Fume afterheat recovering system by hidden heat process

A technology for waste heat and heat recovery from flue gas, applied in air heaters, fluid heaters, heat exchanger types, etc., can solve problems such as troublesome installation and maintenance on site, decrease heat exchange efficiency, affect combustion, etc., and achieve good environmental protection effects. , easy installation and maintenance, and the effect of reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

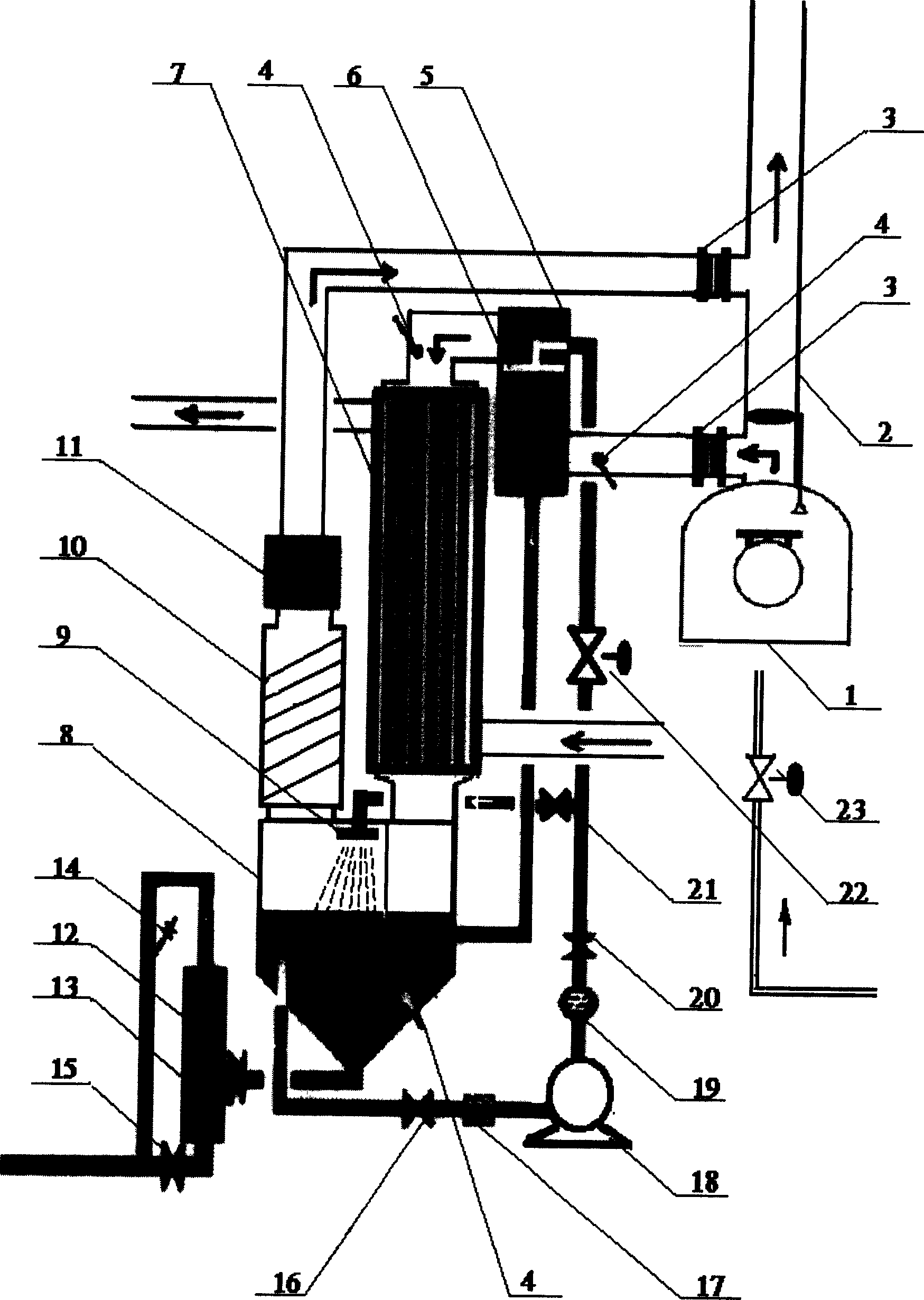

[0021] The specific embodiment of the present invention will be further described below in conjunction with the accompanying drawings:

[0022] Recovery device chimney 2, temperature sensor 4, spray cooling tower 5, sprayer 6, heat exchanger 7, acid tank 8, sprayer 9, mist trapping tower 10, The induced draft fan 11, the ash tank 13, the pump 18, and the automatic regulating valve 22 are composed. The upper and lower ends of the baffle plate of the chimney 2 are respectively provided with a flue gas outlet and a flue gas inlet. The flue gas outlet is connected to the spray cooling tower 5 by a pipeline. The temperature sensor 4 is installed on the pipeline entering the spray cooling tower 5 to monitor the temperature of the flue gas entering the spray cooling tower 5 . The spray cooling tower 5 is a steel shell lined with acid-resistant ceramics. There is a medium spray device composed of a sprinkler 6 as the main component in the tower. The outlet of the tower is connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com