Multilayer coextruded surface-layer pre-crosslinked adhesive film

A multi-layer co-extrusion and surface layer technology, applied in adhesives, film/sheet adhesives, photovoltaic power generation, etc., can solve problems such as unclear color interface, color penetration of the upper and lower layers, and affect the appearance of components, etc., to achieve suitable For large-scale promotion and application, the effect of simple structure and ingenious design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

Not crosslinked

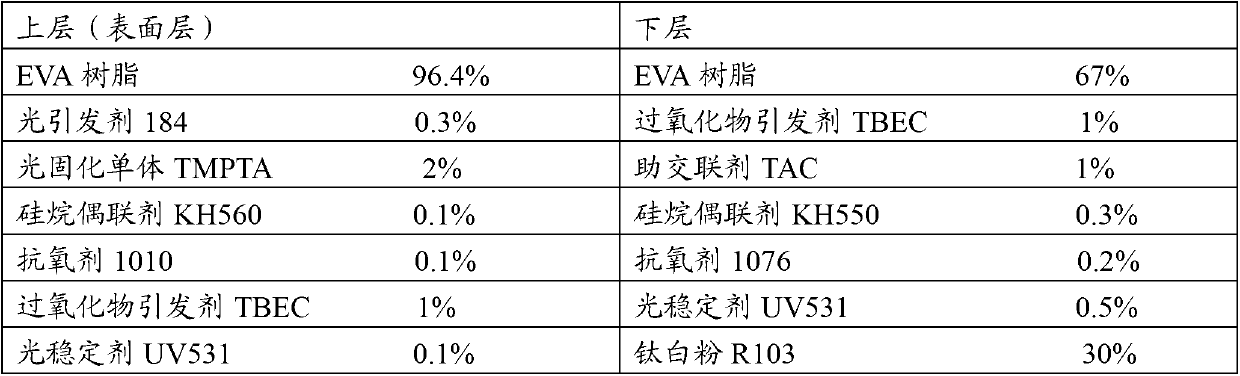

[0029] The composition of the upper and lower layers is as follows:

[0030]

[0031] The produced double-layer co-extruded EVA film is irradiated by ultraviolet light, and the upper layer (surface layer) faces the ultraviolet light tube. The ultraviolet light adopts an inorganic lamp, and the intensity of the lamp is 1800 milliwatts / square centimeter, and the time is 3 seconds. The test method of the degree of cross-linking is that xylene is extracted for 4 hours at 140° C. with a spherical flask equipped with a condenser tube, and the ratio of the weight of EVA that cannot be dissolved in xylene to the original weight is compared.

[0032] Place the above adhesive film and the transparent EVA adhesive film on the lower side and the upper side of the solar battery sheet respectively. The adhesive film on the upper side is an ordinary transparent adhesive film. After lamination, it was found that the surface of the white layer was smooth, and th...

Embodiment 2

slightly crosslinked

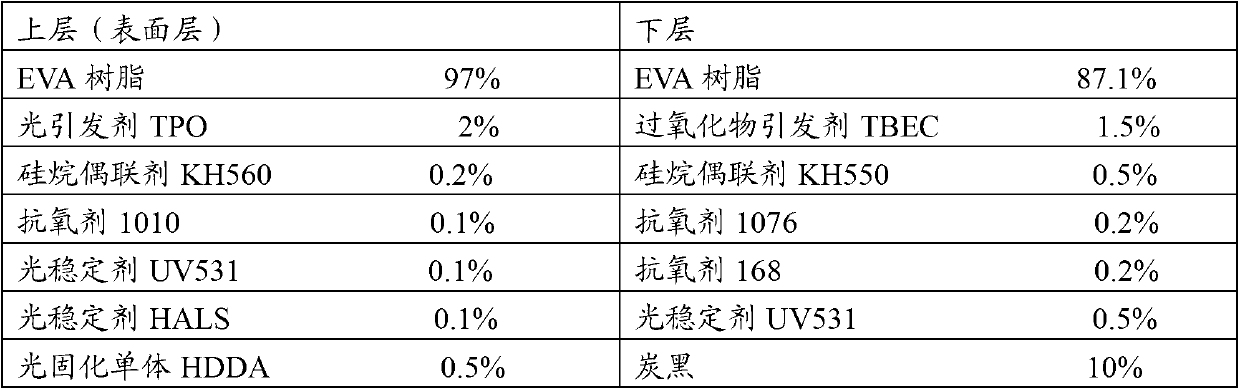

[0037] The composition of the upper and lower layers is as follows:

[0038]

[0039] The surface layer of the above adhesive film was pre-crosslinked by ultraviolet light similar to that used in Example 1. It is used in solar cell modules with front glass / transparent EVA film / cell sheet / multilayer co-extruded surface layer pre-crosslinked EVA film / back glass structure. The measured pulling force of the multi-layer co-extruded film and the back glass is greater than 60 N / cm. The interface of the black layer of the multi-layer co-extrusion adhesive film is clear, and the black color does not penetrate into the upper side adhesive film, nor does it cover the edge of the battery sheet or cover the welding ribbon connecting the battery sheet. Because the lower layer of the multi-layer co-extrusion film is black, it absorbs heat under ultraviolet radiation. Although there is no photoinitiator, it also leads to resin crosslinking caused by some pe...

Embodiment 3

[0041]

[0042] Except that 4% talcum powder (EVA correspondingly reduces 4%) is added in the formula of upper layer, other is identical with embodiment 1. Lower layer formula is with embodiment 1. After being irradiated by ultraviolet light, it is used for lamination of glass / transparent EVA adhesive film / cell sheet / adhesive film of Example 3 / back plate. The lamination temperature is 145 degrees centigrade and the time is 15 minutes. The type of the back sheet is fluoroplastic / PET / EVA, wherein the EVA is EVA with 8% VA content, and the thickness of the layer is 0.25 mm. After lamination, the interface of the white layer of the lower EVA film was clear, and the white did not seep into the upper transparent film, nor did the white cover the edges of the cells or the solder strips connecting the cells. The lower layer of EVA cannot be separated from the backplane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| mechanical properties | aaaaa | aaaaa |

| cross-linking degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com