A device and recovery method for recovering blast furnace slag waste heat

A recovery method and blast furnace slag technology, applied in the field of steel energy conservation, can solve the problems of difficult recycling of fluid water, low thermal efficiency, complex equipment, etc., and achieve the effects of improving waste heat recovery efficiency, low heat dissipation, and reducing energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

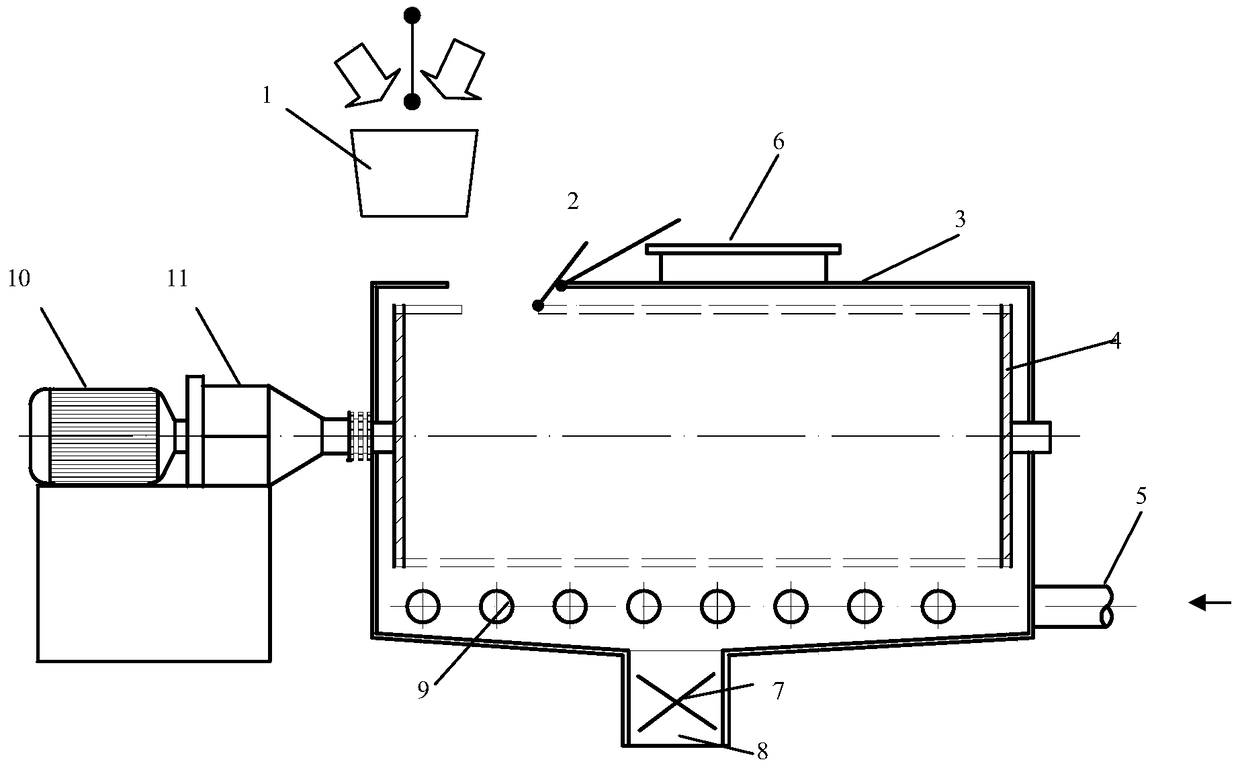

[0018] According to 2580m 3 Take a blast furnace as an example, a single tapping is 420t, slag is 126t, the tapping temperature is 1480°C, and the temperature of the slag reaching the exit of the slag tunnel is 1300°C, so the initial heat of the blast furnace slag is 202GJ. Using this method to recover the waste heat of blast furnace slag, the molten blast furnace slag at 1480°C is mixed with high thermal conductivity metal balls with a diameter of 100mm at room temperature, a thermal conductivity of 155kJ / m·h·°C, and a total weight of 252t in the slag tank; the forming temperature is about It is a solid mixture of blast furnace slag and metal balls at 500°C to 800°C; the ball slag ratio (mass ratio) is 1:2, and the solid mixture of blast furnace slag and steel balls is poured into the rotating metal cage in the heat recovery equipment through the feed gate Inside, the metal cage has an aperture of 55mm and a heat-resistant strength of 20 kgf / mm 2 (600°C), impact toughness 40...

Embodiment 2

[0020] According to 3200m 3 Take a blast furnace as an example, a single tapping is 655t, slag is 196.5t, the tapping temperature is 1480°C, and the temperature of the slag reaching the exit of the slag tunnel is 1300°C, so the initial heat of the blast furnace slag is 311GJ. Using this method to recover the waste heat of blast furnace slag, the molten blast furnace slag at 1480°C is mixed with high thermal conductivity metal balls with a diameter of 150mm at room temperature, a thermal conductivity of 160kJ / m·h·°C, and a total weight of 393t in the slag tank; the formation temperature is about It is a solid mixture of blast furnace slag and metal balls at 500°C to 800°C; the ball slag ratio (mass ratio) is 2, and the solid mixture of blast furnace slag and steel balls is poured into the rotating metal cage in the heat recovery equipment through the feed gate. Metal cage aperture 60mm, heat resistance 20 kgf / mm 2 (600°C), impact toughness 40 kgf / mm 2 (600°C), the metal cage ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com