Patents

Literature

7136results about "Boring/drilling components" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

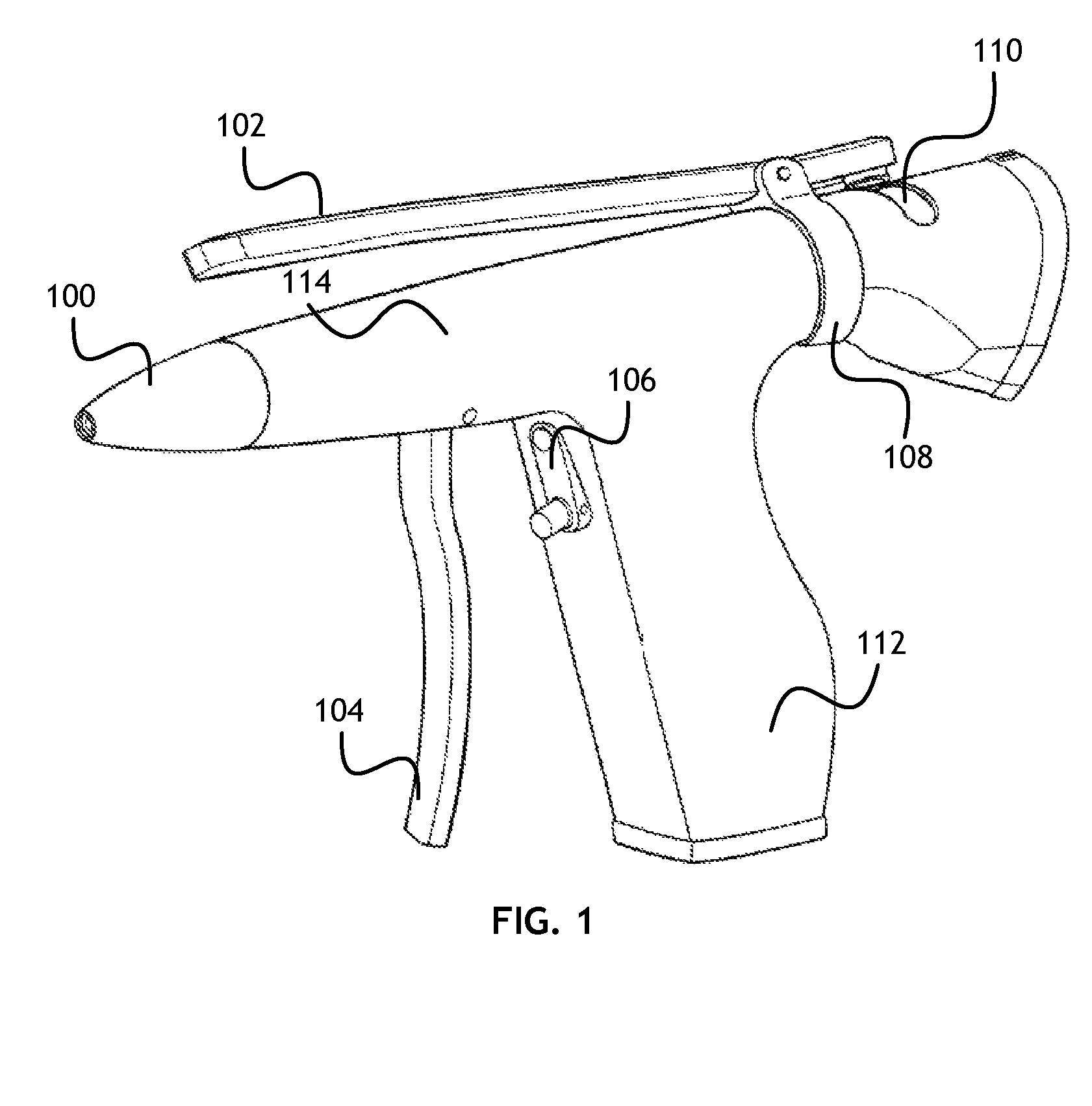

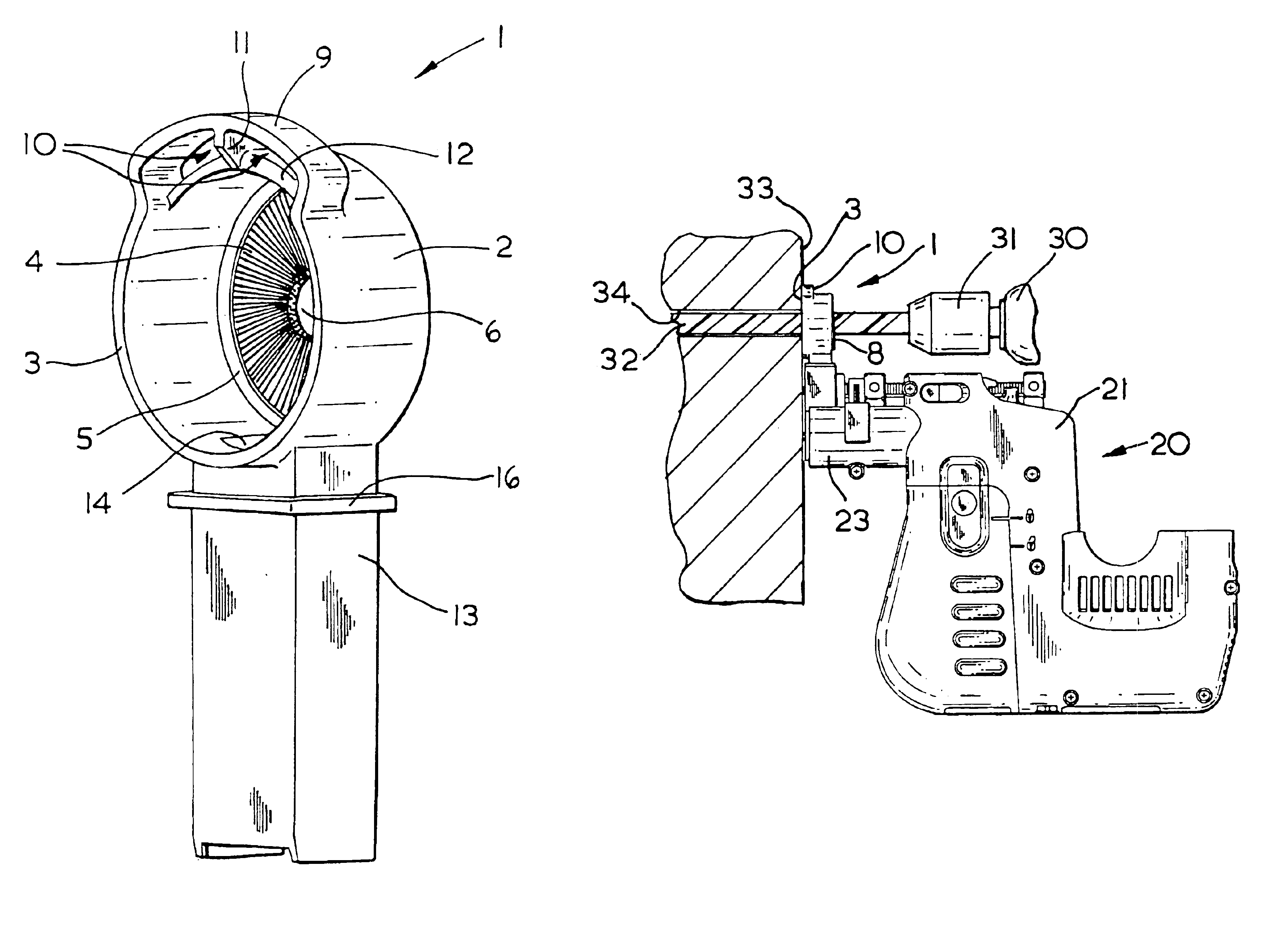

Method and device for ergonomically and ambidextrously operable surgical device

A handheld surgical device includes a multi-position throttle, rotatably attached to the body of the device, to allow for ambidextrous positioning of a motor speed control lever. The motor speed control lever may interact with a speed control sensor in the body of the device capable of detecting the actuation level of the motor speed control lever in any one of two or more positions.

Owner:MICROAIRE SURGICAL INSTR

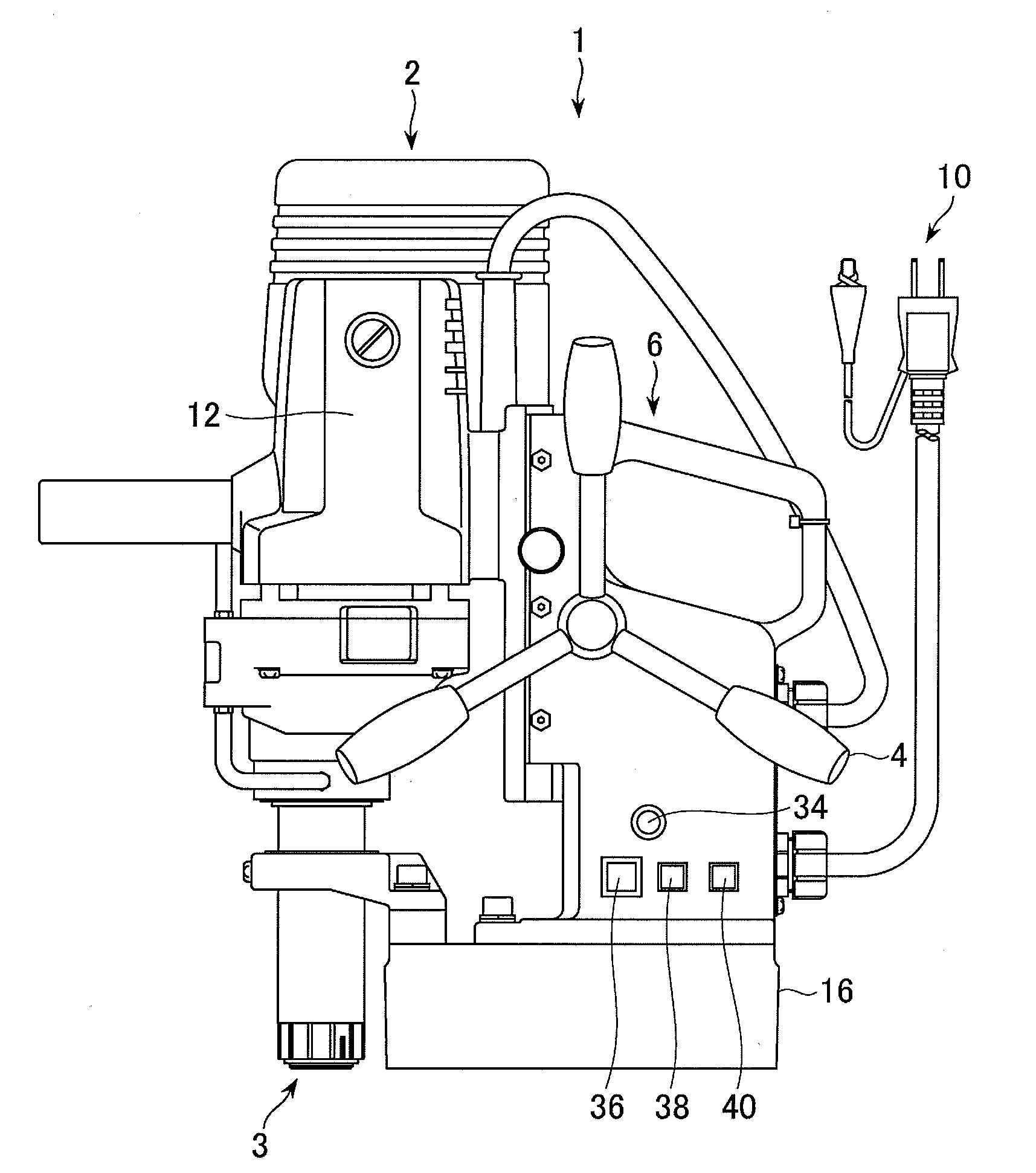

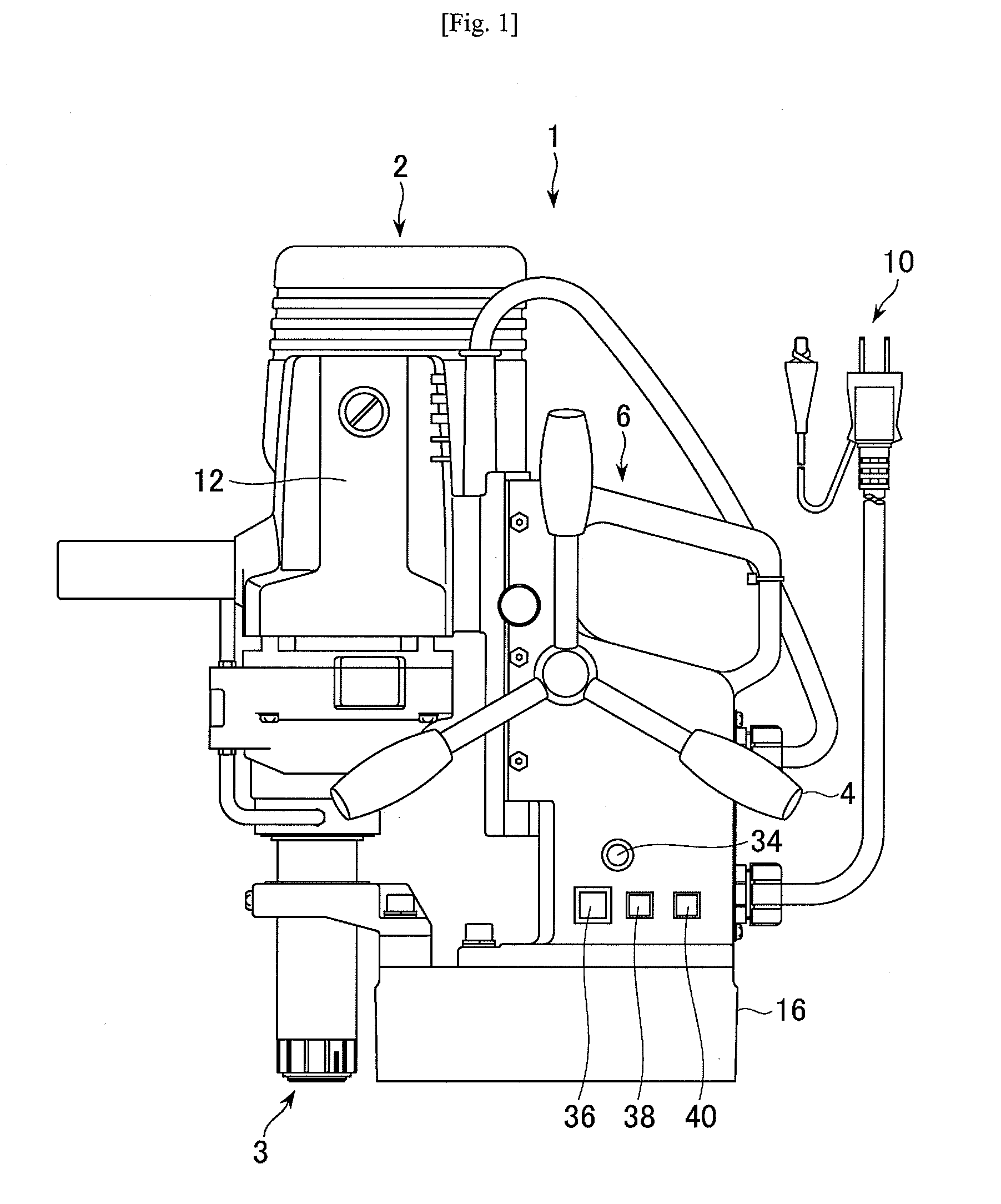

Portable drilling device

ActiveUS7936142B2Easy to operateImprove securityAC motor controlDC motor speed/torque controlFull waveEngineering

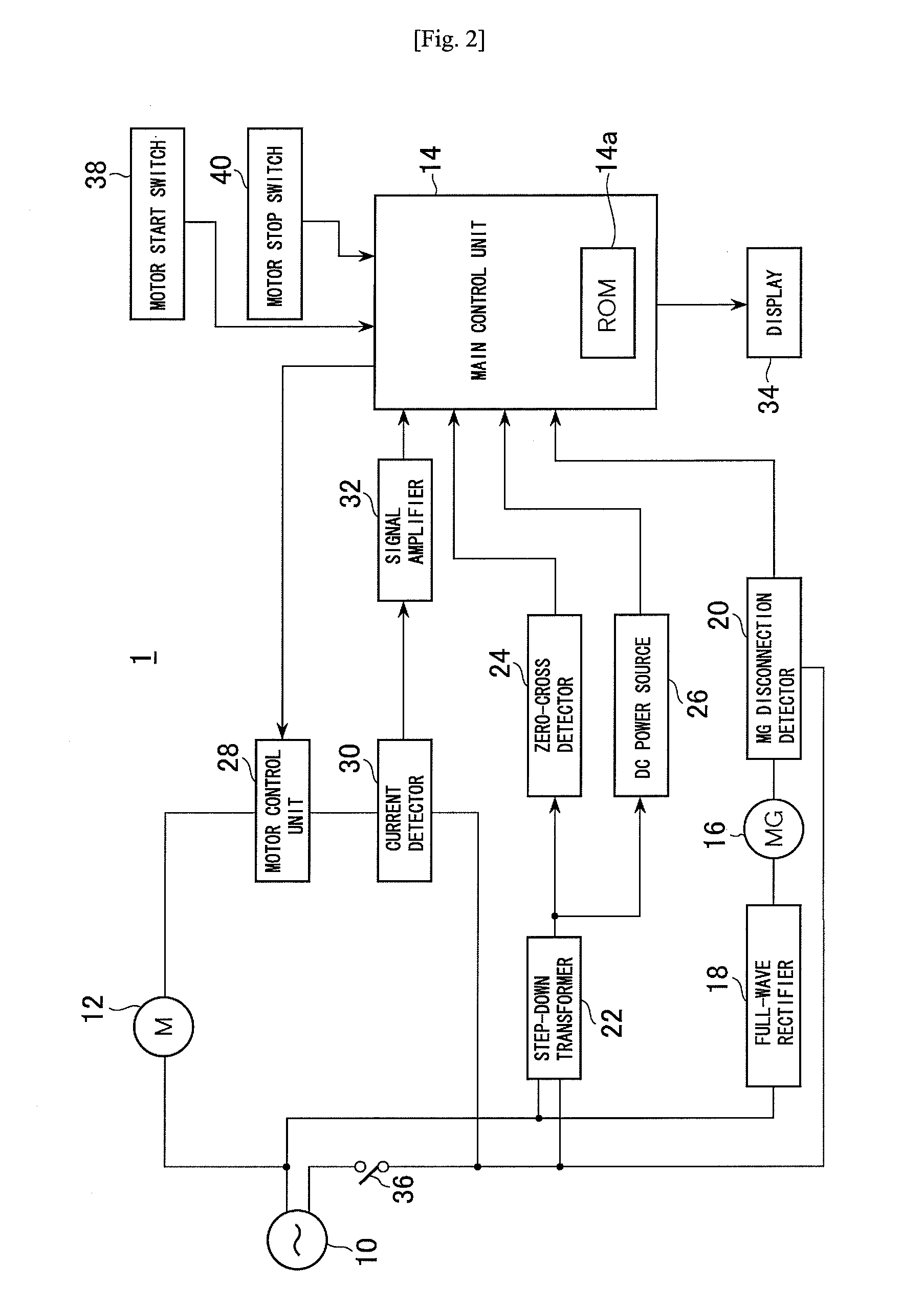

A drilling device prevents recurrence of an overload condition after occurrence of the overload condition, thereby improving operability and safety in the drilling device. A motor for rotating a drill is connected to an AC power source through a motor control unit, a current detector, and a power switch. A magnet is also connected to the AC power source through the power switch and a full-wave rectifier. The motor control unit rotationally drives the motor on the basis of a signal sent from a main control unit according to a state in which a motor start switch is on. The main control unit controls the motor control unit to gradually reduce a supply voltage to the motor when the motor becomes overloaded, to gradually increase the voltage to the normal power supply condition when the overload condition is vanished, and to stop power supply to the motor if the overload condition continues for a predetermined period.

Owner:NITTO KOHKI CO LTD

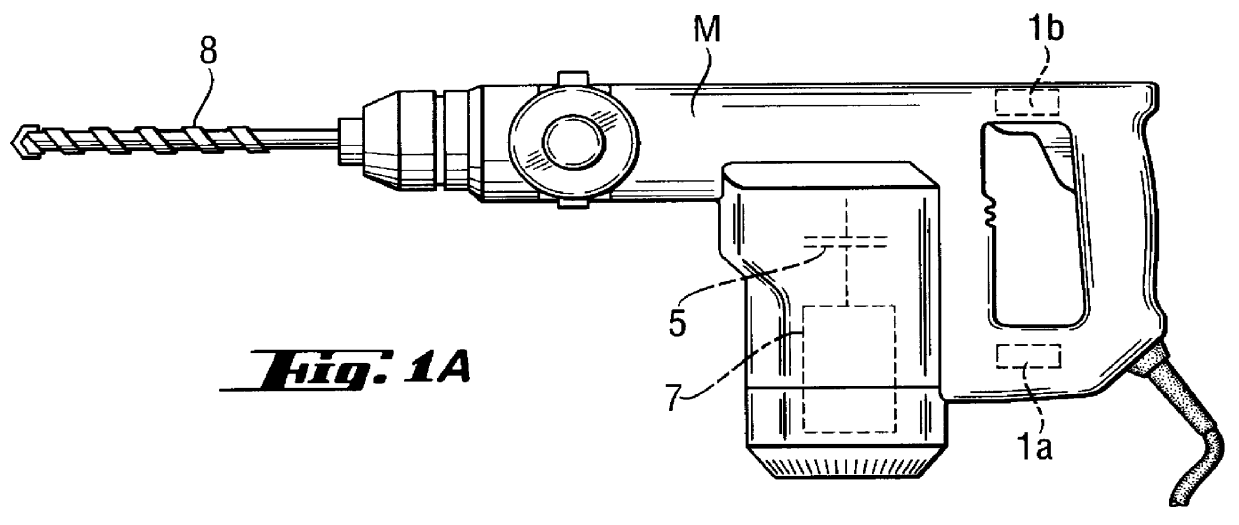

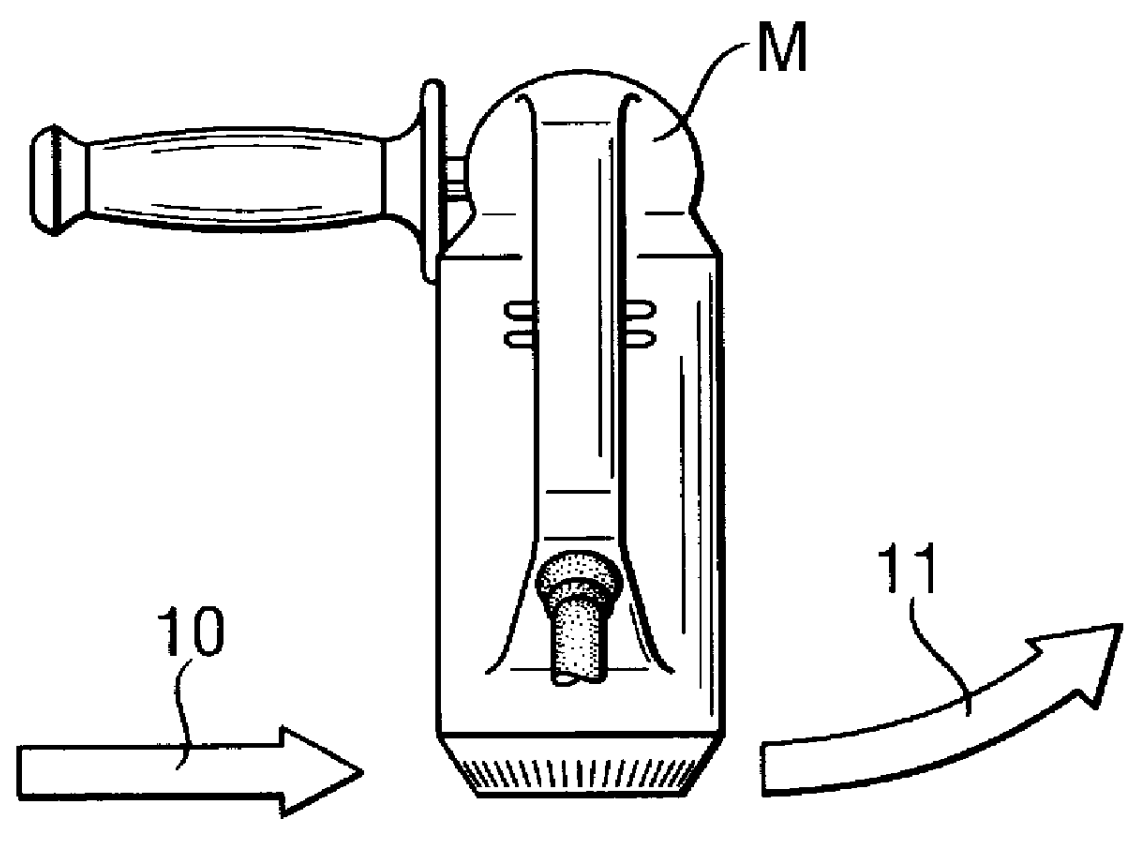

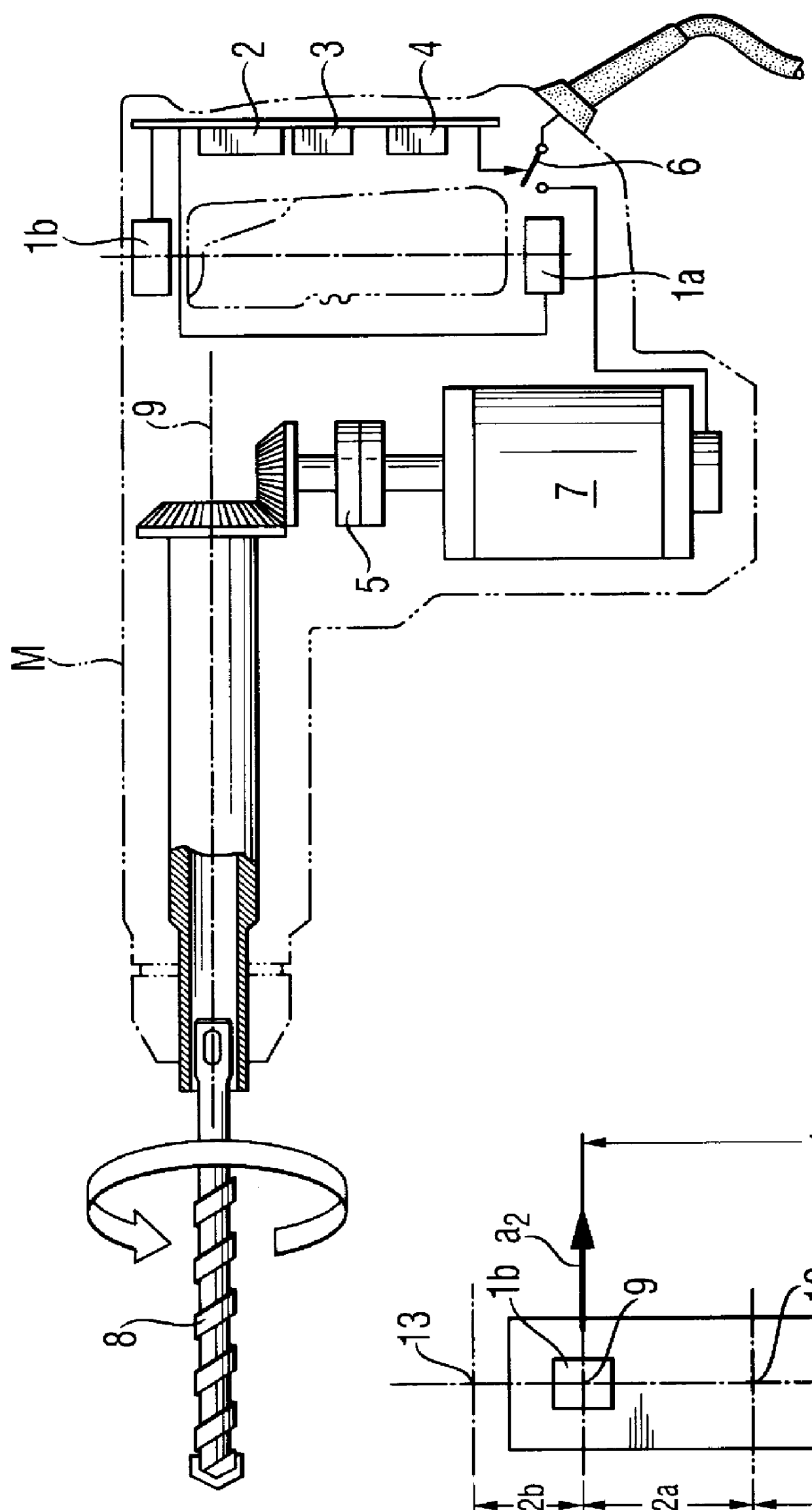

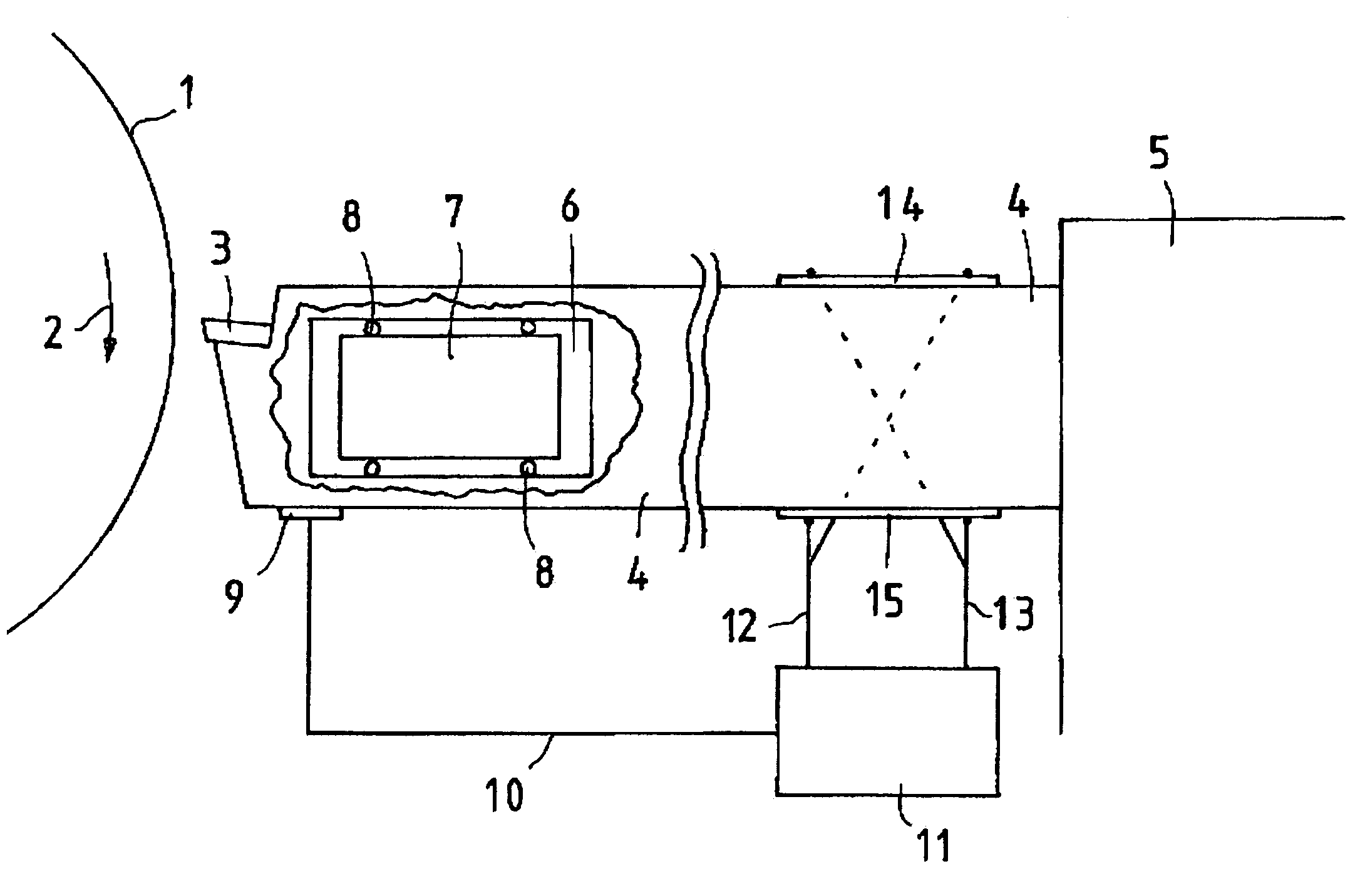

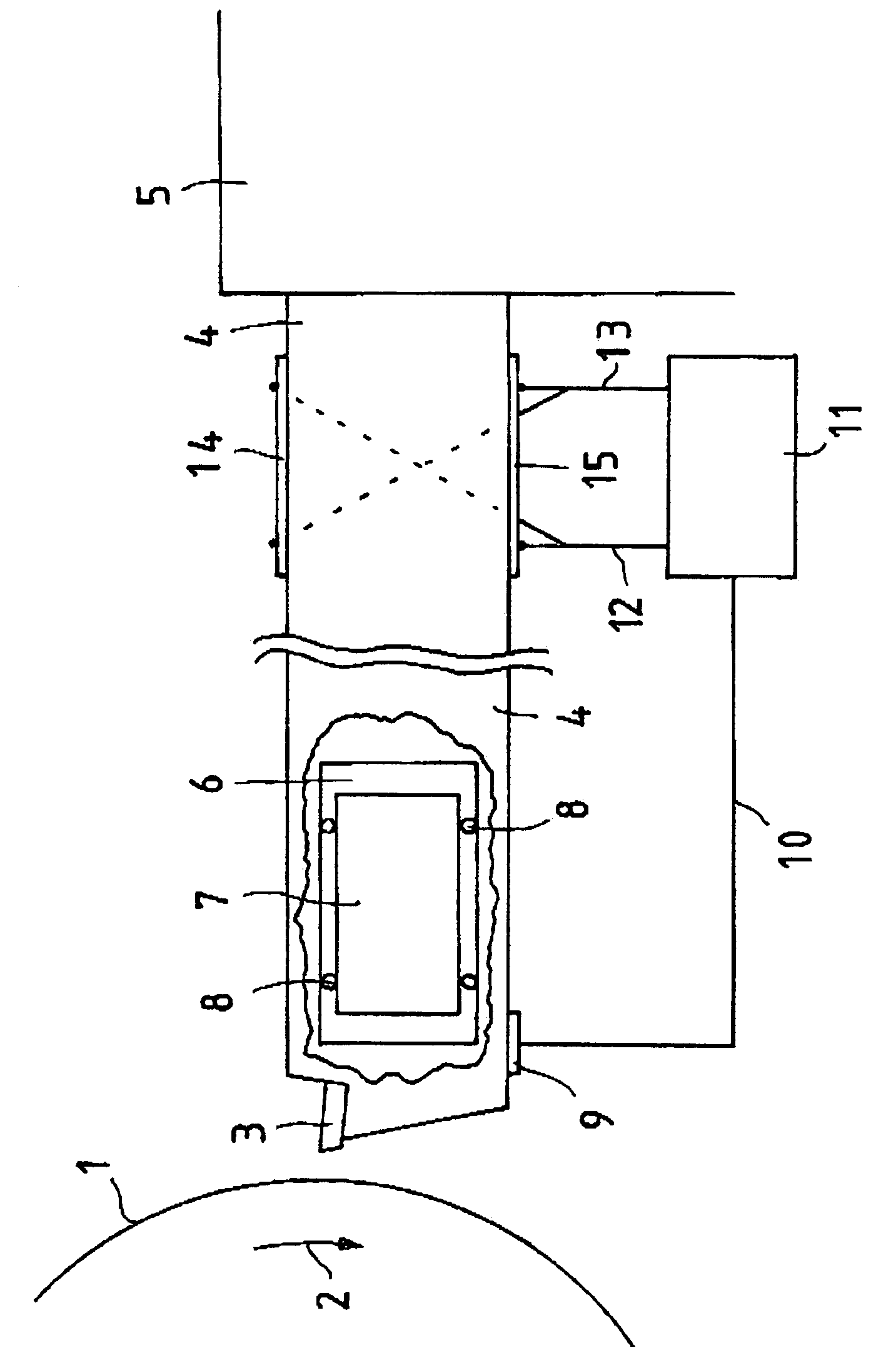

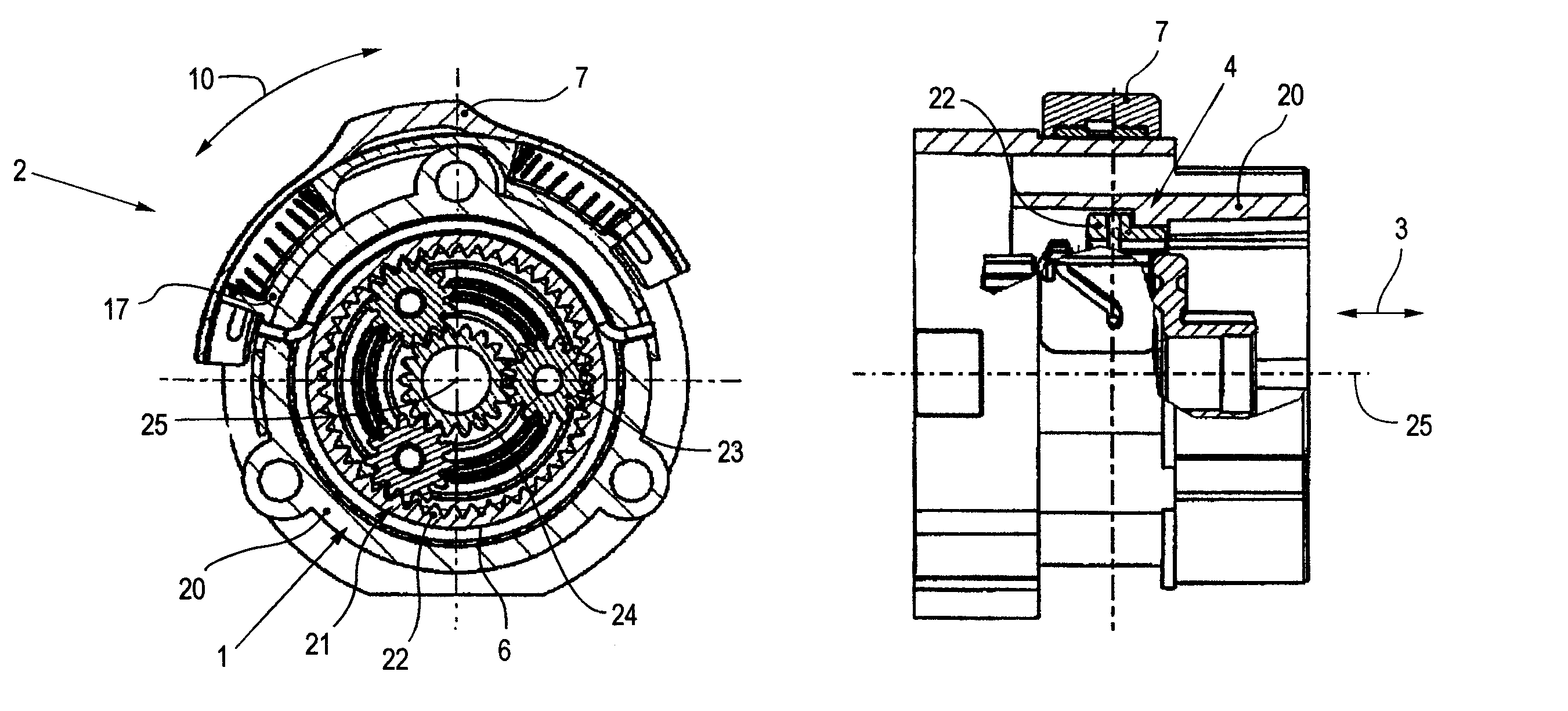

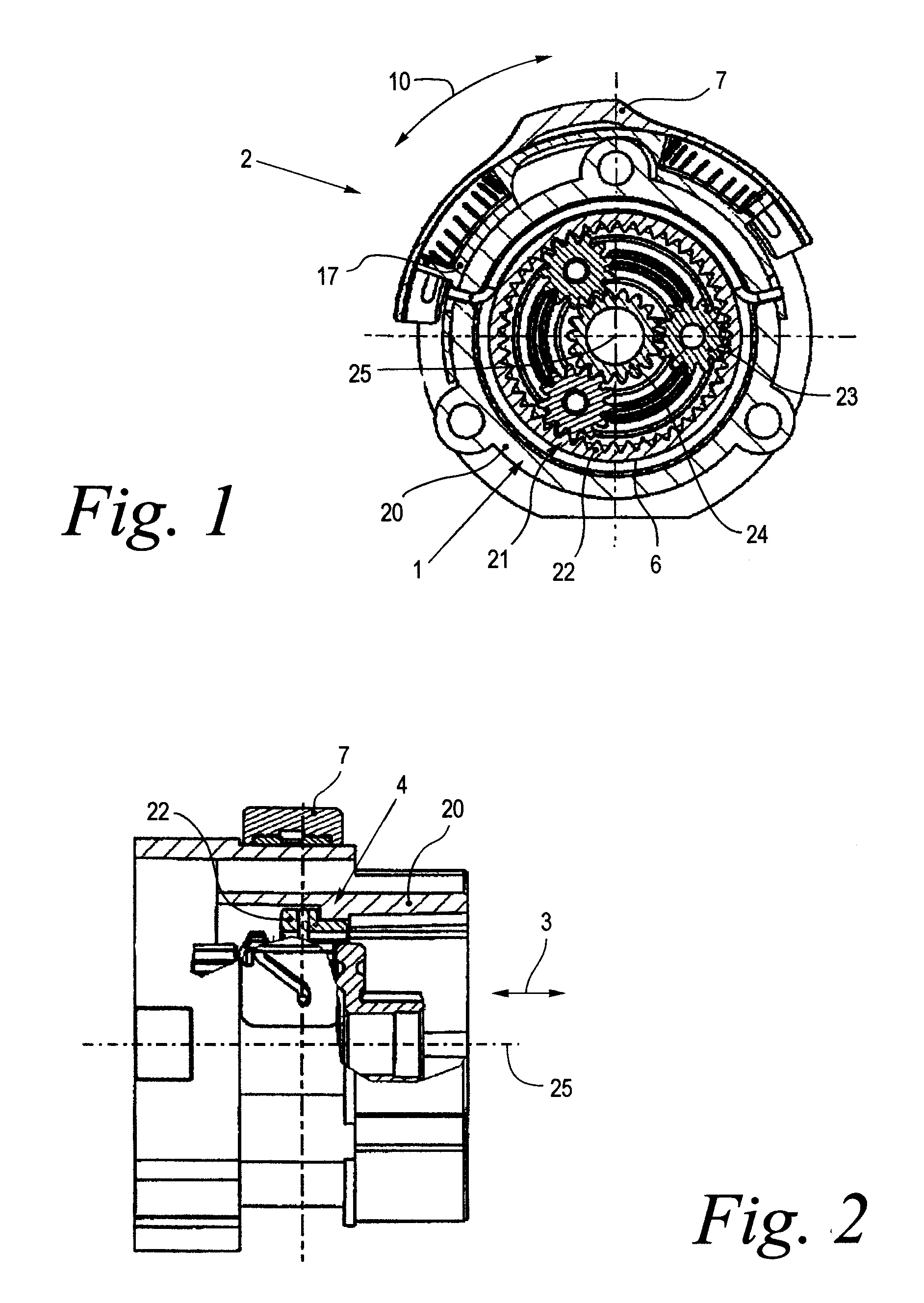

Method of and apparatus for preventing accidents during working with hand-held tools with a rotatable working tool

InactiveUS6111515AAvoid accidentsPortable percussive toolsPortable power-driven toolsElectric machineryHand held

A method of and an apparatus for preventing accidents caused by blockage of a rotatable tool when working with a hand-held tool including the rotatable tool (8), a drive motor (7) for driving the rotatable tool (8), and means (5, 6) for interrupting transmission of a drive torque from the drive motor (7) to the rotatable tool (8) dependent on an operational condition of the hand-held tool, with the method including determining the operational condition of the hand-held tool by measuring displacement of the hand-held tool in space in at least two points of the hand-held tool spatially spaced from each other and spaced from a tool axis; subtracting two obtained displacement measurement variable (a.sub.1, a.sub.2) from each other; and thereafter, calculating an actuation signal that actuates the interrupting means (5, 6); and with the apparatus including sensors and an evaluation circuit for implementing the method.

Owner:HILTI AG

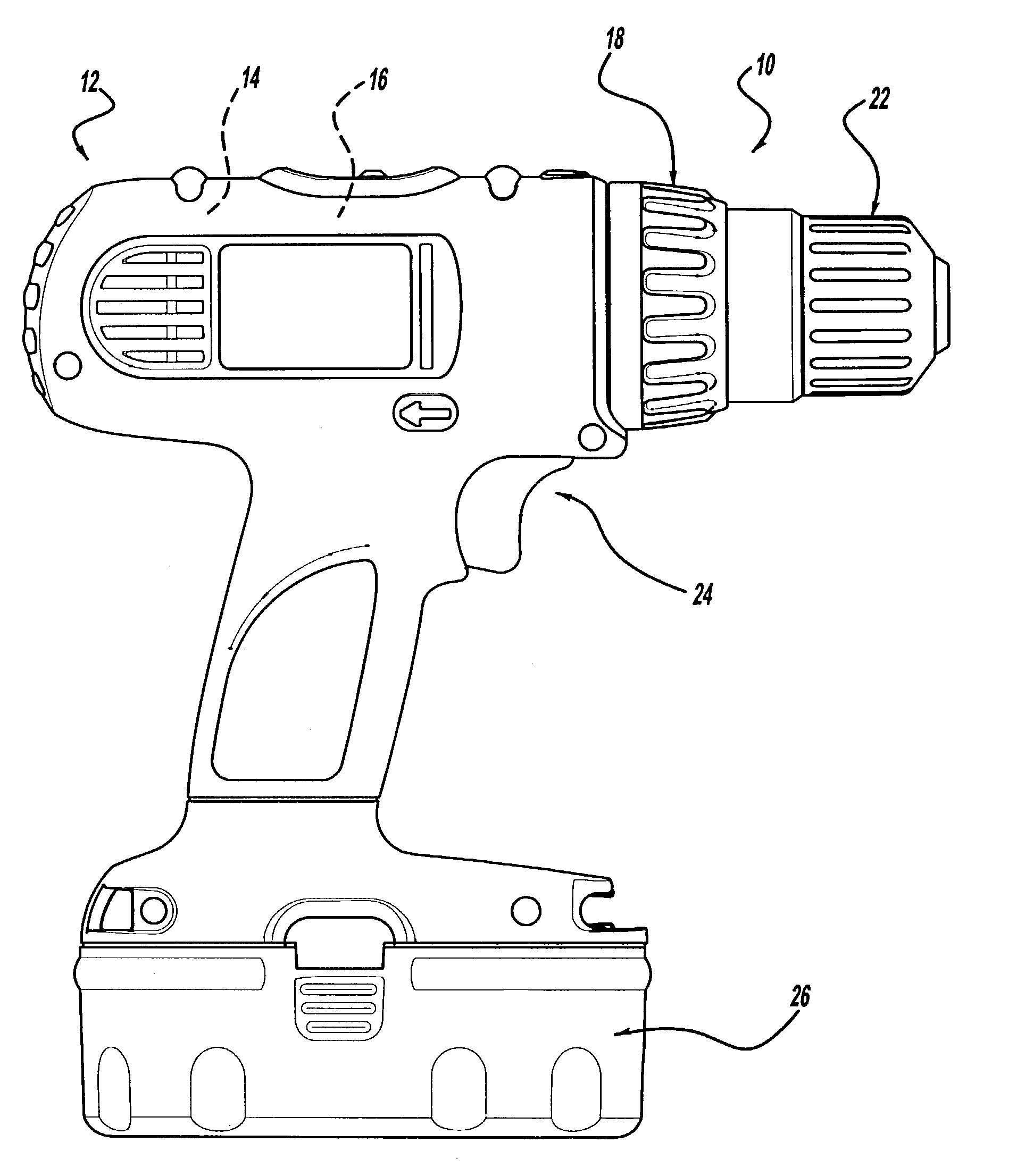

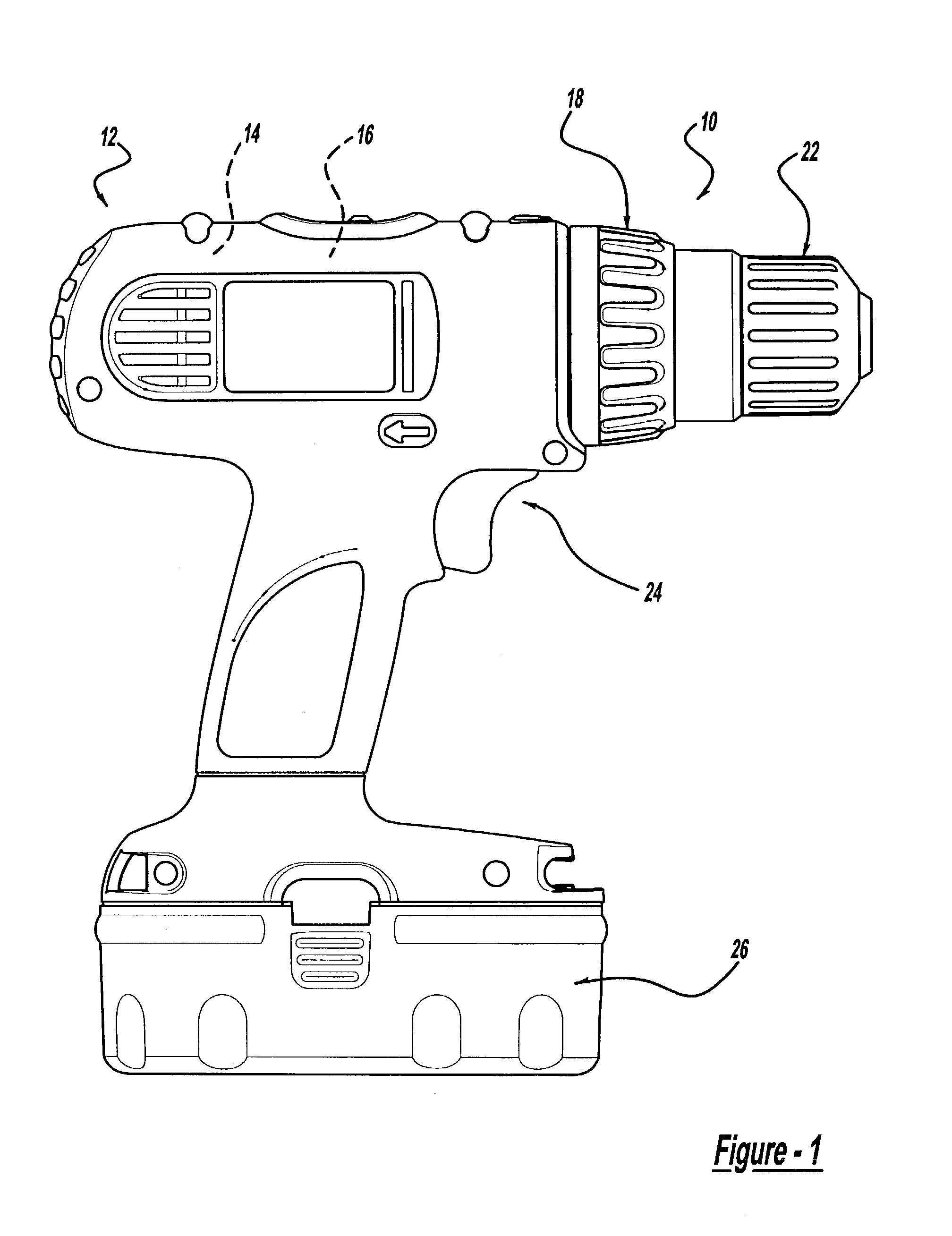

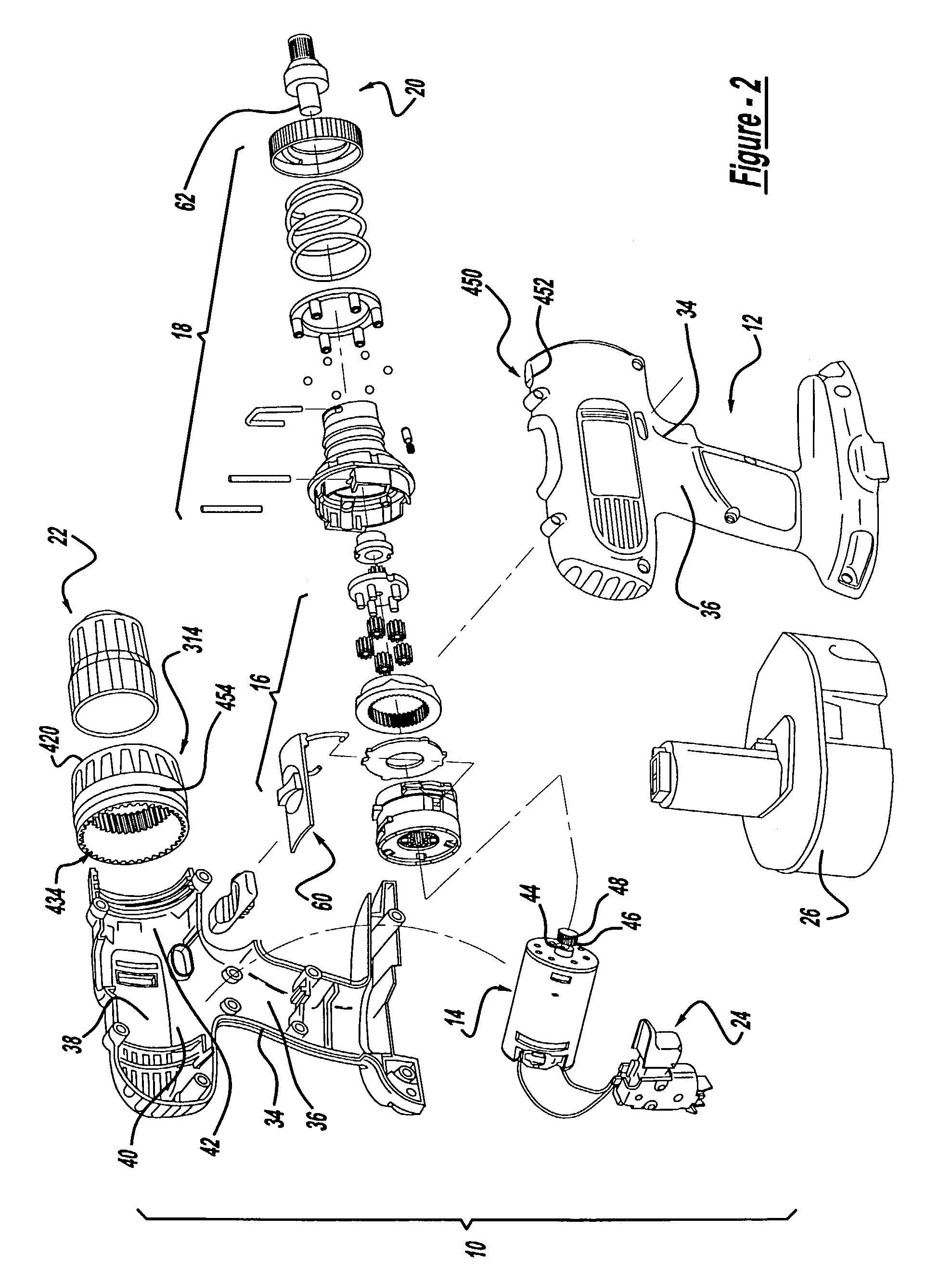

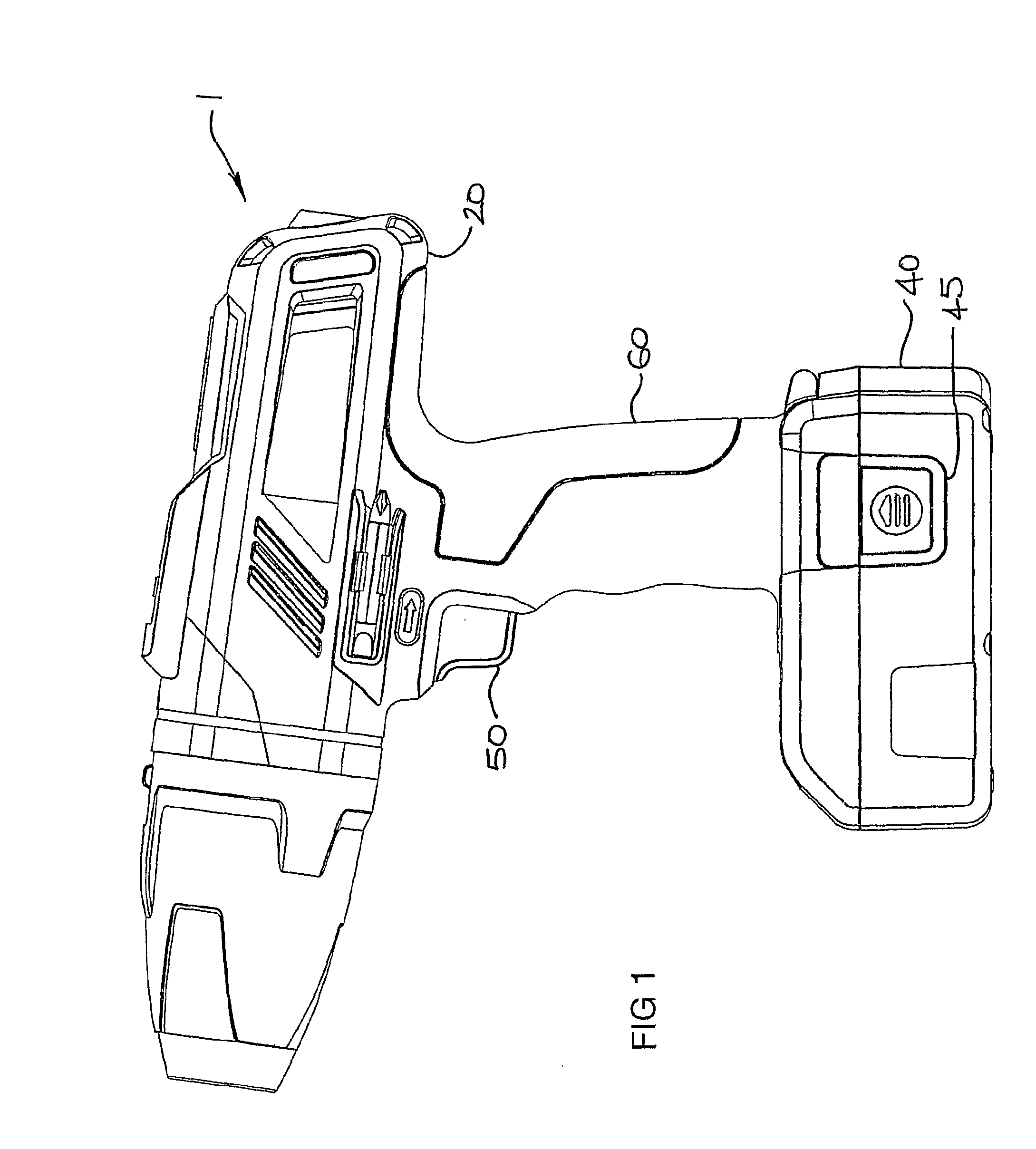

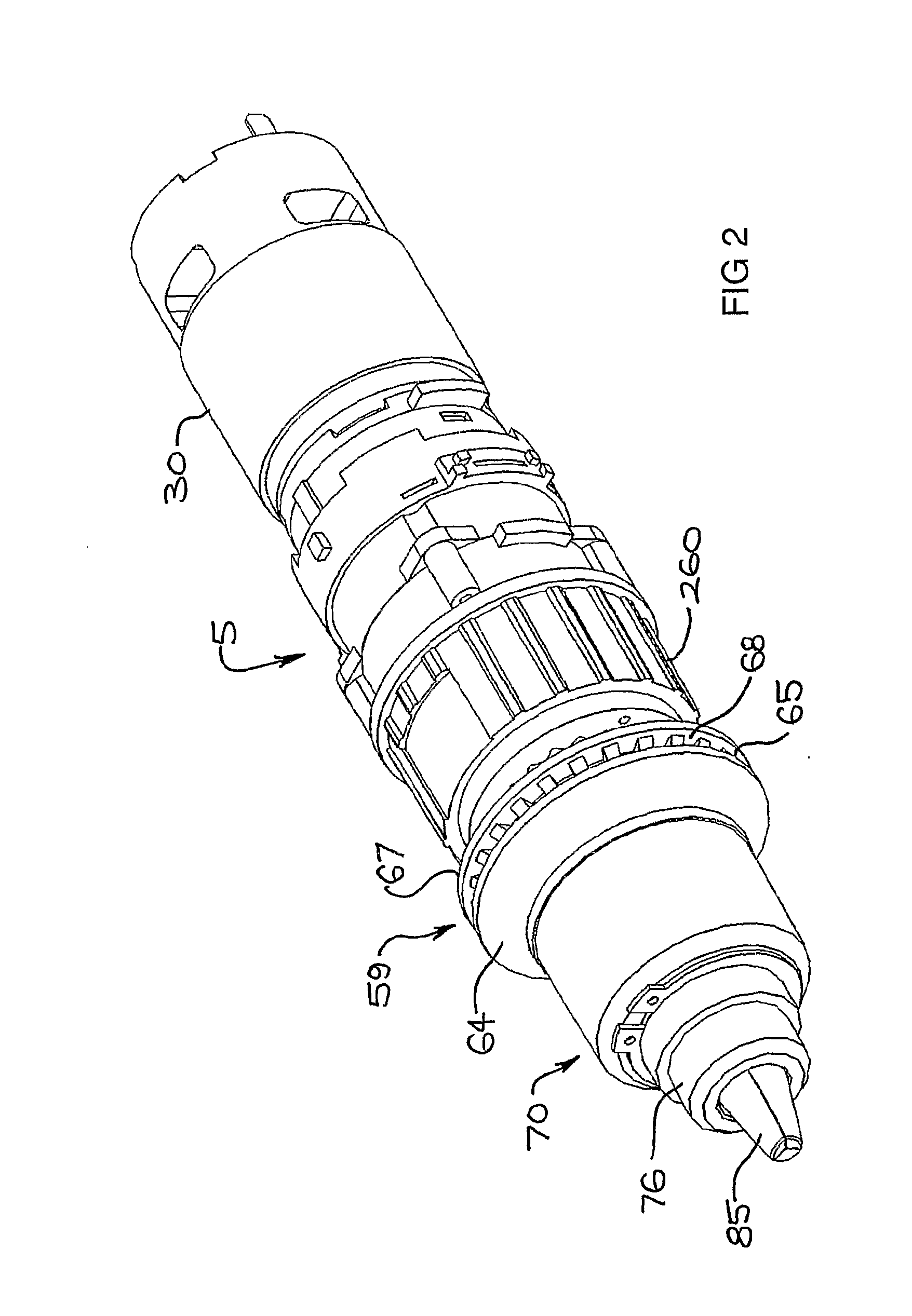

Power drill/driver

ActiveUS7066691B2Limit torsional outputOptimization mechanismThread cutting auxillary apparatusSlip couplingHand heldEngineering

A hand-held power tool having a multi-speed transmission and a clutch. The multi-speed transmission and the clutch are coupled to one another via a set of interconnecting tabs that are slidingly engaged to one another and secured with pins to inhibit the withdrawal of the tabs from one another. The clutch may include a clutch member, a unitarily formed clutch plate and a plurality of engagement members. The clutch plate includes an annular plate member and a plurality of leg members that extend generally perpendicularly from the annular plate member and which bias the engagement members into engagement with the clutch member. The clutch member may be coupled to an element of the multi-speed transmission, such as to the ring gear of a planetary gear set, so as to reduce the overall size of the power tool.

Owner:BLACK & DECKER INC

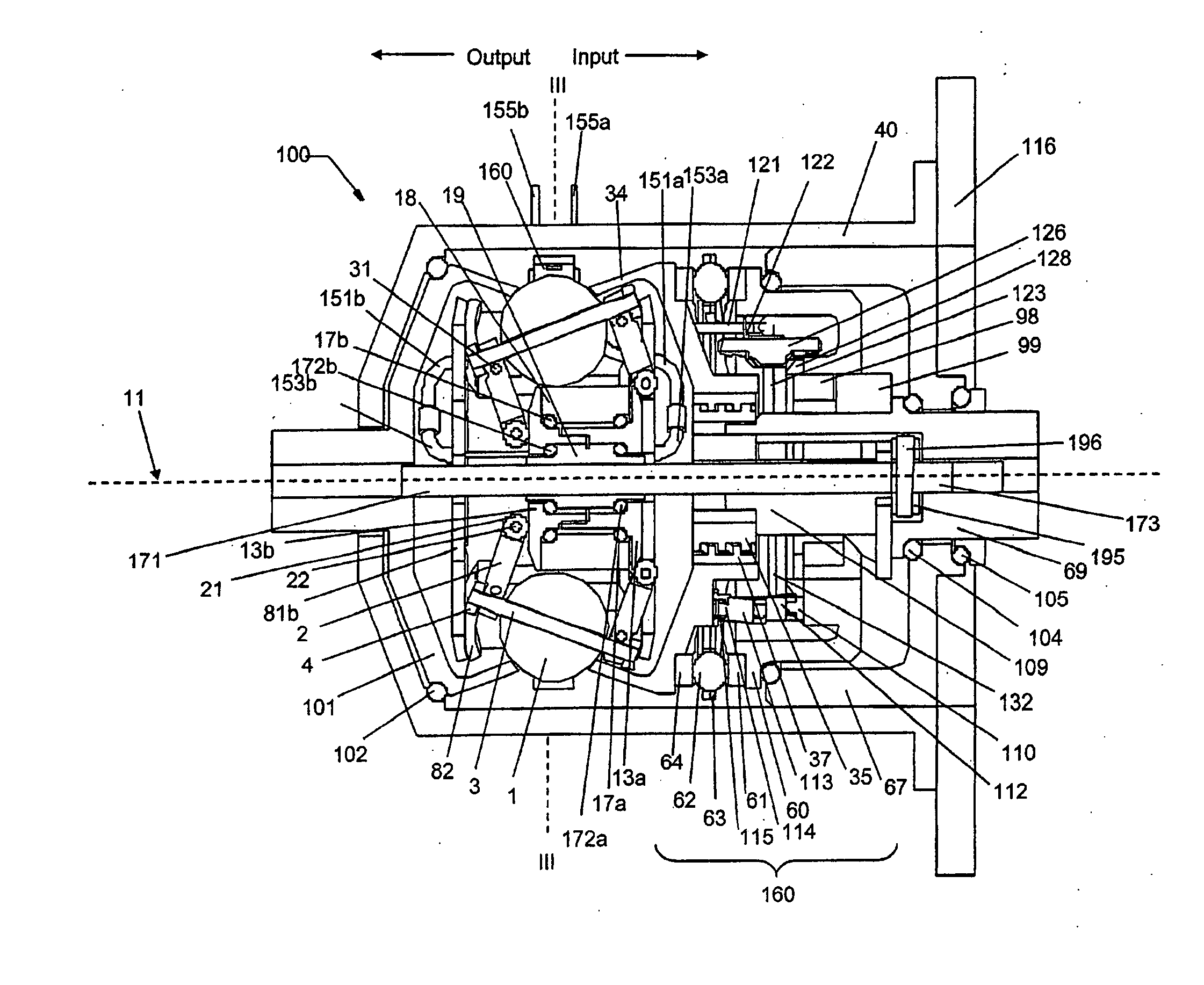

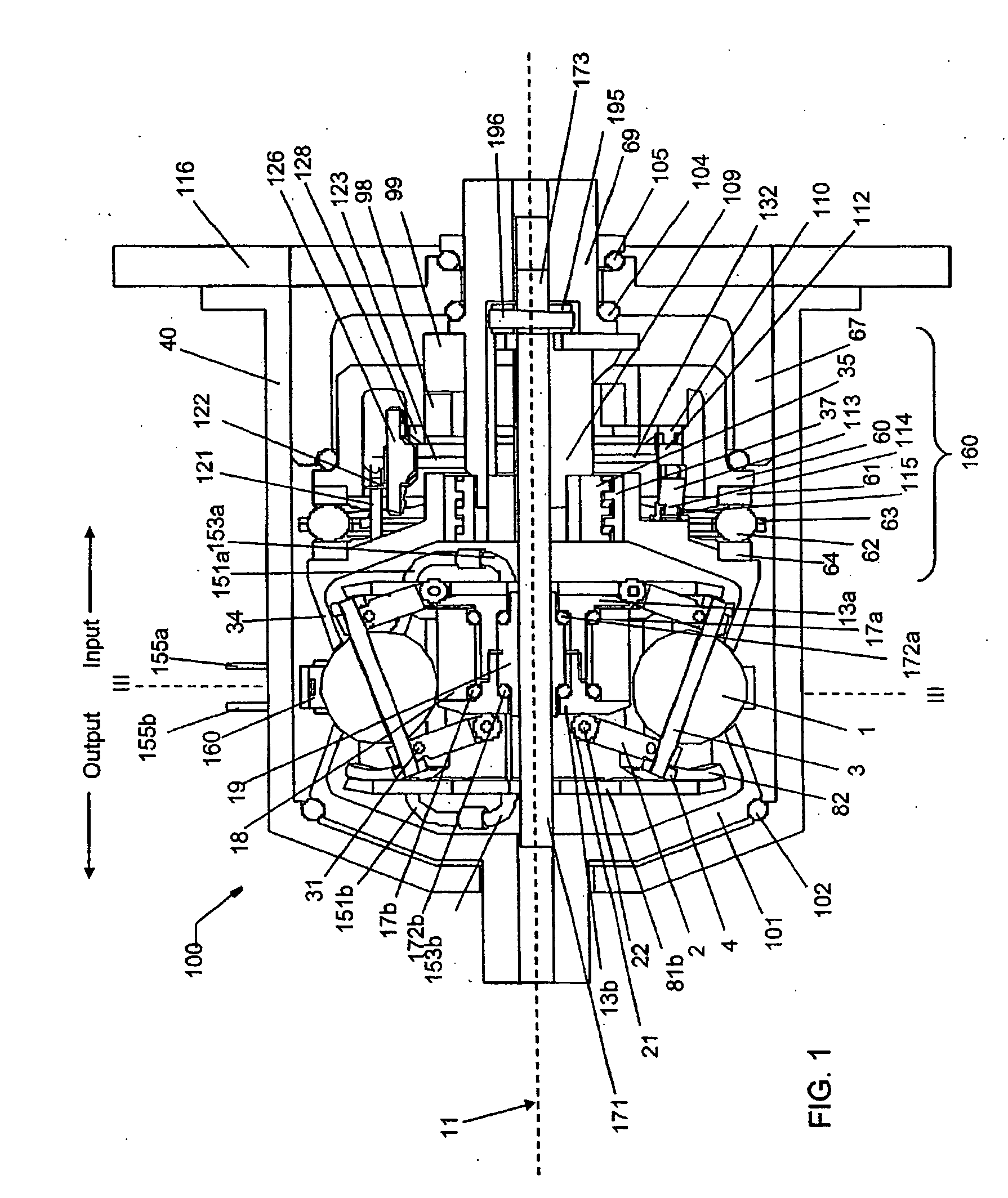

Continuously variable transmission

A variable speed transmission having a plurality of tilting balls and opposing input and output discs is illustrated and described that provides an infinite number of speed combinations over its transmission ratio range. The use of a planetary gear set allows minimum speeds to be in reverse and the unique geometry of the transmission allows all of the power paths to be coaxial, thereby reducing overall size and complexity of the transmission in comparison to transmissions achieving similar transmission ratio ranges.

Owner:FALLBROOK INTPROP COMPANY

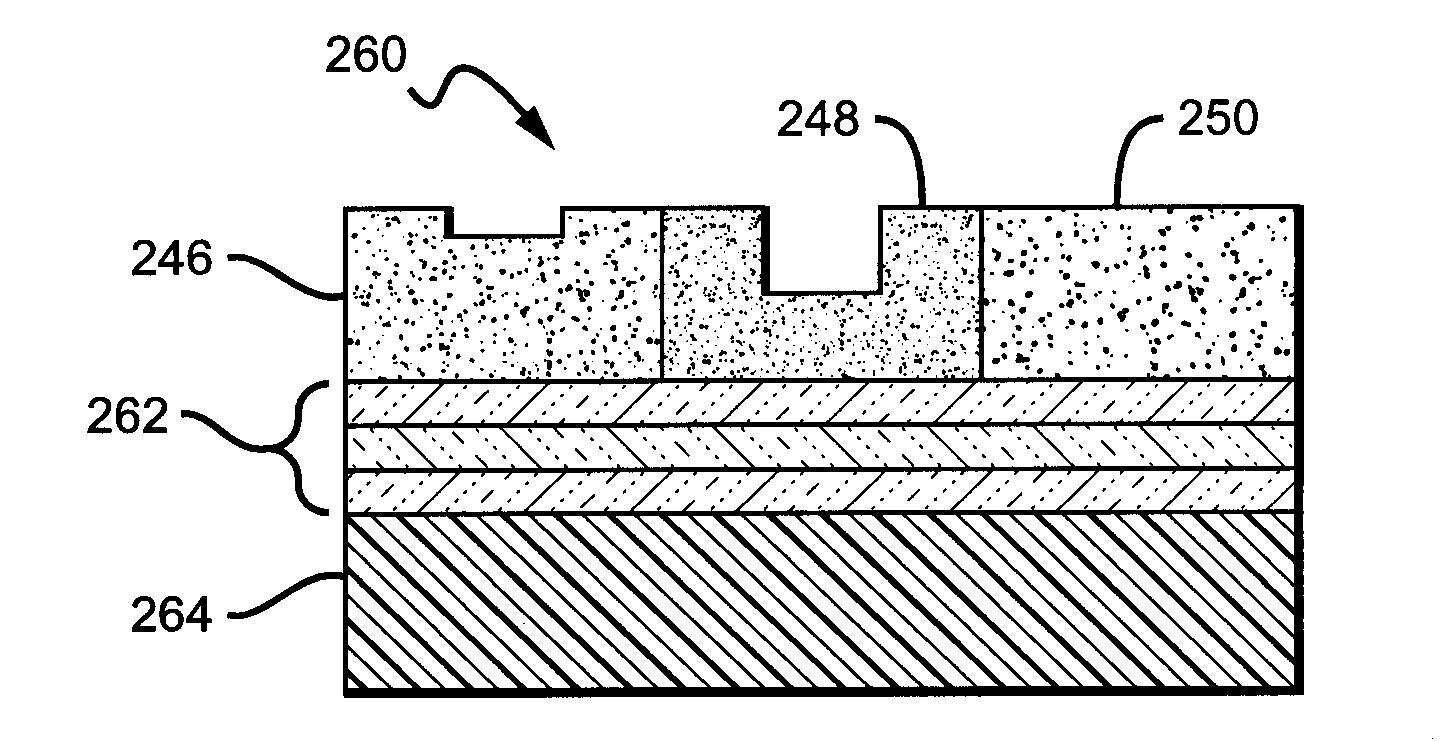

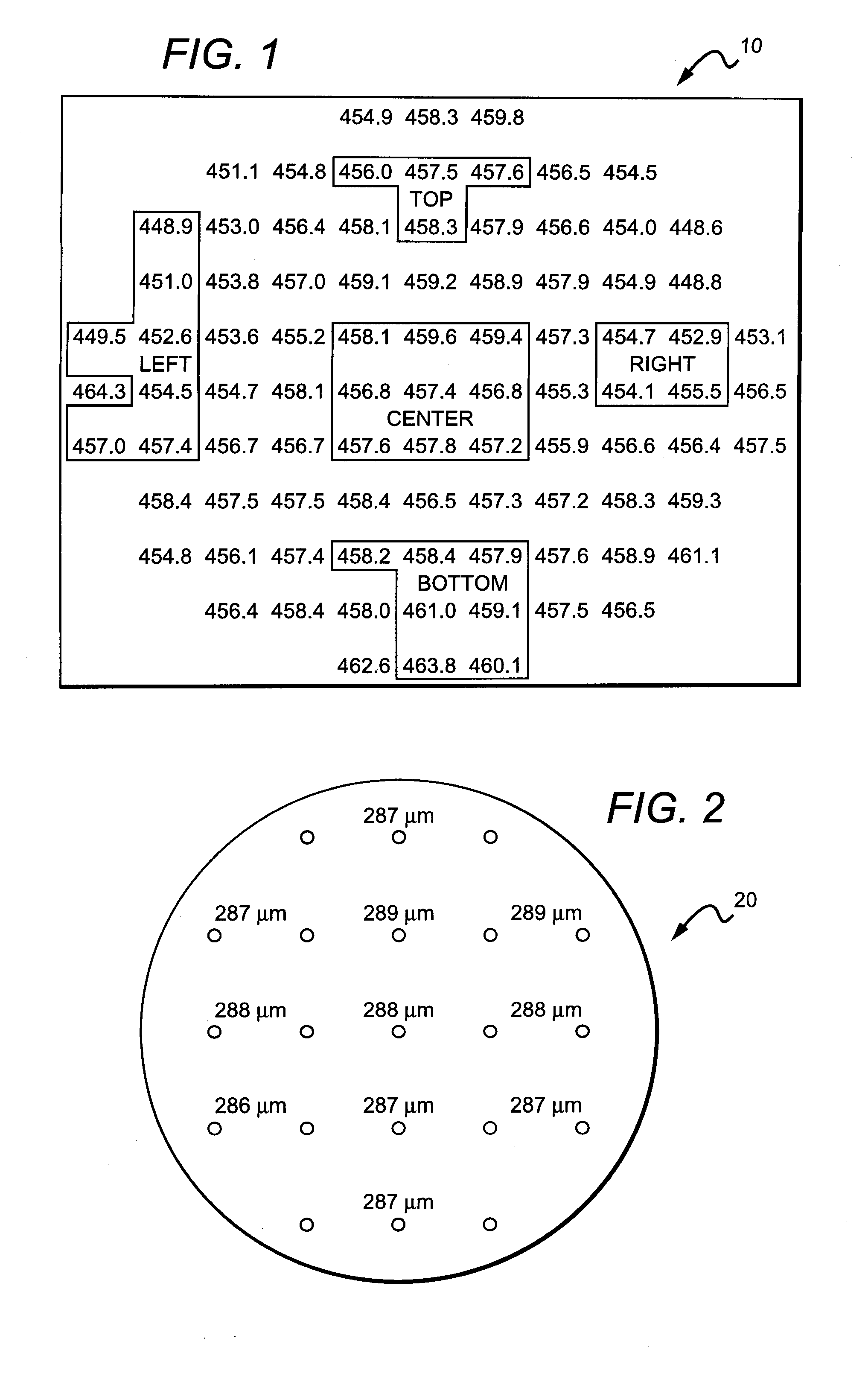

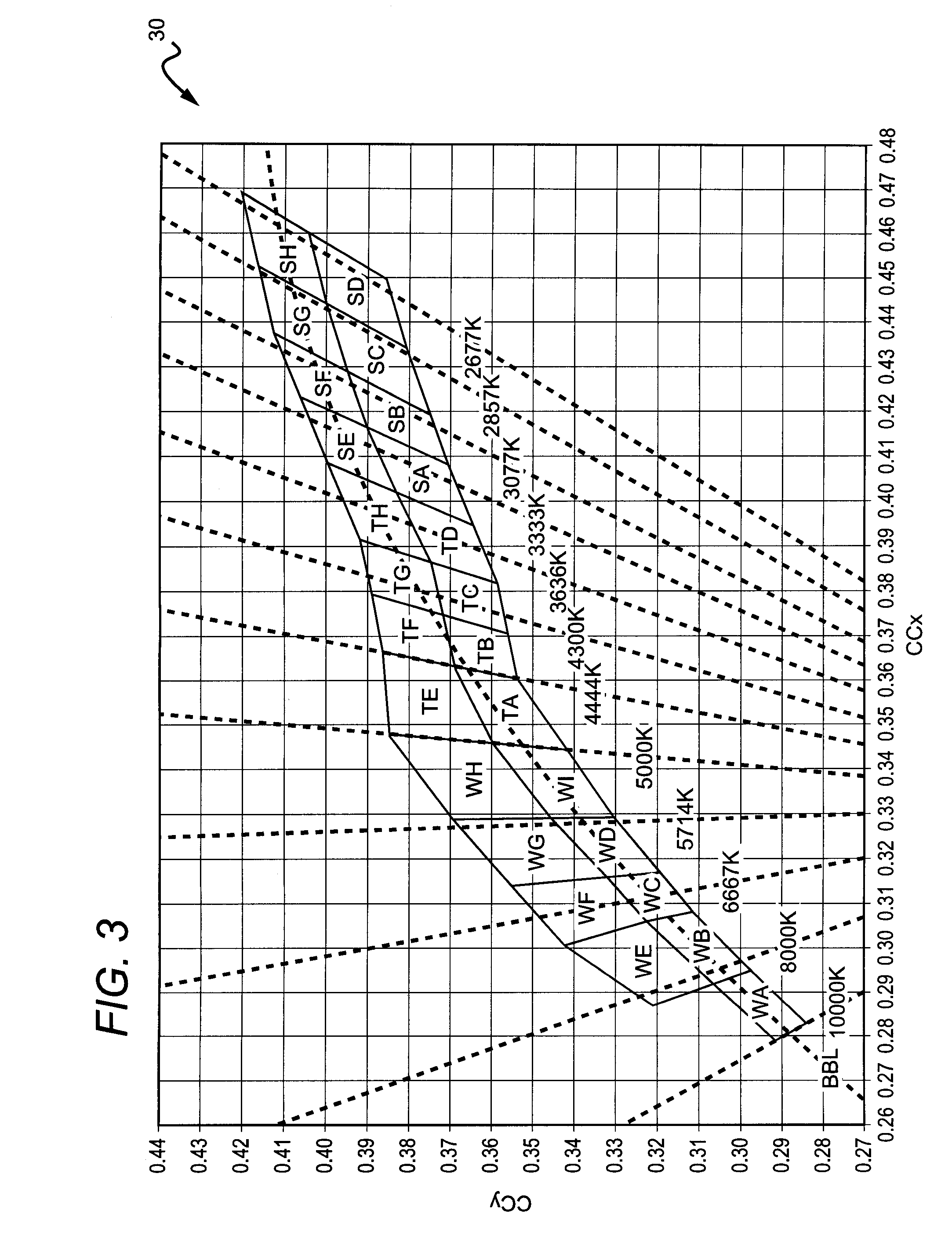

Emission tuning methods and devices fabricated utilizing methods

ActiveUS20090261358A1Controlling emission characteristicHigh yieldSemiconductor/solid-state device testing/measurementSolid-state devicesLight emissionLight-emitting diode

A method for fabricating light emitting diode (LED) chips comprising providing a plurality of LEDs, typically on a wafer, and coating the LEDs with a conversion material so that at least some light from the LEDs passes through the conversion material and is converted. The light emission from the LED chips comprises light from the conversion material, typically in combination with LED light. The emission characteristics of at least some of the LED chips is measured and at least some of the conversion material over the LEDs is removed to alter the emission characteristics of the LED chips. The invention is particularly applicable to fabricating LED chips on a wafer where the LED chips have light emission characteristics that are within a range of target emission characteristics. This target range can fall within an emission region on a CIE curve to reduce the need for binning of the LEDs from the wafer. The emission characteristics of the LED chips in the wafer can be tuned to the desired range by micro-machining the conversion material over the LEDs.

Owner:CREELED INC

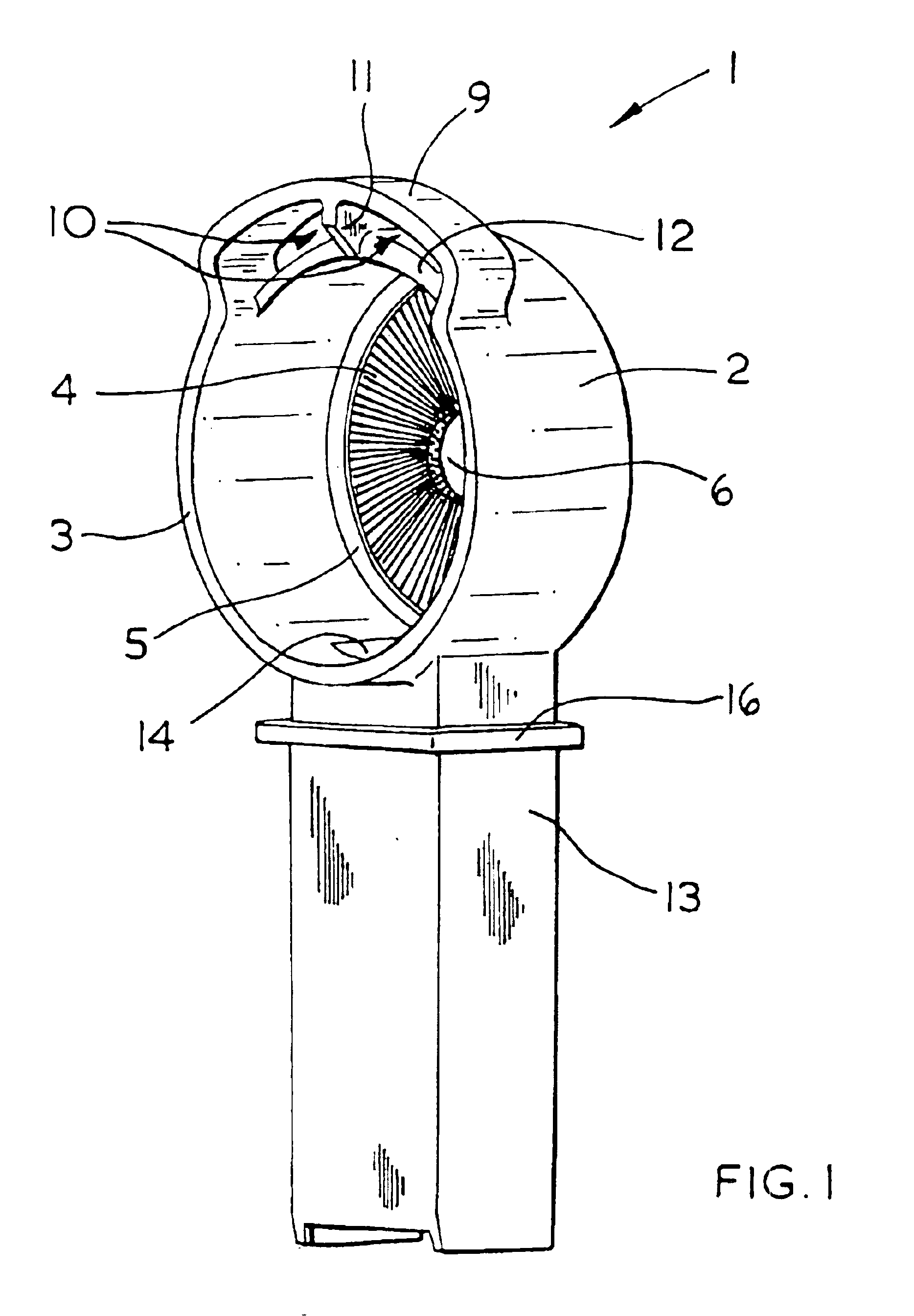

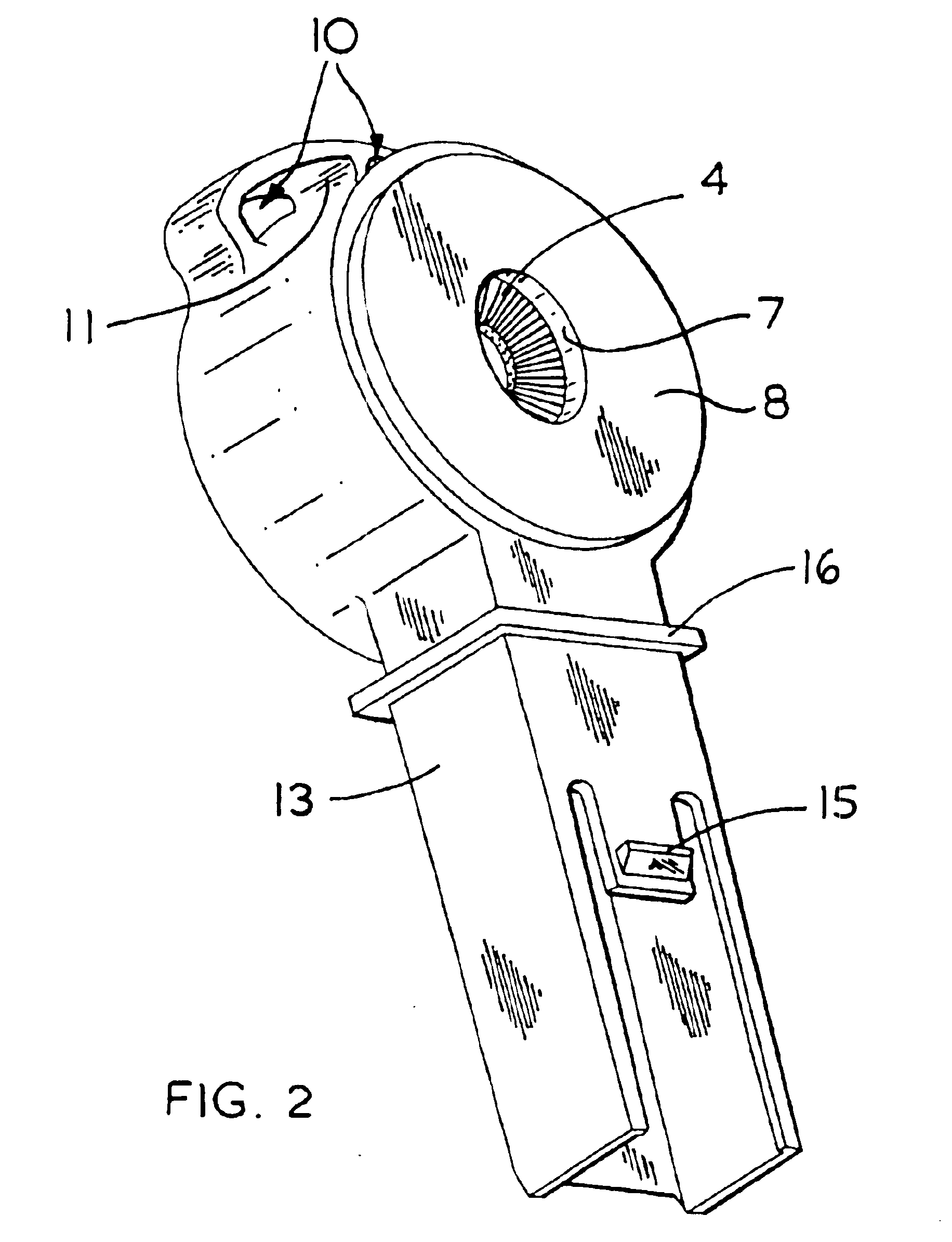

Tool and accessory connecting system

InactiveUS20060104735A1Avoid problemsEasy maintenanceBatteries circuit arrangementsTravelling carriersLocking mechanismEngineering

Carrying systems, connecting systems and methods. The system connects a power tool and a component. In some constructions and in some aspects, the power tool includes a housing and a U-shaped receptacle defined by the housing. In some constructions and in some aspects, the component includes a stud selectively engageable with the receptacle to connect the power tool and the component. A locking mechanism is positioned within the receptacle and includes a cam. The locking mechanism is engageable with the stud to restrict movement of the stud with respect to the receptacle. The stud includes a recess at an end of the stud. The cam is selectively engageable with the recess to retain the stud within the receptacle. The cam is movable between a lock position and a released position. In the locked position, the cam extends into the recess and engages the stud. In the released position, the cam is retracted from the recess and is disengaged with the stud.

Owner:MILWAUKEE ELECTRIC TOOL CORP

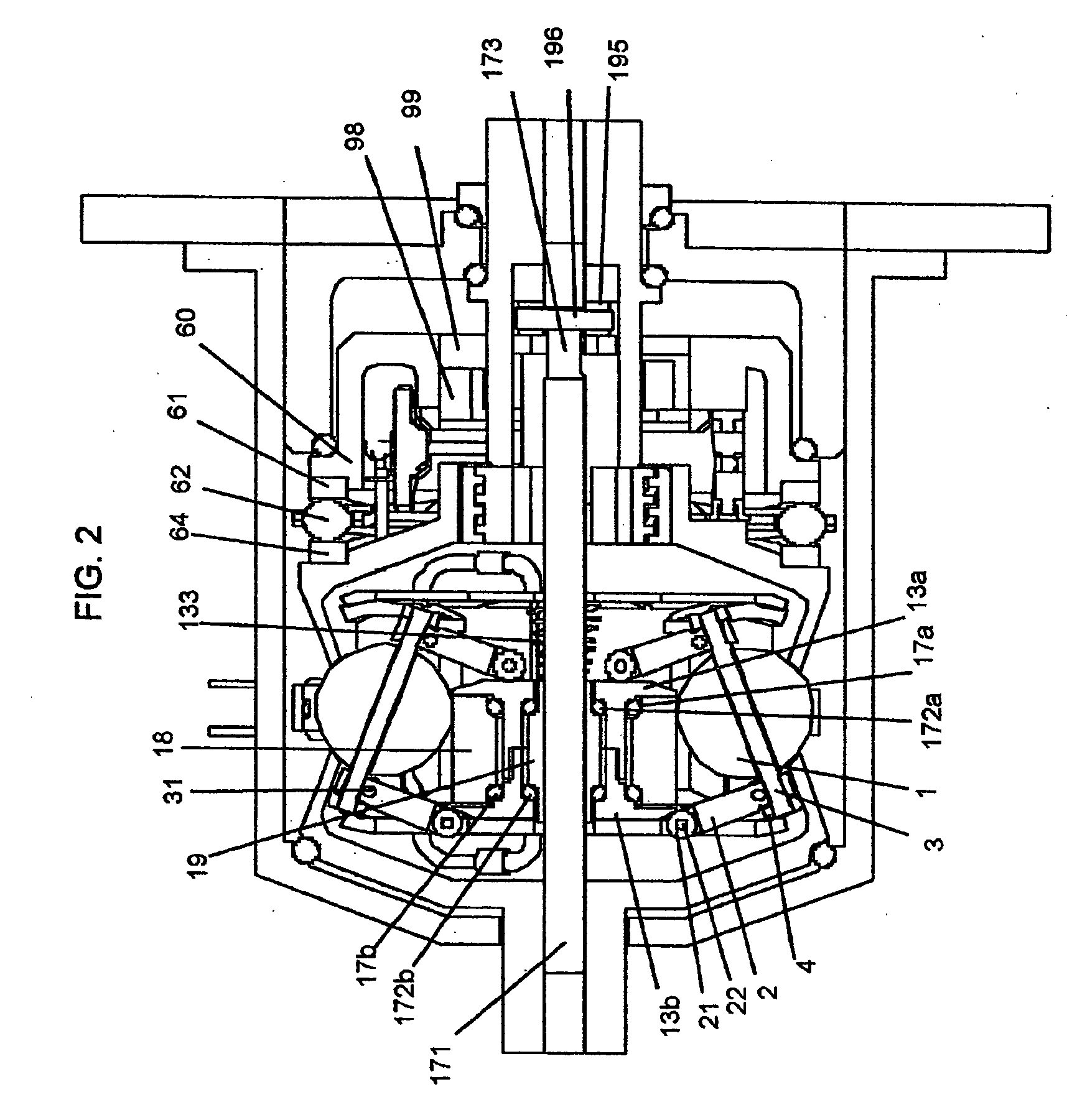

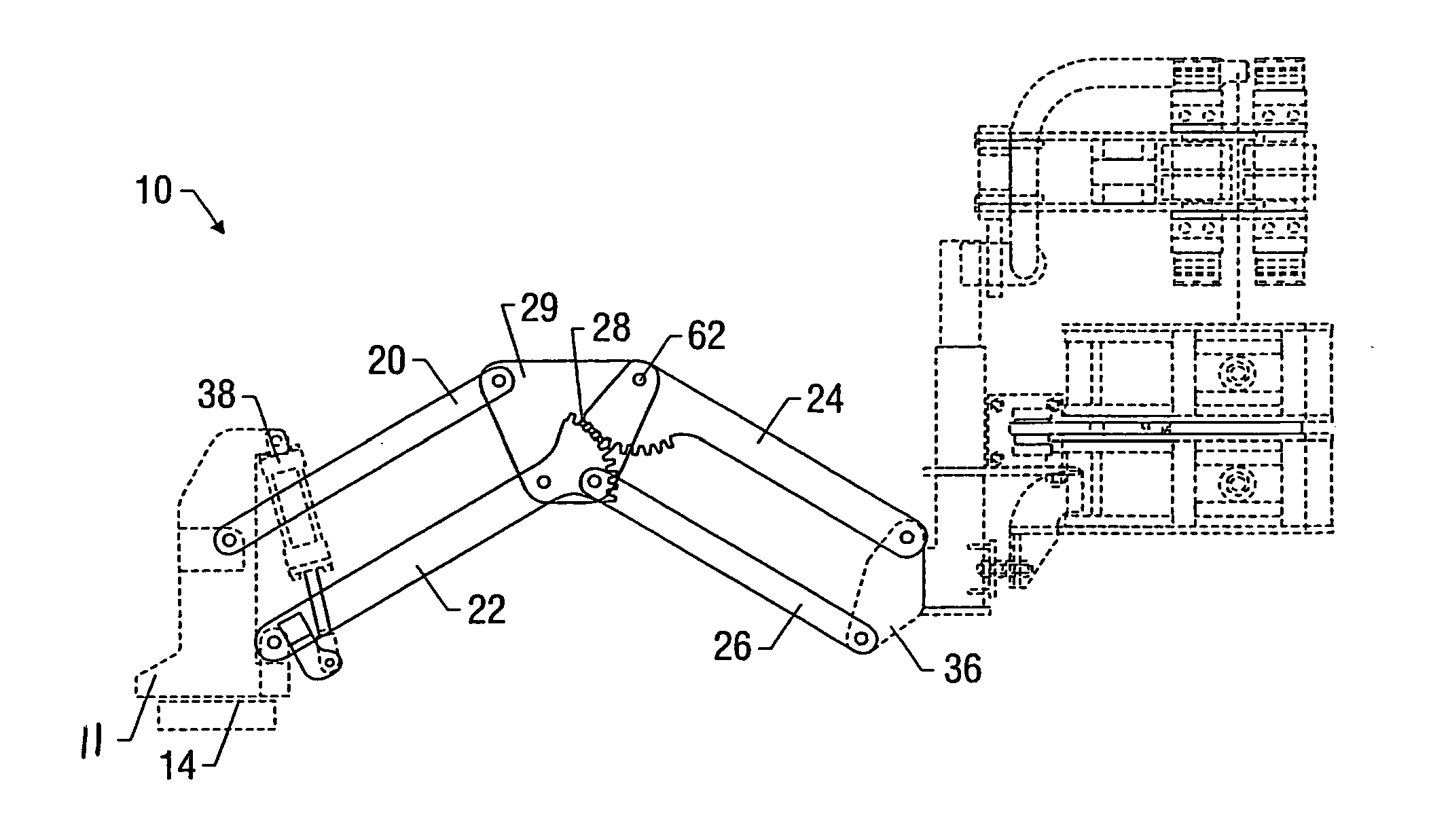

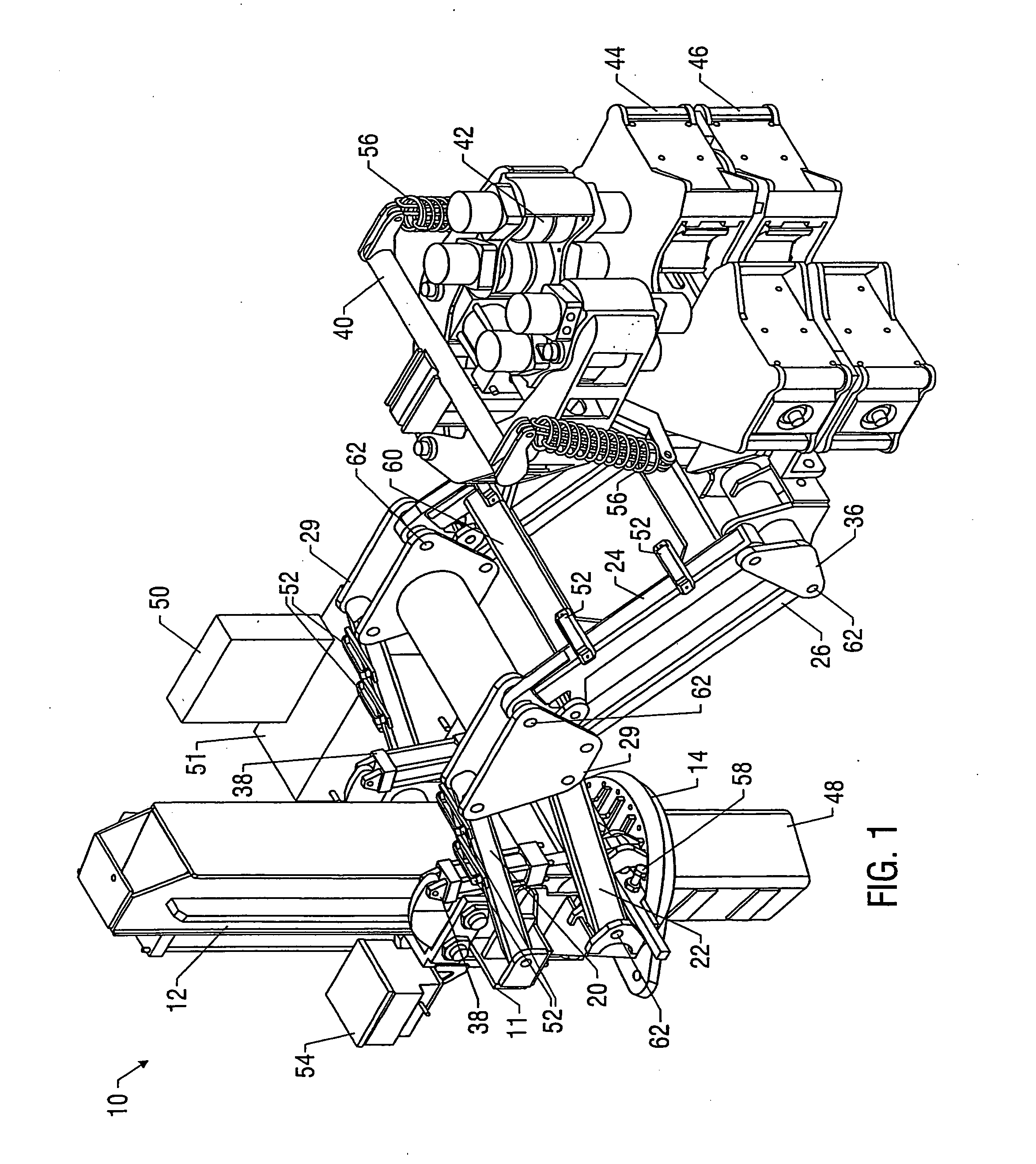

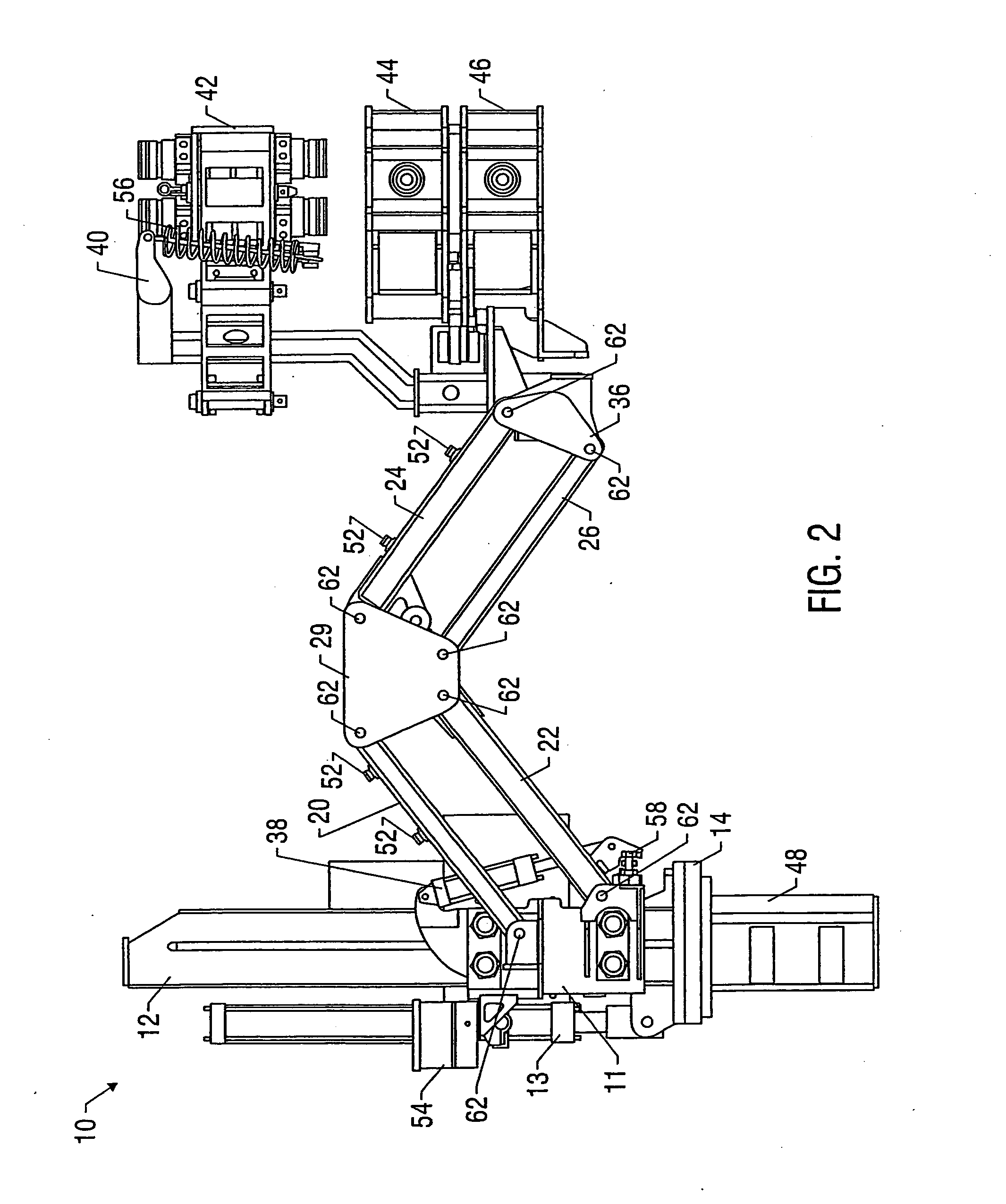

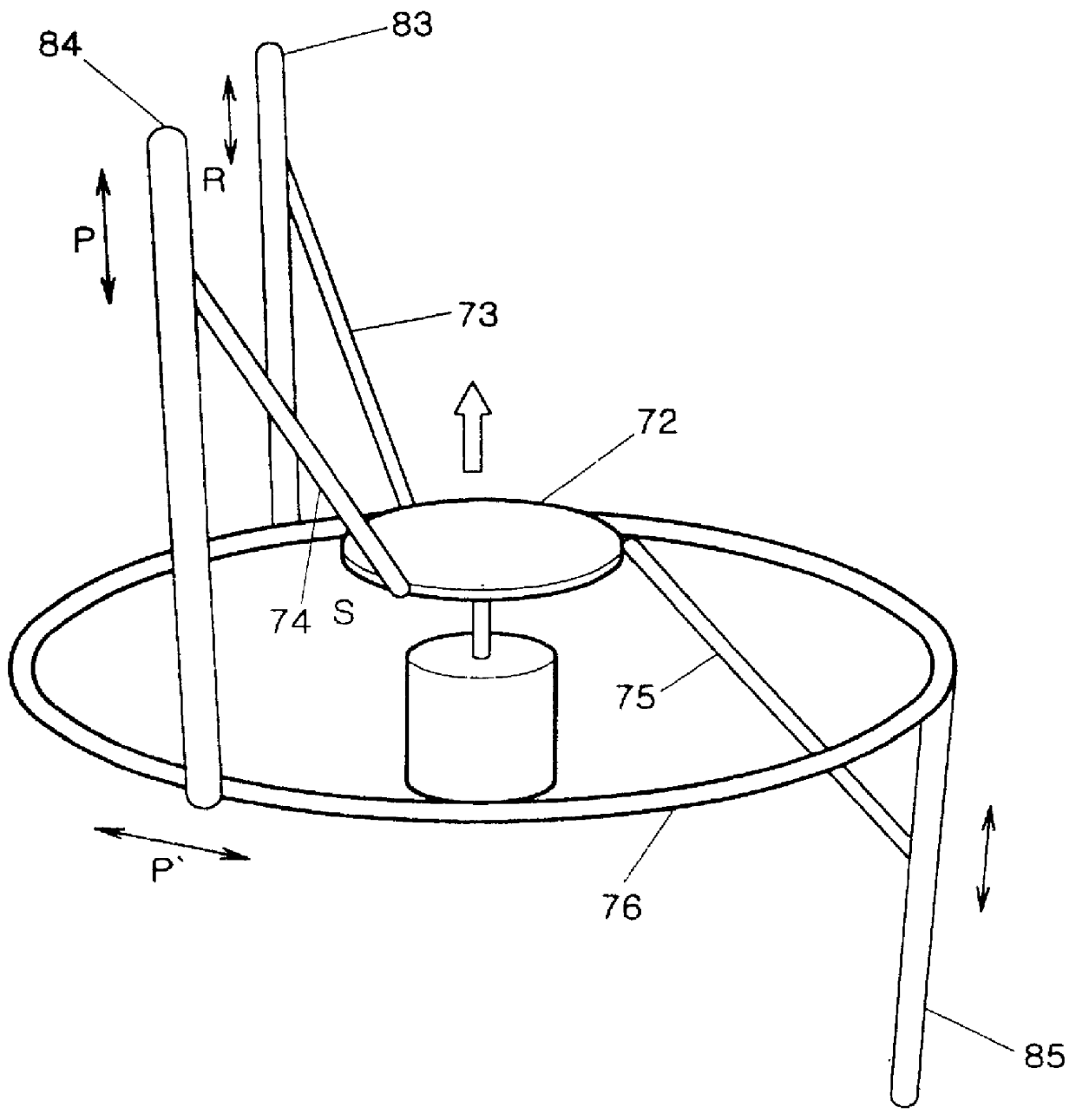

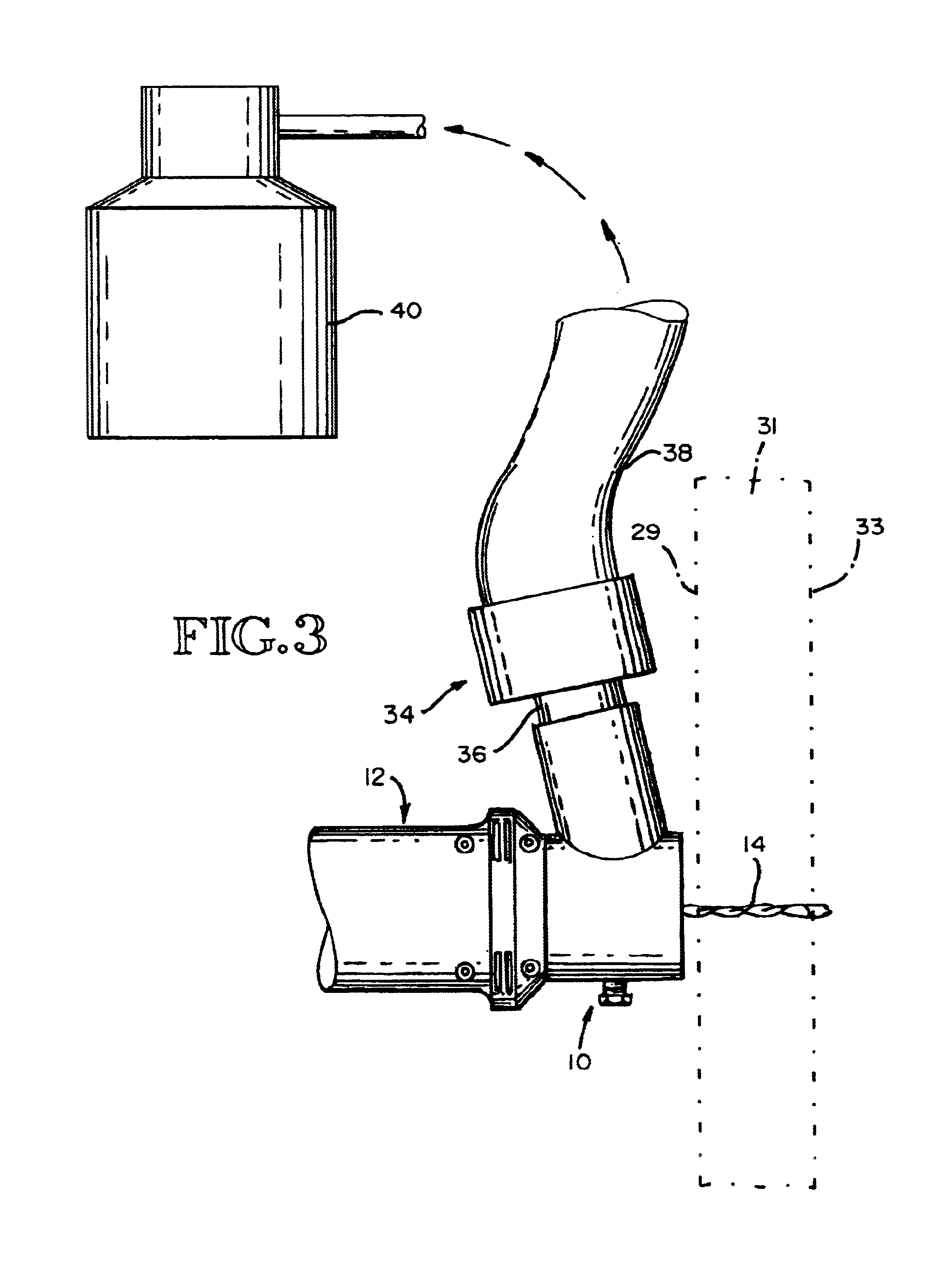

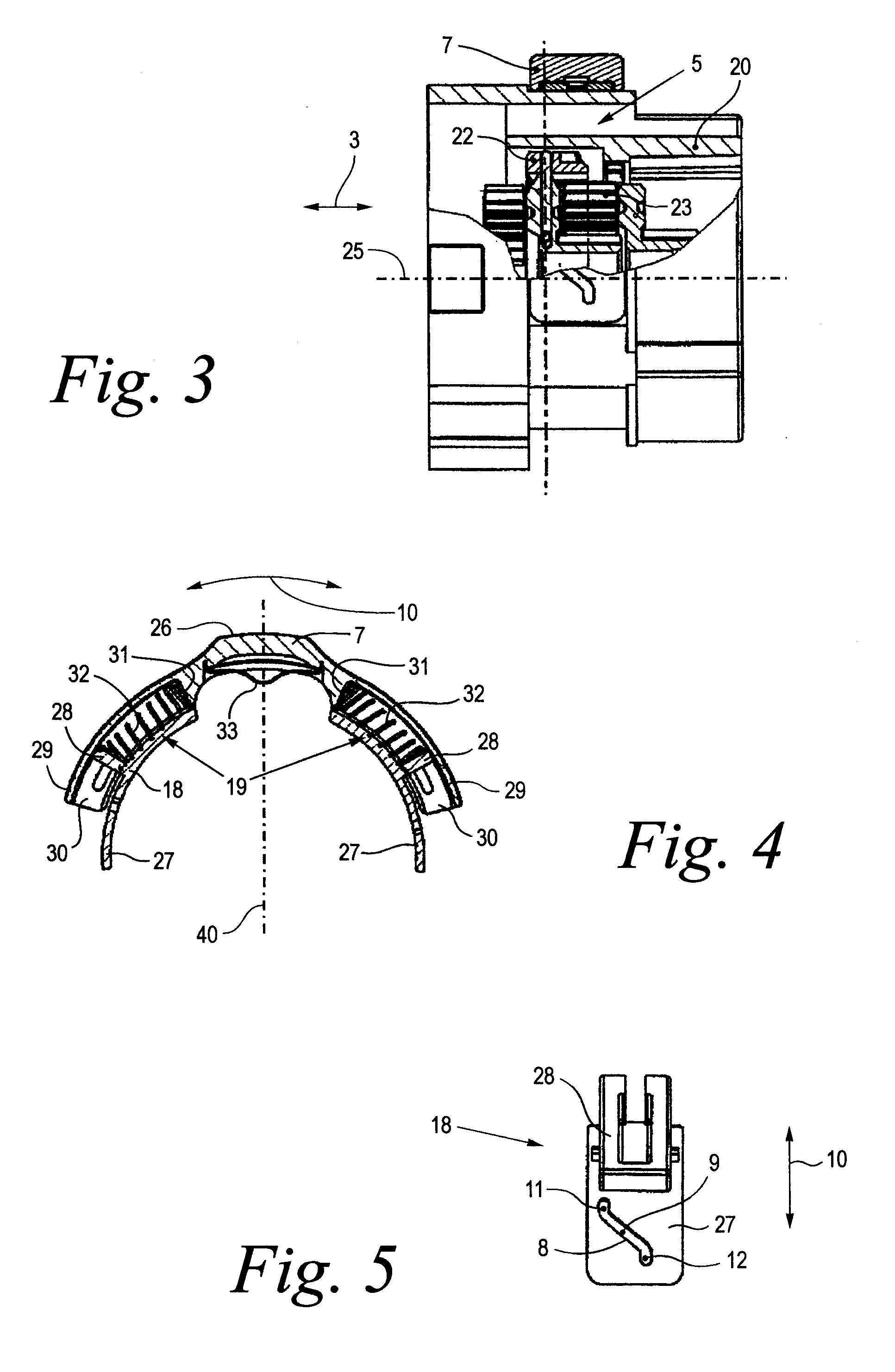

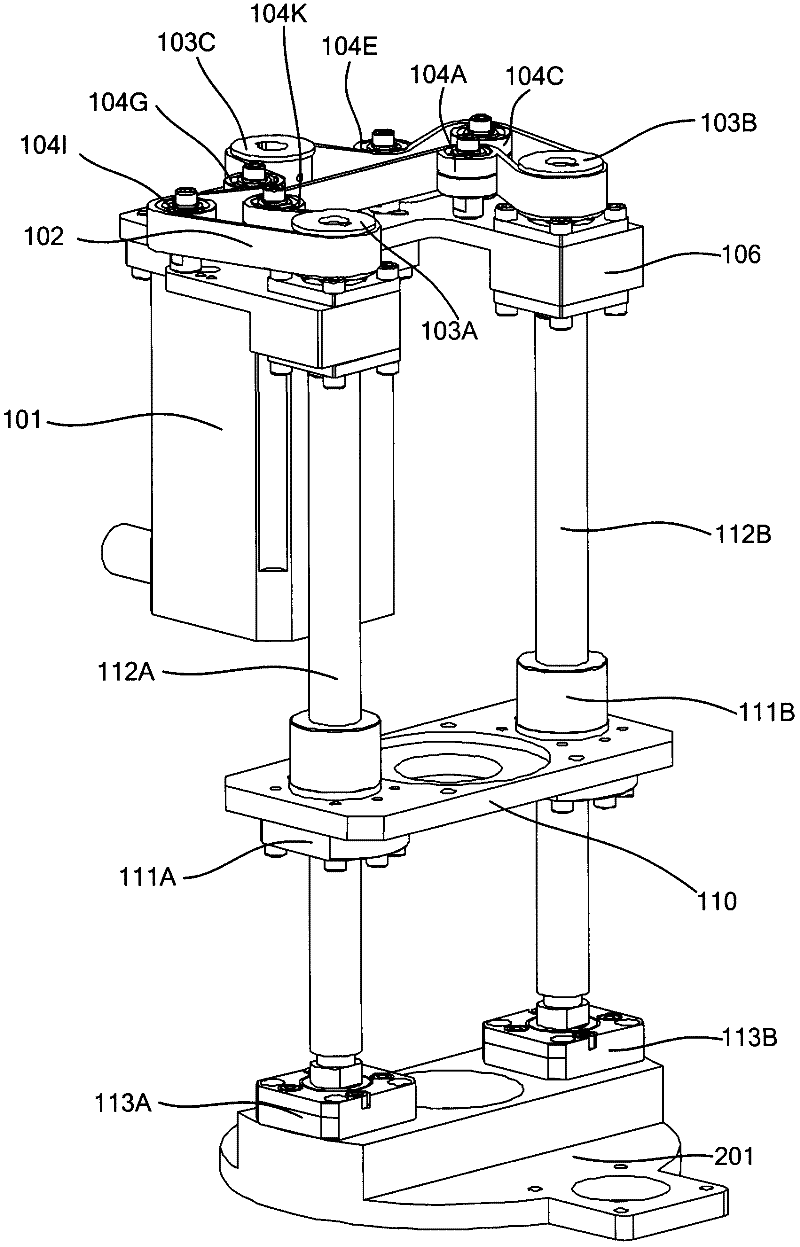

Automated arm for positioning of drilling tools such as an iron roughneck

The invention relates to an apparatus for moving an Iron Roughneck into position to allow making-up or breaking-out of threaded joints in a drill string. The apparatus may also be used to move other drilling equipment into position on the centerline of the well or at mouse holes. A self-balanced, dual synchronized parallelogram arm is utilized to accomplish the movement of the devices. Hydraulic or pneumatic cylinders are used for extension and retraction of the arm rather than to support the tool. The arm may hold the tool in any position without cylinder assistance. The linkage in the synchronized parallelogram may be accomplished by gears, links, slots, or rollers.

Owner:NAT OILWELL DHT

Parallel mechanism for multi-machining type machining center

InactiveUS6135683AImprove robustnessMeasurement/indication equipmentsPlaning/slotting machinesActuatorMachining

A six-degree-of-freedom parallel mechanism is provided for expanding a grade of a spindle. The parallel mechanism has a spindle that turns round a workpiece at a tilting angle of 90 DEG in a workspace, to thereby allow a machining for both vertical and horizontal planes of the workpiece, and a vertical turning process, by a single machining center. A six-axis multi-machining type machining center embodying the parallel mechanism of the present invention is also disclosed. An over-actuated multi-machining type machining center further including over-actuated actuators is presented to solve a problem of driving joints' singularity caused by the parallel mechanism.

Owner:SEOUL NAT UNIV R&DB FOUND

Device and a method for preventing or reducing vibrations in a cutting tool

An arrangement for reducing vibrations in a tool holder (4) with a cutting tool (3) and has a vibration sensor on the tool holder (4) that is connected to a guide unit (11). The tool holder (4) has further two piezo-electric actuators 14 and 15.Under the influence of the vibration sensor (9), the guide unit (11) provides an electric alternating current that is actively guided over time so that the actuators movably affect the tool holder (4) to reduce the vibrations in this. To also be able to dampen transients in the tool holder (4) this is movably connected with a passive dampening arrangement that is independent of the guide unit (11) and that is based on the principle of a springing (8) suspended mass (7). The invention also relates to a method for reducing vibrations. The vibrations in the tool holder are sensed and a corresponding signal is provided to a guide unit that over time provides actively guided signals to the actuators. The tool holder is also passively influenced by a dampening arrangement that is independent of the guide unit.

Owner:CLAESSON INGVAR +4

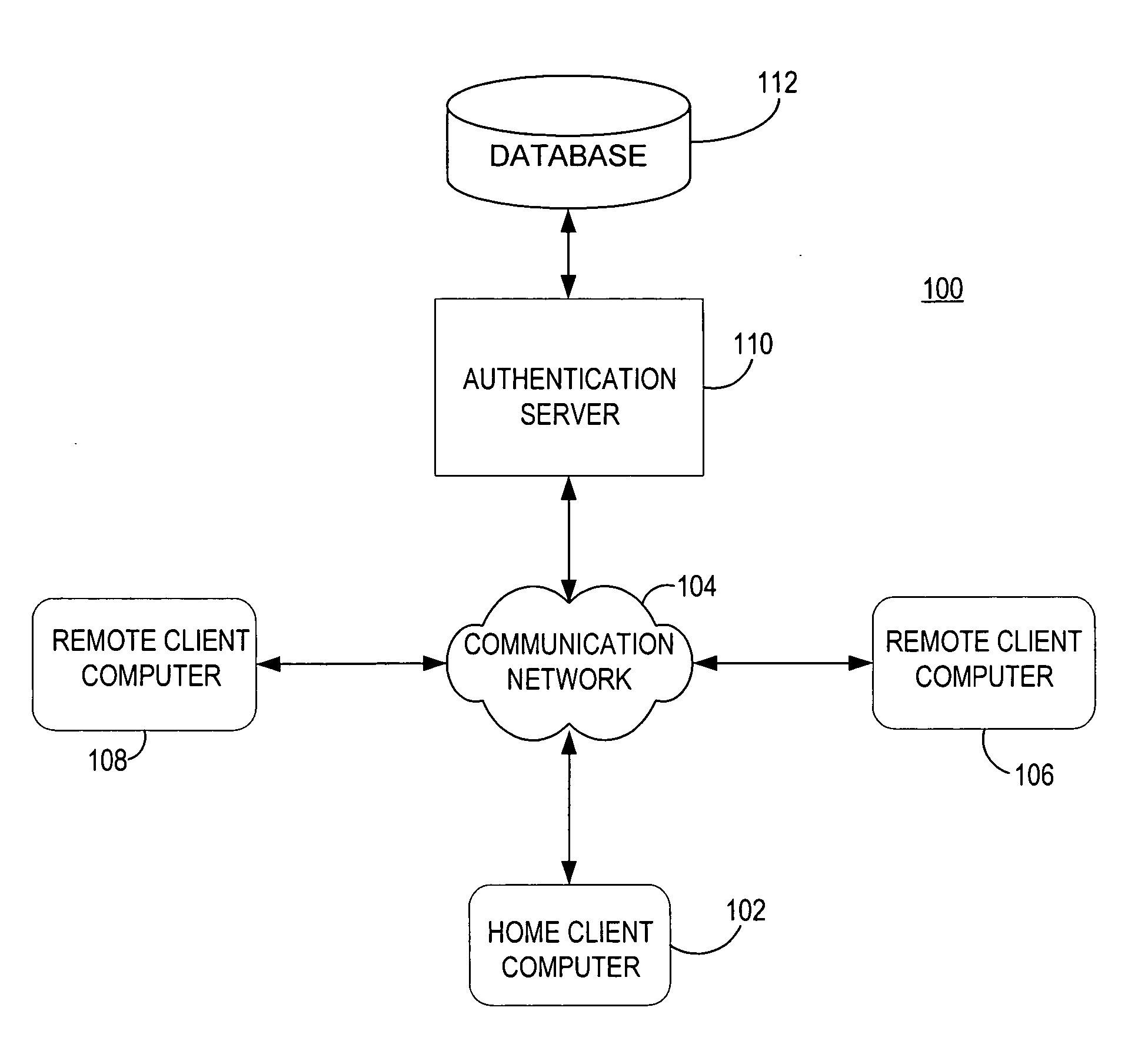

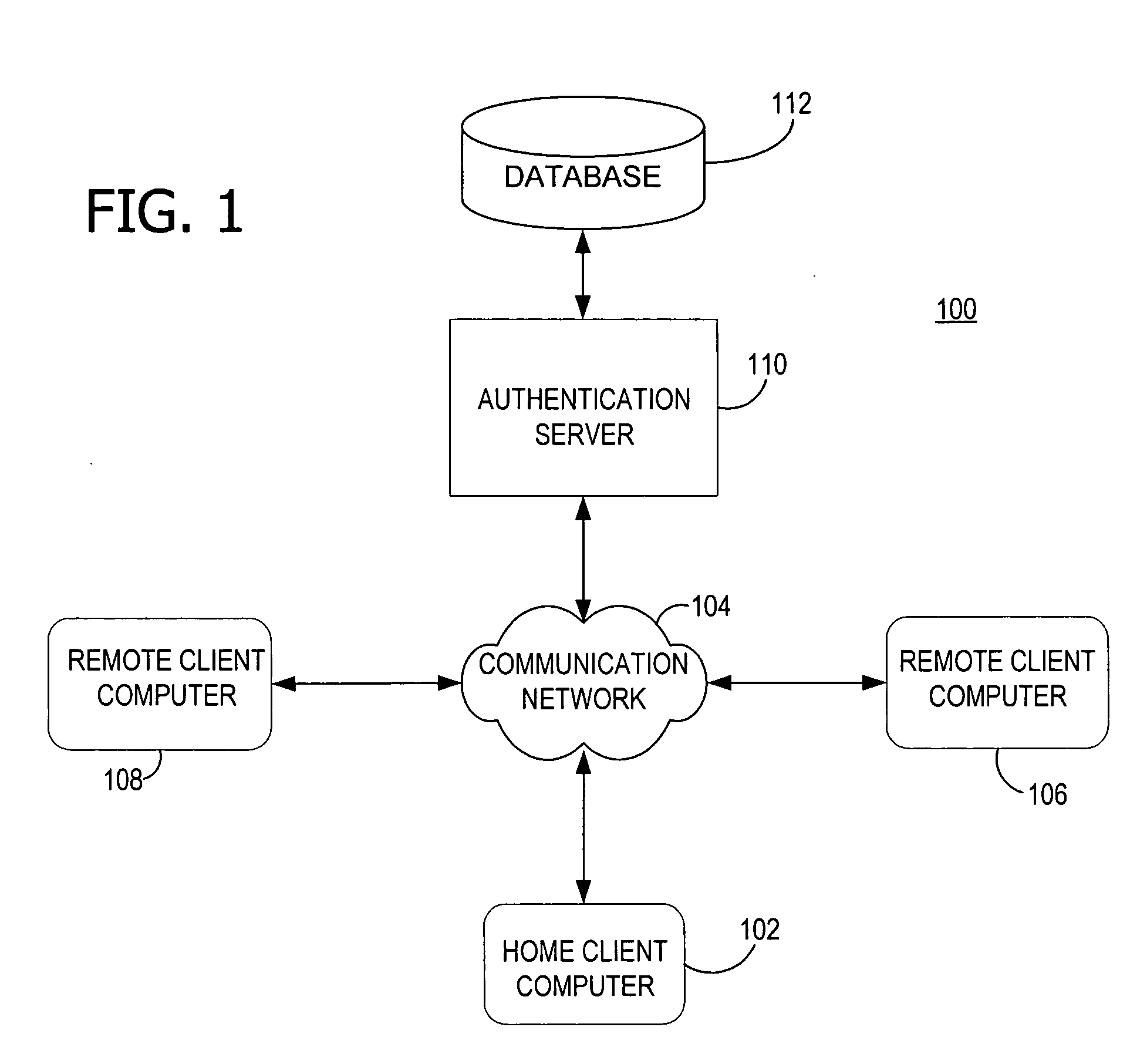

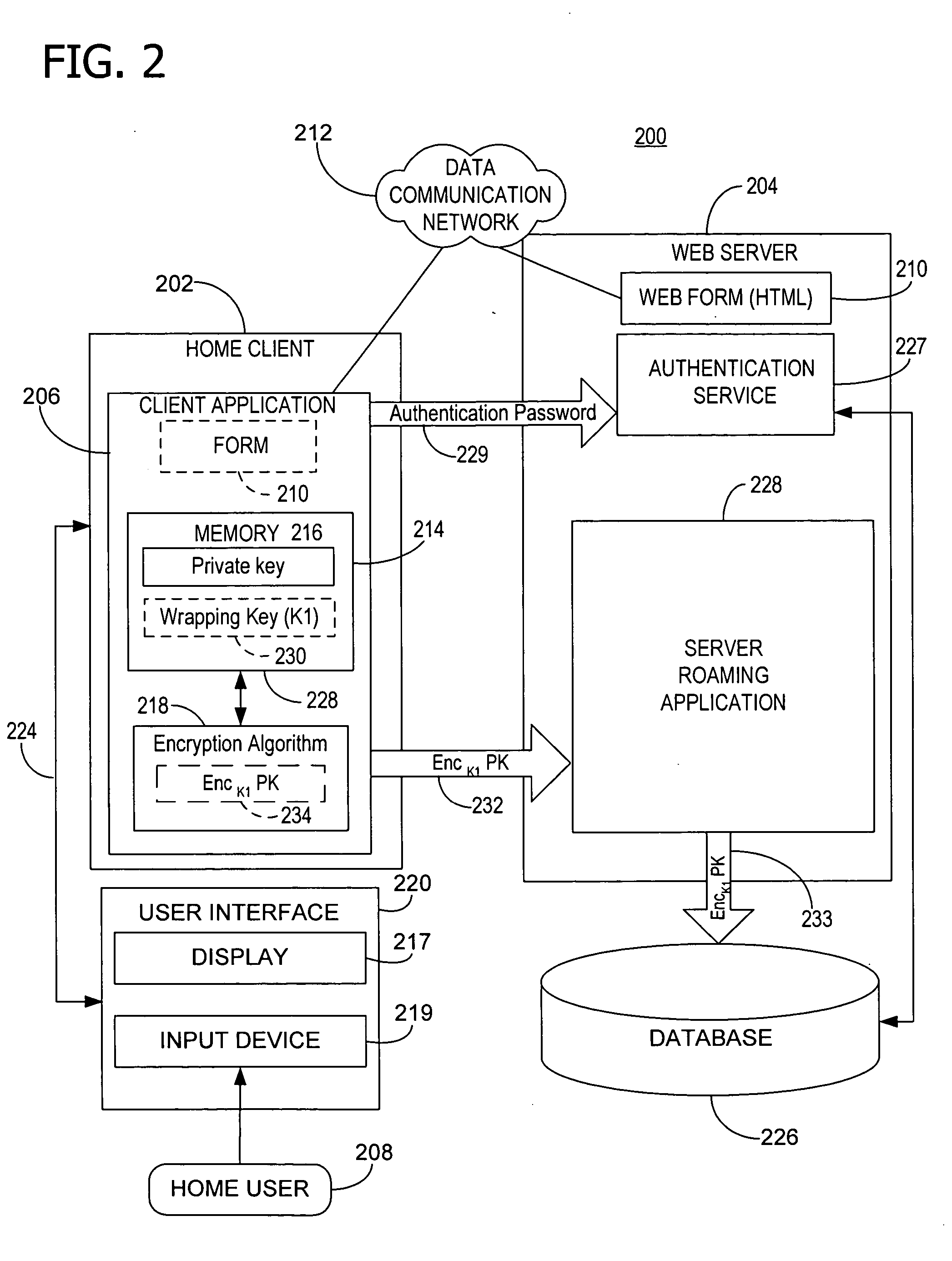

Method and system for recovering password protected private data via a communication network without exposing the private data

InactiveUS20050223216A1Improved roaming of private informationImprove network securityKey distribution for secure communicationData processing applicationsPasswordNetwork link

A system and method for securely roaming private data from a first client computer to a second client computer linked via a communication network. A user of the first client computer executes a home client application and designates private data for roaming. The home client application generates a first key in response to a password, and encrypts the designated private data as a function of the first key. The server receives and stores the encrypted private data. A user of the second computer executes a roaming client application and requests transfer of the encrypted private data from the server. The roaming client application generates the first key in response to the password, and decrypts encrypted private data transferred from the server to obtain the private data. The invention further provides users the ability to retrieve encrypted private from the server even when the user cannot remember the password associated with the first key. Also, the server has no knowledge of the private data nor the keys.

Owner:MICROSOFT TECH LICENSING LLC

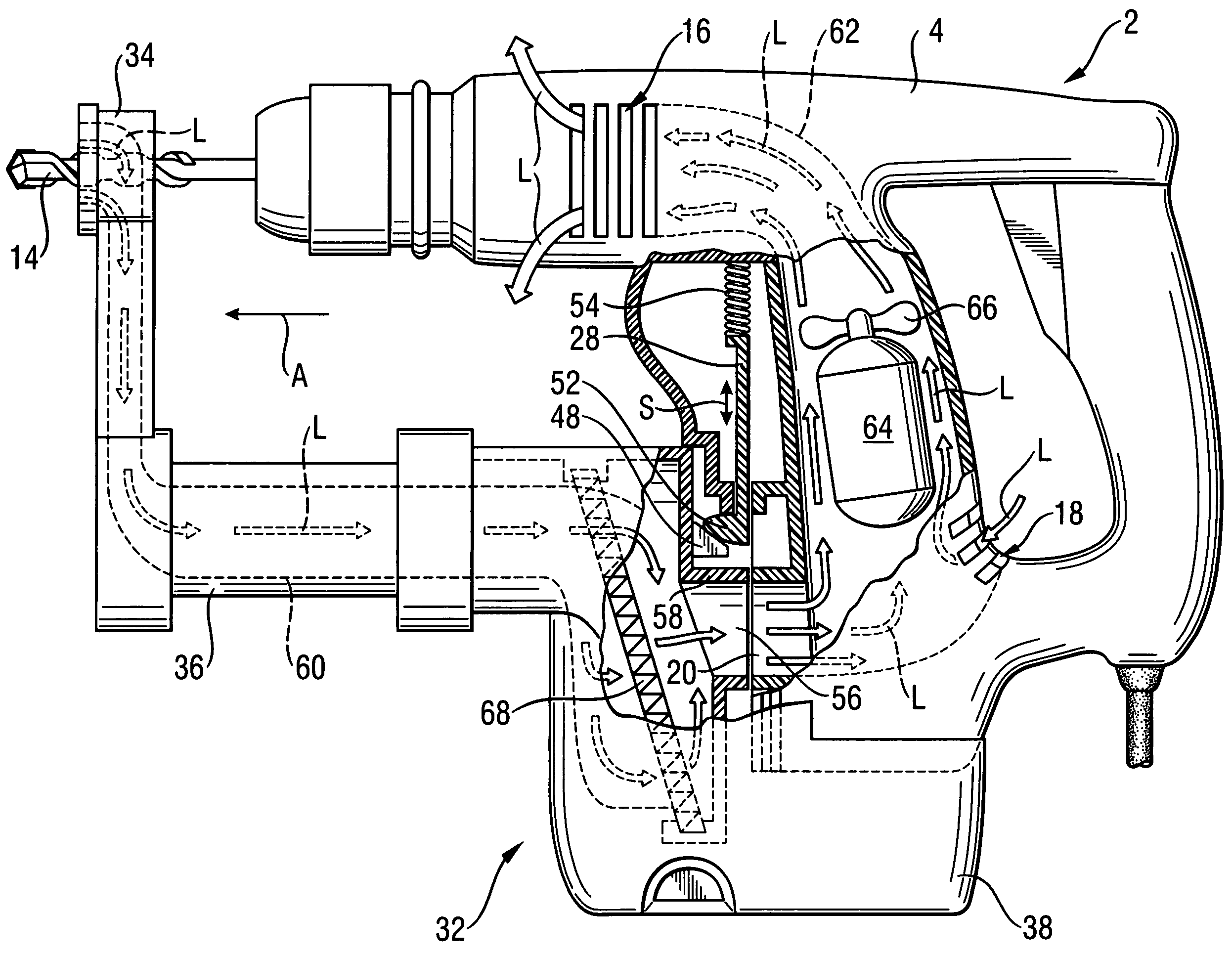

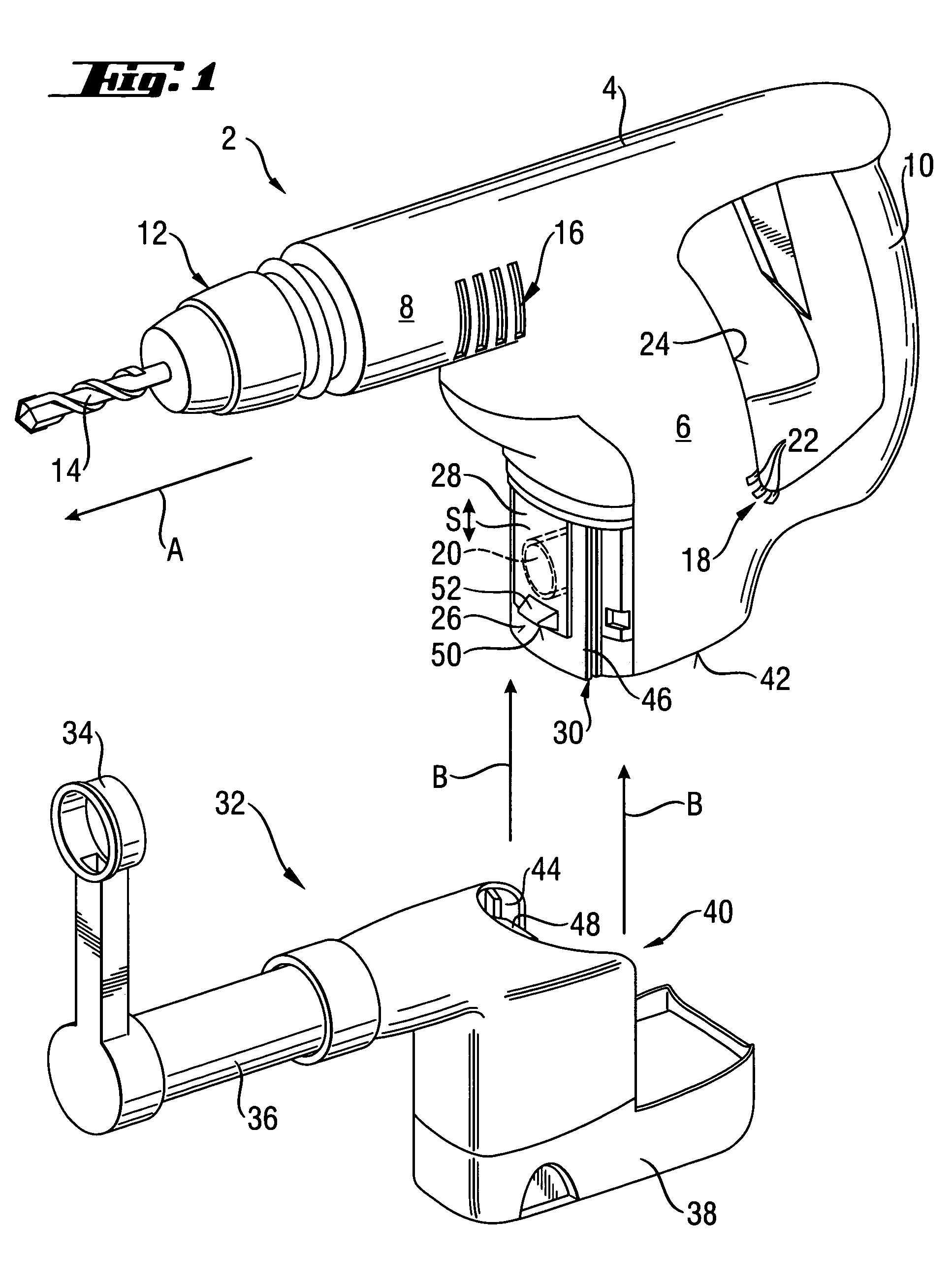

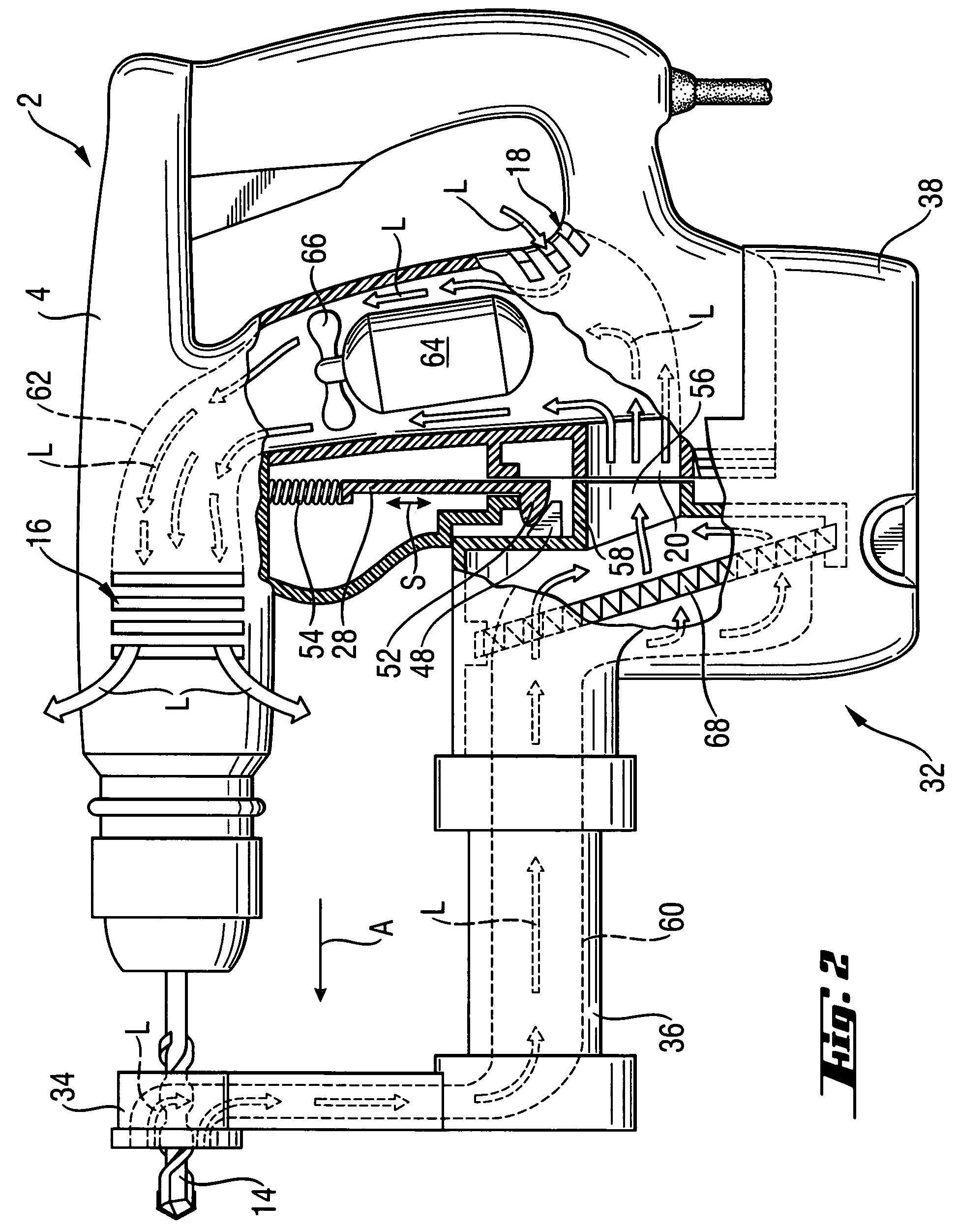

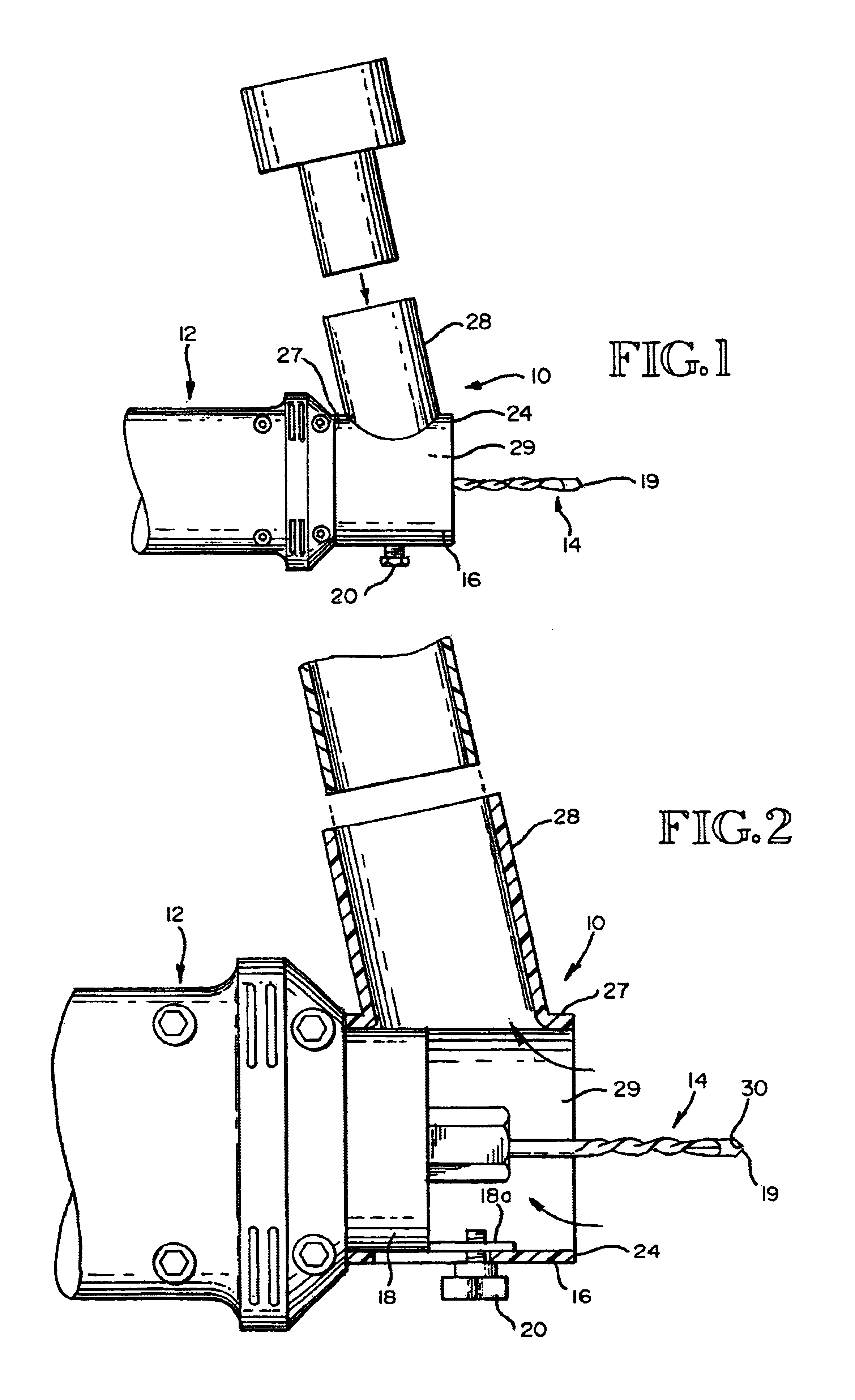

Hand-held power tool with a dust suction module

InactiveUS7354226B2Cost-effectiveAccurate guidanceThread cutting feeding devicesDrilling rodsSeparated stateHand held

A hand-held power tool (2) connectable with a dust suction module (32) includes a motor (64) and an air flow generator (66) which for cooling the motor (64) is located, together with the motor (64), in air flow path (62) between an air inlet and an air outlet (16) both formed in the tool housing, (4, 6), with an air inlet having a side opening (18) and a connection opening (20) connectable with the suction path (60) of the dust suction module (32) and the dust suction module (32) having a suction conduit (58) for connecting the suction path (60) with the air flow path (62) and adjoining the connection opening (20) in a connected condition of the dust suction module (32) with the power tool, and with the power tool (2) further having a closing member provided on the connection opening (20), operable by the dust suction module (32), and having, in an attached position of the dust section module (32), an open position, and having a closed position in the detached condition of the dust suction module (32).

Owner:HILTI AG

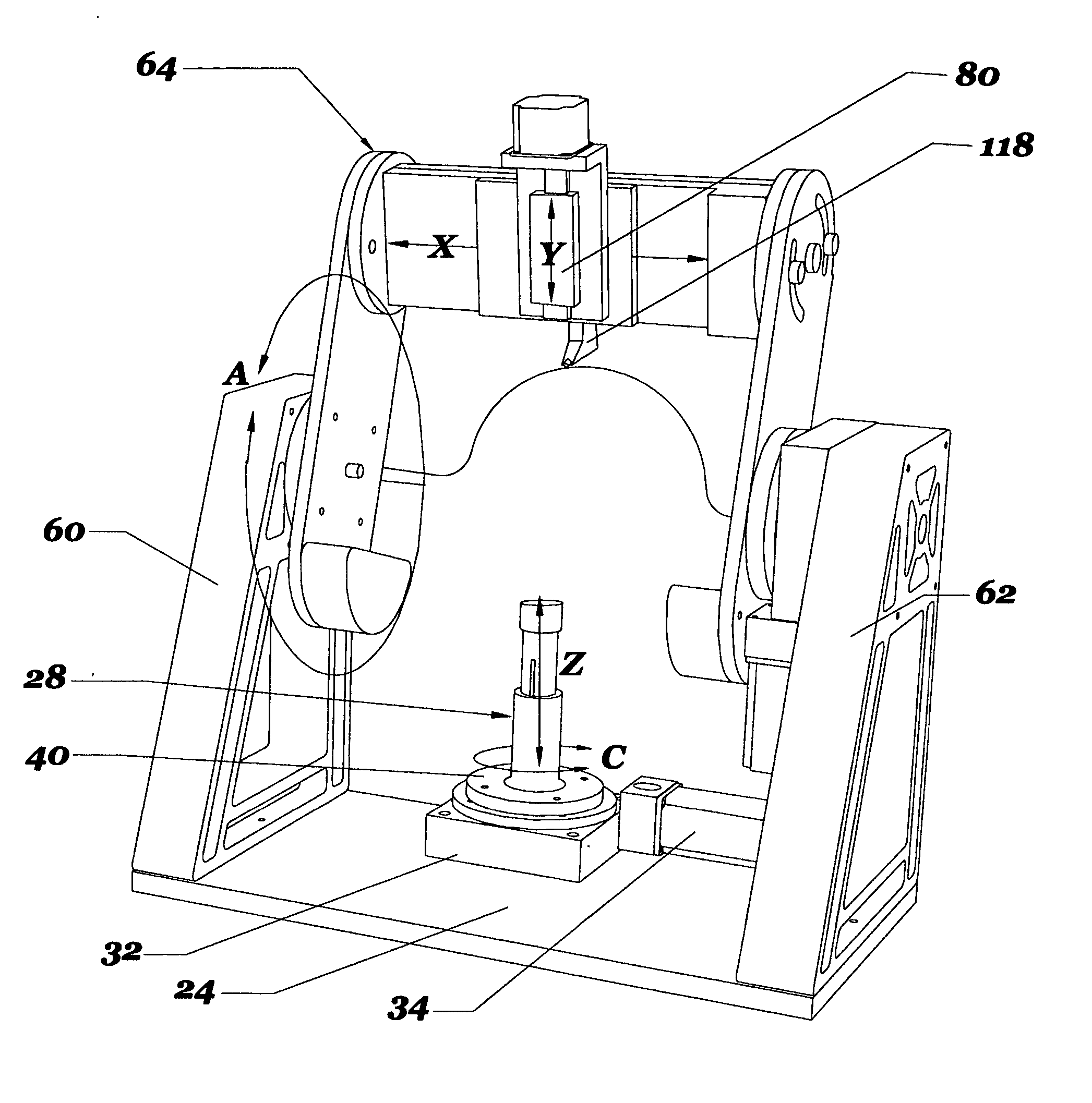

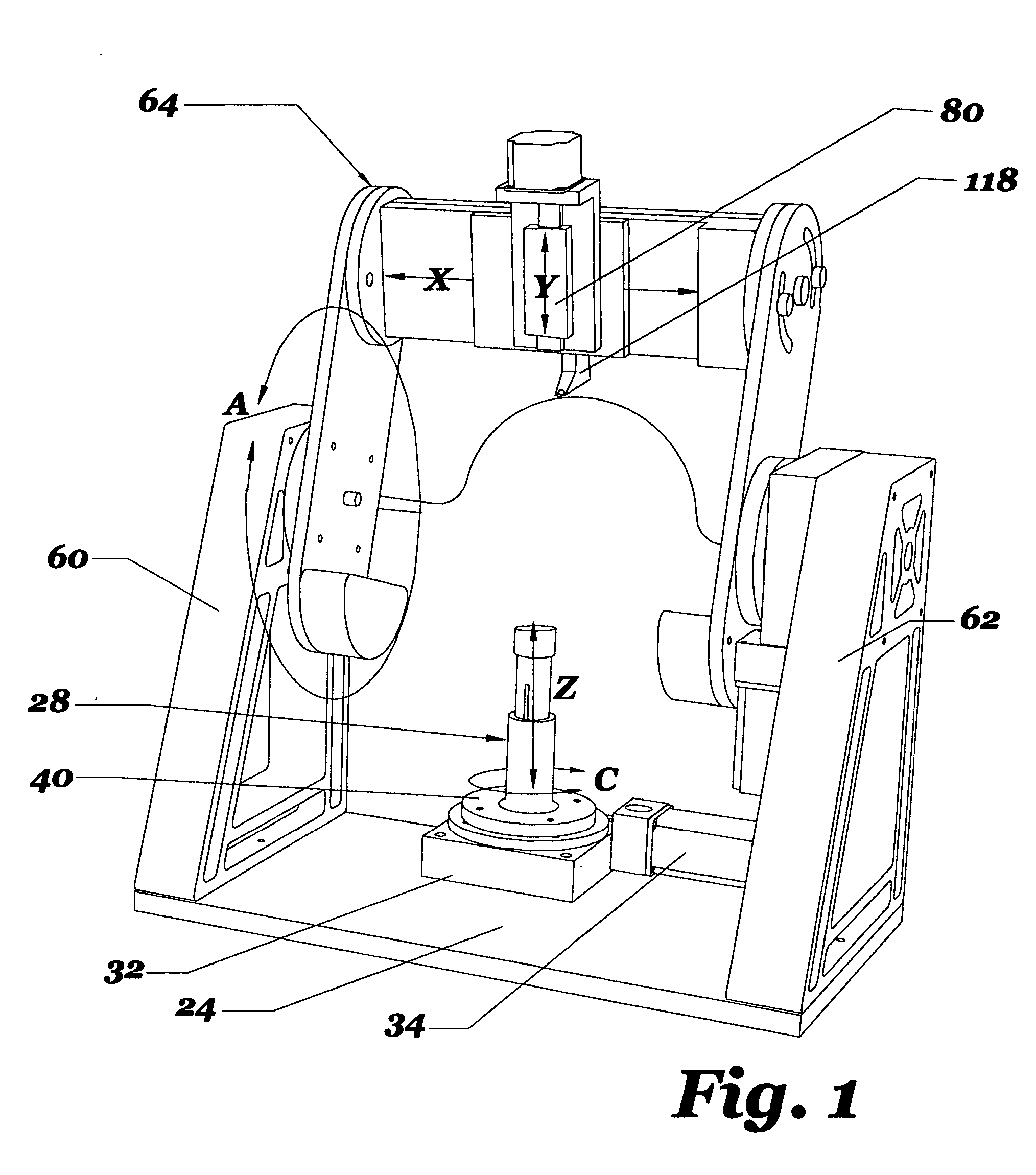

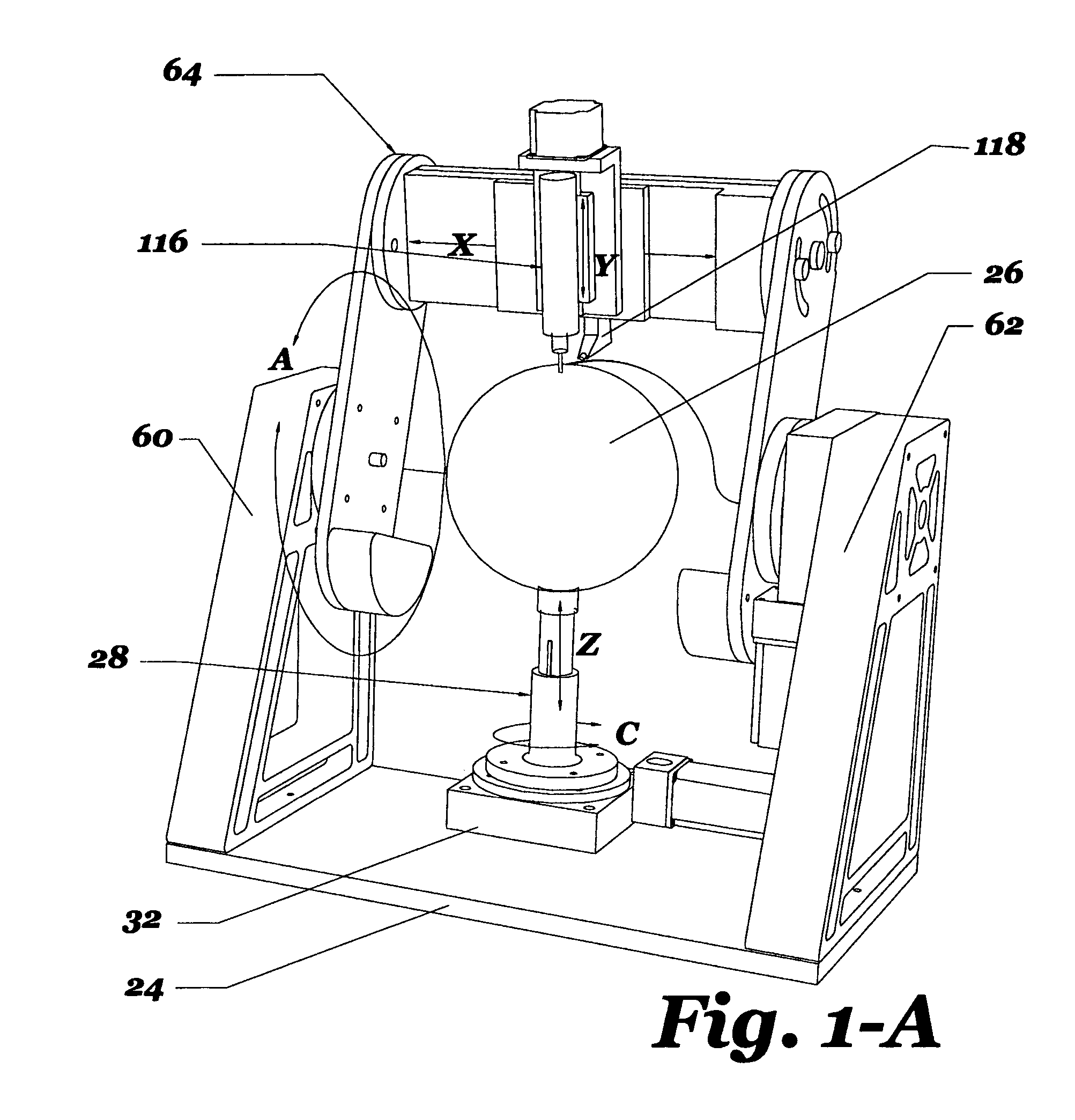

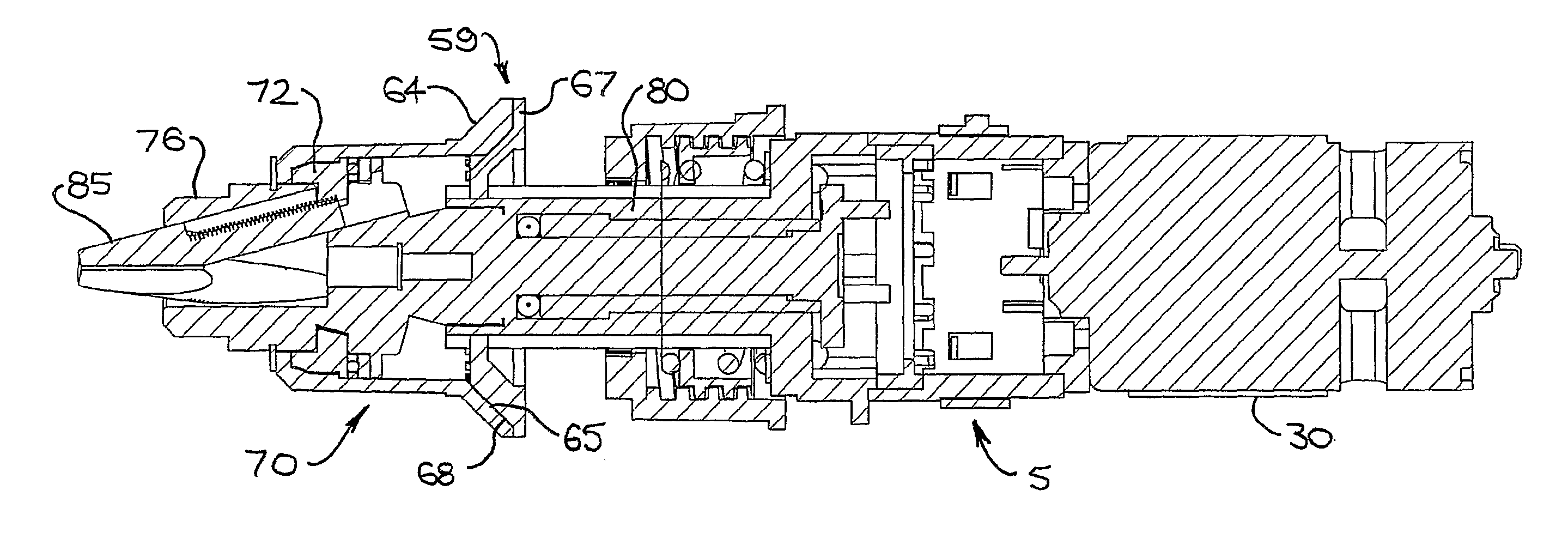

Multi-axis, processor-controlled, toolhead positioner

InactiveUS20060242818A1Programme-controlled manipulatorPlaning/slotting machinesRotational axisEngineering

A multi-axis, computerized numerically-controlled (CNC) toolhead positioning device with six degrees of freedom of movement while utilizing only five axes of movement, comprising a rotating workpiece mount assembly (28) and a rotating gantry (64) with a mounted toolhead assembly base (80). Perpendicular rotational axes about a mounted workpiece (26) provide the capability to perform specific toolhead operations on the arcuate surface of the workpiece (26), subject to the type of mounted toolhead assembly. The computer (120) uses CNC software to integrate operator instructions, machining operations, and the sequence of operations into an automatic and coherent machining package.

Owner:PRECISION SPHERICAL

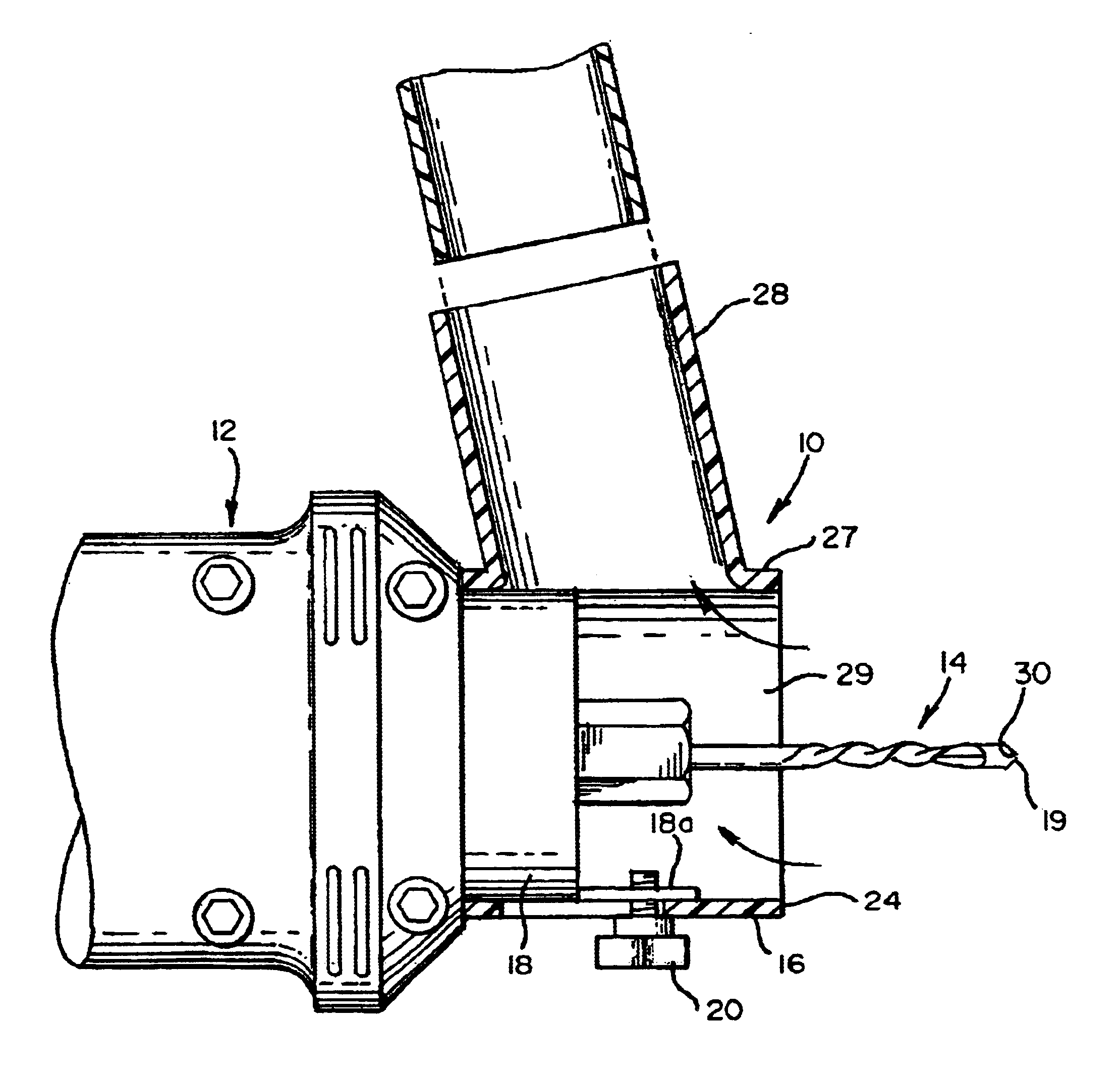

Dust collector attachment for a spiral power tool

The dust attachment which is used with a spiral saw power tool includes a first attachment portion which at a rear end has a substantially dust-tight fit with a mounting head portion of the tool. The other (forward) end extends beyond a forward edge of the mounting head portion, but such that the spiral saw bit extends beyond the forward edge of the attachment portion by a distance which is slightly greater than that of the thickness of the workpiece. An attaching member such as a screw secures the dust attachment portion to the tool. An dust exit tube extends from a side surface of the attachment portion and communicates with the interior of the attachment portion. The dust exit tube extends at an angle away from the attachment portion toward the rear end thereof.

Owner:WEISS STEPHEN F

Dust extraction shroud for a power tool

A dust extraction shroud for a drill, which surrounds a drill bit and which lies adjacent the work surface, comprises a body portion defining a first inlet adapted to engage the work surface and to surround the location at which said bit penetrates the surface. The shroud body further defines a first outlet connected to a source of suction and a third inlet for allowing the bit to pass through said body portion. A first sealing means is arranged in said third inlet for surrounding said bit and resisting the flow of air. Wherein said body portion includes at least one protruding portion defining a second inlet between said protruding portion and an adjacent part of said body, and on a side of said protruding portion remote from the first inlet. The second inlet admits air to enter said body portion and travel to the first outlet.

Owner:BLACK & DECKER INC

Switchable gearbox of a handheld power tool

InactiveUS7044882B2Simplified and operationally safe selectionToothed gearingsPortable power-driven toolsEngineeringPower tool

A switchable gearbox of a handheld power tool has a gear having a first switching stage and a second switching stage arranged sequentially in an axial direction of the gear, wherein the gear comprises a gear arrangement movable in the axial direction of the gear between the first and second switching stages. An actuator is rotatable about an axis parallel to the axial direction of the gear. At least one shifting gate is rotatable together with the actuator wherein the shifting gate interacts with the gear arrangement for moving the gear arrangement in the axial direction. The shifting gate has a central area extending linearly and at a slant relative to a circumferential direction of the gear and end sections on each end of the central area, wherein the end sections extend parallel to the circumferential direction.

Owner:ATLAS COPCO ELECTRIC TOOLS

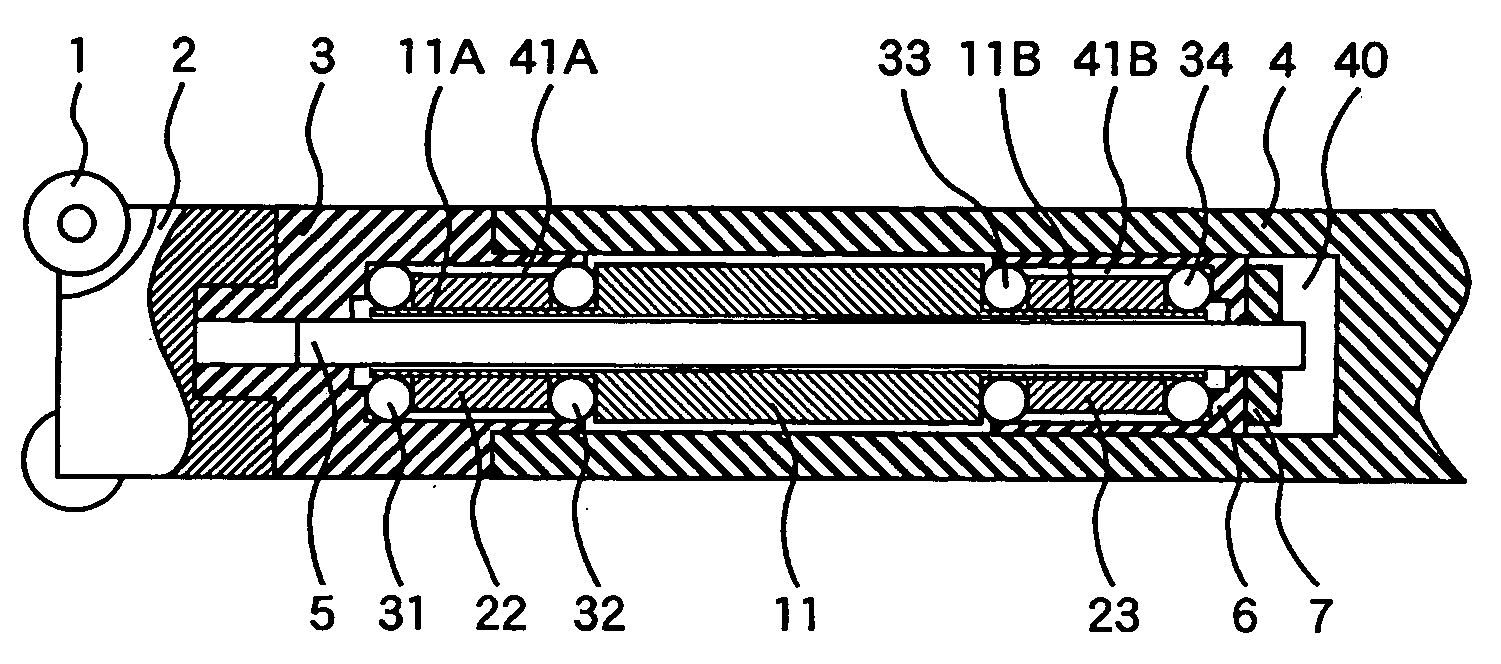

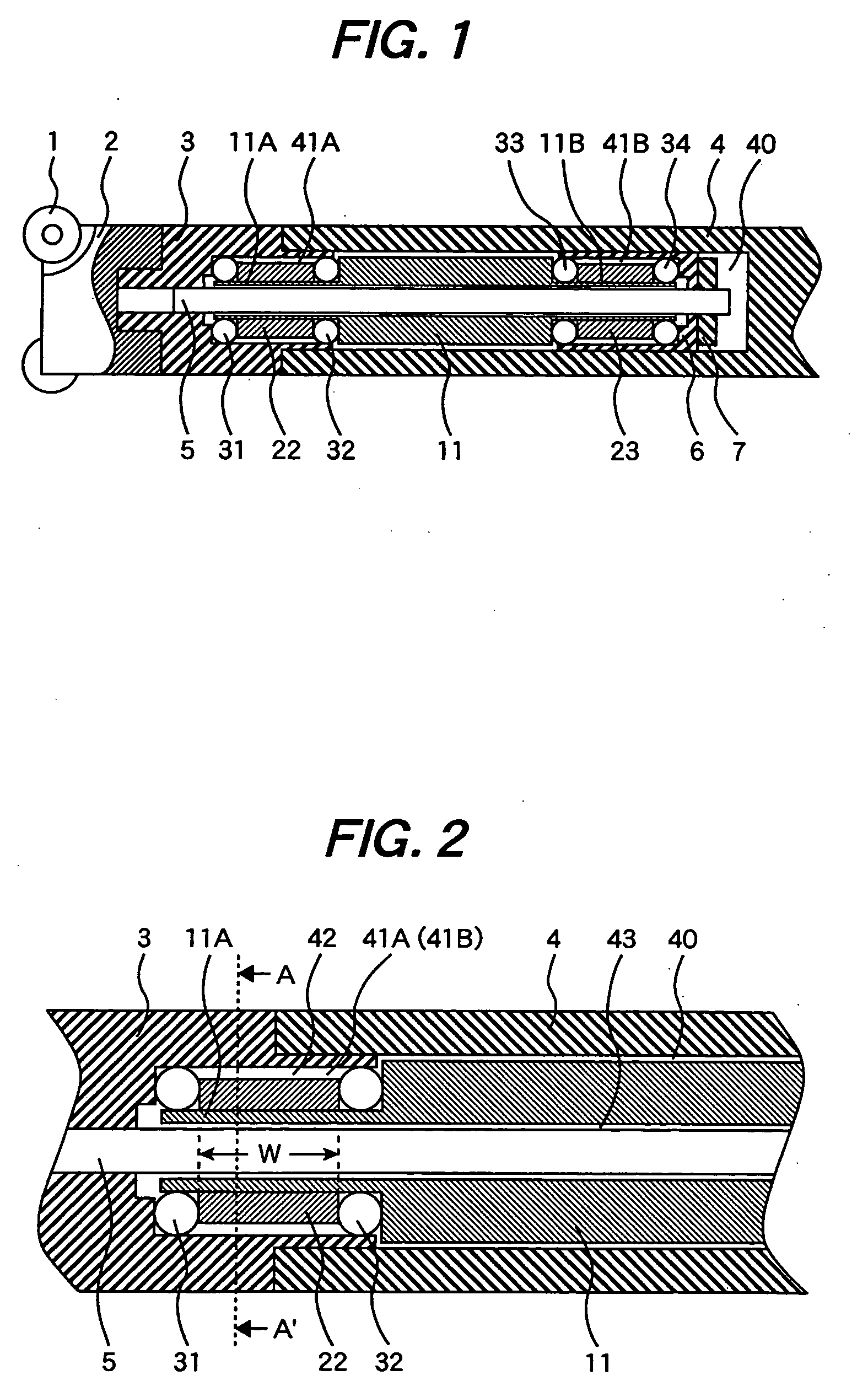

Tool having damper, cutting method using the same, and manufacturing method of impeller or guide vane of fluid machine

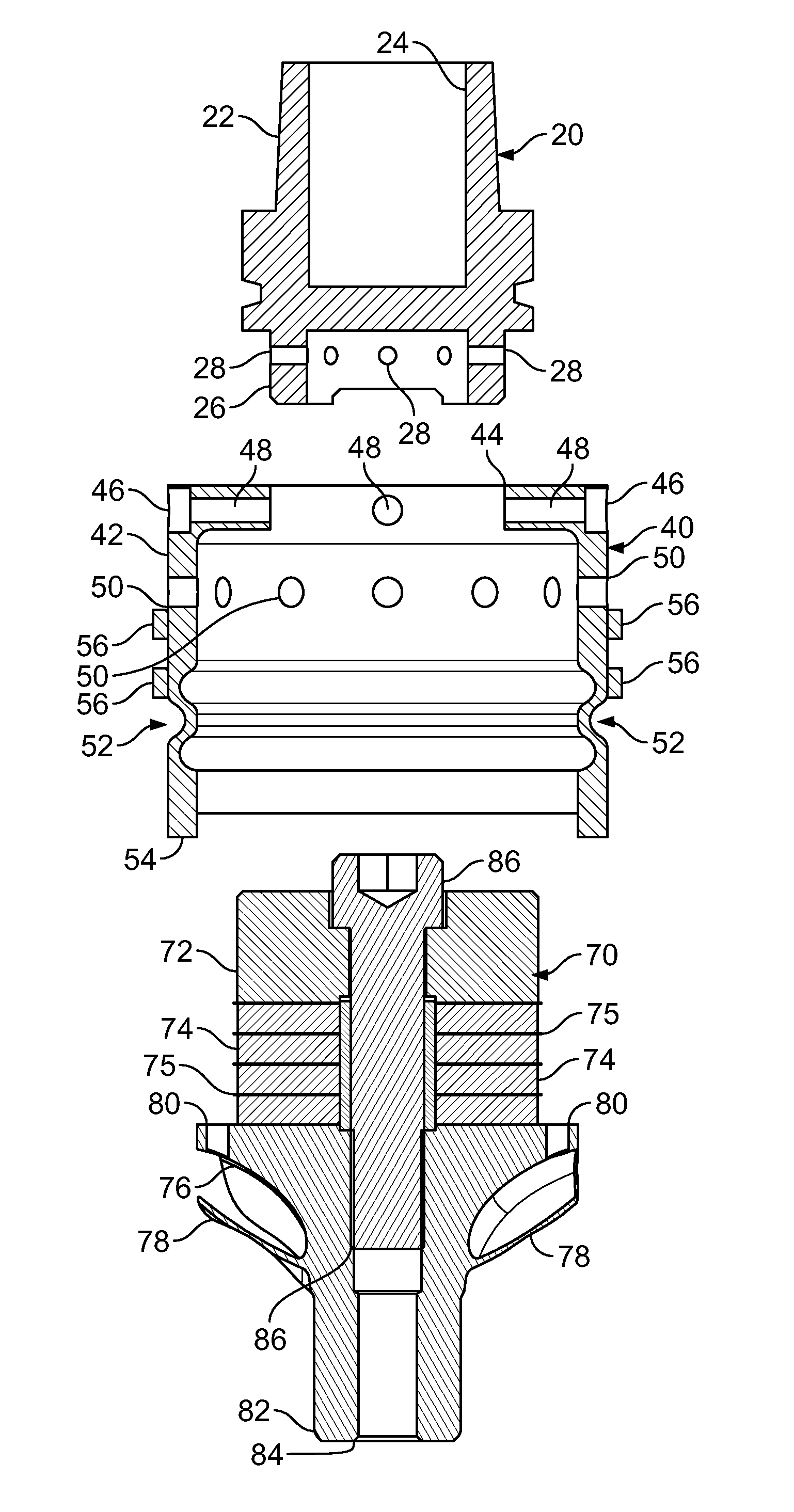

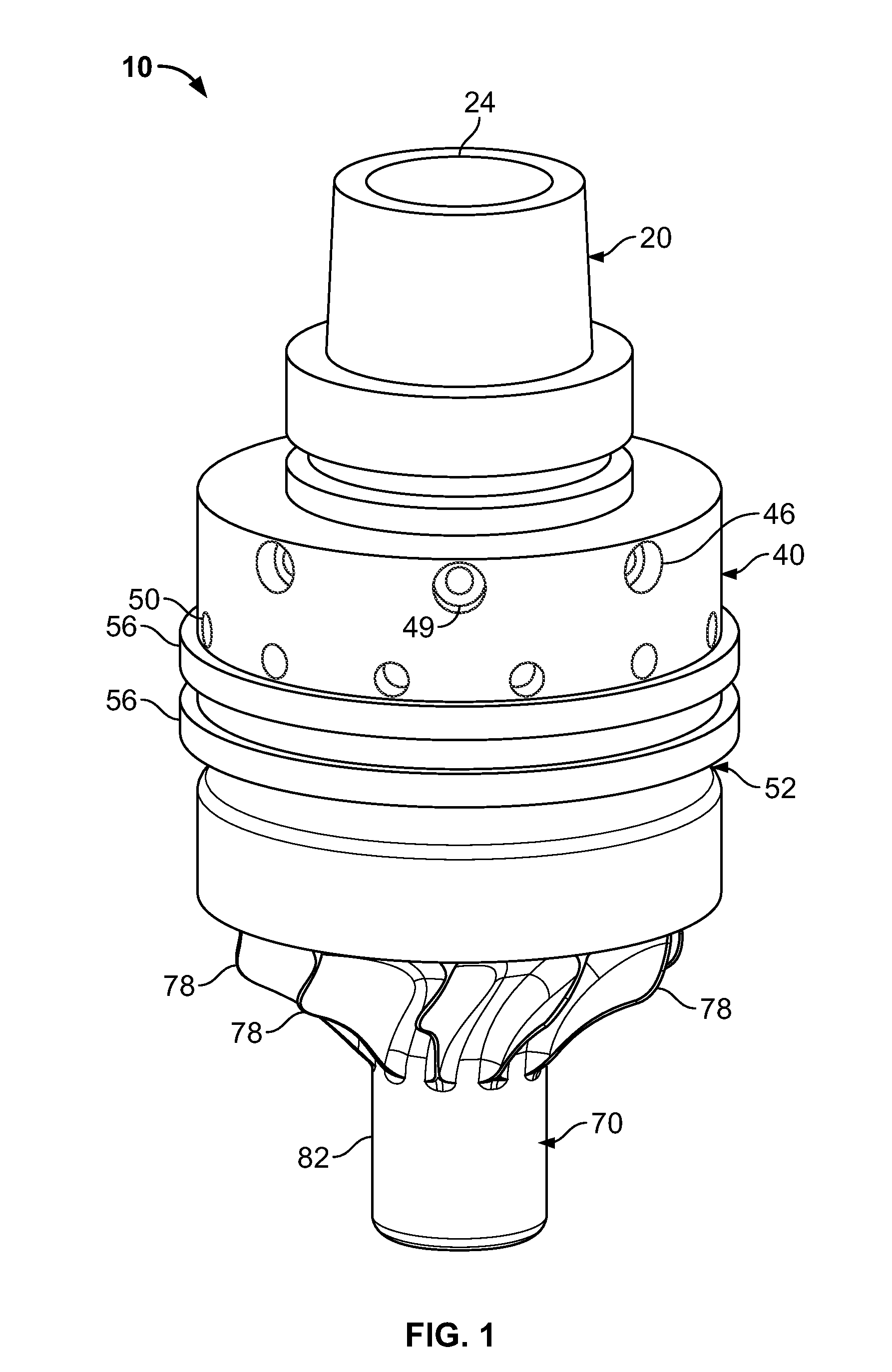

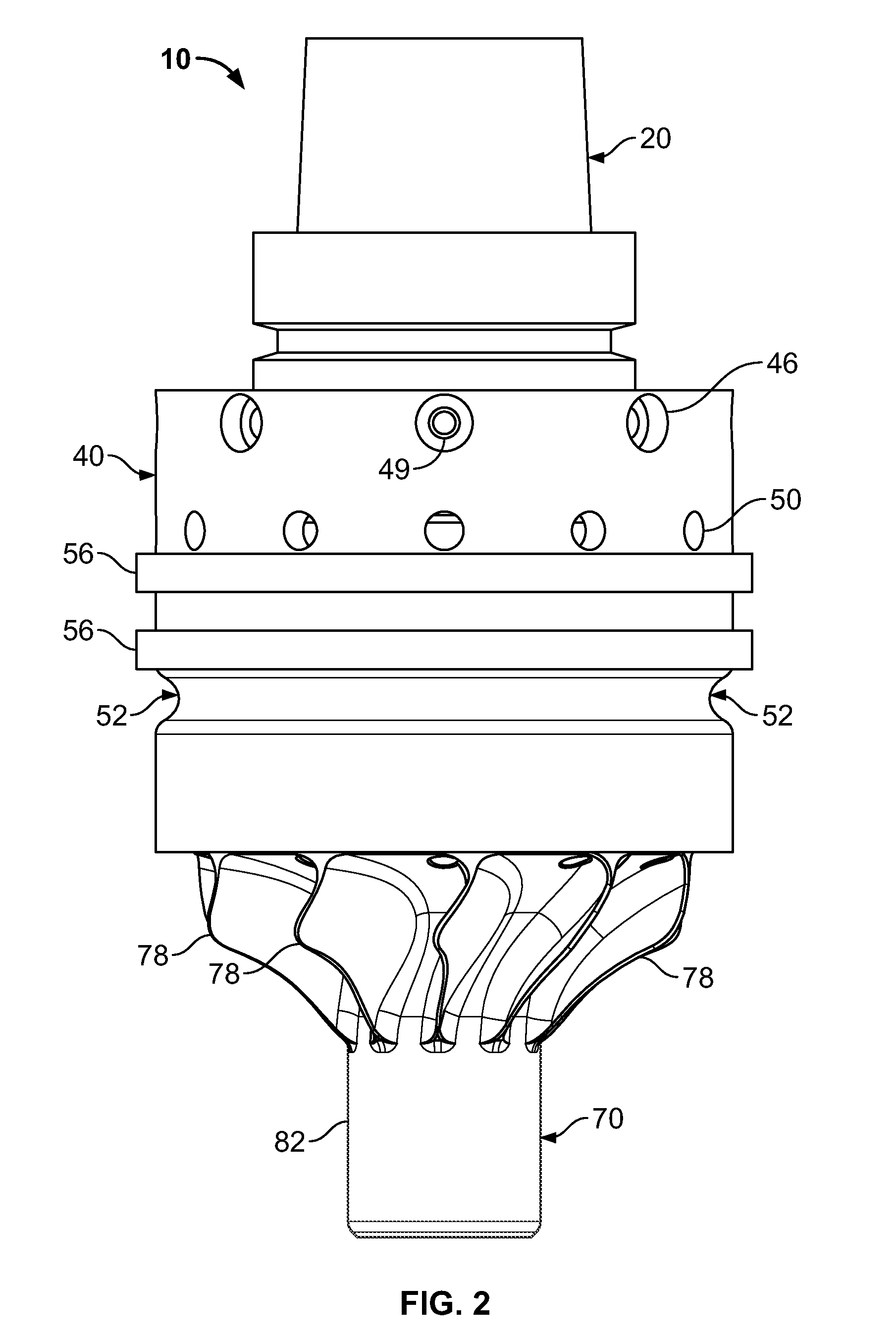

InactiveUS20060275090A1Easy to adjustEasy to manufactureMilling cuttersBoring barsImpellerDynamic stiffness

Disclosed herein is the structure of a damper that is capable of improving the degree of freedom in design to optimize the damping characteristics of the damper and is capable of allowing the damper to be easily optimized and manufactured for a wide variety of dynamic stiffness characteristics of a tool body, and a manufacturing method using the same. A plurality of ring-shaped elastic members are disposed at opposite ends of a weight part. The weight part is connected to the tool body via the elastic members. Consequently, the weight part is moved relative to the tool body. The plurality of elastic members are mounted while spacers are disposed between the elastic members, and the spacers are moved with respect to the weight part in the axial direction thereof. A viscous fluid is filled in the region surrounded by the outer circumferential surfaces of the spacers, the elastic members, and the inner surface of a hollow part of the tool body. Consequently, it is possible to damp the relative movement of the weight part with respect to the tool body.

Owner:HITACHI TOOL ENG LTD

High-accuracy hole forming device for aircraft wall panel and a method of high-accuracy hole forming device

ActiveCN102756138AGuaranteed surface qualityOptimum working parametersAutomatic control devicesMeasurement/indication equipmentsControl systemClosed loop feedback

The invention provides a high-accuracy hole forming device for an aircraft wall panel and a method of the high-accuracy hole forming device. A main shaft module is used for feeding an electric main shaft along a hole forming axis; a feeding module is used for guaranteeing movement of the main shaft module and a pressure pin normal leveling module in the hole forming axis and providing pressure for a pressure pin to be abutted against the wall panel; the pressure pin normal leveling module is used for guaranteeing the stability of the wall panel in the hole forming process; the feeding module is matched with a grating scale module for work to realize accurate control over the hole forming feeding displacement; a visual alignment module and a control system form a closed loop feedback loop; positional deviation error of a projection point of a hole forming main shaft on the wall panel surface and an actual hole forming point can be measured and fed back in real time; and correction is performed through the closed loop system to guarantee that the positional accuracy of a formed hole is within a tolerance requirement range. According to the high-accuracy hole forming device, the positional accuracy, the surface roughness and the dimensional accuracy of the hole can meet the design requirements well; and meanwhile, slanting holes and oblique holes are not formed in the hole forming process, the temperature of a hole forming region is kept at a normal working temperature and the chip removal is normal.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

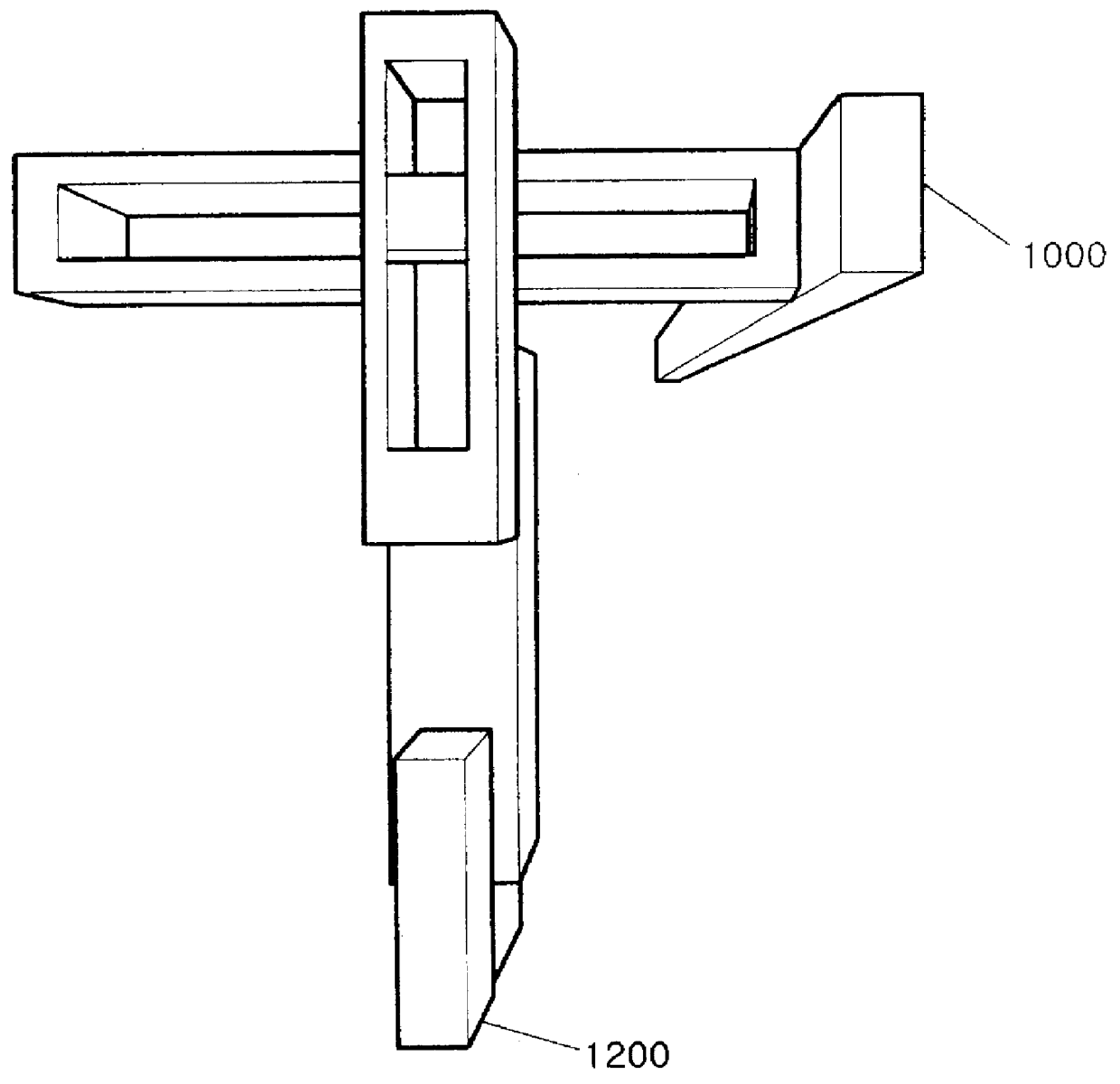

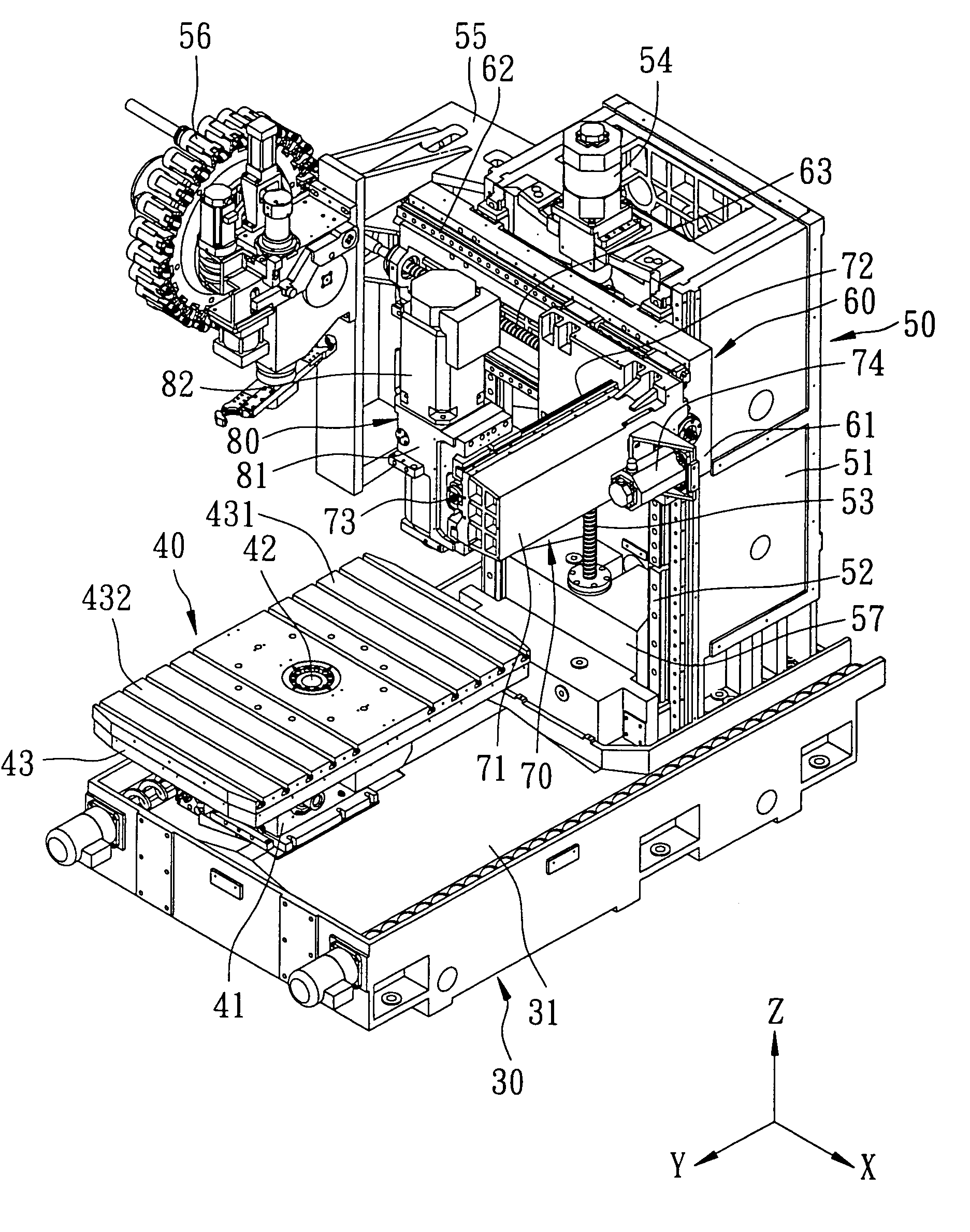

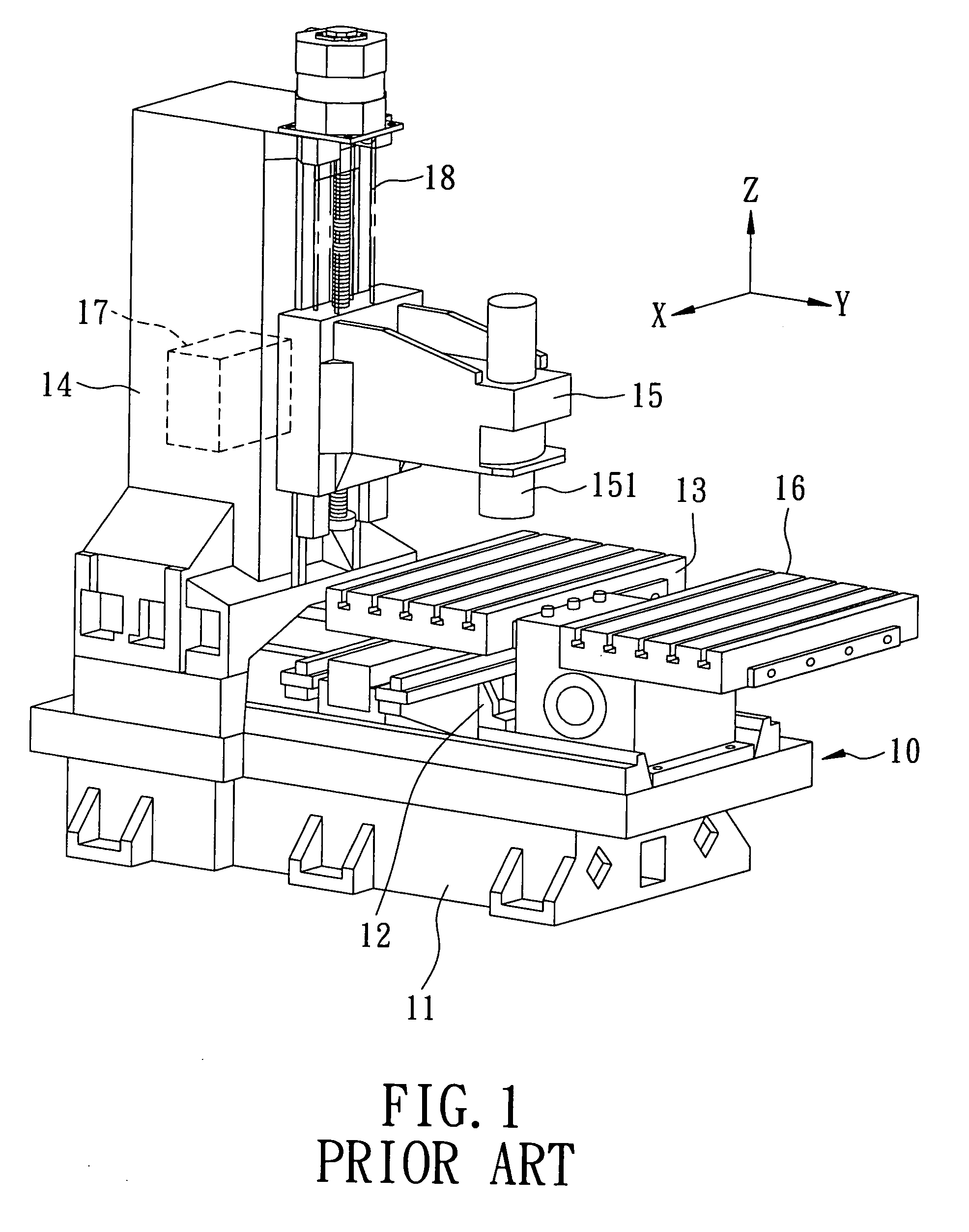

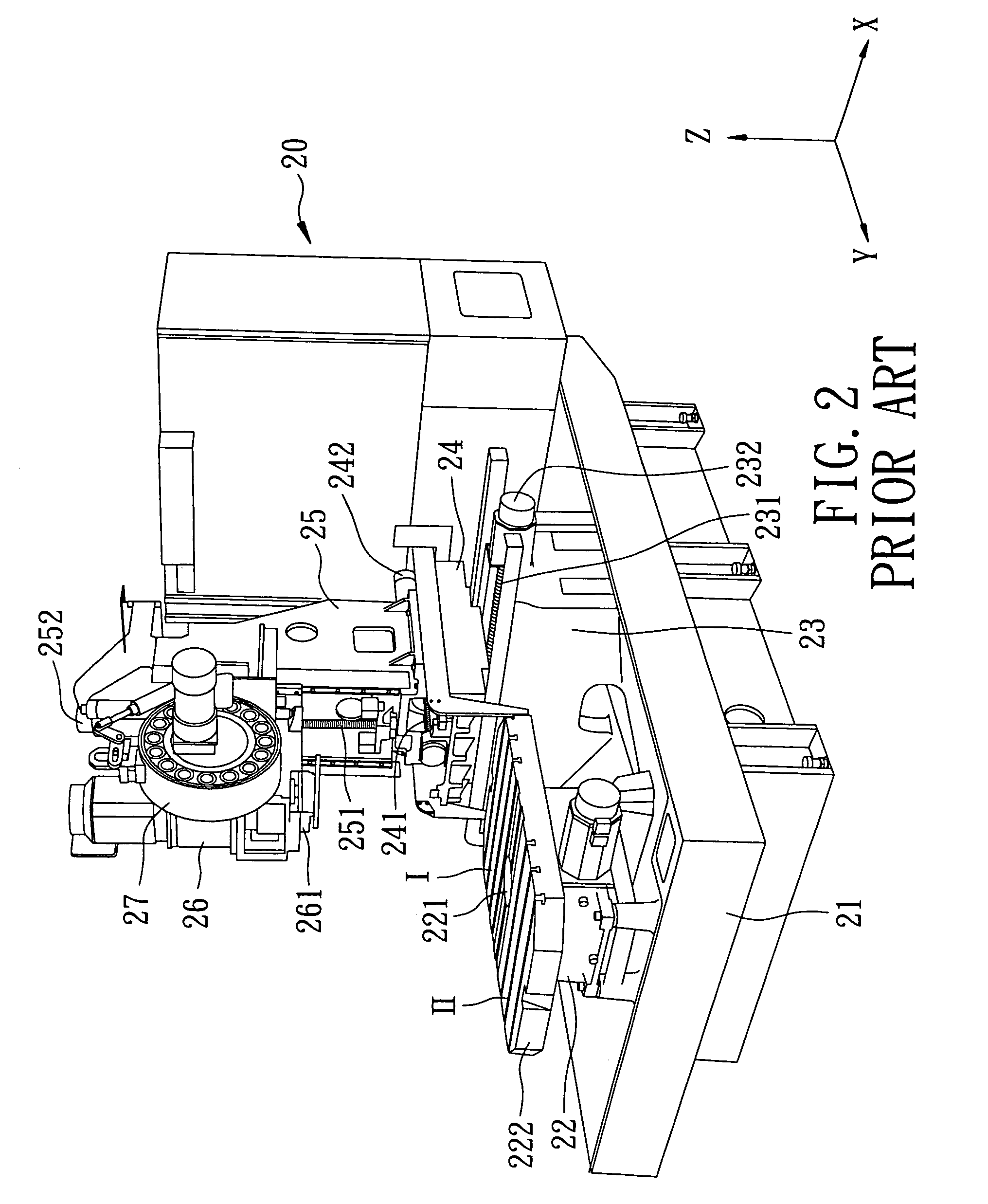

CNC machine tool

InactiveUS7147595B1Reduce loadUnnecessary movementPlaning/slotting machinesMilling machinesNumerical controlEngineering

A CNC machine tool includes a worktable supporting two workpieces and rotatable on a base so as to exchange the positions of the workpieces. A post member is fixed on the base. A first horizontal rail unit is movable vertically on the post member. A second horizontal rail unit is movable on the first horizontal rail unit along a first horizontal direction. A spindle head unit is movable on the second horizontal rail unit along a second horizontal direction perpendicular to the first horizontal direction.

Owner:CHEN HSI KUAN

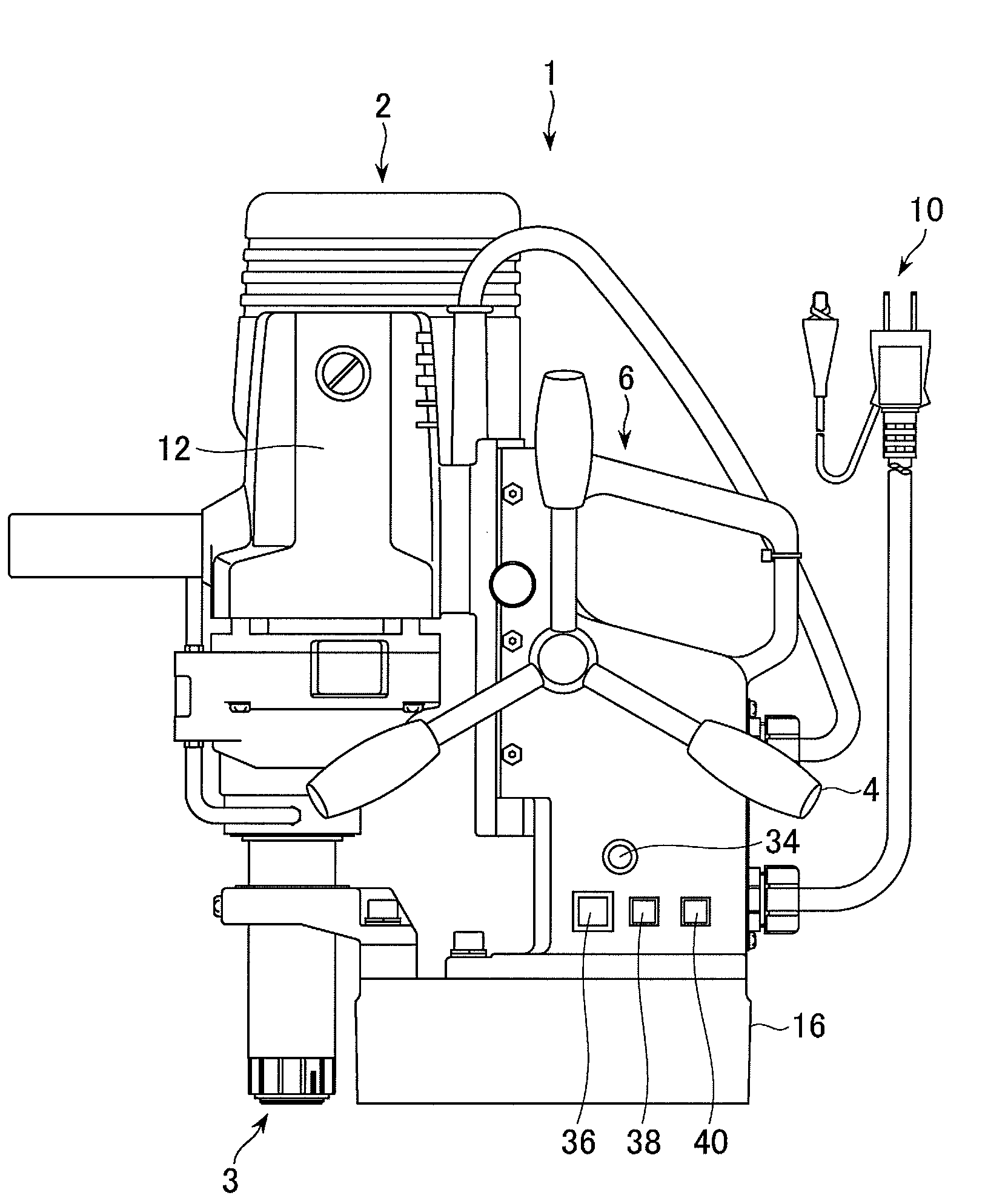

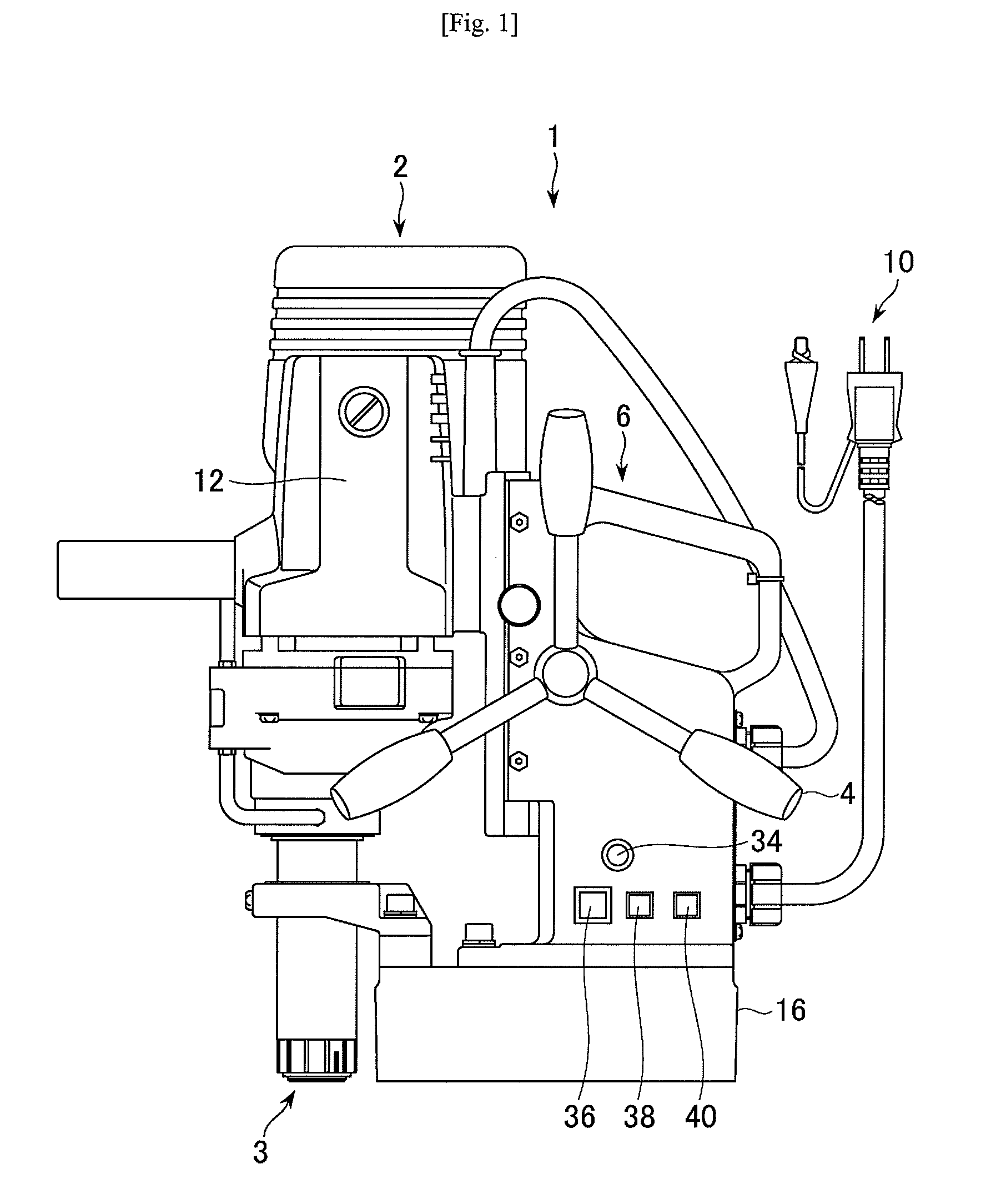

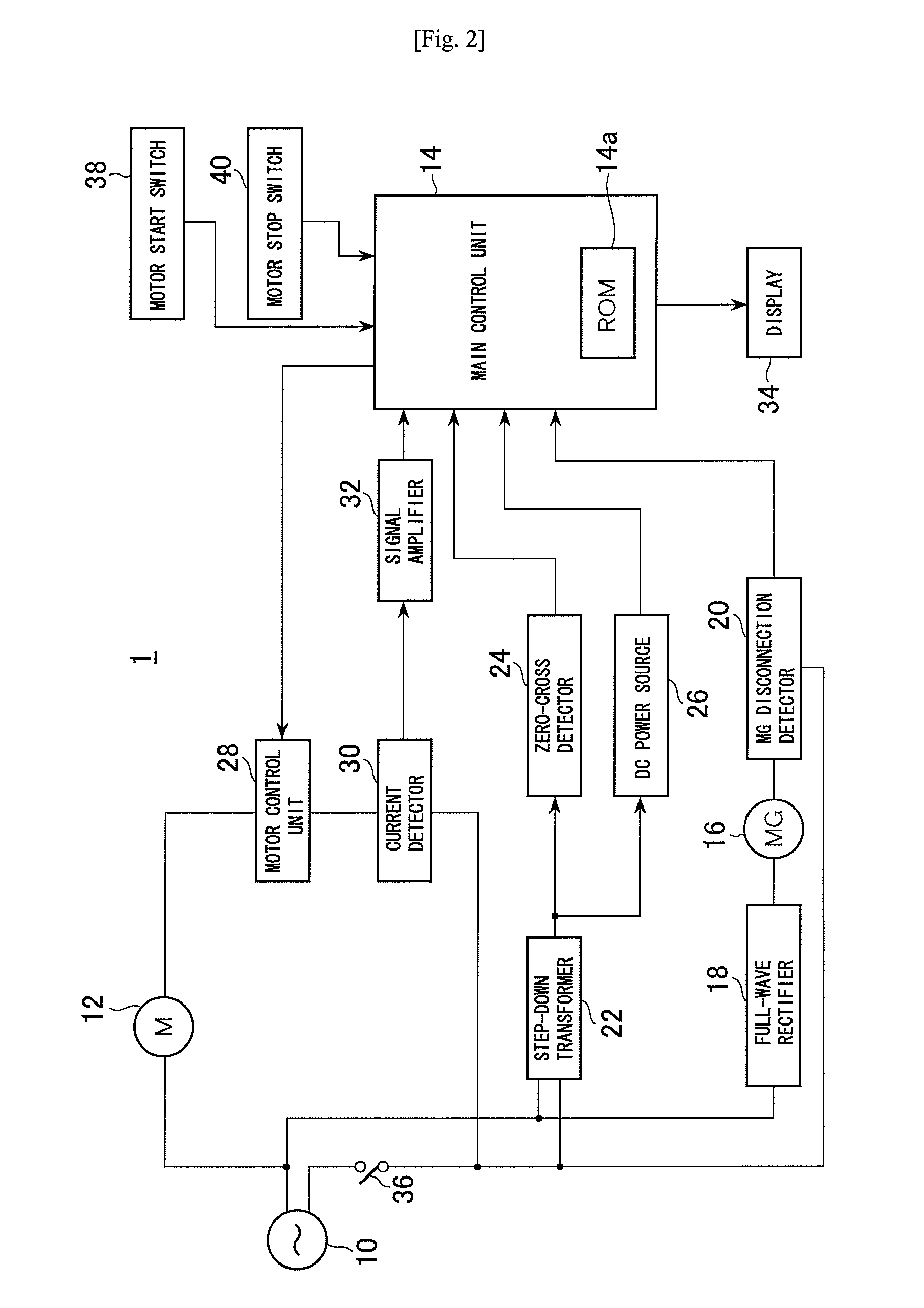

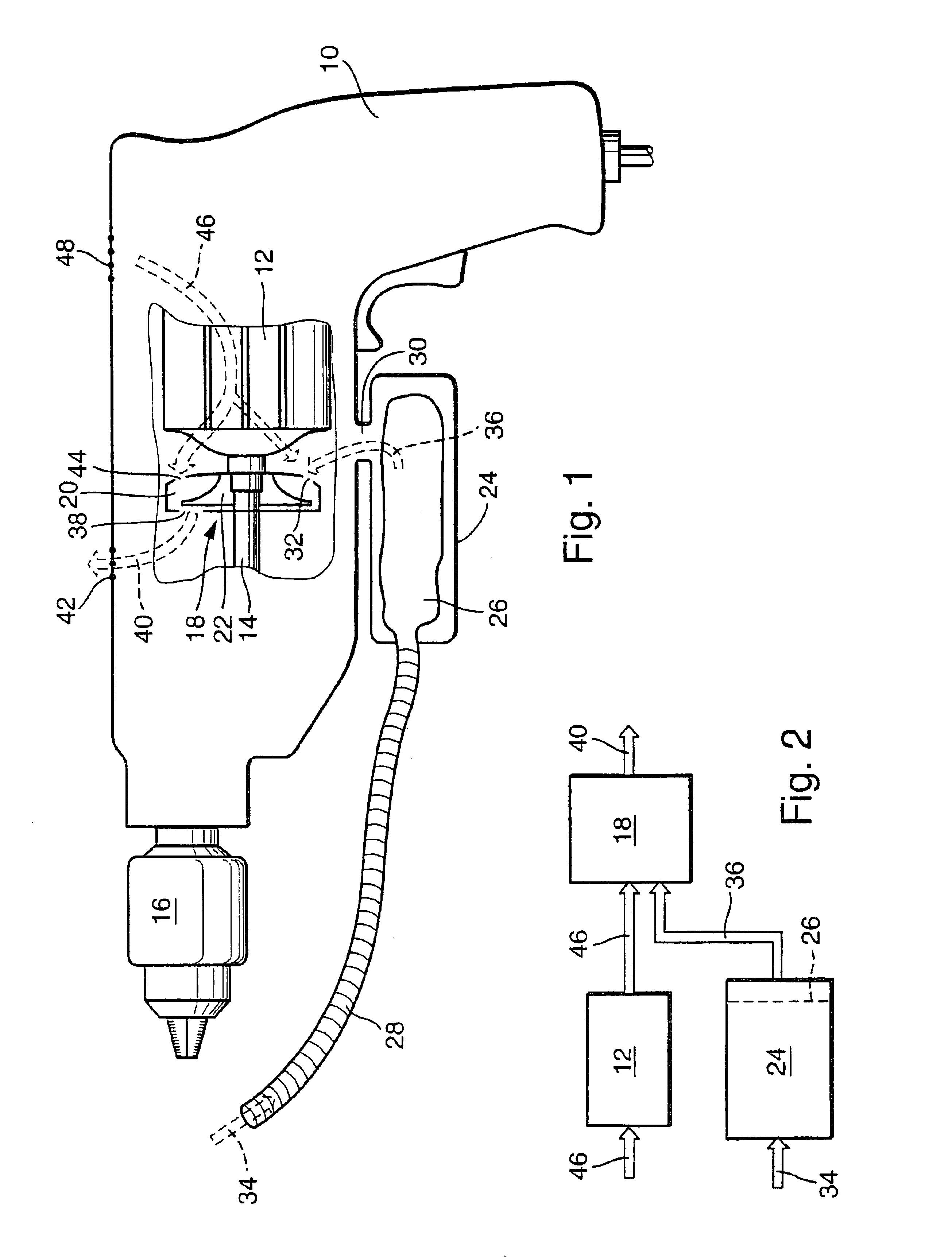

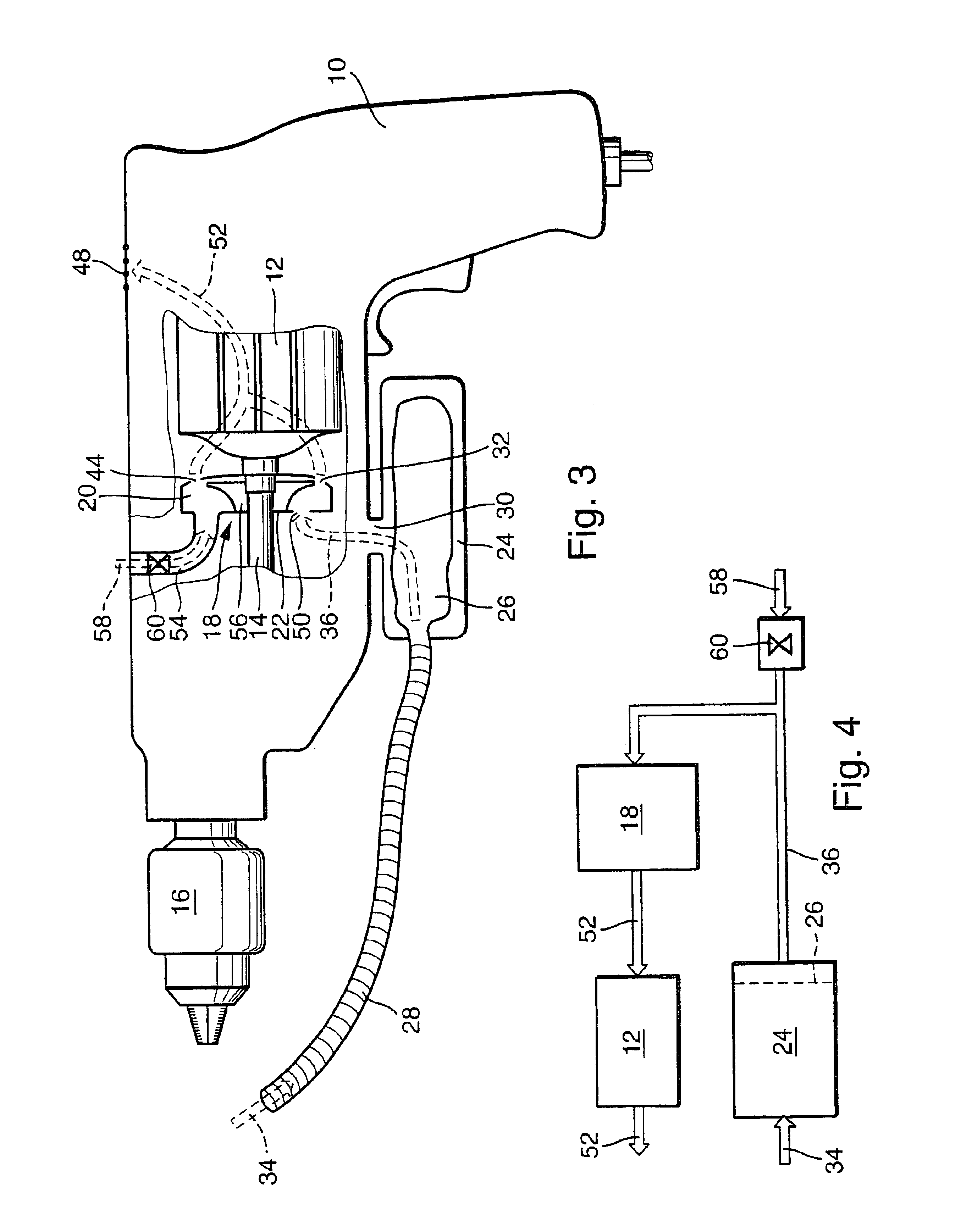

Portable drilling device

ActiveUS20090196696A1Reduce power supply voltageEasy to operateDC motor speed/torque controlAC motor controlFull waveEngineering

It is an object of the present invention to prevent recurrence of an overload condition after occurrence of the overload condition, thereby improving operability and safety in a drilling device. A motor 12 for rotating a drill is connected to an AC power source 10 through a motor control unit 28, a current detector 30, and a power switch 36. A magnet 16 is also connected to the AC power source 10 through the power switch 36 and a full-wave rectifier 18. The motor control unit 28 rotationally drives the motor on the basis of a signal sent from a main control unit according to a state in which a motor start switch 38 is on. The main control unit 14 controls the motor control unit 28 to gradually reduce a supply voltage to the motor 12 when the motor 12 becomes overloaded, to gradually increase the voltage to the normal power supply condition when the overload condition is vanished, and to stop power supply to the motor 12 if the overload condition continues for a predetermined period.

Owner:NITTO KOHKI CO LTD

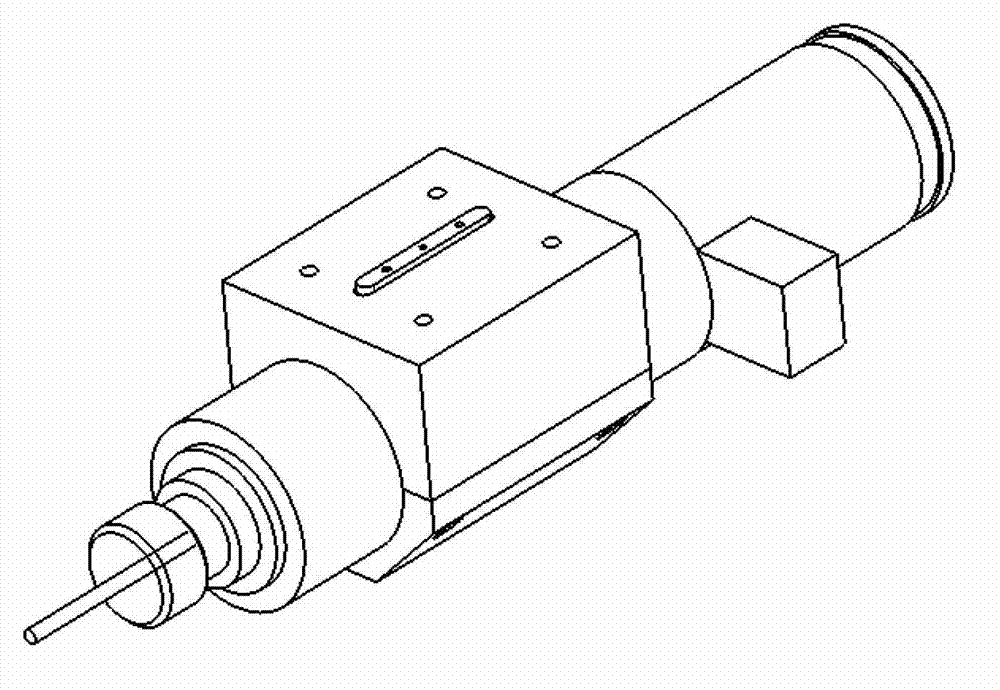

Ultrasonic machining module

A device for use in a machining system, including an ultrasonic transducer, wherein the ultrasonic transducer is adapted to receive a tool bit; a housing adapted to be both compatible with the machining system and to receive the ultrasonic transducer, wherein the housing is operative to isolate all radial and other vibrations generated by the ultrasonic transducer except the axial vibrations transmitted to the tool bit; and a tool holder, wherein the tool holder and the top portion of the housing are mechanically coupled to one another.

Owner:EDISON IND INNOVATION

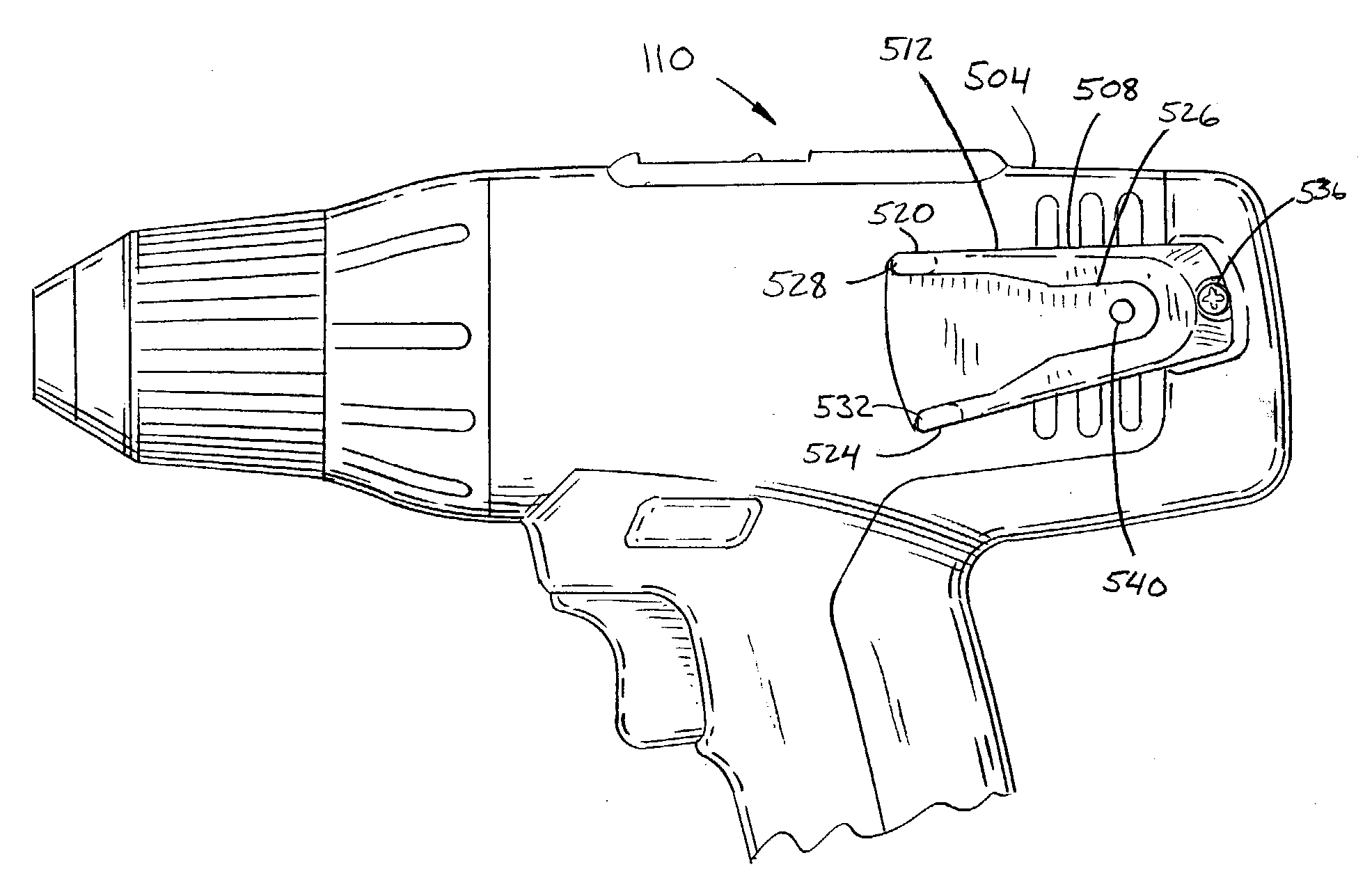

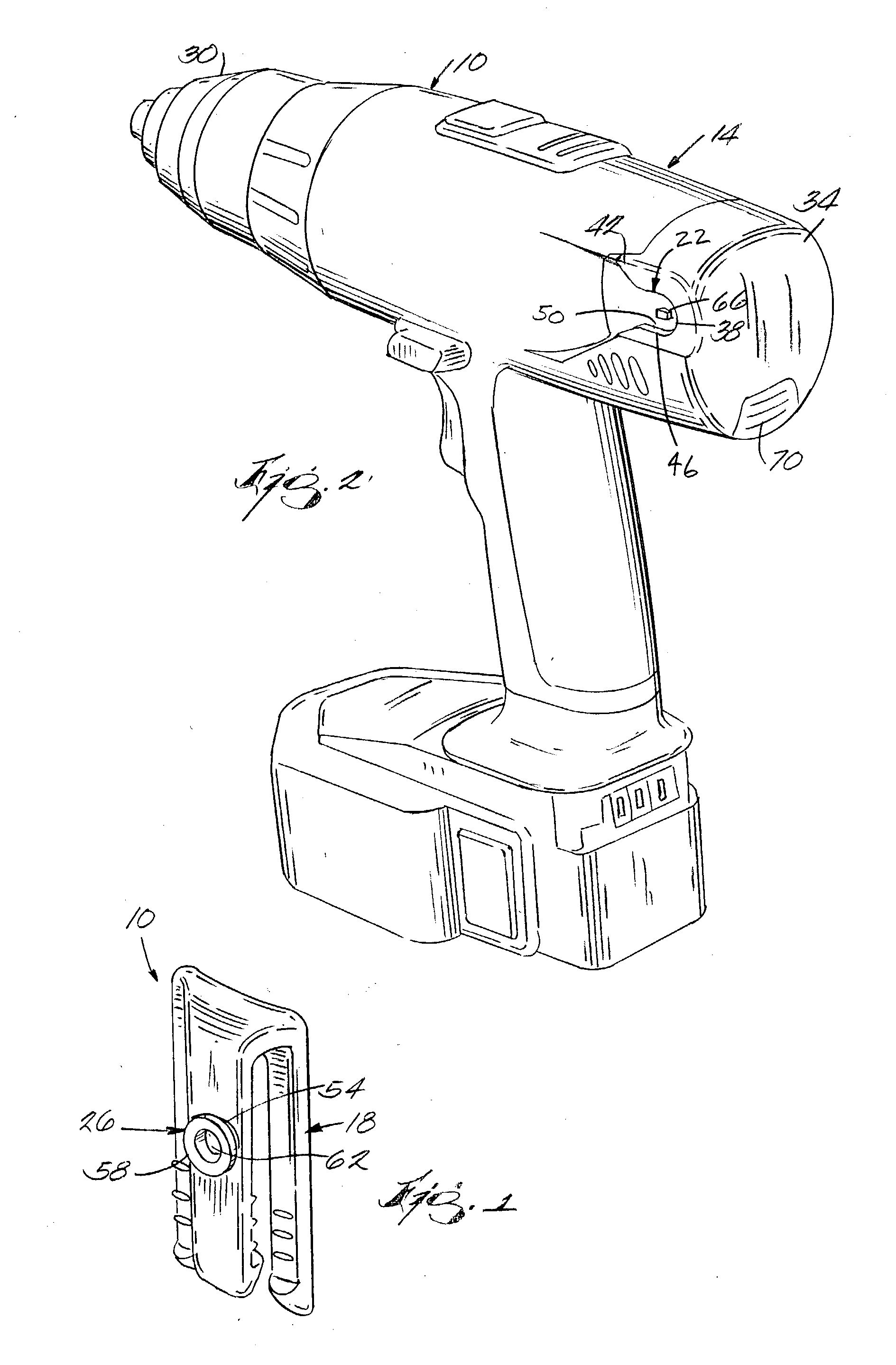

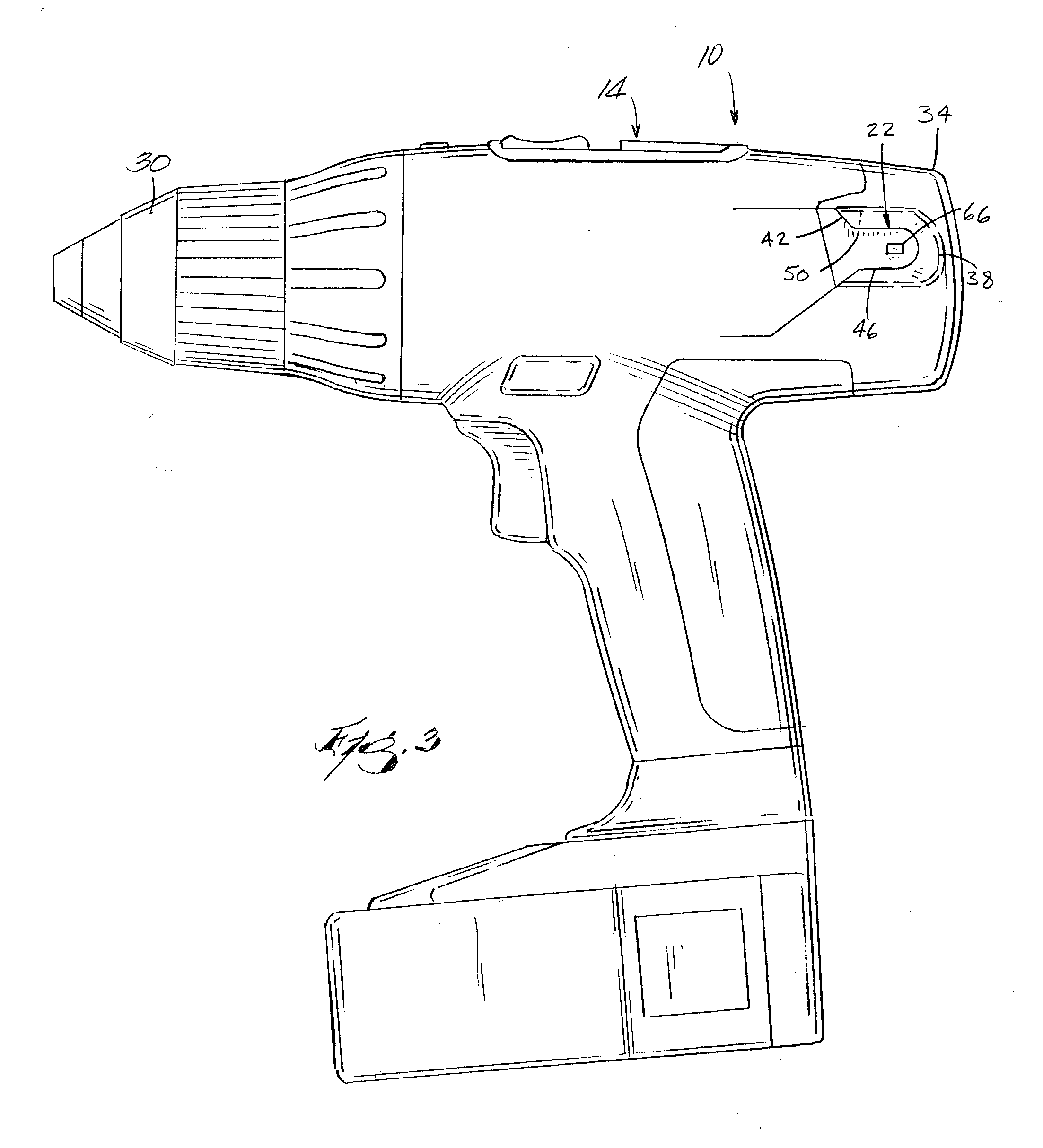

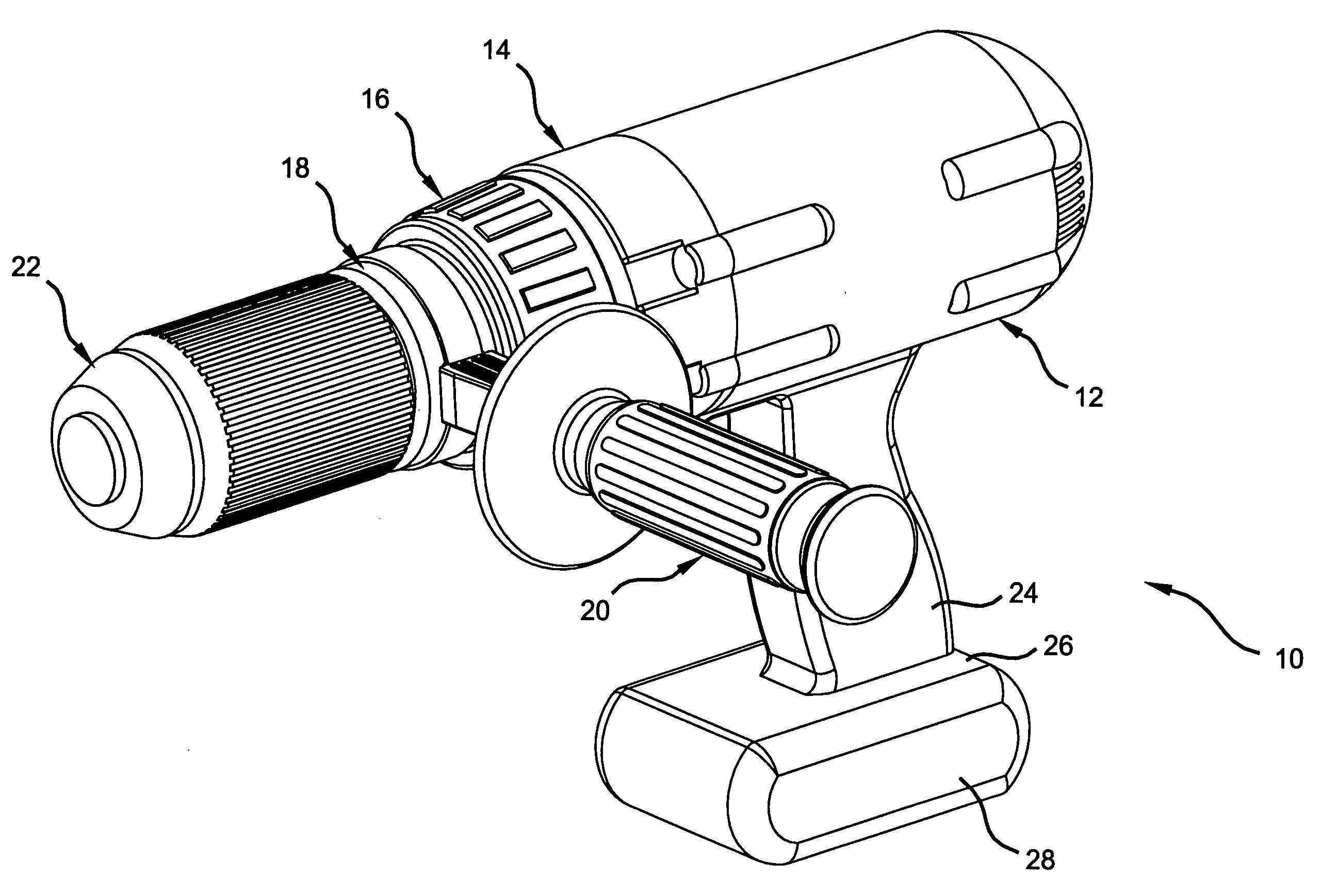

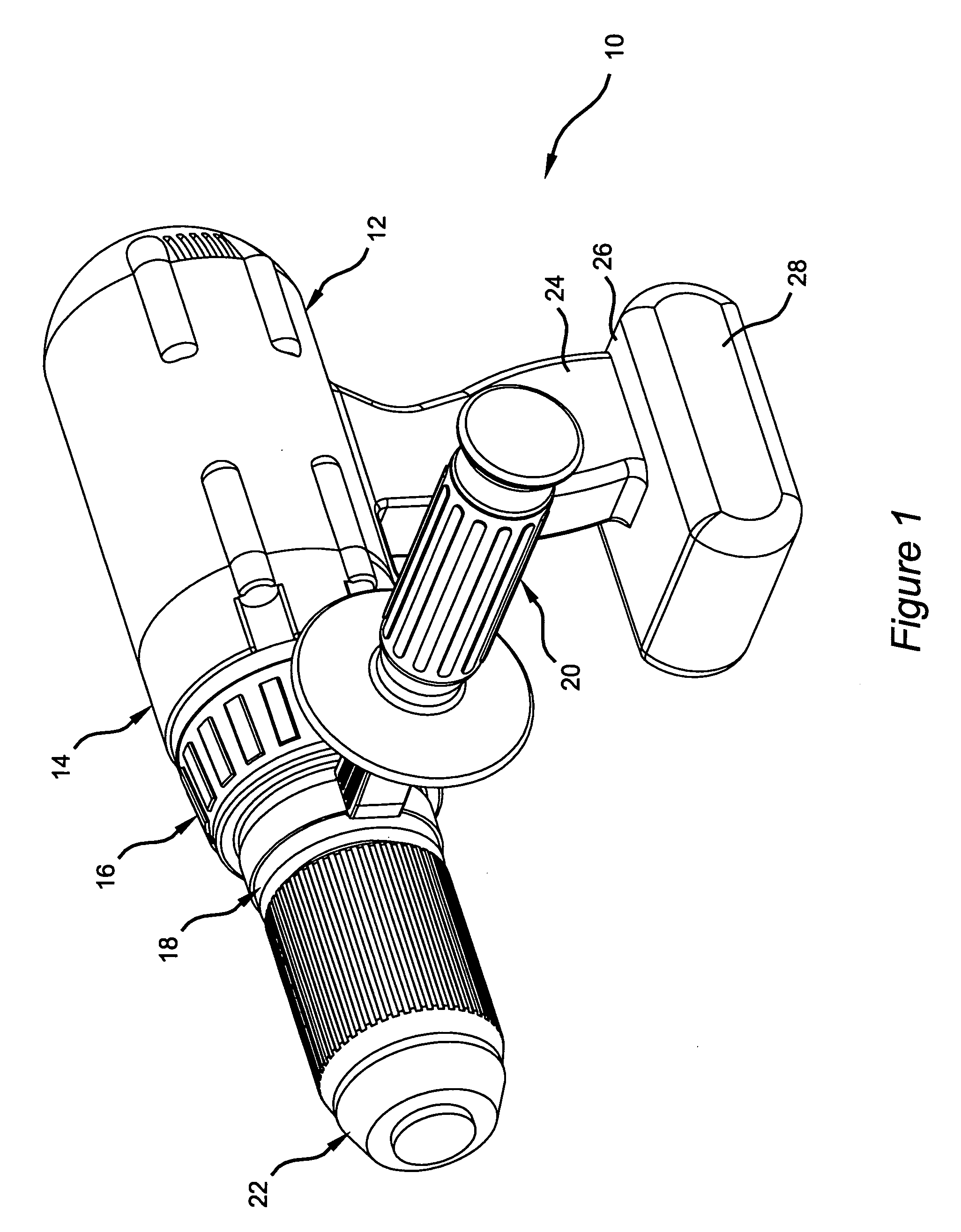

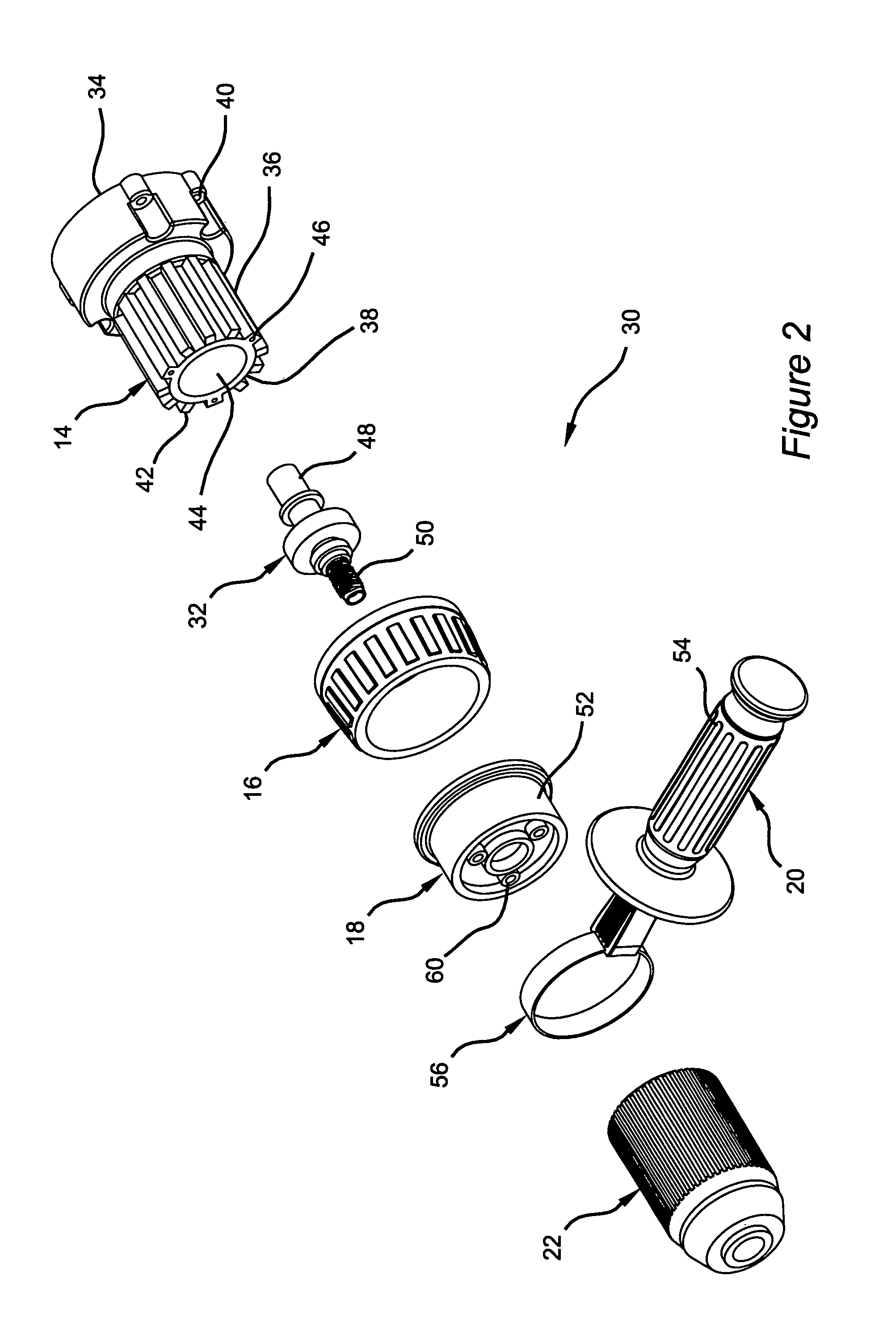

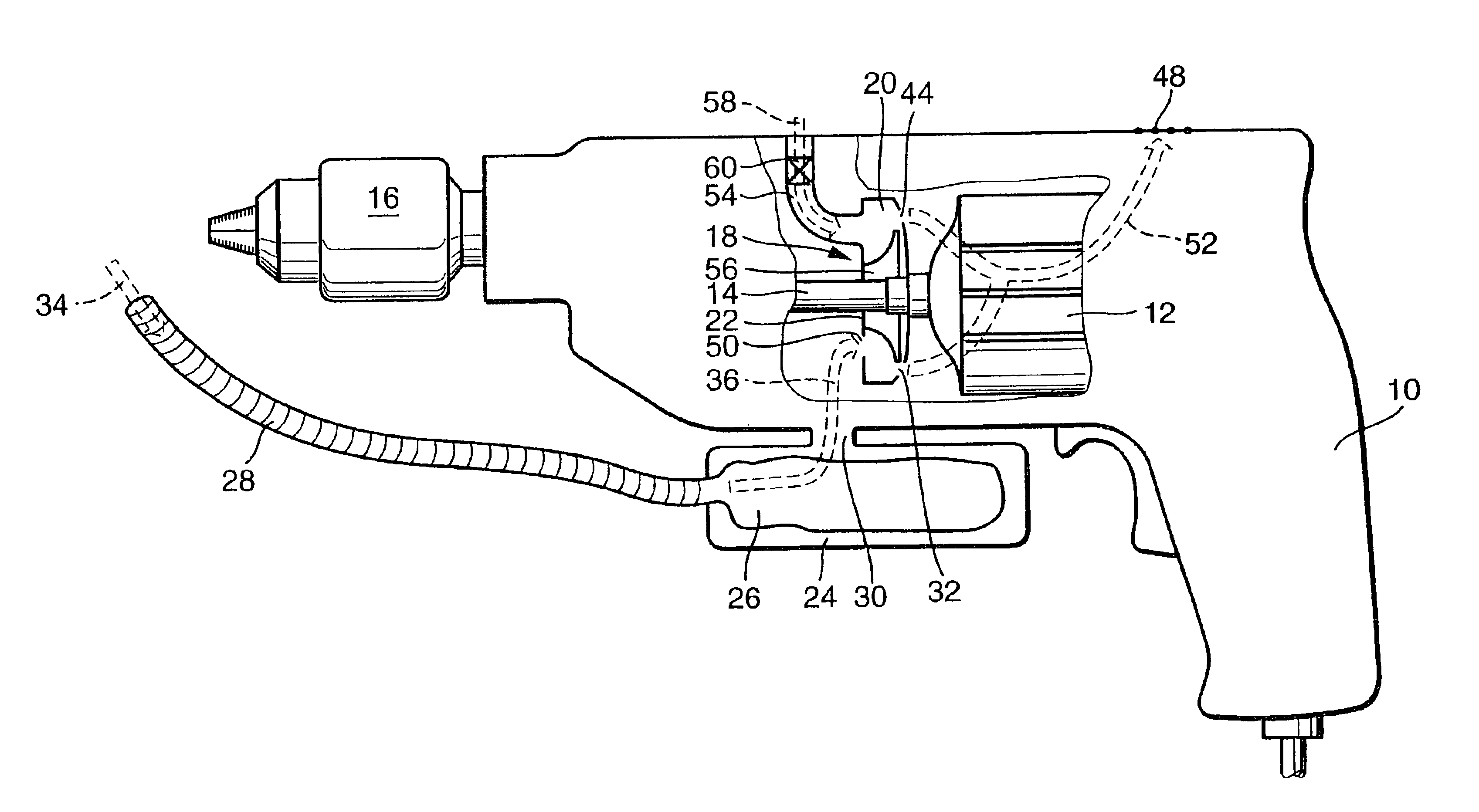

Side handles on drill/drivers

InactiveUS7000709B2Easy to adjustEasy to readTravelling carriersThread cutting machinesEngineeringShaft collar

A drill / driver is provided that includes a housing, a collar mounted at a front portion of the housing, a side handle mounting area provided forward of the collar, a handle mounted to the side handle mounting area, and a chuck mounted forward of the side handle mounting area. With the side handle mounted in front of the collar, easier access to the adjusting collar and easier reading of the collar settings is achieved.

Owner:BLACK & DECKER INC

Hand tool comprising a dust suction device

The dust removal device comprises a fan (18), a dust collection receptacle (24), and a suction passage (28). The dust collection receptacle (24) equipped with a dust filter (26) is located in the path of air flow (34, 36) between the suction passage (28) and the fan (18). The dust is therefore filtered out of the air stream before it reaches the fan, which prevents dust-induced wear. It is also possible to use the same fan for engine cooling as well as dust removal.

Owner:ROBERT BOSCH GMBH

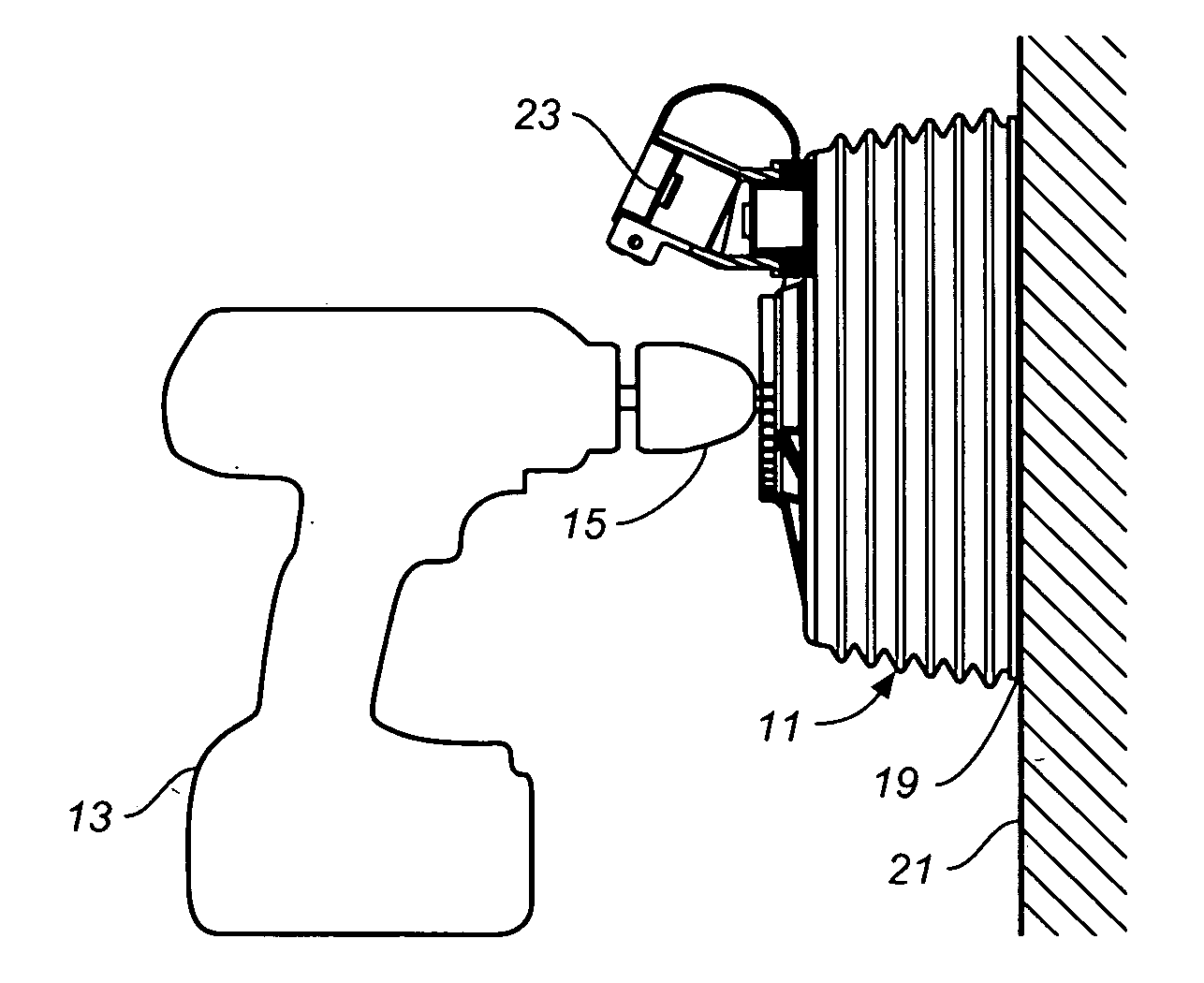

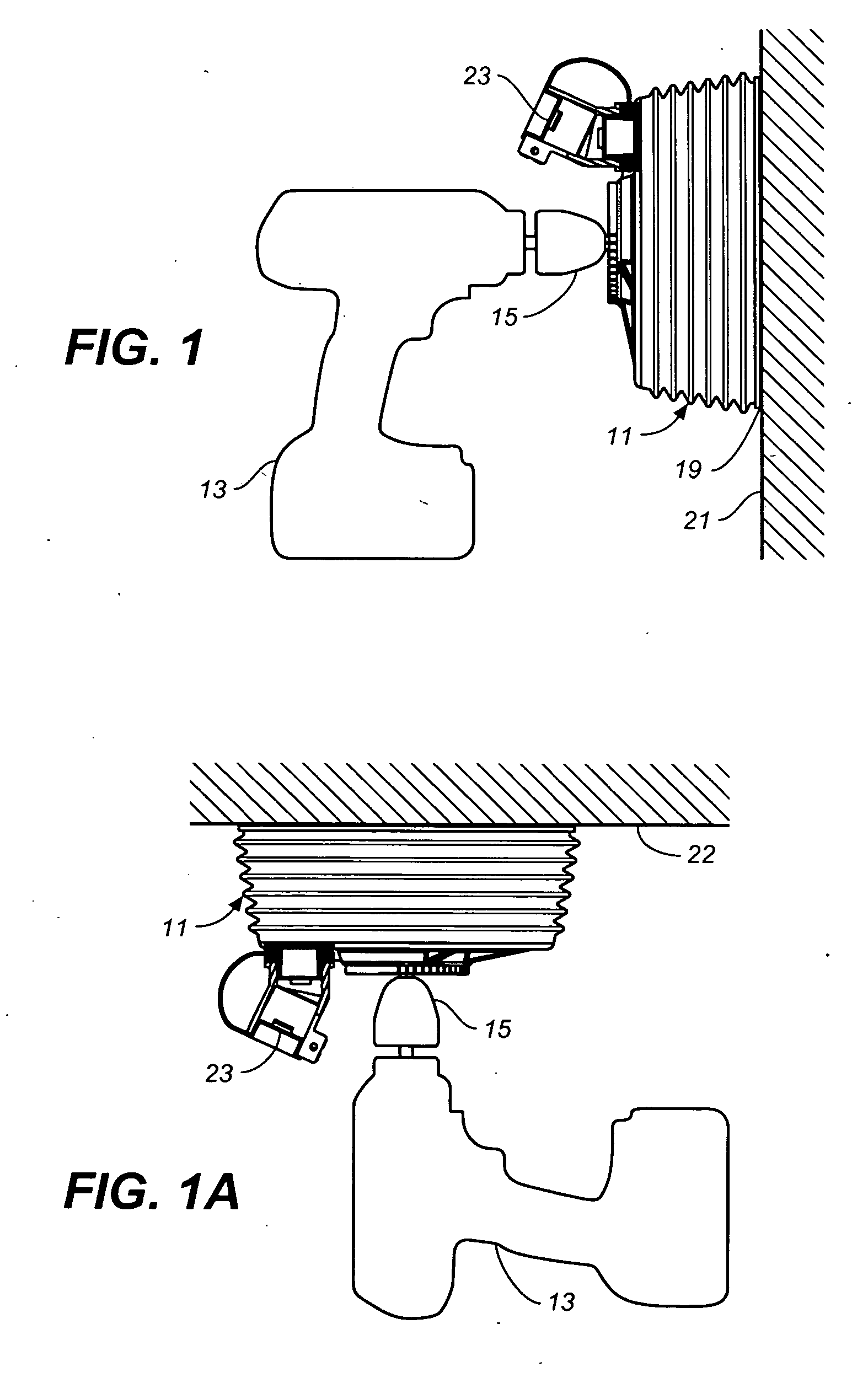

Debris shield for a rotary tool or machine

ActiveUS20070065242A1Eliminate needReduce needDrilling/boring measurement devicesThread cutting feeding devicesHole sawEngineering

A debris shield for a rotary tool or machine for collecting debris generated while cutting or drilling holes in a work surface has a debris collection housing having a top structure, side walls depending from said top cover structure to form a debris collection chamber, an open bottom with a surface contact rim, and a compression axis extending through the housing's top structure and bottom opening. In one aspect of the invention, the debris collection housing is a bellows housing with a vacuum port, and has a shank-holding and vent assembly in top structure of the bellows housing for receiving and rotatably holding the shank of a rotary surface working implement such as a drill bit, spade bit or hole saw. In another aspect of the invention the debris collection housing can be either a bellows type housing or rigid housing, and can have a vacuum port or not. In this aspect of the invention, the housing is provided with a chuck-arbor assembly having a chuck end and an arbor end rotatably mounted in the top structure of said debris collection housing so that it lies on a rotary axis that is substantially parallel to the compression axis of said debris collection housing. The chuck end of said chuck-arbor assembly is situated within said housing for receiving and holding the arbor end of a surface working implement, and the arbor end of said chuck-arbor assembly projects above the top structure of said housing such that the arbor end of said chuck-arbor assembly can be inserted into the chuck of a rotary tool such as a handle drill. In one embodiment, compression along the compression axis is provided by means of a bellows type housing; in another embodiment compression is provided by a chuck-arbor assembly having a spring loaded shaft which is slidably mounted in the top structure of the housing, such that the chuck end of the chuck-arbor assembly can be made to advance against the restoring force of the spring loaded shaft toward a work surface.

Owner:SKRADSKI THOMAS J

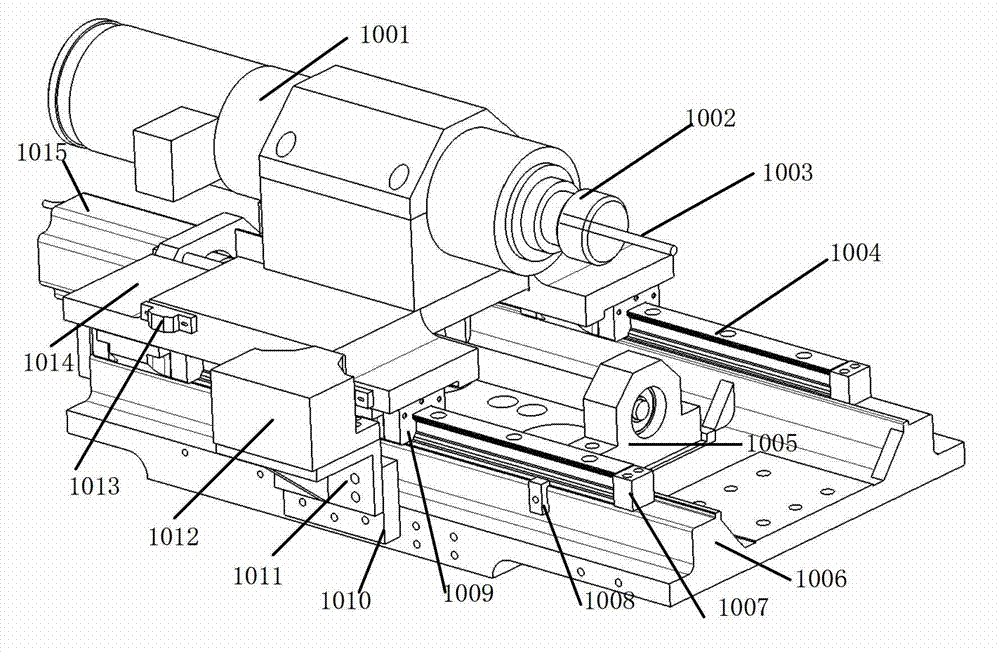

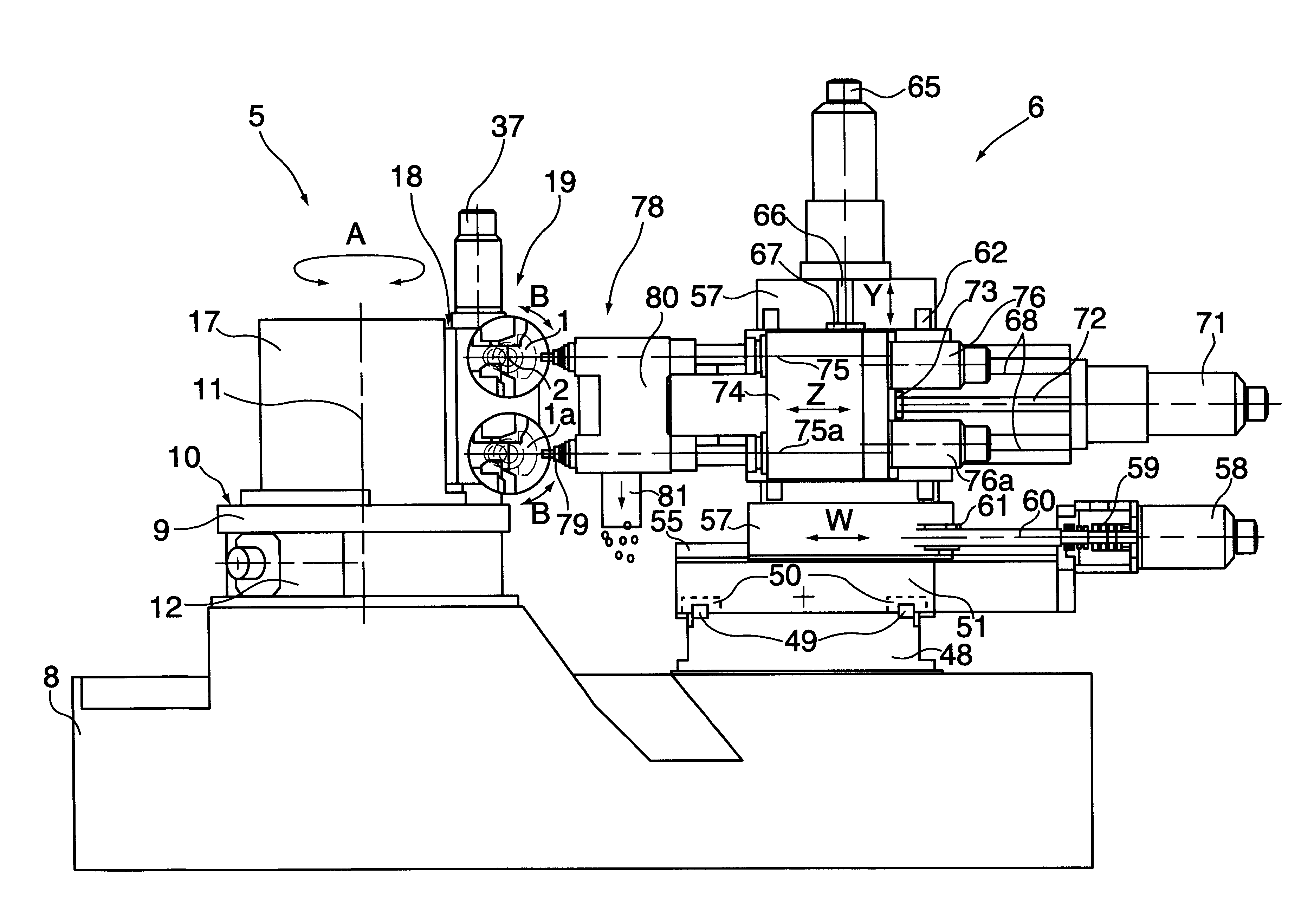

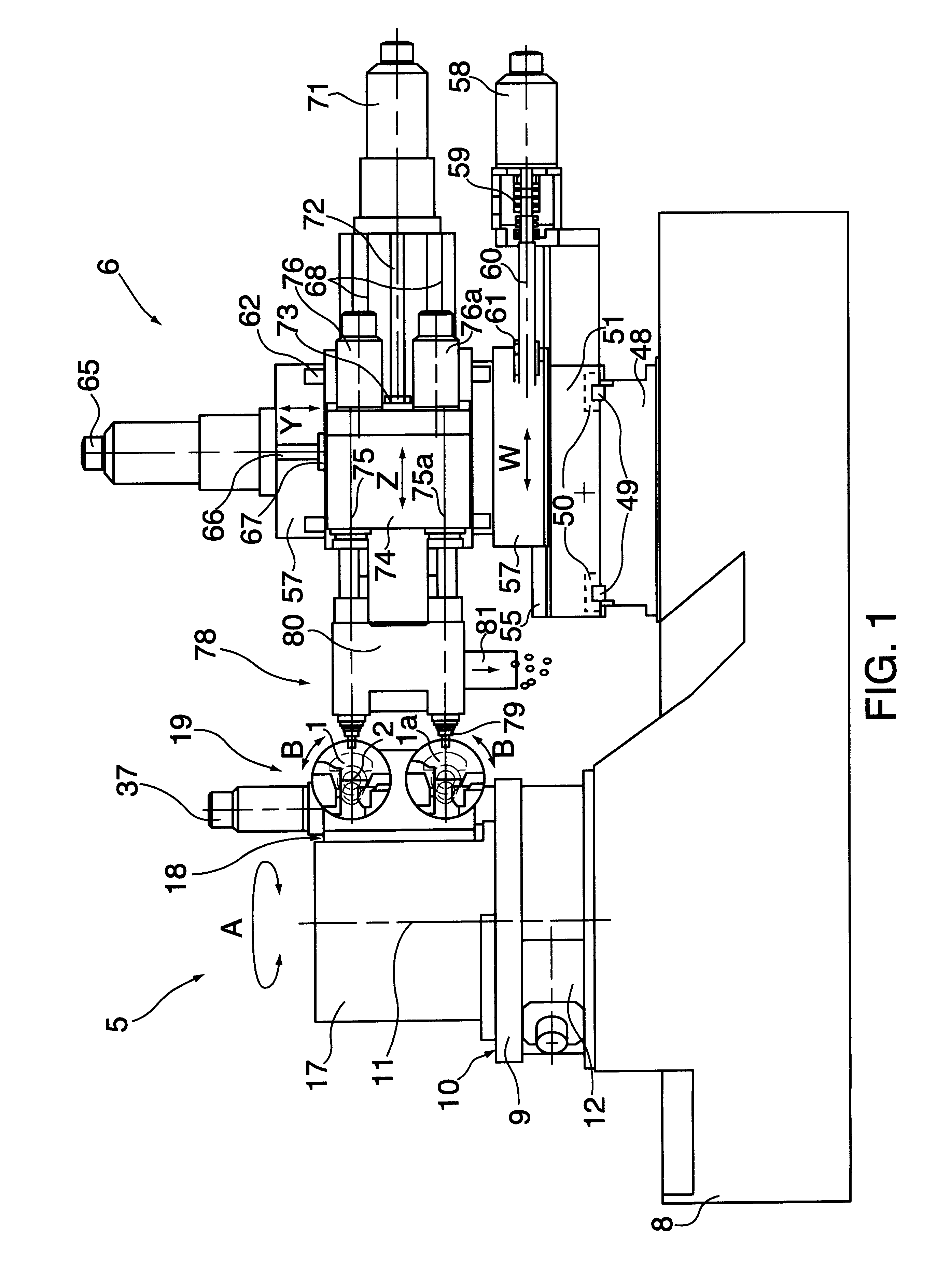

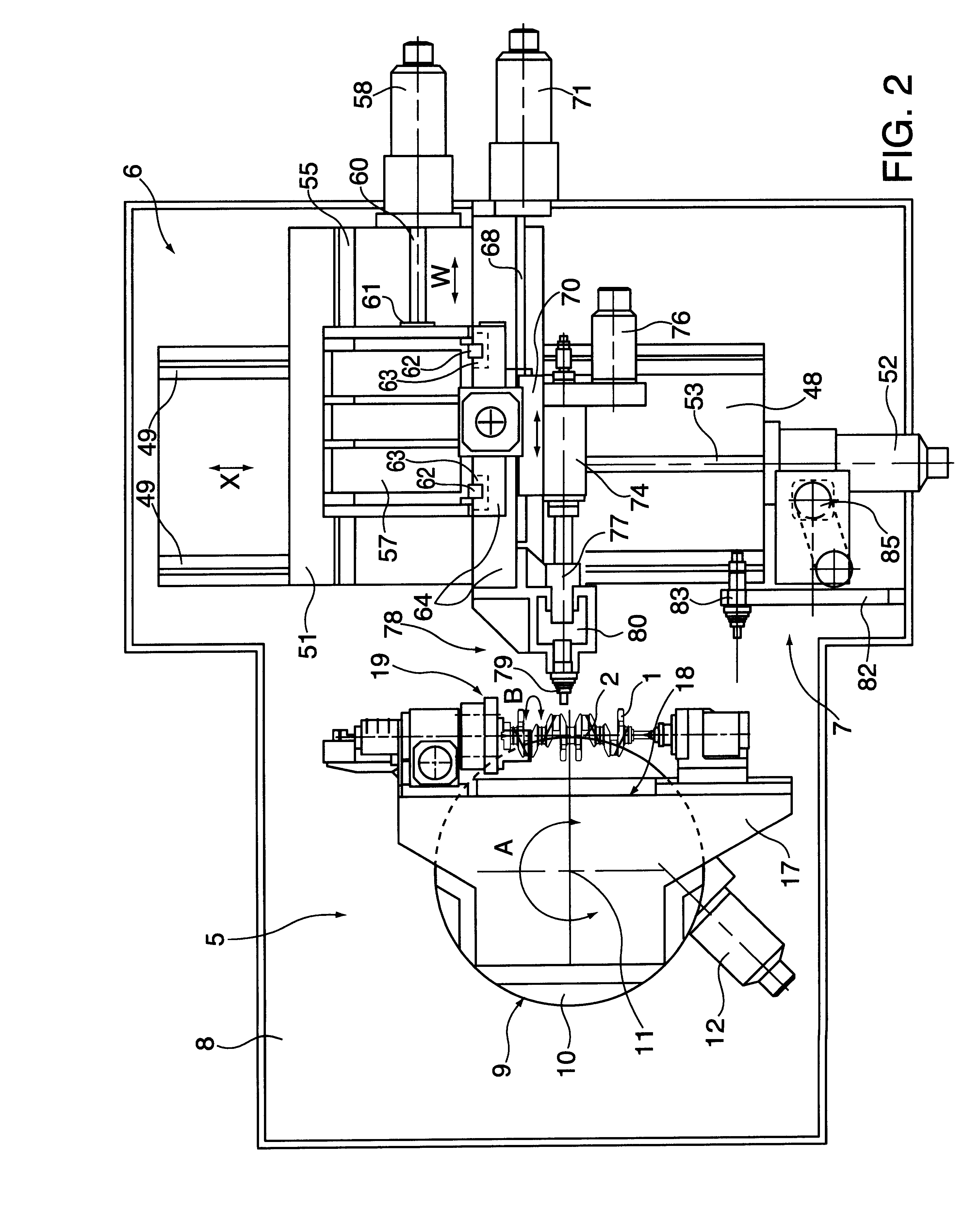

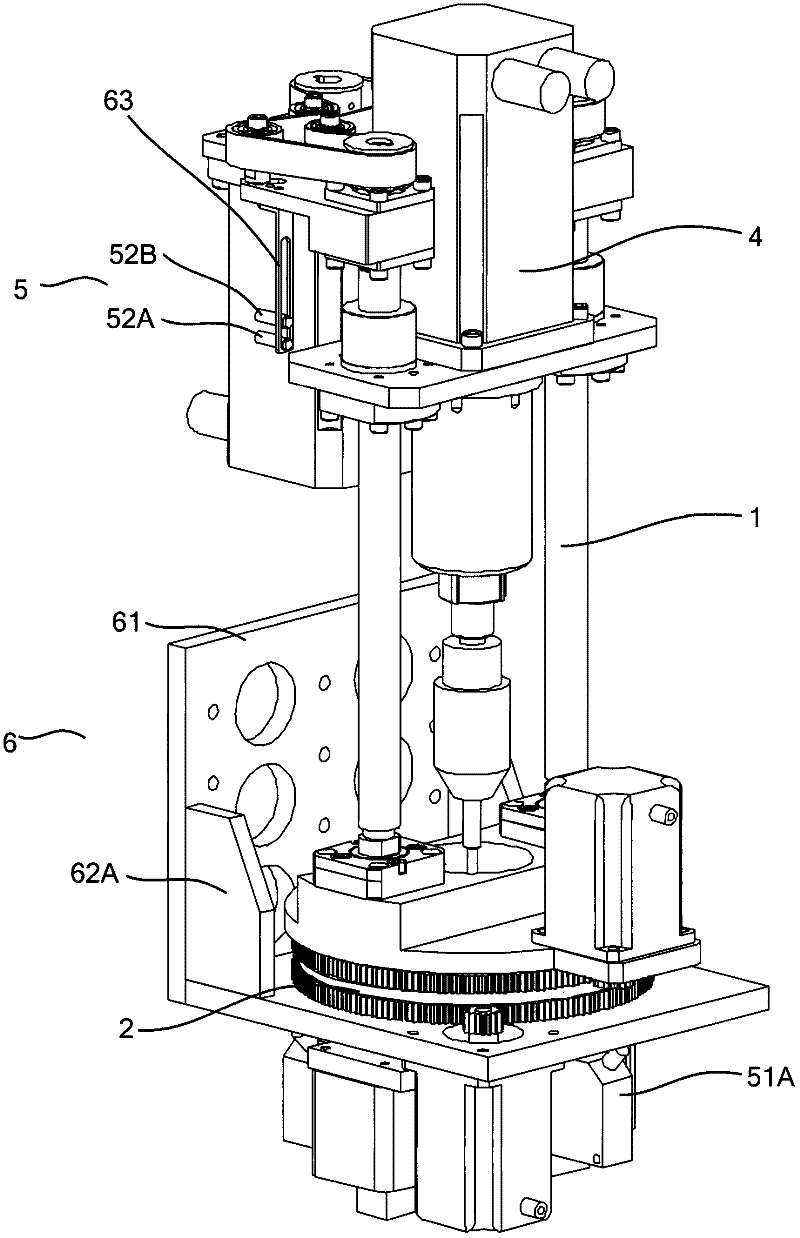

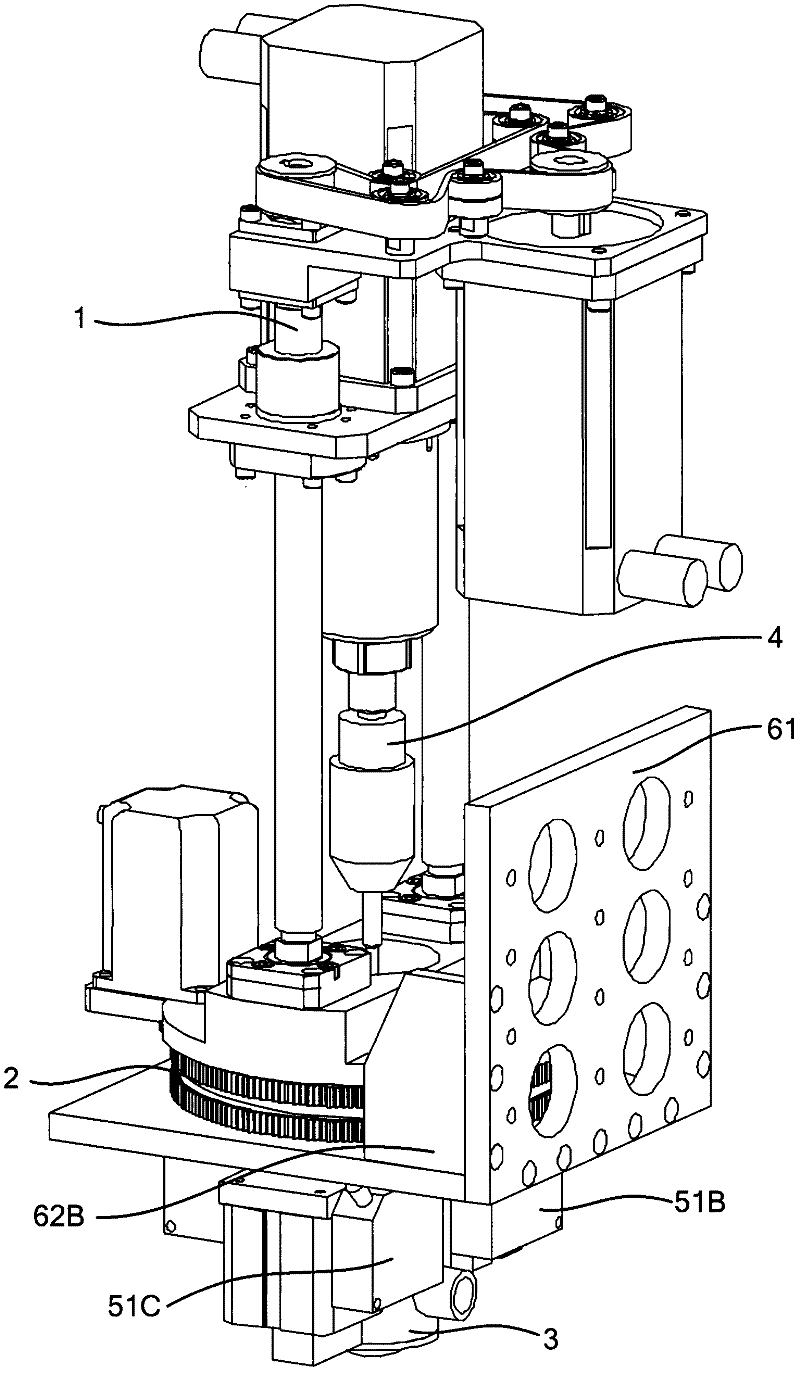

Machine for drilling oil holes in crankshafts

InactiveUS6203478B1Remove complicationsEliminate investmentCrankshaftsThread cutting machinesEngineeringCo ordinate

A machine for drilling oil-holes in crankshafts and the corresponding procedure. It can be used to drill one, two or more crankshafts per cycle. Each crankshaft can revolve on its own axis. The unit described is mounted on a horizontally-faced rotary table with vertical rotating axis, to place the crankshafts at different angles to the Z axis of the machining module, maintaining the horizontal position of the longitudinal axes of the crankshafts. Facing the unit is the machining module, provided with two horizontal spindles, drill tool-holders, with their corresponding guide bushings and parallel to each other, one on top of the other, at the same distance as the two crankshafts. The module has movement in three co-ordinates: axis X (horizontal-transverse), Y (vertical ) and Z (horizontal-presenting tools). A fourth axis W, (with additional module and independent action), moves parallel to Z and carries the guide bushings. It is provided with an automatic changeover, (tool+bushing or just the bushing), incorporating simultaneously the pair of spindles.

Owner:ETXE TAR SA

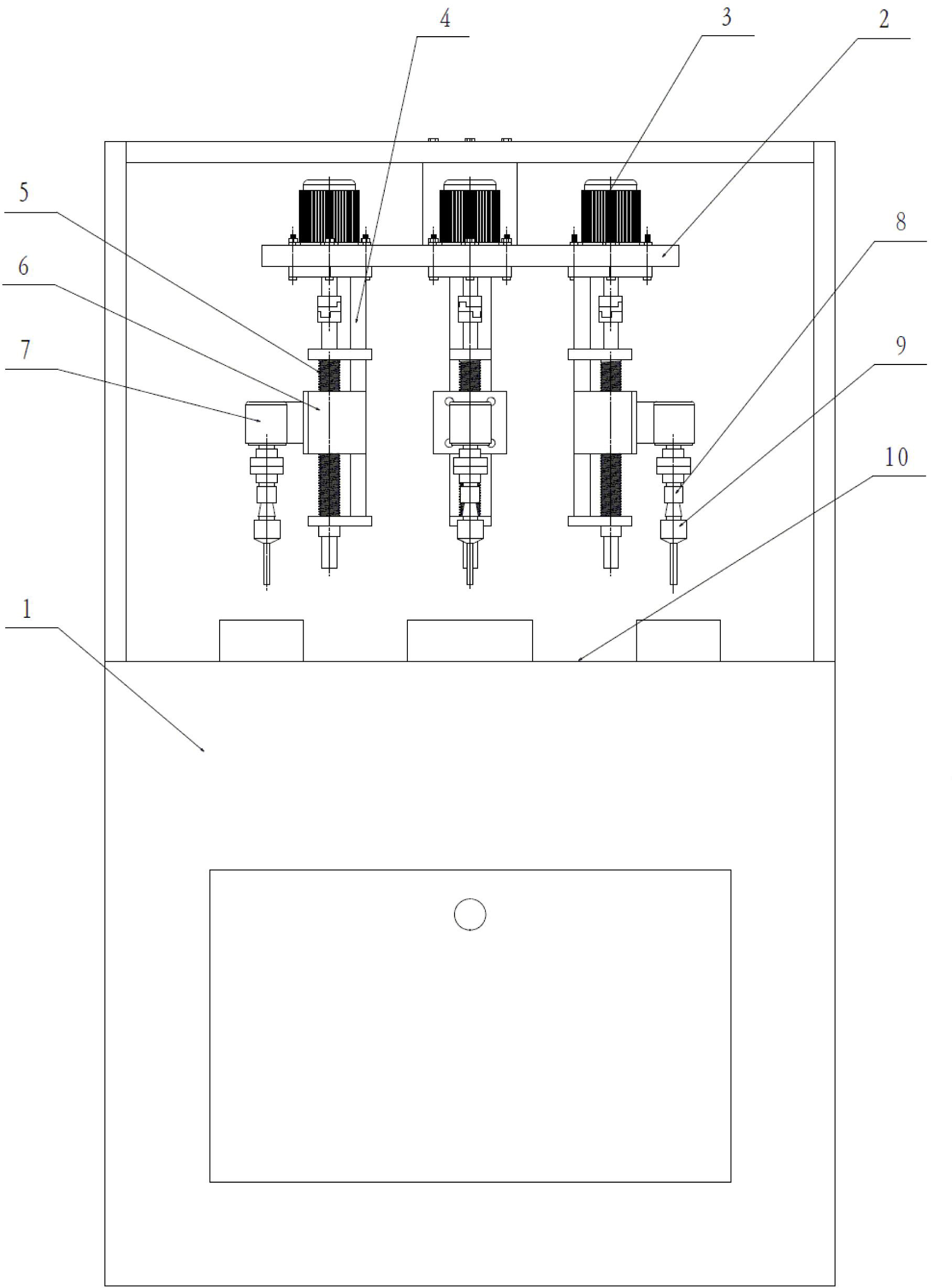

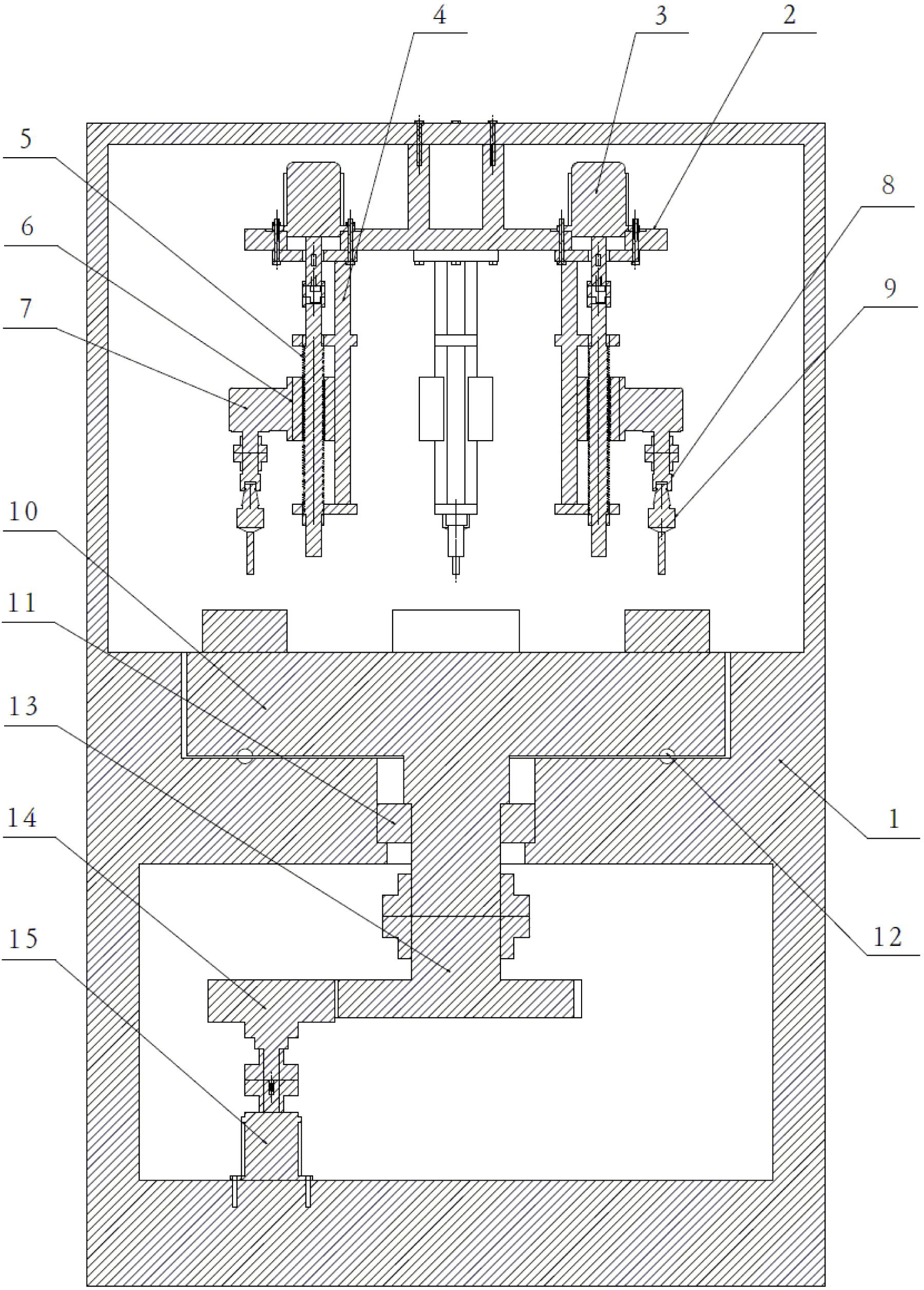

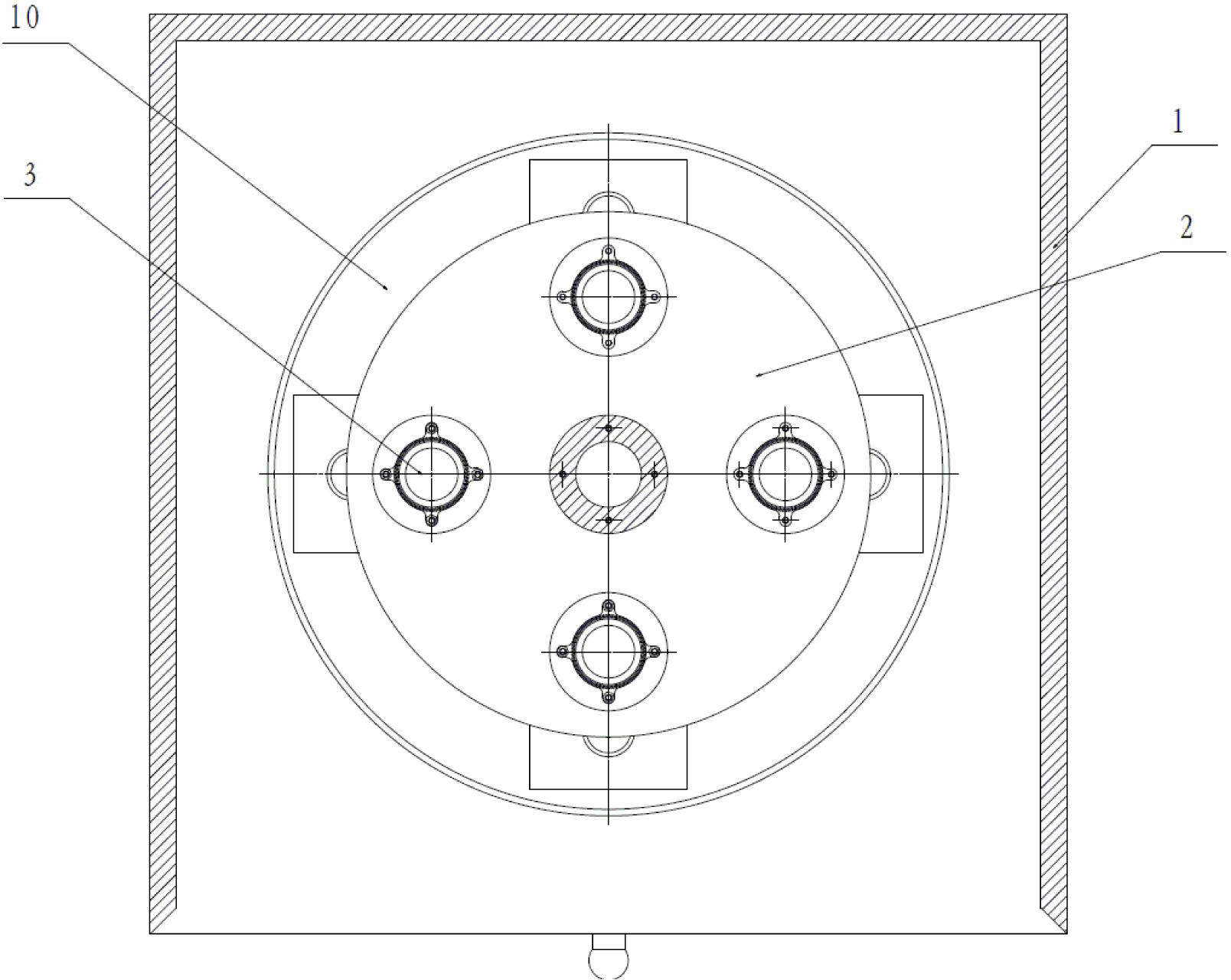

Multi-station speed-governing numerically-controlled drilling machine

InactiveCN102009201AIncrease productivityReduce the number of employeesFeeding apparatusOther manufacturing equipments/toolsControl theoryMachine tool

The invention provides a multi-station speed-governing numerically-controlled drilling machine, which comprises a machine tool body in vertical arrangement. A rotary table device and a tool are arranged on the machine tool body. The tool is arranged above the rotary table device. The rotary table device comprises a rotary motion control servo motor and a rotary table, and drives the rotation of the rotary table by the rotary motion control servo motor. A plurality of stations are arranged on the rotary table. The tool comprises a plurality of integral type tool units. Each integral type tool unit is connected with a feed servo motor, and controls the feeding of the tool in the integral type tool units by using the feed servo motor. Each integral type tool unit is provided with a speed-governing motor, and controls the rotation speed of the tool by the speed-governing motor. The multi-station speed-governing numerically-controlled drilling machine machines a plurality of parts at the same time and finishes the multi-operation machining of the same one hole or hole system by the rotation of the rotary table so as to machine the multi-station streamline part, improve the production efficiency and reduce the labor number.

Owner:林颖

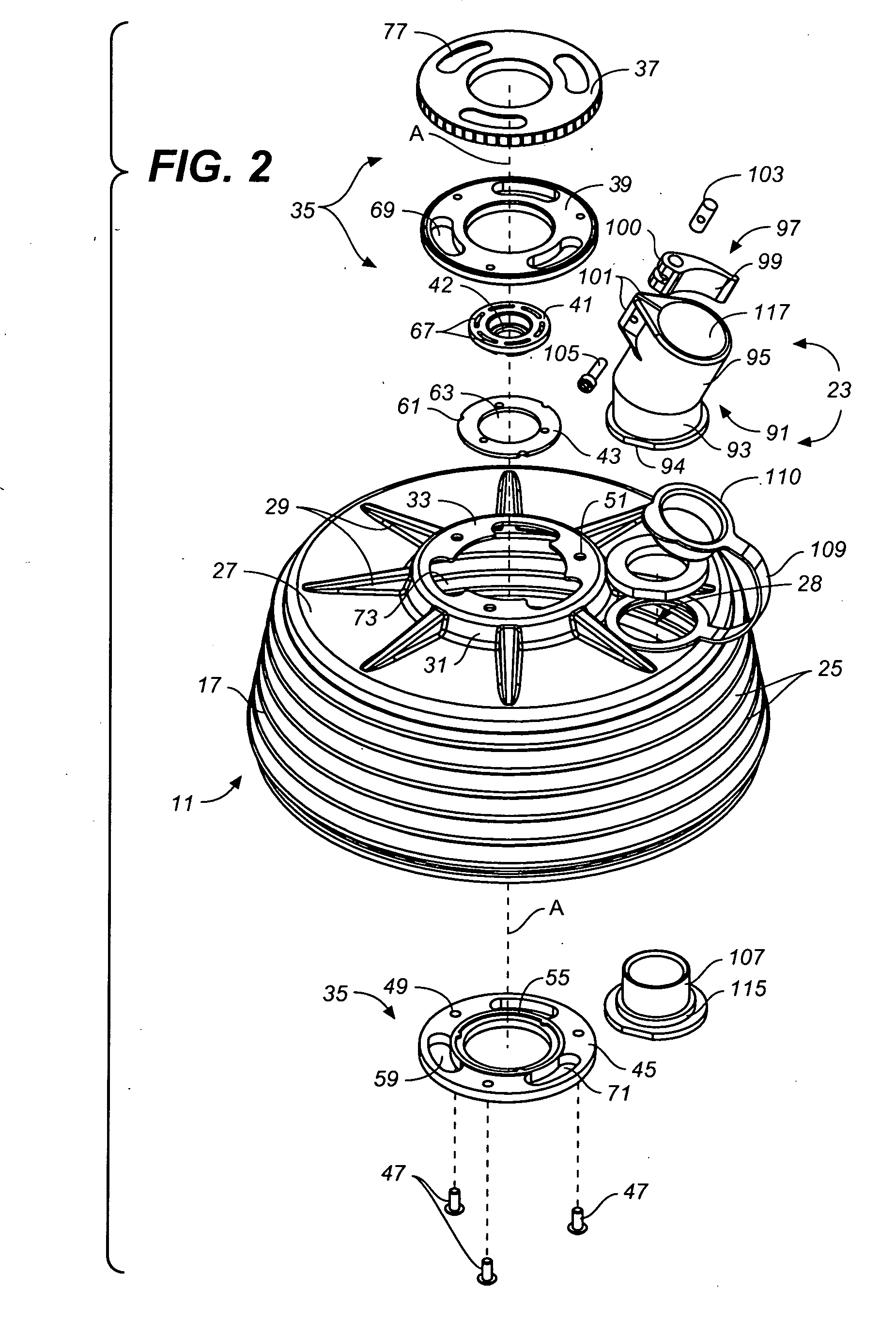

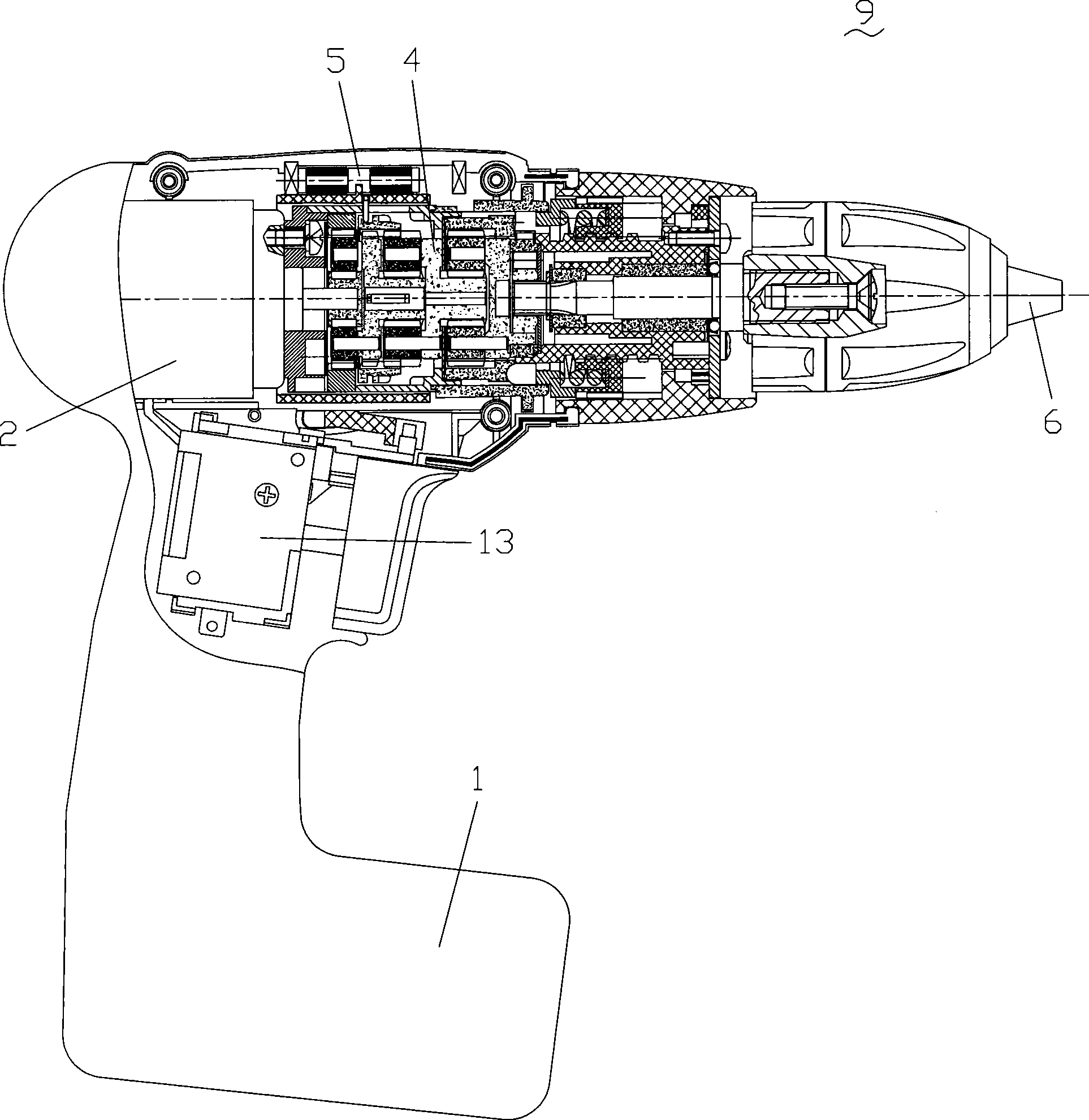

Mechanical Assembly For A Power Tool

InactiveUS20100200257A1Shorten the lengthFacilitates power toolTurning machine accessoriesThread cutting machinesPower toolDriving mode

The invention relates to a mechanical assembly for a power tool, and a power tool incorporating the mechanical assembly. The mechanical assembly includes a first member having a first axis and a first engagement portion inclined relative to the first axis and a second member having a second axis and a second engagement portion inclined relative to the second axis. The first and second engagement portions engage each other by movement of the first and second members relative to each other in the direction of at least one of the axes. The power tool includes a power tool body and a rotatable driven member being operable for releasably gripping a working element, the driven member having a drive mode in which rotation of the driven member drives the working element relative to the power tool body and an adjustment mode in which rotation of the driven member causes the driven member to either grip the working element or release the working element or both. The power tool also includes means for adjusting the driven member between the modes which includes the mechanical assembly wherein the first and second engagement portions engage each other by movement of the first and second members relative to each other in the direction of at least one of the axes and wherein engagement between the first and second engagement portions adjusts the driven member to the adjustment mode and disengagement between the first and second engagement portions adjusts the driven member to the drive mode. The power tool may also include a first torque control means that is operable for controlling the amount of torque applied to the driven member by the power drive when in the drive mode and a second torque control means that is operable for controlling the amount of torque applied to the driven member by the power drive when in the adjustment mode. The power tool may further include a gearbox with one or more speeds and a switch with two or more positions that is operable for selecting the modes, the gear speeds and the first and second torque control means.

Owner:DEMAIN TECH

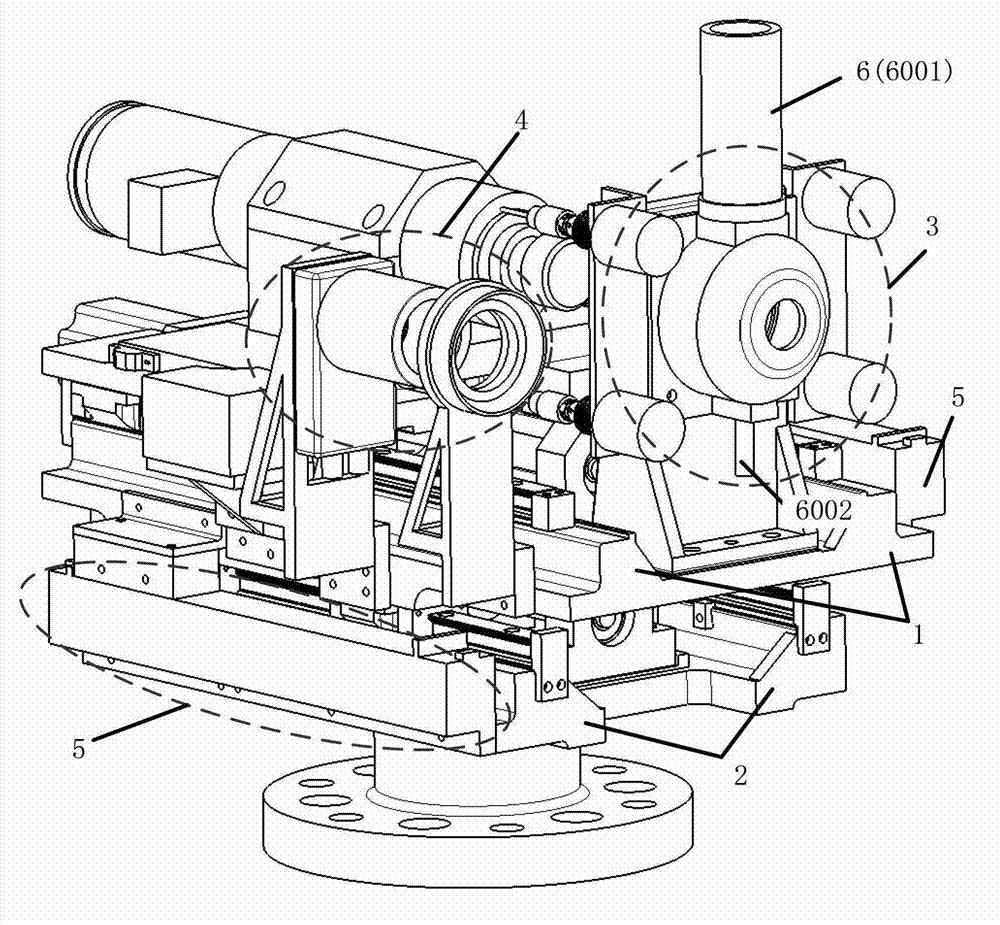

Aviation hole-forming robot end effector capable of adjusting attitude

InactiveCN102513575AFree replacementImprove hole making efficiencyPositioning apparatusBoring/drilling componentsAviationRotary stage

The invention provides an aviation hole-forming robot end effector which is suitable for plane skin drilling and can be used for automatically adjusting the attitude. The end effector comprises a leading screw feeding module, a binary angle adjusting mechanism, a compacting chip-absorbing module, a drilling module and a sensor module. The leading screw feeding module mainly comprises a leading screw driving motor, a synchronous transmission component and a dual-ball leading screw and is used for realizing feeding motion of drilling; the binary angle adjusting mechanism mainly comprises a stepping motor, a transmission gear, a wedge-shaped turn table and a spherical hinge and is used for realizing the automatic adjustment of the tail end attitude; the compacting chip-absorbing module mainly comprises a cylinder, a pressing cylinder, a cylinder connecting rod and a compacting head and is used for realizing compaction of a skin and the absorption of metal drill chips; the drilling module mainly comprises a drilling servo motor, a transmission shaft, a drill chuck and a drill bit and is used for realizing high-accuracy drilling; and the sensor module comprises a proximity sensor and a laser distance-measuring sensor and is used for realizing zero addressing and limiting of the movement of a main shaft, and the measurement of the normal line of a drilling point.

Owner:袁培江

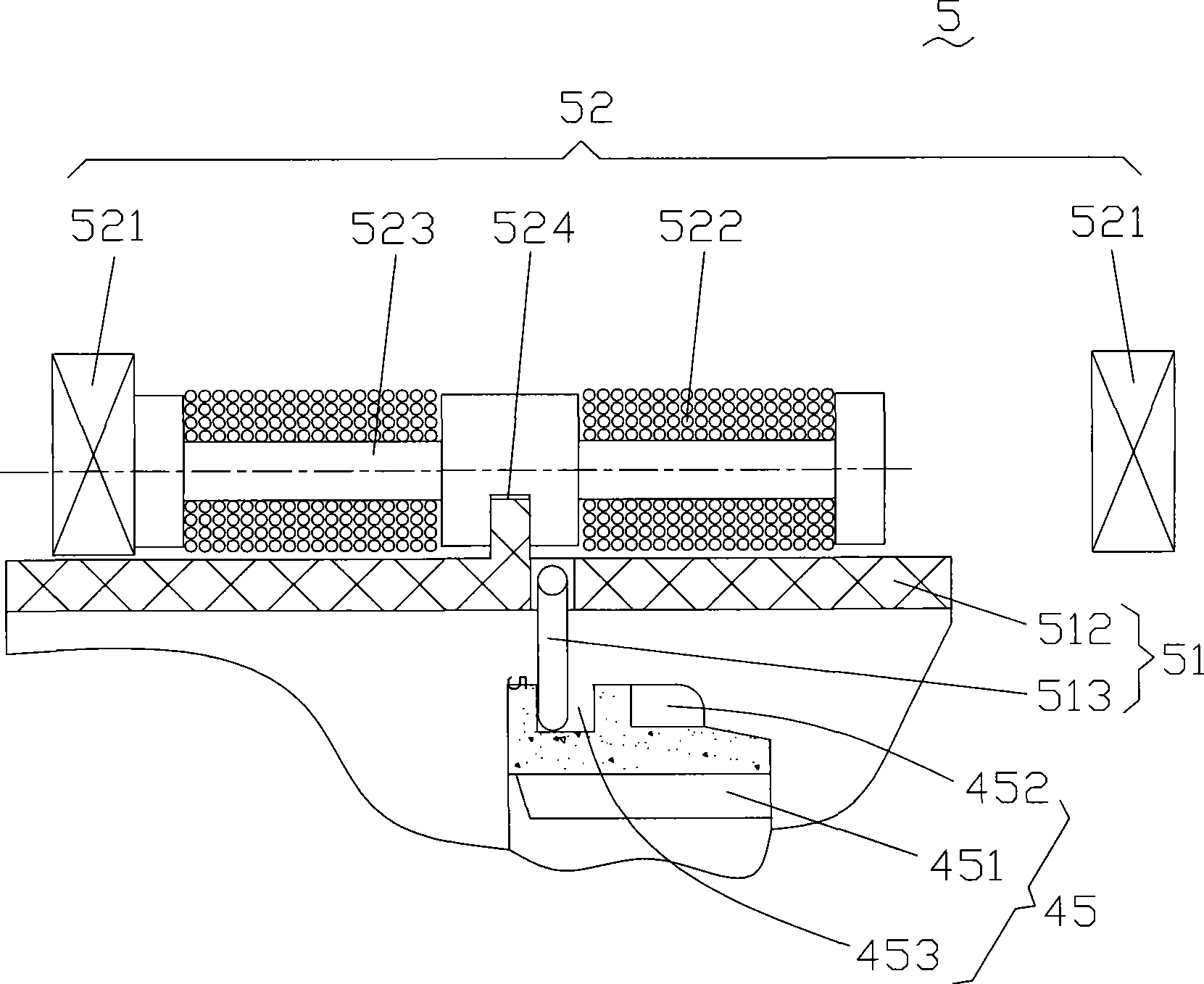

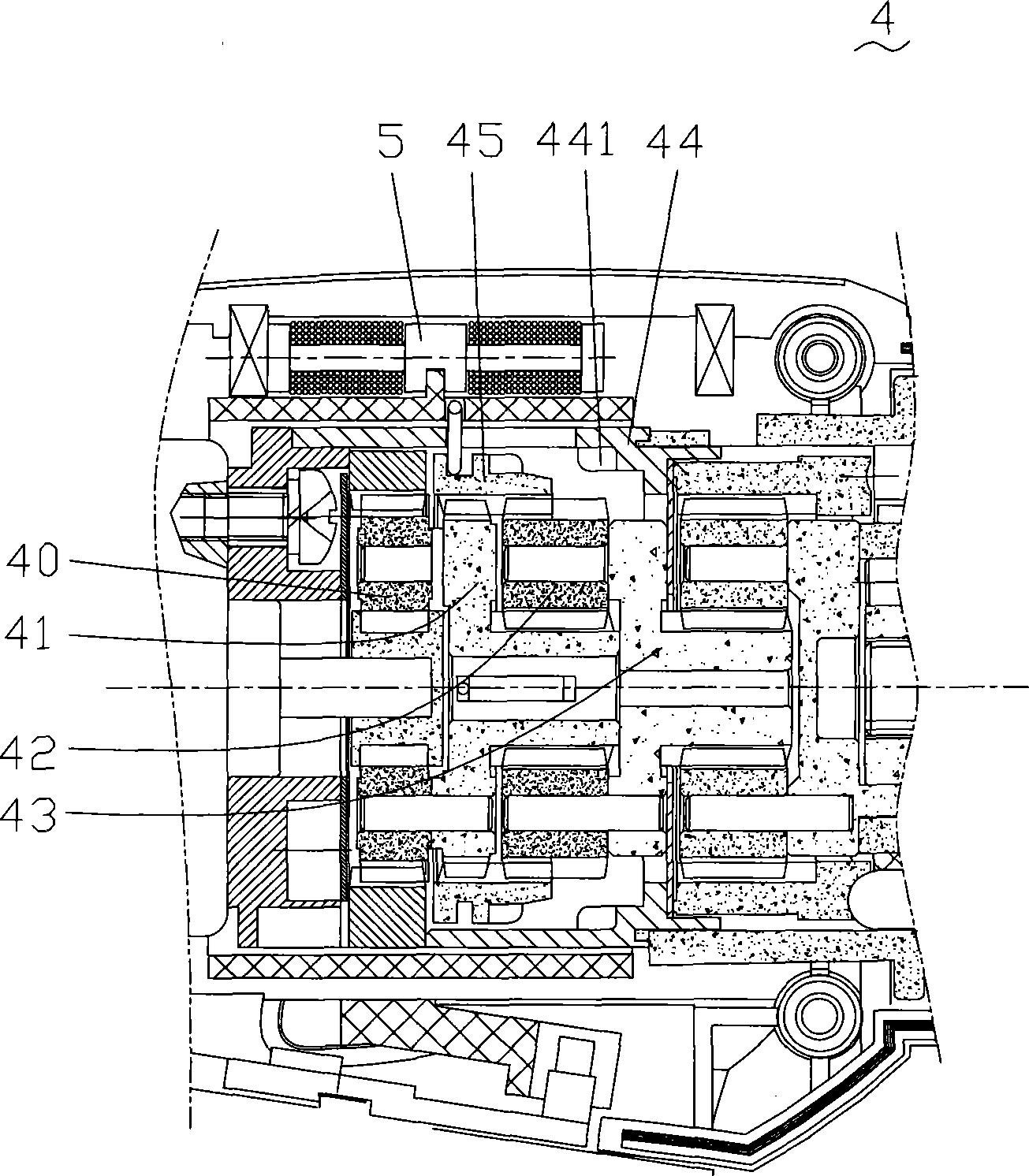

Speed changing tool and speed changing control method thereof

ActiveCN101377229ASimple structureRealize automatic switchingToothed gearingsGearing controlLoad torqueControl system

The present invention discloses a gear shifting tool, and comprises a motor, an output shaft, a gear transmission mechanism connecting the motor and the output shaft and a control system. The control system comprises a control unit and a driving device; the driving device is provided with a movable component which can move between a first position and a second position in the gear transmission mechanism; and when the movable component is arranged in the first position and the second position, the output shaft has different output characteristics. When the load torque is changed into the preset value, the control unit first regulates the torque transmitted to the gear transmission mechanism from the motor, and then controls the driving device to realize the automatic gear shifting. The present invention can solve the mis-engagement problem in the automatic gear shifting process, improves the electrical performances of the tool, and prolongs the service life of the tool.

Owner:POSITEC POWER TOOLS (SUZHOU) CO LTD

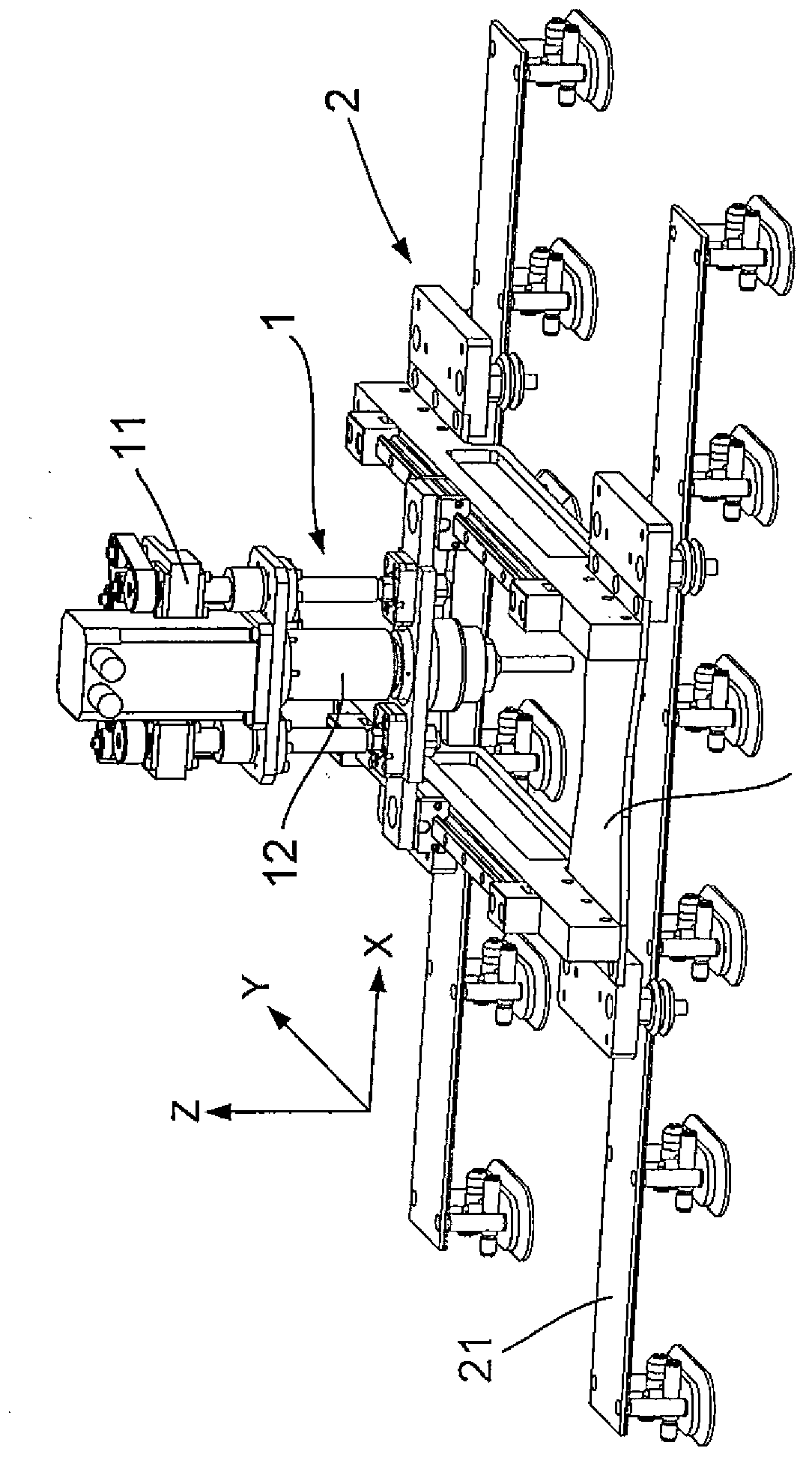

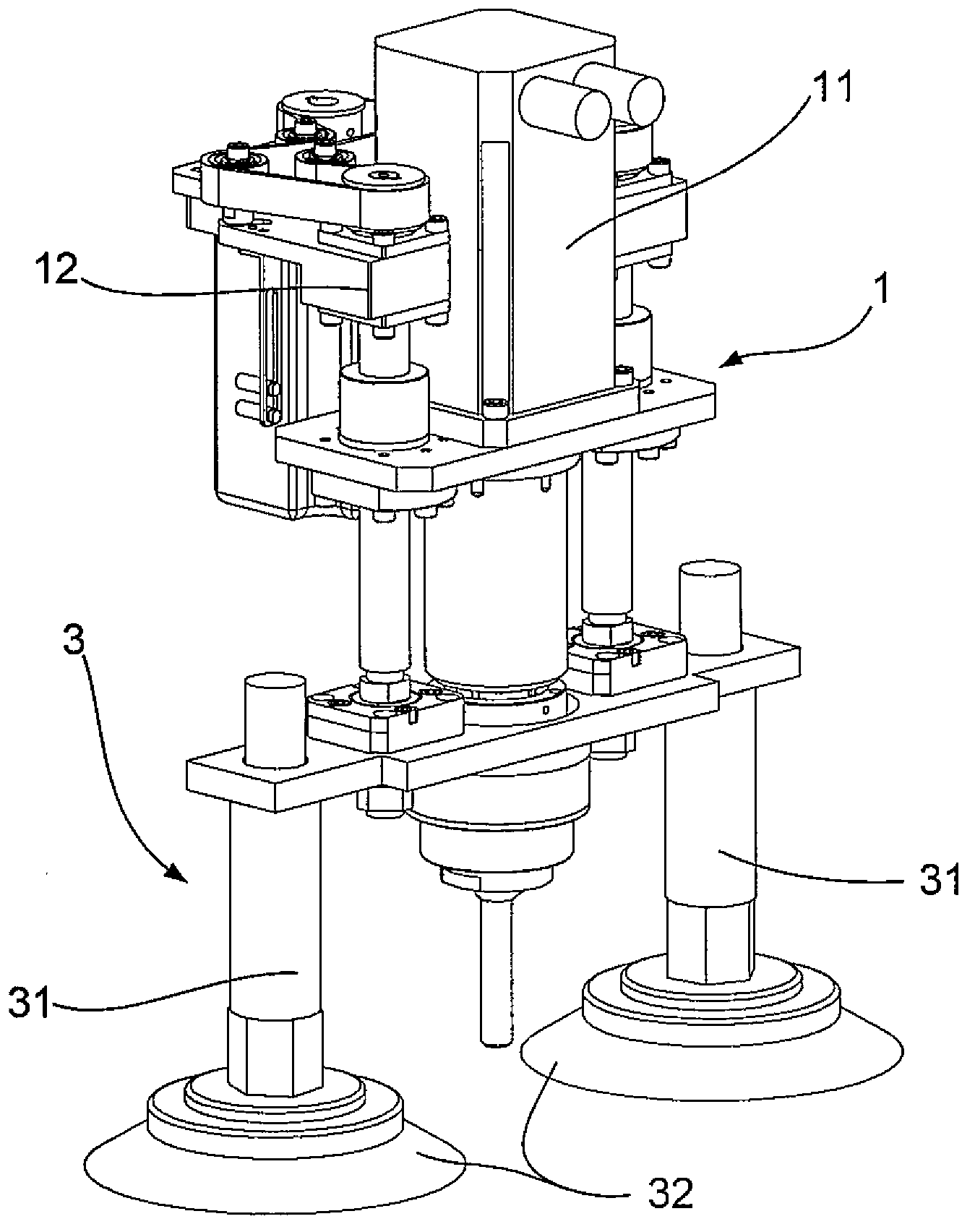

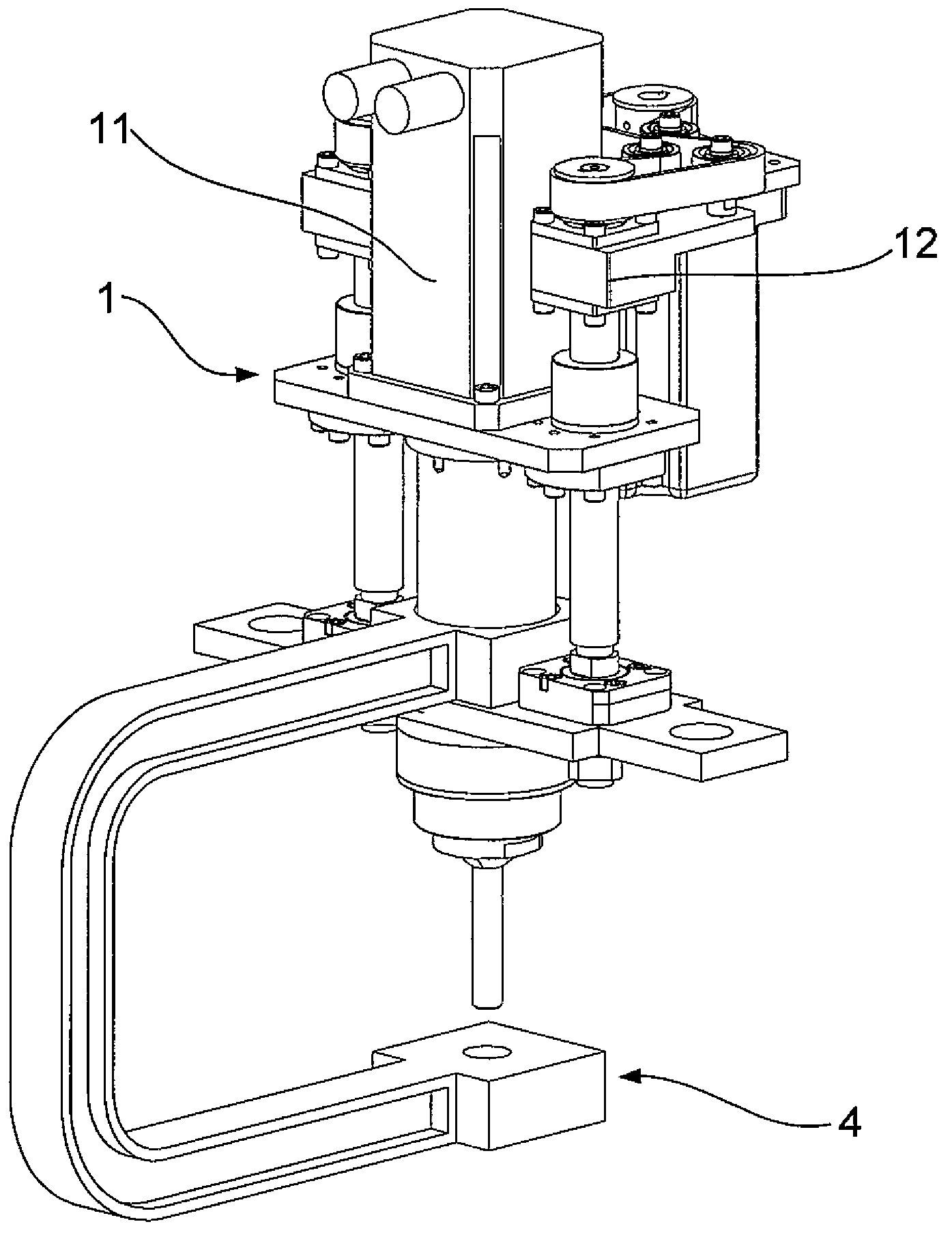

Replaceable precise automatic feeding drill

The invention discloses a replaceable precise automatic feeding drill, which consists of an automatic feeding drill main body and working platforms. Different working platforms can be selected according to different using environments or conditions, and operation of drilling, reaming, counter sinking and the like of machined workpieces are implemented. The working platforms comprise an X-Y flexible track platform (1), a bilateral sucking disc platform (2) and a C-shaped jaw platform (3), wherein the X-Y flexible track platform (1) can adapt to and attract surfaces with different curvatures; the bilateral sucking disc platform (2) can attract the fixed workpieces in a narrow space; and the C-shaped jaw platform (3) can be used for conventional drilling as a bench drill. The invention has the advantages that the automatic feeding drill is precise and portable, can be quickly replaced and can be used for accurately and quickly drilling various different workpieces.

Owner:SHANGHAI AIRCRAFT MFG +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com