Patents

Literature

1086results about How to "Reasonable design structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

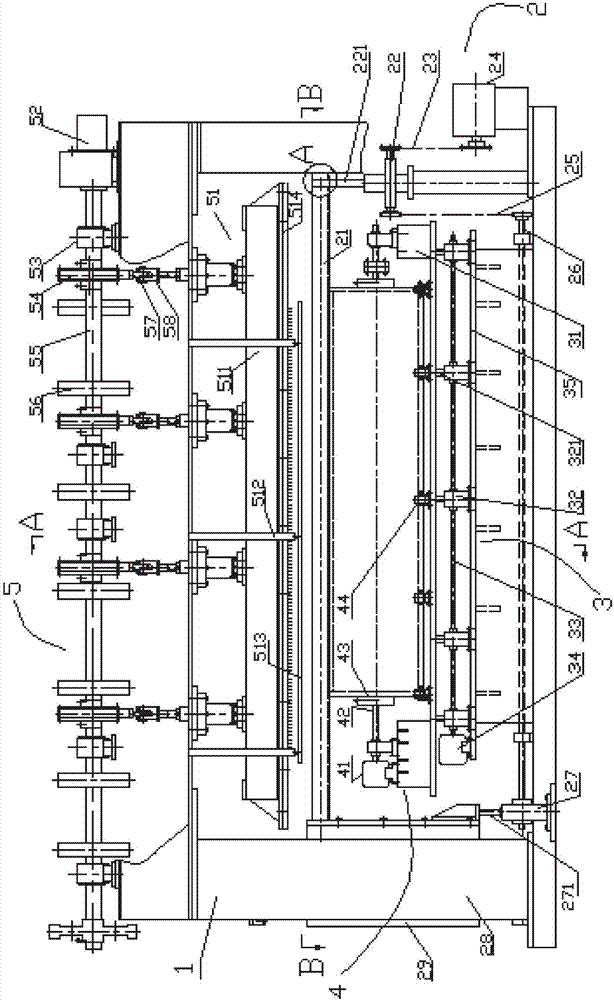

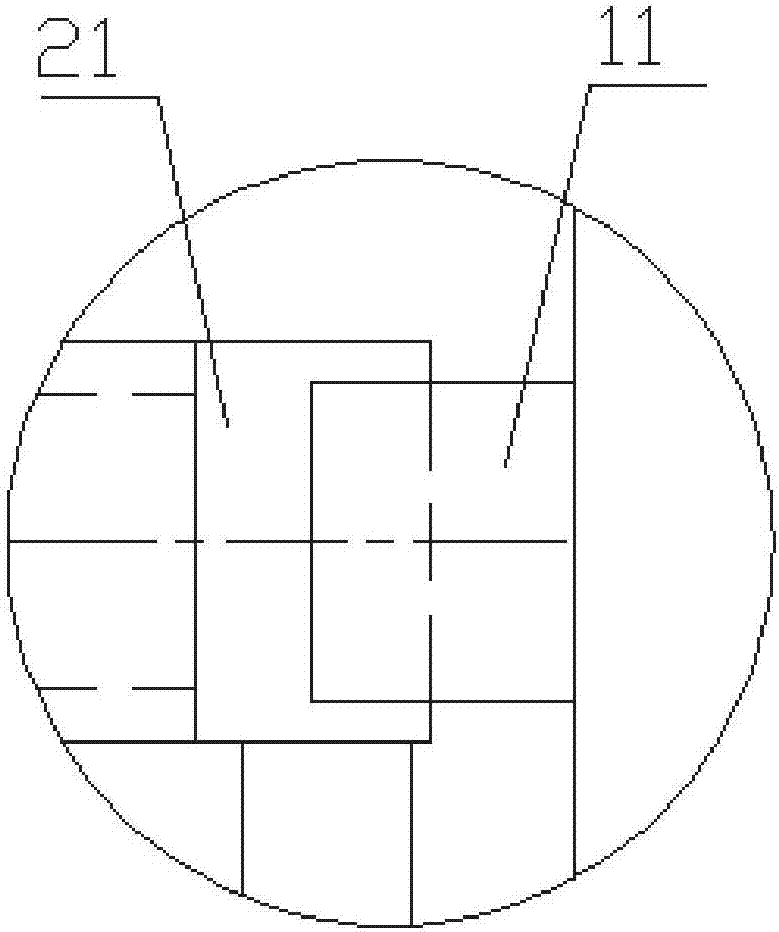

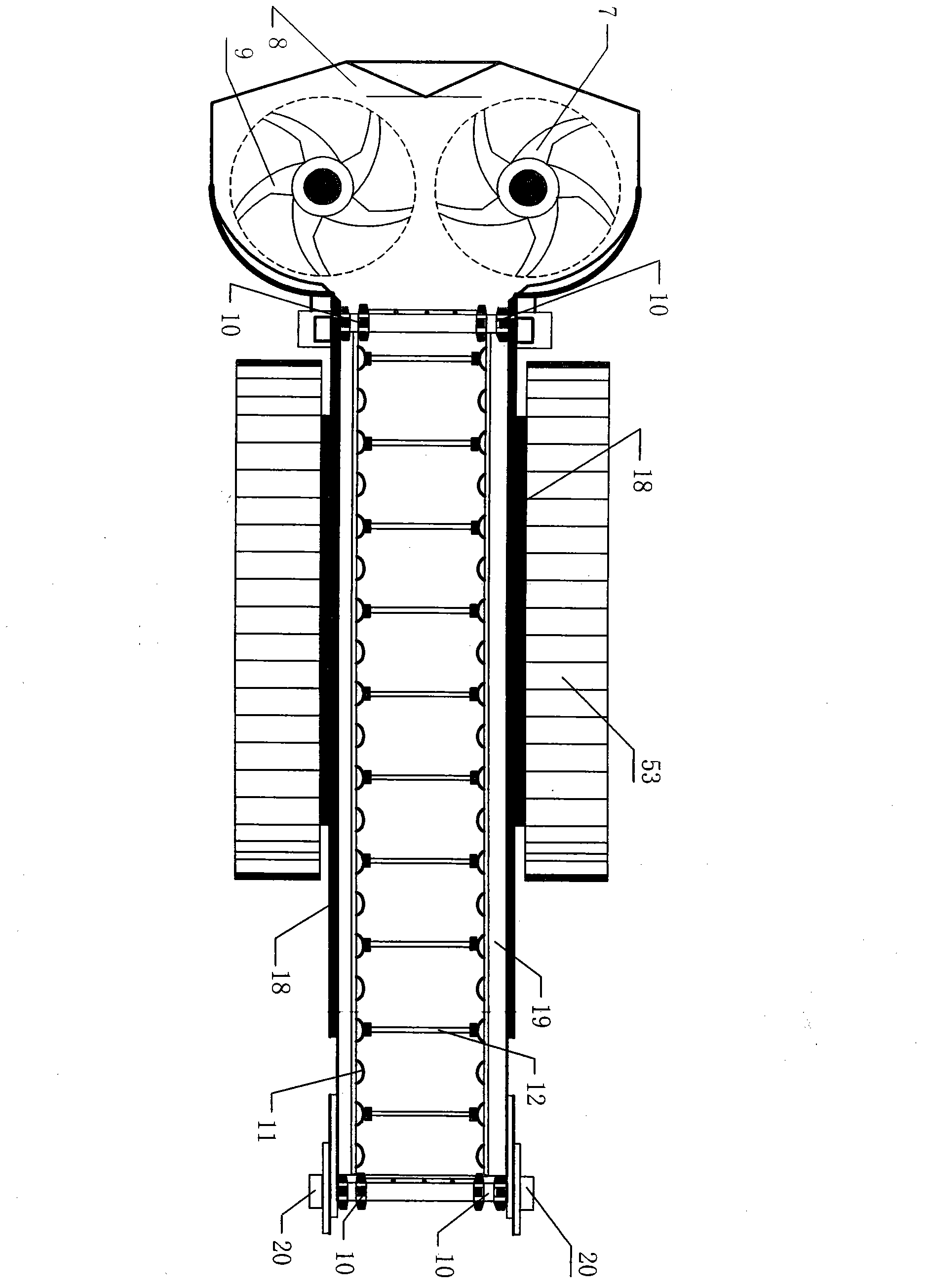

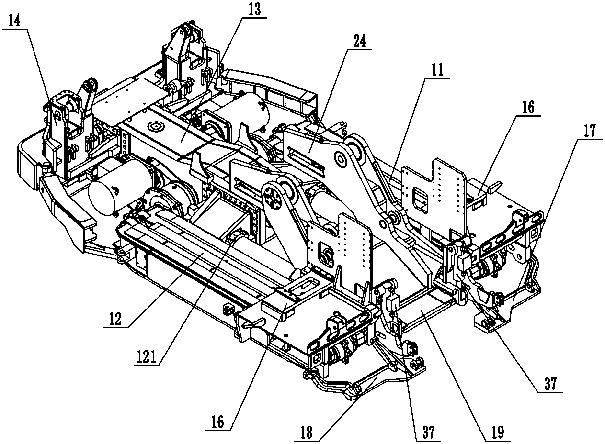

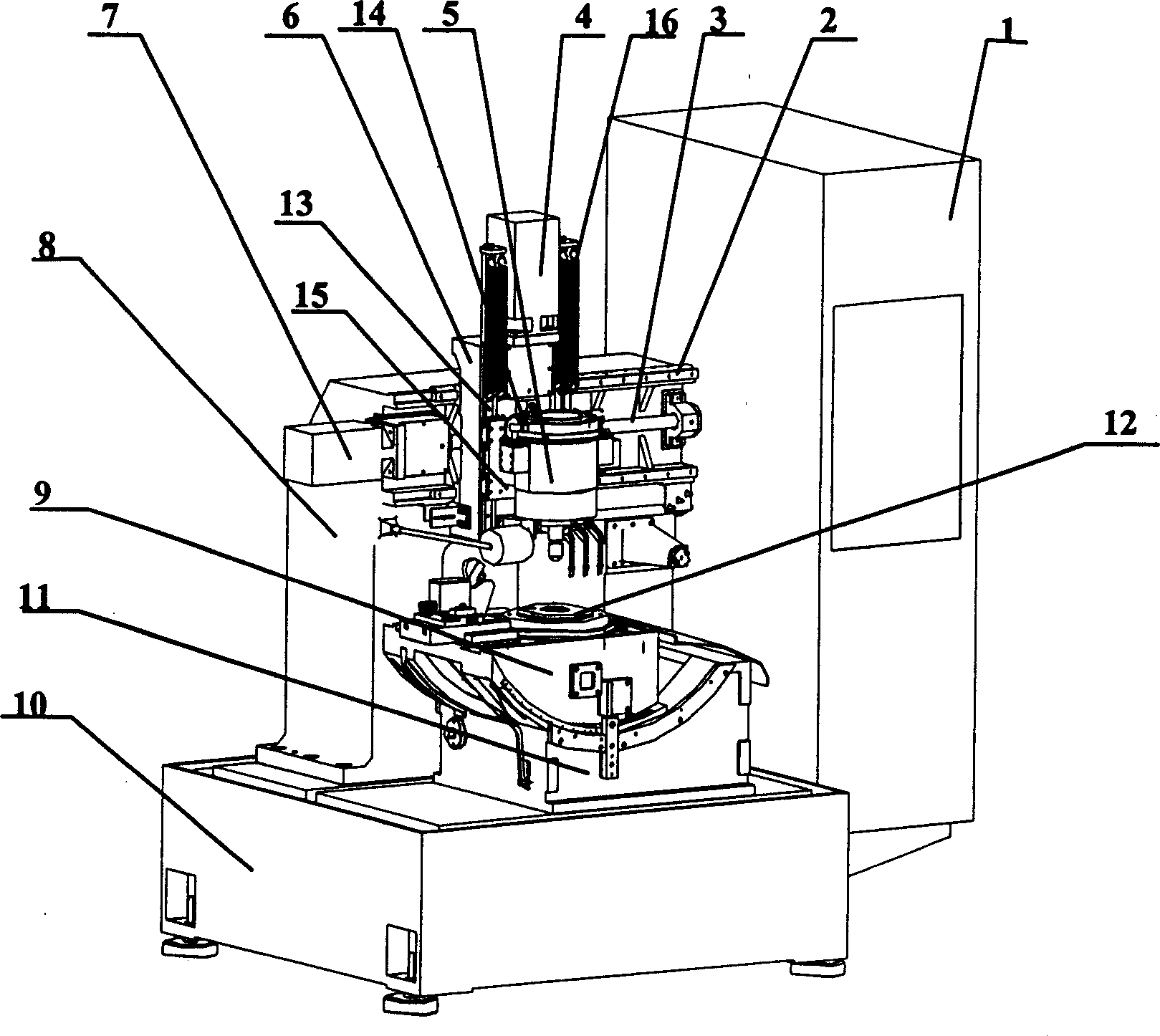

Small diameter felt cover needling machine

InactiveCN106988023AQuality improvementSimple mechanical structureNeedling machinesMechanical engineering

The invention relates to a small diameter felt cover needling machine. The small diameter felt cover needling machine comprises a rack, an assembly and disassembly part, a platform support part, a carrier roller support part and a needling part, the assembly and disassembly part, the platform support part, the carrier roller support part and the needling part are all arranged on the rack, the assembly and disassembly part completes assembly and disassembly of a felt cover product, the needling part completes needling motion, the platform support part is mainly used for achieving support for parts like a drum and motion of a support platform, and the carrier roller support part completes support for a carrier roller. According to the small diameter felt cover needling machine, a felt cover with good quality and a small size can be produced, and the technical problem in the prior art is solved that a common needling machine cannot produce the felt cover with the good quality and the small size.

Owner:SHANGHAI INST OF TECH

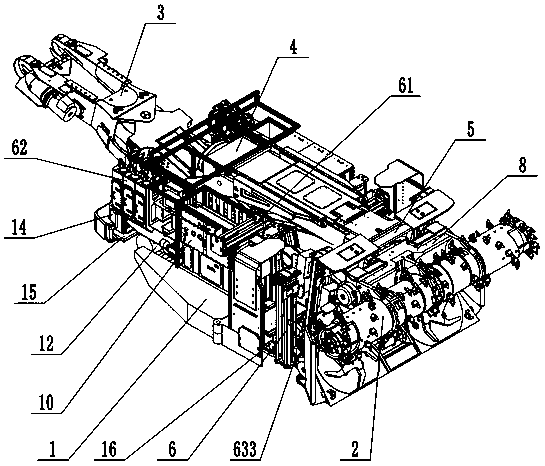

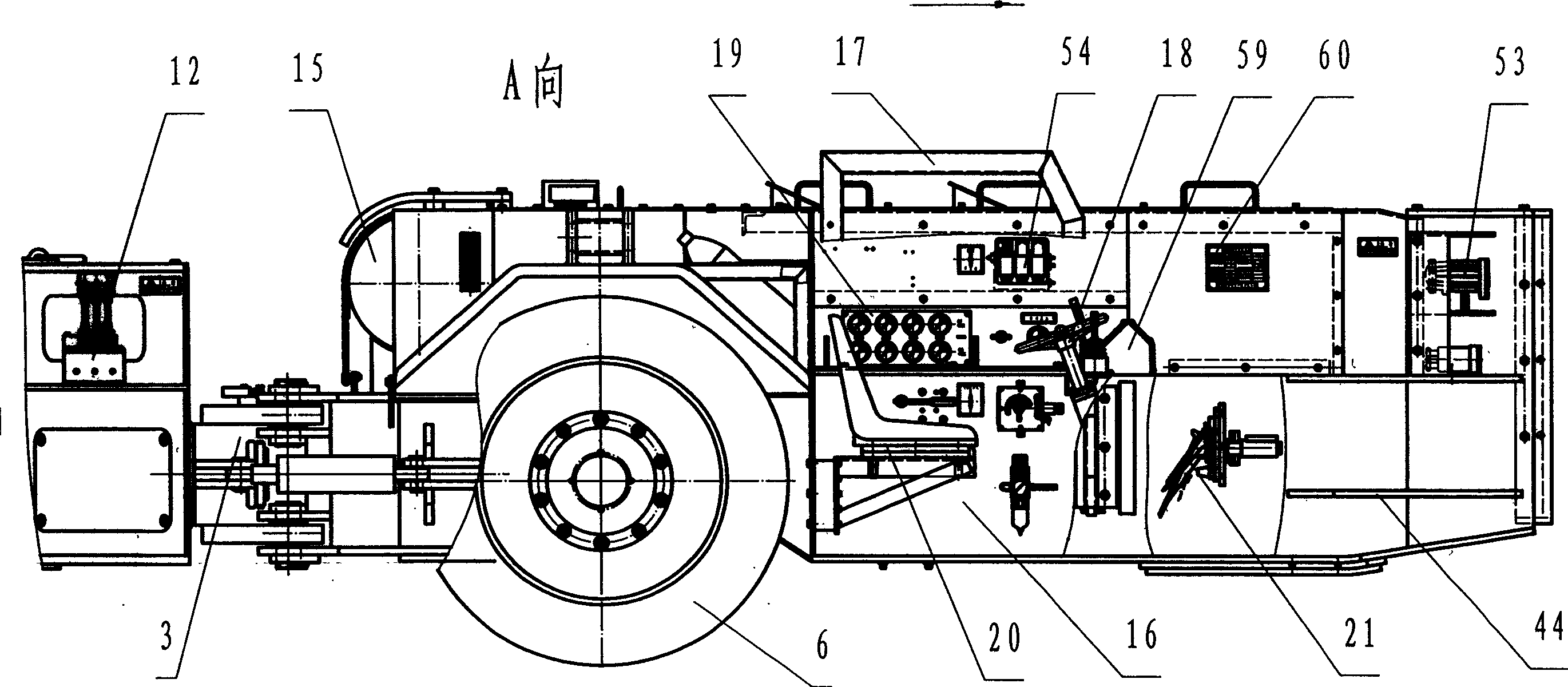

Underground continuous tunnelling machine

ActiveCN101050703AAdvancedFill the research gapDriving meansPropulsionAgricultural engineeringElectric control

The present invention relates to a coal mine underground continuous excavating machine. Its main mechanism includes the following several portions: main machine frame, rear machine frame, cutting mechanism, scooping plate mechanism, conveying mechanism, dust-removing mechanism, traveling mechanism, driving mechanism, hydraulic mechanism, electric control circuit and stable mechanism. Said invention also provides the connection mode of all the above-mentioned portions, and also provides the working principle of said excavating machine and its operation method.

Owner:TAIYUAN INST OF CHINA COAL TECH & ENG GROUP +1

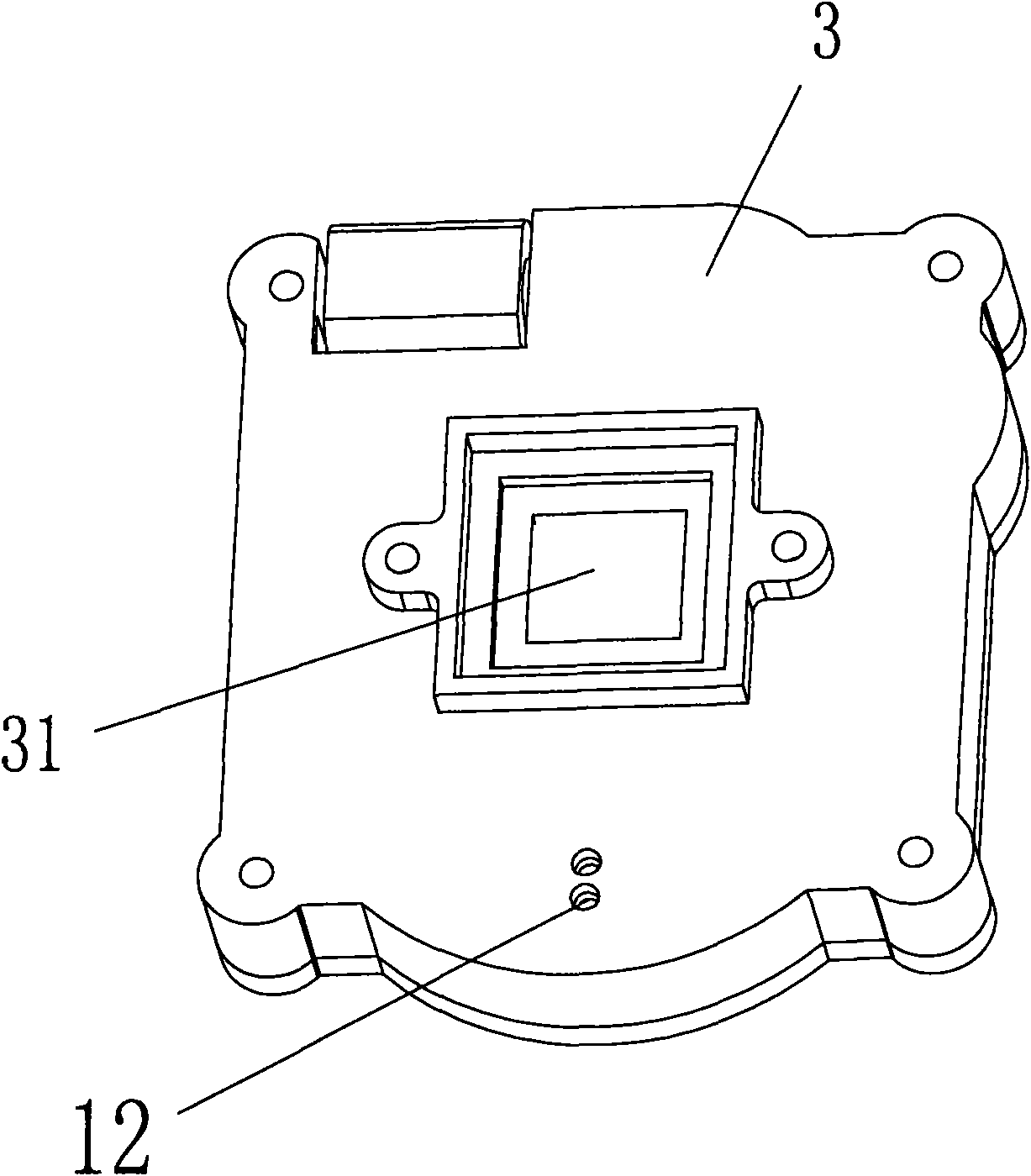

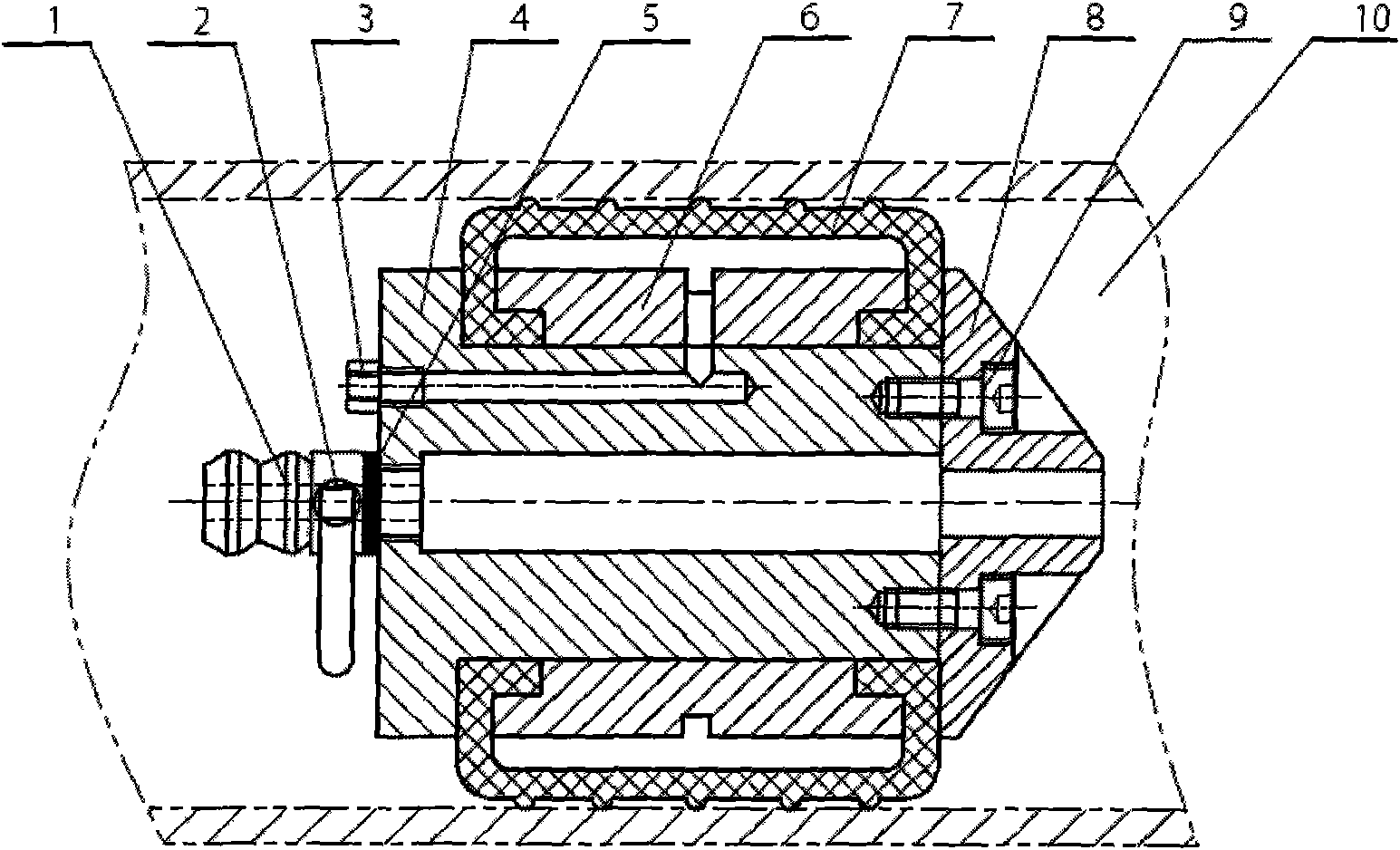

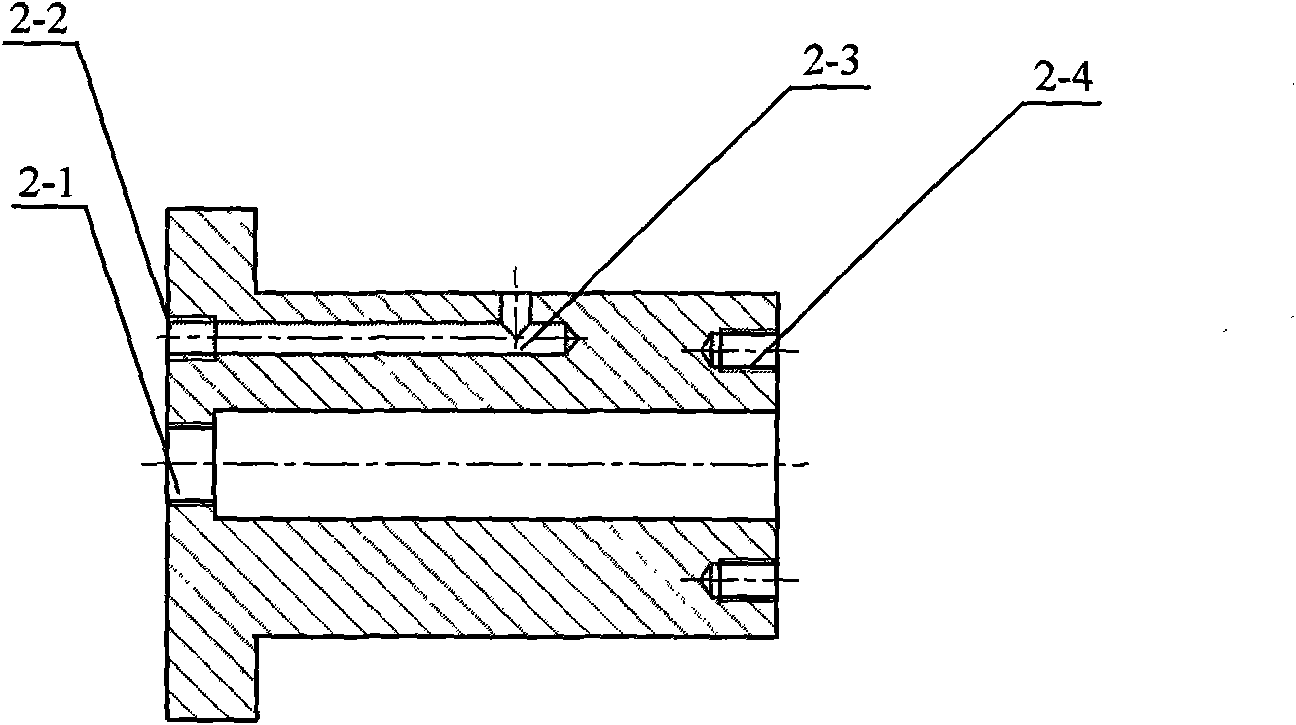

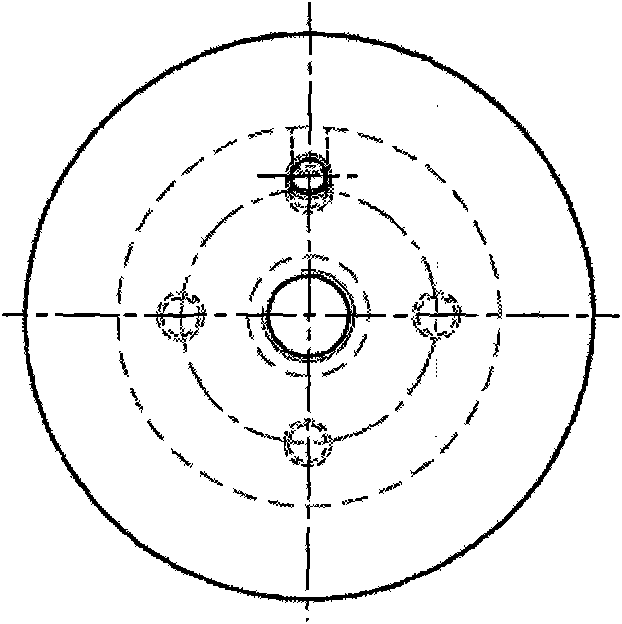

Rotation switching method and device of multiple optical filters of imaging sensor

InactiveCN101806947AReasonable design structureSmall and flexibleUsing optical meansMountingsOpto electronicImage sensor

The invention relates to rotation switching method and device of multiple optical filters of an imaging sensor. The device comprises a machine body, a rotation switching mechanism of optical filters, a photoelectric position sensor, a transmission mechanism, multiple optical filters fixed on the rotation switching mechanism of the optical filters and position notches arranged at the edges of the optical filters, wherein a light sensing window is arranged on the machine body, the rotation switching mechanism of the optical filters is arranged on the machine body, the optical filters fixed on the rotation switching mechanism of the optical filters correspond to the light sensing window, and the photoelectric position sensor corresponds to the position notches. The transmission mechanism drives the rotation switching mechanism of the optical filters to rotate, and the optical filters fixed on the rotation switching mechanism of the optical filters are rotated onto the light sensing window.

Owner:谭懋

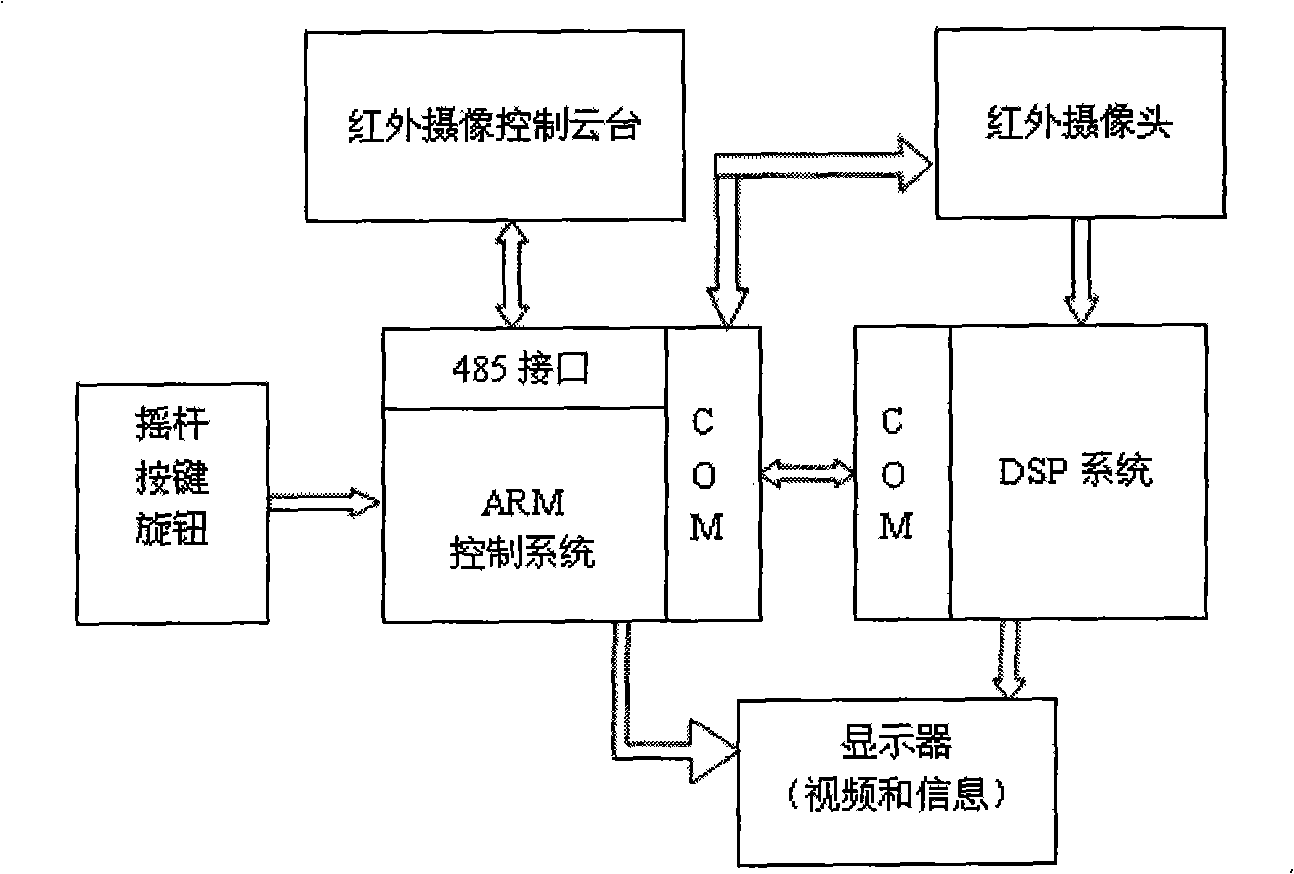

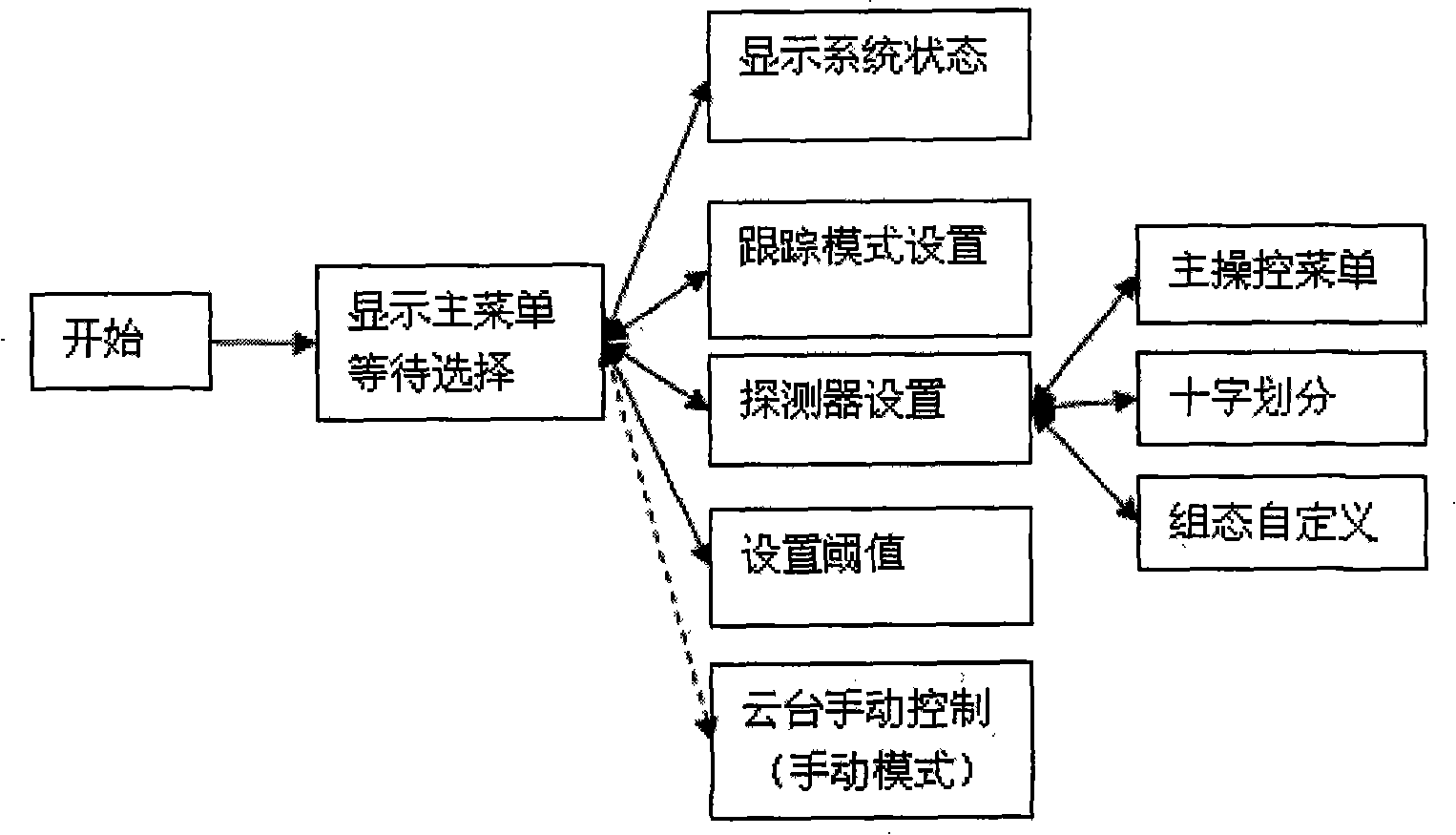

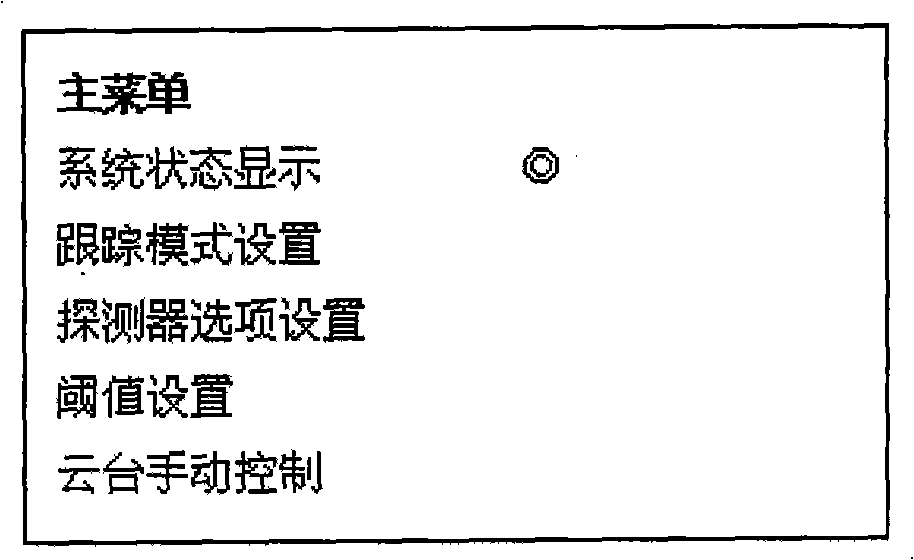

Maritime search and rescue instrument based on infrared detector

InactiveCN101527824AReasonable design structureStable hardware technologyTelevision system detailsOptical detectionMachine visionControl system

The invention relates to a maritime search and rescue instrument based on an infrared detector. The search and rescue instrument is arranged on a search and rescue ship, controls the infrared detector by a DSP system and an embedded control system, and detects a target by a machine vision technology. The maritime search and rescue instrument facilitates identifying and tracing small targets such as persons in water or liferafts during maritime search and rescue, makes search at night possible and improves successful search and rescue rate.

Owner:SHANGHAI MARITIME UNIVERSITY

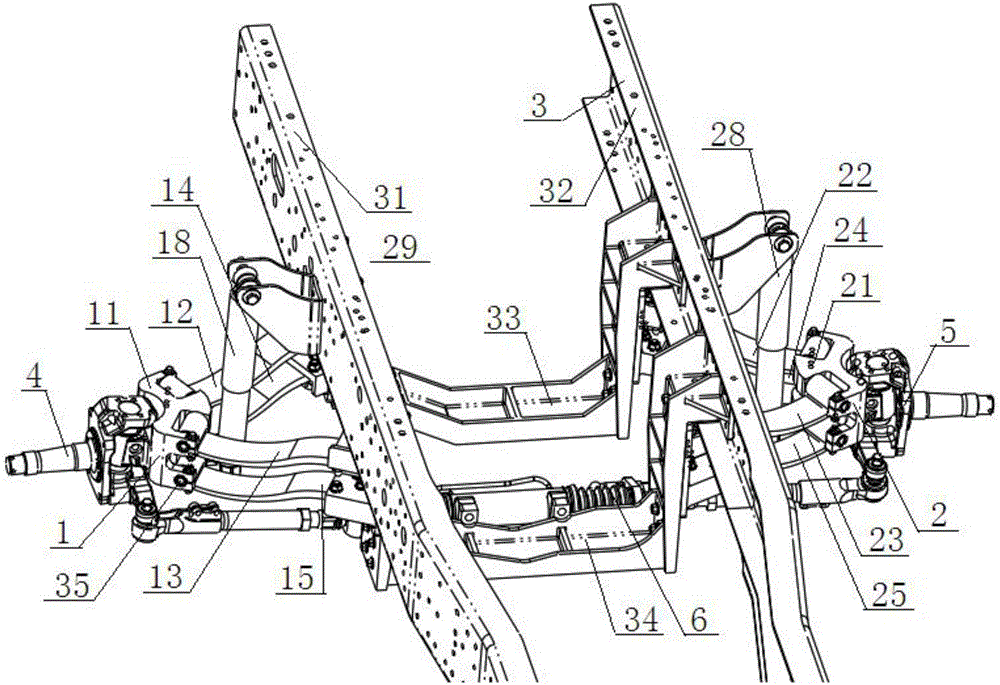

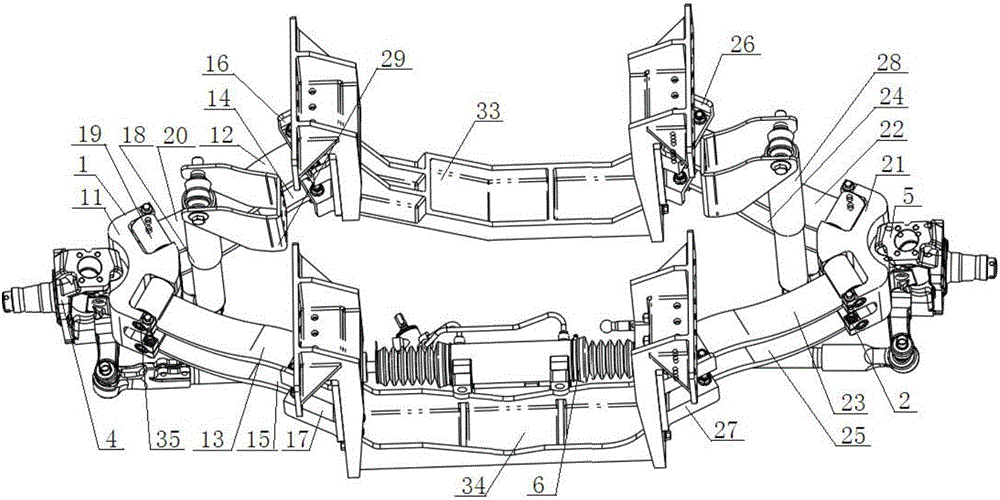

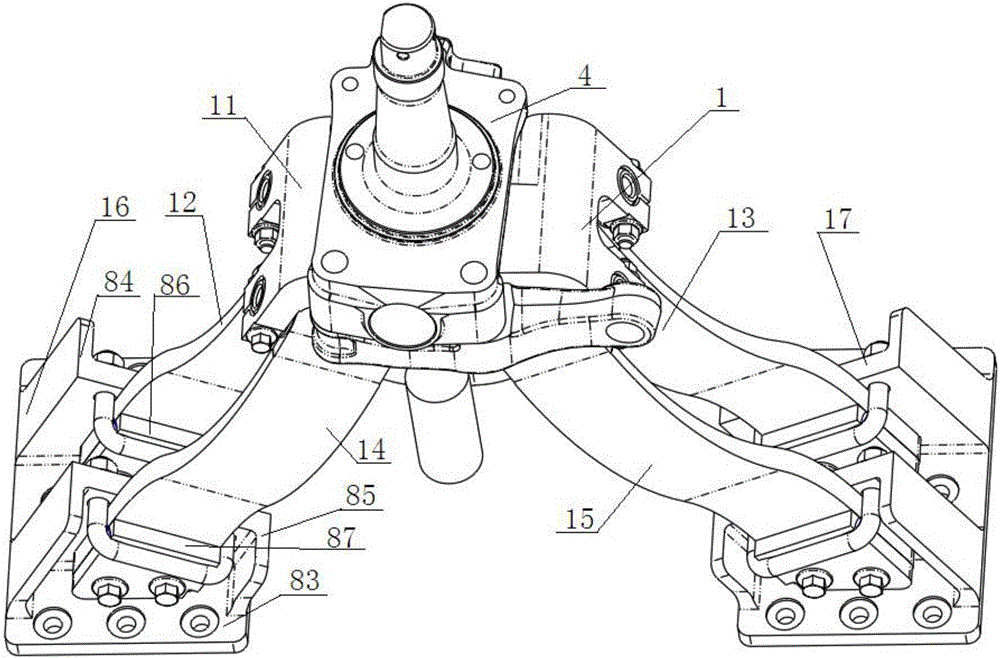

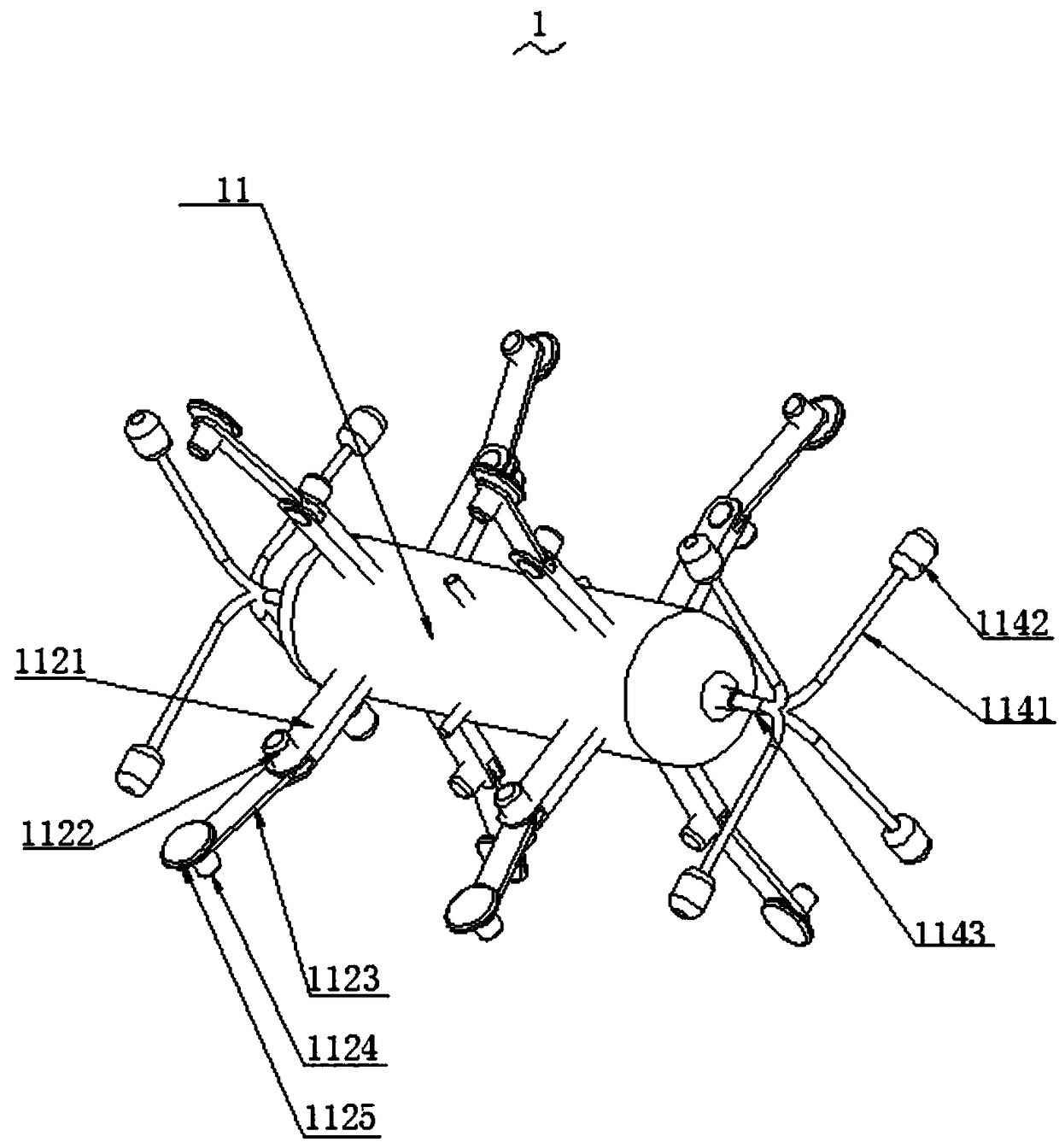

Commercial vehicle single front axle structure with independent suspensions

ActiveCN106394154AImprove the fixing strengthImprove carrying capacityMechanical steering gearsResilient suspensionsVehicle frameOperational stability

A commercial vehicle single front axle structure with independent suspensions comprises the left independent suspension and the right independent suspension which are arranged symmetrically. The left independent suspension is connected with the right independent suspension through a vehicle frame. The vehicle frame comprises a left longitudinal beam and a right longitudinal beam which are symmetrically arranged. The left longitudinal beam is fixedly connected with the right longitudinal beam through a front pocket beam and a rear pocket beam. The independent suspensions are connected with the front pocket beam and the rear pocket beam through connection brackets and four plate springs correspondingly. The bottoms of the connection brackets are connected with the longitudinal beams through shock absorbers. A gear rack steering system is connected with steering knuckles. The commercial vehicle single front axle structure is reasonable, high in mechanical strength, good in bearing characteristic and conductive to improving the smoothness and operation stability of a whole vehicle.

Owner:DONGFENG COMML VEHICLE CO LTD

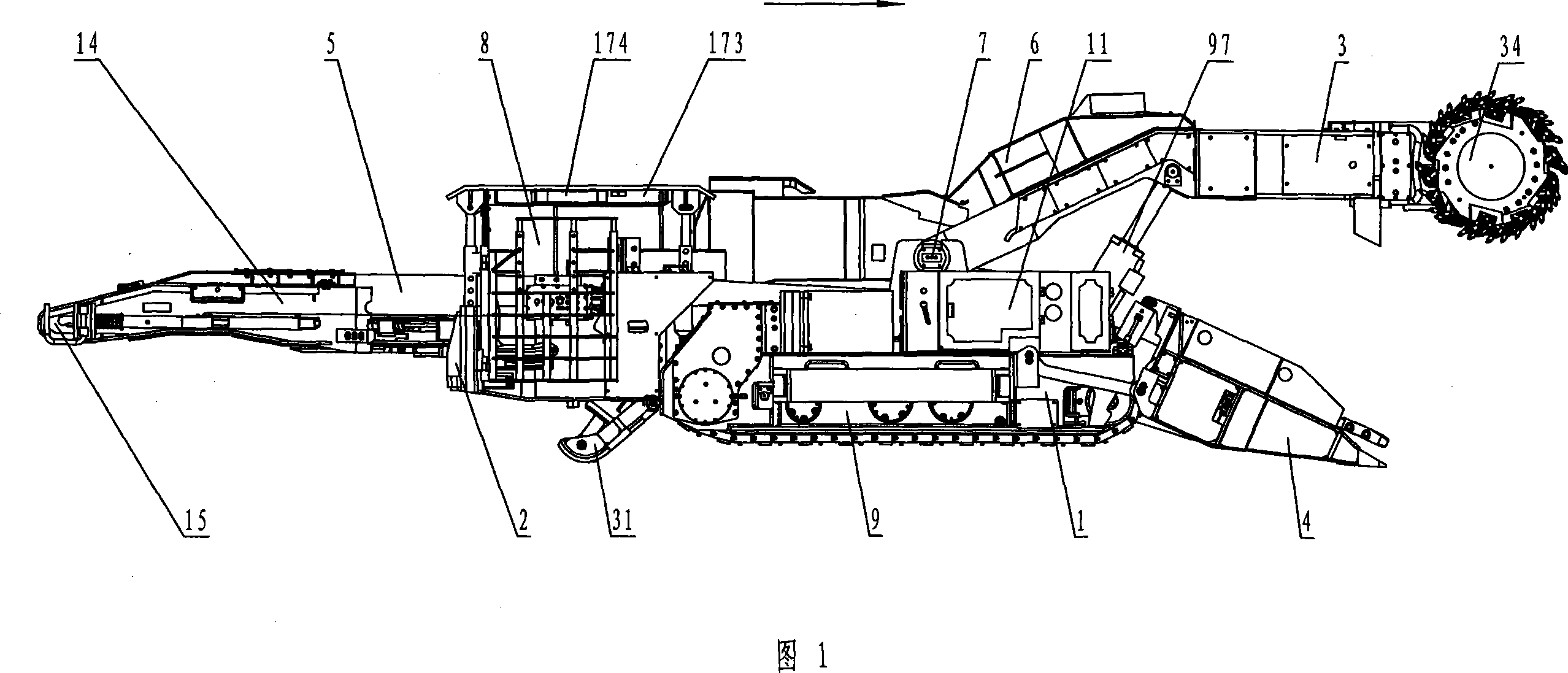

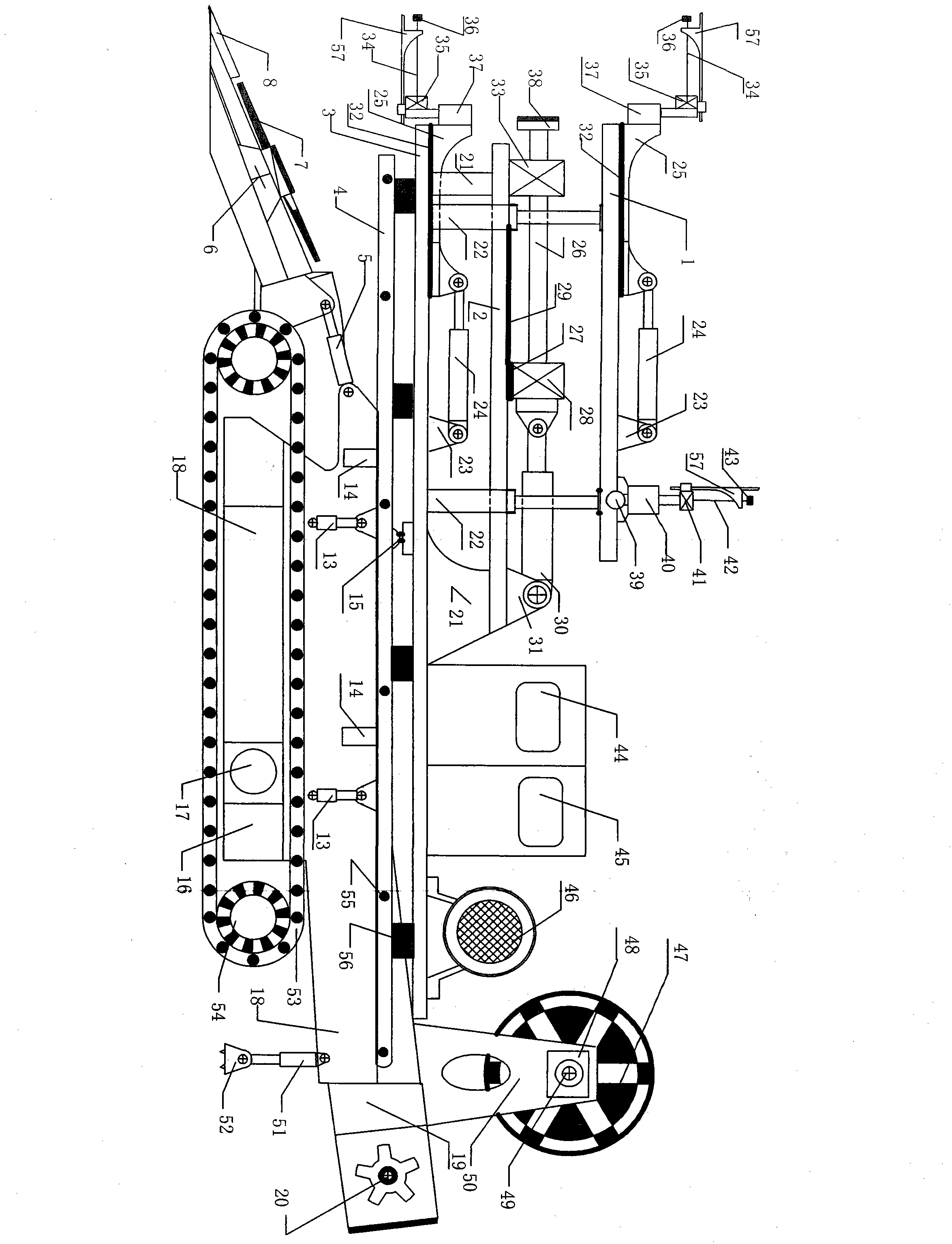

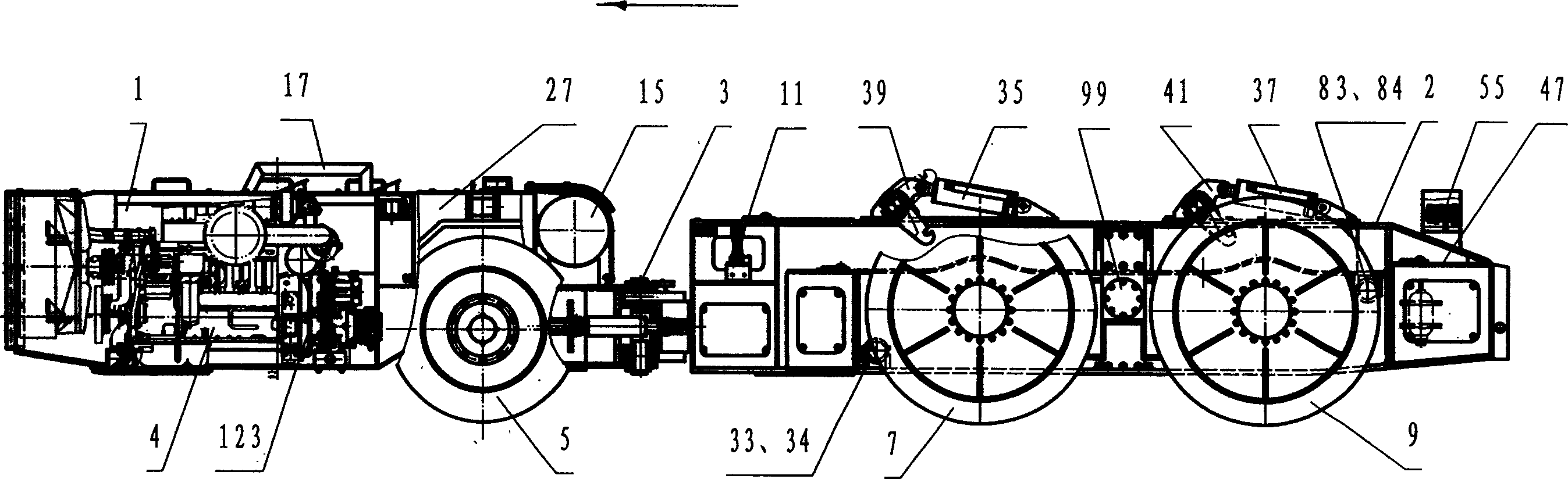

Multifunctional underground roadway tunneling locomotive

InactiveCN103233746AThe blasting shock wave is smallReasonable design structureTunnelsAnchoring boltsCoalDrilling machines

A multifunctional underground roadway tunneling locomotive is provided with a locomotive with functions of walking, rock drilling, loading, transporting, bolt supporting and the like; a drill bit of a rock drilling part adopts a diamond drill bit; the drilling rate is dozen times of that of the prior art; especially the large-diameter diamond drilling machine of the drilling part can be used for drill a large hole in the middle of a working surface to serve as a blasting cut hole to create a free surface to the blasting cut hole, so that the deep blasting in a straight hole is achieved. The multifunctional underground roadway tunneling locomotive is a new idea of blasting the underground tunneled roadway at home and abroad. The deep blasting of the straight hole enables the blasting force to explosives to be completely released in the blasting cut hole in the rock surface of the working surface, the blasting impact wave to the roadway is small, the rock crushing rate is high, the loading and transporting are facilitated, the usage rate of the blasting hole and the explosives are improved, and the comprehensive cost of the coal mine underground tunneled roadway construction is lowered. The multifunctional underground roadway tunneling locomotive is reasonable in design and structure, convenient to operate, and a brand-new replacing product of the coal mine underground tunneled roadway construction equipment, and suitable for exploitation of metallurgical ore in a tunnel.

Owner:SHUANGYASHAN ZHONGCHUANG MACHINERY MFG

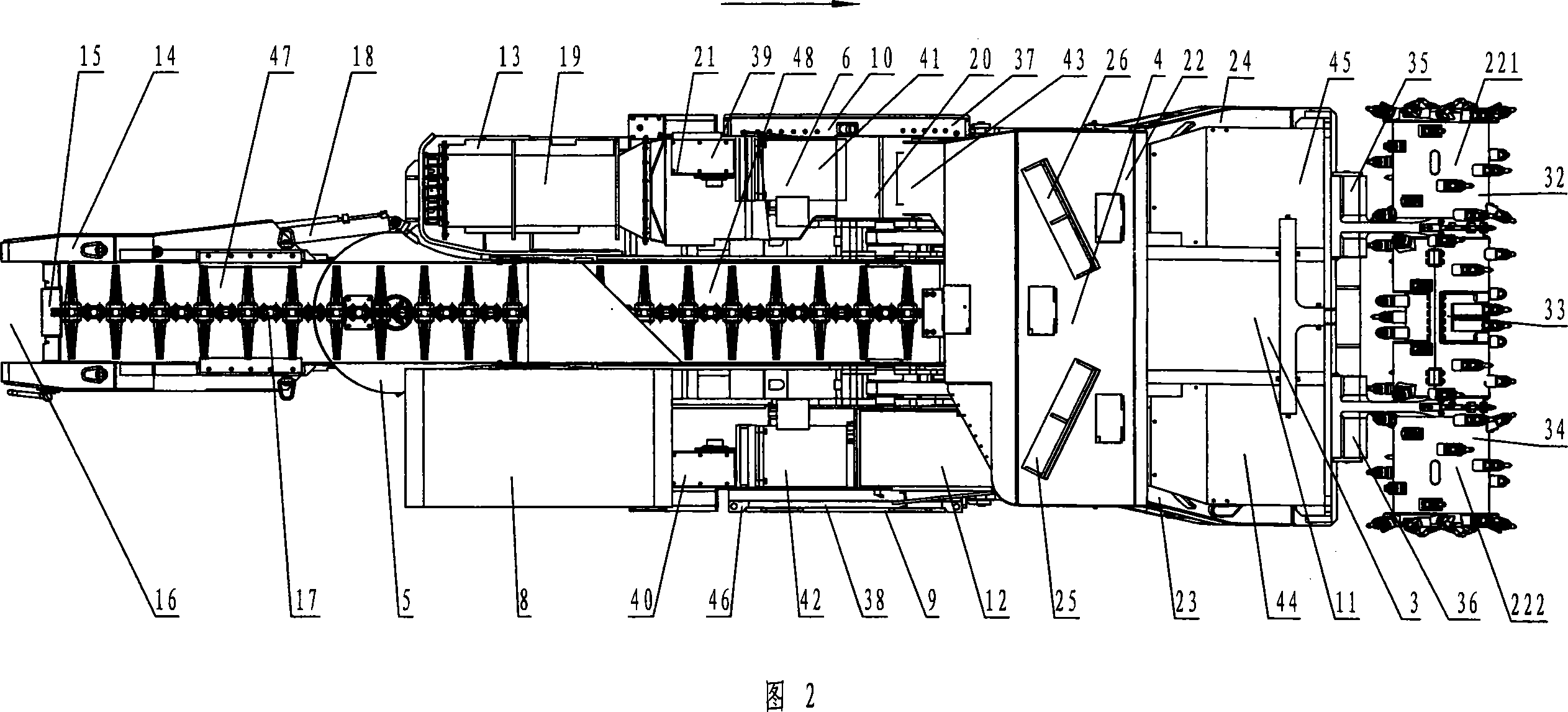

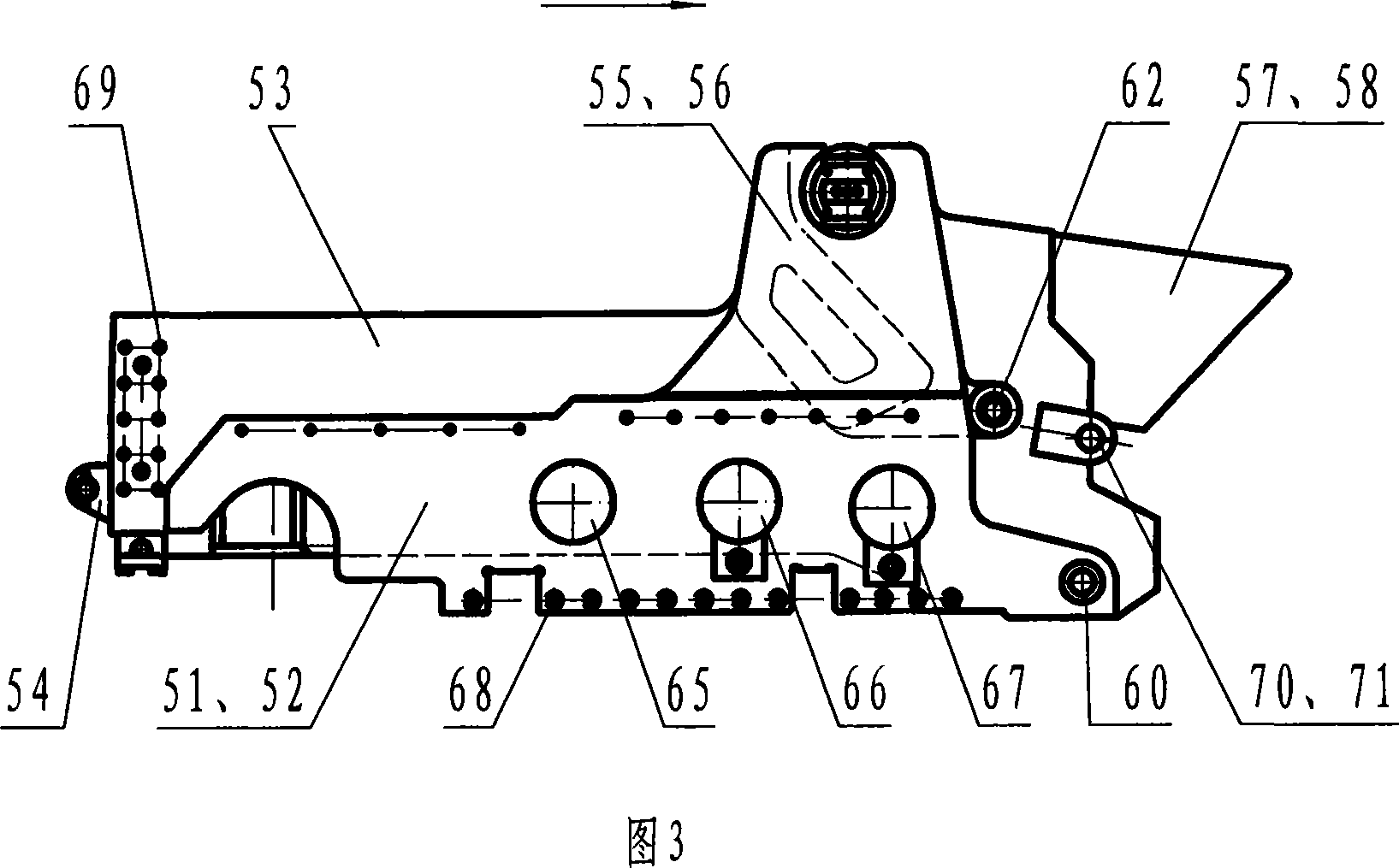

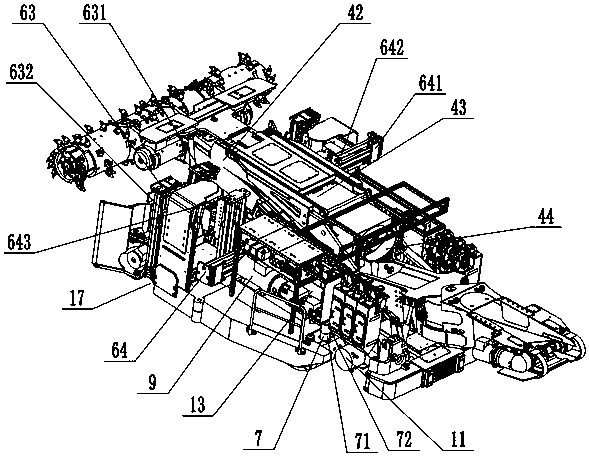

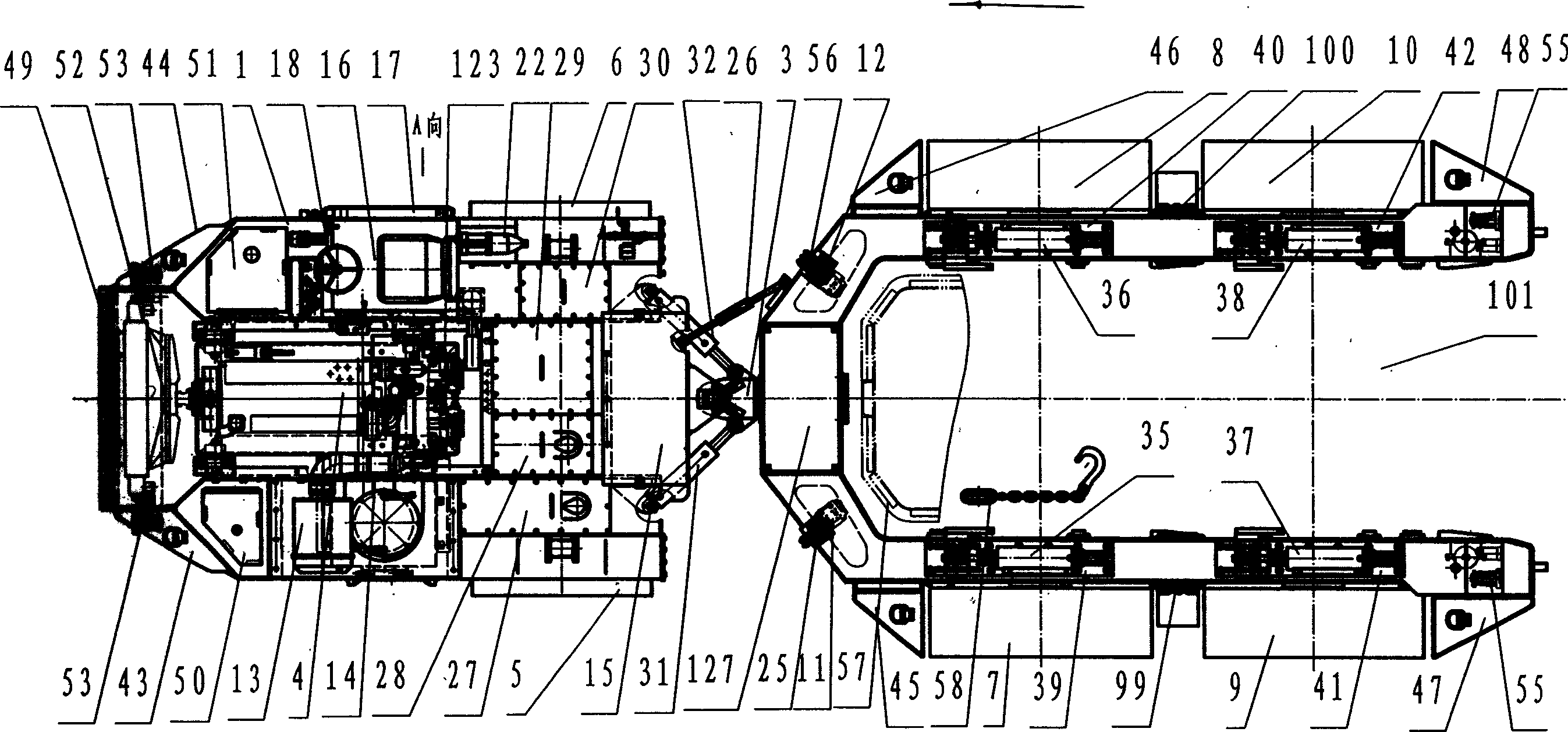

High-adaptability digging and anchoring integrated machine with dual-mode anchor drilling system

PendingCN111075444AAchieving parallel operation of anchor diggingFully automatedPropulsionAnchoring boltsSupporting systemElectric control

The invention provides a high-adaptability digging and anchoring integrated machine with a dual-mode anchor drilling system, and belongs to the technical field of underground coal mining equipment. The high-adaptability digging and anchoring integrated machine comprises a frame main body, a cutting system, a conveying system, a dust removing system, a multifunctional temporary supporting system, the dry-wet dual-mode anchor drilling system, an automatic lubricating system, a water-cooling spraying system, a hydraulic system and an electric control system, wherein a traveling mechanism adopts awide crawler design, so that the adaptability of the digging and anchoring integrated machine to a muddy bottom plate is improved; and the dry-wet dual-mode anchor drilling system has two functions of dry dust removal and wet dust removal, and real-time switching selection is carried out according to the geological conditions of the roadway bottom plate without replacing a drill box. By means ofthe high-adaptability digging and anchoring integrated machine, the problems of muddy of the bottom plate, poor stability of a top side wall and low tunneling efficiency in the rapid coal roadway tunneling under the complex geological conditions are solved; the integrated parallel operation of tunneling, anchor protection, transportation, dust removal and the like of a roadway tunneling working surface is realized; and the efficiency and safety of coal mining and transportation are improved.

Owner:TAIYUAN INST OF CHINA COAL TECH & ENG GROUP +1

Explosion-proof support transporting vehicle for coal mine

ActiveCN1792673AAdvancedReasonable design structureItem transportation vehiclesElectricityControl system

An anti-explosion carrier vehicle for transporting supporting frames or heavy machines in coal mine is composed of front and back machine frames, steering linkwork, diesel engine, hydraulic system, lifting mechanism, clamping unit, admission and exhaust protecting unit, water cooling unit, running mechanism, feeding hopper, and operation control system. The hydraulic drive is used to control running, lifting, clamping and steering. The water, electricity, gas and hydraulic system are controlled in linkage mode. The anti-explosion design is taken.

Owner:TAIYUAN INST OF CHINA COAL TECH & ENG GROUP

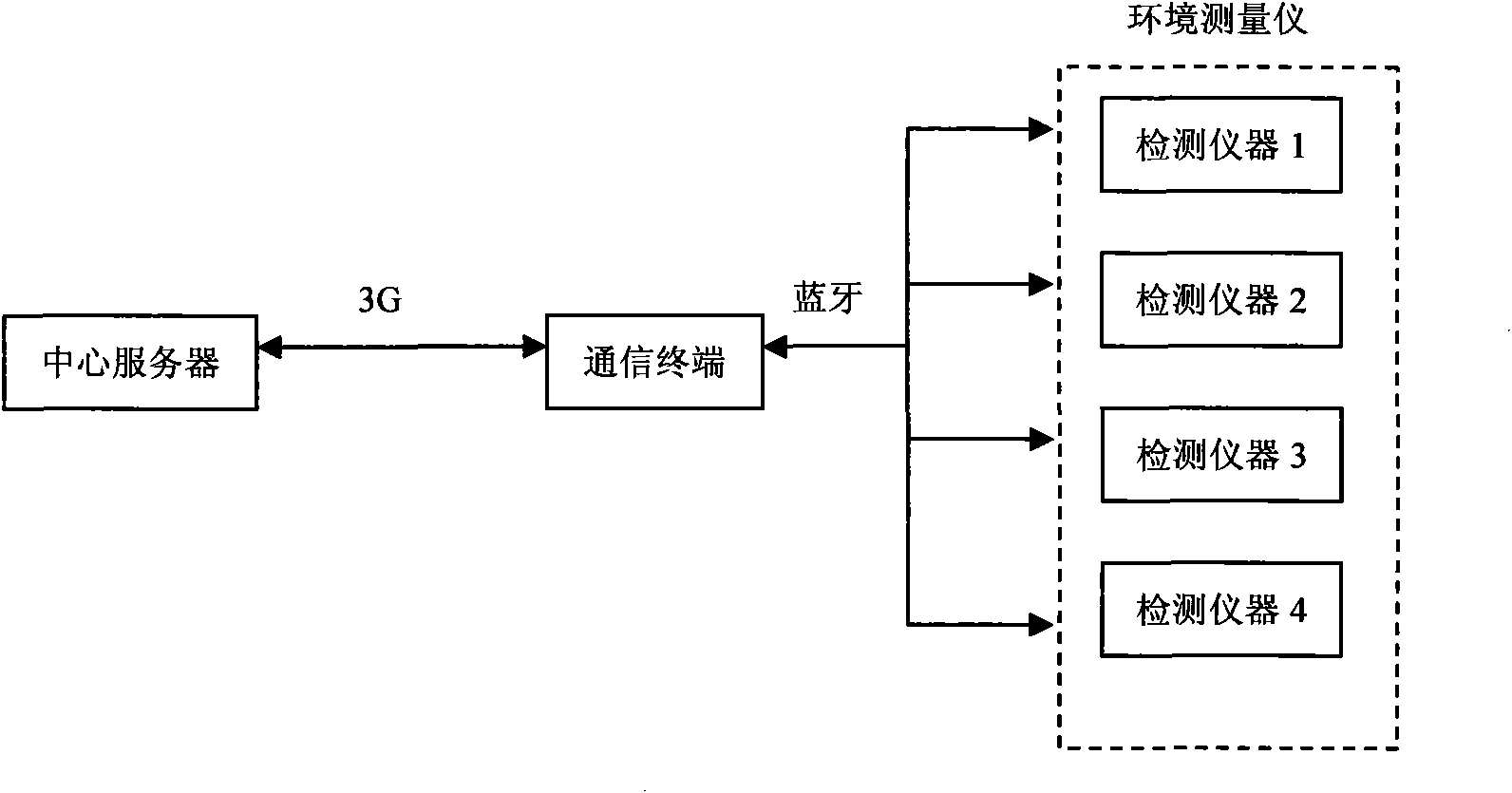

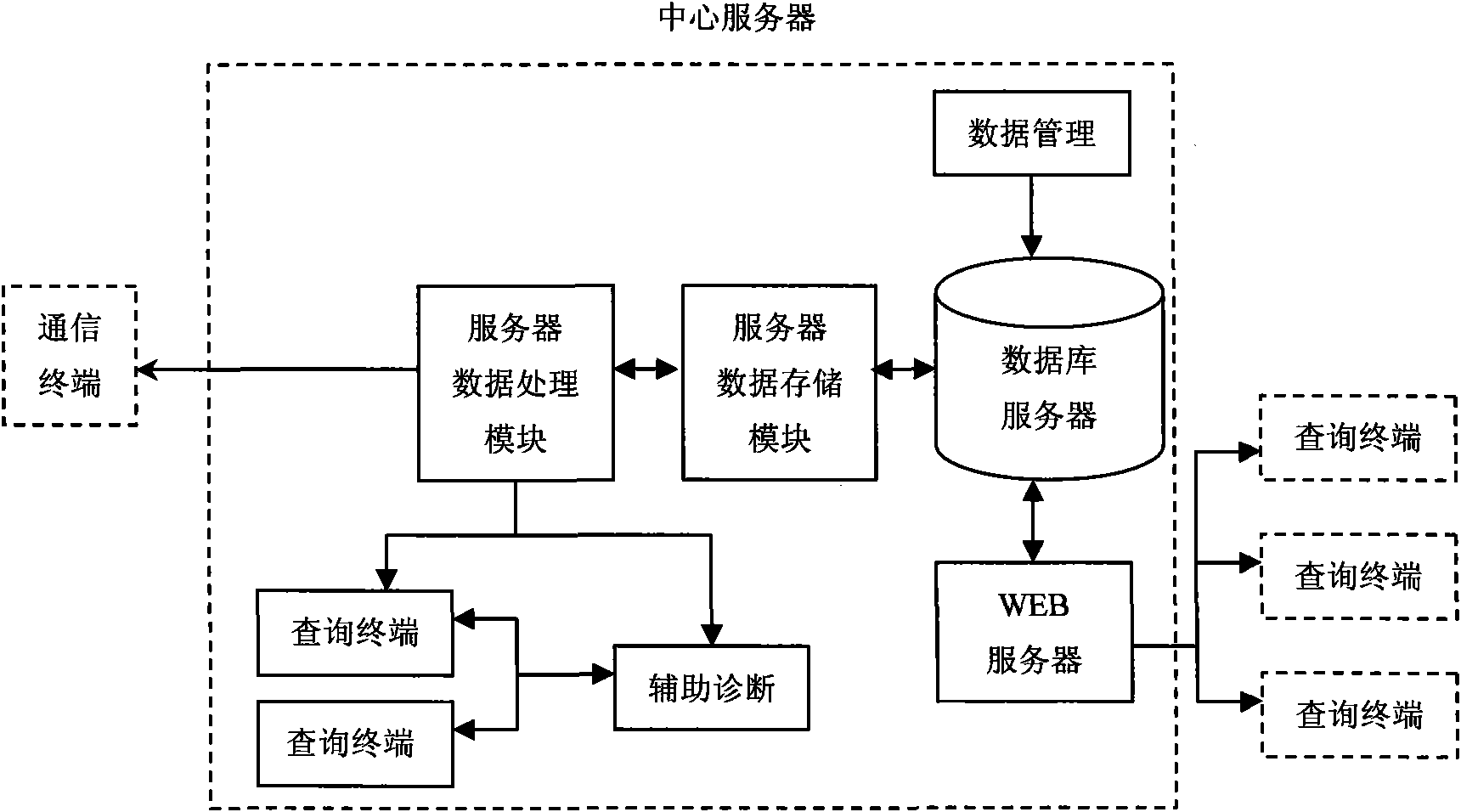

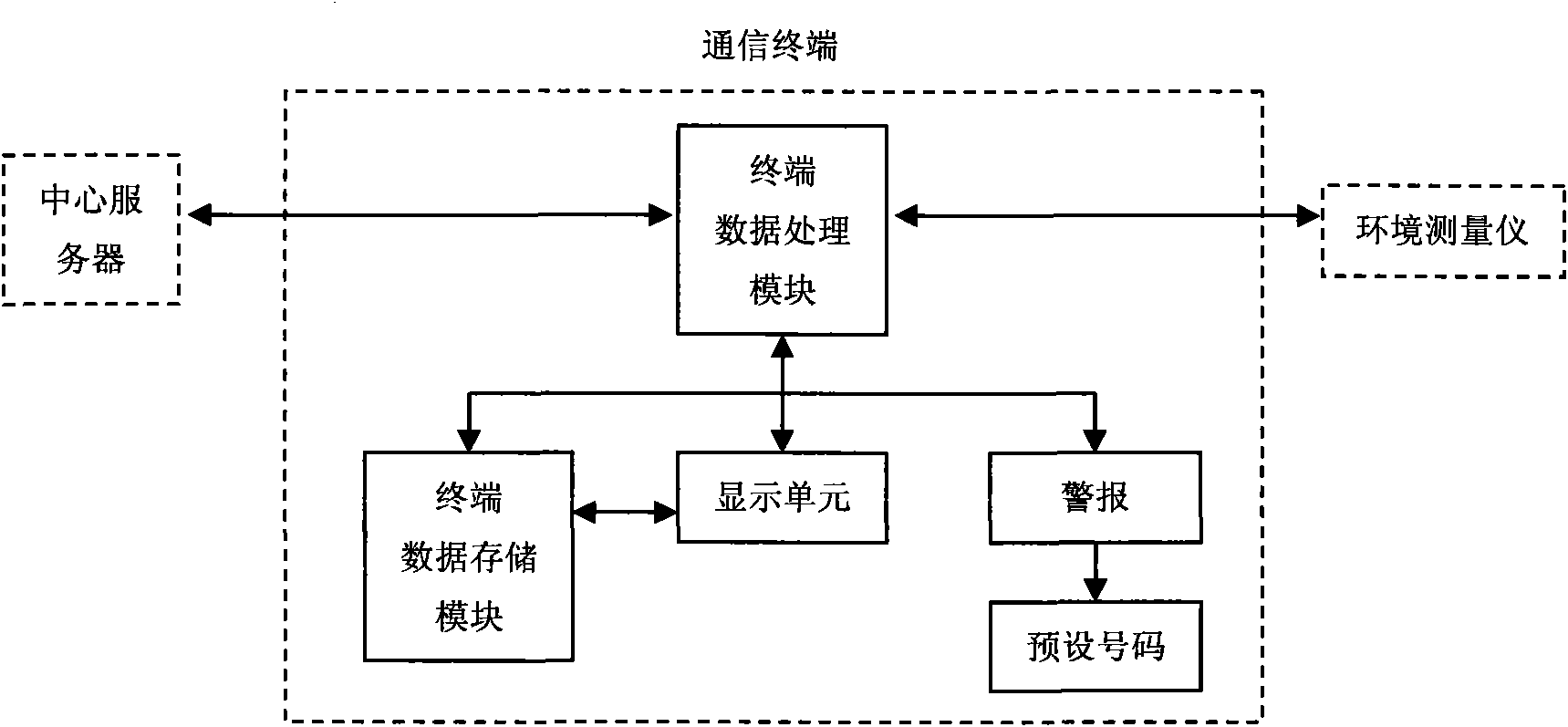

Wireless sensor network-based environment monitoring system

InactiveCN101888408AImprove data transfer performanceImprove accuracyNetwork topologiesTransmissionLine sensorMobile wireless sensor network

The invention discloses a wireless sensor network-based environment monitoring system, which comprises a central server, a communication terminal and an environment monitor, wherein the central server is connected with the communication terminal which is connected with the environment monitor. In the wireless sensor network-based environment monitoring system, due to the adoption of remote data communication, the data transmission performance of the system is greatly improved, the application range is expanded, and the system is particularly suitable for the environment with severe conditions and much interference; moreover, the data detection accuracy is high, the data transmission speed is high and the production cost is low.

Owner:SUZHOU CHANGYIHONG ENVIRONMENTAL TECH

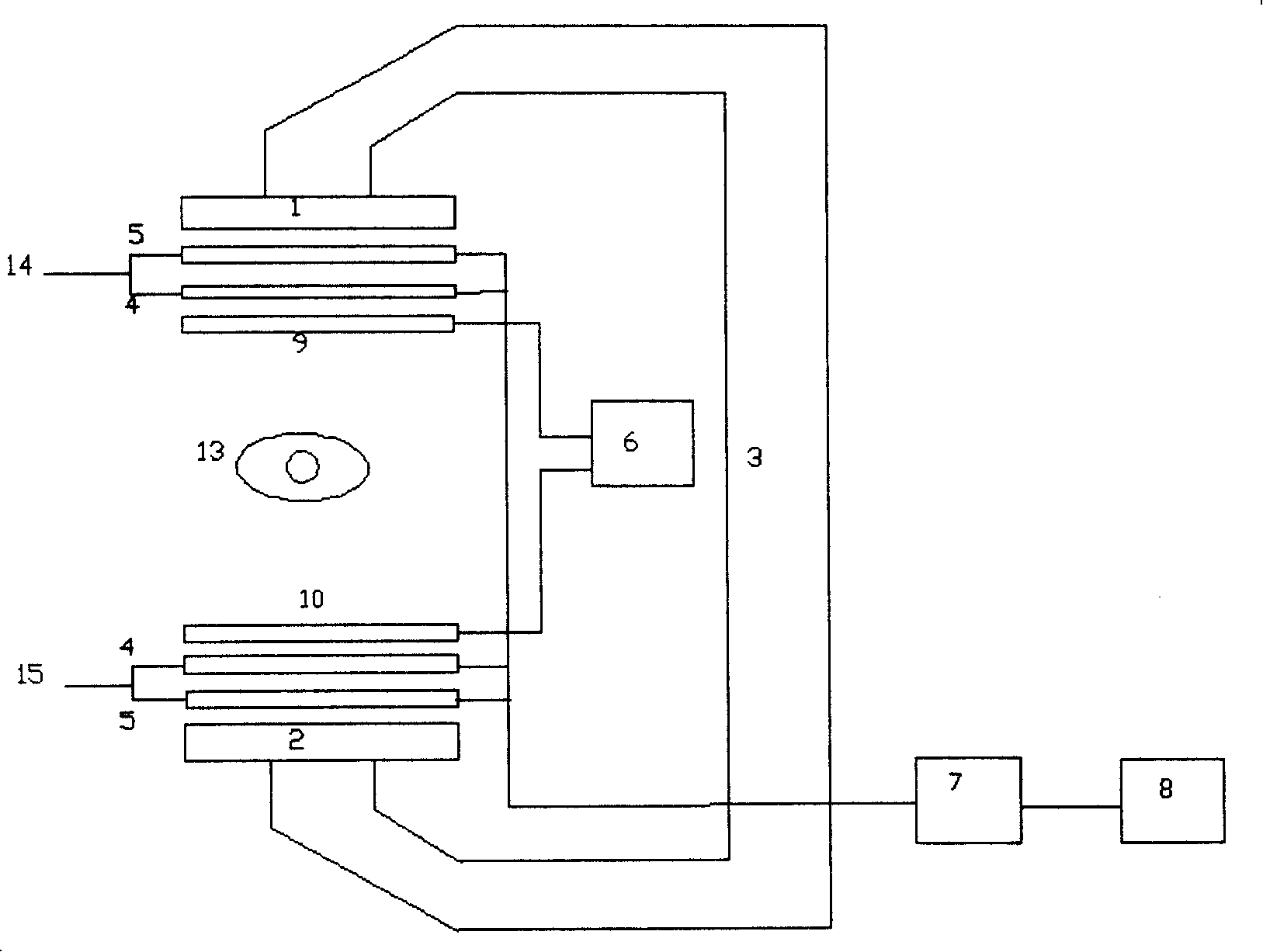

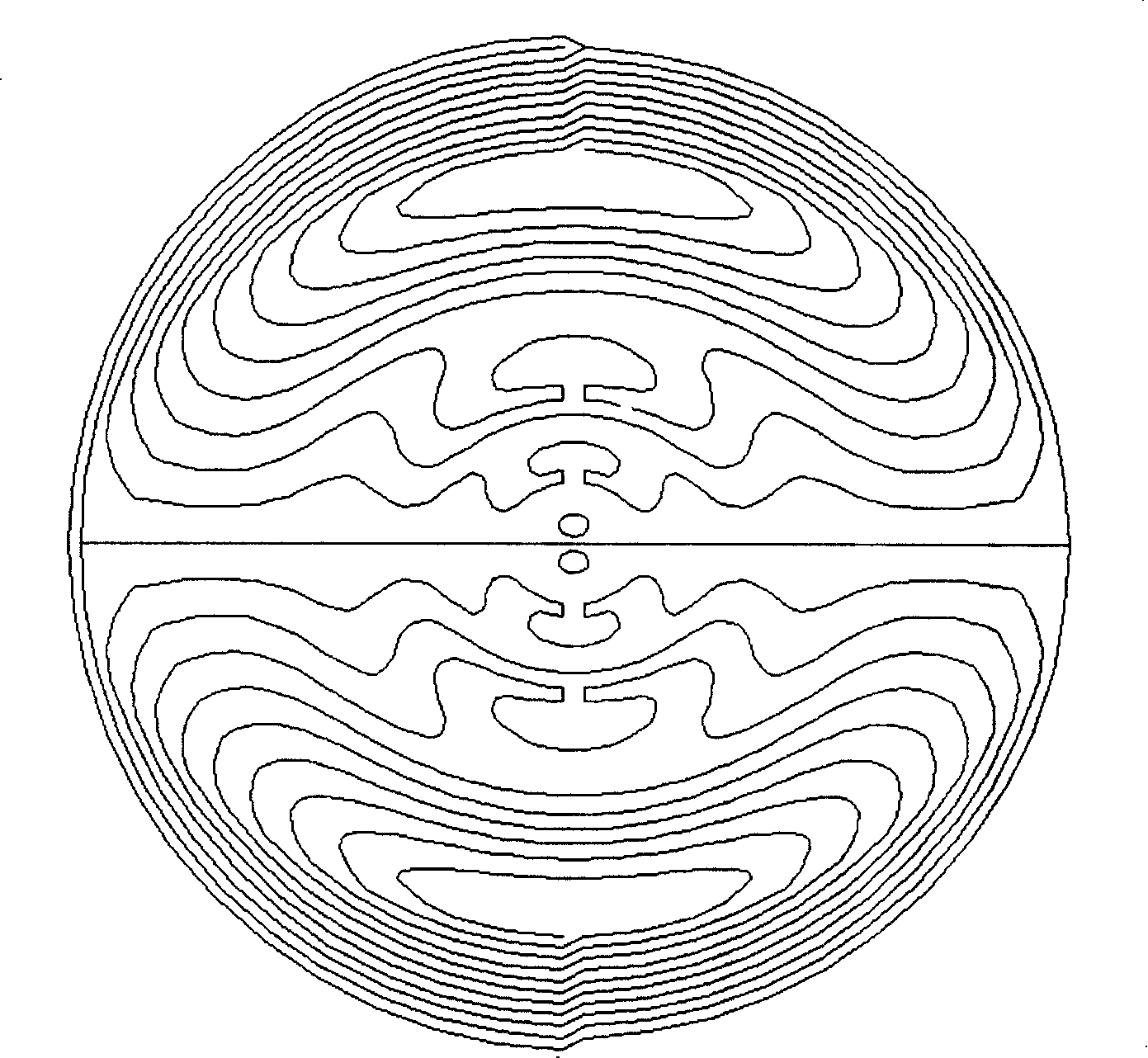

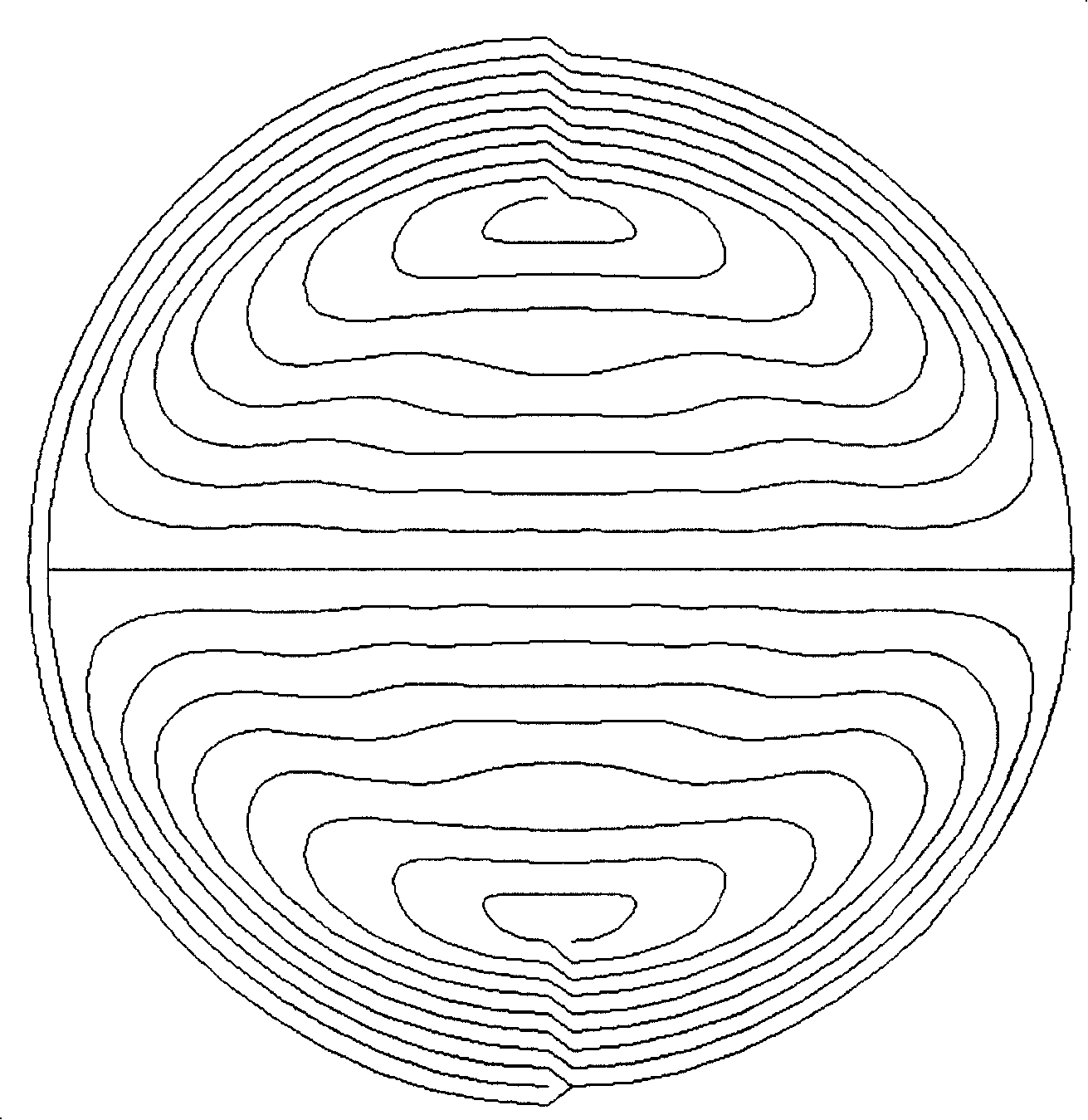

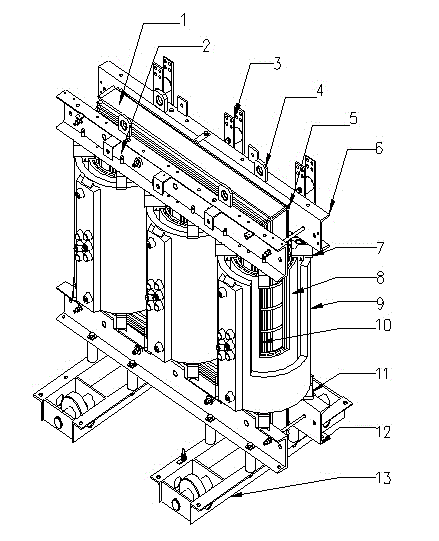

Flat surface active shielded gradient coil preparation method

ActiveCN101191829AUniform linearityMagnetic field switching speed is fastMagnetic measurementsEngineeringSoftware

The invention discloses a method for making flat active shielding gradient coil, relating to the technique of flat active shielding gradient coil used in the MRI system. The method comprises the following steps of: making initial proposal according to the design index; using gradient magnetic field inversion calculation software to perform analog calculation to obtain the original design proposal; using large commercial magnetic field simulation calculation software to perform forward verification calculation to the original design proposal; amending repeatedly the design proposal by means of inversion calculation and forward calculation to obtain the primary proposal of the gradient coil; carrying out trail production of the gradient coil according to the primary proposal; testing the related technical data and enhancing the design proposal according to the result of the test to obtain high-performance flat active shielding gradient coil. The gradient coil made by the method of the invention can generate strong gradient magnetic field with uniform linearity and fast switching and can effectively avoid eddy current.

Owner:BEIJING WANDONG MEDICAL TECH CO LTD +1

Inner plugging air bag for leakage of risk source pipeline and quick plugging method thereof

The invention discloses an inner plugging air bag for leakage of a risk source pipeline and a quick plugging method thereof. The plugging device of the risk source pipeline consists of a sealing mechanism, a flow guide mechanism, a retaining mechanism and a fixing mechanism which are connected with one another. In the method, the plugging air bag, an aeration joint external aeration pump, a flow guide pipe connecting nozzle and a flow guide ball valve are used as plugging flow guide elements; and quick plugging for pipeline leakage is realized by aerating the plugging air bag by using extensibility of the rubber air bag. The inner plugging air bag has a simple structure, light weight and a good plugging effect, can be repeatedly used, is suitable for plugging the risk source pipeline of toxic gas and liquid and the like, and can also be used for inner plugging for leakage of a heat pipeline, a water supply pipeline, a chemical industry pipeline and even a large-sized pipeline.

Owner:TAIYUAN UNIV OF TECH

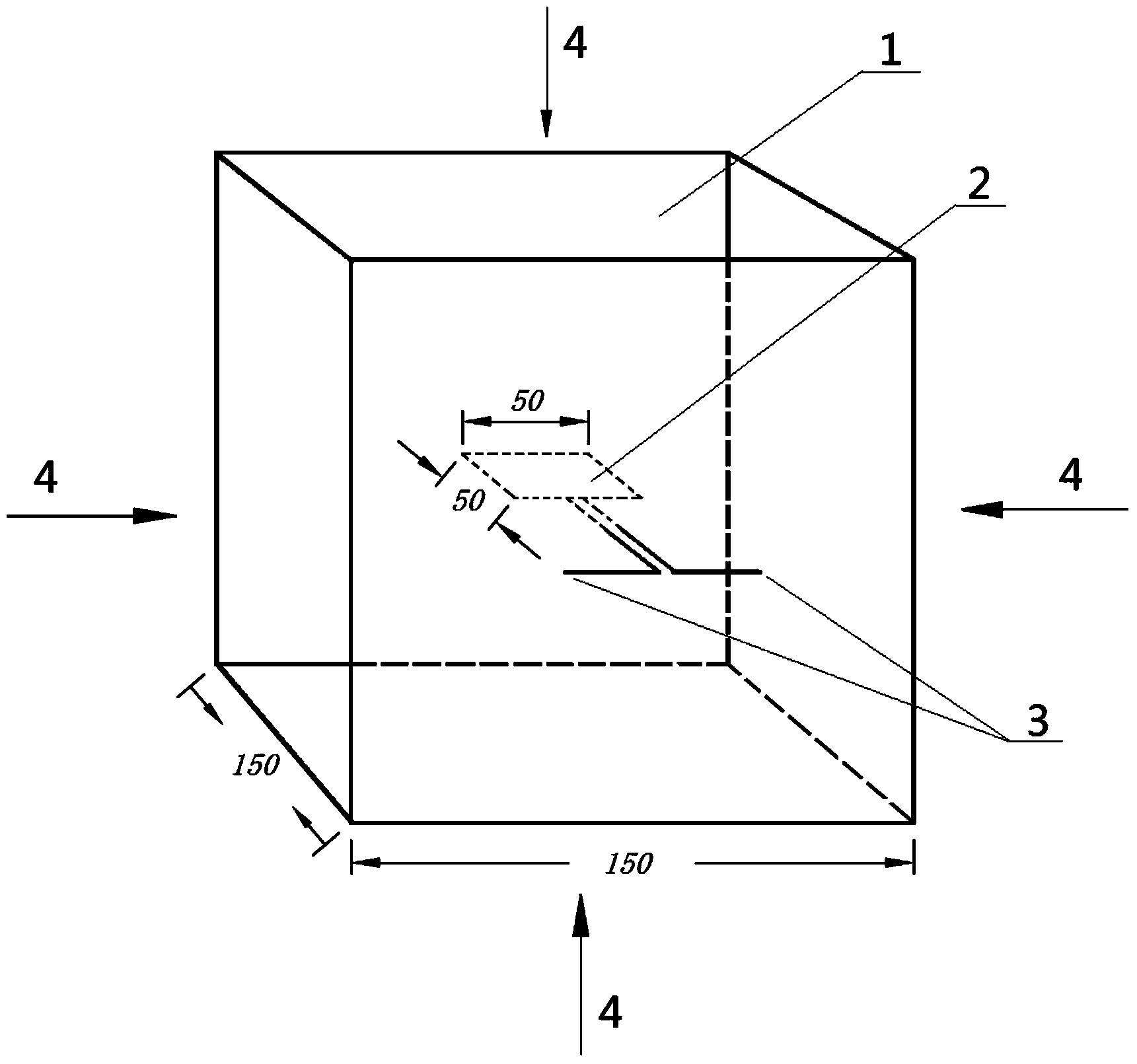

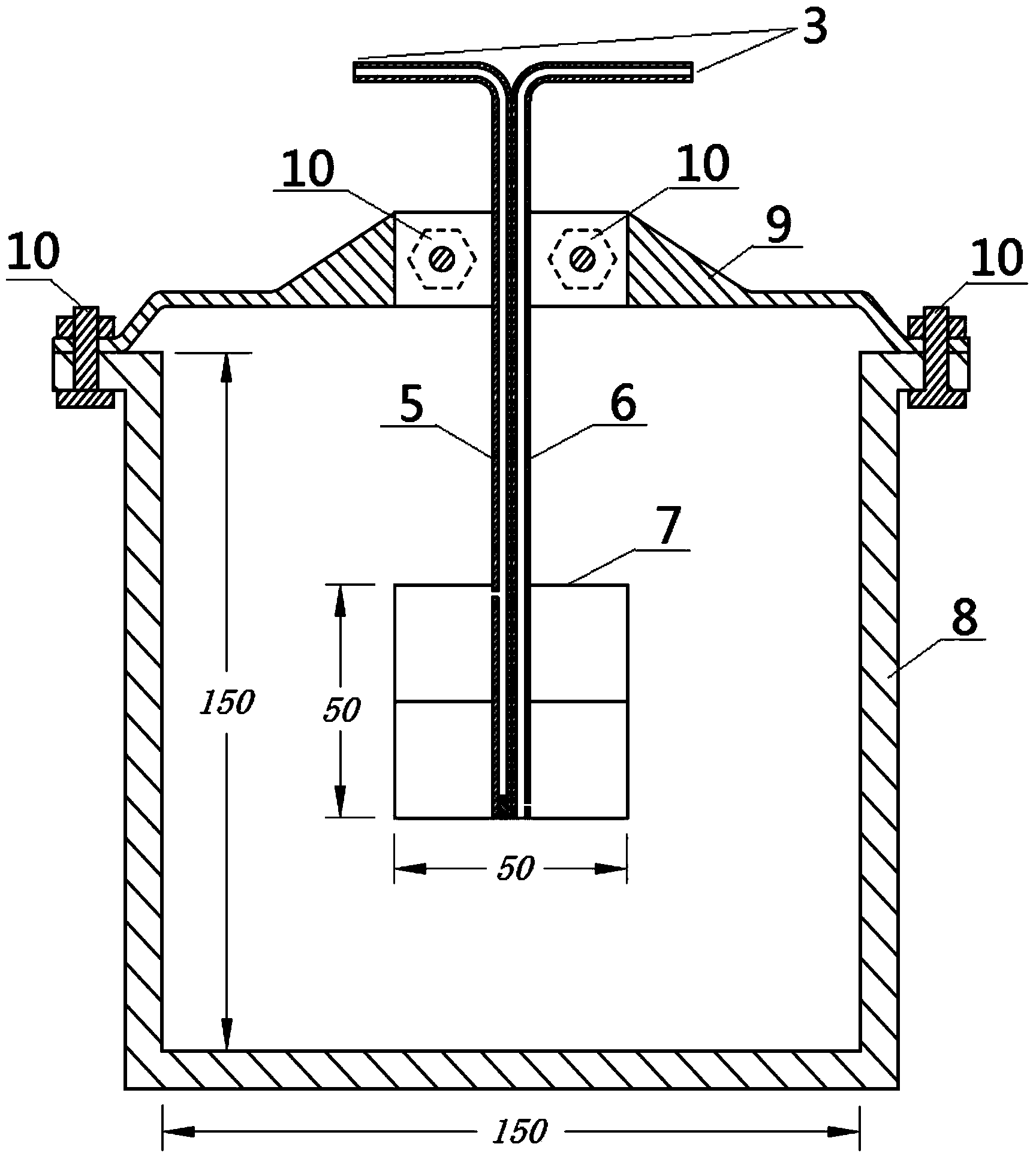

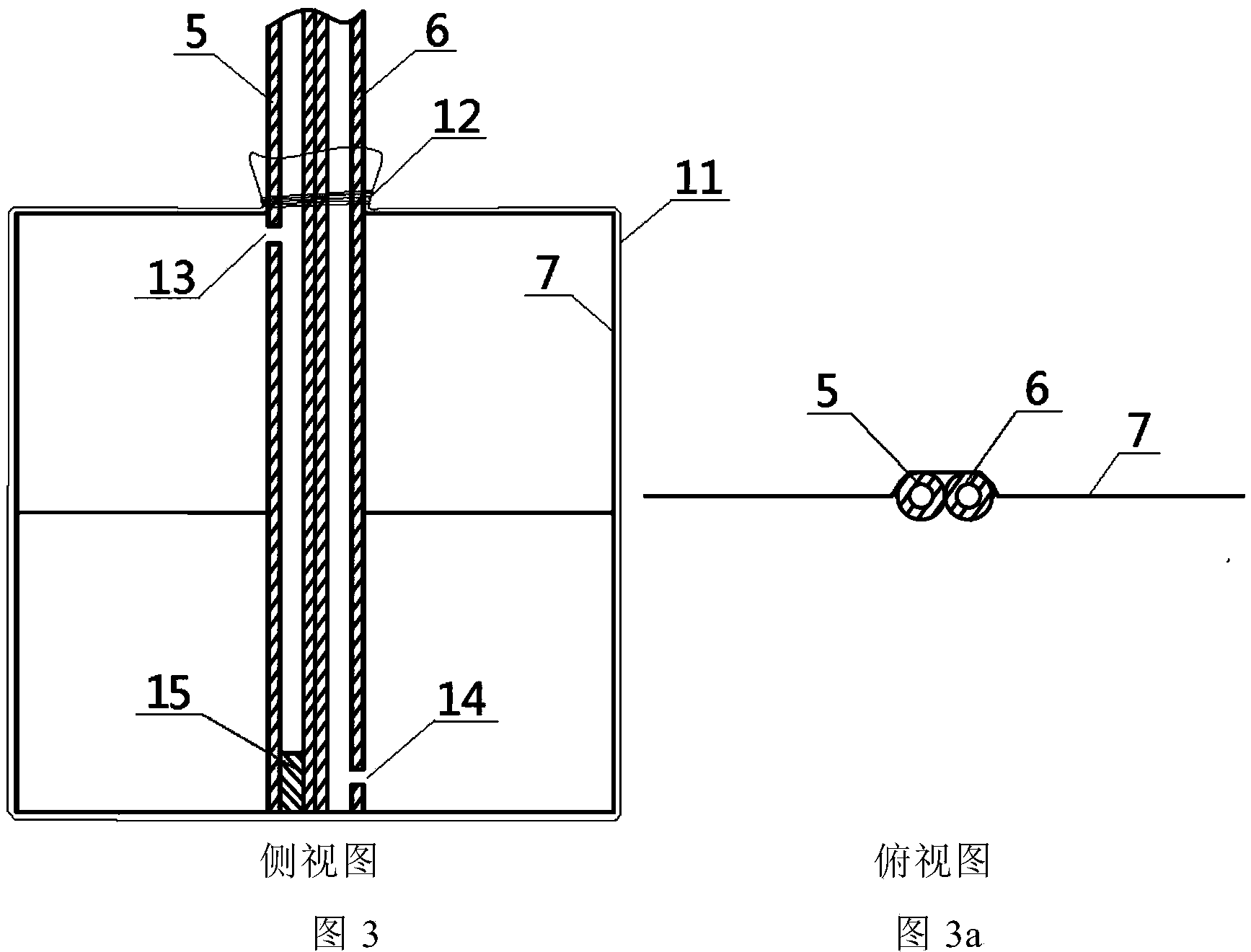

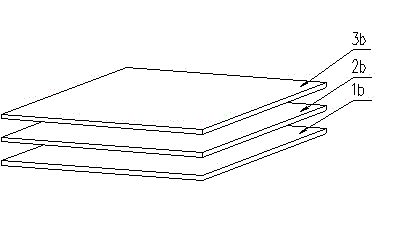

Hydraulic concrete member fracturing simulation experiment design method and device capable of applying biaxial acting force

ActiveCN104237021AMeet the experimental requirementsThe experimental design method is simplePreparing sample for investigationMaterial strength using tensile/compressive forcesPore water pressureHydraulic fracturing

The invention provides a hydraulic concrete member fracturing simulation experiment design method capable of applying biaxial acting force. The method comprises the steps of manufacturing a member for applying water pressure, fixing the member together with a square concrete die, pouring concrete into the die, performing vibration and maintenance, then detaching the die while remaining the member for applying water pressure in the concrete, forming a slit in a concrete test piece, and supplying a channel for applying water pressure to the slit. A biaxial experiment machine applies the set biaxial acting force to the concrete test piece; the member for applying water pressure is used for applying the water pressure to the concrete test piece until the test piece is fractured, and the water pressure applied when the test piece is fractured is recorded. The invention also provides a device used in the method. The method and the device used in the method are simple; the prepared concrete test piece can meet an experiment requirement and can be used for researching hydraulic fracturing of the concrete member in a biaxial stress state.

Owner:CHINA INST OF WATER RESOURCES & HYDROPOWER RES +1

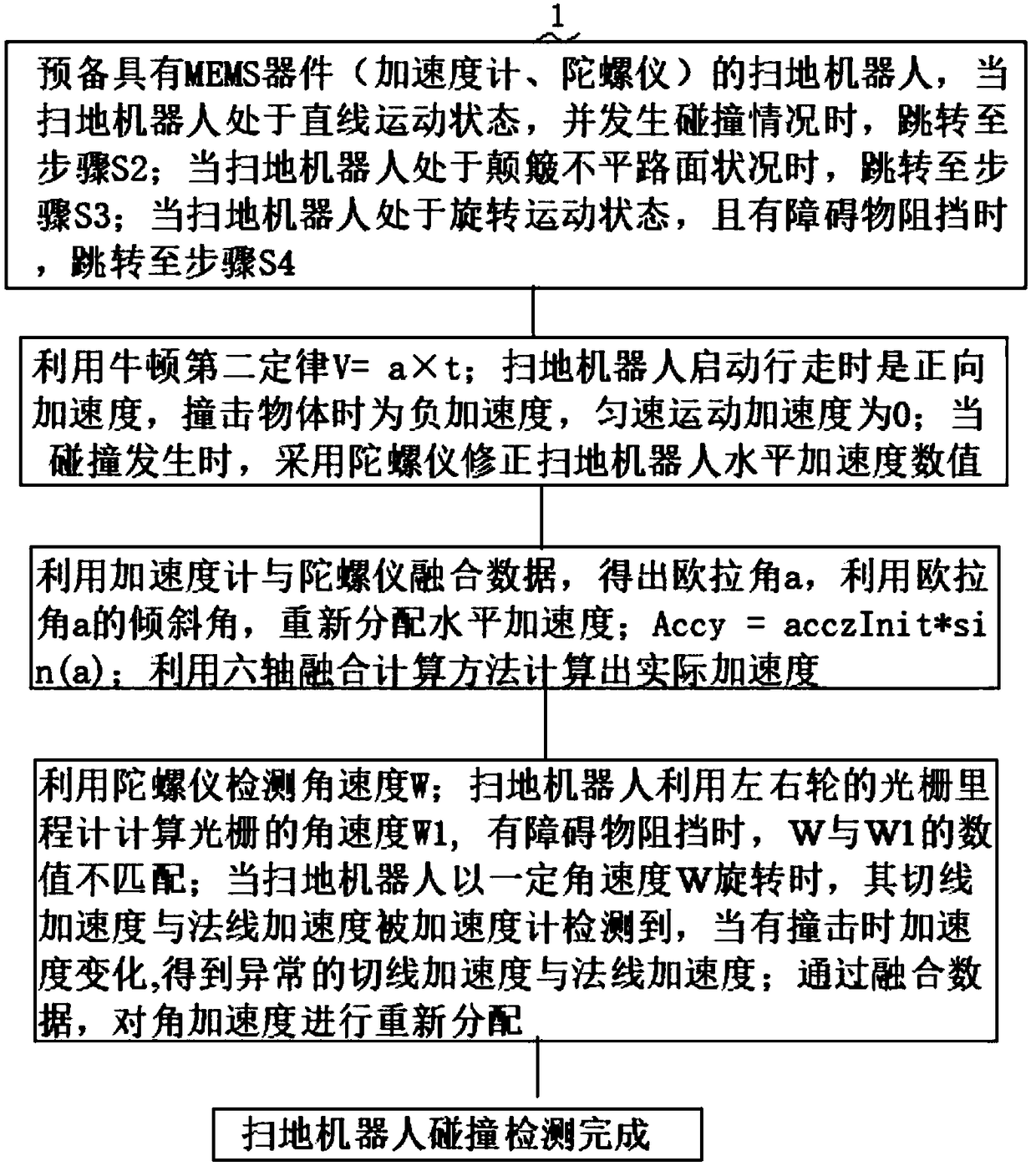

Anti-collision detection method of floor mopping robot

ActiveCN109049006AGuaranteed uptimeReasonable design structureProgramme-controlled manipulatorCarpet cleanersAccelerometerGyroscope

The invention provides an anti-collision detection method of a floor mopping robot. The method comprises following steps that S1, the floor mopping robot with MEMS devices (an accelerometer and a gyroscope) are arranged, when the floor mopping robot is in the straight line motion state, and the collision condition happens, the S2 is executed, when the floor mopping robot is in the jolt uneven roadsurface condition, the S3 is executed, and when the floor mopping robot is in the rotating motion state, and a barrier blocks the robot, the S4 is executed; S2, the Newton's second law V=a*t is used,when the floor mopping robot is started to walk, positive direction acceleration is carried out, when the robot hits against the object, negative acceleration is achieved, and acceleration during uniform motion is zero; when collision happens, the gyroscope is adopted to correct the horizontal acceleration numerical value of the floor mopping robot. Different correction manners are used for carrying out collision detection and correcting, the floor mopping robot can normally and stably run, the design structure is reasonable, and the technical effect is obvious.

Owner:SHENZHEN UMOUSE TECH DEV

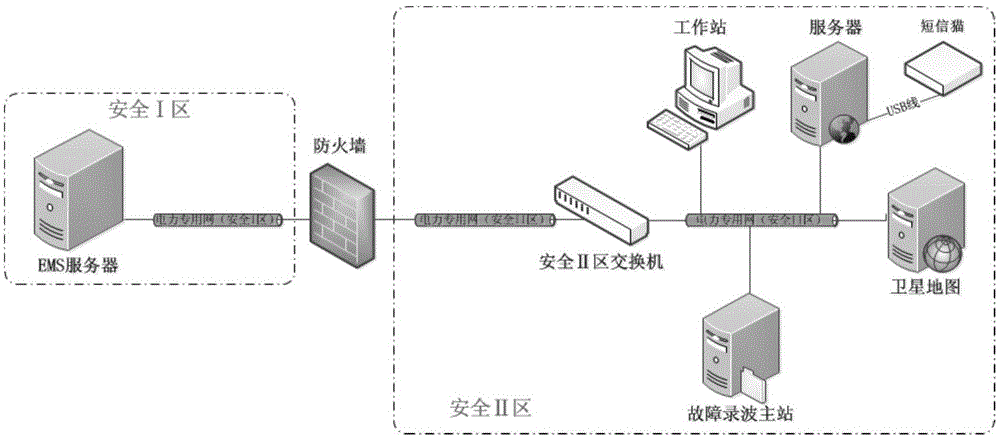

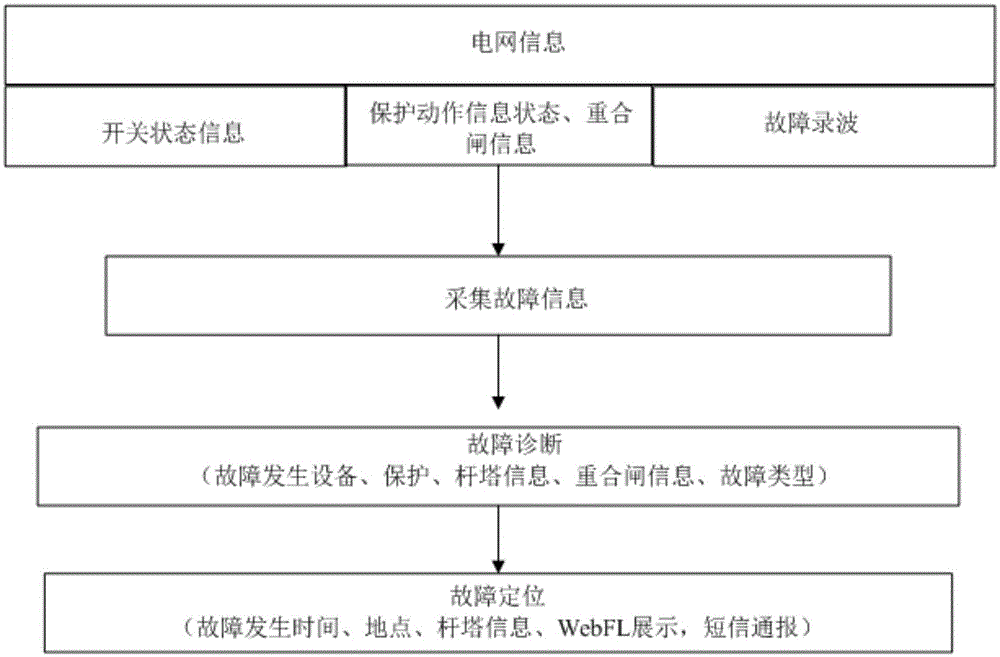

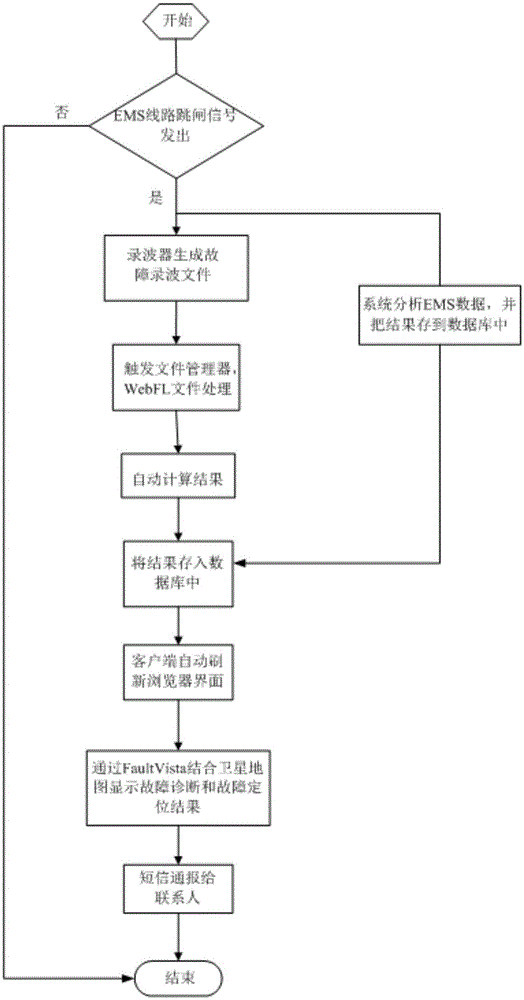

Automatic transmission line fault diagnosis and fault positioning method and system

InactiveCN105158642AReasonable design structureFlexible configurationFault locationAutomatic transmissionLine model

The invention discloses an automatic transmission line fault diagnosis and fault positioning method and a system. A system line model is built; when an EMS line tripping signal is sent, EMS data are analyzed, and an analysis result is stored to a database; while the EMS line tripping signal is sent, a fault recorder generates a fault recording file, file management is triggered for fault diagnosis and fault positioning, and the result is stored to the database; a client displays the fault diagnosis and fault positioning result via a browser interface in combination with a satellite map, and the fault diagnosis and fault positioning result is sent in a corresponding short message notification format. By adopting concentrated vector fault recording positioning, problems existing in traveling wave positioning and a fault recording or protection positioning method can be effectively overcome, and positioning accuracy is greatly improved.

Owner:SHANDONG HISING POWER TECH CO LTD

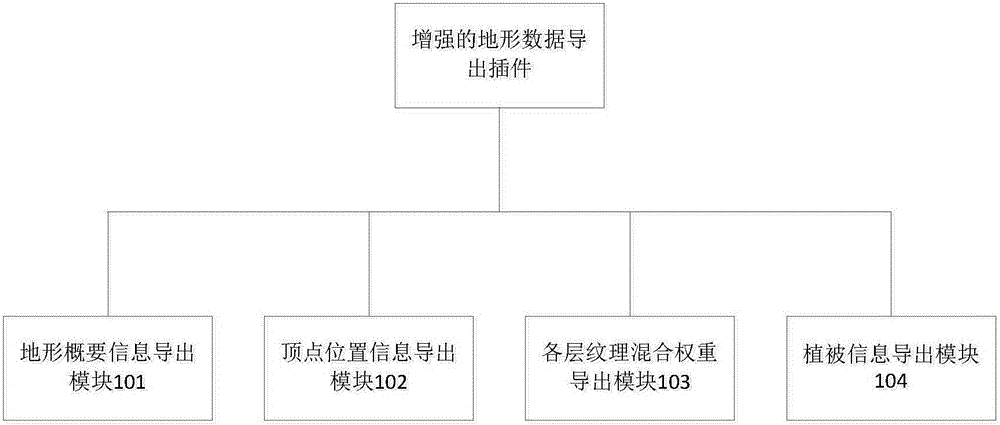

Use method of Unity3D terrain data in Direct3D 11 environment

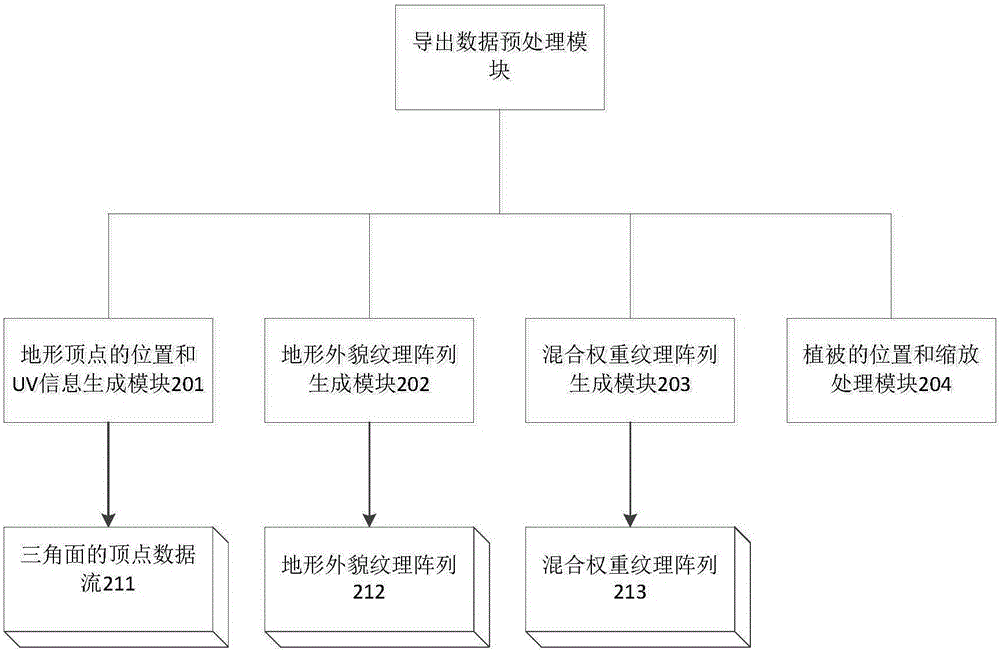

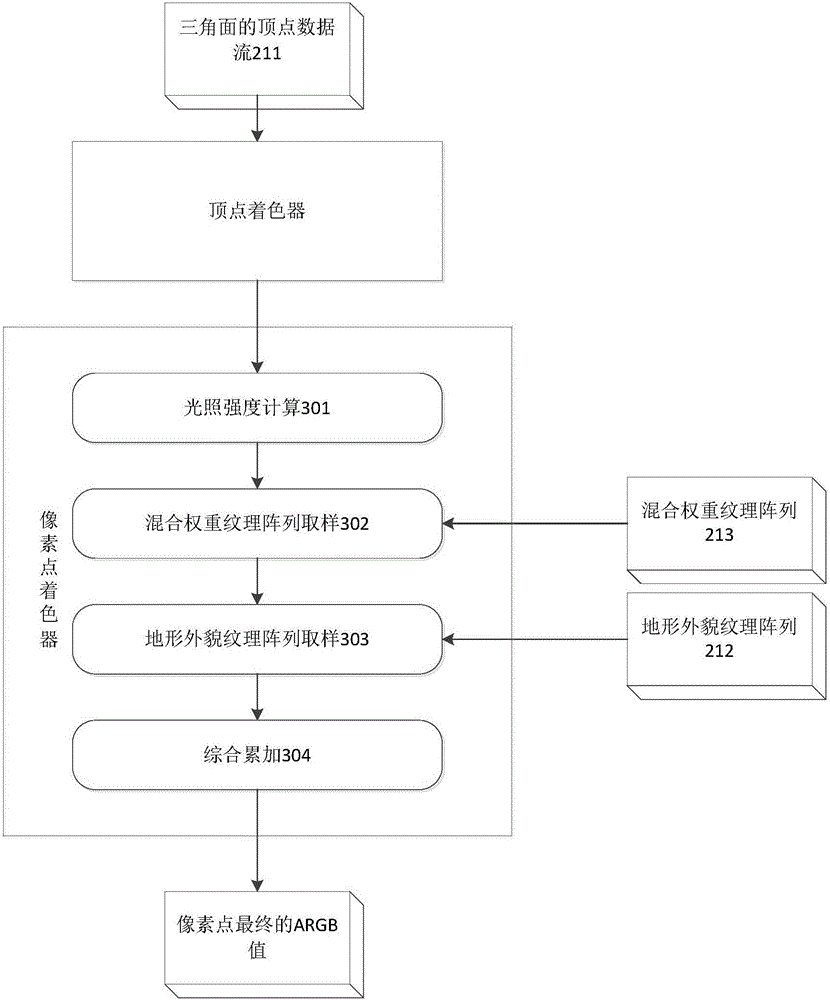

ActiveCN106204735AConvenient and efficient design and productionSolve the disadvantages of cumbersome design and production of terrain modelsDetails involving 3D image data3D modellingTerrainData export

The invention provides a use method of Unity3D terrain data in the Direct3D 11 environment. Enhanced Unity3D terrain export plug-in comprises a plurality of export submodules. A terrain vertex position and UV information generation module reads terrain vertex data exported by an export module, and a corresponding geometrical triangular face is constructed. A terrain appearance texture array generation module reads a required terrain appearance texture file according to information of a texture set in the export module, and a Direct3D 11 terrain appearance texture array is generated. A blend weight texture generation module generates a Direct3D 11 texture including texture blend weight information in the texture set according to the data exported by the export module. A vegetation position and scaling processing module sets three-dimensional space coordinates of plants in a scene according to vegetation information exported by the export module and conducts size scaling adjustment on plant surface patches. A pixel coloring device calculates light of each pixel on a screen on the basis of three-dimensional rendering element resources, texture samples are mixed in the terrain appearance texture array, and an exported terrain is displayed in the Unity3D 11 rendering environment.

Owner:PLA UNIV OF SCI & TECH

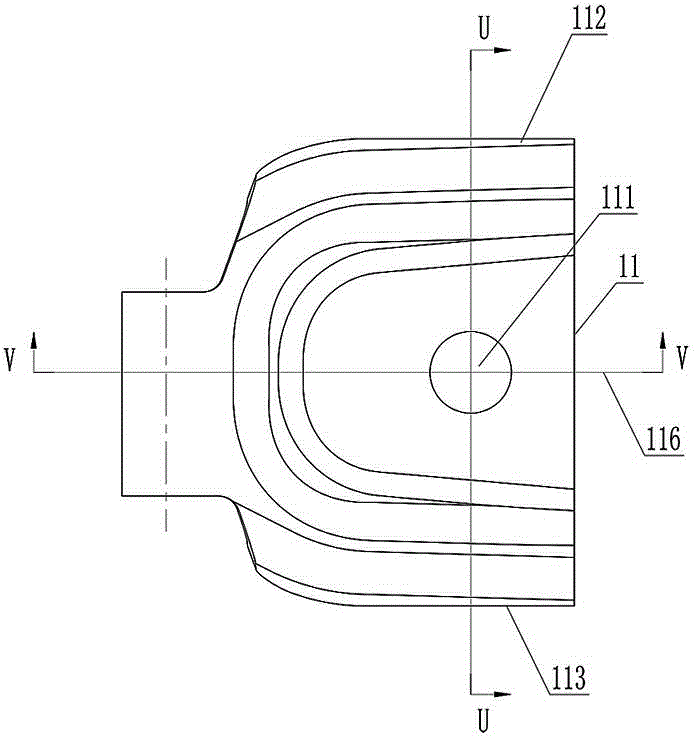

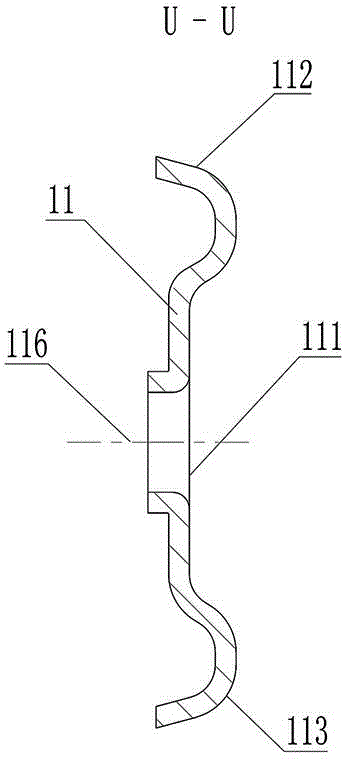

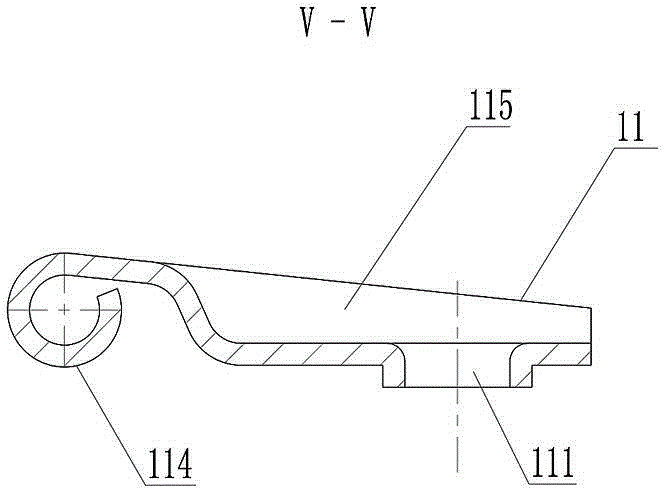

Progressive die for manufacturing automobile seat hinge and method of progressive die

The invention relates to a progressive die for manufacturing an automobile seat hinge and a method of the progressive die. The progressive die for manufacturing the automobile seat hinge is structurally characterized in that according to the progressive die, a trimming die, a pre-forming die, a pre-folding die, a folding die, a pre-bending die, a pre-rolling die, a rolling shaping die and a hole flanging forming die are sequentially arranged, wherein upper dies of the trimming die, the pre-forming die, the pre-folding die, the folding die, the pre-bending die, the pre-rolling die, the rolling shaping die and the hole flanging forming die are the same die seats, and lower dies of the trimming die, the pre-forming die, the pre-folding die, the folding die, the pre-bending die, the pre-rolling die, the rolling shaping die and the hole flanging forming die are the same die seats. The manufacturing method of the progressive die includes the steps that two asymmetric hinges which are connected integrally before final cutting need to be manufactured; the center line of a flanged hole of the first hinge and the center line of a flange hole of the second hinge are distributed in a staggered mode; the first hinge and the second hinge are finally formed through the progressive die which is designed in advance. The manufacturing method includes a trimming process, a pre-forming process, a rolling process and a hole flanging process. According to the progressive die and the preparing method of the progressive die, the overall design and arrangement are more reasonable and more simple, use is convenient and reliable, positioning is accurate, precision is high, two finished hinge products different in shape can be produced through one die, the cost of the progressive die and a steel plate coiled tape is lower, and efficiency is higher.

Owner:ZHEJIANG LONGSHENG AUTO PARTS TECH CO LTD

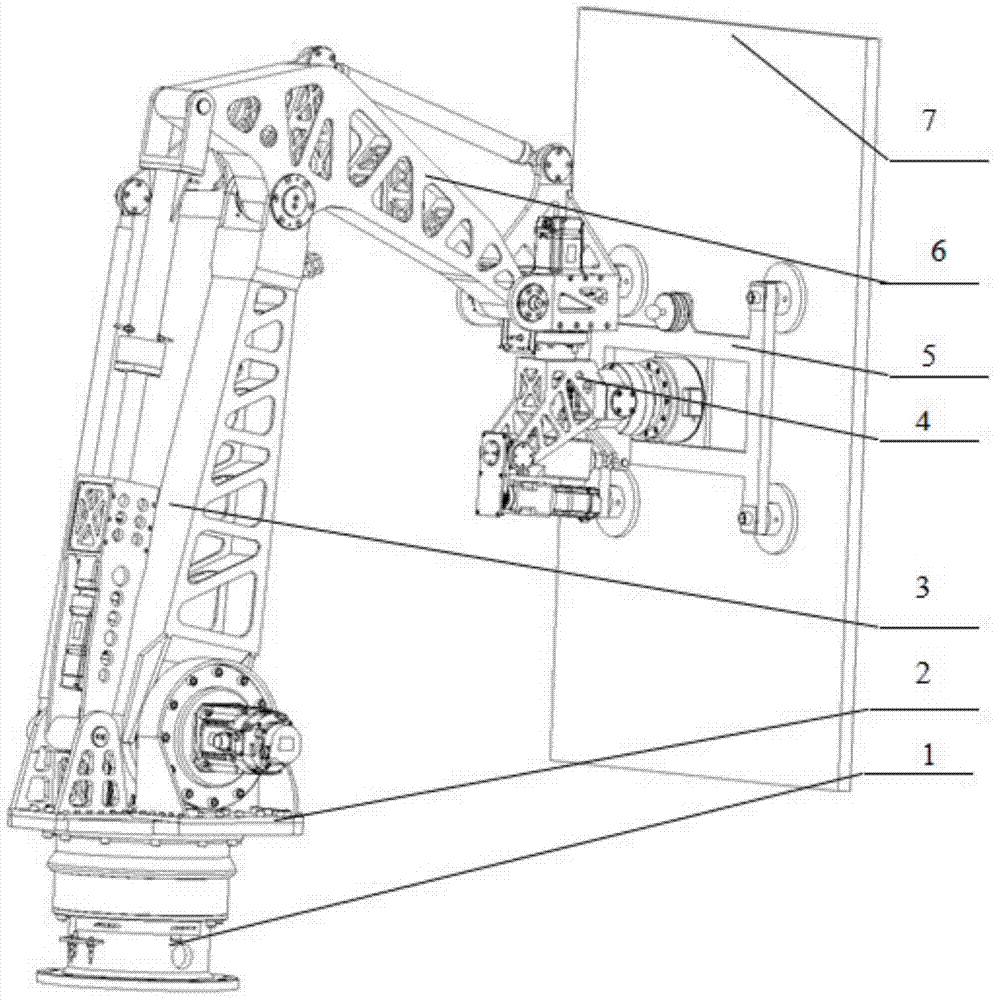

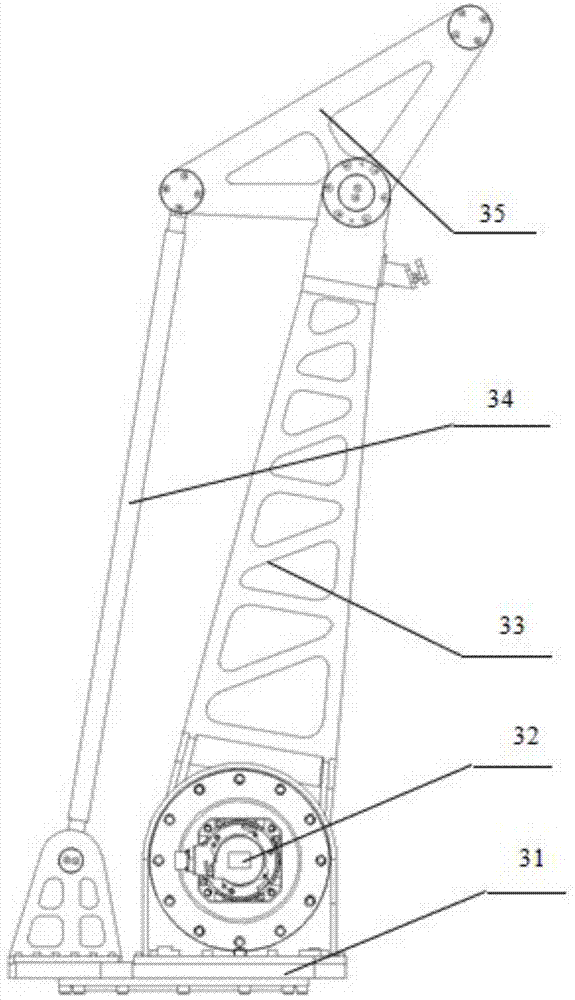

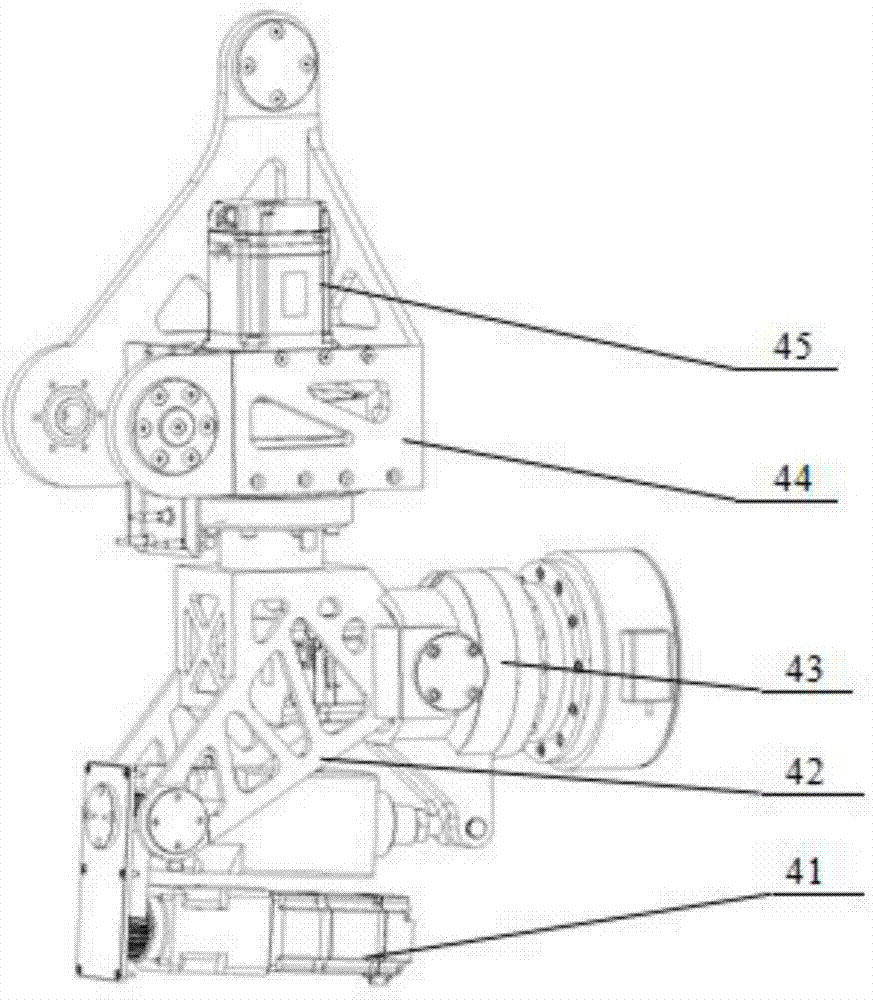

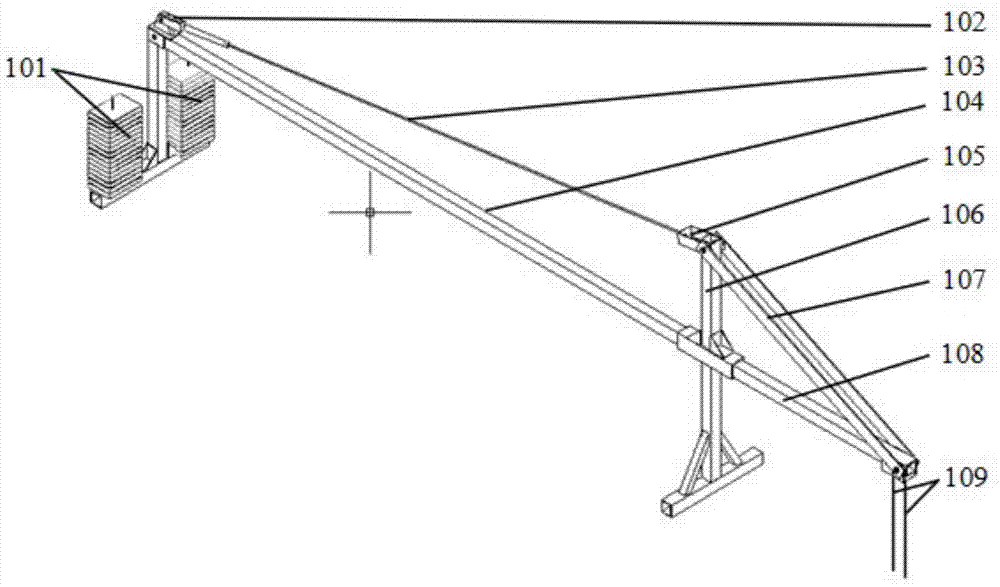

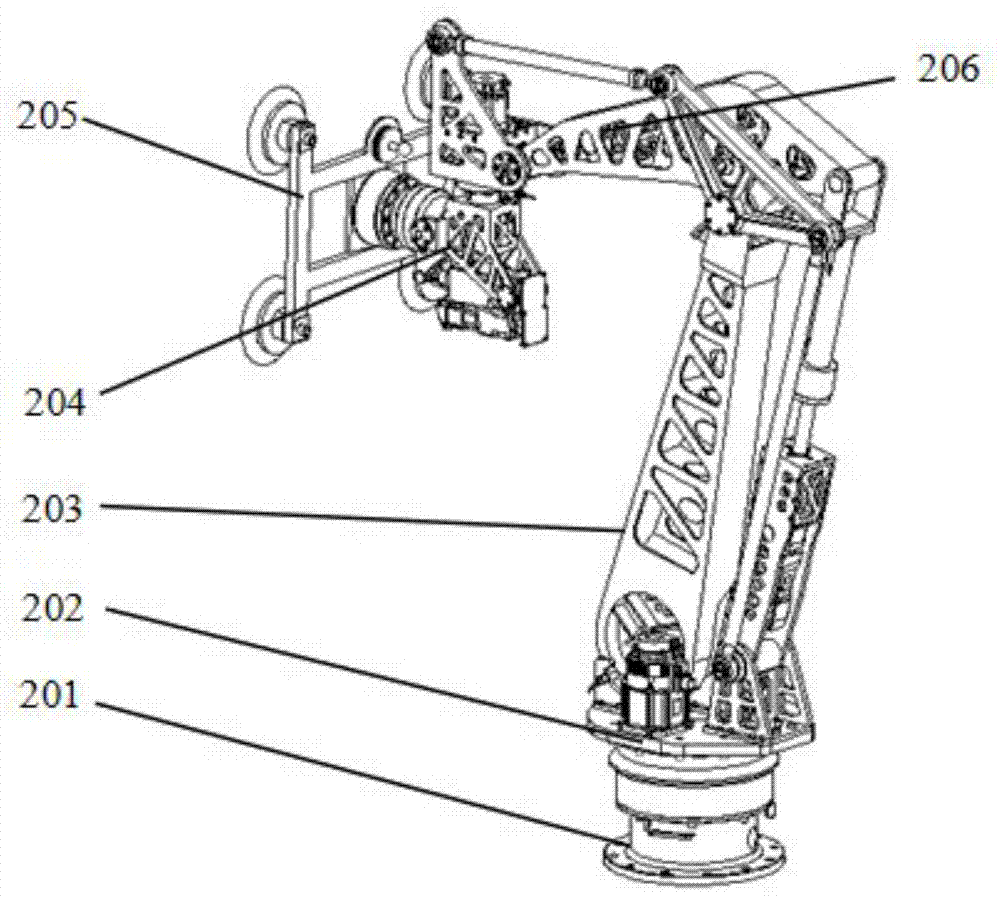

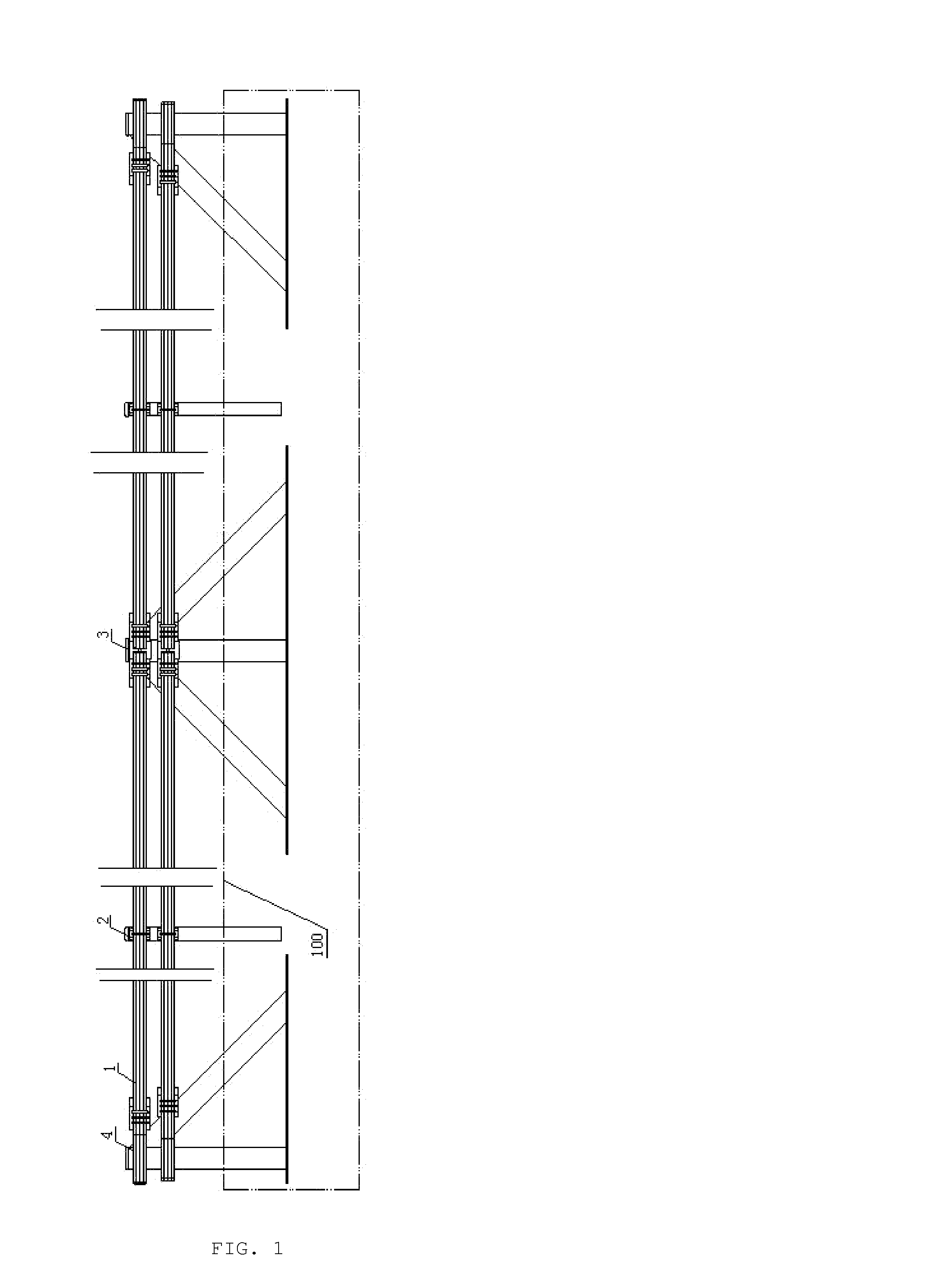

Robot for installing aerial curtain wall

InactiveCN104763160AReduce volumeGuaranteed work spaceBuilding material handlingEngineeringElectric drive

The invention relates to a robot for installing an aerial curtain wall. The robot comprises a base, a rotary frame, a big-arm parallelogram mechanism, an end gesture adjusting device, an end effector and a forearm parallelogram mechanism, wherein the base, the rotary frame, the big-arm parallelogram mechanism, the forearm parallelogram mechanism, the end gesture adjusting device and the end effector are sequentially connected. The robot is characterized in that the end gesture adjusting device comprises an electric drive pusher component, a pitching fixed support, a six-axis motor-RV reducer component, a four-axis motor-RV reducer component and a swinging fixed support, wherein the middle part of the four-axis motor-RV reducer component is fixed on the swinging fixed support, the lower part of the four-axis motor-RV reducer component is connected with the upper end of the pitching fixed support, the left end of the six-axis motor-RV reducer component is fixedly connected with the right end of the pitching fixed support and the lower ends of the pitching fixed support and the six-axis motor-RV reducer component are respectively connected with the electric drive pusher component through hinge pins.

Owner:HEBEI UNIV OF TECH

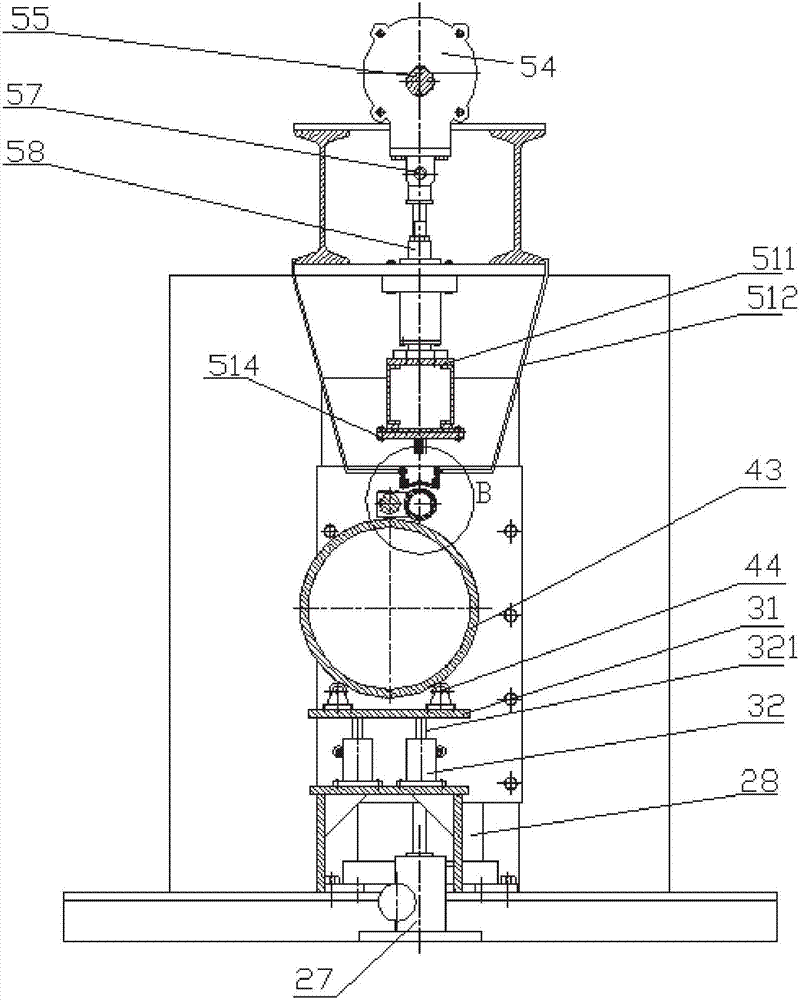

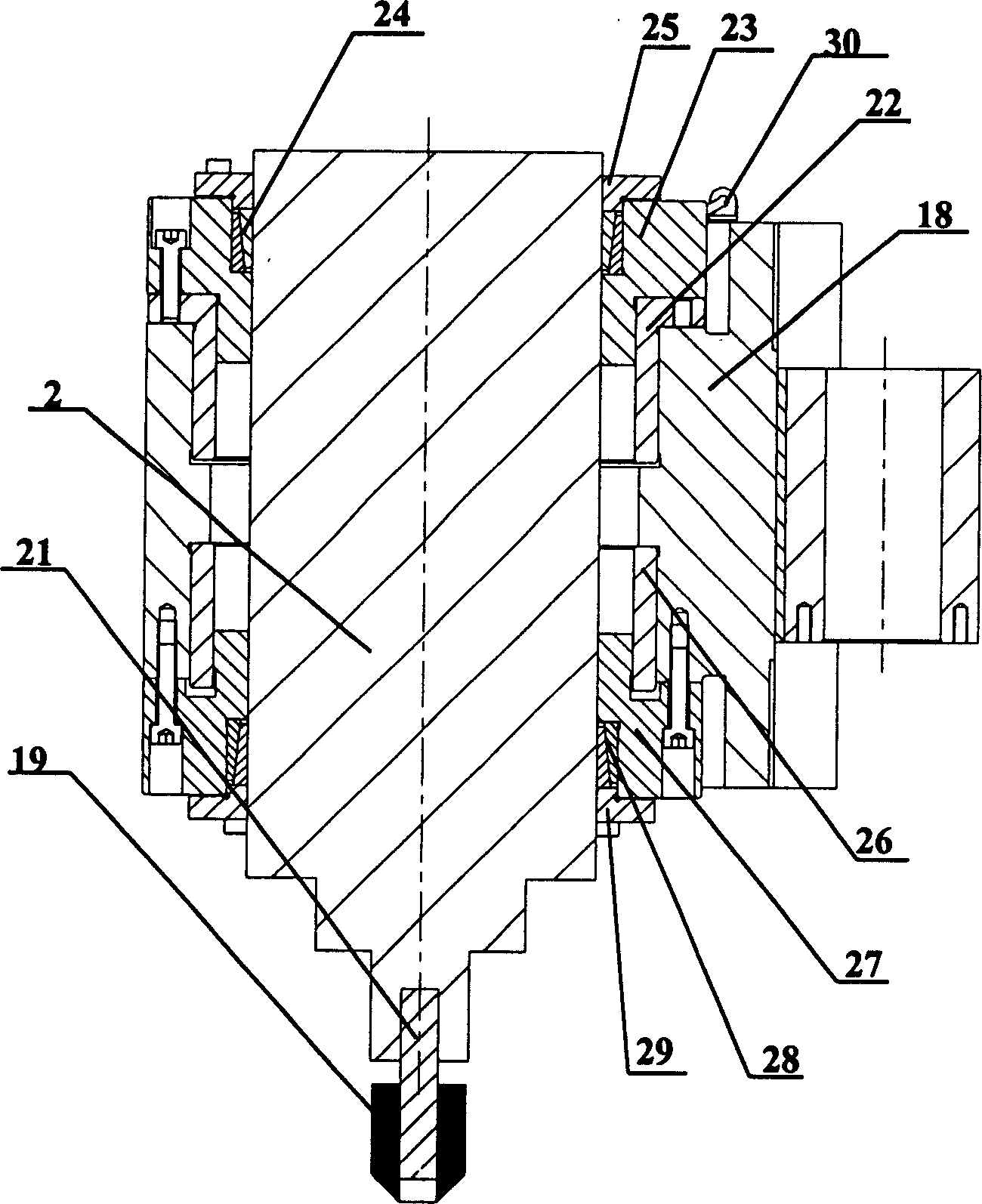

Follow-up clamping device

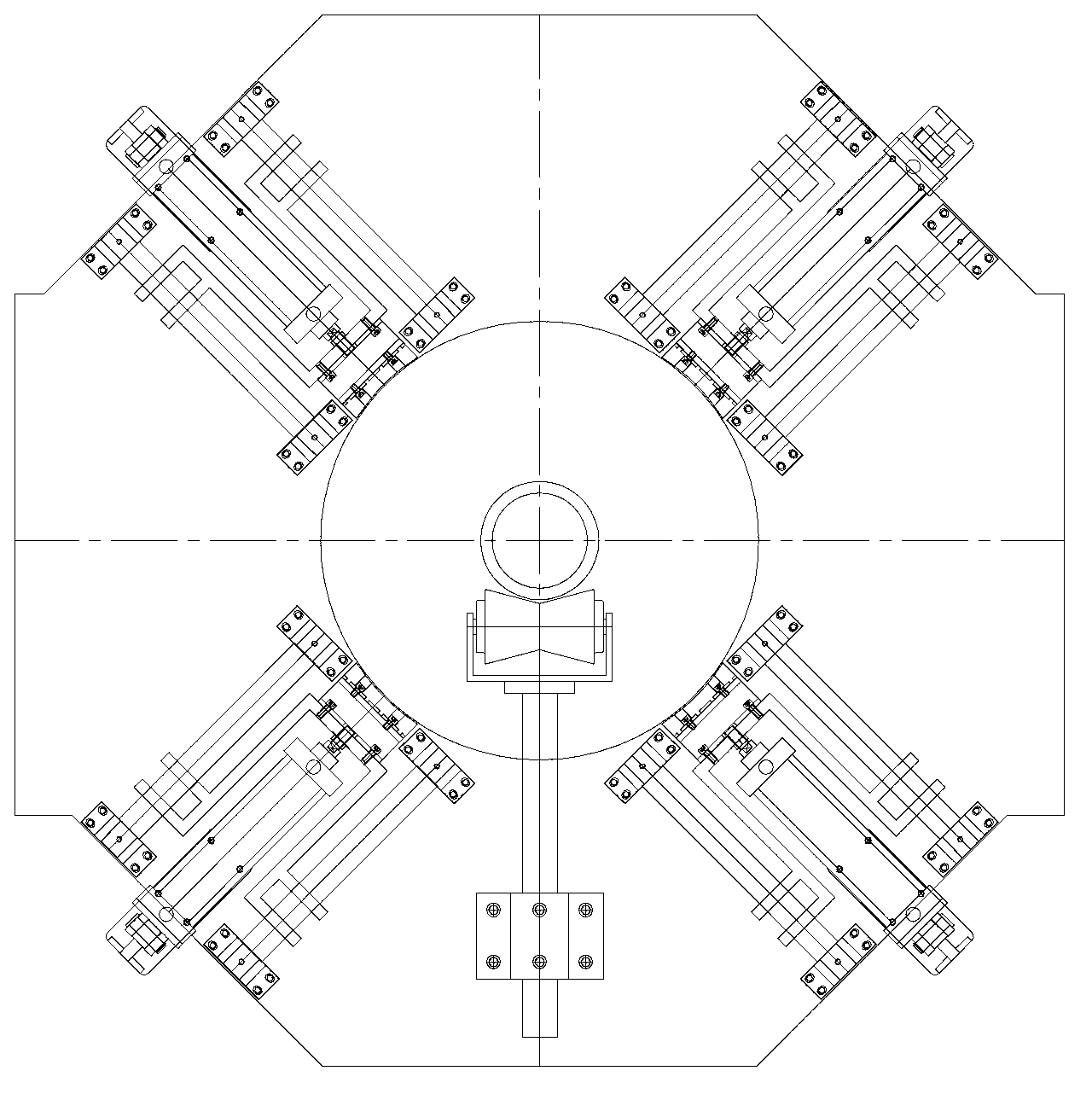

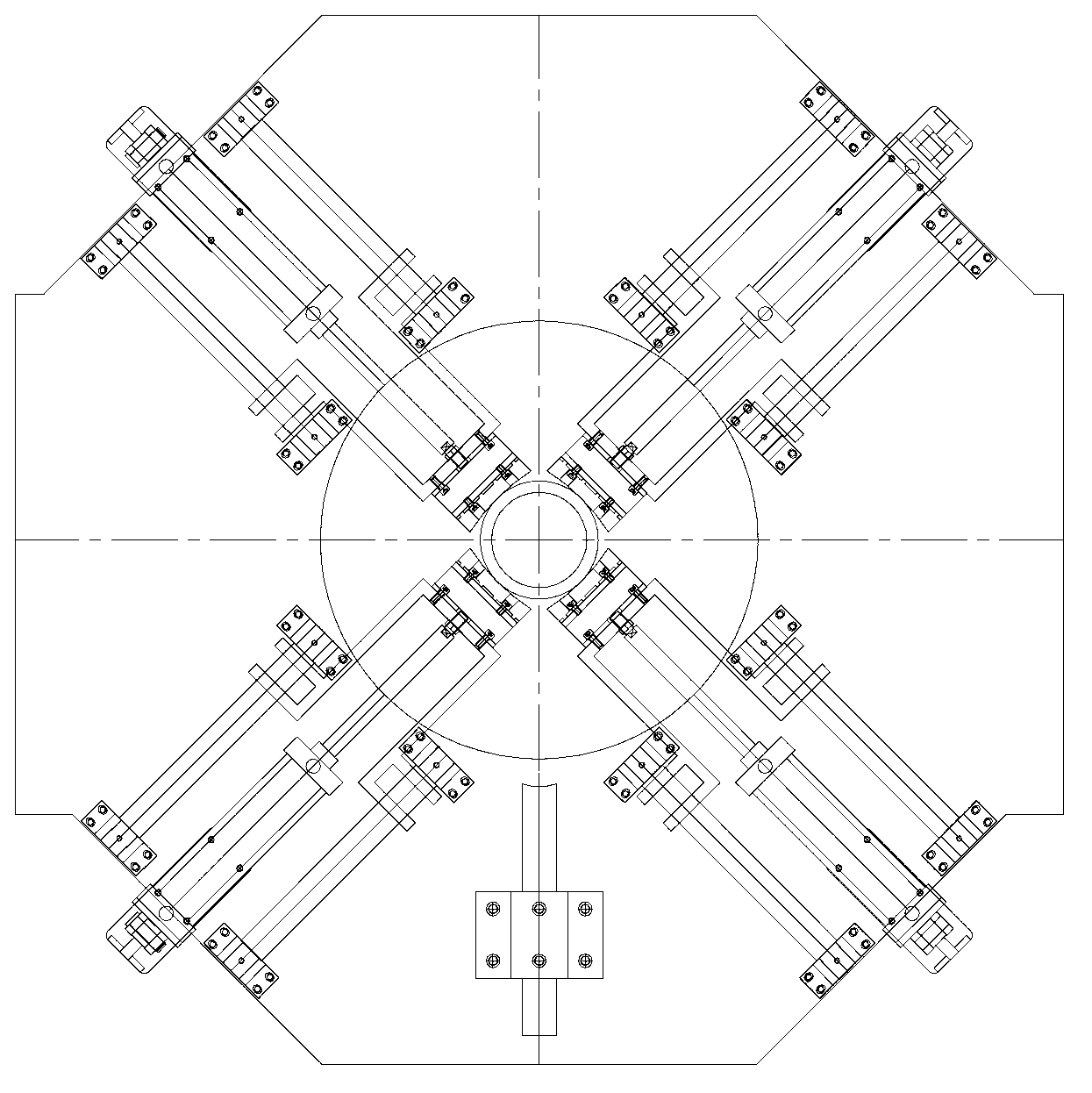

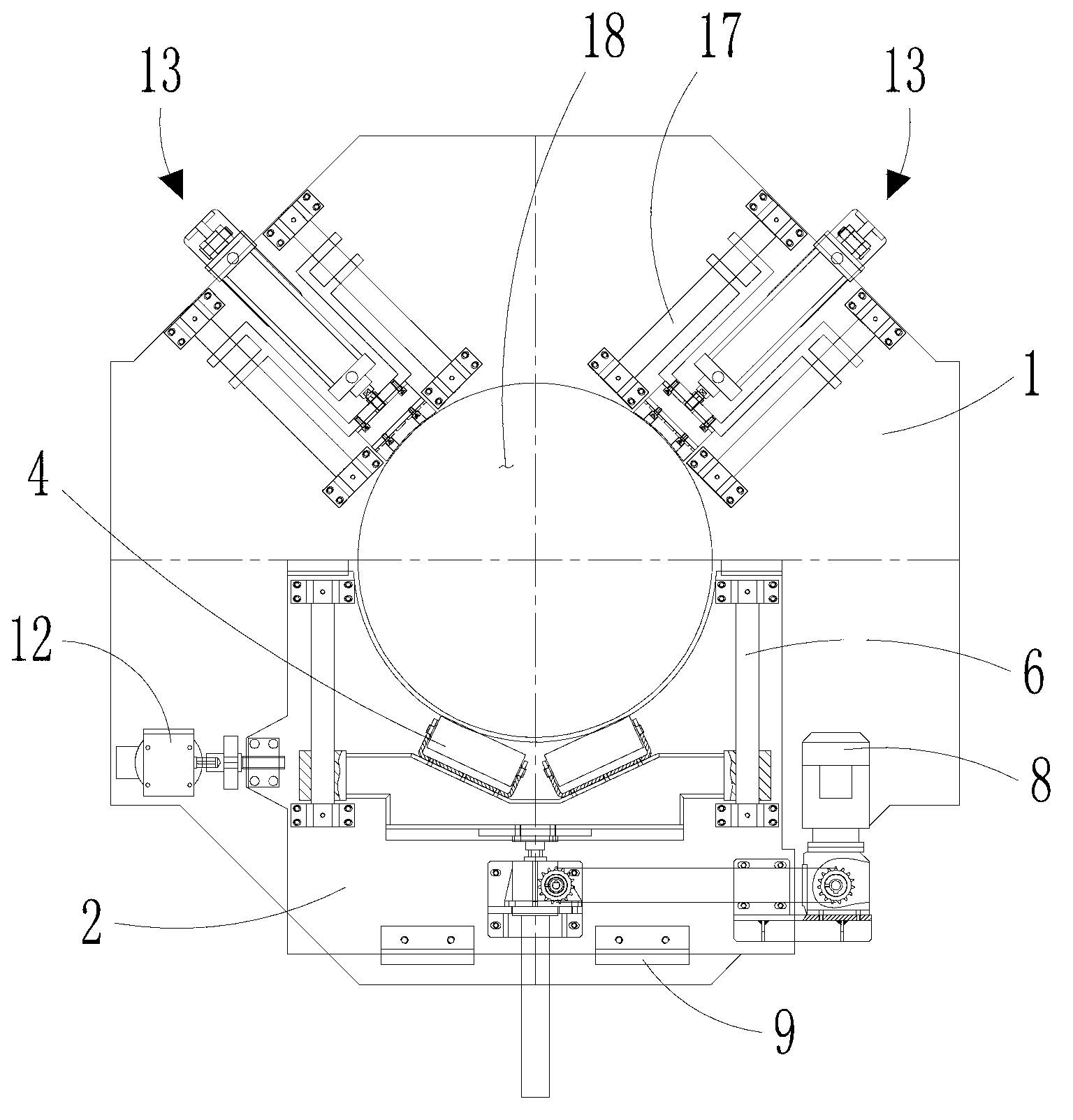

ActiveCN103009144AGuaranteed processing accuracyReasonable design structurePositioning apparatusMetal-working holdersPipe fittingClassical mechanics

The invention discloses a follow-up clamping device for clamping and positioning pipe pieces. The device comprises a first bearing body, a second bearing body arranged on the first bearing body in a sliding manner, a clamping mechanism fixed on the first bearing body, and a bearing mechanism arranged on the second bearing body in a lifting manner, wherein the clamping mechanism comprises two groups of telescopic butting heads forming angles; the two groups of butting heads are symmetrically arranged left and right; the bearing mechanism comprises two rows of rollers symmetrically arranged left and right; rotating axle lines of the rollers in one group are parallel to one another, and are positioned in a same plane; two planes, where the rotating axle lines of the two rows of rollers are positioned, are intersected with each other; the pipe pieces are clamped between the two groups of butting heads and the two rows of rollers; and each of the rollers is arranged along the tangential direction of the pipe pieces. The pipe pieces are stably clamped and positioned through the two rows of rollers and the two groups of butting heads so as to provide guarantee to the technique precision of following operations for the pipe pieces; and the device has a reasonable structure, is easily and reliably adjusted, and is suitable for the pipe pieces with different pipe diameters.

Owner:SUZHOU JWELL MACHINERY

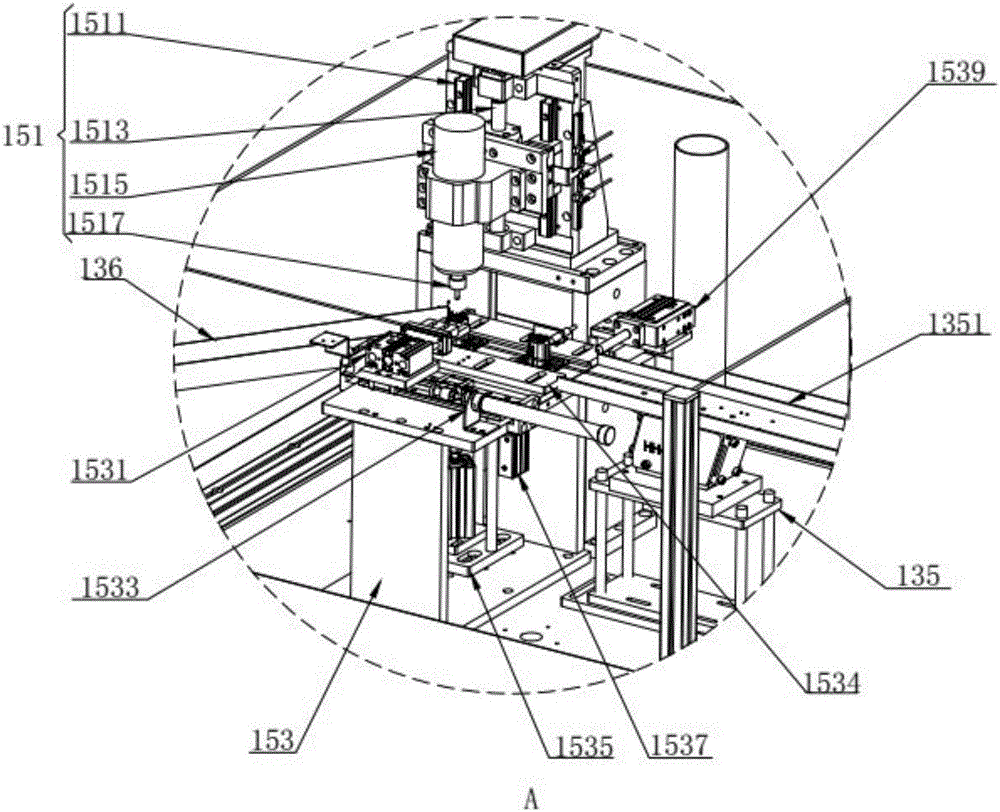

Automatic array drilling machine

ActiveCN105834480AReasonable design structureGuaranteed uptimeAutomatic workpiece supply/removalMetal working apparatusMulti machineEngineering

The invention provides an automatic array drilling machine. The automatic array drilling machine comprises a feeding table and a workbench. The feeding table is provided with a vibration disc. The workbench is provided with an automatic drilling system assembly and an operation system. The vibration disc communicates with the automatic drilling system assembly through a linear vibration track. The automatic drilling system assembly comprises a drill bit mechanism and a drilling platform. The drill bit mechanism is arranged above the drilling platform. The drill bit mechanism comprises a high-speed electric spindle and a drill bit driven by the high-speed electric spindle. The drilling platform is provided with a material guide rail, a pushing air cylinder used for pushing an object to be machined into the portion below the drill bit, and a clamping air cylinder for stabilizing the object. The object to be machined arrives at the part of the material guide rail in the automatic drilling system assembly through the vibration disc via the lineation vibration track, and under pushing of the pushing air cylinder, the object to be machined arrives at the portion below the drill bit of the drill bit mechanism. The one-time machining automatic cycle is finished for four seconds through the automatic array drilling machine, about 20,000 PCS can be produced every day (24 hours), one person can operate multiple machines without operation of specially-assigned persons, and the machining efficiency is high.

Owner:FIND TECH SHENZHEN

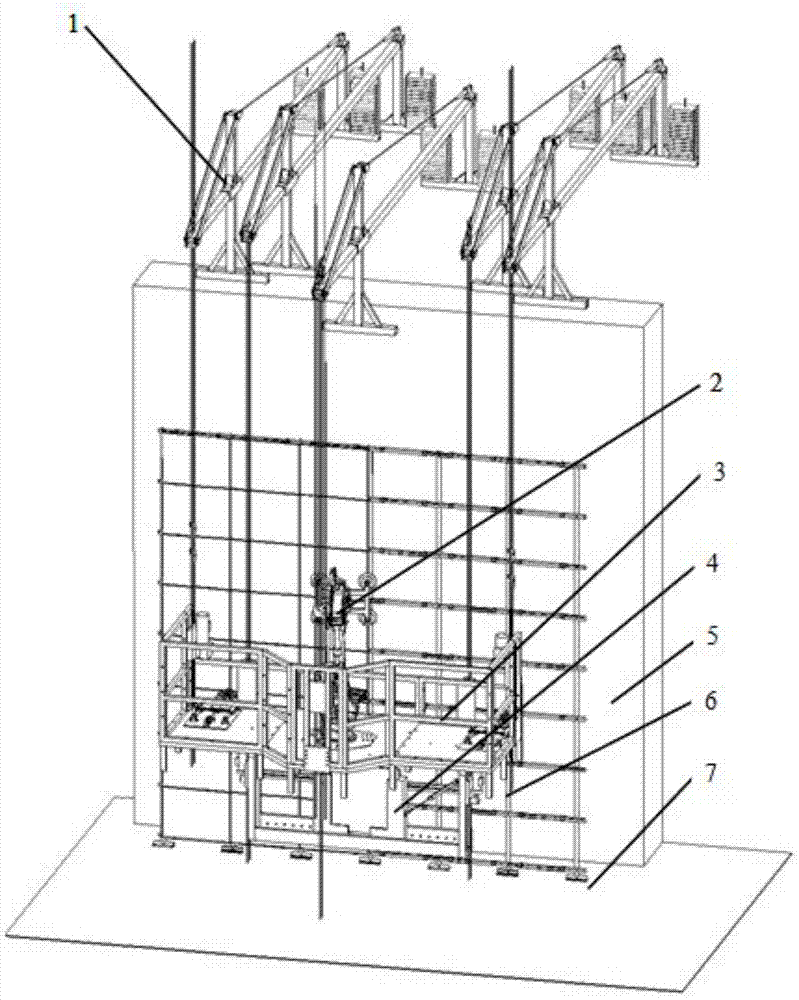

High-altitude board installation mechanical system

The invention relates to a high-altitude board installation mechanical system. The high-altitude board installation mechanical system comprises a suspension mechanism, a manipulator, a high-altitude operation platform and an automatic feeding mechanism, wherein the suspension mechanism is installed on a roof of a building in the working process and bears the suspension work of the high-altitude operation platform; the suspension mechanism is provided with a sling; elevators are arranged on the high-altitude operation platform and the automatic feeding mechanism; the high-altitude operation platform and the automatic feeding mechanism move through mutual cooperation of the corresponding sling and the corresponding elevators; the automatic feeding mechanism is arranged between the high-altitude operation platform and the operation stand surface; the manipulator is installed on the high-altitude operation platform. The high-altitude board installation mechanical system is characterized in that the manipulator has six degrees of freedom and comprises a base, a rotary machine frame, a big arm parallelogram mechanism, a tail end gesture adjusting device, a tail end actuator and a small arm parallelogram mechanism; the base, the rotary machine frame, the big arm parallelogram mechanism, the small arm parallelogram mechanism, the tail end gesture adjusting device and the tail end actuator are sequentially connected.

Owner:HEBEI UNIV OF TECH

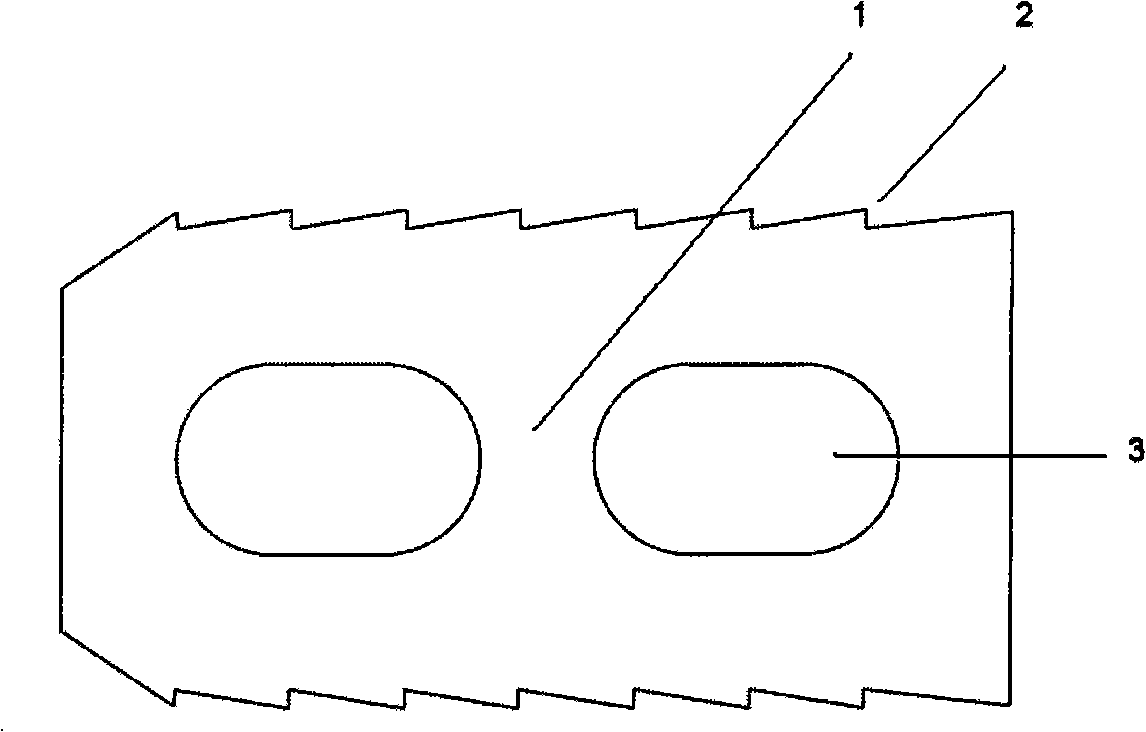

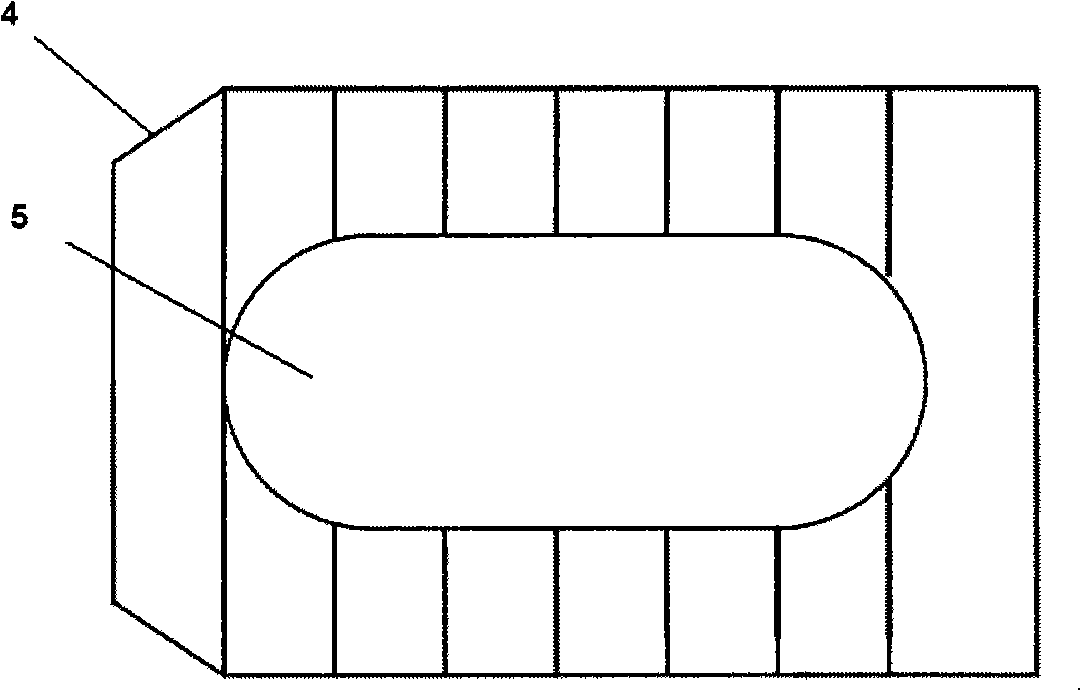

Intervertebral fusion device and method of preparing the same

InactiveCN101254140AReasonable shape and structureReasonable design structureInternal osteosythesisSpinal implantsCarbon compositesSpinal cage

The invention provides an interbody fusion cage for posterior lumbar spinal surgery and a preparation method thereof, and belongs to the application field of biomedical composite materials. The rectangular interbody fusion cage has side surface drainage through-holes, end surface chamfers, and triangle toothed structures on the upper and the bottom surfaces. The preparation method comprises the following steps of profiling the interbody fusion cage with carbon / carbon composite material as target, and preparing hydroxyapatite coating layers on the upper and the bottom surfaces of the interbody fusion cage sequentially by sandblasting pretreatment, plasma spraying, vacuum heat treatment and simulated body fluid immersion. The interbody fusion cage prepared by the inventive method has the advantages of novel material, advanced preparation method, reasonable structural design and good osteoconductivity function.

Owner:SHANDONG UNIV

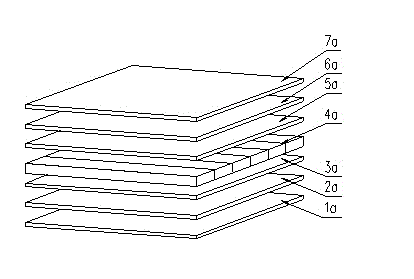

Halogen-free flame retardant epoxy resin composition and dry type transformer poured by same

ActiveCN103146148AReasonable design structureNo pollutionTransformers/inductances coils/windings/connectionsTransformers/inductances magnetic coresEpoxyCombustion

The invention provides a halogen-free flame retardant epoxy resin composition and a dry type transformer poured by the same. The transformer comprises a base, an iron core which is vertically arranged on the base and transformer coils, wherein an upper iron core clamps are arranged above the transformer coil; lower iron core clamps are arranged between the position below the transformer coil and the base; halogen-free flame retardant insulating cushion blocks are respectively arranged between the upper iron core clamps and the transformer coil and between the lower iron core clamps and the transformer coil; the transformer coil comprises a halogen-free flame retardant foil type winding and a halogen-free flame retardant coiling winding; each transformer coil is supported by halogen-free flame retardant foil type coil supporting board, a halogen-free flame retardant iron core clamp insulating piece is arranged between the upper iron core clamp pieces; a conductive copper bar is arranged on the lateral face; and a hanging ring and a pin are further arranged on the upper iron core clamp. According to the transformer provided by the invention, an insulating material is flame-retardant; the burning capacity of a non-metal part is very low; and no smoke exists in high-temperature combustion, and toxic substances are not decomposed, so that no environment pollution is caused, security and environmental friendliness can be achieved.

Owner:PEARL ELECTRIC

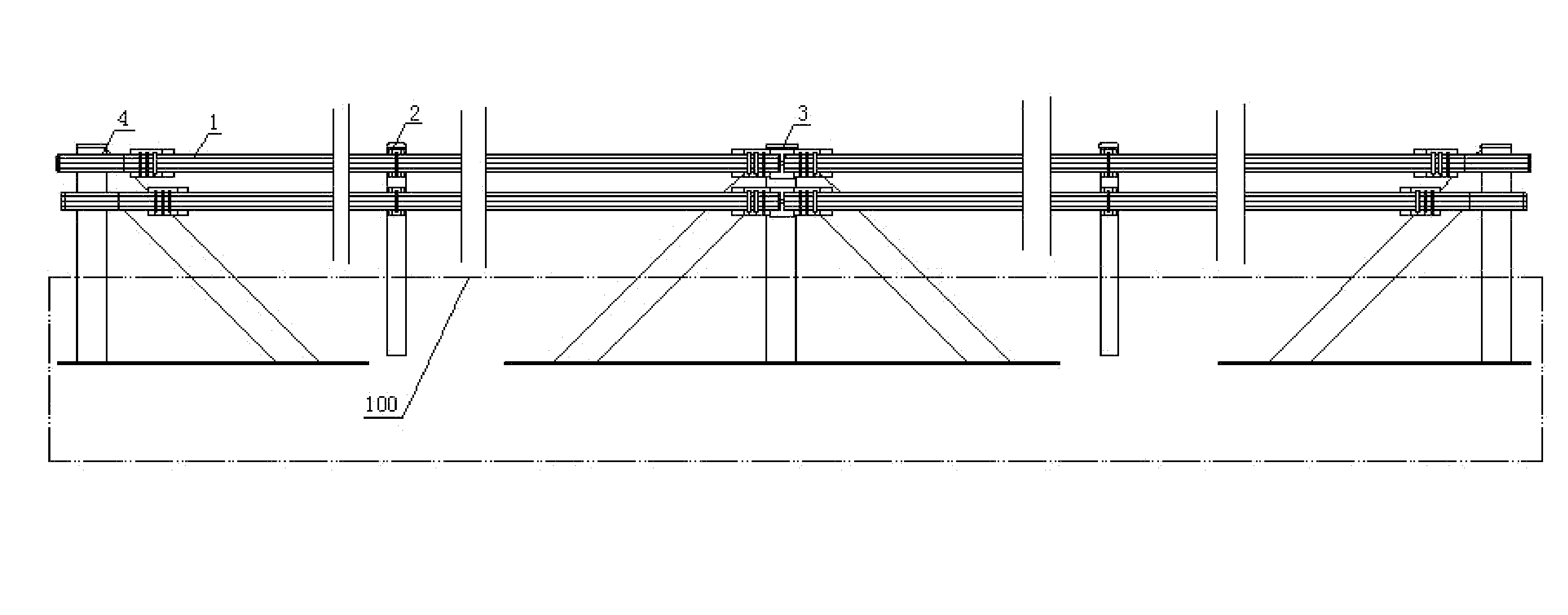

Guardrail device for highway

InactiveUS20140103278A1Reasonable design structureGood anti-collision performancePasturing equipmentRoadway safety arrangementsEngineeringCollision resistance

The present invention involves a kind of guardrail device used for a highway, wherein, said guardrail plate is formed by PVC resin and has reinforcing bands fixed therein; a bracket is set between a small vertical column and the guardrail plate, the bracket being fixed to the small vertical column, the guardrail plate being fixed to the bracket by frame bolts; a middle large vertical column mechanism is comprised of a middle connecting plate, a connecting ring and a guardrail plates having end portions; two guardrail plates wind reversely within the connecting ring; an end large vertical column mechanism comprises a sheath, an end connecting plate and guardrail plates having end portions, the sheath is fixed to the end large vertical column, the outer sheath is wound around by guardrail plates which are fixed to the end connecting plate by frame bolts. The whole design of the invention is reasonable in structure, have good performance of collision resistance, low cost and long life performance. It displays nice cushion property at the moment of vehicle collision and uneasily to impose scratch on the car, which greatly reduce the possibility to cause secondary damage to the passenger and vehicle. Moreover, the material used brings no pollution to the environment, therefore it's green.

Owner:CAI WENXUE

Ceramic ball mill with discharging classifying screen

InactiveCN104741174AImprove grinding efficiencyUniform finenessSievingScreeningScreening effectUltimate tensile strength

The invention discloses a ceramic ball mill with a discharging classifying screen. The ceramic ball mill comprises a hopper, a roller, a transmission mechanism and the like, wherein a first screening plate, a secondary screening plate, a first oversize material hole, a secondary oversize material hole, a first vibrating arm and a secondary vibrating arm are arranged in a classifying screen device at different heights, the first screening plate is arranged on the first vibrating arm by a connecting thread of the first vibrating arm, and a secondary buffer device is also arranged between the upside of the secondary screening plate and the classifying screen device. A ground material is accelerated to be screened through vibration of the classifying screen device, the fineness uniformity, the screening efficiency and the screening effect of a ground product are improved, the action of a vibrating mechanism on the classifying screen device replaces the manual screening operation, the labor intensity is alleviated, impact force of the vibration on the classifying screen device is alleviated due to a first buffer device and the second buffer device, production equipment cannot be damaged easily, and the service life of the production equipment is prolonged.

Owner:广西北流市红日紫砂陶瓷厂

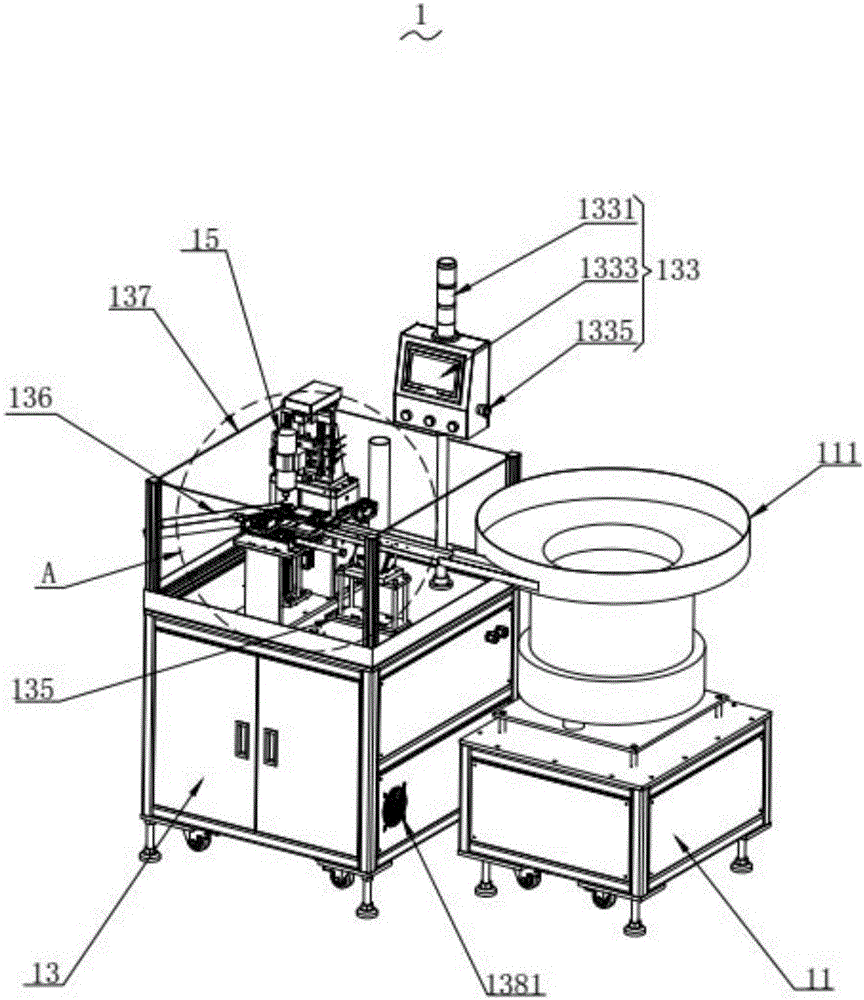

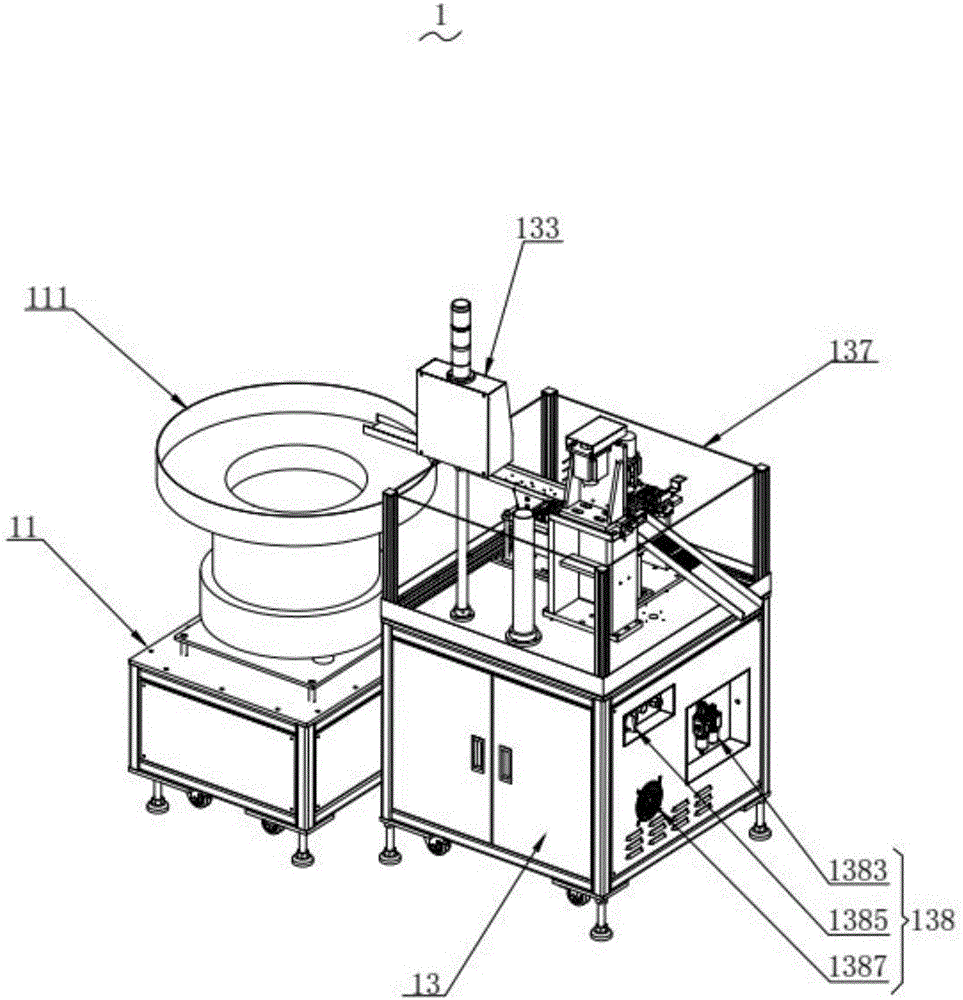

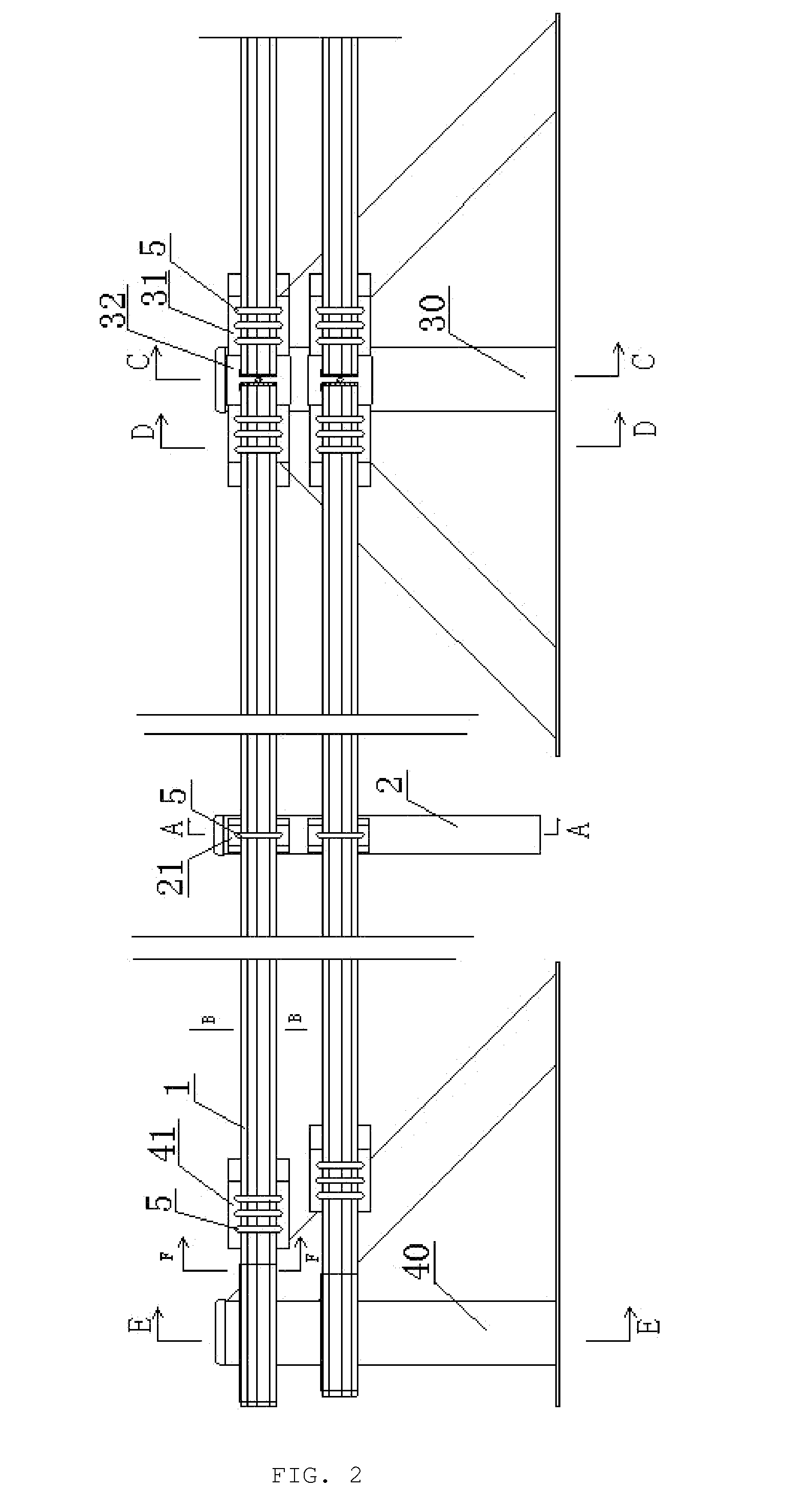

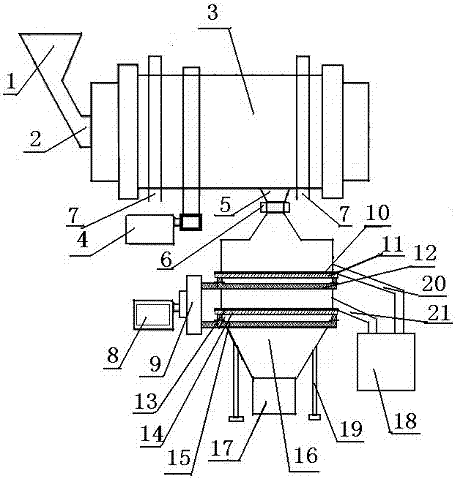

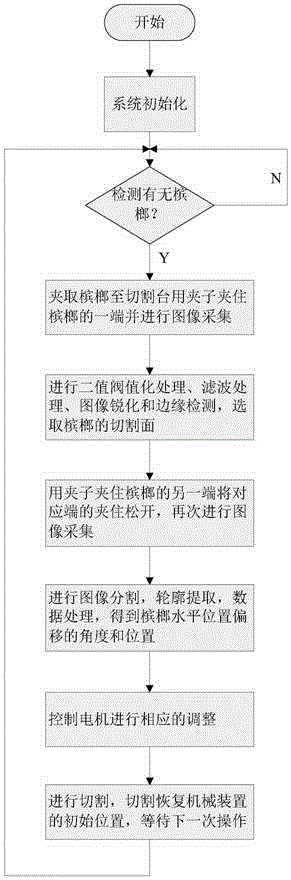

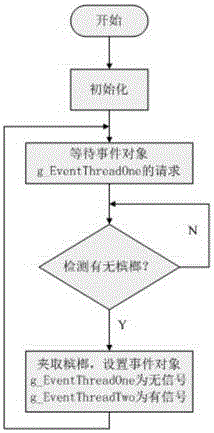

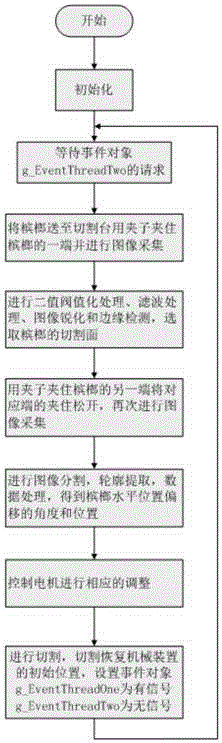

Fully-automatic areca nut processing equipment

ActiveCN106737919APrevent falling outSpeed up entryImage enhancementImage analysisTransfer mechanismFully automatic

The invention discloses fully-automatic areca nut processing equipment. The fully-automatic areca nut processing equipment comprises a first rack (A1) and a second rack (A2). The first rack (A1) is provided with a feeding mechanism (1), a material picking mechanism (2), a first transferring mechanism (3) and a first clamping mechanism (4), wherein the material picking mechanism (2) is connected with the feeding mechanism (1); the first transferring mechanism (3) is located at the downstream position of the material picking mechanism (2); and the first clamping mechanism (4) is arranged on the first transferring mechanism (3). The second rack (A2) is provided with a second transferring mechanism (5), a second clamping mechanism (6), a third clamping mechanism (7), a cutting platform (8), an image acquisition mechanism (9) and a cutting mechanism (10), wherein the second clamping mechanism (6), the third clamping mechanism (7) and the cutting platform (8) are all arranged on the second transferring mechanism (5); the second clamping mechanism (6) is arranged at one side, such as the left side, of the cutting platform (8); the third clamping mechanism (7) is arranged on the other side, such as the right side, of the cutting platform (8); and the image acquisition mechanism (9) and the cutting mechanism (10) are arranged above the cutting platform (8).

Owner:XIANGTAN UNIV +1

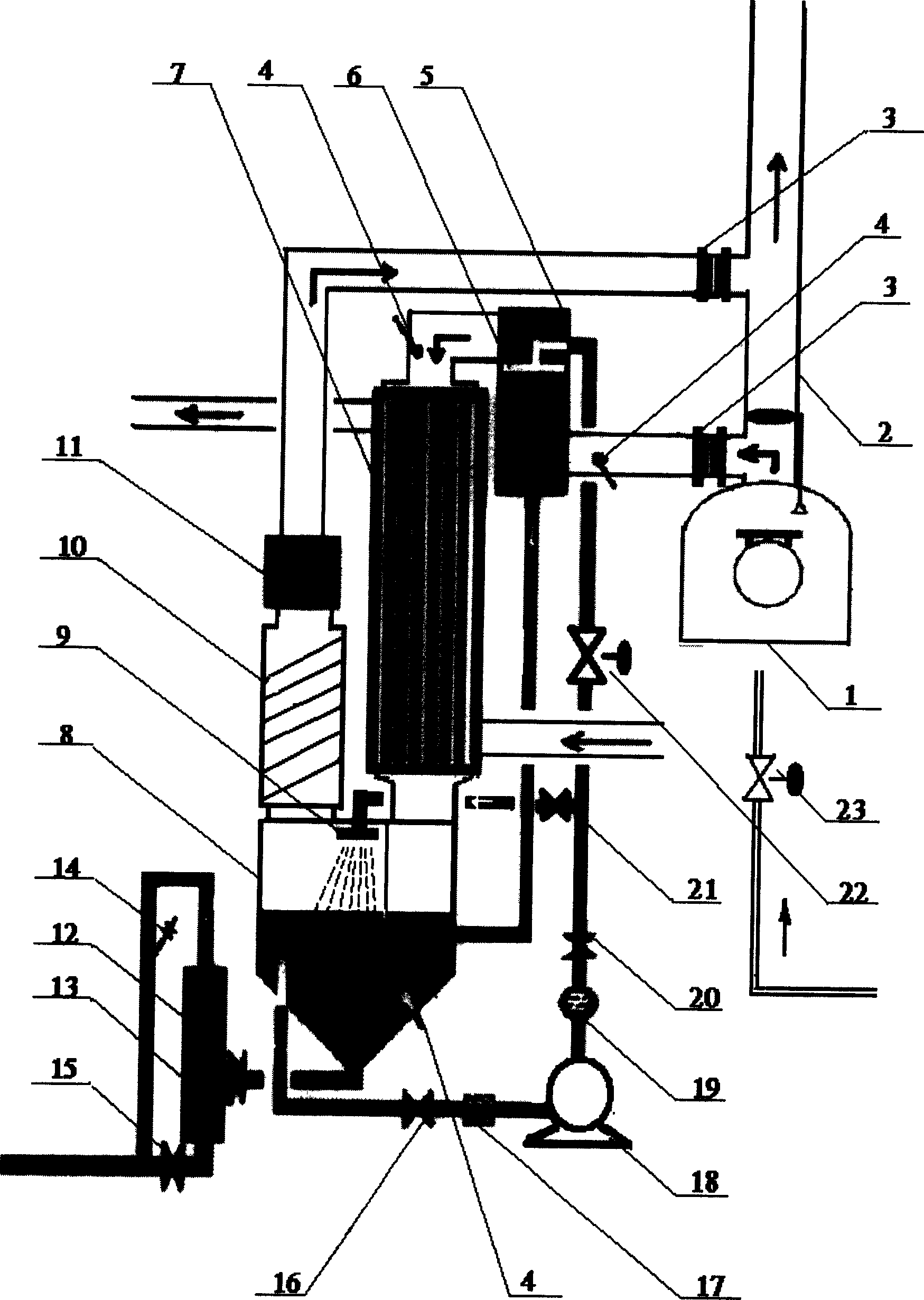

Fume afterheat recovering system by hidden heat process

InactiveCN1563874AReduce pollutionImprove environmental performanceEnergy efficient heating/coolingAir heatersPlate heat exchangerCooling tower

The method includes heat conversion, and heat recovery two procedures: (1) in first procedure, high temperature fume from flue enters into sprinkling cooling tower, where sprinkling media contact to fume. Media are vaporized. Thus, sensible heat in fume is transferred to latent heat; (2) media and fume enter into acid resistant heat exchanger. Media are condenses to release latent heat exchanged to media needed to heat. The recovery system is composed of temp sensor, sprinkling cooling tower, heat exchanger, pump and automatic control valve etc. Features are: compact, lightweight, high reclaiming efficiency.

Owner:杨振东

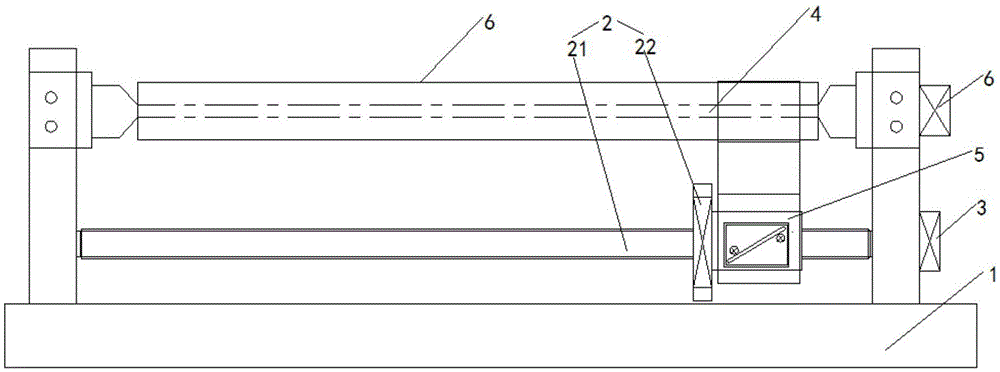

Corrosion-preventing winding device for steel pipe

The invention provides a corrosion-preventing winding device for a steel pipe. The corrosion-preventing winding device comprises a rack, a rotating shaft, a rotating shaft motor, a screw rod and a screw rod drive motor. The rotating shaft is installed above a rack tabletop. The screw rod is installed below the rack tabletop. A screw rod guide rail and the rotating shaft are arranged in parallel. A sliding worktable is arranged on the screw guide rod. One end of the sliding worktable is fixedly provided with a winding coil. A nut in screw fit with the screw rod is arranged on the sliding worktable. The sliding worktable with the winding coil can reciprocate on the screw rod guide rail under the drive of the screw rod. By means of the winding device, screw glass fibers or glass fiber cloth can be wound around a flood-prevention steel pipe automatically through manual work or under the drive of the motor, work is completed at a time, few processes are needed, the corrosion-preventing winding device has the beneficial effects of being reasonable in design structure, convenient to operate, high in efficiency and the like, the labor cost in the construction process is saved, and the working efficiency and the construction quality are improved.

Owner:天津市恒福科技发展有限公司

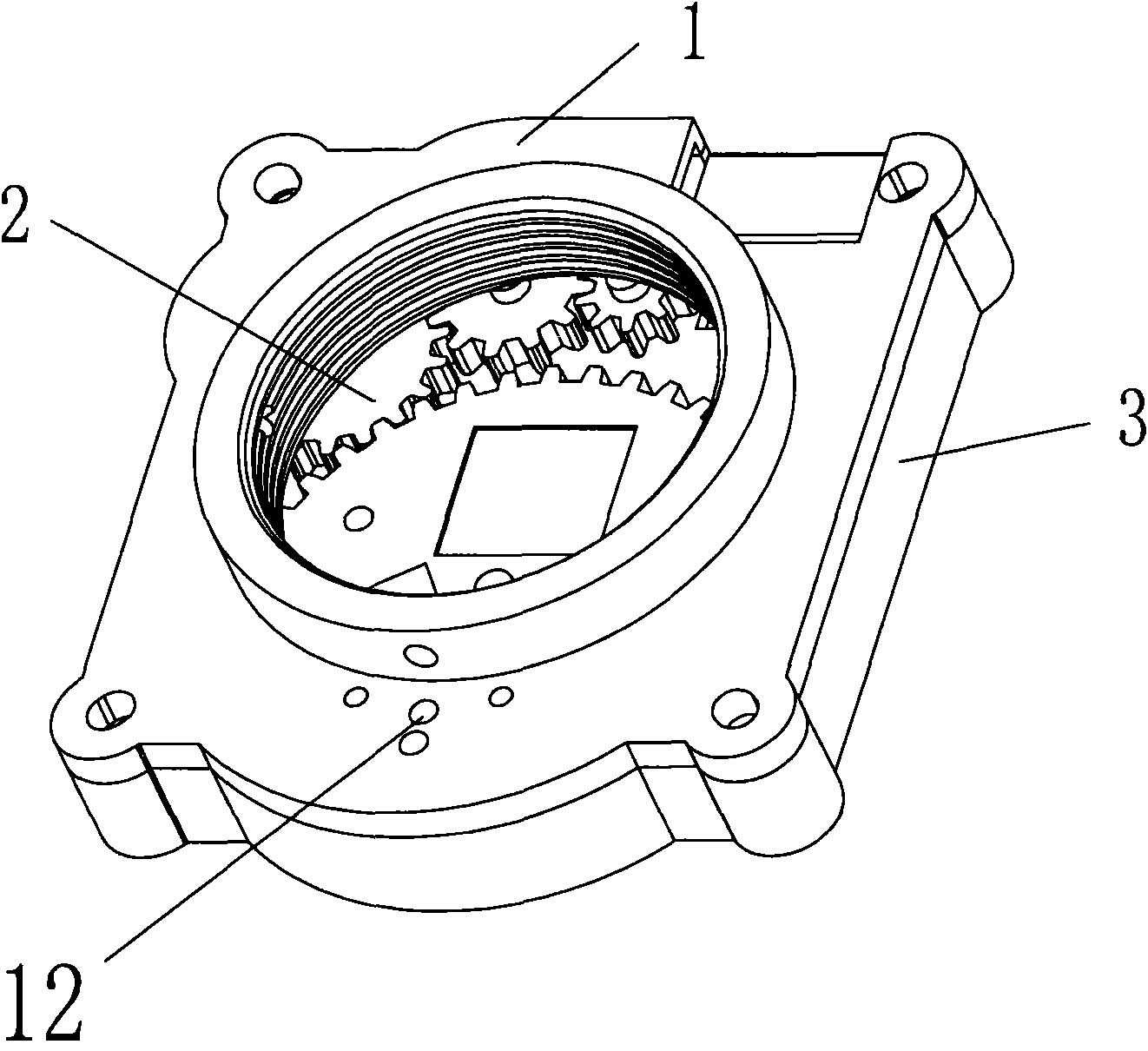

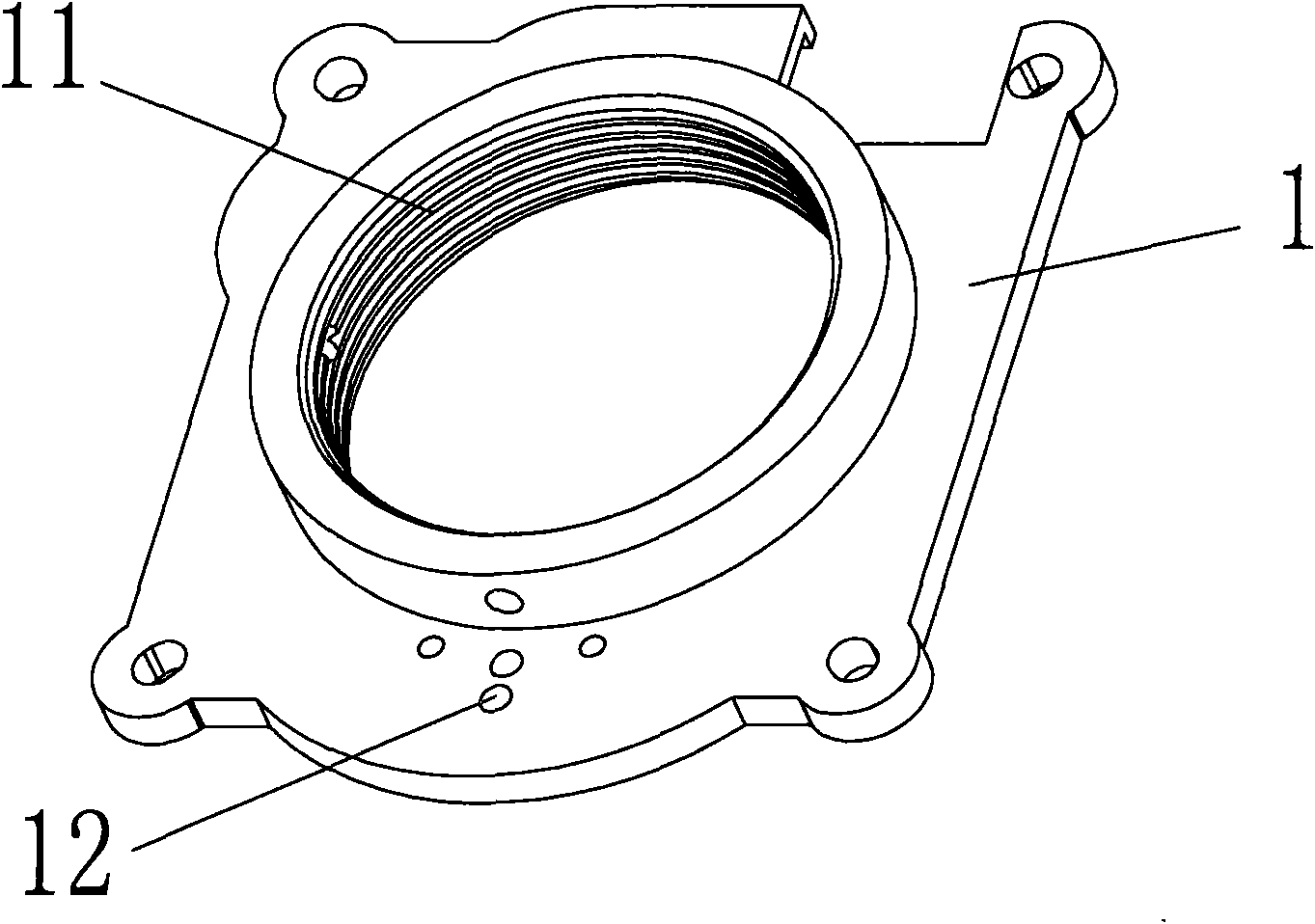

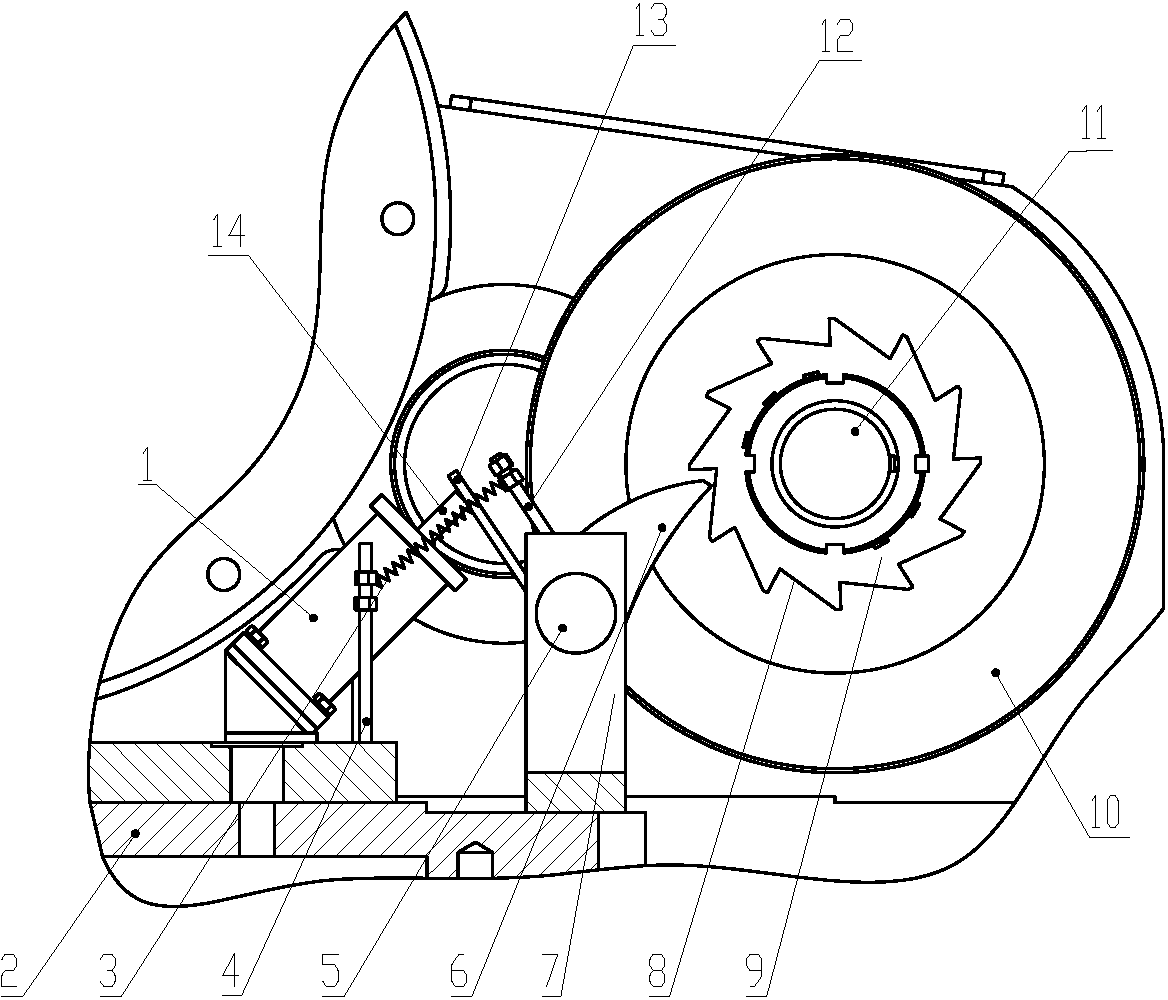

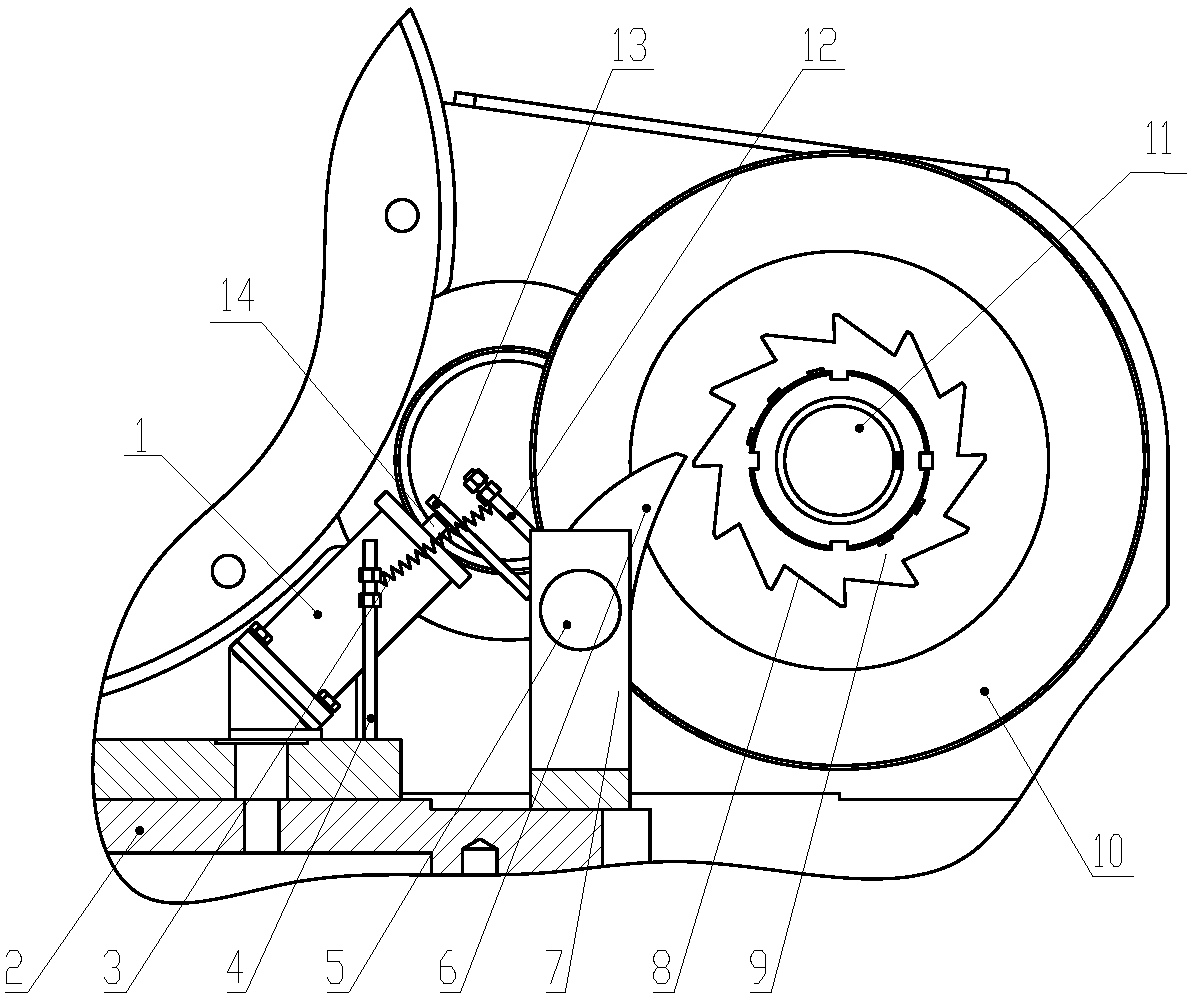

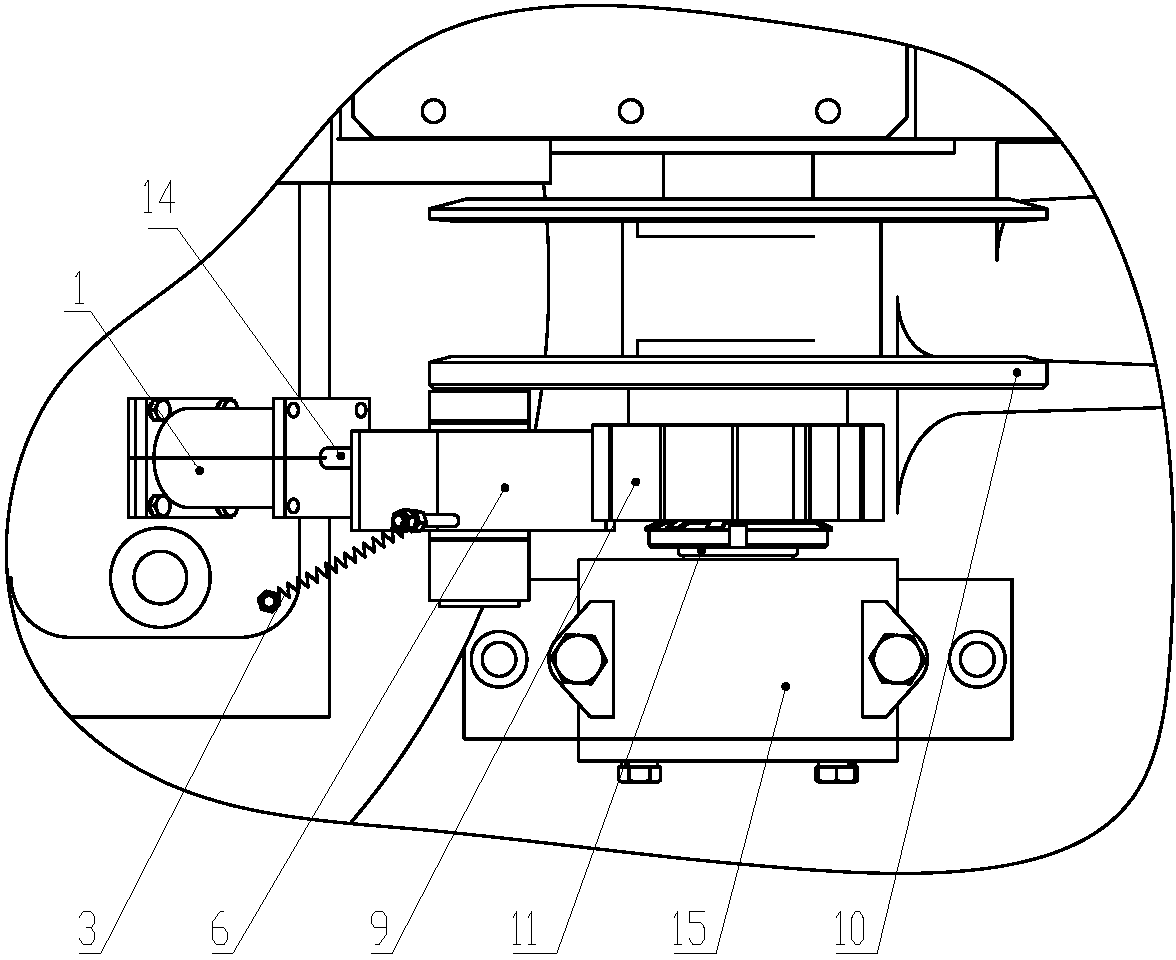

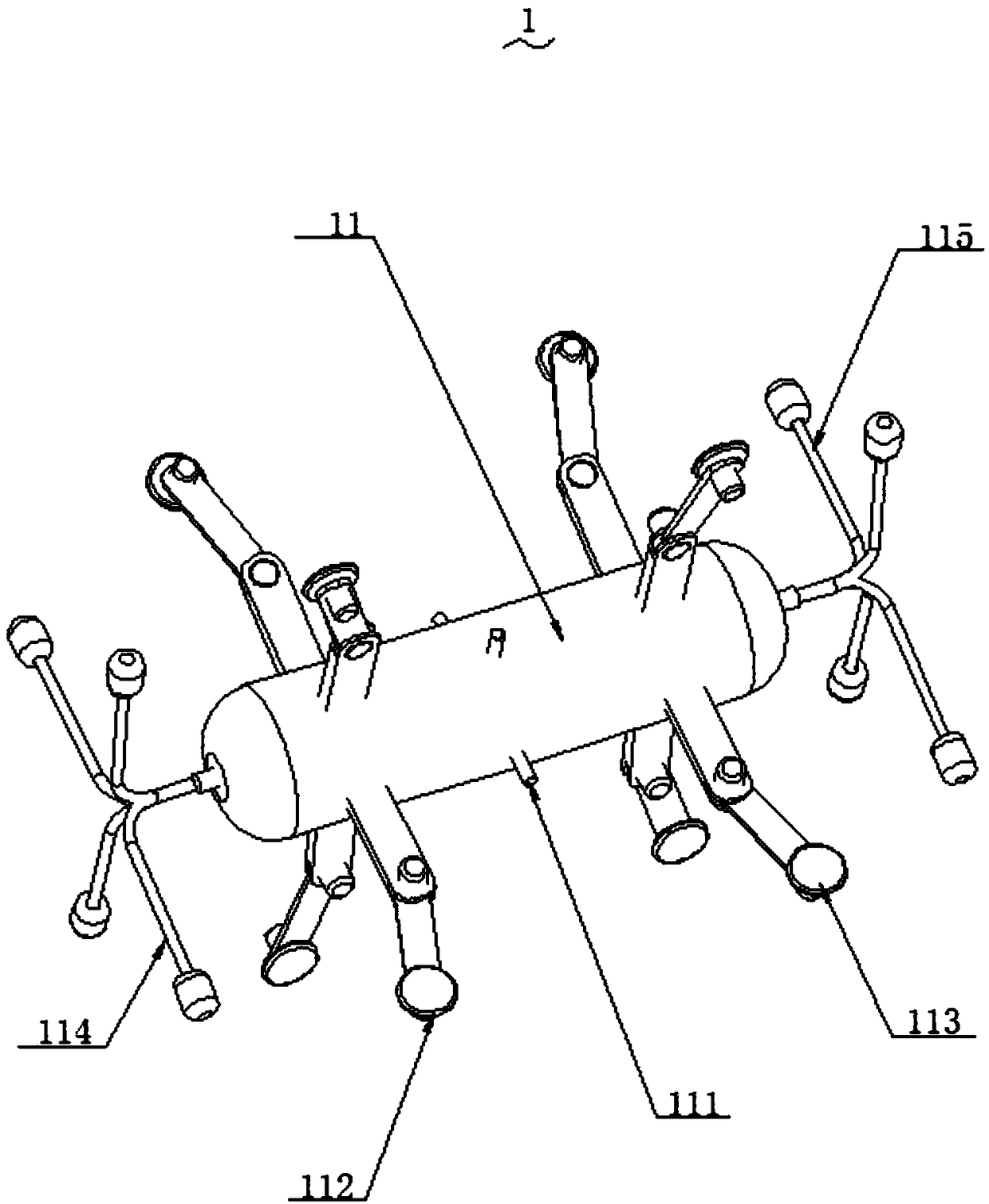

Positioning method and positioning apparatus for rock-loader bucket

ActiveCN104389602AReasonable design structureEasy to operateSlitting machinesSoil-shifting machines/dredgersEngineeringDrive wheel

A positioning method and a positioning apparatus for rock-loader bucket are disclosed and belong to the field of mine loading machineries. The positioning apparatus comprises a control mechanism and a positioning mechanism, the control mechanism is fixedly disposed on the main body of a rock loader, and the positioning mechanism is installed on the main body of the rock loader. The positioning apparatus is characterized in that the control mechanism is provided with a jacking part and a retraction part, and the positioning mechanism is provided with a pawl rotating shaft and a bucket-driving-wheel rotating shaft; the control mechanism jacks up a pawl along the pawl rotating shaft through the jacking part and enables the pawl to be clamped in a positioning ratchet coaxially arranged with a bucket driving wheel, so that a bucket of the rock loader is suspended in an optional working position in a positioning way by locking the bucket driving wheel; and the positioning mechanism pulls back the pawl along the pawl rotating shaft through the retraction part and enables the pawl to break away from the positioning ratchet, the bucket locked by the positioning ratchet recovers rotation, and the bucket of the rock loader is driven to recover running through the bucket driving wheel coaxially arranged with the positioning ratchet. The equipment is reasonable in structure and simple to operate.

Owner:ZIBO DALI MINING MASCH CO LTD

Novel jet cleaning robot for sewage pipes

InactiveCN108252399AGood adaptabilityReasonable structural designSewer cleaningData memoryEngineering

The invention provides a novel jet cleaning robot for sewage pipes. The robot comprises a main robot body and a power supply, a controller, a wireless communication transmission unit, a data memory, an alarm and a temperature sensor arranged inside the main robot body; the main robot body is cylindrical; both ends of the main robot body are provided with a first cleaning mechanism and a second cleaning mechanism; the first cleaning mechanism has the same structure as the second cleaning mechanism, and the first cleaning mechanism comprises a main connecting rod connected with the main robot body and a plurality of separate connecting rods formed in one body with the main connecting rod; the main connecting rod and the separate connecting rods are L-shaped, in the actual use process, because a second supporting arm can be flexibly rotated, the distance between the main robot body and an external pipeline can be changed, good adaptability effects can be achieved, and the robot is reasonable in structure, good in the use effect, and is very suitable for cleaning work of pipelines of different diameters.

Owner:刘肖俊

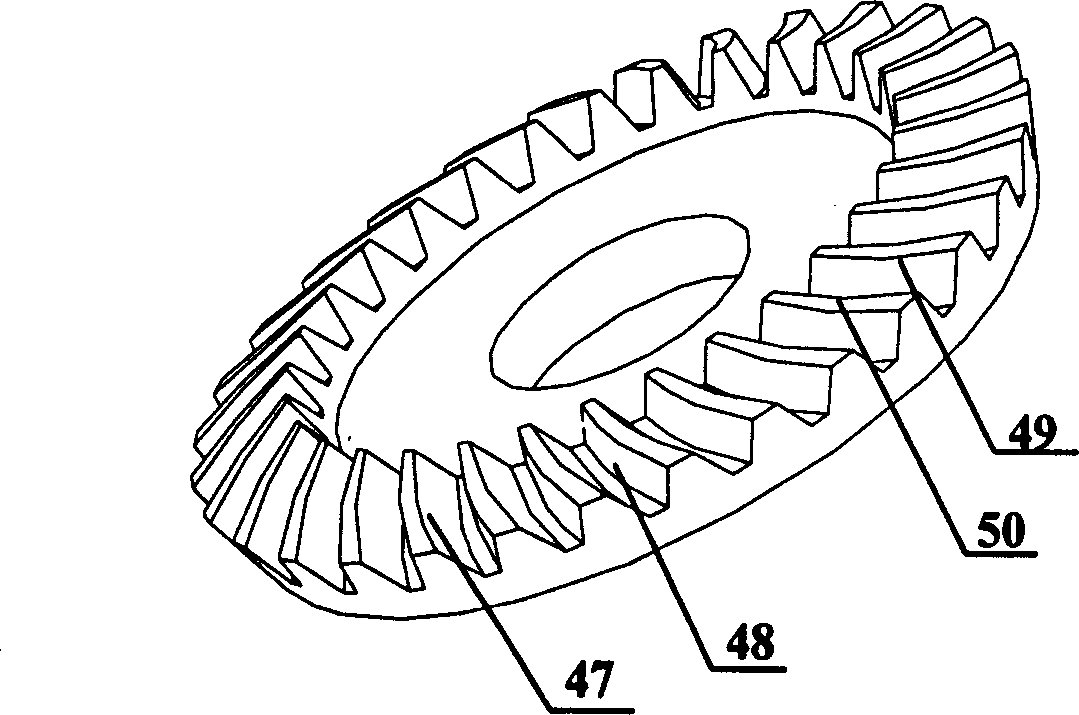

Digital control tooth crest chamfering machine for curved tooth and angle gear

InactiveCN1788901AReasonable design structureWork reliablyEdge grinding machinesLarge fixed membersEngineeringMachine tool

The numerically controlled addendum chamfering machine for curve-tooth bevel gear includes a machine body, an electric control cabinet, uprights, a turnover stage and its pedestal, a horizontal shift mechanism and a vertical shift mechanism on the uprights, a chamfering mechanism on the vertical mechanism, and a main shaft for installing the machined gear. The present invention completes addendum chamfering of curve-tooth bevel gear by means of the three-shaft linkage of the two numerically controlled shafts on the uprights for linear motion and the numerically controlled rotating shaft on the stage. The machine has reasonable structure, reliable operation, high chamfering precision, high effect and high efficiency.

Owner:TIANJIN NO 1 MACHINE TOOL WORKS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com