Patents

Literature

314results about How to "Improve waste heat recovery efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

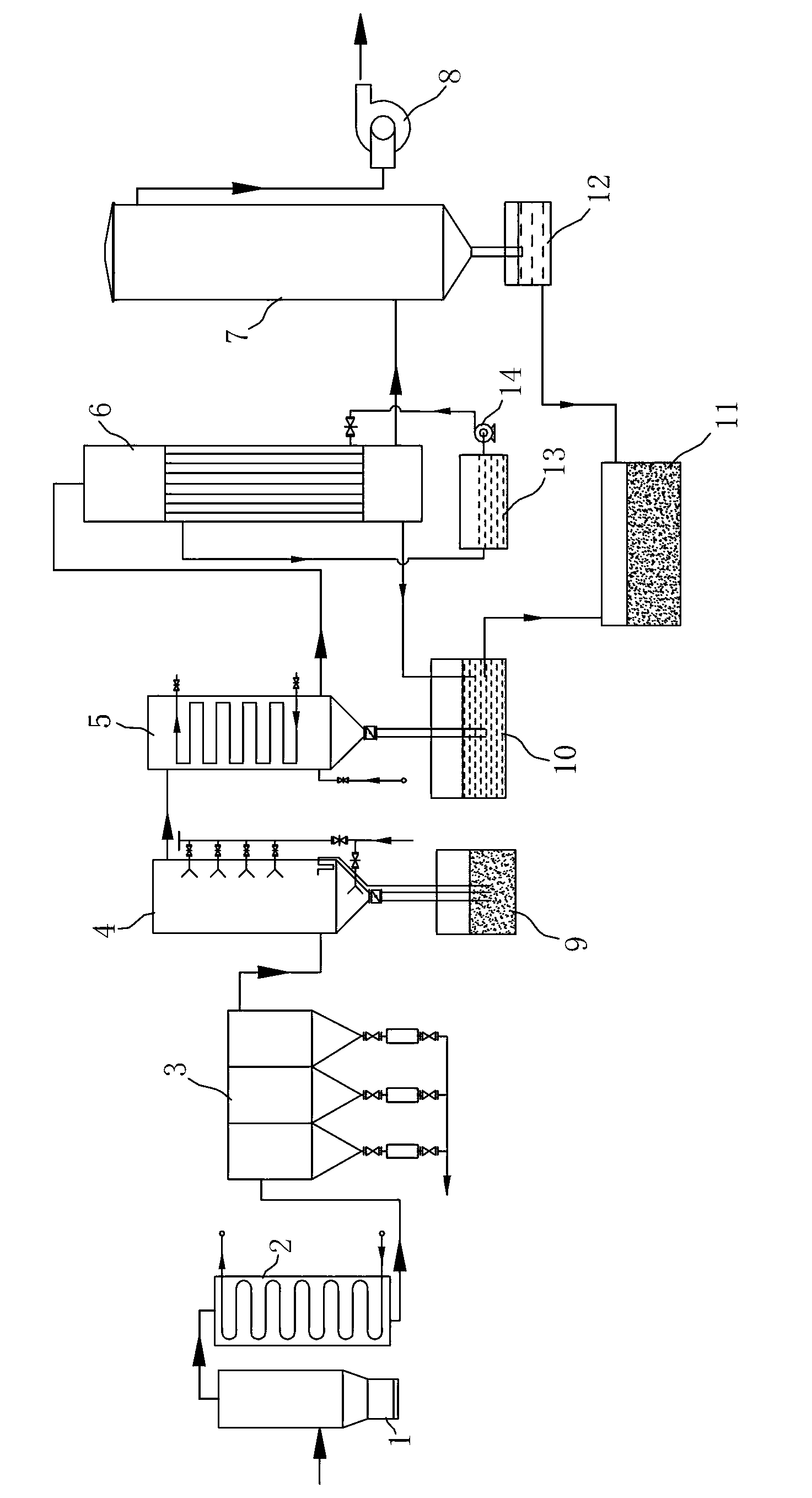

Process for dust removing, cooling and tar oil recovering of pyrolysis coal gas

The invention discloses a process for dust removing, cooling and tar oil recovering of pyrolysis coal gas. The process adopts an overheater, a high-temperature dust remover, an accident quench tower, a waste heat recovering boiler, an indirect cooling device and an electrical tar precipitator which are connected in sequence, and comprises the following steps: pyrolysis coal gas is fed into the overheater to be cooled to 400-700 DEG C, fed into the high-temperature dust remover to be subjected to dust removing, fed into the waste heat recovering boiler to be cooled to 50-100 DEG C and condensed to separate out water and tar oil, fed into the indirect cooling device to be cooled to 10-30 DEG C and further condensed to separate out water and tar oil, and finally fed into the electrical tar precipitator, so that the carried tar oil mist and water mist are recovered. According to the process, dust particles in the coal gas are removed by high-performance dust removing equipment before condensing of tar oil, so as to prevent tar oil and dust separated out through condensation in the coal gas cooling process from being mixed together, improve the quality of tar oil and avoid the problems of equipment blockage and high dust content of tar oil.

Owner:ZHEJIANG UNIV

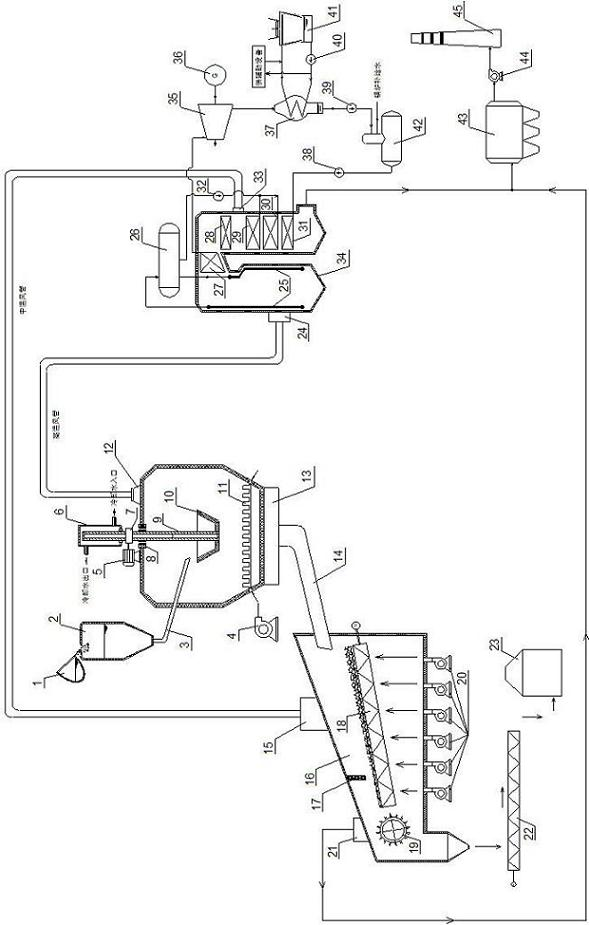

Centrifugal type fusion slag quenching and dry type granulating, and waste heat recovery power generation system and method

ActiveCN102559957ASolve mechanical transmission problemsSolution to short lifeIncreasing energy efficiencyRecycling and recovery technologiesSlagSlow cooling

The invention provides a centrifugal type fusion slag quenching and dry type granulating system and method and a waste heat recovery power generation system and method, belongs to steel metallurgy slag treatment and waste heat recovery technology fields. The system of the invention comprises a slag receiving device, a slag centrifugal type quenching and granulating device, a slag slow cooling device, a waste heat recovery power generation device and an exhaust gas purifying and treating device. The system quenches and granulates the fused slag by the special centrifugal type quenching and granulating device, and rapidly cools the slag into a viterous body state. Then the slag is further slowly cooled by a water-cooled type vibration grate, and the waste heat recovered in the quenching andslow cooling processes generates steam by a binary channel type exhaust-heat boiler, which drives a turbo generator set for power generation. The system and the method effectively resolves the problem of long-time, safety and stabilization operation of a centrifugal type granulation device, and implements fused slag quenching and dry type granulation, and on the basis of non-influence on followedutilization value, the system and the method can high-efficiency and fully recover the high temperature waste heat resource of the slag.

Owner:NANJING KESEN KENEN ENVIRONMENT & ENERGY

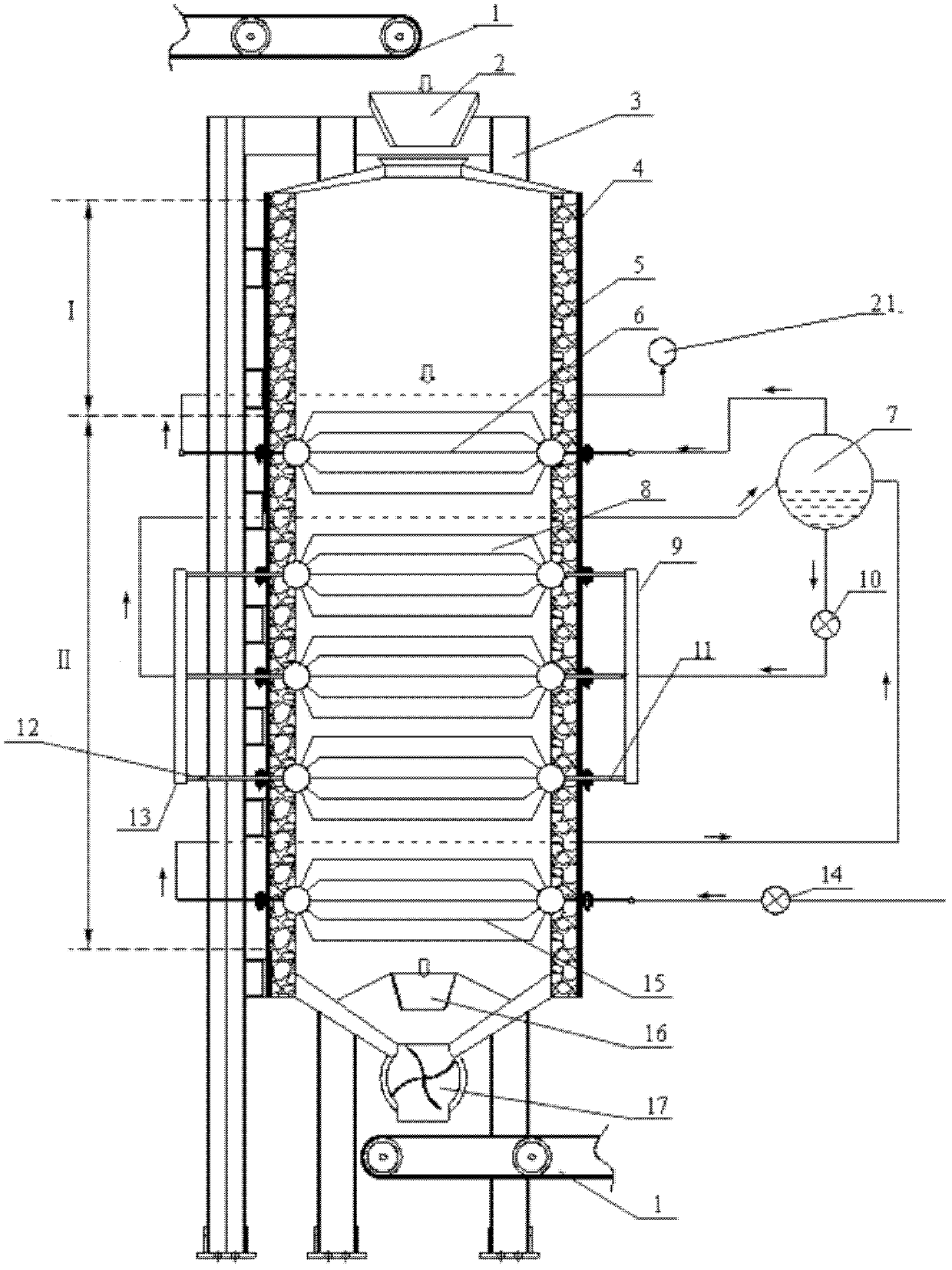

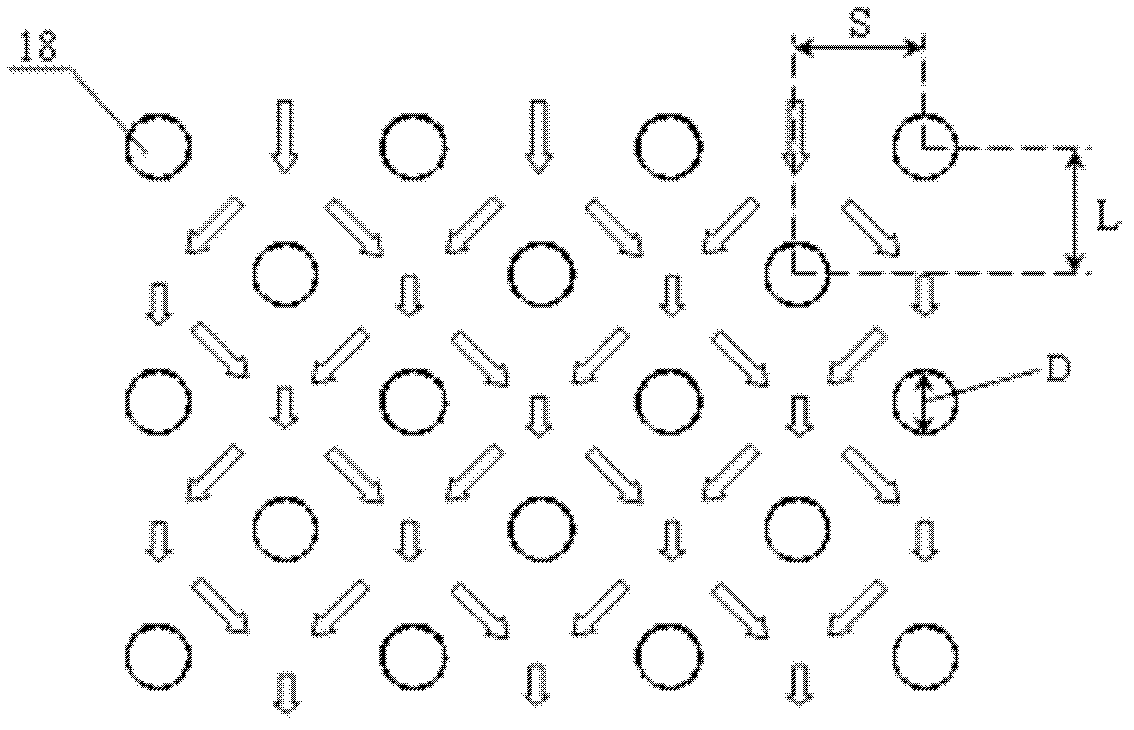

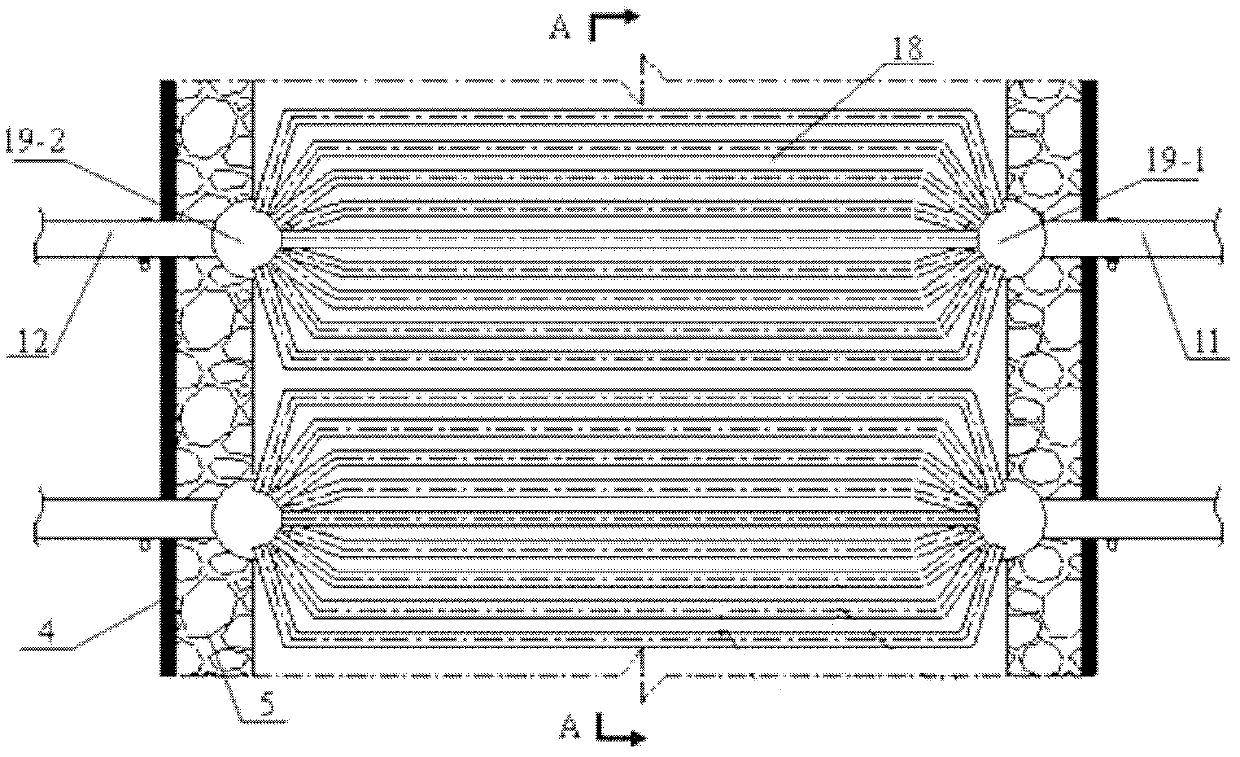

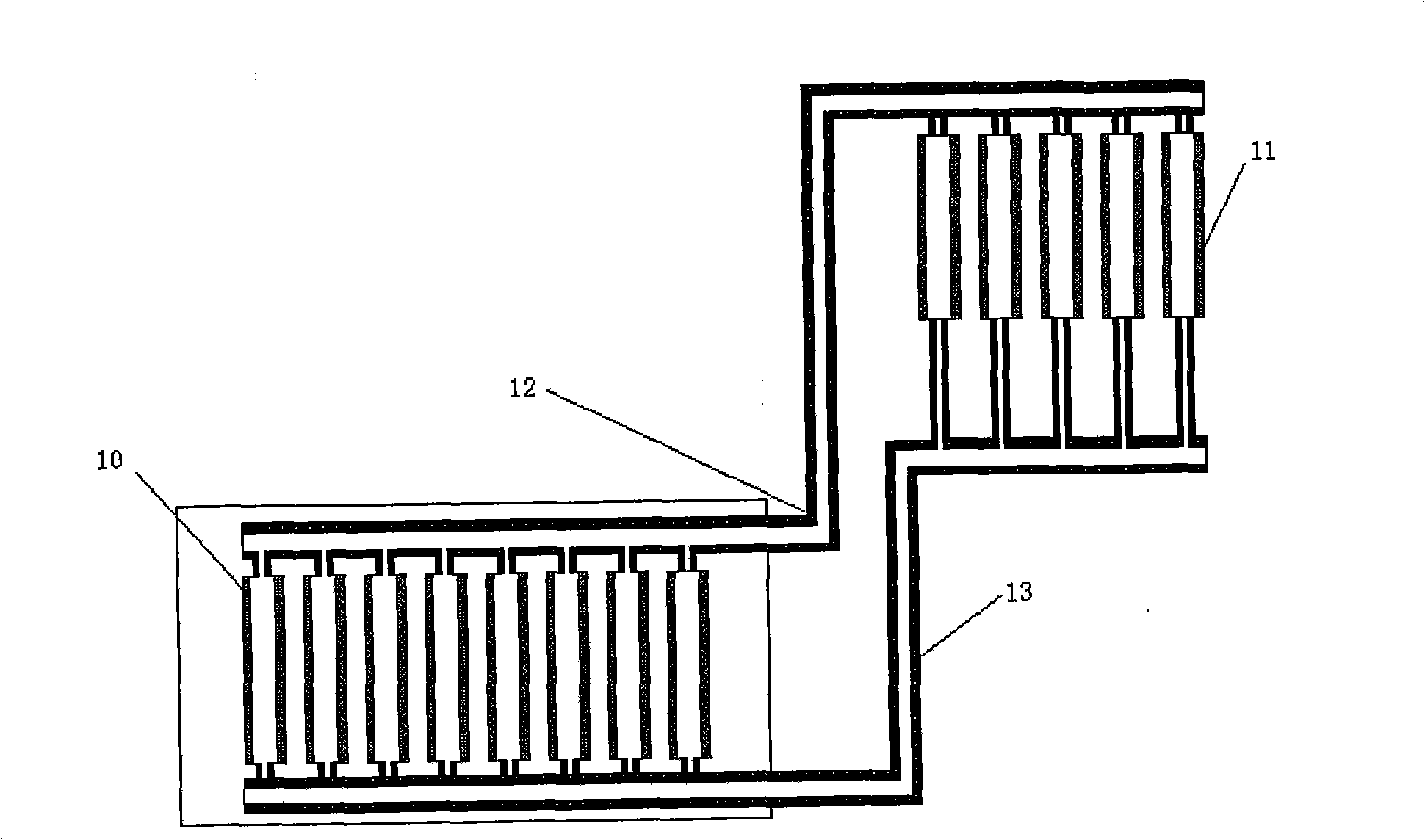

Waste heat recovering device of high-temperature metallurgy slag particles

ActiveCN102433400AEnhanced horizontal mixing heat transferGuaranteed uniformityIncreasing energy efficiencyRecycling and recovery technologiesSlagRefractory

The invention provides a waste heat recovering device of high-temperature metallurgy slag particles. The device comprises a middle hopper, a boiler body, a steam pocket, a superheater, an evaporator, an economizer and a discharging machine, wherein the middle hopper is arranged above the material inlet of the boiler body; a refractory material is arranged in the boiler body and a rectangle cavityis formed; the boiler body is divided into a storage section and a work section from top to bottom; the superheater, the evaporator and the economizer are successively arranged in the work section from top to bottom and respectively consist of single or multiple heat exchange pipe groups; the two ends of each heat exchange pipe are respectively connected to a water inlet header and a water outletheader of each heat exchange pipe group; the water inlet header is connected with an distribution header through a distribution pipe; the water outlet header is connected with a converge header through a converge pipe; the steam pocket is connected with the water outlet header; the outlet end of the superheater is connected with a steam pipe network or steam turbine; and the discharging machine is installed at the outlet of the boiler. By using the waste heat recovering device, uniform heat exchange can be realized, the yield and the quality of the steam are improved, and the recovery efficiency of waste heat is high.

Owner:NORTHEASTERN UNIV

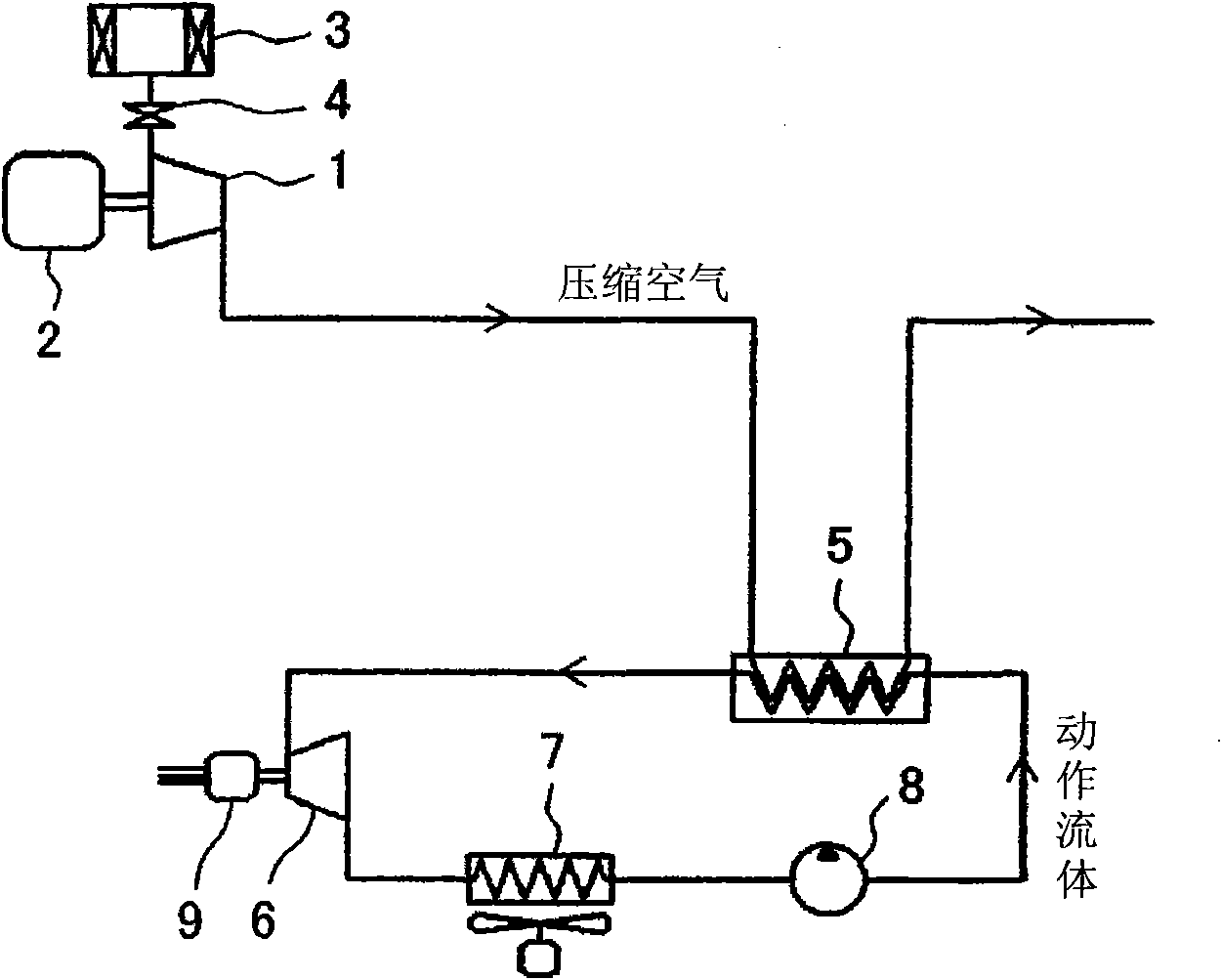

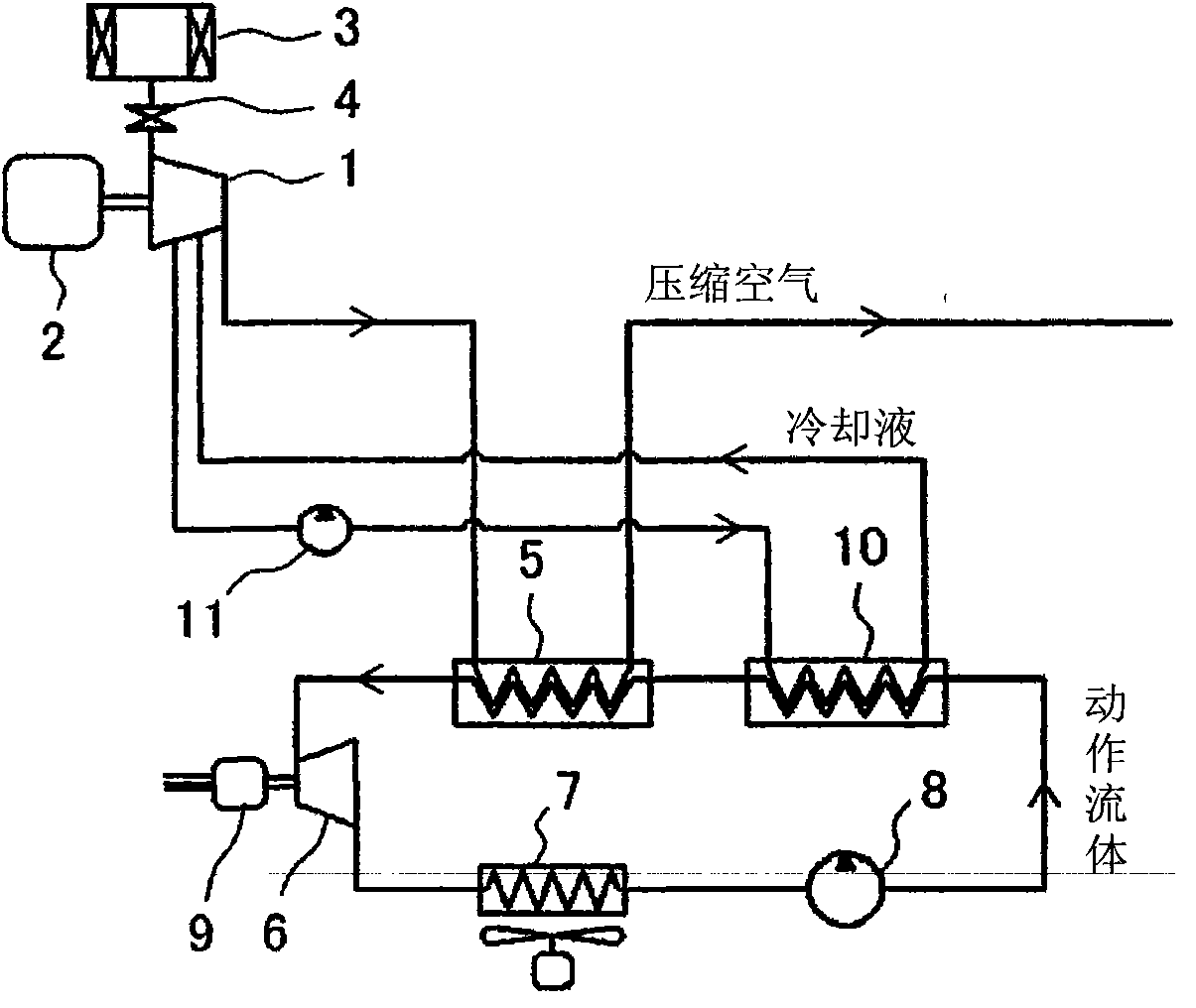

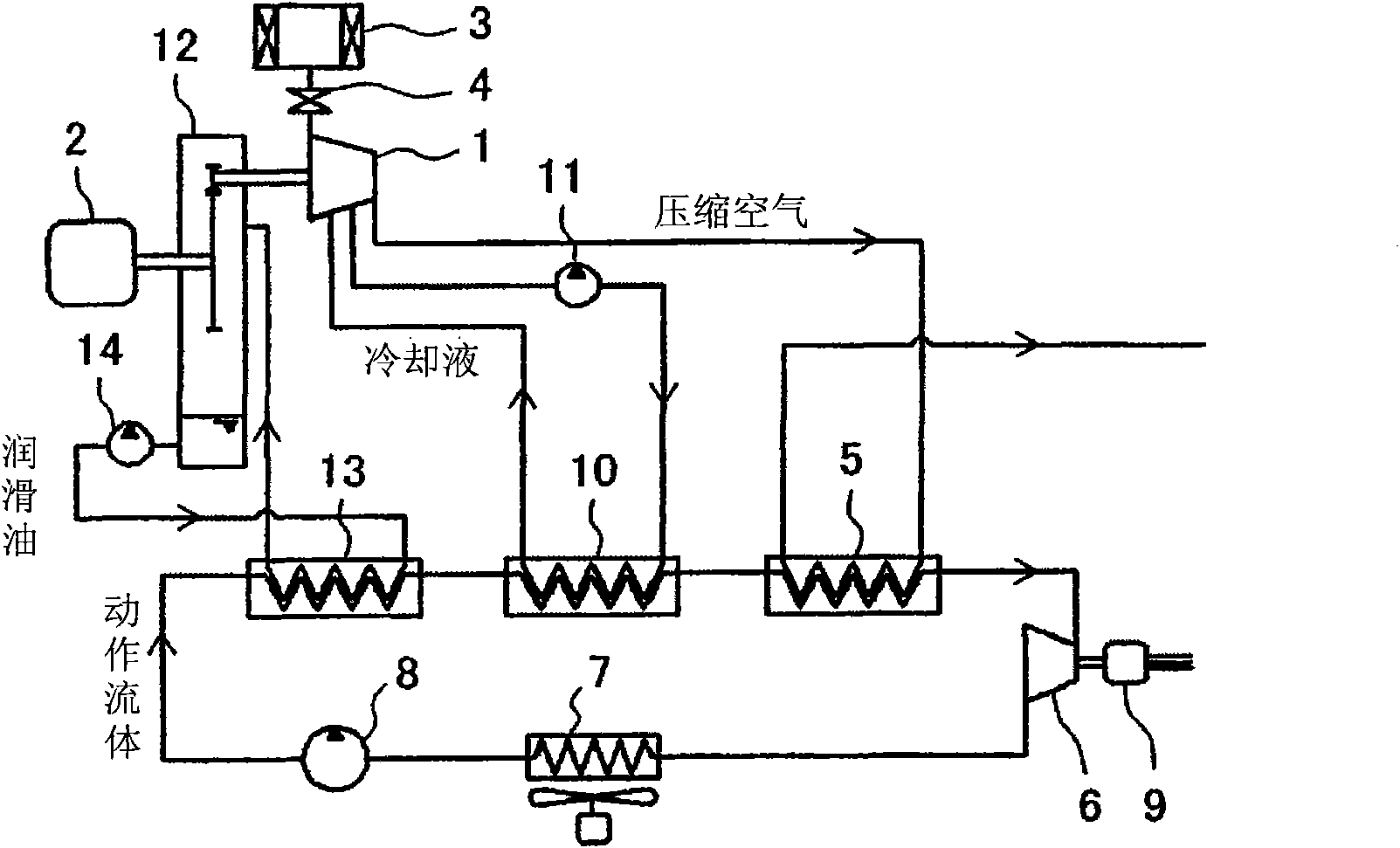

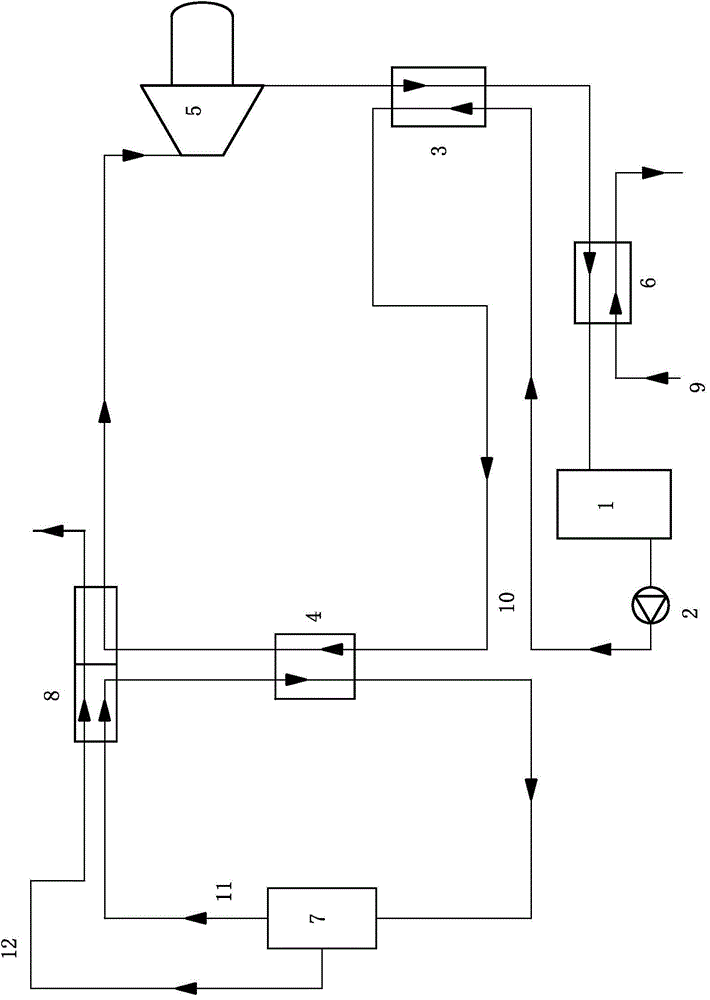

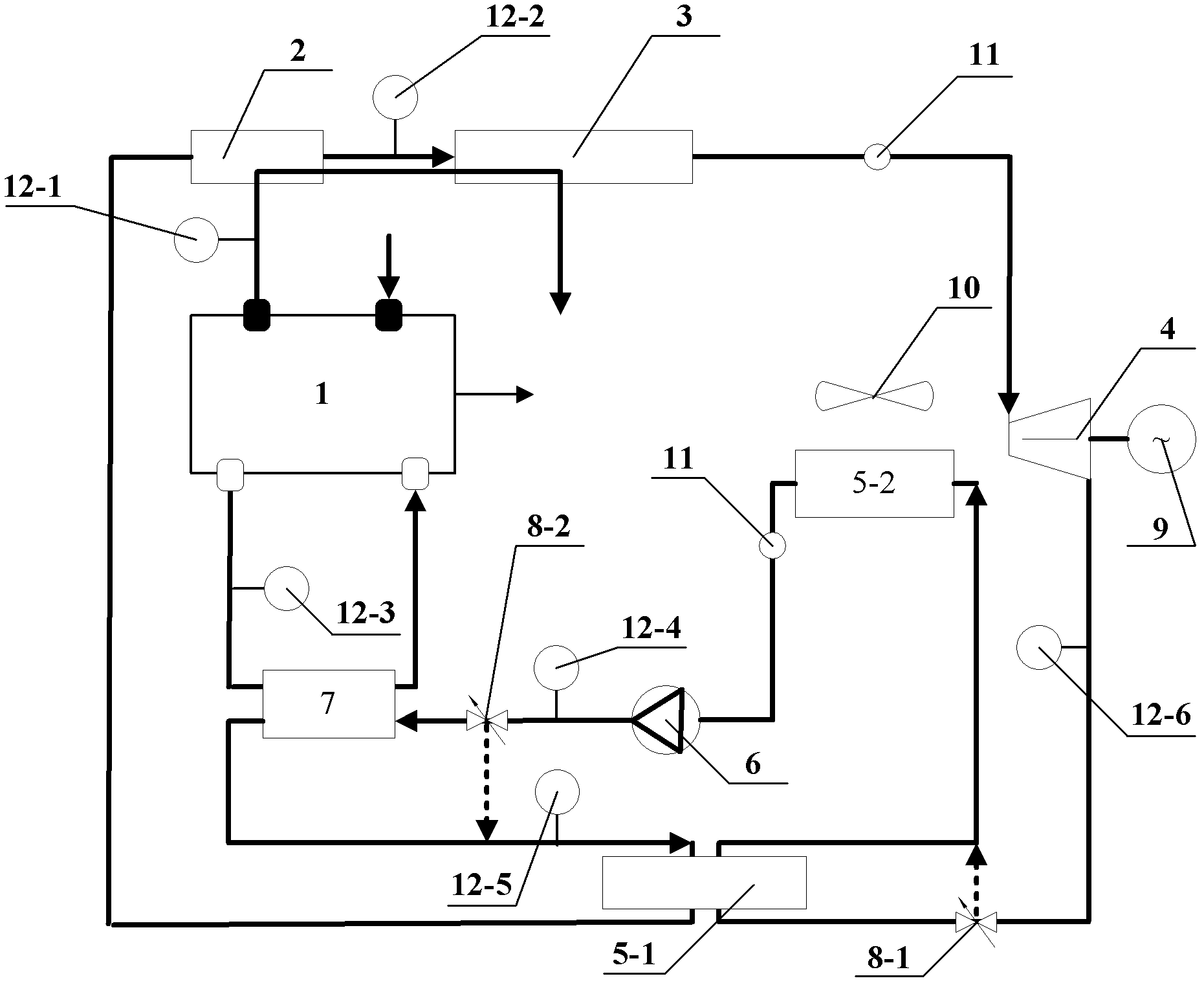

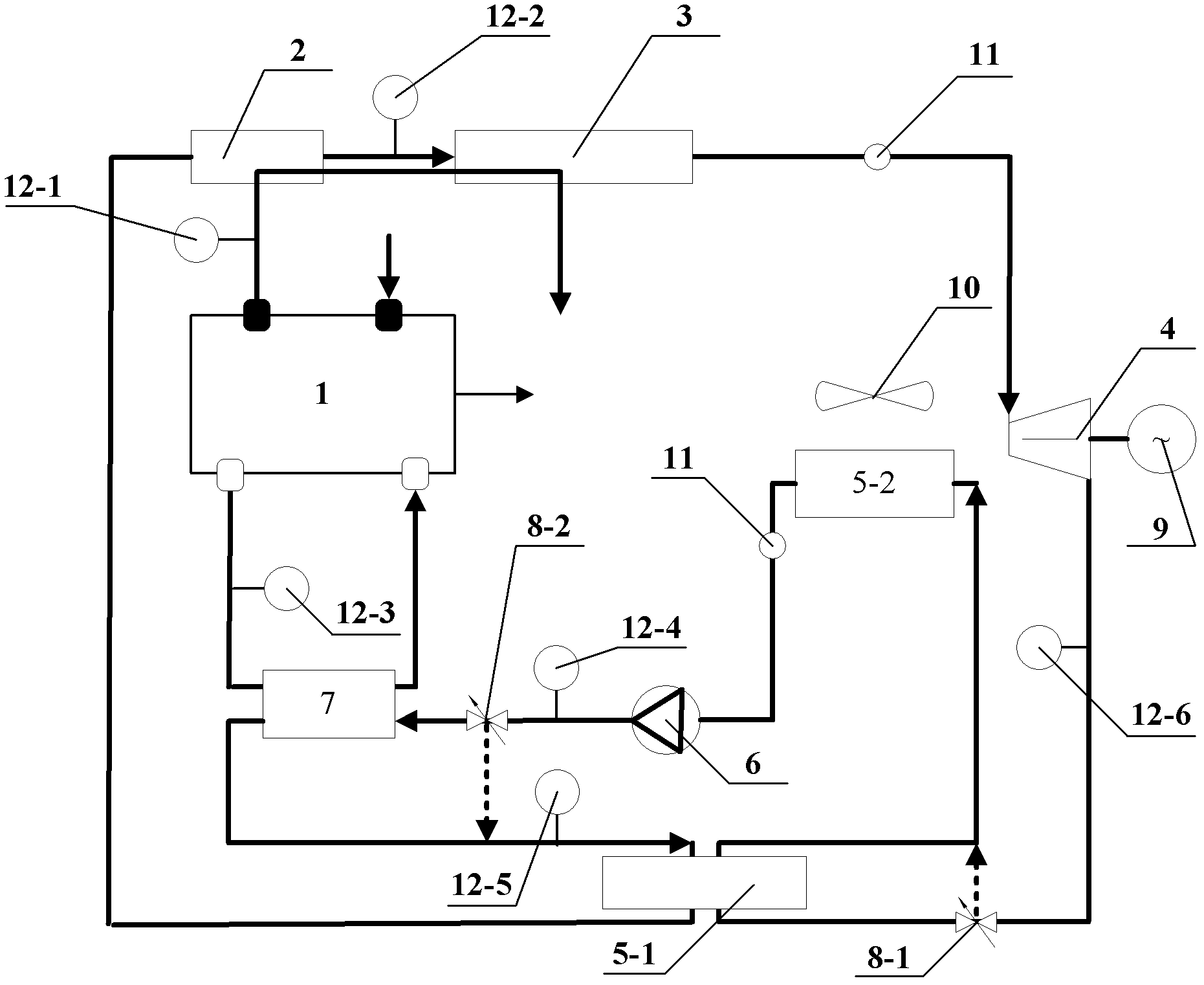

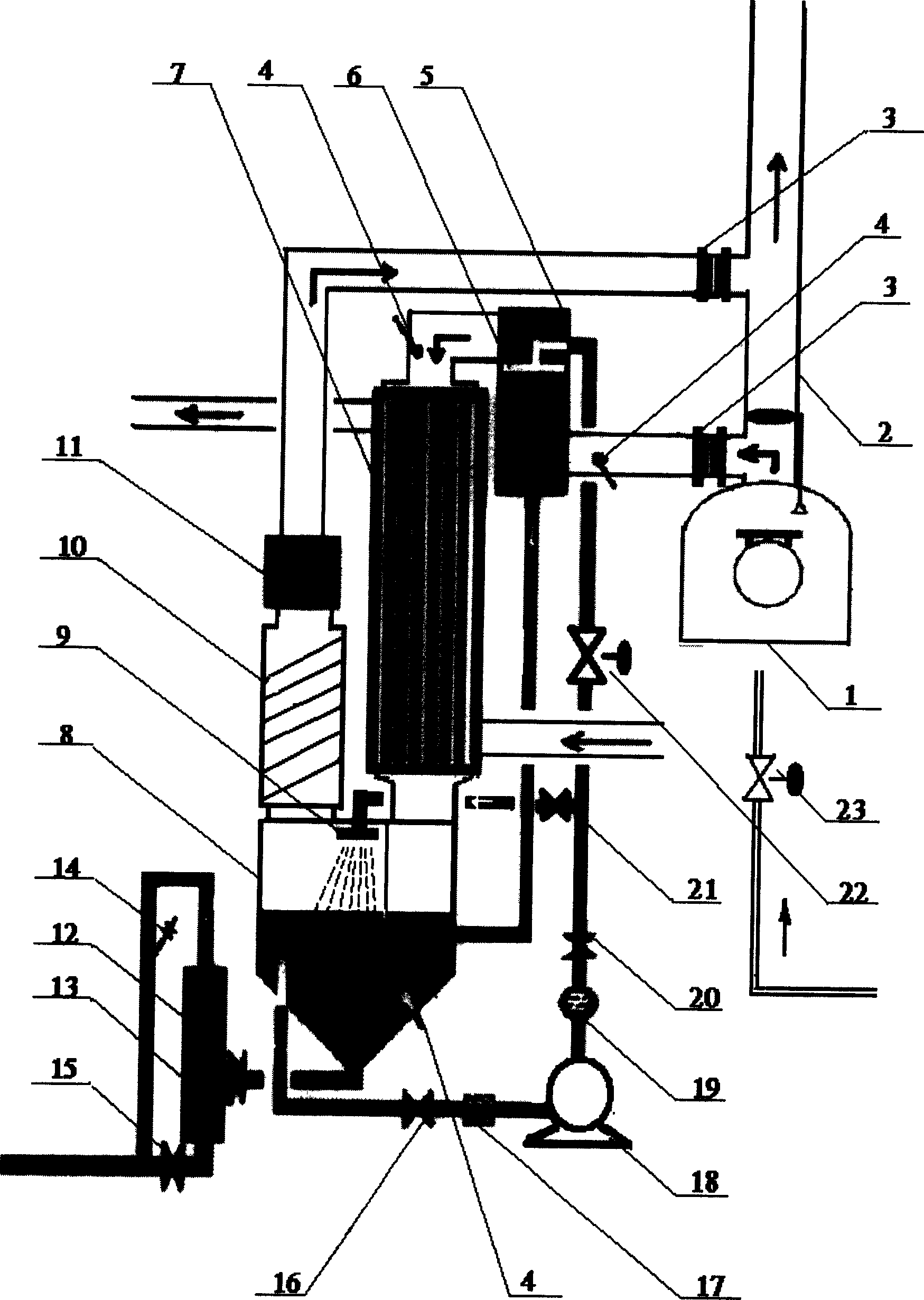

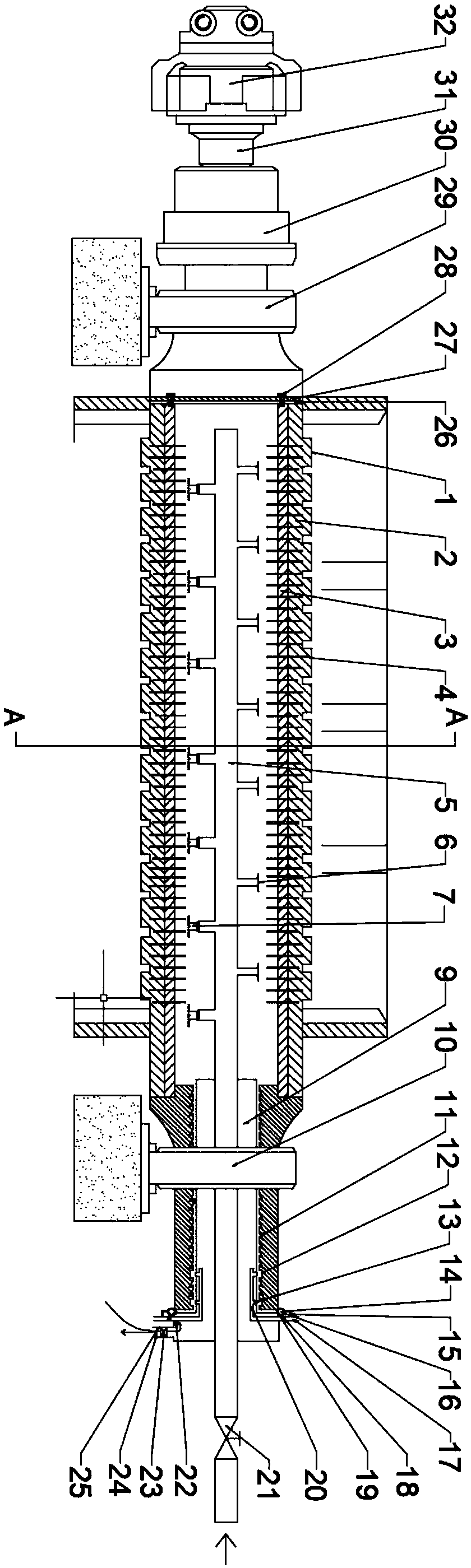

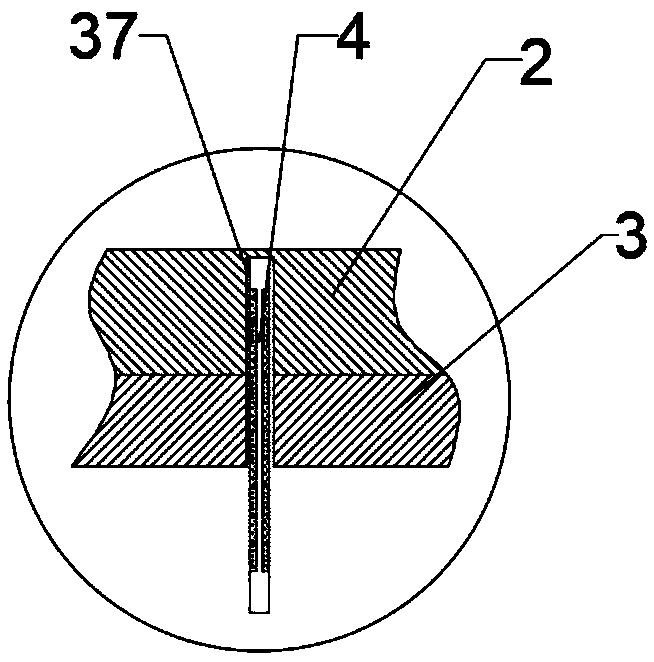

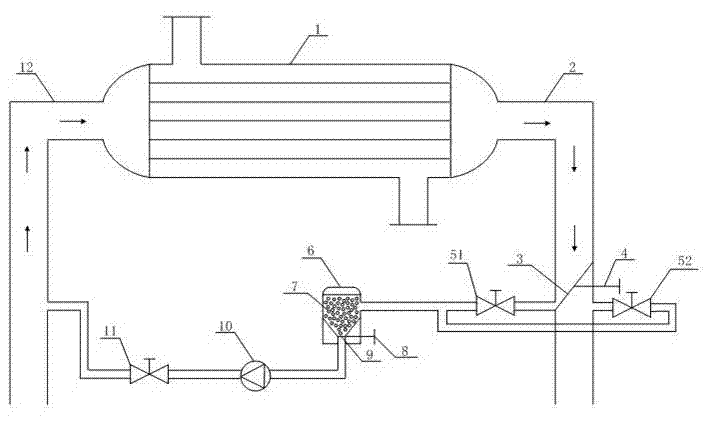

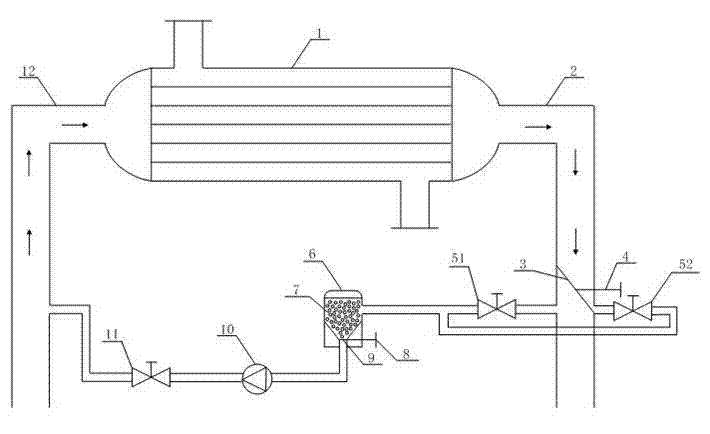

Compressor

ActiveCN101943168AImprove waste heat recovery efficiencyImprove recycling efficiencyRotary/oscillating piston combinations for elastic fluidsEnergy industryWorking fluidEngineering

The invention provides a compressor capable of improving exhaust heat recover efficiency. The compressor is provided with a compressor main body (1) for compressing air, and further comprises a heat exchanger (5) for cooling the compressed air exhausted by the compressor main body (1) by performing heat exchange with a working fluid; an expander (6) for expanding the working fluid which is gasified after being heated by the heat exchanger (5) and generating driving force; a condenser (7) for cooling and liquefying the working fluid supplied by the expander (6) and supplying the liquefied working fluid to the condenser (7) of the heat exchanger (5); and a circulating pump (8) for leading the working fluid to circulate among the heat exchanger (5), the expander (6) and the condenser (7). A Rankine cycle is formed by the heat exchanger (5), the expander (6), the condenser (7) and the circulating pump.

Owner:HITACHI IND EQUIP SYST CO LTD

Liquid state blast furnace slag granulation and multi-roller residual heat recovery system

ActiveCN103642956ARealize cascade utilizationRaise the gradeRecycling and recovery technologiesSteam generation using hot heat carriersLiquid stateSlag

The invention discloses a liquid state blast furnace slag granulation and multi-roller residual heat recovery system. The liquid state blast furnace slag granulation and multi-roller residual heat recovery system comprises a first level vaporized roller granulation bin, a second level vaporized roller storage bin, a third level roller cooler and a residual heat recovery system, wherein a material inlet of the first level vaporized roller granulation bin is provided with a liquid state slag flow groove and a granulation device; the first level vaporized roller granulation bin, the second level vaporized roller storage bin and the third level roller cooler are connected in series, and are all provided with vapor-water inlets and outlets; the residual heat recovery system comprises a water feeding pump, an oxygen removing device and a vapor bag which are communicated through water pipes. According to the invention, high-grade saturated steam can be produced by utilizing residual heat of a blast furnace slag in a gradient mode, and the waste slag utilization grade is improved by the rapid cooling of solid slags; the continuous running in the integral process is not affected by the resting period of a blast furnace.

Owner:无锡市东方环境工程设计研究所有限公司

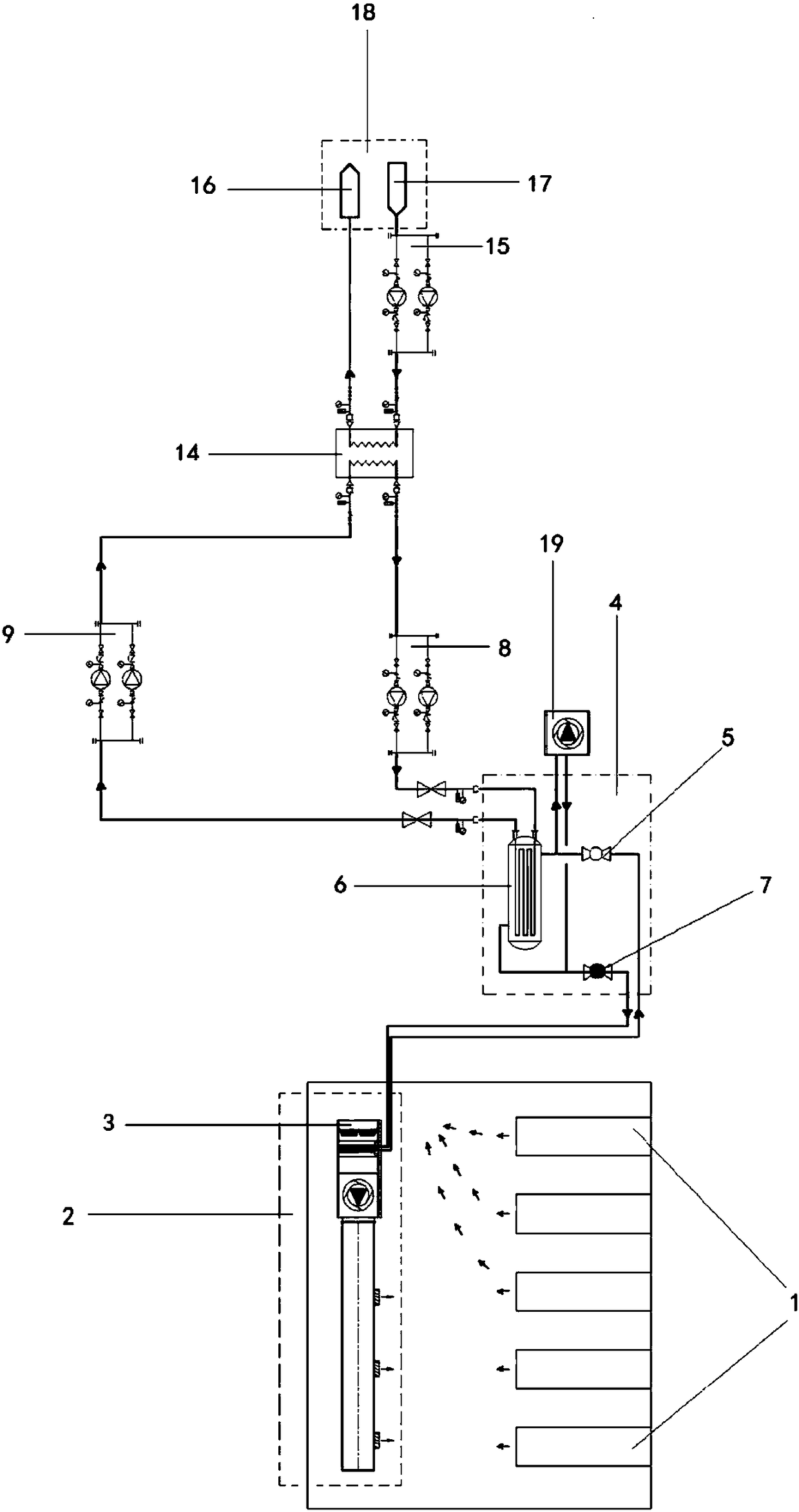

Waste heat power generation system utilizing organic Rankine cycle

InactiveCN103953405AImprove waste heat recovery efficiencyStrong power generation capacityEnergy industrySteam engine plantsOrganic Rankine cycleProcess engineering

The invention discloses a waste heat power generation system utilizing organic Rankine cycle, which comprises a waste heat supply device, the waste heat supply device is connected with a high-temperature waste heat recovery system and is meanwhile connected with a heat conducting medium heater, and the heat conducting medium heater is connected with a low-temperature waste heat recovery system; the high-temperature waste heat recovery system comprises a high-temperature steam circulation pipeline, the high-temperature steam circulation pipeline is connected with a steam power generation branch, at least one exhaust steam heat exchanger and a water circulating pump in series in sequence, and the exhaust steam heat exchanger is connected with an exhaust steam organic Rankine circulation loop; and the low-temperature waste heat recovery system comprises a low-temperature circulation pipeline, the low-temperature circulation pipeline is connected with at least one heat taking medium heat exchanger and an organic working medium circulating pump in series in sequence, and the heat taking medium heat exchanger is connected with the exhaust steam organic Rankine circulation loop. The waste heat power generation system in the invention has the benefits that the investment is low, the maintenance and operation cost is low, the reliability is strong, waste heat can be effectively recycled, the effects of greenness and environment protection are realized, and the waste heat power generation system is suitable for large-scale popularization and use.

Owner:BIHAIZHOU BEIJING ENERGY SAVING EQUIP CO LTD

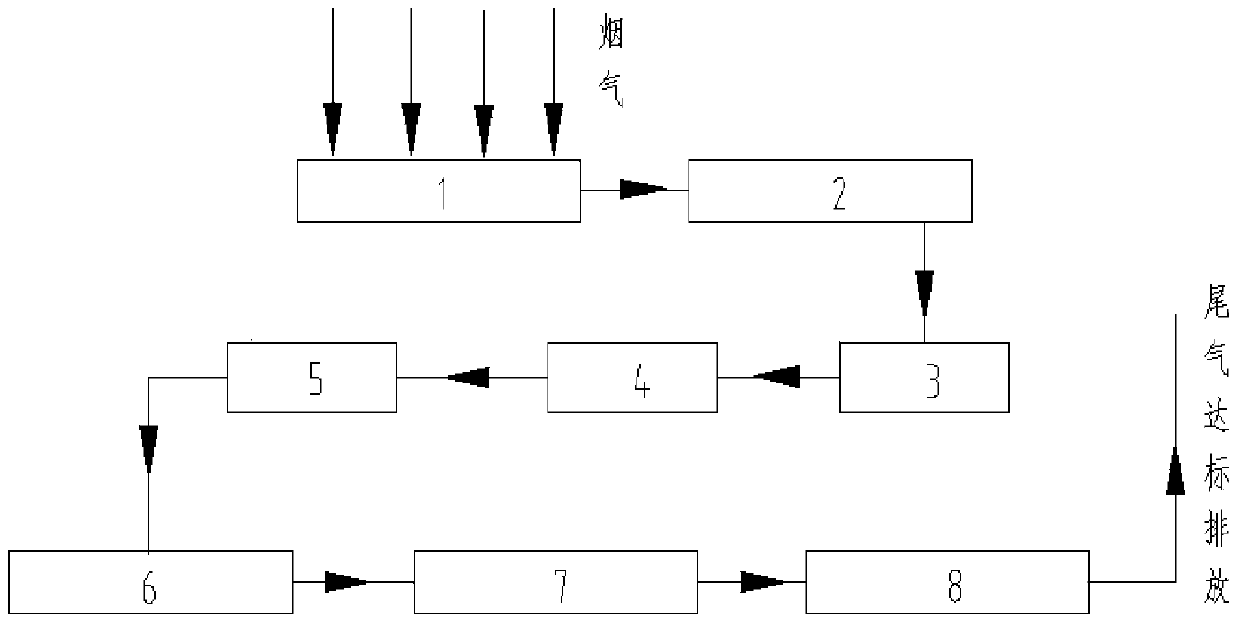

Unit of recovering flue gas waste heat and dust in nonferrous metal smelting

ActiveCN103471404AHigh temperature resistance hasLow densityIncreasing energy efficiencyWaste heat treatmentCounter flowFiltration

The invention relates to a unit of recovering flue gas waste heat and dust in nonferrous metal smelting and belongs to a method of waste heat utilization and waste gas treatment. A waste heat recovery device and a dust recovery device are formed by connecting a counter flow heat exchange waste heat boiler A, a silicon nitride porous ceramic filter, a counter flow heat exchange waste heat boiler B, a counter flow heat exchanger waste heat boiler medium preheater, a plate type passage gas counter flow heat exchanger, a bag filter, and a draught fan through a pipeline or pipes; flue gas subjected to waste heat and dust recovery is subjected to sulfur recovery in a desulfurization shop, and the tail gas can be discharged standardly. The method includes the steps of primary waste heat recovery, filtration, dedusting and purification of high temperature flue gas, secondary waste heat recovery, tertiary waste heat recovery, quaternary waste heat recovery, low temperature filtration and dedusting, sulfur recovery and emission of tail gas under national standard. The device has the advantages that waste heat recovery is efficient, dust recovery is thorough, process control is simple, and recovery cost is low.

Owner:SHANDONG JINSHENG NON FERROUS GRP +1

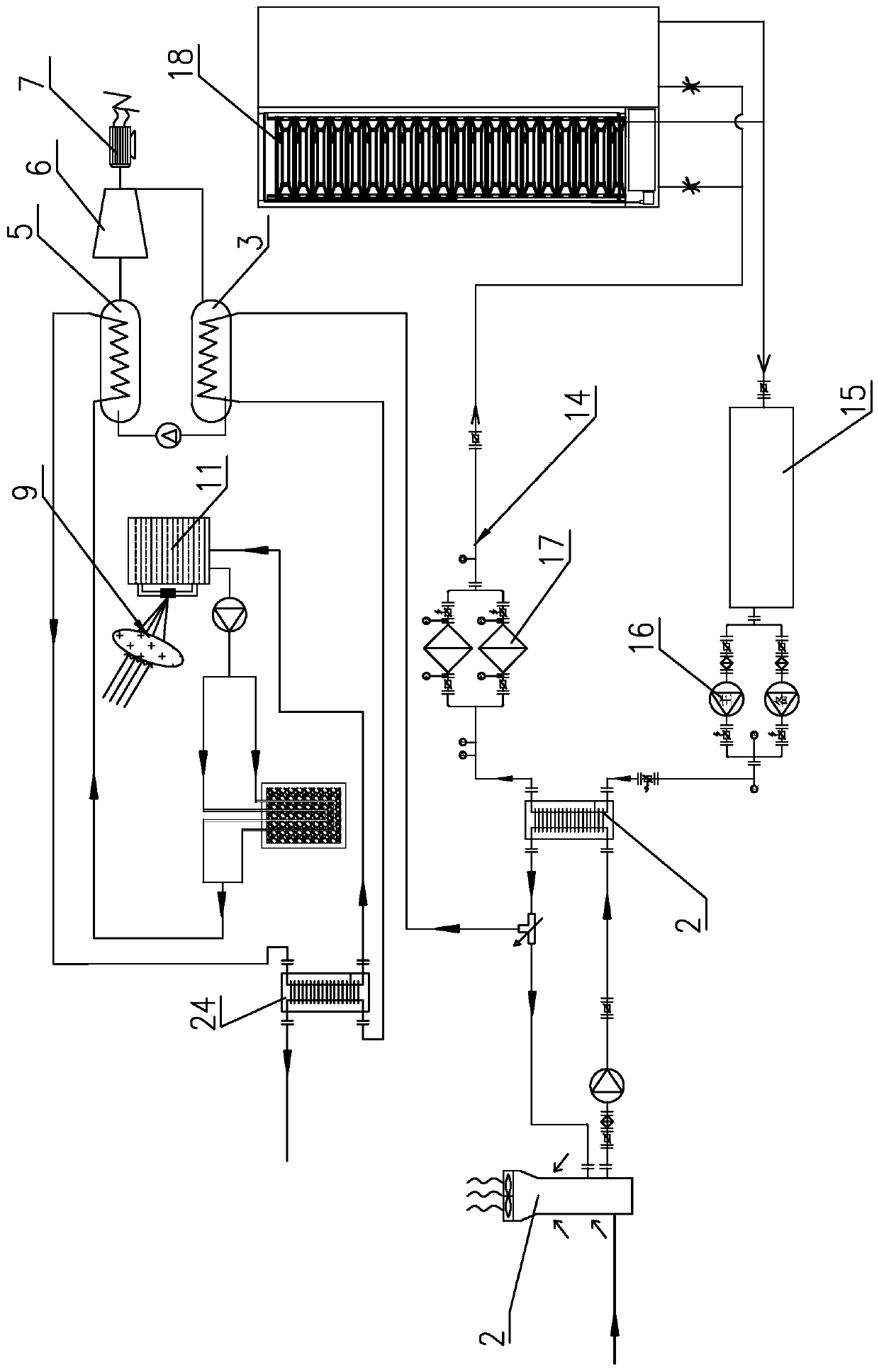

ORC (organic Rankine cycle) system for marine main engine waste heat generation

ActiveCN103982255ASolve the problem that the evaporation pressure is too low and the system efficiency is not highSolve the problem of pyrolysisInternal combustion piston enginesExhaust apparatusOrganic Rankine cycleDiesel engine

The invention discloses an ORC (organic Rankine cycle) system for marine main engine waste heat generation, which comprises an engine tail gas loop, an engine liner water loop, a coolant loop and an external cooling water loop. The ORC system, which is a power system based on the organic Rankine cycle, absorbs the waste heat of engine liner water and engine tail gas. After liner water is adopted to absorb the heat of engine tail gas in the system, the coolant of the ORC system is then heated; meanwhile, the heated coolant is utilized to absorb part of residual heat after heat exchange between the engine tail gas and the liner water. The system can be utilized to effectively solve the problem that the low temperature of marine main engine liner water results in the over-low evaporating pressure and low system efficiency of the ORC system. Meanwhile, because the system utilizes the scheme that tail gas and liner water jointly absorb heat, the problem of coolant pyrolysis caused by direct heat exchange between organic coolant and high-temperature waste heat is solved. While diesel engine waste heat is recovered by the system to the max, the alteration of an existing diesel engine system is little.

Owner:ZHEJIANG YINLUN MACHINERY

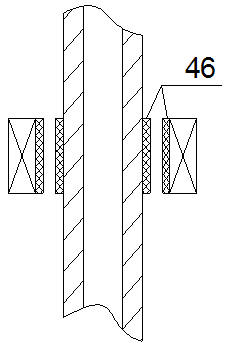

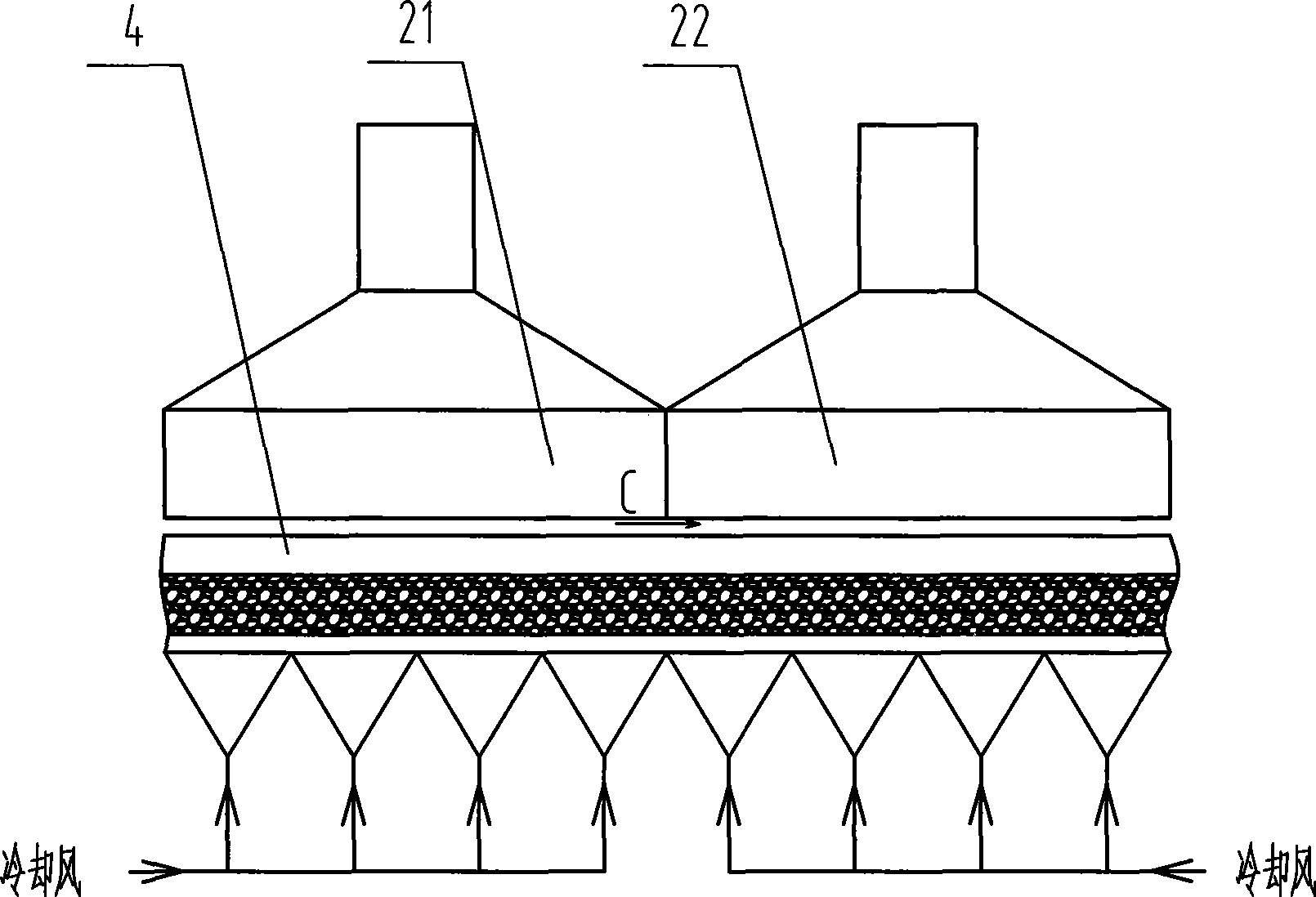

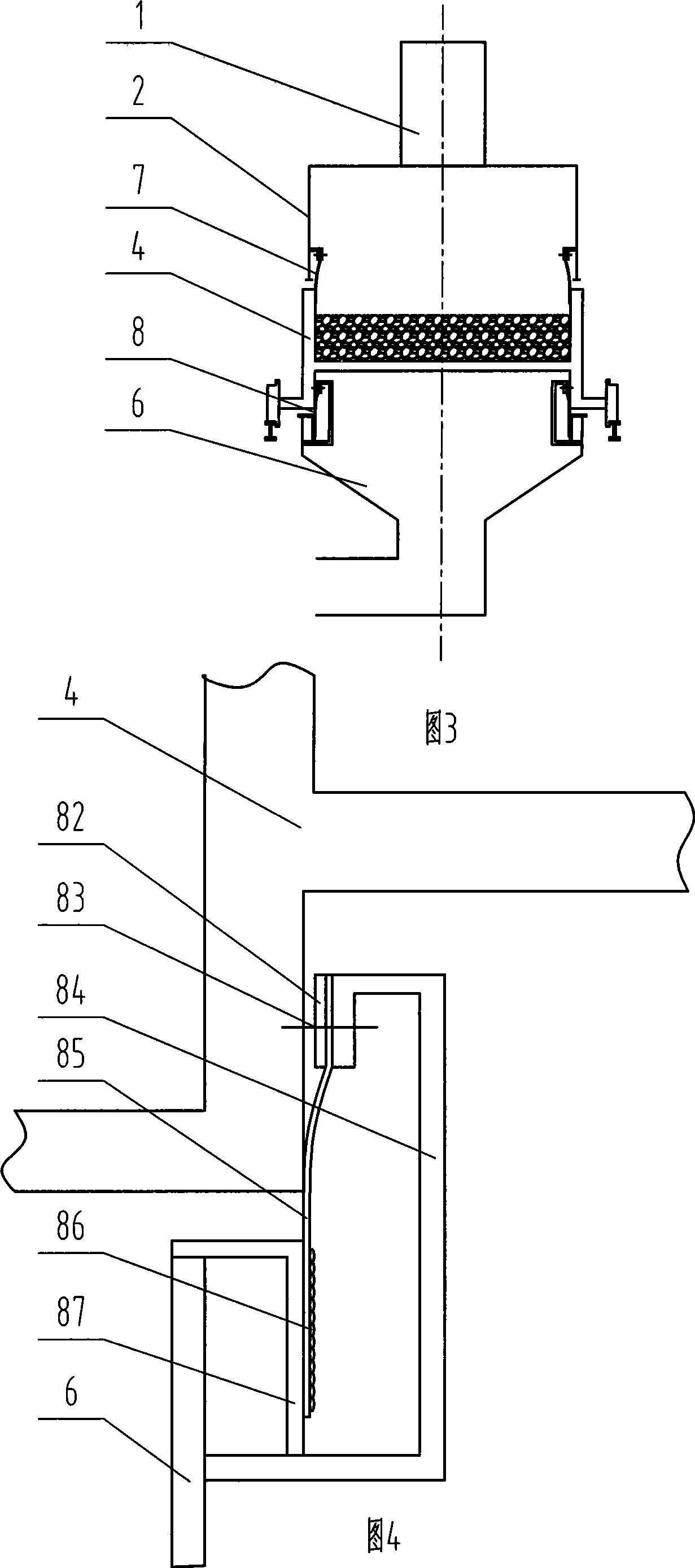

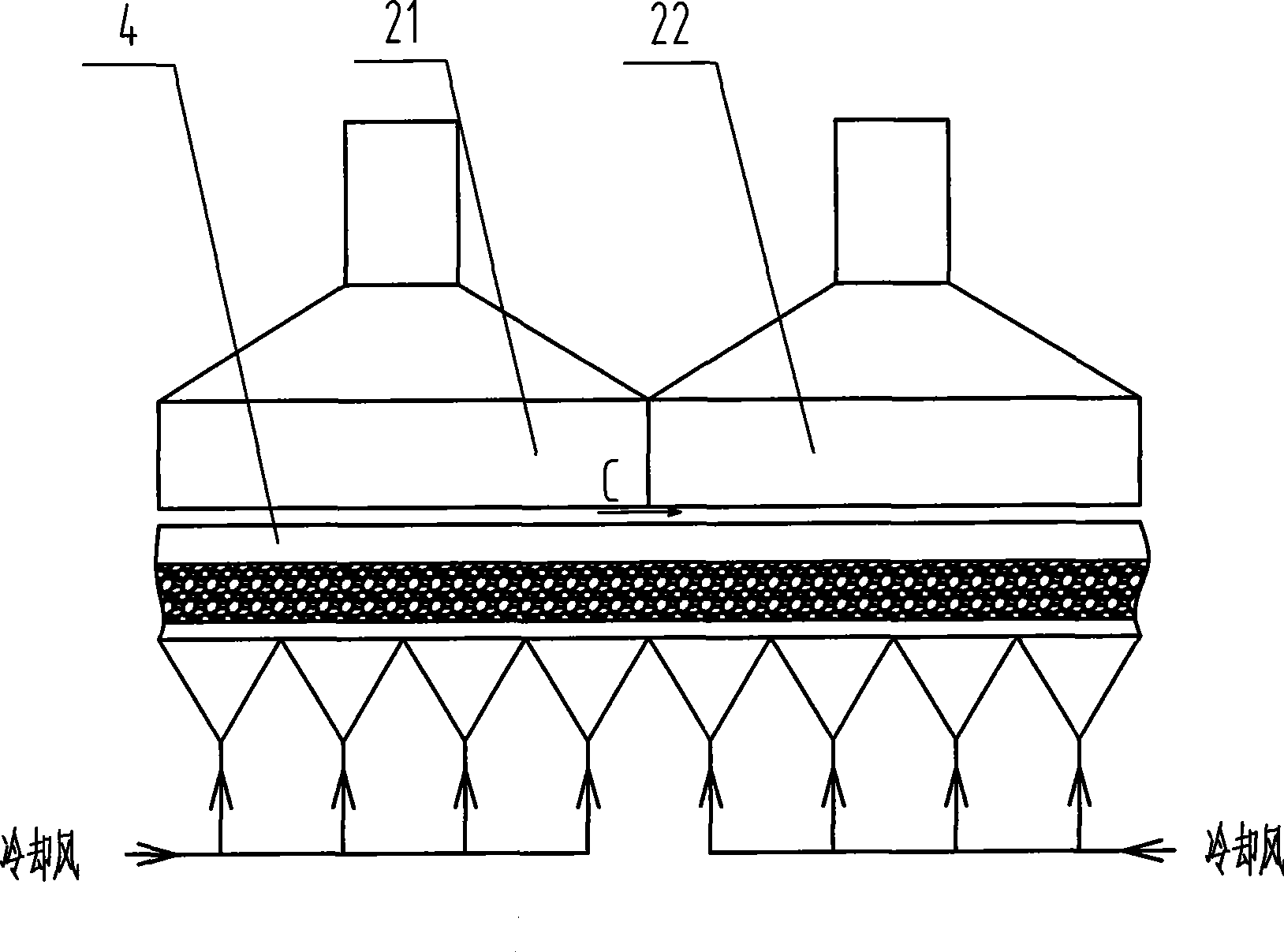

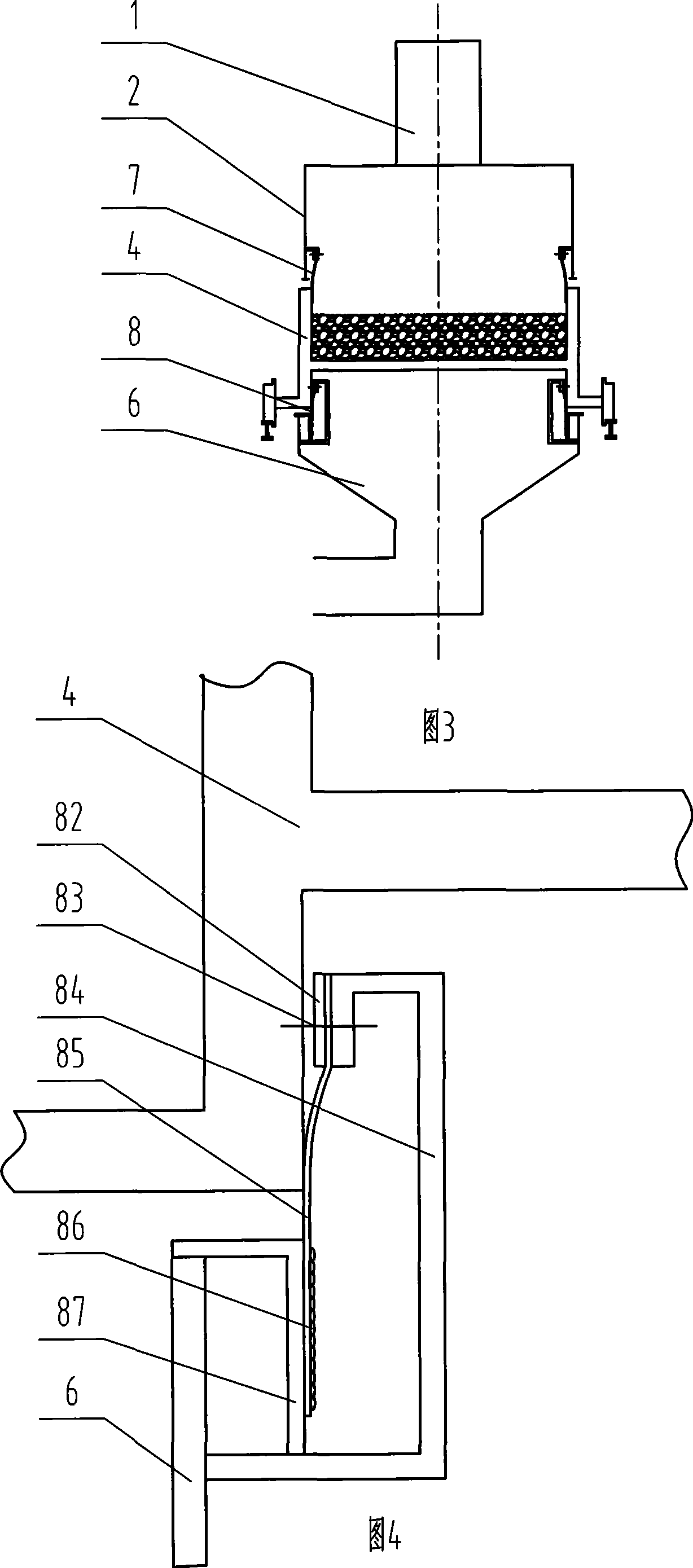

Sintering device, sintering cooler and its suspension sealing device

InactiveCN101368794AReduce power consumptionReduce air leakageEngine sealsEnergy industrySlide plateWaste heat

The invention discloses a sintering cooler and a suspended seal equipment thereof, which can reduce the power consumption of blowers, decrease the air leakage of the equipment, increase the waste heat recovery efficiency and improve the environment. The sintering cooler comprises a plurality of sinter-loading trolleys, a plurality of overhead hoods above the trolleys, bellows below the trolleys, as well as suspended seal devices between every two adjacent hoods on the trolleys; wherein, the slideway of each bellows is glidingly contacted with a flexible slide plate of the corresponding trolley; the upper ends of the suspended seal devices are suspended on the combination part of two adjacent hoods; and the lower ends of the suspended seal devices are overhung on the sinter on the trolleys.

Owner:刘庸

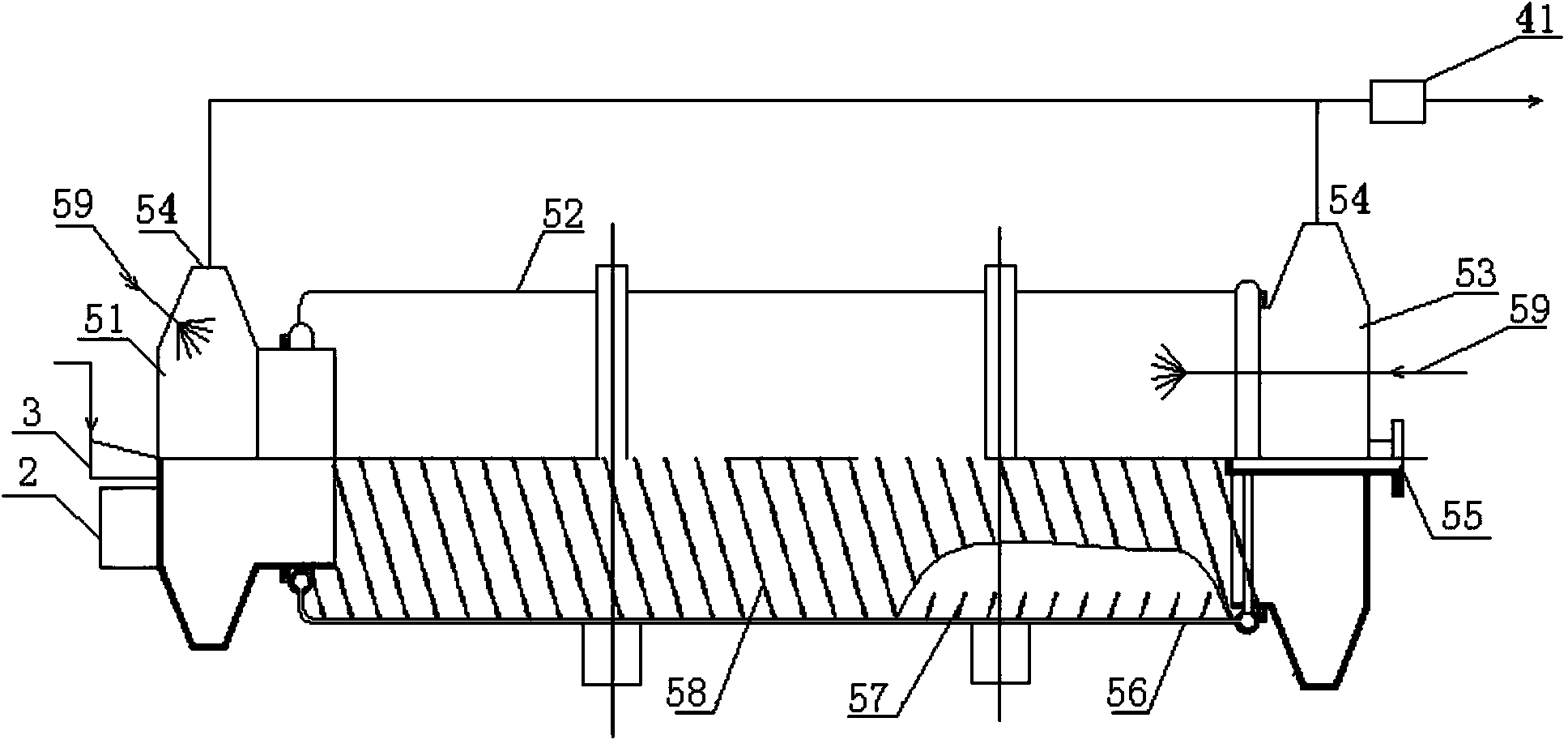

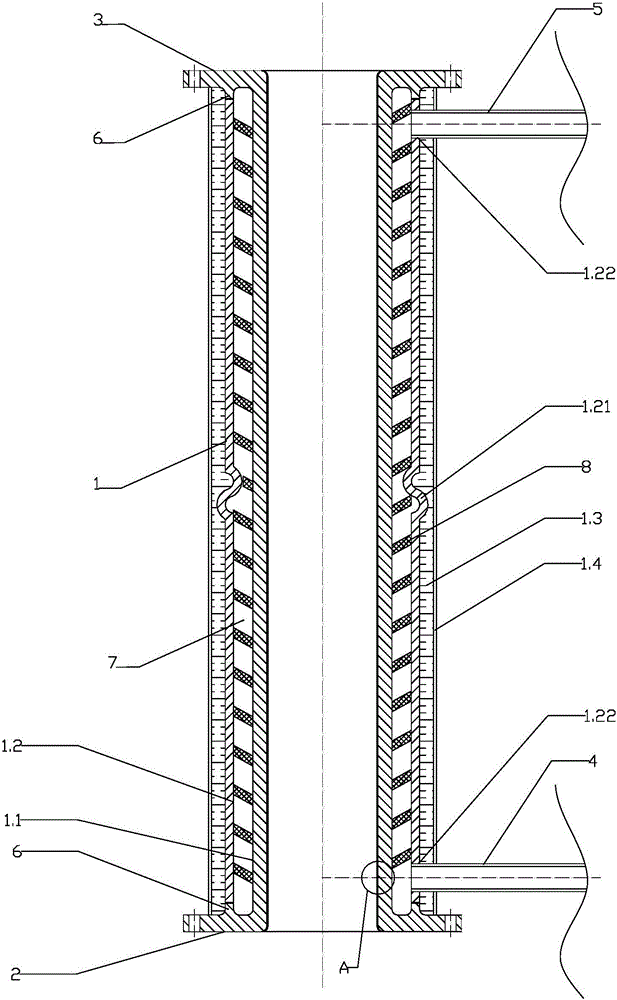

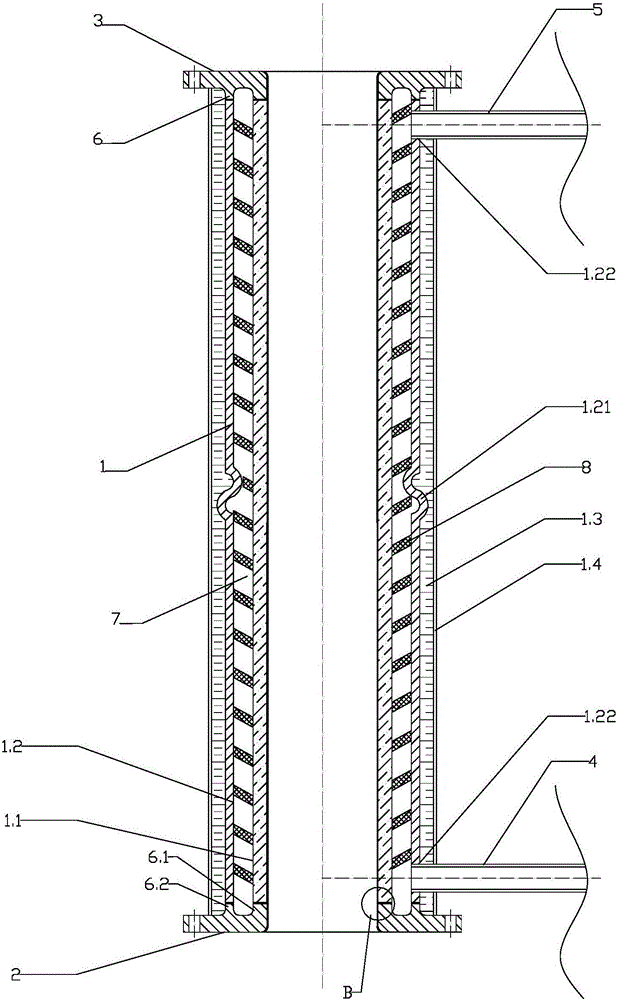

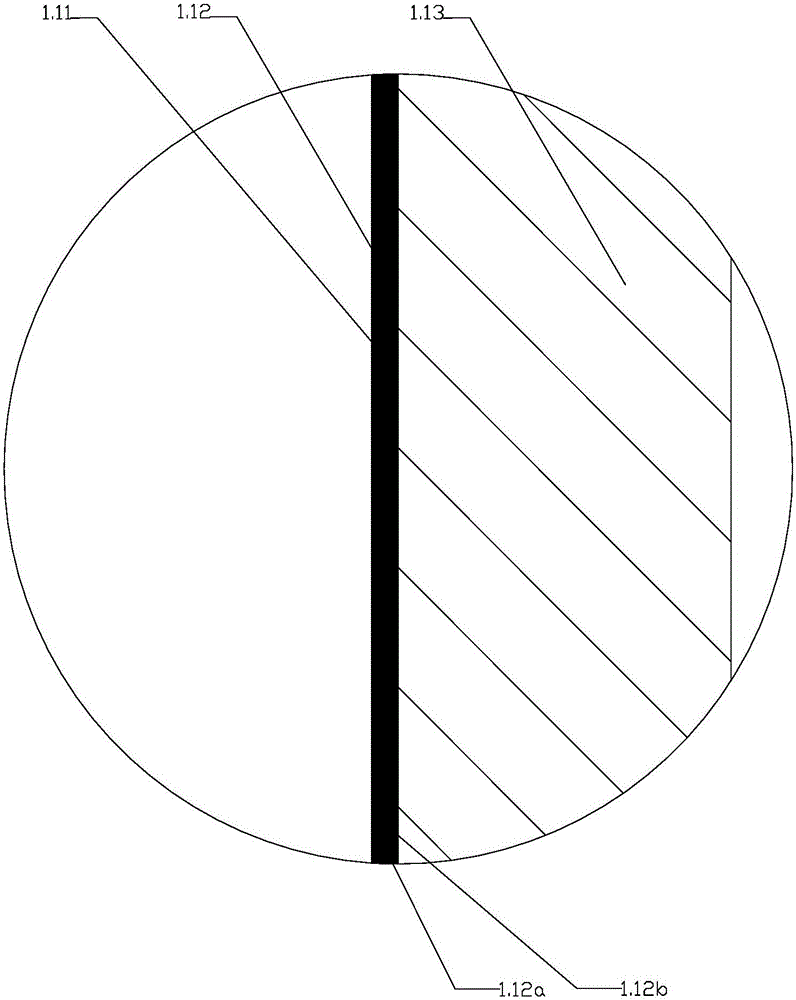

Coke oven ascension pipe raw gas evaporative cooling device and preparation method thereof

InactiveCN105043117APrevent oxidationAvoid carburizationIncreasing energy efficiencyWaste heat treatmentEngineeringCoke oven

The invention discloses a coke oven ascension pipe raw gas evaporative cooling device and a preparation method thereof. The device comprises a cooling pipe, a raw gas inlet flange and a raw gas outlet flange, wherein the raw gas inlet flange and the raw gas outlet flange are connected with the two ends of the cooling pipe respectively. The cooling pipe is sequentially composed of an inner sleeve, an outer sleeve, a heat preservation layer and a protection layer from inside to outside. Through holes are formed in the two ends of the side wall of the outer sleeve respectively. A water inlet steel pipe is installed on the through hole close to the raw gas inlet flange. A vapor outlet steel pipe is installed on the through hole close to the raw gas outlet flange. An annular expansion joint section is arranged at the portion, between the water inlet steel pipe and the vapor outlet steel pipe, of the outer sleeve. The high temperature structural strength and high temperature breakage resistant capacity of the cooling device are remarkably improved, the heat transfer behavior of the pipe wall of the inner sleeve of the cooling device is improved, the radial temperature distribution of the pipe wall is optimized, the efficient function coordination of multiple layers of materials is achieved, and the comprehensive use performance of the inner sleeve is improved; the aim of long-term efficient and stable running of the ascension pipe raw gas evaporative cooling device is finally achieved.

Owner:武汉钢铁有限公司

Waste heat cycling heating power circulating system device of engine

InactiveCN102444439AImprove waste heat recovery efficiencyOvercoming shortcomings in waste heat recovery technologyInternal combustion piston enginesExhaust apparatusAutomotive engineeringFuel oil

The invention discloses a waste heat cycling heating power circulating system device of an engine. The system composition is that an exhaust pipe of the engine is in series connection with a thermoelectric generator and an evaporator. The working medium side of the thermoelectric generator is in series connection with the evaporator, an expander, a heat regenerator, a condenser, a working medium pump and the working medium side of a preheater in sequence through pipelines and returns to the thermoelectric generator through the low-temperature side of the heat regenerator, and a closed circuit circulation system is formed. Bypass valves are respectively arranged between an inlet on the high-temperature side of the heat regenerator and an outside outlet pipeline and between an inlet of the preheater and the outside outlet pipeline. By the utilization of an automatic electrical control system, temperature and pressure of six points of a heating power circulating system are monitored, and the opening and closing of two bypass valves are controlled so that an optimum flow of a working medium of the system is ensured. The waste heat cycling heating power circulating system device overcomes the shortcomings of waste heat recycling of the engine in the prior art, and achieves step utilization of waste heat of the engine and the purposes of improving economy of fuel oil of the engine and reducing emission.

Owner:TIANJIN UNIV

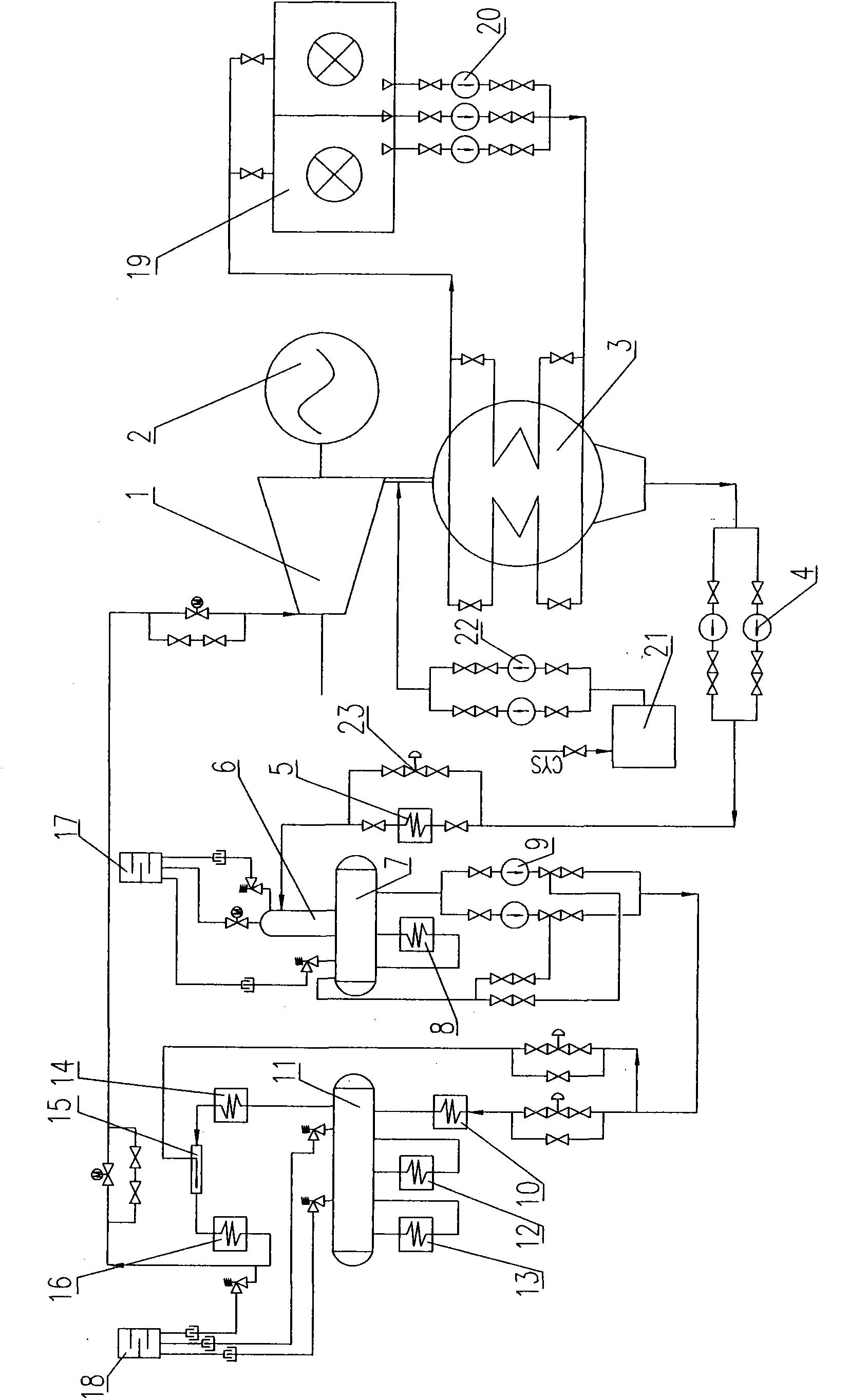

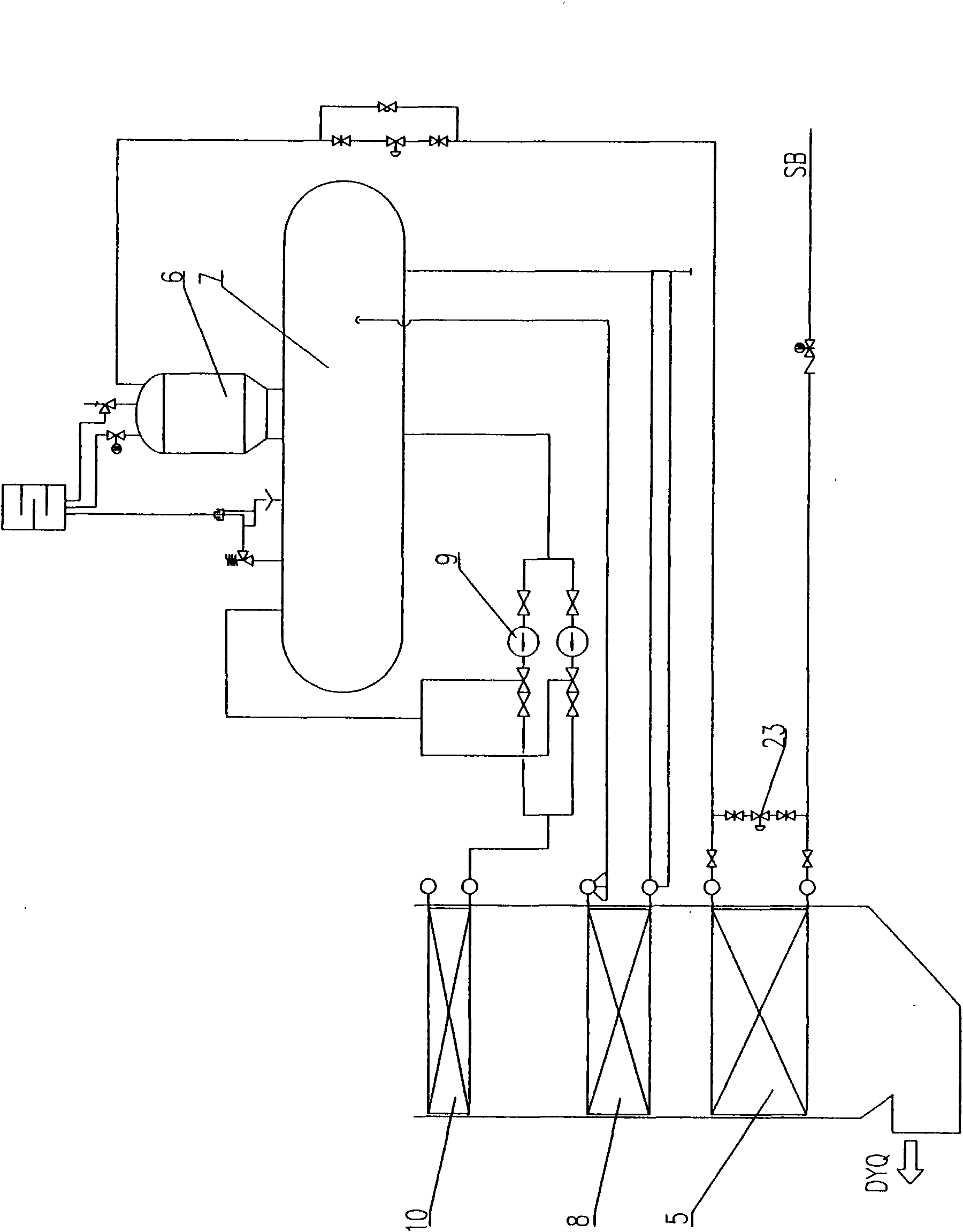

Dry quenching dual pressure high-temperature and high-pressure residual heat power generation system

InactiveCN101655019AContributing to the Sustainable Development GoalsImprove waste heat recovery efficiencyCoke quenchingEnergy inputEngineeringHigh pressure

The invention discloses a dry quenching dual pressure high-temperature and high-pressure residual heat power generation system, which comprises a dry quenching high-temperature and high-pressure superheated steam dual pressure residual heat boiler, a steam turbine generator unit, a condensation device and a condensation water pump, wherein the steam turbine generator unit and the high-pressure superheated steam dual pressure residual heat boiler form a return circuit through the condensation device and the condensation water pump. The dry quenching dual pressure high-temperature and high-pressure residual heat power generation system provided by the invention can fully absorb the energy of smoke and has higher efficiency for recovering residual heat, and the residual heat recovering powergeneration technology reaches the international advanced level by adopting the dual pressure residual heat boiler plus a perfect inert gas recirculation system.

Owner:ZHEJIANG XIZI UNITED ENG

Fume afterheat recovering system by hidden heat process

InactiveCN1563874AReduce pollutionImprove environmental performanceEnergy efficient heating/coolingAir heatersPlate heat exchangerCooling tower

The method includes heat conversion, and heat recovery two procedures: (1) in first procedure, high temperature fume from flue enters into sprinkling cooling tower, where sprinkling media contact to fume. Media are vaporized. Thus, sensible heat in fume is transferred to latent heat; (2) media and fume enter into acid resistant heat exchanger. Media are condenses to release latent heat exchanged to media needed to heat. The recovery system is composed of temp sensor, sprinkling cooling tower, heat exchanger, pump and automatic control valve etc. Features are: compact, lightweight, high reclaiming efficiency.

Owner:杨振东

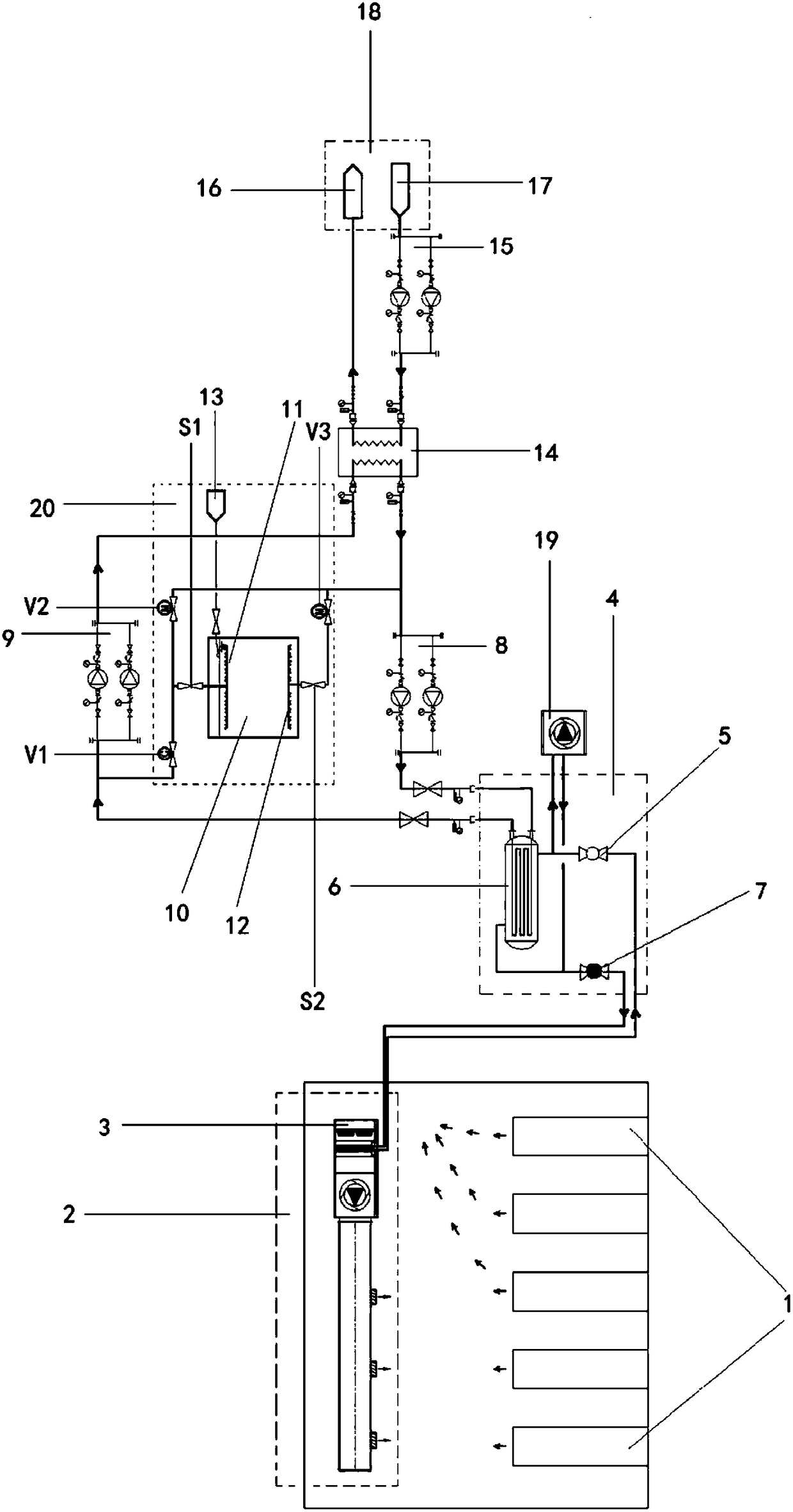

Waste heat recovery system based on data center and control method for waste heat recovery system

PendingCN108469111AImprove waste heat recovery efficiencyImprove cooling effectEnergy recovery in ventilation and heatingMechanical apparatusWaste heat recovery unitData center

The invention discloses a waste heat recovery system based on a data center and a control method for the waste heat recovery system. The waste heat recovery system comprises a waste heat collecting unit, a heat pump unit, a heat storage unit, a waste heat conveying unit and a user end. The waste heat recovery system has the advantages that the waste heat collecting unit collects heat generated ina machine room of the data center, and the heat is transmitted to the user end through the waste heat conveying unit after being compressed and condensed by the heat pump unit; the waste heat recoverysystem further stores a part of waste heat in advance through the heat storage unit, when the waste heat is insufficient, the waste heat is released and used, and therefore the waste heat utilizationrate is increased; the purposes that the indoor waste heat is extracted and utilized, circulating water of a heat supply network is heated, and heat supply is realized can be achieved by the waste heat recovery system; and the heat generated by the machine room of the data center can be recycled and reused by the waste heat recovery system, so that energy waste and environmental pollution causedby emission of the waste heat of the machine room can be avoided.

Owner:ZHONGSHOUNENG ENERGY INVESTMENT BEIJING CO LTD

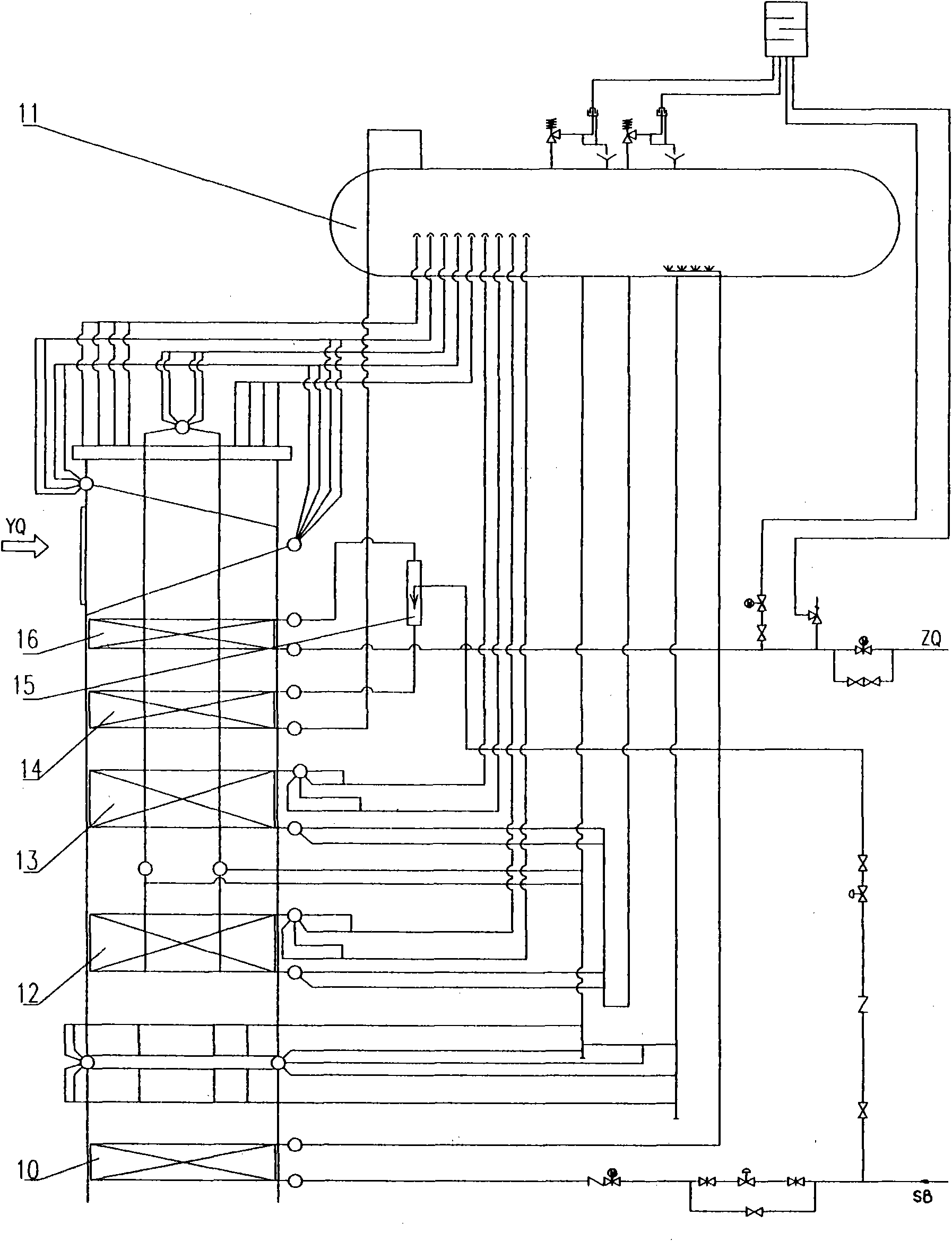

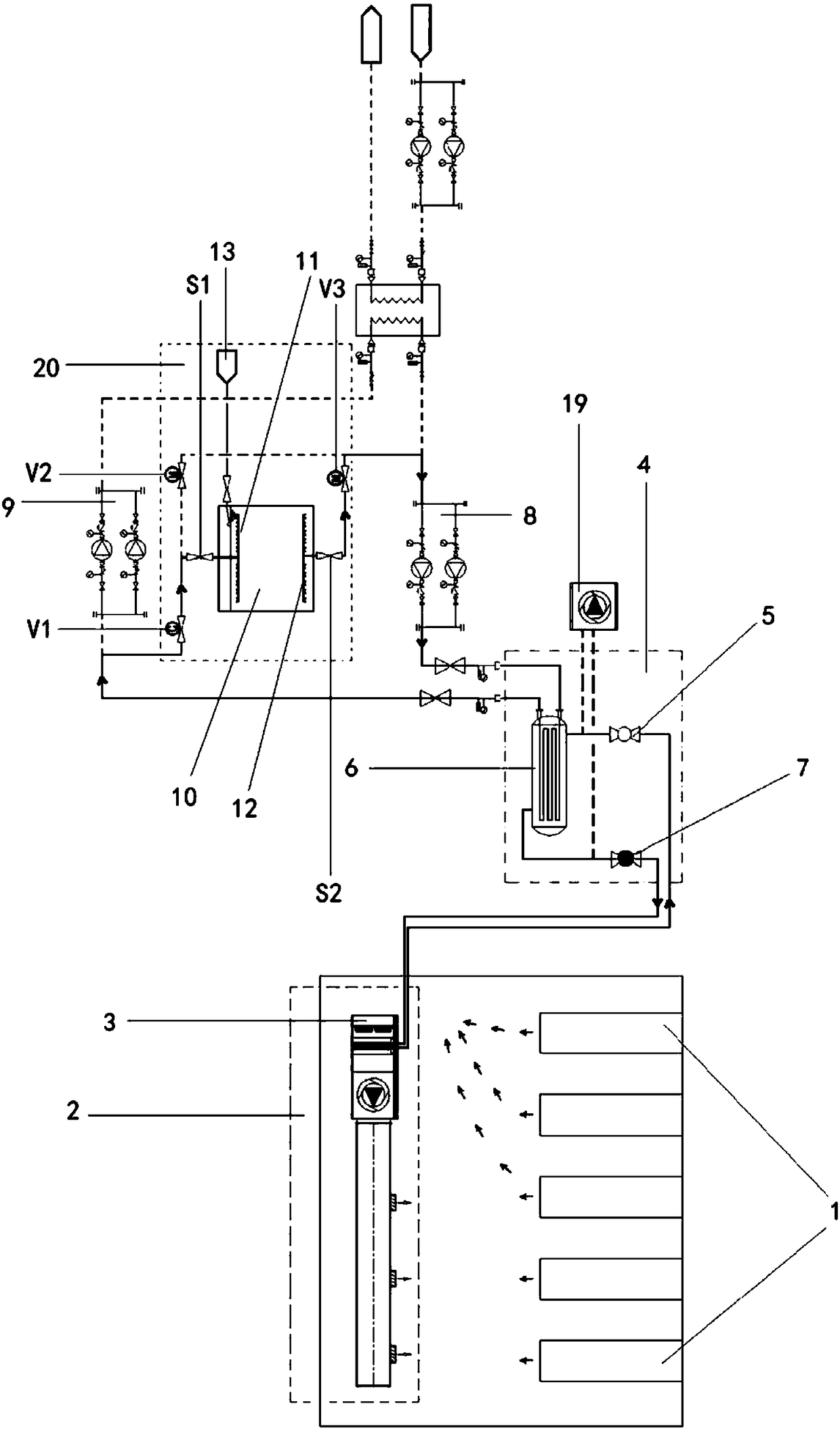

Step-by-step waste heat recovery system and method for electric furnace flue gas on whole temperature section

ActiveCN104061793AEfficient recyclingImprove utilization efficiencyIncreasing energy efficiencySteam superheatersRecuperatorDeaerator

The invention provides a step-by-step waste heat recovery system and method for electric furnace flue gas on the whole temperature section. The step-by-step waste heat recovery system provided by the invention comprises a flue gas subsystem and a steam-water subsystem, wherein the flue gas subsystem comprises an electric furnace, a vaporization flue duct, a low-pressure water supply heat exchanger, a settling chamber with a heat accumulation device, an evaporator, a coal economizer, a low-temperature coal economizer, a dust removal device and a flue gas extractor; the steam-water subsystem comprises a water pump, a deaerator, a boiler feed pump device a steam pocket; the water pump is connected with the low-pressure water supply heat exchanger; the low-pressure water supply heat exchanger is connected with the deaerator; the deaerator, the boiler feed pump, the low-temperature coal economizer, the coal economizer and the steam pocket are connected in sequence; the steam pocket is connected with the evaporator and the vaporization flue duct respectively. Compared with the prior art, owing to the arrangement of the vaporization flue duct between the electric furnace and the combustion settling chamber, the step-by-step waste heat recovery system effectively recovers part of heat of high-temperature flue gas between the electric furnace and the combustion settling chamber, and improves the waste heat recovery efficiency and the utilization efficiency of energy sources.

Owner:SHANGHAI BAOSTEEL ENERGY TECH

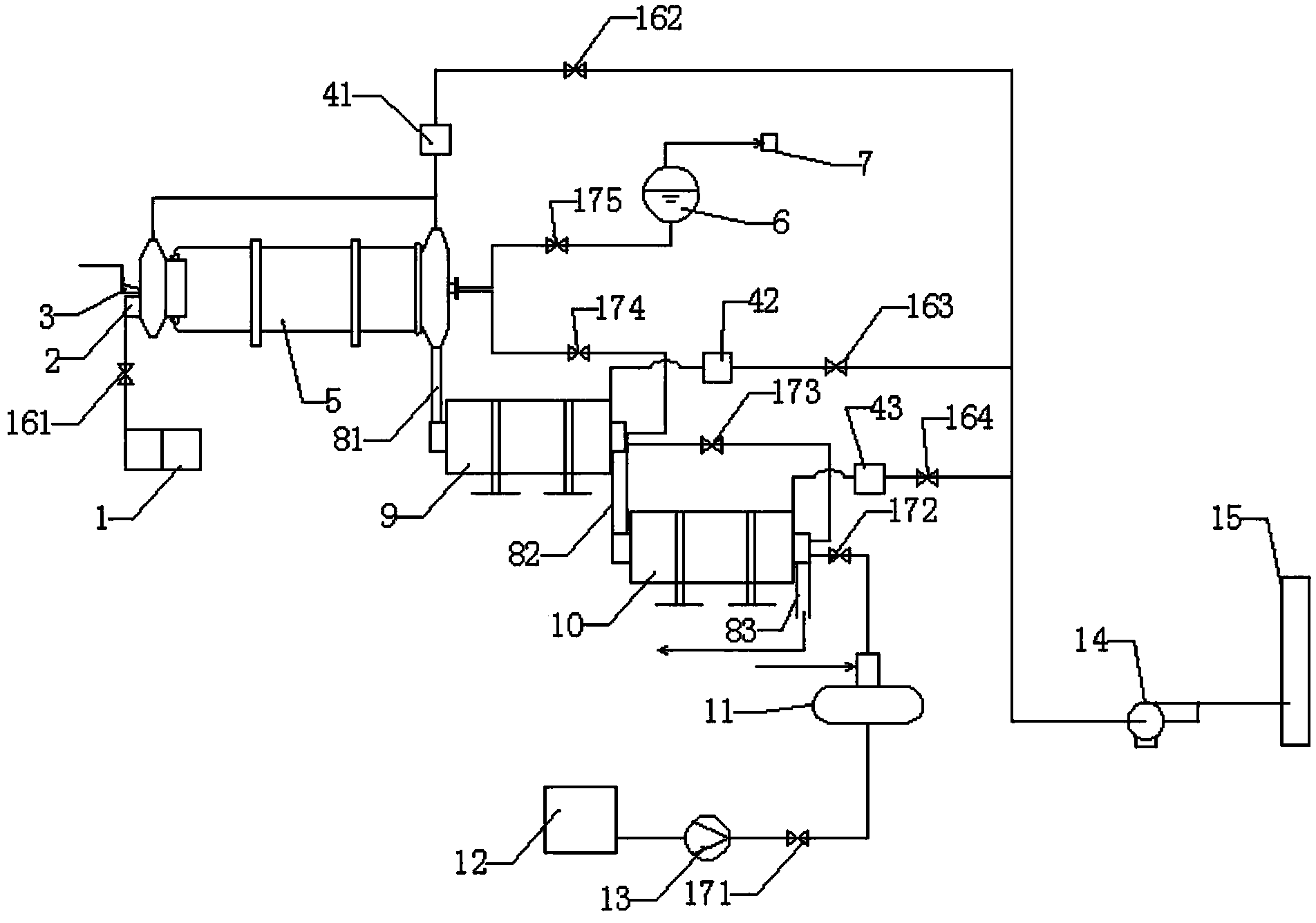

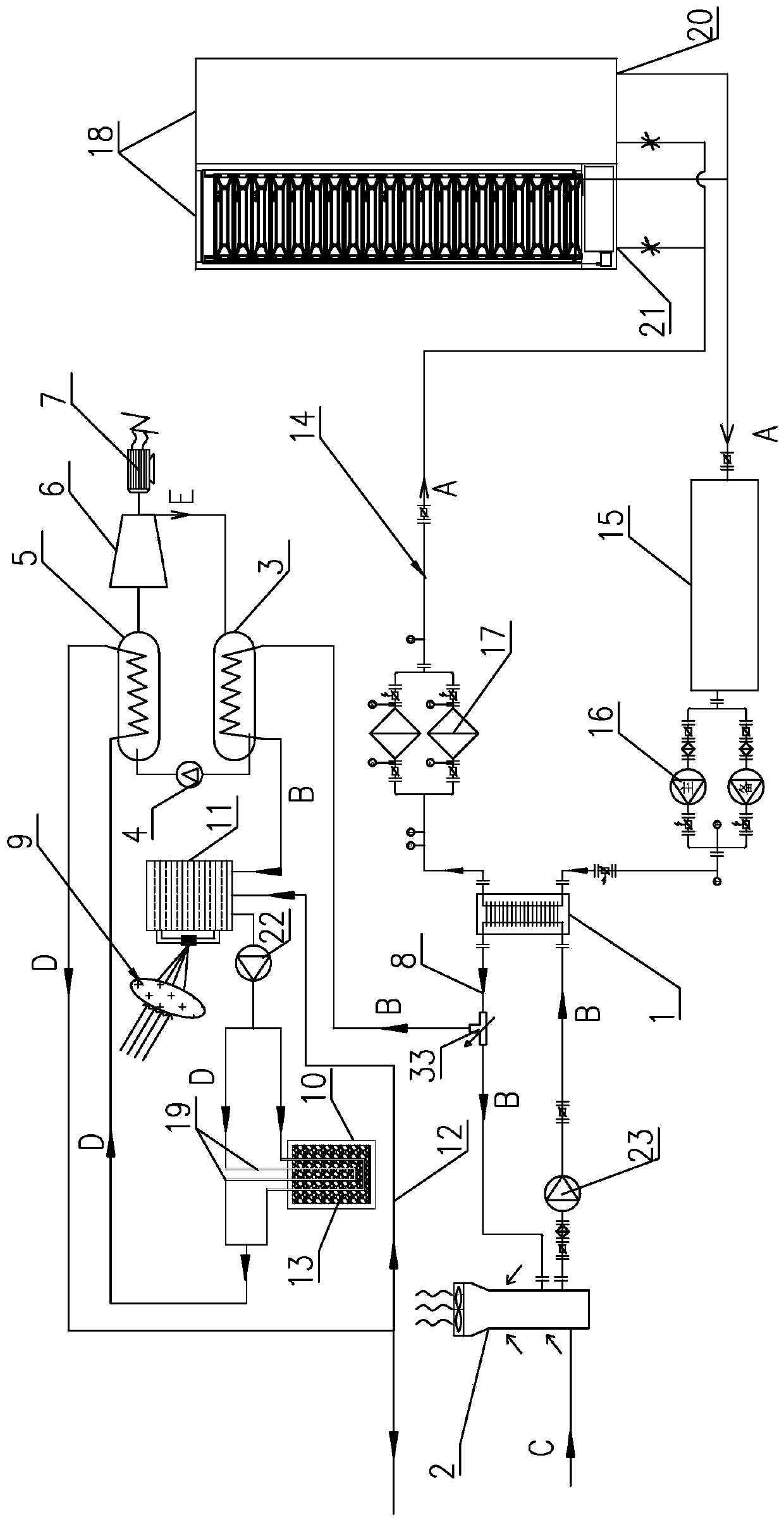

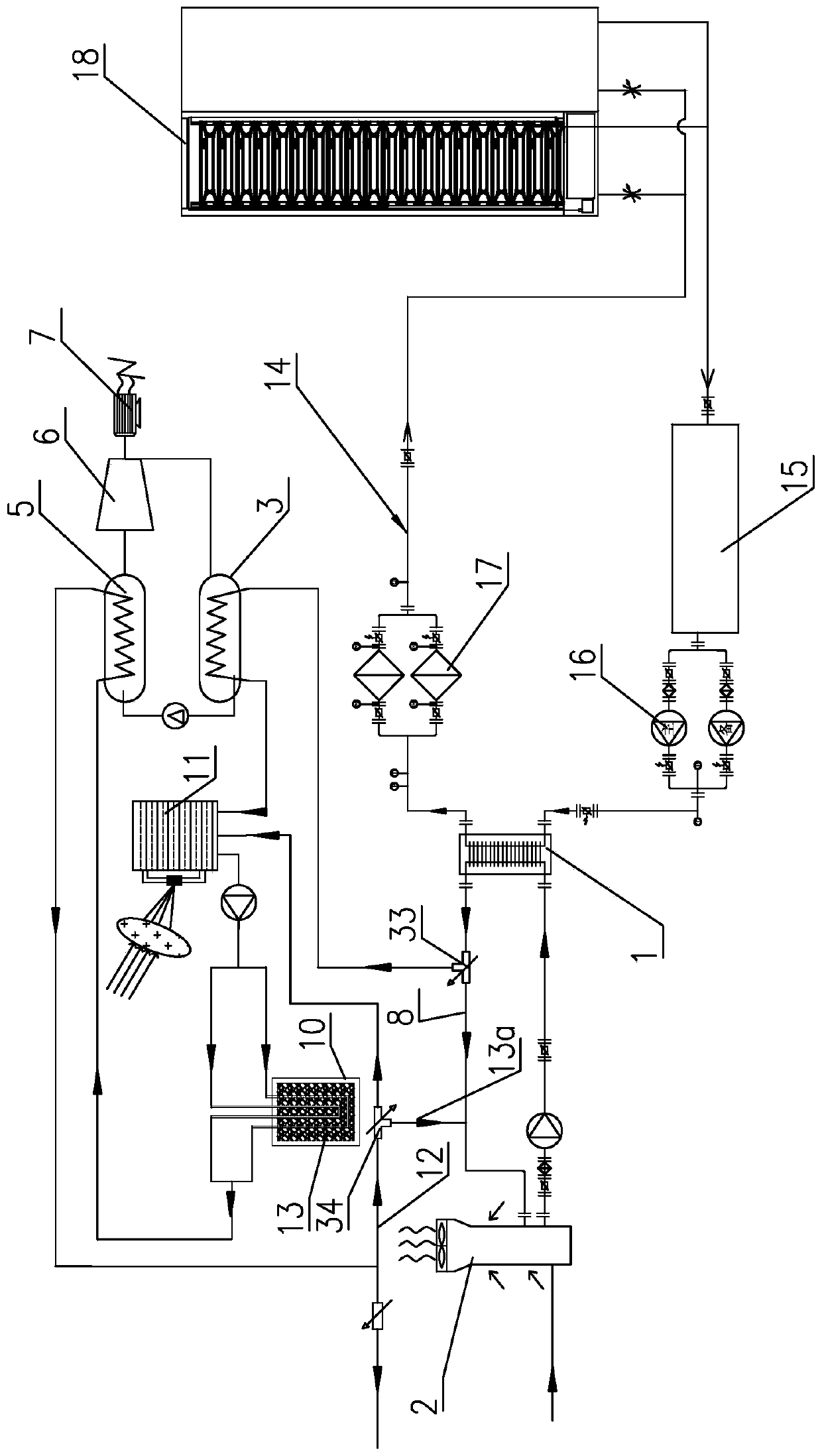

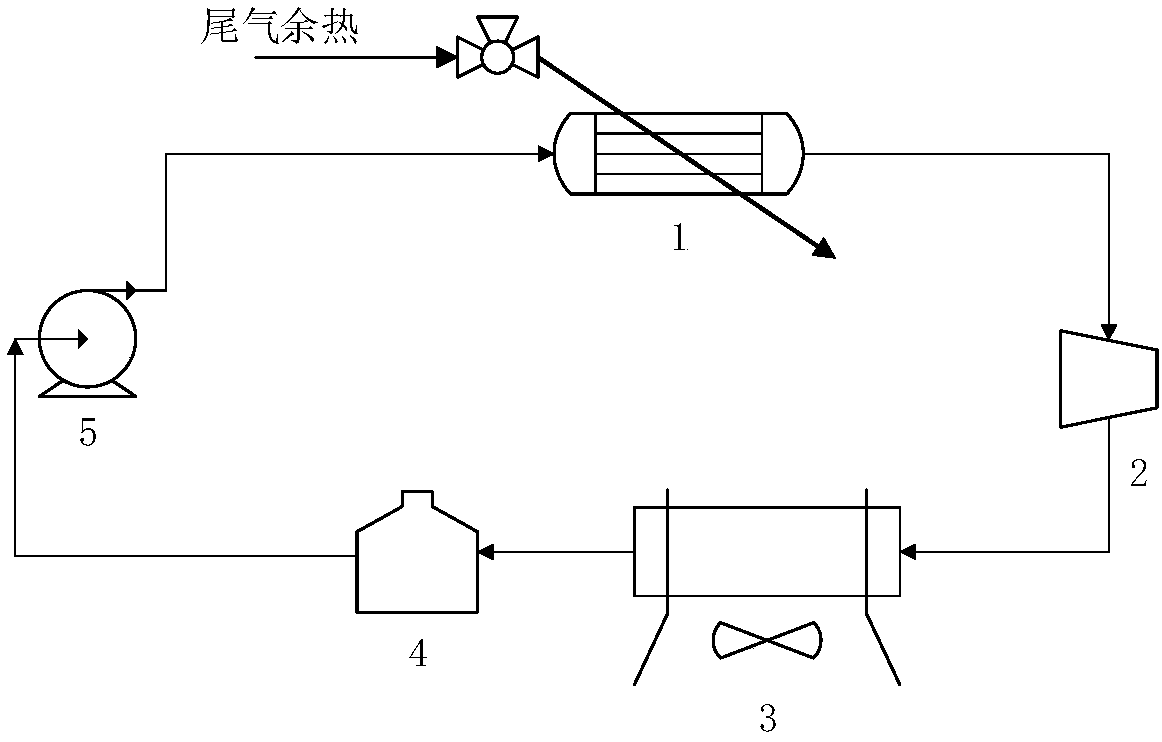

Engine waste heat recovery system based on organic Rankine cycle

InactiveCN104165102AShorter return on investment periodFull recoveryInternal combustion piston enginesEngine componentsElectricityOrganic Rankine cycle

The invention discloses an engine waste heat recovery system based on the organic Rankine cycle. The engine waste heat recovery system based on the organic Rankine cycle comprises an engine tail gas loop, an engine cylinder sleeve water loop, a refrigerant loop and an external cooling water loop. Through the engine waste heat recovery system, waste heat of an engine is fully recovered, much energy is recovered, the recovery efficiency is higher, and the whole system is more stable in operation and more compact in structural arrangement. The engine waste heat recovery system is mainly characterized by comprising a heat source recovery system with engine tail gas and cylinder sleeve water integrated, and a refrigerant ORC system with an evaporator, a condenser, an expander and a refrigerant pump as the main components. By effectively controlling all the components of the system, waste heat of the engine can be recycled, and thus electricity generated by consuming unit fuel oil by the engine can be increased, and the cycle of return on investment of the engine is shortened.

Owner:ZHEJIANG YINLUN MACHINERY

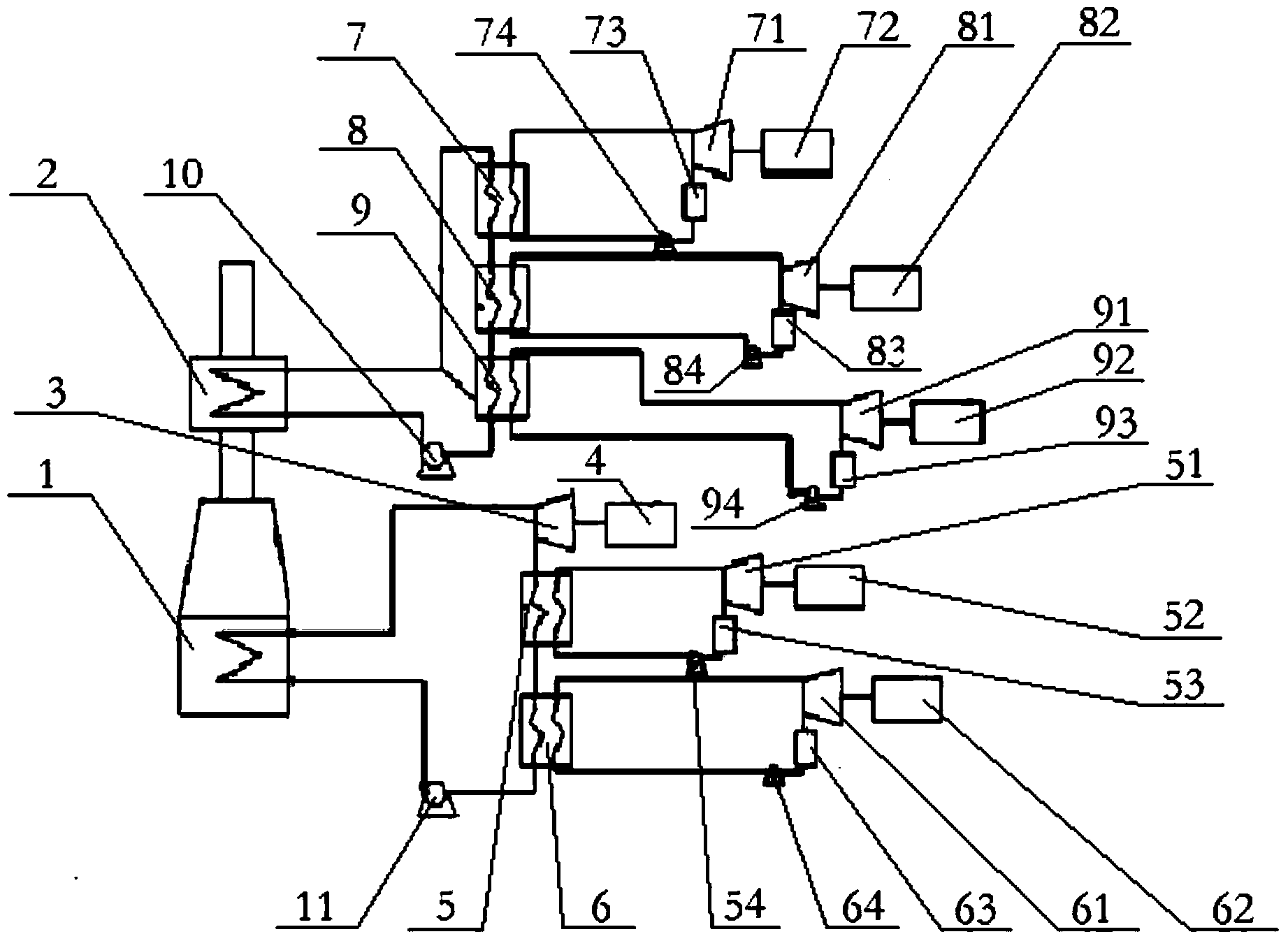

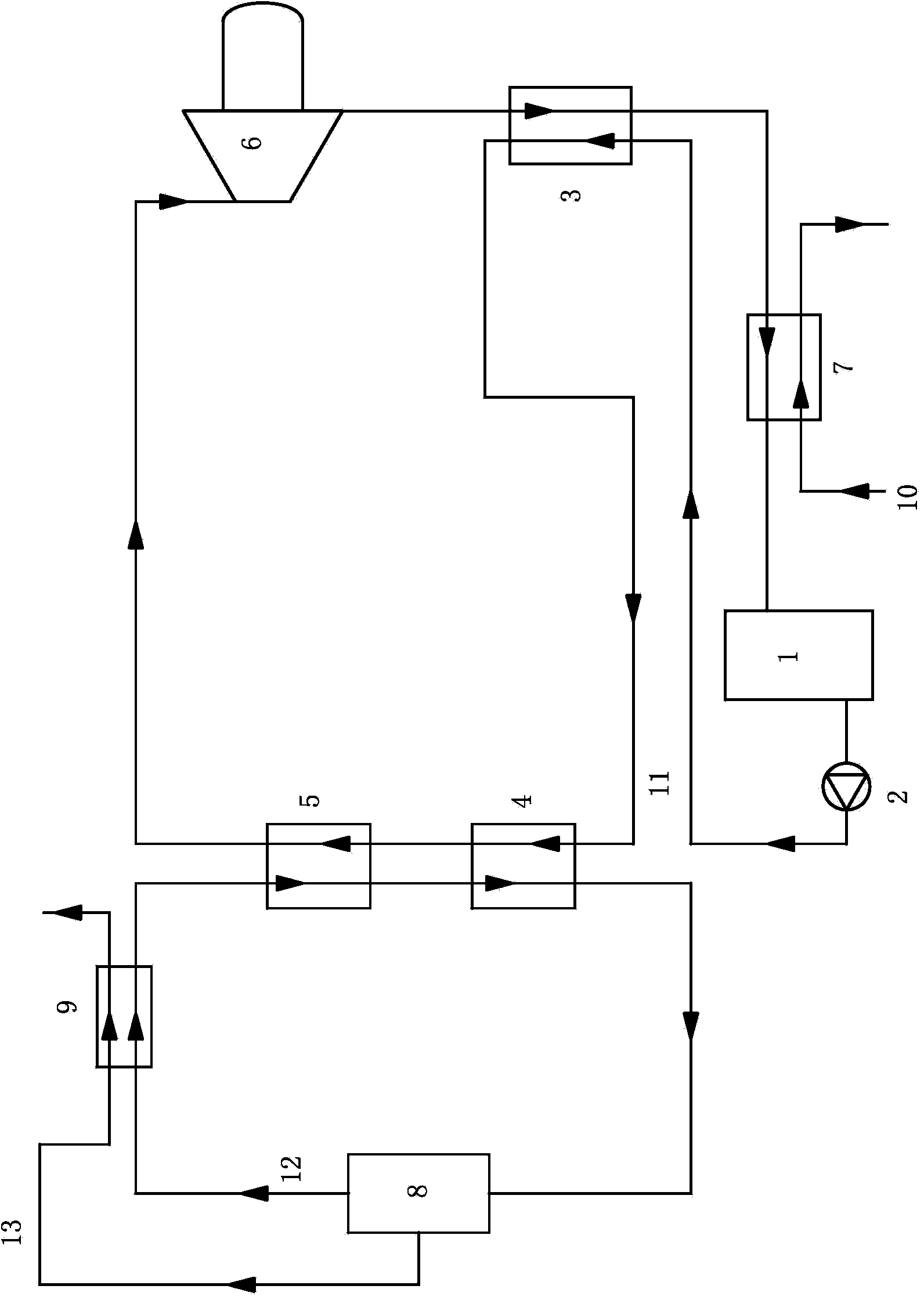

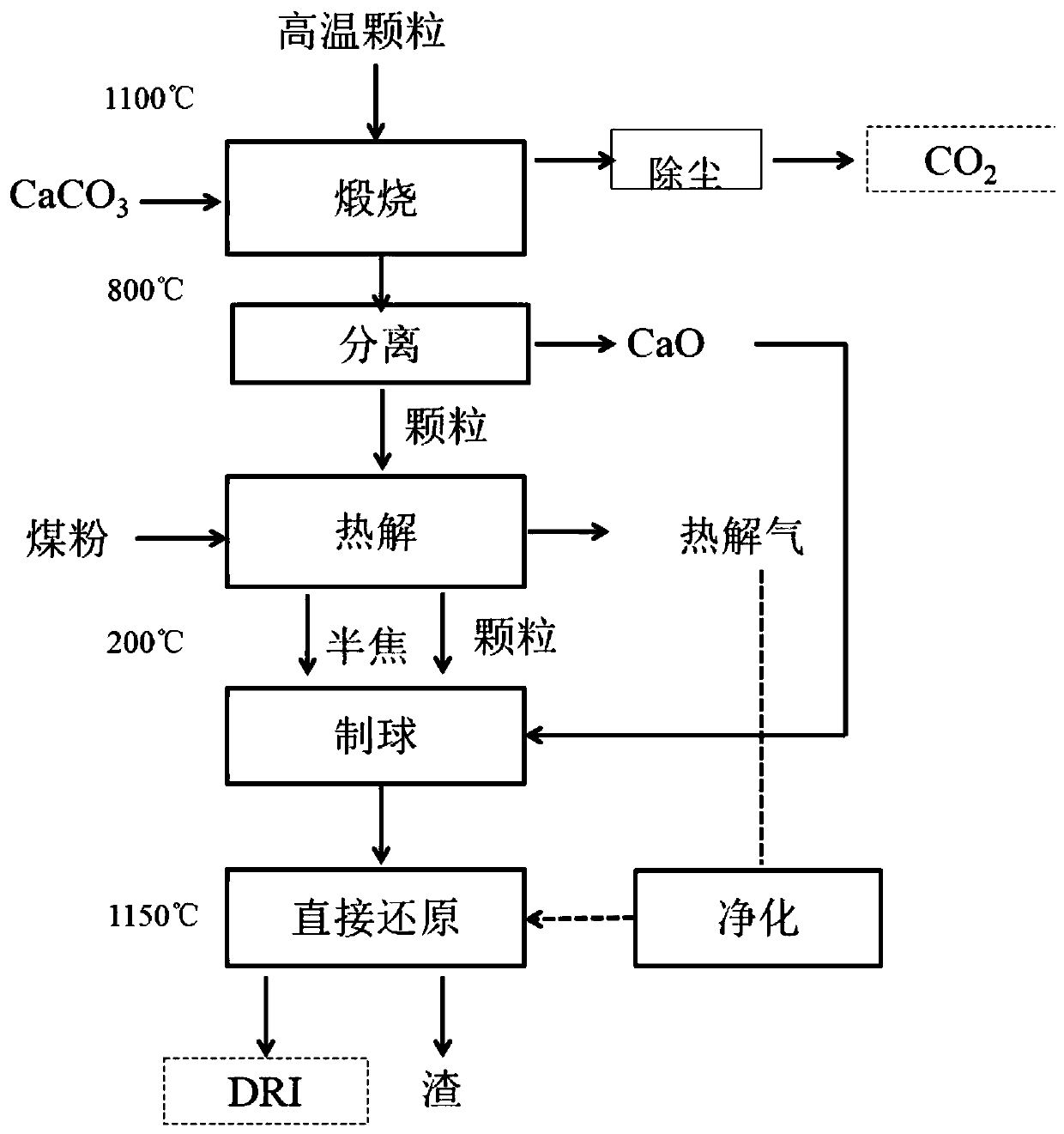

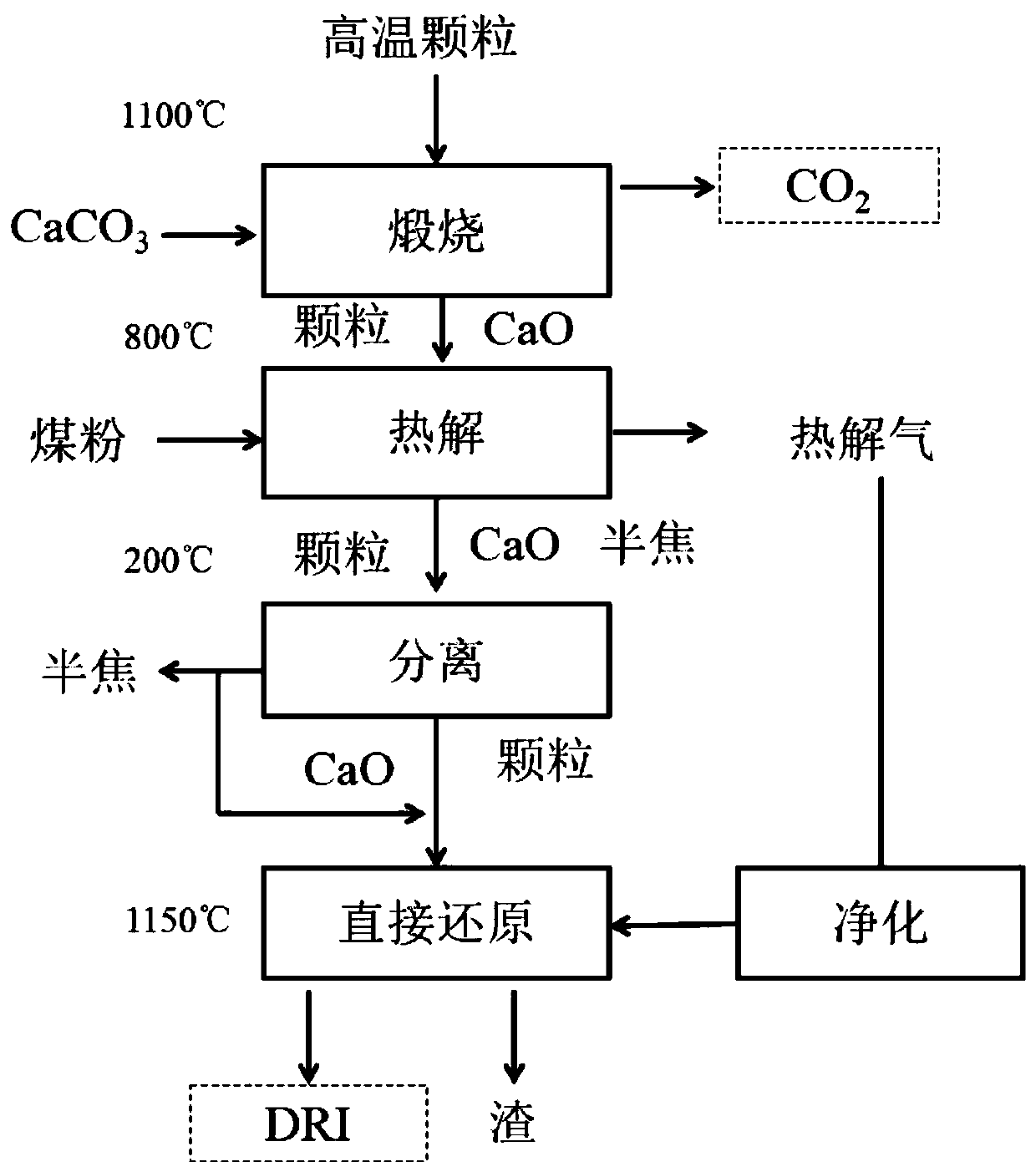

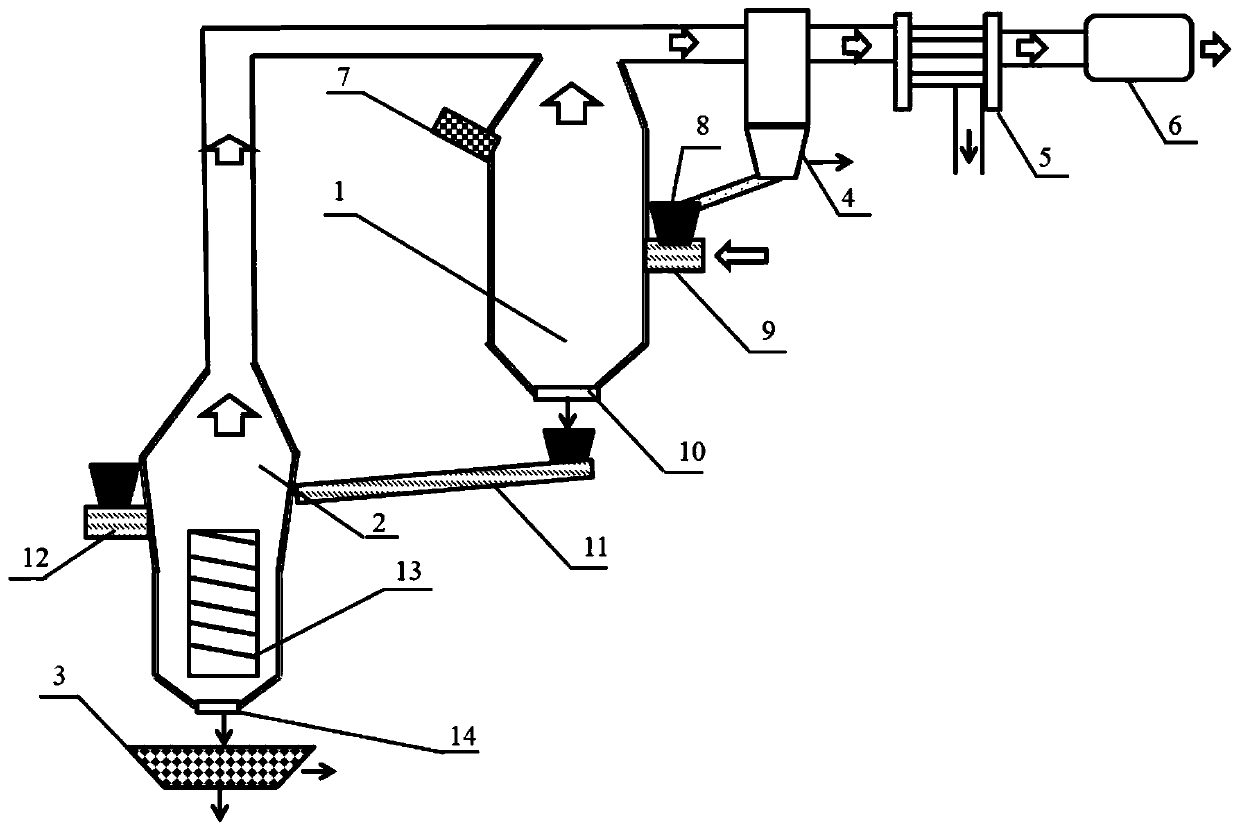

Gradient waste heat recovery and direct reduction system and method for iron-containing metallurgical slag particles

ActiveCN110923387AImprove waste heat recovery efficiencyAchieve in situ consumptionProcess efficiency improvementGas emission reductionMetallurgical slagCoke

The invention discloses a gradient waste heat recovery and direct reduction system and method for iron-containing metallurgical slag particles. The system comprises a waste heat recovery system, a material mixing system and a direct reduction system which are sequentially connected, wherein the waste heat recovery system comprises a calcining furnace, a separator and a pyrolyzing furnace; when a mode A is adopted, the calcining furnace, the separator and the pyrolyzing furnace are sequentially connected; and when a mode B is adopted, the calcining furnace, the pyrolyzing furnace and the separator are sequentially connected. The method comprises the following steps that the iron-containing metallurgical slag particles and a calcium carbonate precursor are calcined in proportion to obtain cooled particles and CaO, the CaO is separated or is added into carbon-containing solid waste together with the particles for pyrolysis to obtain solid semi-coke and cooled particles, the solid semi-coke and the cooled particles enter a stock bin together with the CaO, and after pelletizing is carried out according to needs, direct reduced iron is obtained through reduction. According to the systemand the method, the waste heat of the iron-containing metallurgical slag particles can be efficiently recovered, and the waste heat recovery efficiency, the efficiency and the iron recovery rate are greatly improved; and the particle waste heat is converted into the CaO and the solid semi-coke which are used as a slag forming agent and a reducing agent in the reduction process correspondingly, sothat in-situ consumption of materials is realized, and the system and the method have extremely high social value and economic value.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

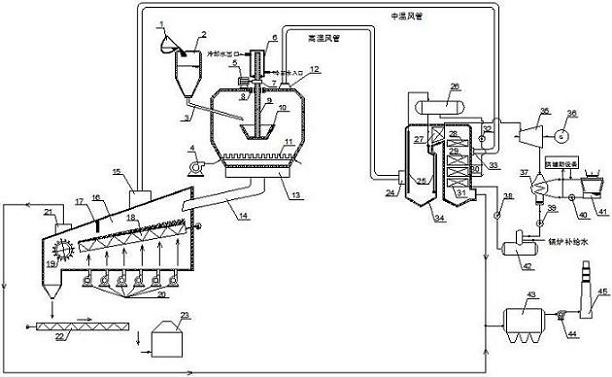

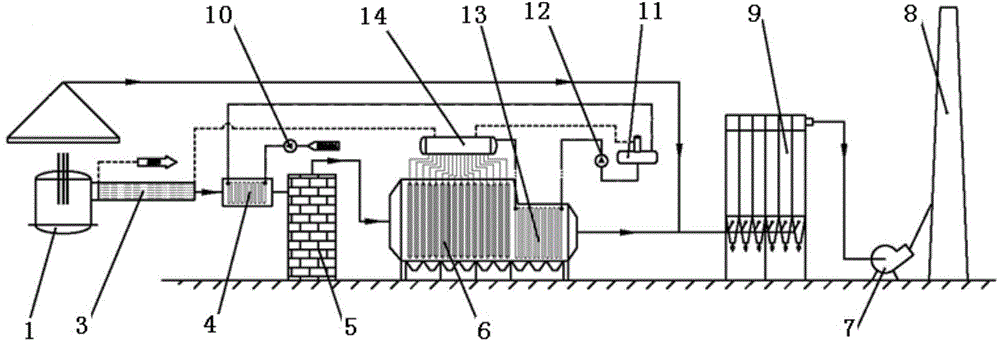

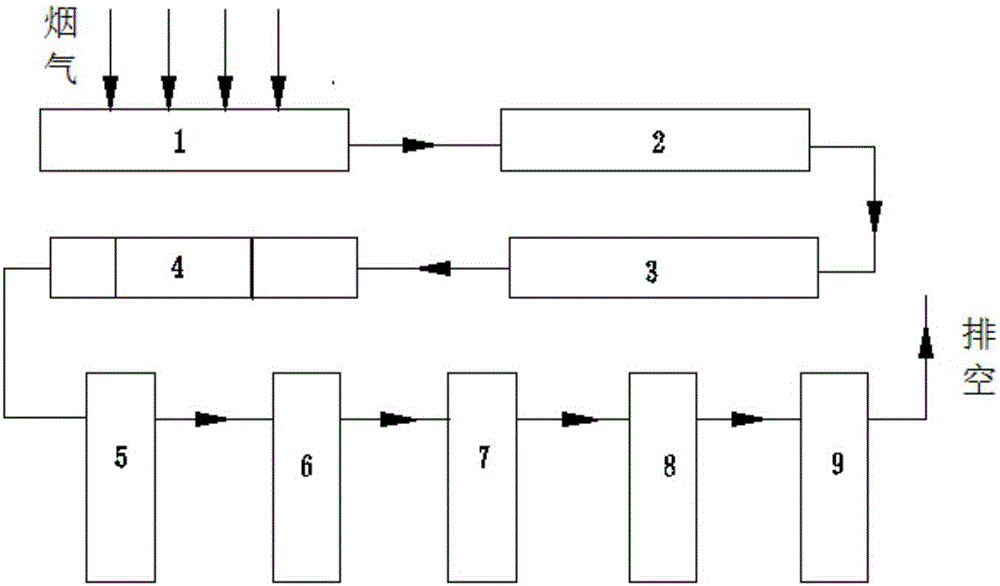

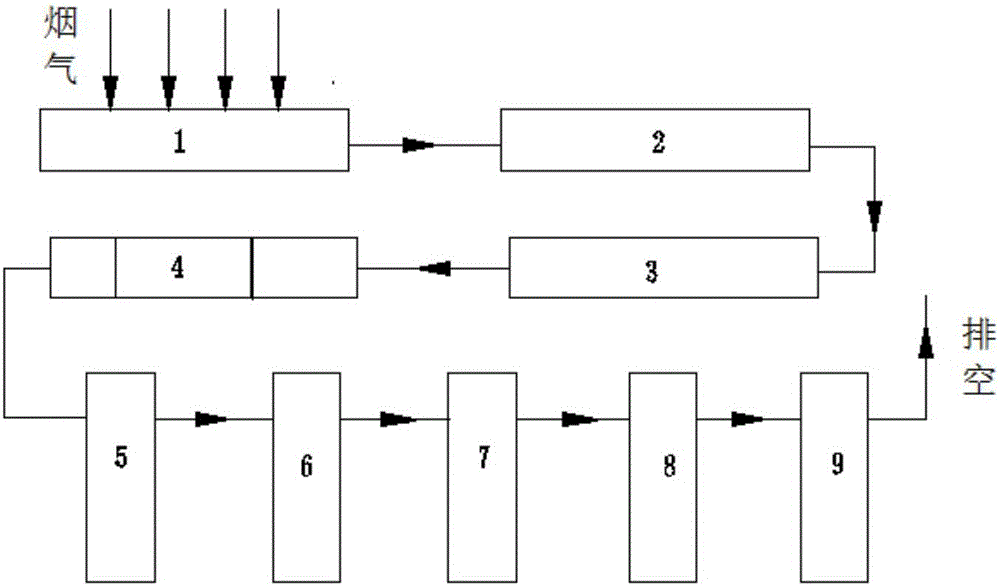

Treatment device of dioxins atmospheric pollutants in high-temperature flue gas

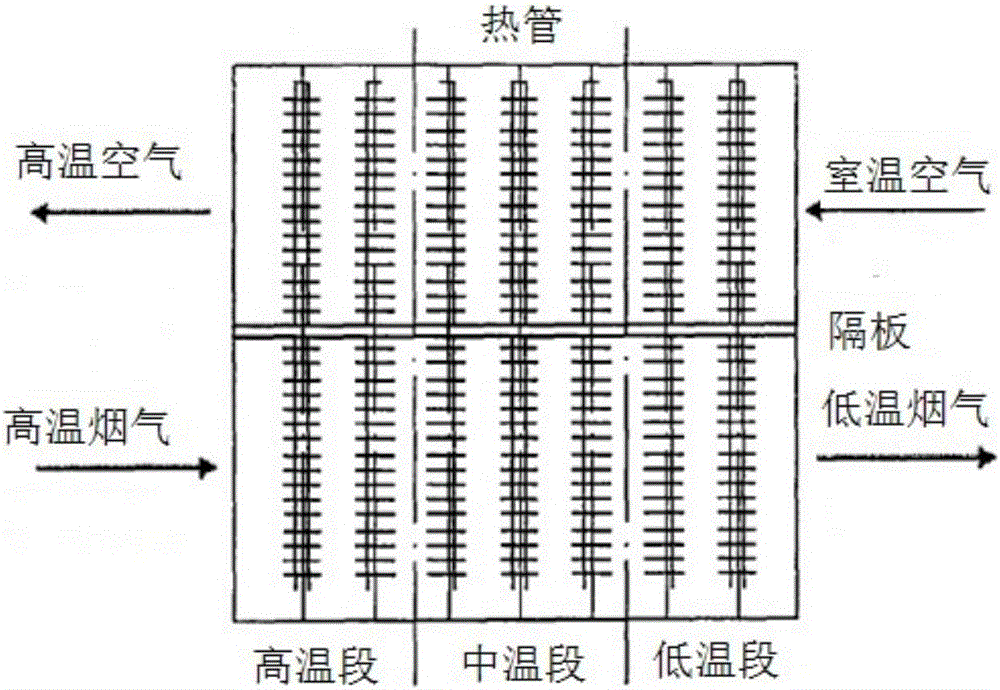

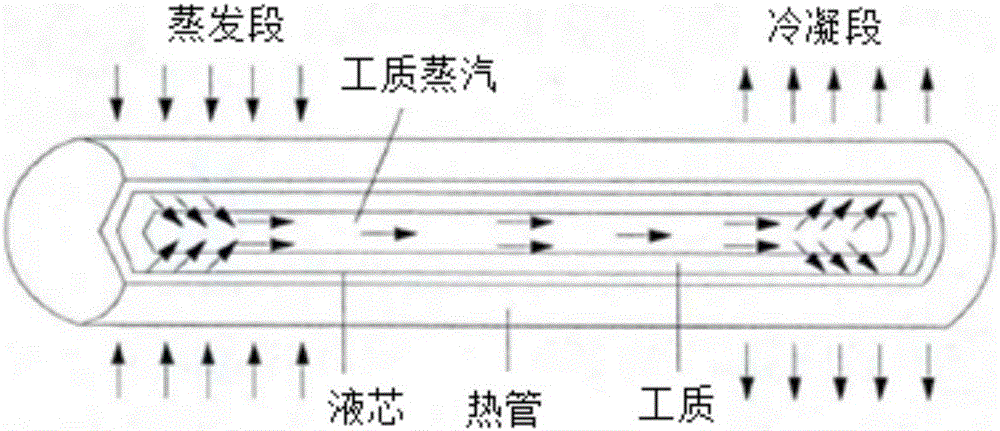

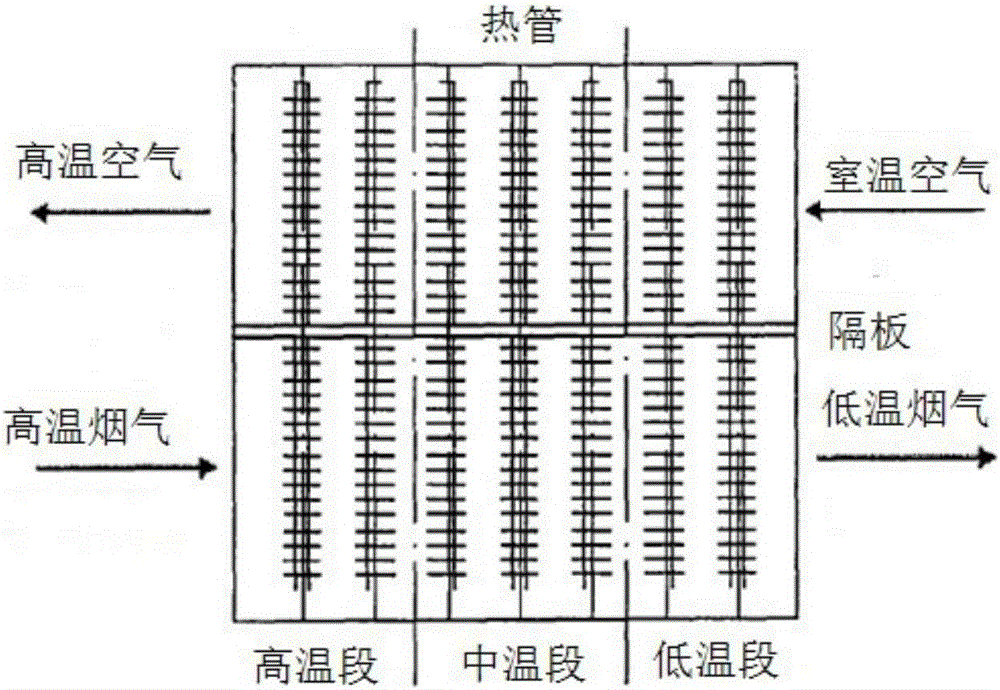

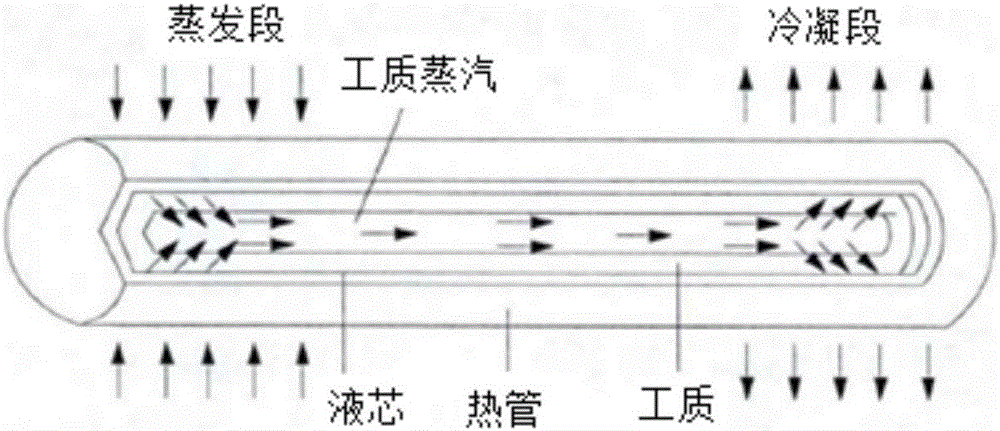

ActiveCN105698199AReduce pollutionReduce the probability of high-temperature gas-phase synthesis of dioxinsGas treatmentDispersed particle filtrationLimit valueHeat pipe heat exchanger

The invention provides a treatment device of dioxins atmospheric pollutants in high-temperature flue gas and belongs to a removal method of organic halogen compounds in flue gas. The treatment device is characterized by comprising the following successively-connected devices: a primary intensification combustion furnace (1), a secondary intensification combustion furnace (2), a silicon nitride porous ceramic filter (3), a countercurrent flow heat-exchange waste heat boiler (4), a combined type heat-pipe heat exchanger (5), a filter bag dust remover (6), an acid gas removal system (7), an active carbon adsorption tower (8) and an induced draft fan (9). The treatment device of the dioxins atmospheric pollutants in the high-temperature flue gas is high in waste heat recycling efficiency and is capable of effectively treating the dioxins atmospheric pollutants carried in the process of generating and treating the high-temperature flue gas; all the items of the atmospheric pollutants are lower than the limit values specified in table 4 of GB18485-2014 "Control Standards of Household Garbage Incineration Pollutants"; the emission amount of the dioxins atmospheric pollutants is smaller than or equal to 0.1ngTEQ / m<3>.

Owner:SHANDONG JINSHENG NON FERROUS GRP

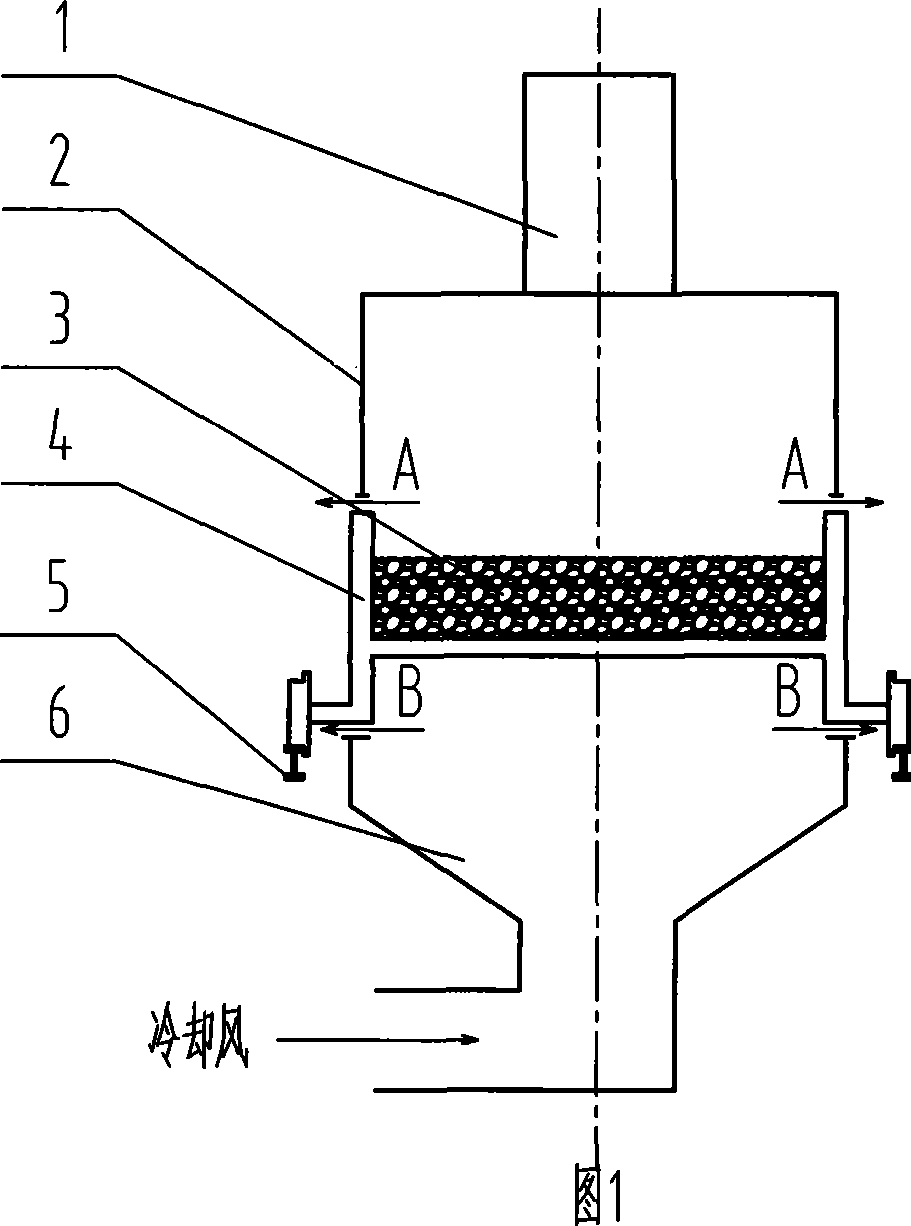

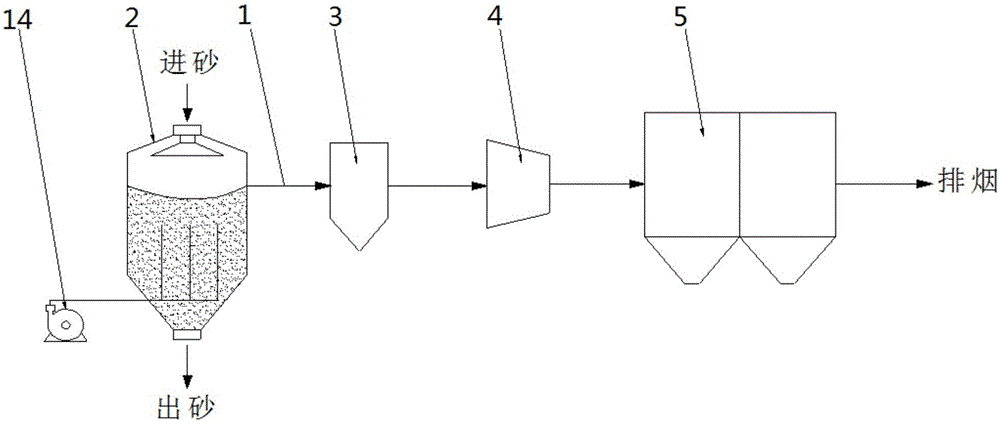

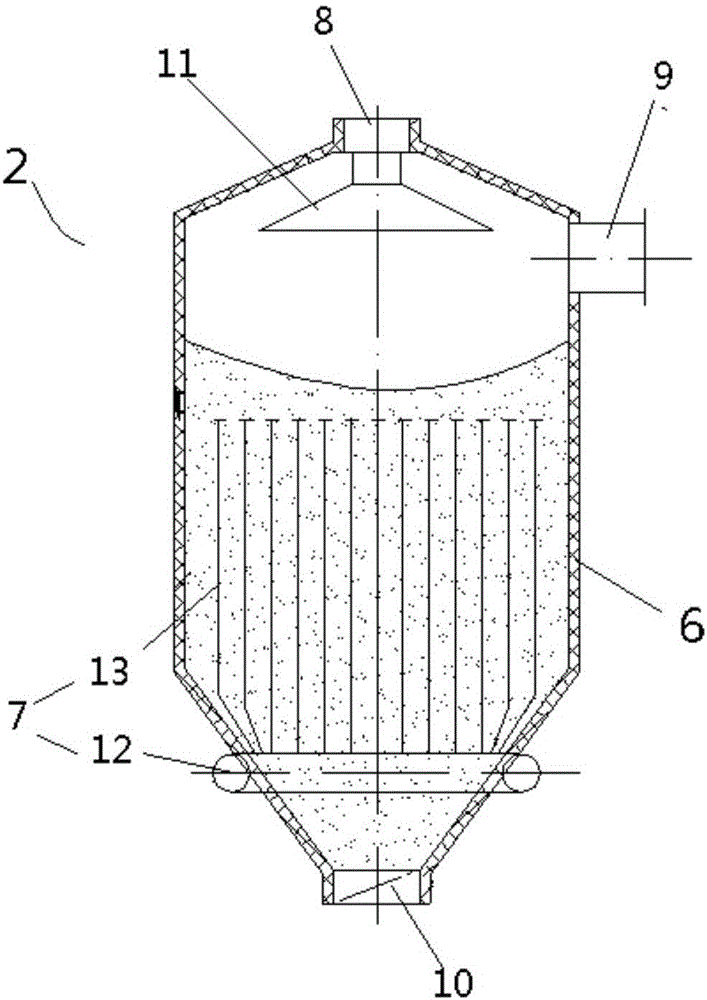

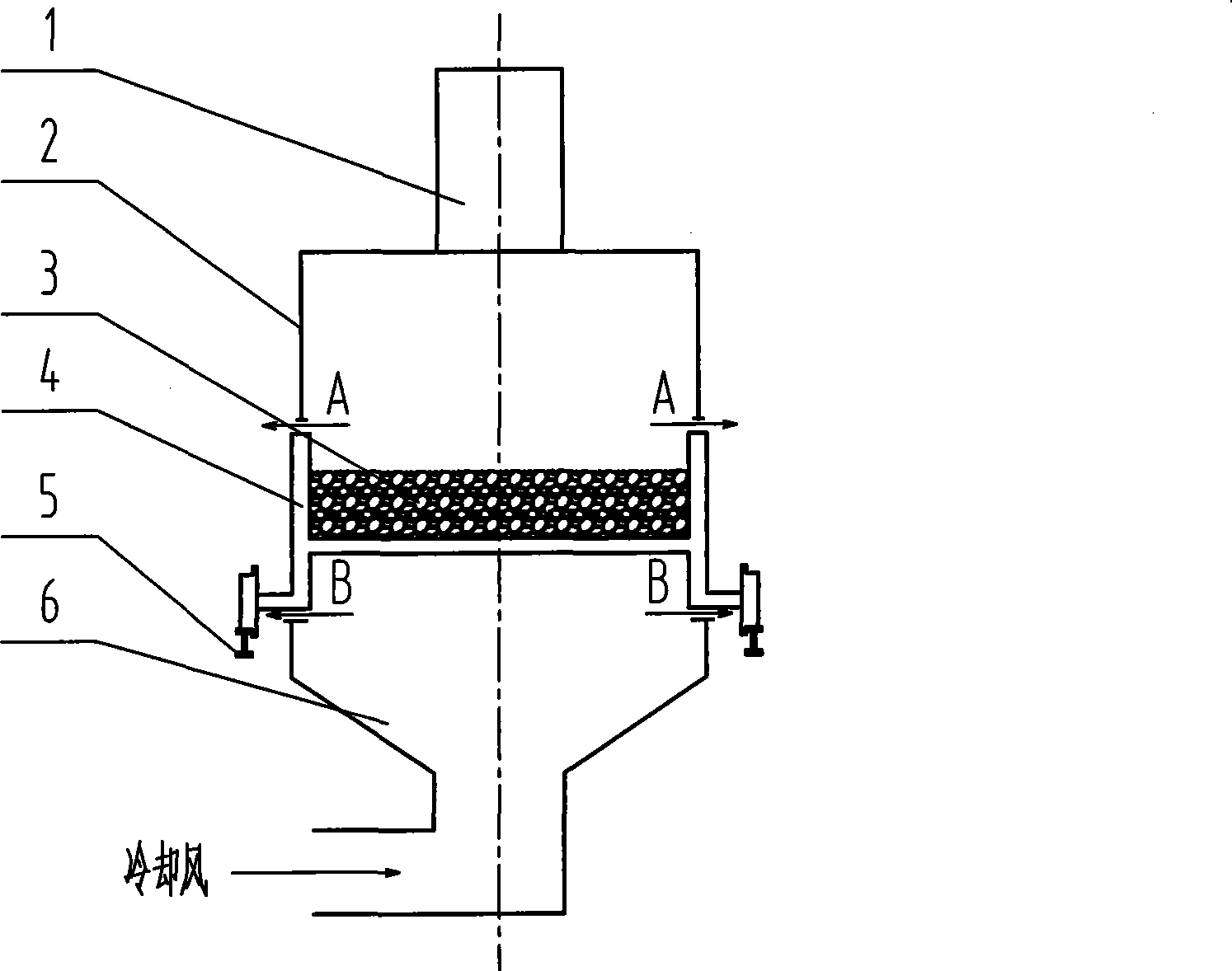

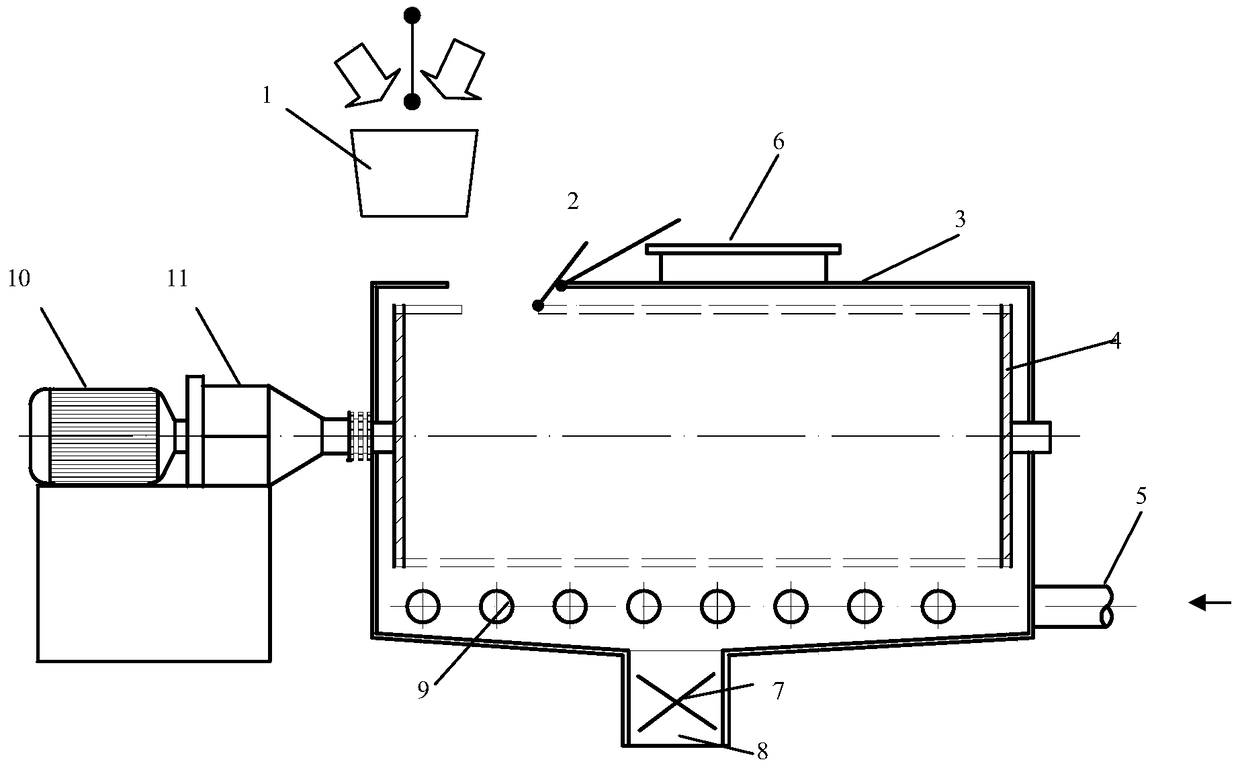

Novel high-temperature recycled sand cooling system and waste heat recovery method

ActiveCN106111889ASpeed up coolingImprove waste heat recovery efficiencyMould handling/dressing devicesEnergy consumptionSand casting

The invention discloses a novel high-temperature recycled sand cooling system and a waste heat recovery method, belonging to the technical field of sand casting structures. The novel high-temperature recycled sand cooling system comprises a vertical-tank primary cooler, a gravity dust collector or a cyclone dust collector, a flue-gas organic rankin generating set and a cloth-bag dust collector, wherein the vertical-tank primary cooler comprises a shell and a cooling apparatus, and the cooling apparatus comprises an air supply bustle pipe and a plurality of heat exchanging air supply branch pipes. The method comprises the following steps: carrying out, by a top fluidized layer, boiling fluidizing and heat exchanging for high-temperature recycled sand, dispersing the primarily-cooled high-temperature recycled sand into a cooling passage formed by heat exchanging air supply branch pipes, and further exchanging the heat of the high-temperature recycled sand in the cooling passage by virtue of cold air in the heat exchanging air supply branch pipes. By virtue of the comprehensive cooling way of heat transferring and fluidizing boiling, the cooling speed of the high-temperature sand is increased; meanwhile, since the air temperature after the heat exchanging is high, the heat recovery efficiency can be improved, and the energy consumption is reduced.

Owner:CMCU ENG

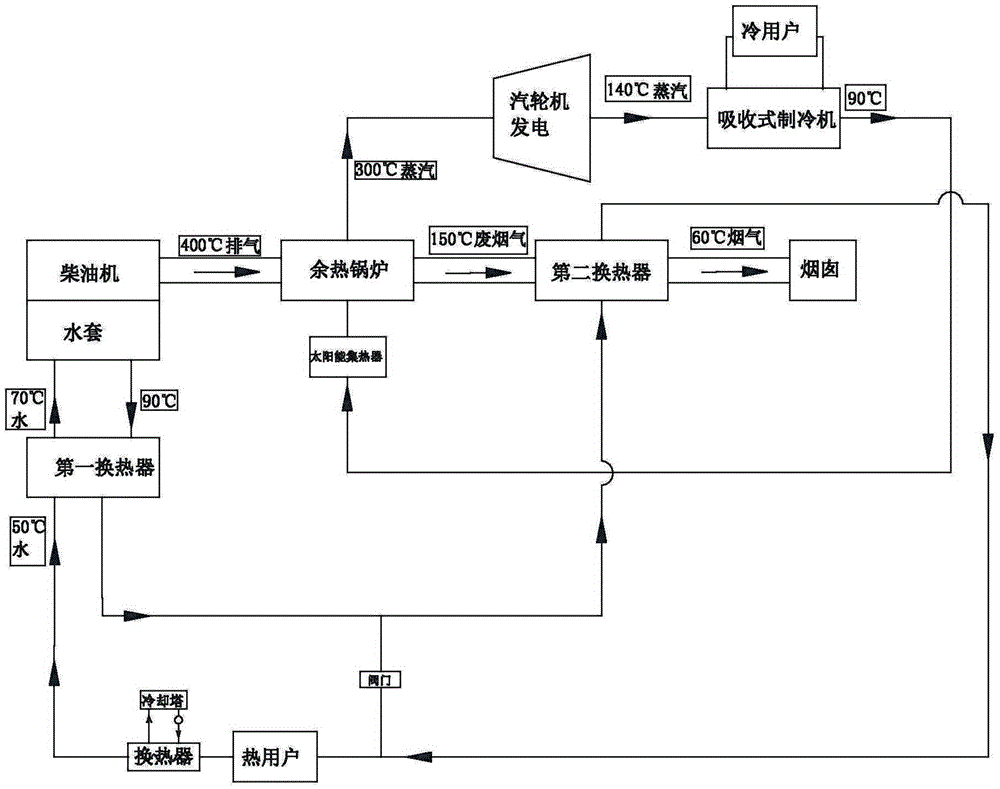

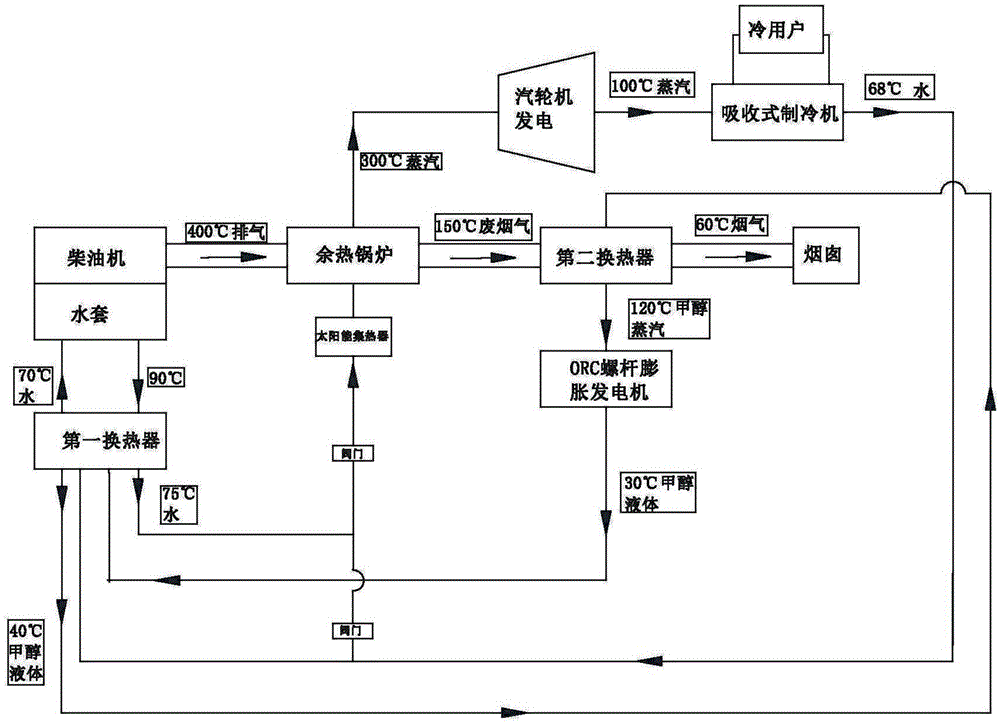

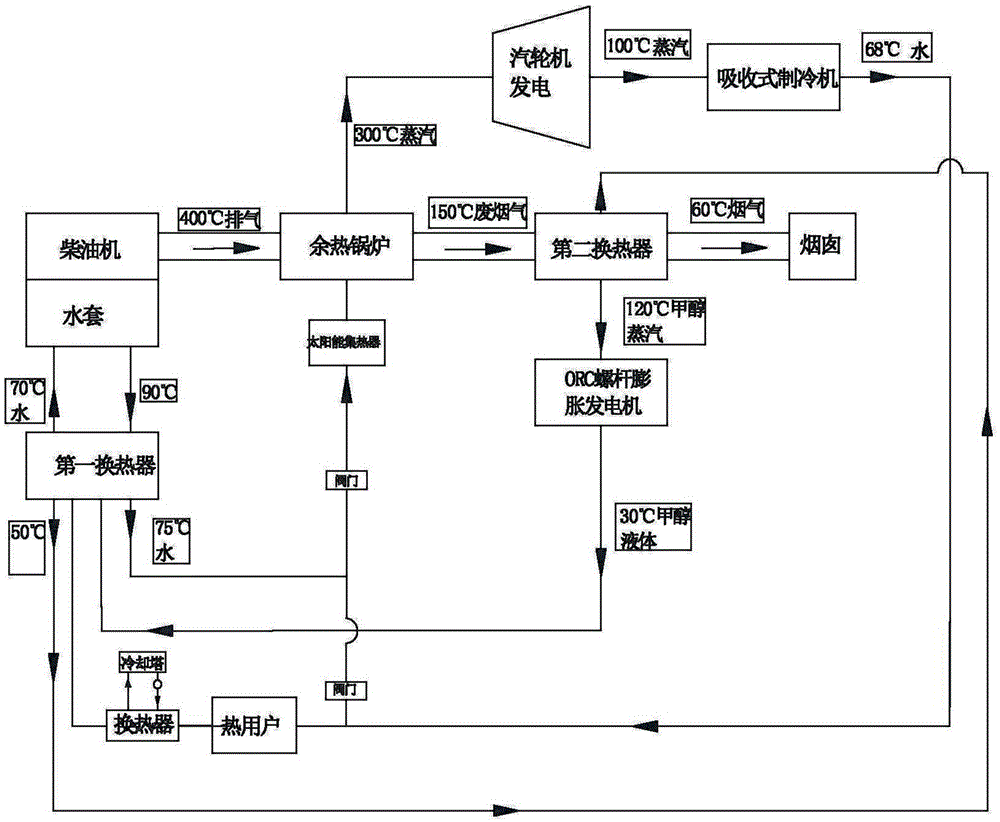

Efficient waste heat recycling comprehensive utilizing system

InactiveCN105485649AEmission reductionImprove waste heat recovery efficiencyClimate change adaptationEnergy efficient heating/coolingWater useSmoke

The invention discloses an efficient waste heat recycling comprehensive utilizing system which comprises a tail gas waste heat recycling subsystem, a cooling water waste heat utilizing subsystem and a power generating cooling subsystem. The tail gas waste heat recycling subsystem comprises a waste heat boiler and a second heat exchanger, wherein the waste heat boiler is connected with a smoke discharging pipe. The efficient waste heat recycling comprehensive utilizing system has the advantages and the beneficial effects that firstly, the waste heat recycling efficiency is high, the high-temperature smoke which is discharged by a diesel engine and a gas engine and is at the temperature of 400 DEG C is cooled to be 60 DEG C through two levels of heat exchange, and heat of a water jacket of the diesel engine and a water jacket of the gas engine is recycled and utilized sufficiently, and the discharging recycling rate reaches 90% or higher; secondly, diesel engine and gas engine cooling and user hot water use can be both achieved, and functions are comprehensive; and thirdly, the total discharging amount of pollutants is greatly reduced, due to the fact that a large amount of steam can be generated through waste heat of smoke, a large amount of fuel is saved and the total discharging amount of main pollutants is also greatly reduced, use of a cylinder jacket water and air cooling fan can be stopped, and energy of a whole unit can be saved by 8% or higher.

Owner:张东 +1

Method for cleanly producing food additive sulfuric acid

The invention belongs to the technical field of food-grade sulfuric acid production, in particular relates to a method for cleanly producing food additive sulfuric acid. The method for cleanly producing food additive sulfuric acid comprises the following steps: (1) sulfur melting; (2) sulfur burning; (3) conversion; (4) absorption and drying; (5) waste heat recovery. The method for cleanly producing food additive sulfuric acid aims at reutilizing waste heat and residual pressure during sulfuric acid production, is based on the purpose of further improving the waste heat and residual pressure utilizing efficiency and adopts hot steam to do work to a back-pressure steam turbine to drive an air blower, and the low-pressure steam after doing work is sold externally. Thereby, the electricity used by the air blower is greatly reduced, the steam after doing work is fully utilized, and not only can the energy waste be avoided, but also economic benefits are created.

Owner:CHIPING COUNTY MINGDA CHEM CO LTD

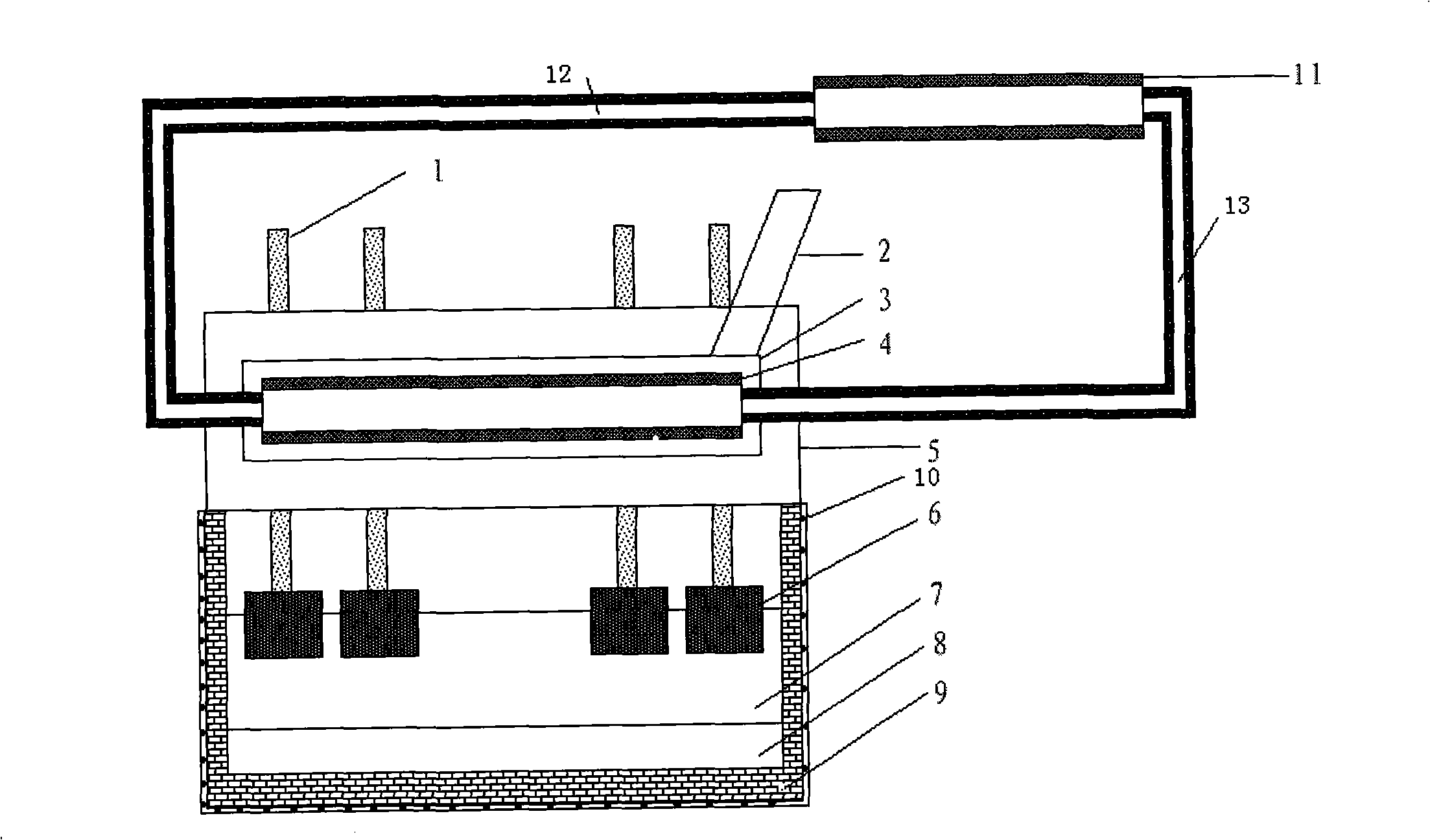

Method and device for reclaiming residual heat emitted by aluminum electrolysis bath

The invention relates to a method and a device thereof for recycling waste heat dissipated from an aluminum cell. The device is formed by that: a first heat exchange pipe which is arranged inside a flue on the upper part of the aluminum cell and on the lower part of a gas collecting system and a second heat exchange pipe which is arranged on the outer shell of the electrolytic cell wall are connected with a condensing system through gas pipes; an outlet of the condensing system is connected with inlets of the first heat exchange pipe and the second heat exchange pipe through return passages. The method comprises the following steps that: the first heat exchange pipe and the second heat exchange pipe are heated by the waste heat generated during the process of aluminum electrolysis of the aluminum cell, and heat exchange media in the heat exchange pipes are gasified and flow to the condensing system; after condensation and recycling of released heat, and heat exchange medium liquid after condensation returns to the first heat exchange pipe and the second heat exchange pipe and then performs reciprocating cycle operation. The method and the device thereof for recycling the waste heat dissipated from the aluminum cell is characterized in that: the structure of the device is simple; the manufacturing cost is low; the heat exchange media can perform cycle operation; the operation cost is low; the waste heat recycling rate is high and can reach 60 percent of the total heat dissipating capacity of the aluminum cell.

Owner:NORTHEASTERN UNIV +1

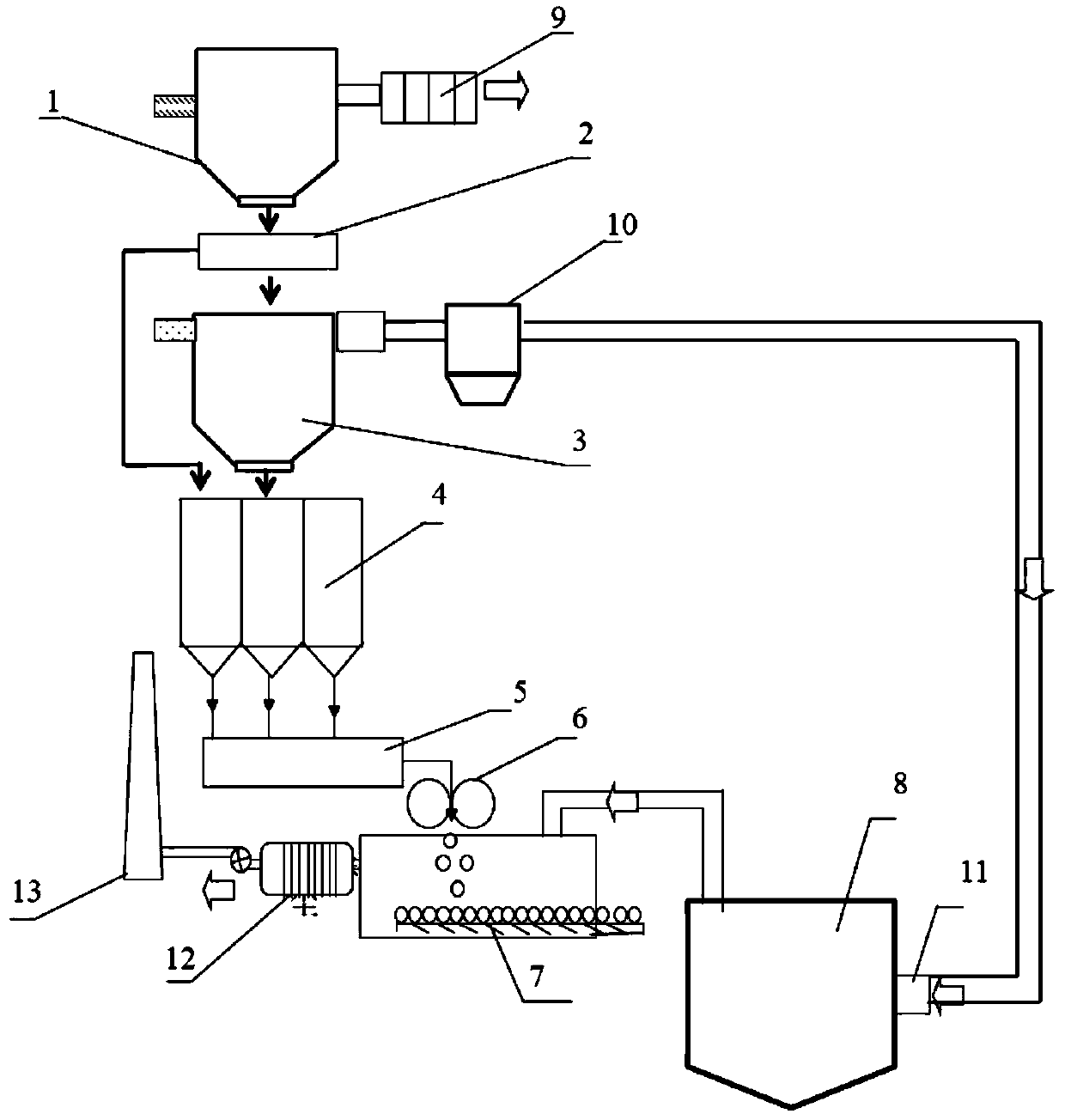

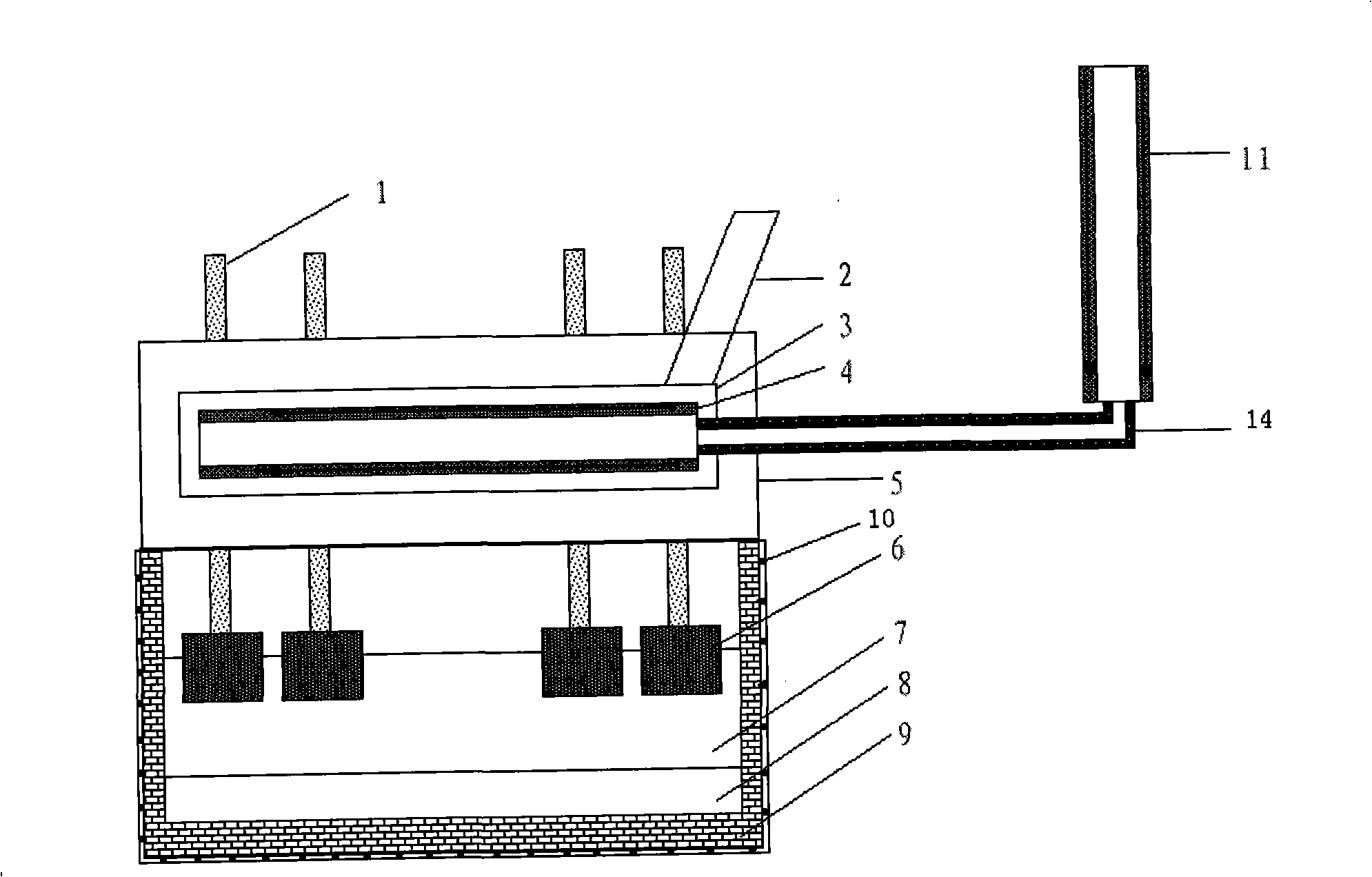

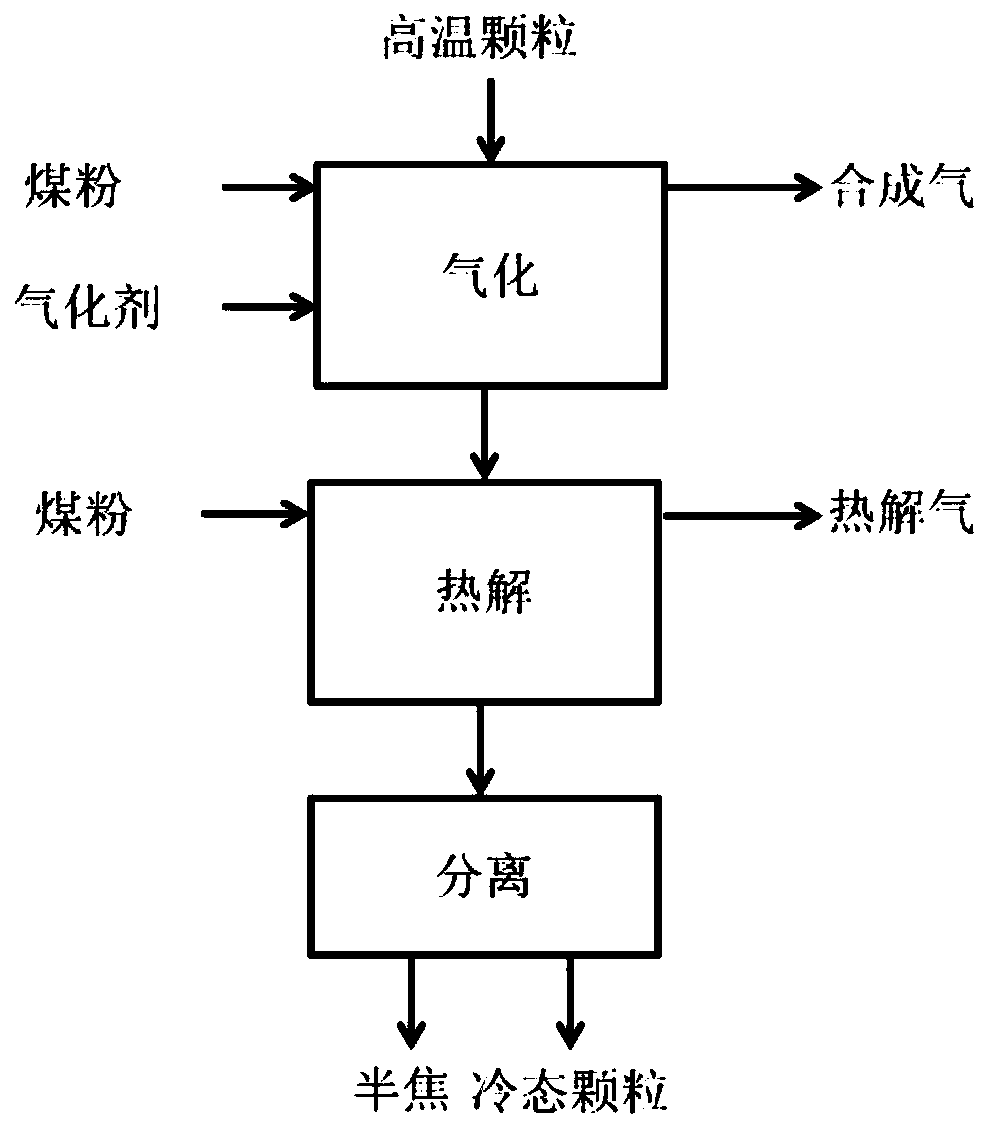

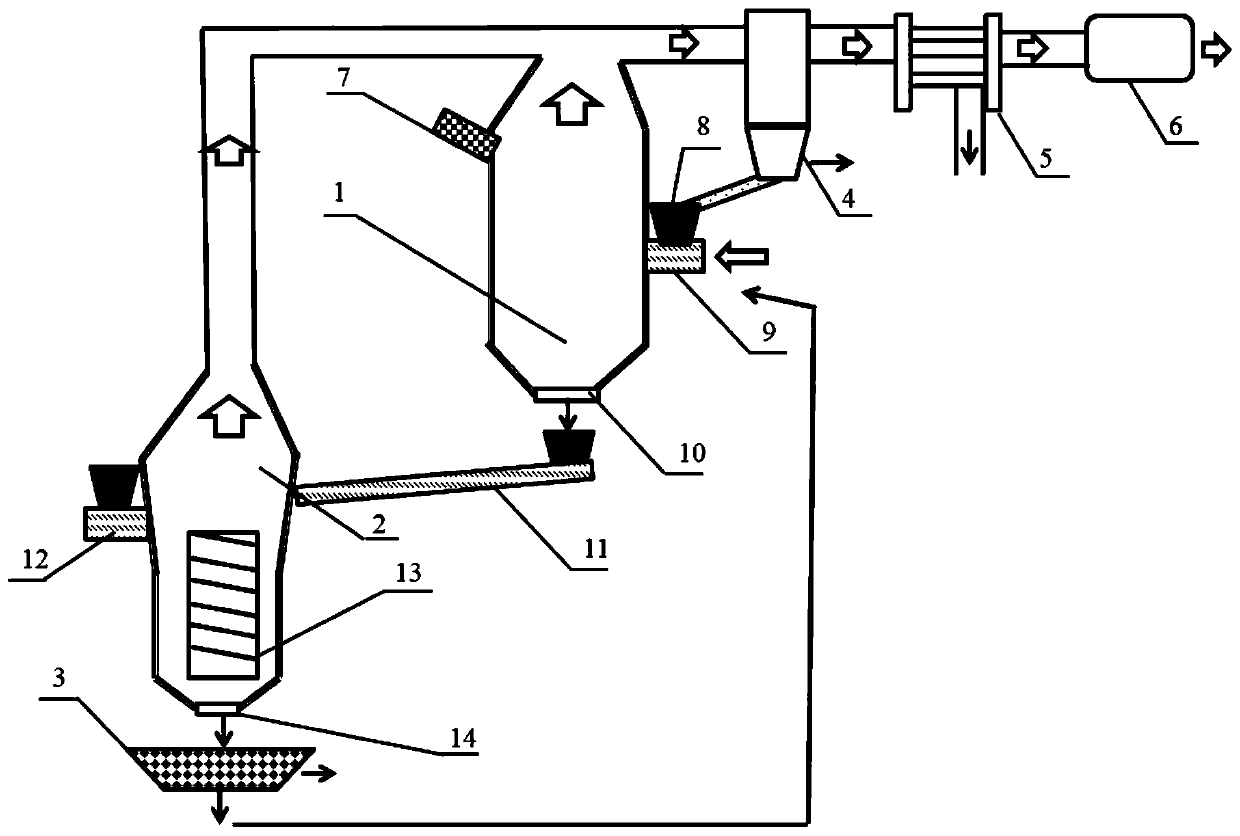

Cascade waste heat recovery device and method utilizing pyrolysis gasification of solid particle heat carrier

ActiveCN110872531AProtect environmentSave resourcesEnergy inputGasification processes detailsHeat carrierChemistry

The invention discloses a cascade waste heat recovery device and method utilizing pyrolysis gasification of a solid particle heat carrier. The device comprises a gasification furnace, a pyrolysis furnace, a solid separator and a flue gas treatment system, the gasification furnace, the pyrolysis furnace and the solid separator are sequentially connected, and flue outlets of the gasification furnaceand the pyrolysis furnace are converged and connected with the flue gas treatment system. The method comprises the following steps: feeding high-temperature particles into the gasification furnace, feeding a carbon-containing solid waste material A into the gasification furnace under the carrying of a gasifying agent, carrying out gasification reaction to generate a combustible gas and primary cooled particles, feeding the cooled particles and a carbon-containing solid waste material B into the pyrolysis furnace for pyrolysis reaction to generate pyrolysis gas and solid semi-coke, and screening to allow the yield of the solid semi-coke to be 20-23% and the content of fixed carbon to be 77-79.1% to obtain coal gas as a gasifier fuel. According to the method, the solid particle waste heat recovery efficiency is improved to 80-84%, the efficiency is improved to 70-77%, meanwhile, combustible clean coal gas with the calorific value of 5000-7000 kJ / m3 can be obtained, and the CO2 emissionis reduced.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

Waste heat recovery system of liquid cooling data center

PendingCN110345549AImprove waste heat recovery efficiencyImprove utilization efficiencySolar heating energySolar heat storageCooling towerData center

The invention discloses a waste heat recovery system of a liquid cooling data center. The waste heat recovery system comprises a first heat exchanger, a heat dissipation system, a solar heat collection and heat storage system and a heat energy utilization system, wherein each system is a circulation loop internally provided with a working medium flow, the first heat exchanger is a part of the heatdissipation system, the heat dissipation system and the solar heat collection and storage system are connected with the heat energy utilization system through a heat exchange pipeline and the solar heat collection and storage system to provide heat energy, and the waste heat of the solar heat collection and heat storage system is used for civil heating. The solar heat collection and heat storagesystem is used for upgrading a low-temperature waste heat source, energy storage is carried out, the input energy fluctuation in the daytime and at night is balanced, the heat source is utilized for heat energy utilization, the waste heat is used for providing hot water and heating for a building, redundant low-grade heat is discharged into the environment through a cooling tower, and the waste heat recovery efficiency of the liquid cooling data center is improved, the energy consumption of the data center is reduced, the energy utilization efficiency is improved, the energy consumption is reduced, and meanwhile, the operation cost of the data center is reduced.

Owner:广东西江数据科技有限公司

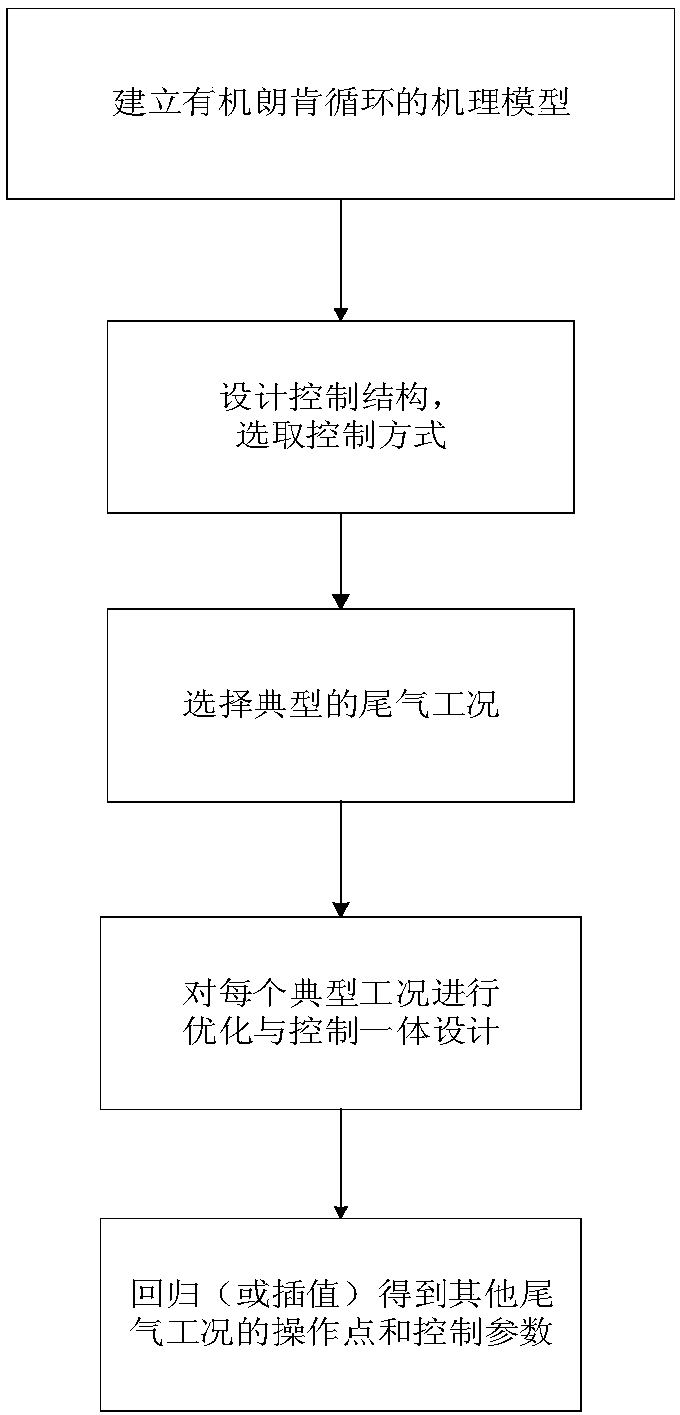

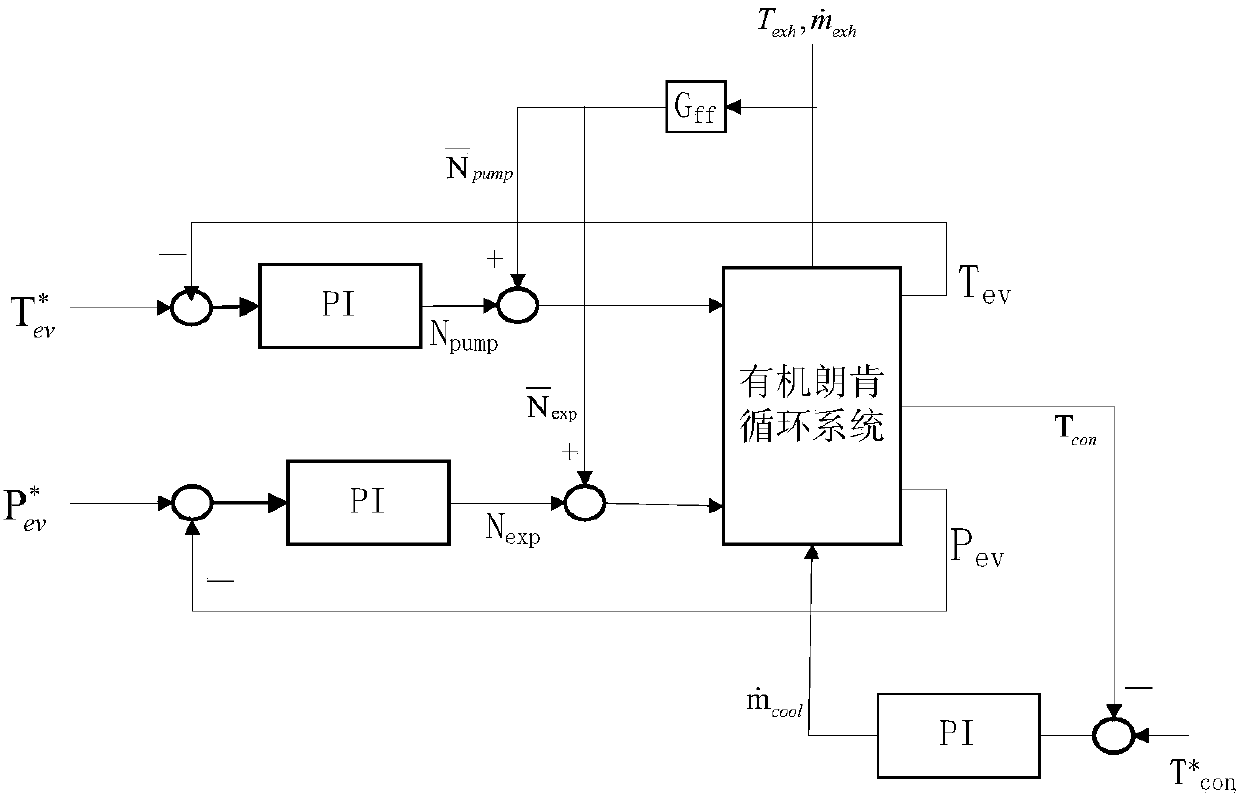

Optimization and control integrated design method for tail gas waste heat recovery organic Rankine cycle

ActiveCN107066655AImprove waste heat recovery efficiencySimple designComputer aided designSpecial data processing applicationsOrganic Rankine cycleControl system

The invention discloses an optimization and control integrated design method for tail gas waste heat recovery organic Rankine cycle. The method comprises the steps of building a mechanism model of a tail gas waste heat recovery organic Rankine cycle system; designing a control structure of the organic Rankine cycle system, designing a controller and a corresponding control equation for the control structure, and forming a closed-loop control system by the designed controller and the mechanism model; selecting tail gas working conditions in a power change range of tail gas waste heat; according to the selected tail gas working conditions and the closed-loop control system, building an integrated optimization model comprising tail gas working condition uncertainty analysis and solving an optimal operation point and an optimal control parameter of the integrated optimization model under each tail gas working condition; and according to the optimal operation point and the corresponding control parameter obtained by optimization solving, obtaining optimal operation points and control parameters corresponding to other tail gas working conditions by utilizing a regression method. The method can improve the waste heat recovery efficiency of the organic Rankine cycle system and is small in online calculation amount and good in robustness.

Owner:ZHEJIANG UNIV

Treatment method for dioxins atmospheric pollutants in household refuse incineration smoke

InactiveCN105864792AIncrease temperatureIncrease high temperature burning timeEmission preventionIndirect heat exchangersLimit valueHeat pipe heat exchanger

The invention provides a treatment method for dioxins atmospheric pollutants in household refuse incineration smoke, and belongs to methods for removing organic halogen compounds in smoke. The method is characterized in that a treatment device is formed by sequentially connecting the following equipment of a primary intensified burning furnace (1), a secondary intensified burning furnace (2), a silicon-nitride porous ceramic filter (3), a countercurrent flow waste heat boiler (4), a combined type heat pipe exchanger (5), a bag dust collector (6), an acid gas removal system (7), an activated carbon adsorption tower (8) and an induced draft fan (9). The treatment method for the dioxins atmospheric pollutants in the household refuse incineration smoke is high in waste heat recovery efficiency and capable of effectively treating the dioxins atmospheric pollutants generated in the household refuse incineration process. All items in the atmospheric pollutants are lower than limiting values regulated in the sheet 4 of the GB18485-2014 household refuse incineration pollutant control standard. The emission of the dioxins atmospheric pollutants is not higher than 0.1 ngTEQ / m<3>.

Owner:陈春光

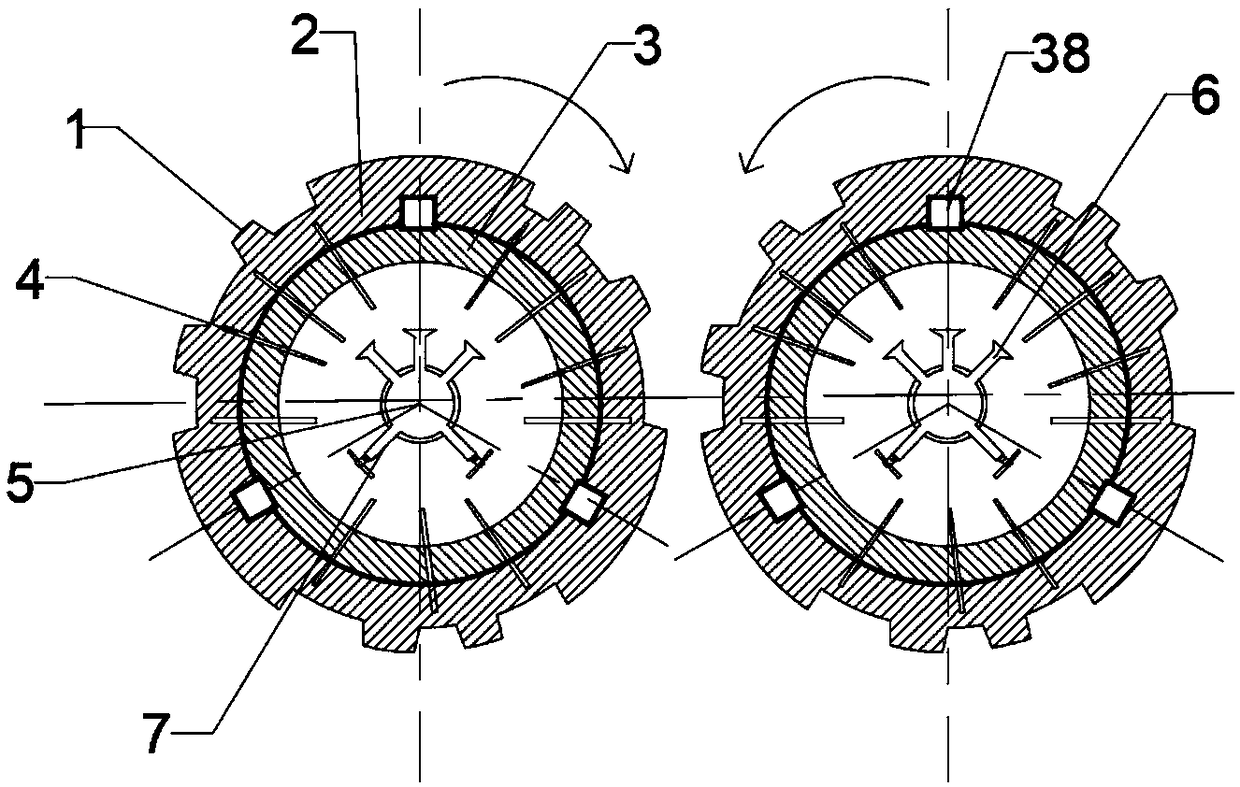

Medium and high temperature roller crusher with high efficiency composite cooling system

ActiveCN109277131AFast heat transferImprove heat transfer performanceGrain treatmentsControl systemHigh pressure water

The invention relates to a medium and high temperature roller crusher with a high efficiency composite cooling system. The medium and high temperature roller crusher with the high efficiency compositecooling system comprises a transmission device, a crushing unit, a miniature heat pipe cooling system, a water cooling system, a driven end sealing system and a measurement and control system, wherein the miniature heat pipe cooling system efficiently dissipates heat to a cavity of a roller through a miniature heat pipe, and symmetric fluid grooves of a micropore accelerate the cooling of the roller; in the water cooling system, a part of high pressure water is sprayed onto the inner wall of the upper part of the cavity of a roller shaft and a condensation section of the heat pipe for heat transfer through a high pressure cooling water spray head, and a part of high pressure water is sprayed out through axial small spray pipes and a radial small spray pipes of an immersion type spray headto generate high-speed jet flow and rotational flow which are in opposite directions, so that accumulated water highly forms turbulence flow; recesses of the inner surface of the roller shaft strengthens the surface heat dissipation; the cooling systems endow the medium and high temperature roller crusher with high efficiency cooling performance; and the driven end sealing system is provided witha reverse thread groove seal, an air cavity seal, and a ring-shaped air bag air seal, so that the good shaft end seal can be realized. The high efficiency cooling sealing characteristic of the mediumand high temperature roller crusher can ensure the safe and reliable operation of the medium and high temperature roller crusher in the medium and high temperature region of a grate cooler.

Owner:XIANGTAN UNIV

Blast furnace slag washing water heat exchanger online washing device

ActiveCN103712513ASolve the problem of downtime cleaningImprove waste heat recovery efficiencyNon-rotary device cleaningSlagEngineering

A blast furnace slag washing water heat exchanger online washing device comprises a ball storage tank, a rubber ball recirculating pump and matched pipelines and valves. A retaining plate controlled by a retaining plate handle is disposed in the ball storage tank. The retaining plate is used for controlling receiving and sending of small balls. A slag washing water inlet pipe of a heat exchanger is connected to a ball sending valve through a branch pipeline. The other end of the ball sending valve is sequentially connected with the rubber ball recirculating pump and the ball storage tank. The pipeline at the other end of the ball storage tank is branched and respectively connected with a forward ball receiving valve and a reverse ball receiving valve. Each of the forward ball receiving valve and the reverse ball receiving valve is connected with the slag washing water outlet pipe through a branch pipeline. A ball receiving net for receiving the small balls is disposed in the slag washing water outlet pipe. The forward and reverse direction of the ball receiving net are controlled by a ball receiving net handle. The washing device has the advantages that the problem of heat exchanger shutdown washing is solved, work efficiency of heat exchangers is increased, slag washing water waste heat recycling efficiency is increased, an automatic washing function is added, the service life of the washing device is prolonged, and work efficiency of the washing device is increased.

Owner:中煤玮坤(北京)节能环保科技有限公司

Sintering device, sintering cooler and its lamination sealing device

InactiveCN101368796AReduce power consumptionReduce air leakageEngine sealsEnergy industryEngineeringSlide plate

The invention discloses a sintering machine or a sintering cooler and a lamination seal equipment thereof, which can reduce the power consumption of blowers, decrease the air leakage of the equipment, increase the waste heat recovery efficiency and improve the environment. The sintering cooler comprises a sinter-loading trolley, an overhead hood above the trolley, a bellows below the trolley, an upper lamination seal device between the hood and the upper part of the trolley, as well as a lower lamination seal device or a lower flexible seal device arranged between the lower part of the trolley and the bellows; wherein, the slideway of the bellows is glidingly contacted with a flexible slide plate of the trolley; the upper lamination seal device is used to seal the gap between the hood and the upper part of the trolley; and the lower lamination seal device or the lower flexible seal device is used to seal the gap between the lower part of the trolley and the bellows.

Owner:锐安得力(北京)安全科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com