Patents

Literature

620results about How to "Avoid frictional damage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

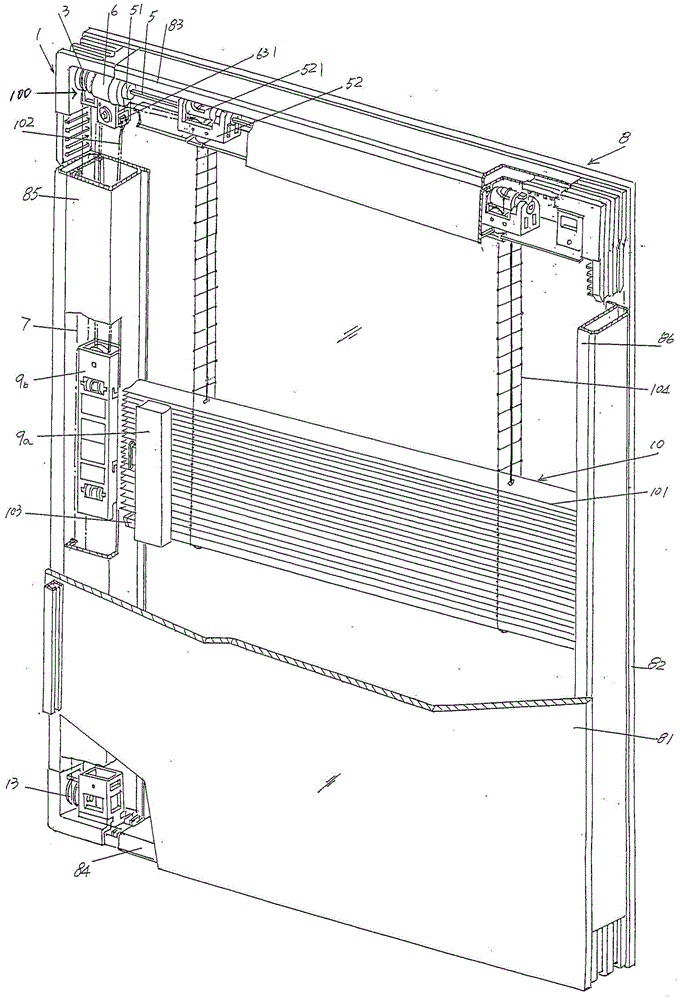

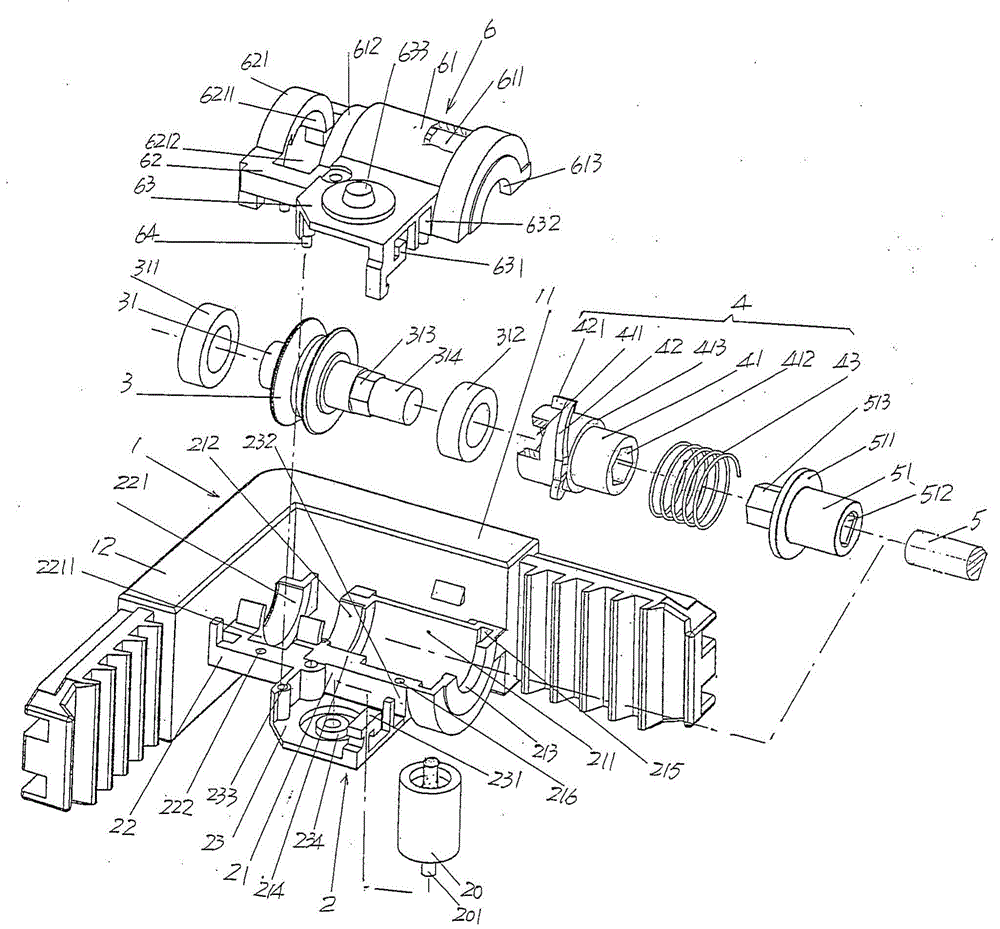

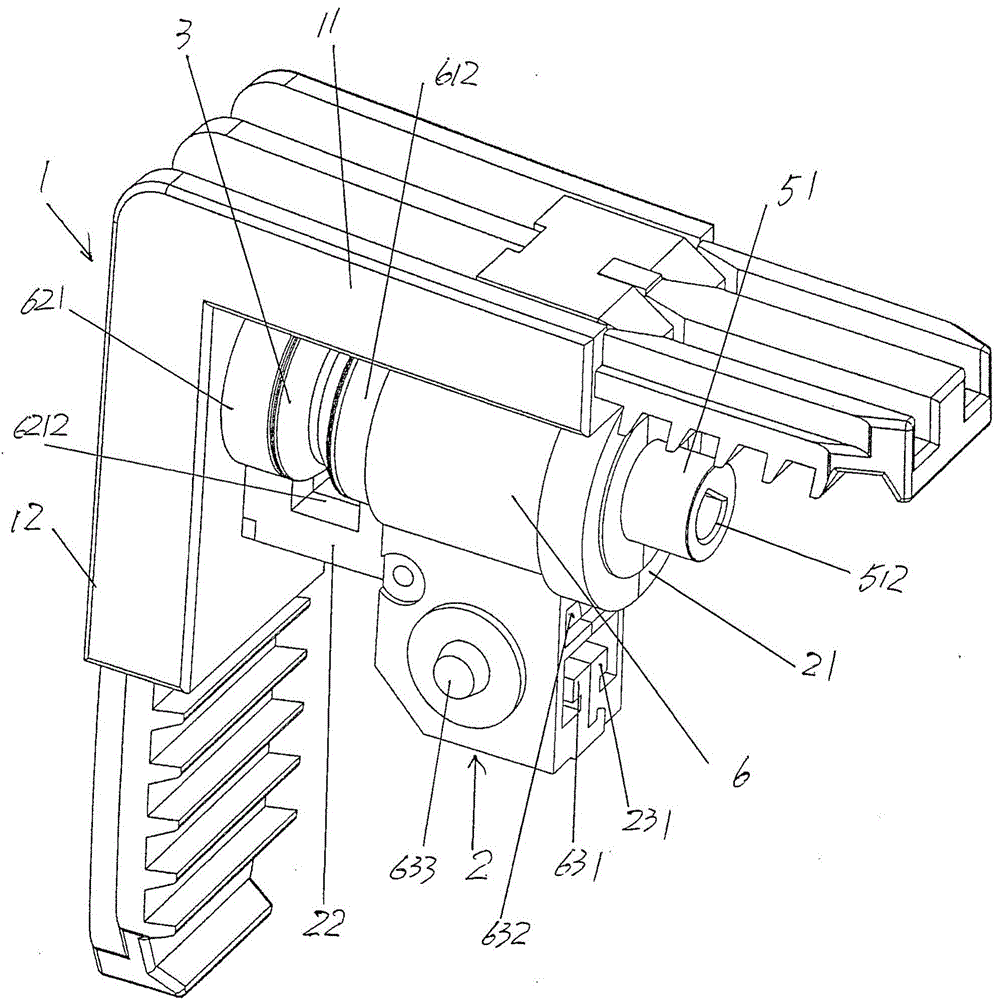

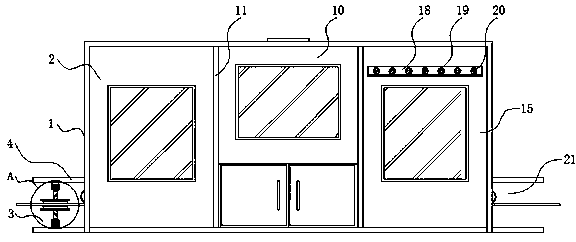

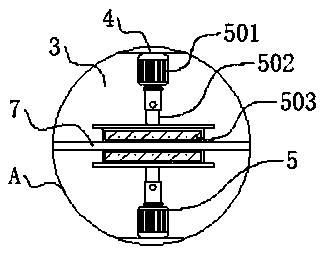

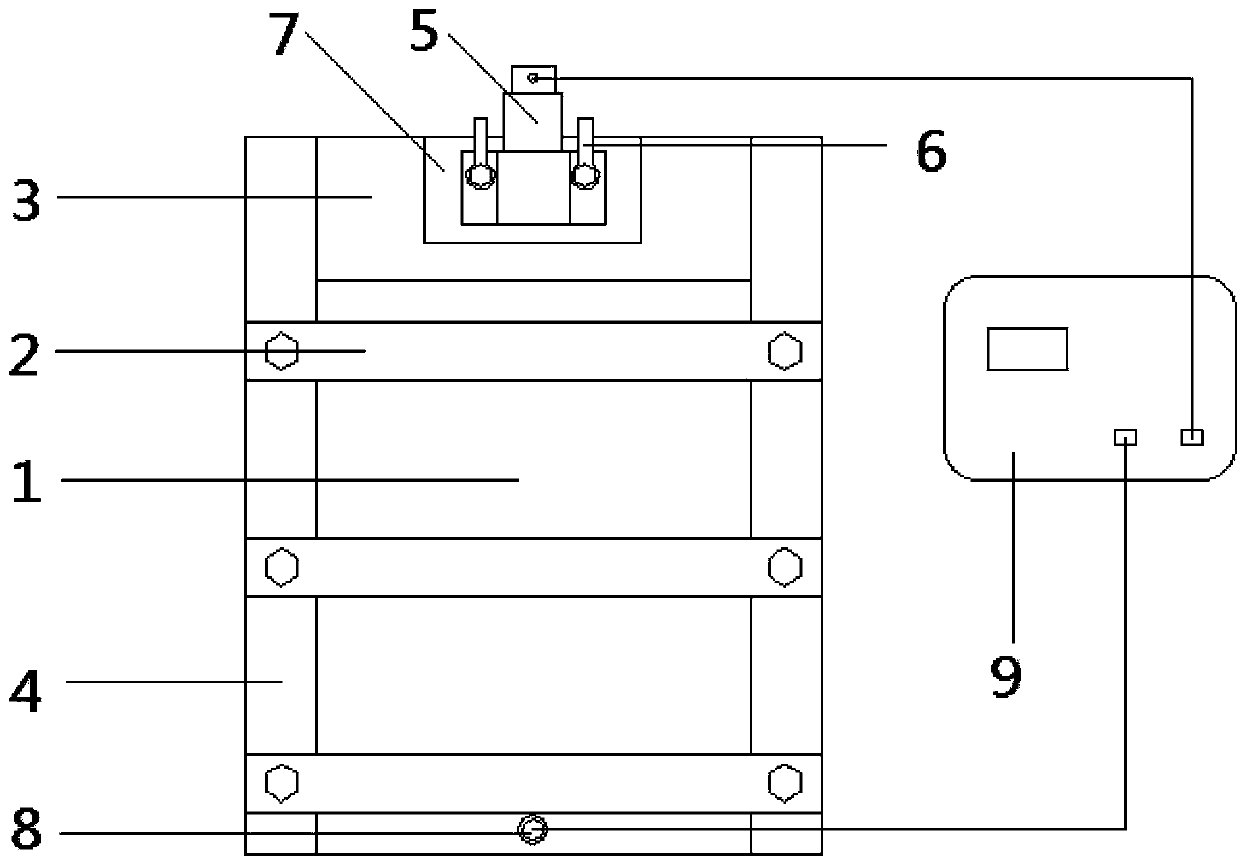

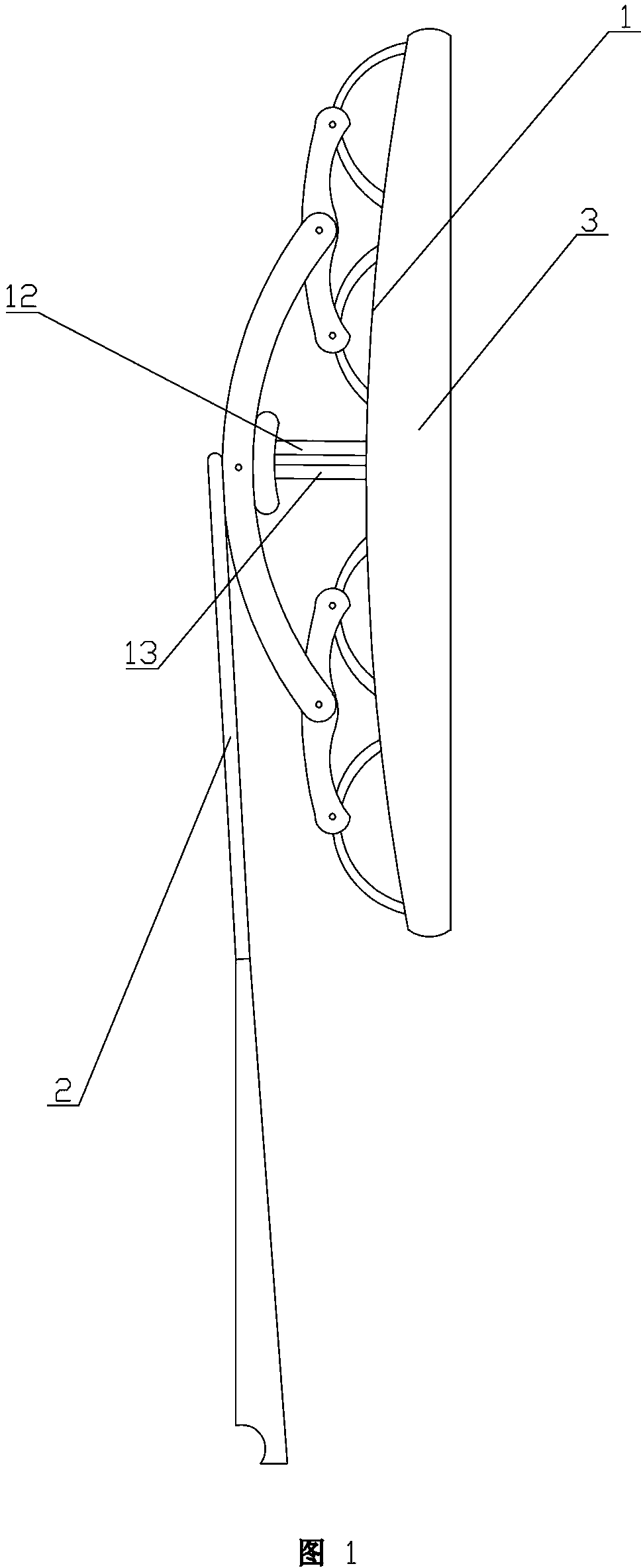

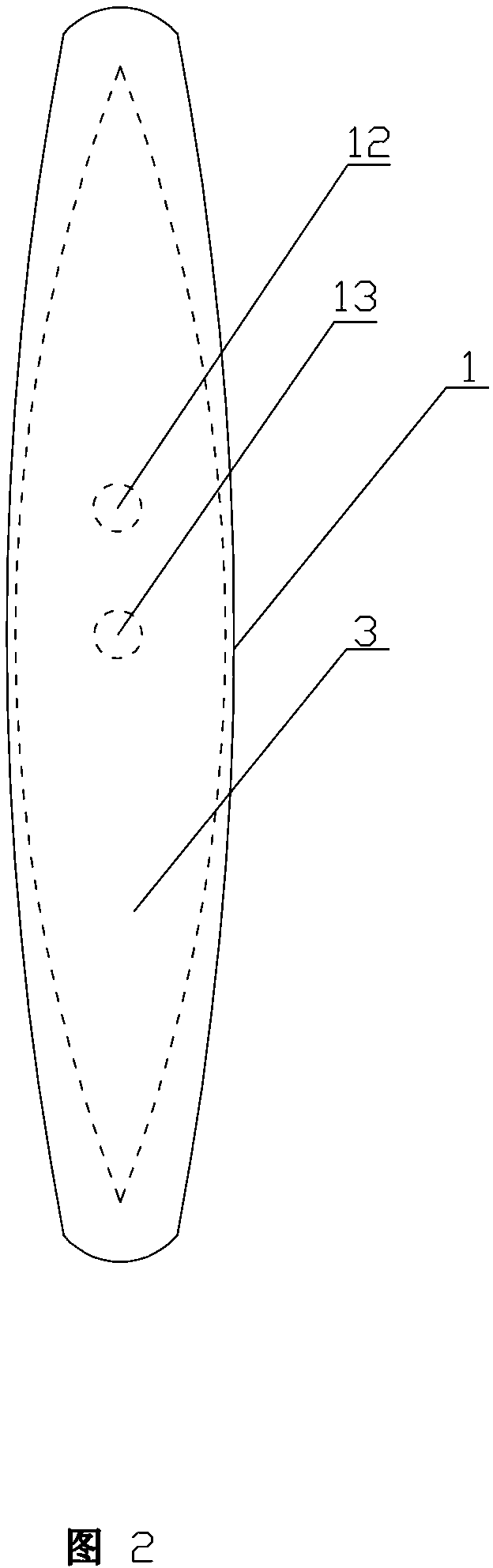

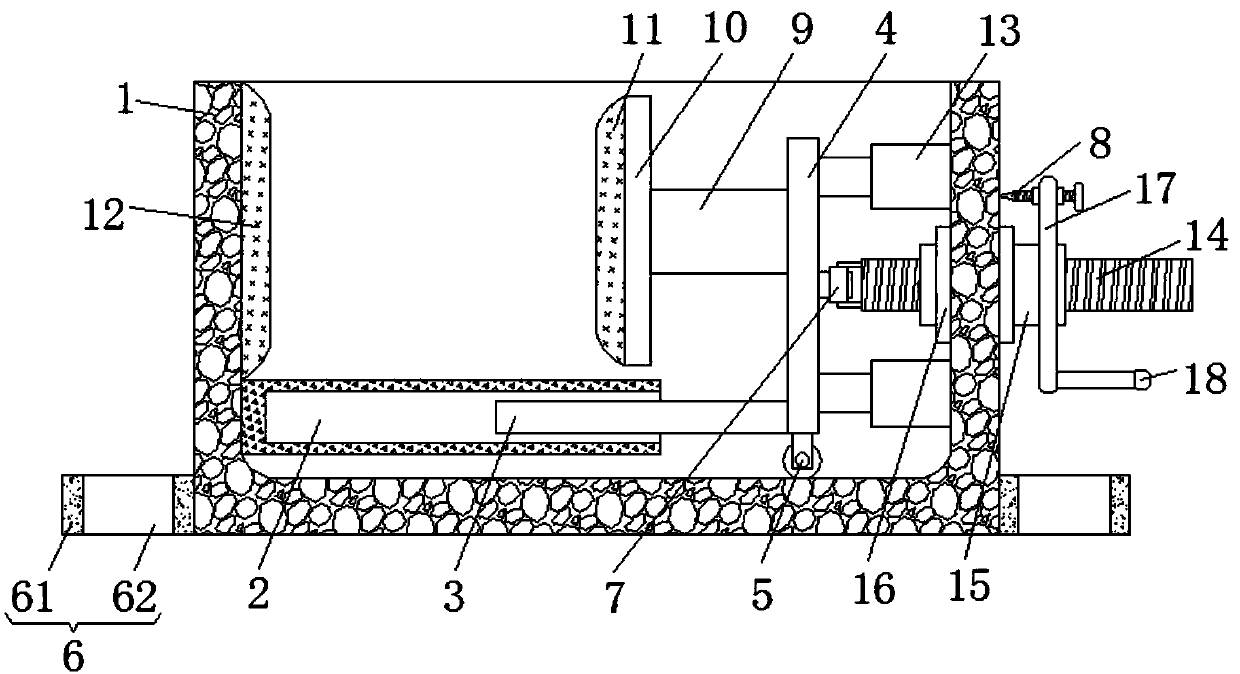

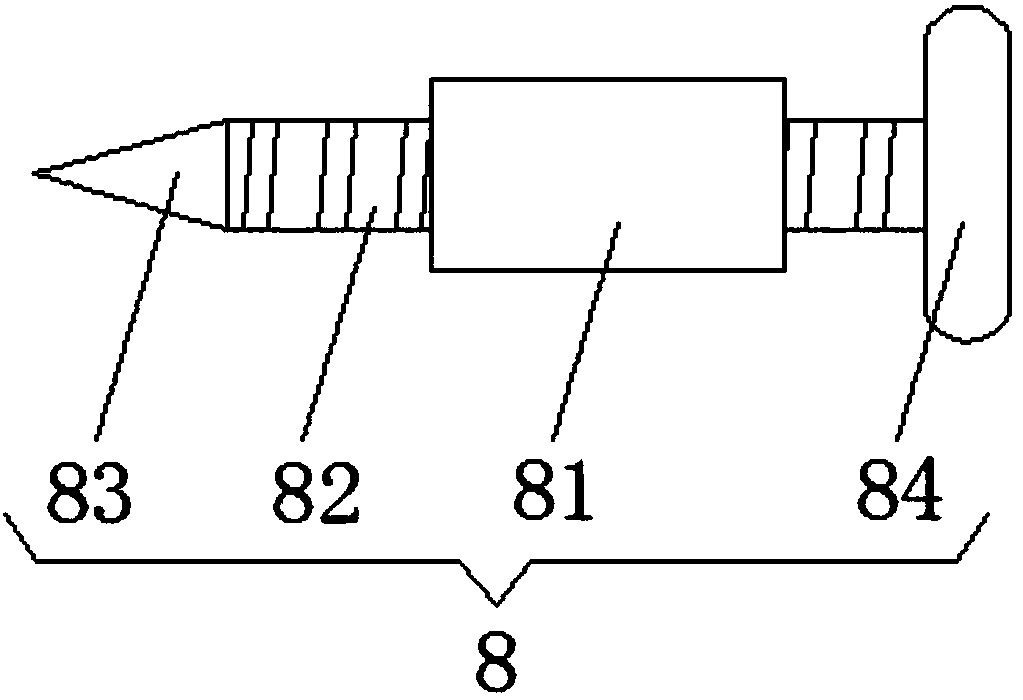

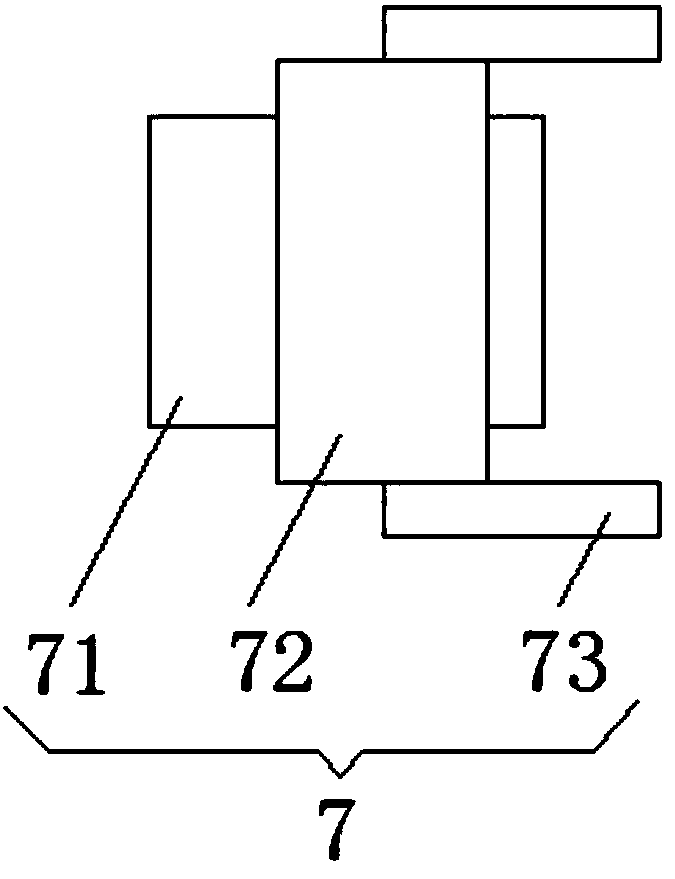

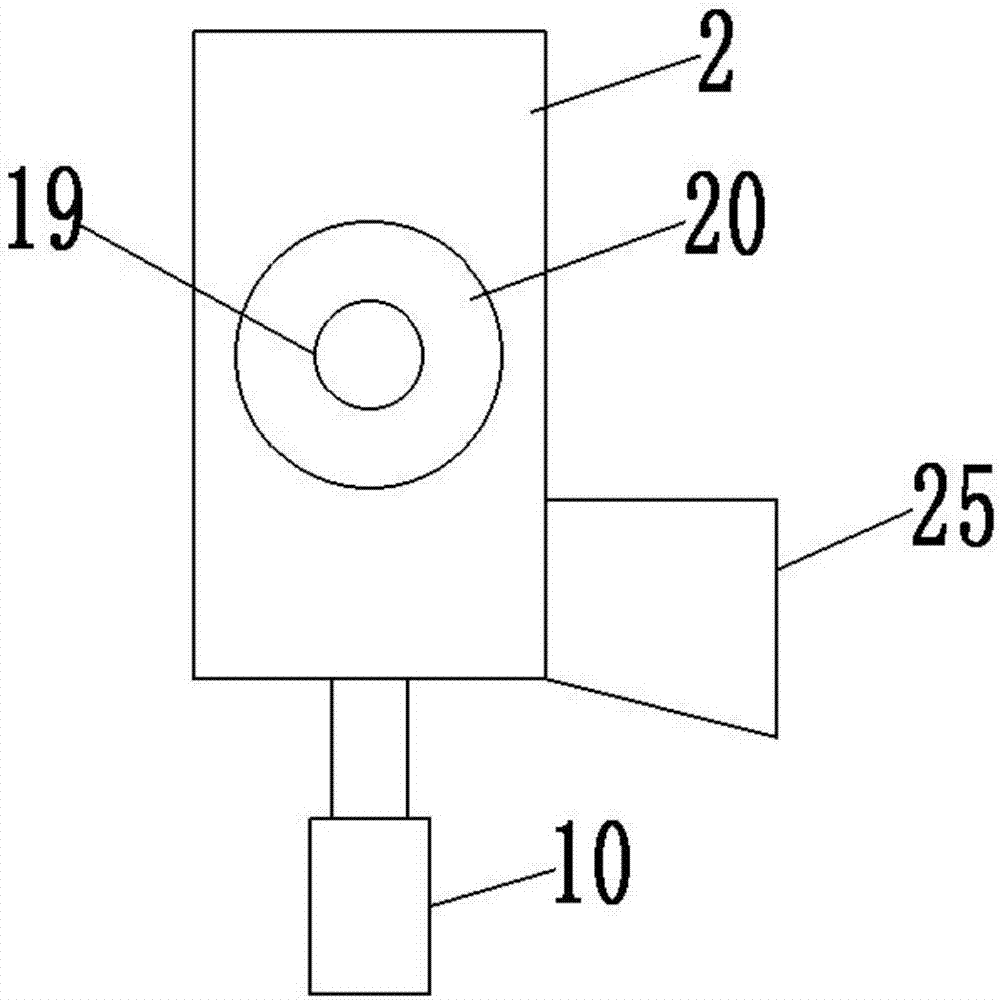

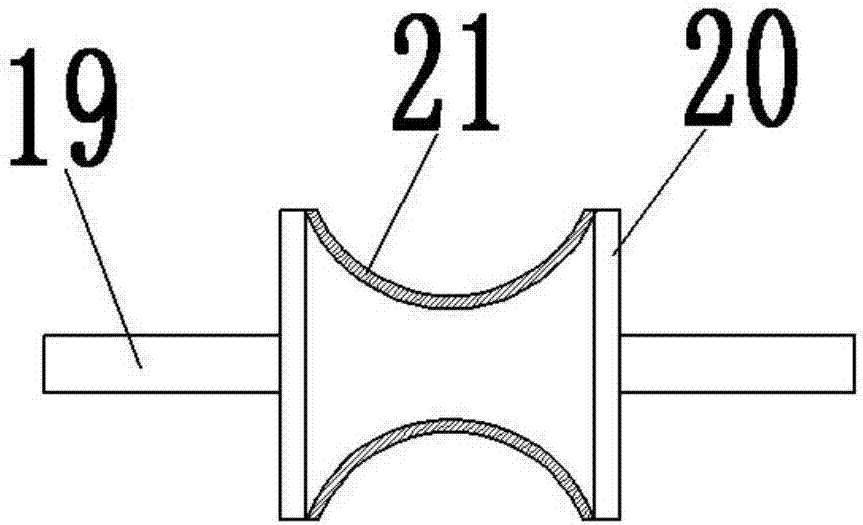

Single-operated double-glazed insulating glass with built-in shutters

ActiveCN105064896BAvoid frictional damageAvoid damageLight protection screensEngineeringVenetian blinds

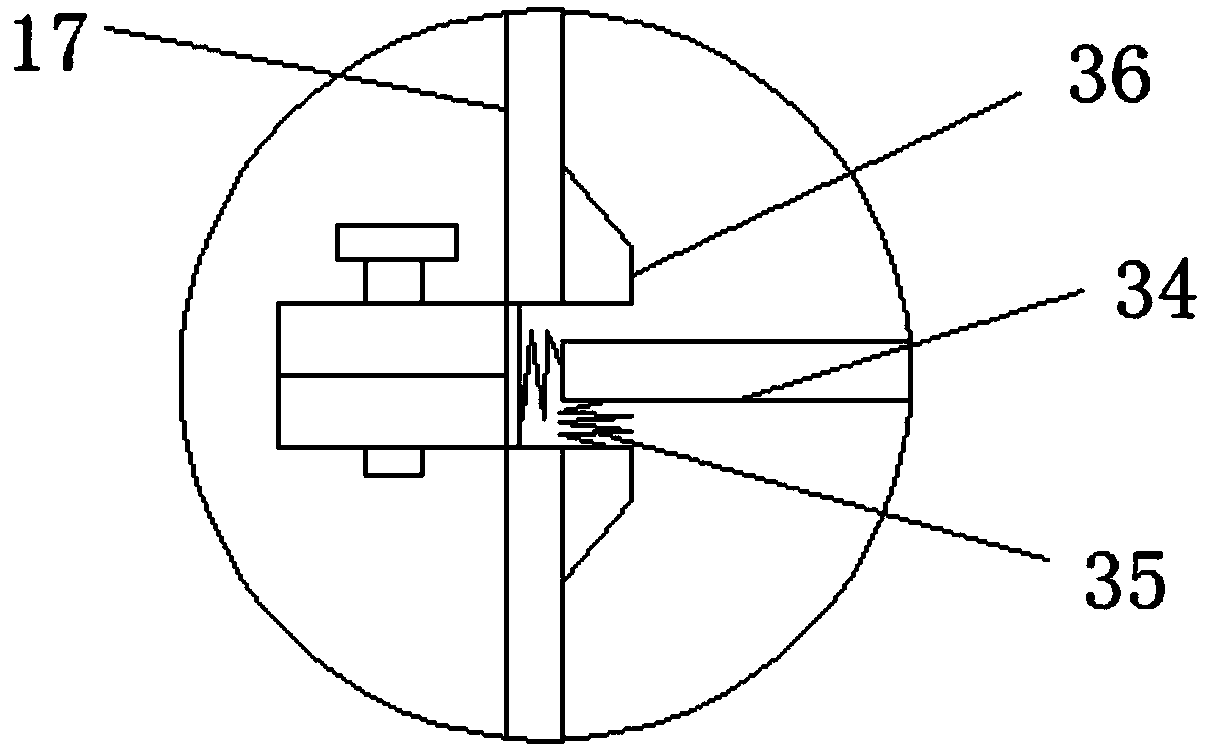

The invention provides a blind window with built-in single-control double-layer hollow glass, and belongs to the technical field of sunshade hollow glass products. The blind window with the built-in single-control double-layer hollow glass comprises a window body and venetian blind blade overturning devices, wherein the window body comprises inner glass, outer glass, an upper transverse frame strip, a lower transverse frame strip, a left longitudinal frame strip and a right longitudinal frame strip; and the venetian blind blade overturning devices are arranged on connectors of corners of a frame of the window body. The blind window with the built-in single-control double-layer hollow glass is characterized in that each venetian blind blade overturning device comprises a supporting mechanism, a blade overturning wheel, a clutch mechanism, a blade overturning shaft and a clutch shielding mechanism; each supporting mechanism is arranged on the connector of the corresponding corner of the frame of the window body; each blade overturning wheel is fixed on a corresponding blade overturning wheel shaft; each clutch mechanism is arranged on the corresponding supporting mechanism; each blade overturning shaft is connected with the right end of a corresponding blade overturning shaft sleeve; and each clutch shielding mechanism is matched with the corresponding supporting mechanism. When each clutch mechanism is connected with the right end of the corresponding blade overturning wheel shaft, each blade overturning wheel drives the corresponding blade overturning wheel shaft; and when blades of a venetian blind are overturned to be closed, the blade overturning wheels rotate independently, movement resistance of a blade overturning traction rope is reduced obviously, the blade overturning traction rope is prevented from being rubbed and damaged, and the blade overturning wheels are prevented from being damaged.

Owner:CHANGSHU ZHONGQIN BUILDING MATERIAL

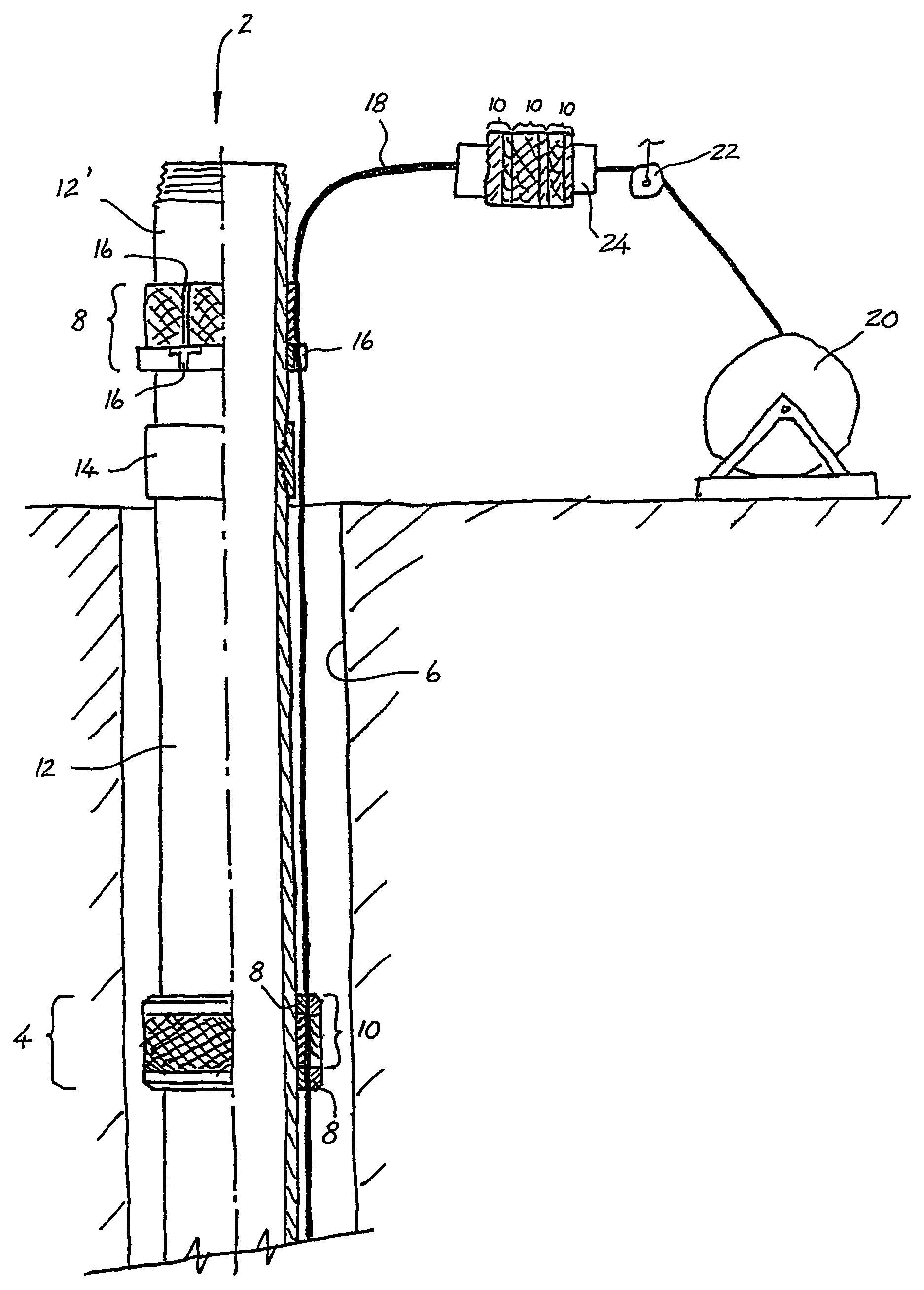

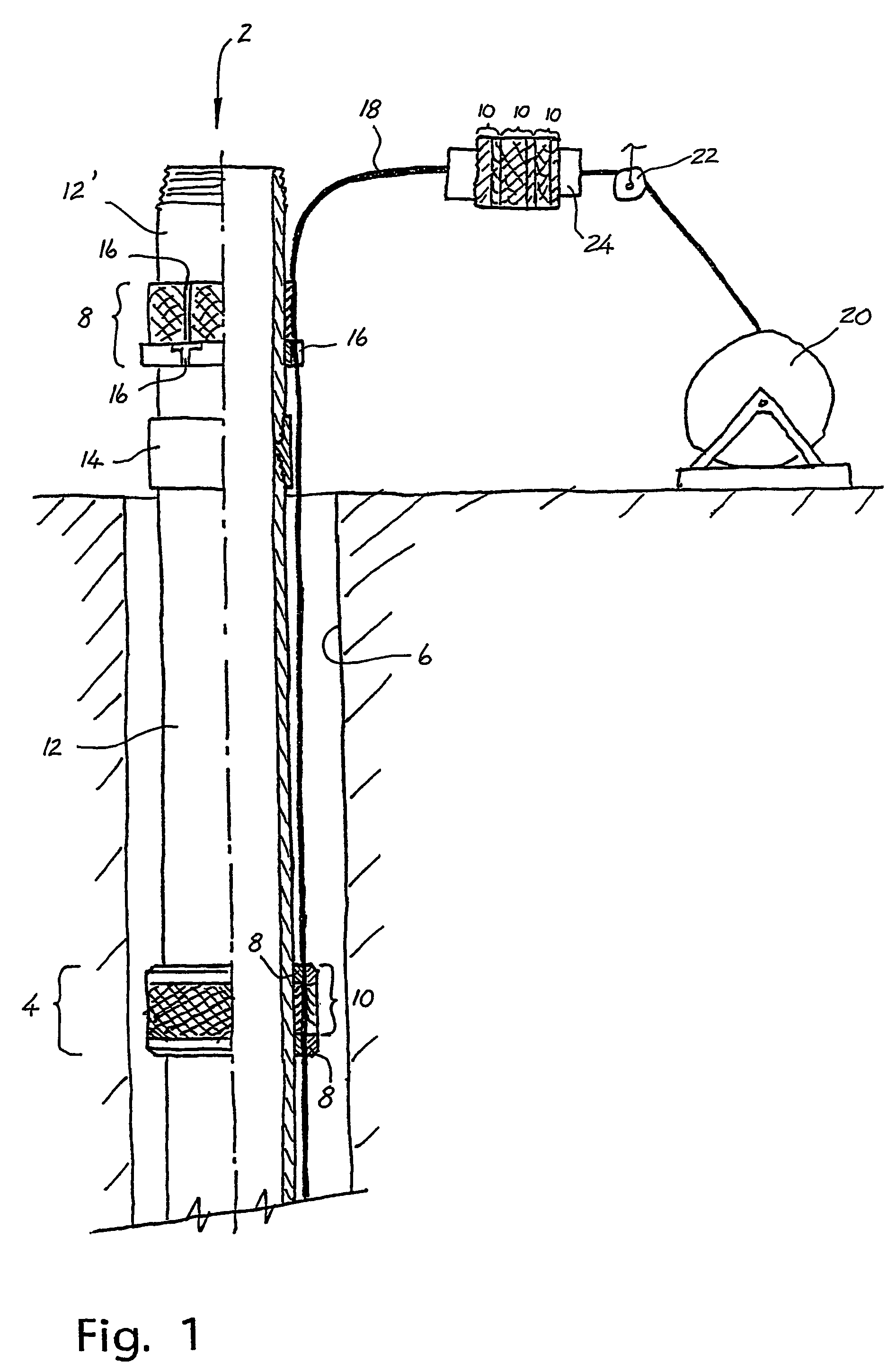

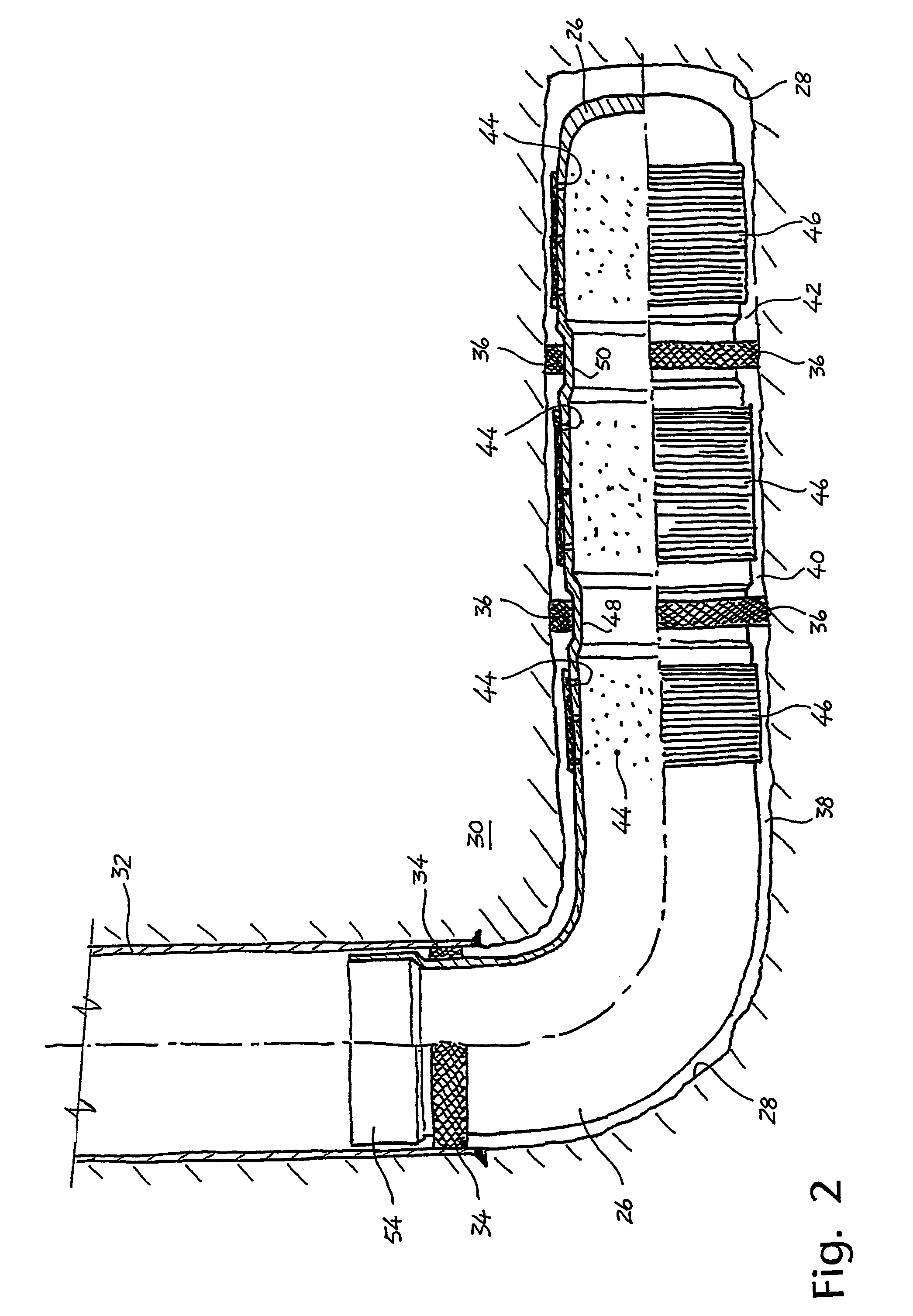

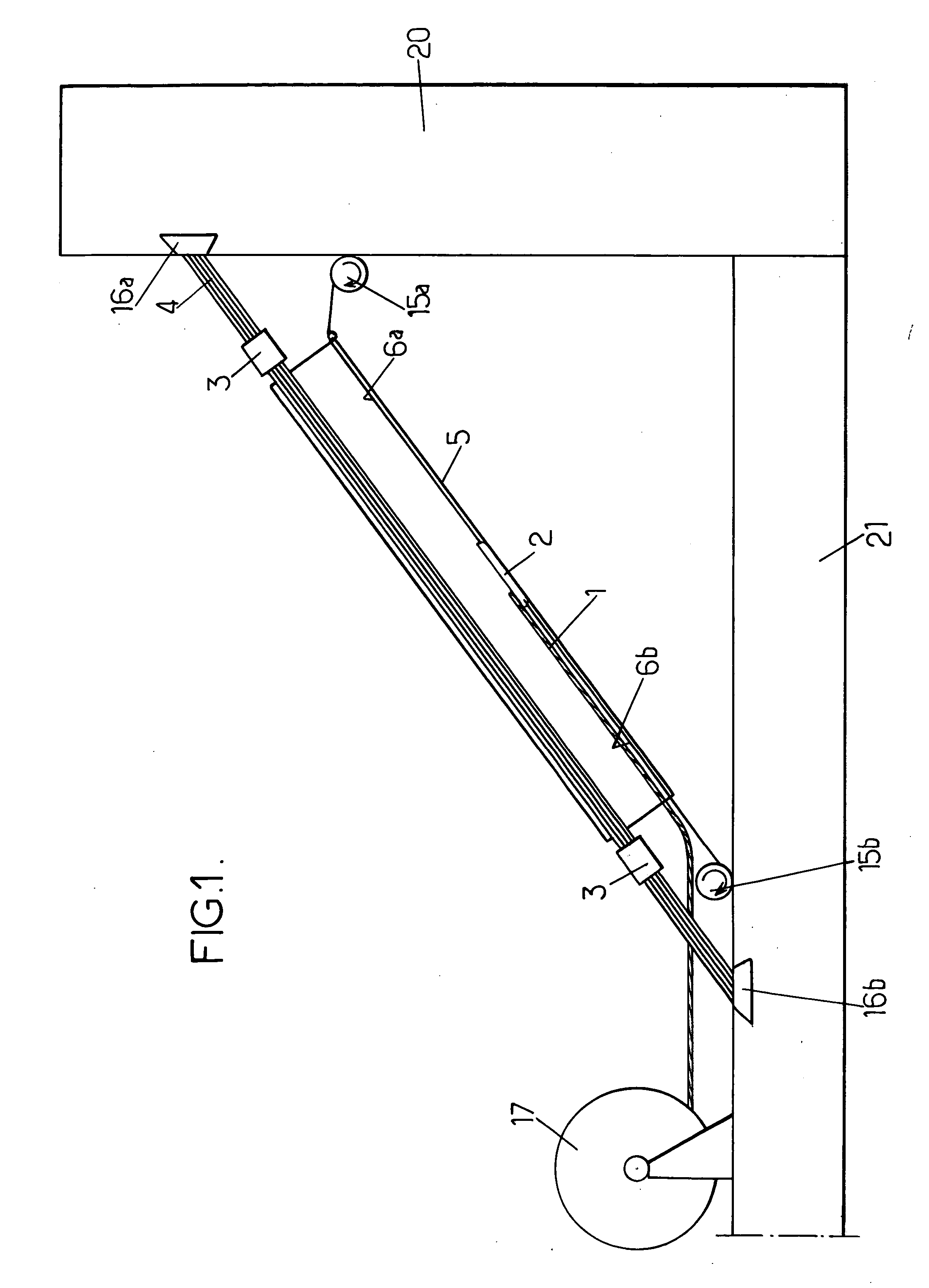

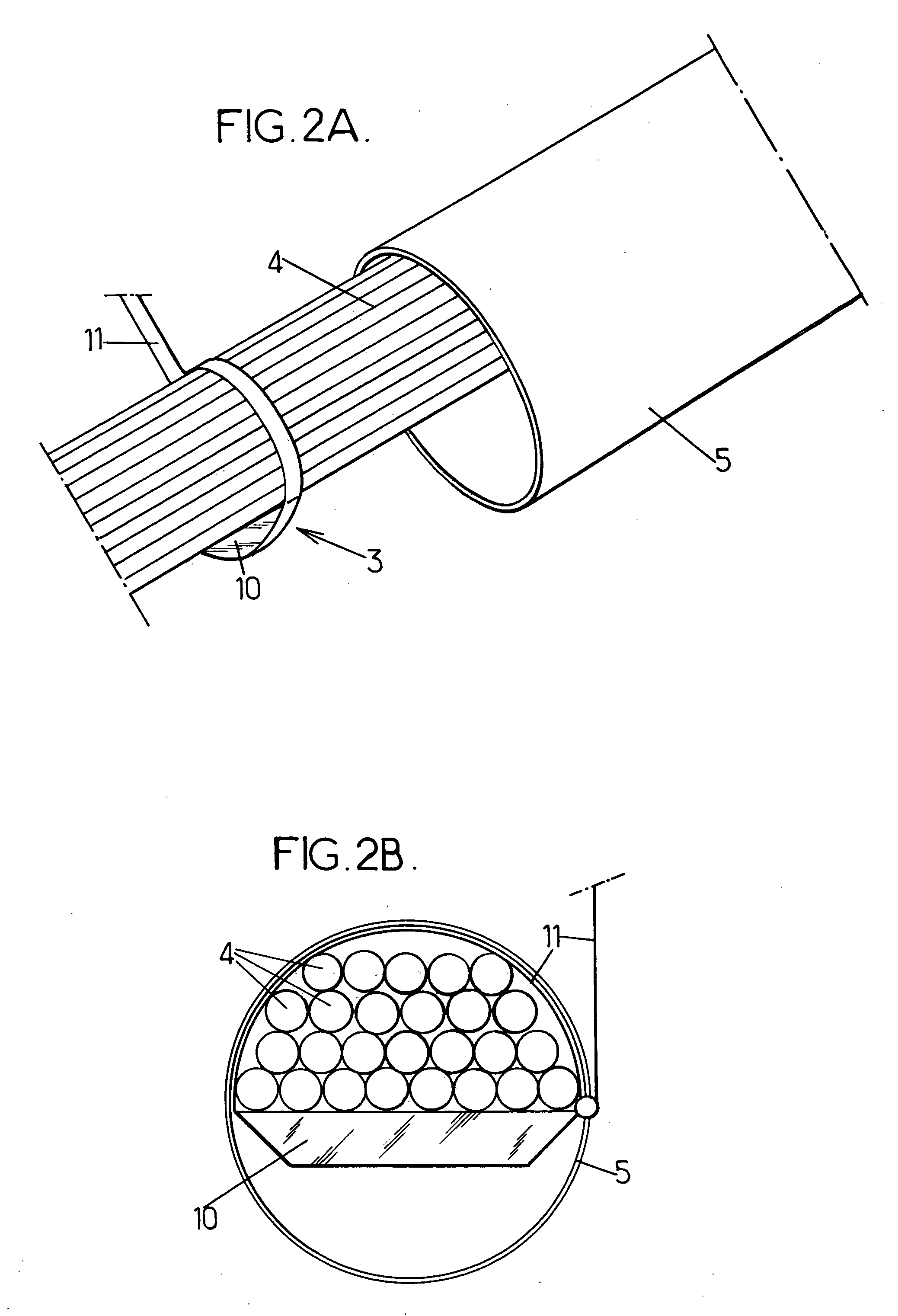

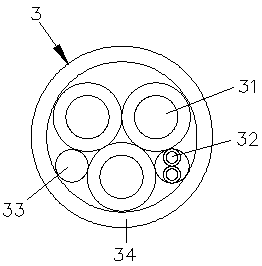

Well packer for a pipe string and a method of leading a line past the well packer

InactiveUS7264061B2Easy to controlDisadvantage is reduced and avoidedDrilling rodsFluid removalLine tubingEngineering

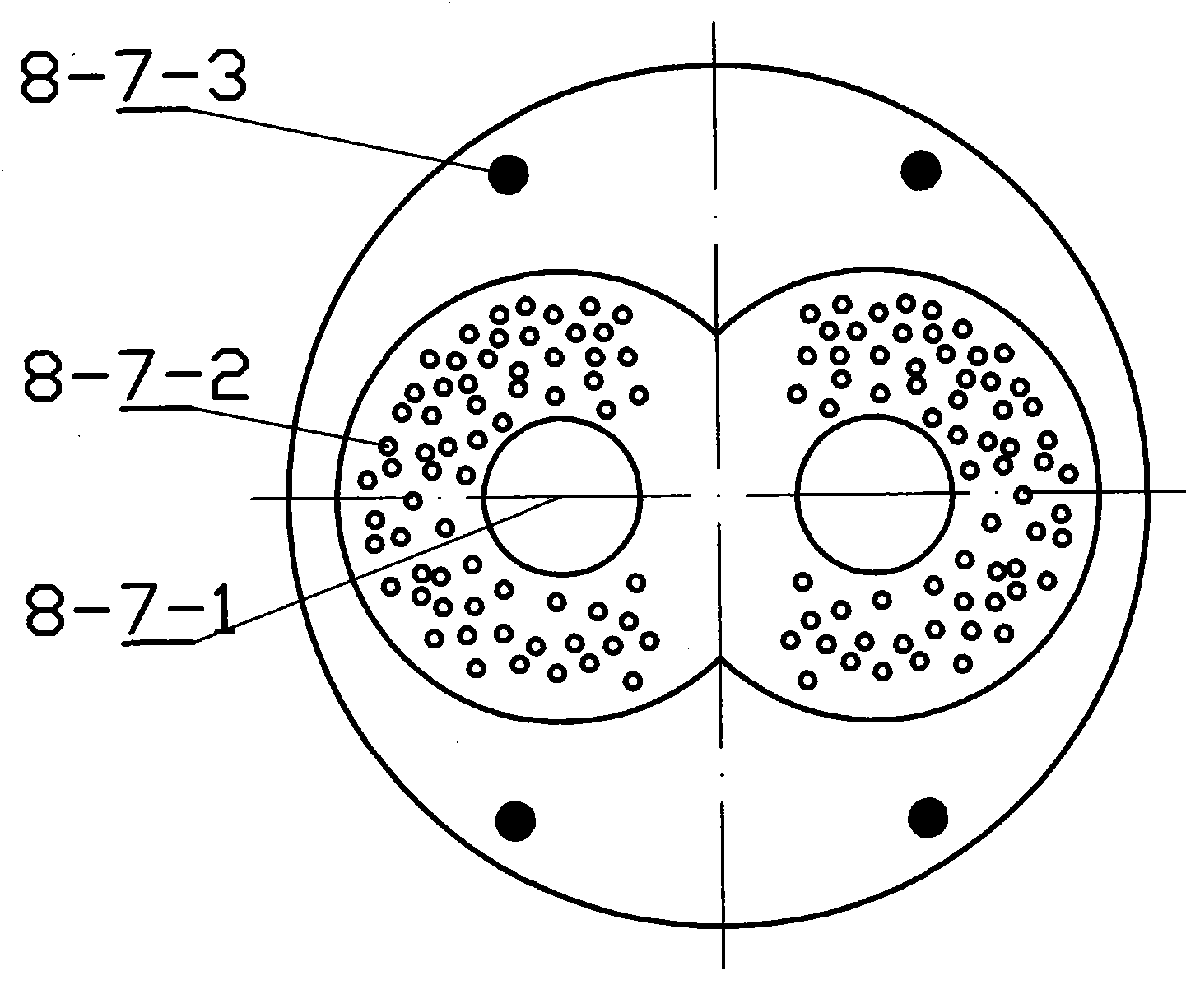

The invention concerns an external well packer (4, 4′, 4″) for a pipe string (2), and also a method of leading at least one line (18) seamlessly past at least one packer (4, 4′, 4″) along the pipe string (2). What is characteristic of the packer (4, 4′, 4″) is that it consists of a continuous inner packer ring (8) and a separate and continuous outer packer ring (10), which in the operating position encloses the inner packer ring (8) in a pressure tight manner. The fitting surface of at least one of the packer rings (8, 10) is provided with at least one through-going line slot (16, 16′), which in the operating position encloses a line (18) in a pressure tight manner. This allows continuous lines (18) to be stretched out past several such packers (4, 4′, 4″).

Owner:RESLINK

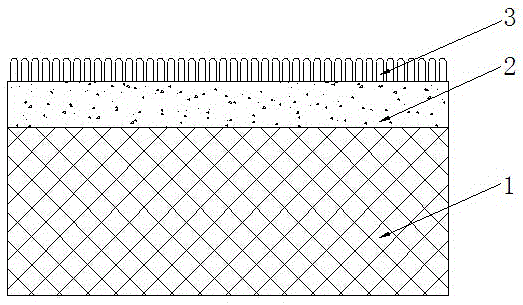

Three-dimensional high simulation ceramic tile with matte glaze surface and preparation method thereof

ActiveCN108727037AExtended service lifeGood three-dimensionalCeramic shaping apparatusAdobeComputer printing

The invention discloses a three-dimensional high simulation ceramic tile with matte glaze surface and a preparation method thereof, the method comprising the following steps: 1) adopting a laser four-dimensional fine carving system to finely carve a digital mold; 2) Positively pressing green body molding; 3) Controlling the water absorption rate of the ceramic tile before glazing at 15%-20% by controlling the drying temperature of the ceramic tile adobe or the biscuiting temperature of the ceramic tile adobe; 4) spraying a small amount of high-titanium impervious ground coat under high pressure; 5) spraying a small amount of matte glaze under high pressure; 6) using a digital ink jet printer to print decorative ink and functional ink; 7) decorating the dry particle frit, and adopting a controllable negative pressure absorbing dry particle frit equipment to absorb excess dry particle frit; 8) sintering to obtain the three-dimensional high imitation ceramic tile with matt glaze surface,the preparation method provided by the invention obtains the three-dimensional high simulation ceramic tile with matte glaze surface with three-dimensional simulation, 2-6 glossy units of glaze surface gloss and lifelike surface decoration effect through the collaborative and innovative preparation including mold sculpture, glaze formula control, high-pressure glaze spraying and effect decoration.

Owner:广东协进陶瓷有限公司

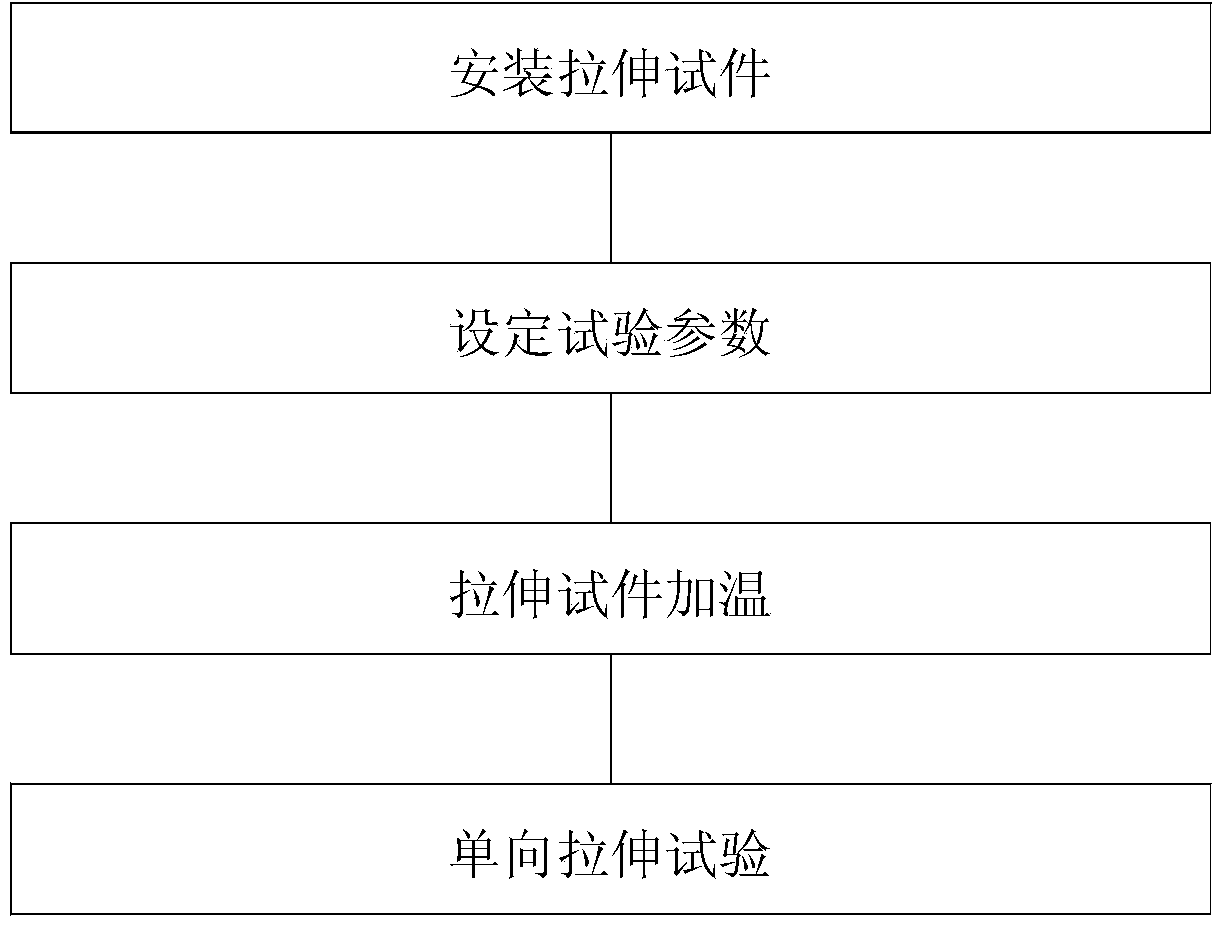

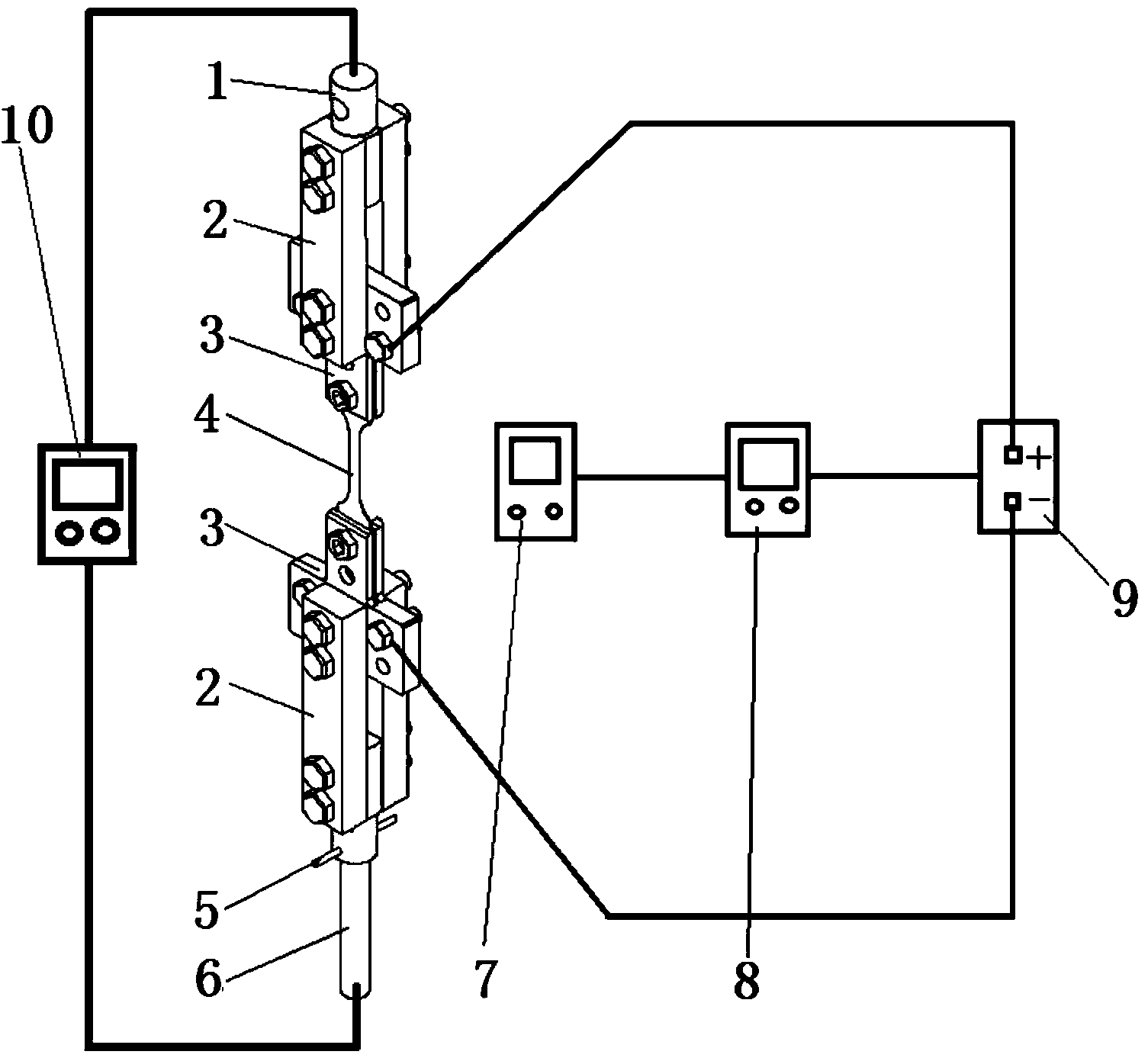

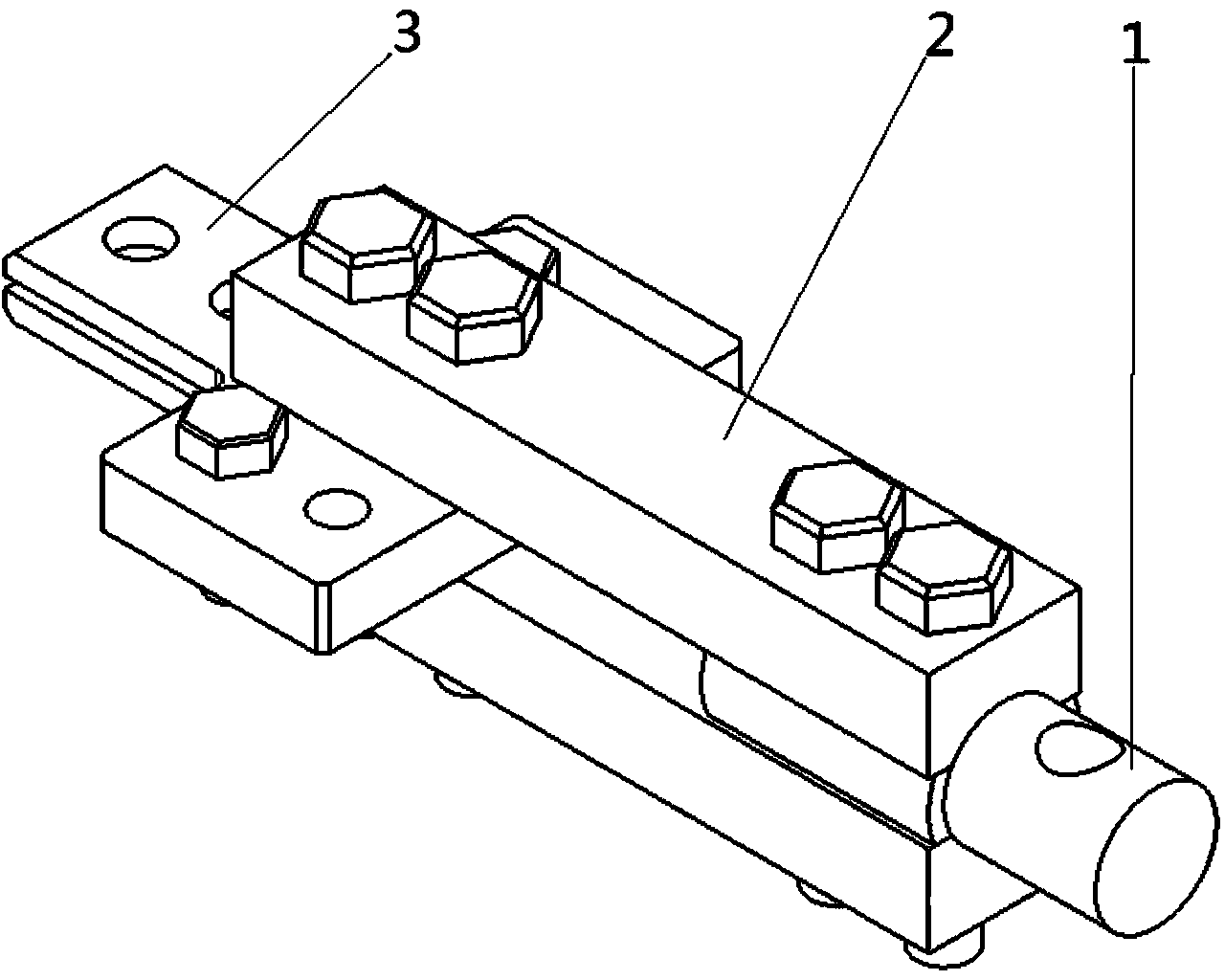

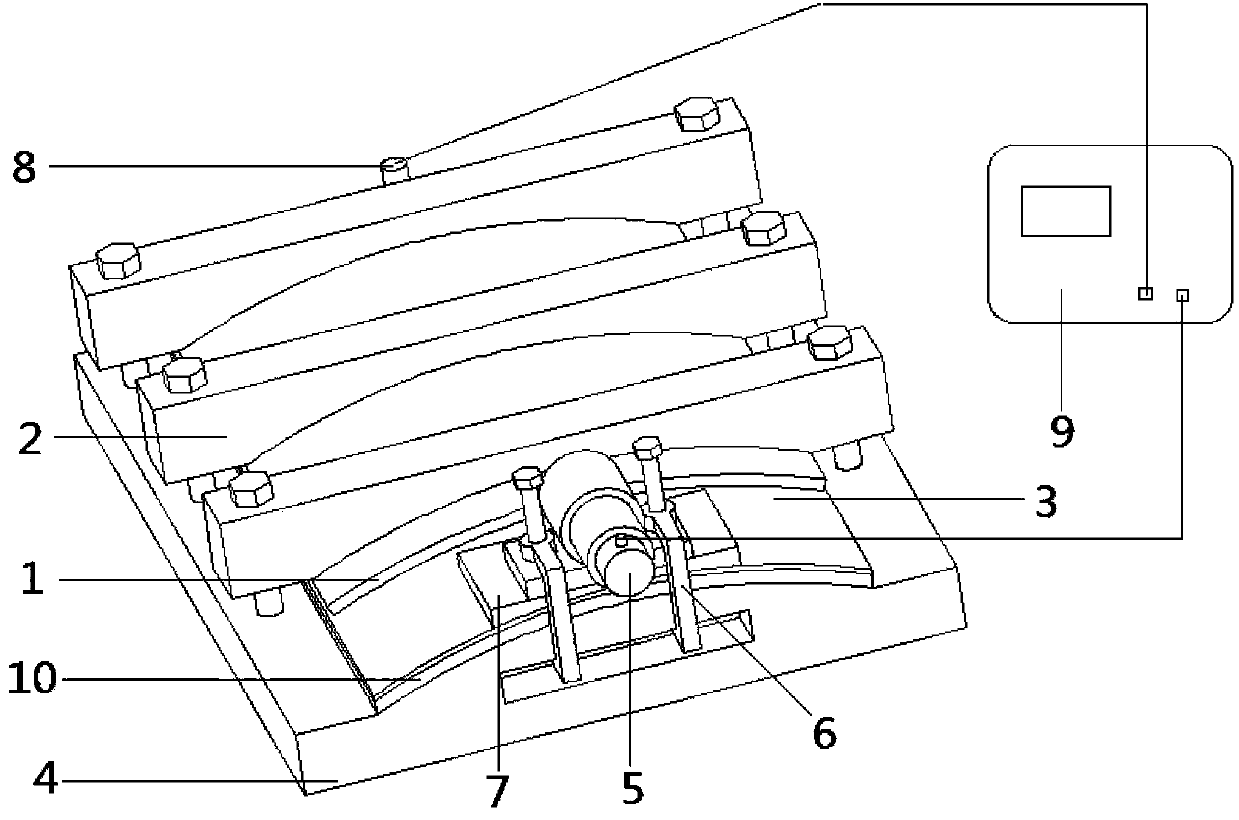

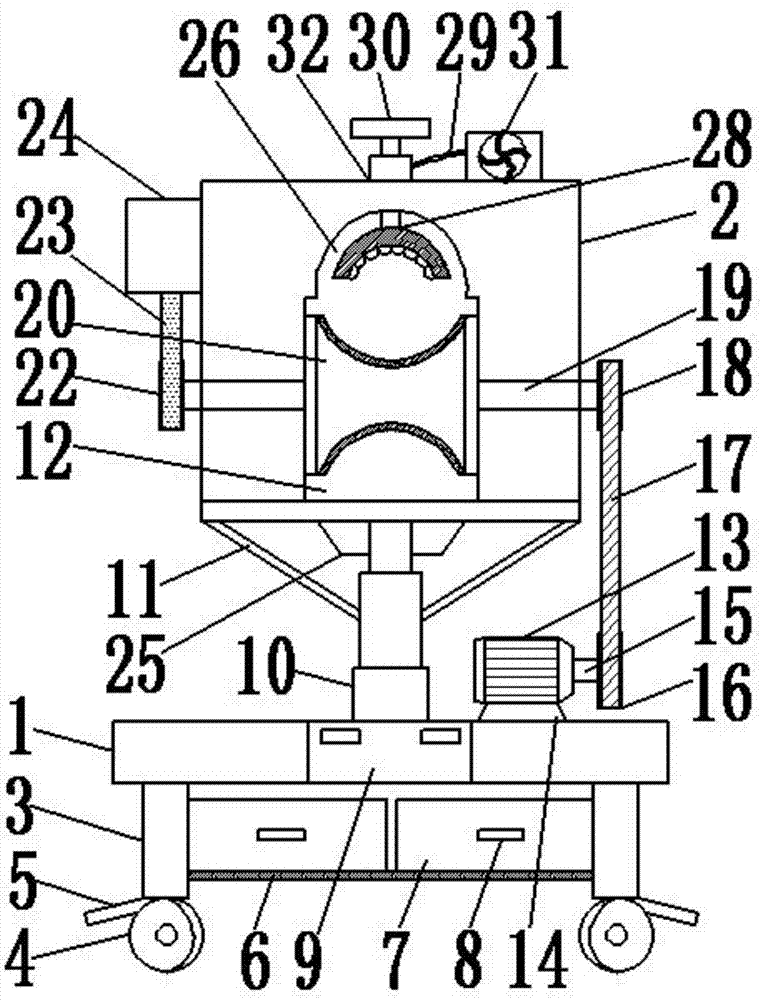

Electrified thermal stretching testing device and stretching testing method

InactiveCN103900911AShort response timeLong use safetyMaterial strength using tensile/compressive forcesTemperature controlStrength of materials

The invention provides an electrified thermal stretching testing device and a stretching testing method. The electrified thermal stretching testing device comprises a unidirectional stretching testing device and a temperature control device, wherein the unidirectional stretching testing device is insulated by a clamp. A temperature measurement unit, a power adjuster and a power supply device in the temperature control device are connected in series. According to the electrified thermal stretching testing device, an infrared temperature measurement sensor is used for monitoring the surface temperature of an electrified stretching testing piece at any time, so that the electrified thermal stretching testing device has the characteristics of rapid responding time, no contact, safety in utilization and long service life. Meanwhile, the temperature of the stretching testing piece in an electrified thermal stretching process can be basically stable so that the temperature of the stretching testing piece can be stabilized at different temperatures so as to be tested, and the research range of mechanical properties of materials is enlarged.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

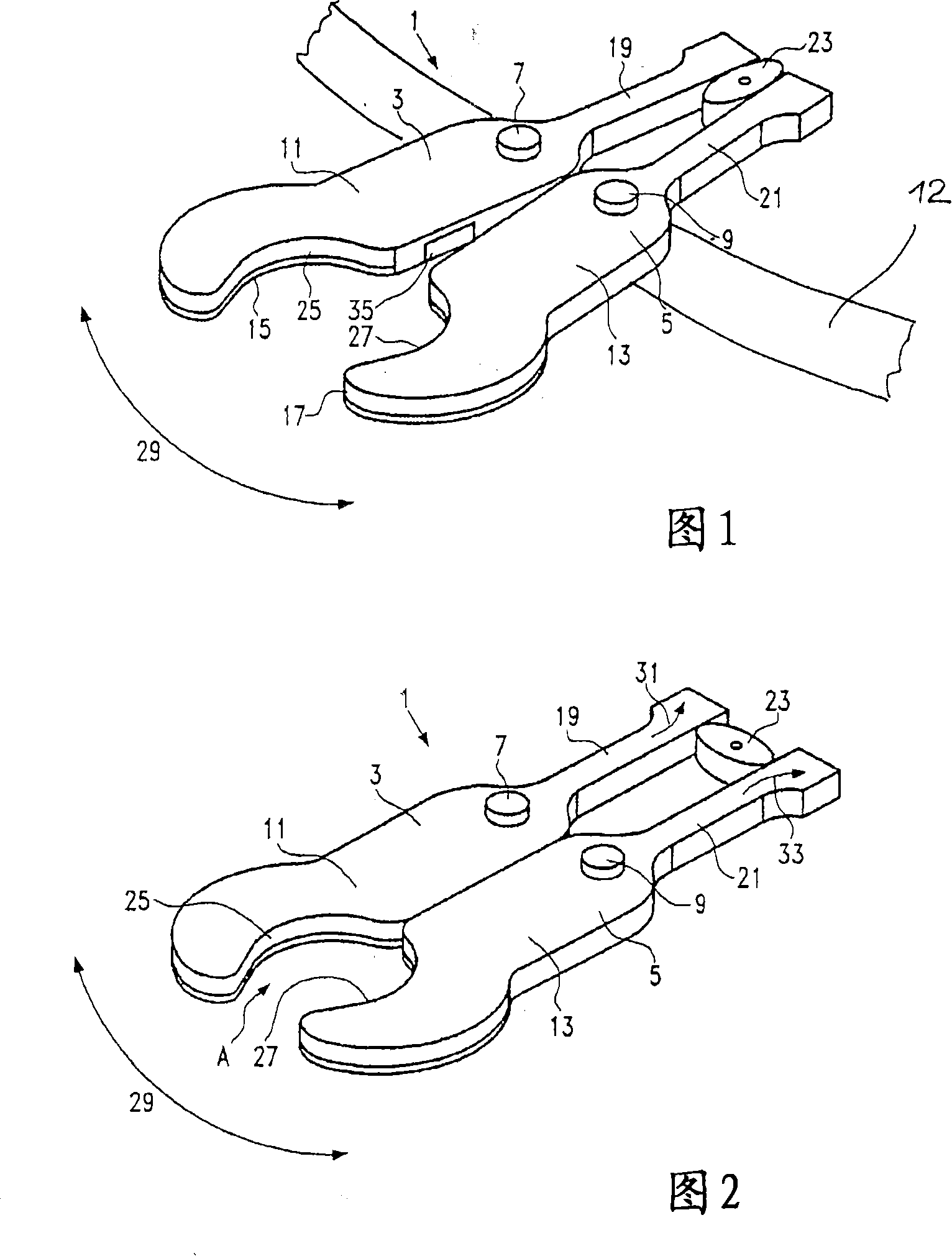

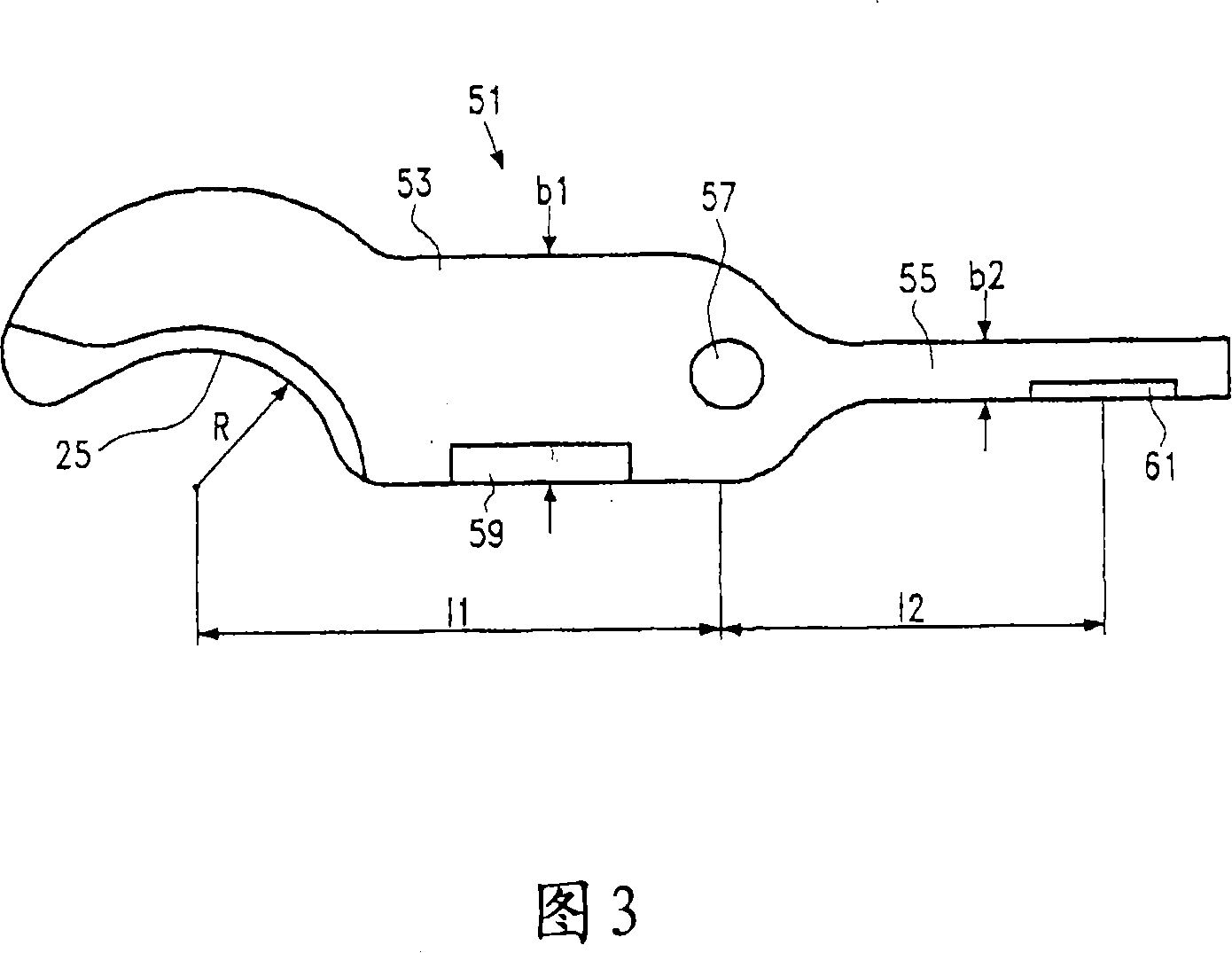

Clamp for holding vessels

Owner:KRONES AG

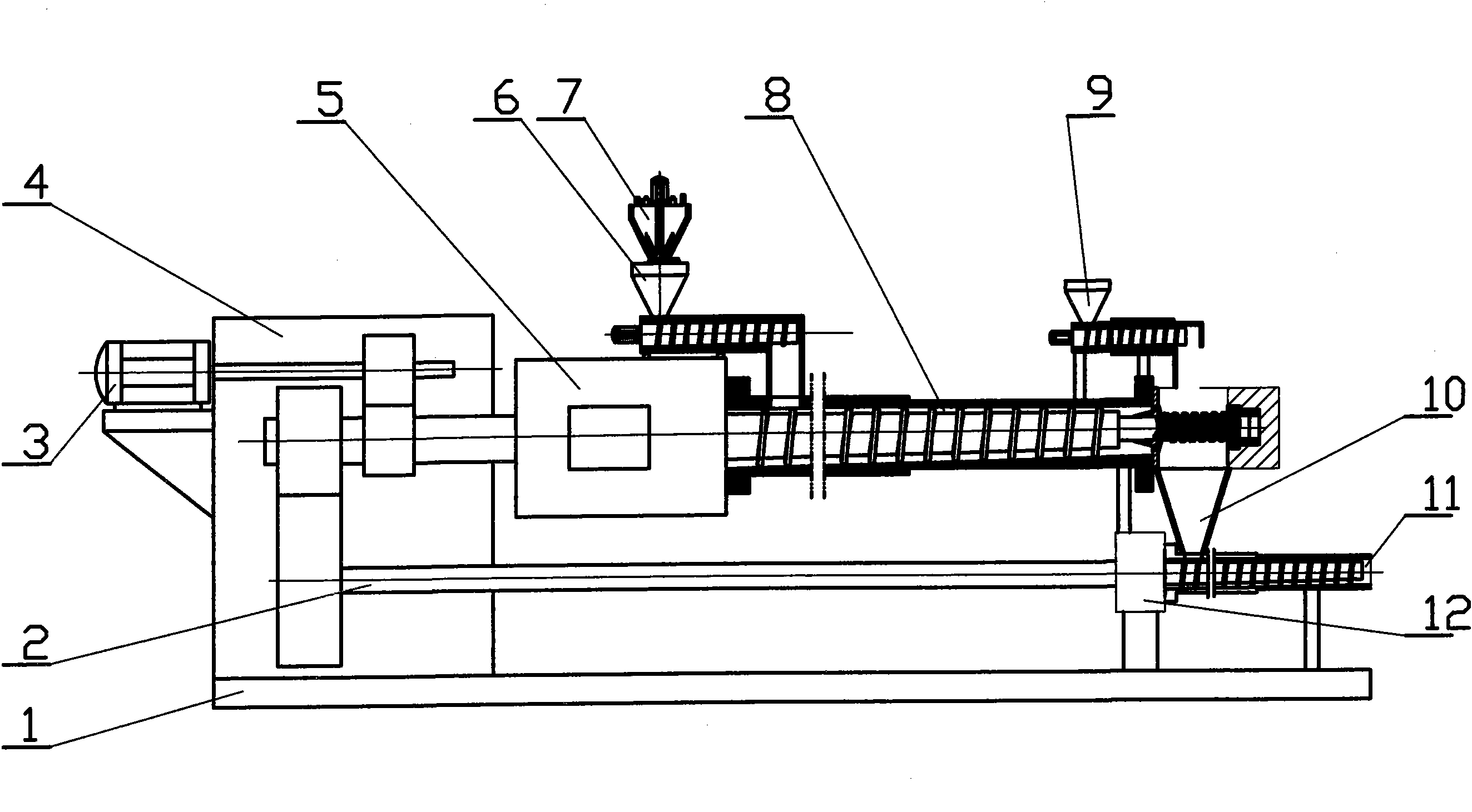

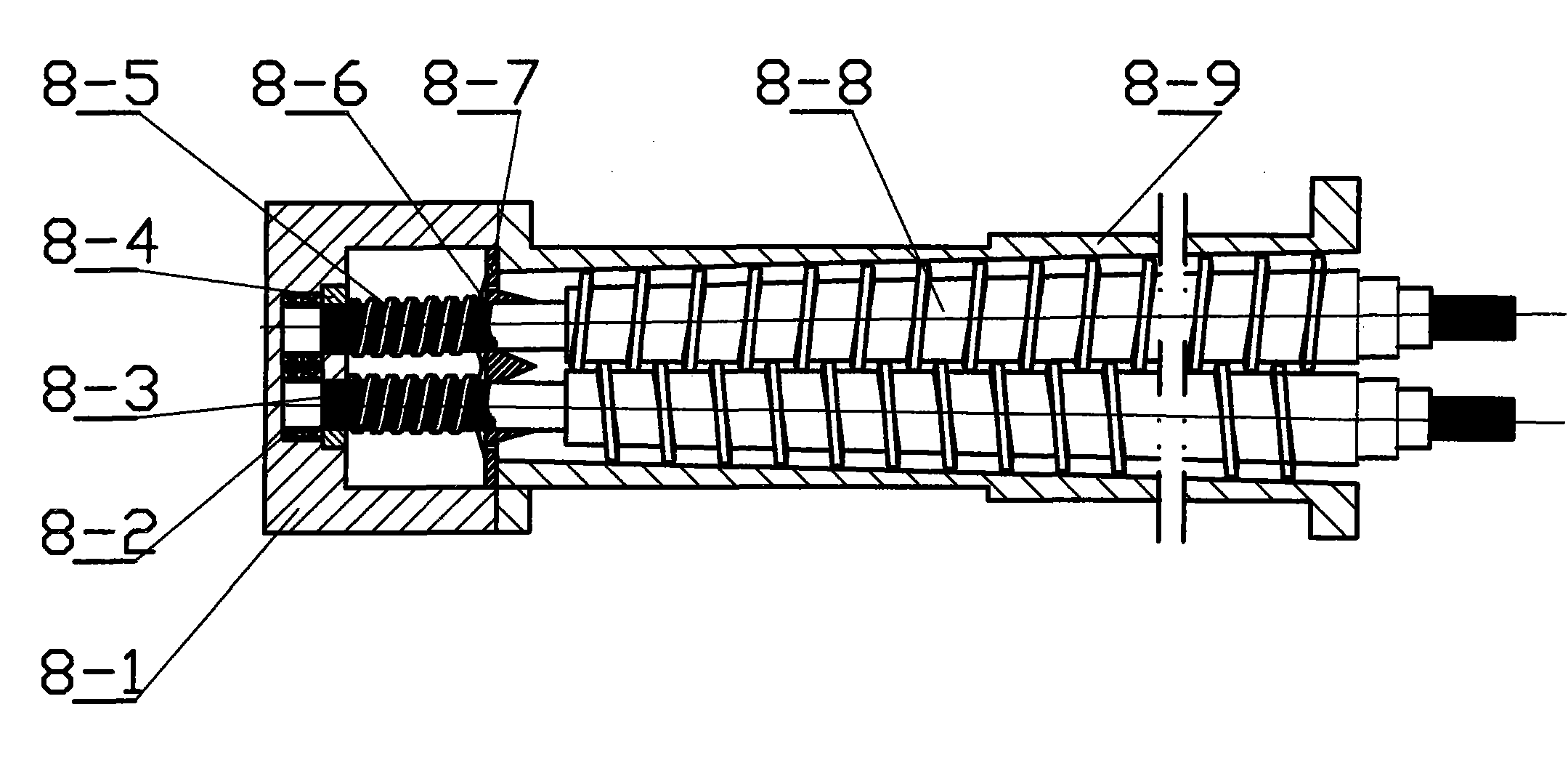

Multifunctional wood-plastic composite material one-step method extruder

A novel multifunctional wood-plastic composite material one-step method extruder is provided. A motor is connected with a twin-screw gear distribution box and a speed-adjusting speed-varying box respectively through a gear speed-varying box and an extending transmission shaft; the gear distribution box is connected with a twin-screw granulator; a material mixing device is connected with the twin-screw granulator through a twin-screw feeder; a master batch feeding device is connected with the twin-screw granulator; a connecting barrel is connected with the twin-screw granulator and a single-screw extruder; the single-screw extruder is connected with the speed-adjusting speed-varying box; all devices are connectedly arranged on a machine base. The extruder is mainly used for extrusion processing of a wood-plastic composite material and composite materials having similar properties, can also be used just for granulation, can complete production by the one-step method after raw materials are mixed, has high efficiency, and saves energy; the extruder completely avoids friction damage of screws and screw tubes, thereby improving the usage usefulness of equipment; the extruder allows extrusion processed products to have various wood imitation patterns; and the extruder can be applied to composite materials with various systems and much extrusion capacity.

Owner:江苏文嘉勄木塑装备制造有限公司

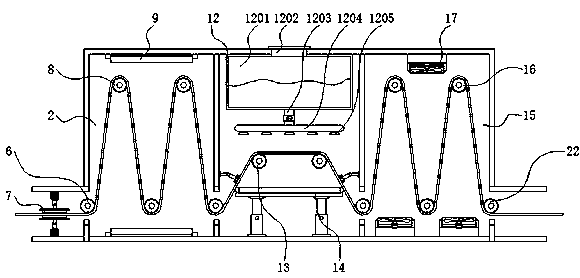

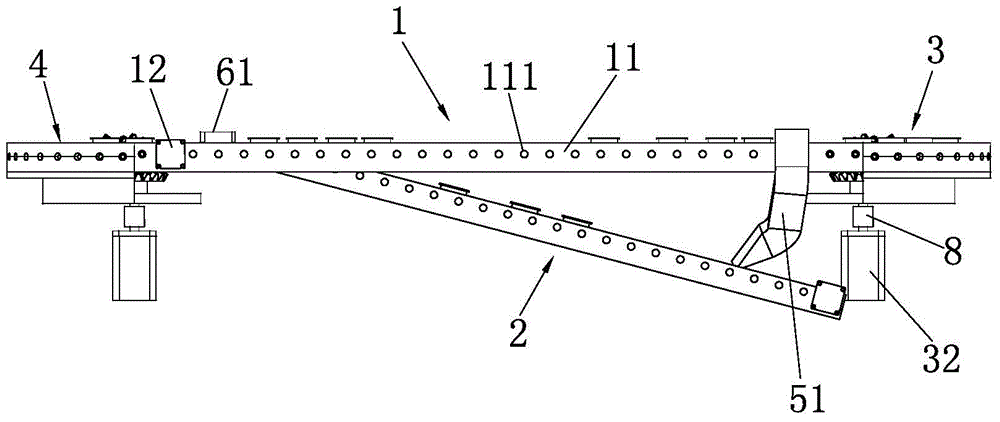

Chemical fiber bobbin continuous transferring and feeding device for chemical fiber processing

ActiveCN111039094AHigh degree of automationSmooth and accurate reciprocating translational movementFilament handlingFiberGear wheel

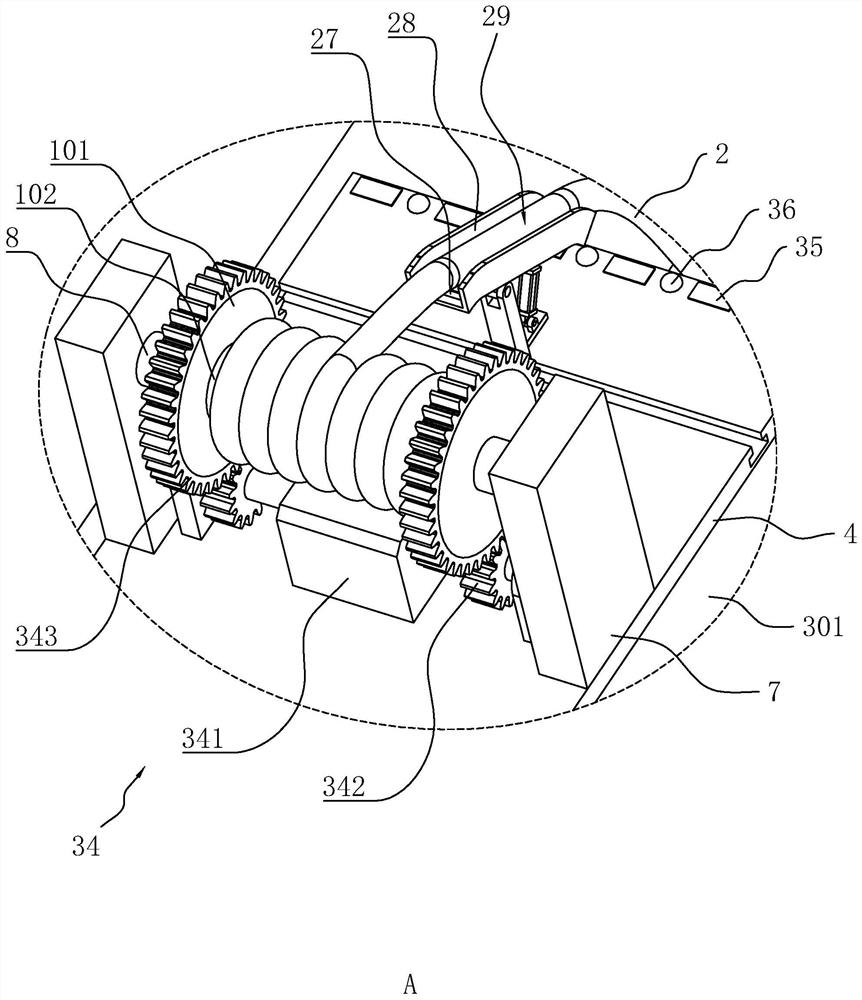

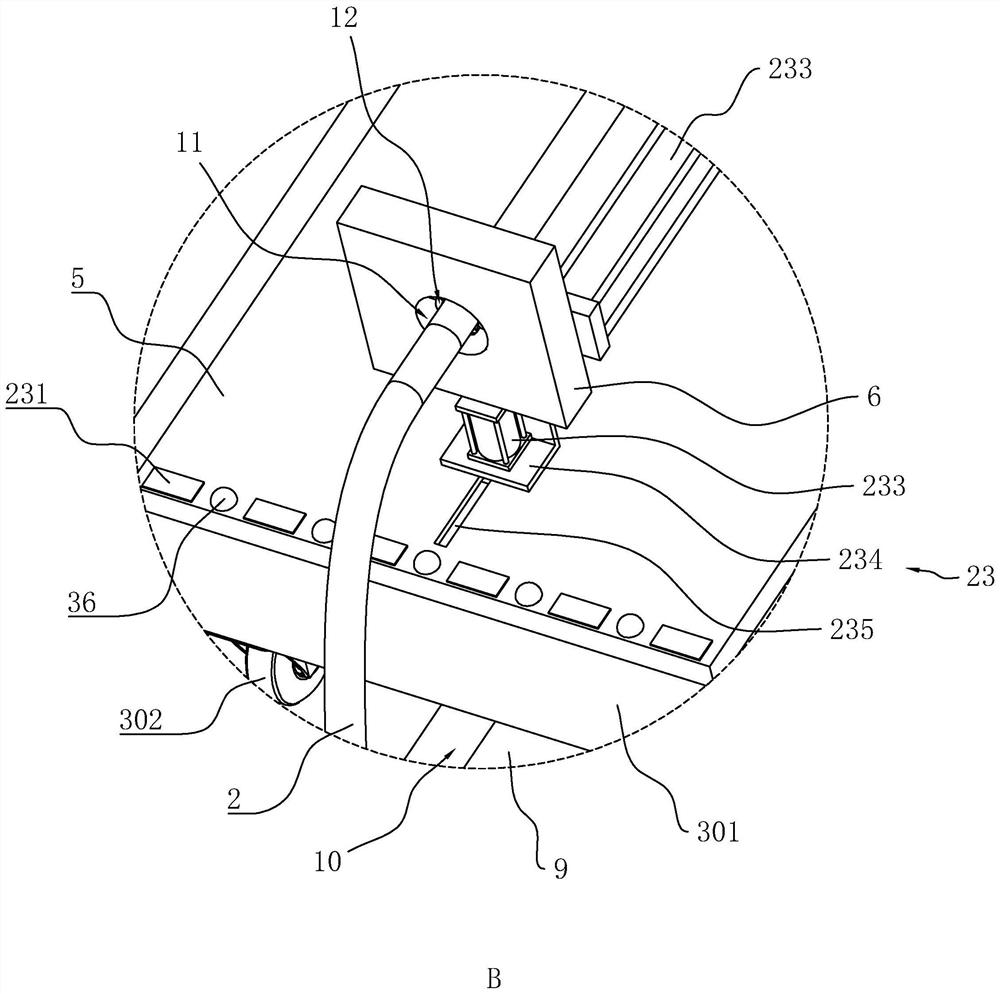

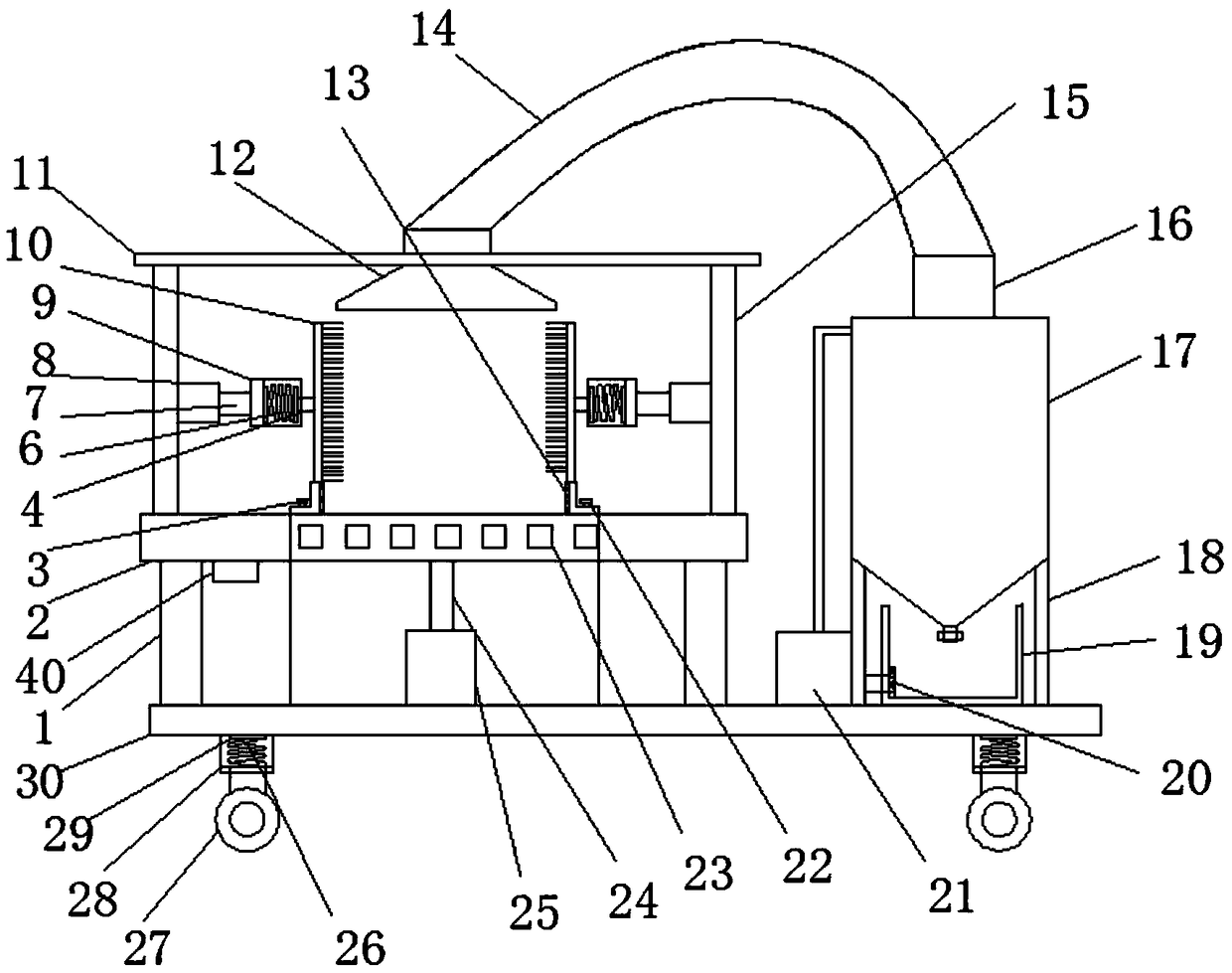

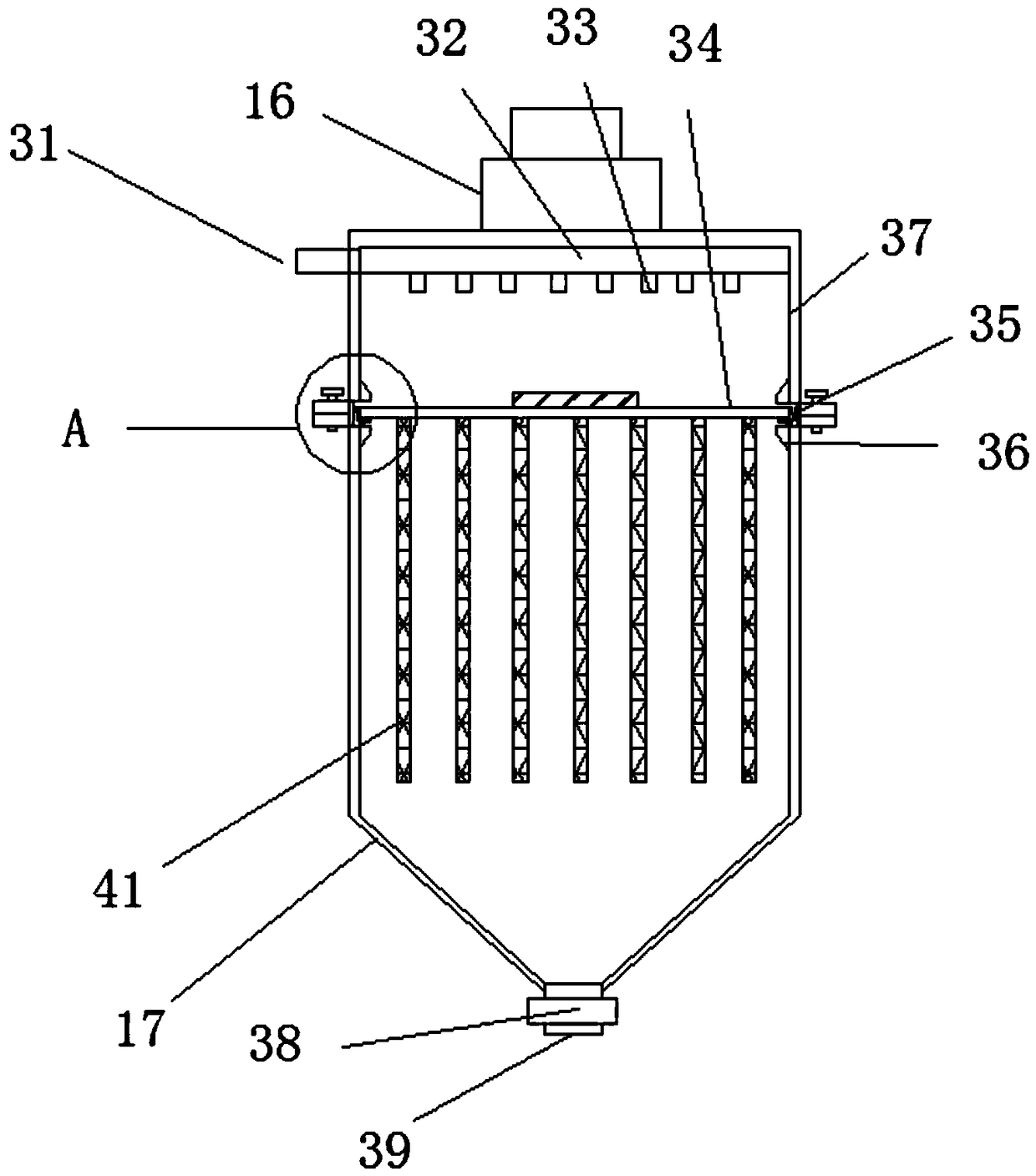

The invention discloses a chemical fiber bobbin continuous transferring and feeding device for chemical fiber processing and belongs to the field of textile processing mechanical equipment. Accordingto the chemical fiber bobbin continuous transferring and feeding device for chemical fiber processing of the invention, a bobbin feeding mechanism is horizontally and fixedly arranged at the lower side of a bobbin guiding support; a bobbin transferring mechanism above one side of the bobbin feeding mechanism is vertically arranged on the bobbin guiding support; a push rod rotating slope is arranged on the upper side of a reciprocating rotating cam; the middle of a reciprocating rotating rod is hinged to the upper side of a rotating rod supporting seat; a bobbin guiding and feeding pipe locatedabove the reciprocating rotating rod is fixedly arranged on the bobbin guiding support; a lifting transferring guide plate is slidably arranged on a lifting fixing sleeve in a vertical direction; a gear rotating support at the lower end of the lifting transferring guide plate is vertically and rotationally connected with a lifting rotating gear; and a bobbin clamping mechanism is fixedly arrangedon one side of the lifting rotating gear in the radial direction of the lifting rotating gear. The chemical fiber bobbin continuous transferring and feeding device is reasonable in structural design,can efficiently, stably and sequentially feed and machine chemical fiber bobbins one by one, is high in automation degree, and meets processing and using requirements.

Owner:桐乡市富昌化纤股份有限公司

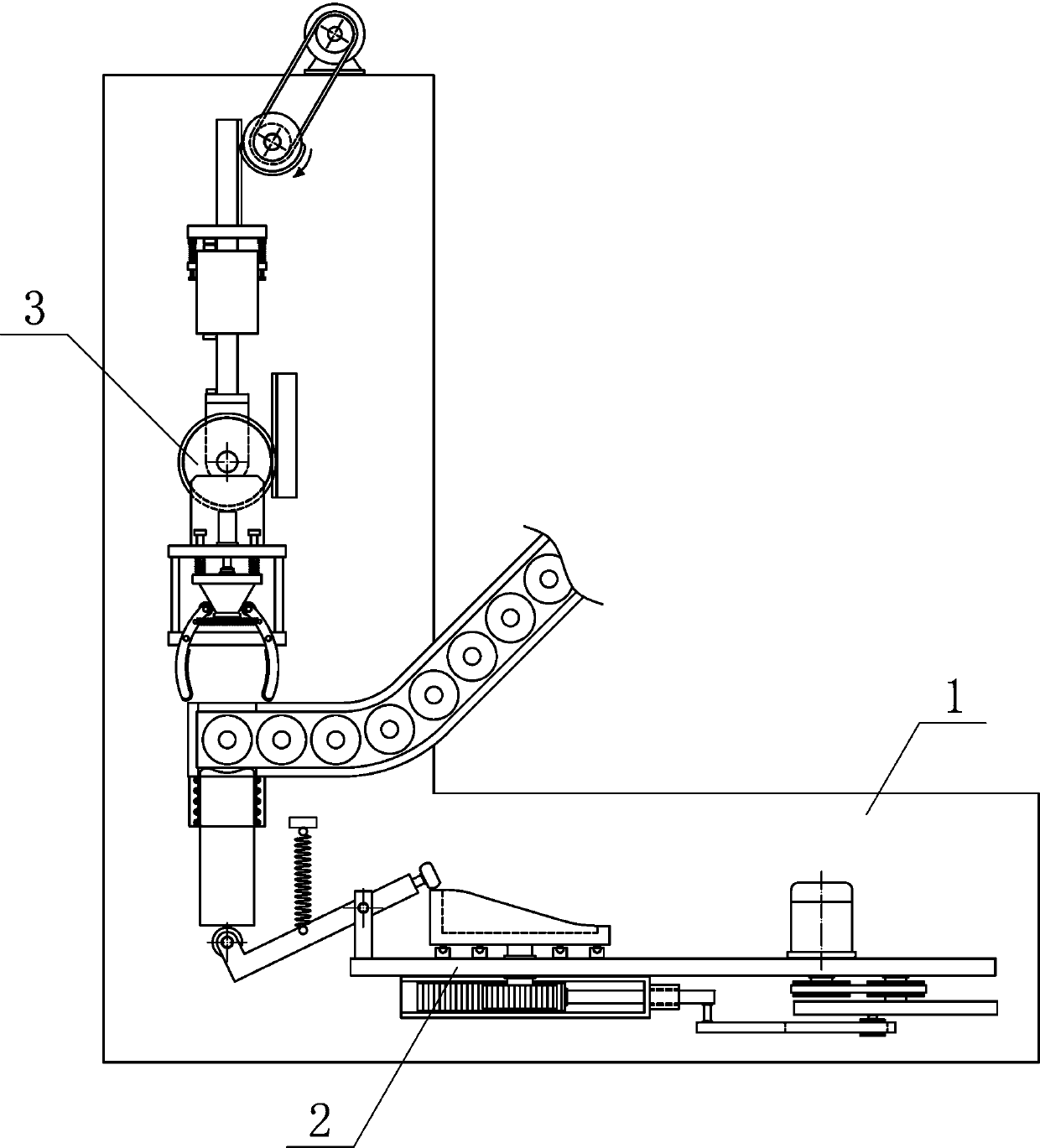

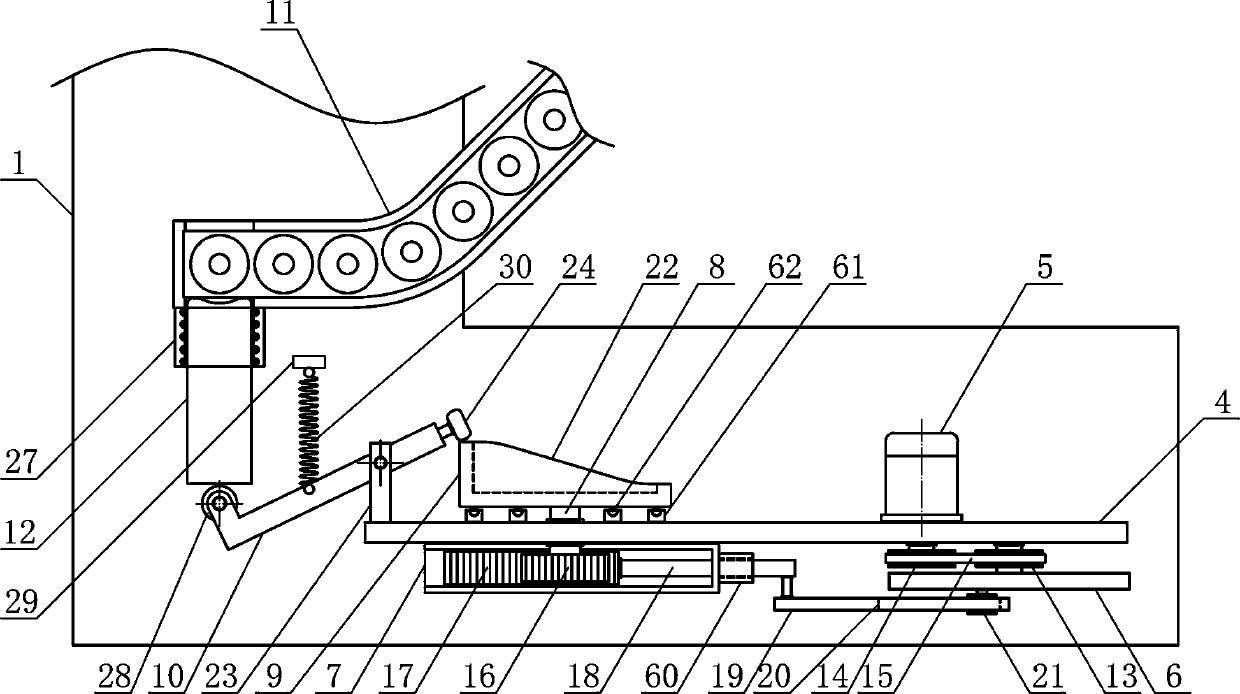

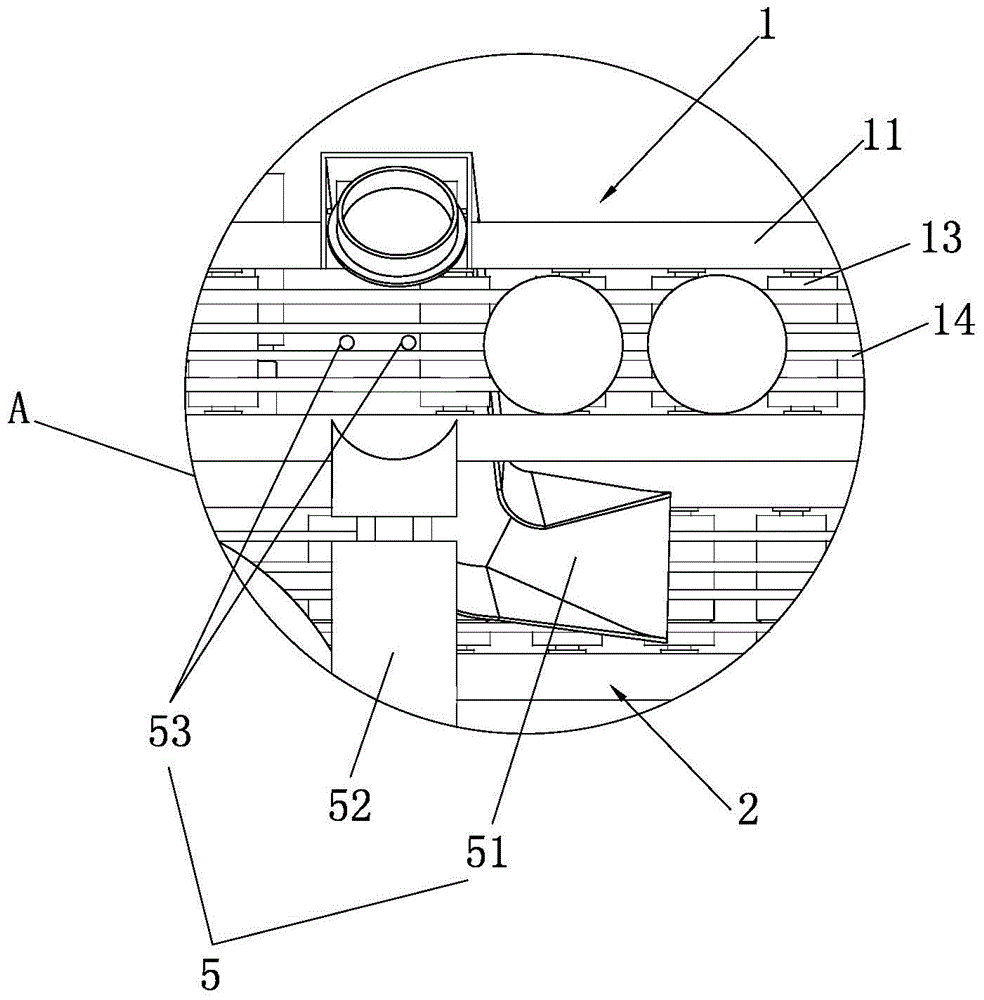

Automatic bottom cap mounting machine

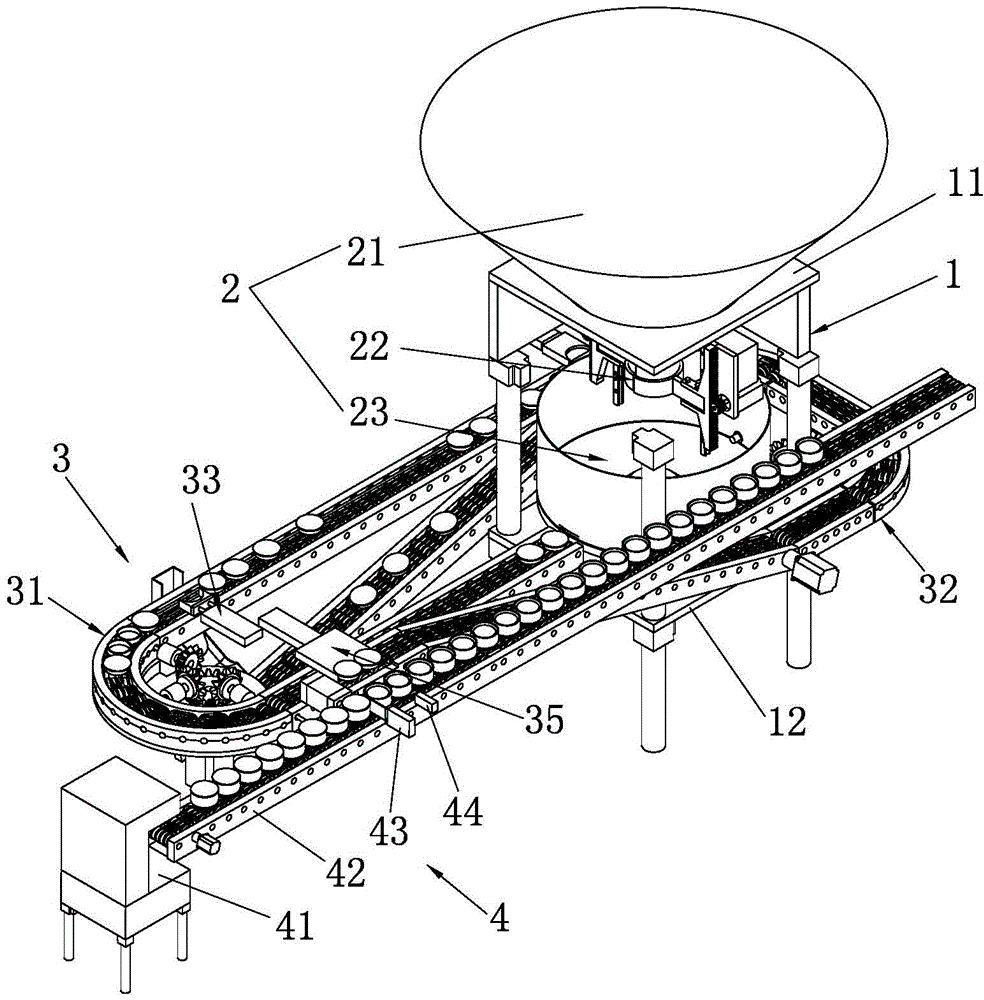

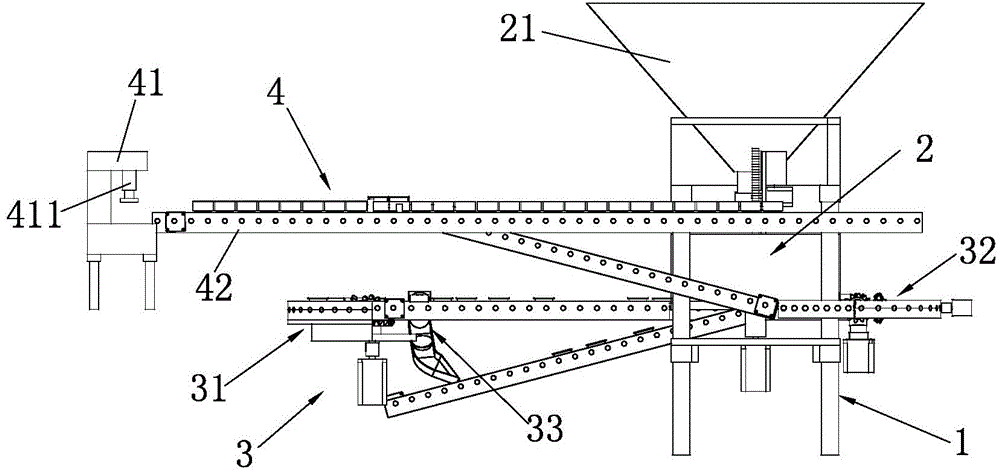

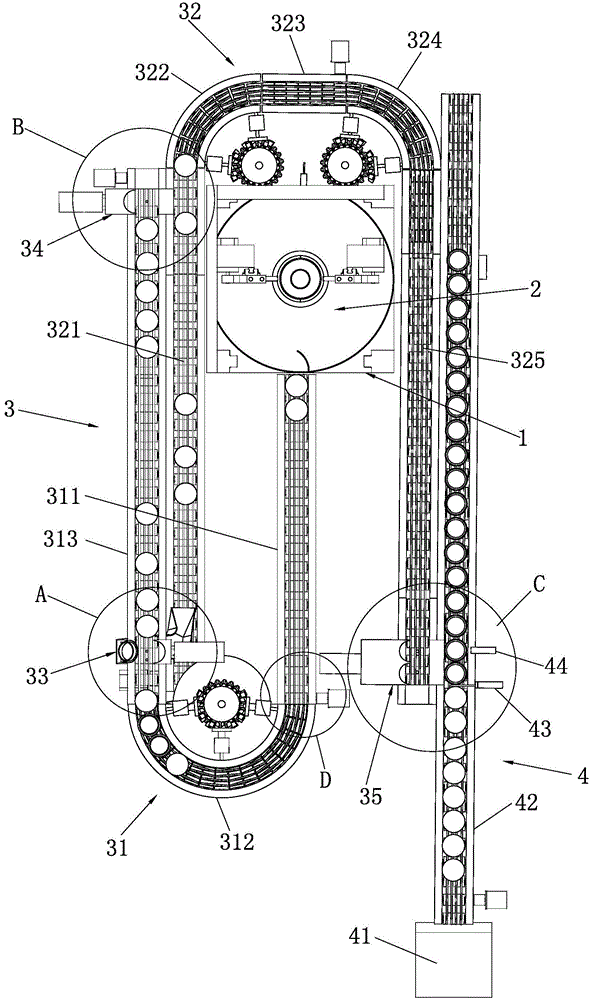

ActiveCN104828760ASimple equipment structureEasy to operateFlanged caps applicationConveyor partsEngineeringMaterial supply

The invention provides an automatic bottom cap mounting machine. The automatic bottom cap mounting machine comprises a machine frame and a control mechanism, wherein a first flat plate and a second flat plate which are arranged up and down in a spaced manner and are used for mounting components are arranged on the machine frame; the control mechanism is used for controlling the operating of the overall automatic bottom cap mounting machine; the automatic bottom cap mounting machine further comprises a material supply device which is used for storing and automatically releasing bottom caps, a cap arranging device which is used for arranging the bottom caps, and a cap compressing device which is used for compressing the bottom caps to bottle bodies, wherein the feeding end of the cap arranging device is connected with the material supply device; the discharge end of the cap arranging device is connected with the cap compressing device. The automatic bottom cap mounting machine is simple in structure, easy to operate, low in manufacturing cost, long in service life and easy to maintain and repair; the production cost and the labor intensity of a worker can be effectively reduced; the cap arranging and compressing effects are good; the production efficiency is greatly improved.

Owner:QUANZHOU HUASHUO IND

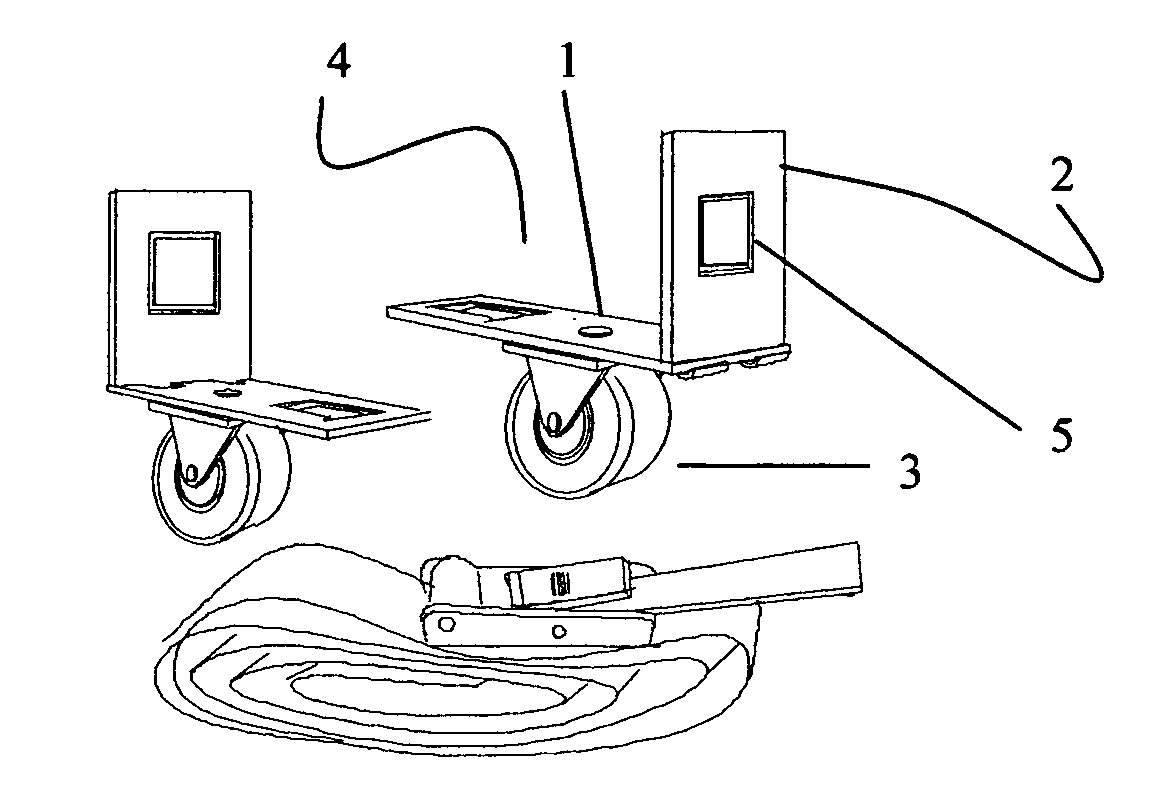

Cable ground laying device

ActiveCN111682455AAvoid affecting power supply reliabilityExtended service lifeApparatus for laying cablesStructural engineeringElectric cables

The invention relates to a cable ground laying device. The invention relates to the technical field of cable laying. The cable ground laying device comprises two trolleys which are oppositely erectedon the ground and located above a cable trench, a pay-off base and a traction base which are installed on the two trolleys respectively, a clamping table which is arranged on the traction base, two supporting tables which are oppositely arranged on the pay-off base, and installation columns which are rotationally arranged on the opposite side walls of the two supporting tables respectively. The side wall of the clamping table is provided with a fixing groove for insertion of a cable. A locking assembly used for fixing the cable is arranged in the fixing groove. An automatic receding assembly used for preventing the cable from making contact with the side wall of the traction base is arranged on the upper surface of the traction base. The two installation columns are fixedly connected withthe two side walls of two cable reels respectively, and a driving assembly used for driving the cable reels to rotate is arranged on the pay-off base. The laying device replaces manpower to drag the cable for laying, which saves time and labor, and improves the cable laying efficiency. Friction damage between the cable and the ground can be prevented, and the power supply reliability of the cableis prevented from being affected.

Owner:南京东瑞水电工程有限公司

Convenient-to-adjust dust removal device for computer production

InactiveCN108889757AGet out quicklyQuick dust removalElectrostatic cleaningDirt cleaningChinese charactersSpray nozzle

The invention belongs to the technical field of computers and particularly relates to a convenient-to-adjust dust removal device for computer production. In order to solve the problems that an existing dust removal device has a poor dust removal effect and is inconvenient to fix and adjust, the following scheme is put forward. The device comprises a base, four first supporting columns distributedat equal intervals are connected to one side of the top of the base through bolts separately, a table body is connected to the tops of the first supporting columns through bolts, and a circular through hole is formed in the top of the table body; a rotation disc is slidingly connected into the circular through hole. According to a dust suction machine, a dust suction hopper is subjected to air suction through a dust suction pipe, dust enters a dust removal hopper, a vibration exciter is connected to the top of a frame shaped like the Chinese character 'tian', and dust on static dust removal brushes can be shaken to the bottom of the dust removal hopper; through a control valve, the dust is discharged into a residue storage pond through a residue discharge port, a high-pressure water pump presses high pressure water into a high pressure water pipe extending in a dust removal hopper cover, the high pressure water is sprayed out through high pressure spray nozzles, the dust removal hopperand the static dust removal brushes can be cleaned, and dust removal can be quickly conducted.

Owner:ZHENGZHOU CHENGHE INFORMATION TECH CO LTD

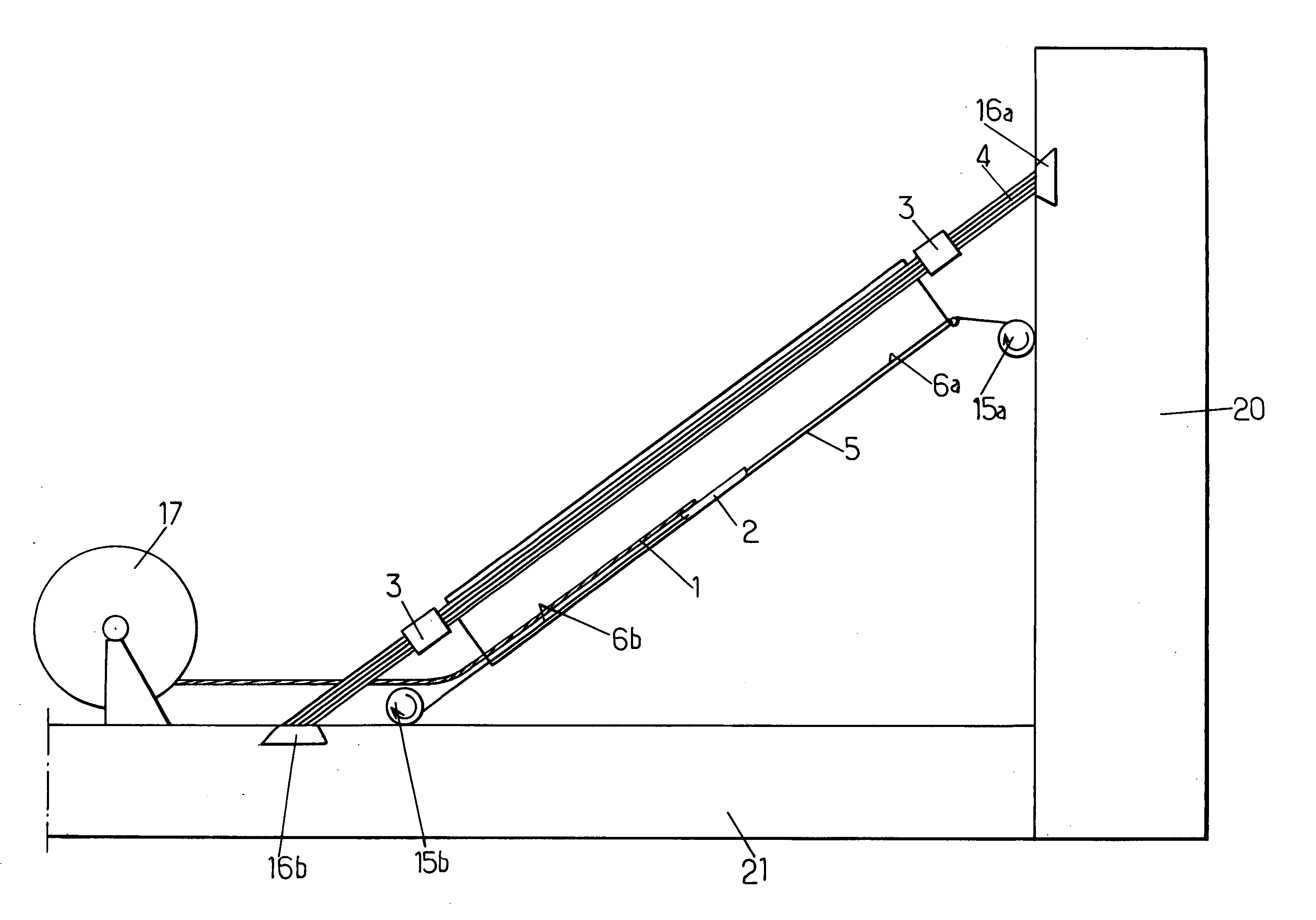

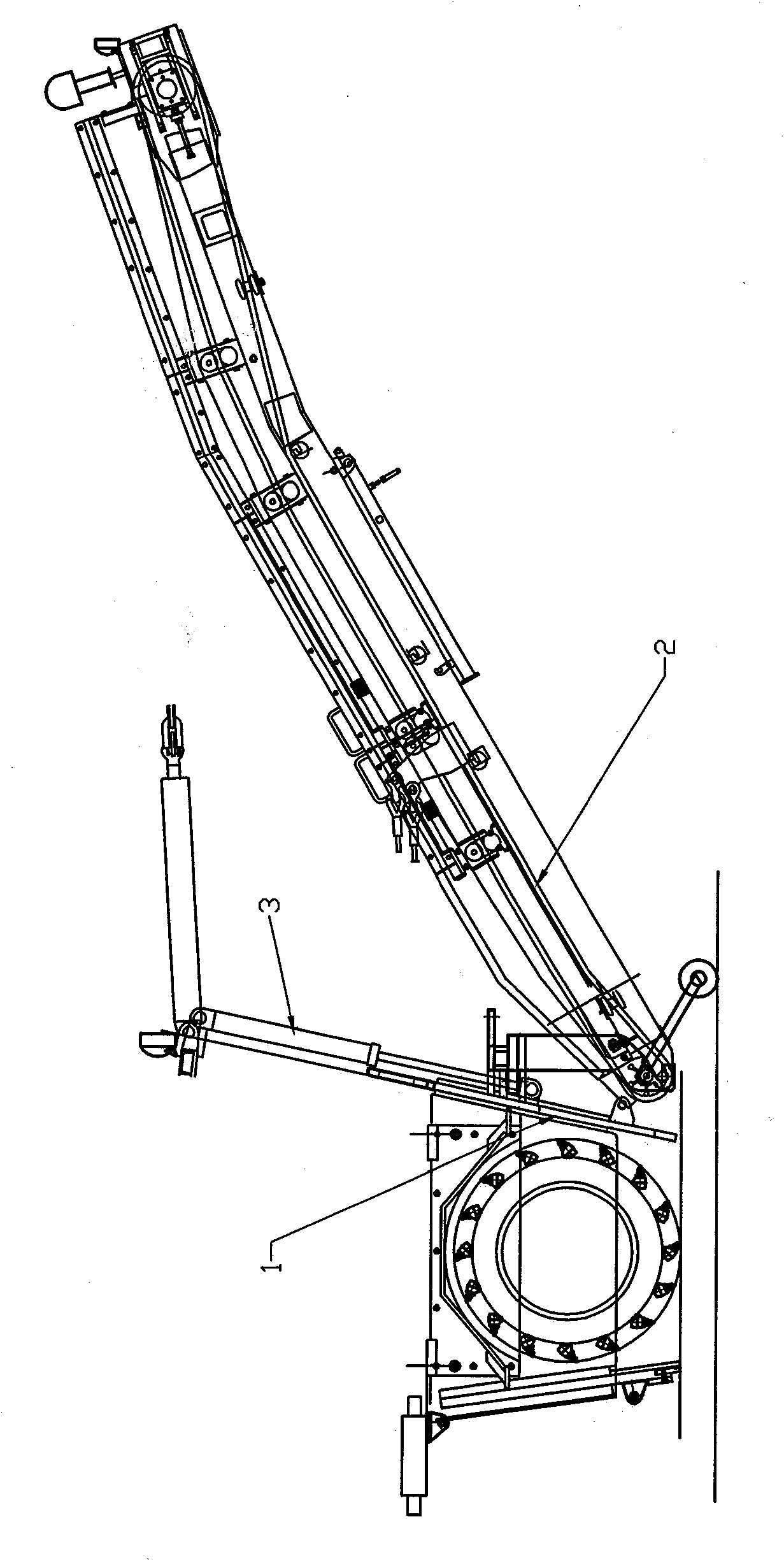

Method for erecting a stay

ActiveUS20060185318A1Avoid frictional damageIncrease the sectionCable-stayed bridgeBuilding repairsEngineeringArchitectural engineering

Owner:FREYSSINET INT STUP

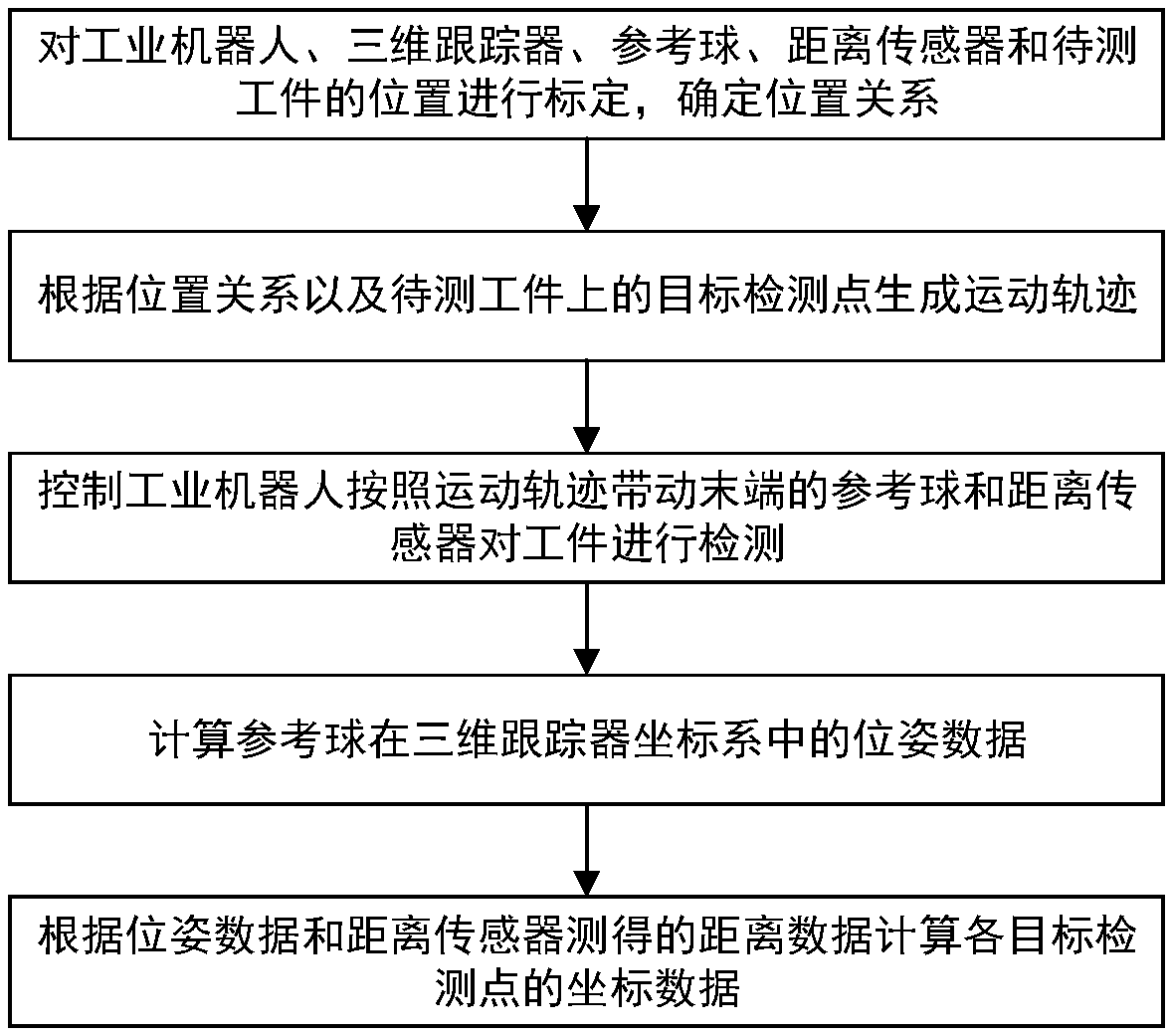

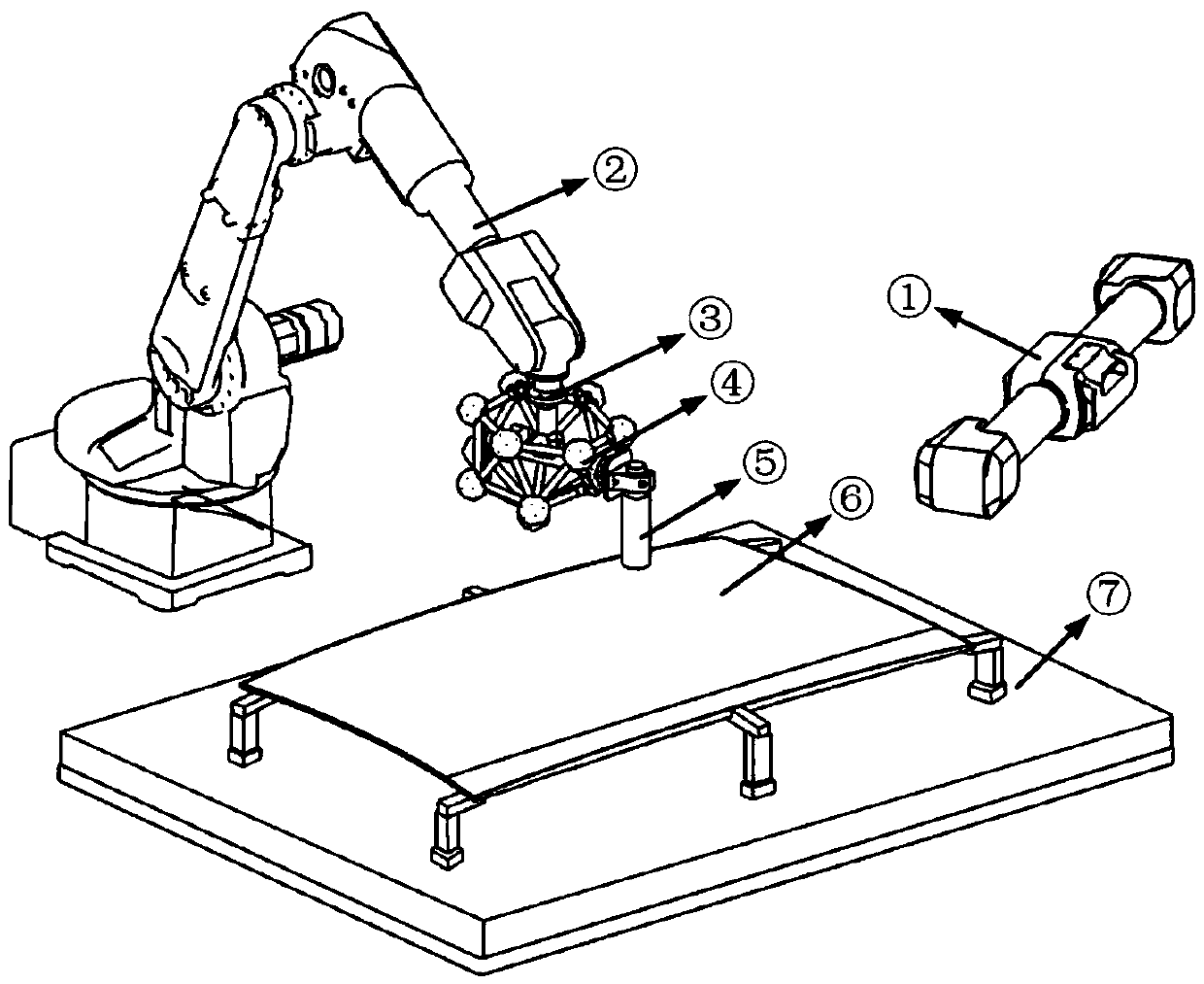

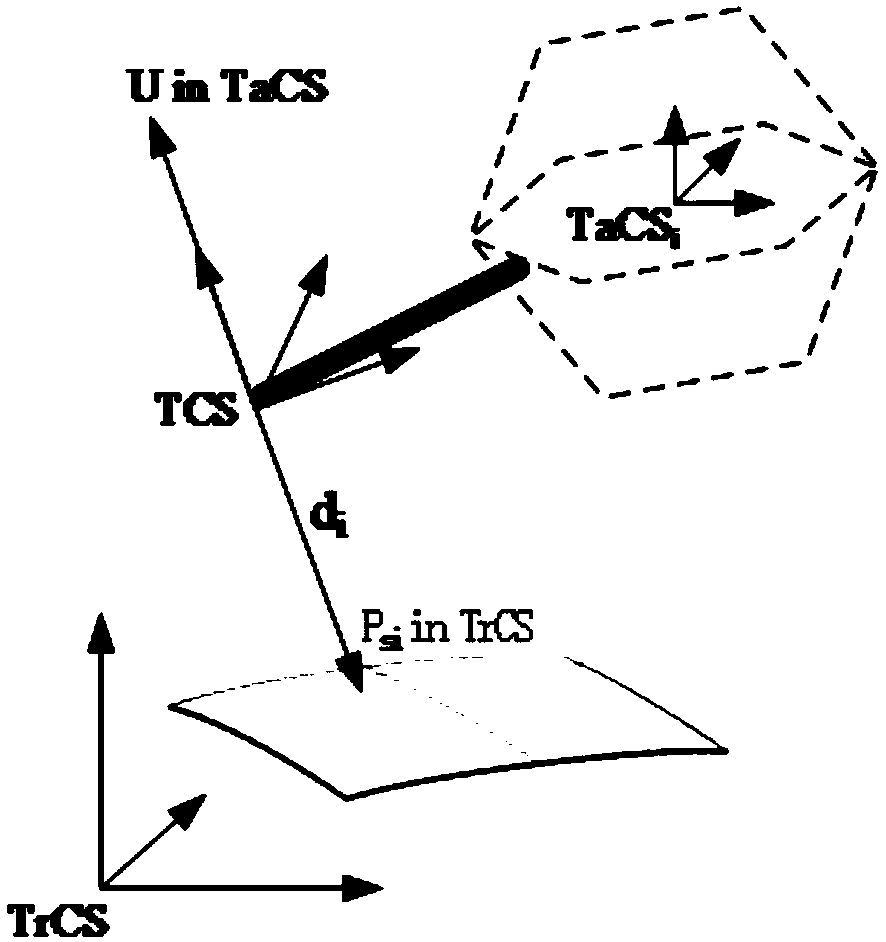

Automatic detecting method and system for product appearance

ActiveCN109579766AAvoid frictional damageRealize flexible detectionMechanical measuring arrangementsWorking environmentEngineering

The invention discloses an automatic detecting method and system for product appearance. The automatic detecting method comprises the following steps that S1, an industrial robot is controlled to drive a reference ball and a distance sensor which are arranged at the tail end of the industrial robot to move according to a preset moving track to enable the reference ball and the distance sensor to detect a target detecting point on a to-be-detected workpiece; S2, a coordinate of target points on the reference ball which is shot in a tracking mode by a three-dimensional tracking device is obtained, and a pose of the reference ball under a coordinate system of the three-dimensional tracking device is calculated; and S3, coordinates of the target detecting points are calculated according to thepose of the reference ball under the coordinate system of the three-dimensional tracking device and distance data detected by the distance sensor. According to the automatic detecting method and system for the product appearance, detection of the appearance of the workpiece is carried out by the industrial robot, workpiece products of various shapes and various sizes can be detected under the condition that detecting equipment does not need to be changed, the detecting precision is high, the automatic detecting method and system can be adapted to complex and changeable working environments, and friction damage in the detecting process of the workpiece is avoided.

Owner:苏州瀚华智造智能技术有限公司

Polyurethane logistics conveyer belt and manufacturing method thereof

ActiveCN105668121AHigh bonding strengthHigh strengthConveyorsLamination ancillary operationsPolyesterFiber

The invention discloses a polyurethane logistics conveyer belt and a manufacturing method of the polyurethane logistics conveyer belt. The polyurethane logistics conveyer belt comprises a middle framework fabric layer, polyurethane adhesive dipped in the middle framework fabric layer and a wear-proof thermoplastic polyurethane elastomer film surface layer. Polyester fiber base fabric is dipped into a polyurethane adhesive solution, dried and shaped, the surface of the polyester fiber base fabric is attached to an extruded thermoplastic polyurethane elastomer film, polishing treatment and other processes are conducted on the back face of the polyester fiber base fabric, and then the polyurethane logistics conveyer belt is manufactured. The conveyer belt is an open conveyer belt, and steel buckle flocking connectors are adopted. Compared with the prior art, the polyurethane logistics conveyer belt has the excellent properties of being low in mass, low in energy consumption, resistant to wear, free of burrs, resistant to low temperature and the like. Especially, flocking is conducted at the positions of the steel buckle connectors, steel buckles and a rolling wheel can be prevented from generating friction damage, and the service life of the conveyer belt is prolonged.

Owner:AA IND BELTING (SHANGHAI) CO LTD

Shell fabric disinfection equipment used for mask processing

InactiveCN111228528AEasy to cleanSmooth rotationMechanical cleaningPressure cleaningUltraviolet lightsDust control

The invention discloses shell fabric disinfection equipment used for mask processing, and relates to the technical field of mask processing. The shell fabric disinfection equipment comprises a machinebody, a disinfection mechanism and a drying chamber, wherein the inner left side of the machine body is provided with a sterilization chamber; a material inlet is arranged on the left lower part of the sterilization chamber; the upper side and the lower side of the outer part of the material inlet are independently fixedly provided with an outer baffle plate; the inner side of each outer baffle plate is provided with a dust removal mechanism; the inner side of the material inlet is provided with a fed material guide roller; the outer side of the fed material guide roller is provided with a shell fabric main body; a first traction roller is installed in the sterilization chamber; the upper side and the lower side of the inner wall of the sterilization chamber are independently provided with an ultraviolet lamp; and a disinfection chamber is arranged in the middle of the machine body. The shell fabric disinfection equipment has the beneficial effects that the arrangement of the dust removal mechanisms is convenient to clean the surface of the shell fabric main body, the position height of a soft hairbrush can be conveniently flexibly regulated through a telescopic rod to enable thesoft hairbrush to be laminated with the surface of the shell fabric main body, and therefore, the outer surface of the shell fabric main body can be subjected to dust removal through two groups of symmetric soft hairbrushes.

Owner:DONGGUAN RONGGONG AUTOMATION TECH CO LTD

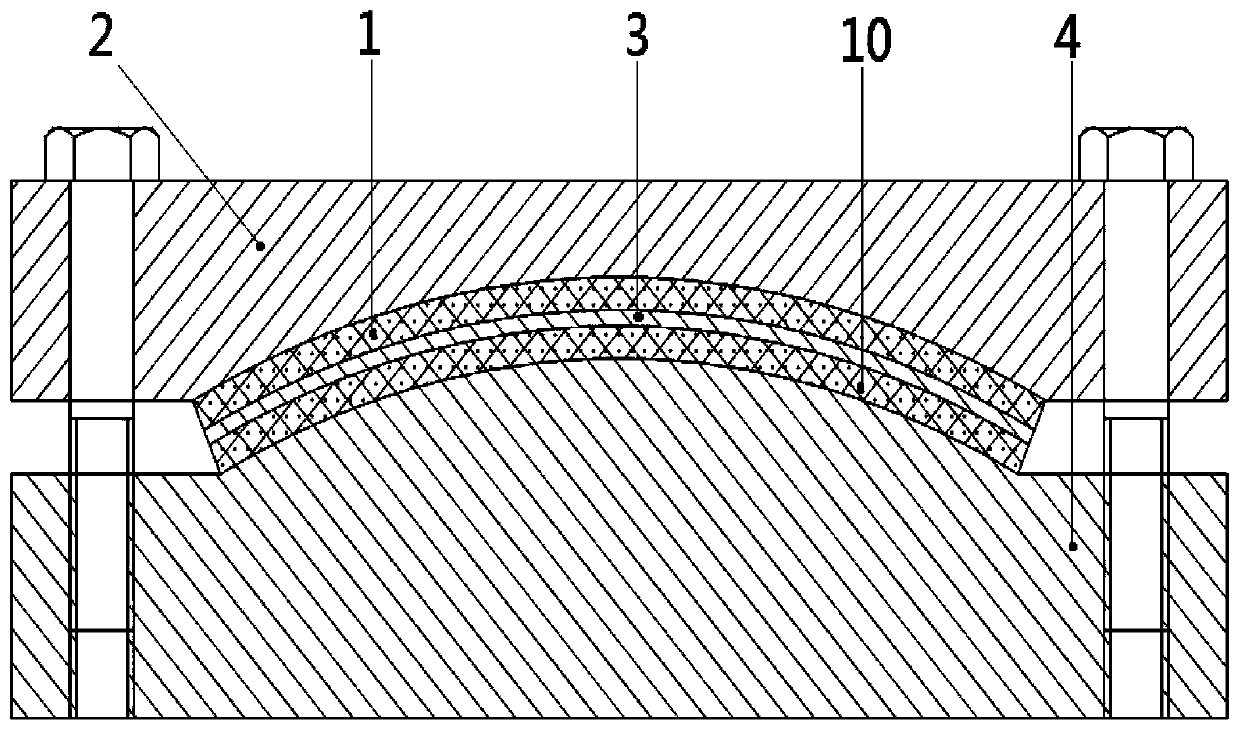

Vibration stress relief formation method and device under elastic deformation condition

The invention relates to a vibration stress relief formation method and a vibration stress relief formation device under an elastic deformation condition. Metal flat plates are enabled to be bent under the effect of a mold, the deformation is within an elastic range, the metal plates can be restored to the original shape after the mold is removed, bending prestress is loaded to the plates under the effect of the mold, a vibration stress relief device is connected, periodic exciting force is produced through a vibration exciter, the plates are enabled to reach a resonance state under the effect of the periodic exciting force, the internal bending prestress of the plates is relieved and homogenized through resonance, the metal plates are enabled to produce certain plastic deformation through the release process of the bending prestress and bent parts with bending radius which is equivalent to the curvature radius of the mold are obtained. The vibration stress relief formation method and the vibration stress relief formation device under the elastic deformation condition have the advantages that the defects that the mold manufacturing cost is high during formation of sheet metal parts and the resilience is difficult to control are overcome, the surface friction damages of the parts and the vibration energy losses during vibration stress relief are decreased, the surface quality of formed parts is improved, the production cycle is shortened and the production cost is decreased.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

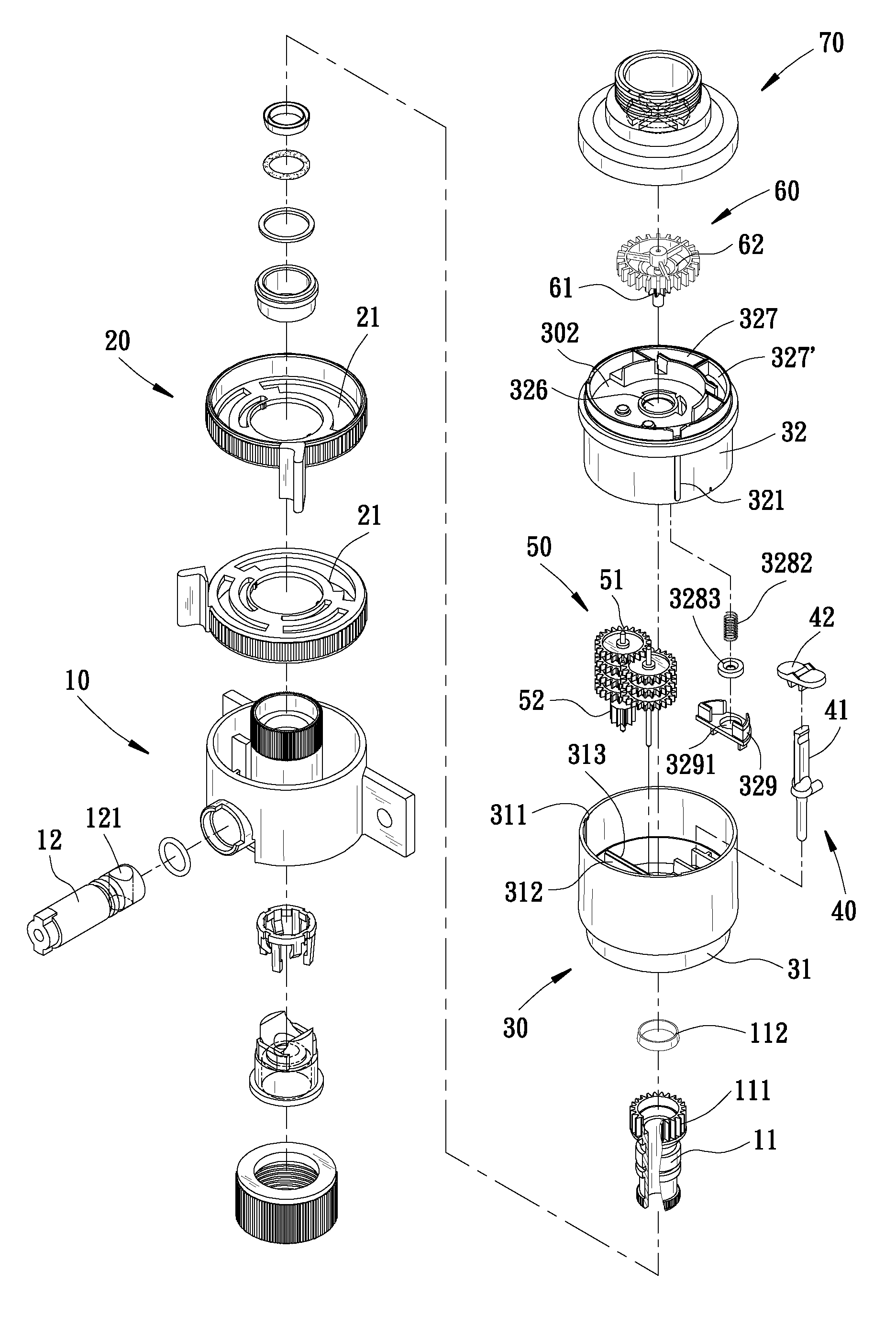

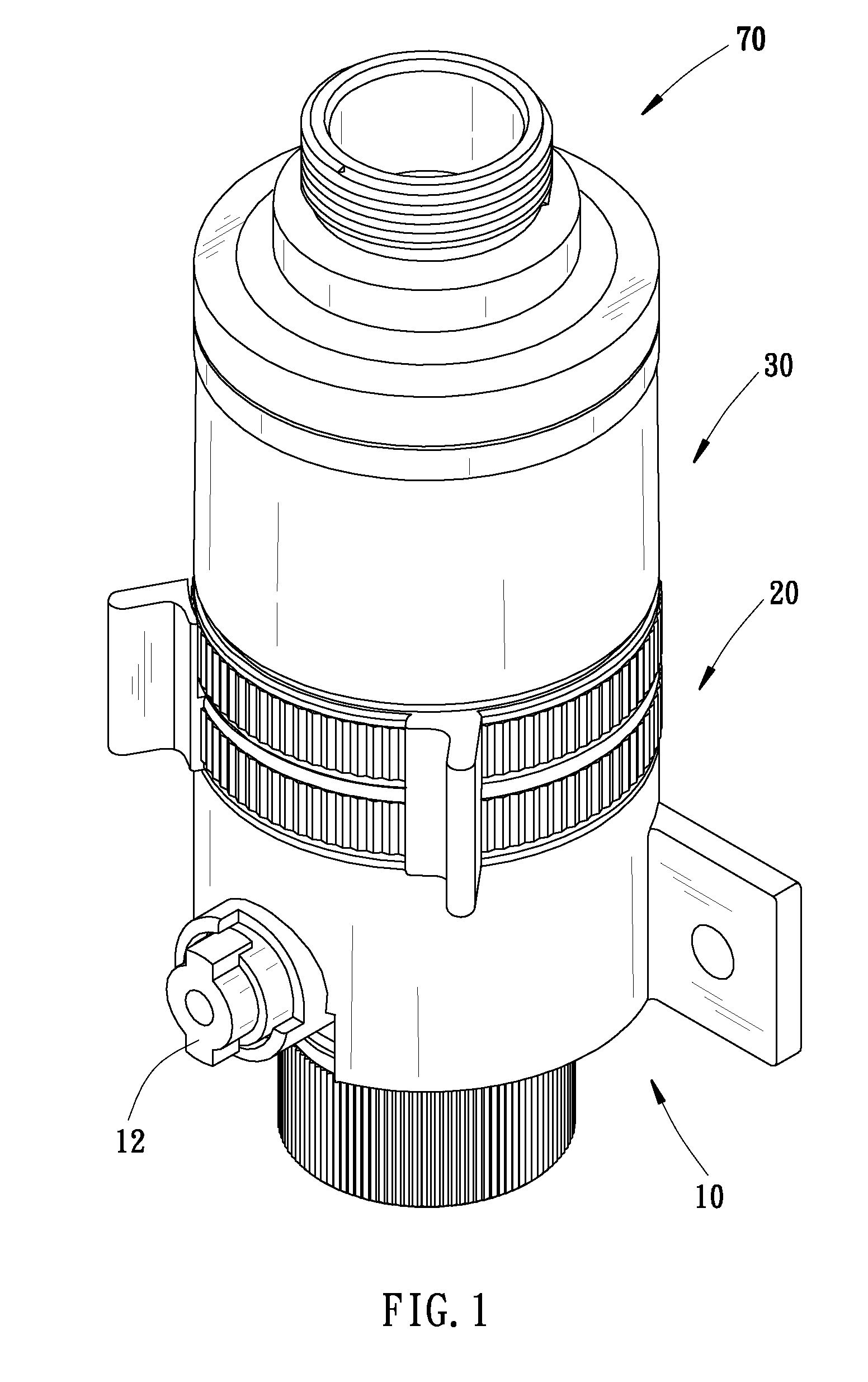

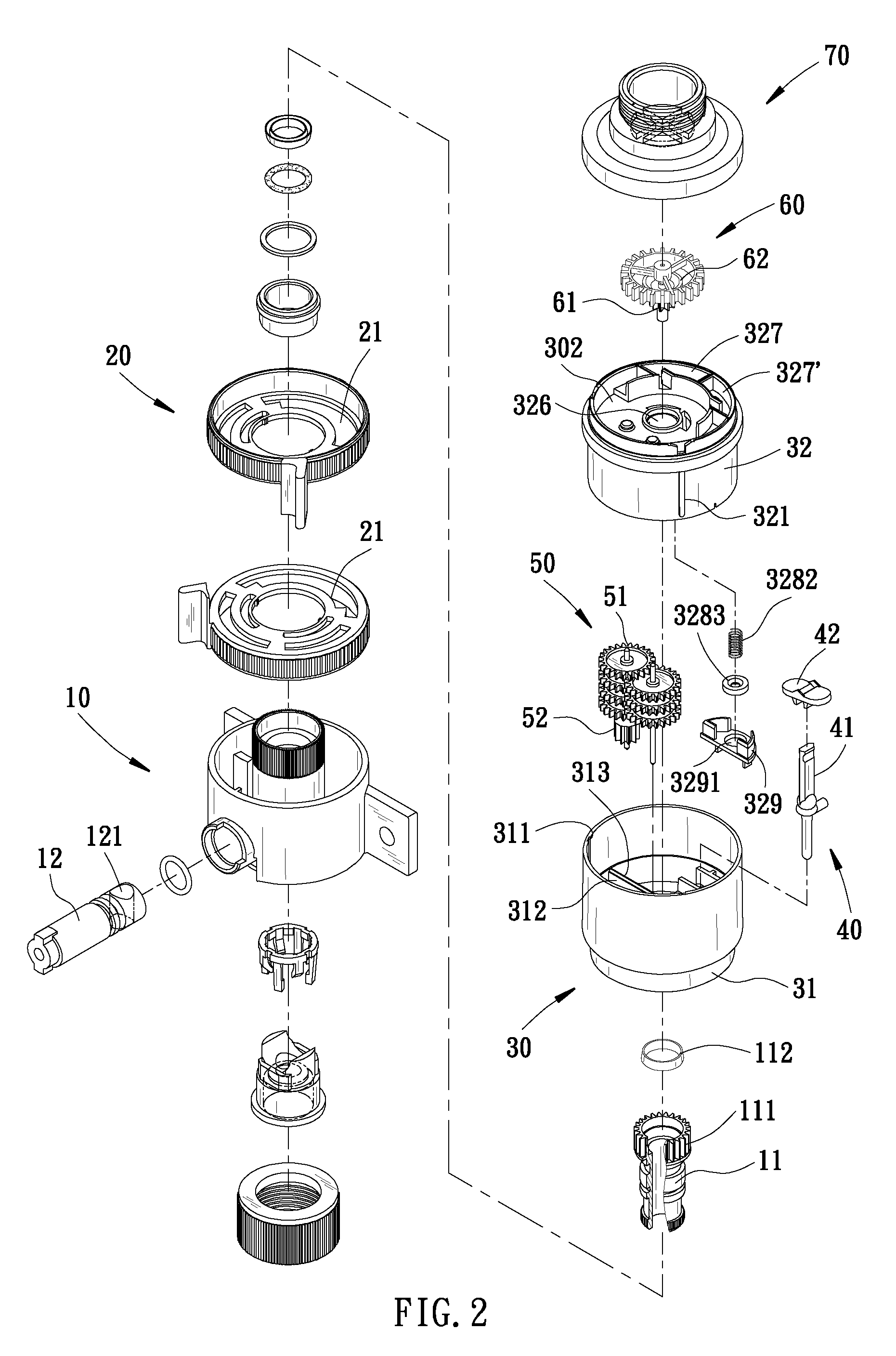

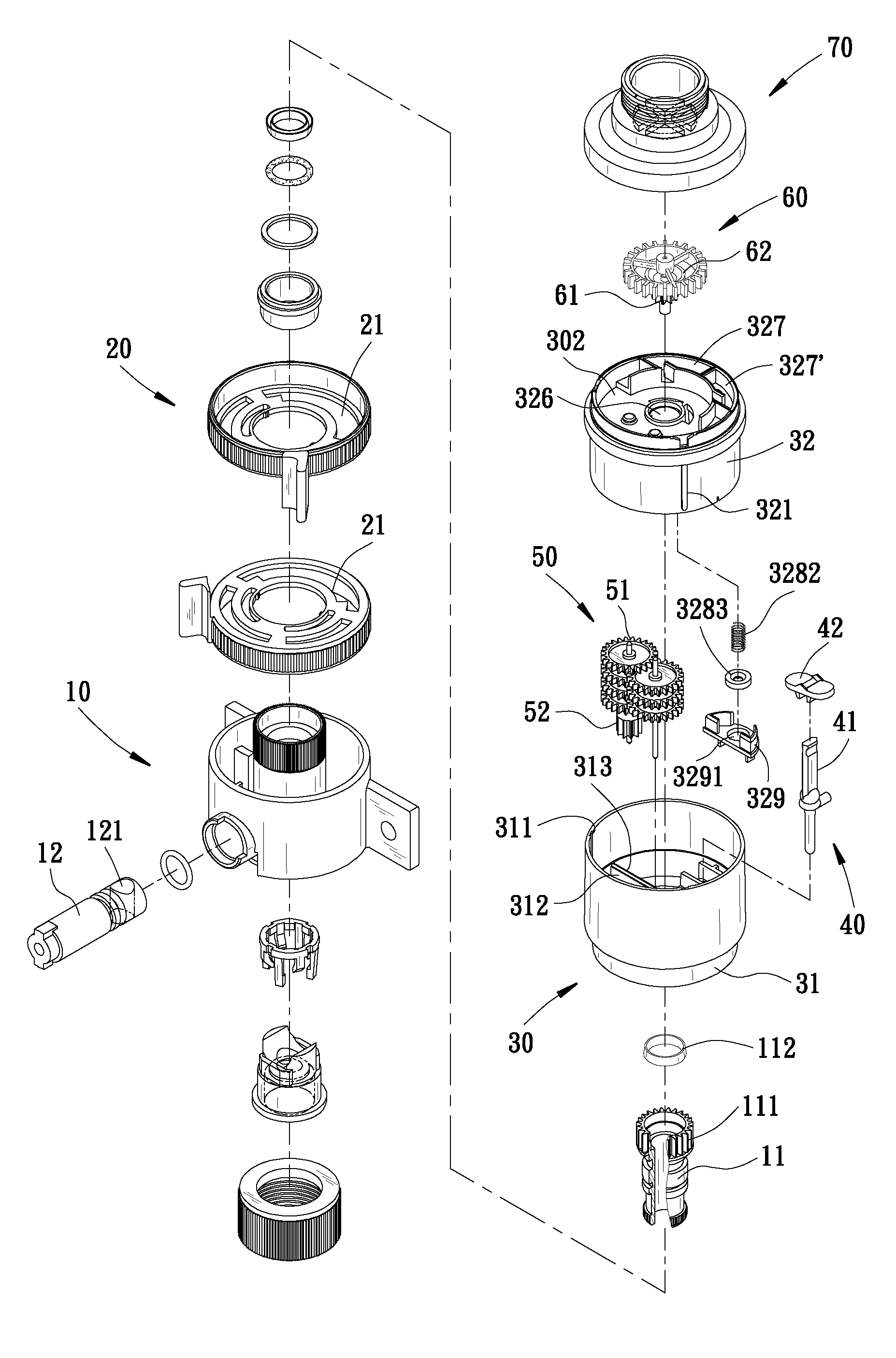

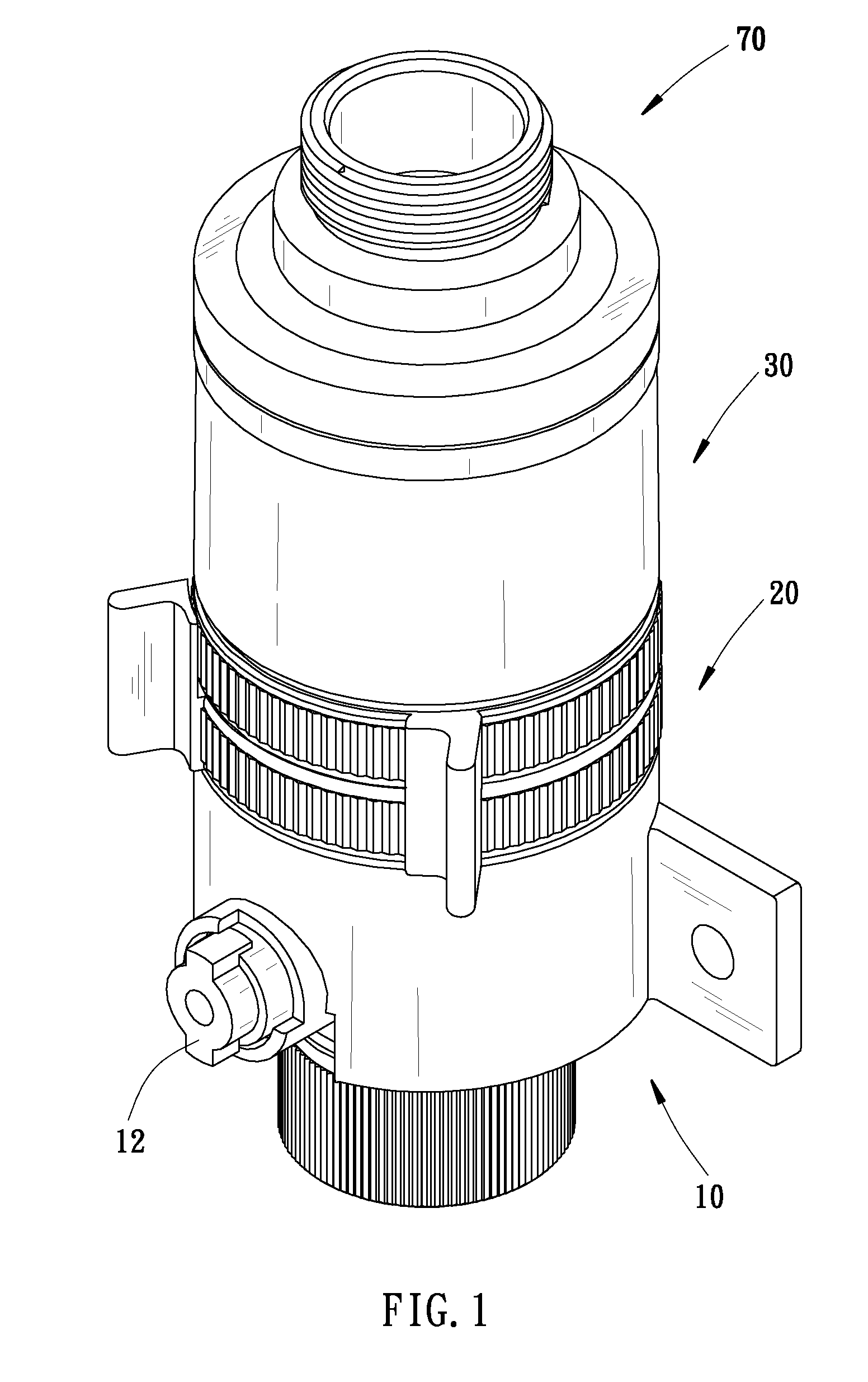

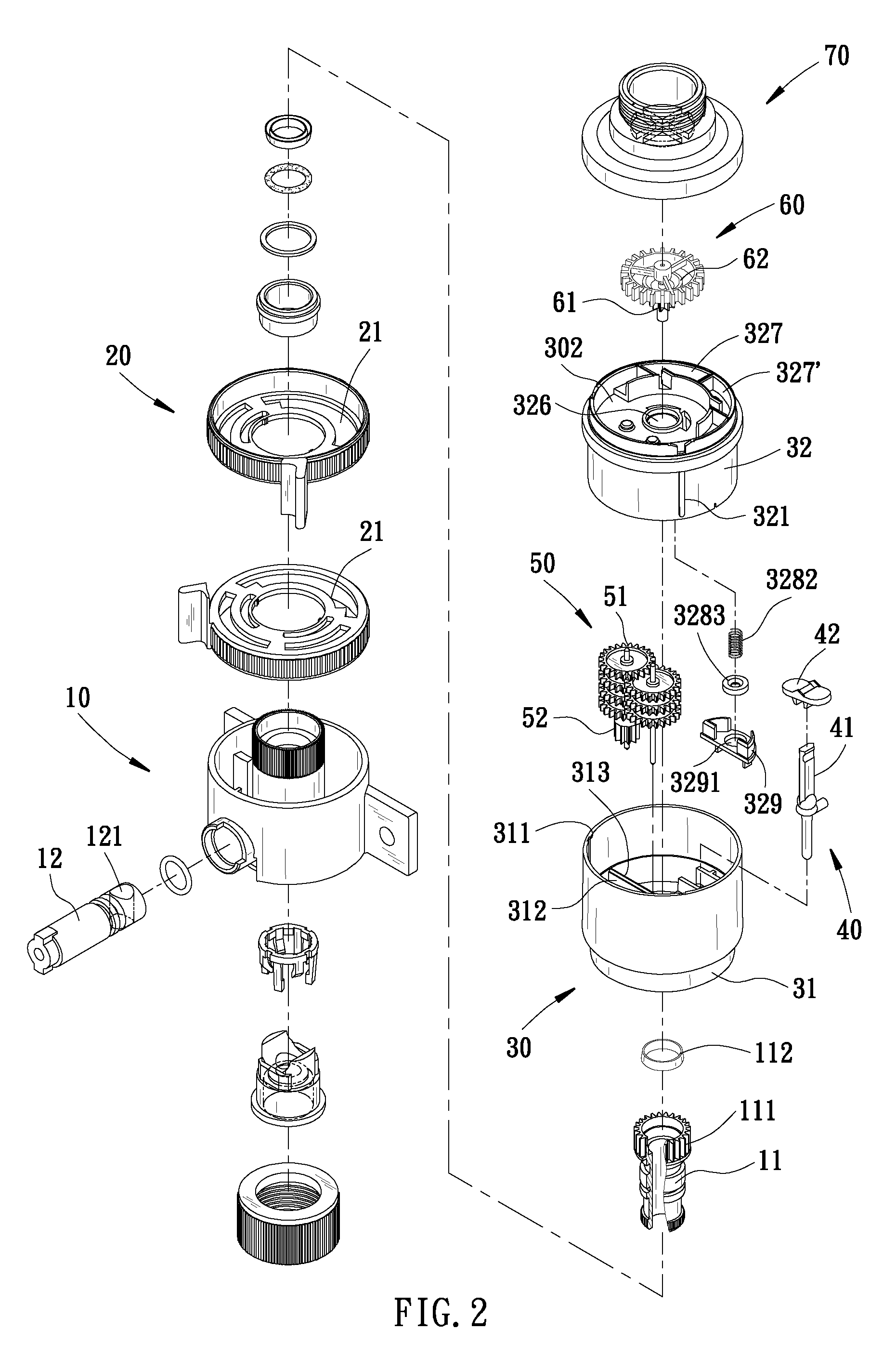

Sprinkler

ActiveUS20100193603A1Optimal balance of temperature and pressureImprove balanceMovable spraying apparatusSpray nozzlesPipingImpeller

An improved sprinkler has a flow altering device to change water direction and control the direction of a blade wheel. A gear set causes a sprinkler head's repetitive rotation. The sprinkler head includes a set of corresponding upper plate and lower plate to divide an interior chamber of the sprinkler head to two chambers: a control chamber and a gear chamber. A water inlet pipe connects only with the control chamber to provide water to enter the control chamber. The upper plate and the lower plate form a filtering channel interconnecting between the control chamber and the gear chamber. The water from the control chamber can flow into the gear chamber through the filtering channel. The filtering channel filters the large / coarser particle debris in the water and the water flowing into the gear chamber can lubricate and cool the gear set in the gear chamber.

Owner:YUAN MEI CORP

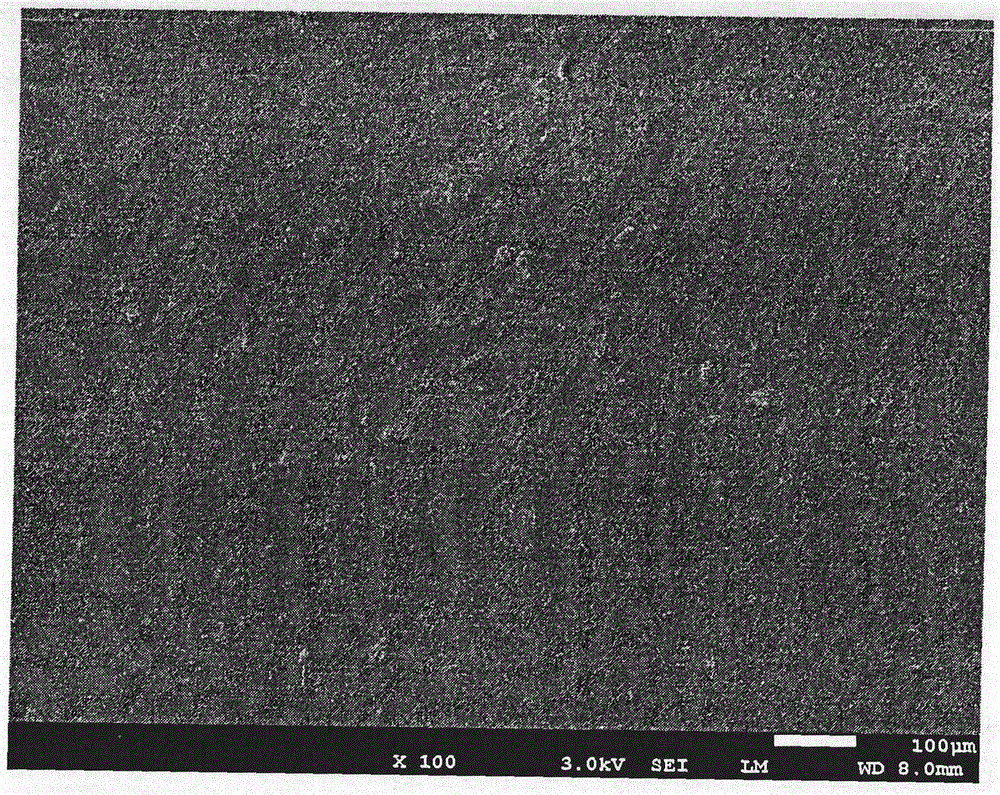

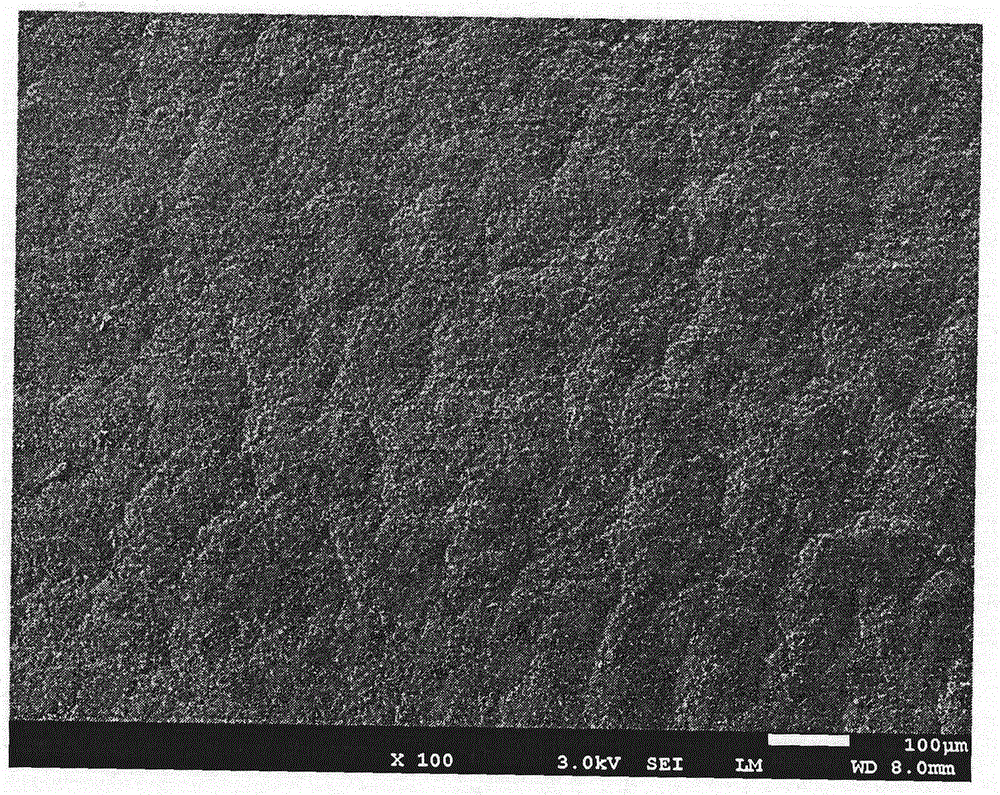

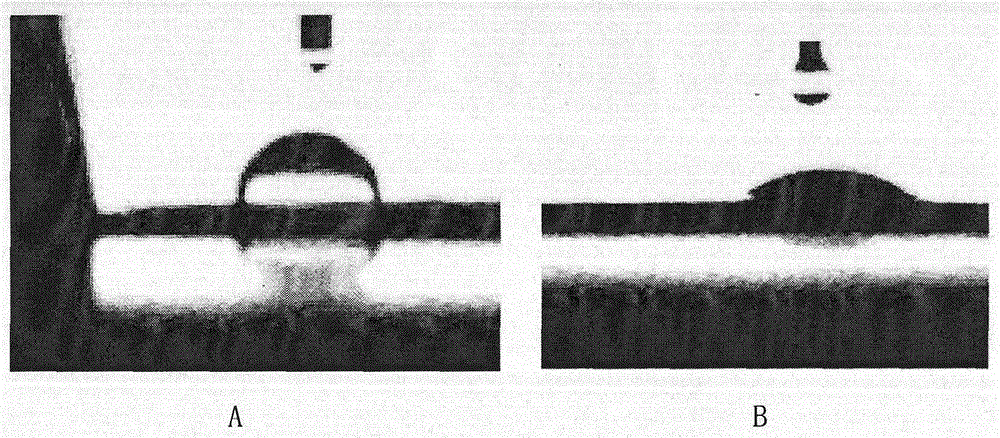

Preparation method of silicone rubber surface hydrophilic coating

InactiveCN105601933AImprove bindingReliable anchoringSurgeryPharmaceutical delivery mechanismHydrophilic coatingPolymer science

The invention relates to a preparation method of a silicone rubber surface hydrophilic coating. The preparation method comprises the following sequential steps: (1) immersing a silicone rubber material in a newly prepared silane coupling agent solution, and keeping reactions for 1.5 hours to obtain surface-aminated silicone rubber; (2) immersing the aminated silicone rubber in an aqueous solution of polyethyleneimine, adjusting the pH value of the solution by using NaOH, and adding epoxy chloropropane into the solution to obtain polyethyleneimine-grafted surface silicone rubber through chemical reactions; and (3) preparing an ethanol solution of polyvinylpyrrolidone, adding a photosensitizer, soaking the polyethyleneimine-grafted surface silicone rubber in the solution, taking out and naturally drying in a dark condition, and transferring into an ultraviolet curing device to receive ultraviolet irradiation to obtain a uniform hydrophilic coating with good lubricating property on the silicone rubber surface. The hydrophilic coating provided by the invention has good adhesion and biocompatibility and is particularly applicable to the field of biomedical materials.

Owner:QINGDAO UNIV OF SCI & TECH

Sprinkler

ActiveUS8746592B2Improve balanceGuaranteed uptimeMovable spraying apparatusSpray nozzlesImpellerGear wheel

Owner:YUAN MEI CORP

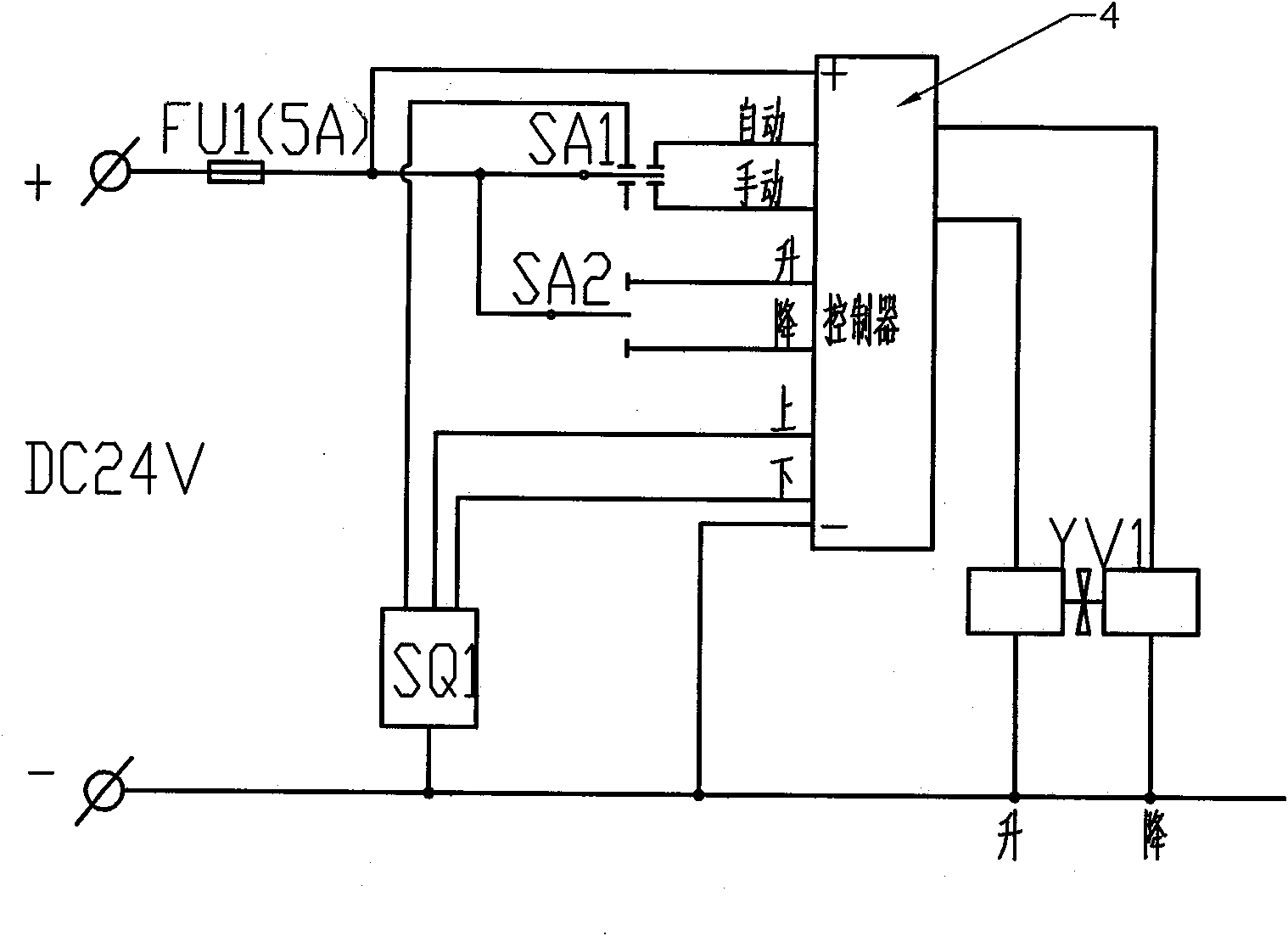

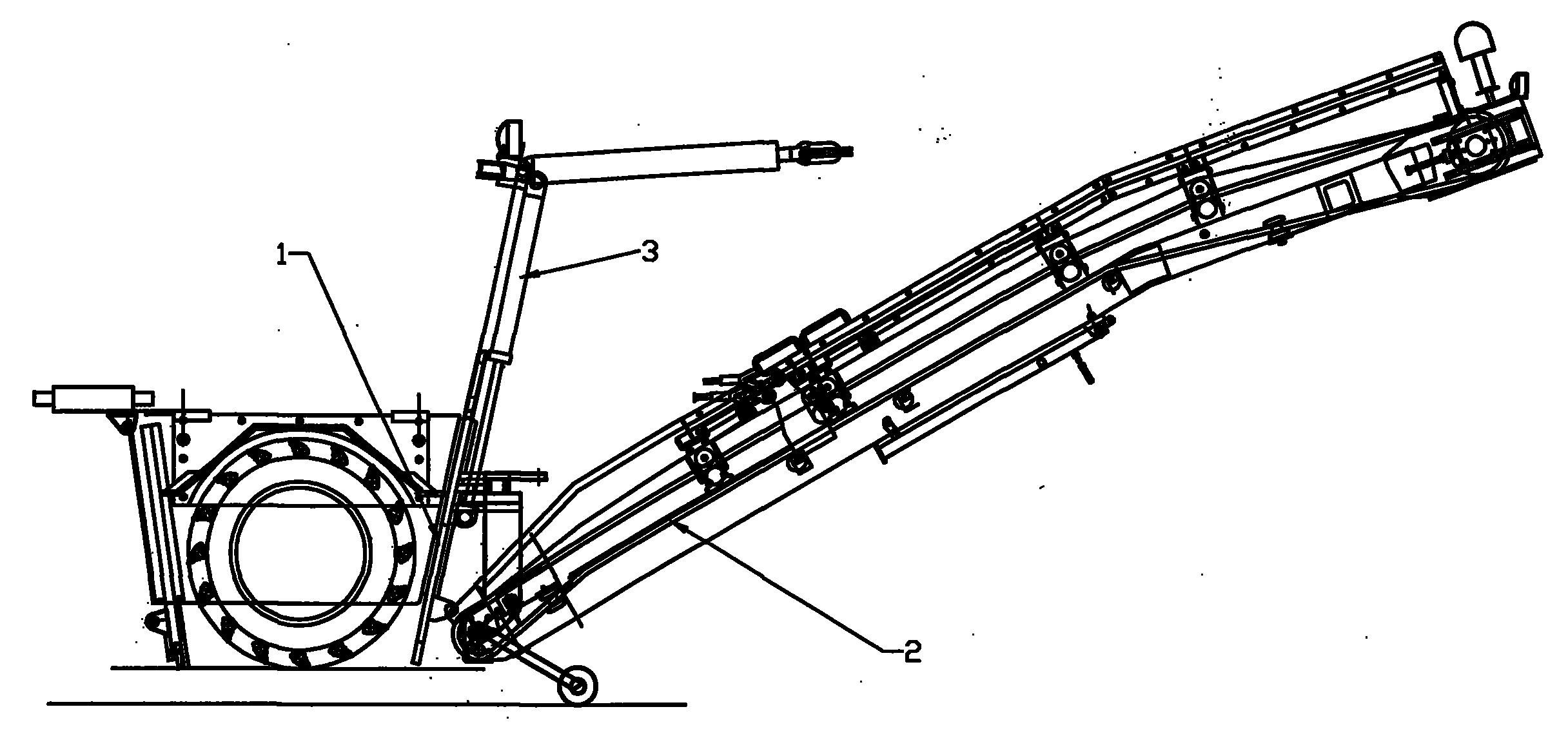

Device for adaptive control of ground clearance of front discharge door of pavement milling machine

InactiveCN101775774AAvoid frictional damageExtended service lifeRoads maintainenceControl without using feedbackAuto regulationHydraulic cylinder

The invention relates to a device for adaptive control of the ground clearance of a front discharge door of a pavement milling machine, which comprises a conveyer bracket connected with the front discharge door of the milling machine, a hydraulic cylinder capable of driving the front discharge door and the conveyer bracket to ascend and descend, and an electromagnetic valve capable of controlling lifting actions of the hydraulic cylinder, wherein the bottom of the conveyer bracket is provided with a position sensor; the device also comprises a controller capable of outputting ascending and descending control commands to the electromagnetic valve; the position sensor can input part of the output ascending or descending control signals to the control signals of the controller; a control signal input part of the controller is also connected with a manual option switch capable of inputting ascending or descending control signals; and the controller is also connected with the position sensor through a state switch. The device can automatically adjust the heights of the front discharge door and a conveyer of the pavement milling machine, and simultaneously has the advantages of high detection accuracy, high use reliability and long service life.

Owner:江苏华通动力重工有限公司(中外合资)

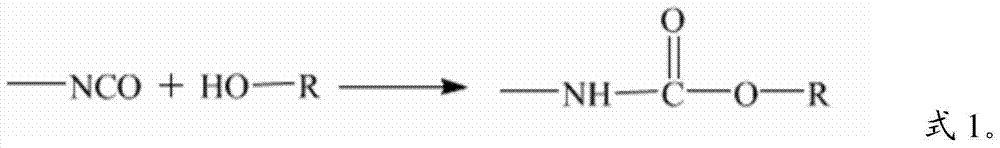

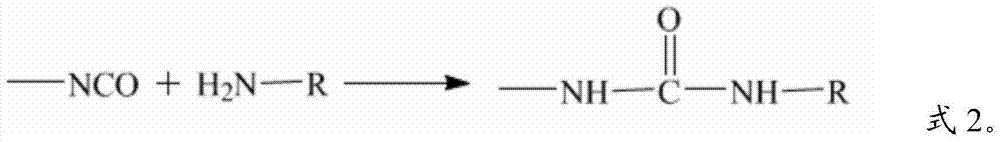

Polyurethane emulsion, preparation method thereof and glass fiber sizing agent

The invention provides a polyurethane emulsion. The polyurethane emulsion is prepared from the following components in percentage by weight: 25-40 percent of polyester diol, 10-30 percent of polyether glycol, 2-10 percent of micromolecular diol, 30-40 percent of aliphatic diisocyanate, 2-10 percent of an amine chain extender and 0-6 percent of a solvent, wherein the micromolecular dihydric alcohol is prepared from dihydric alcohol with the number of carbon atoms being 2-10. The polyurethane emulsion is good in stability and is a nonionic polyurethane emulsion. When being used for preparing a glass fiber sizing agent, the polyurethane emulsion can not generate mutual action with ions ionized from other components of the sizing agent, so that the polyurethane emulsion is prevented from generating demulsifcation, the phenomena of sedimentation and caking of the sizing agent are prevented, and the obtained glass fiber sizing agent is good in stability. The invention provides a preparation method of the polyurethane emulsion and the glass fiber sizing agent.

Owner:CHONGQING POLYCOMP INT

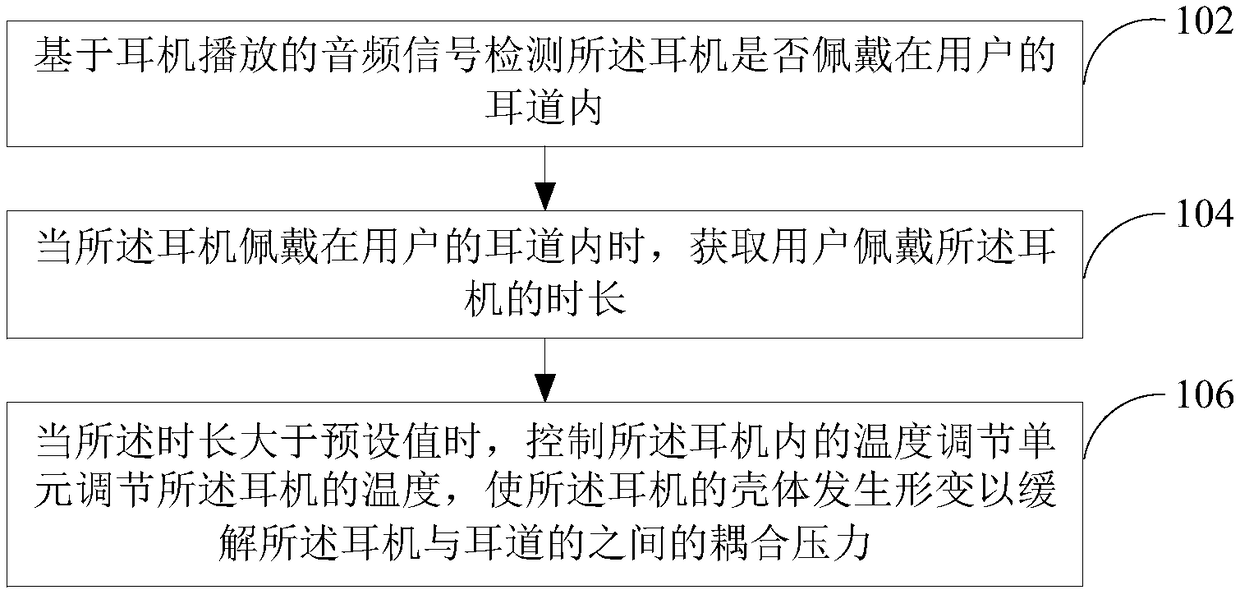

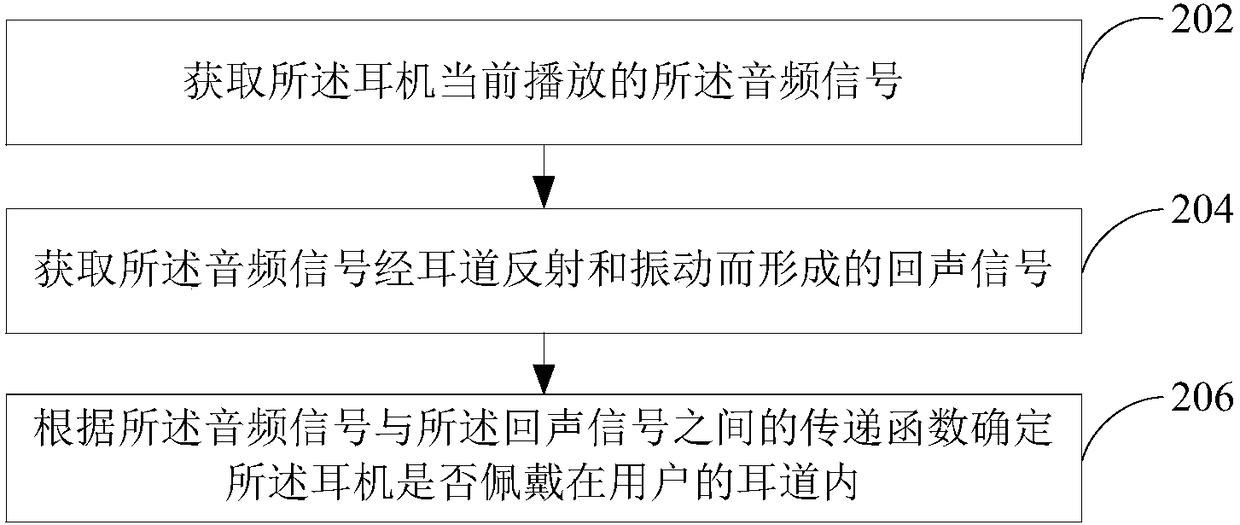

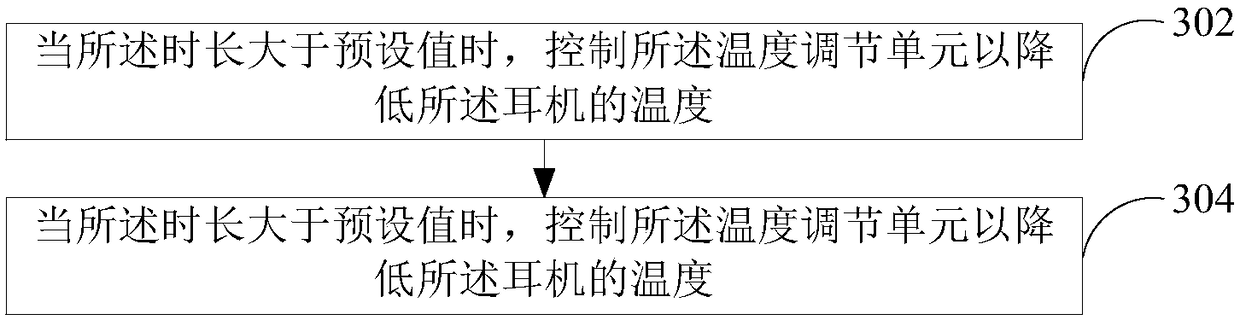

Earphone control method and earphone

InactiveCN108429971AProtect the hearing systemAvoid frictional damageEarpiece/earphone attachmentsCouplingShape-memory alloy

The application relates to an earphone control method and an earphone. The earphone control method comprises the following steps: detecting whether the earphone is worn in the ear canal of a user or not based on an audio signal played by the earphone; acquiring the duration for which the user wears the earphone when the earphone is worn in the ear canal of the user; and when the duration is greater than a preset value, controlling a temperature regulating unit in the earphone to regulate the temperature of the earphone, so that a shell of the earphone deforms to alleviate the coupling pressurebetween the earphone and the ear canal, wherein the shell is made of a shape memory alloy. The friction damage of the earphone to the ear canal caused by the enlargement of the ear canal after wearing the earphone for a long time can be avoided. At the same time, when the shell of the earphone deforms, a small gap exists between the shell of the earphone and the ear canal, so that audio information played by the earphone can spread to the outside of the ears through the gap to weaken the audio signal received by the ears, and further protect the hearing system of the user.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

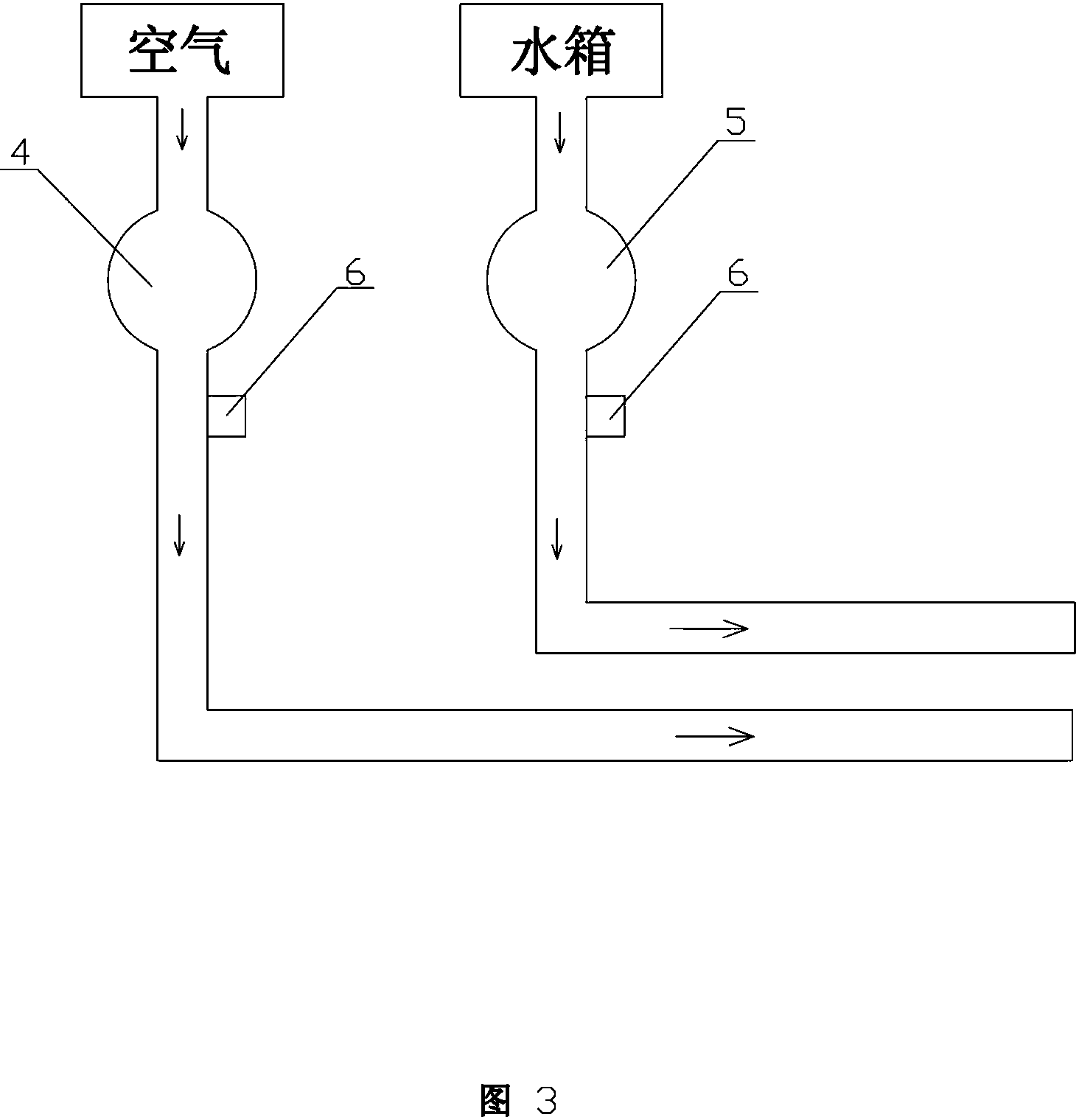

Windscreen wiper

The invention discloses a windscreen wiper which comprises a windscreen wiper swing arm and a windscreen wiper body arranged on the windscreen wiper swing arm, wherein the windscreen wiper body is provided with a fluid cavity; the fluid cavity is provided with an opening which faces a cleaned surface of the automobile glass; the edge of the opening is matched with the cleaned surface of the automobile glass; a water inlet communicated with the fluid cavity is formed in the windscreen wiper body; and when the windscreen wiper body is filled with high-pressure gas or high-pressure liquid by utilizing the fluid cavity formed in the windscreen wiper body, the windscreen wiper body is suspended on the windscreen, and the automobile windscreen is cleaned by utilizing the high-pressure gas or high-pressure liquid under drive of the back-and-forth swing of the windscreen wiper swing arm. The windscreen wiper has unique concept, novel design, simple structure, high practicality and wide market popularization prospects, and the windscreen can be effectively cleaned and is prevented from being damaged.

Owner:滁州天创信息科技有限公司

Charging pile

ActiveCN105356180BSimple structureAvoid frictional damageBatteries circuit arrangementsElectric powerMagnetEngineering

The invention discloses a charging pile. The charging pile includes a charging pile body and a charging cable; the charging pile body is provided with magnets; the charging cable is provided with an iron ring and a large circle spring cable which is bent with the iron ring so as to form a circle-shaped structure; one end of the large circle spring cable is electrically connected with the charging pile; the other end of the large circle spring cable is connected with a charging gun; and the charging gun can be hung on the charging pile body. When the charging pile is not used for charging, the large circle spring cable is in a reset state, and is hung on the charging pile body in a circle form, and the charging cable is absorbed on the magnets by means of the iron ring so as to be fixed on the charging pile, and the charging gun is arranged on the charging pile body; and when the charging pile is used for charging, the charging gun is held, so that the large circle spring cable can be pulled and is made to be separated from the magnets, so that charging can be performed. Compared with the prior art, the charging pile of the invention is advantageous in simple, stable and reliable structure; and the charging pile will swing back and forth due to the blowing of the wind, and will not fall off due to the blowing of the wind; and the charging cable can be prevented from being worn and damaged.

Owner:SHENZHEN WOER HEAT SHRINKABLE MATERIAL +1

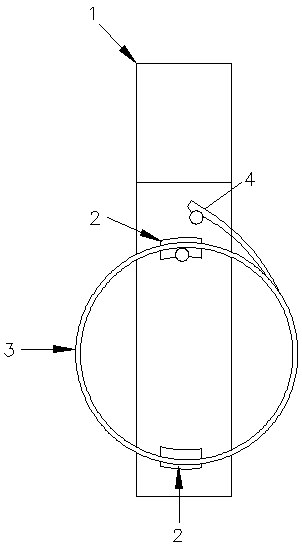

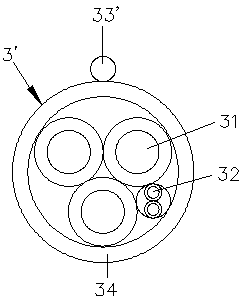

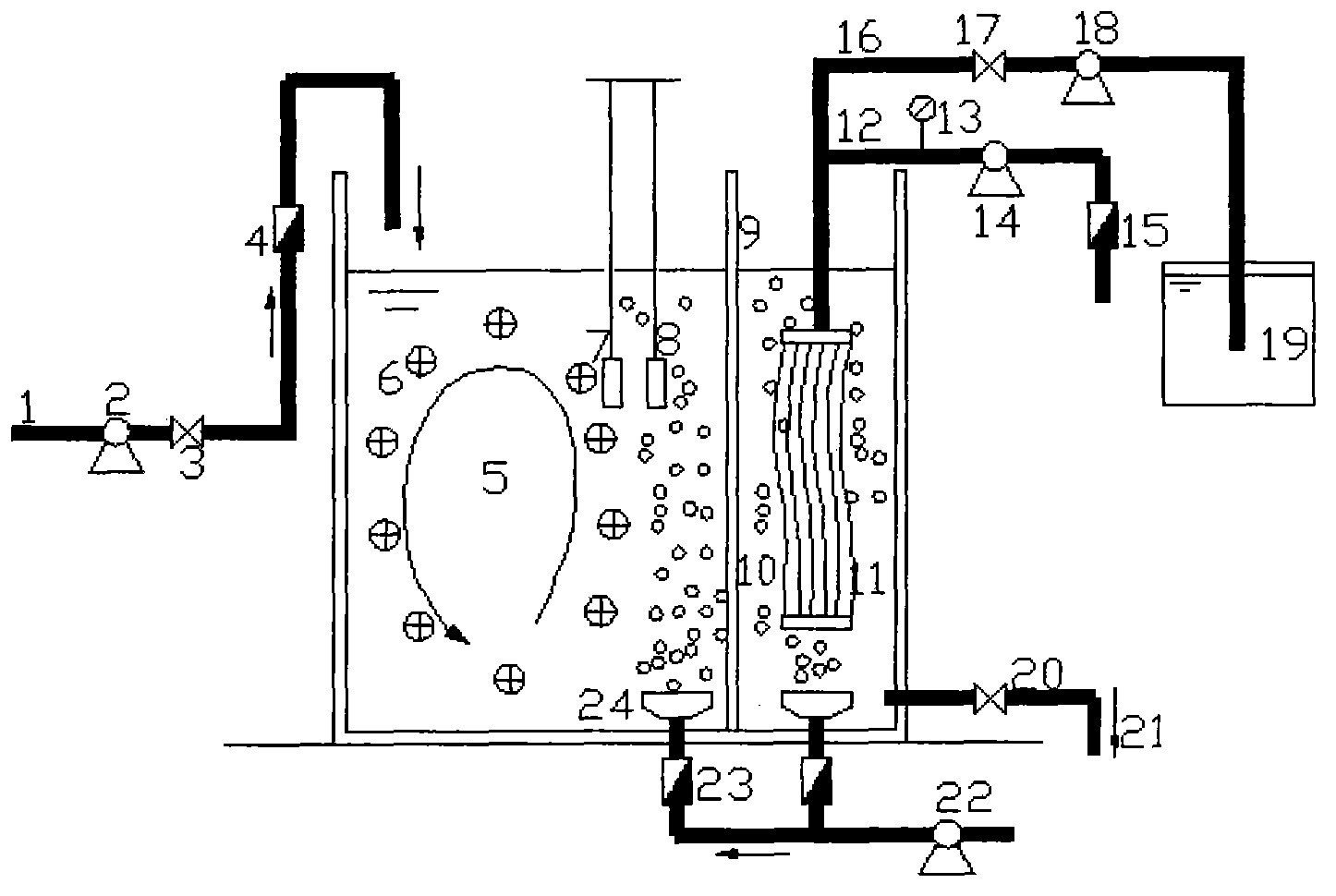

Composite membrane bioreactor for improving particle size distribution of activated sludge and microenvironment

InactiveCN103058371AMeet their respective requirementsRegulationTreatment with aerobic and anaerobic processesParticulatesActivated sludge

A composite membrane bioreactor for improving particle size distribution of activated sludge and a microenvironment comprises an aeration tank connected with a water inlet pipe and a membrane tank connected with a water outlet pipe, wherein the aeration tank is separated from the membrane tank by a partition plate with water distribution round holes, a suspended carrier which cannot pass through the water distribution round holes is arranged in the aeration tank, a membrane component is arranged in the membrane tank, the bottoms of both the aeration tank and the membrane tank are provided with aeration heads to form a bioreactor having microbes growing in both suspension and attachment manners, so that the biomass is substantially increased, the suspended activated sludge and the rich biophase as well as the oxygen deficit or anaerobic microenvironment in the suspended carrier provide good conditions for nitrogen and phosphorus removal, the suspended carrier and a bio-membrane on the surface of the suspended carrier also become attachment carriers for the particulate matters in the suspended activated sludge, meanwhile, the particle size distribution of the activated sludge is improved and the resistance of a membrane surface cake layer is reduced by feeding a filler and regulating the flow state through the aeration tank, a mixed solution can flow into the membrane tank from the aeration tank through the partition plate, and the suspended carrier is blocked in the aeration tank to avoid frictional damage to the membrane component.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

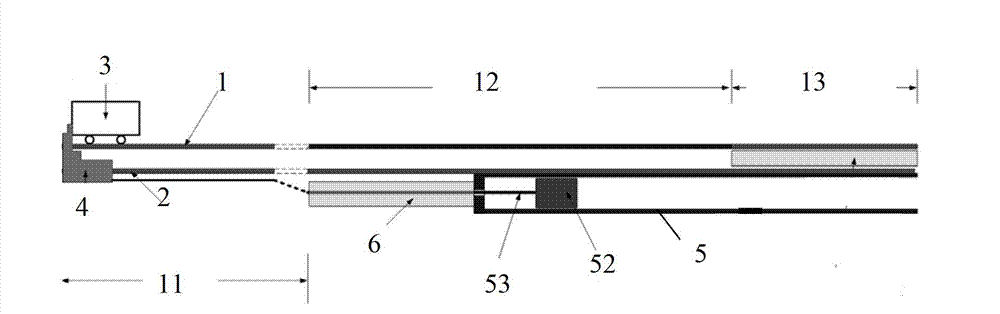

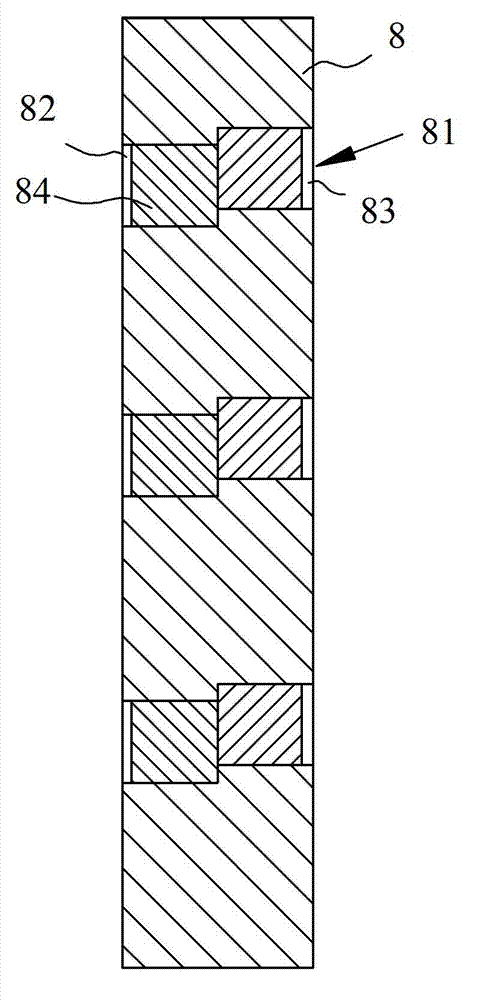

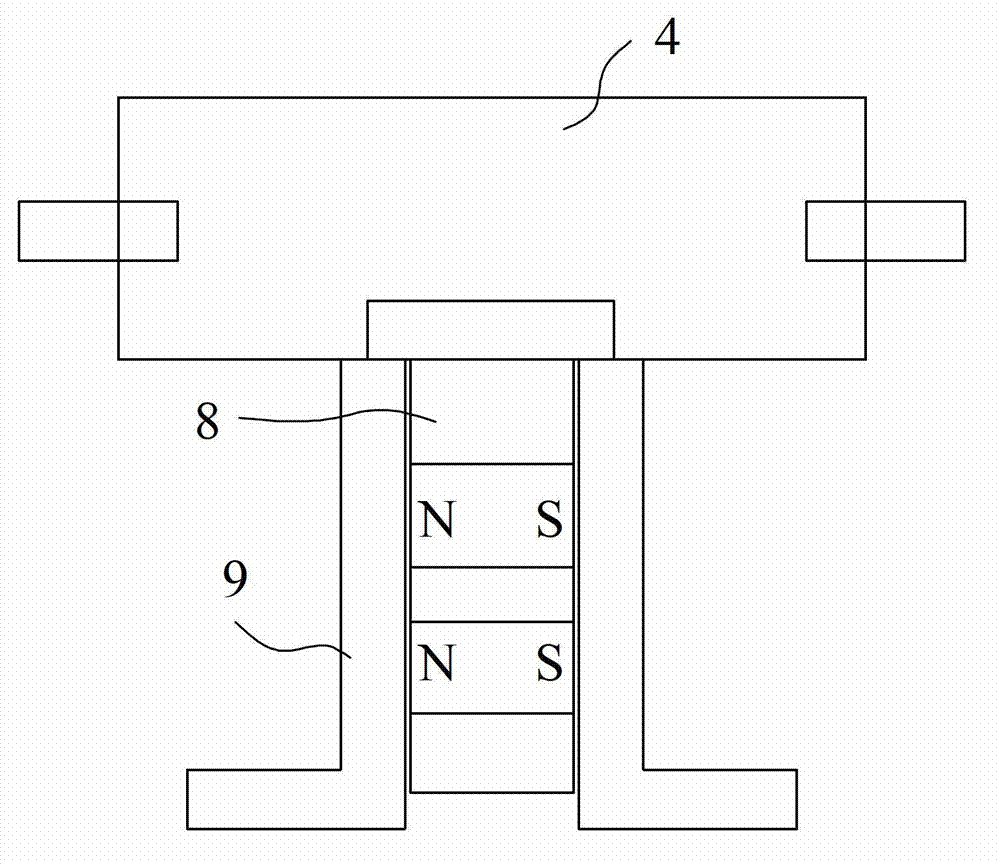

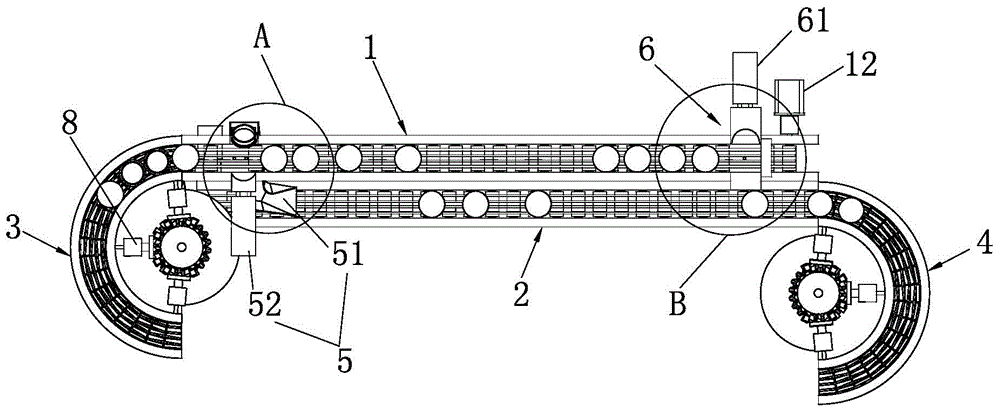

High speed train model experiment platform

The invention discloses a high speed train model experiment platform. The high speed train model experiment platform comprises an experiment track and a trailer track, the trailer track is parallel to the experiment track at an appropriate interval, the experiment track is used for operating a train model, the trailer track is used for operating a trailer which can push the train model to run, the trailer is pulled by a piston mechanism to speed up, the experiment track comprises an acceleration section, an experiment section and a deceleration section, when the trailer passes through the deceleration section, the trailer is decelerated through a trailer magnetic deceleration device, and when the train model passes through the deceleration section, the train model is decelerated through a train model magnetic deceleration device.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

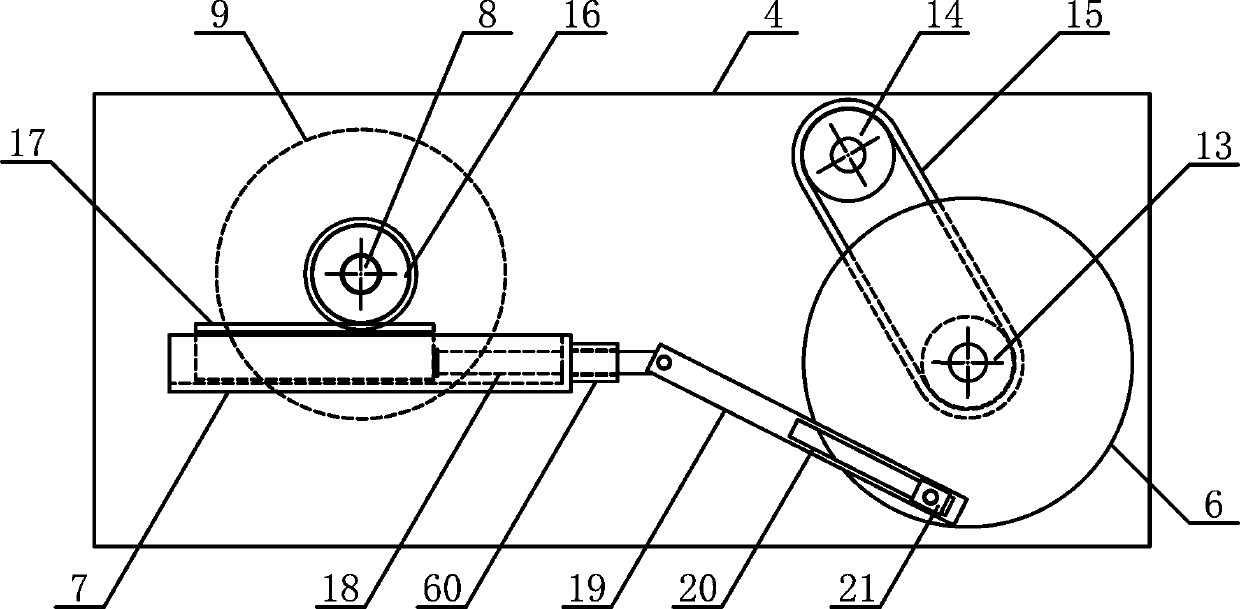

Cap arranging device for automatic bottom cap feeding machine

The invention provides a cap arranging device for an automatic bottom feeding machine. The cap arranging device for the automatic bottom feeding machine comprises a first feeding track, a first arc-shaped conveying track, a second feeding track, a second arc-shaped conveying track and a control mechanism. The higher end of the second feeding track abuts against the right end of the first feeding track. The first arc-shaped conveying track is connected to the left end of the first feeding track. The second arc-shaped conveying track is connected to the end portion of the higher end of the second feeding track. The control mechanism is used for controlling operation of the cap arranging device. The cap arranging device further comprises a bottle cap turning mechanism and a bottle cap pushing mechanism. The bottle cap turning mechanism comprises a bottle cap turning groove, a first cylinder and at least two first inductors. The bottle cap pushing mechanism comprises a second cylinder, a second inductor and a blocking plate. The cap arranging device for the automatic bottom feeding machine is simple in structure, low in manufacturing cost and long in service life; production cost can be effectively reduced, and the labor intensity of workers can be effectively relieved; the cap arranging speed is high, and the cap arranging effect is good; production efficiency can be effectively improved, and the occupied space of equipment can be effectively reduced.

Owner:QUANZHOU HUASHUO IND

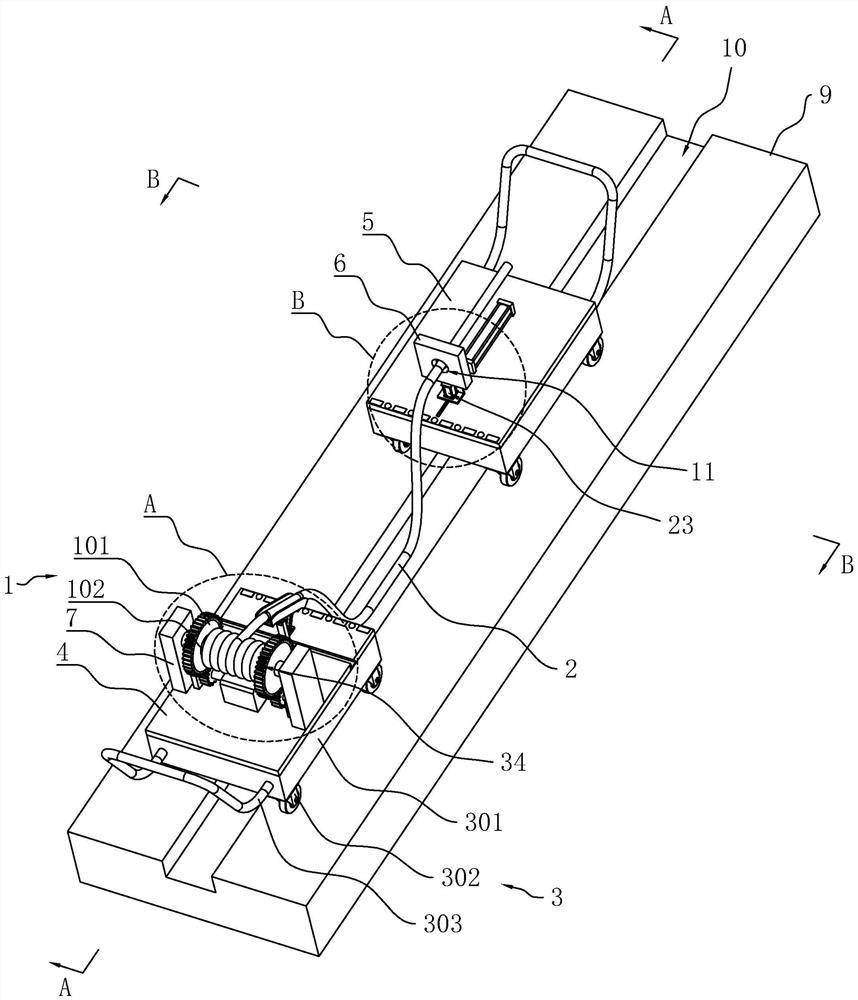

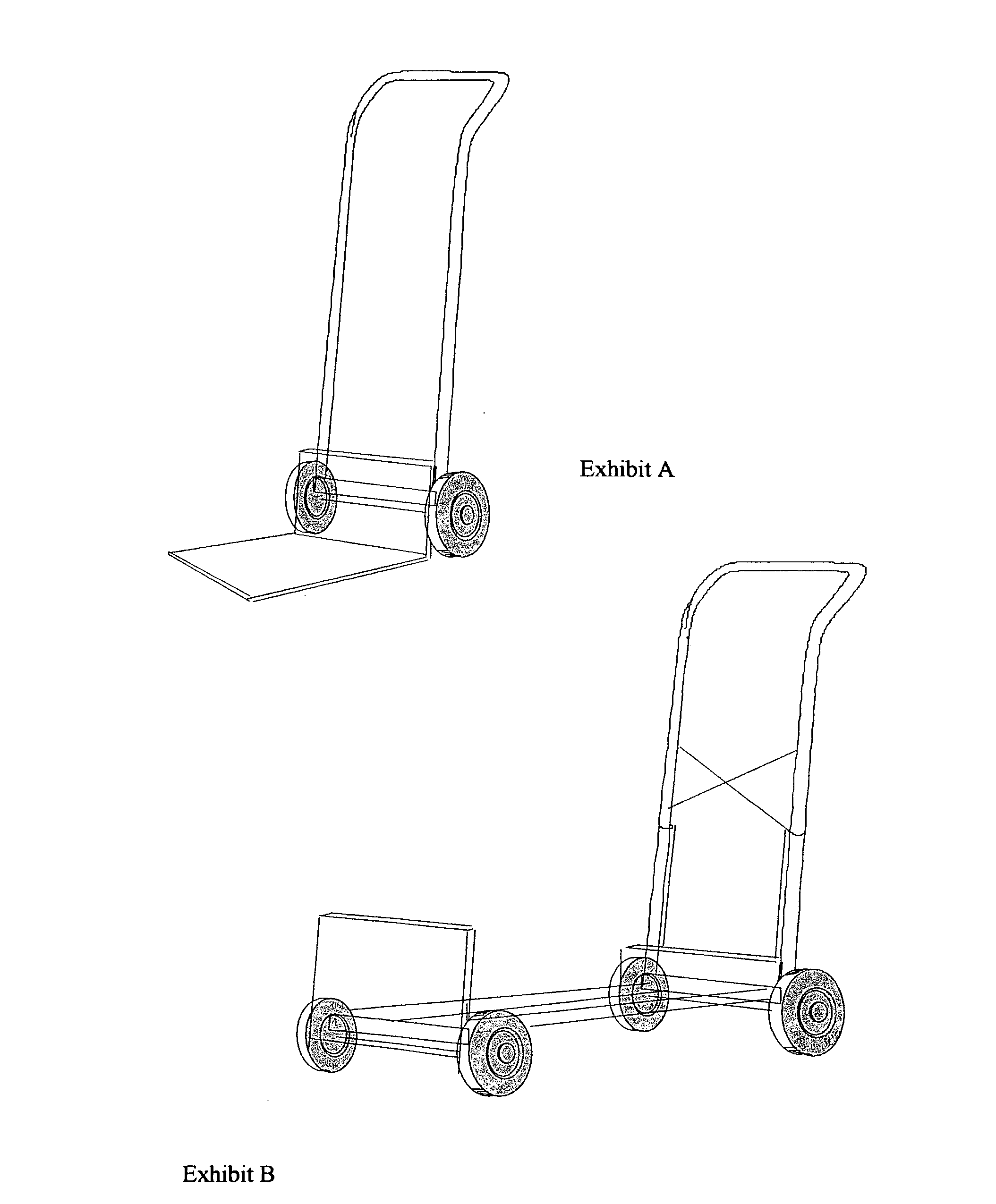

Carriage platform assembly

InactiveUS20060182566A1Assist mobilityAvoid frictional damageSupporting partsHand carts with one axisEngineeringMechanical engineering

Owner:RUSSO THOMAS L

Stably and firmly mounted new energy automobile power distribution box

InactiveCN107799690AEasy to installAvoid frictional damageCell component detailsBatteriesNew energyRoad surface

The invention discloses a stably and firmly mounted new energy automobile power distribution box. The new energy automobile power distribution box comprises a placement box; the left side surface of the placement box is fixedly connected with a shell; a sliding plate is arranged in the shell in a sleeving manner; the right side surface of the sliding plate is fixedly connected with a vertical plate; the bottom end of the vertical plate is fixedly connected with two pulleys; the bottom ends of the two pulleys are both glidingly connected with the bottom of the inner wall of the placement box; the left side surface of the vertical plate is fixedly connected with the right side surface of an extrusion plate through a transverse rod; and the left side surface of the extrusion plate is fixedlyconnected with a first cotton cushion. According to the stably and firmly mounted new energy automobile power distribution box, by virtue of setting of the placement box, the extrusion plate, the transverse rod, a first screw thread column, a screw thread cylinder, a first bearing, a rotary plate, a locking apparatus, a first handle, the shell and the sliding plate, friction generated between thebattery pack and the inner wall of the placement box caused by vibration when the automobile runs on a jolty road can be avoided, thereby a friction-caused damage phenomenon of the battery pack can beavoided, and ensuring the service life of the battery pack.

Owner:CHENGDU CHUANGNIAN TECH CO LTD

Traction device

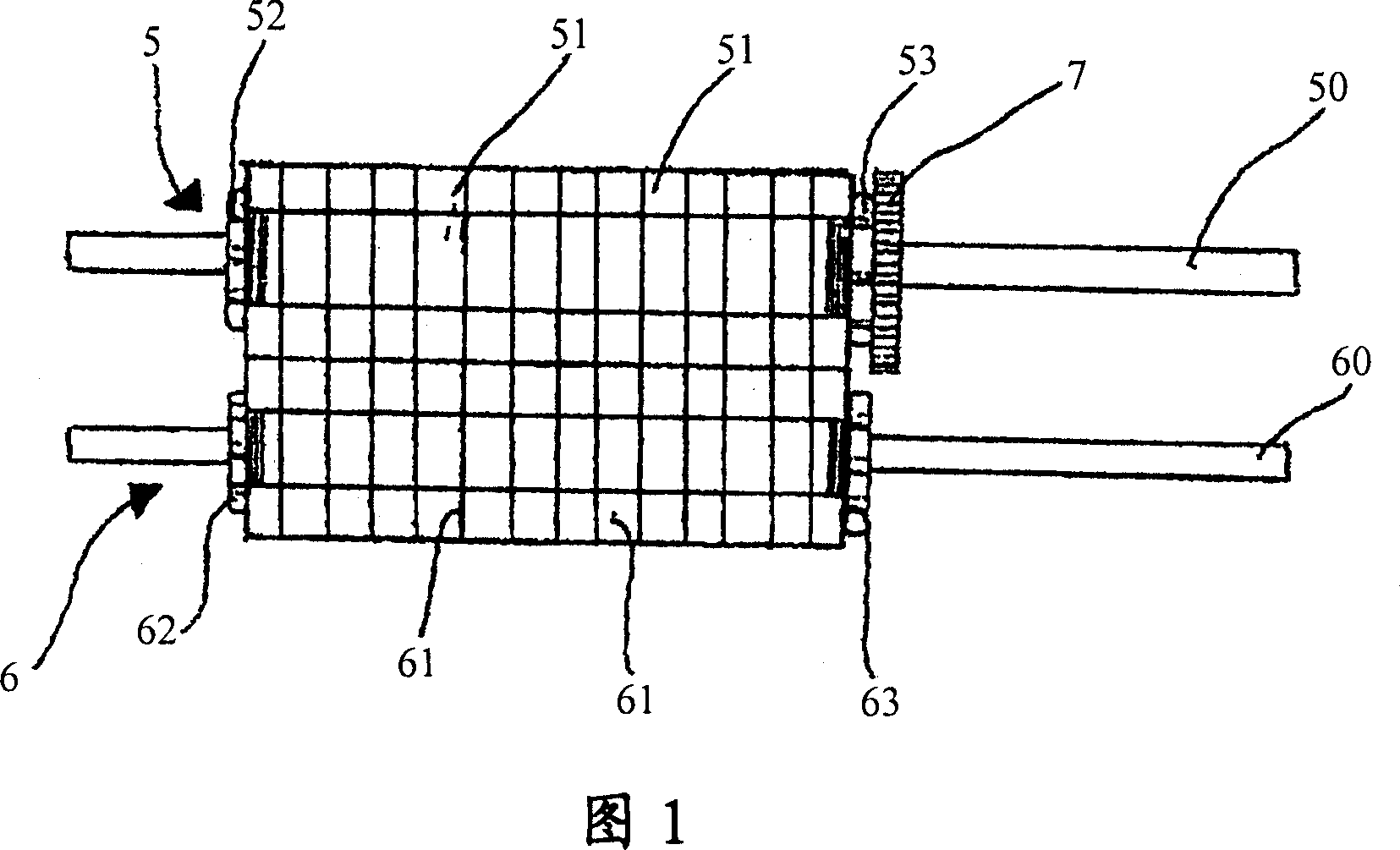

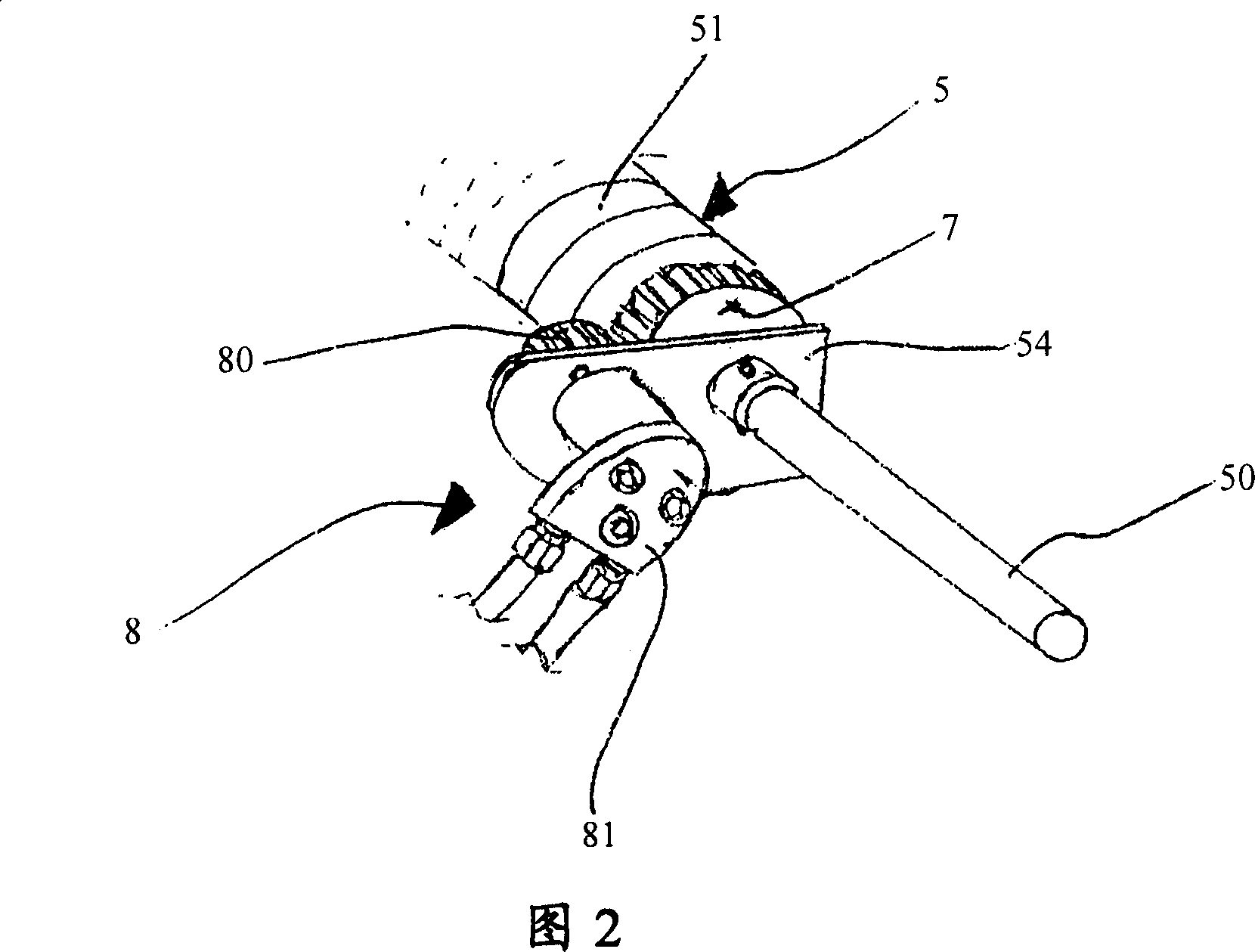

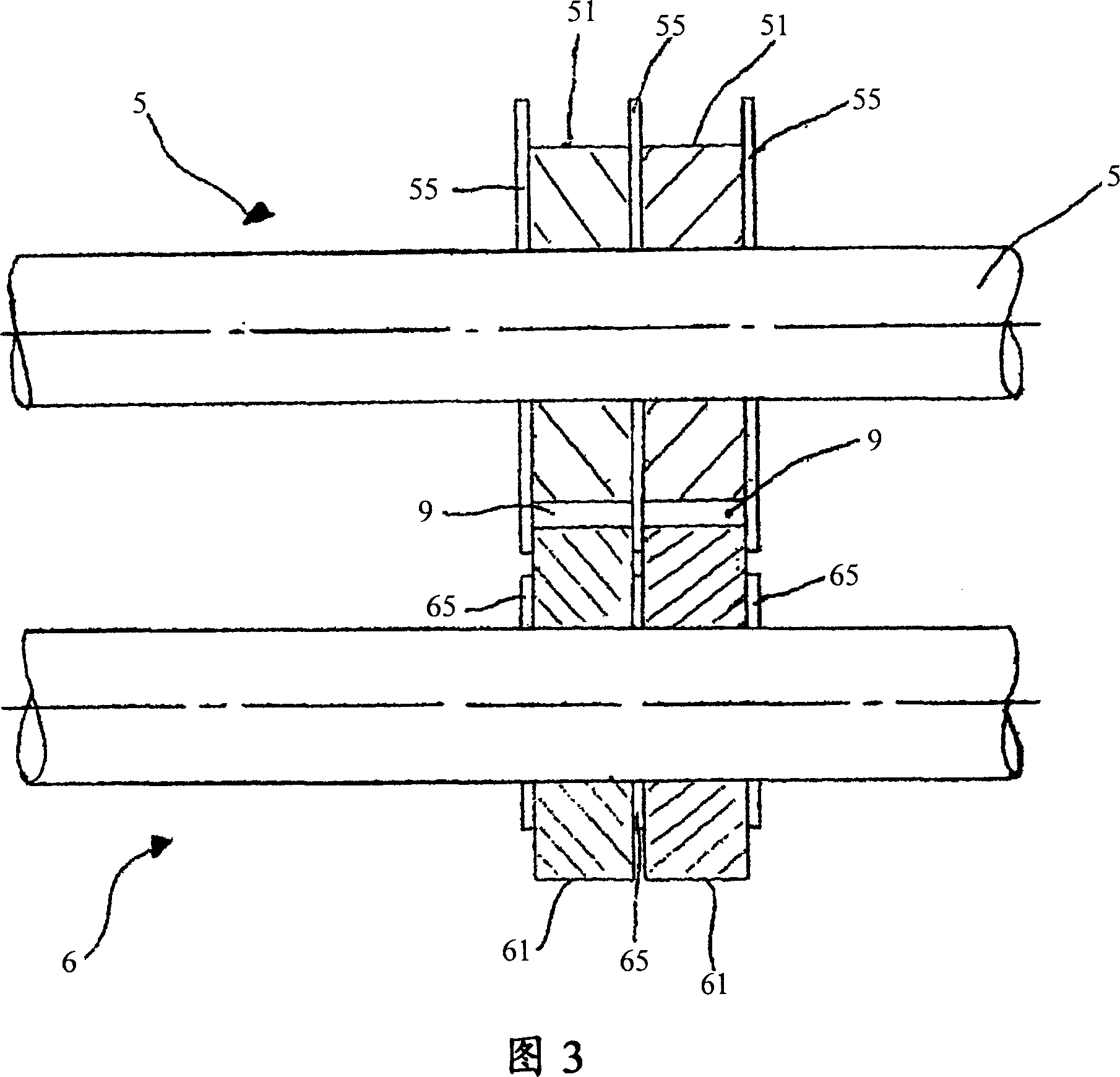

The invention relates to a traction device (1) for straining at least a flat winding strip in a winding process. The traction device (1) comprises at least two rotary rollers (5, 6) connecting with each other through the circumference to guide the flat winding strip to pass through the rollers, wherein at least one roller (5) is connected to a motor driving system (8) for controlling roller speed, thus a predetermined tension is generated on the flat winding strip during the winding process.

Owner:NICO STEEL SOLUTION SINGAPORE

Pipe burying pay-off device for water conservancy construction and with length recording function

InactiveCN107500043AControl laying speedAvoid cloggingFilament handlingCleaning using toolsDrive wheelTransmission belt

The invention discloses a pipe burying pay-off device for water conservancy construction and with a length recording function. The pipe burying pay-off device for water conservancy construction and with the length recording function comprises a supporting base and a pay-off box; the lower end of the supporting base is connected with supporting legs; walking wheels are arranged at the bottom ends of the supporting legs; a hydraulic lifting column is arranged in the right middle of the upper end of the supporting base; the top end of the hydraulic lifting column is connected to the bottom end of the pay-off box; a through groove is formed in the pay-off box; a pay-off roller is arranged in the through groove; a rotating shaft is arranged in the pay-off roller; a transmission wheel is arranged on a right side suspension arm of the rotating shaft; the transmission wheel is connected to a driving wheel through a belt; a rotating wheel is hung on a left side suspension arm of the rotating shaft; the rotating wheel is connected to a distance measuring box through a transmission belt; a sleeve is fixedly arranged in the right middle of the top end of the pay-off box; a hollow pipe is connected in the sleeve in a sliding manner; and the bottom end of the hollow pipe is connected with a pressing and holding plate. The pipe burying pay-off device for water conservancy construction and with the length recording function is simple in structure and convenient to use, and due to the arrangement of the distance measuring box, a cable laying speed during construction can be controlled.

Owner:沈利丹

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com