Simple assembly structure air fryer

An assembly structure and technology of air fryer, which can be applied to appliances for frying things in oil, household appliances, applications, etc., can solve the problems of unfavorable shell cooling, difficult assembly and maintenance, and inconvenient after-sales maintenance, so as to improve product competition Force, save installation process, accelerate the effect of surface heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

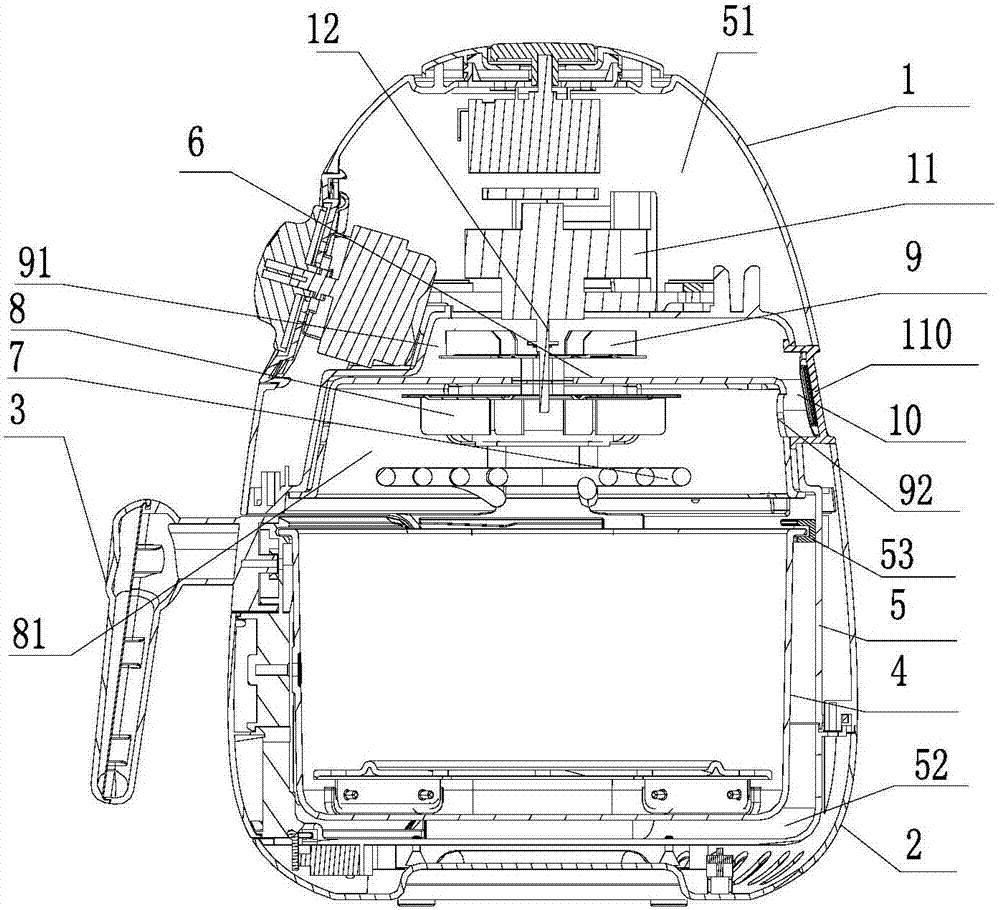

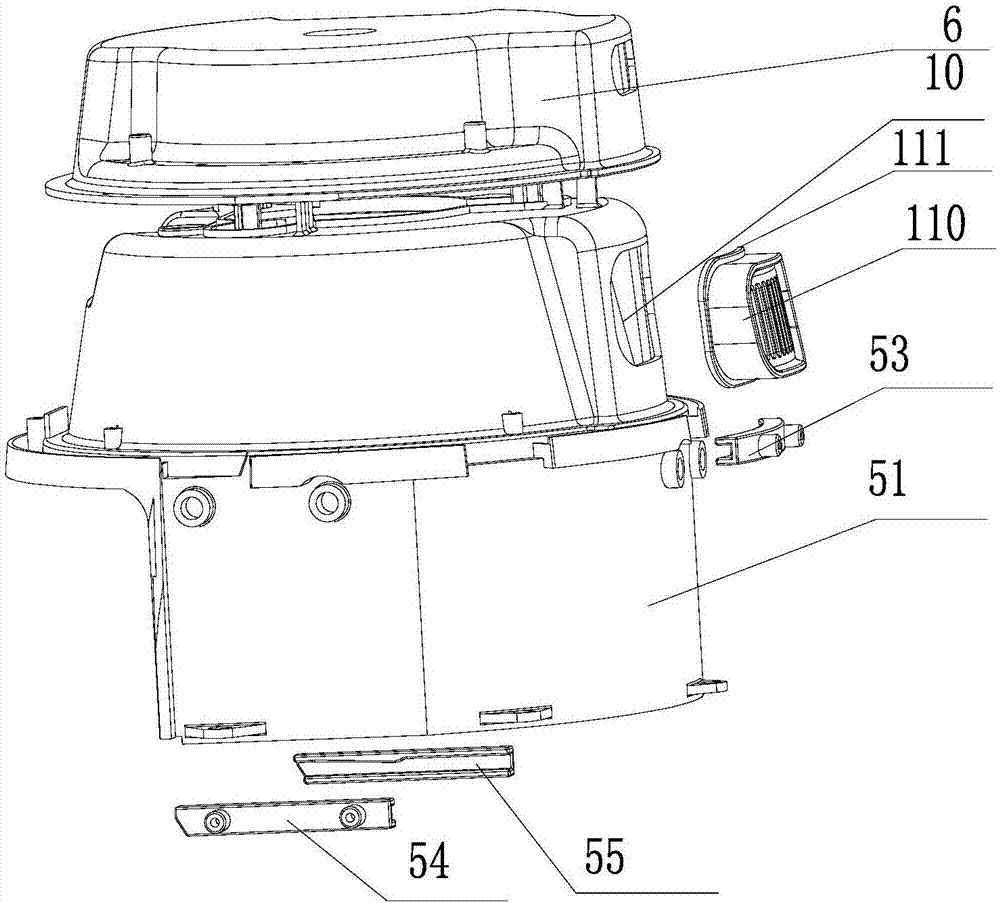

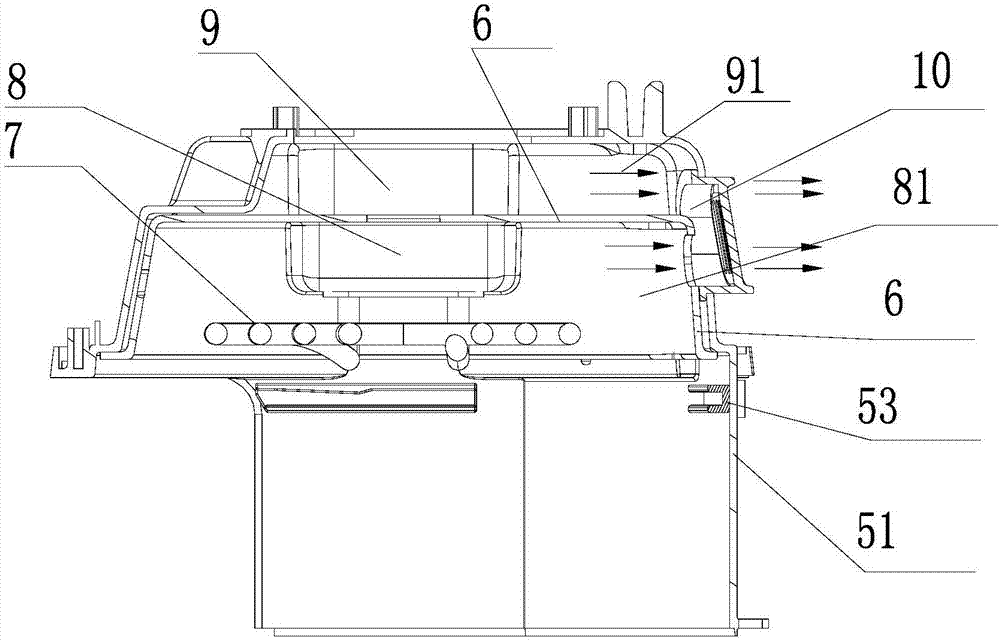

[0016] figure 1 , figure 2 with Figure 4 As shown, the present invention discloses an air fryer with a simple assembly structure, which includes an upper casing 1, a lower casing 2 connected to the upper casing 1, and a handle 3 arranged on the side of the upper casing 1; The above-mentioned upper casing 1 is connected with the lower casing 2 to form an inner chamber 5; The cavity 4 is composed of; the upper cavity 51 forms a cold air flow channel 91 and a hot air flow channel 81 through the heating pipe cover 6, and the upper position of the cold air flow channel 92 is provided with a motor 11, and the motor 11 passes through the rotating shaft 12 Vertically pass through the cold air passage 91 and the heating pipe cover 6 to be rotatably connected with the hot air fan 8 arranged in the hot air passage 81, and the cold air fan 9 coaxially connected with the rotating shaft 12 is arranged in the cold air passage 91, and The air flow channel 81 is provided with a heat pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com