Replaceable precise automatic feeding drill

A technology of automatic feed drilling and automatic feed, which is applied in the direction of boring/drilling, portable drilling rigs, drilling/drilling equipment, etc., can solve problems such as dwelling, and achieve the effect of saving physical strength and improving drilling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The present invention will be further described in detail below in conjunction with the accompanying drawings.

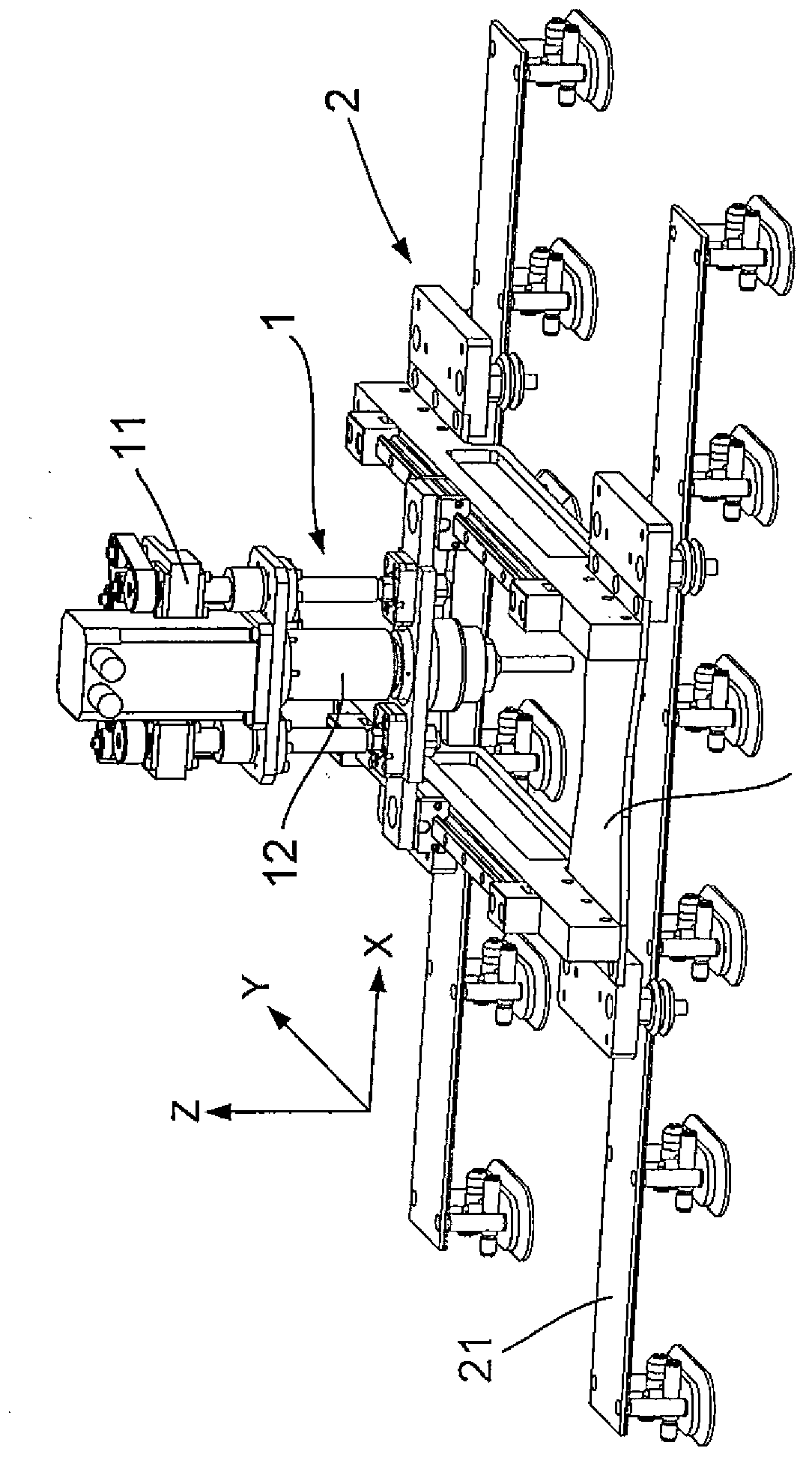

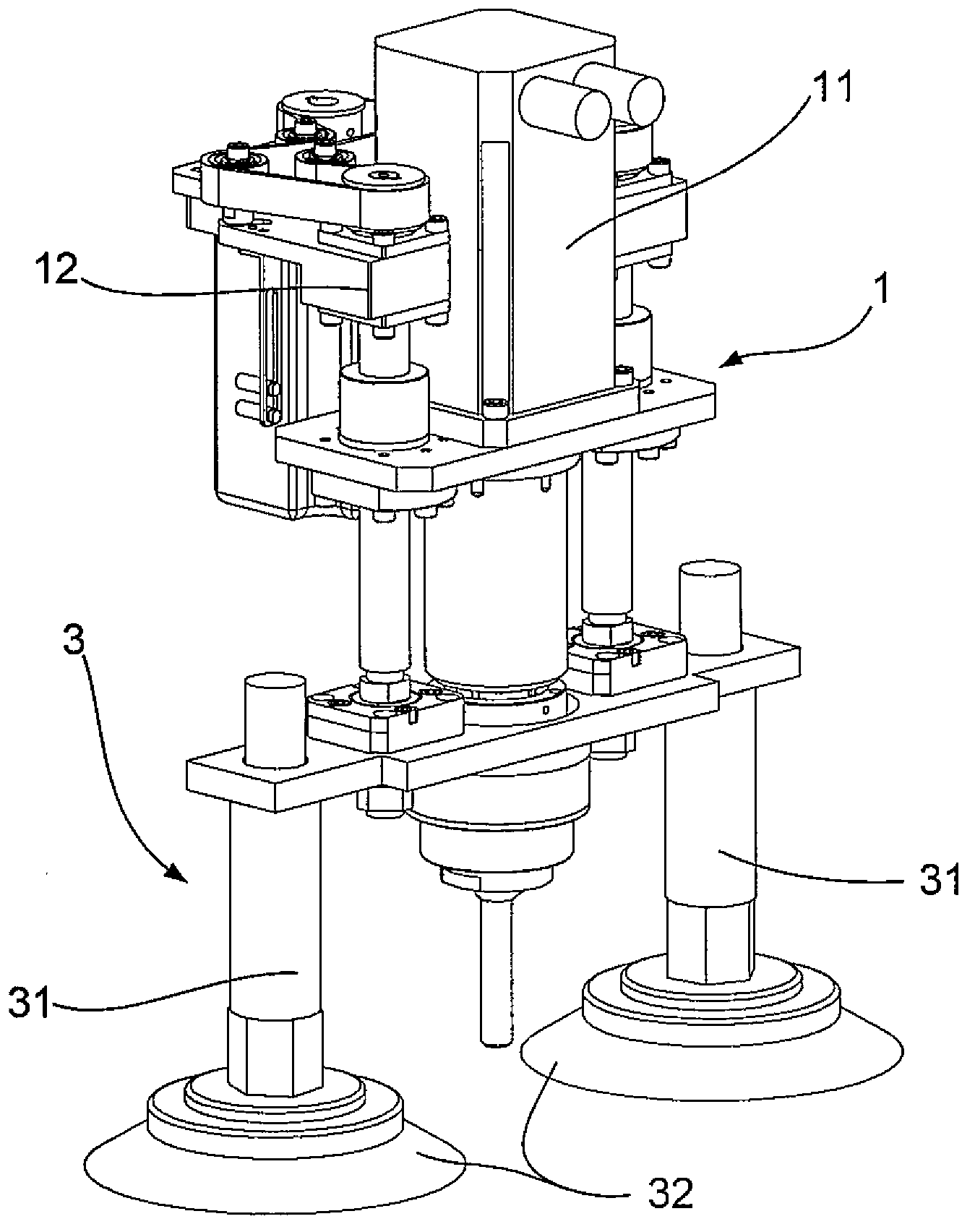

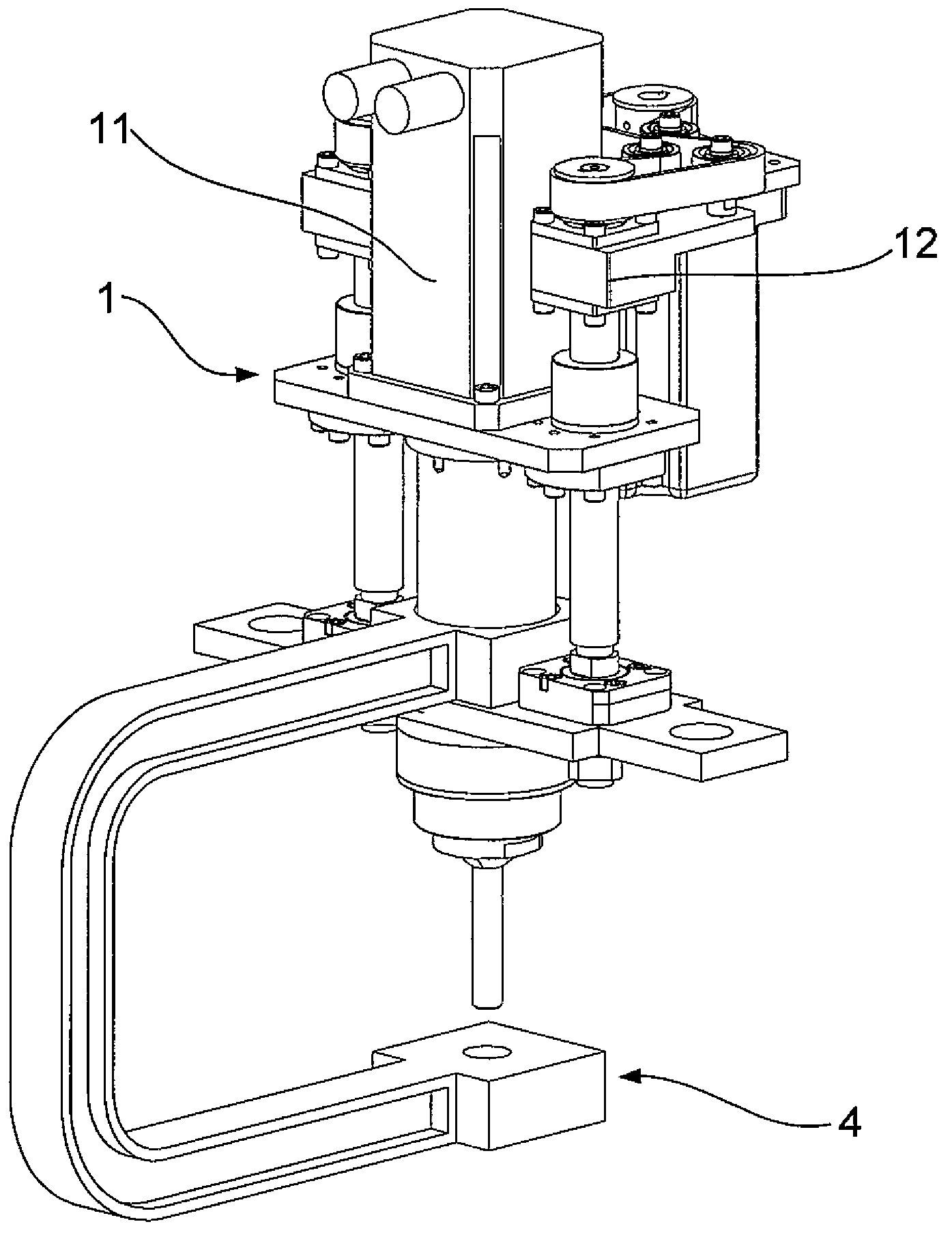

[0057] see figure 1 , figure 2 and image 3 Shown, the present invention is made up of automatic feed drill main part 1 and working platform. The working platform has three platforms: X-Y flexible track platform 2, double-sided suction cup platform 3 or C-shaped jaw platform 4. The main part 1 of the self-feed drill can be quickly installed on any one of the platforms for drilling according to specific conditions.

[0058] (1) Automatic feed drill body

[0059] see Figure 4 , Figure 5 and Figure 6 As shown, the main body of the automatic feed drill includes: an automatic feed drill main shaft transmission part 11 , an automatic feed drill main shaft drilling part 12 and a screw feed part 13 .

[0060] 1. Automatic feed drill spindle transmission part

[0061] see Figure 5 As shown, the automatic feed drill spindle transmission part 11 includes:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com