Angle-adjustable drilling machine

A technology of drilling machine and angle adjustment device, which is applied in the direction of boring/drilling, drilling/drilling equipment, parts of boring machine/drilling machine, etc. Difficulty and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

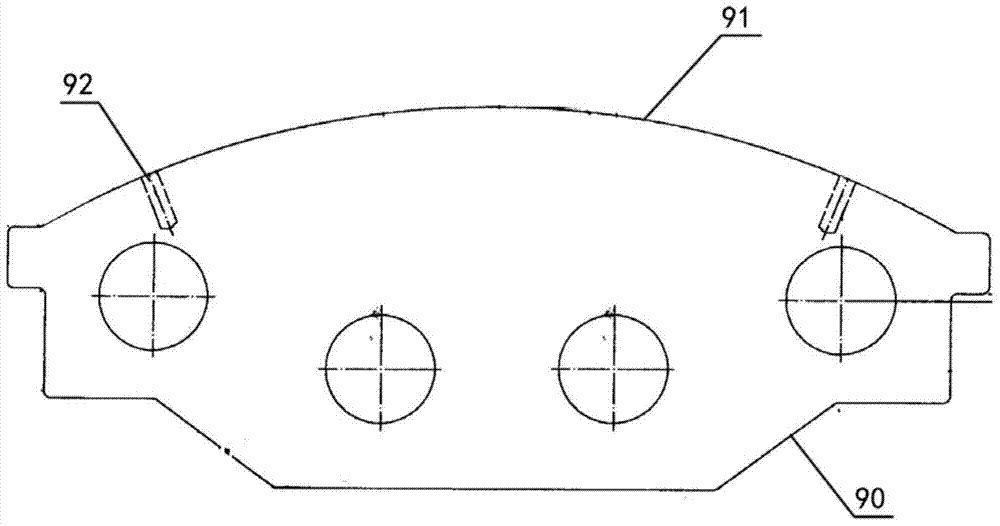

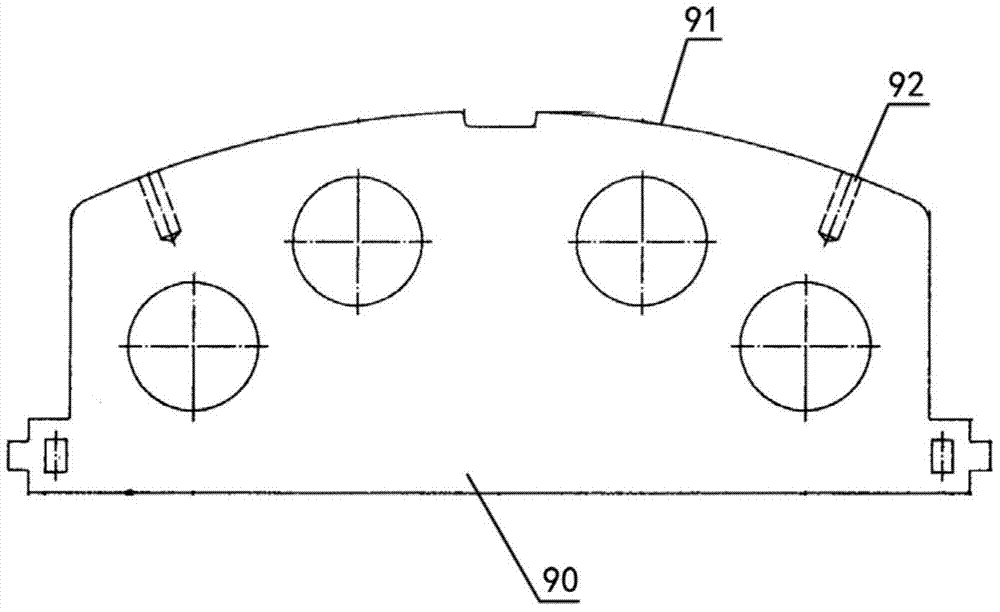

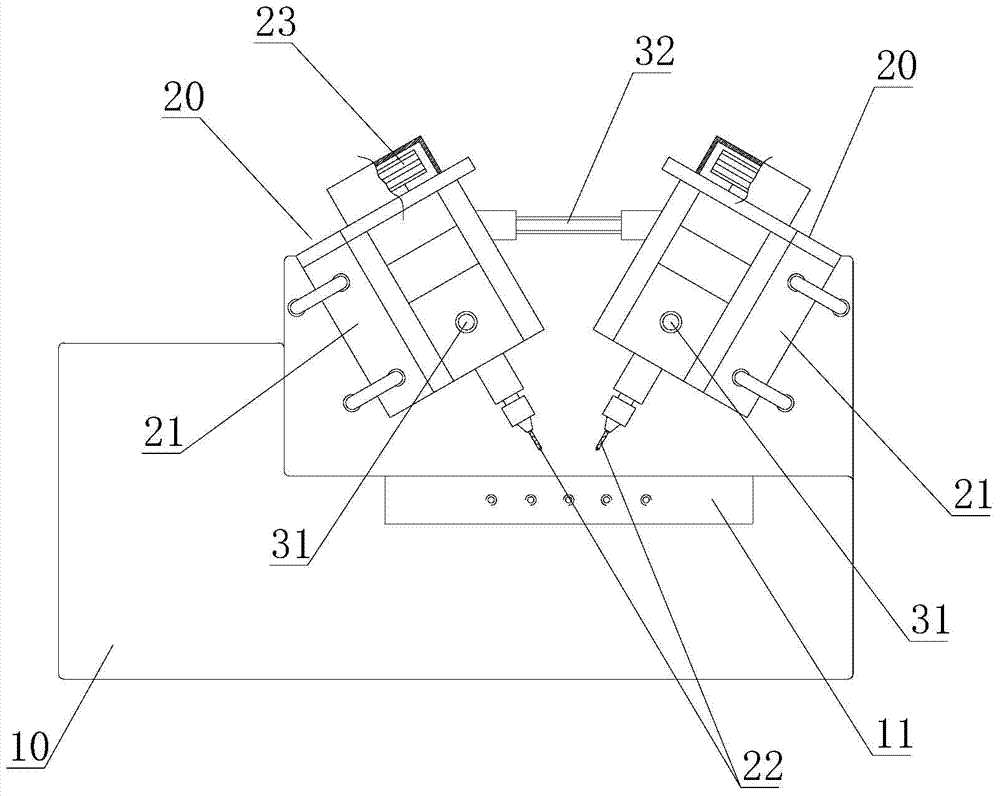

[0021] This embodiment is based on the scheme provided above and is specially used for processing such as figure 1 , 2 The angle adjustable drilling machine of brake pad steel backing plate 90 is shown. It can be seen from the figure that a hole 92 needs to be drilled on the left and right sides of the arc-shaped side 91 of the brake pad steel liner 90, so in order to maximize the production efficiency of this product, in this embodiment, an angle-adjustable drill The hole machine is equipped with two drilling devices at the same time. Correspondingly, the shaft 31 of the angle adjustment device also includes two. In order to ensure the synchronous adjustment of the two drilling devices, the two shafts 31 should also be spaced at the same height and be aligned with each other. The processing platform is arranged relatively fixedly, and furthermore, one of the drilling devices 20 is respectively socketed on each shaft 31 . Further, in this embodiment, the core part of the adj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com