Patents

Literature

662results about How to "Avoid size" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

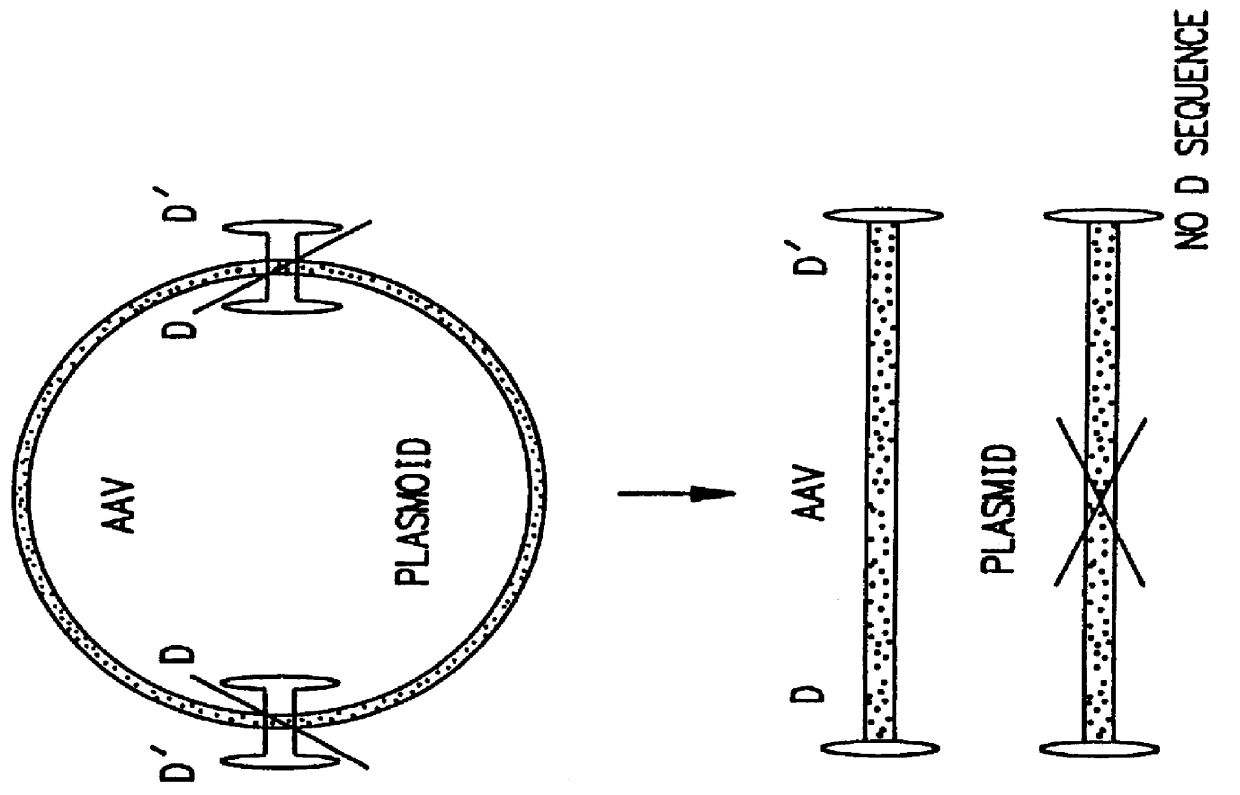

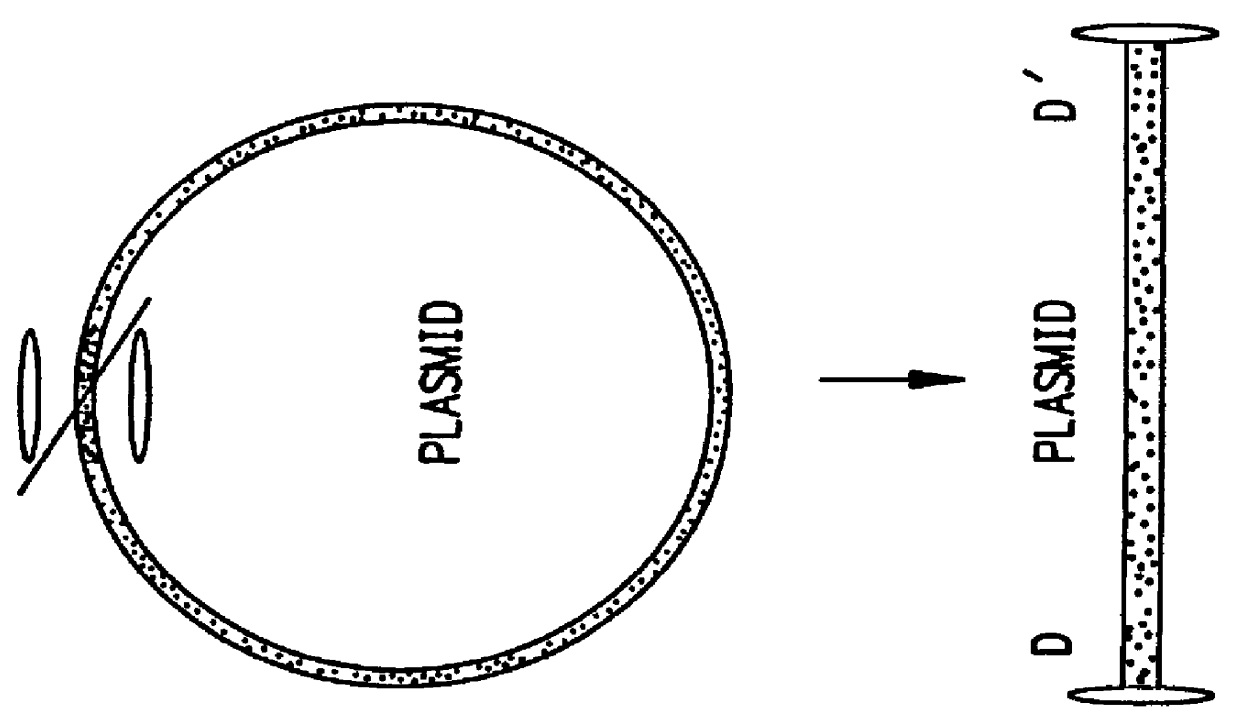

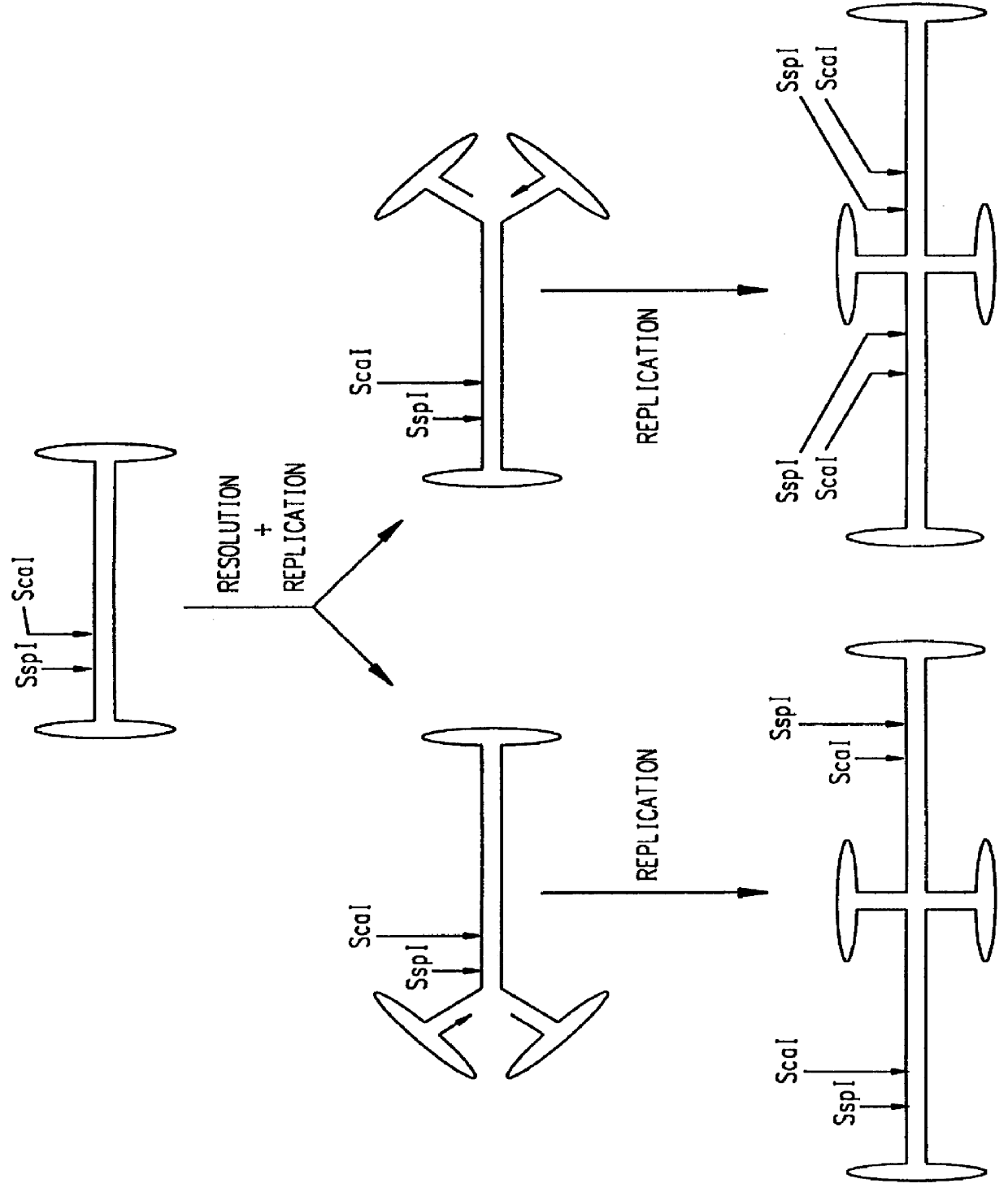

Recombinant viral vector system

InactiveUS6057152ARemoving any size restraintConvenient efficient meanSugar derivativesGenetic material ingredientsViral vectorRecombinant virus

The present invention relates to a system for replication and encapsidation of recombinant DNA fragments into virus particles comprised of adenovirus associated viral (AAV) capsid proteins. The invention provides an means of obtaining recombinant viral stocks that may be used to treat patients suffering from genetic diseases.

Owner:UNIVERSITY OF PITTSBURGH

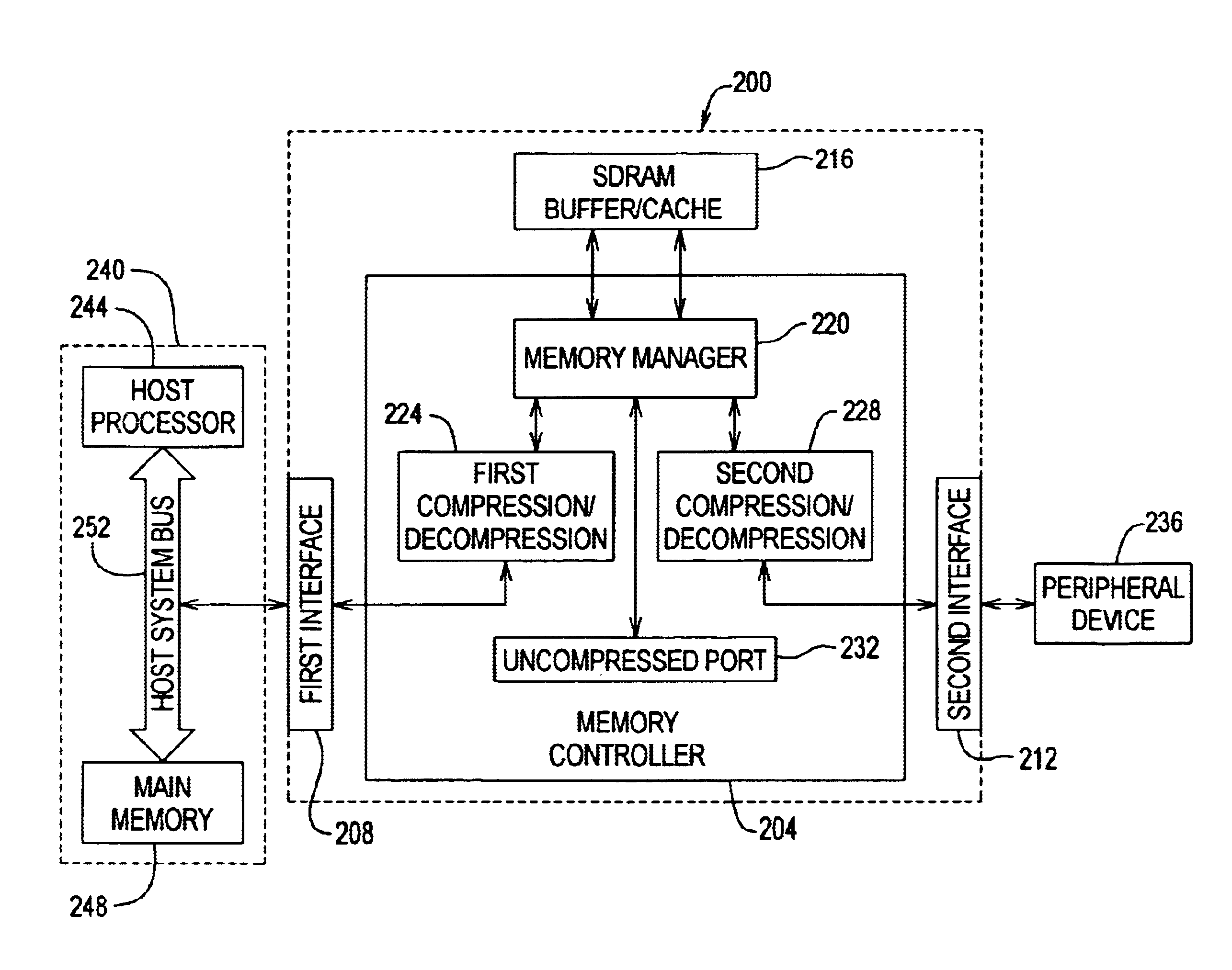

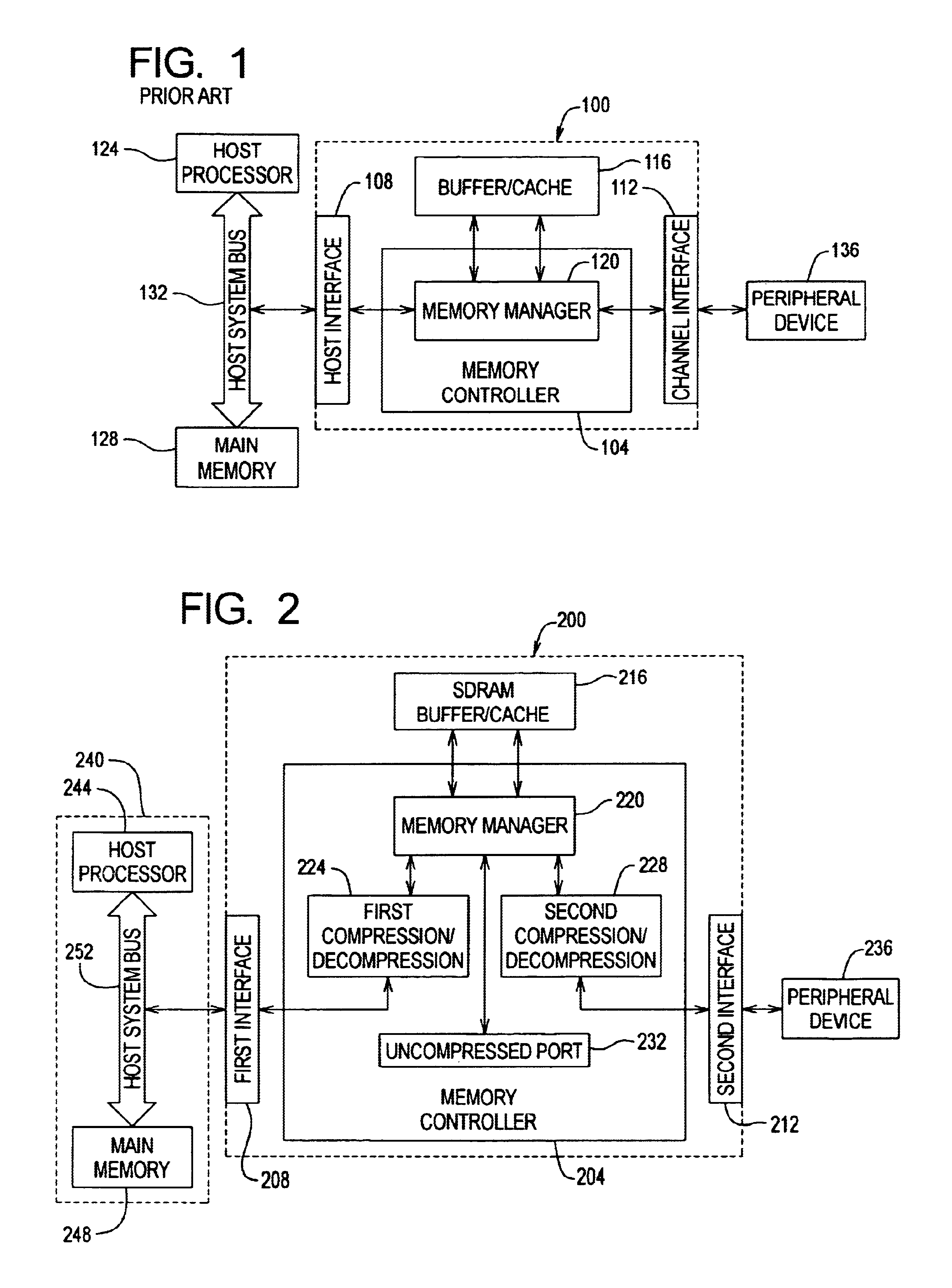

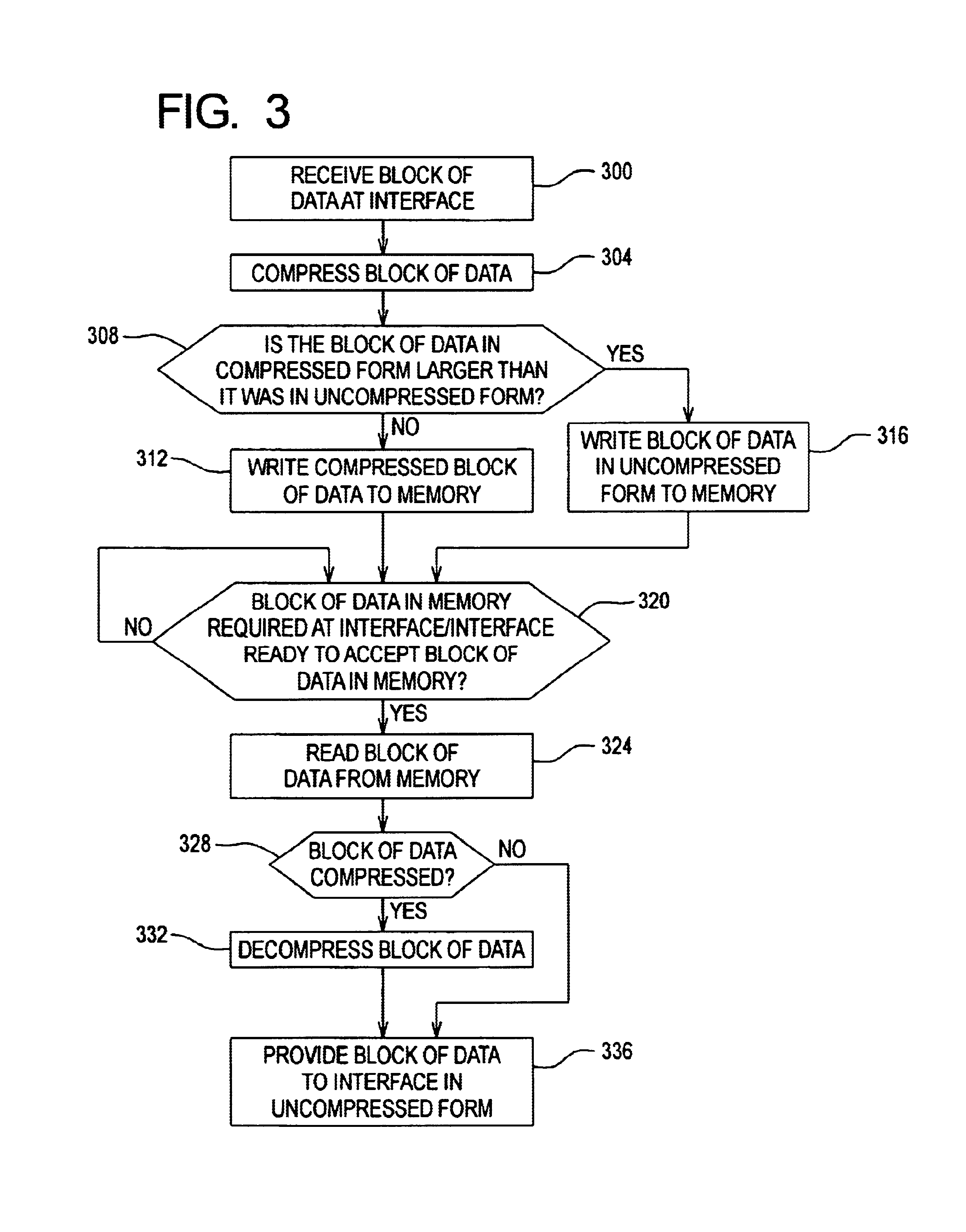

Method and apparatus for using data compression as a means of increasing buffer bandwidth

InactiveUS6883079B1Increase effective bandwidthEffective bandwidth of memoryMemory architecture accessing/allocationInput/output to record carriersData compressionMemory controller

A method and apparatus for increasing the bandwidth of a memory controller system are provided. According to the invention, data received at an interface of a memory controller system is compressed in the memory controller by a compression engine for storage in associated memory. The address of the data written to memory is maintained in a memory controller. When data is read from the memory for provision to an interface of the memory controller, the memory manager retrieves the data from memory and provides it to a decompression engine. The decompression engine restores the data to its original, uncompressed form. The data is then provided to the appropriate interface.

Owner:MAXTOR

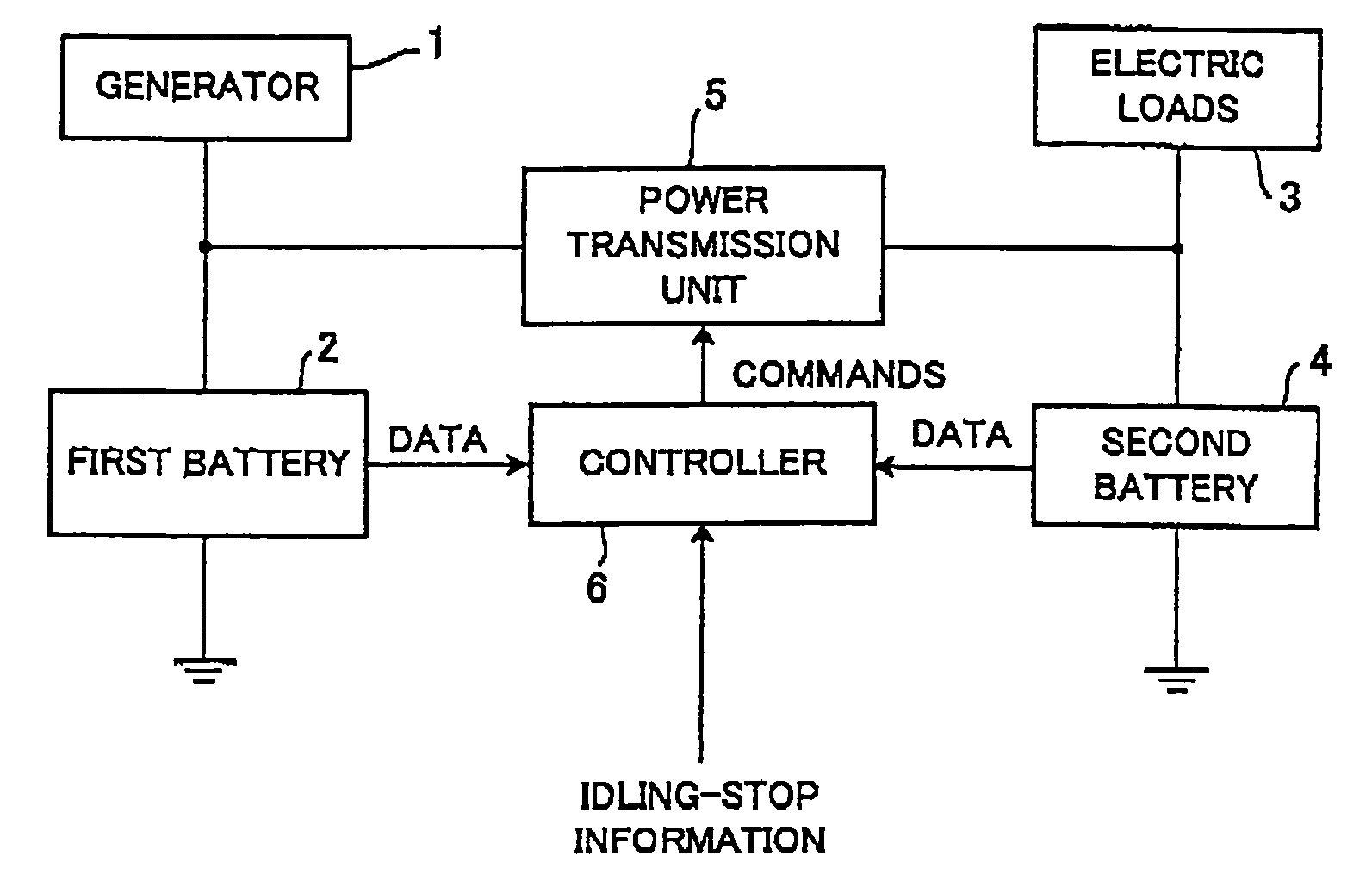

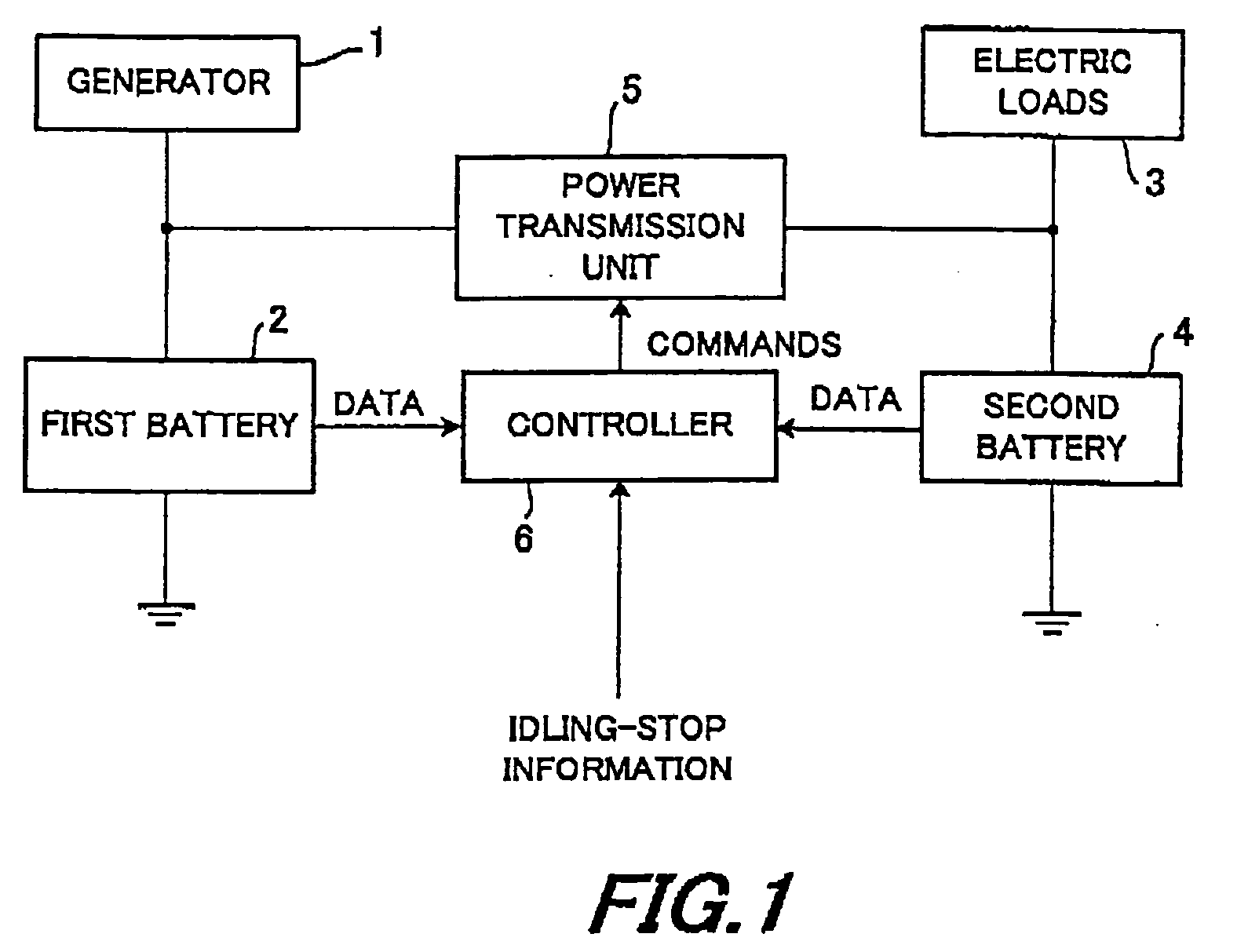

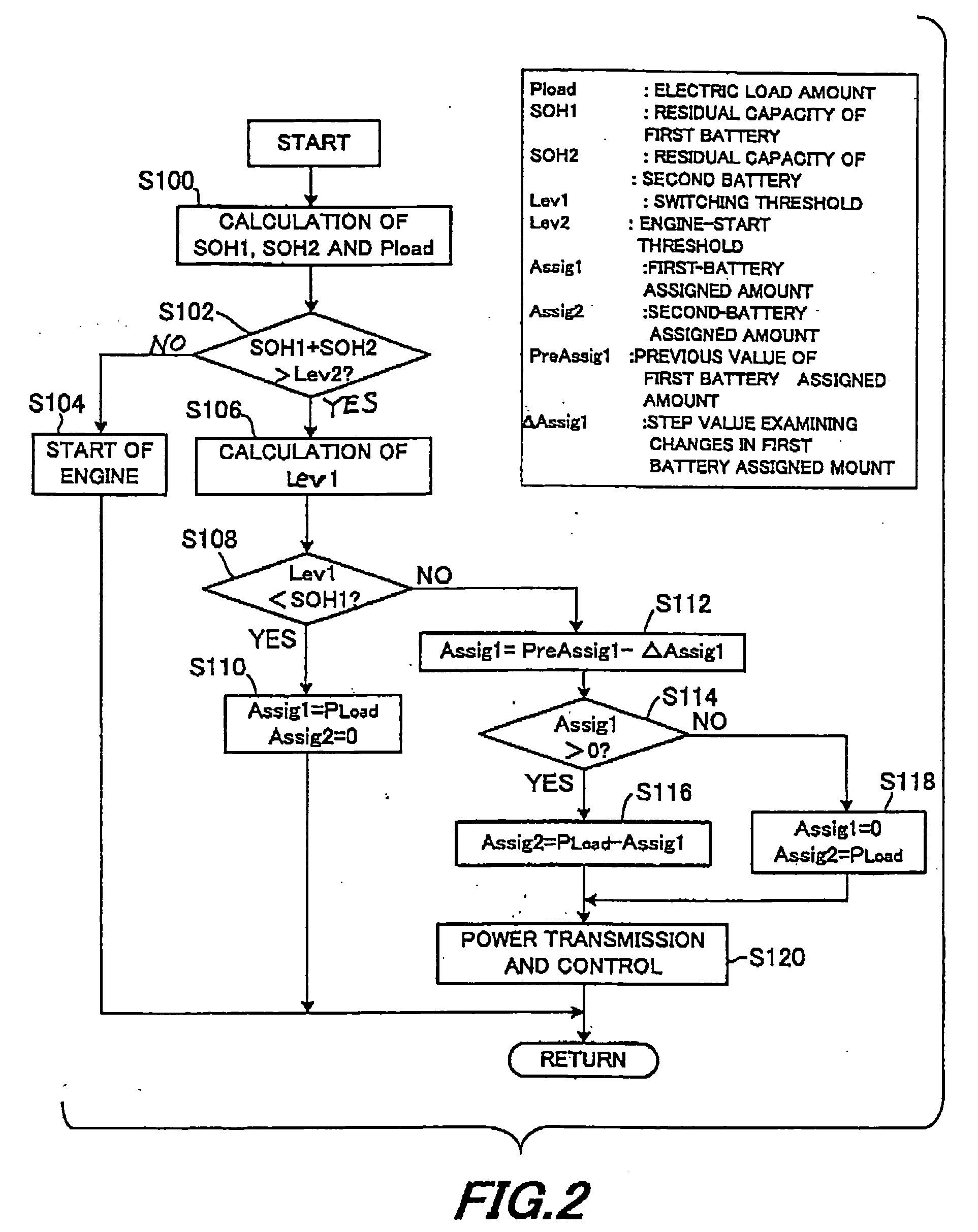

On-vehicle power supplying apparatus with two power supplies

InactiveUS20060058897A1Fuel consumption be improveLong life timeBatteries circuit arrangementsLevel controlElectrical batteryElectricity

Owner:DENSO CORP

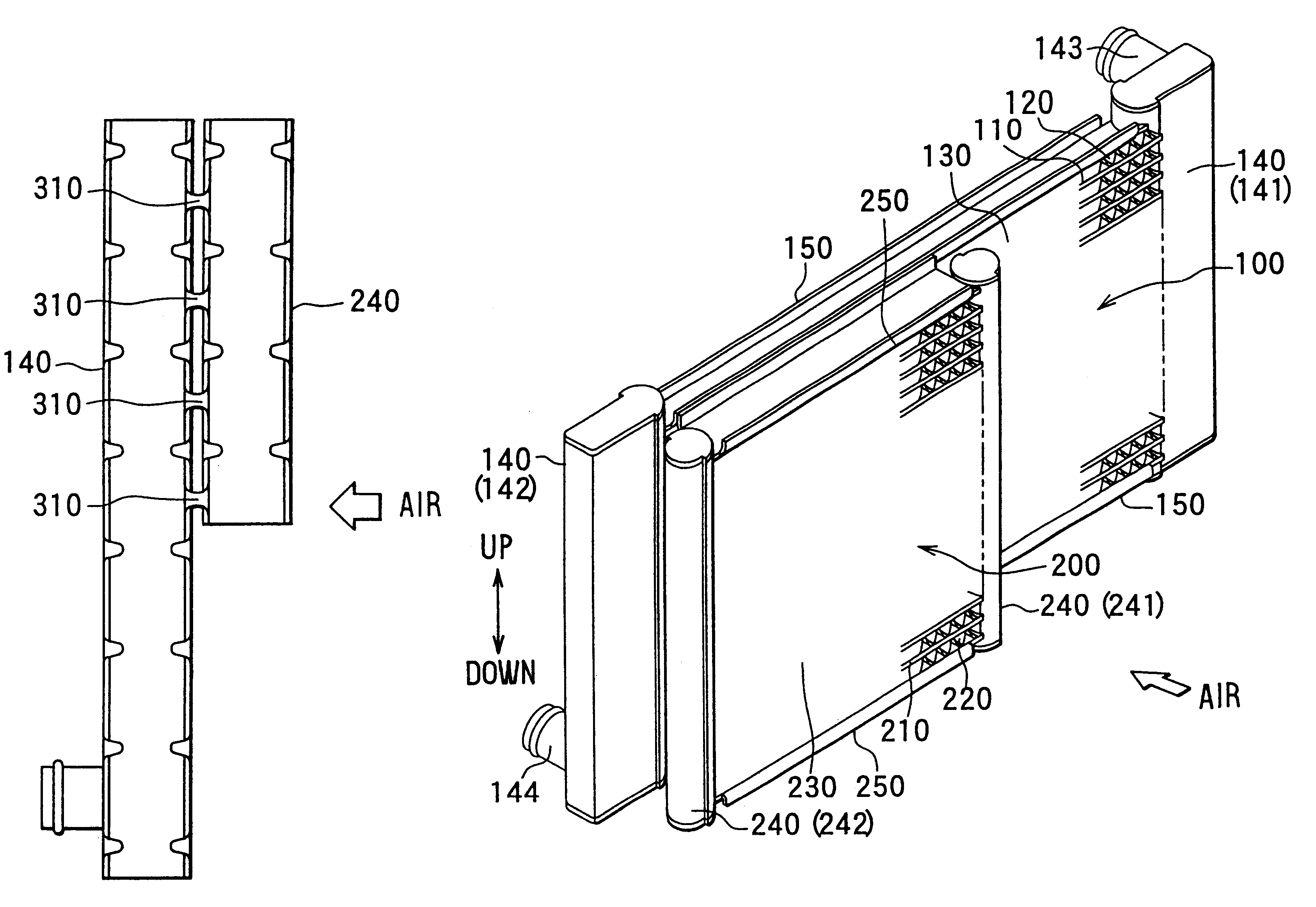

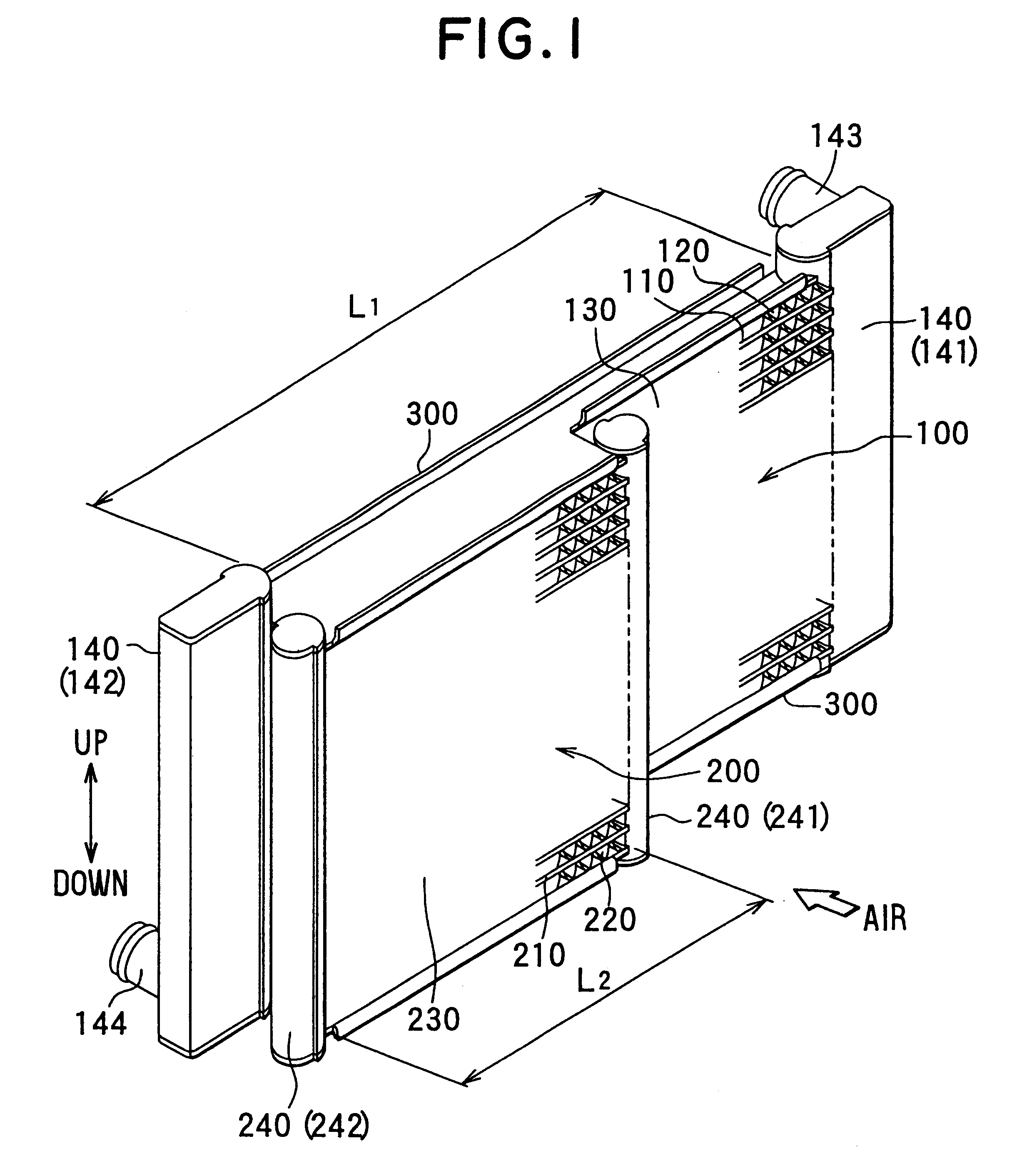

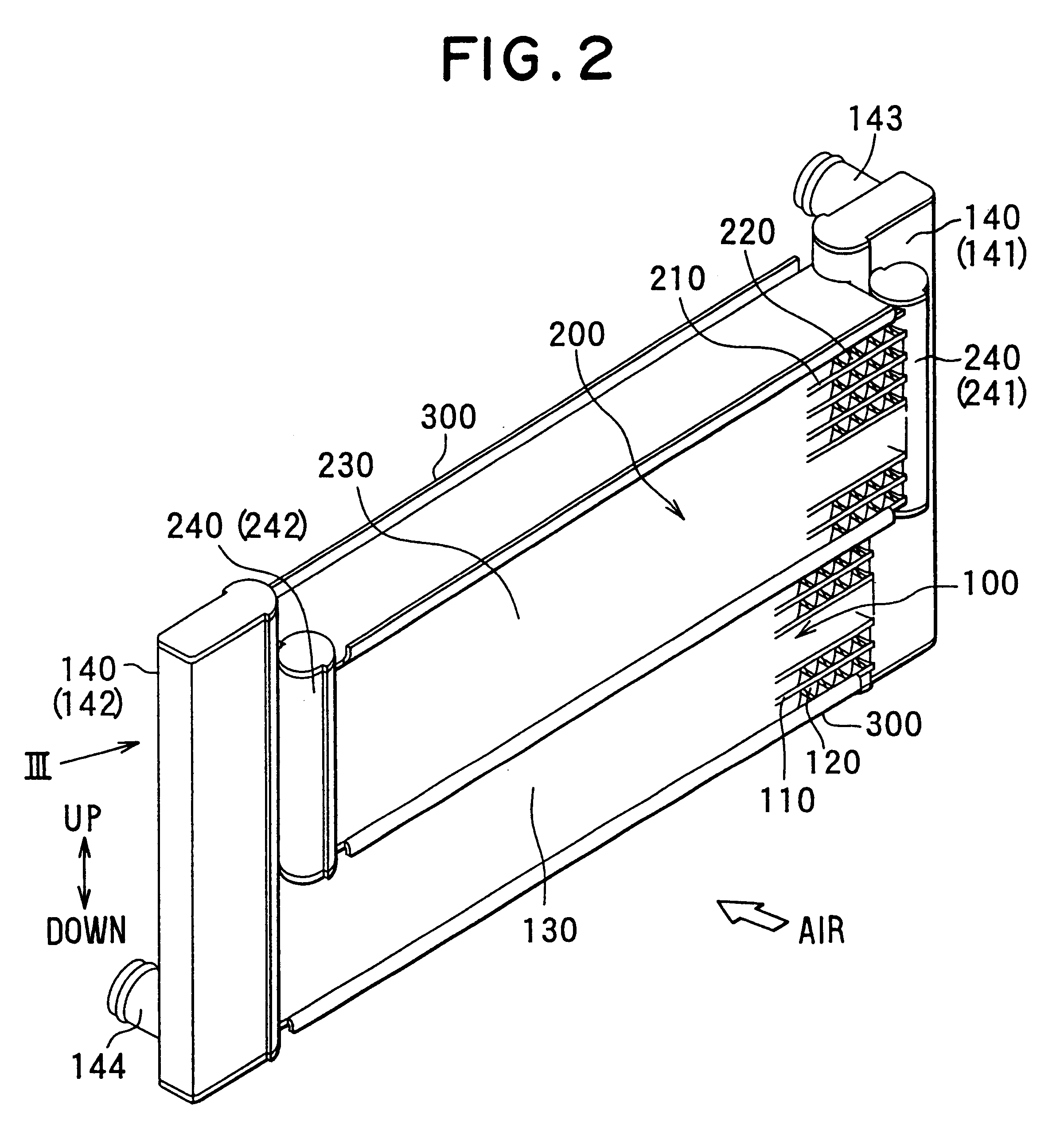

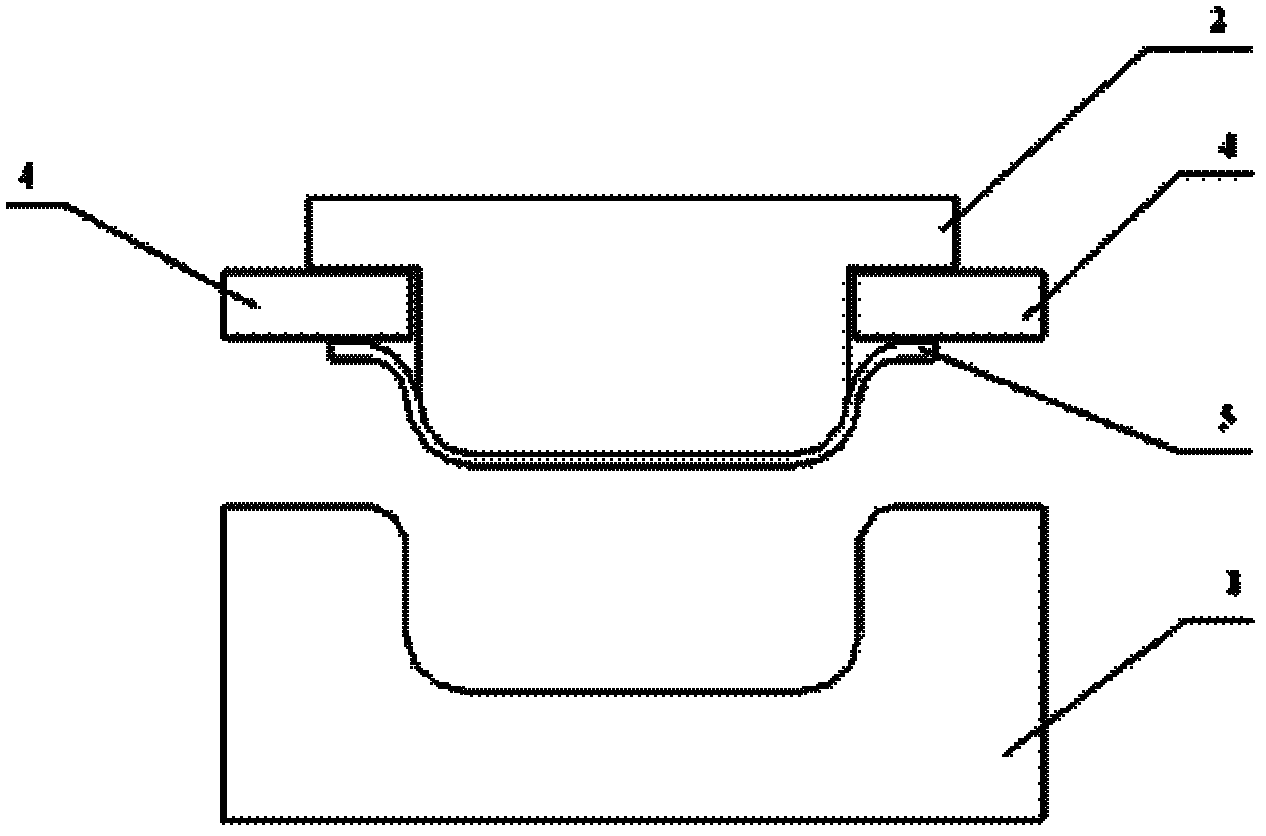

Double heat exchanger

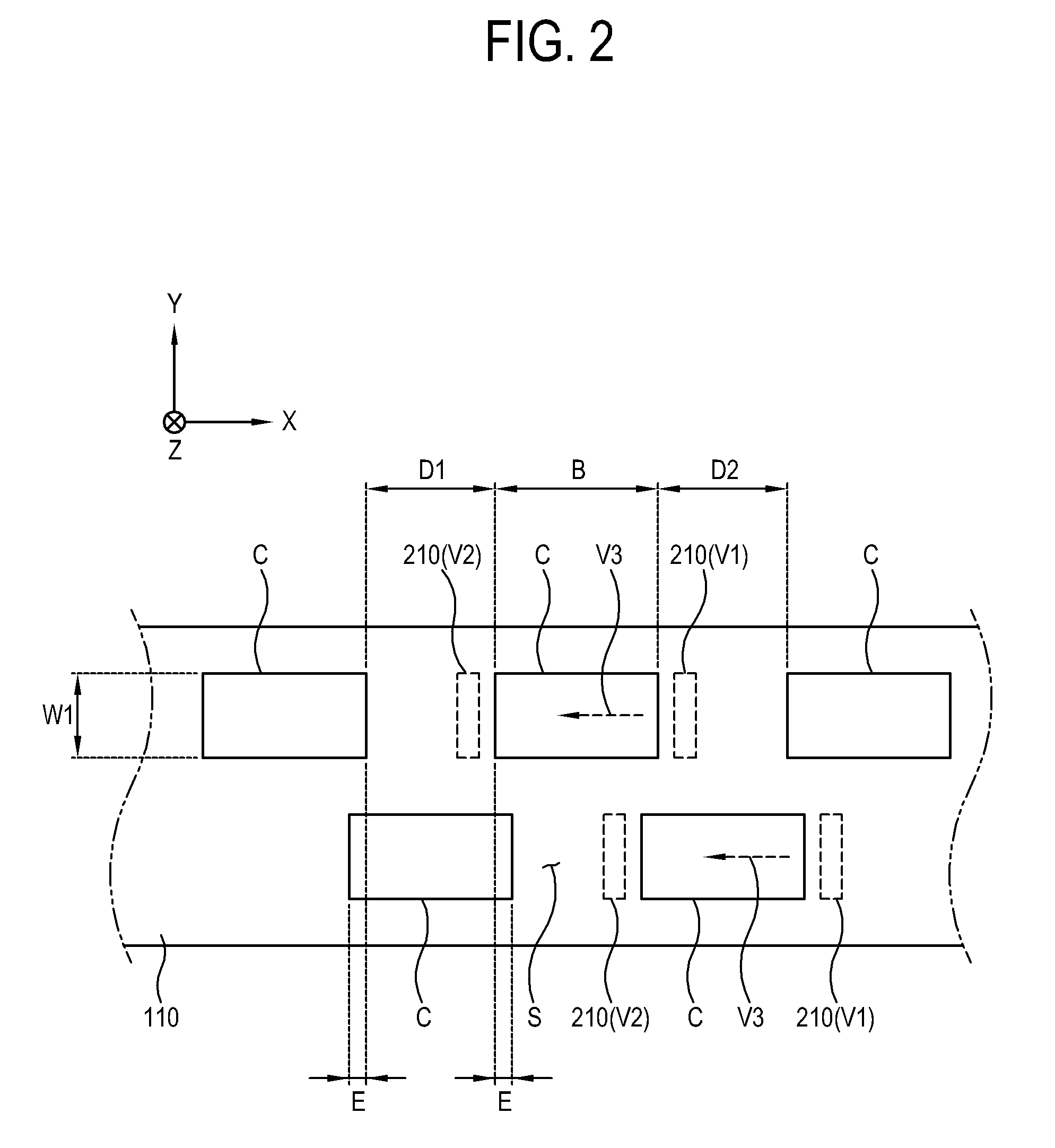

InactiveUS6408939B1Reduced heat exchange capacityAvoid sizeHeat exhanger finsStationary conduit assembliesEngineeringHeat spreader

In a double heat exchange, a radiator and a condenser are integrated through a side plate for reinforcing the radiator and the condenser, and a longitudinal dimension of condenser tubes is made smaller than a longitudinal dimension of radiator tubes. Therefore, a core area of the condenser becomes smaller than that of the radiator. Thus, heat-exchanging capacity of the condenser is restricted from being increased more than a necessary capacity, and size and performance of the double heat exchanger are restricted from being increased more than necessary conditions.

Owner:DENSO CORP

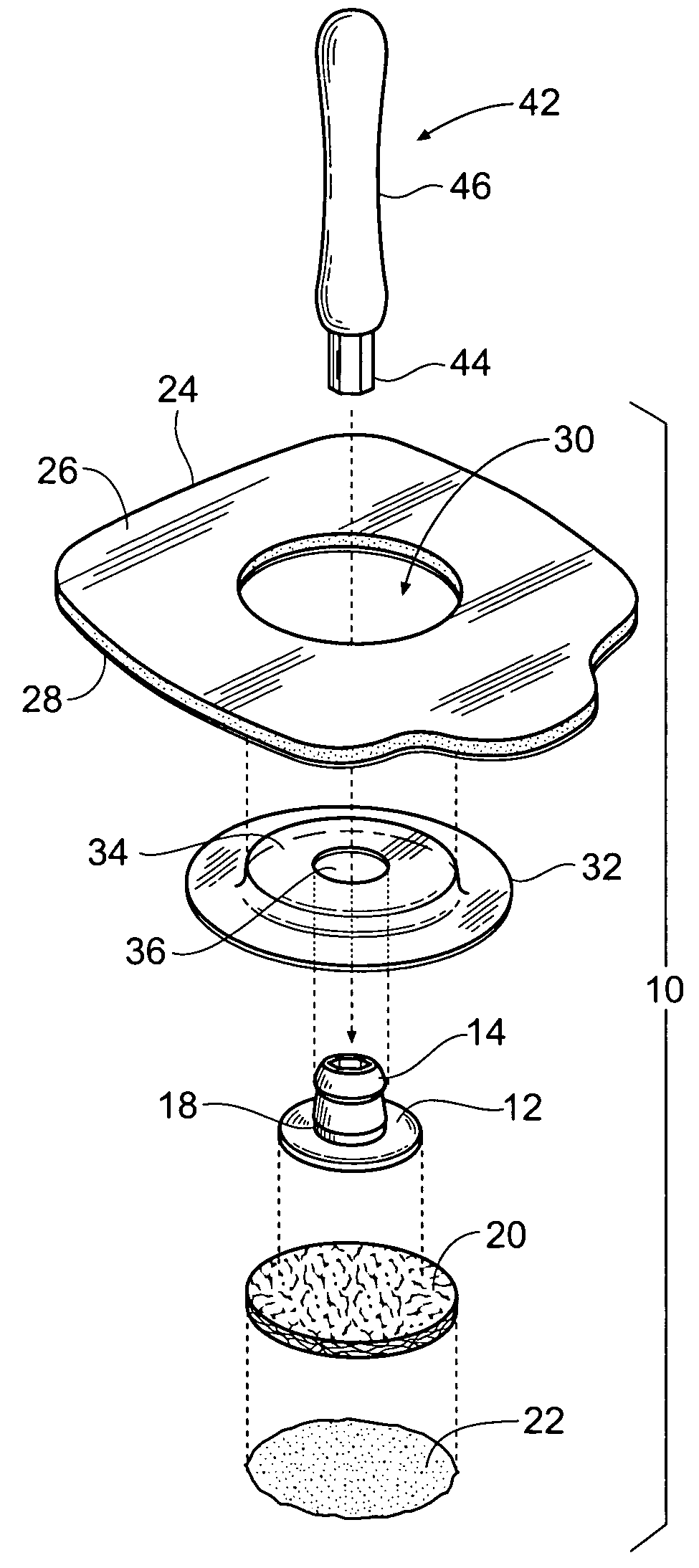

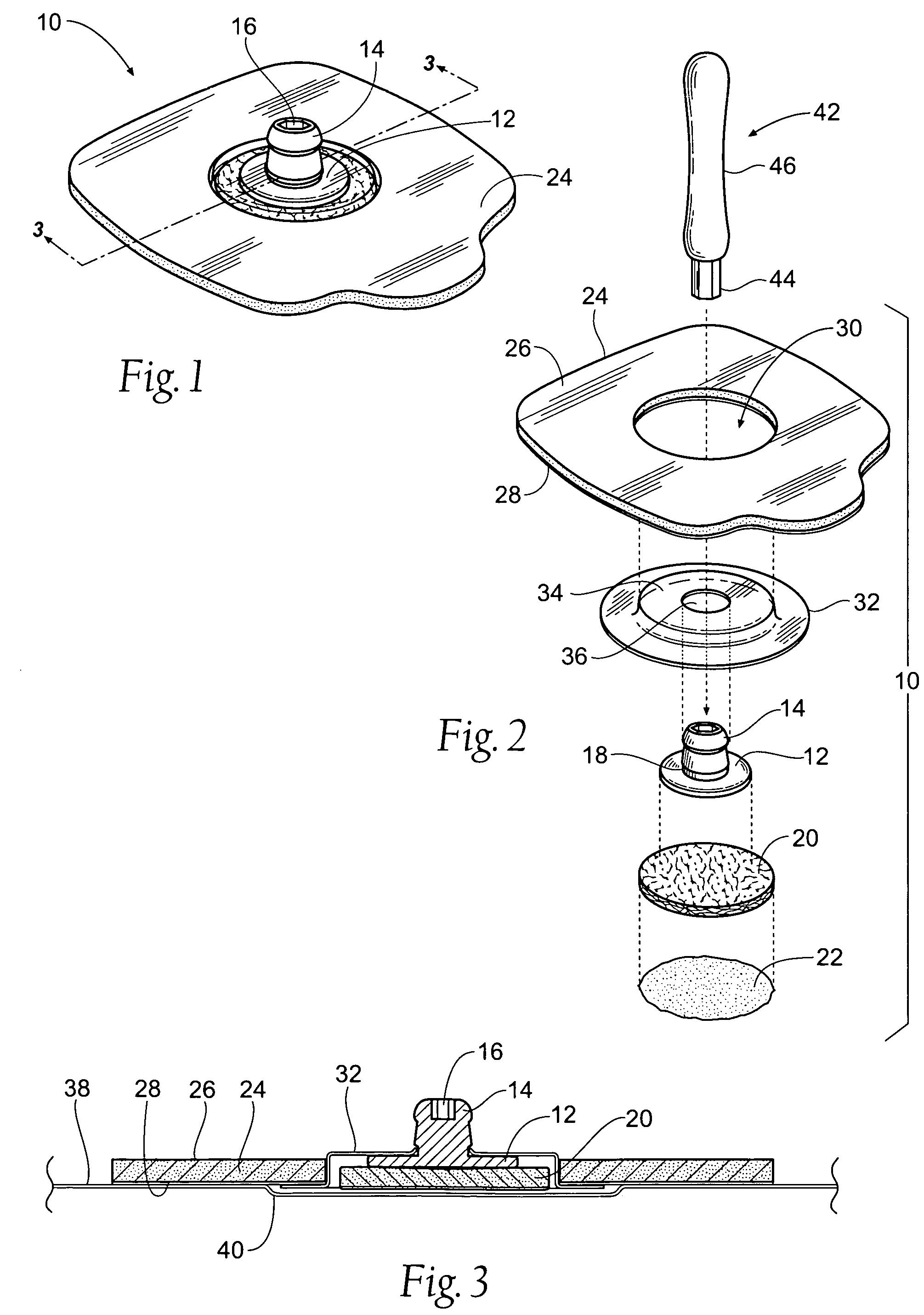

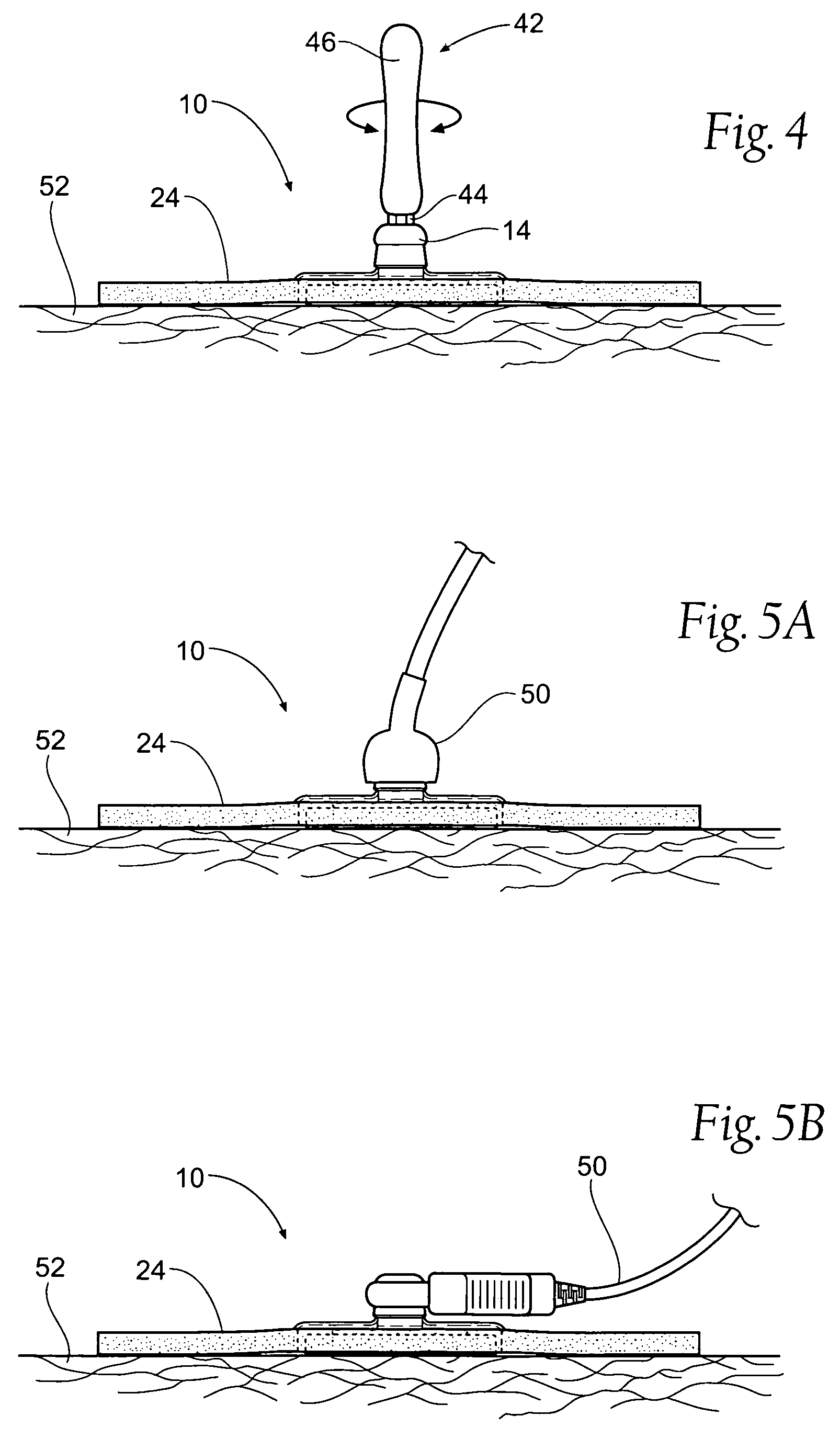

ECG monitoring electrode

A self-prepping ECG electrode assembly is provided. The electrode assembly includes an electrode element, an electrode stud, an abrasive member, an electrolyte gel, a cover member and a securing member. The electrode element and electrode stud are adapted to be rotatable within the electrode assembly. The electrode assembly may be used with a drive tool. The electrode assembly may be placed on the skin of a patient. The skin of the patient may be prepped for an ECG by inserting the drive tool into a bore formed in the electrode stud and turning the drive tool to achieve an oscillating rotation. In this manner the abrasive pad preps the patient's skin for the ECG procedure.

Owner:TIEGS MARK

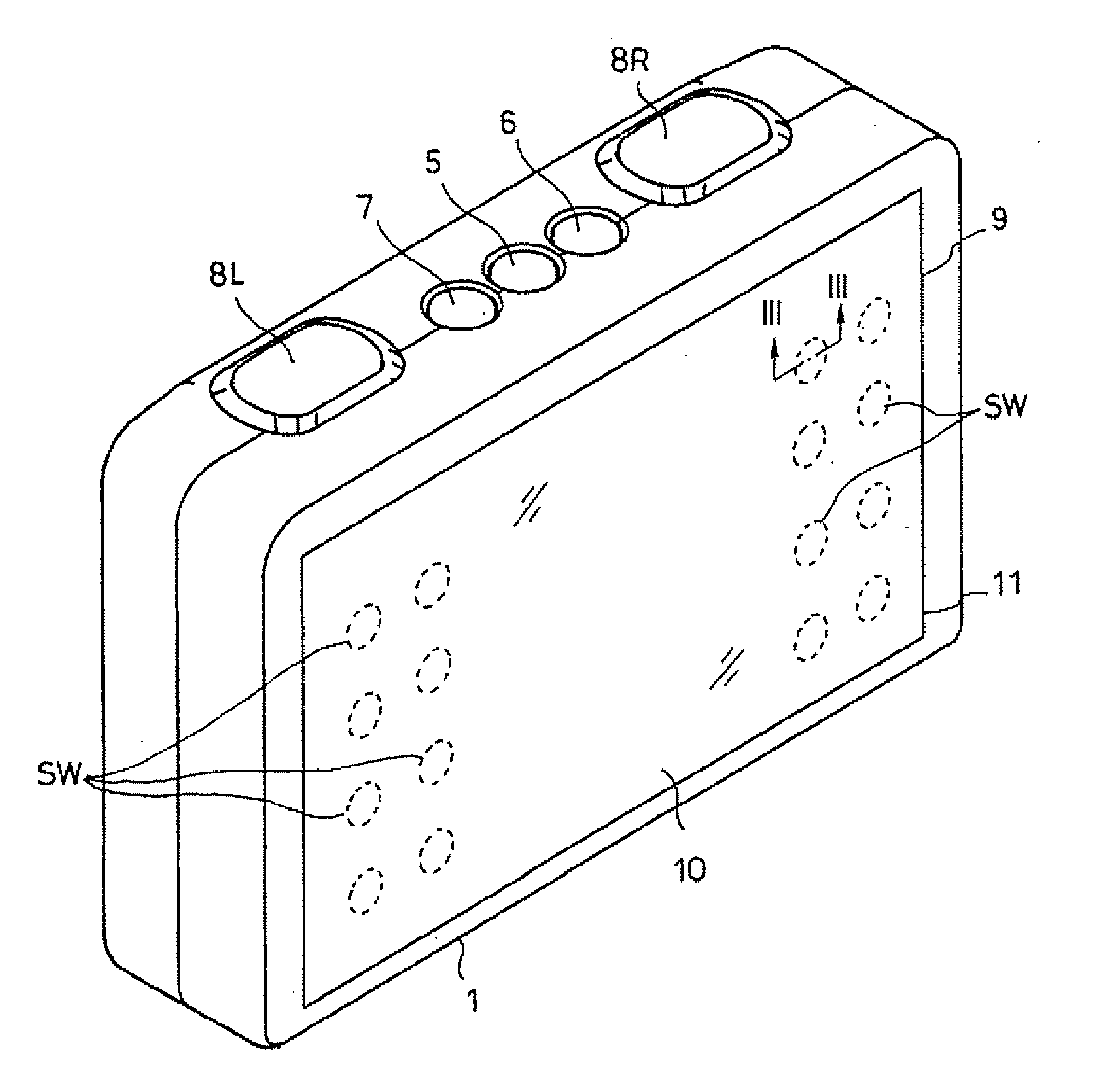

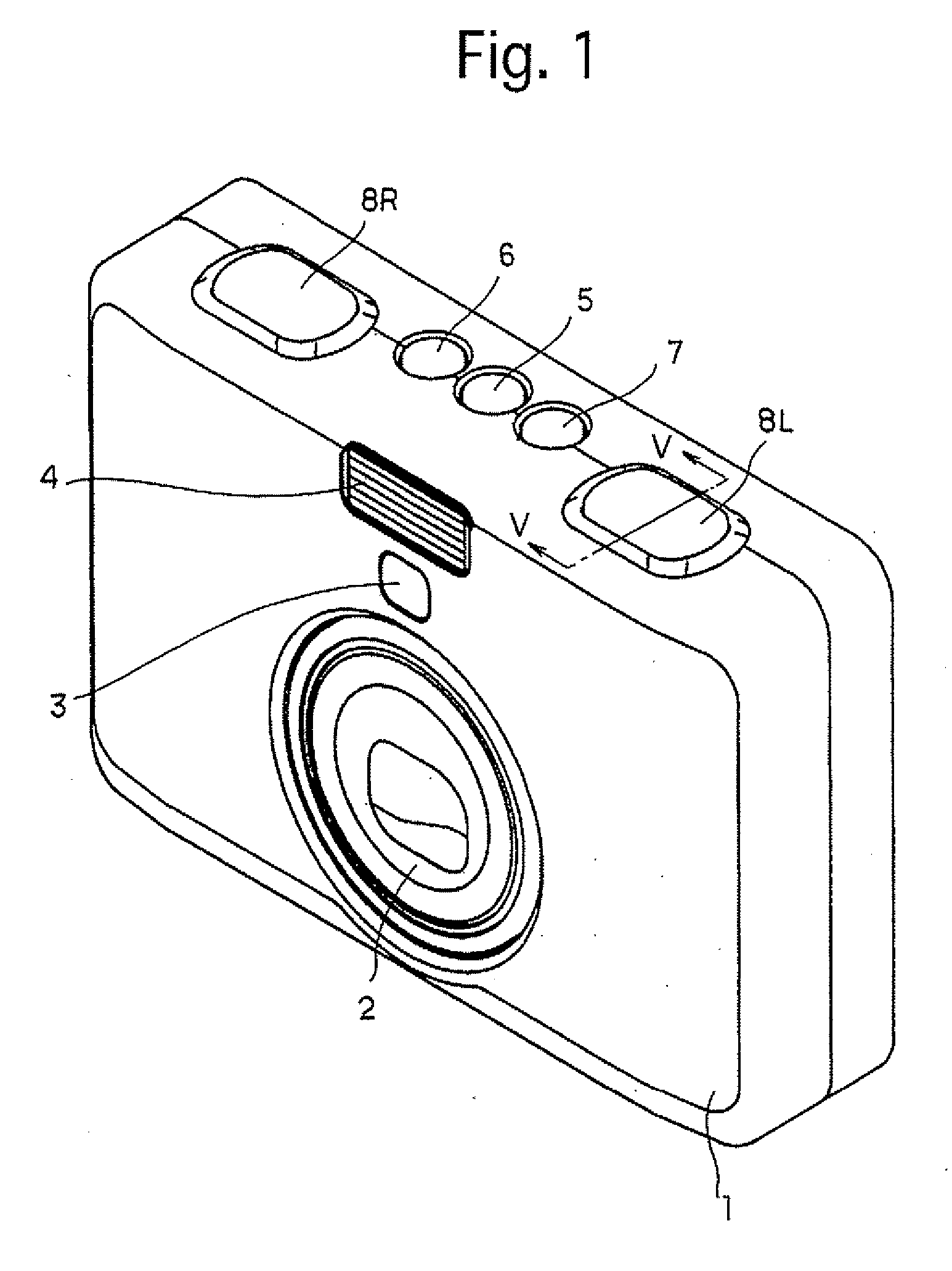

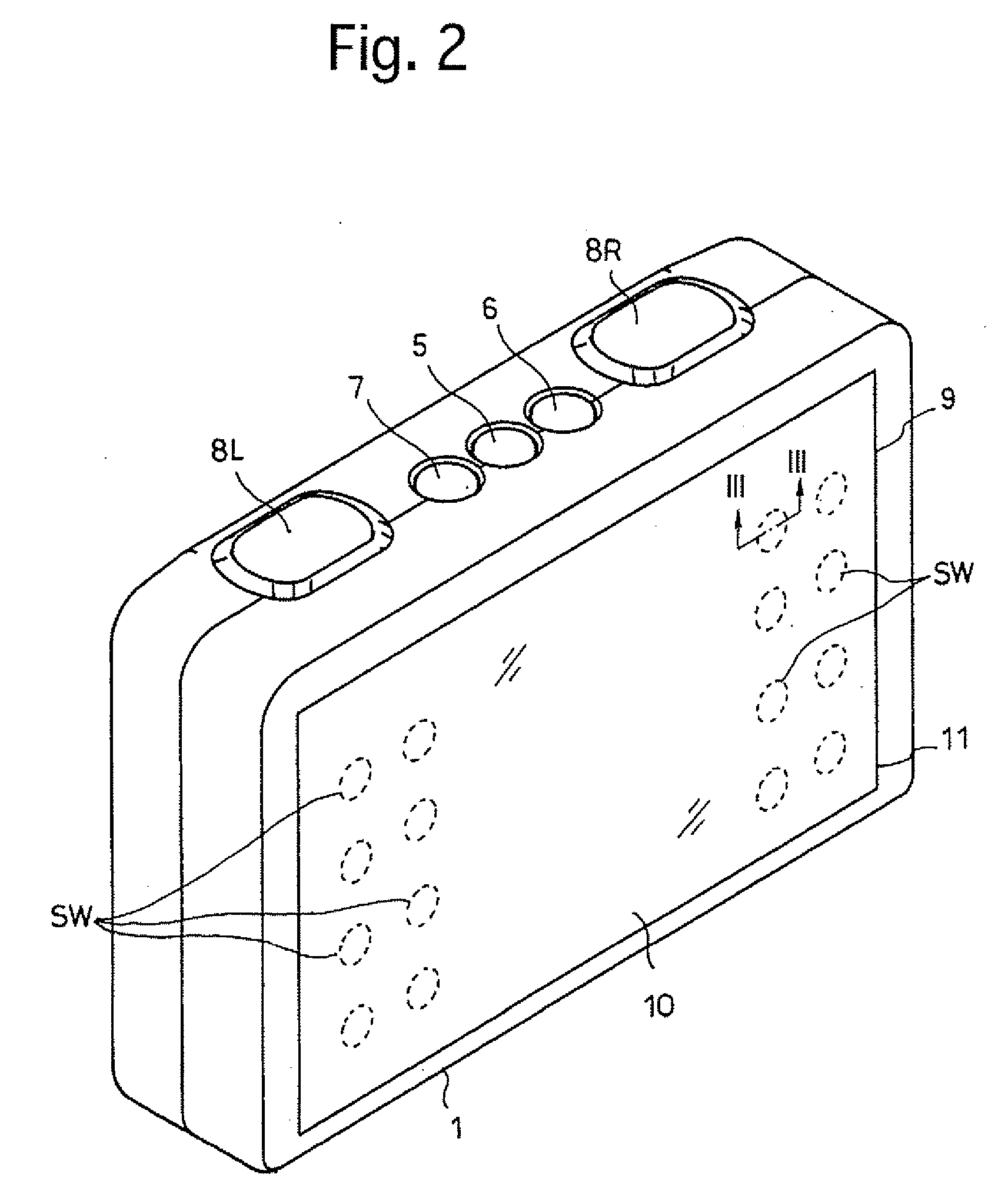

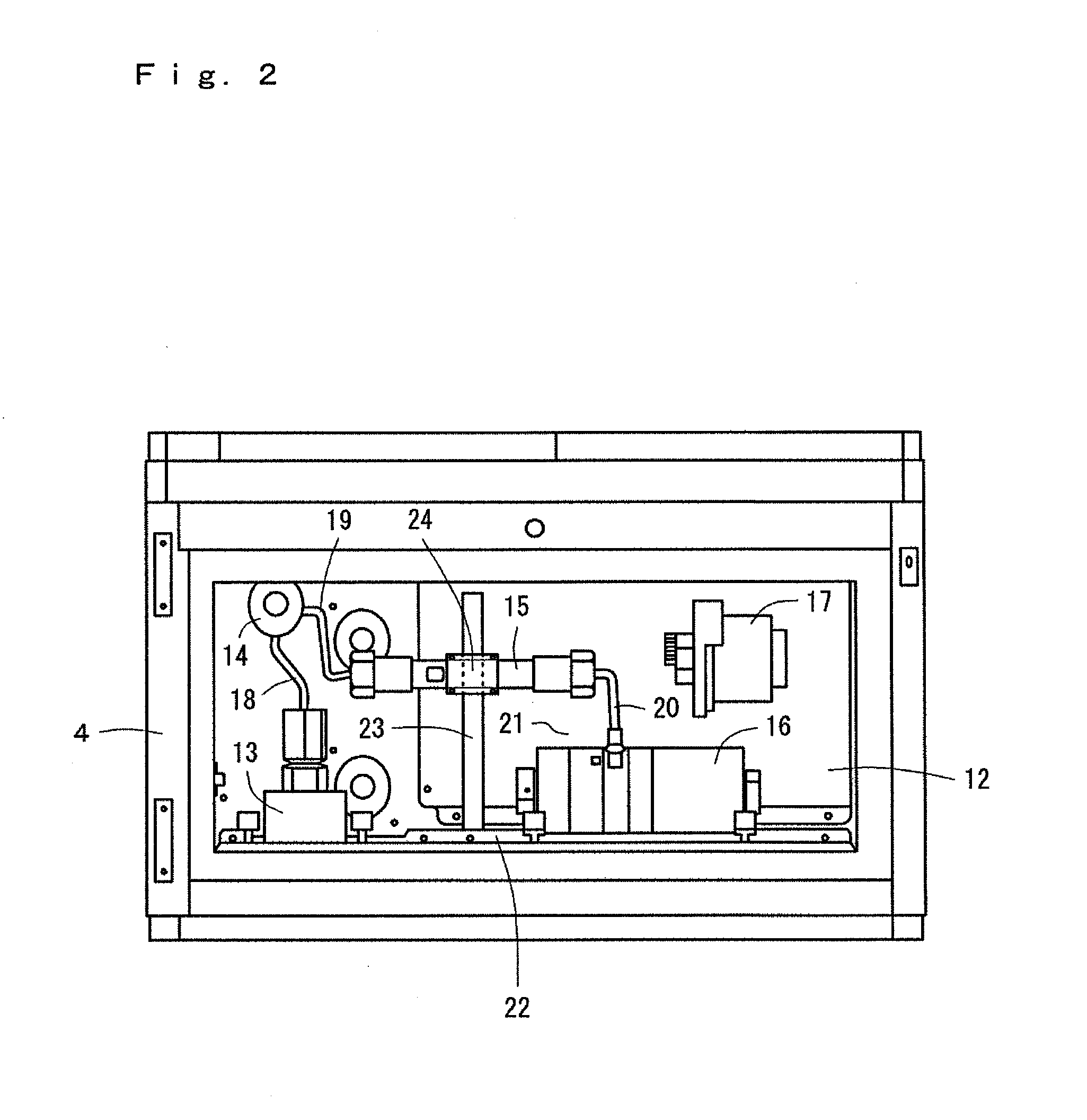

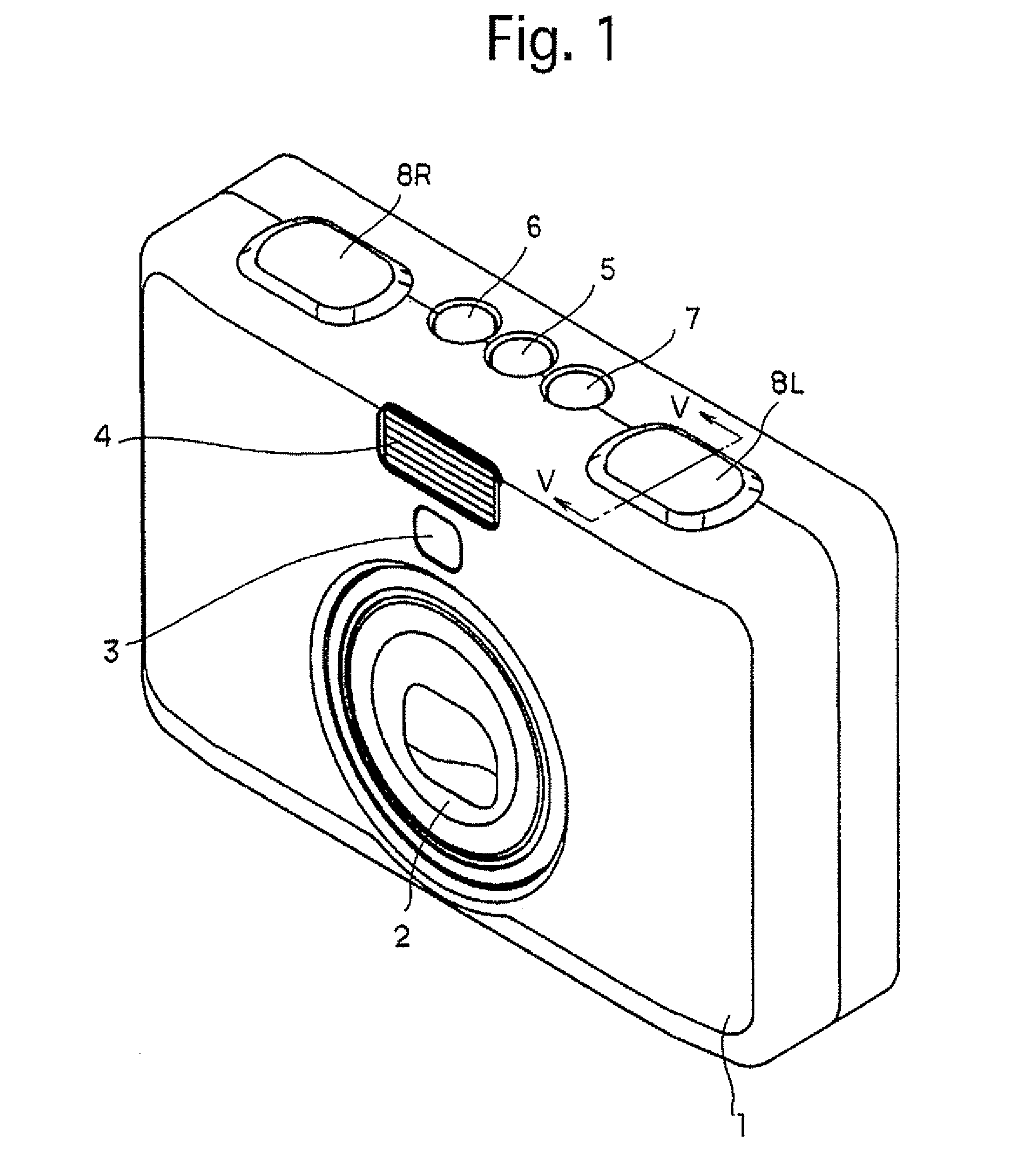

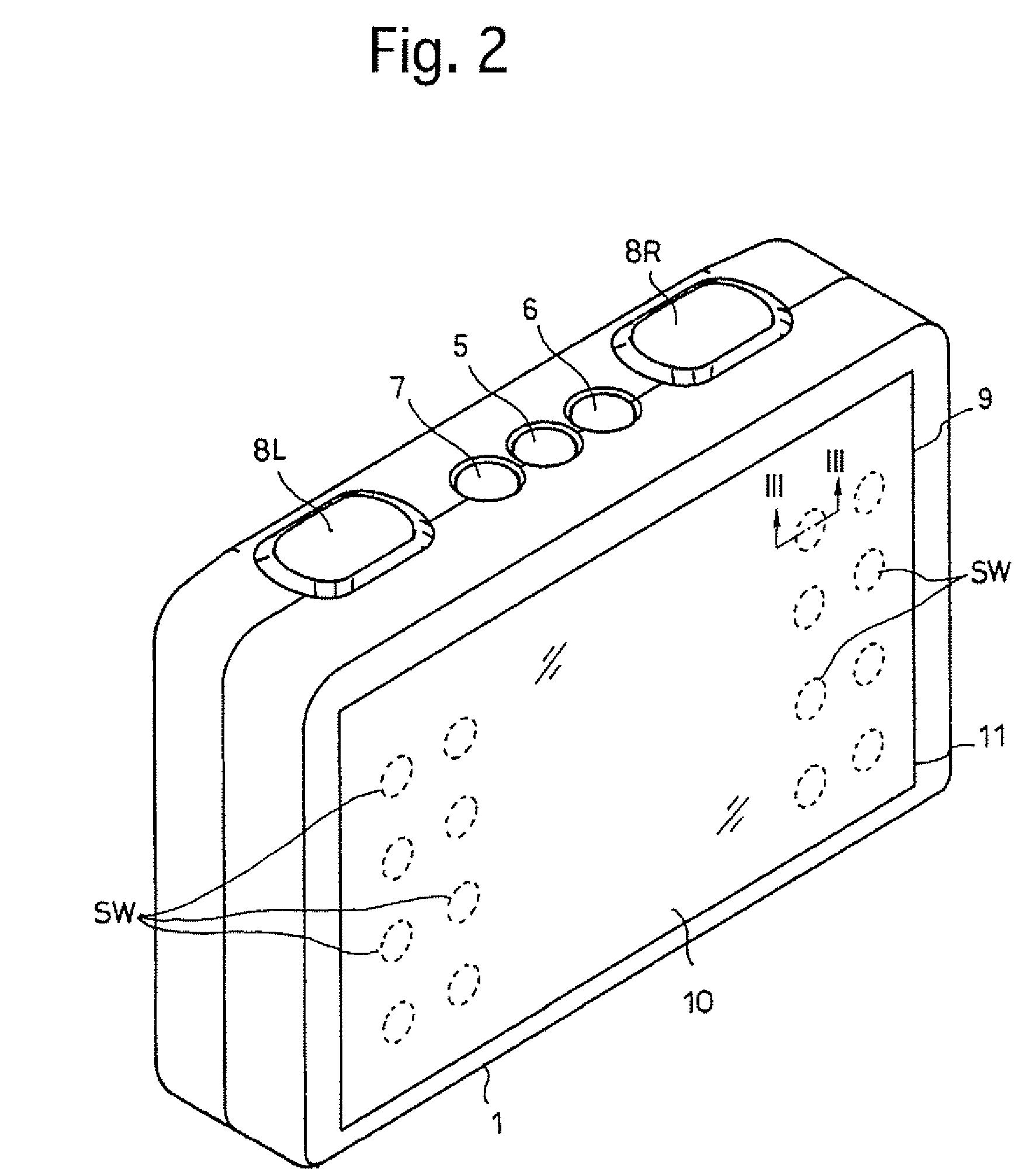

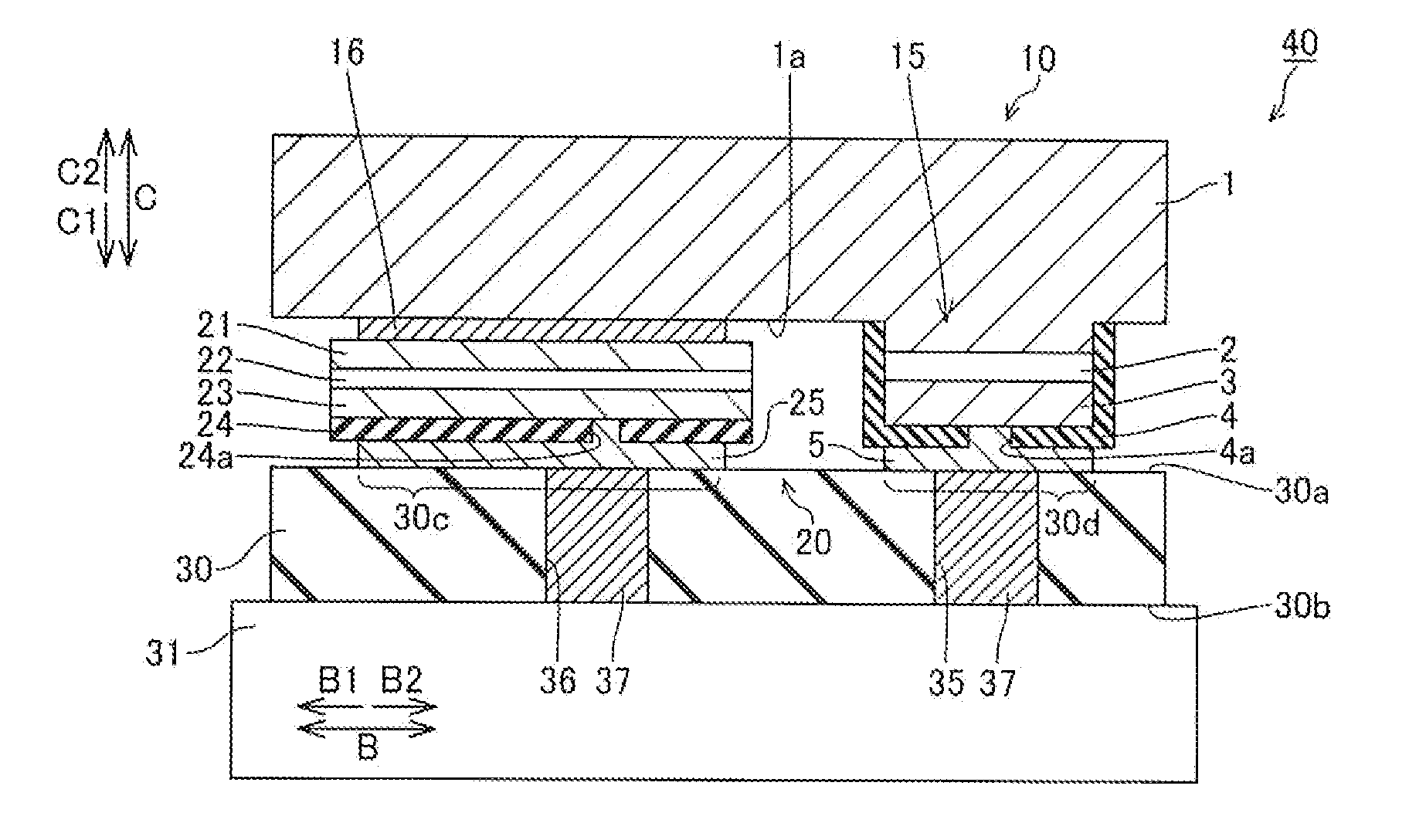

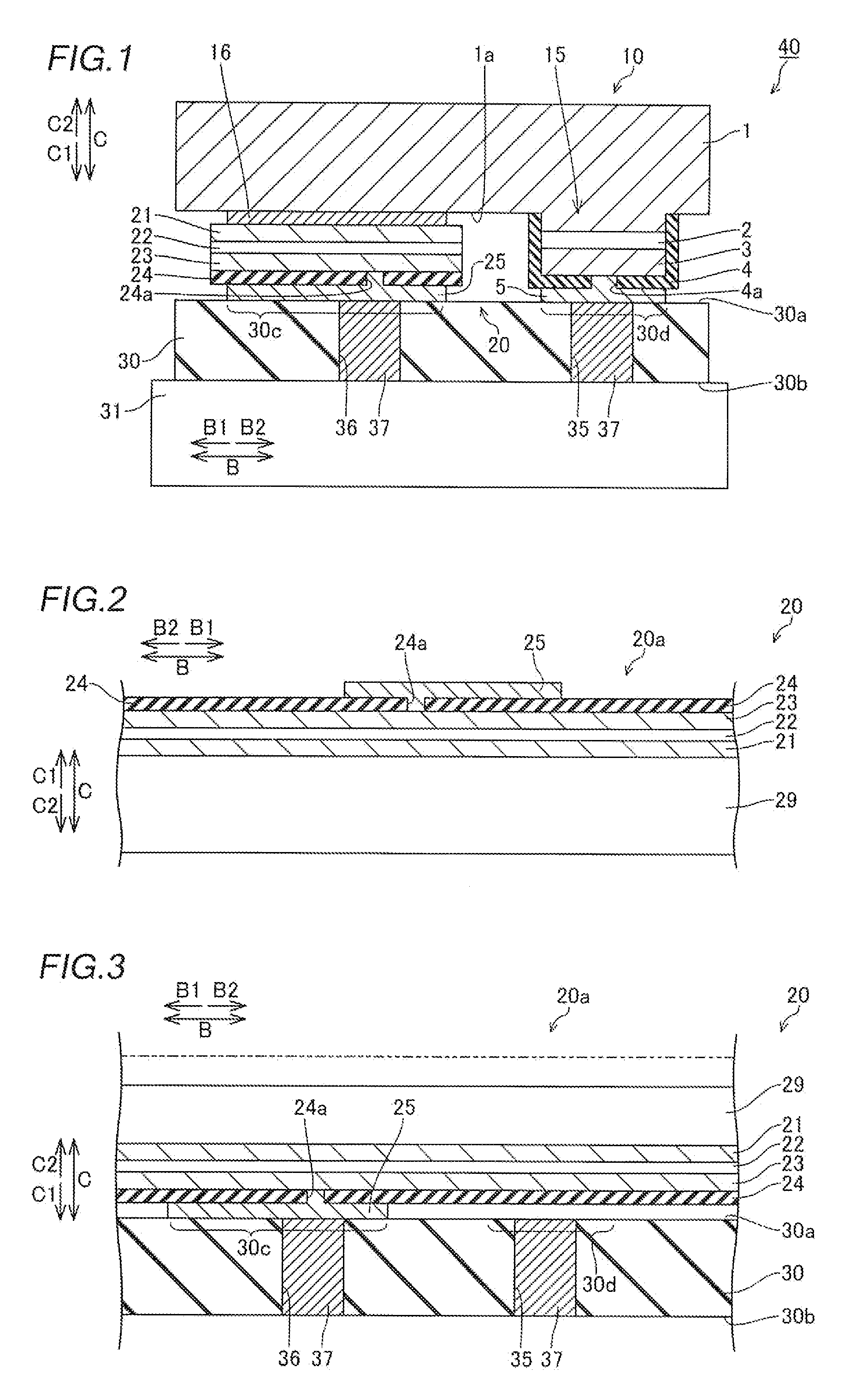

Electroluminescent display device and a digital camera using an electroluminescent display device

InactiveUS20070019942A1Reliably activatedEasy to operateTelevision system detailsStatic indicating devicesComputer scienceDigital camera

An electroluminescent display device includes an electroluminescent display, and at least one switch which is positioned adjacent to an inner surface of the electroluminescent display, the switch being activated upon an outer surface of the electroluminescent display being pressed to resiliently deform the switch.

Owner:RICOH IMAGING COMPANY

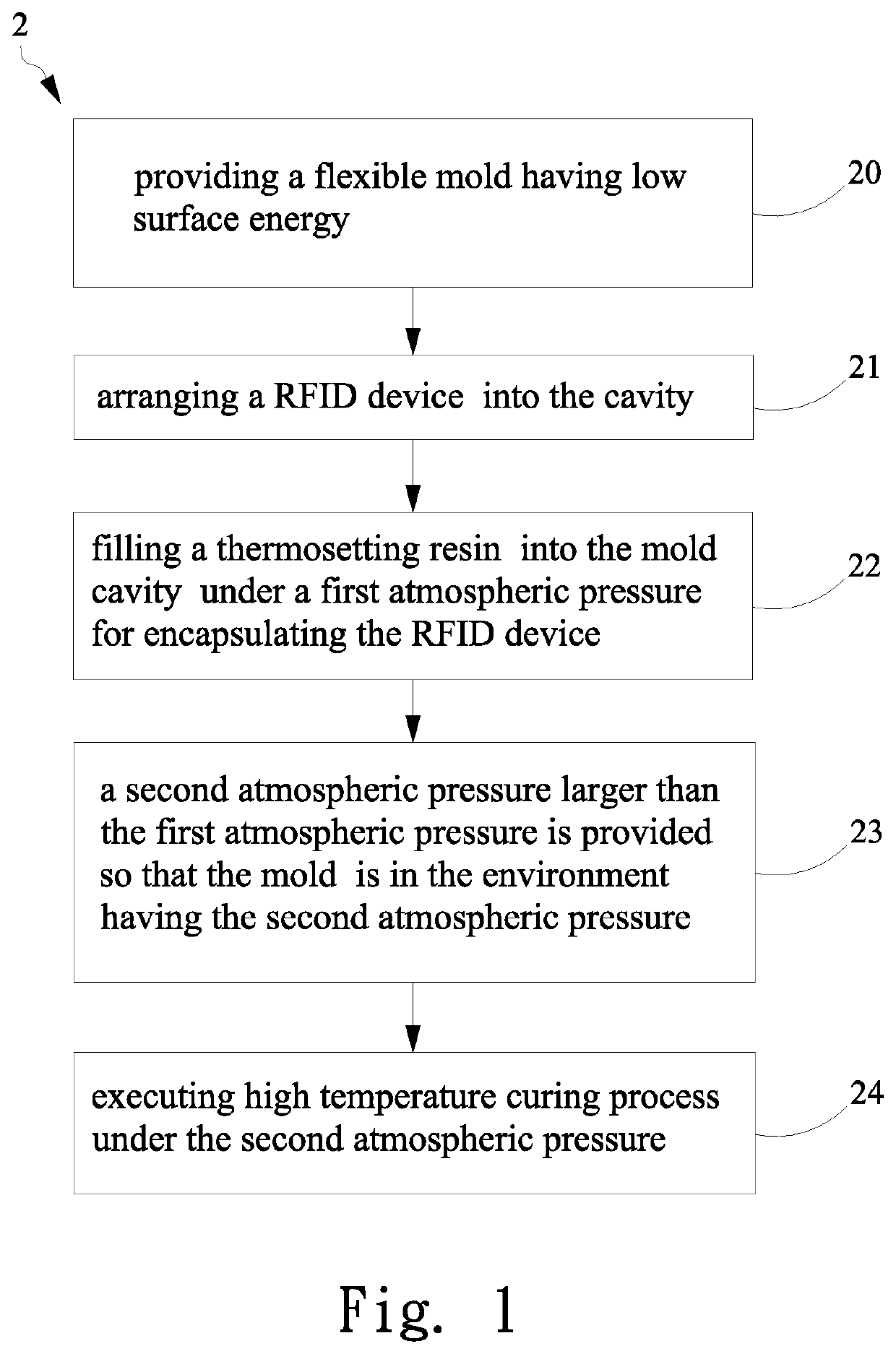

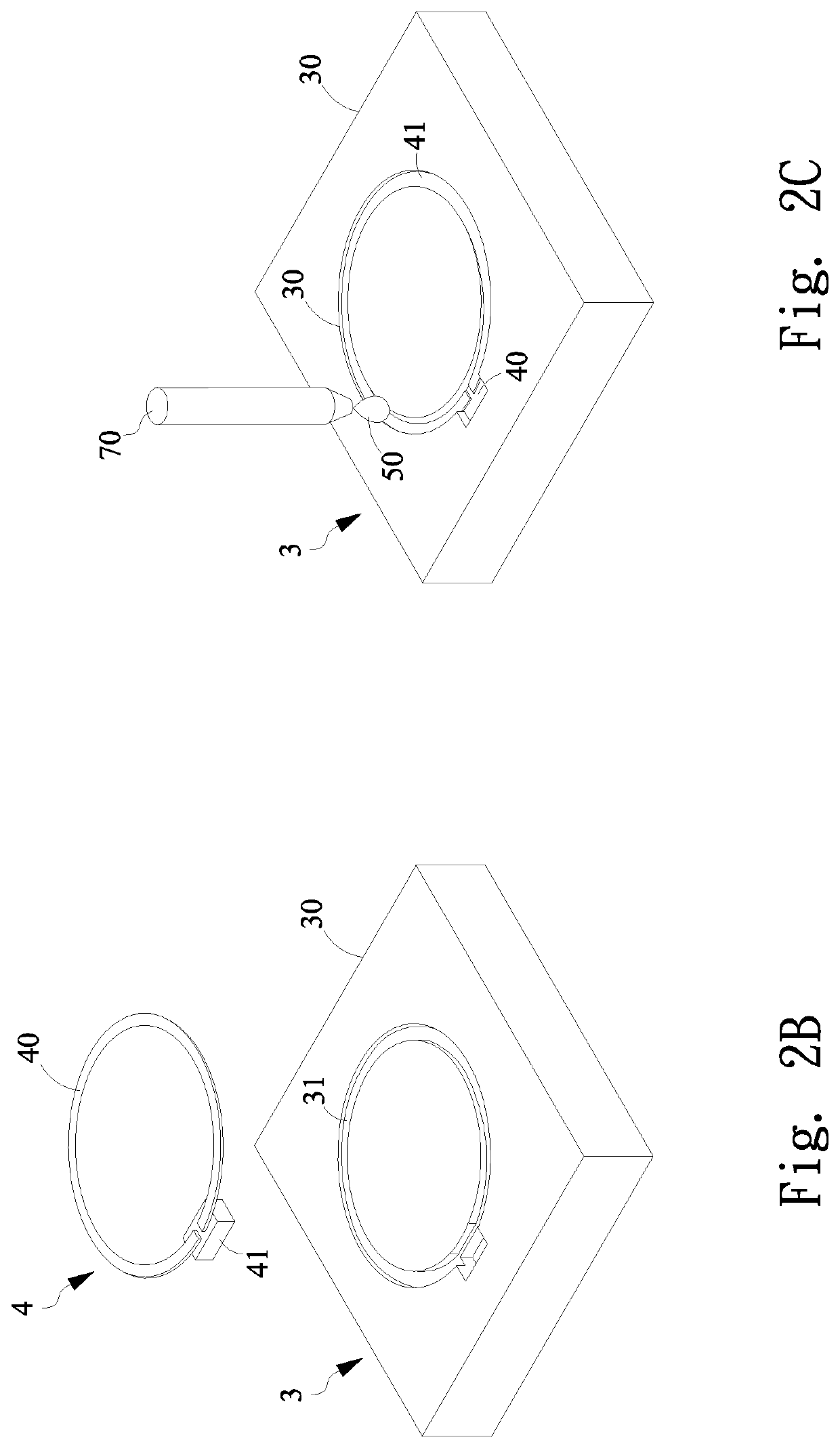

System and method for packaging frequency identification device and RFID device formed thereof

ActiveUS10611067B2Increase speed of cross-link curing effectInhibition formationDomestic articlesRecord carriers used with machinesIdentification devicePressure control

The present invention provides a system and method for packaging RFID device, in which a flexible mold with low surface energy having a mold cavity formed on a surface thereof is provided, an RFID device having RFID chip and antenna coupled thereto is then arranged in the mold cavity, a thermosetting material is filled in the mold cavity under a first atmospheric pressure produced by a pressure controlling device whereby the RFID device is completely covered by the thermosetting material, after that, the pressure controlling device provides a second atmospheric pressure higher than the first atmospheric pressure under a temperature lower than the curing temperature of the thermosetting material, and finally, the temperature is increased to the curing temperature under the second atmospheric pressure for curing the thermosetting material thereby forming an RFID package having the RFID device and the thermosetting material covered the RFID device.

Owner:SECURITAG ASSEMBLY GROUP

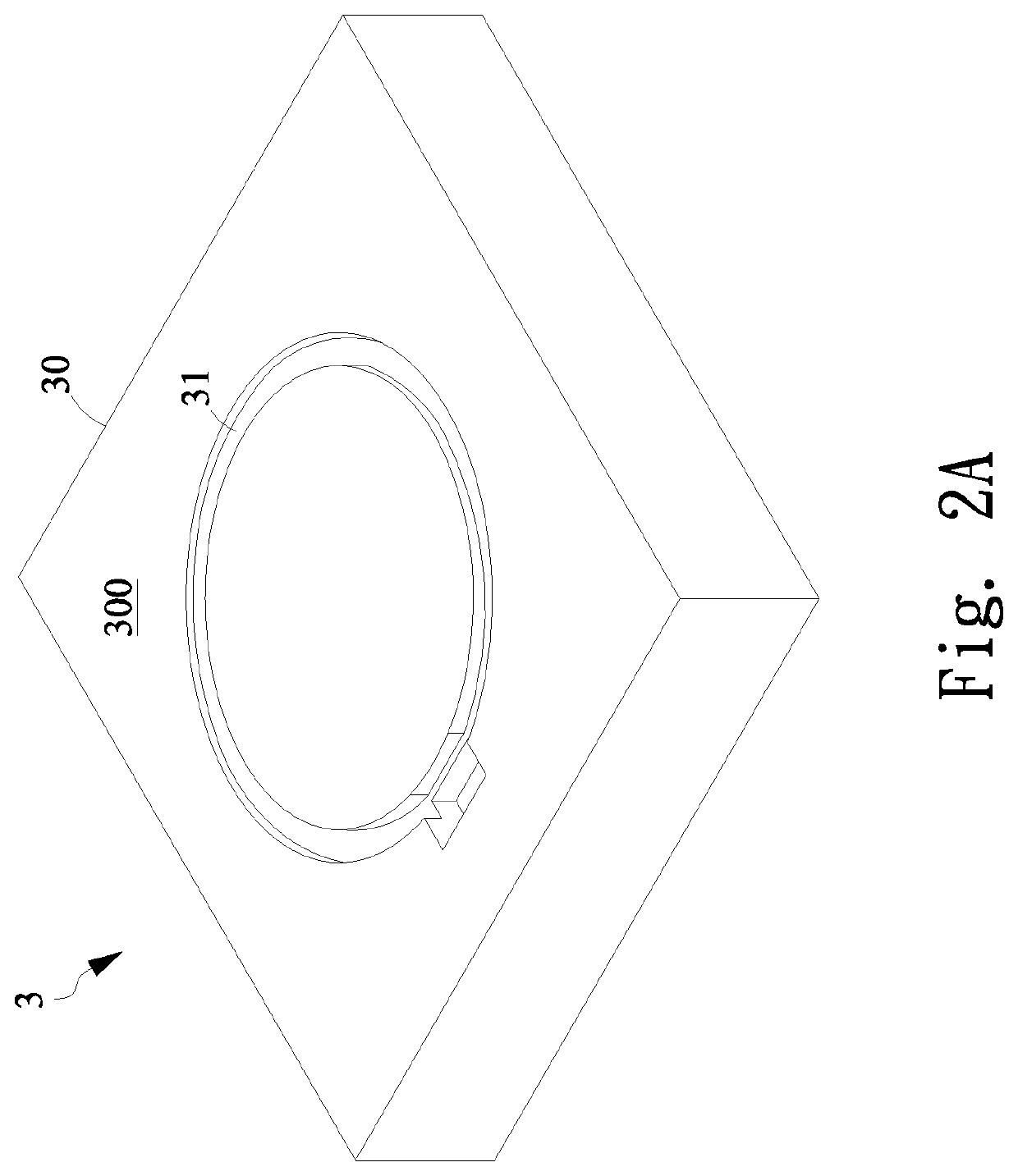

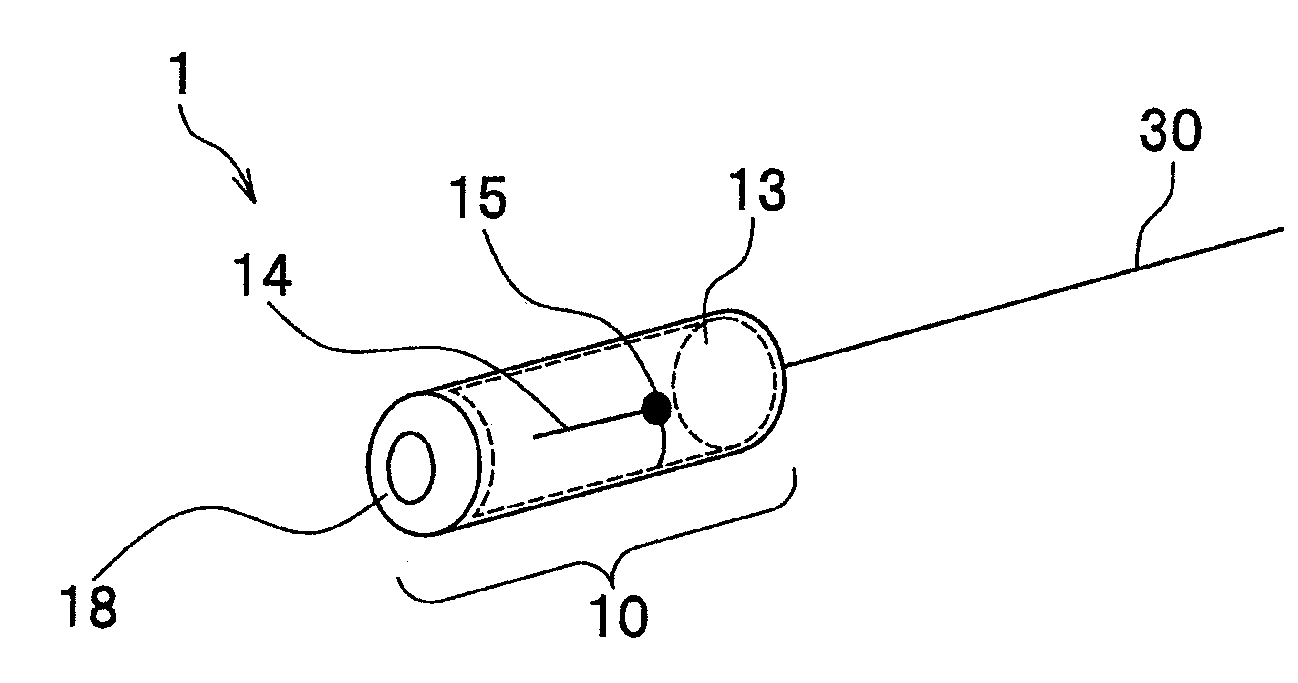

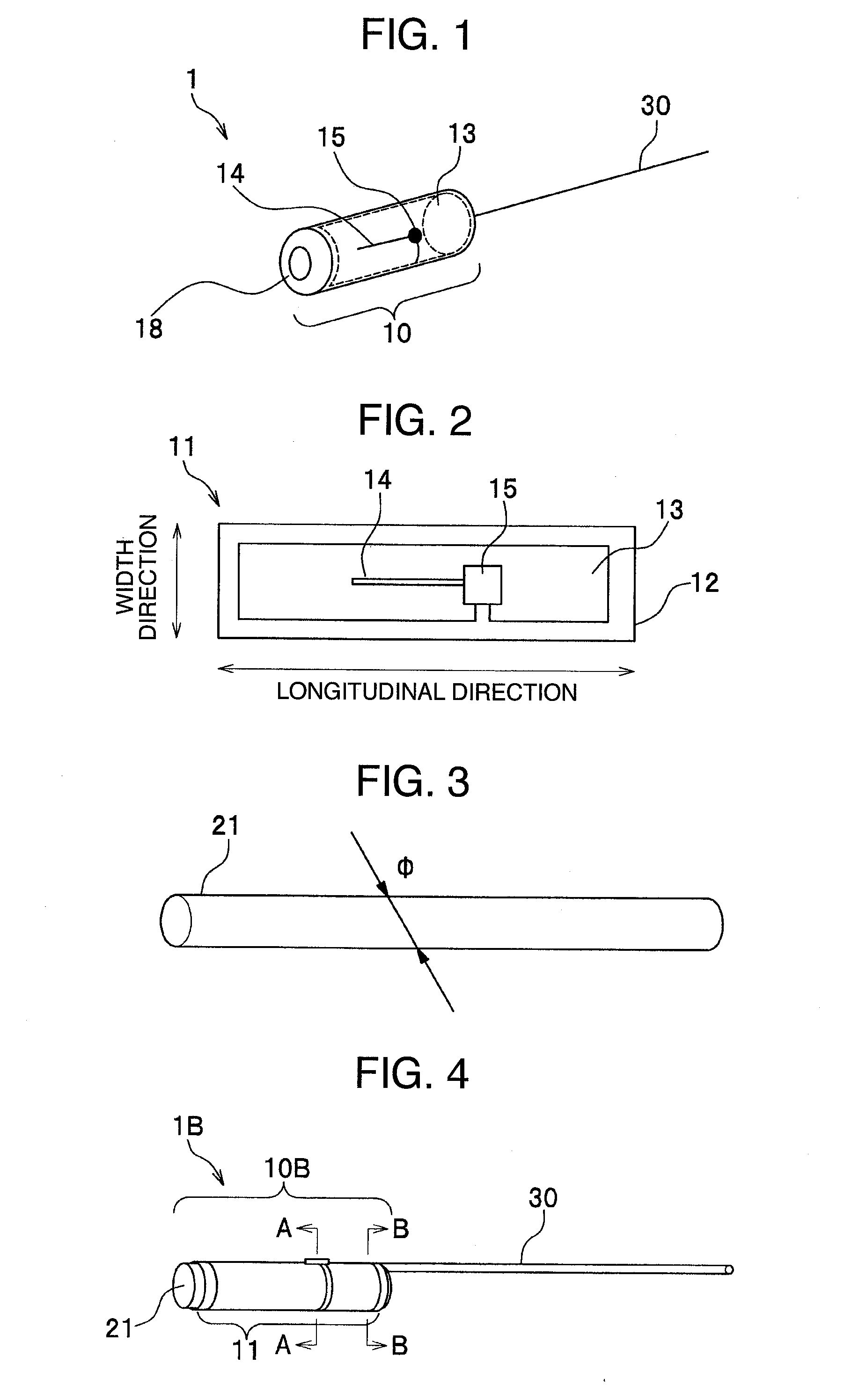

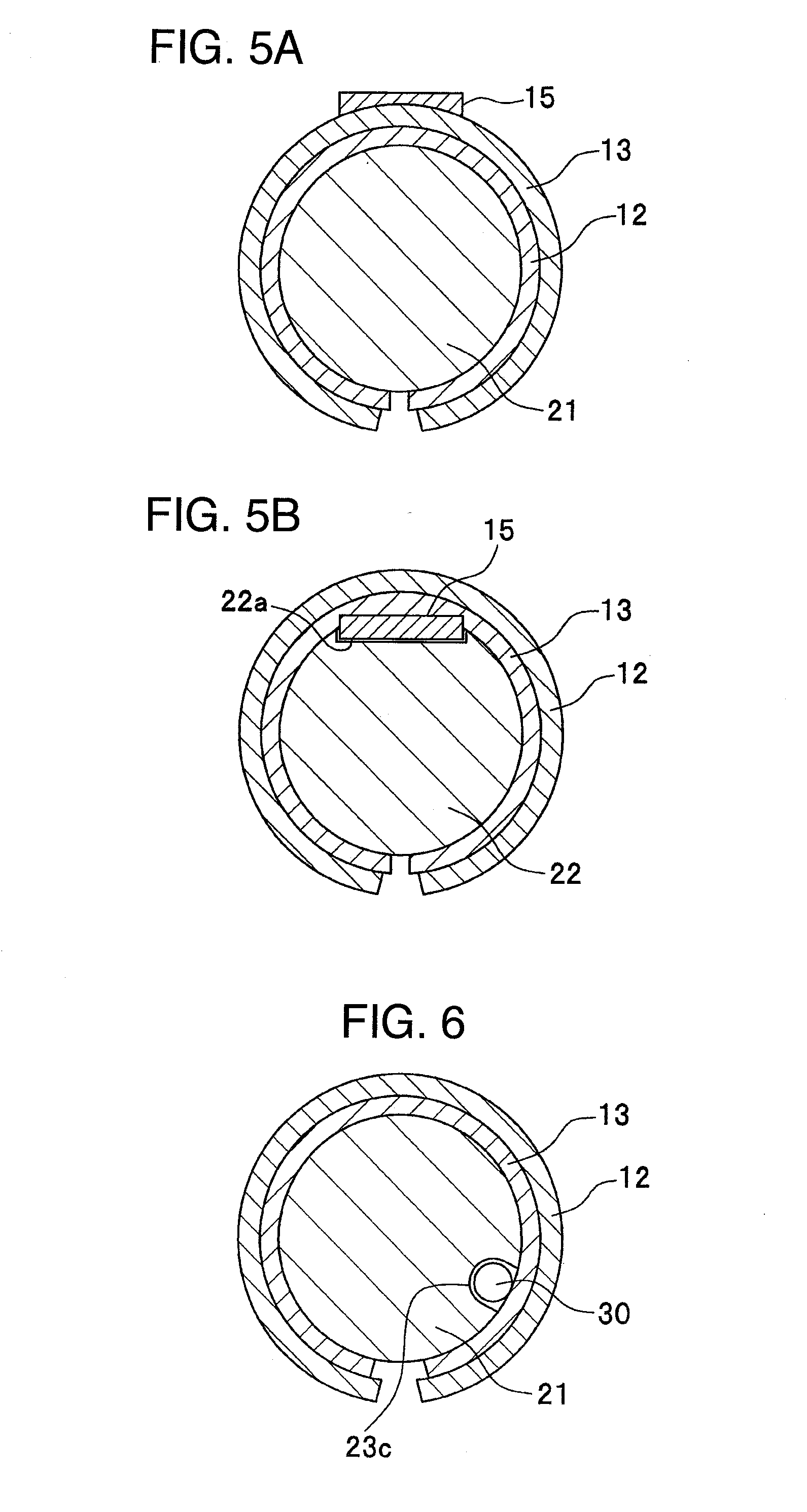

Biological implantation RFID tags and insertion jig therefor

InactiveUS20080106419A1Improve communication performanceAvoid sizeDiagnosticsSurgical needlesSmall animalSubcutaneous implantation

The present invention provides a biological implantation RFID tag which can be subcutaneously implanted in a small animal without significantly stressing it and which exhibits improved communication performance, and an insertion jig used to implant the biological implantation RFID tag in the living body of a small animal. A biological implantation RFID tag is implanted in the living body of a small animal to transmit and receive an electromagnetic wave to and from the exterior of the living body to allow an ID assigned to the animal to be read. The biological implantation RFID tag includes an inlet having an IC chip that stores the ID and a main antenna, a support around which the inlet is wound to form an inlet portion, and an auxiliary antenna connected to the main antenna to extend it. Implanting the biological implantation RFID tag in the living body allows the inlet portion to be implanted in a subcutaneous tissue layer with most of the auxiliary antenna projecting out from the living body.

Owner:HITACHI LTD

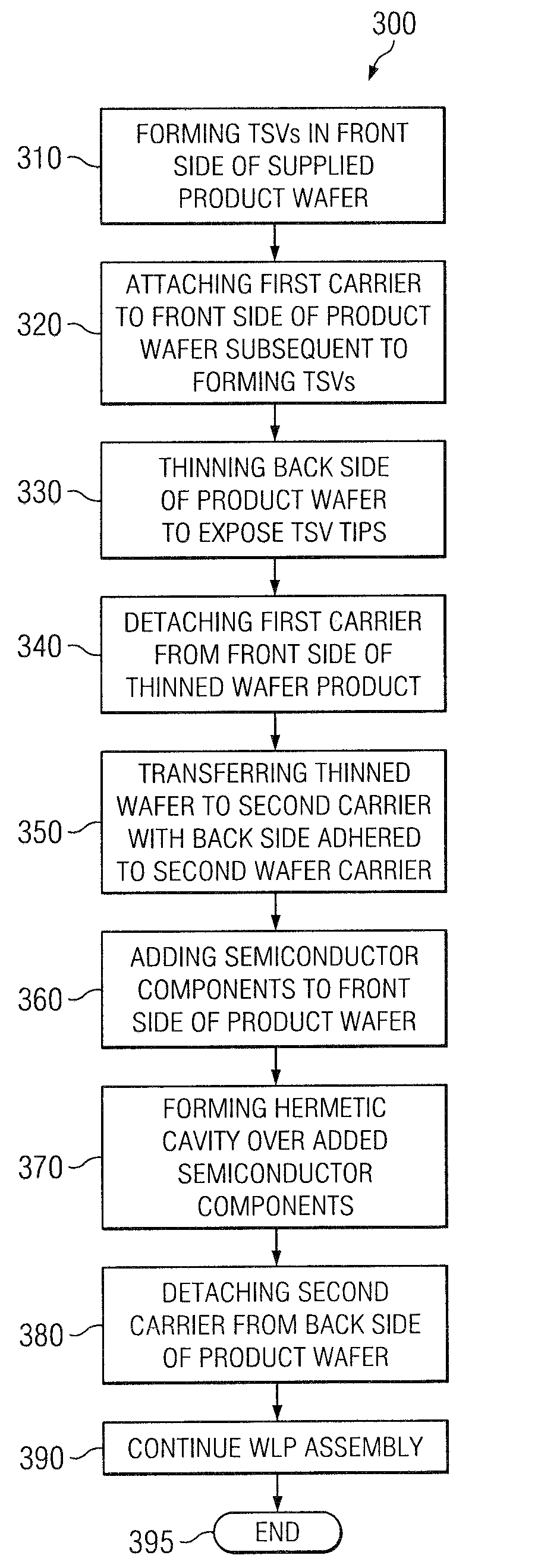

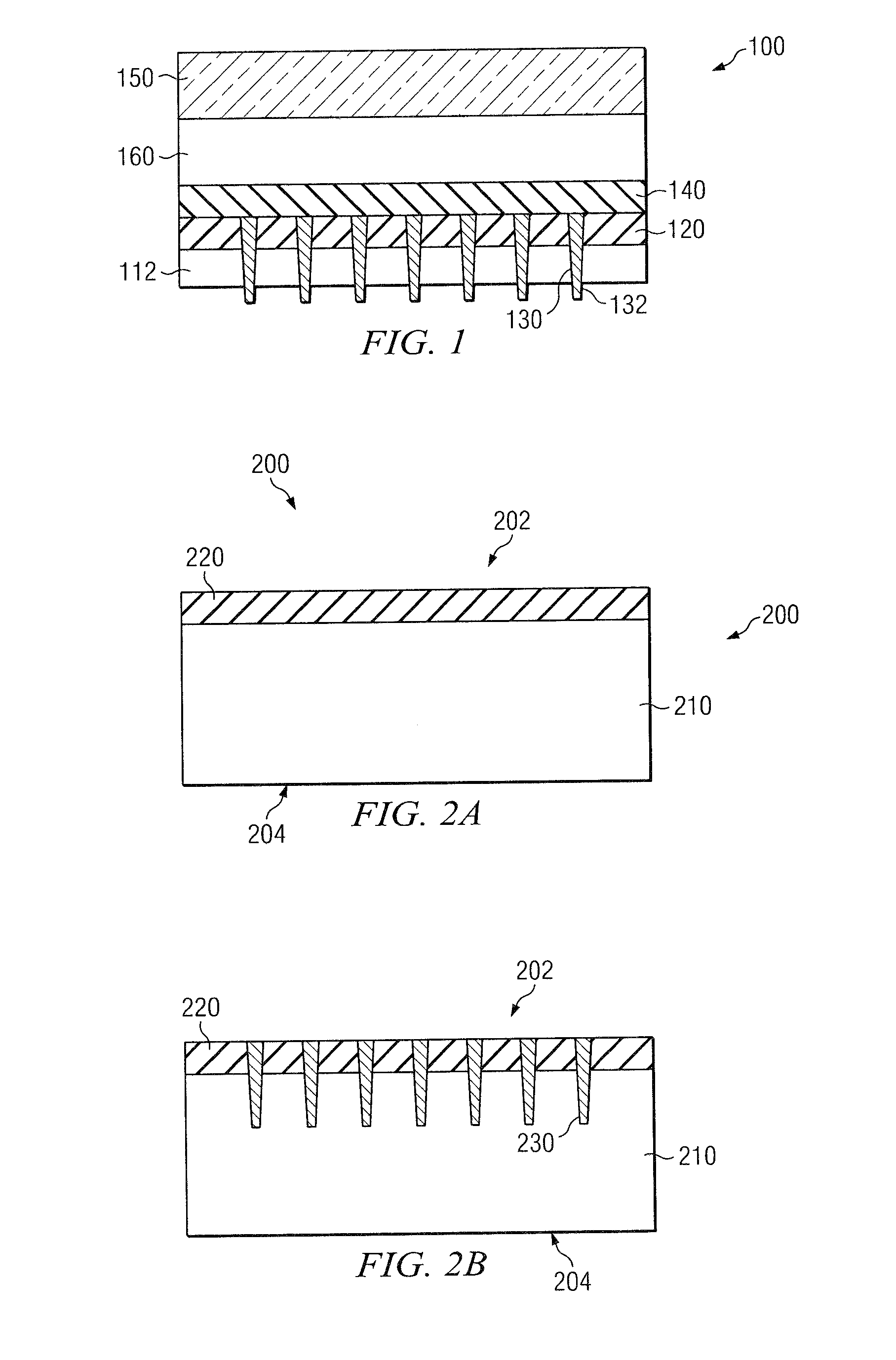

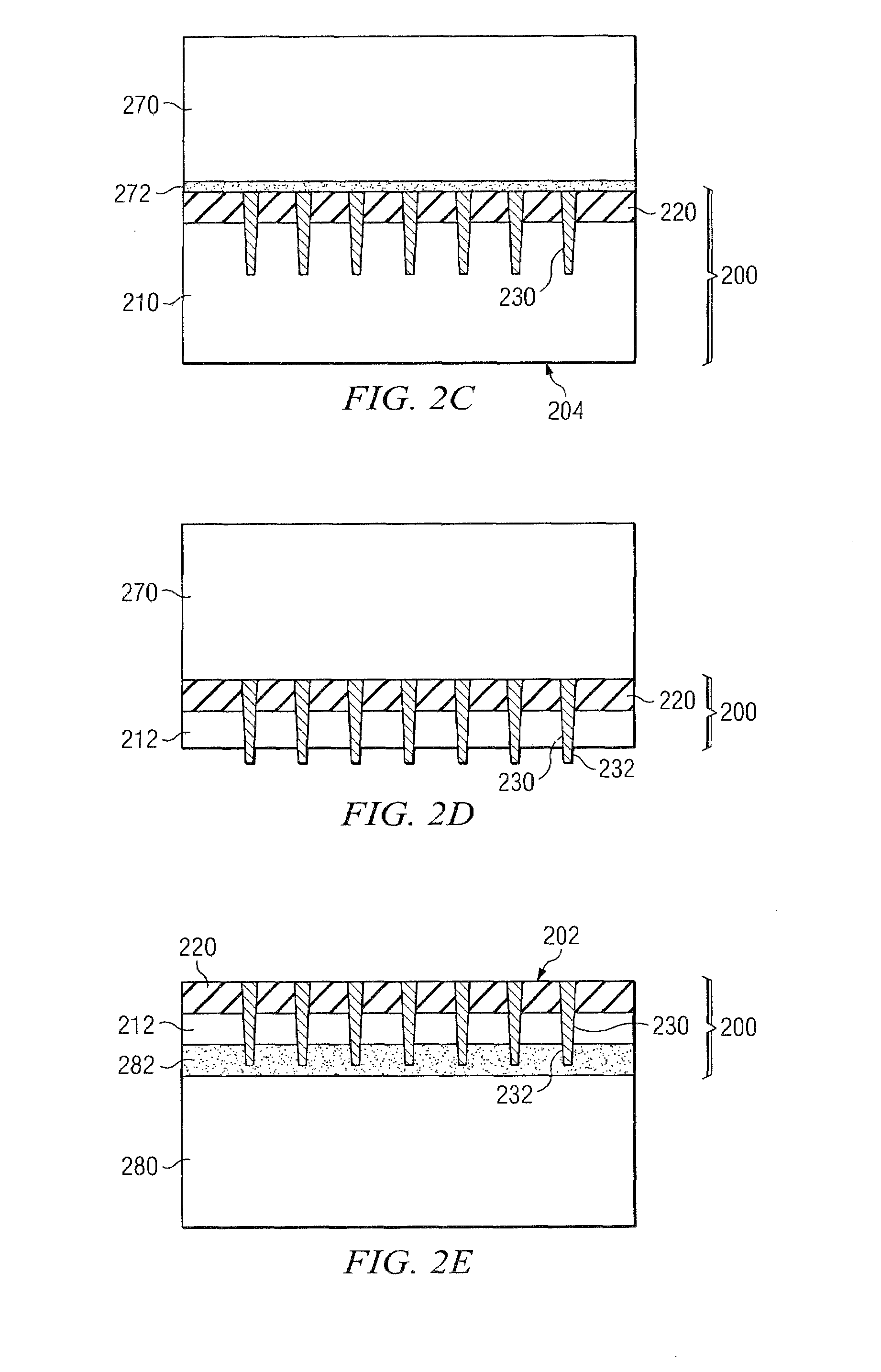

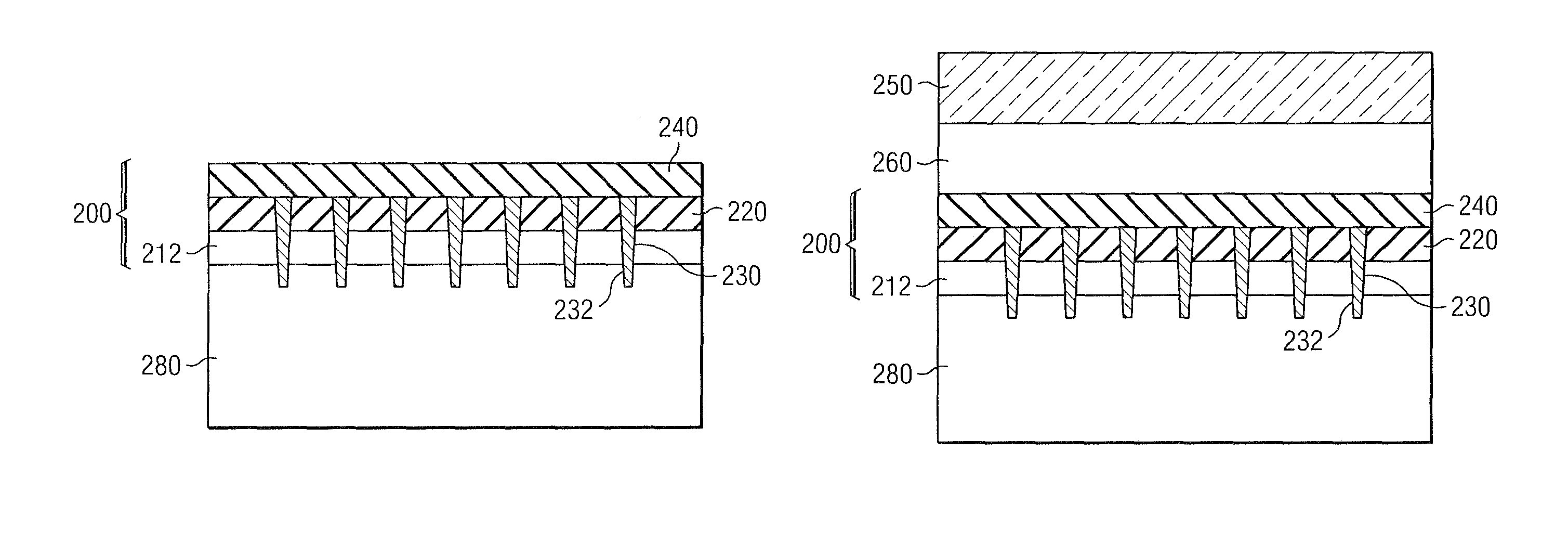

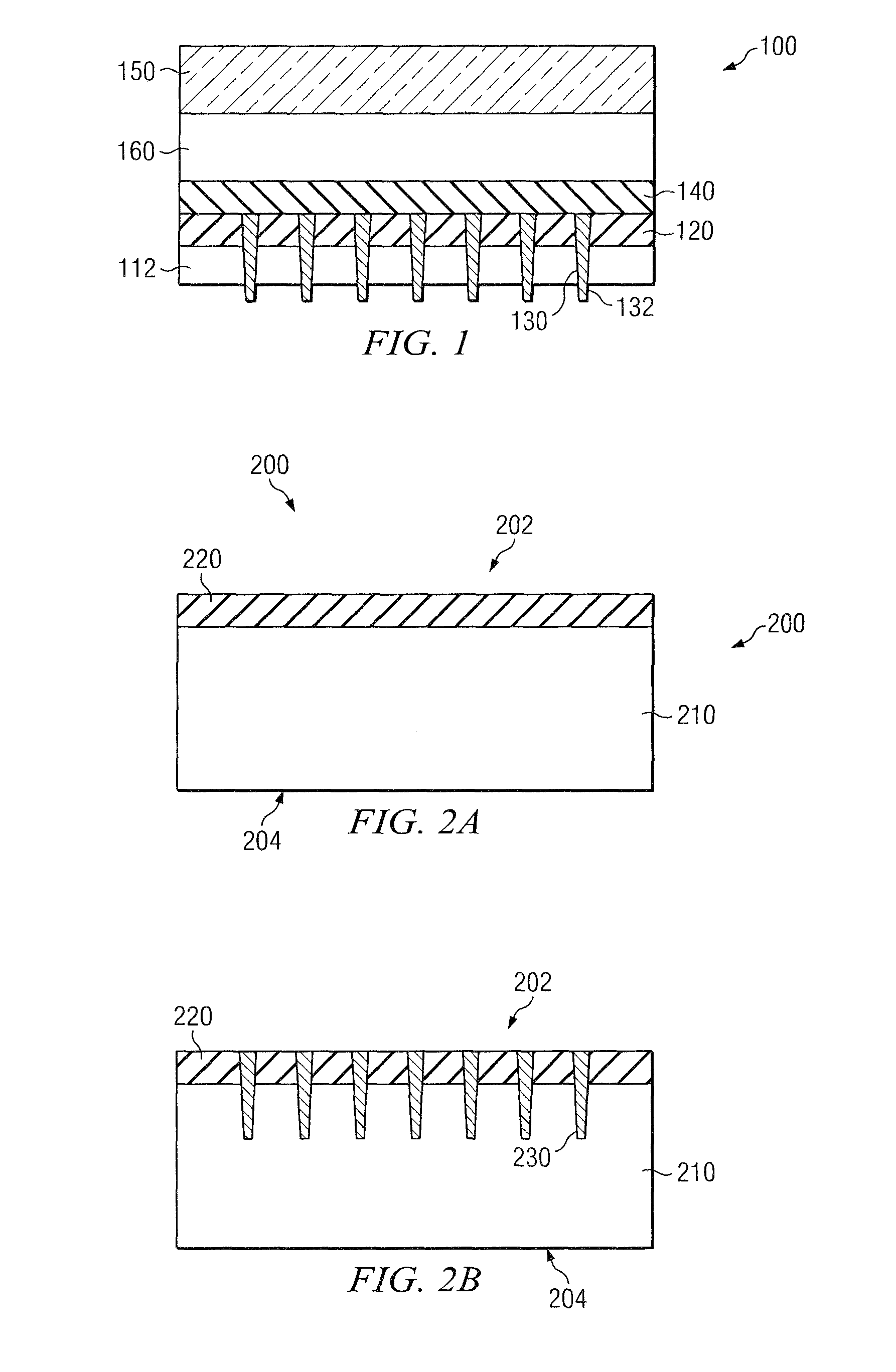

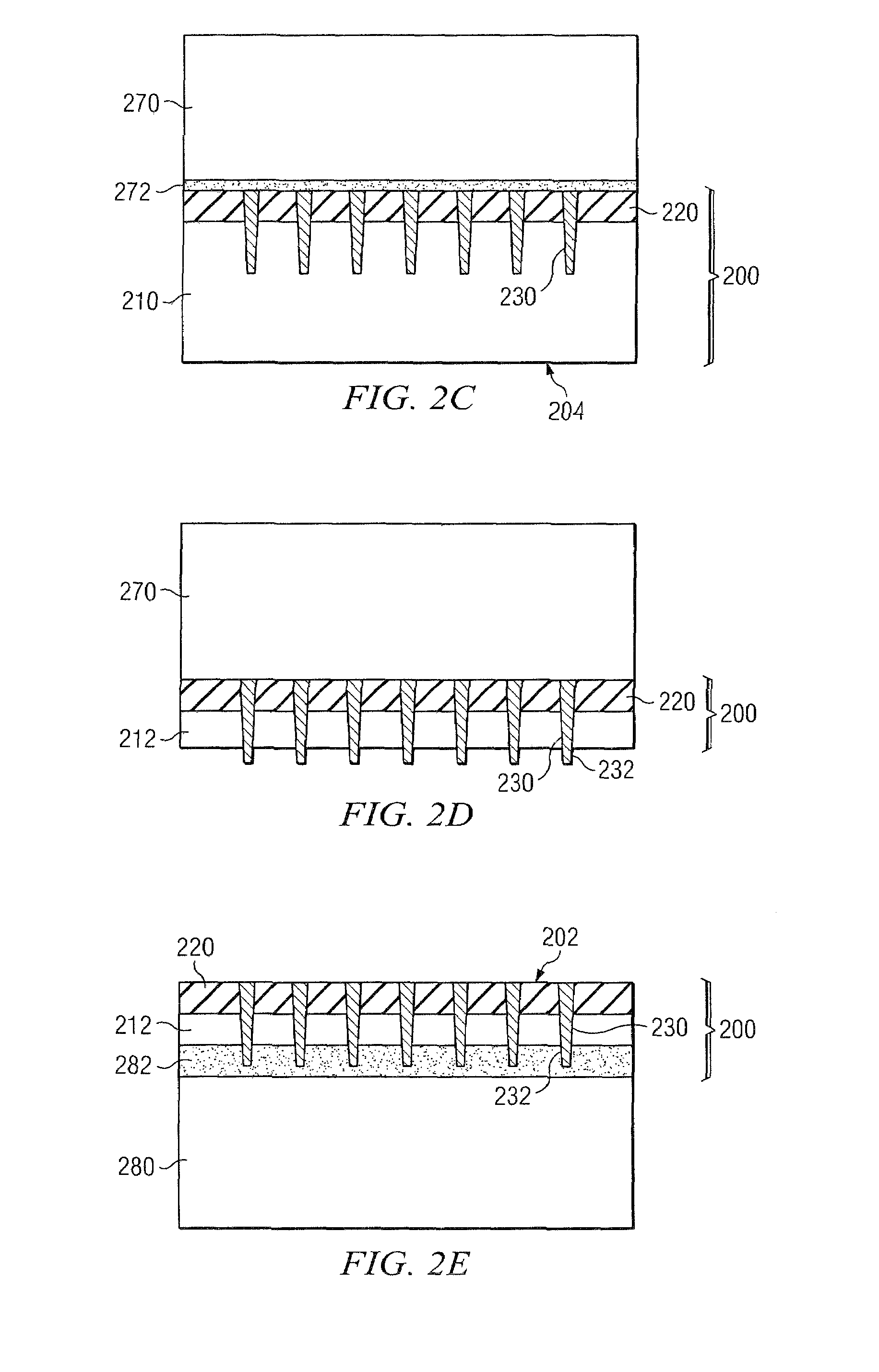

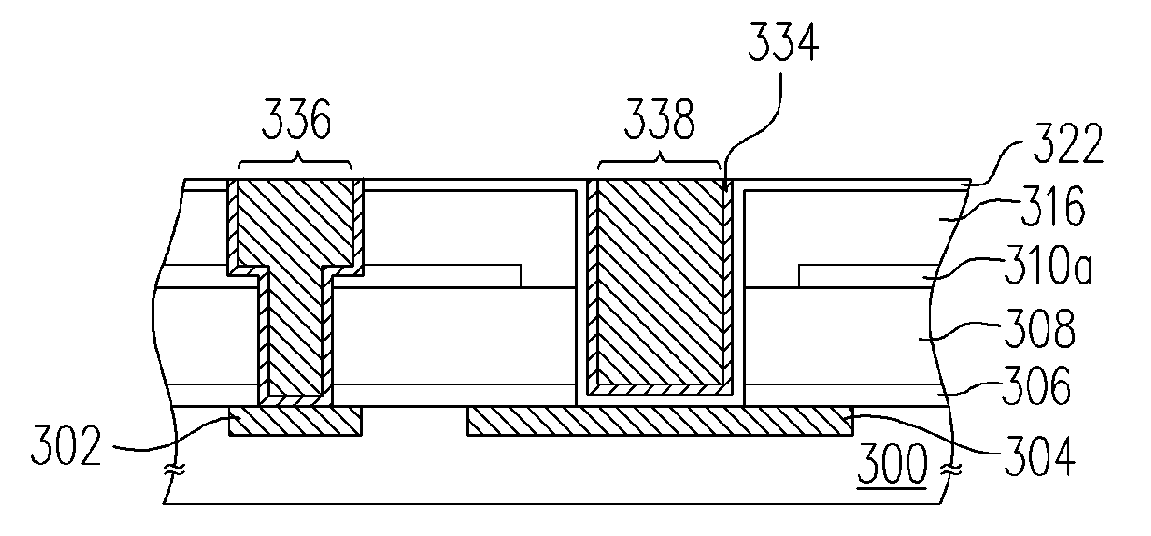

Double wafer carrier process for creating integrated circuit die with through-silicon vias and micro-electro-mechanical systems protected by a hermetic cavity created at the wafer level

ActiveUS20090280602A1Avoid sizeReduce mold sizeSemiconductor/solid-state device detailsSolid-state devicesEngineeringSilicon

A TSV-MEMS packaging process is provided. The process includes forming TSVs in the front side of the product wafer, and attaching a first carrier to the front side of the product wafer, subsequent to forming TSVs. The process further includes thinning the back side of the product wafer to expose TSV tips, detaching the first carrier from the front side of the product wafer, and transferring the thinned wafer to a second carrier with back side adhered to the second wafer carrier. Semiconductor components are added to the front side of the product wafer, followed by forming a hermetic cavity over the added semiconductor components, and detaching the second carrier from the back side of the product wafer. Wafer level processing continues after detaching the second carrier.

Owner:TEXAS INSTR INC

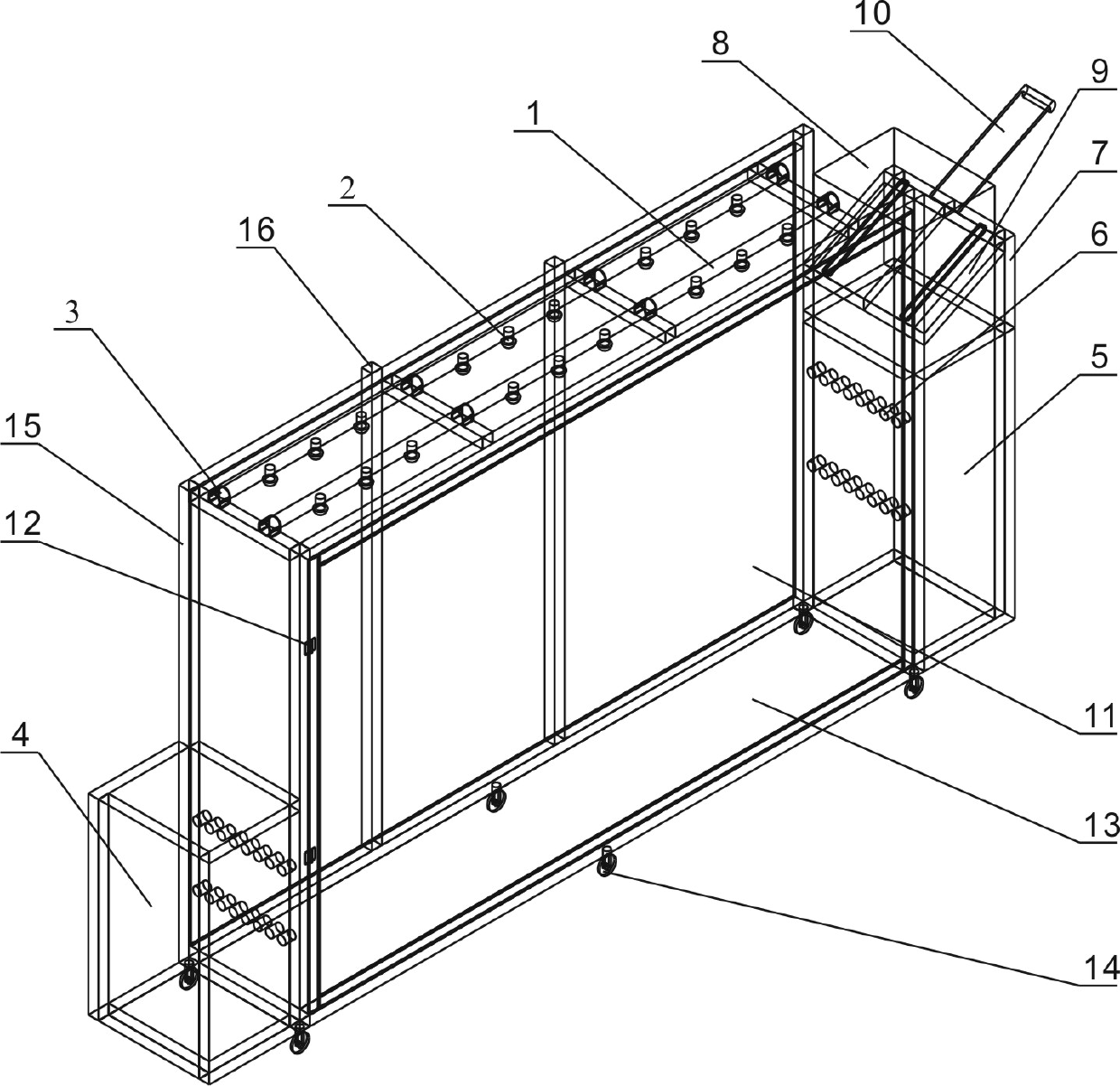

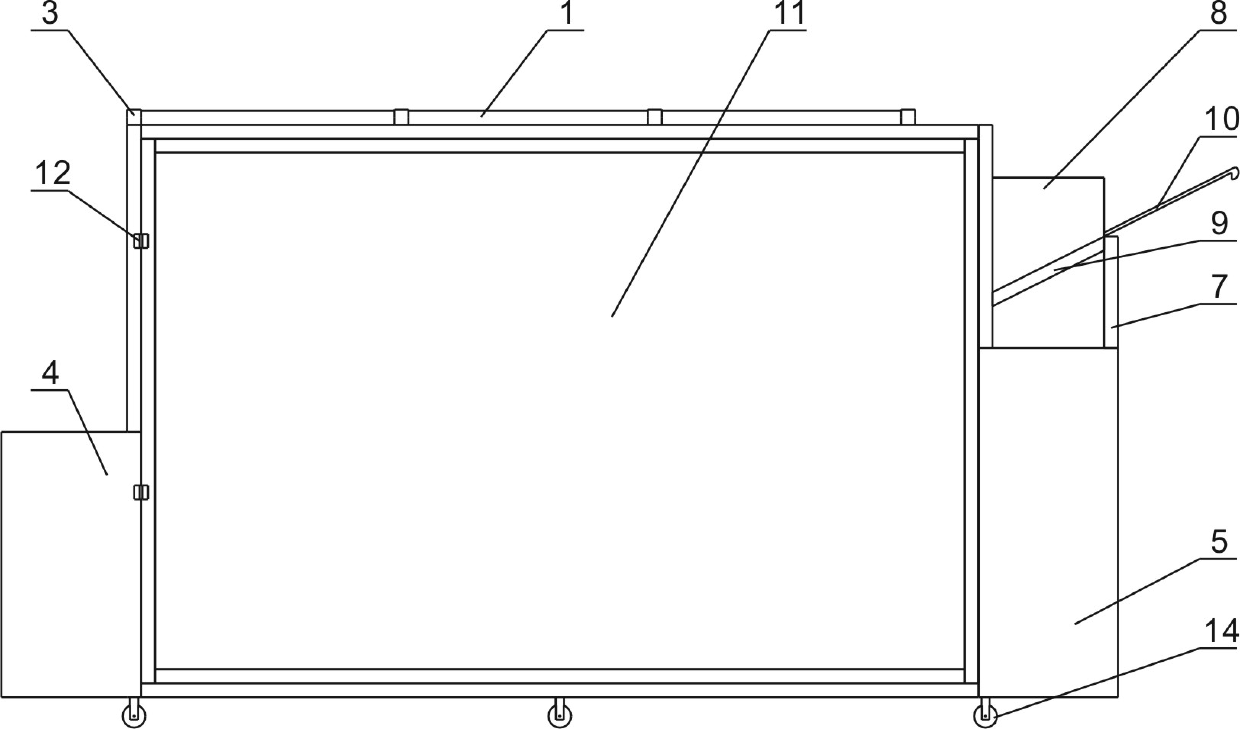

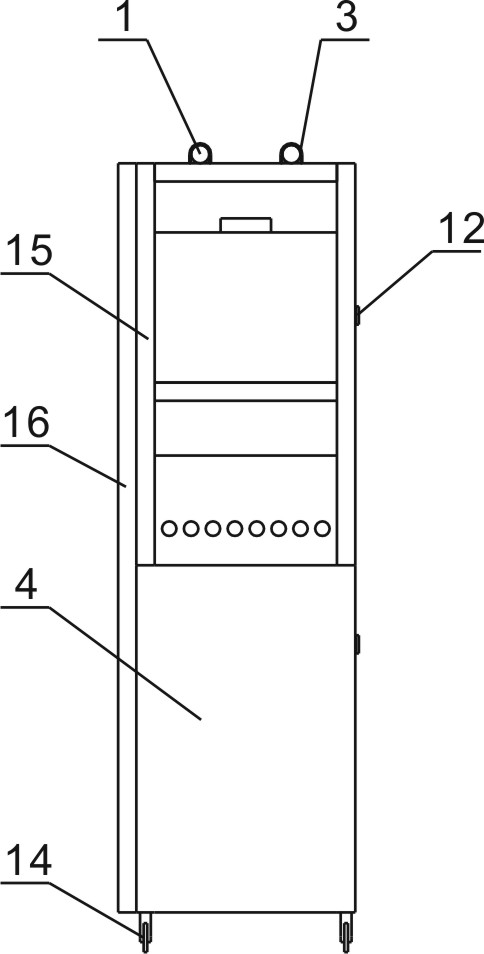

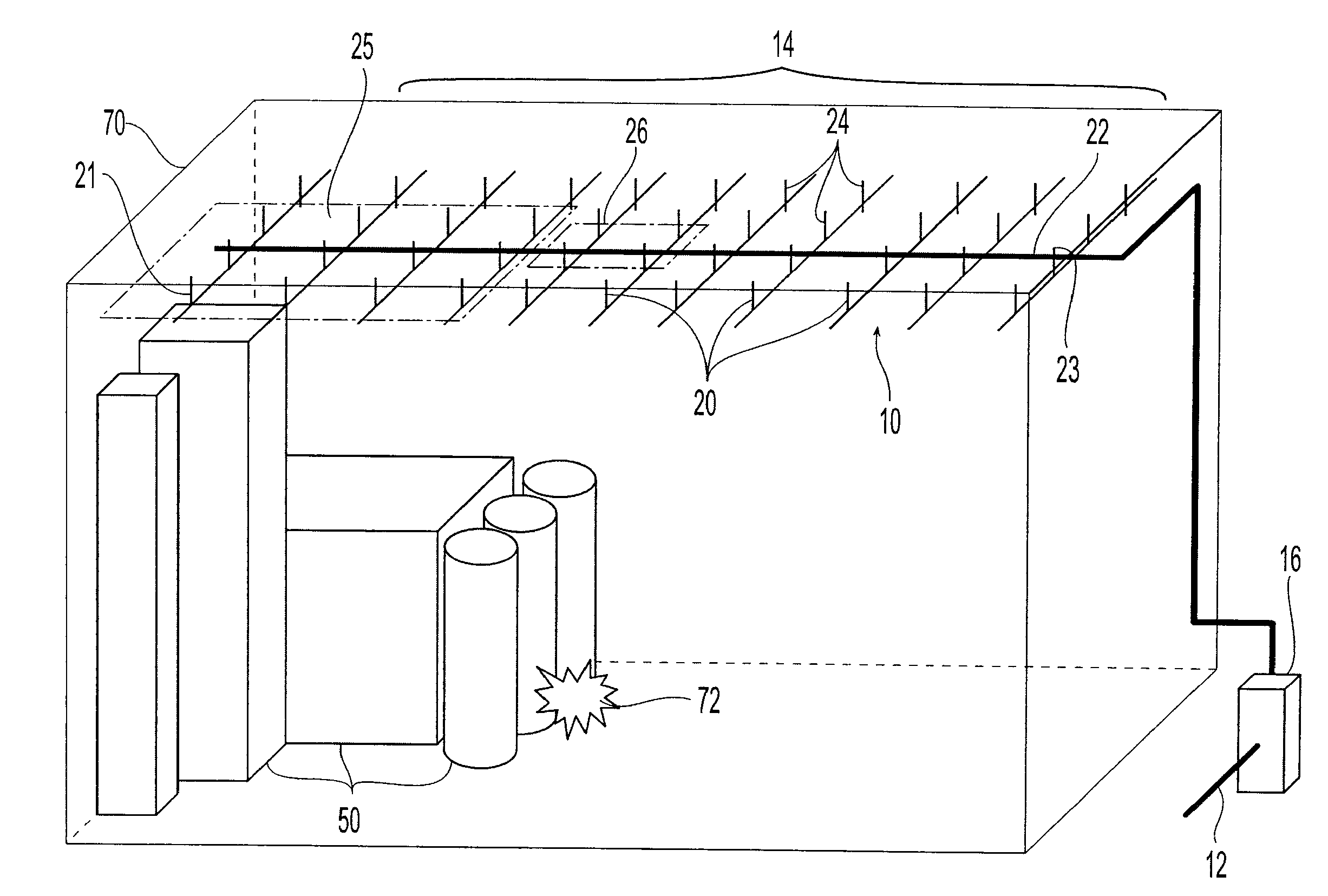

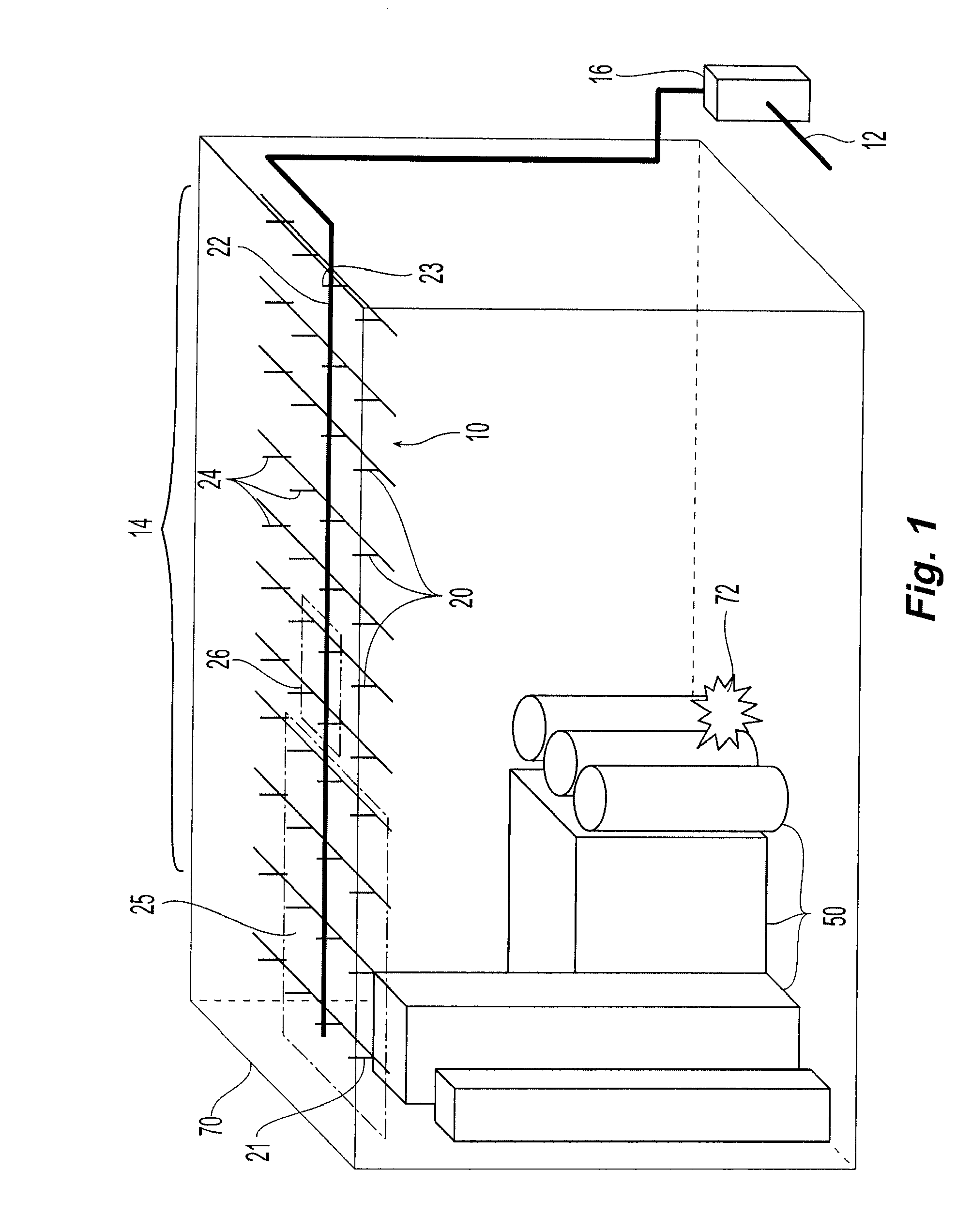

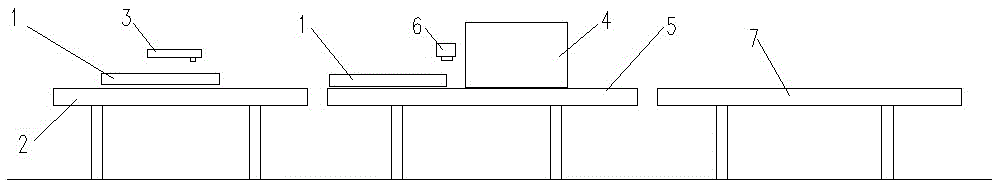

Multi-operating mode frame type portable landslide testing device for geomechanical model

ActiveCN102681028AReduce sizeOvercome the cycleEarth material testingGeological measurementsLandslideEngineering

A multi-operating mode frame type portable landslide testing device for a geomechanical model belongs to the field of geological hazard model test. The testing device comprises a frame-beam-type testing bed, a rainfall simulator, a water level regulator and a self-weight horizontal loading mechanism, wherein the frame-beam-type testing bed mainly comprises a cuboid framework, a front panel, a rear panel and a base plate; the rainfall simulator is arranged at the top of the frame-beam-type testing bed and comprises a plurality of spraying pipes and nozzles on the spraying pipes and is used for simulating rainfall in the frame-beam-type testing bed; the water level regulator comprises a left-side trough and a right-side trough respectively formed on the left and the right sides of the frame-beam-type testing bed, and a plurality of drainage holes are respectively formed on the right panel of the left-side trough and the left panel of the right-side trough and used for changing the water levels of water level simulation libraries in the left-side trough and the right-side trough; and the self-weight horizontal loading mechanism is arranged above the right-side trough and used for bearing weights, so as to exert horizontal load to the landslide model in the frame-beam-type testing bed.

Owner:中部知光技术转移有限公司

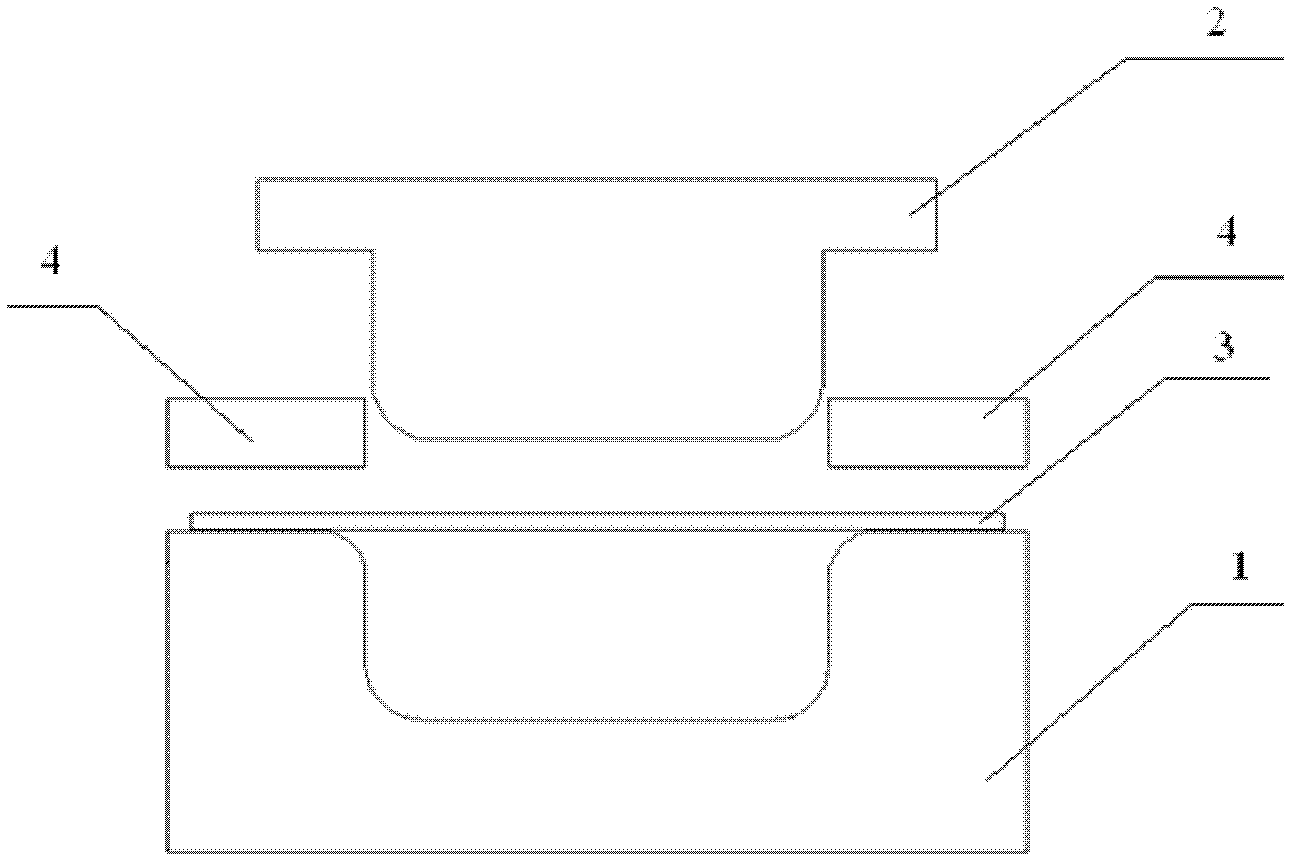

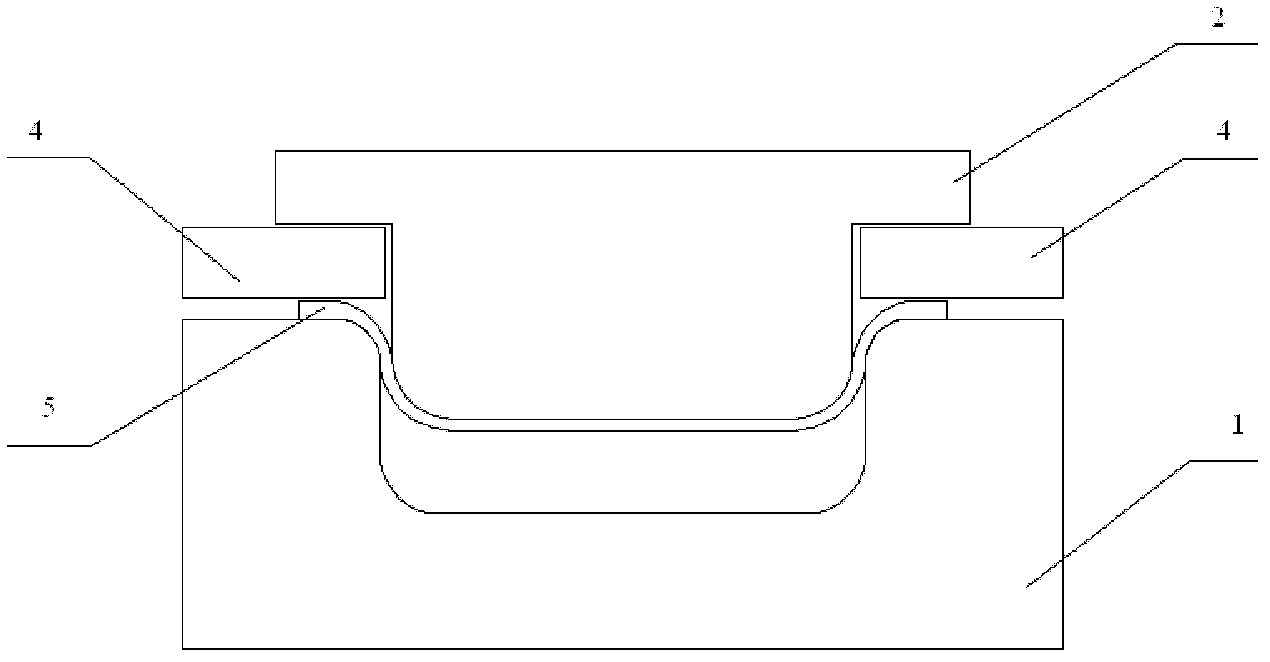

Cold-hot compound die molding method for aluminum alloy sheet metal component

ActiveCN102615201ADimensionally stableDimensional change, shape stability can be obtained directly through one-time formingShaping toolsMetalAluminium alloy

The invention discloses a cold-hot compound die molding method for an aluminum alloy sheet metal component, and relates to a molding method for a sheet metal component. The invention aims to solve the technical problems that the conventional hot-state molding method for the aluminum alloy sheet metal component is low in molding efficiency and can easily cause local crinkles and fractures, and provides the cold-hot compound die molding method for the aluminum alloy sheet metal component. The cold-hot compound die molding method comprises the following steps of: 1, heating a lower die to a temperature of between 200 and 900 DEG C; 2, placing an aluminum alloy plate blank on the lower die and heating the aluminum alloy plate blank to the deformation temperature of the aluminum alloy plate blank; 3, closing the die to press the aluminum alloy plate blank into the aluminum alloy sheet metal component; 4, separating the aluminum alloy sheet metal component, an upper die and a blank holder from the lower die; and 5, cooling the upper die and the blank holder, keeping the temperature for a certain period of time, and taking the aluminum alloy sheet metal component down to finish the cold-hot compound die molding of the aluminum alloy sheet metal component. According to the method, a cold-hot compound die in which the upper die is in a cold state and the lower die is in a hot state is adopted to mold the aluminum alloy sheet metal component. The cold-hot compound die molding method is suitable for making the aluminum alloy sheet metal component.

Owner:天津哈工永兴科技有限公司

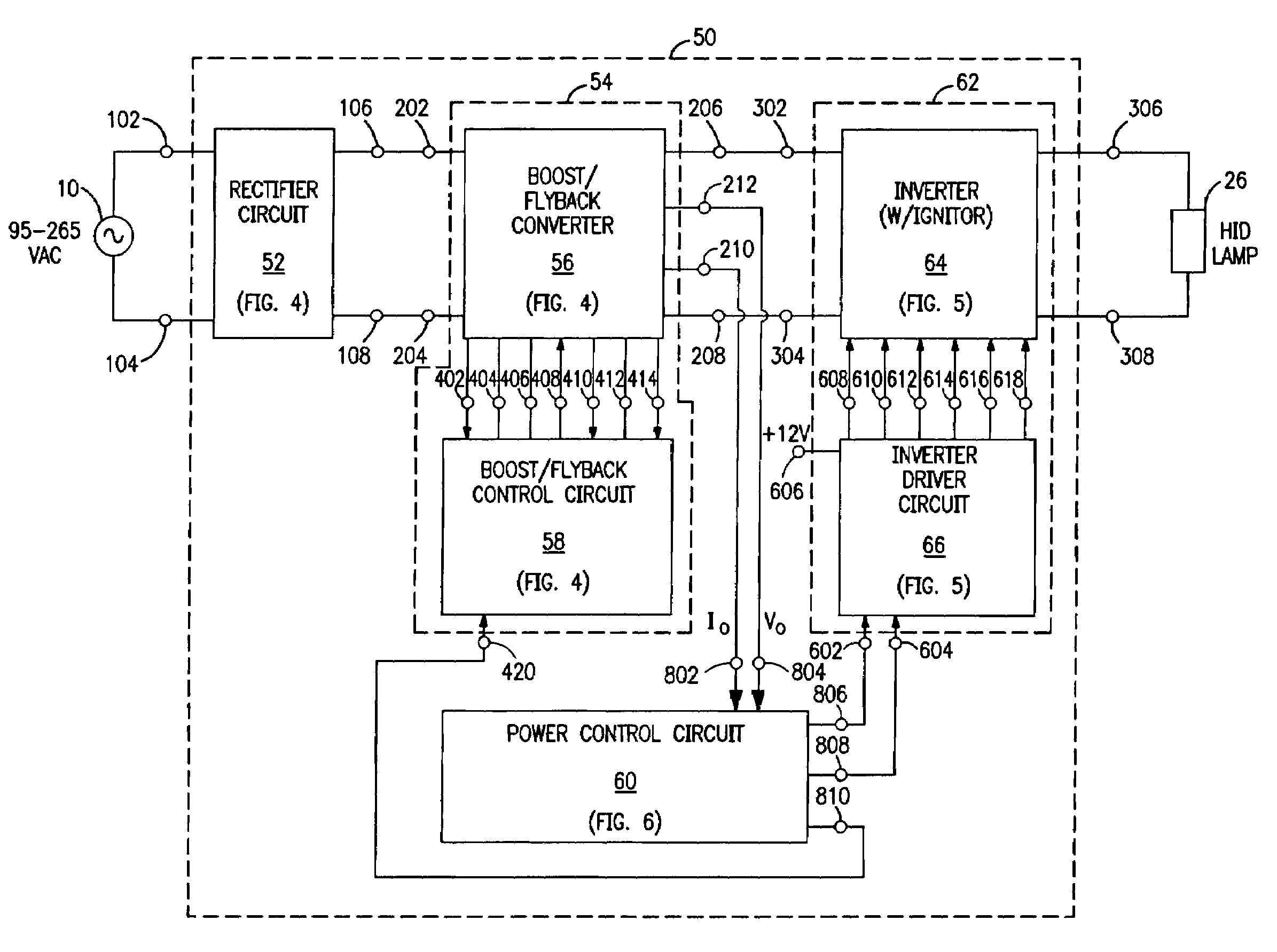

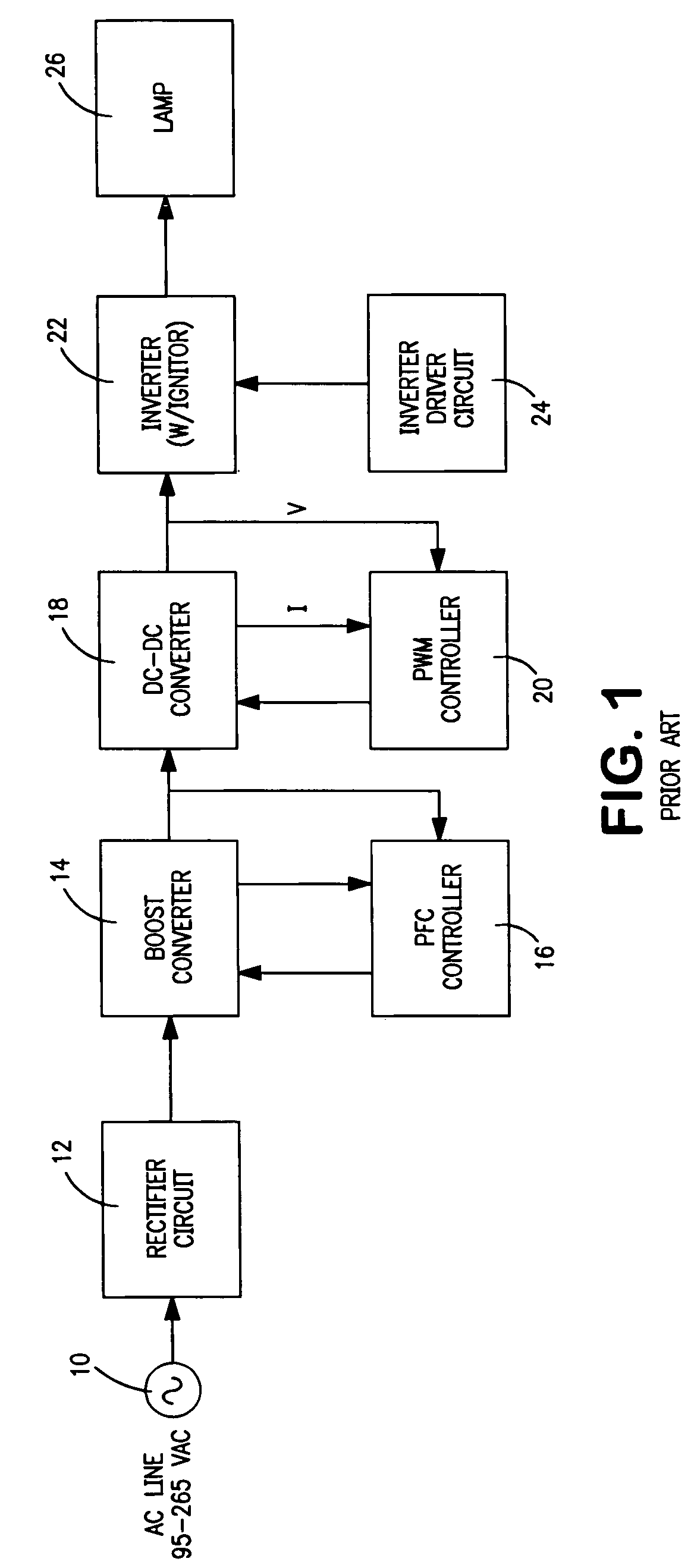

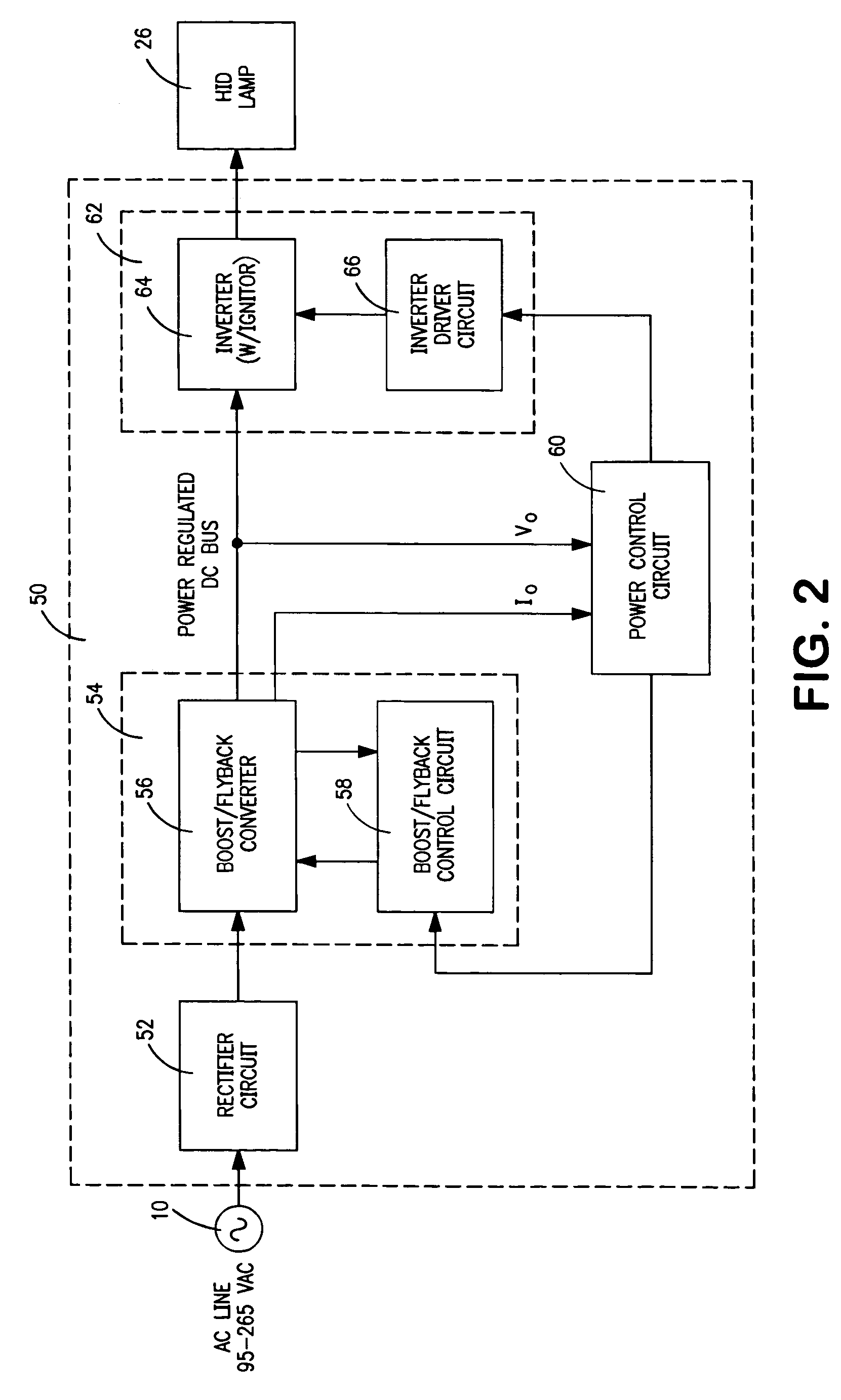

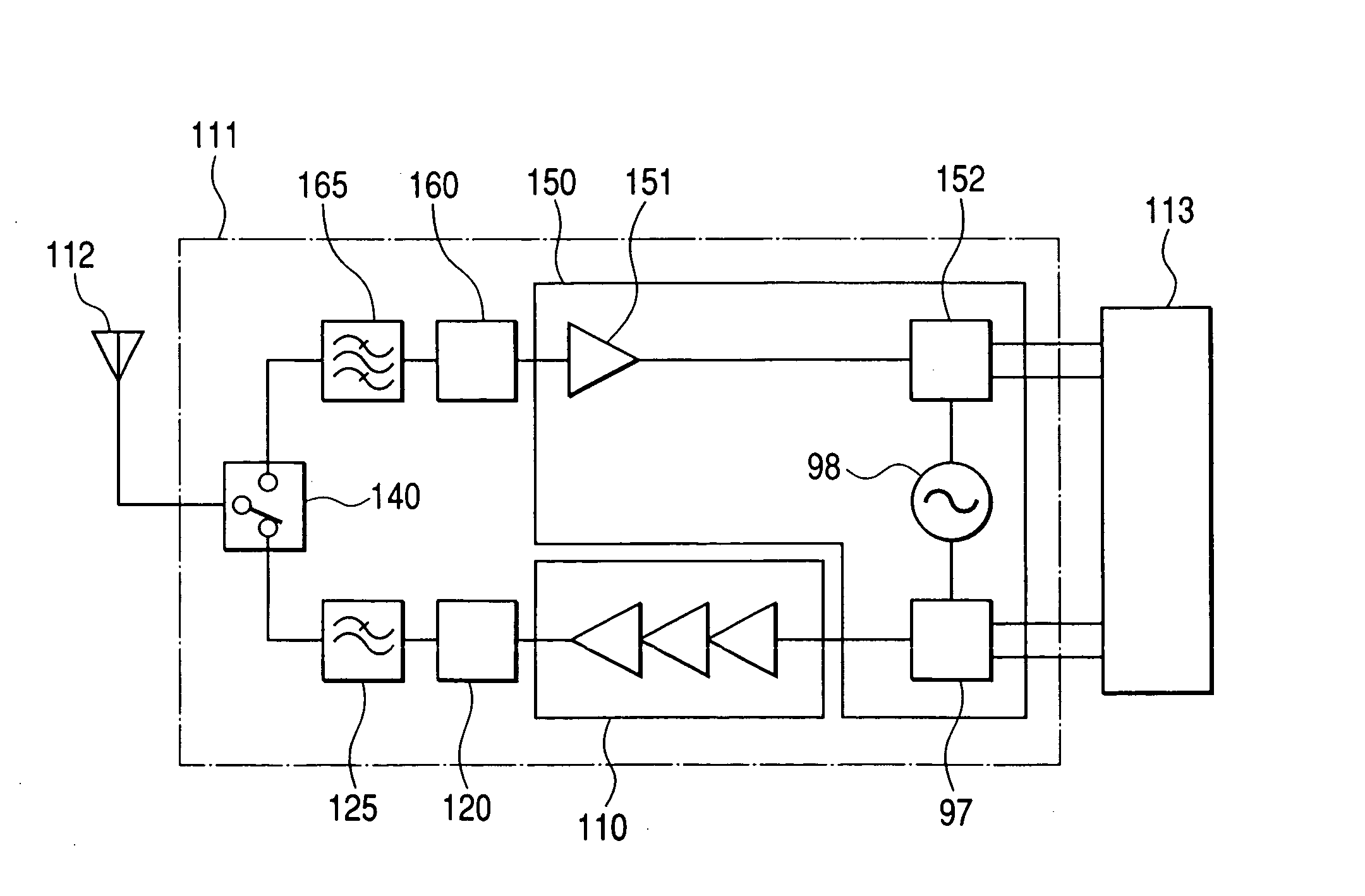

Method and circuit for regulating power in a high intensity discharge lamp

InactiveUS7187136B2Reliable powerLow costElectrical apparatusElectric light circuit arrangementEngineeringHigh intensity

A circuit for controlling power to a high intensity discharge lamp is disclosed. The circuit according to one embodiment of the invention comprises a rectifier circuit coupled to receive an alternating current line voltage, and a boost / flyback converter coupled to the rectifier circuit which outputs a regulated DC bus voltage. A power control circuit also couples a feedback signal to the boost / flyback converter to regulate the power output of the boost / flyback converter. A method of controlling power to a high intensity discharge lamp is also disclosed. The method comprises steps of generating a DC voltage for the high intensity discharge lamp by way of a boost / flyback converter; monitoring the DC voltage and the current generated in the boost / flyback converter; and modifying the power output by the boost / flyback converter to regulate power based upon the voltage and the current.

Owner:OSRAM SYLVANIA INC

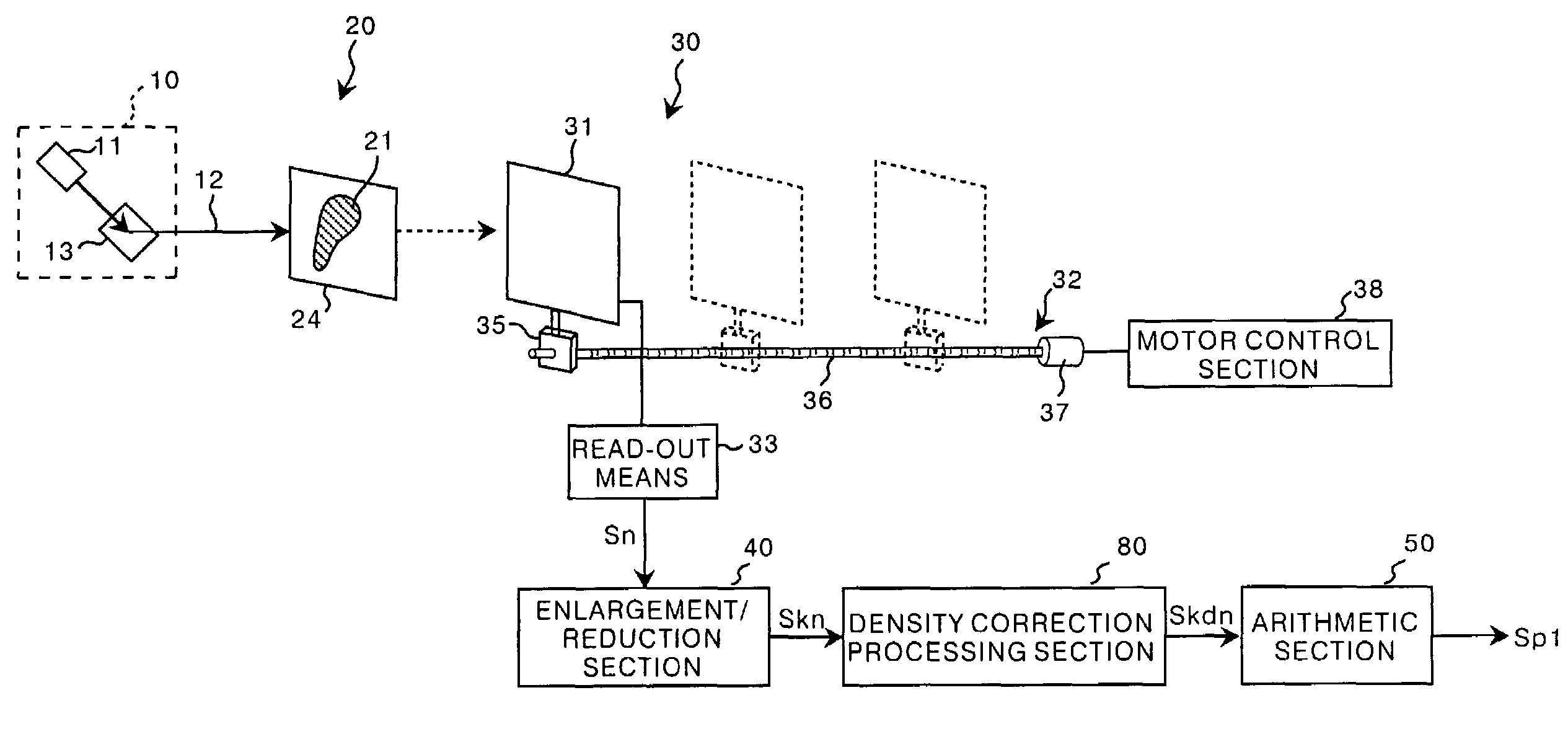

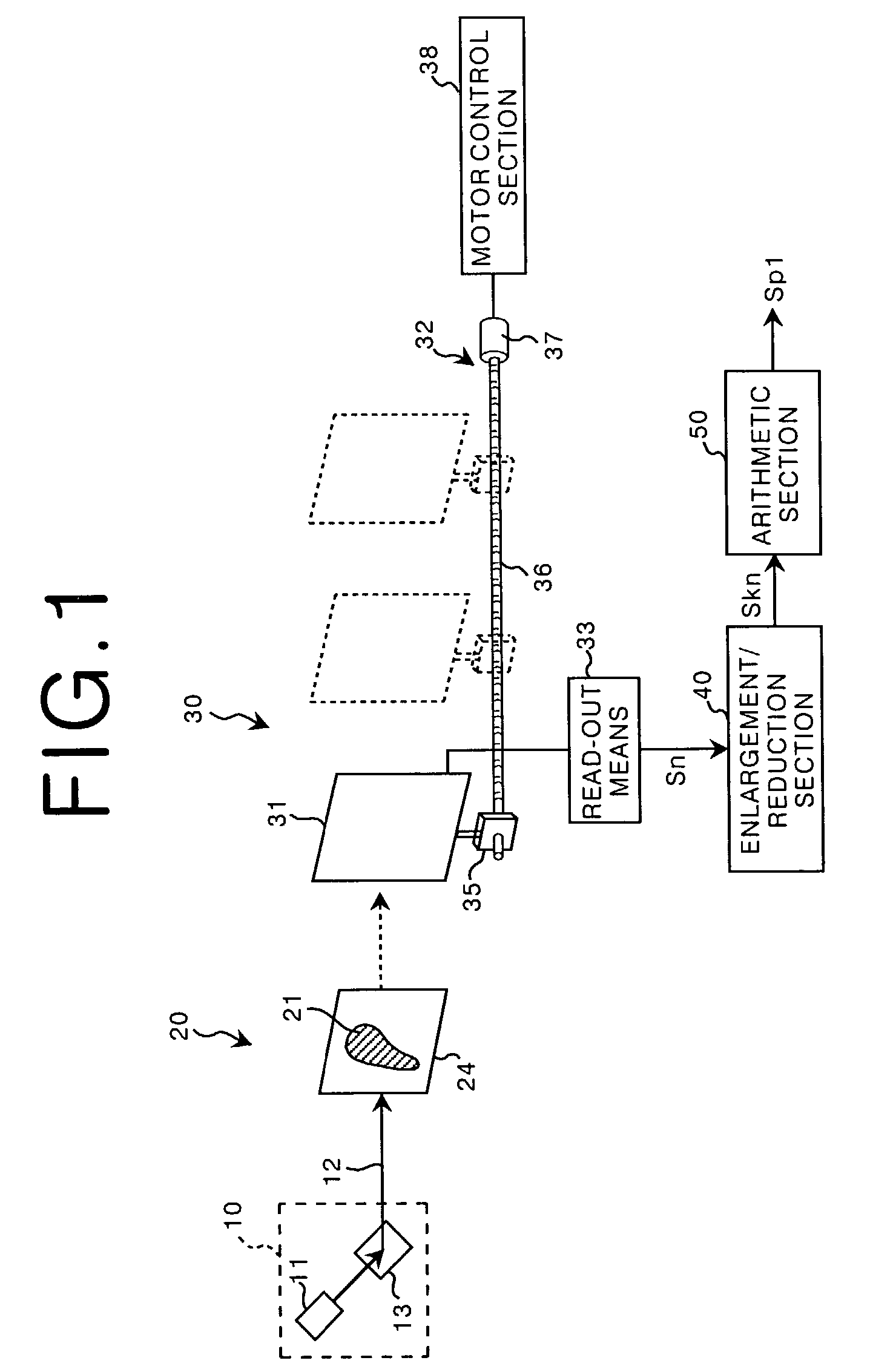

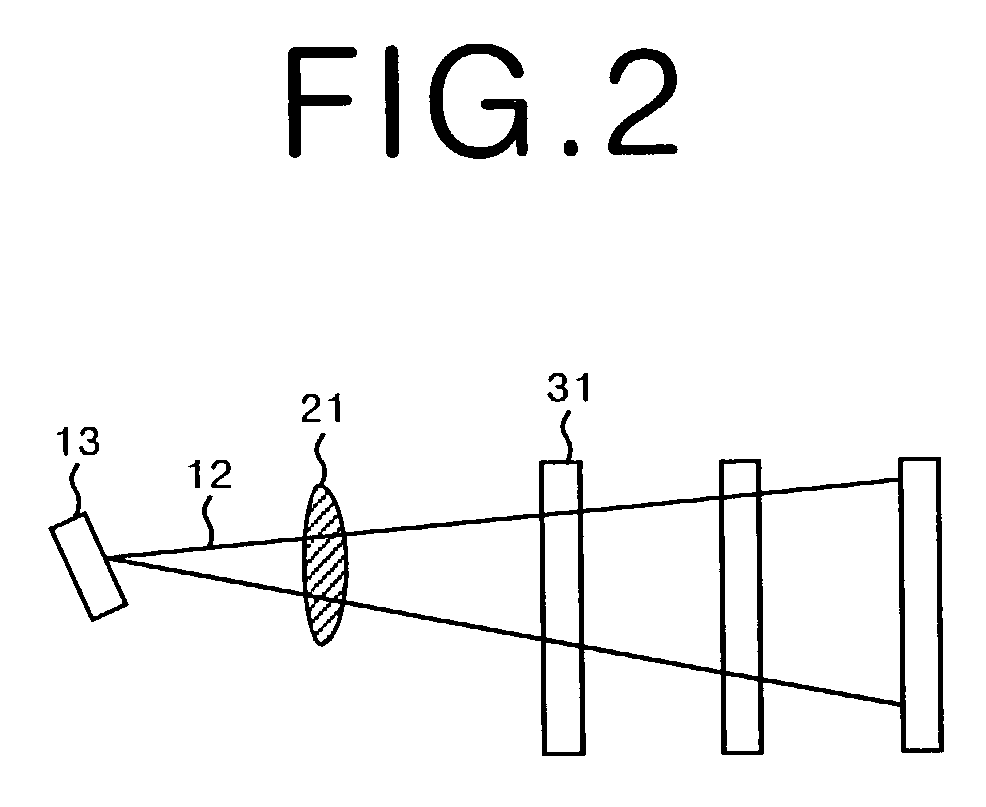

Method of and apparatus for generating phase contrast image

InactiveUS7346204B2Avoid position shiftSame sizeImage enhancementTelevision system detailsPhase-contrast imagingPhysics

A phase contrast image is generated on the basis of a plurality of radiation images of an object taken in imaging positions which are different from each other in the distance from the object. An enlargement / reduction processing is carried out on the radiation images as taken in the imaging positions according to the distances between the imaging positions so that the radiation images become substantially the same in their sizes, and a phase contrast image is generated on the basis of the radiation images thus processed.

Owner:FUJIFILM CORP +1

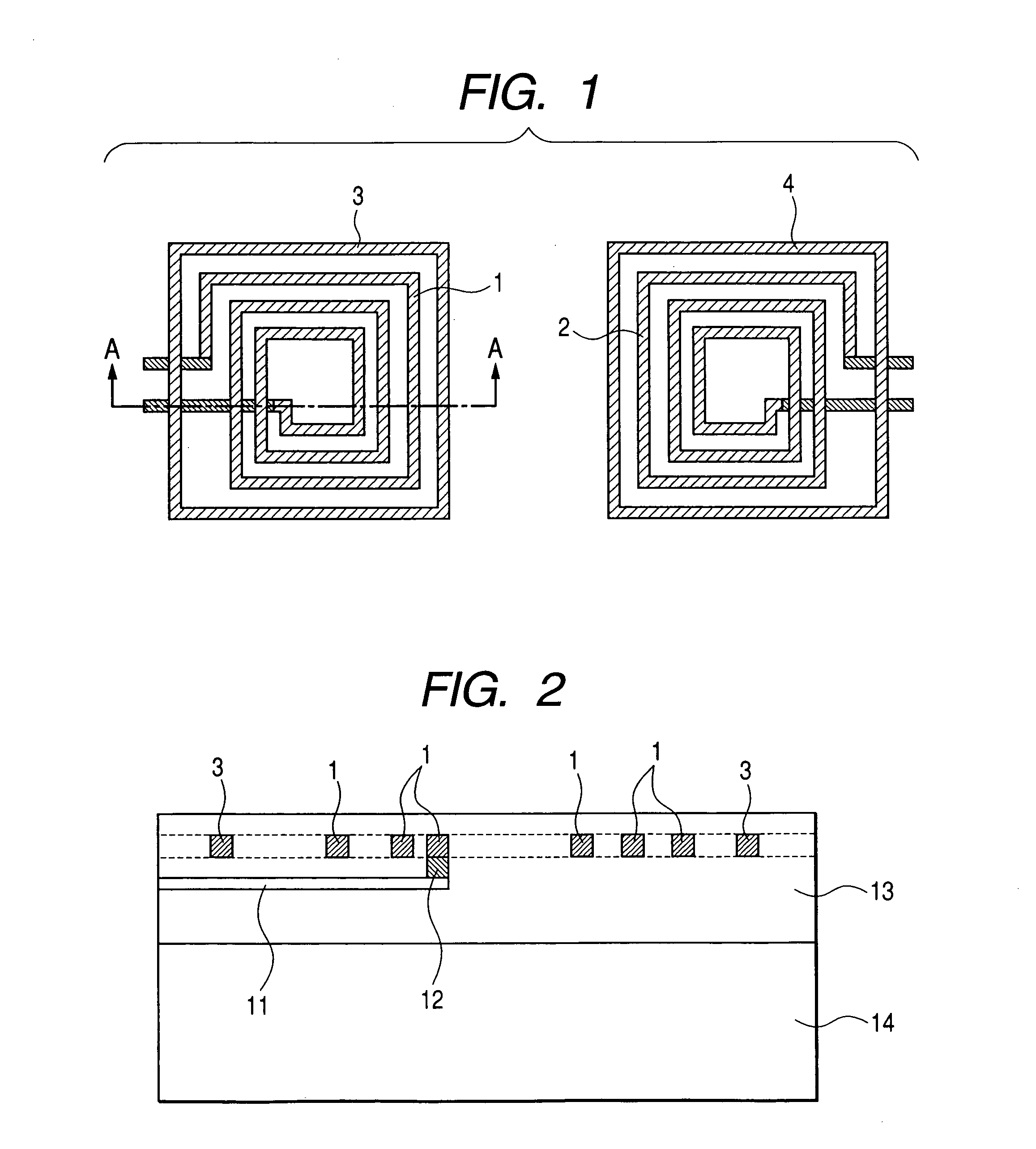

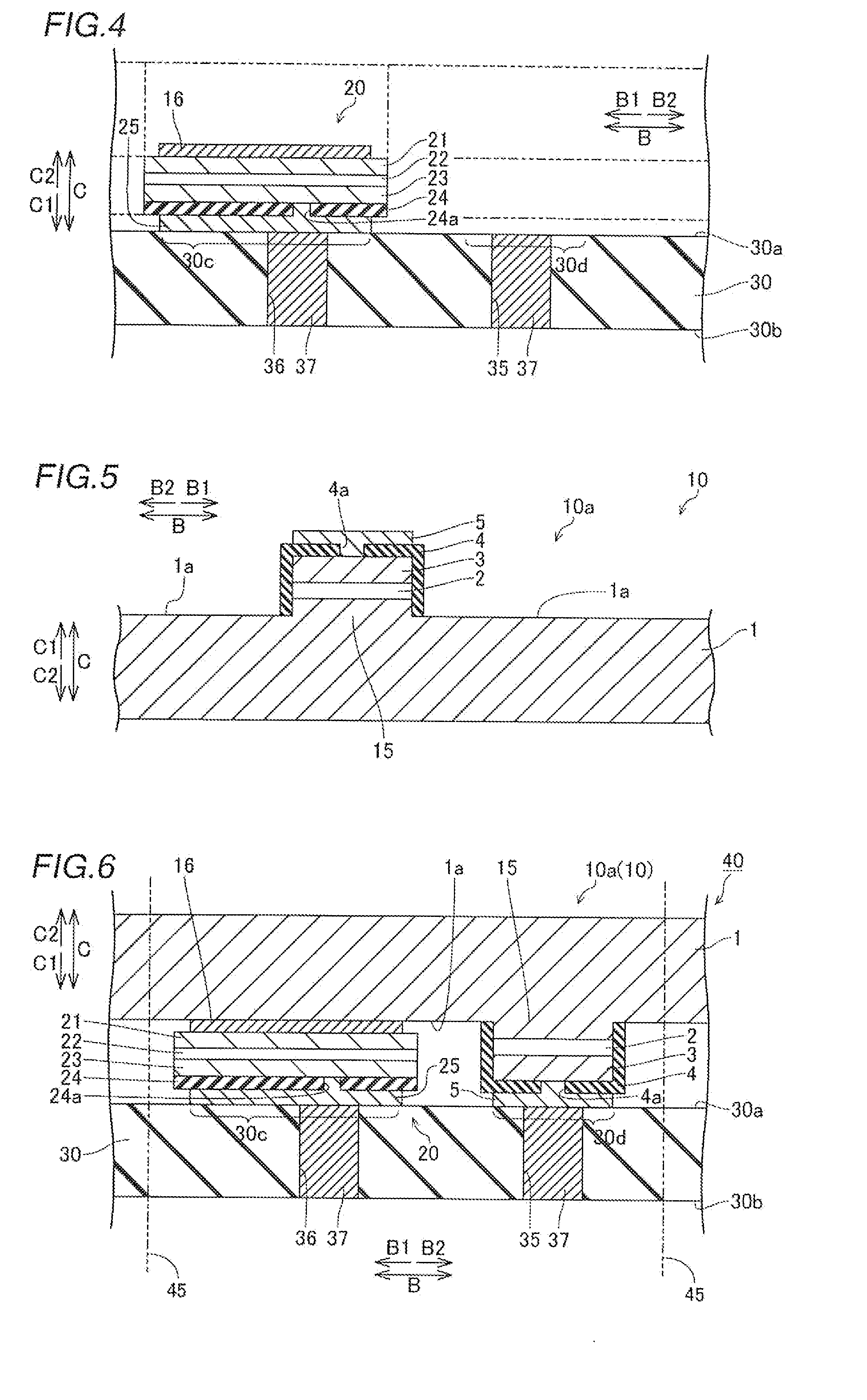

Semiconductor devices with inductors

ActiveUS20060038621A1Reduce distractionsInhibitionSemiconductor/solid-state device detailsTransformers/inductances coils/windings/connectionsCarrier signalLocal oscillator

Semiconductor devices provided with high performance high-frequency circuits that reduce interference caused by inductors are provided. In the semiconductor device including a modulator circuit to modulate a carrier wave by a base band signal to output an RF signal and a demodulator circuit to demodulate the RF signal by use of the carrier wave to gain the base band signal and a local oscillator to generate the carrier wave, inductors respectively having a closed loop wire are adopted. Interference caused by mutual inductance is reduced by the closed loop wire. For example, where inductors are adopted in the modulator circuit, a closed loop wire is disposed around the outer periphery of the inductors.

Owner:RENESAS ELECTRONICS CORP

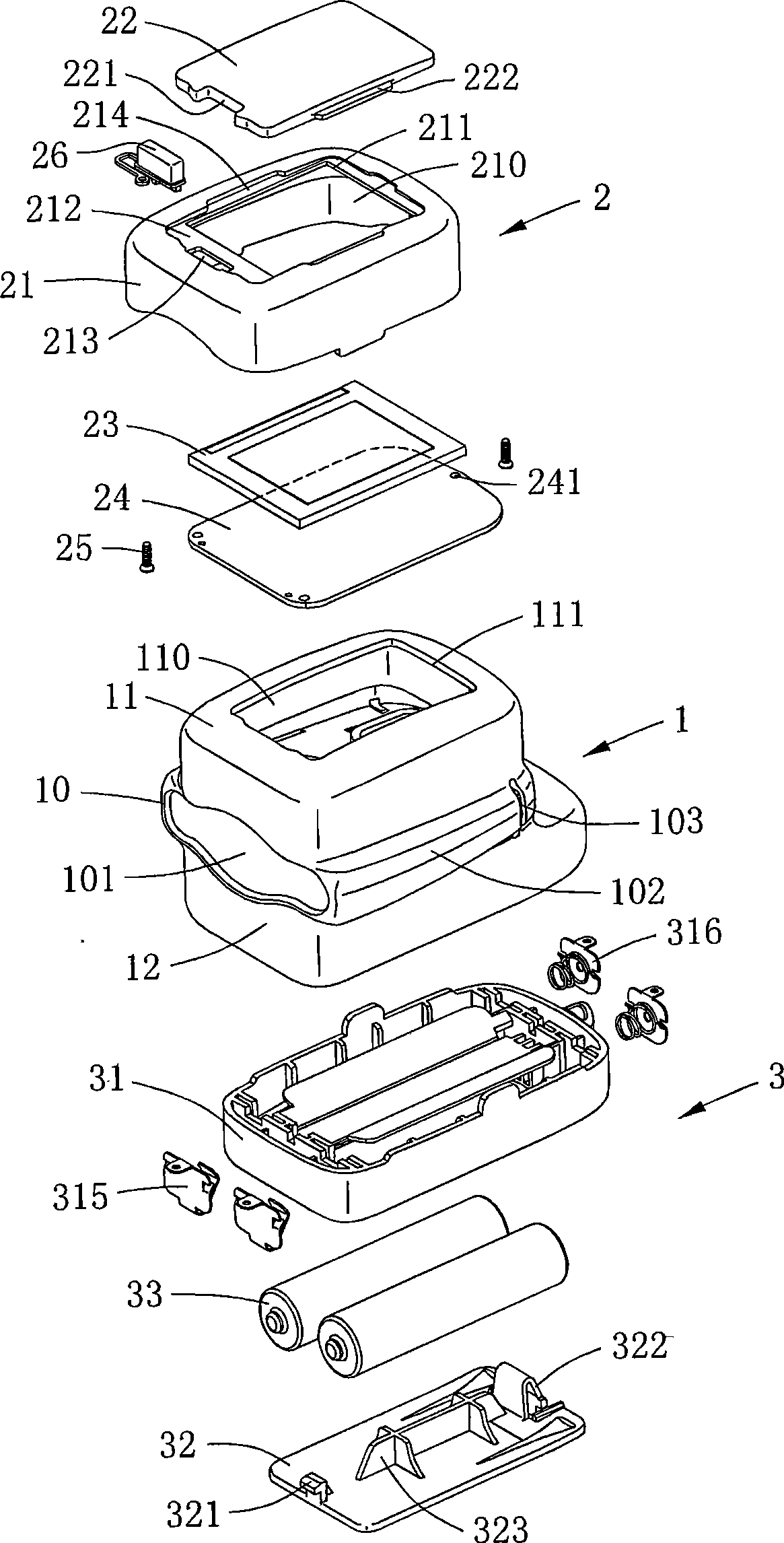

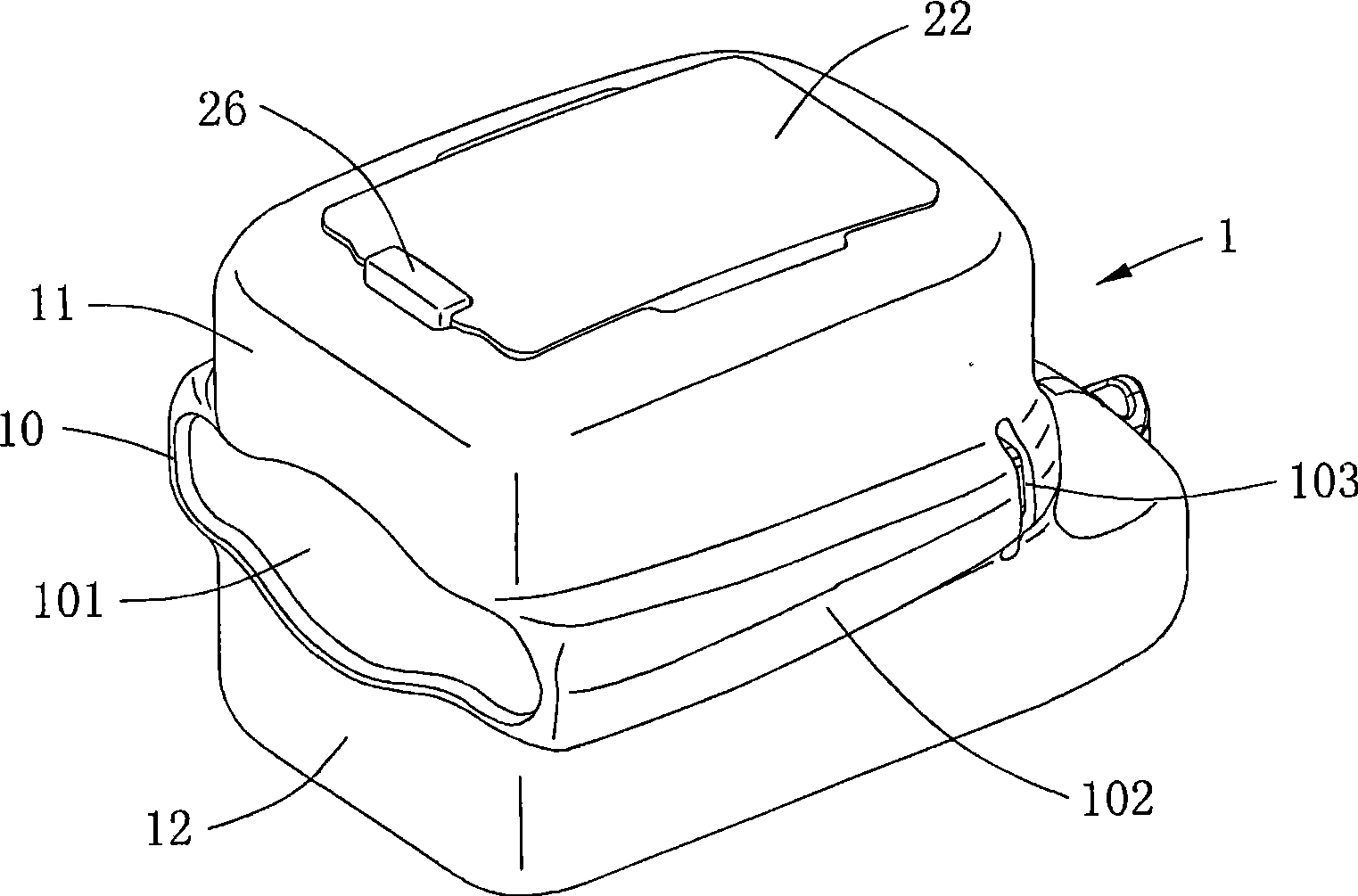

Finger type instrument for detecting sphygmus and blood oxygen saturation

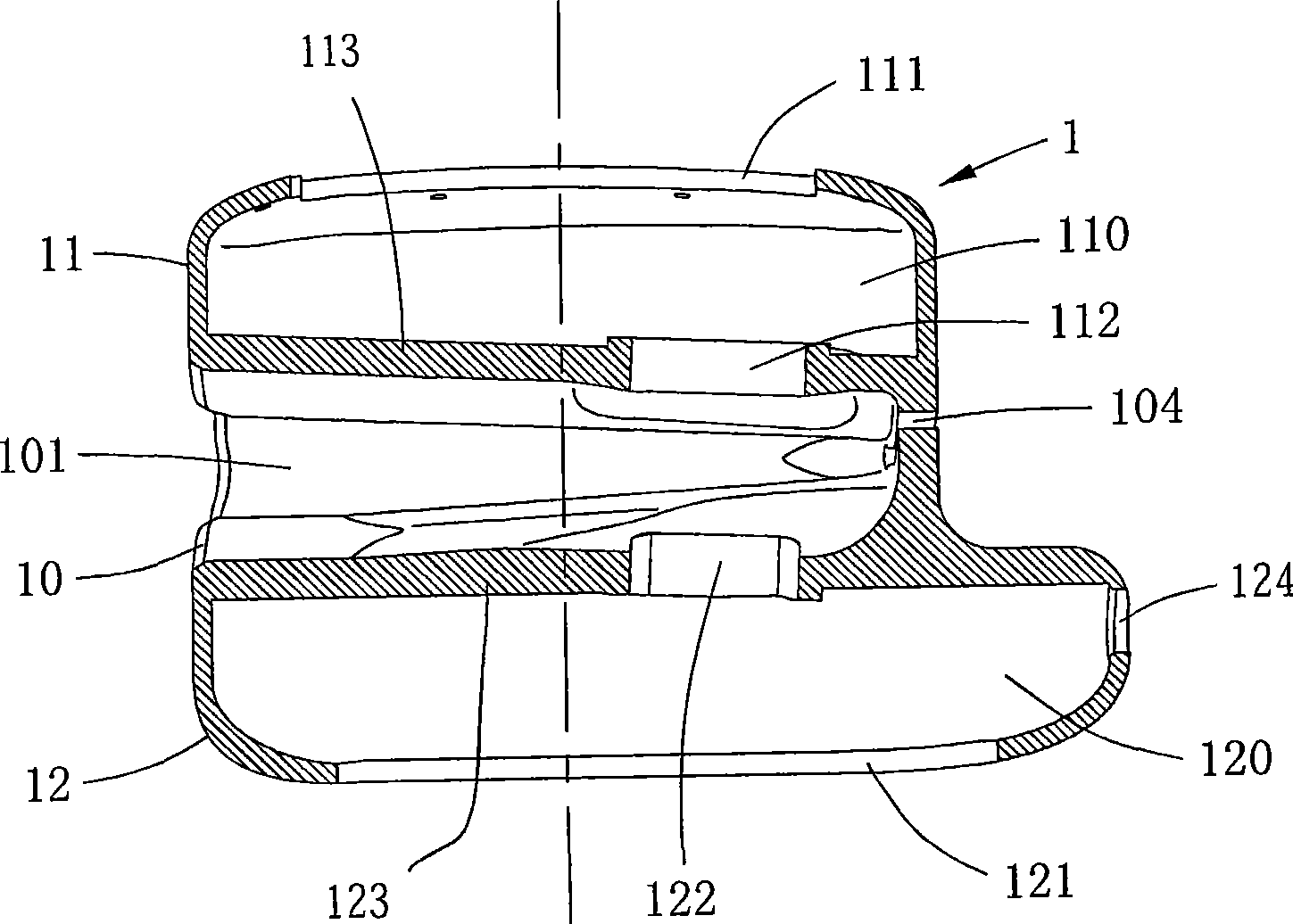

InactiveCN101411618AAvoid sizeEffective protectionDiagnostic recording/measuringSensorsPulse oximetersEngineering

The invention discloses a finger pulse oximeter, which relates to the field of the detection of pulse and blood oxygen saturation. The finger pulse oximeter comprises a detection host and a soft shell, wherein the detection host comprises a circuit board, a display screen electrically connected with the circuit board and so on, the soft shell comprises a soft finger cot which is provided with insert holes for fingers of examinees to insert, and a first receiving part which is integrated with the soft finger cot and is provided with a first receiving chamber, and the circuit board and the display screen of the detection host are received and fixed in the first receiving chamber. The finger pulse oximeter overcomes the pressure difference existing in the prior product caused by different finger thicknesses of the examinees, and ensures that the fingers are closely contacted with a photoelectric device, thereby effectively eliminating the influence of the pressure and ambient light on the detection accuracy, effectively protecting the host, and preventing the break and damage caused by falling or impact.

Owner:潘卫江

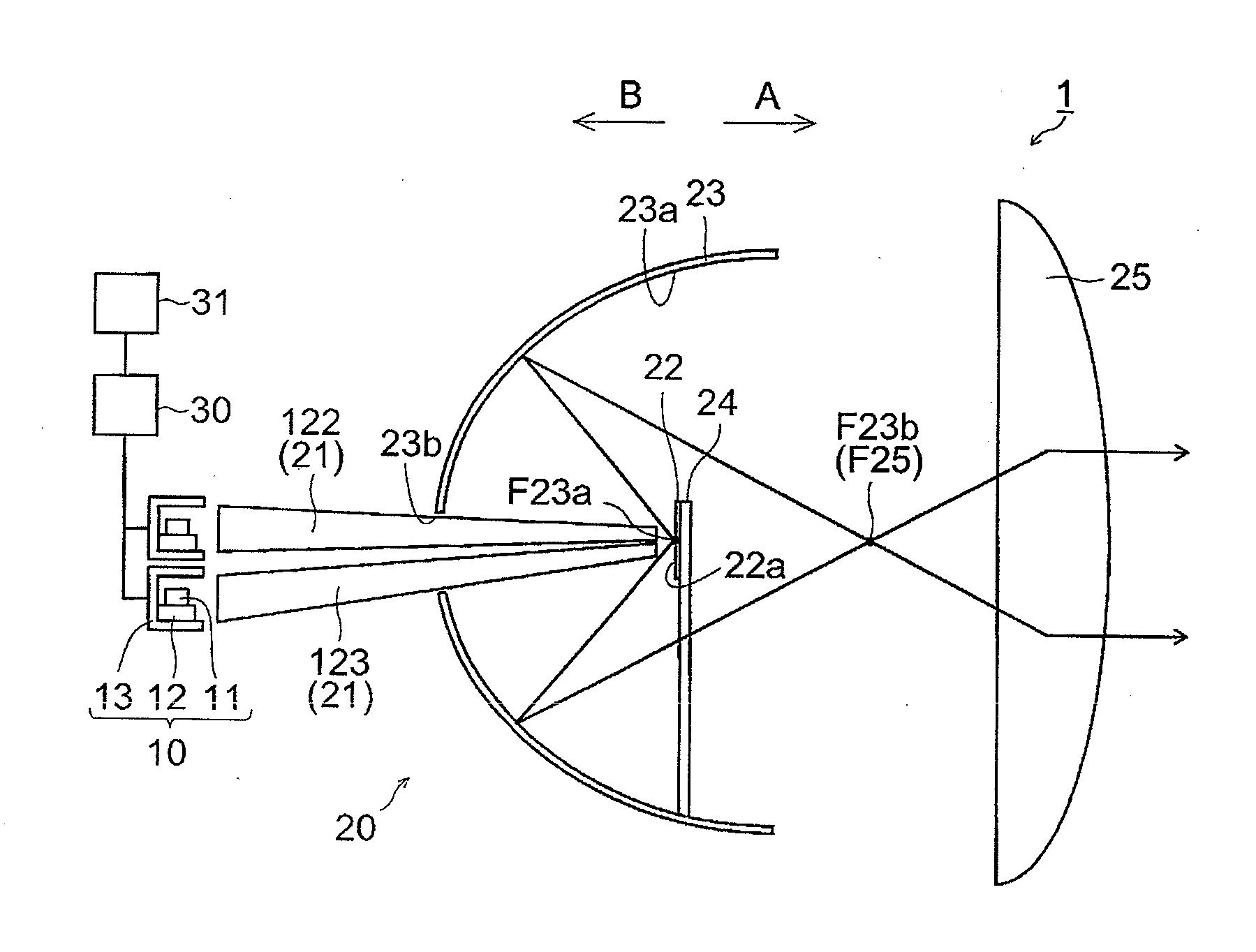

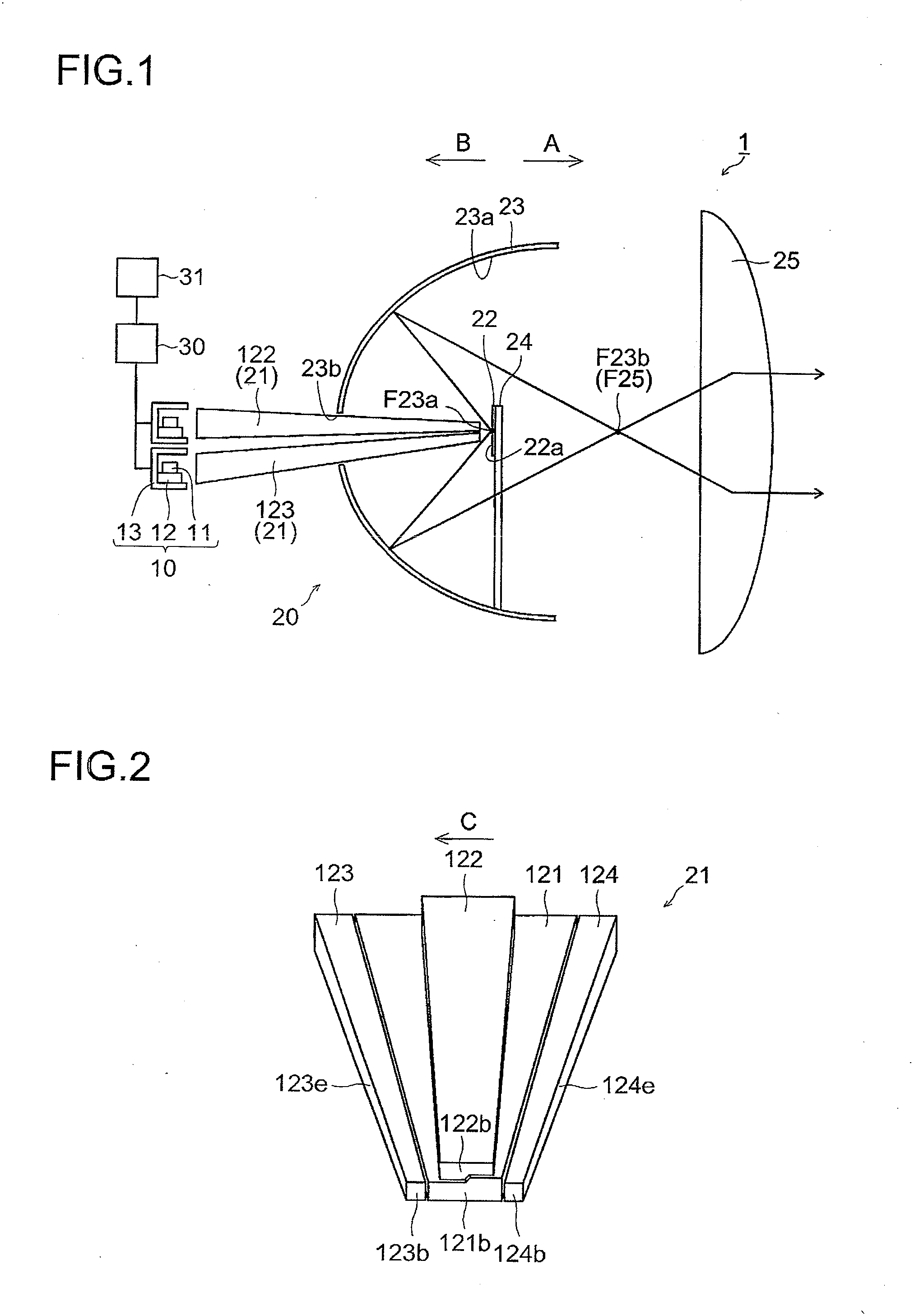

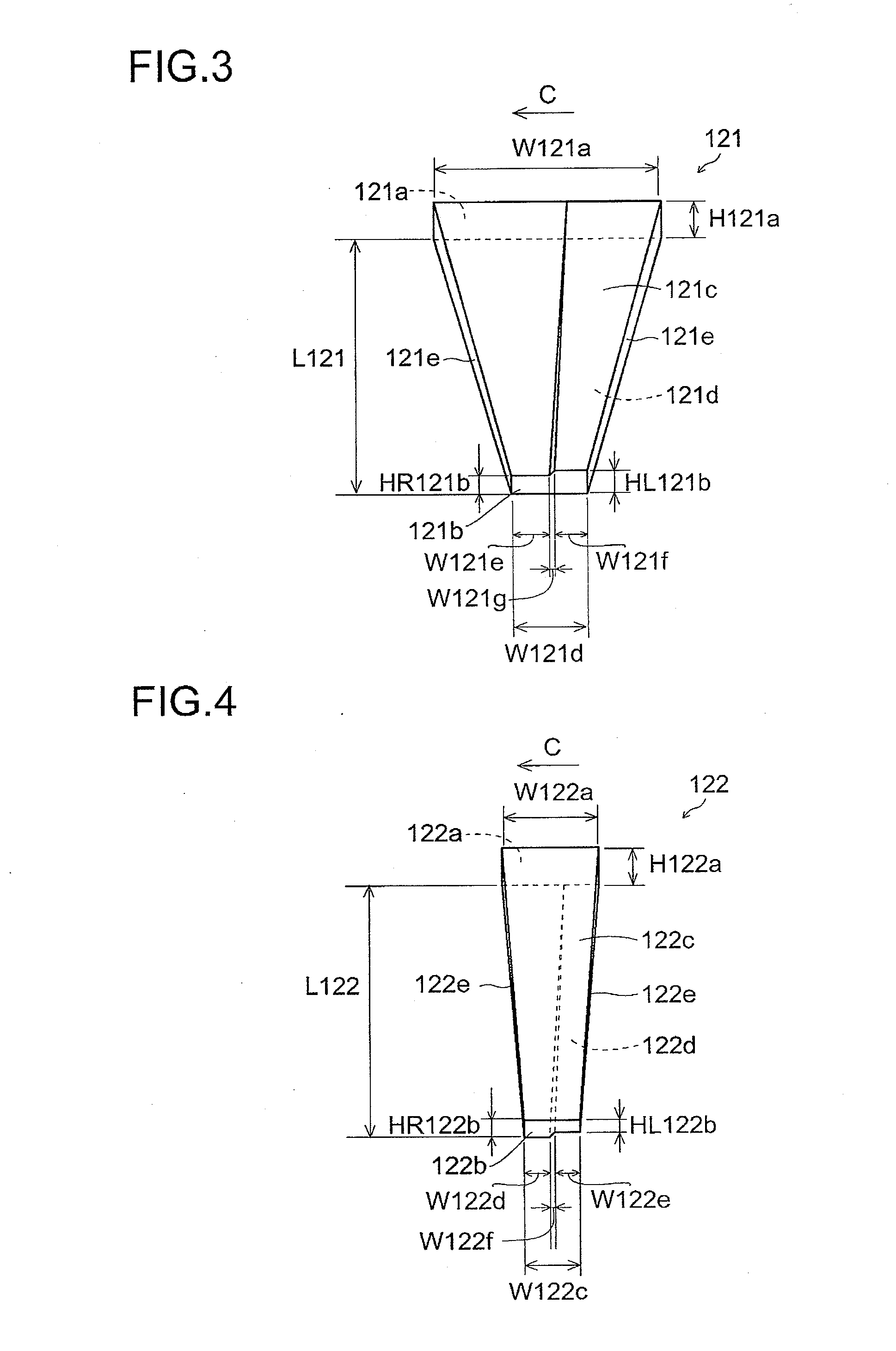

Light projection device and light guide member used in same

Owner:SHARP FUKUYAMA LASER CO LTD

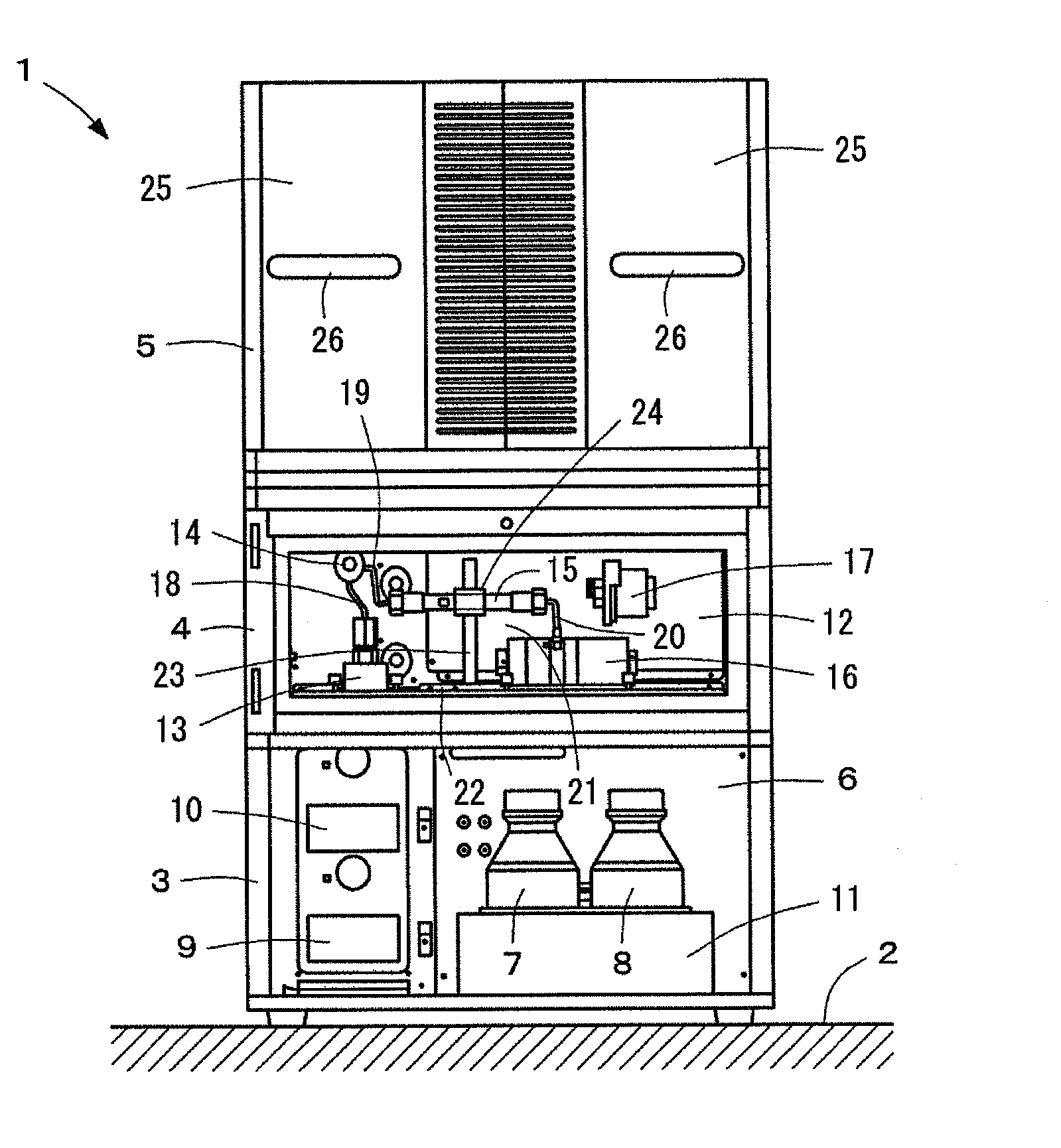

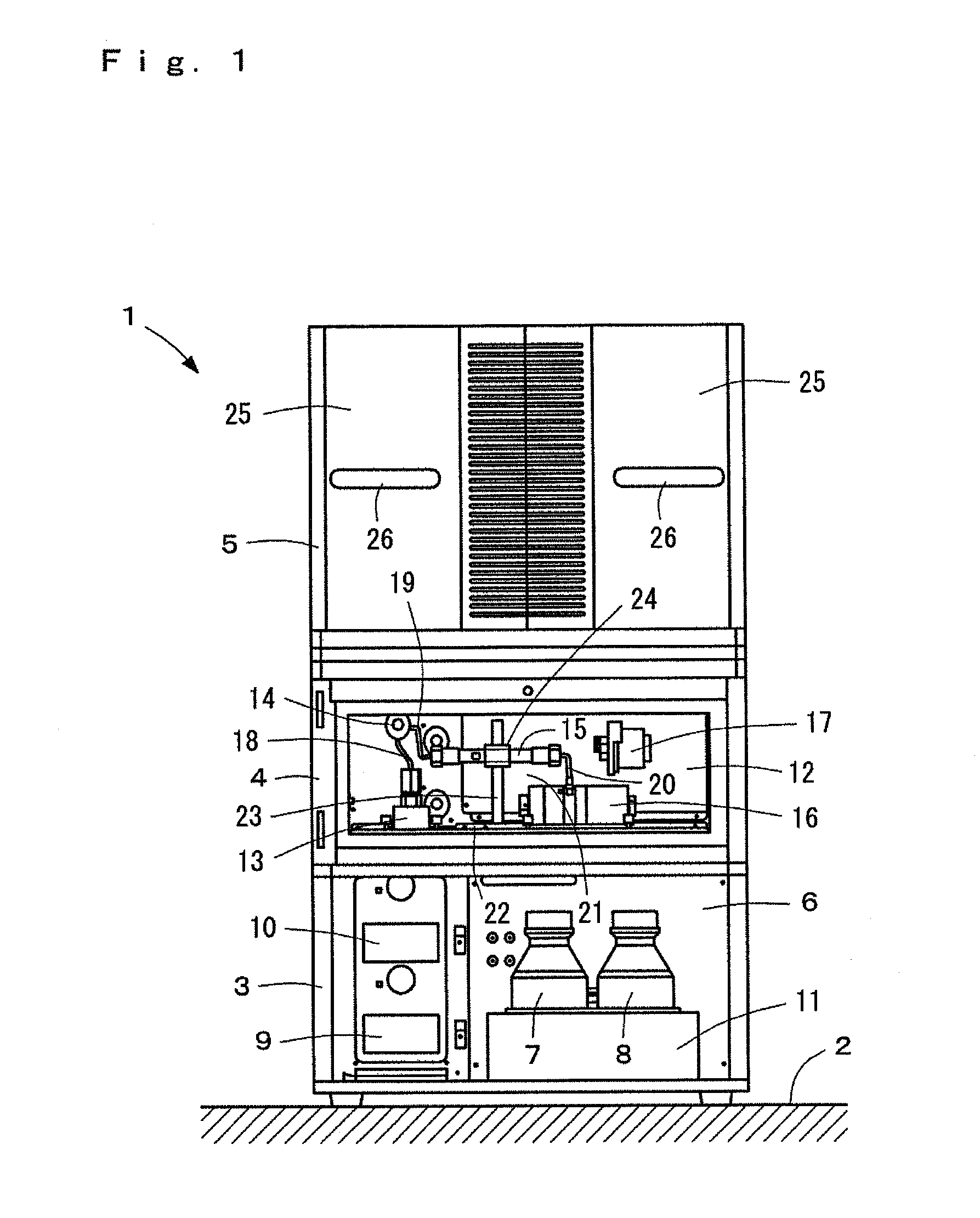

Liquid chromatograph

InactiveUS20110167898A1Reduce dead volumeImprove analytical precisionComponent separationSurface/boundary effectDiffusionInjection port

A liquid chromatograph provided here is adapted to enable the lengths of tubing for connecting the respective constituent elements thereof to be minimized by making the positions of the respective constituent elements including a detector and a column movable and adjustable in order to reduce the dead volume in a liquid chromatograph system in plumbing and increase the analytical precision through prevention of diffusion of samples and rapid sending of a mixed liquid solvent. Furthermore, in order to prevent cross-contamination due to residues of samples and cleaning liquid in a flow channel of the liquid chromatograph system, an injection port in which a needle can be inserted is so provided as to communicate directly with a flow channel of an injection valve.

Owner:GL SCI

Electroluminescent display device and a digital camera using an electroluminescent display device

InactiveUS7606483B2Reliably activatedEasy to operateTelevision system detailsStatic indicating devicesComputer scienceDigital camera

An electroluminescent display device includes an electroluminescent display, andat least one switch which is positioned adjacent to an inner surface of the electroluminescent display, the switch being activated upon an outer surface of the electroluminescent display being pressed to resiliently deform the switch.

Owner:RICOH IMAGING COMPANY

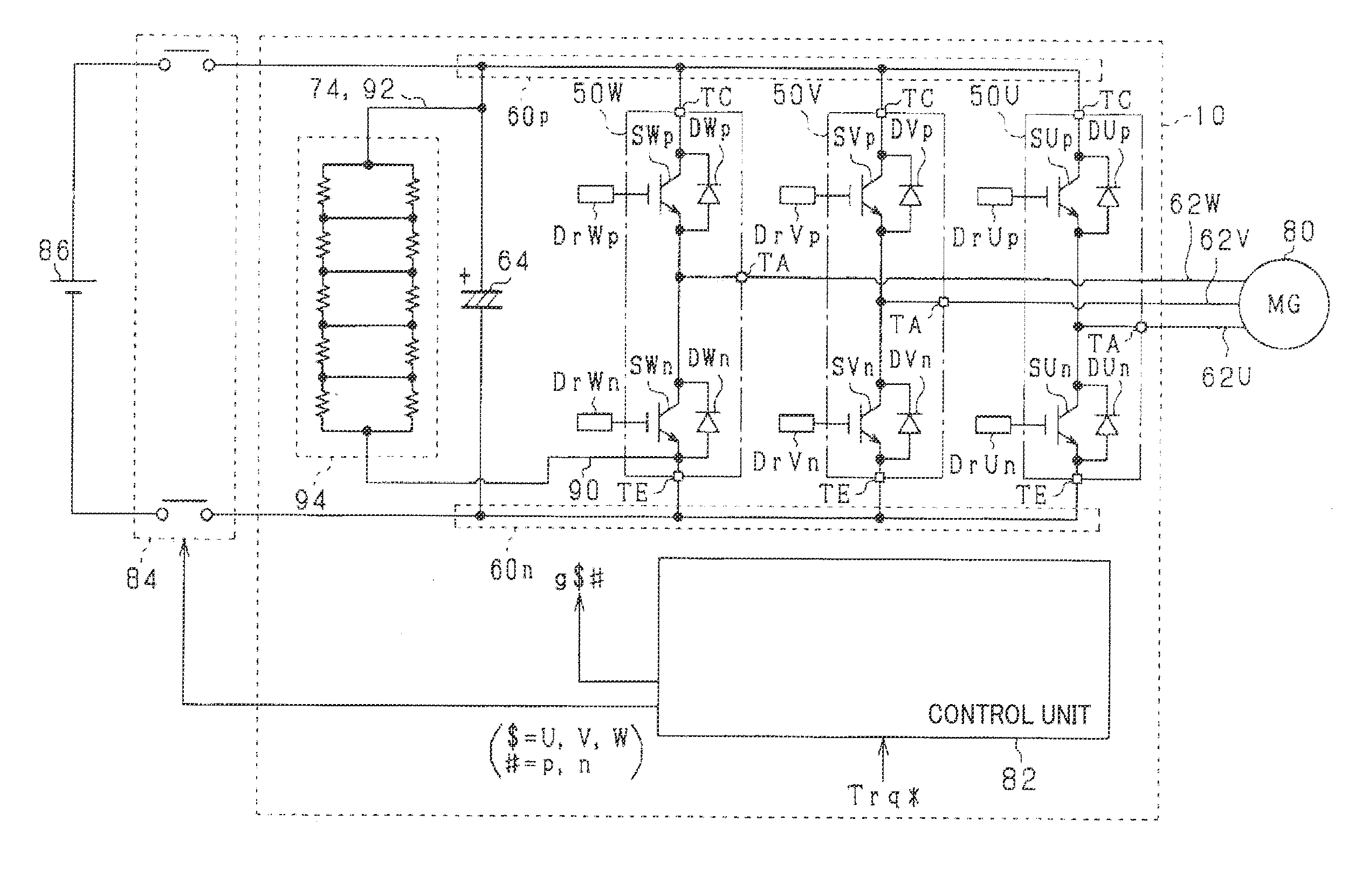

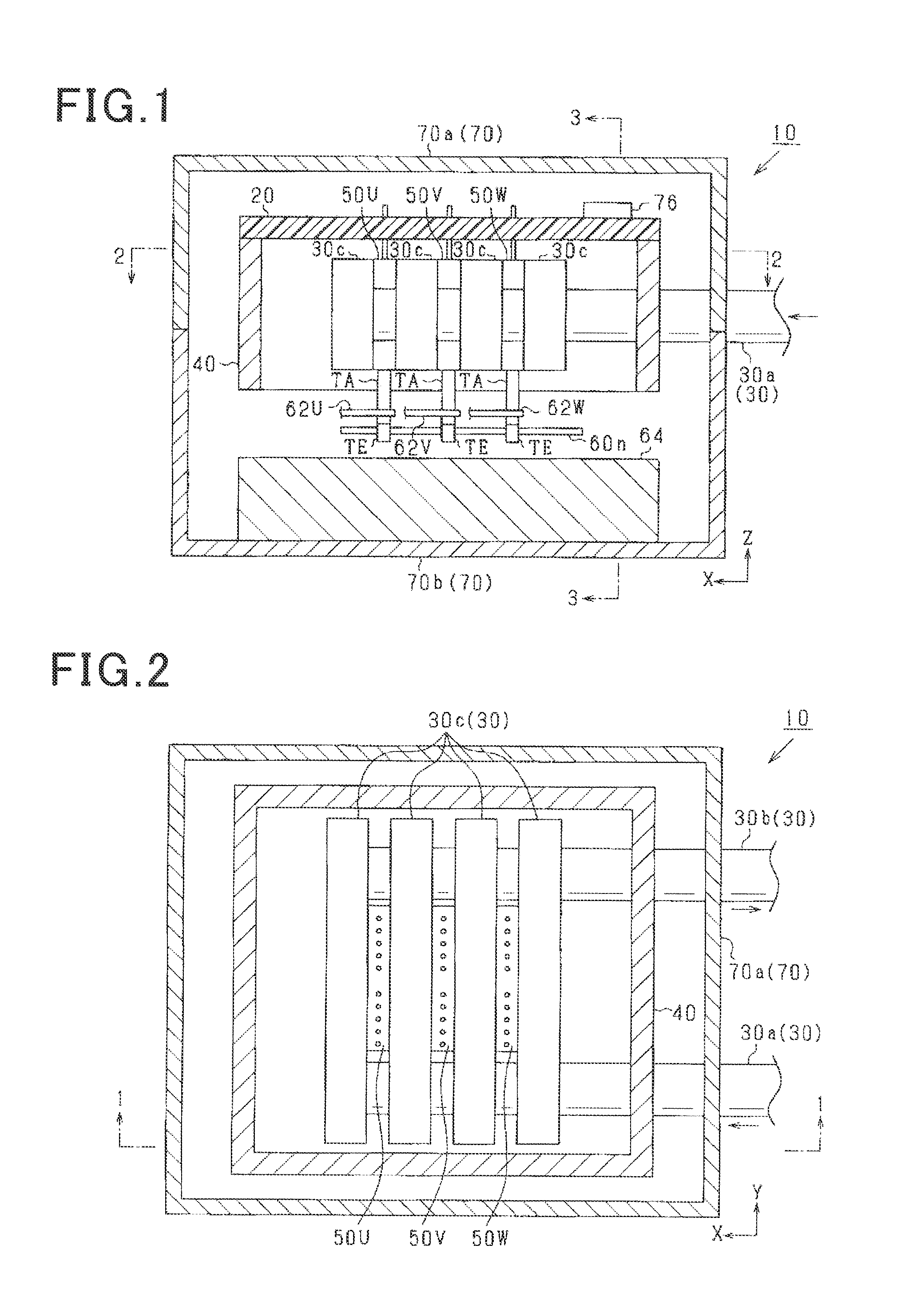

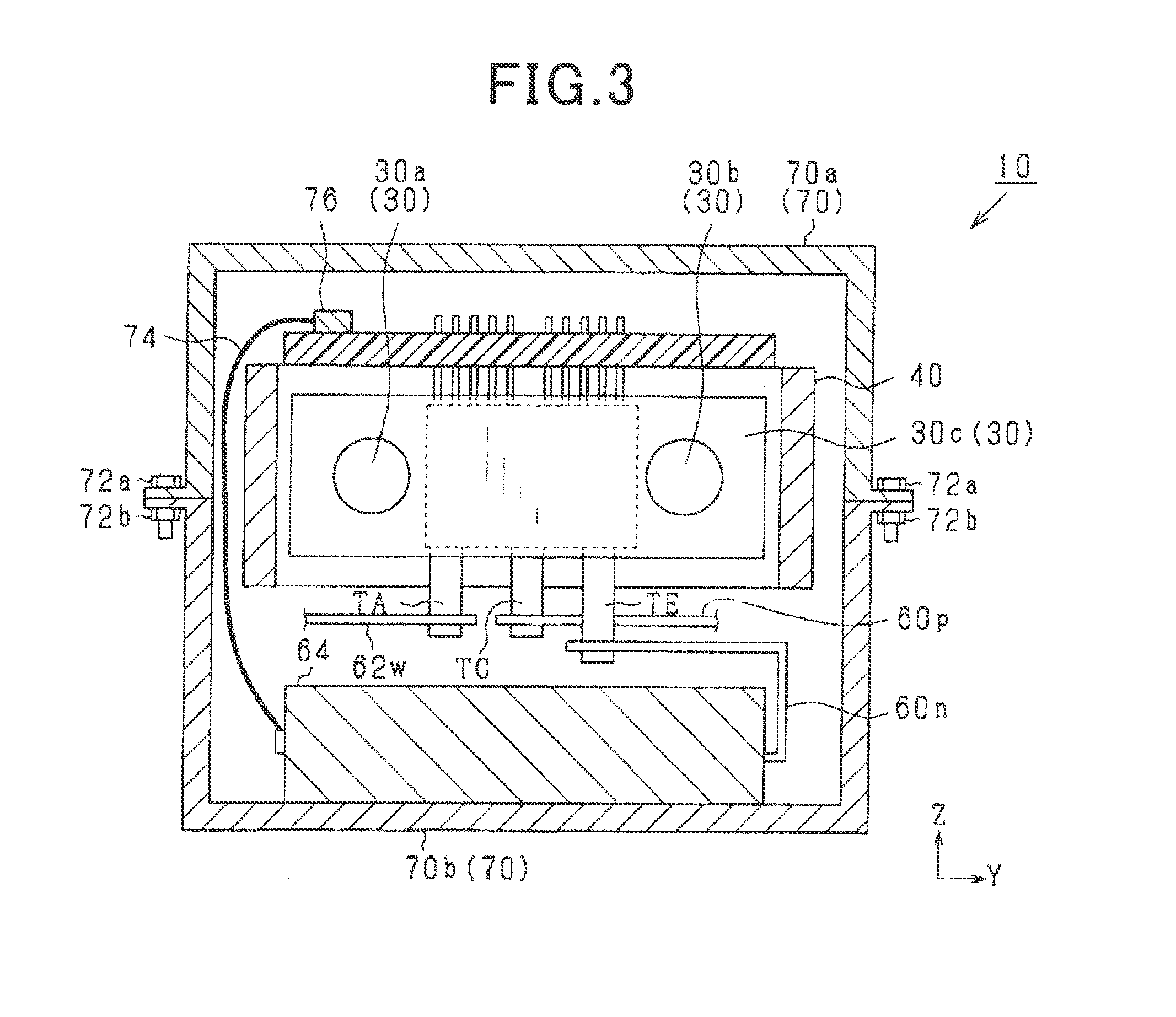

Power converter including smoothing capacitor and discharge resistor

ActiveUS20140369099A1Large sizeReliability of the power converter is favorably prevented from being impairedConversion with intermediate conversion to dcConversion constructional detailsSemiconductorResistor

A power converter includes a body including a switching element; a plurality of semiconductor modules each having a control terminal projected from the body; a circuit board controlling the switching element; a cooler that cools the semiconductor modules; a smoothing capacitor smoothing direct-current voltage applied to the switching element; a discharge resistor disposed on a surface of the circuit board and electrically connected parallel to the smoothing capacitor. The semiconductor modules are mounted on the circuit board with the control terminal, the discharge resistor includes a first connecting portion at one end of the discharge resistor in a longitudinal direction thereof and a second connecting portion at an other end of the discharge resistor in the longitudinal direction, and the first connecting portion is connected to the control terminal via a wiring pattern provided on the surface of the circuit board.

Owner:DENSO CORP

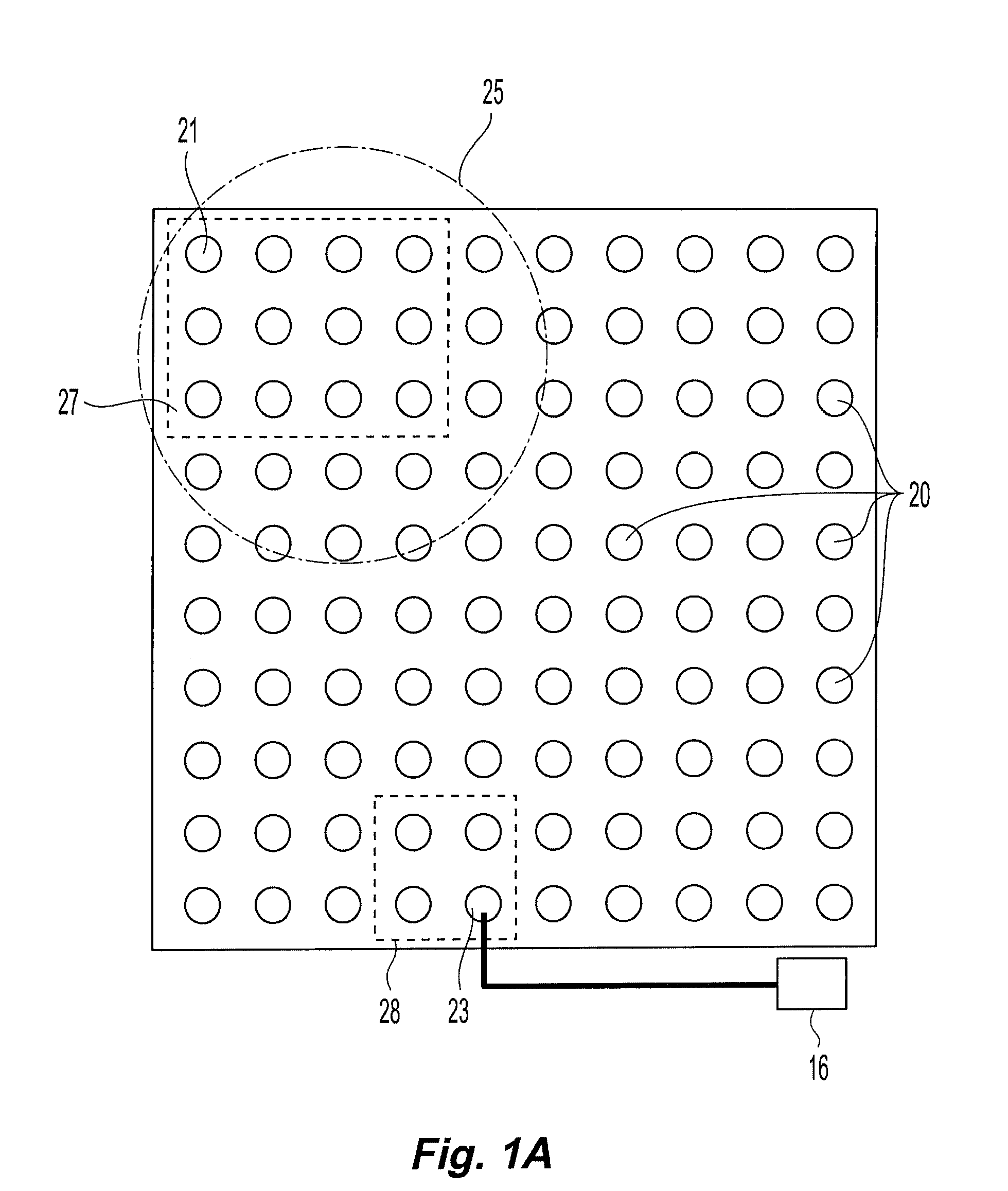

Ceiling-only dry sprinkler systems and methods for addressing a storage occupancy fire

ActiveUS20080319716A1Minimizing overall hydraulic demandReduce heat releaseFire rescueSpecial data processing applicationsDelayed periodsSystems design

A ceiling-only dry sprinkler system configured to address a storage occupancy fire event with a sprinkler operational area sufficient in size to surround and drown the fire. The system and method preferably provide for the surround and effect by activating one or more initial sprinklers, delaying fluid flow to the initial activated sprinklers for a defined delay period to permit the thermal activation of a subsequent one or more sprinklers so as to form the preferred sprinkler operational area. The sprinklers of the operational area are preferably configured so as to provide sufficient fluid volume and cooling to address the fire-event with a surround and drown configuration. The defined delay period is of a defined period having a maximum and a minimum. The preferred sprinkler system is adapted for fire protection of storage commodities and provides a ceiling only system that eliminates or otherwise minimizes the economic disadvantages and design penalties of current dry sprinkler system design.

Owner:TYCO FIRE PRODS LP

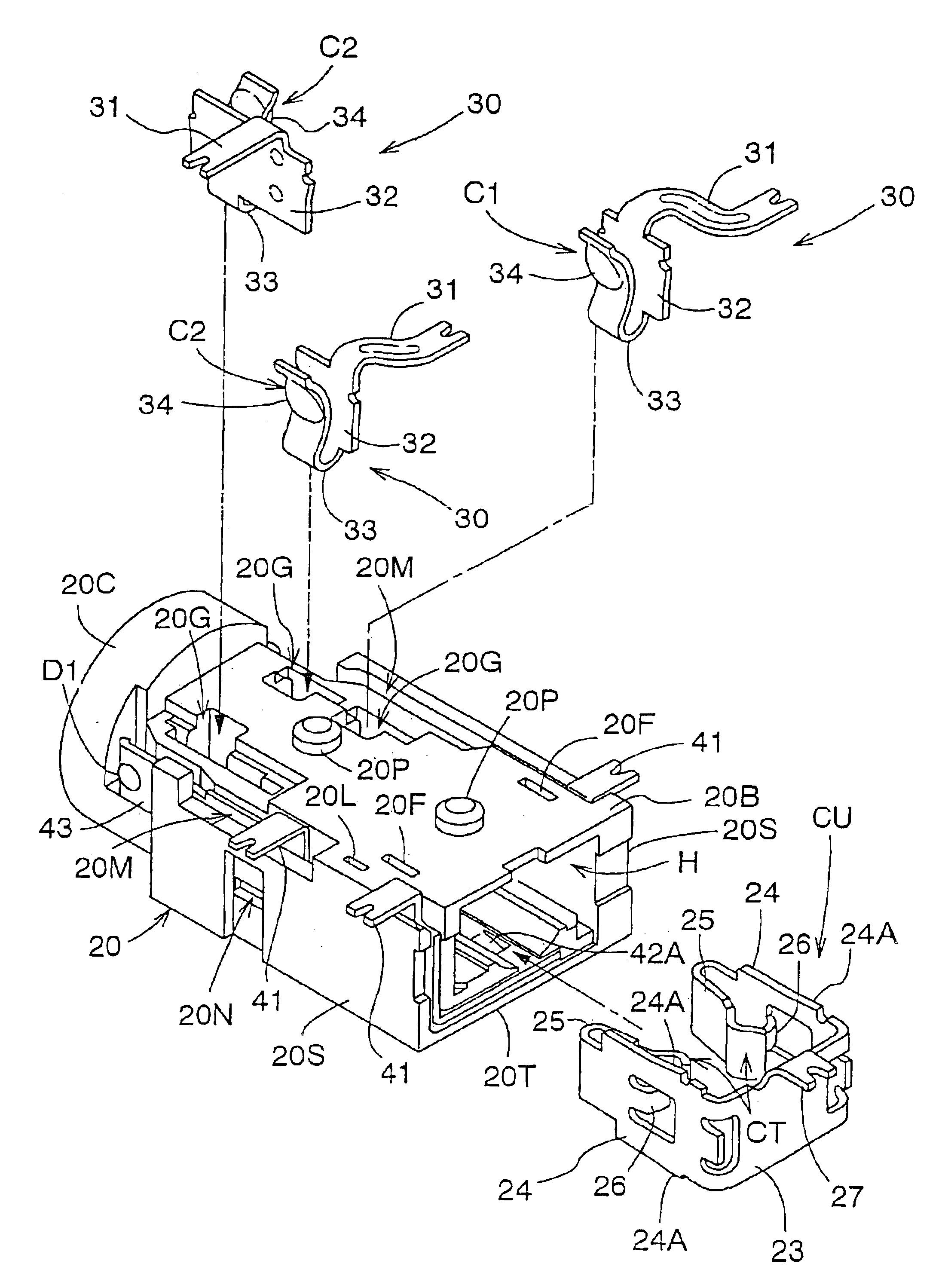

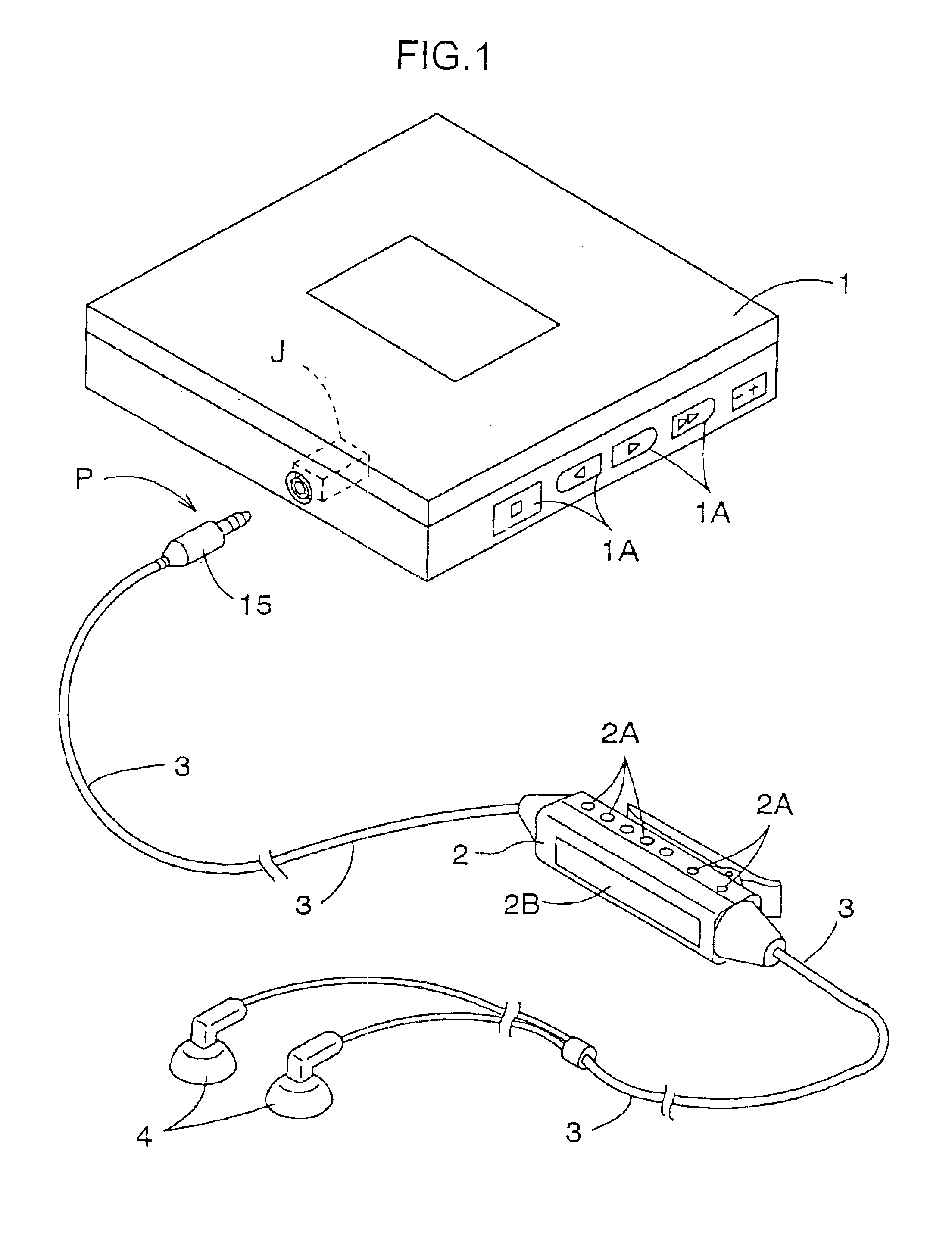

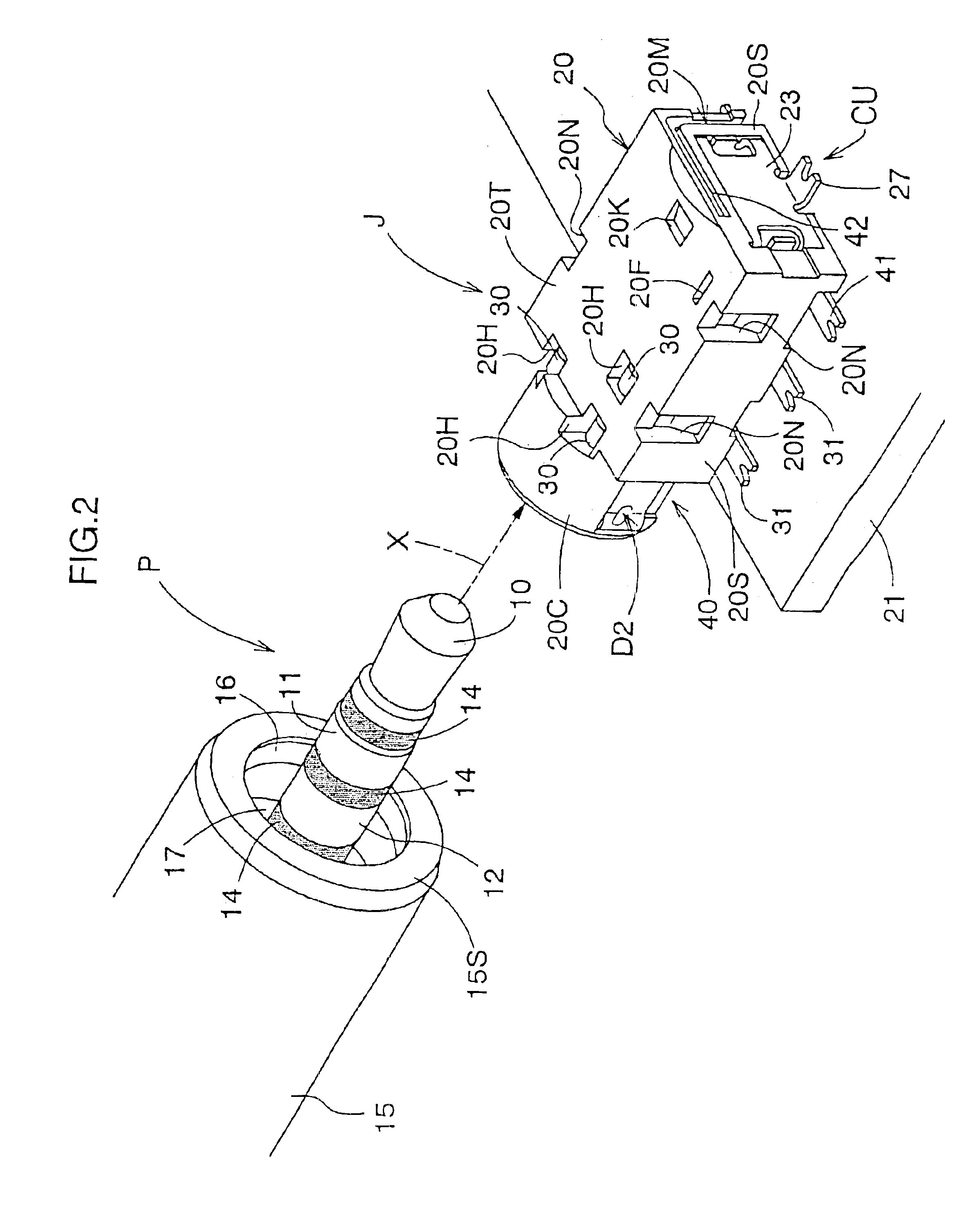

Jack

InactiveUS6869315B2Reliable holdAvoid sizeTwo pole connectionsTwo-part coupling devicesElectrical conductorBiomedical engineering

In order to configure a jack (J) that realizes a favorable conductive state by bringing a tip electrode (10) at a front end of a plug (P) into reliable contact with a contact without making the jack bigger, a contact unit (CU) having a pair of tip contacts (CT) that contact the tip electrode (10) at the front end of the plug (P) in an embracing fashion is incorporated in a body (20). The contact unit (CU) is made of a linking portion (23), intermediate portions (24) that extend from both ends of the linking portion (23) towards an aperture side of the plug insertion hole (H), and folded portions (25) that are folded over from the ends of the intermediate portions (24) to the inner end side of the plug insertion hole (H), projecting into the plug insertion hole (H), the contact unit being formed in one piece by bending a band-shaped conductor, such as a copper alloy, and the tip contacts (CT) being formed on a free end side of the folded portions (25).

Owner:HOSIDEN CORP

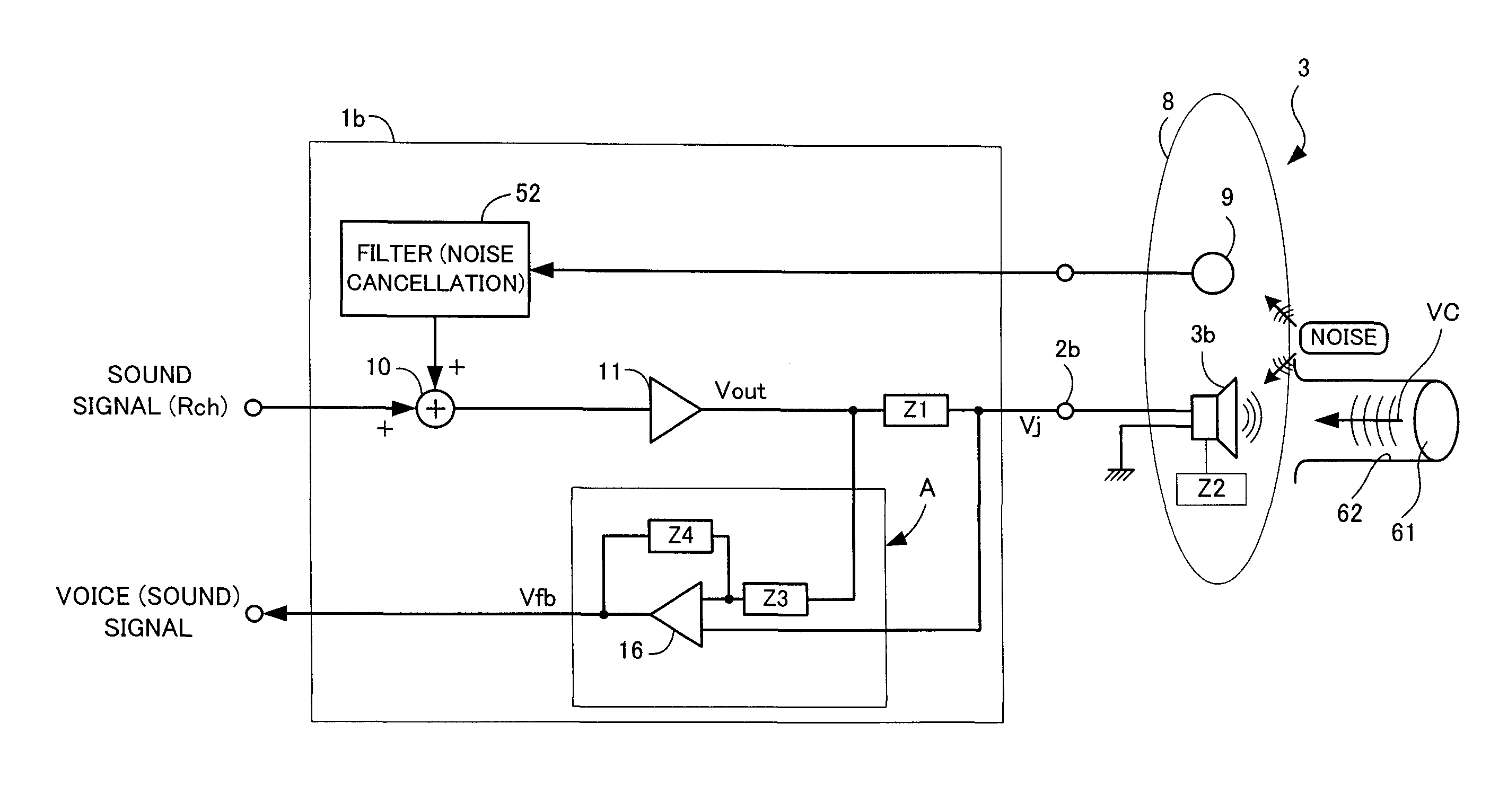

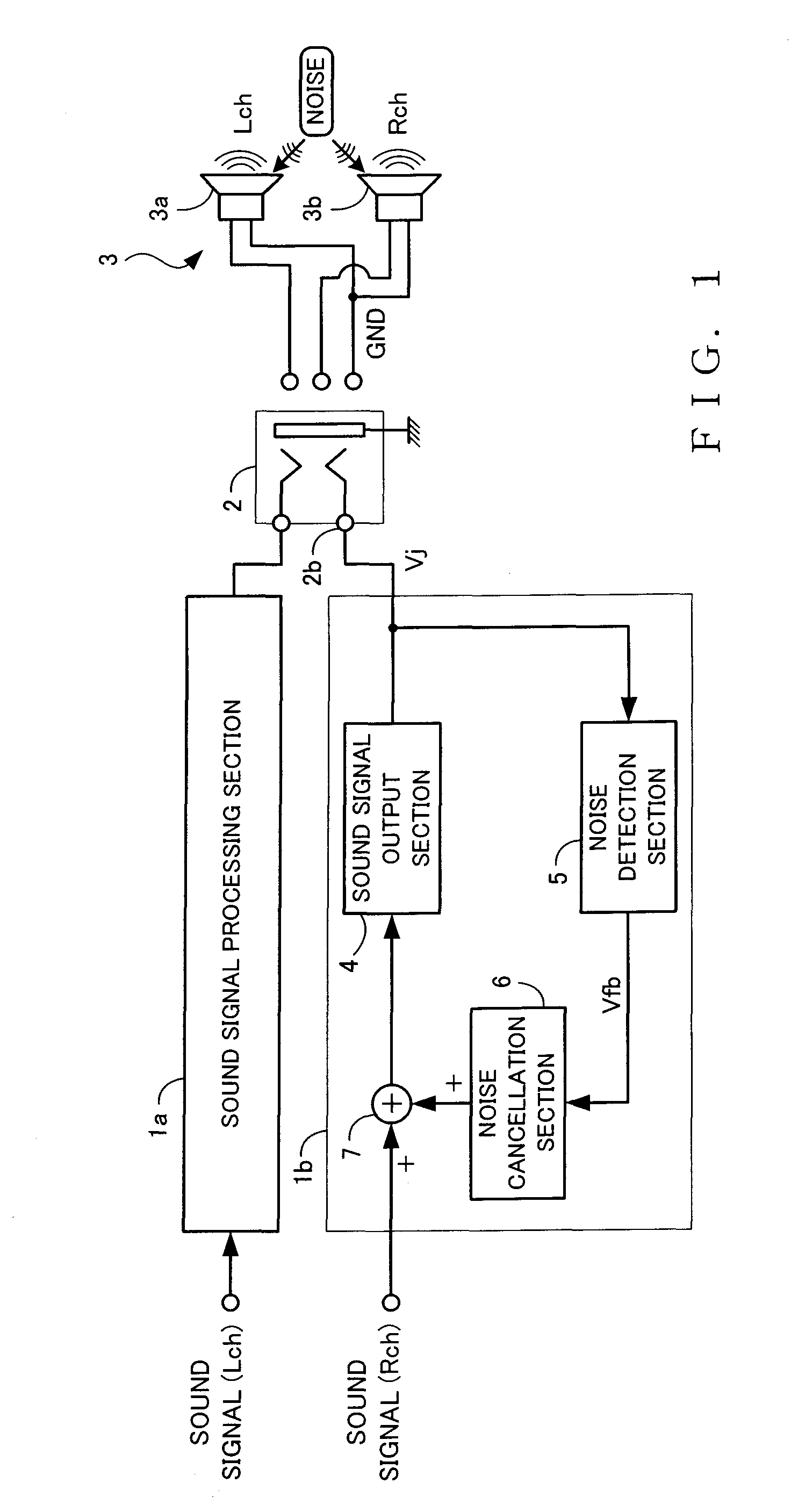

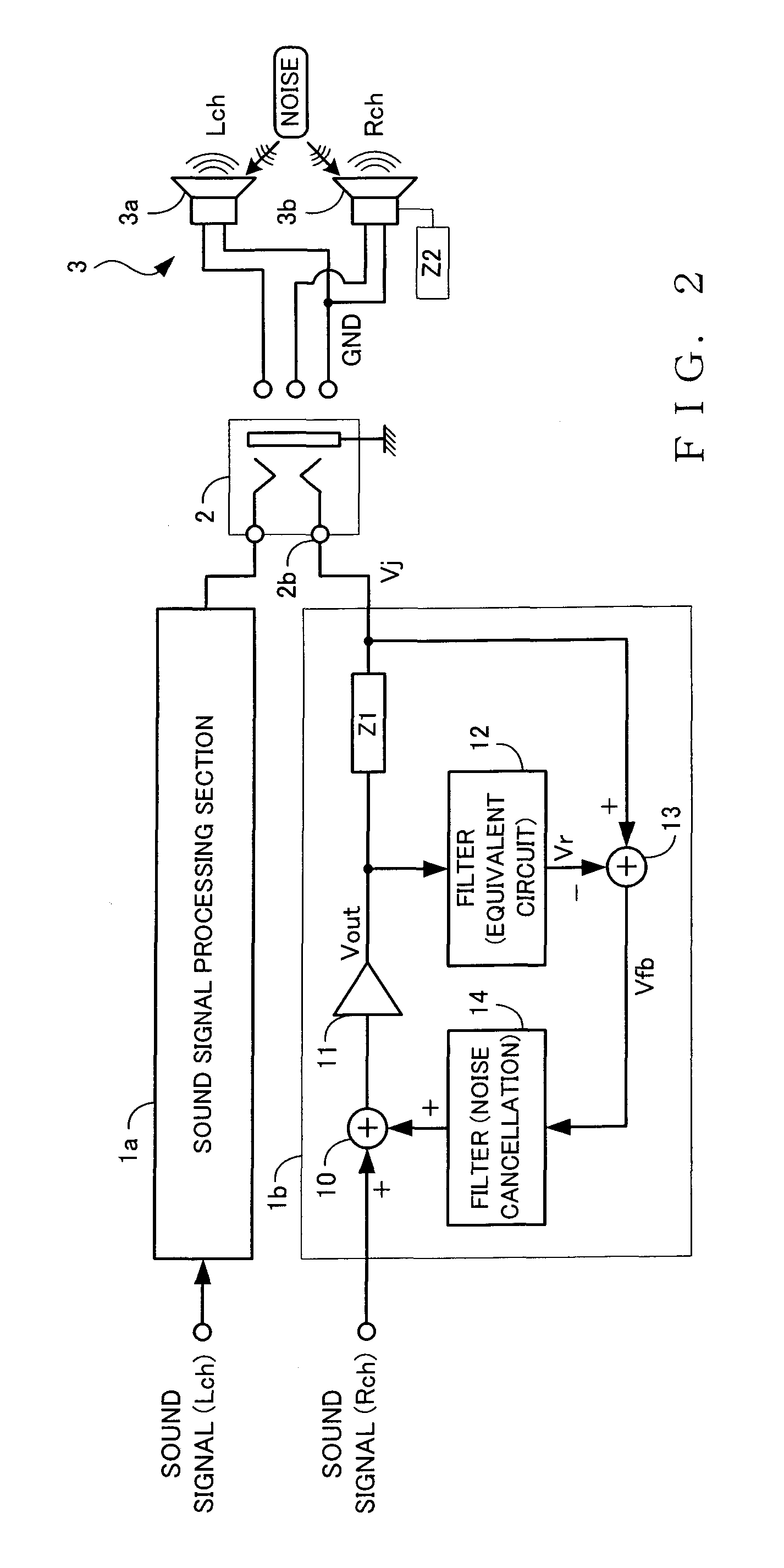

Ambient noise removal device

InactiveUS20110002476A1Low costSmall sizeEar treatmentEarpiece/earphone attachmentsEnvironmental noiseNoise removal

An ambient noise removal device includes: a sound signal output section that outputs a sound signal to thereby drive a speaker; a noise detection section that detects an electromotive force produced in the speaker by ambient noise; and a noise cancellation section that generates, on the basis of the electromotive force, a signal of an opposite phase from the ambient noise and adds the generated signal to the sound signal to thereby cancel the ambient noise.

Owner:YAMAHA CORP

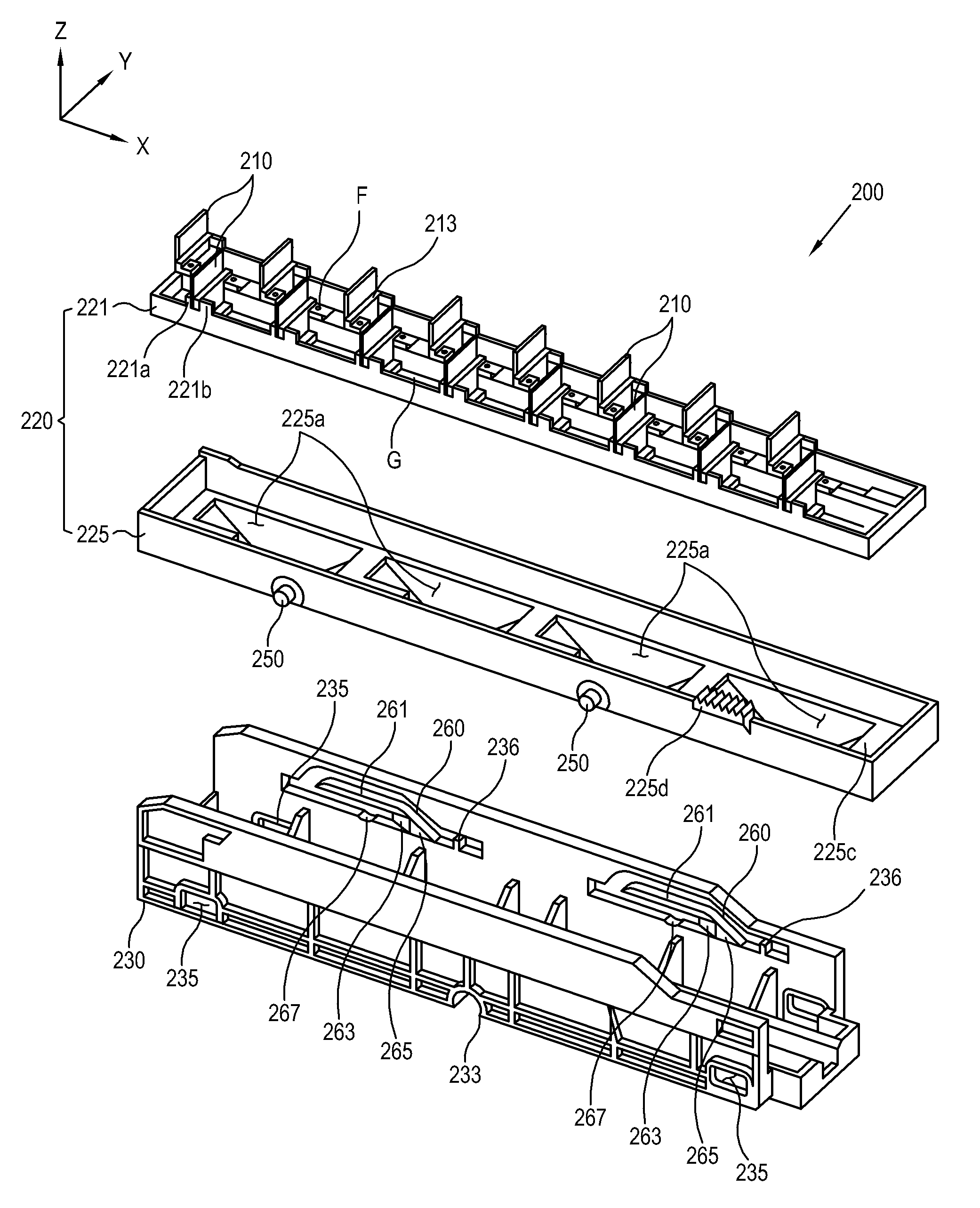

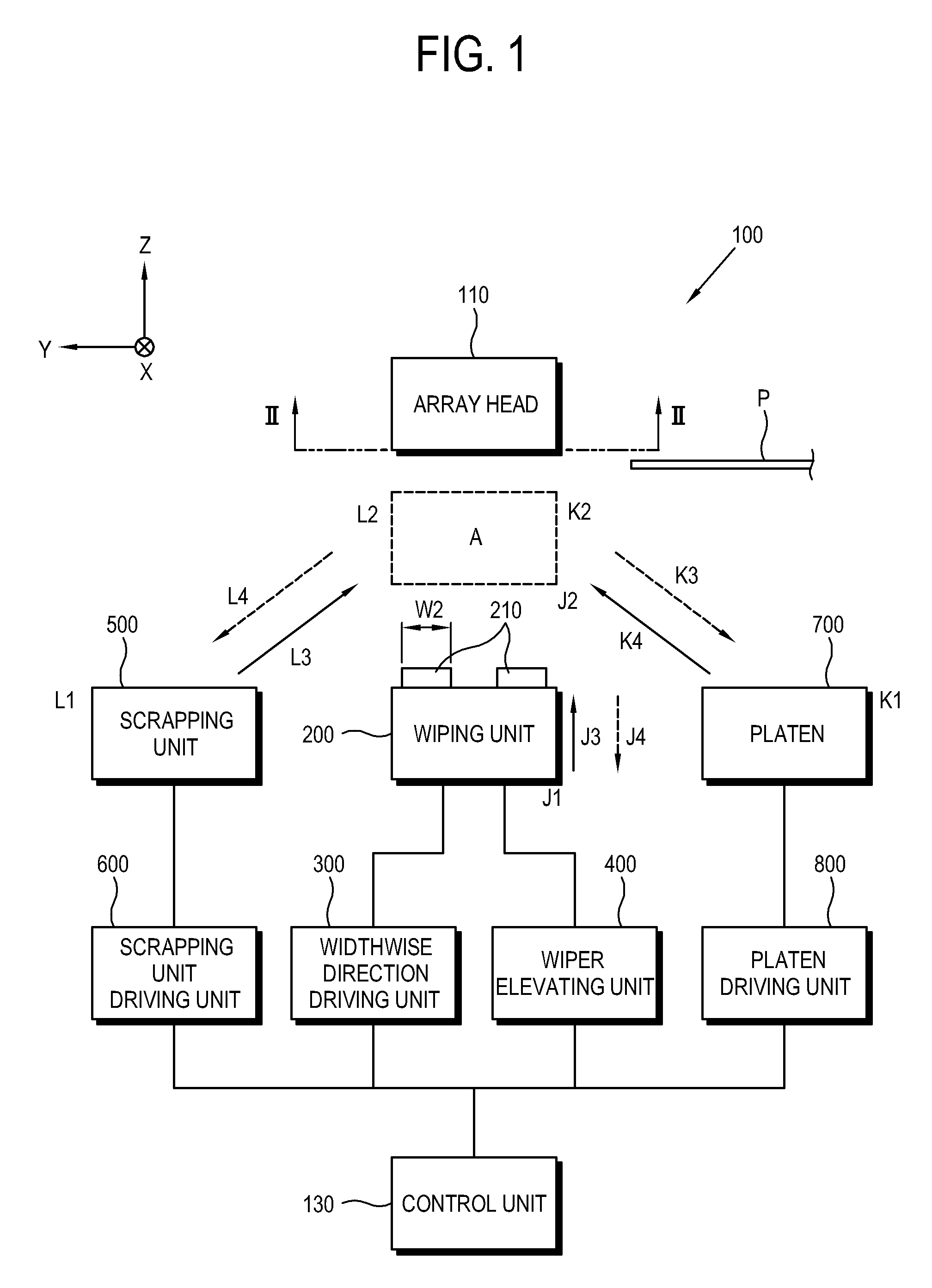

Scrapping unit and image forming apparatus having the same, and cleaning methods thereof

InactiveUS20110043568A1Reduce maintenance costIncrease image sizeOther printing apparatusSupport surfaceCleaning methods

A scrapping unit and an image forming apparatus having the same, and cleaning methods thereof to improve a maintenance performance. The scrapping unit cleans a polluted member disposed in an image forming apparatus and stained by a polluting material. The scrapping unit may include an endless belt to circulate between an exposed position where a surface of the endless belt is exposed toward the polluted member, and a non-exposed position where the surface of the endless belt is not exposed with respect to the polluted member, and a belt support frame which includes a belt support surface to support the endless belt so that the endless belt can be unfolded in the exposed position, and a storing space to store the endless belt so that the endless belt can be folded in the non-exposed position.

Owner:HEWLETT PACKARD DEV CO LP

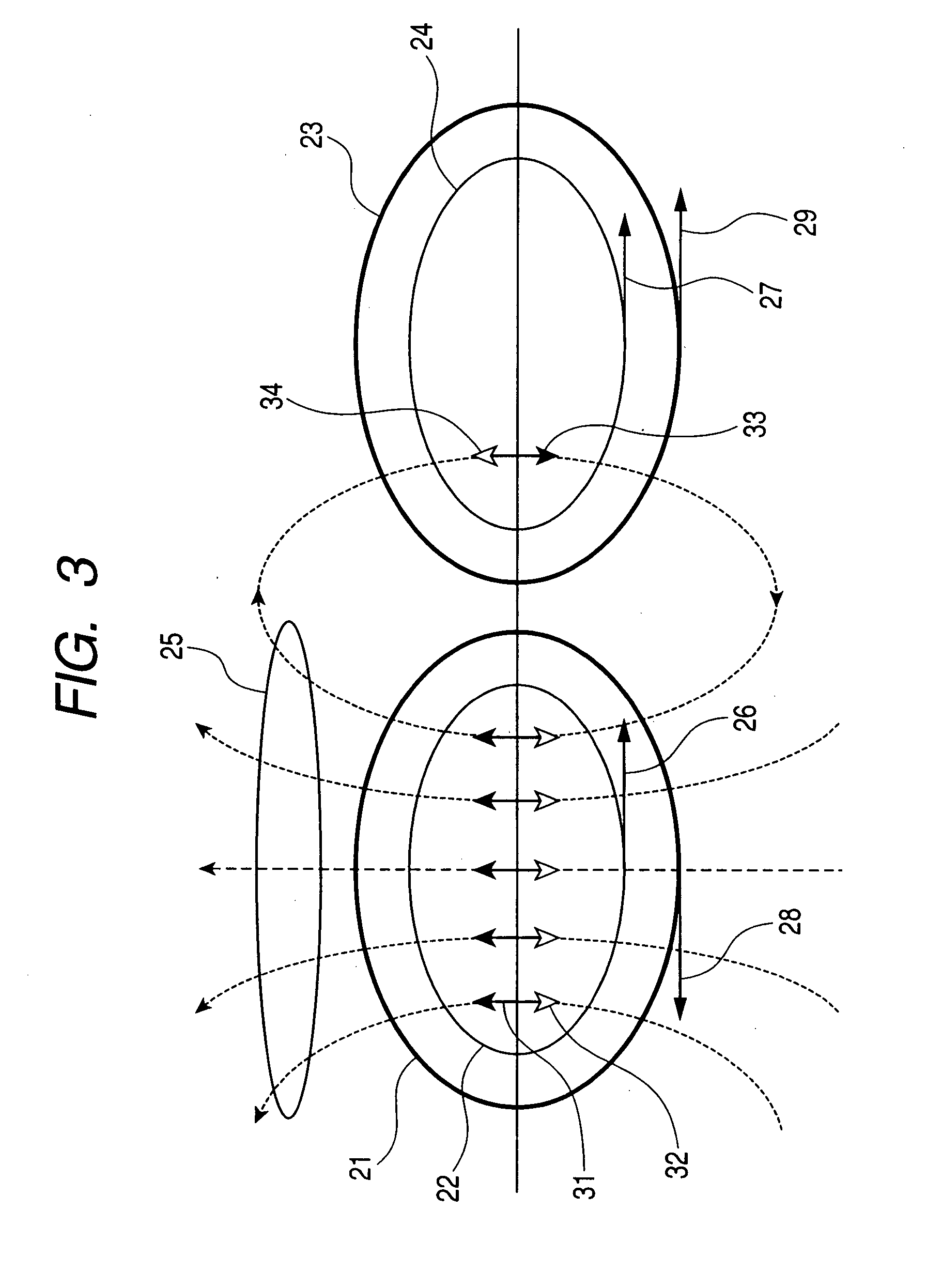

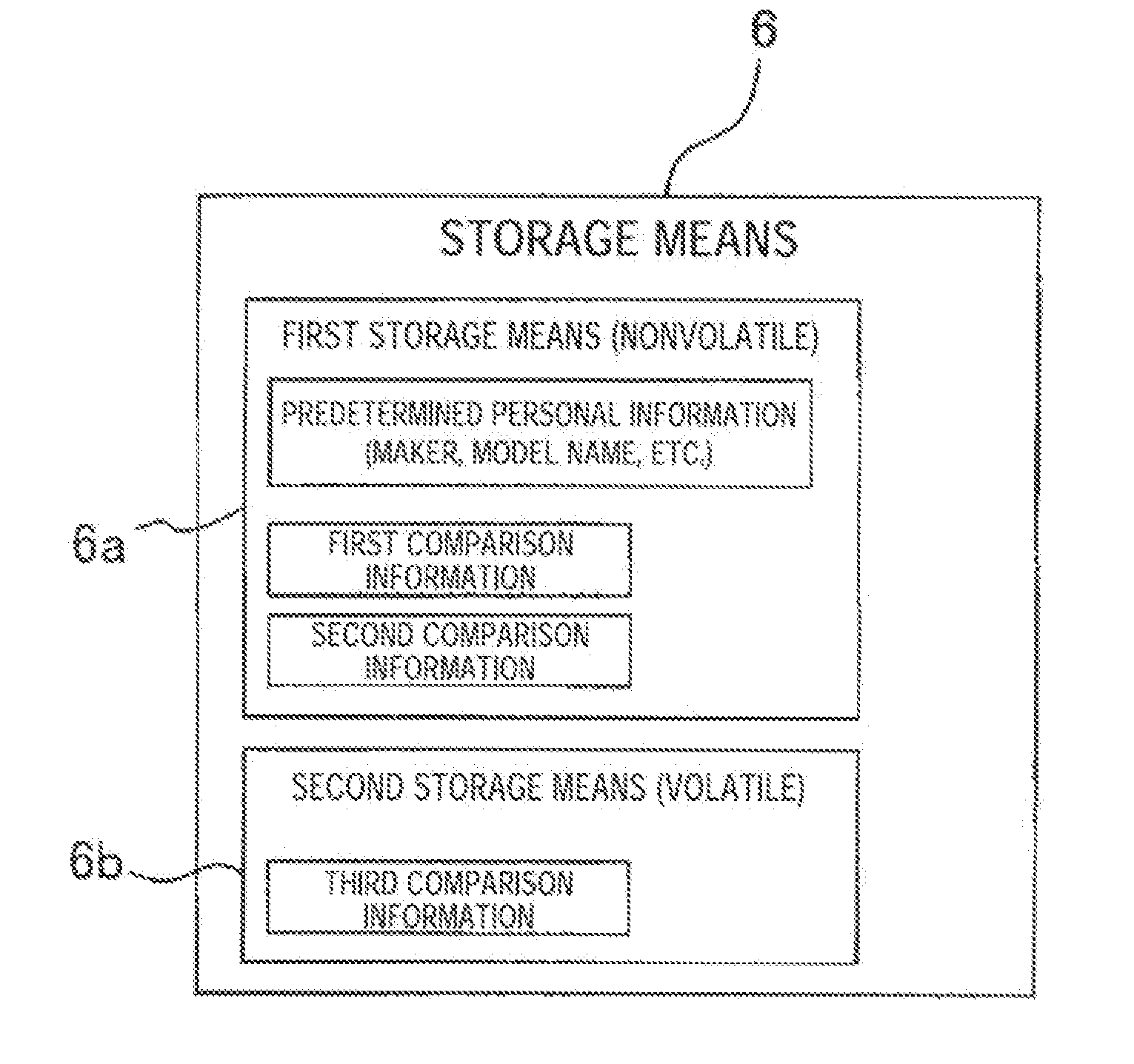

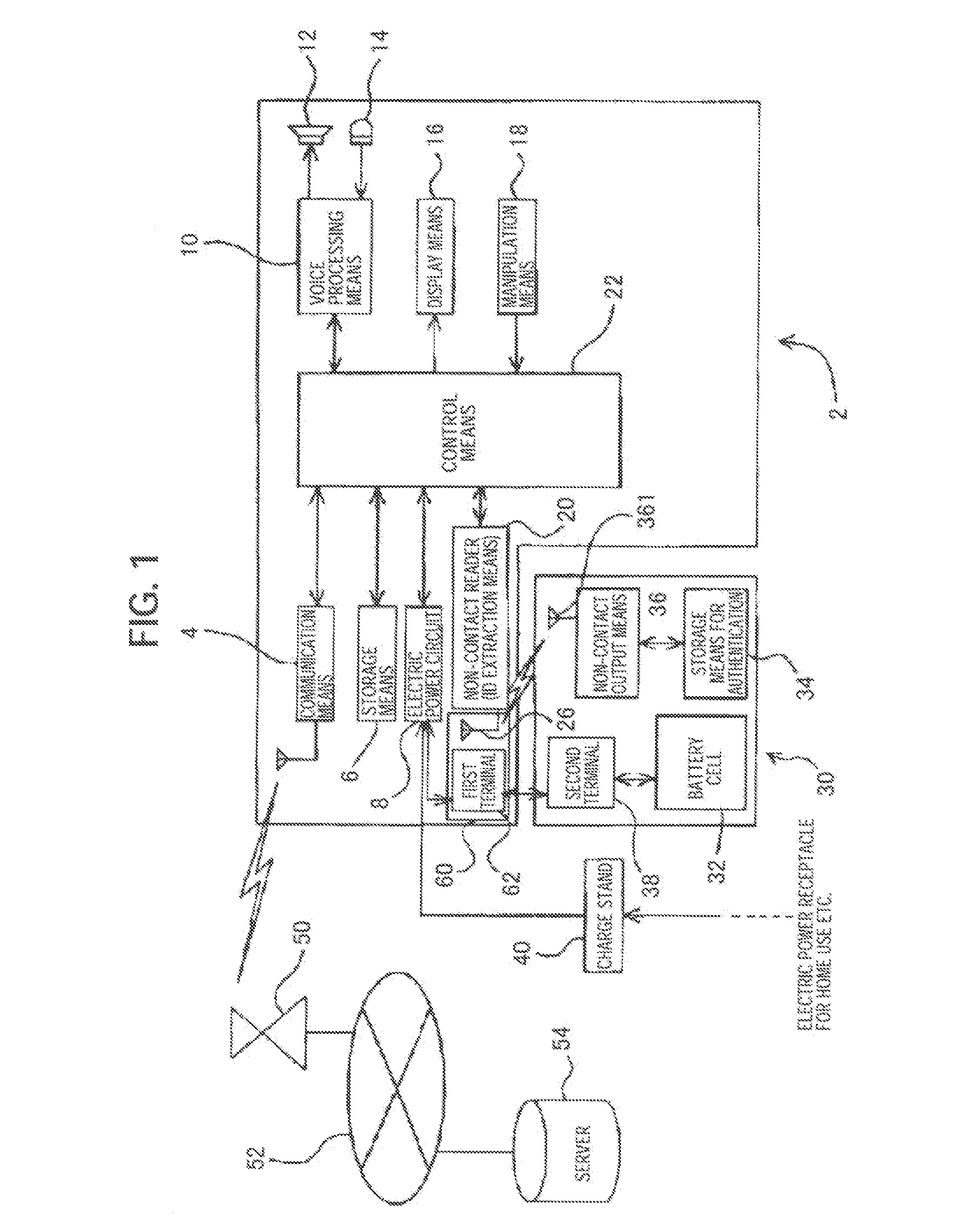

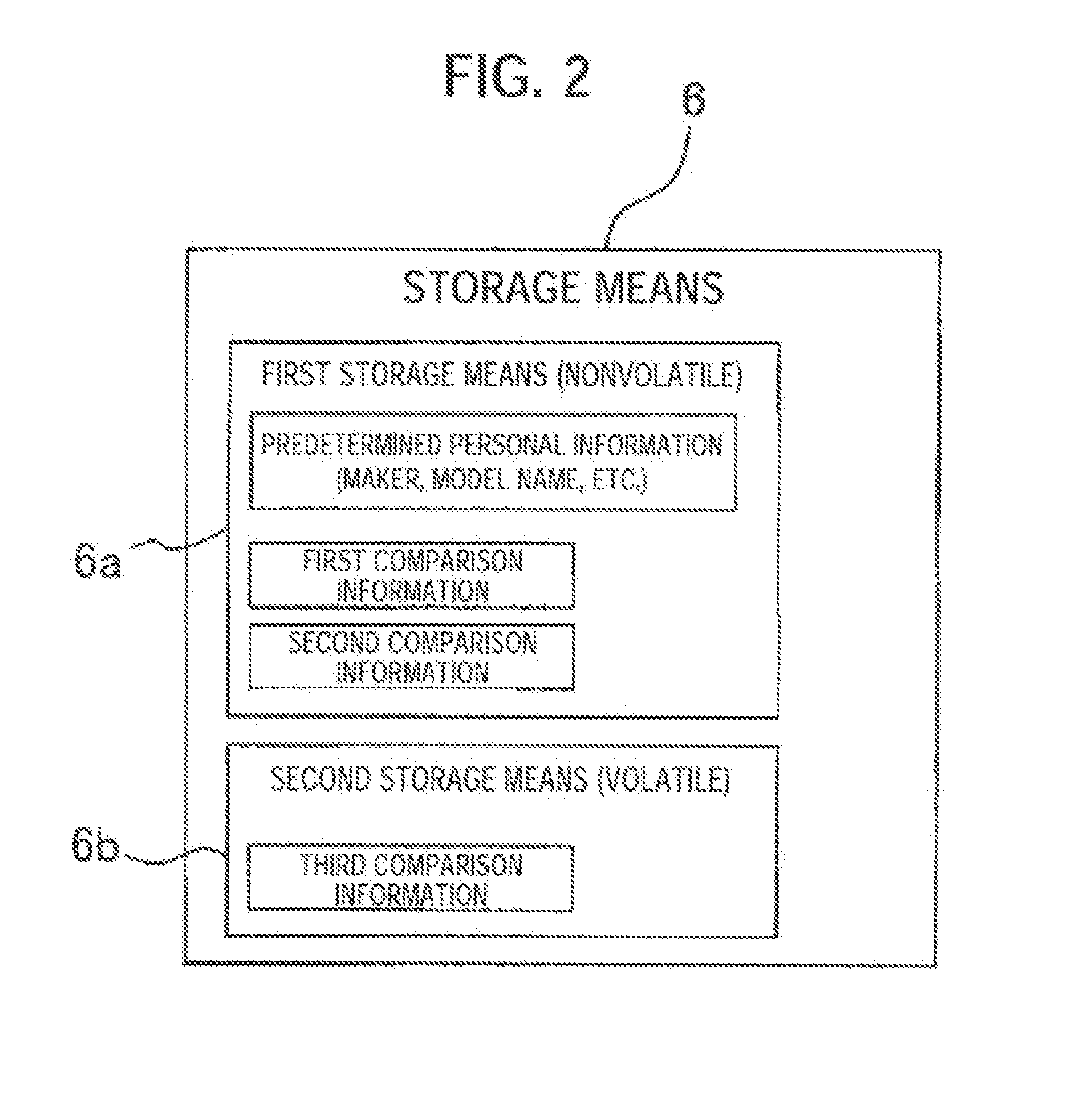

Charge System, Mobile Electronic Device, Cell Terminal Used for Them, and Secondary Cell

InactiveUS20100171460A1Increase consumptionAvoid sizeLoop antennas with ferromagnetic coreAntenna supports/mountingsInformation controlEngineering

It is possible to prevent charge of an incompatible secondary cell while suppressing the size of a mobile electronic device and a secondary cell without increasing power consumption so as to prevent damage of the secondary cell or the mobile electronic device by charge. A detachable secondary cell (30) supplies power to a mobile electronic device (2). The mobile electronic device (2) includes: a cell terminal (60) which outputs and inputs power to / from the mounted secondary cell (30); non-contact information extraction means (20) which performs a magnetic field communication; a loop antenna (26) which transmits / receives a signal using an electromagnetic wave by the non-contact information extraction means (20); and control means (22) which acquires particular information outputted from the non-contact information extraction means (20) and controls charge of the secondary cell (30) according to the acquired particular information. The loop antenna (26) is arranged in the cell terminal (60).

Owner:KYOCERA CORP

Cerium dioxide nanoparticle-containing fuel additive

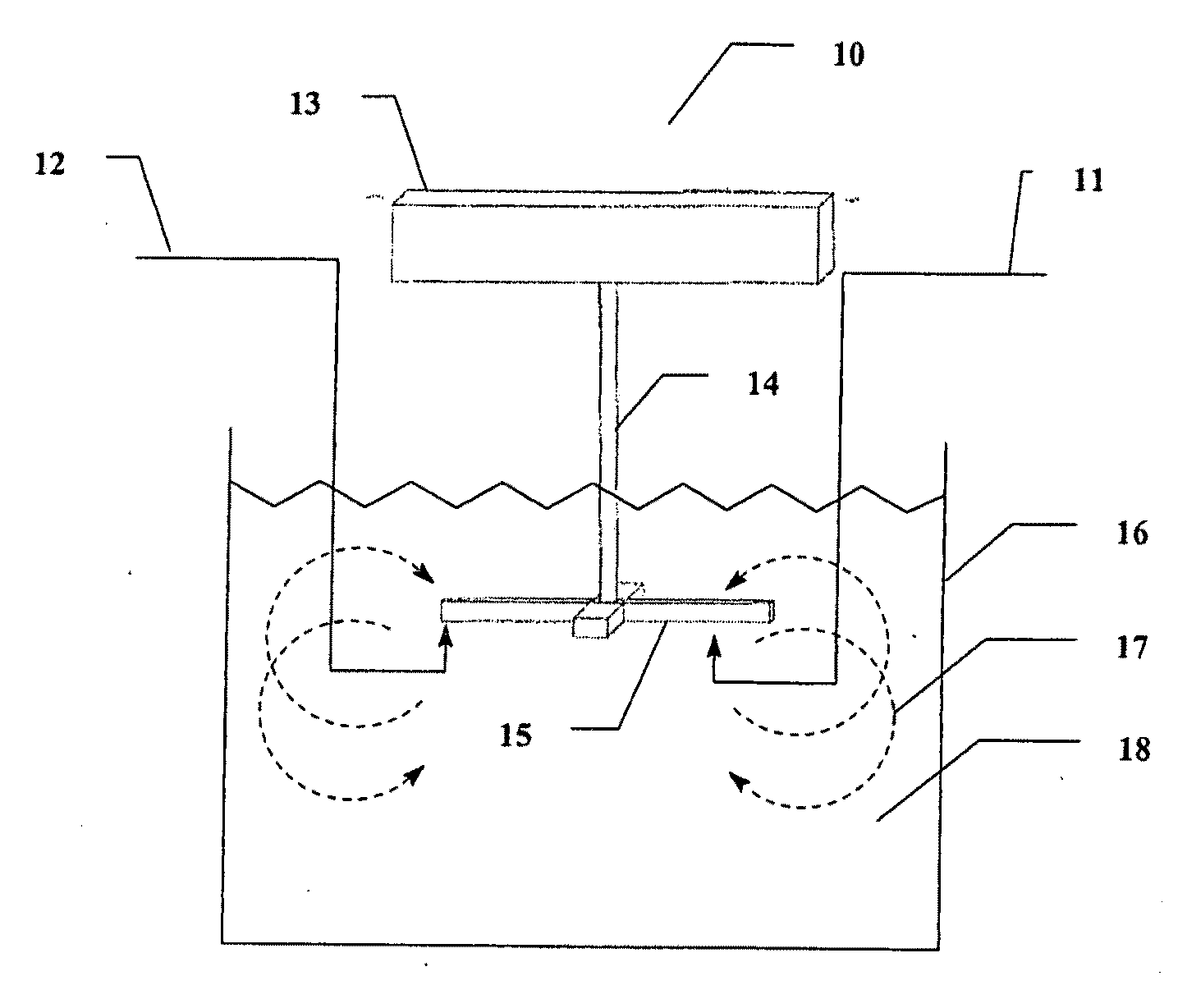

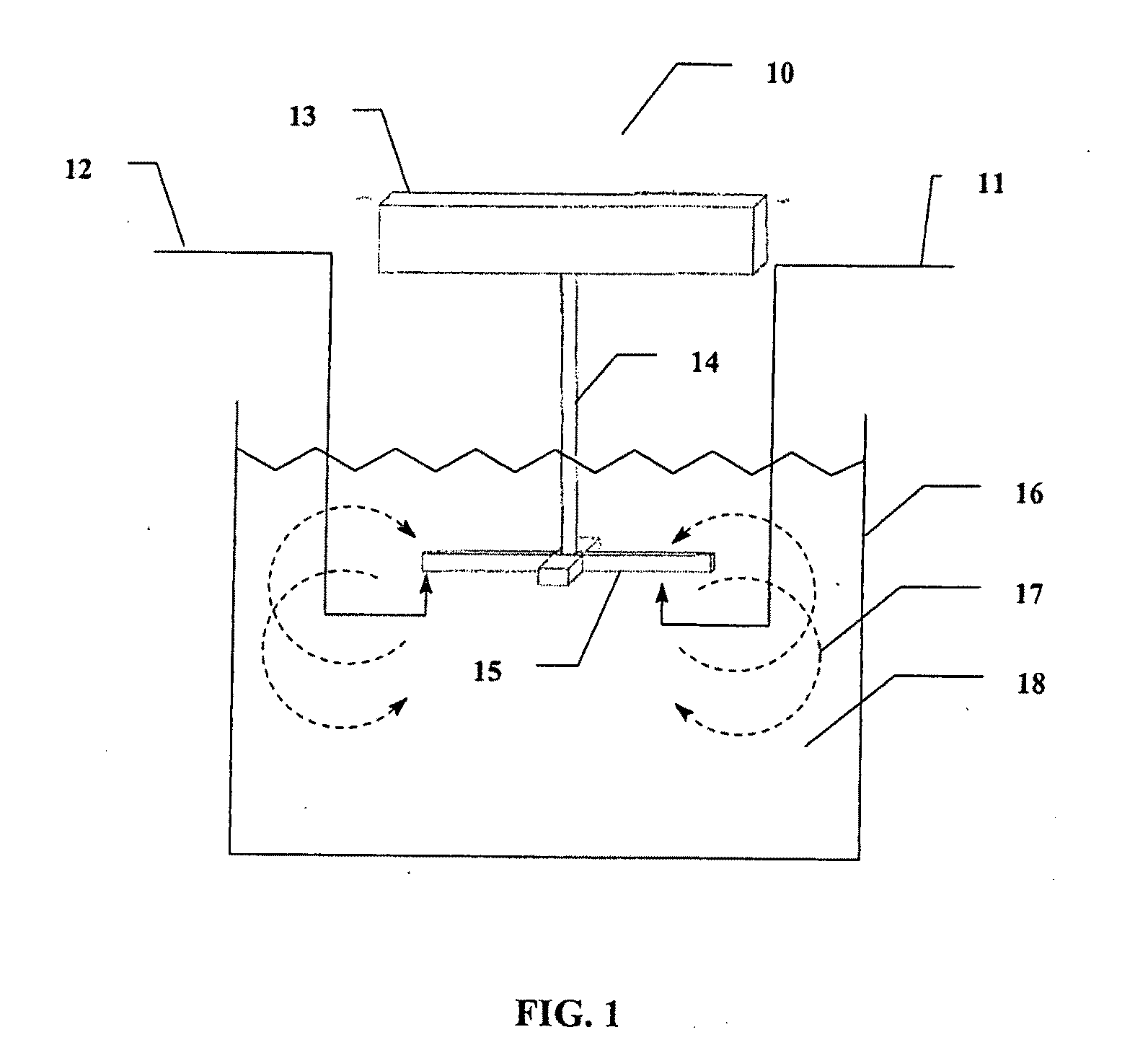

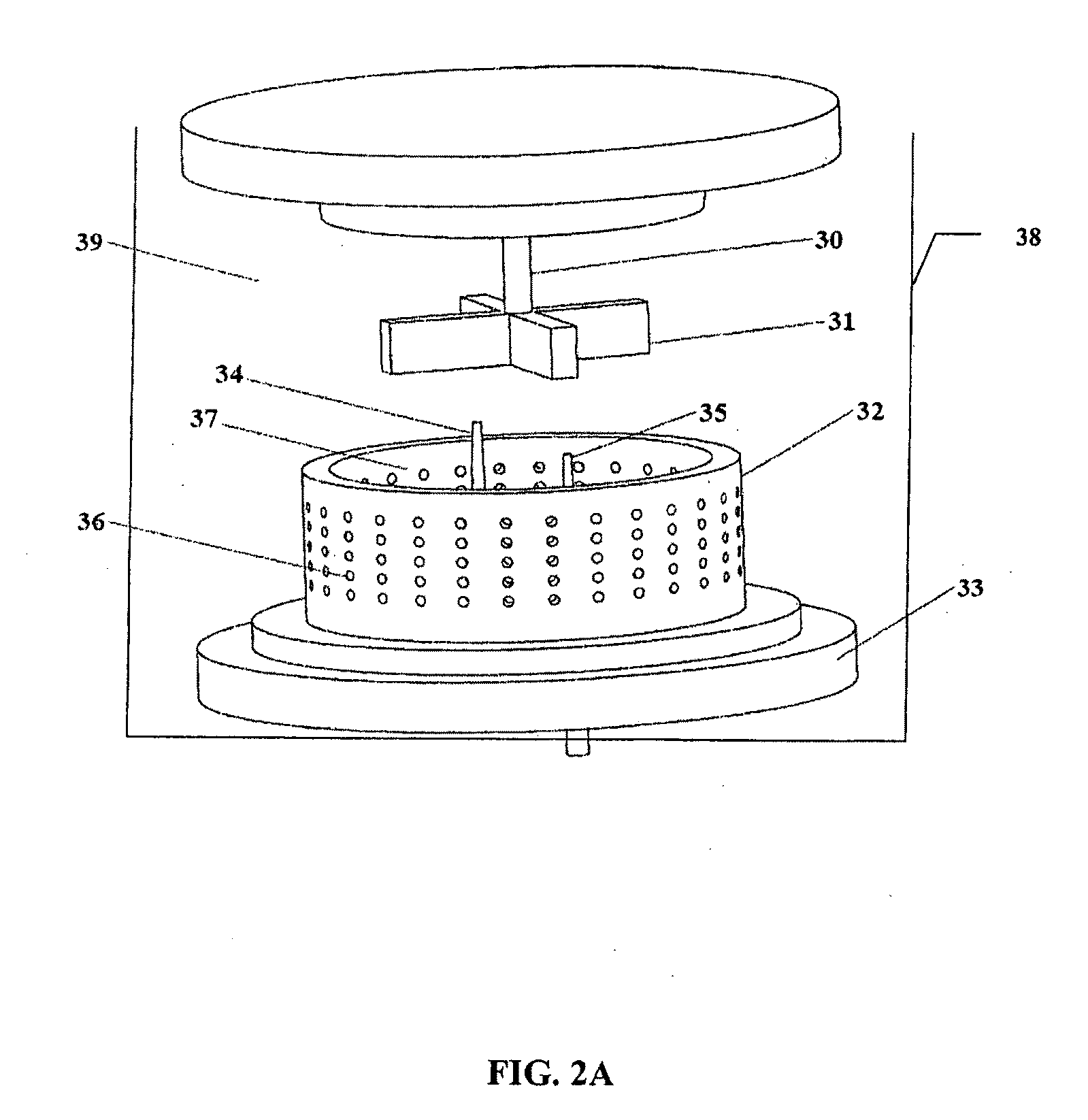

InactiveUS20100199547A1Increase engine powerFacilitate fuel combustionMaterial nanotechnologyRotary stirring mixersNanoparticleCerium

A fuel additive composition includes: a) a reverse-micellar composition having an aqueous disperse phase that includes cerium dioxide nanoparticles in a continuous phase that includes a hydrocarbon liquid, a surfactant, and optionally a co-surfactant and b) a reverse micellar composition having an aqueous disperse phase that includes a cetane improver effective for improving engine power during fuel combustion. A method of making a cerium-containing fuel additive includes the steps of: a) providing a mixture of a nonpolar solvent, a surfactant, and a co-surfactant; and b) combining the mixture with an aqueous suspension of stabilized cerium dioxide nanoparticles.

Owner:CERION

Double wafer carrier process for creating integrated circuit die with through-silicon vias and micro-electro-mechanical systems protected by a hermetic cavity created at the wafer level

ActiveUS7960840B2Avoid sizeReduce mold sizeSemiconductor/solid-state device detailsSolid-state devicesEngineeringThrough-silicon via

A TSV-MEMS packaging process is provided. The process includes forming TSVs in the front side of the product wafer, and attaching a first carrier to the front side of the product wafer, subsequent to forming TSVs. The process further includes thinning the back side of the product wafer to expose TSV tips, detaching the first carrier from the front side of the product wafer, and transferring the thinned wafer to a second carrier with back side adhered to the second wafer carrier. Semiconductor components are added to the front side of the product wafer, followed by forming a hermetic cavity over the added semiconductor components, and detaching the second carrier from the back side of the product wafer. Wafer level processing continues after detaching the second carrier.

Owner:TEXAS INSTR INC

Semiconductor Laser Apparatus

InactiveUS20110188532A1Easy to adjustReduce thicknessSemiconductor laser arrangementsSolid-state devicesDevice formSemiconductor

This semiconductor laser apparatus includes a first semiconductor laser device having a first surface and a second surface, an integrated laser device formed by a second semiconductor laser device and a third semiconductor laser device having a third surface and a fourth surface, and a support substrate. The third surface is bonded onto a first region of the support substrate, a first section of the first surface overlaps with at least part of the fourth surface, and a second section of the first surface is bonded to a second region of the support substrate.

Owner:SANYO ELECTRIC CO LTD

Glass cutting method and device

ActiveCN105541098AFacilitate flexible secondary processingIncrease productivityGlass severing apparatusGlass productionControl systemCutting glass

The present invention discloses a glass cutting method, a two-dimensional code is set on a glass substrate before glass cutting, two-dimensional code information is read before the glass cutting, and inputted into a control system, the control system interprets the two-dimensional code information and generates a cutting path according to interpretation information, and a cutting device cuts the glass substrate according to the cutting path. According to the method, different sizes and different shapes of glass to be cut can be optimized and arranged, the utilization rate of the glass substrate can be improved, the workload of manual input of parameters can be reduced, the relative position of the two-dimensional code on the cut glass is more precision, production efficiency of the glass subsequent processing can be improved, mixed production of different specifications of glass can be achieved, positional deviation increase, large glass size scattering difference and other defects caused by a plurality of times of repeated positioning can be avoided, and flexible secondary processing of the glass can be facilitated. The present invention also discloses the glass cutting device for cutting the glass substrate by use of the method.

Owner:LUOYANG LANDGLASS TECH CO LTD

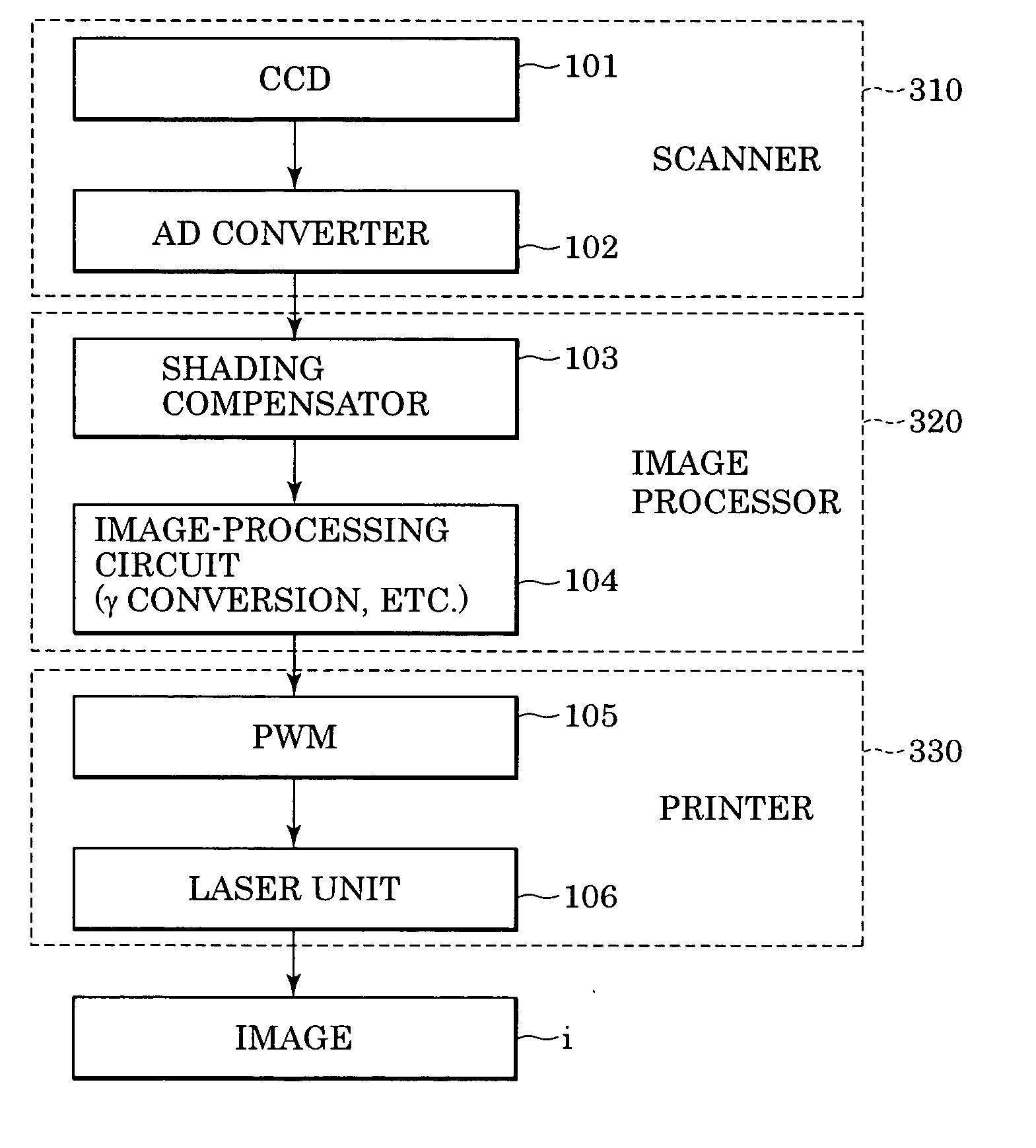

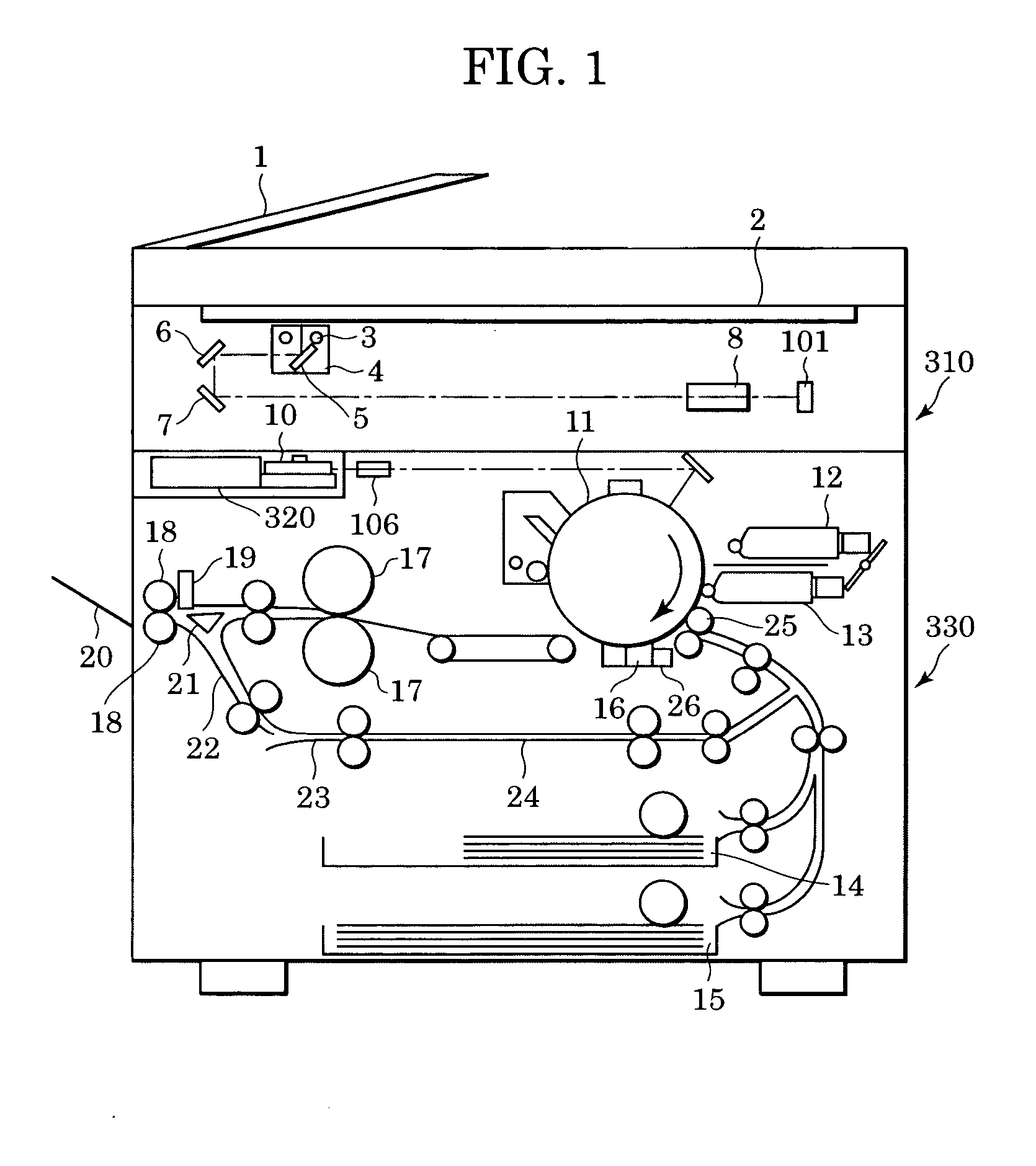

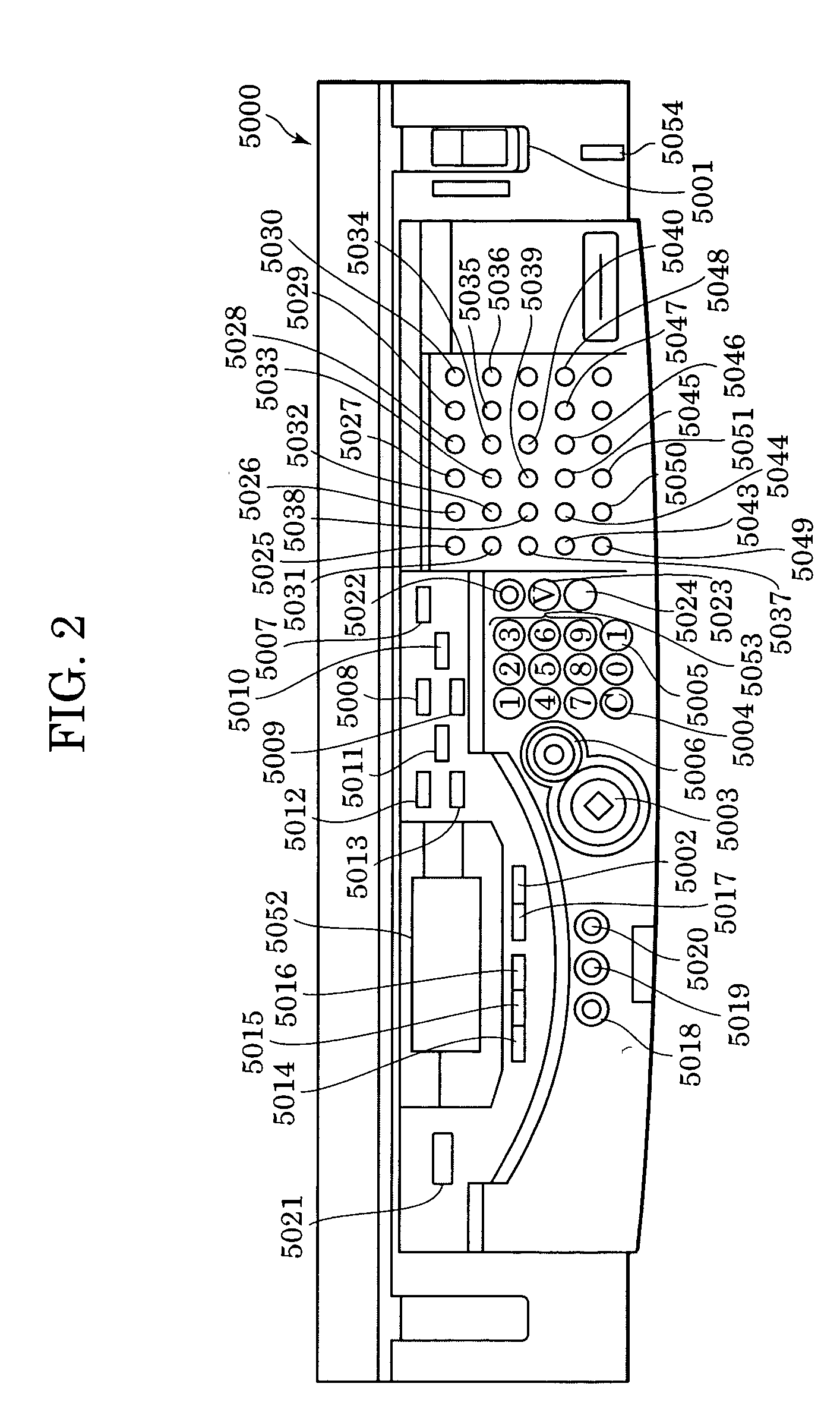

Image formation device

InactiveUS20050158062A1Avoid sizeElectrographic process apparatusPrintingImage formationRotational rate

An image formation device changes the rotational rate of a polygon motor, i.e. the main-scanning rate, and selects one of pulse width conversion tables when an image formation is performed multiple times on a single sheet of transfer paper. The changing of the main-scanning rate is for preventing inconsistent sizes between a first recorded image and a second recorded image caused by shrinkage of transfer paper. The pulse width conversion tables allow the pulse widths to be modulated.

Owner:CANON KK

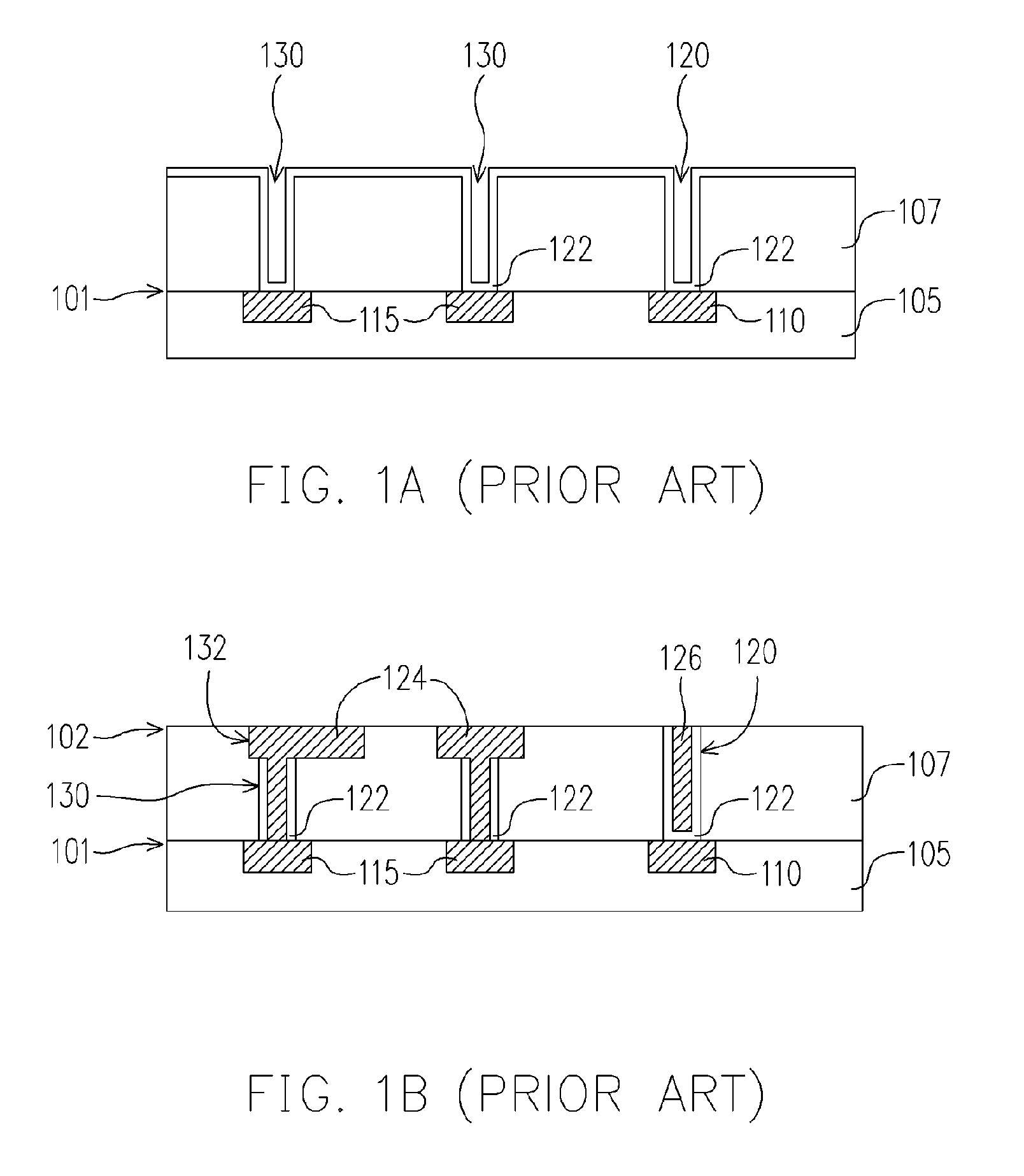

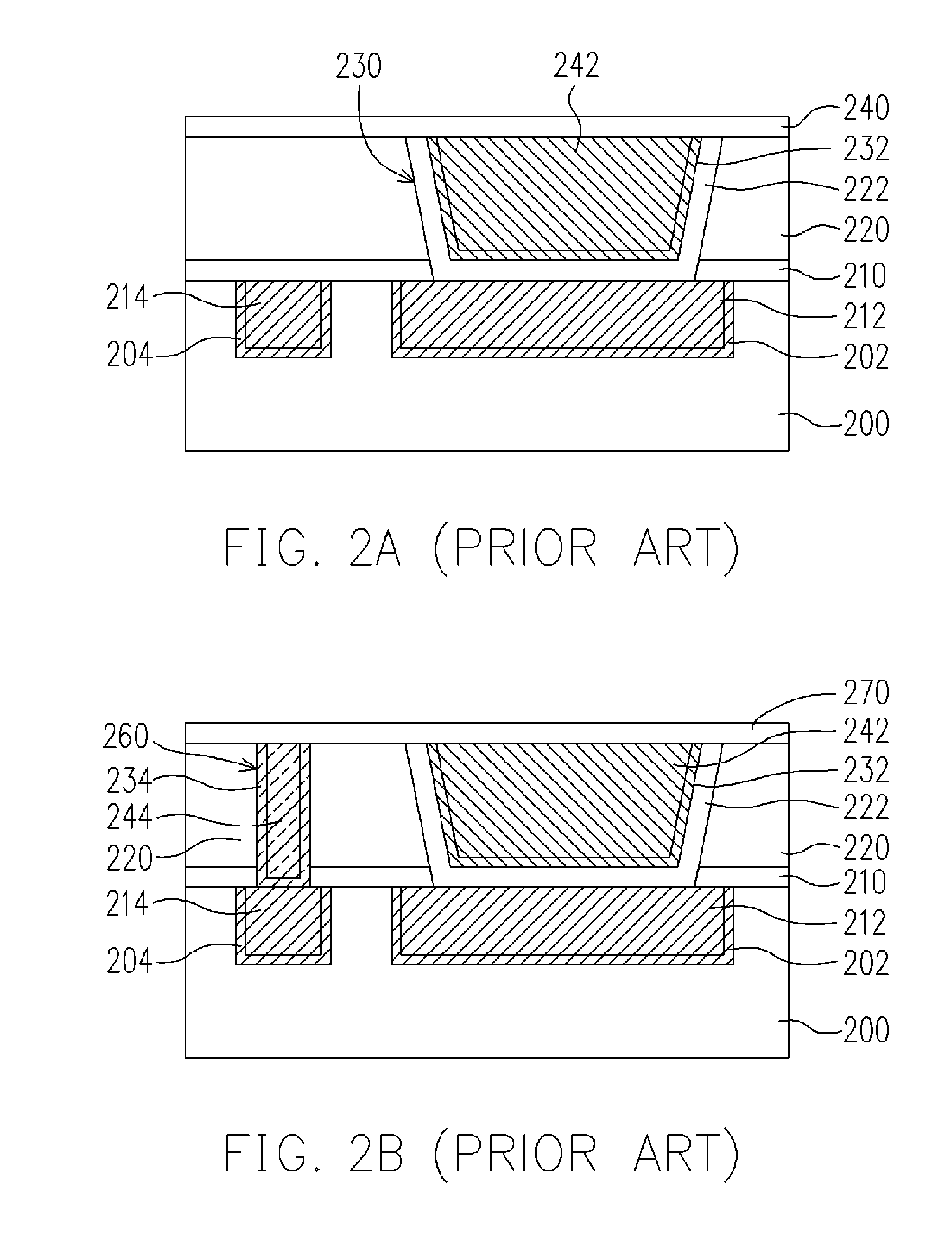

Method of manufacturing semiconductor device

ActiveUS20050233519A1Reduce stepsLow costSemiconductor/solid-state device detailsSolid-state devicesDevice materialDielectric layer

A method of manufacturing a semiconductor device. The method comprises steps of providing a substrate having a first metal layer and a second metal layer formed thereon. A first dielectric layer, an etching stop layer having a first opening located above the first metal layer and a second opening located above the second metal layer and a second dielectric layer are formed sequentially. A portion of the first dielectric layer and a portion of the second dielectric layer are removed to form a first trench exposing the first metal layer. A capacitor dielectric layer is formed over the substrate. A third opening is formed in the capacitor dielectric layer. A portion of the second dielectric layer and a portion of the first dielectric layer exposed by the third opening are removed to form an opening. A metal layer is formed to fill out the first trench and the opening.

Owner:NEXCHIP SEMICON CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com