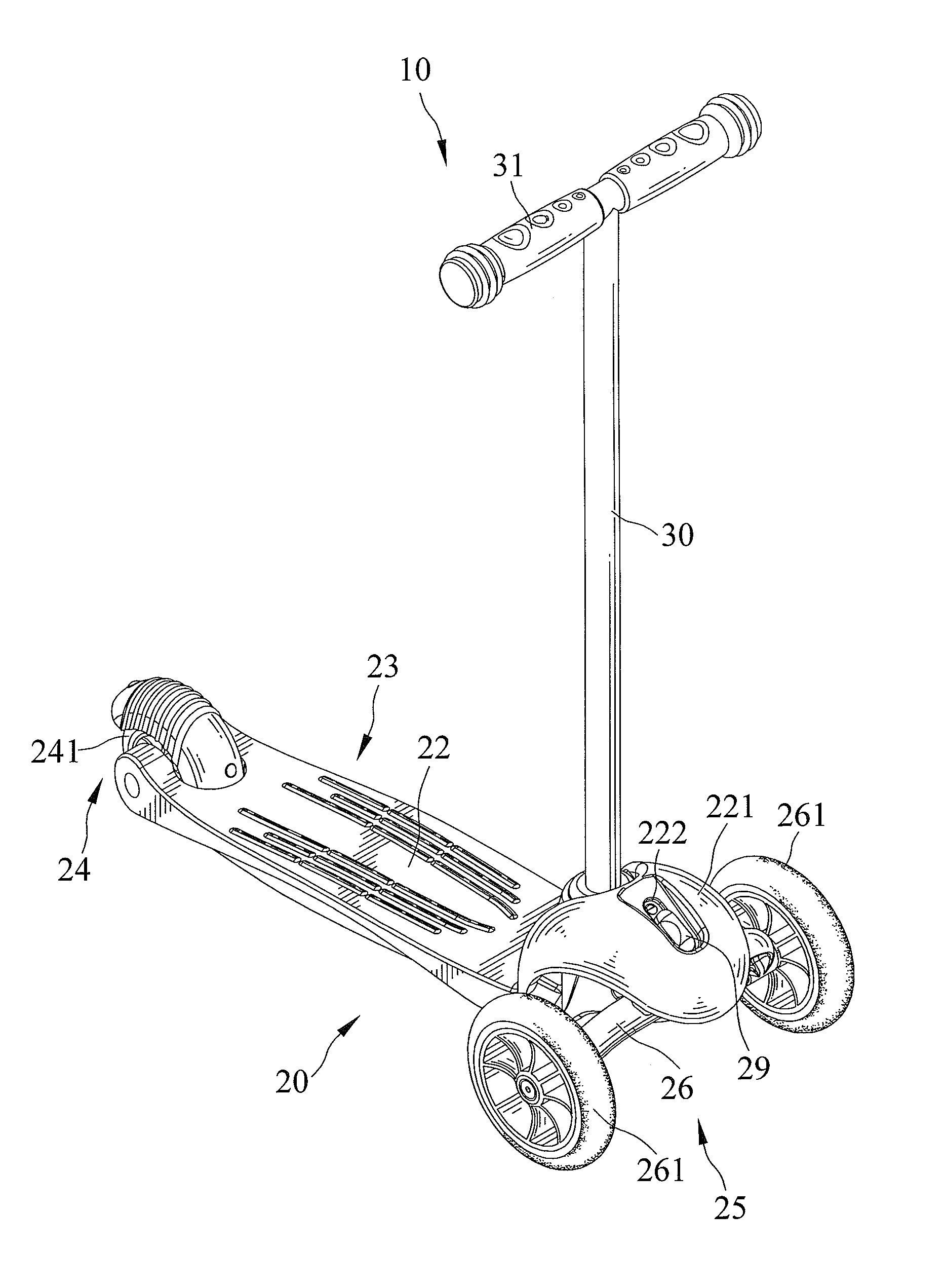

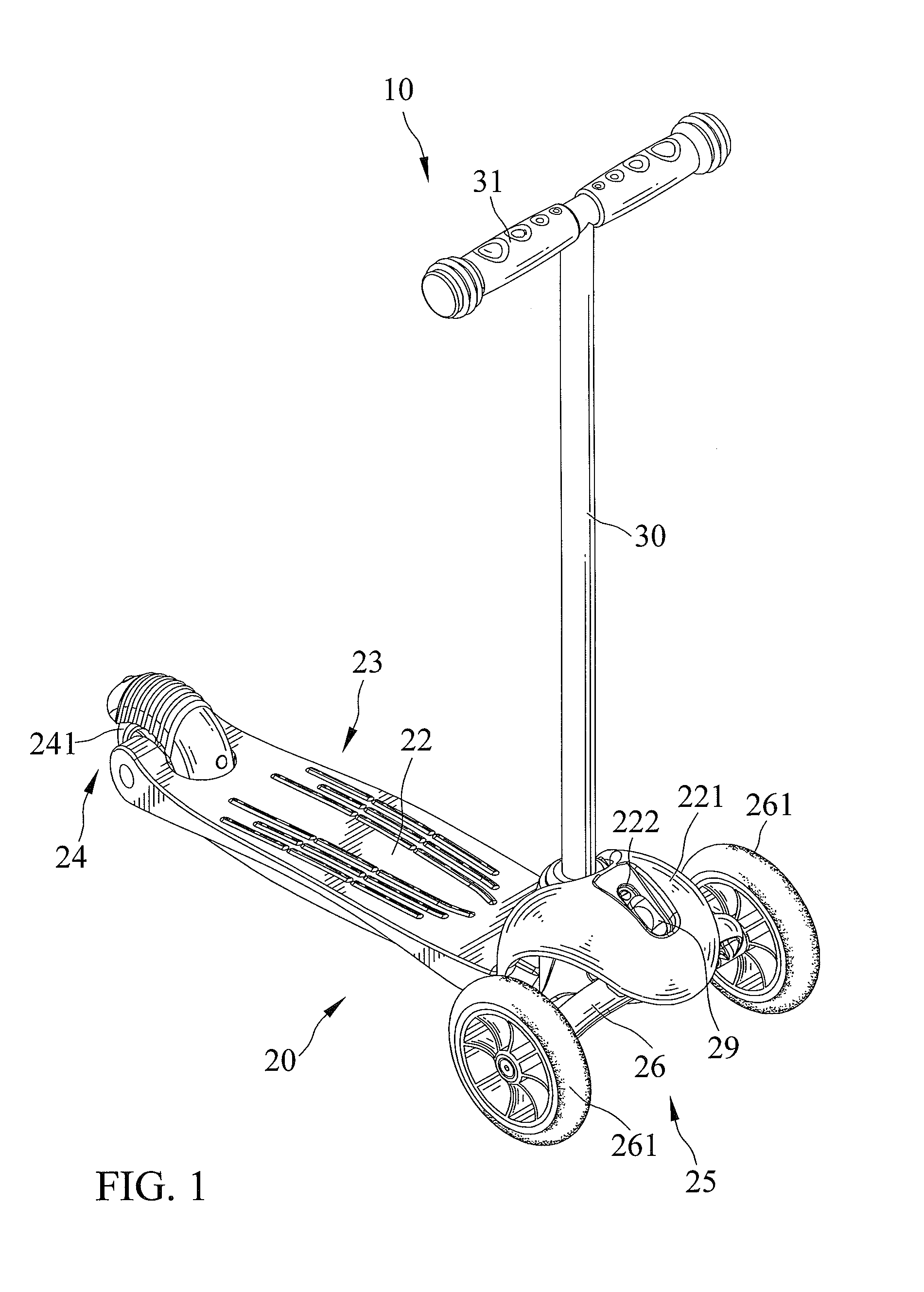

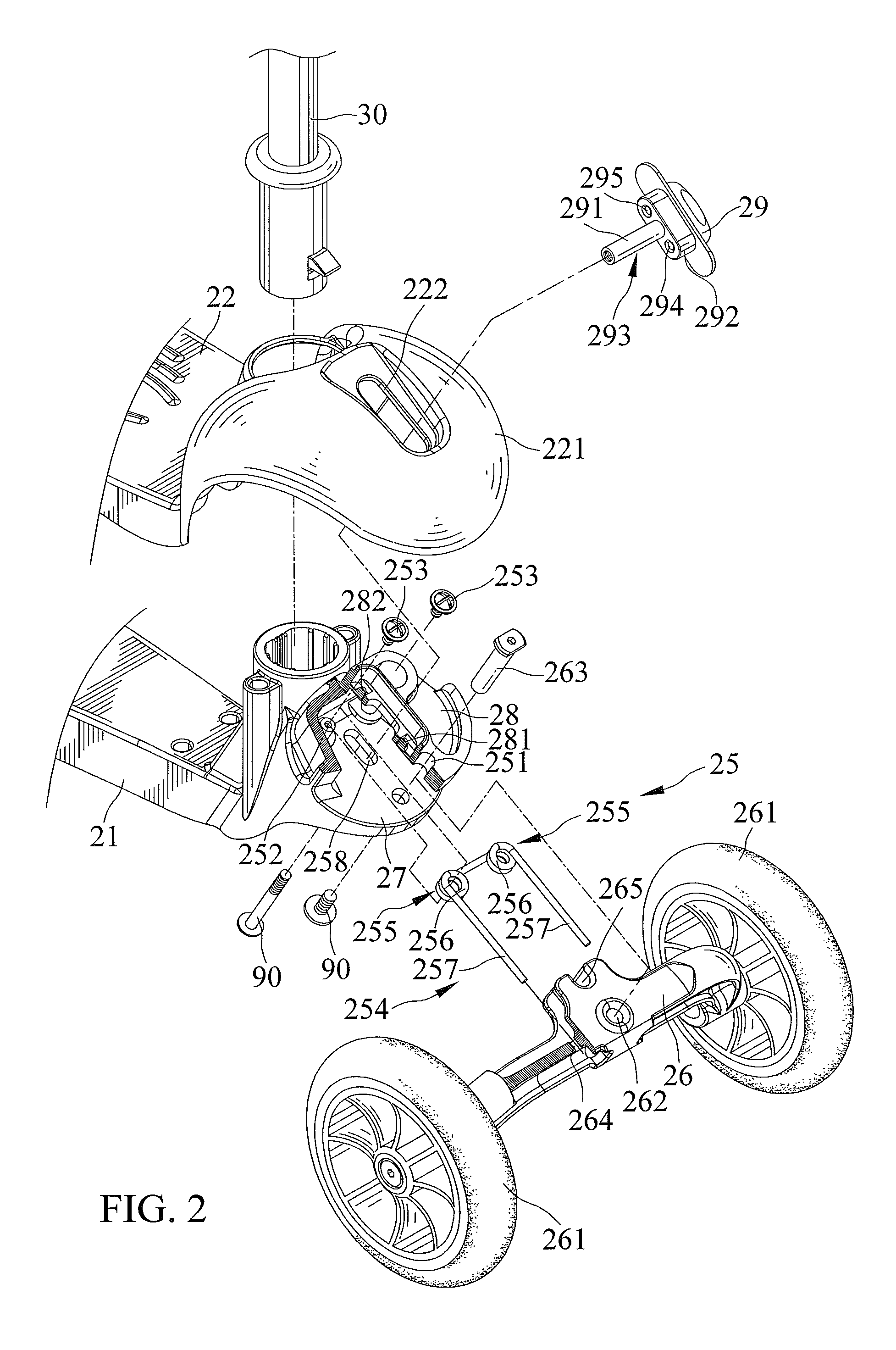

Scooter

A scooter includes a deck assembly and a handlebar. The deck assembly includes a posterior portion and an anterior portion. The posterior portion is pivotally connected with a rear wheel. The anterior portion is pivotally connected with a wheel shaft. A pair of front wheels is pivotally connected with two opposite ends of the wheel shaft. The anterior portion has a first sliding slot. The wheel shaft has an engaging recess. An engaging member is sildably received in the first sliding slot to selectively engage with the engaging recess between first and second positions. The wheel shaft is fixed with respect to the anterior portion in the first position.

Owner:CHEN WANG CHUAN

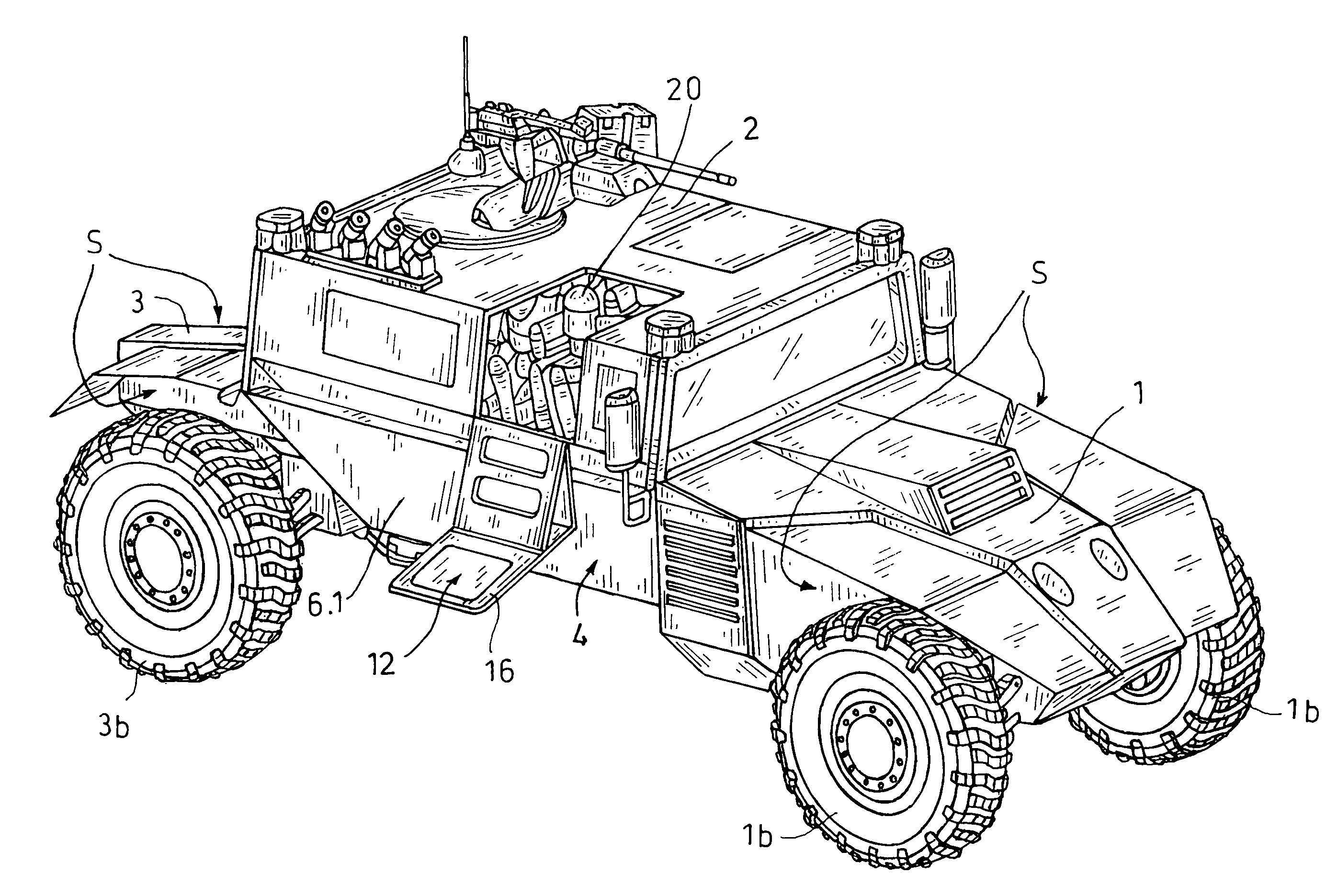

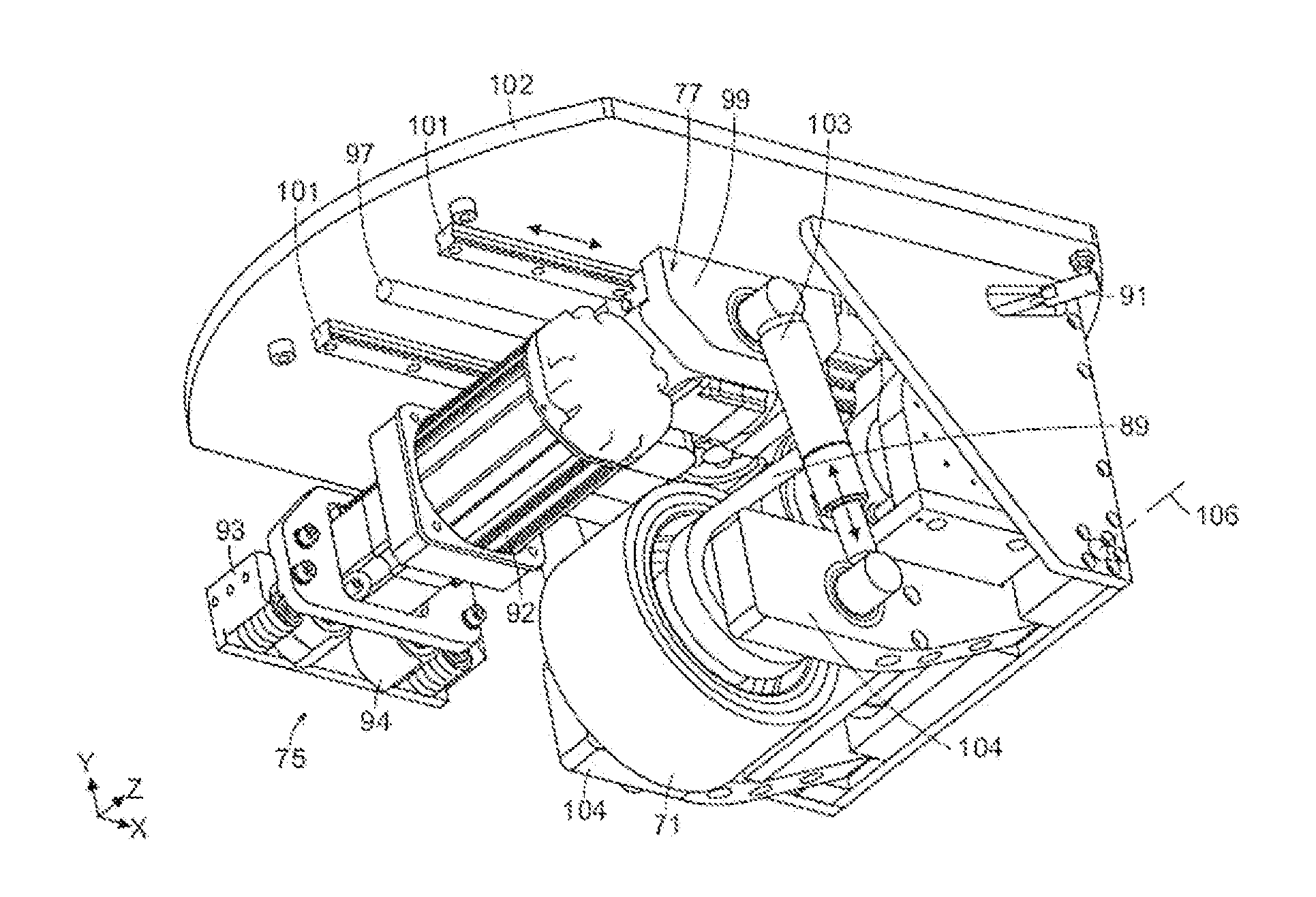

Mine protection vehicle system

A mine protection vehicle system is proposed wherein a military wheeled vehicle is provided with a high degree of mine protection. Preferably the vehicle has a three-sectioned vehicle construction that includes a front building block, a main building block and rear building block. The building blocks are separable from one another. The main building block may be designed to be slanted toward the bottom and double walled. A cabin, serving to provide a crew space, is hung up on support structure of the main building block. Wheel axles and drives are built into the front and / or rear building block; however, no wheel axle is disposed below the main building block.

Owner:RHEINMETALL LANDSYST

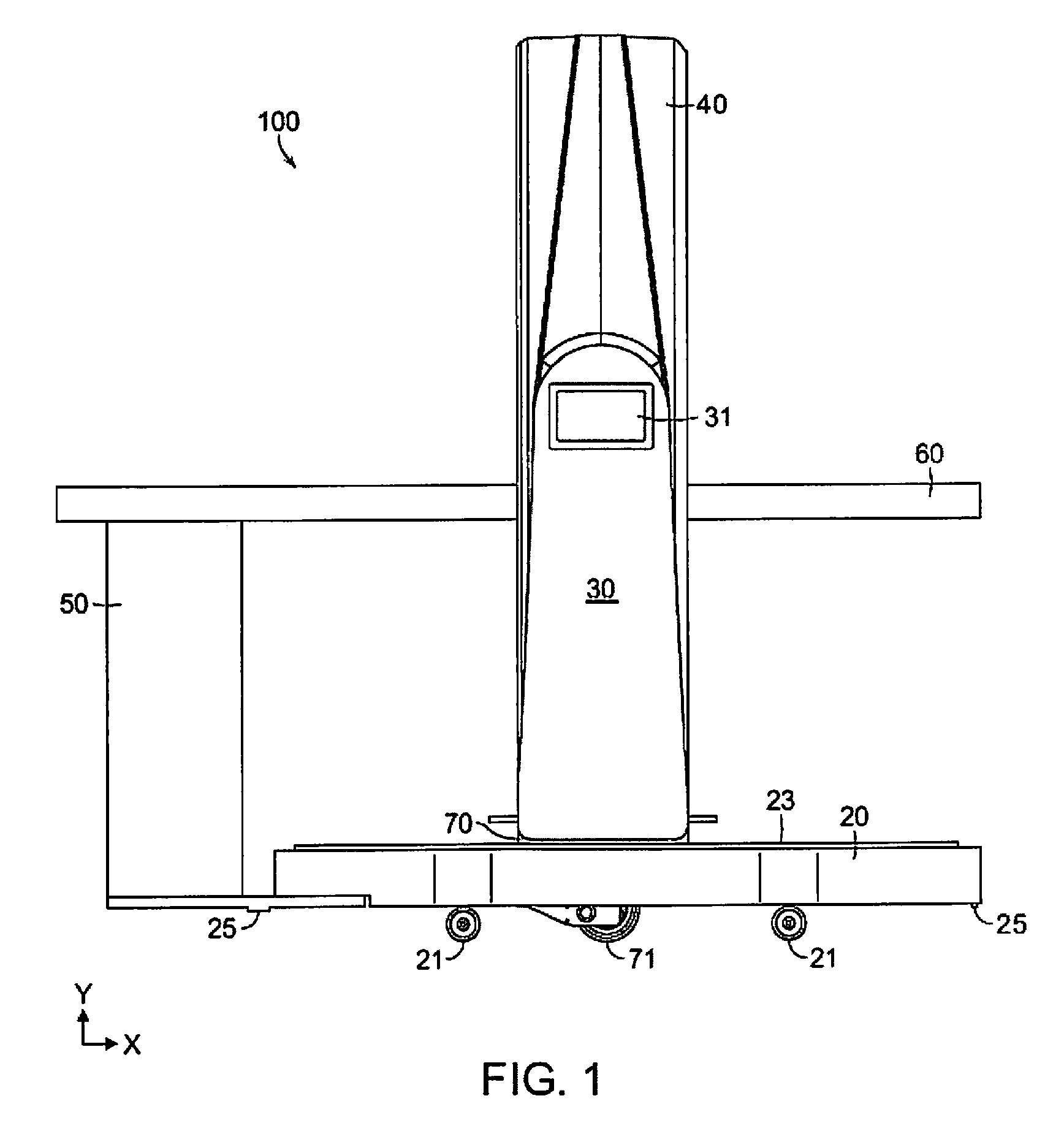

Caster system for mobile apparatus

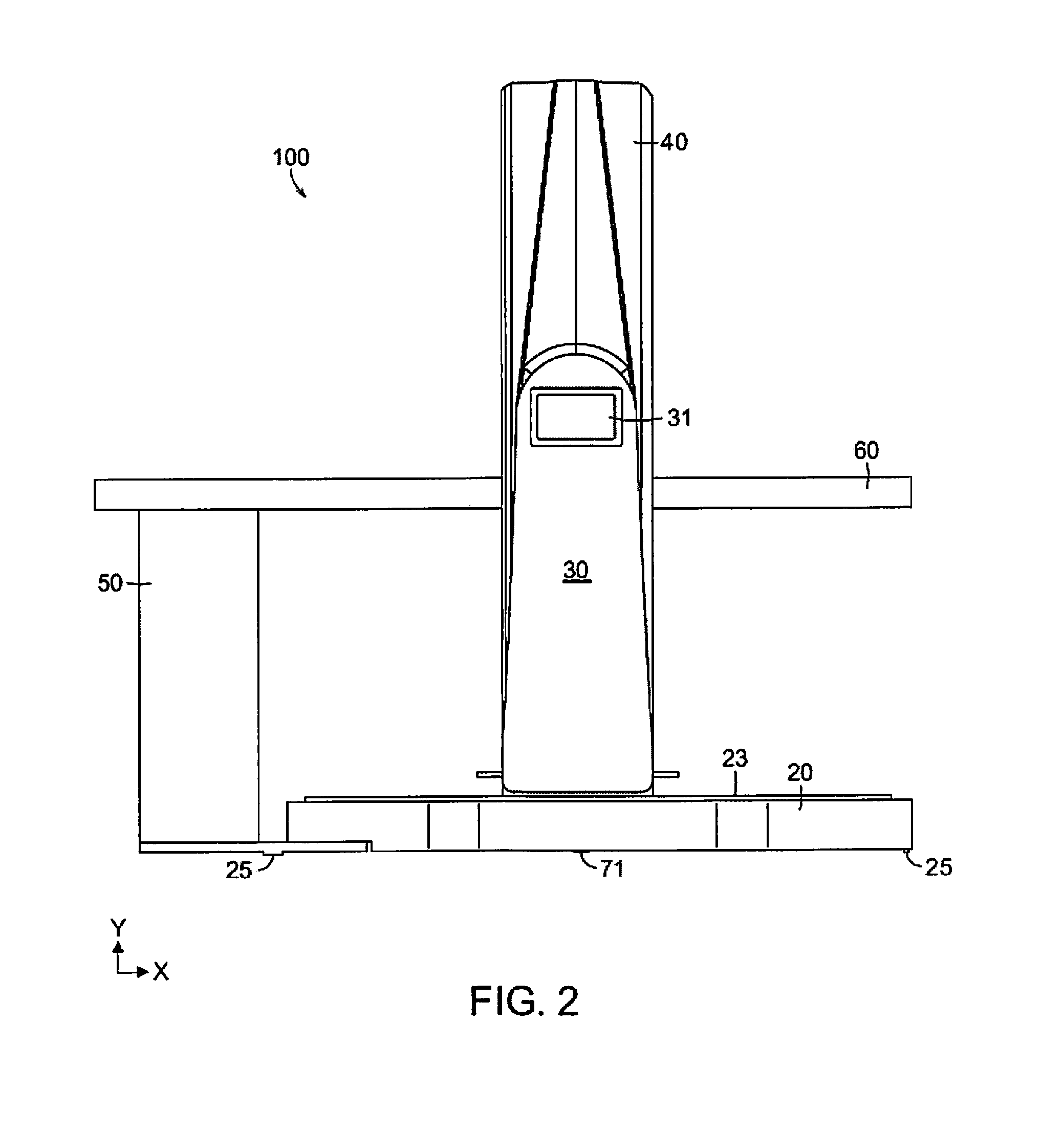

ActiveUS20140265182A1Braking element arrangementsCarriage/perambulator with multiple axesRotational axisTransfer mode

A mobile imaging device includes a base having at least one caster, a first drive mechanism that moves the system in a transport mode and translates an imaging component relative to the base in a scan mode, and a second drive mechanism that extends caster relative to the base to raise the base off the ground in the transport mode, and retracts the caster relative to the base to lower the base to the ground in the scan mode. A caster system for a mobile apparatus includes a base containing a housing and a caster, attached to the base, the caster having a wheel defining a wheel axis and a swivel joint defining a swivel axis and a pivot point defining a pivot axis, wherein the caster pivots on the pivot axis as the caster is retracted into the housing and extended out of the housing.

Owner:MOBIUS IMAGING

Device for self-determination position of a robot

InactiveUS20060293808A1Vehicle position/course/altitude controlConverting sensor outputDrive wheelReduction drive

The present invention relates to a device of self-determination position of a robot, and said device includes: a robot body; at least two driving wheels locating in two opposed sides of the robot body; a decelerator, connecting with a wheel shaft of said driving wheels through a power inputting portion; a motor, connecting with said power inputting portion of the decelerator through an outputting shaft; at least two driven wheels providing on the robot body, on which there are a plurality of grids around circumference direction taking the wheel shaft as the center; and at least two pairs of sensors, locating in one of outsides of each driven wheels, respectively, wherein said each pair of sensors include an emitting part and a receiving part facing toward said emitting part, moreover, through said grids, said receiving part can receive signals sent from the emitting part. According to the present invention, when said driving wheels lose steps or slip, the driven wheels do not move in respect to the ground, so that said sensors would not output signals about rotation of the wheels. It therefore can really represent the movement relation between said robot body and the ground.

Owner:ECOVACS ROBOTICS (SUZHOU ) CO LTD

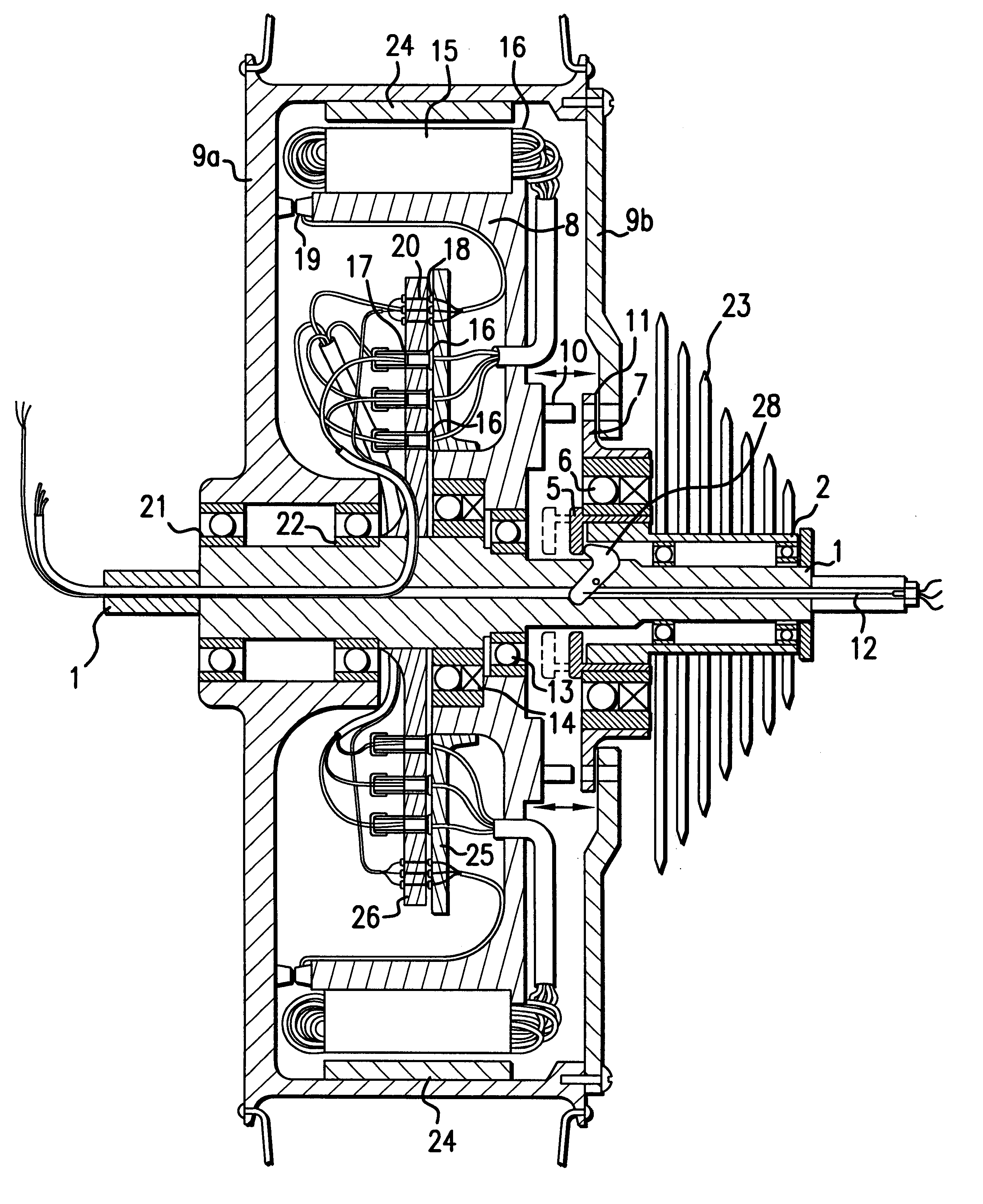

Washing machine deceleration clutch, washing machine and washing mode thereof

ActiveCN101210372ATumble fullImprove cleaning rateToothed gearingsOther washing machinesWater flowClutch

A decelerating clutch of a washer and the washer and a washing mode thereof relates to the technical field of washer. An output shaft of the decelerating clutch includes a small wave wheel shaft, a large wave wheel shaft and an inner barrel shaft, wherein the small wave wheel shaft is supported in the large wave wheel shaft, and the large wave wheel shaft is supported in the inner barrel shaft. By adopting the deceleration mechanism of the decelerating clutch, the invention can simultaneously drive a large wave wheel, a small wave wheel and an inner barrel to rotate. A washer manufactured by using the decelerating clutch comprises a small wave wheel and a large wave wheel, wherein the small wave wheel is fixedly arranged on the small wave wheel shaft and positioned at the middle portion of the large wave wheel; the large wave wheel is fixedly arranged on the large wave wheel shaft; and the inner barrel is fixedly arranged on the inner barrel shaft. The washer manufactured by using the decelerating clutch is operated in such a mode that the small wave wheel, the large wave wheel and the inner barrel make reciprocating rotation in mutually reverse directions at different speeds and different rotation angles by a ratio in two directions to produce complex and crossing shock water flow to scrub and clean the clothes, thus completely rotating the clothes, achieving strong scrubbing force and improving the cleaning rate.

Owner:NINGGUO JULONG IND

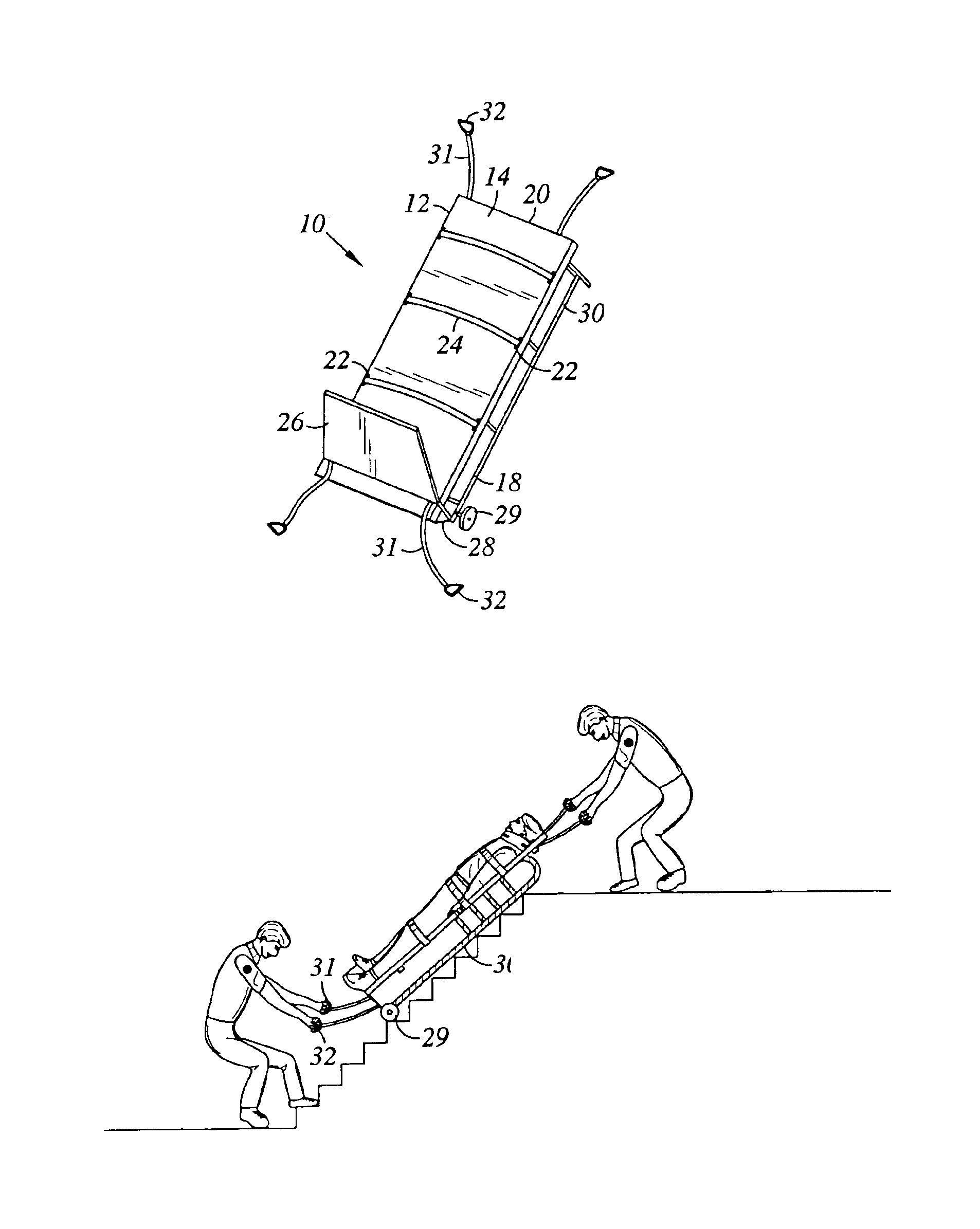

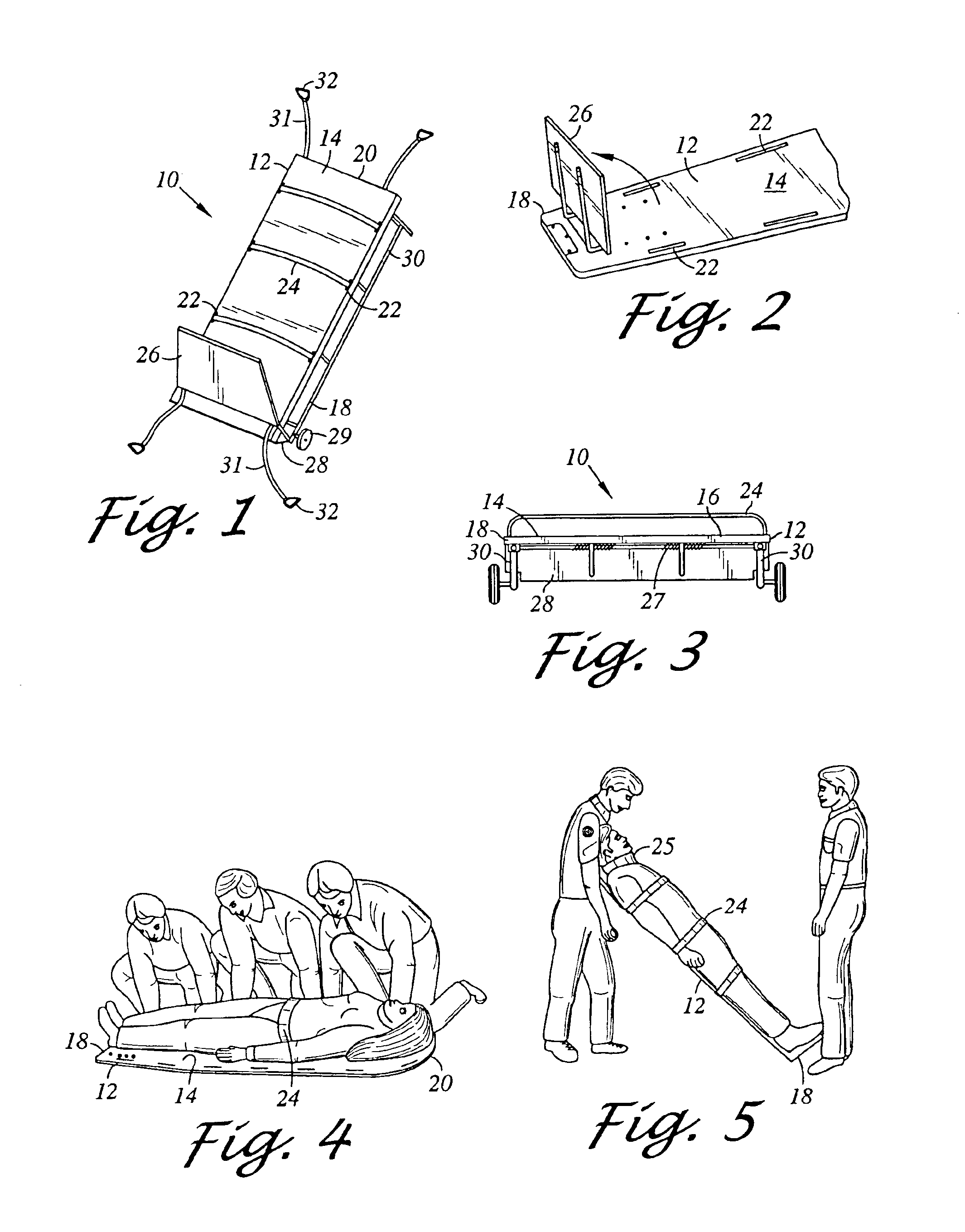

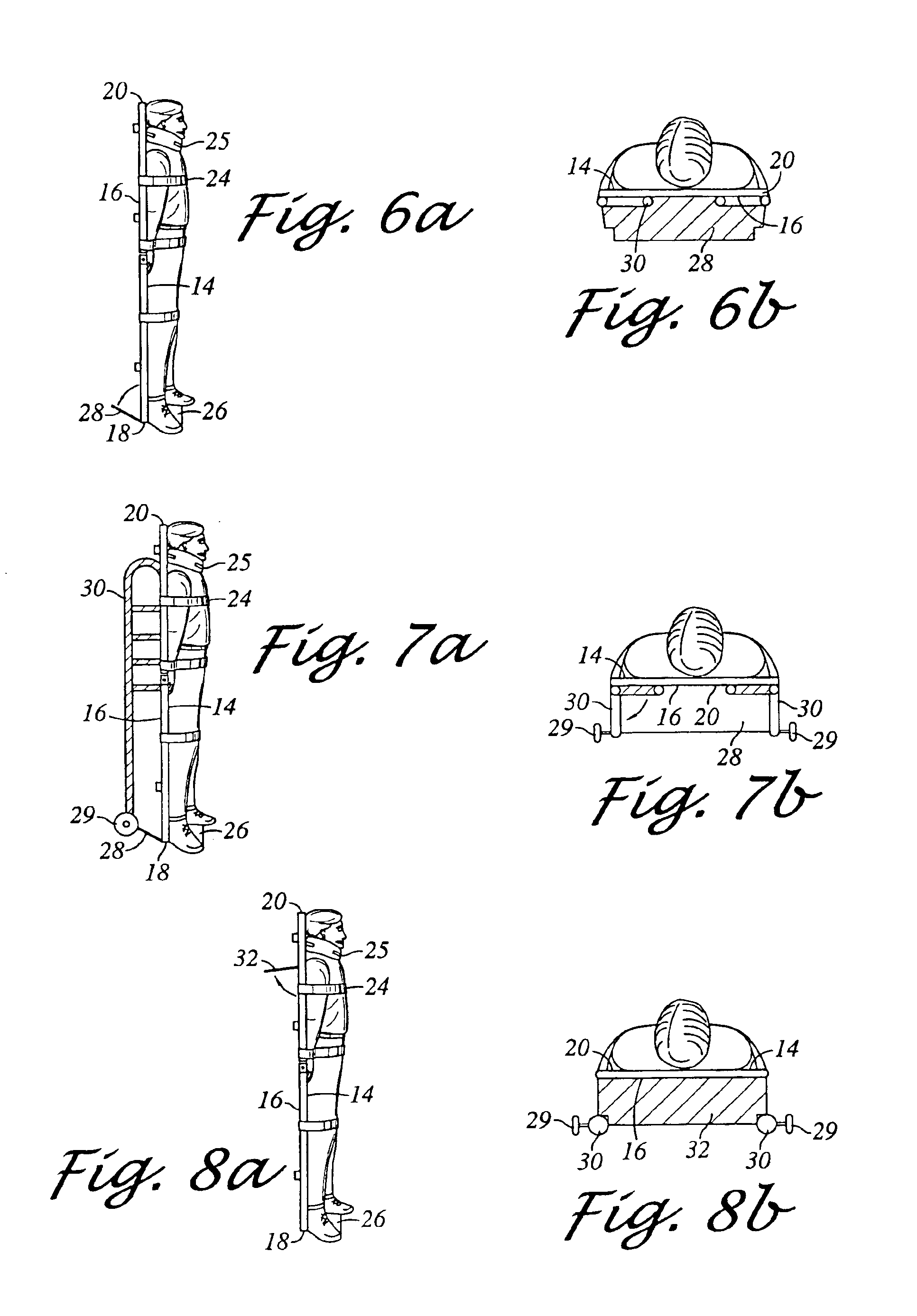

Patient transport board

A patient transport board comprises a flat, rigid board having a surface on which the patient lays and restraining straps for securing the patient. A pair of foldable rail members can be extended to serve as runners for moving the patient down a flight of stairs. A skid plate is provided at the foot end of the board to allow the board to be used in an upright mode for maneuvering in tight areas. In one embodiment wheel and axle assemblies are affixed at the lower end of the rail members to make easier movement of the patient transport board in an upright orientation. In another embodiment track assemblies allow for movement over rough or uneven surfaces when the patient transport board is in an upright orientation. Components of the patient transport board are foldable or removable so the board can be readily placed on a gurney or stored.

Owner:TULETTE JAMES

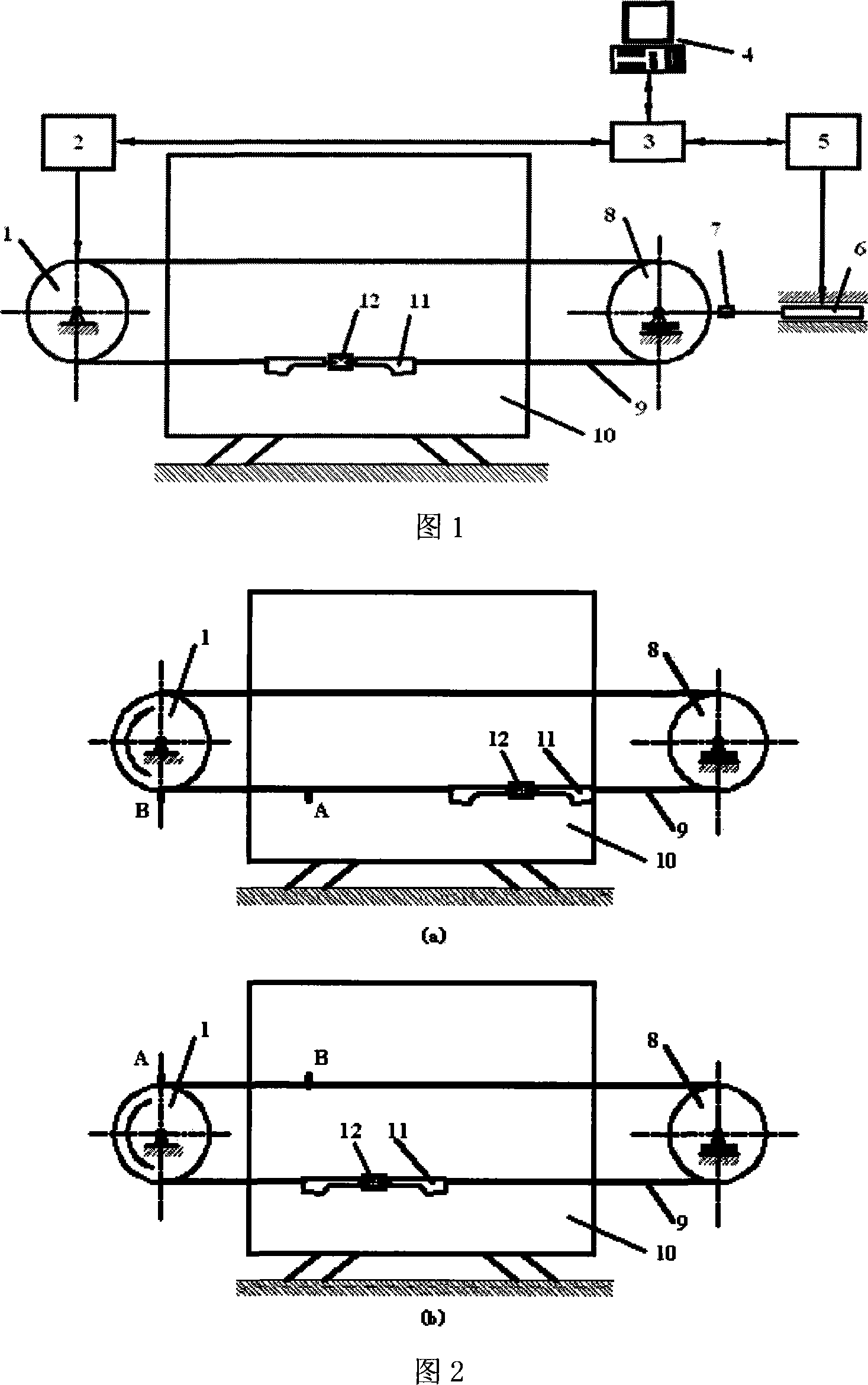

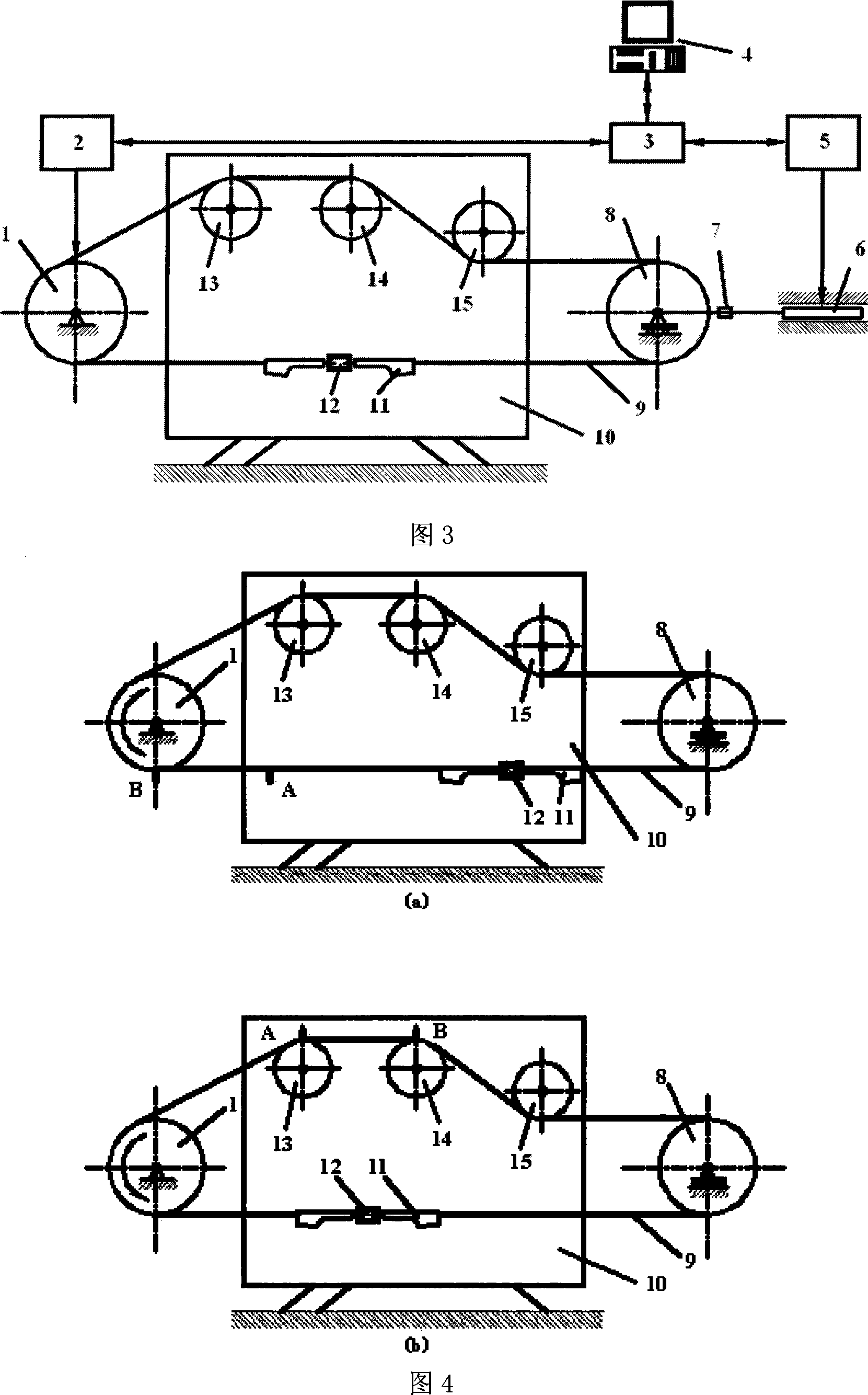

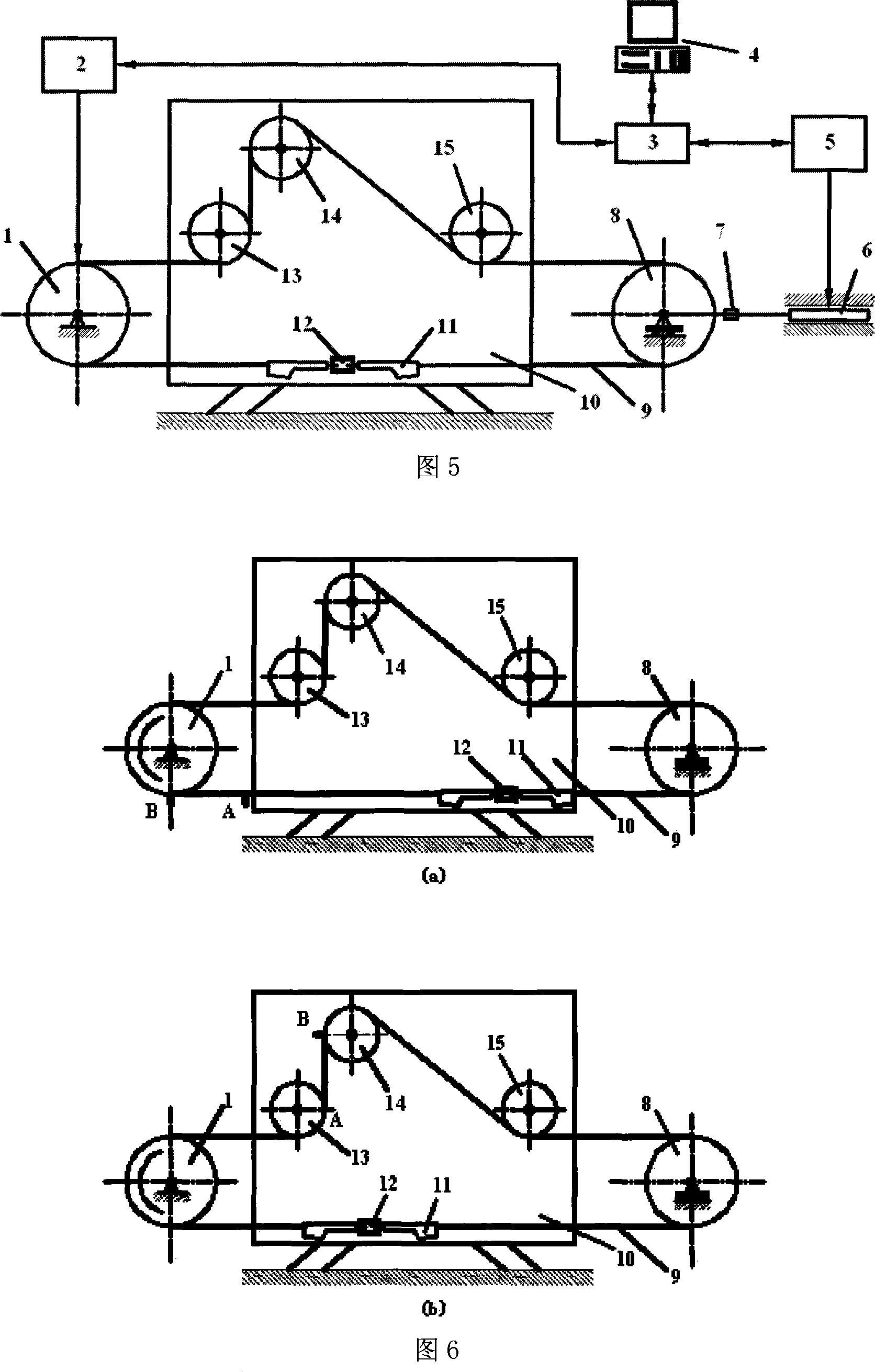

Elevator armored rope bending fatigue state experimental bench

InactiveCN101216397AAvoid heavy operationsCompact structureMaterial strength using repeated/pulsating forcesHydraulic cylinderPull force

A bending fatigue test platform of wire rope for an elevator in the field of mechanical technology comprises a traction wheel, a frequency-variable motor, a data collecting and control device, a host computer platform, a hydraulic pump, a hydraulic cylinder, a tension sensor, a tension pulley, a wire rope, a rope head device, a connection terminal and a guide support, wherein the traction wheel and the tension wheel are positioned on both ends of the test platform; the guide support is positioned between the traction wheel and the tension pulley; the wire rope is wound in the grooves of the traction wheel, the guide wheel of the guide support and the tension pulley; the shaft of the tension wheel is connected with the tension sensor; the tension sensor is connected with the hydraulic cylinder; the hydraulic cylinder is connected with a hydraulic pump; the frequency-variable motor, the hydraulic pump and the tension sensor are connected with the data collecting and control device; and the data collecting and control device is connected with the host computer platform, which is in charge of monitoring, recording and control. The invention can adjust the wrap angle, the bending state, the tension and the travel of the bending fatigue test of wire rope more flexibly.

Owner:SHANGHAI JIAO TONG UNIV

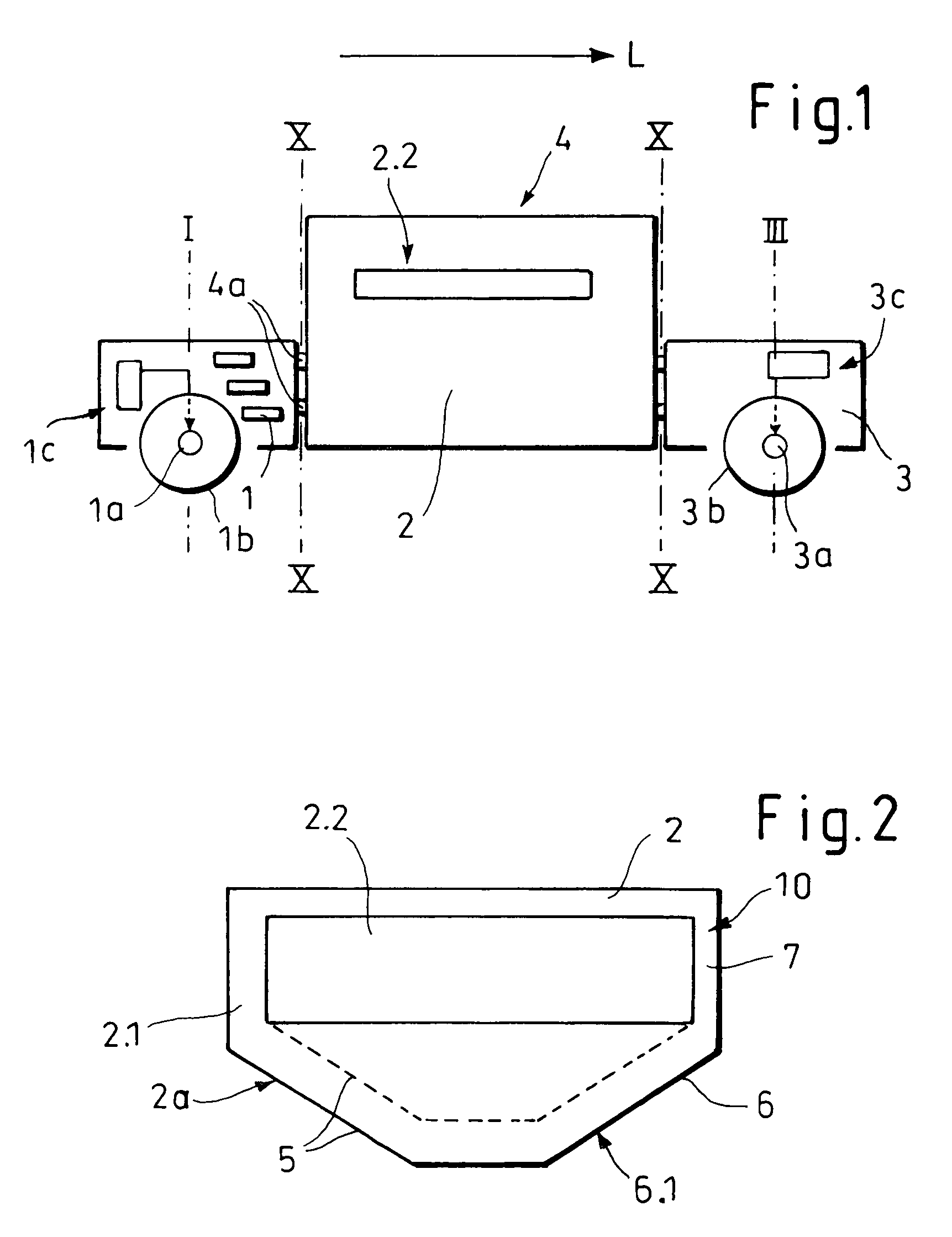

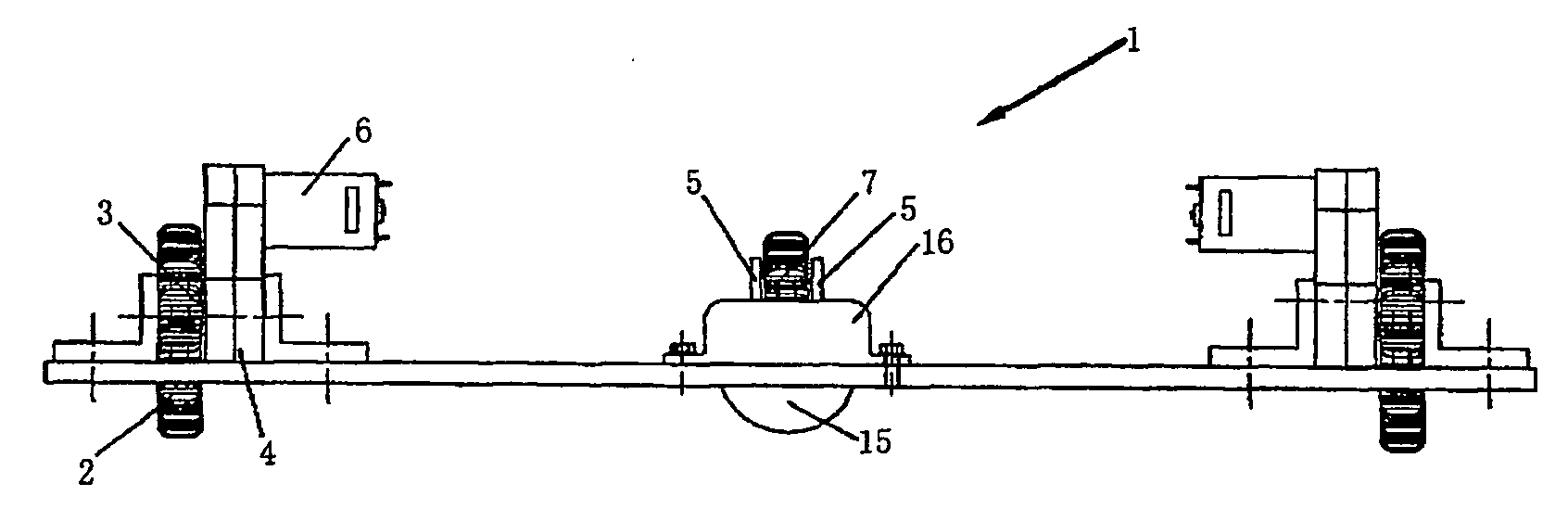

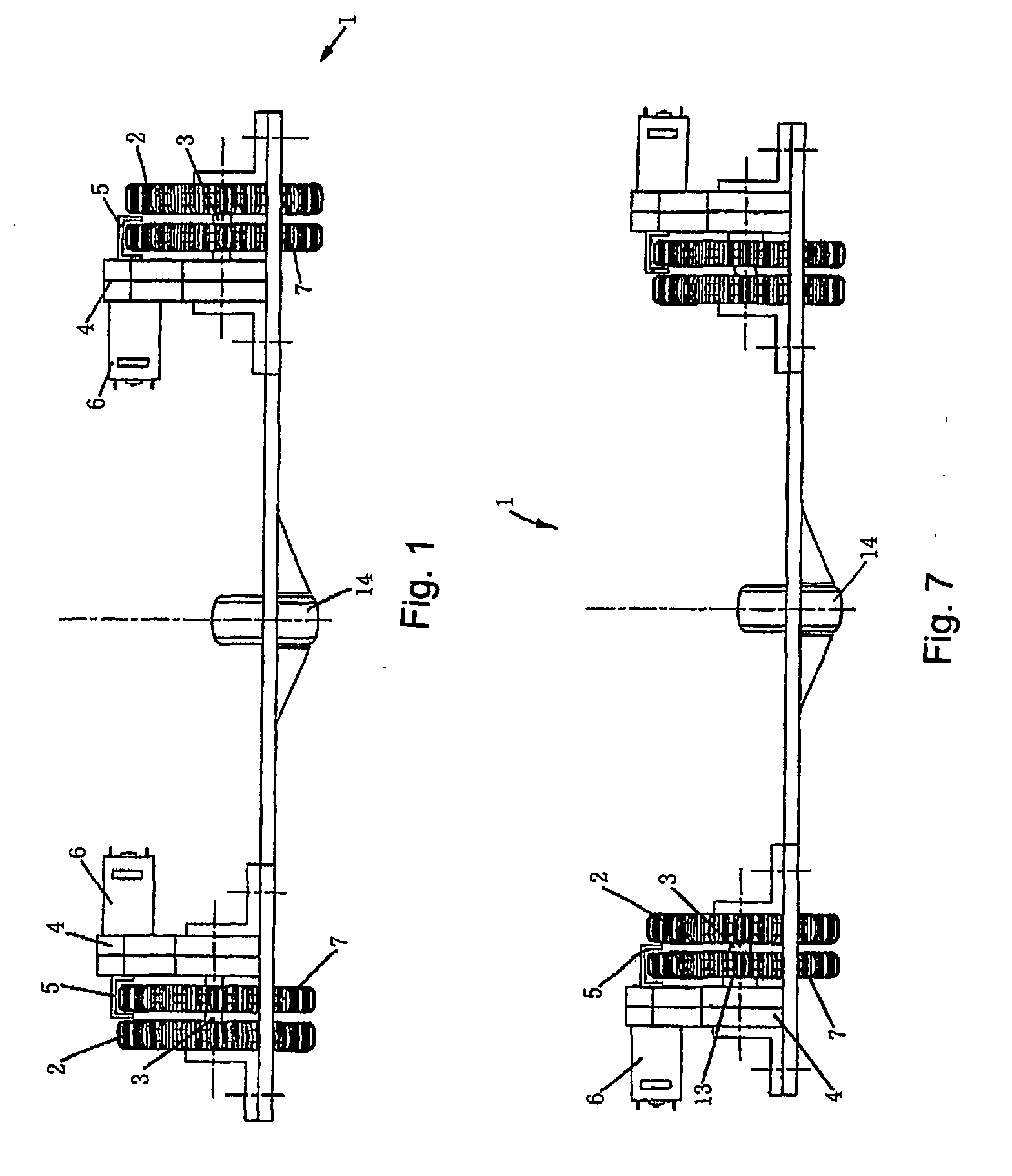

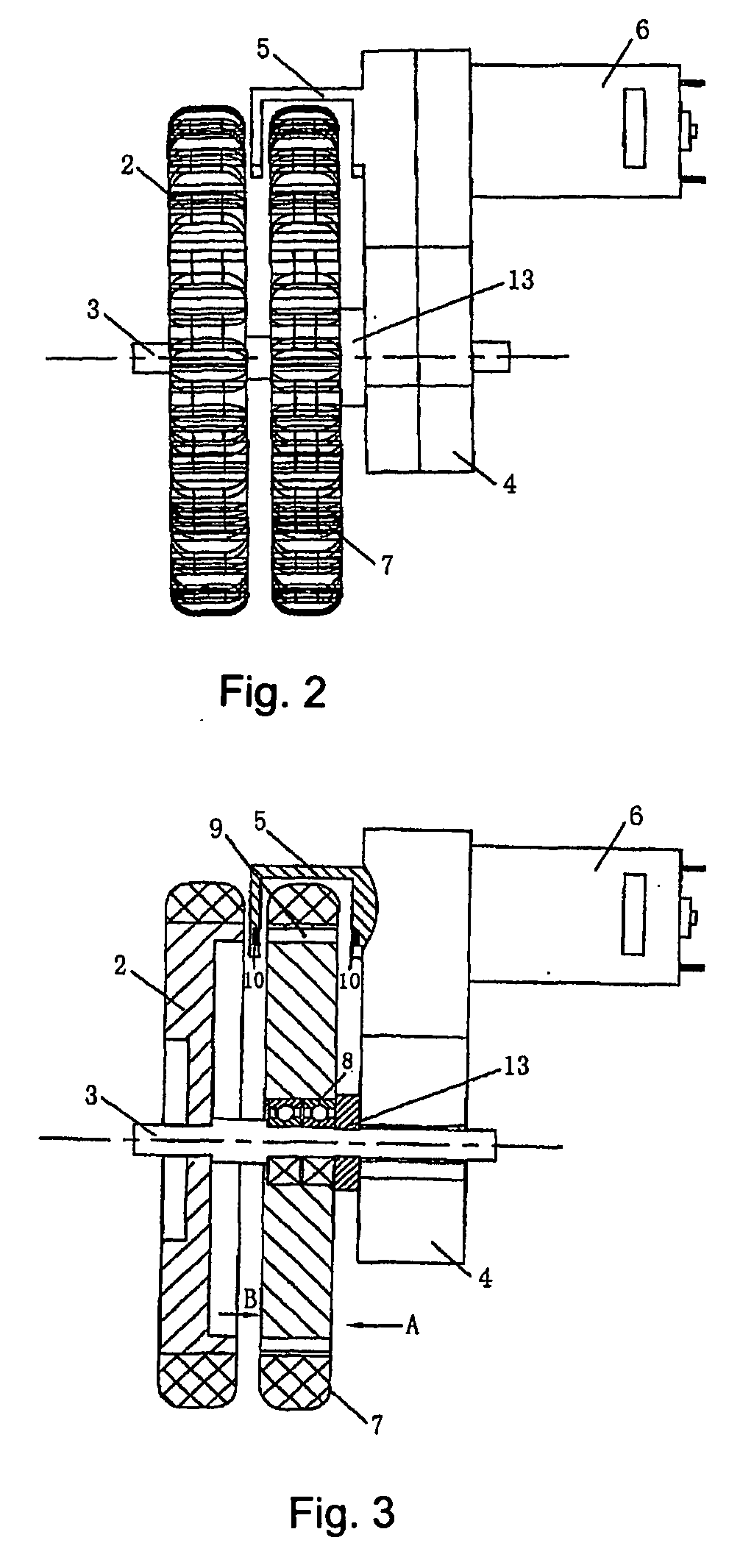

Traveling mechanism in a lifting arrangement which is moveable on rails

InactiveUS6058849AGuaranteed uptimeAvoid destructionMonorailsRailway componentsHorizontal forceFree rotation

A traveling mechanism for a lifting device, especially for a lifting device having a laterally cantilevering boom, is movable on rails with at least two running wheels. A connection element for attaching a load to said traveling mechanism is supported in the rail by the running wheels which are arranged on both sides of the connection element. The connection element has, at the region projecting down out of the rail, at least one running roller which is freely rotatable about a horizontal axis and rolls on a horizontal outer running surface of the rail. To effectively divert horizontal forces and uniformly distribute the vertical forces to the running wheels, running wheel axles are rigidly connected with a running wheel carrier, and the running wheel carrier and connection element are swivelably connected by a universal type joint. In addition, at least one support roller is rotatably mounted at the connection element in the interior of the rail. The support roller freely rotates about a vertical axis and rolls along at least one of the side surfaces to transmit horizontal forces to the rail.

Owner:TEREX MHPS

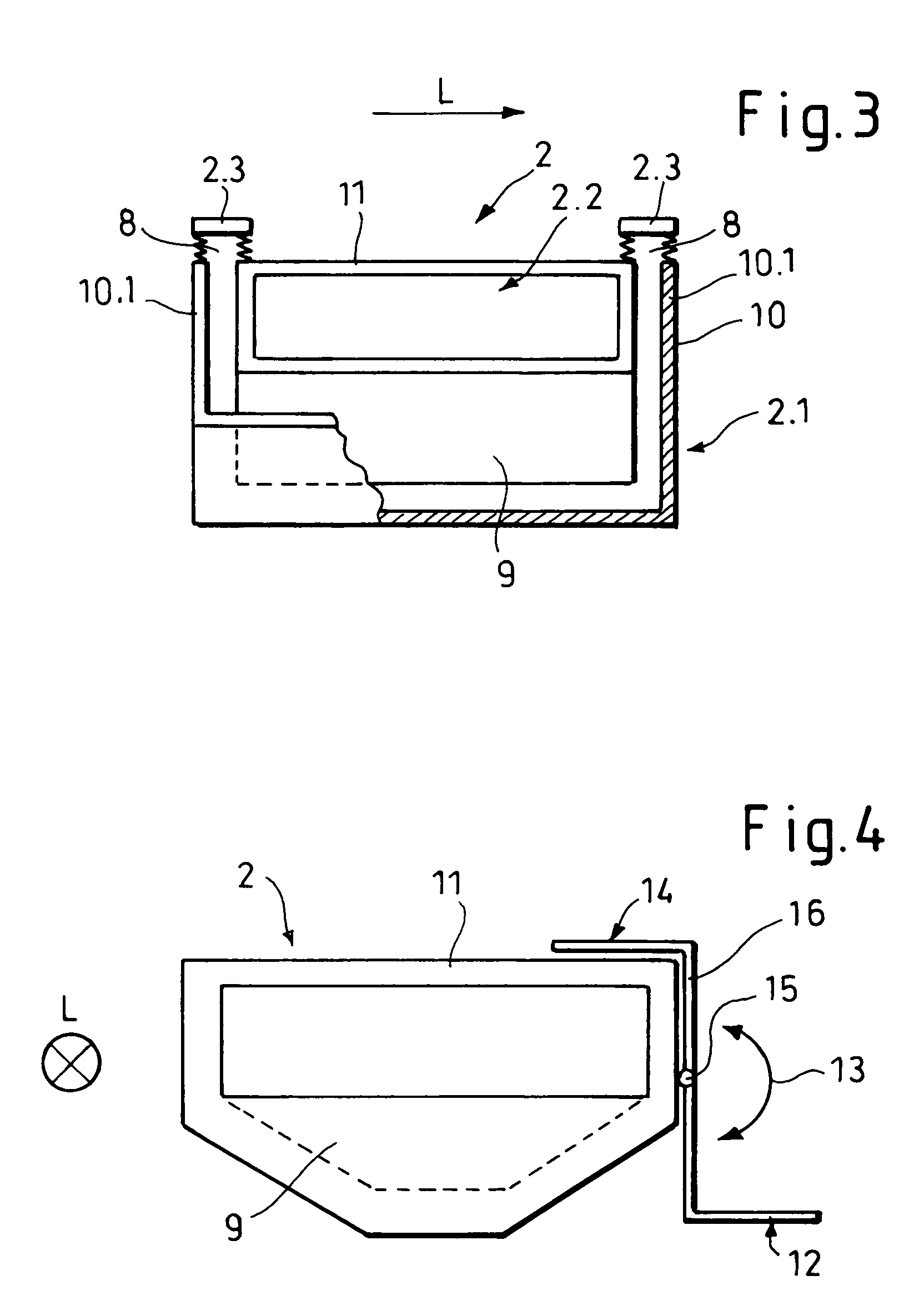

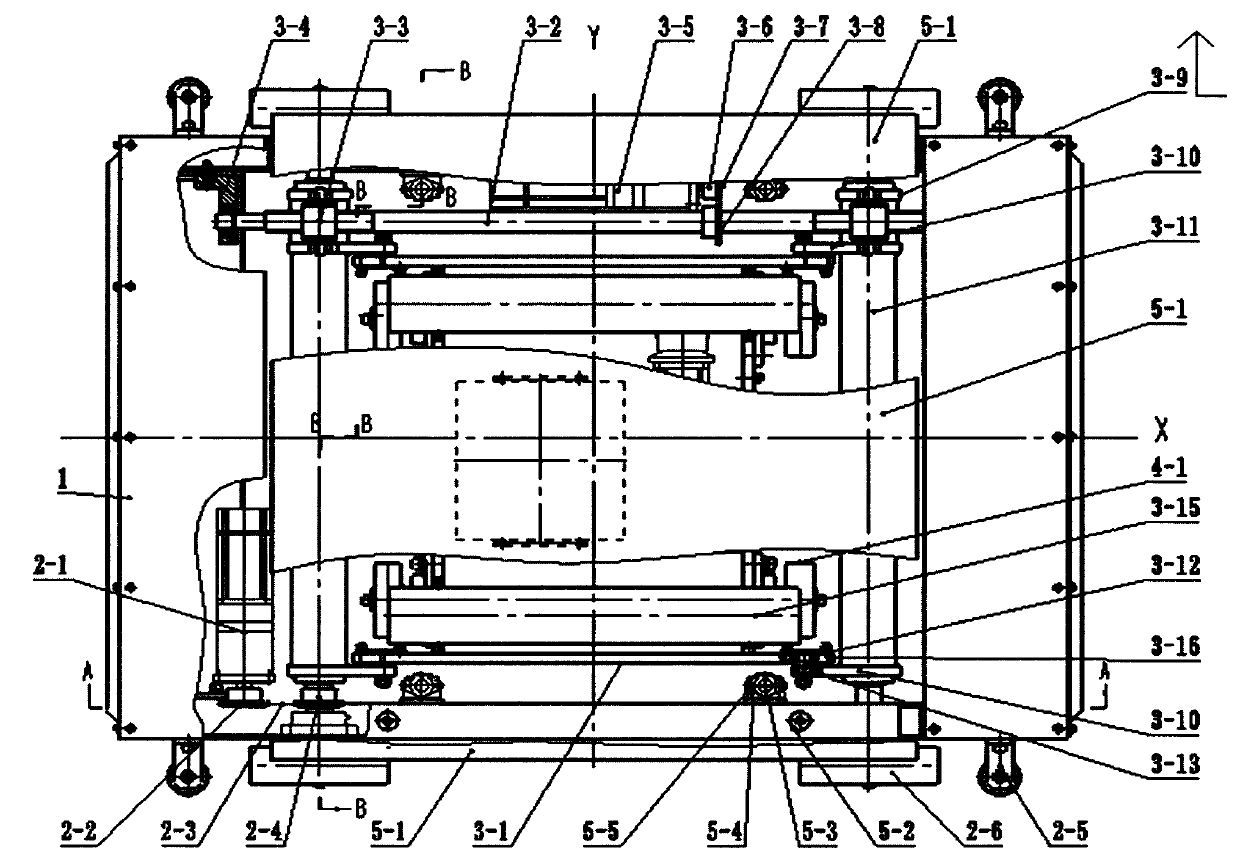

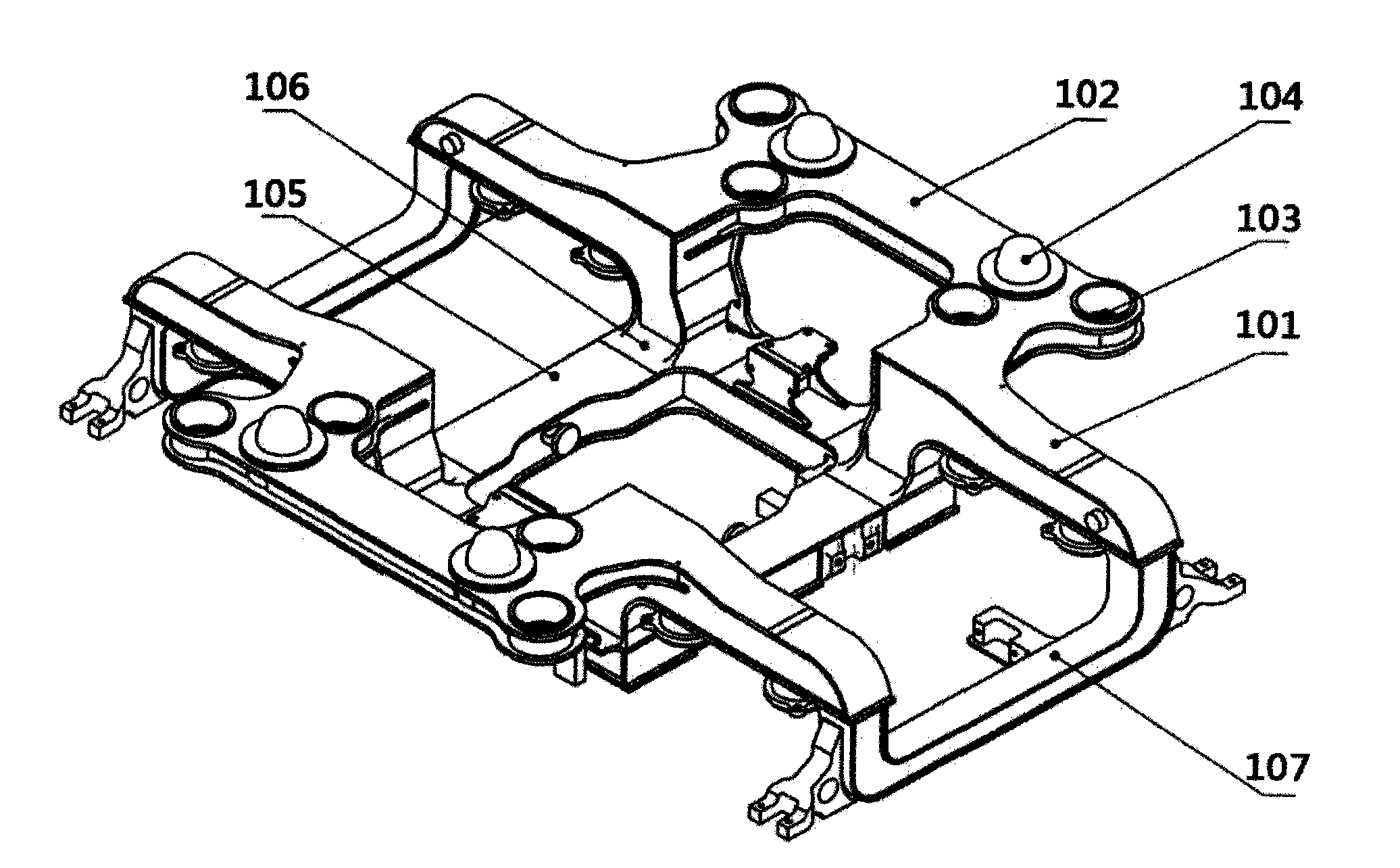

Shuttling car walking along crossed track

InactiveCN103101737ASimple structureSmall footprintStorage devicesMechanical conveyorsTrackwayEngineering

The invention relates to logistics storage equipment, in particular to a shuttling car walking along a crossed track. The shuttling car comprises a car body, a longitudinal walking mechanism, lifting mechanisms, horizontal walking mechanisms, a carrier device and an electric system. The car body is a fundamental component which installs and fixes all components, and the longitudinal walking mechanism is arranged on the car body. The lifting mechanisms are respectively arranged on the car body and a longitudinal wheel axle of the longitudinal walking mechanism, the horizontal walking mechanisms are arranged on lifting supports of the lifting mechanisms, the carrier device is arranged on the car body, and the electric system is connected with servo motors of all mechanisms and arranged in spaces of interiors of the lifting supports. The shuttling car has the function of walking along the crossed track, simplifies a system structure applied in a storage logistics system, can save occupied area, and improves operation efficiency. Servo driving technology and digital control are adopted, and positioning is accurate. A charging battery is adopted as a power source to achieve wireless traveling, conveniently and flexibly move, and have wide application prospect.

Owner:QILU UNIV OF TECH

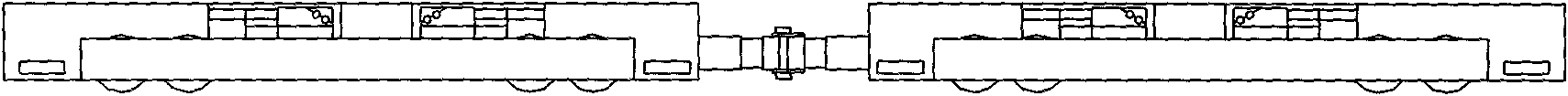

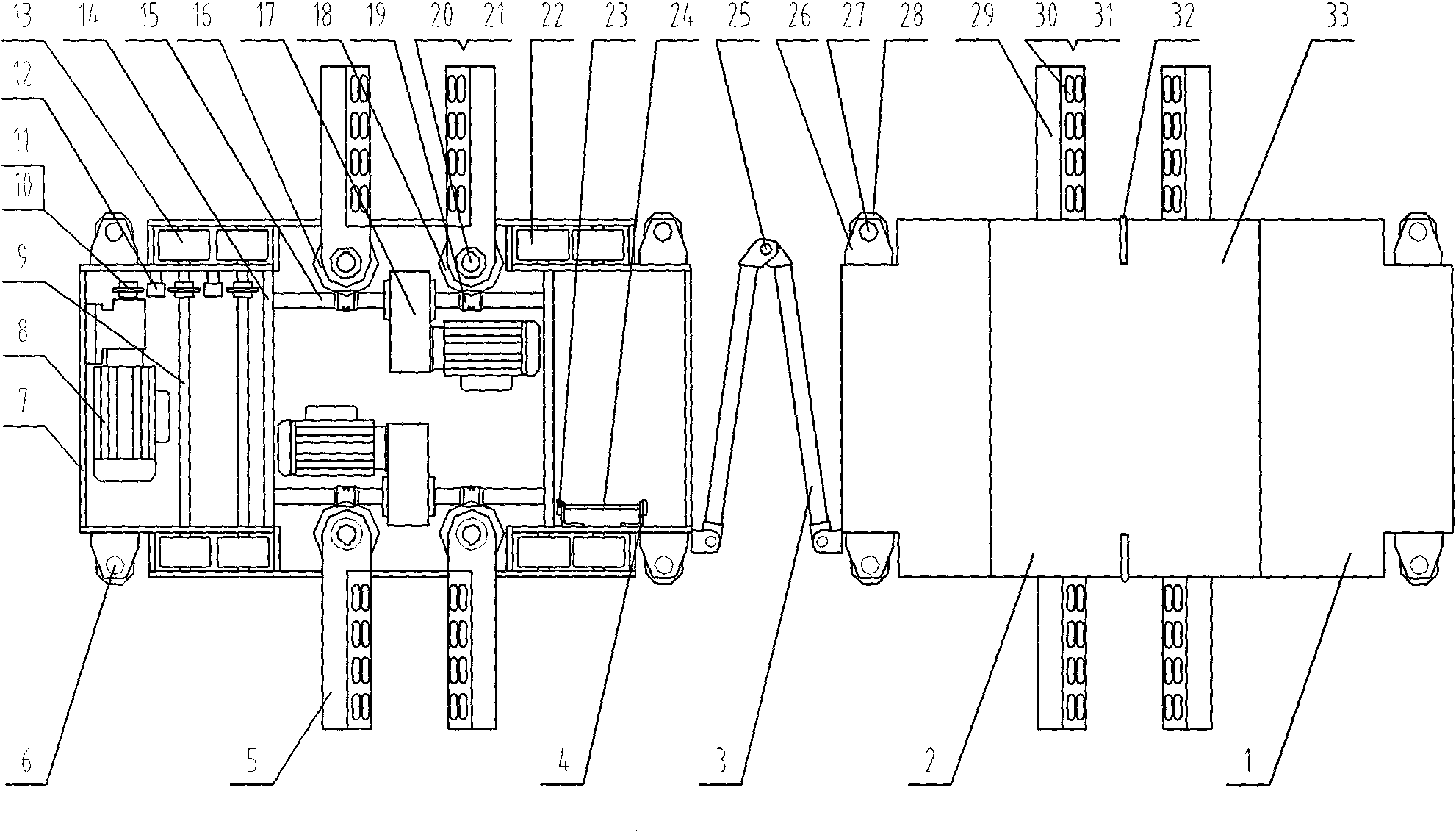

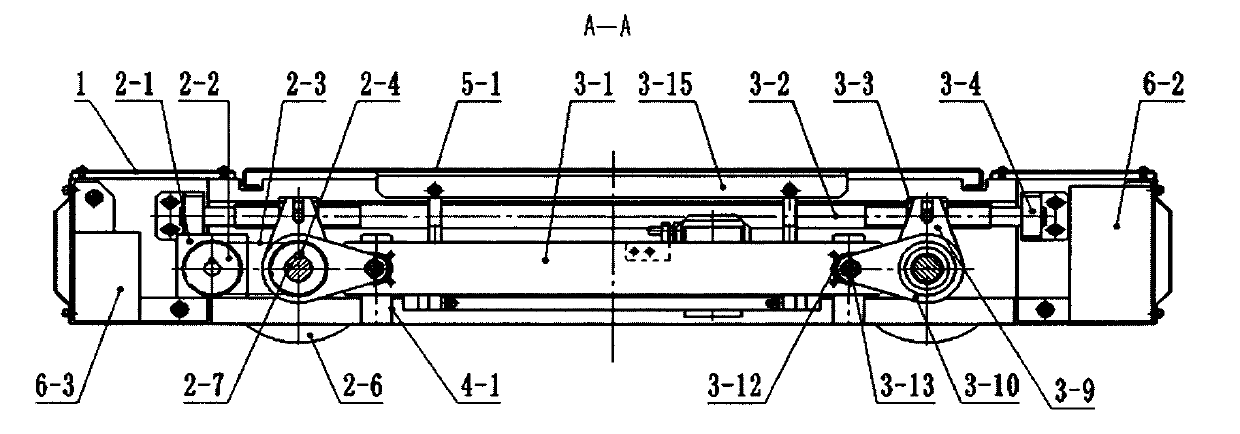

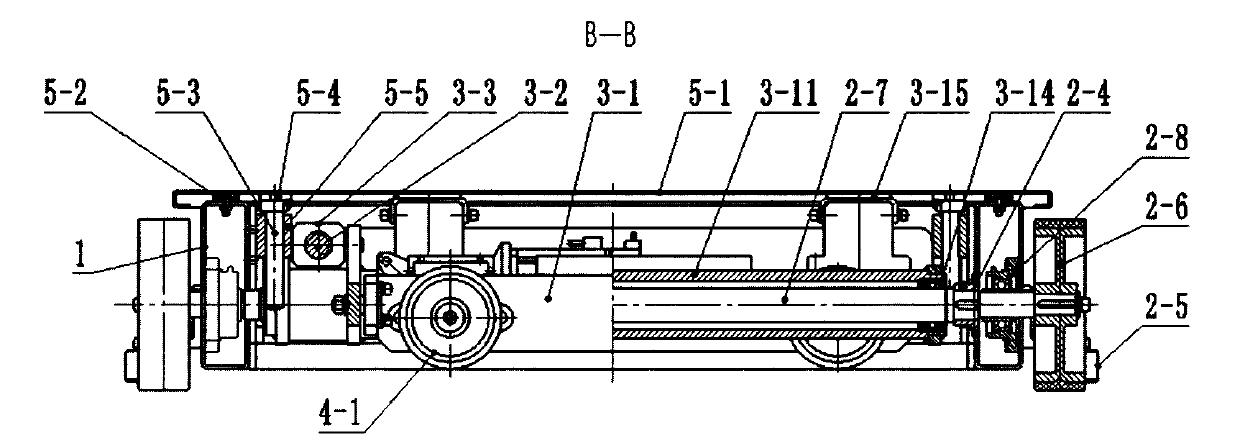

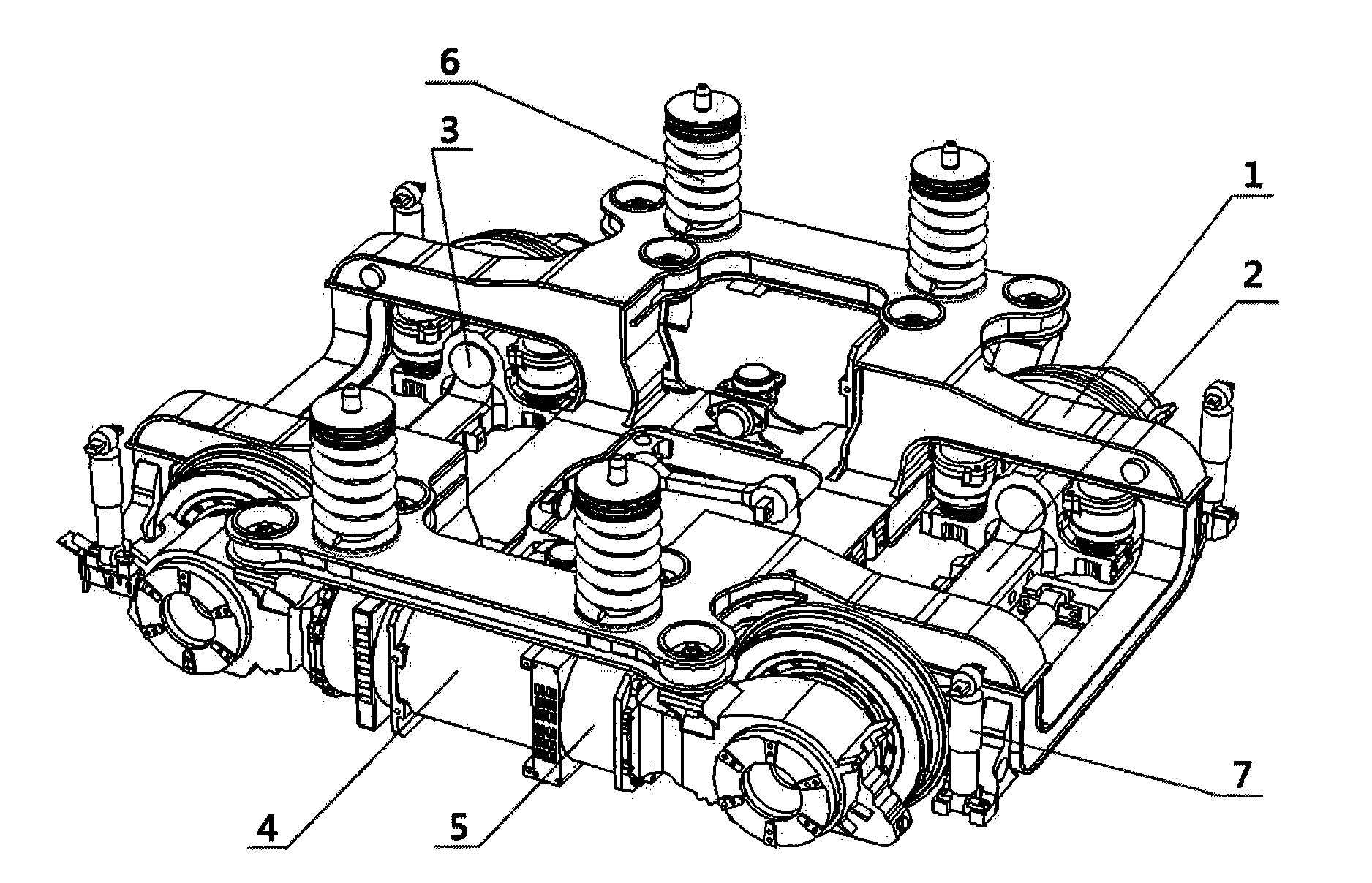

Power bogie with independent wheels for 100 percent low-floor light rail vehicles

The invention discloses a power bogie with independent wheels for 100 percent low-floor light rail vehicles. The power bogie with the independent wheels comprises a framework, an axle mechanism, primary springs, secondary springs, secondary vertical and transverse dampers, a double-pull rod traction mechanism, the longitudinal driving mechanism of an elastically frame-suspended motor and a hydraulic brake unit, wherein the side beams of the framework are cantilevers which protrude outward; two short shafts are supported by bearing units and connected with elastic wheels respectively; an axle consists of the two short shafts; two wheels on the same side of the bogie are fixed on a motor-driven shaft; a motor is coupled with two gear boxes; a brake system is integrated with a traction motor; the four secondary vertical dampers are arranged at the four corners of the framework; the secondary transverse dampers are arranged at the two ends of the framework; and a parallel double-pull rod traction system is arranged on the inner side of the framework. The requirement of 100 percent low floor on vehicle bodies is really realized by the high-strength welded framework, the independent wheel axle mechanism, the primary springs and the secondary springs which are rationally structured, the optimal secondary vertical and transverse dampers, the parallel double-pull rod traction device with internal traction, the longitudinal drive of the elastically frame-suspended motor, and the hydraulic brake unit which is integrated with the traction motor.

Owner:CRRC CHANGCHUN RAILWAY VEHICLES CO LTD

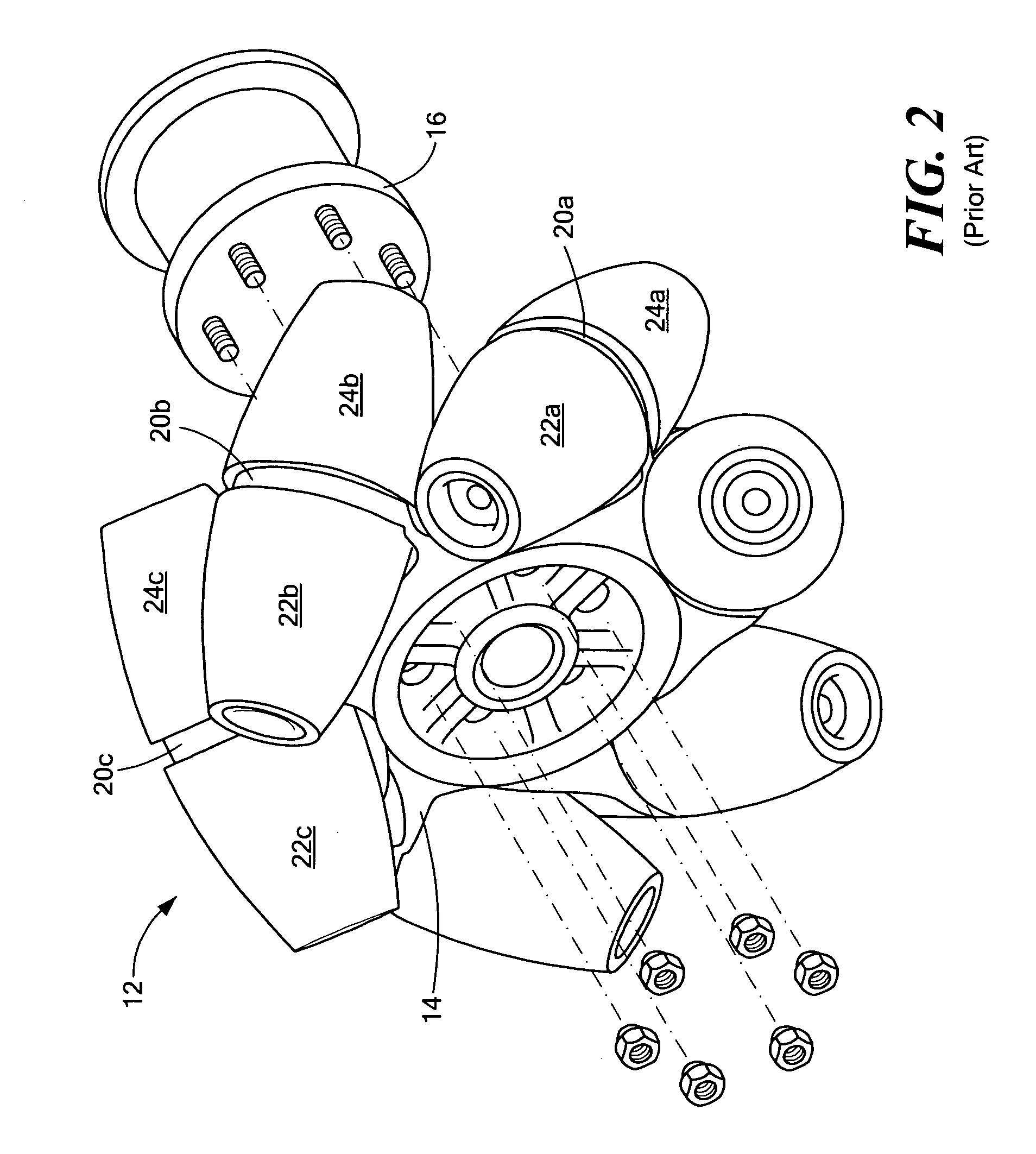

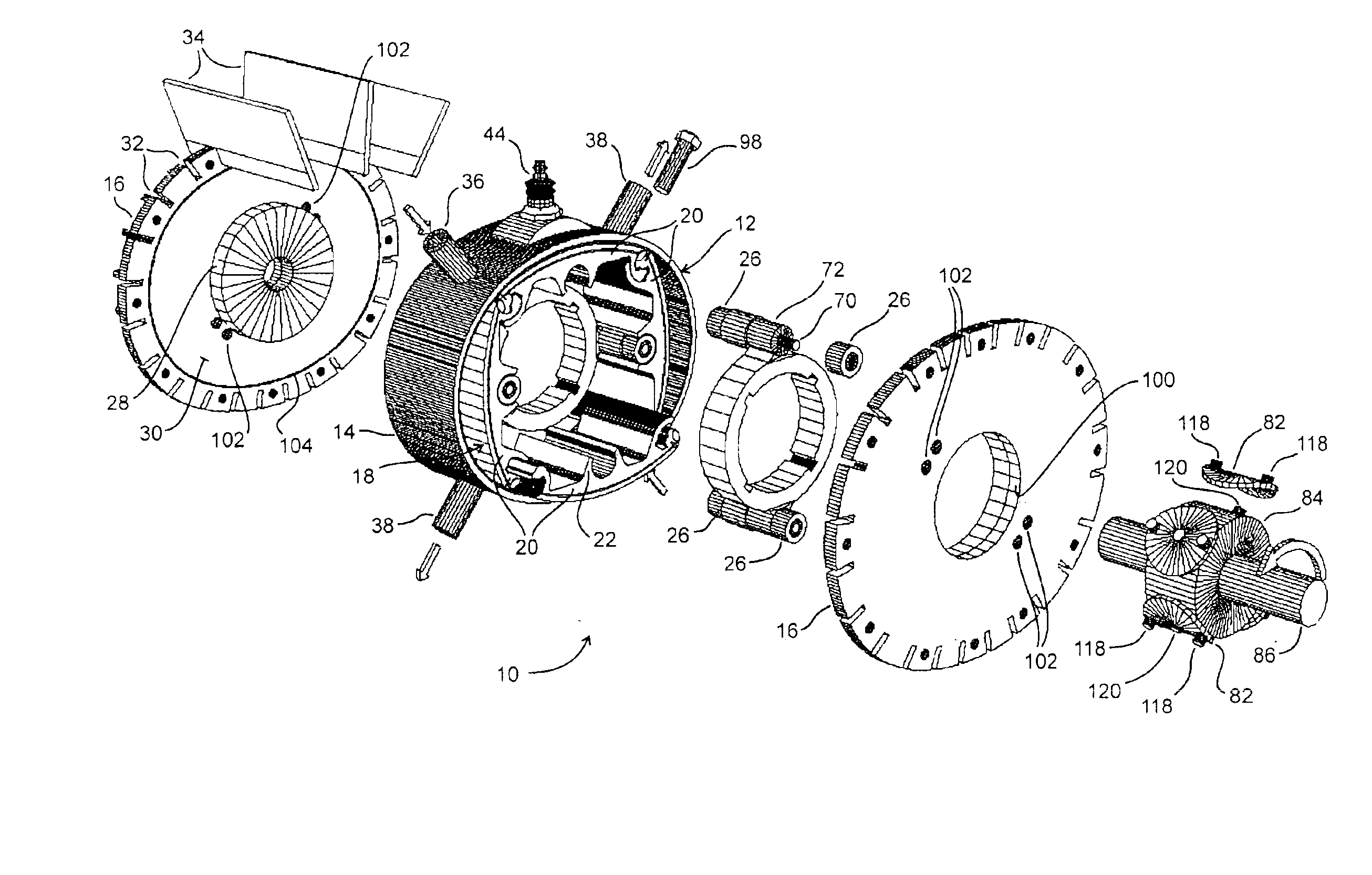

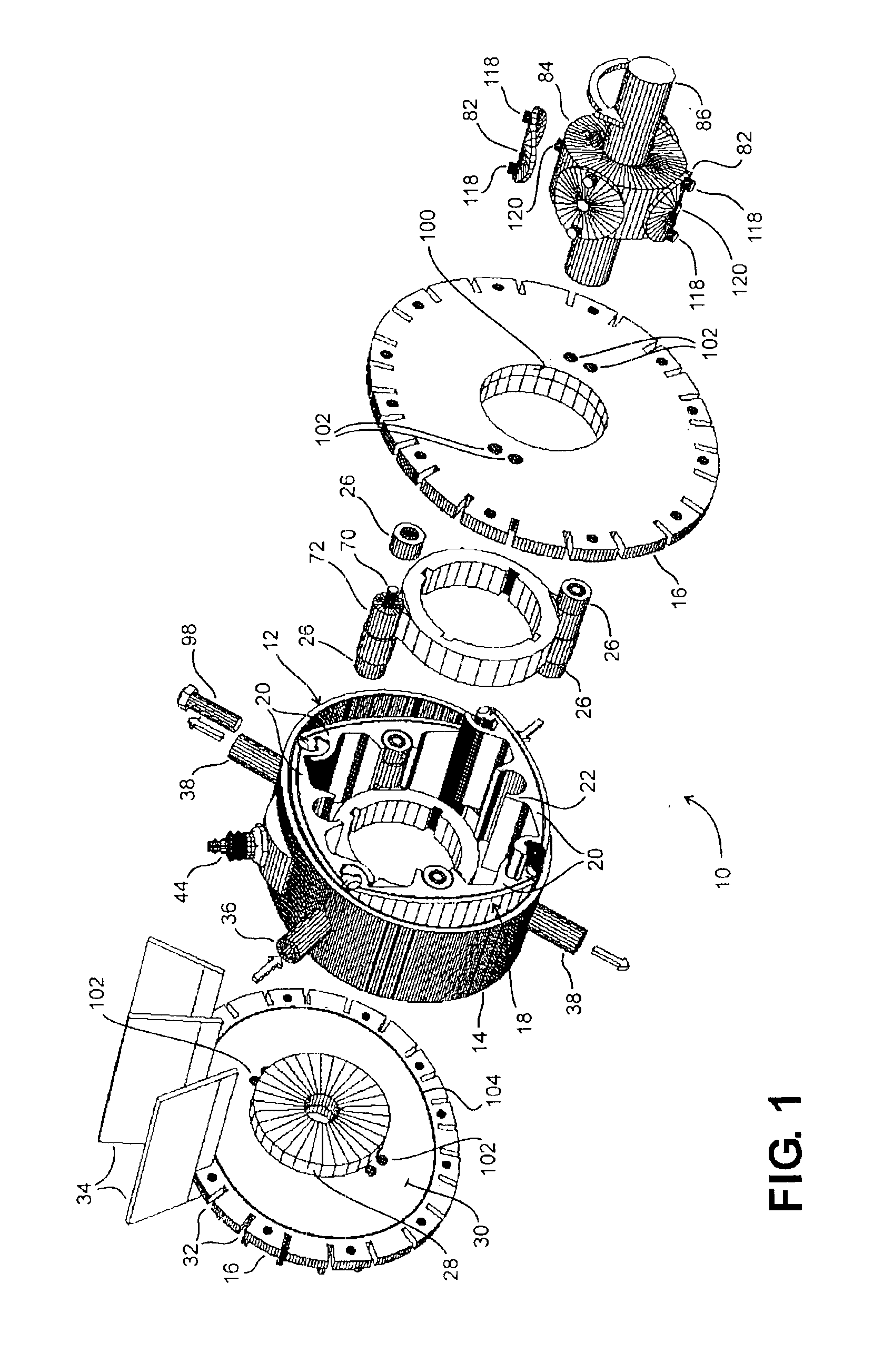

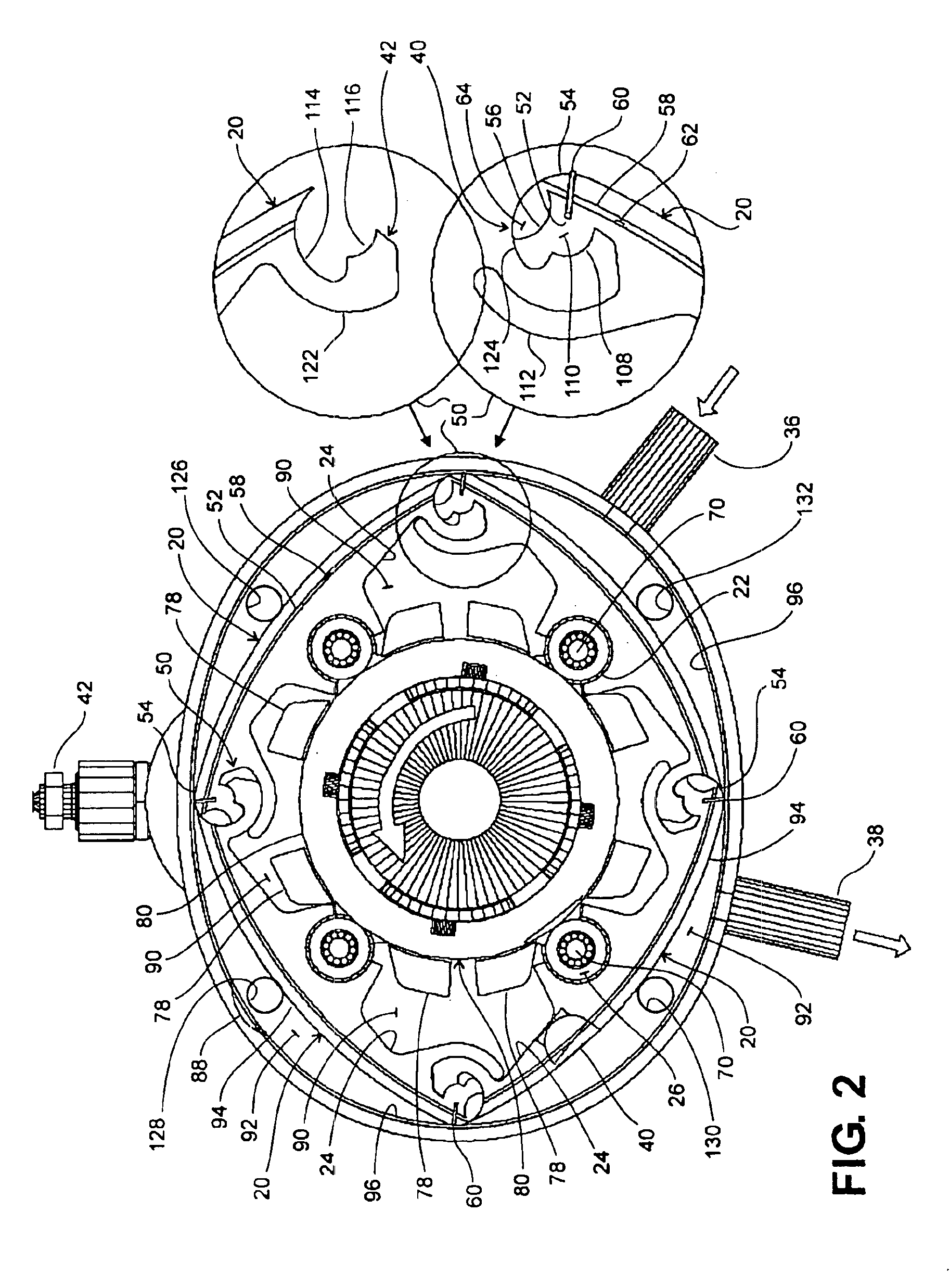

Quasiturbine (Qurbine) rotor with central annular support and ventilation

InactiveUS6899075B2Minimizing surface to volume ratioReduce flow turbulenceInternal combustion piston enginesOscillating piston enginesQuasiturbineWheel and axle

The Quasiturbine (Qurbine in short) uses a rotor arrangement peripherally supported by four rolling carriages, the carriages taking the pivoting blade pressure-load of the blades forming the rotor, and transferring the load to the opposite internal contoured housing wall. The present invention discloses a central, annular, rotor support for the rotor geometry defined by the pivoting blades and associated wheel-bearings, while still maintaining the important center-free engine characteristic. The pressure-load on each pivoting blade is taken by its own set of wheel-bearings rolling on annular tracks attached to the central area of the lateral side covers forming part of the stator casing. This central, annular, rotor support could generally apply to all the family of Quasiturbine rotor arrangements and particularly to the limit case here considered, where the previous carriage design is replaced by a cylindrical pivoting blade joint as presented in the present patent, and for which an efficient solution of the five bodies rotary engine sealing problem is given.

Owner:SAINT HILAIRE ROXAN +3

Scroll cable detecting robot

The invention discloses a spiral line cable detecting robot which consists of a cart, an upper and a lower supporting hugging devices symmetrically distributed along the cable which are connected together. The robot is characterized in that the active cart is provided with a climbing device and a magnetic absorbing device; two supporting horizontal levers are provided with hugging devices; the climbing device includes a lithium battery fixed in the cart and a DC motor fixed on one side of the driving wheel in the cart; power of the DC motor is supplied by the lithium battery, and the DC motor drives the driving wheel of the cart to rotate by a drive axle, so as to drive the whole robot to spirally climb along a water transmission line of the cable; the hugging devices and the magnetic absorbing device work together to tightly press the driving wheel onto the surface of the cable. The climbing device can rotate for any degree relative to the cart, so as to adapt to the water transmission line with different thread pitch; power supply by the lithium battery is more suitable for the environment of high-altitude operation; the robot is also provided with a descending device, which is safer and more reliable in use. The invention has simple and reasonable structure, is convenient in maintenance, can have high climbing speed, is applicable in detection of the spiral line cable of large cable-stayed bridges as well as lamps and other rod types.

Owner:SOUTHEAST UNIV

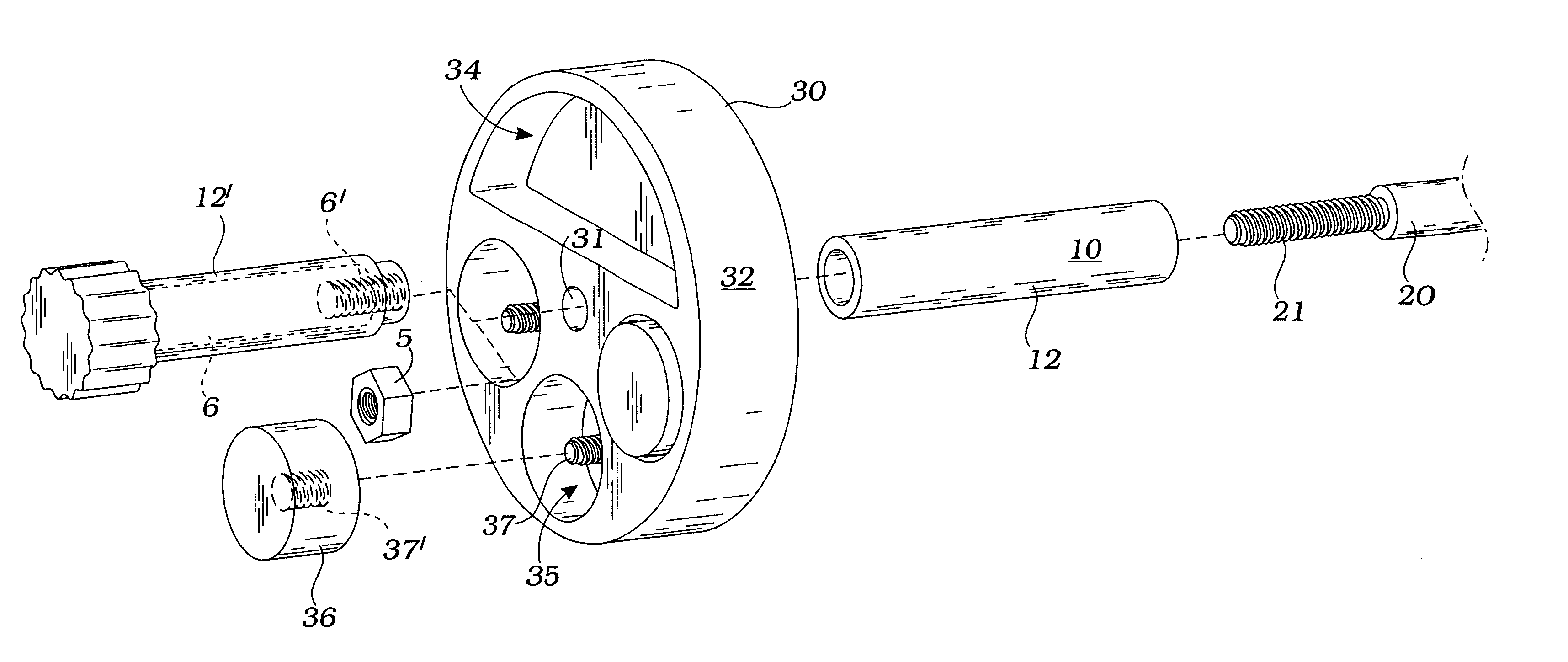

Specialty weight training apparatus and method

A dumbbell type apparatus comprises a hand gripping surface mounted on an axle and engaging a pair of spaced apart circular wheel-weights rotationally engaged with the axle. The weights provide peripheral outfacing surfaces for rolling the apparatus on a floor surface. Each of the weights has a non-concentrically placed center of mass, whereby with the hand gripping surface held in one hand, the apparatus may be rotated causing the wheel-weights to spin and to thereby exercise the arm holding the apparatus.

Owner:ELLEDGE MILES

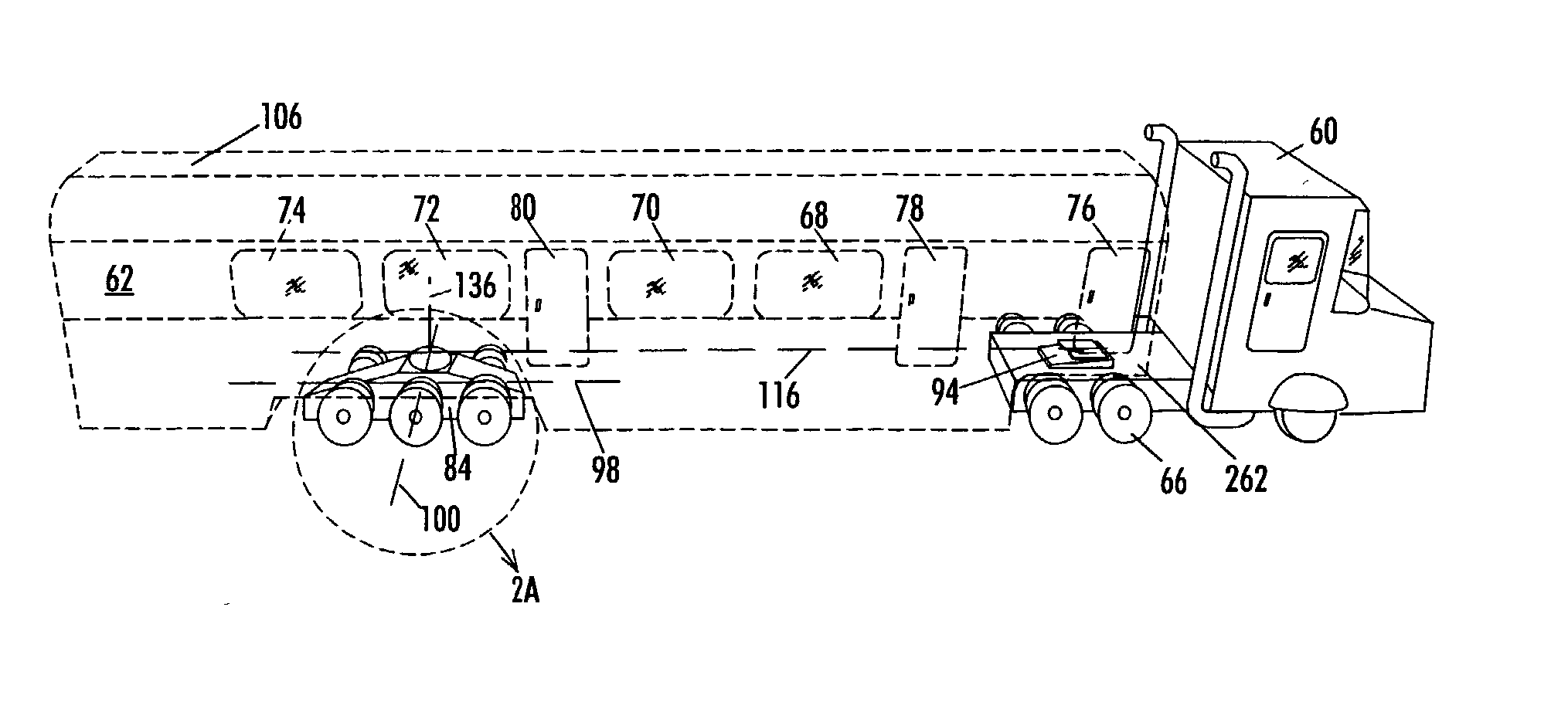

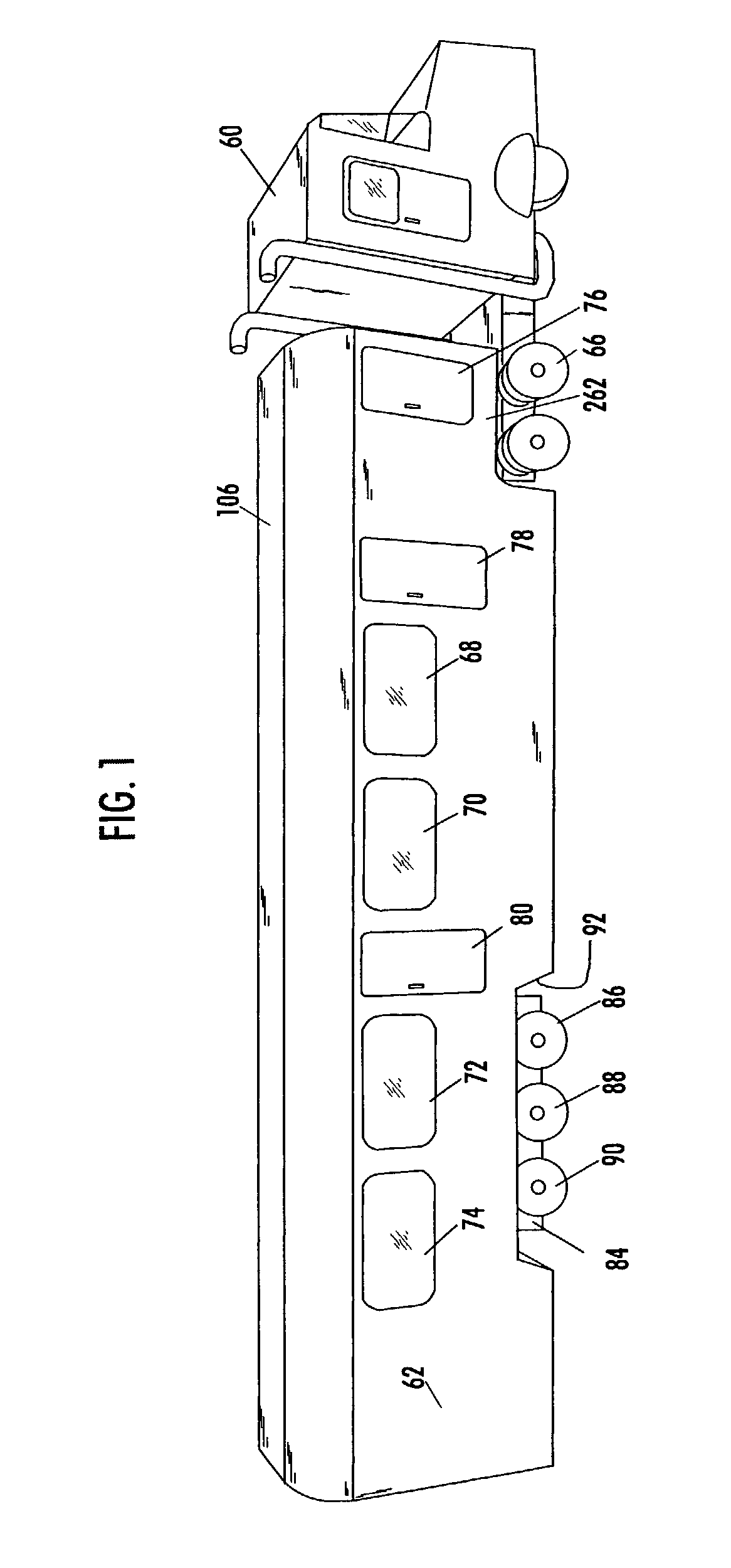

Modular passenger semi-trailer with pneumatic unipoint suspension

A modular passenger semi trailer incorporating a vehicle construction technique in which the assembled passenger and alternate industrial embodiment modules observe structural strength, weight and balance and fail safe design considerations. The modular passenger semi trailer cabin module, including all interior seating and equipment, is assembled as a single unit upon a single, top, flat production joint face of the lower structure module, that module having a plurality of closed box beam compartments. A substantially sized cylinder compartment at the rear of the vehicle houses a pneumatically, reciprocally operative piston assembly containing a unipoint suspension which operates cooperatively with a wheel unit in the lower portion of the compartment. The wheel unit is captively located by a wheel shaft and cam block, swivel block external members, sandwiched, acting cooperatively within a forward and aft set of vertically disposed guideplates, the wheel unit operative along its vertical, longitudinal and lateral axis.

Owner:SPARLING JAMES DOUGLAS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com