Vacuum stirring composite granule reinforcing aluminium-based composite material and preparation technique thereof

A composite particle and vacuum mixing technology, which is applied in the field of composite materials, can solve problems such as uneven distribution, poor wettability between particles and the matrix, and high porosity, and achieve the effect of improving the composite effect, good interface bonding, and low porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

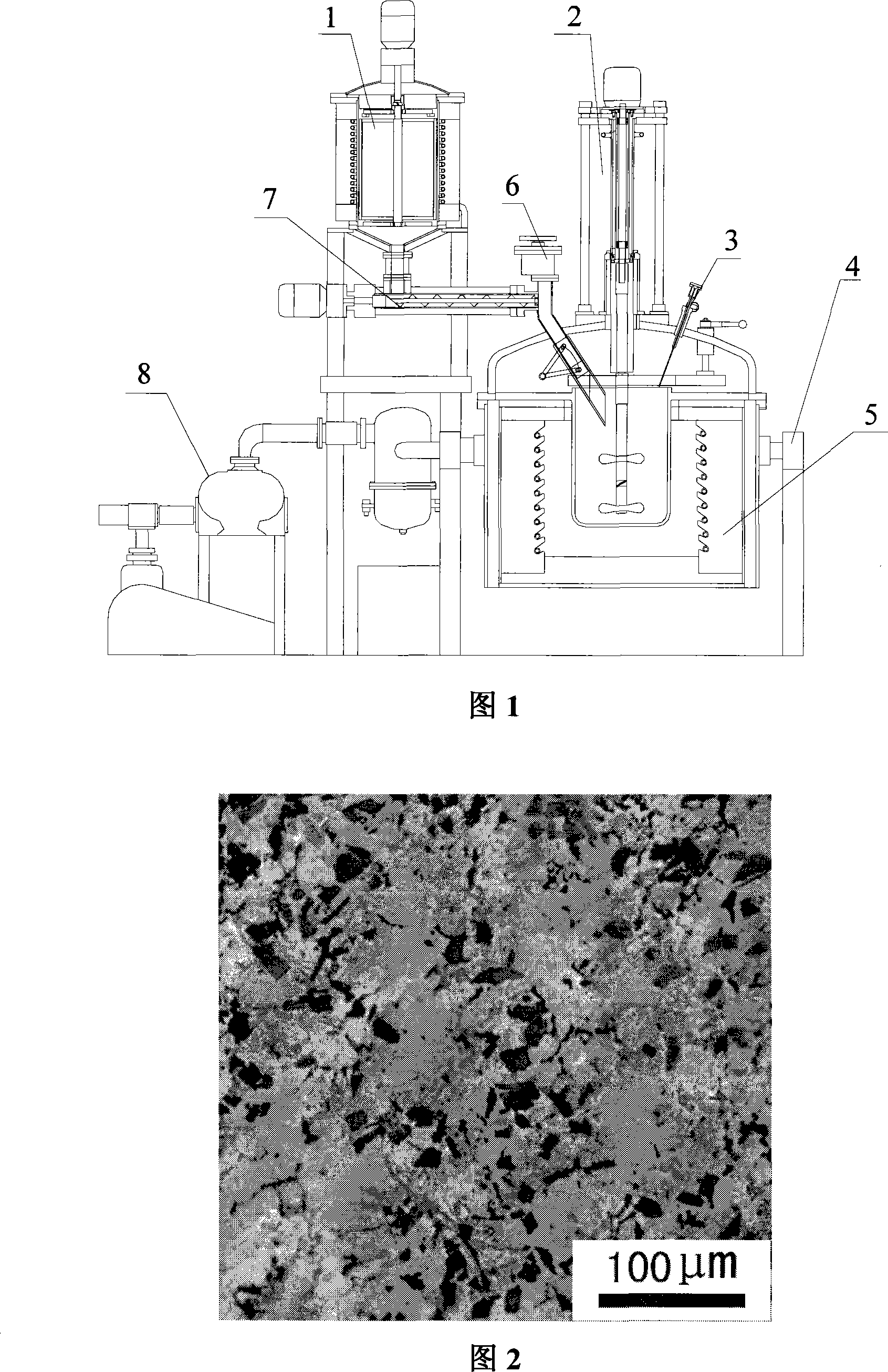

Method used

Image

Examples

Embodiment 1

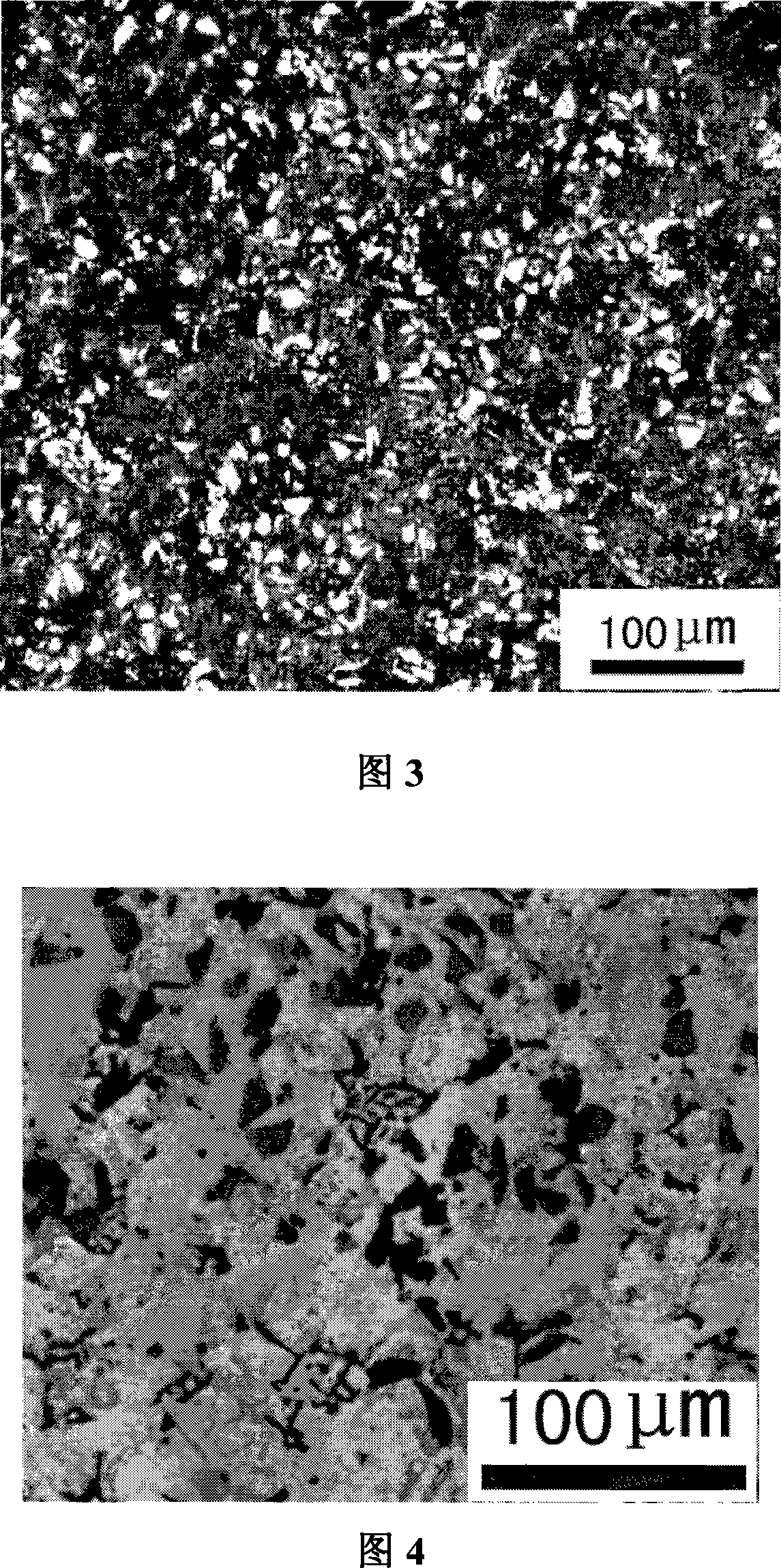

[0038] Material preparation: α-SiC is used as reinforcing particles, aluminum strontium and aluminum rare earth are used as modifiers. Weigh 1.2kg of SiC and 5.5kg of aluminum alloy according to the weight ratio of SiC and aluminum alloy of 1:4.5, the aluminum alloy is ZL108, and the particle size of SiC is W14. 27.5 g of aluminum strontium and 27.5 g of aluminum strontium and 27.5 g of aluminum strontium were weighed with the weight ratio of aluminum strontium, aluminum rare earth and aluminum alloy being 0.1:20.

[0039] Sieve 1.2kg of SiC to remove united particle clusters and other impurities. Put the SiC particles into the pretreatment furnace 1 for roasting pretreatment when the base aluminum alloy is put into the crucible. The temperature is set at 600°C to remove particles. Contaminants such as impurities and adsorbed moisture on the surface.

[0040] Stirring and compounding: the matrix ZL108 aluminum alloy is put into the vacuum resistance furnace 5 for melting, and...

Embodiment 2

[0047] Material preparation: α-SiC is used as reinforcing particles, aluminum strontium and aluminum rare earth are used as modifiers. Weigh 0.343 kg of SiC and 5.5 kg of aluminum alloy according to the weight ratio of SiC and aluminum alloy of 1:16, the aluminum alloy is 6061, and the particle size of SiC is W14.

[0048] Sieve 0.343kg of SiC to remove united particle clusters and other impurities. Put the SiC particles into the pretreatment furnace 1 for roasting pretreatment when the base aluminum alloy is put into the crucible. The temperature is set at 300°C to remove the particles. Contaminants such as impurities and adsorbed moisture on the surface.

[0049] Stirring and compounding: put the base 6061 aluminum alloy into the vacuum resistance furnace 5 for melting, and set the temperature at 730°C. After the alloy is completely melted, slag removal and refining are carried out. After the matrix alloy is smelted and refined, vacuumize to a vacuum degree of 0.005MPa, an...

Embodiment 3

[0056] Material preparation: α-SiC is used as reinforcing particles, aluminum strontium and aluminum rare earth are used as modifiers. 2.07 kg of SiC and 7.1 kg of aluminum alloy were weighed according to the weight ratio of SiC and aluminum alloy of 1:3.4, the aluminum alloy was A356, and the particle size of SiC was W14. 32 g of aluminum strontium and 32 g of aluminum strontium were weighed at a weight ratio of aluminum strontium, aluminum rare earth and aluminum alloy of 0.1:22.

[0057] Sieve 2.07kg of SiC to remove united particle clusters and other impurities. Put the SiC particles into the pretreatment furnace 1 for roasting pretreatment when the base aluminum alloy is put into the crucible. The temperature is set at 800°C to remove the particles. Contaminants such as impurities and adsorbed moisture on the surface.

[0058] Stirring and compounding: the matrix A356 aluminum alloy is put into the vacuum resistance furnace 5 for melting, and the temperature is set at 73...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com