Surface hole drilling device for non-excavation construction pipelines

A drilling device and trenchless technology, applied in positioning devices, boring/drilling, drilling/drilling equipment, etc., can solve problems such as low efficiency, inability to achieve automatic continuous production, and low drilling accuracy , to achieve high drilling accuracy, improve flexibility and working range, and improve drilling efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

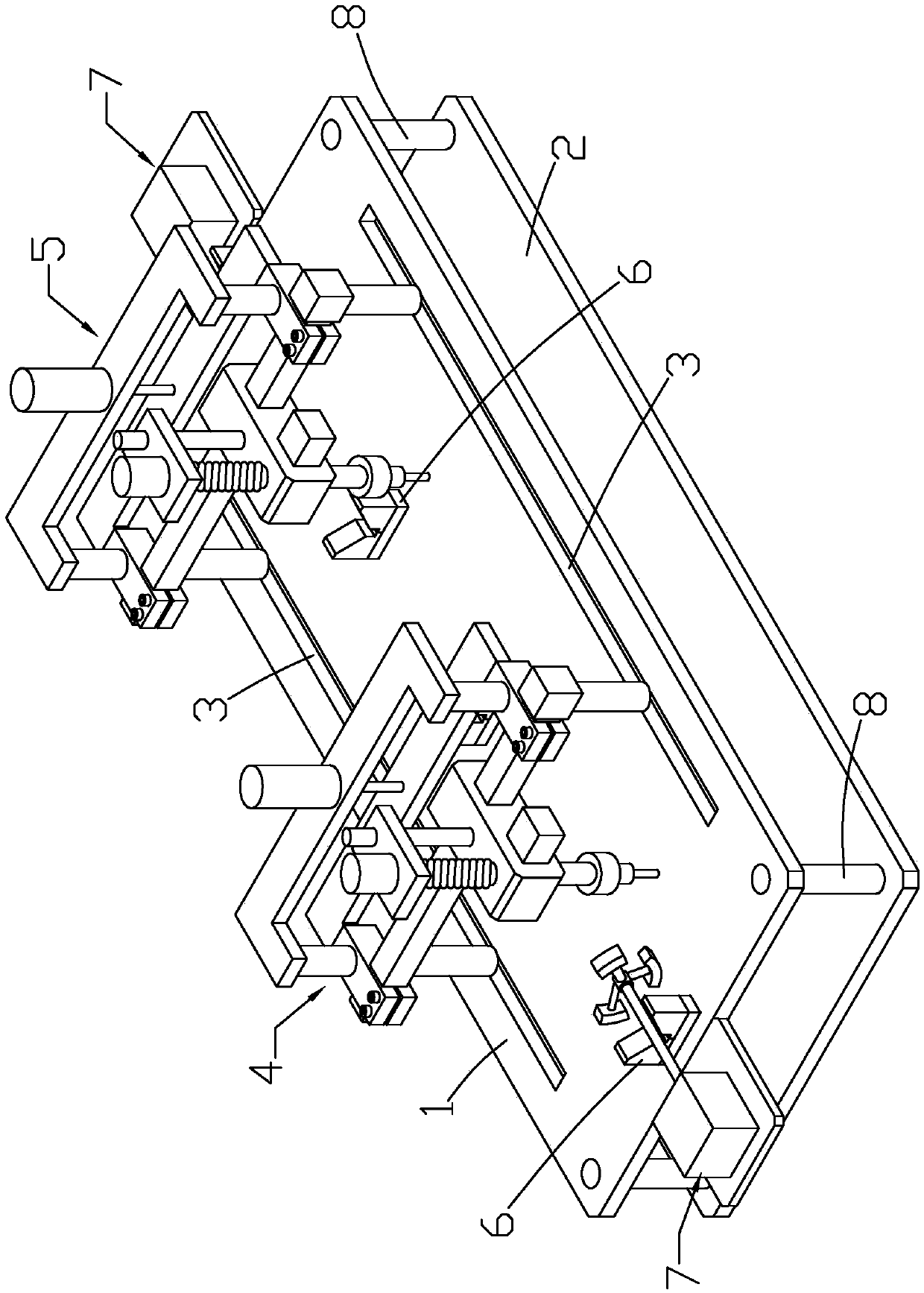

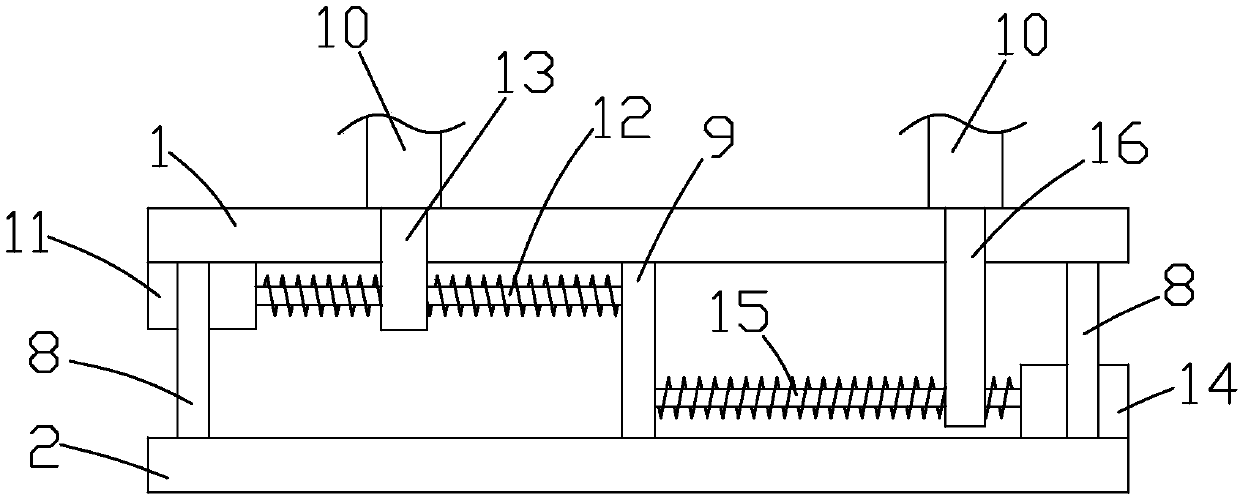

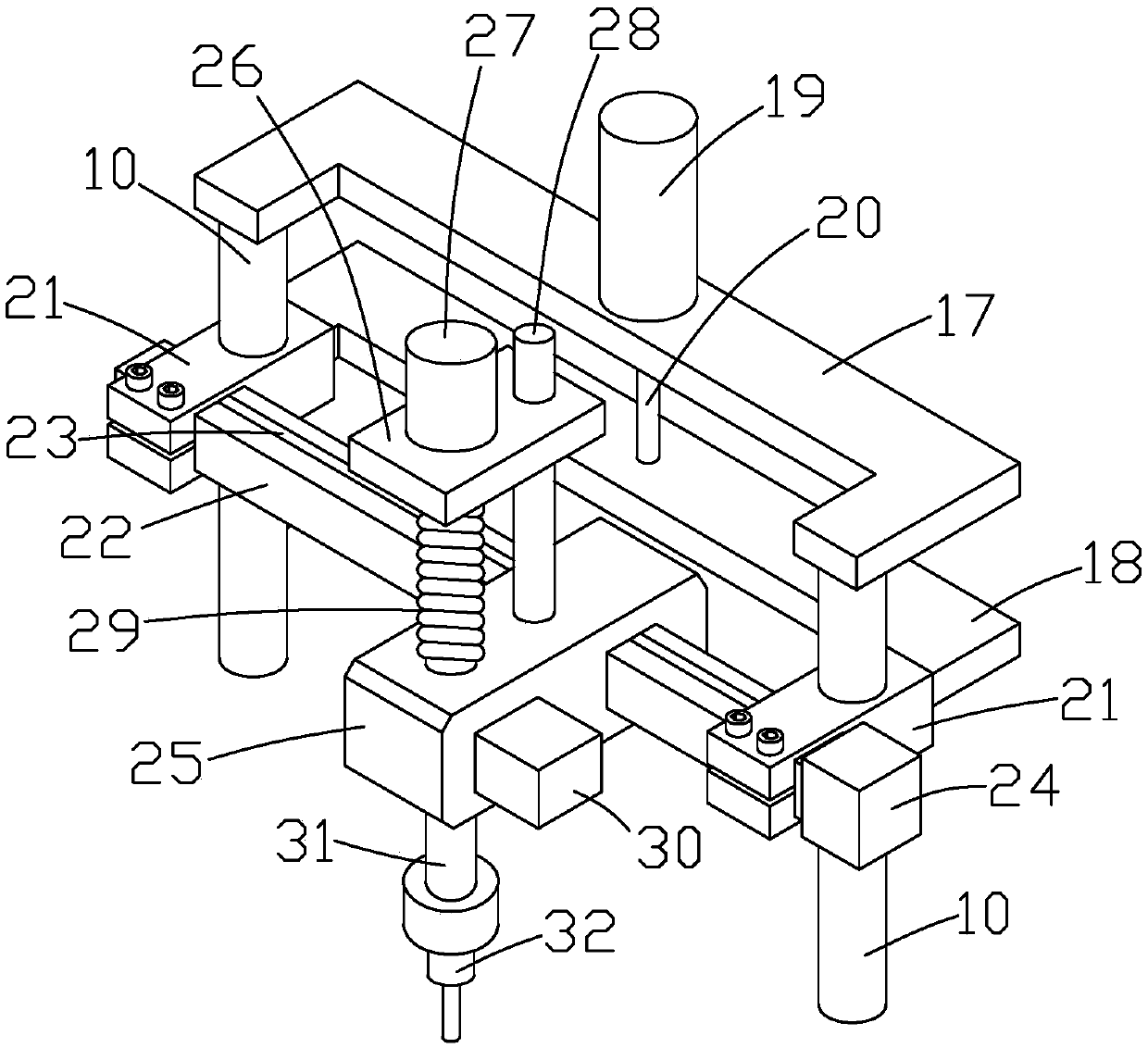

[0030] like Figure 1 to Figure 6 As shown, it is a surface drilling device for non-excavation construction pipelines of the present invention, including a base plate 1, a base plate 2, a first drilling mechanism 4, a second drilling mechanism 5 and a pipeline rotation mechanism 7, and the base plate 2 Located below the base plate 1, the base plate 1 is fixedly connected to the base plate 2 through a support rod 8, two guide grooves 3 are arranged in parallel on the top surface of the base plate 1, and the first drilling mechanism 4 and the second drilling mechanism 5 are connected to the guide grooves in a movable manner. 3, the first drilling mechanism 4 and the second drilling mechanism 5 all include a crossbeam 17, a lifting plate 18, a cantilever 22 and a drilling assembly. A hydraulic cylinder 19 is provided, and the hydraulic cylinder 19 is connected to the lifting plate 18 through the piston rod 20. The lifting plate 18 is located below the beam 17, and the two ends of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com