Patents

Literature

2281 results about "Aluminum matrix composites" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

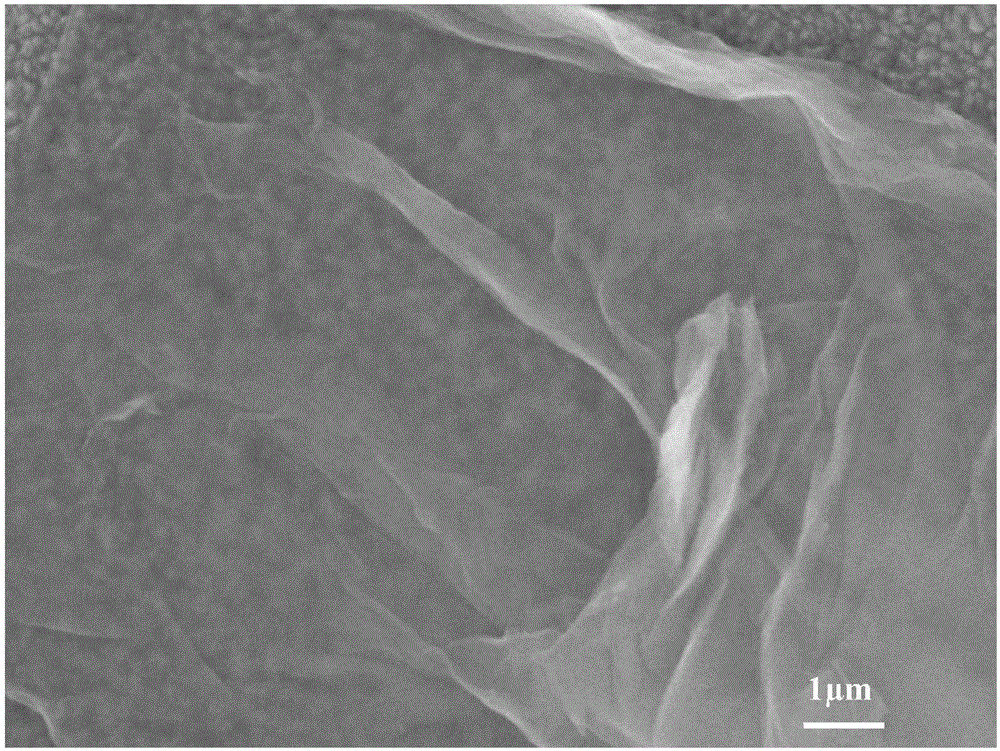

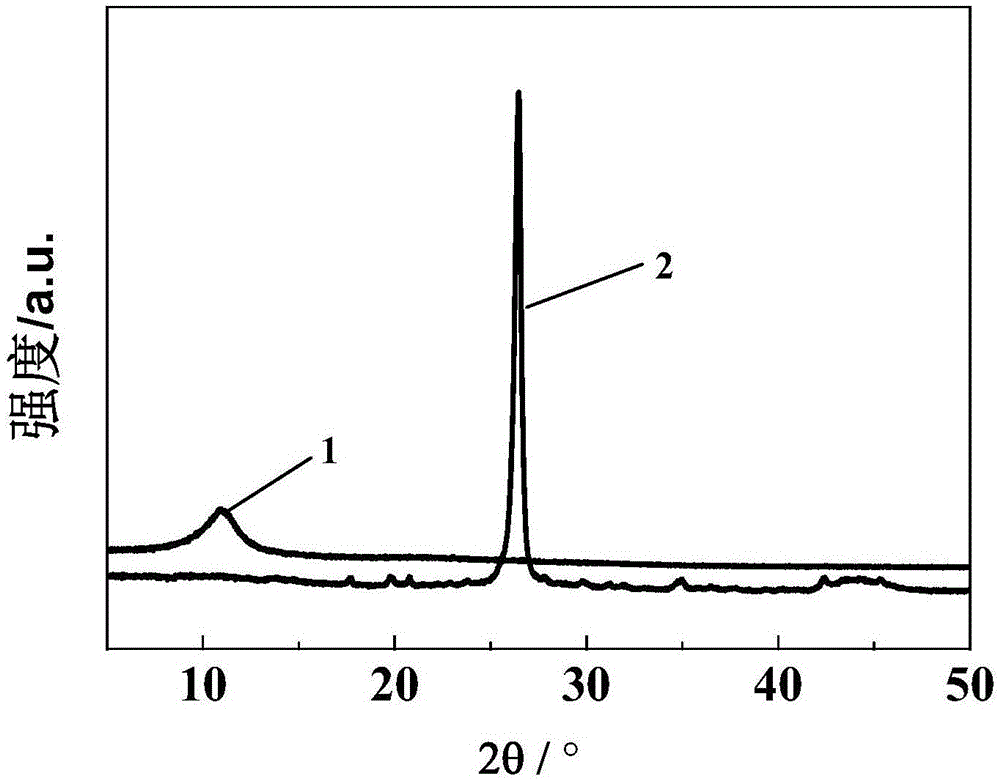

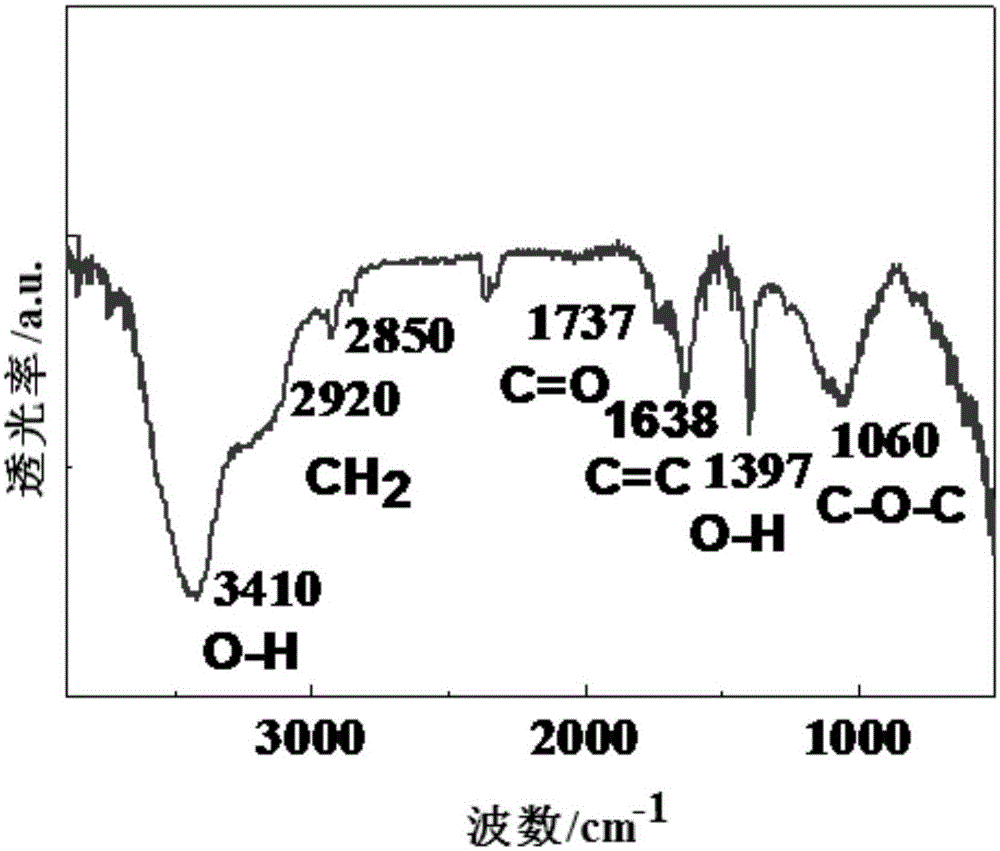

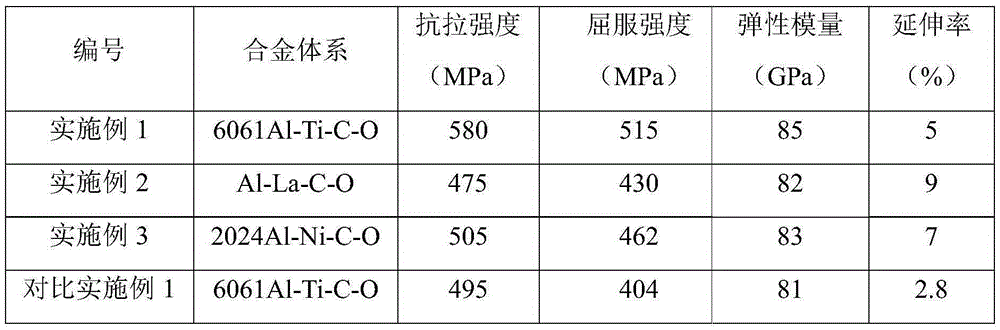

Method for preparing grapheme reinforced aluminum matrix composite material

The invention relates to a method for preparing a grapheme reinforced aluminum matrix composite material. The method aims at solving the technical problems that in an existing method for preparing the grapheme reinforced aluminum matrix composite material, the grapheme dispersibility is poor, and agglomeration is prone to happening. The method includes the steps that (1) oxidized grapheme is prepared; (2) surface modification on aluminum powder is carried out; (3) oxidized grapheme-aluminum composite powder is prepared; and (4) the grapheme reinforced aluminum matrix composite material is prepared. An electrostatic self-assembly method is adopted in the method, so that graphene is evenly dispersed in an aluminum matrix to enable the graphene to be more evenly dispersed, phenomena of damage to graphene size and work hardening generated on the aluminum matrix during ball-milling treatment are avoided, and graphene agglomeration is prevented; in addition, the mechanical property of the composite material is obviously improved; and compared with a pure aluminum material, the strength of extension is improved by 10%-20%, and the hardness is improved by 10%-30%.

Owner:HARBIN UNIV OF SCI & TECH

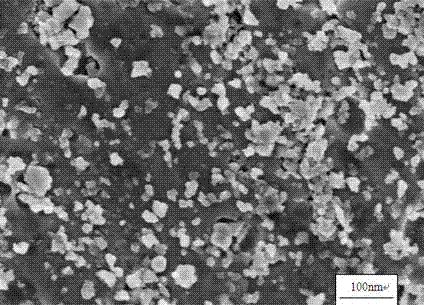

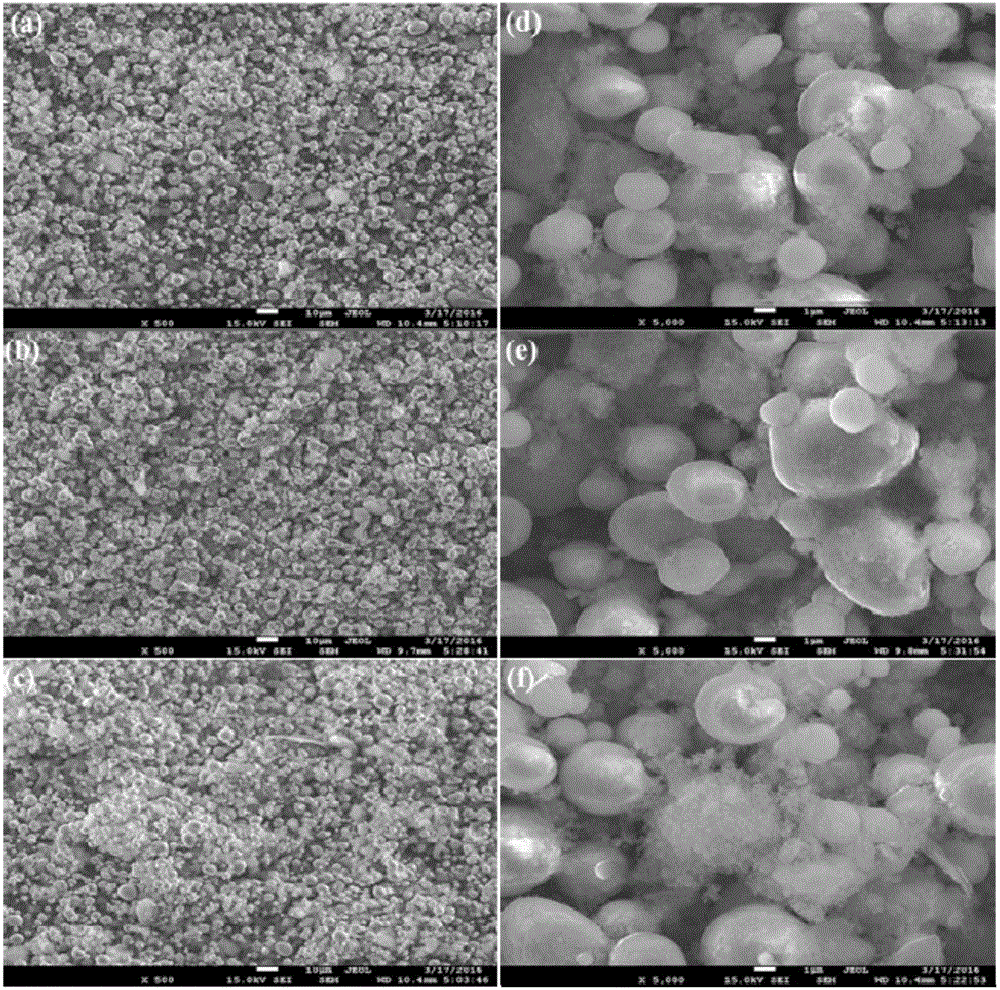

Preparation method of nano silicon carbide reinforced aluminum-based composite material

InactiveCN103045914AAvoid reunionEvenly distributedIncreasing energy efficiencyNano siliconHigh energy

The invention discloses a preparation method of laser forming nano particle reinforced aluminum-based composite material, belonging to the technical field of particle reinforced aluminum-based composite materials. The method comprises the steps of: (1) selecting SiC powder with purity of more than 99.9% and granularity of 40-60 nanometers, and AlSi10Mg powder with purity of more than 99.9% and granularity of 15-30 micrometers; (2) mixing the powders, wherein the weight of the SiC powder is 3%-10% of the total weight of the mixed powder; (3) putting the mixed powder into a planetary high-energy ball mill for milling; (4) taking the milled powder for SLM forming; and (5) repeating the step (4) until a three-dimensional block sample is completed. According to the method provided by the invention, the aluminum-based composite material with uniform microscopic structures can be prepared.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

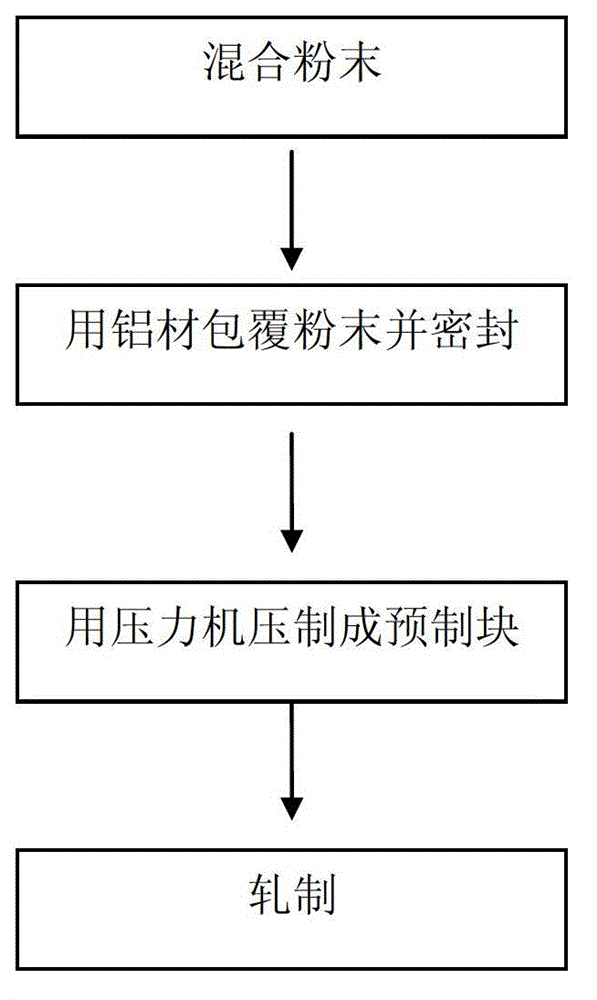

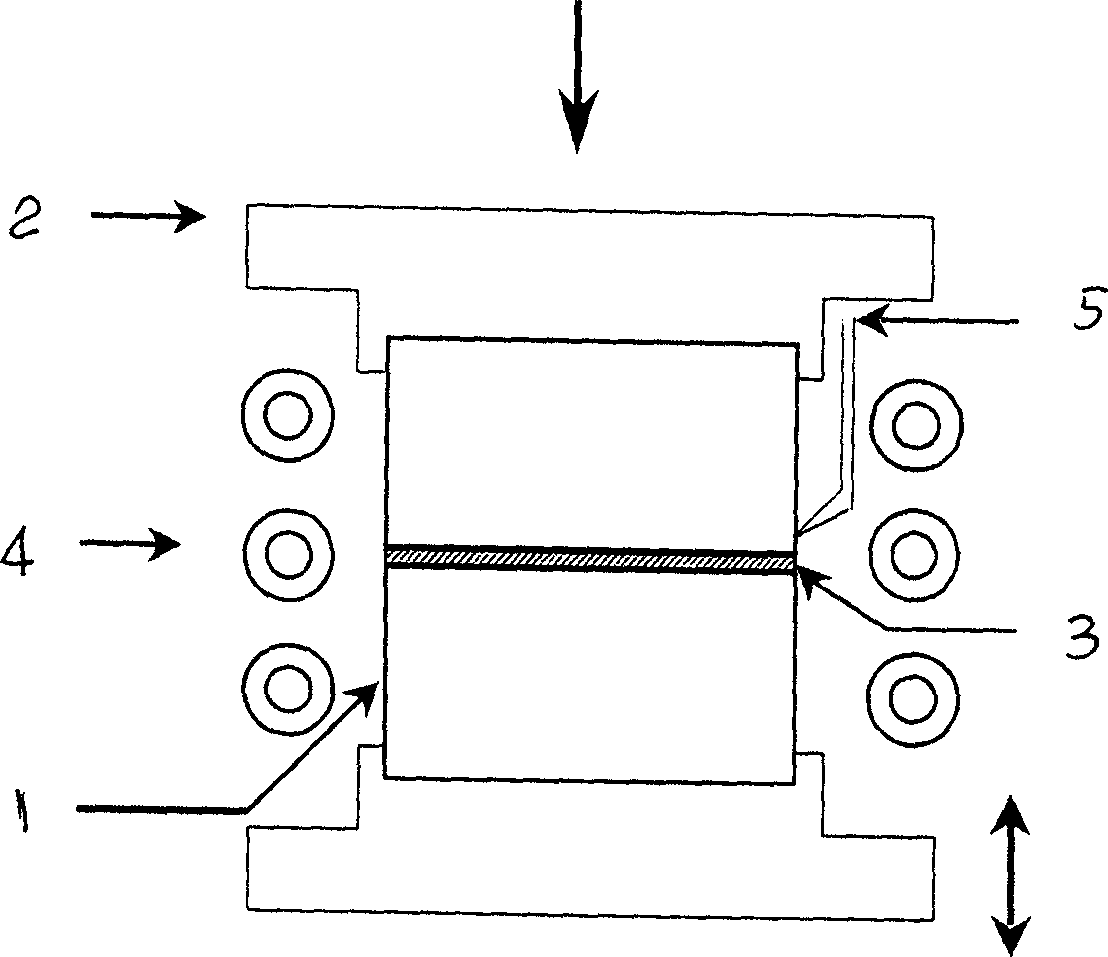

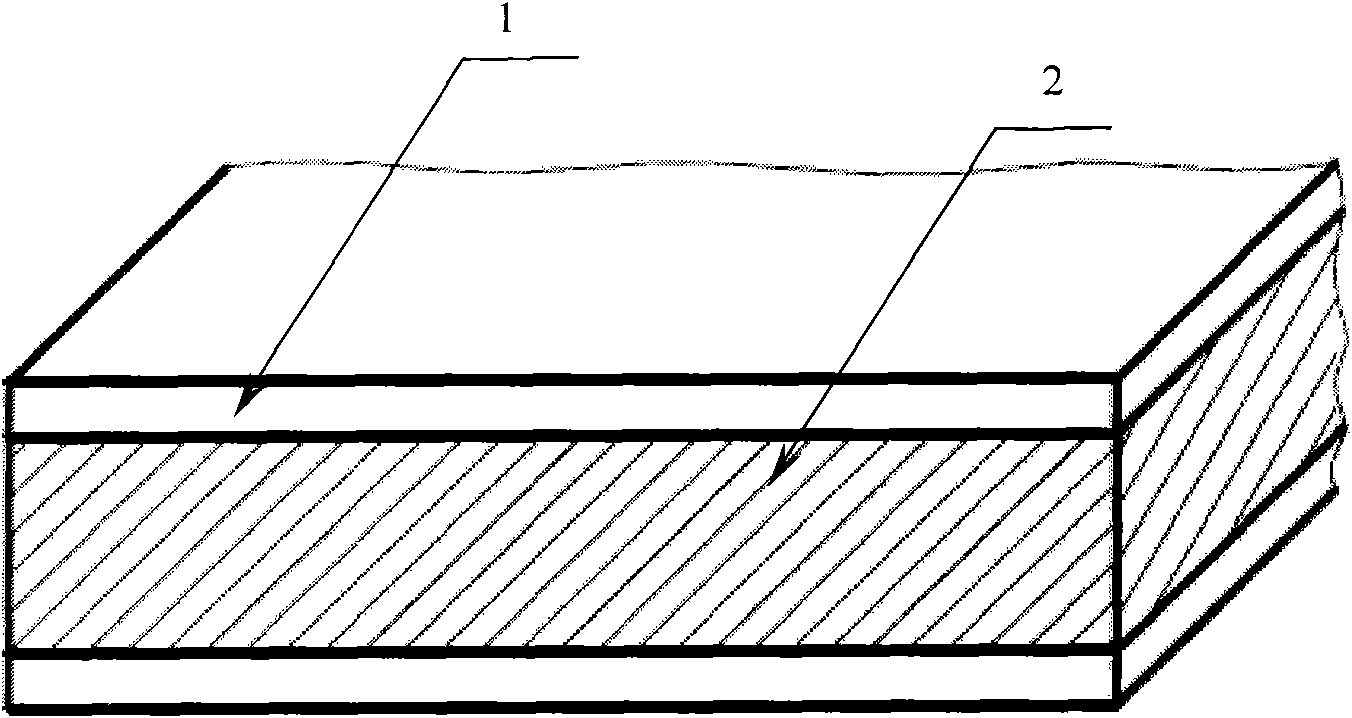

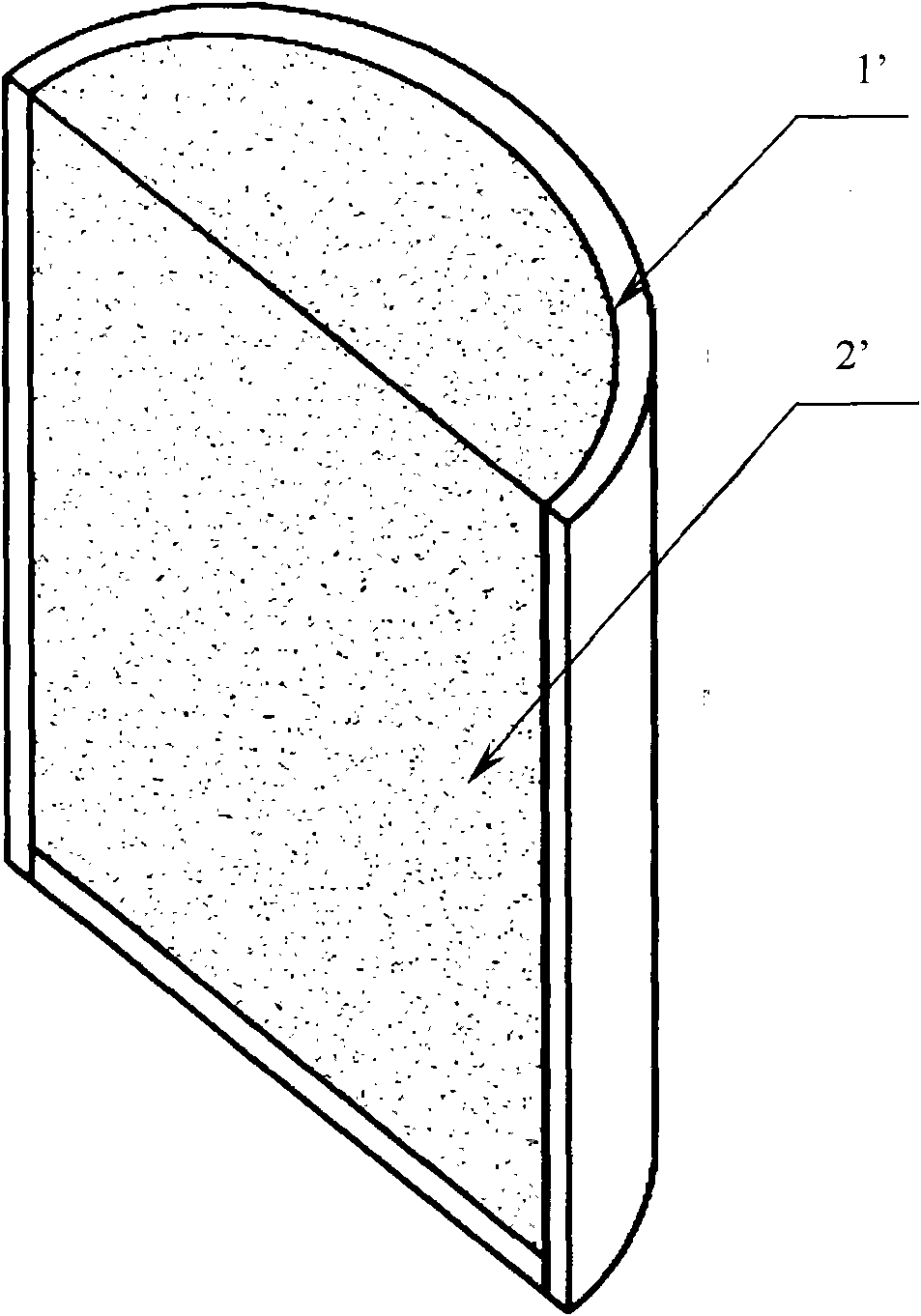

Preparation method for carbon nanomaterial enhanced aluminum base composite material

The invention discloses a preparation method for a carbon nanomaterial enhanced aluminum base composite material, which is similar to a powder metallurgy method, i.e. an aluminum material cladding powder processing and forming method. The preparation method is mainly used for solving the problem of precise mould requirement in the powder metallurgy process. The method is realized by the following steps of: 1) carrying out annealing treatment to pure aluminum or aluminum alloy material, carrying out alkali liquor cleaning and clean water cleaning to the surface of the pure aluminum or aluminum alloy material, and airing or drying after cleaning; 2) fully mixing and evenly stirring the pure aluminum or aluminum alloy powder with carbon nanomaterial at a certain ratio, i.e. at the mass fraction of the carbon nanomaterial of 0.1-8%; 3) cladding mixed powder by the pure aluminum or aluminum alloy material processed in step 1, compacting, sealing, and pressing into a precast block by a press; and 4) rolling the precast block obtained in step 3 into a final finished product. The preparation method for the carbon nanomaterial enhanced aluminum base composite material, which is disclosed by the invention, has the advantages of low cost, short flow, simpleness in operation and easiness in realizing industrialization.

Owner:NORTHEASTERN UNIV

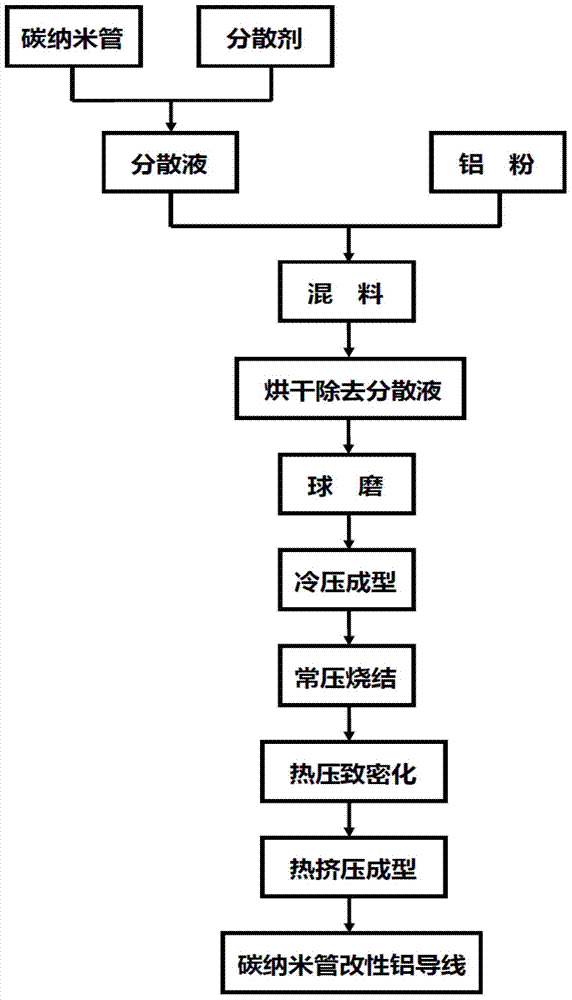

Preparation method of carbon nano tube-reinforced aluminum base composite material

ActiveCN103614672AAvoid the disadvantages of difficult sinteringWell mixedCarbon nanotubeWear resistance

The invention discloses a preparation method of a carbon nano tube-reinforced aluminum base composite material. The preparation method comprises the following steps: (1), uniformly dispersing carbon nano tubes into a dispersant which has chemical inertness on pure aluminum powder or aluminum alloy powder to obtain carbon nano tube dispersion liquid; (2), uniformly mixing the carbon nano tube dispersion liquid with the pure aluminum powder or the aluminum alloy powder, and drying to remove the dispersant to obtain a material mixture; (3), carrying out ball-milling onto the material mixture under protection of inert gases; and (4), carrying out cold pressing, normal-pressure sintering, hot-pressing and densifying under an atmospheric environment and hot-extrusion forming onto the ball-milled material mixture in sequence to obtain the carbon nano tube-reinforced aluminum base composite material. The preparation method disclosed by the invention further can reinforce the aluminum base body by utilizing co-action of base body processing and hardening, crystalline grain fining and reinforcing while bringing the excellent mechanical performances of the carbon nano tubes into play to reinforce the aluminum base body, so that tensile strength and wear resistance of the composite material are greatly improved; moreover, the carbon nano tube-reinforced aluminum base composite material with excellent performances can be industrially produced on a large scale.

Owner:STATE GRID CORP OF CHINA +3

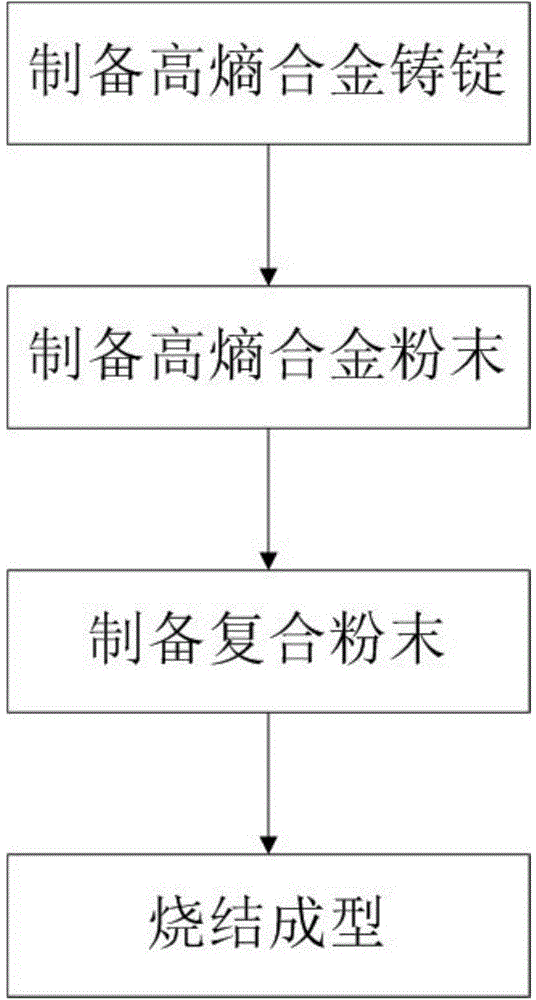

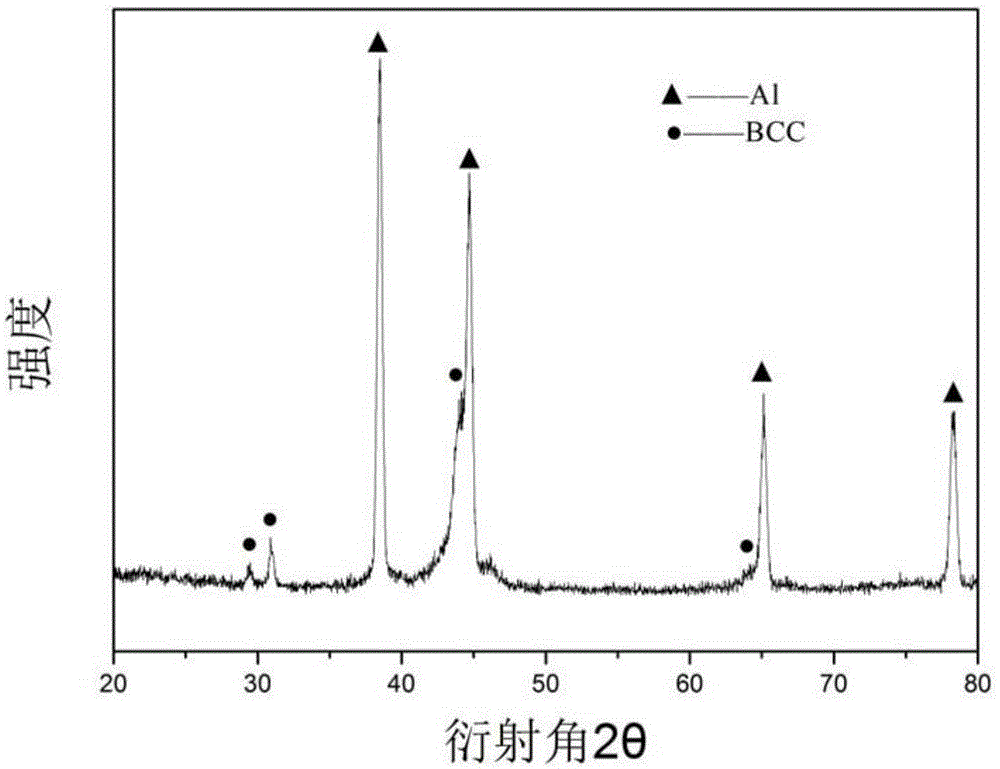

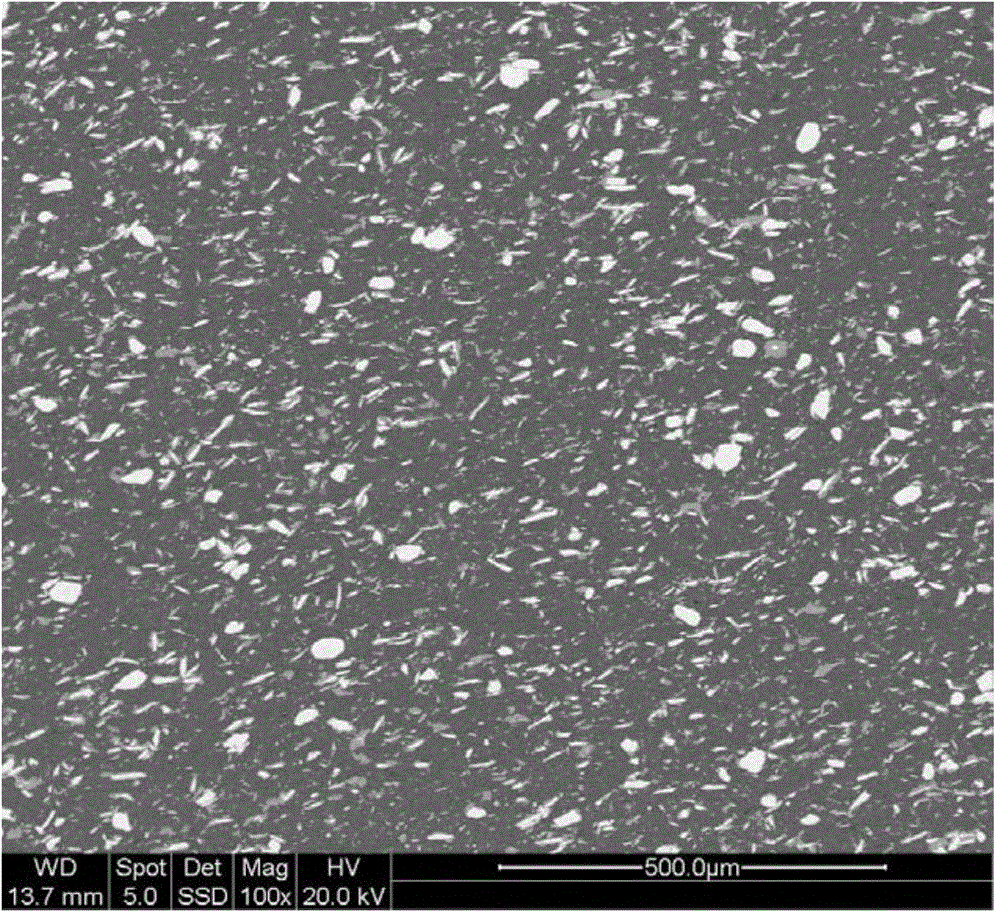

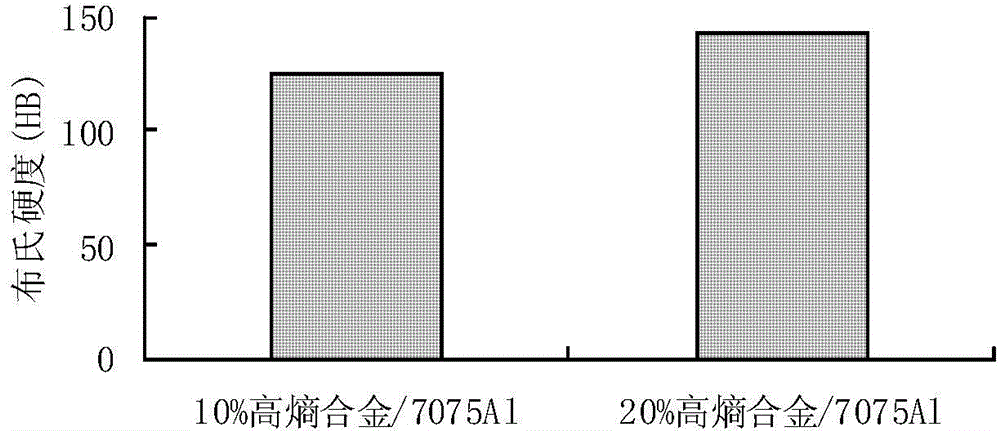

High-entropy alloy particle-reinforced aluminum-based composite material and preparation method thereof

The invention discloses a high-entropy alloy particle-reinforced aluminum-based composite material and a preparation method thereof, and belongs to the field of preparation of composite materials. The problems of influence on material densification and difficulty in the simultaneous improvement of strength and plasticity of the composite material due to own brittleness of a conventional metal-based reinforcement phase and limitation to sintering temperature are solved. The aluminum-based composite material is formed by the ball-milling mixing and sintering forming of a matrix phase and a reinforcement phase, wherein the volume ratio of the matrix phase aluminum and the reinforcement phase high-entropy alloy particles AlCoCrFeNiTi0.5 is 1: 4 to 1: 9. The preparation method for the high-entropy alloy particle-reinforced aluminum-based composite material comprises a step of preparing a high-entropy alloy ingot, a step of preparing high-entropy alloy powder, a step of preparing composite powder and a sintering forming step. According to the high-entropy alloy particle-reinforced aluminum-based composite material and the preparation method thereof, a process is simple, lower in energy consumption and cost and easy to implement, the tensile strength of the prepared high-entropy alloy particle-reinforced aluminum-based composite material is strengthened by 32.4 to 90.1 percent, the elongation of the high-entropy alloy particle-reinforced aluminum-based composite material is improved by 29.6 to 52.0 percent, and the comprehensive performance of the aluminum-based composite material is improved.

Owner:HUAZHONG UNIV OF SCI & TECH

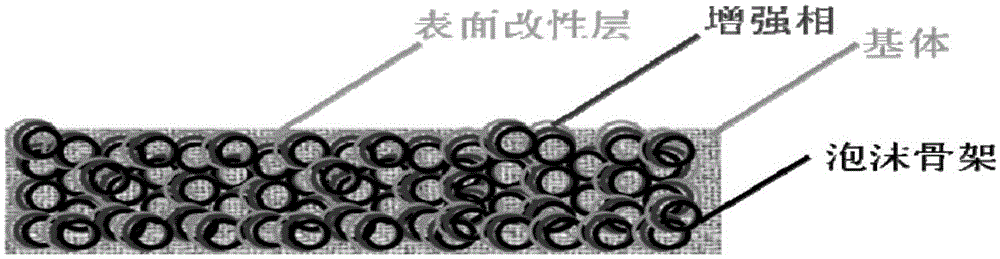

Foam graphene skeleton reinforced aluminum-base composite material and preparation method thereof

ActiveCN105603265ADoes not reduce ductilityReduce negative impactChemical vapor deposition coatingThree-dimensional spaceCarbon nanotube

The invention discloses a foam graphene skeleton reinforced aluminum-base composite material and a preparation method thereof. The composite material consists of a foam substrate, a graphene reinforcing layer and a base material or is added with reinforcing particles, wherein the foam substrate is foam metal, foam ceramic or foam carbon; the base material comprises aluminum and an aluminum base alloy; and the reinforcing particles are at least one of high-thermal conductivity diamond powder, graphene and carbon nanotubes or a combination of more or high-thermal conductivity low-expansion ceramic particles for improving the mechanical strength of the composite material and reducing the coefficient of thermal expansion. In the composite material disclosed by the invention, since graphene and aluminum are continuously distributed in a three-dimensional space to form a network interpenetrating structure, remarkable influence on the thermal and electric properties of the material caused by the compound interface is weakened, the reinforcing phase can form a whole without reducing the good plasticity and toughness of the metal base in the composite material, and the heat conduction efficiency and electric conduction efficiency of the reinforcing body are maximized, so that the thermal conductivity, electric conductivity and mechanical strength of the composite material are remarkably improved over traditional composite materials; and therefore, the foam graphene skeleton reinforced aluminum-base composite material is a novel multifunctional composite material with great potential.

Owner:CENT SOUTH UNIV

High-entropy alloy reinforced aluminum-based composite material and preparation method thereof

ActiveCN104388764AImprove the bonding strength of the interfaceImprove the state of the interfaceHigh entropy alloysRoom temperature

The invention belongs to the technical field of composite materials and discloses a high-entropy alloy reinforced aluminum-based composite material and a preparation method thereof. The composite material takes high-entropy alloy as a reinforcing phase and takes aluminum alloy as a base body. The preparation method of the composite material comprises the following steps: packaging high-entropy alloy particles and aluminum alloy powder into a ball milling tank, sealing and mixing the powder for 5-25 hours to obtain a mixed material; packaging the mixed material into a bag; applying a pressure of 5MPa to 15MPa at room temperature to compact the mixed material in the bag to obtain a semi-finished product; putting the compacted semi-finished product into thermal extruding equipment, preheating the semi-finished product to 400-480 DEG C, preheating a mold to 200-400 DEG C, keeping the temperature of the semi-finished product and the mold for 1-3 hours to finish the preheating process, and then performing hot extrusion formation at an extrusion pressure of 5MPa to 15MPa and at an extrusion ratio of 4 to 25 to obtain the high-entropy alloy reinforced aluminum-based composite material.

Owner:GUANGDONG XINGFA ALUMINUM +1

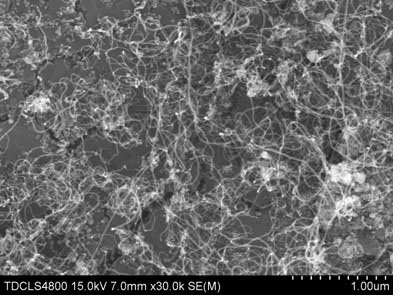

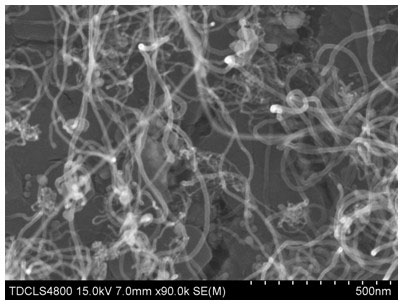

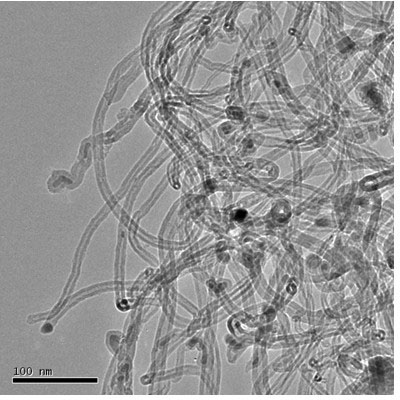

Vapour deposition in situ reaction method for preparing carbon nanotube reinforced aluminium matrix composite material

InactiveCN1730688AGood dispersionAvoid distractionChemical vapor deposition coatingMetal/metal-oxides/metal-hydroxide catalystsGas phaseCarbon nanotube

The invention provides a process for preparing carbon nano tube reinforced aluminum base composite material through gaseous phase in-situ reaction, which comprises using aluminum-base powder as carrying agent, preparing Ni catalyst with chemical deposition precipitation process, obtaining Al-Ni composite powder, preparing carbon nano tube on composite powder in-situ through chemical deposition precipitation process.

Owner:TIANJIN UNIV

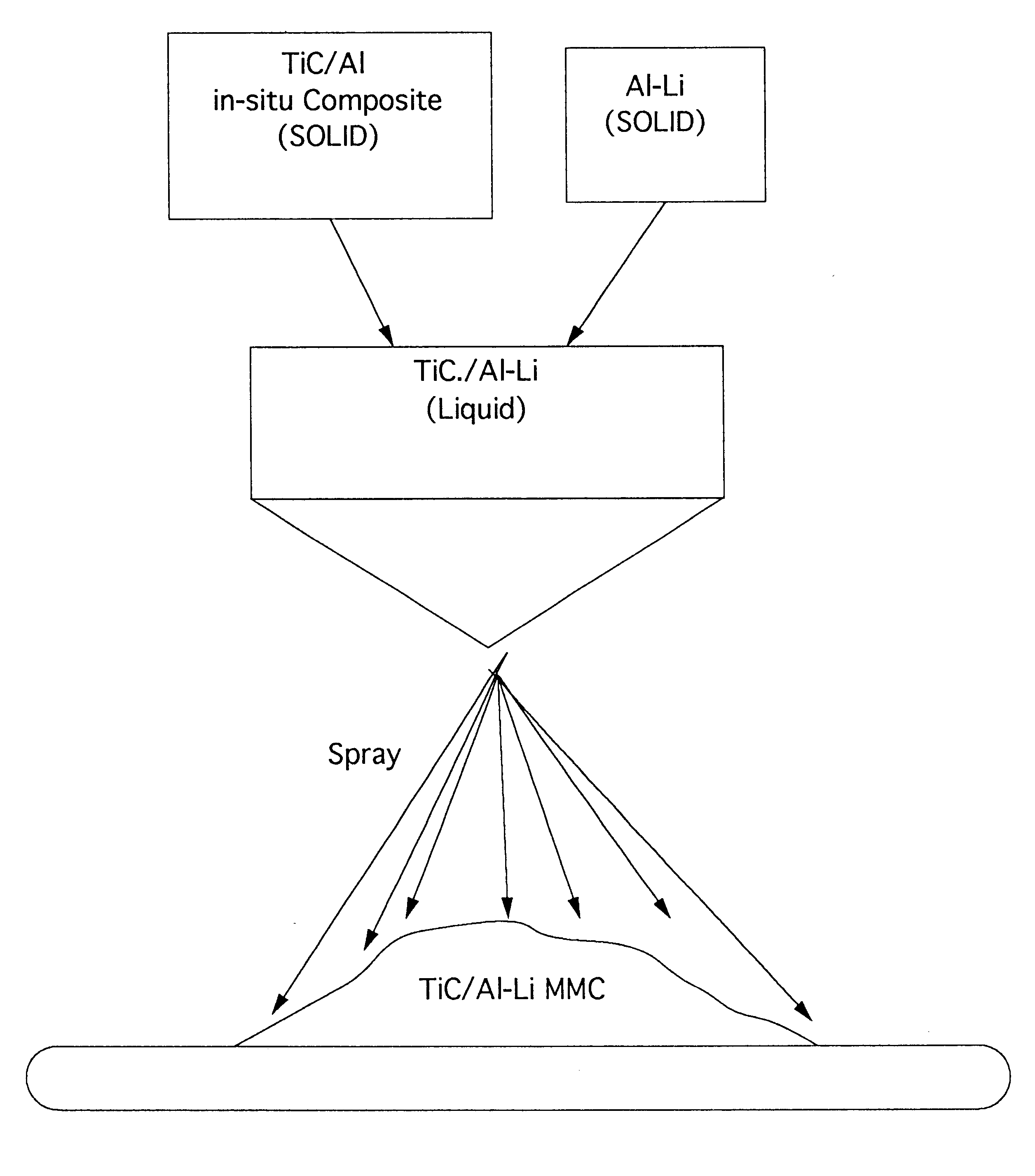

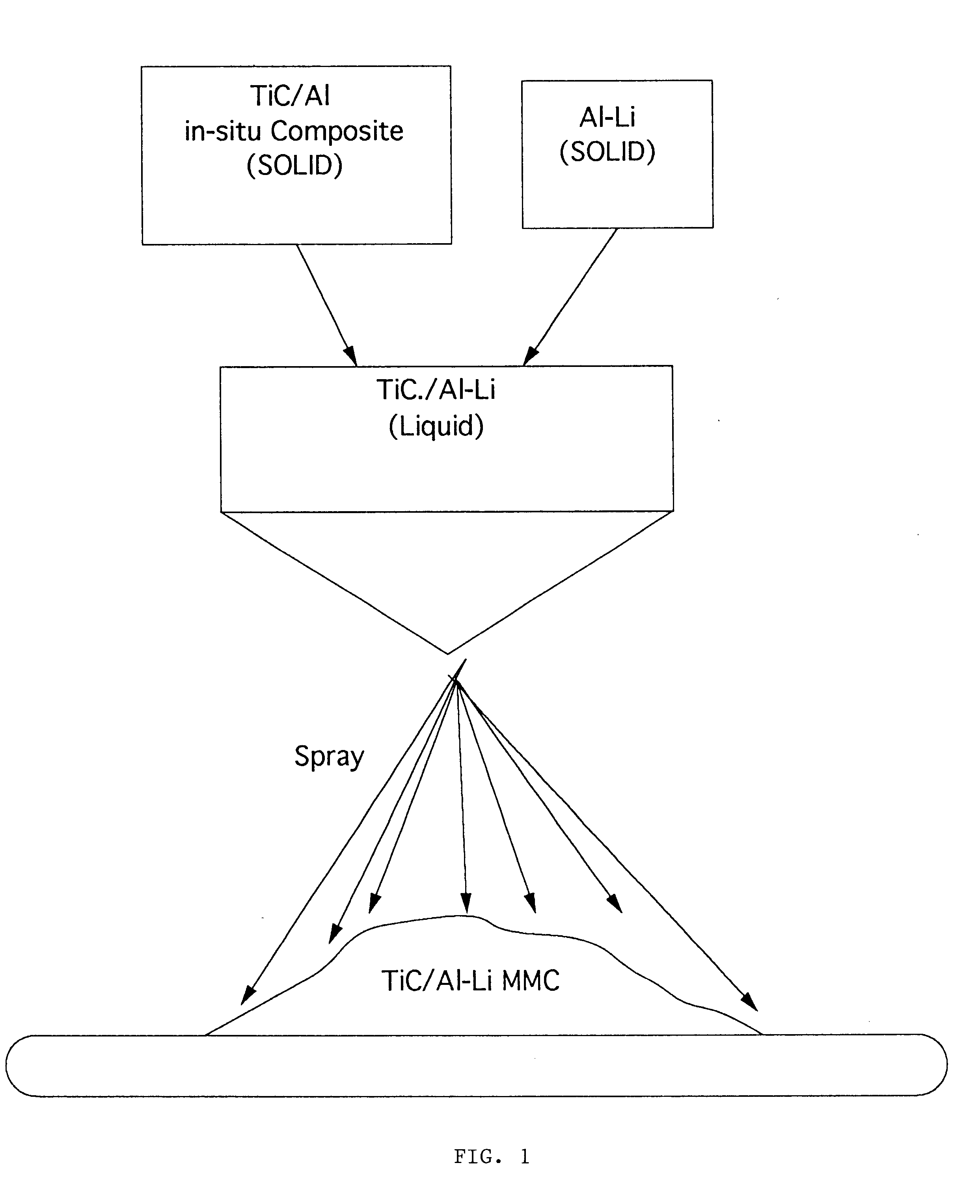

Aluminum-lithium alloy

A method for mixing an in-situ aluminum matrix composite with an aluminum-litium alloy via the spray deposition process to obtain an Al-Li composite.

Owner:ARMY UNITED STATES OF AMERICA AS REPRENSENTED BY THE SEC OF

A kind of in-situ nano-tic ceramic particle reinforced aluminum matrix composite material and preparation method thereof

ActiveCN102260814APure surfaceImprove the bonding strength of the interfaceChemical reactionGraphite

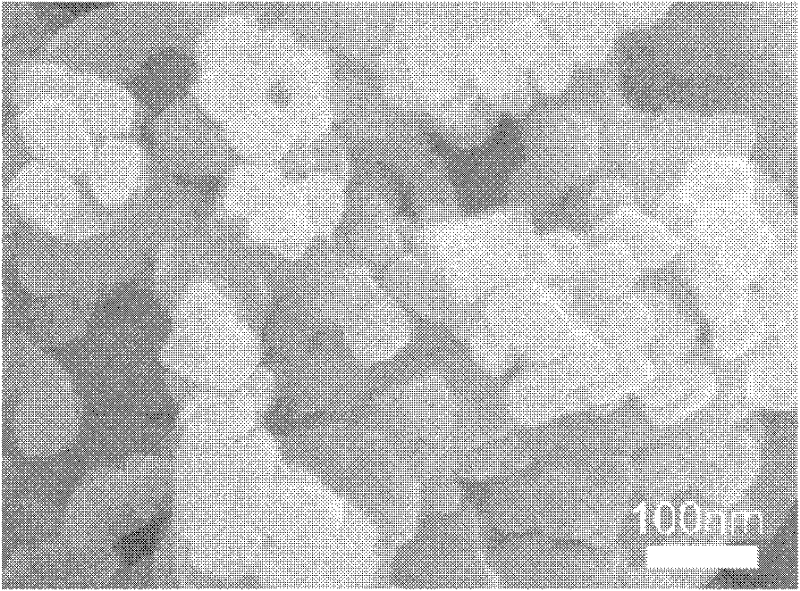

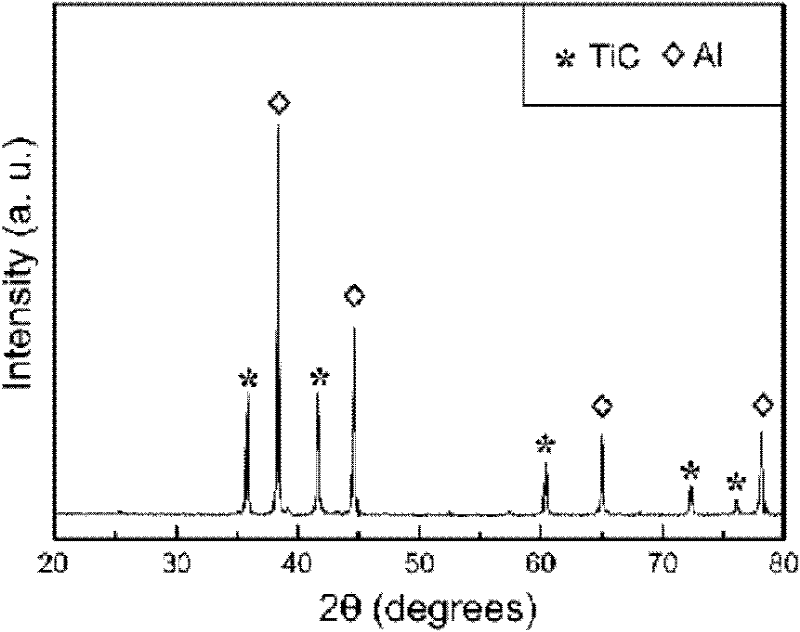

The invention relates to an in situ nano TiC ceramic particle reinforced aluminum based composite material and a preparation method thereof. According to the invention, an in situ nano TiC ceramic particle reinforced aluminum or aluminum alloy based composite material is prepared by using a combustion synthesis chemical reaction method and a hot-press technology; and the size of the TiC ceramic particle synthesized by an in situ reaction is below 100 nm, and the weight percentage content of the TiC ceramic particle is 3-30. The preparation method comprises the following steps: 1) mixing reactant powder materials in a certain proportion and then making blanks; 2) evenly mixing in a drum-type ball mill and a triturator in turn; 3) pressing at the room temperature so as to form reaction prefabricated blocks; and 4) putting a graphite mould with the prefabricated blocks in a vacuum / atmosphere protected combustion reaction furnace with a hydraulic device and then initiating a combustion reaction, immediately applying an axial pressure of 40+ / -5 MPa to the prefabricated blocks once the combustion reaction occurs, and cooling the prefabricated blocks to room temperature along with the furnace after keeping the pressure for 30-40 seconds, so as to synthesize the nano TiC ceramic particle reinforced pure aluminum or aluminum alloy based composite material.

Owner:JILIN UNIV

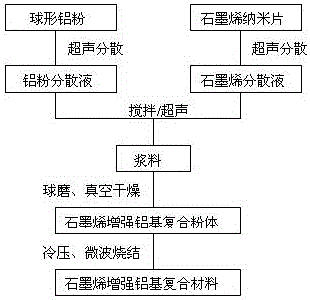

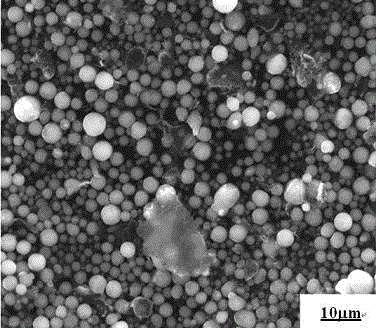

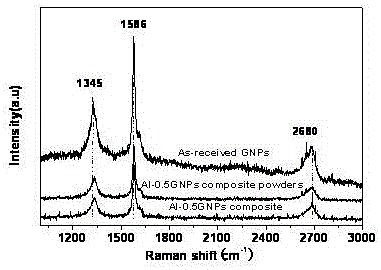

Method for preparing graphene reinforced aluminum matrix composite material by microwave sintering

The invention discloses a method for preparing a graphene reinforced aluminum matrix composite material by microwave sintering, comprising the steps of: taking graphene nano microchips and aluminum powder as raw materials, carrying out ultrasonic treatment to respectively prepare graphene dispersion liquid and aluminum powder dispersion liquid; mixing the two kinds of dispersion liquid, and carrying out low temperature ball milling, vacuum drying, press forming and microwave sintering to obtain the graphene reinforced aluminum matrix composite material with high density, high strength and high thermal conductivity. The method adopts an ethanol ultrasonic dispersion and ball milling combined method to enable the graphene to evenly disperse in the aluminum matrix, and adopts a microwave sintering technology, thus shortening the preparation time and being highly efficient and energy-saving; the production process is safe and pollution-free, and simultaneously the prepared graphene reinforced aluminum matrix composite material has high density and good heat-conducting property.

Owner:NANCHANG HANGKONG UNIVERSITY

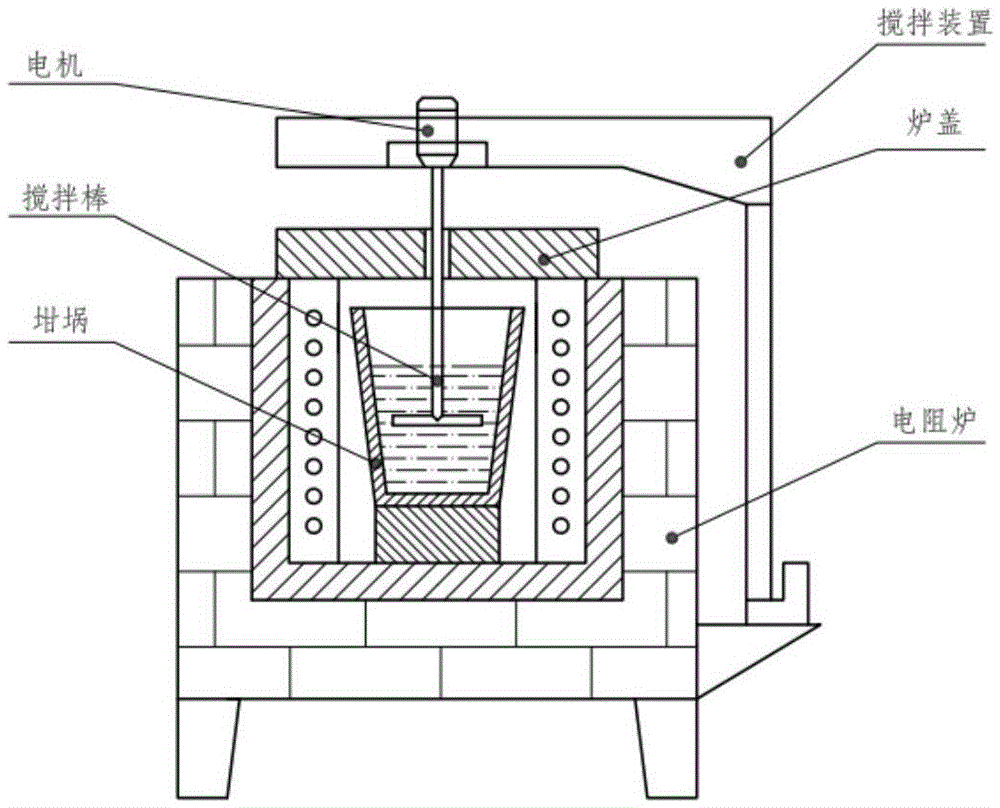

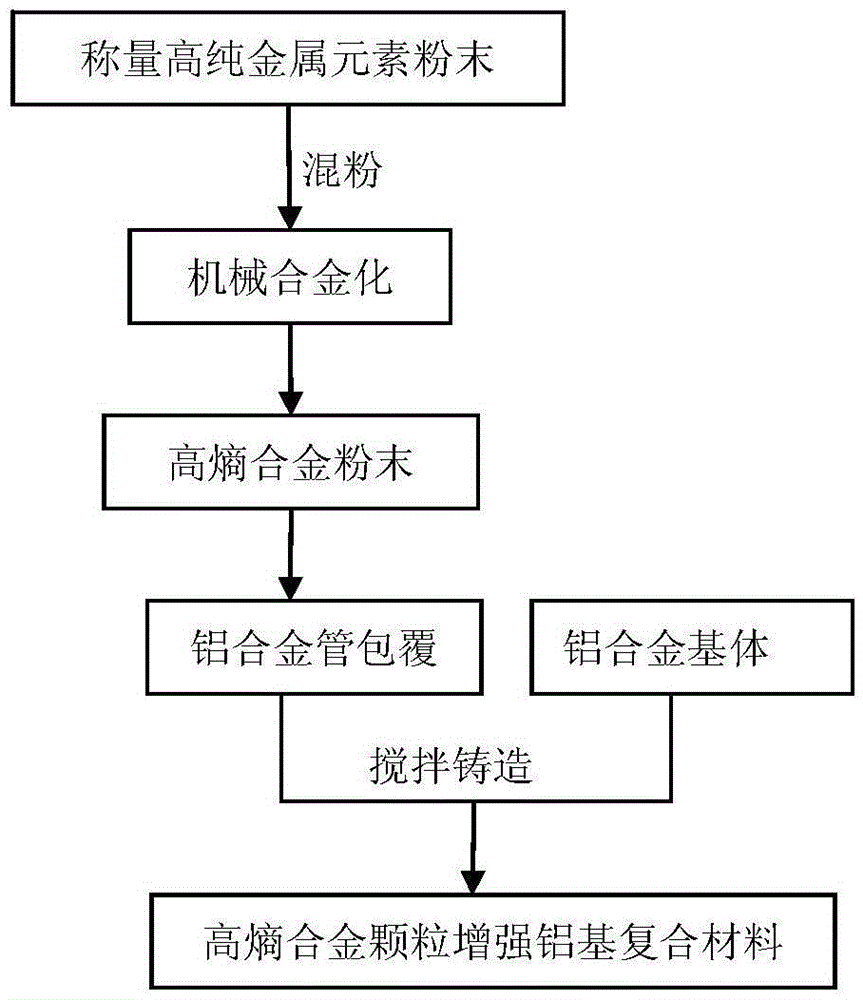

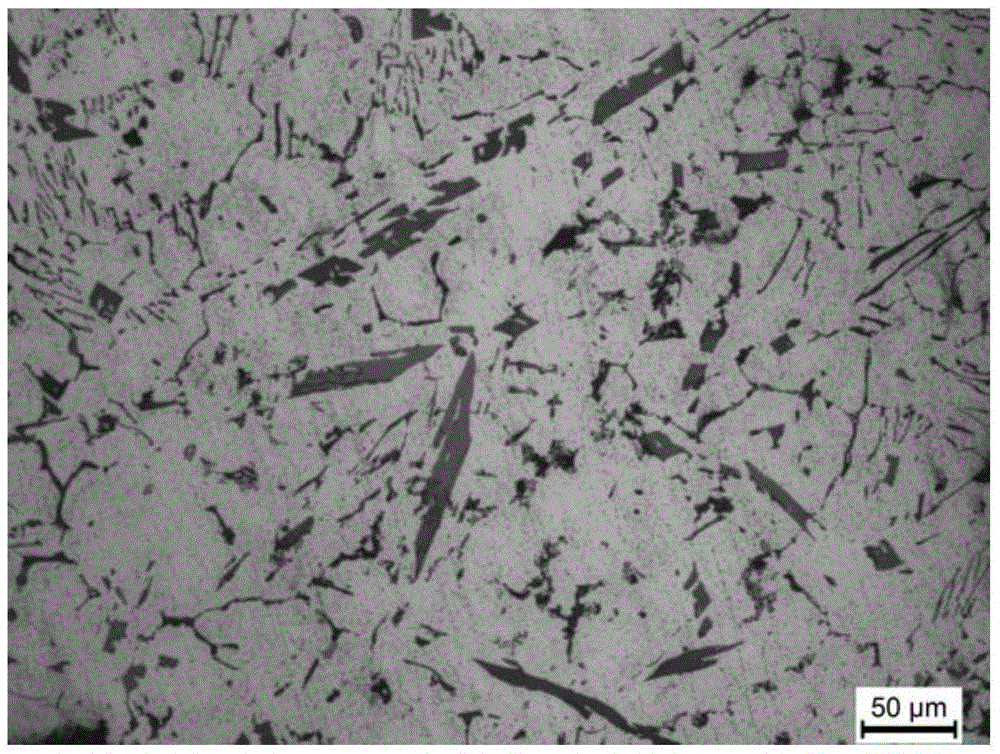

High-entropy alloy particle reinforced aluminum base composite material and stirring casting preparation process thereof

The invention discloses a high-entropy alloy particle reinforced aluminum base composite material and a stirring casting preparation process thereof. The preparation process adopts mechanical alloying to prepare high-entropy alloy powder and screen to obtain high-entropy alloy particles; the high-entropy alloy particles are sealed by adopting an aluminum alloy pipe having the same material with a basal body; the aluminum alloy pipe weighed in a segmented manner is added in the molten basal body; the high-entropy alloy particles are dispersed by a stirring mode; and the high-entropy alloy particle reinforced aluminum base composite material is prepared by a casting process. The high-entropy alloy particles are 0.1-35%; aluminum alloys are 65-99.9%; and the sum of the two is 1. The high-entropy alloy particles in the structure of the prepared composite material are uniformly dispersed; the high-entropy alloy and aluminum alloy interface bonding compatibility is excellent; the strength and the toughness are excellent; the preparation process is simple; the powder has no need to be treated; the cost is low; the stability is good; and the composite material is suitable for large-batch production and standard production, and is excellent in promotion and application prospect.

Owner:GUANGDONG XINGFA ALUMINUM +1

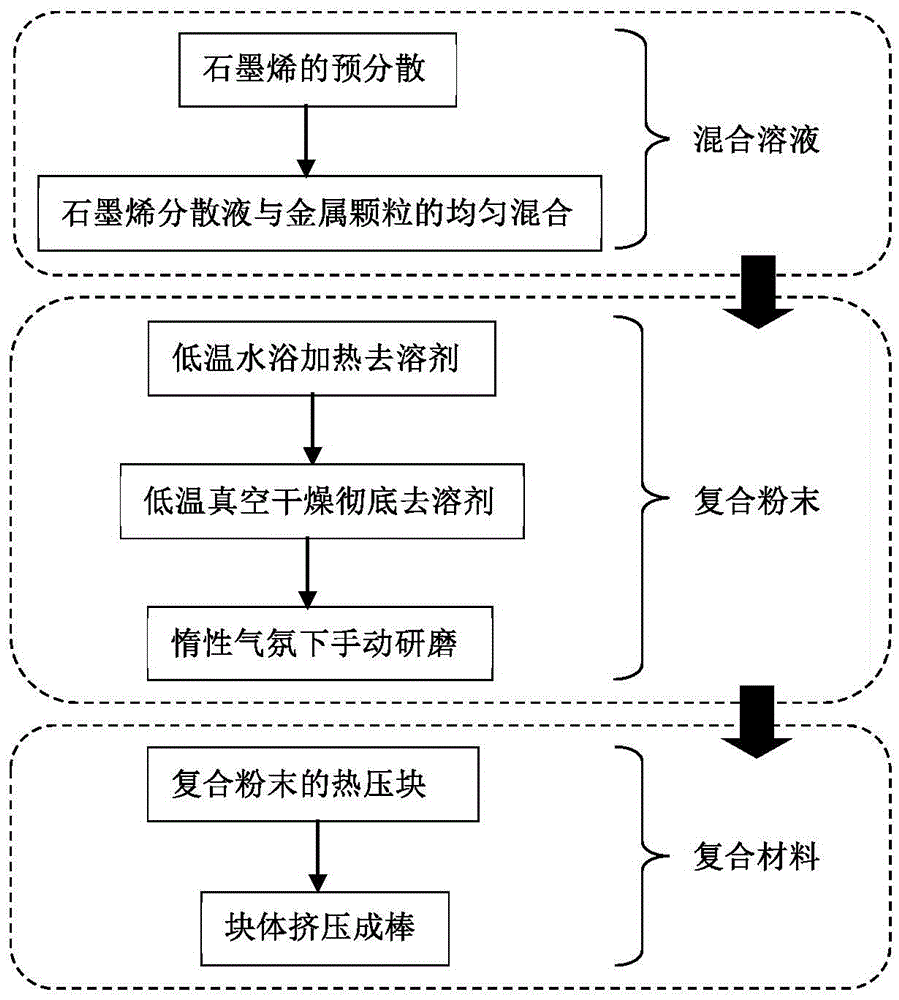

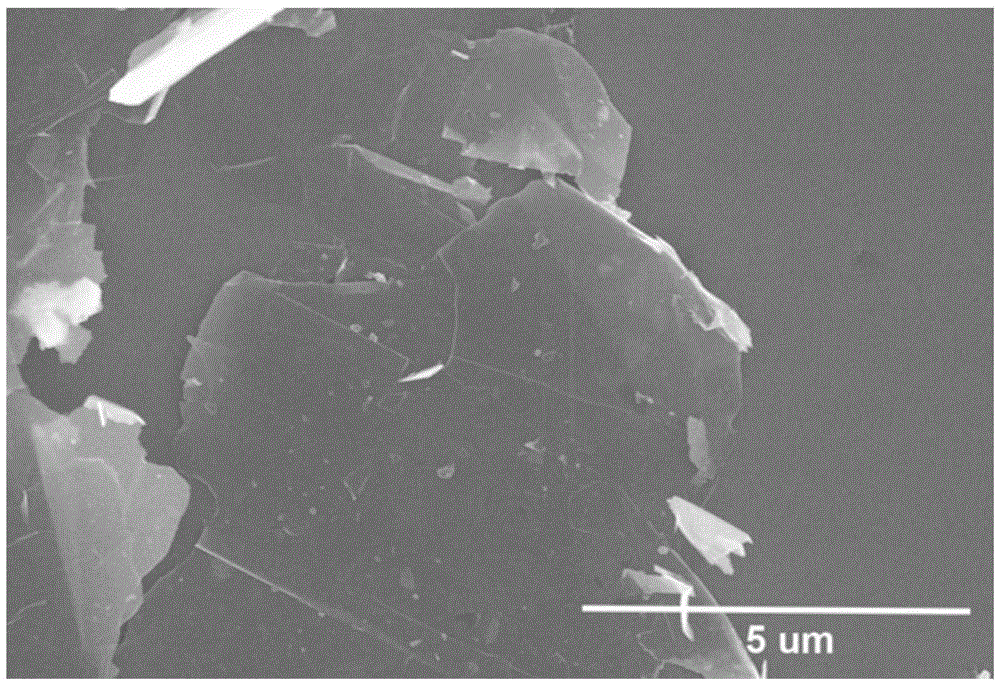

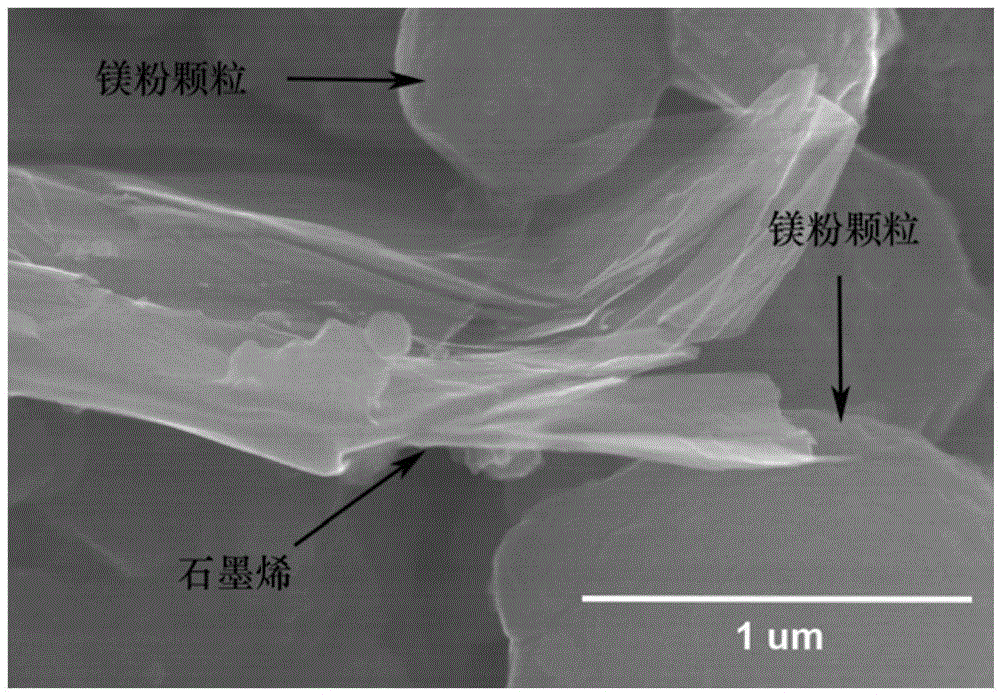

Graphene-reinforced magnesium-aluminium matrix composite material and preparation method thereof

The invention discloses a graphene-reinforced magnesium-aluminium matrix composite material and a preparation method thereof, and belongs to the technical field of composite materials. The preparation method comprises the following steps: dissolving graphene in an appropriate amount of ethanol solution and ultrasonically dispersing, then intermittently adding a metal powder in the solution, and ultrasonically dispersing and mechanically stirring simultaneously to obtain graphene / metal particle mixed solution with high dispersibility; sequentially carrying out the operations of heating in a low-temperature water bath to remove a solvent, drying in vacuum to obtain a powder, and continuously manually grinding the powder under an inert atmosphere, on the mixed solution, so as to obtain a graphene / metal particle composite powder with uniform dispersion; and carrying out hot-pressing on the composite powder into blocks, carrying out hot extrusion, and finally obtaining the graphene / metal matrix composite material. The preparation process disclosed by the invention is simple, environment-friendly, and free from addition of a non-volatile organic dispersant; low-temperature inert protection is adopted during the process of preparing the composite powder, and high own dispersion of graphene and high dispersion thereof in a metal matrix are achieved while the structural integrity of a graphene reinforcement is kept; and the preparation method is suitable for preparing the high-performance graphene-reinforced metal matrix composite material.

Owner:BEIJING UNIV OF TECH

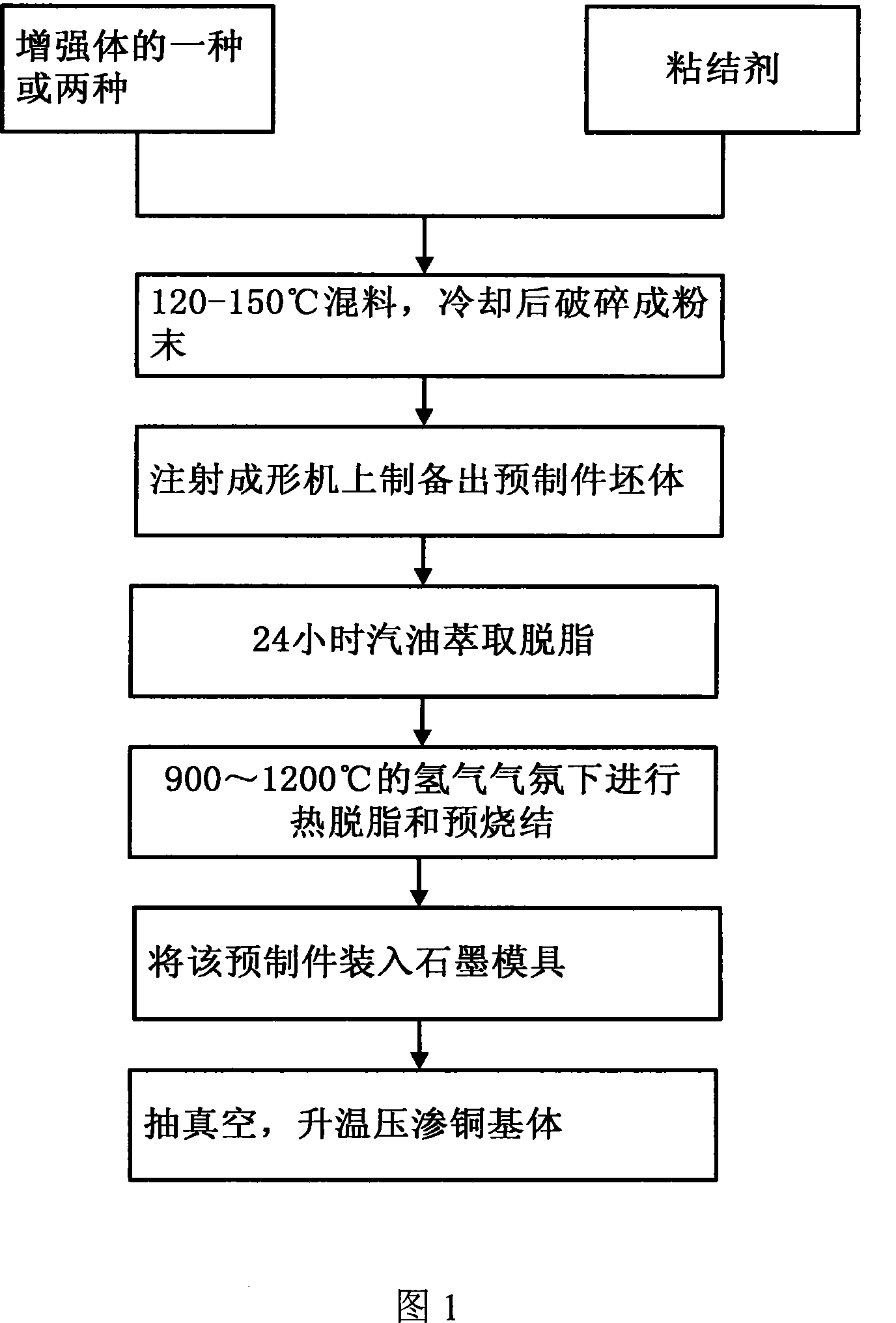

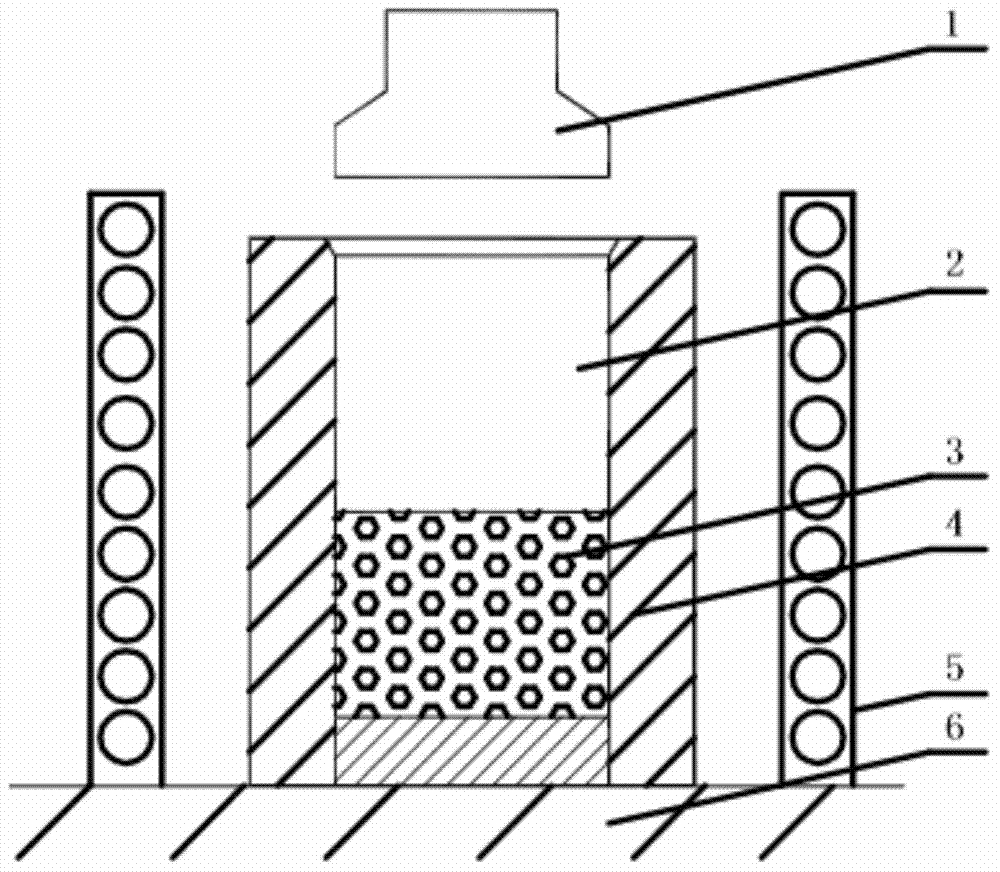

High heat conductivity copper-base composite material and preparation method thereof

The invention belongs to the technical field of preparation of electronic packaging materials, and particularly designs a copper-based composite material with high thermal conductivity and a preparation method thereof. The copper-based composite material is made of a reinforcement and a binder through a prefabricated injection molding process to make a reinforcement prefabricated part, wherein the size of the reinforcement particle is 7-60 μm, and it is composed of silicon carbide particles, diamond particles or aluminum nitride particles. One or two of them; the copper matrix is directly placed on the reinforcement preform, wherein the copper matrix is electrolytic copper or oxygen-free copper, and the volume ratio of the reinforcement to the copper matrix is 50-75%: 25-50 %, made by pressure infiltration process. The preparation method adopts the injection molding process of the prefabricated part and the pressure impregnation process to prepare the high thermal conductivity copper matrix composite material. The thermal conductivity of the copper-based composite material in the present invention is higher than that of the aluminum-based composite material with the same reinforcement system, the material itself has low density and small thermal expansion coefficient, which meets the requirement of light weight of the packaging material.

Owner:GRIMAT ENG INST CO LTD

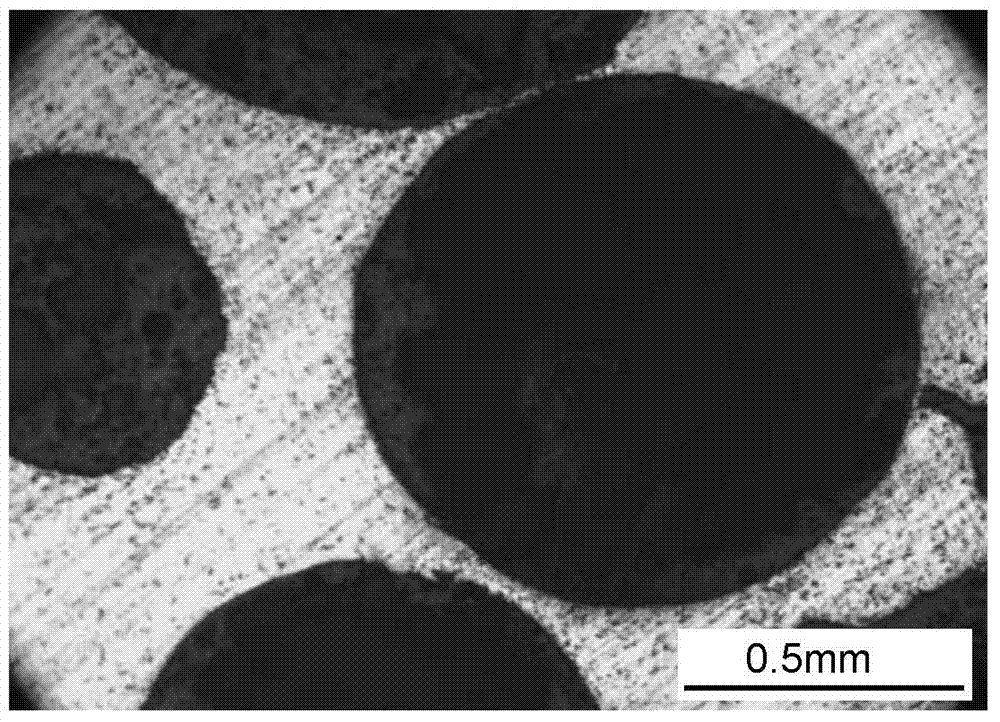

Preparation method for Al2O3 hollow sphere/aluminum porous composite material

ActiveCN103614586AImprove mechanical propertiesAdjustable sizeMold removalAluminum matrix composites

The invention provides a preparation method for an Al2O3 hollow sphere / aluminum porous composite material, relates to a preparation method for an aluminum-based porous composite material, which solves the problems that the strength of a traditional foam aluminum material is low, the process conditions are harsh and the cost is high in an existing preparation method. The preparation method 1 comprises the following steps: step 1. filling an Al2O3 hollow sphere; step 2. pre-heating; step 3. pouring; step 4. pressurizing and immersing; and step 5. maintaining pressure, cooling and carrying out de-molding to obtain the Al2O3 hollow sphere / aluminum porous composite material. The preparation method 2 comprises the following steps: step 1. mixing the Al2O3 hollow spheres with different grain diameters and filling; step 2. pre-heating; step 3. pouring; step 4. pressurizing and immersing; and step 5. maintaining pressure, cooling and de-molding to obtain the Al2O3 hollow sphere / aluminum porous composite material. The Al2O3 hollow sphere / aluminum porous composite material is prepared by immersing aluminum or aluminum alloy into a gap between Al2O3 hollow ball prefabricated blocks; porous structure characterizes of the Al2O3 hollow spheres are maintained and a strengthening mechanism of the aluminum-based composite material is introduced, so that the mechanical properties of materials are improved. According to the preparation method, the operation is convenient, the cost is low, the process is simple, and the production cost is reduced.

Owner:HARBIN INST OF TECH

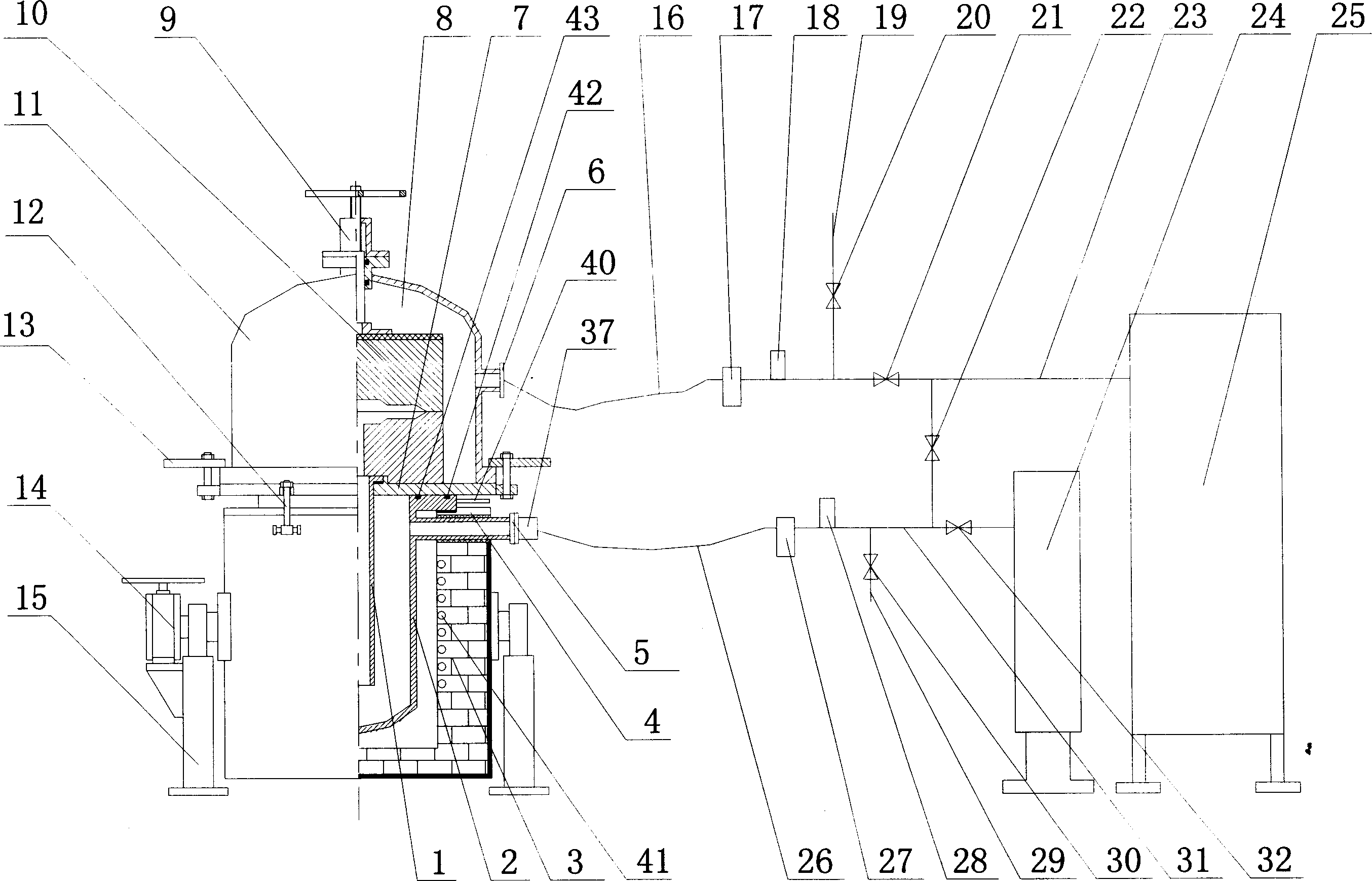

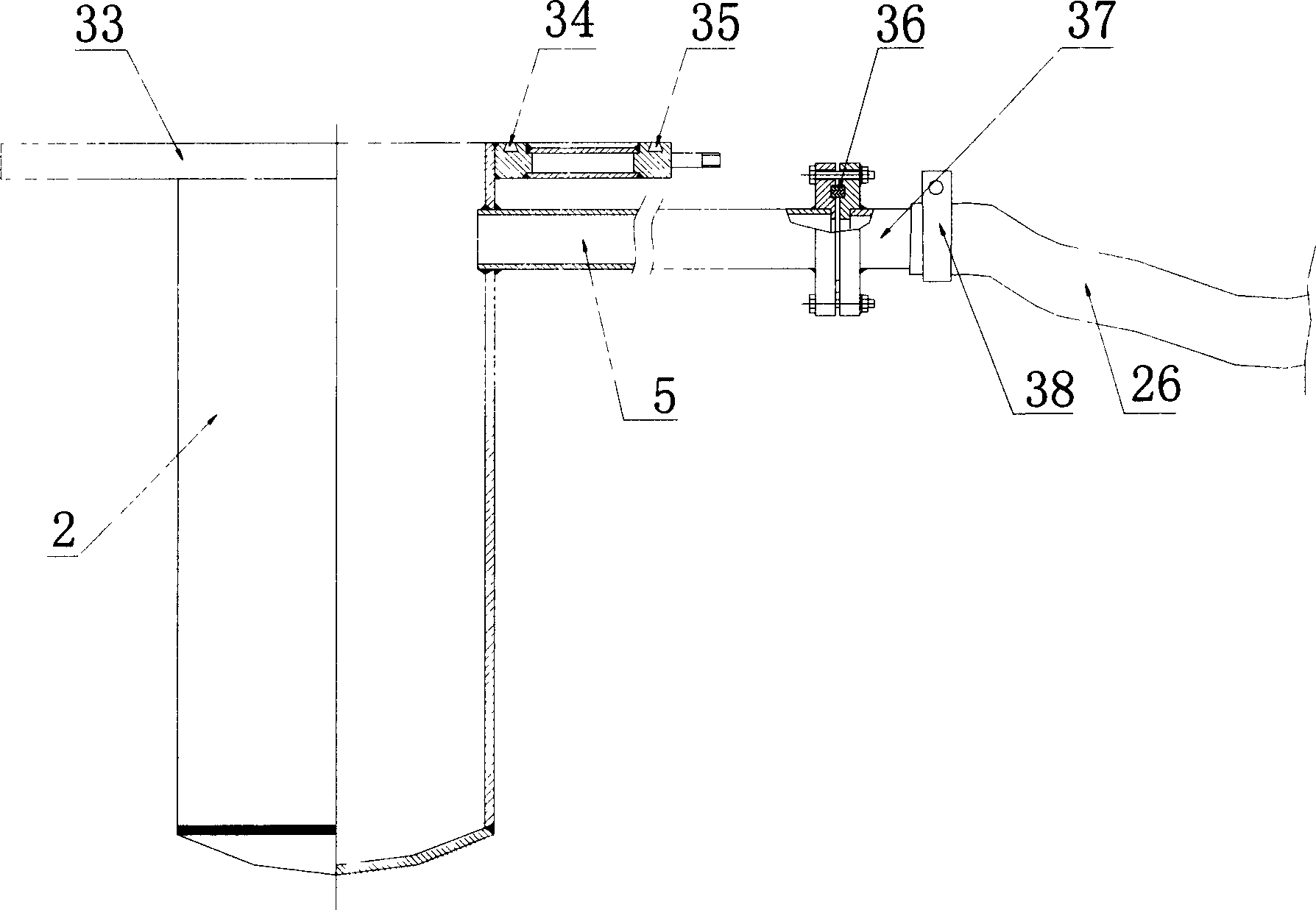

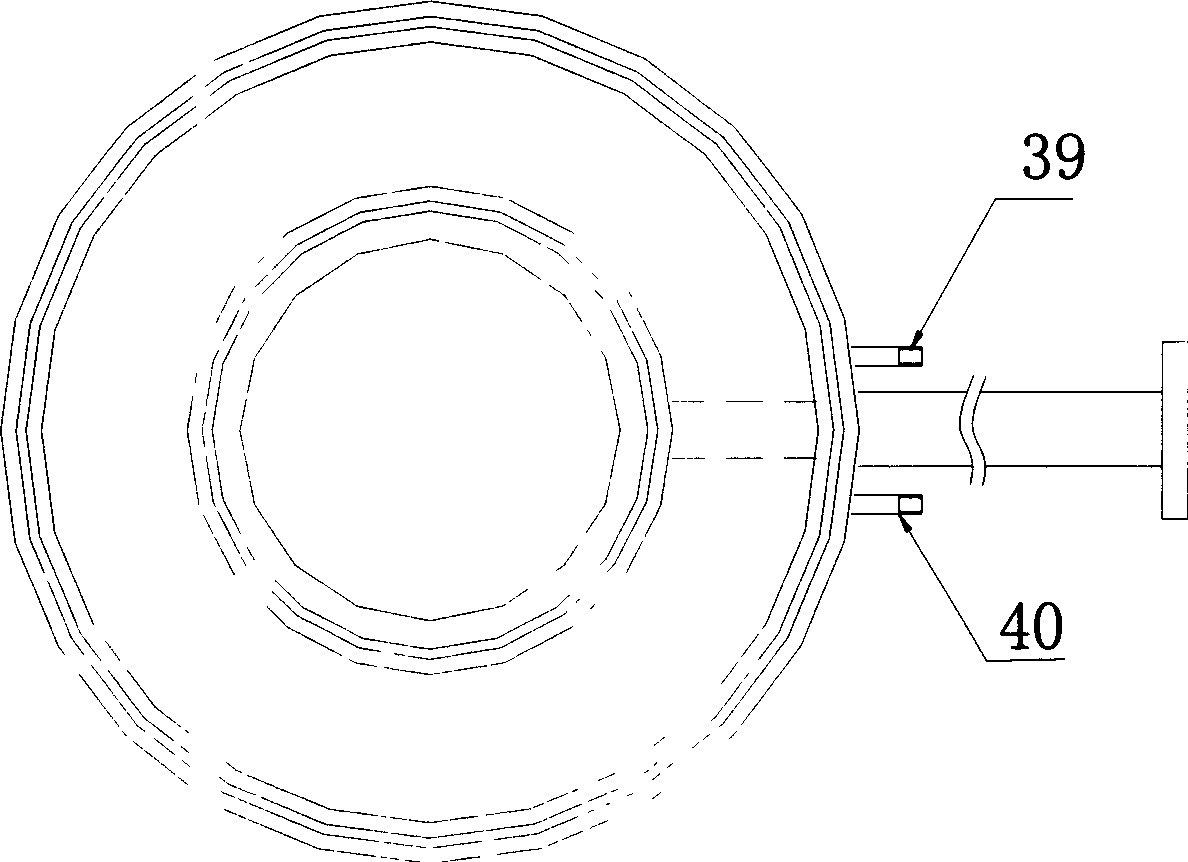

Pressure adjustable casting method and crucible therefor

Owner:BEIJING JIAOTONG UNIV

Silicon carbide reinforced aluminum-based composite material and its preparation method

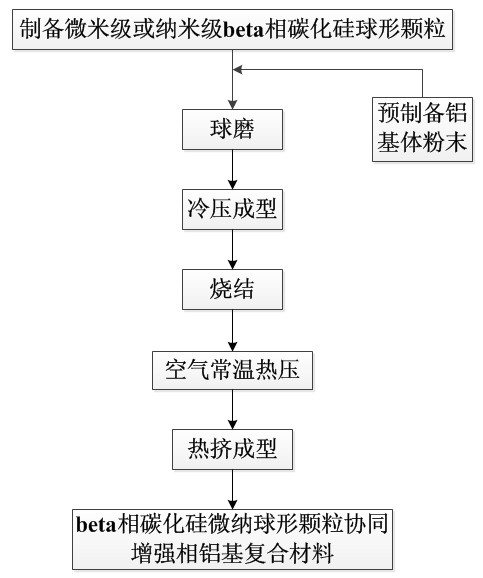

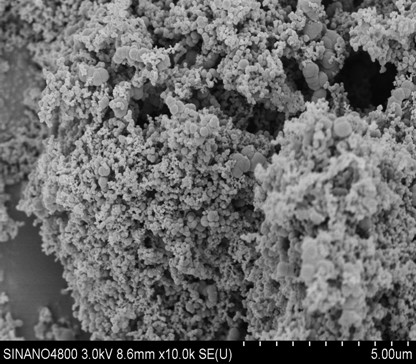

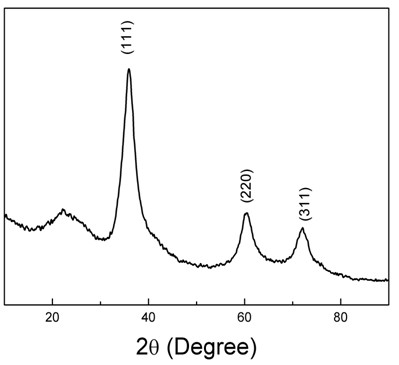

The invention relates to a silicon carbide reinforced aluminum-based composite material and its preparation method. The composite material is characterized by being composited by micron-scale and nano-scale beta-phase silicon carbide spherical particles and an aluminum substrate, with the beta-phase silicon carbide spherical particles distributed in the aluminum substrate to form a synergistic reinforced phase. The preparation method is summarized to be mainly composed of: pre-preparing beta-phase silicon carbide spherical particles, adding aluminum substrate powder and the beta-phase silicon carbide spherical particles accounting for 0-25wt% of the composite material into a ball mill for ball milling treatment, and conducting cold press molding, sintering, as well as air hot pressing sequentially, and finally carrying out hot extrusion molding to obtain a molded product of the composite material. Specifically, the particle size of the aluminum substrate powder is 1micrometer to 100micrometers. The technical scheme of the invention innovatively uses spherical particulate beta-phase silicon carbide and makes use of the synergistic reinforcement effect of the micron and nano-silicon carbide particles, substantially improves the strength, toughness, abrasion resistance and others of the aluminum-based composite material. The preparation process is simple, and the cost input is effectively reduced.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI +1

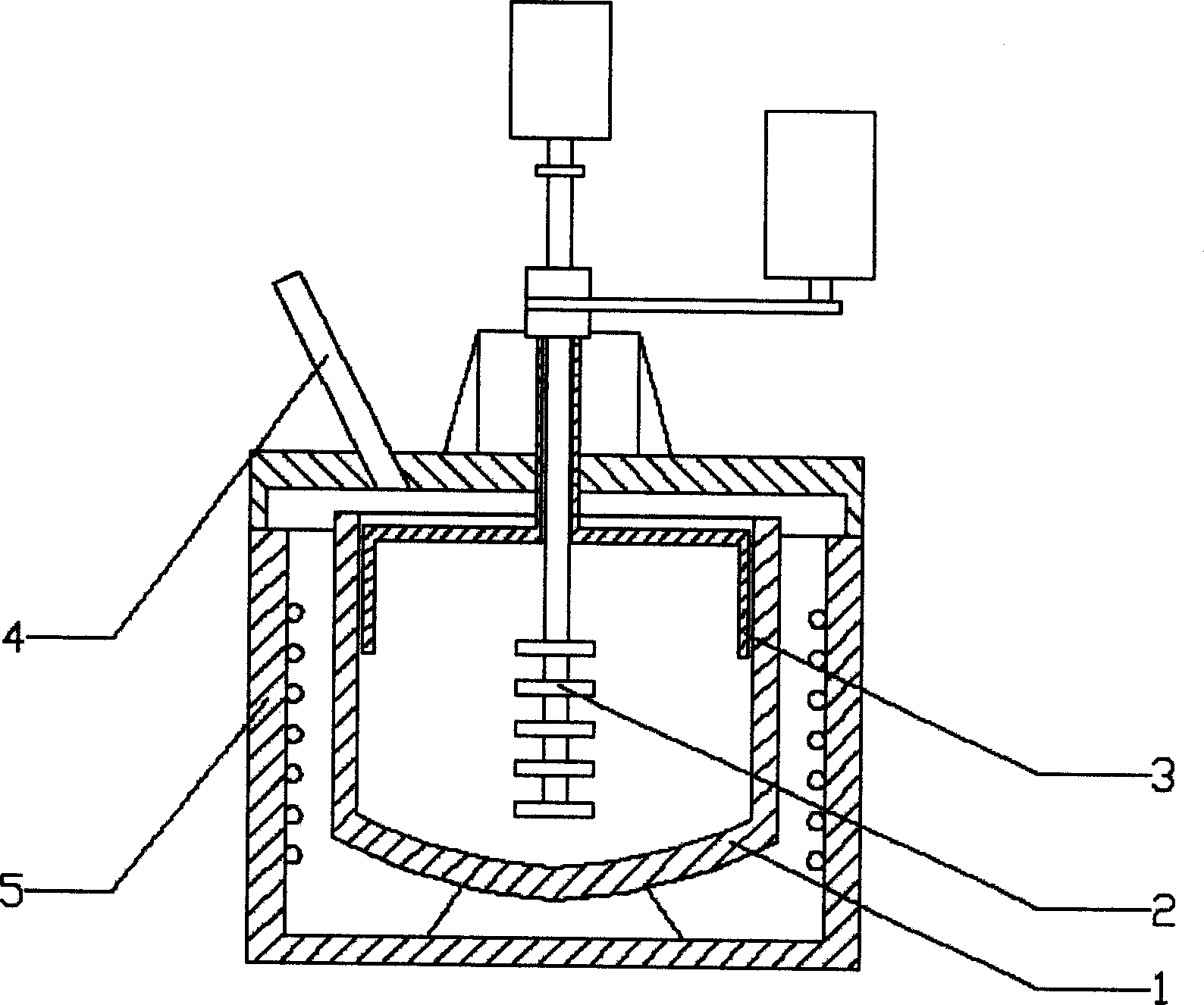

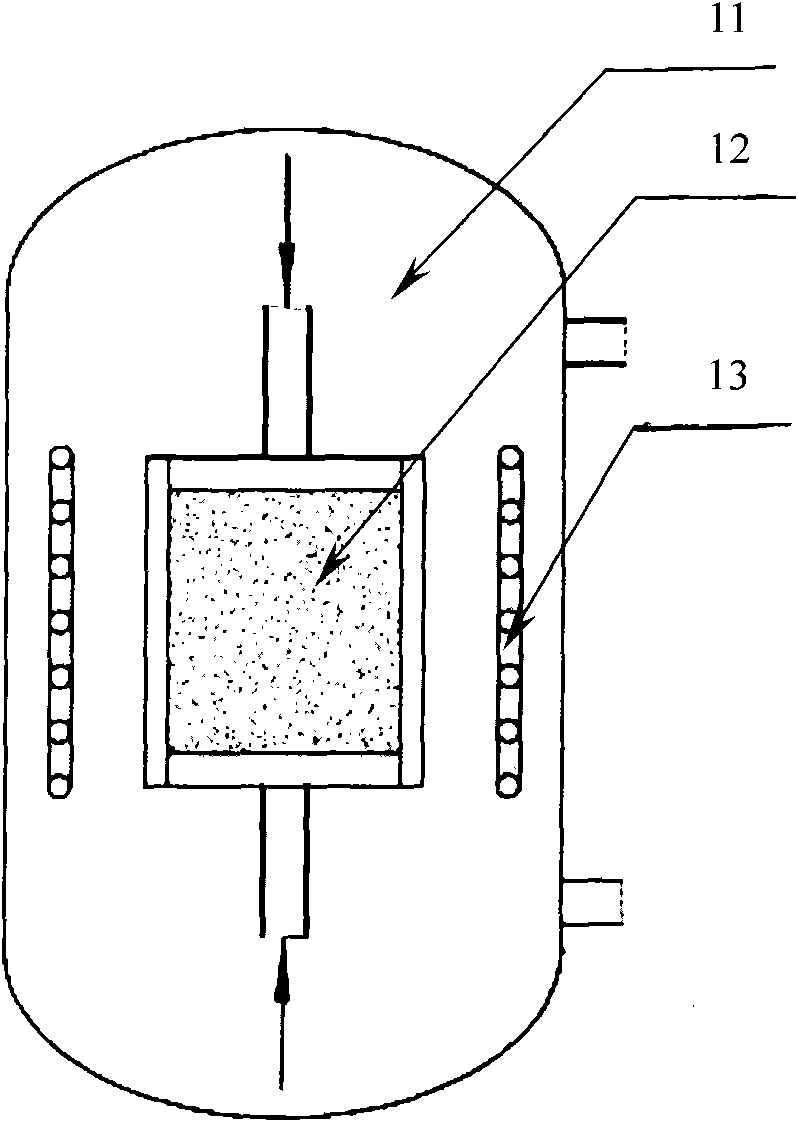

Vacuum mechanical dual-stirring casting method for preparing granule reinforced aluminium-base composite material

The present invention relates to a vacuum mechanical double-stirring casting method for preparing granule reinforced aluminium base composite material. Said method includes the following steps: melting and purifying aluminium material, cooling and deslagging; under the condition of vacuum reverse slowly internal stirring to implement degassing process, adding the pretreated reinforcing granules onto the deslagged aluminium liquid surface, internal and external forward simultaneously stirring, mixing the reinforcing granules into the melt, stoping external stirring, under the condition of retaining stable liquid surface high-speed internal stirring so as to make the reinforcing granules be uniformly distributed in the liquid, heating, internal and external reverse double stirring and slowly rotating to implement degassing; adding alternant and fining agent, internal stirring slowly rotating so as to make them be mixed into melt and uniformly distributed, removing vacuum, tapping and casting to obtain ingot casting.

Owner:BEIJING JIAOTONG UNIV

Method for preparing carbon nanotube reinforced aluminum-based composite material

InactiveCN102424919AImprove mechanical propertiesEnhanced interface bindingCarbon nanotubeAluminum substrate

The invention relates to a method for preparing a carbon nanotube reinforced aluminum-based composite material and belongs to a technique for preparing aluminum-based composite materials. The method comprises: preparing composite powder in which carbon nanotubes are uniformly distributed on the surface of aluminum powder by using cobalt as a catalyst and by using a chemical vapor deposition process; allowing the carbon nanotubes to reach deep parts of the aluminum powder substrate by using a ball milling process; densifying the composite powder by a pressing and sintering process or hot pressing process to obtain a blocky material; and obtaining the carbon nanotube reinforced aluminum-based composite material through hot extrusion forming. The method has the advantages that: the aluminum particle bridging function of carbon nanotubes is fully played, and the interface combination between carbon nanotubes and the aluminum substrate is strengthened; and the ball milling time is relatively short, so the damage to the structure of carbon nanotubes in a ball milling process is avoided. The composite material prepared by the method has a much higher mechanical property than that of pure aluminum substrate and thus, has a bright industrial application prospect.

Owner:TIANJIN UNIV

Method for preparing aluminum based composite material enhanced by granules in situ

An in-situ particles reinforced Al-base composition contains Zn (5-10 Wt%), Mg (1-3), Cu (2-4), Cr (0.1-0.5), reinforcing TiB2 particles (0.1-40) and Al (rest). Its preparing process includes such steps as heating high-purity industrial Al in crucible, covering it by high-temp covering agent, heating, adding the dried mixture of KBF4 and K2TiF6, mechanical stirring while reaction, taking out by-product, adding alloy and refining agent (Al-alloy), refining, casting, homogenizing, turning to remove skin, hot squeezing and sosoloid ageing. Its advantage is high mechanical performance.

Owner:SHANGHAI JIAO TONG UNIV

Carbon nanotube reinforced aluminum based composite material and its vacuum hot pressing prepn. method

InactiveCN1834280AImprove wear resistanceImprove anti-friction performanceDistilled waterCarbon nanotube

This invention discloses a method for preparing carbon nanotube-reinforced aluminum-based composite by vacuum hot pressing. The composite, comprising carbon nanotubes 0.1-5 wt.% and aluminum alloy powders 95-99.9 wt.%, is prepared by: (1) immersing carbon nanotubes in mixed acids, and adding surfactant; (2) dispersing; (3) filtrating, and washing carbon nanotubes with distilled water to neutrality; (4) performing two-step ball milling; (5) vacuum drying; (6) hot pressing in vacuum; and (7) hot extruding to obtain carbon nanotube-reinforced aluminum-based composite. This invention improves the capacity of aluminum alloy matrix in resisting abrasion, reducing friction, self-lubricating, surface wettability and mechanical properties.

Owner:HARBIN INST OF TECH

Carbon nano tubes (CNTs) and graphene nano flakes (GNFs) synergetic enhanced aluminum-based composite and preparation method

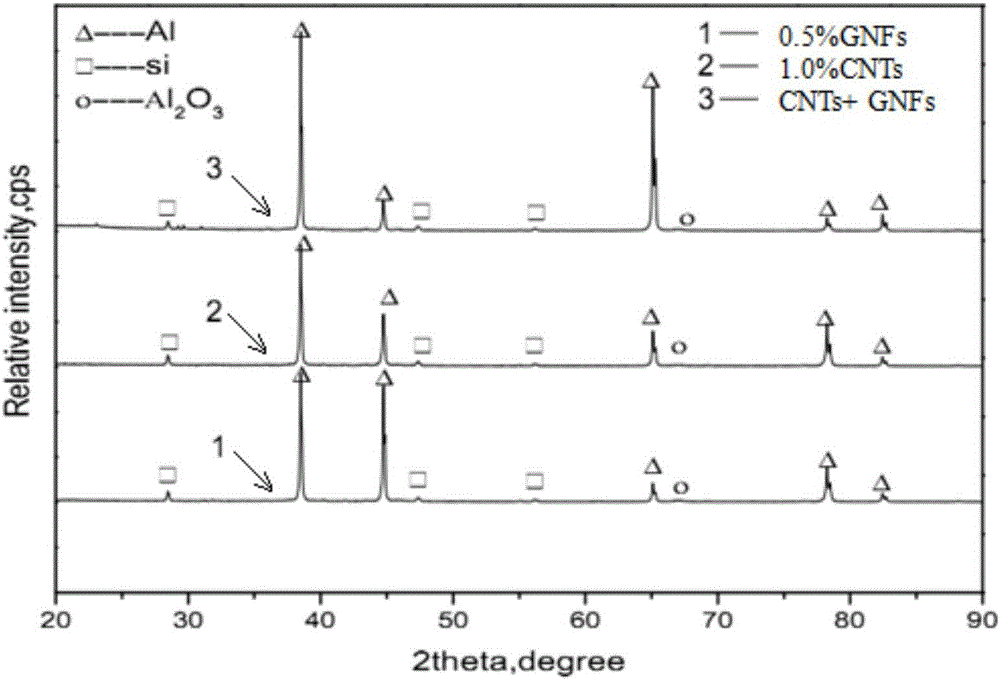

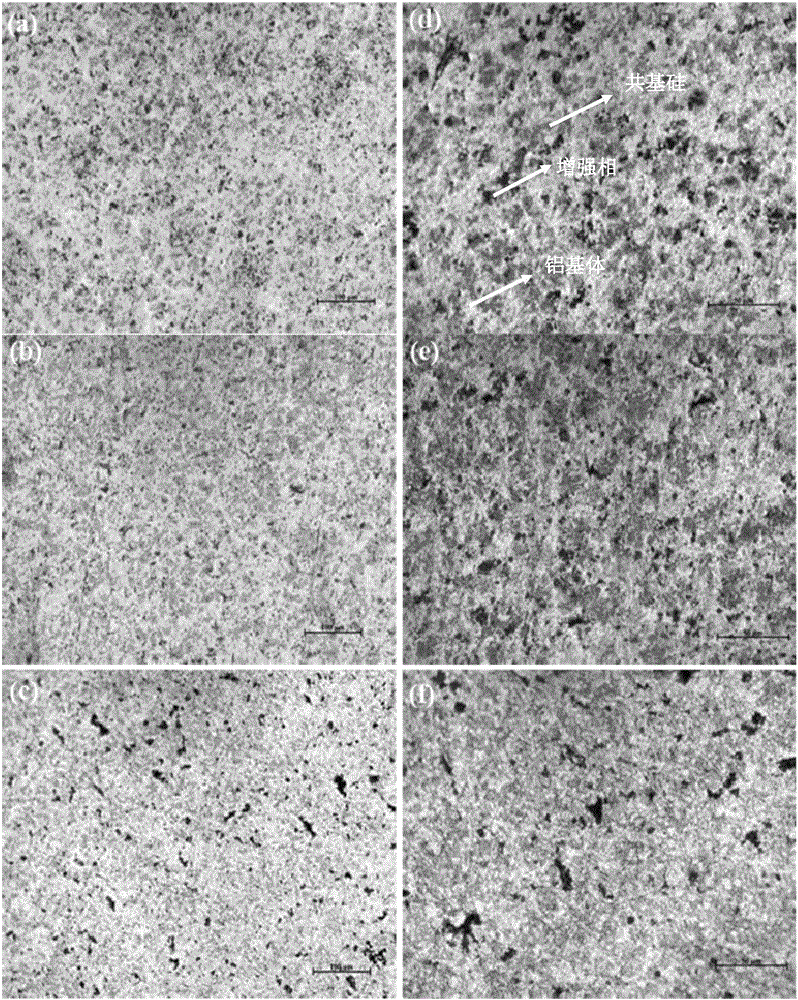

The invention discloses a GNFs / CNTs synergetic enhanced Al / Si / Al2O3 composite. The aluminum-based composite sample is mainly prepared from one or more of Al, SiO2, CNTs and GNFs. The CNTs and the GNFs are subjected to surface modification through gallic acid and rutin, and through combination with an in-situ reaction and a powder metallurgy technology, a CNTs independently enhanced aluminum-based composite, a GNFs independently enhanced aluminum-based composite and the CNTs and GNFs mixing enhanced aluminum-based composite with an Al / Si alloy as a matrix are prepared. The results show that 1, among the three composites, the 1% CNTs enhanced composite has the most excellent mechanical properties as well as the highest compactness, hardness and tensile strength; and 2, strengthening mechanisms of the CNTs enhanced aluminum-based composite mainly include the thermal expansion coefficient mismatch enhancement, Orowan enhancement and load transfer enhancement. The invention further discloses a preparation method of the aluminum-based composite. According to the method, the process is simple, production is easy, and broad application prospects are achieved.

Owner:SOUTHWEST JIAOTONG UNIV

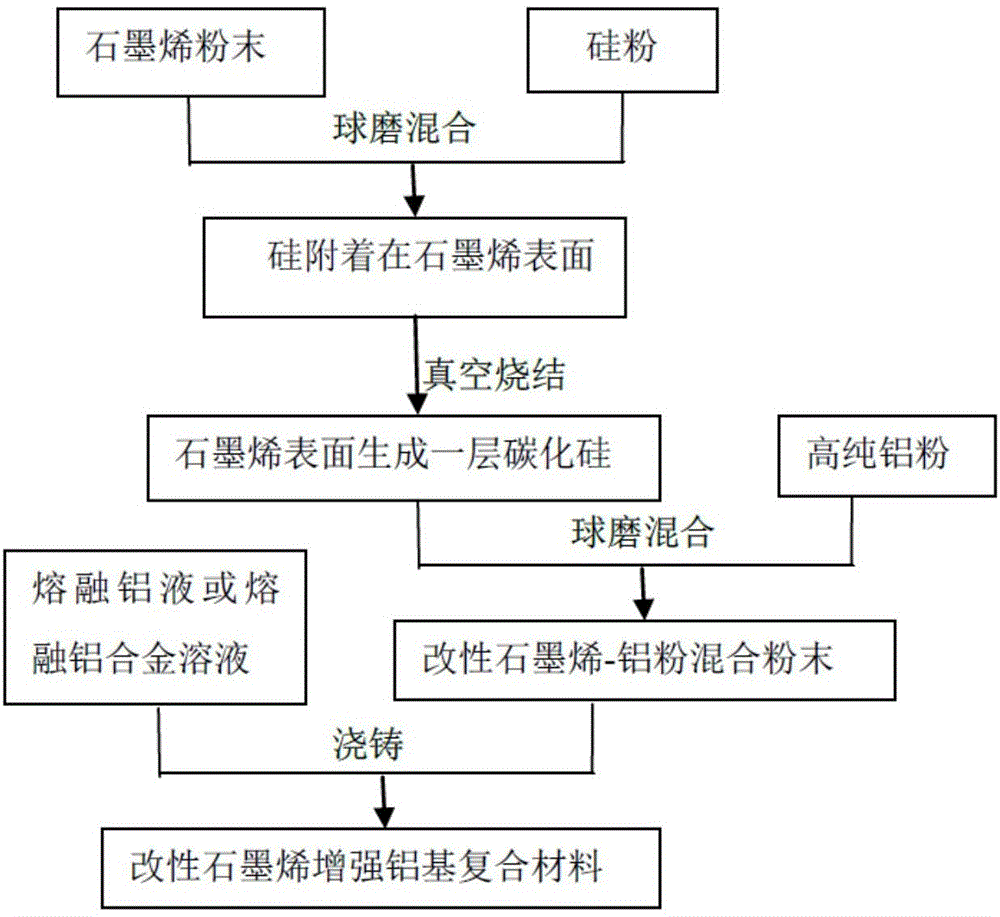

Modified graphene-reinforced aluminum matrix composite material and preparation method thereof

The invention discloses a modified graphene-reinforced aluminum matrix composite material and a preparation method thereof. The method includes the steps that graphene powder, silica powder, grinding balls and stearic acid are placed into a ball grinding mill, liquid nitrogen is filled in till all the grinding balls are immersed and then ball milling is performed, and mixed powder is obtained and dried; the dried mixed powder is sintered, so that modified graphene is obtained; the modified graphene, high-purity aluminum powder, grinding balls and stearic acid are put into the ball grinding mill, liquid nitrogen is filled in for ball milling, modified graphene-aluminum powder mixed powder is obtained, and drying is further performed; and the dried modified graphene-aluminum powder mixed powder is added into a molten aluminum or molten aluminum alloy solution to be evenly stirred, and casting is carried out. By the adoption of the method, graphene is modified, good wettability between the graphene and an aluminum matrix can be obtained, and the bonding strength of the graphene and the aluminum matrix is improved. By blending different molten aluminum or molten aluminum alloy solutions, graphene-reinforced aluminum matrix composite material billets of various specifications can be obtained by means of casting, and batch production is achieved.

Owner:YINBANG CLAD MATERIAL

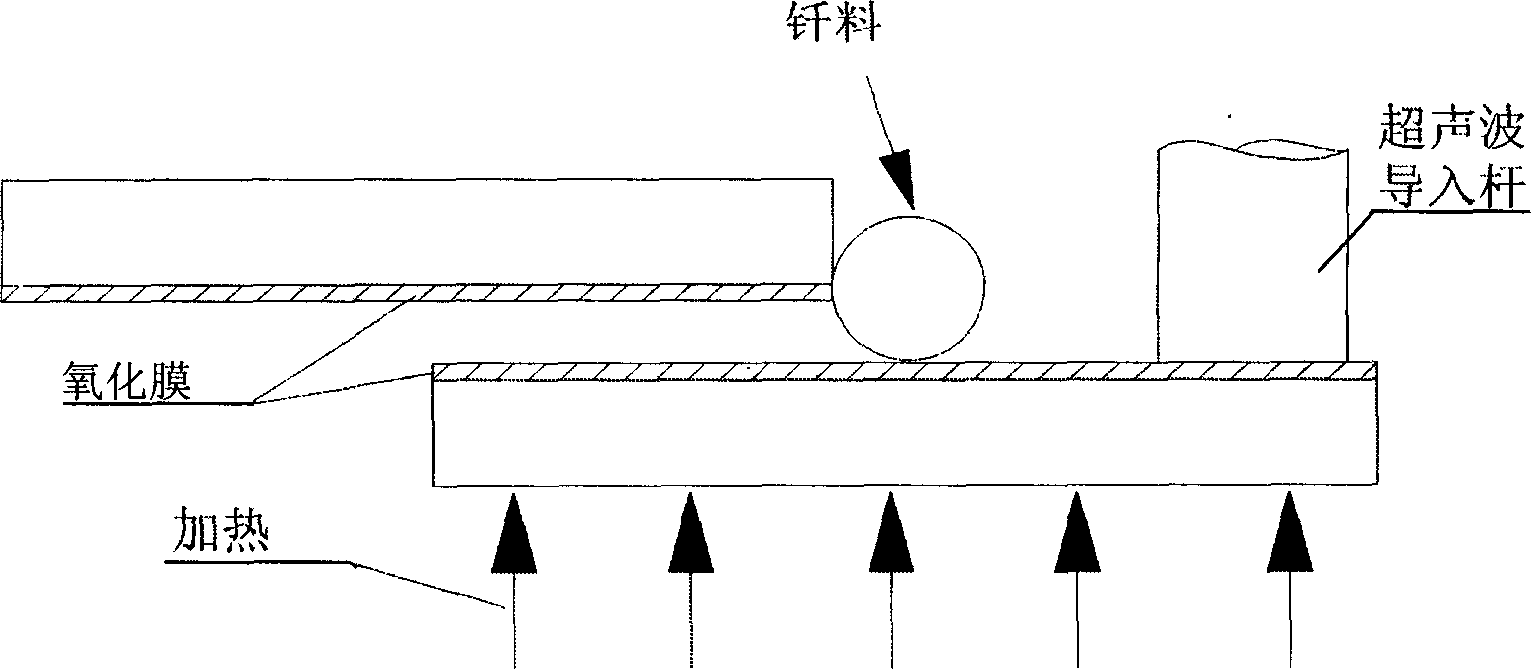

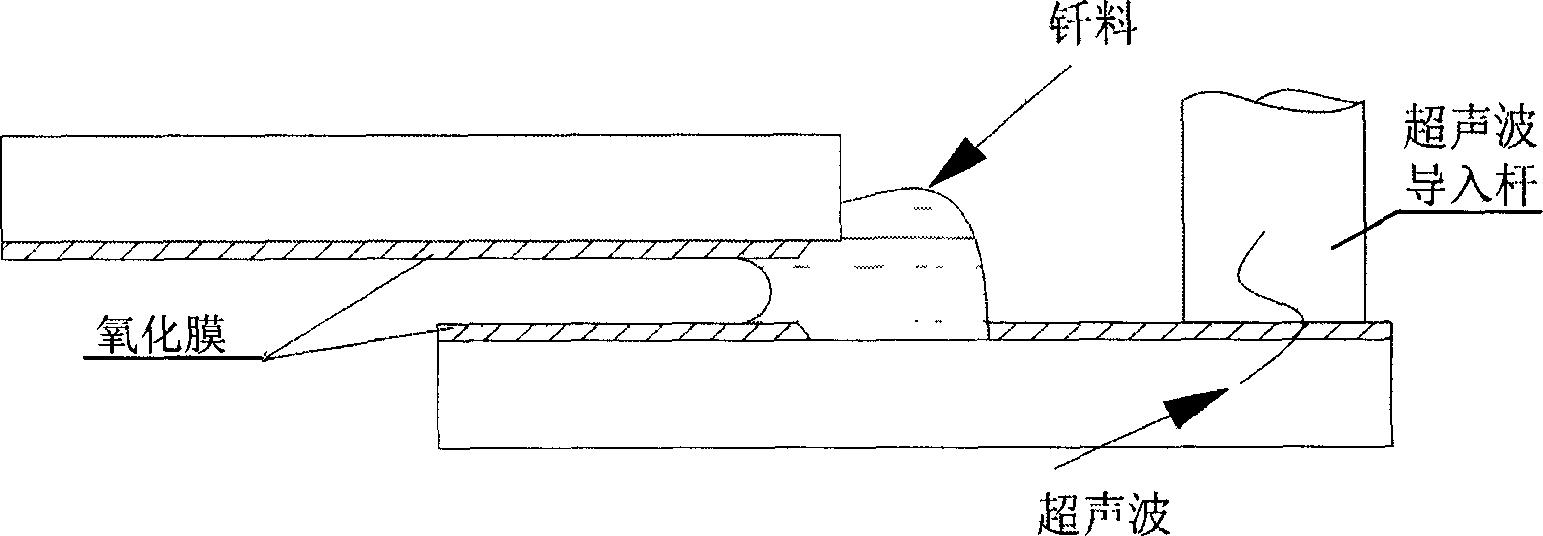

Aluminium base composite material ultrasonic wave fine welding method

InactiveCN1644291AAvoid WeldingEfficient weldingNon-electric welding apparatusUltrasonic vibrationMaterials science

An ultrasonic capillary welding method for the Al-base composite material includes such steps as arranging upper and lower parts to be welded in such manner that the gap between them is 10-300 microns, putting the flux close to lap end, heating to smelt the flux, holding the temp, pressing the ultrasonic head onto surface of the part to be welded, and applying ultrasonic vibration for 0.5-15 S. Its advantages are high welding quality, low welding temp, and high speed.

Owner:HARBIN INST OF TECH

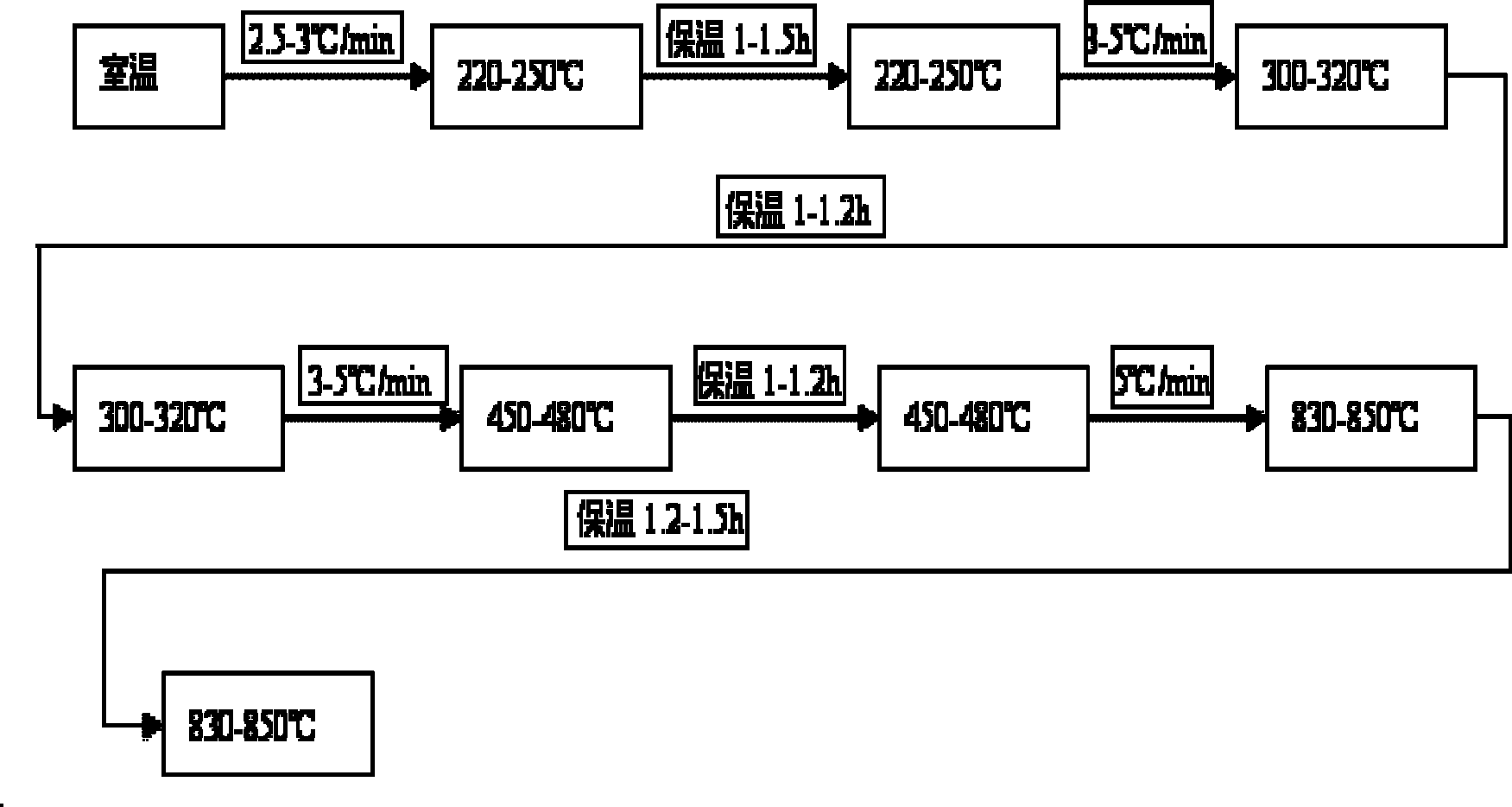

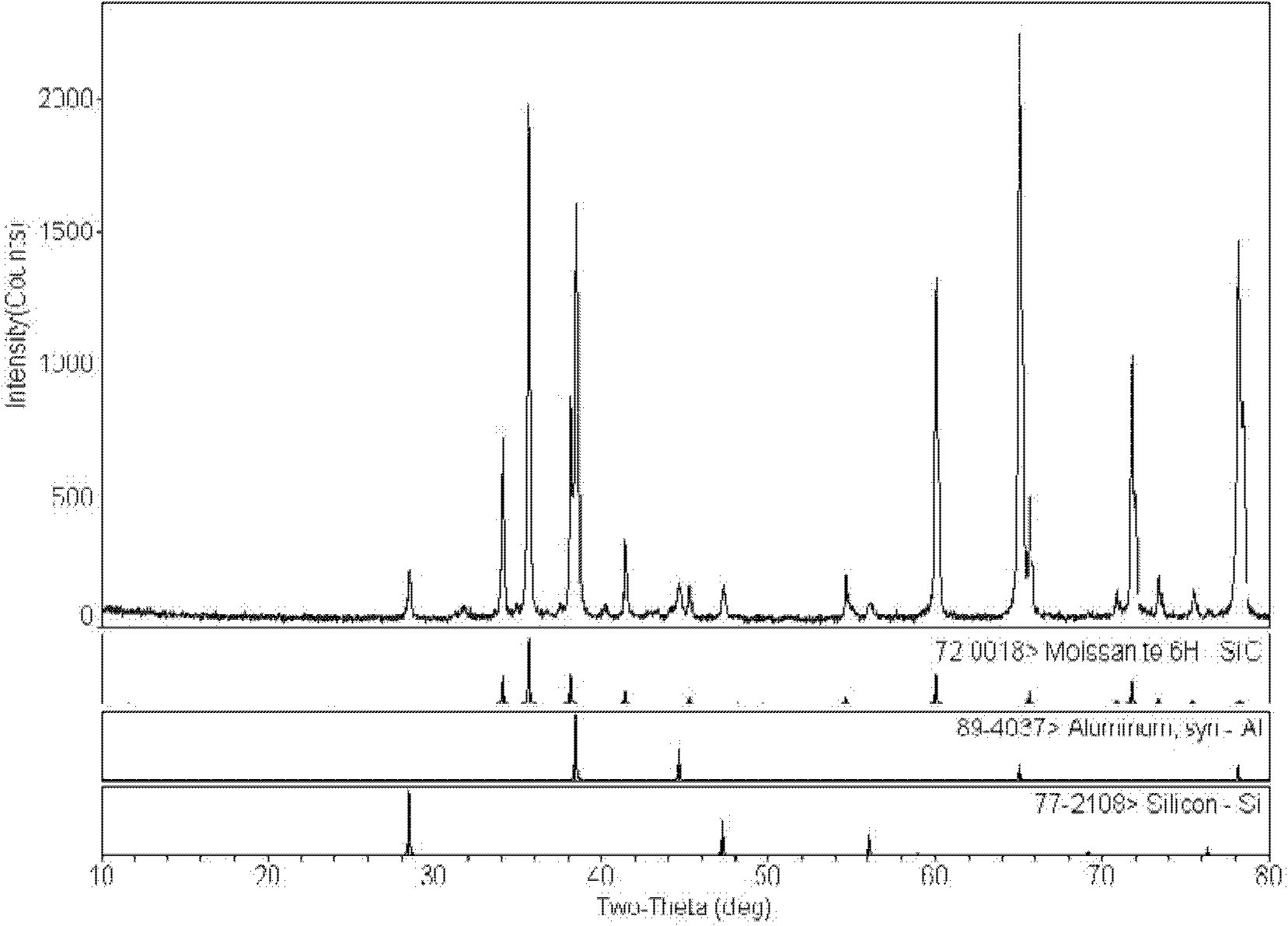

Preparation method of carborundum particle reinforced aluminum matrix composite material with high volume fraction

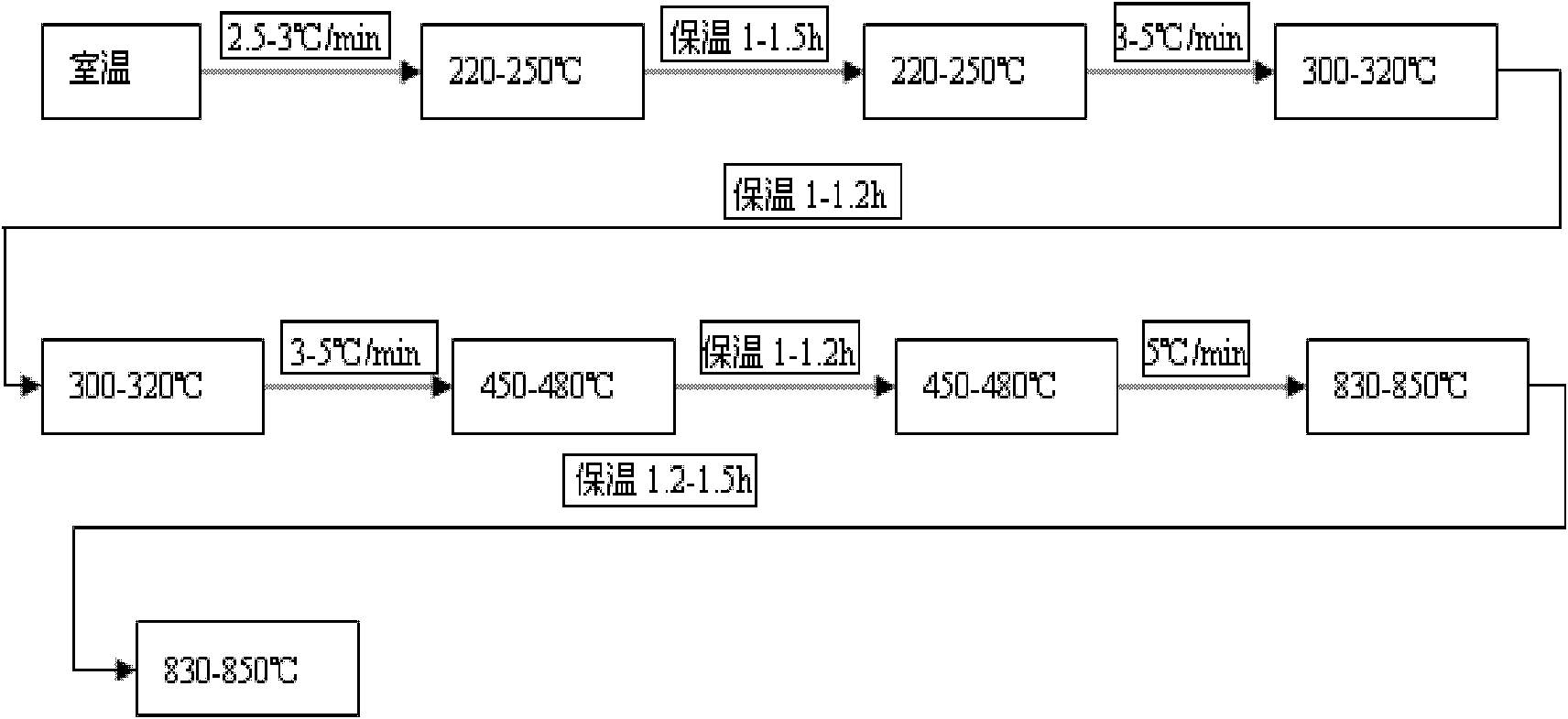

The invention discloses a preparation method of a carborundum particle reinforced aluminum matrix composite material with high volume fraction. The method adopts a low temperature multi-stage sintering technology, wherein a sintering temperature needed by the low temperature multi-stage sintering technology is obviously lower than a sintering temperature (over 1000 DEG C) needed by the prior arts at home and abroad. In the invention, carborundum powder and aluminium alloy are utilized as raw materials to prepare the carborundum particle reinforced aluminum matrix composite material, wherein volume fraction of the carborundum powder can be adjusted in a range of 50 to 75%. Through utilizing the method provided by the invention, the problems which are in the prior arts and comprise a high sintering temperature, easy generation of impurity phases and a harmful interface phase Al4C3, high equipment requirements, high energy consumption, poor overall performances of composite material products, etc. are solved. The method provided by the invention has the advantages of simple processes and low cost.

Owner:HUNAN HANGTIAN CHENGYUAN PRECISION MACHINERY

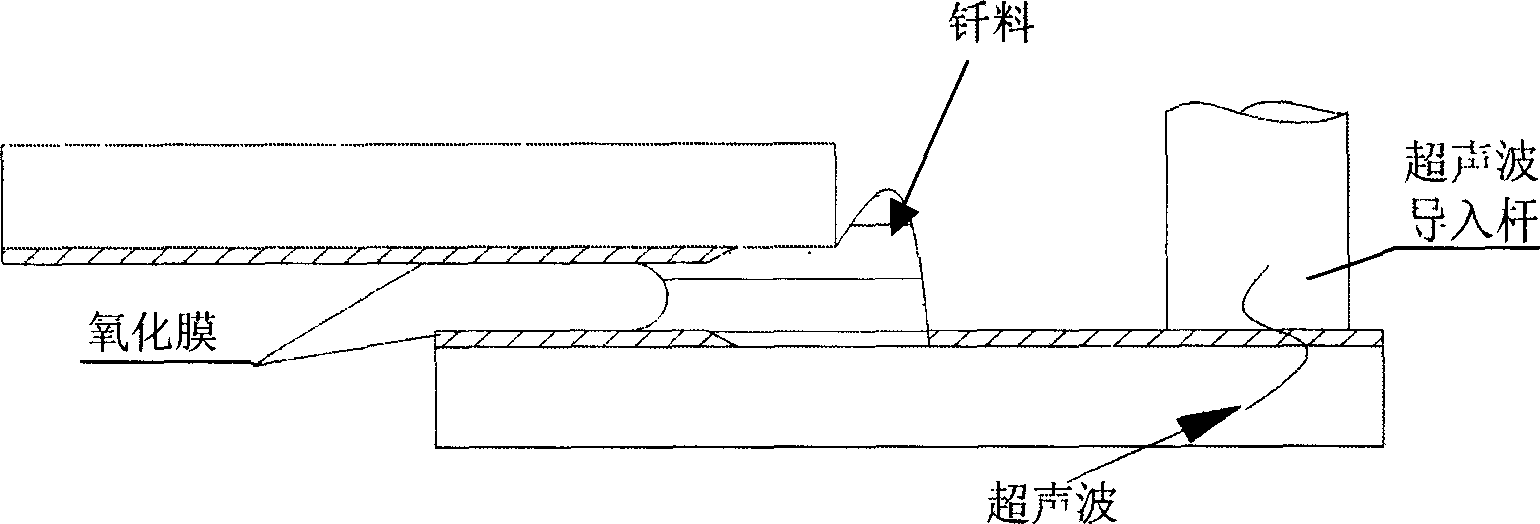

Filling composite welding flux vibrating liquid phase welding method for non-continuous strengthening aluminium base composite material

InactiveCN1792531AStrong welding flexibilityReduce performanceWelding/cutting media/materialsSoldering mediaComposite constructionButt joint

A liquid-phase vibration welding method by filling composite flux for noncontinuously reinforced Al-base composition includes such steps as abrading two surface to be welded, ultrasonic washing in acetone, drying in the air, fixing by fixture in opposite mode, filling composite flux between two surfaces, heating to smelt the flux, vibrating while pressing, and cooling.

Owner:HARBIN INST OF TECH

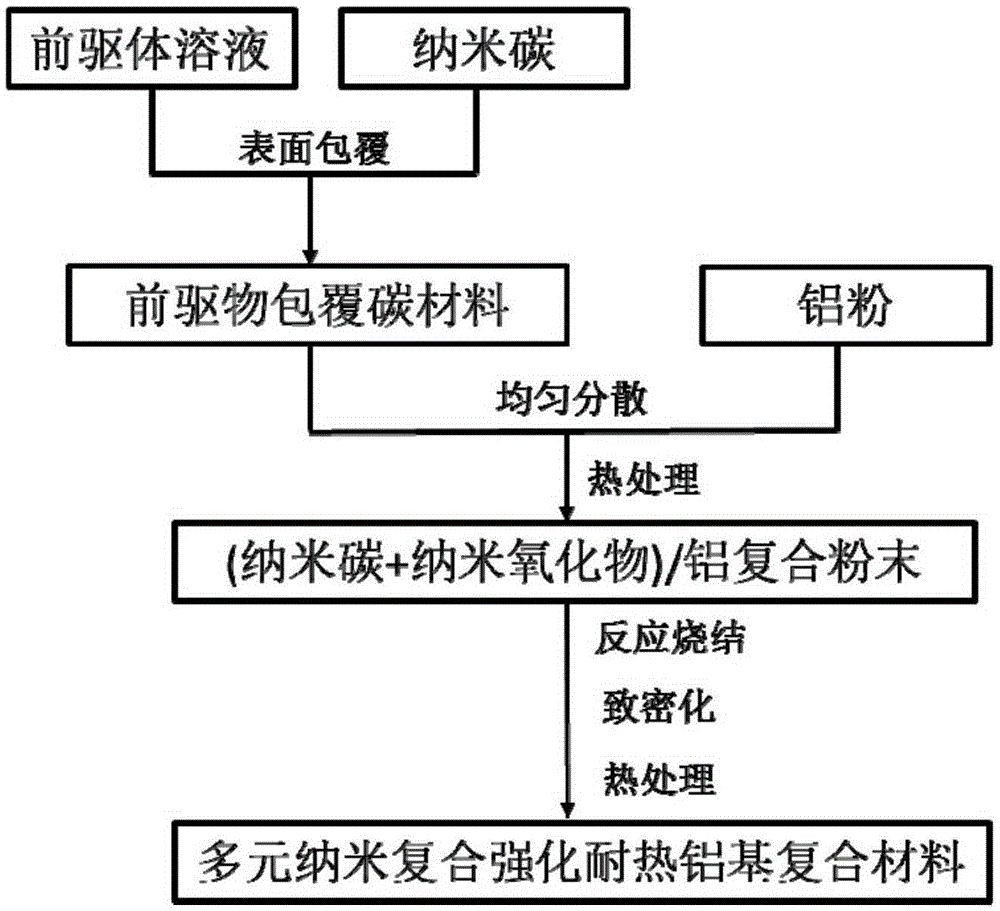

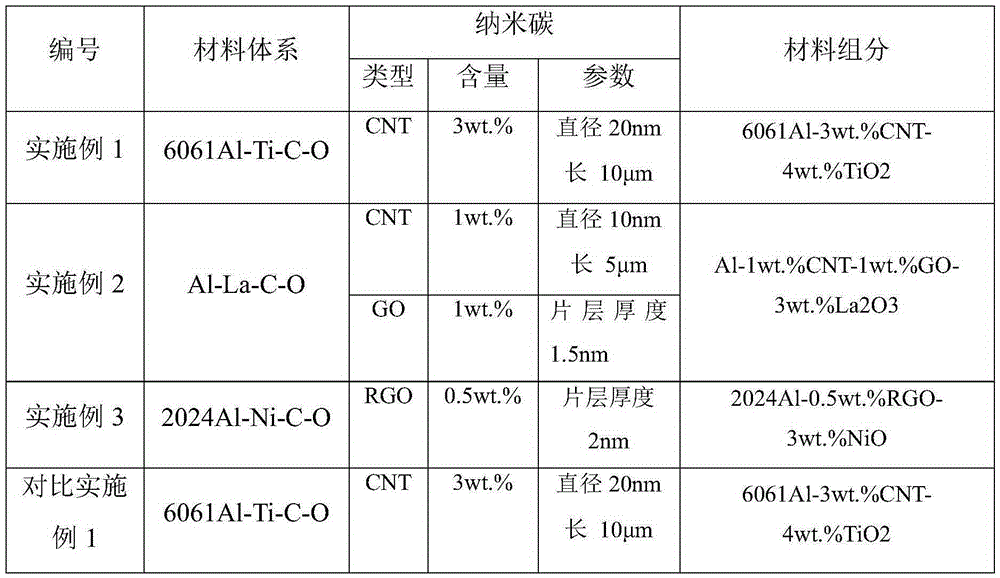

Preparing method of multielement nanometer composite strengthening thermal-resisting aluminum matrix composite

The invention provides a preparing method of a multielement nanometer composite strengthening thermal-resisting aluminum matrix composite. The surface of nanocarbon is coated with a metal ion precursor in advance, the nanocarbon is evenly scattered in aluminum powder, the precursor is converted into oxide through thermal treatment, reactive sintering and densifying treatment are carried out on the obtained composite powder, and the multielement nanometer strengthening aluminum matrix composite is obtained. The nanocarbon has the high specific surface area, the feature size of the nanocarbon is far larger than that of the nanometer oxide, and therefore a proper amount of nanometer oxide can be loaded and evenly led into the aluminum powder, metallic oxide, carbide, an intermetallic compound and other multielement nanometer strengthening phases are generated through the in-situ reaction, and the tissue stability and the thermal resistance of the aluminum matrix composite are improved coordinately. The method achieves the purposes of even leading of high-volume-content multielement nanometer strengthening phases and the space occupation control, and the conventional powder metallurgy technology can be adopted for preparing the multielement nanometer composite strengthening thermal-resisting aluminum matrix composite.

Owner:SHANGHAI JIAO TONG UNIV

Aluminium-plated particle reinforced aluminum-matrix composite material and preparation method thereof

InactiveCN102114719AEnhanced powder densificationImprove mechanical propertiesMetal layered productsSurface layerElectromagnetic shielding

The invention belongs to the technical filed of particle reinforced aluminum-matrix composite materials and in particular relates to an aluminium-plated particle reinforced aluminum-matrix composite material and a preparation method thereof. The aluminium-plated particle reinforced aluminum-matrix composite material is characterized in that the surface layer of the aluminium-plated particle reinforced aluminum-matrix composite material is made of pure aluminium, and the core interlayer of the aluminium-plated particle reinforced aluminum-matrix composite material is composed of a particle reinforced aluminum-matrix composite material. The aluminium plating of the aluminium-plated particle reinforced aluminum-matrix composite material is realized in the process of carrying out vacuum hotpressing or hot isostatic pressing by using a powder metallurgic method. The method disclosed by the invention comprises the following steps: carrying out powder densification on particle reinforced aluminum-matrix composite materials through vacuum hotpressing or hot isostatic pressing, and simultaneously, carrying out metallurgical bonding on an aluminum die-sleeve and a composite material blank at high temperature and high pressure so as to obtained the aluminium-plated particle reinforced aluminum-matrix composite material. The aluminium-plated particle reinforced aluminum-matrix composite material can be subjected to one or more subsequent processing such as extrusion, forging, rolling and heat treatment so as to obtain various aluminium-plated particle reinforced aluminum-matrix composite materials with different specifications and properties. The aluminium-plated particle reinforced aluminum-matrix composite material can be applied to occasions with anticorrosion or electromagnetic shielding demands.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

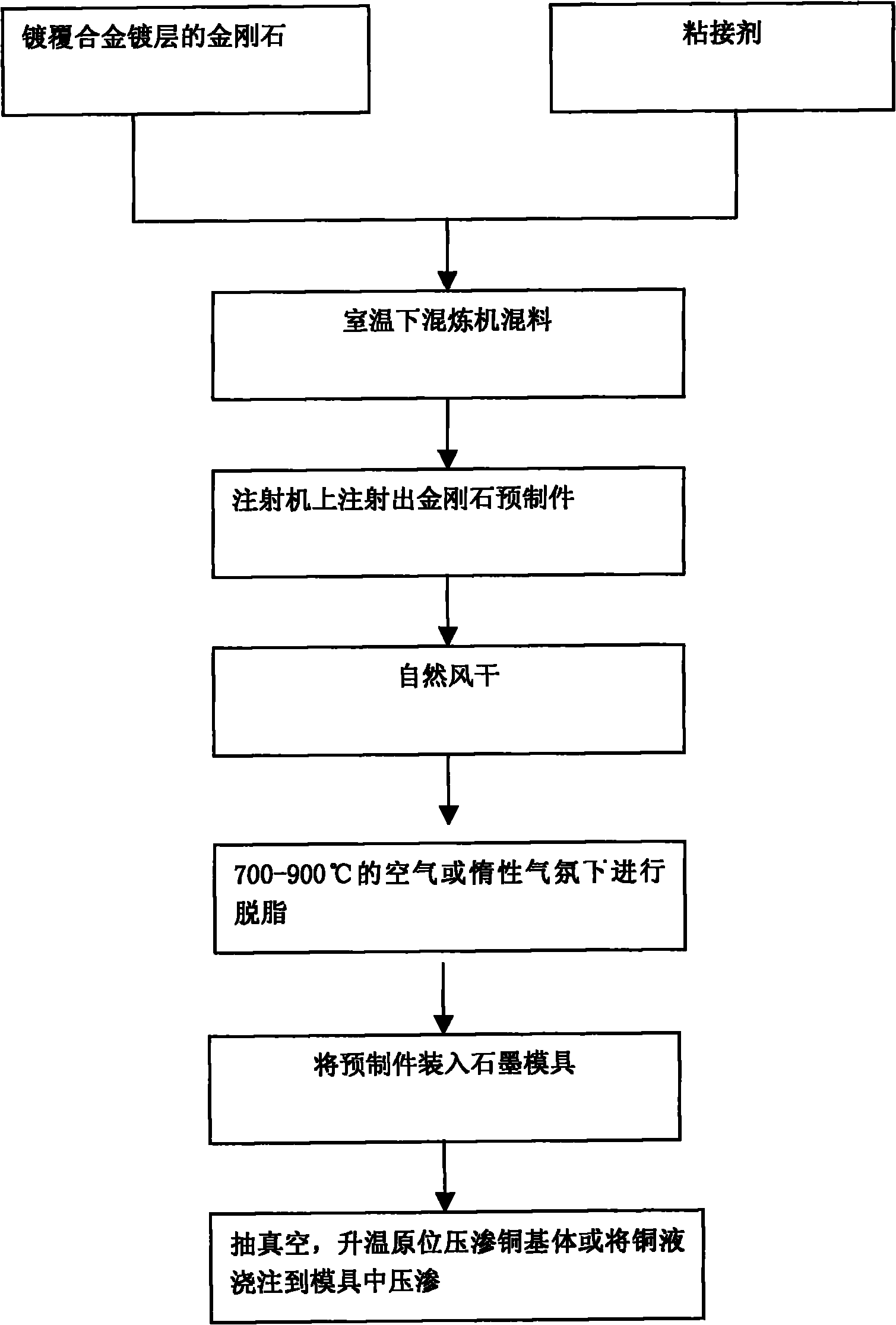

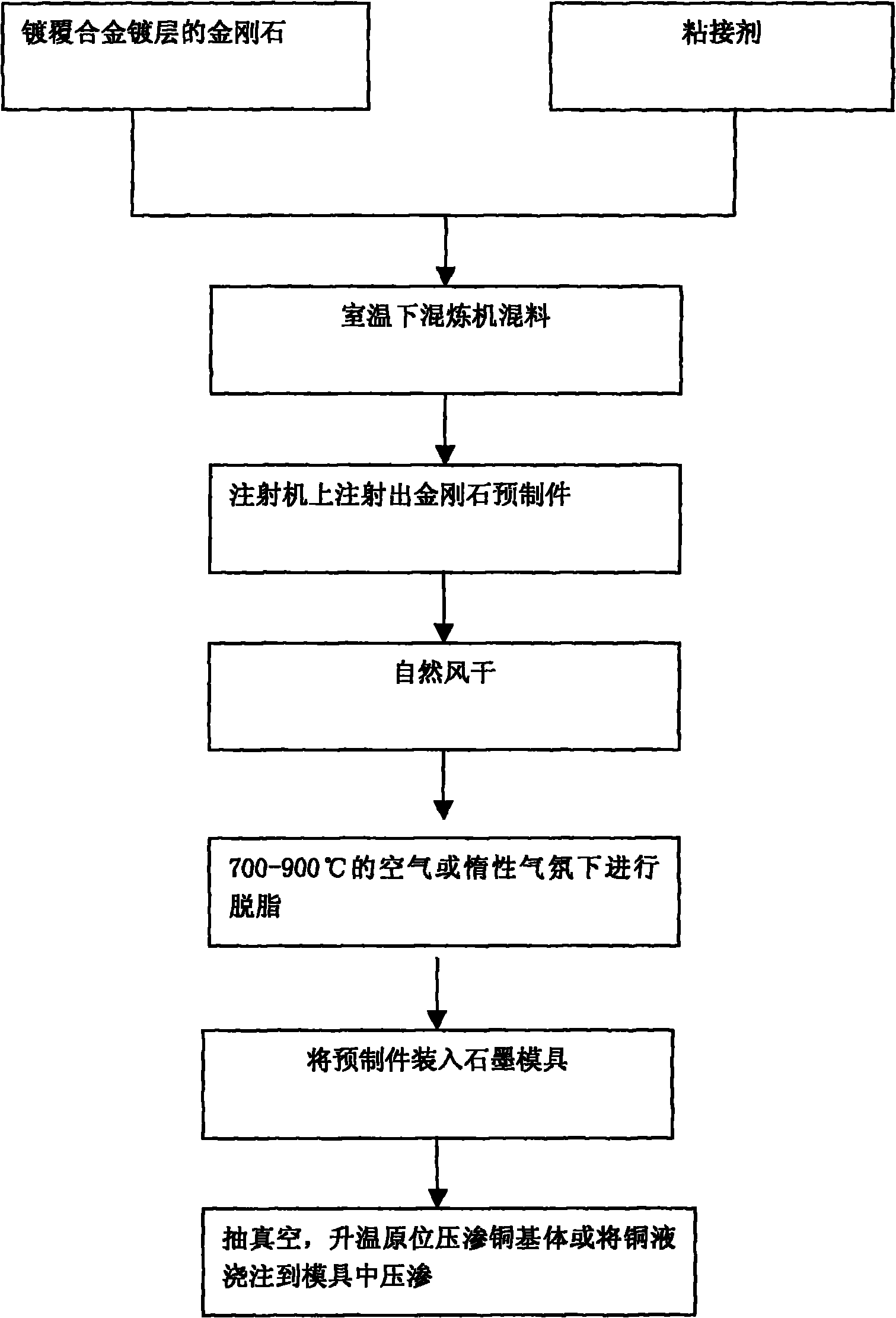

High heat-conducting copper-based composite material and preparation method thereof

InactiveCN101831584ALow densitySmall coefficient of thermal expansionVacuum evaporation coatingSputtering coatingInterfacial thermal resistanceThermal expansion

The invention relates to a high heat-conducting copper-based composite material and a preparation method thereof, belonging to the technical field of electronic packaging materials. The copper-based composite material consists of 50-80 percent by volume of electroplated diamond particles and 20-50 percent by volume of copper. The electroplated diamond particles and a caking agent are mixed according to the volume ratio of 1:1-4:1 and are produced into a diamond prefabricated part by using an injection forming process of the prefabricated part; and a copper matrix is directly placed on the diamond prefabricated part or is melt and poured on the diamond prefabricated part to be produced into the high heat-conducting copper-based composite material by using a pressure infiltration process. The copper-based composite material has higher heat conductivity ratio than that of an aluminum-based composite material; by plating the surface of diamond, the interface bonding of the matrix copper and the diamond can be improved and the interface heat resistance can be reduced; in addition, the material has low density and small thermal expansion coefficient and meets the requirement for light quality of packaging materials.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

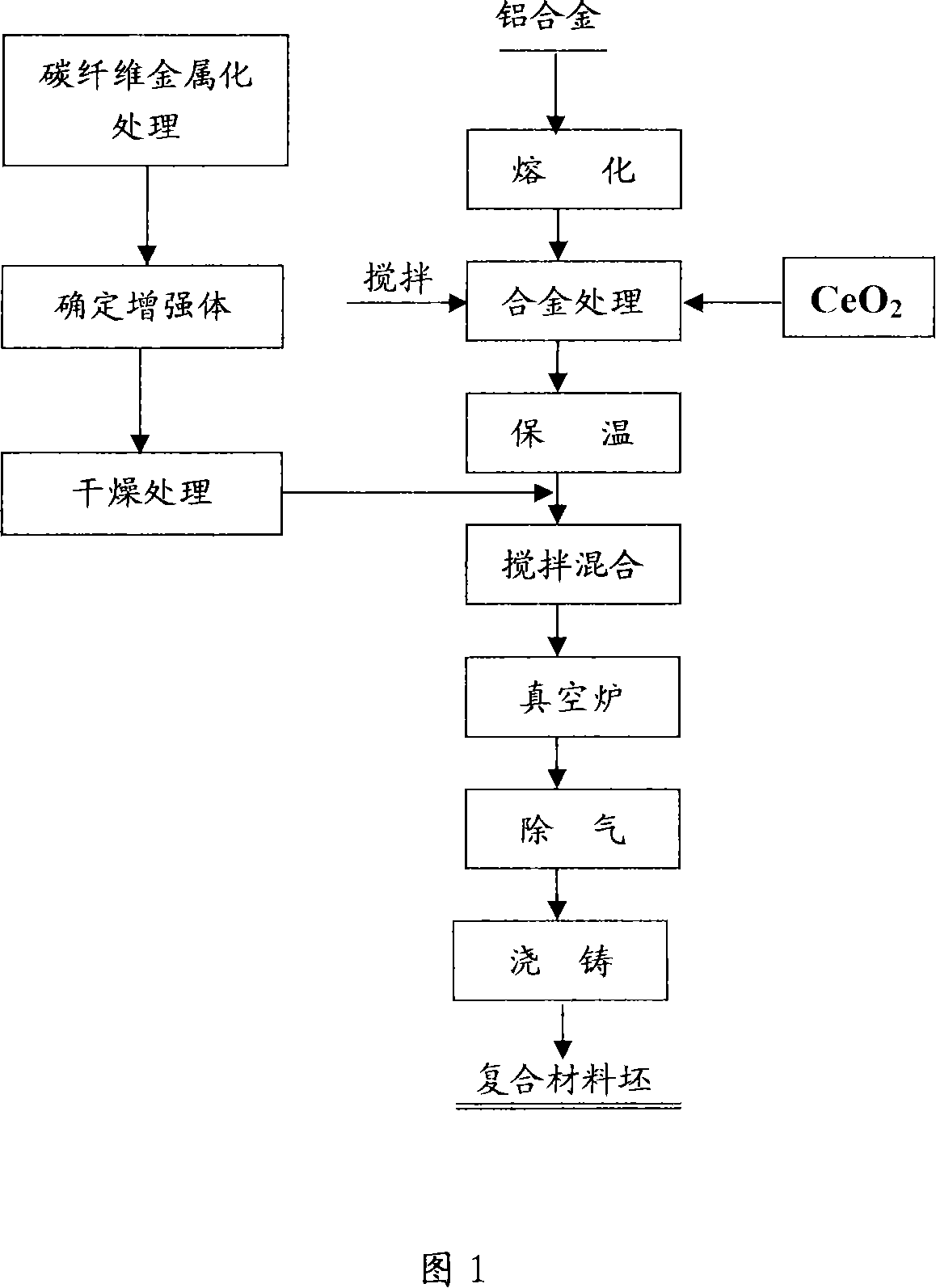

Method for preparing Al-base composite material

InactiveCN101058866APromote wettingImprove uniformityLiquid/solution decomposition chemical coatingVacuum furnaceAluminum matrix composites

The invention discloses a making method of aluminium-based composite material, which comprises the following steps: fusing the aluminium based alloy at 750 deg. c; adding the alloy into 0. 15-0. 35wt% CeO2 powder; stirring; alloying; insulating; adding reinforcer during insulating to stir; transmitting the material into vacuum furnace to degas; casting; making the aluminium based material; selecting carbon fiber as the base of reinforcer; metalizing the surface; setting the quantity of reinforcer as 3-5% as carbon fiber.

Owner:NORTHEASTERN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com