Patents

Literature

48results about How to "Improve locking ability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

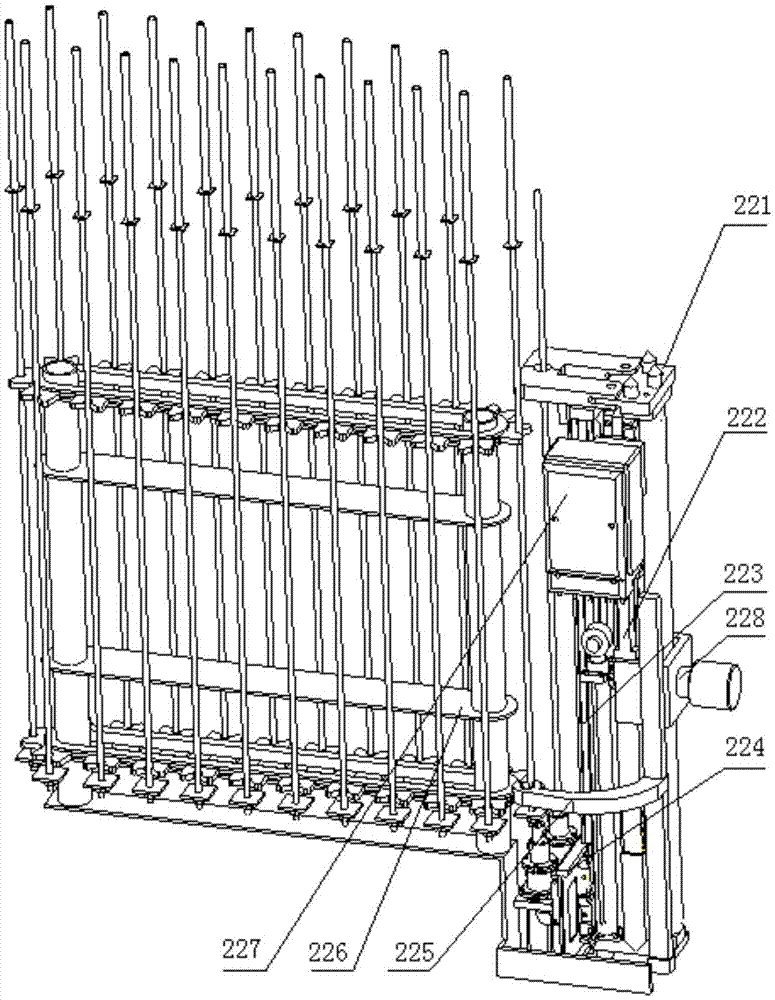

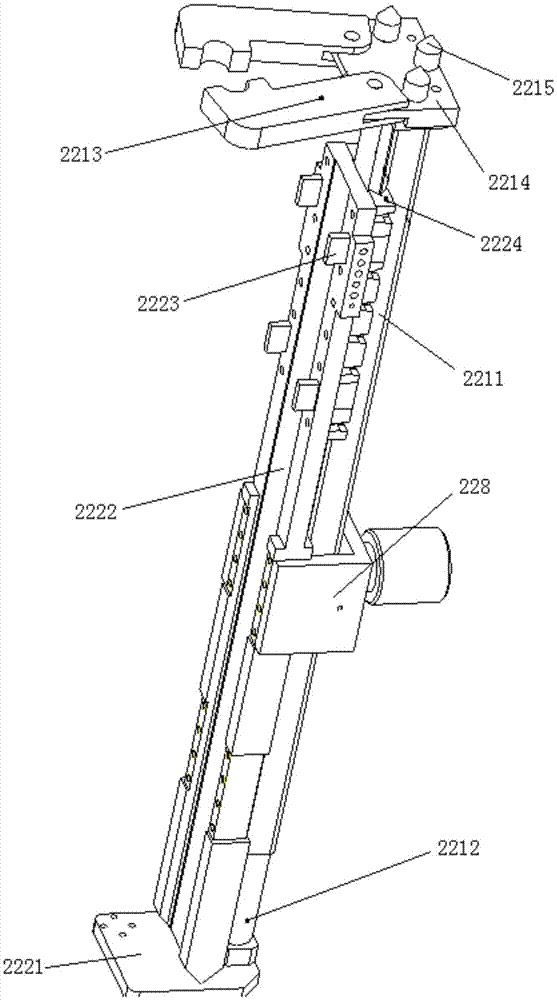

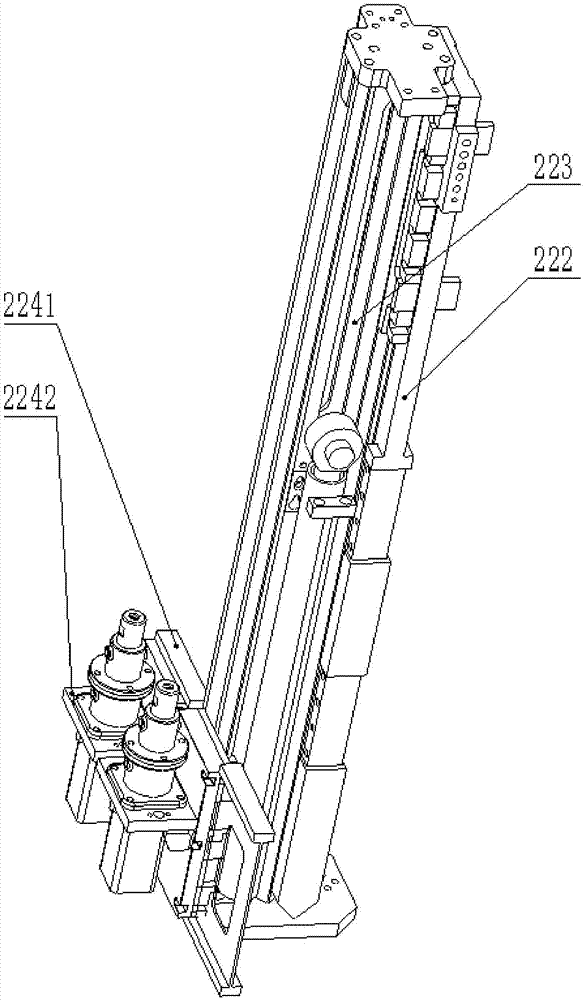

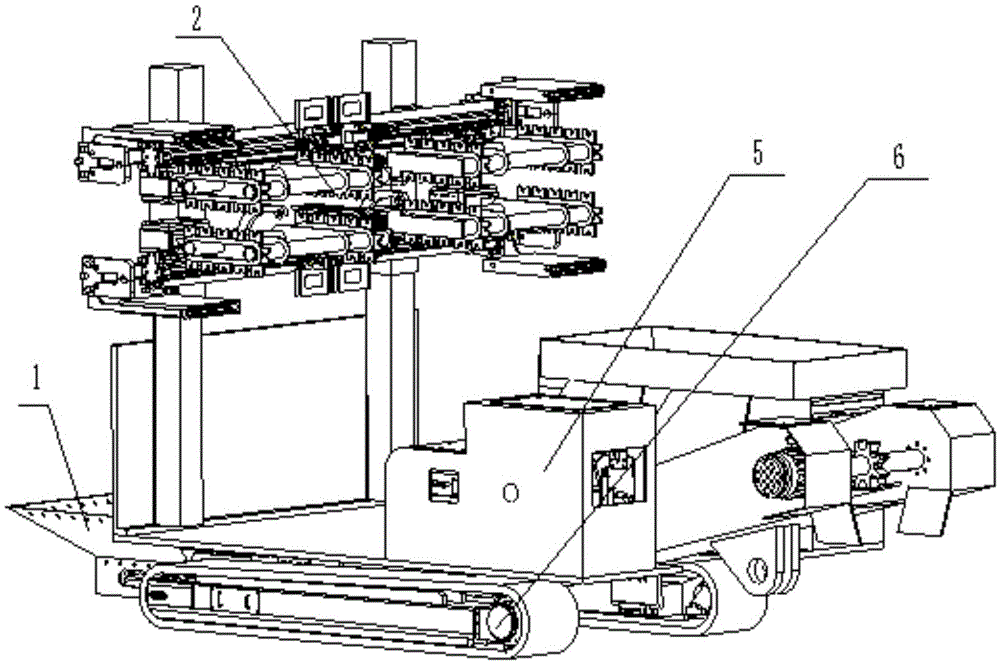

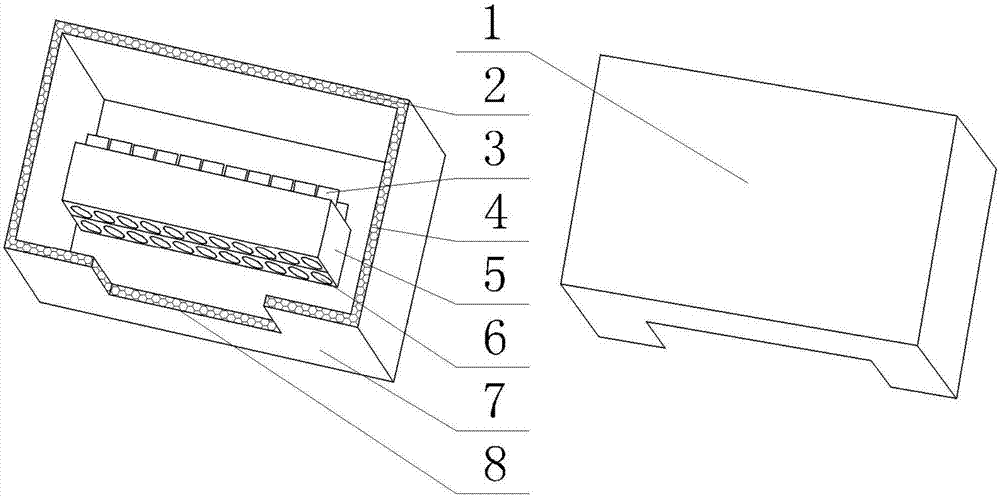

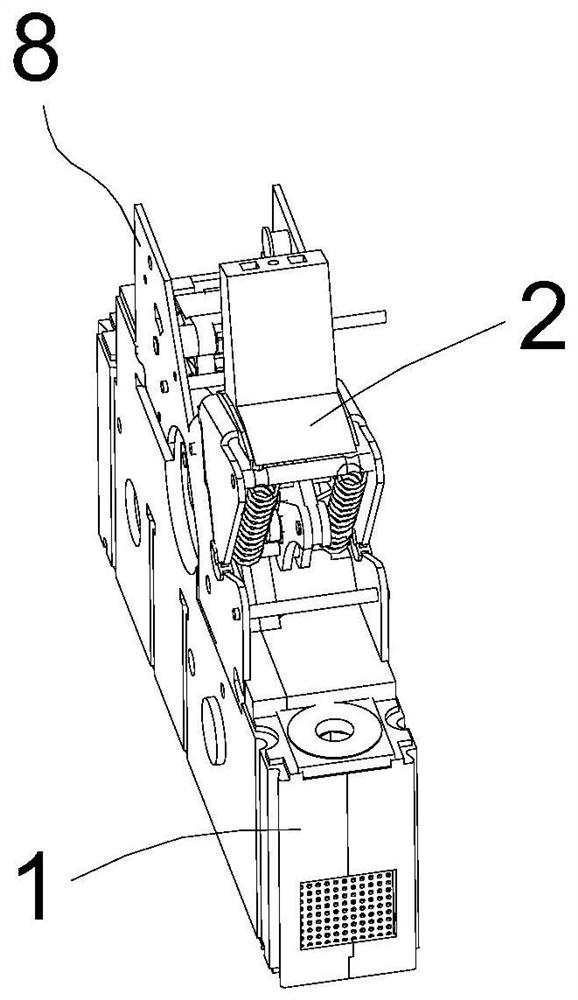

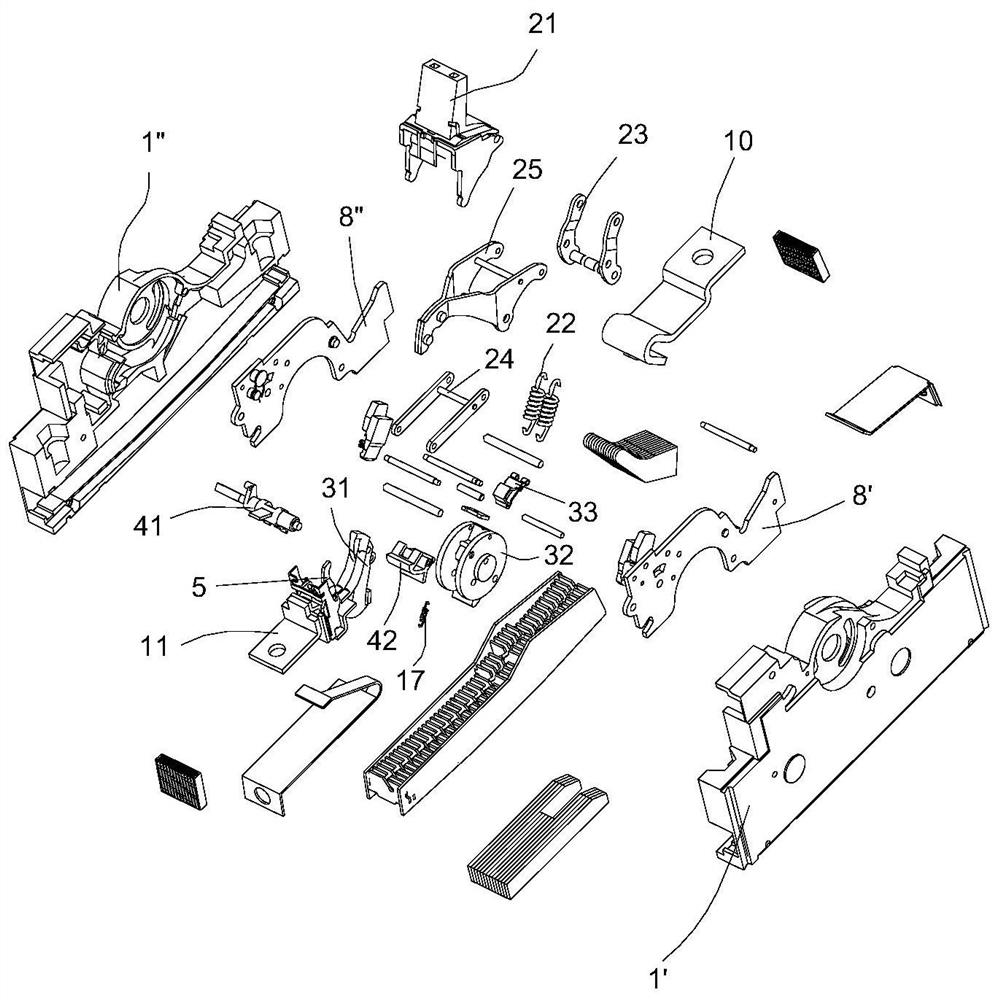

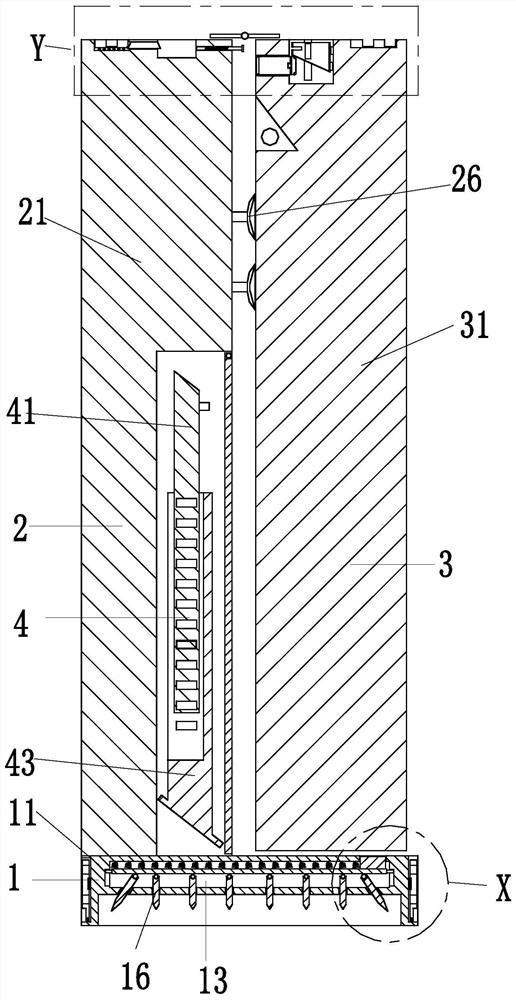

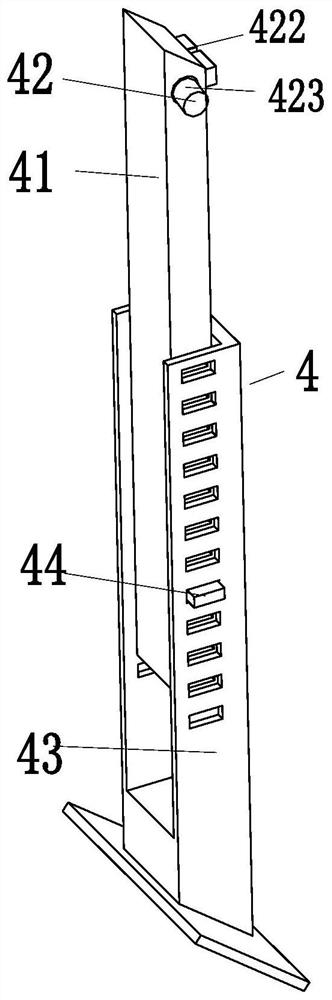

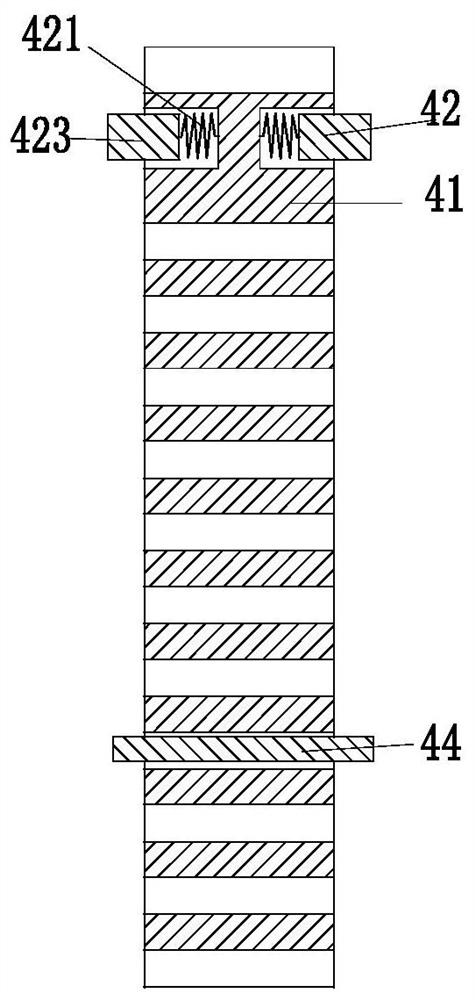

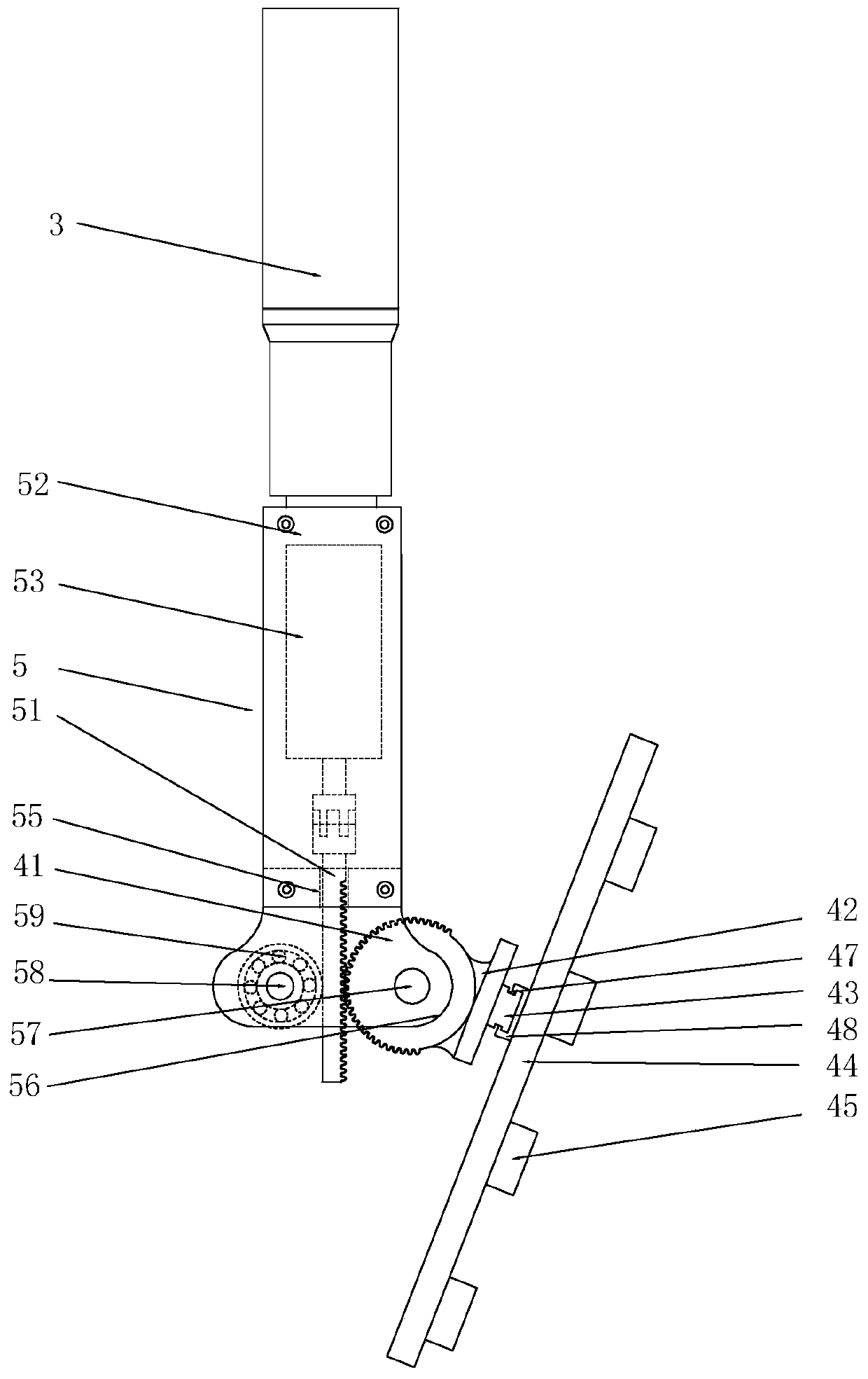

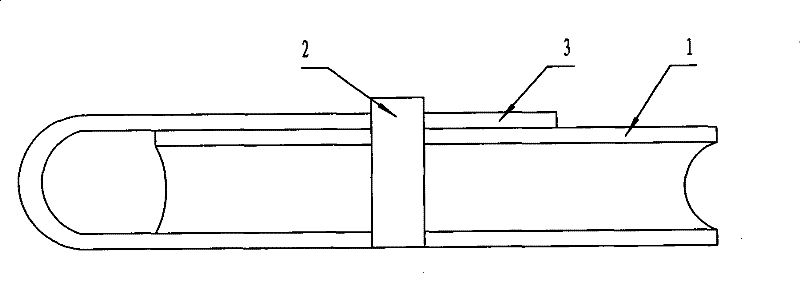

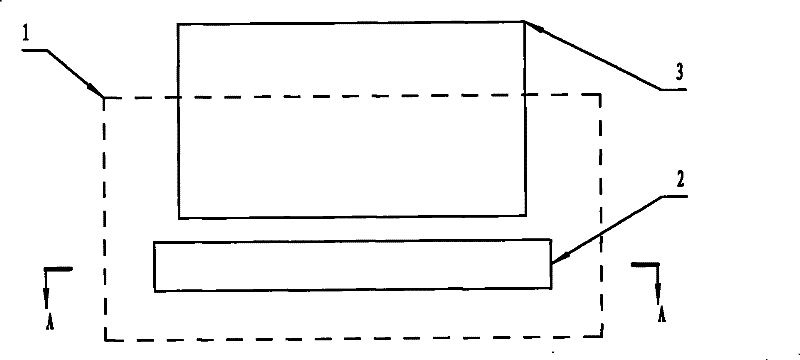

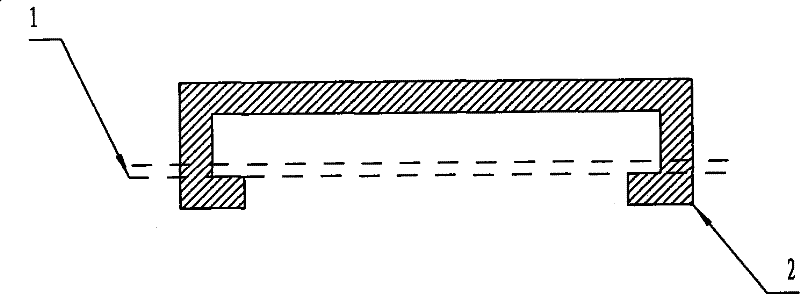

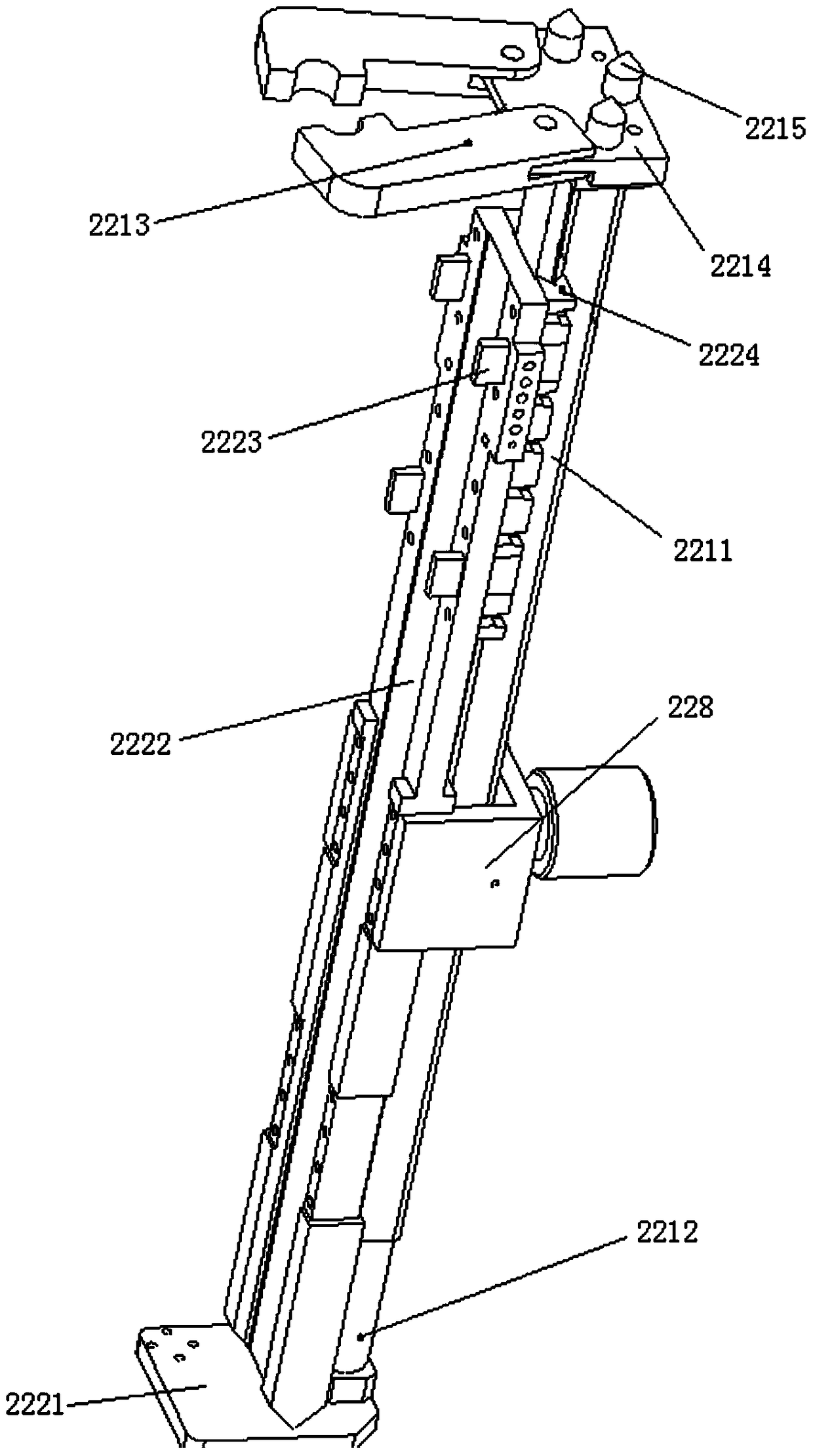

Anchor rod jacking drilling machine and anchor rod jacking drilling carriage with same

ActiveCN105443037AImprove locking abilityMechanizationDerricks/mastsAnchoring boltsUltimate tensile strengthTransferring (function)

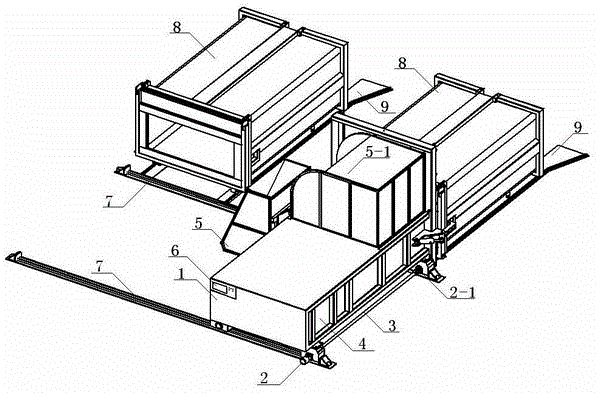

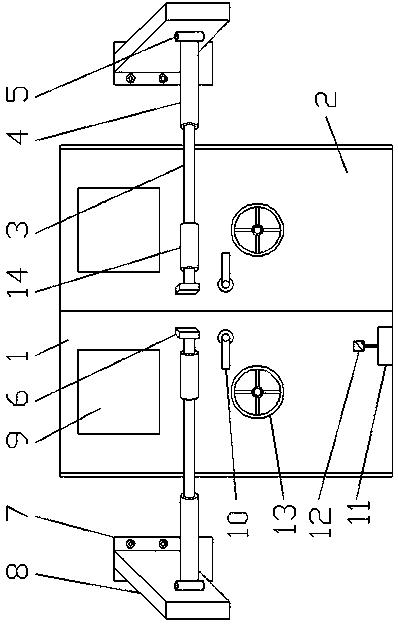

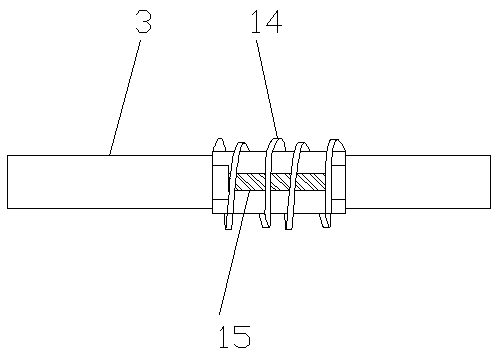

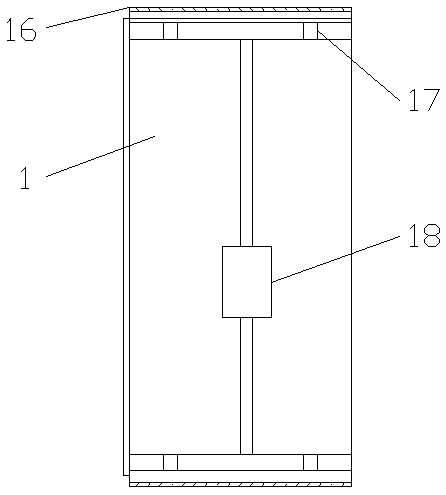

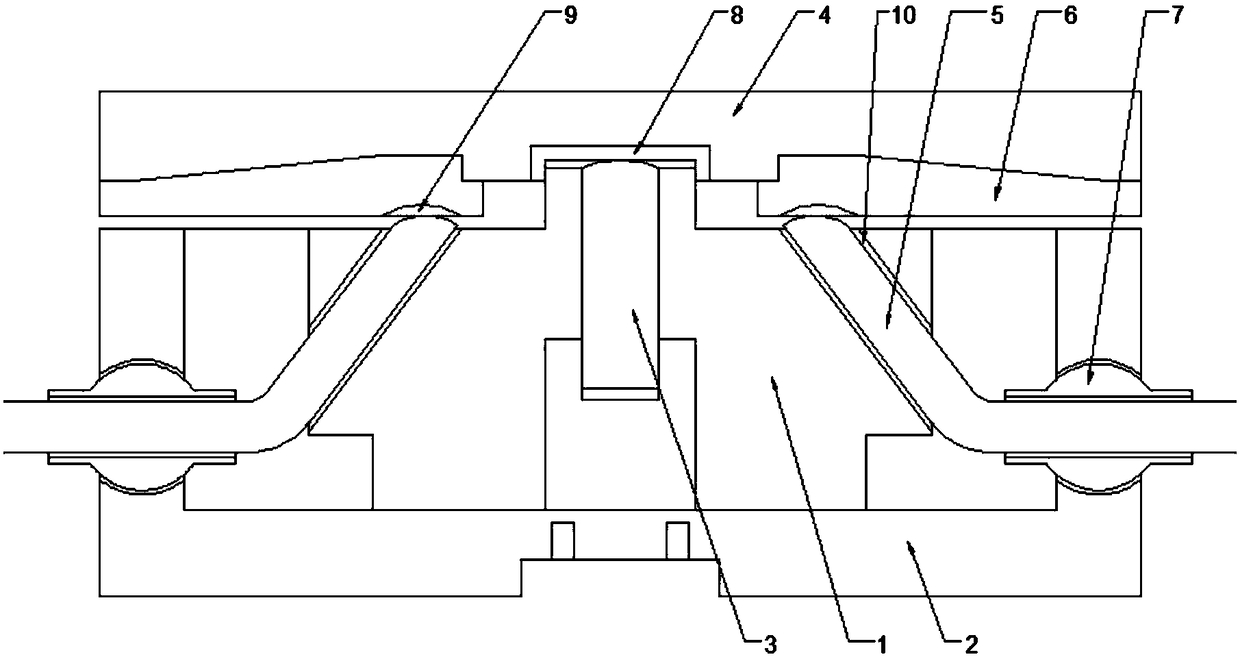

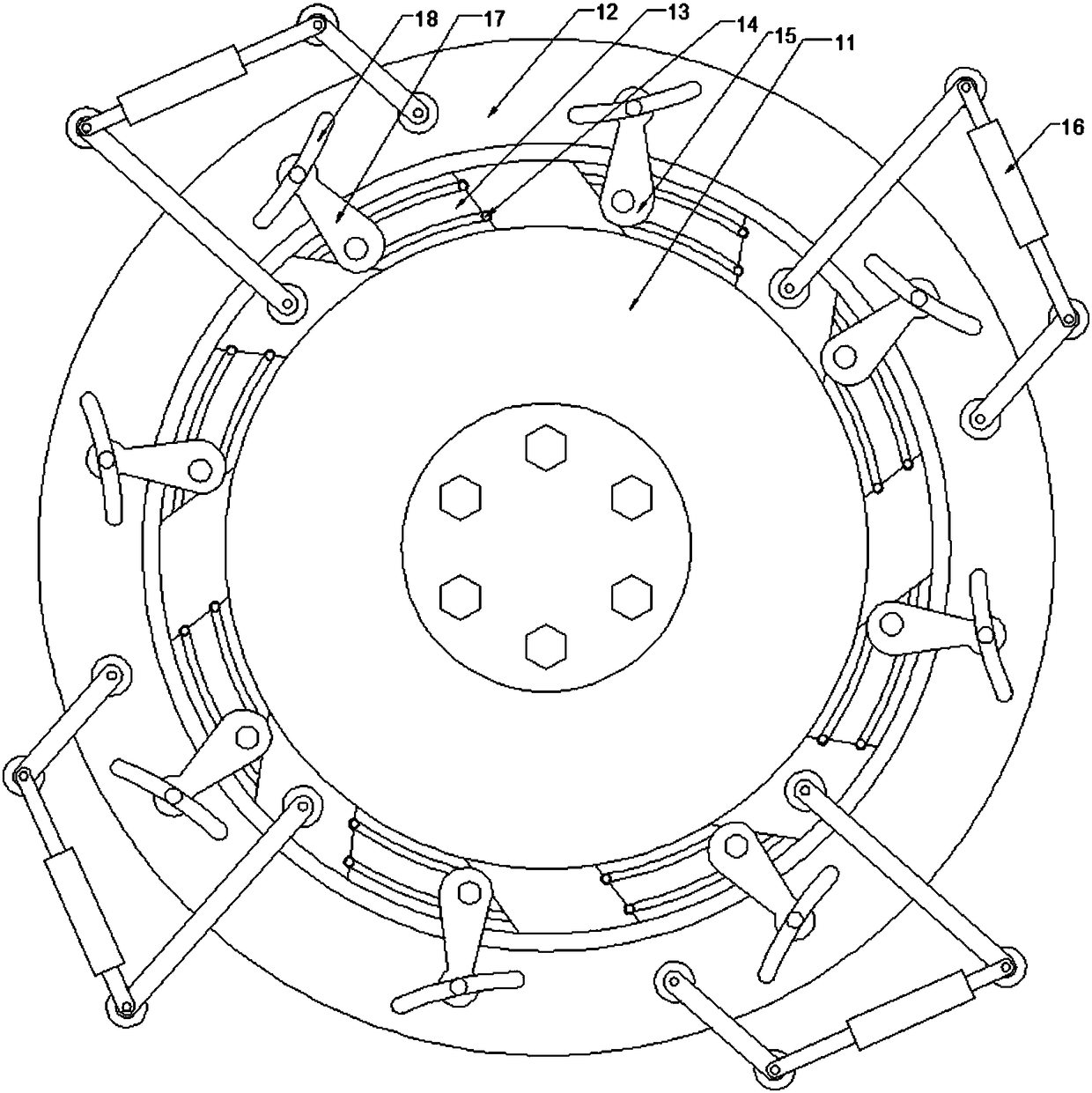

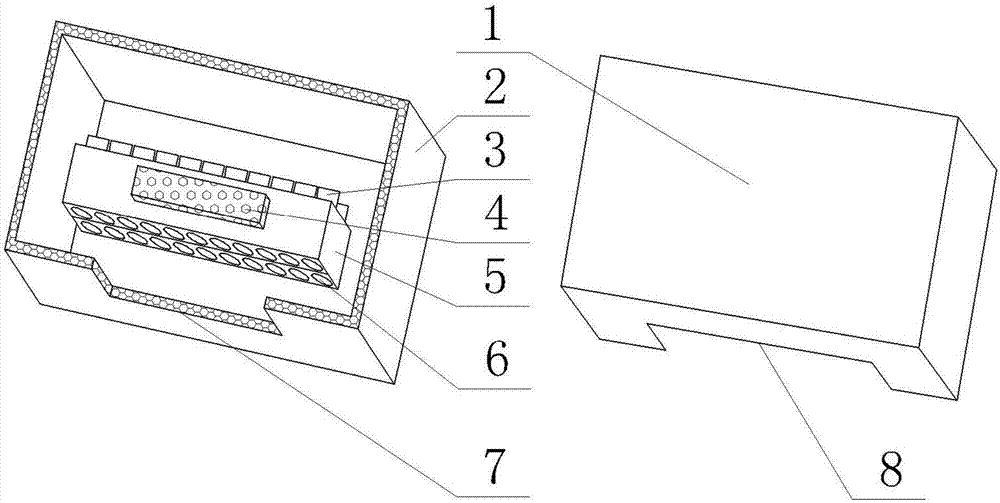

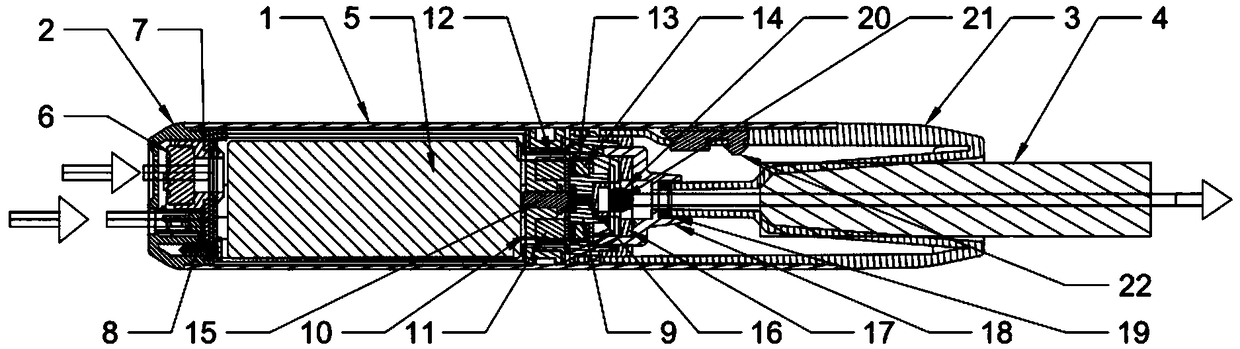

The invention discloses an anchor rod jacking mechanism which comprises a fixing mechanism, a supporting mechanism, a sliding block and a drill box mechanism. The fixing mechanism comprises a base, a stand plate and a connecting seat. Protrusions for fixing guide blocks are arranged on the stand plate. The supporting mechanism and the sliding block are in sliding connection with the opposite side faces of the stand plate through the guide blocks respectively. One end of the supporting mechanism and one end of the slide block are connected with base through telescopic oil cylinders. The drill box mechanism comprises a bottom frame and two independent drill box sliding seats. The bottom frame is connected with the base, and the drill box sliding seats can horizontally move along the bottom frame. When the drill box sliding seats move to the sliding block, the drill box sliding seats can be connected with the other guide rail face of the sliding block and slide along the sliding block. The invention further discloses an anchor rod jacking drilling carriage with a drilling machine. The anchor rod jacking drilling carriage comprises a four-wall anchor rod jacking drilling carriage body and a six-arm anchor rod jacking drilling carriage body. The drilling machine in the anchor rod jacking drilling carriage can work at the same time. Fast supporting operation on a top plate can be achieved, the structure is compact, and multiple functions are achieved. The anchor rod jacking mechanism and the anchor rod jacking drilling carriage operate in cooperation with heading equipment to complete the supporting and transferring function synchronously, operating personnel are greatly reduced, the labor intensity is lowered, and the supporting efficiency and safety are improved.

Owner:蒲长晏

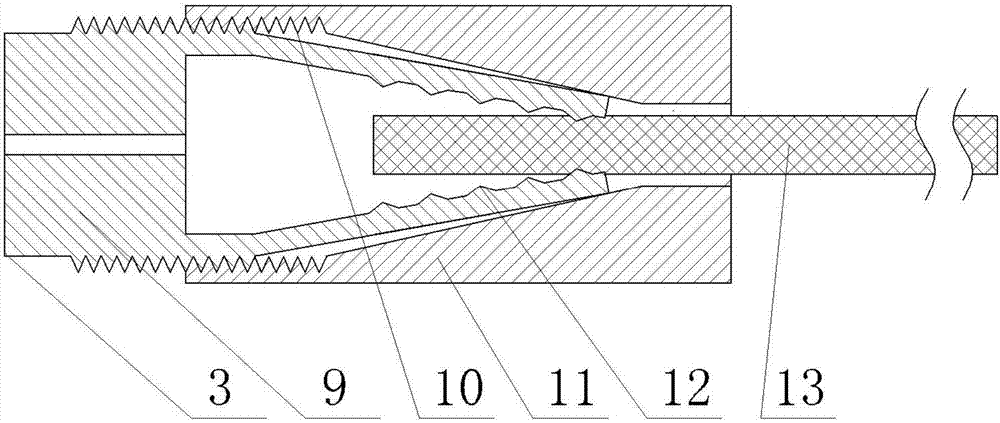

Joint mechanism

InactiveUS6109815AAvoid contactImprove locking abilityYielding couplingCouplings for rigid shaftsEngineeringActuator

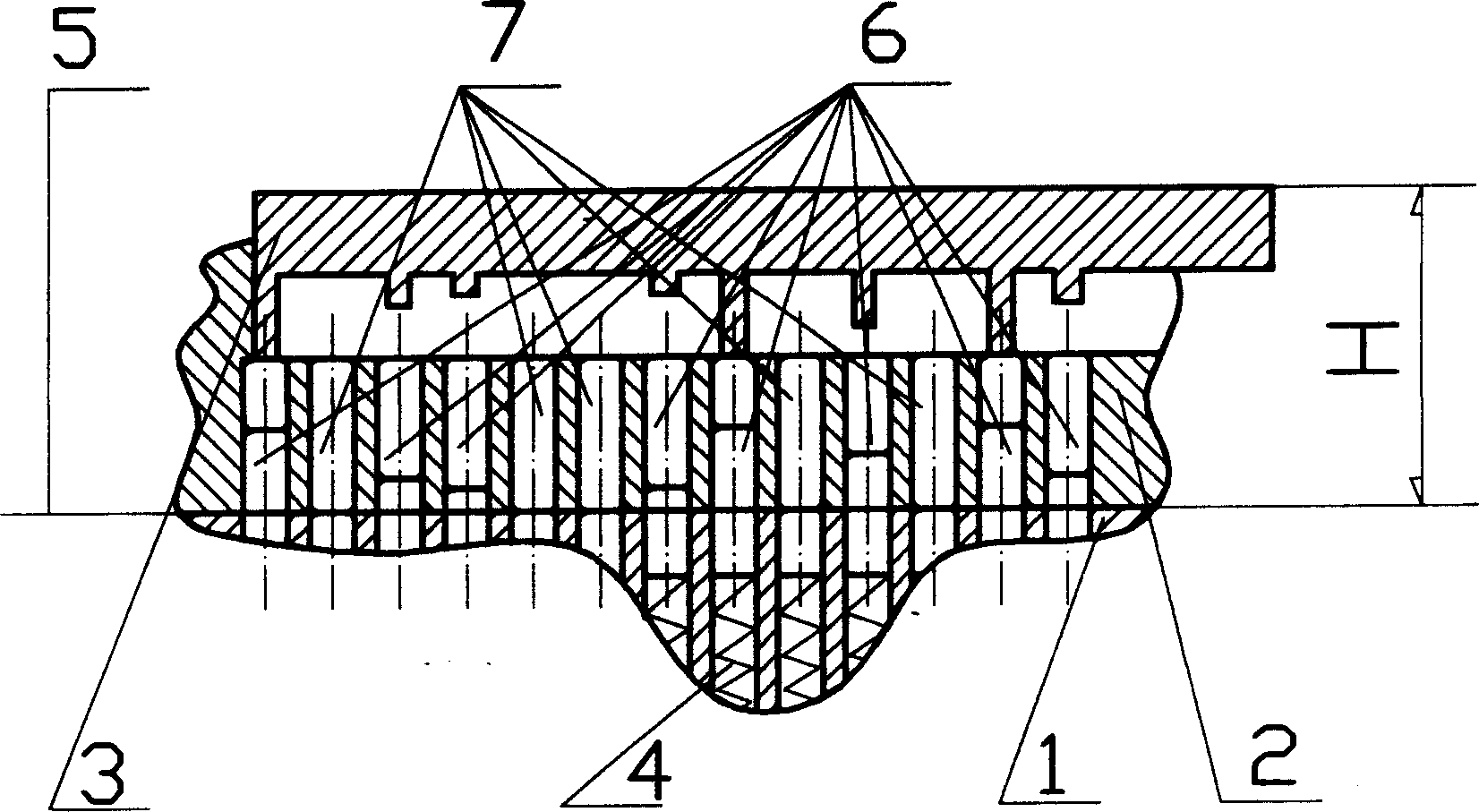

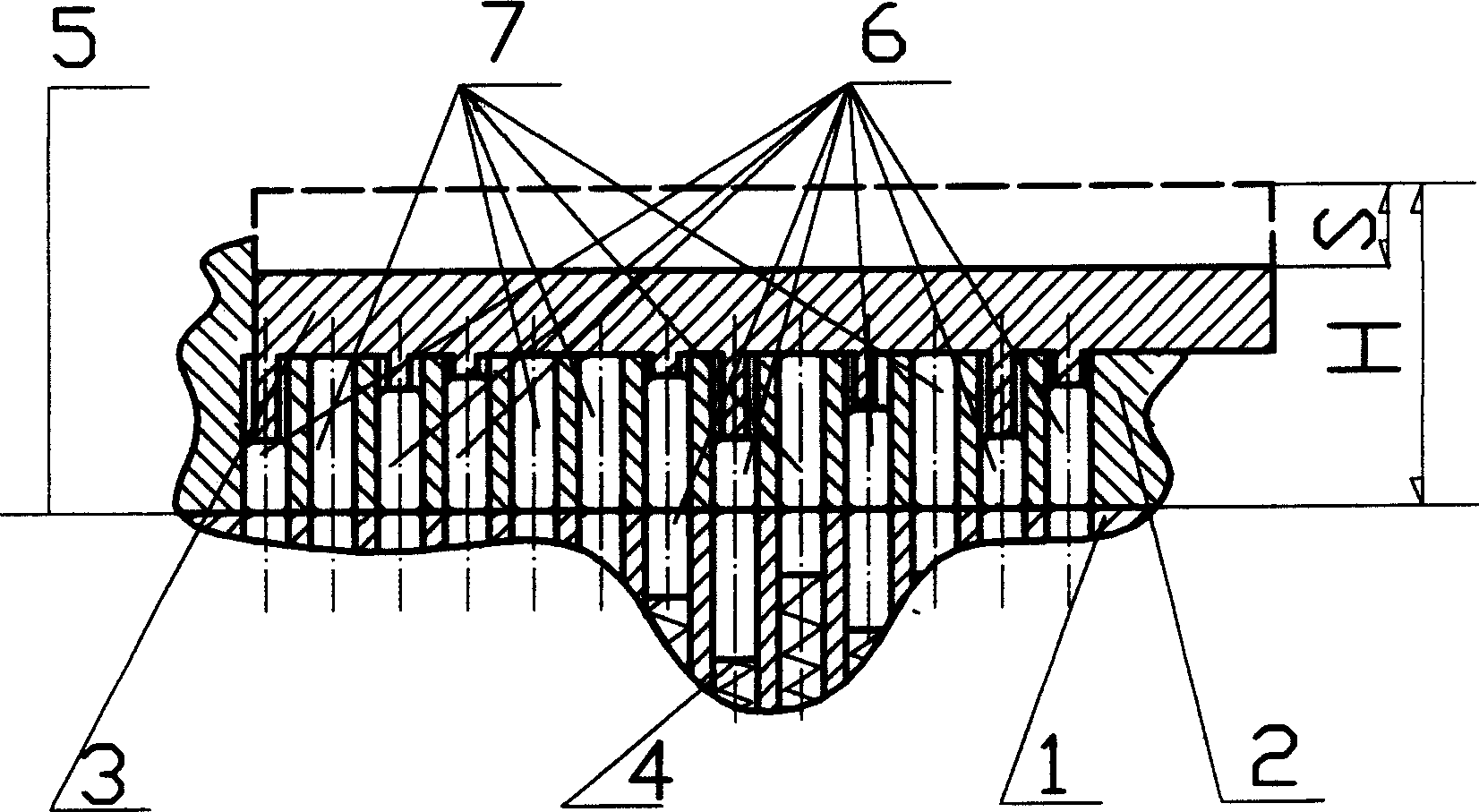

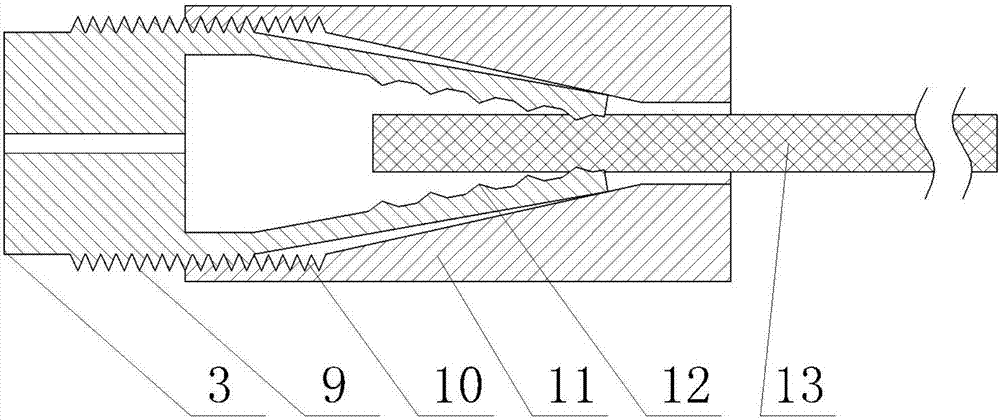

PCT No. PCT / EP95 / 04311 Sec. 371 Date Aug. 28, 1998 Sec. 102(e) Date Aug. 28, 1998 PCT Filed Nov. 3, 1995 PCT Pub. No. WO97 / 17548 PCT Pub. Date May 15, 1997In an angularly adjustable, releasably lockable ball joint, the ball has a surface covered with polygonal patterns of spaced apart protuberances, the protuberances define concavities. An actuator tip is provided to penetrate at least one concavity and simultaneously contact the protuberances if the pattern to lock the ball and actuator together, thereby fixing the orientation of shanks attached to the ball and actuator.

Owner:MERLO WERNER O

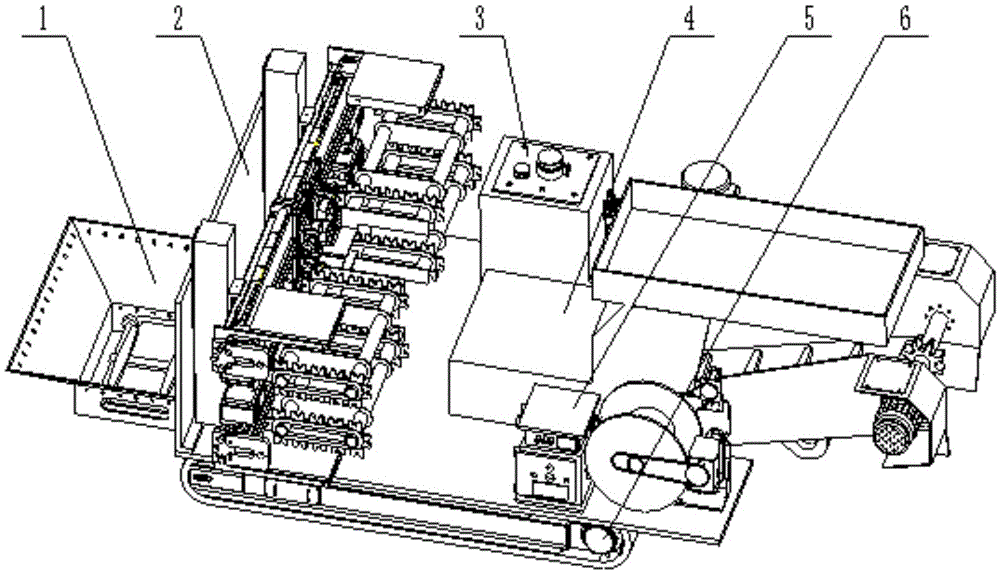

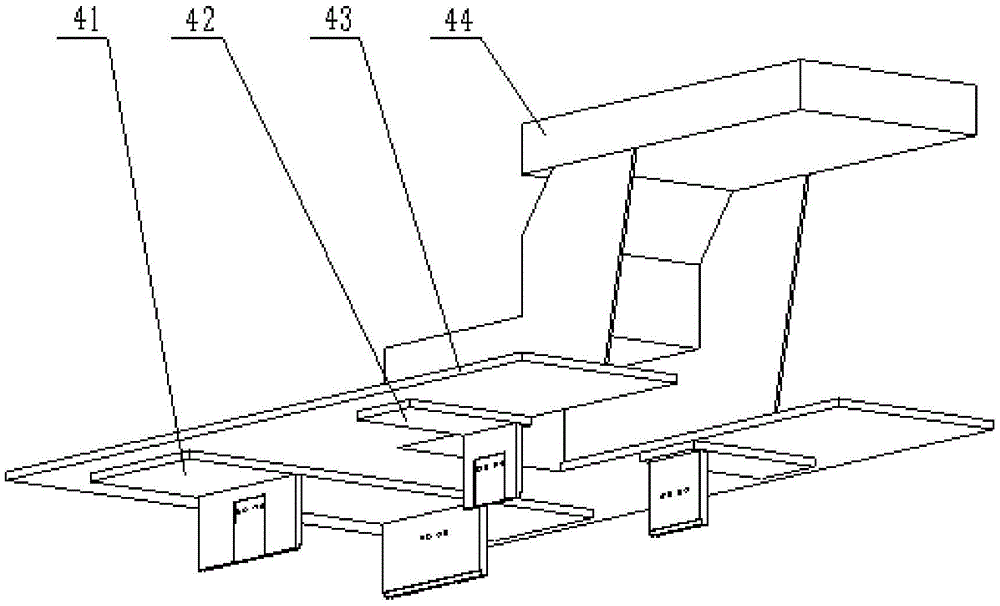

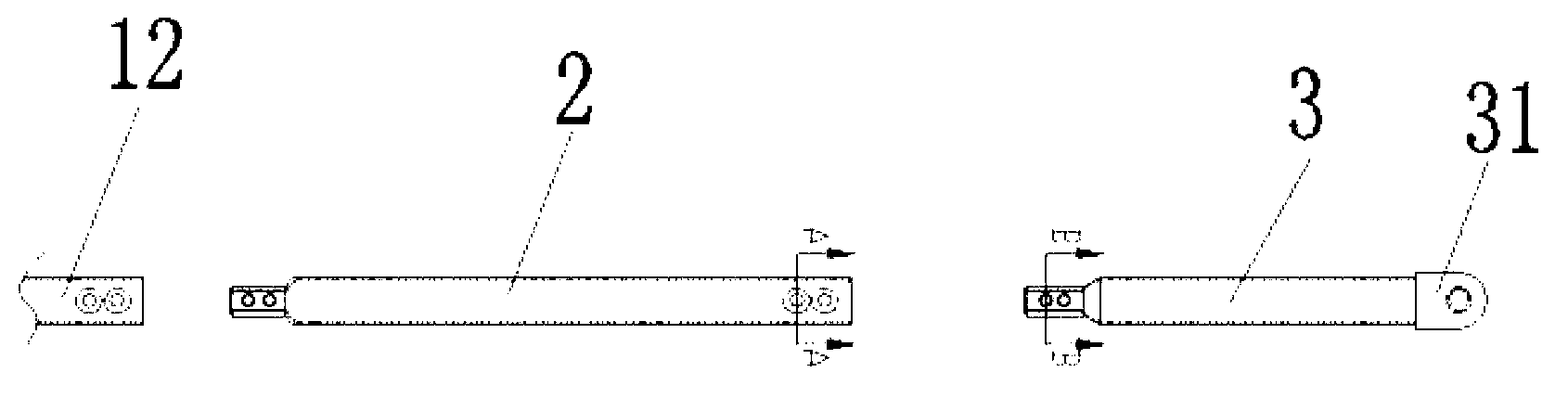

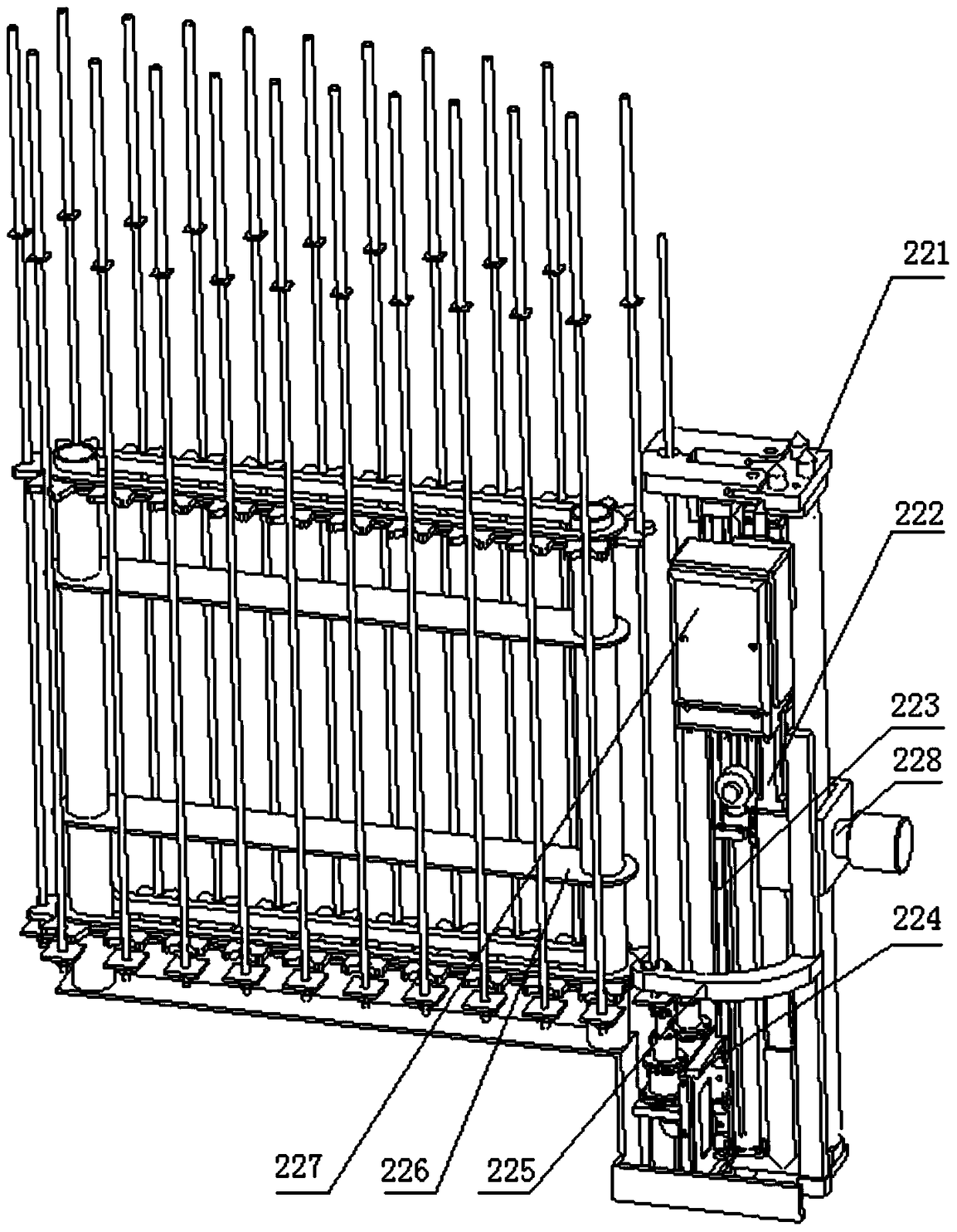

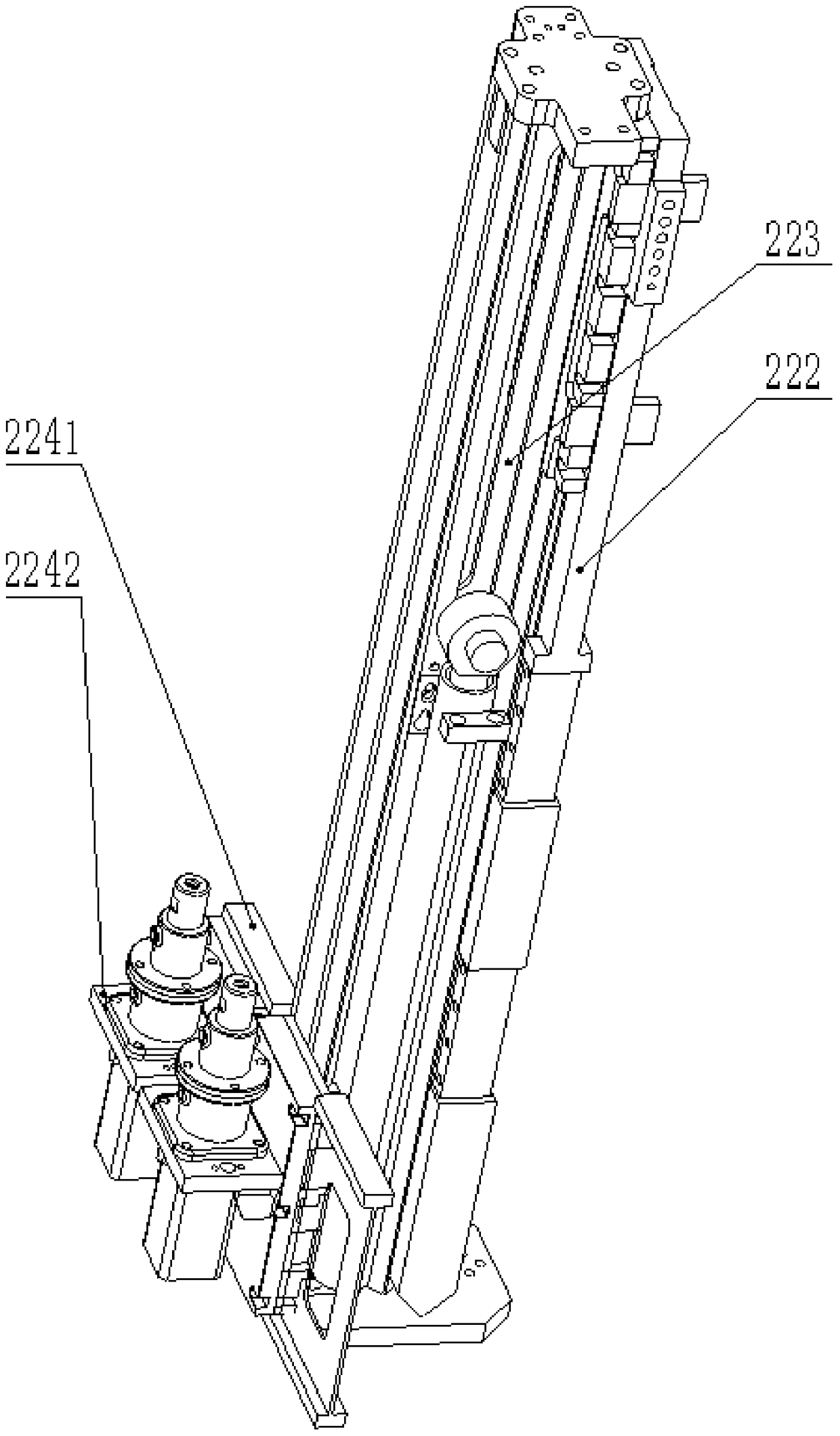

Side bolt drilling machine and side bolt drilling carriage with same

ActiveCN105626108ALarge storage capacityMeet construction needsDerricks/mastsAnchoring boltsEngineeringRock bolt

The invention discloses a side bolt drilling machine which comprises a fixing mechanism, a supporting mechanism, a sliding rack, a drilling box mechanism and a cartridge conveying box. The fixing mechanism comprises a base, a vertical plate and a connecting seat. Protrusions for fixing guide blocks are arranged on the vertical plate. The supporting mechanism and the sliding rack are in sliding connection with the opposite side faces of the vertical plate respectively through the guide blocks, and one end of the supporting mechanism and one end of the sliding rack are connected with the base through a telescopic oil cylinder. The drilling box mechanism comprises a bottom rack and two independent drilling box sliding seats. The bottom rack is fixedly connected with the base, the drilling box sliding seats can horizontally move along the bottom rack, and when the drilling box sliding seats move to the sliding rack, the drilling box sliding seats can be connected with the other guide rail face of the sliding rack and slide along the sliding rack. The cartridge conveying box is used for completing the automatic cartridge feeding procedure of the drilling machine. The invention further discloses a side bolt drilling carriage with the drilling machine. By means of automatic cartridge feeding and automatic anchor bolt mounting, mechanization and automation of anchor bolt supporting work are achieved, the construction needs of a plurality of rows of side bolts can be met, and the side bolt drilling carriage works in cooperation with heading equipment to synchronously complete side bolt supporting and transferring functions.

Owner:LANG FANG JING LONG GRAND IND MACHINERY CO LTD

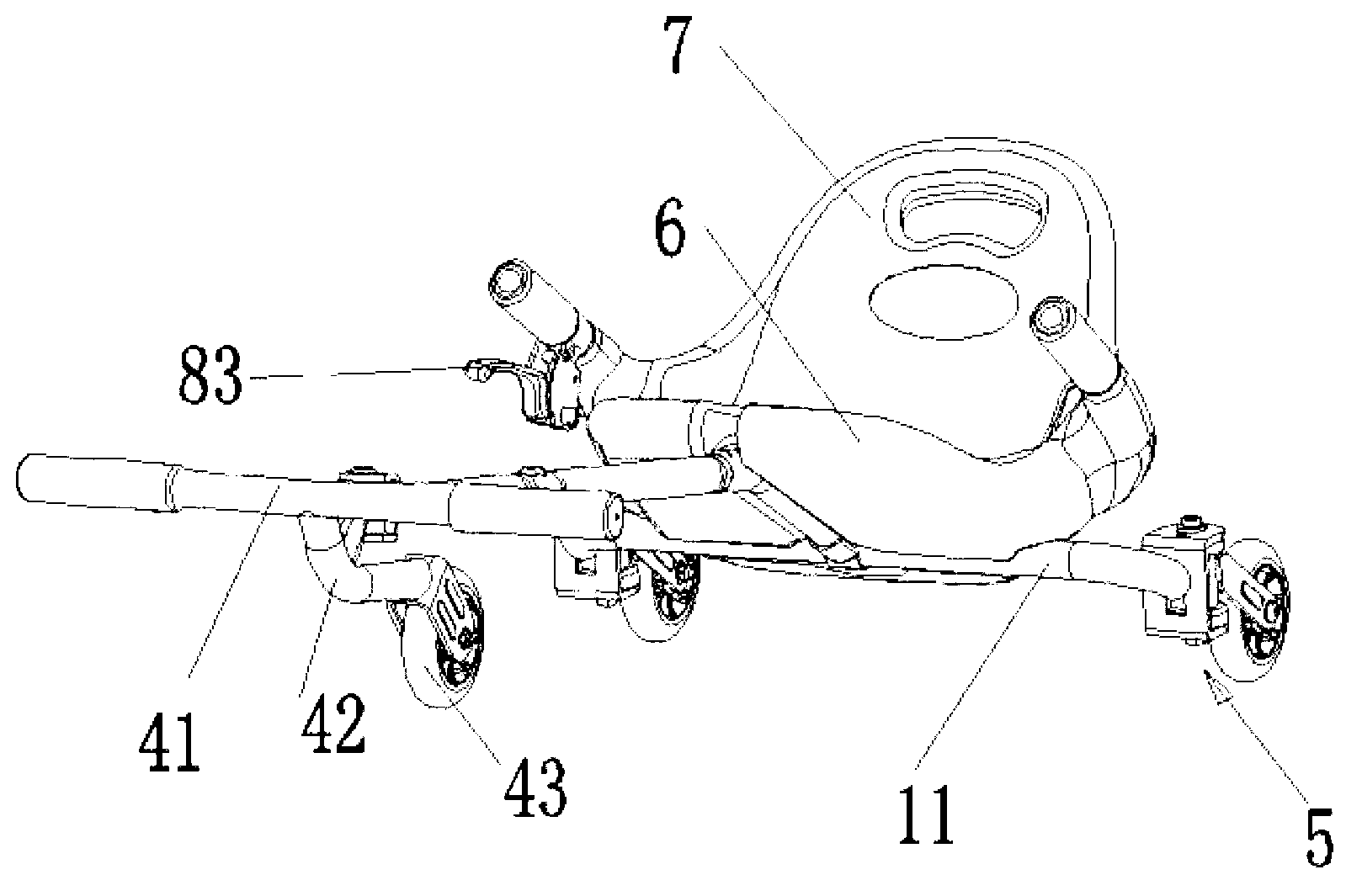

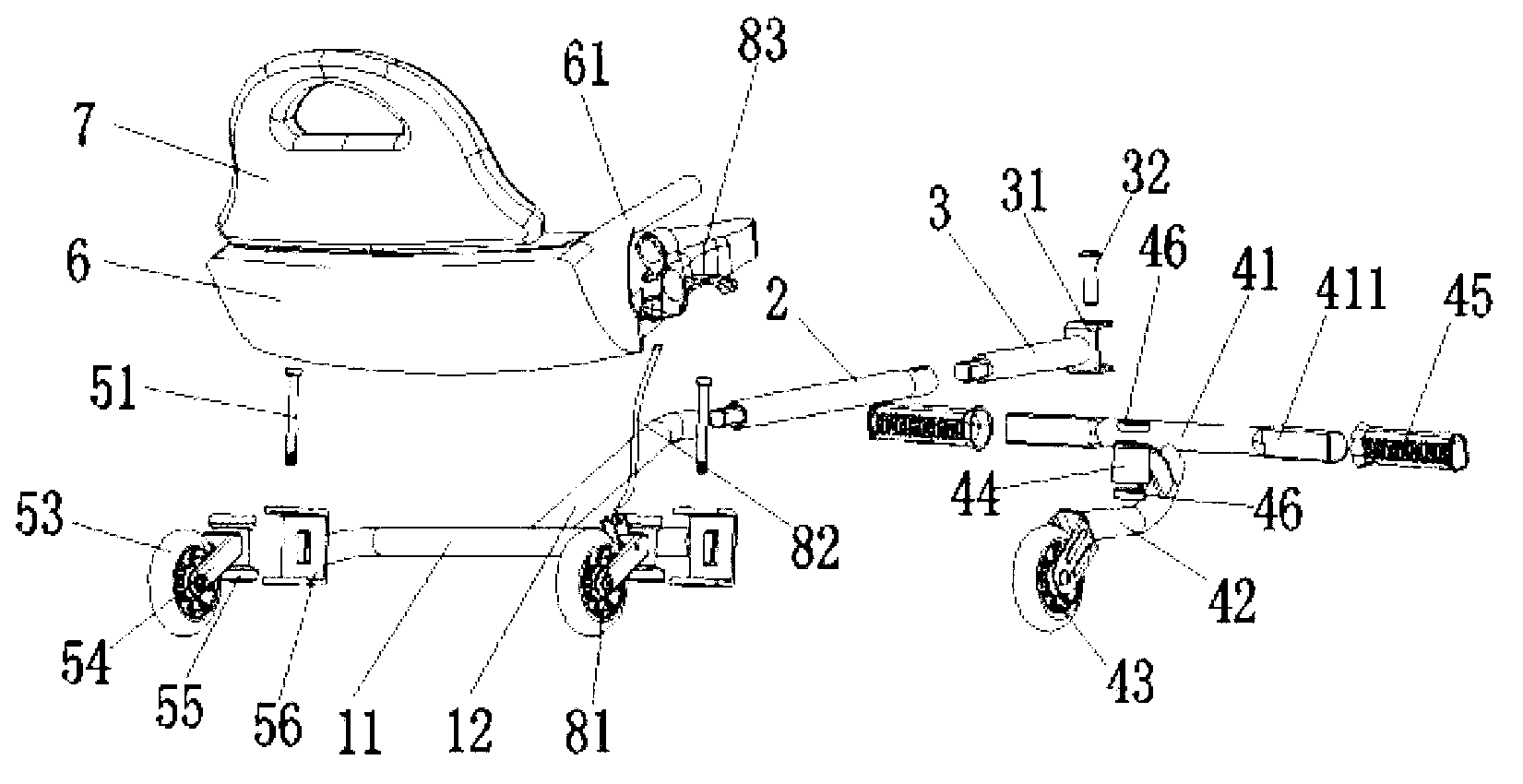

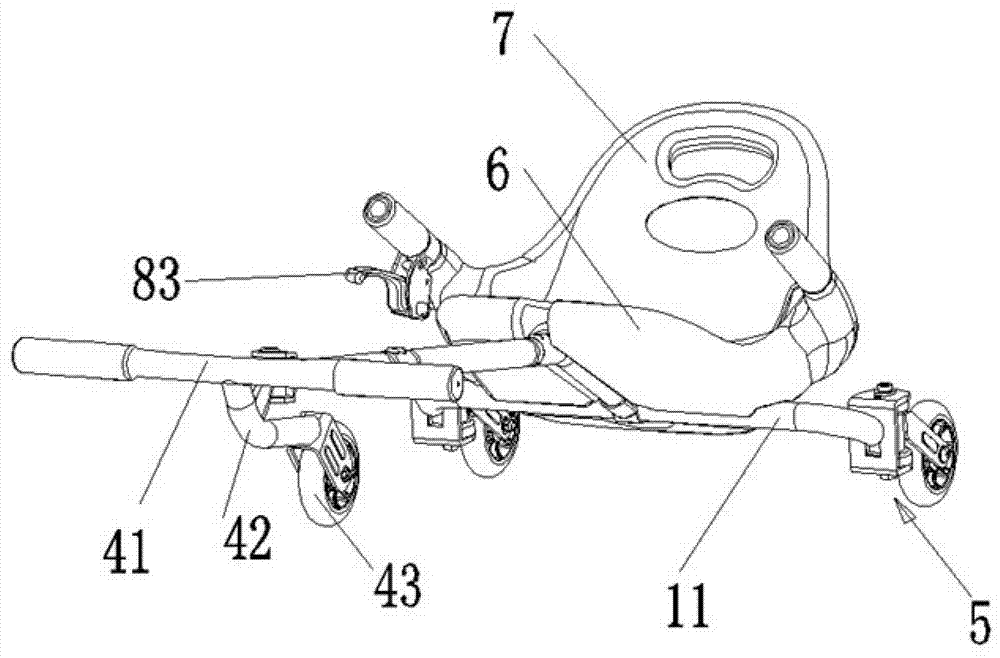

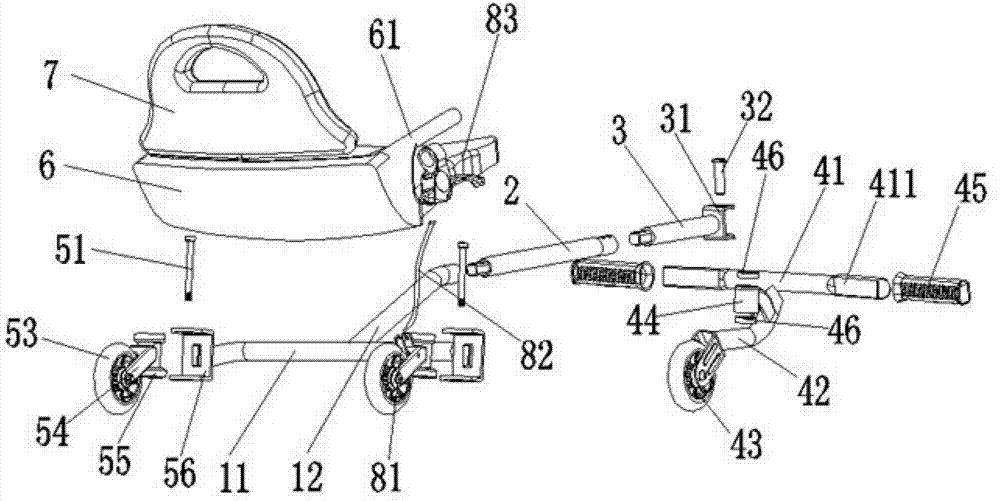

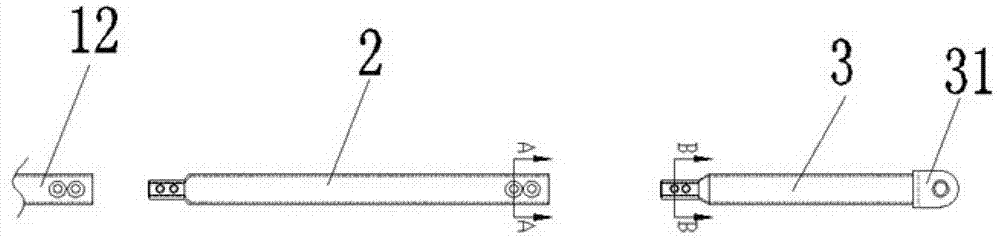

Novel twist car

InactiveCN103231762ASave materialDoes not affect development and growthCyclesCycle brakesControl engineeringTorsion spring

The invention discloses a novel twist car which comprises a main frame assembly, a front connecting pipe and a swing assembly connected in sequence, wherein the main frame assembly comprises a rear wheel pipe with two moving wheels mounted at the two ends and a main frame pipe with one end fixed to the middle of the rear wheel pipe; a T-shaped structure formed by the rear wheel pipe and the main frame pipe is provided with a seat cushion and a backrest cushion; the swing assembly comprises a pedal pipe and a swing pipe with one end fixed to the middle of the pedal pipe and a guide wheel mounted at the other end; one end of the front connecting pipe is rotationally fixed with a socket pipe; the other end of the front connecting pipe is fixedly connected with the corresponding end part of the main frame pipe; each moving wheel is provided with a moving return mechanism; the moving return mechanism comprises a fixing seat which is fixed to the end part of the rear wheel pipe and is of a C-shaped structure, a rotating pipe rotationally fixed in a groove in the fixing seat through a positioning shaft and a bearing, and a swing arm with one end fixed to the side part of the rotating pipe; a moving wheel is mounted at the other end of the swing arm; and the positioning shaft is also sheathed with a torsion spring capable of driving the rotating pipe to return. The novel twist car is simple and reliable in structure, flexible in operation and comfortable for the seat.

Owner:KUNSHAN JIAN XIANG WEI MECHANICAL TECH

Preparation method of lead frame with rough side wall

ActiveCN112133640AIncrease roughnessImprove air tightnessSemiconductor/solid-state device detailsSolid-state devicesDevice materialStructural engineering

The invention belongs to the technical field of semiconductor devices, and particularly relates to a preparation method of a lead frame with a rough side wall. According to the invention, the upper surface of the lead frame is firstly subjected to single-sided brown oxidation, then a semi-etched region and the side wall are subjected to super-roughening treatment after electroplating and etching,and the side wall and the semi-etched region form a rough surface with good roughness by controlling super-roughening process conditions, so that the binding force of the contact region of the lead frame and plastic packaging resin is increased. The lower surface of the lead frame is not roughened, and the pre-electroplated layer with the smooth surface is only formed in the exposed bonding pad area, so that the surface roughening area is reduced; meanwhile, the lower surface is not prone to adhering to overflowing materials generated in the plastic package process, the cleaning difficulty isreduced, the process is simplified, and the roughening and electroplating cost is saved. The side wall of the lead frame has good roughness, the air tightness and reliability of an integrated circuitpackaging body are improved, and the defects of layering, cracking and the like are reduced.

Owner:NINGBO KANGQIANG ELECTRONICS CO LTD

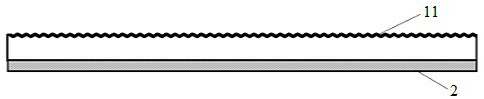

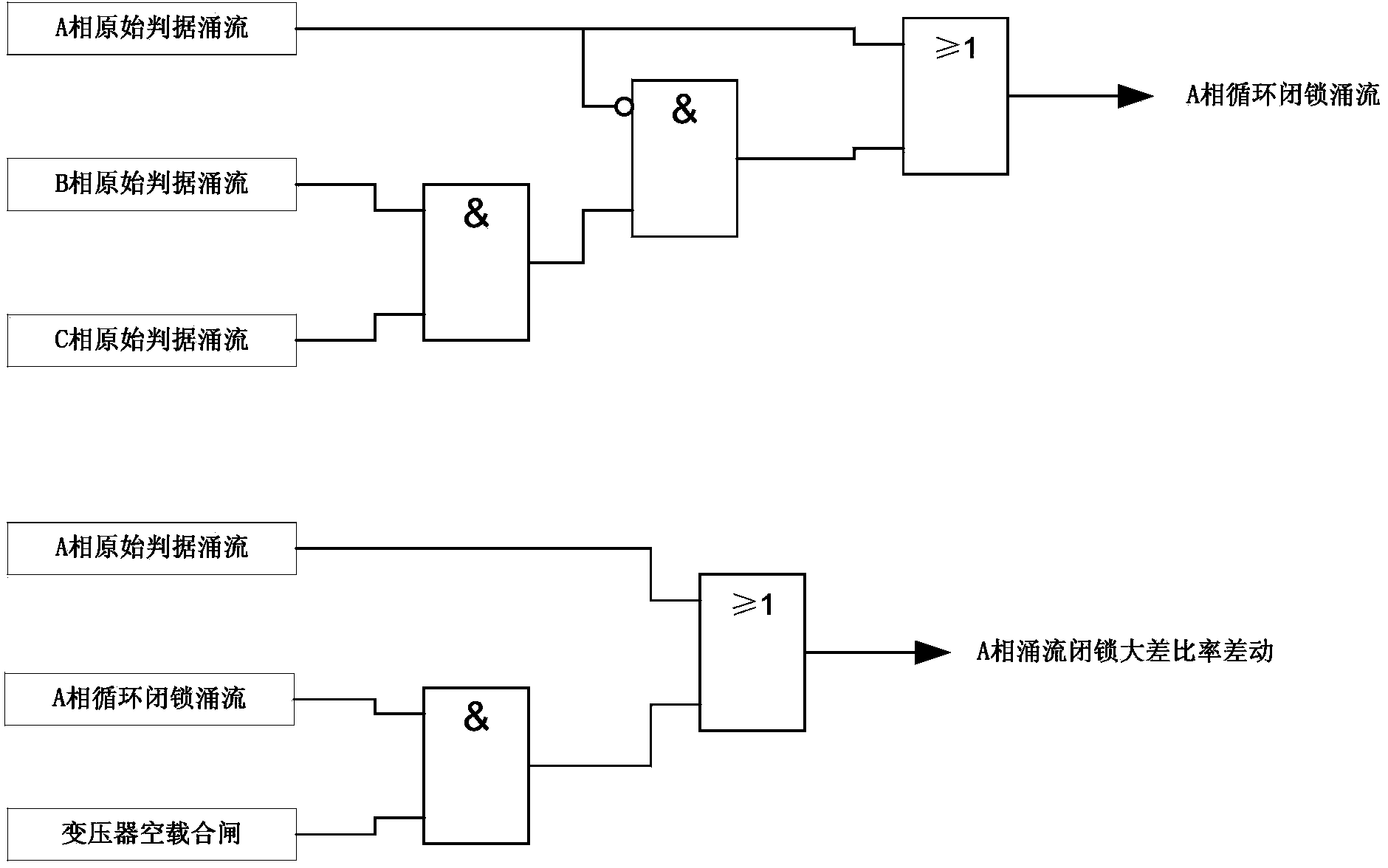

Locking method for large-difference percentage differential protection magnetizing inrush current of converter transformer

ActiveCN104269827AImprove locking abilityMove quicklyEmergency protective circuit arrangementsEngineeringInrush current

The invention provides a locking method for large-difference percentage differential protection magnetizing inrush current of a converter transformer. The working manner of the locking method is that when the converter transformer is idled, a cycled locked inrush current criterion is used for judging the magnetizing inrush current, and after the inrush current criterion is met, the current converting large-different percentage differential protection function is locked. The locking capability of the magnetizing inrush current in the process that current converting is changed into idling is improved, and large-different percentage differential protection false operation in the process that current converting is changed into idling is avoided.

Owner:NR ELECTRIC CO LTD +2

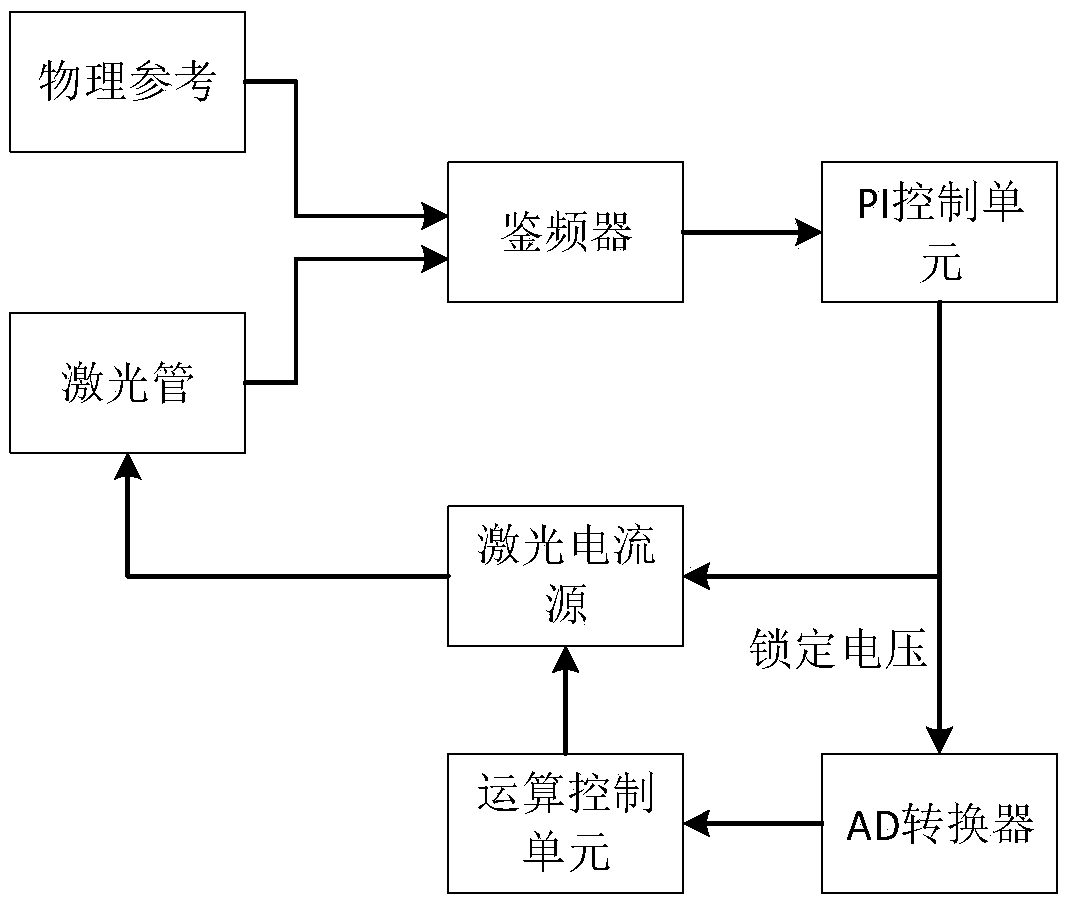

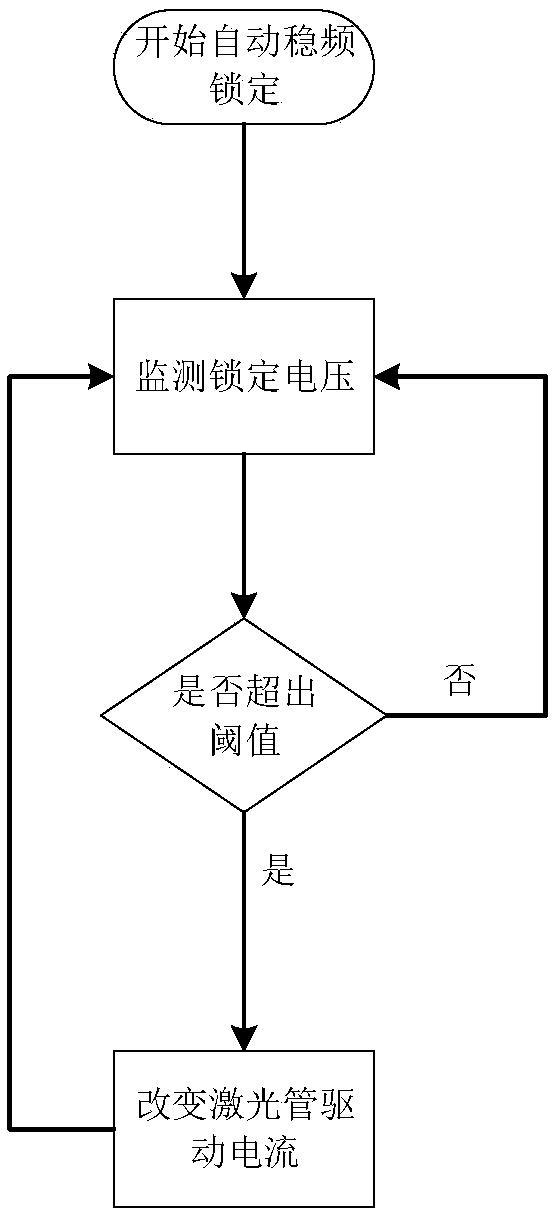

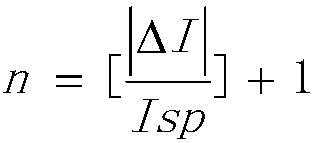

Method for prolonging average fault-free working time of laser frequency stabilization system

ActiveCN109412010AImprove locking abilityImprove stabilityLaser detailsSemiconductor lasersFault freeVoltage

The invention discloses a method for prolonging average fault-free working time of a laser frequency stabilization system. A locking voltage value output from a PI control unit in a laser automatic frequency stabilization system is sampled, and the locking voltage value is slowly returned to a central value of an action range by adjusting a current value output to a laser tube when that a voltageexceeds a threshold is monitored. By the method, the locking capability of the laser automatic frequency stabilization system can be improved, the locking stability is improved, so that the average fault-free working e of the laser frequency stabilization system is prolonged.

Owner:陕西聚力思创通信科技有限公司

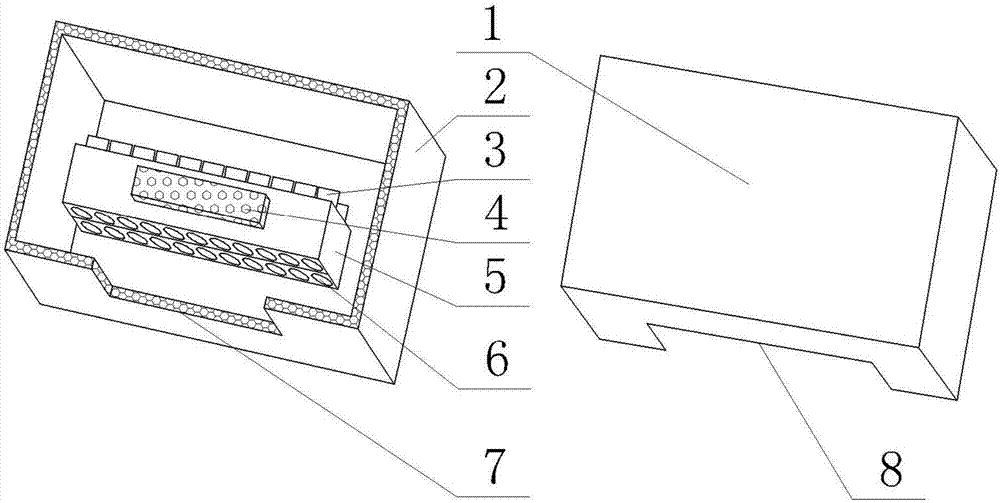

Waterproof and anti-loosening junction box

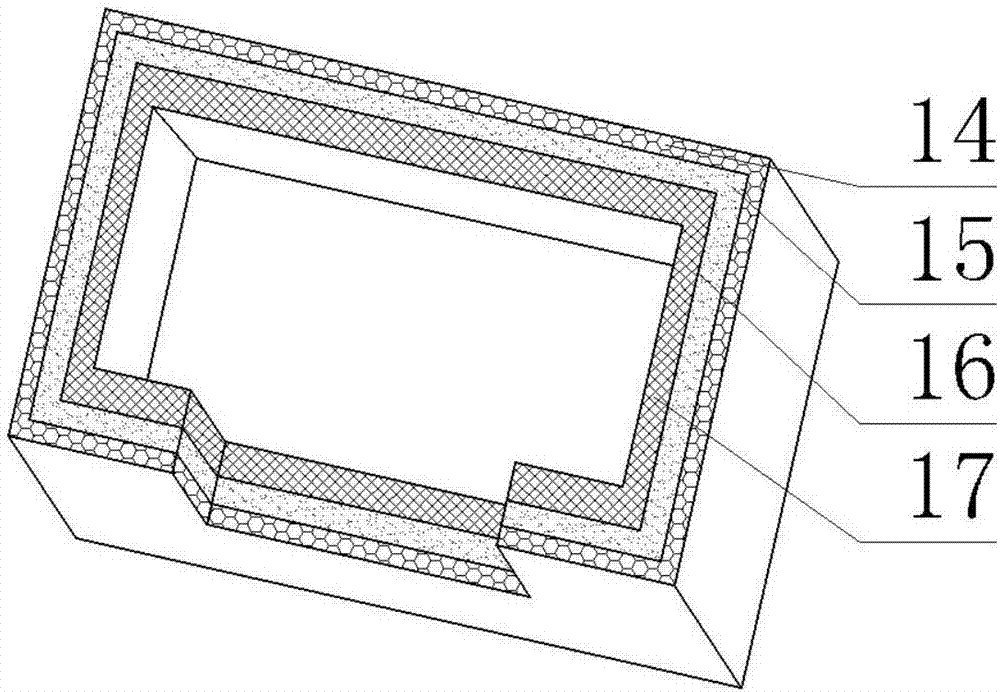

InactiveCN106921080APrevent penetrationImprove connection reliabilityElectrically conductive connectionsCouplings bases/casesSharp toothCorrosion

The invention relates to a waterproof and anti-loosening junction box. The waterproof and anti-loosening junction box comprises a junction box, a cover shell and a wiring structure; a first wiring groove is formed in the bottom of the junction box; a second wiring groove is formed in the cover shell; the wiring structure is a socket type integrated wiring block, and a wiring socket integrated in the wiring structure faces to the first wiring groove; the wiring socket comprises a socket main body provided with a guiding conical surface and screw thread sleeves, and a rotary pressing structure provided with screwing screw threads and a conical surface; and one end of the rotary pressing structure is a screwing end while the other end is a pressing conical surface with pressing sharp teeth. The waterproof and anti-loosening junction box has the advantages of corrosion resistance, aging resistance, anti-loosening property of wiring terminals, capability of preventing electricity stealing, high reliability and the like.

Owner:张敬敏

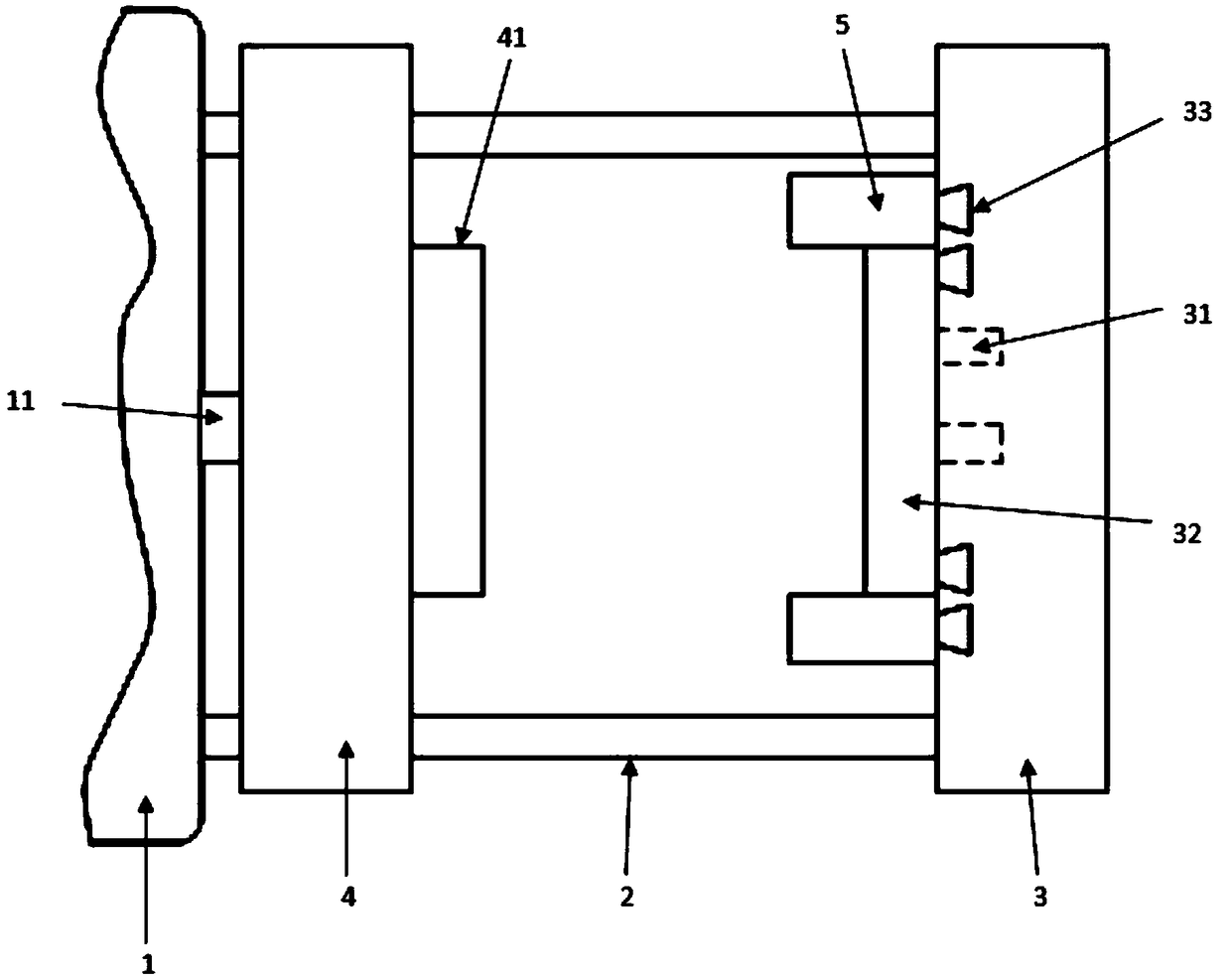

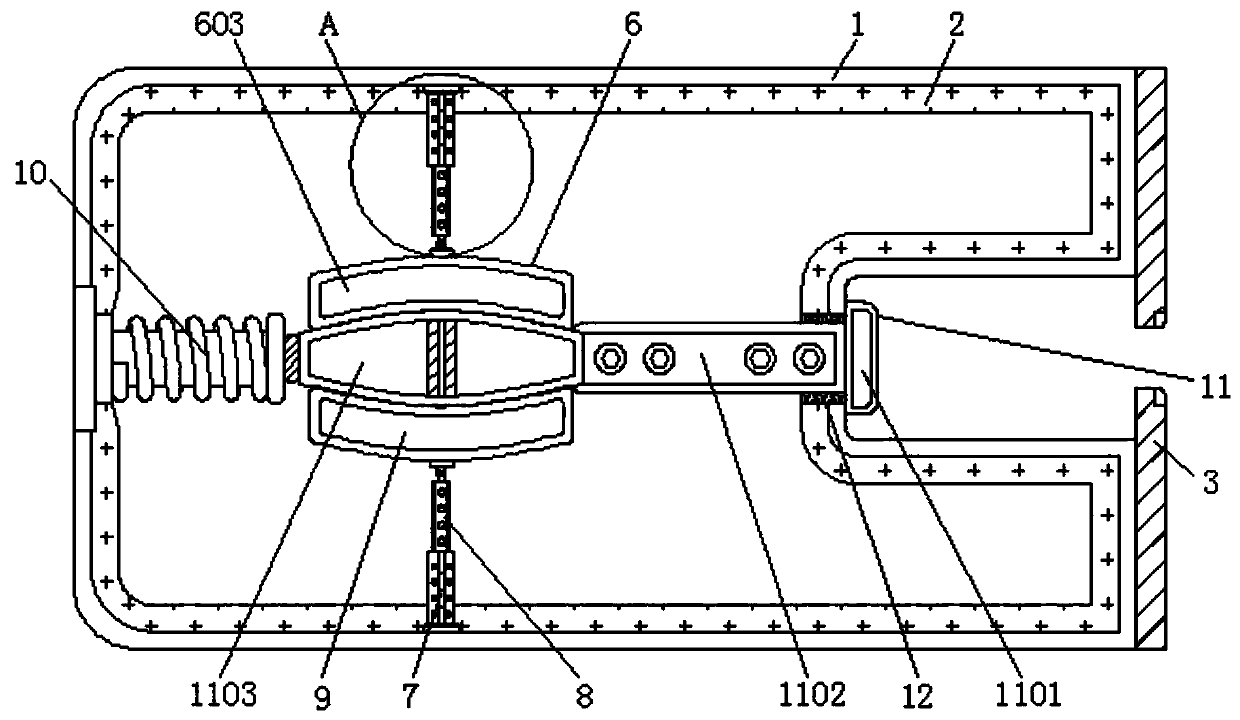

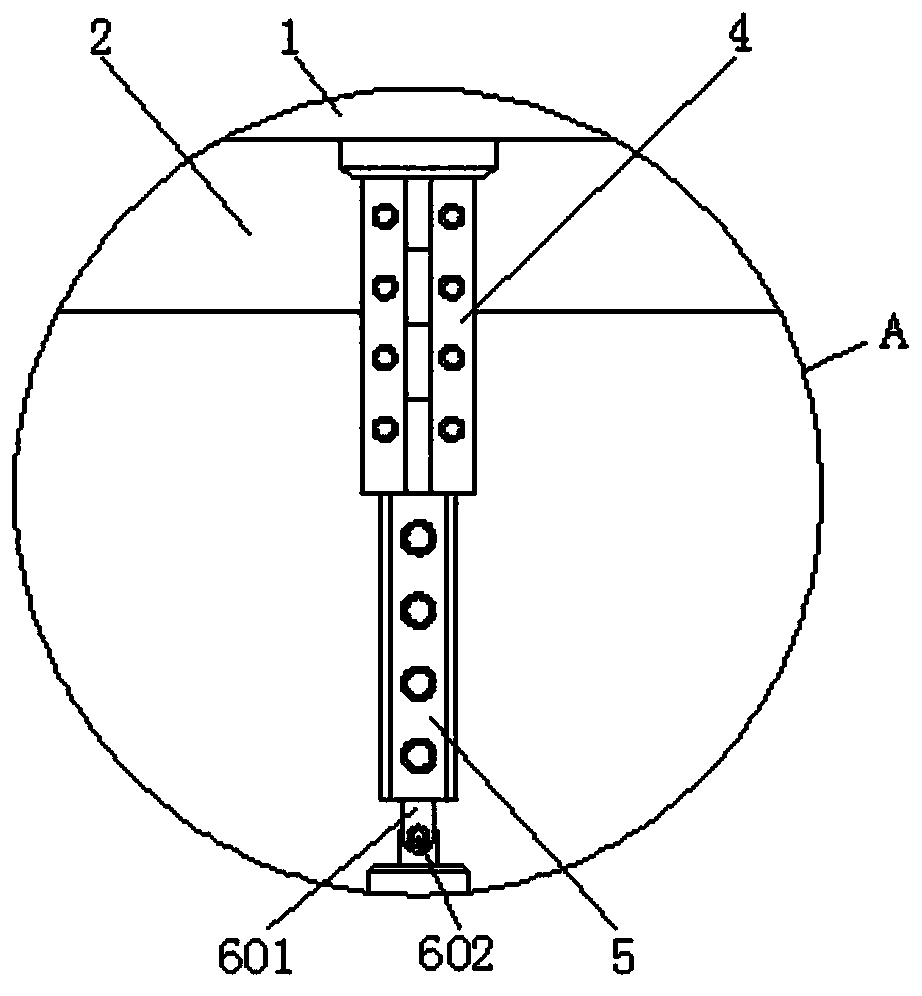

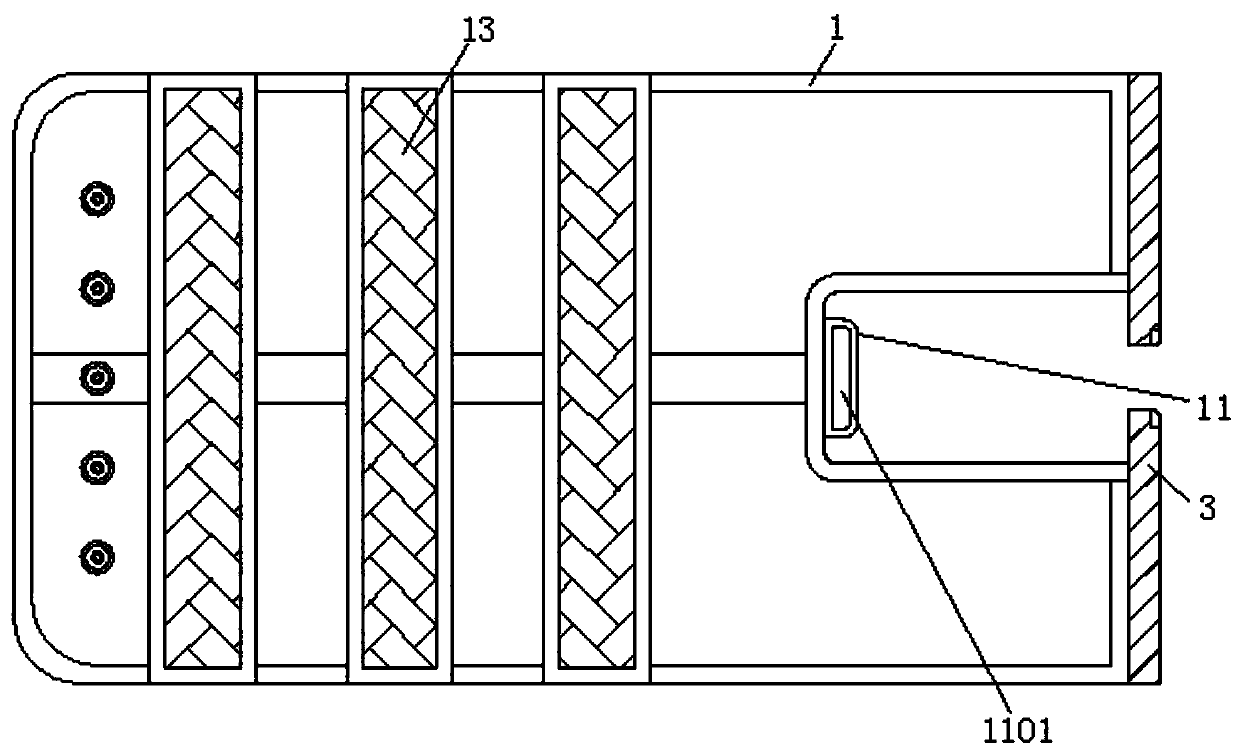

Electromagnetic mold locking injection molding machine

The invention relates to the technical field of an injection molding machine, in particular to an electromagnetic mold locking injection molding machine. The electromagnetic mold locking injection molding machine comprises a machine frame, guide posts, a back seat and a movable plate and is characterized in that the four guide posts are arranged between the machine frame and the back seat; the movable plate movably sleeves on the guide post in a penetrating way; a walking trolley is arranged on the movable plate in a way of corresponding to the guide post so that the movable plate can move forwards and backwards along the guide posts; a fixed mold is arranged at one side, facing the movable plate, of the back seat; a movable mold is arranged at one side, facing the back seat, of the movable plate; a plurality of clamp grooves are respectively formed in the back seat and are positioned above and under of the screw bolts; the clamp grooves are connected with an electromagnet through clamp heads clamped into the clamp groove; the electromagnet is arranged at the front end of the back seat and is directly in contact with the movable plate; the locking capability is greatly improved; aplurality of clamp grooves are installed; the clamp grooves with the corresponding height can be selected for installing the electromagnet according to different molds; the transverse position of theelectromagnet in the clamp grooves can be selected according to the size of the molds.

Owner:广州毅达塑胶五金模具有限公司

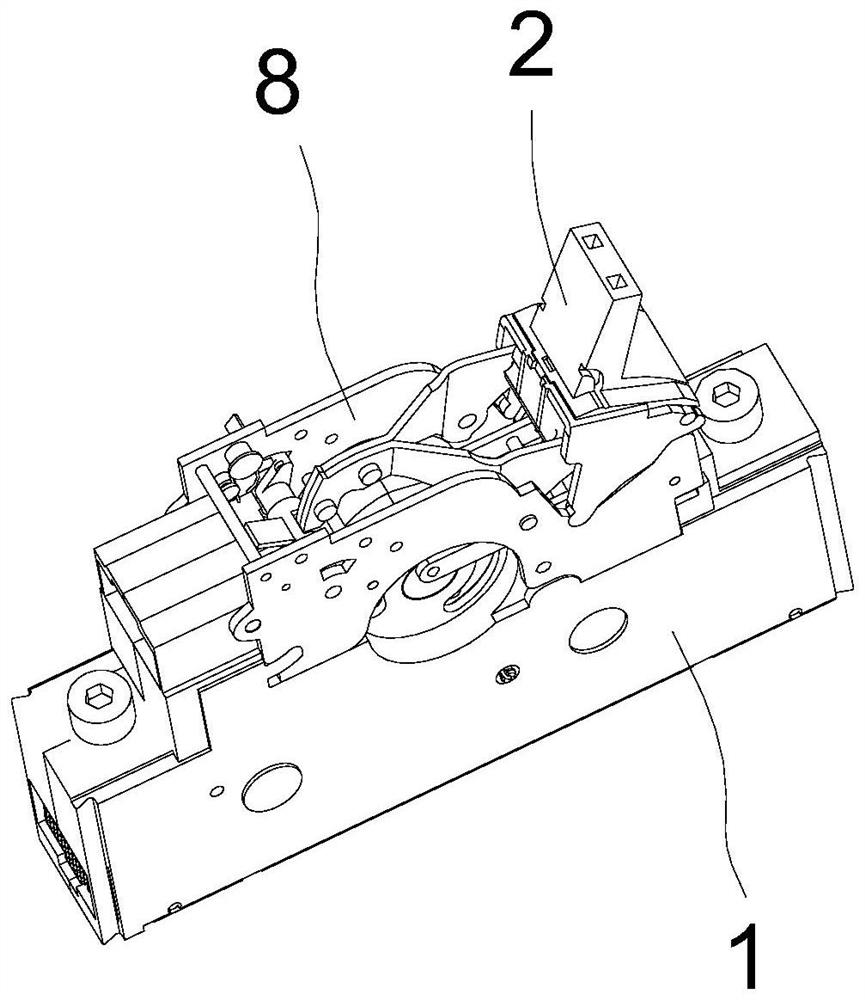

Circuit breaker

PendingCN111834161AIncrease exerciseAvoid violent collisionsHigh-tension/heavy-dress switchesAir-break switchesMechanical impactMechanical property

The invention relates to a circuit breaker, and specifically relates to an improvement of the layout structure of the circuit breaker. According to the invention, the swinging range of a moving contact is limited by a limiting mechanism by means of arranging the limiting mechanism and using elastic force for driving movement, excessive motion amount of the moving contact is prevented, violent collision between the moving contact and a static contact or other parts is avoided, overshoot generated during switching-on and switching-off is reduced, and the mechanical property is improved. When thelimiting mechanism is used for limiting, the generated impact counterforce acts on a buffer device formed by a tension spring and a connecting rod in an operating mechanism to absorb the impact energy, so that the mechanical impact on the mechanism during opening and closing is reduced, the mechanical strength is improved, the impact on a tripping piece is reduced, and the lock catch performanceis improved.

Owner:XIAMEN HONGFA ELECTRICAL SAFETY & CONTROLS CO LTD

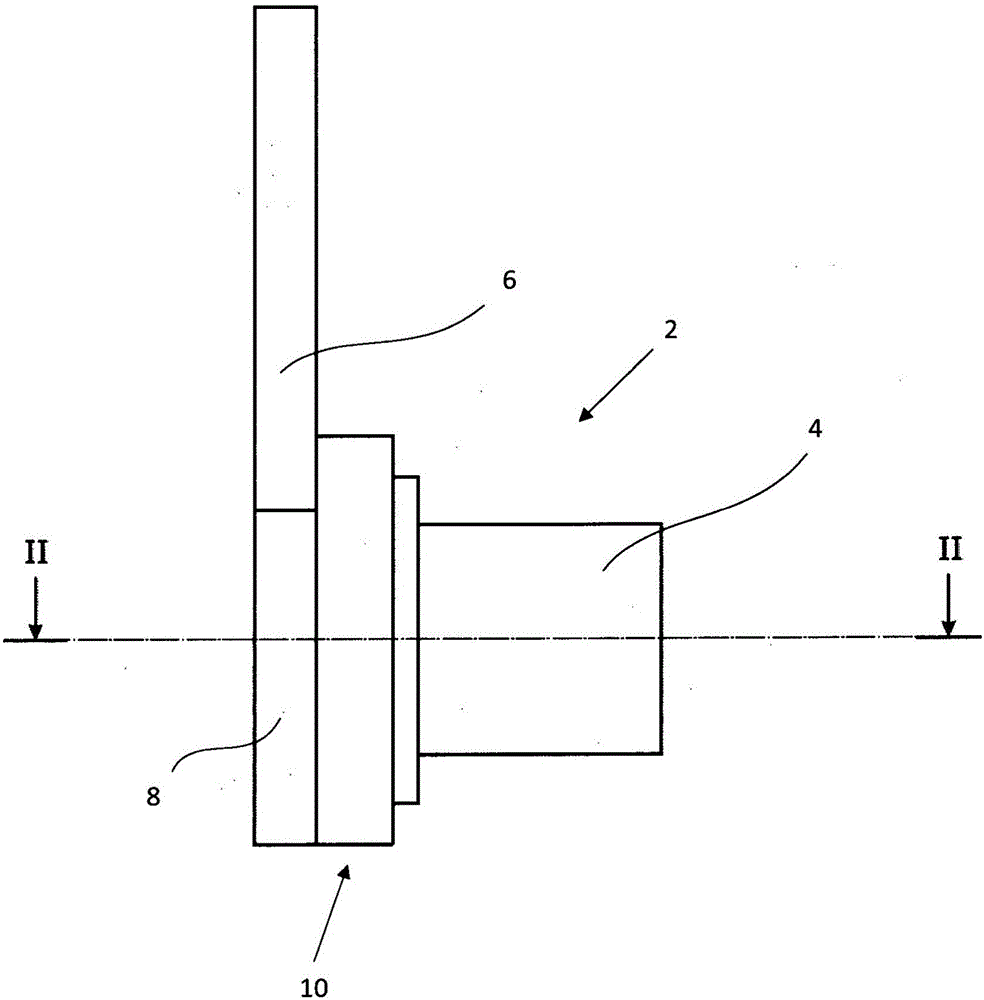

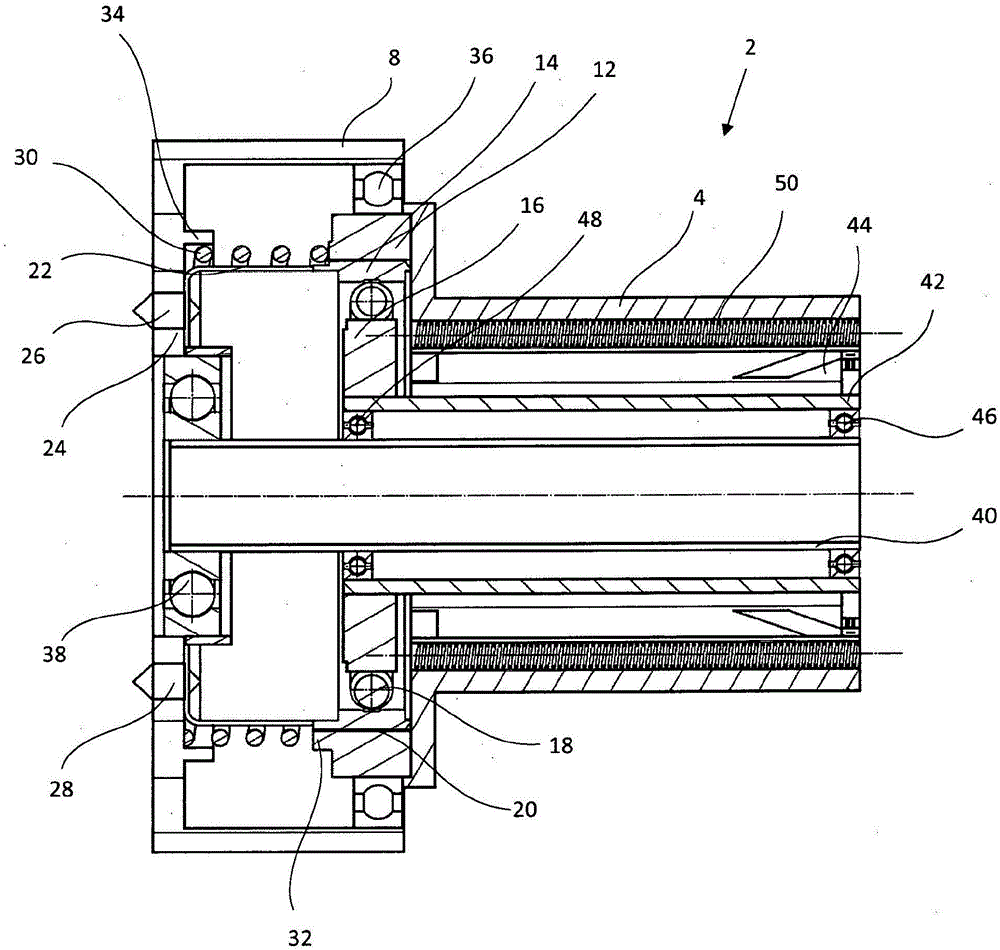

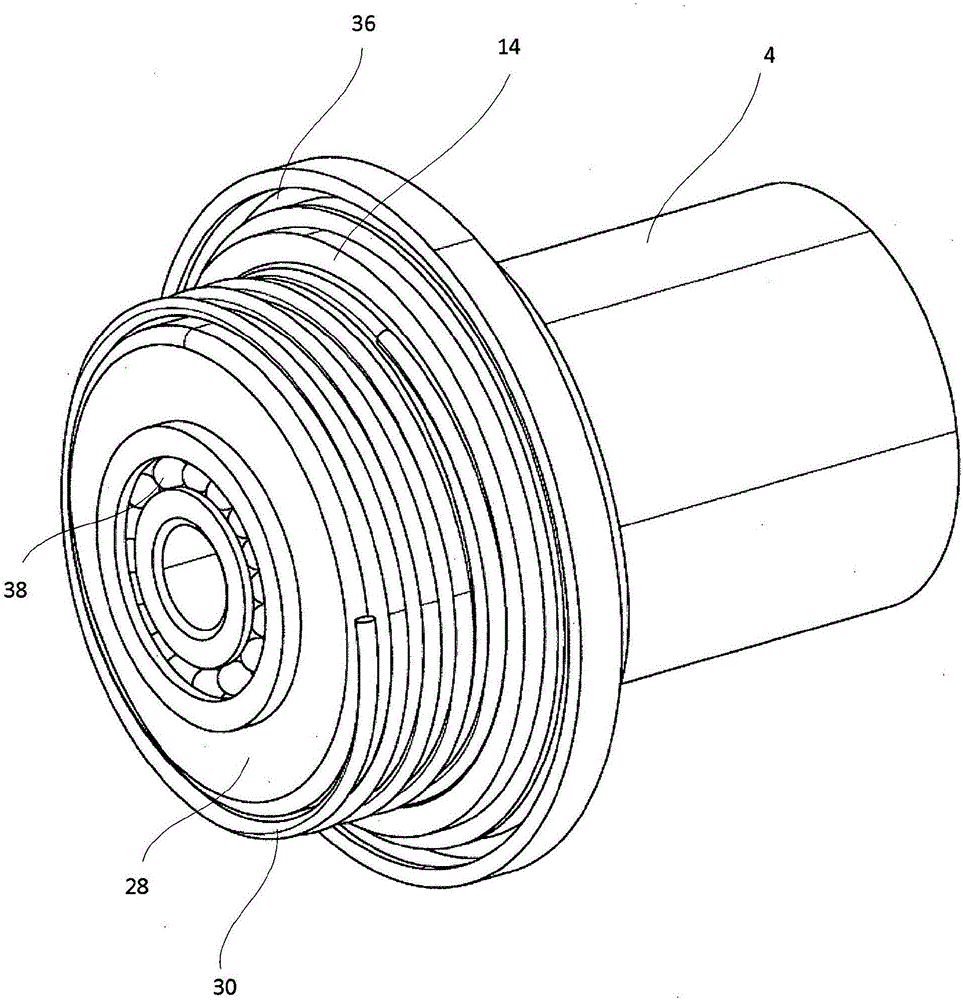

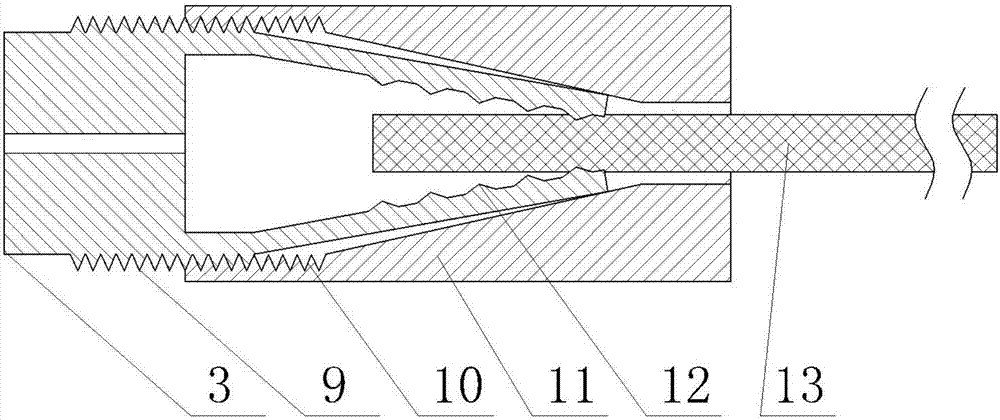

Electromechanical rotational damper with tension and compression stop

ActiveCN106062413AImprove locking abilitySmall inner diameterAuxillary drivesNon-rotating vibration suppressionHarmonicEngineering

A rotational damper (2) having a damper housing (4) which surrounds an electromagnetic damper motor and is fastened via a fastening part to a first mass, and having a coupling lever (6) which is mounted pivotably with respect to the damper housing (4) and is connected to a second mass, a strain wave gear mechanism (10) for vibration damping which has a rigid unit (12) which has an internal toothing system and is connected to the damper housing (4), and a flexible unit (14) which has an external toothing system and is connected to the fastening part. The two units of the strain wave gear mechanism (10) are coupled to one another in a positively locking manner via the toothing systems in order to transmit and / or convert a rotational movement. A wave generator is mounted rotatably in the flexible unit (14), upon the rotation of which wave generator the flexible unit is deformed. A wrap spring (30) is arranged in an operative connection with the flexible unit (14), which wrap spring (30) is connected on one side to the coupling lever (6) and on the other side to the fastening part, in each case fixedly so as to rotate with it, wherein the wrap spring (30) is designed in order to lock the strain wave gear mechanism (10) by way of deformation of the flexible unit (14) in the case of predefined pivoting of the coupling lever (6) with respect to the fastening part.

Owner:AUDI AG

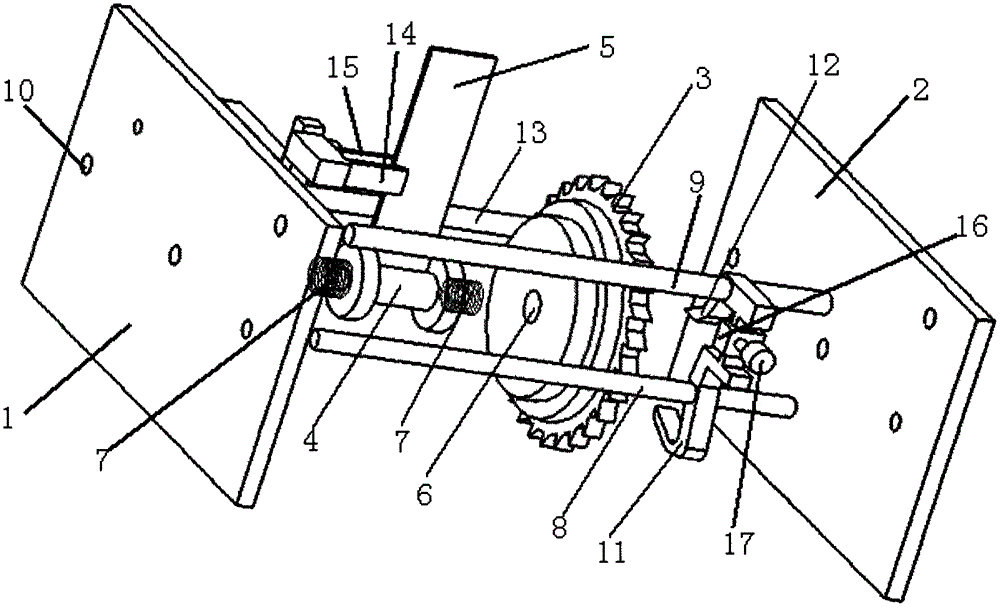

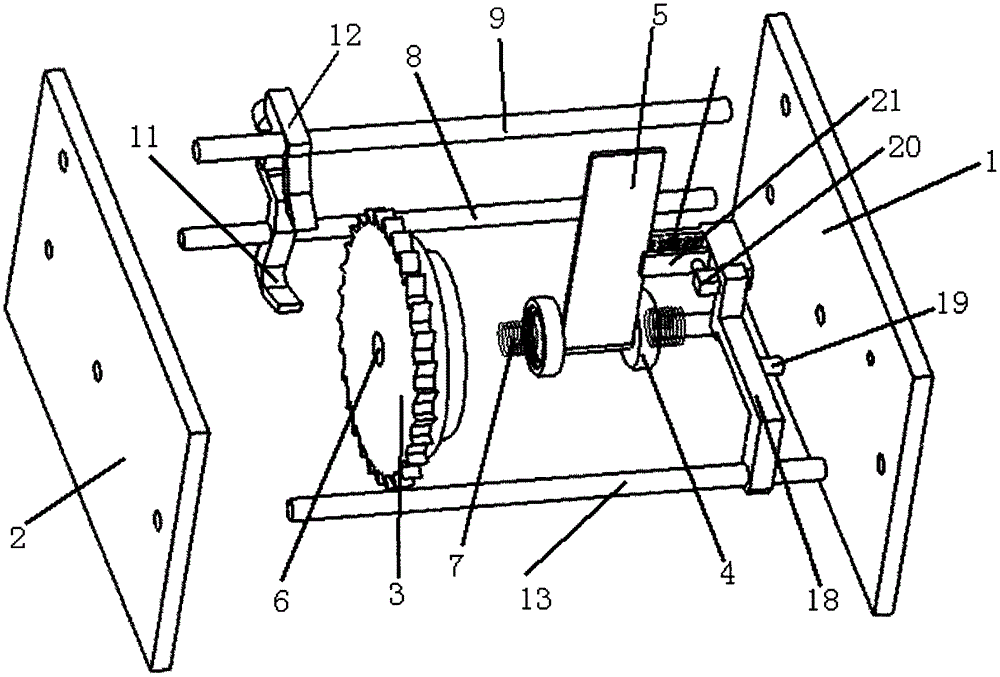

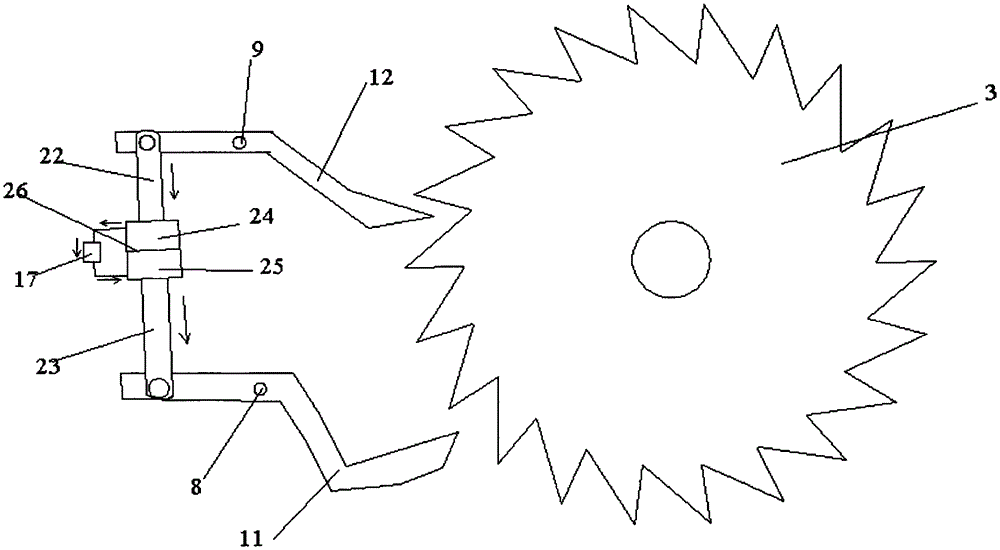

Seat belt retractor

ActiveCN105398417AImprove locking abilityImprove safety and reliabilityBelt retractorsTorsion springSeat belt

The invention provides a seat belt retractor. The seat belt retractor comprises a mounting plate I, a mounting plate II, a ratchet wheel, a scroll, a safety belt, torsion springs, a pawl I, a pawl II and a safety belt clamping device, wherein the ratchet wheel is fixedly connected with the scroll; the ratchet wheel and the scroll are mounted between the mounting plate I and the mounting plate II; the safety belt is wound on the scroll; two ends of the scroll are provided with the torsion springs; between the mounting plate I and the mounting plate II, the pawl I, the pawl II and the safety belt clamping device are arranged in a position corresponding to the ratchet wheel; and moreover, in case of emergency braking of an automobile, the pawl I and the pawl II cooperate with each other to mutually lock the rotation of the ratchet wheel; meanwhile, the safety belt clamping device clamps the safety belt. According to the invention, as the pawl I and the pawl II cooperate with each other to mutually lock the ratchet wheel and the safety belt is clamped at the same time, the locking capacity of the seat belt retractor is improved from different perspectives and the safety and reliability of the automobile during running are also improved.

Owner:江西维珂赛福航空科技有限公司

Multi-split garbage compression equipment with hydraulic motor driving transverse moving mechanism

InactiveCN104973369AReduce idle timeImprove efficiencyRefuse transferringLoading/unloadingHydraulic motorButt joint

The invention discloses multi-split garbage compression equipment with a hydraulic motor driving transverse moving mechanism. The multi-split garbage compression equipment is specifically composed of a compressor body, a hydraulic cycloid motor, compressor walking wheels, a transmission shaft, a hydraulic pump station, a garbage hopper, a compression bin, a compression head, a control electric disc, a camera, compressor walking guide rails, wagon boxes and wagon box guide rails. According to the equipment, the idle time of a compressor is greatly shortened, and the using efficiency of the equipment is improved. The transverse moving driving mechanism of the equipment has the beneficial effects that the size is small and exquisite, the structure is simple, the speed is adjustable, the output torque is large, running is stable, the noise is avoided, the equipment is resistant to aqueous cleaning, and operation is easy, convenient and safe; when the equipment is in butt joint with the wagon boxes, the precision is high; and after fuel is cut off, the hydraulic cycloid motor is high in locking capacity.

Owner:SHANDONG JINGHUA ENVIRONMENTAL SCI & TECH

Coal mine air door locking device

InactiveCN111365059AImprove locking abilityImprove shock absorptionBuilding braking devicesPower-operated mechanismHydraulic cylinderStructural engineering

The invention discloses a coal mine air door locking device, and relates to the technical field of air door locking. The coal mine air door locking device comprises a left air door, a right air door and push rods. The right air door is arranged on the right part of the left air door, and observation windows are arranged at the upper ends of the left air door and the right air door. Door lock handles are arranged at the middle inner side ends of the left air door and the right air door. Door end fixing plates are welded to the tops of the door lock handles, the push rods are arranged on the outer ends of the door end fixing plates, first hydraulic cylinders are arranged on the outer ends of the push rods, the outer ends of the first hydraulic cylinders are connected with rotating shafts, wall end fixing plates are arranged at the outer ends of the rotating shafts, a wind sensor is arranged at the bottom of the left air door, sealing plates are arranged at the tops and bottoms of the inner sides of the left air door and the right air door, a positioning groove is formed in the inner side end of the left air door, and a sealing positioning bump is arranged at the inner side end of theright air door. The opening and closing of the buffer and shock absorption are convenient, the air doors are automatically closed, the wind is intelligently detected, effective sealing and blocking can be achieved, and air leakage is prevented.

Owner:沈建廷

Pressure-bearing rotary support device for construction

The invention relates to a pressure-bearing rotary support device for construction. The pressure-bearing rotary support device for construction comprises a rotating disk, a supporting base and a clamping mechanism. The rotating disk is disposed on the supporting base, the supporting base is internally provided with a supporting component, and the clamping mechanism is disposed at the periphery ofthe supporting base. A supporting block is arranged in the supporting base, and a plurality of sliding holes are formed in the supporting block. The rotating disk is connected to the upper part of thesupporting block, the middle part of the supporting block is connected with a central ejector rod, and a supporting ejector rod is arranged in each sliding hole. The central ejector rod is in contactwith the middle part of the rotating disk, and the supporting ejector rods are in contact with the rotating disk. The supporting base comprises an annular supporting frame, and pushing holes are formed in the inner wall of the supporting frame. The clamping mechanism comprises a connecting disk, the outer edge of the connecting disk is fixedly provided with an annular fixing frame, and a plurality of clamping holes corresponding to the pushing holes are formed in the fixing frame. After being bent, the supporting ejector rods penetrate through the pushing holes, and are fixed in the clampingholes. The inner side wall of each clamping hole is connected with a clamping cam bit, the clamping cam bits are connected with swing arms, and the swing arms are connected with a driving ring, and the fixing frame is in linear drive connection with the driving ring.

Owner:张超

Locking intensification design for mechanical cylinder lock

InactiveCN1664286ASimple actionCompensation cracked rateCylinder locksEngineeringMechanical engineering

Owner:姜仁忠

Anti-corrosion drop-proof electricity stealing prevention junction box and manufacturing method therefor

InactiveCN106959383AImprove waterproof performanceImprove shielding effectElectrically conductive connectionsTime integral measurementInternal pressureElectricity

The invention relates to a corrosion-resistant, detachment-proof and anti-stealing junction box, comprising a junction box, a cover and a wiring structure; A second wiring slot matching the first wiring slot is provided; the wiring structure is a socket-type integrated junction block, and the integrated wiring socket in it faces the first wiring slot; the wiring socket includes a socket main body and a spinning structure, wherein The main body of the socket includes a guide cone, a threaded sleeve and a socket for the metal core of the wire to be inserted. There is a pressing tapered surface with pressing tines inside; a photosensitive signal element is arranged on the side of the integrated terminal block facing the casing, which includes a battery, a photoresistor and a signal transmitting device. The invention has the advantages of anti-corrosion, anti-aging, anti-loosening of connection terminals, anti-electricity stealing, anti-interference and the like.

Owner:张敬敏

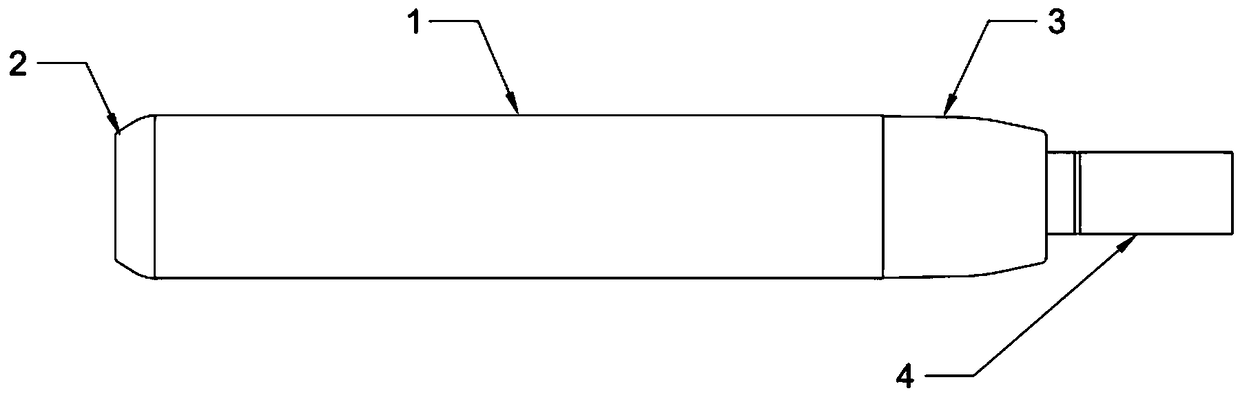

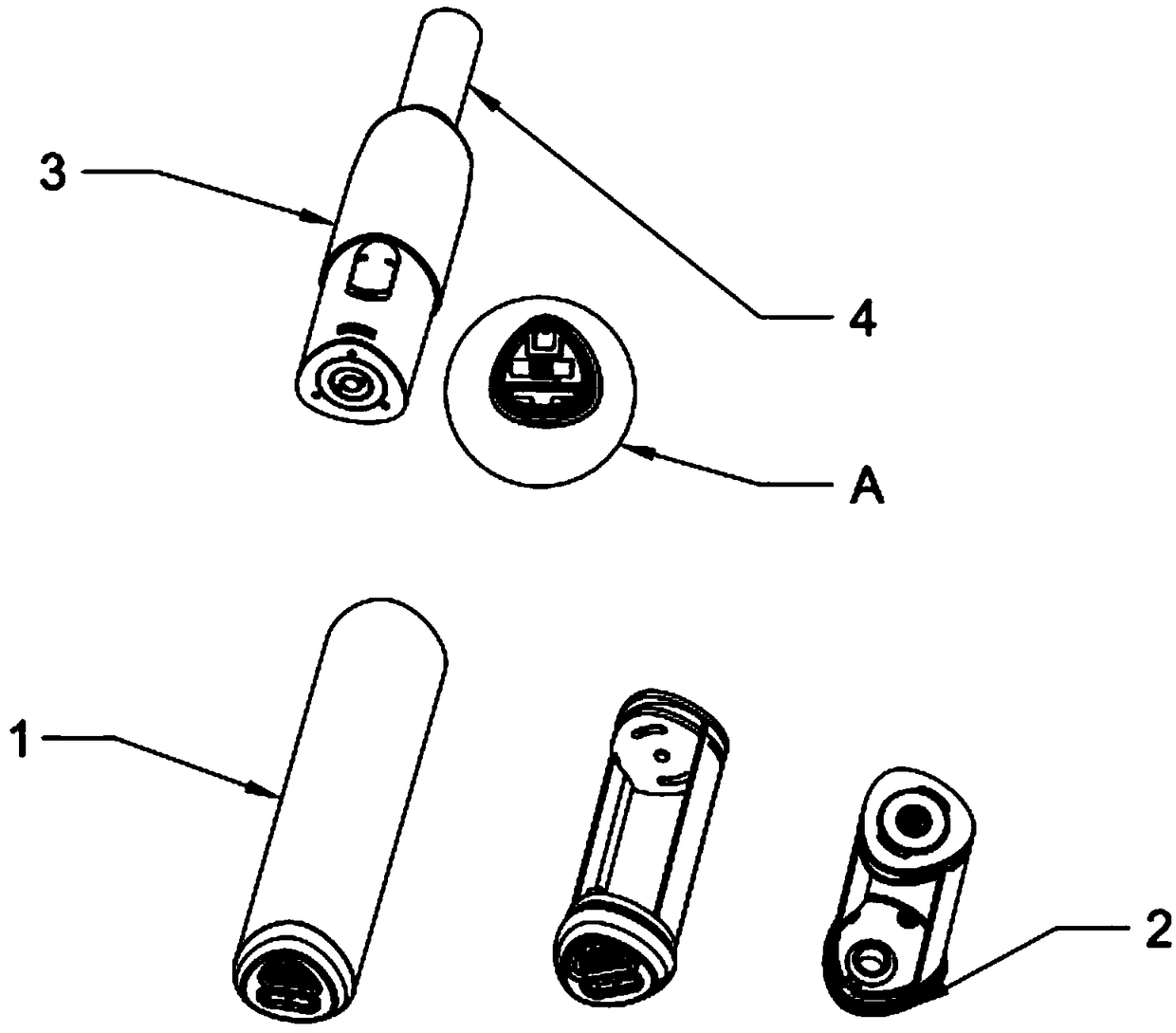

Safety electronic cigarette allowing tar recharging

PendingCN109480344AIncrease inhalationStrong absorption capacityTobacco devicesTarElectronic cigarette

The invention discloses a safety electronic cigarette allowing tar recharging, which comprises an aluminum tube. One end of the aluminum tube is provided with a battery rear cover in inserted manner;the other end of the aluminum tube is provided with a tar compartment in inserted manner; the other end of the tar compartment is provided with a filter tip in inserted manner; a microphone, microphone silica gel, a battery, a battery head, magnet I, iron shell I, iron shell II, magnet II and a tar compartment bottom cover are arranged in the aluminum tube sequentially from the battery rear coverto the tar compartment; a PCBA (printed circuit board assembly) is arranged on the lateral side of the microphone silica gel and is fixed to the battery rear cover through screws; a spring electrode is arranged in the middle of the battery head; a cartridge positive electrode is arranged in the middle of the tar compartment bottom cover; the spring electrode is in inserted connection with the cartridge positive electrode; a silica gel nebulizing chamber, a nebulizing chamber upper cover and tar-sealing silica gel are arranged sequentially from the tar compartment bottom cover to a cylindricalhollow duct in the tar compartment; a heating wire is arranged in the silica gel nebulizing chamber and is provided with a cotton stick. The safety electronic cigarette has the advantages of simple structure, prevention of tar splashing, prevention of inhaling tar and condensate, rechargeability of tar and the like.

Owner:深圳前海呼吸科技有限公司

Drop-proof electricity stealing prevention junction box

InactiveCN106961026AMake up for the lossImprove waterproof performanceElectrically conductive connectionsTime integral measurementElectricityPhotoresistor

The invention relates to an anti-detachment and anti-stealing junction box, comprising a junction box, a casing and a wiring structure; a first wiring slot is arranged on the bottom of the junction box, and a second wiring slot is arranged on the casing; the wiring structure is a socket type The integrated wiring block has an integrated wiring socket facing the first wiring slot; the top surface of the integrated wiring block is provided with a photosensitive signal element, which includes a battery, a photoresistor and a signal emitting device; the wiring socket includes a guide cone surface, a thread The sleeve and the main body of the socket for the wire metal core to be inserted are provided with a tapered surface and a spinning structure that matches with the threaded sleeve to tighten the thread. A pressing cone with pressing tines is arranged inside; the junction box and the cover are provided with corresponding snap structures. The invention has the advantages of waterproof, anti-dropping of connecting terminals, prevention of electricity stealing, and high reliability.

Owner:张敬敏

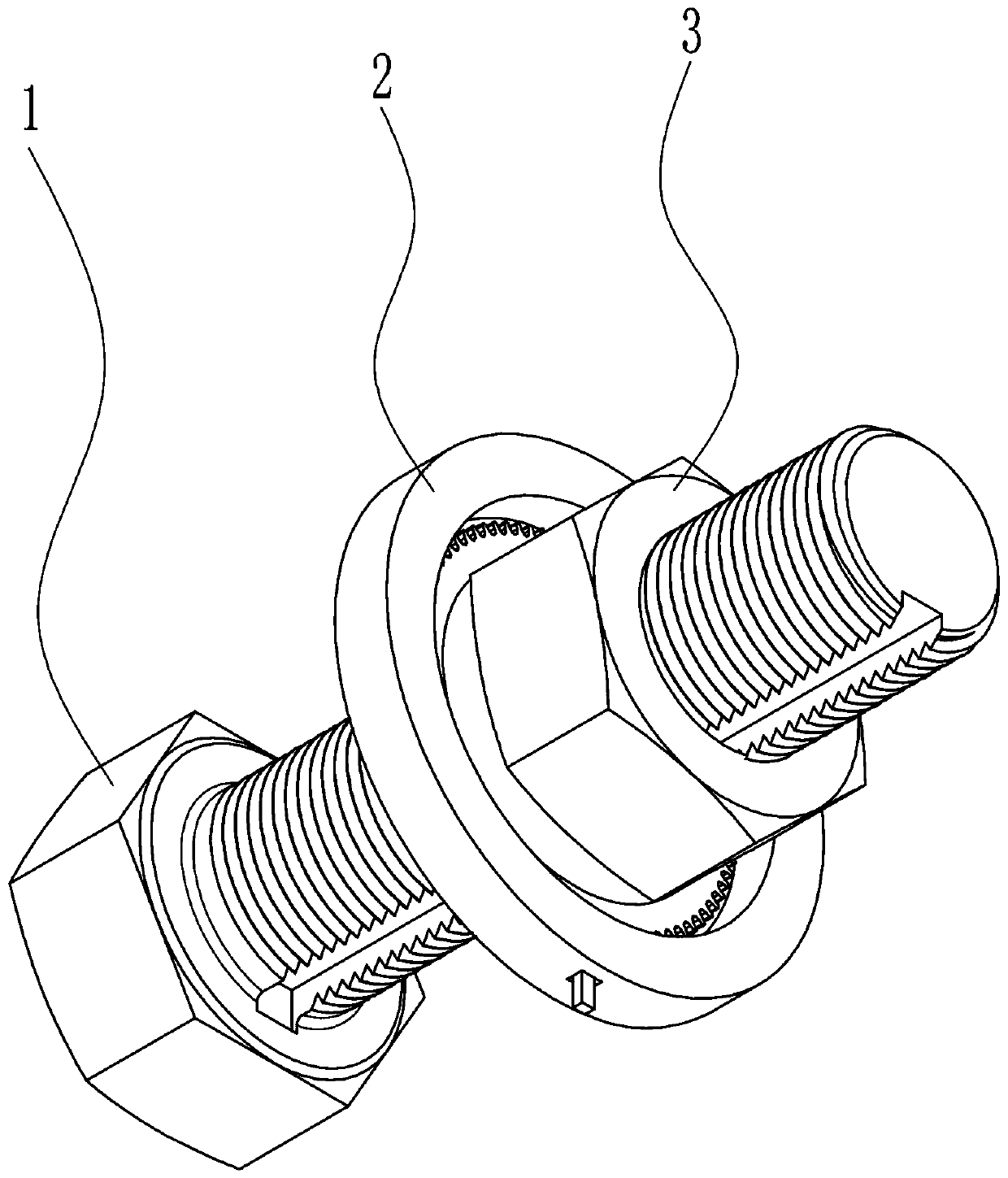

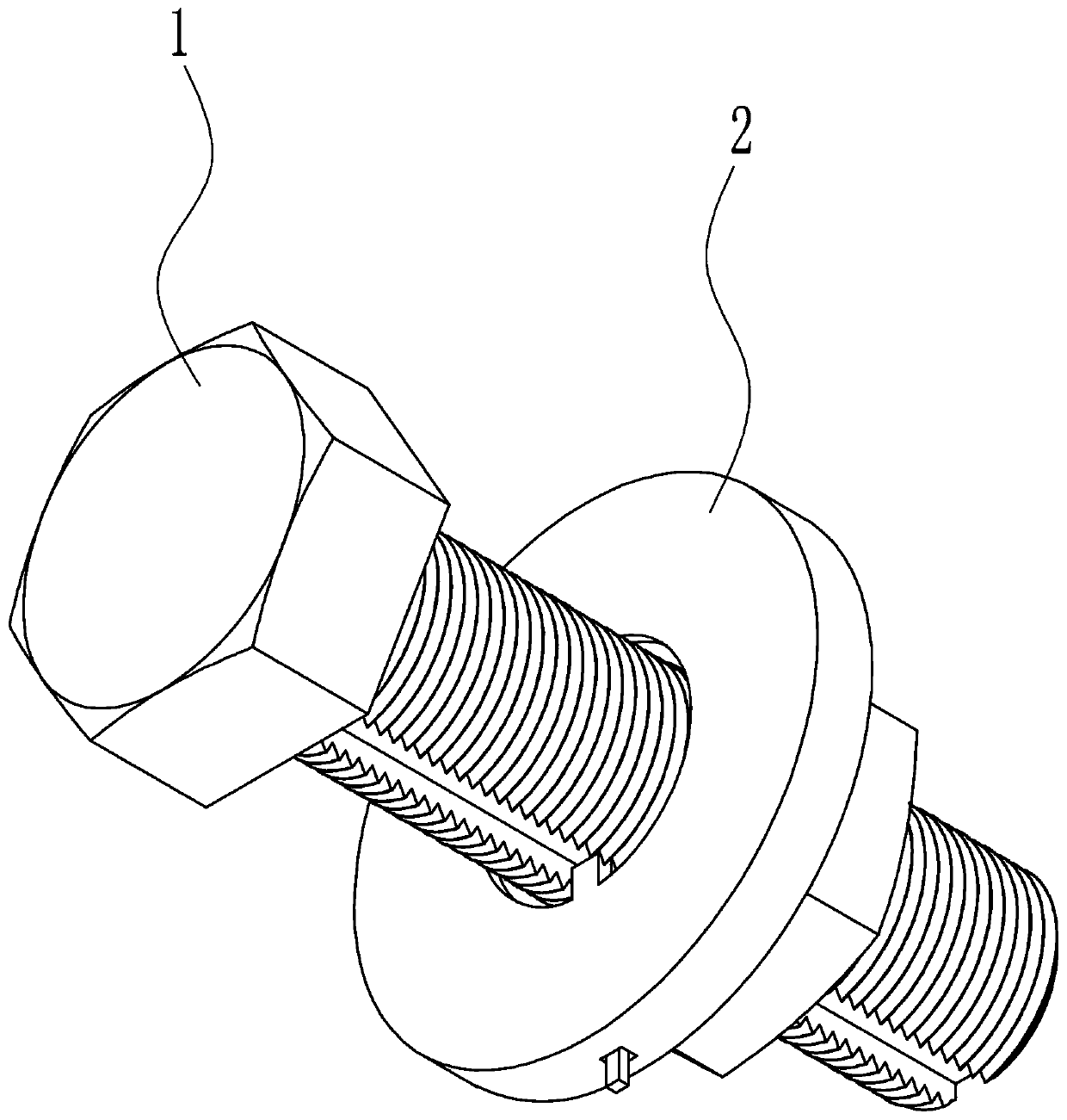

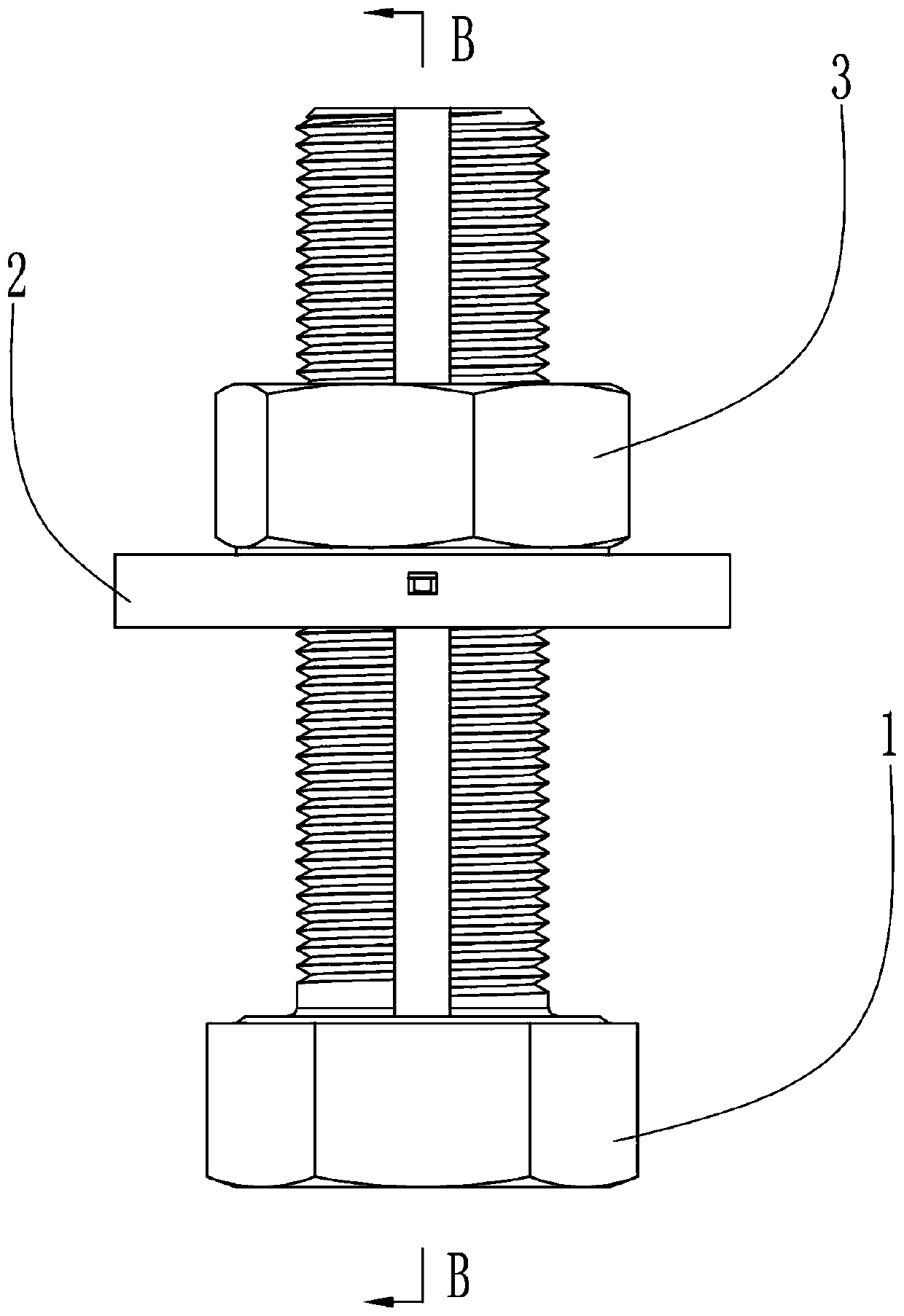

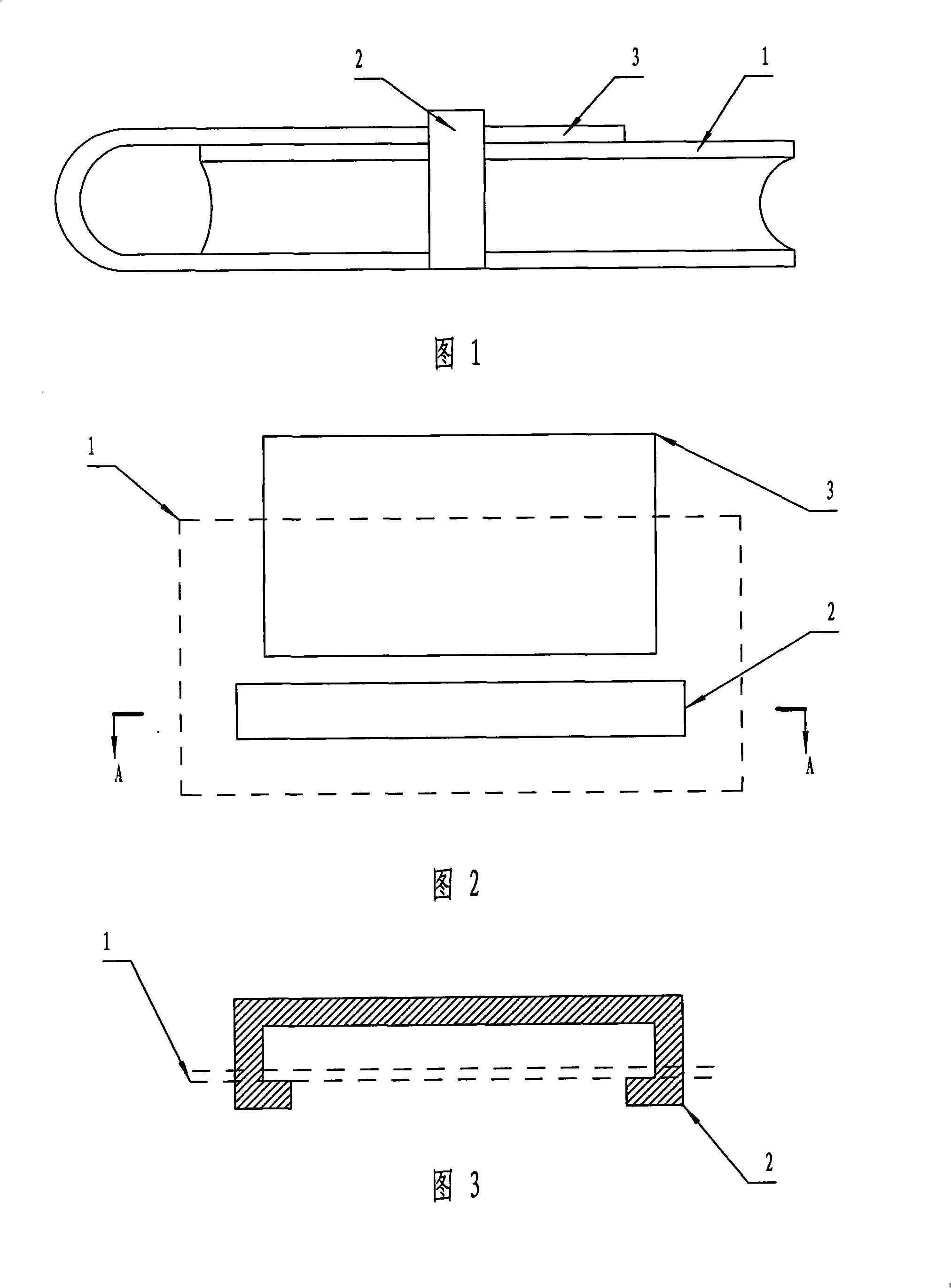

Check bolt assembly

The invention discloses a check bolt assembly. The check bolt assembly is aimed at solving the technical problem that when certain vibration happens, the connection structure between connecting objects which is formed by existing nuts and bolts easily looses. The check bolt assembly comprises a locking bolt, a locking gasket and a locking nut, wherein the locking bolt is in threaded connection with the locking nut; the locking gasket is arranged between the locking bolt and the locking nut; the locking nut is fit to the locking gasket; a locking groove is vertically formed in a threaded rod part of the locking bolt in a through manner; locking teeth II for positioning and locking are arranged at the bottom of the locking nut; an inner ring of the locking gasket is provided with a locking bulge which is matched with the locking groove and can slide vertically in the locking groove; and a bulge wall is arranged on the outer edge part of the locking gasket. According to the technical scheme, the effective locking of the nut and bolt fastening connection structure is realized, and the stable and safe operation of the connection structure and even the entire device is ensured; and meanwhile, the requirement on the production precision is low, and the processing is convenient and simple.

Owner:张小春

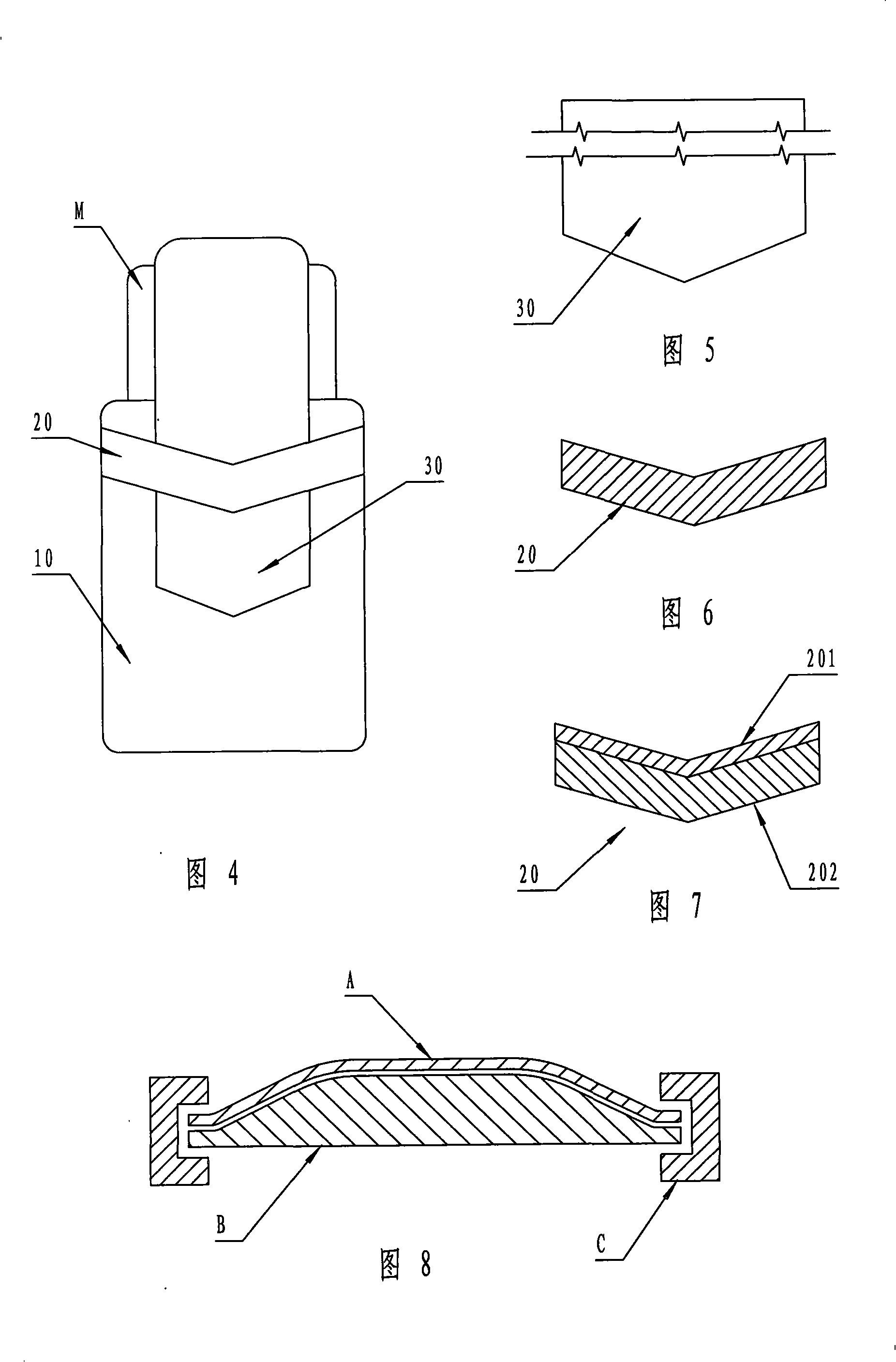

Leather button structure of packaging piece and decoration

InactiveCN101292803AIncrease appreciation interestAccurate and fast insertion actionOther accessoriesBucklesBusiness cardEngineering

The invention discloses a leather button structure with easy piercing, firm locking and artistic appearance, of package and decoration articles. The leather button structure of the invention comprises a package article and a decoration article body and a piercing ring and a tongue fixed on the body, wherein, the front view of the piercing ring is V-shaped and the front views of two edge lines at the utmost front end of the tongue are also V-shaped; the V-shaped inner included angle of the piercing ring is larger than that of the tongue and is an obtuse angle; the front view of the piercing ring shows a straight line in the middle of the ring and both ends of the straight line are respectively connected with a curve in a flat and transition way and the other end of two curves is connected with the package article body or the decoration article body. In addition, the piercing ring is made from a single block of sheet stock and otherwise two blocks of sheet material and the side faces of adjacent sheet materials are combined and bonded under a heating condition to form an integrated body. The leather button structure of the invention is mainly applied to high-grade package articles and decoration articles such as cell phone leather cases, business card holders.

Owner:缪利群

twist car

InactiveCN103231762BDoes not affect development and growthSave materialCyclesCycle brakesControl engineeringTorsion spring

The invention discloses a novel twist car which comprises a main frame assembly, a front connecting pipe and a swing assembly connected in sequence, wherein the main frame assembly comprises a rear wheel pipe with two moving wheels mounted at the two ends and a main frame pipe with one end fixed to the middle of the rear wheel pipe; a T-shaped structure formed by the rear wheel pipe and the main frame pipe is provided with a seat cushion and a backrest cushion; the swing assembly comprises a pedal pipe and a swing pipe with one end fixed to the middle of the pedal pipe and a guide wheel mounted at the other end; one end of the front connecting pipe is rotationally fixed with a socket pipe; the other end of the front connecting pipe is fixedly connected with the corresponding end part of the main frame pipe; each moving wheel is provided with a moving return mechanism; the moving return mechanism comprises a fixing seat which is fixed to the end part of the rear wheel pipe and is of a C-shaped structure, a rotating pipe rotationally fixed in a groove in the fixing seat through a positioning shaft and a bearing, and a swing arm with one end fixed to the side part of the rotating pipe; a moving wheel is mounted at the other end of the swing arm; and the positioning shaft is also sheathed with a torsion spring capable of driving the rotating pipe to return. The novel twist car is simple and reliable in structure, flexible in operation and comfortable for the seat.

Owner:KUNSHAN JIAN XIANG WEI MECHANICAL TECH

Fabricated building wall and mounting method thereof

InactiveCN111945924AReduce the difficulty of transportationGuaranteed tightnessWallsStructural deformationArchitectural engineering

The invention relates to a fabricated building wall and a mounting method thereof. The fabricated building wall comprises a fixed base, a fixed wall unit, an assembled wall unit and a supporting unit,wherein the fixed wall unit is arranged at the upper end of the fixed base, the upper end of the fixed wall unit is connected with the assembled wall unit through a hinge, and the supporting unit isplaced in the fixed wall unit. According to the wall and the method, the problems that according to an existing fabricated building wall, the structure is often fixedly formed, and the structural deformation is difficult to conduct, so that a large-capacity carriage is needed for transportation in the transportation process; and when the existing fabricated building wall is arranged on the ground,the existing fabricated building wall is usually fixedly arranged on the ground by means of the cohesiveness of cement and mortar, and the building wall is usually damaged after being disassembled sothat the building wall cannot be repeatedly used in the later period, and resource saving is not facilitated.

Owner:严玉春

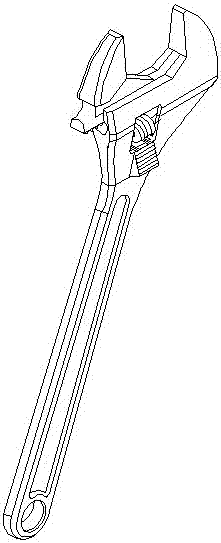

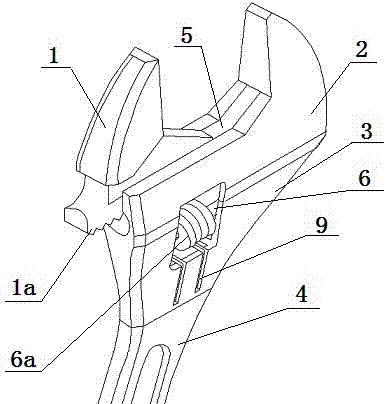

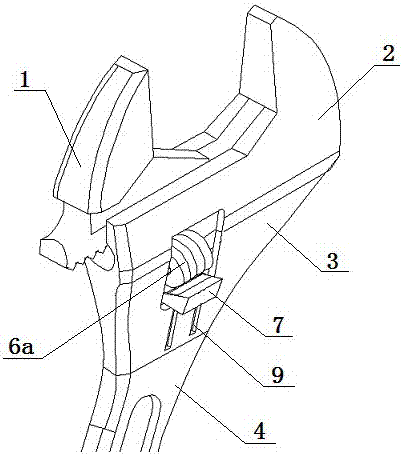

Locking type monkey spanner

The invention relates to a locking wrench used for assembling and disassembling electrical equipment in a power system, which includes a wrench body, a movable wrench and a locking device. , the upper end surface of the connecting neck is provided with a concave chute, the side of the connecting neck is provided with an insertion hole, and a worm is arranged in the insertion hole, the lower end surface of the movable wrench is provided with a slide bar with teeth, and the movable wrench The mouth is embedded in the concave chute of the neck through the sliding rod with teeth, and the teeth and the worm mesh with each other; the locking device includes a pad, and an angle α is formed between the top surface and the bottom surface of the pad, and the pad The two sides of the bottom surface of the block are respectively provided with supporting legs, and the other end of the supporting legs is respectively provided with a slider, and the neck is also provided with two tracks matched with the sliders, and the tracks on the neck are arranged along the neck. The side of the upper part extends upwards to the insertion hole, the track extends to the edge of the insertion hole, and the other side vertically extends to the bottom surface of the insertion hole, and the slider is embedded in the track.

Owner:WEIHAI WENDENG POWER SUPPLY CO OF STATE GRID SHANDONG ELECTRIC POWER CO

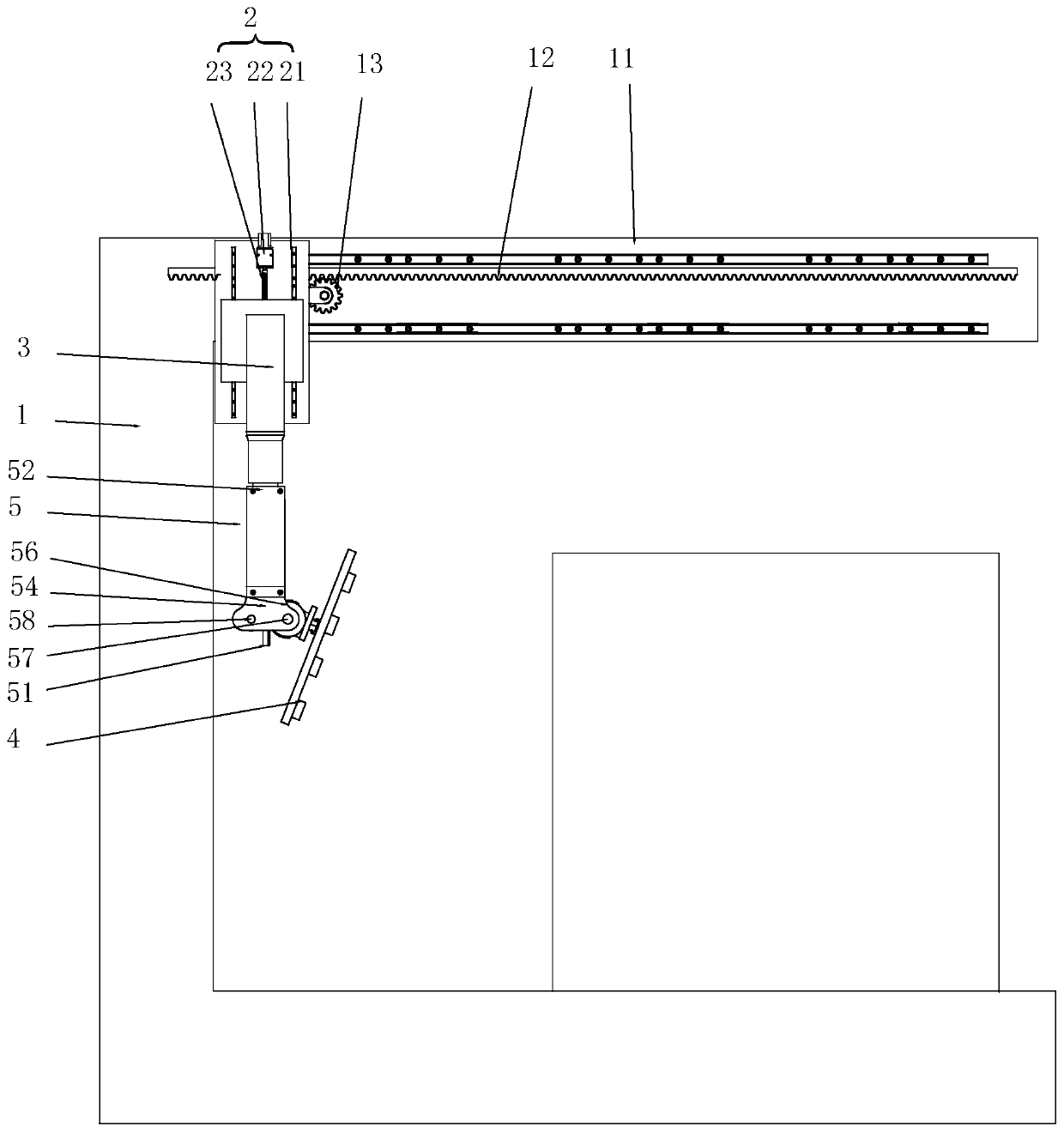

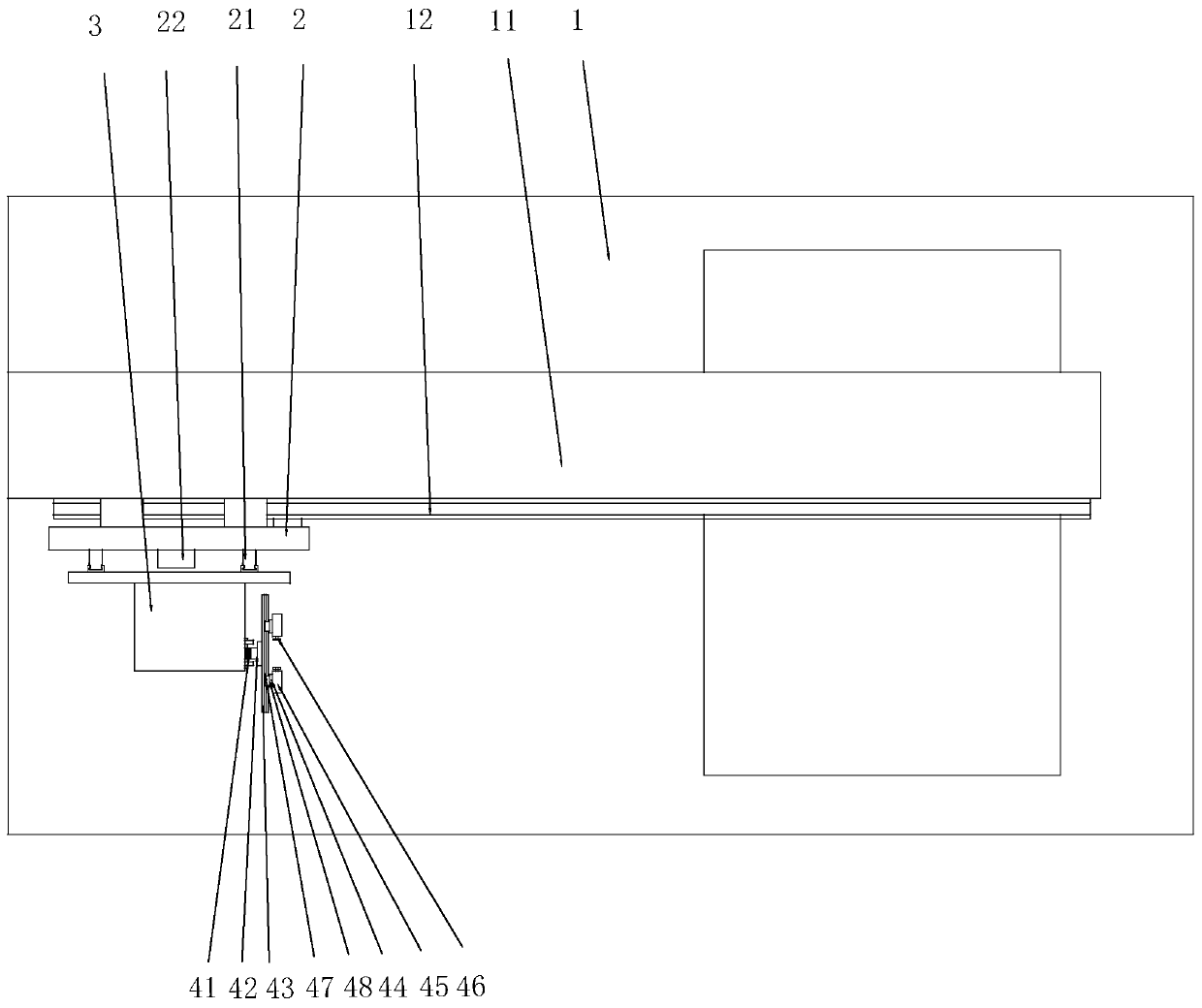

Charging head shell injection molding machine discharge mechanism

The invention discloses a charging head shell injection molding machine discharge mechanism. The injection molding machine discharge mechanism comprises a rack, a sliding seat slidably arranged on therack, a rotary arm liftably arranged on the sliding seat and a turnover clamping frame used for clamping a workpiece. The turnover clamping frame is rotatably arranged at the tail end of the rotary arm. An angle adjusting mechanism used for adjusting the turnover angle of the turnover clamping frame is arranged on the rotary arm. According to the injection molding machine discharge mechanism, thesliding seat and the liftable rotary arm constitute a manipulator with the three-axis function; the turnover clamping frame can turn over relative to the rotary arm so that the whole turnover clamping frame can adapt to different space angles of material taking angles, and the adaptability of a whole material taking mechanism is improved. In order to lock the angle of the turnover clamping anglebetter, the charging head shell injection molding machine discharge mechanism adjusts and locks the angle of the whole turnover clamping frame through cooperation of a toothed bar and an arc-shaped toothed plate.

Owner:广东力德诺电子科技有限公司

Methods of reducing biofilm and/or planktonic contamination

PendingUS20210053093A1Improve hygieneReduce exposureLayered productsCleaning equipmentBiofilmPlankton

A method of reducing biofilm and / or planktonic contamination from a surface using a fibrous structure, the method comprising the steps of:i) applying water to the surface or to the fibrous structure; andii) wiping the surface with the fibrous structure; and wherein the fibrous structure is:a) a two-dimensional fibrous structure comprising a core and a scrim wherein the core is more hydrophilic than the scrim; orb) a three-dimensional fibrous structure comprising a sheet and a gather strip element joined to the sheet, the gather strip element comprising plural superimposed layers folded upon one another, a plurality of said layers having strips extending outwardly.

Owner:THE PROCTER & GAMBLE COMPANY

Locking device for high and low voltage switchgear

PendingCN109801800ASimple structureReduce manufacturing costElectric switchesHigh volume manufacturingLow voltage

The invention discloses a locking device for a high and low voltage switchgear, comprising a main body, an insulating sealing gasket and a second hydraulic rod, wherein one side of the main body is fixedly welded with a limiting plate; the upper end of the inner wall of the main body is fixedly welded with a first hydraulic rod; the lower end of the first hydraulic rod is connected with a first telescopic rod through a key; the lower end of the first telescopic rod is provided with a disassembling assembly; the insulating sealing gasket is adhesively fixed to the outer side of the first hydraulic rod; the second hydraulic rod is fixedly welded on the bottom part of the inner wall of the main body; and the upper end of the second hydraulic rod is connected with a second telescopic rod through a key. According to the locking device for the high and low voltage switchgear, the structure is simpler, the locking performance can be realized through a simple mechanical structure, the production cost is lower, mass production and use are facilitated, and when maintenance is needed, part replacement can be directly carried out in the locking device through the disassembling structure, and when the switchgear is used normally, the locking device can be ejected through a reset structure, and more time and labor are saved in operation and use.

Owner:江苏宏强电气集团有限公司

Leather button structure of packaging piece and decoration

InactiveCN101292803BIncrease appreciation interestAccurate and fast insertion actionOther accessoriesBucklesEngineeringBiomedical engineering

A leather button structure for a package or a decoration includes a package or decoration body, and a piercing ring and a tongue fixed on the body, which is characterized in that the front view of the piercing ring is V-shaped and the front view of the utmost front end of the tongue is also V-shaped; the V-shaped inner included angle of the piercing ring is larger than that of the tongue and is an obtuse angle; the longitudinal section shape of the piercing ring is a curved surface shape with the middle high and two sides low, the middle part is a straight line with two ends respectively smoothly and transitionally connected to a segment of curve, the other ends of the two curves are connected to the package or the decoration, the piercing ring is shaped by at least two sheet materials, and the side faces of the adjacent sheet materials are spliced into a whole through heat bonding. The leather button structure of the invention has strong locking capacity. The V-shaped leather piercing button makes the package or the decoration more beautiful, especially the V-shaped tongue and the piercing ring made of two sheet materials with different color are brighter.

Owner:缪利群

A kind of preparation method of lead frame with rough side wall

ActiveCN112133640BImprove bindingImprove air tightnessSemiconductor/solid-state device detailsSolid-state devicesDevice materialStructural engineering

Owner:NINGBO KANGQIANG ELECTRONICS CO LTD

A top bolt drilling rig and a top bolt drilling rig comprising the same

ActiveCN105443037BImprove locking abilityMechanizationDerricks/mastsAnchoring boltsRock boltCarriage

The invention discloses an anchor rod jacking mechanism which comprises a fixing mechanism, a supporting mechanism, a sliding block and a drill box mechanism. The fixing mechanism comprises a base, a stand plate and a connecting seat. Protrusions for fixing guide blocks are arranged on the stand plate. The supporting mechanism and the sliding block are in sliding connection with the opposite side faces of the stand plate through the guide blocks respectively. One end of the supporting mechanism and one end of the slide block are connected with base through telescopic oil cylinders. The drill box mechanism comprises a bottom frame and two independent drill box sliding seats. The bottom frame is connected with the base, and the drill box sliding seats can horizontally move along the bottom frame. When the drill box sliding seats move to the sliding block, the drill box sliding seats can be connected with the other guide rail face of the sliding block and slide along the sliding block. The invention further discloses an anchor rod jacking drilling carriage with a drilling machine. The anchor rod jacking drilling carriage comprises a four-wall anchor rod jacking drilling carriage body and a six-arm anchor rod jacking drilling carriage body. The drilling machine in the anchor rod jacking drilling carriage can work at the same time. Fast supporting operation on a top plate can be achieved, the structure is compact, and multiple functions are achieved. The anchor rod jacking mechanism and the anchor rod jacking drilling carriage operate in cooperation with heading equipment to complete the supporting and transferring function synchronously, operating personnel are greatly reduced, the labor intensity is lowered, and the supporting efficiency and safety are improved.

Owner:LANG FANG JING LONG GRAND IND MACHINERY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com