Radiation pre-crosslinked ethylene-vinyl acetate (EVA) resin film and preparation method thereof

A vinyl acetate, pre-crosslinking technology, applied in the field of plastic films, can solve the problems of dirty processing equipment, poor dimensional stability, poor dimensional stability, etc., to improve dimensional stability and heat resistance, easy to use and Transportation, suitable for large-scale promotion and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

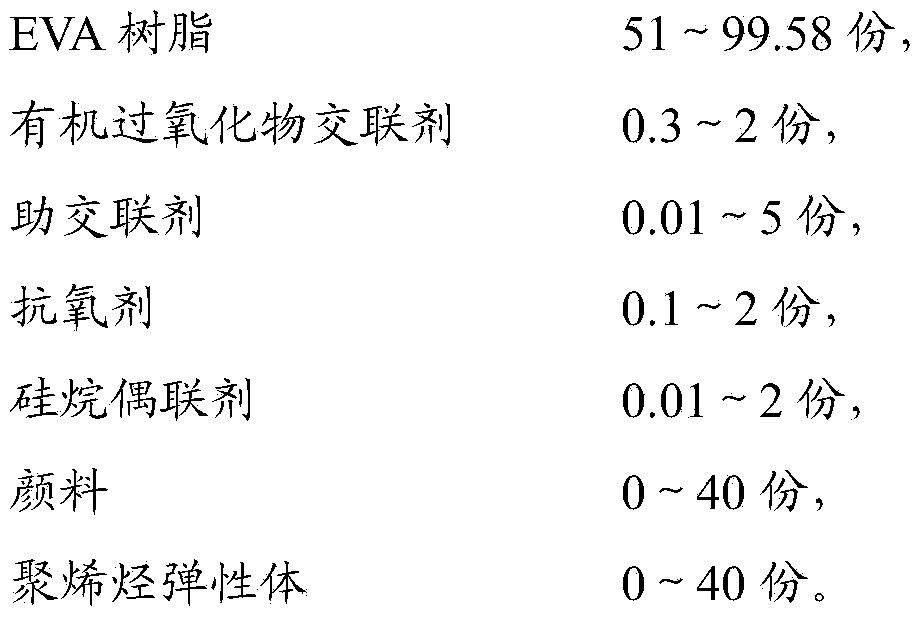

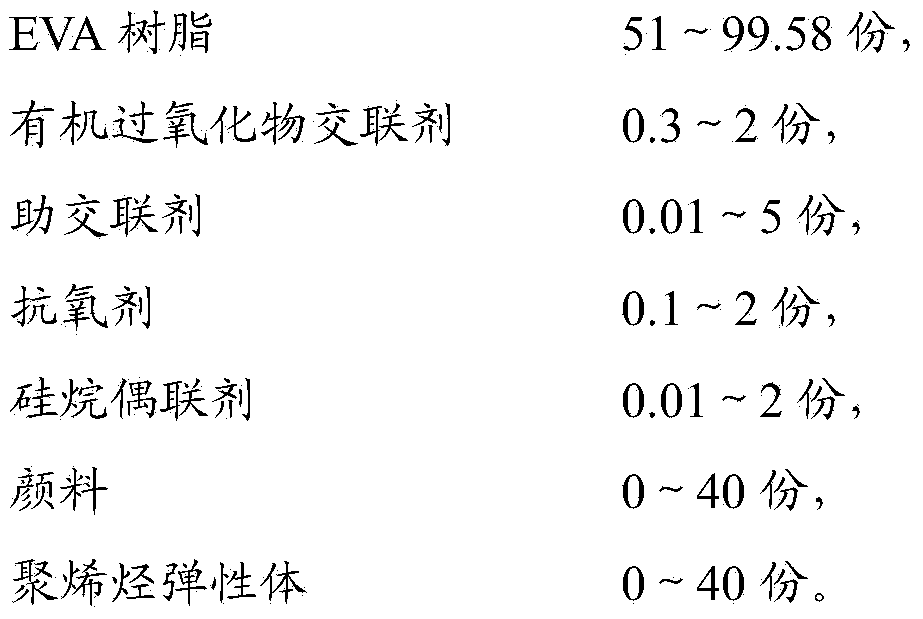

[0025] The formula of EVA film is as follows:

[0026]

[0027] The above components are fully mixed and then added to the extruder. The temperature of the extruder is 110°C, and the temperature of the mold is 110°C; extrude through a T-shaped flat die to form a film, wind up, and radiate to obtain radiation pre-crosslinked ethylene- Vinyl acetate resin film. The thickness of the EVA film is 2 mm, and the length of a single roll is 200 meters; the EVA film is wound with a three-inch paper core.

[0028] The EVA film was passed under the electron beam generator and rolled onto another three inch paper core. The radiation is electron beam radiation with an intensity of 30KGY. The degree of cross-linking of the EVA film was measured after irradiation, and the range was between 25% and 35%. The pre-crosslinked EVA film is cut into the same size as the double-layer glass and placed between the double-layer glass, vacuumed and pressurized and heated to 200 degrees Celsius for ...

Embodiment 2

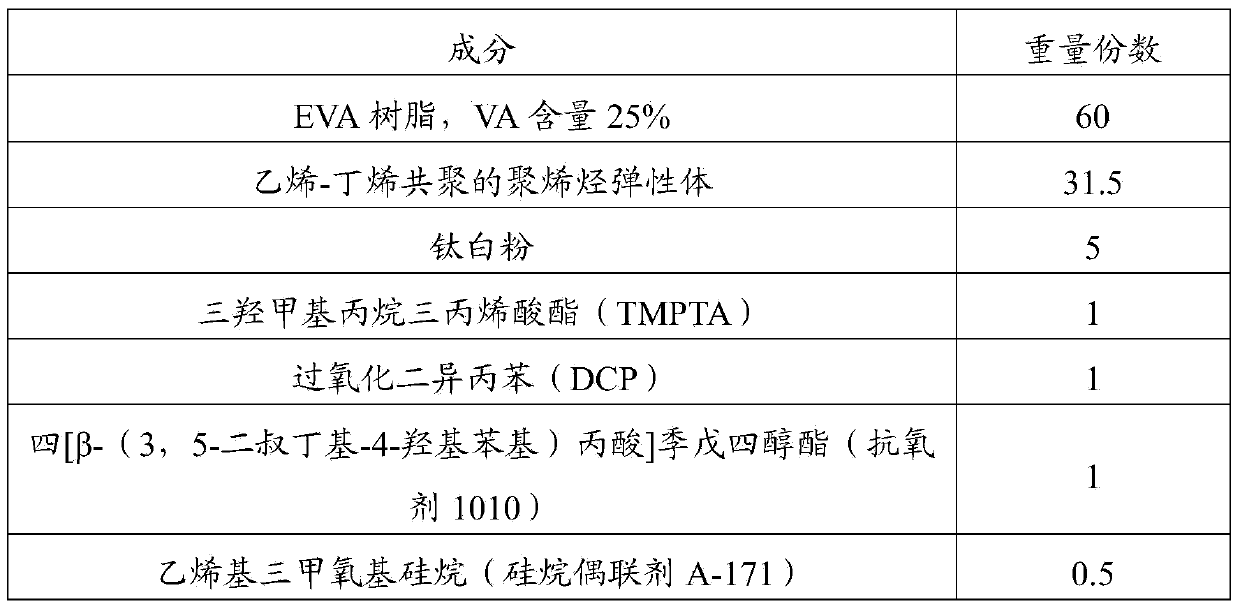

[0030] The formula of EVA film is as follows:

[0031] Element

parts by weight

EVA resin, VA content 28%

78

Ultrafine barium sulfate (4000 mesh)

19.5

Triallyl cyanurate (TAC)

0.5

tert-butyl peroxy-2-ethylhexyl carbonate (TBEC)

1

Bis(2,2,6,6-tetramethyl-4-piperidine) sebacate (antioxidant 770)

0.5

3-Methacryloxypropyltrimethoxysilane (A-174)

0.5

[0032] The above components are fully mixed and then added to the extruder. The temperature of the extruder is 90°C, and the temperature of the mold is 90°C; it is extruded into a film through a T-shaped flat die, wound up, and irradiated to obtain radiation pre-crosslinked ethylene- Vinyl acetate resin film. The thickness of the EVA film is 0.1 mm; the EVA film is wound with a 3-inch paper core.

[0033] The EVA film after winding is a roll film with a length of 100 meters. The whole film is placed under the electron beam, and the radiation dose ...

Embodiment 3

[0036] The formula of EVA film is as follows:

[0037] Element

parts by weight

EVA resin, VA content 33%

92.5

5

Triallyl isocyanurate (TAIC)

1

2,5-Dimethyl-2,5-bis(tert-butylperoxy)hexane (two dipenta)

0.5

N,N'-di-sec-butyl-p-phenylenediamine (Antioxidant 4720)

0.5

Vinyltrimethoxysilane (silane coupling agent A-171)

0.5

[0038] The above components are fully mixed and then added to the extruder. The temperature of the extruder is 100°C, and the mold temperature is 102°C; extruded into a film through a T-shaped flat die, wound up, and irradiated to obtain radiation pre-crosslinked ethylene- Vinyl acetate resin film. The thickness of the EVA film is 0.7 mm, and the length of a single roll is 300 meters; the EVA film is wound with a three-inch paper core.

[0039] Place the EVA film as a whole under the X-ray generating device, and the radiation intensity is 100KGY. The degree o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com