Patents

Literature

6752 results about "Ethylene-vinyl acetate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

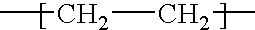

Ethylene-vinyl acetate (EVA), also known as poly (ethylene-vinyl acetate) (PEVA), is the copolymer of ethylene and vinyl acetate. The weight percent vinyl acetate usually varies from 10 to 40%, with the remainder being ethylene.

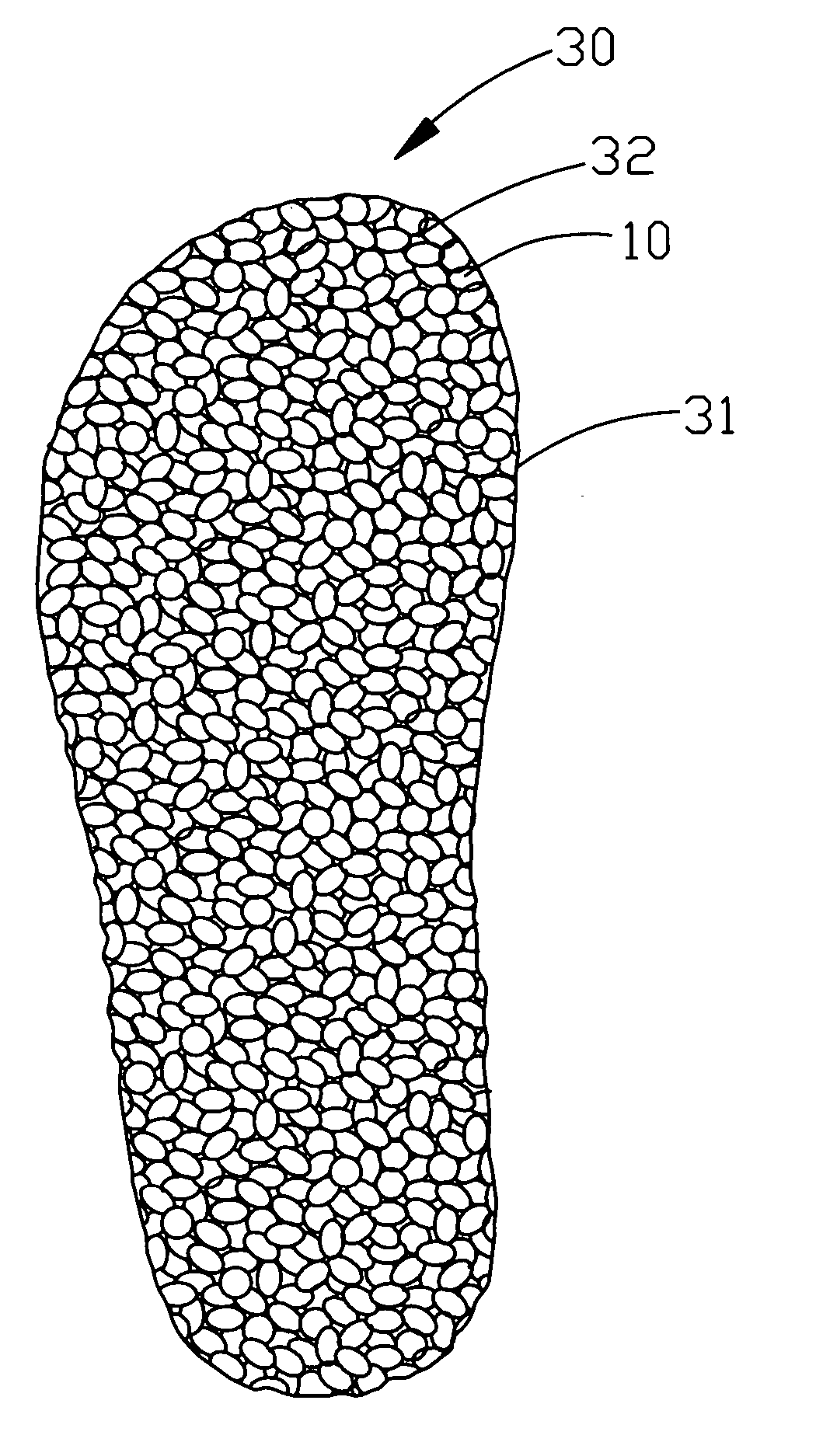

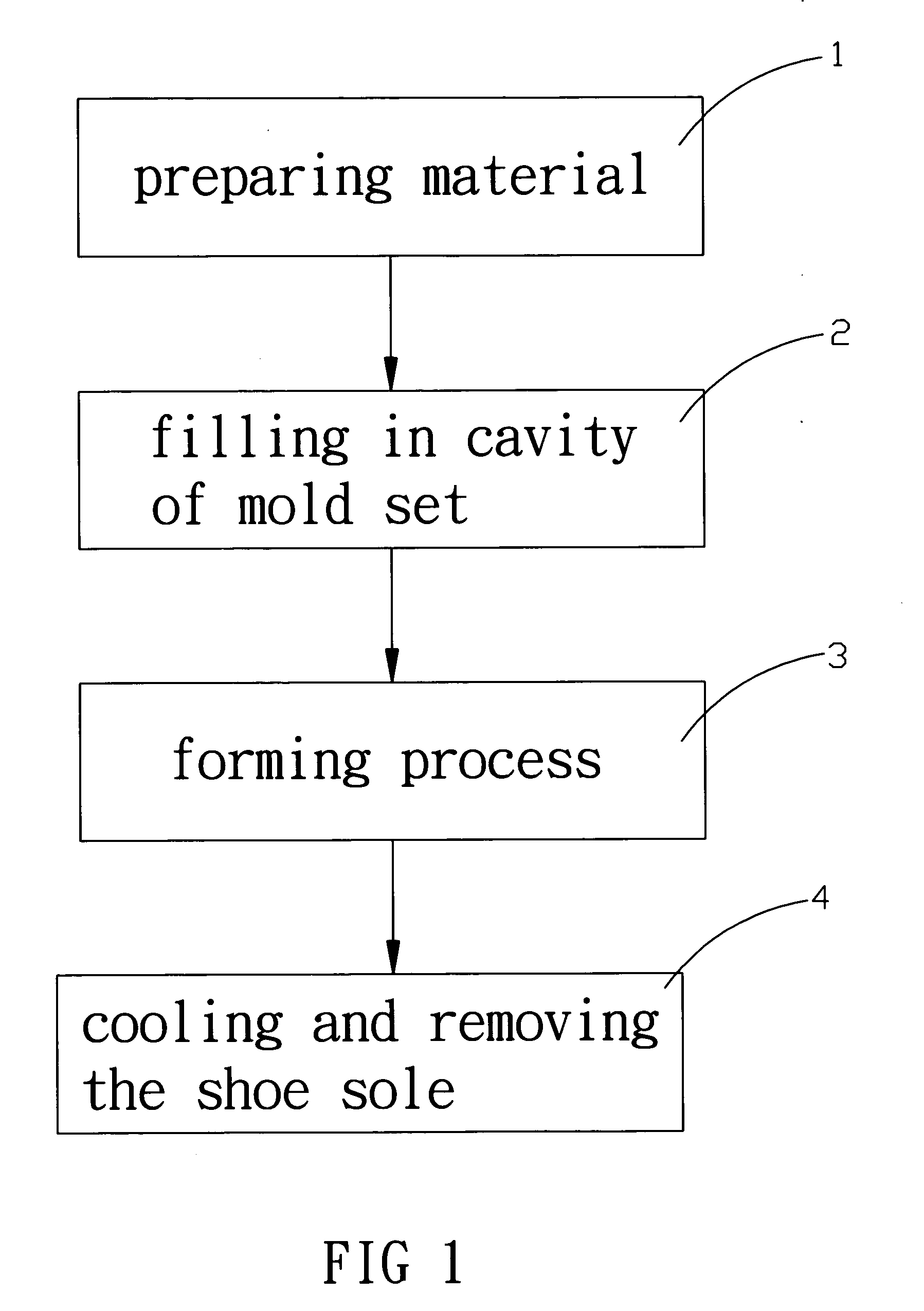

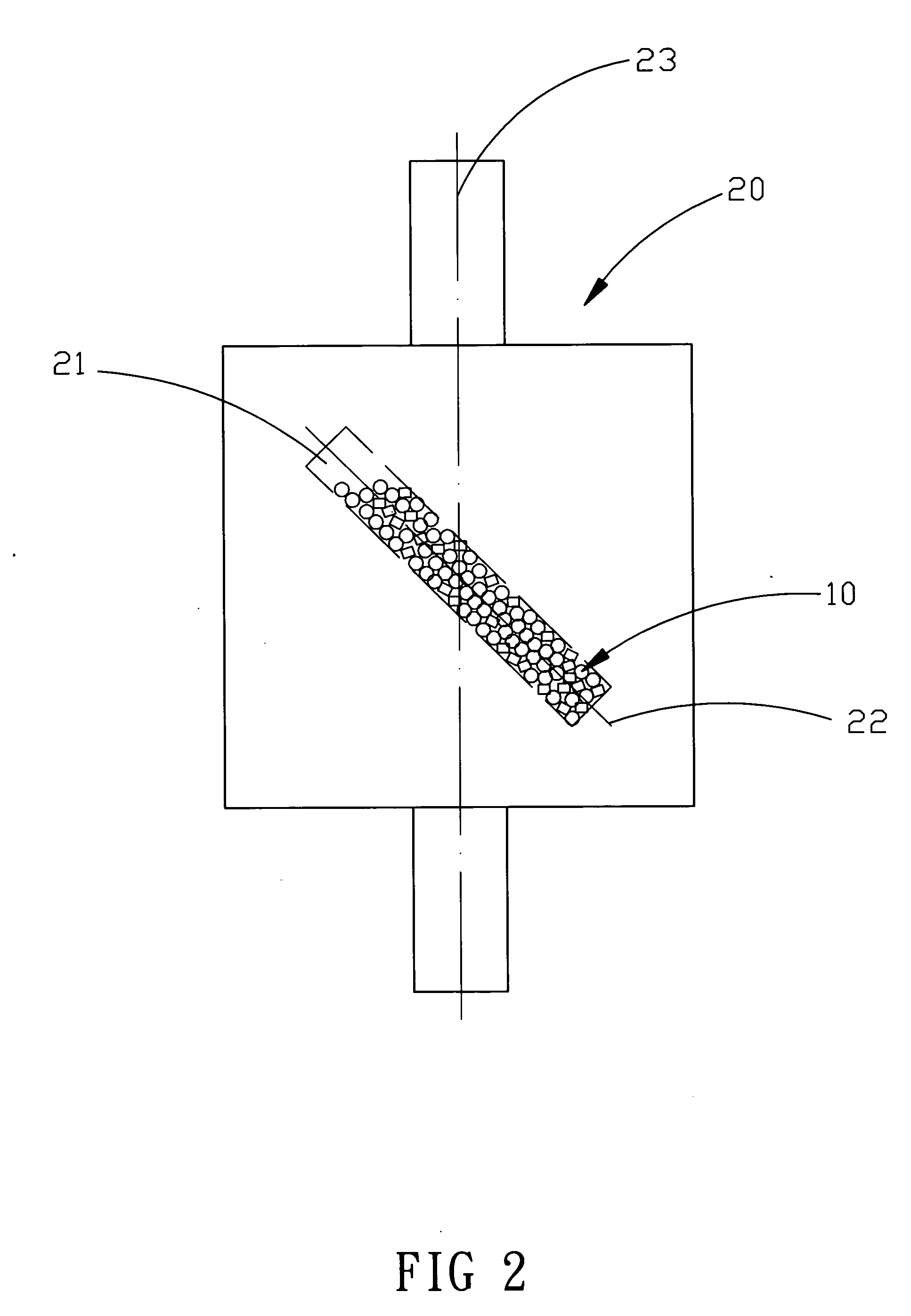

Shoe shole and method for making the same

A shoe sole is composed of particles of Ethylene Vinyl Acetate and the particles are connected with each other with gaps defined between the particles so as to form irregular surface of the shoe sole. The sole is made by filling the particles to 77% to 87% of volume of a cavity in a mold set, wherein an angle 40 to 50 degrees is clamped between a spinning axis of the cavity and an axis to which the mold set is rotated about. The mold set is then heated to 140 to 160 degrees Celsius and spins the mold set about the spinning axis 22 to 32 minutes. After cooling the mold set, the shoe sole is formed and is removed from the cavity.

Owner:LIU DONG LONG

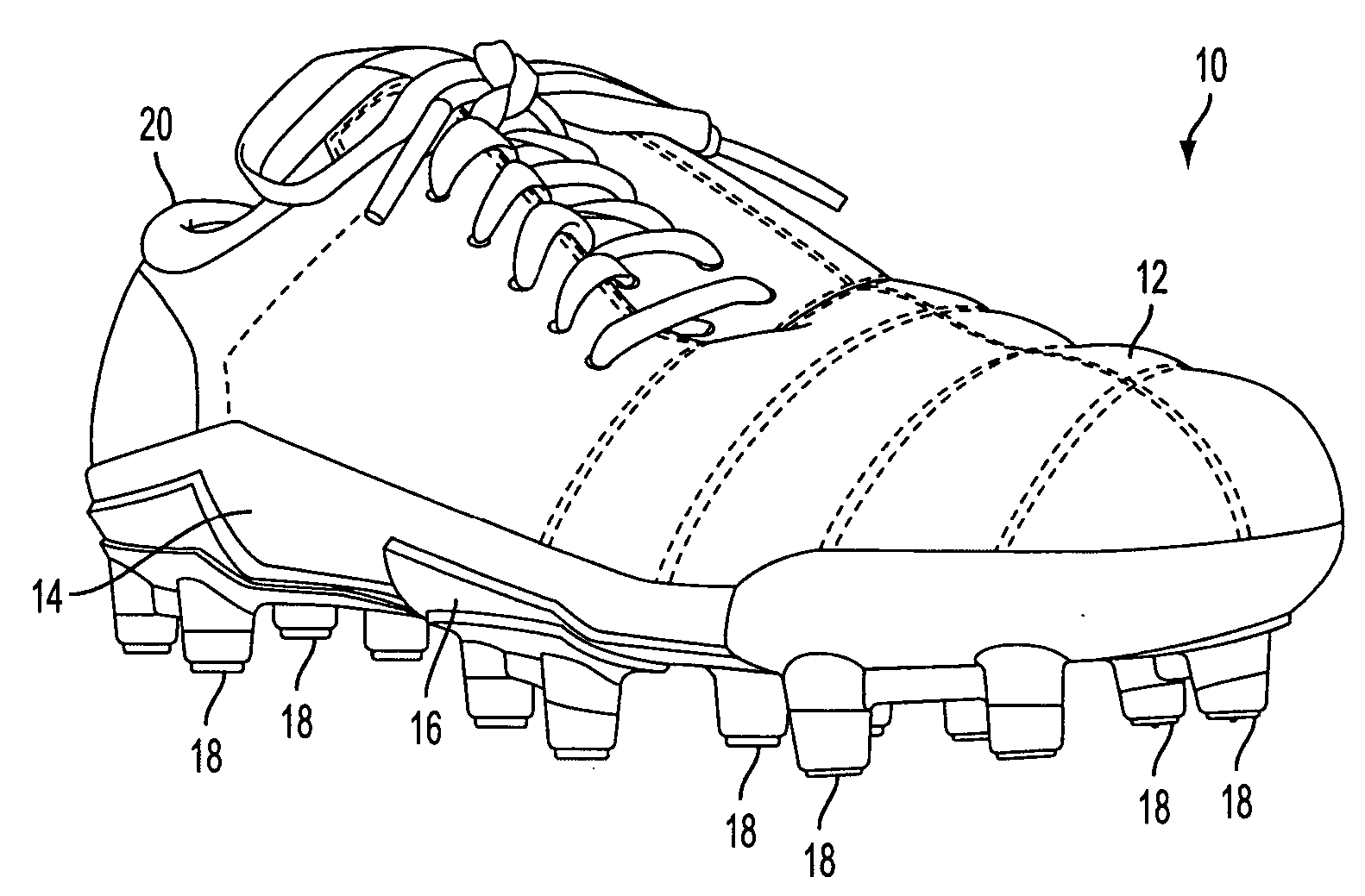

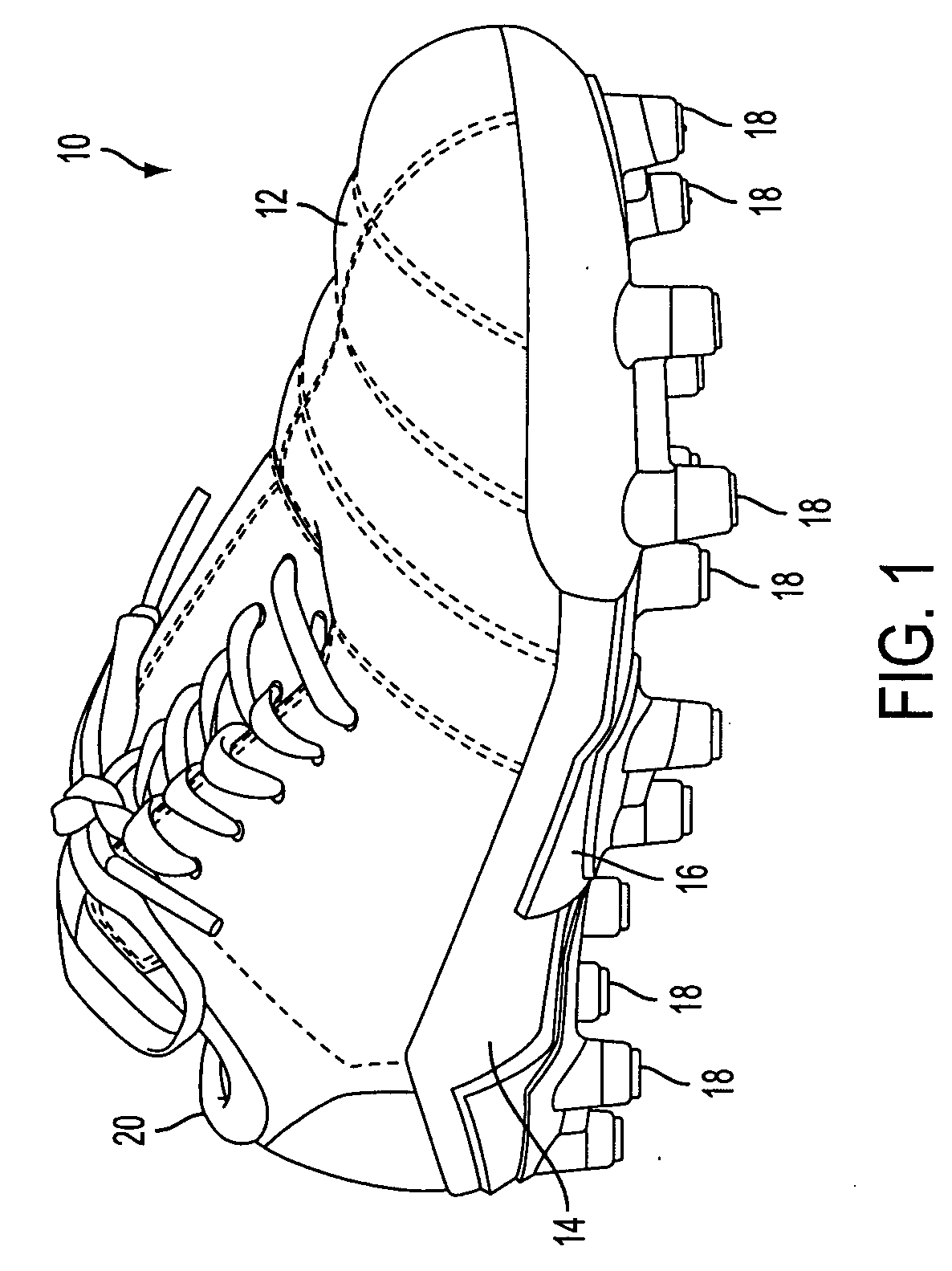

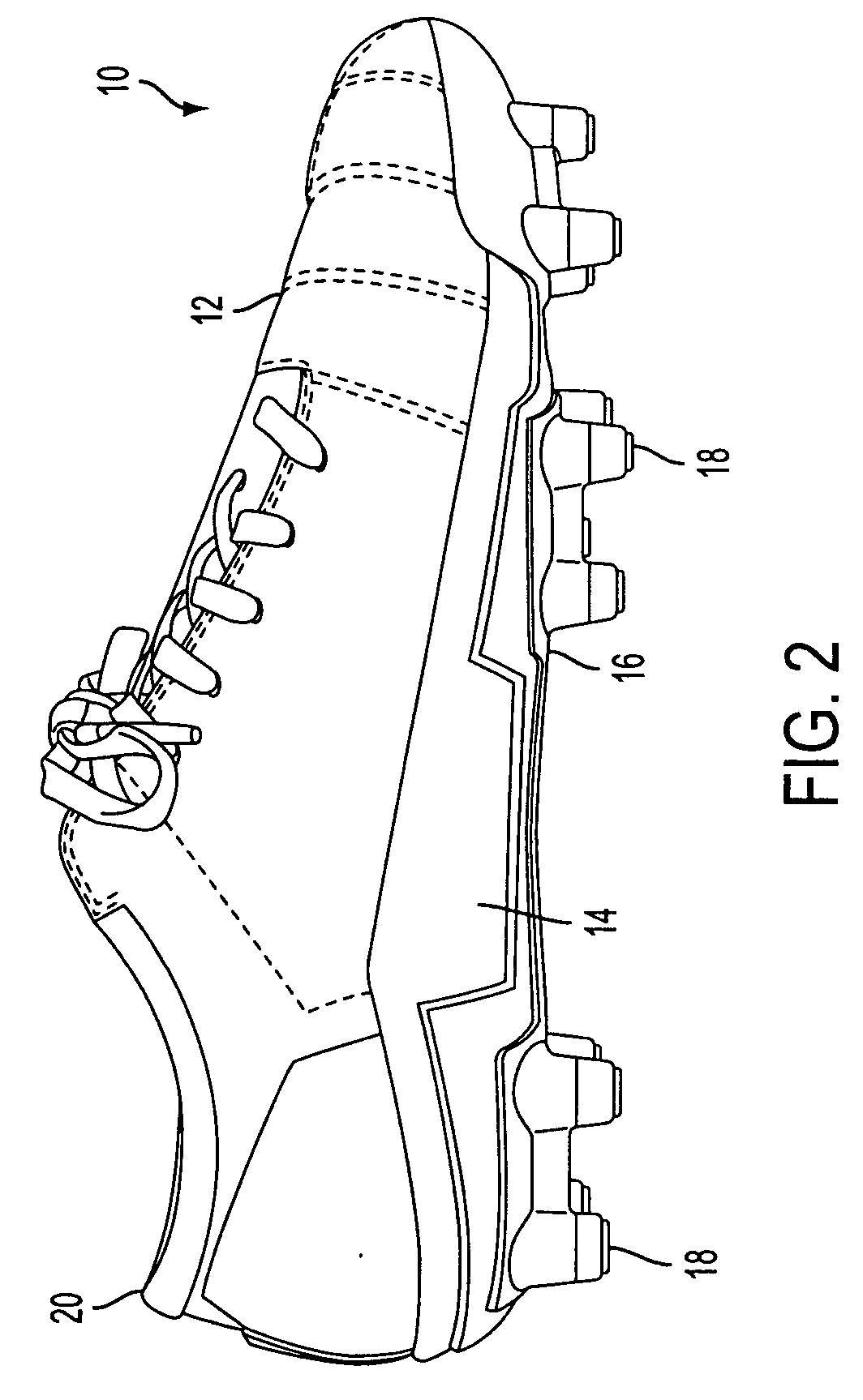

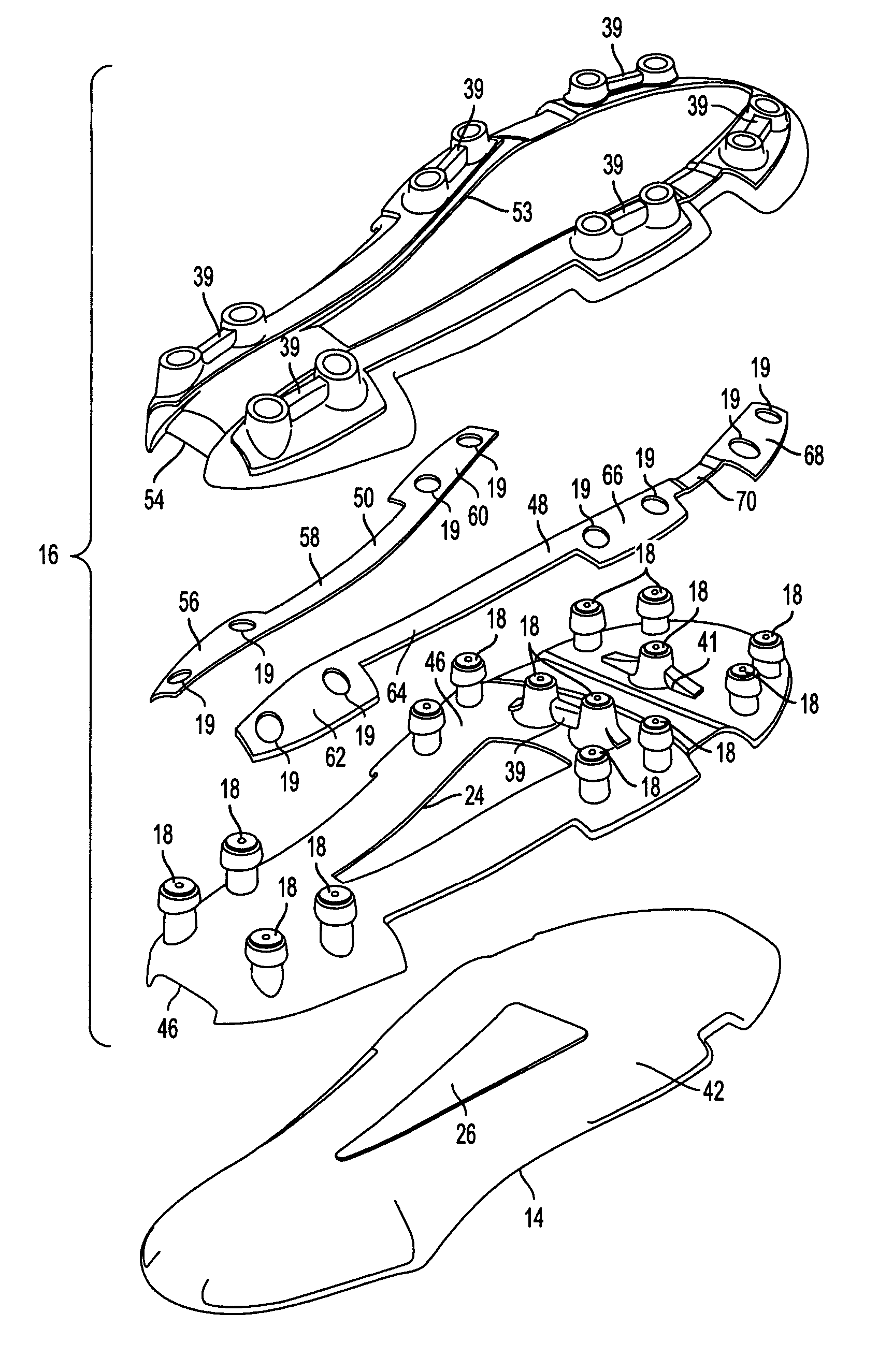

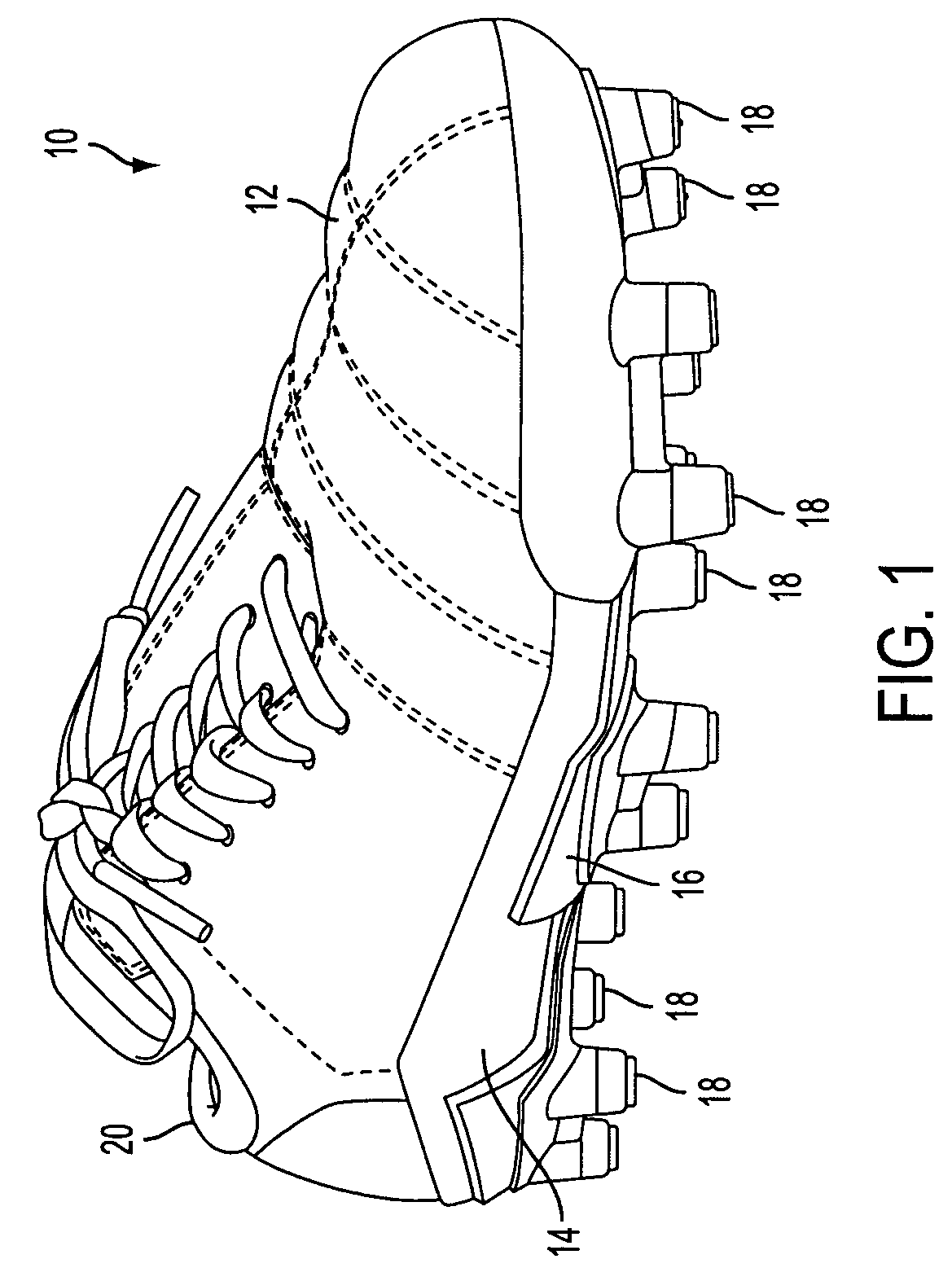

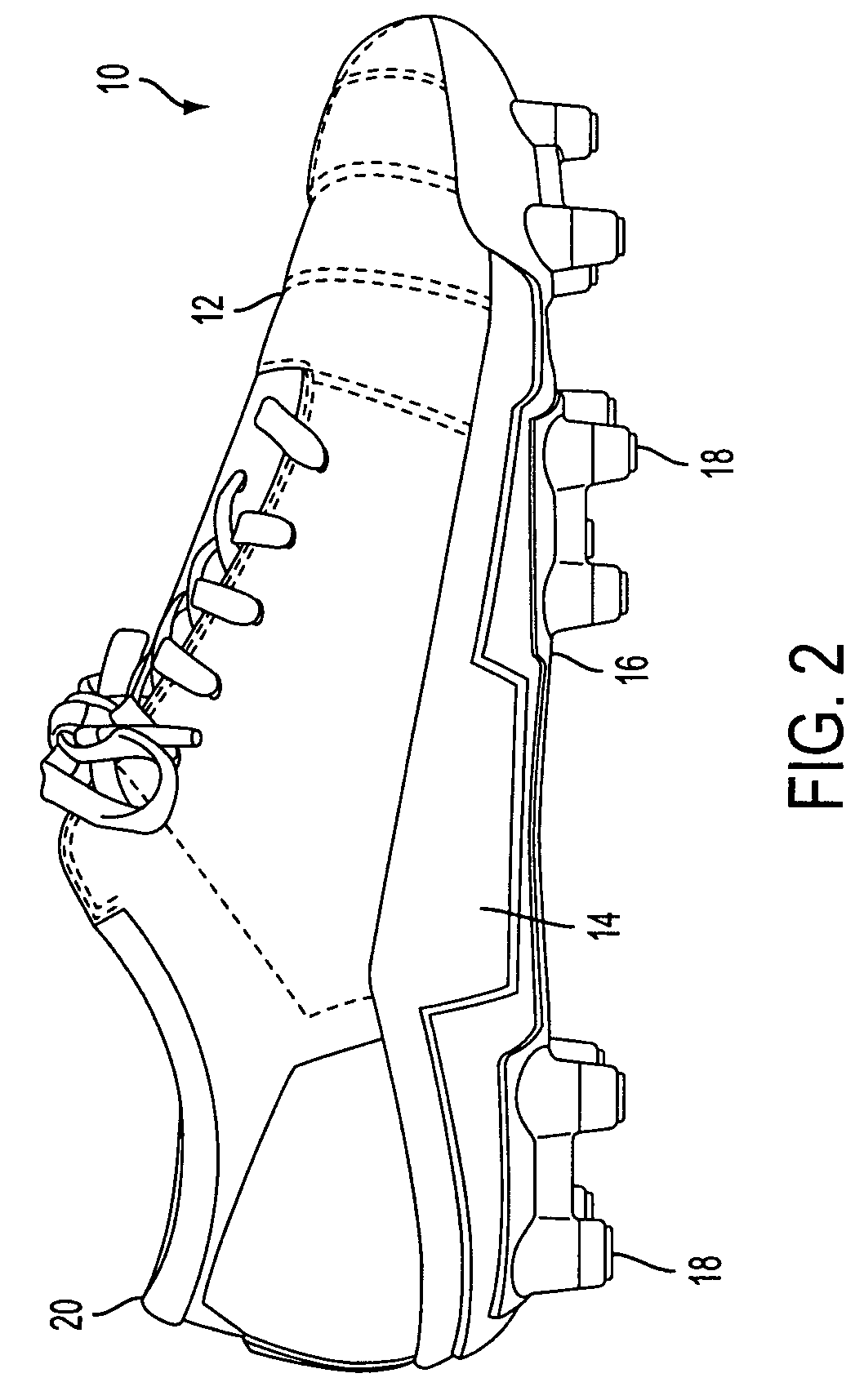

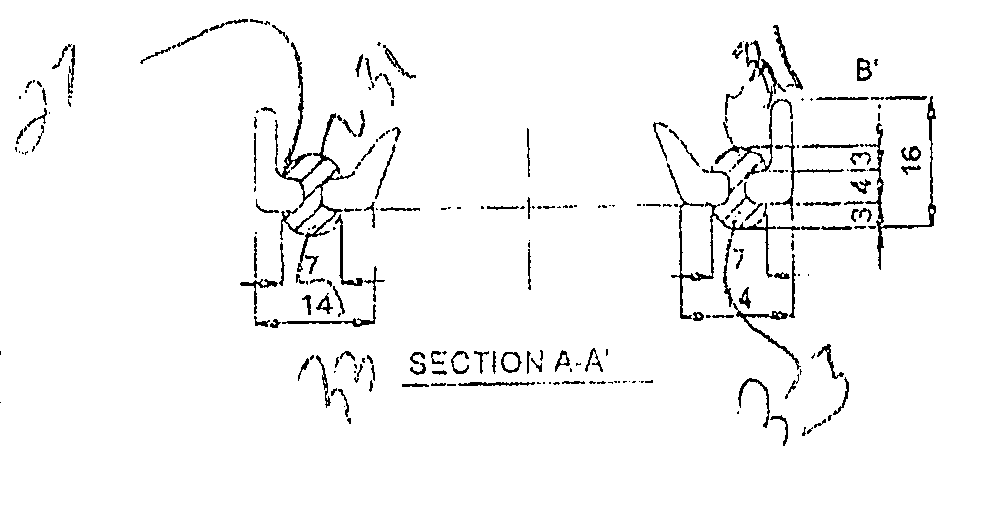

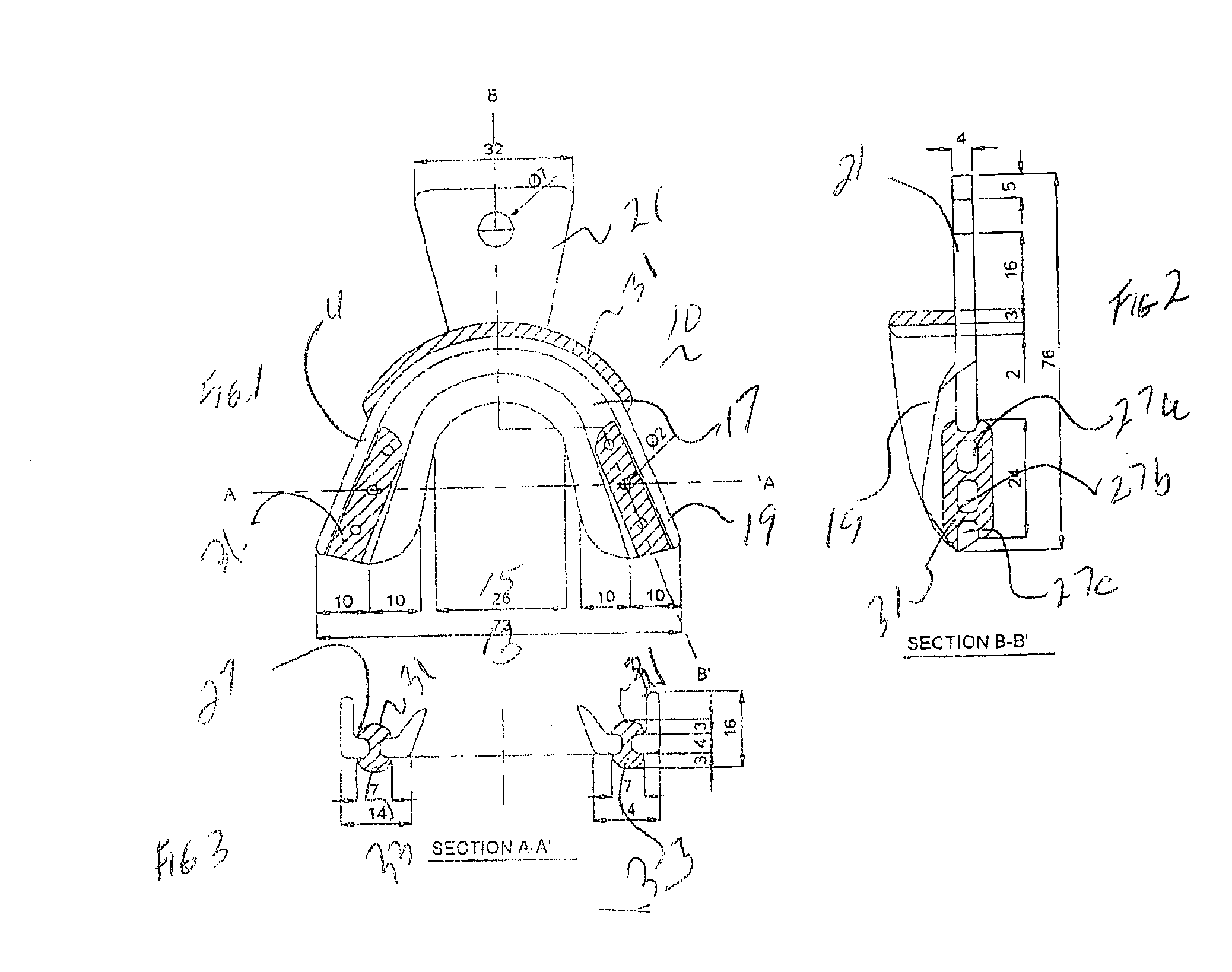

Soccer shoe having independently supported lateral and medial sides

A soccer shoe includes an upper and a cleat assembly coupled to the upper. The cleat assembly further includes a medial support bar located on the medial side and a lateral support bar located on the lateral side. A portion of the cleat assembly located near a midfoot section of the medial support bar is stiffer than a portion of the cleat assembly located near a midfoot section of the lateral support bar. The medial support bar extends approximately from a region corresponding to the rear of the calcaneous of a properly fitted wearer to approximately the head of the first metatarsal of the wearer. The lateral support bar extends approximately from a region corresponding to the rear of the calcaneous of the wearer to approximately the head of the fifth metatarsal of the wearer. The cleat assembly is bonded to a cushioning midsole formed from heated and compressed ethylene vinyl acetate foam. The upper lacks a full-length lasting board and is bonded directly to the cushioning midsole. A lining covers a padded collar and extends inside a foot-receiving region of the shoe, with a portion of the foot-receiving region around a wearer's heel being substantially free of discontinuities.

Owner:NIKE INC

Soccer shoe having independently supported lateral and medial sides

A soccer shoe includes an upper and a cleat assembly coupled to the upper. The cleat assembly further includes a medial support bar located on the medial side and a lateral support bar located on the lateral side. A portion of the cleat assembly located near a midfoot section of the medial support bar is stiffer than a portion of the cleat assembly located near a midfoot section of the lateral support bar. The medial support bar extends approximately from a region corresponding to the rear of the calcaneous of a properly fitted wearer to approximately the head of the first metatarsal of the wearer. The lateral support bar extends approximately from a region corresponding to the rear of the calcaneous of the wearer to approximately the head of the fifth metatarsal of the wearer. The cleat assembly is bonded to a cushioning midsole formed from heated and compressed ethylene vinyl acetate foam. The upper lacks a full-length lasting board and is bonded directly to the cushioning midsole. A lining covers a padded collar and extends inside a foot-receiving region of the shoe, with a portion of the foot-receiving region around a wearer's heel being substantially free of discontinuities.

Owner:NIKE INC

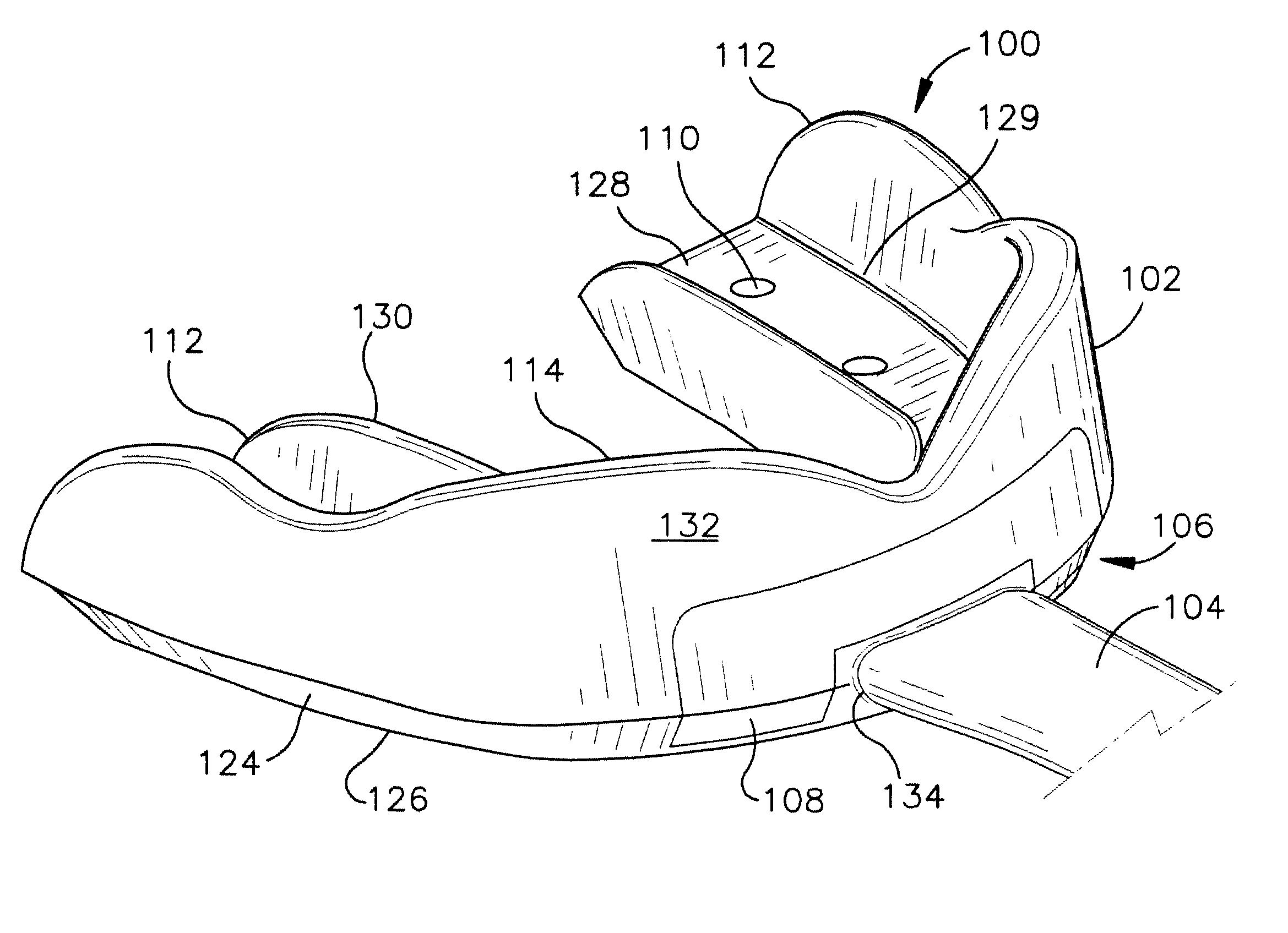

Mouthguard and method of making

The present invention relates to a bilayer mouthguard fabricated from a high impact thermoplastic polymer blend having the ability to absorb, attenuate, and dissipate shock forces and a method of fabricating a mouthguard. The present invention utilizes a polymer blend comprising ethylene vinyl acetate and a thermoplastic urethane. The bilayer mouthguard has a U-shape base and is defined by inner lingual and outer labial walls, a channel for receiving the upper jaw and teeth, cushion pads laying within the U-shape base, and in certain designs a transition support portion extending forward from the posterior cushion pads connecting with an anterior impact brace that extends into the outer labial wall.

Owner:SPORTSGUARD LAB

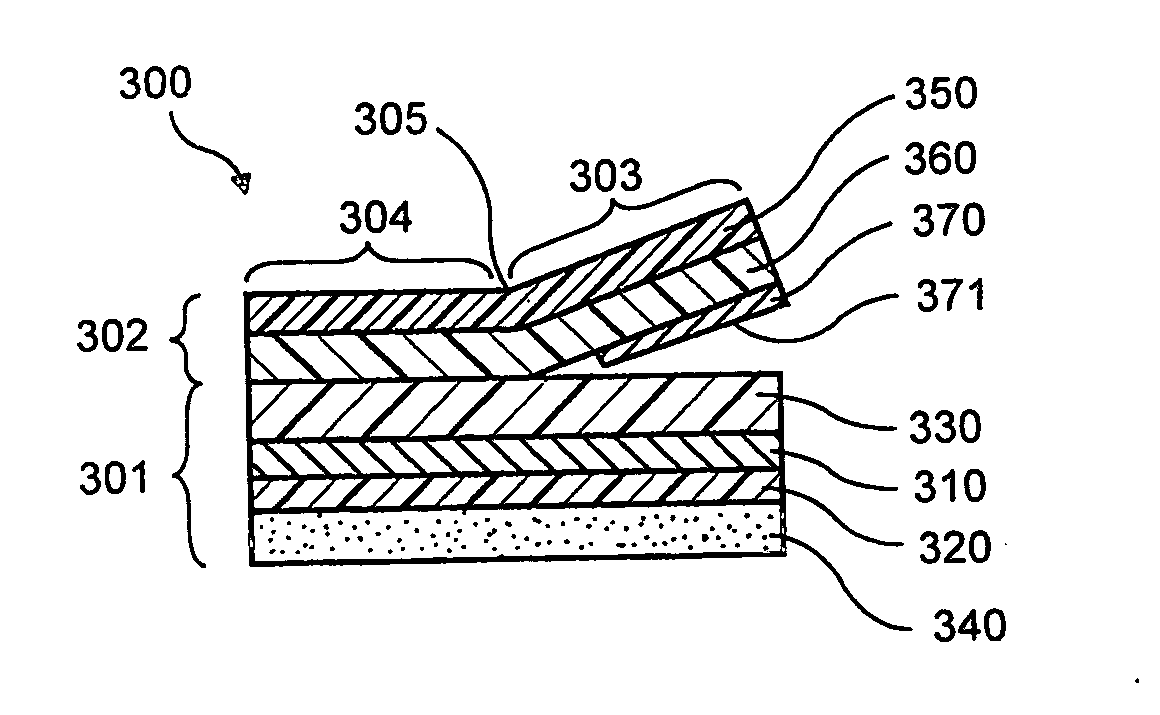

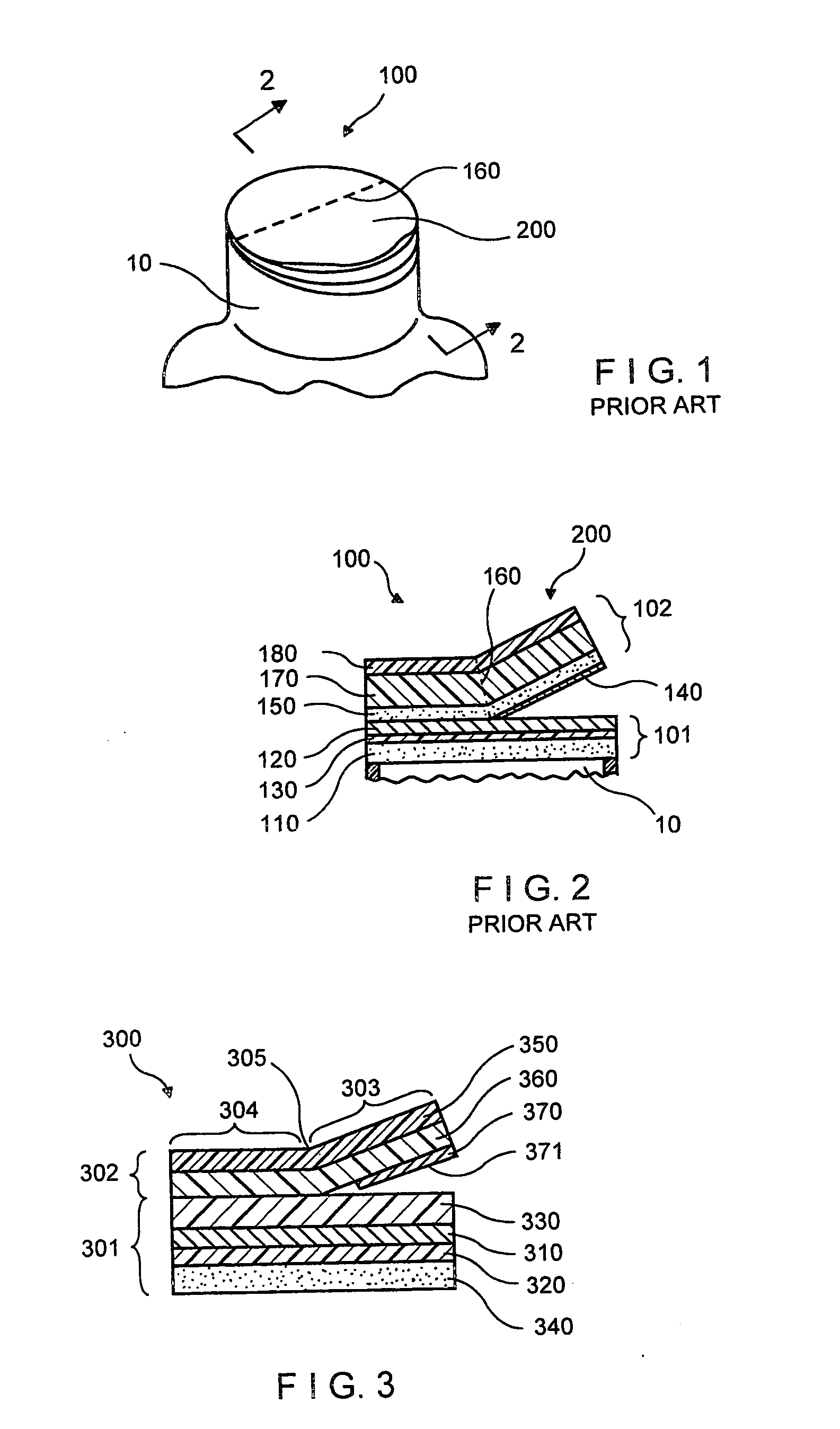

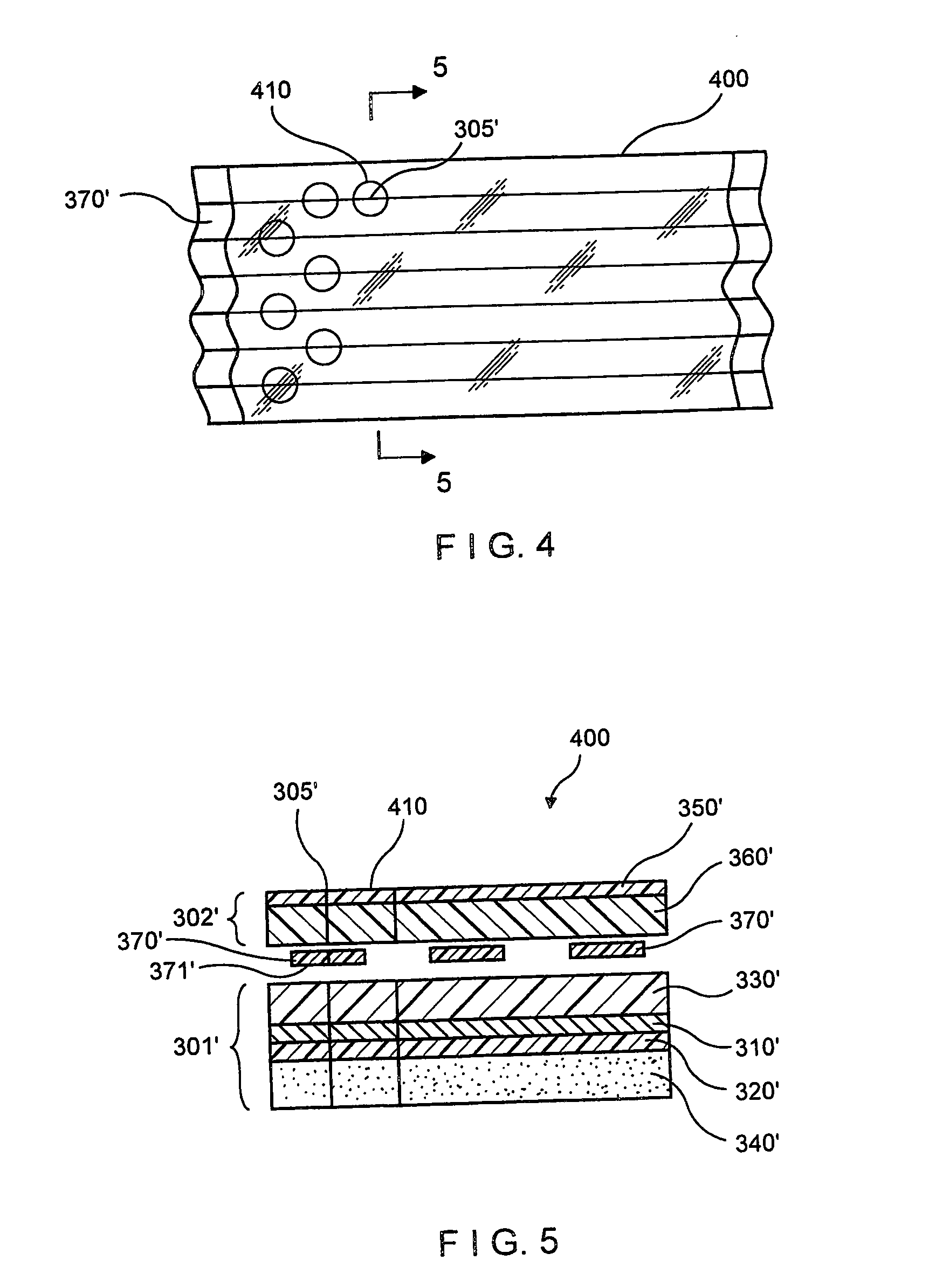

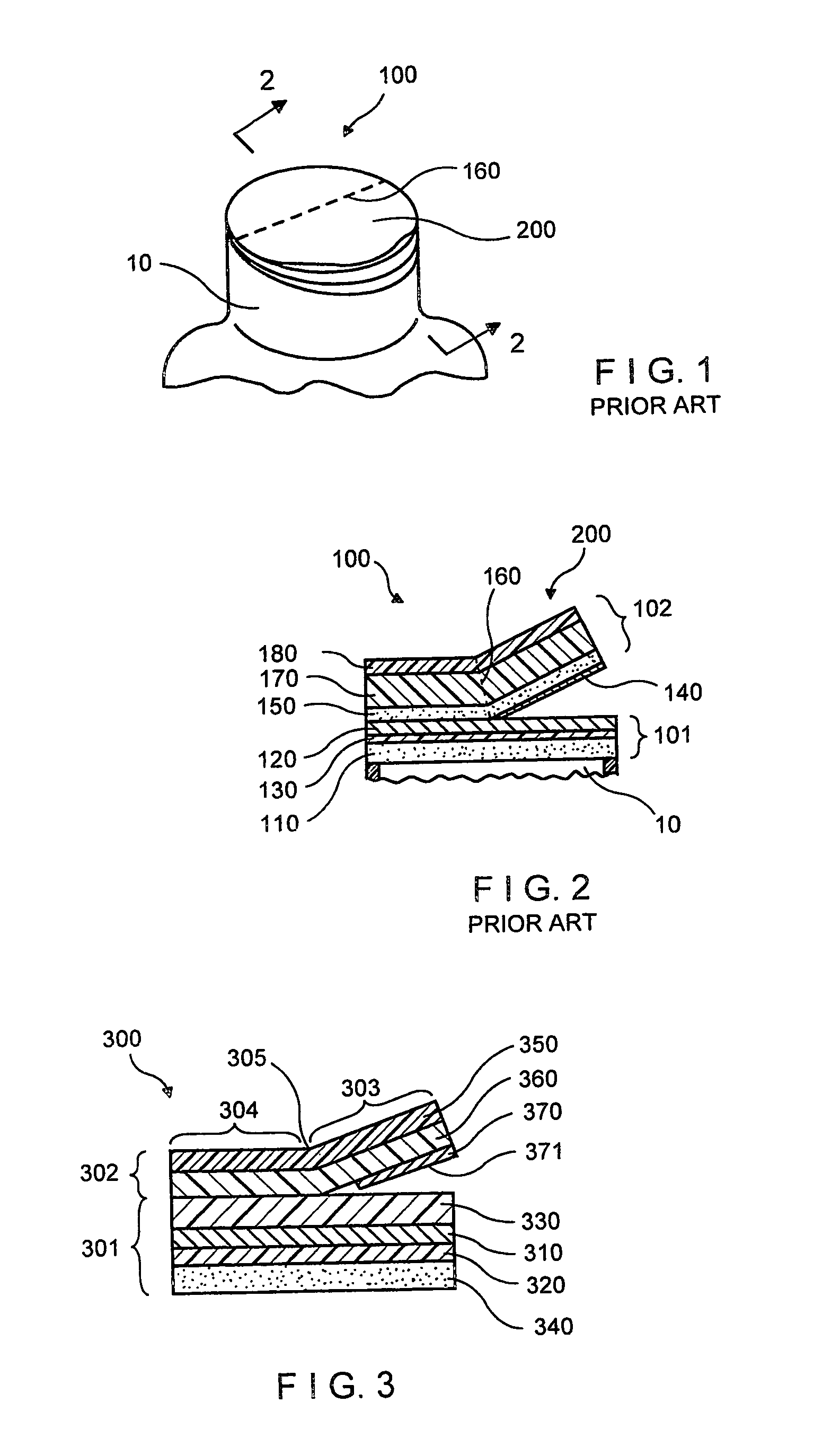

Polymer lined sealing member for a container

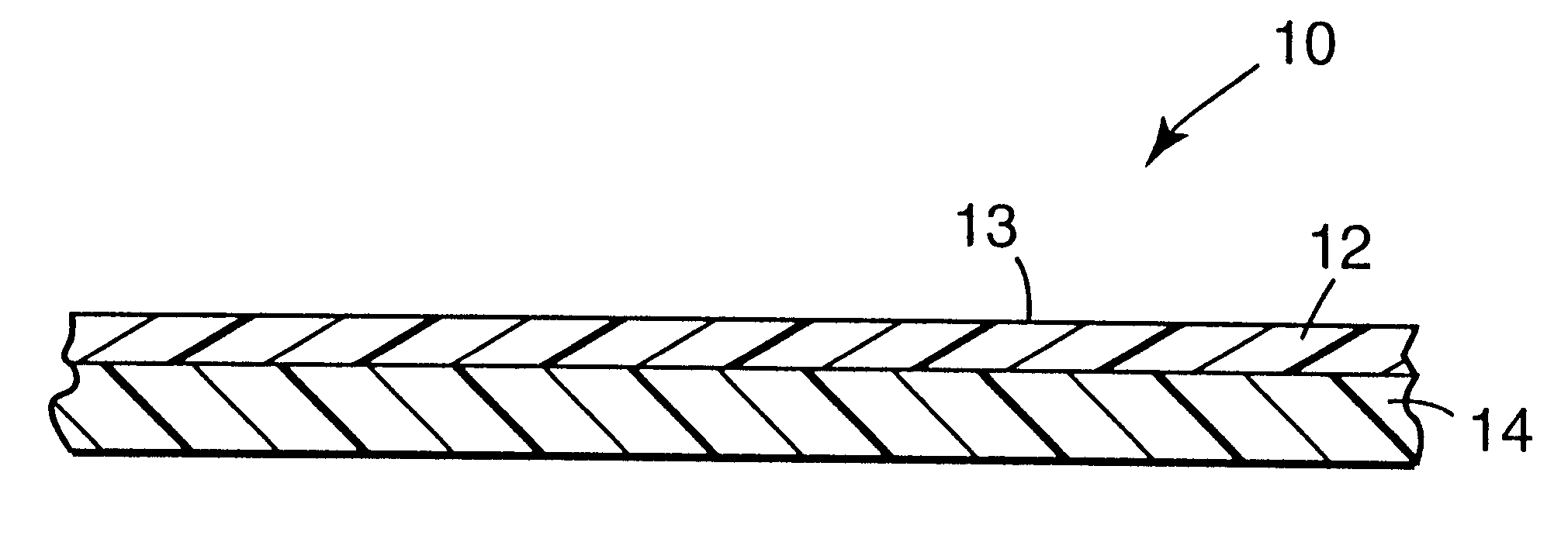

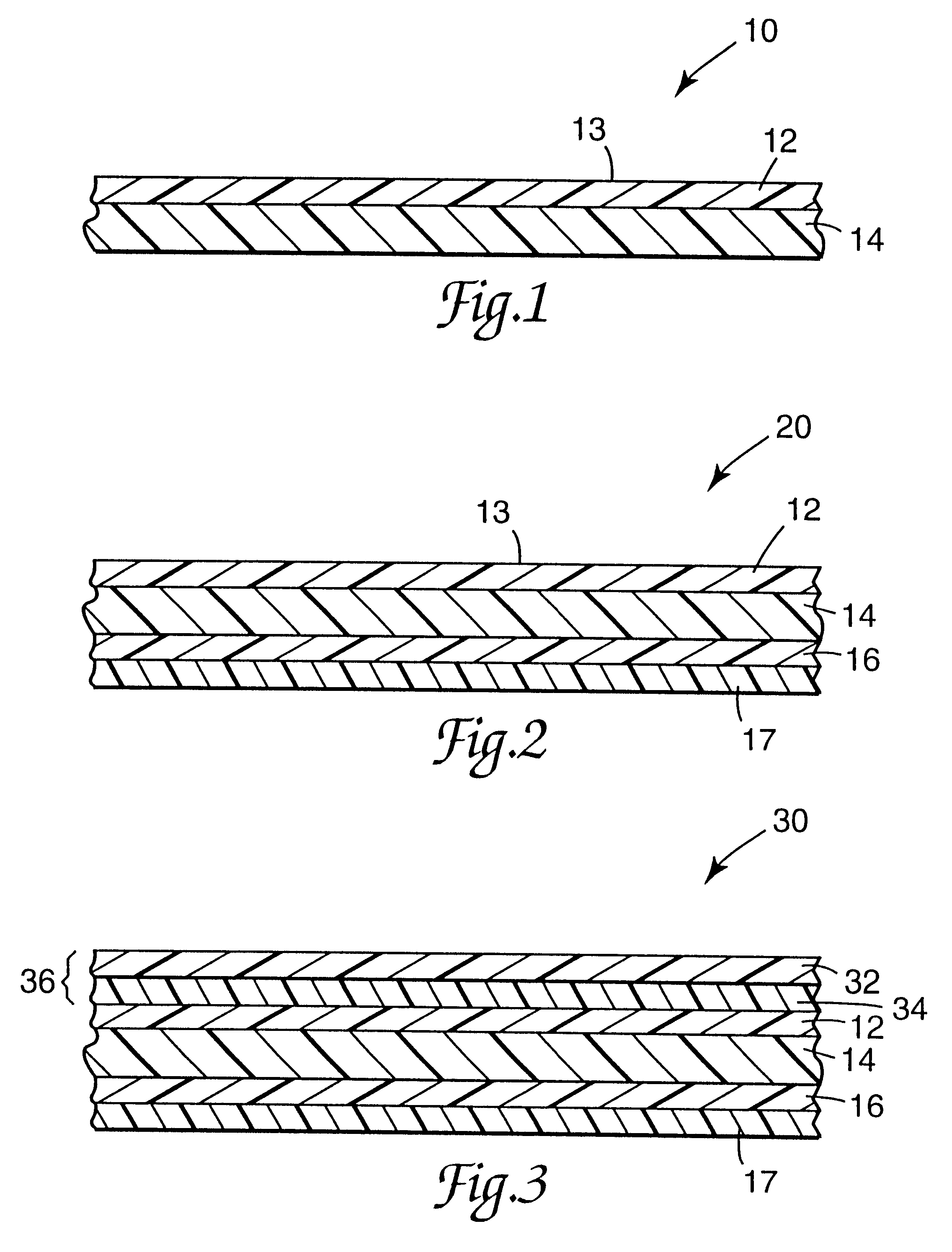

InactiveUS6866926B1High strengthIncreased durabilitySynthetic resin layered productsThin material handlingEngineeringBottle

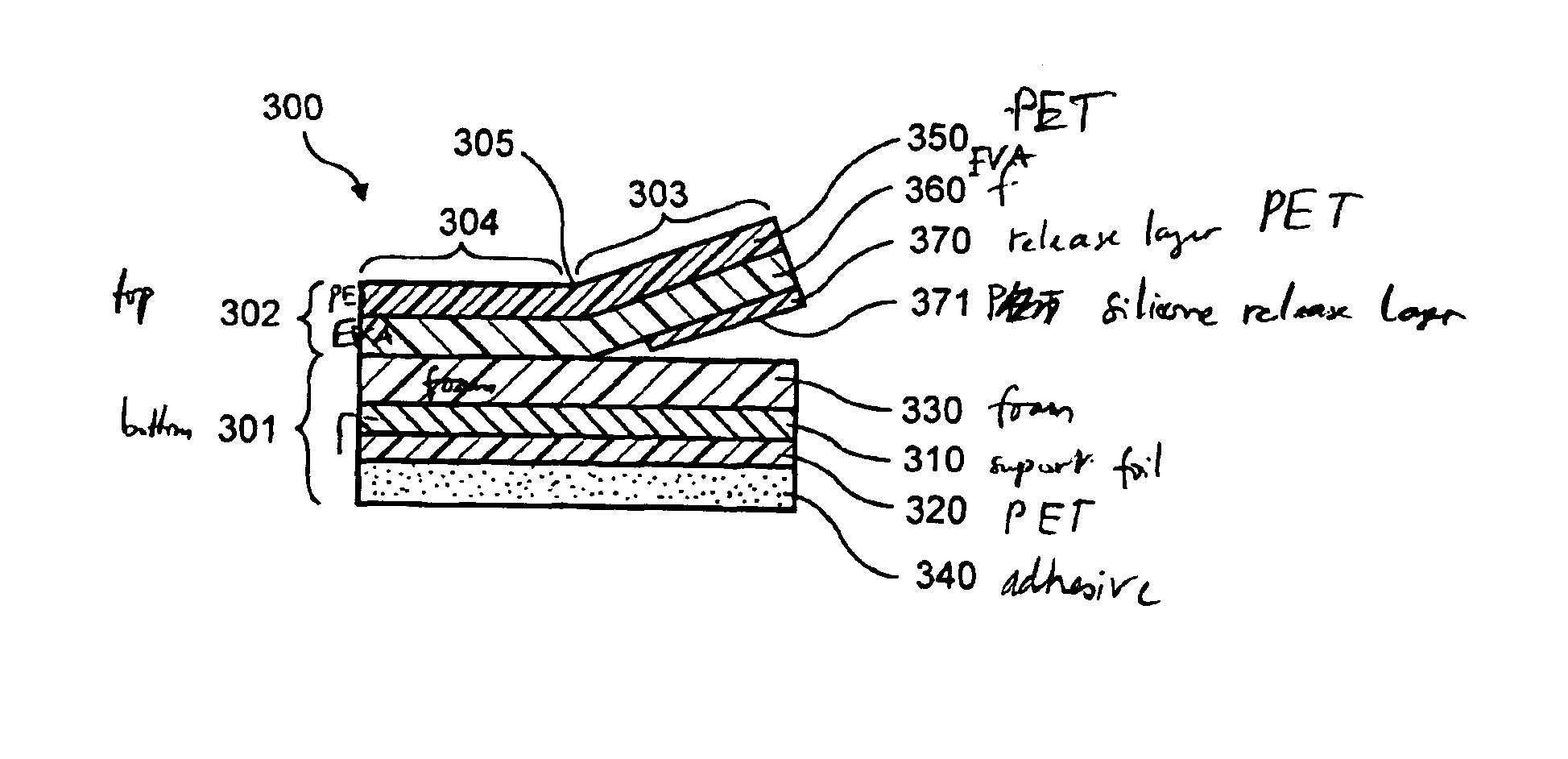

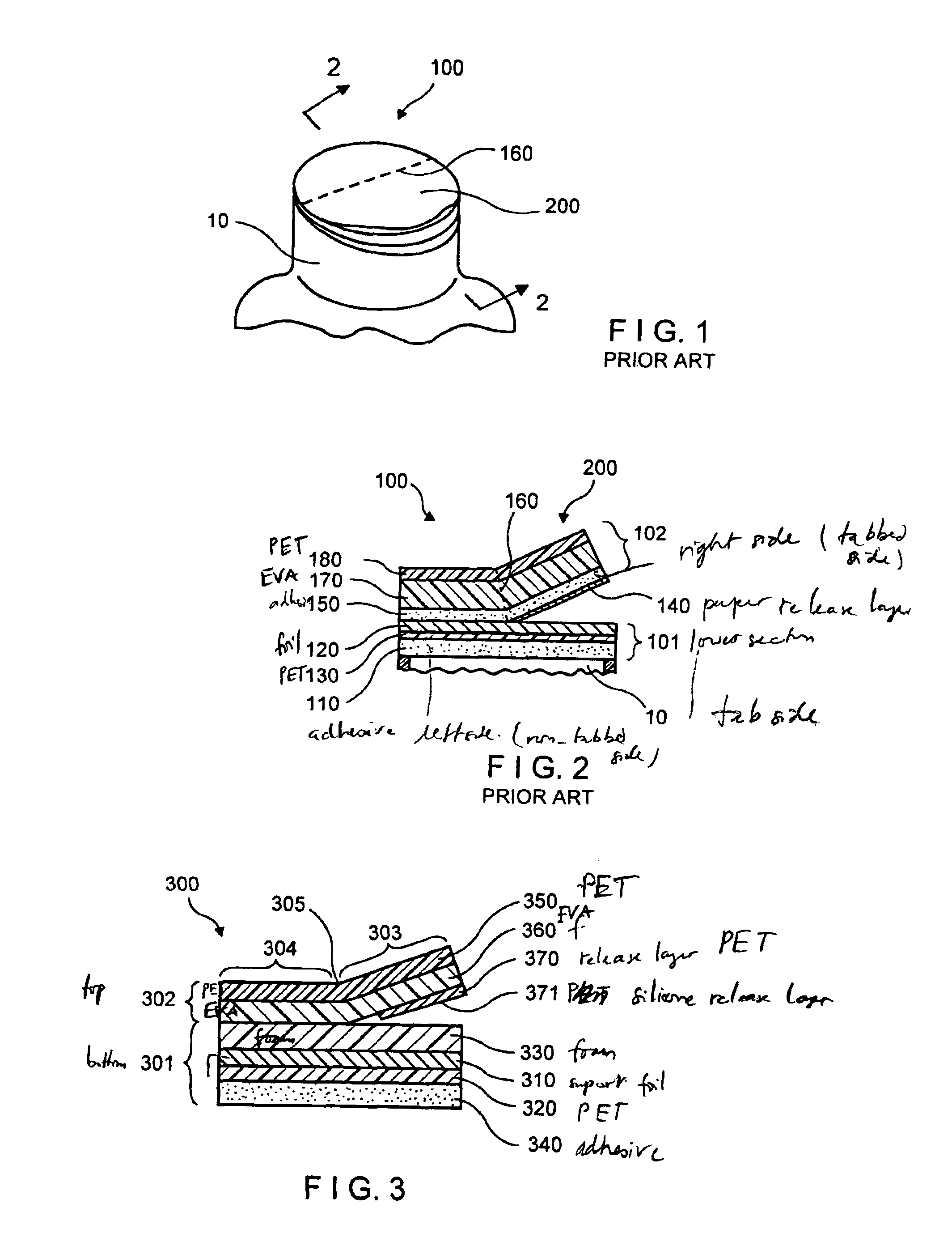

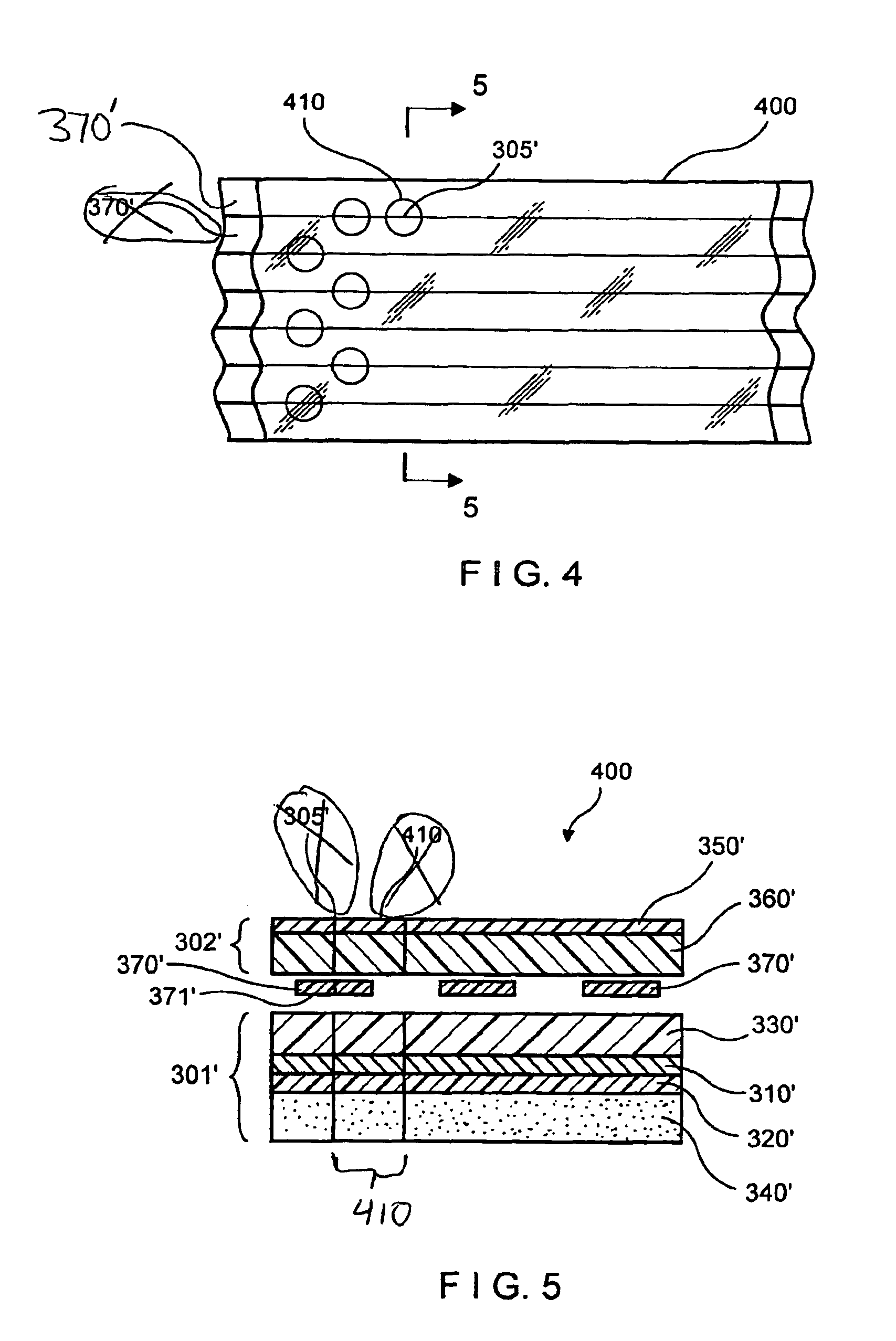

A seal and method of manufacture is provided for sealing containers such as bottles, jars and the like. The seal (closure) can be formed with a lower sheetlike structure having a foam layer thereon. The lower structure can include foil and have a polymer layer, such as a PET layer thereunder A sealant layer can be provided under the bottom surface of the PET layer to bond the seal to a container opening. The polymer foam is advantageously polyethylene foam. Seals in accordance with preferred embodiments of the invention also include a top portion, which can be only partially bonded (directly or indirectly) to the bottom portion, so as to leave a tab portion extended therefrom. The top portion is advantageously bonded from periphery to periphery of the bottom portion and at or slightly offset from the diameter (middle) of the bottom portion. The top portion is advantageously formed with polymer material, such as an ethylene vinyl acetate (EVA) layer, having a layer of PET bonded on the top thereof. A release strip, which can have a release layer coated on the bottom thereof can be adhered to the top or bottom structures and used to prevent the tab from adhering to the lower structure.

Owner:SELIG SEALING PROD INC

Environmentally friendly polylactide-based composite formulations

Polymeric materials and products, including sheet flooring materials prepared from the polymeric materials, and processes for preparing the polymeric materials, are disclosed. The polymeric materials include a polylactic acid-based polymer in combination with plasticizer and a compatibilizer, and optionally include a filler. The polymeric material can include between about 30 to about 50 percent by weight polyvinyl chloride, polyethylene glycol, polyglycolide, ethylene vinyl acetate, polycarbonate, polycaprolactone, polyhydroxyalkanoates, or polyolefins modified with polar groups, for example, ionomers. The plasticizer is typically an epoxidized vegetable oil or esterified and epoxidized vegetable oil and is typically present in an amount of between about 10 and about 50% by weight. In some embodiments, the compatibilizer is a polyolefin modified with one or more polar functional groups, and is typically present in an amount of between about 5 and about 10% by weight. The material can be used in decorative surface coverings, such as a floor coverings, particularly when it is in the form of a polymeric sheet. The polymeric material can be present in at least one layer of a floor covering, which floor covering can also include one or more additional layers such as wear layers, foamed or foamable layers, top coat layers and design layers. The additional layers can also include the polymeric material.

Owner:AFI LICENSING

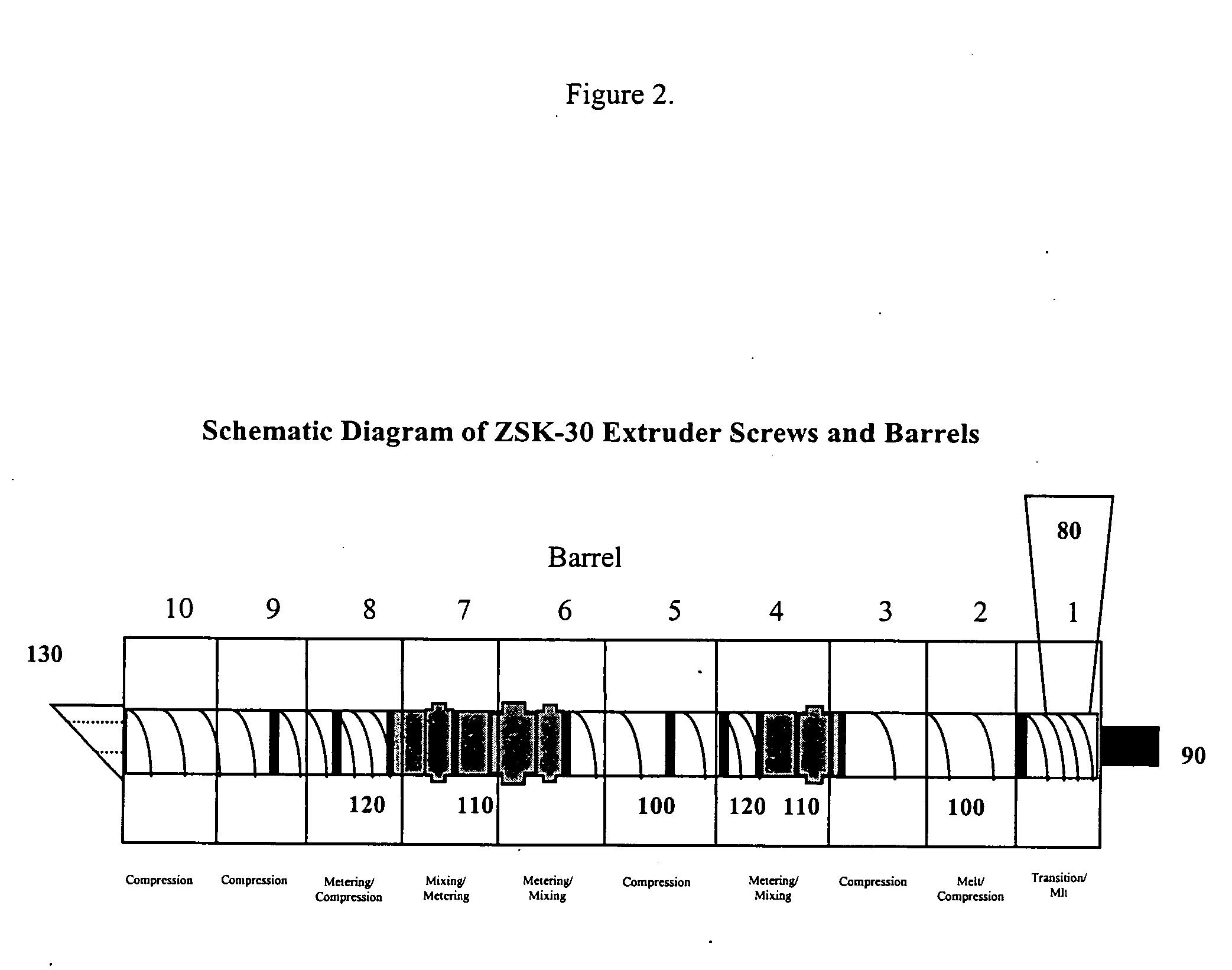

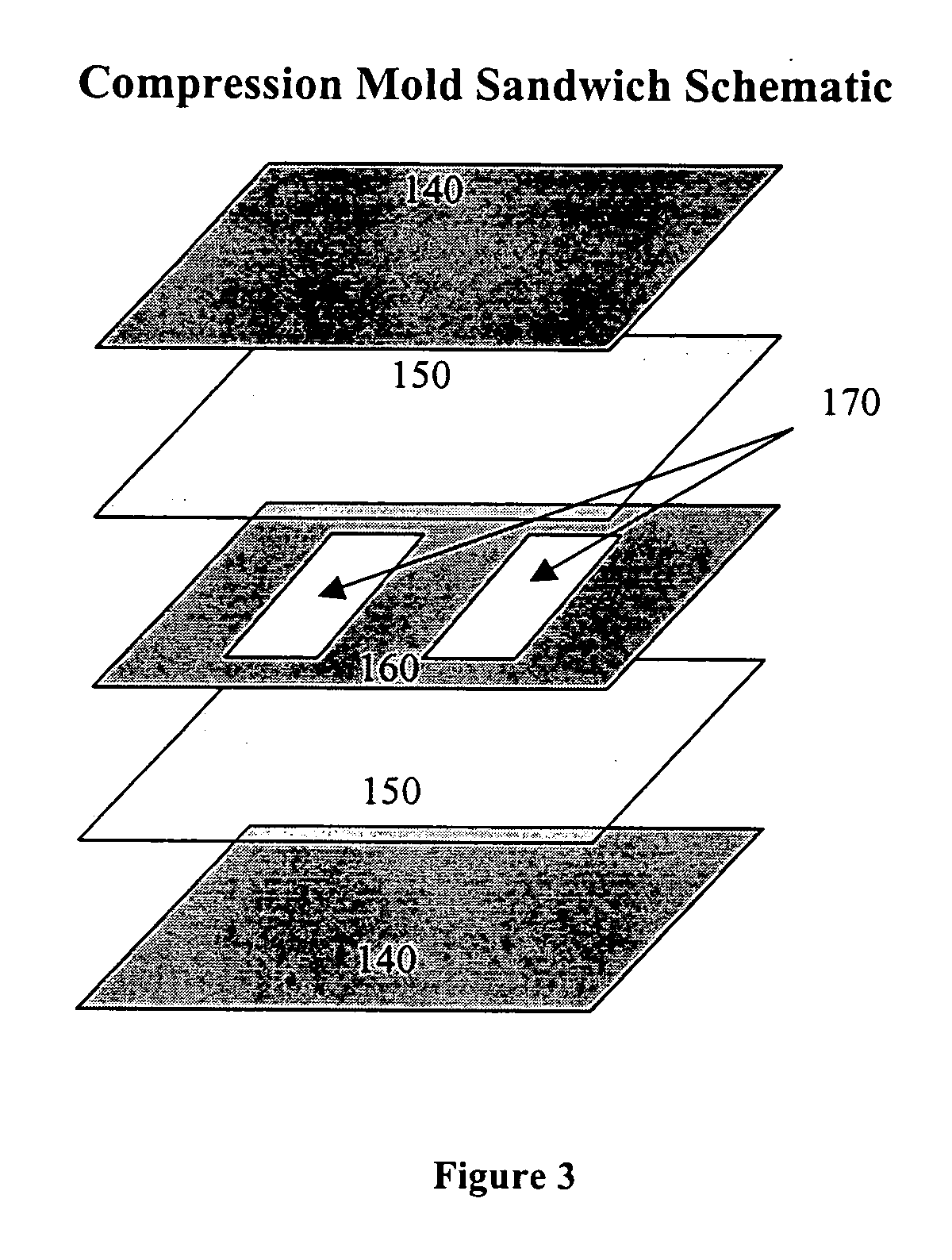

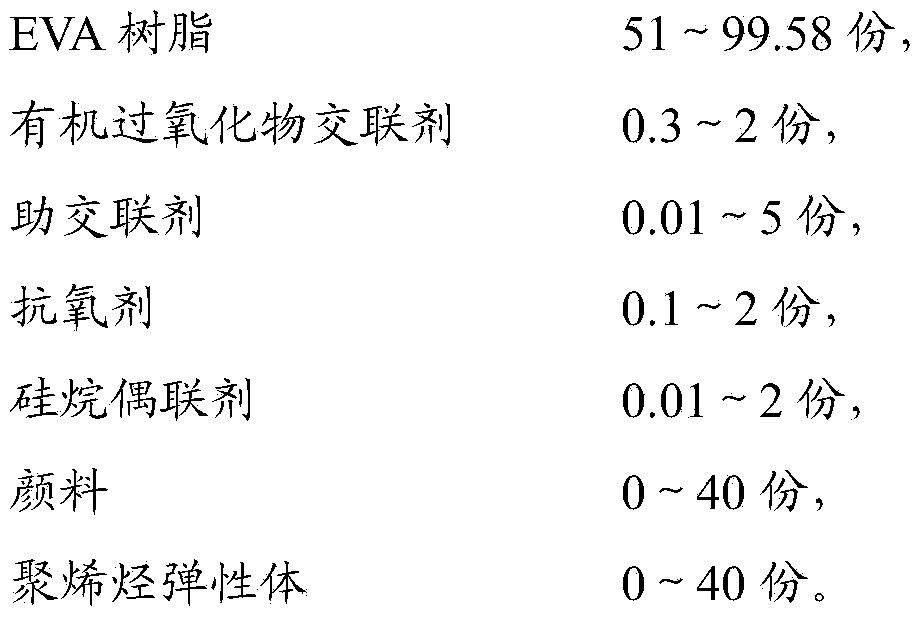

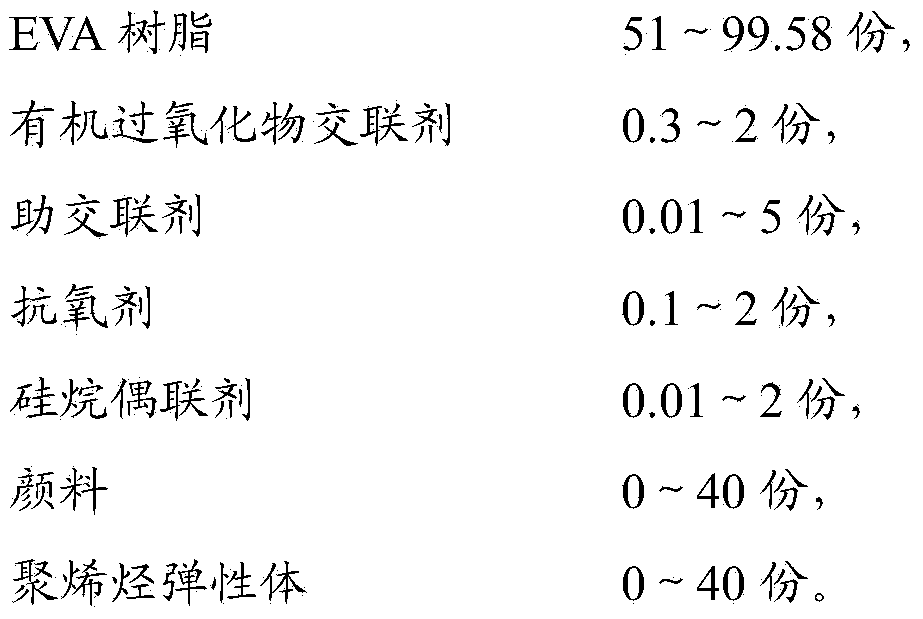

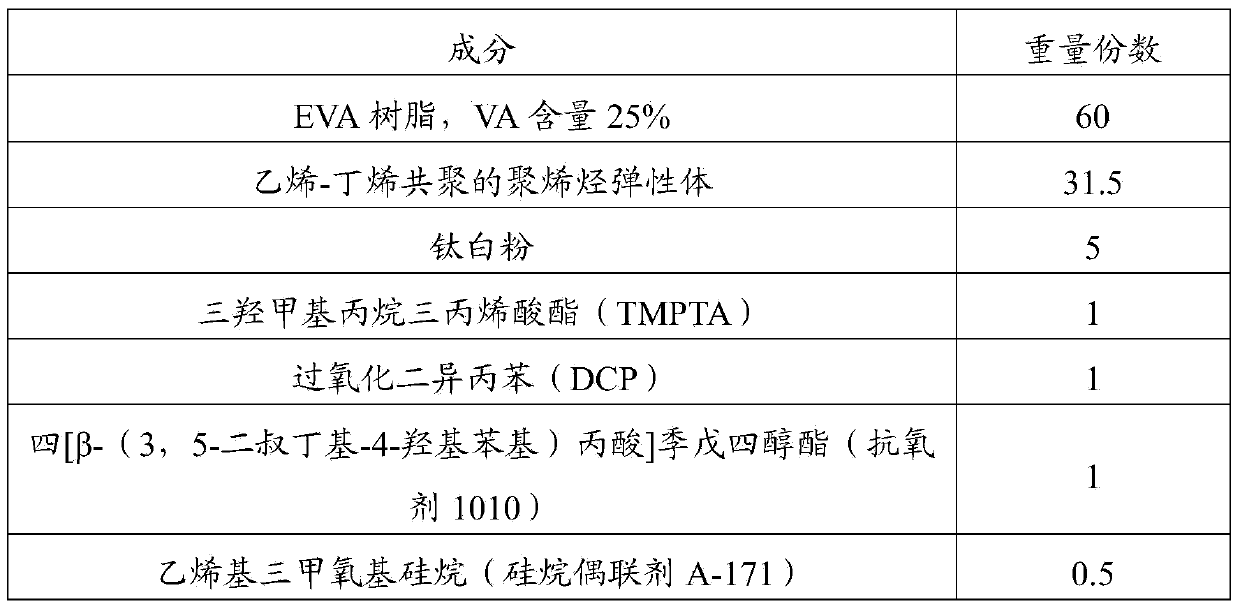

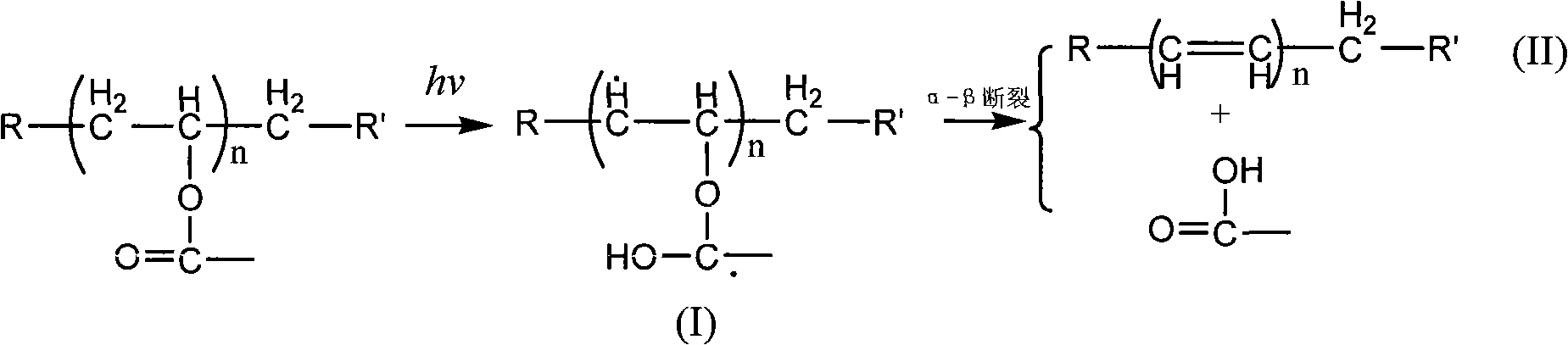

Radiation pre-crosslinked ethylene-vinyl acetate (EVA) resin film and preparation method thereof

ActiveCN103804774AGood dimensional stabilityImprove heat resistanceNon-macromolecular adhesive additivesFilm/foil adhesivesElastomerPolyolefin

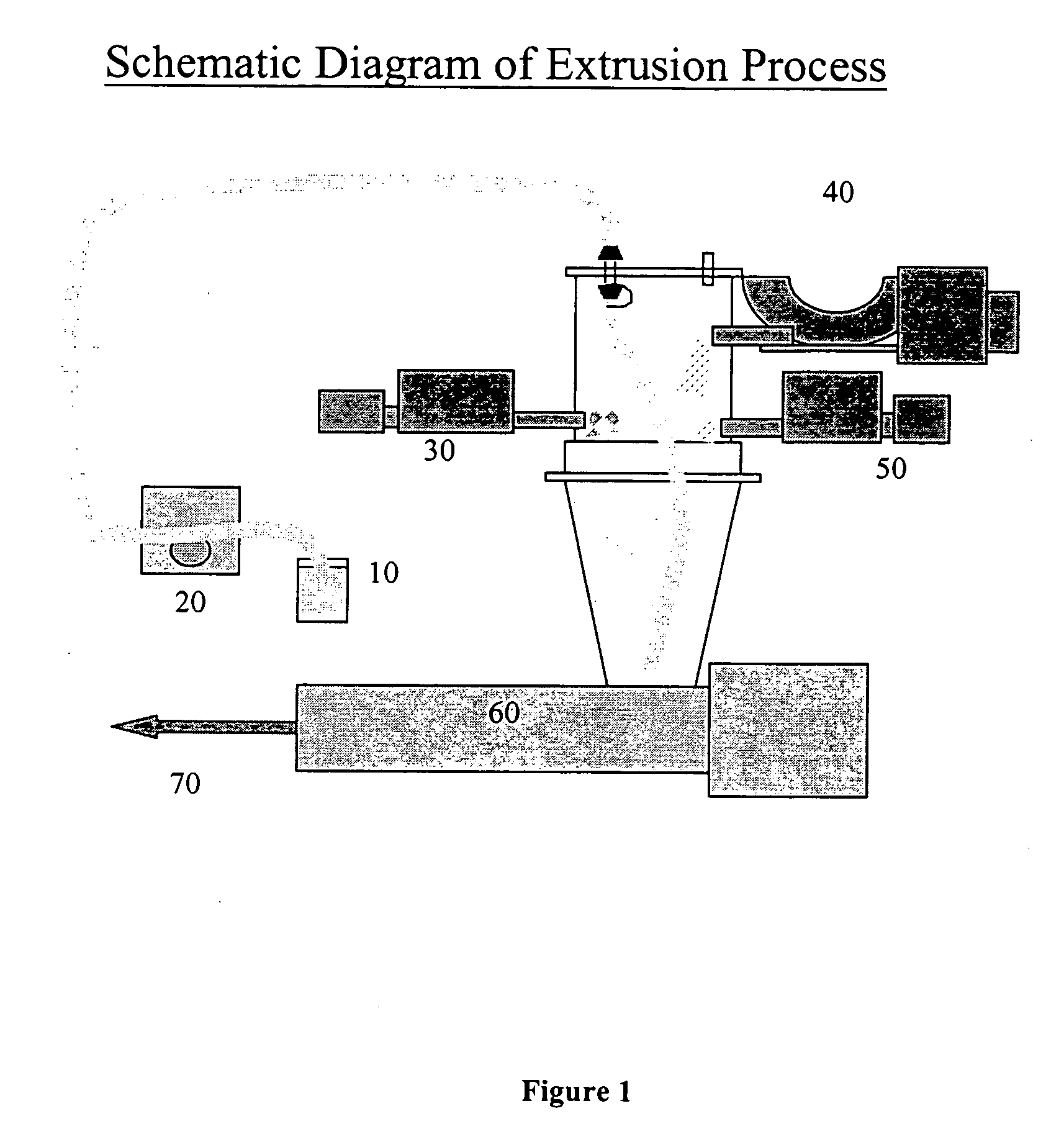

The invention discloses a radiation pre-crosslinked ethylene-vinyl acetate (EVA) resin film which comprises the following components in parts by weight: 51-99.58 parts of EVA resin, 0.3-2 parts of organic peroxide crosslinking agent, 0.01-5 parts of assistant crosslinking agent, 0.1-2 parts of antioxidant, 0.01-2 parts of silane coupling agent, 0-40 parts of pigment and 0-40 parts of polyolefin elastomer. The invention also discloses a preparation method of the radiation pre-crosslinked EVA resin film, which comprises the steps of sufficiently mixing 51-99.58 parts of EVA resin, 0.3-2 parts of organic peroxide crosslinking agent, 0.01-5 parts of assistant crosslinking agent, 0.1-2 parts of antioxidant, 0.01-2 parts of silane coupling agent, 0-40 parts of pigment and 0-40 parts of polyolefin elastomer, and adding into an extruder; extruding and forming a film through a T-shaped flat mould; rolling and radiating to obtain the radiation pre-crosslinked EVA resin film. Since the film is partially crosslinked before use, the dimensional stability and heat resistance of the film are remarkably improved, thus the film is suitable for large-scale popularization and application.

Owner:SHANGHAI HIUV NEW MATERIALS

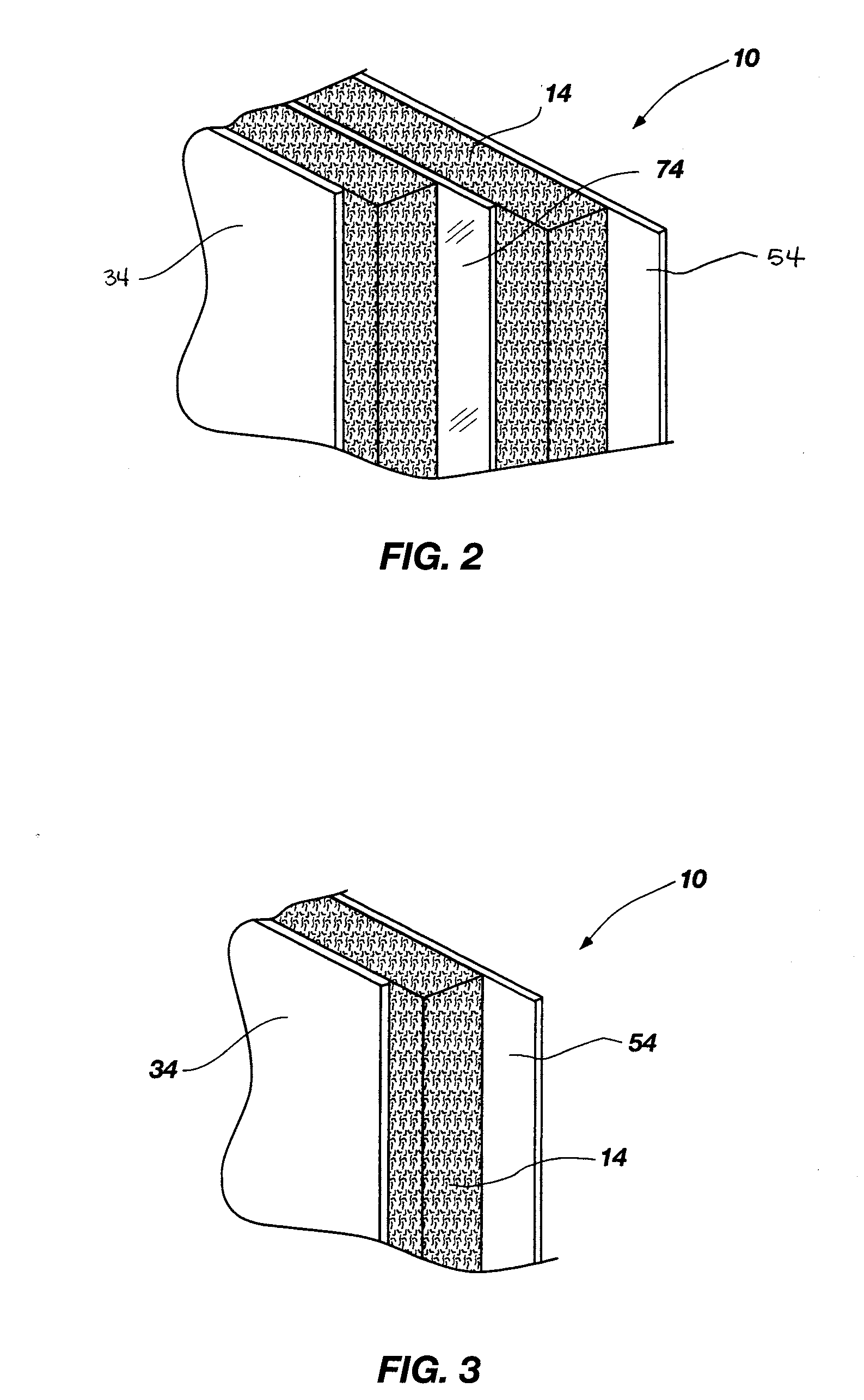

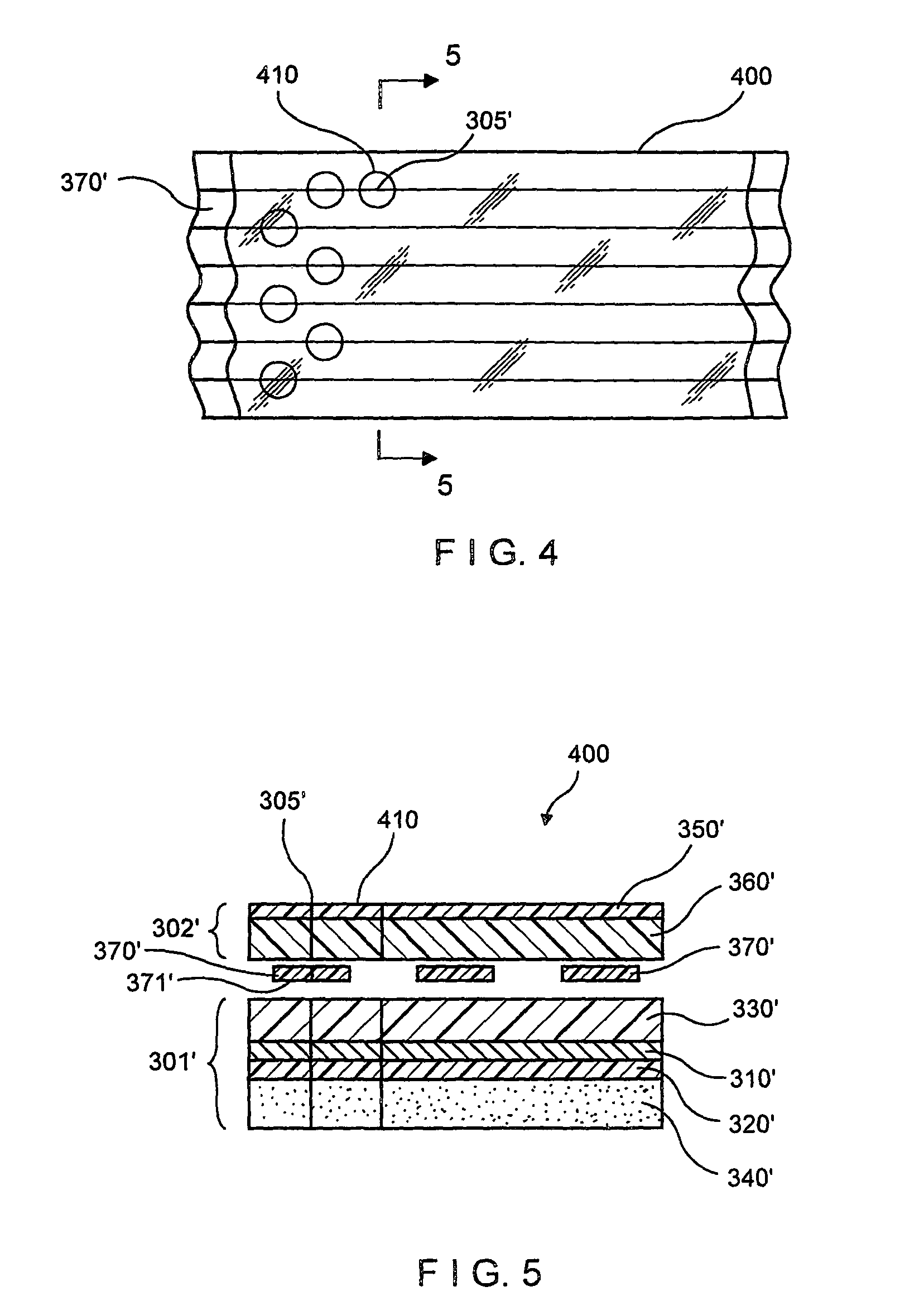

Pull-tab sealing member with improved heat distribution for a container

A seal and method of manufacture is provided for sealing containers such as bottles, jars and the like. The seal (i.e., closure) is formed with a lower sheet-like structure having a non-foam, heat-distributing layer thereon. The lower structure includes a foil support layer and has a polymer layer, such as a PET layer disposed on its bottom surface. A heat-activated sealant layer is provided under the bottom surface of the PET layer to bond the seal to a container opening. The non-foam, heat-distributing layer is preferably a polyolefin film. Seals in accordance with preferred embodiments of the invention also include a top portion, which is only partially bonded (directly or indirectly) to the bottom portion, so as to leave a tab portion extending from the seal. The top portion is advantageously bonded from periphery to periphery of the bottom portion and at or slightly offset from the diameter (middle) of the bottom portion. The top portion is advantageously formed with polymer material, such as an ethylene vinyl acetate (EVA) layer, having a layer of PET bonded on the top thereof. A release strip, which can have a release layer coated on the bottom thereof, is adhered to the top or bottom structures and used to prevent the tab from adhering to the lower structure.

Owner:SELIG SEALING PROD INC

Image receptor medium containing ethylene vinyl acetate carbon monoxide terpolymer

An image receptor medium including an image reception layer having two major opposing surfaces. The image reception layer comprises a terpolymer of ethylene vinyl acetate carbon monoxide, optionally blended with at least one other polymer that can be wherein the image reception layer further comprises at least one other polymer blended with the terpolymer, wherein the other polymer is selected from the group consisting of ethylene vinyl acetate resins, ethylene (meth)acrylic acid copolymer resins, polyethylene resins, polypropylene resins, ionomers, acid-modified or acid / acrylate modified ethylene vinyl acetates and a polymer comprising at least two monoethylenically unsaturated monomeric units, wherein one monomeric unit comprises a substituted alkene where each branch comprises from 1 to about 8 carbon atoms and wherein one other monomeric unit comprises a (meth)acrylic acid ester of a nontertiary alkyl alcohol in which the alkyl group contains from 1 to about 12 carbon atoms and can include heteroatoms in the alkyl chain and in which the alcohol can be linear, branched, or cyclic in nature, and combinations of such other polymers thereof. Alternatively, the image receptor medium includes a substrate layer comprising a polymer substrate layer having two major opposing surfaces and an image reception layer on a first major surface of the substrate layer. The image reception layer has an outer surface for receiving images, and comprises a terpolymer identified above. Either embodiment of the image receptor medium may further include an optional prime layer, an optional adhesive layer, and an optional inkjet layer.

Owner:3M INNOVATIVE PROPERTIES CO

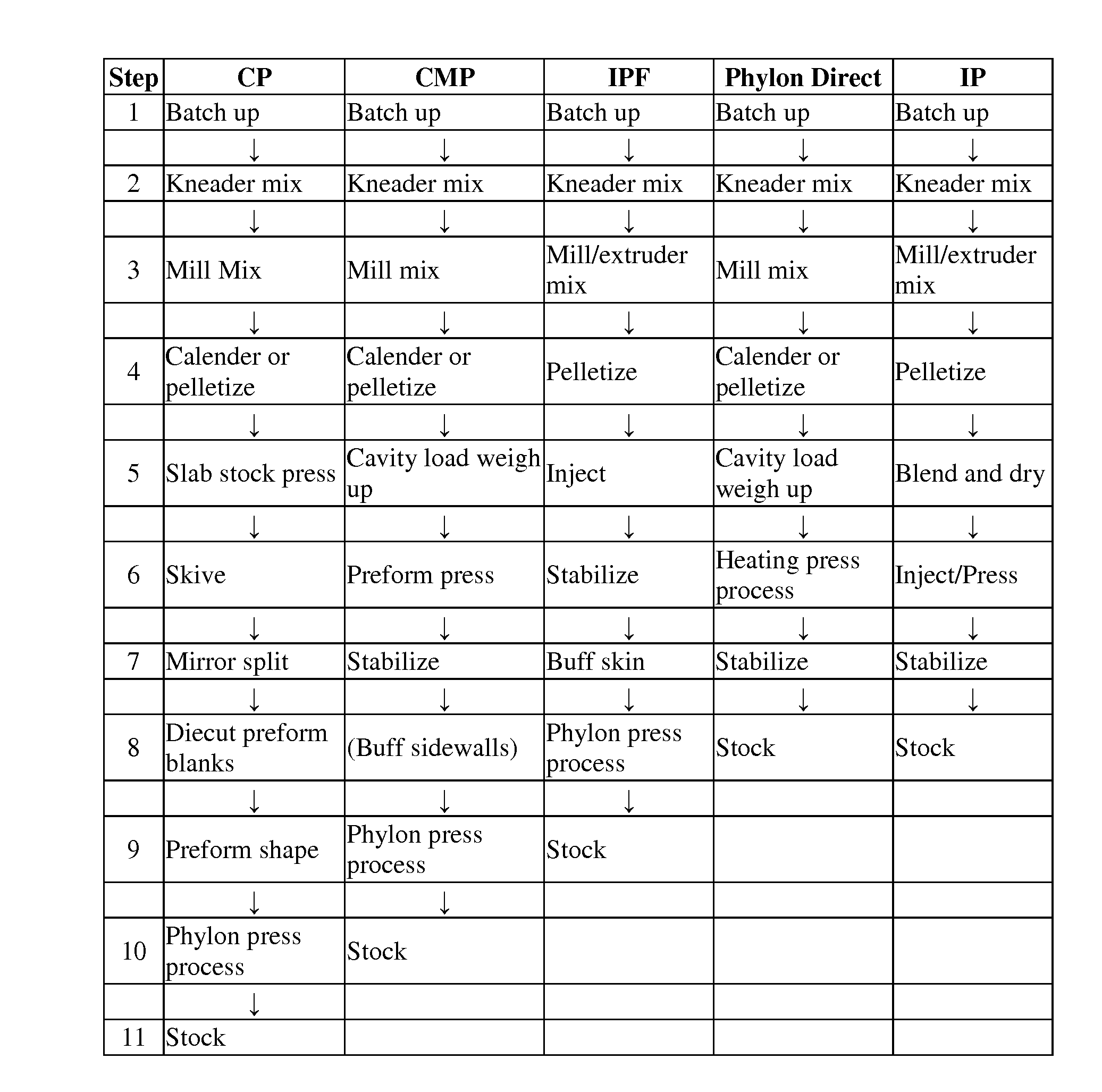

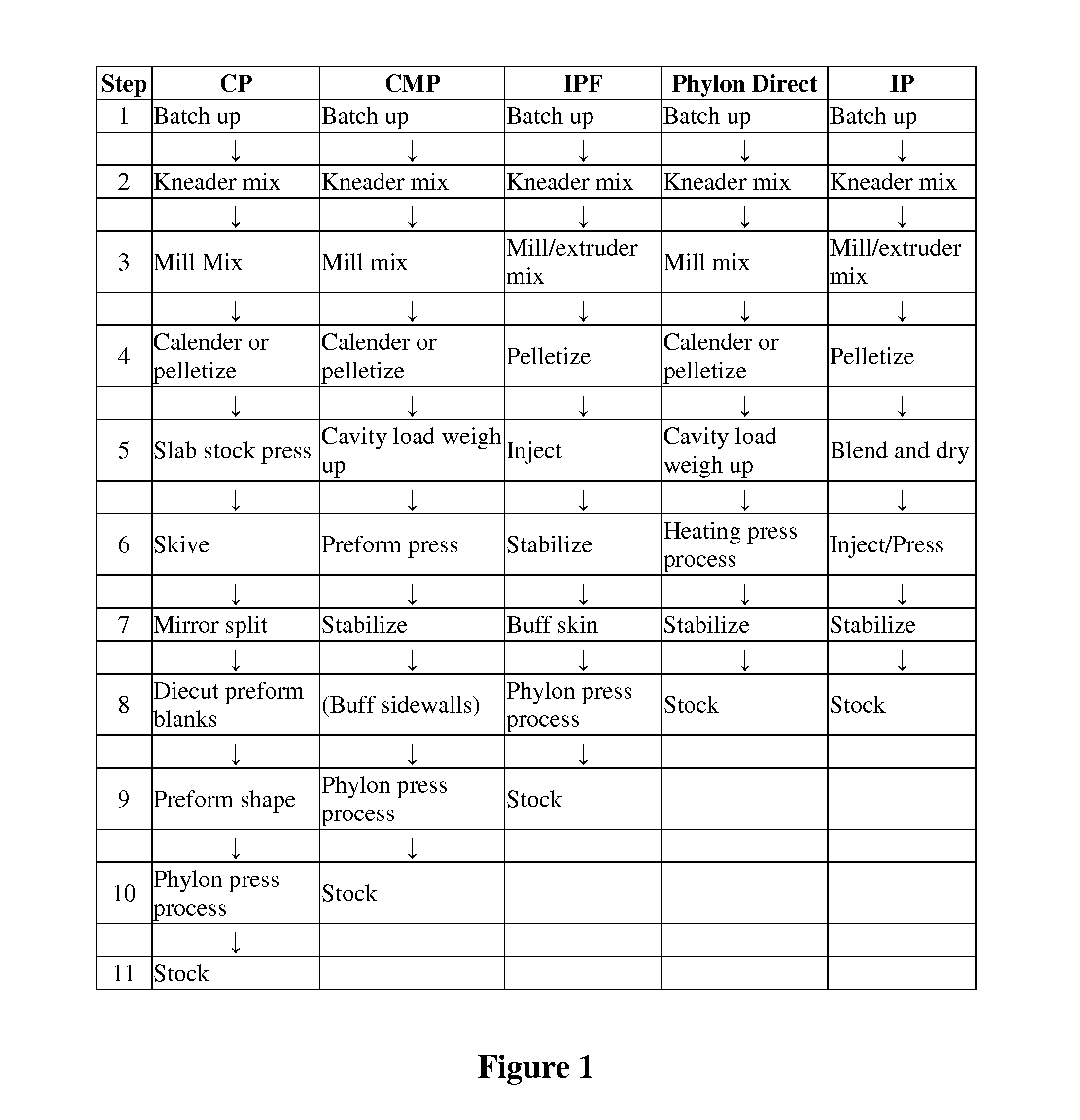

Eva recycling method

ActiveUS20140066530A1Good physical propertiesMore rubberySolesPlastic recyclingFoaming agentPetroleum resin

A method of recycling scrap ethylene-vinyl acetate (EVA) foam involves foaming and crosslinking a blend containing virgin EVA resin and scrap EVA foam, as well as a crosslinking agent and blowing agent for the EVA resin. The blend further contains a compatibilizer, which is a hydrogenated petroleum resin.

Owner:NIKE INTERNATIONAL LTD

Non-crosslinking halogen-free flame-retardant cable insulating material or sheath material and preparation method thereof

ActiveCN103012941ACause damageReduce manufacturing costPlastic/resin/waxes insulatorsInsulated cablesElastomerHalogen

The invention discloses a non-crosslinking halogen-free flame-retardant cable insulating material or sheath material, comprising the following components in part by weight: 100 parts of ethylene and ethylene copolymer and / or ethylene propylene diene monomer, 0-20parts of compatilizer, 20-250 parts of halogen-free flame retardant, 0-5 parts of antioxidant, 0-5 parts of lubricating agent, 0-40 parts of polymeric elastomer, 0-3 parts of coupling agent, and 0-20parts of color master batch, wherein the ethylene and ethylene copolymer are selected from one or more of the following materials: ethylene-vinyl acetate copolymer, ethylene-methyl acrylate copolymer, ethylene-ethyl acrylate copolymer and the like. According to the halogen-free flame-retardant cable insulating material or sheath material, the insulating layer or the sheath layer prepared by the uncrosslinked halogen-free flame-retardant cable insulating material or sheath material can be adaptive to the environment at -40 to 80 DEG C, and the material can not generate poisonous gases such as halogen hydride in case of fire, so that harm to lives and property loss can not be caused by the poisonous gases such as halogen hydride; and besides, the production cost of the material is low.

Owner:SHENZHEN WOER NEW ENERGY ELECTRICAL TECH CO LTD

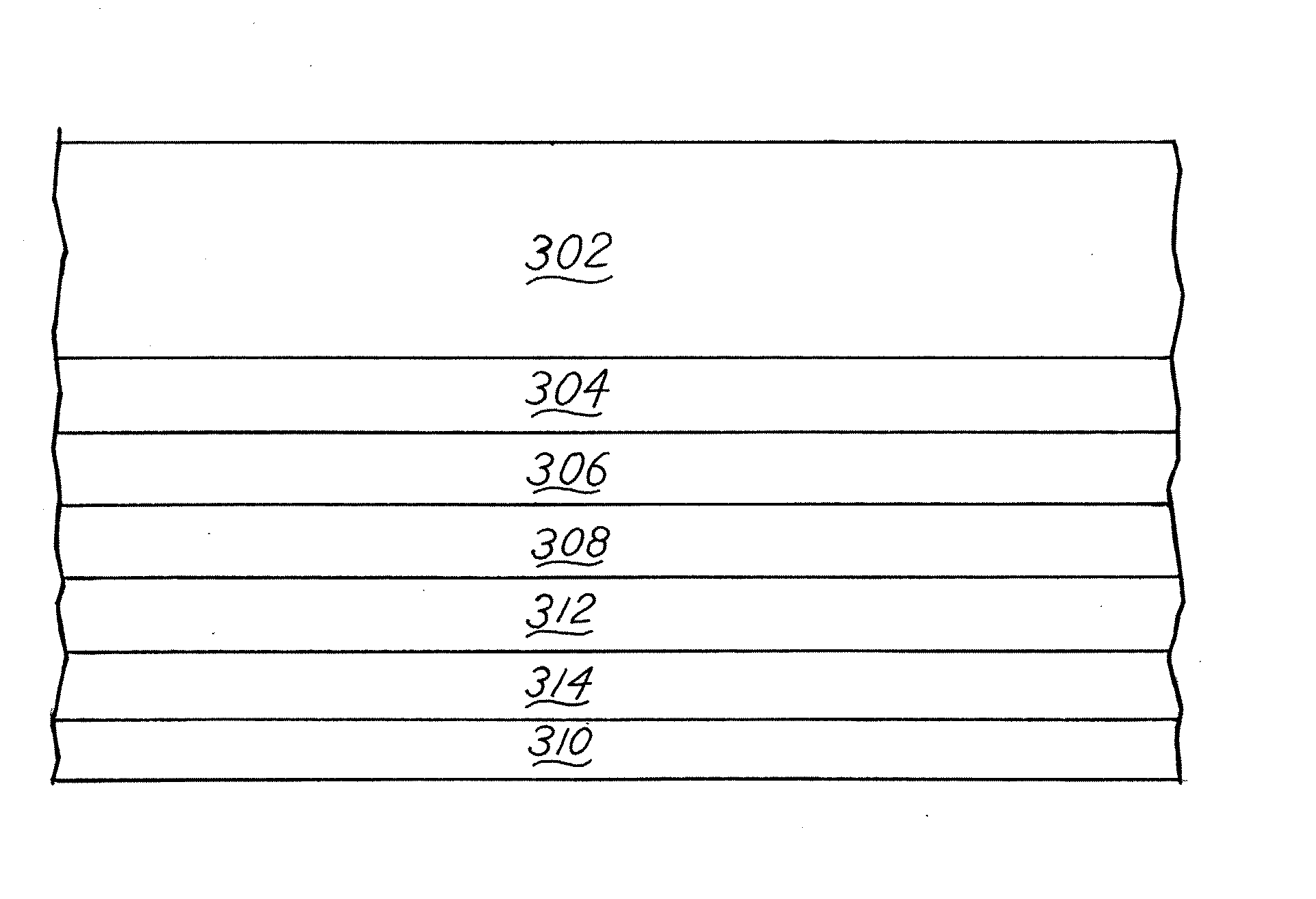

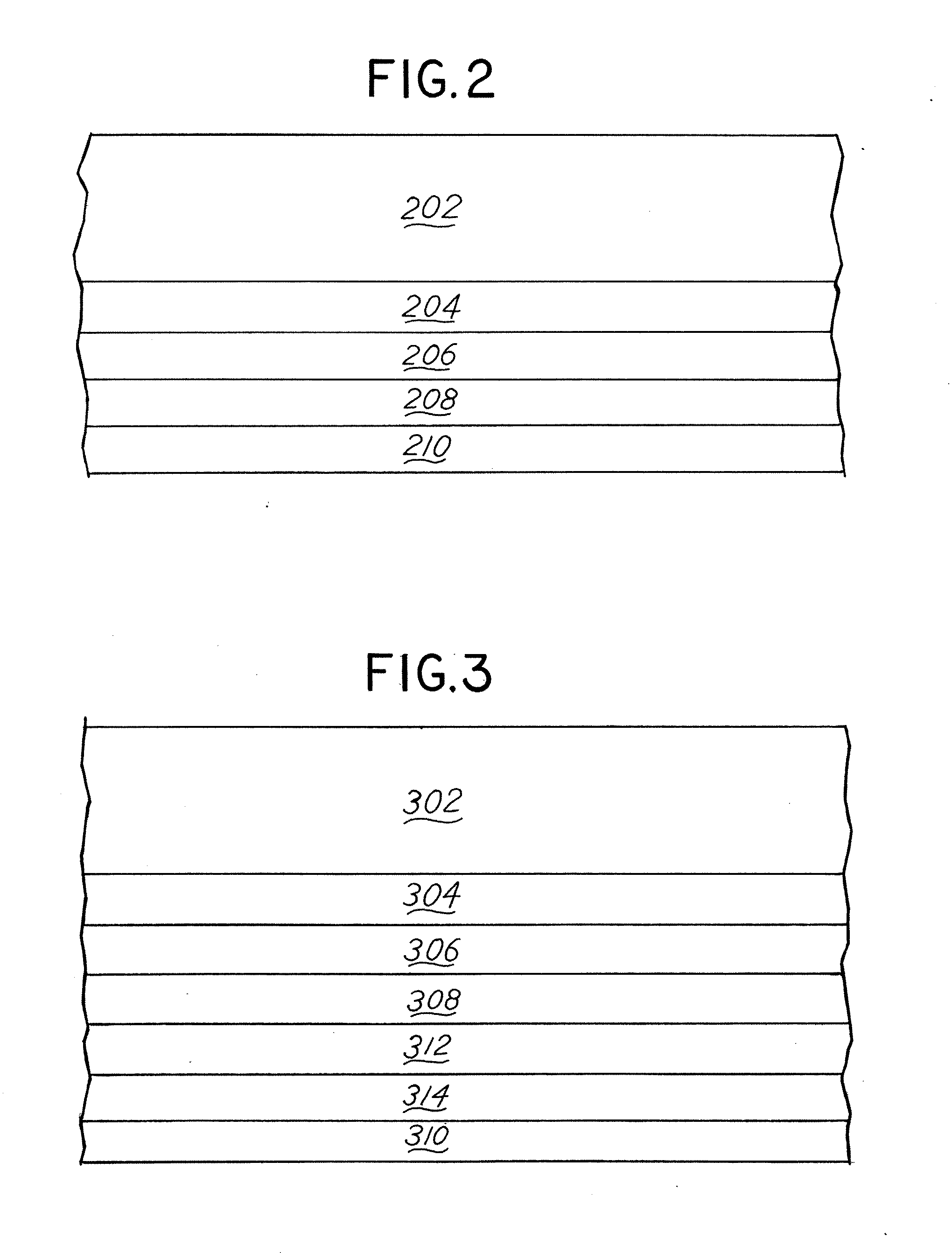

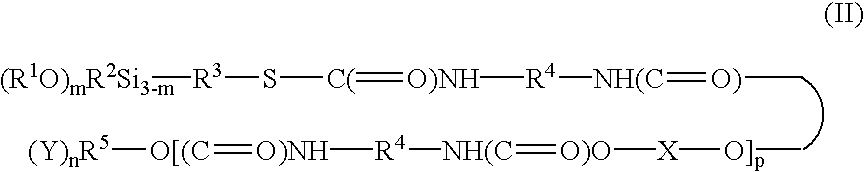

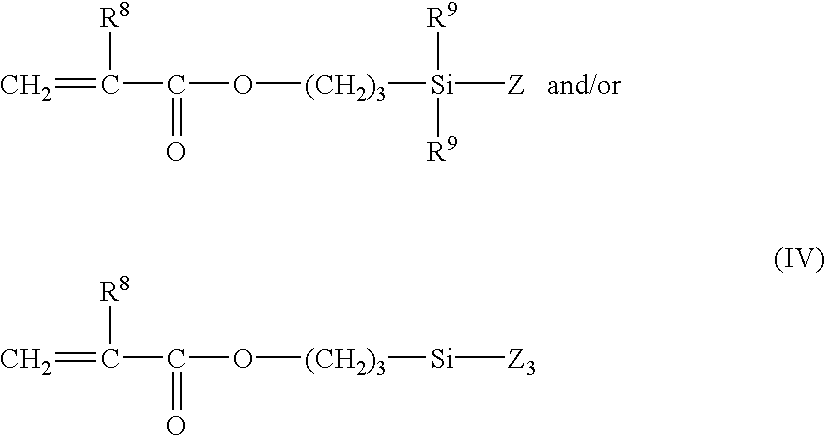

Polymer interlayers comprising ethylene-vinyl acetate copolymer

InactiveUS20070122629A1Improve clarityImprove thermal stabilitySynthetic resin layered productsGlass/slag layered productsPolymer scienceGlass sheet

The present invention is in the field of polymer interlayers used in multiple layer glass panels, and specifically the present invention is in the field of polymer interlayers comprising a polymer sheet comprising an ethylene-vinyl acetate copolymer.

Owner:SOLUTIA INC

Ultraviolet-light deeply cross-linked halogen-free flame-retardant polyolefin cable material and method for preparing ultraviolet-light deeply cross-linked halogen-free flame-retardant polyolefin cable insulating or sheathing layer from same

ActiveCN102153802AEnhanced cross-linking efficiencyIncreased uniform photocrosslinking depthPlastic/resin/waxes insulatorsInsulated cablesCross-linkPolyolefin

The invention relates to ultraviolet-light deeply cross-linked halogen-free flame-retardant polyolefin cable material and a method for preparing an ultraviolet-light deeply cross-linked halogen-free flame-retardant polyolefin cable insulating or sheathing layer from the same. The method comprises the following steps: adding a metal hydroxide flame retardant, a cationic photoinitiator, a free radical photoinitiator, a multi-functional cross-linking agent, a compound antioxidant, a flame-retardant synergist, a synergistic smoke suppressant and a processing aid to polyethylene or grafted and modified polyethylene and / or ethylene vinyl acetate or grafted and modified copolymer thereof which are used as base materials, compounding, mixing the materials uniformly according to the proportion, granulating, extruding to prepare the ultraviolet-light cross-linked halogen-free flame-retardant polyolefin cable insulating or sheathing layer, and immediately irradiating with a specific ultraviolet-light source to obtain the deeply cross-linked halogen-free flame-retardant polyolefin cable insulating or sheathing layer. The cross-linking equipment used for preparing the novel material by using anovel technology has low investment, and the process is simple and environmental friendly, saves energy, ensures high production efficiency and low cost and good quality of product and can be widely used for producing high-performance special wire and cable products and the like.

Owner:HEILONGJIANG MINGXIANG TECH

High temperature self-crosslinking halogen-free flame retardant cable insulation material or sheath material and method for preparing high temperature self-crosslinking halogen-free flame retardant cable insulation material or sheath material

ActiveCN103012940AReduce manufacturing costPlastic/resin/waxes insulatorsInsulated cablesElastomerPolymer science

The invention discloses a high temperature self-crosslinking halogen-free flame retardant cable insulation material or sheath material. The cable insulation material or sheath material comprises the following components in parts by weight: 100 parts of ethylene and copolymer thereof and / or ethylene propylene diene monomer, 0-20 parts of compatilizer, 20-250 parts of halogen-free flame retardant, 0-5 parts of antioxidant, 0-5 parts of lubricating agent, 0.01-5 parts of peroxide crosslinking agent, 0-40 parts of polymer elastomer, 0-3 parts of coupling agent and 0-20 parts of color masterbatch; and the ethylene and the copolymer thereof are selected from one or a plurality of the following materials of ethylene-vinyl acetate copolymer, ethylene-methyl acrylate copolymer, ethylene-ethyl acrylate and the like. The high temperature peroxide crosslinking agent crosslinks under the temperature condition of above 150 DEG C only, during a cable material mixing extrusion and insulating layer or sheath layer formation process, chemical crosslinking or micro-crosslinking cannot be caused, but the high temperature peroxide crosslinking agent generates a crosslinking function when the temperature is higher than 150 DEG C in the case of fire, so that the production cost is lowered.

Owner:SHENZHEN WOER HEAT SHRINKABLE MATERIAL +1

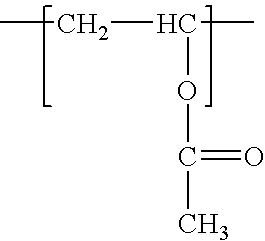

High-elasticity sneaker air cushion sole and production method thereof

The invention provides a high-elasticity sneaker air cushion sole and a production method thereof and researches a sneaker sole with high elasticity, high wear resistance and low hardness. The high-elasticity sneaker air cushion sole comprises a phylon (MD) midsole, an air cushion and a large sole which are sequentially and fixedly connected with one another from top to bottom, wherein an ethylene-vinyl acetate copolymer (EVA) cushion piece is assembled on a heel part of the air cushion; and the material formula of the MD midsole comprises the following components in parts by weight: 40-60 parts of EVA, 0-20 parts of ethylene propylene ternary gel, 0-30 parts of polyolefin elastomer (POE), 0-10 parts of talcum powder, 2.0-4.0 parts of a foaming agent, 0.6-1.0 part of a bridging agent, 1.0-2.0 part of a zinc oxide desulfurizing agent, 0.6-1.2 parts of stearic acid, 0.5-1.0 part of zinc stearate, 0.8-1.5 parts of a flow promotor and 0.3-0.8 part of a bridging addition agent.

Owner:新侨伟(福建)鞋服有限公司

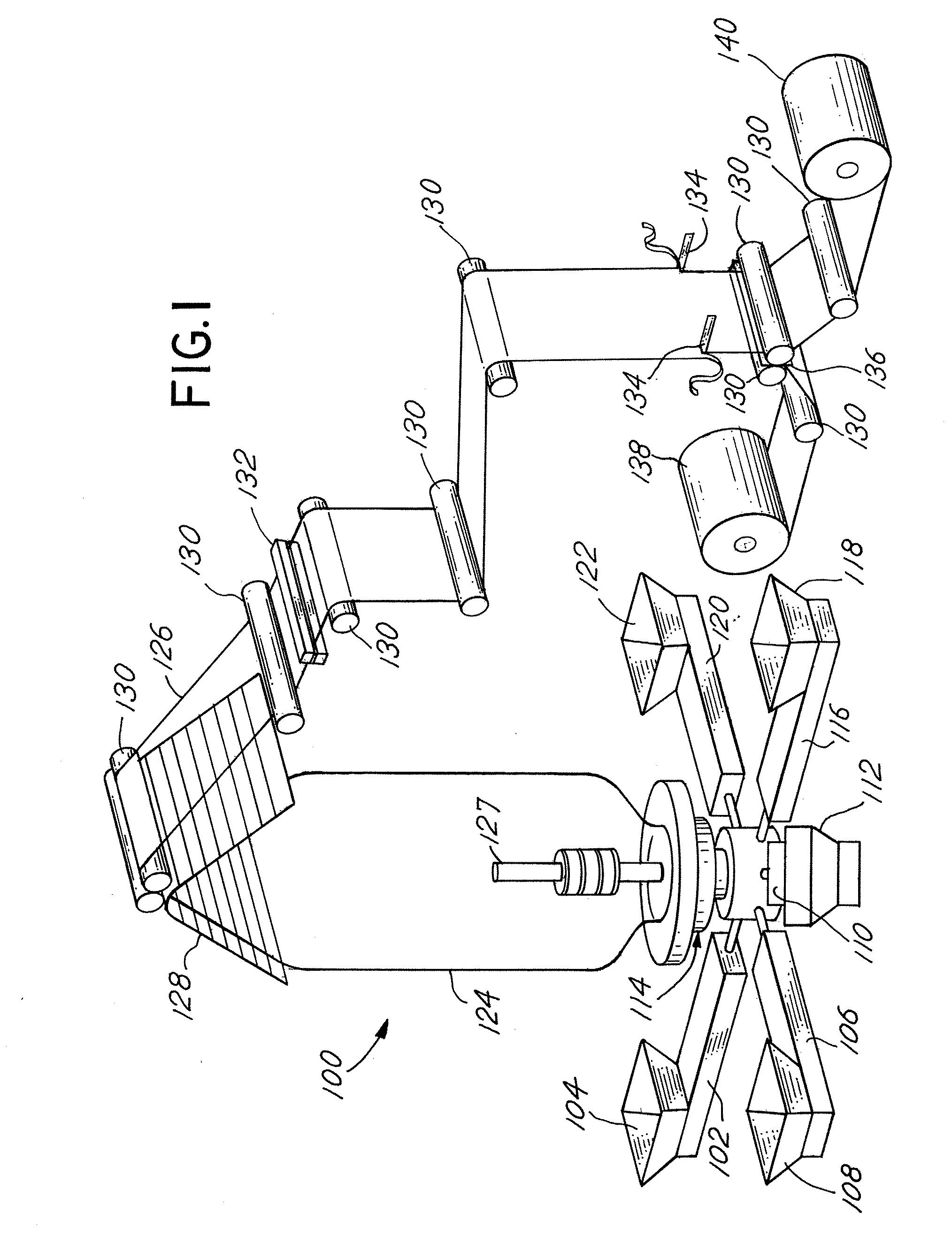

Coextruded film with polylactic acid (PLA) and Ethylene Vinyl Acetate (EVA)

InactiveUS20080026171A1Synthetic resin layered productsMonocomponent synthetic polymer artificial filamentPolyolefinSealant

A multilayer film comprising, in order, a polyolefin or extrudable layer, a first layer comprising ethylene vinyl acetate (EVA), and a layer comprising polylactic acid (PLA). In a preferred embodiment, the multilayer film comprises, in order, a polyolefin layer, a first layer comprising ethylene vinyl acetate (EVA), a core layer comprising polylactic acid (PLA), a second layer comprising EVA, and a sealant layer. A method and system for forming the multilayer film is also disclosed.

Owner:BEMIS COMPANY INC

Filler masterbatch used for increasing polarity of polypropylene and preparation method thereof

The invention discloses a filler masterbatch used for increasing the polarity of polypropylene and a preparation method thereof. The filler masterbatch is characterized by comprising the following components by weight percent: 50%-79% of inorganic filler, 15%-30% of carrier, 5%-17% of polar additive and 1%-3% of processing additive; and the polar additive is one or more of thermoplastic polyurethane resin (TPU), maleic anhydride grafted polypropylene, epoxy resin, ethylene acrylate, ethylene vinyl acetate, polyether amine and polybutylene polyol. In the preparation method of the invention, the added carrier can not improve the polarity of polypropylene, the inorganic filler is used to increase the rigidity of the material; the key is to introduce the polar additive with high unipolarity, thus the filler masterbatch used for increasing the polarity of polypropylene can be prepared; when the filler masterbatch is combined with the polypropylene material for production, the surface polarity of the filled and modified polypropylene material can be increased, the surface energy of the filled and modified polypropylene can be reduced, the dimension stability can be increased, the modified polypropylene material can have good paint adhesion and the material can be used to form exterior trimming parts such as bumpers and interior trimming parts such instrument panels.

Owner:KINGFA SCI & TECH CO LTD +3

Blends of aliphatic-aromatic copolyesters with ethylene-vinyl acetate copolymers

ActiveUS7241838B2Excellent fragmentation and breakdownImprove melt strengthPaper coatingSpecial tyresPolymer scienceCopolyester

Disclosed are blends of aliphatic-aromatic copolyesters with poly(ethylene-co-vinyl acetate) copolymers and shaped articles prepared therefrom. These blends have higher melt strength than the aliphatic-aromatic copolyester alone and exhibit increased melt strength and better processability. In addition, the blends and shaped articles show bio-disintegration and / or biodegradability in a composting environment.

Owner:EASTMAN CHEM CO

Ultraviolet crosslinked expansion type flame-retardant polyolefin cable insulation sheath material and preparation thereof

ActiveCN101481475AAdd lessHigh flame retardant efficiencyPlastic/resin/waxes insulatorsInsulated cablesPolyolefinProcedure Agents

The invention discloses an insulating and sheathing material of ultraviolet light crosslinking expanding type phosphorus nitrogen flaming resistance polyolefine cables and a preparation method thereof. The invention is characterized in that polyethylene / PEMA and / or ethylene vinyl acetate or maleic anhydride grafted ethylene vinyl acetate or acid amide grafted ethylene vinyl acetate copolymer are taken as base, added with expanding type phosphorus nitrogen halogen-free flame retardants, light trigger, polyfunctional group cross linker and chemical inhibitor and matched with flaming retardant synergistic agent, antismoke agent and processing aid, and then squeezed out and pelleted into photo-crosslinking flame retardant cable materials; and then the flame retardant cable materials are melted and extruded on a cable conductor wire core and clad into an insulating layer and a sheathing layer; hereupon the ultraviolet light irradiation crosslinking is carried on the insulating layer or the sheathing layer. Via detecting, the oxygen index of the insulating layer or the sheathing layer is larger than 30%, the vertical flaming experiment passes through UL-94 V0 level, the tensile strength is larger than 12Mpa, the elongation at break is larger than 350%, and the electric volume resistivity is larger than 8*10 omega.cm.

Owner:HONGLONGJIANG ORIENT SCI & TECH +1

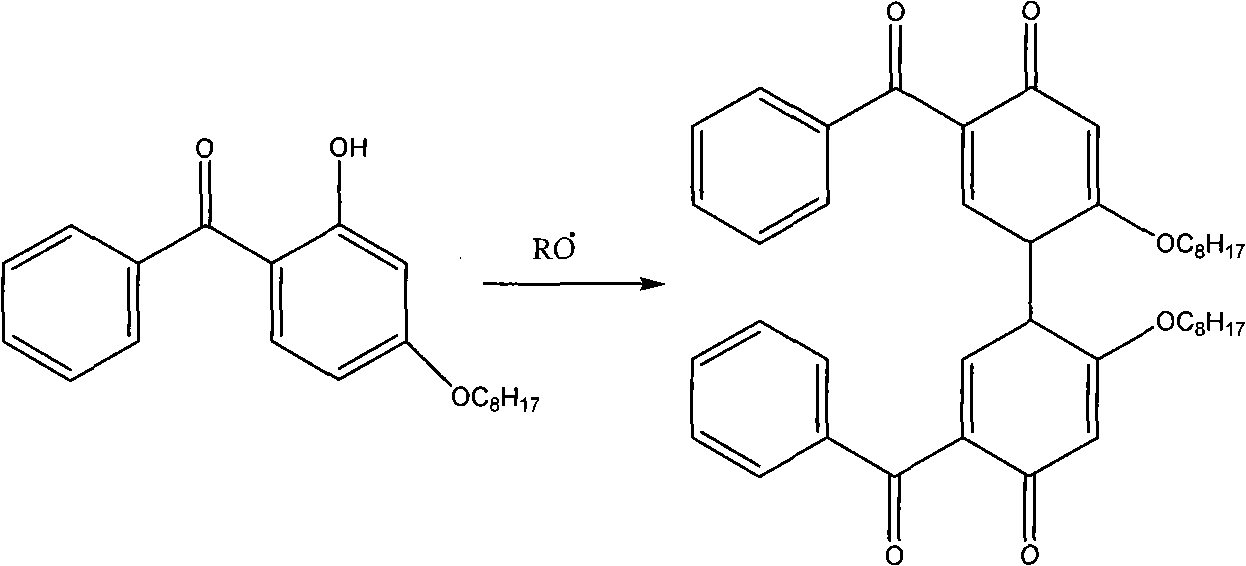

Novel EVA adhesive film

InactiveCN101353558AStrong free radical capture abilityGeneration of blockingFilm/foil adhesivesElectrical equipmentLight energyAdhesive

The invention provides an EVA adhesive film without adding uvioresistant absorbent, which is prepared mainly by the raw materials according to the mass ratio as follows: ethylene-vinyl acetate copolymer, 100 parts; peroxide type crosslinking agent 0.1 to 10 parts, phenolic or phosphite type antioxidant 0.05 to 5 parts; and hindered amine light stabilizer, 0.01 to 5 parts. As the ultraviolet absorbent is not used, the EVA adhesive film obtained does not produce ultra-violet cut-off, leads the solar modules to receive UV district light energy, thereby having higher photoelectric conversion efficiency and excellent uvioresistant anti-aging property, and guaranteeing the service life of PV modules.

Owner:HANGZHOU FIRST APPLIED MATERIAL CO LTD

Sound Attenuation Building Material And System

A shear panel building material that includes a first facing membrane, a core matrix disposed on a face of the first facing membrane, and a semi-rigid or rigid material attached to the core matrix. The core matrix can include microspheres having a size of about 200 microns to about 800 microns, sodium silicate, and ethylene vinyl acetate. In one aspect, the shear panel is substantially free from glue and cement.

Owner:ASHTECH IND LLC

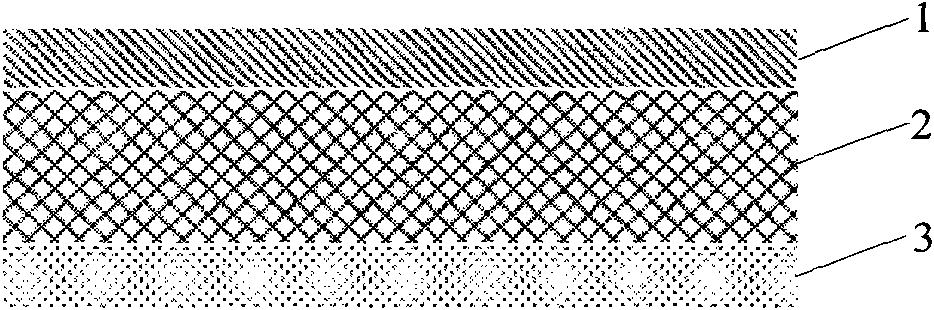

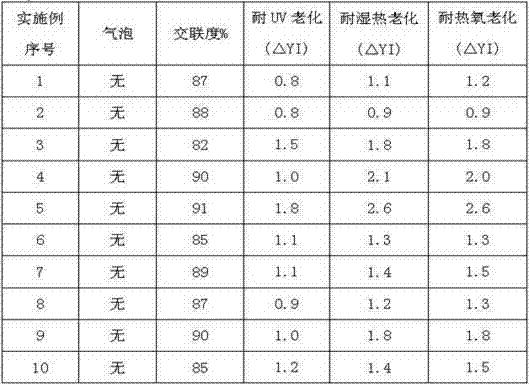

Back panel of solar cell and preparation method thereof

ActiveCN102157591AExtended service lifeMeet the requirementsFinal product manufactureSynthetic resin layered productsComposite filmPolyethylene terephthalate glycol

The invention relates to a back panel of a solar cell and a preparation method thereof. The solar back panel is provided with three polymer film layers from top to bottom, namely an adhesive weatherable layer, an adhesive reinforcing layer and an adhesive moisture-retarding layer, wherein the adhesive weatherable layer is a PVDF(polyvinylidene fluoride) / EVA (ethylene vinyl acetate) alloy layer, the adhesive reinforcing layer is a PET (polyethylene terephthalate) / PMMA (polymethyl methacrylate) alloy layer, and the adhesive moisture-retarding layer is a PVDF / PVB (polyvinyl butyral) alloy layer. In the preparation method, a multi-layer melting and co-extrusion method is adopted for realizing interface-free fusion of the three film layers, and a composite film can achieve good dimensional stability by online high-temperature shaping. The structure of the back panel of the solar cell only comprises the three layers, an adhesive layer does not need to be used, the preparation process is simple, the steps of sizing and hot-pressing are omitted, and the production efficiency is high; and simultaneously, the back panel has excellent performances and is in line with the packaging requirements of the solar cell.

Owner:SHANDONG DONGYUE POLYMER MATERIAL

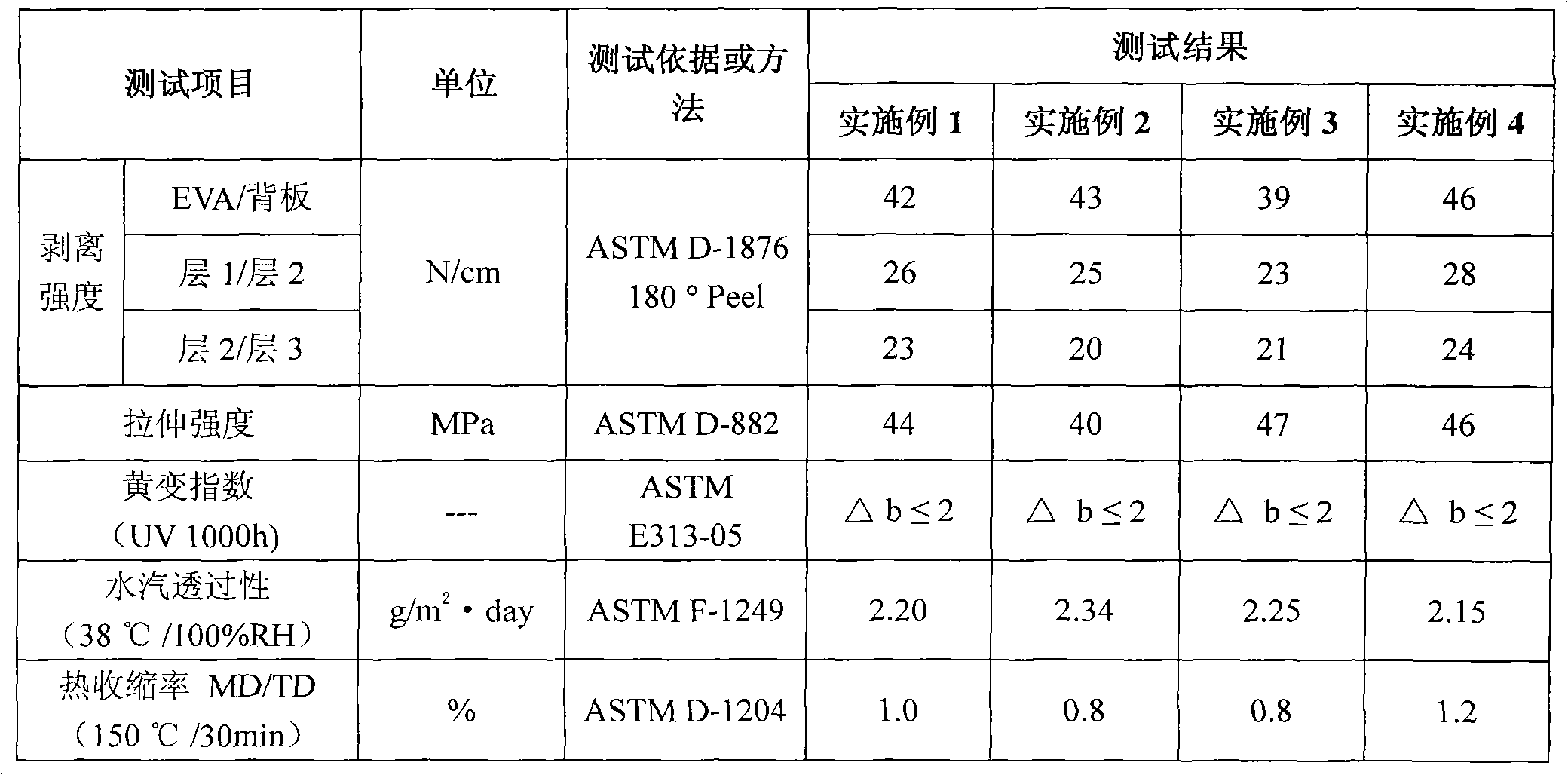

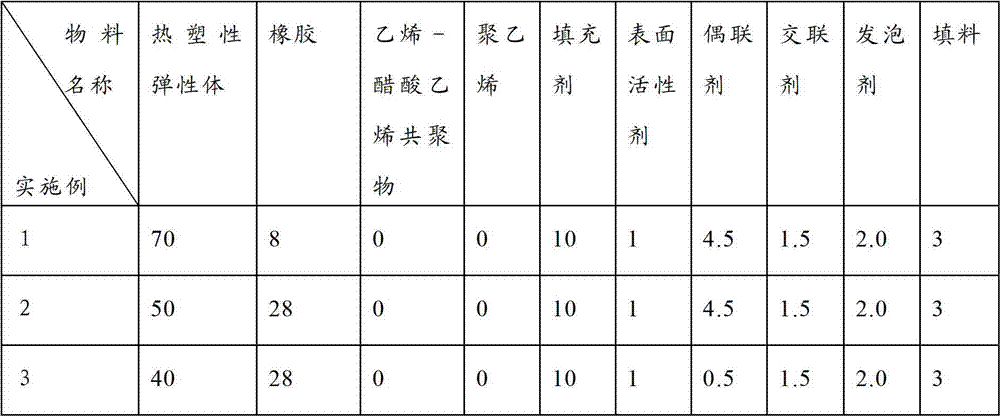

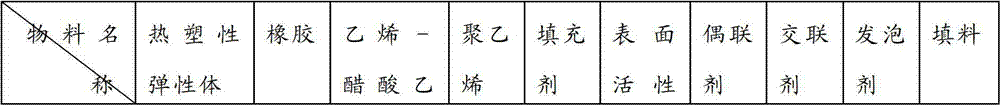

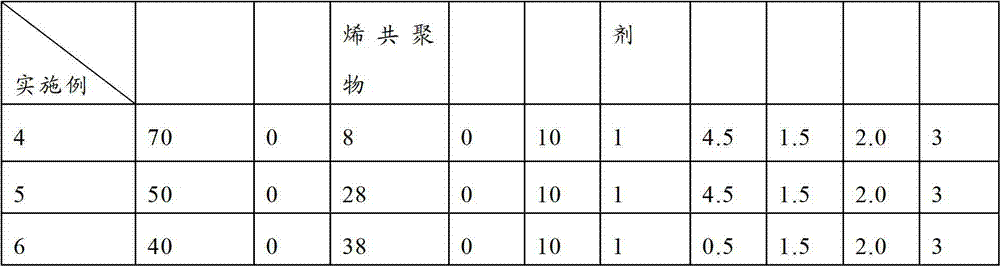

Foaming composition for wear and skid resistant sole, and preparation method thereof

The invention provides a foaming composition for a wear and skid resistant sole. The foaming composition comprises 30-90wt% of a thermoplastic elastomer, 0-50wt% of rubber, 0-30wt% of an ethylene-vinyl acetate copolymer, 0-30wt% of polyethylene, 5-20wt% of a filler, 0.5-2wt% of a surfactant, 0.5-4wt% of a coupling agent, 0.5-3wt% of a cross-linking agent, 1-4wt% of a foaming agent and 1-5wt% of a filler. The foaming composition simultaneously has the wear resistance and the skid resistance, and also has the respective superior characteristics of traditional rubber and PU. The invention also provides a preparation method of the foaming composition for a wear and skid resistant sole.

Owner:ANTA CHINA

Ethylene-vinyl acetate copolymer packaging thin film

InactiveCN102391568AEnhanced network structureImprove moisture resistancePhotovoltaic energy generationSemiconductor devicesPolymer scienceNetwork structure

The invention discloses an ethylene-vinyl acetate copolymer packaging thin film, which is used for packaging solar cell components. The thin film is prepared from the following raw materials in part by weight: 100 parts of an ethylene-vinyl acetate copolymer, 0.1 to 2.0 parts of crosslinking agent, 0.1 to 10.0 parts of aid crosslinking agent and a proper amount of aid. The ethylene-vinyl acetate copolymer contains 25 to 33 percent of vinylacetate, and the ratio of the amount of the aid crosslinking agent and the crosslinking agent is 1:10 to 10:1. In the invention, the introduction of the aid improves the network structure of crosslinked resin, improves crosslinking efficiency, greatly reduces the dosage and residue of the crosslinking agent greatly and avoids aging phenomenon caused by residual crosslinking agent, and the prepared thin film has higher dampness and heat resistance, high ultraviolet resistance, high thermal-oxidative aging resistance and the like and has long service life.

Owner:DONGFANG TURBINE CO LTD

Pull-tab sealing member with improved heat distribution for a container

ActiveUS8057896B2Improve heat distributionImprove sealingCapsClosure using stoppersPolyolefinEngineering

Owner:SELIG SEALING PROD INC

Film-reinforced glasses

InactiveUS20030111159A1Small thicknessImprove permeabilitySynthetic resin layered productsLaminationSilicon dioxideGlass sheet

The present invention provides a film-reinforced glass, which has excellent impact resistance, penetration resistance and durability and which can be easily prepared. The constitution of the glass consists of one glass plate and a film comprising an organic polymer which is superposed thereon through a transparent adhesive layer, wherein the transparent adhesive layer comprises a first transparent adhesive layer of polyvinyl butyral and a second transparent adhesive layer of ethylene-vinyl acetate copolymer; or wherein a hard coat layer consisting of a cured layer formed from a curable resin containing fine particles of silica is provided on the surface of the organic polymer film on the side in noncontact with the transparent adhesive layer.

Owner:BRIDGESTONE CORP

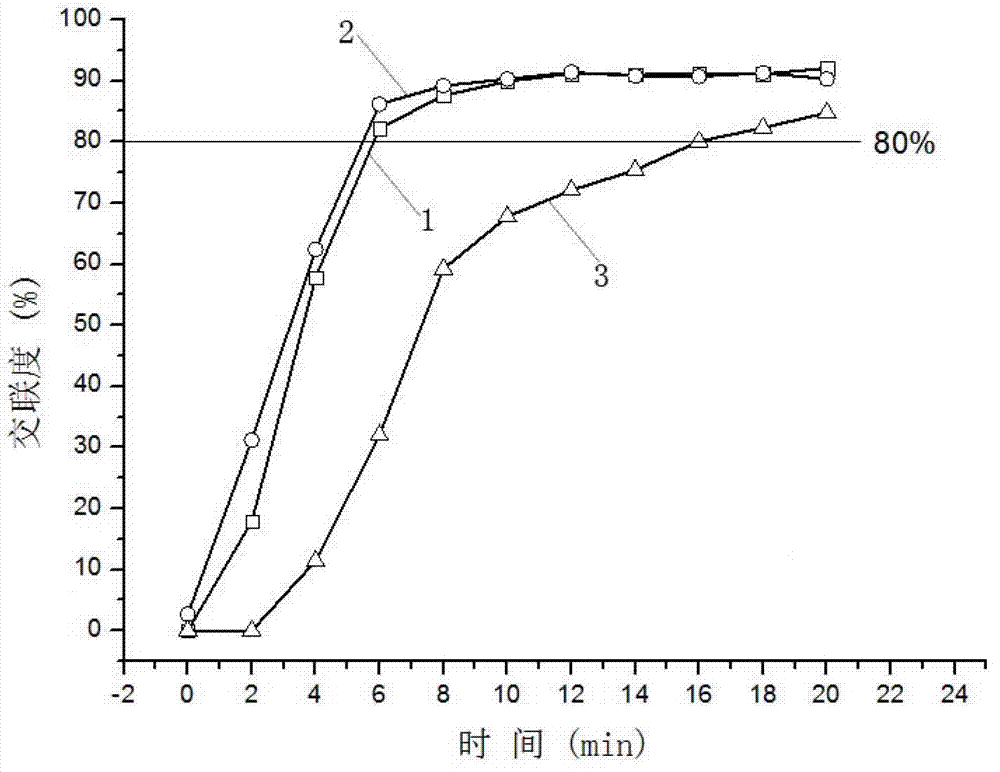

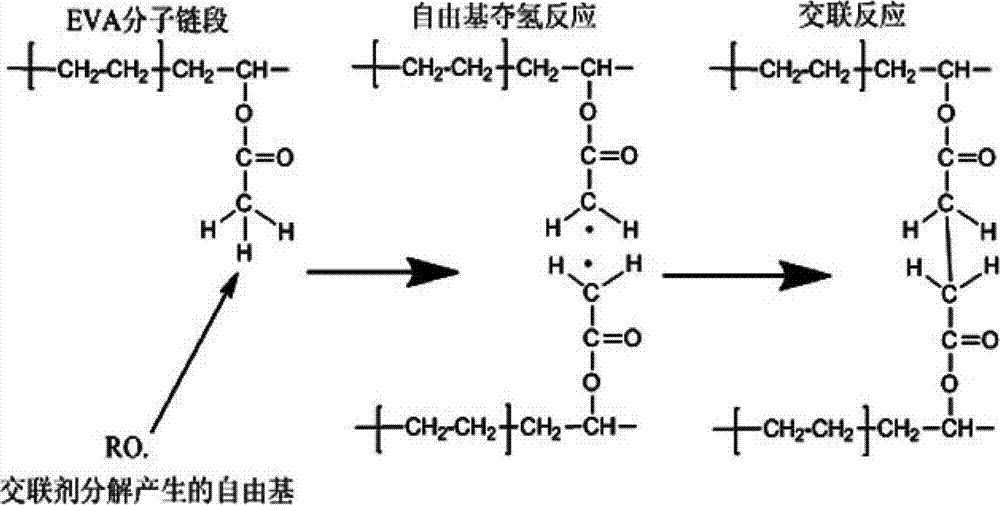

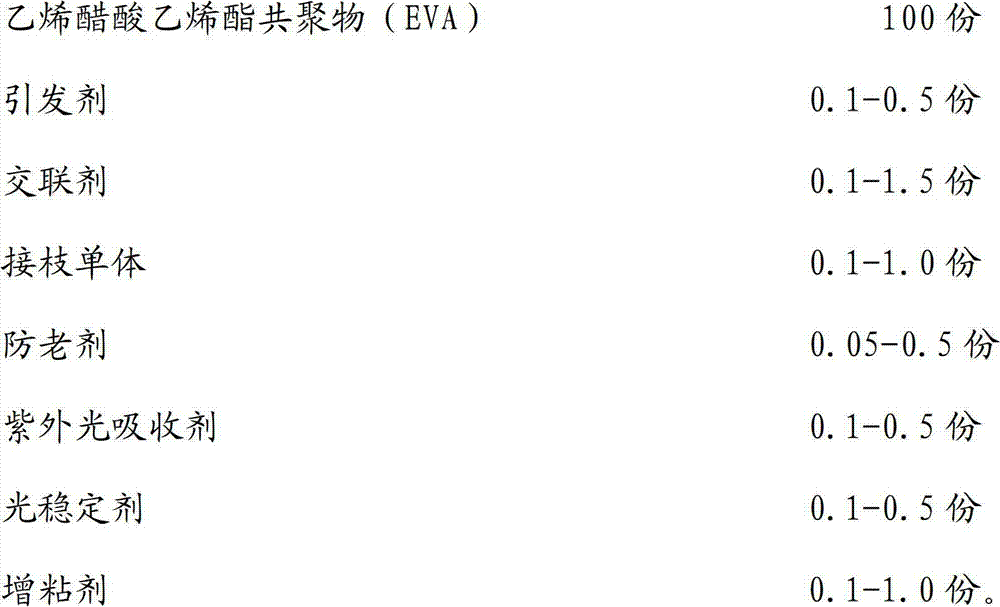

Low temperature super-fast setting EVA (Ethylene Vinyl Acetate) coating

ActiveCN103045105AHigh decomposition temperatureImprove cross-linking efficiencyNon-macromolecular adhesive additivesFilm/foil adhesivesTackifierMaterials science

The invention discloses a low temperature super-fast setting EVA (Ethylene Vinyl Acetate) coating which comprises the following components in parts by weight: 100 parts of EVA copolymer, 0.1-0.5 part of initiator, 0.1-1.5 parts of cross-linking agent, 0.1-1.0 part of grafting monomer, 0.05-0.5 part of antiager, 0.1-0.5 part of ultraviolet absorber, 0.1-0.5 part of optical stabilizer and 0.1-1.0 part of tackifier. According to the EVA coating provided by the invention, the packaging efficiency of an assembly can be improved to a greater extent, the stability of assembly production is ensured, and meanwhile, the laminating temperature does not need to be raised and excessive cross-linking agent does not need to be added.

Owner:JIANGSU LUSHAN PHOTOVOLTAIC TECH +1

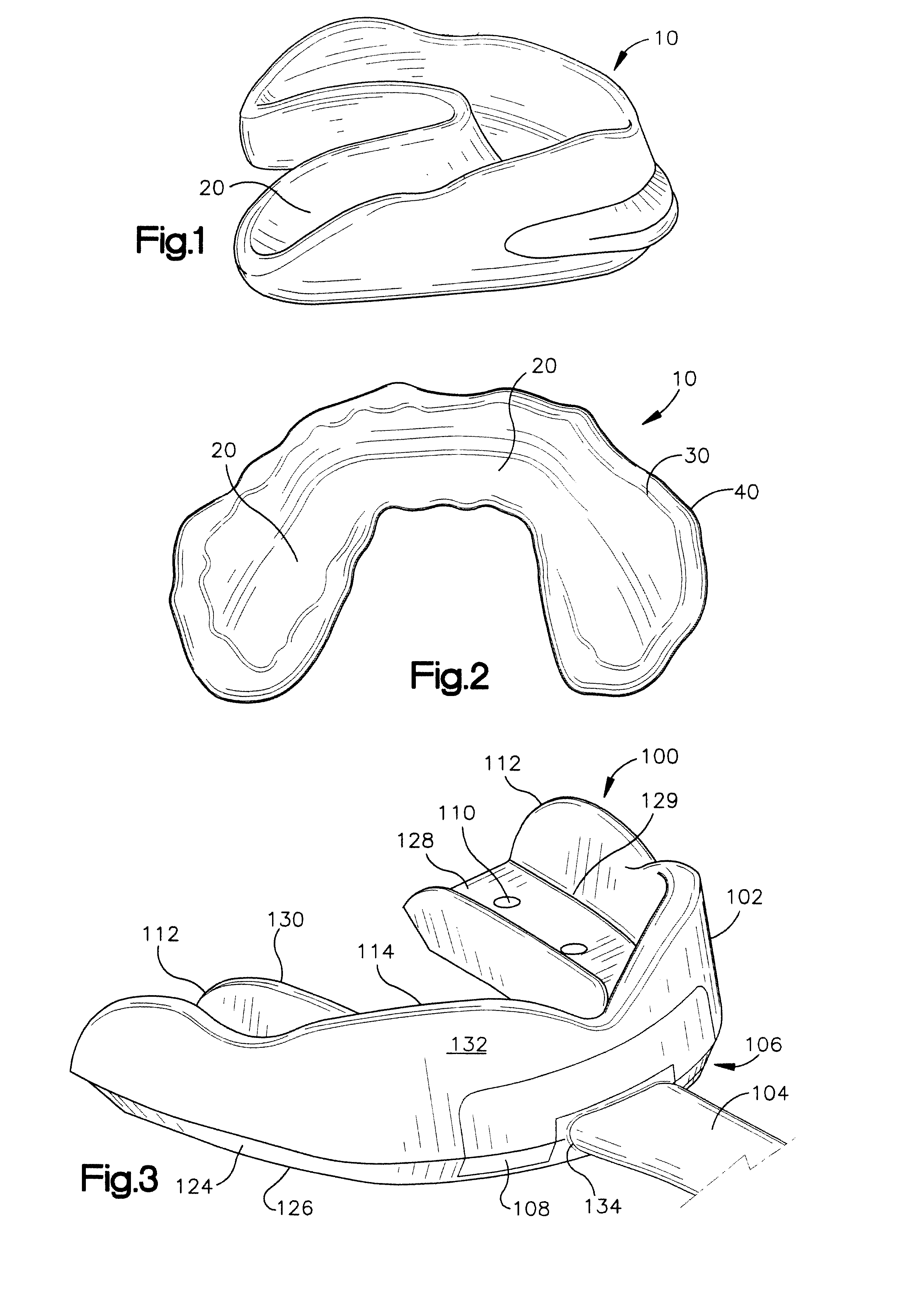

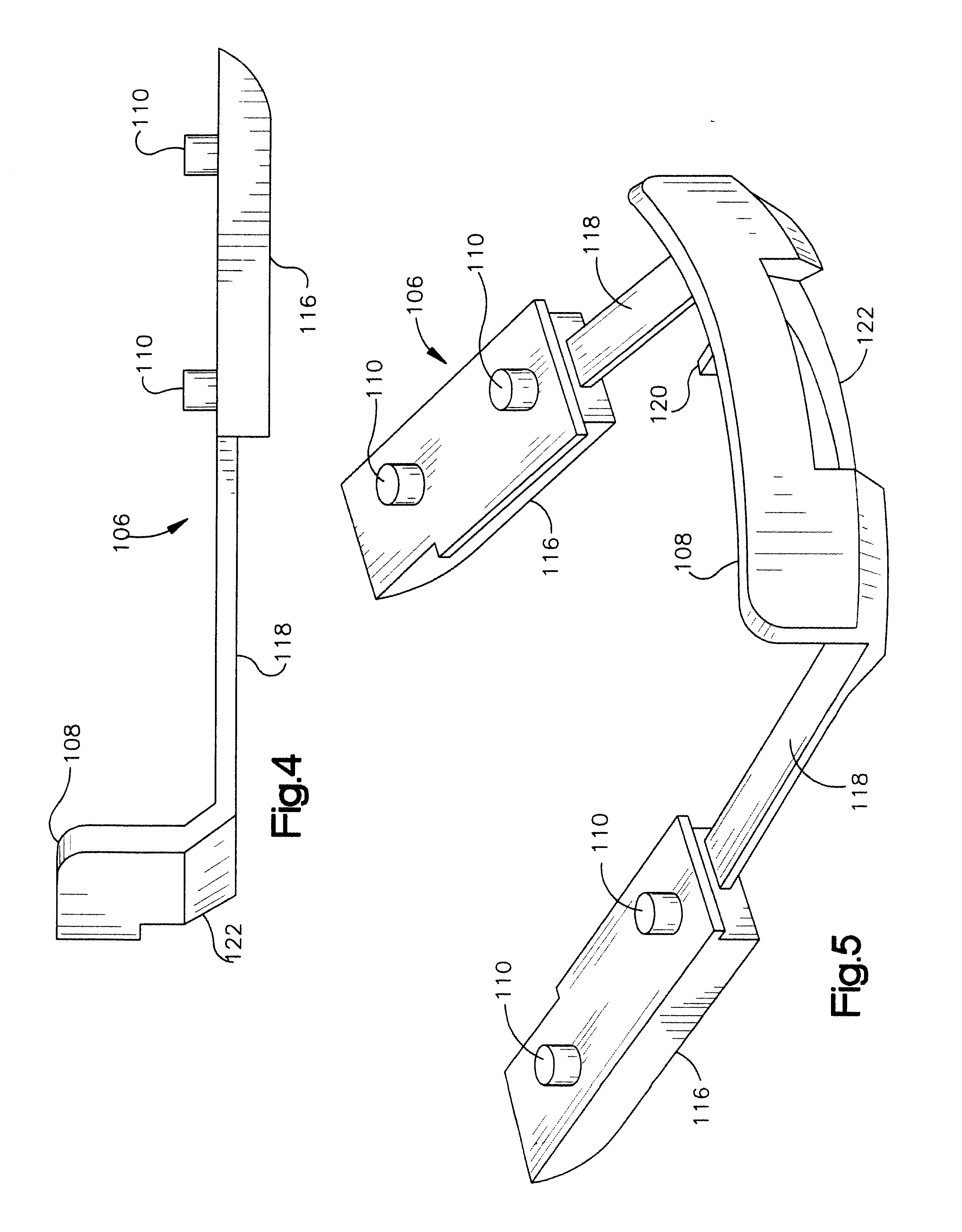

Mouthguard

InactiveUS20050115571A1Improve shock absorptionMaximum protectionTeeth fillingSport apparatusMouthguardEngineering

A mouthguard for use by athletes in competition and the like, including a first portion formed from a ethylene vinyl acetate copolymer material and having a teeth engaging shape and having a freezing point of less than 130° F. The first portion is formed into a tray having a generally U-shape with a tab extending out from the tray. The tray has a plurality of holes therein. A second portion formed from a block styrene copolymer is mounted on the first portion such that part of the second portion extends through the plurality of holes in the first portion to lock the two portions together. The second portion is formed from a gel material having sufficient softness to protect the user from damage during use in the athletic competition.

Owner:JACOBS SCOTT

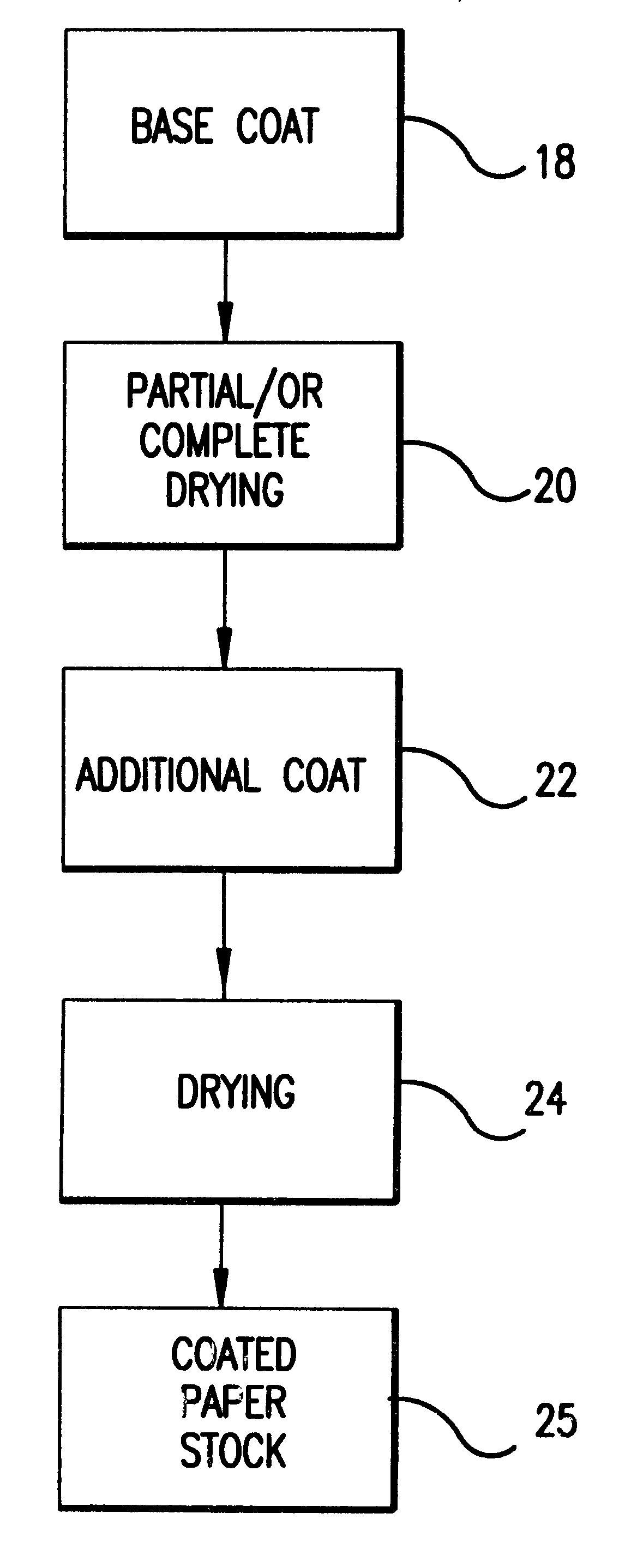

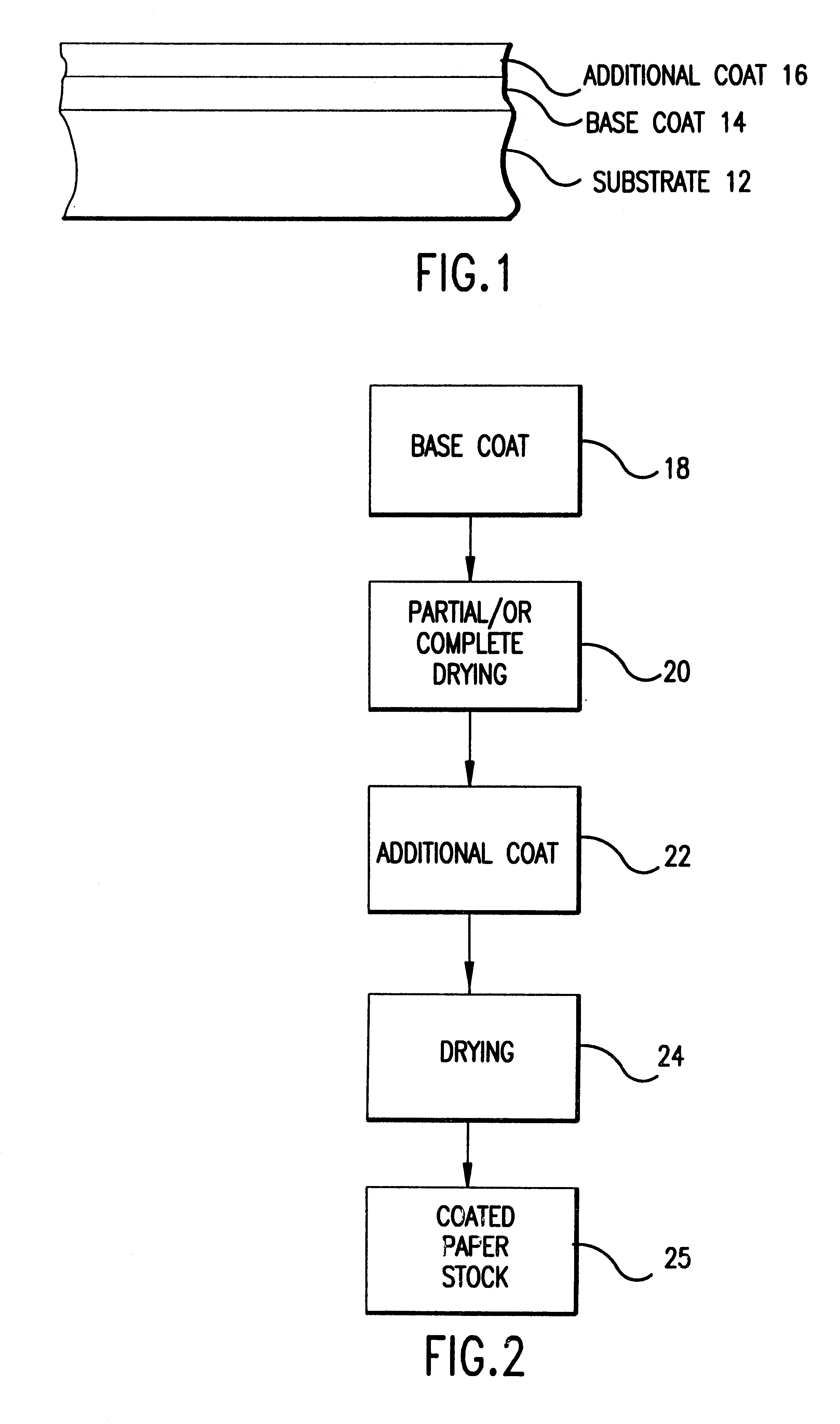

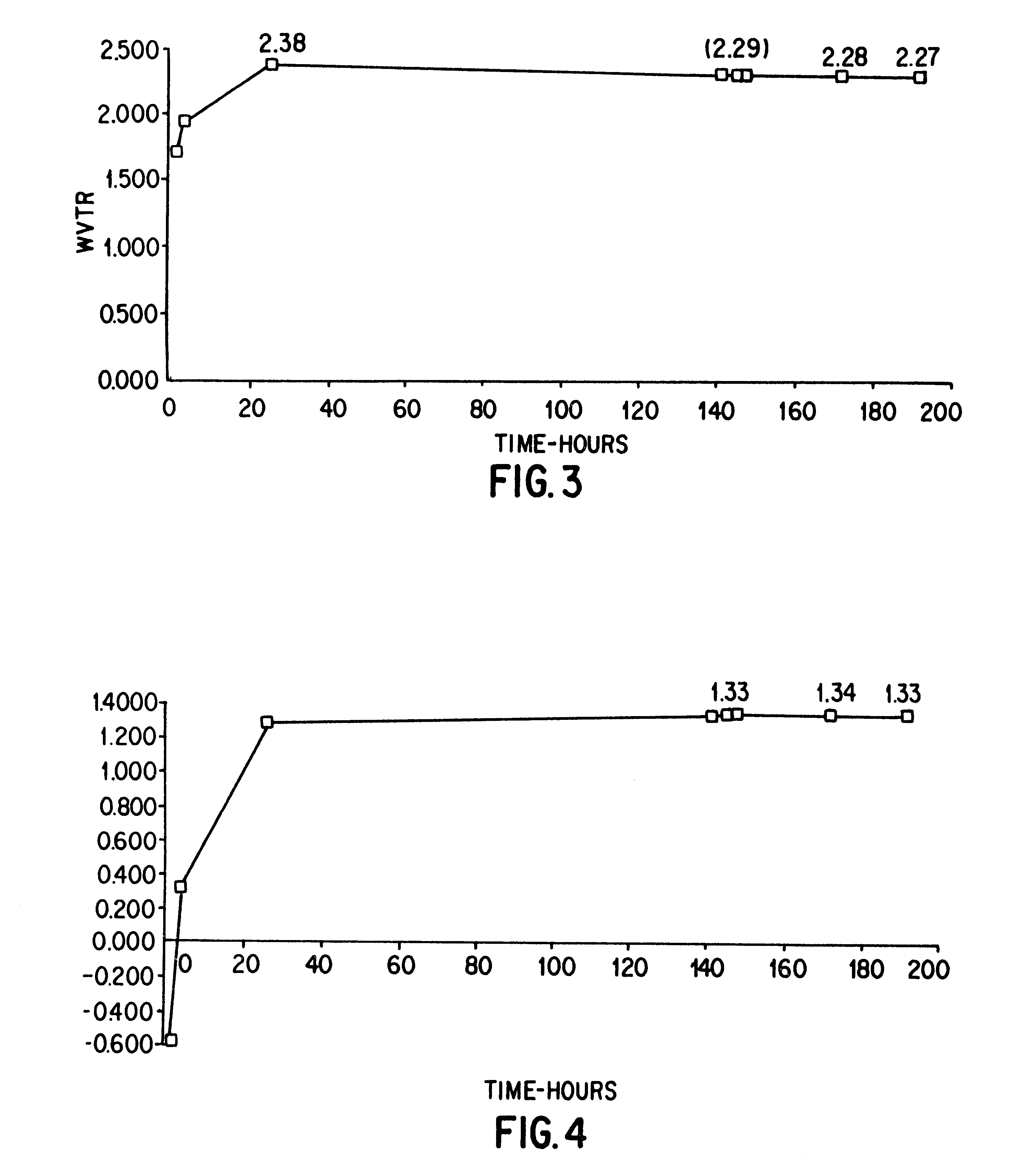

Recyclable and repulpable ream wrap and related methods of manufacture

InactiveUS6548120B1Reduce penetrationReduce drying demandFlexible coversWrappersWater basedPolymer science

Recyclable and repulpable coated paper stock, preferably for use as ream wrap, comprising a substrate coated on at least one surface with a base coat and at least one additional coat over said base coat. Both coats are water based dispersions of a polymer selected from the group consisting of acrylic polymers, acrylic copolymers, polyvinyl acetate, polyvinyl alcohol, ethylene-vinyl acetate, polyvinyl chloride, styrene butadiene copolymers, polyvinylidiene chloride and its copolymers, or starch. The wax free coating forms a pin-hole free continuous film on the substrate which is resistant to water and water vapor. The invention also includes processes for making and recycling the invented coated paper stocks.

Owner:COATING EXCELLENCE INT

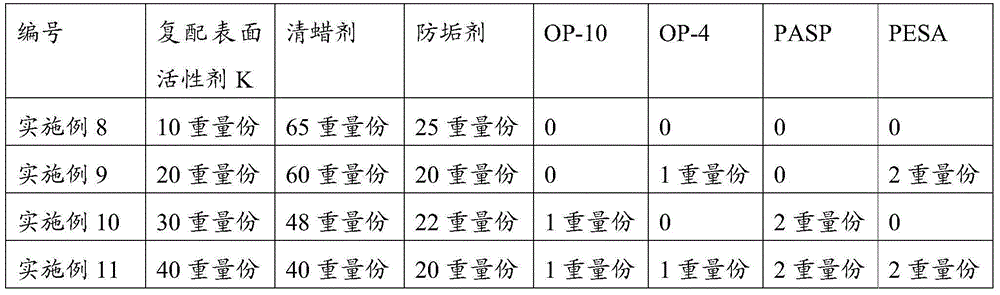

A soluble antiscale wax control ball

ActiveCN105441051ASolubleImprove wax removal effectDrilling compositionCarvacryl acetateCleansing Agents

A soluble antiscale wax control ball is disclosed. The soluble antiscale wax control ball comprises surfactants, wax cleaning agents and an antiscale agent RX-613. The surfactants comprise sodium alkylbenzenethiosulphonate, Ninol and polyoxyethylene alkyl ether. The wax cleaning agents comprise ethylene-vinyl acetate copolymer and polyethylene. The soluble antiscale wax control ball is advantaged by being soluble and having functions of preventing scaling and wax precipitation of pipelines, being capable of not blocking pipelines, and the like. The soluble antiscale wax control ball can dissolve old scale into crude oil and can prevent crude oil components from scaling onto walls of pipelines, and therefore problems of mechanical wax-cleaning antiscale balls at present, such as pipeline blockage and high running costs, which are caused by pipeline transfiguration, and the like are overcome. Experiment research shows that the soluble antiscale wax control ball can achieve wax-cleaning effects of rubber balls in site and has multiple functions comprising chemical wax cleaning and scale prevention, the comprehensive wax cleaning rate is 85.2%, and the antiscale rate is 82.18%.

Owner:PETROCHINA CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com