Patents

Literature

19580 results about "Cold air" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cool design data center

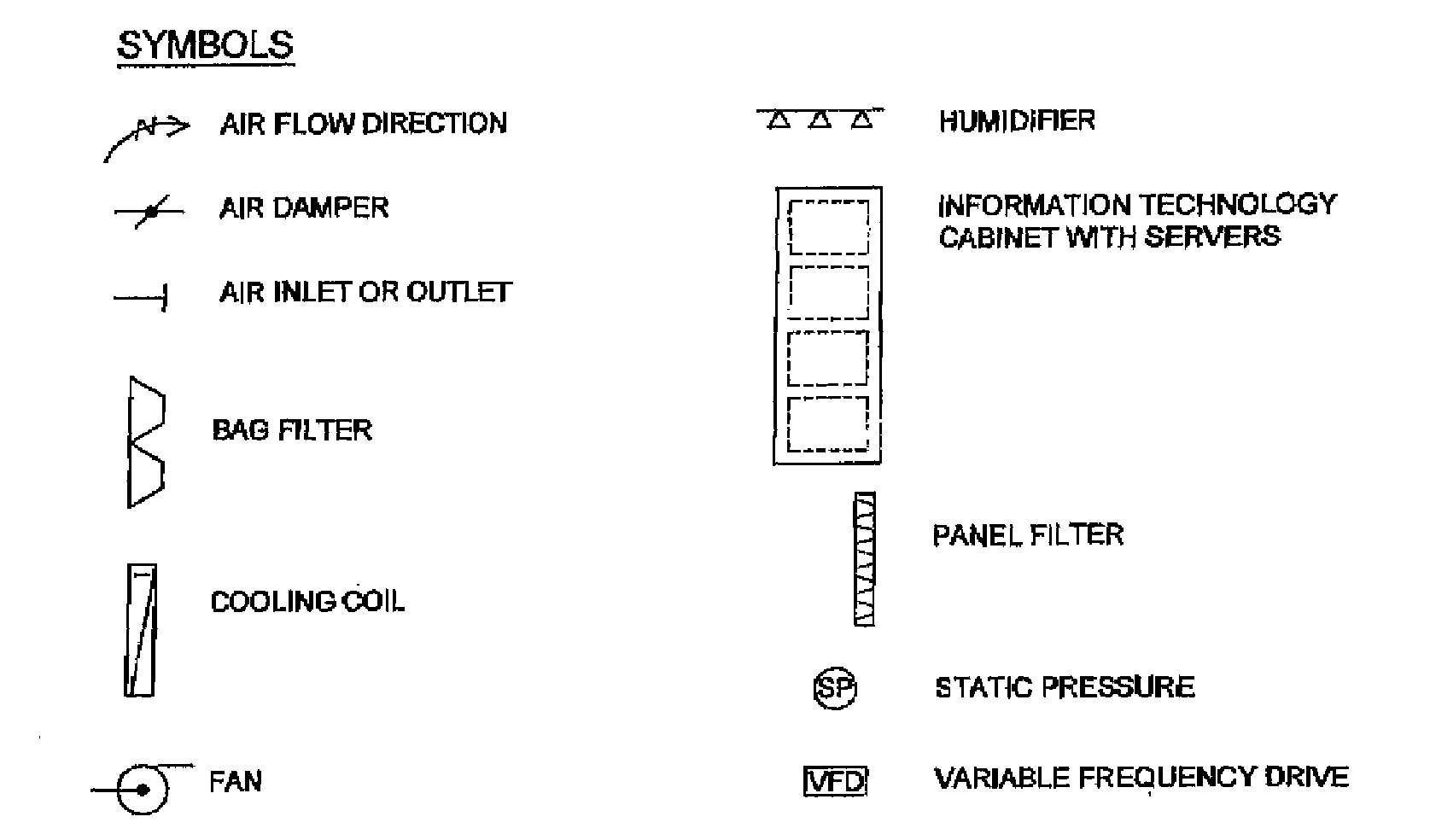

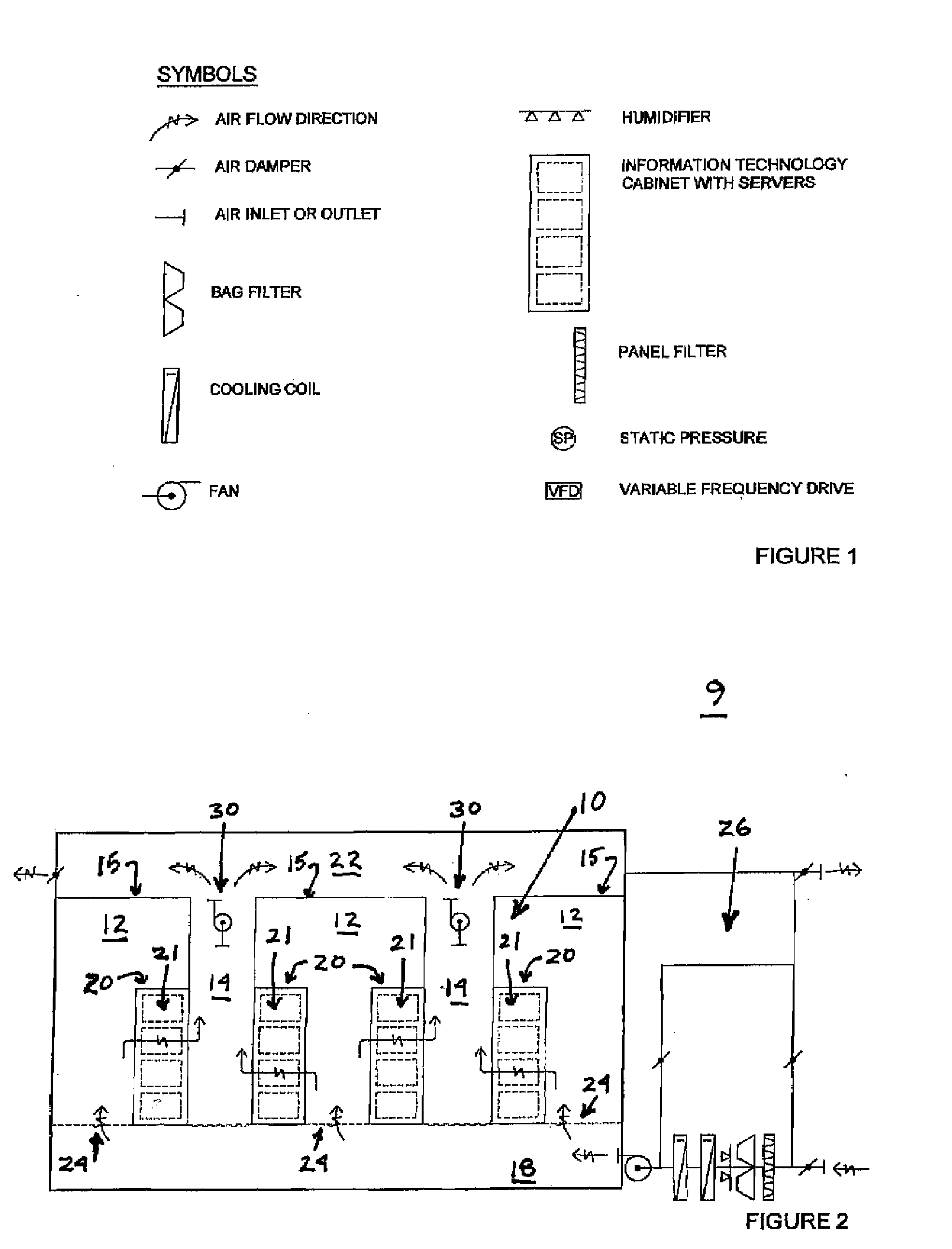

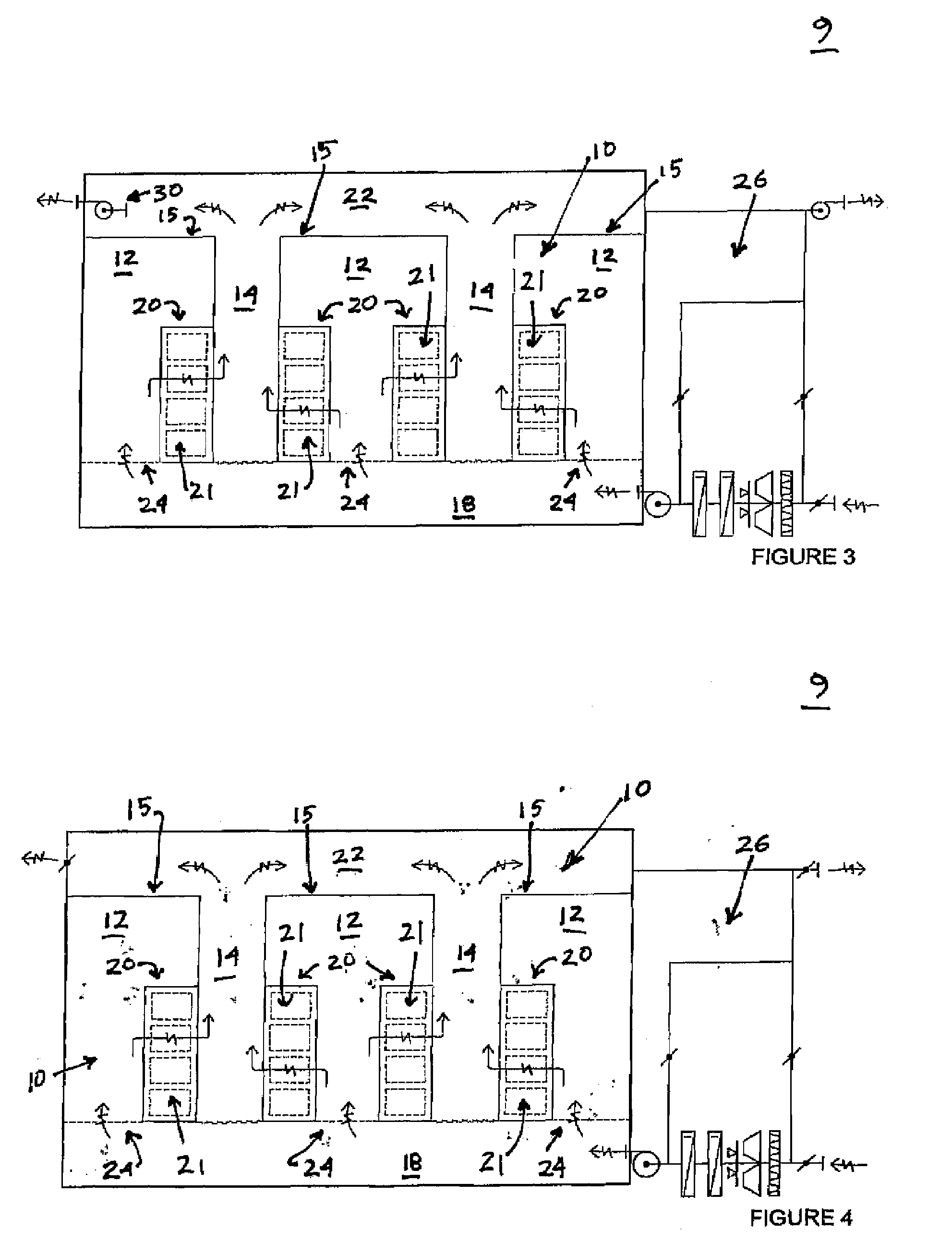

ActiveUS20080185446A1Easy to solveAvoid uneven loadLighting and heating apparatusElectrical apparatus contructional detailsAir managementAir volume

An improved solution for cooling a data center is provided. In an embodiment of the invention, a data center design that combines physical segregation of hot and cold air streams together with a data hall variable air volume system is provided. The invention is a data center design that resolves air management issues of re-circulation, bypass and load balance. Bypass is airflow supplied by the cooling units that directly returns without cooling servers. Recirculation airflow is server discharge warm air that returns directly without being cooled. Load balance is supplying the required server airflow. An embodiment includes physical segregation of cold and hot air streams and by providing variable air volume to match server load. Air segregation is done by enclosing the hot aisle end and above the cabinets. The air conditioning system provides variable air volume to the data hall (cold side) to meet server demands. The cooling plant consists of variable-air-volume air-cooling system, which cools air by air free cooling (economizer) and is supplemented with mechanical cooling in the warmer seasons.

Owner:HEWLETT-PACKARD ENTERPRISE DEV LP

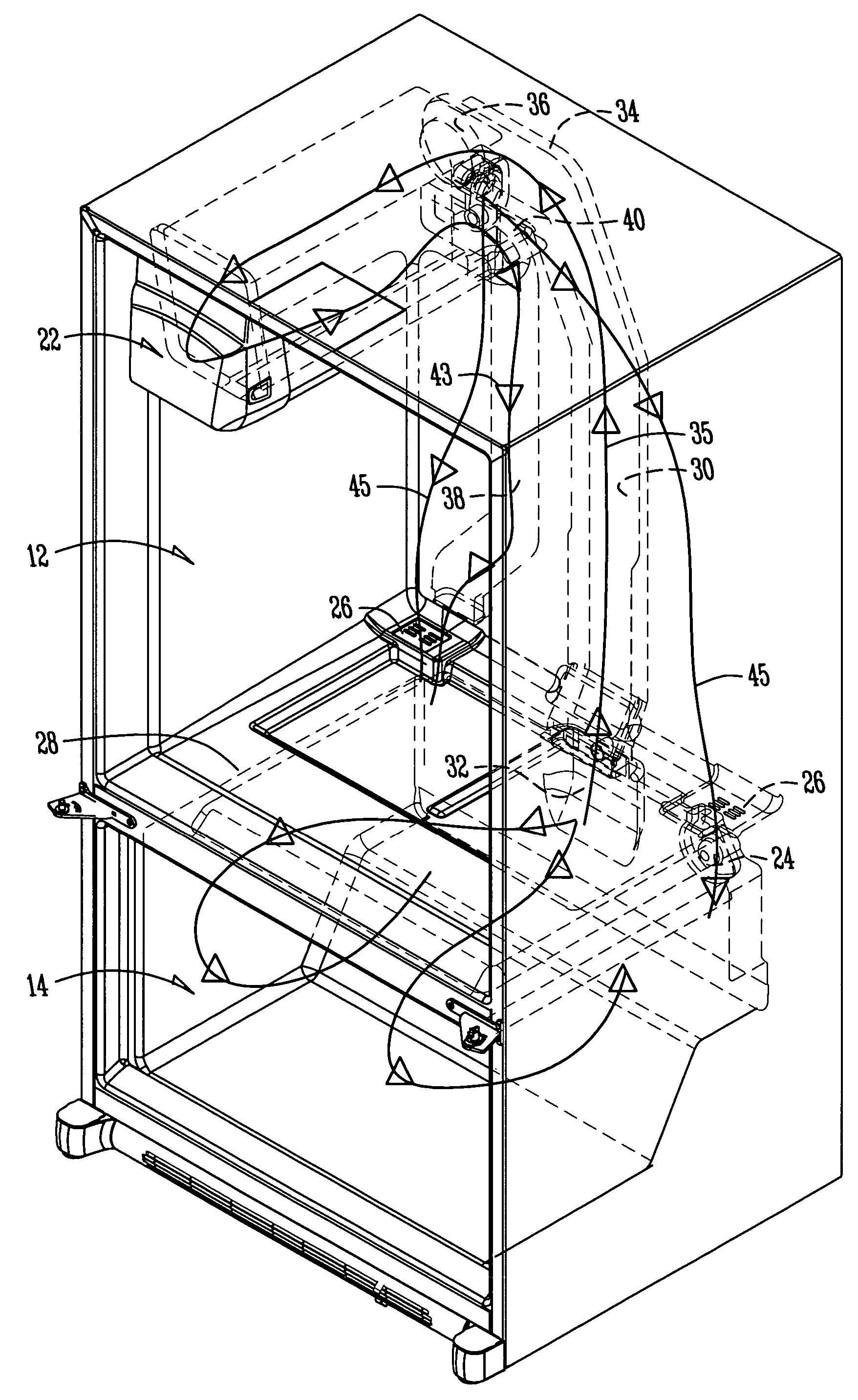

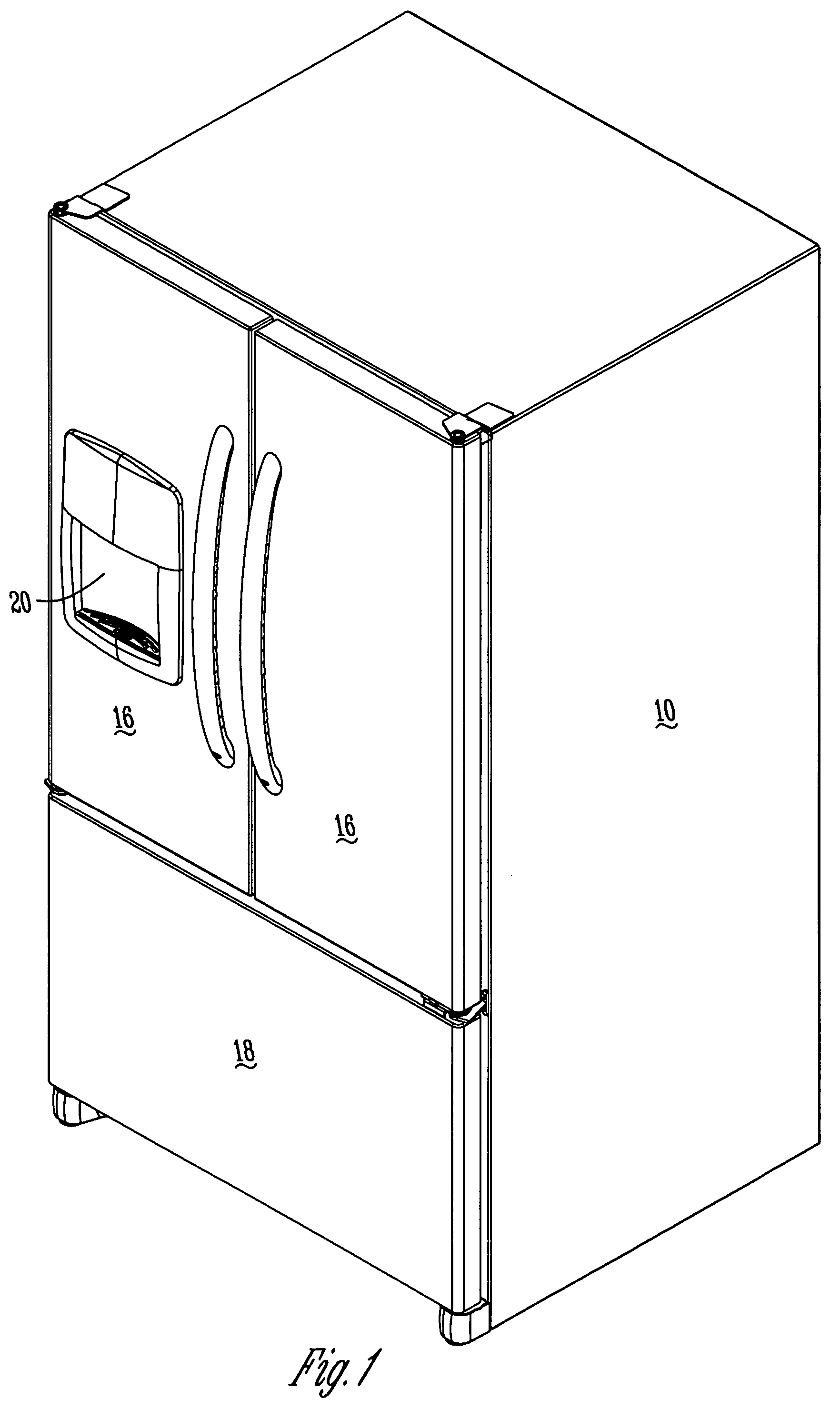

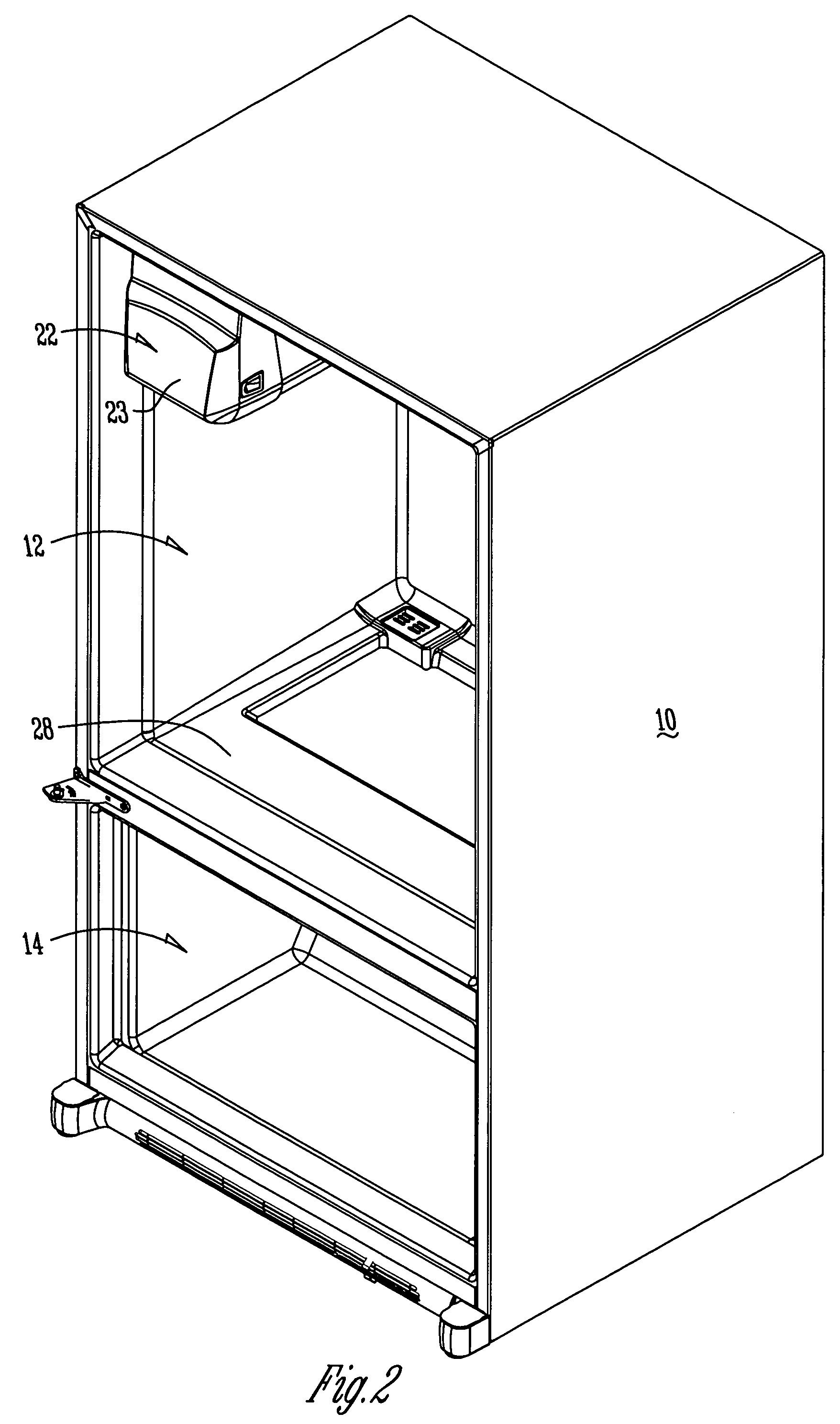

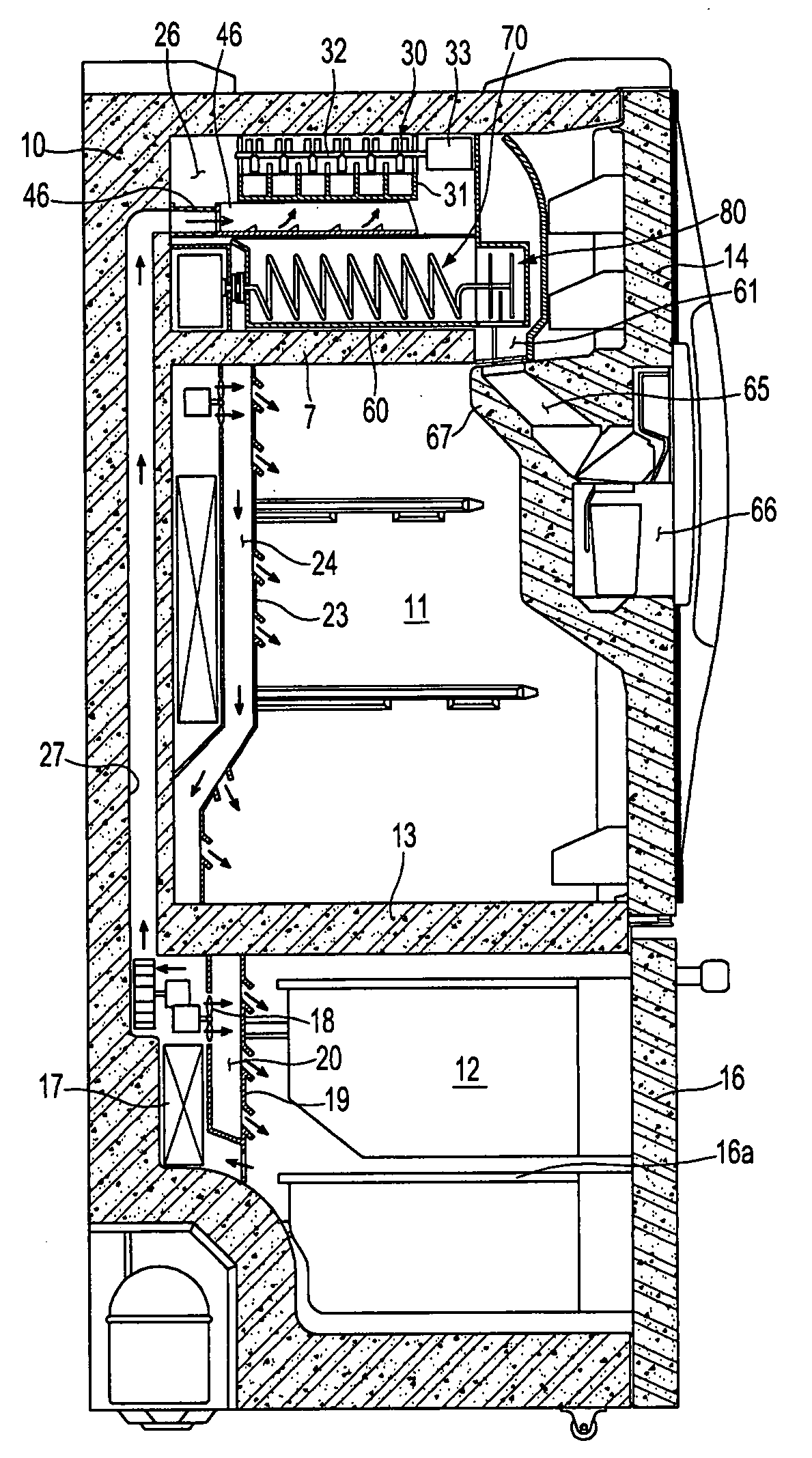

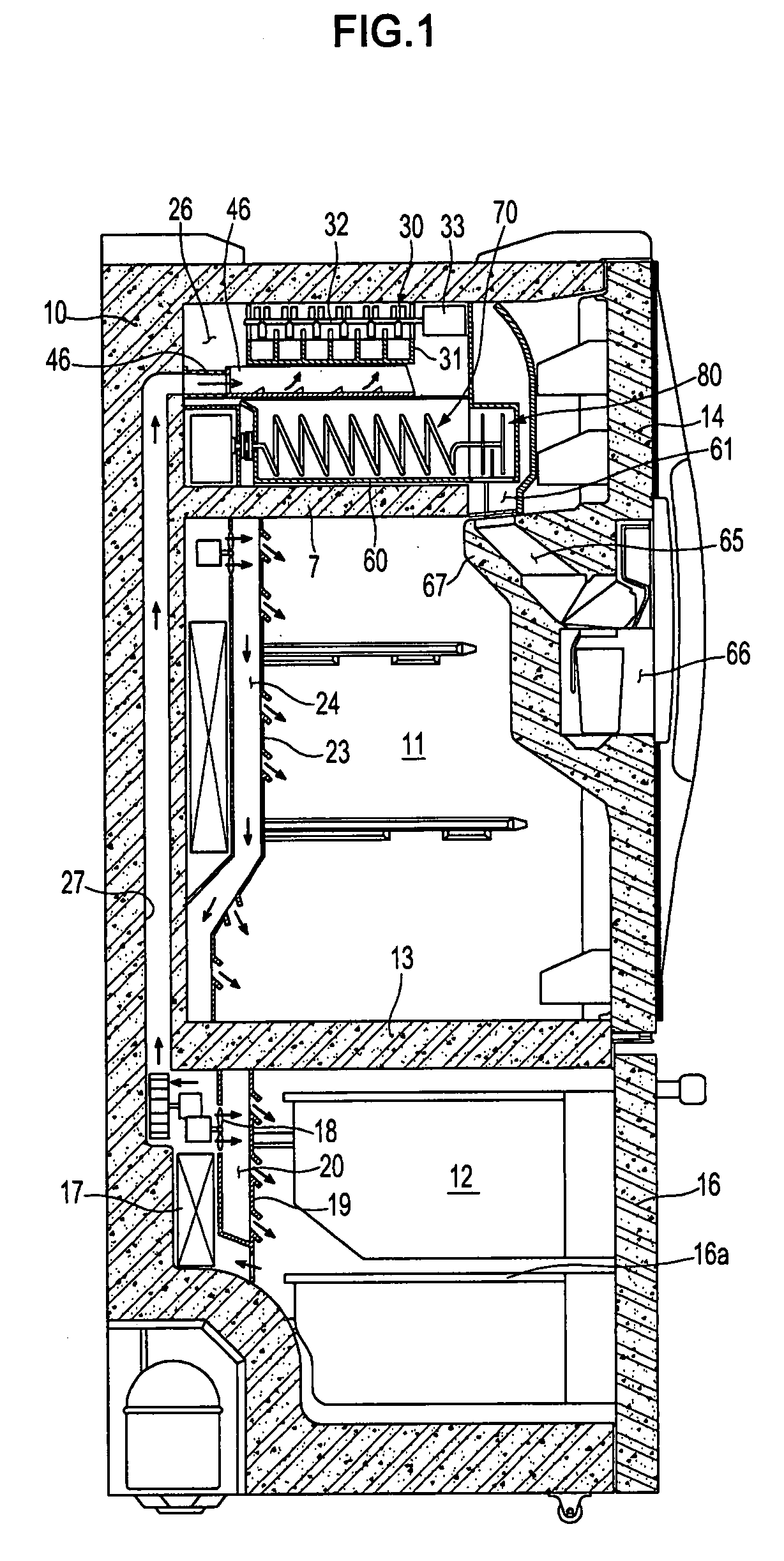

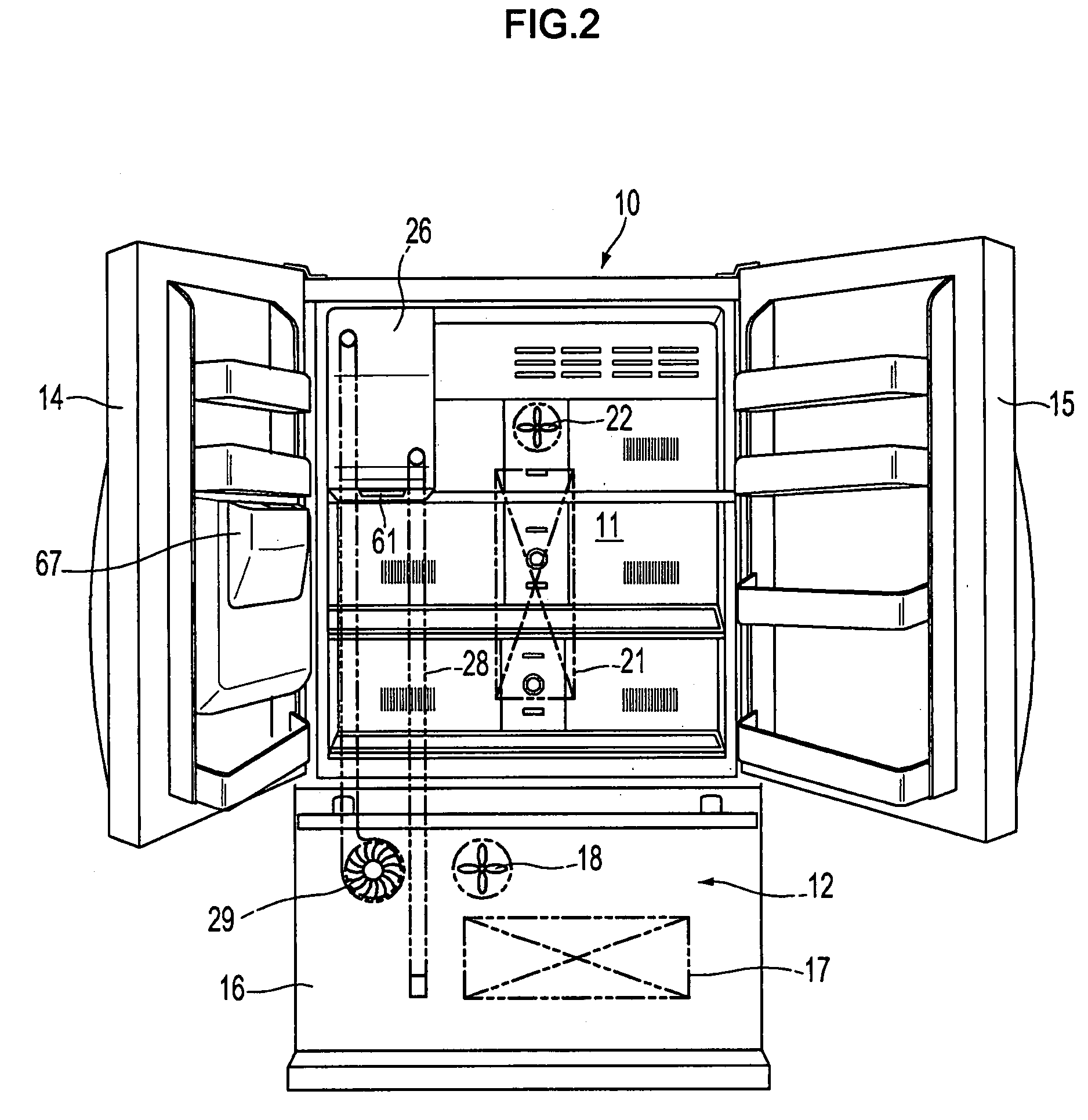

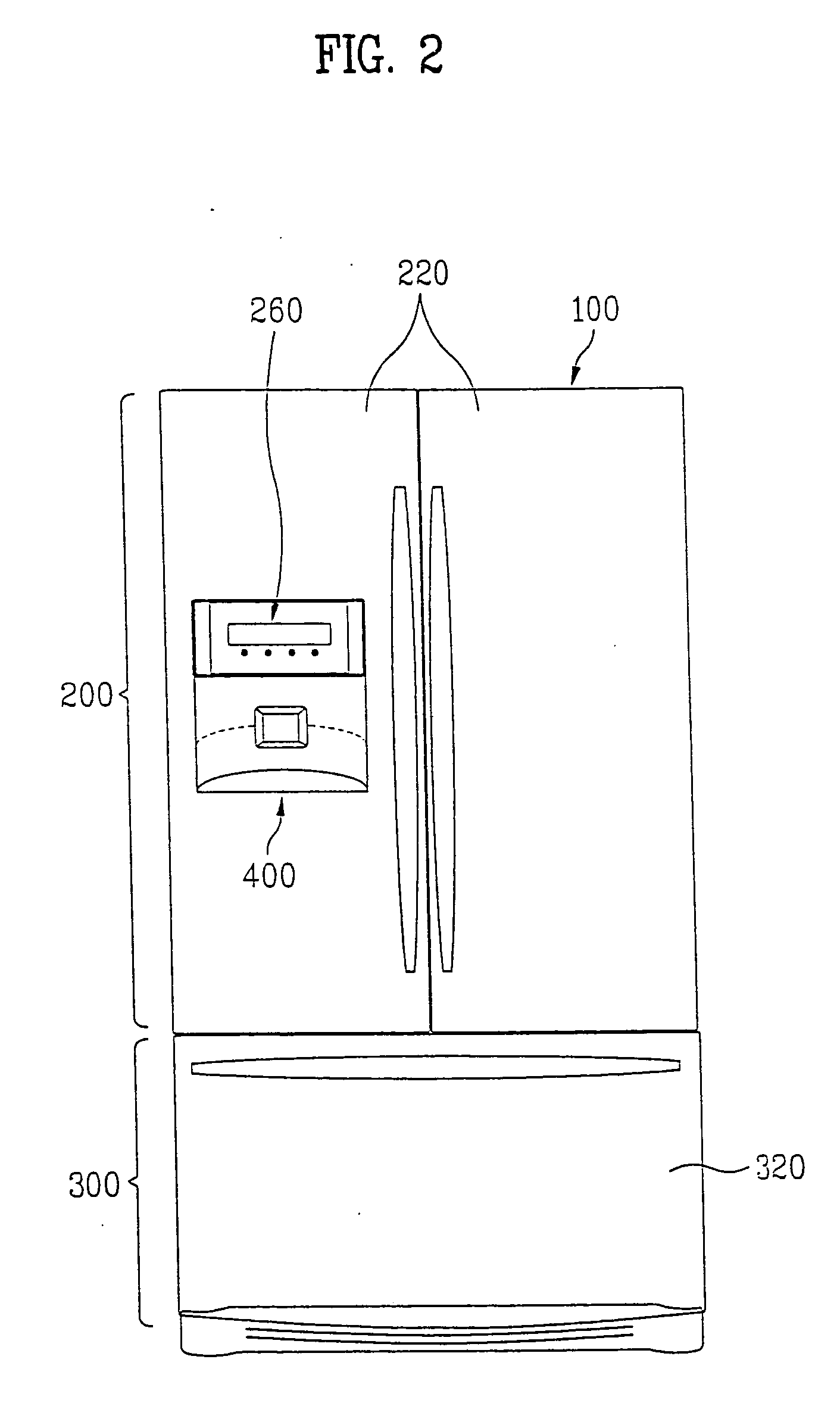

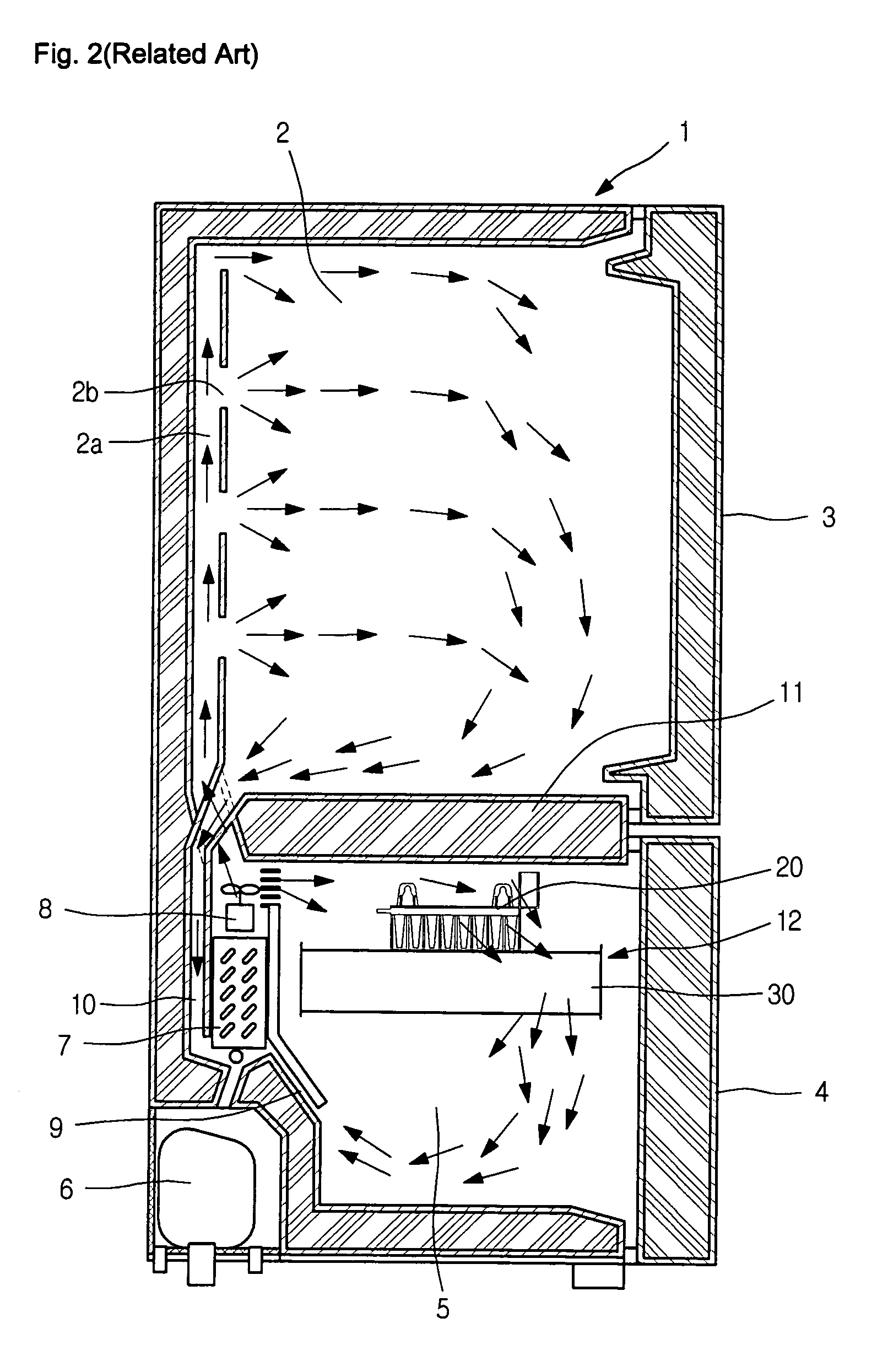

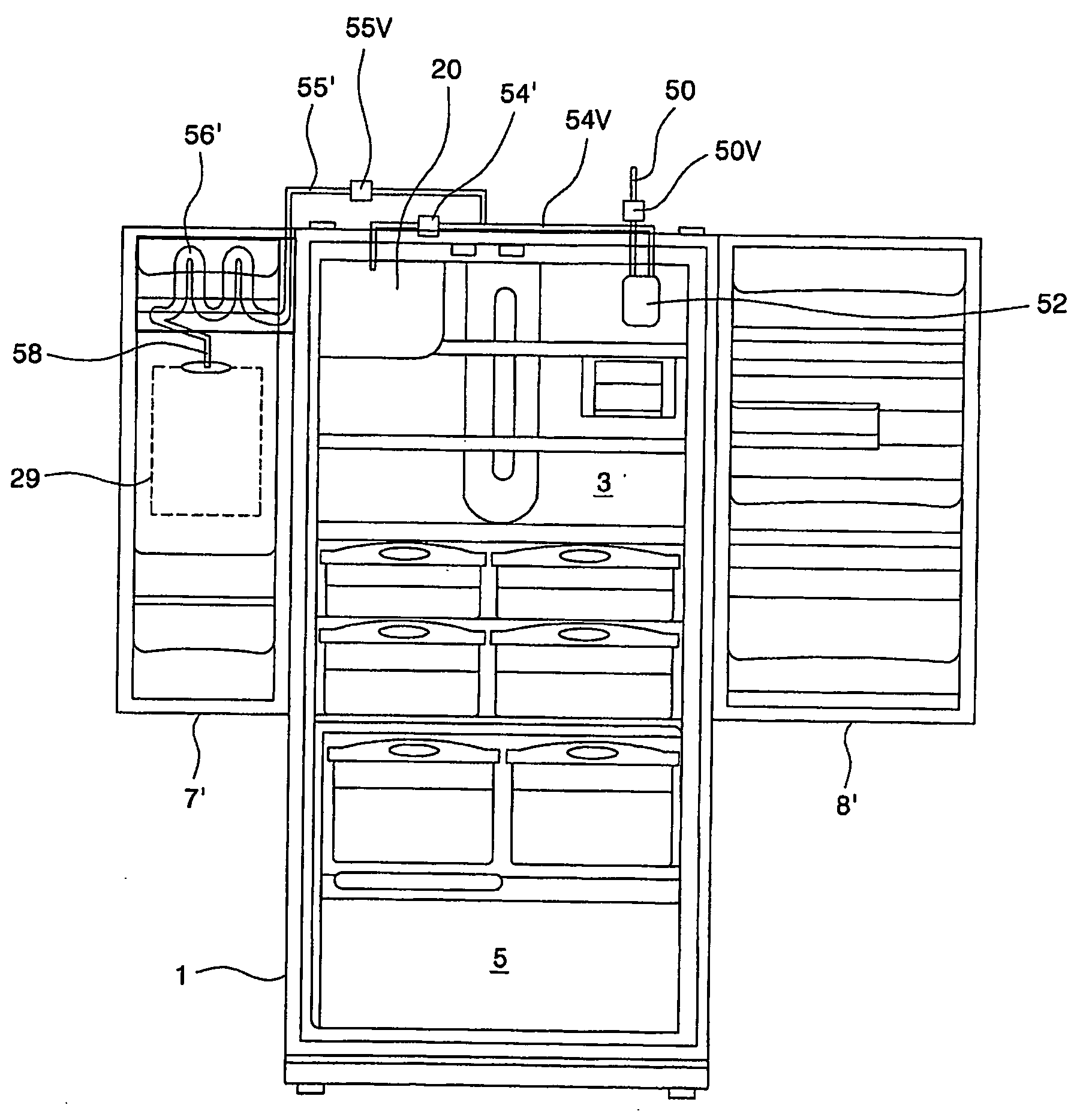

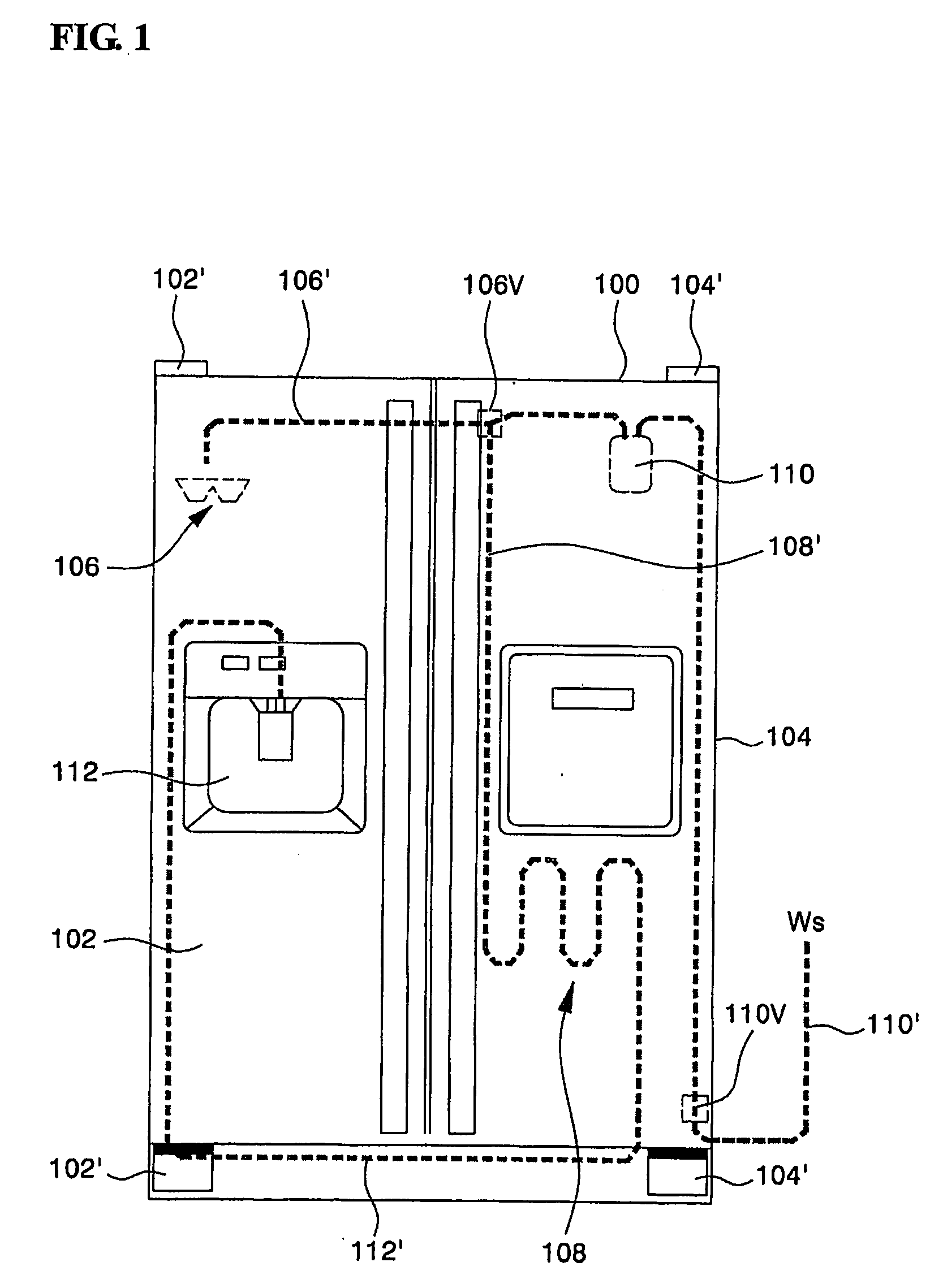

Refrigerator with intermediate temperature icemaking compartment

An icemaking compartment is provided in the refrigerator compartment of a bottom mount refrigerator. An icemaker is within the icemaking compartment. A cold air duct supplies cold air from the freezer compartment to the icemaker. The cold air duct is formed in the rear wall of the refrigerator. A fan controls the flow of air through the cold air duct. A return air duct is provided to direct a portion of the air from the icemaker back to the freezer compartment. An air vent in the icemaker directs another portion of air into the refrigerator compartment.

Owner:WHIRLPOOL CORP

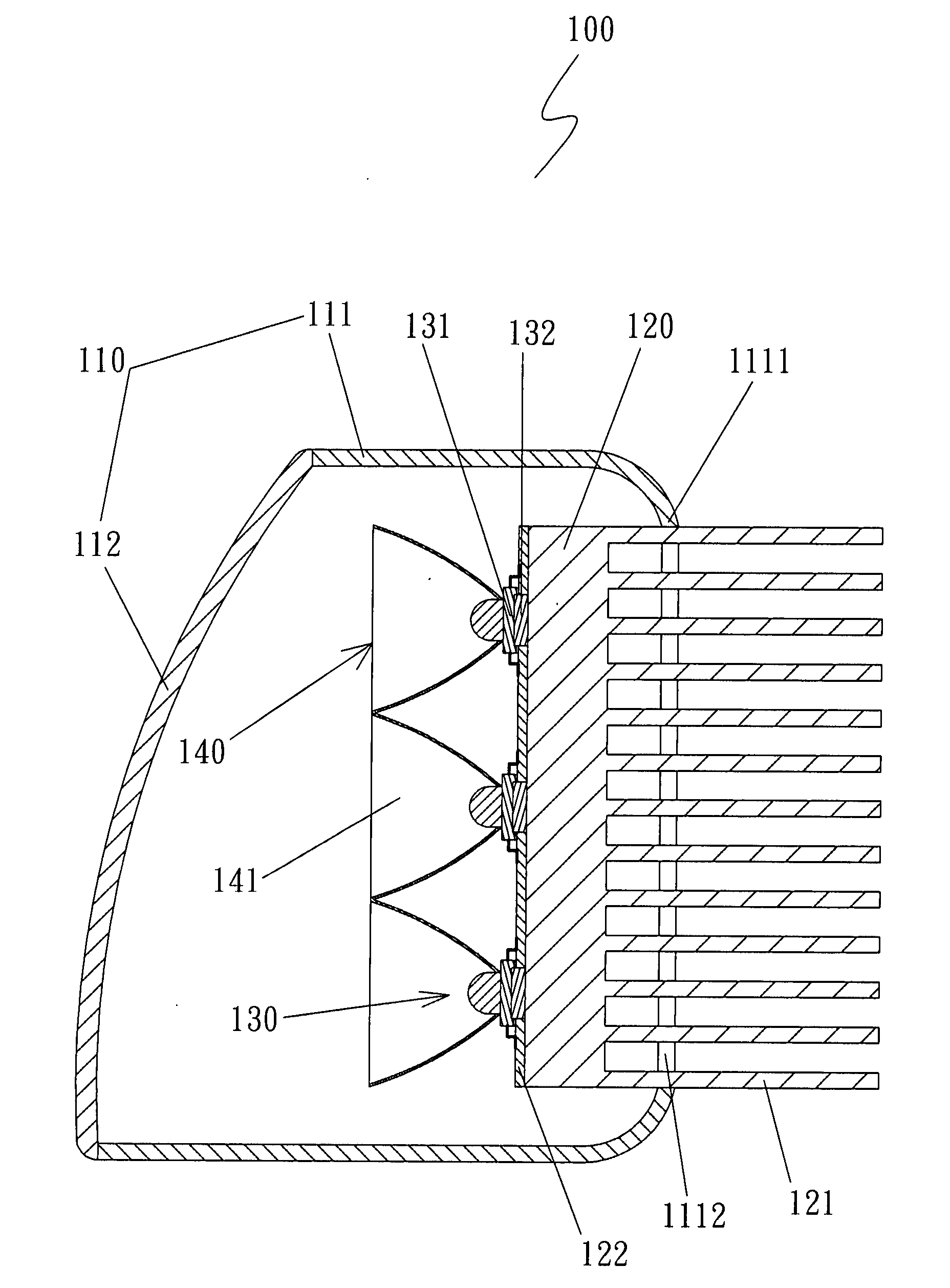

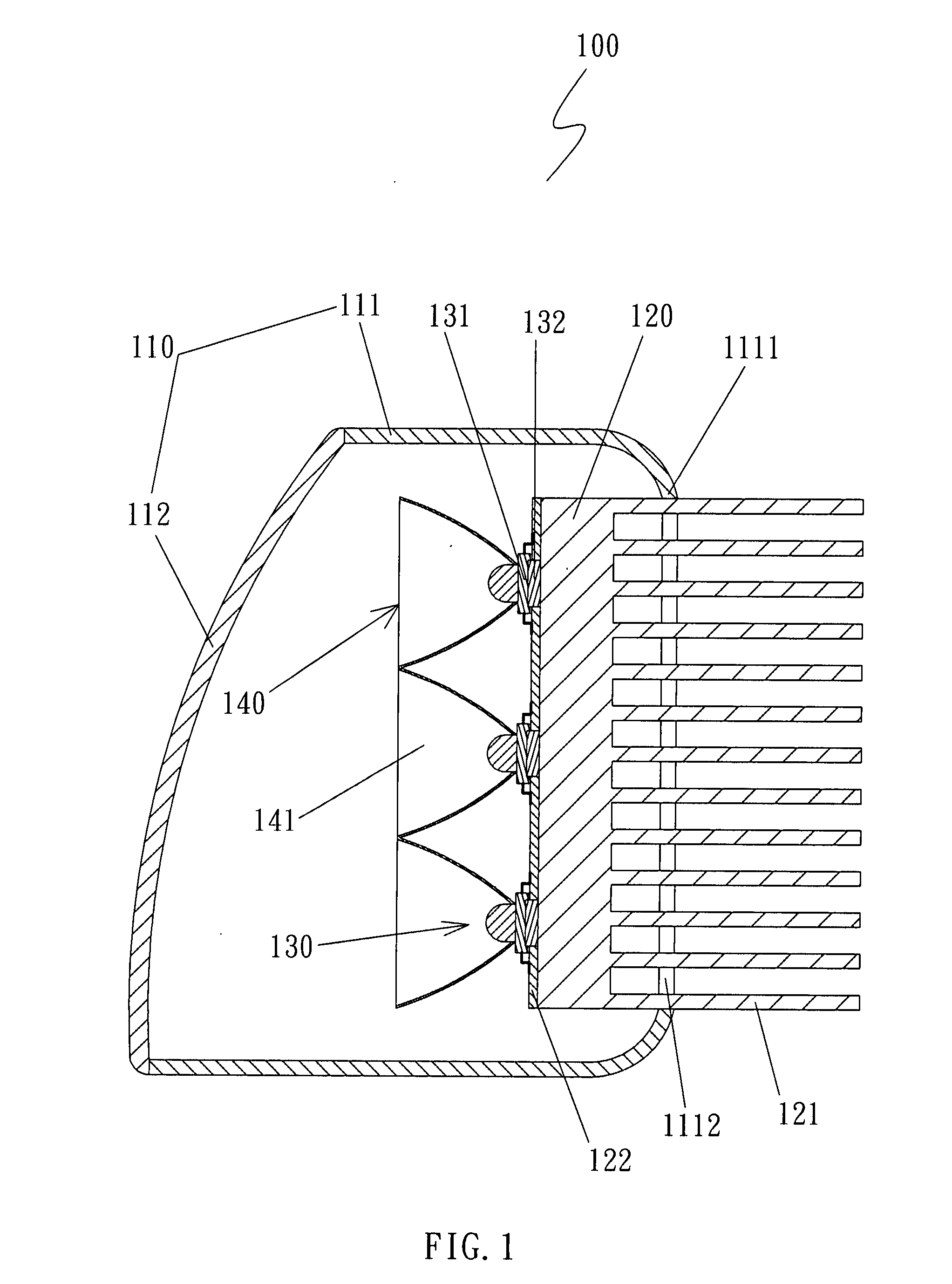

Heat dissipating apparatus for automotive LED lamp

InactiveUS20090059594A1Reduce the temperatureAvoid overall overheatingVehicle headlampsPoint-like light sourceCold airThermal energy

In a heat dissipating apparatus for an automotive LED lamp, the automotive LED lamp includes an automotive lamp set, a heat dissipating module, a plurality of LEDs, and a reflecting unit. The heat dissipating module is wrapped to form an insulation circuit for separating heat energy and electric power of the insulation circuit and heat dissipating module. The LED is electrically connected to the insulation circuit, and a main base of the LED installs a metal conducting plate for conducting the heat produced by the LED to the heat dissipating module. The reflecting unit is installed in the automotive lamp set, so that the heat dissipating module can use a cold air or a liquid coolant as the heat dissipating medium for dissipating heat, preventing a drop of light output caused by an overheat, and avoiding damages to the LED to extend the life expectancy of the automotive LED lamp.

Owner:YIH IND

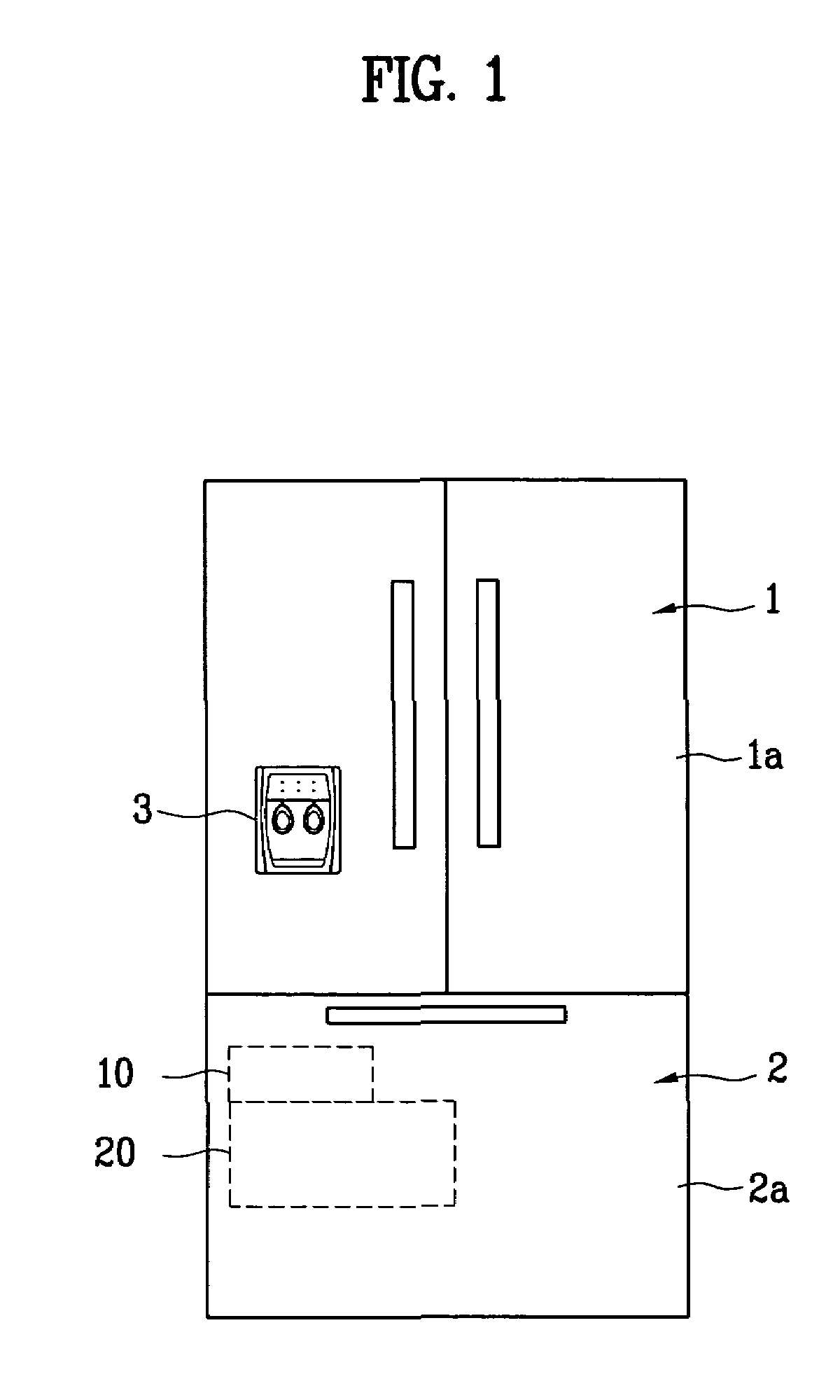

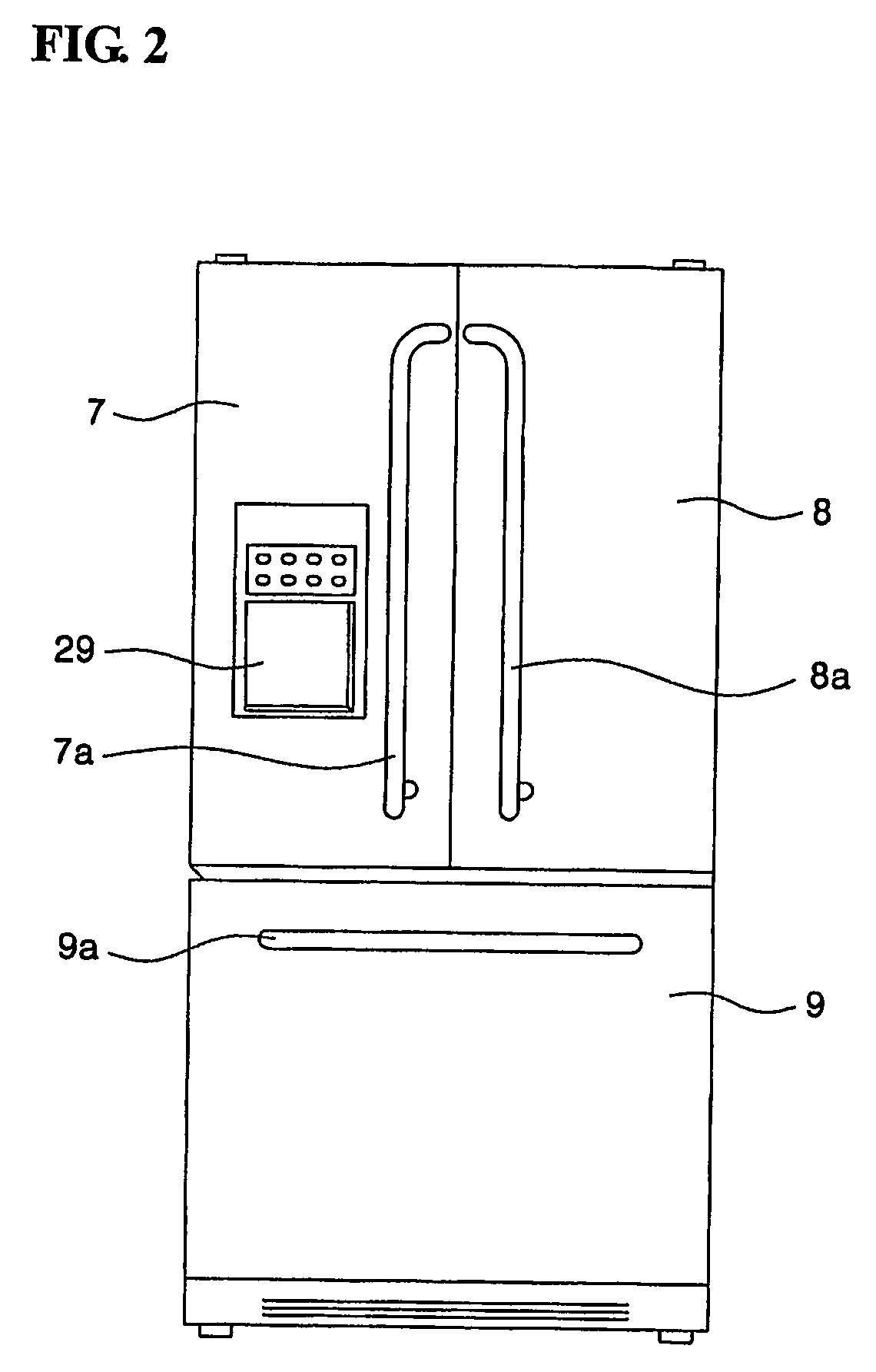

Refrigerator with icemaker

ActiveUS7076967B2Simple structureConvenient for userLighting and heating apparatusIce productionCold airCold store

Refrigerator with an icemaker including a cabinet having a mullion wall for compartmentalization of a freezing chamber and a refrigerating chamber, a case provided to a door on the refrigerating chamber, having a cavity therein, a first duct for supplying cold air from a neighborhood of an evaporator in the freezing chamber to the cavity, the icemaker in the cavity for producing ice, an ice container in the cavity for storing the ice, and a dispenser in the door in communication with the cavity, thereby having ice supplied to a user at an outside of the refrigerator through a dispenser provided to the door.

Owner:LG ELECTRONICS INC

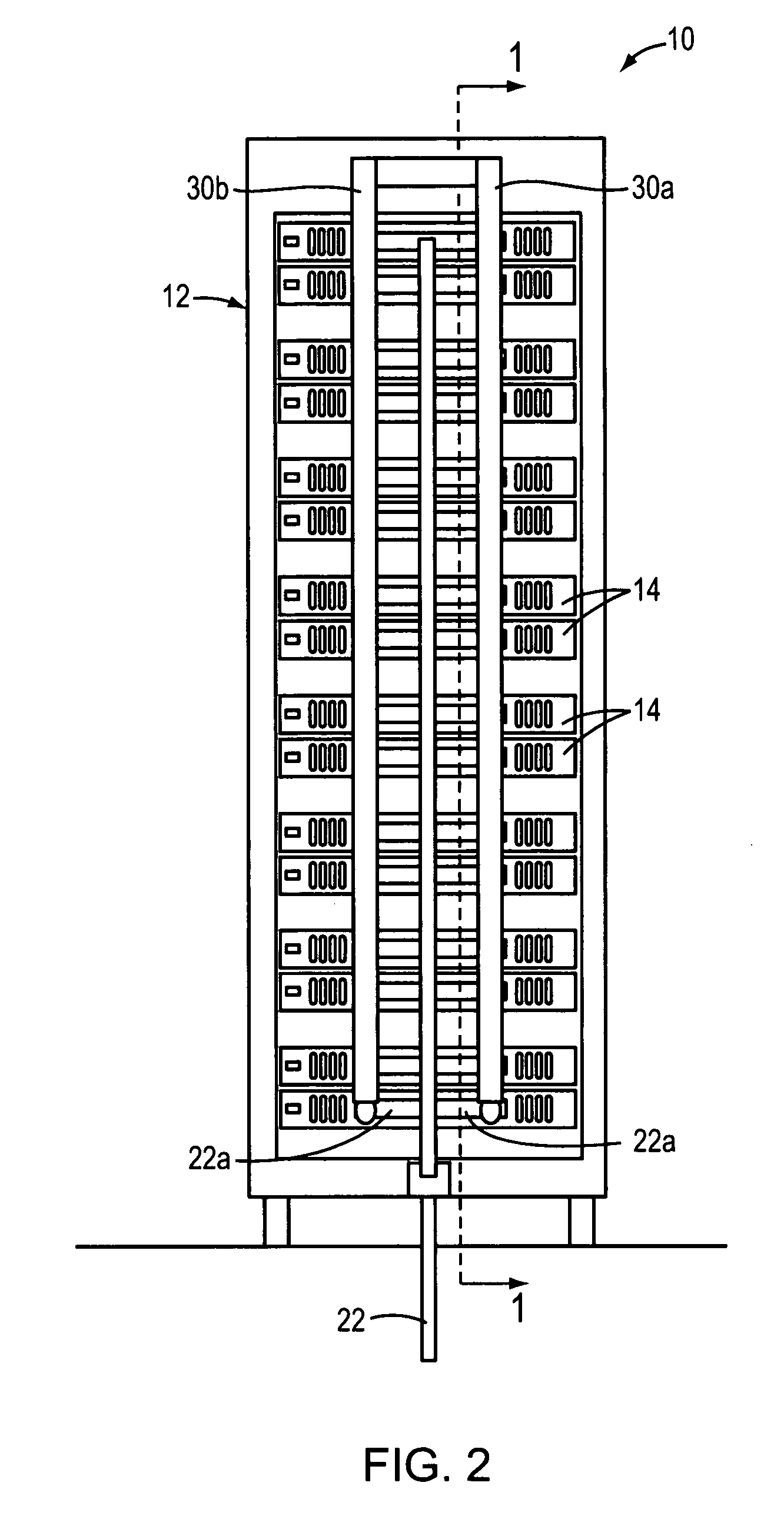

Method and system for providing cooling of components in a data storage system

ActiveUS7751188B1Improve cooling effectConsume high powerDomestic cooling apparatusCompression machinesCold airElectronic systems

Owner:EMC CORP

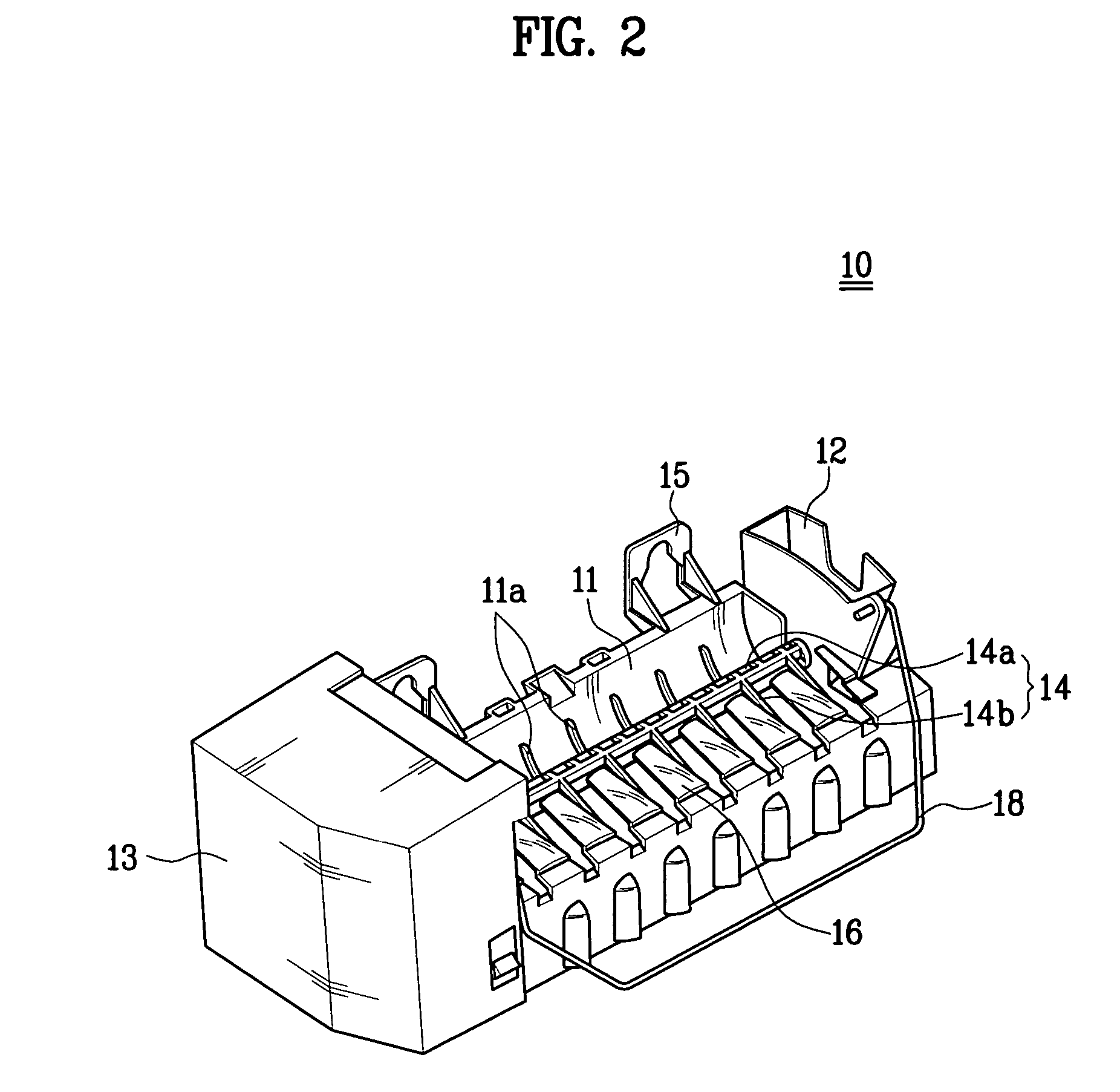

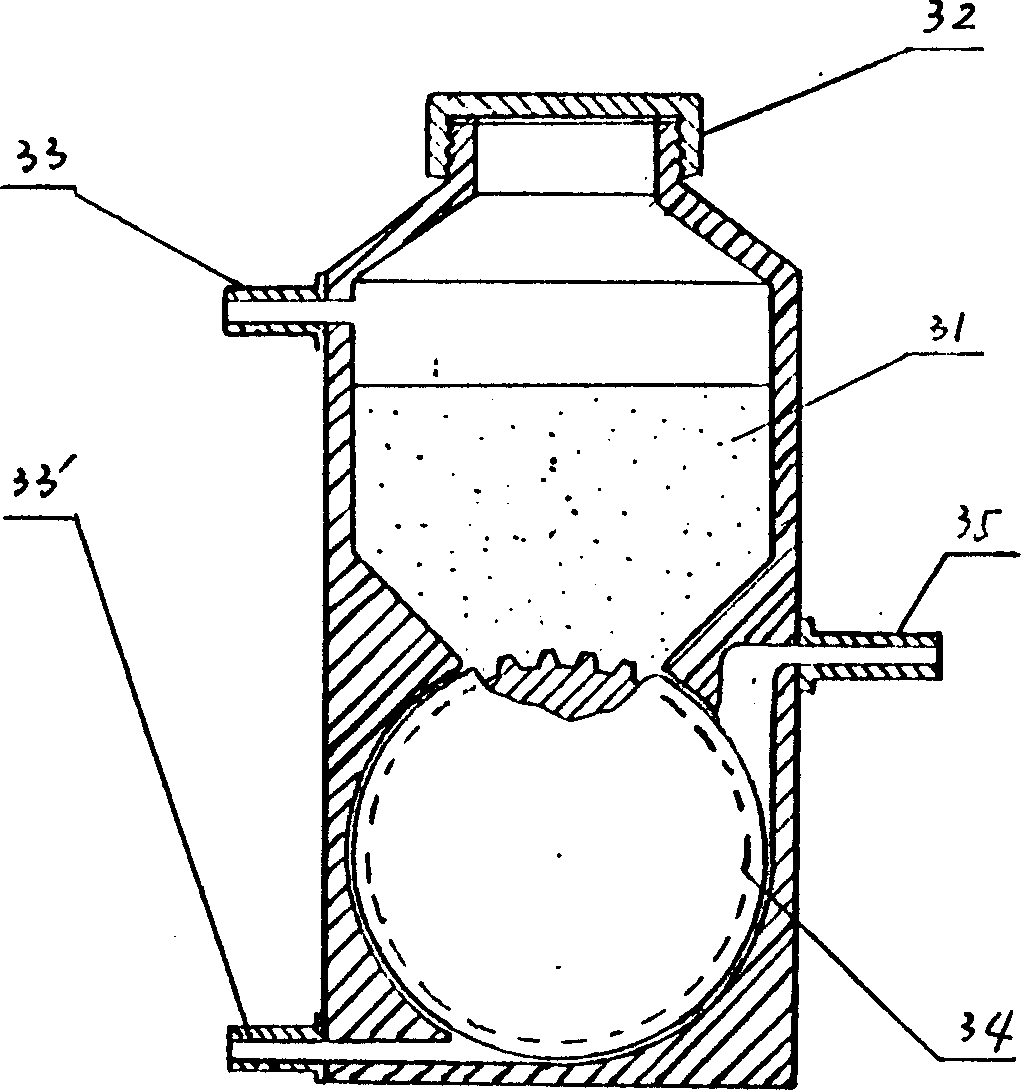

Ice making apparatus and refrigerator having the same

InactiveUS20080034780A1Shorten ice making timeEasy to removeLighting and heating apparatusIce productionCold airEngineering

An ice making apparatus capable of reducing an ice making time be rapid cooling of an ice making tray thereof while guaranteeing the making of transparent ice and a refrigerating having the ice making apparatus. The ice making apparatus includes the ice making tray to freeze water filled therein so as to make ice, and a cold air guiding device to guide cold air to a lower surface of the ice making tray. The cold air guiding device includes a cold air guiding plate installed below the ice making tray to be spaced apart from the lower surface of the ice making tray, and a plurality of protrusions provided at an upper surface of the cold air guiding plate to guide the cold air flowing along the upper surface of the cold air guiding plate in a direction toward the lower surface of the ice making tray.

Owner:SAMSUNG ELECTRONICS CO LTD

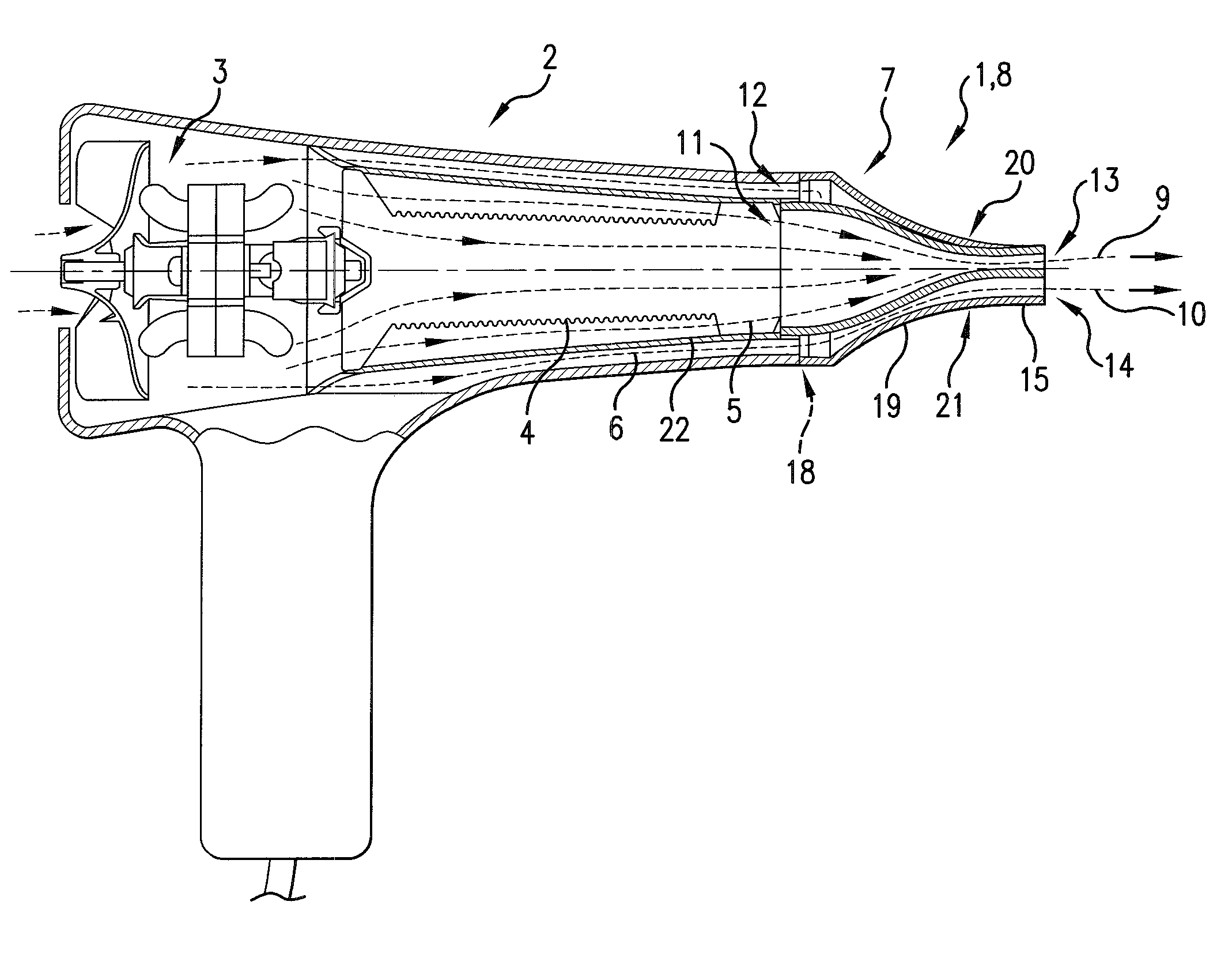

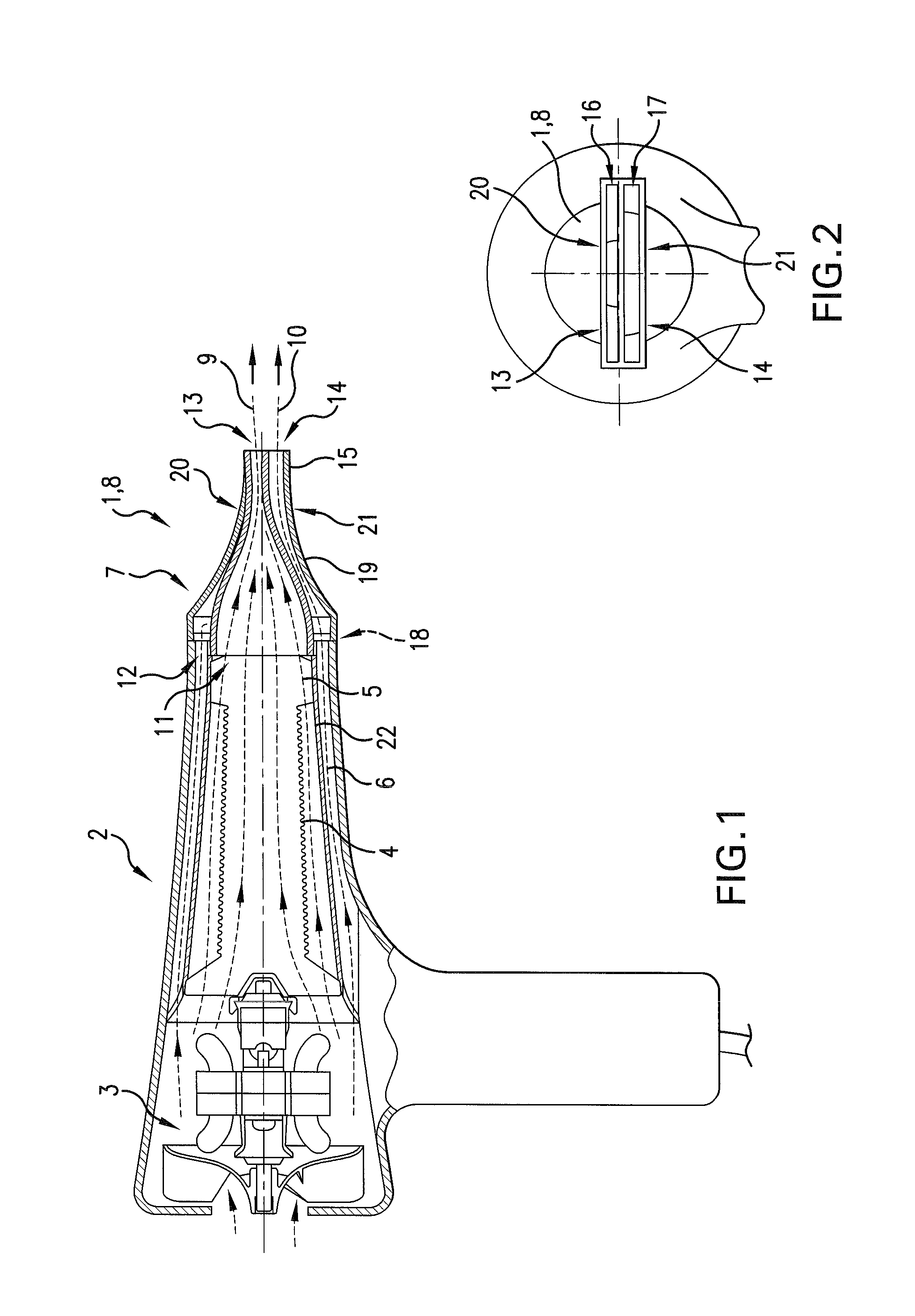

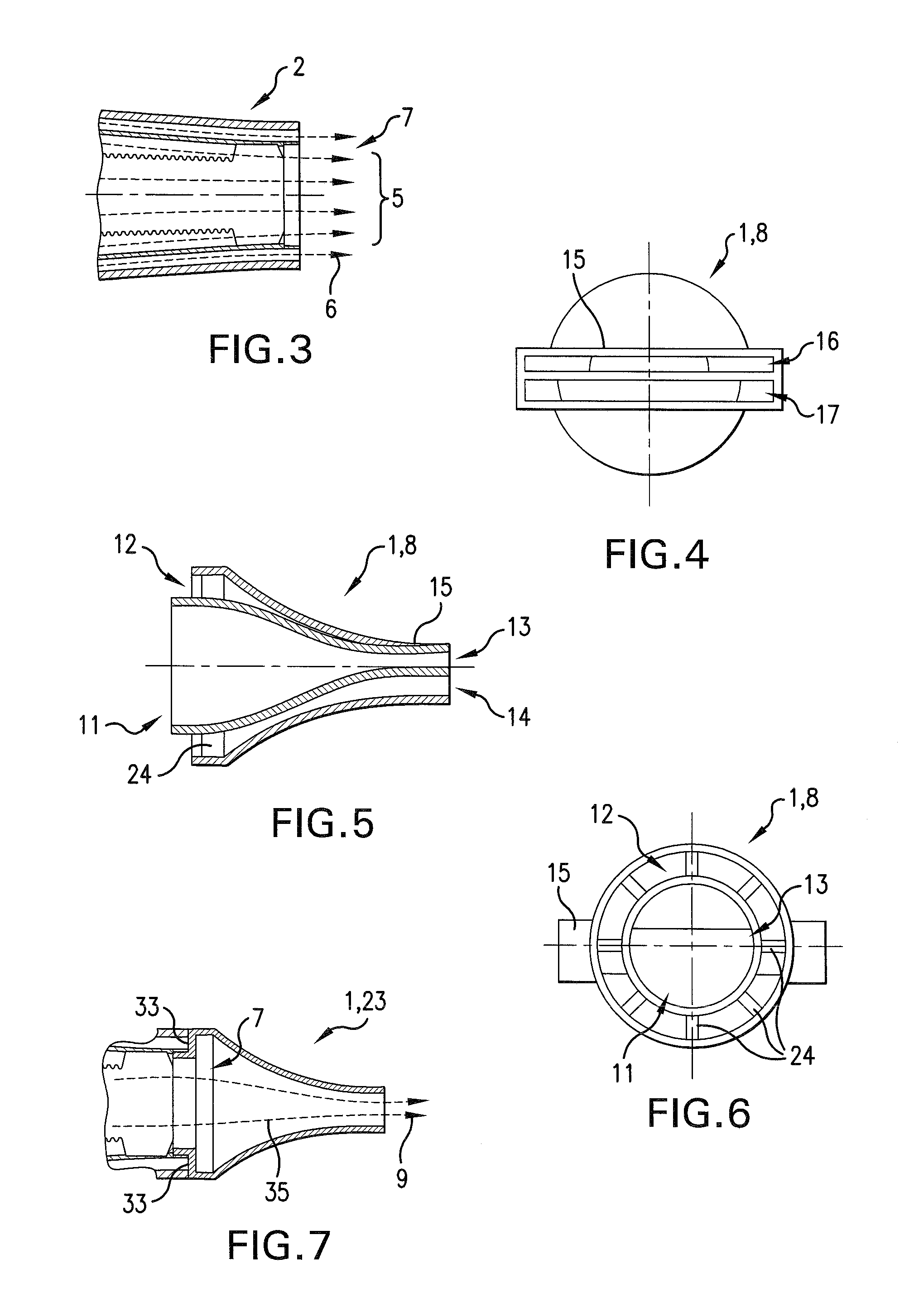

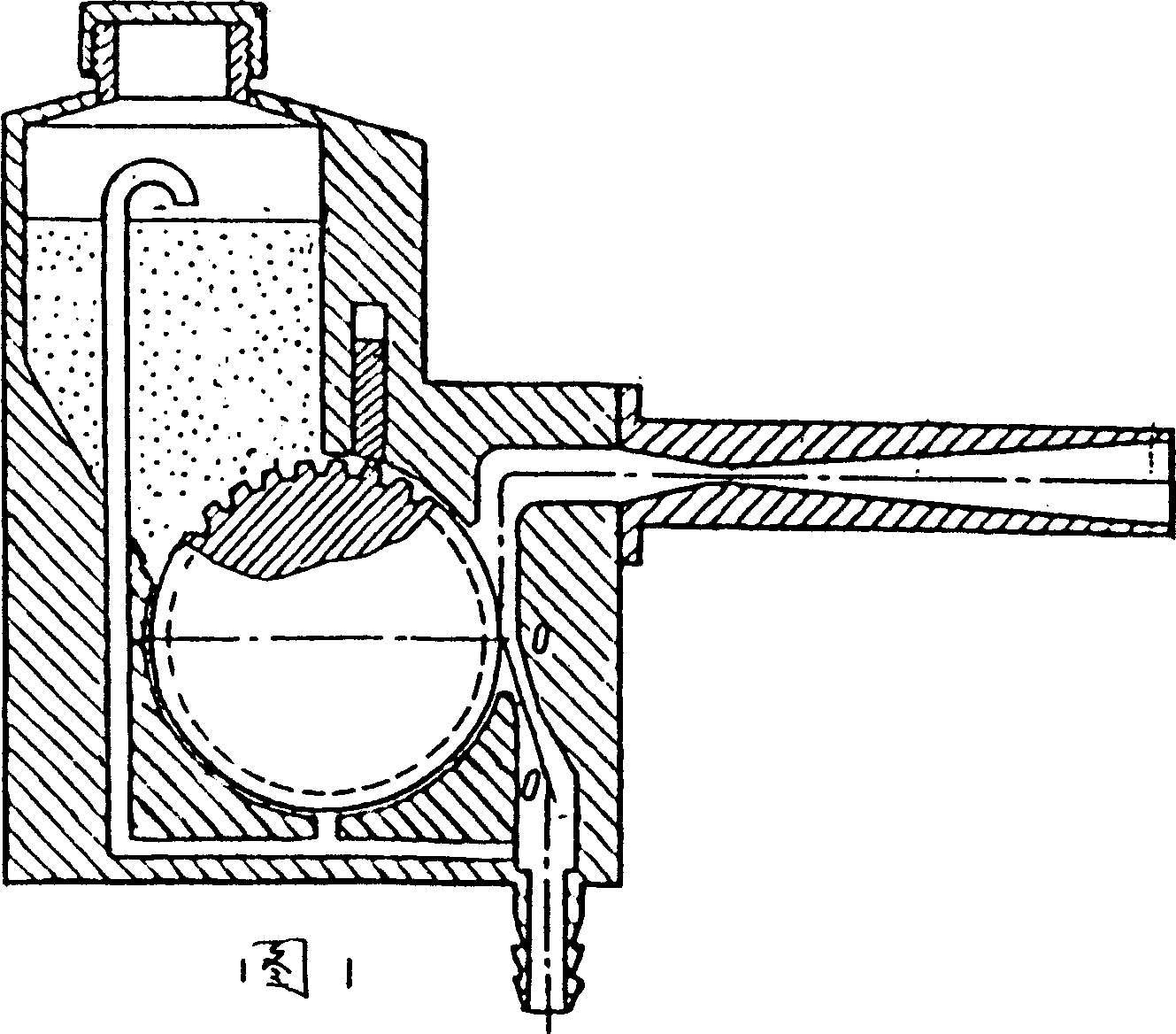

Device for a hot air shower

InactiveUS7412781B2Easy constructionProduced economicallyDrying solid materials with heatCurling-ironsCold airAirflow

The air nozzle attachment (8) for the hair dryer (2) is connectable to the blower opening (7) of the hair dryer and produces a hot-air stream (9) and a cold-air stream (10) that are arranged side-by-side. The air nozzle attachment (8) has a hot-air nozzle (13) and a cold-air nozzle (14) located side-by-side and, on an end connectable to the blower opening (7), has a central conduit entrance (11) and a coaxial conduit entrance (12), which open into the hot-air nozzle (13) and the cold-air nozzle (14) respectively. The air nozzle attachment (8) can be detached again from the dryer (2) and preferably has a snap-on coupling device (18) for connecting the air nozzle attachment to the dryer (2), which permits rotation of the air nozzle attachment.

Owner:WELLA INT OPERATIONS SWITZERLAND SARL

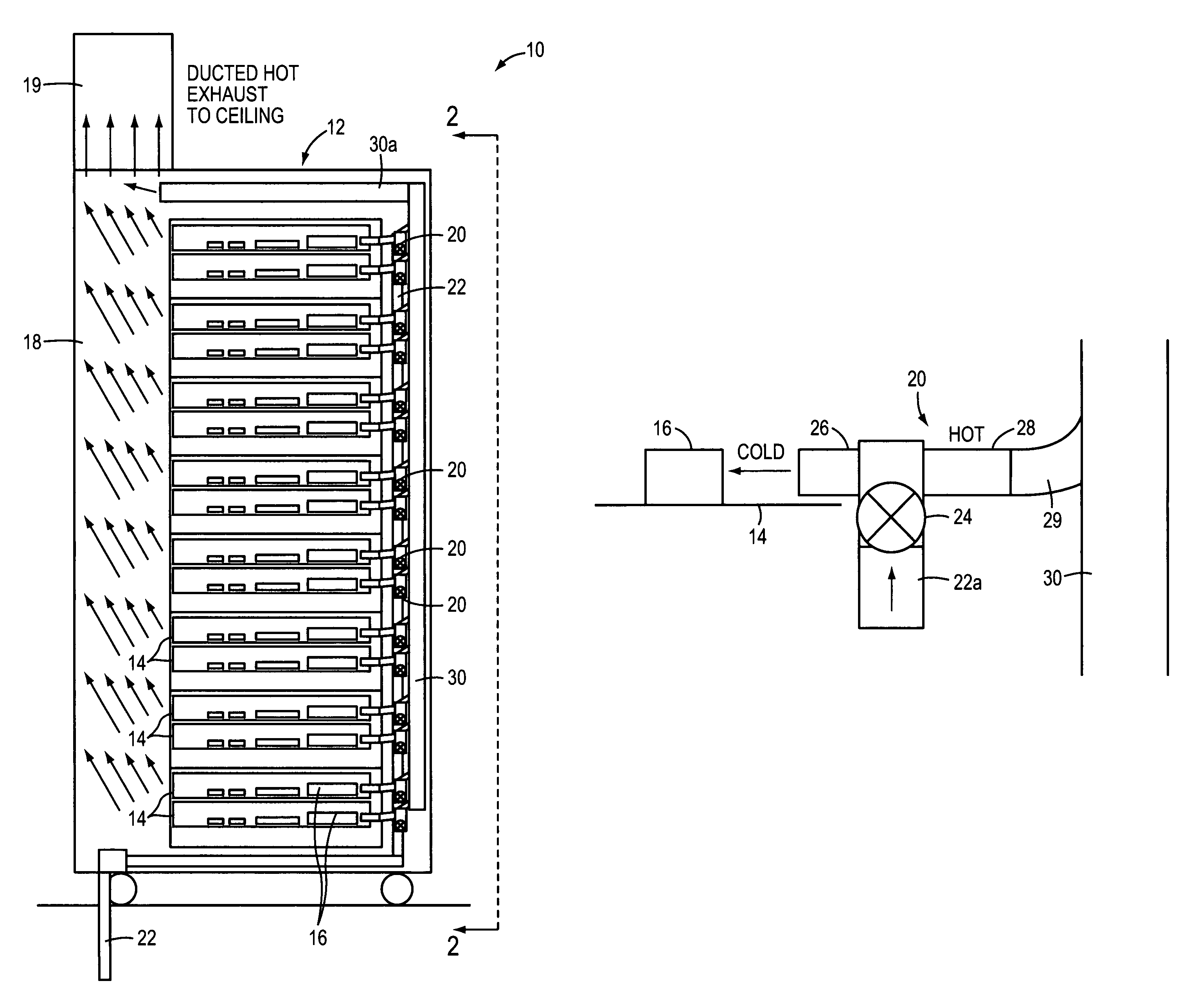

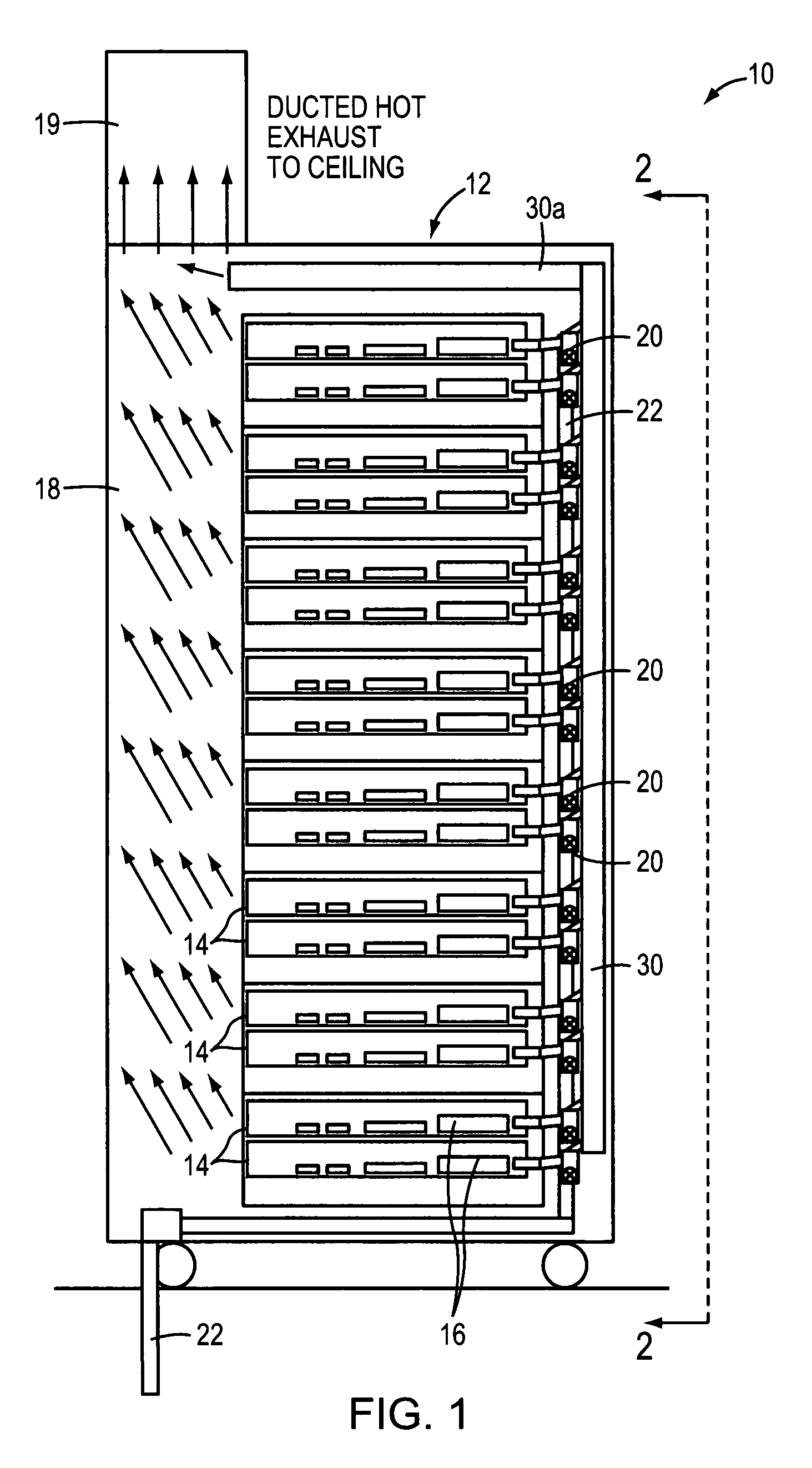

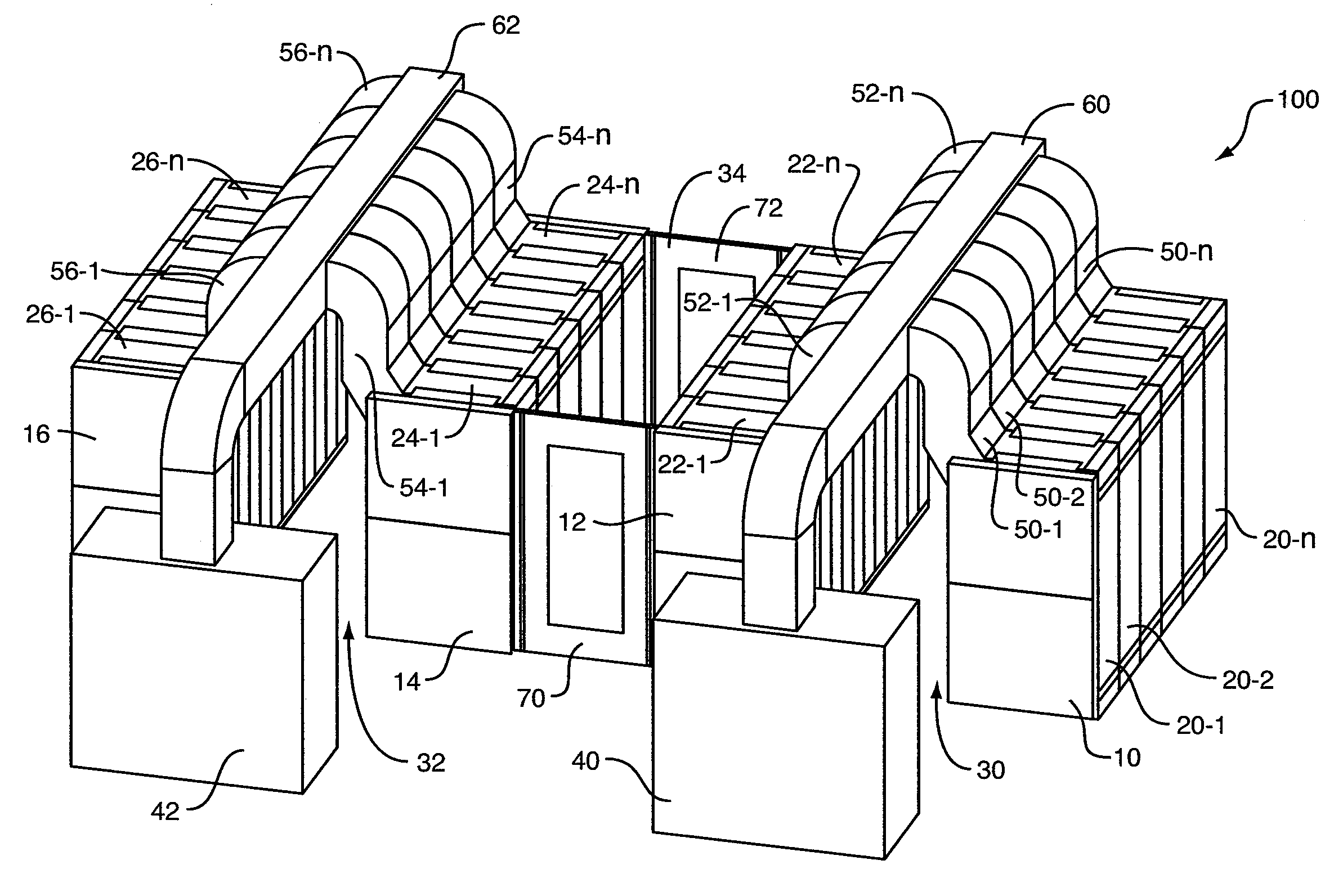

Systems and Methods for Closed Loop Heat Containment with Cold Aisle Isolation for Data Center Cooling

ActiveUS20100216388A1Maximize capacityMaintain depthCasings/cabinets/drawers detailsIndirect heat exchangersCold airData center

The invention combines systems and methods for heat containment and cold air isolation for managing airflow and temperature in data centers. The data center contains at least two rows of cabinets containing heat-generating equipment and arranged to form a cold aisle and a hot aisle. The data center system includes panels or doors at both ends of the cold aisle and an optional cover over the cold aisle to inhibit cooled air supplied by an air conditioning system from exiting the cold aisle and inhibit air warmed by the heat-generating components from entering the cold aisle,. A chimney coupled to the top, rear, or top and rear of the cabinets is configured to exhaust the warmed air into a region above the rows of cabinets. The chimneys may be ducted to a plenum or suspended ceiling or to the intake of the air conditioning system. Baffles and / or fans may be included in the chimneys, ducts, and / or plenums to control the air pressure. The invention may also include one or more data center air conditioning units, and each air conditioning unit may be configured to service one or more rows of cabinets. Alternatively, or in addition, cool air may be supplied by the building's air conditioning system.

Owner:EATON INTELLIGENT POWER LTD

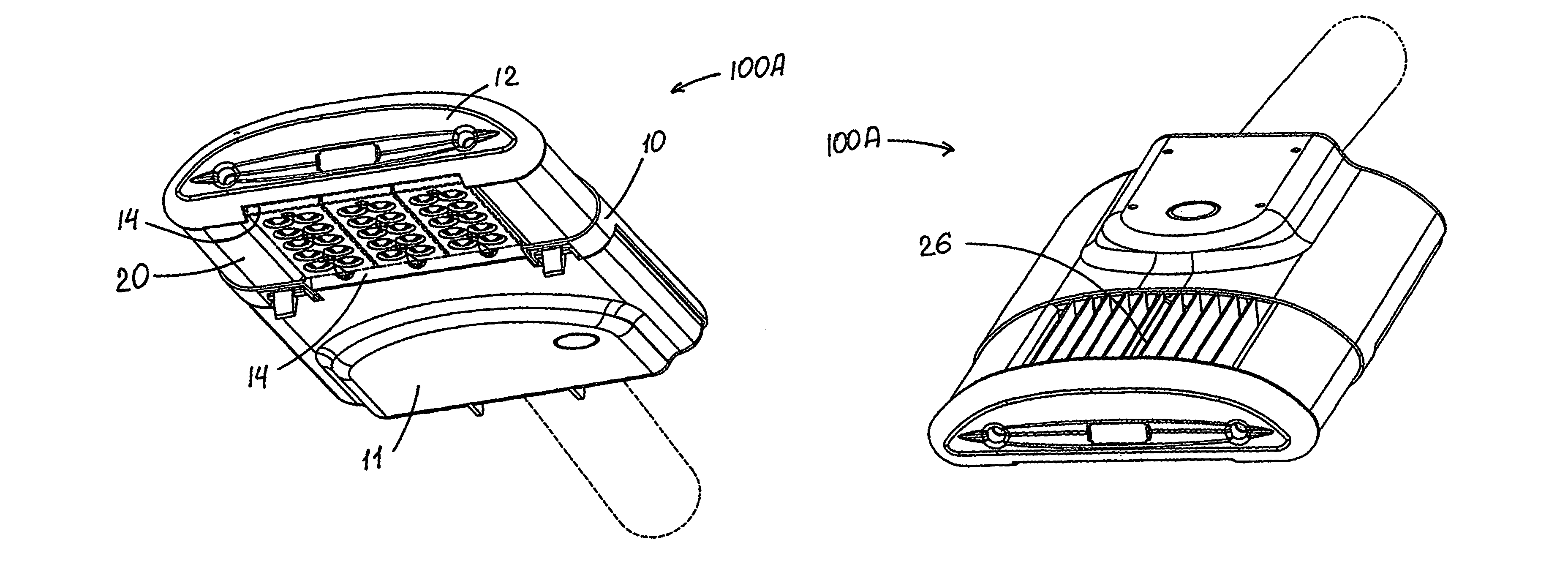

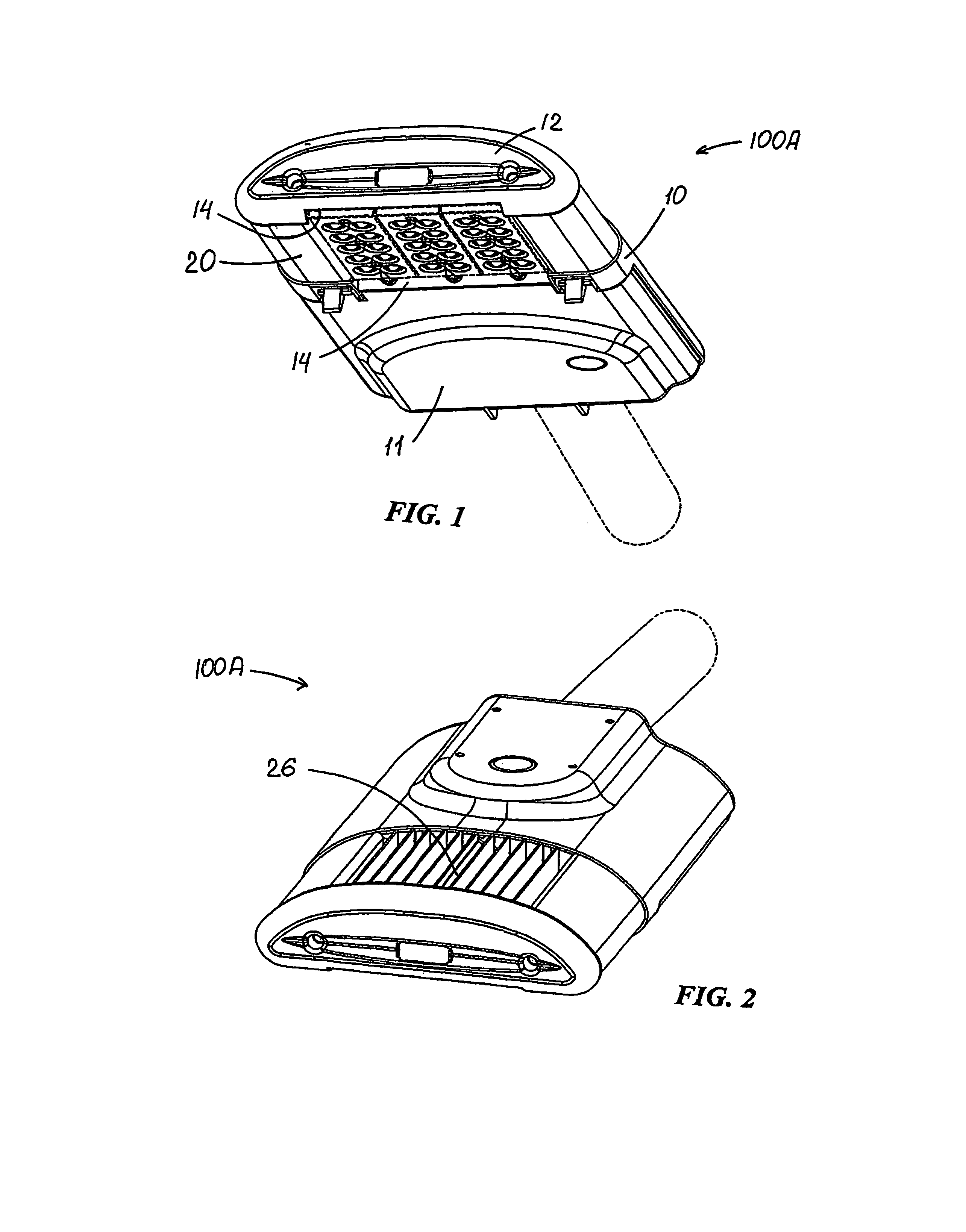

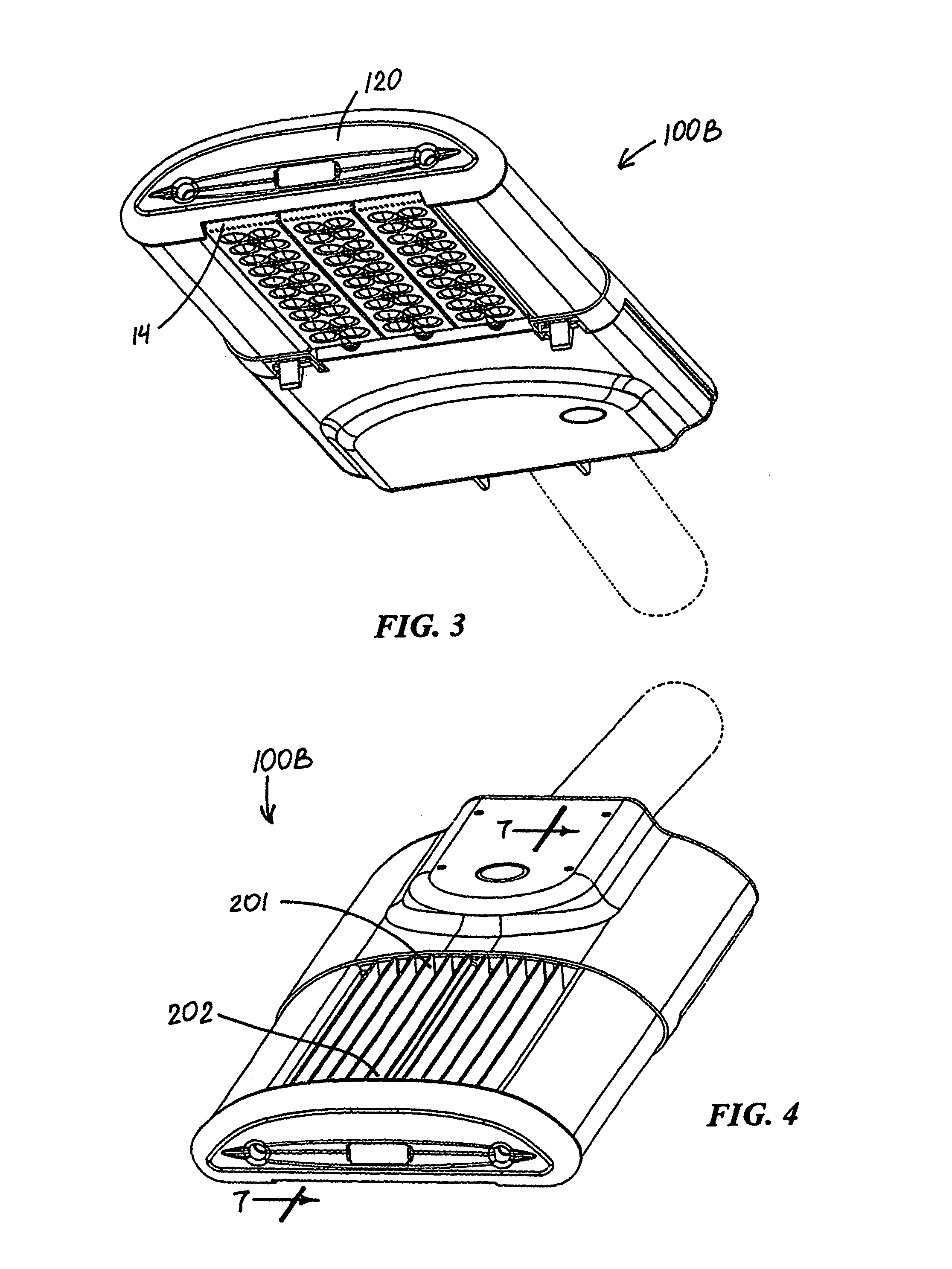

LED light fixture

ActiveUS8092049B2Reduced development and manufacturing costExcellent reliability and durabilityPlanar light sourcesMechanical apparatusCold airEngineering

An LED floodlight fixture includes (1) a housing that has (a) at least one end-portion and (b) a single-piece extrusion including (i) a base having an LED-adjacent surface and an opposite surface and (ii) a heat-dissipating section having heat-dissipating surfaces extending from the opposite surface, and (2) an LED arrangement mounted to the LED-adjacent surface in non-water / air-tight condition with respect to the housing. The housing preferably forms at least one venting gap to provide cool-air ingress to and along the heat-dissipating surfaces by upward flow of heated air therefrom. Additionally and / or alternatively, the base of the single-piece extrusion has one or more venting apertures to provide cool-air ingress for such purpose. One aspect of the invention involves the heat-dissipating section of the extrusion including a closed extruded wireway therealong enclosing wires extending to / from electrical component(s).

Owner:IDEAL IND LIGHTING LLC

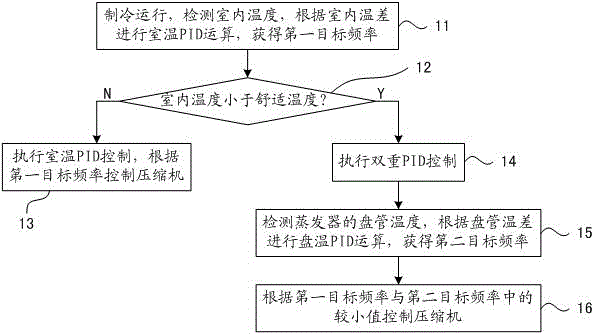

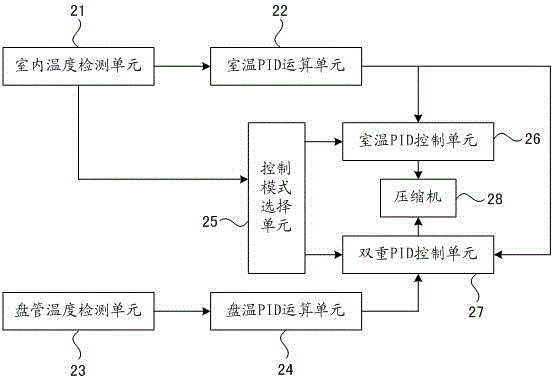

Refrigeration control method, control device and variable frequency air conditioner

ActiveCN104697109AComfortable air temperatureRapid coolingMechanical apparatusSpace heating and ventilation safety systemsCold airProportion integration differentiation

The invention discloses a refrigeration control method, a control device and a variable frequency air conditioner. The method comprises steps as follows: detecting the indoor temperature in the refrigeration operation process, calculating the indoor temperature difference, and performing PID (proportion integration differentiation) operation on room temperature according to the indoor temperature difference to obtain a first target frequency; comparing the indoor temperature with a set comfortable temperature; controlling a compressor according to the first target frequency if the indoor temperature is not lower than the comfortable temperature; if the indoor temperature is lower than the comfortable temperature, detecting the coil temperature of an evaporator of the variable frequency air conditioner, calculating the temperature difference between the coil temperature and a set coil target temperature to obtain a coil temperature difference, and performing PID operation on the coil temperature according to the coil temperature difference to obtain a second target frequency; controlling the compressor according to the smaller one of the first target frequency and the second target frequency. With the adoption of the refrigeration control method, the control device and the variable frequency air conditioner, the problem about refrigeration comfortlessness caused by cold air blown by an existing variable frequency air conditioner can be solved.

Owner:HAIER GRP CORP +1

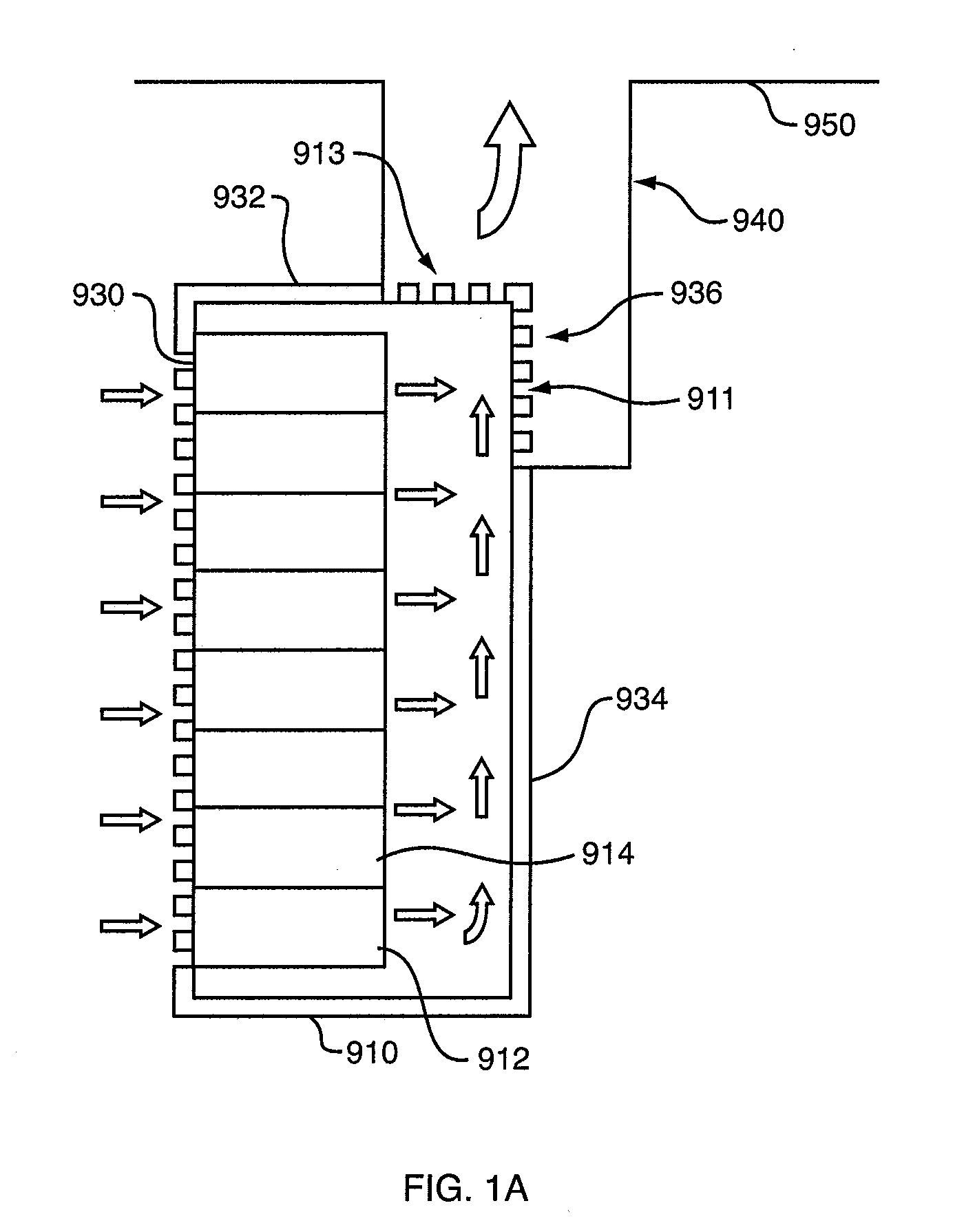

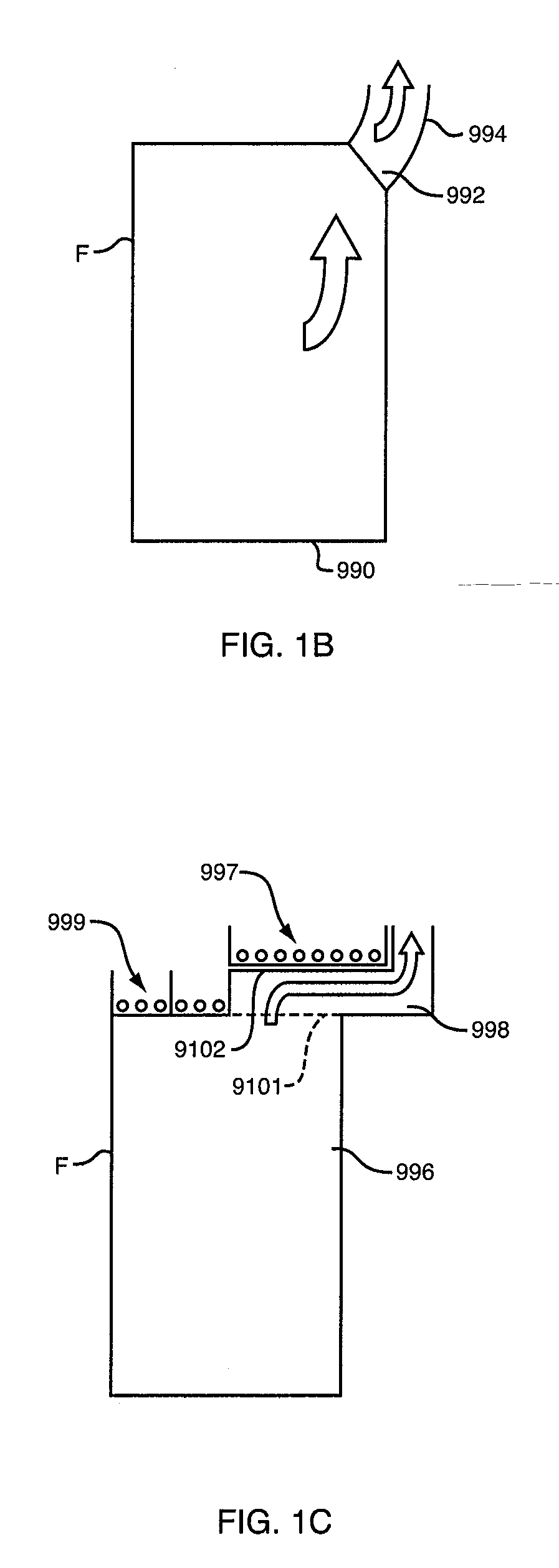

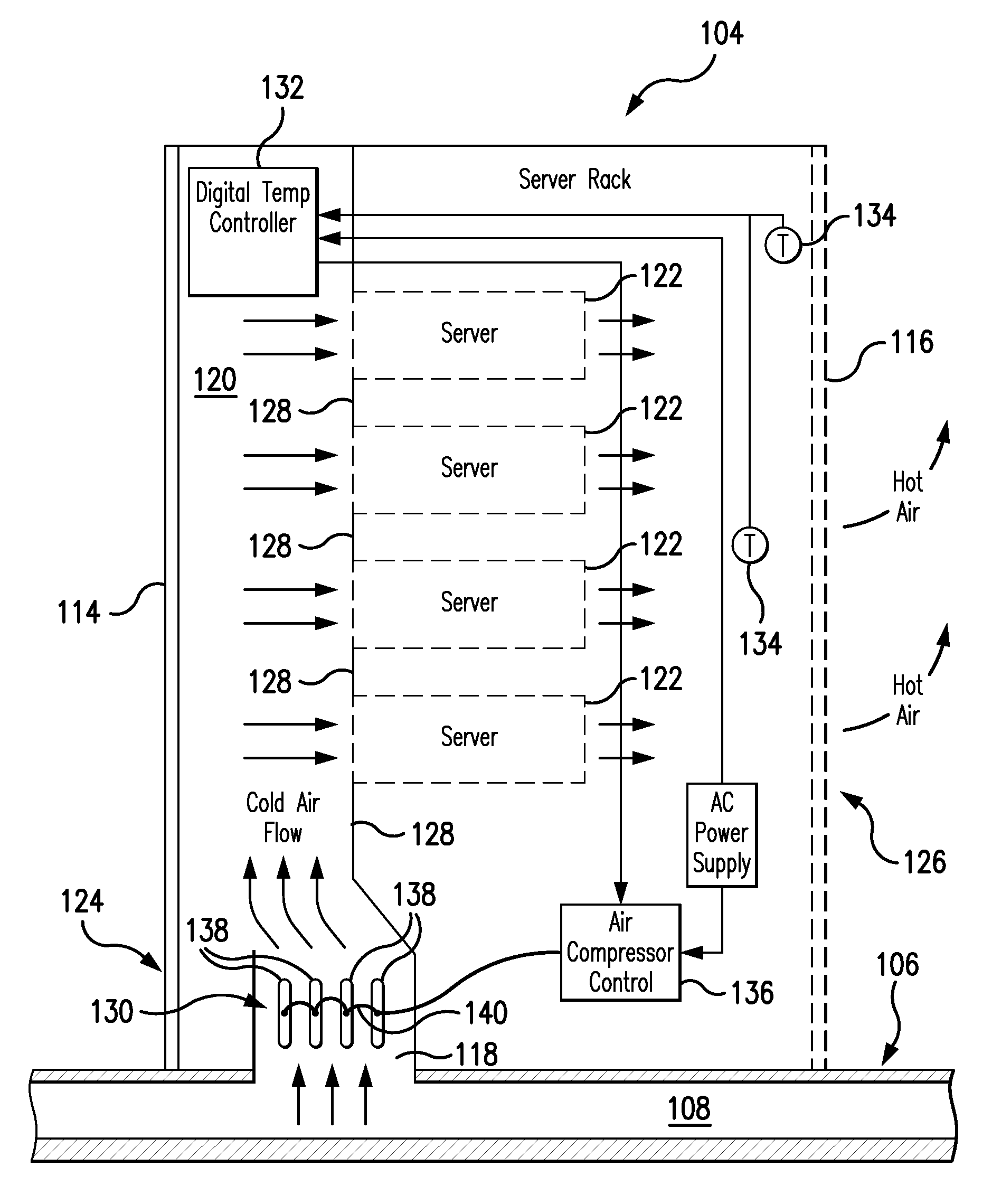

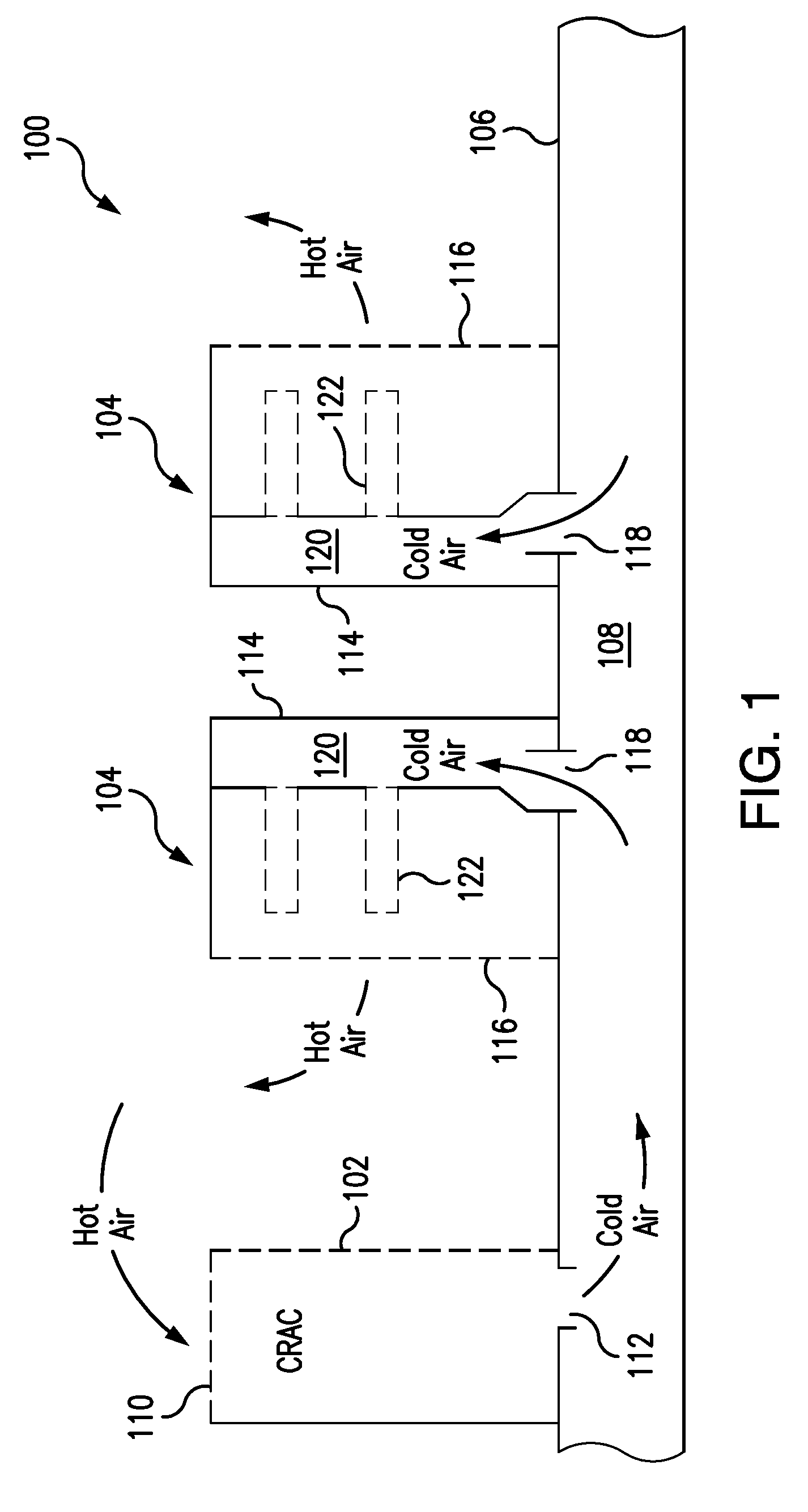

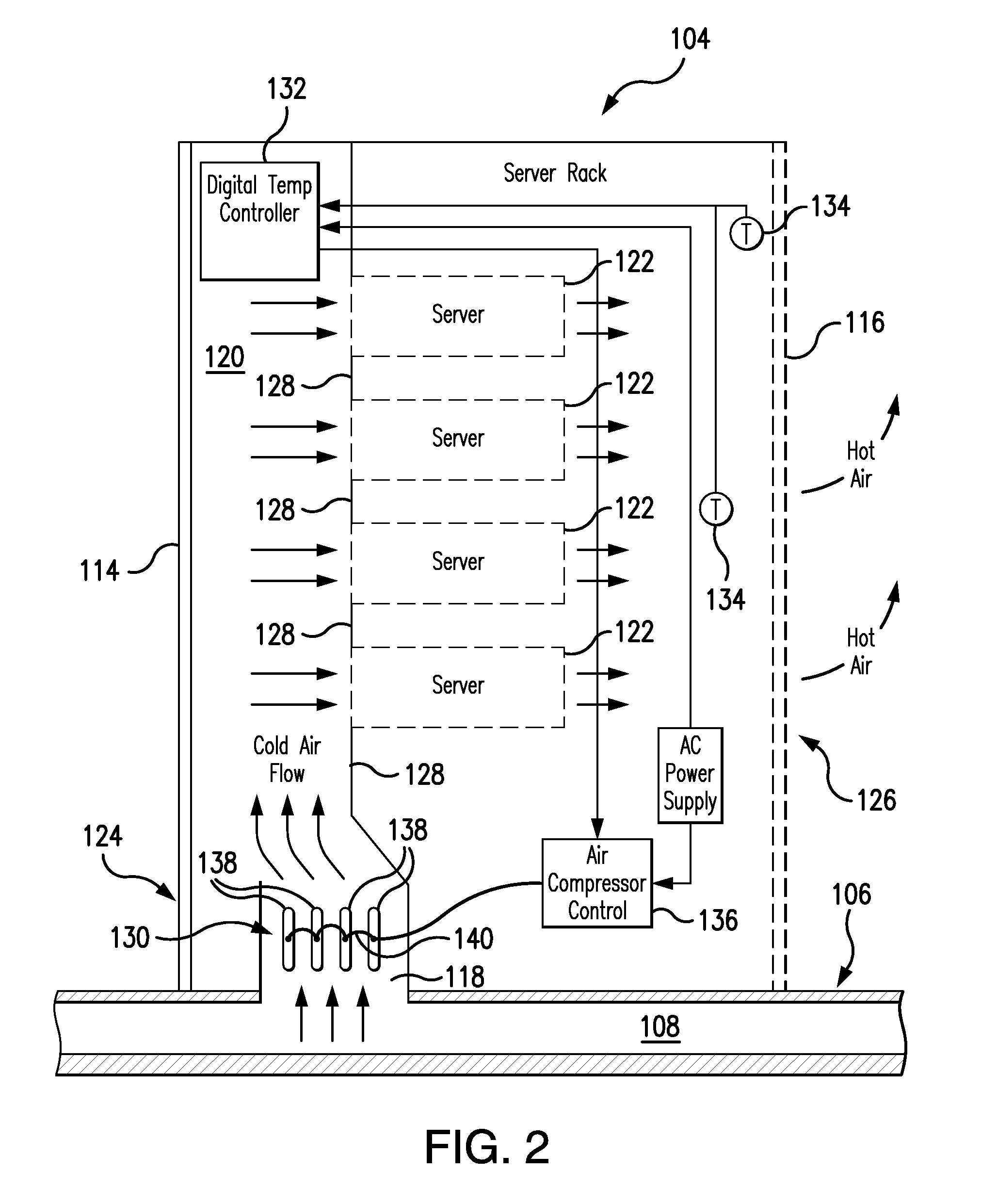

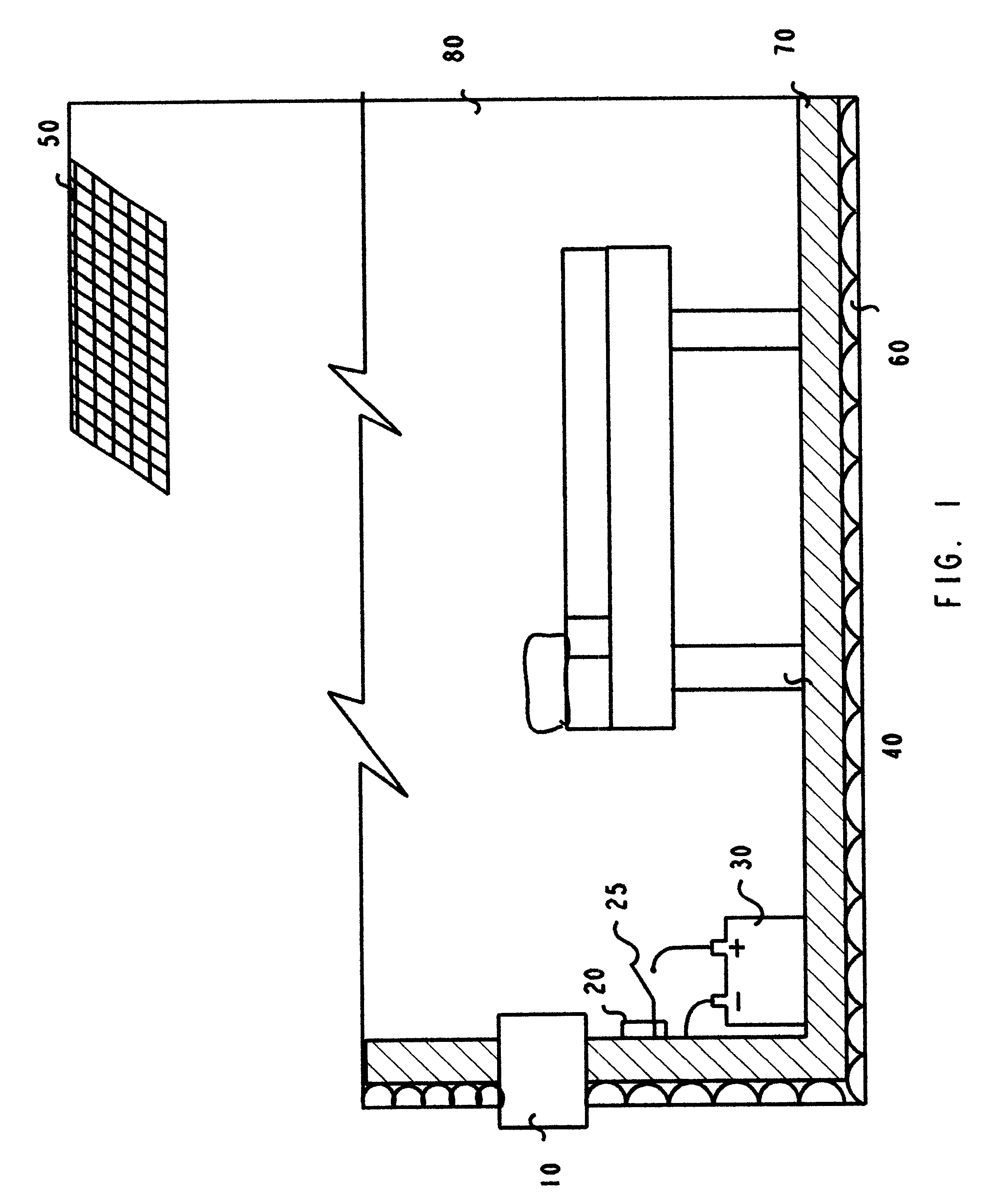

Cooling System for a Computer Server Cabinet in a Data Center

InactiveUS20100317278A1Space heating and ventilation safety systemsDomestic cooling apparatusCold airData center

A system for cooling computer equipment in a data center. The system includes a raised floor defining a pressurized under-floor plenum; a computer room air conditioning unit disposed on the raised floor and having a hot air inlet and a cold air outlet, wherein the cold air outlet is in fluid communication with pressurized under-floor plenum; and a server cabinet housing server equipment and including a pressurized vertical plenum in fluid communication with under-floor plenum via an inlet duct. The server cabinet is configured to receive a cold air stream from the under-floor plenum via the inlet duct into the vertical plenum and draw the cold air across the server equipment to provide cooling without the use of external fans. The system may also include an inflatable airfoil damper assembly disposed within the inlet duct and configured to provide failsafe variable airflow to the vertical plenum within the server cabinet.

Owner:BLACKROCK

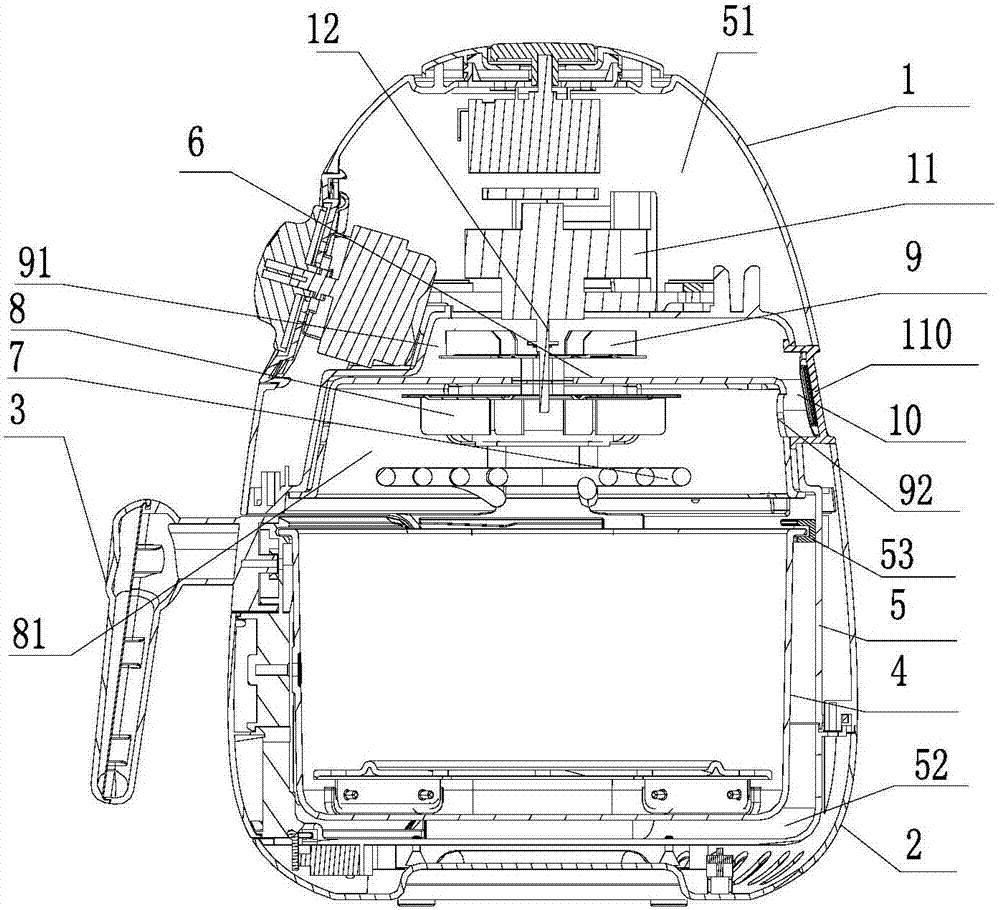

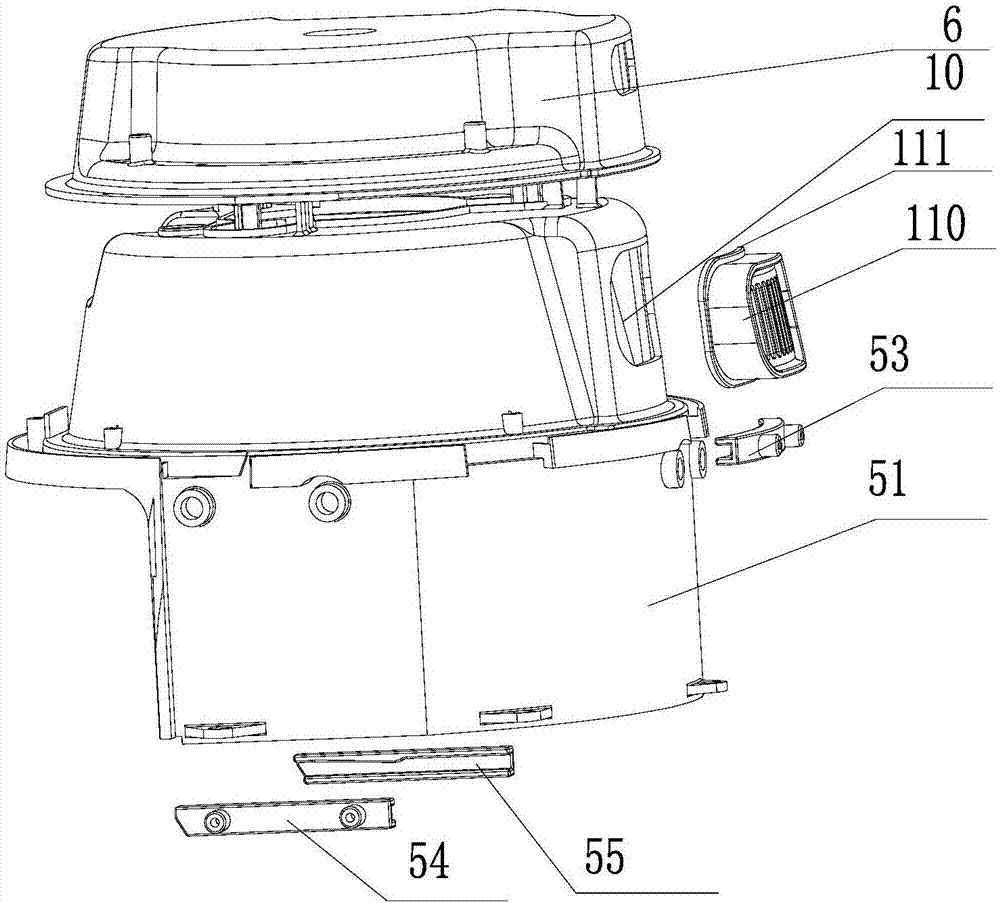

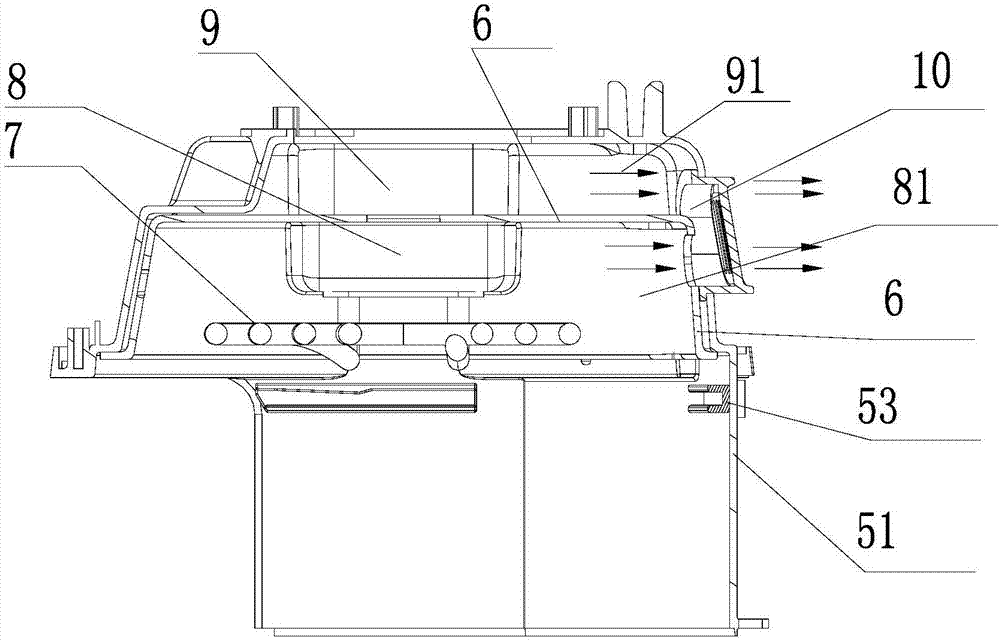

Simple assembly structure air fryer

The invention discloses a simple assembly structure air fryer. The air fryer includes an upper shell body, a lower shell body connected to the upper shell body in a spigot mode and a handle installed on the side of the upper shell body; the upper shell body and the lower shell body are connected in a matching manner to form an inner chamber comprising an upper chamber installed inside the upper shell body, a lower chamber installed inside the lower shell body and a cooking chamber, wherein the upper chamber accounts for two-thirds of the height of the inner chamber and the lower chamber accounts for one-third of the height of the inner chamber. Compared with the prior art, the air fryer overcomes the defects and has a smart design and a rational structure; the structure is improved and renewed to simplify the assembly plan and to save assembling processes; the after-sale maintenance is facilitated; the cost is especially saved and the product competitiveness is strengthened; a cold air blast flow channel is shortened for heat dissipation, the surface heat dissipation is expedited, and the service life of the fryer is prolonged.

Owner:郭鑫

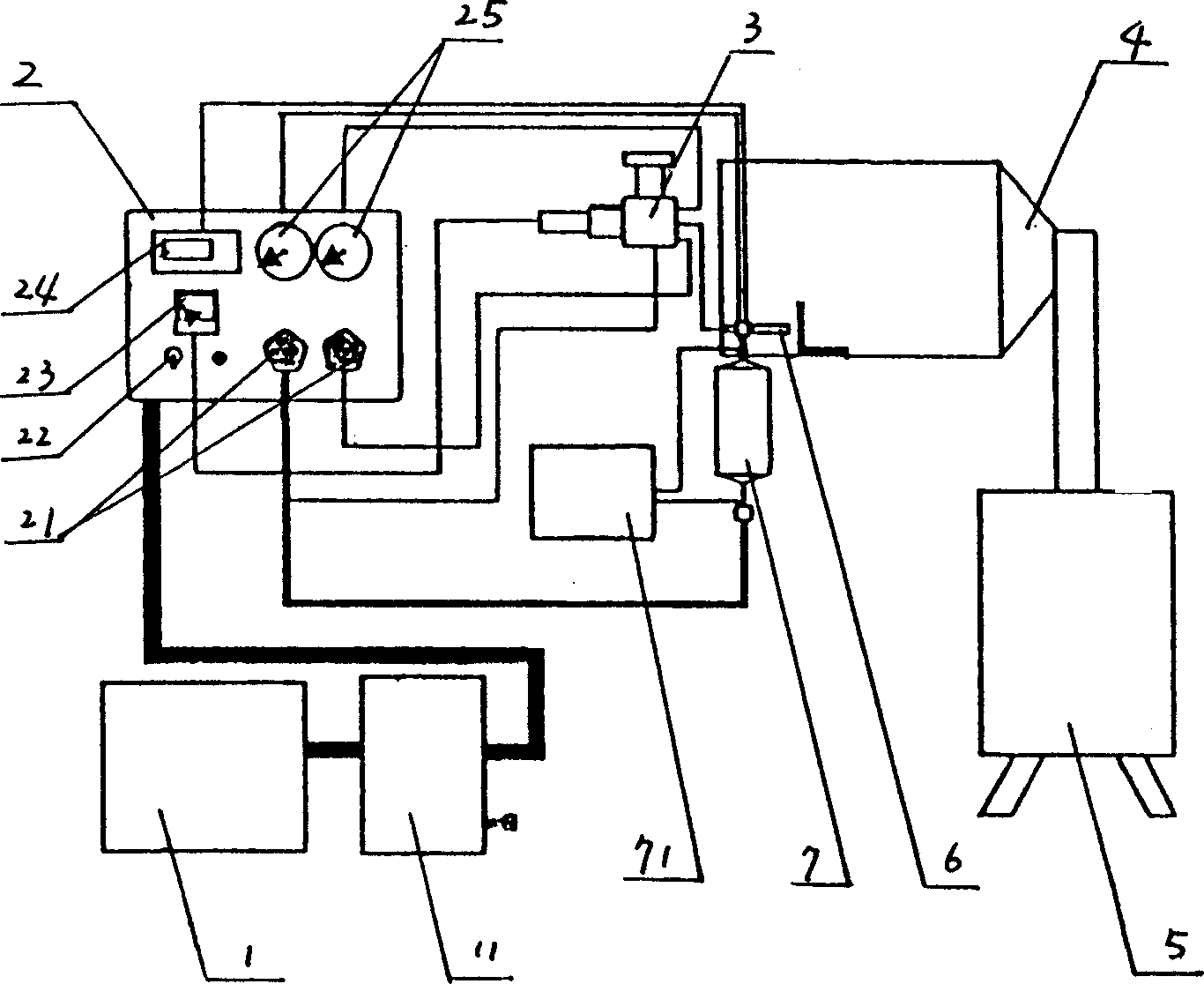

Direct current mini air conditioning system

An air conditioning unit is provided for a parked truck / boat to cool the sleeping cabin. The cabin air conditioner having a cooling unit comprising a cooling chamber with at least one insulated wall having on opposite sides there of a heat sink and a cooling block having there between thermoelectric chip(s) or a high efficient D.C. compressor or cold storage phase change material. The air conditioning unit also comprises an air intake conduit, a cool air conduit, an exhaust conduit and means of supplying power to the cooling unit. A method for cooling the. sleeping cabin through the use of the air conditioning unit disclosed in the invention is also provided.

Owner:SUNDHAR SHAAM P

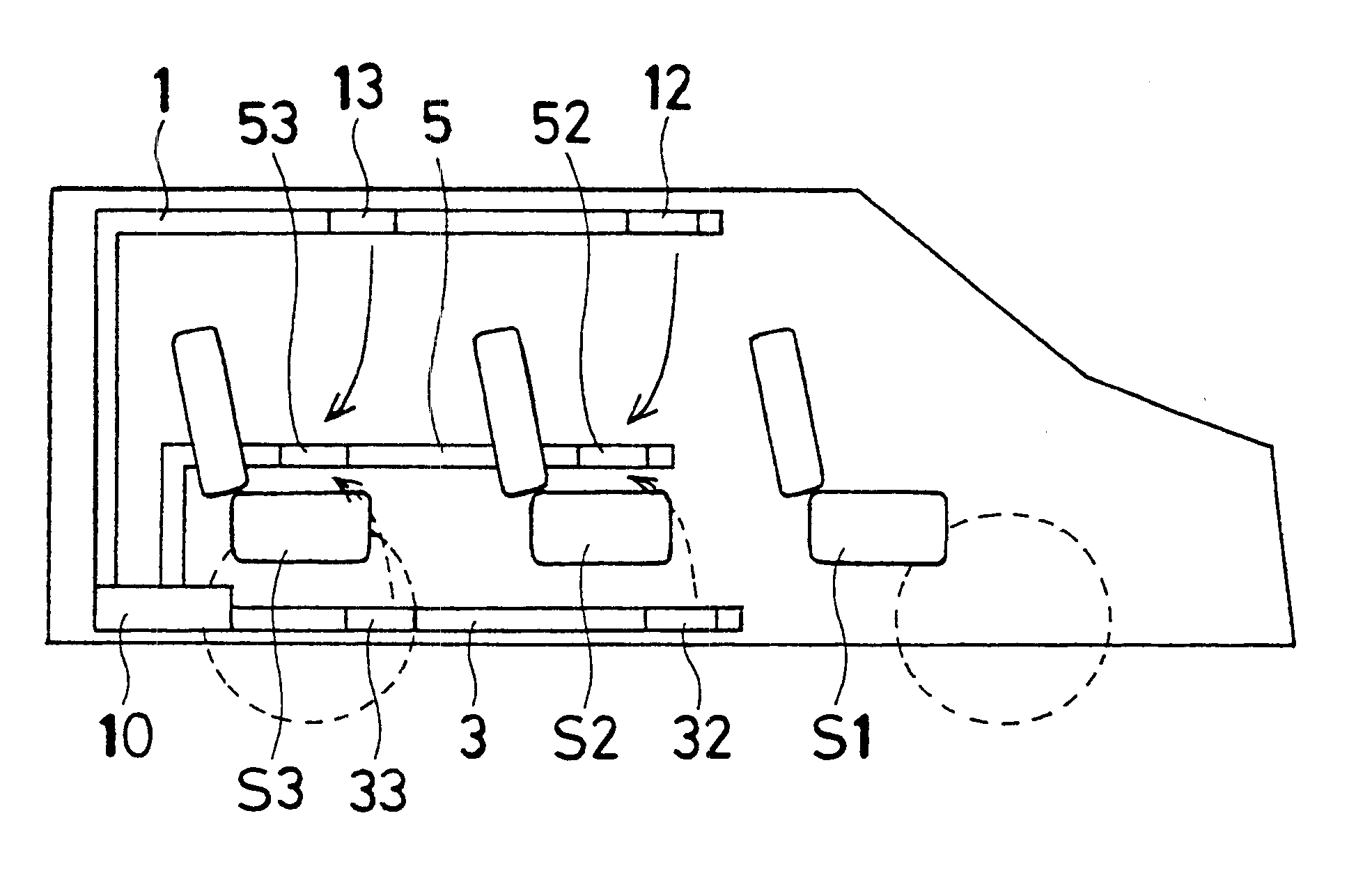

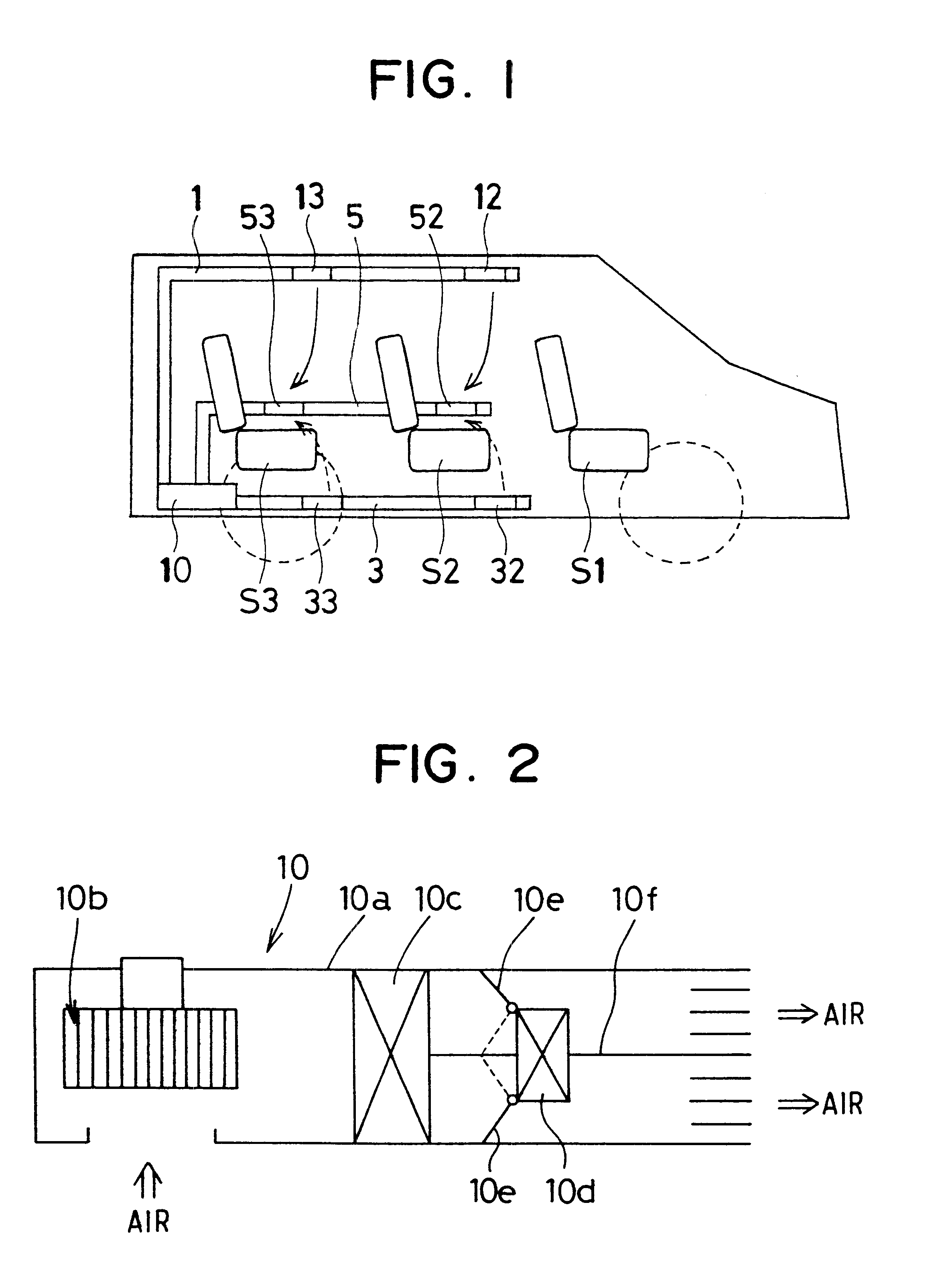

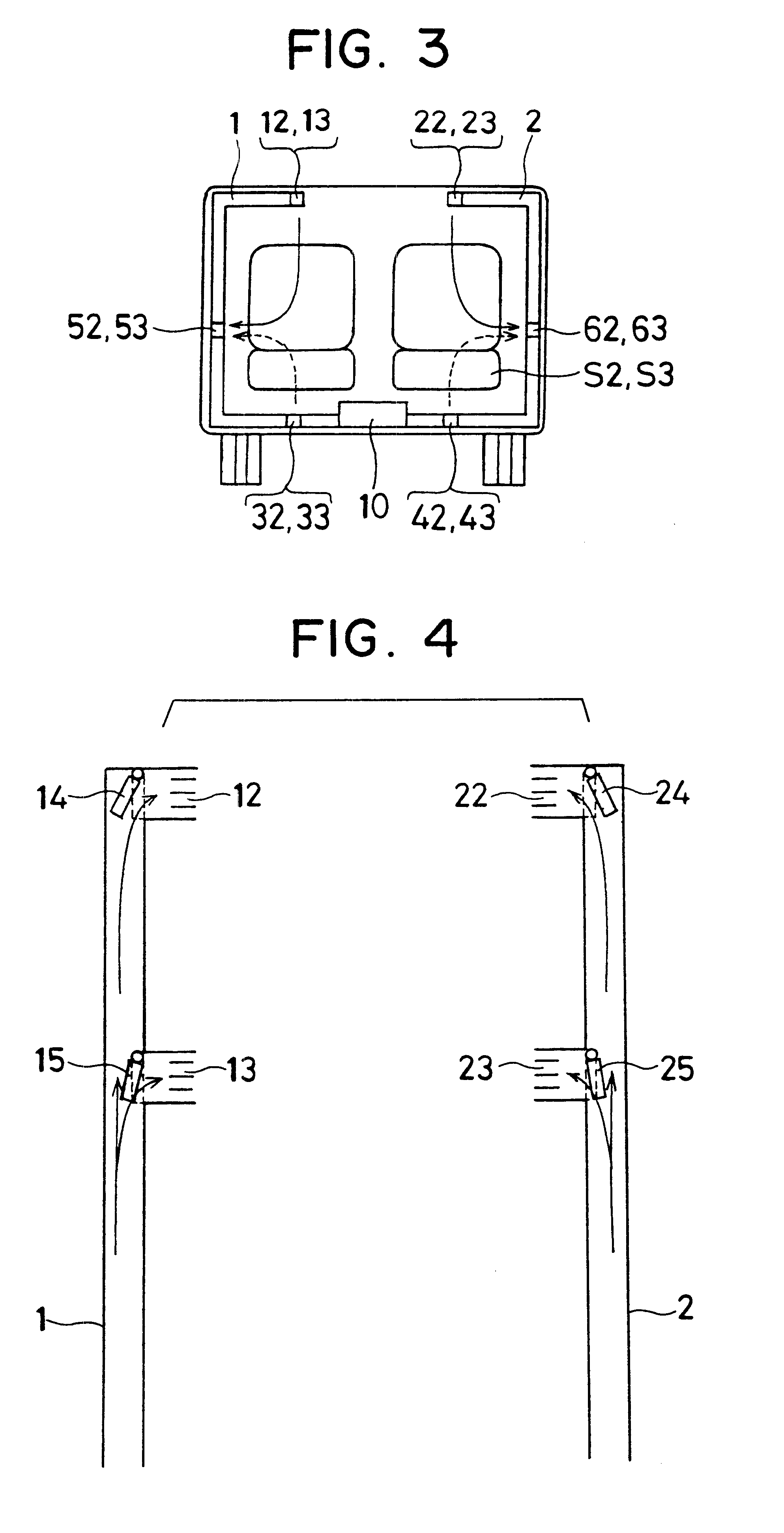

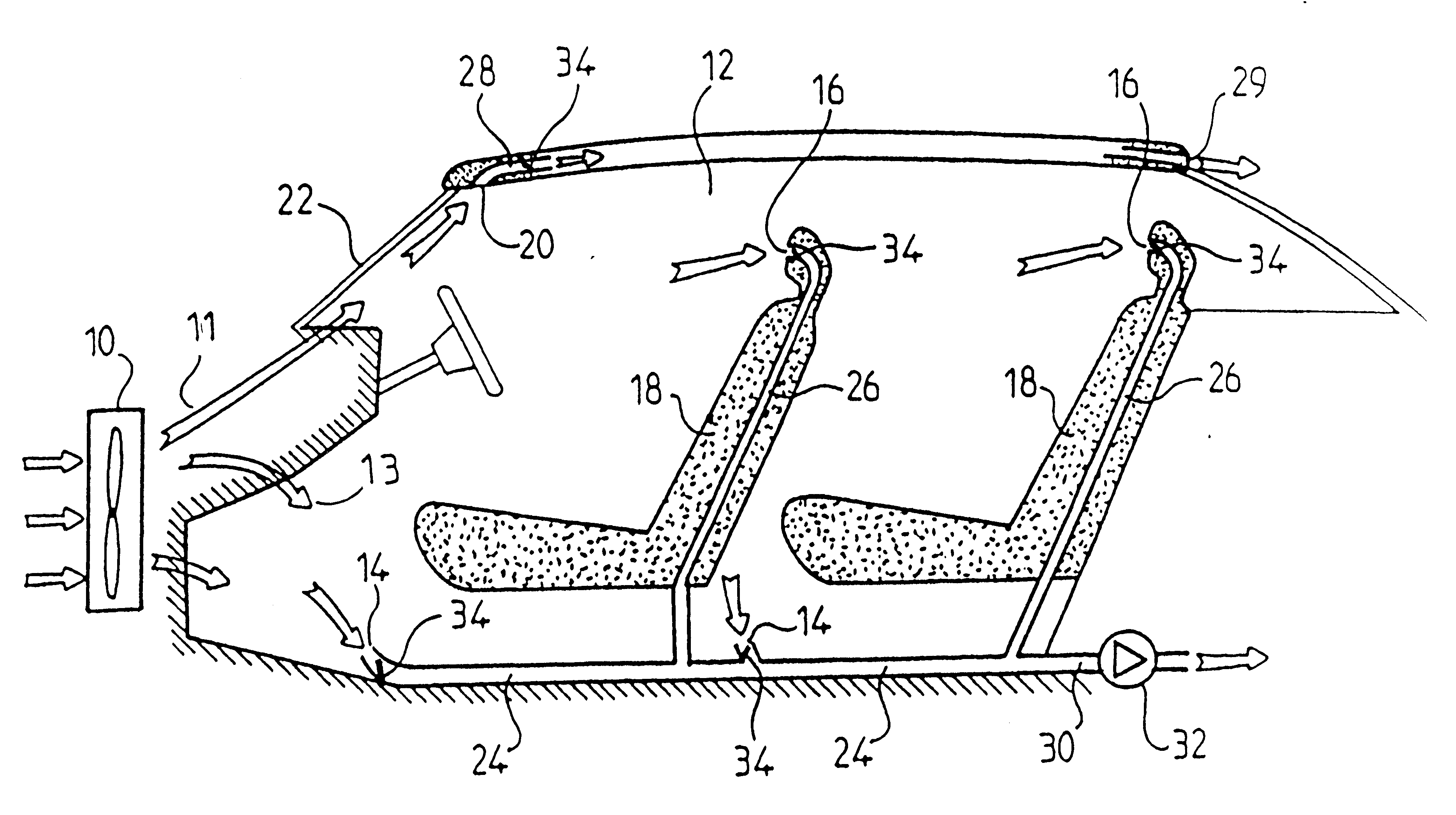

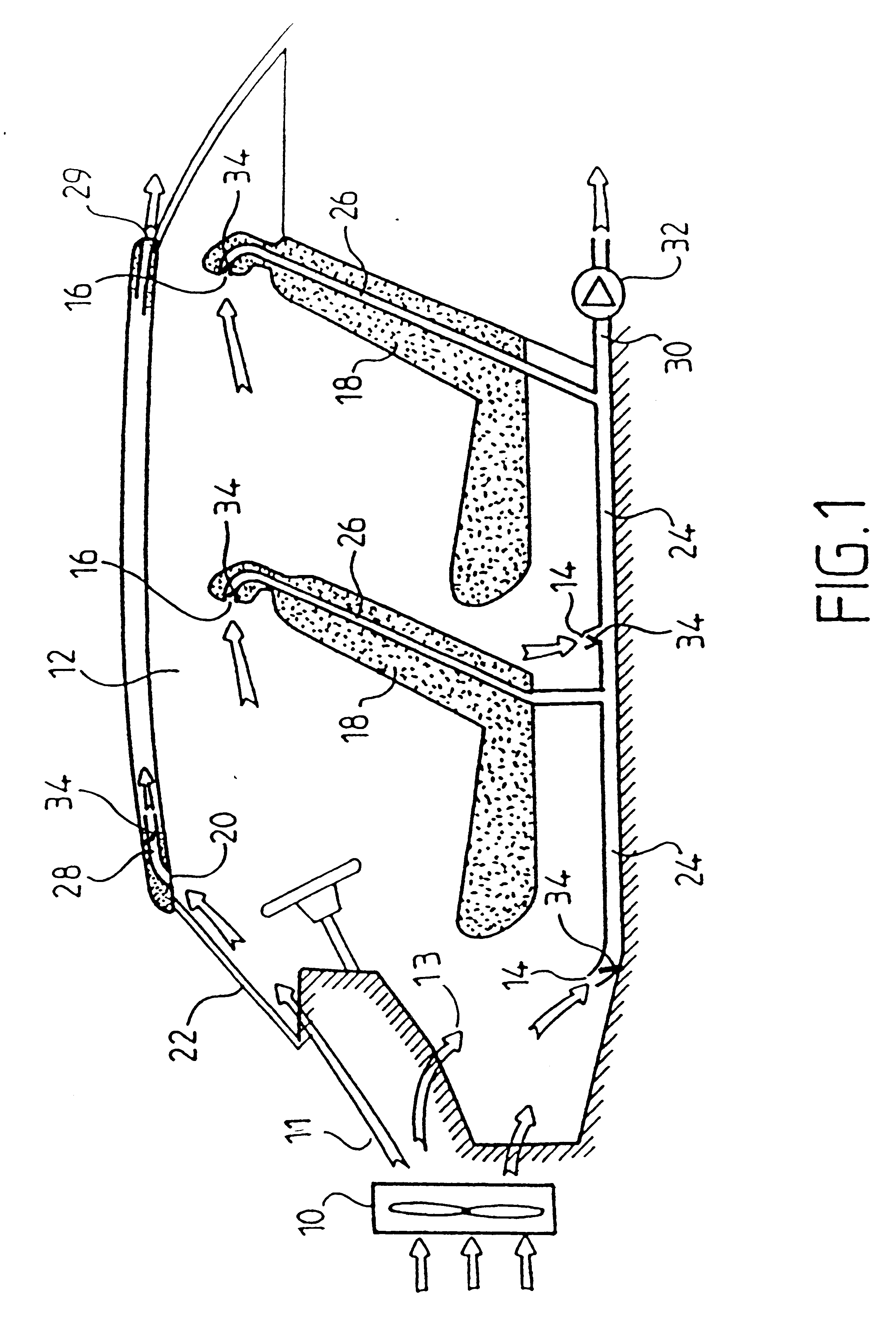

Vehicle air conditioner having air suction port for each seat

InactiveUS6491578B2Improve controlEfficient executionAir-treating devicesSeat heating/ventillating devicesCold airEngineering

In a vehicle air conditioner, each of cool air outlets is provided at an upper side of each seat at second and third seat lines from a most front seat so that cool air from an air conditioning unit is blown from the cool air outlets toward upper sides of the seats, respectively, and each of warm air outlets is provided at a lower side of each seat at the second and third seat lines so that warm air from the air conditioning unit is blown from the warm air outlets toward lower sides of the seats, respectively. In addition, each of suction ports is provided for each corresponding seat at the second and third seat lines so that air inside a passenger compartment is sucked from the suction ports to be returned to the air conditioning unit.

Owner:DENSO CORP

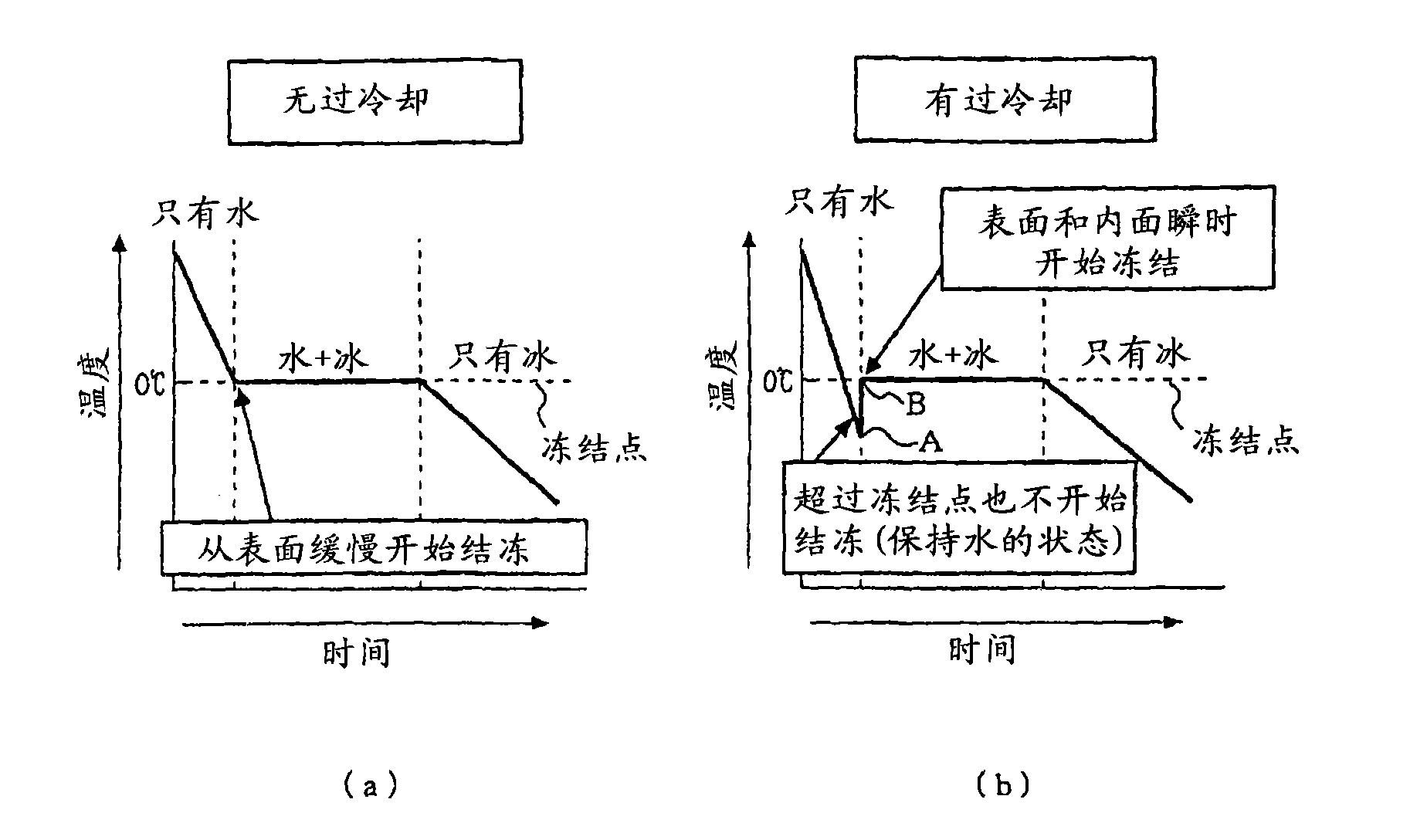

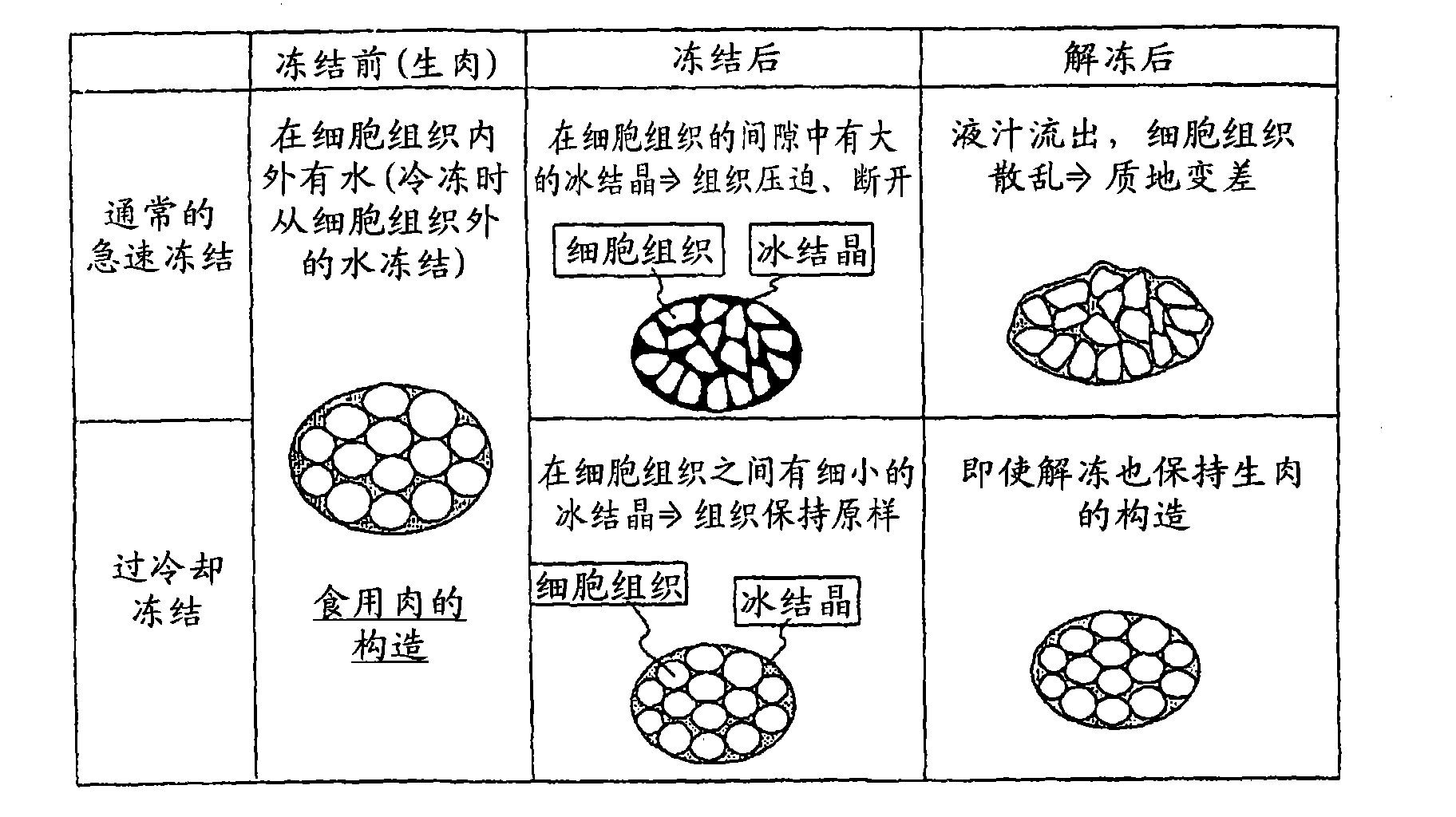

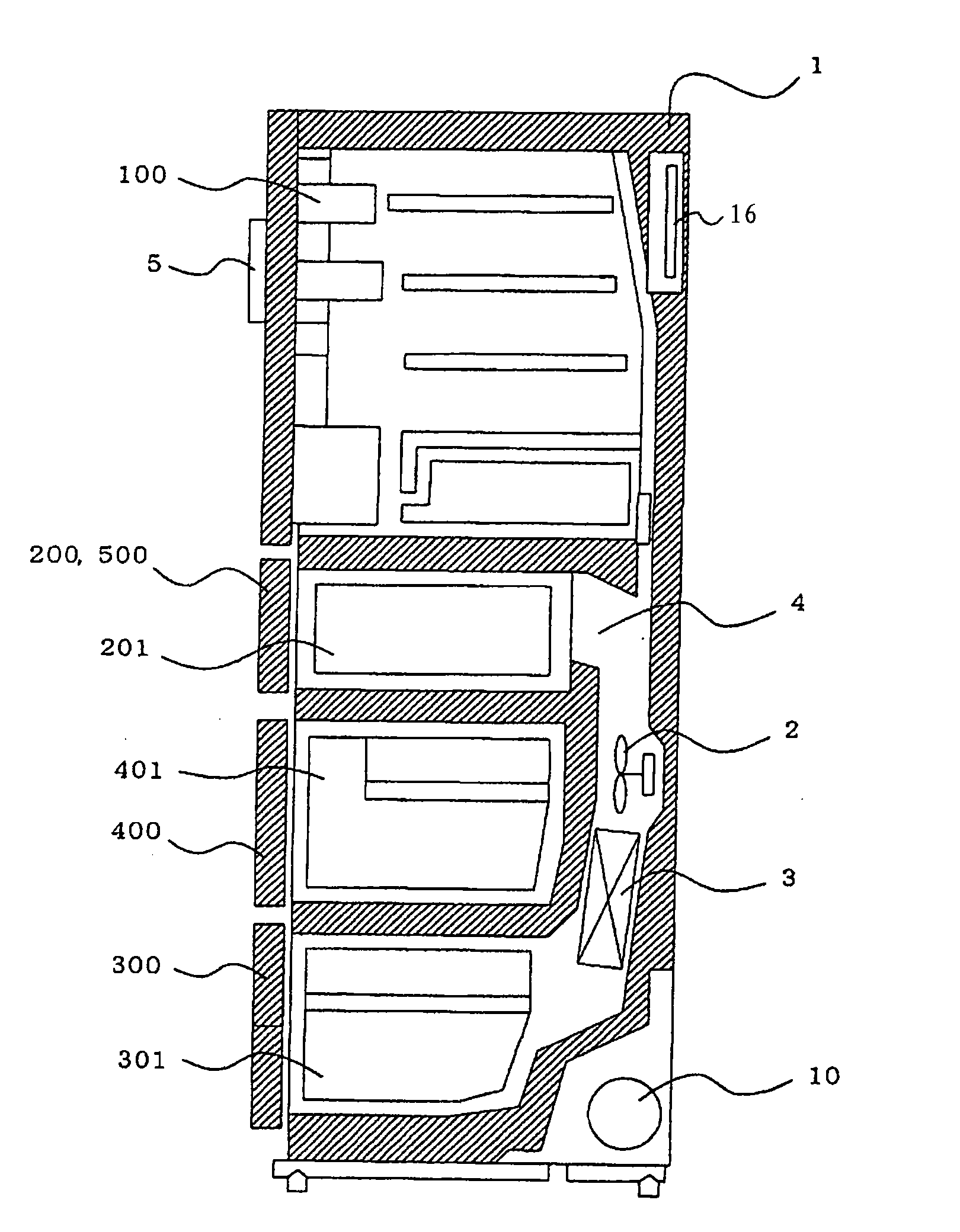

Refrigerator and method of refrigeration

ActiveCN101636625AHigh quality frozenRealize the effect of energy-saving refrigerationLighting and heating apparatusDomestic refrigeratorsCold airFood storage

Supercooling refrigeration being a method of enhancing the quality of food frozen other than the quick freezing method is realized by simple construction, and there are provided a refrigerator and method of refrigeration capable of realizing high-quality freezing by simple construction. The refrigerator is one capable of food storage utilizing cold air generated by cooler (3), comprising supercooling case (81) adapted to hold stored food in a supercooling state such that freezing does not occur even at its freezing point or lower temperature for at least a given period of time. The supercooling case (81) consists of, for example, the downside case of up-and-down two stage case disposed in switching chamber (200) capable of switching to multiple temperature zones.

Owner:MITSUBISHI ELECTRIC CORP

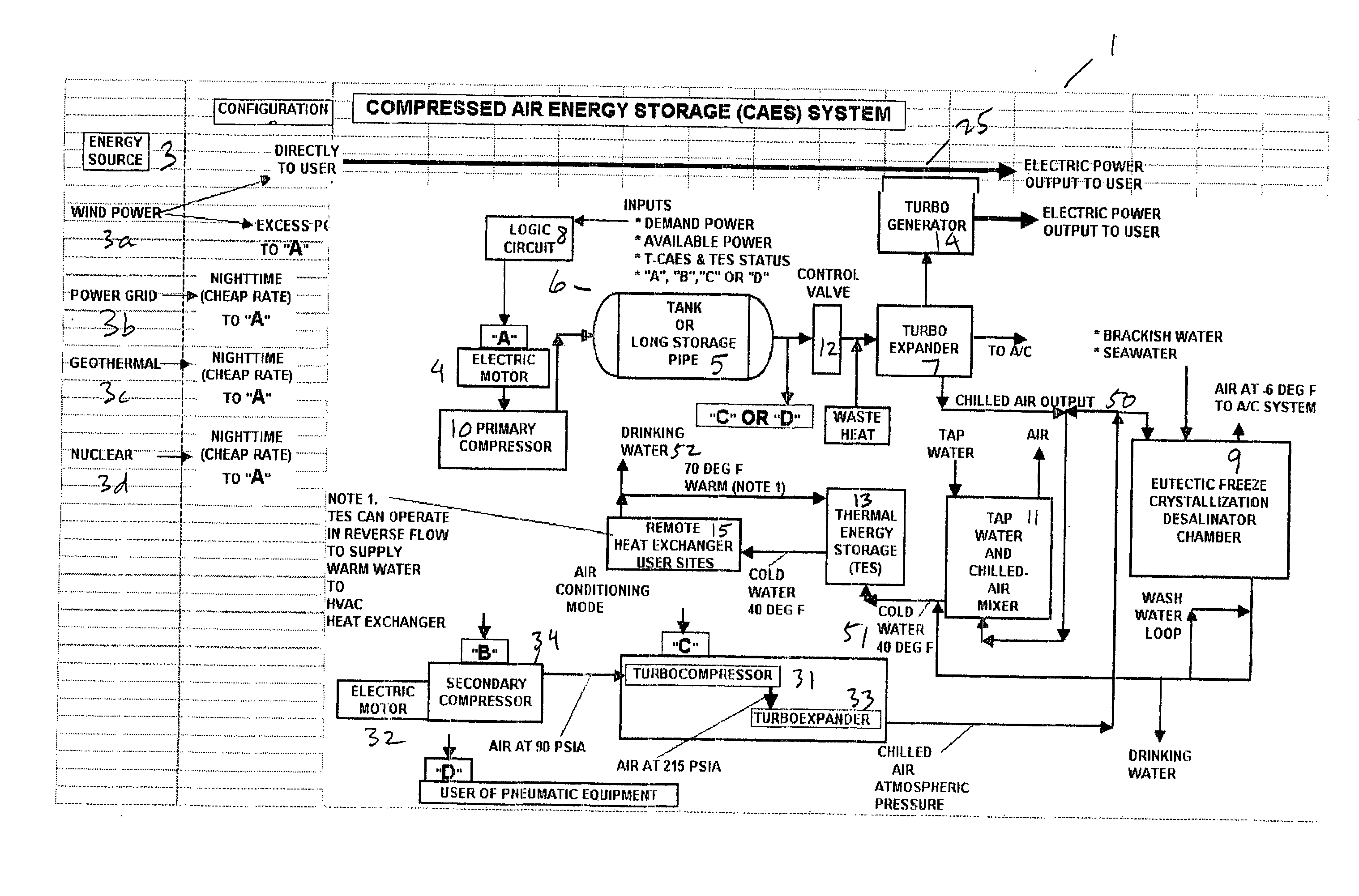

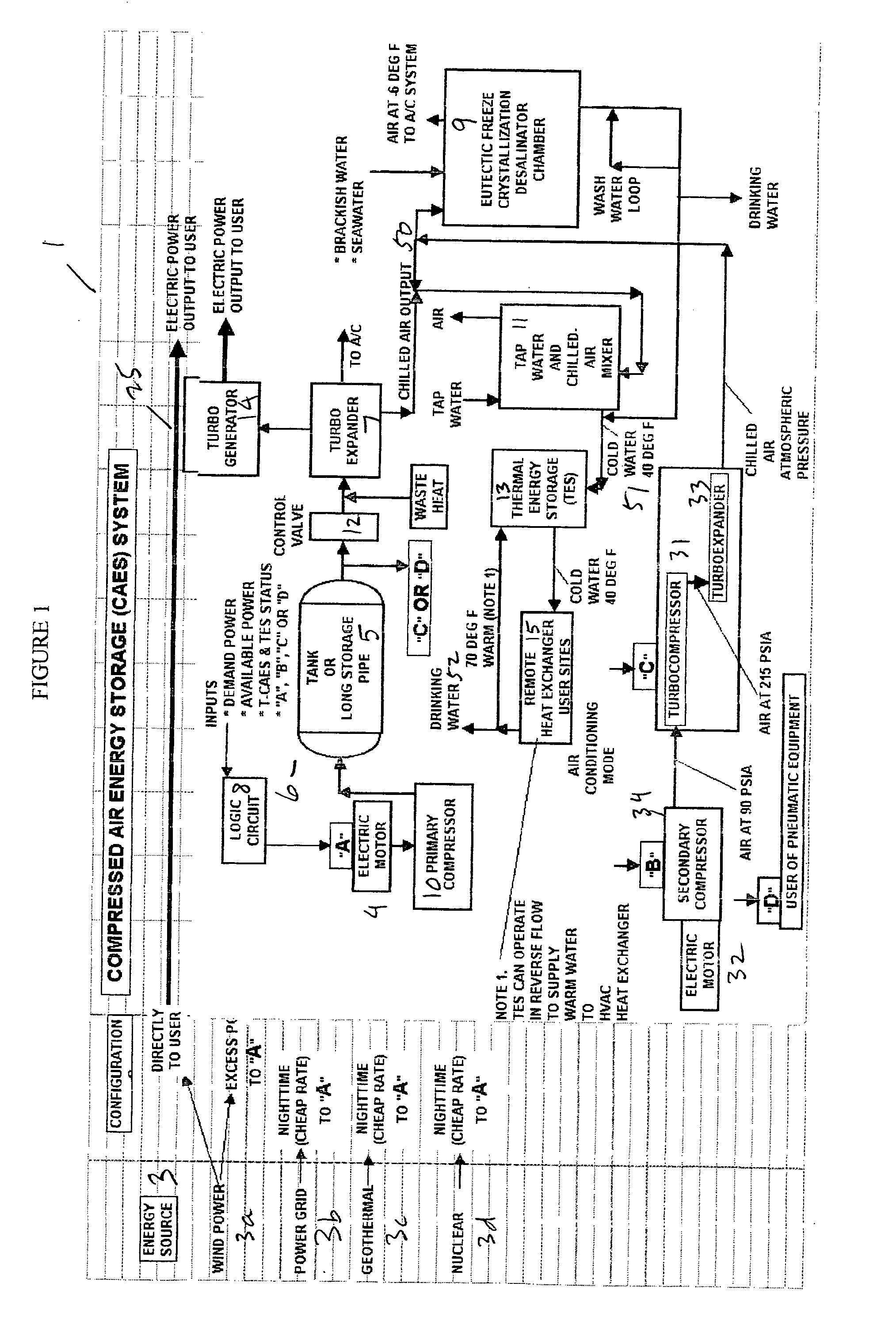

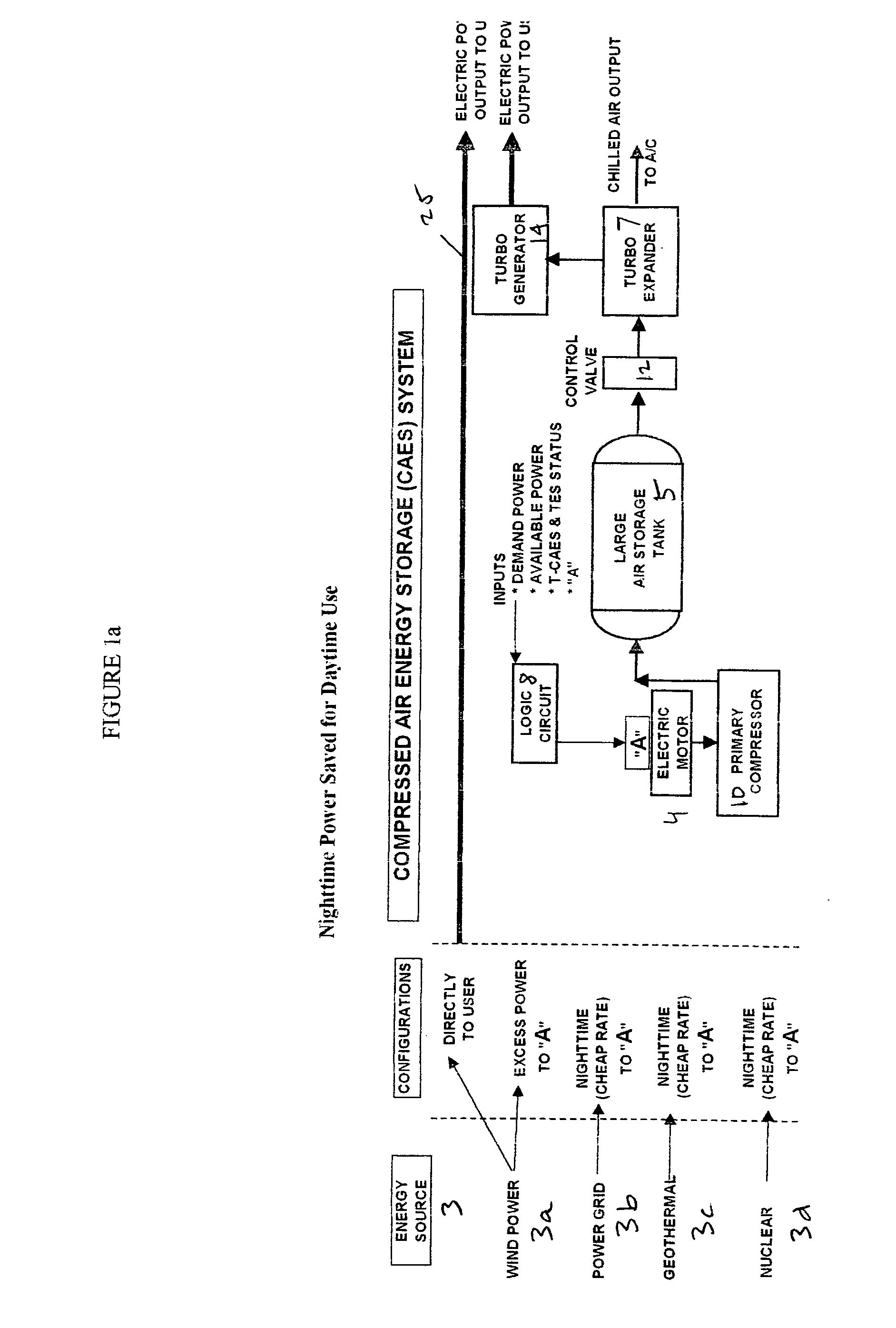

Thermal energy storage system using compressed air energy and/or chilled water from desalination processes

InactiveUS20070234749A1Reducing end-user cost of energyEnergy efficiencyWater treatment parameter controlGeneral water supply conservationThermal energyThermal energy storage system

The invention relates to a universal system for producing cost effective energy particularly for cooling purposes. In one embodiment, wind turbines are used to generate electricity and compressed air energy, wherein the compressed air energy is used to co-generate electricity and chilled air. The chilled air is then used to chill water in either a mixing chamber, or a desalination system, wherein the chilled water is stored in a separation tank, wherein it can later be used to provide cooling for an air conditioning system for a facility. When desalination is used, the system produces chilled fresh drinking water which can be used for air conditioning, and then used as fresh drinking water. Any exhaust chilled air can be used directly for air conditioning.

Owner:ENIS BEN M +1

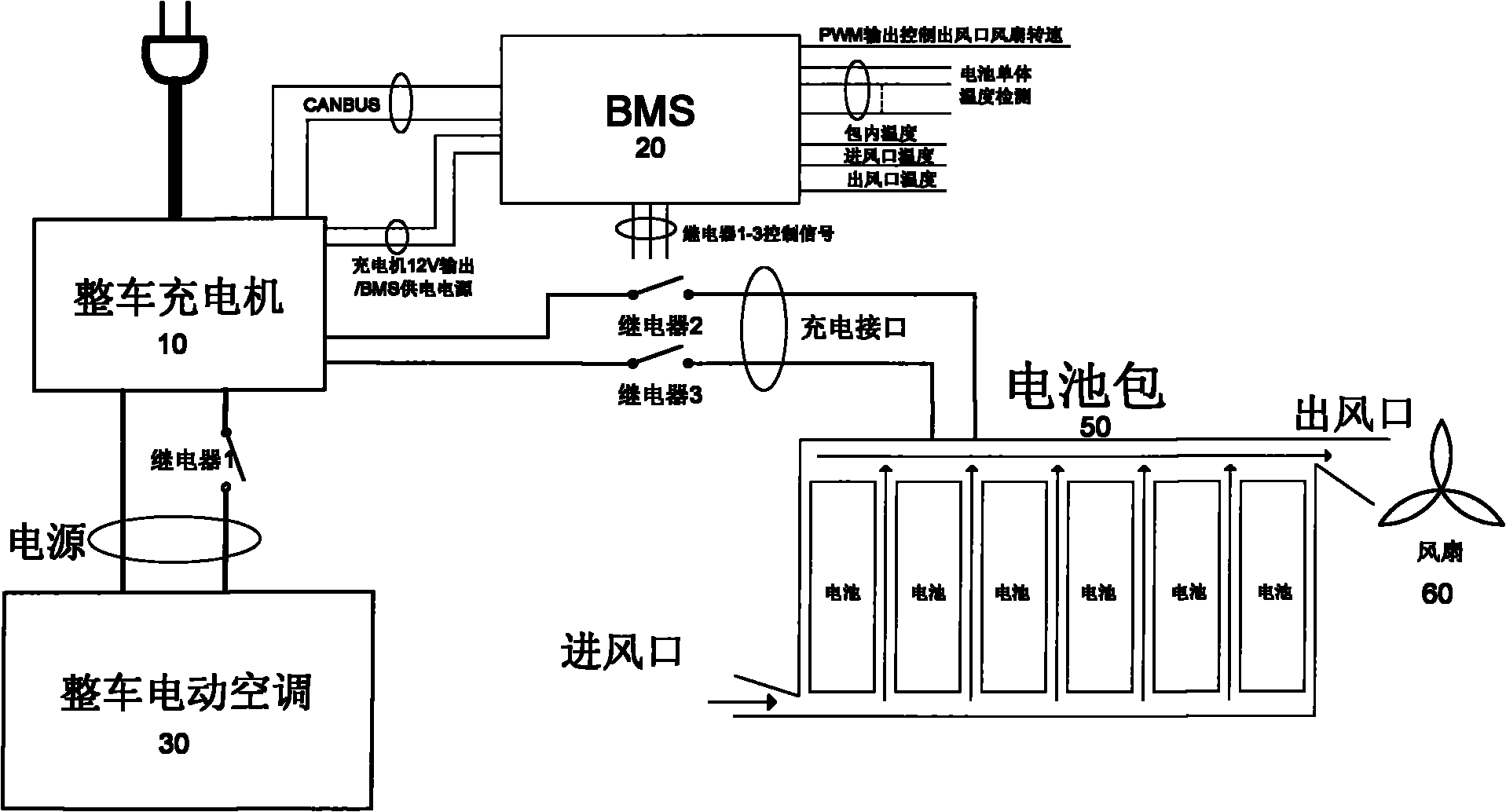

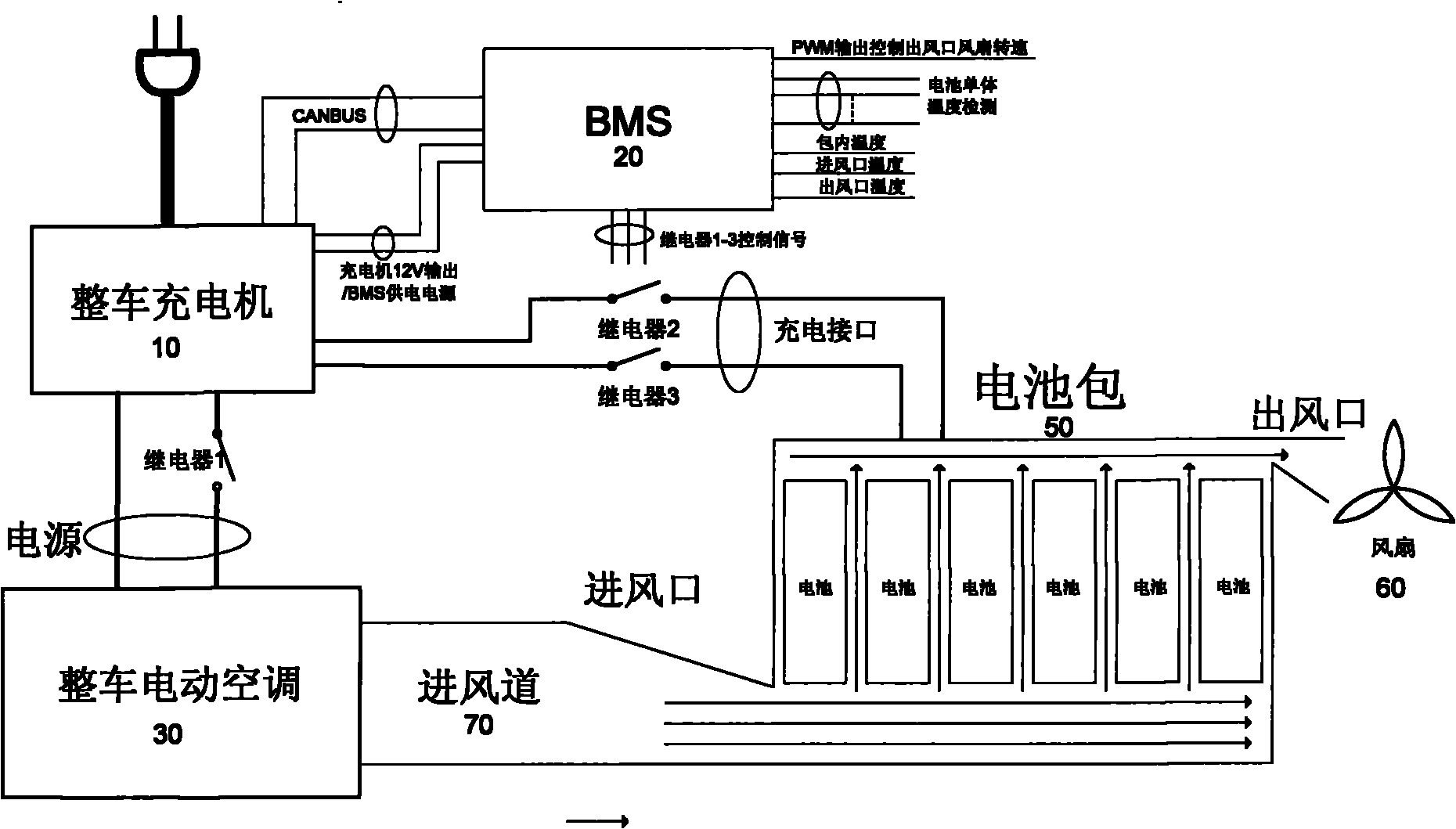

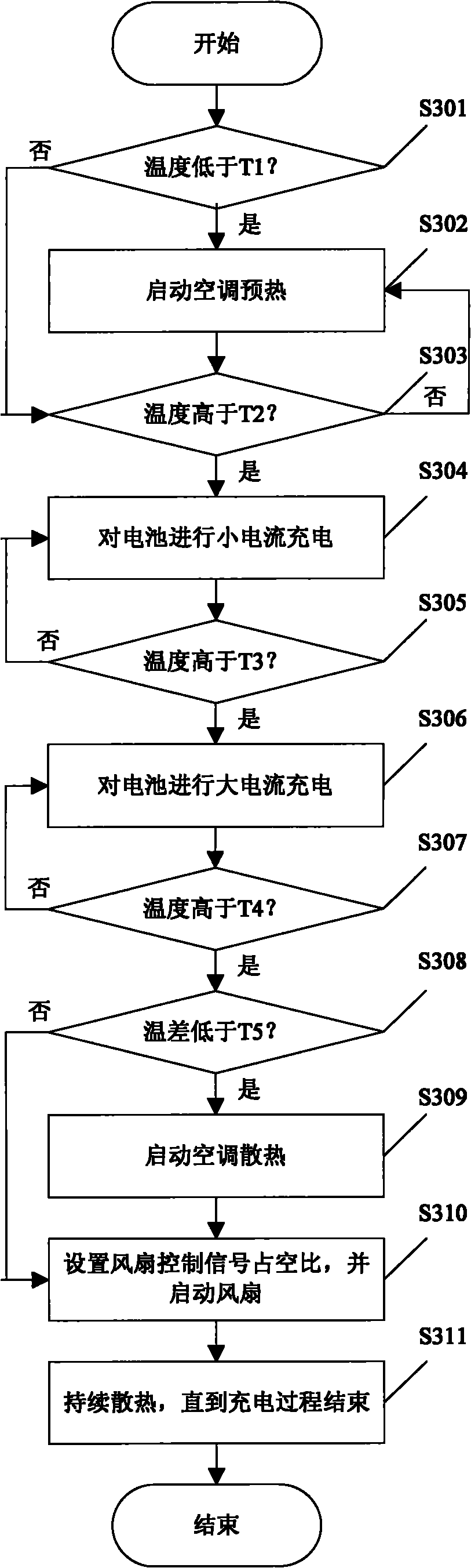

Power battery thermal management system and control method thereof

ActiveCN102139646AGuaranteed thermal balanceCell temperature controlVehicular energy storageCold airPower battery

The invention provides a power battery thermal management system which comprises a complete automobile power-driven air conditioner, a complete automobile charger, an air passage and a battery management system, wherein the air passage is connected with an air outlet of the complete automobile power-driven air conditioner and an air inlet of a battery pack and is used for leading hot air or cold air of the air conditioner into the battery pack; the battery management system is used for controlling the hot air of the air conditioner to be led into the battery pack so as to preheat the battery set in the battery pack when the lowest temperature of a battery module is lower than a first threshold value and controlling the battery set in the battery pack to be charged and discharged after preheating the battery pack; when the highest temperature of the battery module is higher than a second threshold value and the temperature difference between the ambient temperature of the air inlet of the battery pack and the temperature of the battery module is lower than a third threshold, the battery management system controls the cold air of the air conditioner to be led to the battery pack so as to dissipate heat in the battery set in the battery pack. Accordingly, the invention provides a control method of the thermal management system. The invention can lead the battery pack to be charged and discharged in the allowable temperature range and ensure the heat balance among the battery modules and prevent the battery from being overcharged and overdischarged.

Owner:CHERY AUTOMOBILE CO LTD

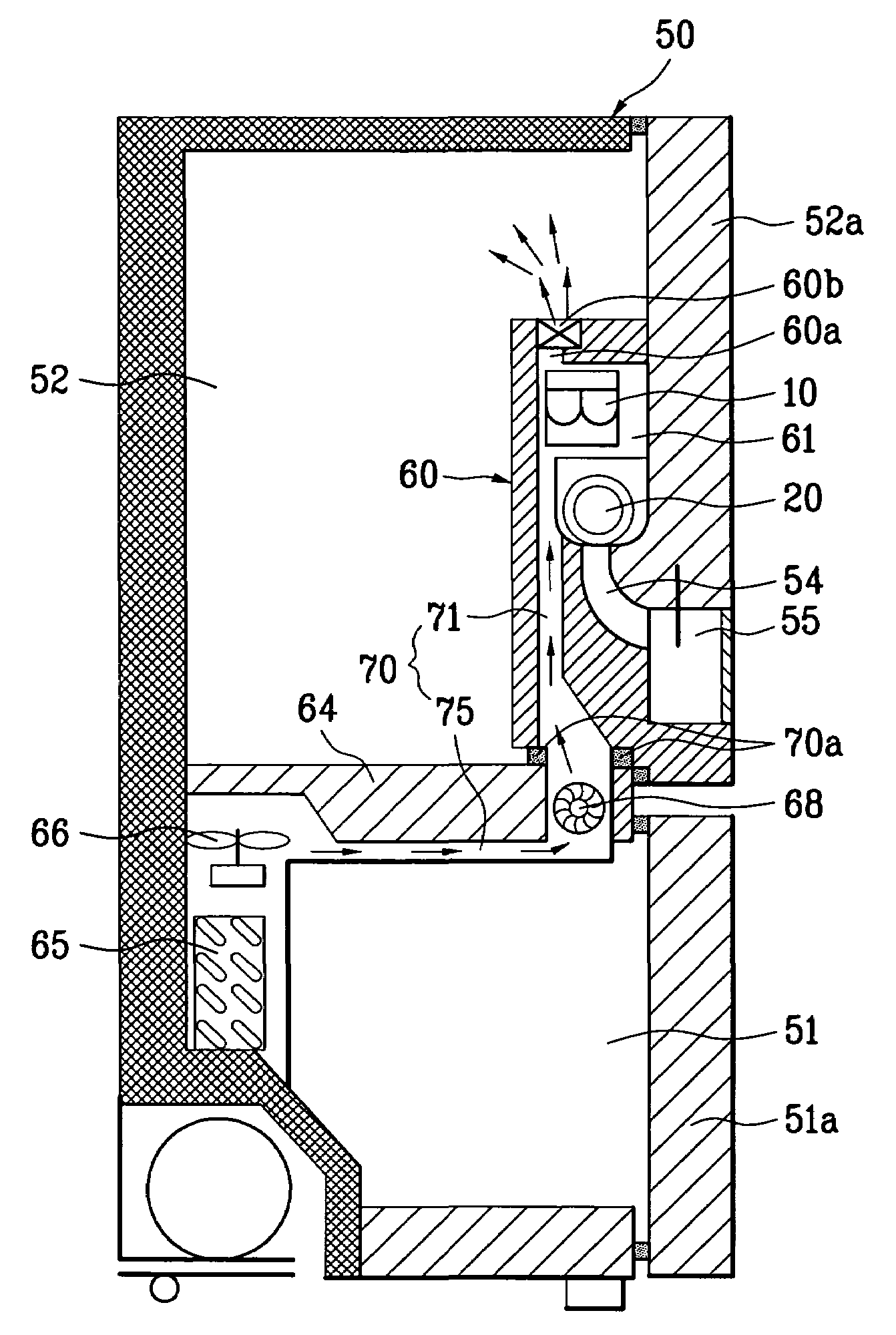

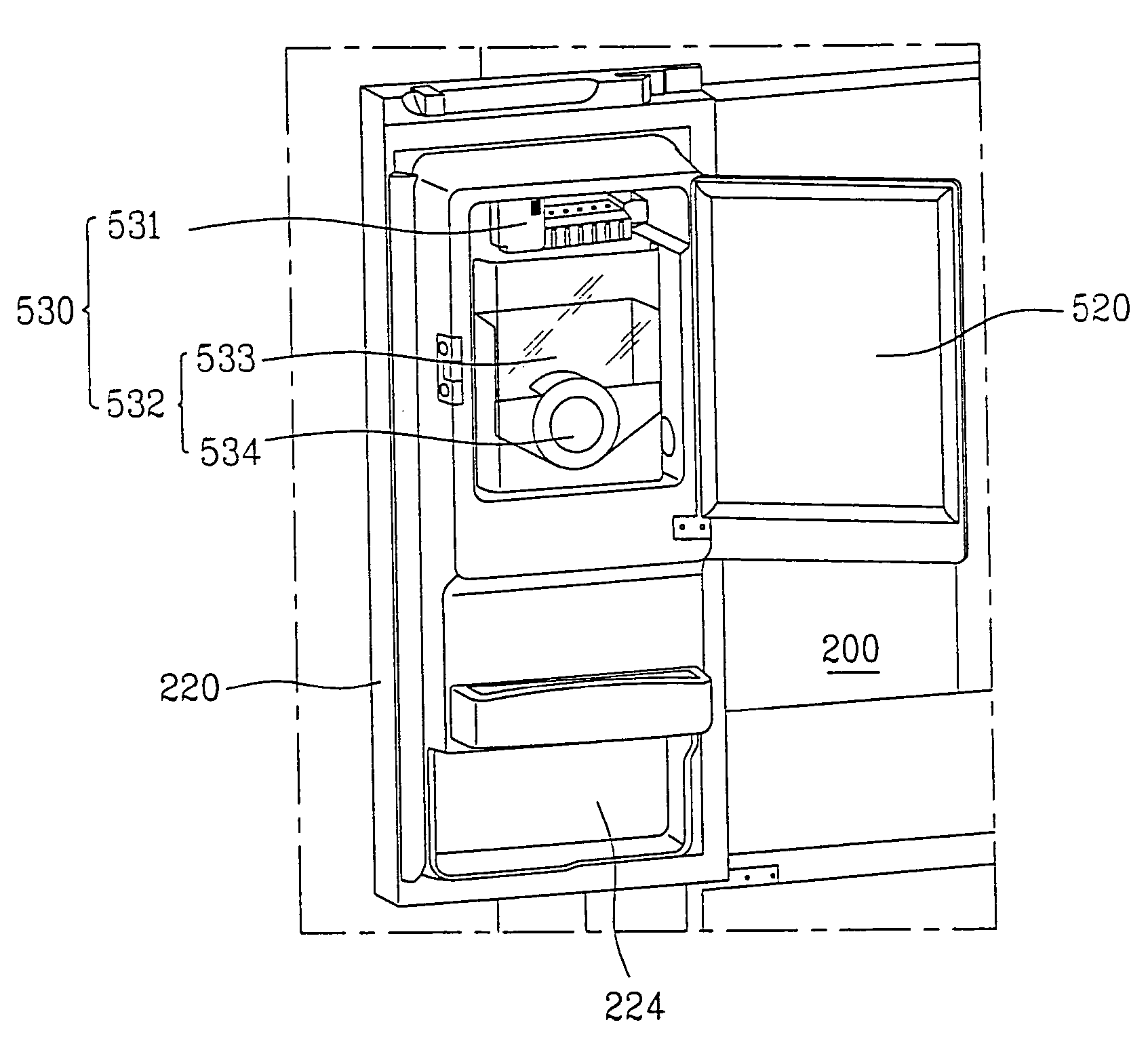

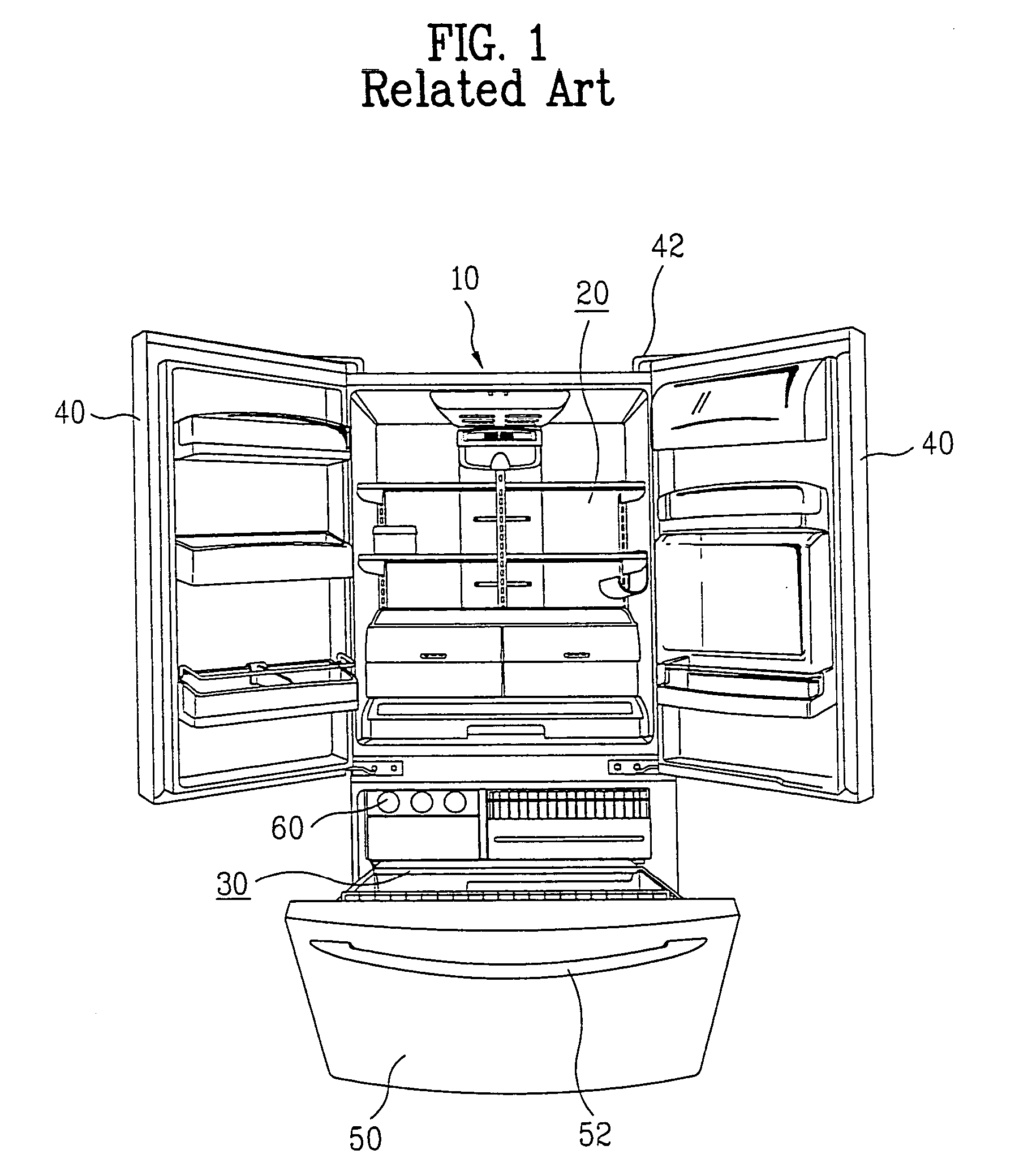

Refrigerator

ActiveUS20060196214A1Reduce in quantityLighting and heating apparatusIce productionCold airEngineering

A refrigerator has a freezing chamber at the bottom, and a refrigerating chamber over the freezing chamber. The refrigerator includes an ice making unit and an ice dispenser mounted in a refrigerating chamber door that allows ice to be dispensed without opening the door. A sub-PCB is mounted in the refrigerating chamber door for controlling operations of the ice making unit and the dispenser. A cold air supply duct supplies cold air from a cold air supply unit to the ice making unit.

Owner:LG ELECTRONICS INC

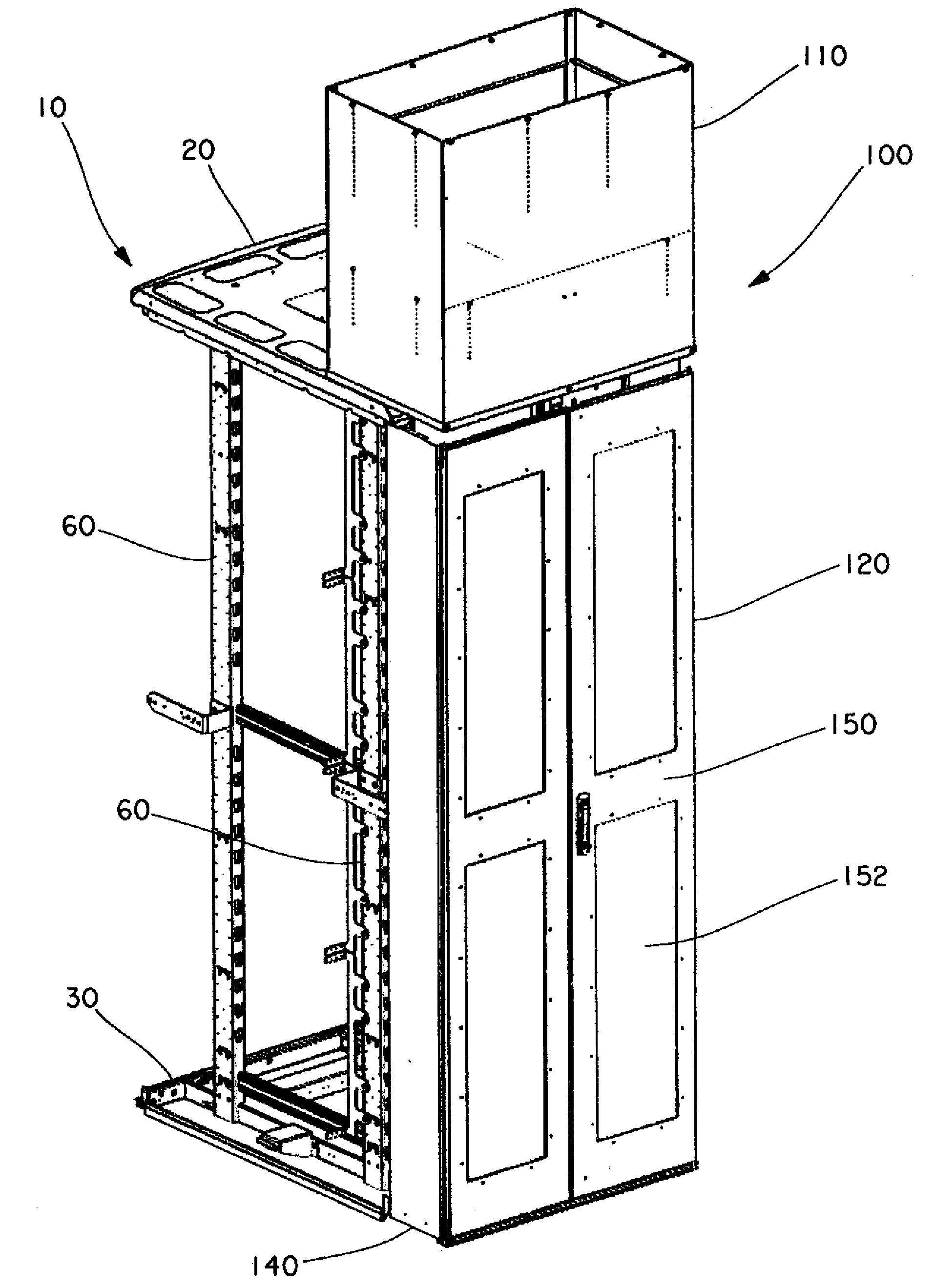

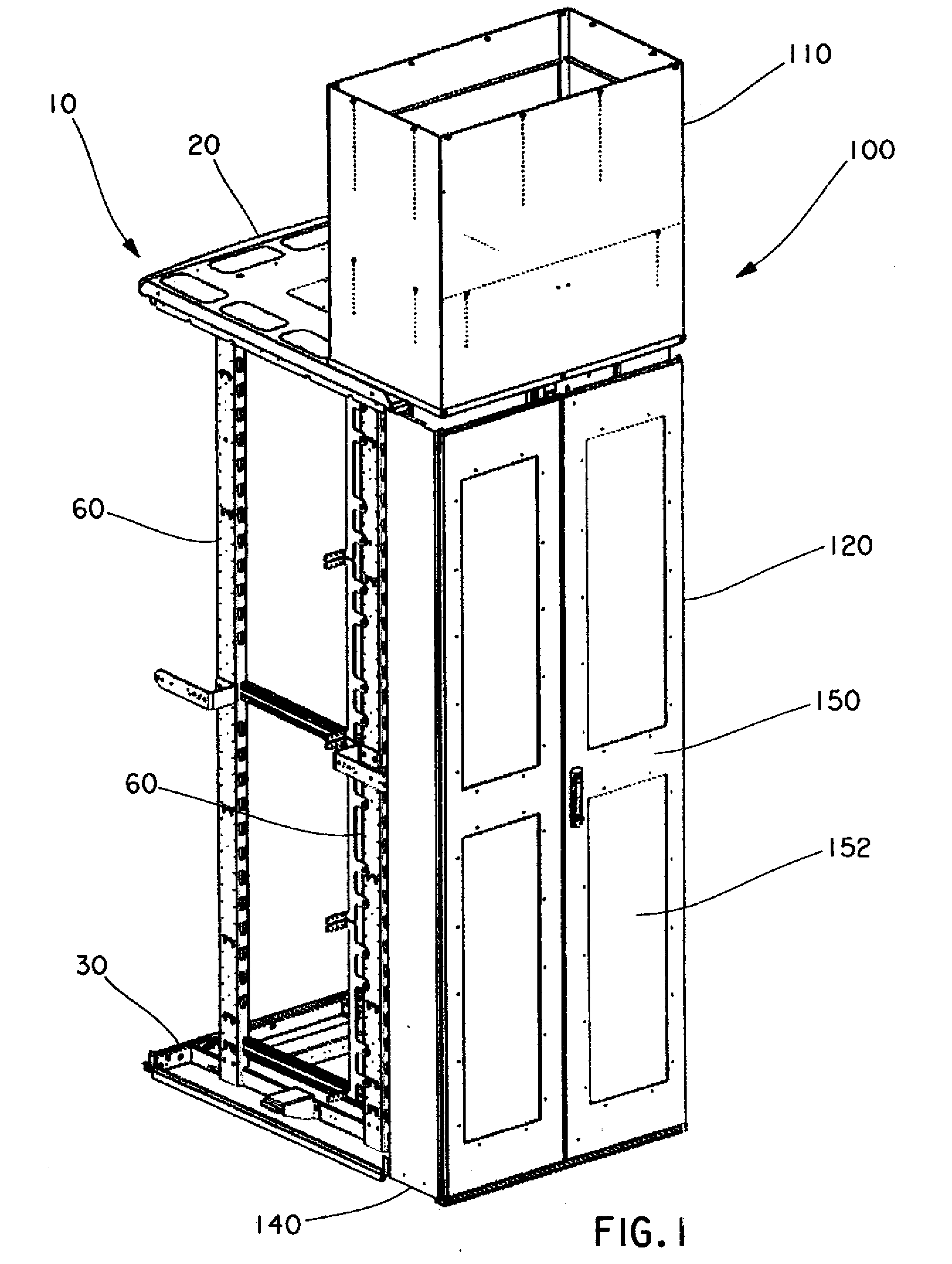

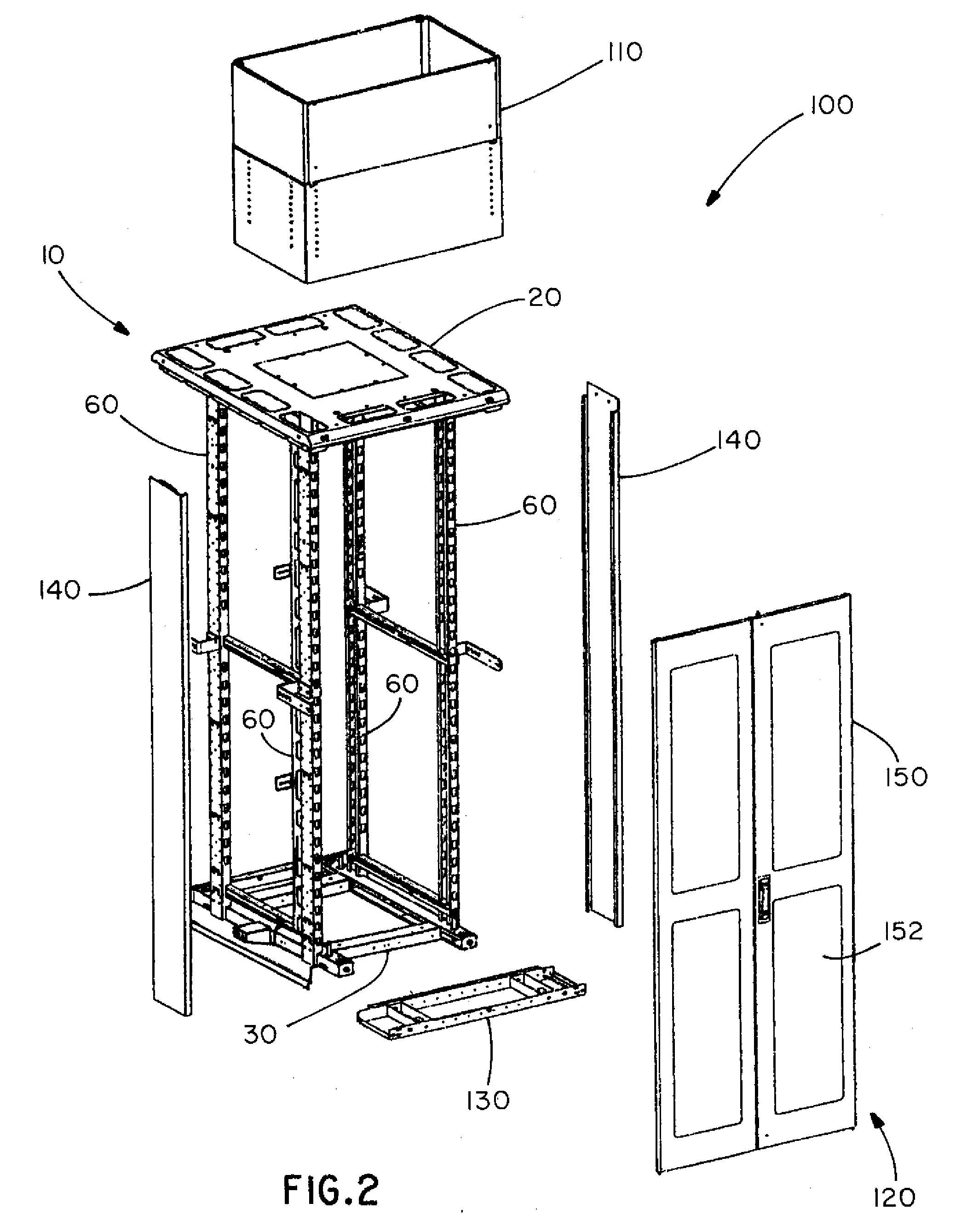

Passive Cooling Systems for Network Cabinet

ActiveUS20100003911A1Easy to installEasy to shareDucting arrangementsLighting and heating apparatusCold airEngineering

Certain embodiments of the present invention provide a cooling duct assembly for electronic equipment installed in a cabinet. The cooling duct assembly comprises at least one main duct in fluid communication with a front portion of the cabinet. The at least one main duct receives cold air from the front portion of the cabinet and routes the cold air toward a back portion of the cabinet. Additionally, the cooling duct assembly comprises at least one side duct in fluid communication with the at least one main duct. The at least one side duct receives the cold air from the at least one main duct and routes the cold air to at least one side air intake opening on the electronic equipment.

Owner:PANDUIT

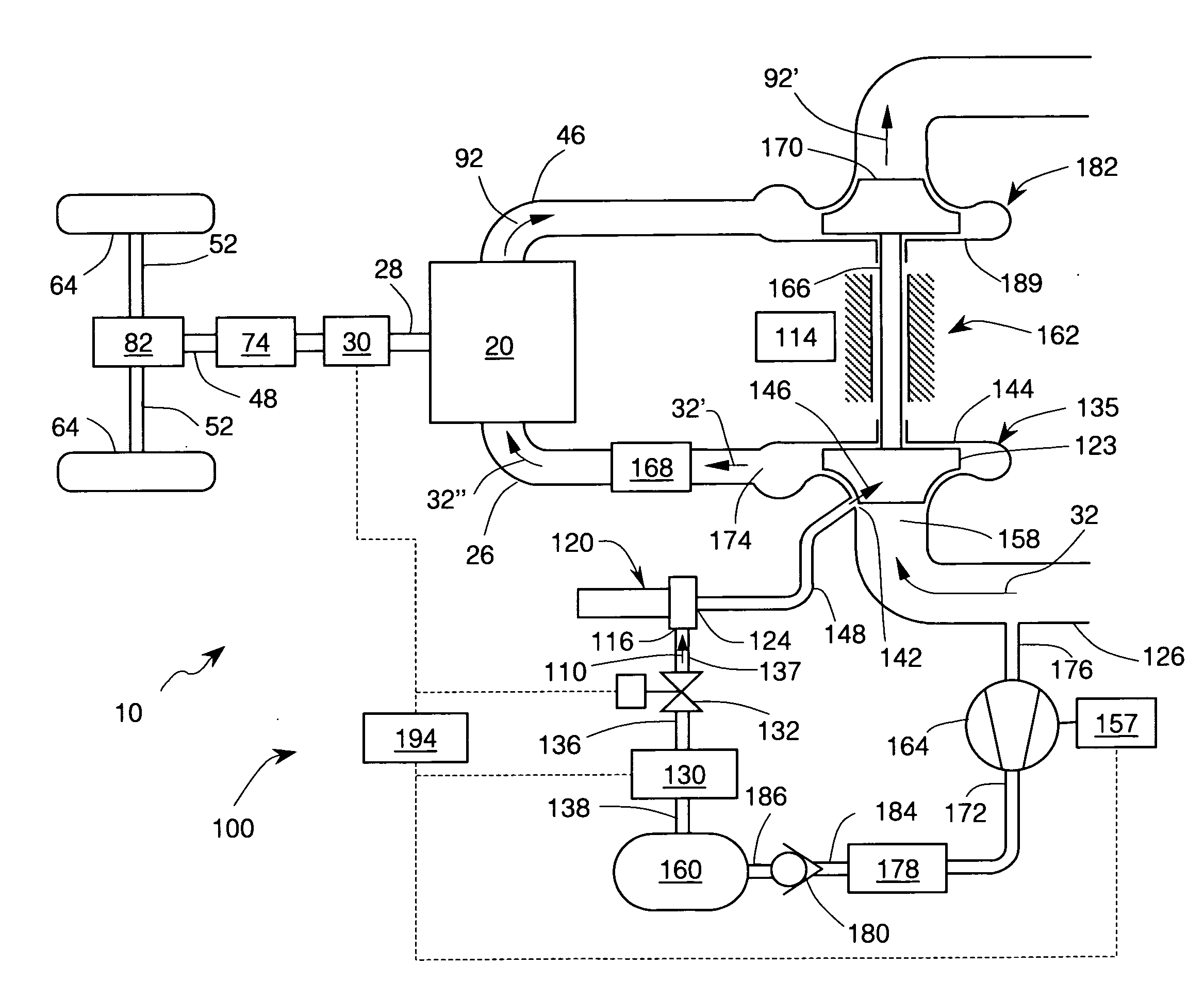

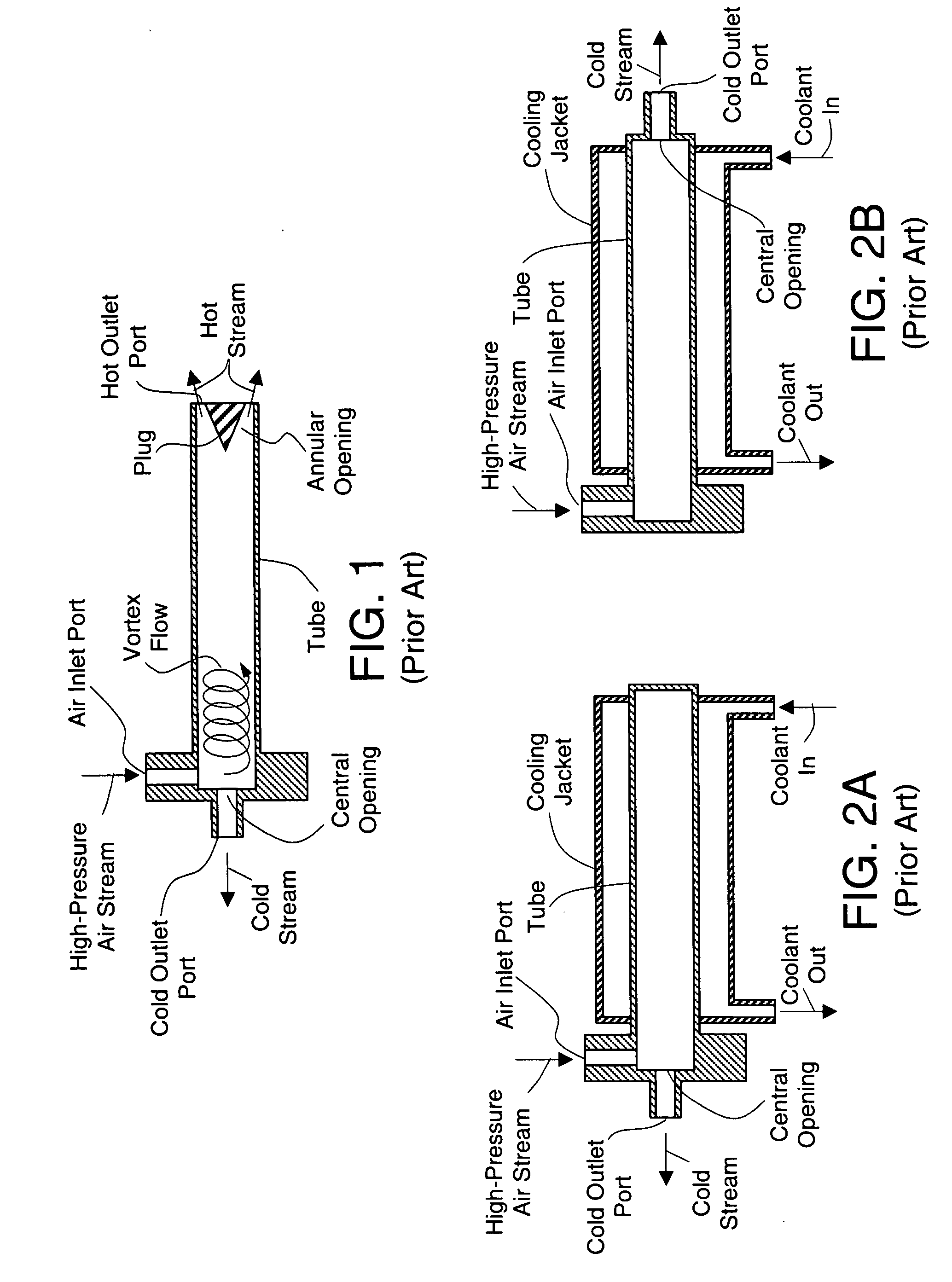

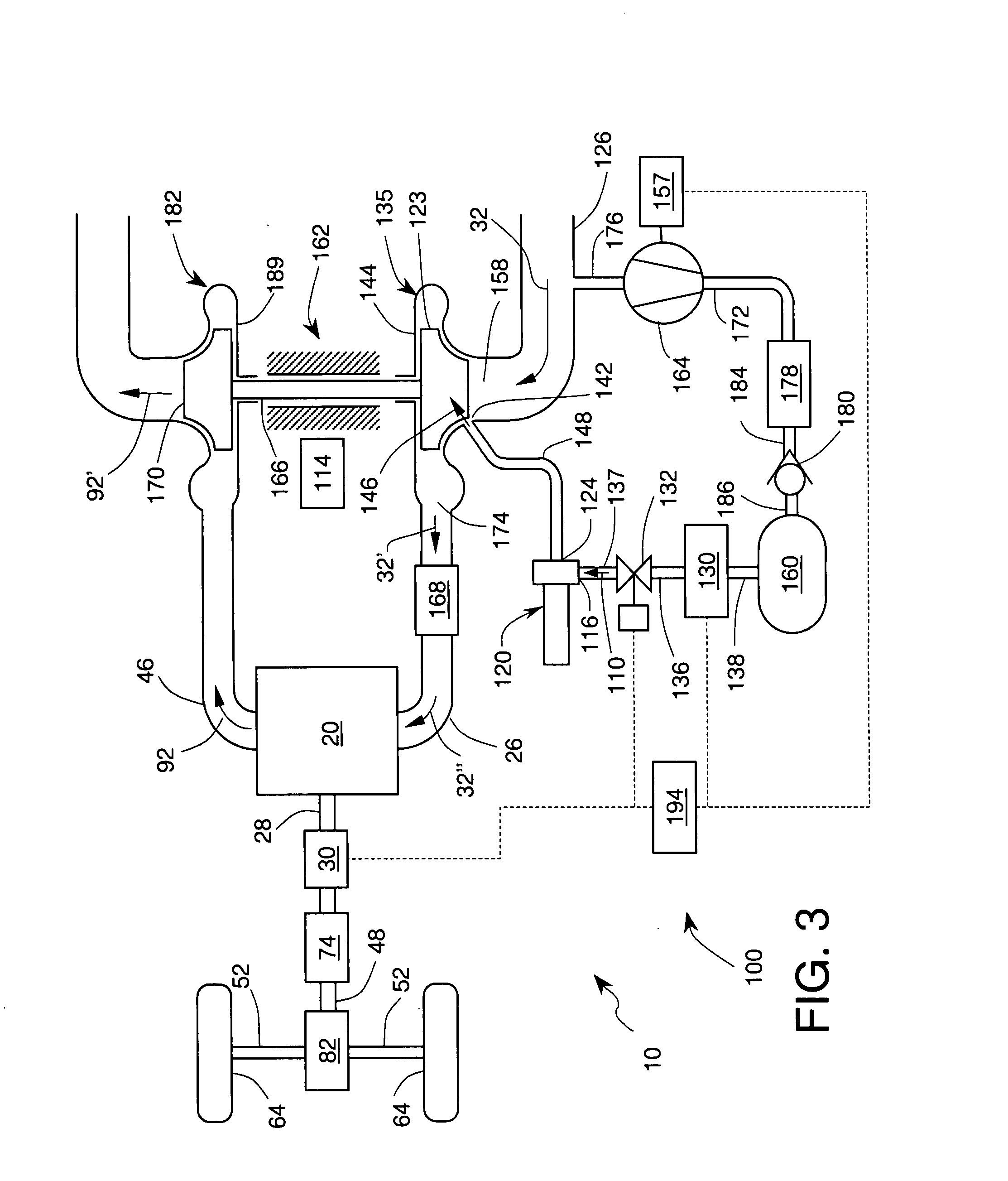

Turbocharged internal combustion engine system

InactiveUS20080133110A1Increase compressor surge limitIncrease compressor speedElectrical controlInternal combustion piston enginesCold airImpeller

The present invention relates to a turbocharged internal combustion engine (ICE) system having fast response to increased power demand and reduced response time lag. The system includes a vortex tube for delivering cold air into the turbocharger compressor where it may be used to cool the impeller, and / or accelerate the impeller rotational speed, and / or favorably shift the compressor surge line at low speeds and high loads. Cold air from the vortex tube may be also used to operate an ejector pump in the intake duct which further compresses intake air and increases engine charge weight during periods of high power demand. In addition to increasing engine output power, delivery of cold air into engine intake also reduces engine pre-ignition (knocking) thereby reducing emissions. The invention also relates to a method for operating a turbocharged internal combustion engine.

Owner:AGWEST

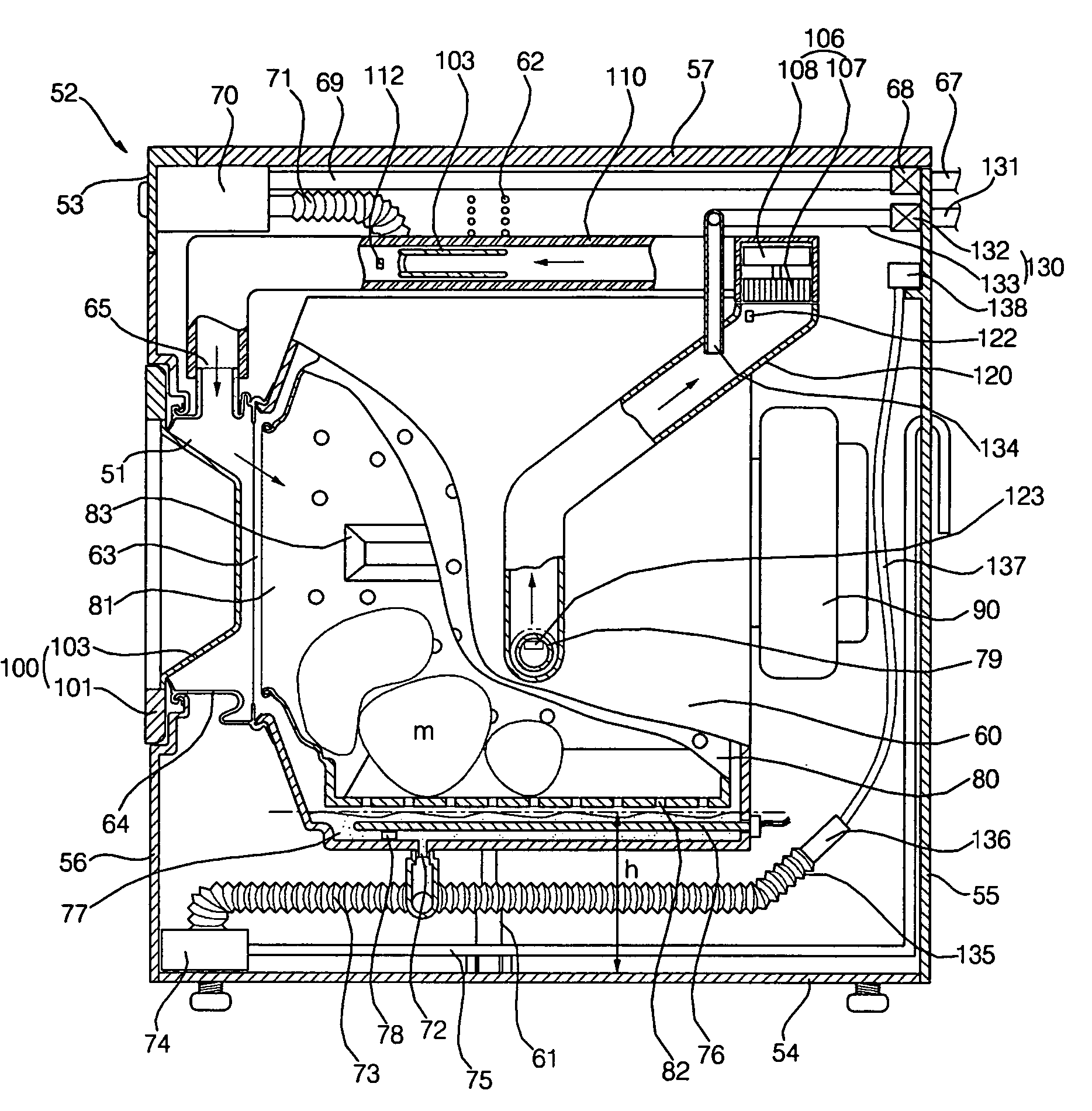

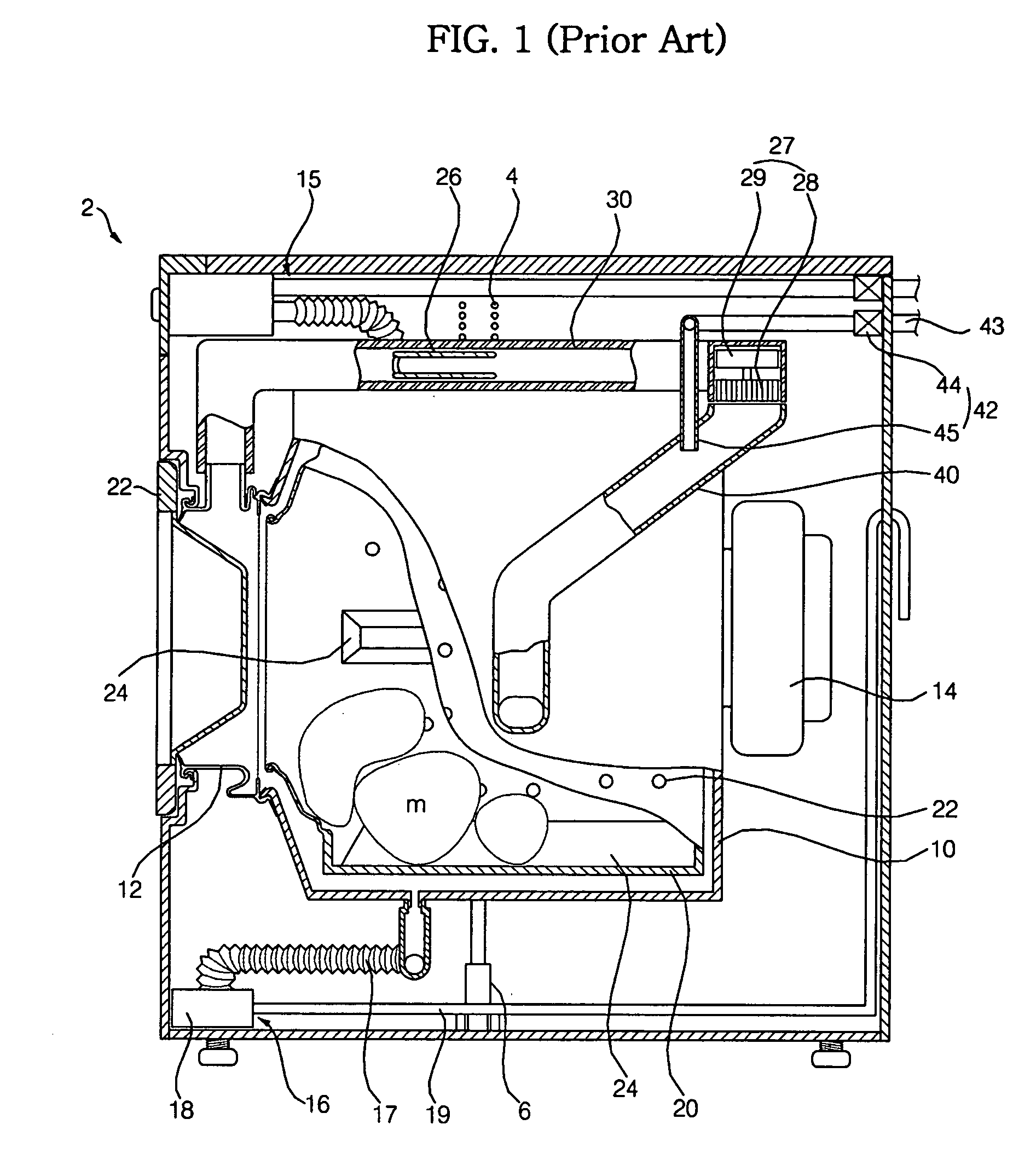

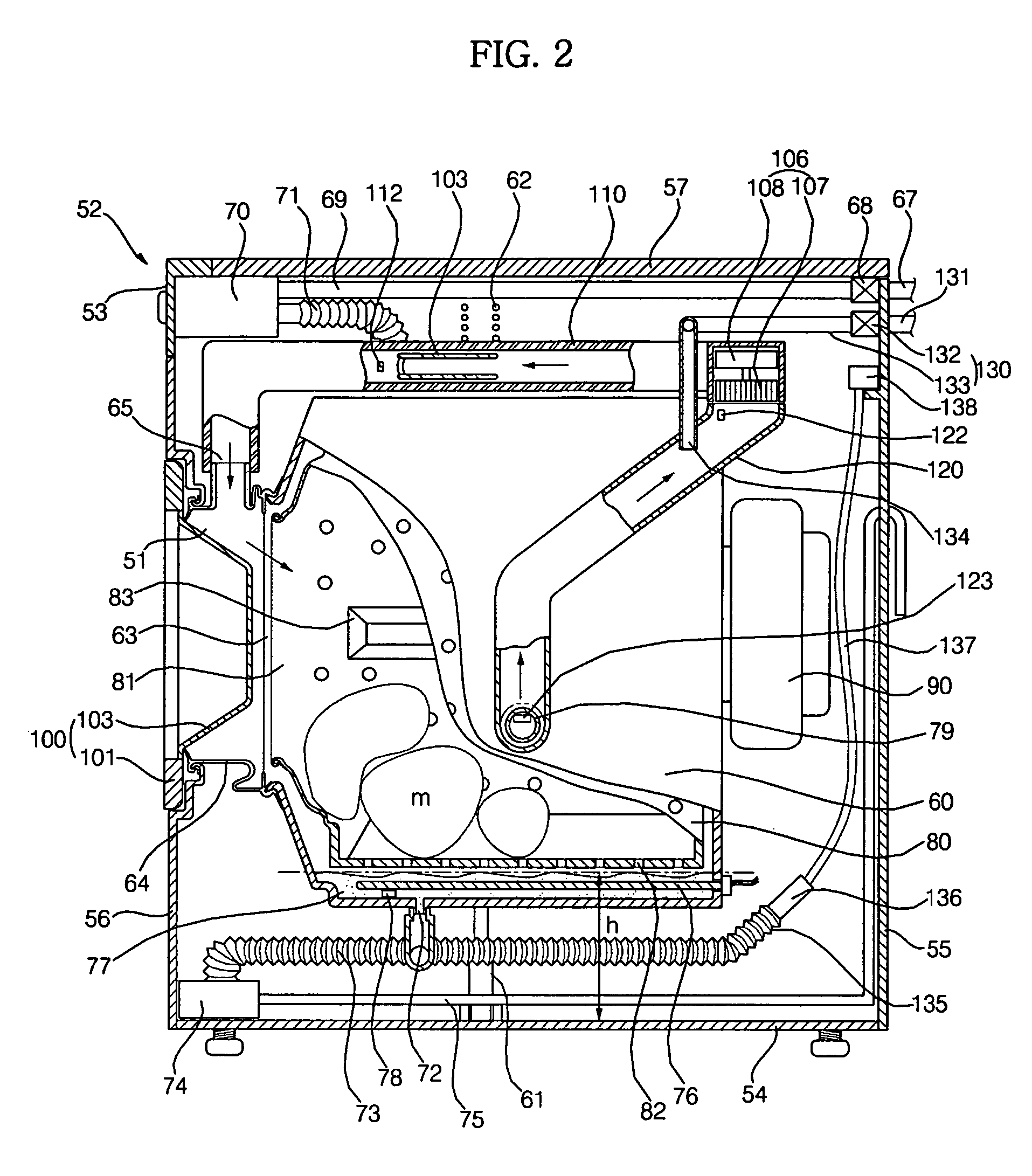

Drying control apparatus and method of washing and drying machine

InactiveUS20060137105A1Improve condensation effectMinimizing rateOther washing machinesWashing machine with receptaclesCold airProcess engineering

A drying control method and apparatus of a washing and drying machine, in which cooling water dropped from a condensation duct to a tub accelerates the condensation of moisture contained in circulated air so as to improve condensing capability, a cold air drying time is differently set according to load so that when the load is small, a drying time is shortened, and the drying of laundry is rapidly performed, a power consumption rate is minimized, or a cooling water consumption rate is minimized according to user's desire, and a drying operation is controlled using a difference between a temperature of air and a temperature of cooling water so that the drying operation is efficiently performed according to load conditions so as to improve the drying capability.

Owner:LG ELECTRONICS INC

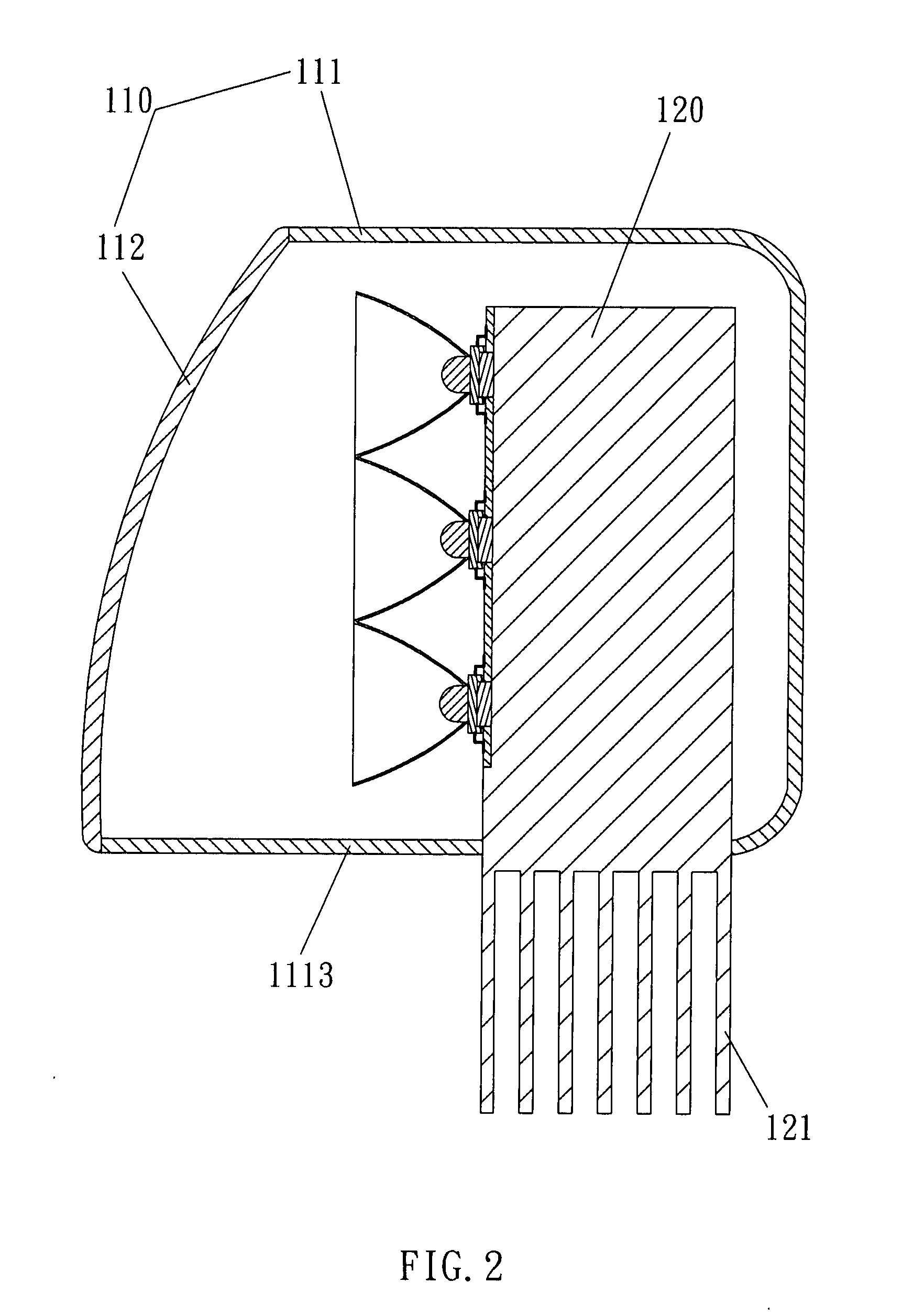

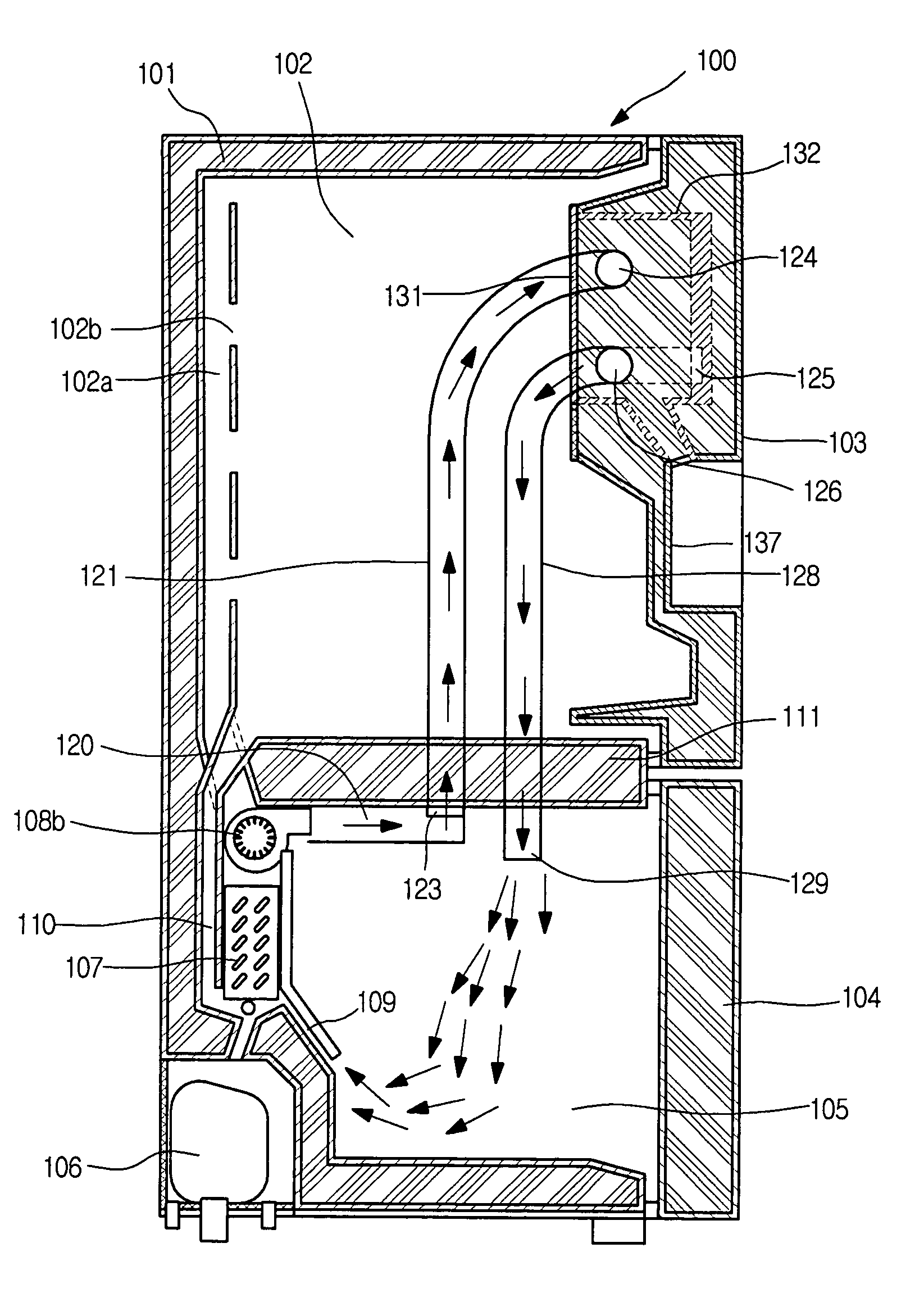

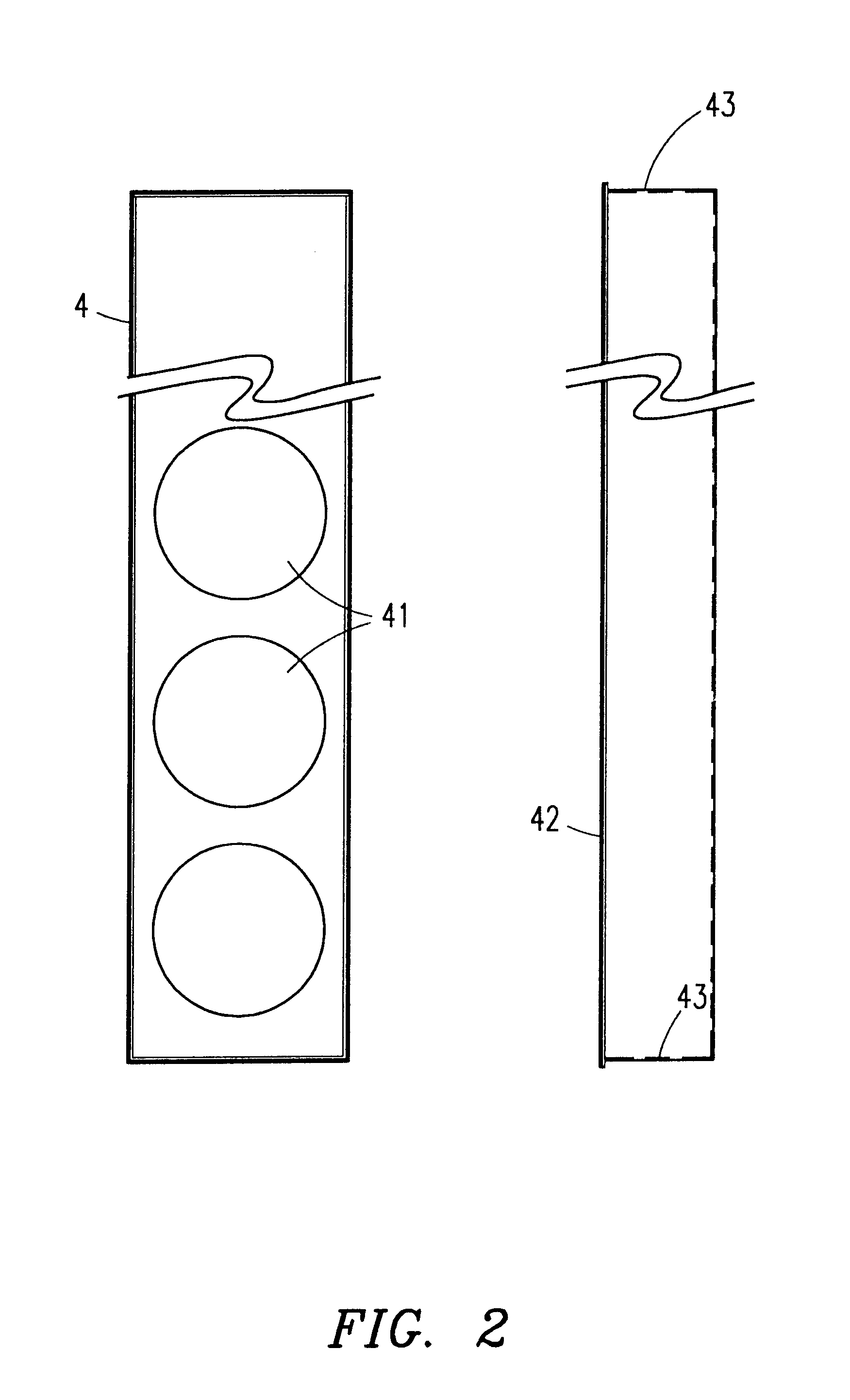

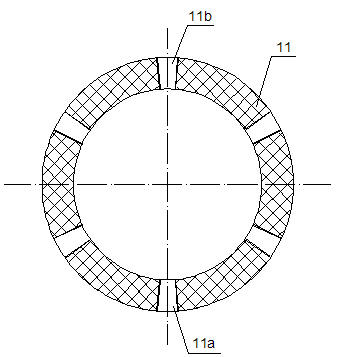

Cold air guide structure of ice-making chamber of cold chamber door

Owner:LG ELECTRONICS INC

Installation for heating and/or ventilating the passenger compartment of a vehicle employing selective extraction of air

InactiveUS6497275B1Increase in exchangeImprove ventilationVehicle seatsAir-treating devicesCold airAirflow

A fan causes a flow of cold air and warm air into the internal space of the passenger compartment of a vehicle. Air extraction channels connected to corresponding extraction vents are distributed at different locations in the passenger compartment. Controllable flaps selectively apportion and control the distribution of the extracted airflow between the different extraction channels.

Owner:VALEO SYST THERMIQUES

Cold air driven spray painter

InactiveCN1403210AImprove powder feeding methodImprove powder feeding efficiencyLiquid surface applicatorsMolten spray coatingCold airUltrasonic nozzle

The spray painter consists of ultrasonic nozzle, heater, powder feeder and other parts. The ultrasonic nozzle is mounted in the inlet of the spraying chamber, and the controller connected to the air compressor with air tank is connected via a powder feeding switch and pressure regulating switch to the heater and the powder feeder. The heater has one end connected to the ultrasonic nozzle. There is one powder recovering unit in the outlet of the spraying chamber. The ultrasonic nozzle is connected with the powder feeder and consists of three parts of contracting section, throat and expanding section. The present invention has high powder feeding efficiency, long service life and no oxidation.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Overhead cooling system with selectively positioned paths of airflow

InactiveUS6564858B1Great and great efficiencyImprove efficiencyAir heatersModifications for standard racks/cabinetsNuclear engineeringCoolant

A method and system are disclosed for cooling a heat generating object. A coolant is passed through a heat exchanger so that heated air passing through the heat exchanger is cooled. A fan unit is selectively positioned adjacent to a first side of the heat exchanger. When activated, the fan unit draws the cooled air through the heat exchanger and directs the cooled air towards the heat generating object. The fan unit may be repositioned along a second side of the heat exchanger so as to redefine the flow of air drawn from and directed towards the heat generating object.

Owner:VERTIV CORP

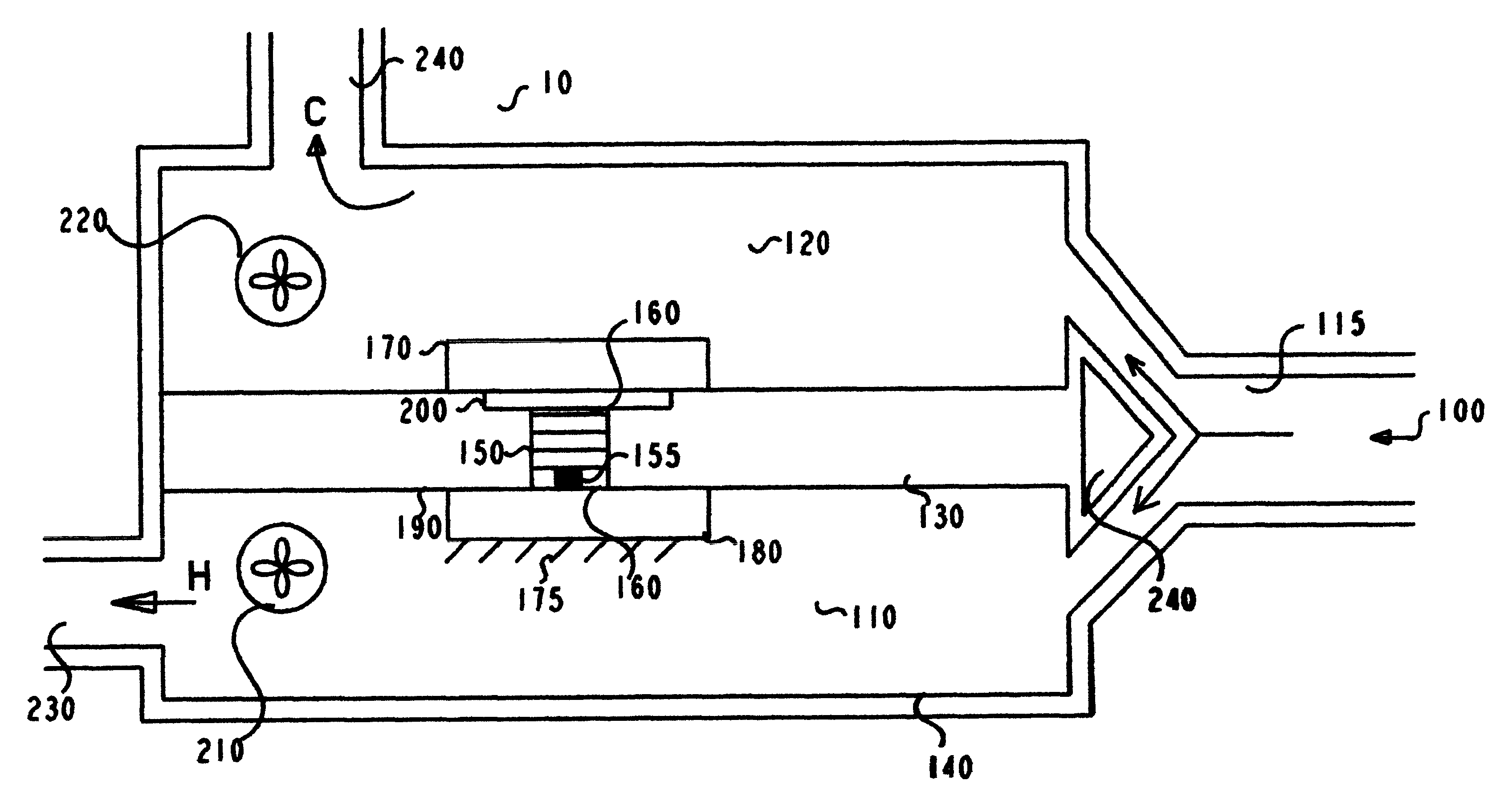

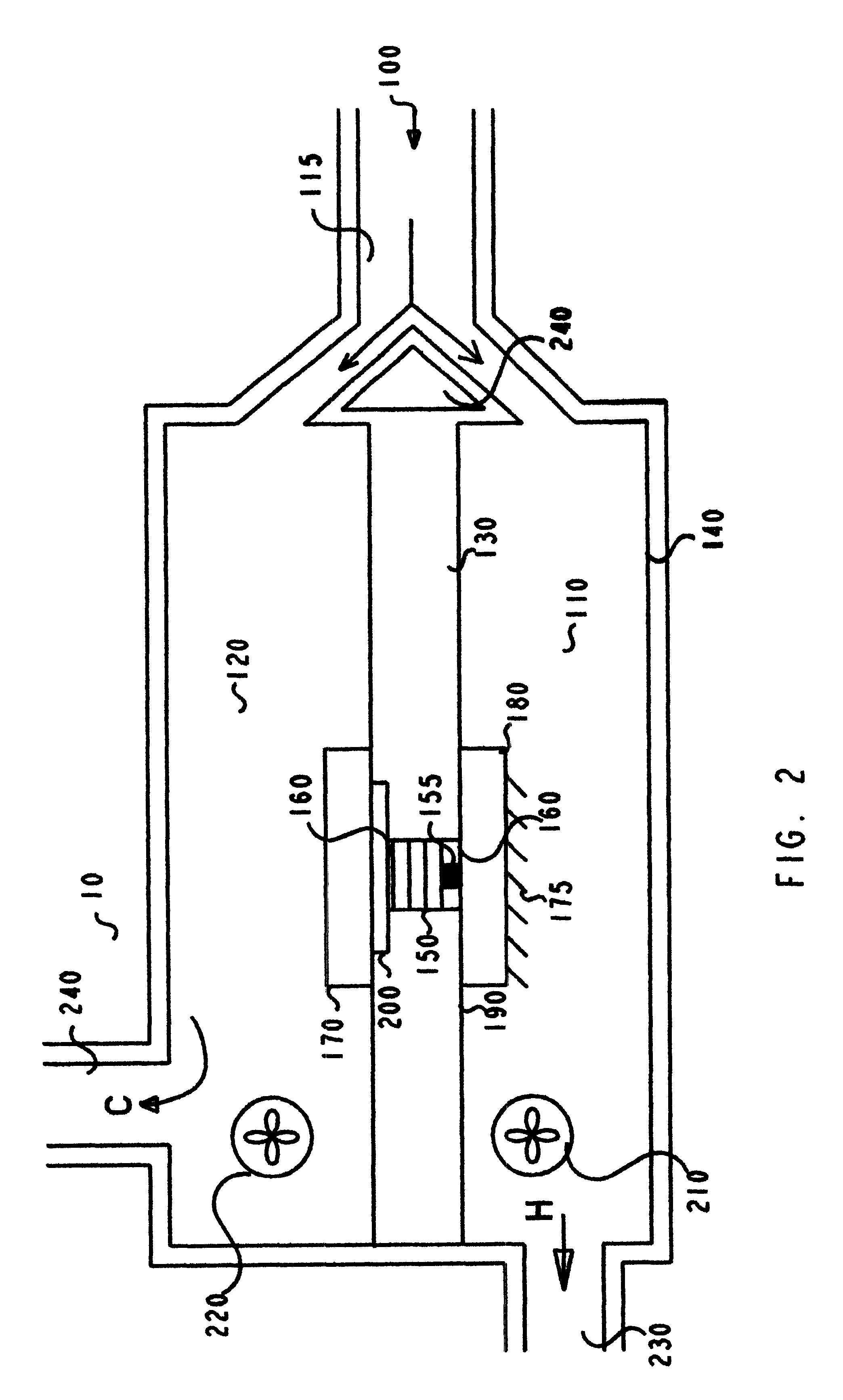

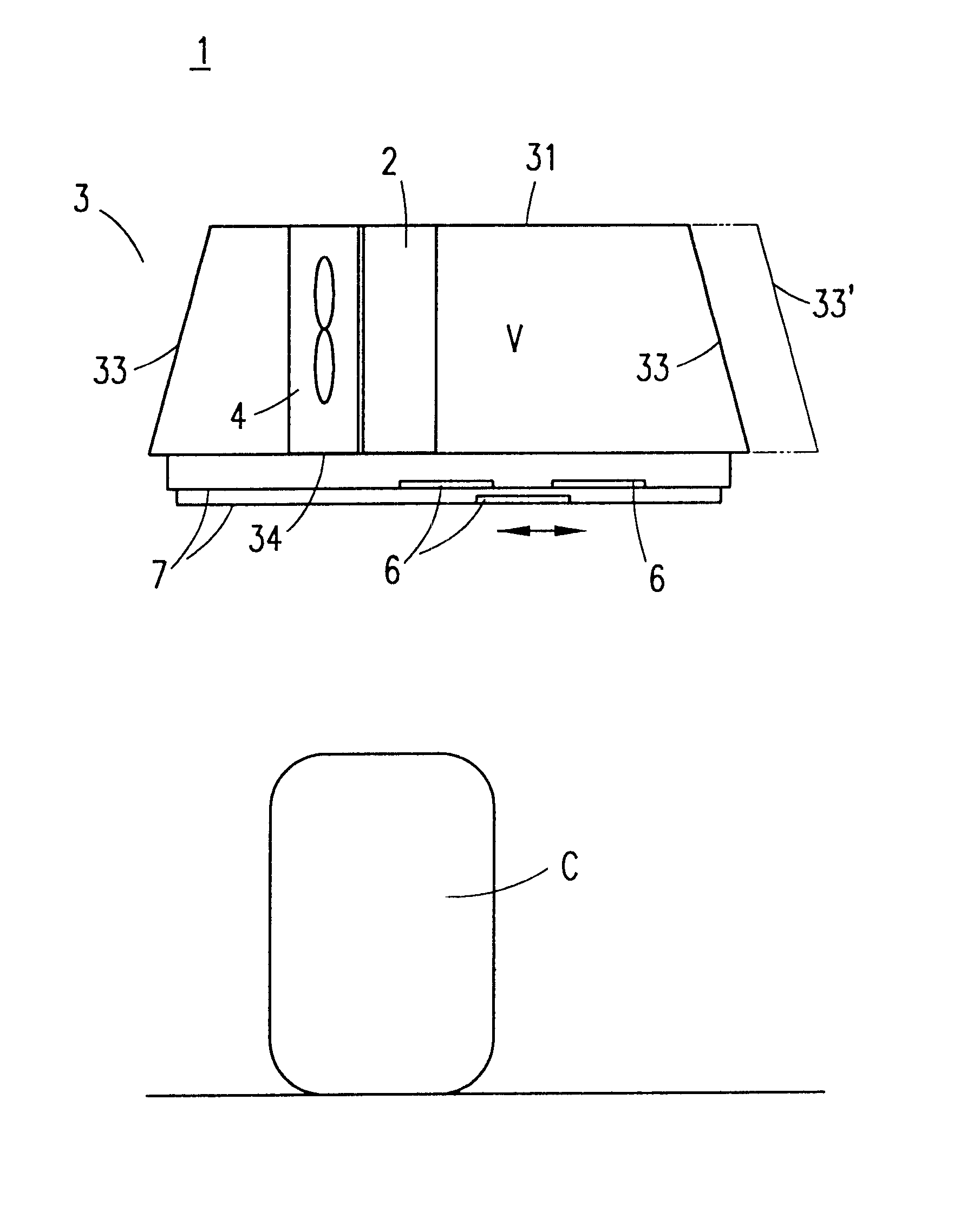

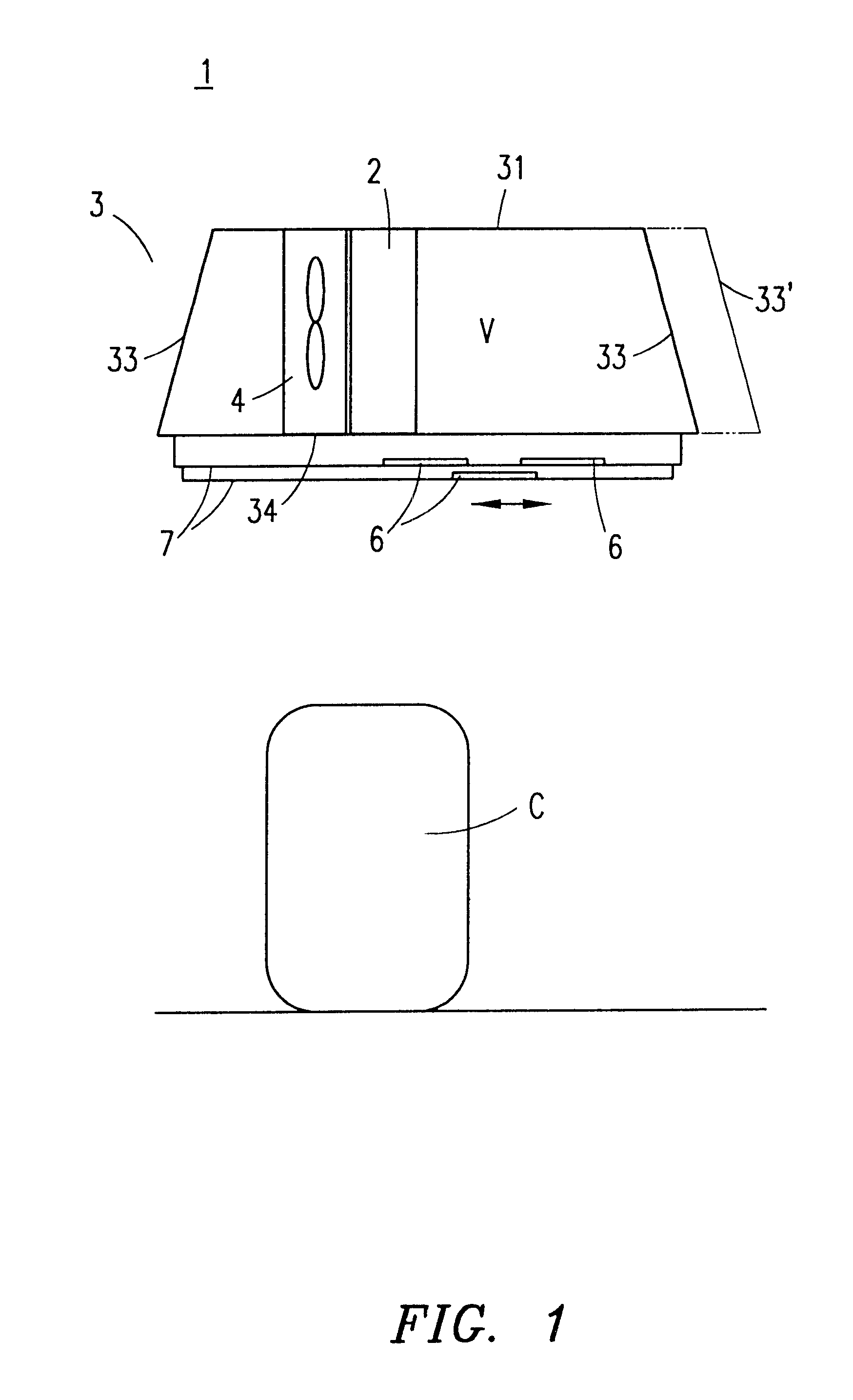

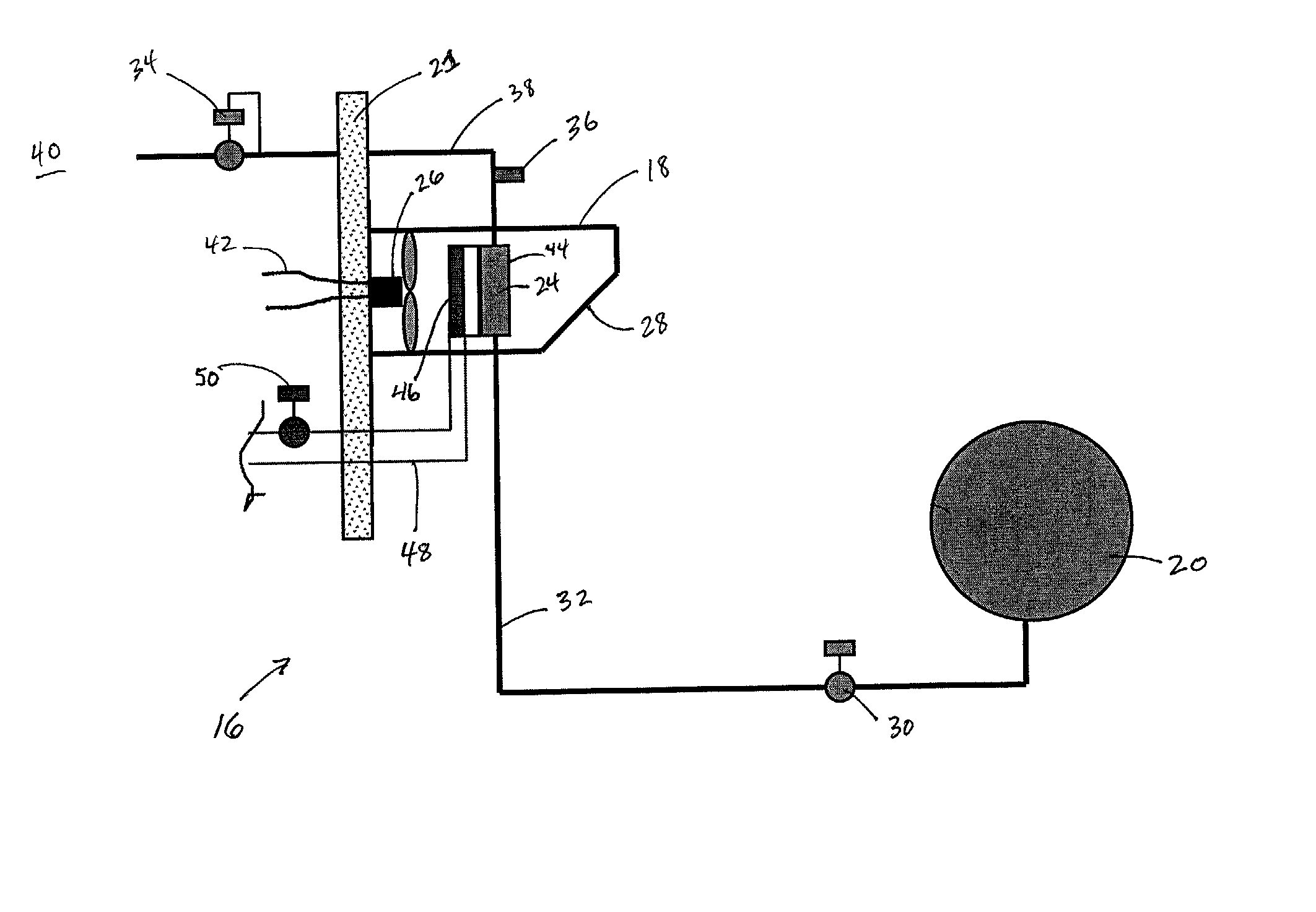

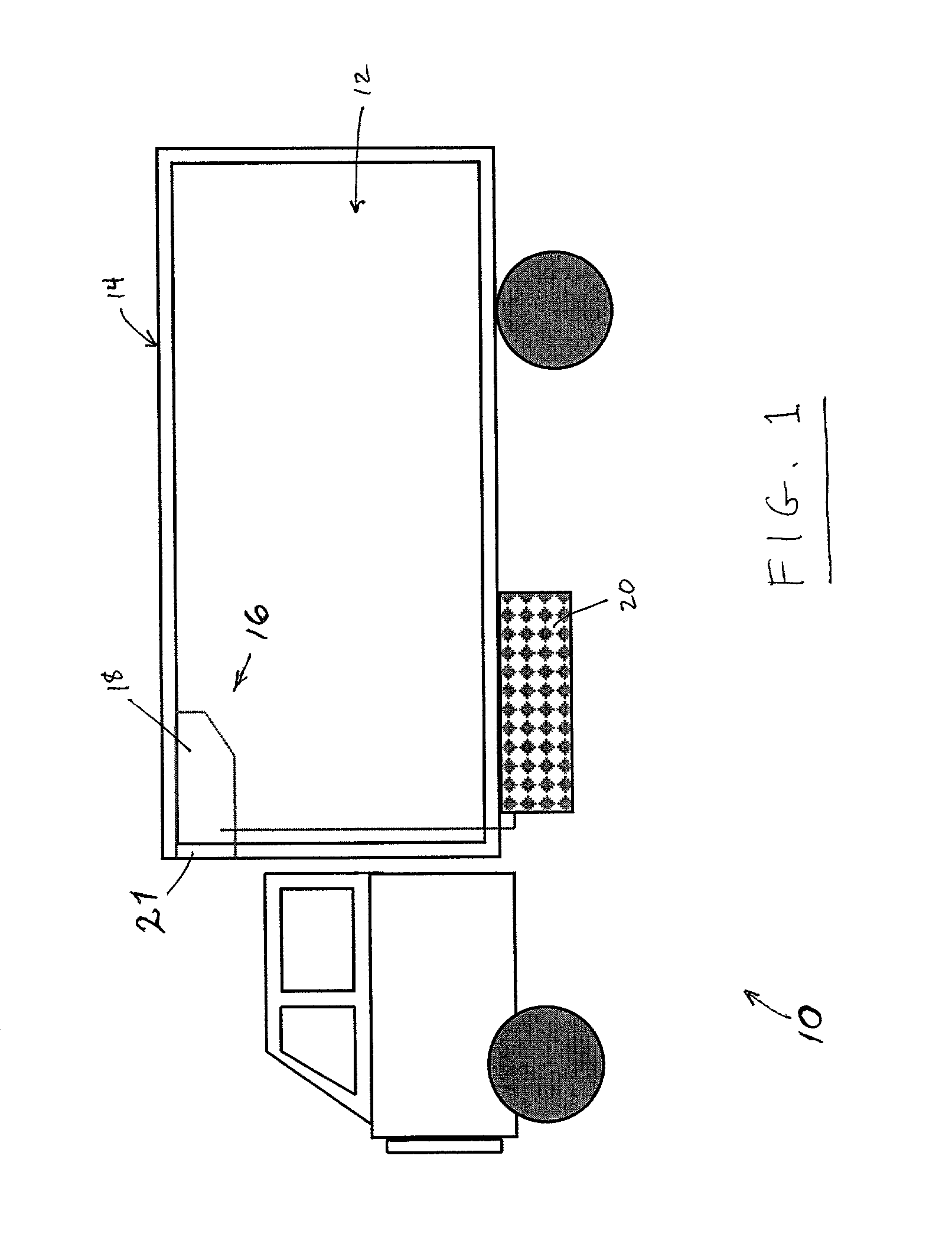

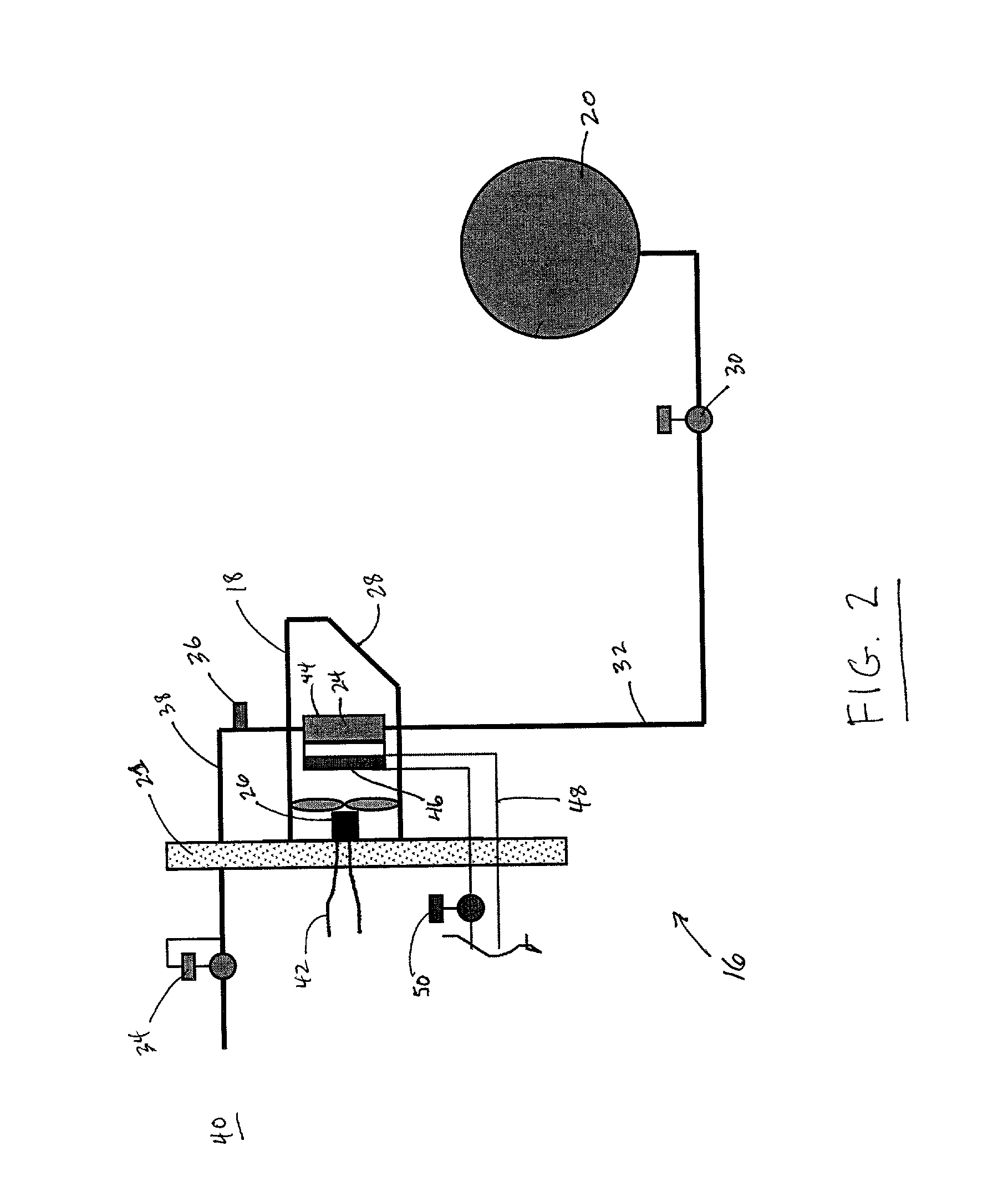

Cryogenic refrigeration unit suited for delivery vehicles

InactiveUS20020129613A1Reduce the temperatureNot contaminate atmosphereAir-treating devicesRefrigerated goods vehicleAir cycleDelivery vehicle

An apparatus to refrigerate the cargo space of delivery vehicles. It provides an environmentally friendly alternative to conventional mechanical a / c and refrigeration units. Cooling is provided by controlled evaporation of a liquefied gas such as CO.sub.2 or nitrogen. Defrost and heating requirements, if needed, are provided by hot engine coolant or by electric heaters powered from the vehicle electrical system. Airflow for the evaporator and for circulation in the temperature controlled space is provided by a blower which is mechanically or electrically driven from vehicle power. This invention can also be applied to multi-temperature control applications. The apparatus is compact and is particularly suited for small inner city delivery vehicles. FIG. 1: The sketch shows an inner city delivery truck for which this invention is most suitable. Refrigerated goods are placed in roller cages that are designed to maximize cargo hauled by use of roller cages that extend to within 2 inches of the ceiling. The evaporator section of this invention is mounted at or near the front wall of the truck and is separated from the cargo by a vertical bulkhead. The conditioned air is delivered at the bottom of the truck to avoid top freeze of perishable cargo that is in close proximity to the ceiling. FIG. 2: This shows the piping schematic and is similar to the invention described in U.S. Application Serial No. 60 / 238,929 (the '929 application) incorporated herein by reference. FIG. 2 shows the engine coolant coil located ahead of the CO.sub.2 coil in the direction of airflow. This prevents the coldest air from coming in contact with the engine coolant--in the cooling mode the air leaving the CO.sub.2 coil can be as low as -50.degree. F. for frozen load applications and this may cause the engine coolant to start freezing. Arrangements must be made to circulate air between the two coils in defrost mode. One means to accomplish this is to place a damper at the outlet of the evaporator section and run the fans. The damper would be closed during defrost. Another method is to place the engine coolant coil on the discharge side of the CO.sub.2 coil and use a cut-out switch if the engine coolant temperature drops below a predetermined value. In this arrangement there is no need for the damper arrangement as the heat will rise to melt any frost on the CO.sub.2 coil. If electric heat is used for defrost and heating freezing of the engine coolant is not a concern and the heaters can be fastened to the discharge side of the CO.sub.2 coil. An electric stand-by mode can be provided to power the system for cooling, heating and defrost when the vehicle is parked with the engine off. A plug-in electrical cable can provide the power needed for the controls, the fans and for heating and defrost. The figure shows the electric heaters attached on the discharge side of the CO.sub.2 coil. Operation: Detailed description is in the '929 application except for the following: The evaporator section is designed for vertical installation to maximize cargo space. Air is discharged at the bottom but may be a conventional top discharge if needed for specific applications. Conventional methods can be used to provide defrost and heating. If engine coolant is used for a heat source, it is preferable to thermally isolate the CO.sub.2 coil from the engine coolant coil to avoid freezing the coolant. The evaporator blower may be located on the inlet side of the coils rather than as shown in the figures. Unique Features: 1. Absence of a conventional condensing section on the exterior of the vehicle makes this an ideal refrigeration unit for small inner city delivery vehicles. Many of the truck cabs are now almost full height (same as the truck body) and there is limited space for the condensing section. 2. Cold plates can be used and still maximize cargo cube. However, this invention has 30-40% less weight than comparable "cold plate" systems. 3. Other features are described in the '929 application.]

Owner:THERMO KING CORP

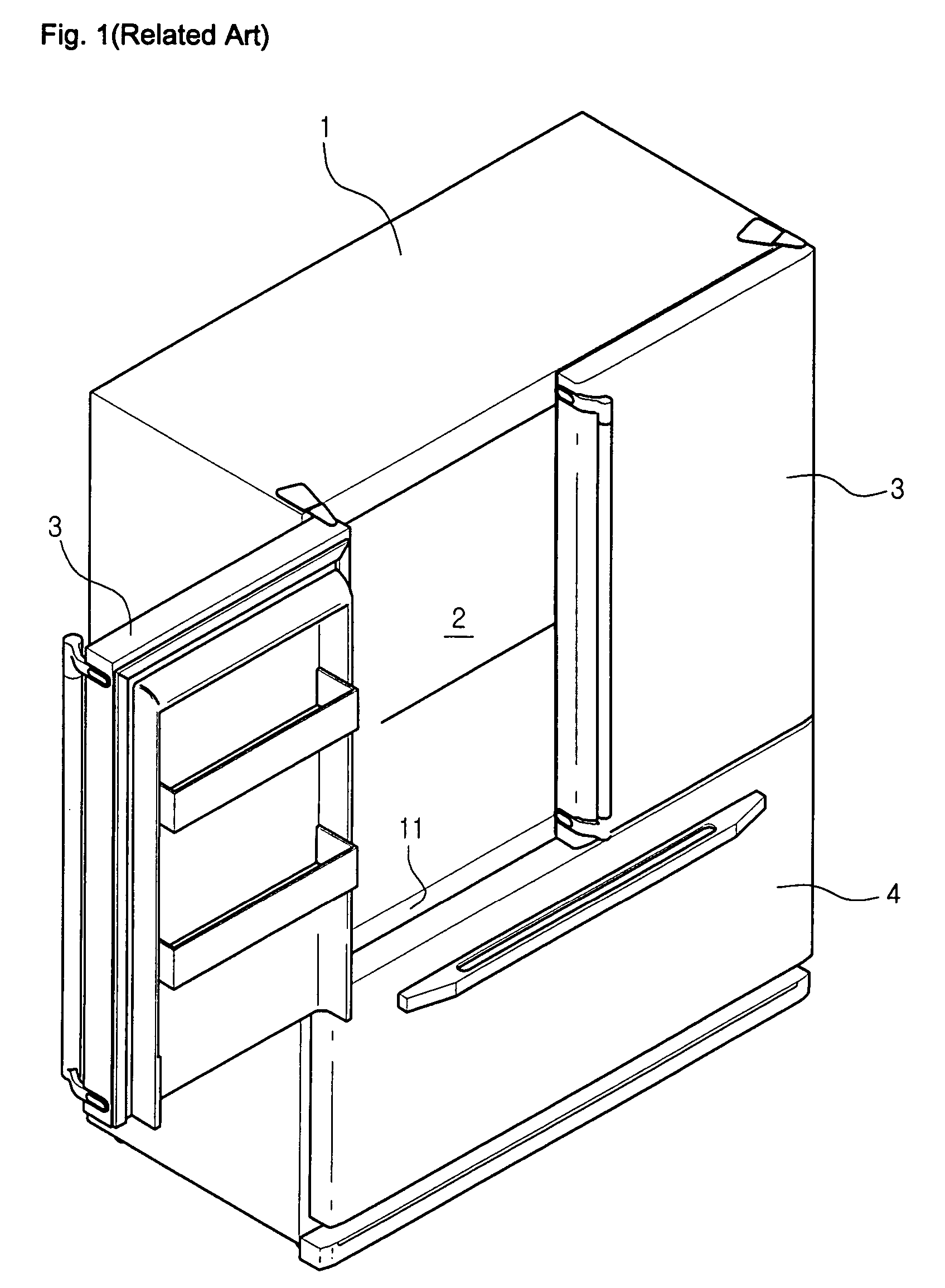

Refrigerator

ActiveUS20060218961A1Loss of storage spaceReduce lossesLighting and heating apparatusIce productionCold airIce storage

In the related art refrigerator, its structure for supplying water to a dispenser and water tank was complicated. In addition, since an icemaker is installed in a refrigerating chamber of the refrigerator, there is a problem in that the water supplied into the icemaker is frozen. Furthermore, if the icemaker is installed in the freezing chamber of the refrigerator in which the refrigerating chamber is formed at a lower portion thereof and a refrigerating chamber is formed at an upper portion thereof, there is another problem in that it is difficult to control the temperature in the refrigerating chamber or ice-making capability of the icemaker is lowered. The present invention is directed to a refrigerator. According to an aspect of the present invention for solving the above problems, there is provided a refrigerator including a refrigerating chamber formed at a relatively upper portion of a refrigerator body and a freezing chamber formed at a relatively lower portion of the refrigerator body, which comprises an ice-making chamber which is partitioned in the refrigerating chamber by means of insulating walls and includes an icemaker for making ice and an ice storage for storing the ice made in the icemaker, a first heat exchanger for generating cold air to regulate the temperature in the ice-making chamber, and a second heat exchanger for generating cold air to regulate the temperature in the freezing and refrigerating chambers, wherein the first and second heat exchanger are components of a heat exchange cycle. According to the refrigerator of the present invention so configured, there are advantages in that the temperature in the refrigerating chamber can be accurately controlled, the loss of cold air can be minimized and the structures for supplying water into the icemaker and the dispenser can be simplified.

Owner:LG ELECTRONICS INC

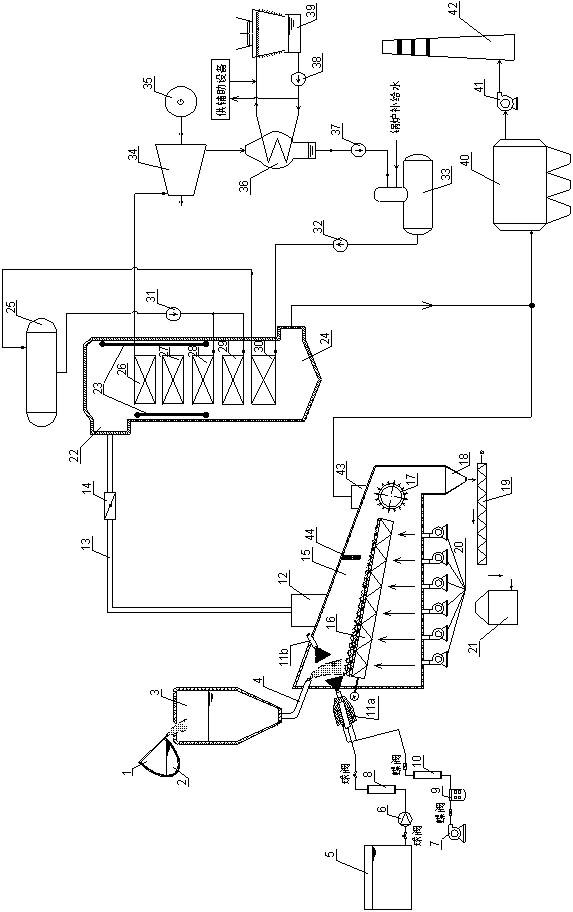

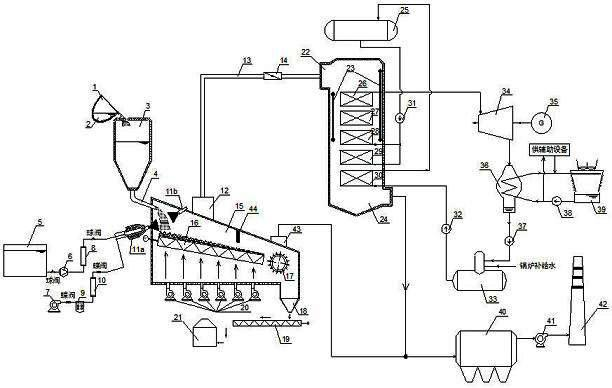

Melting furnace slag quenching dry type granulation and sensible heat recovery generating system and method using same

ActiveCN102433401AReduce cooling air volumeReduce power consumptionIncreasing energy efficiencyRecycling and recovery technologiesSlagHigh pressure water

The invention provides a melting furnace slag quenching dry type granulation and sensible heat recovery generating system and a method using the same and belongs to the technical field of steel metallurgy furnace slag treatment and complementary energy recovery. The melting furnace slag quenching dry type granulation and sensible heat recovery generating system provided by the invention comprisesa slag-receiving device, a high-pressure water-air pulverization furnace slag quenching and granulating device, a furnace slag slow-cooling device, a sensible heat recovery generating device and a waste gas purification treatment device. According to the invention, the melting furnace slag is quenched and granulated by utilizing the high-pressure water-air pulverization device, so that the melting furnace slag is rapidly cooled to be in a glassy state; and then through a water-cooled type vibration grid plate, the melting furnace slag in the glassy state is further subjected to heat exchange with cold air so as to facilitate the subsequent recovery of the sensible heat. By the system provided by the invention, the melting furnace slag is quenched and granulated, and the high-temperature sensible heat resource of the furnace slag is sufficiently recovered and is used for generation on the basis that the water activity quality of the furnace slag is not influenced.

Owner:NANJING KESEN KENEN ENVIRONMENT & ENERGY

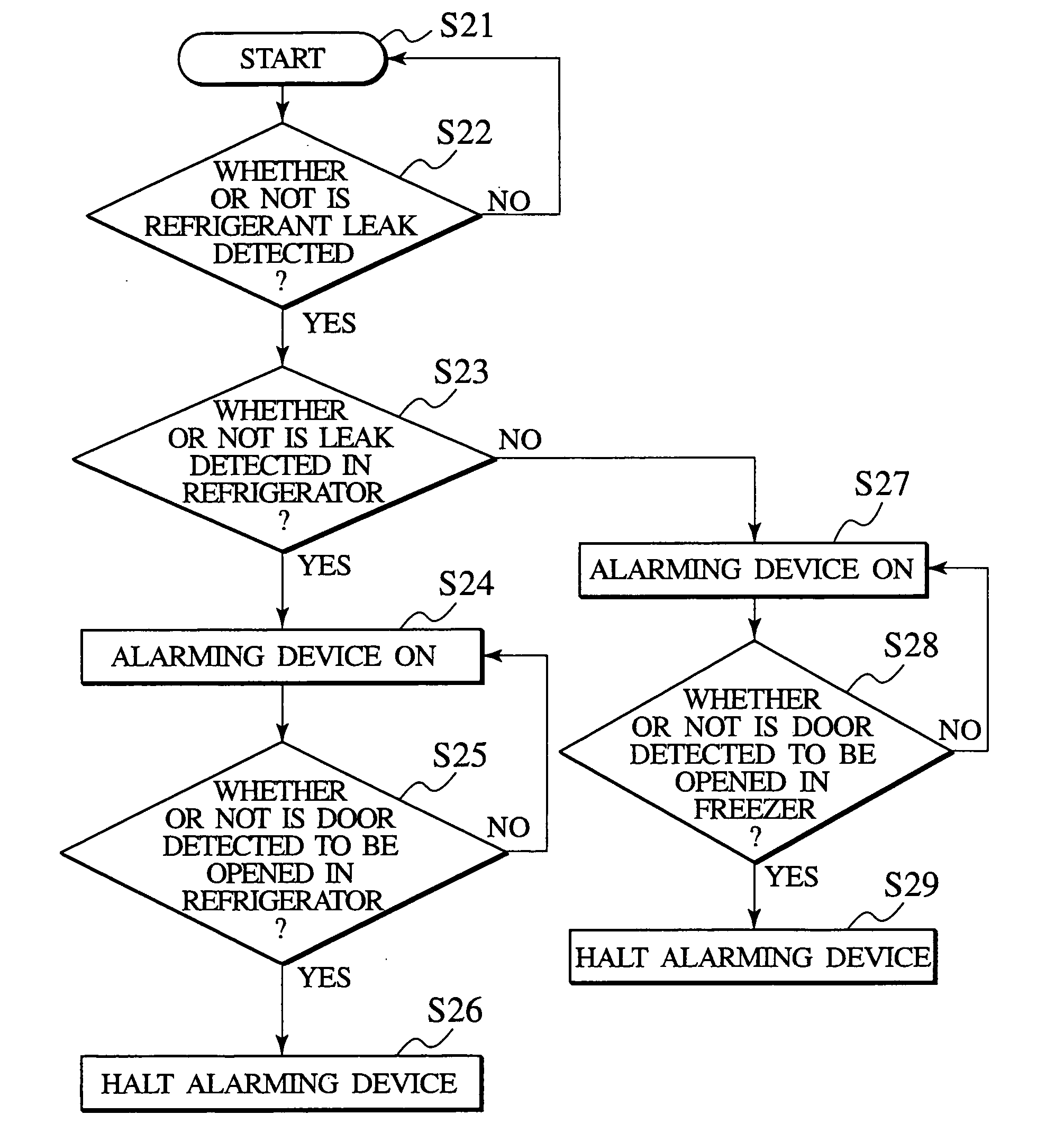

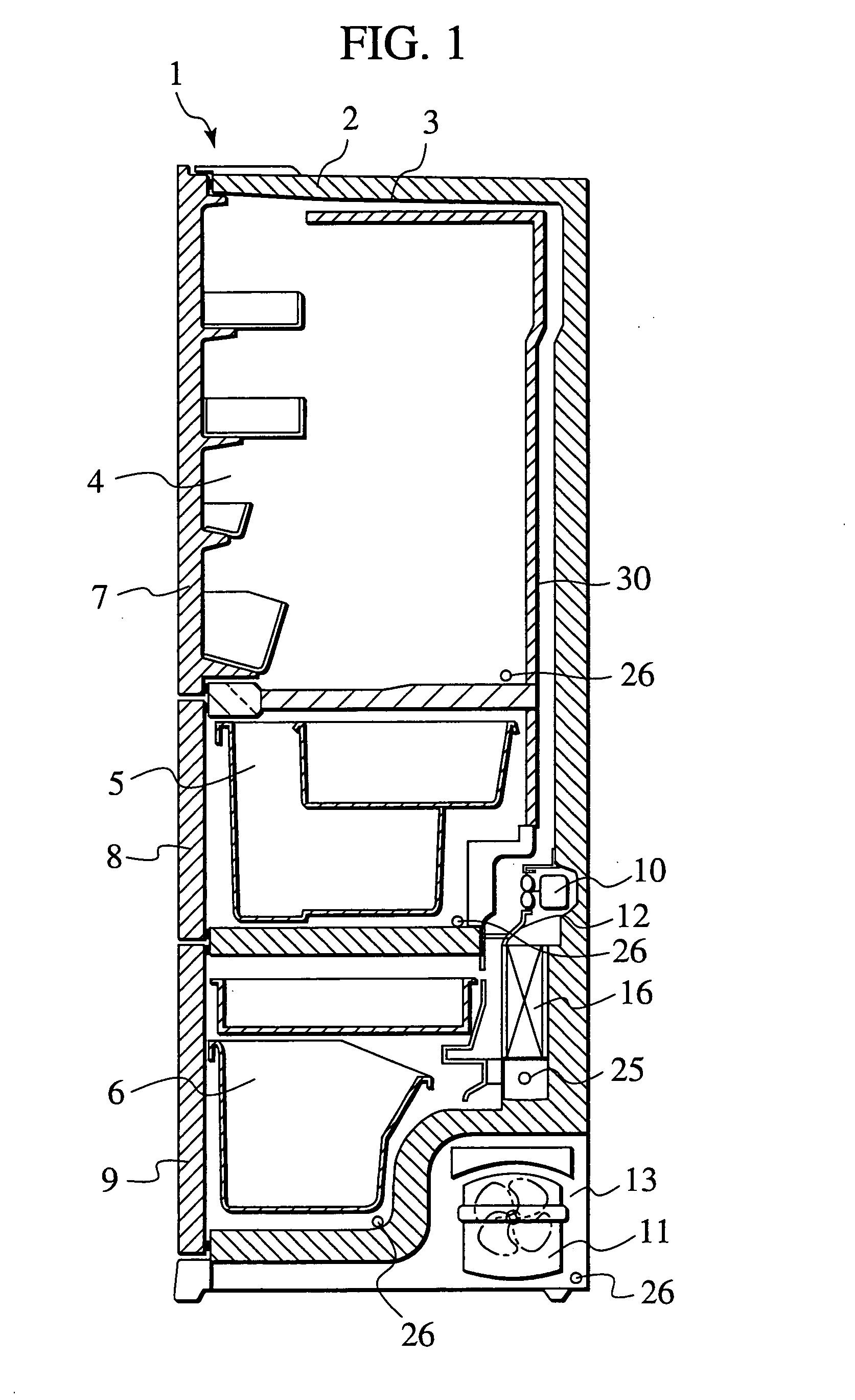

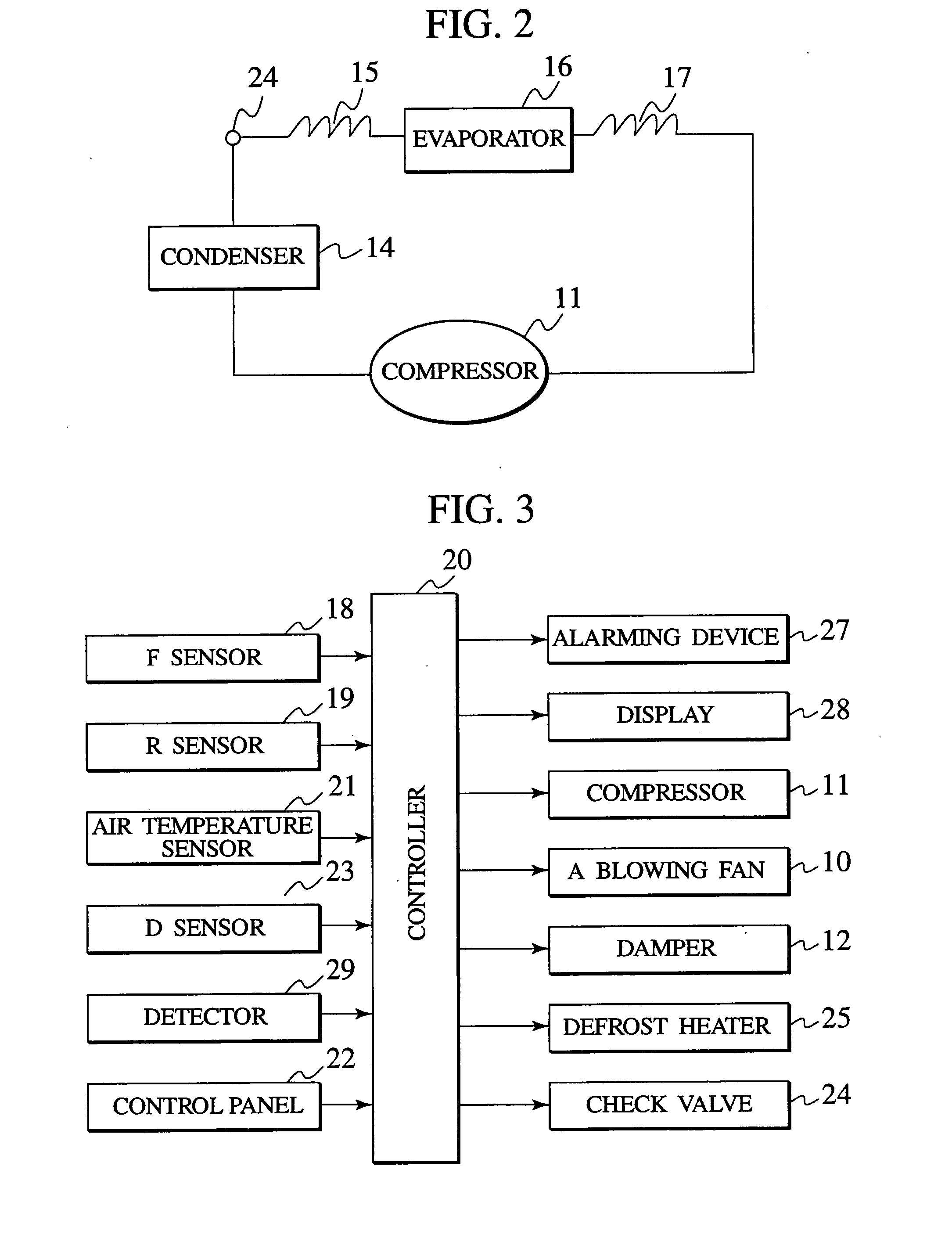

Refrigerator having alarm device for alarming leakage of refrigerant

A detector (29) detects that a refrigerant gas has leaked from a refrigeration cycle, or detects in advance that a refrigerant is to leak. The alarming device (27) gives users an alarming signal warning against the refrigerant leak. The alarming device (27) is caused to stop giving an alarming signal after users open doors of storage compartments including a refrigerator compartment (4), a vegetable storage compartment (5) and a freezer compartment (6). For example, after all the doors of the storage compartments are opened, giving the alarming signal is stopped. Otherwise, giving the alarming signal is stopped after the door of a storage compartment into which cold air flows by causing a damper (12) to open is opened.

Owner:TOYOBO CO LTD +1

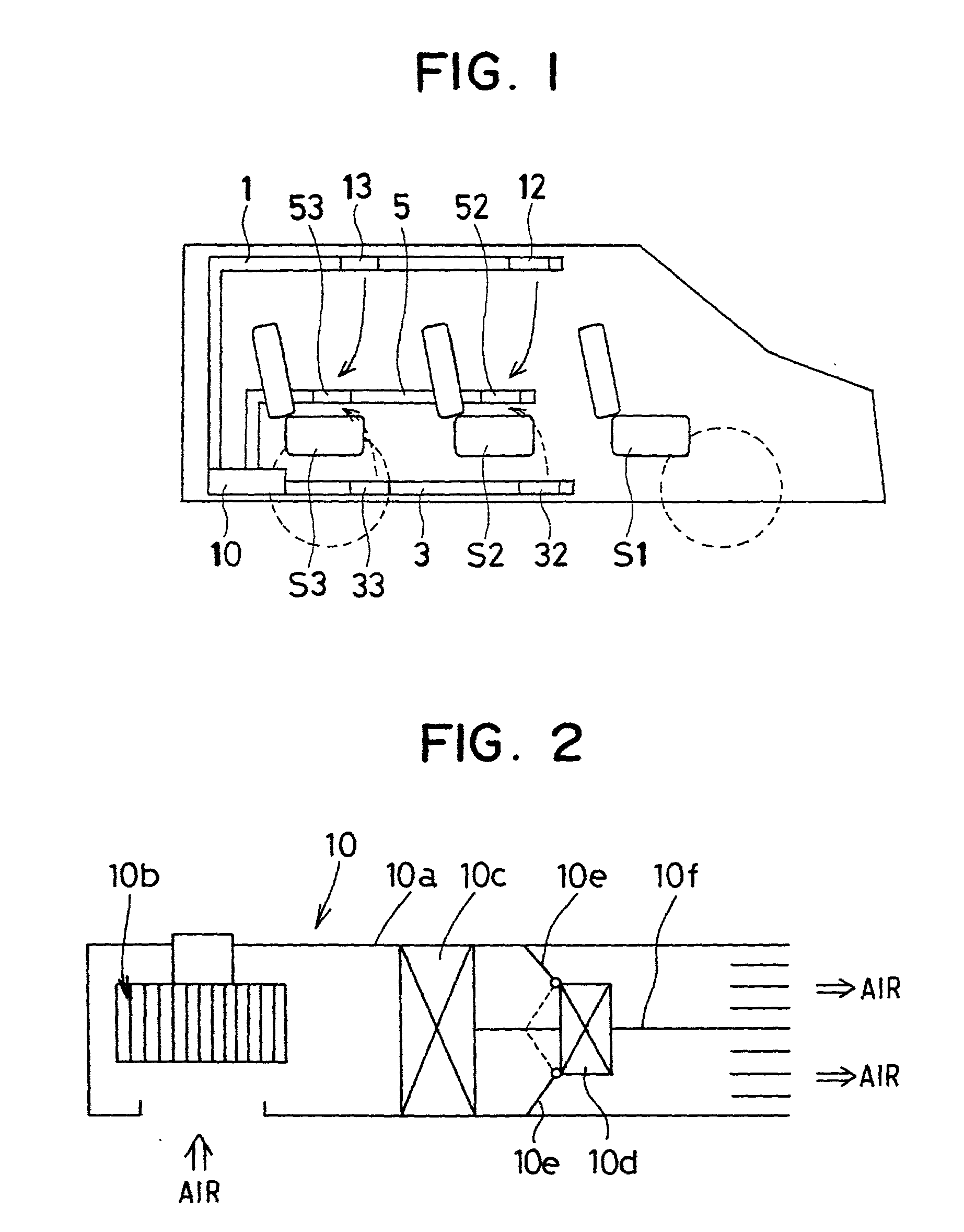

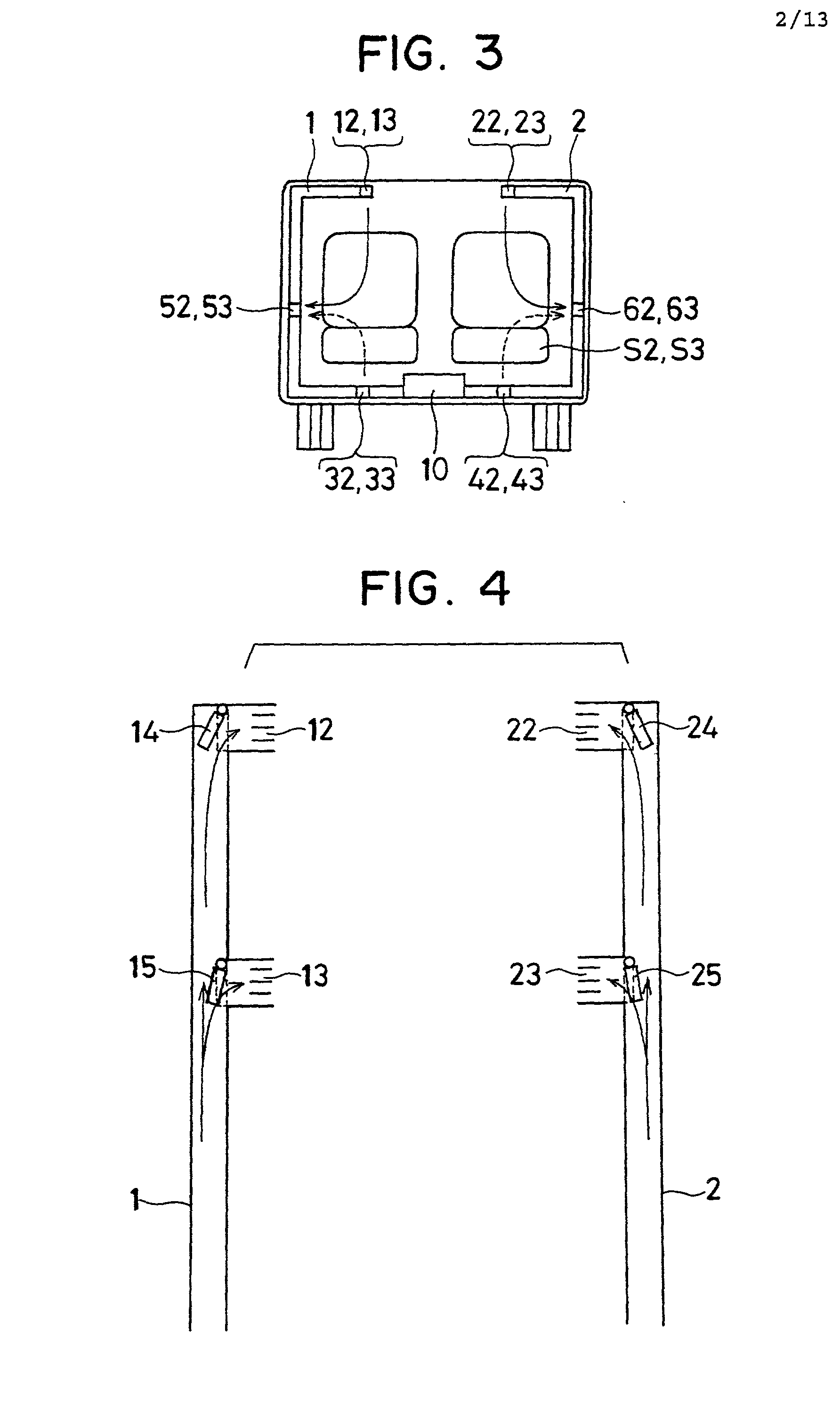

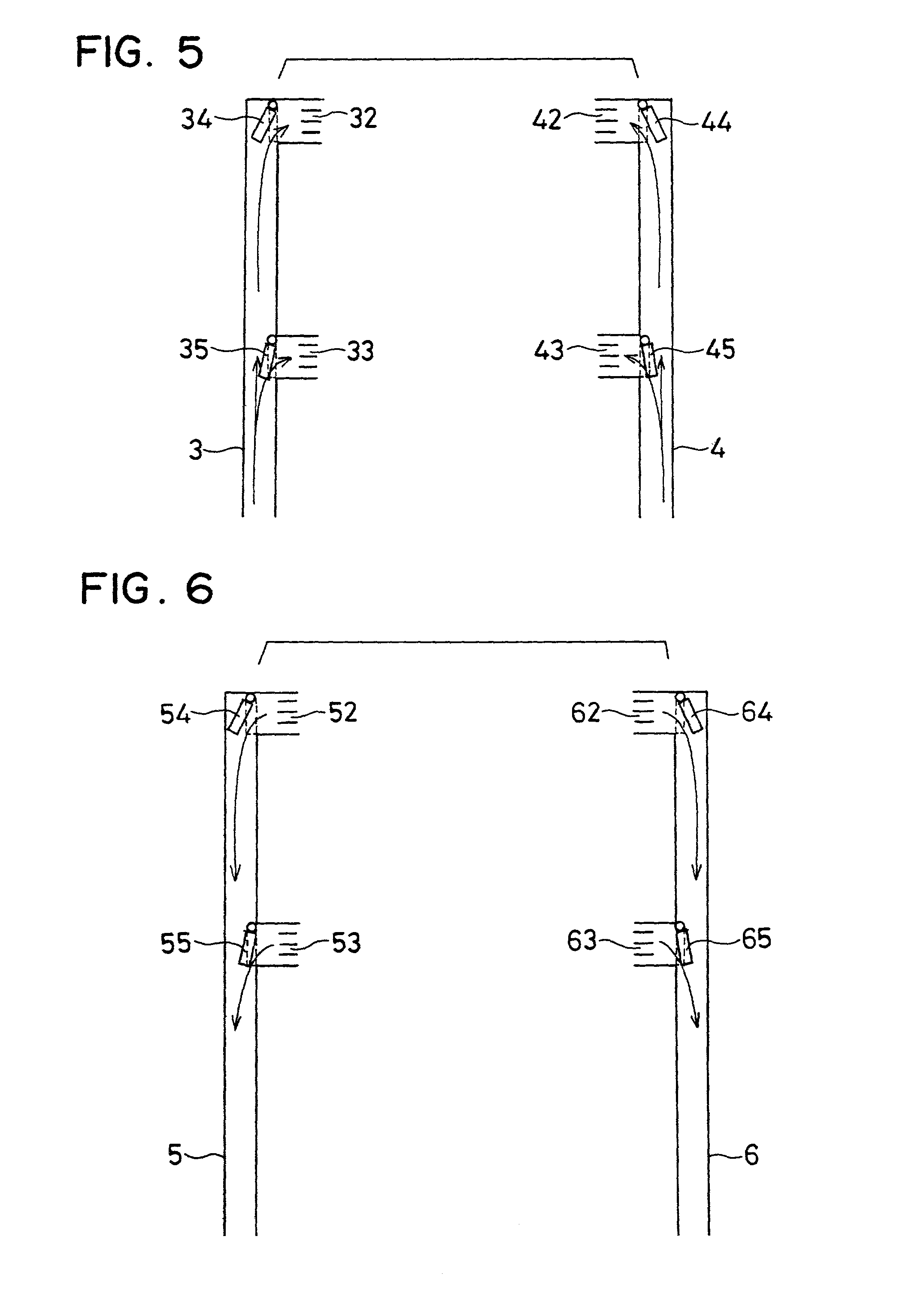

Vehicle air conditioner having air suction port for each seat

InactiveUS20010029162A1Improve controlEfficient executionAir-treating devicesSeat heating/ventillating devicesCold airEngineering

In a vehicle air conditioner, each of cool air outlets is provided at an upper side of each seat at second and third seat lines from a most front seat so that cool air from an air conditioning unit is blown from the cool air outlets toward upper sides of the seats, respectively, and each of warm air outlets is provided at a lower side of each seat at the second and third seat lines so that warm air from the air conditioning unit is blown from the warm air outlets toward lower sides of the seats, respectively. In addition, each of suction ports is provided for each corresponding seat at the second and third seat lines so that air inside a passenger compartment is sucked from the suction ports to be returned to the air conditioning unit.

Owner:DENSO CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com