Patents

Literature

1469results about How to "Avoid clumping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

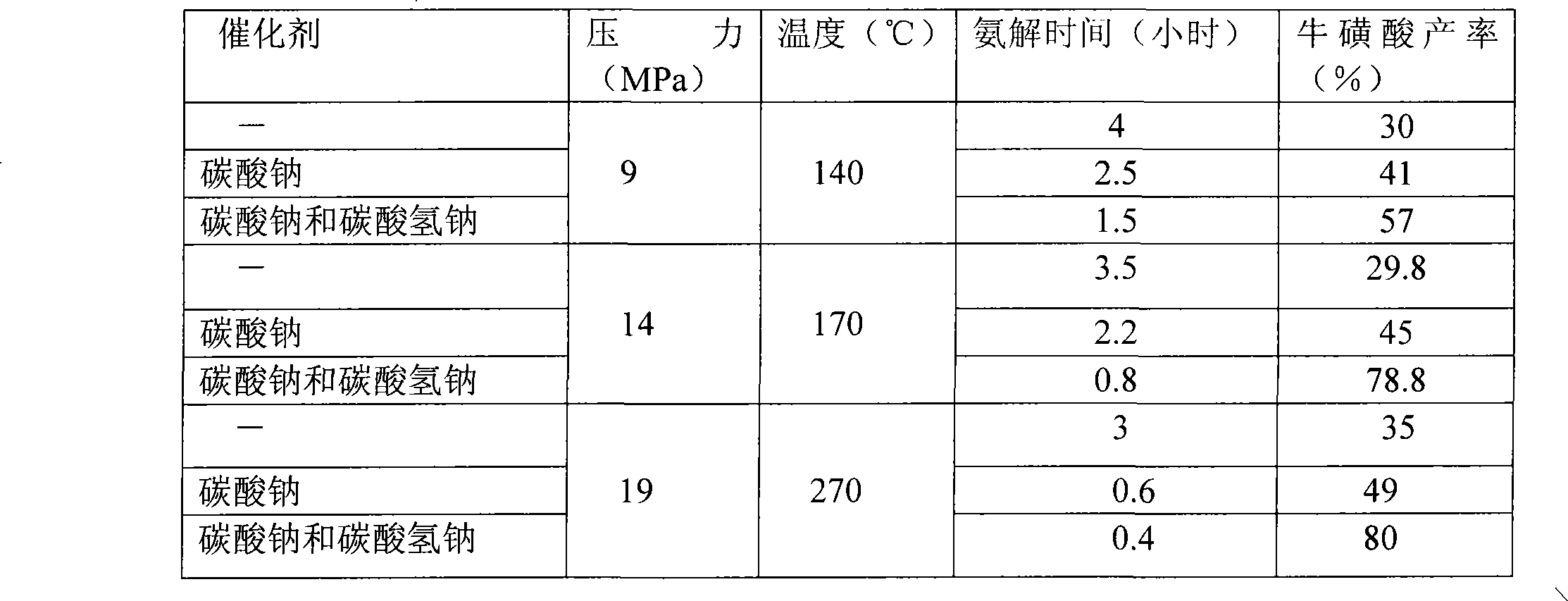

Method for preparing taurine

The invention relates to a method for preparing taurine, comprising the following steps: epoxy ethane and sodium bisulfite are reacted under 0.05 to 0.1MPa, with pH value of 6.5 to 7.5 and at a temperature between 75 and 85 DEG C to form hydroxyethyl sodium sulfonate; the hydroxyethyl sodium sulfonate and liquid ammonia are subjected to ammonolysis reaction at under 14 to 21MPa and at a temperature between 160 and 280 DEG C to form ammonolysis solution containing sodium taurate; and the ammonolysis solution is evaporated to remove ammonia, neutralized by sulphuric acid, concentrated, crystallized, separated, pre-dried in a boiling drying device or a vibration fluidization drying device, and then added into a microwave drying device to be dried and sterilized to obtain the taurine. The method for synthesizing the taurine has the advantages of short time, high yield and lower cost, and is easy for industrialized production. The water content of a taurine wet product can be reduced to below 0.30 percent through combined application of pre-drying of the boiling drying device or the vibration fluidization drying device and microwave drying, and simultaneously the device has the function of sterilizing.

Owner:王代龙 +1

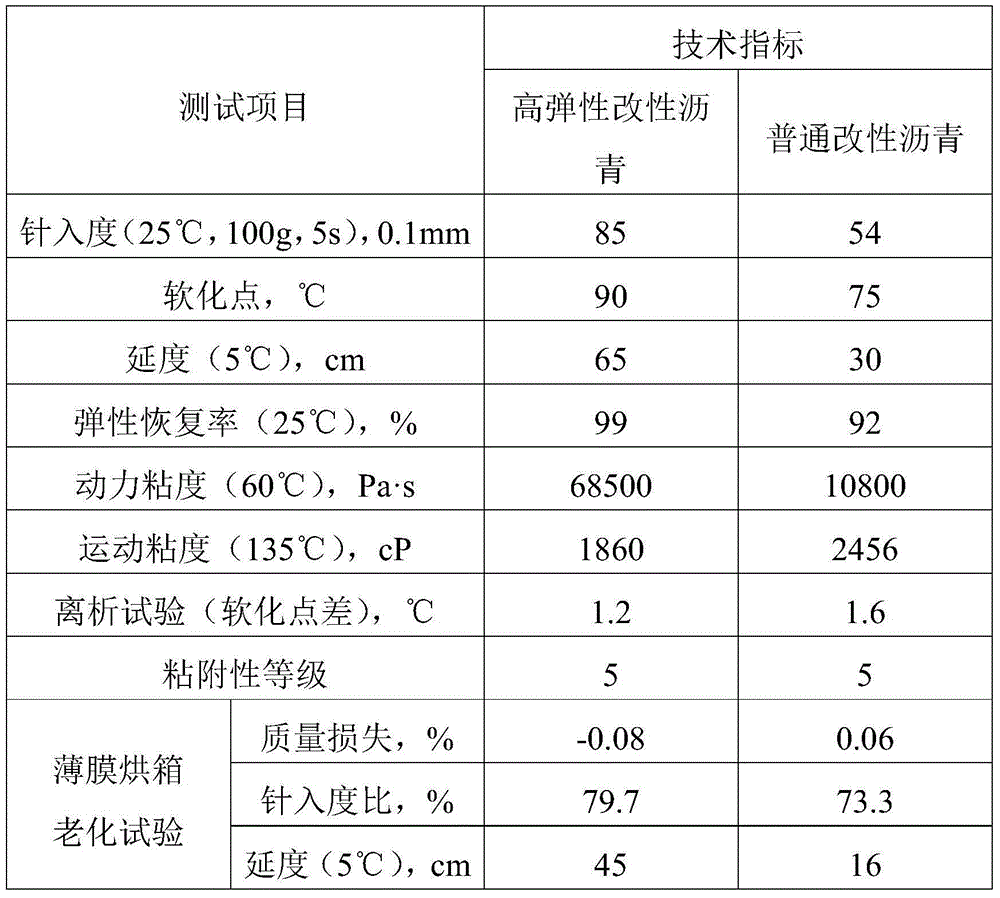

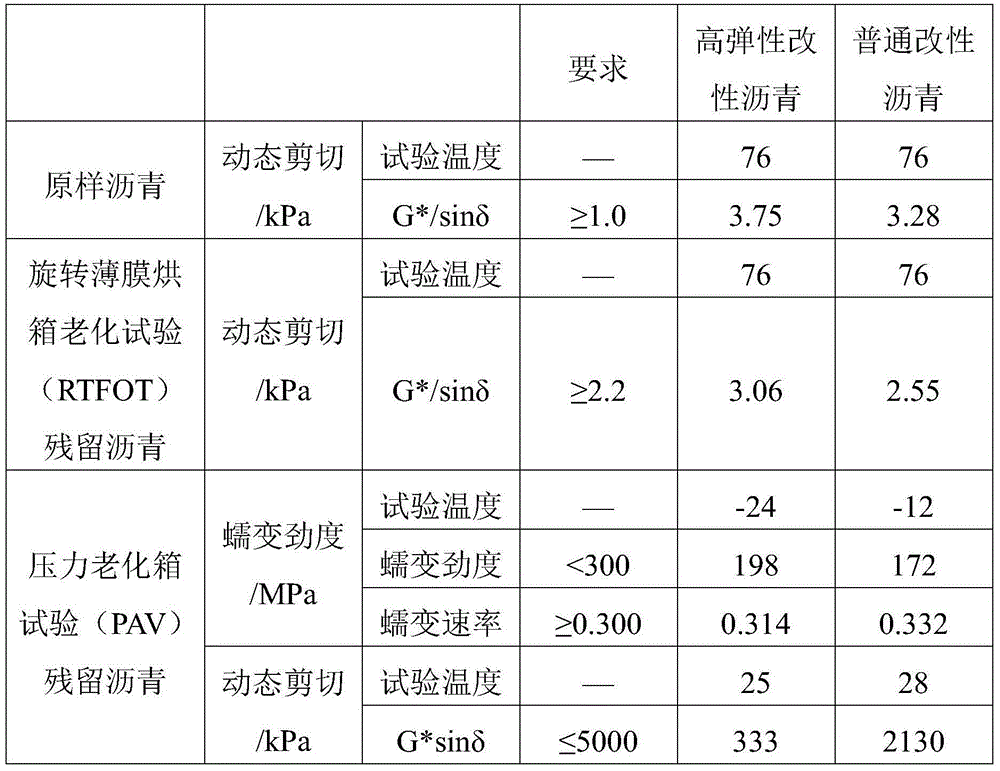

High-elasticity asphalt modified composition, modifier, modified asphalt, modified asphalt mixture and preparation method

ActiveCN104629391AImproved high temperature stability and elastic recoveryReduce melt viscosityBuilding insulationsButadiene-styrene rubberPlasticizer

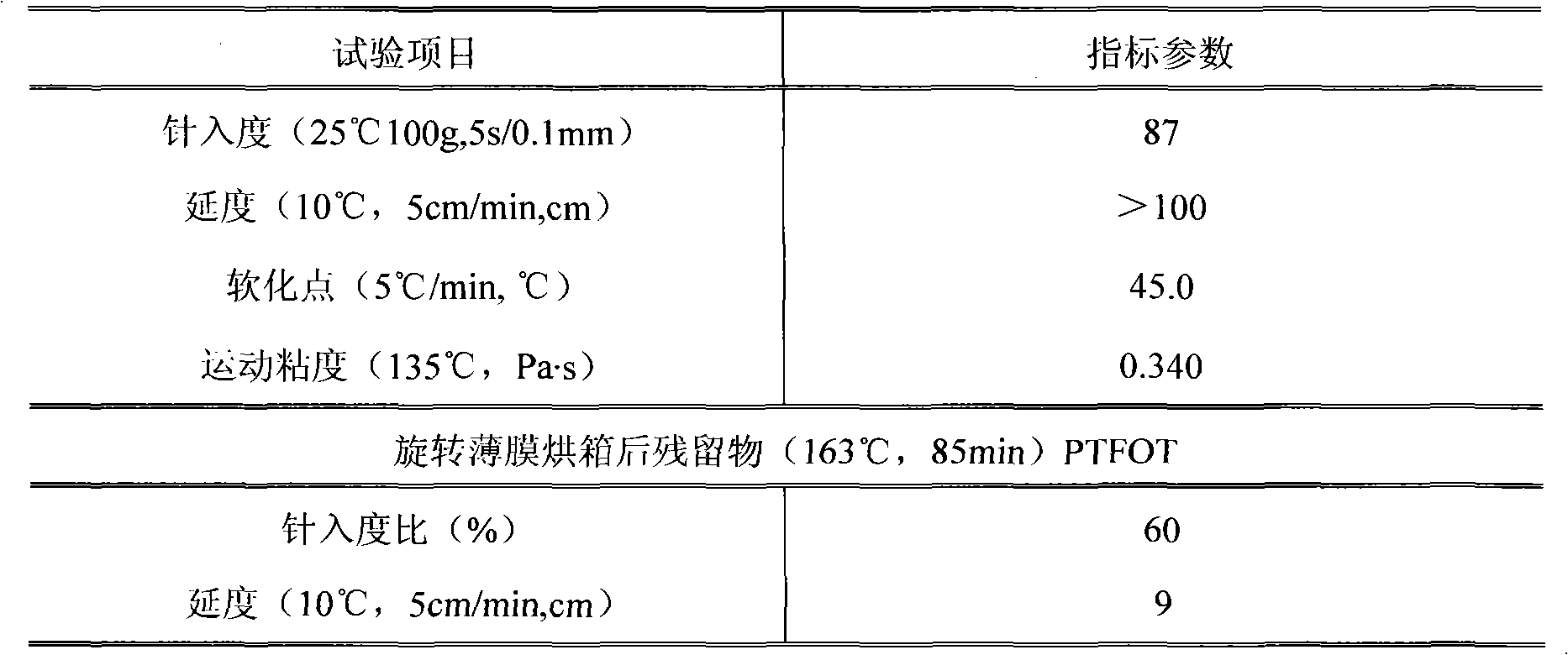

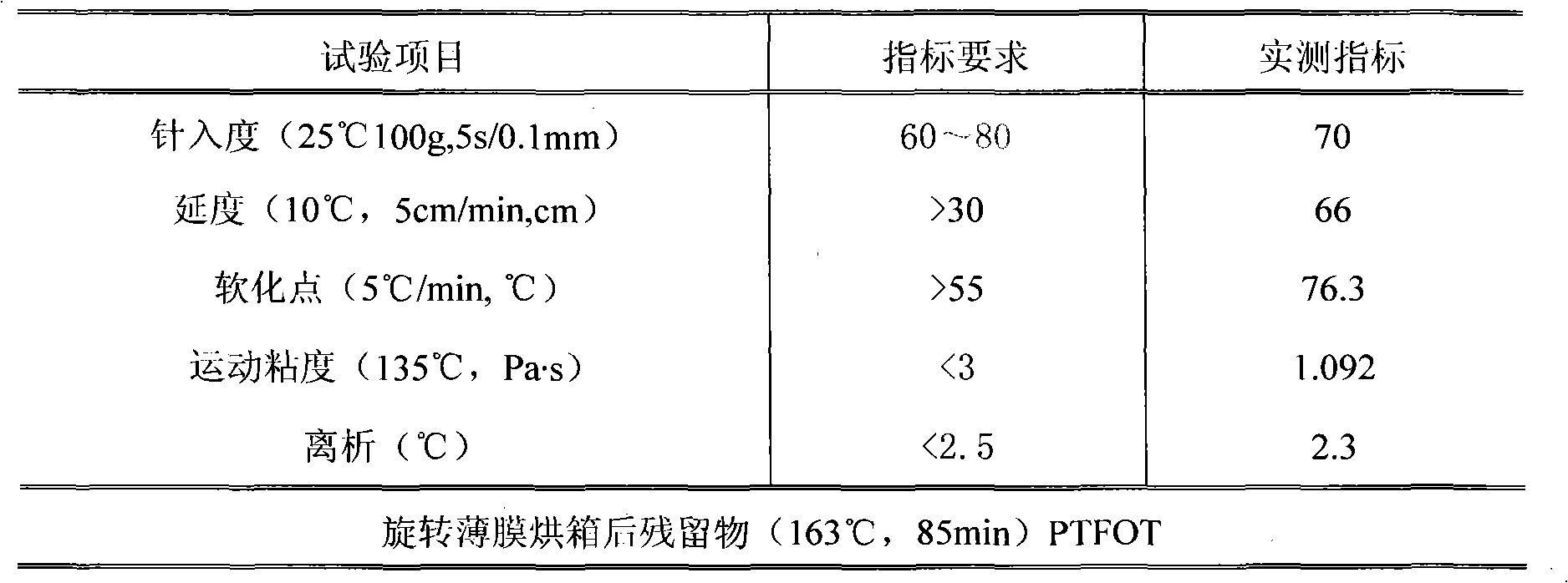

The invention relates to a high-elasticity asphalt modified composition, a modifier, modified asphalt, a modified asphalt mixture and a preparation method. The modified composition comprises 100 parts of a styrene-butadiene-styrene segmented copolymer, 20-40 parts of a tackifier, 20-40 parts of a softener, 3-8 parts of a warm mixing agent, 15-40 parts of a plasticizer and 2-6 parts of a stabilizer. The preparation method of the modifier comprises the following steps: (1) mixing the styrene-butadiene-styrene segmented copolymer, the tackifier and the warm mixing agent according to a formula to obtain a melt; and (2) mixing the softener, the plasticizer and the stabilizer with the melt, and then extruding, cooling and dicing. The modified asphalt is prepared by doping the modifier into matrix asphalt and uniformly mixing. The modified asphalt mixture is prepared by mixing the modified asphalt and a raw material of a mineral mixture. The modified asphalt provided by the invention has good high-temperature and low-temperature stabilities and anti-fatigue capacity, and the modified asphalt mixture is strong in construction workability and good in pavement performance.

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP

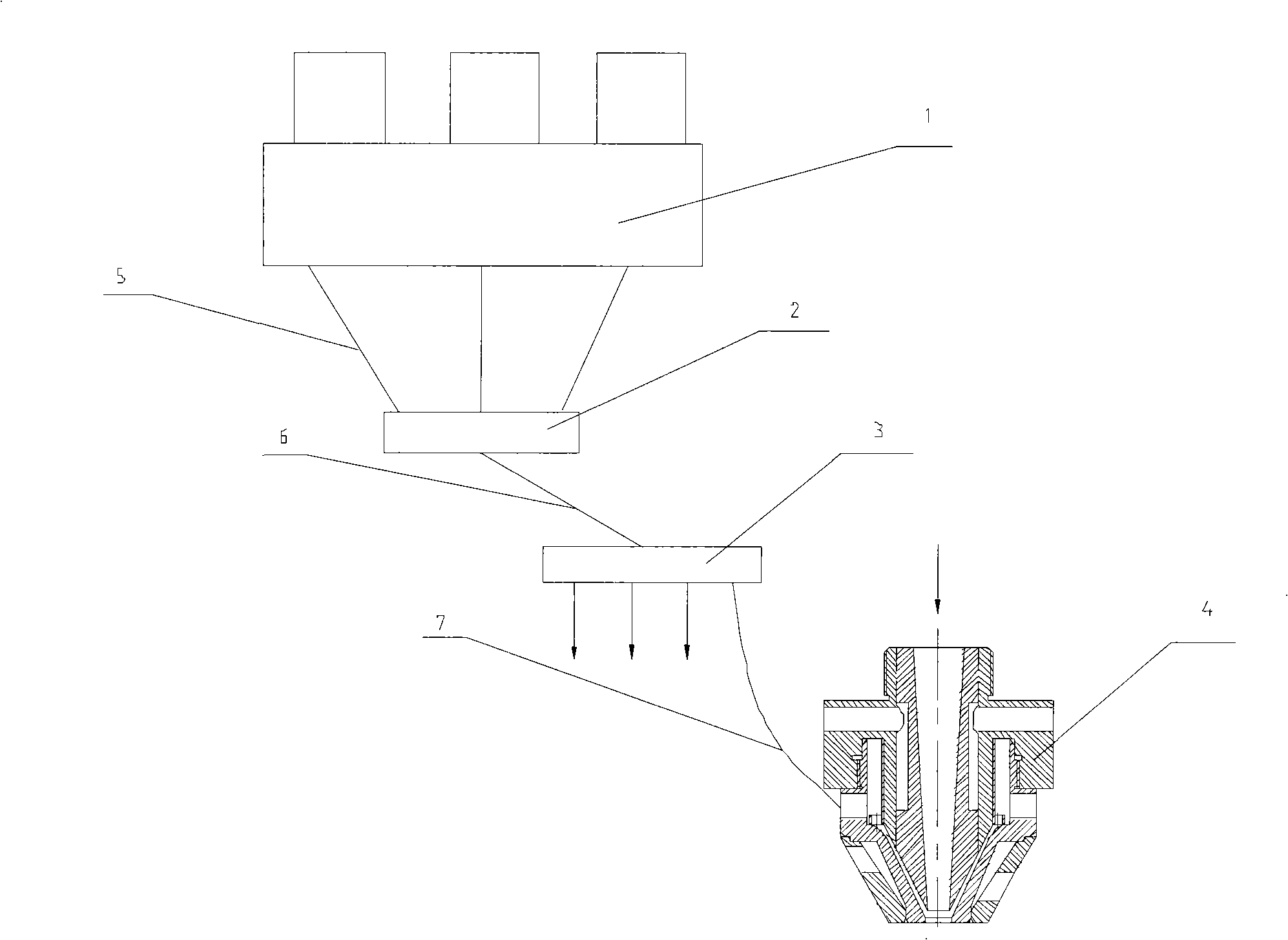

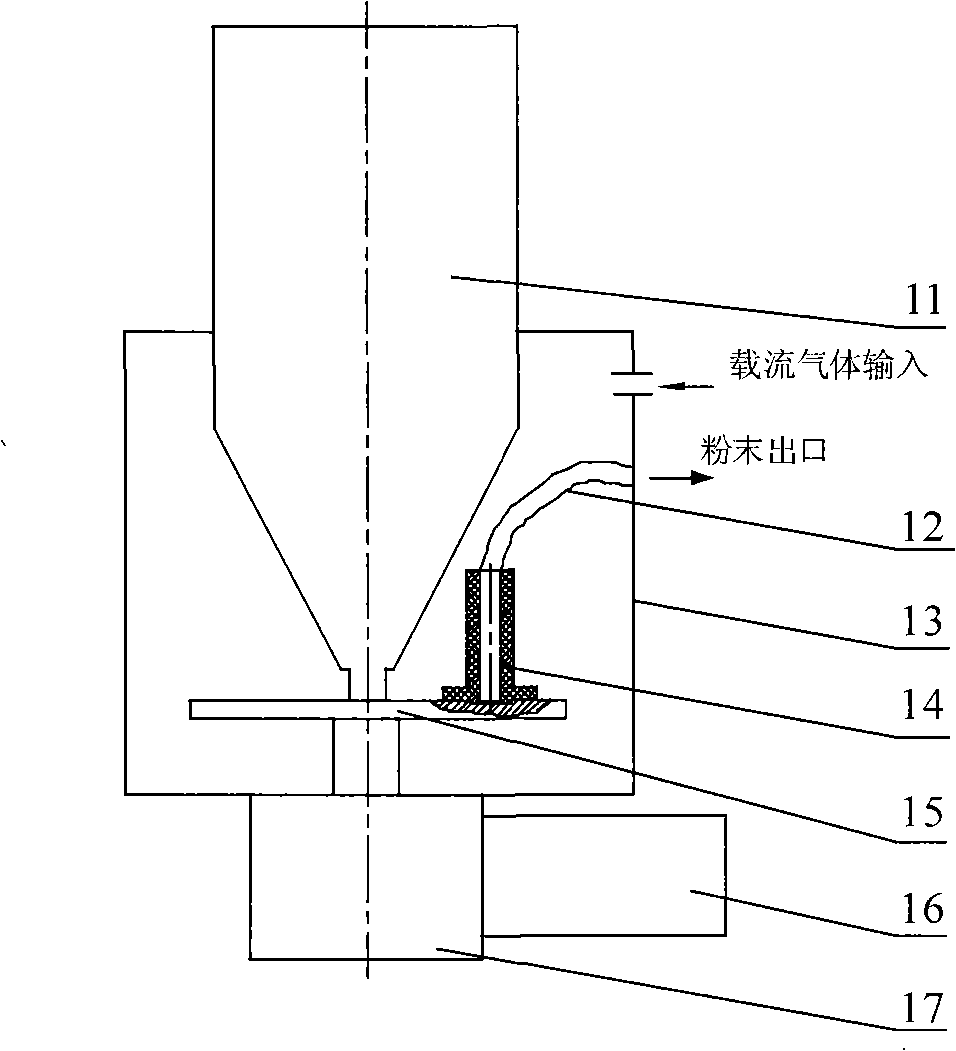

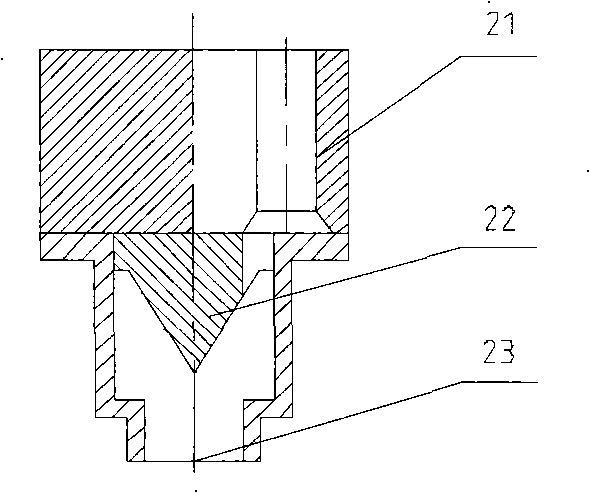

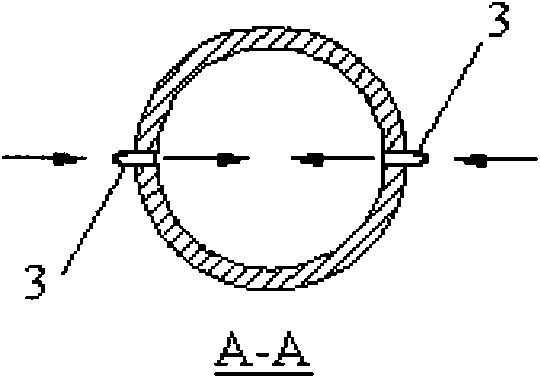

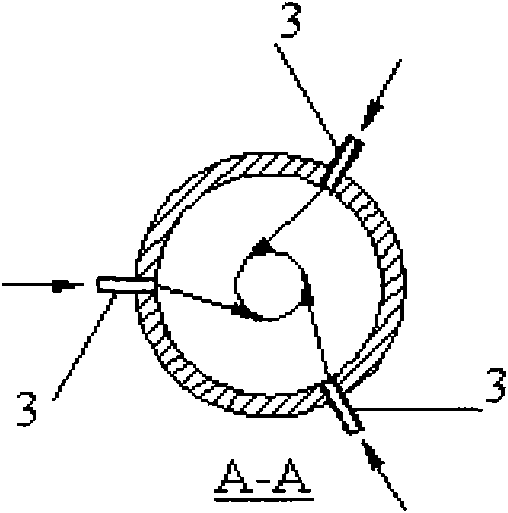

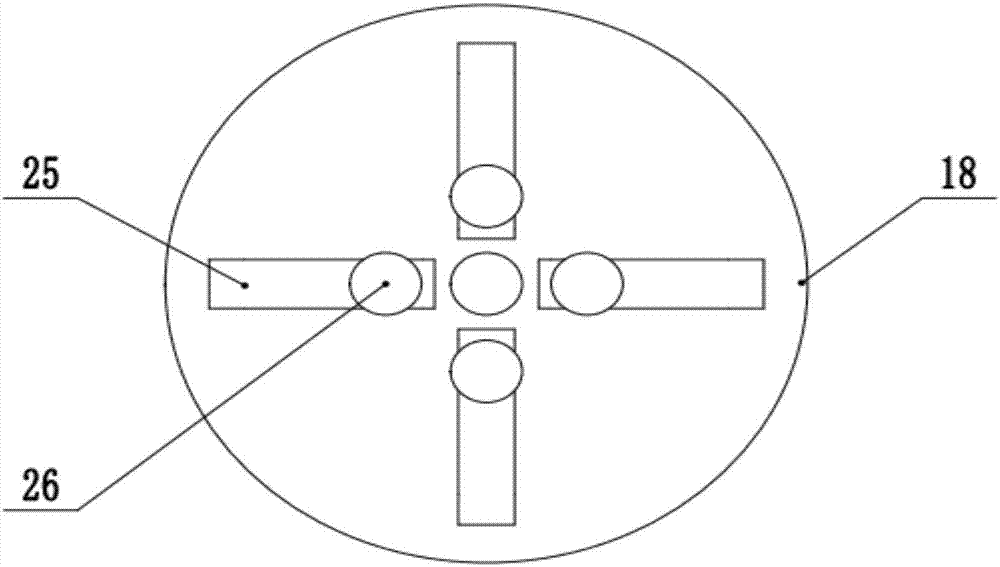

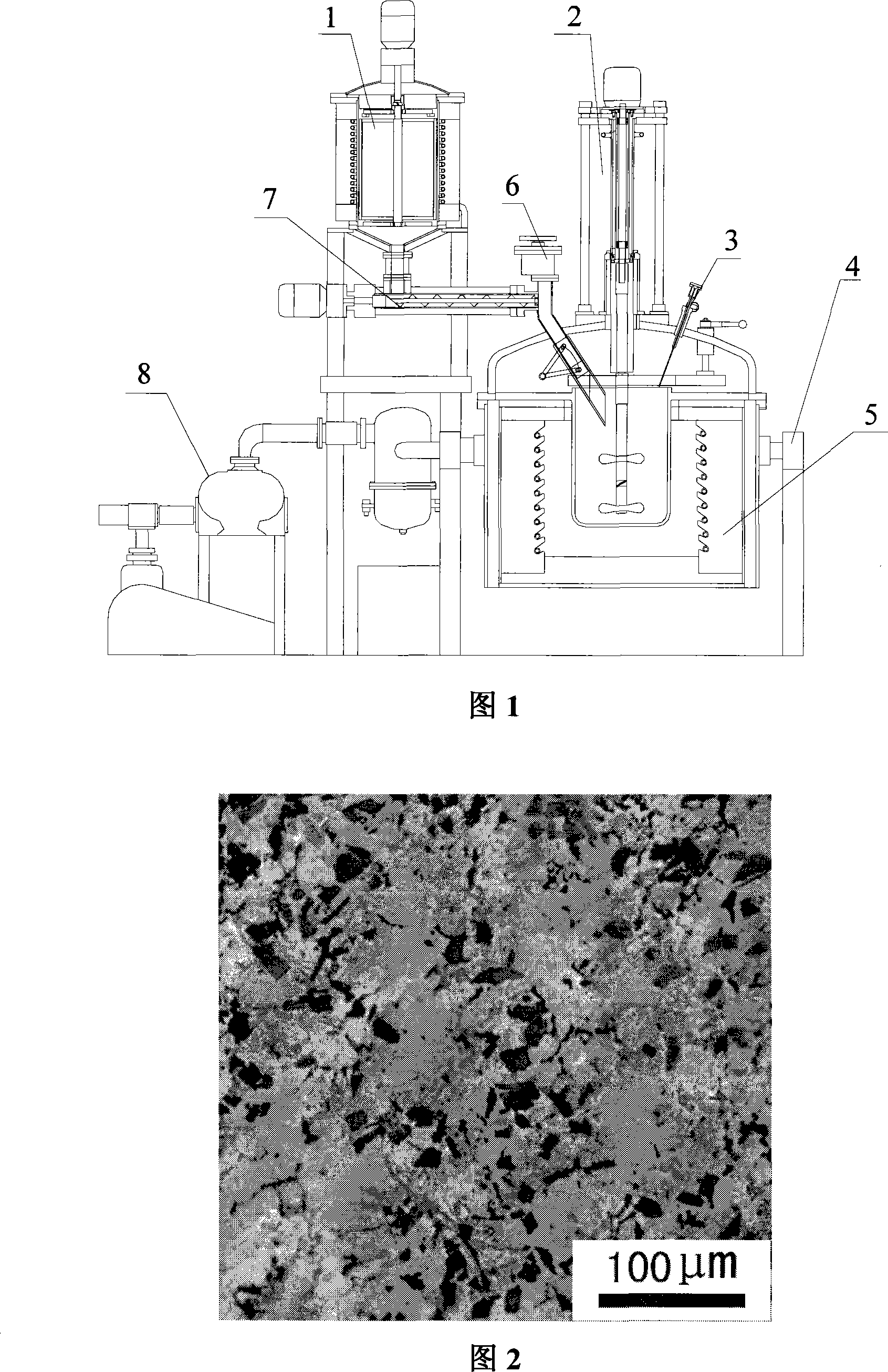

Coaxial powder feeding system for quickly molding and producing functional gradient material with laser

InactiveCN101342640AWell mixedImprove uniformityIncreasing energy efficiencyLaser beam welding apparatusNozzleRapid prototyping

The invention relates to a coaxial powder feeding system of laser rapid prototyping preparation function gradient material, comprising a powder inlet device, and the powder is absorbed and conveyed by carrier gas. The powder inlet device is communicated with a powder mixer through a first conveying pipe. The powder mixer is used for mixing the powder which has been conveyed. The mixed powder enters into a powder separate device through a second conveying pie. The powder separate device is used for separating the mixed powder into multi-path. The powder separate device is communicated with the powder inlet of a nozzle through a third conveying pipe. The nozzle makes the multi-path powder flock together in a molten pool formed by laser. The function gradient material is prepared under the cladding action of laser and powder. The mix of the powder is uniform. The coaxial powder feeding system has good power feeding property, which can realize the optimum processing, and at the same time, can be suitable for different processing distances. The powder utilization rate is high. The manufacturing accuracy is good. At the same time, the powder conveying distance can be adjusted with a certain scope, and so the coaxial powder feeding system can not be limited to the manufacturing space.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

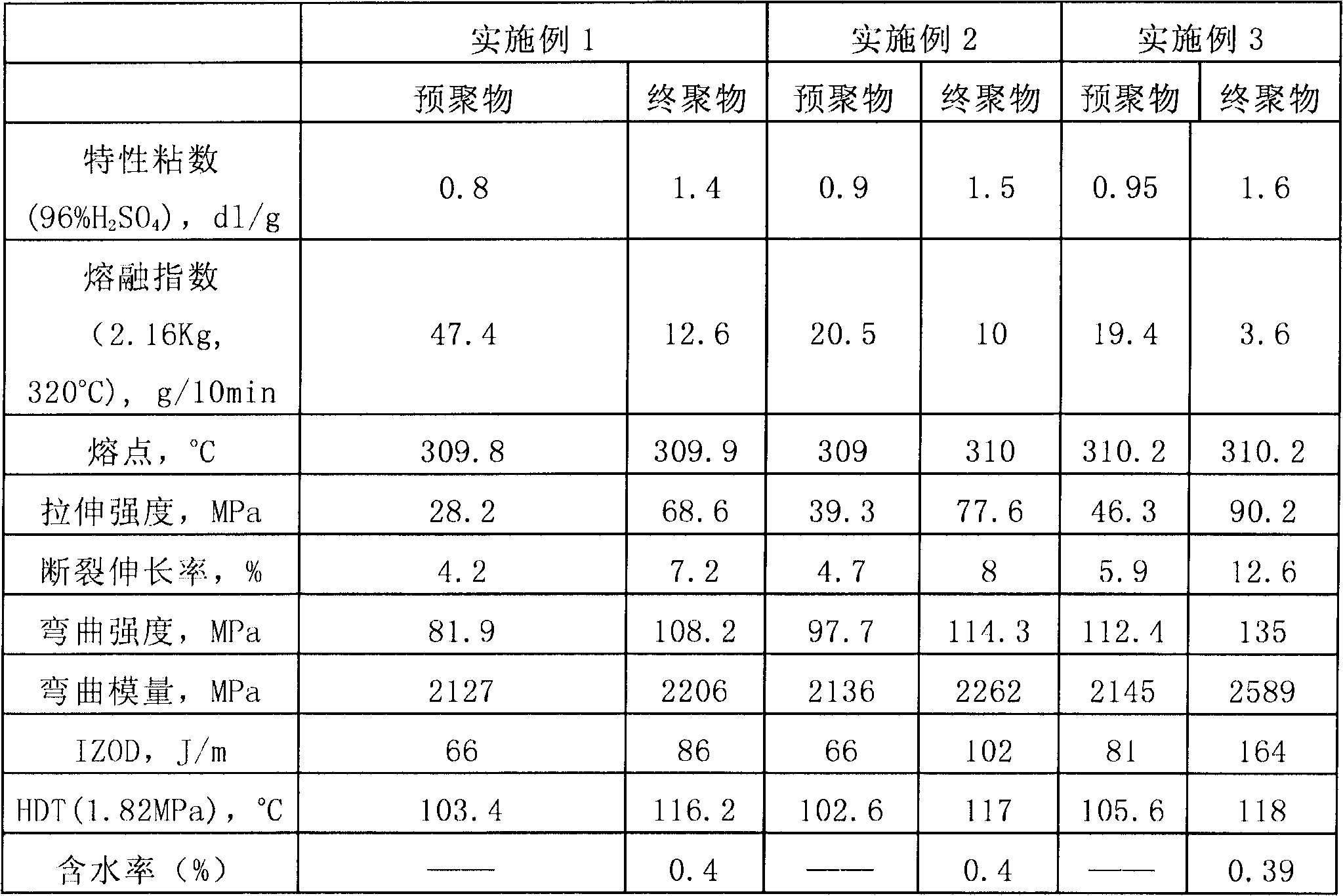

Homopolymer and copolymer of long-carbon-chain semi-aromatic high-temperature-resistant polyamide and synthesis method thereof

The invention provides a method for synthesizing a homopolymer and a copolymer of long-carbon-chain semi-aromatic high-temperature-resistant polyamide and polymerization products obtained by the method. The method comprises the following steps of: (a) prepolymerizing terephthalic acid and 1,10-decanediamine in a molar ratio of 1:(1.00-1.02) and optional copolymerization components to obtain a prepolymer that the intrinsic viscosity is controlled to be between 0.4 and 1.1dl / g; and (b) performing solid-phase polymerization on the prepolymer in step (a) to obtain the long-carbon-chain semi-aromatic high-temperature-resistant polyamide PA10T or the copolymer thereof, wherein the intrinsic viscosity is controlled to be between 1.2 and 2.6dl / g.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

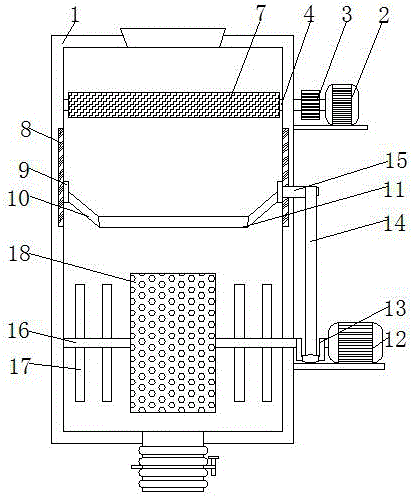

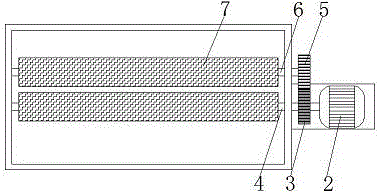

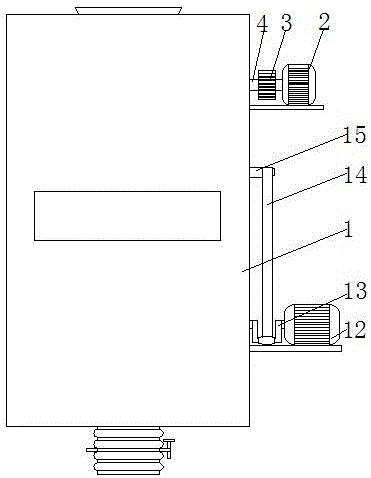

Chemical engineering raw material mixing and stirring device convenient for screening

The invention discloses a chemical engineering raw material mixing and stirring device convenient for screening. The device comprises a stirring box, the top of the stirring box is provided with a material inlet, the bottom of the stirring box is provided with a material outlet, one side of the stirring box is provided with a first motor through a carrier plate, the output end of the first motor is fixedly connected with the axle center of one side of a driving gear, the axle center, opposite to the first motor, of the driving gear is fixedly connected with one end of a driving rotating rod, and the other end of the driving rotating rod traverses through the stirring box, and is movably connected with the internal of the stirring box. A crushing roller is improved, teeth on the crushing roller can crush a chemical engineering raw material, the crushed chemical engineering raw material is screened under the cooperation of a filter screen frame, a stirring screen is improved, and the stirring screen can drive a stirring shaft and a stirring filter screen to simultaneously rotate through the rotating shaft and can stir the chemical engineering raw material in order to realize the screening and breaking effects in the stirring process.

Owner:洛阳毅兴石化电器仪表设备有限公司

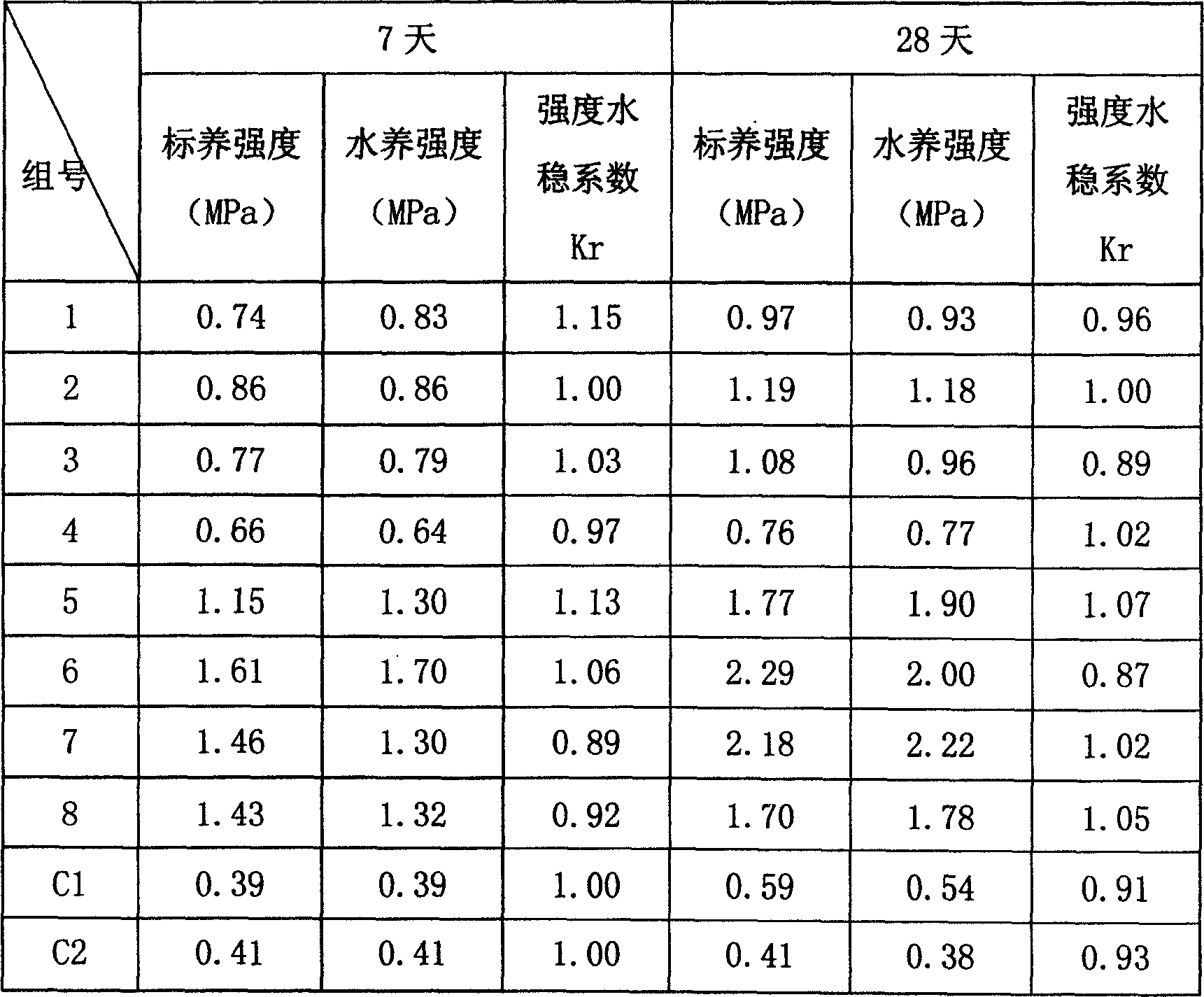

Soil solidifying agent

The soil curing agent as one kind of engineering material for curing and stabilizing various kinds of soil is especially suitable for curing silt and other kinds of low viscosity soil. The soil curing agent has main cement material comprising ore powder, flyash and water, as well as proper amount of alkali exciting component, expanding component and surfactant, and is prepared through mixing the materials and grinding to Blaine fineness of 3000-5000 sq m / kg. Specifically, it consists of mineral admixture 40-60 wt%, cement 15-25 wt%, alkali exciting component 5-15 wt%, expanding component 15-25 wt% and surfactant 0.01-0.1 wt%.

Owner:SOUTHEAST UNIV

Nanocomposite diatom ooze material and construction method thereof

The invention discloses a nanocomposite diatom ooze material and a construction method thereof. The material consists of a diatom ooze powder material and nano-titanium dioxide dispersion liquid, wherein the diatom ooze powder material consists of calcined diatomite, quartz sand, gray calcium powder, bentonite, wollastonite, seaweed gel, cellulose ether and negative ion powder. The construction method comprises the following steps of: mixing the diatom ooze powder material and water according to the weight ratio of 1:0.9 in the field; after stirring for 15 minutes by using an electric stirrer, performing batch-scraping coating texture modeling construction; uniformly spraying the nano-titanium dioxide dispersion liquid, namely photocatalyst solution to a construction surface by using a spraying gun after the surface is dried; and drying for 48 hours. By using the construction method, the problems that nano-titanium dioxide powder is difficult to disperse and easy to agglomerate, and has large additive amount, the production cost is high, and a nano-titanium dioxide material is wasted in the preparation process of the diatom ooze are solved, the functionality of the diatom ooze for purifying and decomposing harmful gases is improved, and the overall cost of the product is reduced.

Owner:JILIN PROVINCE LANSHE DIATOM NEW MATERIALS

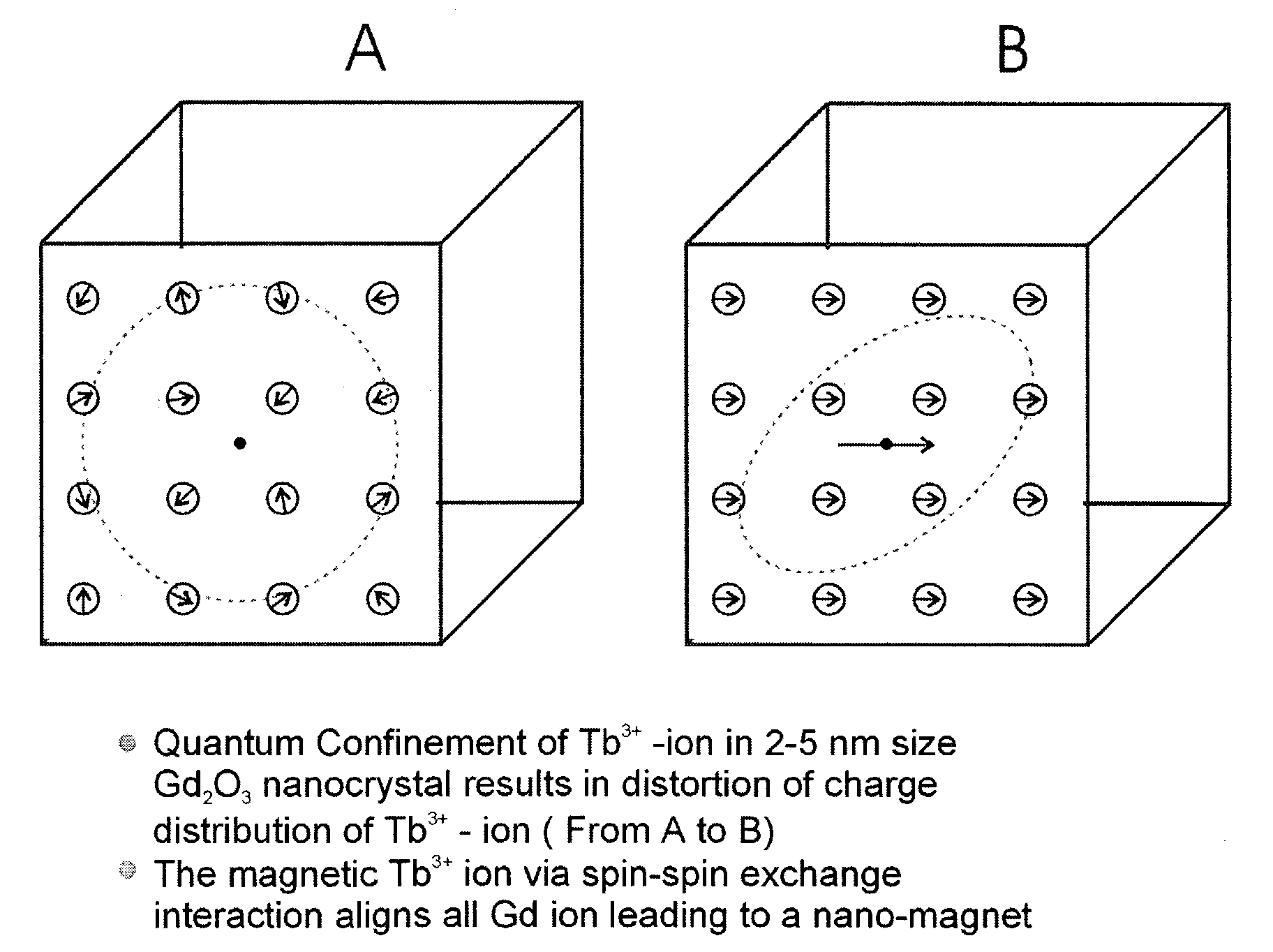

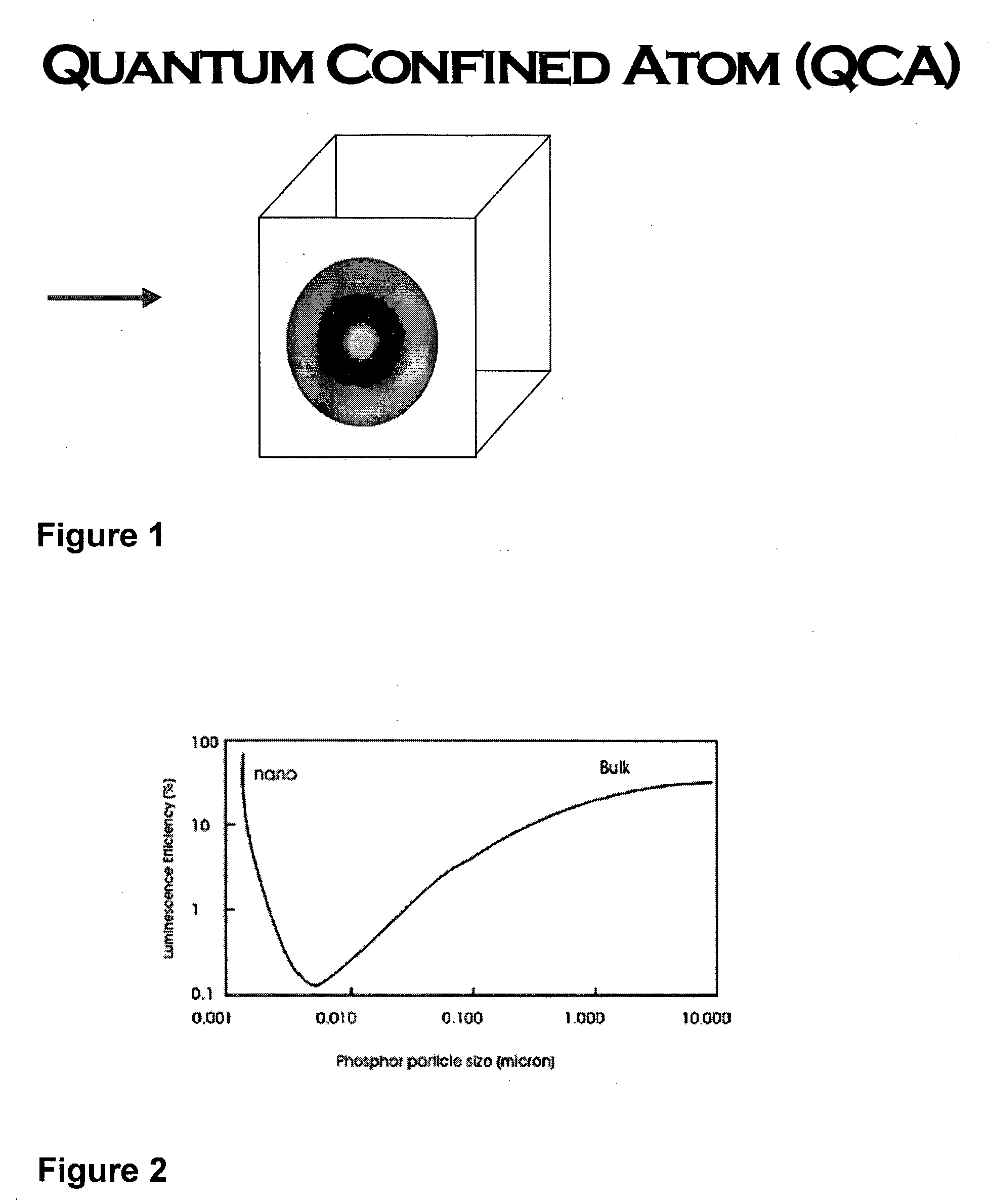

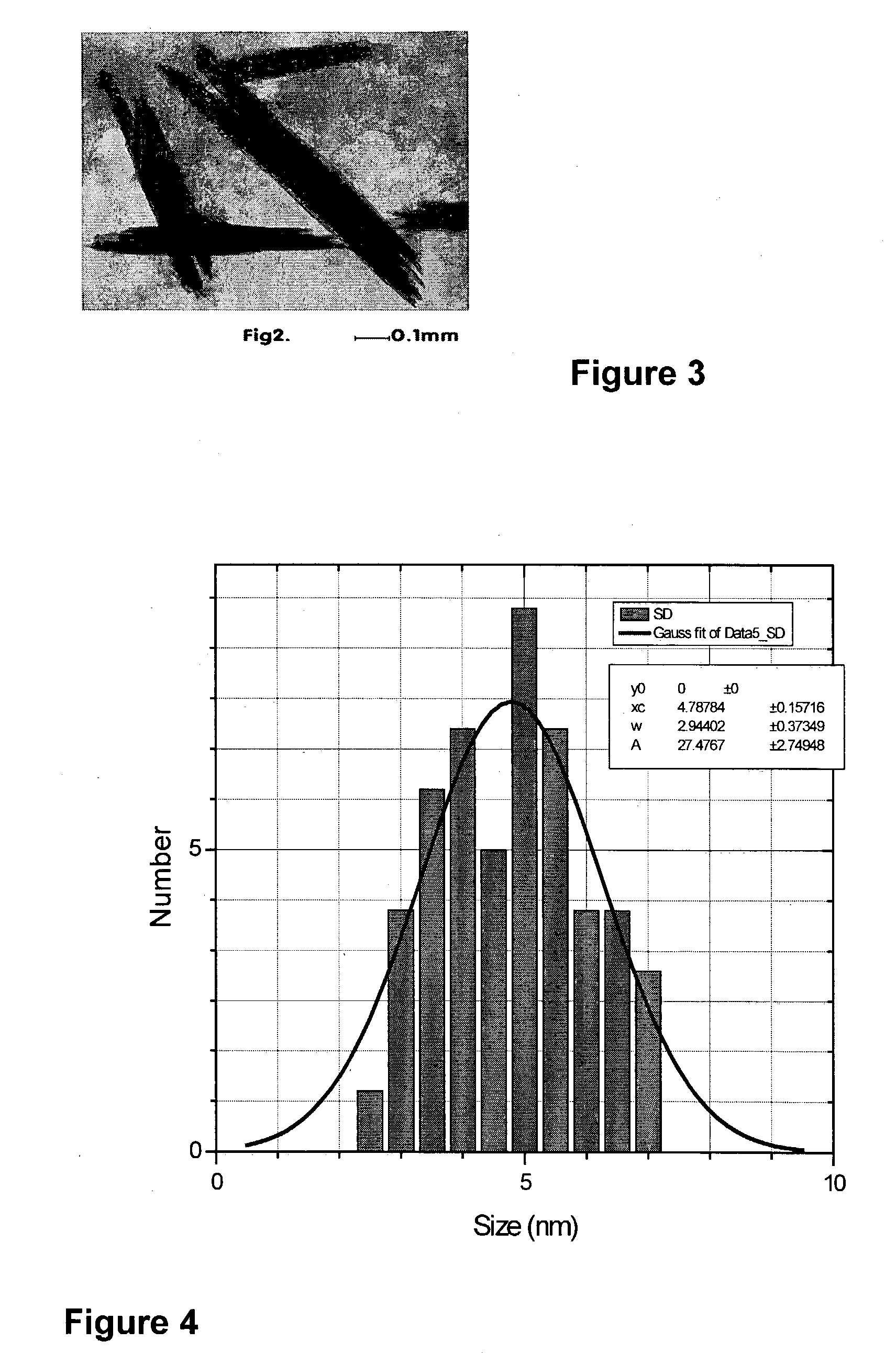

Self-aligning QCA based nanomaterials

InactiveUS7175778B1Unique luminescent and optical propertyAvoid clumpingNanomagnetismMagnetic paintsOptical properties of carbon nanotubesDopant

The present application is directed to the preparation and use of a class of nanoparticles called Quantum Confined Atoms or QCA's. A QCA is a particle of material comprising a plurality of host atoms in a nanoparticle of a size of less than 10 nm with a single atom of a dopant (or activator) confined within. The QCA's have unique luminescent and optical properties and thus can act as a very efficient nanophosphor which generate polarized light and can operate as a laser and a nanomagnet. An anti-agglomeration coating surrounding the nanoparticles can prevent clumping and loss of the enhanced properties.

Owner:NANOCRYSTALS TECH

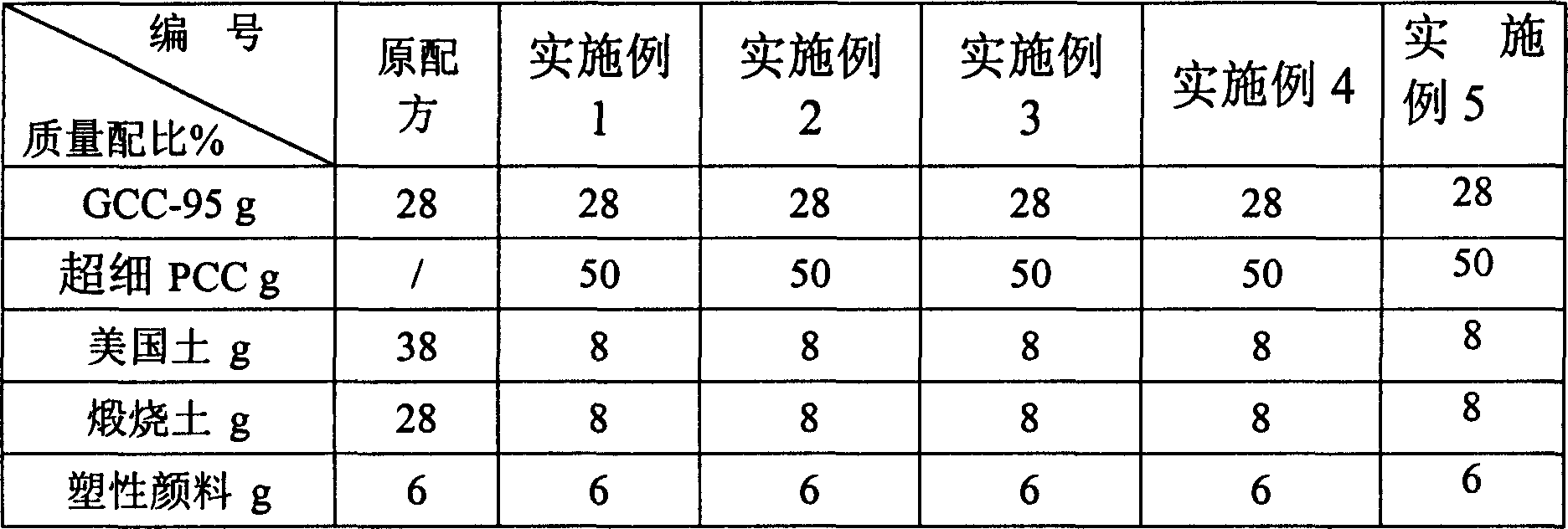

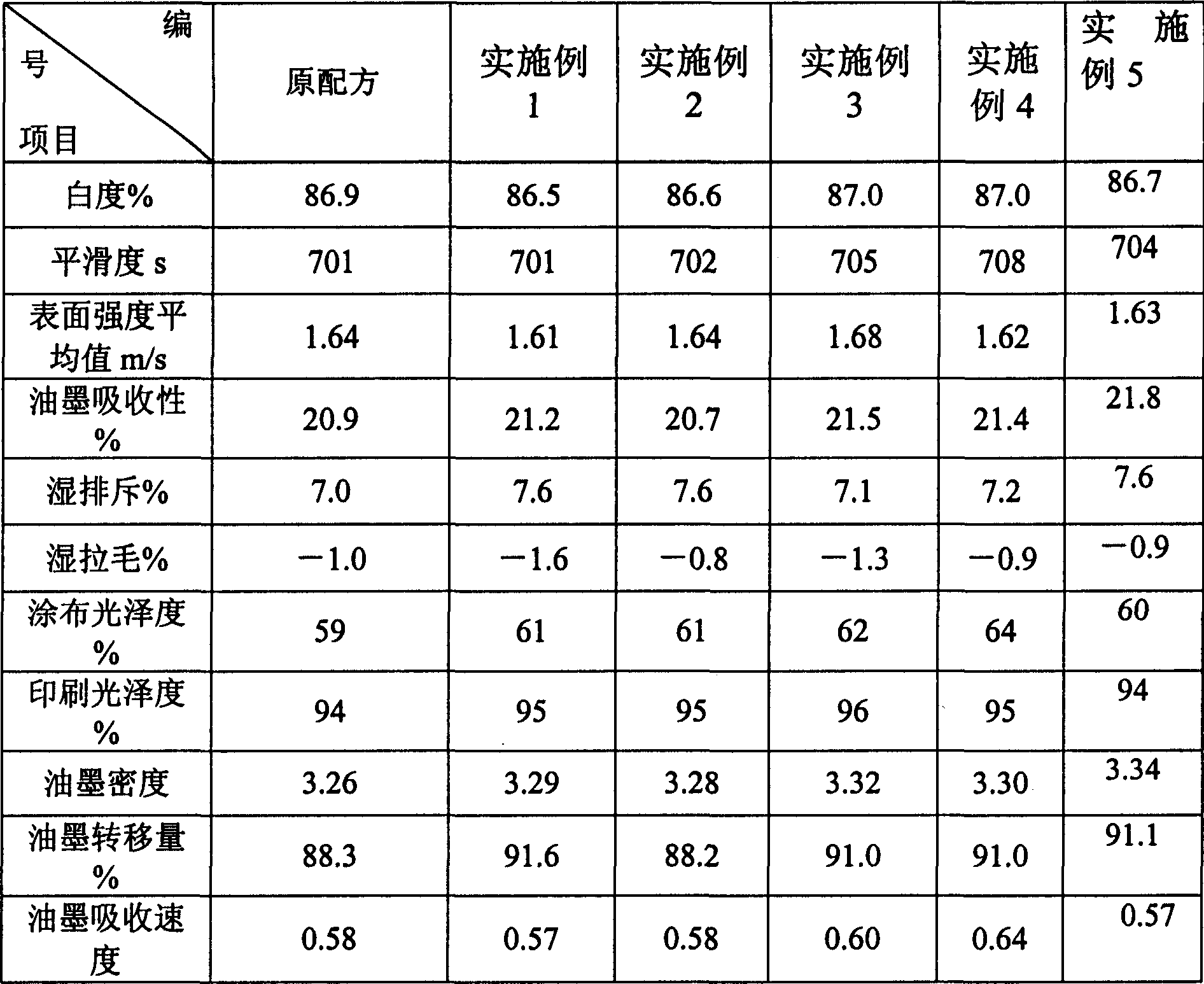

Process for preparing superfine light calcium carbonate

ActiveCN1884085AHigh whitenessReduce manufacturing costCalcium/strontium/barium carbonatesCoatings with pigmentsPhosphatePyrophosphate

The invention discloses a preparing method of super-fine lightweight calcium carbonate, which comprises the following steps: adding disperser in the calcium hydroxide slurry; sending the slurry to the grinding equipment; inputting carbon dioxide from bottom of grinding equipment to carbonize; synchronizing grinding and carbonizing. The disperser is one or two of phosphate, sodium polyacrylate, triethanolamine, sodium pyrophosphate, sodium polyphosphate or hexametaphosphate. The even grain size of super-fine calcium carbonate is 0.2-2.0 mum with 60-100 percent grain number with less than 2 mum grain size, which is fit for paper making filler or paper coating dye.

Owner:SHANGHAI DONGSHENG NEW MATERIALS

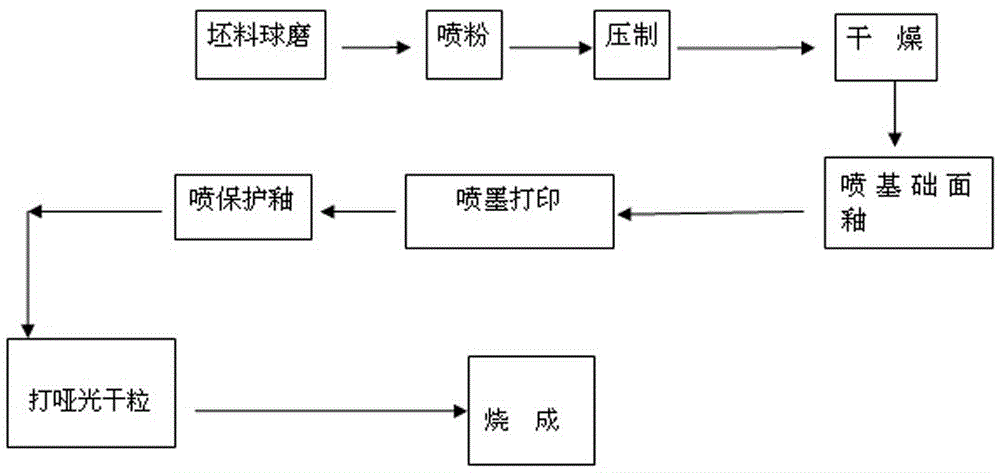

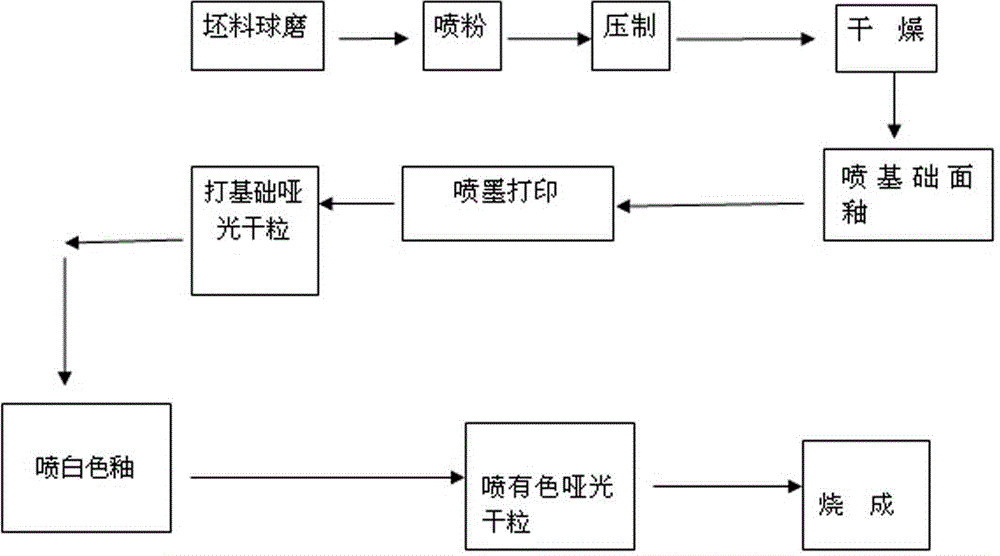

Dry particle glaze rock simulated ceramic tile production process

The invention provides a dry particle glaze rock simulated ceramic tile production process, which relates to a ceramic production process, in particular to a production process of a rock simulated ceramic tile. The rock simulated ceramic tile comprises a ceramic tile body and a glaze surface, and is characterized in that the glaze surface is prepared from the following ingredients including 25 to 40 percent of basic surface glaze, 15 to 25 percent of protection glaze, 0 to 0.05 percent of mica sheets, 4 to 6 percent of water washing ball soil slurry, 15 to 25 percent of gluewater, 5 to 10 percent of inorganic cermic ink, 8 to 15 percent of white dull gloss dry particles, 0 to 12 percent of colored dull gloss dry particles, 0.5 to 1.5 percent of aluminum oxide slurry and 0.02 to 0.04 percent of dispergators. The production process comprises a single-point product manufacturing process and a multi-point product manufacturing process. The problems of poor accumulation effect of the existing dull gloss dry particles on the tile surface and flowing of gluewater into a glaze jar are solved; in addition, the dry particles with strong three-dimensional effects can be obtained through firing in one step; the visual layering effect of products is good; the hardness and the wear-resistant degree are both superior to those of the existing product.

Owner:FOSHAN NANOGRESS BUILDING MATERIALS CO LTD

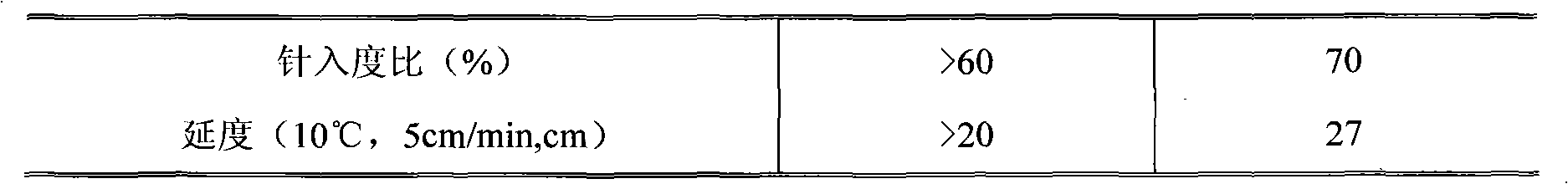

SBS modified asphalt stabilizer and preparation method thereof

The invention discloses a stabilizer, in particular to a stabilizer used for SBS modified asphalt and a preparation method thereof; the stabilizer is prepared from the following raw materials according to the parts by weight: 0.5-5 parts of sulfur, 0.2-5 parts of aromatic heterocyclic multifunctional olefin monomers and 90-100 parts of aromatic heavy oils. The invention adopts sulfur as main reactant and aromatic heavy oils as dispersant; the reactant and the reaction promoter can be dissolved in the dispersant to promote the uniform mixing between the reactant and a reaction promoter, increase the uniformity of the reaction of the stabilizer and substrate asphalt and avoid the agglomerate phenomenon caused by locally over crosslinking; the heterocyclic multifunctional olefin monomers areused as the reaction promoter so as to increase the reaction efficiency of the main reactant and the crosslink rate. The invention solves the problems well that SBS is easy to separate from the substrate asphalt and the storage is not stable in the production process of SBS polymer modified asphalt.

Owner:XIAN ZHONGLI ASPHALT CO LTD

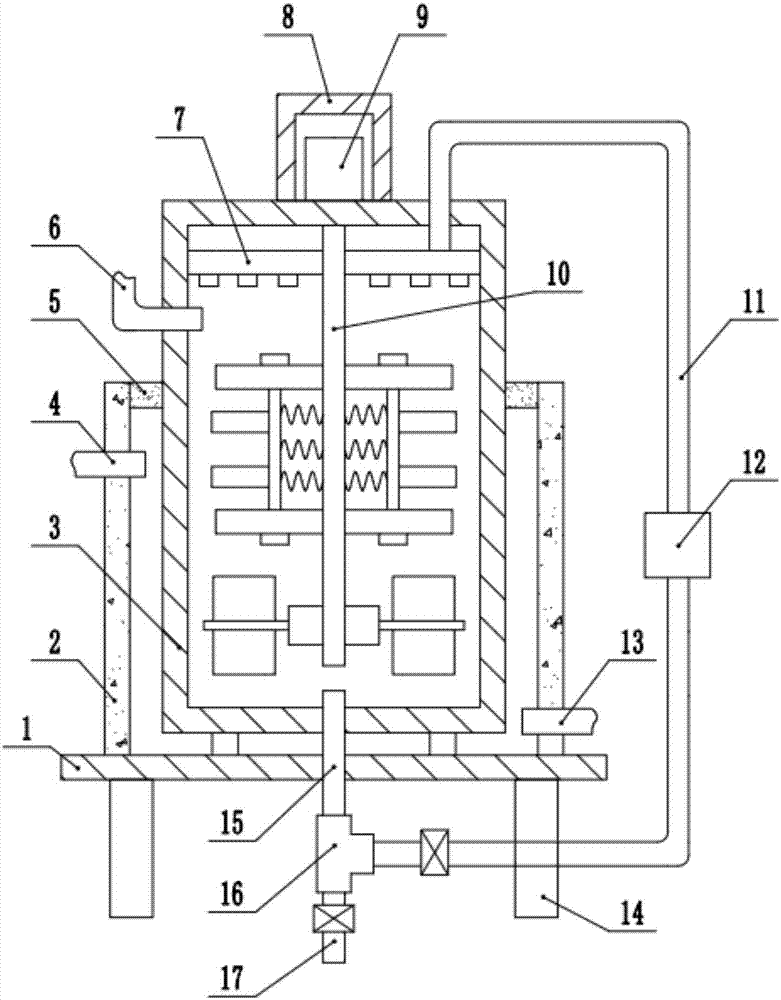

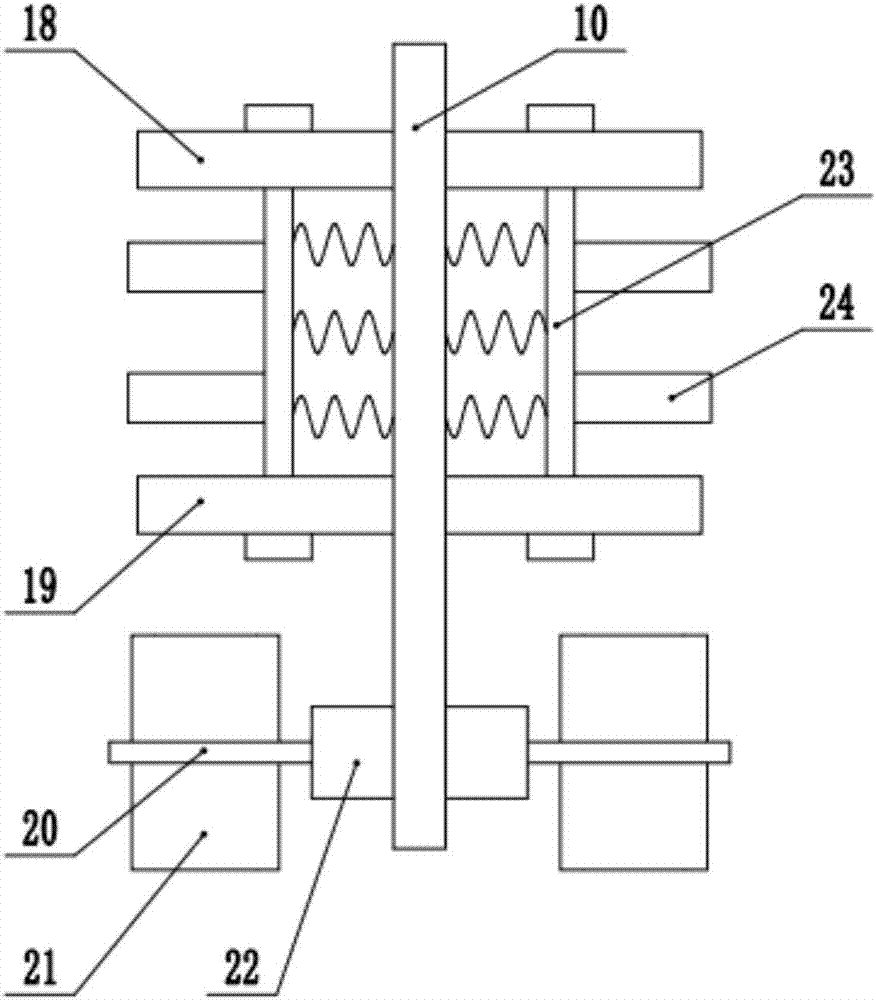

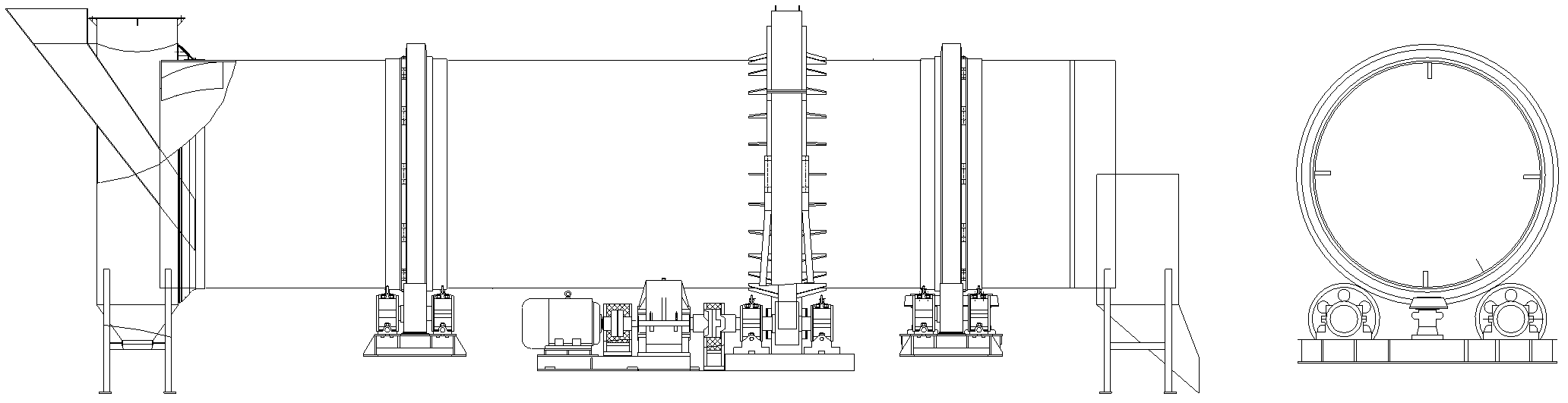

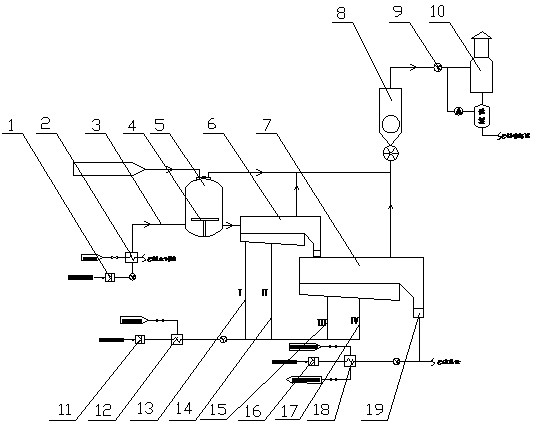

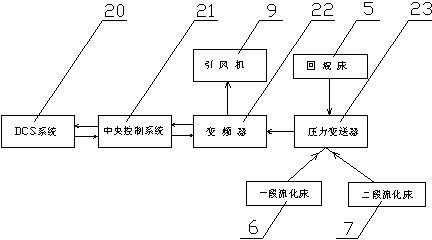

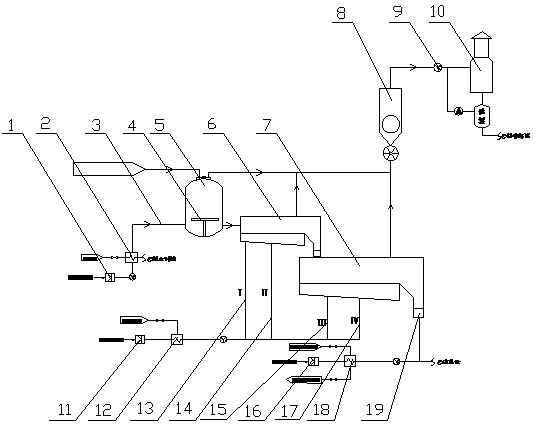

Method and device for jet/preoxidation/pyrolysis/fluidized bed gasification of carbon-containing solid fuel

ActiveCN102120936AReduce the possibility of sticking and cokingImprove adaptabilityGranular/pulverulent flues gasificationFluidized bed gasifierThumb opposition

The invention belongs to the field of energy utilization of a solid fuel, and relates to a method and gasifier for jet / preoxidation / pyrolysis / fluidized bed gasification of a carbon-containing solid fuel. The method provided by the invention comprises steps as follows: by using oxygen-containing gasifying agent gas as a carrier, carbon-containing solid fuel particles are fed into a fluidized bed gasification furnace in a high-speed jet mode, so that the fuel particles are previously subjected to oxidation and pyrolysis in the high-speed jet and are highly dispersed; and the carbon-containing solid fuel particles are subjected to intensified pyrolysis in a dilute-phase region of the fluidized bed gasification furnace, and then, the formed semicokes of the carbon-containing solid fuel particles are moved into a dense-phase bed of the fluidized bed gasification furnace to participate in burning gasification reaction so as to generate crude gas or synthetic gas accompanied with fine semicoke particles and hot ash of the carbon-containing solid fuel. The method provided by the invention can be widely applied to various kinds of coal. The body of the fluidized bed gasification furnace ofthe jet / preoxidation / pyrolysis / fluidized bed gasification device is provided with fuel nozzles which are arranged at the circumference of the fluidized bed gasification furnace in an opposition, diagonal opposition or tangential circle mode.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

High-efficiency paint stirring and mixing device capable of automatically turning

InactiveCN107020031AStir wellAvoid condensationFlow mixersRotary stirring mixersCircular discEngineering

The invention discloses a high-efficiency paint stirring and mixing device capable of automatically turning. The device comprises a base, a heating seat, a stirring barrel, a stirring motor and a stirring shaft, wherein the heating seat is fixedly arranged on the base; the stirring barrel is fixedly mounted inside the heating seat; the output end of the stirring motor is fixedly connected with a stirring shaft; an upper disc and a lower disc are arranged on the stirring shaft; a plurality of stirring blades are arranged on the outer side of the vertical stirring shaft; two turning motors are symmetrically arranged at the bottom of the stirring shaft; the output ends of the turning motors are fixedly connected with the vertical stirring shaft; a turning plate is arranged on the vertical stirring shaft. The heating seat is arranged on the outer side of the stirring barrel, so that paint is heated in the stirring process and is prevented from being condensed into pieces; the turning plate is arranged at the bottom of the stirring shaft, so that the paint is prevented from being stacked at the bottom of the stirring barrel; therefore, the paint is uniformly stirred, and the stirring efficiency is improved.

Owner:六安市智奇工业设计有限公司

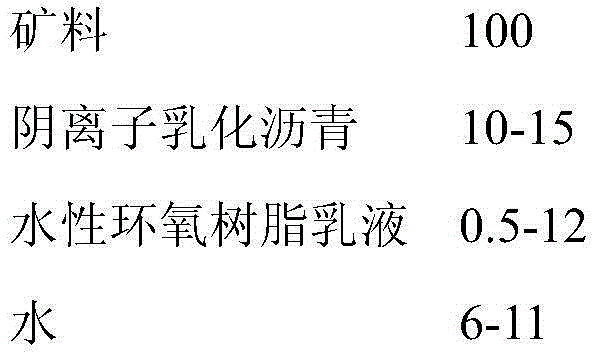

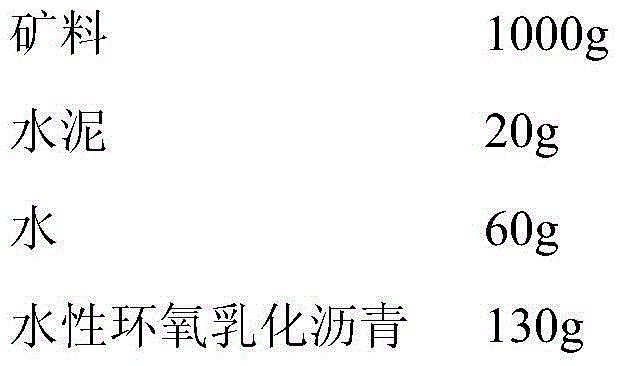

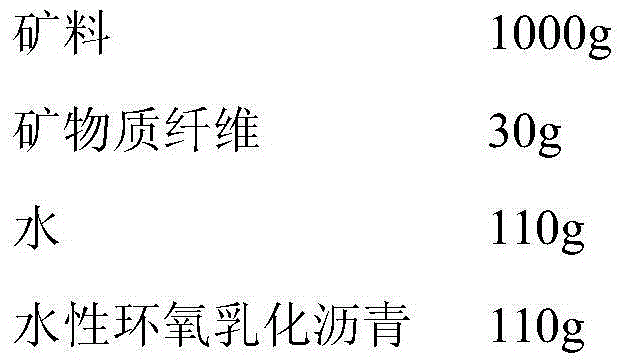

A water-borne epoxy resin-emulsified bitumen micro-surfacing mixture and a preparing method thereof

The invention discloses a water-borne epoxy resin-emulsified bitumen micro-surfacing mixture. The micro-surfacing mixture comprises following raw materials by weight: 100 parts of mineral aggregate, 10-15 parts of anionic emulsified bitumen, 0.5-12 parts of a water-borne epoxy resin emulsion and 6-11 parts of water. A preparing method of the micro-surfacing mixture is also disclosed. The method includes preparing the mineral aggregate, mixing the water-borne epoxy resin emulsion and the emulsified bitumen to obtain emulsified bitumen modified with water-borne epoxy resin, adding the water into the prepared mineral aggregate, adding the emulsified bitumen modified with the water-borne epoxy resin, fully stirring and curing, or the method includes preparing the mineral aggregate, adding the water into the prepared mineral aggregate, adding the water-borne epoxy resin emulsion and the emulsified bitumen, fully stirring and curing. The prepared micro-surfacing mixture is good in adhesiveness with stone, good in compatibility with the emulsified bitumen, good in stability, and capable of greatly improving wear resistance, resistance to water damage and rutting resistance of micro-surfacing and prolonging service lifetime of a road surface.

Owner:BEIJING UNIV OF CIVIL ENG & ARCHITECTURE +2

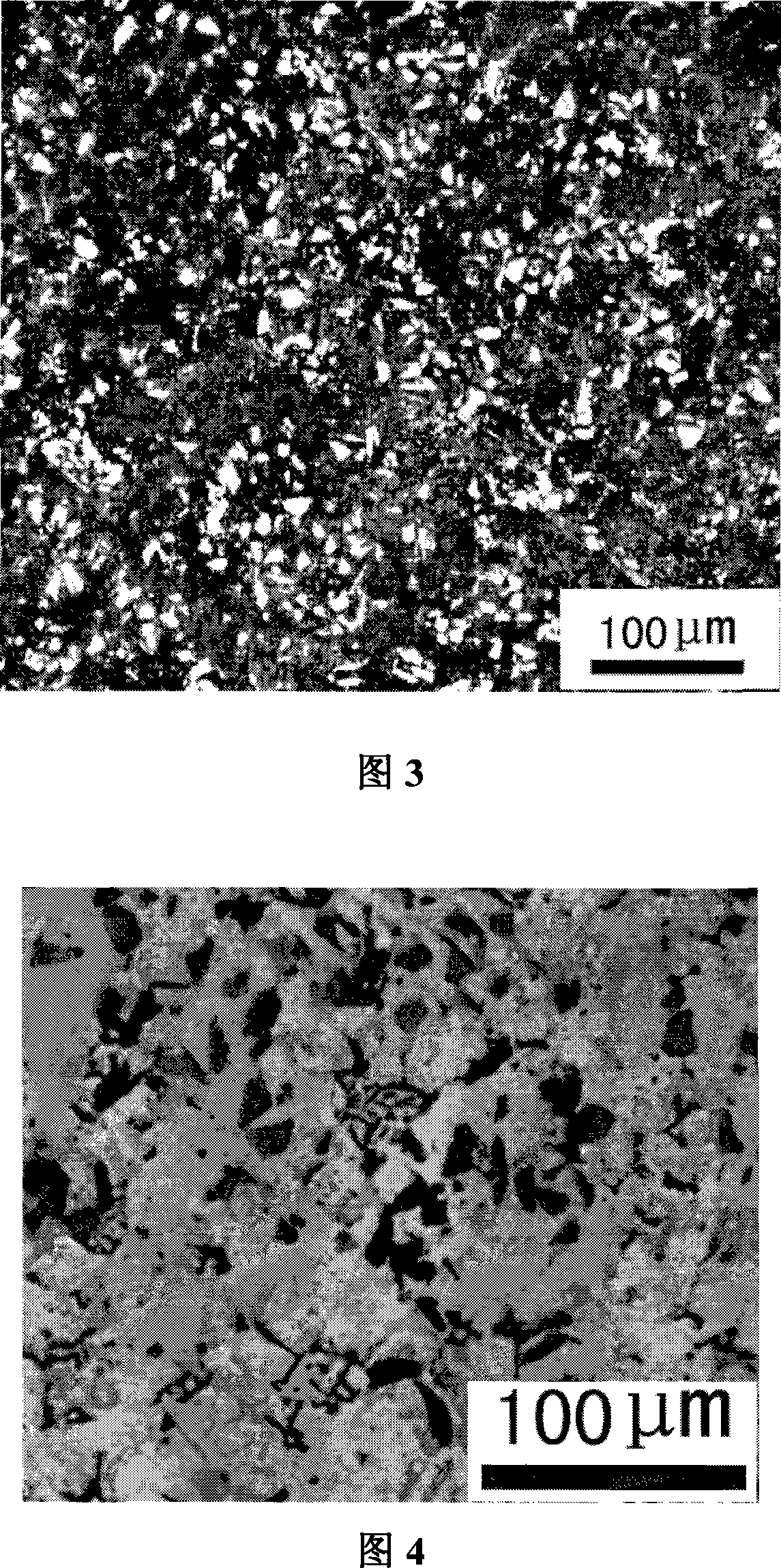

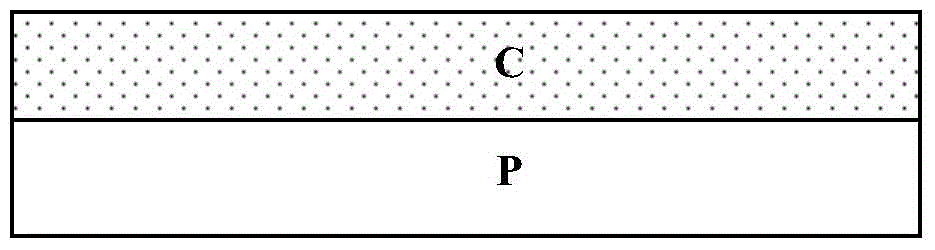

Vacuum stirring composite granule reinforcing aluminium-based composite material and preparation technique thereof

The invention relates to a composite material of vacuum churning composite granule enhanced aluminum matrix and a preparation technique, which comprises: Si 0-15Wt%, Mg 0-1.5Wt%, Cu 0-2.0Wt%, Mn 0-1.0Wt%, Cr 0-0.4Wt%, Ti 0-0.2Wt%, SiC 0.1-20% (volume proportion). Firstly base alloy is smelted, slag is removed, and refined, churned slowly in vacuum to complete degassing procedure for base melt, the pre-treated enhanced granule is continuously added into the aluminum base melt, mechanical churning to roll the granule into the melt, after the granule is completely rolled in the melt, strong churning and slow churning in reverse direction are conducted so as to disperse the granule evenly in the base; the temperature raises, modifier and refiner are added; the vacuum is dismounted, and placed in static, the floating slag is removed above the melt, and cast. The composition between the granule and the base is realized via vacuum mechanical churning, the joining interface is good, the enhanced granule is evenly dispersed in the base, the prepared composite material has low porosity rate, which is easy to realize industrial mass production.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND +1

Selenium-enriched five-cereal nutritional instant powder and preparation method thereof

ActiveCN106234926AMeet selenium supplement requirementsImprove neurological functionFood scienceAlcoholSoft materials

The invention provides a selenium-enriched five-cereal nutritional instant powder and a preparation method thereof, not only realizes the preparation of instant composite coarse cereal powder under the no addition condition, and has the advantages that the product taste is fine, has the fragrance of puffing coarse cereals, the selenium quantification can be realized, and the product is suitable for demands for selenium supplementation of crowds with selenium deficiency. The five-cereal nutritional instant powder rich in selenium comprises selenium-enriched rice and various cereals as well as auxiliary materials, can be selenium-containing hair nourishing brain strengthening nutrient powder, selenium-containing children's nutrient powder, selenium-containing blood and qi nourishing nutrient powder or selenium-enriched liver nourishing and protecting nutrient powder. The preparation method comprises the steps of soaking fresh five cereals taken as raw materials, mixing the soaked five cereals and water, drying and smashing to obtain five-cereal powder; mixing the five-cereal powder and ethyl alcohol to prepare soft material, then carrying out granulation to obtain five-cereal instant particles; and drying the five-cereal instant particles to obtain the five-cereal instant powder. The preparation method for the five-cereal nutritional instant powder is simple, the obtained five-cereal instant powder is easy to dissolve, the instant time is less than 20 seconds, and the agglomeration probability is low.

Owner:INST OF AGRO FOOD SCI & TECH CHINESE ACADEMY OF AGRI SCI

Preparation method of natural flake graphite-based negative electrode material

The invention discloses a preparation method of a natural flake graphite-based negative electrode material. The method specifically comprises the following steps of: (1) crushing and processing natural flake graphite, carrying out purifying and drying, then infiltrating the product with a phenolic resin solution, finally evaporating the used solvent, and carrying out pre-carbonization on the obtained graphite under nitrogen protection of 550-750 DEG C; (2) adding the pre-carbonized graphite obtained in the step (1) to pitch coke micro powder for mixing, carrying out shaping and crushing until the tap density is 0.95-1.00g / cm<3>, adding the crushed graphite to dimethicone for mixing, carrying out pre-carbonization under nitrogen protection of 550-750 DEG C and carrying out sieving and magnetic deironing; and (3) carrying out carbonization treatment on the pre-carbonized graphite obtained in the step (2) under nitrogen protection of 950-1250 DEG C to obtain the natural flake graphite-based negative electrode material. The negative electrode material is high in yield, good in material liquid absorption and holdup properties and good in electrochemical properties.

Owner:内蒙古丰辉新材料科技有限公司

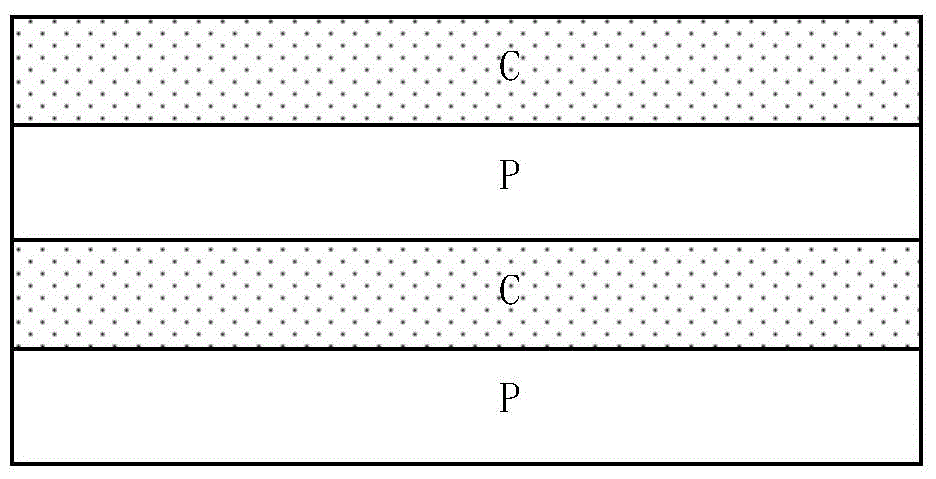

Ceramic/polymer composite with high dielectric constant and preparation method thereof

ActiveCN104985896AImprove bindingAvoid clumpingSynthetic resin layered productsDielectric lossSolvent

The invention discloses a ceramic / polymer composite with a high dielectric constant and a preparation method thereof. The preparation method comprises the following steps: step 1, dissolving a silane coupling agent in a first solvent to prepare a first solution; step 2, mixing ceramic powder with the first solution to prepare a suspension liquid; step 3, dissolving a polymer material in a second solvent to prepare a second solution; step 4, mixing the suspension liquid with the second solution to prepare ceramic / polymer composite slurry; step 5, after preparing the ceramic / polymer composite slurry into solid thin films, modifying the solid thin films by using a heat treatment method; step 6, pressing the sides together, with larger polymer densities, of the two solid thin films to prepare a multilayered composite. According to the ceramic / polymer composite obtained through the preparation method, the microstructure is more uniform, the dielectric constant is greatly increased, the dielectric loss is reduced, and the dielectric property is more excellent; the preparation method can be widely used in the field of preparation of composites.

Owner:佛山国防科技工业技术成果产业化应用推广中心

Preparation method of hydroxyl-ferric oxide/graphene oxide composite material and application of hydroxyl-ferric oxide/graphene oxide composite material

InactiveCN106215862AAvoid clumpingMaintain a two-dimensional structureOther chemical processesWater contaminantsWastewaterOxide composite

The invention relates to a preparation method of a hydroxyl-ferric oxide / graphene oxide composite material and application of the hydroxyl-ferric oxide / graphene oxide composite material. The hydroxyl-ferric oxide / graphene oxide composite material is formed by mixing a turbid liquid of graphene oxide and a turbid liquid of hydroxyl-ferric oxide according to the volume ratio of 1: (1-2), dispersing, and compounding by a hydrothermal method. The prepared hydroxyl-ferric oxide / graphene oxide composite material is used for treating phenol-containing wastewater; 0.5 to 5 g of the hydroxyl-ferric oxide / graphene oxide composite adsorption material is fed into 1,000 ml of the wastewater with the chlorophenol concentration of 10 to 60 mg / l, and then fully oscillated on a constant-temperature shaking table, the water temperature is controlled to be at 25 DEG C, and after reaction is conducted for 3 h, the wastewater is filtered. Detection shows that the chlorophenol removal rate is 87 to 93.2 percent, the chlorophenol concentration of discharged water is 1.3 to 5.2 mg / l, and the adsorption amount is 11 to 17.4 mg / l.

Owner:TIANJIN UNIV

Production process of convenient preserved egg and pork congee

The invention relates to a production process of convenient preserved egg and pork congee, which belongs to the technical field of food processing. The production process comprises the following steps of: curing rice and sticky rice, pre-cooking the rice and the sticky rice, processing preserved eggs and fresh pork, and canning the food. The convenient preserved egg and pork congee is prepared by mixing the rice and the sticky rice according to a certain ratio and matching appropriate auxiliary ingredients. The preserved egg and pork congee is full of nutriments, is capable of promoting appetite and the digestive absorption of nutrients and improving iron-deficiency anemia, is less in cholesterol, has the functions of warming spleen and stomach and is suitable for being appropriately taken by ordinary people. Meanwhile, the convenient preserved egg and pork congee conforms to a modern diet concept and is fast food for supplementing nutrients of modern people with a rapid pace of life.

Owner:遂宁市三丰食品有限公司

Full water-soluble nitro compound fertilizer and preparation method thereof

ActiveCN102417421APrevent particles from sticking and agglomeratingAvoid clumpingFertilizer mixturesAmmonium sulfateChemistry

The invention discloses a full water-soluble nitro compound fertilizer and a preparation method thereof. The full water-soluble nitro compound fertilizer uses modified ammonium nitrate and / or ammonium sulfate as the nitrogen source, industrial monoammonium phosphate or potassium dihydrogen phosphate as the phosphorus source, potassium chloride and / or potassium sulfate as the potassium fertilizer, and ethylene diamine tetraacetic acid (EDTA) complex or boric fertilizer as the medium and trace element additive, wherein the weight ratio of the components is as follows: the ratio of the modified ammonium nitrate to the industrial monoammonium phosphate to the potassium fertilizer to the EDTA complex or boric fertilizer is 1:(0.3-0.8):(0.5-0.9):(0-0.2); or the ratio of the modified ammonium nitrate to the potassium dihydrogen phosphate to the potassium fertilizer to the EDTA complex or boric fertilizer is 1:(0.3-0.7):(0.2-0.5):(0-0.3), and the effective nutriments (N+P2O5+K2O) account for 48% or above; or the ratio of the modified ammonium nitrate to the ammonium sulfate to the industrial monoammonium phosphate to the potassium sulfate to the EDTA complex or boric fertilizer is 1:(0.10-0.95):(0.05-0.50):(0.25-0.75):(0-0.2). The preparation method mainly comprises the following steps: pulping, granulating, cooling and coating, wherein a multiple-step melting and mixing pulping method is used in the pulping step. By coating isolating membranes on the surfaces of the fertilizer granules to prevent the granules from bonding and agglomerating, the compound fertilizer can be used for spraying and trickle irrigation.

Owner:广东拉多美化肥有限公司

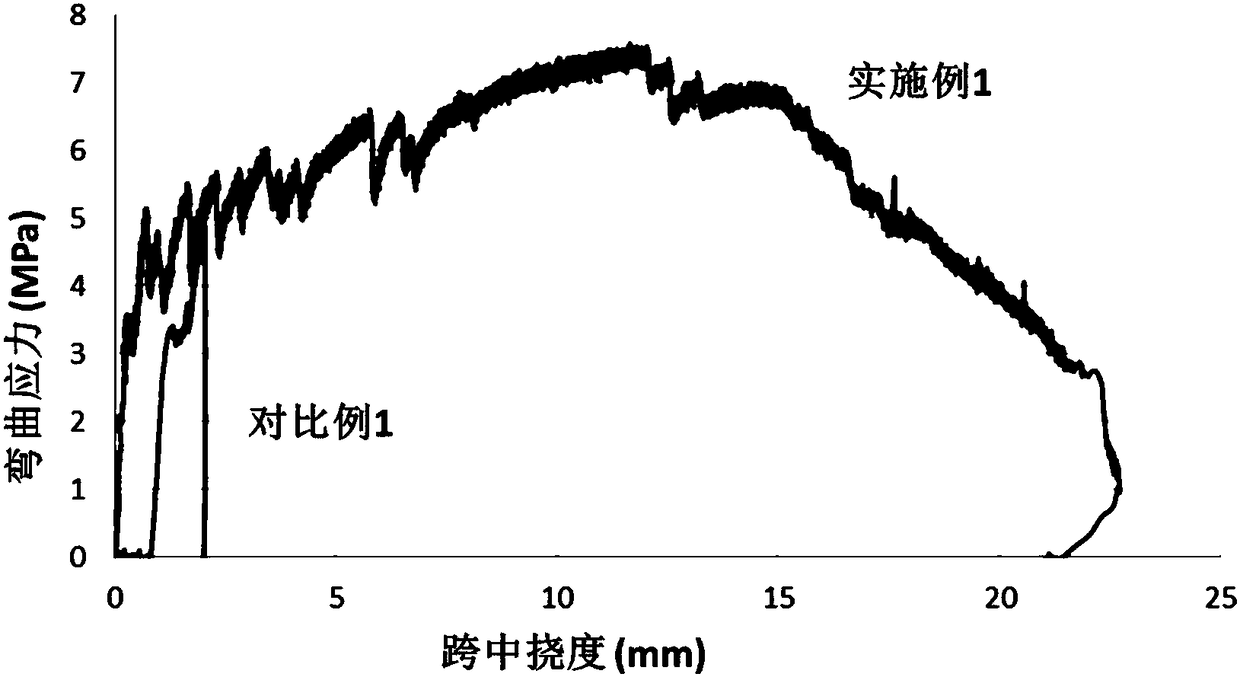

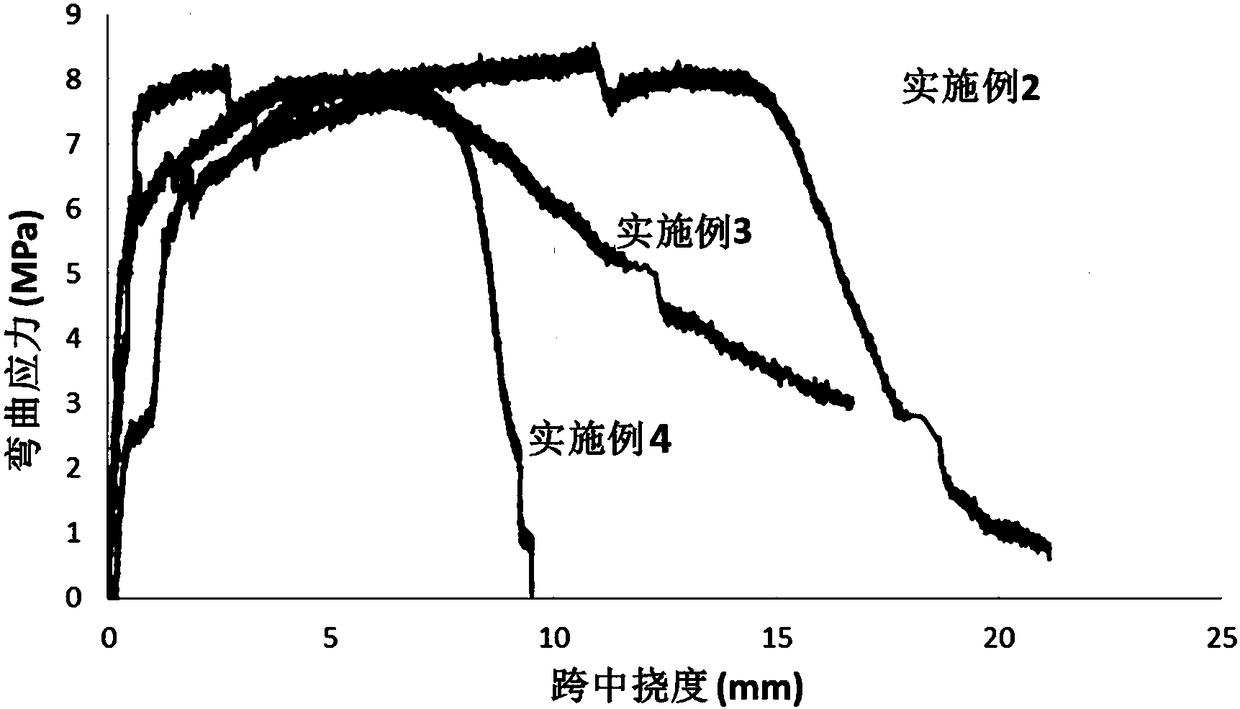

PVA-basalt hybrid fiber high-toughness concrete capable of realizing 3D printing and use method thereof

ActiveCN108129102AHigh mechanical strengthImprove impact resistanceAdditive manufacturing apparatusAdditive ingredientPortland cement

The invention relates to PVA-basalt hybrid fiber high-toughness concrete capable of realizing 3D printing and a use method thereof. Through being metered in parts by weight, the concrete is preparedfrom the following ingredients including 0.8 to 1.2 parts of fast hardening ordinary Portland cement, 0.96 to 1.44 parts of grade F fly ash, 0.64 to 0.96 part of quartz sand (with the particle diameter range being 0.075 to 0.15mm), 0.29 to 0.43 part of water, 0.005 to 0.01 part of water reducing agents, 0.0017 to 0.0018 part of PVA fiber and 0.0043 to 0.0078 part of basalt fiber. According to thematerials of the concrete, the PVA fiber and the basalt fiber are used for optimizing and improving the intensity and the toughness of the concrete material; the printing performance is high; the intensity is high; the cost is low; the practical engineering application of the 3D printing concrete can be favorably promoted.

Owner:HEBEI UNIV OF TECH

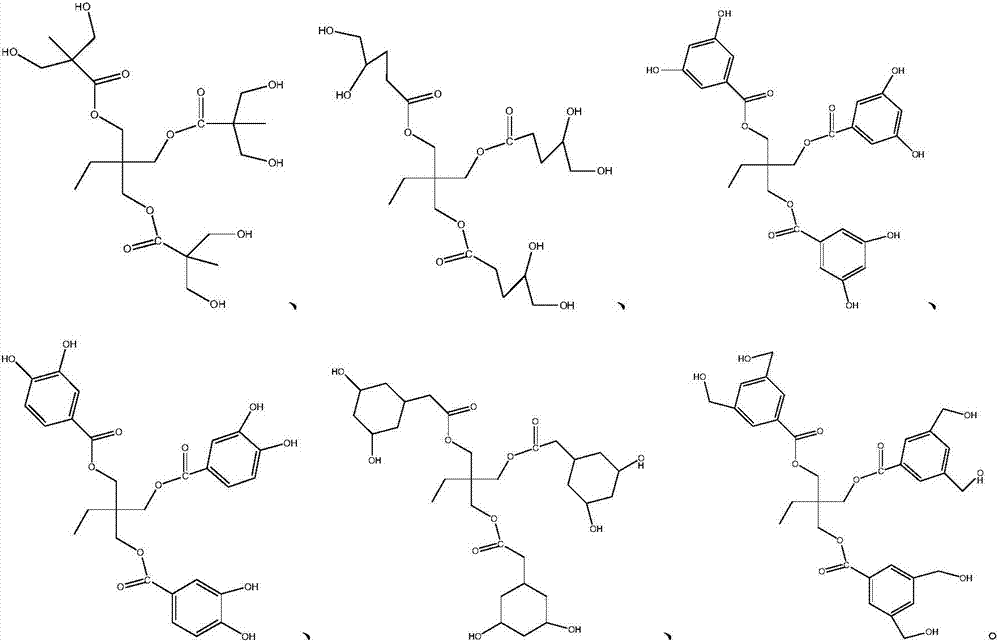

Preparation method of isocyanates

ActiveCN107337615AAvoid yellowingAvoid reactionIsocyanic acid derivatives preparationOrganic compound preparationHigh concentrationPolyester

The invention discloses a preparation method of isocyanates. A high-concentration isocyanate actinic solution is prepared based on a salification phosgenation reaction, and a polyester hyperdispersant is added in a diamine salification procedure; and anchoring groups of the hyperdispersant are converted into tertiary amine salts which are adsorbed to the surface of diamine hydrochloride particles in the salification procedure, and steric hindrance is formed through the solvation chain, so that hydrochloride particles are separated, thereby avoiding the phenomena of aggregation, agglomeration and the like, obviously enhancing the salification concentration and effects, and further greatly enhancing the yield of the isocyanate product.

Owner:WANHUA CHEM GRP CO LTD

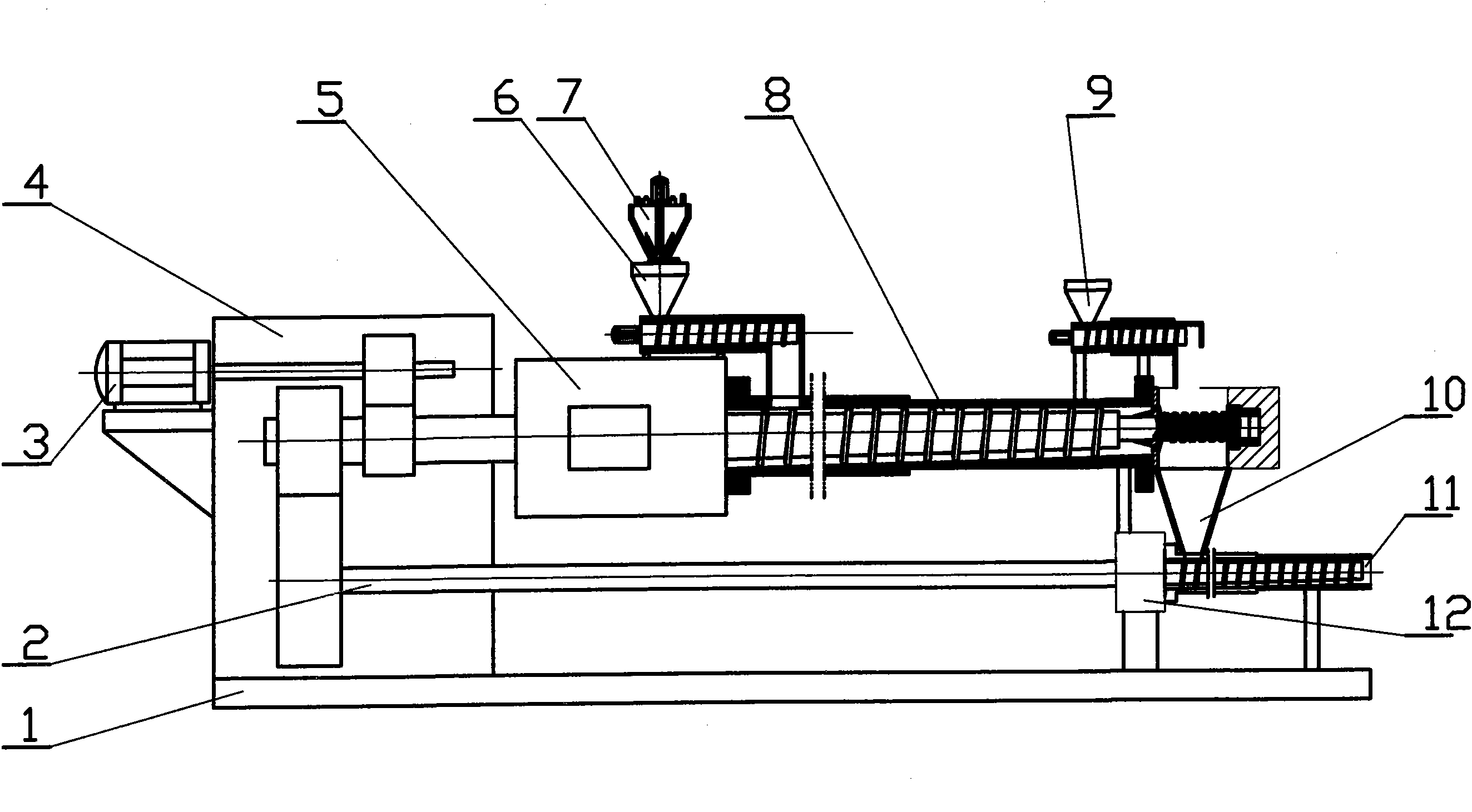

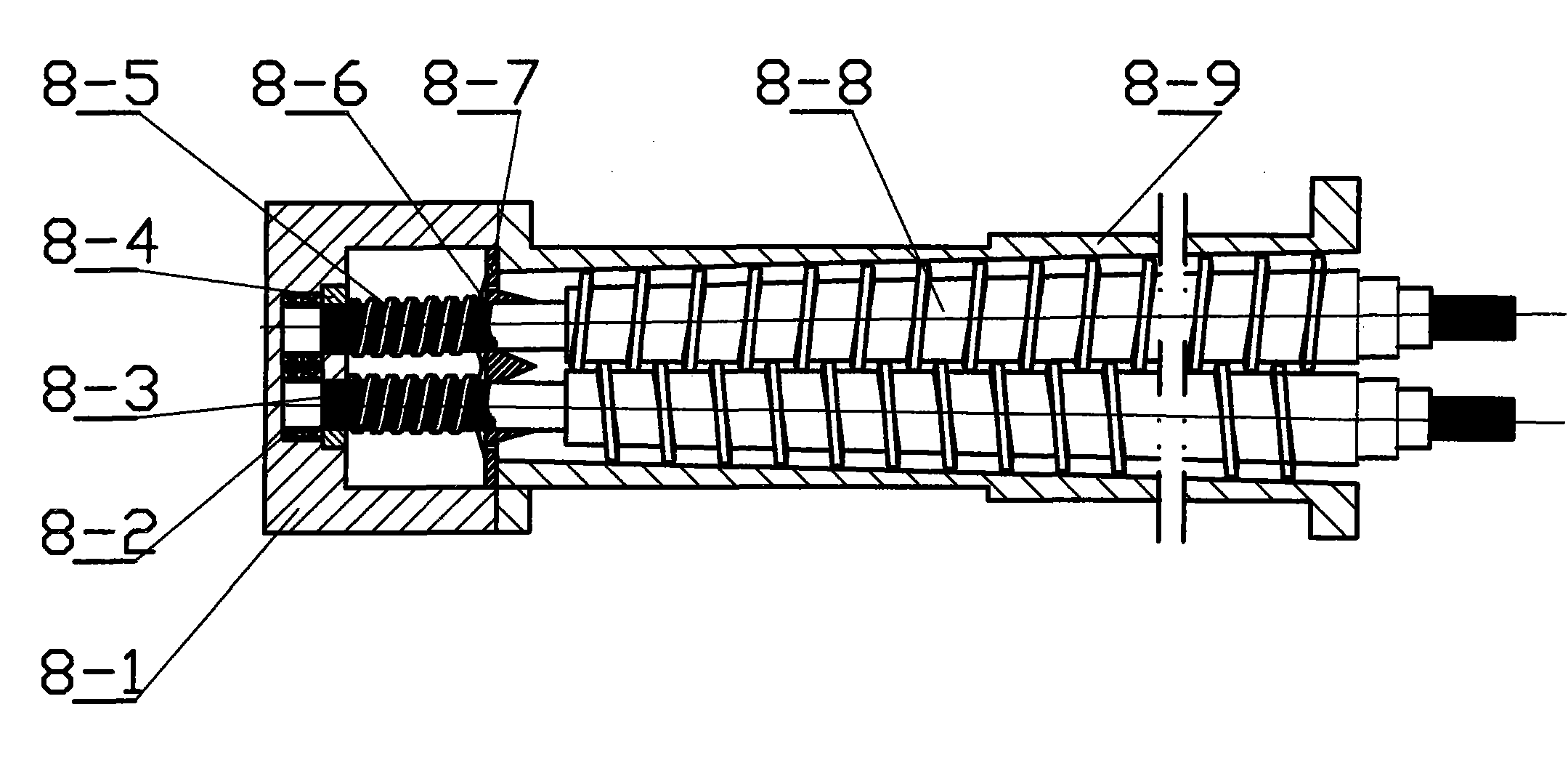

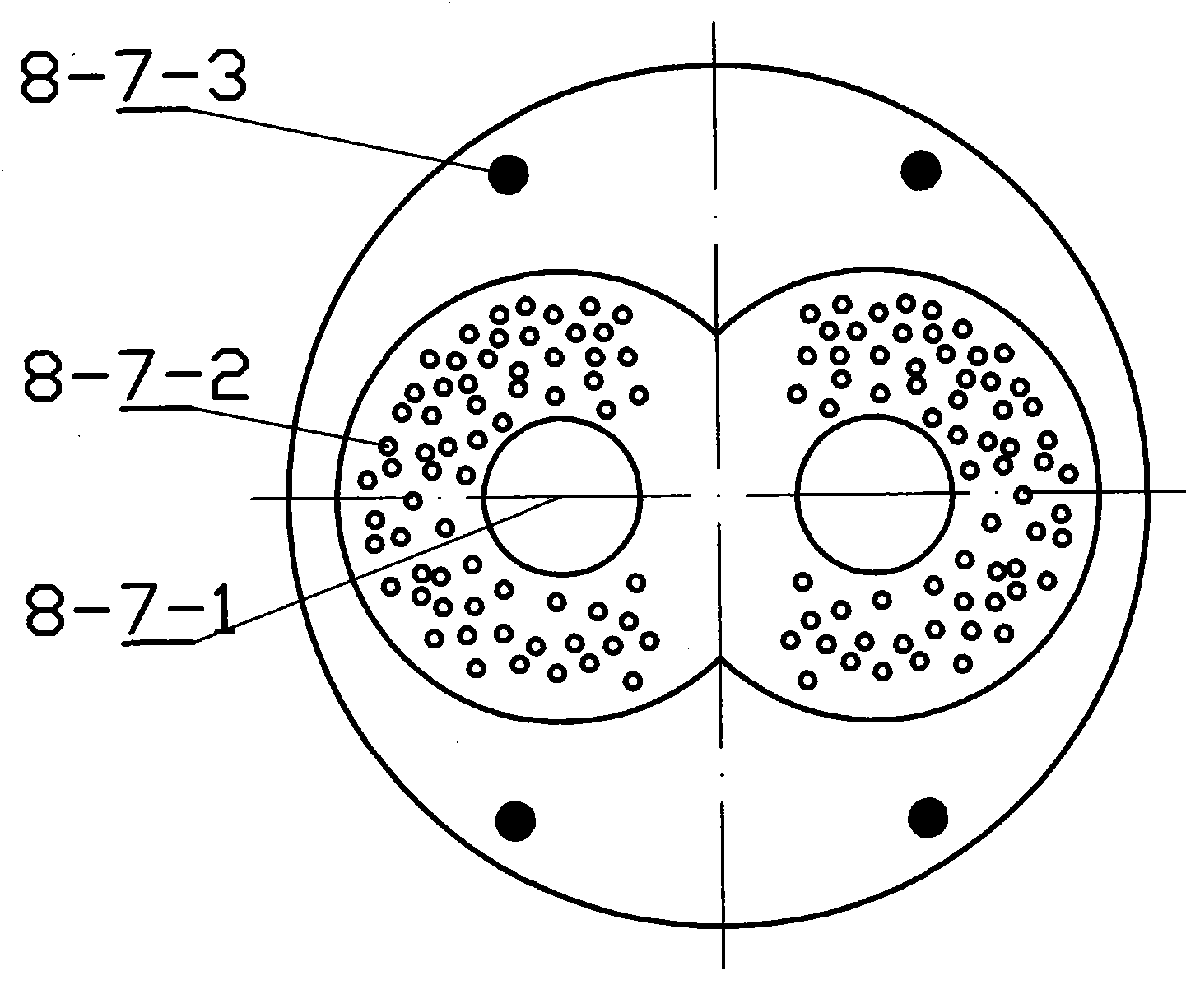

Multifunctional wood-plastic composite material one-step method extruder

A novel multifunctional wood-plastic composite material one-step method extruder is provided. A motor is connected with a twin-screw gear distribution box and a speed-adjusting speed-varying box respectively through a gear speed-varying box and an extending transmission shaft; the gear distribution box is connected with a twin-screw granulator; a material mixing device is connected with the twin-screw granulator through a twin-screw feeder; a master batch feeding device is connected with the twin-screw granulator; a connecting barrel is connected with the twin-screw granulator and a single-screw extruder; the single-screw extruder is connected with the speed-adjusting speed-varying box; all devices are connectedly arranged on a machine base. The extruder is mainly used for extrusion processing of a wood-plastic composite material and composite materials having similar properties, can also be used just for granulation, can complete production by the one-step method after raw materials are mixed, has high efficiency, and saves energy; the extruder completely avoids friction damage of screws and screw tubes, thereby improving the usage usefulness of equipment; the extruder allows extrusion processed products to have various wood imitation patterns; and the extruder can be applied to composite materials with various systems and much extrusion capacity.

Owner:江苏文嘉勄木塑装备制造有限公司

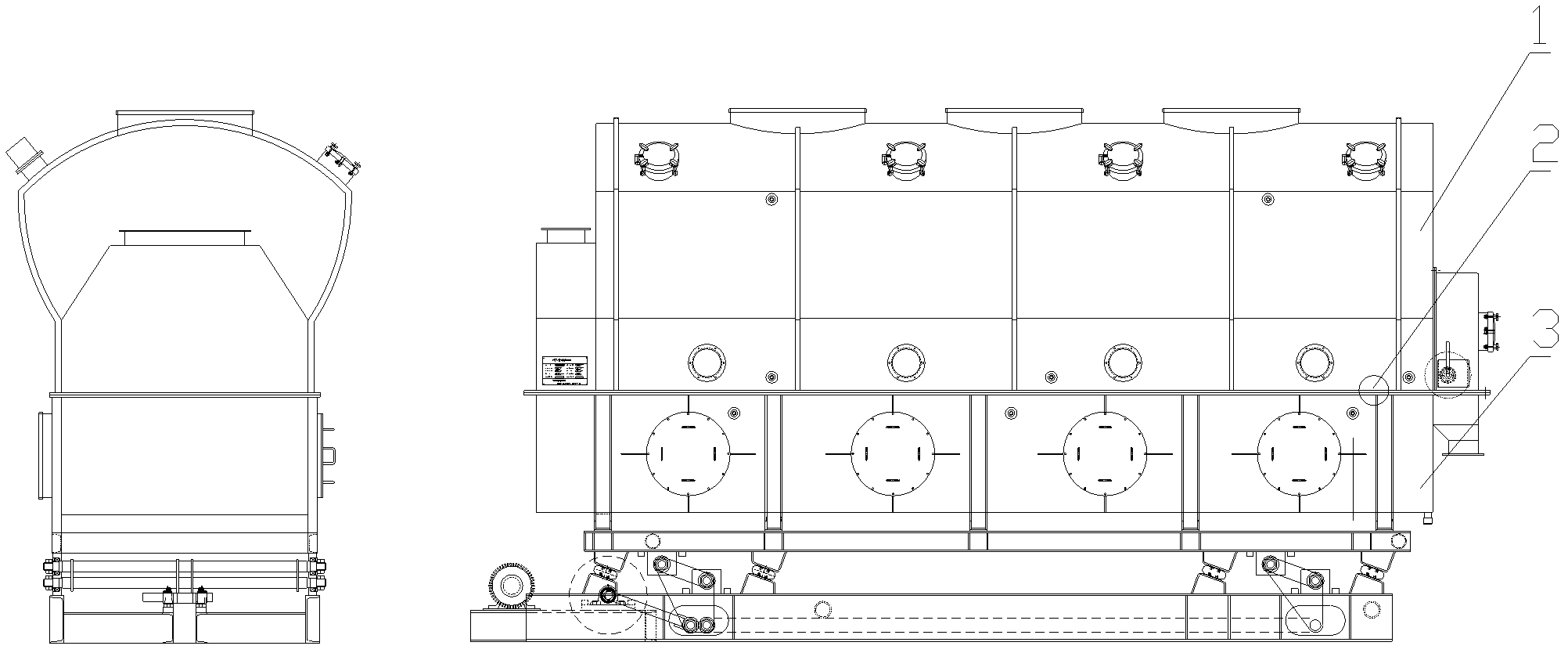

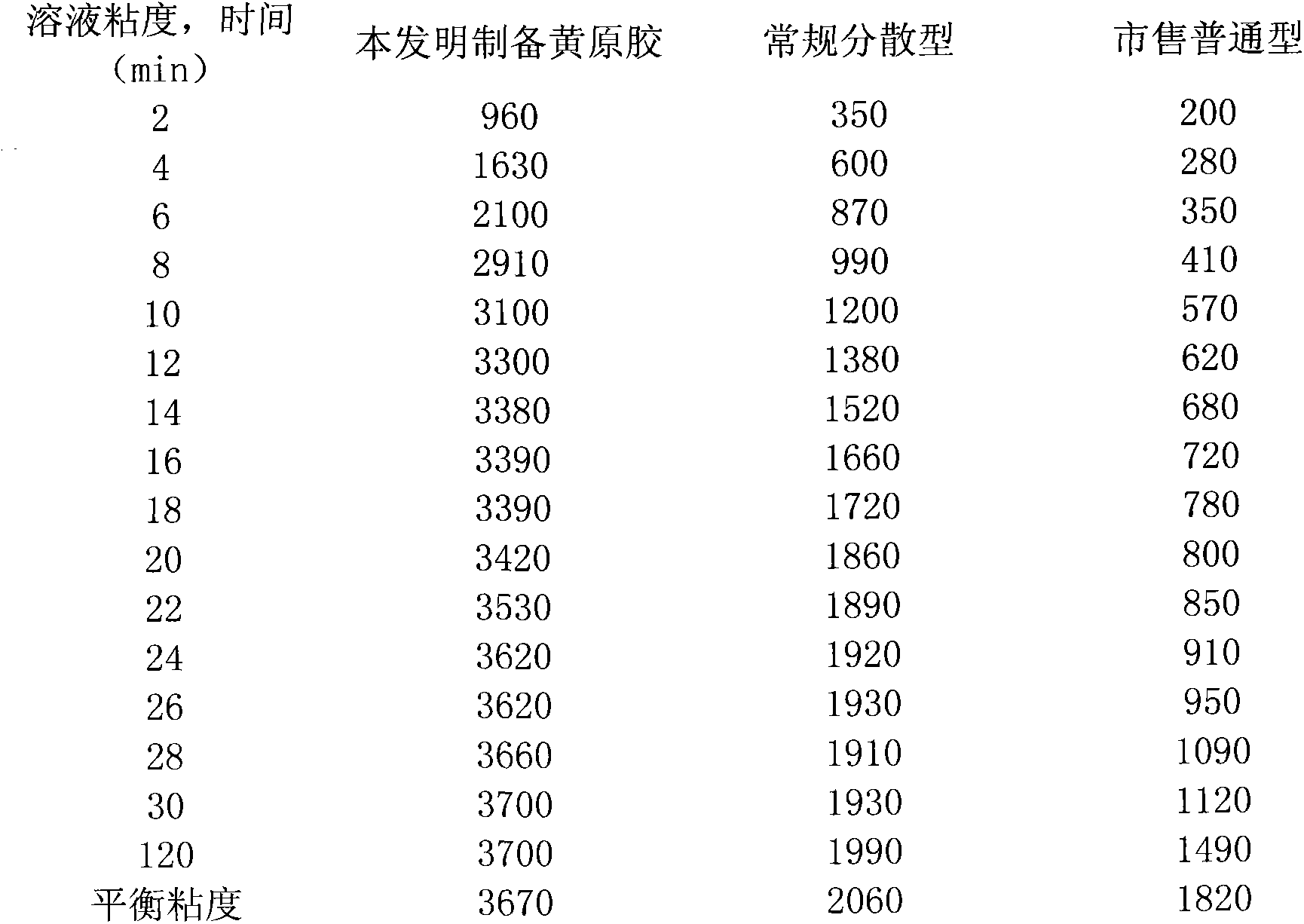

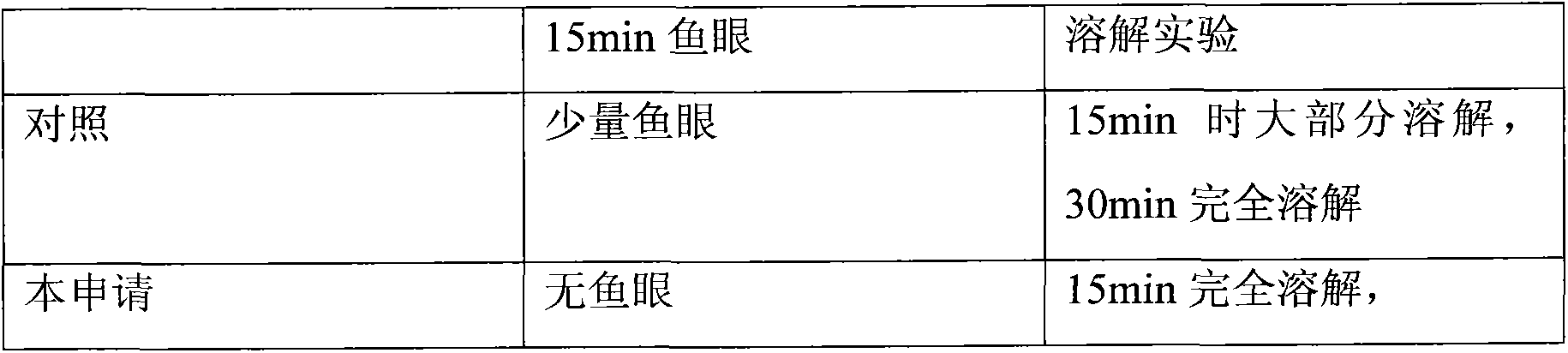

Producing method of instant xanthan gum

ActiveCN103074408AImprove physiological activityQuality improvementMicroorganism based processesFermentationMicrobiological TechniquesXanthan gum

The invention belongs to the technical field of microorganisms and discloses a producing method of instant xanthan gum. The producing method comprises the steps of preparing a fermentation liquid, preparing xanthan gum particles and a xanthan gum solution, and adding a surfactant. The yield of the xanthan gum prepared by the method is high, the xanthan gum is dissolved fast, is free from fisheyes, can be used for industrial production and has a wide application prospect.

Owner:SHANDONG FUFENG FERMENTATION CO LTD

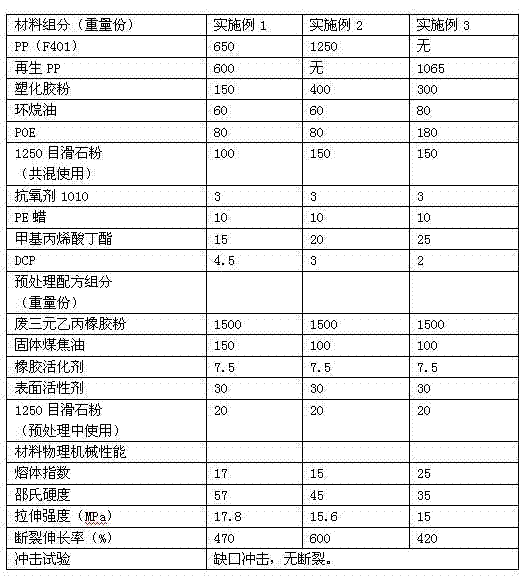

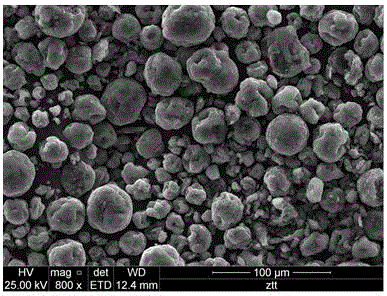

EPDM/polypropylene thermoplastic elastomer and preparation process thereof

ActiveCN103756129APrevent rubber powder from agglomeratingImprove the activation effectWaxButyl methacrylate

The invention relates to an EPDM (Ethylene-Propylene-Diene Monomer) / polypropylene thermoplastic elastomer and a preparation process thereof. The EPDM / polypropylene thermoplastic elastomer is characterized by comprising the following components in parts by weight: 1065-1250 parts of PP (Poly Propylene ) raw material, 150-550 parts of plasticized rubber powder, 60-80 parts of naphthenic oil, 80-180 parts of POE (Poly Olefin Elastomer), 100-150 parts of 250-mesh talcum powder, 3-7 parts of antioxidant 1010, 10-30 parts of PE (Poly Ethylene) wax, 15-45 parts of butyl methacrylate and 4.5-15 parts of DCP, wherein the plasticized rubber powder is obtained from the waste ethylene -propylene-diene monomer powder through preprocessing, and a formula for the preprocessing includes 1500 parts by weight of 80-mesh waste ethylene -propylene-diene monomer powder, 100-200 parts by weight of solid coal tar, 5-10 parts by weight of activator, 20-40 parts by weight of surfactant and 20-40 parts by weight of 1250-mesh talcum powder. The thermoplastic elastomer is wide in hardness change range, high in strength, and remarkably improved in physical and mechanical properties.

Owner:辽宁瑞德橡塑科技有限公司

Method for preparation of instant crispy Abelmoschus esculentus by three-stage pulse spouting negative pressure low-frequency microwave drying

InactiveCN104522552AImprove uniformityImprove qualityFruits/vegetable preservation by heatingFood preparationAbelmoschusFruits and vegetables

Belonging to the technical field of fruit and vegetable food processing, the invention relates to a method for preparation of instant crispy Abelmoschus esculentus by three-stage pulse spouting negative pressure low-frequency microwave drying. The main process includes: using fresh Abelmoschus esculentus as the raw material, and carrying out material selection and grading, cleaning and impurity removal, blanching and color protection, cooling and draining, negative pressure microwave spouting drying, packaging and storage. The method provided by the invention adopts the microwave drying technology, shortens the drying time, and reduces the energy consumption of drying. Pulse spouting is in favor of improving the uniformity of material drying, and can enhance the quality of dried Abelmoschus esculentus product. At the same time, microwave drying treatment under a vacuum environment can effectively keep the content of chlorophyll, mucus glycoprotein and flavones in Abelmoschus esculentus. The method provided by the invention does not need to perform cutting treatment on the raw material, maintains integrity of the Abelmoschus esculentus tissue, is easy to operate, safe and environment-friendly, and can realize continuous and automated clean production. The obtained instant crispy Abelmoschus esculentus finished product has a yellow-green value a* of about -11.35, a chlorophyll retention amount of about 0.147mg / g, a mucus glycoprotein retention amount of about 0.107mg / g, and crispness of 1800-2000g.

Owner:JIANGSU ZITENG HORTICULTURAL GREENING ENG CO LTD +1

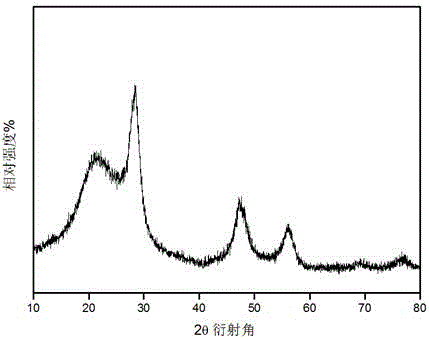

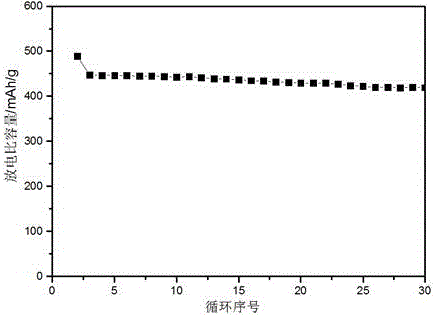

Preparation method of SiOx/C surface-coated graphite cathode material

The invention discloses a preparation method of an SiOx / C surface-coated graphite cathode material. The preparation method comprises the steps of preparing an SiOx / C material precursor by taking SiOx, asphalt and an organic acid solution as raw materials, adding graphite, and preparing a sample by spray granulation and high-temperature pyrolysis by an additive, resin and a curing agent. According to the preparation method, a volume effect of a silicon material can be effectively alleviated in charging and discharging processes, so that the cycling stability is improved; the first cycling efficiency of the silicon material is 82.42% and the reversible specific capacity is 488.2mAh / g at 0.1C multiplying power; and a framework formed by utilizing solidification of the resin can effectively avoid adhesion and agglomeration between grains in a carbonization process of the additive, so that the prepared material has the characteristics of good dispersity and good uniformity and has the advantages of mass production and low cost.

Owner:ZHONGTIAN ENERGY STORAGE TECH

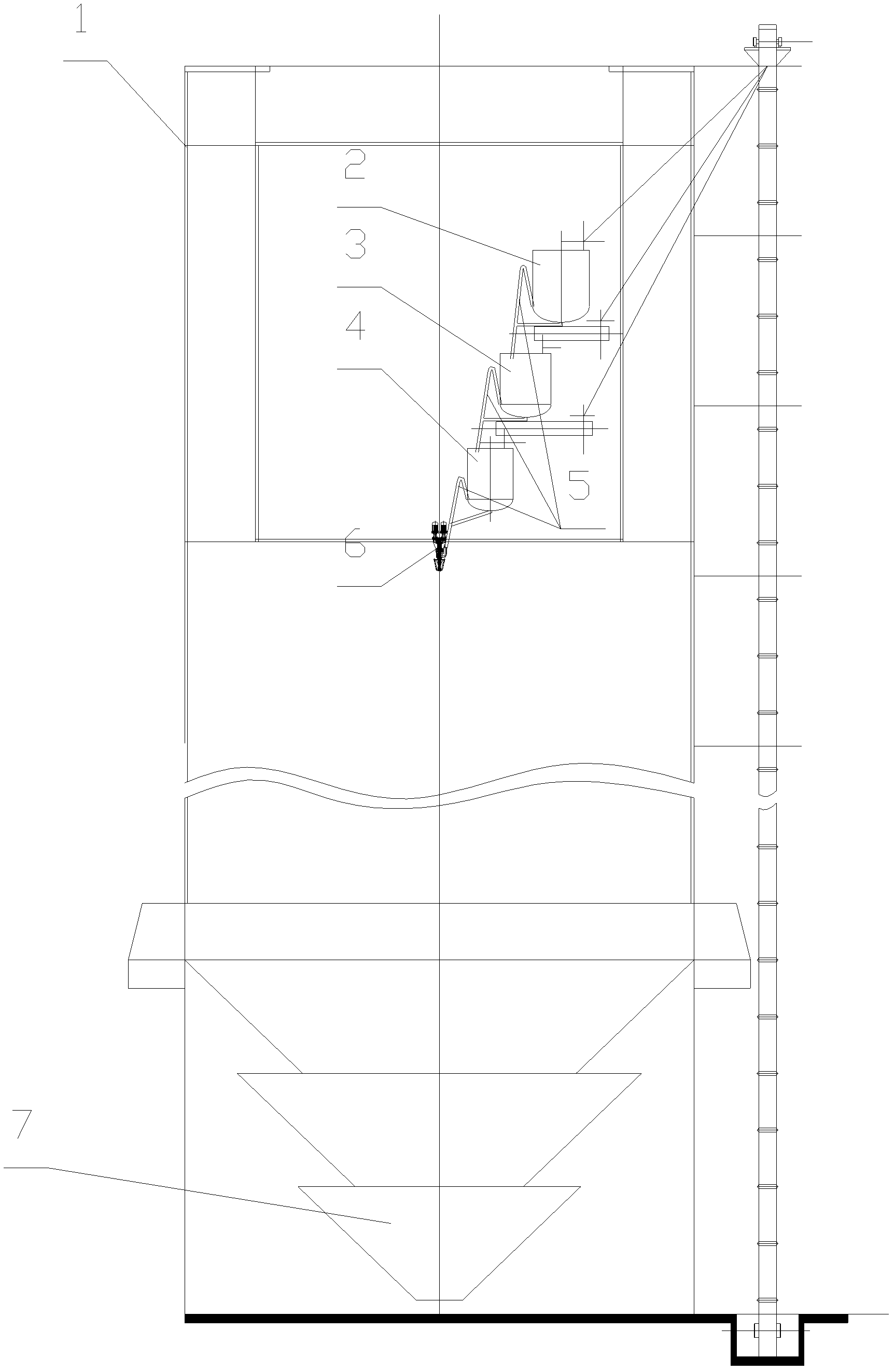

Anhydrous dextrose drying device and drying process

ActiveCN102435049AImprove continuityGuaranteed boiling effectDrying solid materials with heatHearth type furnacesFluidized bedChange color

The invention belongs to the technical field of biomedicine, in particular relates to an anhydrous dextrose drying device and a drying process. The technical scheme is that the anhydrous dextrose drying device comprises a fluidized bed and a back mixing bed. The fluidized bed comprises a first-section fluidized bed and a second-section fluidized bed. The lower portion of the back mixing bed is connected with an air inlet pipe I through an air feeder I, a heater I is arranged on the air inlet pipe I, an air inlet pipe II and an air inlet pipe III are respectively connected with the first-section fluidized bed, an air inlet pipe IV and an air inlet pipe V are respectively connected with the second-section fluidized bed, an air feeder II is respectively connected with the air inlet pipe II, the air inlet pipe III, the air inlet pipe IV and the air inlet pipe V through a heat exchanger II, so that the phenomena that finished products are apt to change colors and blocked caused by high temperature of materials caused by continuous drying can be avoided.

Owner:XIWANG PHARMA

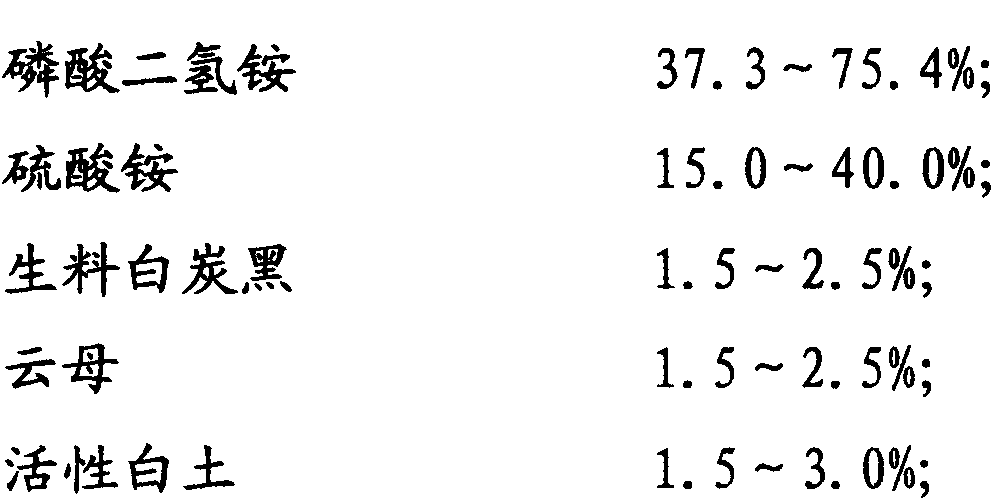

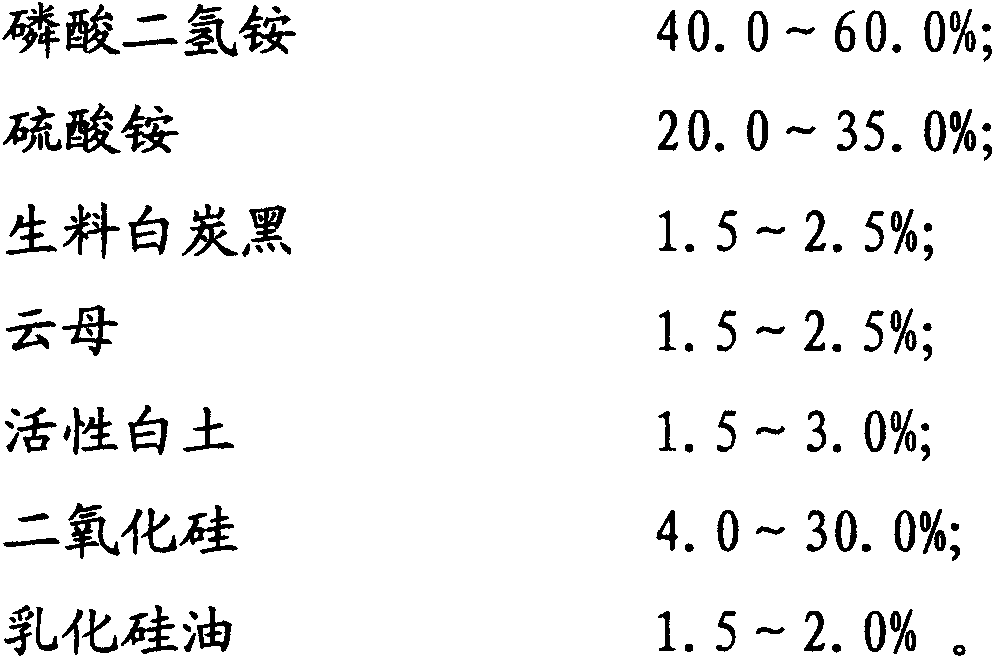

Dry powder extinguishing agent and method for preparing dry powder extinguishing agent from ammonium dihydrogen phosphate

The invention discloses a dry powder extinguishing agent and a method for preparing the dry powder extinguishing agent from ammonium dihydrogen phosphate. The dry powder extinguishing agent is prepared from the following components in percentage by mass: 37.3%-75.4% of ammonium dihydrogen phosphate, 15.0%-40.0% of ammonium sulfate, 1.5%-2.5% of raw white carbon black, 1.5%-2.5% of mica, 1.5%-3.0% of active hargil, 3.7%-41.8% of silicon dioxide and 1.4%-2.0% of emulsified silicone oil. Compared with the prior art, the dry powder extinguishing agent disclosed by the invention has the advantages that the raw white carbon black is used for replacing lyophobic white carbon black so that the cost of the dry powder extinguishing agent can be reduced; the raw white carbon black does not need to be independently silicified and a technological process is simplified; the manual cost and the energy source consumption are reduced; silicon dioxide is used as an auxiliary medium and calcium carbonate does not exist, so that a caking phenomenon of a dry powder agent is avoided; and the dry powder extinguishing agent disclosed by the invention has good mobility and good extinguishing effect.

Owner:TAICANG JINGHAIXING FIRE EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com