Multi-position automatic drilling machine for greenhouse accessory machining

A technology for greenhouses and drilling machines, which is used in metal processing, boring/drilling, metal processing equipment, etc., can solve problems such as rework, scrap, increase labor and production input costs, and achieve a reasonable design structure and improve economy. Benefit, the effect of reducing labor and production cost inputs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

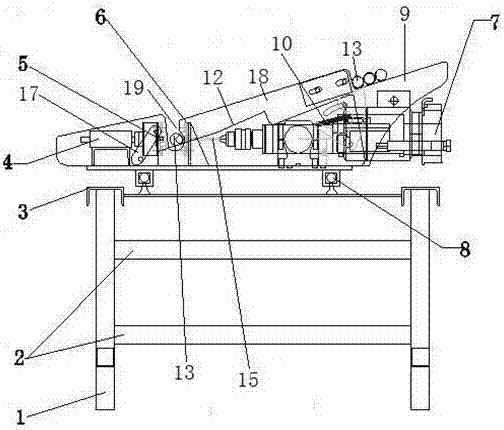

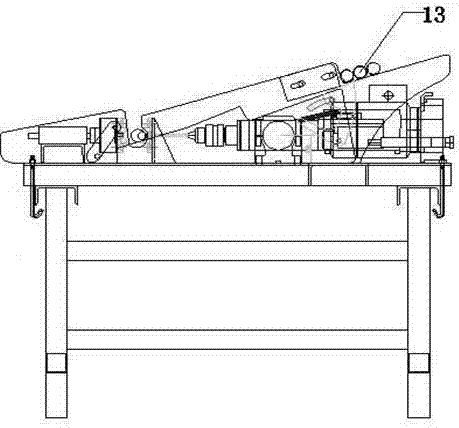

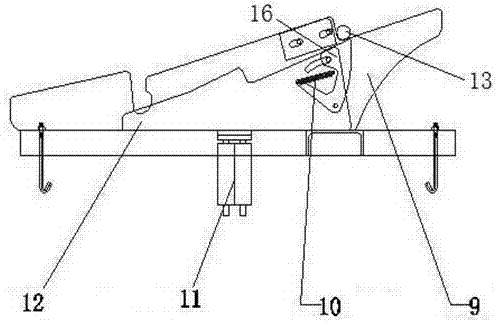

[0017] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 and Figure 7 Shown is a multi-position automatic drilling machine for processing greenhouse accessories, consisting of a frame 1, a number of beams 2 fixed to the frame 1, a number of oblique supports 14, and grooves arranged on the frame 1 Steel 3, and the drilling assembly and unloading assembly arranged on the frame 1; the drilling assembly includes the motor 7 on the frame 1, and the static guide provided on the frame 1 and used in conjunction with the motor 7 Plate 9, and the support ear plate 18 that is arranged on the frame 1 and cooperates with the static guide plate 9, and the circular tube limit groove 19 that is arranged on the support ear plate 18, and is arranged on the frame 1 and is connected with The motor 7, the first cylinder 4 used in conjunction with the static guide plate 9, the movable chuck 5, the static chuck 6, and the drill bit 15 arranged on the motor 7, wherein one...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com