Patents

Literature

2473results about How to "Realize mass production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

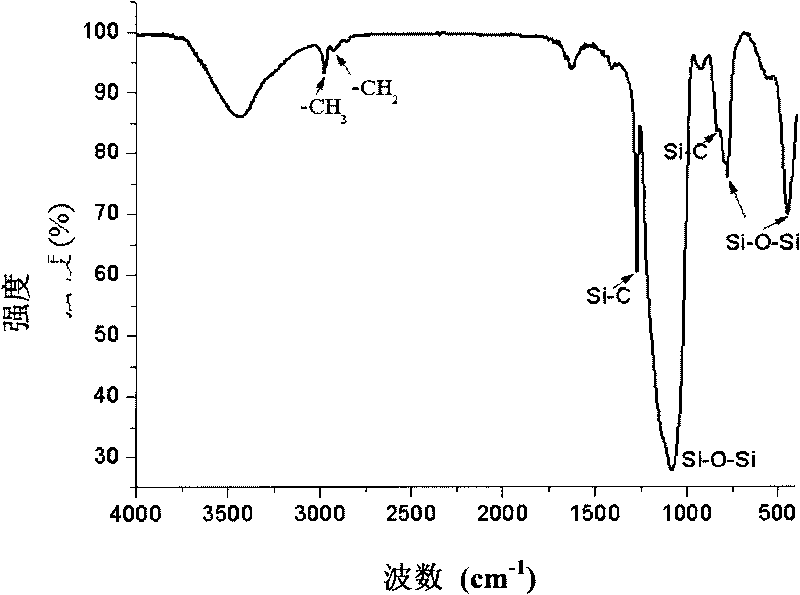

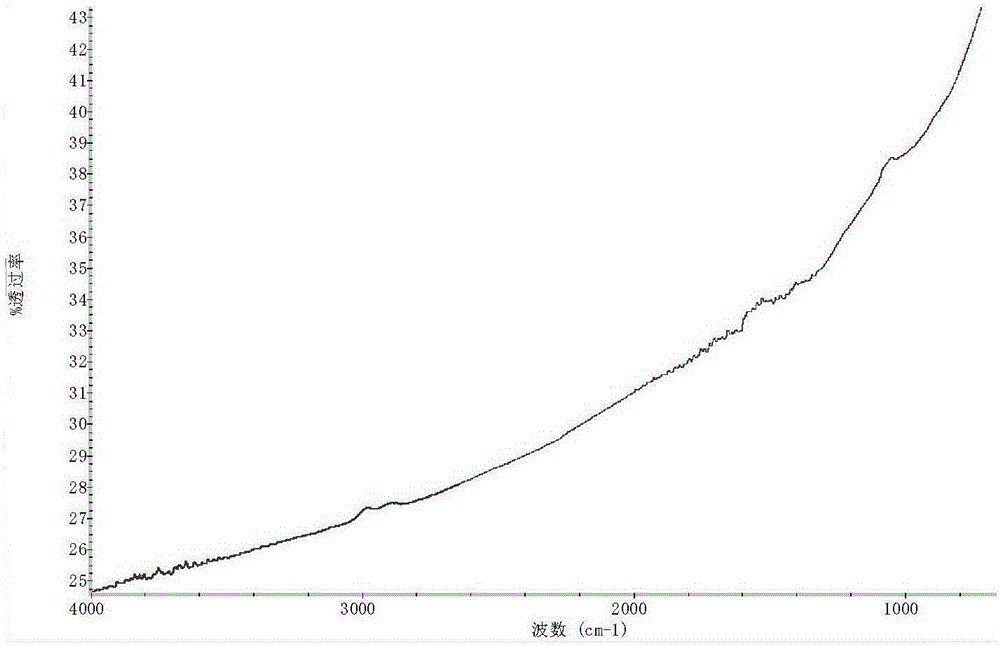

Method for preparing silica aerogel material

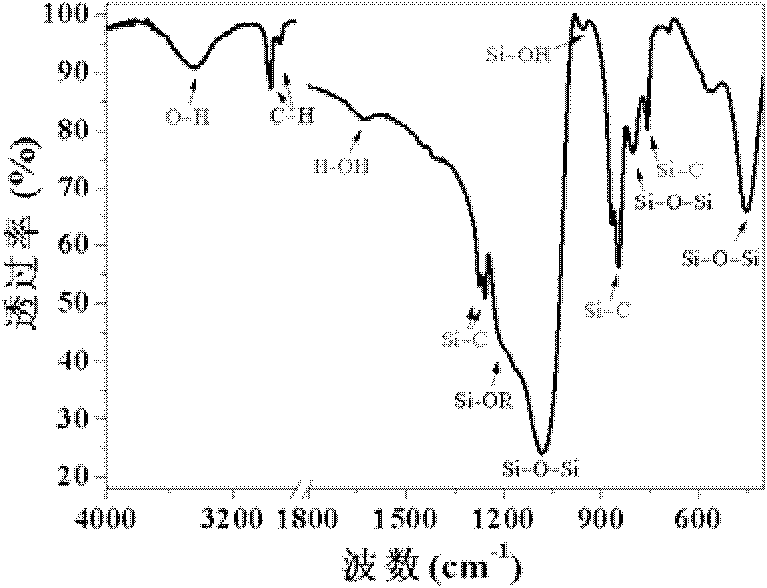

The invention discloses a method for preparing a silica aerogel material and relates to the method for preparing the aerogel material, in particular to the method for rapidly preparing a transparent SiO2 aerogel by being based on the sol-gel technology and adopting secondary modification and normal pressure drying. The invention provides the method for preparing the silica aerogel material, and the method has simple technology, short cycle, low cost and good safety and is conductive to large-scale production. Tetraethoxysilane is adopted as a silicon source, methyl trimethoxysilane or methyl triethoxysilane is taken as a modifier of a co-precursor, anhydrous ethanol is taken as a solvent, and hydrochloric acid and ammonia are taken as catalysts. The sol-gel acid-base two-step method is adopted for catalysis, thereby preparing the SiO2 wet gel; and the further modification is carried out on a wet gel sample after aging treatment under certain conditions, and the normal pressure low-temperature drying is finally carried out in air atmosphere, thereby preparing the SiO2 aerogel. The equipment cost during the preparation technology is low, the product has good performances and the reaction process is controllable.

Owner:中科润资科技股份有限公司

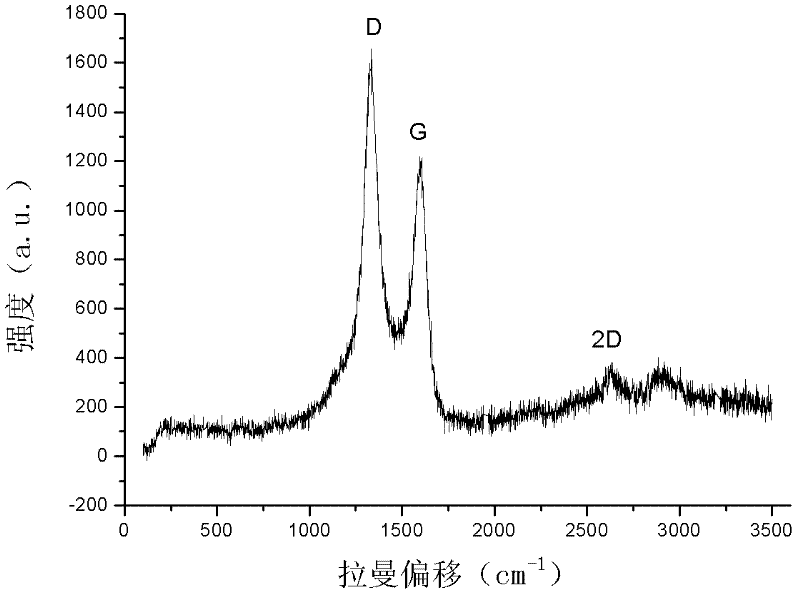

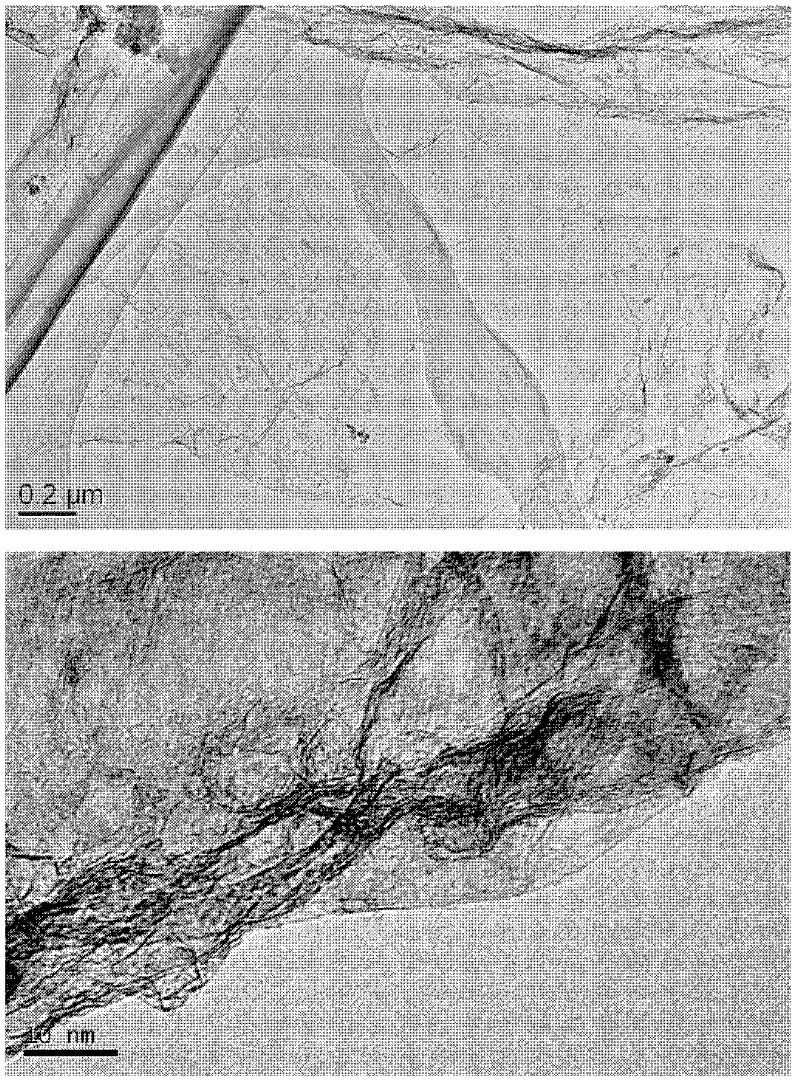

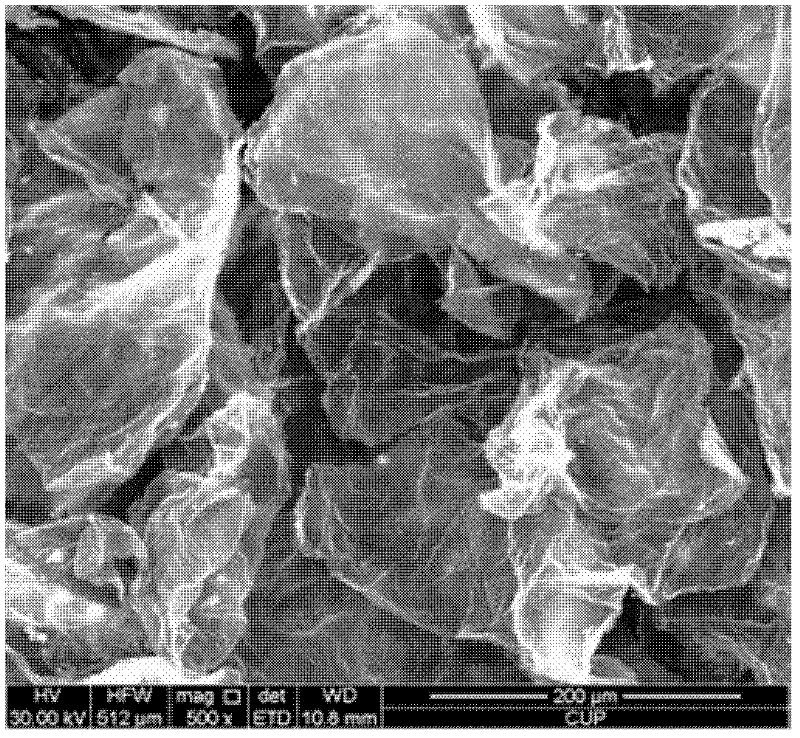

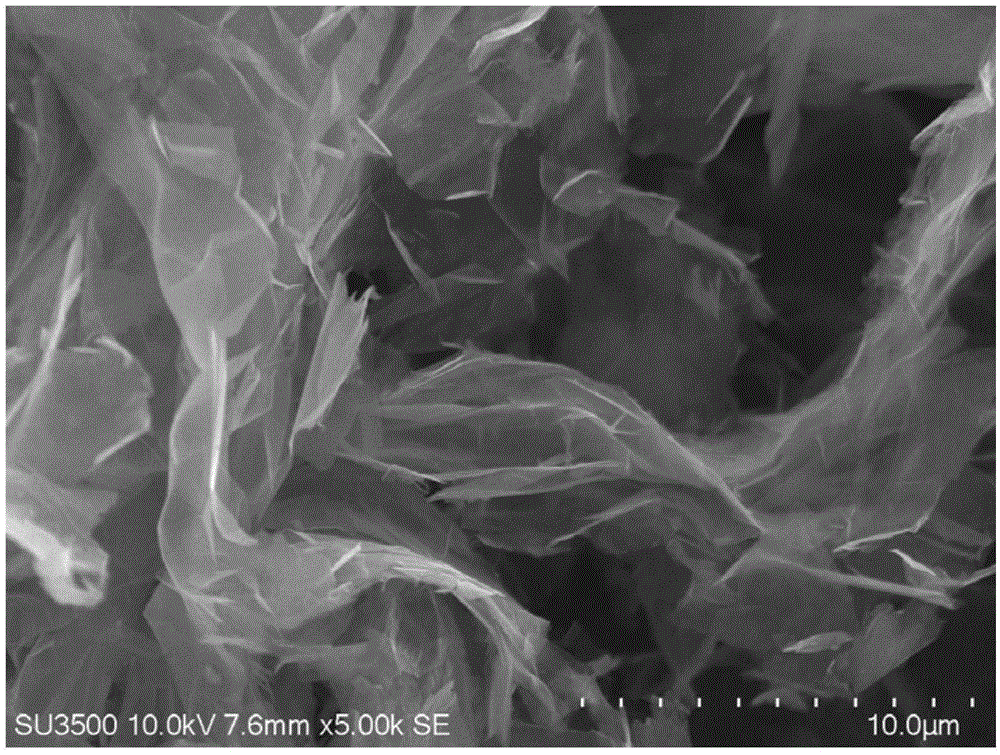

Preparation method of grapheme or doped graphene or graphene complex

The invention belongs to the technical field of the preparation of carbon material and provides a preparation method of grapheme or doped graphene or graphene complex. The grapheme or doped graphene or graphene complex is prepared by using the chemical vapor deposition method or liquid-phase impregnation method by taking kaolin, montmorillonite, vermiculite, mica, brucite, pseudoboehmite and other lamellar compounds as the template agent. Due to the adoption of the method, the grapheme or doped graphene or graphene complex with the lamella size of hundreds of microns can be prepared, and the batch preparation of the grapheme materials can be realized conveniently.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

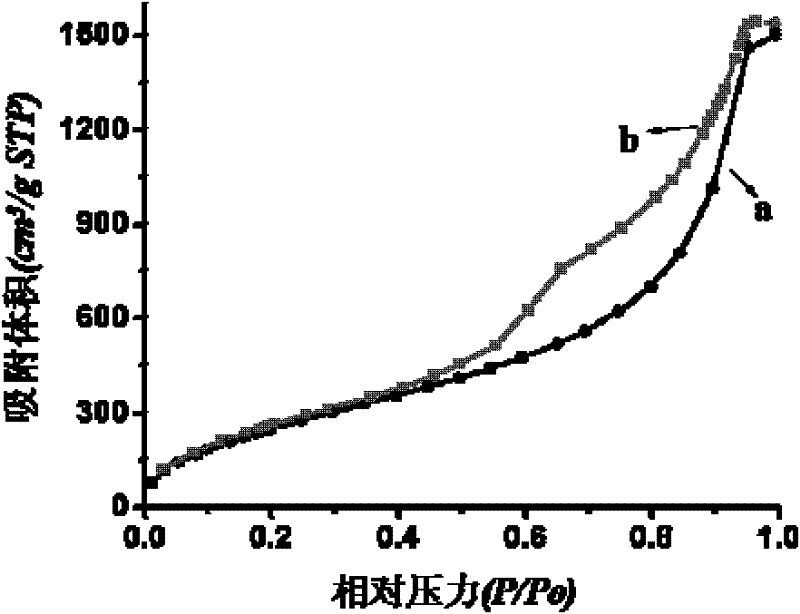

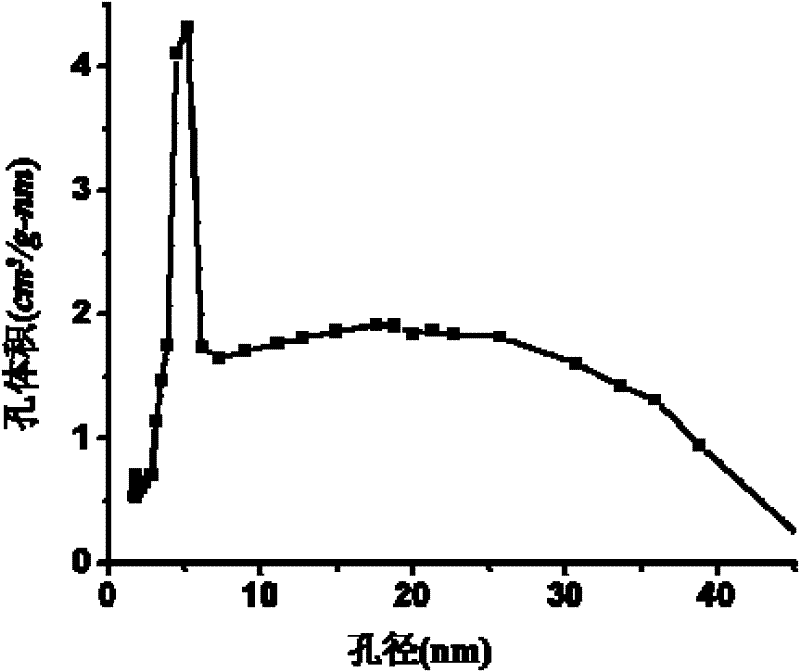

Method for preparing foam material reinforced silica aerogel composite material

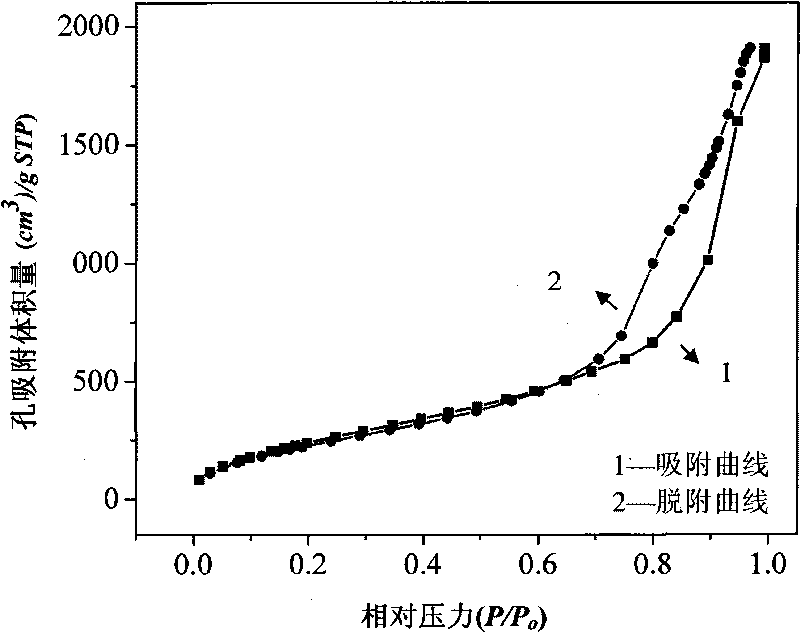

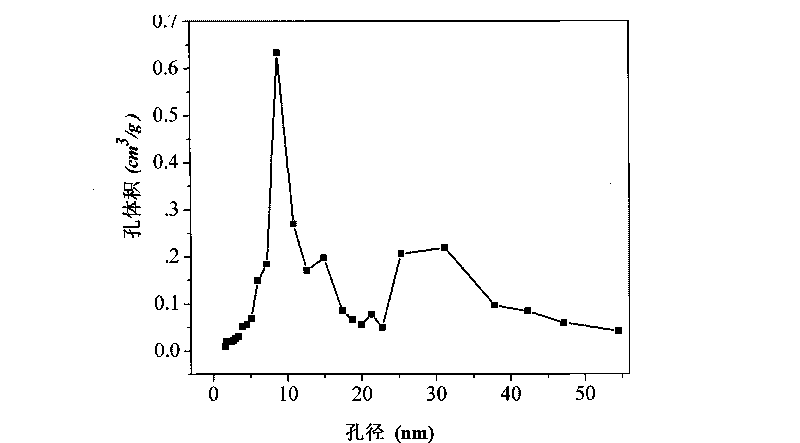

The invention discloses a method for preparing a foam material reinforced silica aerogel composite material and relates to silica aerogel. The method comprises the following steps of: preparing silica plural gel and aging the silica plural gel, modifying and drying. Through test, porosity is 80 t o 95 percent, density is 0.15 to 0.5g / cm<3>, the Brunauer-Emmett-Teller (BET) specific surface area is 600 to 1,100m<2> / g, and a water contact angle is 130 to 160 degrees; the foam material reinforced silica aerogel composite material is super hydrophobic; aerogel pore size distribution is relativelycentralized and the pore size of the aerogel is 2 to 50nm; and coefficient of heat conductivity is 0.01 to 0.035 W / (m.K), compression strength is 0.3 to 2Mpa (2 percent deformation), and elastic modulus is 1 to 5 Mpa. Meanwhile, the foam material reinforced silica aerogel composite material has good heat insulation performance, and adsorption performance, environment-friendliness and the other excellent performance. The method is simple, is short in a cycle, low in cost, and high in safety, and contributes to large-scale production; and by the method, excellent performance of the aerogel can be kept and the mechanical property of aerogel can be improved.

Owner:ZHONGKE RUNZI (CHONGQING) ENERGY SAVING TECH CO LTD

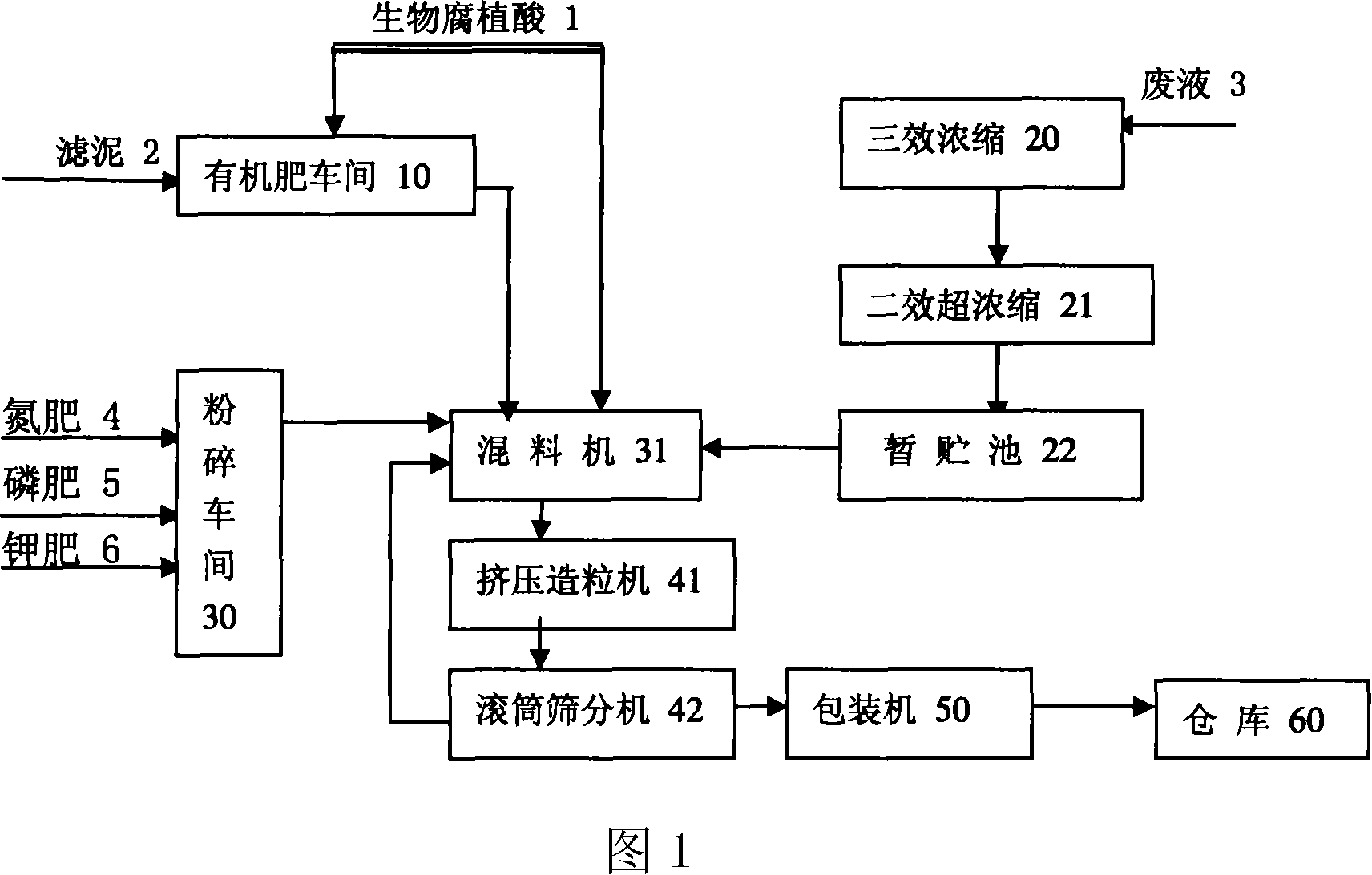

Method of manufacturing organic, inorganic compound fertilizer with molasses zymolysis waste liquor and lime sludge

InactiveCN101108779AImprove efficiencyLow efficiencyBio-organic fraction processingClimate change adaptationLiquid wasteContinuous fermentation

The invention provides a method producing the organic-inorganic compound fertilizer by the molasses fermentation waste liquor and the lime sludge, which relates to a method producing the fertilizer through fermentation and solves the problem of reclaiming and processing the molasses fermentation waste liquor continuously on a large scale. The method of the invention is that the biological humic acid with weight per cent of 0.4 per cent to 0.6 per cent and made by the bagasse is mixed with the lime sludge of 65 per cent to 68 per cent, bagasse powder of 10 per cent to 12 per cent, wheat bran of 1.5 per cent to 2.5 per cent and regulator of 16 per cent to 25 per cent to ferment fully and continuously in a shorter time. The fermented materials with water of 10 per cent to 12 per cent are gained after opening and drying and are crushed into the lime sludge organic fertilizer. The molasses fermentation waste liquor with water of 90 per cent is condensed to the hyperconcentration liquor with water of 26 per cent to 28 per cent by the three-effect forced circulating concentration system and then through the two-effect scraping and steaming hyperconcentration system. The hyperconcentration liquor of 30 per cent to 33 per cent and the biological humic acid of 9 per cent to 10 per cent are stirred and mixed uniformly based on the weight per cent and are added with the fertilizer of 32 per cent to 34 per cent and the lime sludge organic fertilizer of 25 per cent to 27 per cent to stir to produce the organic-inorganic compound fertilizer through dry extrusion and prilling.

Owner:越百年创新肥业(海南)有限公司

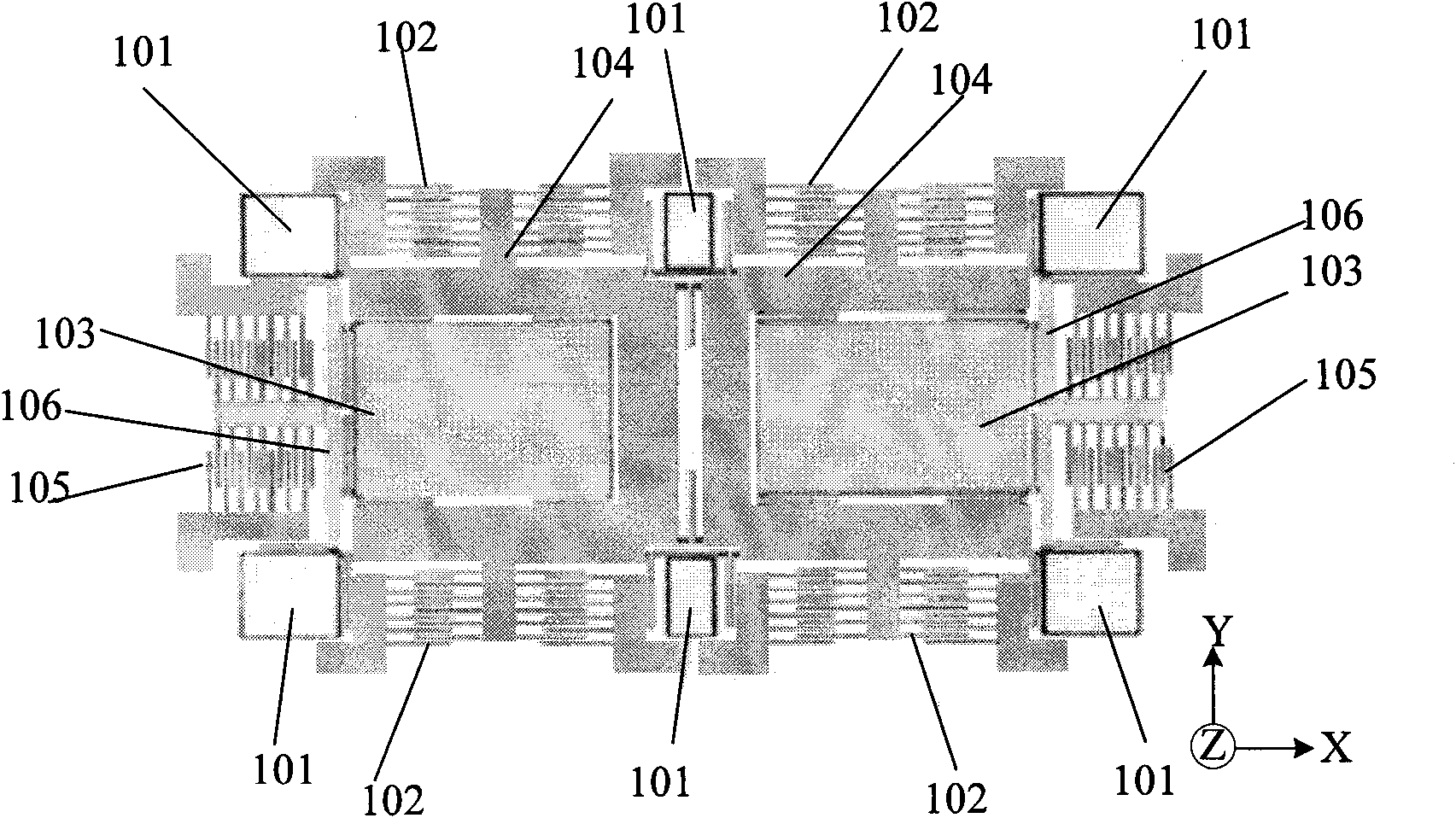

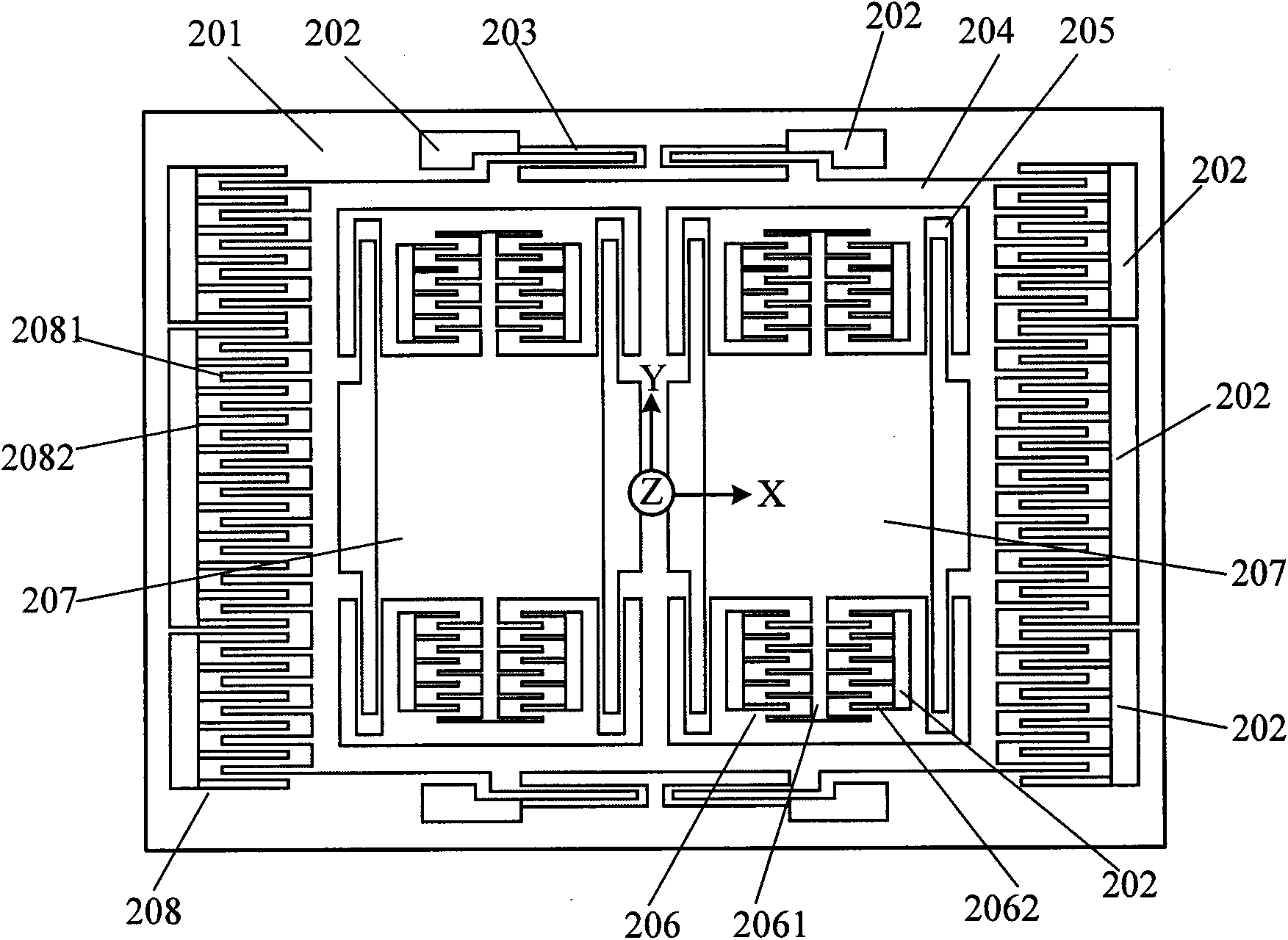

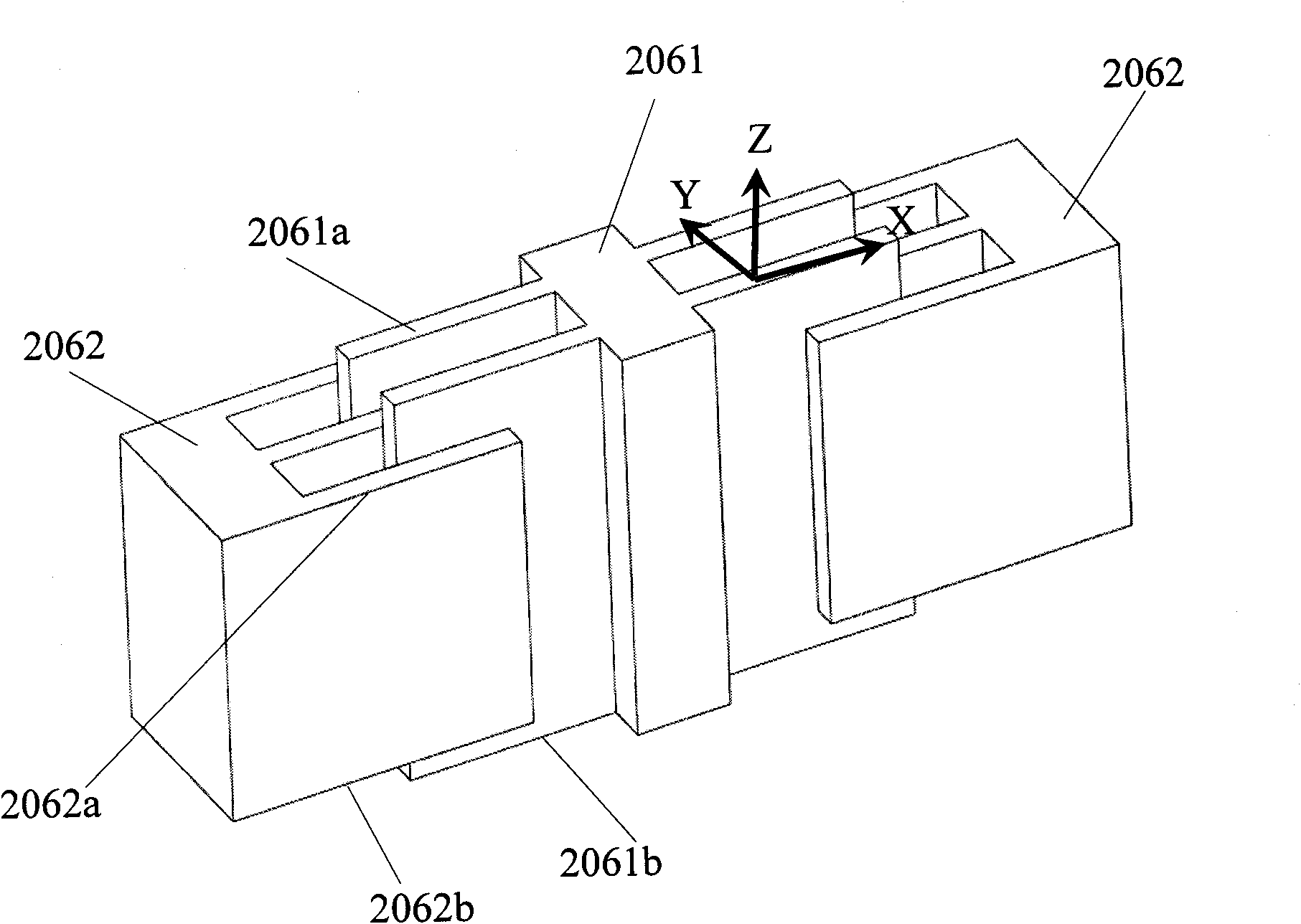

Capacitive micromachined tuning fork gyroscope

InactiveCN102062604ASuppress couplingNo changeTelevision system detailsImpedence networksCapacitanceTuning fork

The invention provides a capacitive micromachined tuning fork gyroscope. The gyroscope is the symmetrical dual-mass structural gyroscope, comprising a substrate and a framework arranged in the centre of the substrate, wherein the middle of the framework is provided with a framework beam perpendicular to the framework; two detection mass blocks are symmetrically arranged in the framework with the framework beam as a symmetry axis, and four corners of each detection mass block are connected with the framework and the framework beam through at least four drive beams; decoupling drive comb capacitors are respectively arranged at both ends of each detection mass block in the direction of a vertical axis; detection comb capacitors are symmetrically arranged on both outer sides of the framework in the direction of a horizontal axis; at least four detection beams are arranged on both outer sides of the framework in the direction of the vertical axis; and the detection beams are distributed symmetrically relative to the vertical axis and the horizontal axis and are fixed on the substrate through corresponding anchor points. According to the capacitive horizontal-axis micromachined tuning fork gyroscope provided by the invention, the mechanical coupling between the detection mode and the driving mode of the micromachined tuning fork gyroscope can be solved easily and effectively.

Owner:PEKING UNIV

Graphene aqueous slurry, and preparation method thereof

The invention belongs to the field of graphene material, and provides a graphene aqueous slurry, and a preparation method thereof. The graphene aqueous slurry comprises an aqueous dispersion liquid and a graphene material dispersed in the aqueous dispersion liquid, wherein the aqueous dispersion liquid contains a surfactant. The preparation method comprises following steps: graphite oxide solid or expansible graphite solid is taken as a raw material, and expansion treatment is carried out so as to prepare expanded graphite; the expanded graphite is immersed into an aqueous stripping liquid for infiltration treatment so as to obtain a mixture containing the expanded graphite; the mixture containing the expanded graphite is subjected to high-speed shearing or ultrasonic treatment so as to remove the aqueous stripping liquid so as to obtain a graphene wet material; the graphene wet material is added into the aqueous dispersion liquid, and high-speed shearing is carried out so as to obtain the graphene aqueous slurry.

Owner:SHENZHEN GUOCHUANG JIAWEI GRAPHENE TECH CO LTD

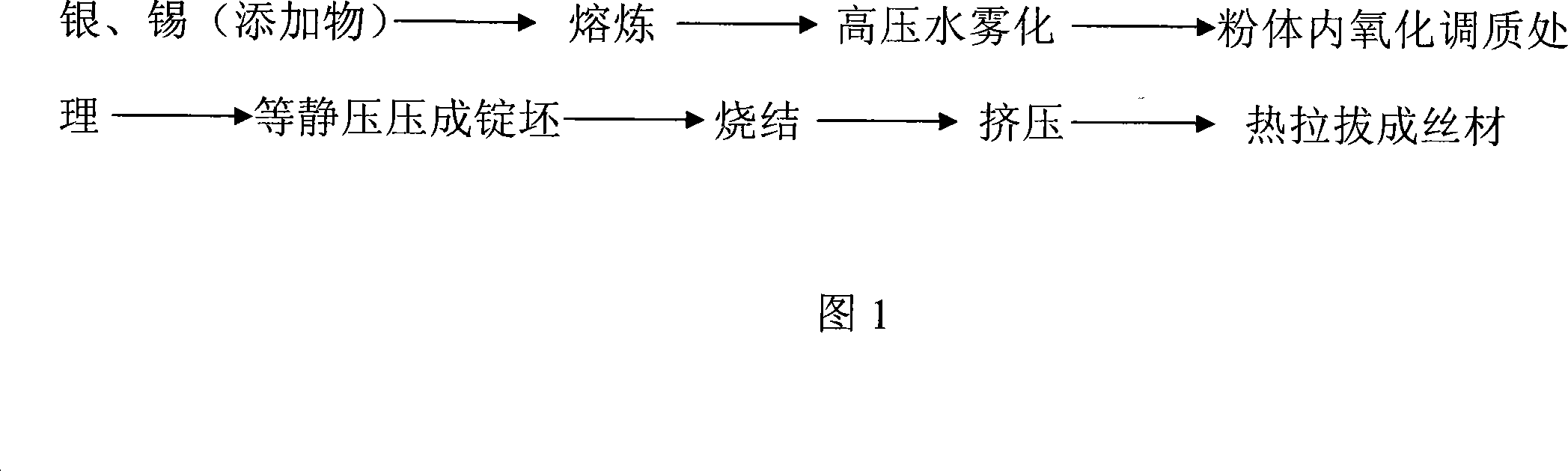

Method of preparing novel silver tin oxide silk electrical contact material

InactiveCN101202169AGranularity is easy to controlImprove surface activityContactsIntermediate frequencyElectric properties

The invention relates to a novel preparing method of a material used for a silver tin oxide wire electric contact. The invention has a process that the material prepared by silver, tin and additives according to a certain proportion is put into an intermediate frequency smelter for melting; a high pressure water atomizing device is adopted for high pressure alloy atomization; atomized alloy powder is dried and oxidated for modification; an isostatic pressing ingot is formed after isostatic pressing treatment; the ingot is agglomerated in a heating furnace; the agglomerated ingot is delivered into an extruding machine to extrude wires; the extruded wire is pulled and annealed to get a finished wire. The material property and electric property of the silver tin oxide wire electric contact material manufactured by the method can satisfy the use condition with high requirement.

Owner:FUDA ALLOY MATERIALS

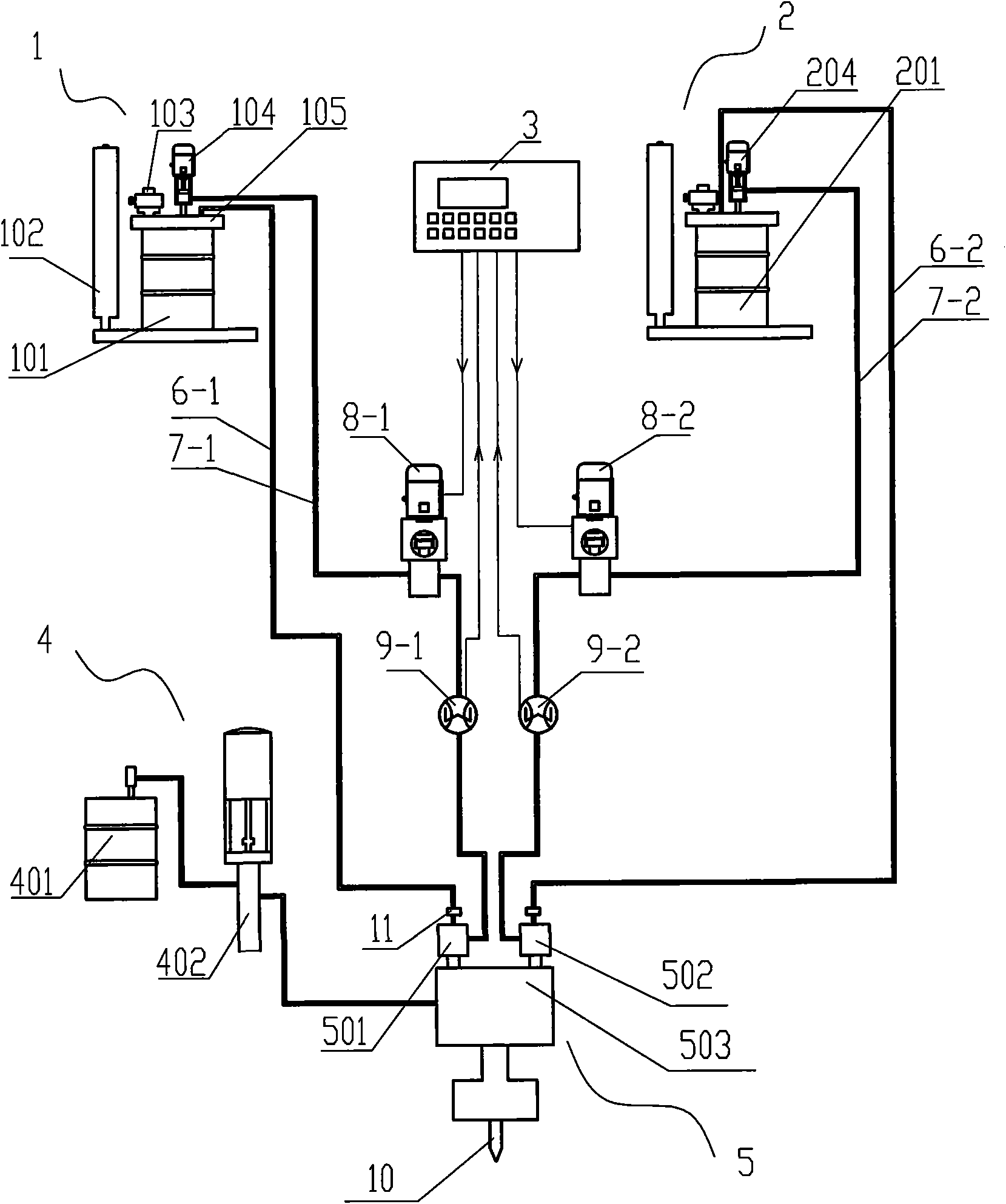

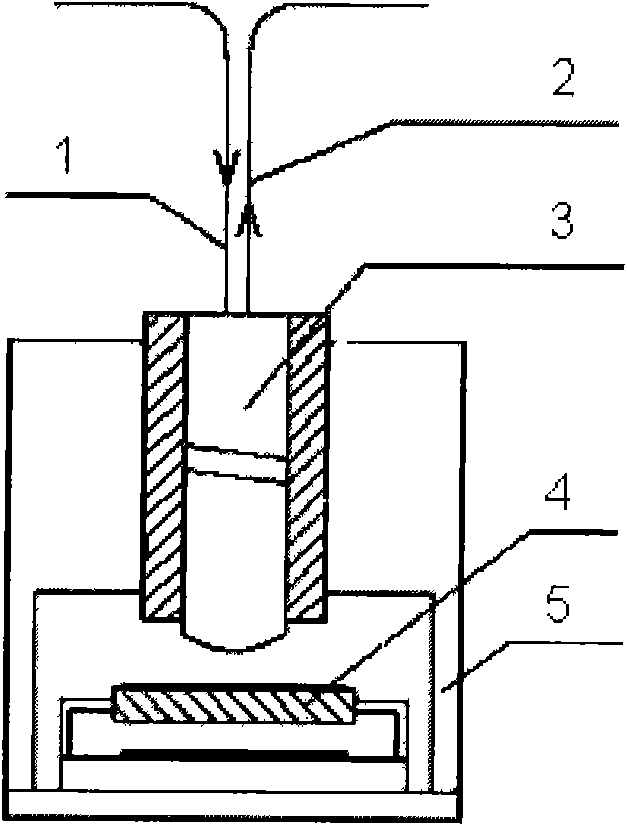

Two-component spraying system

InactiveCN101850312AHigh trafficWide range of proportional adjustmentLiquid spraying apparatusProgrammable logic controllerEngineering

The invention discloses a two-component spraying system which comprises a first material conveying system, a second material conveying system and a spray gun, wherein the structure of the first material conveying system is identical to that of the second material conveying system; a discharge port of a first material conveying pump of the first material conveying system is communicated with a mixing device through a first material conveying pipe; a first gear pump and a first flow meter are sequentially arranged on the first material conveying pipe; the output end of the mixing device is connected with the spray gun; the output end of a programmable logic controller (PLC) is respectively connected with the control ends of the first gear pump and a second gear pump; and the output ends of the first flow meter and a second flow meter are respectively connected with the input end of the PLC. In the invention, the PLC and the flow meters are used for accurately controlling the flow and the ratio of two-component coatings, and the flow and the ratio are automatically regulated by utilizing programs; and the ratio regulation range of two components is wider.

Owner:河北新兴铸管有限公司

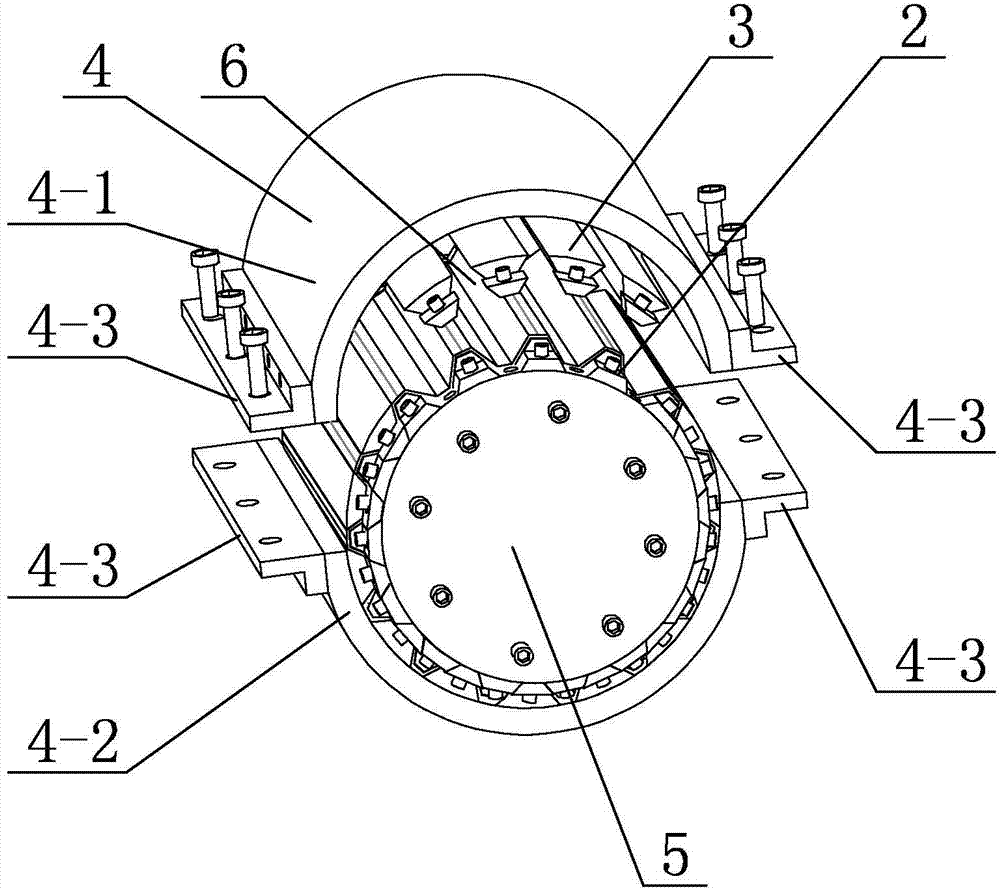

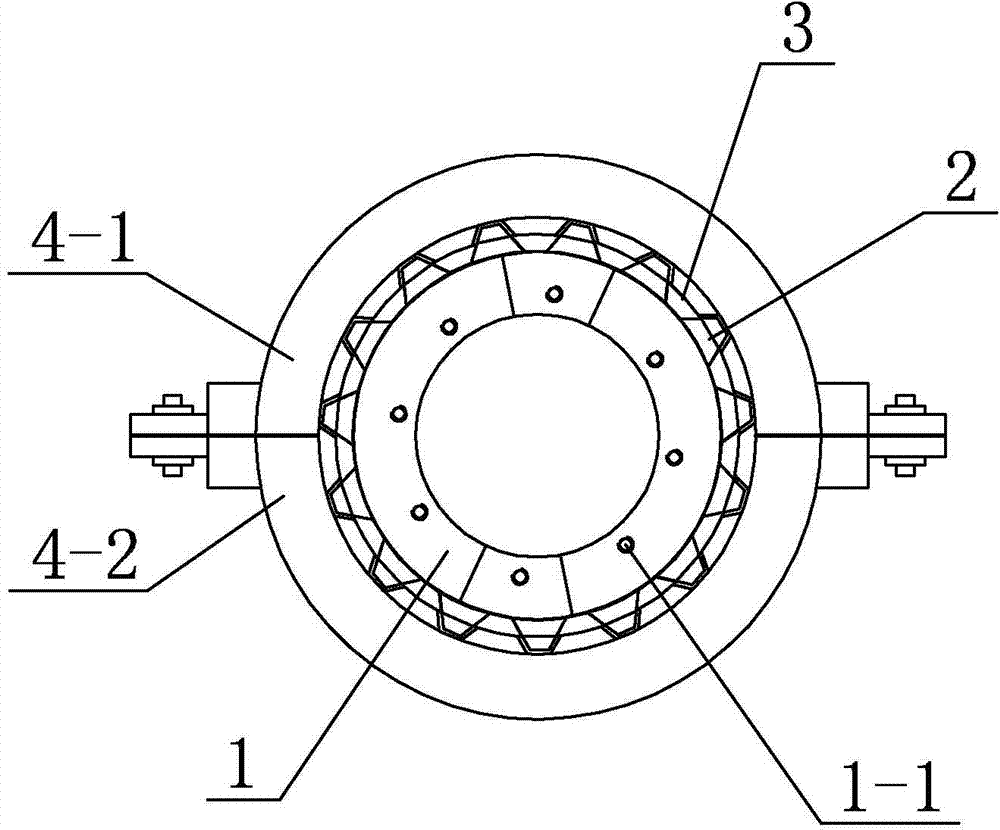

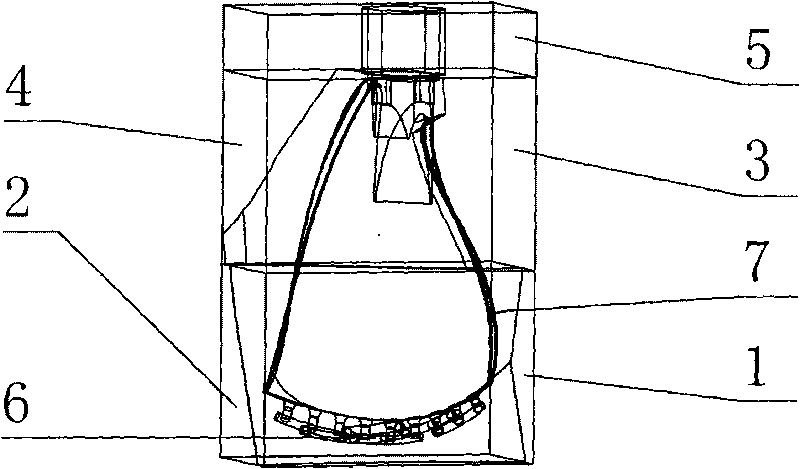

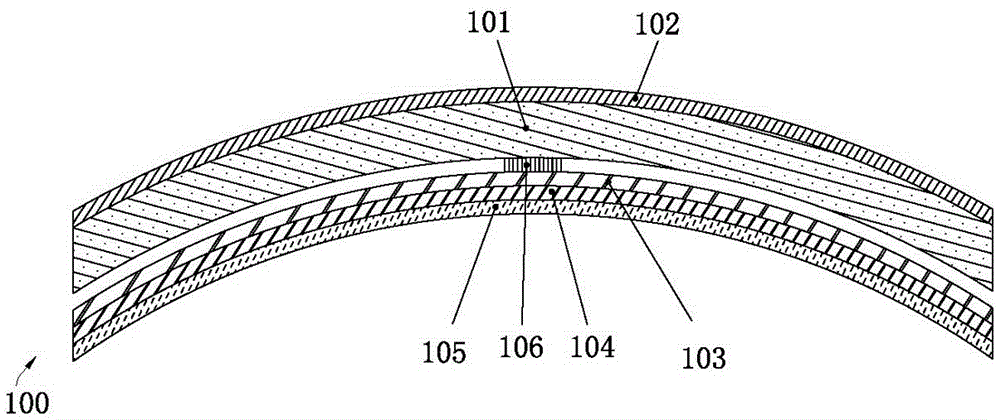

Assembling mold for all-composite corrugated sandwich cylindrical shells

InactiveCN104723579AGuaranteed to be stable and not deformedPrevent fiber entanglementEngineeringFilament winding

The invention discloses an assembling mold for all-composite corrugated sandwich cylindrical shells and relates to the assembling mold with an aim to overcome shortcomings about lack of special mold during production of existing all-composite corrugated sandwich cylindrical shells, skins and plates are not easy to be connected during production of other sandwich cylindrical shell, filament winding cannot be avoided, and the production process is complicated and not easy to for mass production. A core column is a split-type hollow column, two end caps are respectively detachably connected to the top surface and the bottom surface of the core column, multiple inner core strips and multiple outer core strips are alternatively arranged on the outer periphery of the core column along the axial direction of the core column, each inner core strip and each outer core strip are arranged at an interval, and a clamping fixture sleeves the core column provided with the inner core strips and the outer core strips. The cylindrical shells different in thickness can be produced, and mass production can be realized. The assembling mold is used for production of the all-composite corrugated sandwich cylindrical shells.

Owner:HARBIN INST OF TECH

Full automatic aluminium section bar cutter device

InactiveCN101352770AImprove accuracyReduce randomnessMetal sawing devicesMetal-working feeding devicesAssurance qualityEngineering

The invention discloses a full-automatic aluminum cutting device which aims at solving the problem of low manual feeding efficiency of the existing aluminum cutting device and provides a safe and convenient full-automatic aluminum cutting device which can ensure the quality. The device of the invention includes: a feed device, a bracket and a cutting saw arranged on the bracket; the feed device includes an upper clamping part, a lower clamping part, a horizontal feed part and a locating part. The device fully uses machines to replace manual operation, thus not only enhancing the accuracy, increasing the efficiency, reducing the cost, but also saving the human labor and materials as well as enhancing the safety performance.

Owner:TIANJIN SANTROLL ELECTRIC SCI & TECH

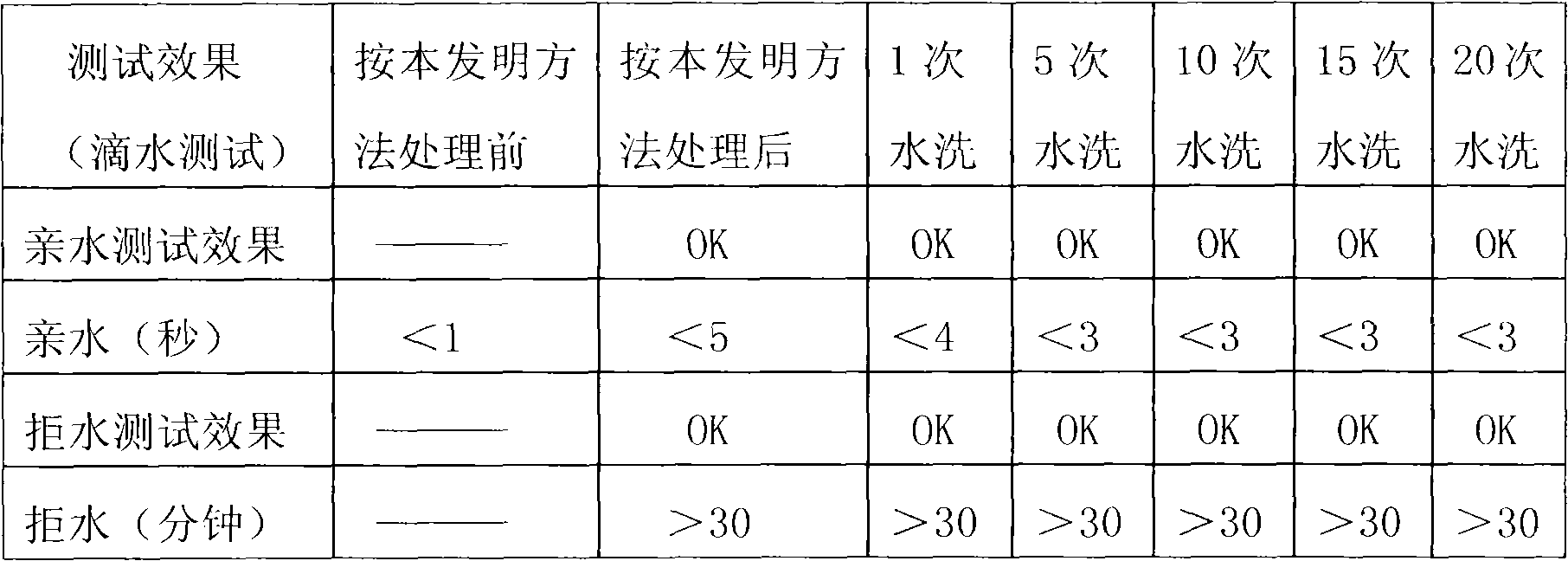

Method for processing double face fabric with single-side moisture transferring and cooling functions

ActiveCN102134777APrevent backflow of moistureModerate costFabric breaking/softeningWeft knittingSpecial effectsMoisture transfer

The invention relates to a method for processing a double face fabric with single-side moisture transferring and cooling functions, which is characterized in that the yarn for weaving the inner layer of the fabric is made of cool nylon fiber FLYCOOL, and the yarn for weaving the outer layer of the fabric is made of all common garment fiber. The method comprises the basic processing steps of gray fabric preparing, pretreating, dyeing or whitening, softening and thermosetting finishing. The fabric obtains the single-side moisture transfer property through thermosetting finishing. The fabric with single-side moisture transfer property has simple technological design, stability in production, easiness for operation, high working efficiency, large-scale production and an obvious single-side moisture transfer effect, the product has good performance uniformity, and the fabric shows a composite special effect function, i.e. the fabric shows a single-side moisture transfer and moisture absorption fast dry mechanism and a cooling function. The wearing comfortableness of sports wear is increased, and the sports wear is cool and comfortable to wear, has strong wearability and can especially meet the wearing requirement of people doing a large amount of exercises in summer.

Owner:QINGDAO JIFA GROUP

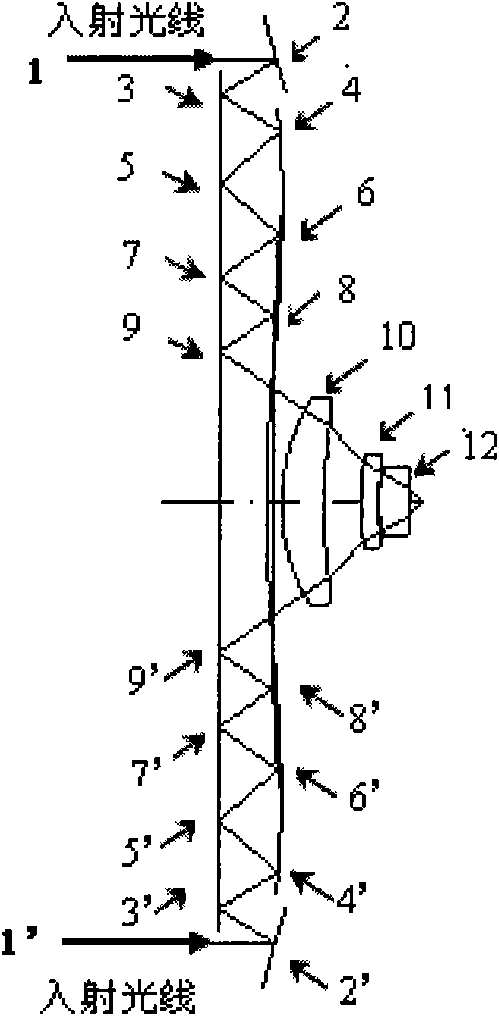

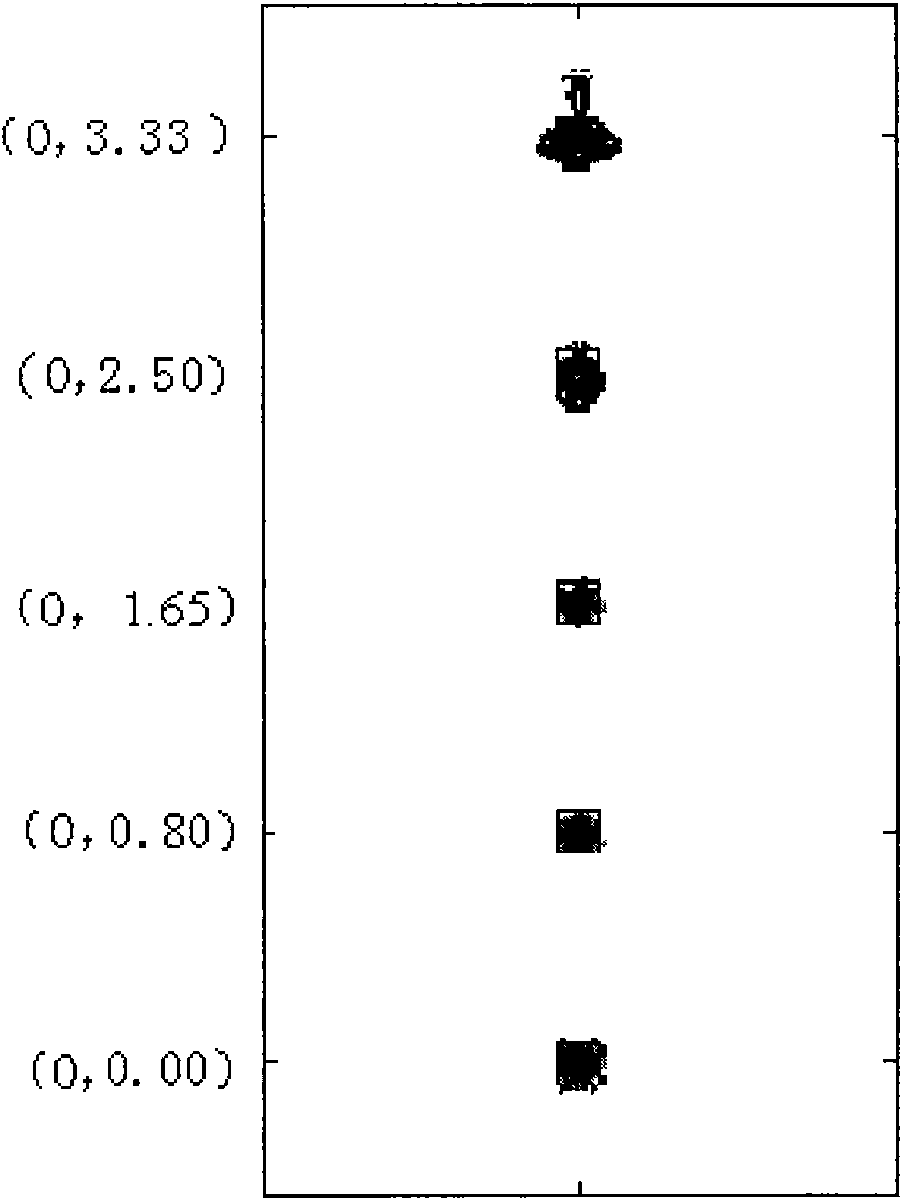

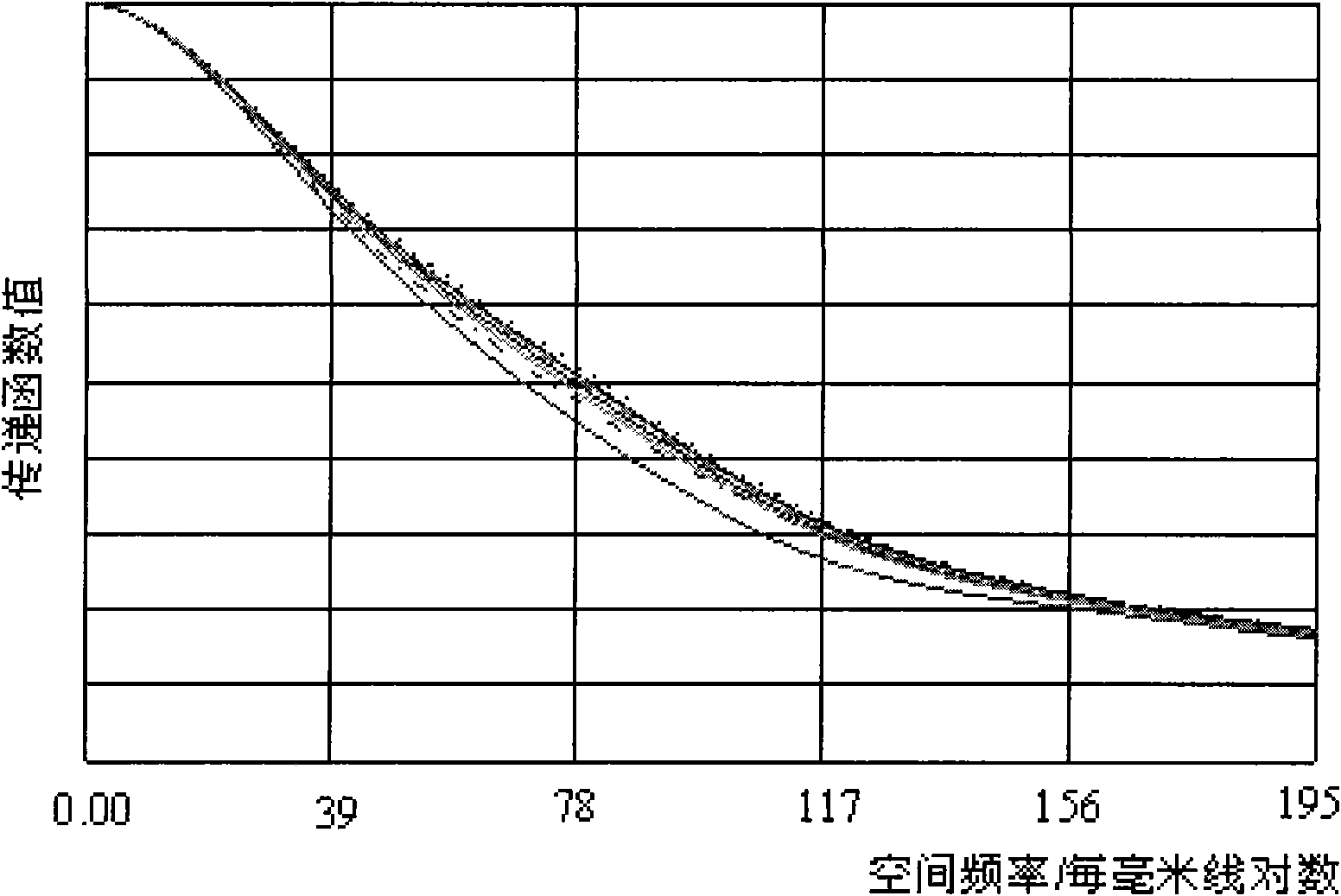

Annular aperture ultrathin optical imaging system

InactiveCN101581828AReduce volumeCompact structureOptical elementsCamera lensHigh volume manufacturing

The invention discloses an annular aperture ultrathin optical imaging system which can be used for a portable small-scale camera, a mobile phone lens or other civil optical imaging systems. The annular aperture ultrathin optical imaging system comprises a flat lens and a compensator; and the clear aperture is annular. The front surface of the flat lens is a plane reflector, while the rear surface has four coaxial annular high-order aspheric reflectors on the same substrate; and air is adopted as a light transmission medium. The system can obviously reduce the size and the weight while keeping good imaging quality and provide an effective method for improving a conventional refraction system. Compared with a common small-scale lens, the lens has the characteristics of good imaging quality, large numerical aperture, simple assembly and adjustment, low cost, portability, easy processing, suitability for large-batch production and the like.

Owner:SUZHOU UNIV

Method for mass preparing hollow nanometer carbon cages

InactiveCN1583552AEasy to operateSuitable for large-scale industrial productionNano-carbonHigh volume manufacturingDistilled water

A process for preparing a lot of hollow carbone nanocages includes such steps as proportionally mixing metallic carbonyl liquid with low-carbon organic liquid to obtain reaction solution, heating reactor while introducing inertial gas to it, pumping said reaction solution into the reactor to obtain solid carbon nanocages, putting them in pure nitric acid or the mixture of nitric acid and distilled water, ultrasonic oscillating, heating, reflux cooling, diluting by distilled water, laying aside for deposition, and baking the deposited substance.

Owner:SHANGHAI JIAO TONG UNIV

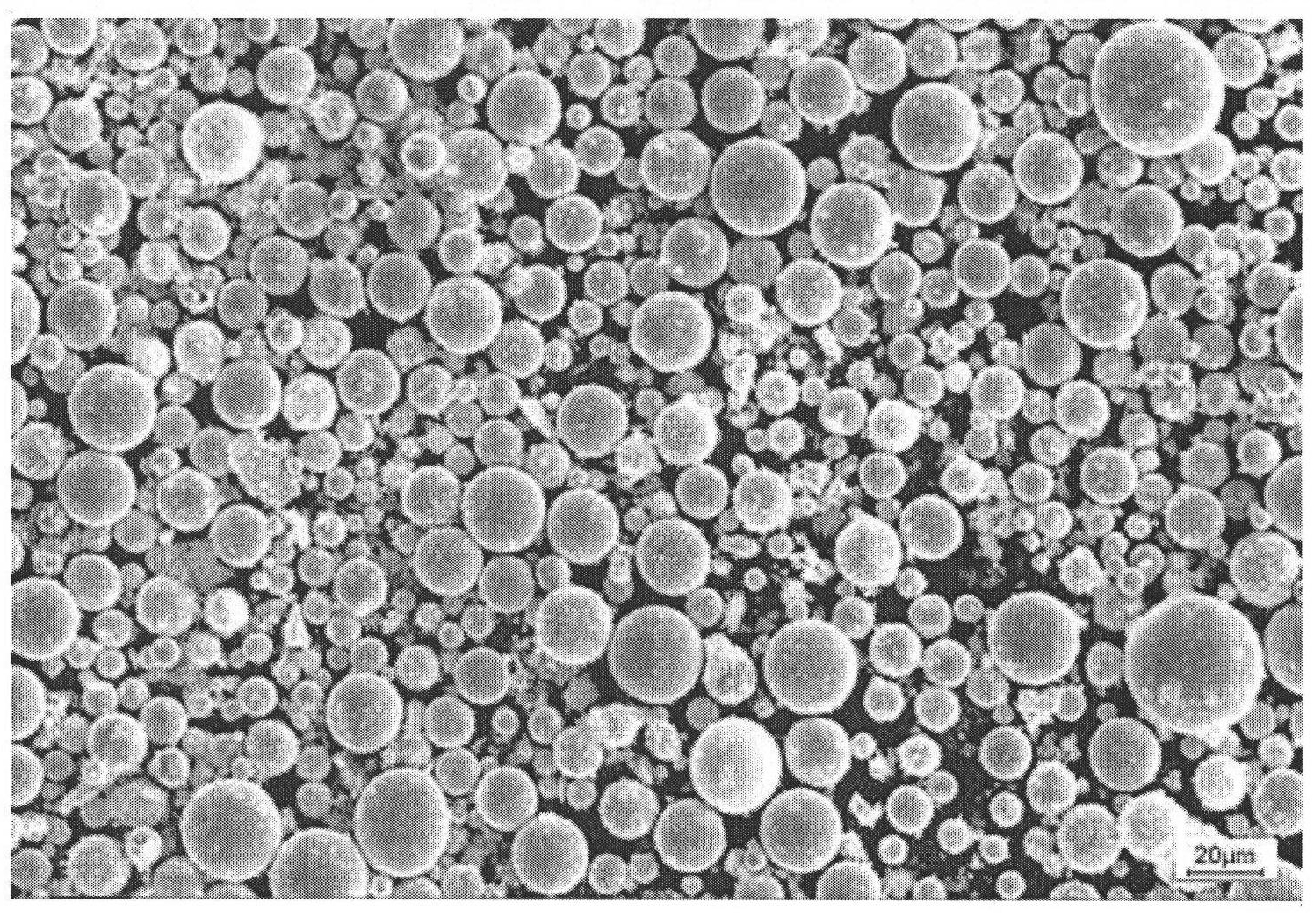

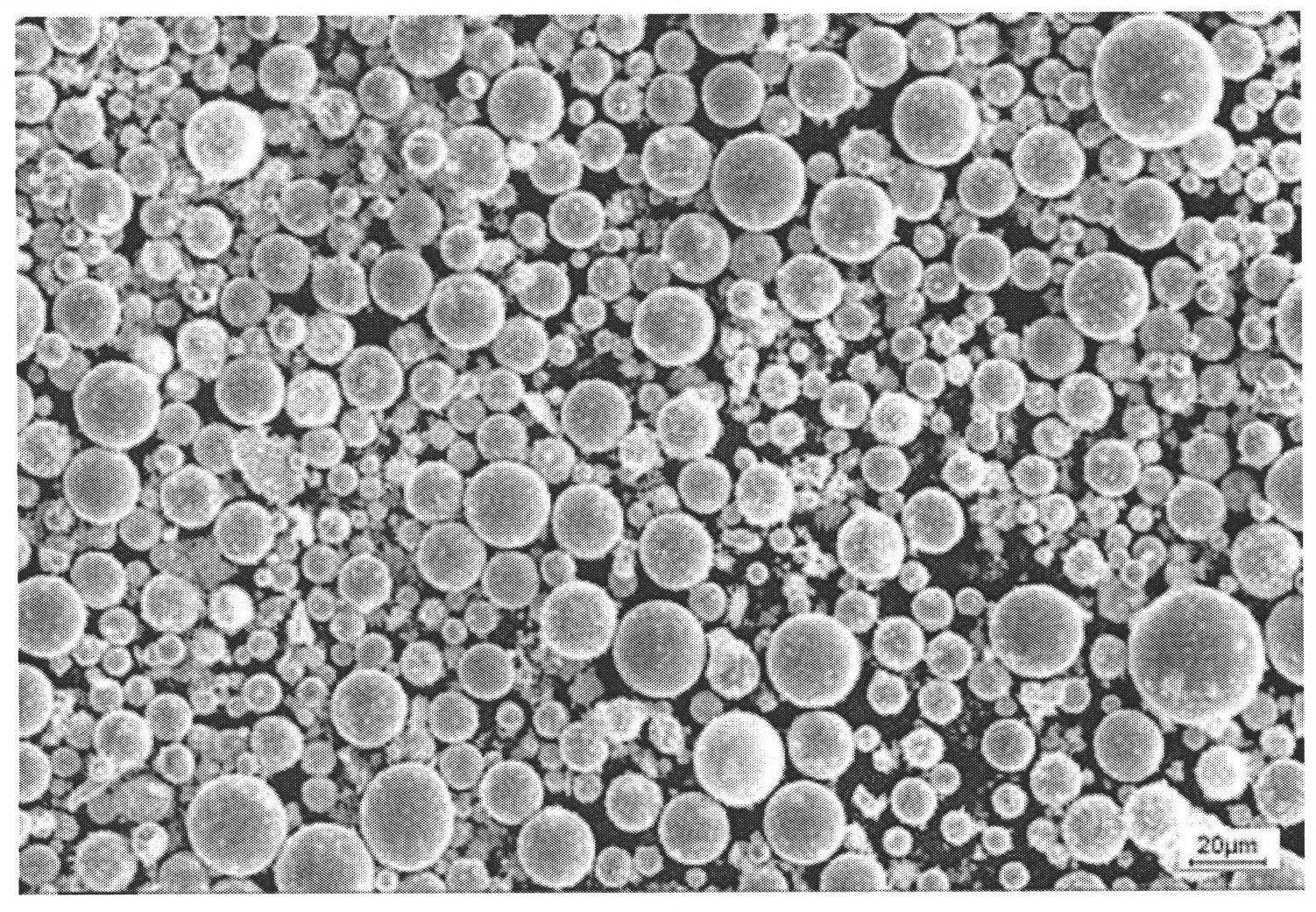

Method for largely preparing superfine spherical titanium aluminium-based alloyed powder

The invention provides a method for largely preparing superfine spherical titanium aluminium-based alloyed powder, which belongs to the technical field of powder preparation. The method comprises the following steps: smelting high-purity aluminium and titanium sponge as main raw materials and Al-Nb intermediate alloy, Ti-B alloy, tungsten powder and high-purity yttrium scraps as auxiliary raw materials into an alloy cast ingot in a vacuum consumable electrode arc skull furnace or a vacuum induction furnace; then carrying out coarse crushing and vortex airflow milling to prepare irregular superfine alloy powder; and finally carrying out plasma spheroidization of radio frequency (RF) and the like to prepare the superfine spherical titanium aluminium-based alloyed powder. The prepared alloy powder has the advantages of high purity, fine particle size, narrow particle size distribution, good uniformity, high sphericity, good flowability and the like and can meet the demands of the technical industrial production of injection forming, gel injection molding forming, thermal spraying and the like.

Owner:UNIV OF SCI & TECH BEIJING

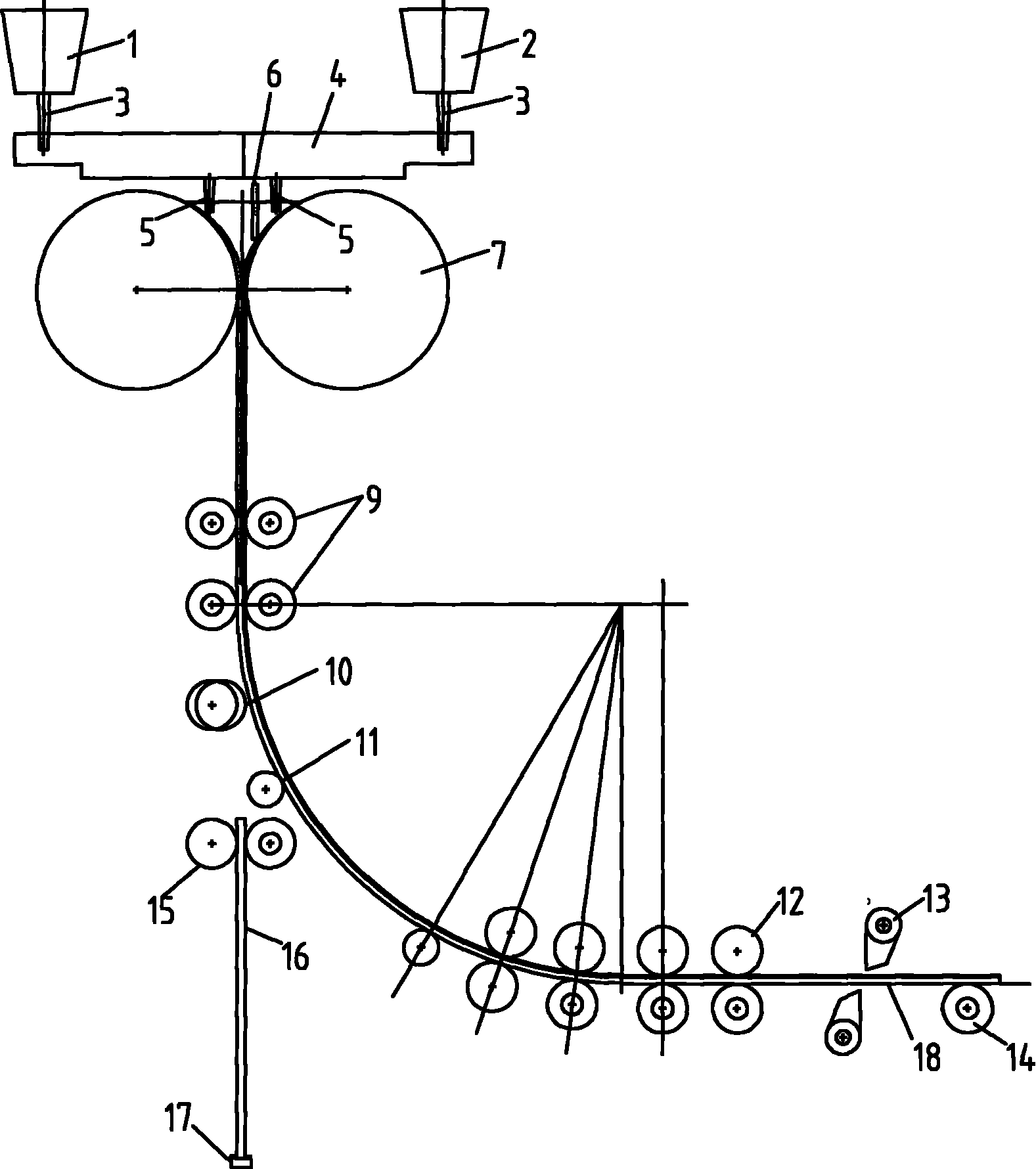

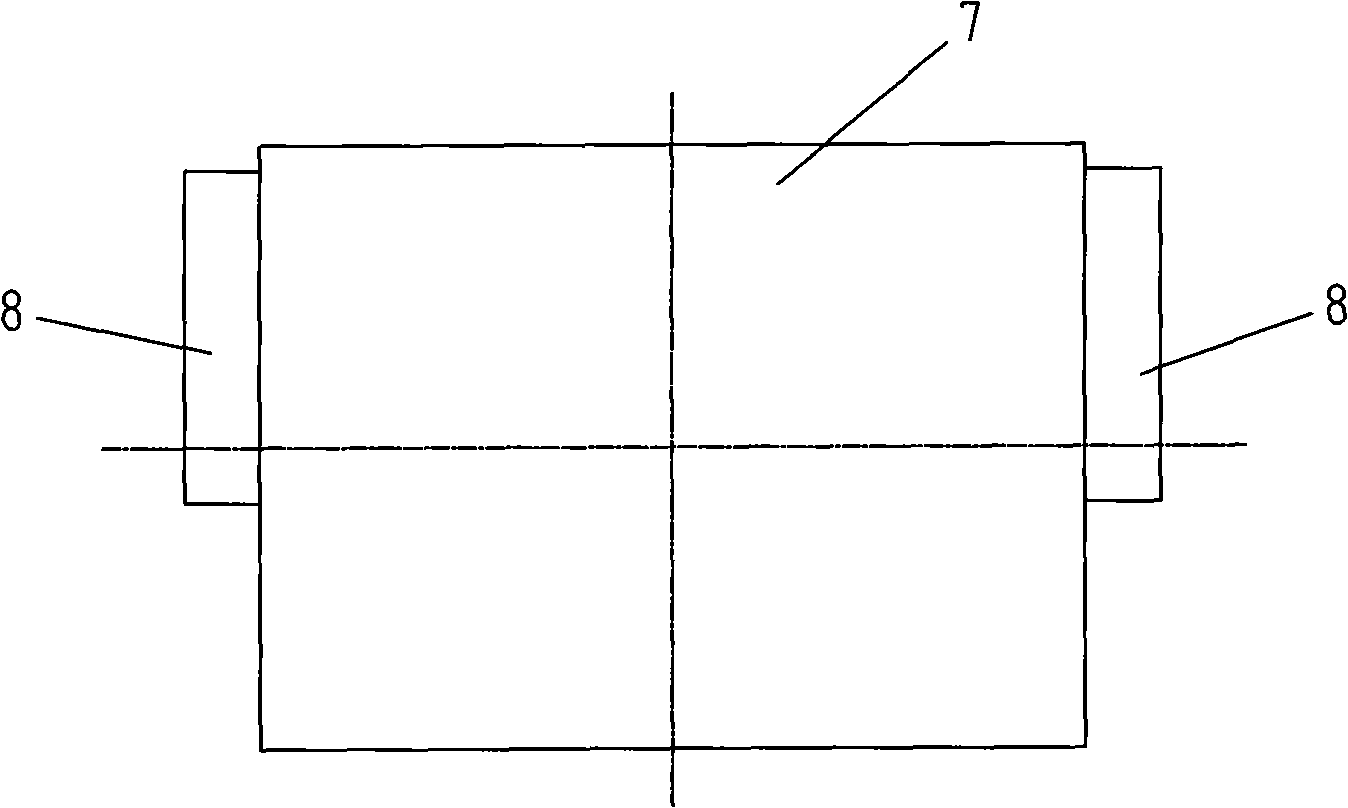

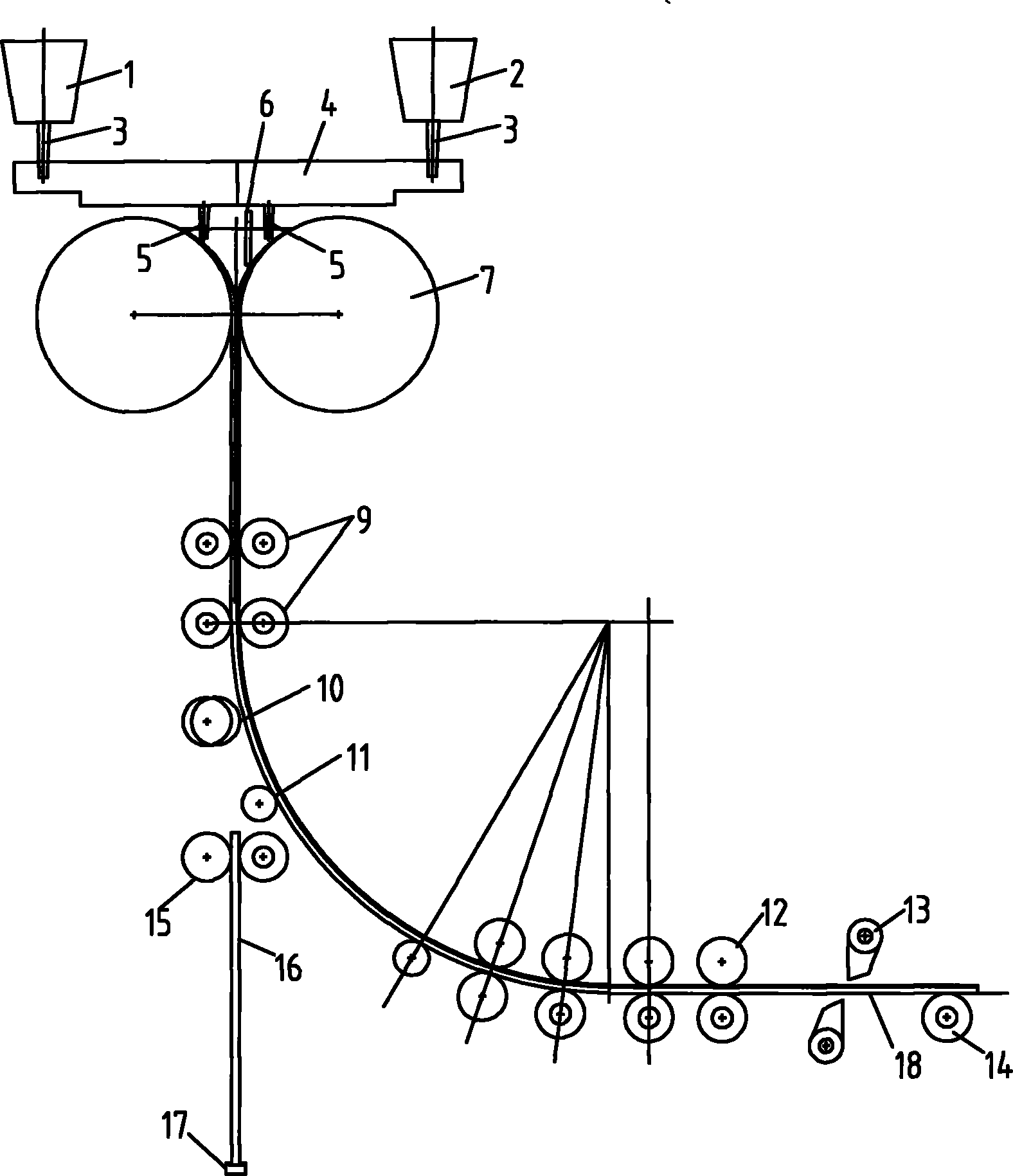

Continuous casting method of liquid-phase composite slab

The invention provides a continuous casting method of a liquid-phase composite slab. A continuous casting device comprises a composite casting system, a roll type crystallizer, a pinch and bending device, a withdrawing-straightening device, a shearing device and a dummy bar system. A base material metal pouring ladle and a composite material metal pouring ladle pour metal solution into a roll type crystallizer molten pool formed by crystallizing rolls and side seal plates via submerged nozzles. An intermediate diaphragm separates the molten pool into a base material dissolved cavity and a composite material dissolved cavity. The base material metal solution and the composite material metal solution are respectively solidified into slab shells on the crystallizing rolls, the crystallizing rolls synchronously rotate in the reverse direction and the metal slab shells move downward along with rotation of the crystallizing rolls. The base material metal liquid interacts with the composite material metal solid-liquid interface to realize metallurgical fusion and composition of the interface, and is bonded into the composite slab at the exit of the roll crystallizer. The composite casting slab is transferred by pinch rolls and bent into arc by a bending roll, and then enters the withdrawing-straightening section through a guide roll to be horizontally straightened. The composite casting slab keeps on moving forward to the roll way in a shear zone to be cut to length by swinging shears and then is moved out.

Owner:CHINA FIRST HEAVY IND +1

Casting method of large water turbine blade

ActiveCN101716655AUnique process methodRigid enoughFoundry mouldsFoundry coresWater turbineMaterials science

The invention relates to a stereoscopic core assembly casting method of a water turbine blade, in particular to a casting method of a large water turbine blade. The casting method is characterized in that the casting method comprises the steps of designing process, making a core box, making a core bar, making a core, patching a sand core, assembling the cores, putting the cores into a sand box, paving a spure, sounding the sand core with silica sand, assembling the box, pressing the box, pouring, cutting a dead head, tempering, detecting a mold line, grinding and shotblasting. The casting method obviously shortens production cycle, reduces equipment capacity requirements for blade production, is simple in operation and easy to control and achieves blade mass production.

Owner:KOCEL EQUIP

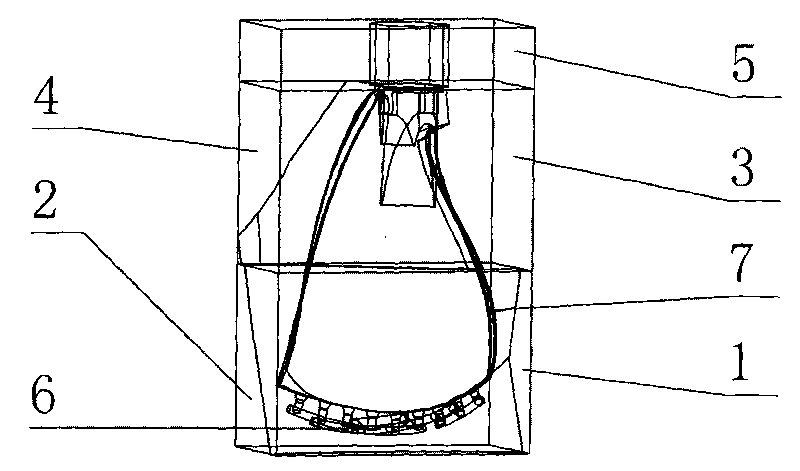

Method of manufacturing flexible stress sensor based on nano conductive material

ActiveCN106500886AHigh sensitivityImprove scalabilityForce measurementCarbon nanotubeConductive materials

The invention discloses a method of manufacturing a flexible micro membrane surface stress biosensor based on a nano conductive material. Particularly, a simple method is used for combining the nano conductive material and a flexible substrate, and the sensitivity and the telescopic performance of the stress sensor are further improved. Firstly, a flexible material (such as PDMS) is used as a raw material to make a flexible template with a groove; then, the nano conductive material (such as carbon nanotubes or silver nanowires) is used for filling the groove in the template; electrodes are led out from two ends of the filled nano conductive material; and finally, a flexible polymer material (such as PDMS) is used for fixing the nano material and the electrodes at the upper layer, and the structure stability is enhanced (the step can be omitted according to actual demands). The method of the invention has the advantages that the process is simple; the cost is low; the controllability is strong; the manufactured flexible stress sensor based on the nano conductive material is high in sensitivity, high in stability and good in flexibility; and possibilities are provided for realizing miniaturization, low cost and batch production.

Owner:TAIYUAN UNIV OF TECH

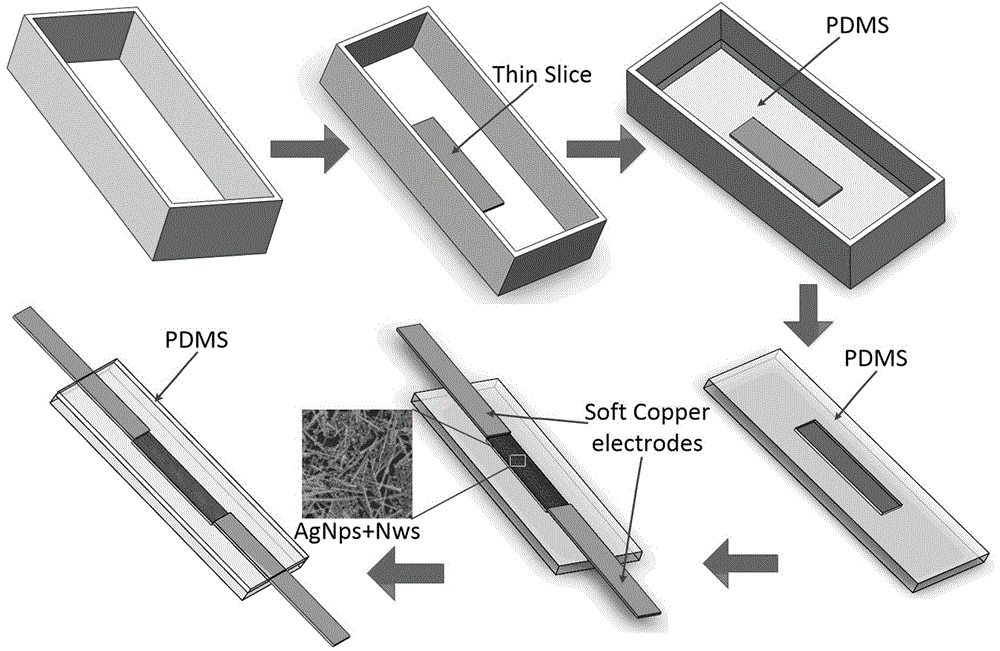

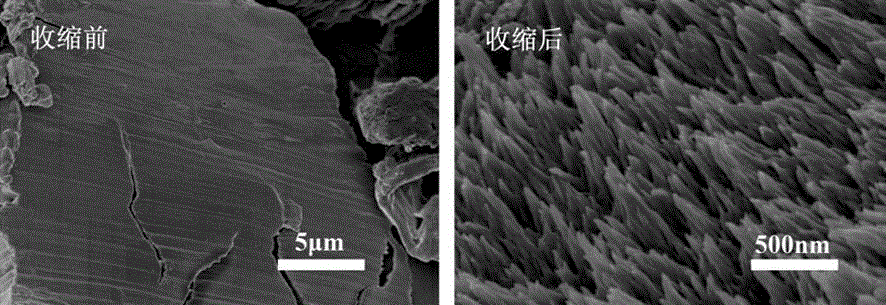

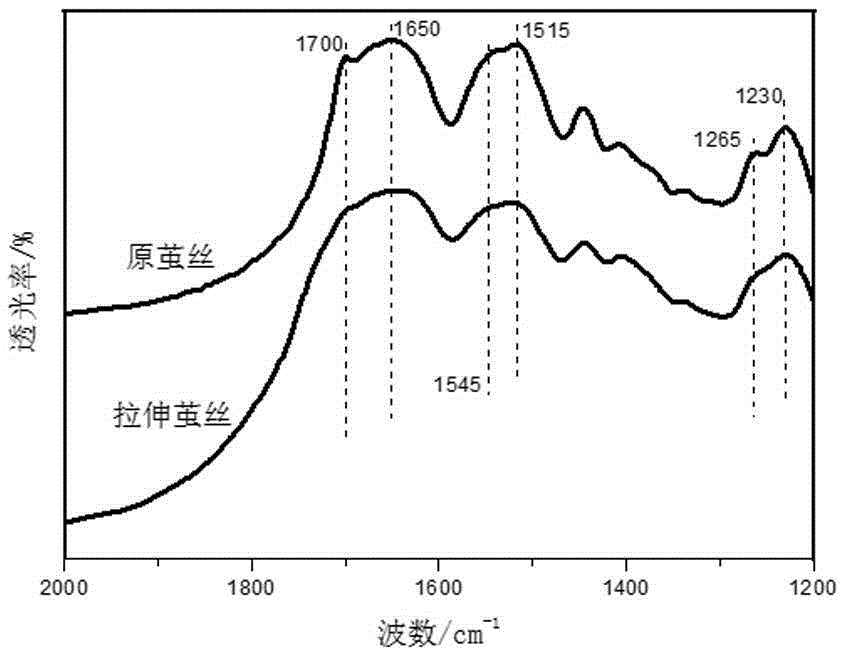

High-performance natural silk fiber and preparation method thereof

ActiveCN105256544AImprove mechanical propertiesHigh breaking strengthAnimal fibresYarnInorganic salts

The invention discloses a high-performance natural silk fiber and a preparation method thereof. High-performance silk fiber is formed by taking cocoon silk, raw silk, twisted silk or silk weaving yarn as raw materials and then performing contracting or stretching. The method specifically comprises the steps that inorganic salt, acid and water are mixed according to a certain ratio to prepare a silk swelling solution; the silk fiber is immersed into the swelling solution, and then stretching or contracting is performed; lastly, rinsing with clear water, neutralizing treating and drying are performed to obtain the high-performance natural silk fiber. The preparation method is simple, effective and short in process, the breaking strength of the silk fiber prepared through the method is comparable with that of spider silk, and therefore the high-performance natural silk fiber is suitable for application of the advanced technical fields of artificial ligaments, ophthalmological sutures, protective garments and the like.

Owner:NANTONG TEXTILE & SILK IND TECH RES INST

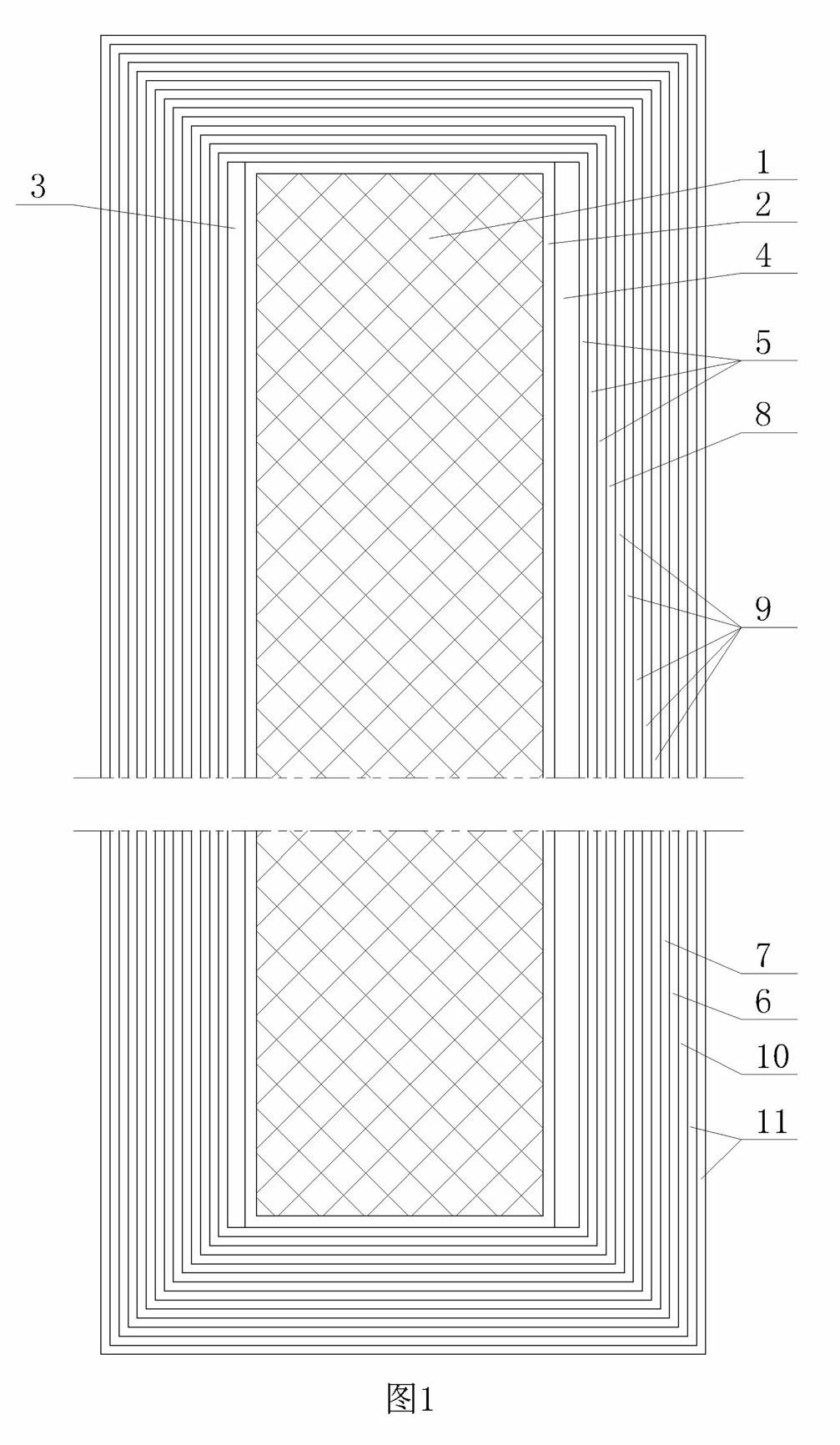

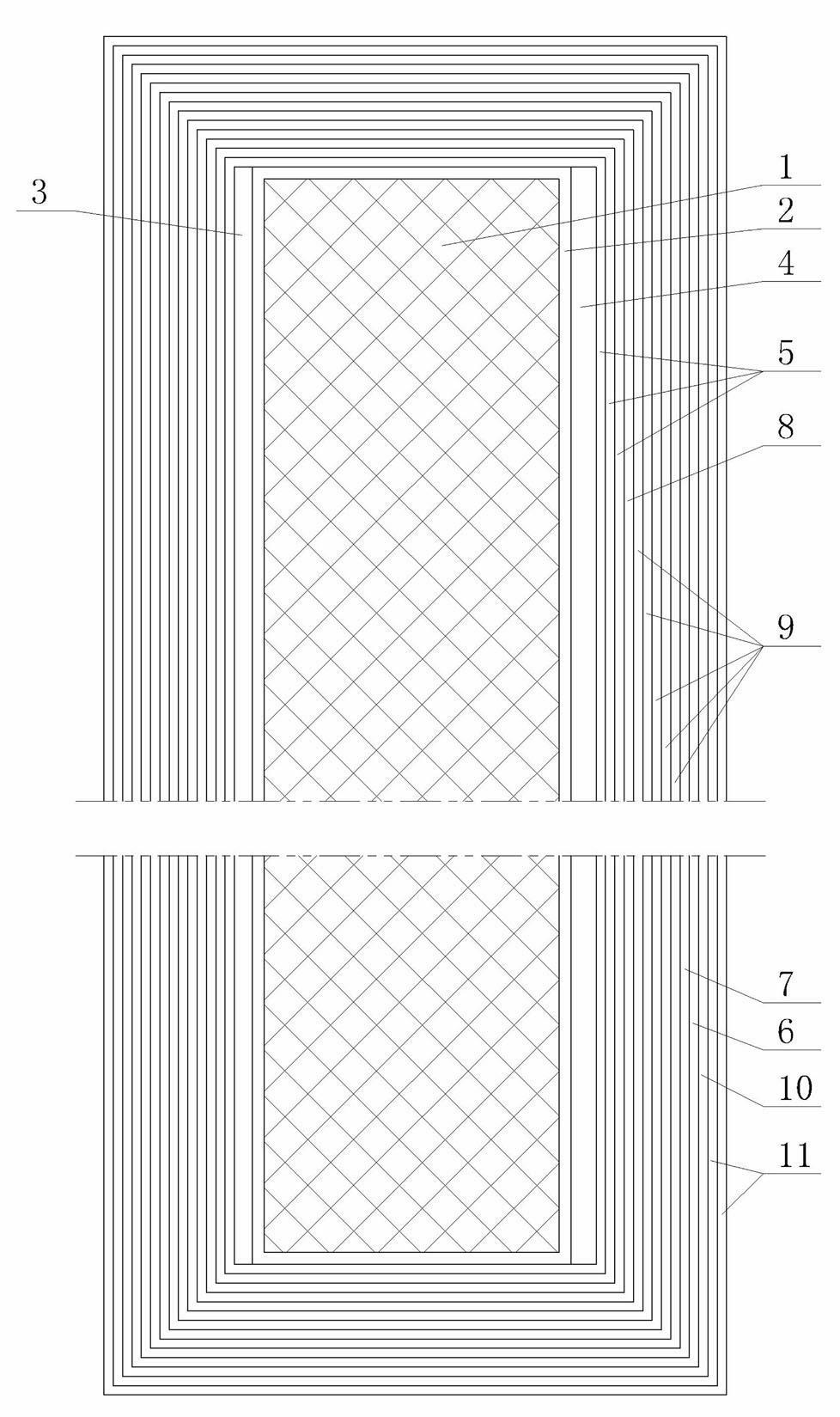

Building inner and outer wall decorating plate and manufacturing method thereof

ActiveCN102425284ASolve Adhesion ProblemsSolve the problems of transfer printing technologyCovering/liningsPretreated surfacesCalcium silicateCross-link

The invention discloses a method for building inner and outer wall decorating plate, which comprises two flows, each flow including steps of: a primer line processing flow: (1) thickness sanding and dedusting, (2) roller painting back seal coat and curing into a first UV seal coat layer, (3) roller painting UV penetrant twice, (4) leveling by infrared ray, (5) coating UV putty at the front and UV curing and generating a UV putty layer, (6) roller painting the UV seal coat for three times and respectively curing and generating three second UV seal coat layers, (7) fine sanding; and a roller painting finish line flow: (1) dedusting, (2) roller painting UV glue and generating a first UV glue layer, (3) coating the UV finish for five times and curing and generating five UV finish layers. The decorating plate can solve the problems that a UV curing penetrating agent is strongly, quickly and deeply penetrated into a fiber reinforced calcium silicate slab or a fiber cement slab, deeply cured to form a film and subjected to stereo chemical netlike cross-linking reaction with UV putty and UV sealing paint, and thoroughly solves the problem of adhesive force between the decorative surface layer and a substrate.

Owner:山东鲁泰装配式装修材料有限公司

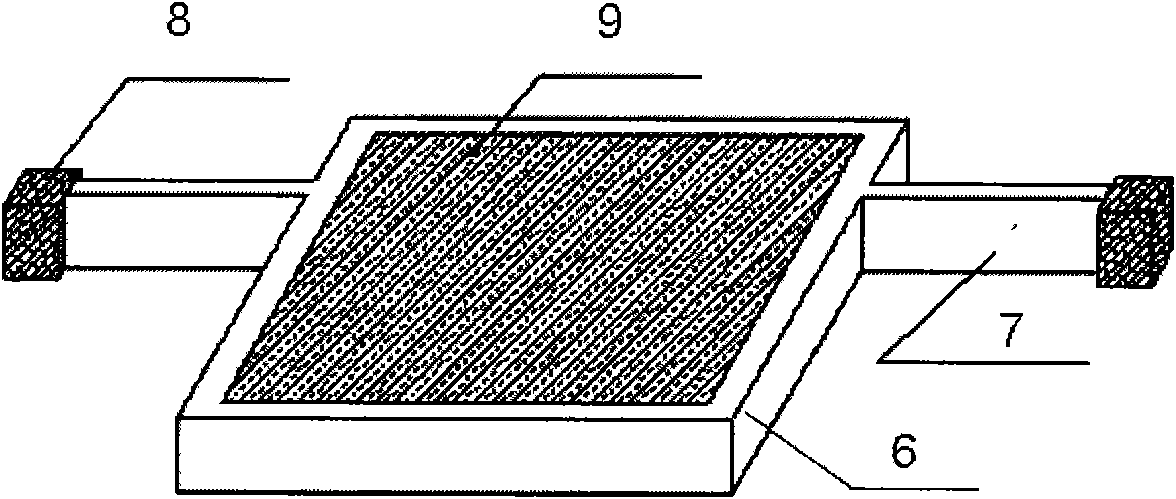

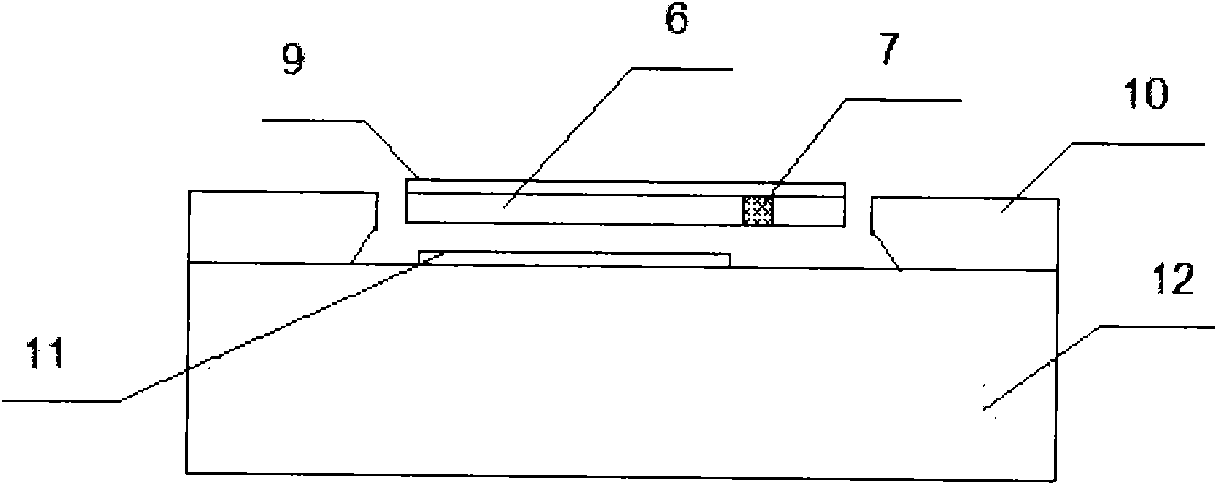

Optical fiber vibration sensing head and manufacturing method thereof

InactiveCN101608944AWide operating frequency rangeAggressive and obviously mass-producedSubsonic/sonic/ultrasonic wave measurementPhotomechanical apparatusFiberVibration acceleration

The invention discloses an optical fiber vibration sensing head, which consists of a vibration sensitive chip, a dual fiber collimator and an encapsulation shell, wherein the inside of the encapsulation shell under the dual fiber collimator is provided with a cavity, the vibration sensitive chip is arranged in the cavity and consists of micro light reflector, a silicon supporting frame and a substrate glass sheet; the silicon supporting frame is bonded with the substrate glass sheet; the micro light reflector is arranged in the silicon supporting frame; a damping air cavity is reserved between the micro light reflector and the substrate glass sheet; two sides of the micro light reflector is symmetrically provided with torsion shafts; and one end of each of the torsion shaft is connected with the silicon supporting frame. An MEMS process is used to integrate a MEMS vibration sensitive chip. Based on an asymmetric torsion micro light reflector structure, the MEMS vibration sensitive chip can be manufactured in batch. The torsion shafts are used as elastic elements, and the micro light reflector is used as a sensitive mass block to reflect vibration acceleration. The damping air cavity is used for controlling the damping characteristic of torsion. The invention has the advantages of batch production, low cost and high consistency.

Owner:上海前所光电科技有限公司

Degradable polylactic acid diblock copolymer, preparation method and application to modified polylactic acid

The invention discloses a degradable polylactic acid diblock copolymer, a preparation method and application to modified polylactic acid, solving the problems of instable performance, high preparation cost and unsuitability for industrialized continuous production of modified polylactic resin in the prior art. The preparation method of the degradable polylactic acid diblock copolymer comprises the following steps of: adding dried and dewatered polylactic acid A with an end group being hydroxy into a reaction device under the protection of an inert atmosphere, adding diisocyanate B, heating to 185-190 DEG C, reacting with stirring for 5-8h, adding degradable high polymer C containing hydroxy, reacting with stirring for 1-2h at the temperature of 185-190 DEG C, adding the diisocyanate B, and reacting at the temperature of 185-190 DEG C until the stirring is difficult to obtain the degradable polylactic acid diblock copolymer. The degradable polylactic acid diblock copolymer disclosed by the invention is good in compatibility with the polylactic resin, is used for modifying the polylactic resin, is capable of remarkably improving processing property and mechanical property of the polylactic resin, and has the elongation at break reaching 60 percent.

Owner:CHANGZHOU INST OF ENERGY STORAGE MATERIALS &DEVICES

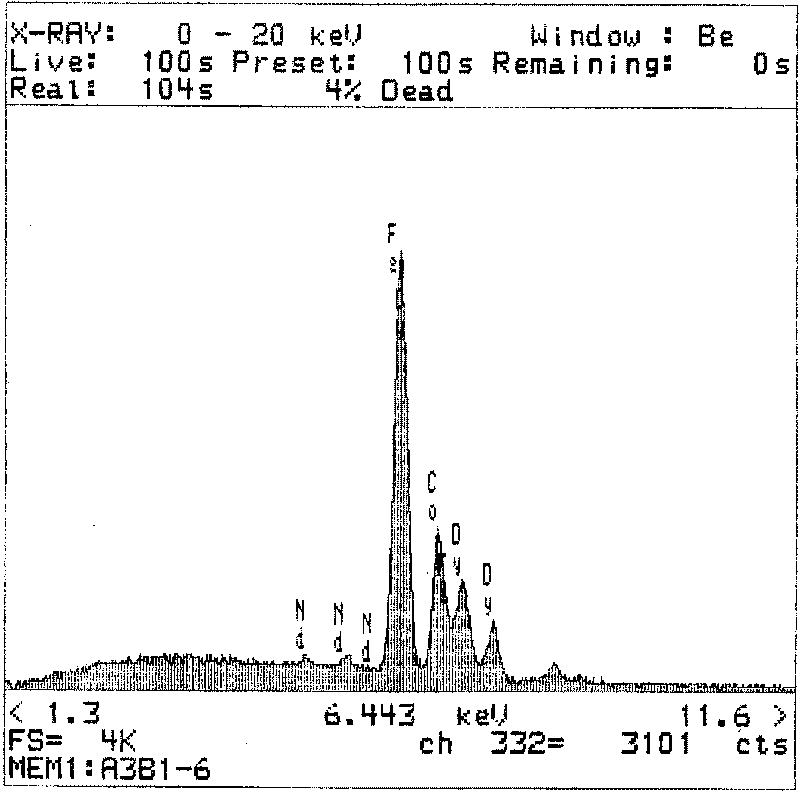

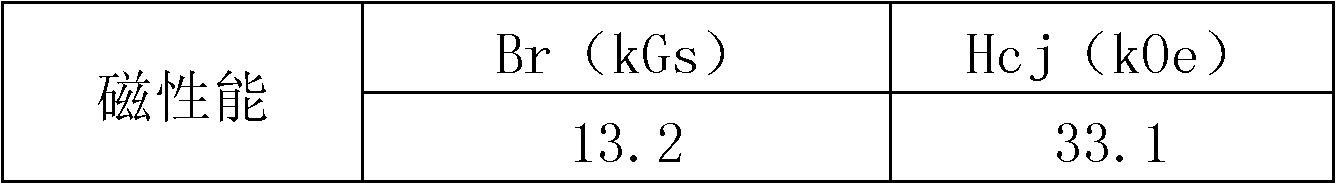

Manufacturing method of high-residual magnetism high-coercive force rare earth permanent magnetic material

ActiveCN101707107AImprove coercive forceImprove absorption process efficiencyMagnetic materialsRare earthSintered magnets

The invention discloses a manufacturing method of a high-residual magnetism high-coercive force rare earth permanent magnetic material, which comprises the processing steps of master alloy preparation, crushing, molding, sintering to manufacture sintered magnets, aging treatment, machining and surface treatment, and is characterized in that after the processing step of sintering to manufacture the sintered magnets R1-T-B-M1, the sintered magnets are embedded into a mixed powder consisting of one or more components of HR2M2 and R3 oxide, R4 fluoride and R5 oxyfluoride, the magnets are separated from each other, and conducting absorption on the sintered magnets embedded in the mixed powder in vacuum or inactive gas at the temperature equal to or less than the sintering temperature of the magnets for 1-20 hours. In the method, the coercive force of the permanent magnetic material is significantly improved under the condition that residual magnetism basically does not change, the absorption efficiency is improved simultaneously, mass production can be achieved, and larger-sized high-residual magnetism high-coercive force rare earth permanent magnetic material of can be produced.

Owner:YANTAI DONGXING MAGNETIC MATERIALS INC

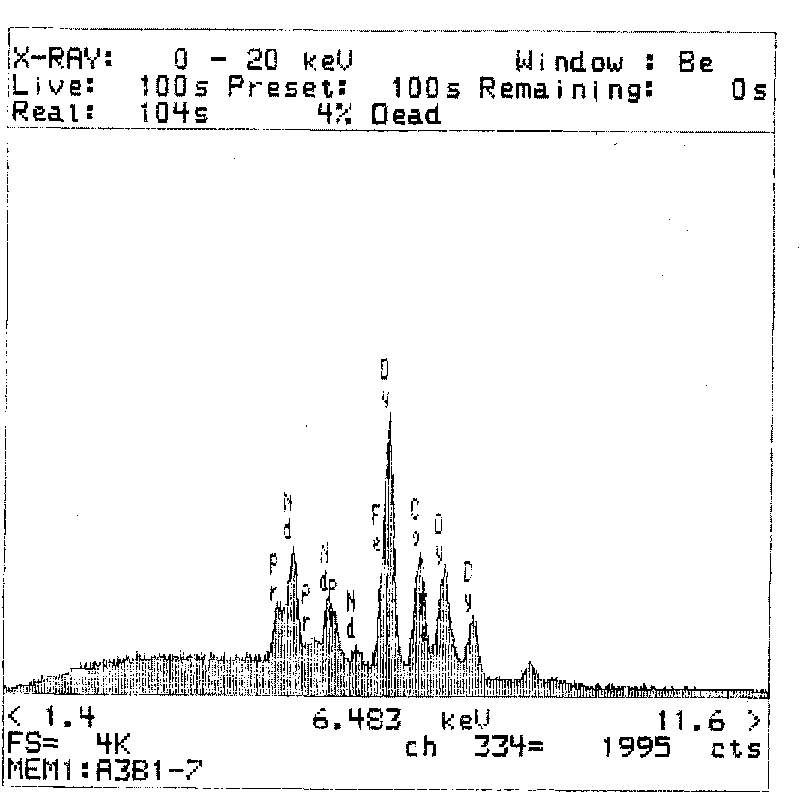

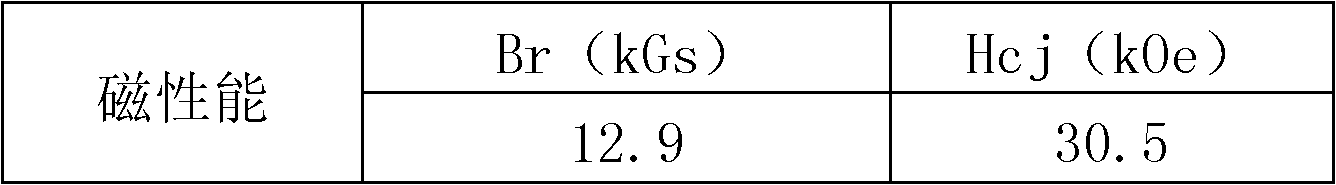

High-performance rare earth permanent magnet sintered magnet and manufacturing method thereof

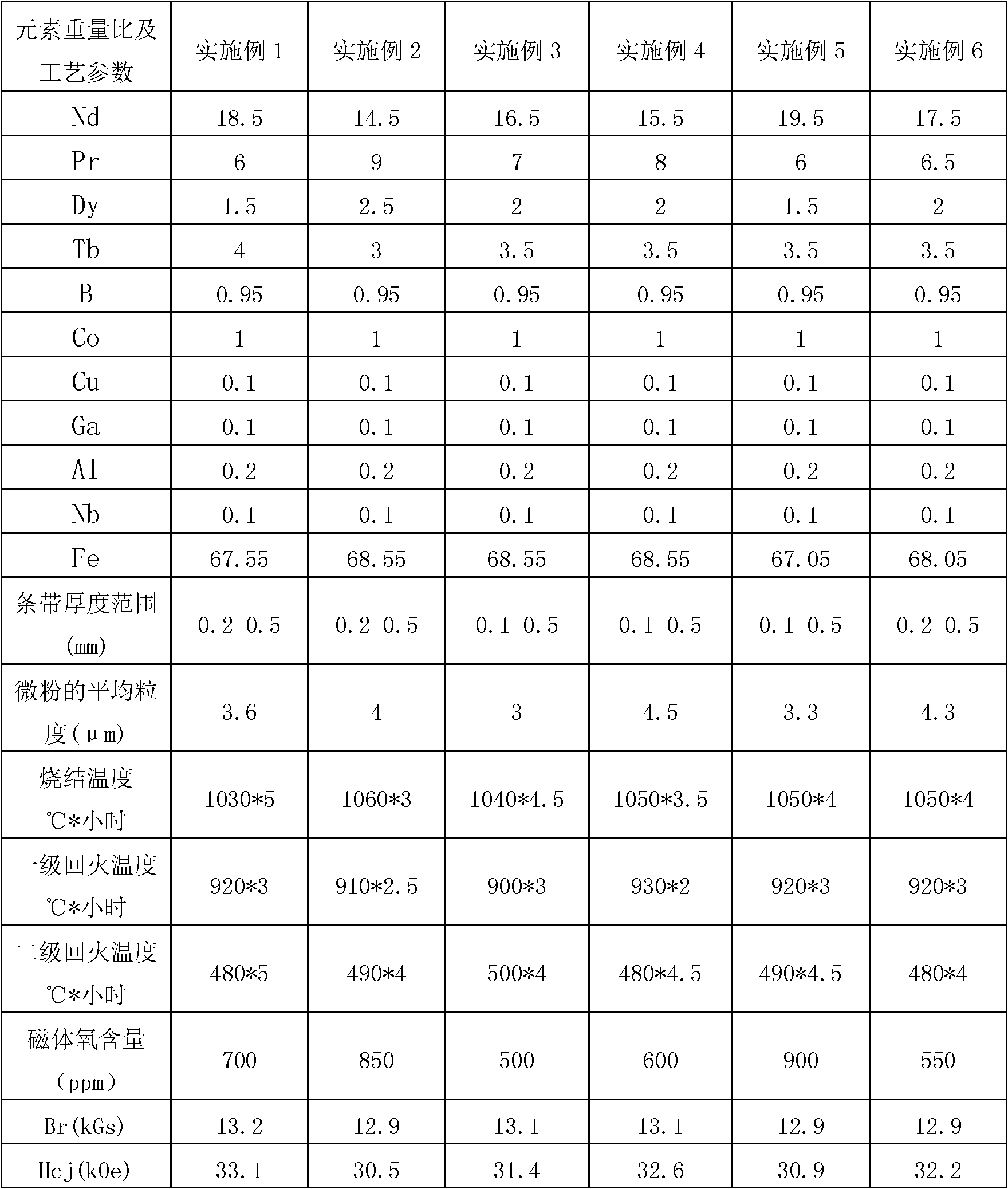

The invention provides a rare earth sintered magnet and a manufacturing method thereof. The magnetic property residual magnetism Br of the magnet is between 12.8 and 13.3 kGs, the intrinsic coercivity Hcj is more than or equal to 30 kOe, and the content of oxygen in the magnet is between 500 and 900 ppm. The rare earth sintered magnet is prepared by the manufacturing process that: a smelting procedure is a vacuum quick-setting process, and the thickness of produced sheet alloys is between 0.1 and 0.5mm; a hydrogen decrepitation process is used for production in an intermediate crushing procedure; a jet mill is used for production in a micro powder manufacturing procedure, and the average particle size of micro powder is between 3.0 and 4.5 mu m; a compression procedure is used for compression molding under the environment of anaerobic inert gas; and a sintering procedure is used for sintering and aging by means of a vacuum sintering furnace.

Owner:SANVAC BEIJING MAGNETICS +1

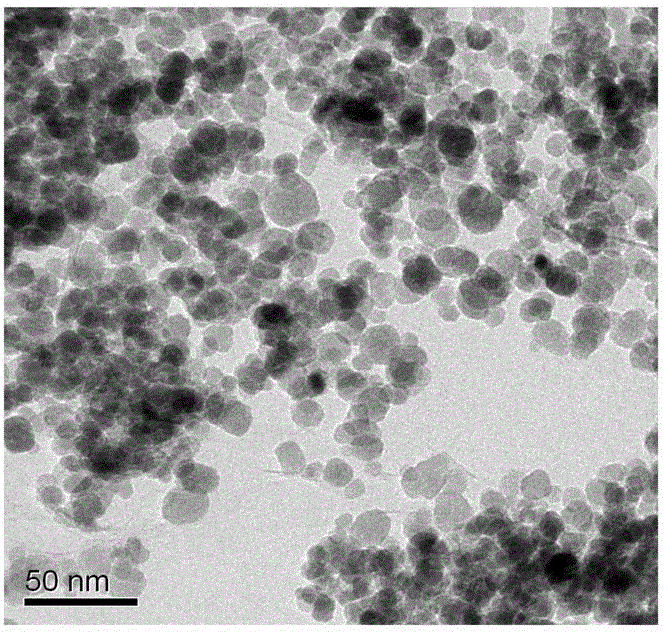

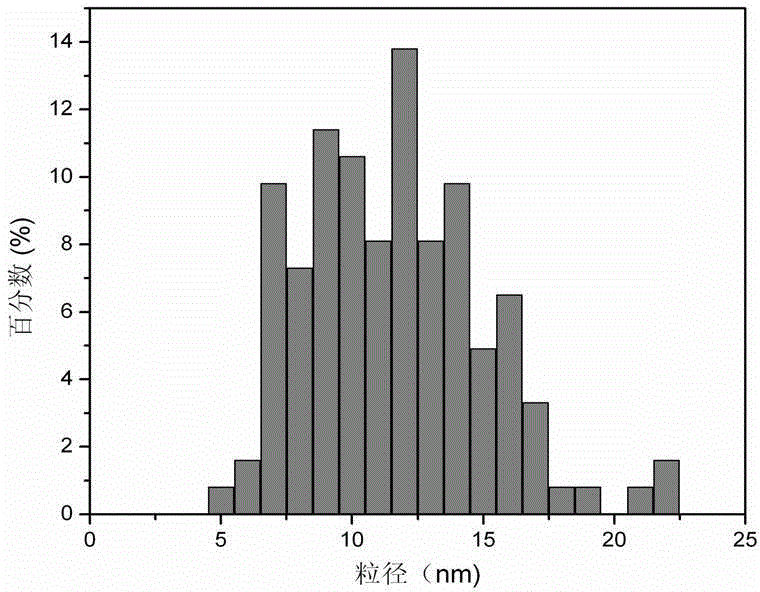

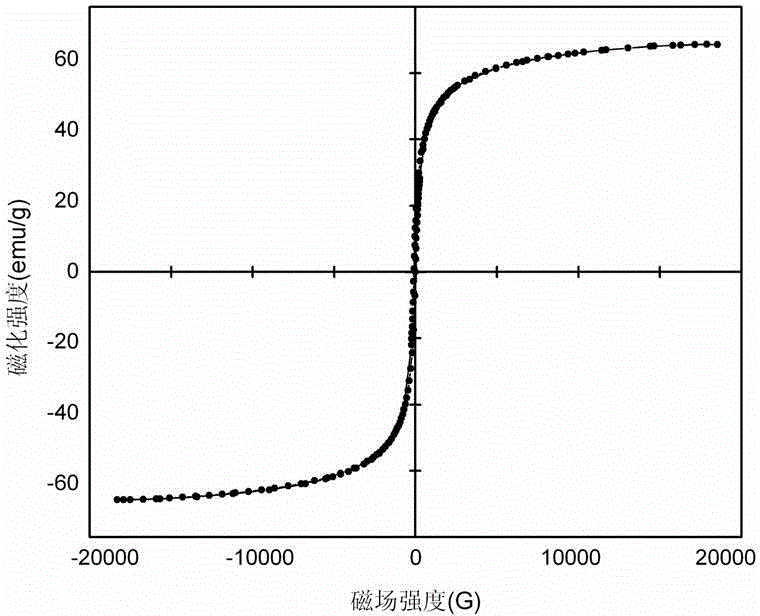

Magnetic graphene oxide nanometer compound, preparation method and application thereof

InactiveCN103947675AImprove antibacterial propertiesHas antibacterial activityBiocideDisinfectantsDisinfection by-productNanoparticle

The invention discloses a magnetic graphene oxide nanometer compound, a preparation method and application thereof. The magnetic graphene oxide nanometer compound comprises graphene oxide, and the surface of graphene oxide is loaded with iron oxides magnetic nanometer particles. The preparation method comprises preparation of a graphene oxide dispersion liquid, preparation of an iron oxides magnetic nanometer particle dispersion liquid and preparation of the magnetic graphene oxide nanometer compound. The magnetic graphene oxide nanometer compound is applicable to water sterilization. The magnetic graphene oxide nanometer compound disclosed by the invention is excellent in antibacterial performance, efficient and easy to separate, the preparation method is simple and low in cost, the water sterilization processing effect is good, disinfection by-products is not easy to generate and secondary pollution is not easy to cause.

Owner:HUNAN UNIV

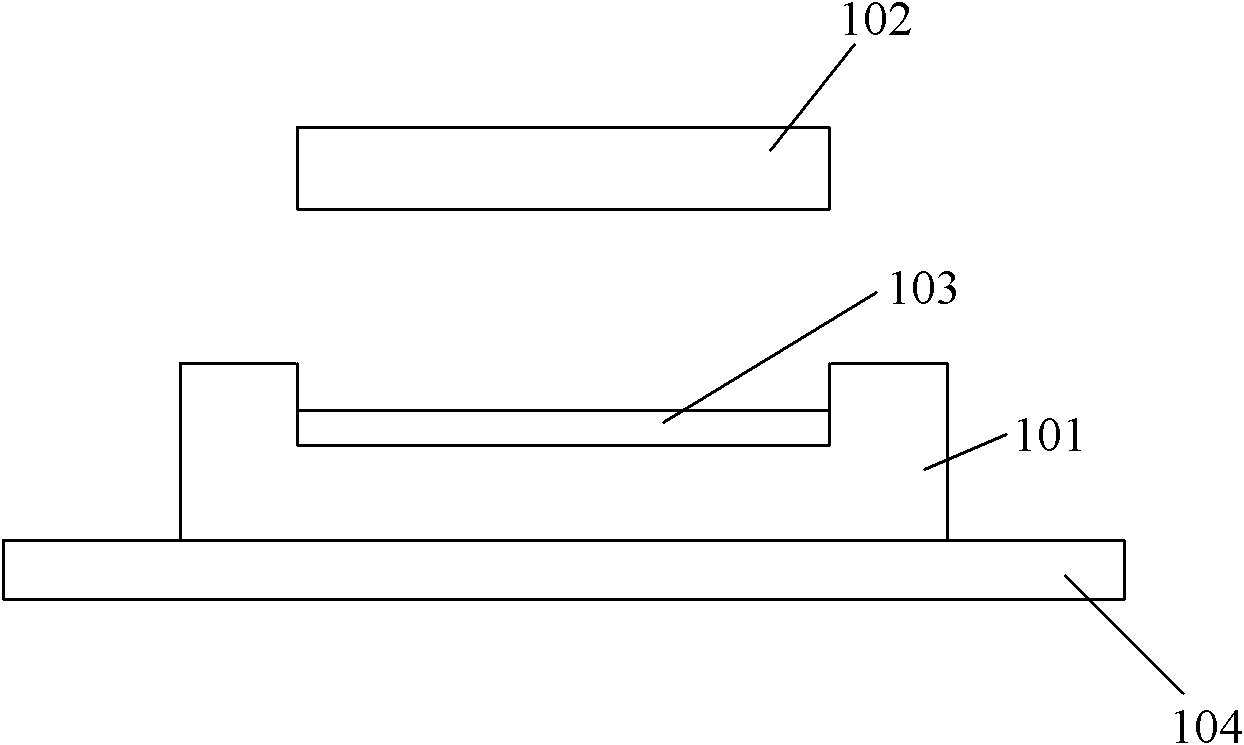

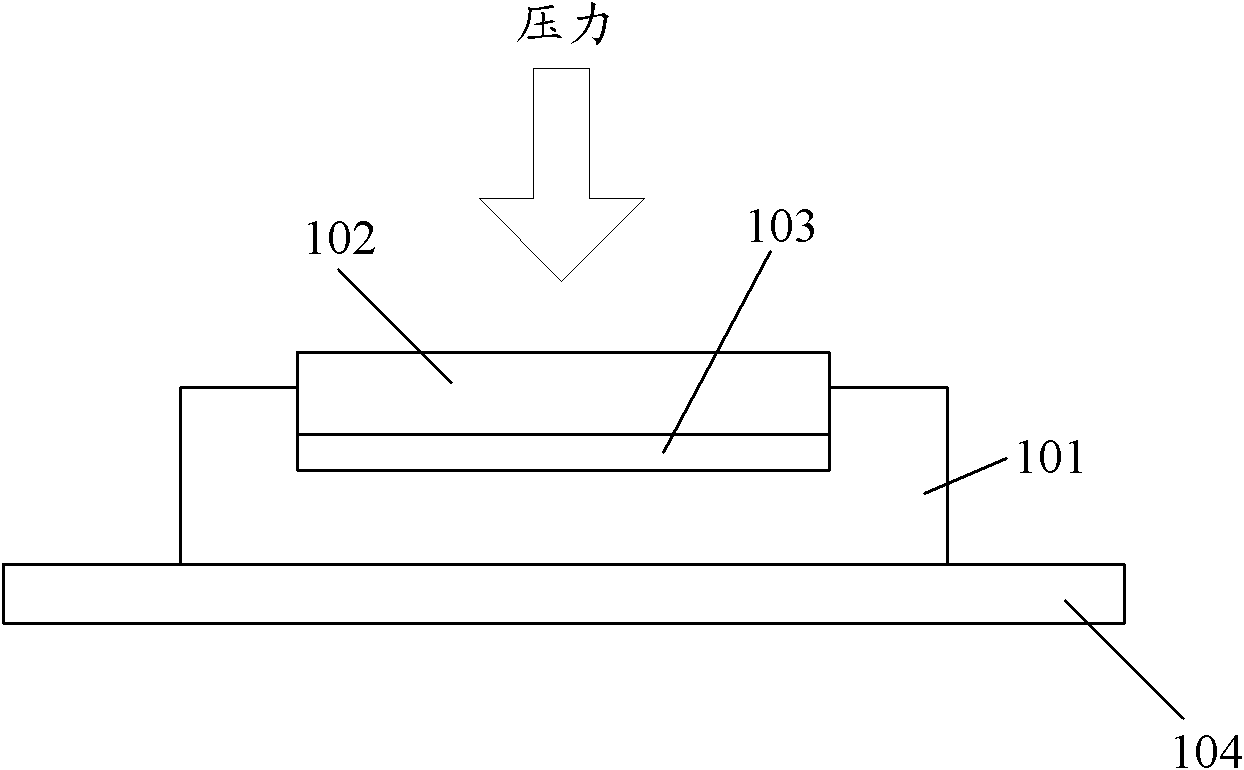

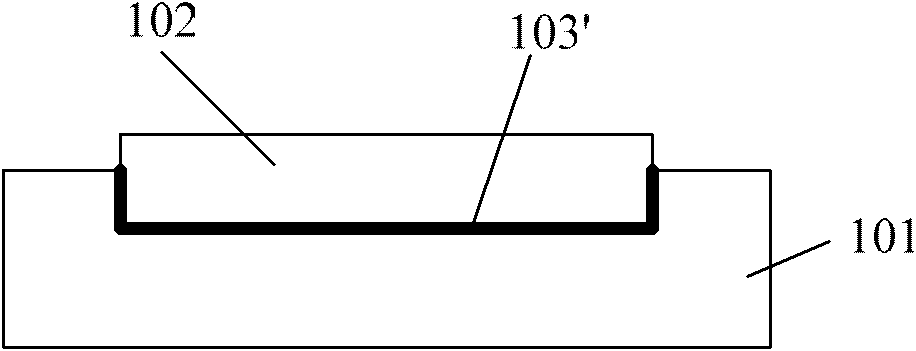

Welding method for target and back plate

InactiveCN102133669ARealize mass productionIncrease productivityElectric discharge tubesVacuum evaporation coatingBatch productionBackplane

The invention relates to a welding method for a target and a back plate, comprising the steps of: providing the target and the back plate; adding welding flux on welding surfaces of the target and the back plate, and matching the target and the back plate; putting the target and the back plate after being matched into a coil; applying current to the coil, carrying induction heating on the target and the back plate after being matched, and then welding the heated target and the heated back plate into a target component; and cooling the target component. In the welding method, fast heating can be carried out on the target and the back plate as well as the welding flux so as to finish the braze welding of the target and the back plate to form the target component, so that the production efficiency can be improved, and the large-batch production of the target component can be realized.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

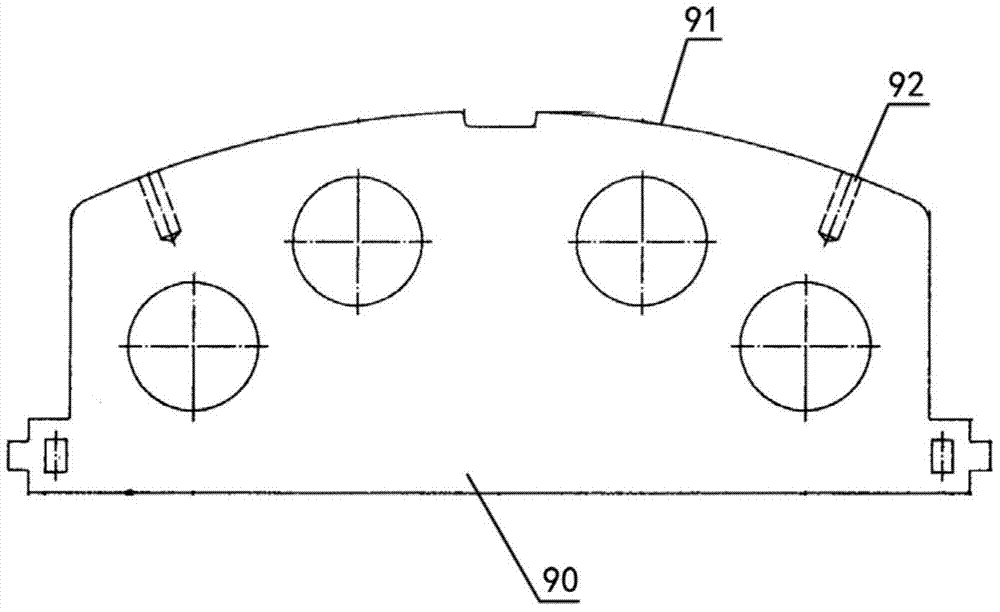

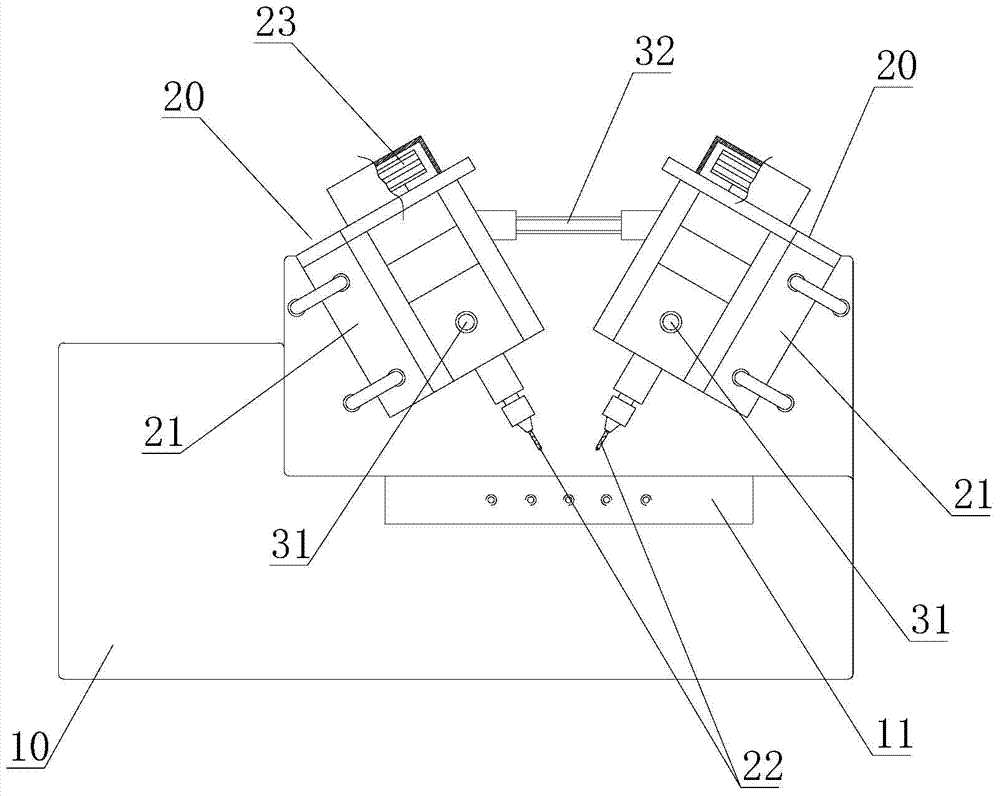

Angle-adjustable drilling machine

ActiveCN103752892AEasy to adjustRealize mass productionLarge fixed membersBoring/drilling componentsHigh volume manufacturingDrilling machines

The invention provides an angle-adjustable drilling machine comprising a base frame and a drilling device. A machining platform is erected on the base frame, and the drilling device is arranged above the machining platform. The angle-adjustable drilling machine is further characterized by comprising an angle adjusting device; the angle adjusting device comprises an adjusting mechanism and a shaft, and the shaft is correspondingly fixed to the machining platform, and is pivoted to the drilling device; the adjusting mechanism and the drilling device are connected to adjust and limit the inclined angle. The angle-adjustable drilling machine has the advantages that the angle adjusting device is arranged for the drilling machine, so that a drill bit can be conveniently adjusted to different required angles to perform hole-drilling operations on a horizontal plane, and components required to be provided with inclined holes can be produced in large scale.

Owner:FUJIAN HUARI AUTOMOTIVE PARTS

Silver zinc oxide electric contact material and preparation method thereof

InactiveCN101944441AEasy to oxidizeUniform metallographic structureFinal product manufactureContactsPunchingZinc alloys

The invention discloses a silver zinc oxide electric contact material and a preparation method thereof, and belongs to the technical field of electrical materials. The method comprises the following steps of: melting and ingoting silver, zinc and additives in a smelter according to a certain weight ratio, sintering and extruding into strips, and drawing to form a silver-zinc alloy wire material; oxidizing the silver-zinc alloy wire material to obtain a silver zinc oxide wire material; cutting the wire material into pieces by an open-back inclinable press, pressing the cut pieces in a steel die to manufacture an extruded stock, and sintering and extruding the cut pieces to manufacture a plate or a wire material; polishing the surface of the extruded plate, performing hot rolling on silver, rolling, punching and molding; and drawing, annealing and drawing the extruded wire material to a finished product wire material with phi of between 0.5 and 3.0mm to produce the rivet electric contact. In the method, the silver-zinc wire material is used for oxidation, so the alloy is easily oxidized without special oxidizing equipment; the metallographic phase of the material has uniform tissue without an oxidation zinc lean region or oxidation aggregation, and the consistency of the material performance, high compactness and good processing performance can be ensured; the method can realize mass production and has low production cost; and the production process and the material per se have no pollution to the environment.

Owner:YANGZHOU LEYIN ALLOY TECH

Preparation method for high reliability large-scale silicon nitride ceramic material

ActiveCN101538162ASuit one's needsImprove performance indicatorsHigh volume manufacturingPerformance index

The invention provides a preparation method for high reliability large-scale silicon nitride ceramic material, which comprises the following steps: a sintering aid is added into silicon nitride powder and well bended in medium to prepare a ground paste; the ground paste is dried and then formed by isostatic cool pressing; atmosphere pressure sintering is carried out. The density of the silicon nitride bearing ball prepared by atmosphere pressure sintering is larger than 98.5%, the strength is 700-900 MPa, the fracture toughness property is 8-9MPa-m<1 / 2>, and the hardness is larger than 15 GPa; after hot isosotatic pressing treatment, the density of the silicon nitride bearing ball is larger than 99%, the strength is 800-1000 MPa, the fracture toughness property is 8-10MPa-m<1 / 2>, and the hardness is larger than 15 GPa; compared with the large-scale silicon nitride products prepared by the existing atmospheric pressure sintering process, the performance indexes of the silicon nitride ceramic material can fully meet the requirement of high-power aerogenerator on the large-scale bearing ball; the large quantities of production can be realized with relatively low manufacture cost.

Owner:BEIJING SINOMA SYNTHETIC CRYSTALS CO LTD +1

Mobile phone shell with 3D structure and processing technology thereof

The invention discloses a mobile phone shell with a 3D structure. The shell comprises a surface shell body and a bottom shell body. The surface shell body and the bottom shell body comprise sheet material layers which are made of a transparent material and possess outer transparent surfaces and inner transparent surfaces, hardening layers which form on the outer transparent surfaces and possess a predetermined thickness, local printing layers which form at any local positions of the inner transparent surfaces, texture transfer printing layers which form on the inner transparent surfaces and cover the local printing layers, vacuum electroplated layers and printing ink layers, wherein the vacuum electroplated layers and the printing ink layers are successively superimposed with the texture transfer printing layers. The invention also discloses a processing technology. By using the mobile phone shell with the 3D structure, on one hand, the shell possesses light transmittance performance which is similar to the light transmittance performance of glass, simultaneously can bear a large impact force and can not be fragmented so that a durability problem during a usage process is solved, and the shell accords with human engineering of a hand portion of a person and satisfies a customized demand of a consumer; on the other hand, through the above technology, mass production in industry is realized and production cost is reduced.

Owner:东莞市汇诚塑胶金属制品有限公司

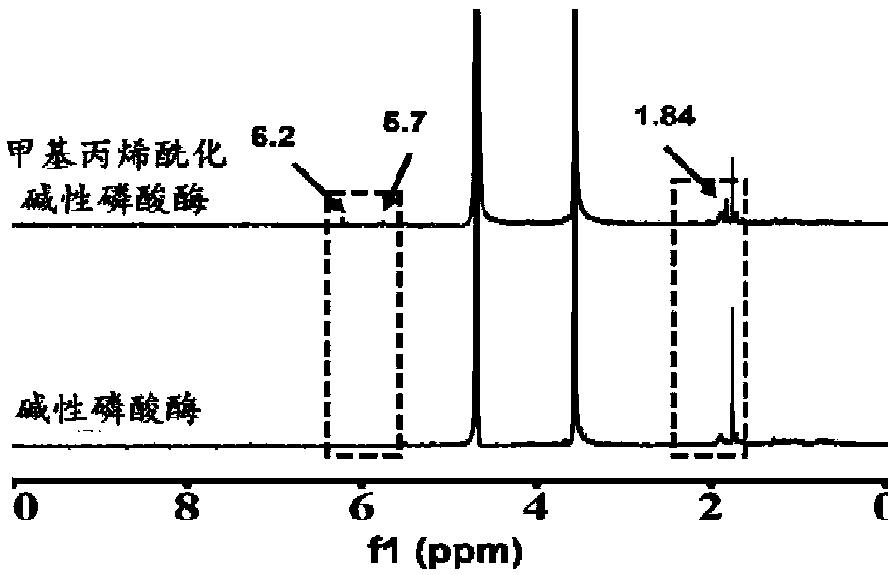

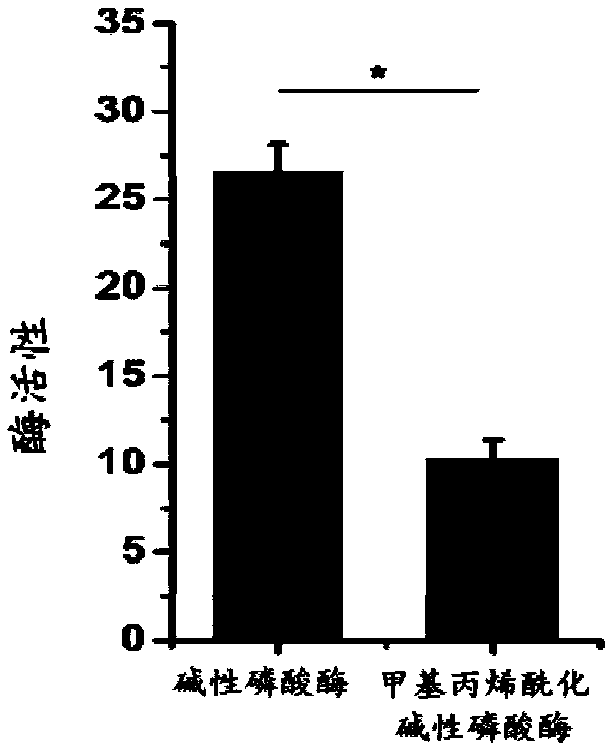

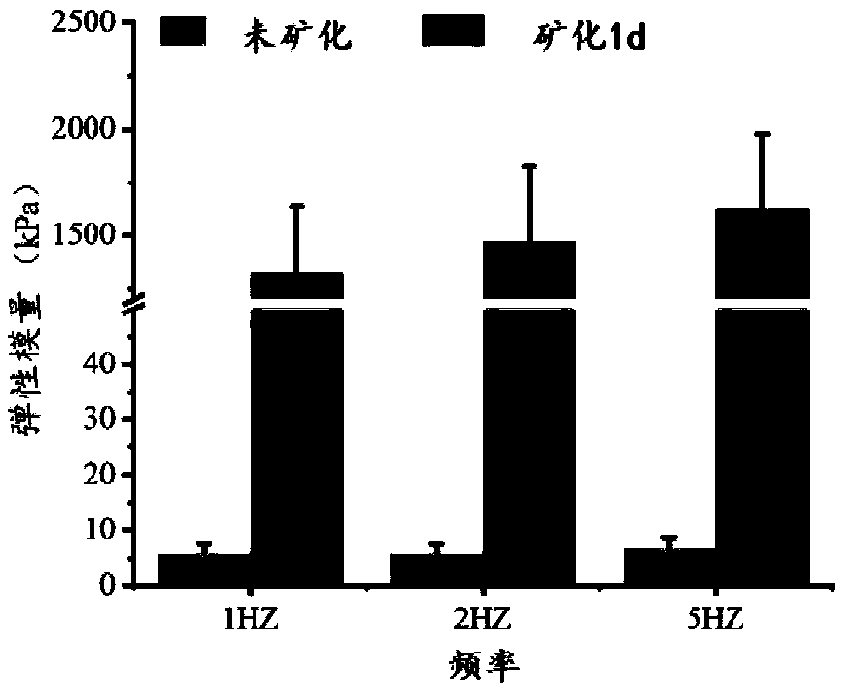

Preparation methods of mineralized hydrogel and biomimetic mineralized bone repair material

The invention discloses preparation methods of mineralized hydrogel and a biomimetic mineralized bone repair material. The mineralized hydrogel is prepared by using a photoactivated biomacromoleculesand a photoactivated phosphatase as raw materials; hydrogel is formed by initiating cross-linking by means of light irradiation or initiating polymerization cross-linking by means of a radical initiator; when the hydrogel is put into mineralized liquid, phosphatase can promote the uniform deposition of phosphate in the gel, so that the uniformly mineralized hydrogel is obtained. Phosphoprotein-like molecules are added during the preparation of the hydrogel; the phosphoprotein-like molecules can promote the uniform deposition of phosphate along a molecular network of biomacromolecules, so thatthe high-strength mineralized hydrogel can be obtained. When the phosphoprotein-like molecules and cells are added during the preparation of the hydrogel, the in-situ loading of the cells can be realized, and the enzyme in a process of bone physiological mineralization can be simulated so as to promote a phosphate mineralization process, so that the biomimetic mineralized bone repair material withhigh strength can be obtained, and the personalized customization of the bionic mineralized bone repair material can be realized; therefore, the preparation methods have a broad application prospectin the field of bone tissue engineering.

Owner:SICHUAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com