Patents

Literature

1490results about How to "Avoid position shift" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Floating plane touch input device and method

InactiveUS20120038577A1Easy to detectAvoid mechanical complexityTransmission systemsStands/trestlesDisplay deviceTouchscreen

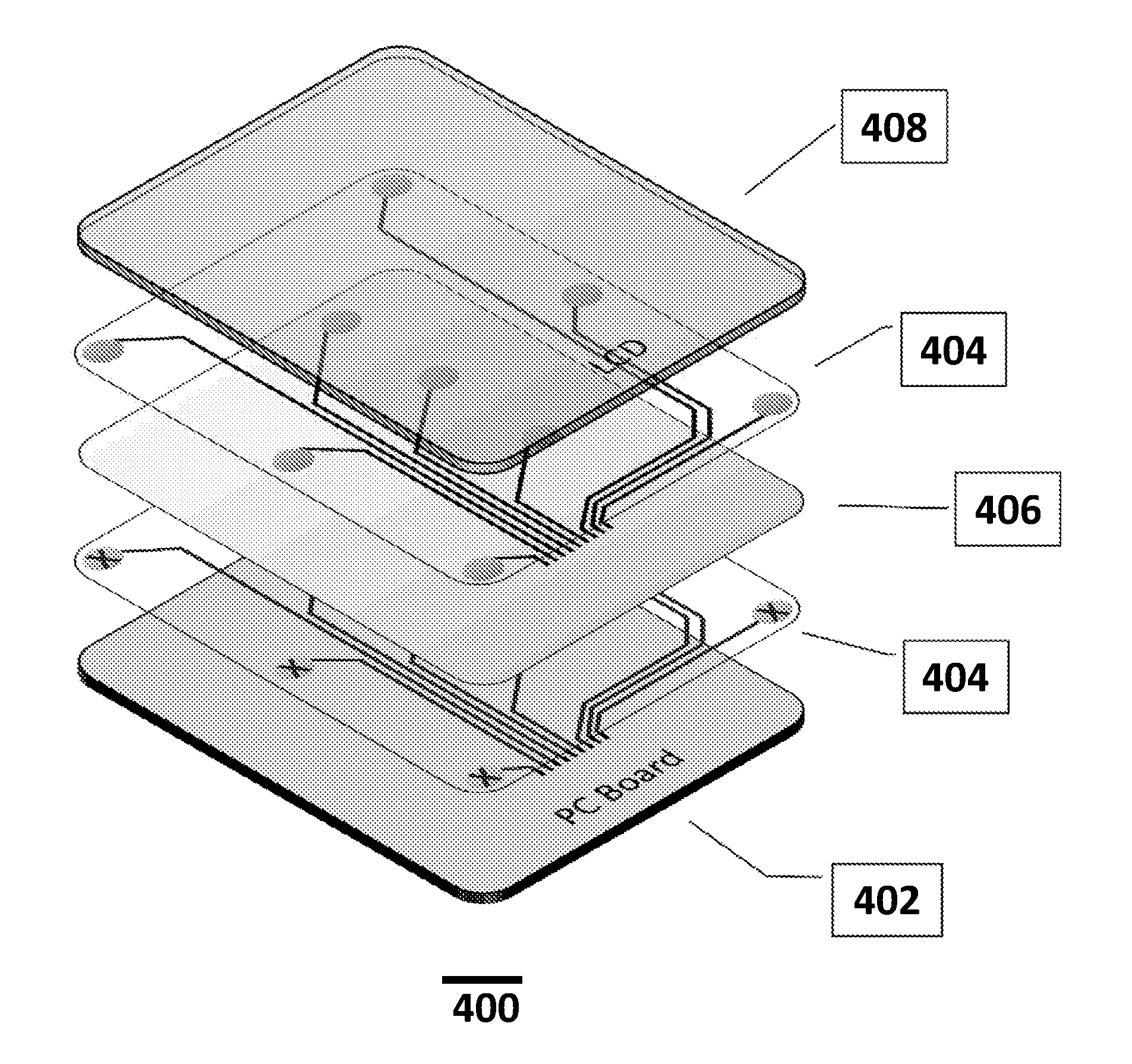

A touch input device and method for manufacturing a touch input device are described. Each embodiment includes a touch surface, a mounting fixture, a sensing-suspension system, and a locating system. The touch surface may be an integral component of a host system, such as a display, which would result in a touch screen, or a touchpad input device. The touch surface is a floating plane, where the suspension positions, attaches and motion-enables the touch surface within the host system, and where the force exerted on the touch surface causes displacement of the touch surface, which motion is interpreted to calculate a touch location.

Owner:FLOATINGTOUCH

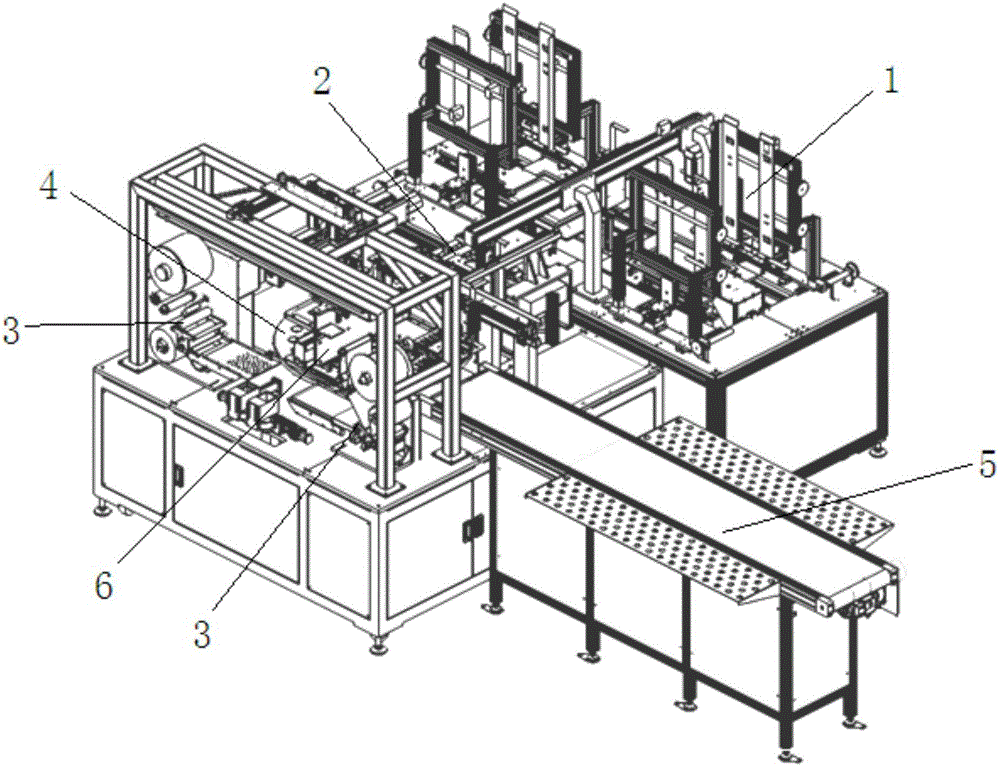

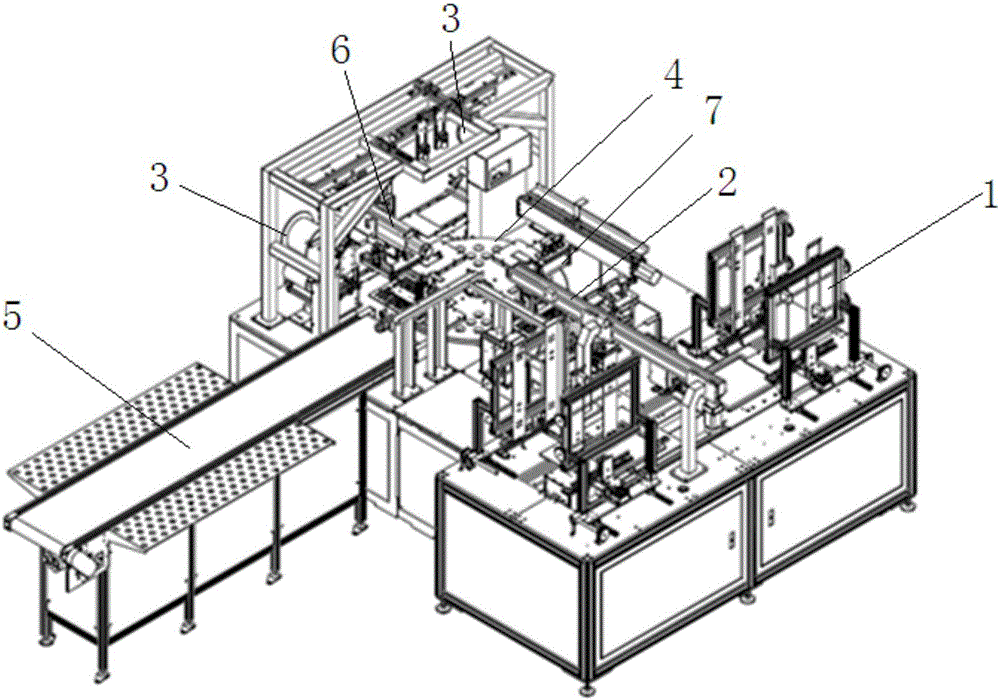

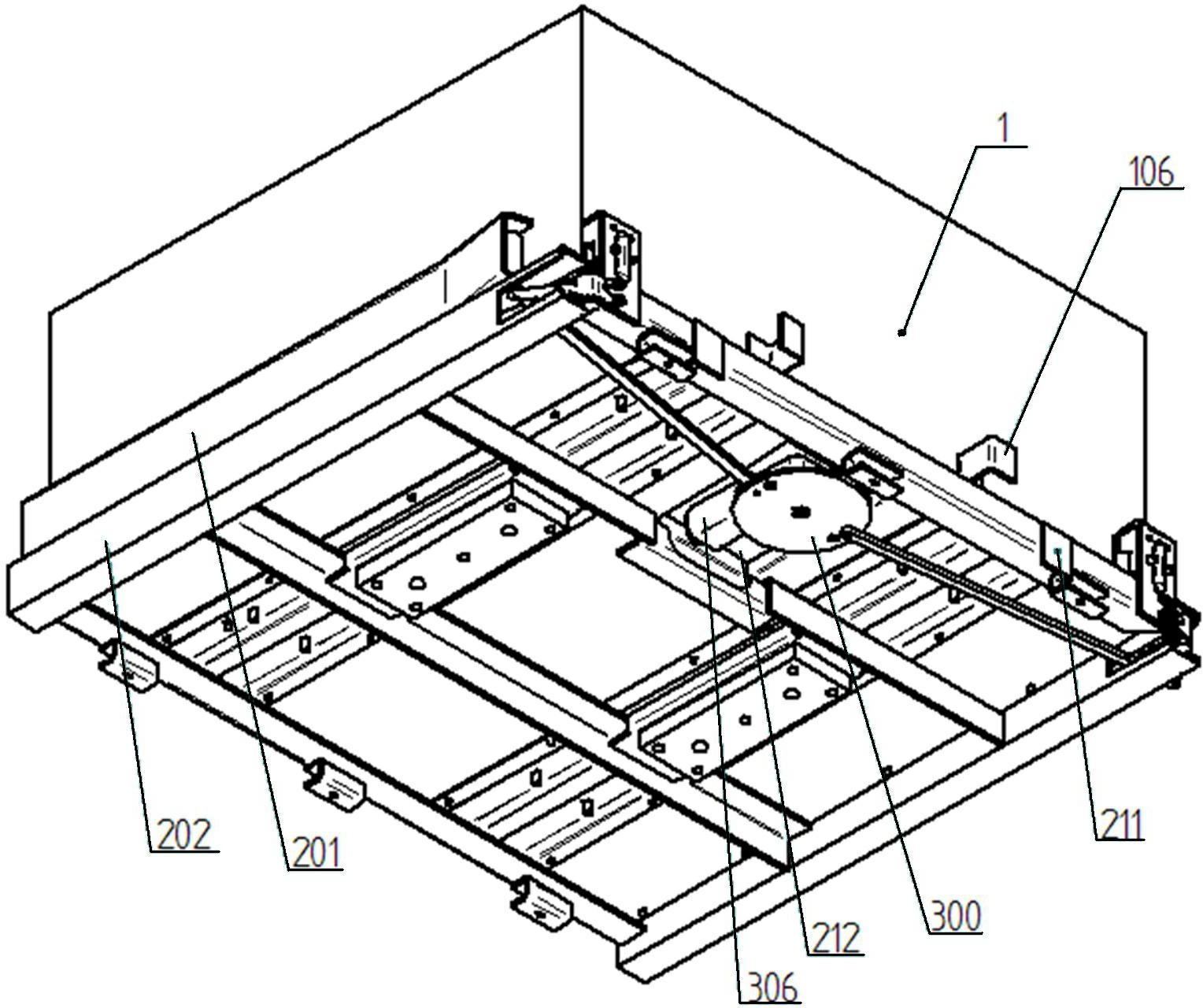

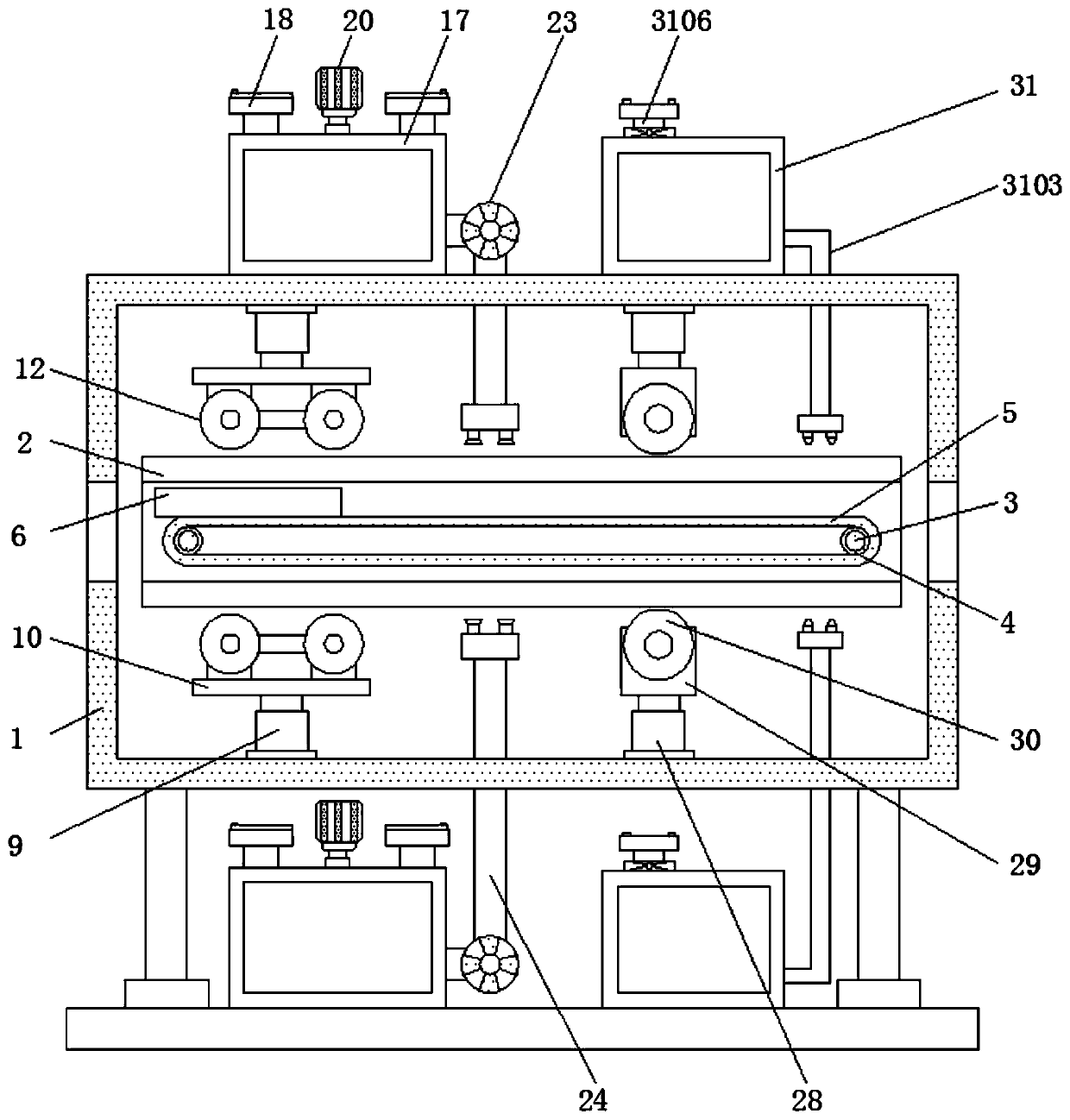

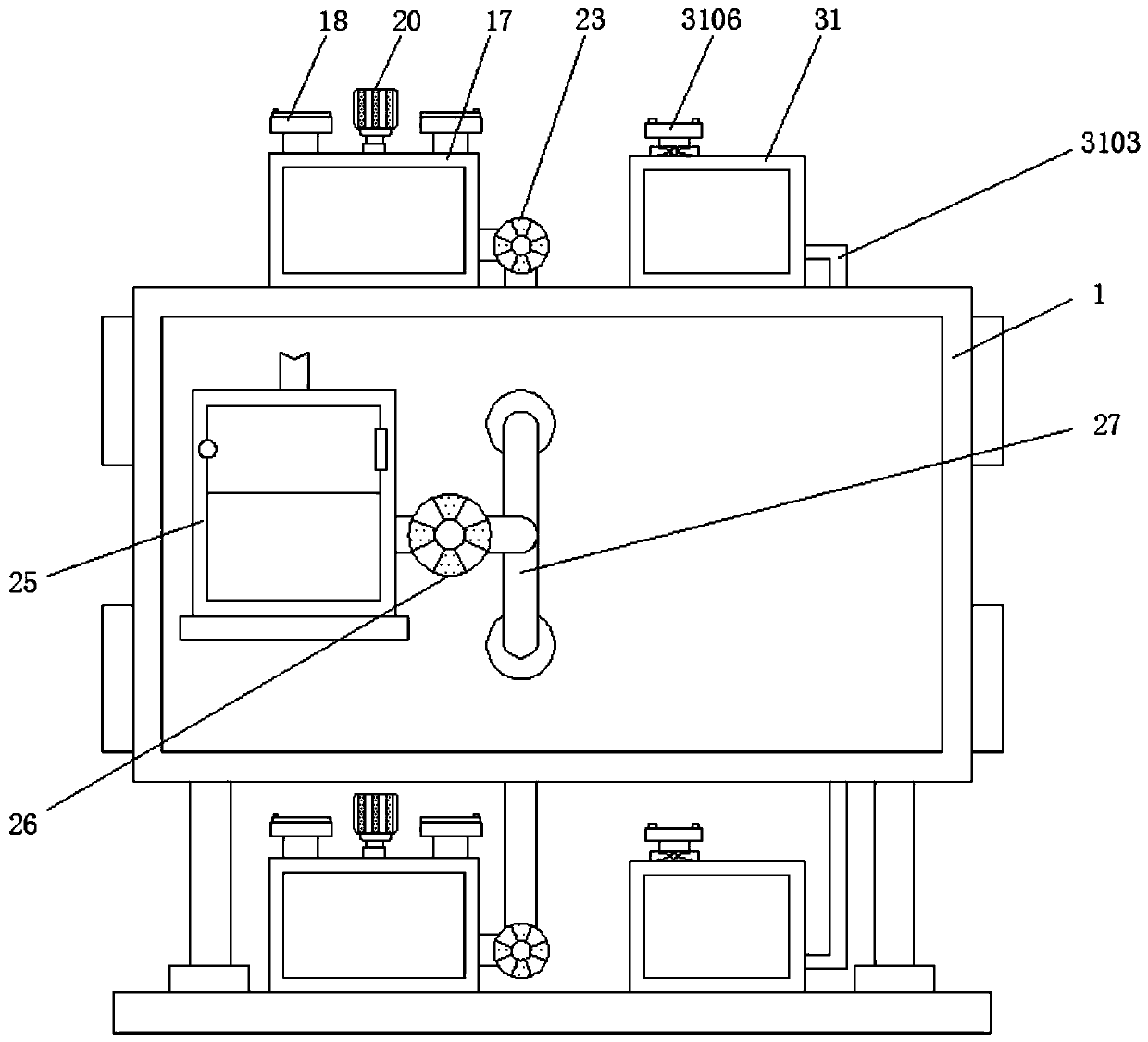

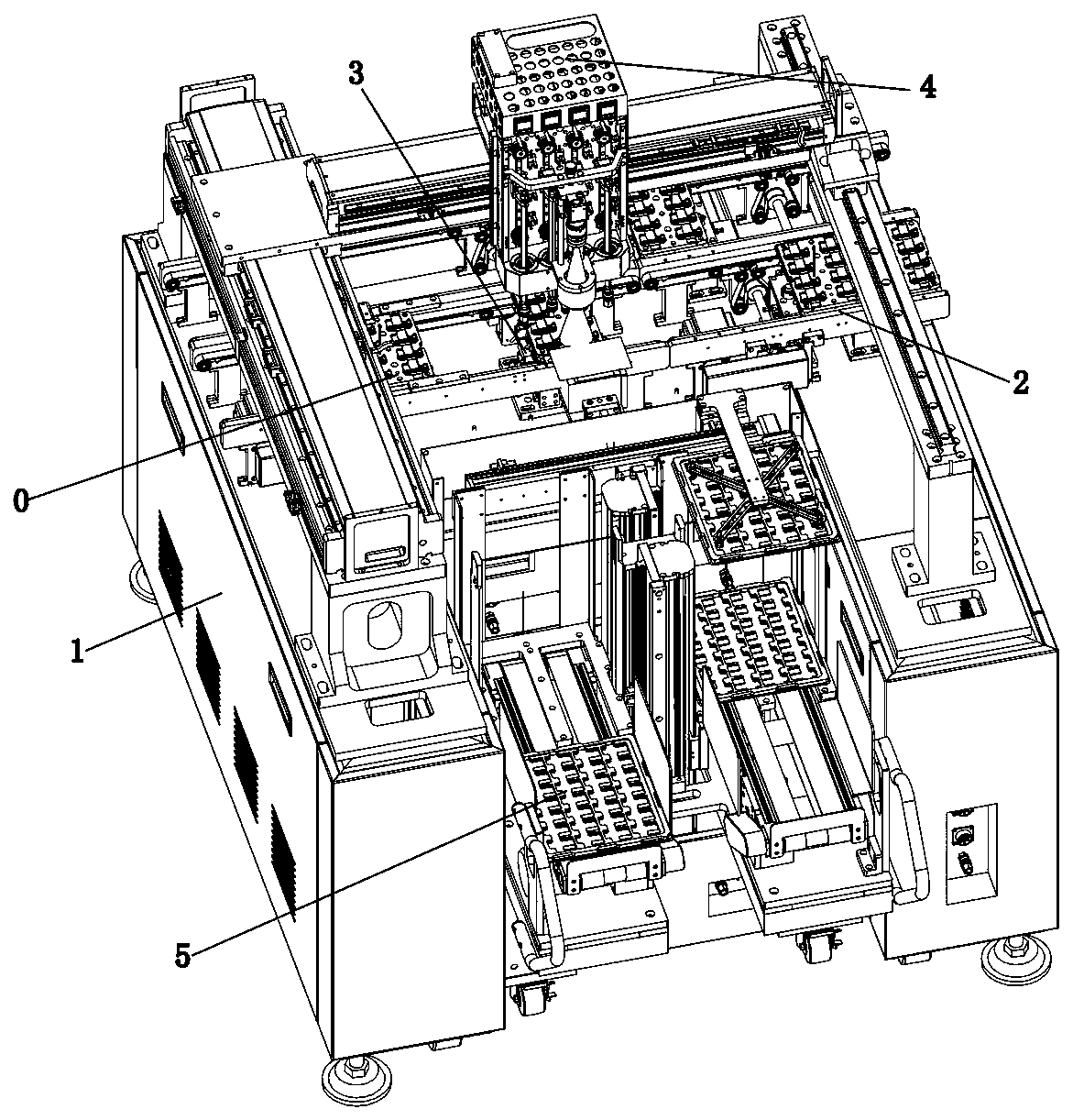

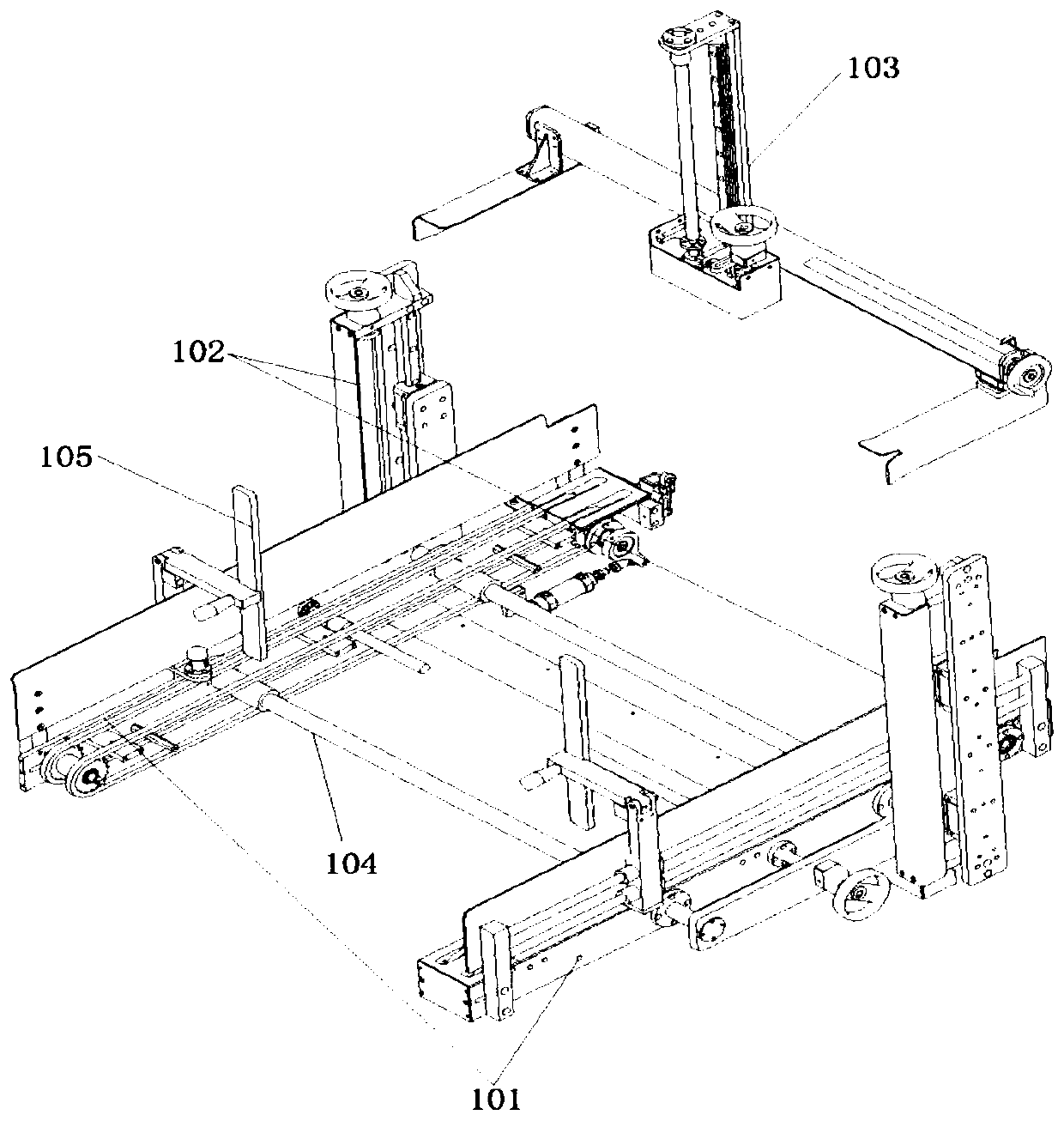

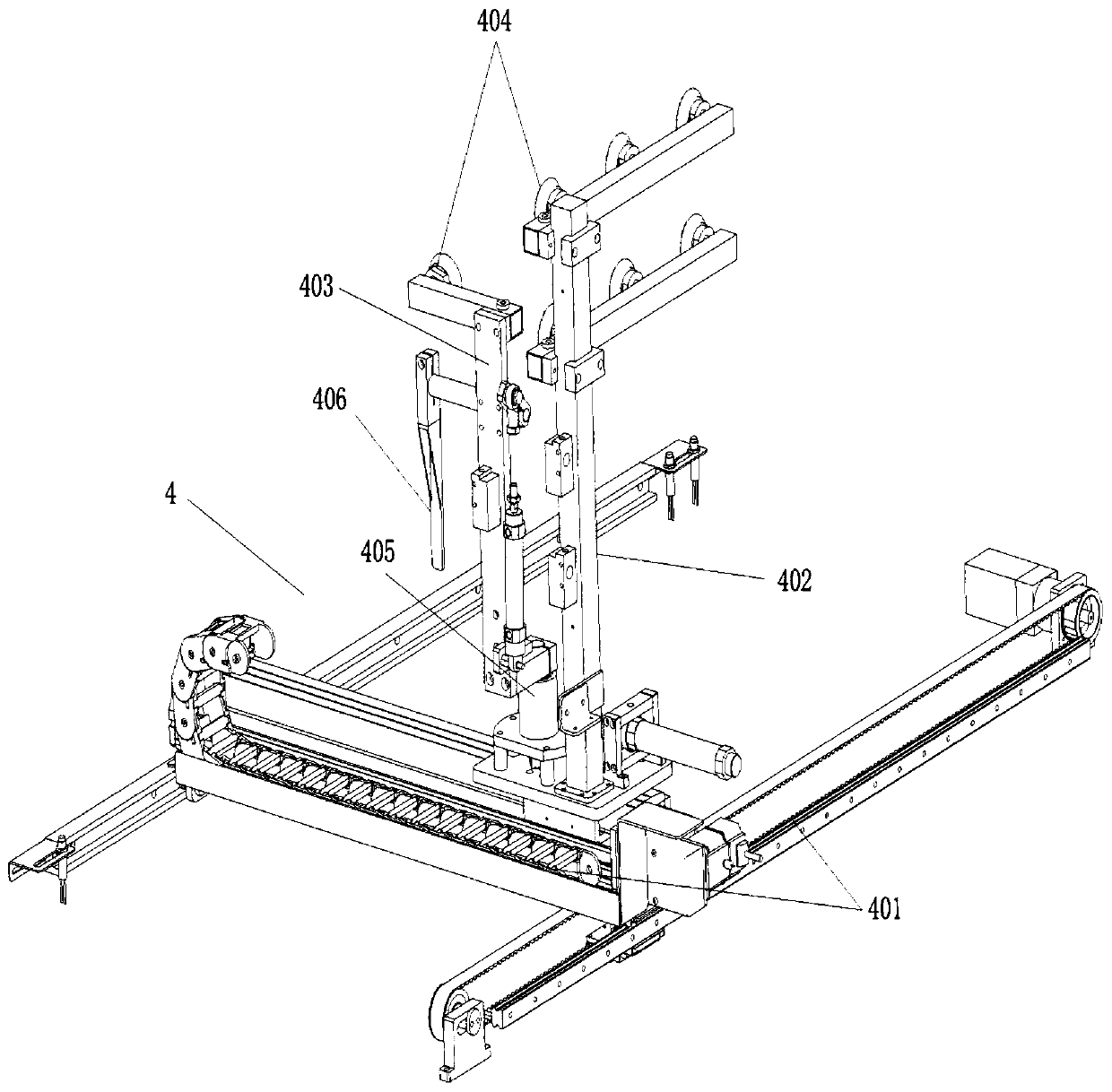

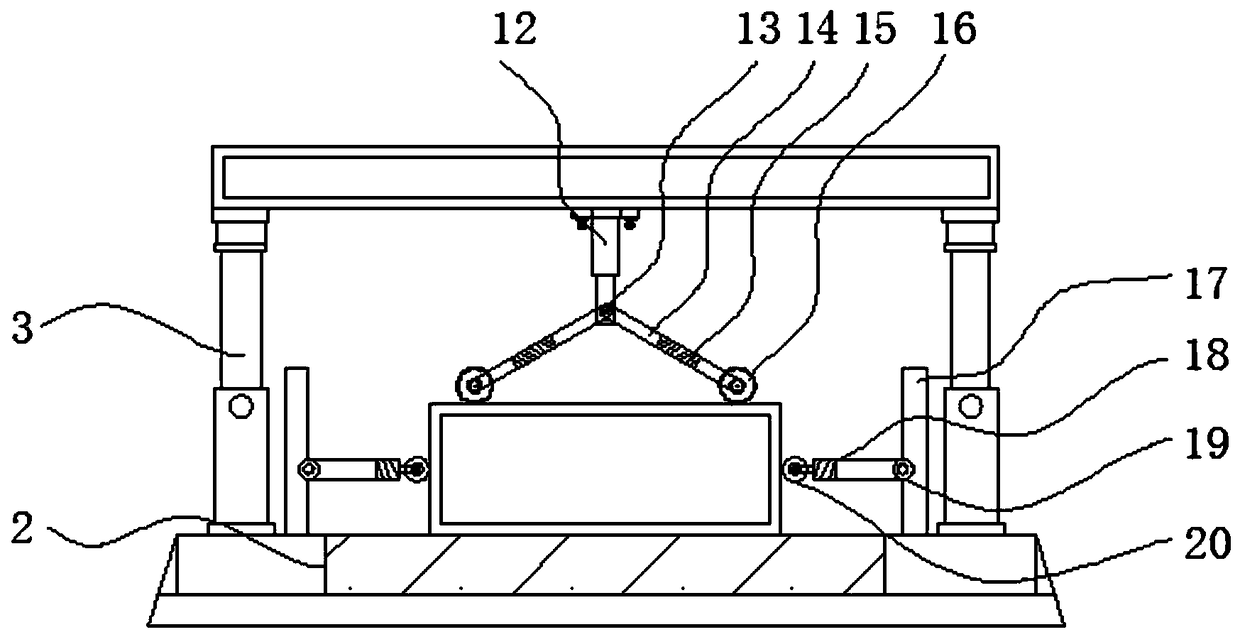

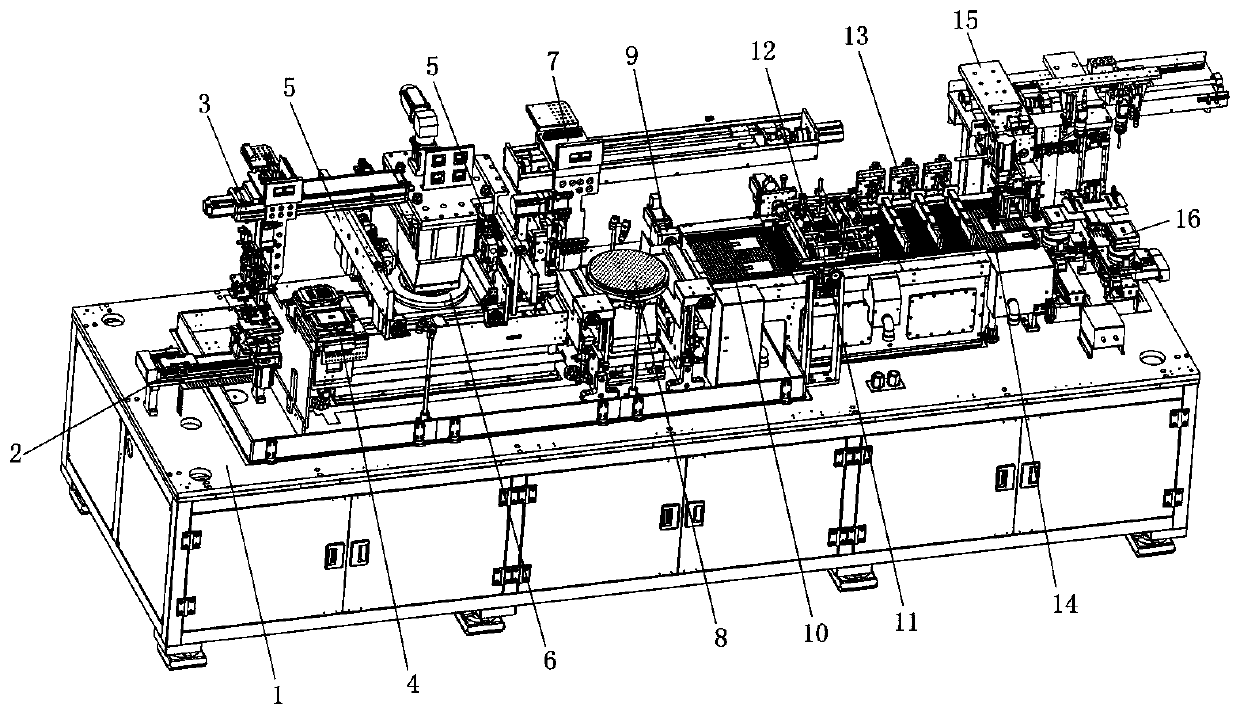

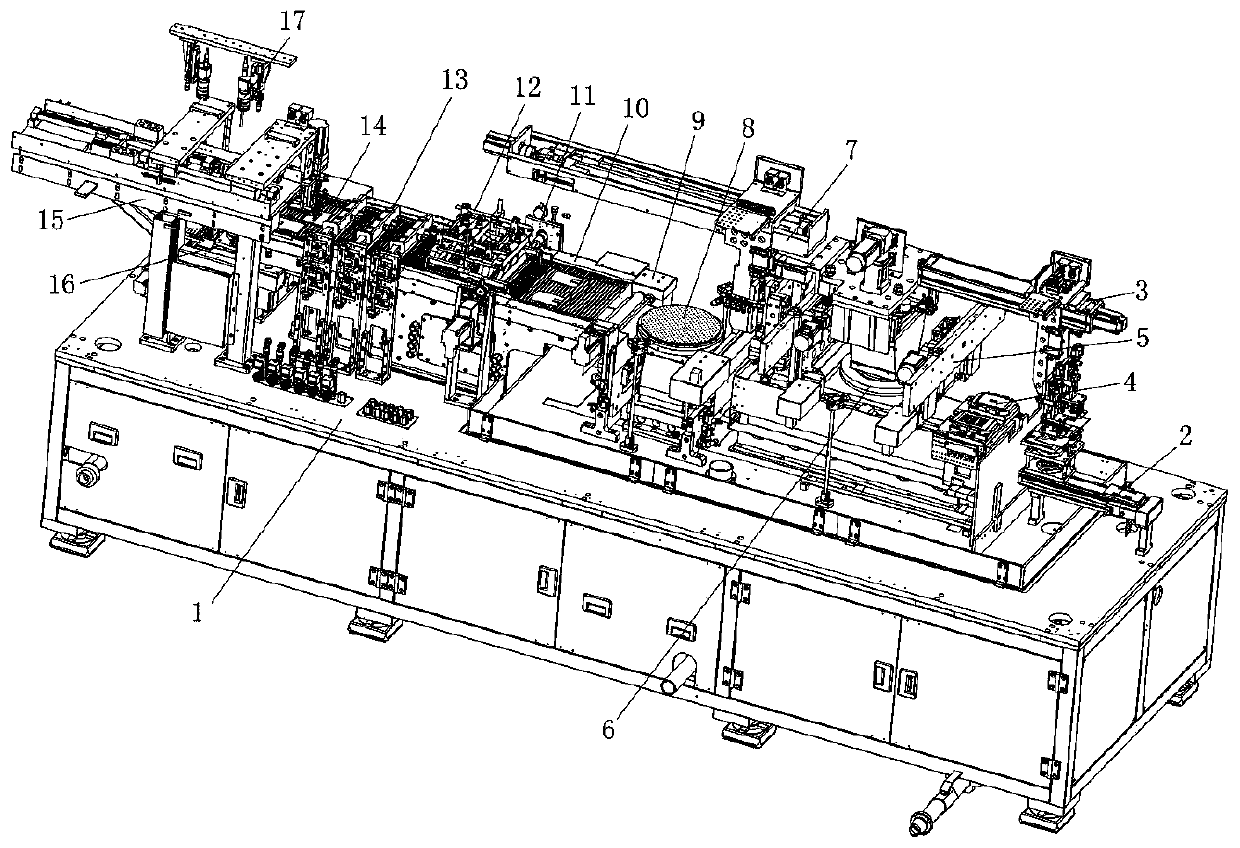

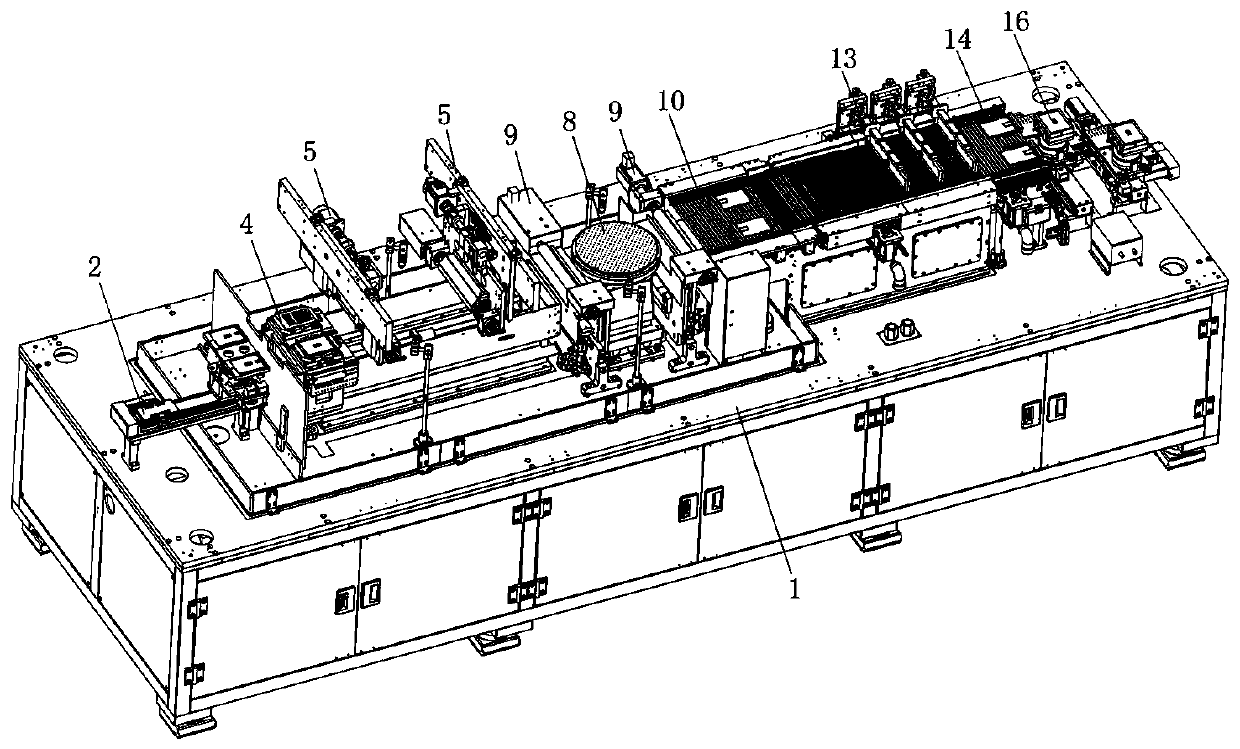

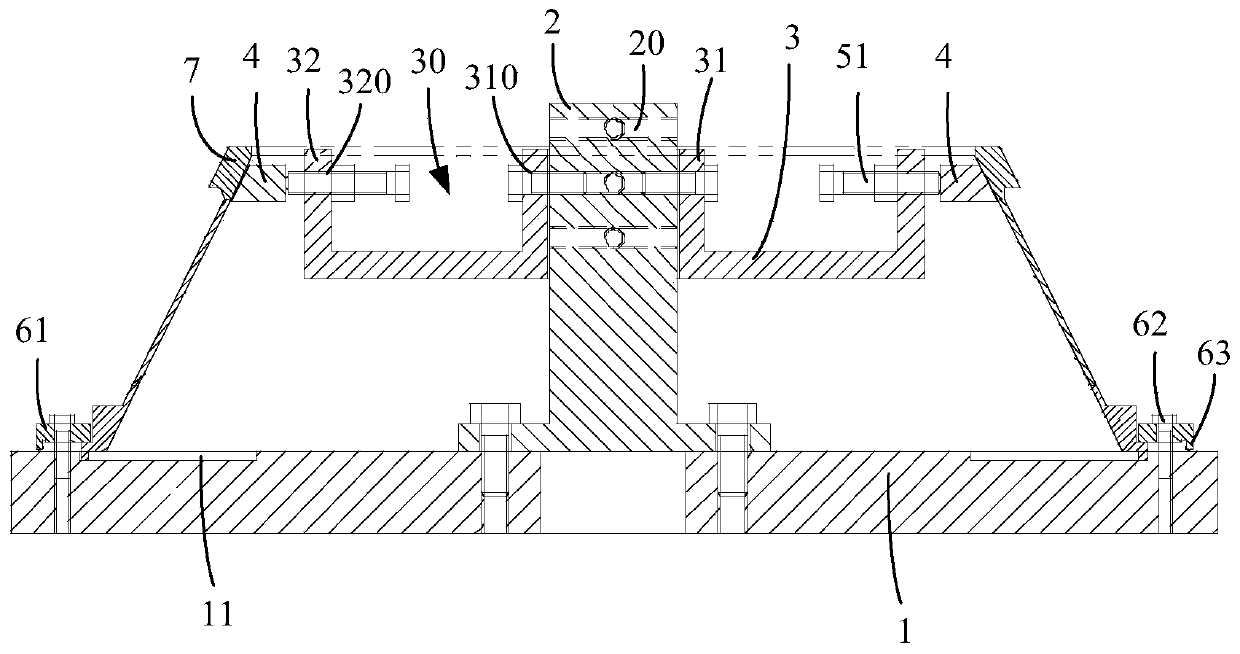

Automatic film sticking machine

ActiveCN106428746AFast and effective film applicationImprove the efficiency of automatic film applicationPackagingEngineeringElectrical and Electronics engineering

The invention discloses an automatic film sticking machine. The machine comprises an automatic feeding mechanism, a pre-positioning mechanism, a film sticking automatic stripping mechanism, a film sticking station conversion mechanism, an automatic film sticking mechanism and a finished product output mechanism; according to the automatic feeding mechanism, an element to be subject to film sticking is taken out and conveyed to the pre-positioning mechanism, the pre-positioning mechanism carries out position pre-adjustment on the element to be subject to film sticking, the element to be subject to film sticking and position pre-adjustment is placed on the film sticking station conversion mechanism, the automatic film sticking mechanism enables a sticking film stripped from the film sticking automatic stripping mechanism to be pasted and covered on the element to be subject to film sticking on the film sticking station conversion mechanism, and the element subject to film sticking is output through the finished product output mechanism for quality inspection. The automatic film sticking machine can be suitable for single-layer or multi-layer rapid effective film sticking, full-automatic feeding, cleaning, sticking film stripping, sticking film absorbing and film sticking are achieved, time and labor are saved, the automatic film sticking efficiency is improved, the film sticking yield is high, and the good application prospect is achieved.

Owner:JIANGSU BVM INTELLIGENT TECH

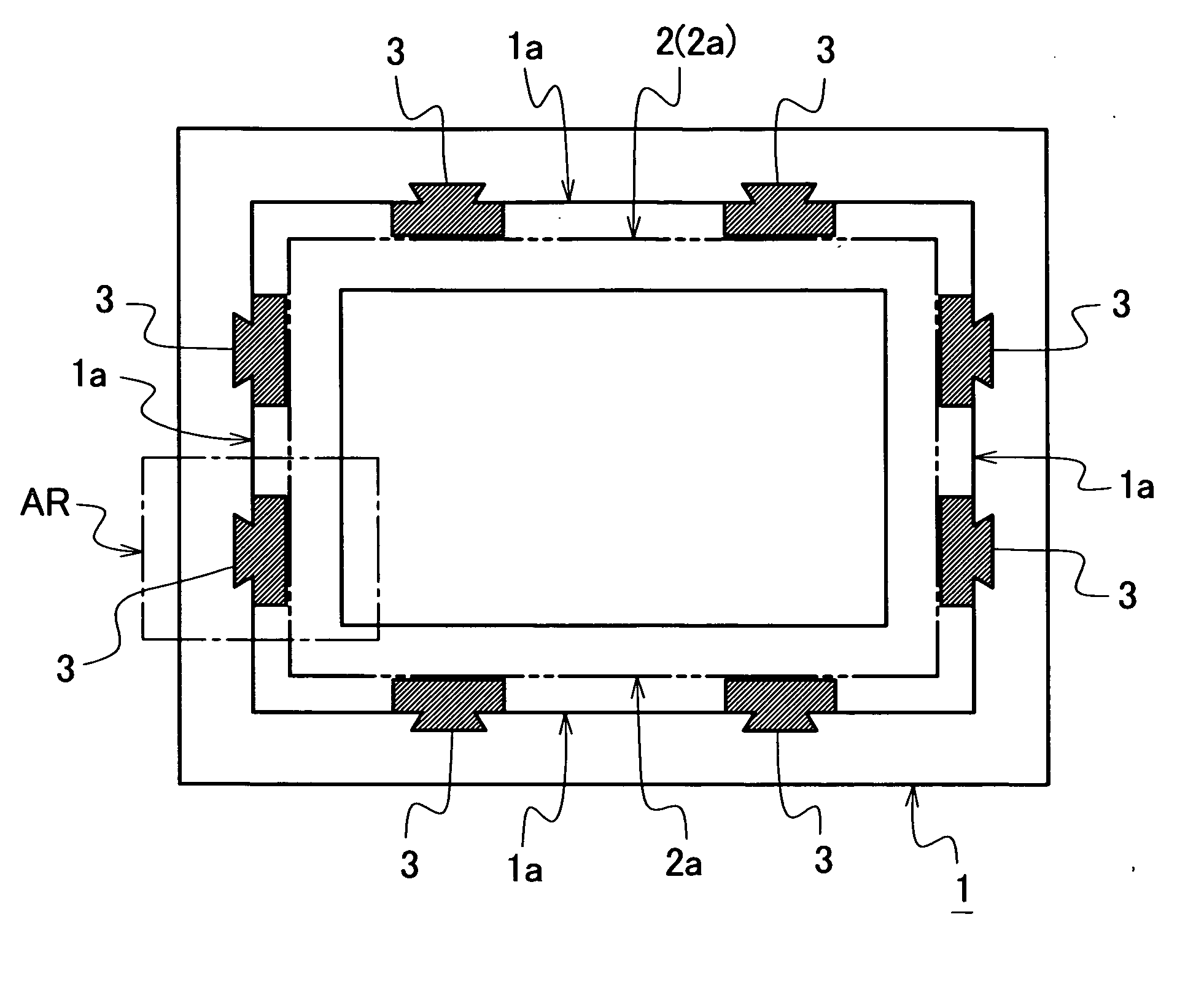

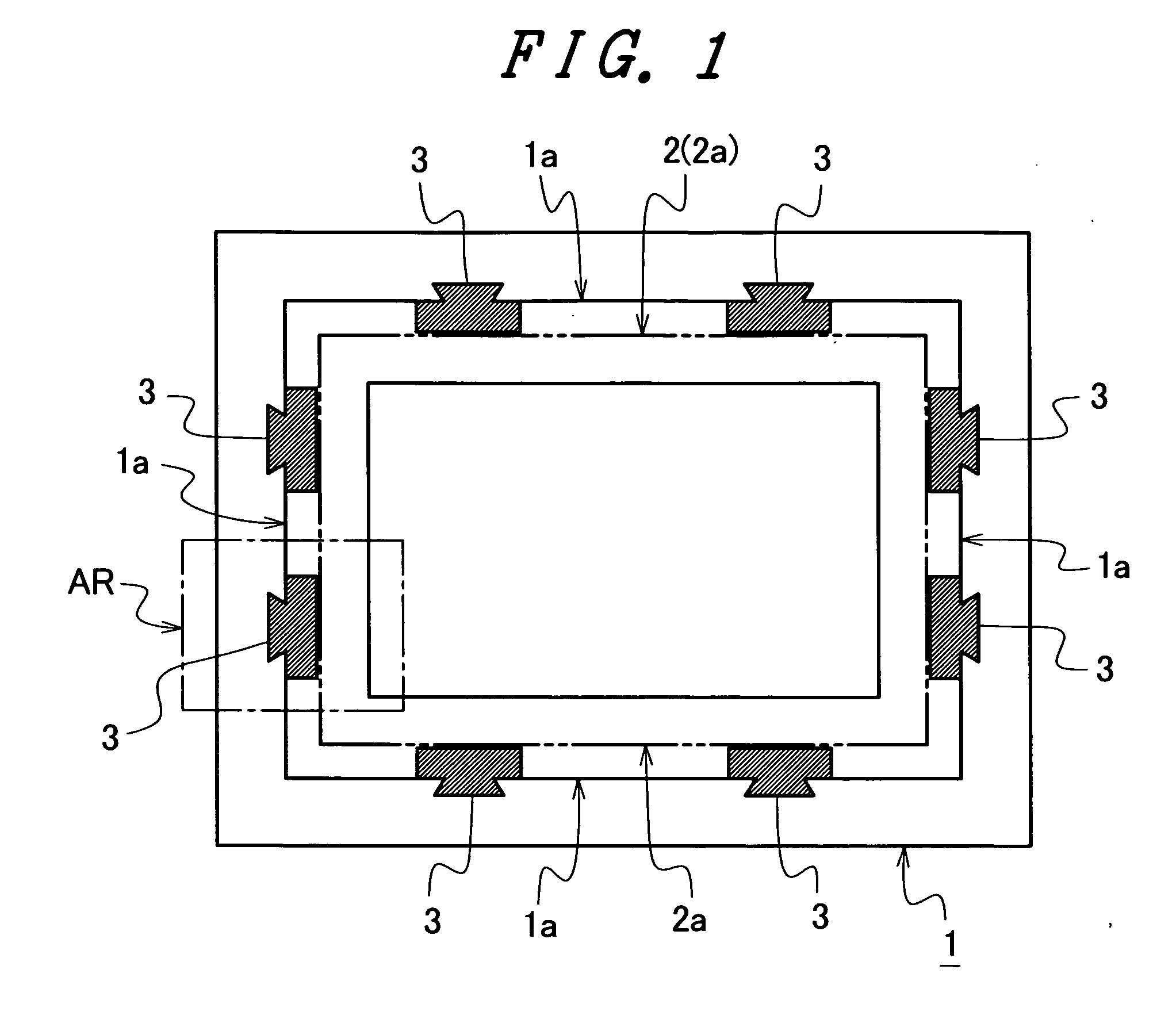

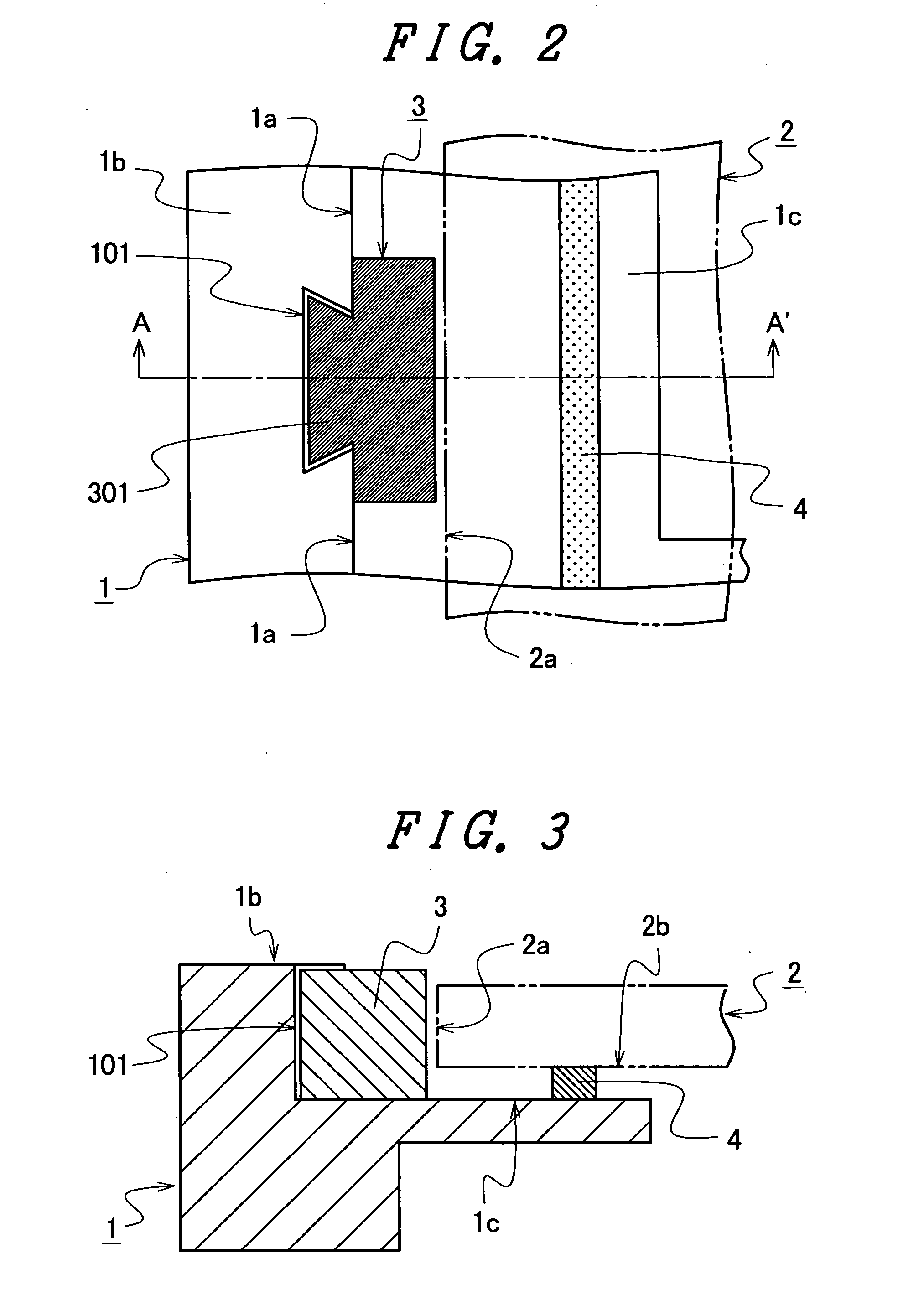

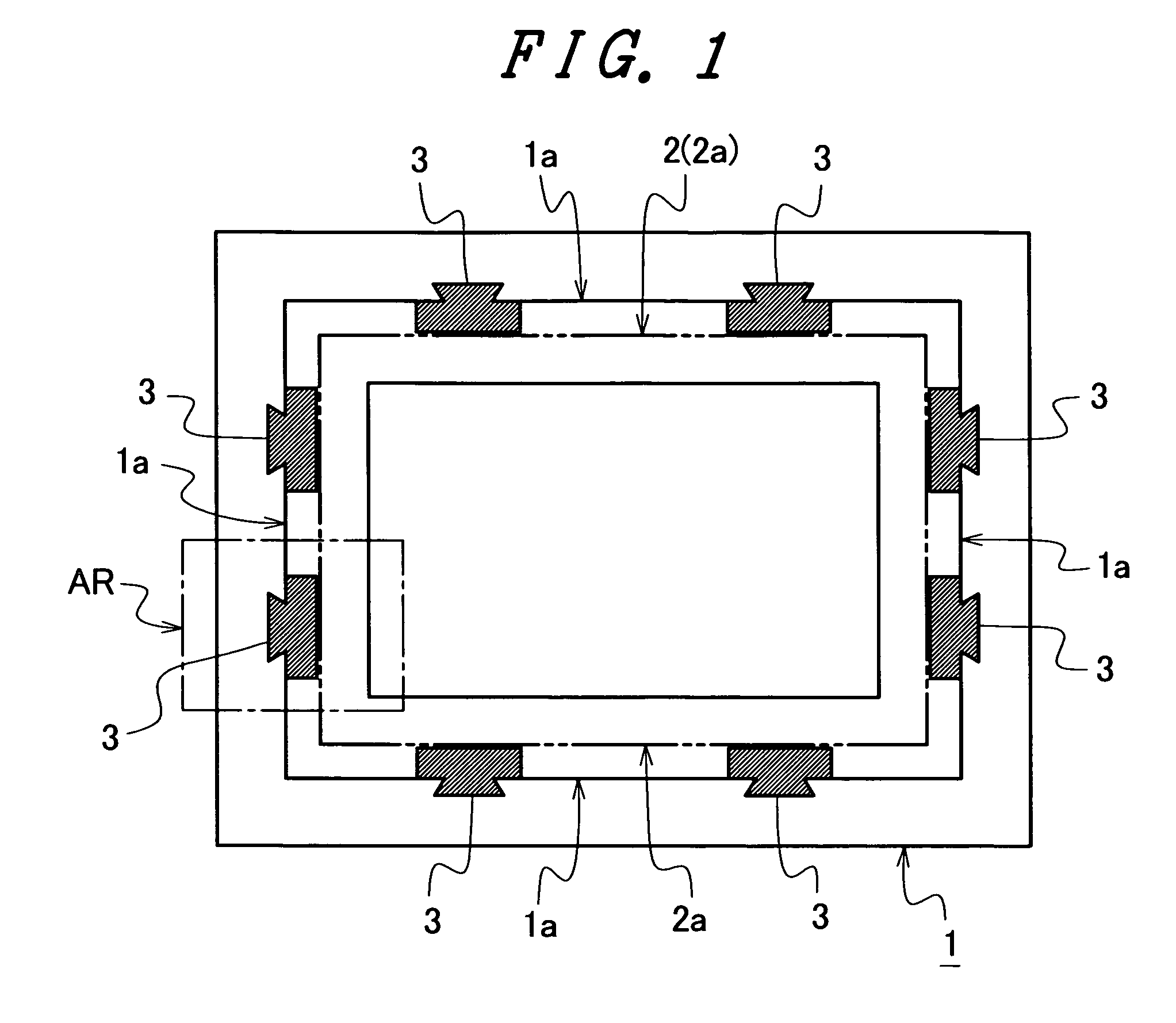

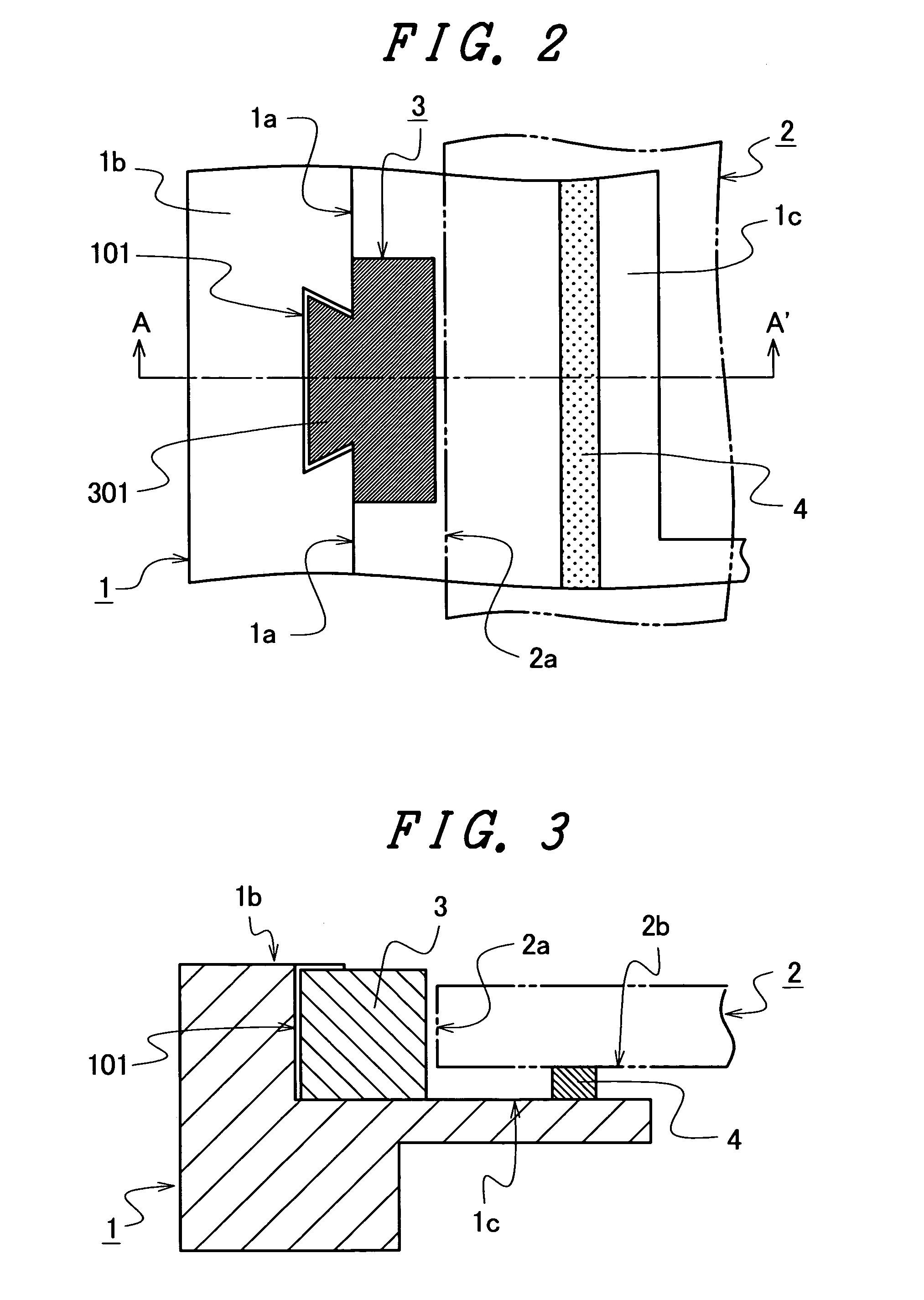

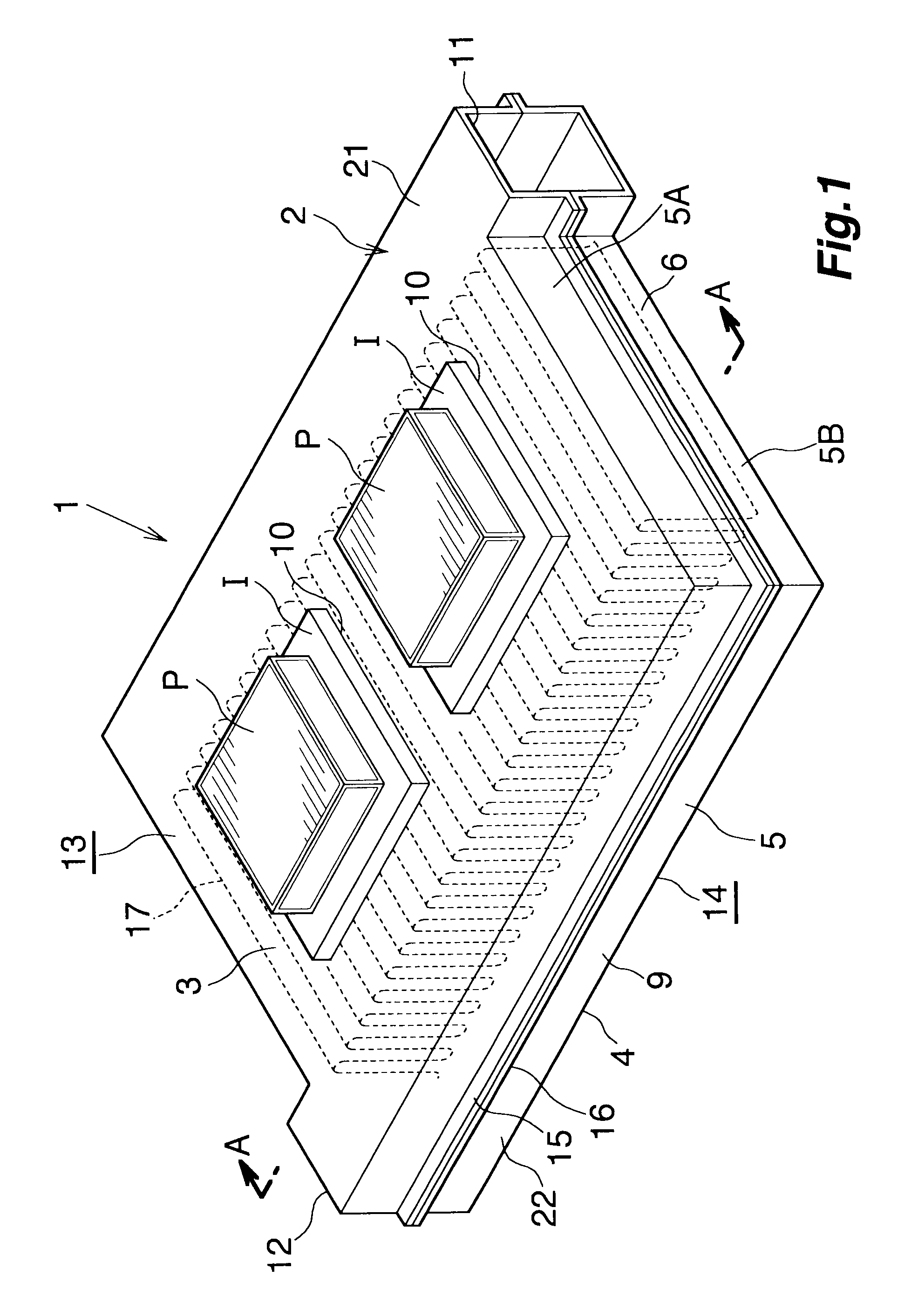

Display device

ActiveUS20070115401A1Prevent be breakPrevents position shiftNon-linear opticsLiquid-crystal displayBiomedical engineering

An object of the invention is to facilitate attachment of a spacer to a support member in an assembling process of a liquid crystal display device. A display device includes: a display panel, a support member that supports the display panel and a spacer that is interposed between a cut end surface of the display panel and a first surface of the support member, the first surface facing the cut end surface of the display panel. The support member has a recess that opens through the first surface and a second surface, which is connected to the first surface and extends away from the display panel. The spacer includes a spacer position securing portion inserted in the space of the recess of the support member and a buffer portion that is integral with the spacer position securing portion and protrudes from the open end at the first surface of the support member toward the cut end surface of the display panel.

Owner:PANASONIC LIQUID CRYSTAL DISPLAY CO LTD

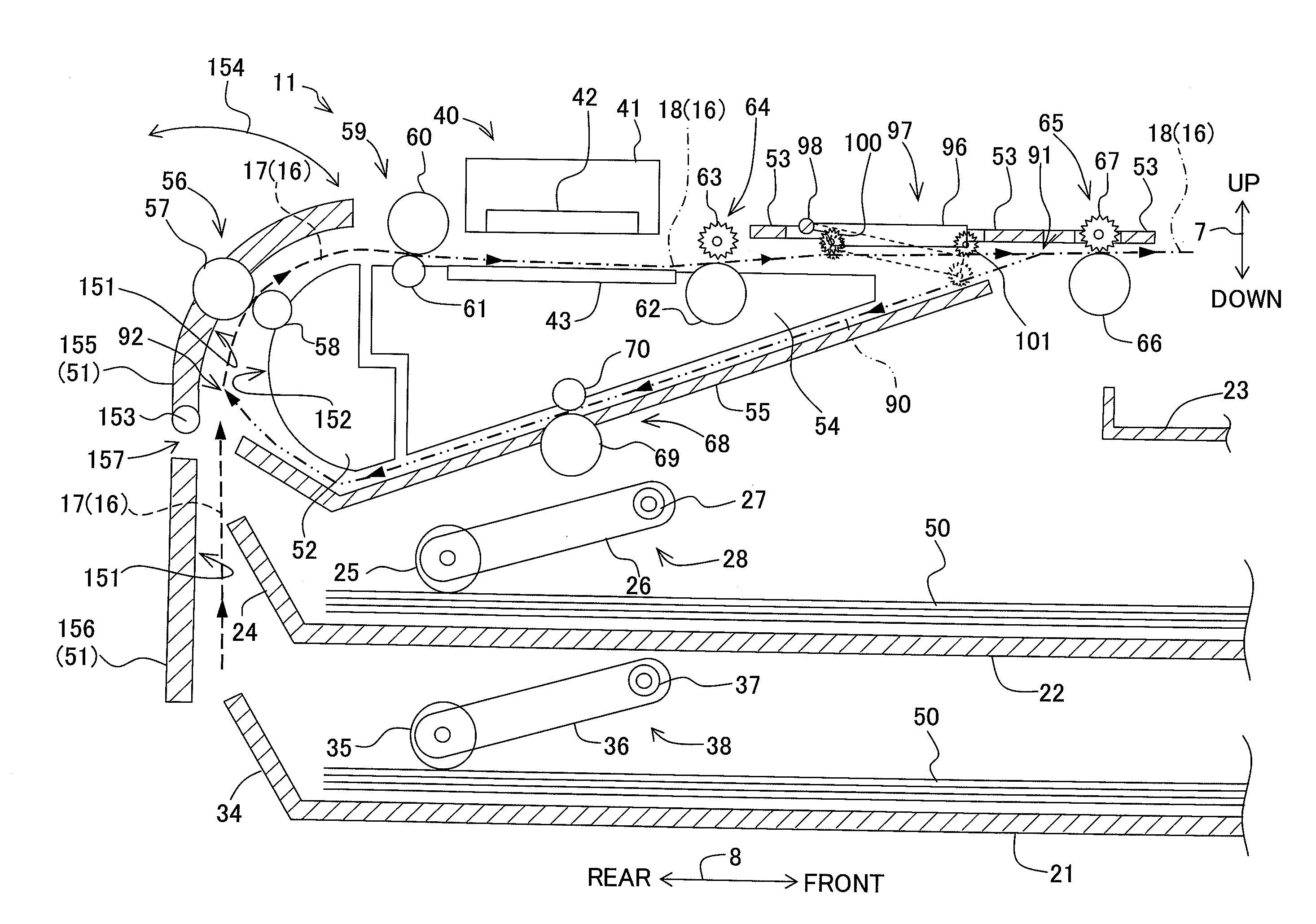

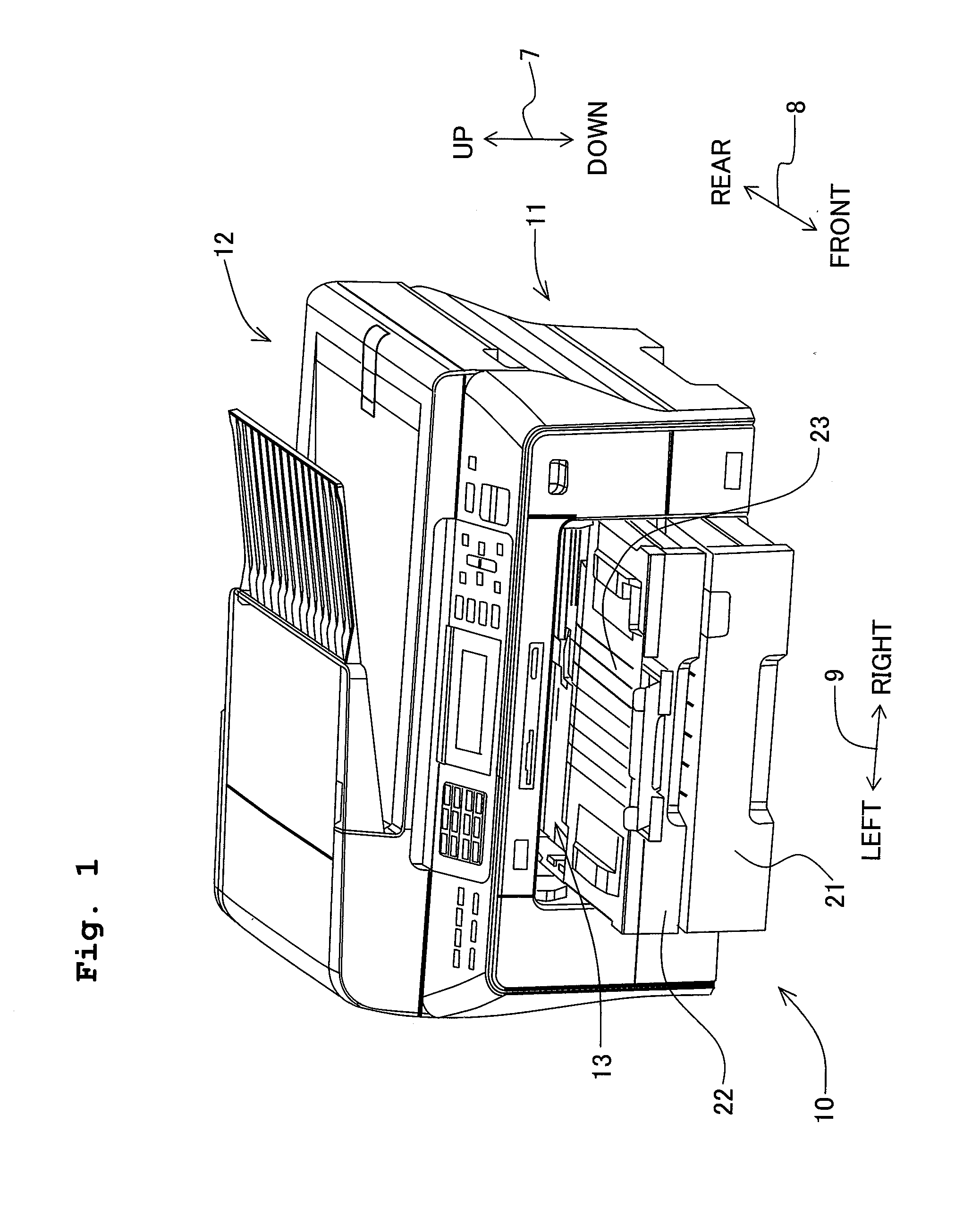

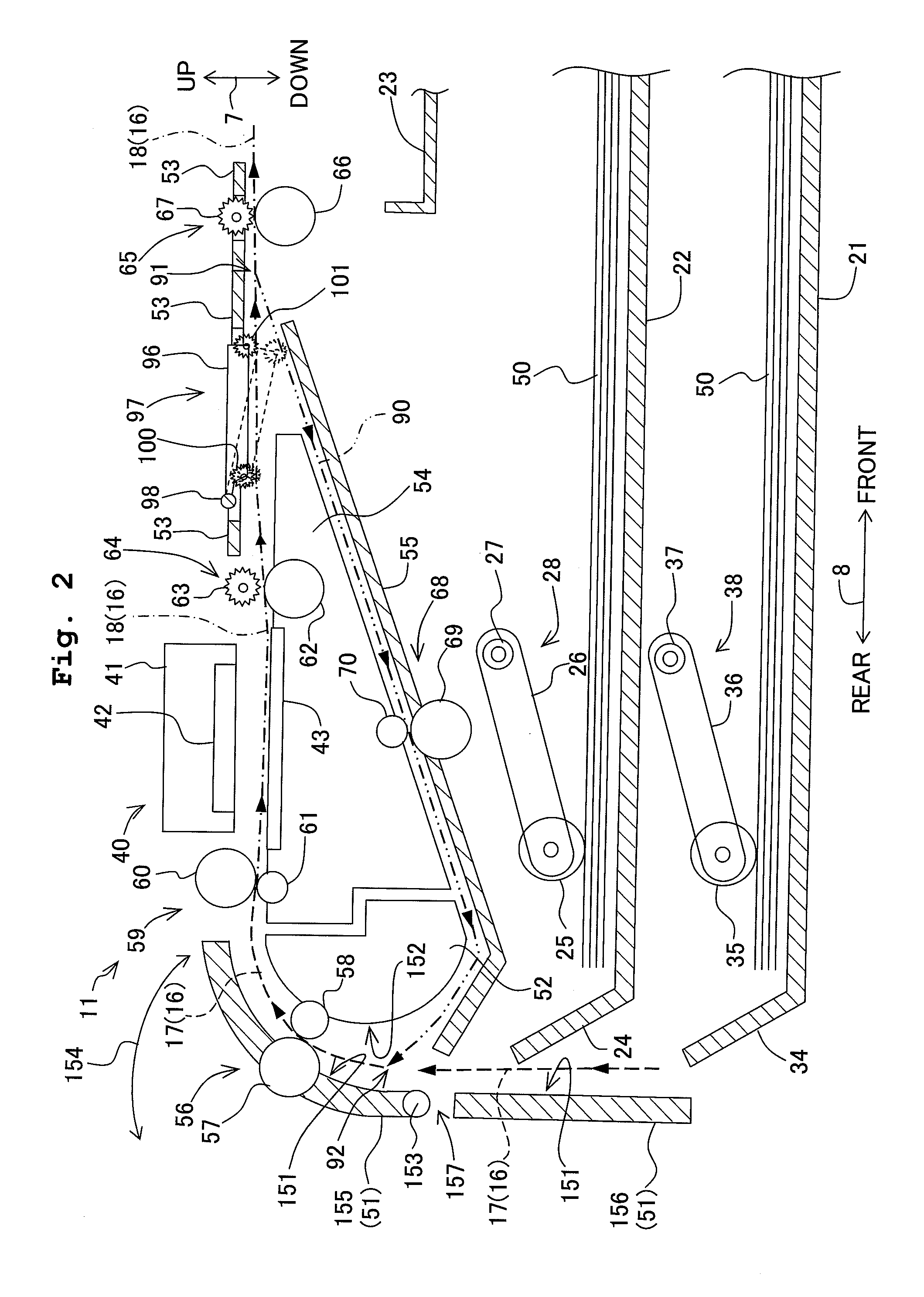

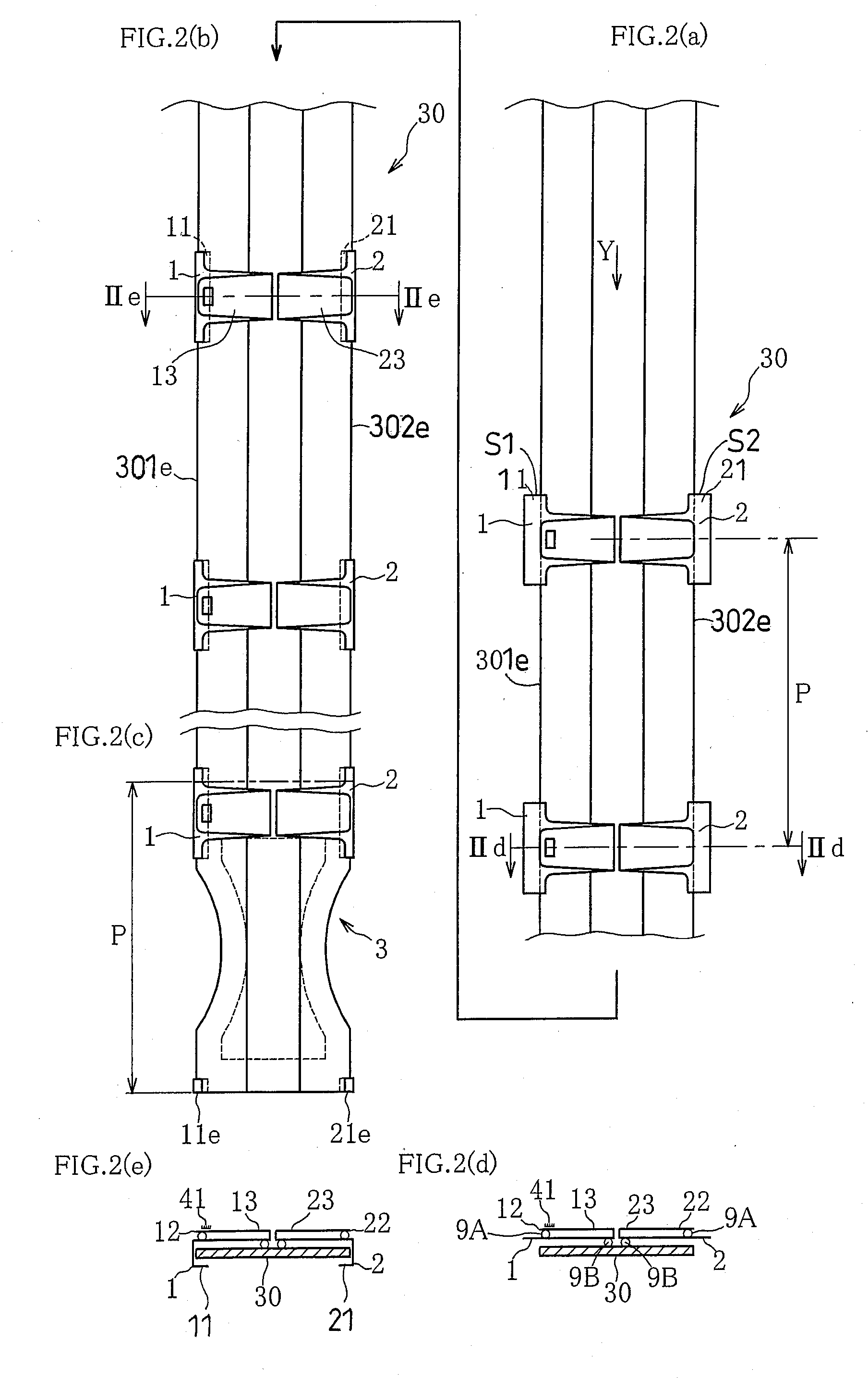

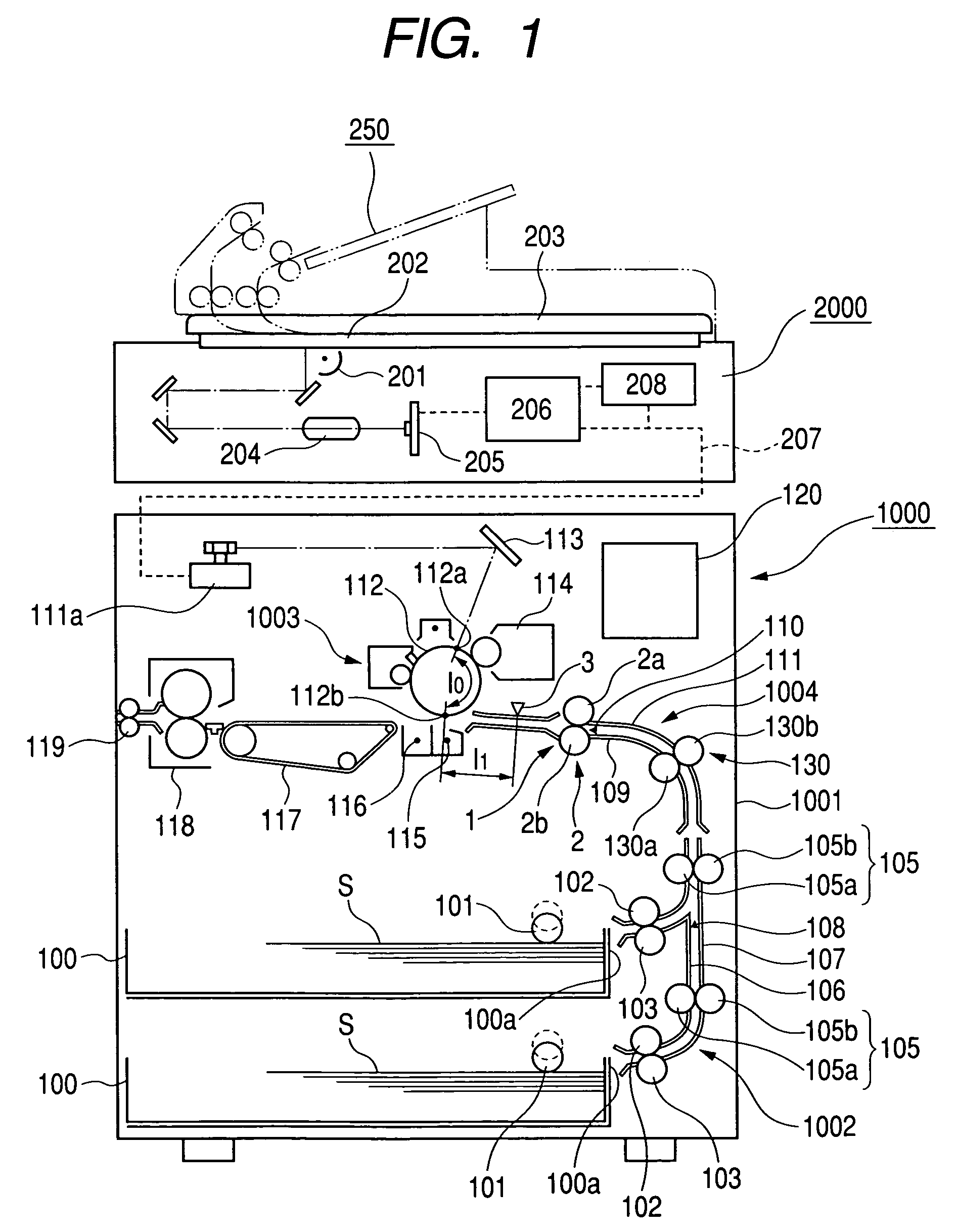

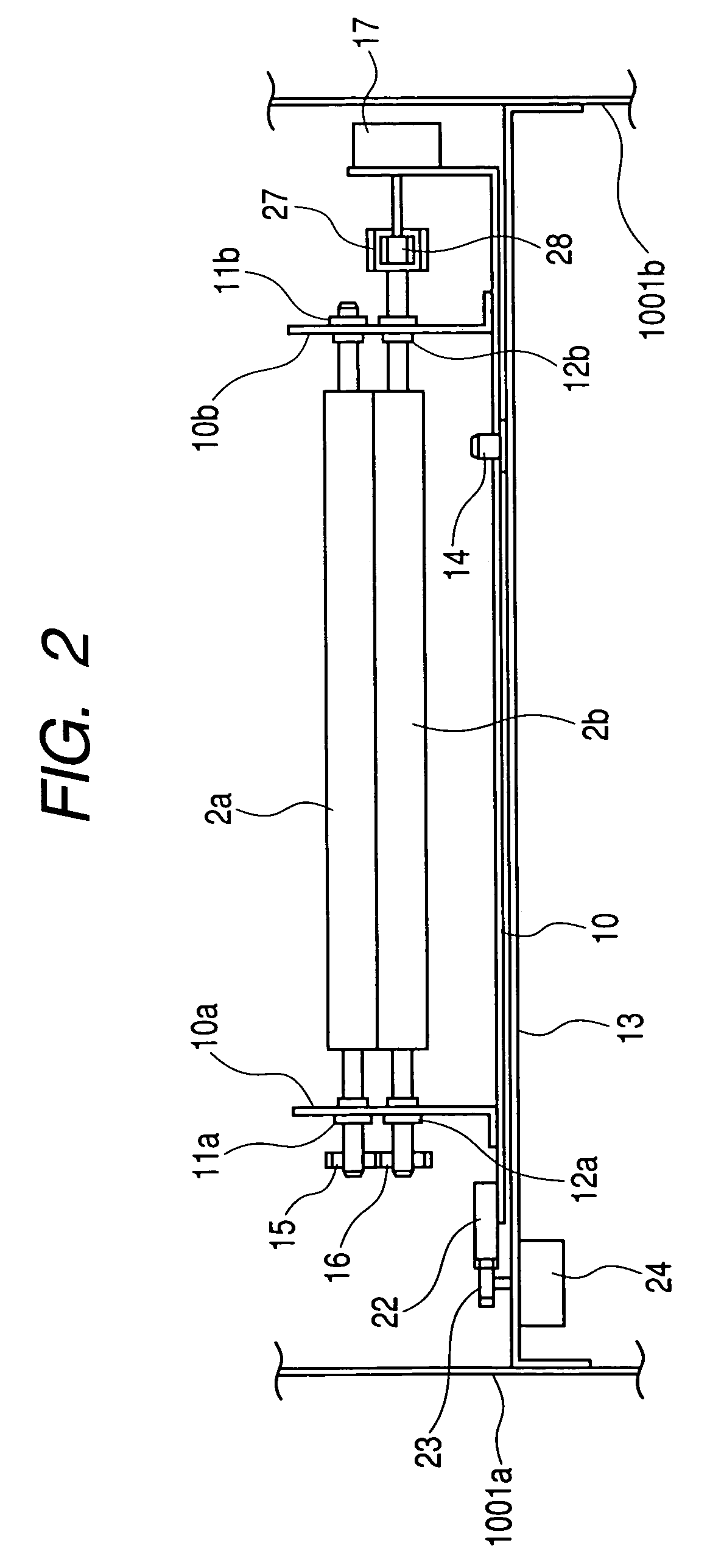

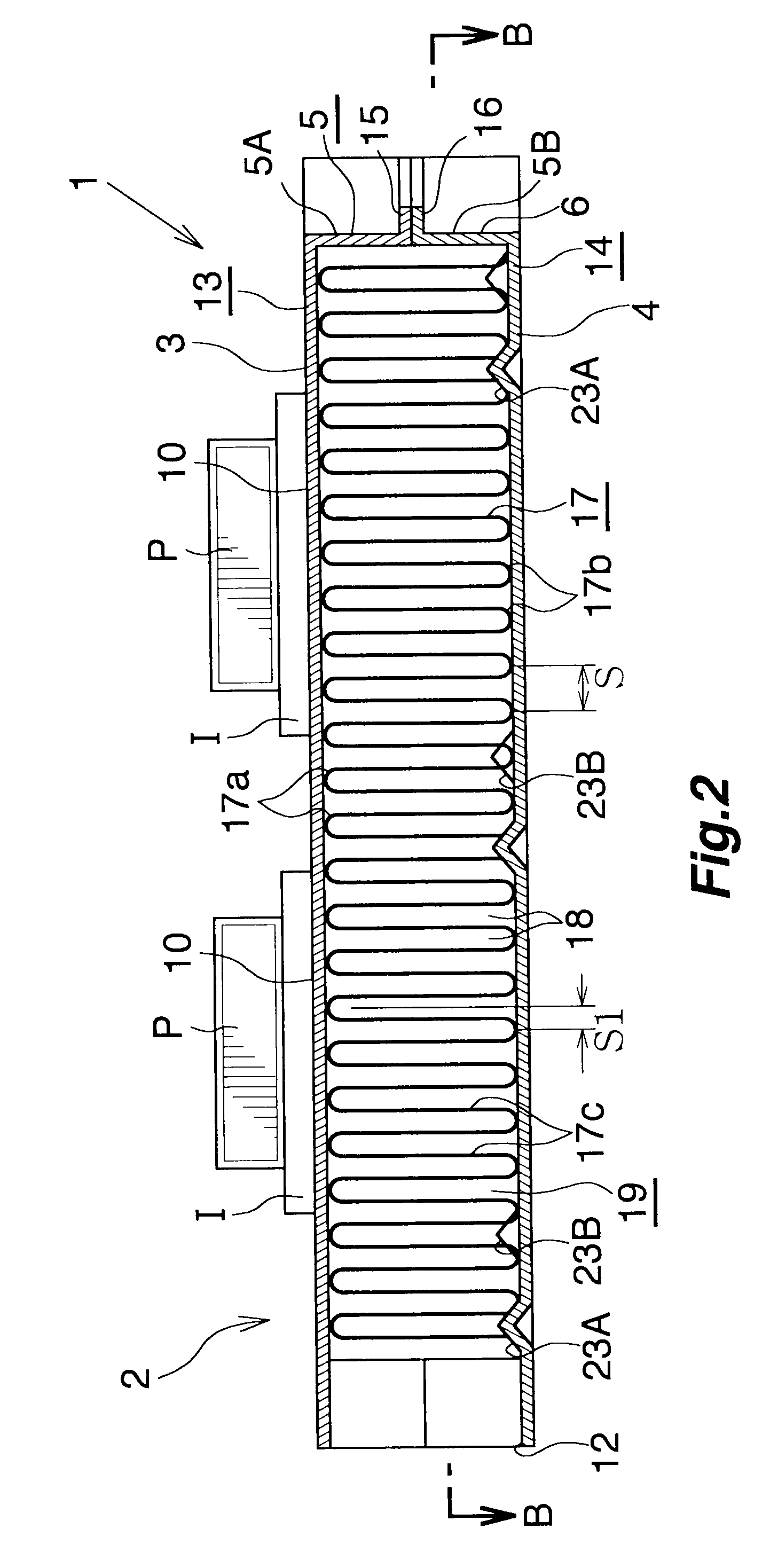

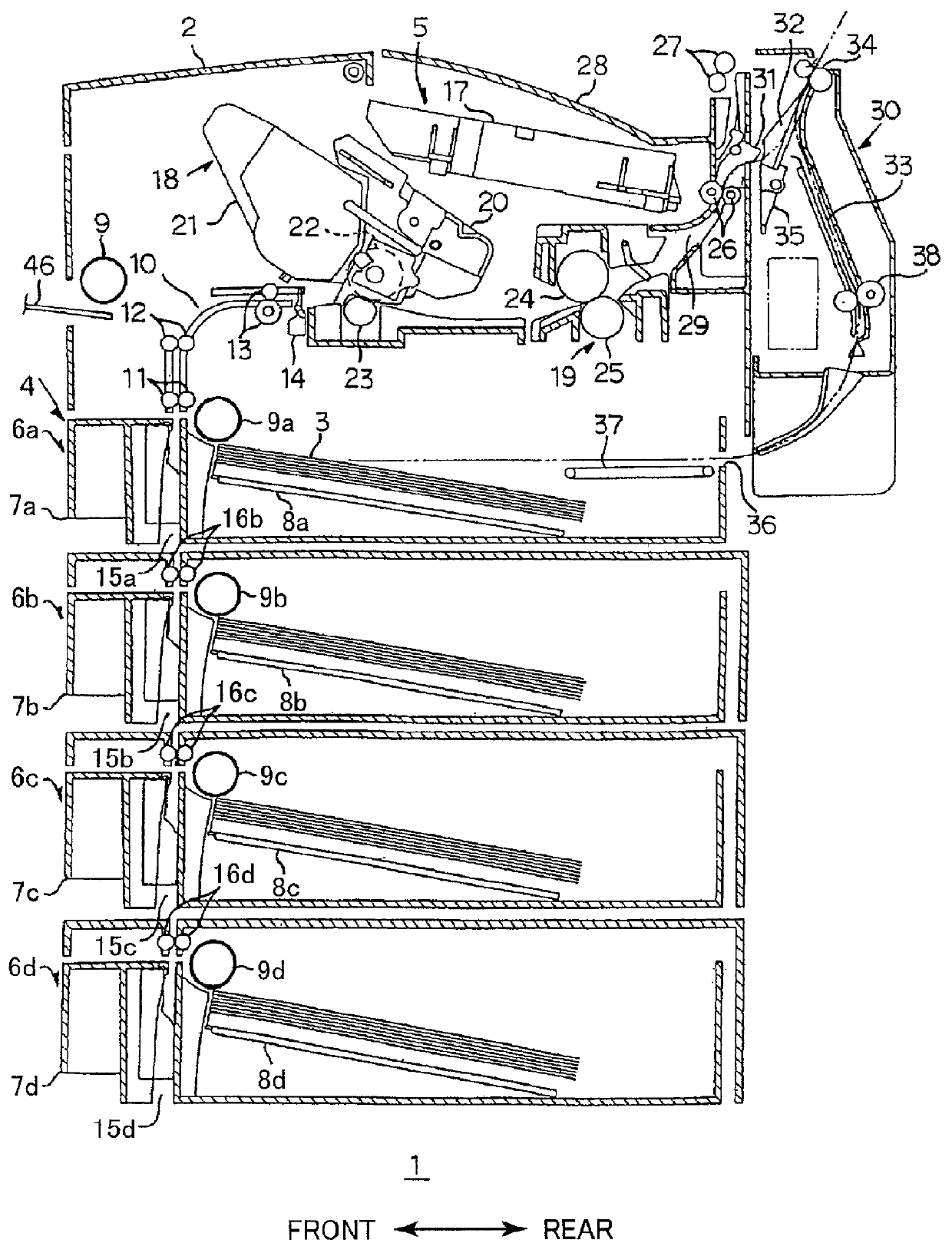

Image recording apparatus

ActiveUS20110311294A1Reduce inhibitionAvoid position shiftOther printing apparatusArticle feedersImage recordingEngineering

There is provided an image recording apparatus including a transporting path, a recording section, a first and second rollers pinching the recording medium therebetween, a supporting member which rotatably supports the second roller, a holding member which is movable along a transporting direction of the recording medium, a bias applying member which applies a bias on the holding member, in an opposite direction opposite to the transporting direction and a load member which generates a load in the opposite direction, with respect to the recording medium.

Owner:BROTHER KOGYO KK

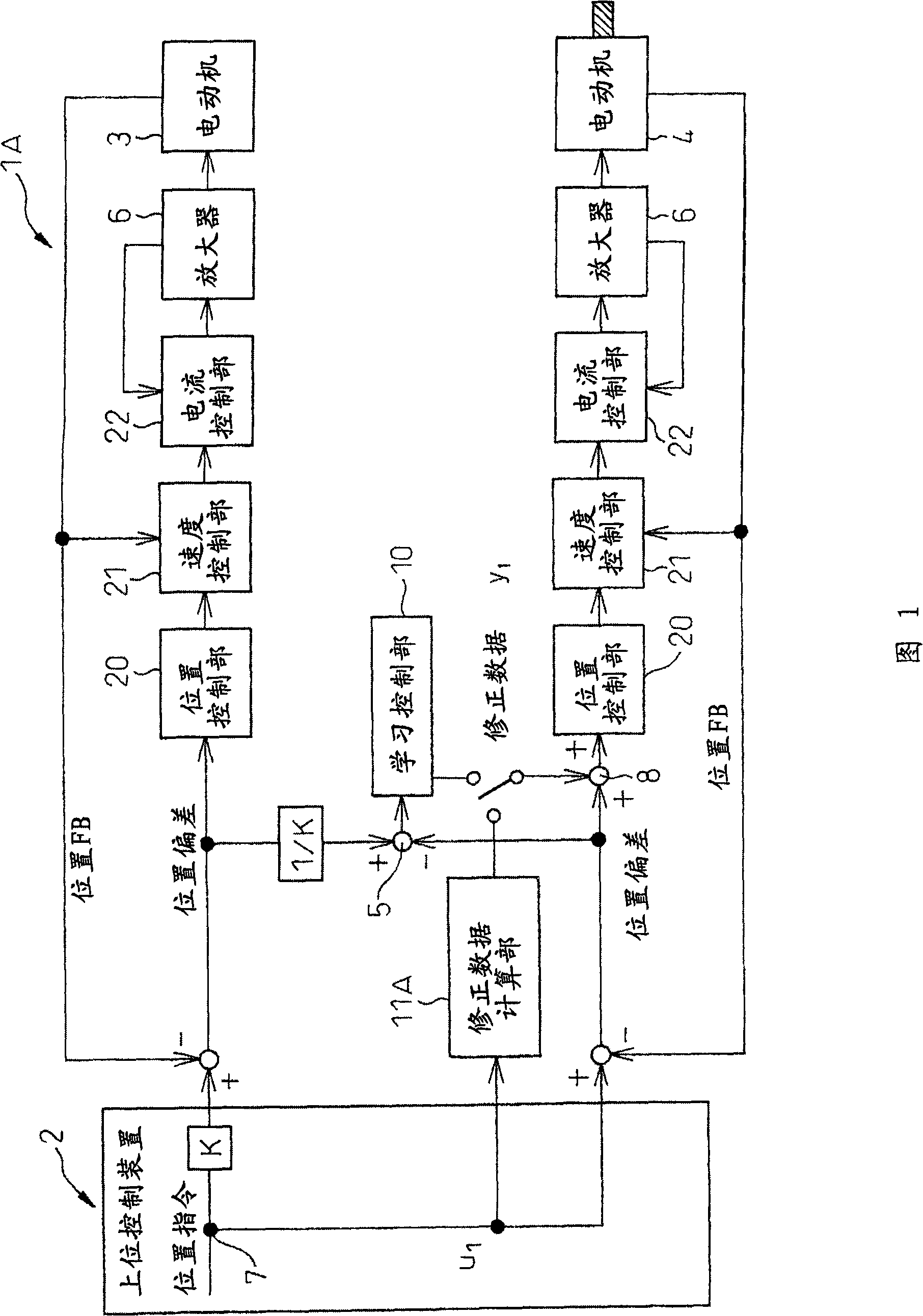

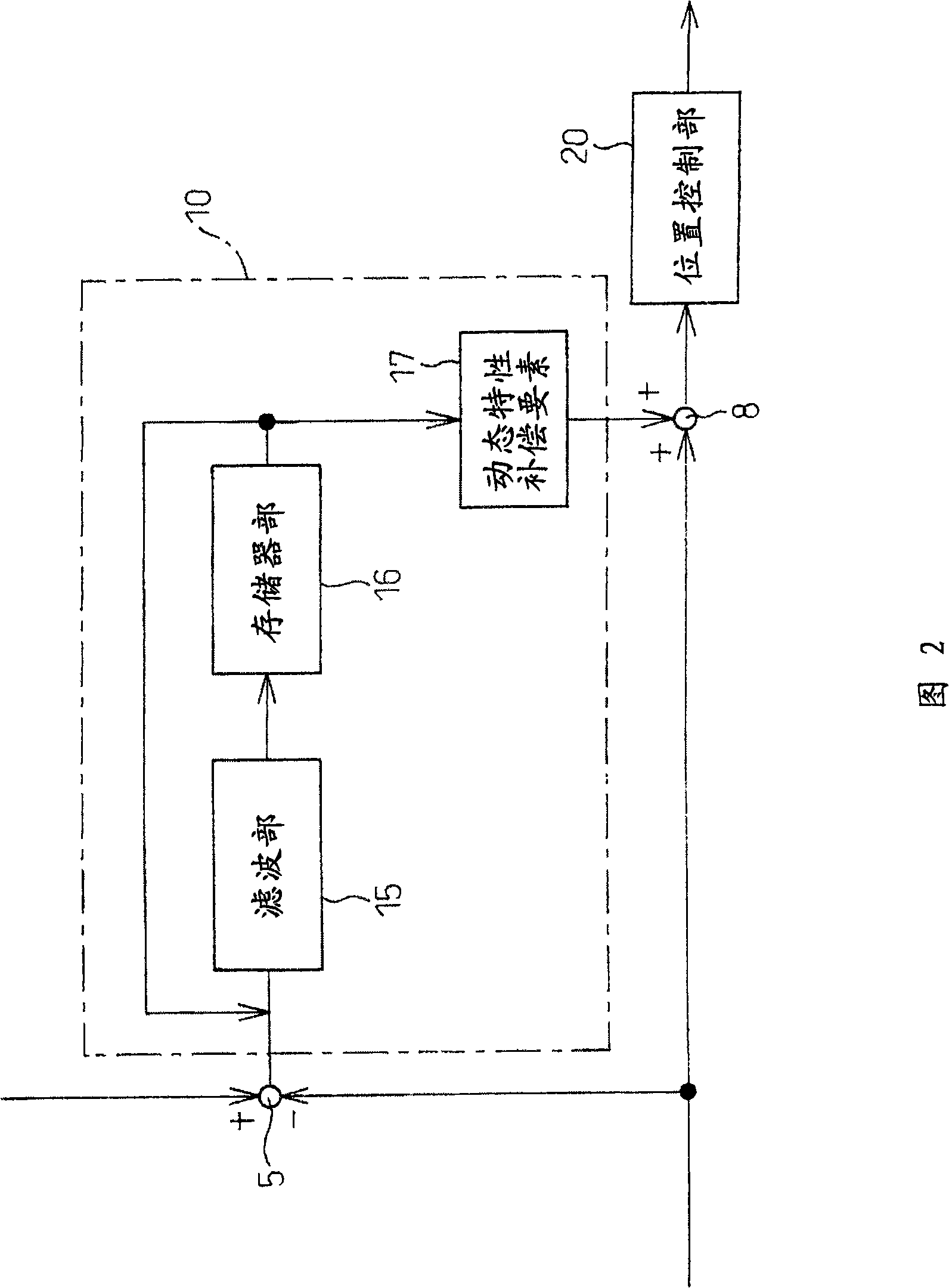

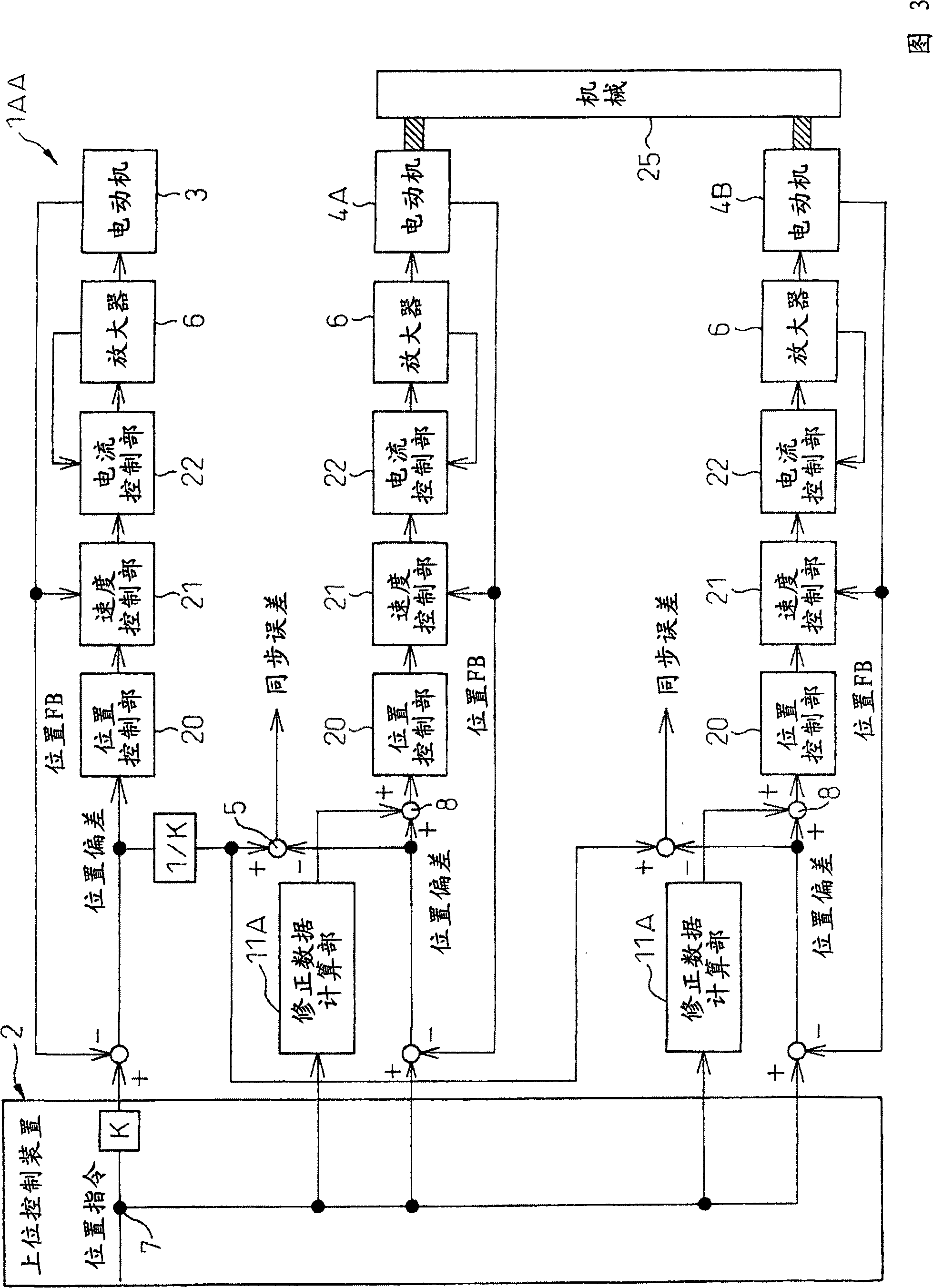

Servo controller

InactiveCN101261509AHigh repeatabilityAvoid position shiftThread cutting machinesNumerical controlSynchronous controlDrive shaft

A servo controller for synchronously controlling a master driving source for driving a driving shaft and a slave driving source for driving a driven shaft, having a position control section that performs a position control based on a positional deviation which is a difference between a position command value given to the slave driving source and a feedback value detected from the slave driving source, an operational section that calculates a synchronization error which is a difference of the positional deviation between the master driving source and the slave driving source, and a correction data calculating section that calculates first correction data for correcting the positional deviation of the slave driving source.

Owner:FANUC LTD

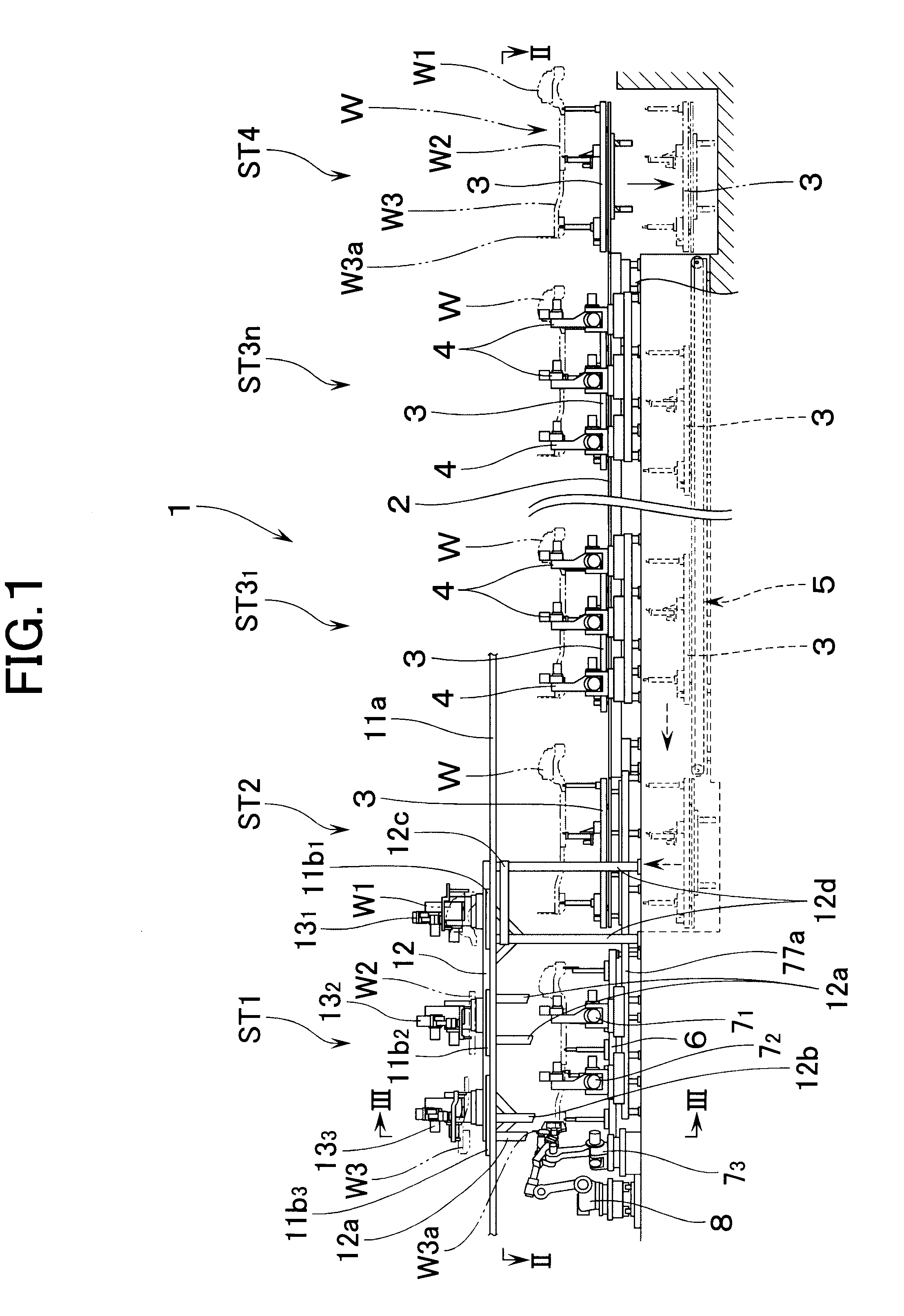

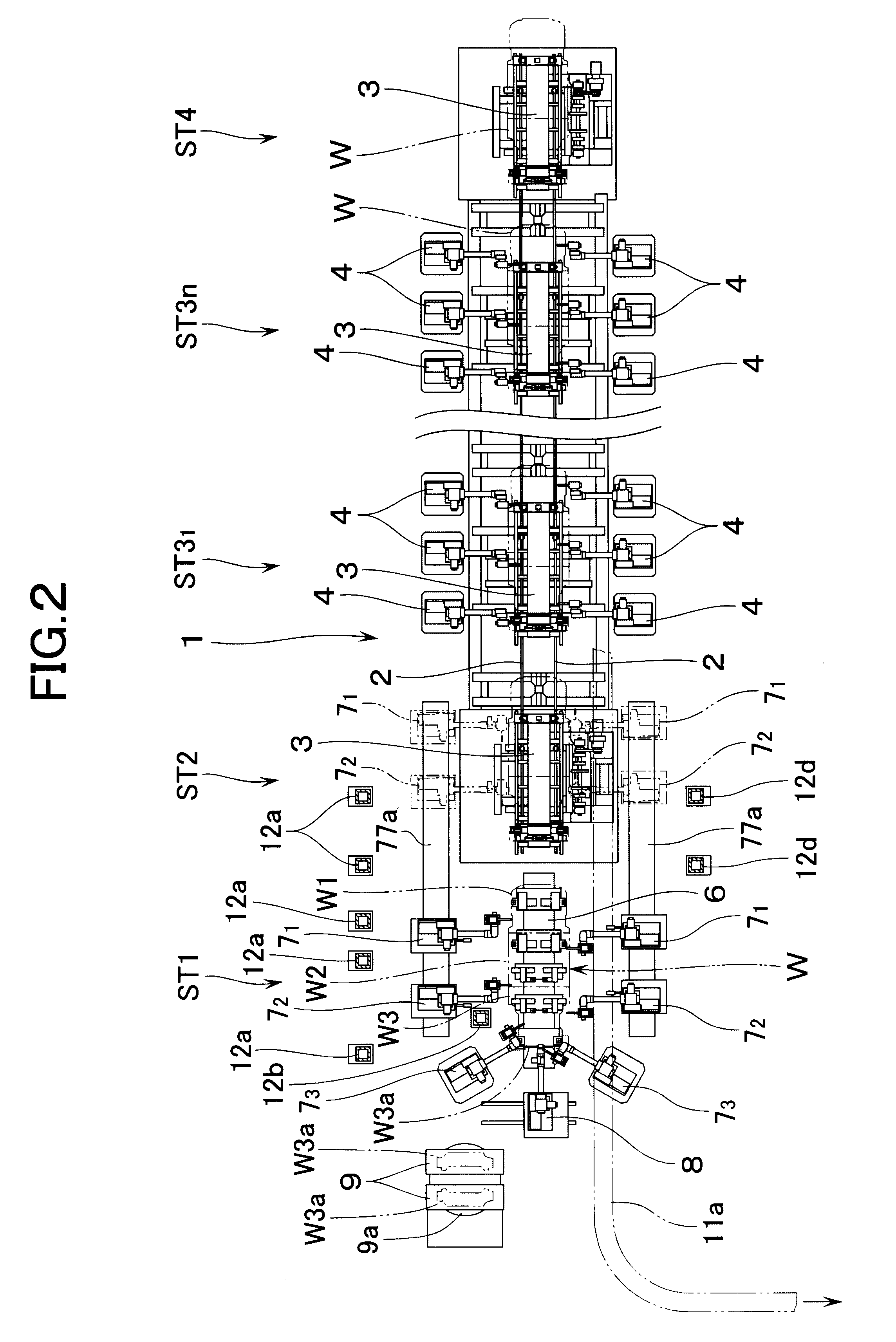

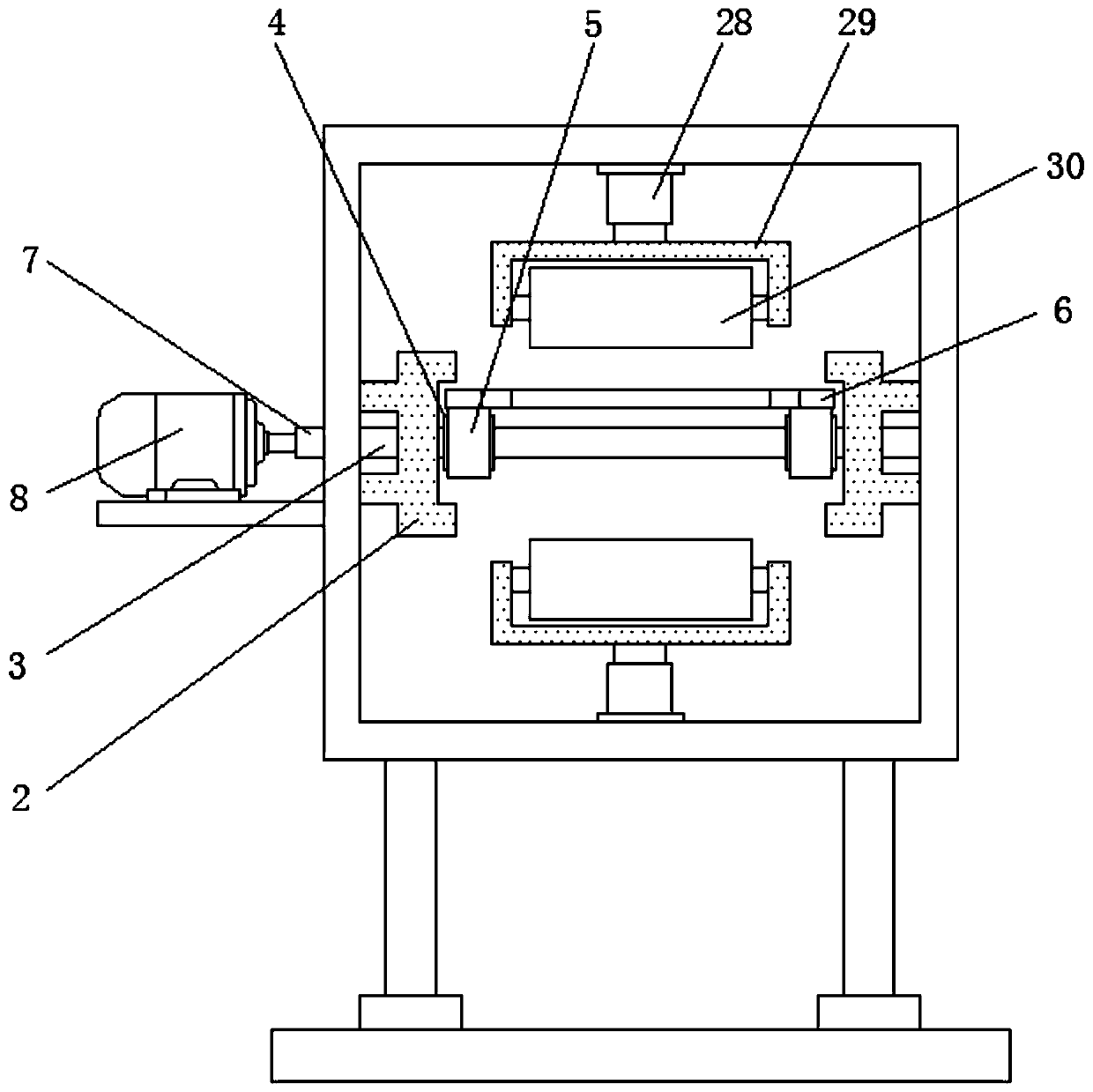

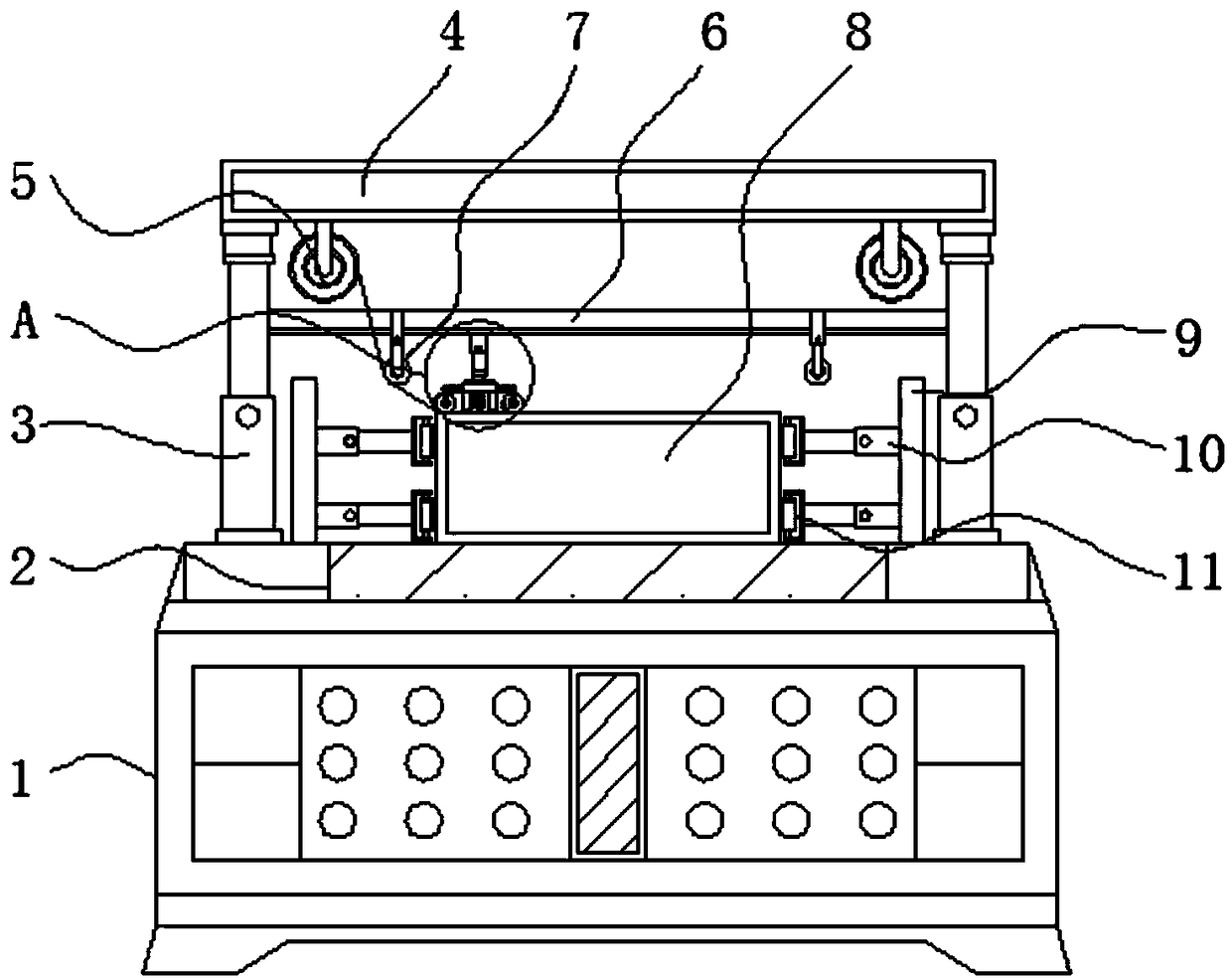

Apparatus for assembling floor of vehicle

InactiveUS6339204B1Small sizeFast shippingResistance electrode holdersWelding/cutting auxillary devicesDual purposeWelding

The floor of a motor vehicle which is assembled in a floor assembly station is transported to a subsequent station using at least two welding robots on each lateral side of the floor assembly station. These welding robots are constituted into dual-purpose welding robots for performing both welding work and transporting work. After the assembling of the floor has been finished, the floor is supported at four lateral and longitudinal jack-up points through the workpiece receiving member by the cooperation of these dual-purpose welding robots, and is transported from the floor assembly station to the subsequent station.

Owner:HONDA MOTOR CO LTD

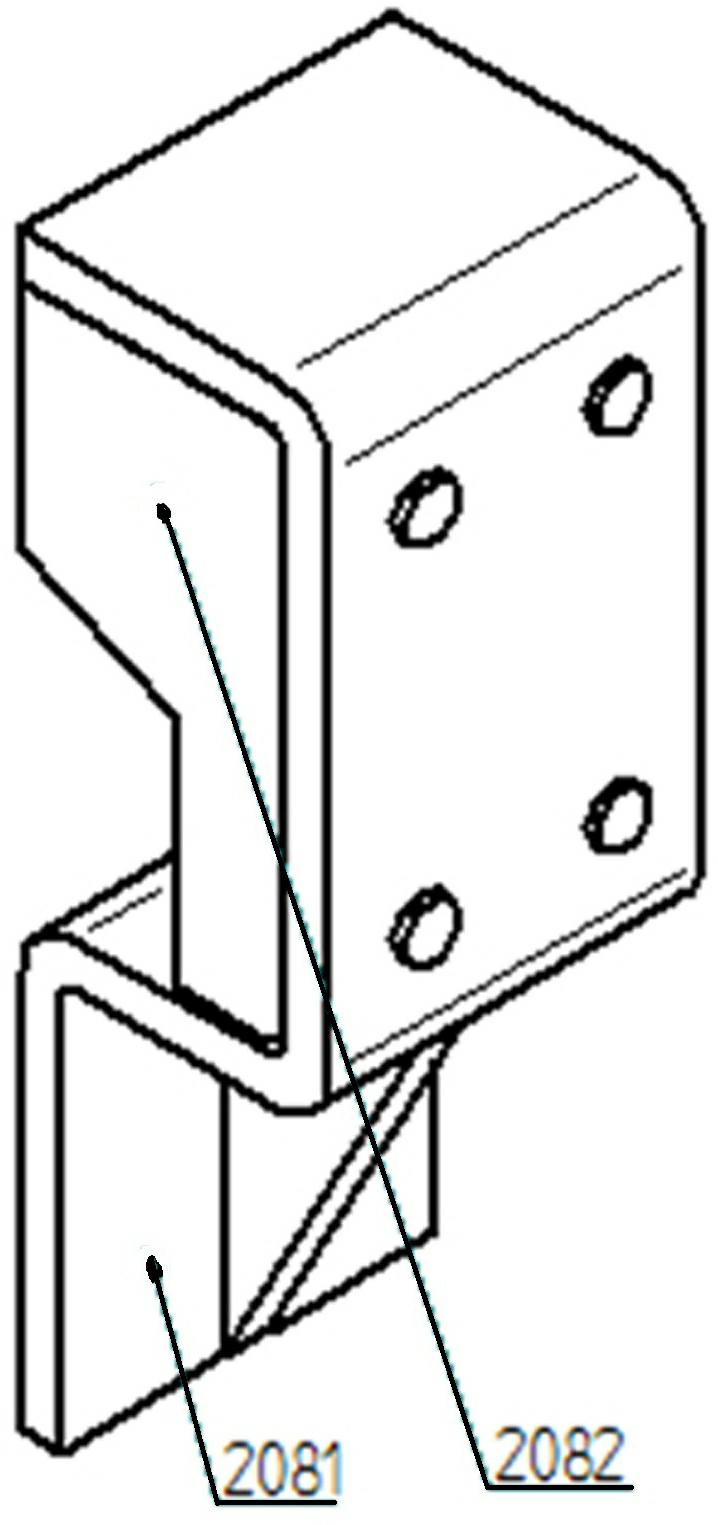

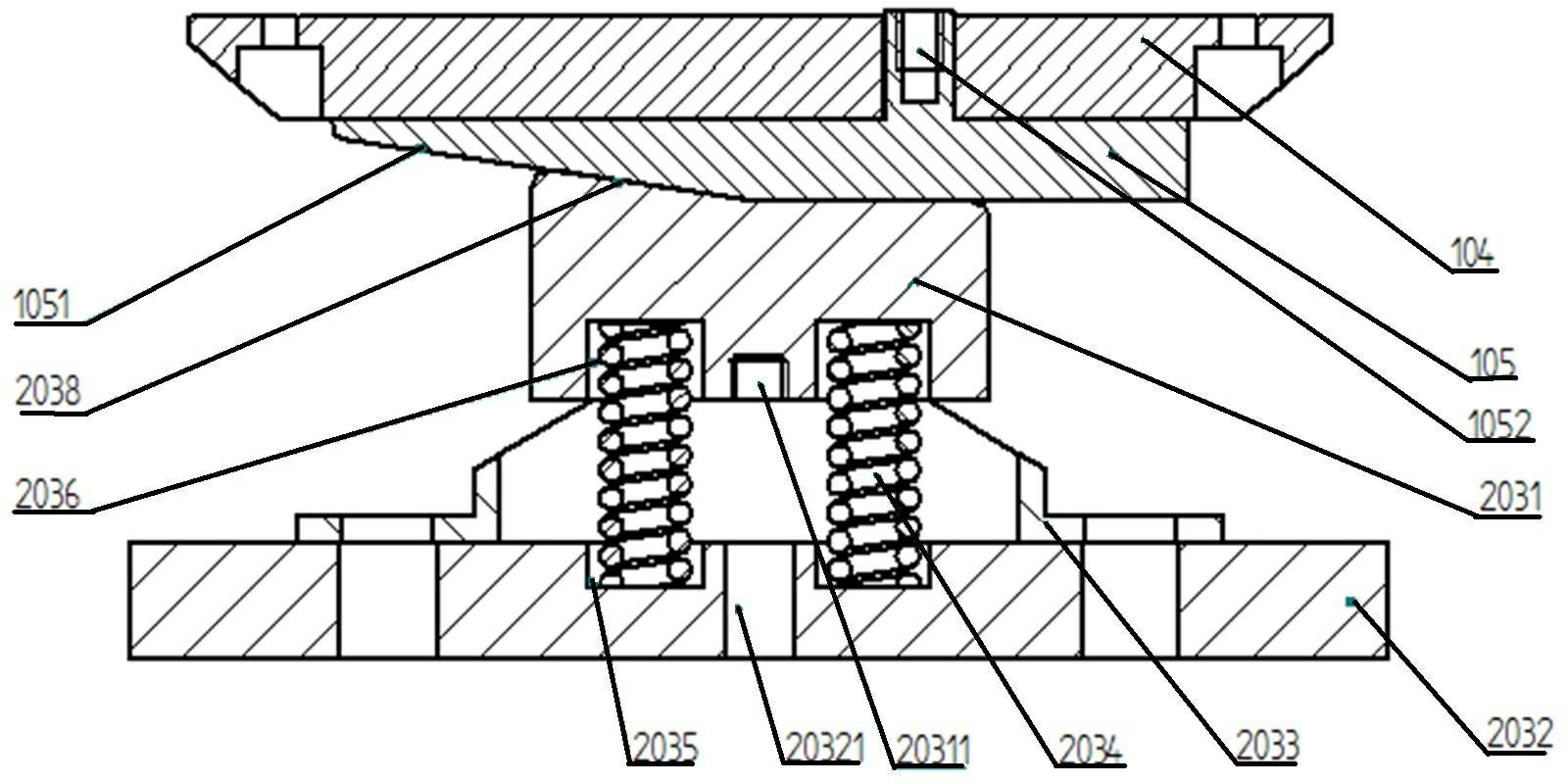

Bottom power taking self-locking electric bus battery box system capable of quickly changing battery

ActiveCN102303589AEasy to installPositioning constraints resolvedElectric propulsion mountingElectric vehicle charging technologyElectricityPower battery

The invention discloses a bottom power taking self-locking electric bus battery box system capable of quickly changing a battery. The system comprises a battery box (1), a tray (2) used for bearing the battery box and arranged on an electric bus, mobile equipment (4) for conveying the battery box, and a grabbing device (5) arranged on the mobile equipment; and a battery box locking and unlocking device (3) is arranged on the tray. Through the system, automatic assembly of the battery box in the electric bus battery box system is realized, and the problems of over positioning, deformation of power wire connection pegs, breakage, arc discharge, welding, difficulty in automatically realizing unlocking due to impact of the battery box to a bolt of a locking mechanism in jolt and deformation of the battery box due to impact in jolt. The system is reasonable, reliable, simple and compact in structure, and can full-automatically, quickly and conveniently realize quick change of the power battery.

Owner:KUNMING SHIPBUILDING EQUIP

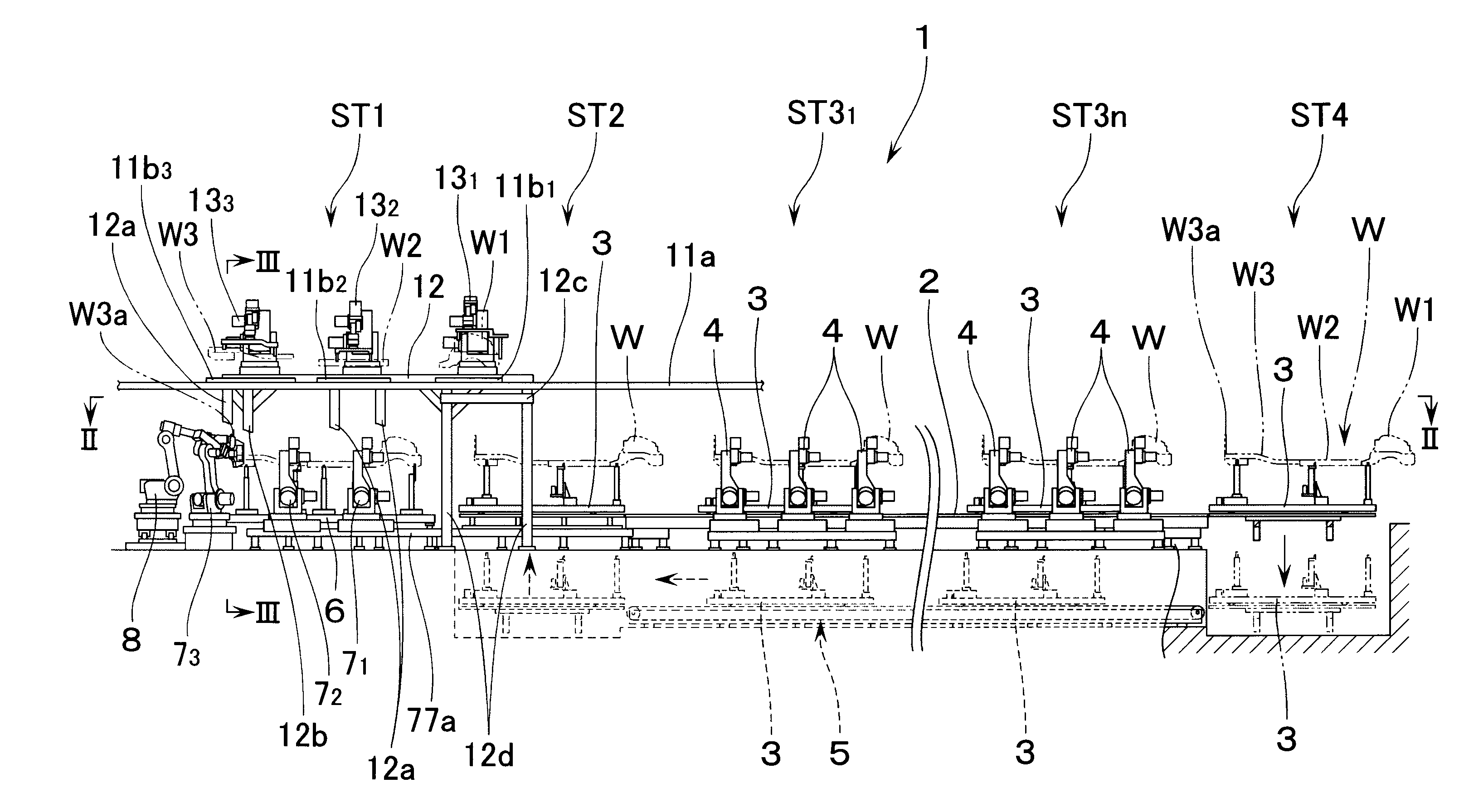

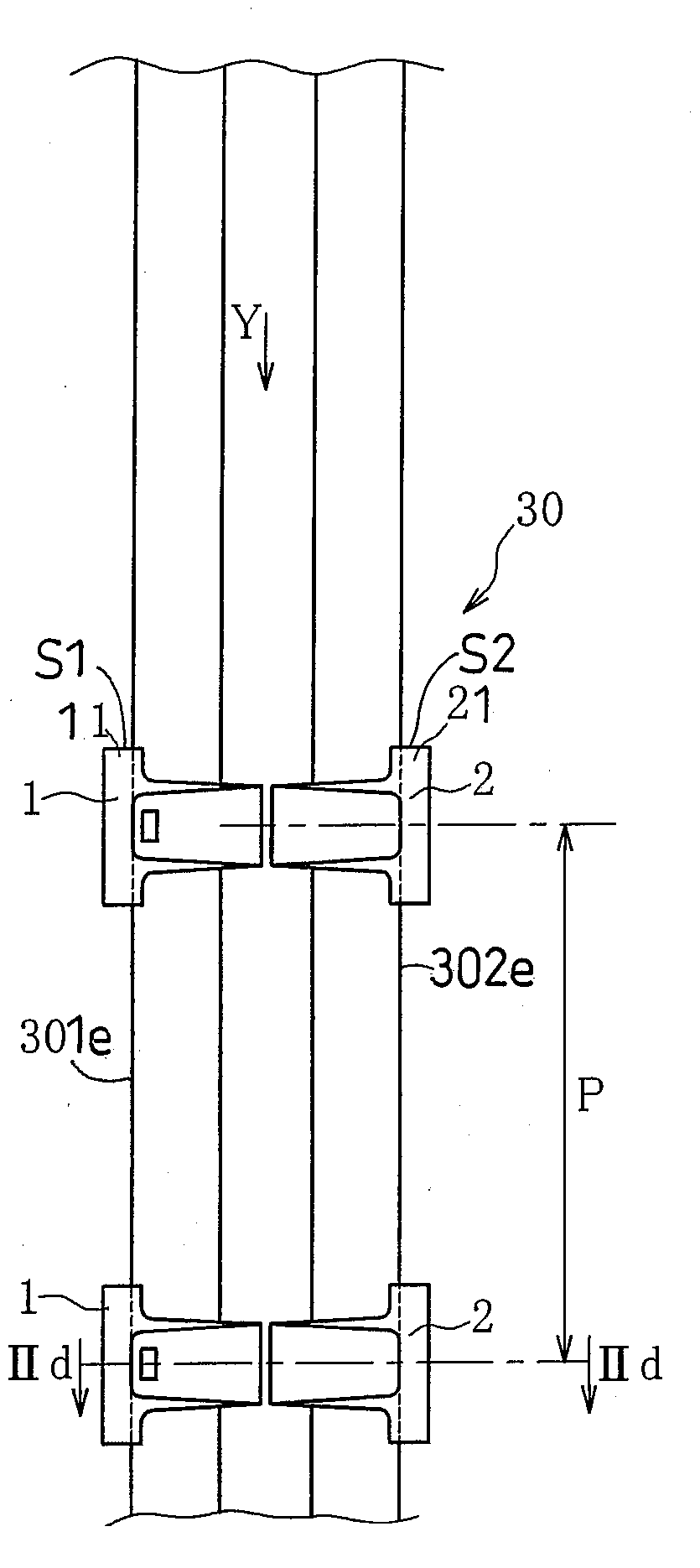

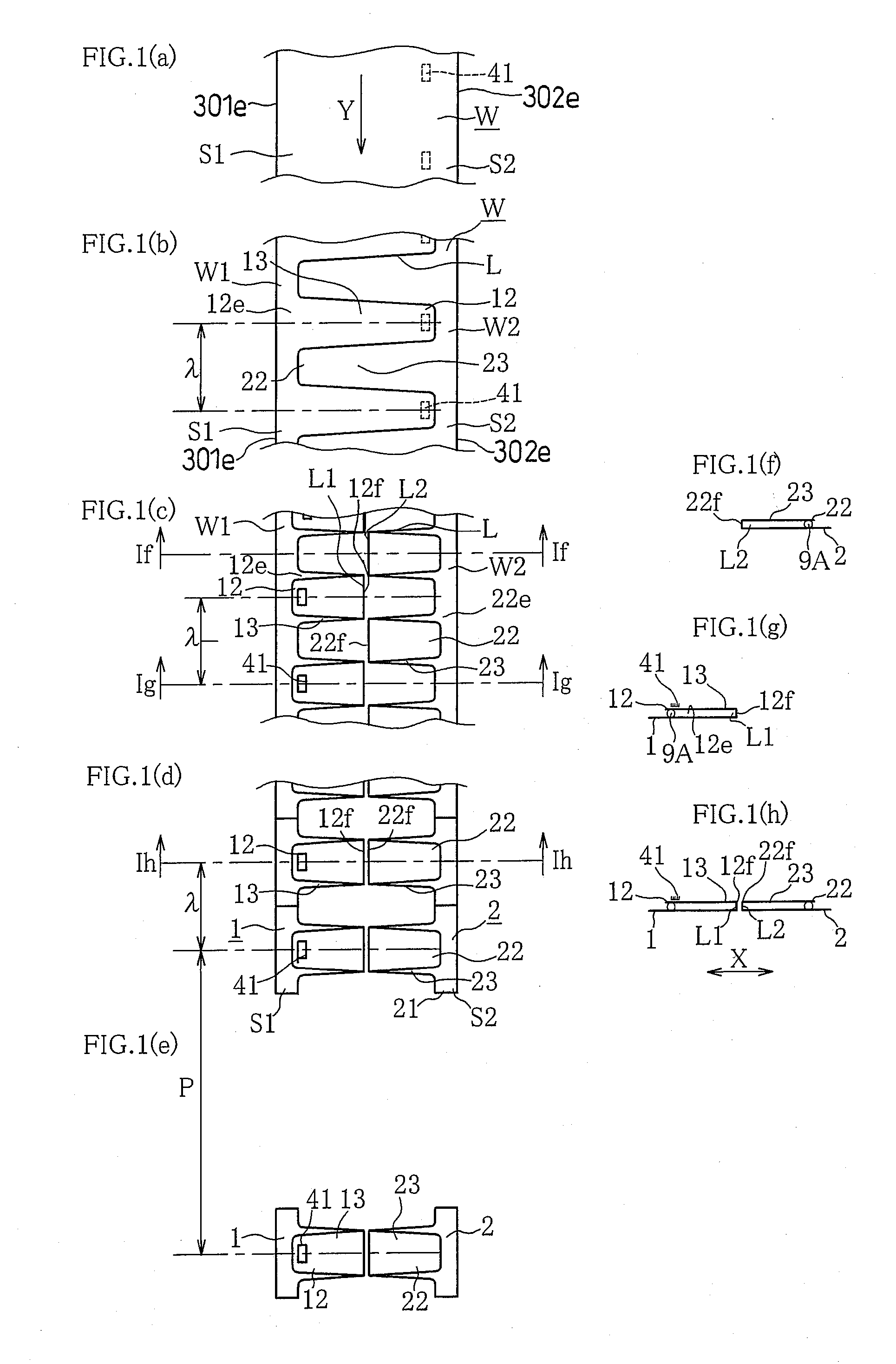

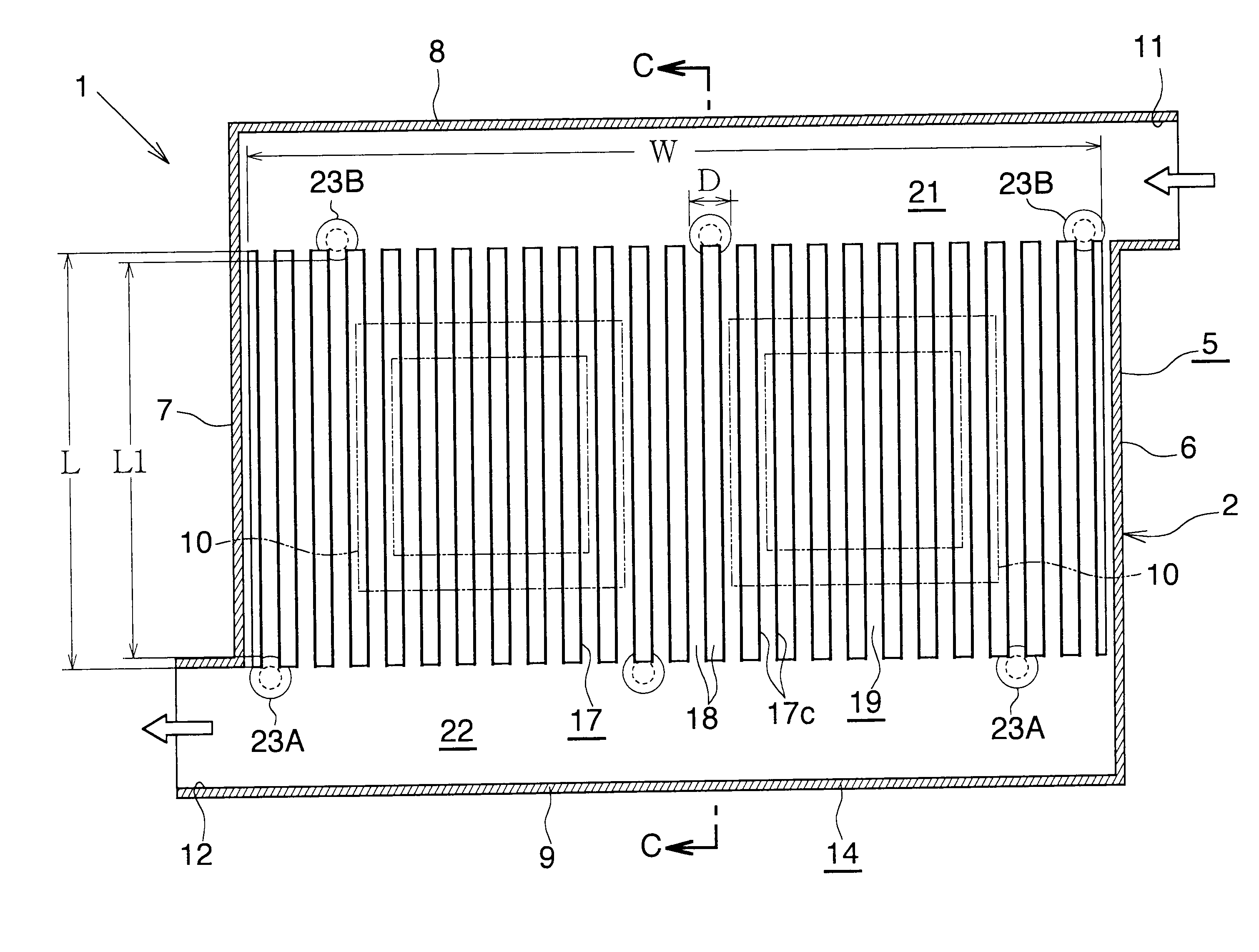

Method for producing diaper

InactiveUS20090126864A1Improve appearanceIncrease widthLayered productsAbsorbent padsEngineeringLeather belt

A method for producing a diaper of the present invention includes the steps of: folding back a first strip-shaped portion 13 and a second strip-shaped portion 23; successively forming pairs of first and second belts 1 and 2 by cutting first and second separate webs W1 and W2; placing pairs of the first and second belts 1 and 2 at a predetermined interval P in a carrying direction Y of a continuous piece; temporarily attaching the first and second belts 1 and 2 to a portion of the continuous piece to be a back portion; fixing the belts 1 and 2 to the continuous piece; and severing the continuous piece with the belts 1 and 2 fixed thereon at a predetermined pitch into individual diapers.

Owner:ZUIKO CORP

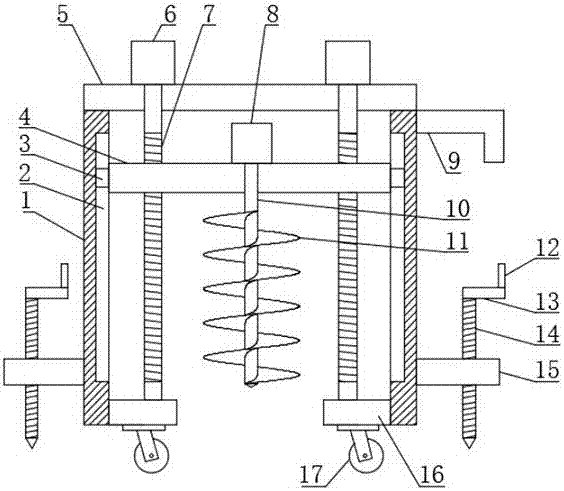

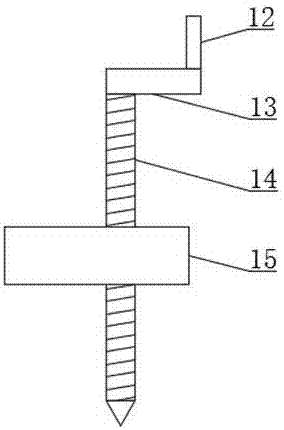

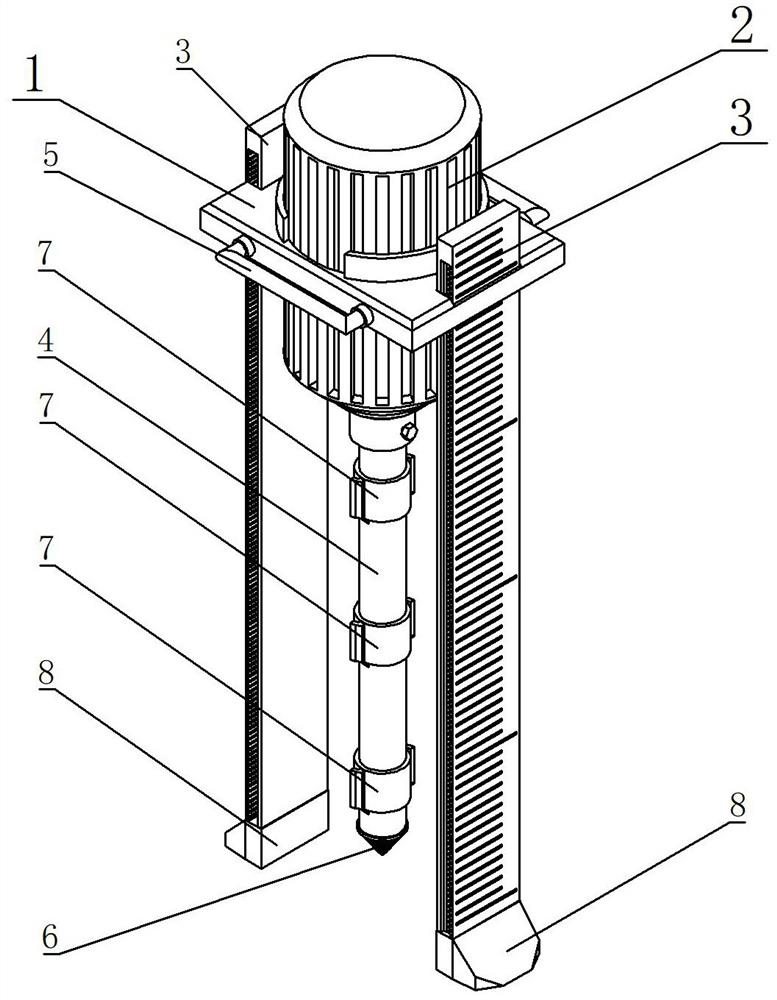

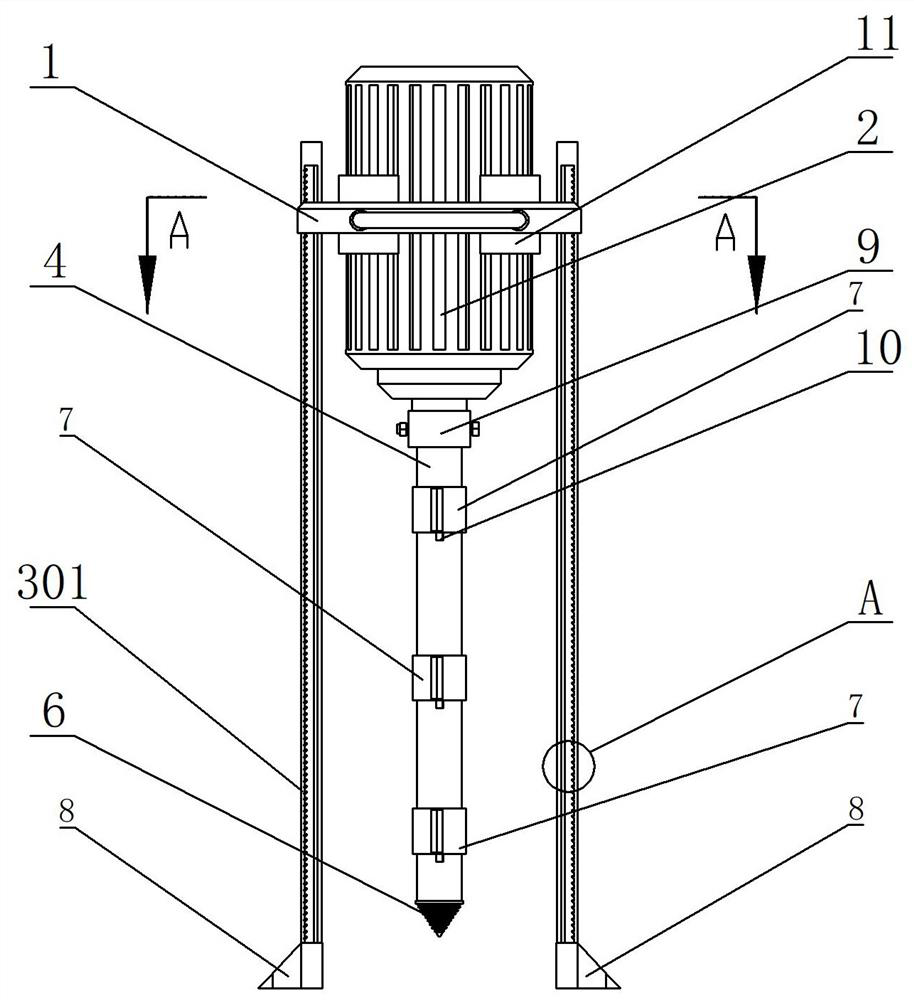

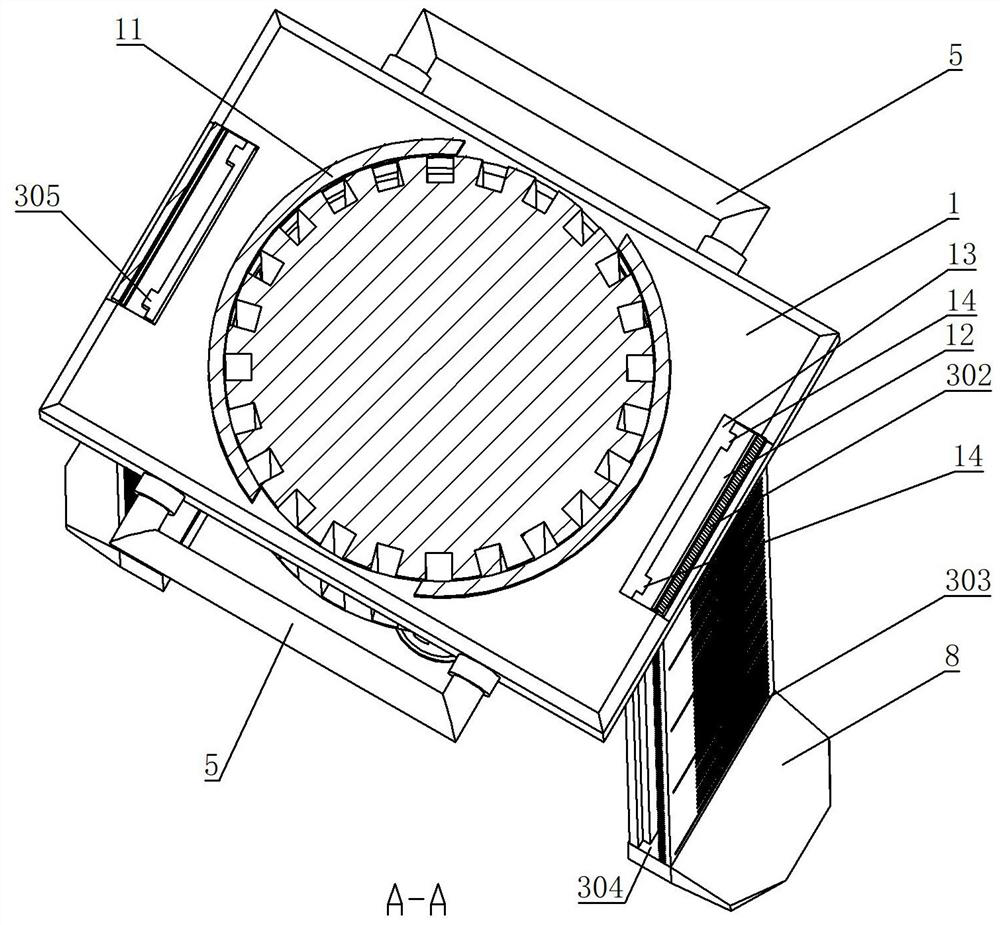

Agricultural sapling earth auger provided with fixing device

InactiveCN107333493AReduce the amount of manual laborAvoid position shiftPlantingFurrow making/coveringArchitectural engineeringSeedling

The present invention discloses an agricultural saplings digging machine with a fixed device, including the top board, which is fixed on the left and right sides of the top plate with a branch board.There is a lifting plate connection. The top motor is set on the top of the lifting board. The second motor bottom motor shaft is connected with a drill rod. The drill rod is equipped with a spiral blade. The spiral blade is located below the lifting plate.In a motor, the first motor bottom motor axis is connected to a lifting screw, which connects the lifting screw through the lifting plate and the lifting plate thread, which is fixed at the bottom of the lift plate with a base, which rotates the bottom of the lift screw and the base.The present invention drives up and down the upper and lower movements through the rotation of the lifting screw, which makes the spiral blade move the pits automatically. There is no need to control manual control during the pit process, reducing the amount of labor labor.

Owner:YANCHENG CITY LONG XIANG MACHINERY MFG PLANT

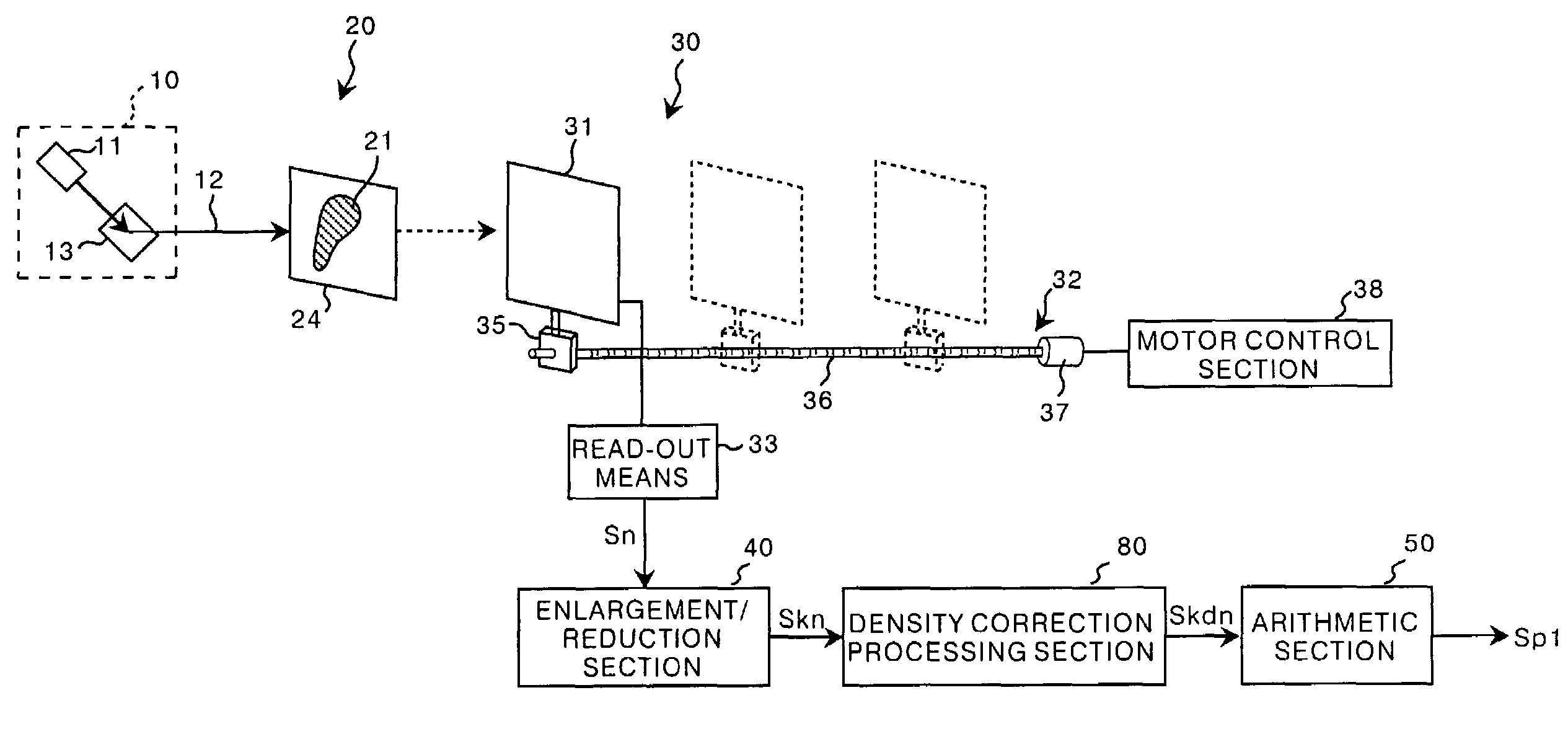

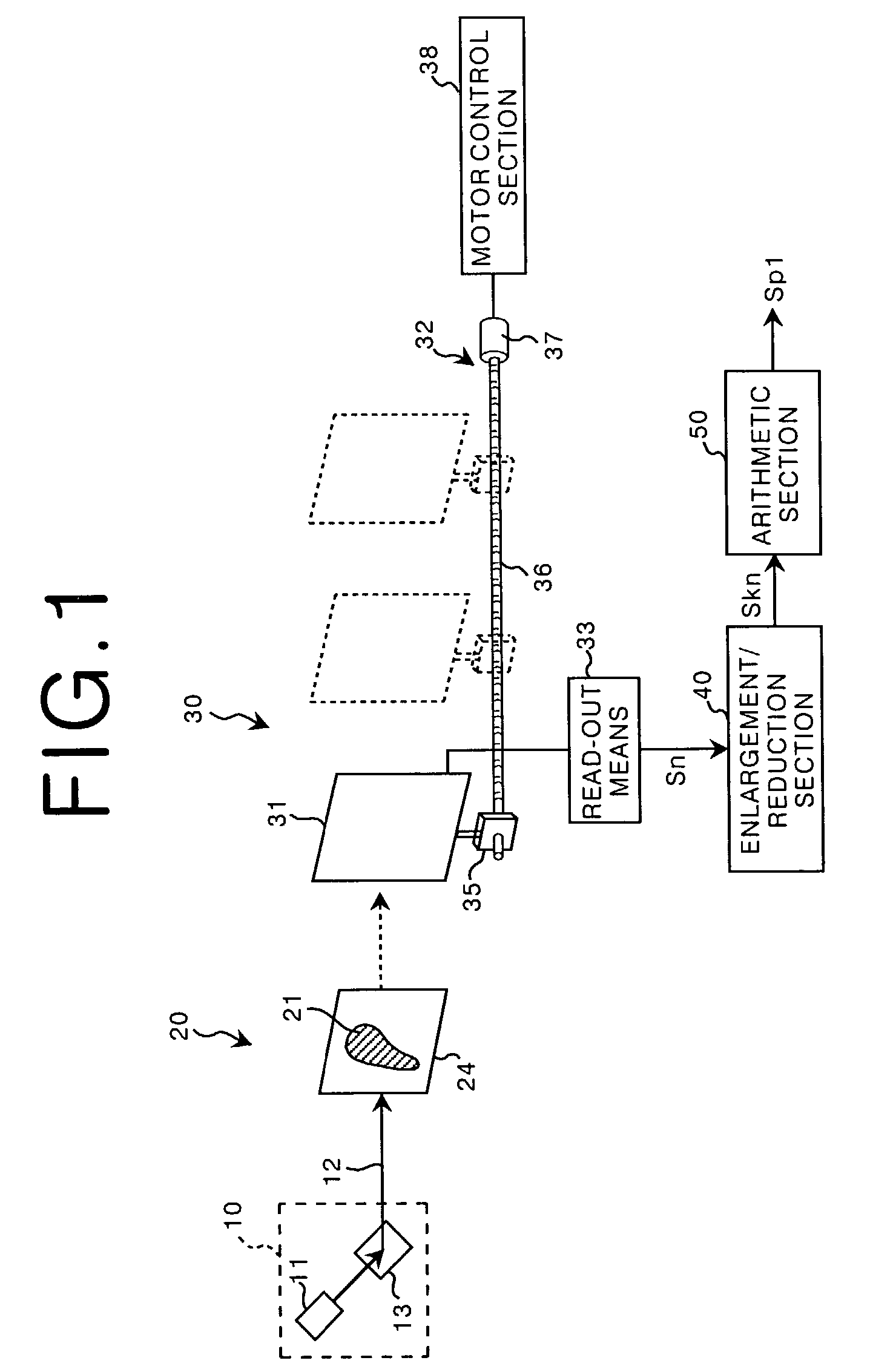

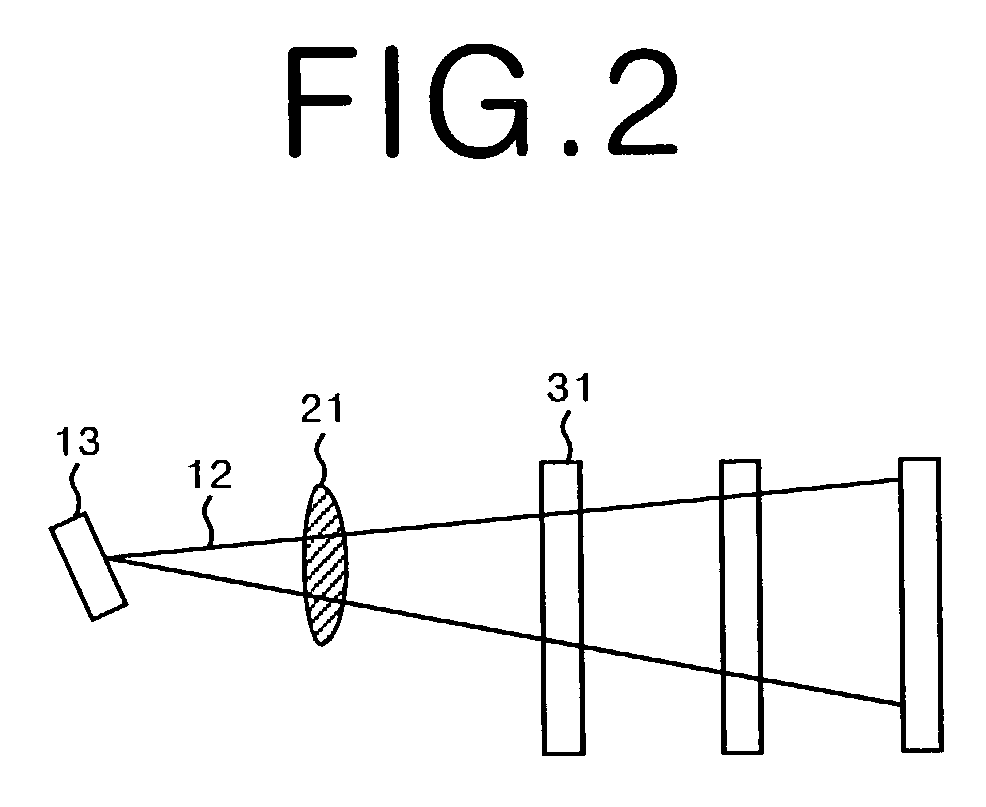

Method of and apparatus for generating phase contrast image

InactiveUS7346204B2Avoid position shiftSame sizeImage enhancementTelevision system detailsPhase-contrast imagingPhysics

A phase contrast image is generated on the basis of a plurality of radiation images of an object taken in imaging positions which are different from each other in the distance from the object. An enlargement / reduction processing is carried out on the radiation images as taken in the imaging positions according to the distances between the imaging positions so that the radiation images become substantially the same in their sizes, and a phase contrast image is generated on the basis of the radiation images thus processed.

Owner:FUJIFILM CORP +1

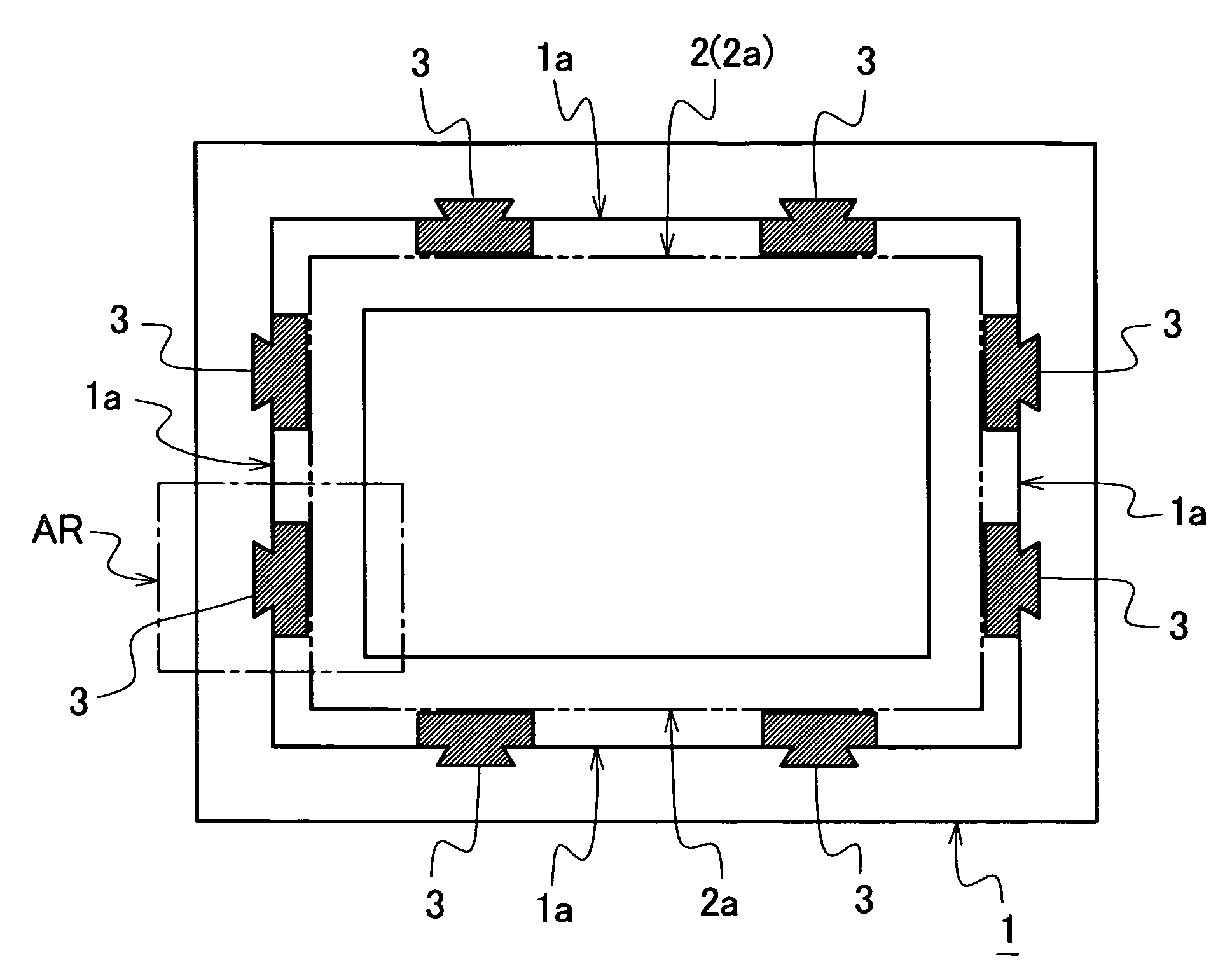

Display device

ActiveUS7626654B2Good adhesionAvoid position shiftNon-linear opticsLiquid-crystal displayDisplay device

An object of the invention is to facilitate attachment of a spacer to a support member in an assembling process of a liquid crystal display device. A display device includes: a display panel, a support member that supports the display panel and a spacer that is interposed between a cut end surface of the display panel and a first surface of the support member, the first surface facing the cut end surface of the display panel. The support member has a recess that opens through the first surface and a second surface, which is connected to the first surface and extends away from the display panel. The spacer includes a spacer position securing portion inserted in the space of the recess of the support member and a buffer portion that is integral with the spacer position securing portion and protrudes from the open end at the first surface of the support member toward the cut end surface of the display panel.

Owner:PANASONIC INTELLECTUAL PROPERTY CORP OF AMERICA +1

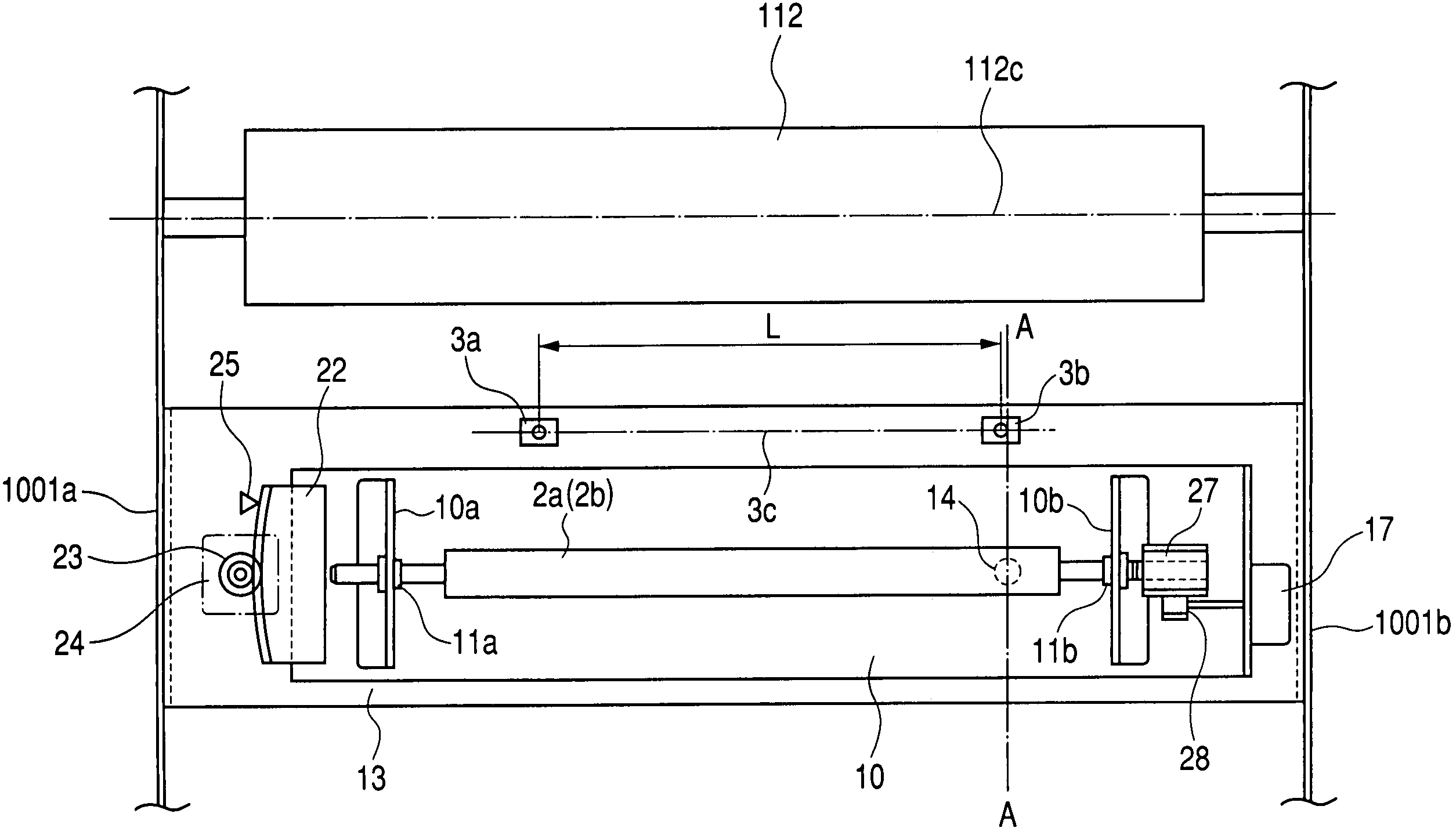

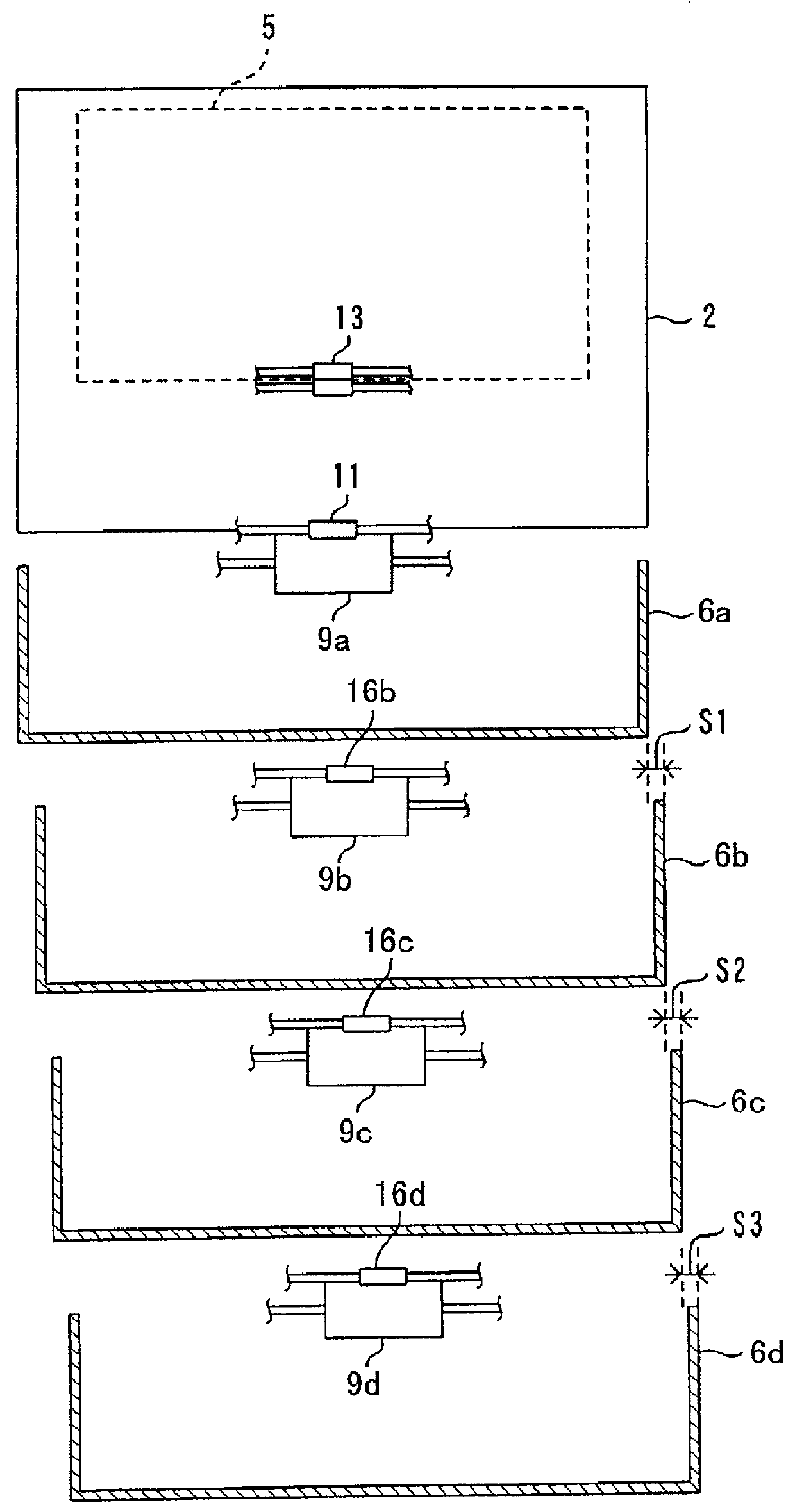

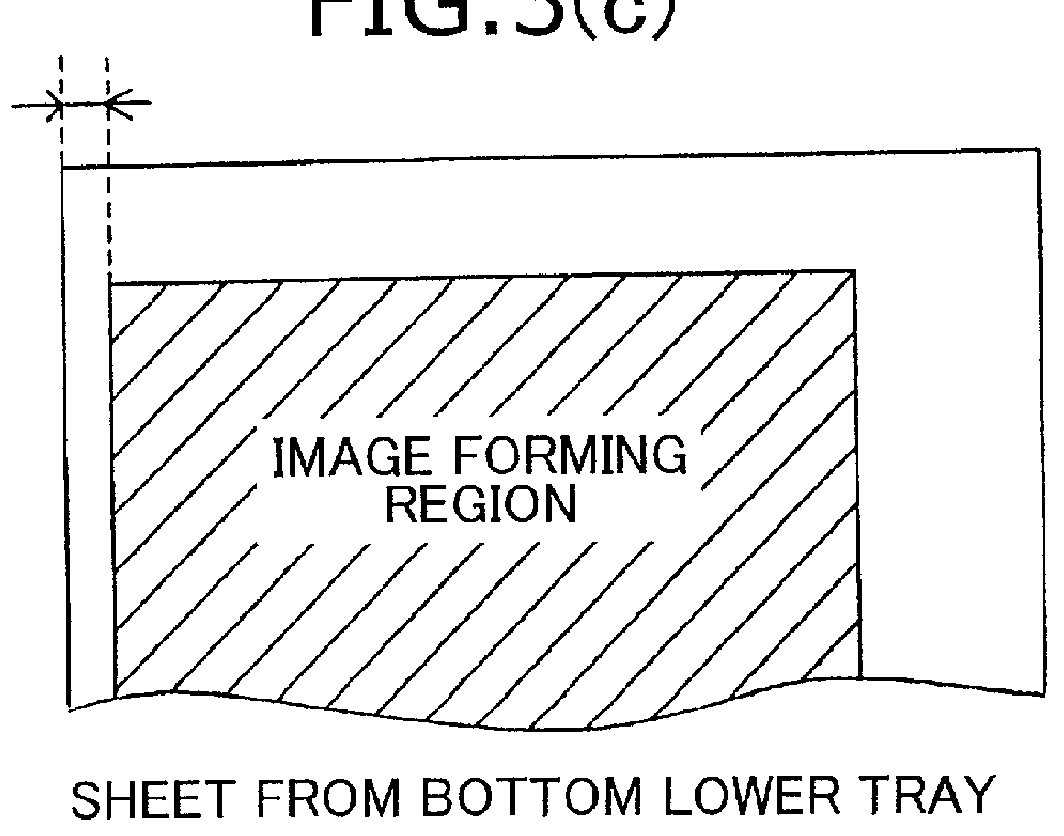

Pivotal sheet conveying apparatus for skew correction and image forming apparatus

InactiveUS7319842B2Improve accuracyAvoid position shiftRegistering devicesFunction indicatorsEngineeringMechanical engineering

To provide a sheet conveying apparatus capable of enhancing an accuracy of correcting a skew of a sheet, and of preventing position shift of a sheet. The present invention provides a sheet conveying apparatus for conveying a sheet by a sheet conveying unit disposed along a sheet conveying path, including: a skew detection sensor for detecting a skew of the sheet with respect to a sheet conveying direction by a plurality of detection sensors disposed in a direction intersecting perpendicularly the sheet conveying direction; and a skew correction roller adapted to be pivotally moved in a direction of correction of a skew of the sheet in a state with the skewed sheet being held on the basis of a detection signal from the skew detection sensor, in which one of the plurality of detection sensors of the skew detection sensor is disposed nearly on an extension line from a pivotal movement center of the skew correction roller in the sheet conveying direction.

Owner:CANON KK

Liquid-cooled-type cooling device

ActiveUS20100051235A1Positional shiftProper disposalSafety devices for heat exchange apparatusSemiconductor/solid-state device detailsEngineeringMechanical engineering

Owner:RESONAC CORP

Spraying device for building material machining

ActiveCN110653110AAvoid occlusionPlay a limiting effectPretreated surfacesCleaning using toolsConstruction engineeringStructural engineering

The invention discloses a spraying device for building material machining. The spraying device for building material machining comprises a device body, material supplying boxes and treating boxes; connecting plates are arranged at the inner ends of first hydraulic telescopic rods; cleaning rolls are rotatably connected to the inner side walls of first U-shaped frames, second rotation shafts penetrate through the back side walls of the first U-shaped frames, and the second rotation shafts on the left sides are connected with second motors; the treating boxes are arranged on the front side faceand the back side face of the device body and arranged on the left sides of first motors; first fans are arranged on the right sides of the treating boxes and connected with suction pipes; and secondhydraulic telescopic rods are arranged on the upper side wall and the lower side wall of the device body, second U-shaped frames are arranged at the inner ends of the second hydraulic telescopic rods,and flattening rolls are rotatably connected to the inner side walls of the second U-shaped frames. According to the spraying device for building material machining, a coating in the material supplying boxes is sprayed to building plates through spraying pipes at the upper end and the lower end, and the two faces of the building plates can be simultaneously sprayed.

Owner:徐州思达新技术开发有限公司

Automatic film tearing machine for accessory assembly

ActiveCN109334215AAvoid position shiftGuaranteed assembly accuracyLamination ancillary operationsLaminationTectorial membraneGlass sheet

The invention discloses an automatic film tearing machine for accessory assembly. The automatic film tearing machine comprises a transmission mechanism, a positioning and supporting mechanism, a filmtearing mechanism and a feed box, wherein the transmission mechanism is horizontally arranged on a rack; the positioning and supporting mechanism is arranged at a film-tearing station; the film tearing mechanism is arranged above the film-tearing station; the film tearing mechanism comprises a rotating component, a film clamping component and a pressing component; the film clamping component and the pressing component are respectively connected to the output end of the rotating component; the film clamping component and the pressing component comprise at least two groups, and every two groupsare arranged at an interval; the output ends of the film clamping component and the pressing component are downwards obliquely arranged opposite to each other; the feed box is arranged below the filmtearing mechanism and has an upward opening; after the protective film on gum is torn out by the film tearing mechanism, the torn protective film is put in the feed box. The automatic film tearing machine for accessory assembly disclosed by the invention is applicable to automatic whole line assembly of accessories, multiple films are torn each time, the film tearing efficiency is effectively improved, position offset of the gum or the glass sheet in the film tearing process is effectively avoided, and the assembling precision and quality are ensured.

Owner:SHENZHEN NUOFENG OPTOELECTRONICS EQUIP

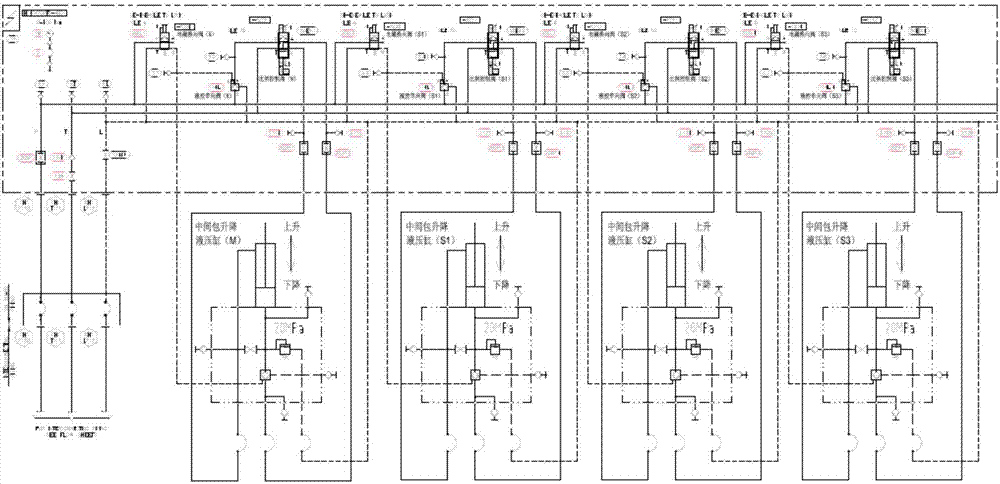

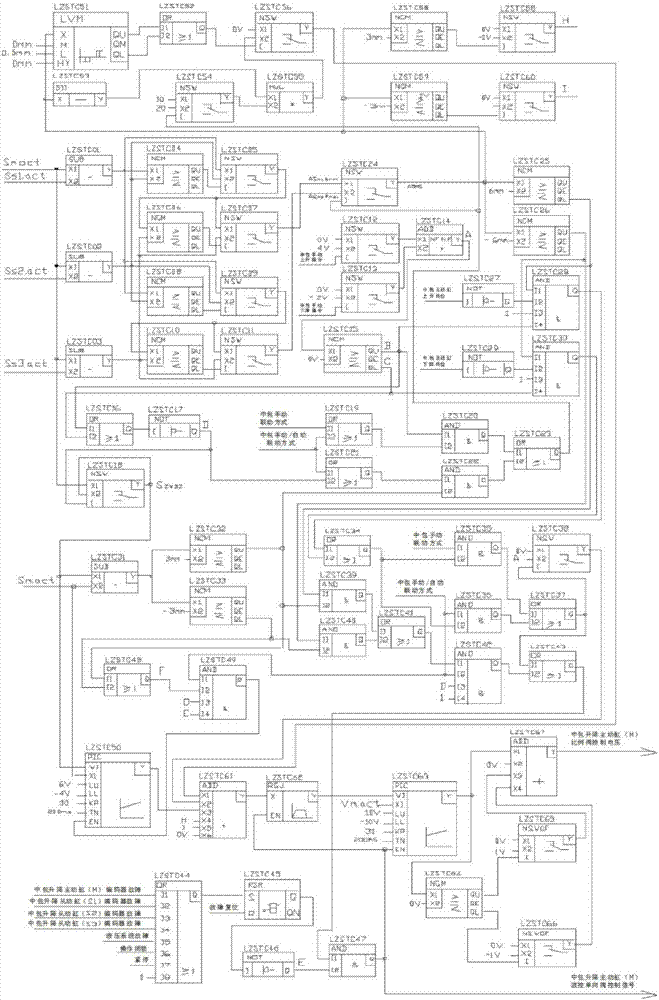

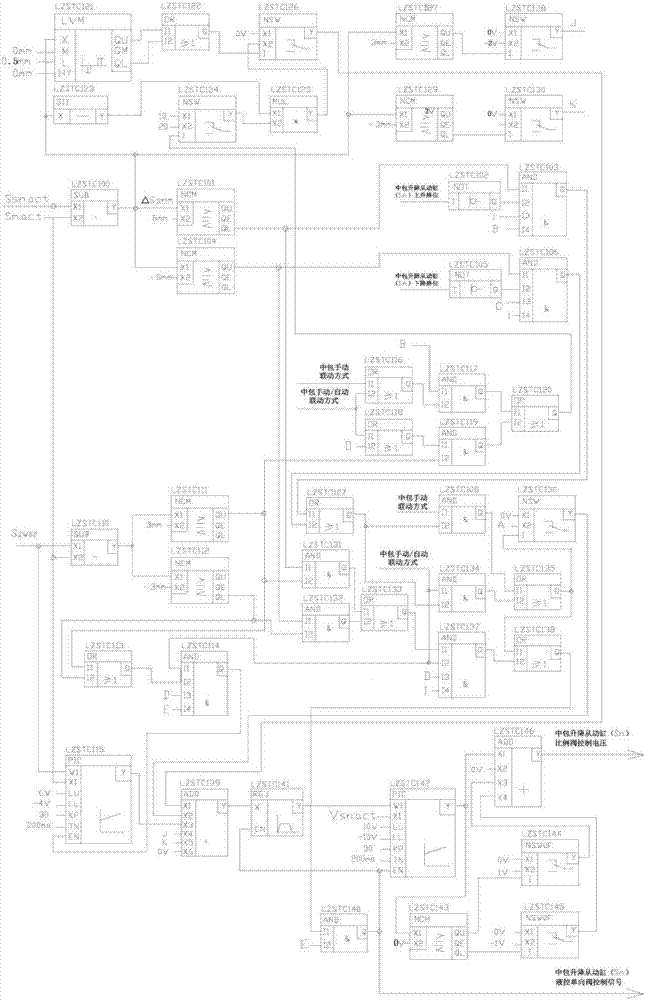

Synchronous control method based on continuous-casting tundish lifting hydraulic cylinder synchronous control system

InactiveCN107314000ARealize synchronized movementAvoid position shiftMelt-holding vesselsServomotorsHydraulic cylinderControl system

The invention belongs to the field of hydraulic transmission control, and provides a synchronous control method based on a continuous-casting tundish lifting hydraulic cylinder synchronous control system. According to the method, the position deviation, beyond a set range, between a driving hydraulic cylinder and a driven hydraulic cylinder is corrected through a driving and driven hydraulic cylinder synchronous position deviation speed correction unit; if the position deviation between the driving hydraulic cylinder and the driven hydraulic cylinder is beyond the set maximum allowable position deviation, the driving hydraulic cylinder at the higher speed or the driven hydraulic cylinder at the higher speed is controlled to stop moving through a driving and driven hydraulic cylinder synchronous position deviation overrun control unit and a driven hydraulic cylinder synchronous position deviation overrun control unit till the position deviation between the driving hydraulic cylinder and the driven hydraulic cylinder is smaller than the set maximum allowable position deviation again; and a driving and driven hydraulic cylinder automatic position holding and control unit is used for preventing position deviation of the driving hydraulic cylinder and the driven hydraulic cylinder in absence of manual instructions. In this way, by adoption of the synchronous control method, under the conditions that leakage of the hydraulic cylinders occurs, the manufacturing accuracy degrees of hydraulic elements are different and loads are nonuniform, synchronous movement of the driving hydraulic cylinder and the driven hydraulic cylinder can be achieved.

Owner:MAANSHAN IRON & STEEL CO LTD

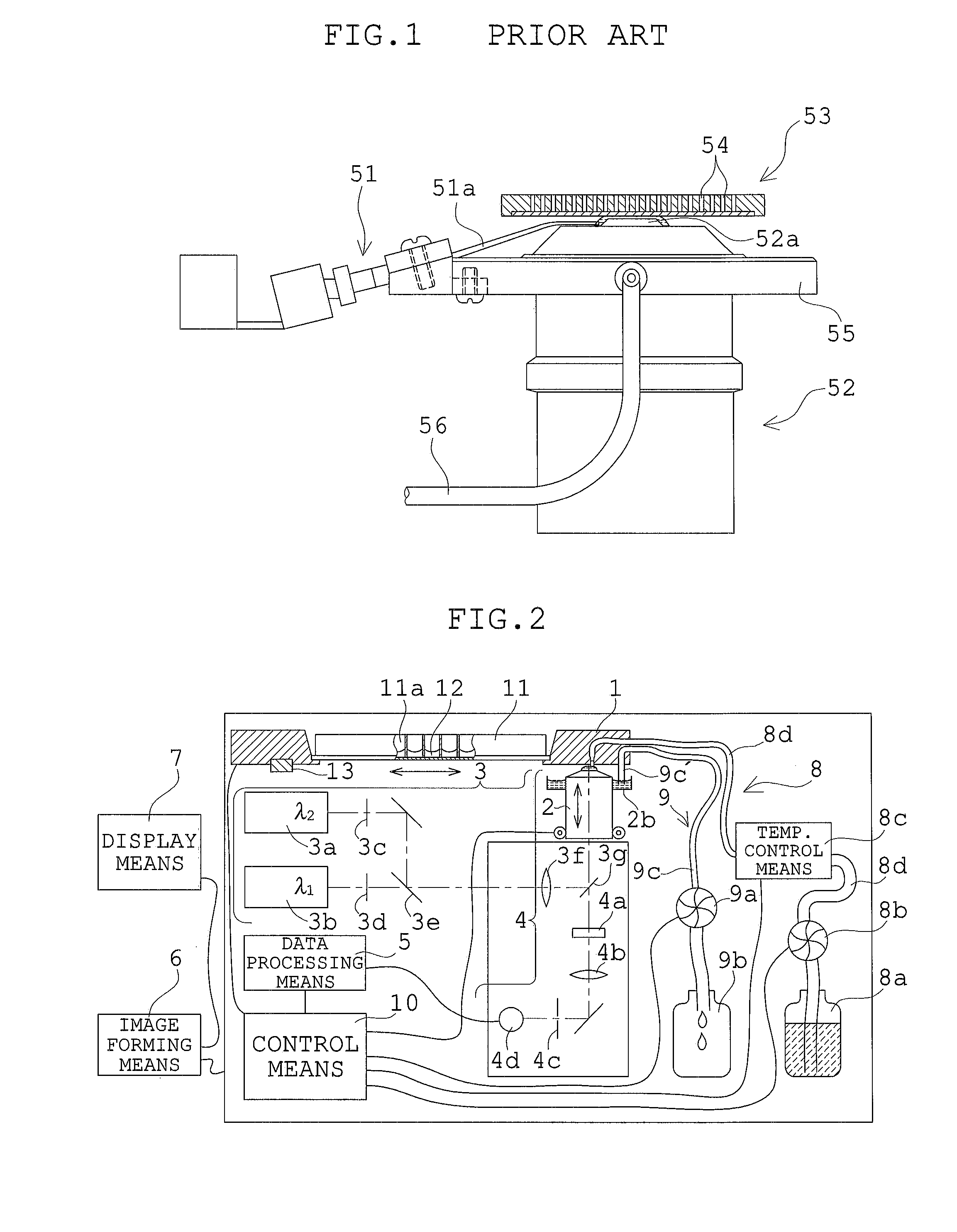

Image forming device

InactiveUS20010053300A1Avoid position shiftForming accuratelyElectrographic process apparatusPrintingEngineeringElectrical and Electronics engineering

An image forming device includes a plurality of recording medium supply units, an offset amount memory, and a timing control unit. The recording medium supply units supply recording media. The offset amount memory stores an offset amount for each recording medium supply unit. Each offset amount is for compensating for positional shift in a recording medium supplied from a corresponding recording medium supply unit. The timing control unit retrieves, from offset amount memory, an offset amount corresponding to a presently used recording medium supply unit and performs image forming operations at a timing corrected by the retrieved offset amount.

Owner:BROTHER KOGYO KK

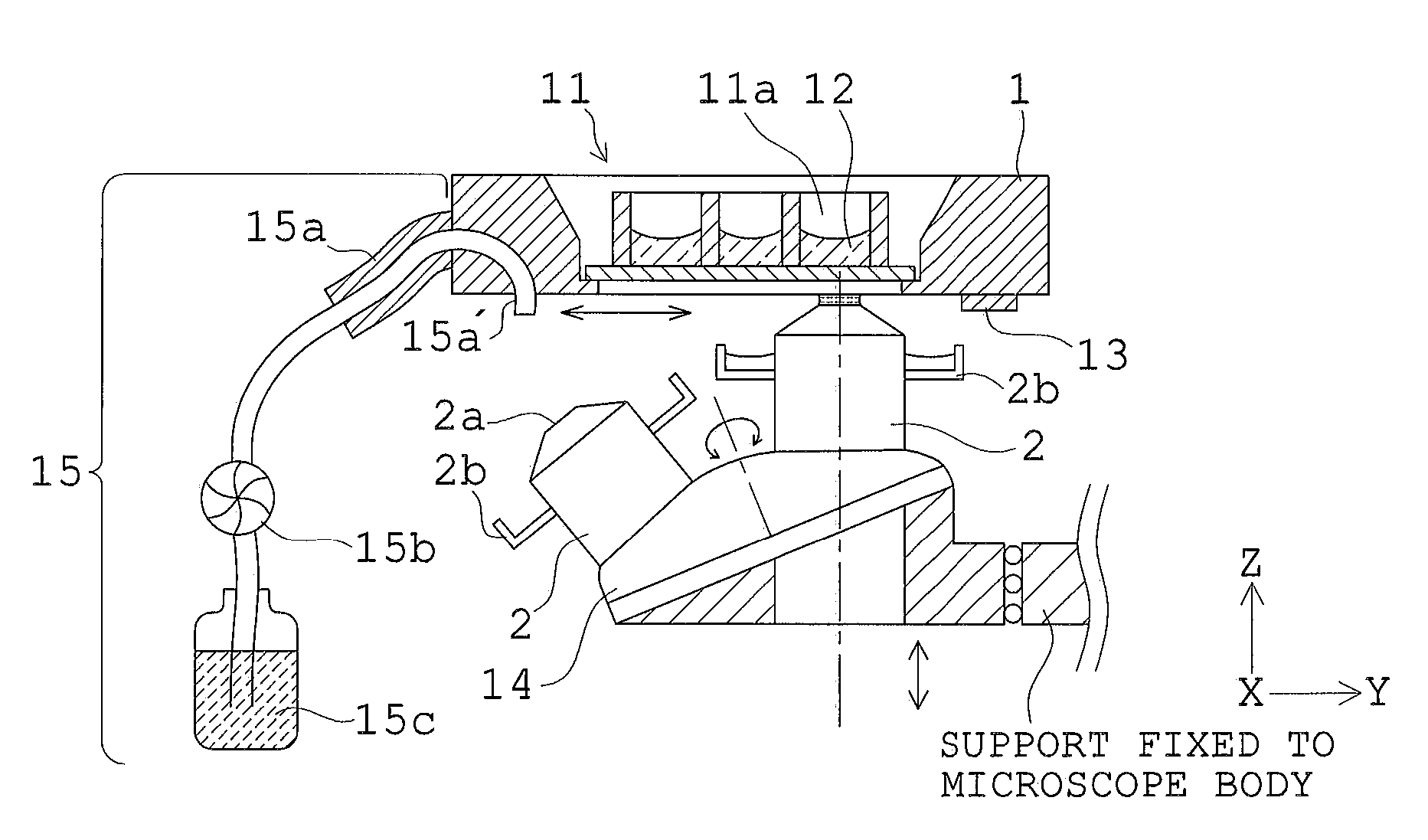

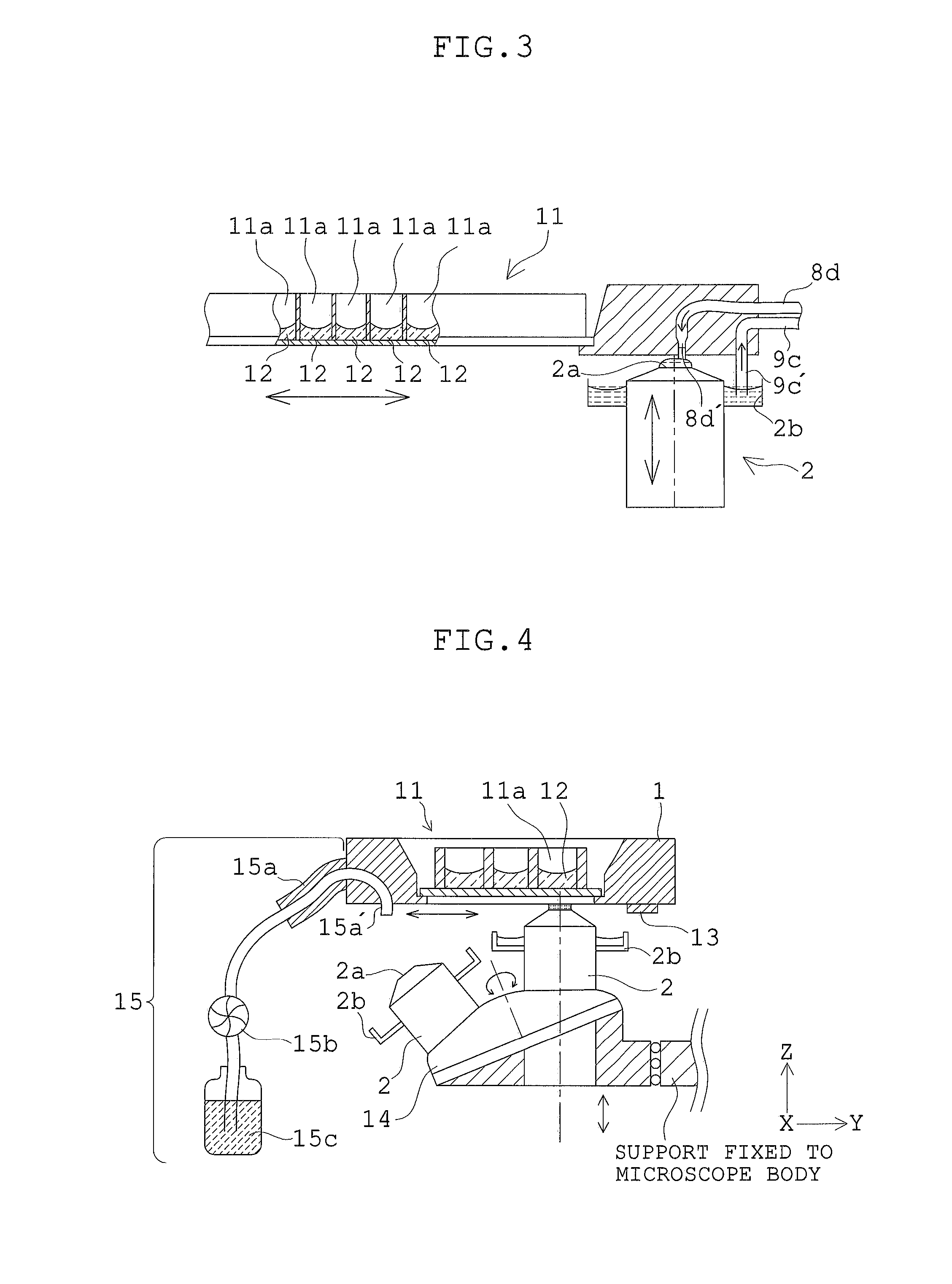

Observation apparatus provided with immersion objective lens

ActiveUS20080170292A1Avoid position shiftEasily contaminatedMicroscopesMountingsPosition controlLiquid injection

An observation apparatus for observing an observation object mounted at an observation position on a stage through an immersion objective lens placed below the observation object. The observation apparatus has a liquid pouring device, constructed to be relatively movable with respect to the immersion objective lens, pouring a liquid on a top lens surface of the immersion objective lens from the upper side of the immersion objective lens at a distance from the observation position on the stage; and a position control device automatically adjusting relative positions of a liquid pouring position of the liquid pouring device and the immersion objective lens and automatically adjusting relative positions of the immersion objective lens on which the liquid is poured by the liquid pouring device and a desired observation position on the stage.

Owner:EVIDENT CORP

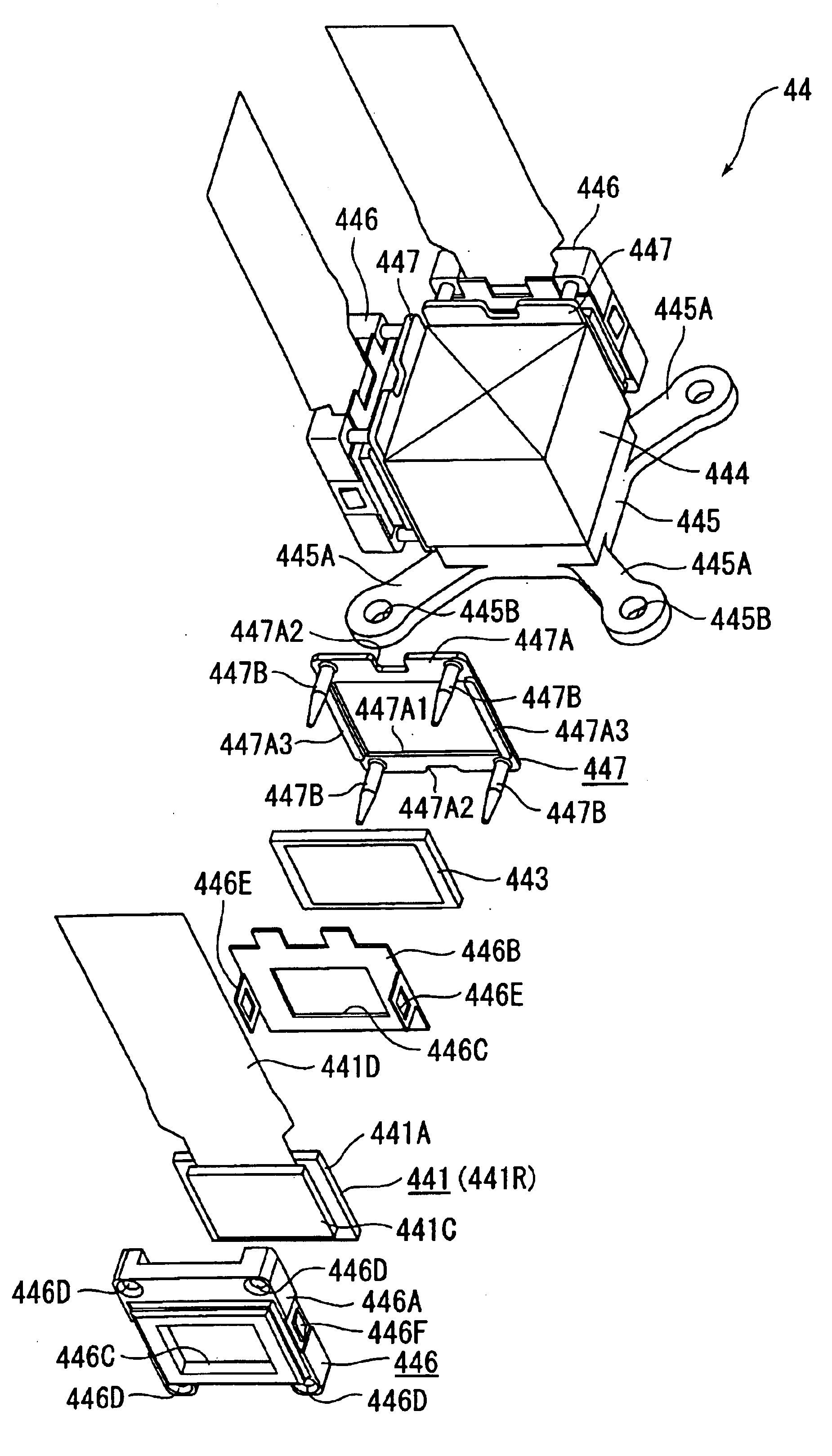

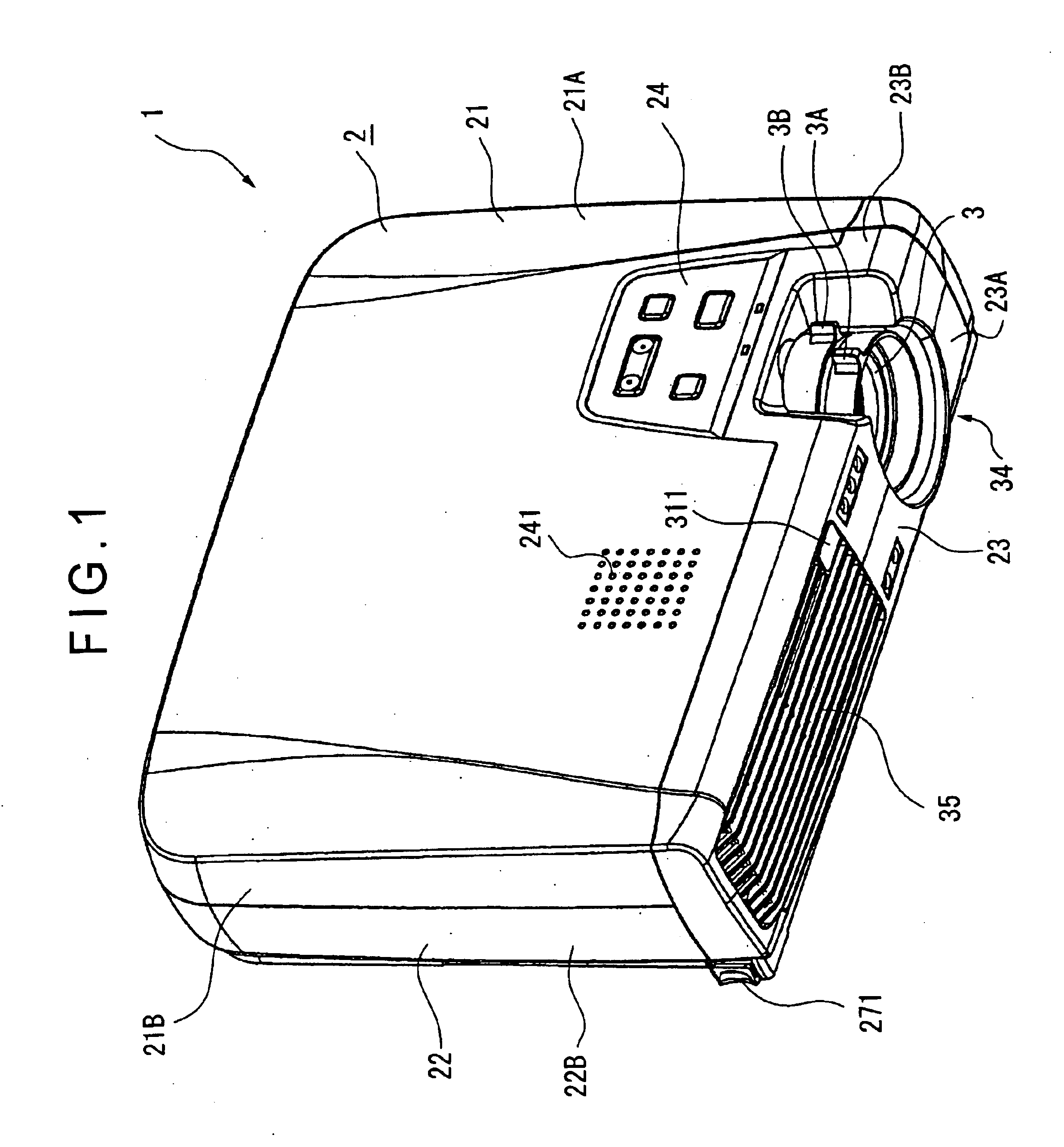

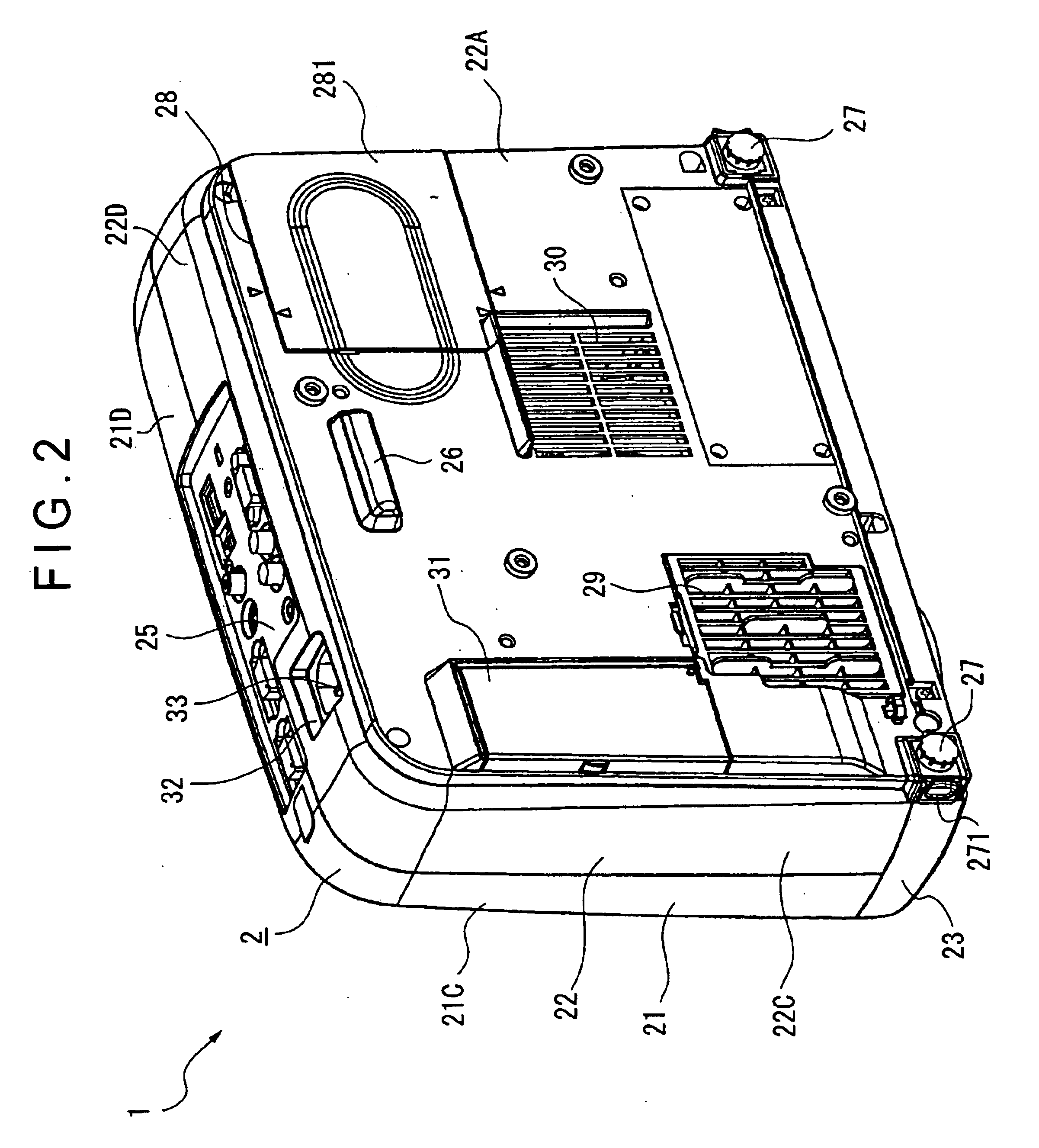

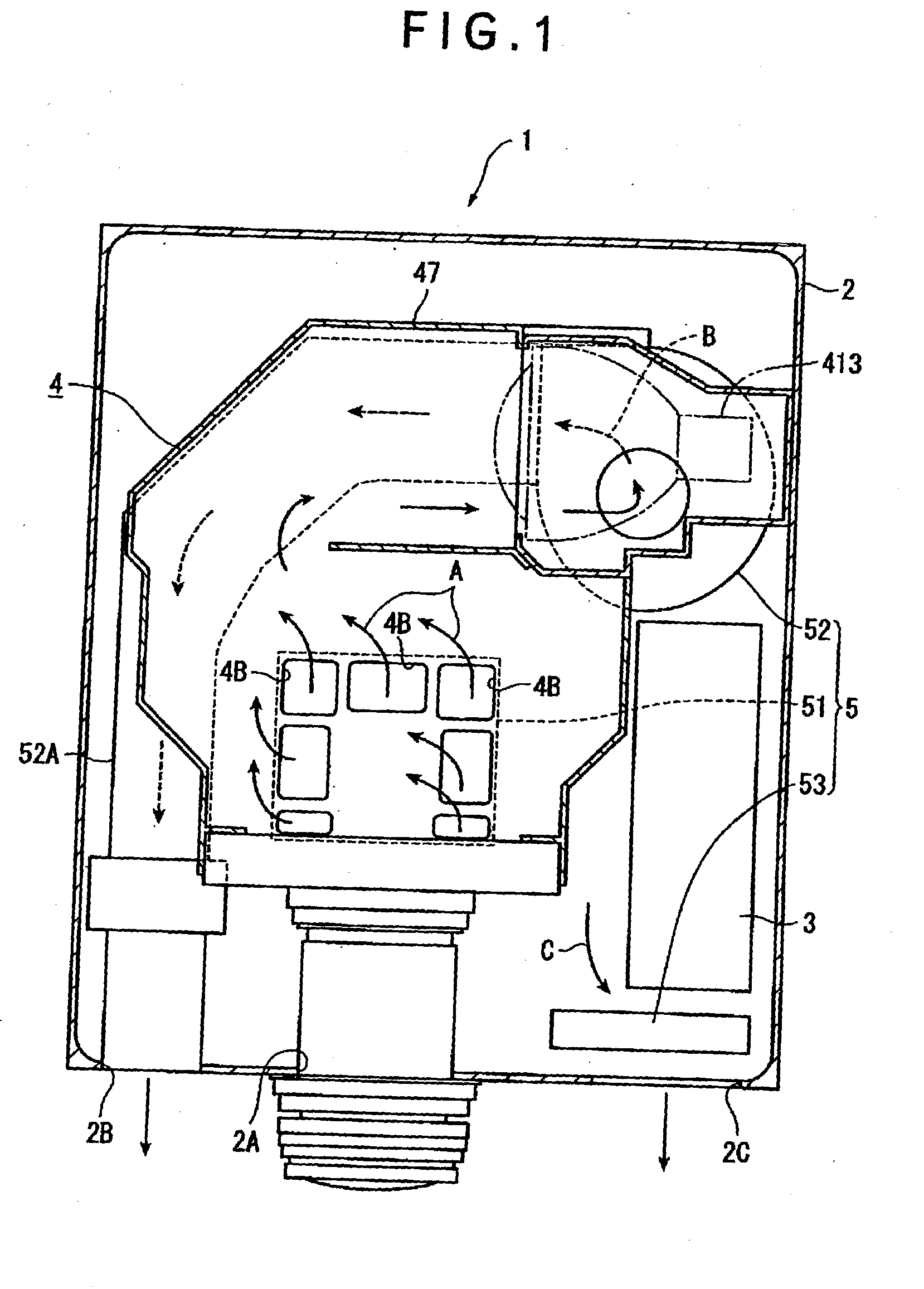

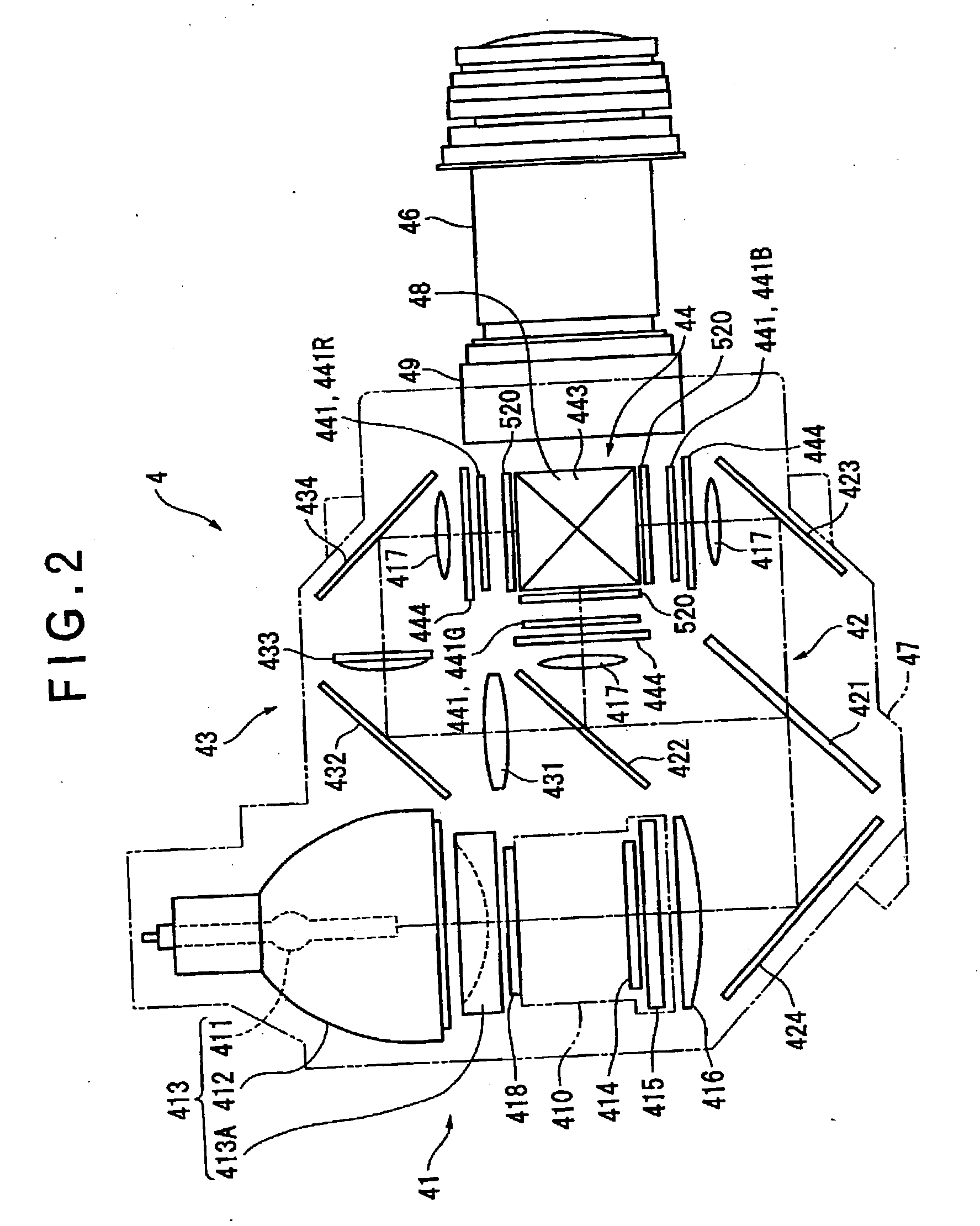

Optical device and projector

ActiveUS6866389B2ObtainedProjected image is blockedProjectorsNon-linear opticsDichroic prismImage formation

An optical device (44) has a holding frame (446) that holds a liquid crystal panel (441) as an optical modulator and has an opening (446C) at a part corresponding to an image formation area of the liquid crystal panel (441), and a panel fixing plate (447) disposed between the holding frame (446) and a cross dichroic prism (444). The panel fixing plate (447) is made of a component having a thermal expansion coefficient lying midway between the thermal expansion coefficients of the holding frame (446) and the cross dichroic prism (444). The liquid crystal panel (441) is fixed on a side of the cross dichroic prism (444) through the holding frame (446) and the panel fixing plate (447). Accordingly, a thermal stress generated on the boundaries between the panel fixing plate (447), and the holding frame (446) and the cross dichroic prism (444) are reduced, thereby preventing the position shift of the liquid crystal panel (441).

Owner:SEIKO EPSON CORP

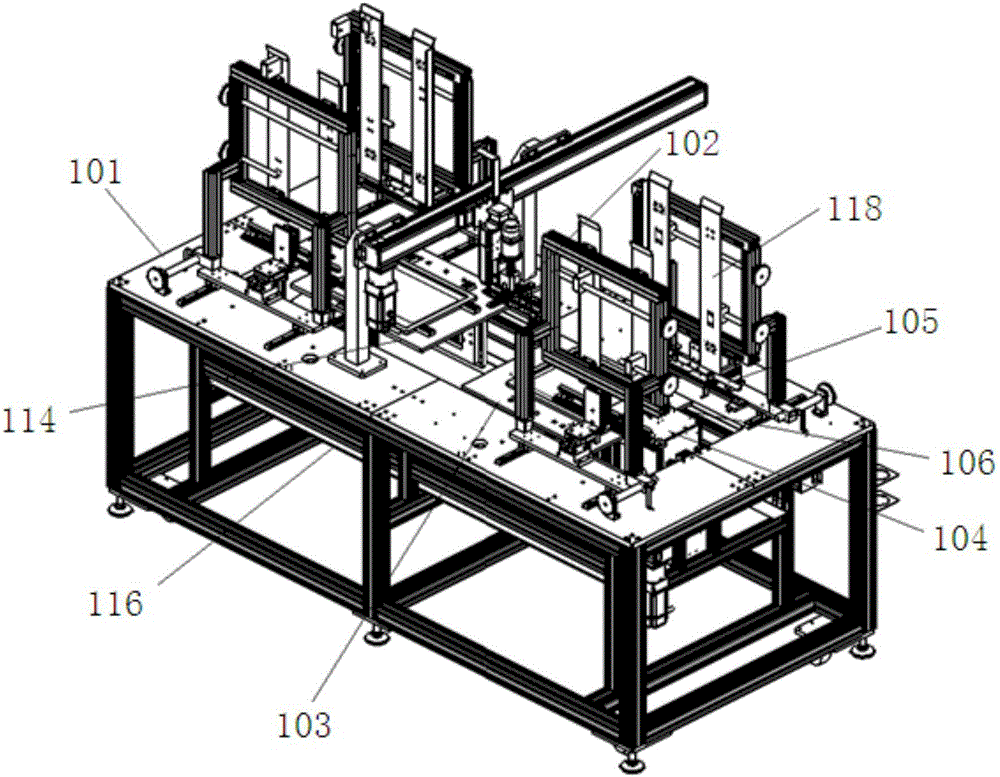

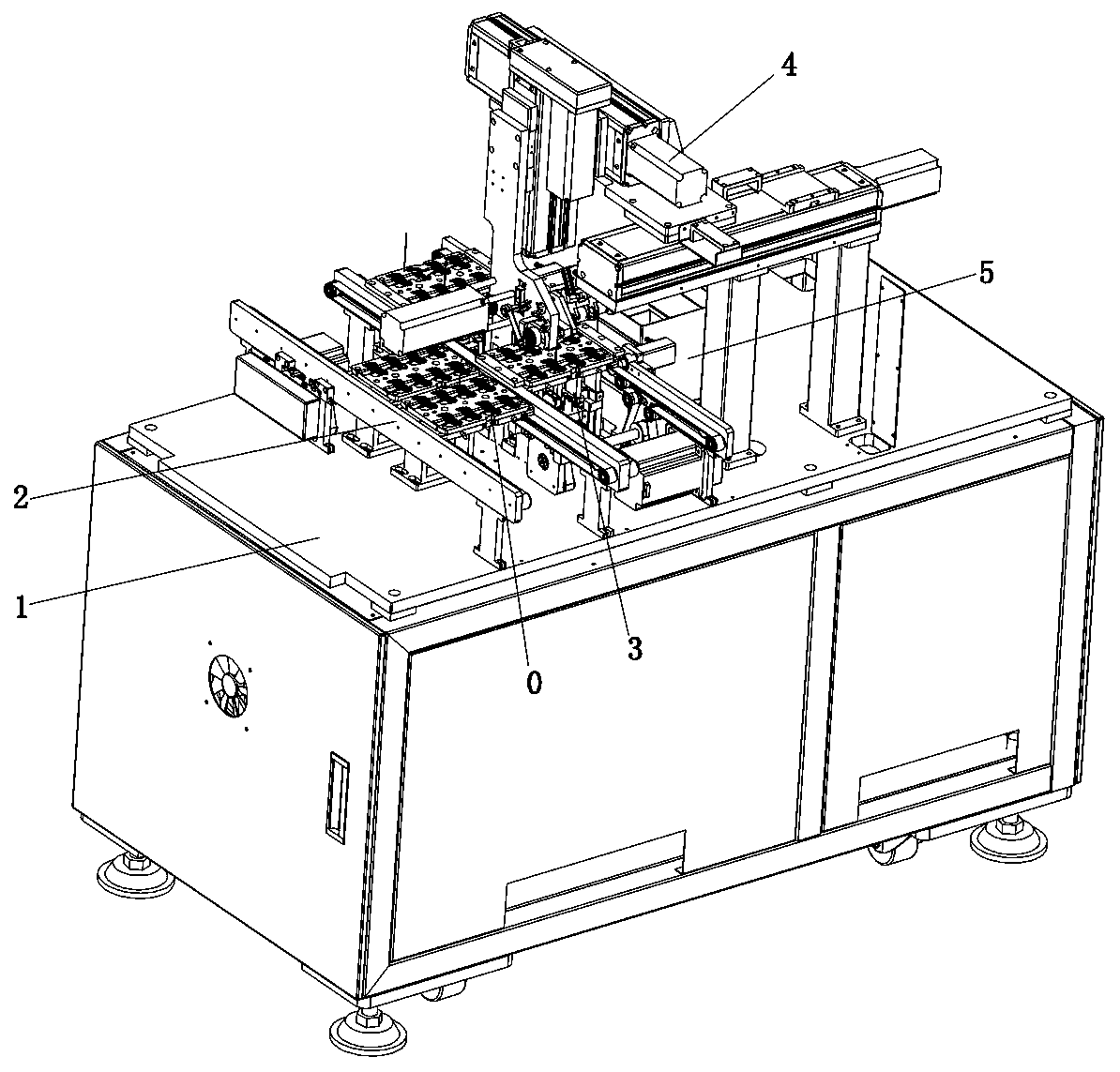

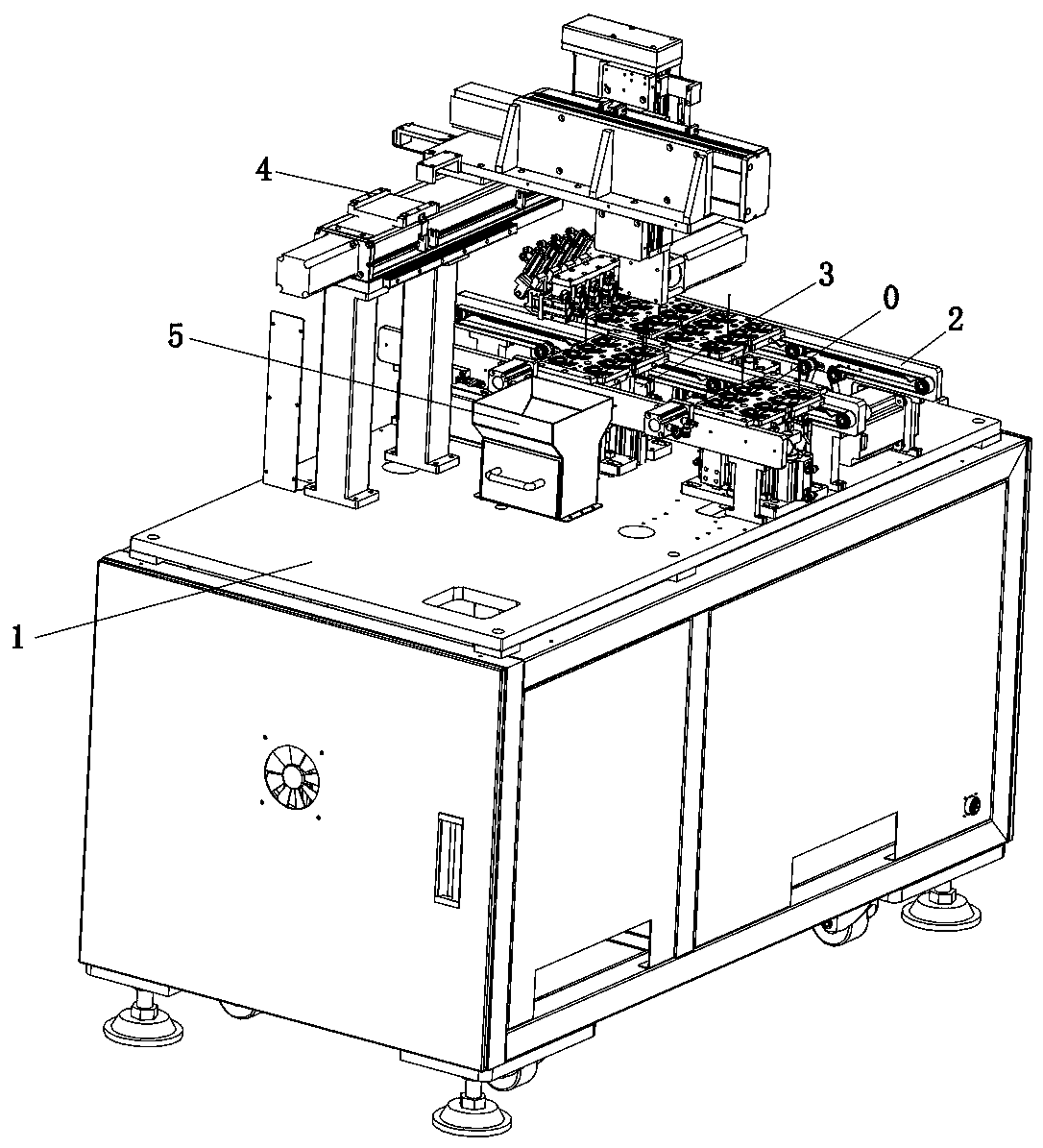

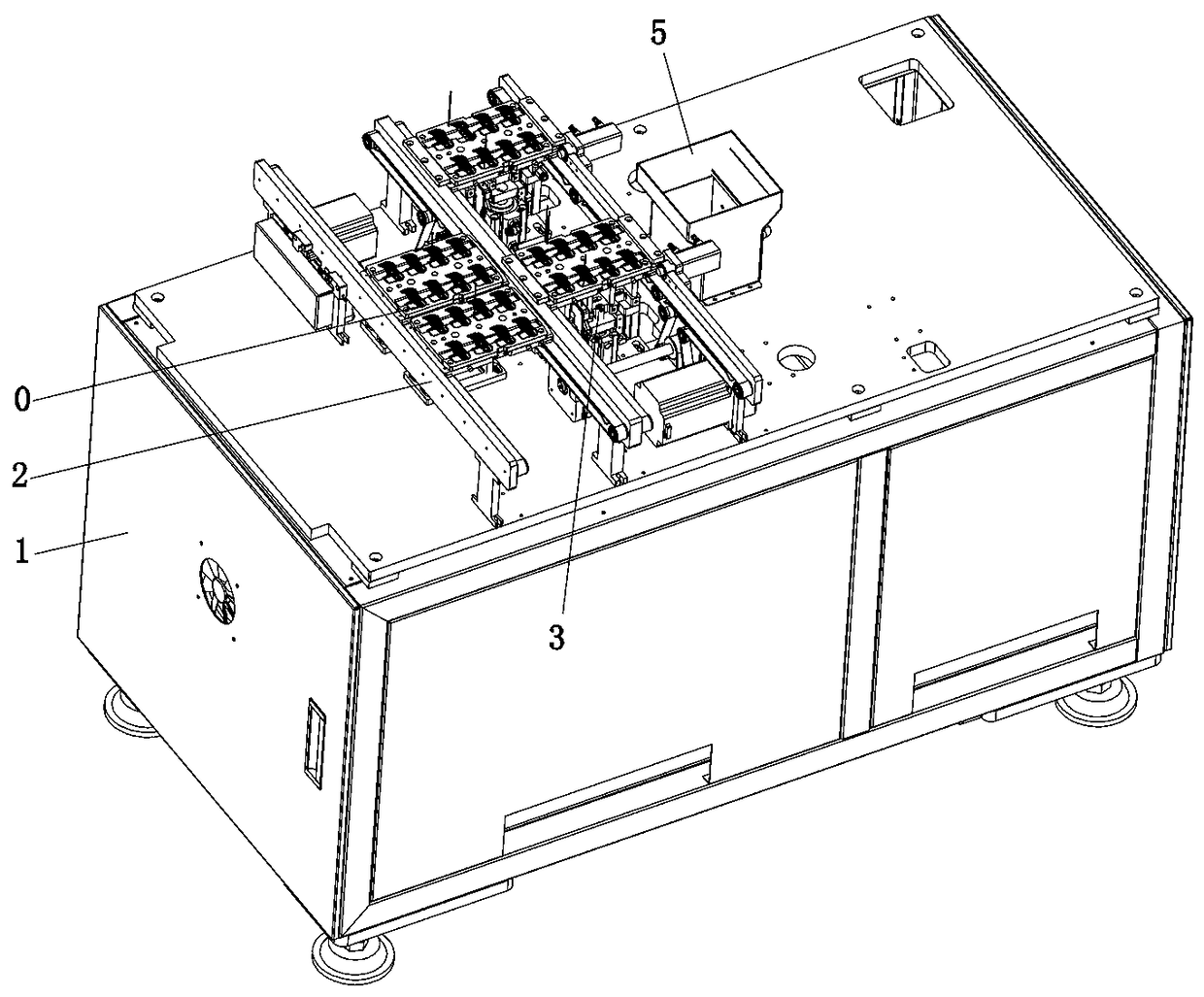

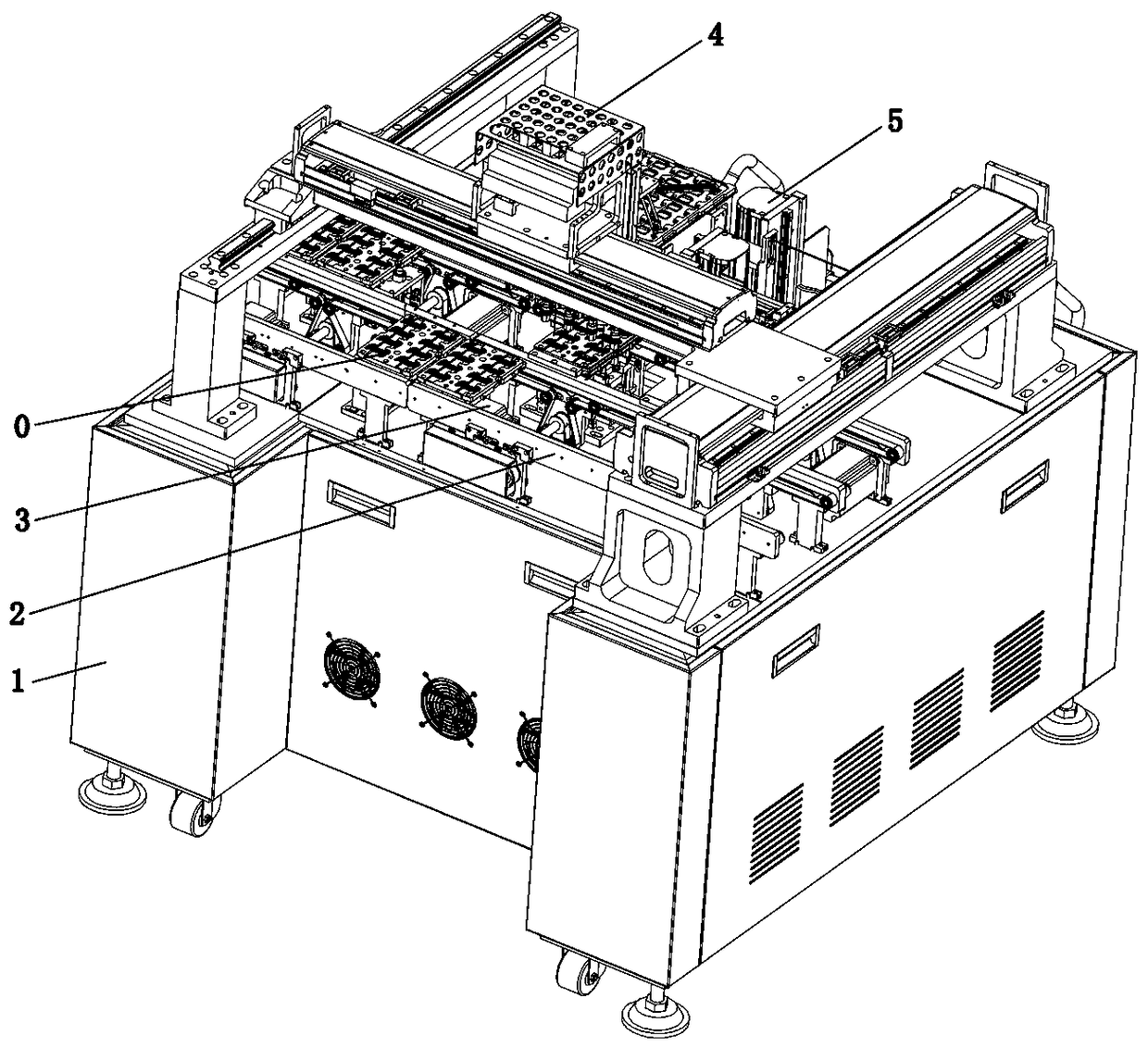

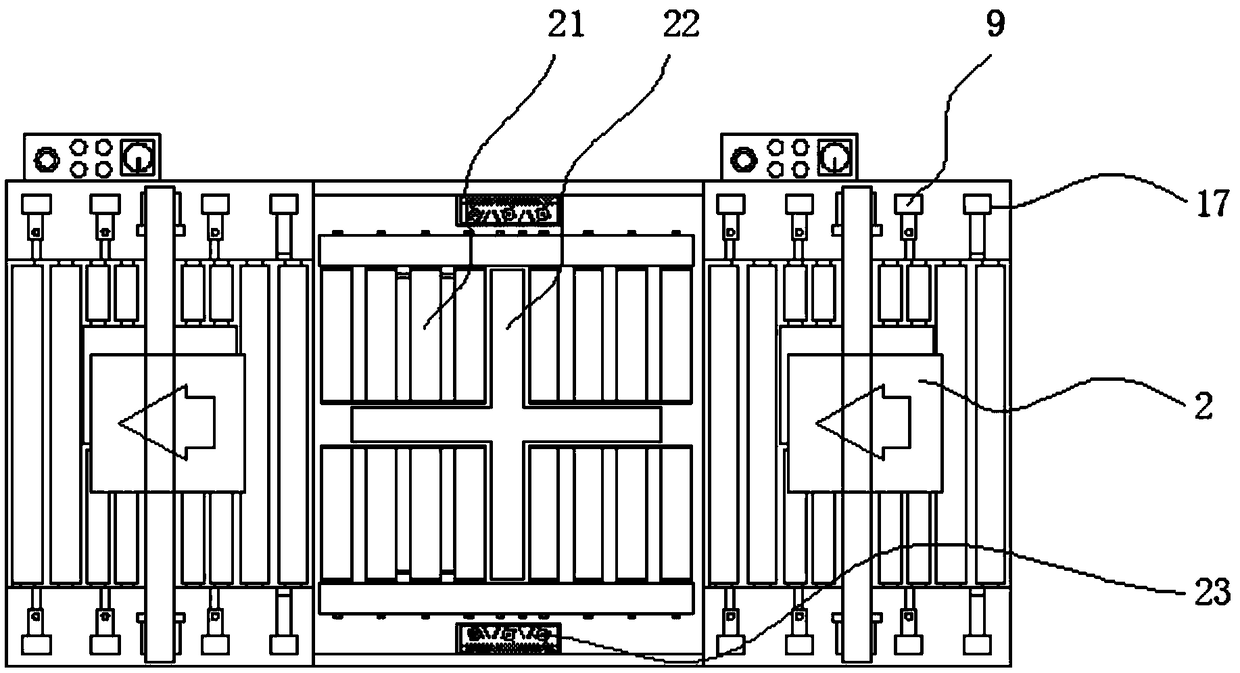

Automatic precise assembly machine

InactiveCN109317967AReduce the frequency of replacement and retransmissionAvoid position shiftAssembly machinesEngineeringGlass sheet

The invention discloses an automatic precise assembly machine. The automatic precise assembly machine comprises a conveying mechanism, a positioning and support mechanism, an assembly mechanism and aloading mechanism; the conveying mechanism is horizontally arranged on the frame; a synchronous belt is arranged on the inner side of the conveying mechanism; a tool for loading materials is placed onthe synchronous belt; at least two through grooves are formed in the tool; materials to be assembled are placed in the through grooves; and the assembly modules once absorb multiple materials from the loading mechanism, and assemble the materials to fittings in the through grooves of the tool. Through downward absorption fixation and flexible support of glass sheets, the displacement of the glasssheets in the assembly process is prevented, so that the assembly precision is guaranteed, the pressure crushing condition of the glass sheets is prevented, the loading and unloading time is shortened, the centralized unloading and loading of multiple products once are realized, the tray replacing and reloading time is shortened, and the overall production capacity is effectively improved.

Owner:SHENZHEN NUOFENG OPTOELECTRONICS EQUIP

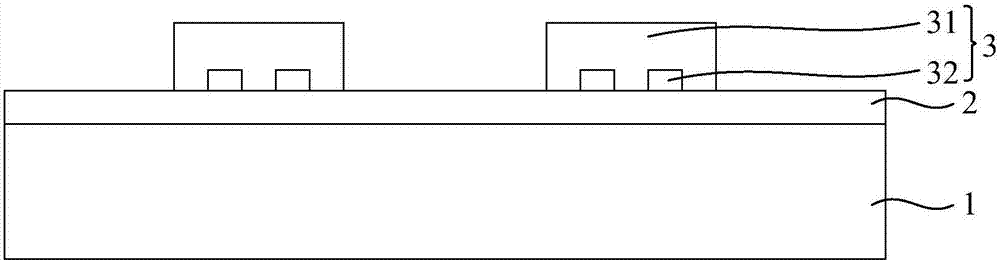

Fan-out single die packaging structure, and preparation method thereof

InactiveCN107104058AQuality assuranceAvoid position shiftSemiconductor/solid-state device detailsSolid-state devicesLaser etchingRedistribution layer

The invention provides a fan-out single die packaging structure, and a preparation method thereof. The preparation method comprises the following steps: a carrier is provided, and a bonding layer is formed on the carrier; chip structures are formed on the bonding layer; a plastic packaging layer is formed on the bonding layer, wherein the chip structures are coated by the plastic packaging layer; the carrier and the bonding layer are removed to expose the chip structures; a first dielectric layer is formed on the plastic packaging layer with the exposed chip structures, and photoetching is carried out on the first dielectric layer to form first openings through which contact pads are exposed; a redistribution layer is formed on the first dielectric layer and the contact pads, and photoetching is carried out on the redistribution layer to form second openings through which the first dielectric layer is exposed; a second dielectric layer is formed on the redistribution layer and the first dielectric layer, and laser etching is carried out on the second dielectric layer to form third openings through which the redistribution layer is exposed; and welded ball bumps are formed on the third openings. The fan-out single die packaging structure and the preparation method thereof provided by the invention have the advantage that the problem of high manufacturing cost of the conventional fan-out packaging process is solved.

Owner:SJ SEMICON JIANGYIN CORP

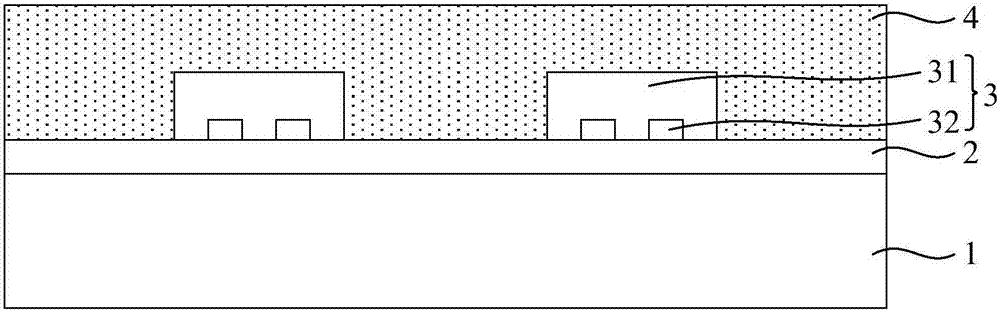

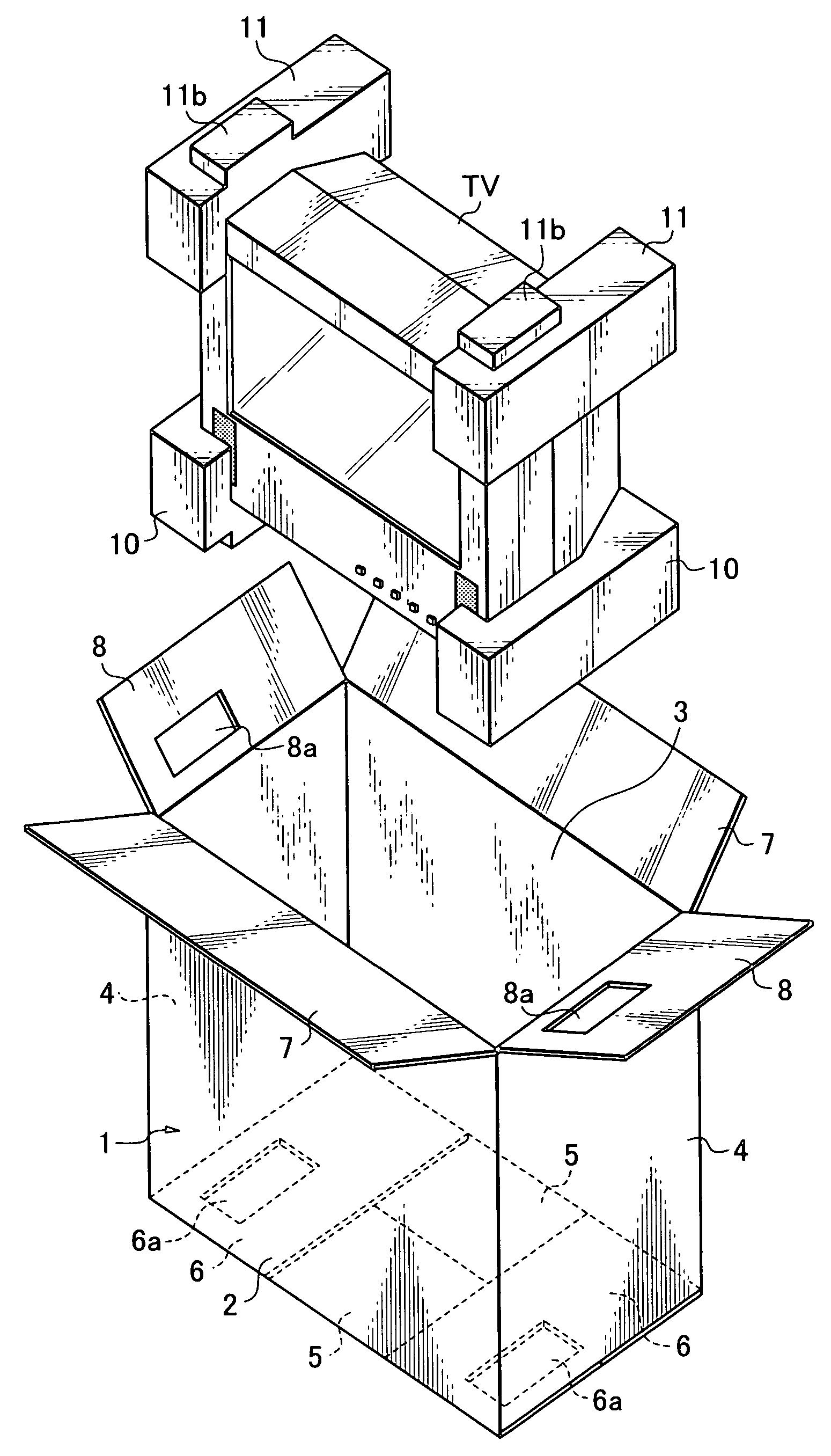

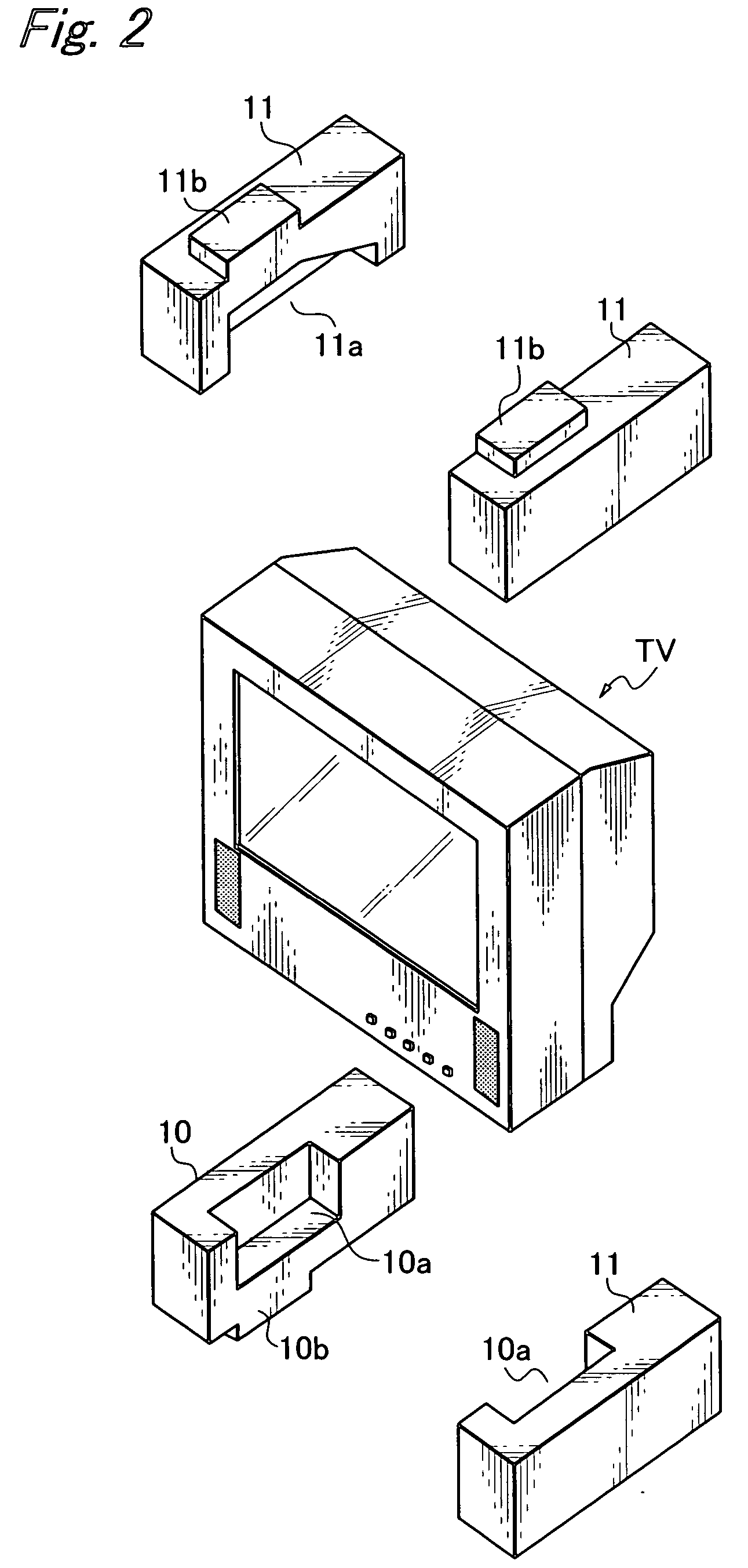

Packaging material provided with cushioning members

InactiveUS20050161366A1Improve package strengthExternal appearance is not spoiledContainers to prevent mechanical damagePaper/cardboard containersCushioningEngineering

To improve cushioning effect for a packaged object without causing cost increase and prevent positional shift of cushioning members without causing lowering of the strength and durability of a packaging box, a packaging material includes a packaging box and cushioning members, a bottom panel and a cover panel of the packaging box being made of inwardly bendable inner flaps and outer flaps respectively, each of the inner flaps being provided with at least a through hole, the cushioning members being provided in inner side surfaces thereof with recesses in which corner portions or side portions of an object to be packaged are fitted, and on outer side surfaces thereof with cushioning projections fitted in the through holes of the inner flaps, the length of the cushioning projections being set larger than the thickness of the inner flaps so as to form a clearance between the inner flaps and cushioning projections when the cushioning members are housed in the packaging box.

Owner:ORION ELECTRIC CO LTD

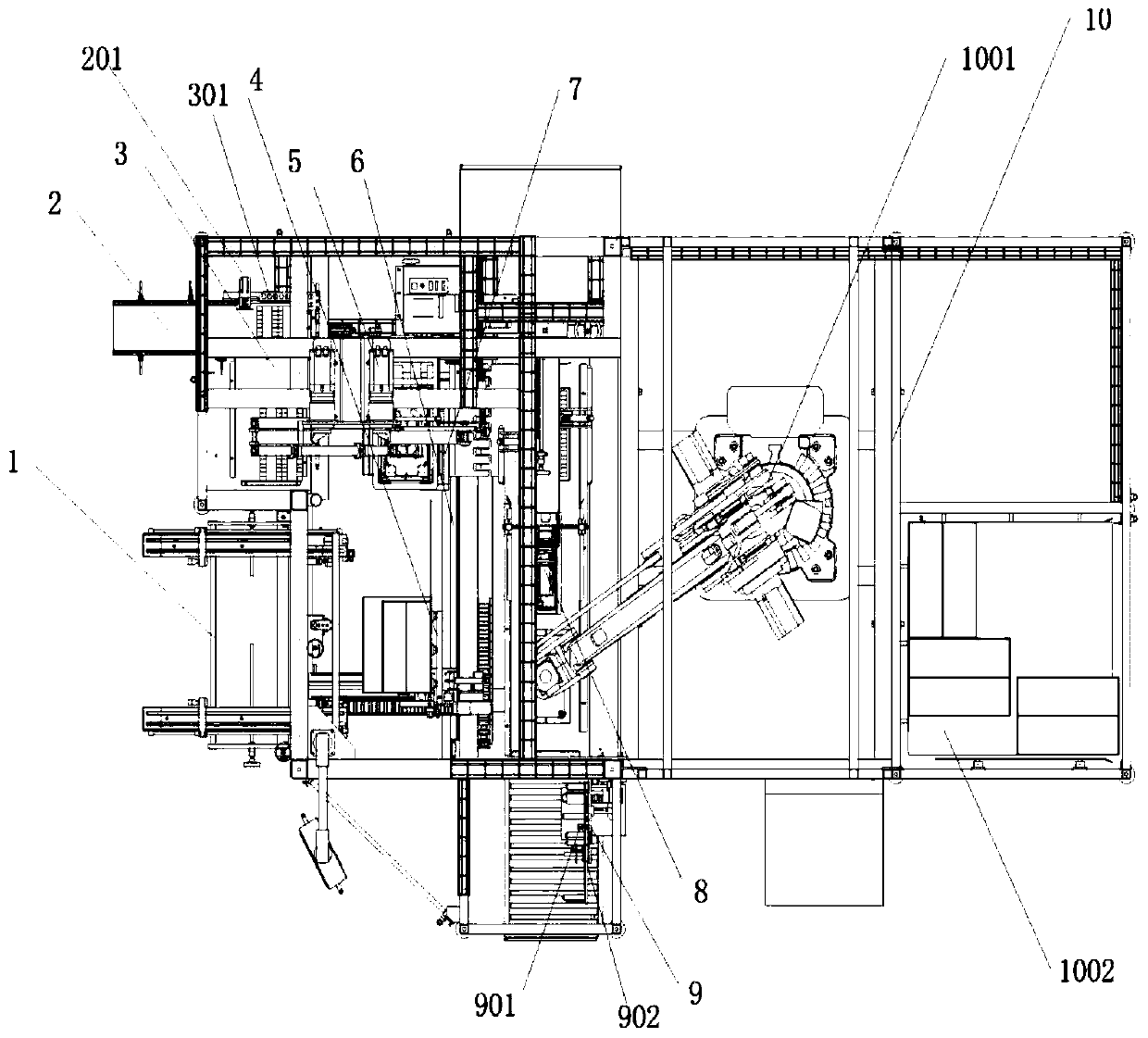

Full-automatic intelligent opening, sealing, packing and stacking integrated machine

PendingCN110626558AReduce frictionSmooth transmissionConveyorsWrapper twisting/gatheringControl systemCarton

The invention discloses a full-automatic intelligent opening, sealing, packing and stacking integrated machine which comprises an article arranging part, an automatic carton opening, packing and sealing part, a carton labeling and detecting part, a carton stacking treatment part and a PLC control system, wherein the article arranging part comprises a feeding transporting mechanism, an arranging mechanism and a platform in sequence; the feeding transporting mechanism is used for transferring materials; the arranging mechanism is used for arranging required carton packing articles; the automaticcarton opening, packing and sealing part comprises a carton storing mechanism, a servo carton opening mechanism, a carton propping-open mechanism, a carton pushing mechanism and a carton sealing structure in sequence; the carton storing mechanism is used for storing empty cartons; and the carton stacking treatment part comprises a tray positioning mechanism and a stacking robot in sequence. The full-automatic intelligent opening, sealing, packing and stacking integrated machine has the beneficial effects that through the jointed combination of multiple groups of mechanical structures, electromechanical integration is highly integrated, automatic arrangement and counting of products, automatic carton opening, carton packing, carton sealing, labeling and detecting and carton stacking are achieved, the number of operating personnel is greatly decreased, the space is saved, and the production efficiency is improved.

Owner:合肥哈工龙延智能装备有限公司

Anti-shift full-automatic box sealing machine with disinfecting function

InactiveCN109159995AAvoid position shiftDoes not affect transmissionWrapper twisting/gatheringCartonPaper adhesive tape

The invention relates to an anti-shift full-automatic box sealing machine with a disinfecting function. The anti-shift full-automatic box sealing machine with the disinfecting function comprises a machine body and a steering plate, the left side of the machine body is provided with roller shafts, the steering plate is arranged in the middles of the roller shafts, a conveyor belt is arranged abovethe machine body, and first hydraulic rods are fixedly connected above the machine body; a top plate is arranged above the first hydraulic rods, moreover, paper adhesive tape is arranged on the lowerside of the top plate, a fixing plate is fixed below the paper adhesive tape, and adhesive tape tensioning rollers are arranged on two sides below the fixing plate; and a paper box is arranged on theconveyor belt, moreover, first fixing rods are fixed to the two sides of the paper box, electric push rods are arranged on the inner sides of the first fixing rods, and rolling wheels are arranged onthe inner sides of the electric push rods. According to the anti-shift full-automatic box sealing machine with the disinfecting function, the rolling wheels are arranged so that the position shiftingof the paper box can be prevented, and meanwhile, the rolling wheels can roll along with the movement of the paper box, so that conveying of the paper box is not influenced.

Owner:广东全过程工程咨询有限公司

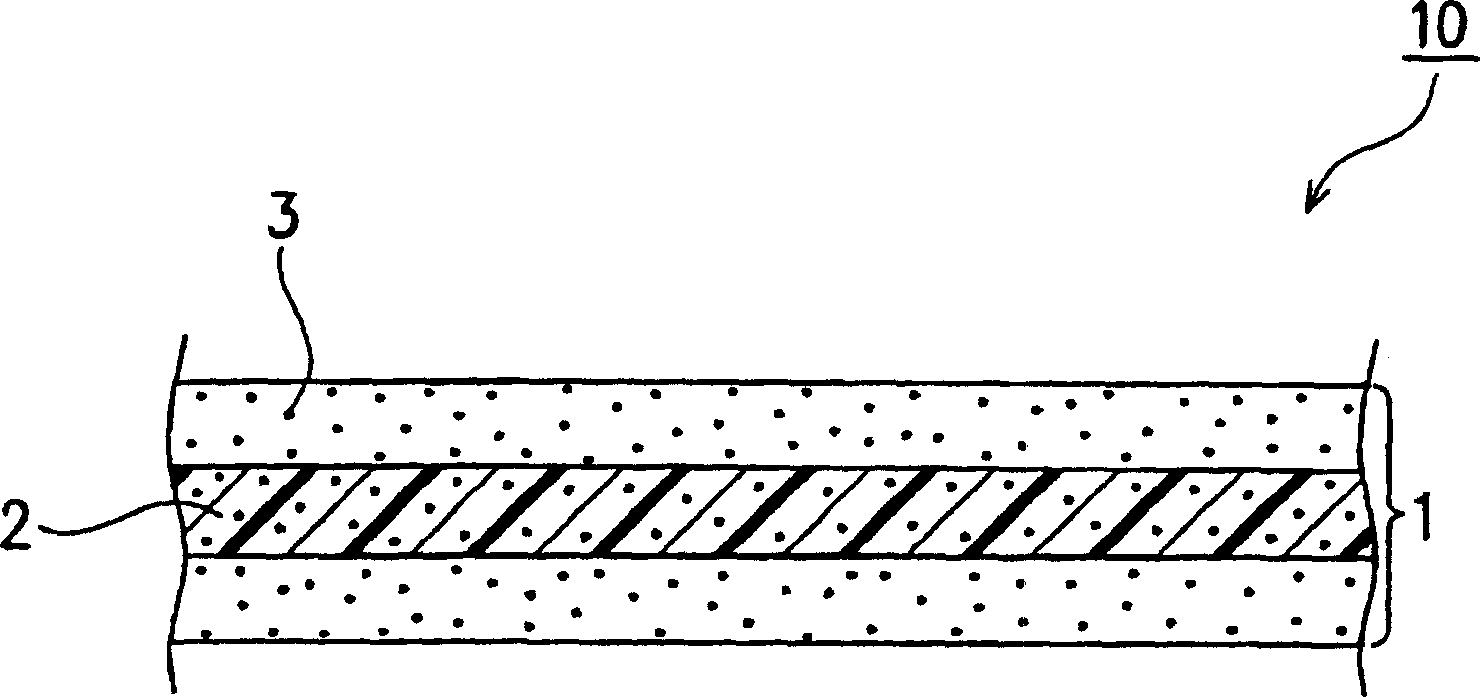

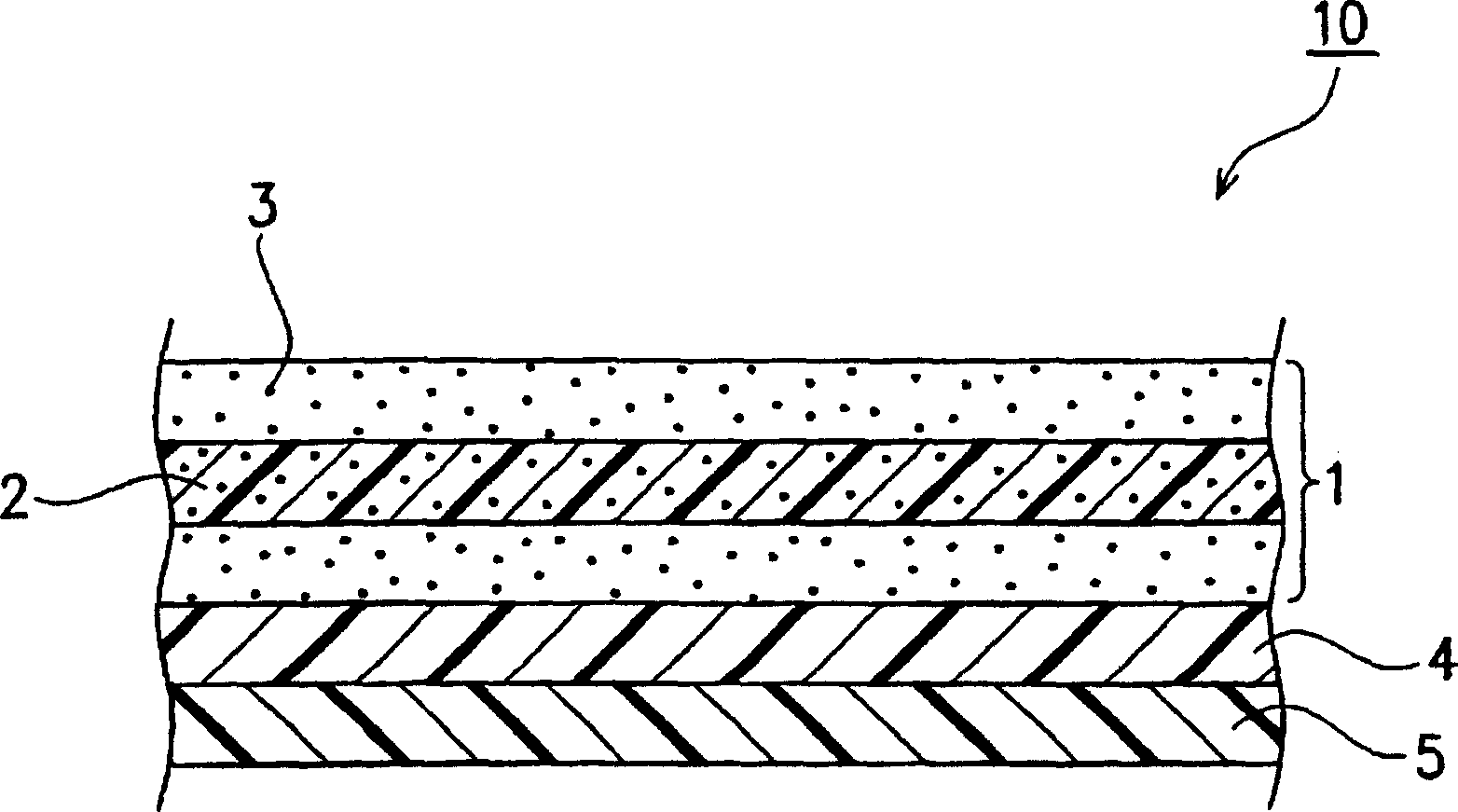

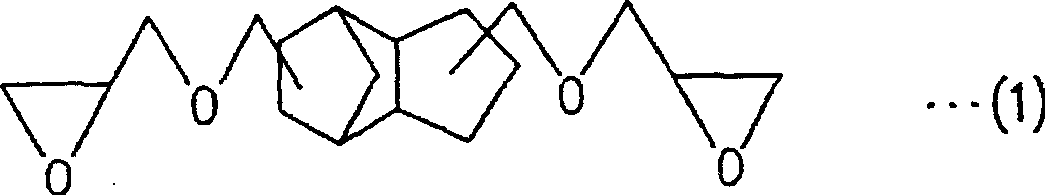

Resin sheet, liquid crystal cell substrate, liquid crystal display, substrate for electroluminescent display, electroluminescent display, and substrate for solar cell

InactiveCN1886447AAvoid position shiftAchieve lightweightDiffusing elementsElectroluminescent light sourcesGlass fiberInorganic particle

A resin sheet having an excellent light-transmitting property for not lowering the display quality of a display or the like is disclosed The resin sheet is characterized by comprising a resin curing layer wherein a fabric-like body made of glass fibers and inorganic particles are contained in a resin, and by having a haze value of not more than 10%.Resin sheet is reduced in weight and thickness, improved in impact resistance, and suppressed in thermal shrinkage / expansion. Also disclosed are a substrate for displays, display, and substrate for solar cells comprising such a resin sheet.

Owner:NITTO DENKO CORP

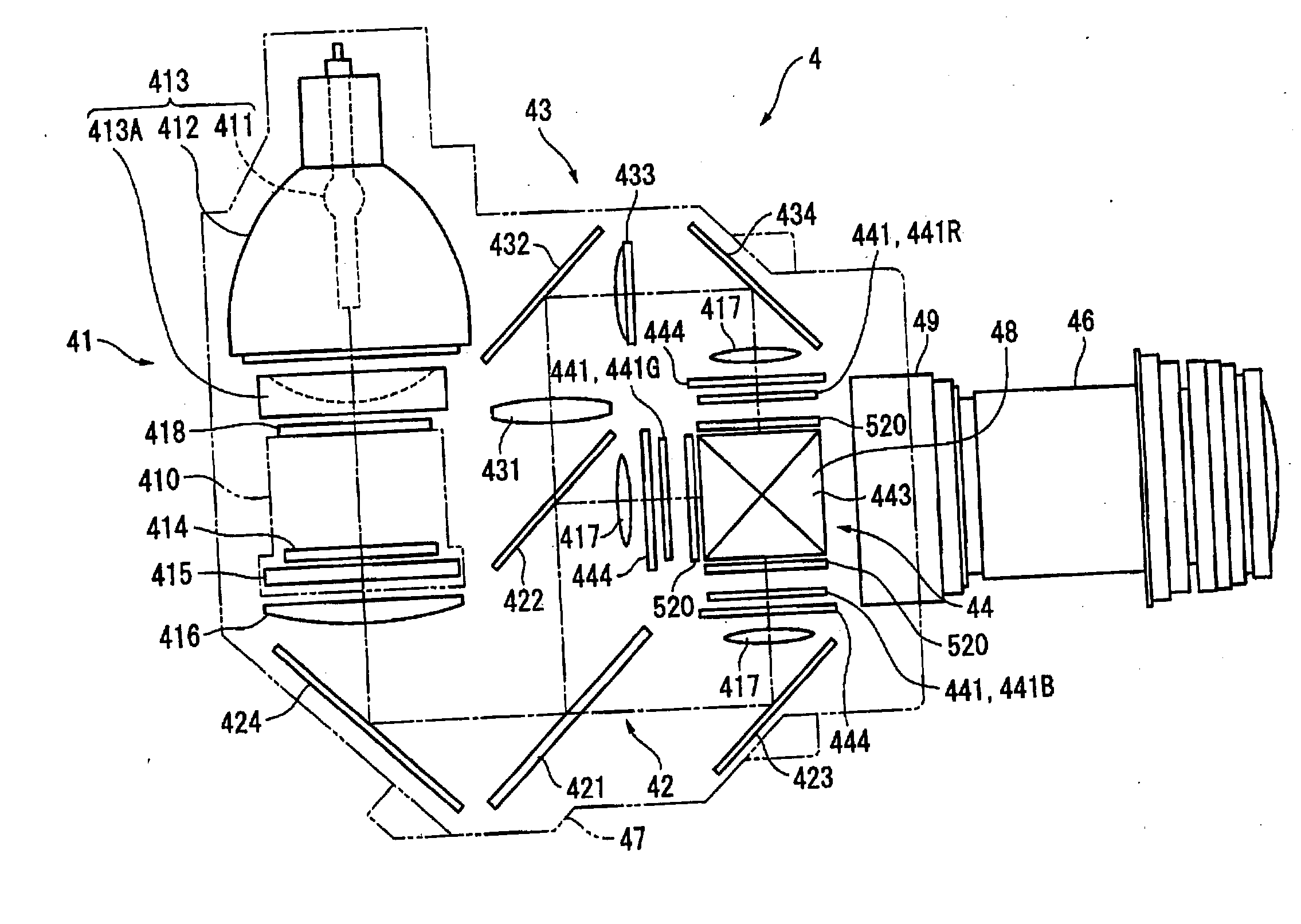

Optical device and projector having the optical device

InactiveUS20040032665A1Improve image qualityAvoid position shiftTelevision system detailsProjectorsDichroic prismEngineering

An optical device has: a metal cooling device (500) disposed between a liquid crystal panel (441) and a light-incident side of a cross dichroic prism (443) and having a holding surface for holding polarization plates (521, 522) attached with a polarization films (521A and 522A) in a mutually spaced manner, the cooling device cooling the polarization films; a base (445) provided on the upper and lower sides of the cross dichroic prism (443) and having a cooling device attachment surface (449A) for the cooling device (500) to be attached; and a fixing member (600) provided on a light-incident side of the cross dichroic prism for locating and fixing the liquid crystal panel (441) on the light-incident side, the fixing member (600) being formed with a attachment surface (631) on which a pin (730) for mounting the liquid crystal panel (441) is formed.

Owner:SEIKO EPSON CORP

Soil stratified sampling device for hydrogeological survey

ActiveCN113358409AEasy to drill downEasy to controlWithdrawing sample devicesElectric machineAgricultural engineering

The invention provides a soil stratified sampling device for hydrogeological survey which comprises a supporting fixing plate and a motor, the center of the supporting fixing plate is hollow, a motor positioning clamp is integrally mounted in the supporting fixing plate, the motor is fixedly mounted in the motor positioning clamp in a limiting manner, and a sampling mounting pipe is mounted at the output end of the lower end of the motor through a connecting ring; a plurality of sampling assemblies are mounted in the sampling mounting pipe in a penetrating manner. According to the sampling device, soil of different layers can be sampled in a classified mode through the sampling assemblies, and simultaneous collection is achieved. Compared with the prior art, the situation that multiple times of repeated treatment are needed due to the fact that only one kind of soil can be sampled at a time is avoided; and the position of the supporting fixing plate can be slid through a movable assembly, so that personnel can drill soil conveniently, and compared with the prior art, the problem that deviation is caused by position deviation due to the fact that no supports are arranged on the two sides is effectively solved.

Owner:山东省地质矿产勘查开发局第四地质大队

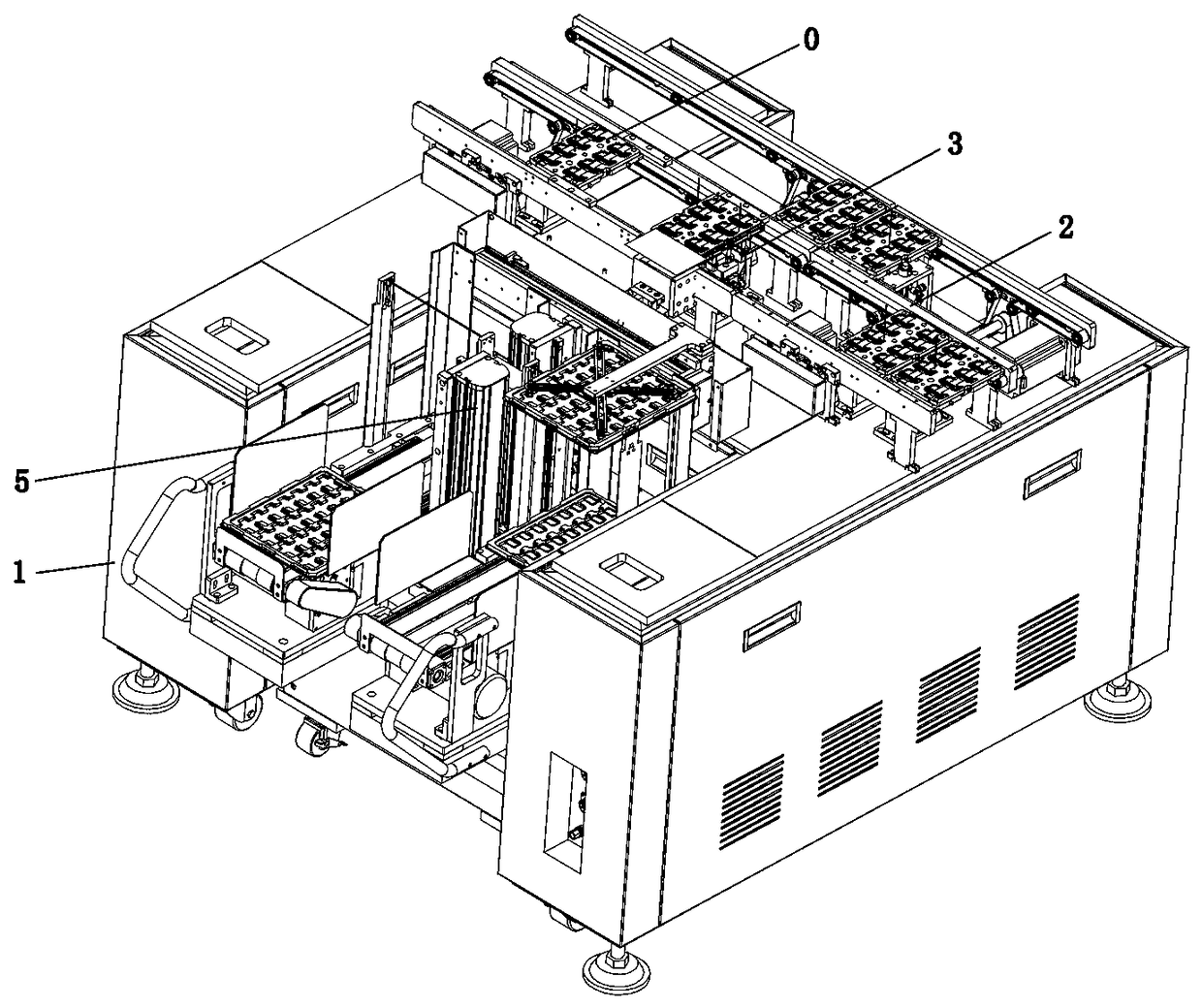

Full-automatic grinding and cleaning machine and grinding and cleaning technology thereof

ActiveCN109955145AAvoid position shiftAvoid positionLapping machinesFlexible article cleaningTransmission channelManipulator

The invention discloses a full-automatic grinding and cleaning machine and a grinding and cleaning technology thereof. The full-automatic grinding and cleaning machine comprises a feeding part, a CF cleaning part, a TFT cleaning part, a two-fluid cleaning and drying part, and a discharging part, wherein the feeding part, the CF cleaning part, the TFT cleaning part, the two-fluid cleaning and drying part and the discharging part are sequentially arranged on a machine table in the flow direction of glass pieces; the to-be-cleaned glass pieces are sequentially transported from the feeding part tothe CF cleaning part, a CF surface is cleaned through the CF cleaning part, the TFR surface is cleaned through the TFT cleaning part, and the CF surface and the TFT surface are cleaned by the two-fluid cleaning and drying part simultaneously and then dried, and the dried glass pieces are discharged and exported through the discharging part. According to the full-automatic grinding and cleaning machine and the grinding and cleaning technology thereof, transmission of the small and micro-sized glass pieces is effectively realized, and the problems of positional displacement and motion interference of the glass pieces in the two-fluid cleaning and drying process are effectively avoided; and rotating, material splitting, and exporting of the glass pieces are realized through cooperation of adouble-glass transmission channel formed by a gap between adjacent conveying rollers in an upward extending mode and a discharging mechanical arm, the height of a brush can be controlled in real time,displacement of the glass pieces is avoided, and the cleaning efficiency of the brush and the real-time cleaning versatility of the brush are effectively improved.

Owner:SHENZHEN ETMADE AUTOMATION EQUIP

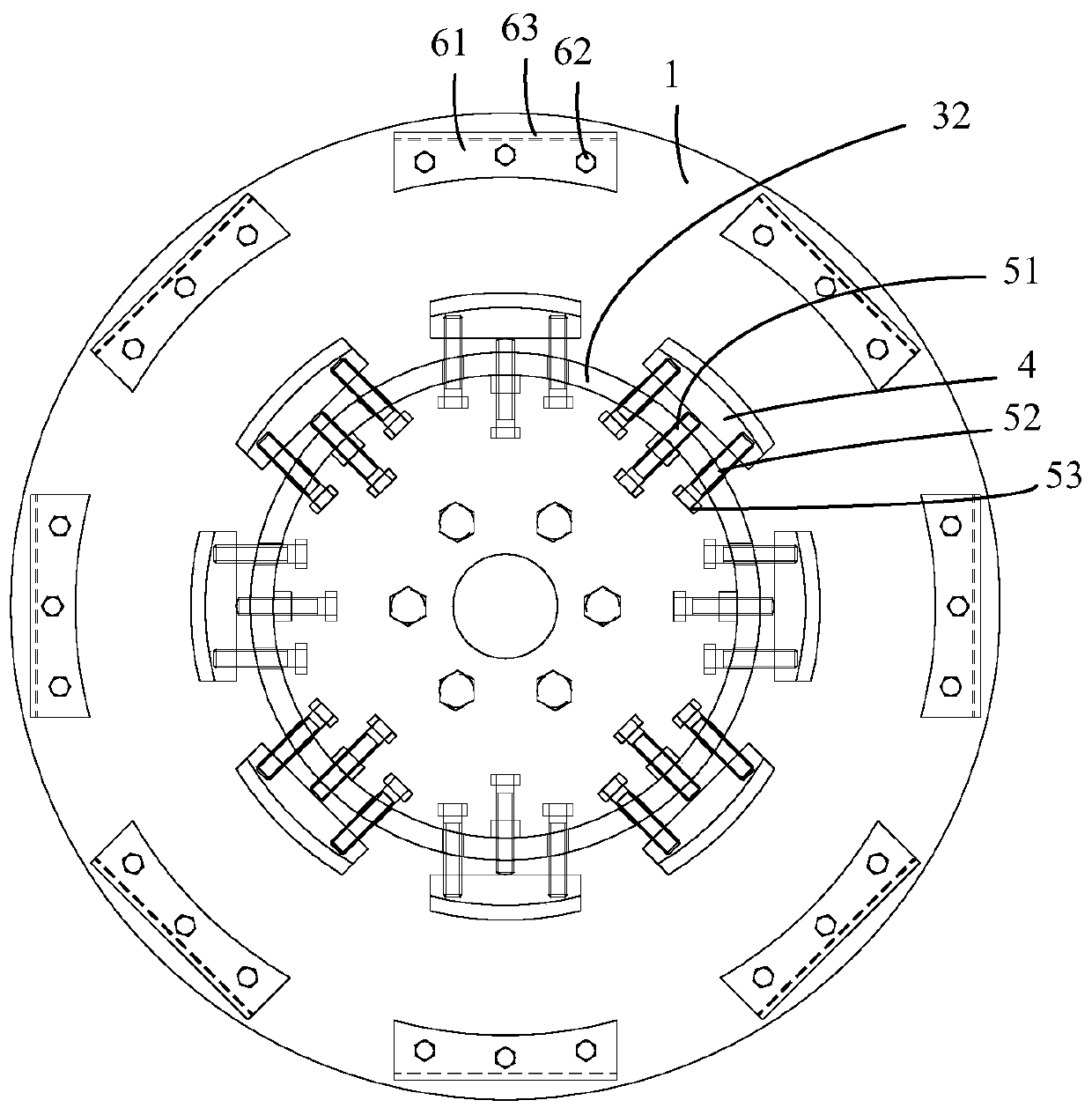

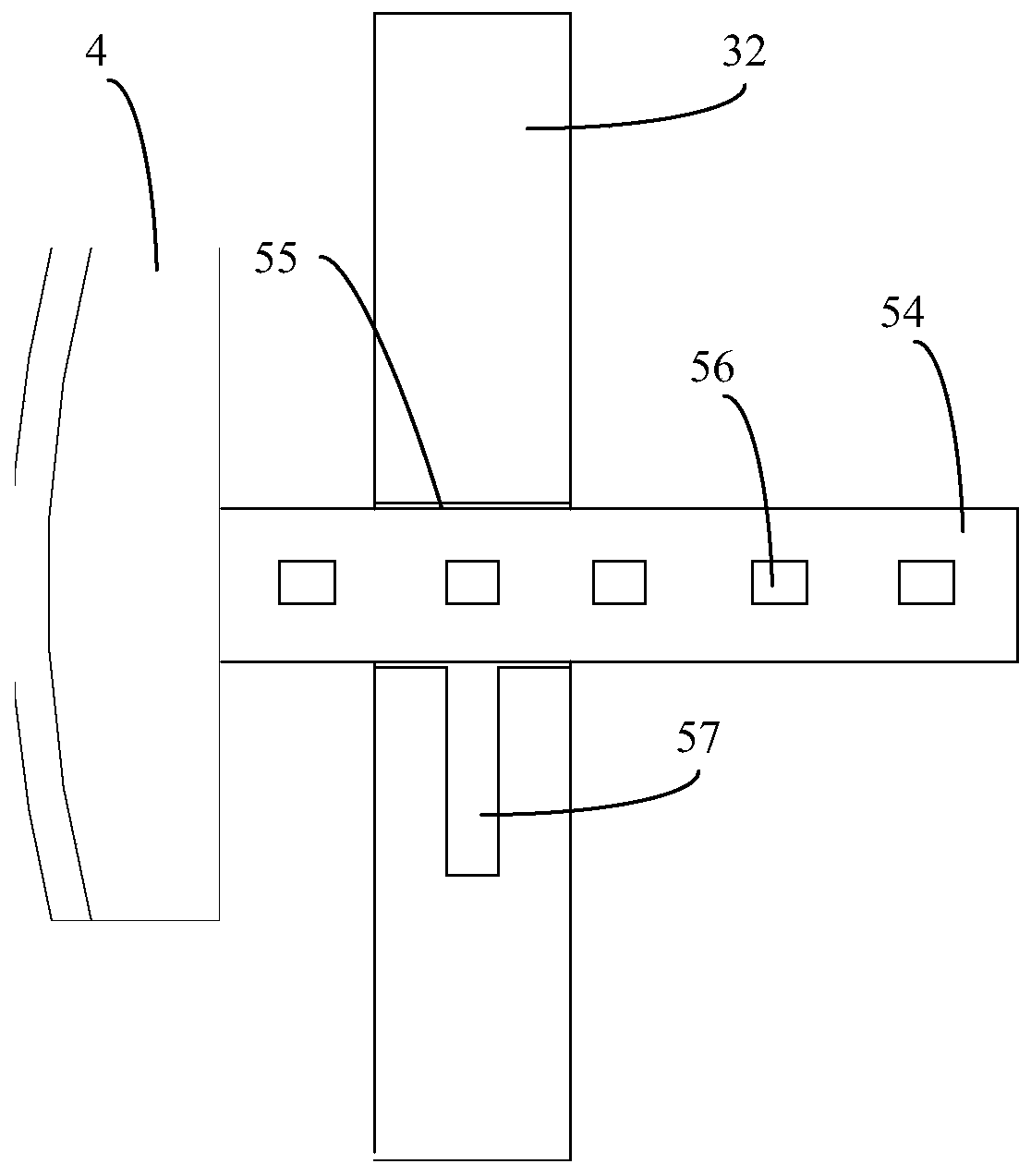

Clamping device for taper-cylindrical workpiece

ActiveCN109773518AAvoid position shiftPrevent slippingPositioning apparatusMetal-working holdersProcessing accuracyMachining process

The invention discloses a clamping device for a taper-cylindrical workpiece. The clamping device includes a positioning disc, a positioning strut, a supporting ring, an expanding block, a position adjusting piece and a pressure plate assembly, an annular positioning groove is formed in the side face of the positioning disc, the annular side wall with the large diameter inside the annular positioning groove is used for fitting the outer wall of a flange at one end of the taper-cylindrical workpiece, the positioning strut is located on one side face of the positioning disc and coaxially arrangedon the positioning disc, and the supporting ring is coaxial mounted on the positioning strut in a sleeving mode; and the supporting ring is detachably connected with the positioning strut, the expanding block is located on the outer edge side of the supporting ring, the expanding block is movably connected with the supporting ring, the end face, deviating from the positioning strut, of the expanding block is fitted with the inner wall of the taper-cylindrical workpiece, the positioning adjusting piece is configured to control the expanding block to slide in the radial direction of the supporting ring, and the pressure plate assembly is used for pressing and mounting one end of the taper-cylindrical workpiece on one side face of the positioning disc. The clamping device can prevent the position offset of the taper-cylindrical workpiece in the machining process, and the processing precision is improved.

Owner:WUHAN MARINE MACHINERY PLANT

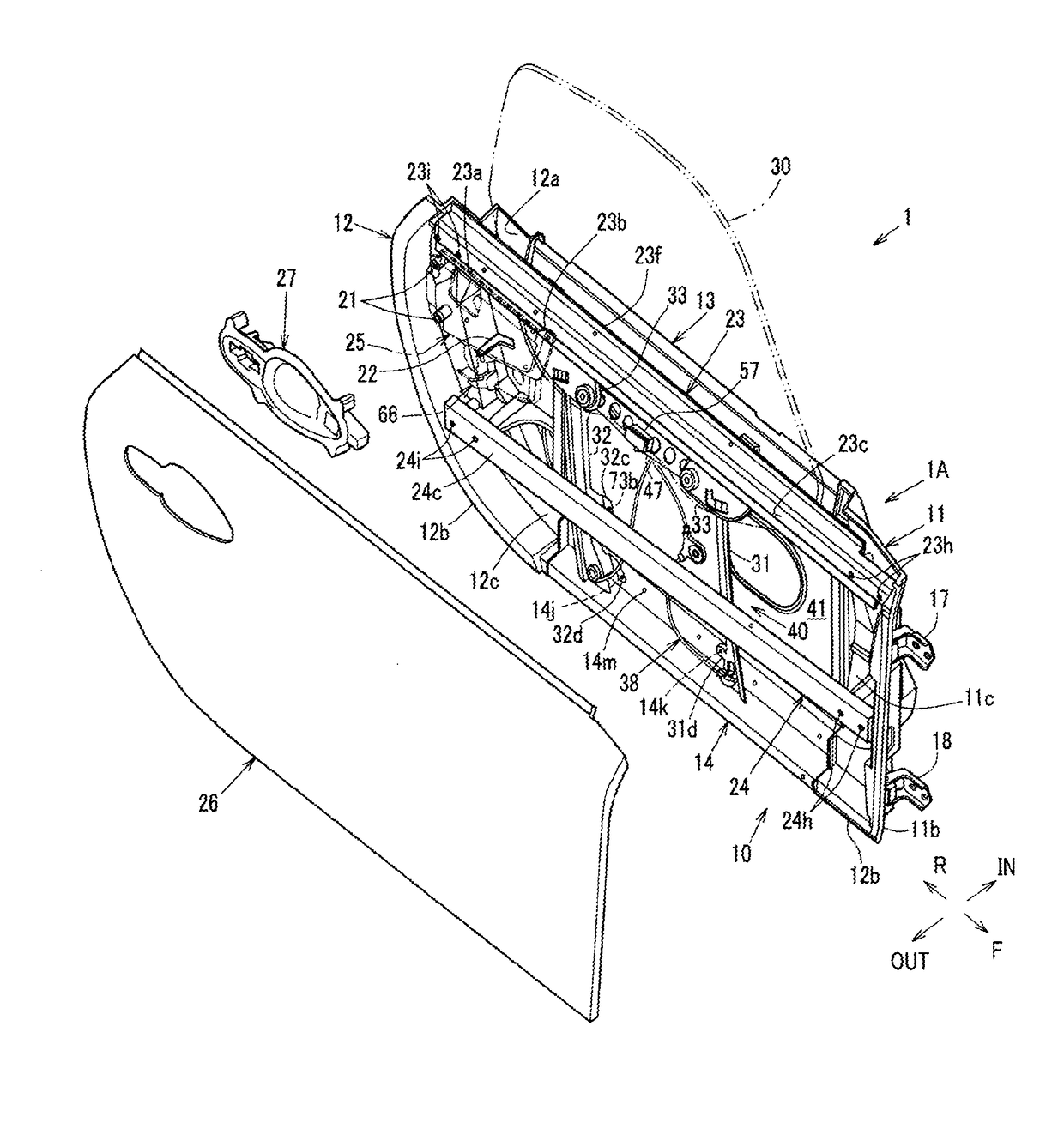

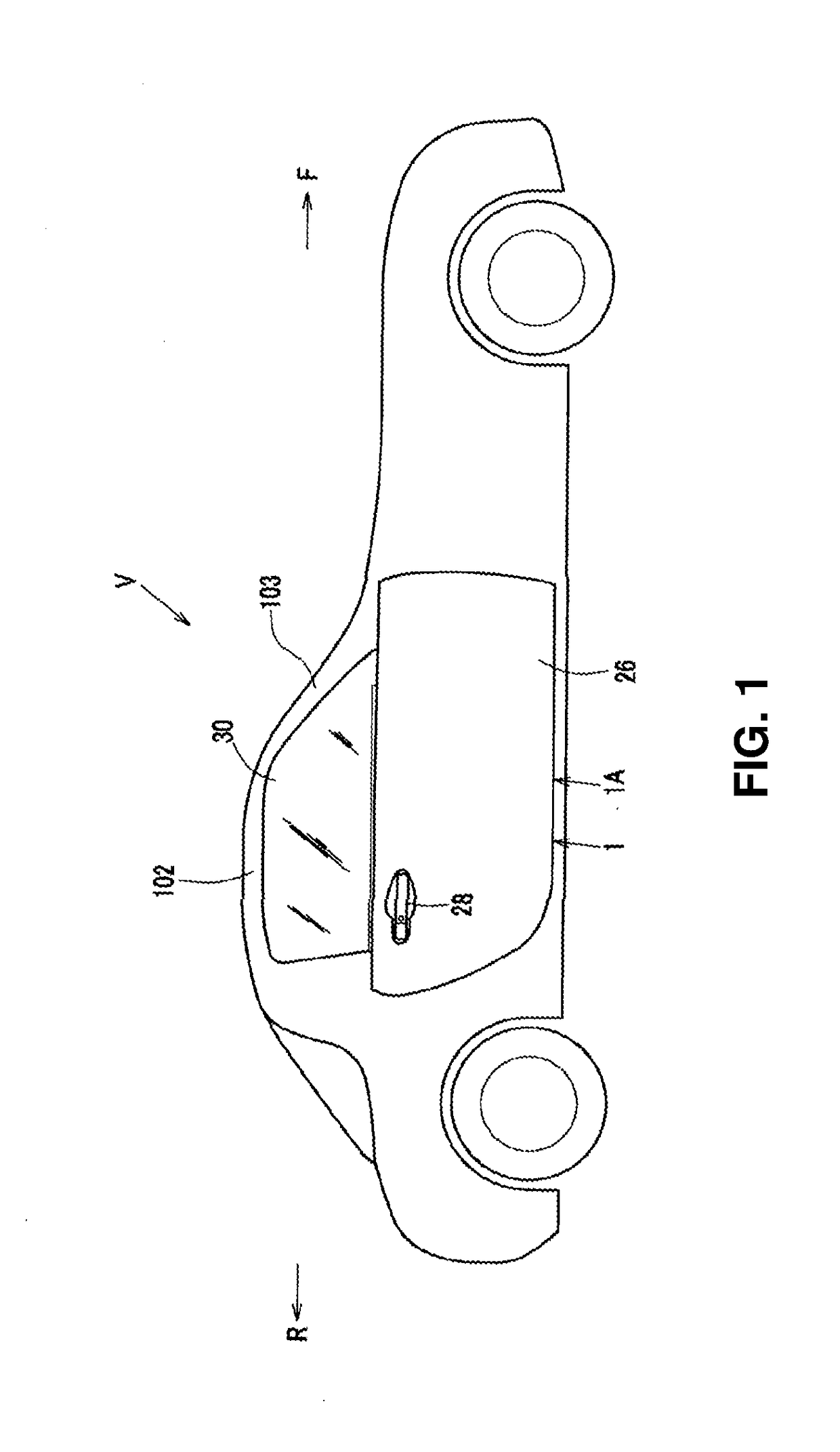

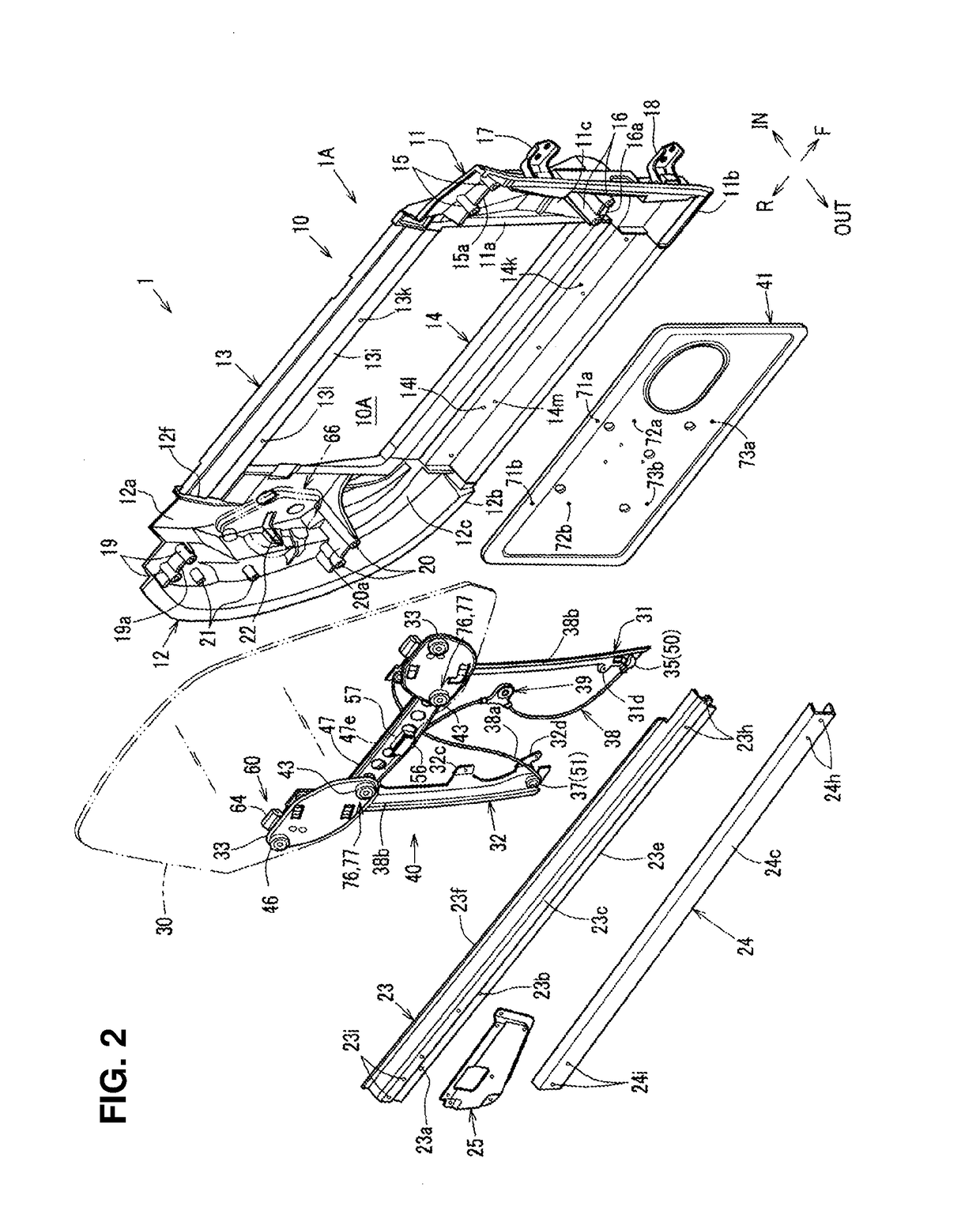

Door structure of automotive vehicle

Vertical frame portions provided at both side portions of a door frame are a light-metal casting, plural connecting frames, which are a light-meal hollow extrusion molding, connect the vertical frame portions, the vertical frame portions are provided with protrusion portions which engage with inward connecting frames in a longitudinal direction, plural attachment portions which attach the outward connecting frames and the vertical frame portion are provided at different points in the longitudinal direction, and an outward connecting frame is provided with an upper rib which engages with an engagement recess portion provided at an upper portion of a door outer panel formed in a non-planar shape.

Owner:MAZDA MOTOR CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com