Patents

Literature

36results about How to "Stable drilling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

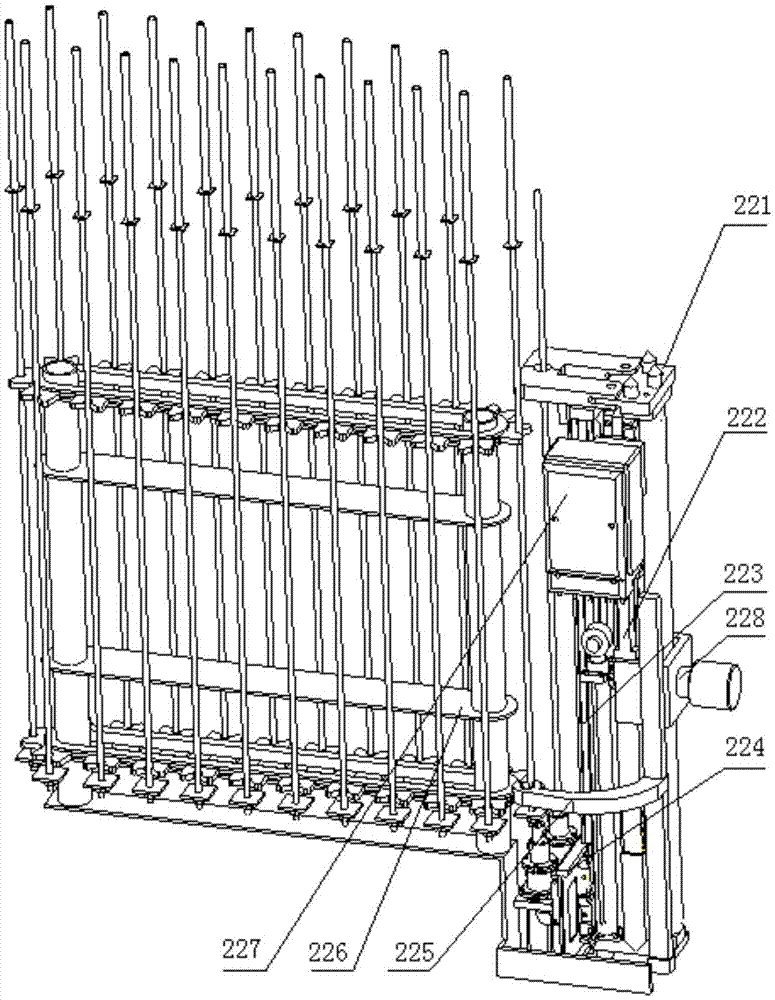

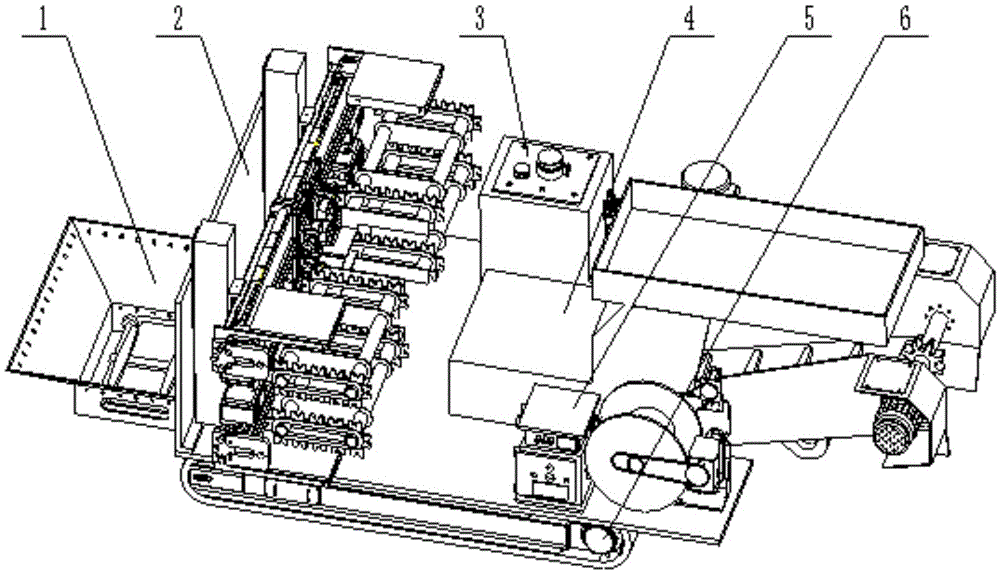

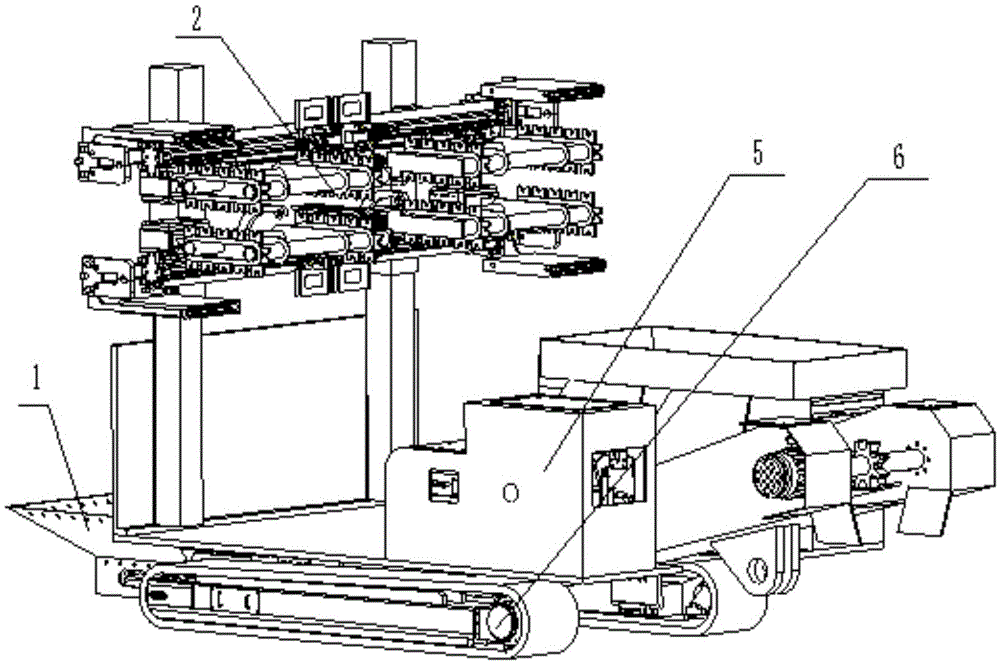

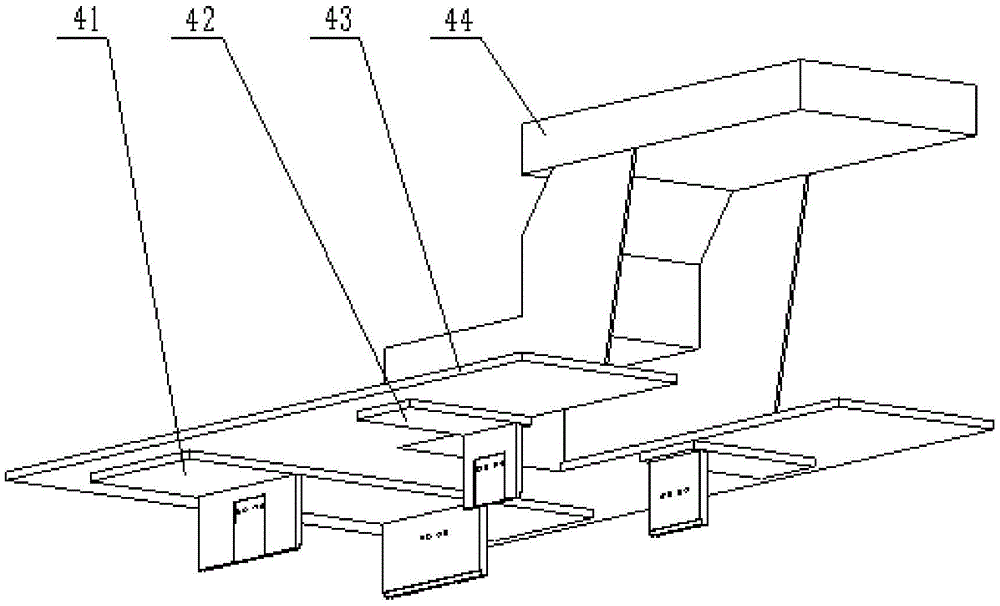

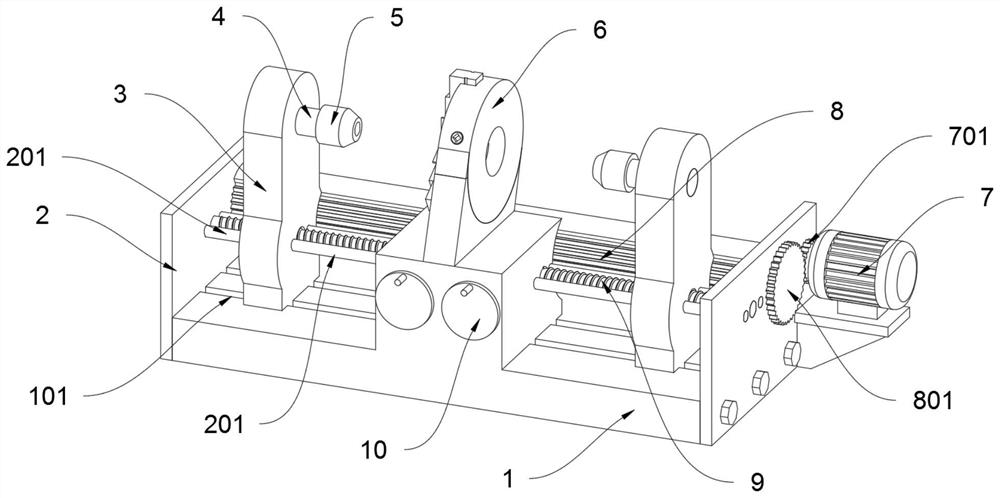

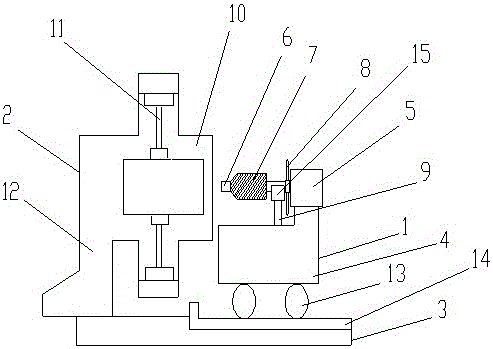

Anchor rod jacking drilling machine and anchor rod jacking drilling carriage with same

ActiveCN105443037AImprove locking abilityMechanizationDerricks/mastsAnchoring boltsUltimate tensile strengthTransferring (function)

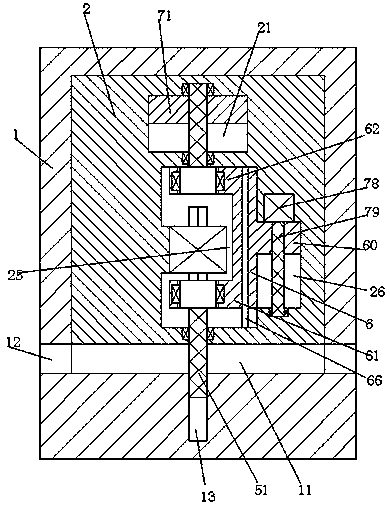

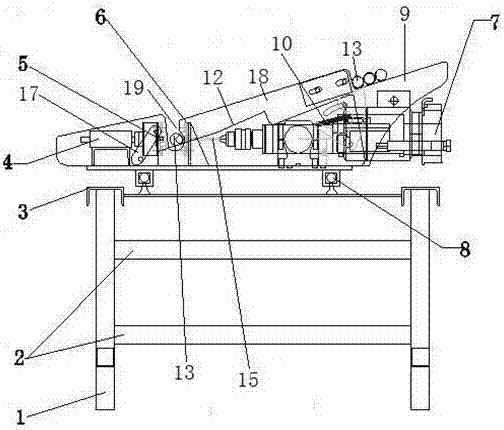

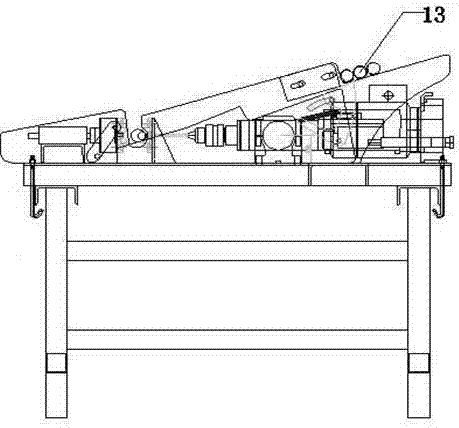

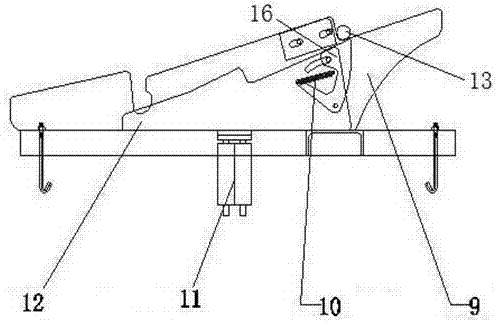

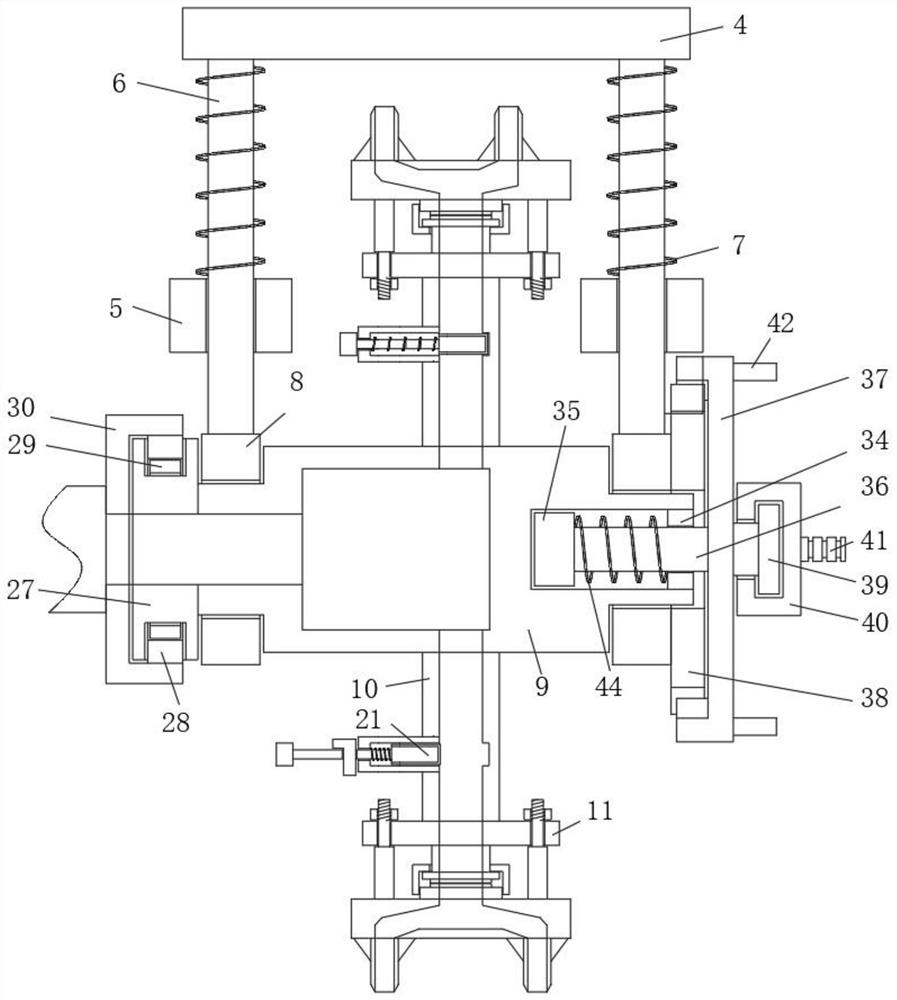

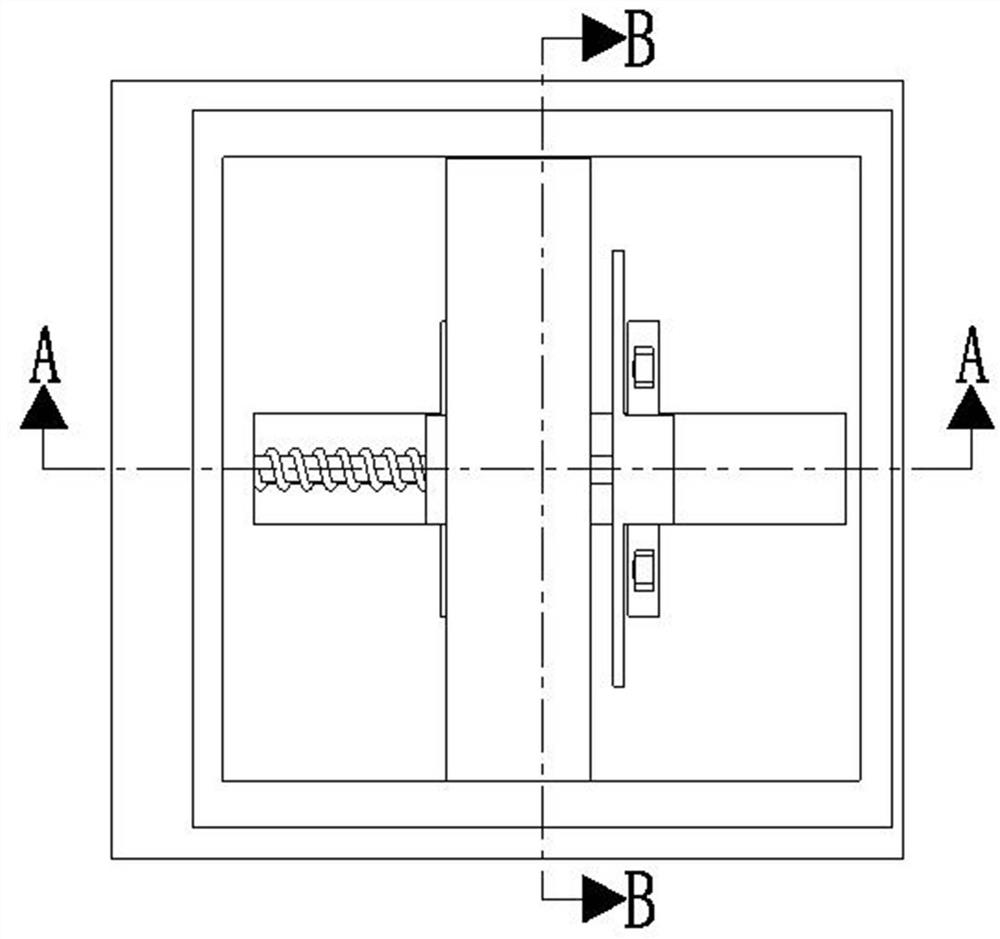

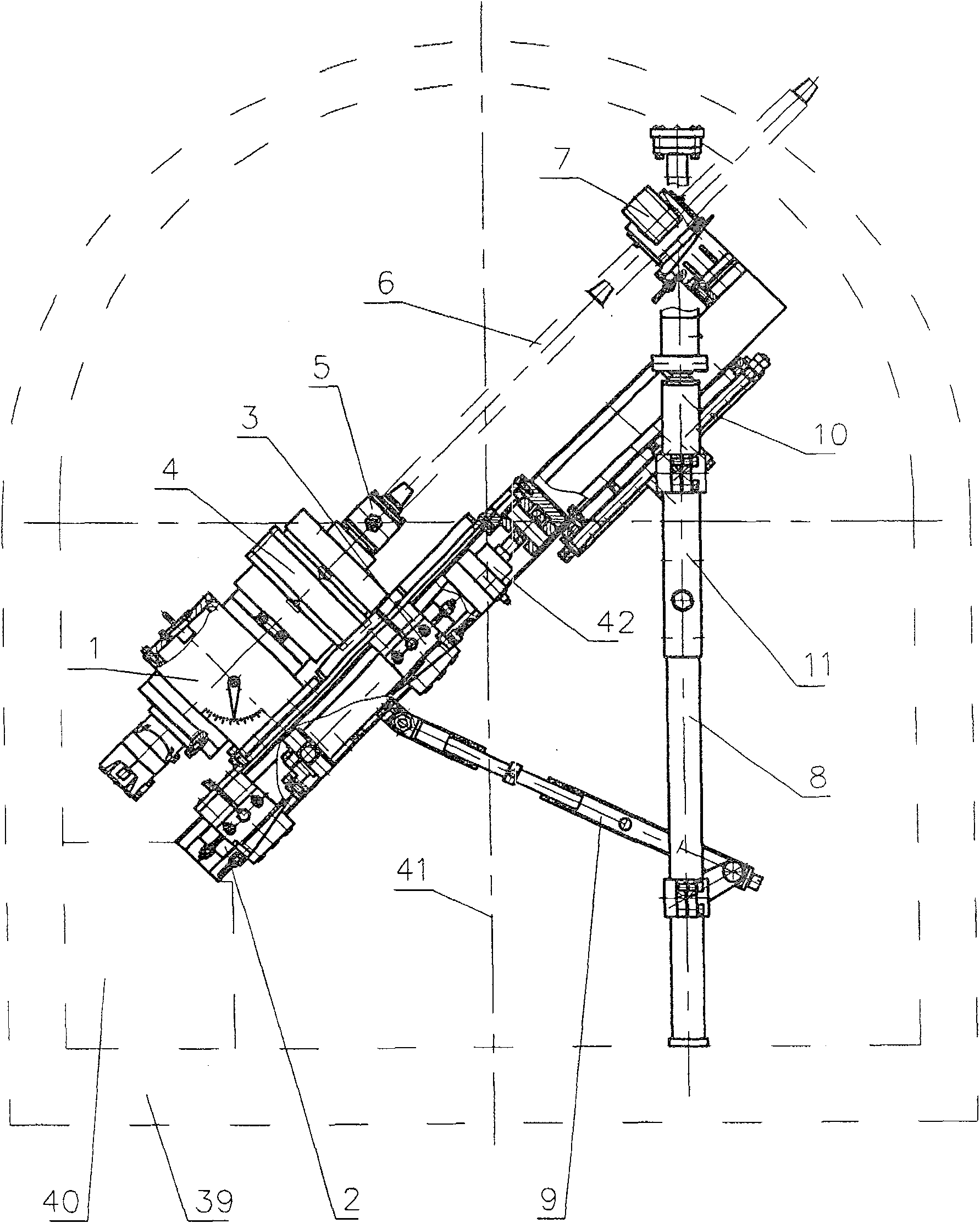

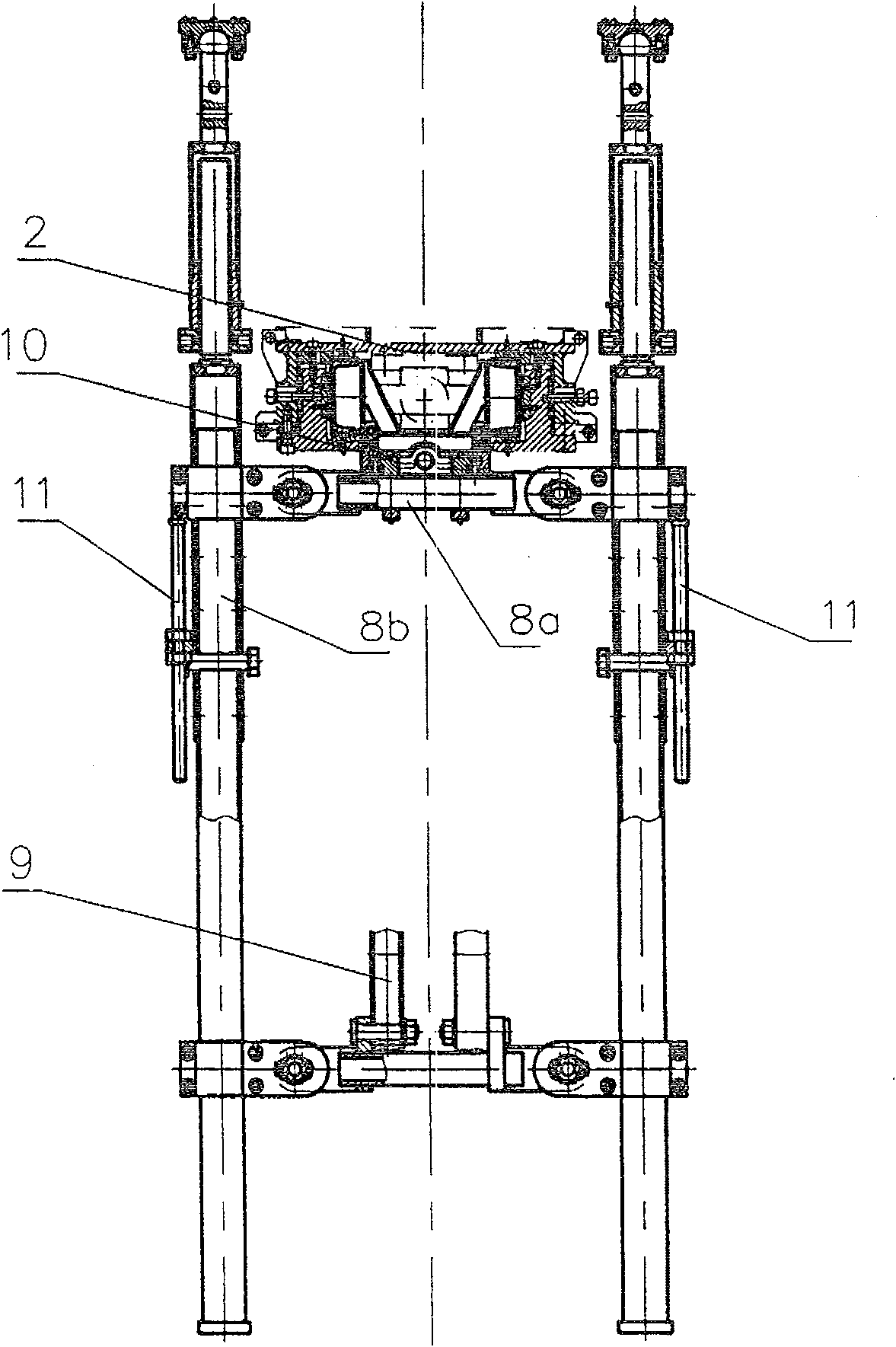

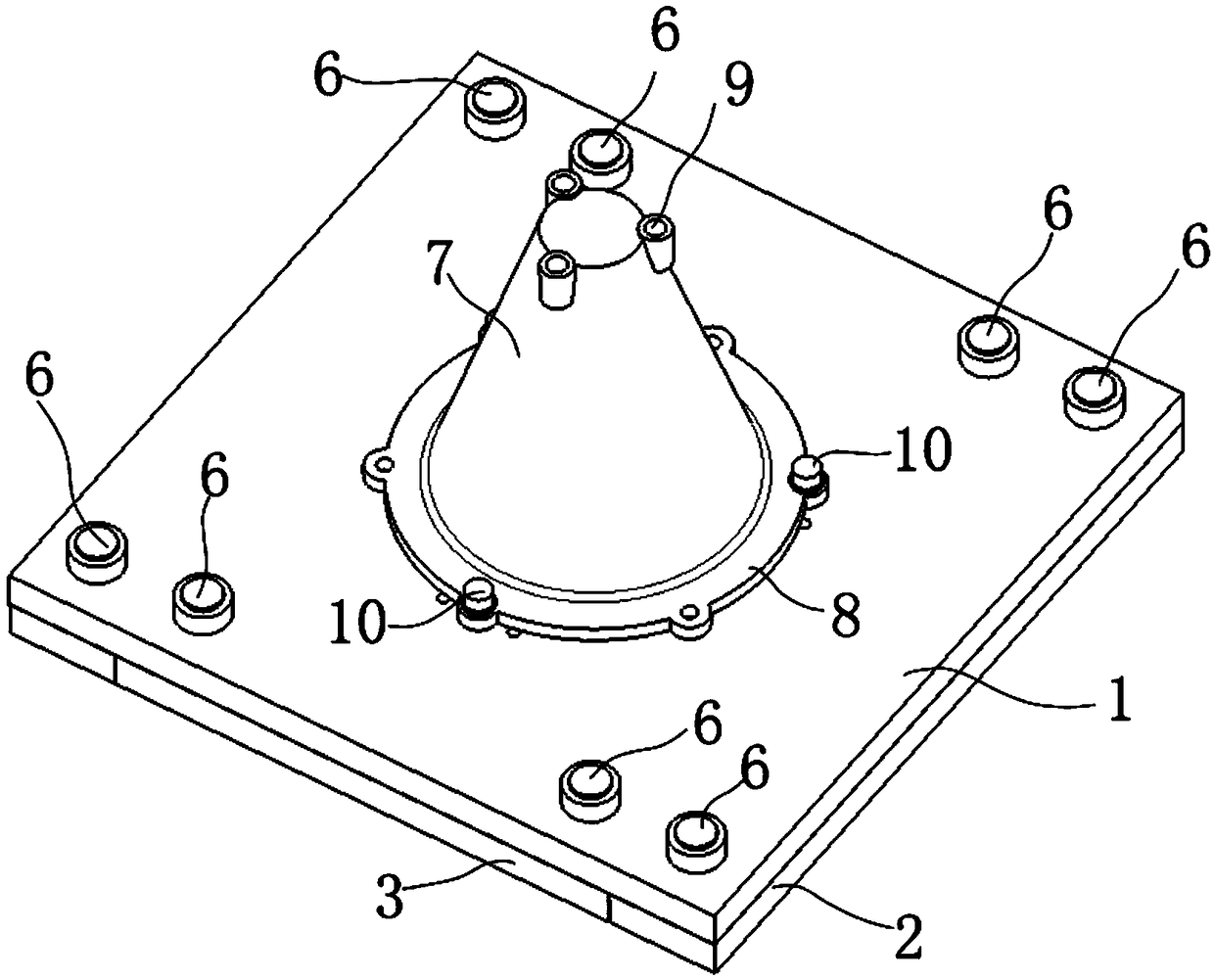

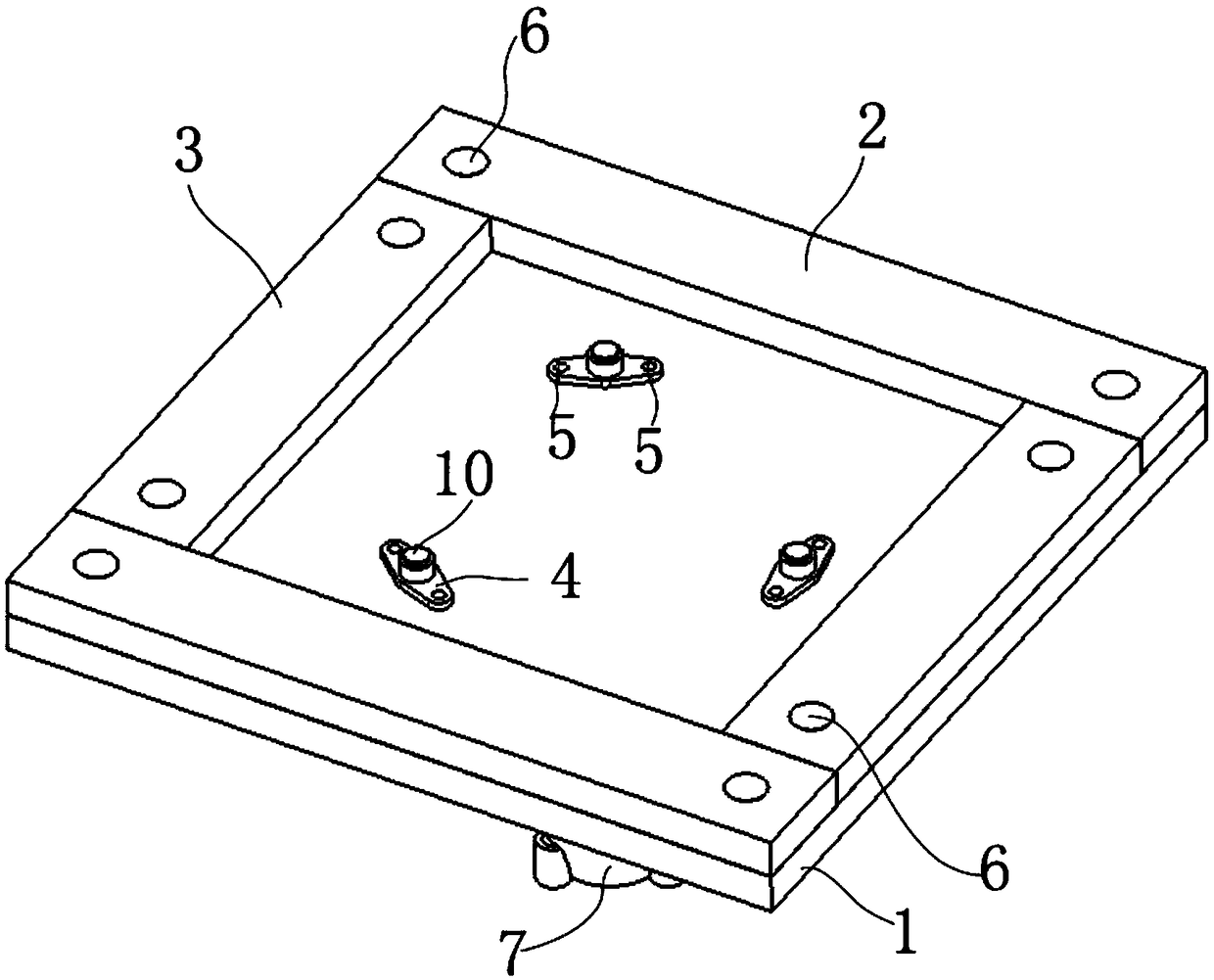

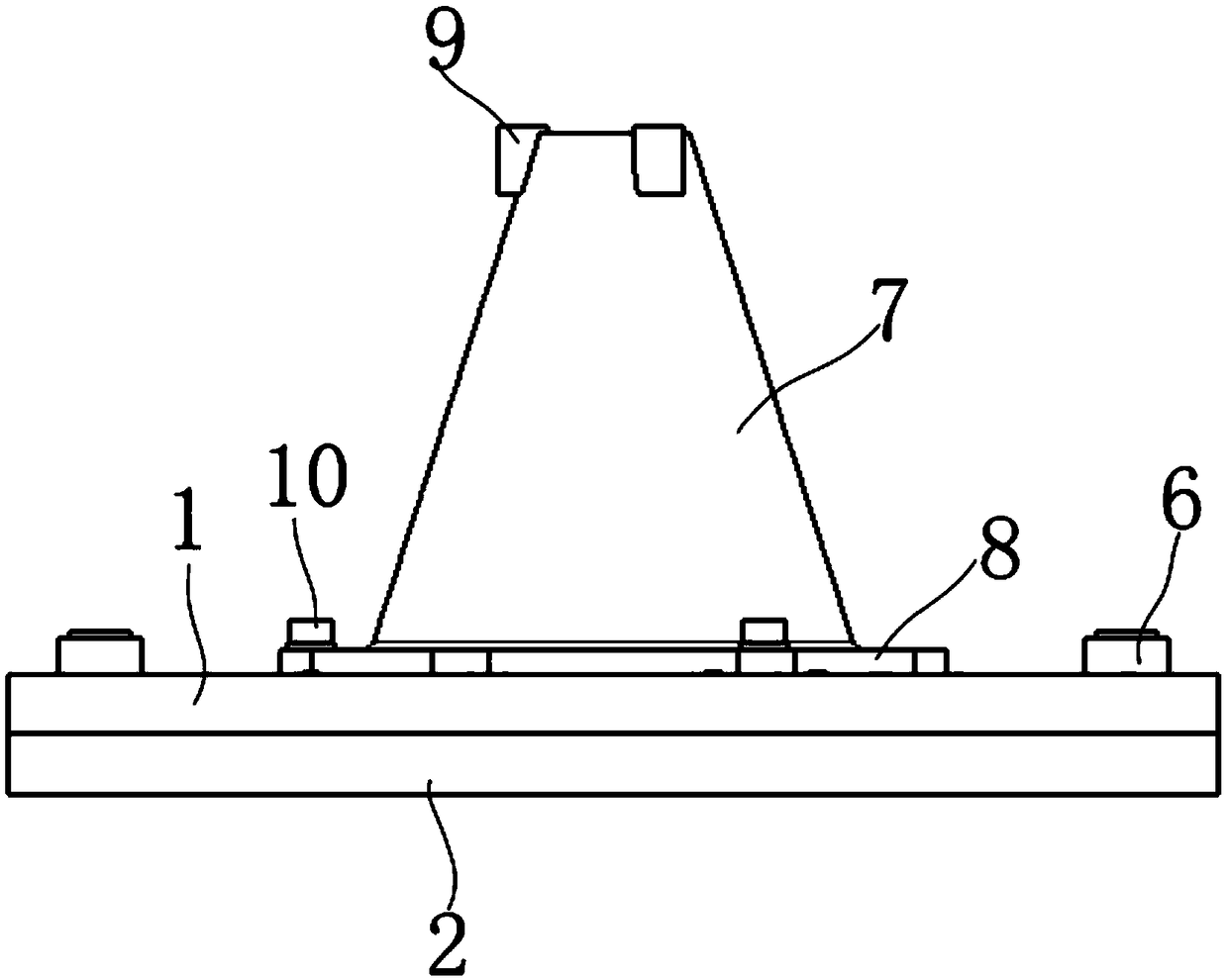

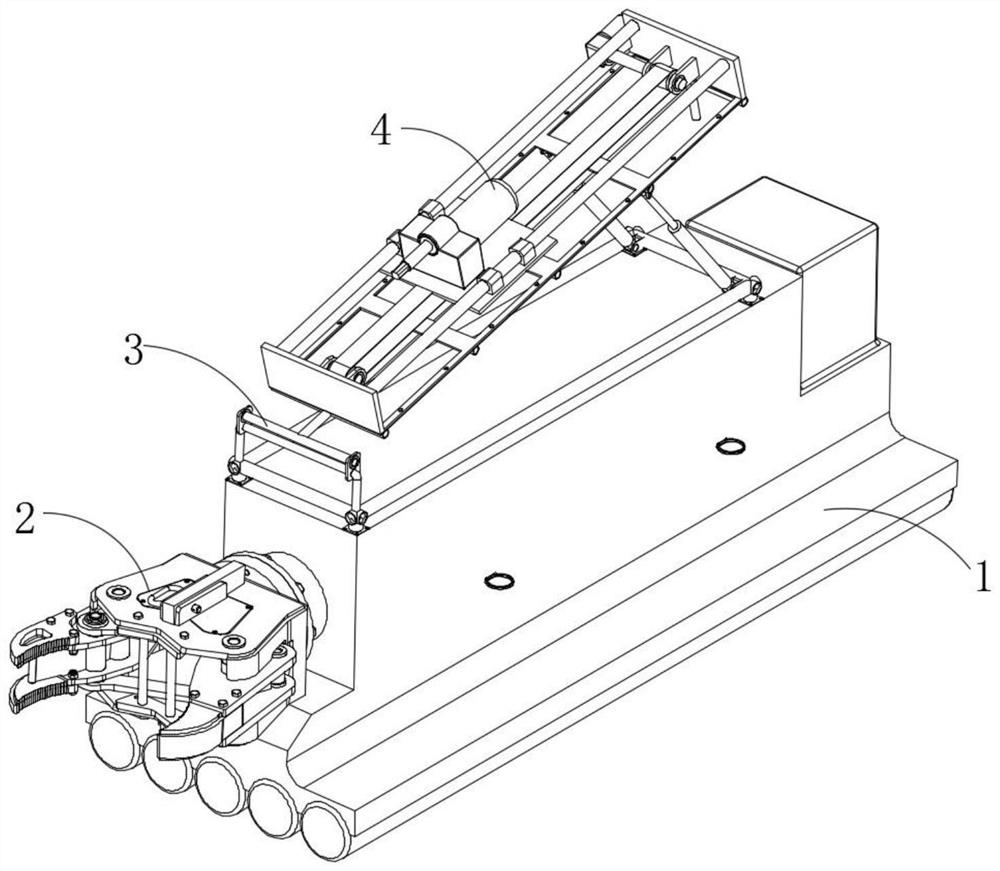

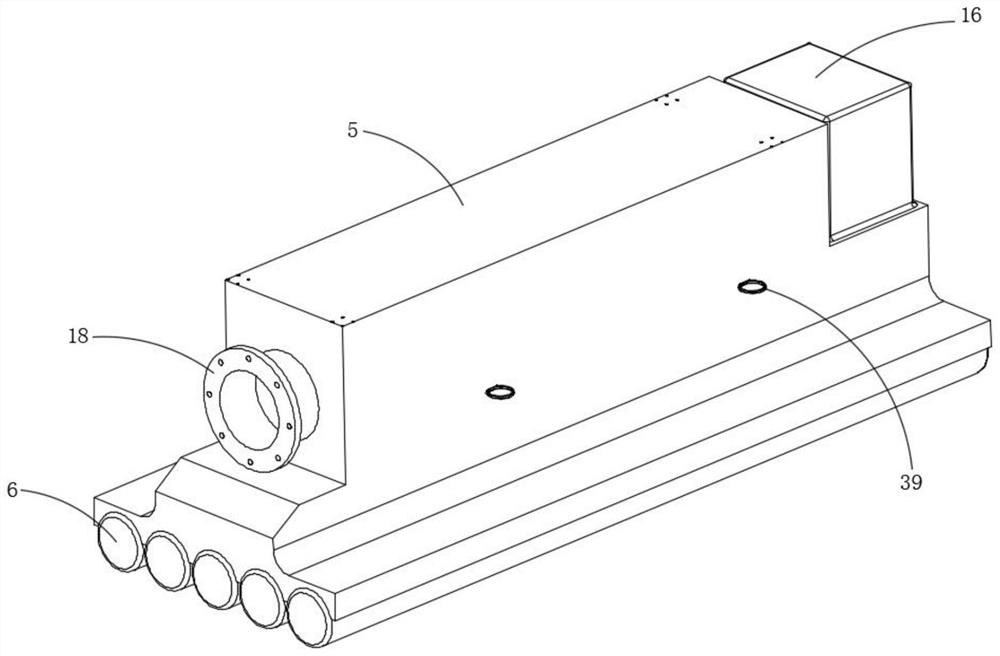

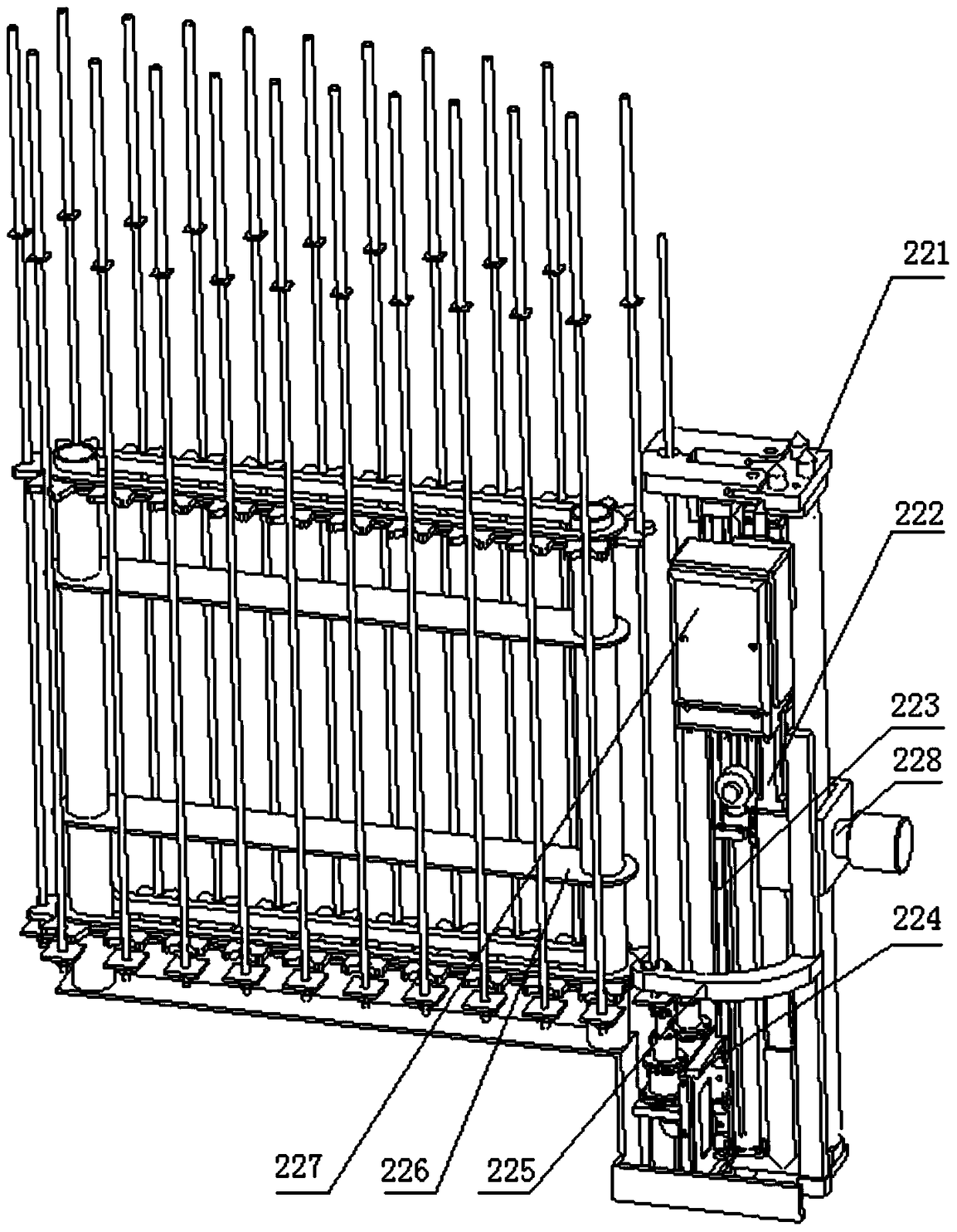

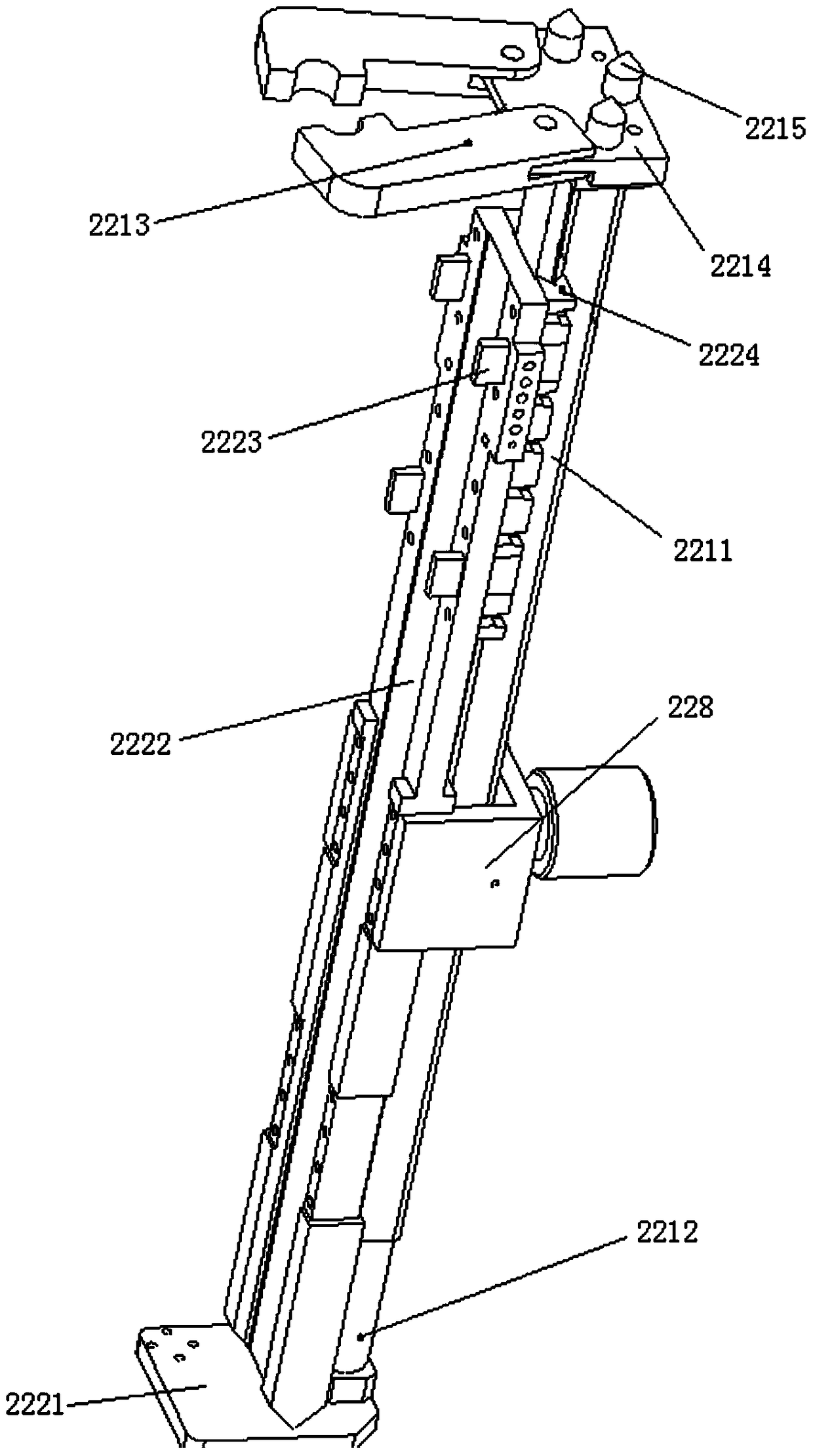

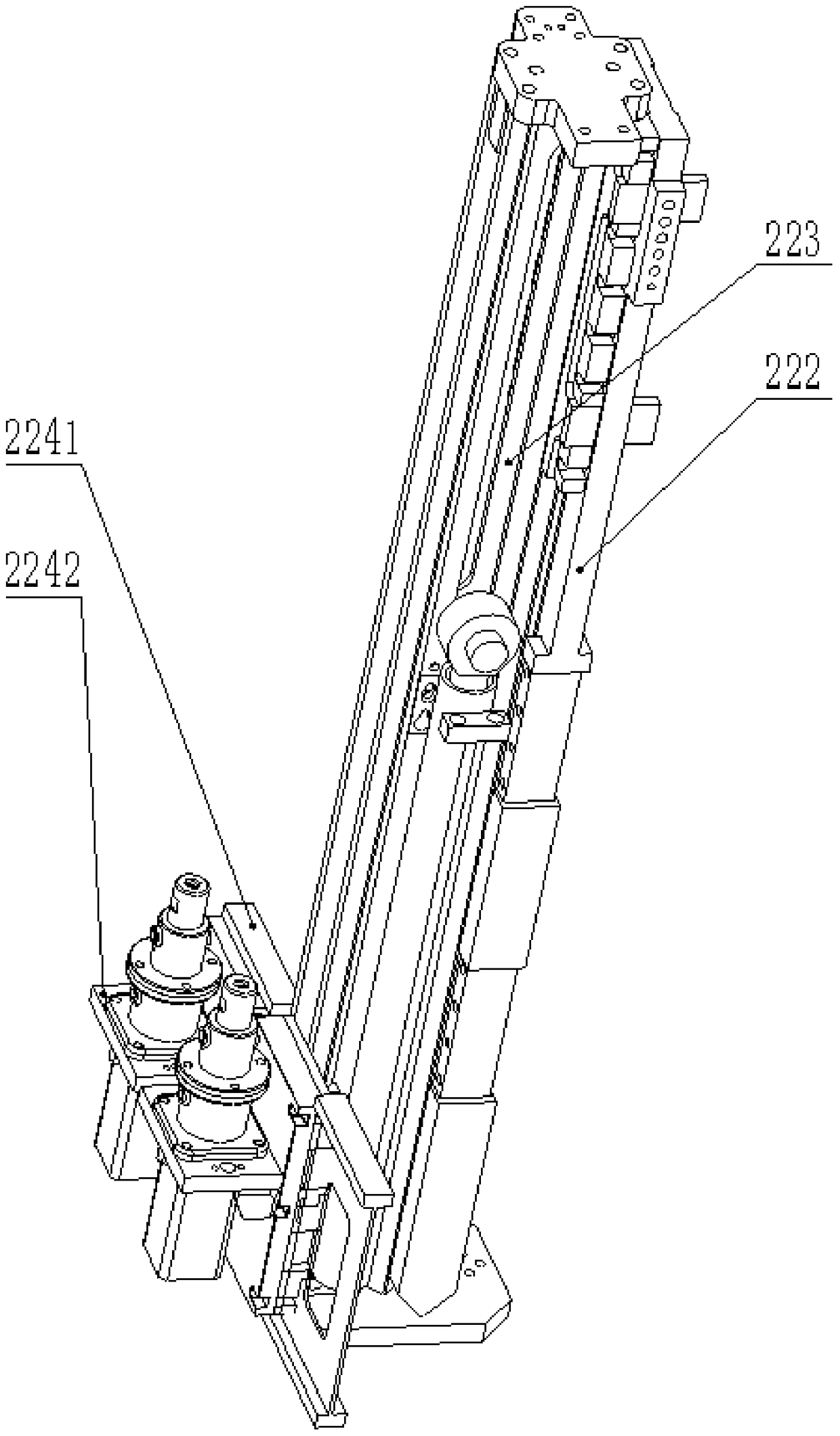

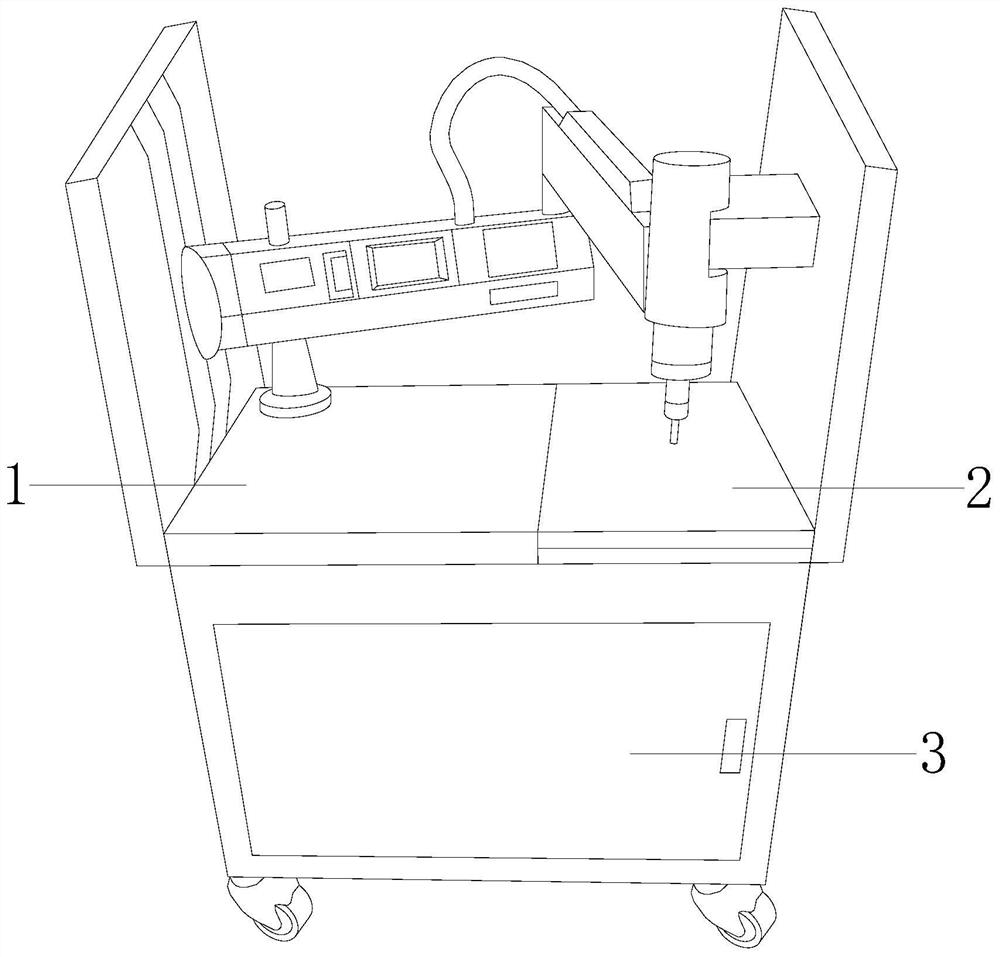

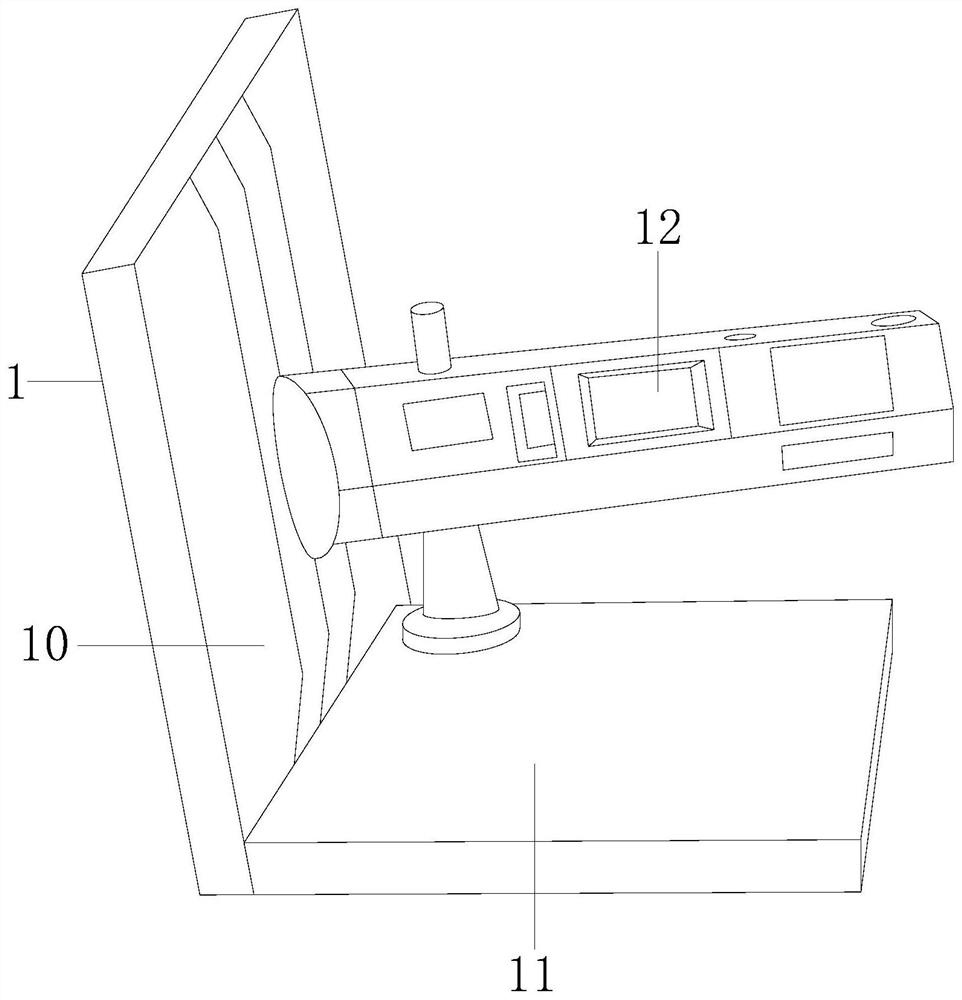

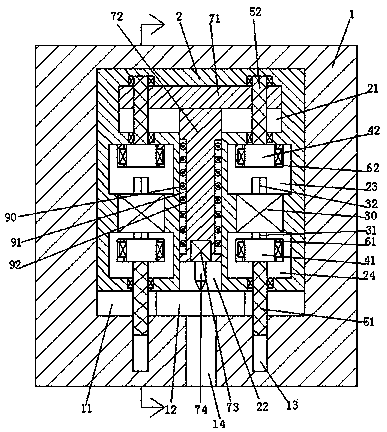

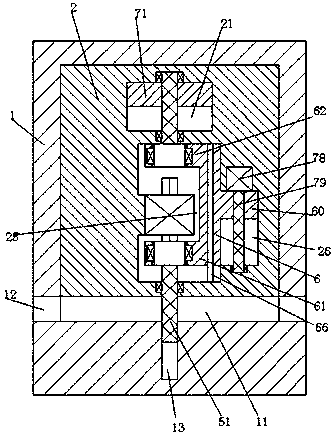

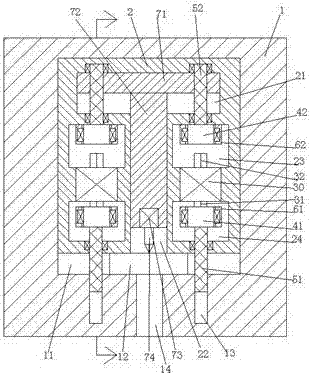

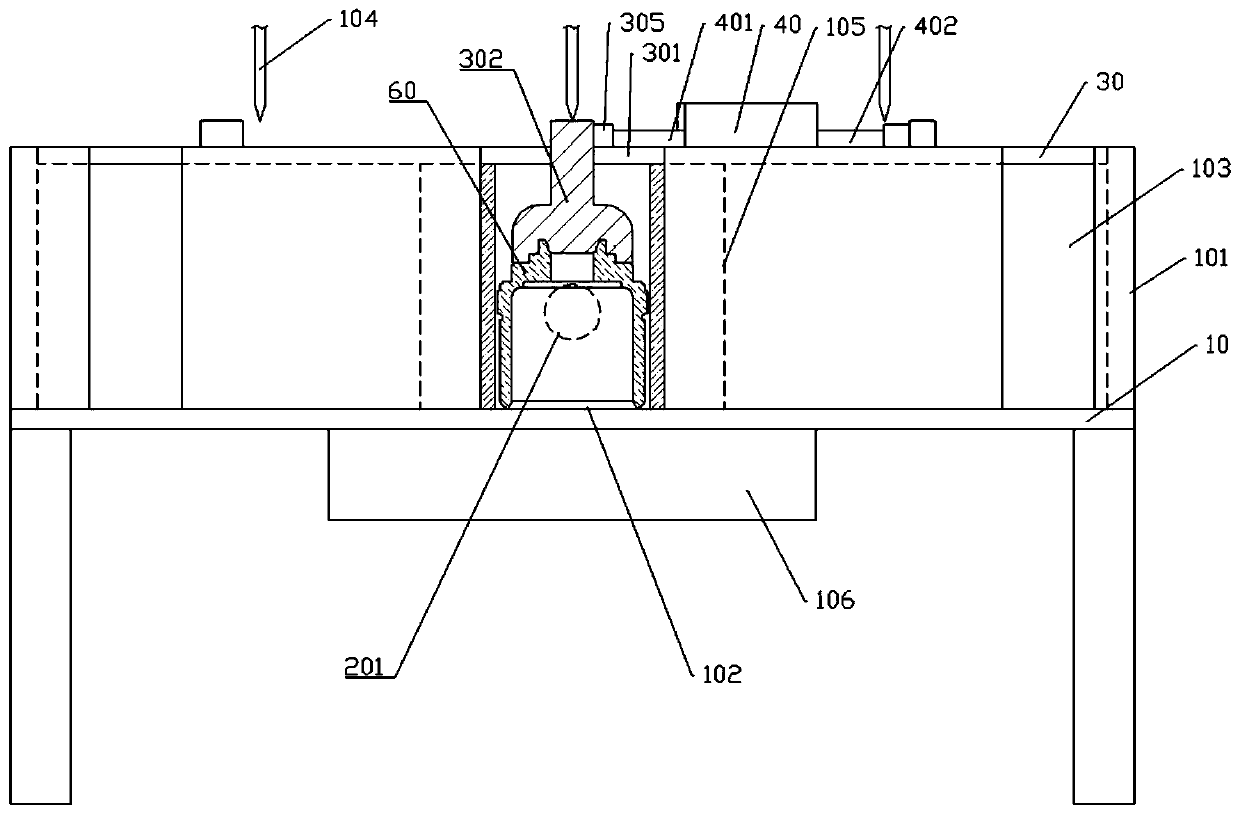

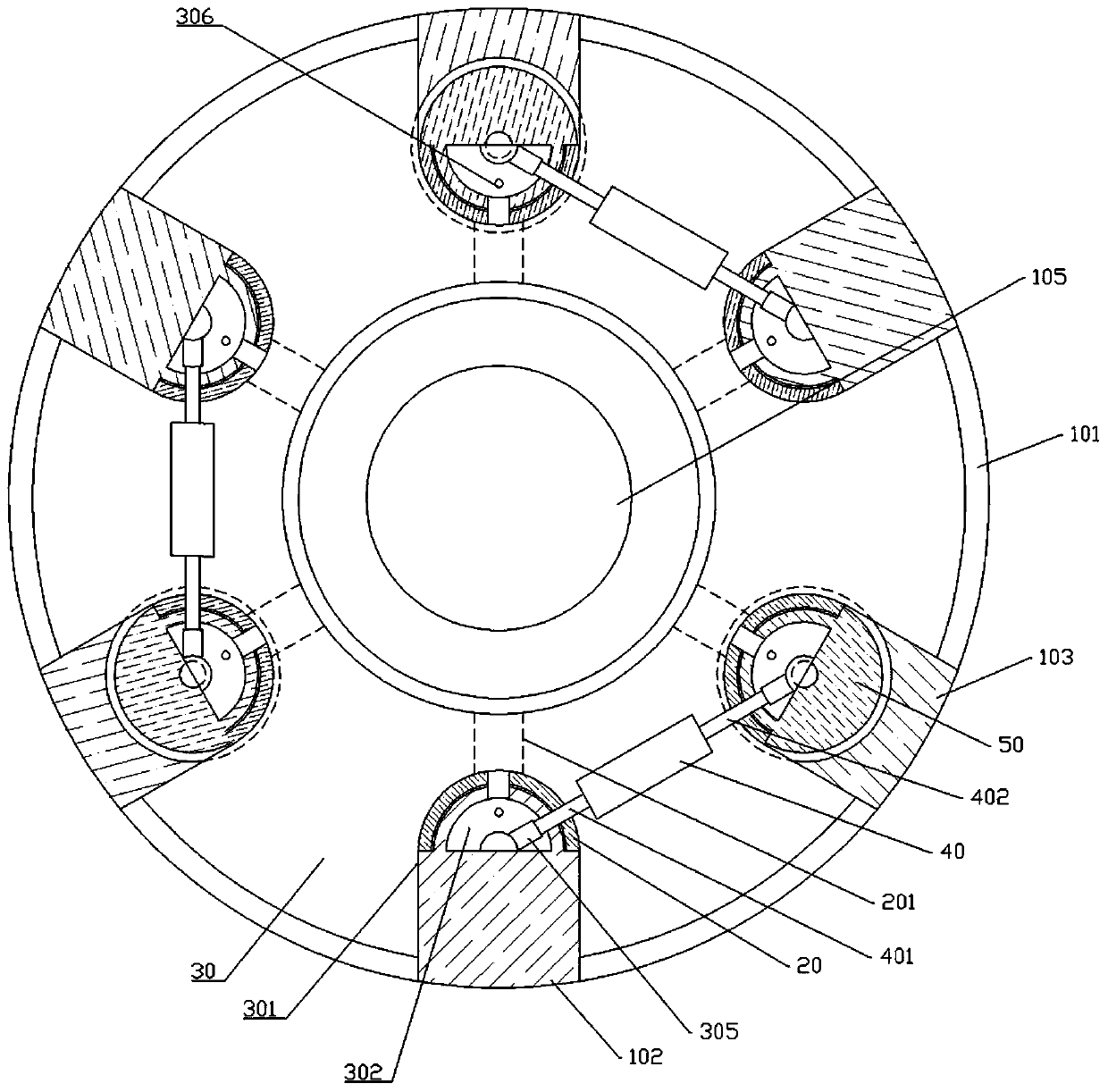

The invention discloses an anchor rod jacking mechanism which comprises a fixing mechanism, a supporting mechanism, a sliding block and a drill box mechanism. The fixing mechanism comprises a base, a stand plate and a connecting seat. Protrusions for fixing guide blocks are arranged on the stand plate. The supporting mechanism and the sliding block are in sliding connection with the opposite side faces of the stand plate through the guide blocks respectively. One end of the supporting mechanism and one end of the slide block are connected with base through telescopic oil cylinders. The drill box mechanism comprises a bottom frame and two independent drill box sliding seats. The bottom frame is connected with the base, and the drill box sliding seats can horizontally move along the bottom frame. When the drill box sliding seats move to the sliding block, the drill box sliding seats can be connected with the other guide rail face of the sliding block and slide along the sliding block. The invention further discloses an anchor rod jacking drilling carriage with a drilling machine. The anchor rod jacking drilling carriage comprises a four-wall anchor rod jacking drilling carriage body and a six-arm anchor rod jacking drilling carriage body. The drilling machine in the anchor rod jacking drilling carriage can work at the same time. Fast supporting operation on a top plate can be achieved, the structure is compact, and multiple functions are achieved. The anchor rod jacking mechanism and the anchor rod jacking drilling carriage operate in cooperation with heading equipment to complete the supporting and transferring function synchronously, operating personnel are greatly reduced, the labor intensity is lowered, and the supporting efficiency and safety are improved.

Owner:蒲长晏

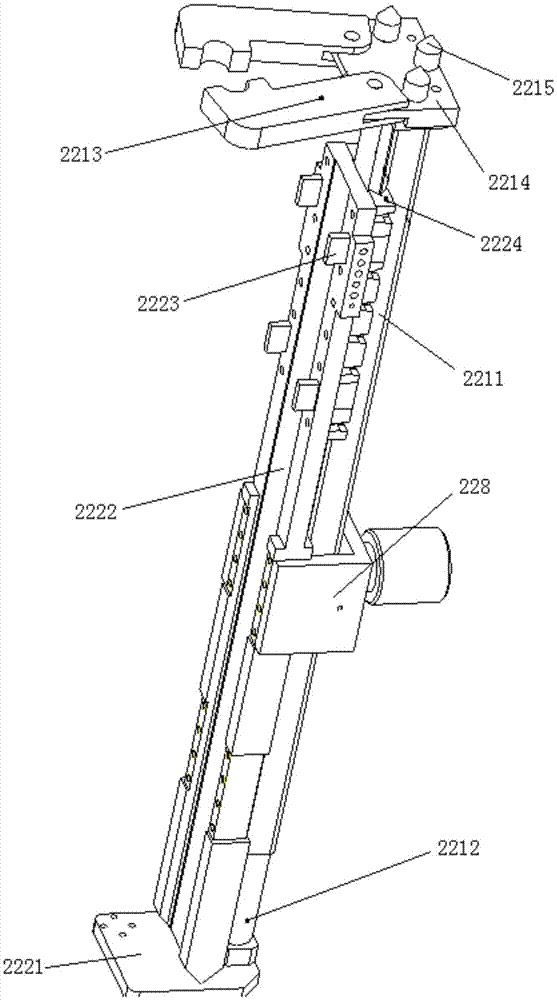

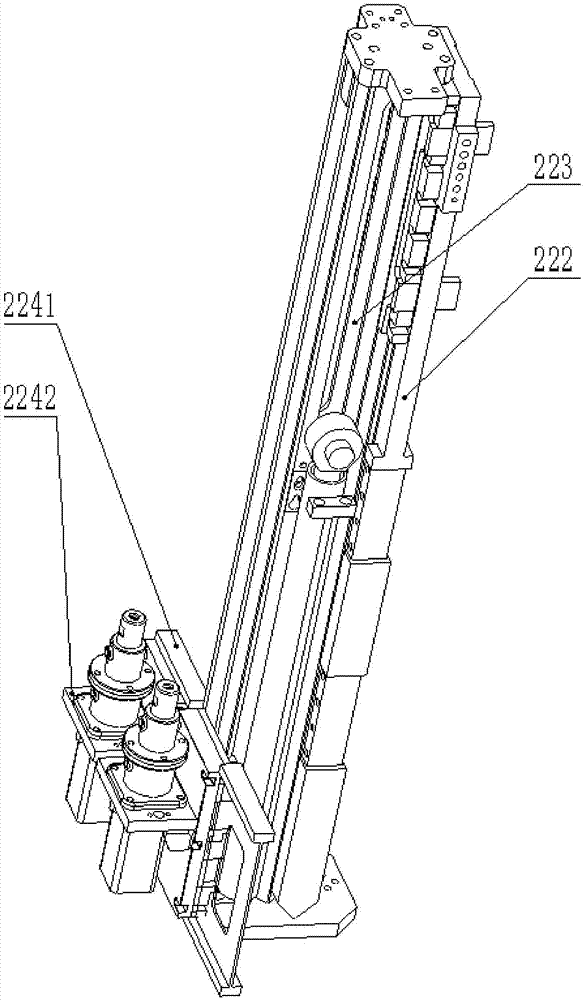

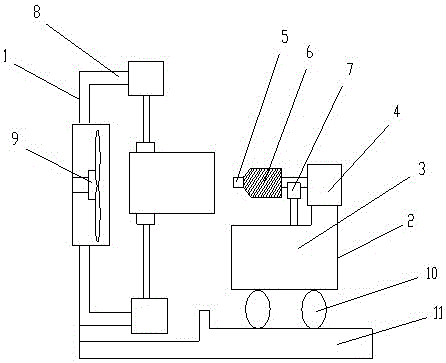

Side bolt drilling machine and side bolt drilling carriage with same

ActiveCN105626108ALarge storage capacityMeet construction needsDerricks/mastsAnchoring boltsEngineeringRock bolt

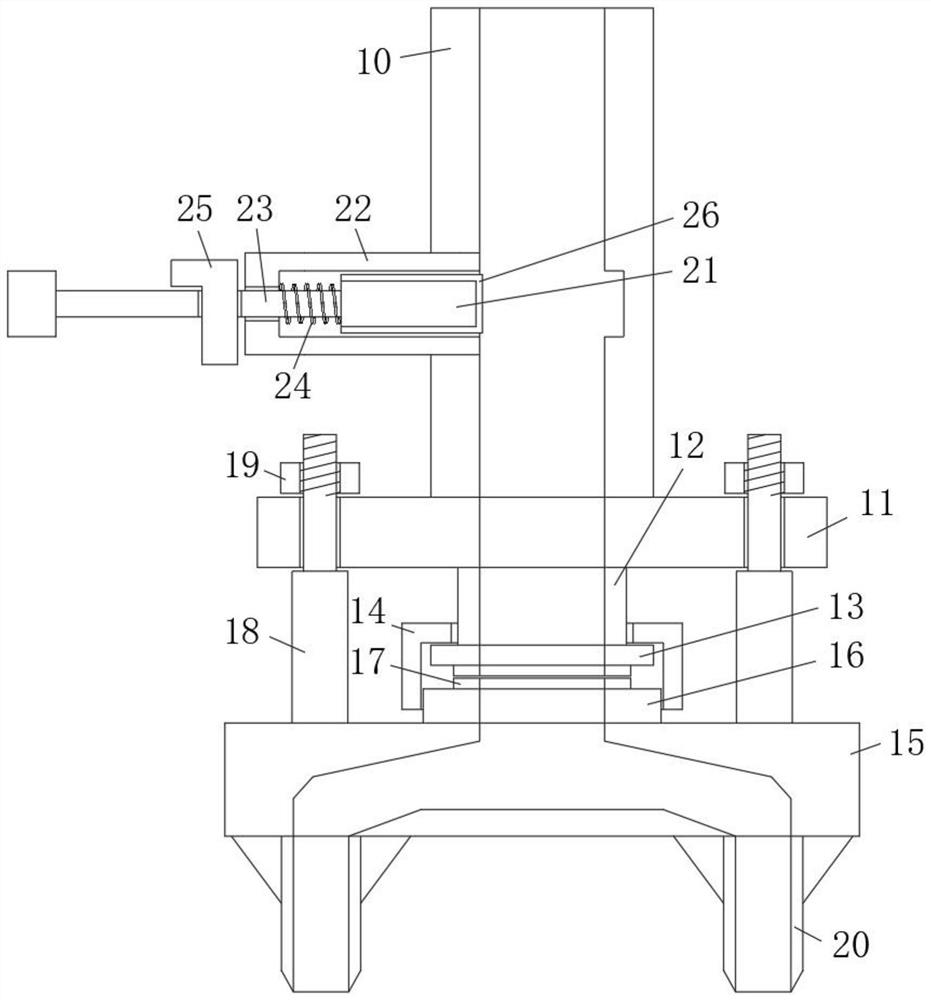

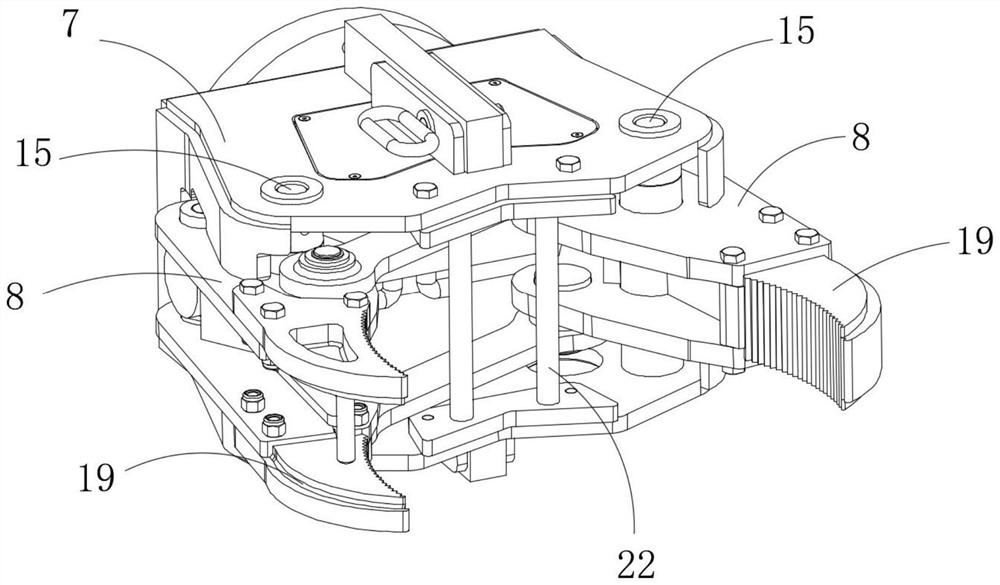

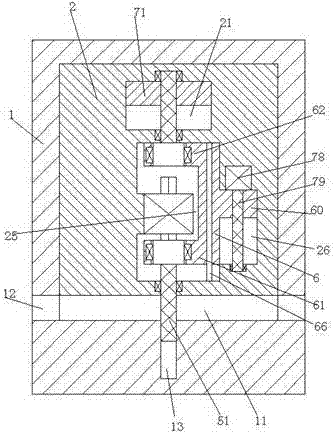

The invention discloses a side bolt drilling machine which comprises a fixing mechanism, a supporting mechanism, a sliding rack, a drilling box mechanism and a cartridge conveying box. The fixing mechanism comprises a base, a vertical plate and a connecting seat. Protrusions for fixing guide blocks are arranged on the vertical plate. The supporting mechanism and the sliding rack are in sliding connection with the opposite side faces of the vertical plate respectively through the guide blocks, and one end of the supporting mechanism and one end of the sliding rack are connected with the base through a telescopic oil cylinder. The drilling box mechanism comprises a bottom rack and two independent drilling box sliding seats. The bottom rack is fixedly connected with the base, the drilling box sliding seats can horizontally move along the bottom rack, and when the drilling box sliding seats move to the sliding rack, the drilling box sliding seats can be connected with the other guide rail face of the sliding rack and slide along the sliding rack. The cartridge conveying box is used for completing the automatic cartridge feeding procedure of the drilling machine. The invention further discloses a side bolt drilling carriage with the drilling machine. By means of automatic cartridge feeding and automatic anchor bolt mounting, mechanization and automation of anchor bolt supporting work are achieved, the construction needs of a plurality of rows of side bolts can be met, and the side bolt drilling carriage works in cooperation with heading equipment to synchronously complete side bolt supporting and transferring functions.

Owner:LANG FANG JING LONG GRAND IND MACHINERY CO LTD

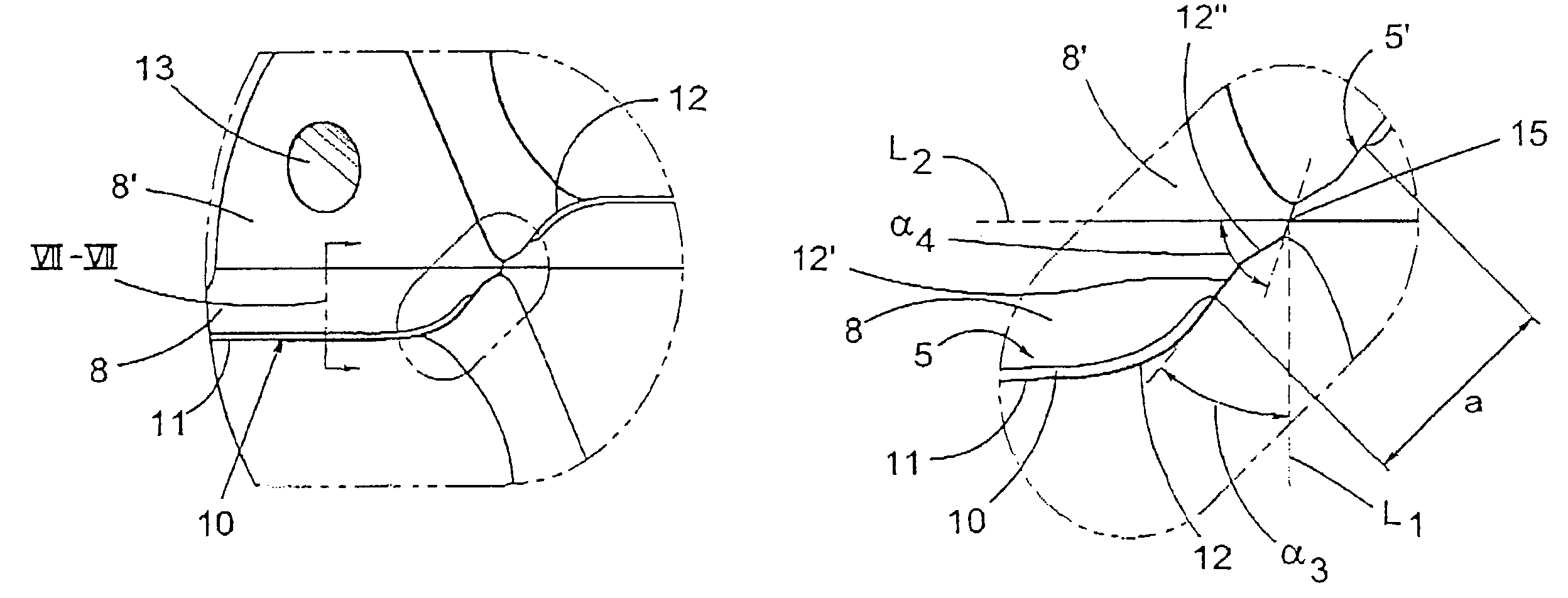

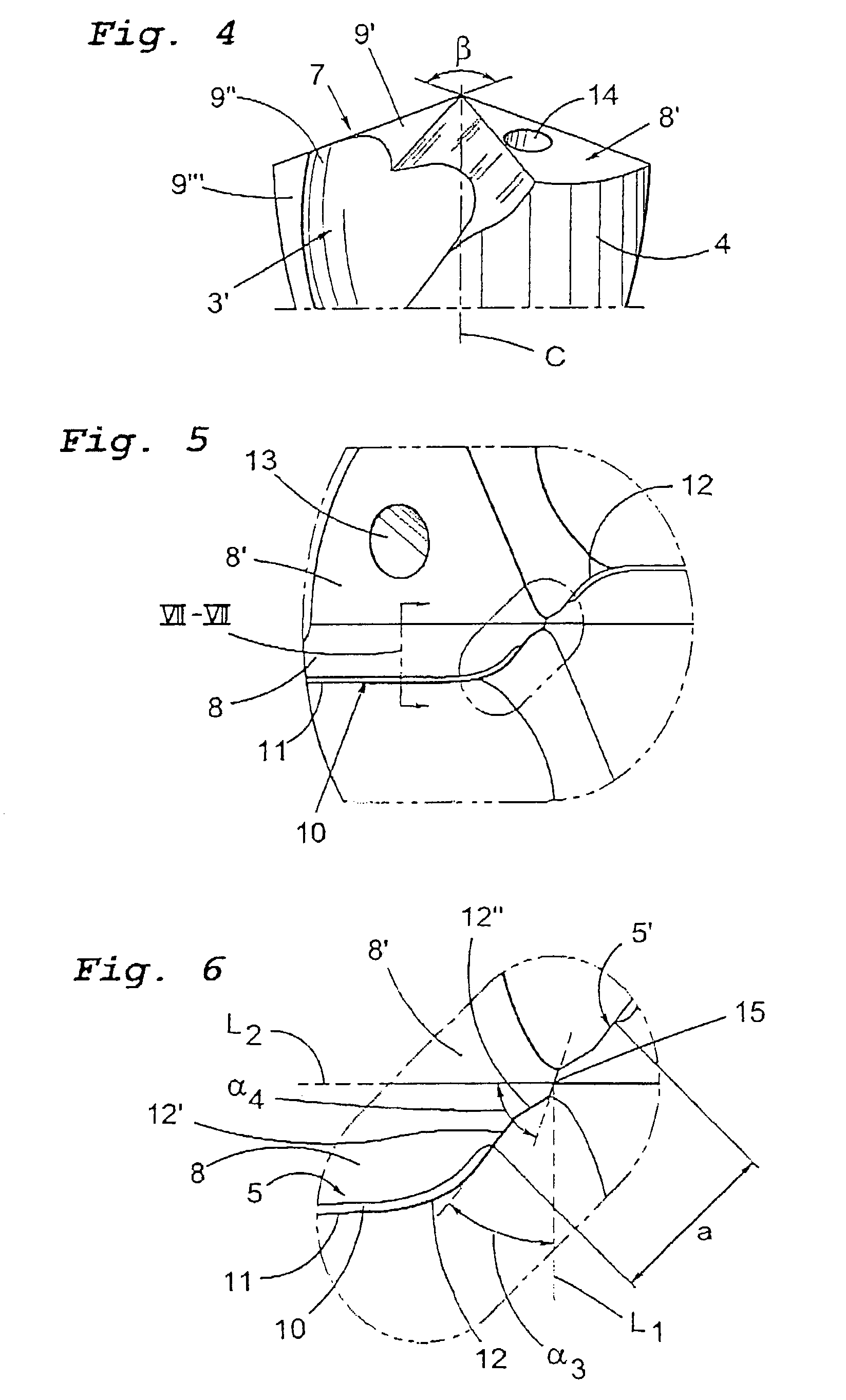

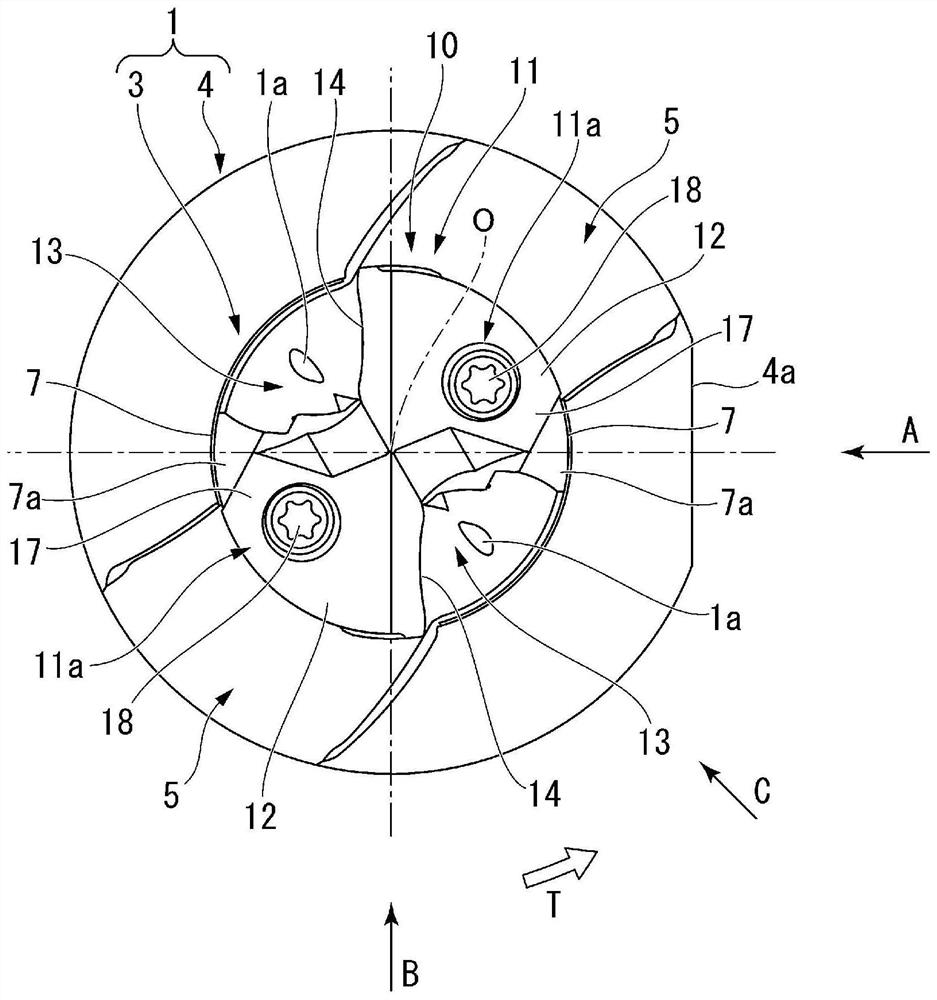

Drilling tool for holemaking in metallic workpieces

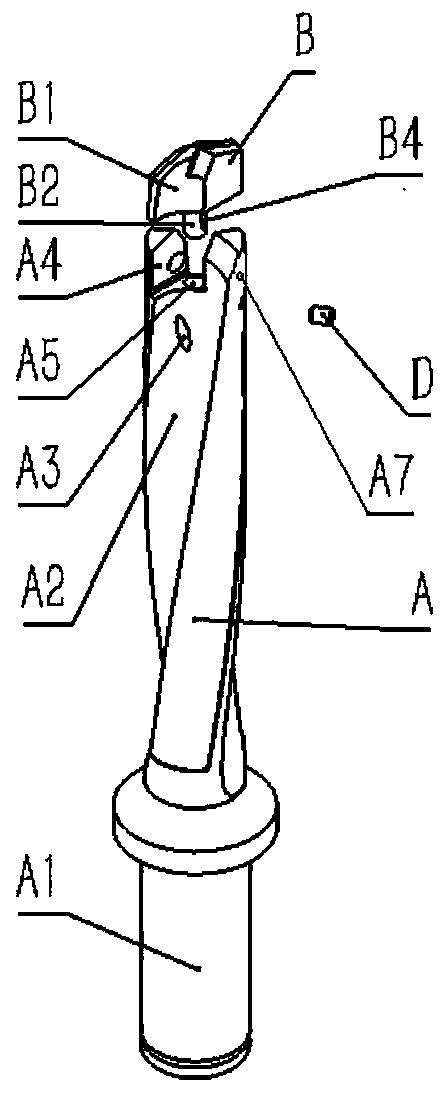

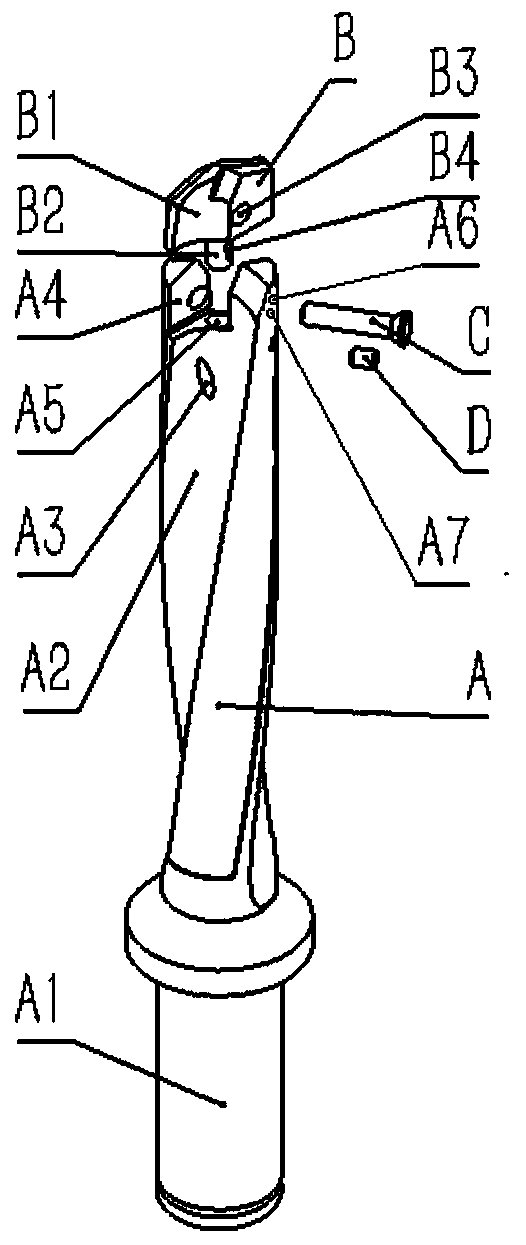

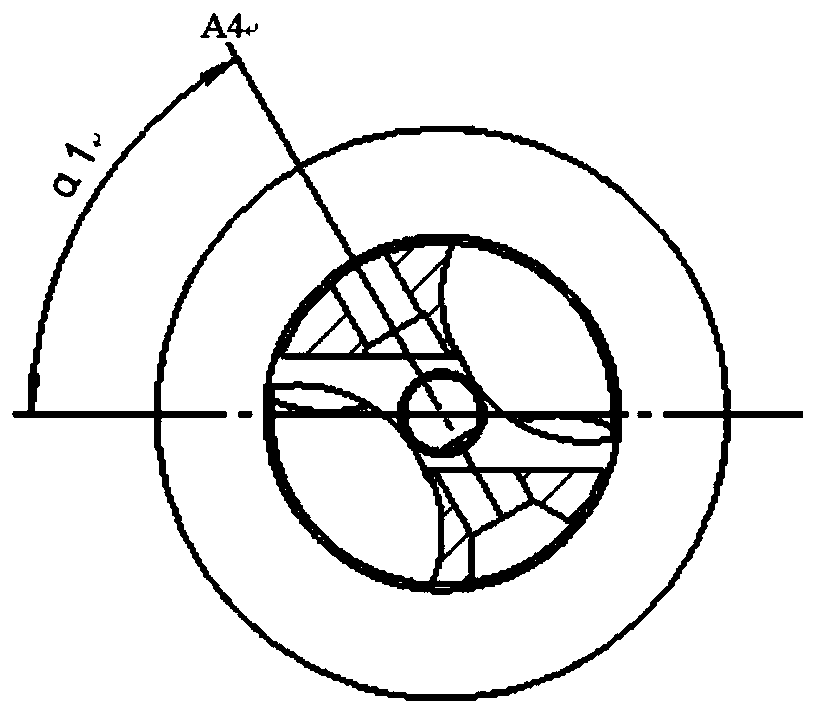

ActiveUS7241085B2Improve centering abilityGood centering abilityWood turning toolsTransportation and packagingFluteLevel line

A drill comprises a shaft with chip conveying flutes and a drill head at its forward end with at least two cutting inserts. Each cutting insert is provided with at least one cutting edge which is delimited between a chipbreaking surface and first relief surface and which includes an outer straight edge. In the proximity of the center axis of the shaft, a curved cutting edge section is provided, to which there is connected an adjacent enforcement bevel. The cutting edge is in direct proximity to a center axis, and is terminated by a chisel edge between the cutting inserts to serve as a centering core portion. The curved cutting edge section is inwardly followed by a primary straight portion without an adjacent enforcement bevel in a direction that is oriented at an angle of between approximately 40–50° in relation to a horizontal line that extends through the center axis of the drill.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

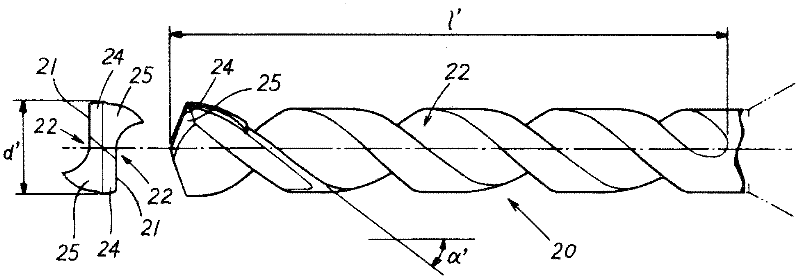

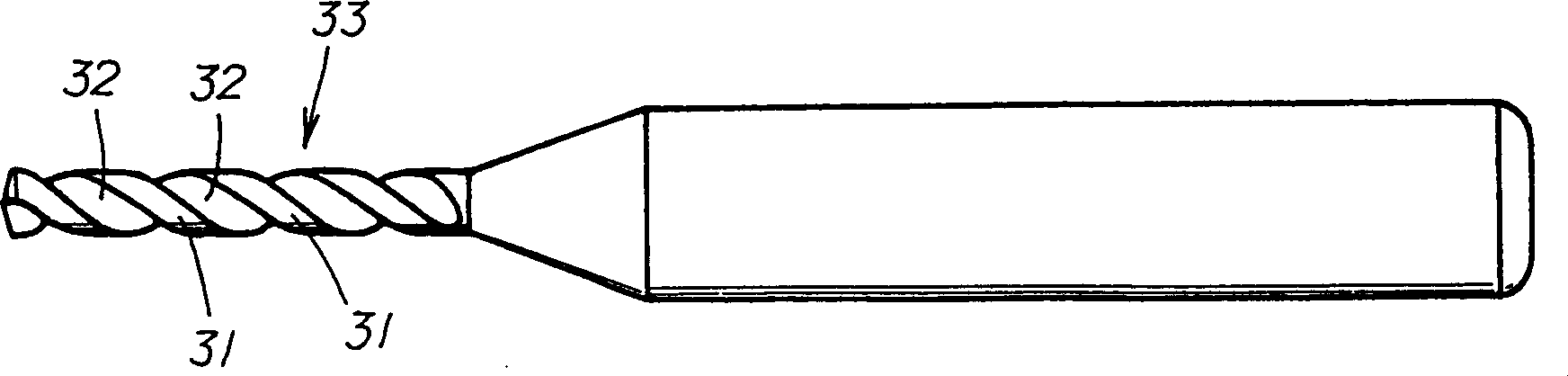

Drilling tool

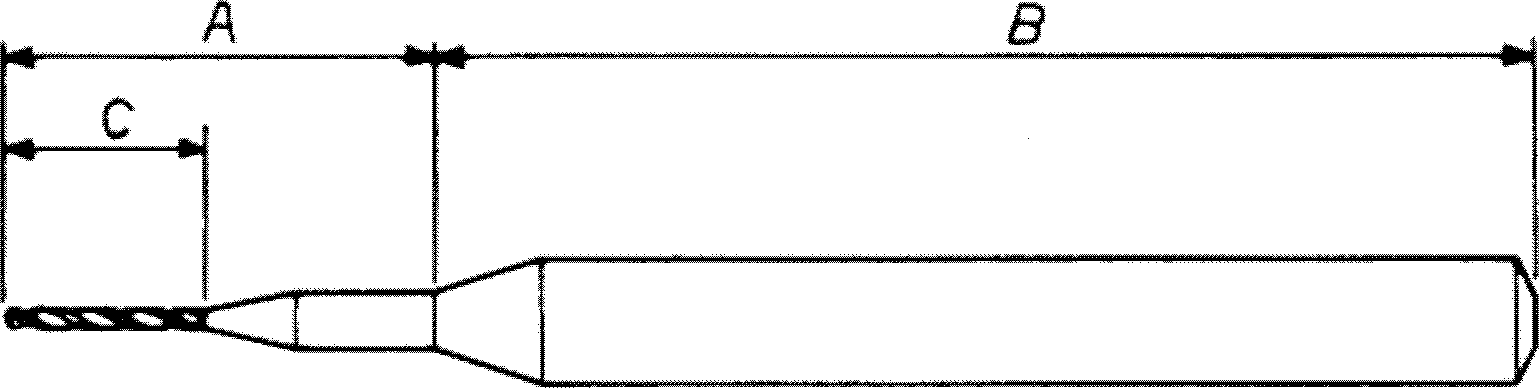

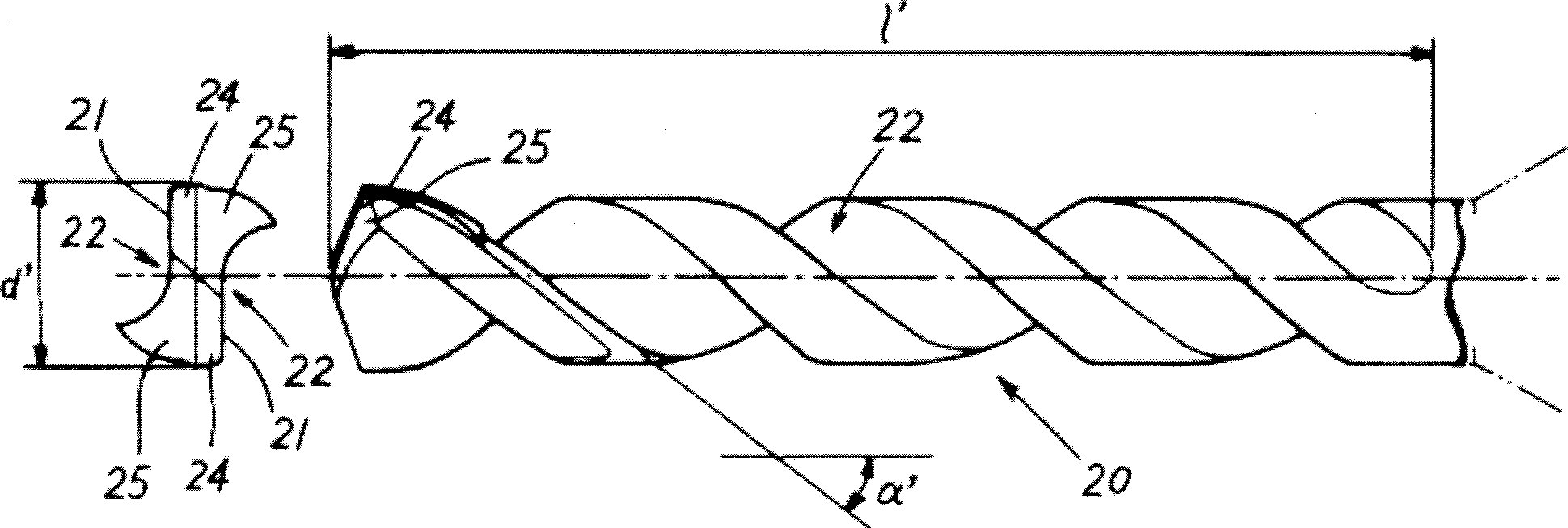

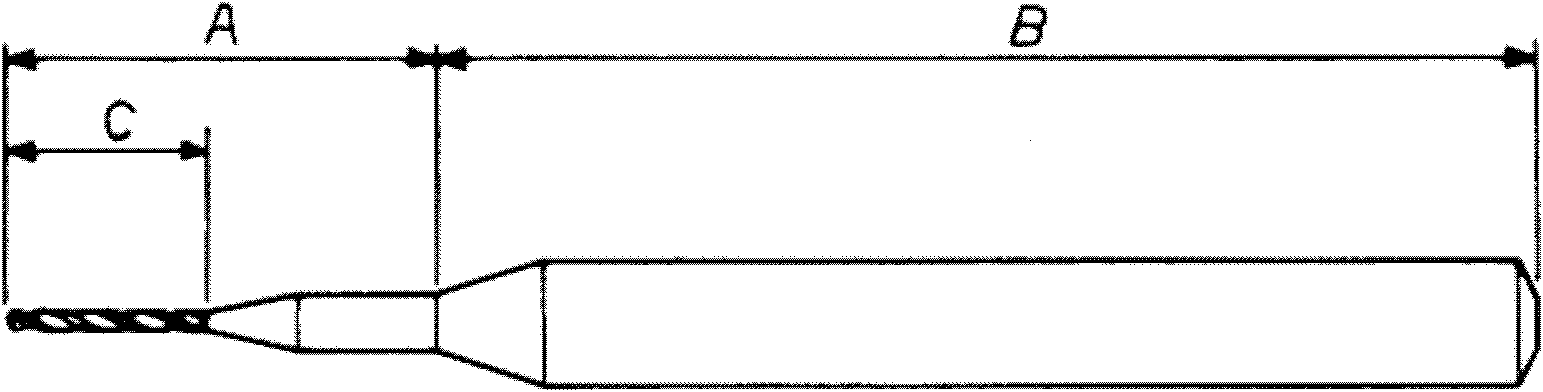

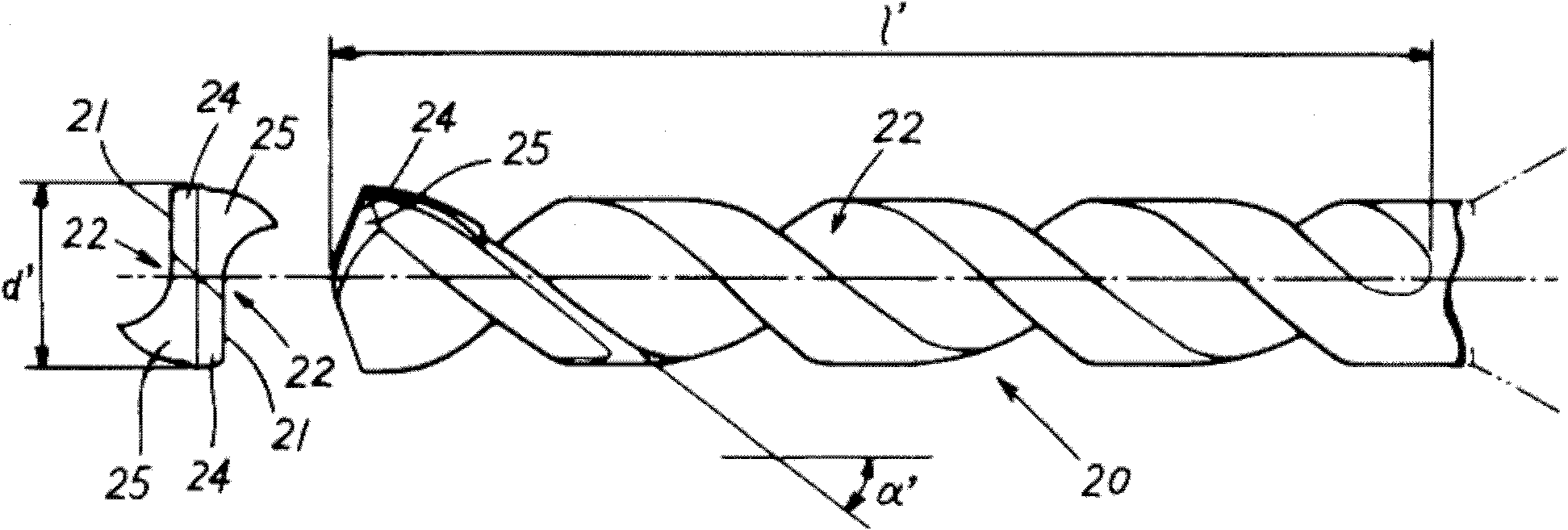

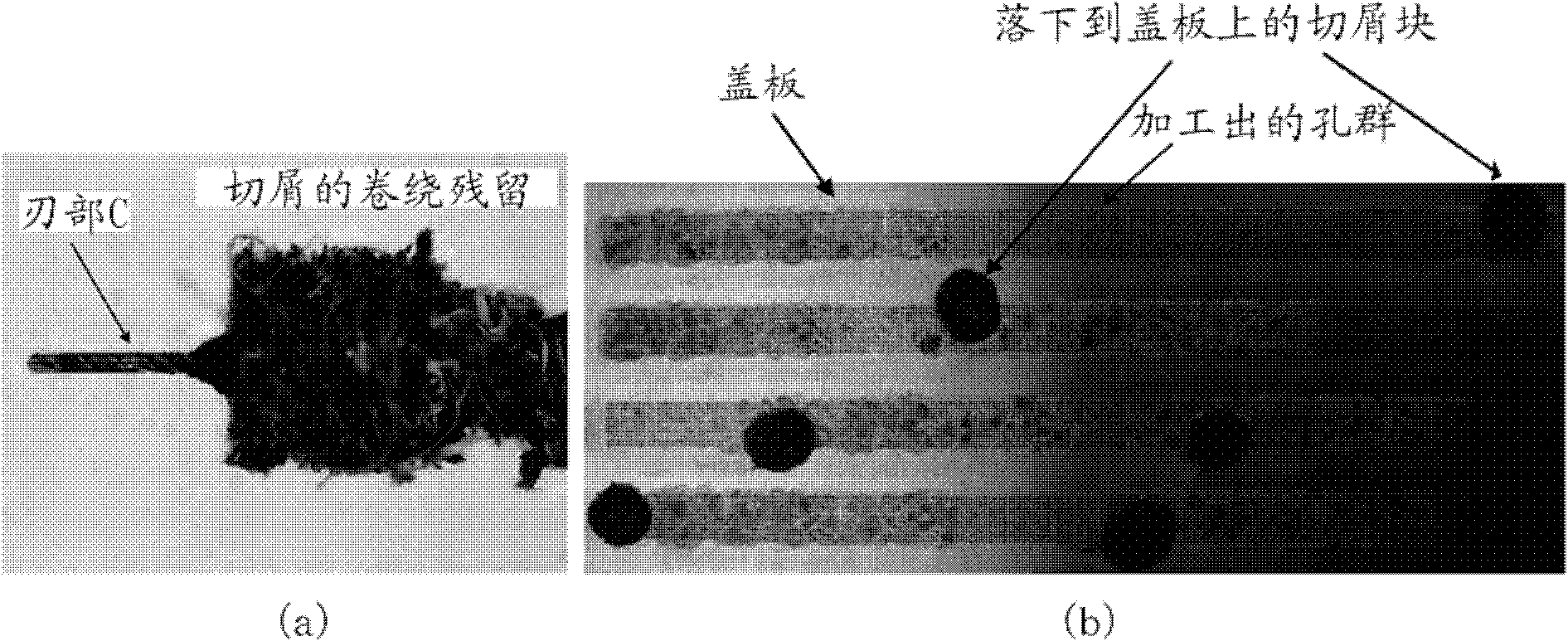

ActiveCN102476209AAvoid windingLong breakage lifeTransportation and packagingPrinted circuit manufactureEngineeringDrill bit

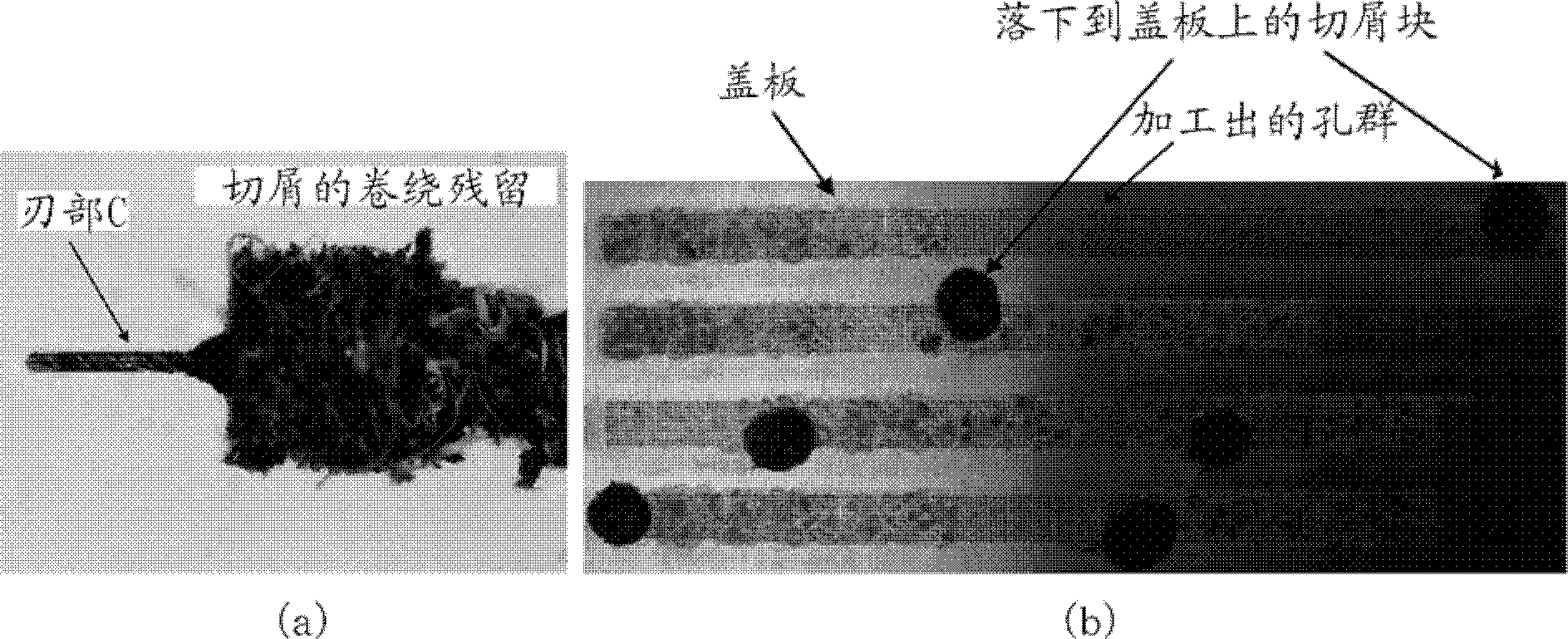

Provided is a drilling tool, capable of preventing the cuttings from coiling. Even a drill with a small diameter can have a relatively long anti-damaging lifetime and realize excellent hole-site precision, stable drill processing, and excellent practical applicability. The tail end of the tool body is provided with one or a plurality of cutting edges. The periphery of the tool body is provided with a plurality of helical chip rooms in the direction toward base end side from tail end of the tool. The chip rooms comprise one main groove and more than one auxiliary grooves, wherein the auxiliary grooves are connected with the main groove at the midway section of the main groove. Moreover, the helical angles of the main groove and the auxiliary grooves are designed to have roughly equal angles from the connection setting section set by the connection between the main groove and the auxiliary grooves. The length of the auxiliary grooves is designed to be 50% to 95% of the length of the main groove. Also, the auxiliary grooves are set to be parallel to the main groove within a range from the connection setting section to a predetermined position away from the terminal of the main groove.

Owner:UNION TOOL

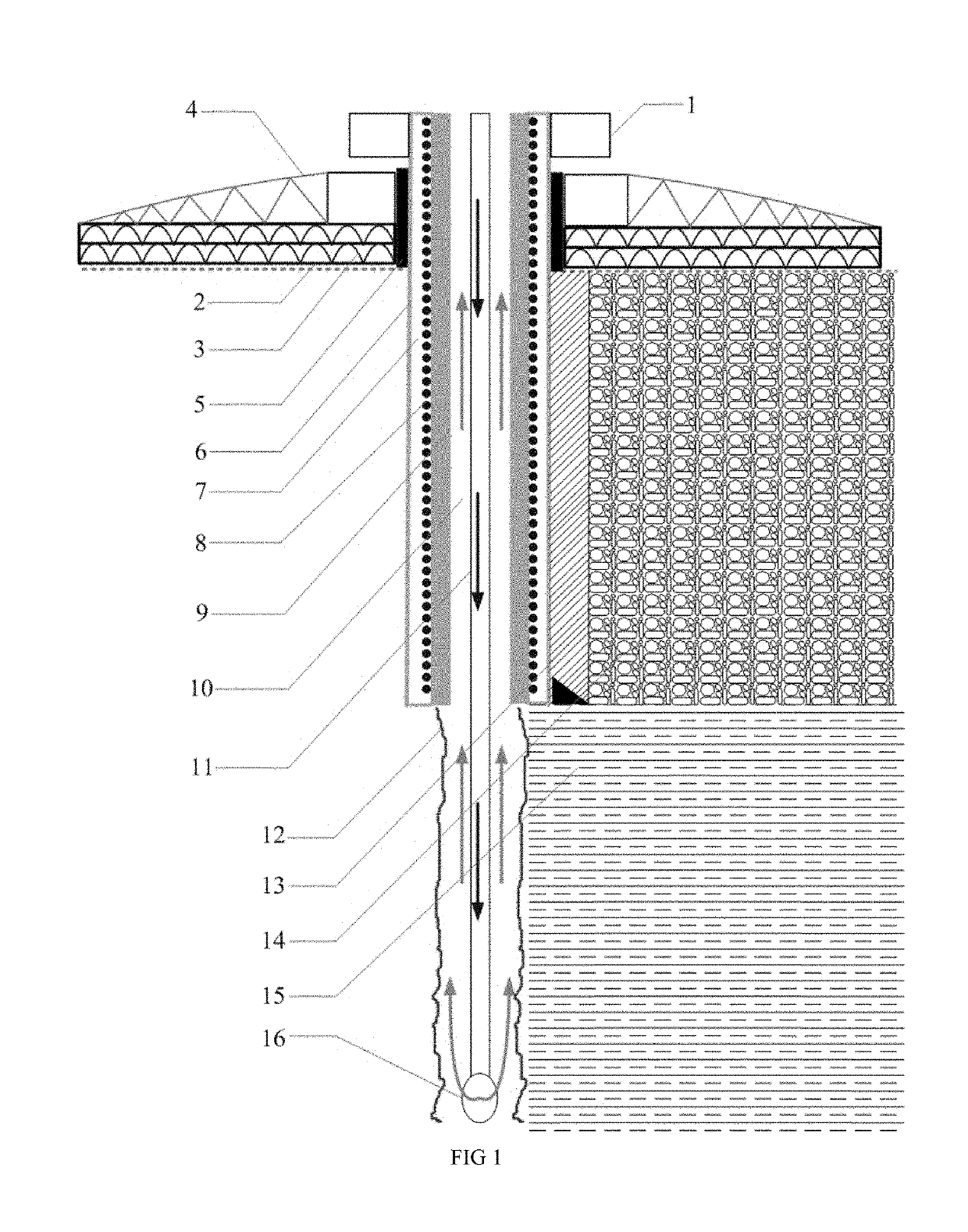

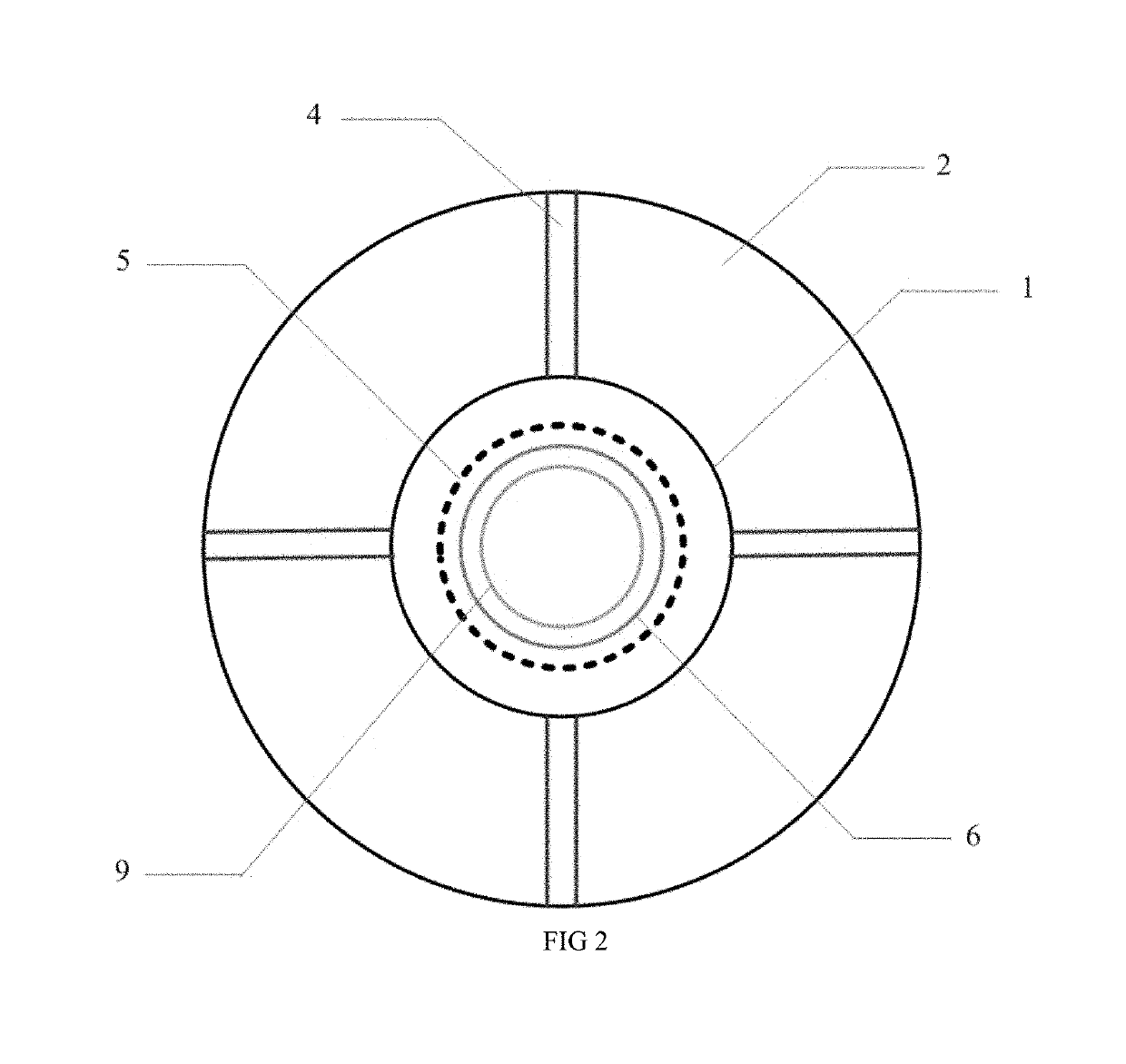

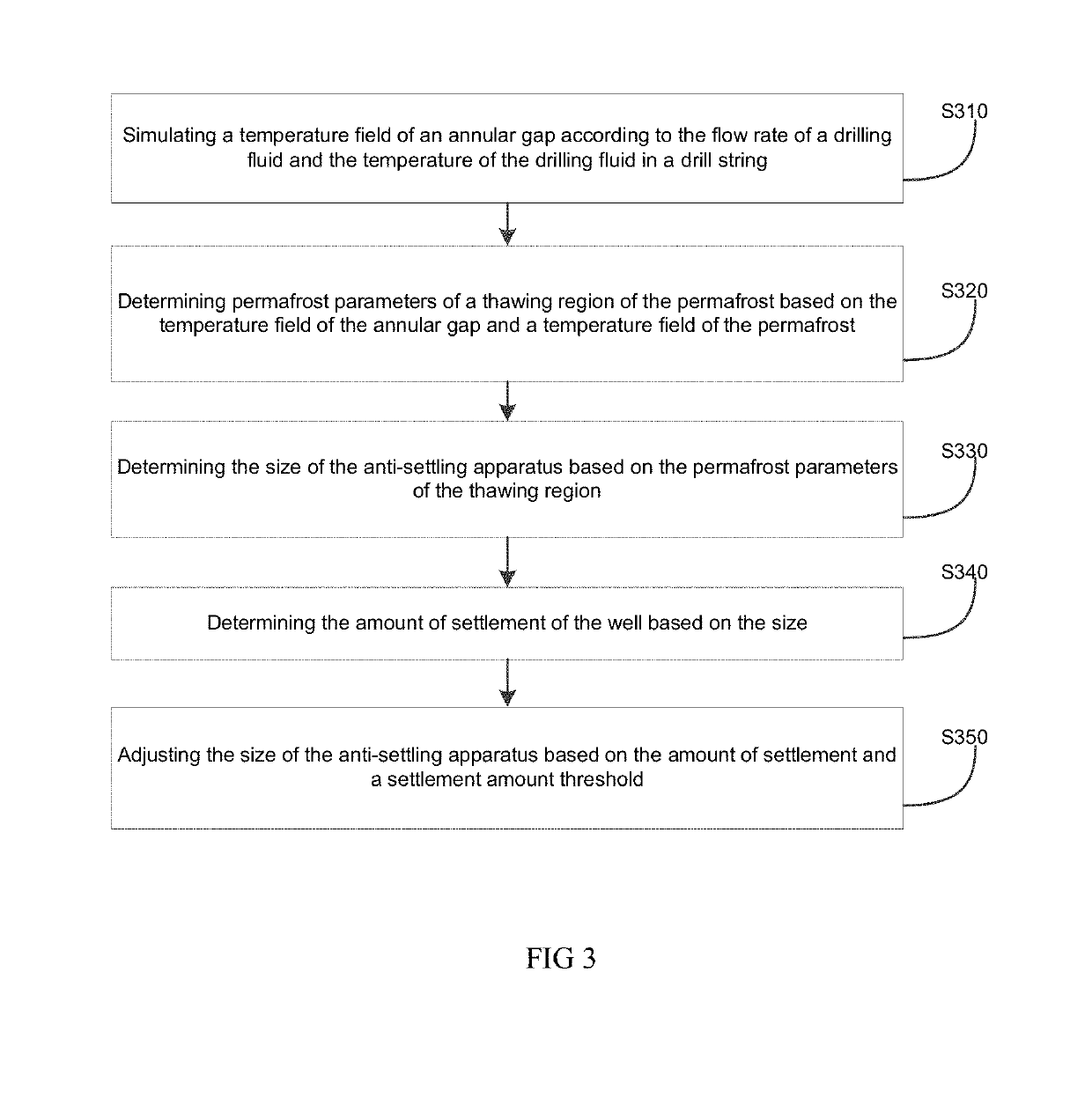

Anti-settling Apparatus and Method and Apparatus for Checking the Same, and Apparatus for Preventing Settlement of Well

InactiveUS20190178046A1Reduce settlementSettlement of the well can be reducedConstructionsFlushingEngineeringMechanical engineering

The present invention relates to the field of drilling, and provides an anti-settling apparatus and a method and apparatus for checking the same, and an apparatus for preventing settlement of a well. The anti-settling apparatus of the present invention is installed in the wellhead region of the well during drilling to prevent the well from settlement. The anti-settling apparatus generally includes: an anti-settling base having an opening corresponding to the wellhead formed at the center thereof, the anti-settling base being disposed in the wellhead region during drilling; and an interlocking member 5 disposed at the opening to connect and fix a casing provided in the well with the anti-settling base. The apparatus for preventing settlement of a well comprises the anti-settling apparatus and checking method for the anti-settling apparatus.

Owner:CIMC OFFSHORE ENG INST +1

Double-head coaxial boring and milling machining device for machining

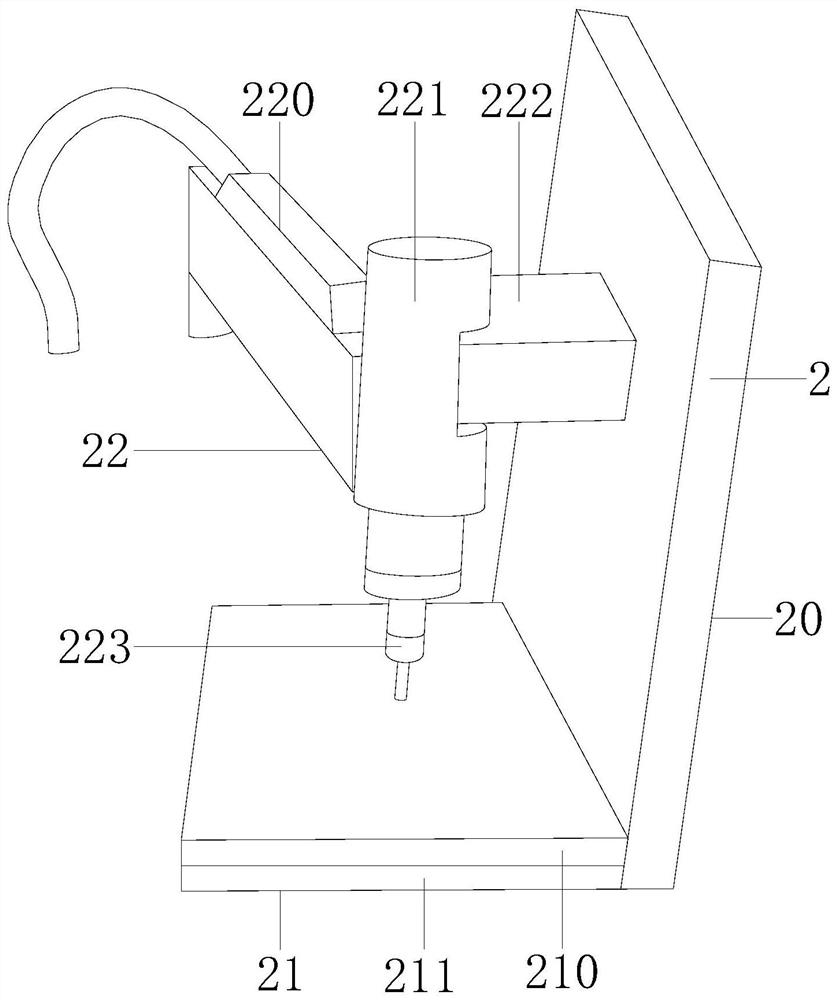

PendingCN112589151AAccurate drilling positioningFlexible and convenient operationBoring/drilling componentsBoring/drilling machinesMachine toolMachining

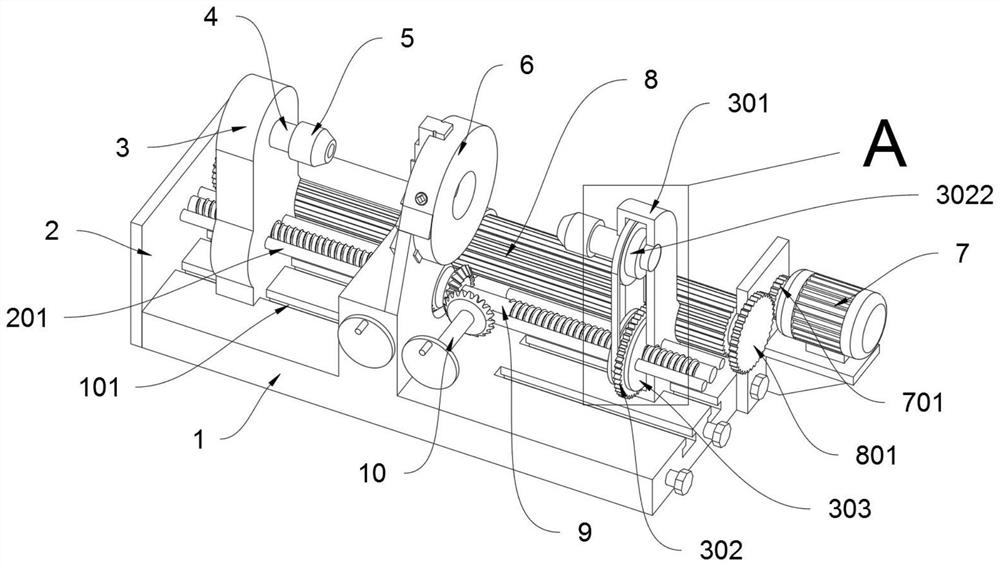

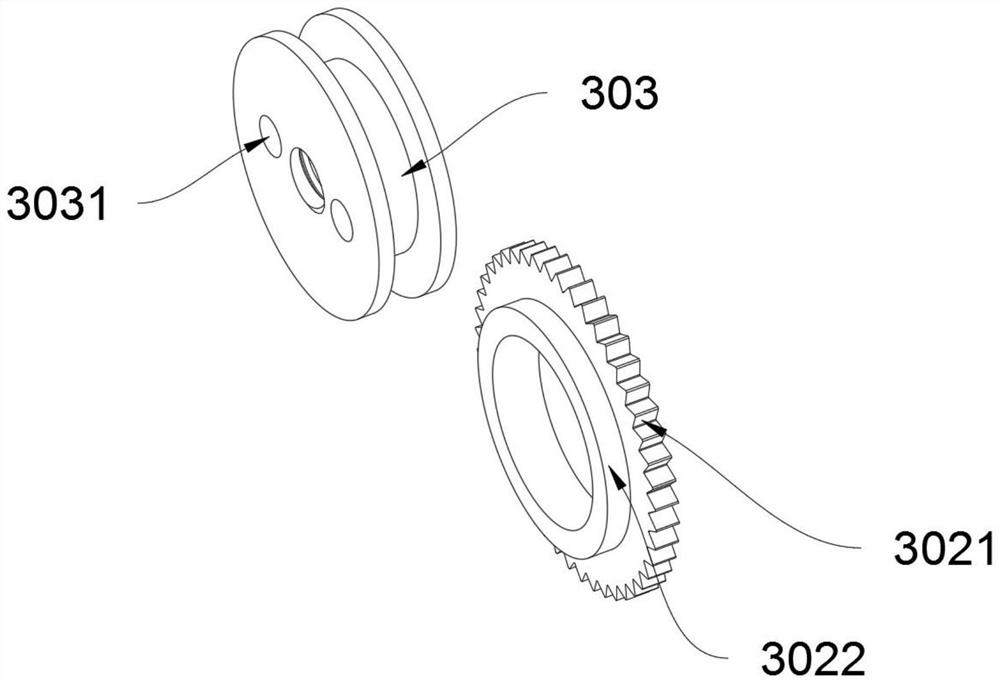

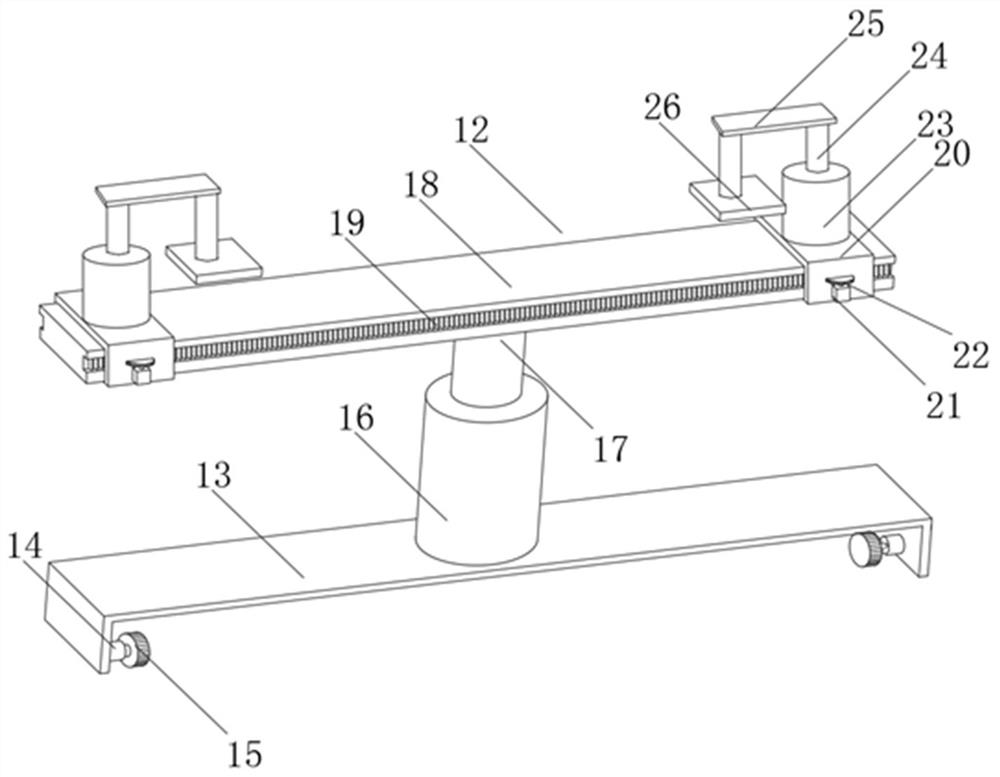

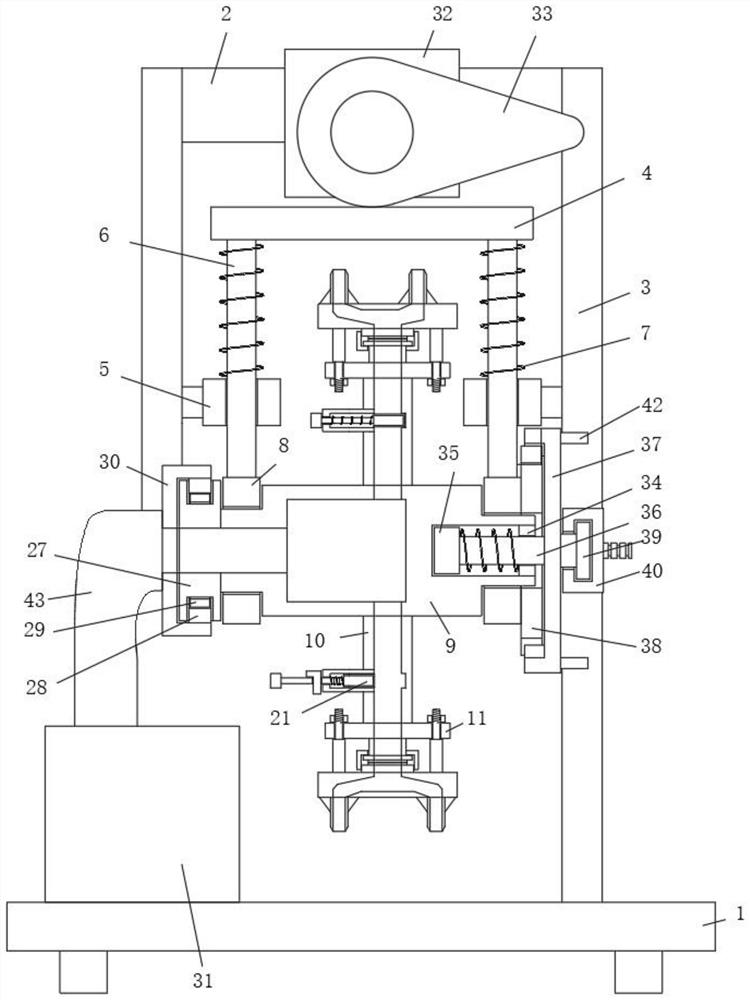

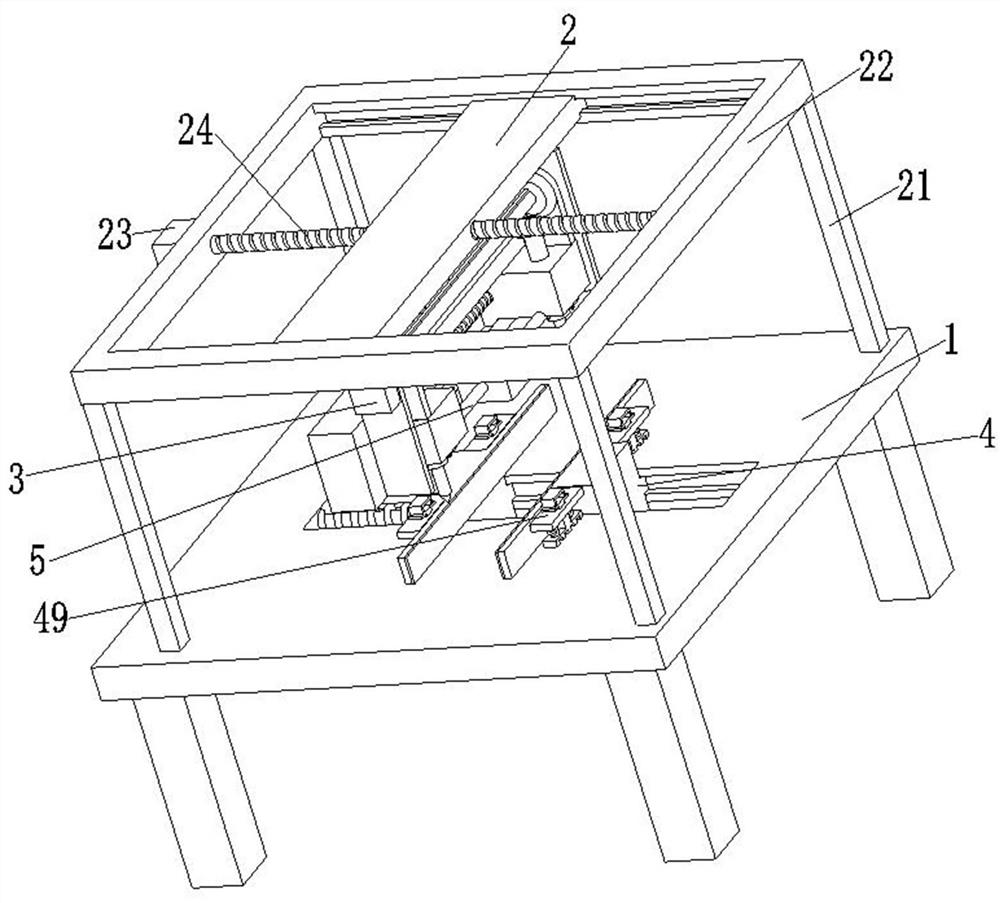

The invention discloses a double-head coaxial boring and milling machining device for machining, relates to the technical field of machining, and solves the problems that an existing machine tool canonly drill one end of a shaft part at a time, the other end of the shaft part can be drilled only by clamping the part again, the steps are tedious, hole sites at the two ends of the part are prone todeviation, and the production precision of parts is influenced. The double-head coaxial boring and milling machining device for machining comprises coaxial machining mechanisms, and the number of thecoaxial machining mechanisms is two. When the device is used for drilling the two ends of the shaft part, drill bits of two drill bit clamps can be coaxially driven to rotate through a transmission shaft, the two coaxial machining mechanisms can independently move, so that operation of drilling the two ends of the shaft part can be completed at the same time, one-time forming is achieved, the part does not need to be clamped again, drilling positioning is accurate, the operation is convenient and flexible, machining efficiency is high, and practicability and flexibility of the device are improved.

Owner:胡天娇

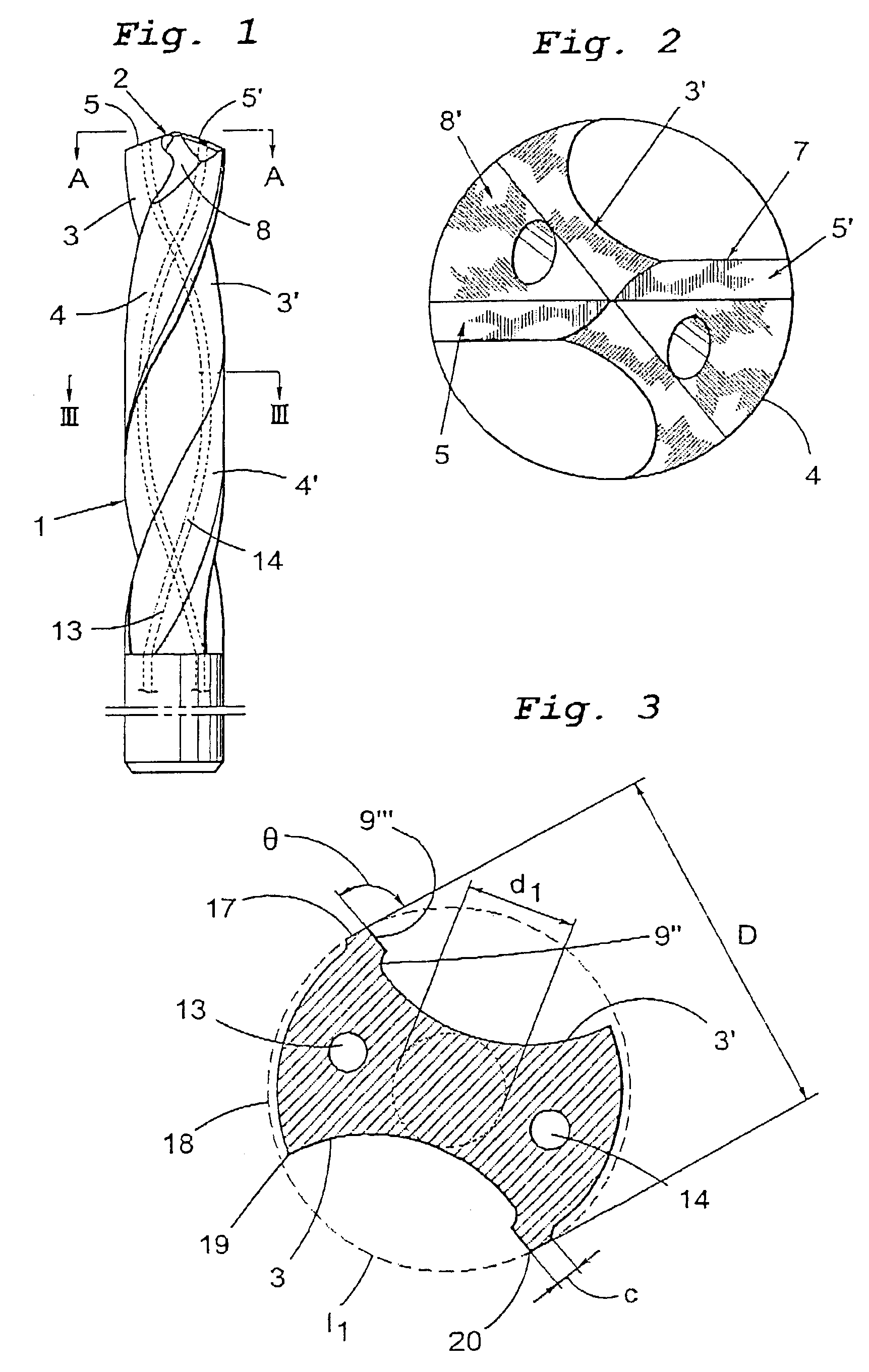

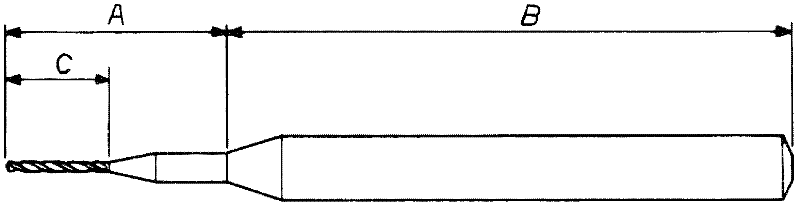

Drilling tool

ActiveCN102310215BAvoid windingLong breakage lifeTransportation and packagingPrinted circuit manufactureEngineeringBiomedical engineering

The invention provides a drilling tool, which is capable of preventing chip winding and capable of stably drilling holes by using a small-diameter drill bit with a diameter smaller than 0.7 mm, in particular smaller than 0.4 mm, and achieves long breakage-resistant lifetime and excellent practicability. The tail end of a tool body (1) is equipped with one or more cutting blades. Multiple helical chip-evacuating grooves are formed in the outer circumference of the tool body (1) from the tail end of the tool body to the base end, wherein the multiple chip-evacuating grooves at least comprise one main groove (2a) and one auxiliary groove (2b). The one or more auxiliary grooves (2b) are joined with the main groove (2a) at the halfway portion of the main grove (2a). In addition, the join portion (6) where the main groove (2a) and the auxiliary groove (2b) are joined has class difference (7).

Owner:UNION TOOL

Cutting Tool for Drilling

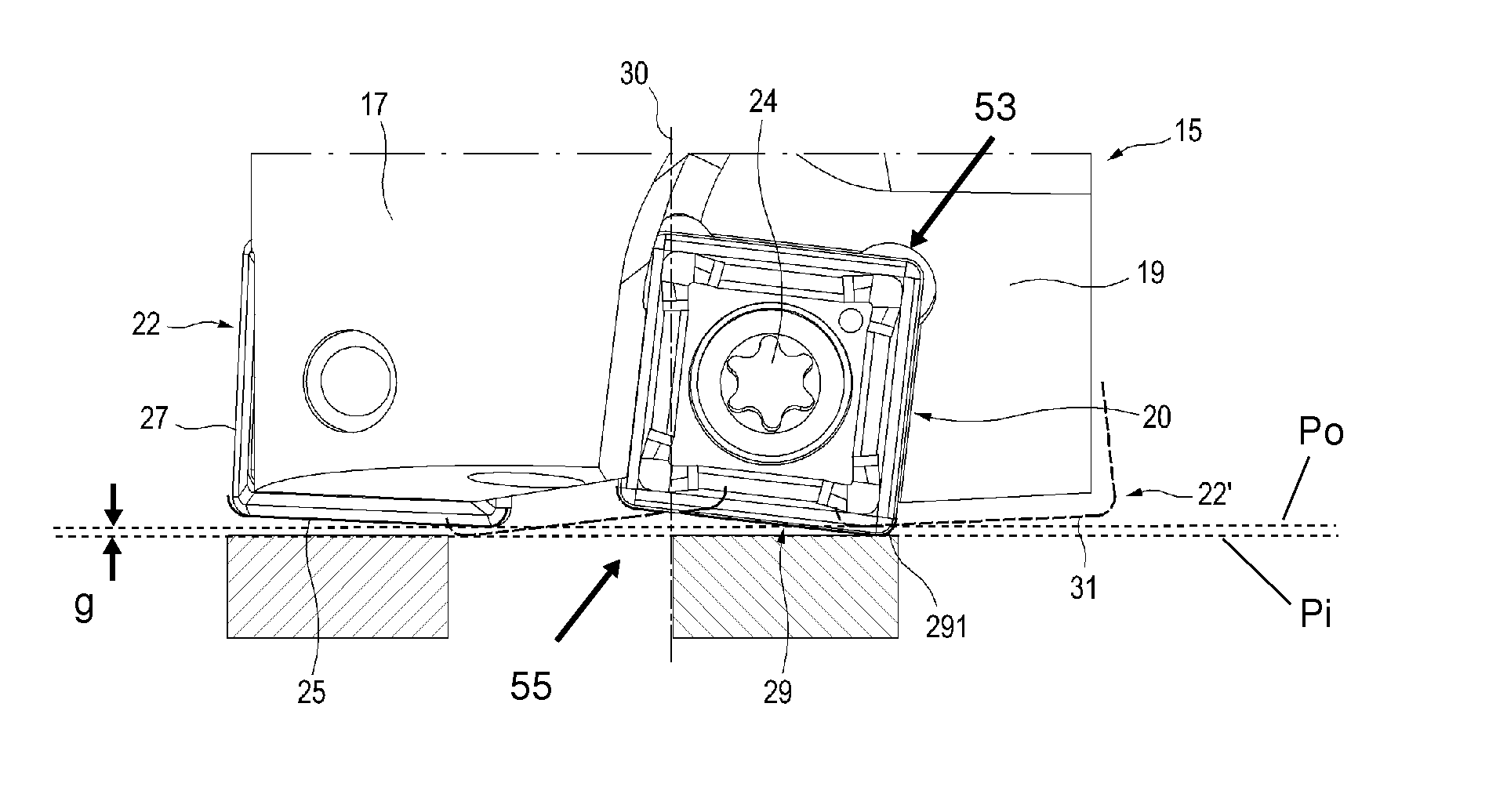

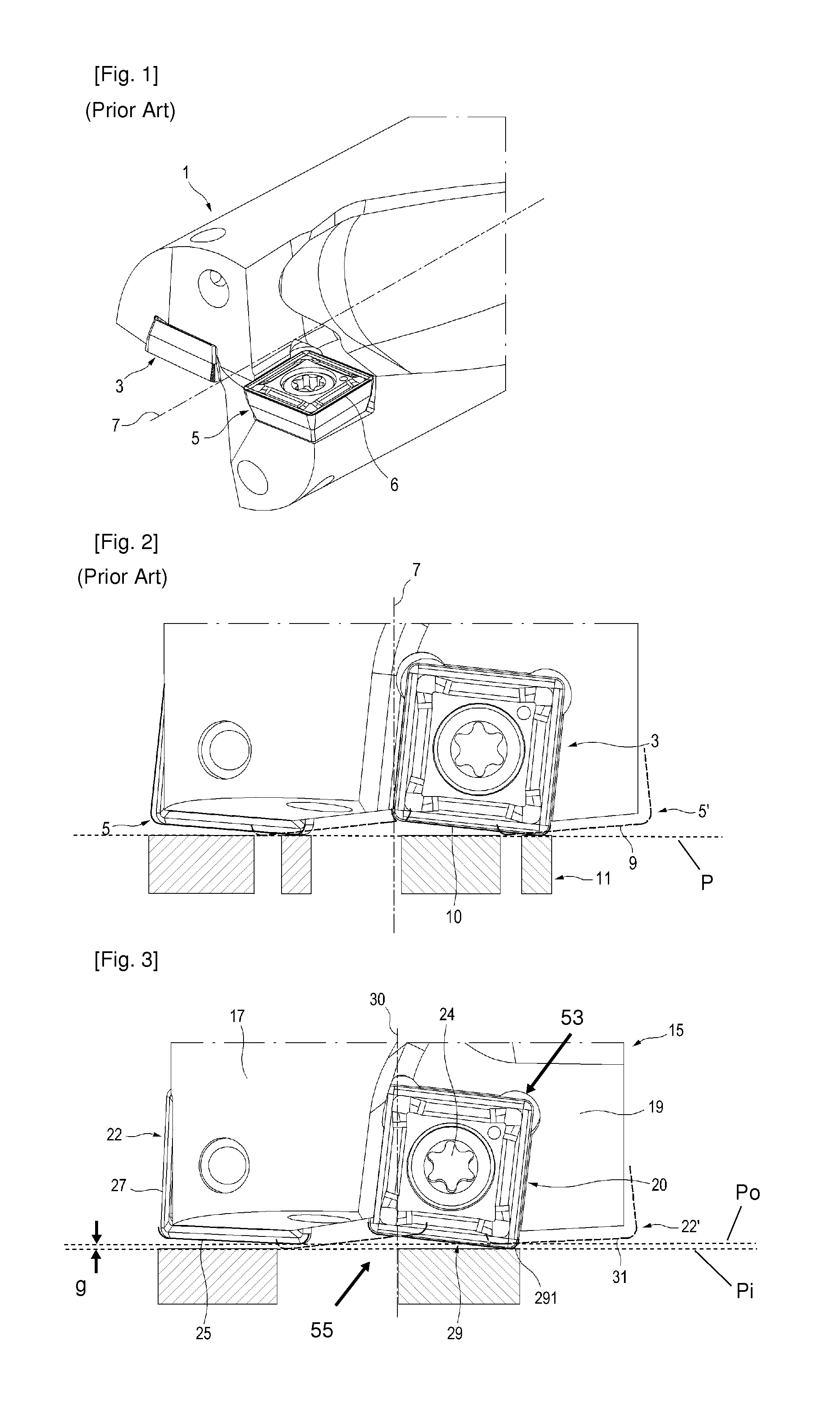

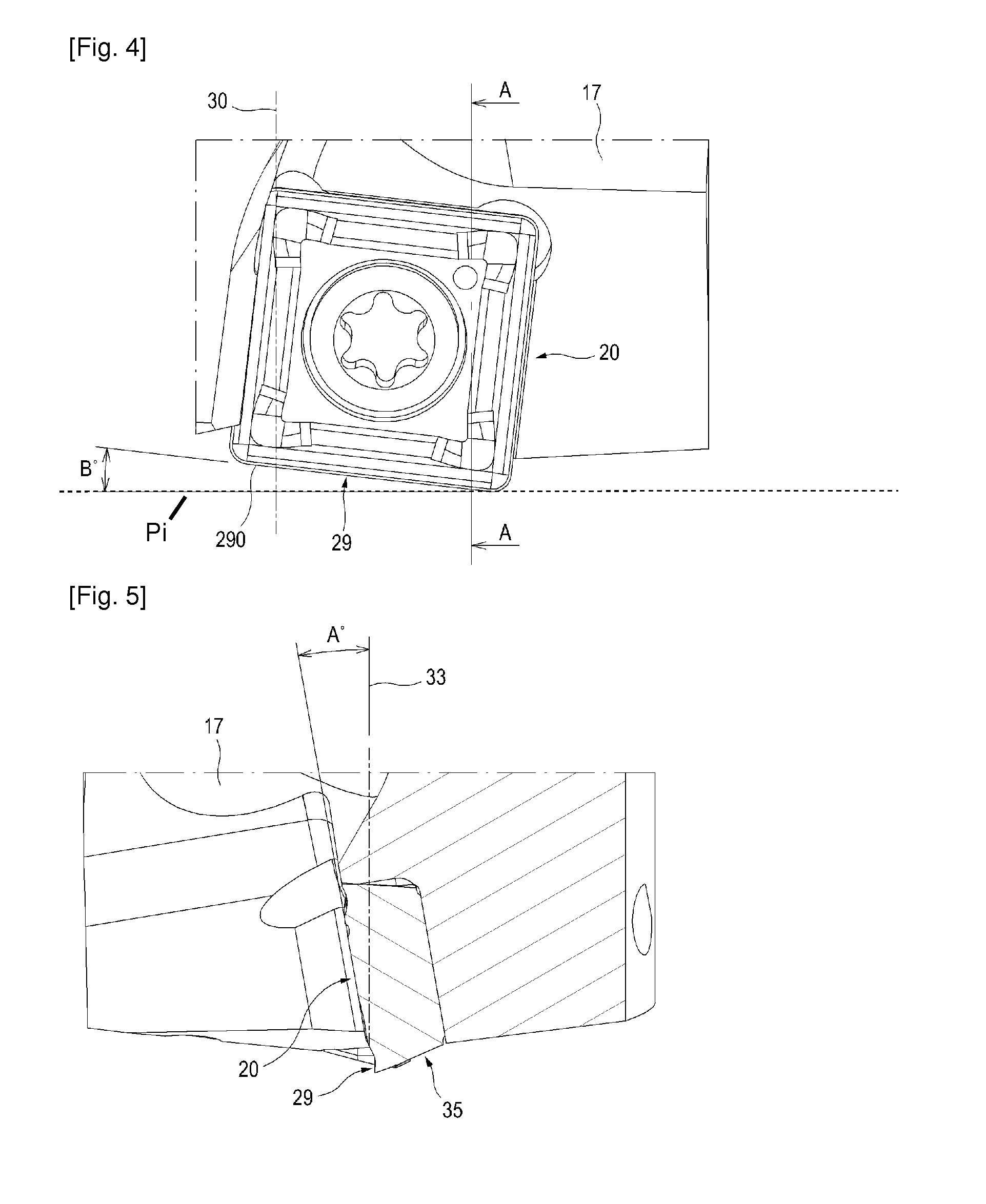

InactiveUS20110229281A1Stable drillingWood turning toolsTransportation and packagingEngineeringMechanical engineering

A cutting tool for drilling has cutting inserts in the same shape and is capable of discharging a chip in a chip flute. The cutting tool includes: a body having a lower end facing a direction of drilling, a central axis of rotation and at least two chip flutes; and indexable inner and outer cutting inserts each disposed in an insert pocket formed at the lower end of the body and at a forward end of a corresponding chip flute. The inner cutting insert is located closer to the central axis of the body than the outer cutting insert. The inner and outer cutting inserts have the same shape and include lower cutting edges for depth cutting during drilling. The lower cutting edge of the inner cutting insert is disposed lower than the lower cutting edge of an imaginary cutting insert at a position where the inner cutting insert is overlapped with the imaginary cutting insert where the outer cutting insert is rotated by approximately a half-turn relative to the central axis.

Owner:TAEGUTEC

Carbon hollow bar machining device with waste collecting function

The invention discloses a carbon hollow bar machining device with a waste collecting function. The carbon hollow bar machining device comprises a carbon bar trepanning machine and a waste collecting device. The carbon bar trepanning machine and the waste collecting device are both arranged on a base. The carbon bar trepanning machine is provided with a machining platform. A motor is fixedly arranged at one end of the machining platform and connected with a cutter rod rotary shaft. A blade is arranged at the front end of the cutter rod rotary shaft, an exhaust fan device is arranged at the rear end of the cutter rod rotary shaft, and the lower end of the cutter rod rotary shaft is supported by a mounting bracket. A machining channel is arranged at the rear end of the waste collecting device. Clamping mechanical arms are arranged at the upper end and the lower end of the machining channel. A waste collecting box is arranged at the rear end of the waste collecting device. Rolling wheel devices are arranged at the bottom of the carbon bar trepanning machine. In this way, a carbon bar can be trepanned, meanwhile, chipping removal work can be provided, and waste chippings can be collected.

Owner:WUXI ZHONGQIANG ELECTRIC CARBON CO LTD

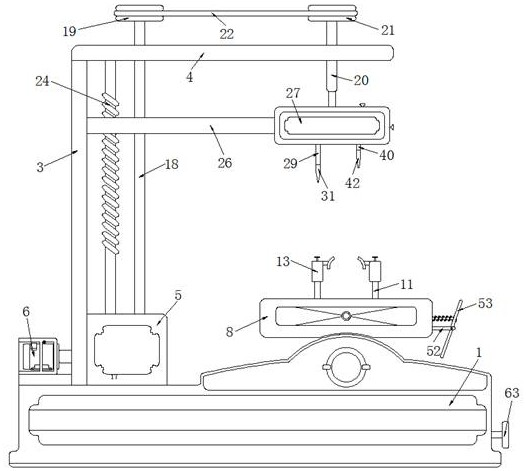

Processing device of carbon hollow bar

The invention discloses a processing device of a carbon hollow bar. The carbon hollow bar comprises a carbon bar fixing machine and a drilling device, wherein a work table is arranged on the drilling device; a motor is fixedly mounted at one end of the work table; a processing cutter rod is arranged on the motor; the rear end of the processing cutter rod is fixedly connected to o the motor; a processing cutter blade is arranged at the front end of the processing cutter rod; a limit supporting block is also arranged on the processing cutter rod; the limit supporting block is fixed on the work table through a bracket; the carbon bar fixing machine is mounted at the front end of the drilling device; mechanical clamping arms are respectively arranged at the upper end and the lower end of the carbon bar fixing machine; a blast blower is arranged in the center of the carbon bar fixing machine. Through the manner, the processing device disclosed by the invention can stably drill holes in a carbon bar, and scraps in the carbon bar can be cleaned in time after the cutter retracts; the processing cutter is stable to work; the limit supporting block is arranged at the bottom in a supporting manner, so that the working stability is improved.

Owner:无锡中强电碳有限公司

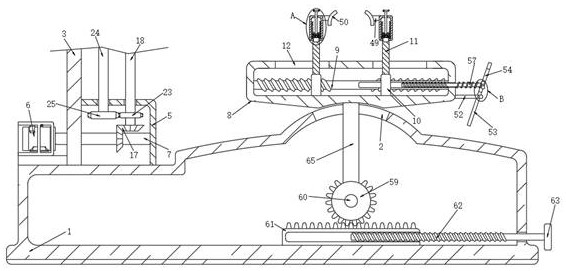

Plate drilling device

InactiveCN107855554APrevent scratching the surface of the boardSimple device structureFeeding apparatusPositioning apparatusEngineering

The invention provides a plate drilling device. The plate drilling device comprises a machine body, wherein a sliding cavity is formed in the machine body, and a sliding frame body is arranged in thesliding cavity in an up-and-down sliding mode. A first sliding groove with a downward opening is formed in the center of the sliding frame body, a second sliding groove communicating with the first sliding groove is formed in the upper end of the first sliding groove and in the sliding frame body, a linkage plate is arranged in the second sliding groove in an up-and-down sliding mode, a lifting strip is arranged in the first sliding groove in an up-and-down sliding mode, and the upper end of the lifting strip is fixedly connected with the linkage plate. The lower end of the lifting strip is fixedly provided with a drilling motor, the lower end of the drilling motor is in power connection with a drilling tool, an upper mounting groove and a lower mounting groove are symmetrically formed inthe left side and the right side of the sliding frame body, a conversion motor is fixedly arranged between the upper mounting groove and the lower mounting groove, the upper end and the lower end of the conversion motor are in power connection with an upper power shaft and a lower power shaft respectively, and a communication groove for communicating the upper mounting groove and the lower mounting groove is formed in the portion between the upper mounting groove and the lower mounting groove and at the rear end of the conversion motor.

Owner:CIXI XINCHANG IND PROD DESIGN

Drilling tool

PendingCN111097945ANot easy to damageIncrease in sizeTransportation and packagingTrepanning drillsTool bitThermodynamics

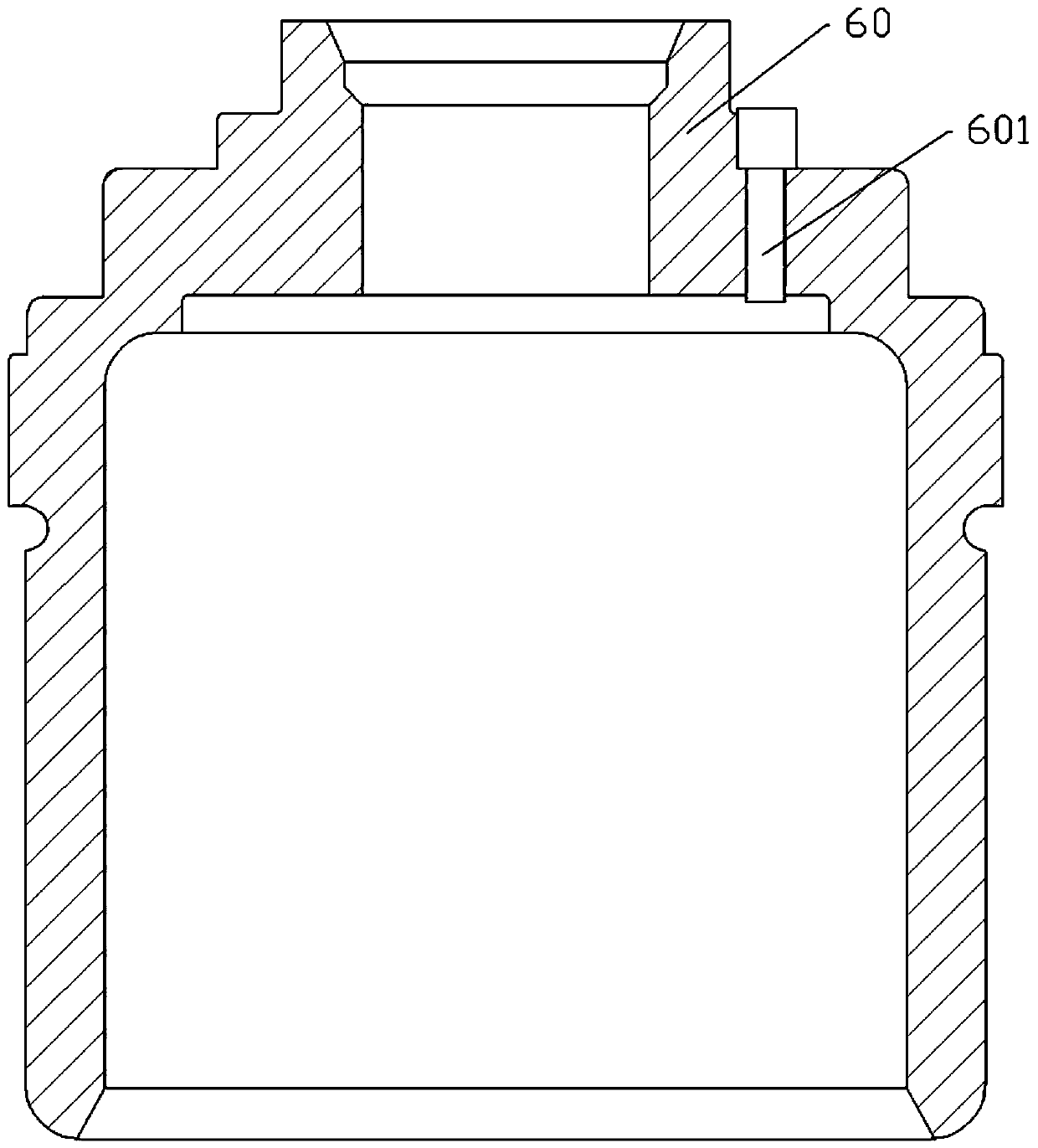

The invention provides a drilling tool. The drilling tool comprises a drilling tool body and a drilling tool bit, wherein a clamping handle and a first spiral groove are arranged on the drilling toolbody; a second spiral groove is arranged on the drilling tool bit; the second spiral groove is communicated with the first spiral groove; a cooling water hole is arranged on the drilling tool body; athird groove is also arranged on the drilling tool body; a positioning pin hole is arranged on the bottom surface of the third groove; a cylinder is arranged at the bottom of the drilling tool bit; the drilling tool bit is inserted into the positioning pin hole through the cylinder so as to be arranged in the third groove; and an inclined surface is arranged on the cylinder, a first threaded through hole is arranged at a preset position below one side wall of the third groove, a first screw penetrates through the first threaded through hole and clamps the cylinder through the inclined surface,and then the drilling tool bit is locked. According to the scheme, on the premise of keeping the clamping precision, the effective locking times are increased in multiple levels, and the drilling tool has high drilling efficiency.

Owner:无锡湾流精工科技有限公司

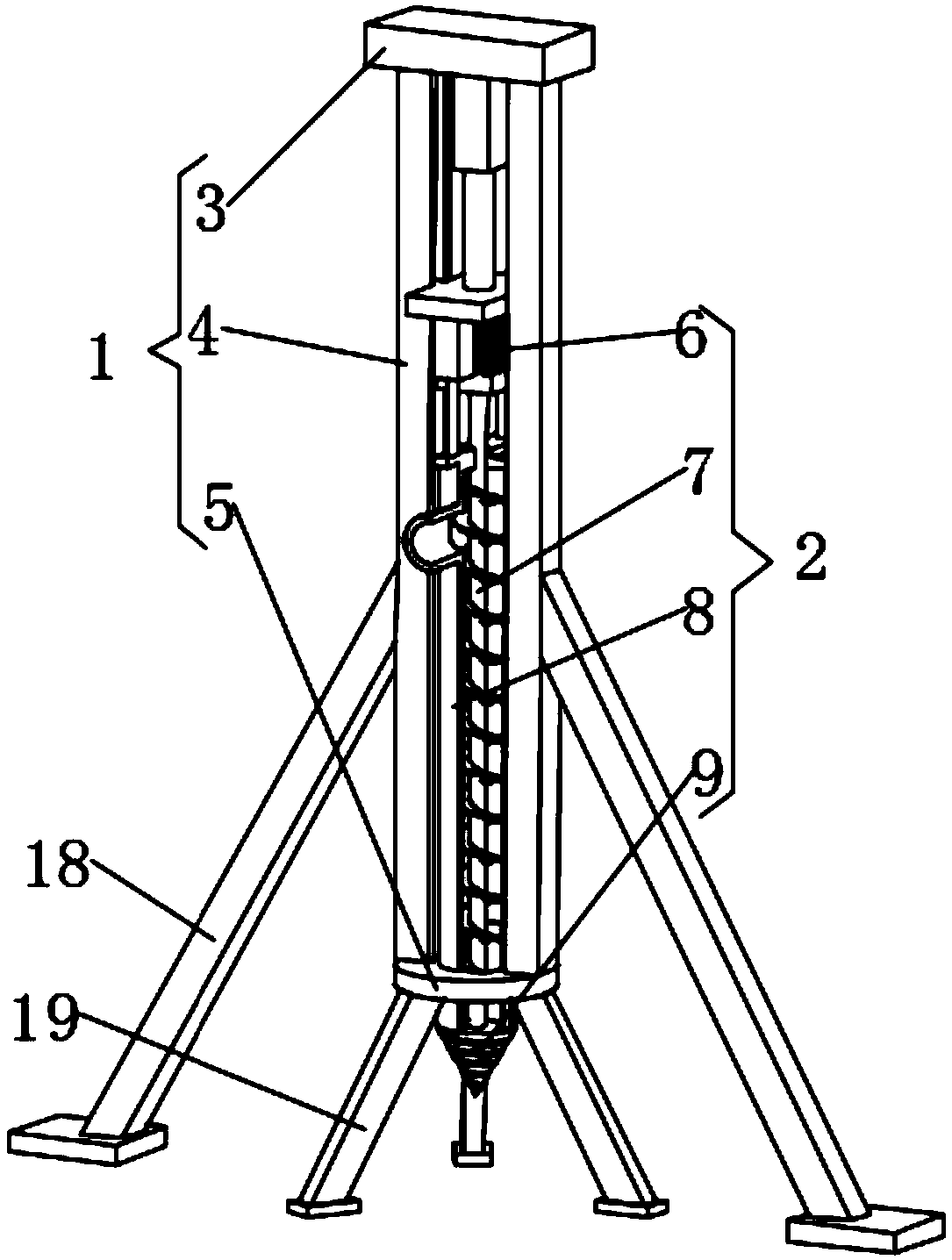

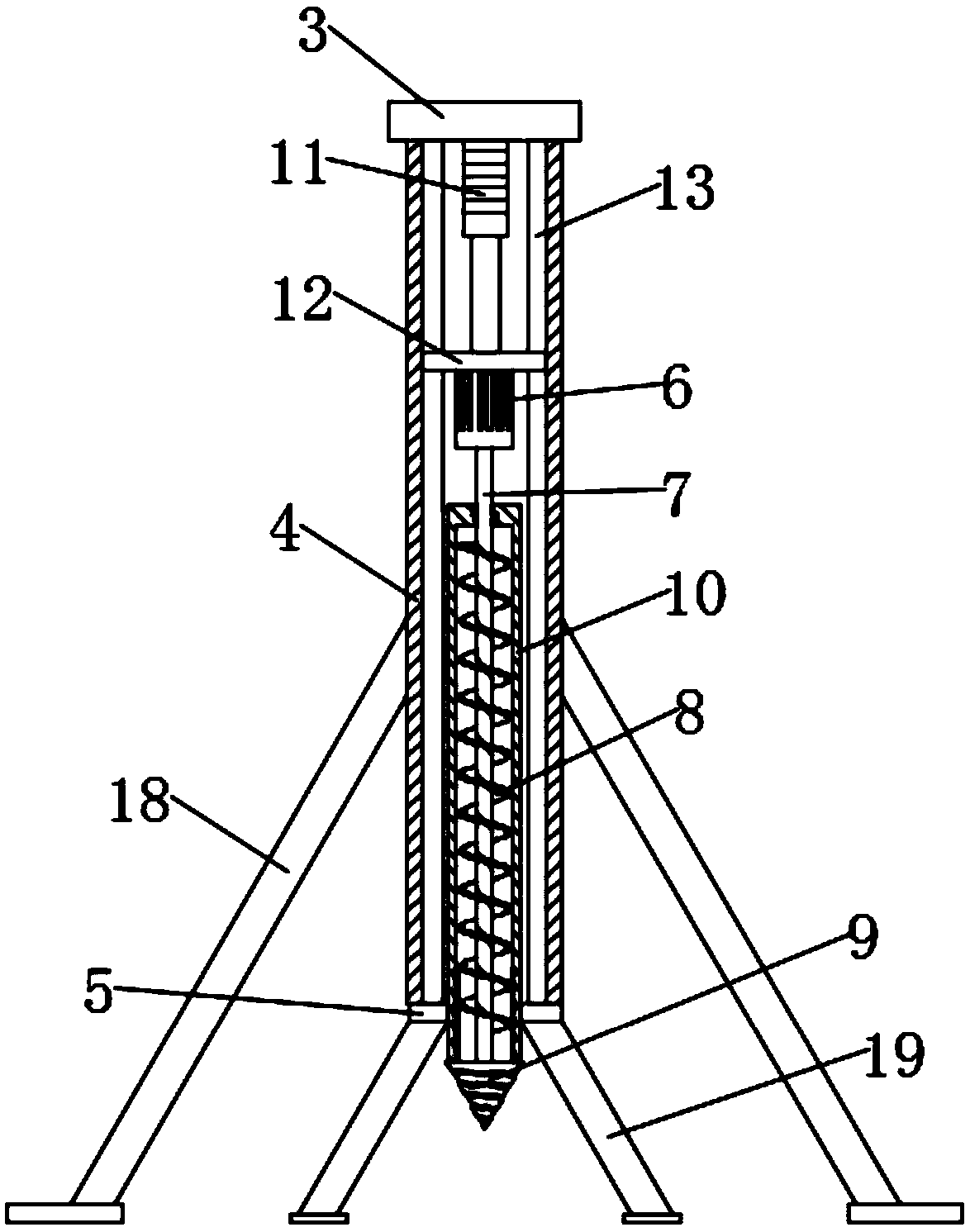

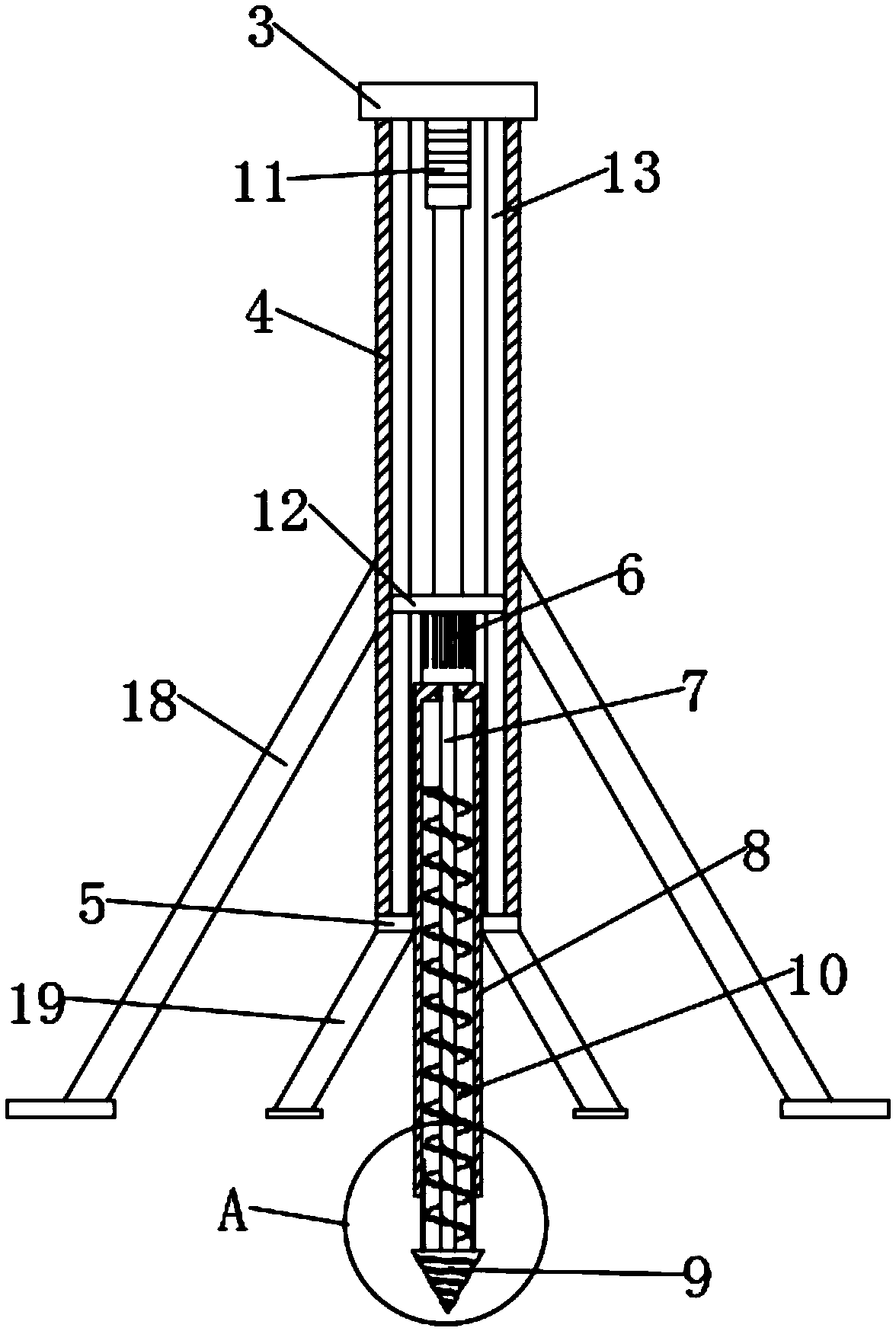

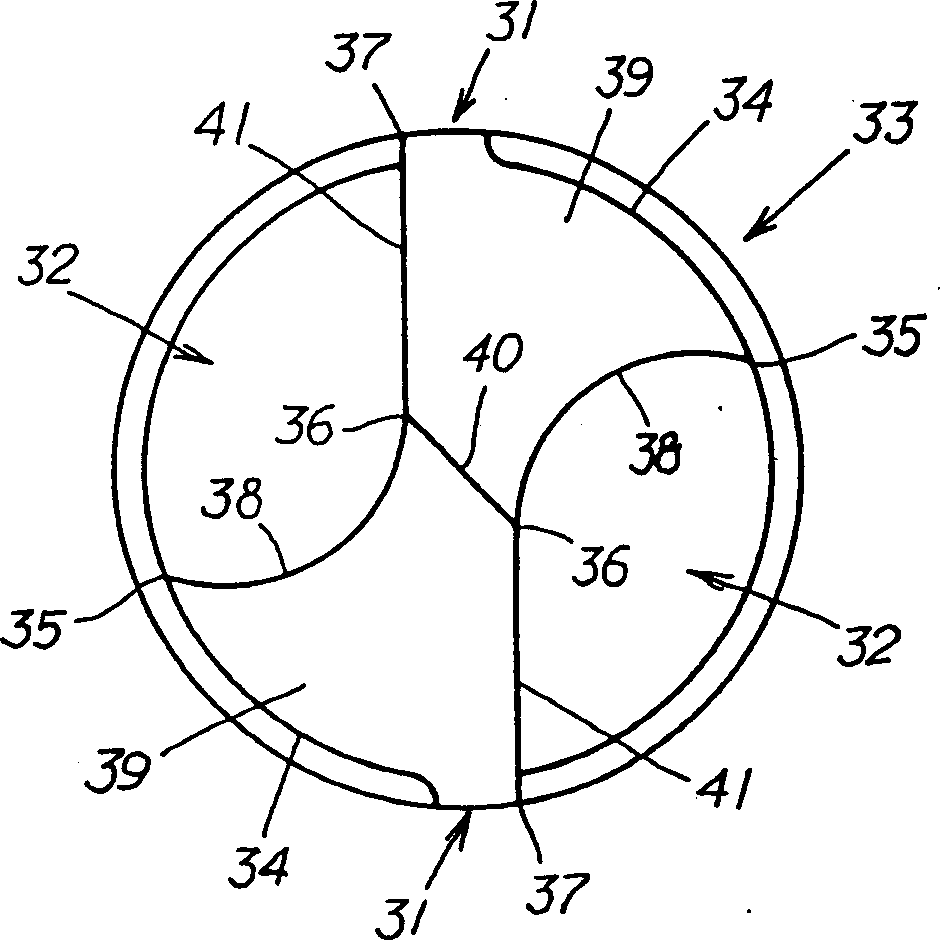

Extraction drilling machine for landfill gas recovery

ActiveCN109184580AStable drillingWon't leakDrilling rodsConstructionsHelical bladeWorking environment

The invention discloses an extraction drilling machine for landfill gas recovery, which comprises a support mechanism and a working mechanism, wherein the support mechanism includes a main supportingtop plate, a guide column and a bottom supporting frame, and the working mechanism includes a motor, a driving rod, a gas guide cylinder and a drill bit. In the working mechanism of the invention, thedriving rod connected with the drill bit is externally sleeved with the gas guide cylinder, and the outer wall of the driving rod is provided with a helical blade shaped gas extracting blade. When the driving rod rotates, the drill bit can be driven to drill a hole, the gas extracting blade can further enable the gas guide cylinder to have an upward extraction force, so that the waste gas can bedirectly extracted when the drill bit drills to the waste gas, the working process is enabled to be simple, and there is no need to replace equipment. In addition, the extraction drilling machine doesnot result in great leakage of the waste gas, thereby protecting the good working environment.

Owner:嘉兴金旅燕科技有限公司

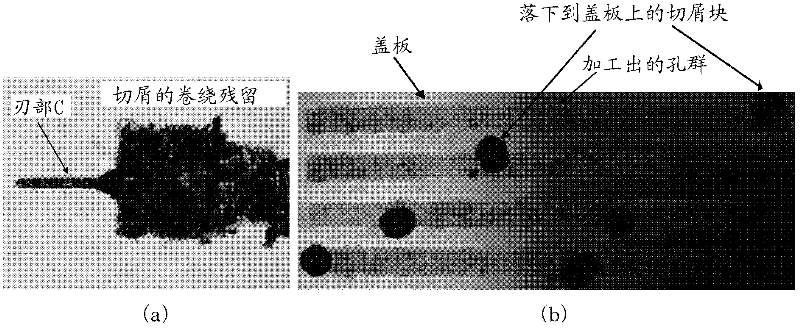

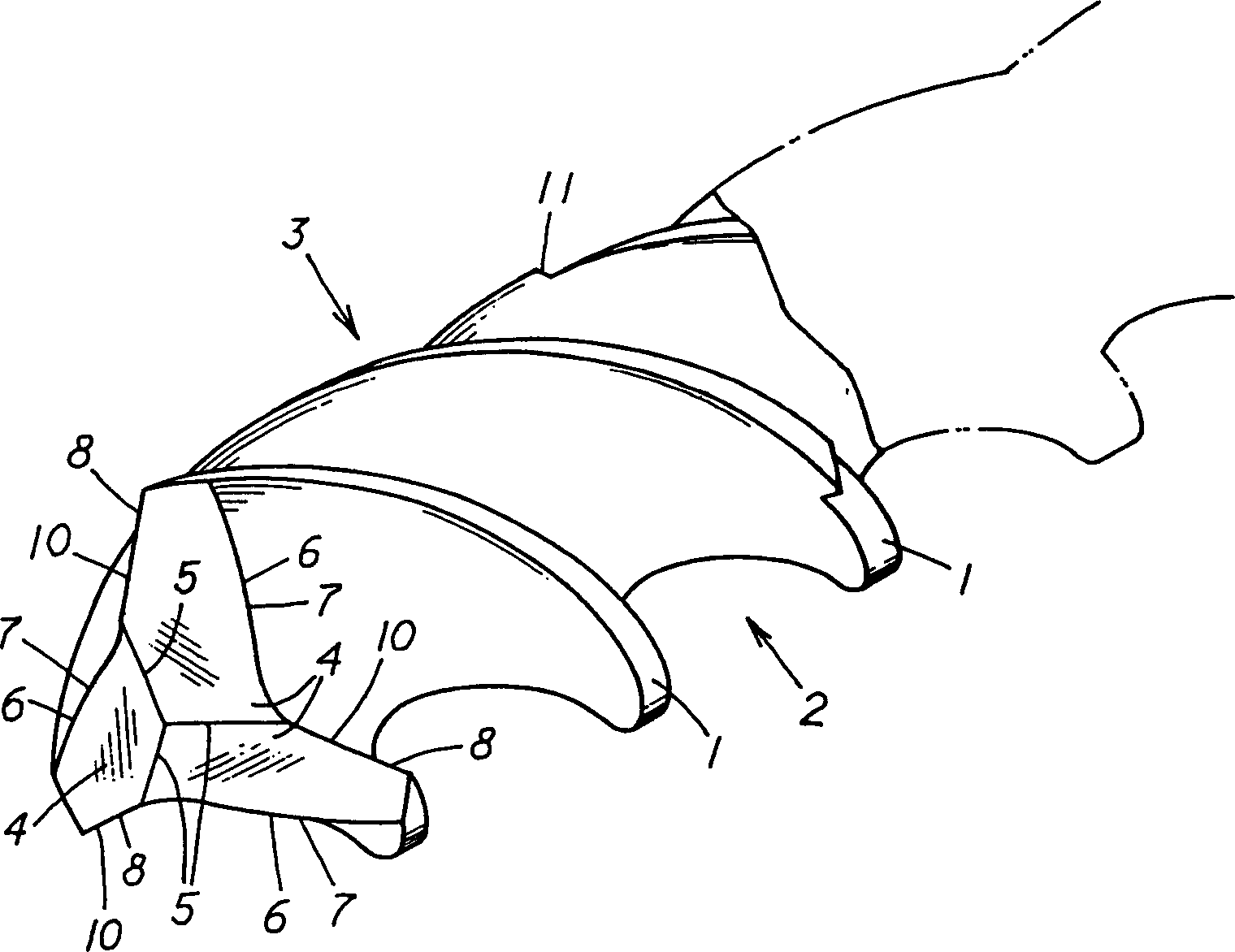

Drilling bit

InactiveCN1460571AEfficient dischargePrevents the malady of staying in the chip flute 2Printed circuit detailsTransportation and packagingChiselHigh intensity

The object of the present invention is to provide a drill that is long in length and has a small diameter, and at the same time, features a high strength capable of advancing straight forwards as well as being capable of drilling holes having excellent inner wall roughness so as to enhance the applicability of the drill. The solution of the present invention is a drill 3 comprising plural chip discharge grooves 2 helically formed on a peripheral surface, a margin section 1 provided between the chip discharge grooves 2, and cutting edge 8 formed on a tip thereof. The drill 3 is made of ultra-hardened alloy and includes more than three chip discharge grooves 2. A flank 4 is provided at a front face of each of the margin section 1, to form more than three chisel edges 5 by crossing adjoining chisel edges. Intersections of the three chisels 5 form an acute point. An opposite face of a cutting face 10 of the margin section 1 is provided with a swelling section 7 extending towards the chip discharge grooves 2.

Owner:UNION TOOL +1

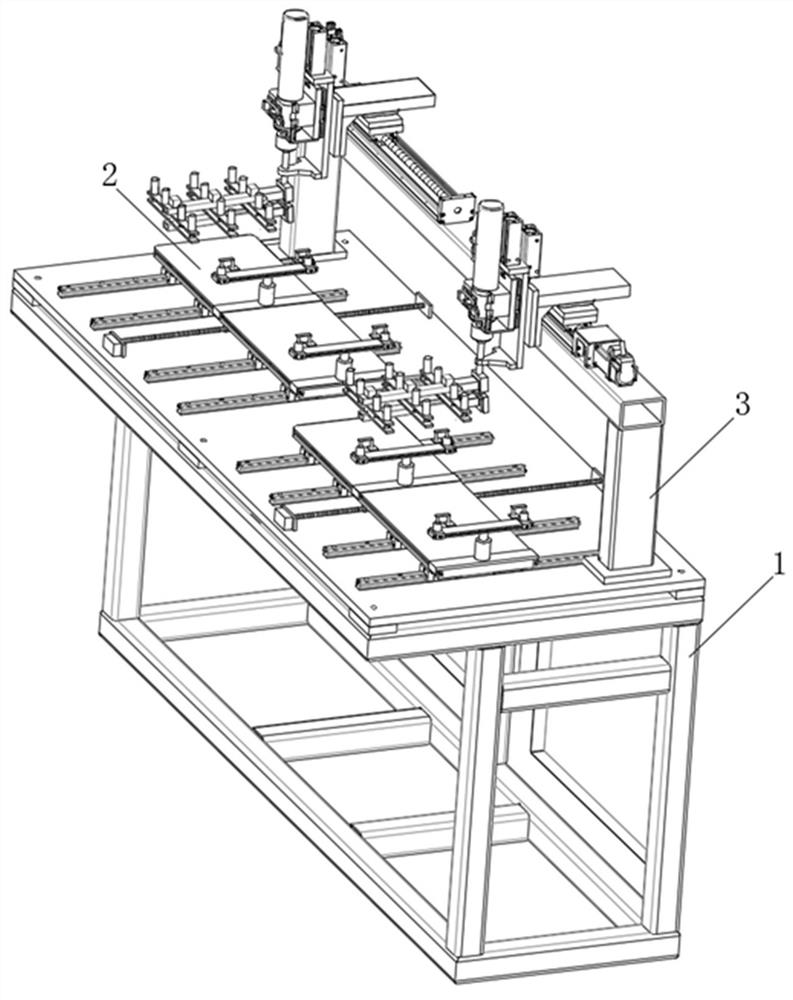

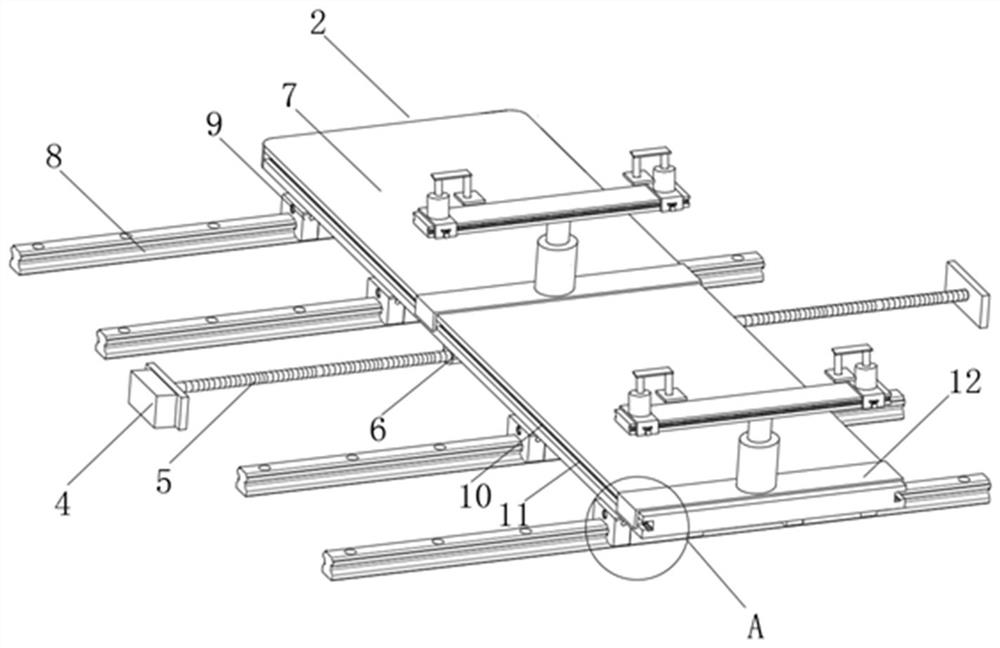

Tapping equipment for machining automobile oil pan guard plate, and working method thereof

InactiveCN112157457AGuaranteed tightnessHigh precisionFeeding apparatusPositioning apparatusElectric machineryDrill floor

The invention discloses tapping equipment for machining an automobile oil pan guard plate, and a working method thereof. The tapping equipment comprises a supporting frame, two supporting tables and adrill moving table; the two supporting tables are arranged on the two sides of the top of the supporting frame separately, and the drill moving table is arranged at one end of the top of the supporting frame; each supporting table comprises a motor I, a sleeve rail and a sliding disc I; and the motor I is arranged at one end of the middle part of the supporting table, and one end of the motor I is rotatably connected with a lead screw I through an output shaft. The tapping equipment has the beneficial effects that four drilling bases are arranged on each rotary disc, and drill bits in different sizes and models can be installed on each drilling base; it is guaranteed that the equipment can be used for rapidly drilling holes in different diameters in an oil pan guard plate, and the use diversity of the equipment and the efficiency of drilling holes in different oil pan guard plates are improved; the equipment is higher in tapping precision and efficiency for oil pan guard plates in different sizes; and the equipment is high in working automation degree, has good social benefits, and is suitable for popularization and application.

Owner:马鞍山贺辉信息科技有限公司

Precise drilling fixing device for arc-shaped surface of hardware product

PendingCN114425630AEasy to adjustStable drillingPositioning apparatusMetal working apparatusElectric machineryEngineering

Owner:鲍可昌

Multi-position automatic drilling machine for greenhouse accessory machining

PendingCN107243664AEfficient drillingPrecision DrillingMetal working apparatusBoring/drilling machinesEconomic benefitsProcess engineering

The invention belongs to the technical field of greenhouse accessory application and particularly discloses a multi-position automatic drilling machine for greenhouse accessory machining. The multi-position automatic drilling machine for greenhouse accessory machining is composed of a machine frame, a plurality of cross beams, a plurality of diagonal bracings, channel steel arranged on the machine frame, a drilling assembly and a discharging assembly, wherein the cross beams and the diagonal bracings fix the machine frame, and the drilling assembly and the discharging assembly are arranged on the machine frame. The multi-position automatic drilling machine for greenhouse accessory machining has the beneficial effects of being reasonable in design and structure, capable of efficiently, accurately and stably conducting intelligent drilling operation on a film rolling rod to be machined, lowering the labor and production cost investment and increasing the economic benefits.

Owner:江苏润城温室科技有限公司

Perforating device for capacitor film machining

InactiveCN113334489AConvenient location changeStable drillingMetal working apparatusEngineeringWaste material

The invention discloses a perforating device for capacitor film machining. The perforating device comprises a bottom plate, two rotating cylinder mounting rings are arranged on the vertical upper side of the bottom plate, a middle shaft cylinder is rotationally erected between the two rotating cylinder mounting rings, a plurality of mounting mechanisms are arranged on the outer side of the middle shaft cylinder in a divergent mode, a cutting assembly is detachably mounted at the end of each mounting mechanism, a downward-pressing assembly is arranged at the top of the middle shaft cylinder, a suction cavity is formed in one end of the middle shaft cylinder, a dust collector is further mounted on the top side of the bottom plate, a communicating pipe is mounted on the dust collector, one end of the communicating pipe communicates with the suction cavity, a fixing mechanism is arranged between the middle shaft cylinder and each rotating cylinder mounting ring, and each mounting mechanism comprises a side pipe fixedly connected with the middle shaft cylinder. The perforating device is high in applicability, can meet the perforating requirements of different capacitor films, can collect waste materials in time, is convenient to use, is ingenious and stable in structure, reduces the production cost, and meets the use requirements of people in production and life.

Owner:东莞市普隆电子有限公司

Vertical numerical control drilling machine for machining mining machine parts

ActiveCN114523135APrevent slidingReliable positioning and clampingLarge fixed membersPositioning apparatusNumerical controlMachine parts

The invention relates to the technical field of numerical control drilling machines, in particular to a vertical numerical control drilling machine for mining machine part machining, which comprises a discharging plate, an adjusting mechanism, a drilling mechanism and a positioning mechanism, the adjusting mechanism is mounted on the discharging plate, the drilling mechanism is mounted on the adjusting mechanism, and the positioning mechanism is mounted at the bottom of the discharging plate. The drilling machine can solve the following problems that when a vertical numerical control drilling machine conducts drilling operation on mining machine parts, a traditional vertical numerical control drilling machine cannot conduct stable clamping operation on a workpiece, the workpiece is prone to moving during drilling, and the drilling efficiency and quality of the workpiece are affected; and secondly, when the numerical control drilling machine works, a drill bit rotating at a high speed can generate a large amount of heat, the drill bit cannot be cooled in time, the loss of the drill bit is accelerated due to the overhigh temperature, the service life of the drill bit is shortened, and meanwhile, the machining precision can be influenced to a certain extent.

Owner:南通立伟重工机械有限公司

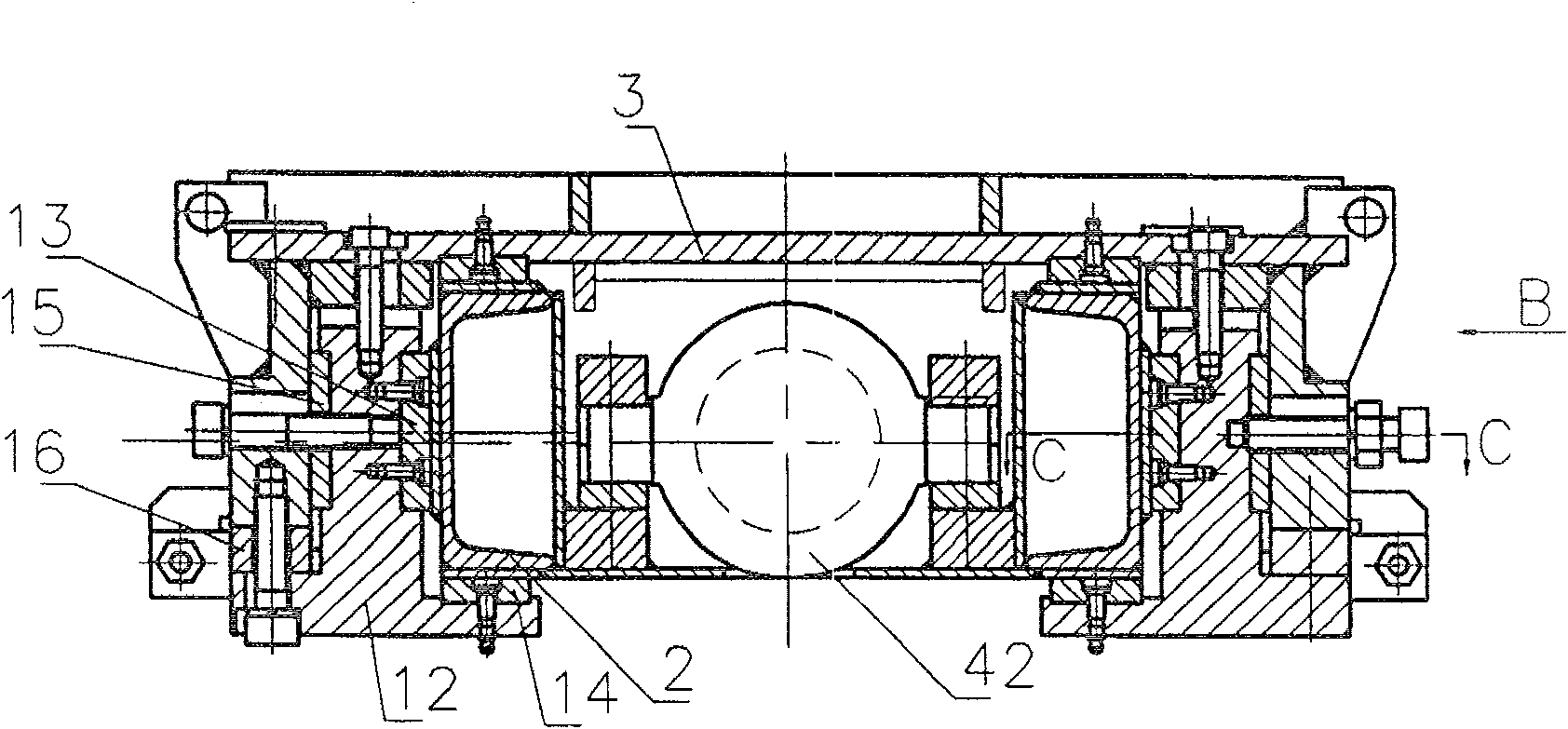

Full-hydraulic multifunctional driller for gas extraction, drainage and discharge

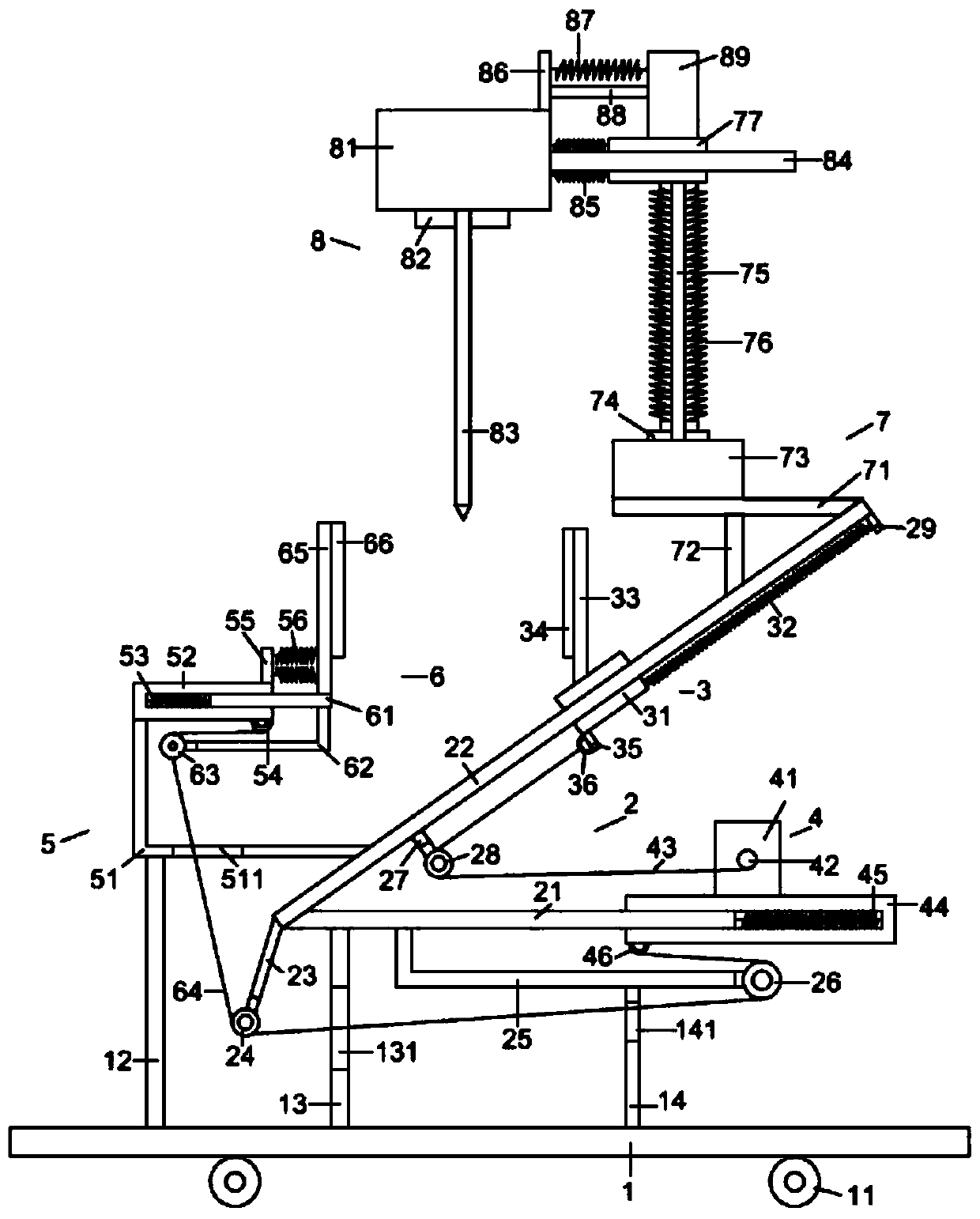

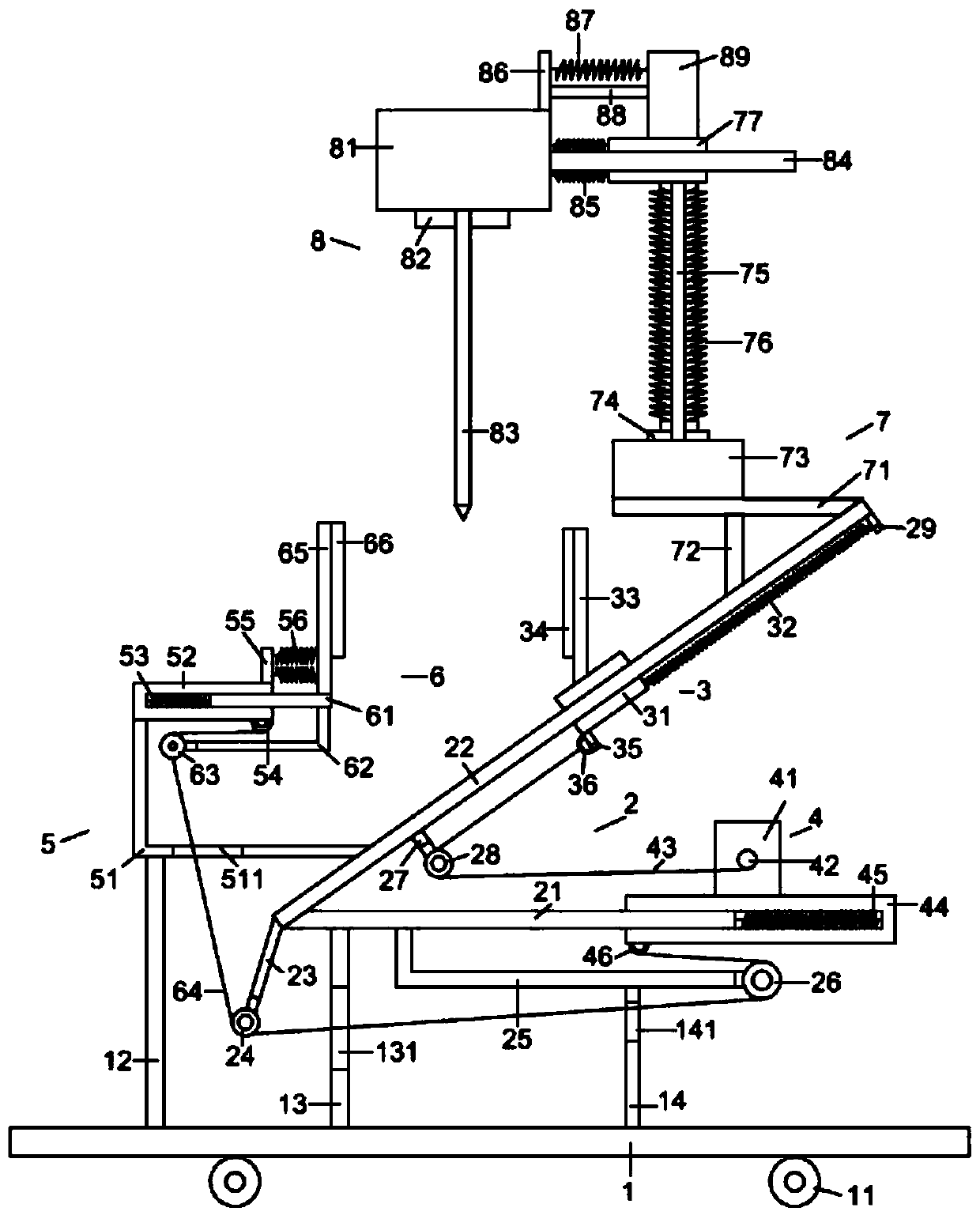

InactiveCN100575656CHigh guiding precisionReasonable forceConstructionsDerricks/mastsEngineeringCopper

This invention relates to one whole hydraulic oil discharge multi-function drilling machine, wherein, the rack is connected to column frame beam through wire beam screw structure and the column frame beam two ends are connected to column through wire beam; the supportive bar is composed of three sections with middle section is wire bar and other two set with T shape socket; the middle socket and rack outside and down side are set with copper board; the middle socket and drag board limit are set with gap adjust wedge block.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

Airplane APU rear bearing cavity maintaining tool

The invention discloses an airplane APU rear bearing cavity maintaining tool for airplanes of the Boeing 737 series, the Airbus A320 series and the like. A flange protruding edge is arranged on the front end face of a rear bearing cavity in an APU of the series of airplane and evenly provided with bolt holes distributed along the circular ring. The rear end face of the rear bearing cavity is provided with bolt holes distributed along the circular ring. The bolt holes in the rear end face are internally provided with self-locking threaded sleeves with bolts. The maintaining tool comprises a base capable of being fixedly connected with a bench drill. One plane of the base is used for being detachably connected with the not-to-be-maintained end of the rear bearing cavity, namely the end faceof the flange protruding edge. According to the provided maintaining tool, the rear bearing cavity can be subjected to drilling machining after the rear bearing cavity is fixed to the bench drill, andthe maintaining efficiency is improved.

Owner:中国南方航空股份有限公司

Bridge demolition construction method and equipment thereof

The invention provides a bridge demolition construction method and equipment thereof. The equipment comprises a floating mechanism, a clamping mechanism arranged at one end of the floating mechanism, an inclination angle adjusting mechanism arranged at the top of the floating mechanism and a drilling mechanism installed on the inclination angle adjusting mechanism. According to the bridge demolition construction equipment, drilling operation can be stably conducted on the side wall of a water surface pier on the water surface, and after drilling is conducted, blasting personnel can conduct blasting demolition on the pier after charging explosives into a hole. The bridge demolition construction equipment is high in reliability and automation degree, the problem that blast holes are difficult to drill when water surface piers are demolited at present is effectively solved, the construction safety and convenience of workers are improved, and the construction efficiency of the workers is effectively improved.

Owner:CHONGQING VOCATIONAL COLLEGE OF TRANSPORTATION

Novel aviation component machining drilling equipment in aviation field

InactiveCN109967774AEffective Drilling TreatmentEffective clampingFeeding apparatusPositioning apparatusAviationDrill

Novel aviation component machining drilling equipment in the aviation field comprises a bottom plate, a positioning device located above the bottom plate, a first clamping device arranged on the positioning device, a motor device, a support device, a second clamping device arranged on the support device, an electric cylinder device arranged on the positioning device and a drill rod device arrangedon the electric cylinder device. The novel aviation component machining drilling equipment in the aviation field can achieve effective drilling treatment on aviation components, the drilling efficiency is high, operation is simple, usage is convenient, the aviation components can be stably clamped during drilling, clamping is stable, stable drilling work can be conducted on the components duringdrilling, meanwhile, the position of a drill rod can be adjusted, accordingly, the positions, needing to be drilled, on the aviation components are drilled, the drilling work is flexible, and the existing drilling requirement can be effectively met.

Owner:张舒维

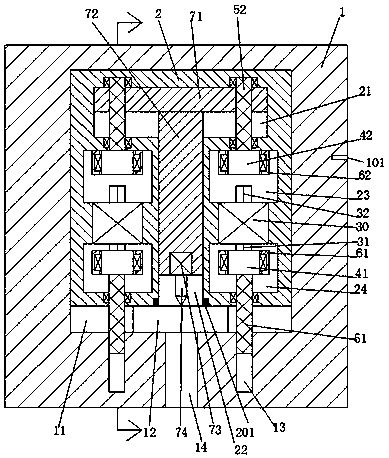

A top bolt drilling rig and a top bolt drilling rig comprising the same

ActiveCN105443037BImprove locking abilityMechanizationDerricks/mastsAnchoring boltsRock boltCarriage

The invention discloses an anchor rod jacking mechanism which comprises a fixing mechanism, a supporting mechanism, a sliding block and a drill box mechanism. The fixing mechanism comprises a base, a stand plate and a connecting seat. Protrusions for fixing guide blocks are arranged on the stand plate. The supporting mechanism and the sliding block are in sliding connection with the opposite side faces of the stand plate through the guide blocks respectively. One end of the supporting mechanism and one end of the slide block are connected with base through telescopic oil cylinders. The drill box mechanism comprises a bottom frame and two independent drill box sliding seats. The bottom frame is connected with the base, and the drill box sliding seats can horizontally move along the bottom frame. When the drill box sliding seats move to the sliding block, the drill box sliding seats can be connected with the other guide rail face of the sliding block and slide along the sliding block. The invention further discloses an anchor rod jacking drilling carriage with a drilling machine. The anchor rod jacking drilling carriage comprises a four-wall anchor rod jacking drilling carriage body and a six-arm anchor rod jacking drilling carriage body. The drilling machine in the anchor rod jacking drilling carriage can work at the same time. Fast supporting operation on a top plate can be achieved, the structure is compact, and multiple functions are achieved. The anchor rod jacking mechanism and the anchor rod jacking drilling carriage operate in cooperation with heading equipment to complete the supporting and transferring function synchronously, operating personnel are greatly reduced, the labor intensity is lowered, and the supporting efficiency and safety are improved.

Owner:LANG FANG JING LONG GRAND IND MACHINERY CO LTD

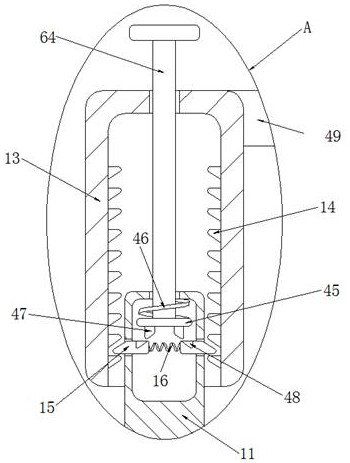

A Tapping Drilling Machine Based on Route Drilling Water Circulation Cooling

ActiveCN110666515BStable drillingAchieve coolingFeeding apparatusOther manufacturing equipments/toolsThermodynamicsWater resources

The invention discloses a tapping drilling machine based on route drilling water circulation cooling. The structure of the tapping drilling machine comprises a left device, a right device and a bottombox, wherein the left device is connected with the right device, the left device, the right device and the bottom box are locked, and the left device is composed of a left side plate, a left bottom plate and a left controller; the left side plate is welded to the left bottom plate, the left bottom plate is locked with a left controller, and the left side plate is in shaft connection with the leftcontroller. According to the tapping drilling machine, a drilling device is driven by the left controller to perform drilling operation, the left controller and the drilling device move under the assistance of the left side plate and a right side plate respectively, a net rail structure assists a drill bit in routing movement for drilling, and a water circulation device performs water circulationcooling; and when the materials which are harder and sharper than the target are drilled, the stability of the drill bit during movement is improved, the phenomenon of cutter sliding and jamming is avoided, the smoothness during walking is high, water circulation type cooling is achieved, and the tapping drilling machine has the advantages of water resource saving and in-place spraying.

Owner:惠安县崇武镇石板然茶叶店

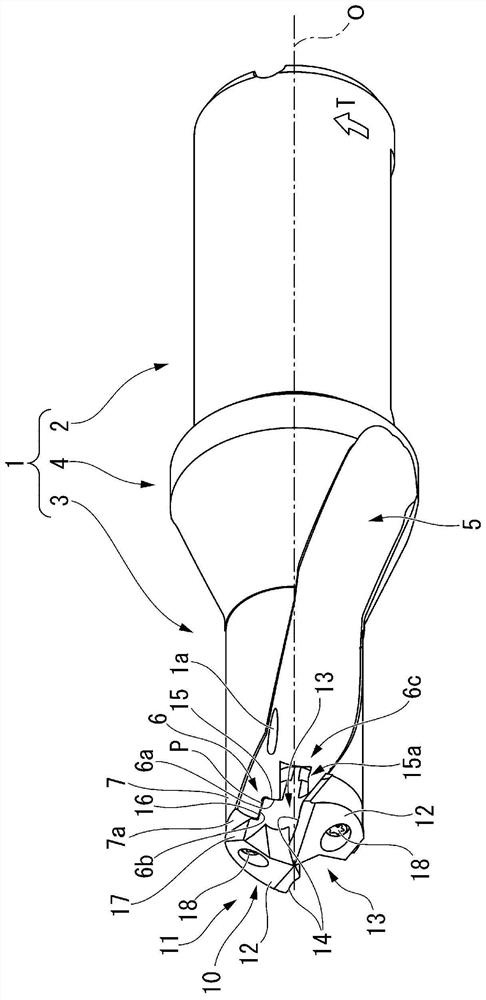

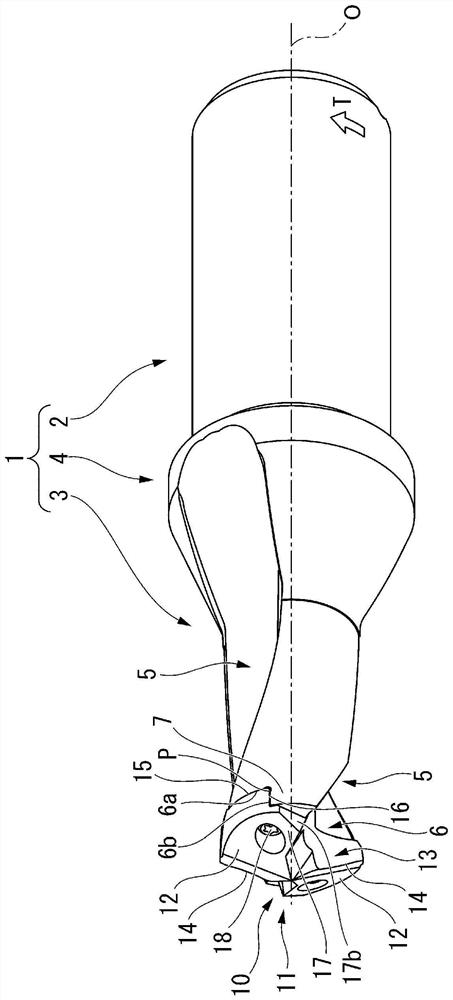

Indexable drill, cutting insert and drill main body

PendingCN113490566ARigidity is not compromisedRelieve stress concentrationTransportation and packagingTwist drillsClassical mechanicsStructural engineering

In this indexable drill, a cutting insert (10) formed having a cutting blade (14) can be detachably attached to an insert attachment seat (6) of a drill main body (1). The insert attachment seat (6) is formed having a bottom surface (6a) which faces the tip of the drill main body (1), and a sidewall (6b) which extends towards the tip and faces the drill rotation direction (T). The cutting insert (10) is formed having a seated surface (15), which faces the back end of the drill main body (1) and is seated on the bottom surface (6a), a contact surface (16), which faces opposite of the drill rotation direction (T) and contacts the side surface (6b), a protrusion (17), which protrudes opposite of the drill rotation direction (T) on the tip side of the contact surface (16), and an attachment hole which passes from a tip flank surface (12) towards the seated surface (15).

Owner:MITSUBISHI MATERIALS CORP

Novel plate drilling machining device

The invention provides a novel plate drilling machining device. The novel plate drilling machining device comprises a machine body, wherein a sliding cavity is formed in the machine body, and a sliding frame body is arranged in the sliding cavity in an up-and-down sliding mode. A first sliding groove with a downward opening is formed in the center of the sliding frame body, a second sliding groovecommunicated with the first sliding groove is formed in the upper end of the first sliding groove in the sliding frame body, a linkage plate is arranged in the second sliding groove in an up-and-downsliding mode, a lifting strip is arranged in the first sliding groove in an up-and-down sliding mode, and the upper end of the lifting strip is fixedly connected with the linkage plate. The lower endof the lifting strip is fixedly provided with a drilling motor, the lower end of the drilling motor is in power connection with a drilling tool, an upper mounting groove and a lower mounting groove are symmetrically formed in the left side and the right side of the sliding frame body, a conversion motor is fixedly arranged between the upper installation groove and the lower installation groove, the upper end and the lower end of the conversion motor are respectively and electrically connected with an upper power shaft and a lower power shaft, between the upper installation groove and the lower installation groove, and a communication groove communicated with the upper installation groove and the lower installation groove is formed in the rear end of the conversion motor.

Owner:CIXI XINCHANG IND PROD DESIGN

A device for drilling holes in a plate

ActiveCN106938349BEasy to pushAvoid scratchesPositioning apparatusBoring/drilling componentsControl engineeringMachining

The invention discloses a plate drilling machining device. The plate drilling machining device comprises a machine body, wherein a sliding cavity is formed in the machine body, a sliding frame body is arranged in the sliding cavity in an up-down sliding mode, a first sliding groove with a downward opening is formed in the center of the sliding frame body, a second sliding groove communicating with the first sliding groove is formed in the upper end of the first sliding groove and in the sliding frame body, a linkage plate is arranged in the second sliding groove in an up-down sliding mode, a lifting strip is arranged in the first sliding groove in an up-down sliding mode, the upper end of the lifting strip is fixedly connected with the linkage plate, a drilling motor is fixedly arranged at the lower end of the lifting strip, the lower end of the drilling motor is in power connection with a drilling tool, an upper installation groove and a lower installation groove are symmetrically formed in the left side and the right side of the sliding frame body, a conversion motor is fixedly arranged between the upper installation groove and the lower installation groove, the upper end and the lower end of the conversion motor are electrically connected with an upper power shaft and a lower power shaft respectively, and a communication groove communicating with the upper installation groove and the lower installation groove is formed between the upper installation groove and the lower installation groove and in the rear end of the conversion motor.

Owner:河北曲富木业有限公司

Clutch sleeve drilling and milling device

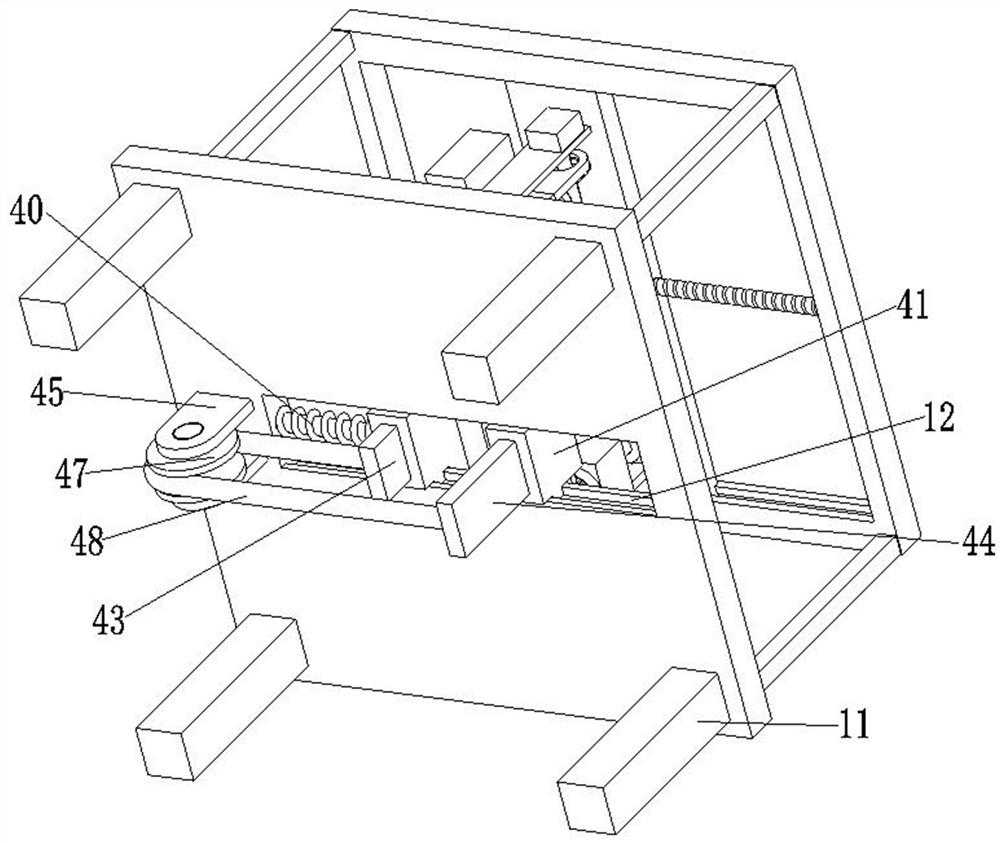

ActiveCN110977479AStable drillingDrilling stopOther manufacturing equipments/toolsMetal working apparatusEngineeringMachining

The invention relates to the field of machining, and particularly discloses a clutch sleeve drilling and milling device. The clutch sleeve drilling and milling device comprises a workbench, a plurality of drill bits and a rotating disc rotationally installed on the workbench, and further comprises a plurality of drilling units and a plurality of clamping units arranged on the rotating disc. Each discharge hole drilling unit comprises a connecting rod and a supporting plate capable of making contact with the outer wall of a clutch sleeve, wherein the connecting rod is arranged in the radial direction of the rotating disc, one end of the connecting rod is fixedly connected with the rotating disc, the other end of the connecting rod is fixedly connected with the outer edge of the supporting plate, and the discharge hole supporting plate is vertically arranged. Each discharge hole clamping unit comprises a suction cup capable of being attached to the upper end of the clutch sleeve and a fixing part for fixing the suction cup, wherein the discharge hole suction cup is coaxially arranged over the corresponding supporting plate. By means of the scheme, drilling and milling can be performed on a plurality of clutch sleeves at the same time, and then the drilling and milling efficiency of the clutch sleeves can be improved.

Owner:贵州友擘机械制造有限公司

Drilling tool

ActiveCN102310215AAvoid windingLong breakage lifeTransportation and packagingPrinted circuit manufactureConductor CoilBiomedical engineering

The invention provides a drilling tool, which is capable of preventing chip winding and capable of stably drilling holes by using a small-diameter drill bit with a diameter smaller than 0.7 mm, in particular smaller than 0.4 mm, and achieves long breakage-resistant lifetime and excellent practicability. The tail end of a tool body (1) is equipped with one or more cutting blades. Multiple helical chip-evacuating grooves are formed in the outer circumference of the tool body (1) from the tail end of the tool body to the base end, wherein the multiple chip-evacuating grooves at least comprise one main groove (2a) and one auxiliary groove (2b). The one or more auxiliary grooves (2b) are joined with the main groove (2a) at the halfway portion of the main grove (2a). In addition, the join portion (6) where the main groove (2a) and the auxiliary groove (2b) are joined has class difference (7).

Owner:UNION TOOL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com