Polyurethane emulsion, preparation method thereof and glass fiber sizing agent

A technology of polyurethane emulsion and polyurethane prepolymer, which is applied in the field of glass fiber sizing agent and polyurethane emulsion, which can solve the problems of sizing agent failure, non-use, and polyurethane emulsion breaking, so as to meet the needs of high-speed wire drawing process and prevent friction Good effect on damage, high elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] The present invention also provides a kind of preparation method of polyurethane emulsion, comprises the following steps:

[0045] A) In terms of mass fraction, mix 25-40% of polyester diol, 10-30% of polyether diol and 2-10% of small molecule diol to obtain a mixture; the small molecule diol Alcohols include one or more of butanediol, hexanediol, neopentyl glycol, propylene glycol, cyclohexanedimethanol and ethylene glycol;

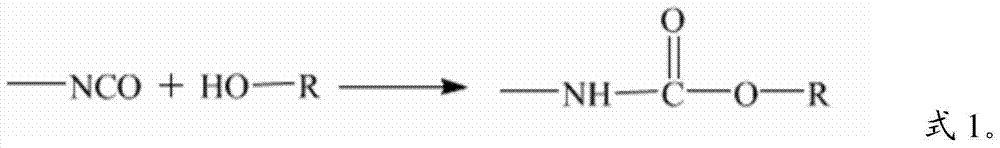

[0046] B) Mixing 30-45% of the aliphatic isocyanate with the mixture obtained in the step A) in terms of mass fraction, and then synthesizing to obtain a polyurethane prepolymer;

[0047] C) In terms of mass fraction, water is mixed with the polyurethane prepolymer obtained in the step B), and emulsified to obtain an emulsified product;

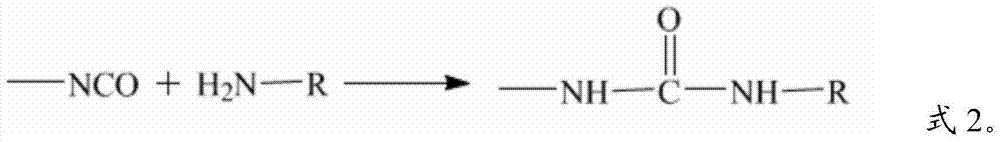

[0048] D) Mixing 2-10% of the amine chain extender with the emulsified product in the step C) in terms of mass fraction to obtain a polyurethane emulsion.

[0049] In terms of mass fraction, the present inventi...

Embodiment 1

[0081] Add 30g of polyethylene glycol, 83.62g of polyneopentyl adipate, and 7.54g of butanediol into the reaction kettle, raise the temperature to 100°C to melt the raw materials, and then vacuumize for 1 hour. N 2 , lower the temperature to 70°C. Weigh 78.85g of isophorone diisocyanate, add it dropwise in the reactor within 1 hour, and control the temperature of the reactor at 70-75°C; take a sample to test that the isocyanate content of the resin reaches the theoretical value (isocyanate index When R is 1.2 to 2.4), a polyurethane prepolymer is obtained.

[0082] Put the polyurethane prepolymer into the shear emulsification tank, add 10g of methylpyrrolidone, cool down to 45°C; increase the shear stirring rate to 800HZ, add 50g of deionized water to the polyurethane prepolymer within 10 minutes; the system appears At the conversion point, keep stirring for 30 minutes, continue to add water, add 400g of deionized water into the shear emulsification tank within 30 minutes, a...

Embodiment 2

[0090] Add 30g of polyethylene glycol, 99.81g of polyneopentyl glycol adipate, and 8.99g of butanediol into the reaction kettle, heat up to 100°C to melt the raw materials, and then vacuumize for 1 hour. N 2 , lower the temperature to 75°C. Weigh 61.20 g of isophorone diisocyanate, add it dropwise in the reactor within 1 hour, and control the temperature of the reactor at 70 to 75° C.; take samples to test that the isocyanate content of the resin reaches the theoretical value (isocyanate index When R is 1.2 to 2.4), a polyurethane prepolymer is obtained.

[0091] Put the polyurethane prepolymer into the shearing emulsification tank, add 10g of methylpyrrolidone, cool down to 45°C; increase the shear stirring rate to 800HZ, add 40g of deionized water to the polyurethane prepolymer within 10 minutes; the system appears transformation point, keep stirring for 30 minutes, continue to add water, add 450g of deionized water into the emulsification shear tank within 30 minutes, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| fluidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com