Patents

Literature

3957results about How to "Improve feeding efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

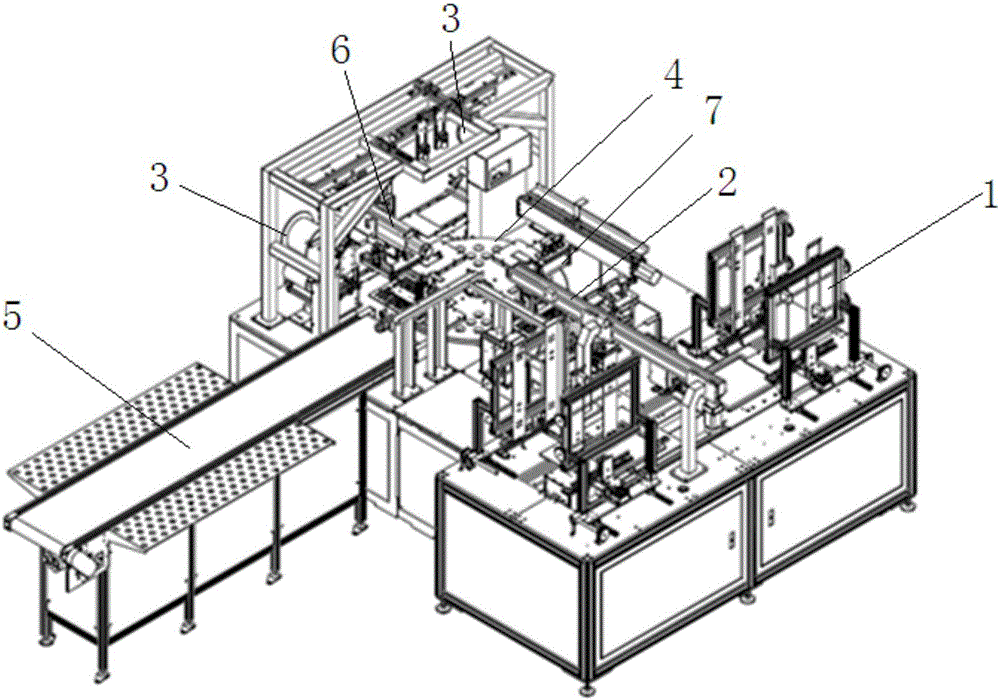

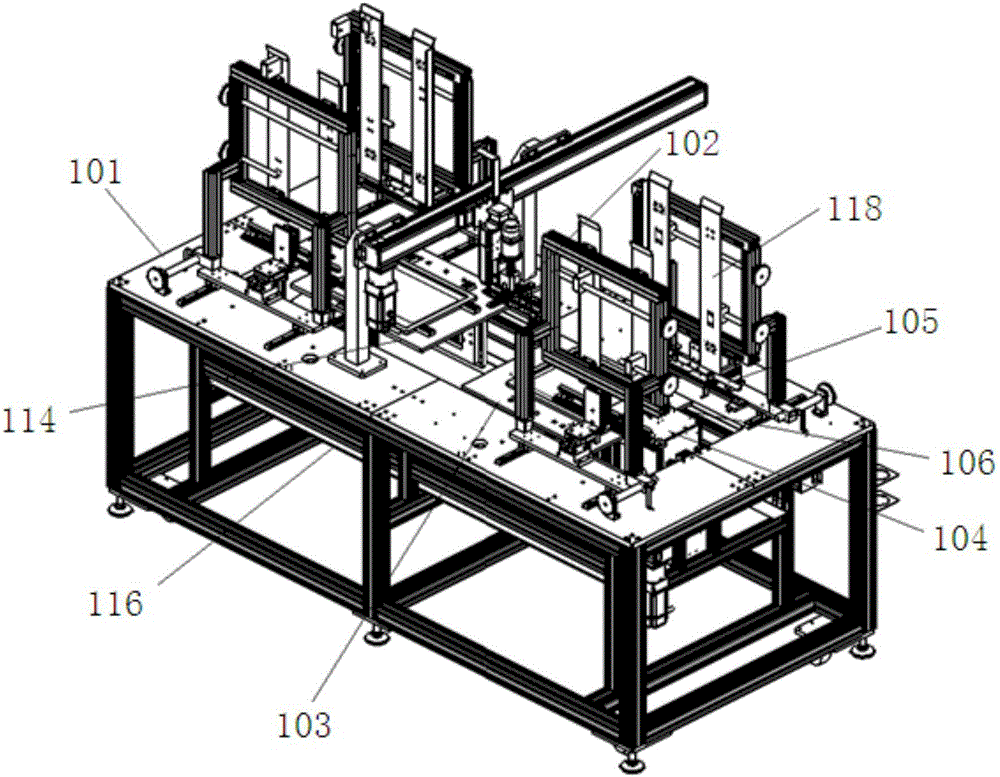

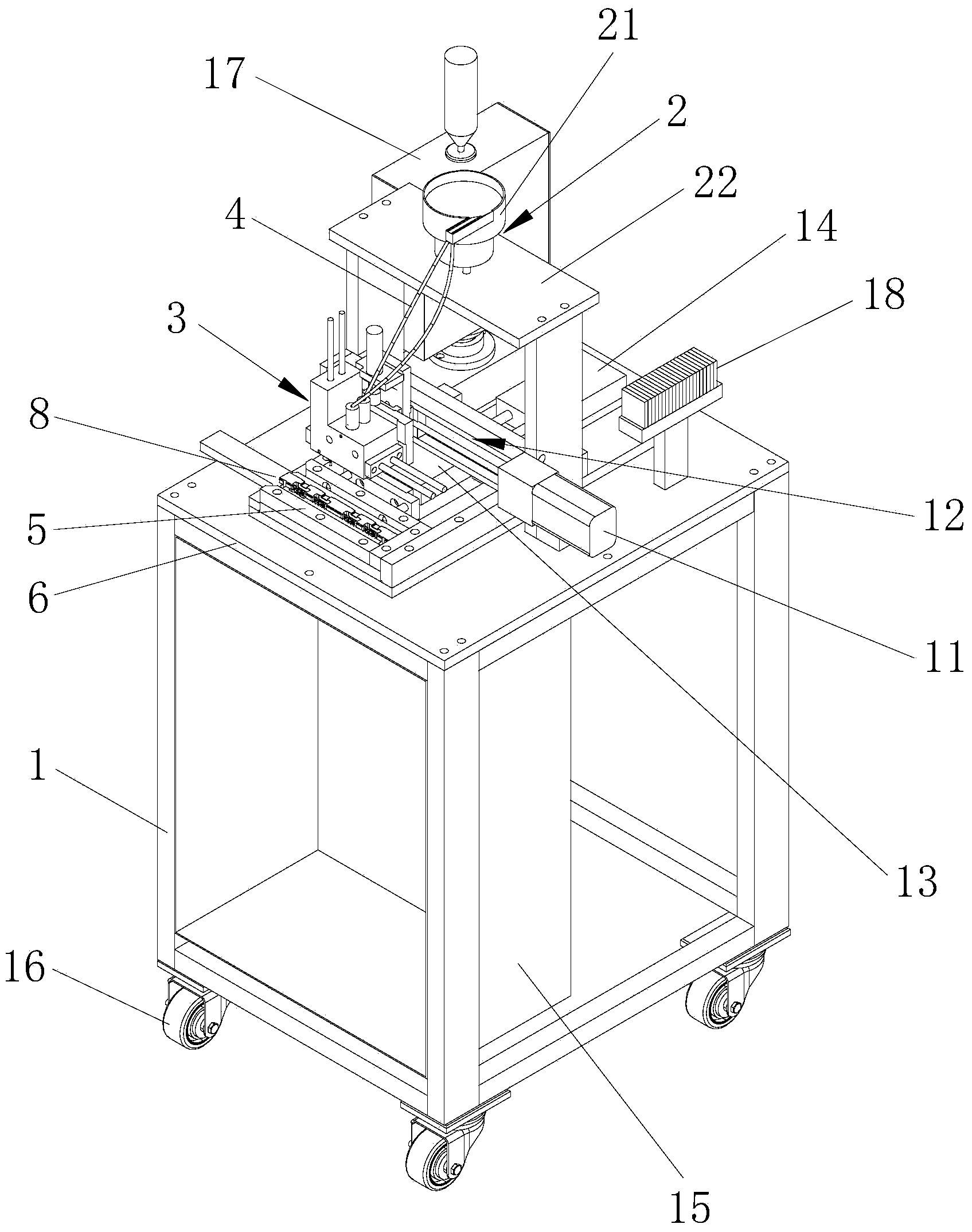

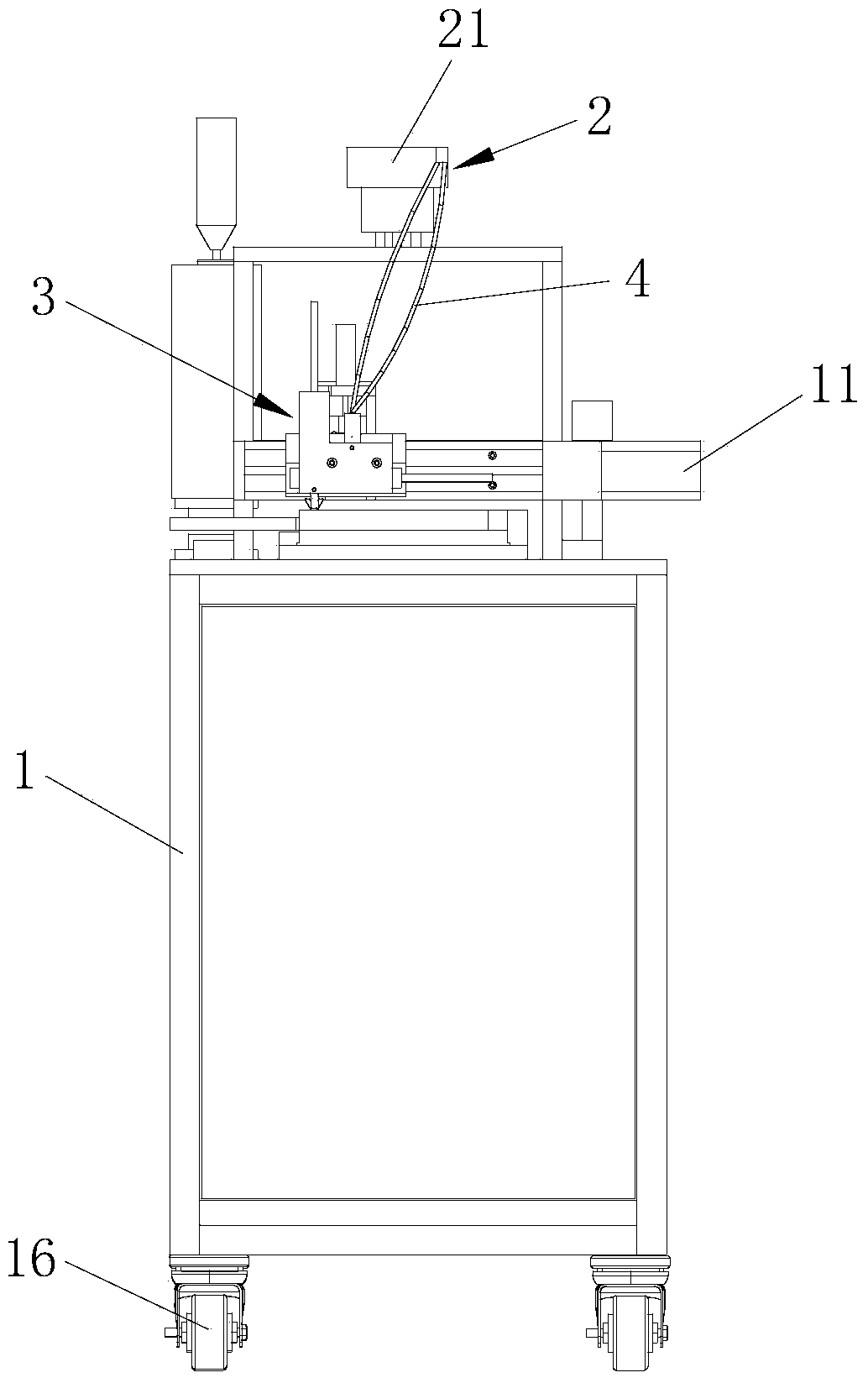

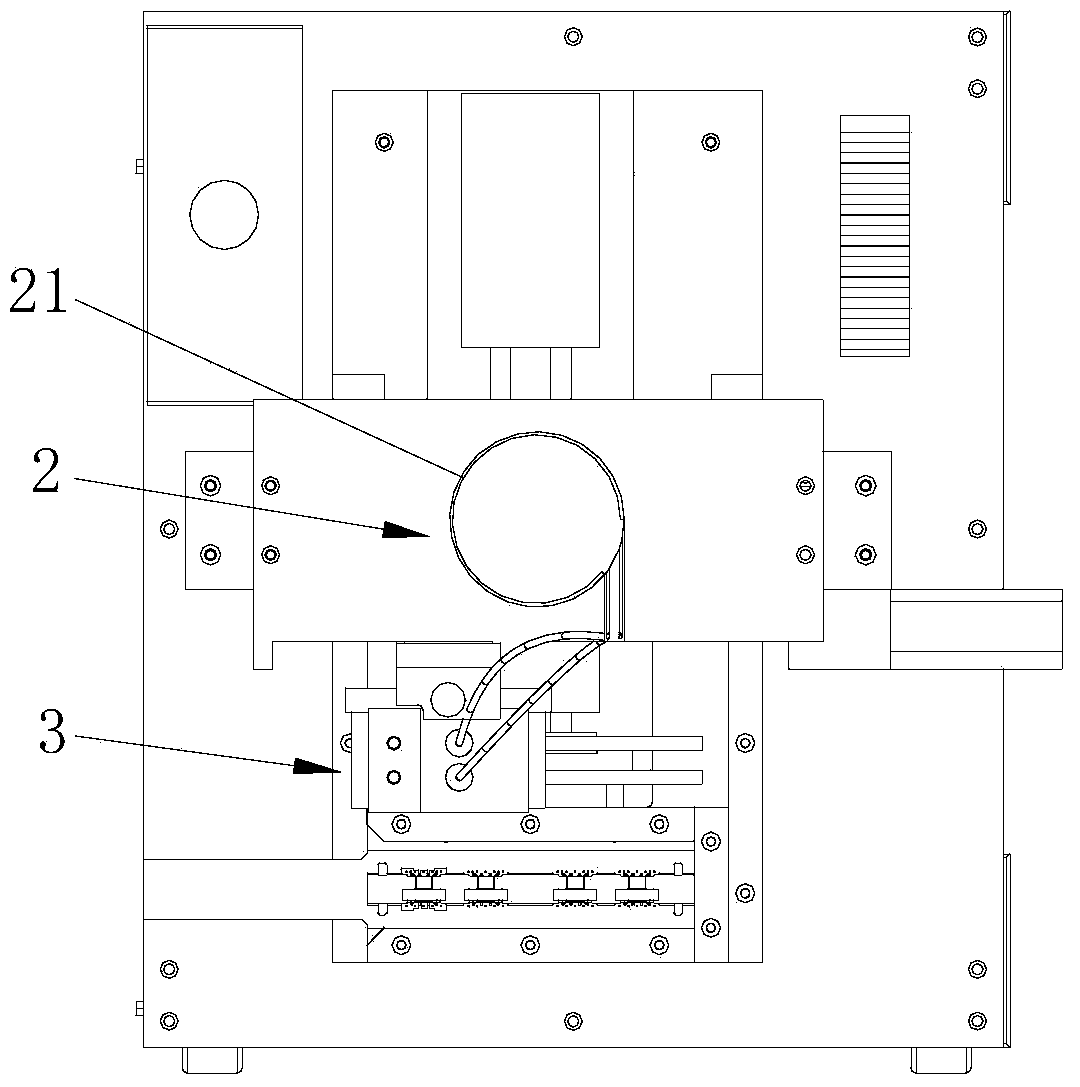

Automatic film sticking machine

ActiveCN106428746AFast and effective film applicationImprove the efficiency of automatic film applicationPackagingEngineeringElectrical and Electronics engineering

The invention discloses an automatic film sticking machine. The machine comprises an automatic feeding mechanism, a pre-positioning mechanism, a film sticking automatic stripping mechanism, a film sticking station conversion mechanism, an automatic film sticking mechanism and a finished product output mechanism; according to the automatic feeding mechanism, an element to be subject to film sticking is taken out and conveyed to the pre-positioning mechanism, the pre-positioning mechanism carries out position pre-adjustment on the element to be subject to film sticking, the element to be subject to film sticking and position pre-adjustment is placed on the film sticking station conversion mechanism, the automatic film sticking mechanism enables a sticking film stripped from the film sticking automatic stripping mechanism to be pasted and covered on the element to be subject to film sticking on the film sticking station conversion mechanism, and the element subject to film sticking is output through the finished product output mechanism for quality inspection. The automatic film sticking machine can be suitable for single-layer or multi-layer rapid effective film sticking, full-automatic feeding, cleaning, sticking film stripping, sticking film absorbing and film sticking are achieved, time and labor are saved, the automatic film sticking efficiency is improved, the film sticking yield is high, and the good application prospect is achieved.

Owner:JIANGSU BVM INTELLIGENT TECH

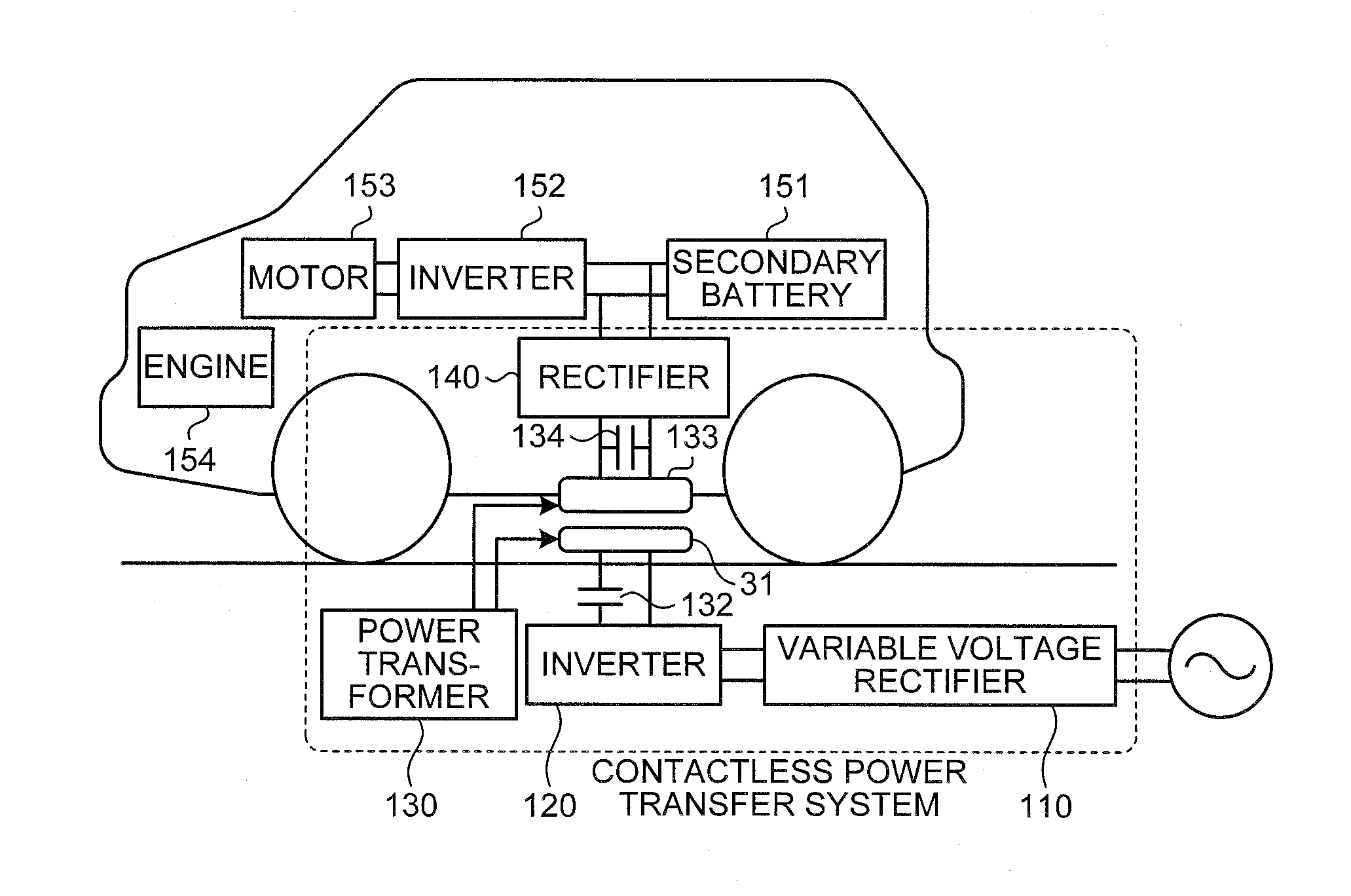

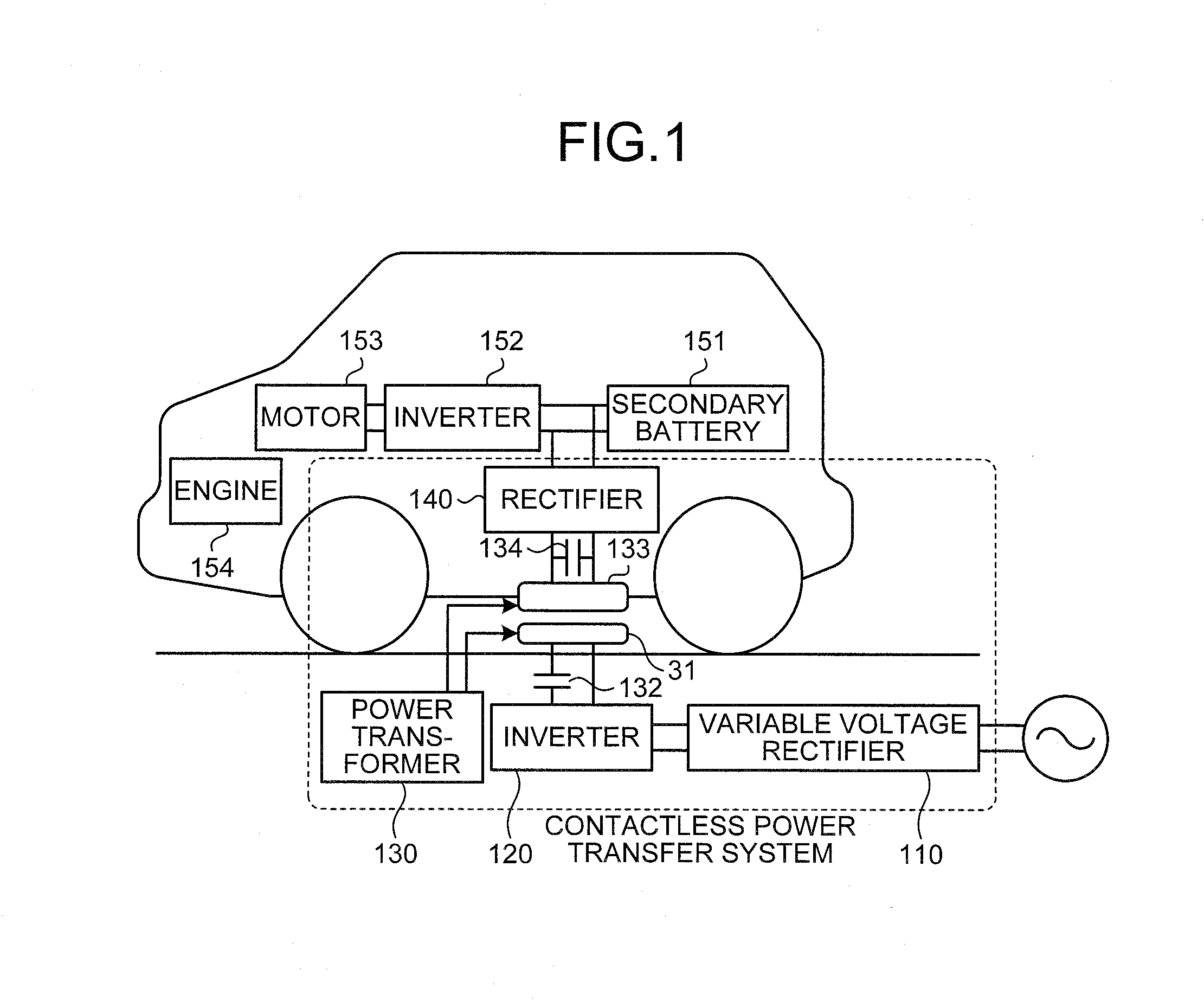

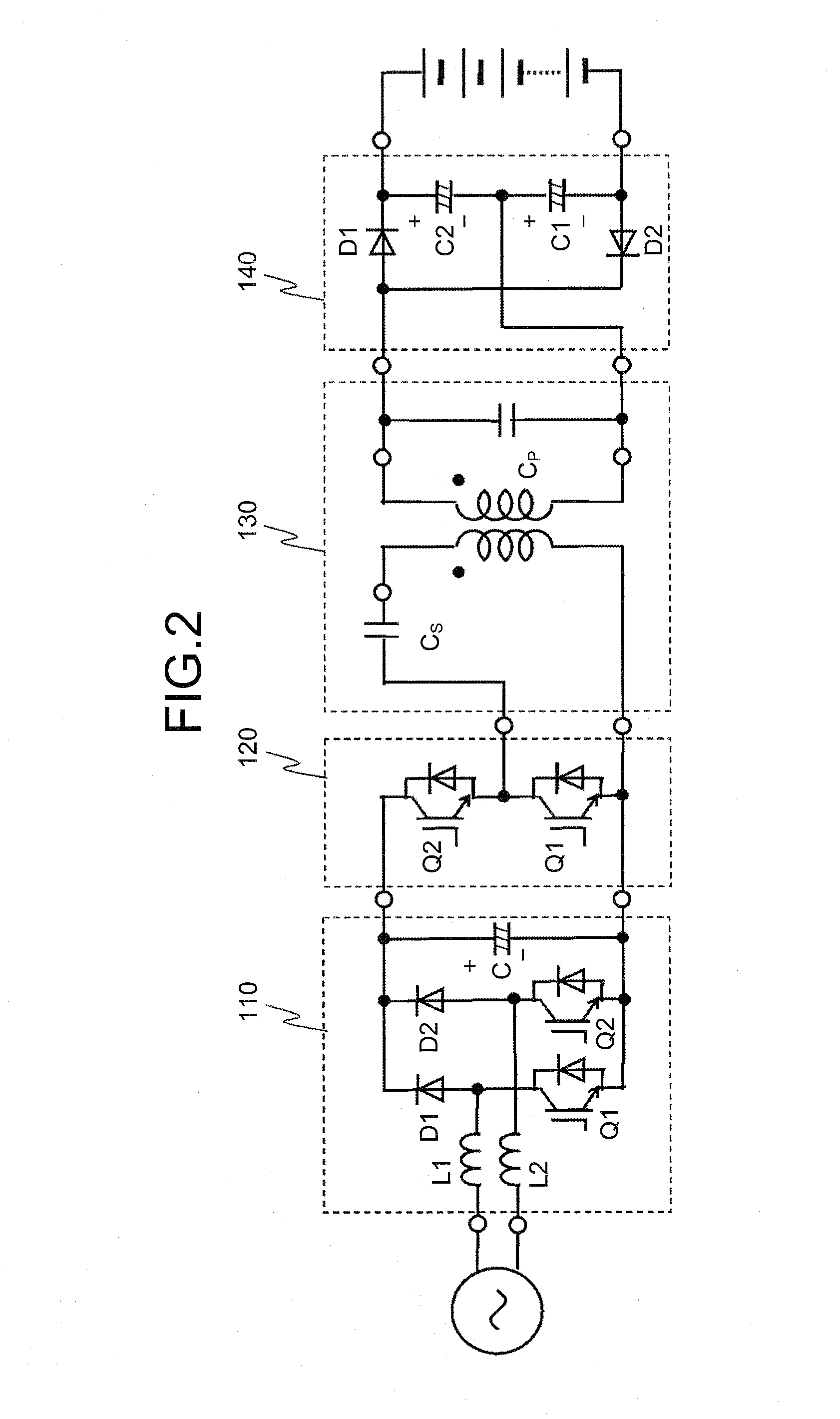

Contactless power transfer system

InactiveUS20130293192A1Easy to controlImprove feeding efficiencyHybrid vehiclesRail devicesElectric power transmissionTransfer system

A half-bridge inverter is used for a high frequency alternating current power supply to be connected to a primary side of a contactless power transformer, and a voltage-doubler rectifier is used to convert a secondary-side alternating current output of the contactless power transformer into a direct current.

Owner:TECHNOVA +1

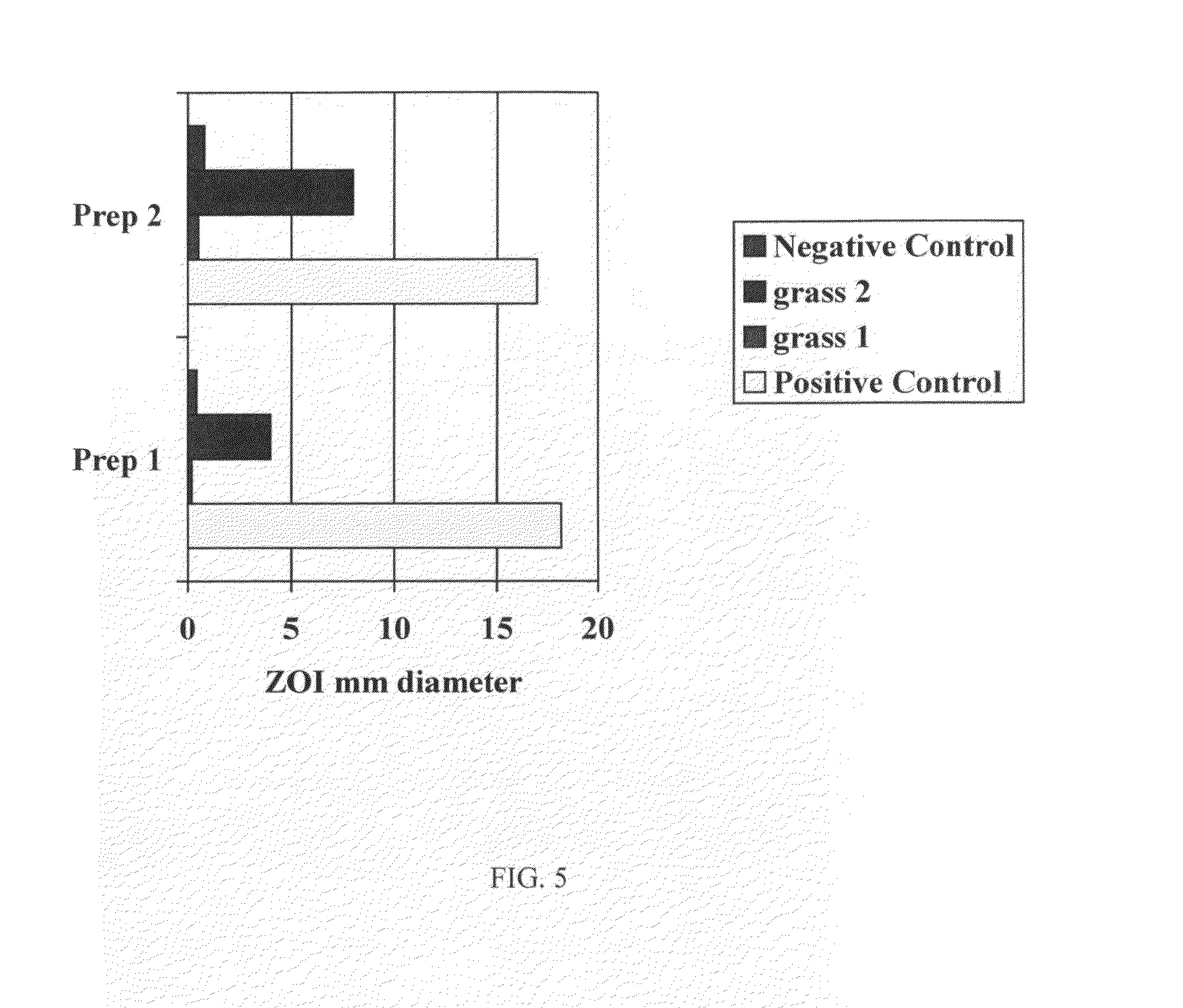

Feed supplement for animals for reducing methane production

InactiveUS20090285931A1Reduce enteric methane emissionImprove performanceAnimal feeding stuffAgriculture gas emission reductionAnimal scienceMethane production

A method for enhancing feed efficiency and reducing enteric methane production in livestock, comprising a formulation of natural plants and plant extracts and chemicals, including propionatic acid glycerol, that when feed to ruminants results in decreased enteric methane production and improved feed efficiency.

Owner:SHELBY NANCY J +1

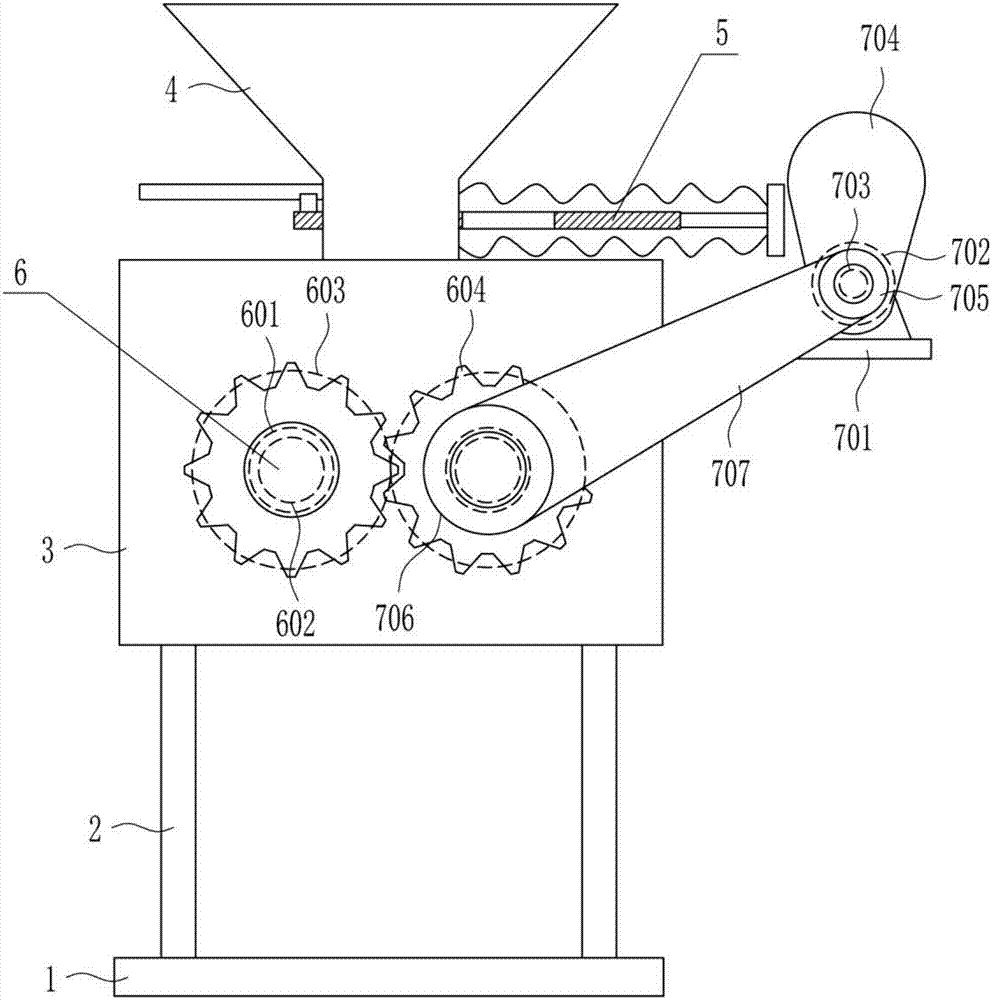

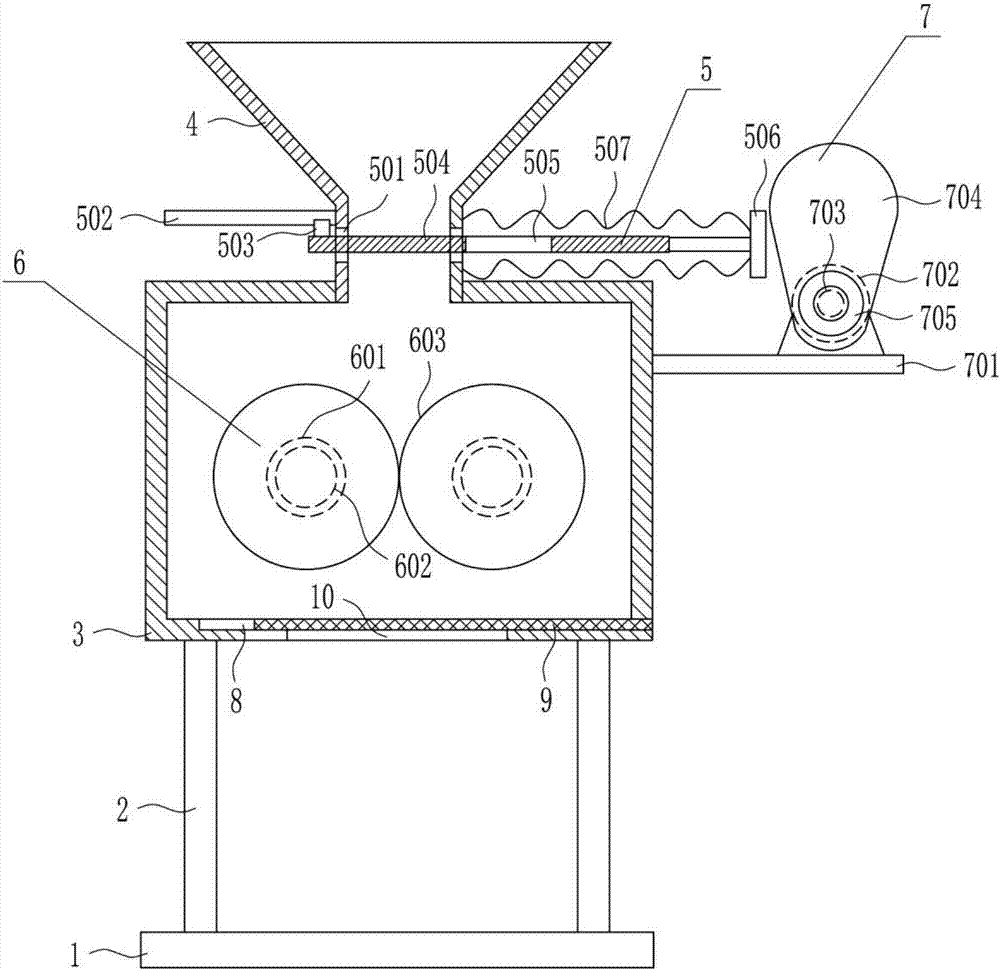

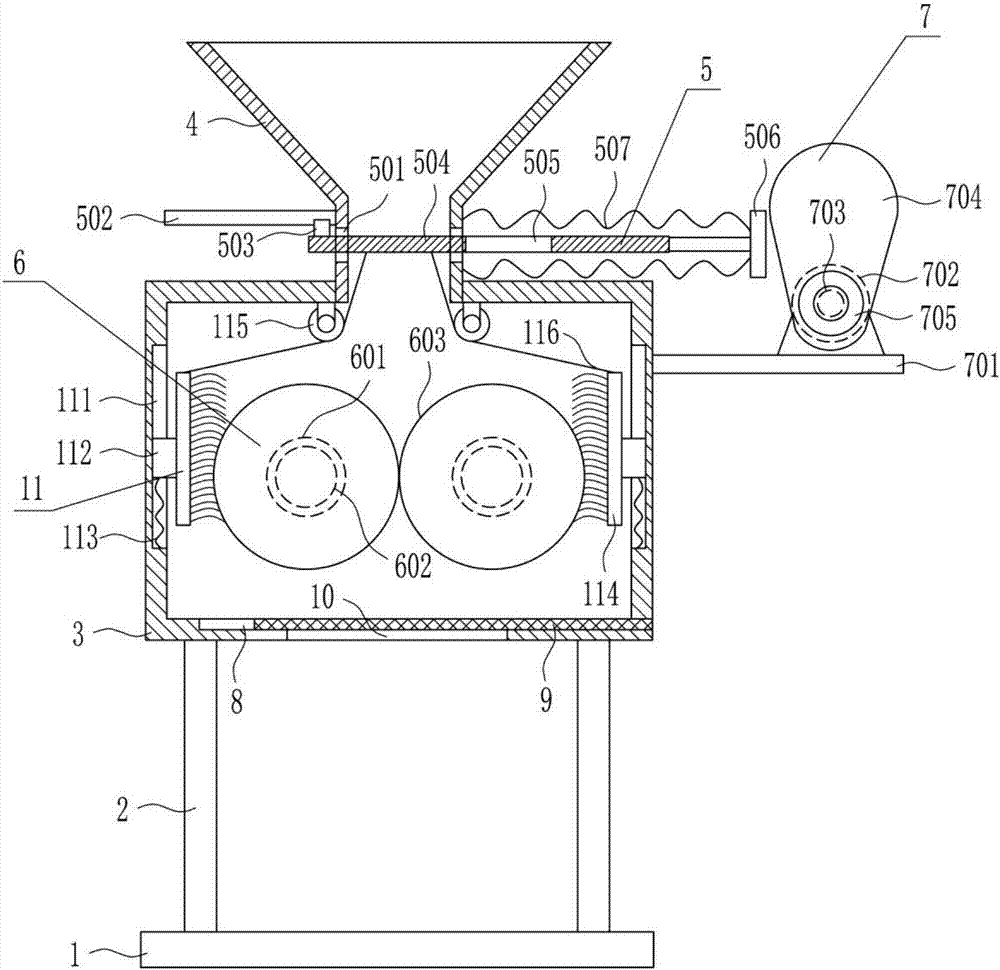

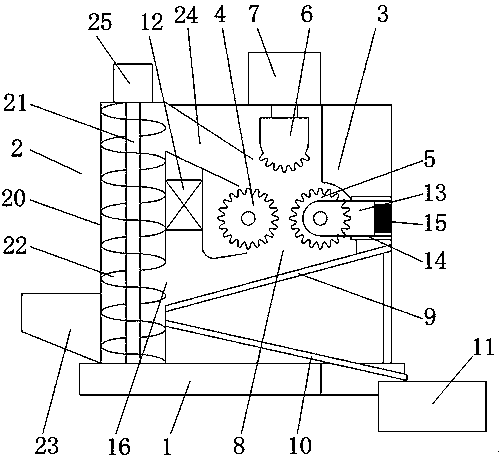

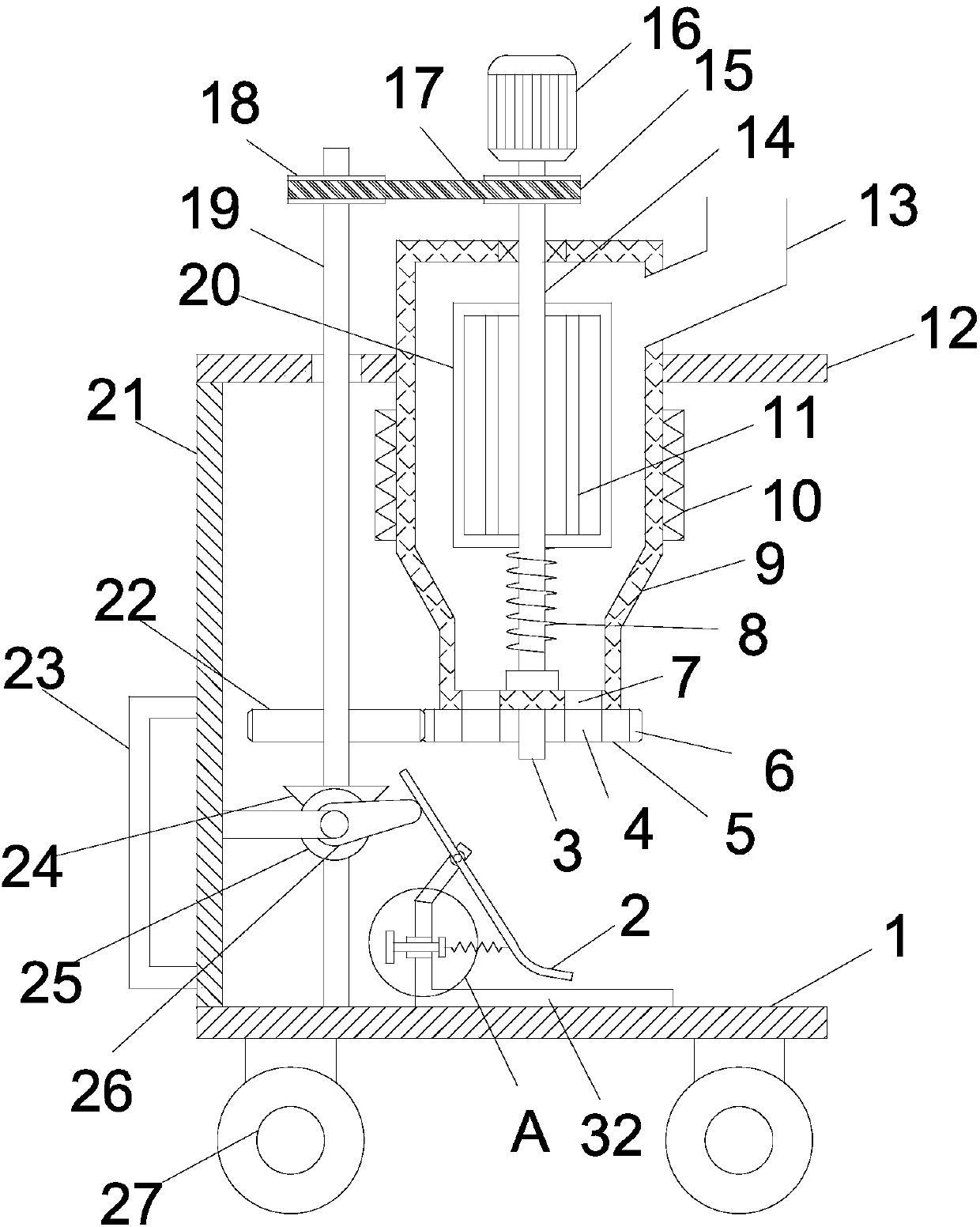

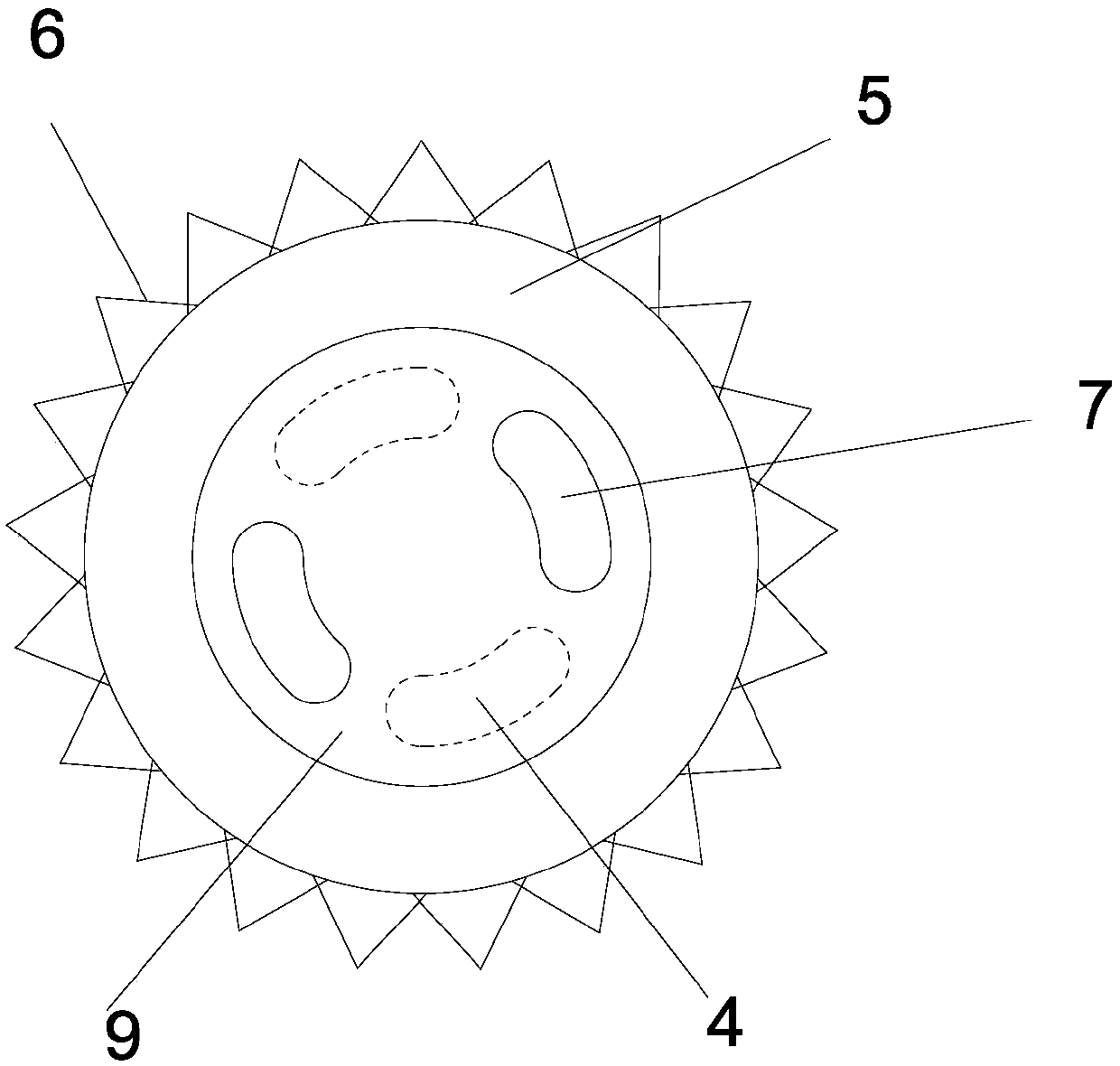

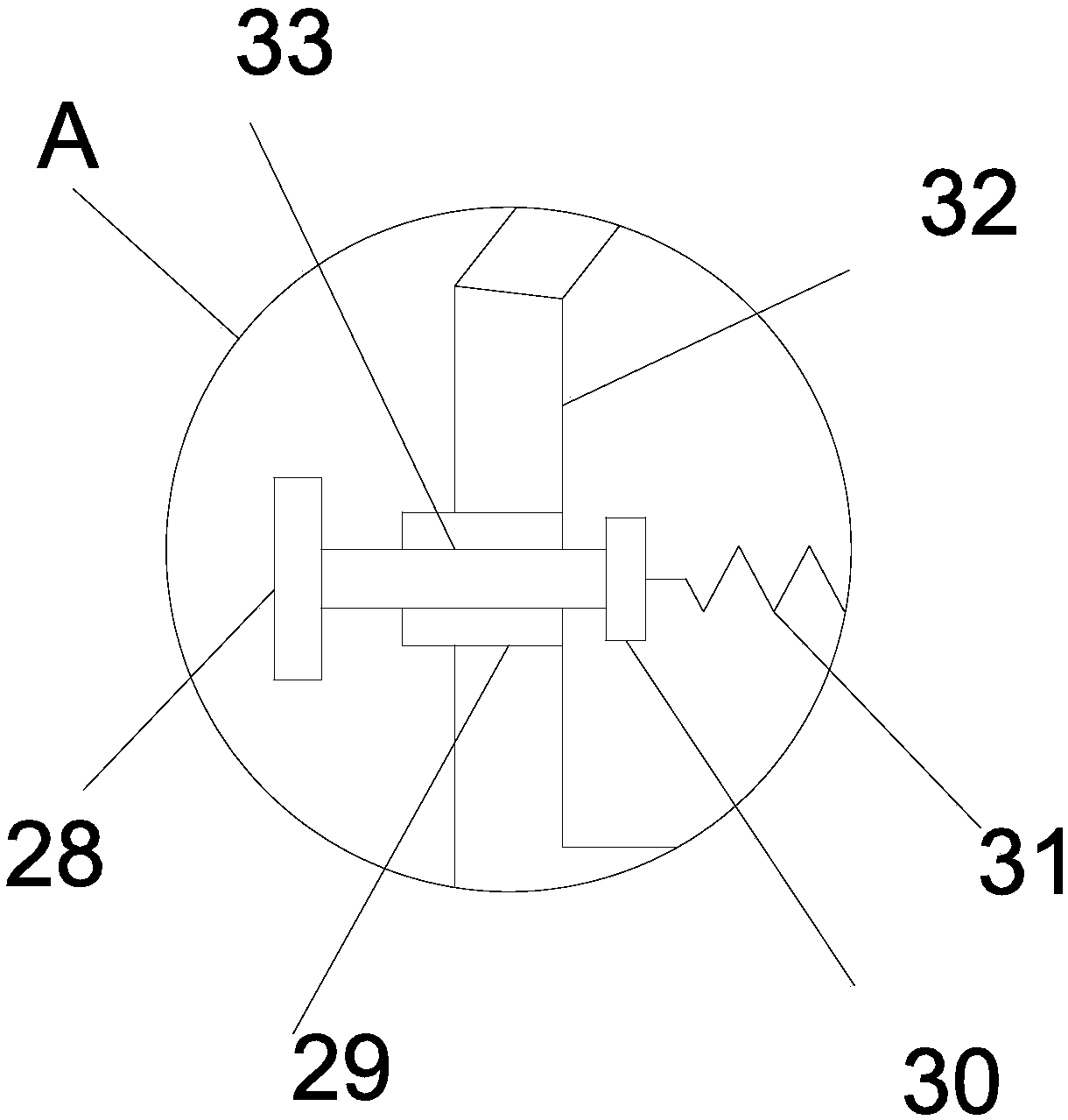

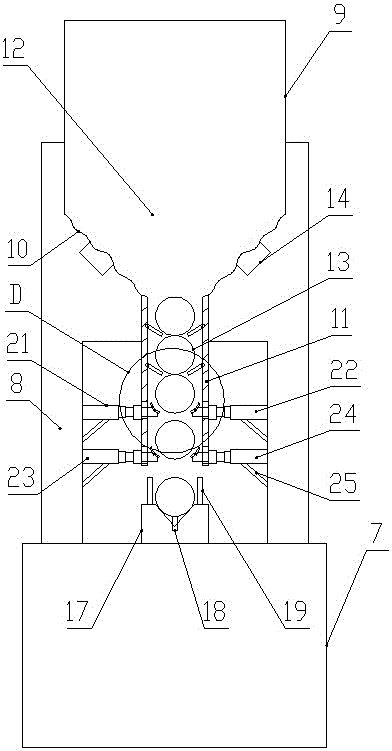

Pellet feed crushing machine for breeding

ActiveCN107971063AAvoid feeding too fastImprove crushing efficiencySievingFeeding-stuffEngineeringMechanical engineering

The invention relates to a crushing machine for breeding, in particular to a pellet feed crushing machine for breeding. The technical problem to be solved is to provide the pellet feed crushing machine for breeding which is time-saving and labor-saving and is capable of improving the crushing efficiency and the feeding efficiency. In order to solve the technical problem, the pellet feed crushing machine for breeding is provided and comprises a base and the like; supporting rods are vertically connected to the left side and the right side of the top of the base correspondingly, a box body is connected between the top ends of the two supporting rods, the top of the box body is provided with a first discharging hopper, a discharging device is arranged in the first discharging hopper, a crushing device is arranged in the box body, and a driving device is arranged on the upper portion of the right side surface of the box body. According to the crushing machine, the driving device can drivethe discharging device and the crushing device to work at the same time, the discharging device performs discharging accordingly to enable the pellet feed in the first discharging hopper to fall intothe box body, the crushing device performs crushing on the pellet feed which falls into the box body accordingly, so that the effect of improving the crushing efficiency is achieved.

Owner:湖南省好运来机电设备有限公司

Building waste processing device and working method thereof

InactiveCN107661791ASmooth and smooth feedingSmooth and smooth crushing processMagnetic separationGrain treatmentsWaste processingArchitectural engineering

The invention discloses a building waste processing device and a working method thereof. The building waste processing device comprises a base, a material lifting device and a crushing cavity, whereinthe material lifting device is vertically arranged on the upper side of the left end of the base, and the crushing cavity is located right above the base and is adjacently connected to the material lifting device; and the material lifting device comprises a vertical lifting cylinder, a lifting rotating shaft, a driving motor and a spiral lifting fin, the lifting rotating shaft is arranged in theaxle center of the lifting cylinder, the driving motor is connected to the top end of the lifting rotating shaft and is fixedly mounted at the top of the lifting cylinder, the spiral lifting fin is welded to the outer part of the lifting rotating shaft, a feeding hopper is connected to the bottom of the left side of the lifting cylinder in a penetration manner, a downward-inclined material conveying pipeline is arranged at the top end of the right side of the lifting cylinder in a penetration manner, a discharging end of the material conveying pipeline deeply penetrates into the crushing cavity, and a fixed shaft crushing roll and a movable shaft crushing roll are mounted in the crushing cavity in parallel. According to the building waste processing device, the working efficiency can be effectively improved, the feeding and crushing processes of the material can be relatively smooth and steady, and the labor and the time are saved; and the building waste processing device is simple andreasonable in structure, convenient to use, practical and efficient.

Owner:陈彬

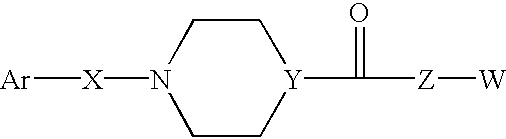

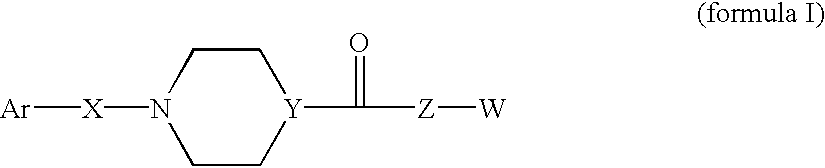

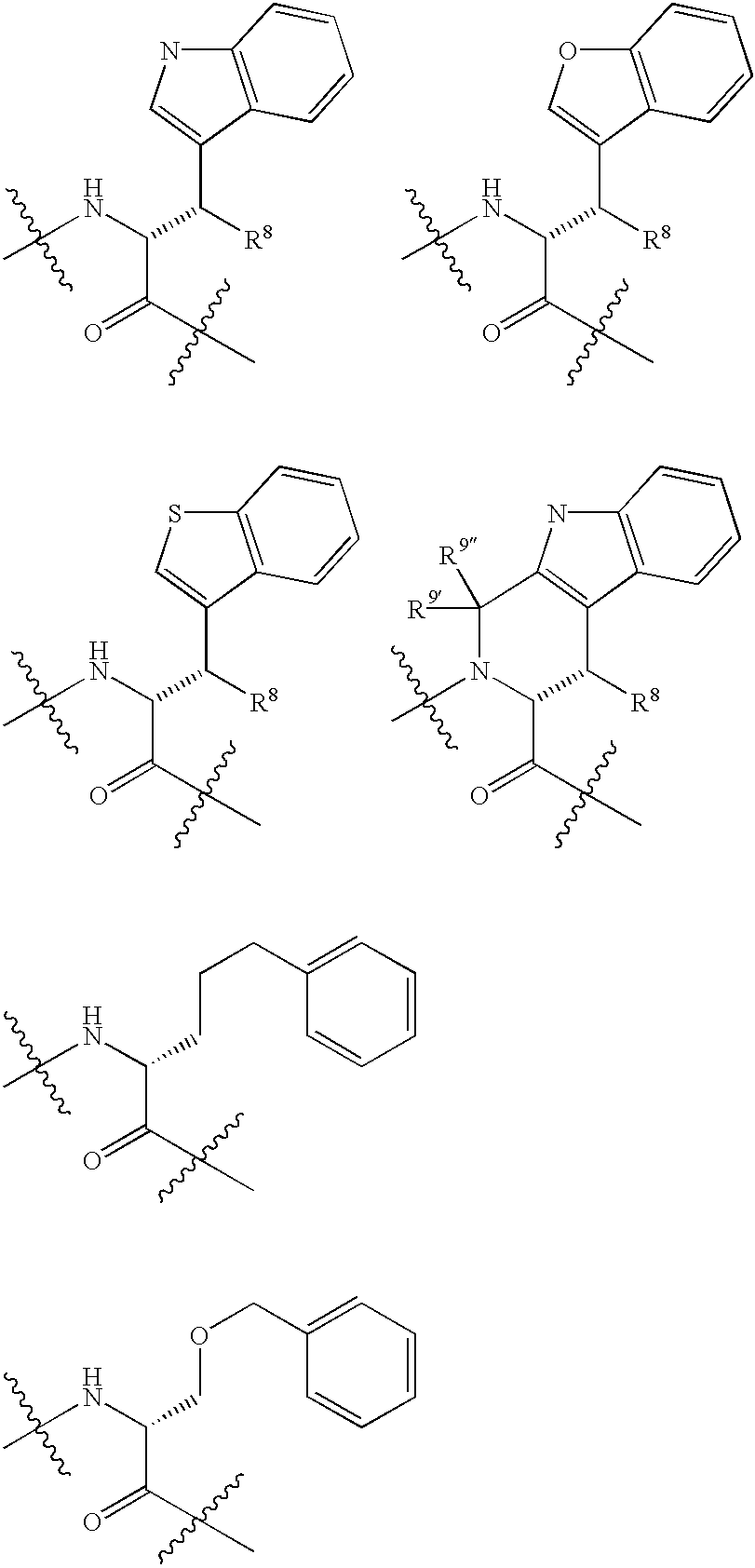

Somatostatin antagonists and agonists that act at the sst subtype 2 receptor

InactiveUS20020128206A1Ease of detectabilityEasy to prepareDipeptide ingredientsMetabolism disorderArylMammal

Compounds according to the formula: 1 and pharmaceutically acceptable salts, solvates or hydrates thereof, wherein group Ar is optionally substituted (C.sub.6-C.sub.10)aryl or (C.sub.1-C.sub.9)heteroaryl; X is a direct link, --CH.sub.2 --, --SO.sub.2 --, --CO--, --CHR.sup.1-- where R.sup.1 is(C.sub.1-C.sub.6) alkyl, or --CR.sup.1'R.sup.1"-where both R.sup.1' and R.sup.1" are, independently, (C.sub.1-C.sub.6)alkyl; Y is N or CH; and Z and W are as herein defined, and pharmaceutical compositions thereof, and methods useful to facilitate secretion of growth hormone(GH) in mammals.

Owner:HAY BRUCE A +2

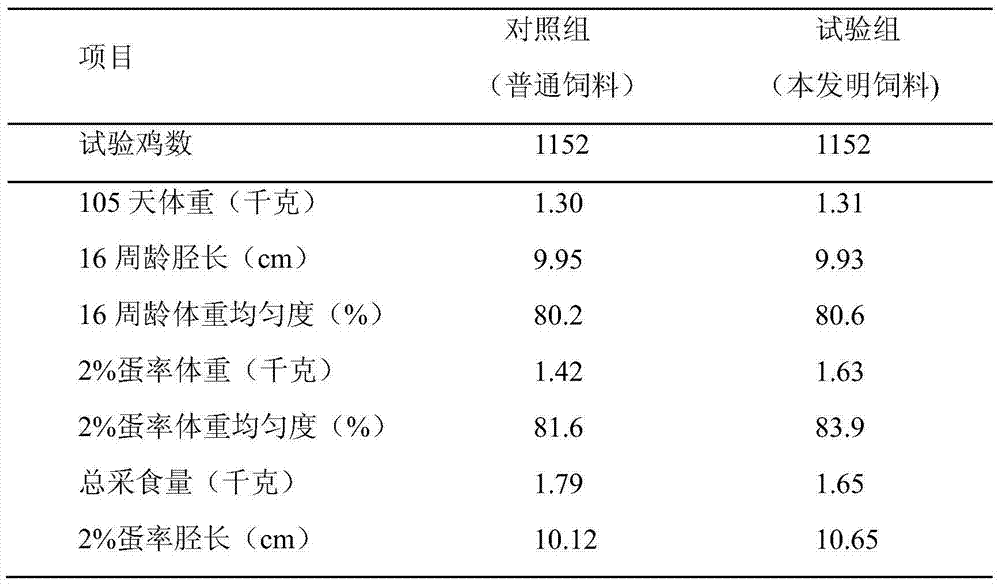

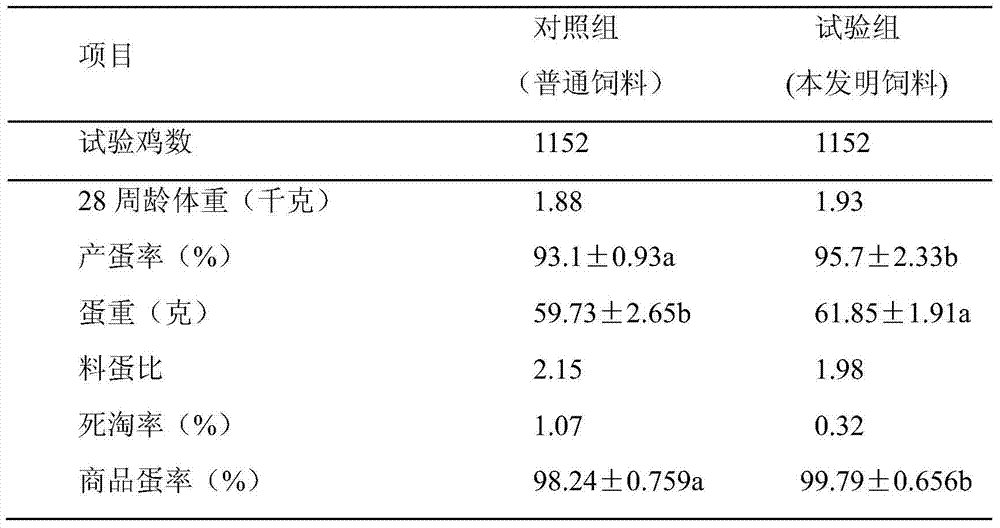

Laying hen feed additive and preparation thereof

ActiveCN103766650APromote digestion and absorptionReduce usageAnimal feeding stuffBiotechnologyAsparagus cochinchinensis

The invention discloses a laying hen feed additive and belongs to the technical field of feed additives. The laying hen feed additive is composed of following components in parts by weight: 35-65 parts of corns, 5-10 parts of rice bran, 4-9 parts of wheat bran, 5-9 parts of peanut meal, 0.5-3 parts of plant oil, 0.2-0.4 part of table salt, 0.1-0.2 part of a calcium element additive, 0.4-2.6 parts of amino acid, 0.05 part of a complex enzyme preparation, 0.012 part of phytase, 0.05-0.12 part of choline chloride, 50-150 parts of vitamin E, 1-5 parts of cordyceps taishanensis powder, 2-6 parts of asparagus cochinchinensis powder, 0.5-1 part of glycyrrhiza uralensis powder, 5-8 parts of a bacillus subtilis CGMCC7926 (China General Microbiological Culture Collection Center 7926) bacterium agent culture, 3-6 parts of a lactobacillus plantarum CGMCC7928 bacterium agent and 1-2 parts of a saccharomyces cerevisiae bacterium agent. The laying hen feed additive sufficiently guarantees that propagative organs of laying hens are completely and rapidly developed; eggs laid on an egg laying initial phase are heavy and large and the peak is high and the egg laying peak is maintained for long time.

Owner:HAIMEN THE XIUYU IND DESIGN CO LTD

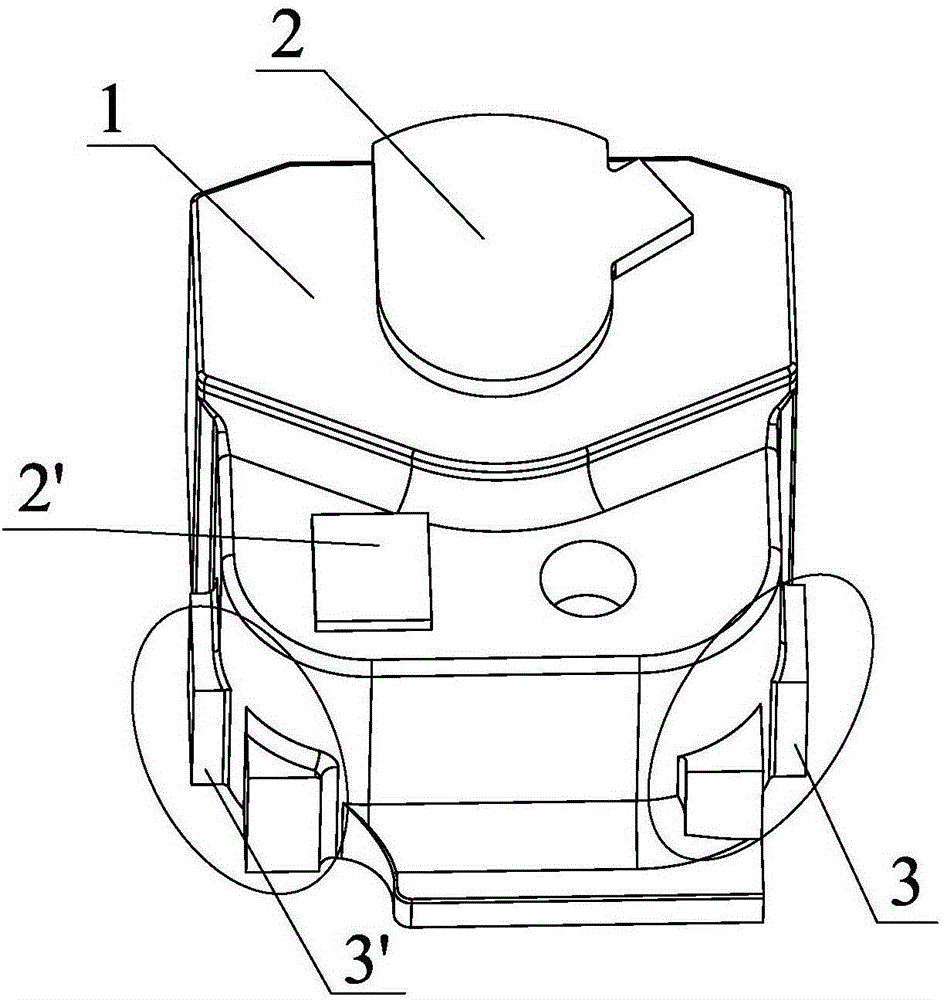

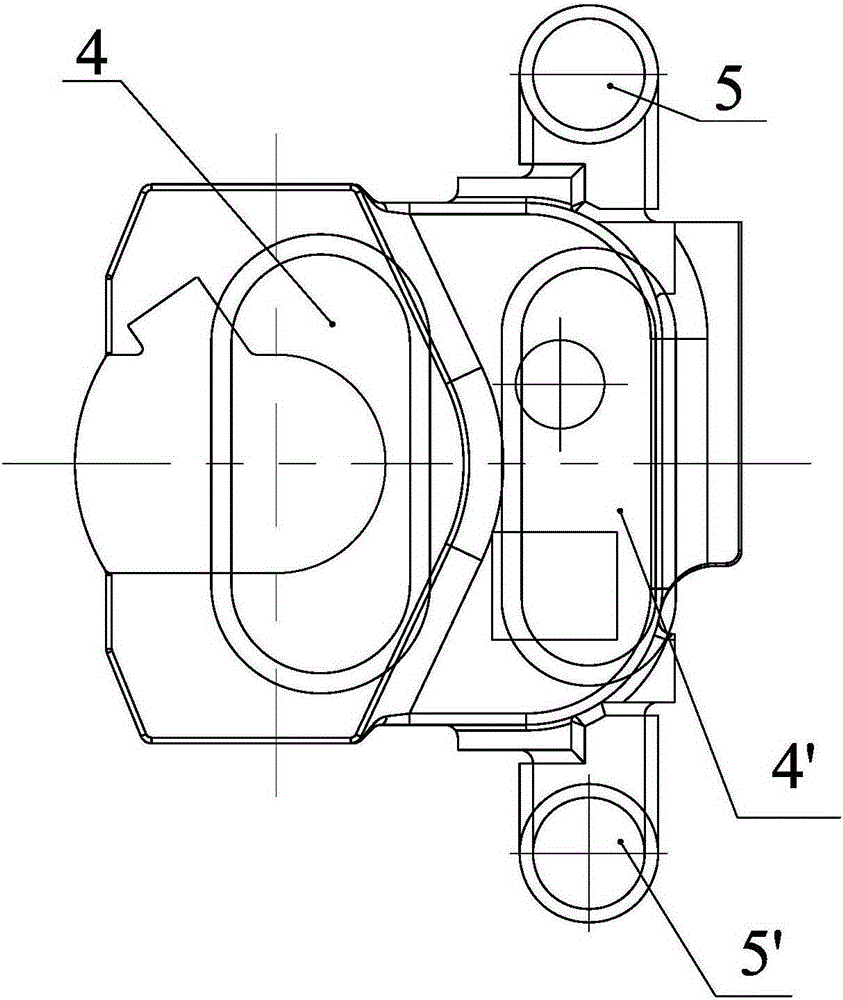

Core assembly moulding sand mould structure for gearbox shell castings and core assembly moulding method

The invention relates to a core assembly moulding sand mould structure for gearbox shell castings and a core assembly moulding method. The core assembly moulding sand mould structure for the gearbox shell castings comprises inner cavity sand cores, outer contour sand cores and a pouring system sand mould for core assembly moulding; The inner cavity sand cores and the outer contour sand cores are assembled to form mould cavities for the shell castings; the upper side of the upper end face of each shell casting is provided with multiple round feeders, and a plurality of chilling blocks are arranged in each outer contour sand core among the corresponding round feeders; supplement structures are arranged in each outer contour sand core corresponding to the sides of side bosses on the lower parts of the side walls of the corresponding shell casting, and an insulating layer is arranged on the outer side of each supplement structure; and ingates communicated with the mould cavities of the corresponding castings are arranged in the pouring system sand mould. According to the core assembly moulding sand mould structure disclosed by the invention, moulding and casting cost of the castings is reduced; the work load of subsequent machining of the castings is reduced; and the production efficiency is improved.

Owner:KOCEL STEEL

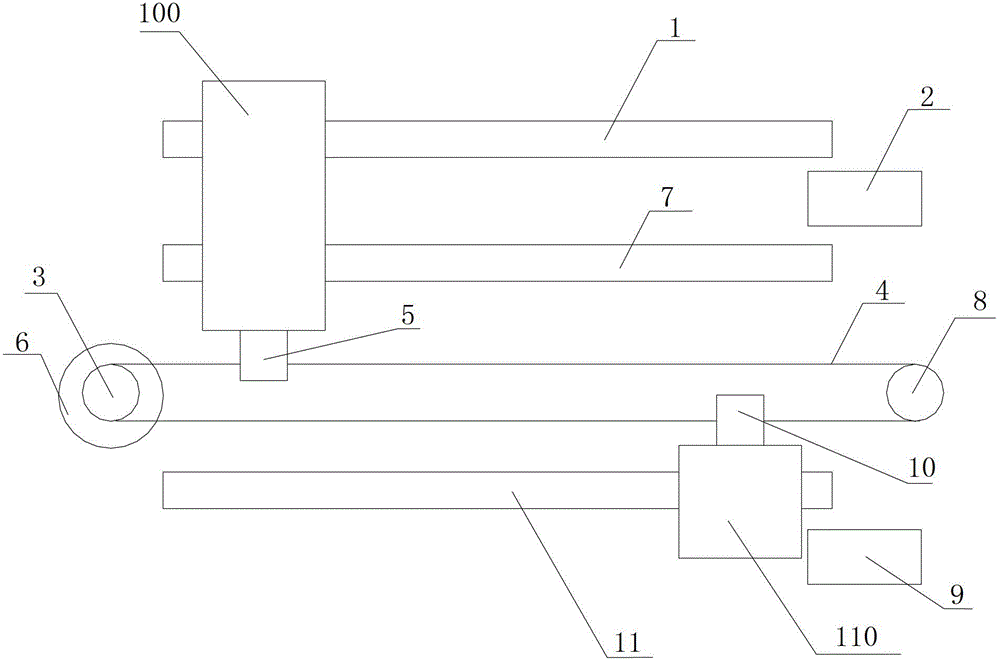

Alternated plate feeding device

InactiveCN102745459ARealize clamping and conveyingCompact structureConveyorsReciprocating motionEngineering

The invention discloses an alternated plate feeding device, which comprises a conveyor belt, at least two plate clamping mechanisms and a slide rail, wherein the conveyor belt comprises a plurality of working sections arranged in parallel, and at least two of all the working sections have opposite conveying directions; the plate clamping mechanisms are fixedly connected to different working sections; and the slide rail is used for bearing reciprocating motion of the plate clamping mechanisms. The alternated plate feeding device does not slip during clamping; and the feeding distance can be conveniently calculated through the conveying distance of the conveyor belt, so that the feeding precision is greatly promoted. In the optimal technical scheme, a first plate clamping mechanism and a second plate clamping mechanism are adopted, so that idle travel is avoided in the feeding process, uninterrupted feeding is realized, and the feeding efficiency is greatly improved; and only one clamping part is required in one feeding stroke, so that the surface of a material is scratched little. The device has the advantages of convenience in control, high feeding precision, little surface scratch, high feeding efficiency and the like.

Owner:ZHEJIANG UNIV

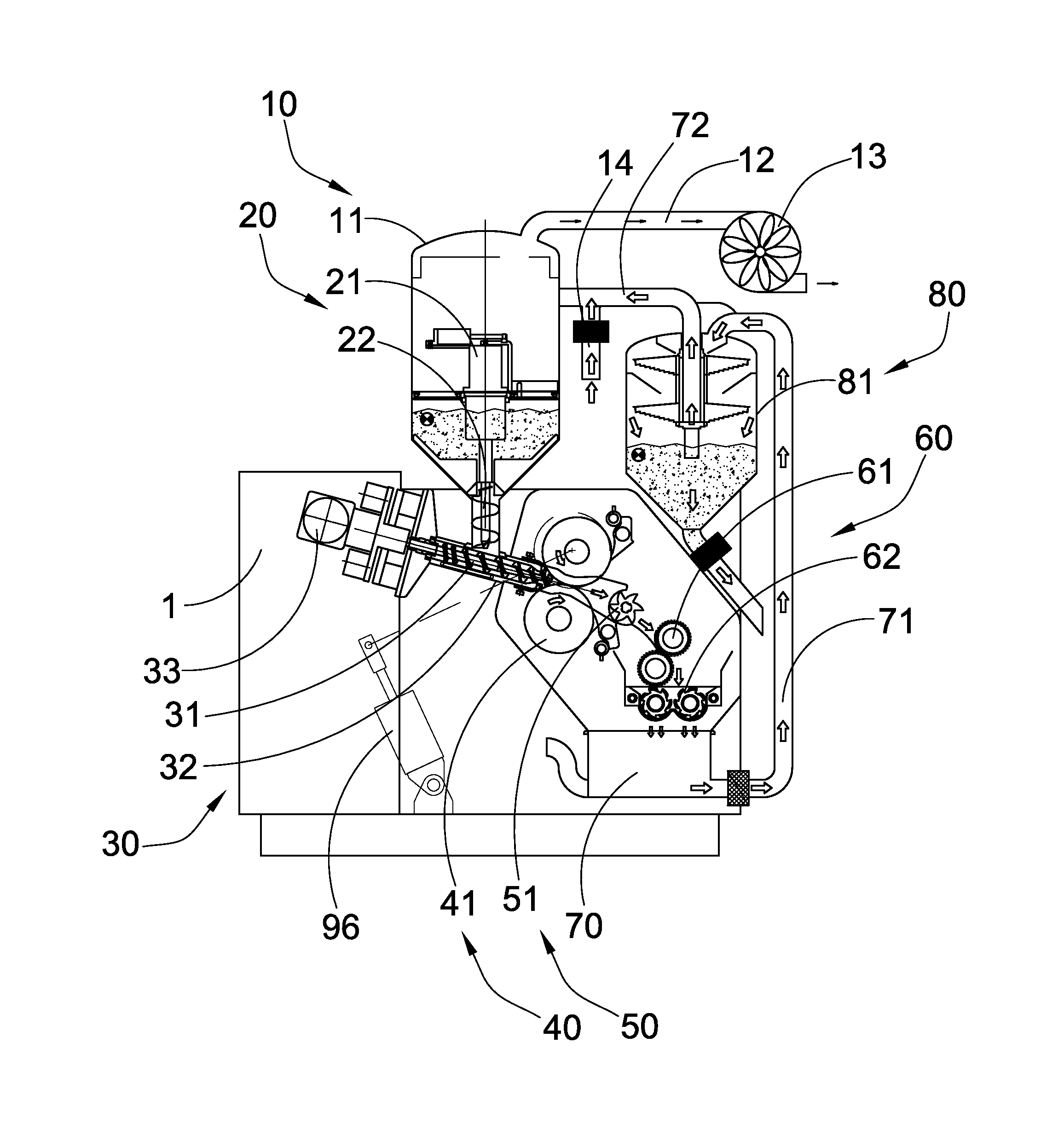

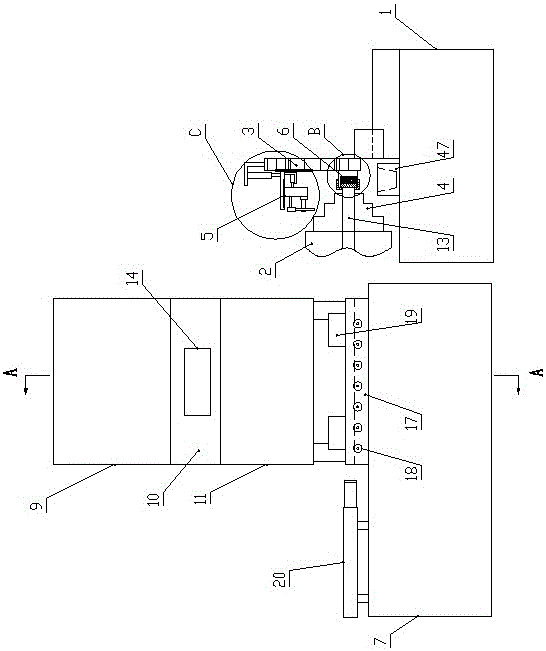

Dry Granulator

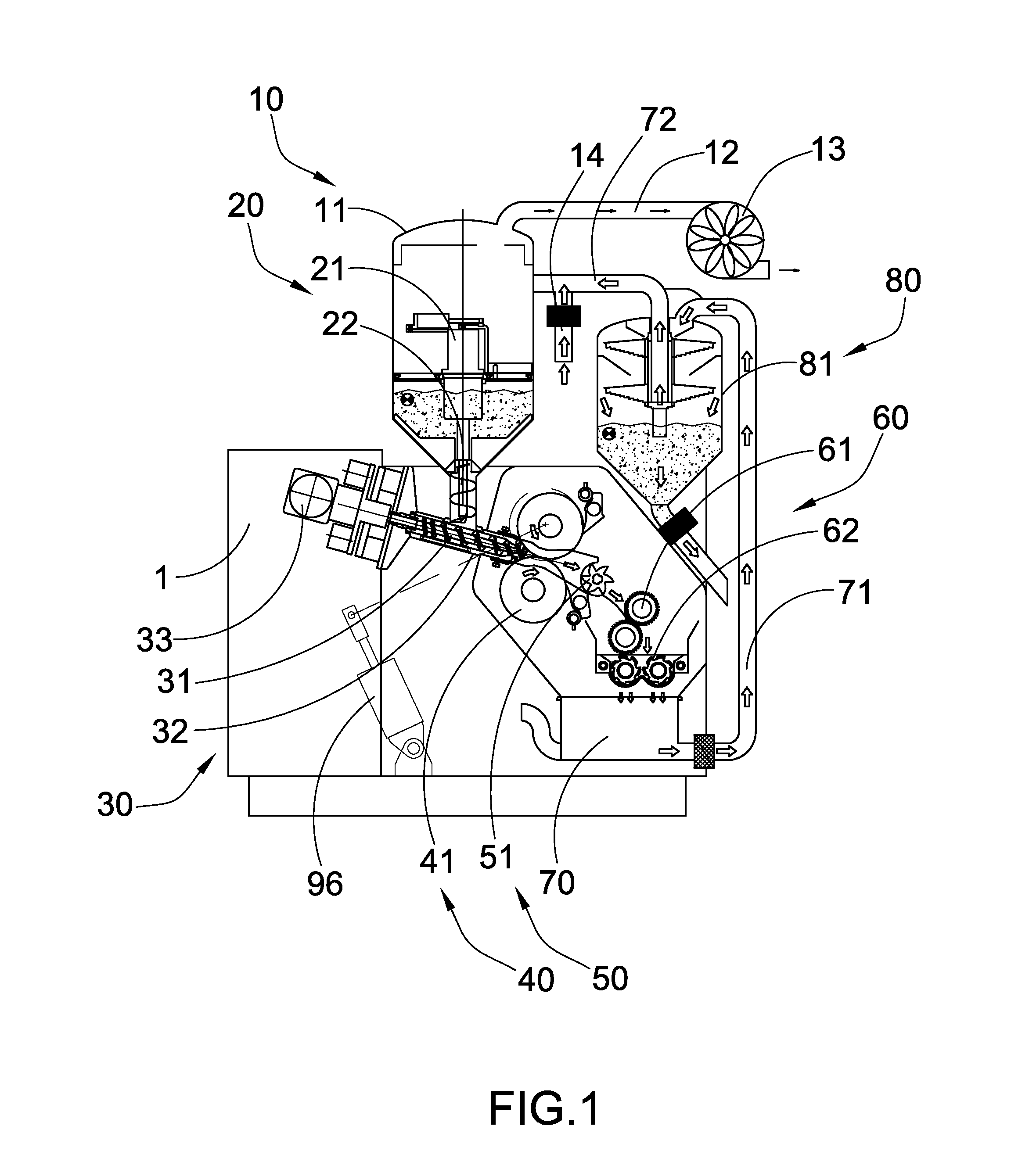

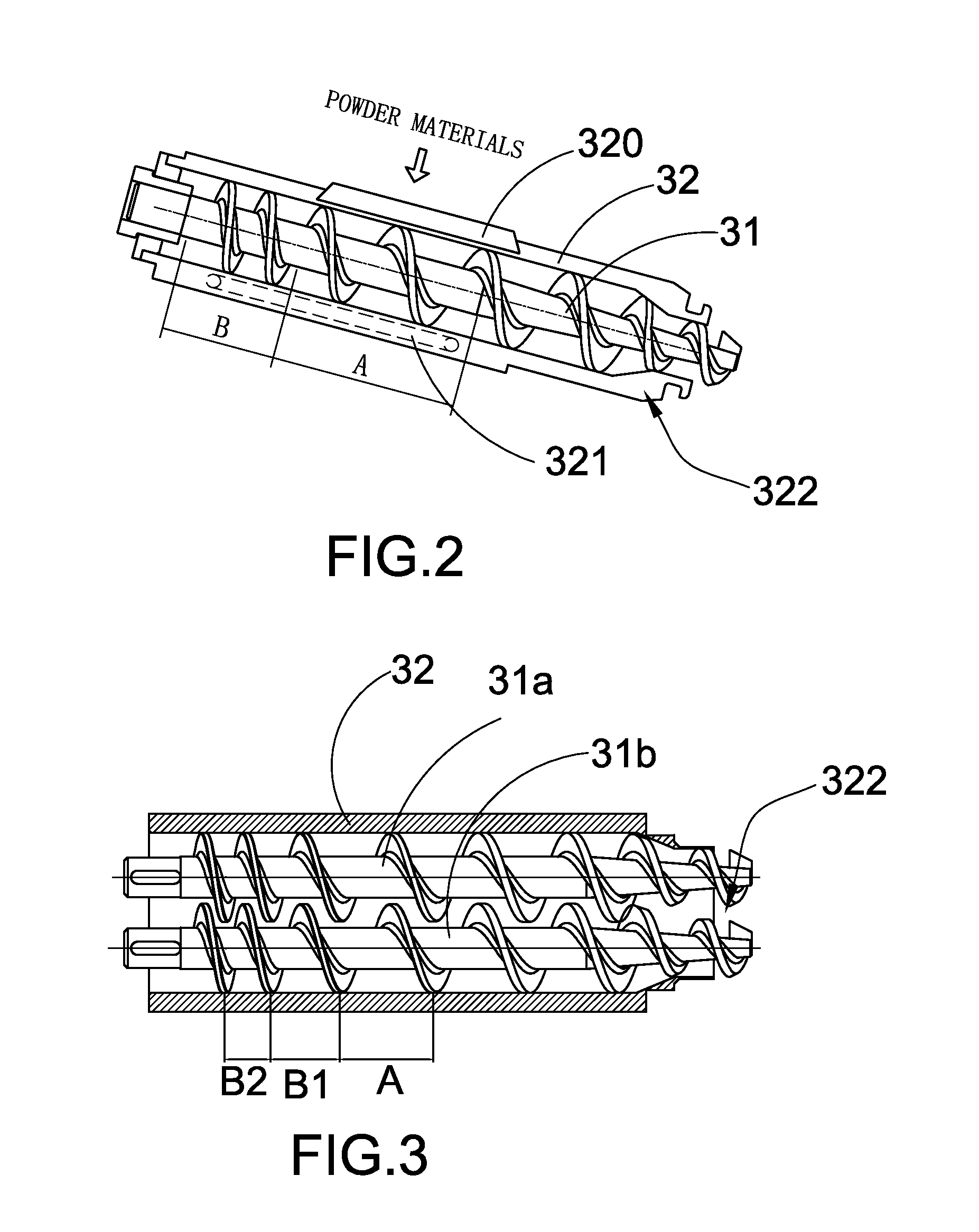

ActiveUS20150239152A1Compact structureImprove sealingDough homogenizationFrozen sweetsHardnessMaterials science

A dry granulator includes a feeding mechanism applied to suck powder materials into the material tanks; a vertical feeding mechanism to deliver the power materials to a bottom outlet of the material tank; a pressing mechanism to compress the powder materials into powder sheets with qualified hardness and thickness; an oblique feeding mechanism to deliver the powder materials to from the vertical feeding mechanism to the pressing mechanism; a crushing mechanism to crush the powder sheets into crushed powder sheets; a granulating mechanism to granulate the crushed powder sheet into finished particles products, so as to deliver to a collection storage; a sieving mechanism to separate the finished particle products with fine powders; a pressing wheel regulator applied to adjust an axial position of the lower and the upper pressing wheel; and a floating sealing device applied to provide a reliable sealing effect for the feeding mechanism.

Owner:ZHEJIANG FUTURE MACHINERY

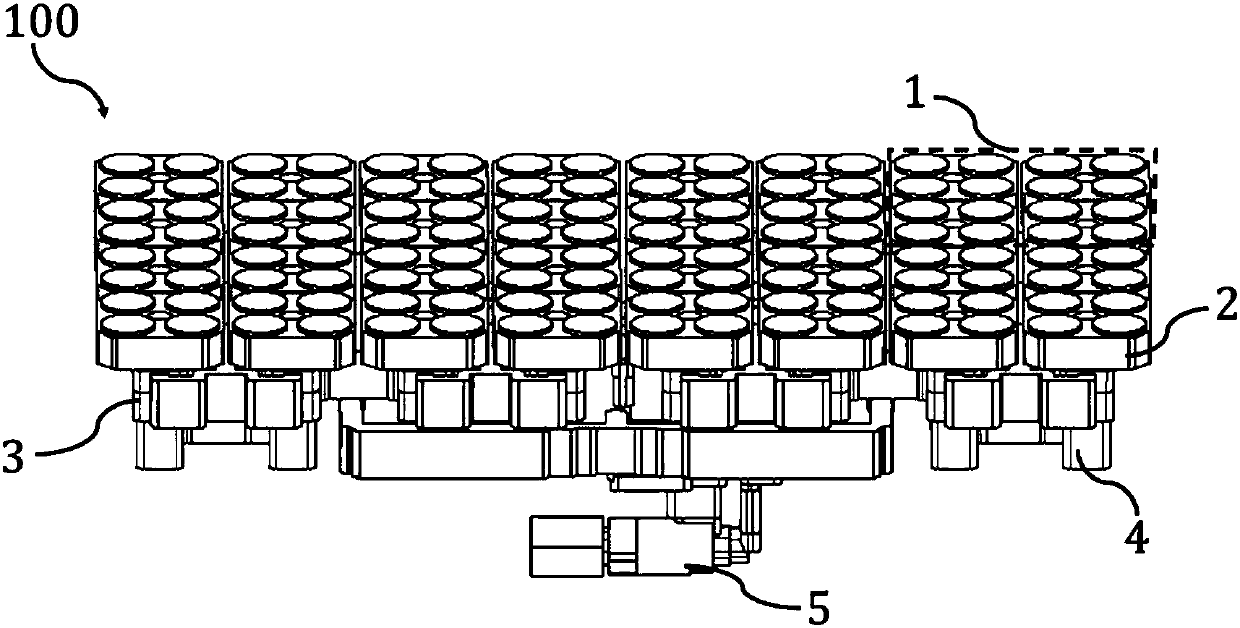

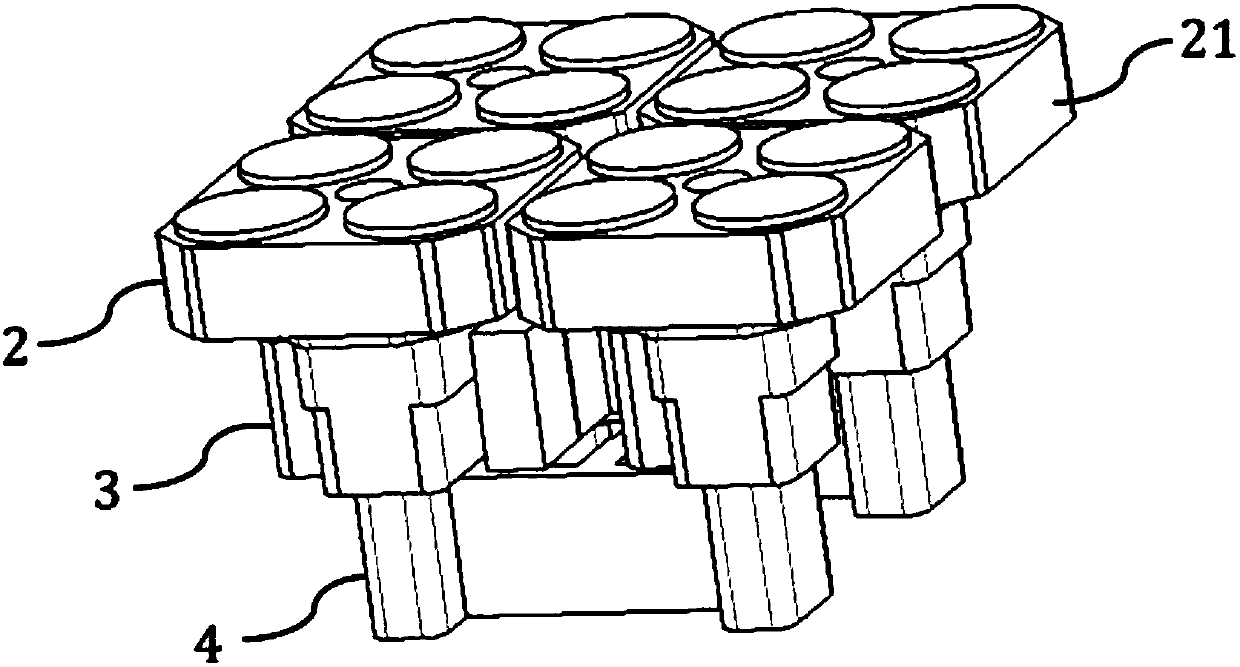

Dual polarization transmit-receive waveguide array antenna

InactiveCN107871935AWorking bandwidthRealization of shared sending and receivingPolarised antenna unit combinationsSpace fed arraysBroadbandOptoelectronics

The invention relates to the field of communication and measurement control and especially relates to a dual polarization transmit-receive waveguide array antenna. The polarization transmit-receive waveguide array antenna includes N broadband dual polarization antenna sub arrays and a polarization adjusting device. Each broadband dual polarization antenna sub array includes a dual polarization opening waveguide array radiation layer and a network feed layer, wherein the dual polarization opening waveguide array radiation layer is arranged above the network feed layer and the polarization adjusting device is arranged below the network feed layer. By adopting the waveguide grid structure for feeding a plate satellite antenna, the working bandwidth of the plate satellite antenna is enlarged,share of transmit-receive of antenna opening and face is realized, radiation grating lobe is reduced and an interface is provided for automatic adjustment of electromagnetic wave polarization direction.

Owner:NANJING CLEANWAVE COMM TECH

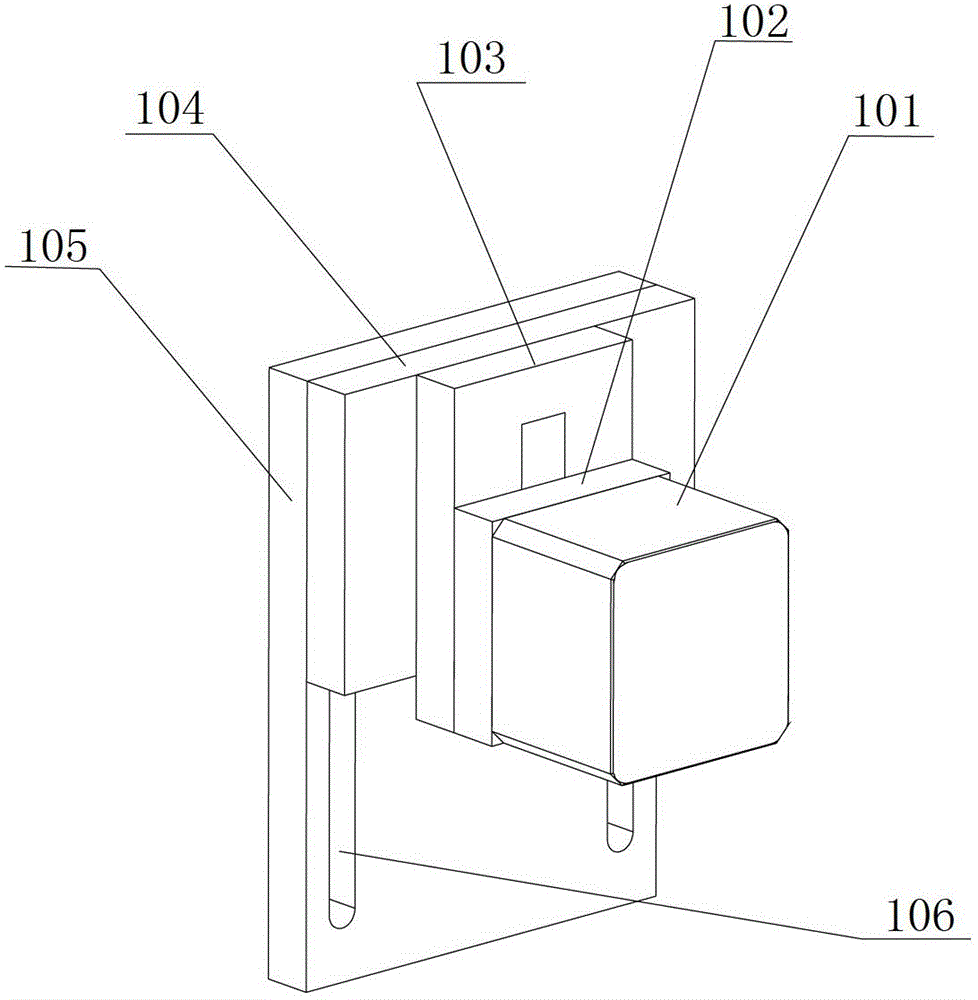

Automatic pin inserting machine for transformer frameworks

The invention relates to the technical field of automatic pin inserting machines, in particular to an automatic pin inserting machine for transformer frameworks. The automatic pin inserting machine comprises a rack, wherein a vibrating feeding device and a pin inserting device are installed on the rack, a discharge hole of the vibrating feeding device is connected with a feeding hole of the pin inserting device through a feeding tube, the pin inserting device comprises a pin inserting block, pin feeding drums, pin feeding cylinders, pin ejecting cylinders, pin nozzles, a downstream cylinder and a downstream linear guide rail, a feeding channel is internally provided with feeding blocks for pushing pins from one side to the other side, a pin ejecting channel is internally provided with pushing rods for pressing the pins pushed by the feeding blocks down to the pin nozzles. When the automatic pin inserting machine works, the vibrating feeding device can send pins to the pin inserting device constantly and rapidly through the feeding tube, the feeding efficiency is high, the pins are not damaged, and the pin inserting quality is guaranteed. The pin nozzles assist in pressing directionally, so that the pins cannot deviate in the pressing process, and the pin inserting of the machine is very precise.

Owner:GANZHOU HEYING AUTO PARTS +1

Body-immunity-enhancing composite Chinese herbal medicine pig feed additive and preparation method thereof

ActiveCN102894207AReduce usageImprove feed utilization efficiencyAnimal feeding stuffAccessory food factorsArray data structureAnimal science

The invention discloses a body-immunity-enhancing composite Chinese herbal medicine pig feed additive and a preparation method thereof. The invention belongs to the field of pig feed additive. The invention provides a technical scheme that the pig feed additive is composed of, by weight: 10-15 parts of eucommia leaf powder, 5-10 parts of echinacea powder, 8-15 parts of wormwood powder, 10-20 parts of purslane powder, 8-15 parts of pine needle powder, 3-6 parts of selenium yeast, 5-8 parts of cellulase, 10-20 parts of a Chinese herbal medicine preparation, 10-15 parts of a bacillus subtilis CGMCC6012 preparation, and 10-25 parts of medicated diet fungi. The preparation method comprises the step that the above materials prepared with a lyophilizing method are well mixed, such that the additive is prepared. According to the invention, through scientific compounding of the natural materials, problems of low animal immunities, excessive antibiotic dosage, and product quality reduction existing in current feed breeding are effectively solved.

Owner:GUANGNAN ZHANJIANG JIAFENG FEED

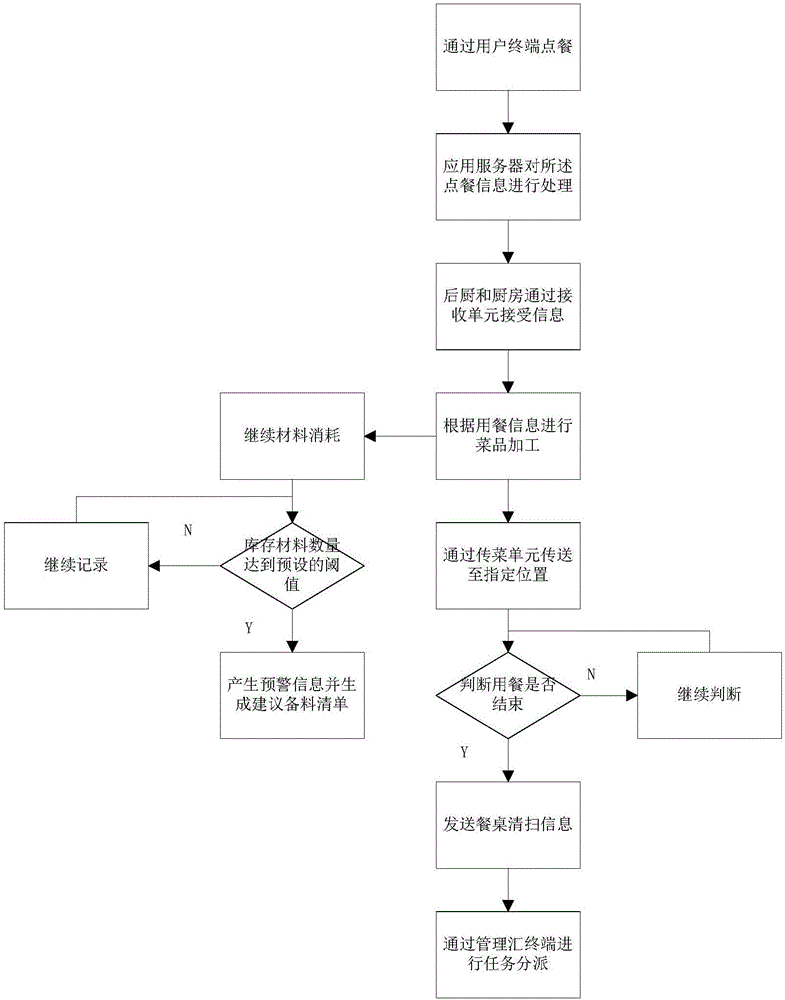

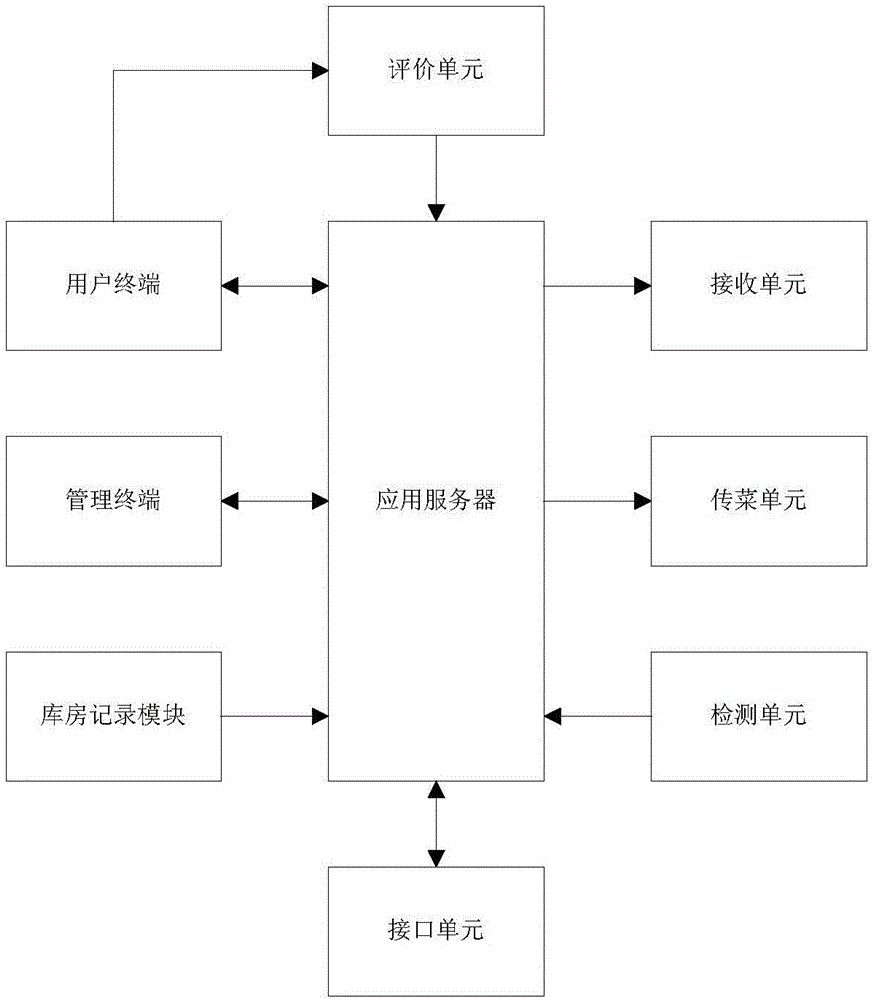

Intelligent restaurant management method and system

InactiveCN106529822AIncrease the number of dinersIncrease incomeResourcesApplication serverApproaches of management

The invention relates to an intelligent restaurant management method and system. The method includes the following steps: food ordering information of a user is transmitted to an application server through a user terminal, and the food ordering information at least includes selected dish information, remark information, dining time and a dining position; and the application server processes the food ordering information, sends processed food ordering information to a receiving unit, and a kitchen and a storehouse complete dish processing according to received information of the receiving unit, and dishes are transferred to the designated position in the food ordering information through a dish transfer unit. The intelligent restaurant management method provided by the invention can provide services such as self-service food ordering and settlement for users, avoids the circumstances of ordering errors and delivery errors caused by human factors, improves the degree of satisfaction of users, and enhances competitiveness of an enterprise.

Owner:赵云龙

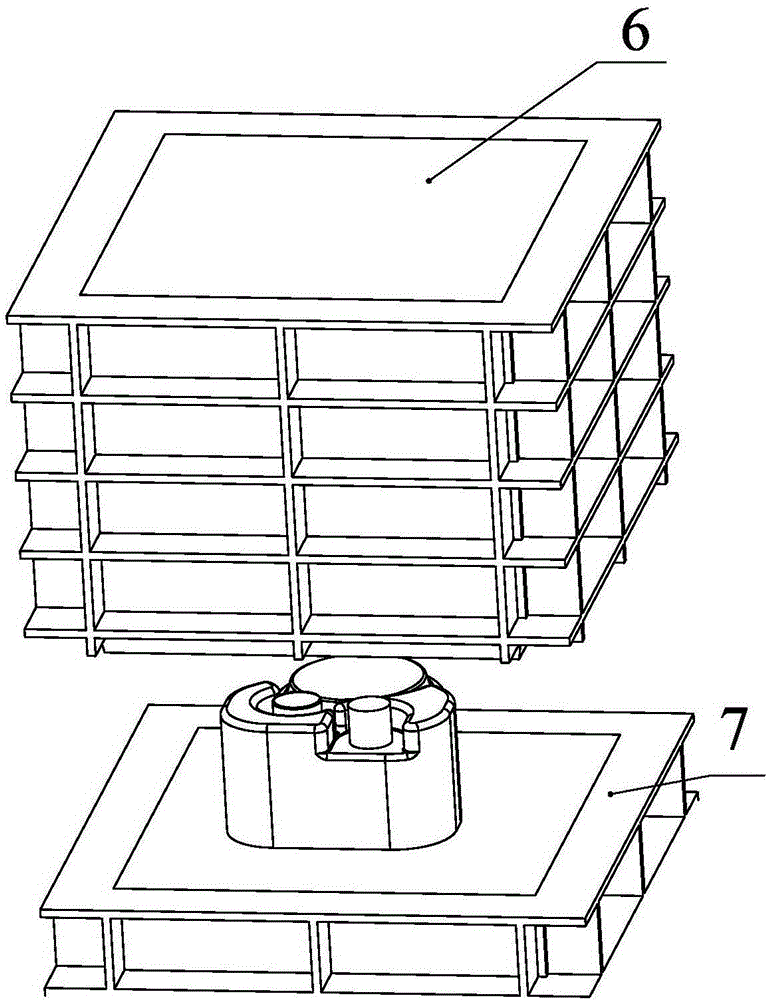

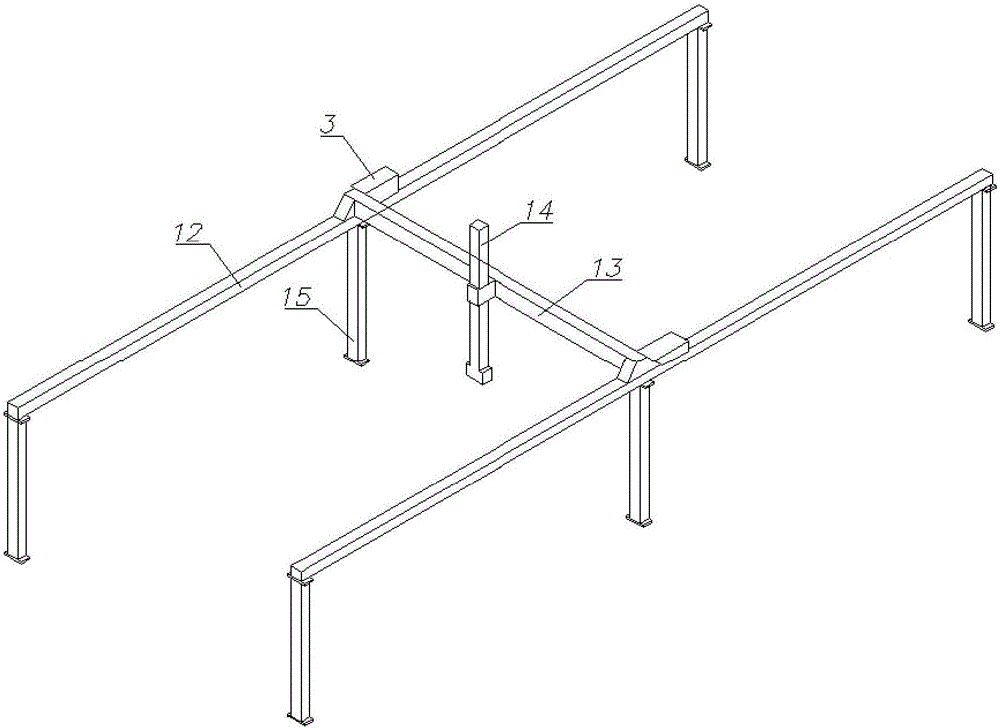

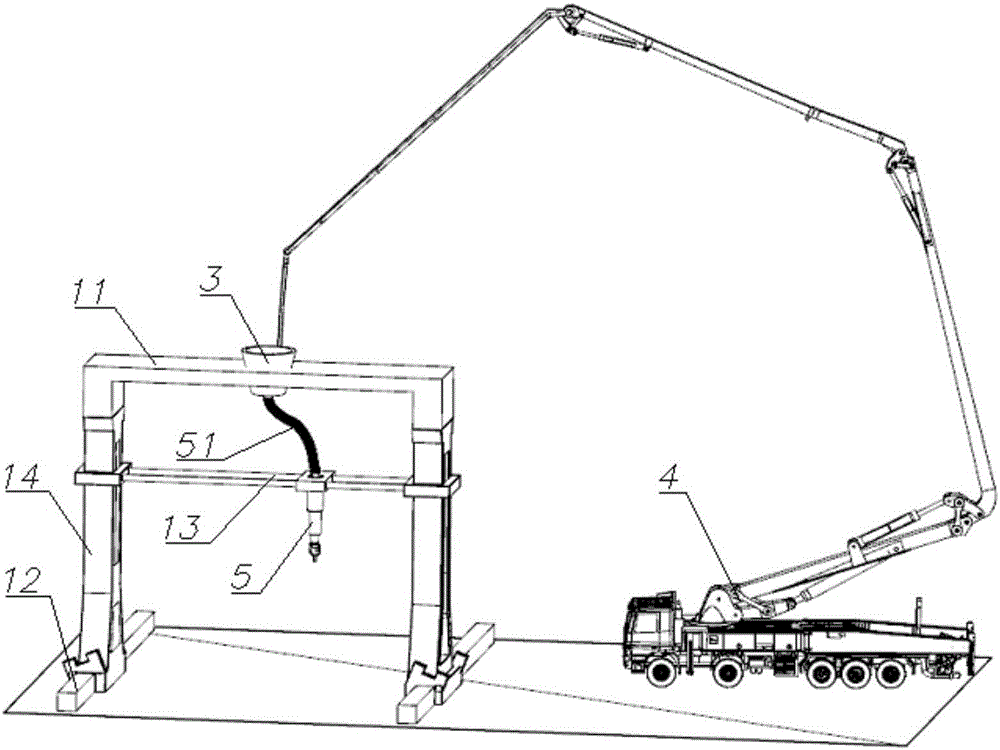

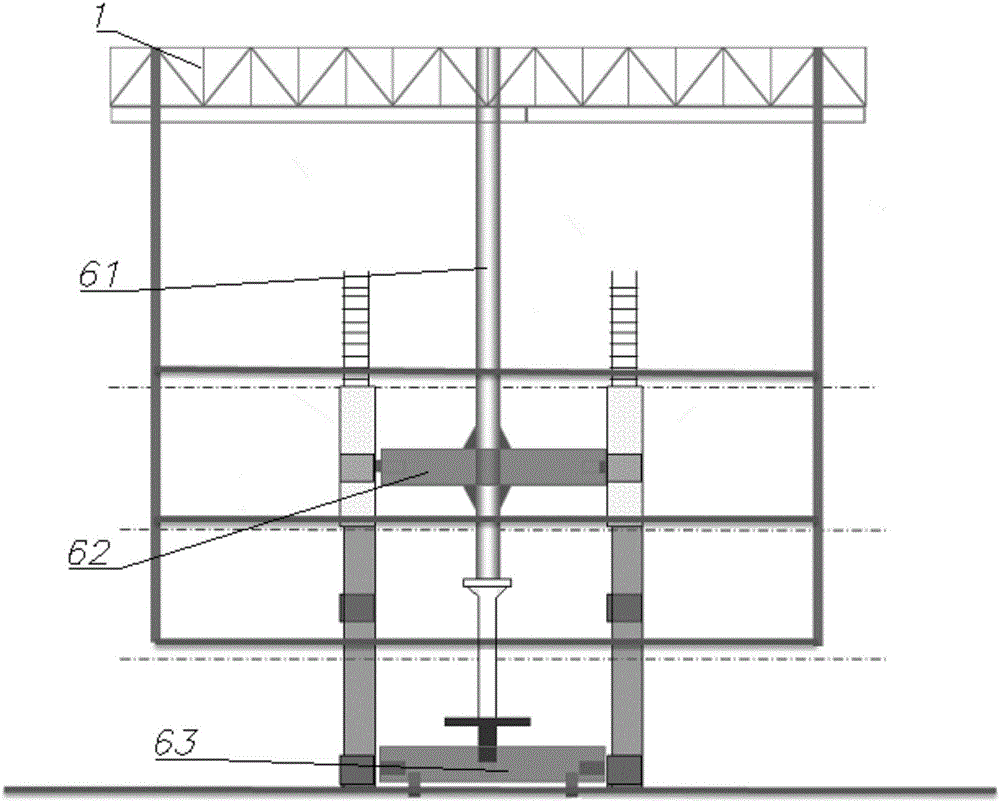

Feeding system for building contour forming

PendingCN106639324AEasy to shapeImprove feeding efficiencyAdditive manufacturing apparatusBuilding material handlingGranularityEngineering

A feeding system for building contour forming comprises a moving supporting platform, an intermediate bunker and a three-dimensional building printing spraying head arranged on the moving supporting platform. The intermediate bunker is arranged on the moving supporting platform and is connected with the three-dimensional building printing spraying head through a feeding pipeline; the intermediate bunker can connect with a traditional pump truck for feeding; and stirred concrete raw materials on the ground are conveyed to the intermediate bunker through a pump machine, and then the materials are supplied to the three-dimensional building printing spraying head through the intermediate bunker. The feeding pipeline just needs to be arranged between the intermediate bunker and the three-dimensional building printing spraying head, the length of the feeding pipeline can be reduced, and the probability of feeding pipeline blocking is reduced. When raw materials with different granularity are conveyed, due to buffering through the intermediate bunker, the raw materials can be selected in wider ranges to be used, and the efficiency of material supplying to the three-dimensional building printing spraying head can be improved.

Owner:BUILDERA CONSTR TECH SHANGHAI CO LTD

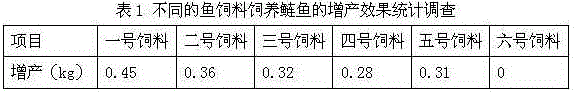

Swelling granular mixed feed for adult pelteobagrus fulvidraco

ActiveCN101579066AGuaranteed normal growthReduce pollutionClimate change adaptationAnimal feeding stuffAdult stageFish oil

The invention discloses a swelling granular mixed feed for adult pelteobagrus fulvidraco, relating to the field of pelteobagrus fulvidraco feed. The feed is suitable for feeding the pelteobagrus fulvidraco in adult stage (namely the pelteobagrus fulvidraco in the adult stage with the weight of more than 20g); the feed is a mixture prepared by all raw materials according to the processing method of swelling granular feeds; according to the weight percentage, the feed comprises the following raw materials of: 36-40% of fish meal, 15.58-19.6% of flour, 3.5-4% of cottonseed meal, 16-20% of soybean meal, 6-7% of maize protamine, 4.5-5.5% of fish oil, 6-7% of beer yeast, 1-1.5% of mineral matters, 0.5-0.6% of choline chloride and 0.2% of multivitamin. Compared with normal mixed feed, the swelling granular mixed feed has the advantages of comprehensive nutrition, high livability, little pollution on culture water, greenness, and no public nuisance.

Owner:福建天马饲料有限公司

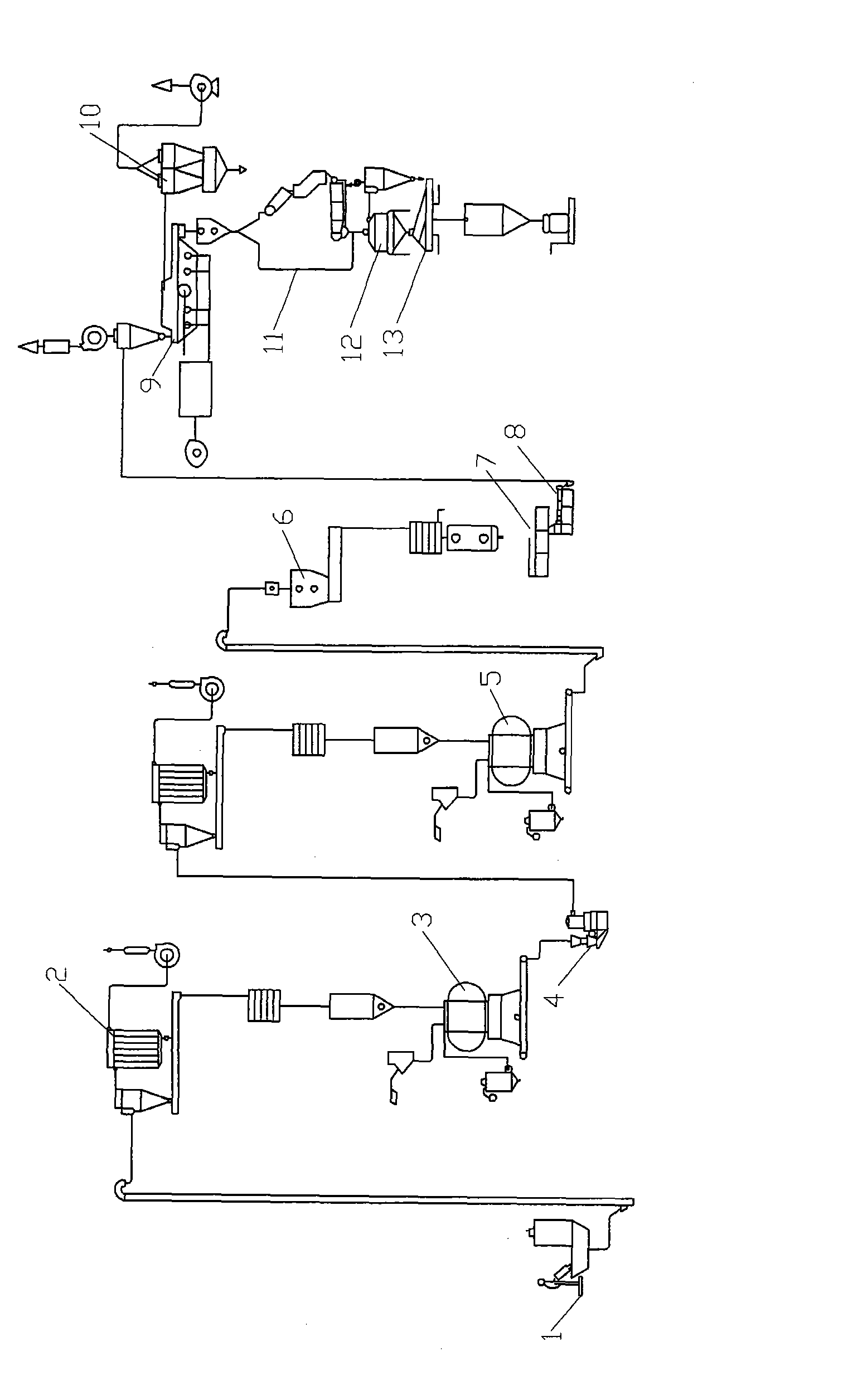

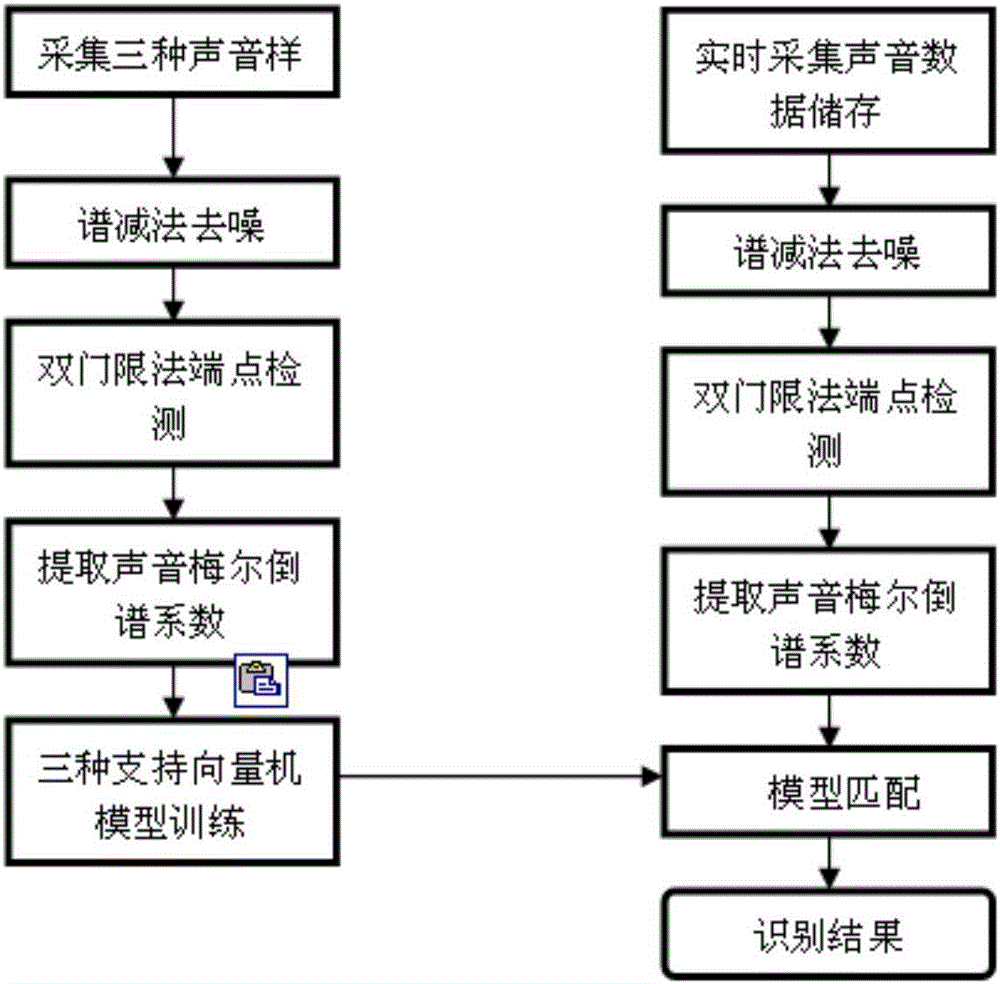

Porcine respiratory disease automatic recognition alarming method

InactiveCN106847262AMonitor health status remotelyImprove feeding efficiencyRespiratory organ evaluationSpeech recognitionSupport vector machineRespirator

The invention discloses a porcine respiratory disease automatic recognition alarming method. The method comprises two steps of constructing a support vector machine model of pig's cough sound and a disease a pig suffering from, collecting the pig's cough sound and recognizing signals. According to the porcine respiratory disease automatic recognition alarming method, pigs' cough sound signals are collected and analyzed through the support vector machine model, the automatic recognition and alarming for a porcine respirator disease are achieved, the pig's health condition can be remotely monitored at an appropriate time, a great number of human and material resources for porcine respiratory disease detection are saved, and the feeding efficiency of pigs is improved.

Owner:HUAZHONG AGRI UNIV

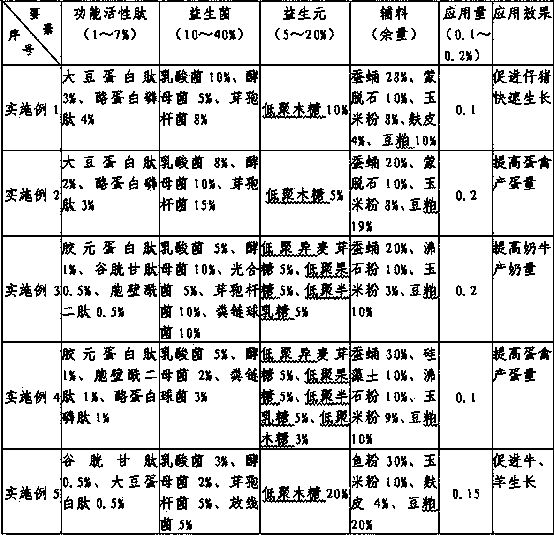

Compound type biological active peptide product for livestock and poultry and application thereof

InactiveCN103636945AWell mixedNo drug residue problemAnimal feeding stuffBiotechnologyIsomaltooligosaccharide

The invention discloses a compound type biological active peptide product for livestock and poultry, which is formed by mixing the following components in percent by mass: 1%-7% of functional active peptide, 10%-40% of probiotics, 5%-20% of prebiotics, and the balance of auxiliary materials, wherein the functional peptide is one or a combination of several of collagen peptide, glutathione, muramyl dipeptide, soybean protein peptide and casein phosphopeptide. The probiotics refers to one or a combination of several of lactic acid bacteria, saccharomycetes, photosynthetic bacteria, actinomycetes, bacillus and streptococcus faecalis. The prebiotics is one or a combination of several of isomalto-oligosaccharide, fructo-oligosaccharide, galactooligosaccharide and xylo-oligosaccharide. The auxiliary materials refer to one or a combination of several of silkworm chrysalis, fish meal, montmorillonite, diatomite, zeolite powder, corn flour, bran and bean pulp. Additive amount of the product accounts for 0.1%-0.2% of the amount of feed, and the feed can be directly fed after the product is added and uniformly mixed. The compound type biological active peptide product disclosed by the invention belongs to the micro-ecological technical product and is green and environment-friendly.

Owner:JIANGSU WEITAILONG BIOTECH

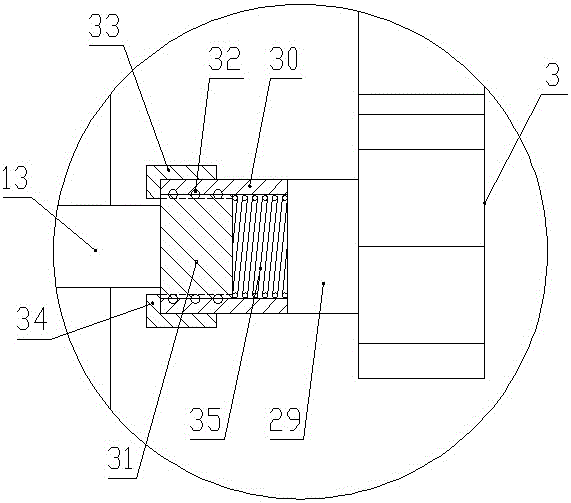

Finger-tenon combing machine of finger-joint material

ActiveCN103978527AConvenient continuous feedingEasy to tidyFinger joining apparatusGear driveFinger joint

The invention discloses a finger-tenon combing machine of a finger-joint material. The finger-tenon combing machine is characterized in that a movable sliding rail is arranged on a combing machine tool body; a pressing clamping plate is supported on a movable platform frame by a pressing cylinder; the pressing clamping plate and a feeding platform surface form a material clamping jaw for clamping wood materials to be combed; one side of the material clamping jaw is provided with a side pressing plate; the movable platform frame is also provided with a towing gear driven by a motor of a movable working platform; the towing gear is in meshed transmission with the towing gear; a tooth-tenon combing and milling device is also provided with an upper wire-groove saw blade and a lower wire-groove saw blade; the horizontal plane of a saw shaft for cutting the saw blades is positioned between the horizontal plane of a saw shaft of the upper wire-groove saw blade and the horizontal plane of a saw shaft of the lower wire-groove saw blade; the tooth-tenon combing and milling device is also provided with a neat-end control sensor; the movable clamping working platform is provided with a feeding control sensor. The finger-tenon combing machine disclosed by the invention has the advantages that the processing accuracy and the wood-material utilization rate are high, the processing quality of the surfaces of the wood materials is excellent, and the whole-machine operation efficiency is high.

Owner:JIANGSU JIANGJIA MACHINERY

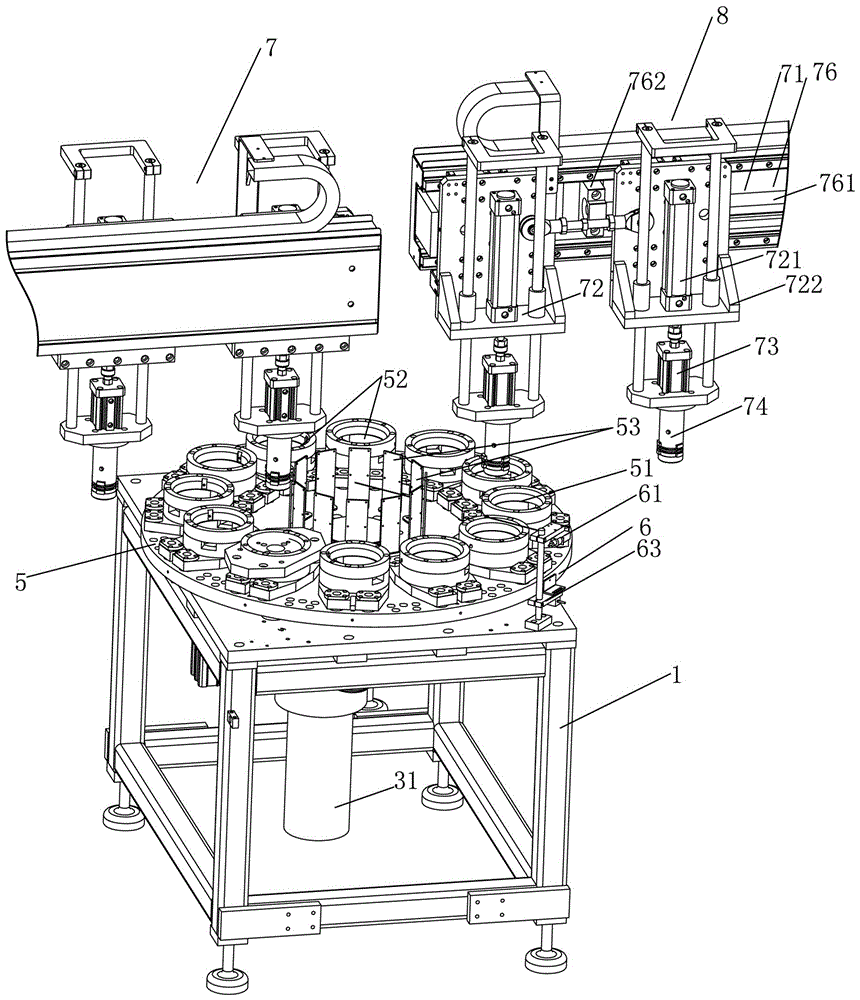

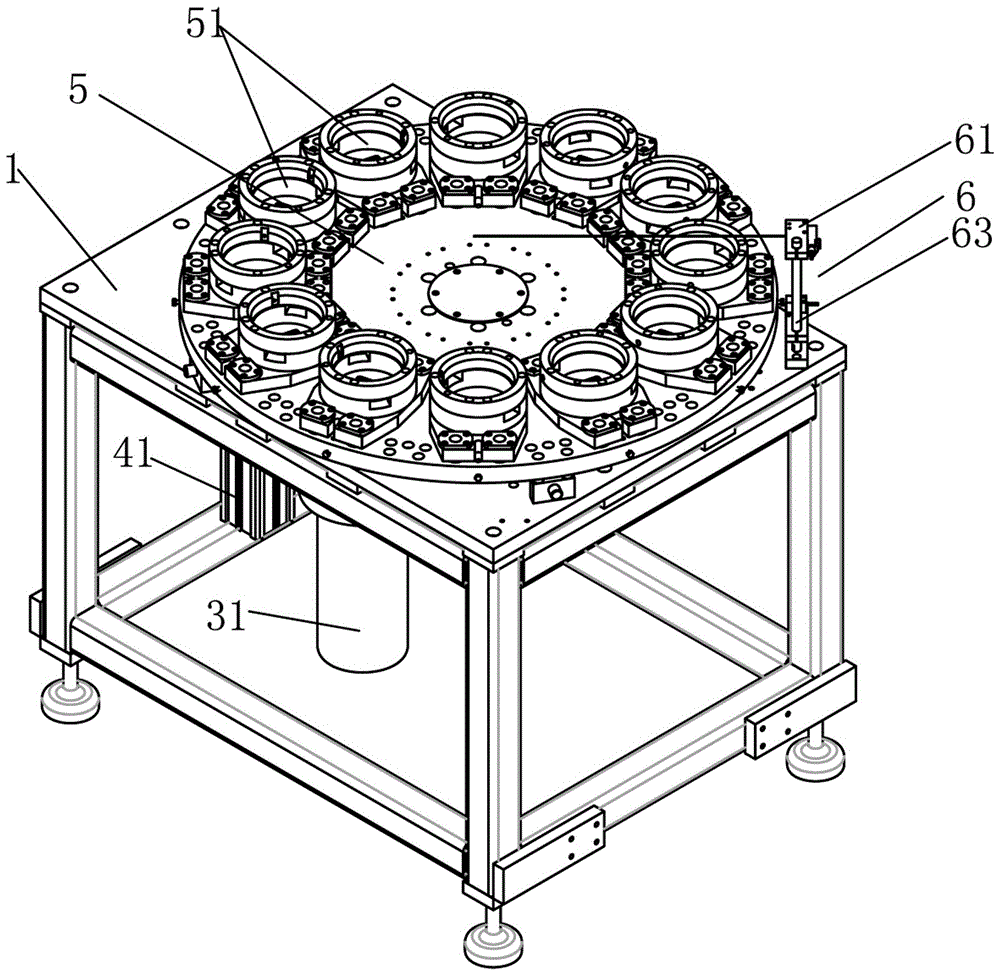

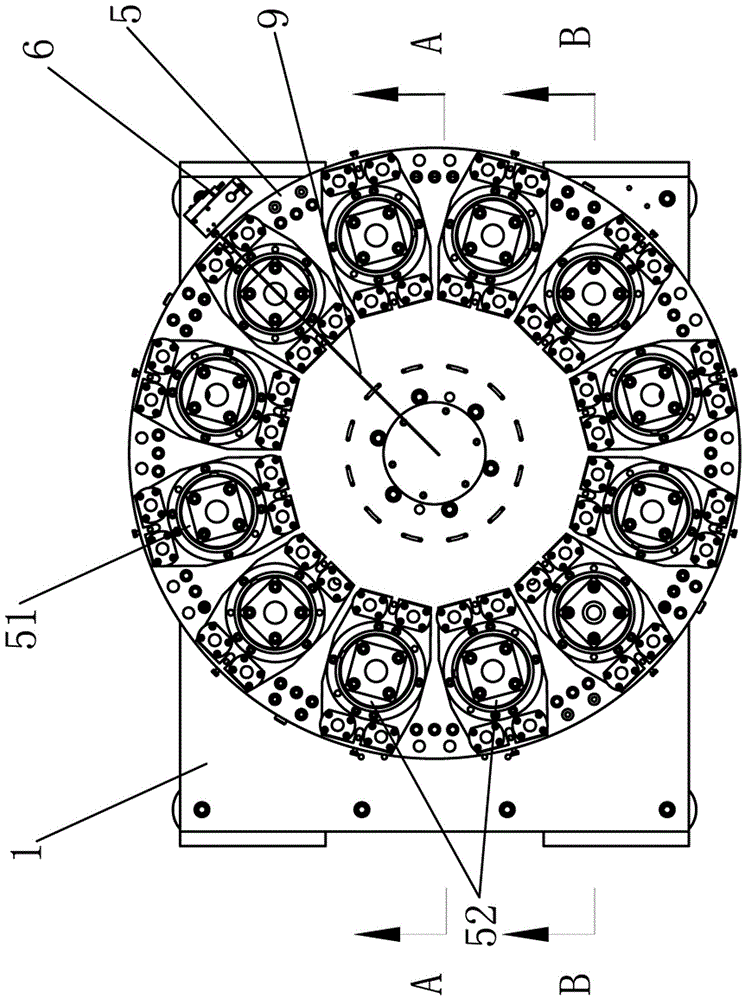

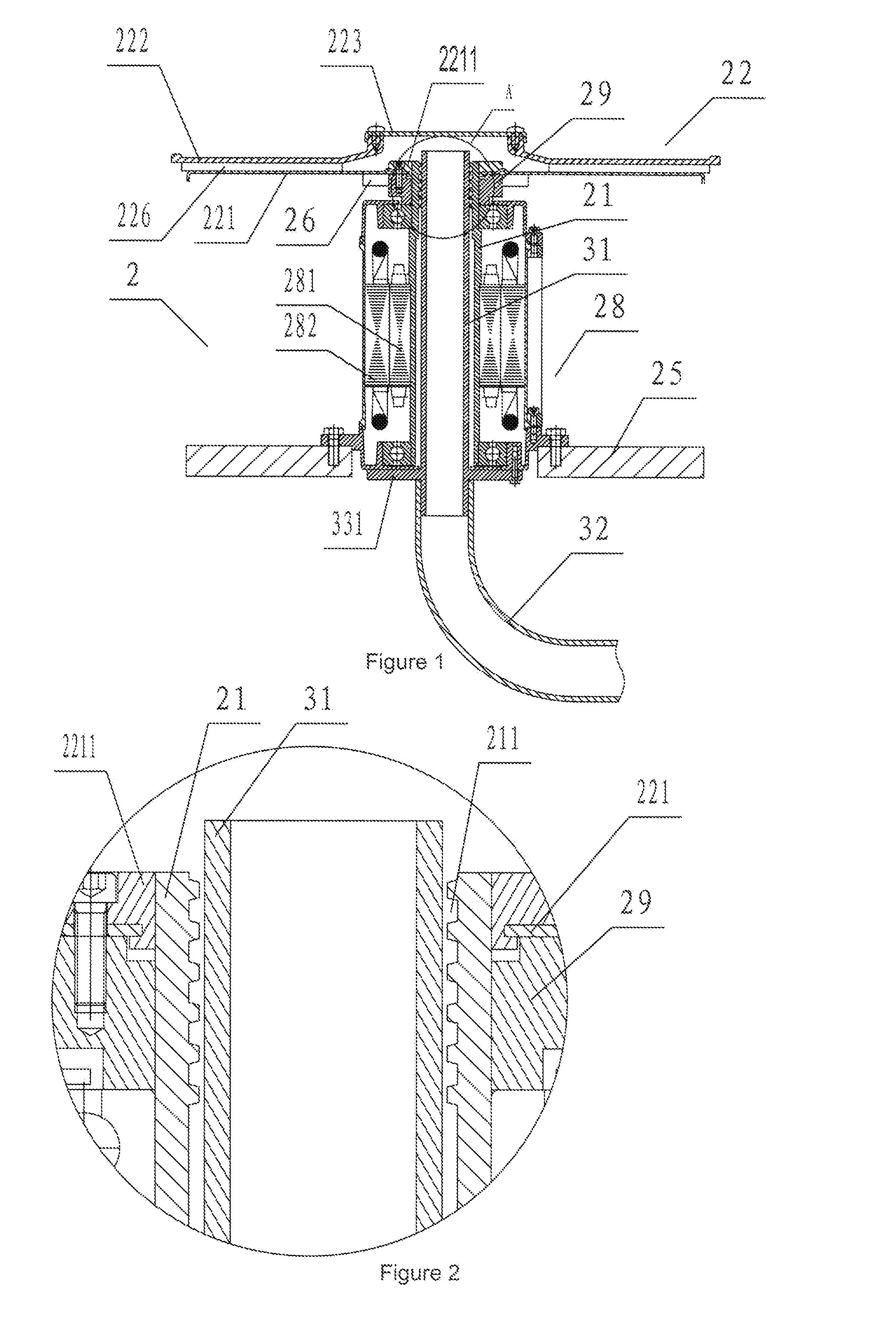

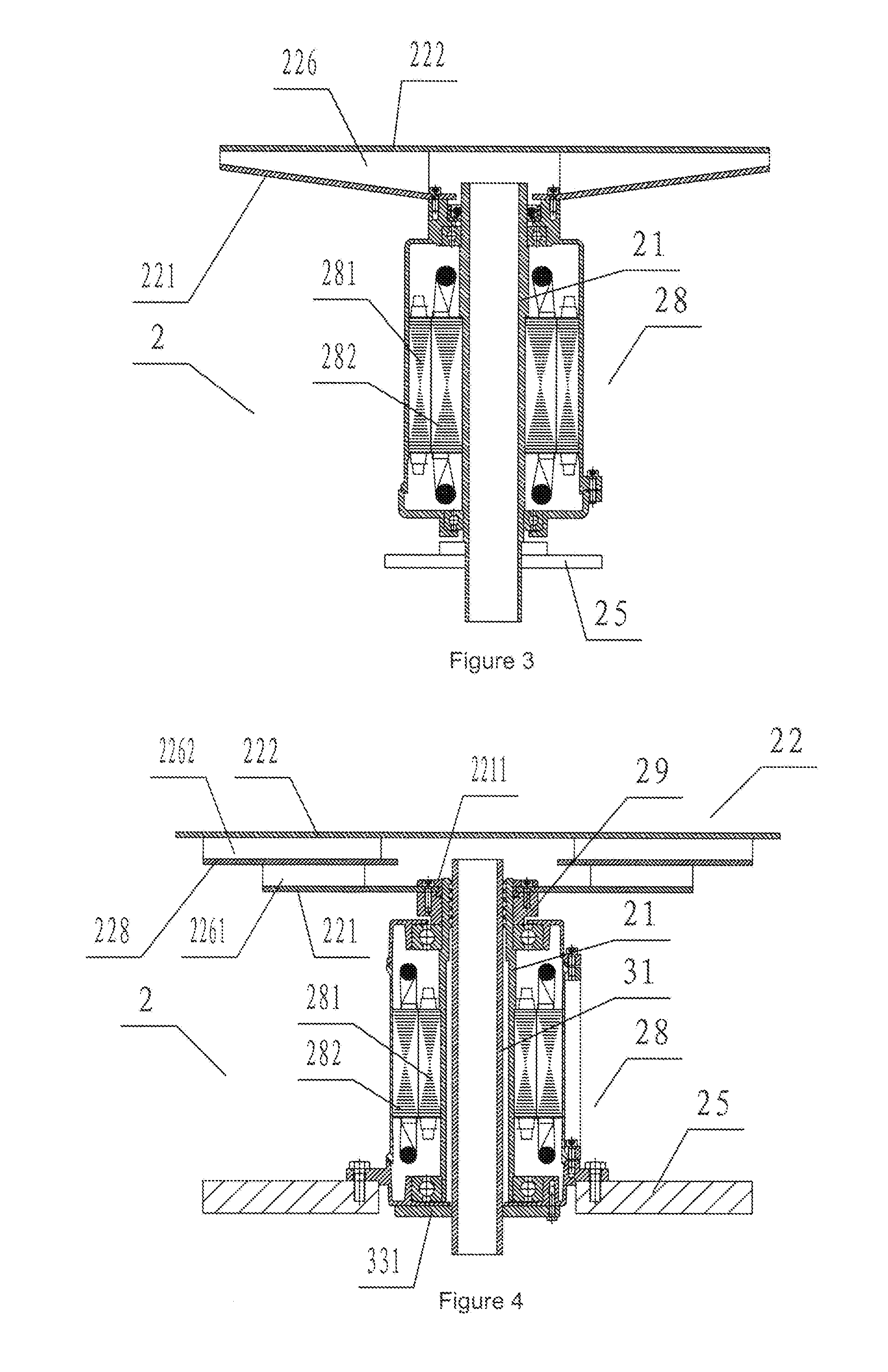

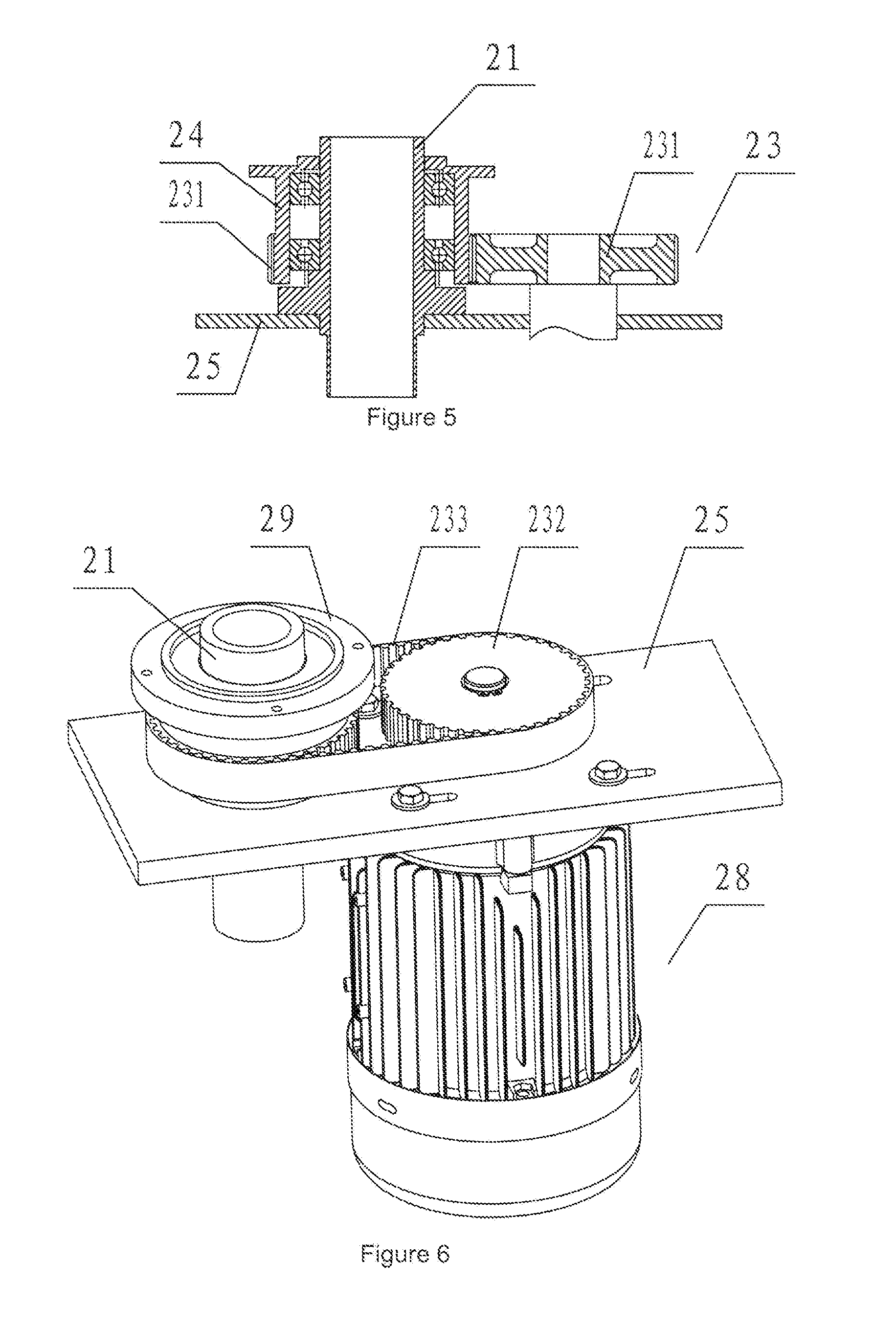

Rotating disc feeding device

PendingCN106628876AImprove feeding efficiencyImprove stabilityControl devices for conveyorsRotary conveyorsEngineeringRotating disc

The invention relates to a rotating disc feeding device. The rotating disc feeding device comprises an engine base, a control device, a feeding rotating disc, a rotating disc driving mechanism, a rotating disc positioning mechanism and left and right feeding arms. The feeding rotating disc is mounted on the engine base and used for conveying workpieces; the rotating disc driving mechanism is used for driving the feeding rotating disc to rotate; the rotating disc positioning mechanism is used for positioning the feeding rotating disc; the left and right feeding arms are used for grabbing and conveying workpieces on feeding tools. A material detection mechanism is used for detecting whether a workpiece is arranged on a feeding tool and convey a signal to the control device. The device further comprises a feeding tool in-place induction mechanism. According to the device disclosed by the invention, due to feeding rotating disc positioning and feeding, the material can be fed on one side of the rotating disc by a worker, the left and right feeding arms are arranged on the other side of the rotating disc for grabbing, and the feeding rotating disc is accurately positioned, so that the left and right feeding arms can conveniently grab the materials. The two left and right feeding arms are matched, so that double-station feeding is realized, the feeding efficiency is high, and the stability is high.

Owner:GUANGDONG SHUNDE SANHE IND AUTOMATION EQUIP CO LTD

Fleshy duck fodder and preparation method thereof

ActiveCN101720871ALow costIncrease production capacityAnimal feeding stuffCalcium biphosphateAnimal science

The invention discloses a fleshy duck fodder and a preparation method thereof. The fleshy duck fodder comprises the following components in parts by weight: 50 to 65 parts of corn, 12 to 25 parts of fine rice bran, 2.5 to 12 parts of cotton dregs, 2 to 12 parts of rapeseed meal, 1 to 6 parts of corn alcohol dregs, 0.5 to 2 parts of corn oil, 0.5 to 2 parts ns of rock powder, 0.2 to 1.5 parts of calcium phosphate secondary, 0.1 to 0.6 part of common salt, 0.2 to 0.8 part of lysine with the consistence of 65%, 0.05 to 0.25 part of methionine, 0.04 to 0.2 part of threonine, 0.01 to 0.1 part of tryptophan, 0.05 to 0.2 part of miscellaneous meal enzyme and 0.5 to 2 parts of premix compound. In the fodder, bean dregs are replaced by the cotton dregs and rapeseed meal, single amino acid and miscellaneous meal enzyme are added, the feed costs of fleshy ducks are greatly reduced, the feed effect to the fleshy ducks is better than the fodder with the bean dregs, the production performance of the fleshy ducks can be obviously enhanced, and the invention has the advantages of wide resources of raw materials, low production cost, high feed efficiency, and the like.

Owner:铁骑力士食品有限责任公司

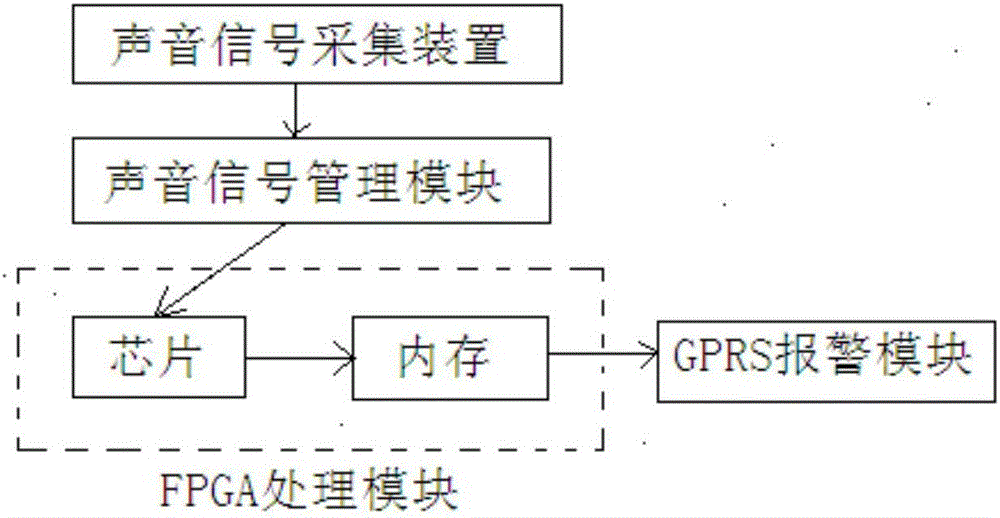

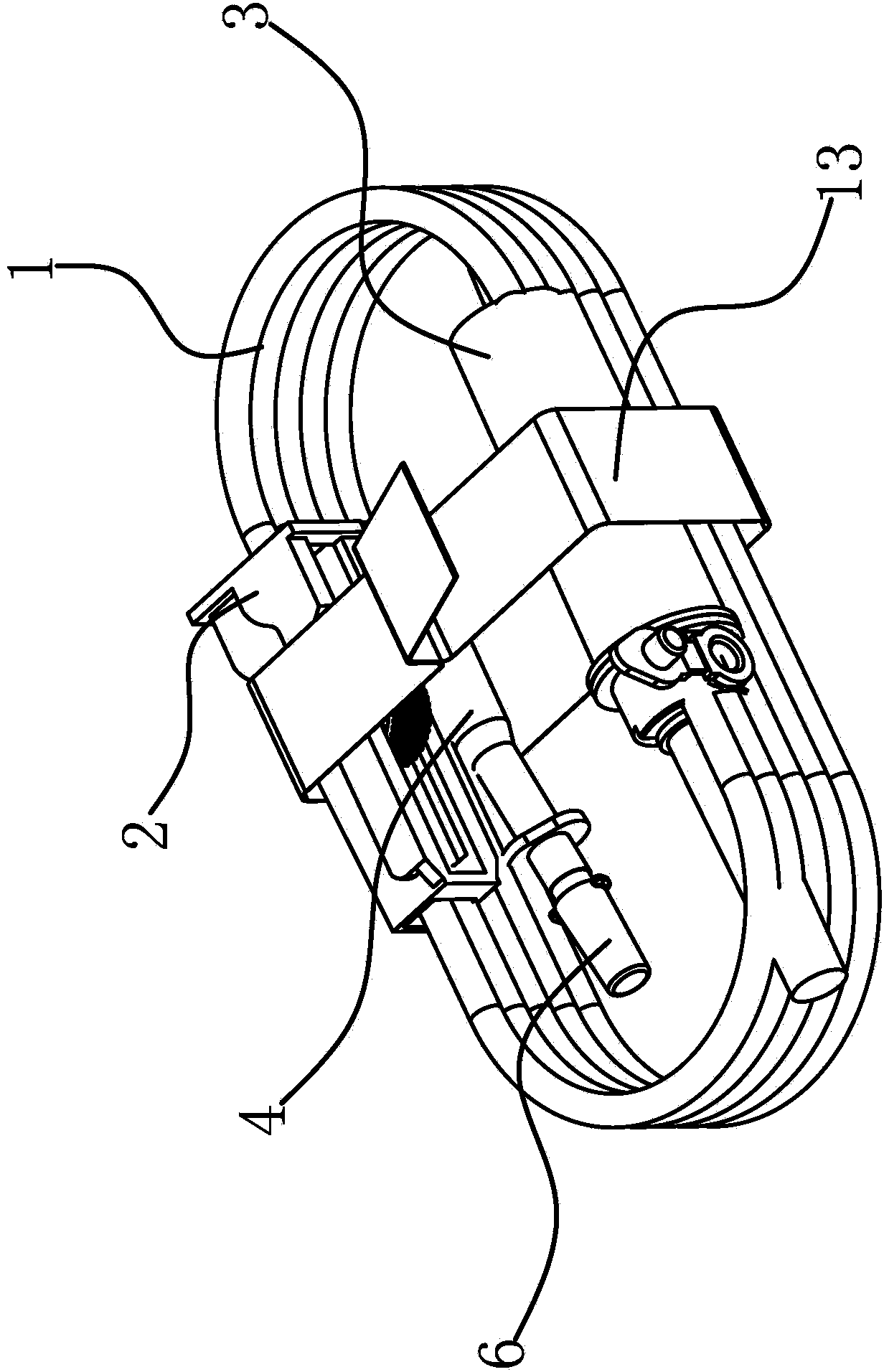

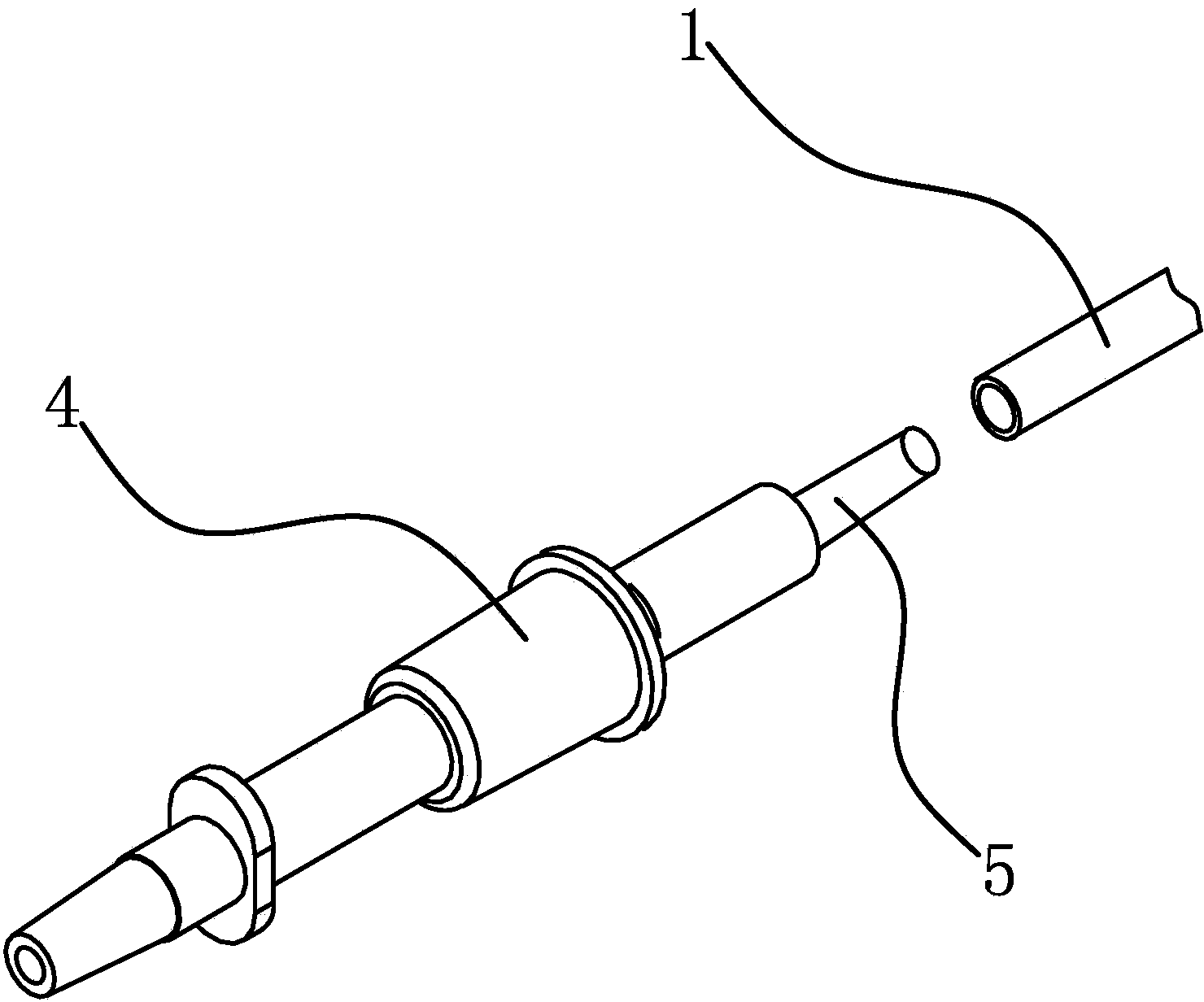

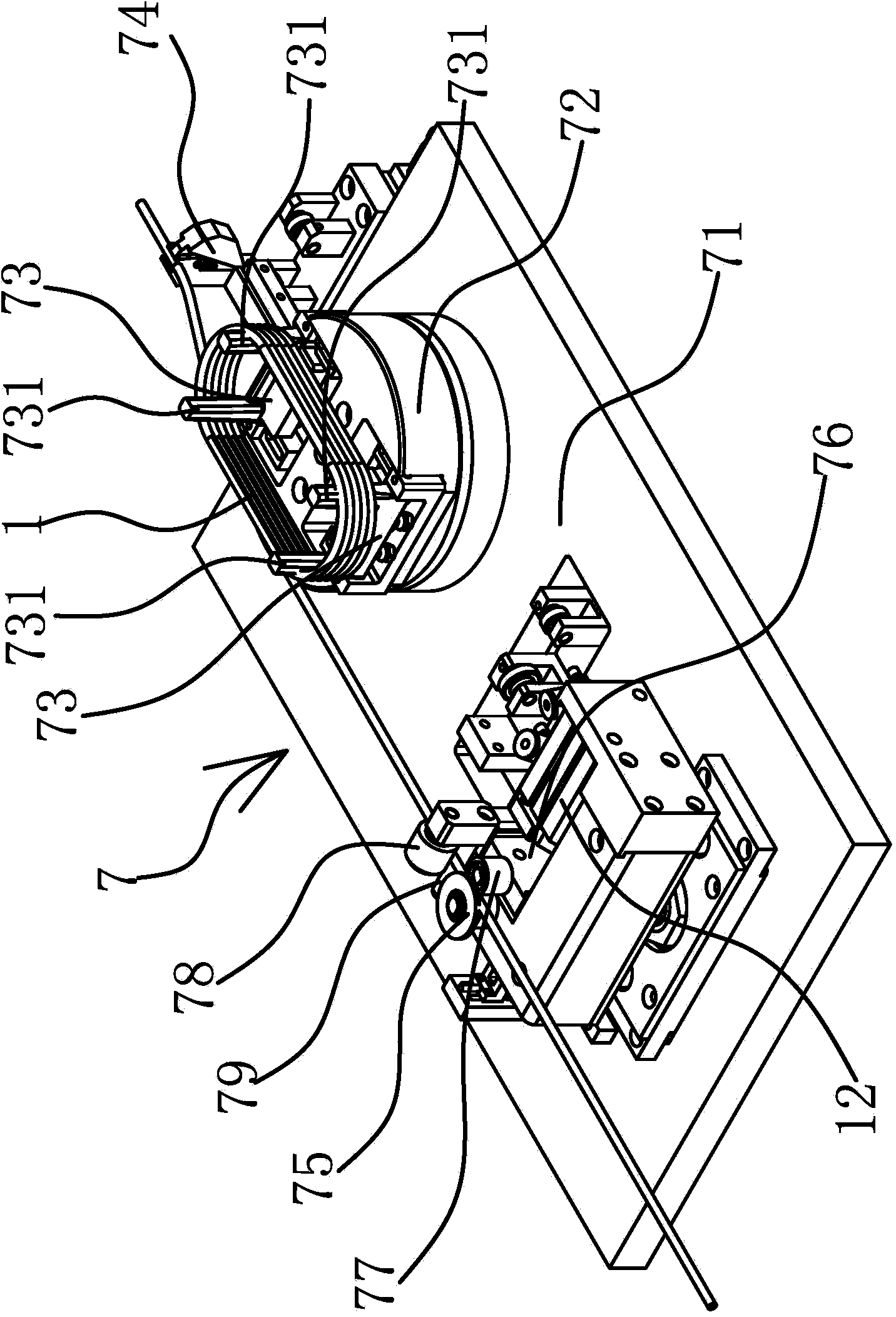

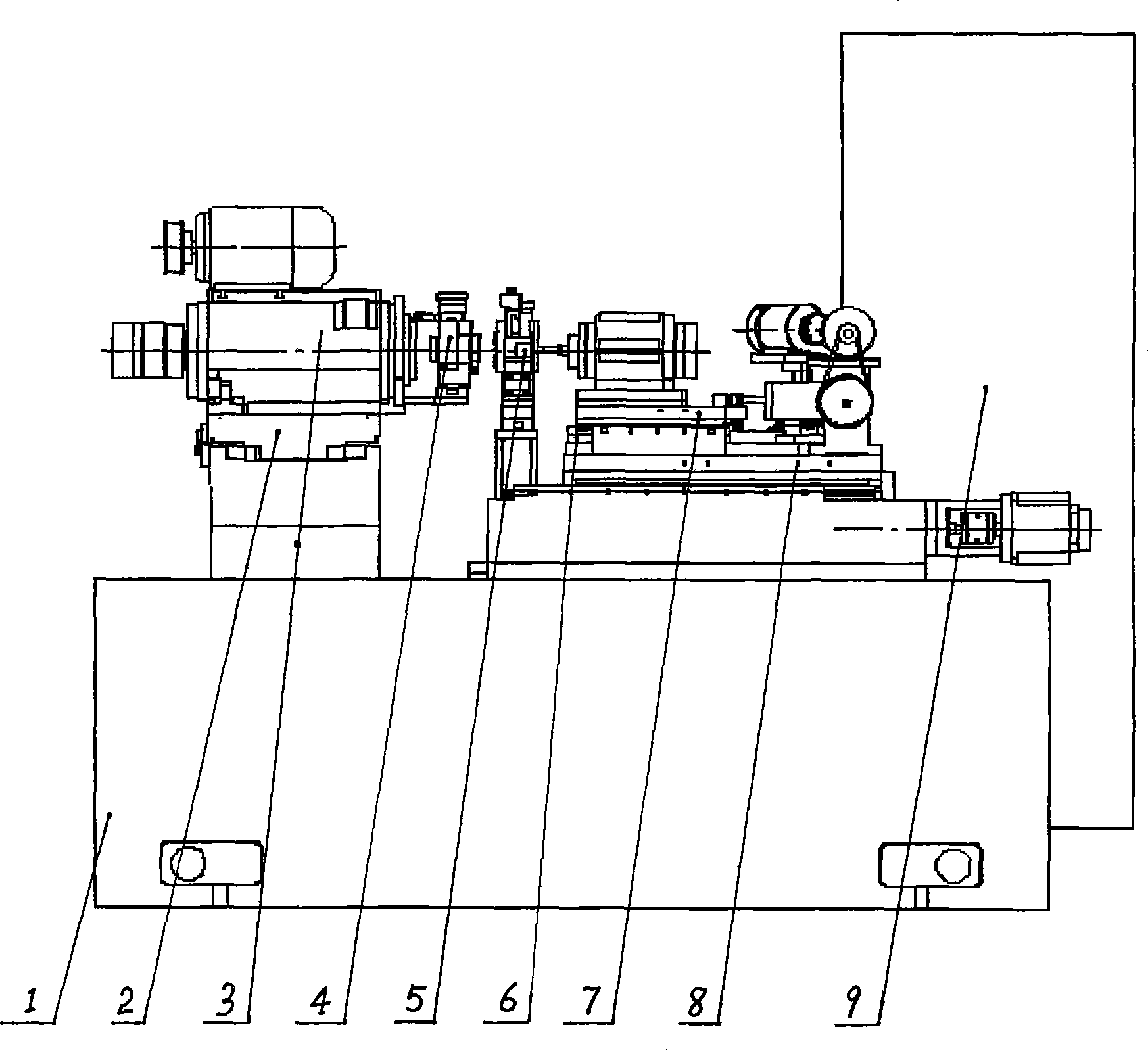

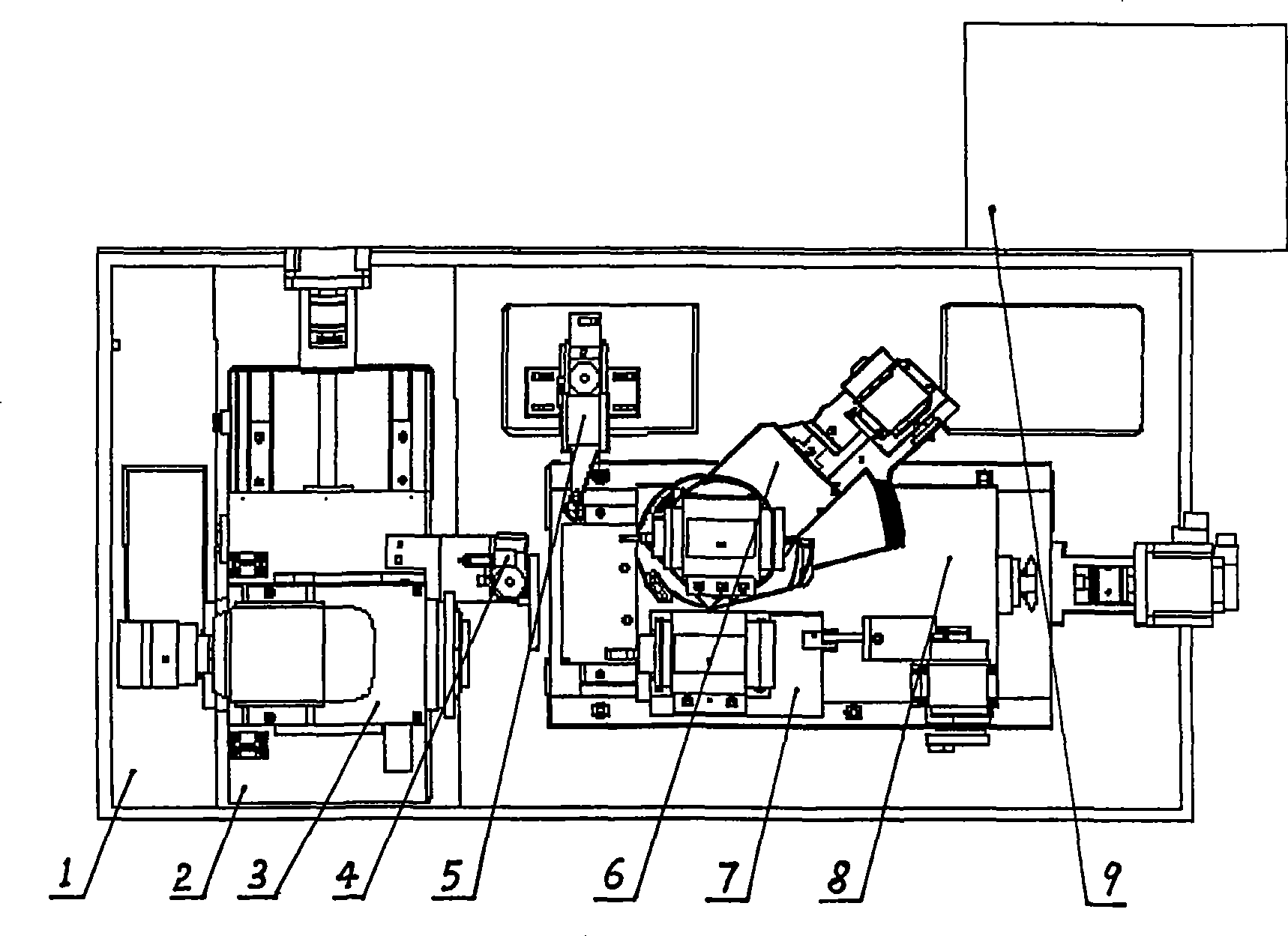

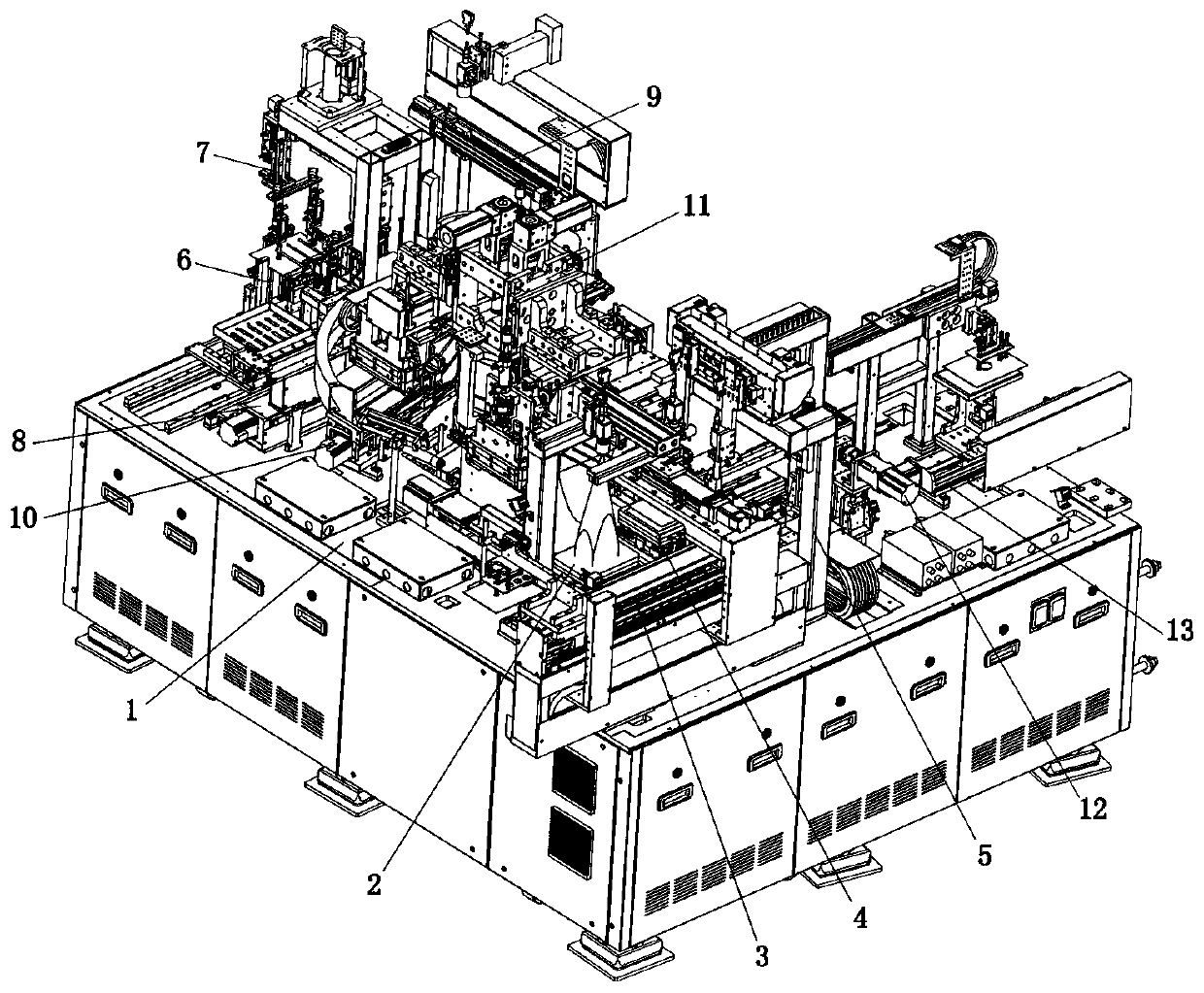

Automatic assembling process for infusion apparatus

The invention provides an automatic assembling process for infusion apparatus, and belongs to the technical field of medical instruments. The automatic assembling process for the infusion apparatus solves the problem that existing infusion apparatus is low in assembling efficiency. The process includes the following procedures, namely, a, medical catheter feeding, b, assembly of other components, c, finished product testing, and d, finished product discharging. According to the automatic assembling process, winding is carried out on medical catheter materials before assembling through a winding device, in addition, a medical catheter keeps in a winding state in the whole assembling process, therefore, the space occupied by the medical catheter is reduced, and feeding efficiency and assembling efficiency are improved. Due to the facts that the two end portions of the wound medical catheter are fixed in length, components on the left end portion and the right end portion of the medical catheter can be assembled at the same time, assembling efficiency is improved, and the assembling period of the infusion apparatus is shortened. In addition, the medical catheter is tied up through a band absorbing mechanism and a welding mechanism, and therefore the wound portion of the medical catheter will not disperse easily in the discharging and packaging process.

Owner:MAIDER MEDICAL IND EQUIP

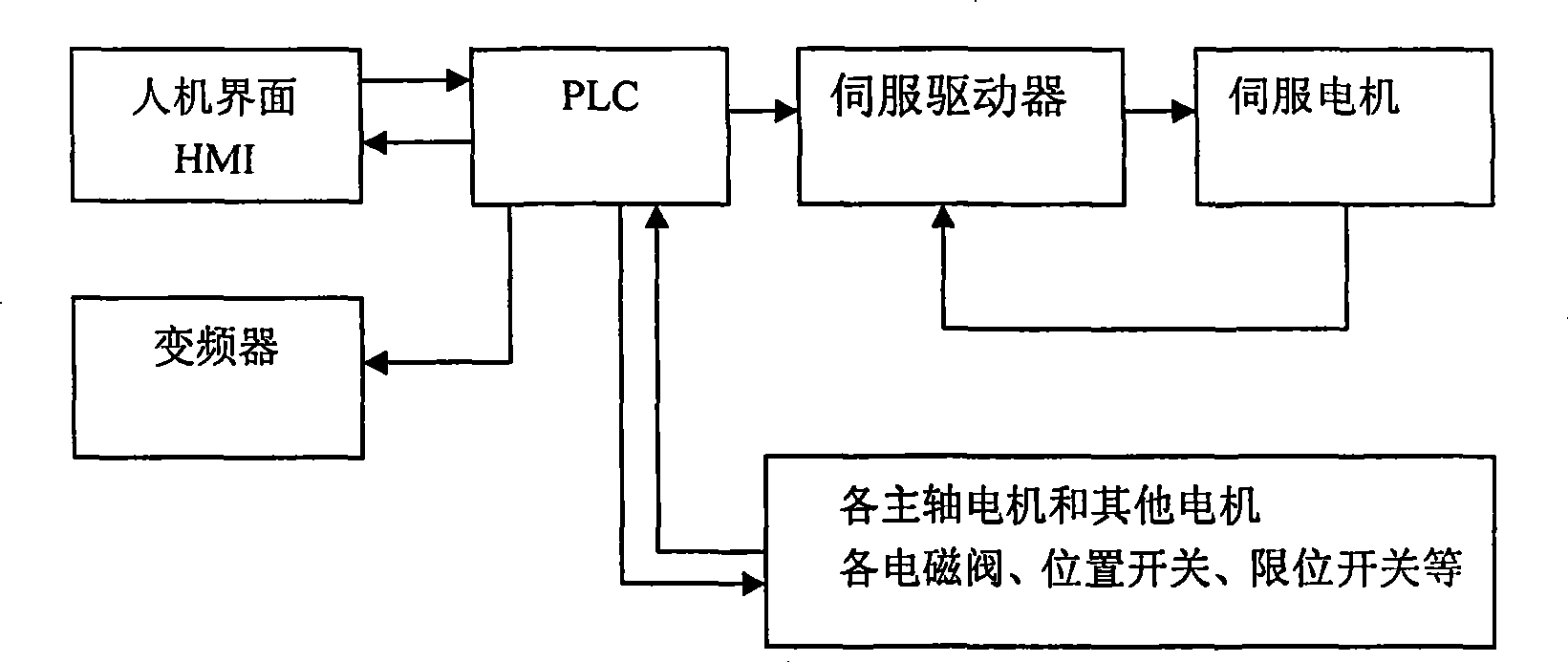

Precise numerical control internal grinder and processing control method thereof

InactiveCN101530978AHigh feed accuracyImprove feeding efficiencyRevolution surface grinding machinesAbrasive surface conditioning devicesNumerical controlBall screw

The invention discloses a precise numerical control internal grinder and processing control method thereof. The grinder comprises a grinder body, a grinder head, a grinding module and an electric control gear. The grinder also comprises a transverse slide mechanism and a longitudinal slide mechanism, wherein, each set of slide mechanism is driven by a servo motor and adopts a ball screw for transmission. The grinder head is arranged on a sliding plate of the transverse slide mechanism. The grinding module also comprises an inner hole grinding module and a conical surface grinding module, wherein, each set of grinding module is respectively arranged on the sliding plate of the longitudinal slide mechanism by a set of independent grinding sliding plate mechanism, and each set of grinding module all comprises a set of independent reciprocating driving mechanism, a grinding tool and a grinding tool rotation drive mechanism. The method refines the processing process and sets proper processing parameter according to best grinding technical curve. A programmable controller finishes accurate grinding processing according to reliable parameter. The invention can improves the processing efficiency and precision of an internal grinder and is particularly fit for parts with inner holes and the conical surfaces which are required to be ground accurately.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

Fodder feeding device for livestock breeding

InactiveCN107810870AIngenious structureEasy to operateAnimal feeding devicesAvicultureLivestockGear cutting

The invention discloses a feed feeding device for animal husbandry, which comprises a bottom plate, on which a vertical plate is fixed vertically, and a horizontal plate is fixed horizontally on the vertical plate; Connection, the rotation type on the rotating shaft has a blanking baffle plate, and a drop hole corresponding to the through hole is vertically opened on the blanking baffle plate, and a driving gear that is meshed with the driven outer ring gear is coaxially fixed on the driven shaft ; The vertical plate is rotatably provided with a driven bevel gear meshed with the driving bevel gear, and a disc-shaped cam is coaxially fixed on the driven bevel gear; the invention has an ingenious structure and is easy to operate. Automatic feeding and spreading, low labor intensity, small labor load, when the feeding stop plate rotates until the falling hole coincides with the through hole, the feed will fall into the storage tank, and then the intermittent falling of the feed will be realized, which avoids the waste of feed and improves the production efficiency. feed efficiency.

Owner:遂昌县宏创技术开发有限公司

Split feed distributor with feed supplied from below and thrown circumferentially

InactiveUS20130215414A1Avoid depositionReduce air resistanceRadiation pyrometryClimate change adaptationFish pondDistributor

A feed distributor used in fish ponds with feed supplied from below and thrown circumferentially comprises a feed-supplying mechanism, a feed-throwing mechanism and a feed-conveying mechanism by which feed supplied from said feed-supplying mechanism is delivered to said feed-throwing mechanism; the feed-supplying mechanism has a hopper which connects with a feed container above and a feed conveyor below. The feed-throwing mechanism has a launching disc with a sealed top, feed outlets in its circumference and a feed inlet below. The launching disc is disposed on a hollow shaft with an inner hole opposed to said feed inlet. The feed-throwing mechanism is disposed in pond and the feed supplying mechanism settles on a bank, feed is sucked into the feed-throwing disc and thrown circumferentially under negative pressure caused by rotation of the launching disc, and has a low crushing rate.

Owner:WEIGUO WU

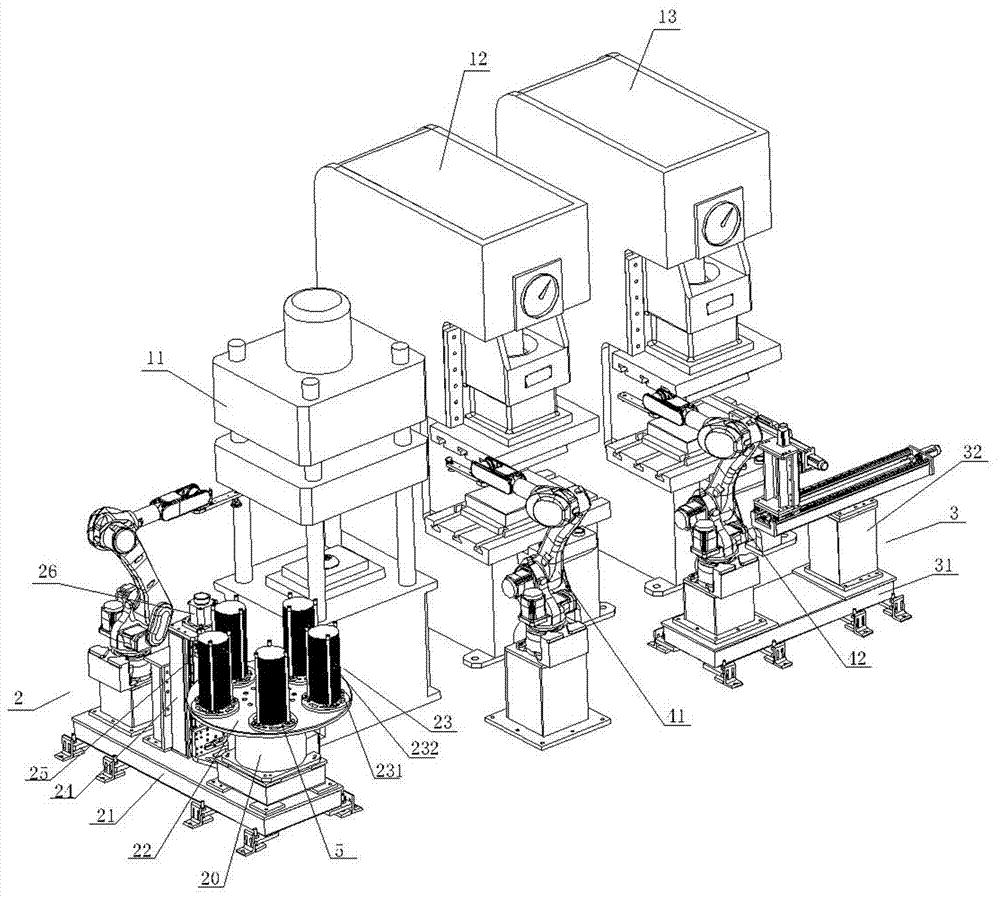

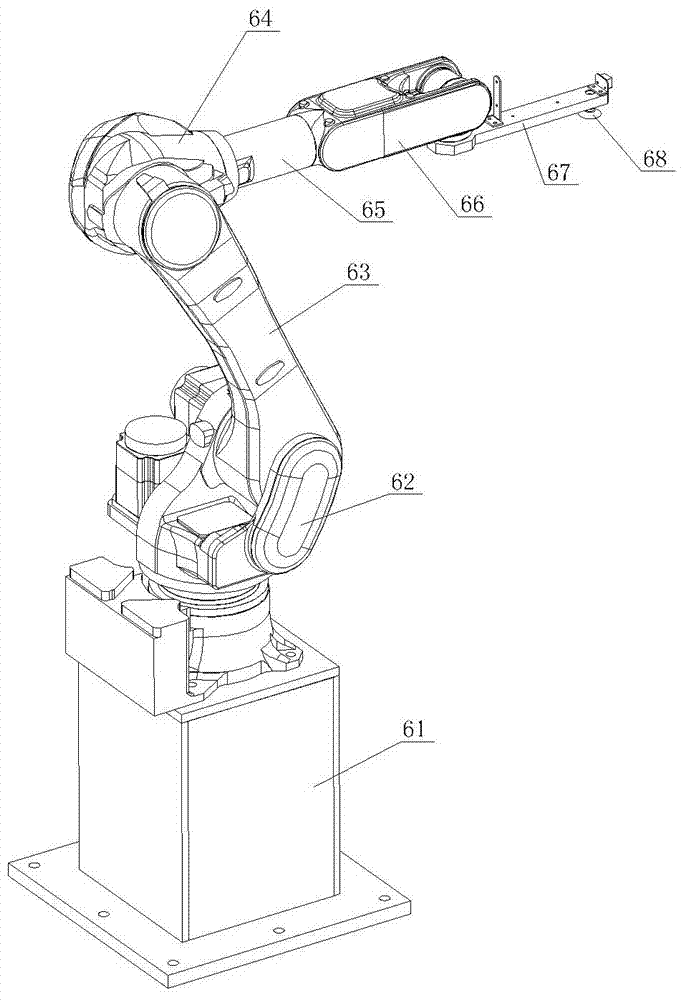

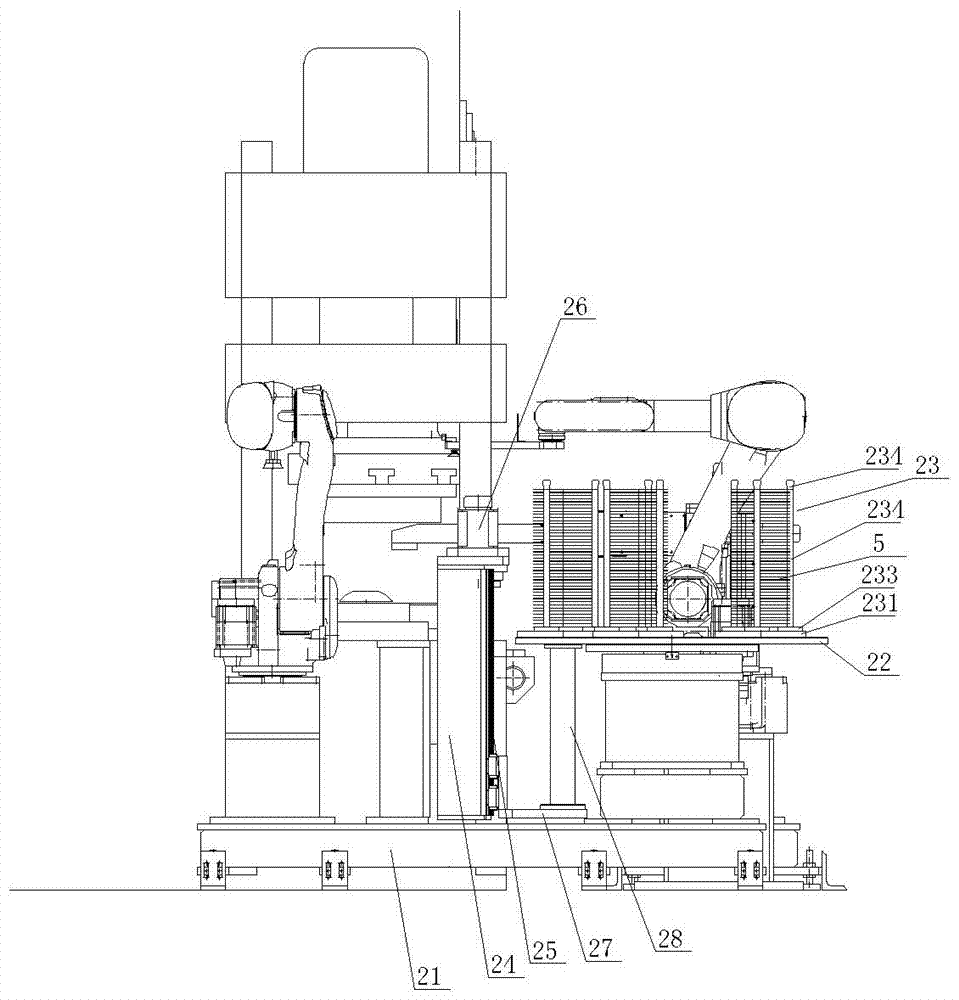

Automatic feed and discharge system of press robot

InactiveCN107159803AConvenient continuous feedingImprove feeding efficiencyMetal-working feeding devicesPositioning devicesNumerical controlAutomatic control

The invention relates to an automatic feed and discharge system of a press robot. The automatic feed and discharge system comprises at least one punch press, an automatic feed device, an automatic discharge device and a computer automatic-control system. The automatic feed device comprises a rotary feeding mechanism and a feed manipulator device, and the computer automatic-control system comprises an integrated chip, a numerical control circuit, a display screen and a control panel; automatic feed, stamping forming and automatic discharge of the punch press, the rotary feeding mechanism, the feed manipulator device and the automatic discharge device are achieved through the computer automatic-control system. By adopting the above structure, the automatic feed and discharge system has the advantages that the machining is quick and accurate, and the machining accuracy is even; the production efficiency is improved, and the manpower cost is reduced; and manual feed and discharge are avoided, and the production safety is improved.

Owner:GUANGZHOU ZHENGBAO PRECISION MACHINERY +1

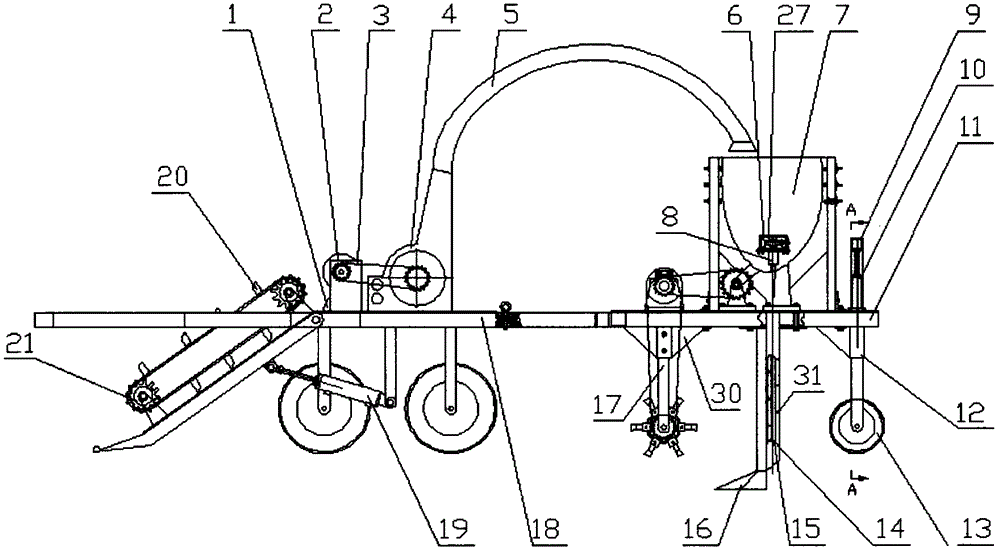

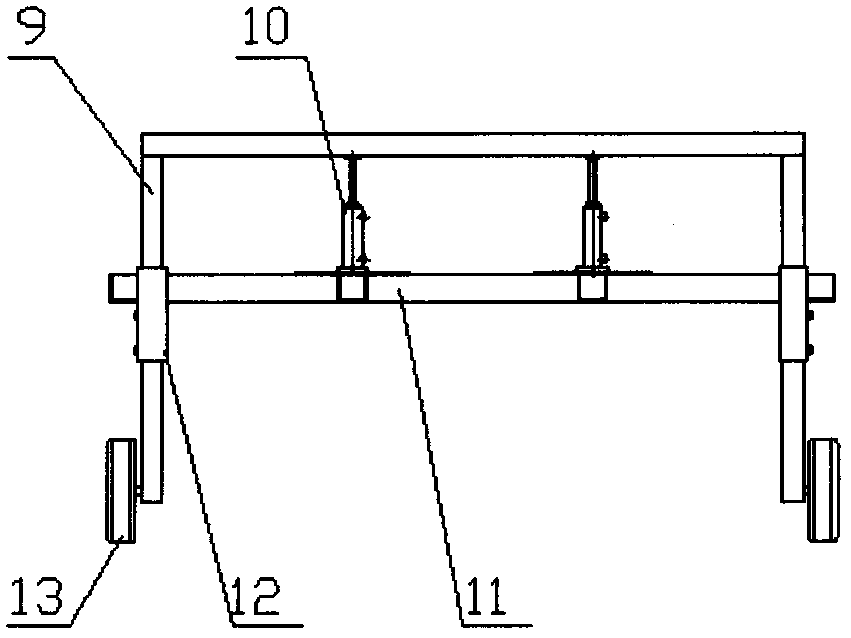

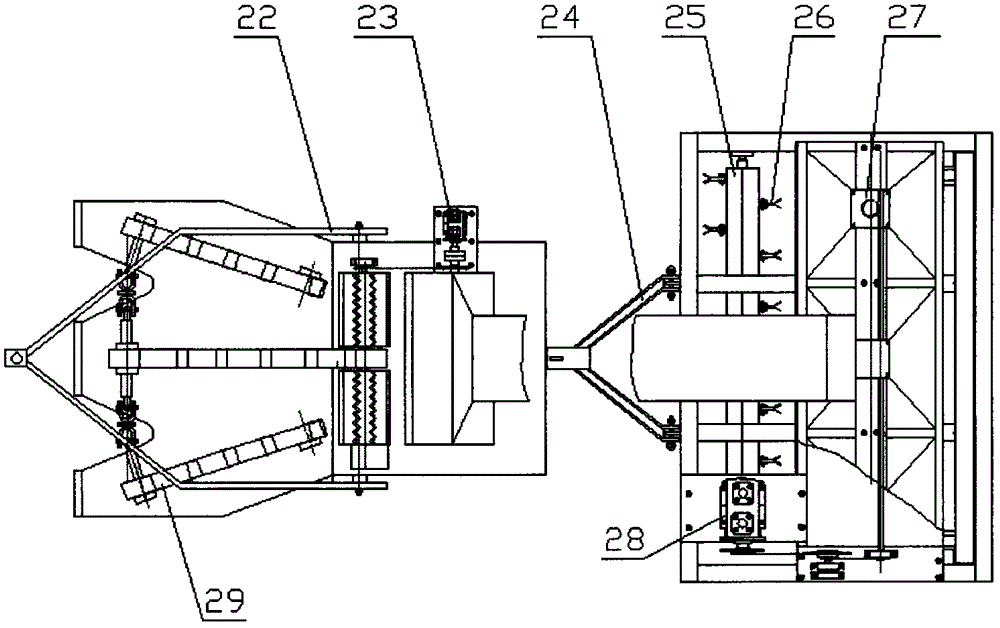

Maize straw three-dimensional returning machine

InactiveCN105210571AGood physical propertiesImprove fertilityLoadersCrop conditionersControl systemAgricultural engineering

The invention relates to a maize straw three-dimensional returning machine which mainly comprises a front frame, a rear frame, a straw picking device, a straw feeding device, a straw crusher, a stubble cleaning mechanism, a straw deep placement device, a hydraulic control depth-limiting mechanism, a front motor, a rear motor, a hydraulic control system assembly and the like. The straw picking device is assembled at the front end of the front frame, the straw feeding device is assembled on the front part of the front frame, the straw crusher is assembled in the rear part of the front frame, the stubble cleaning mechanism is assembled below the front part of the rear frame, the straw deep placement device is assembled in the middle part of the rear frame, the hydraulic control depth-limiting mechanism is assembled in the rear part of the rear frame, the front motor is arranged on the front frame, the rear motor is arranged on the rear frame, and power is provided to the pre-posed motor and the post-posed motor by a hydraulic output system of a tractor. The maize straw three-dimensional returning machine during work is pulled by the tractor, and picks, crushes and deeply places the maize straws in a field as the tractor moves and meanwhile cleans stubbles, so that operations of ground mulching return to field, reclaimed soil return to field and soil deep placement return to field on the maize straws are realized.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

Automatic feeding numerical control lathe

InactiveCN105798332AAvoid shockPrevent flying outMetal working apparatusNumerical controlMaterial storage

The invention discloses an automatic feeding numerical control lathe. The automatic feeding numerical control lathe comprises a lathe body, wherein a hollow spindle is arranged on the lathe body; a sliding rail is arranged on the lathe body along the front and back horizontal direction; a knife rest is slidably arranged on the sliding rail; a hollow chuck is axially and fixedly connected to the front end of the hollow spindle; a cutting mechanism and an electromagnetic adsorption mechanism are arranged on the knife rest; an automatic feeding device is arranged behind the lathe body; the automatic feeding device comprises a material box base; a material box support is fixedly connected onto the material box base; a material storage box, a corrugated pipe elastic joint and a discharging box are sequentially arranged on the material box support from top to bottom in a fixed manner; a vibration motor is arranged on the outer wall of each of the left and right sides of the corrugated pipe elastic joint; a material baffle mechanism is arranged on the lower part of the discharging box; and a material pushing base which is right blow the discharging box is fixedly connected onto the upper surface of the material box base. The automatic feeding numerical control lathe is simple and convenient for operation, high in automatic degree and stable in work; automatic feeding can be realized; non-cutting time is effectively shortened; cutting can be performed rapidly; and the working efficiency is improved.

Owner:HUANGHE S & T COLLEGE

High-protein-content growth-promoting environment-friendly fish feed and preparation method thereof

InactiveCN105767594APromote growthPromote reproductionClimate change adaptationAnimal feeding stuffSynbioticsPhytase

The invention discloses a high-protein-content growth-promoting environment-friendly fish feed. The high-protein-content growth-promoting environment-friendly fish feed comprises the following raw materials: bean cakes, cotton meal, corns, bran, fish meal, rapeseed cakes, spirulina powder, seaweed powder, wheat middling, polygonatum sibiricum powder, fish oil, calcium lactate, calcium dihydrogen phosphate, lysine, methionine, aspartic acid, glutamic acid, a vitamin mixture, minerals, phytase, synbiotics, a traditional Chinese medicine compound additive and a food attractant. The high-protein-content growth-promoting environment-friendly fish feed is rich in nutrition, and rich in contents of proteins, amino acids, vitamins, probiotics and growth substances; thus, the high-protein-content growth-promoting environment-friendly fish feed is capable of effectively promoting growths and breeding of the fishes, and improves yields and qualities of the fishes.

Owner:LIANYUNGANG HENGTU FARMING DEV CO LTD

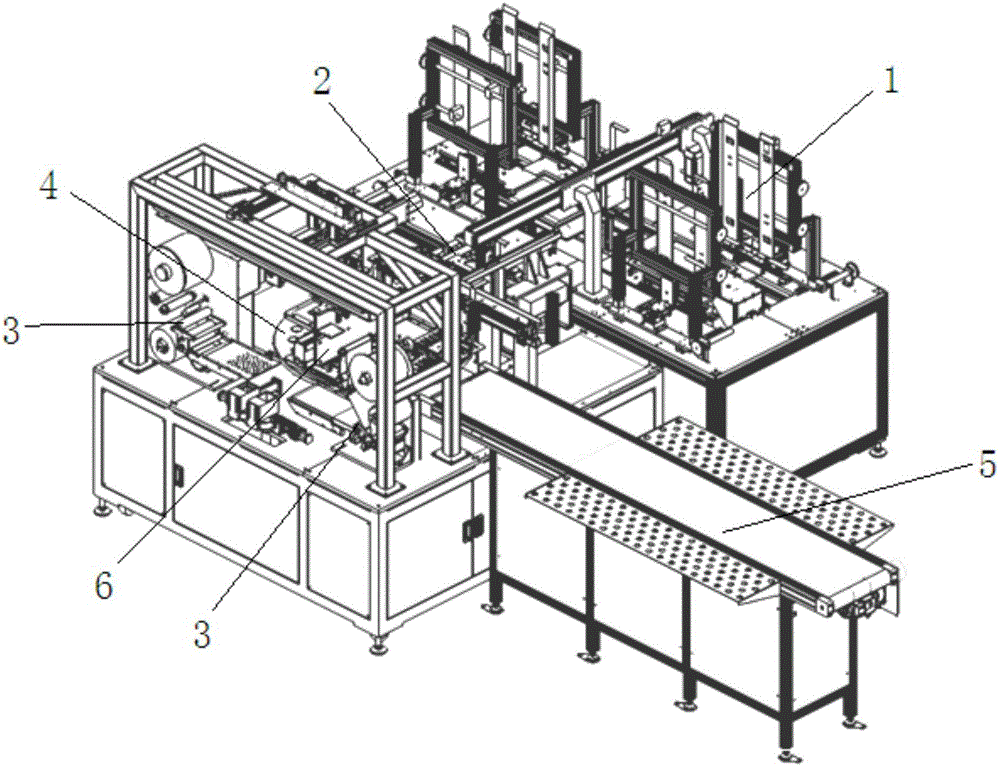

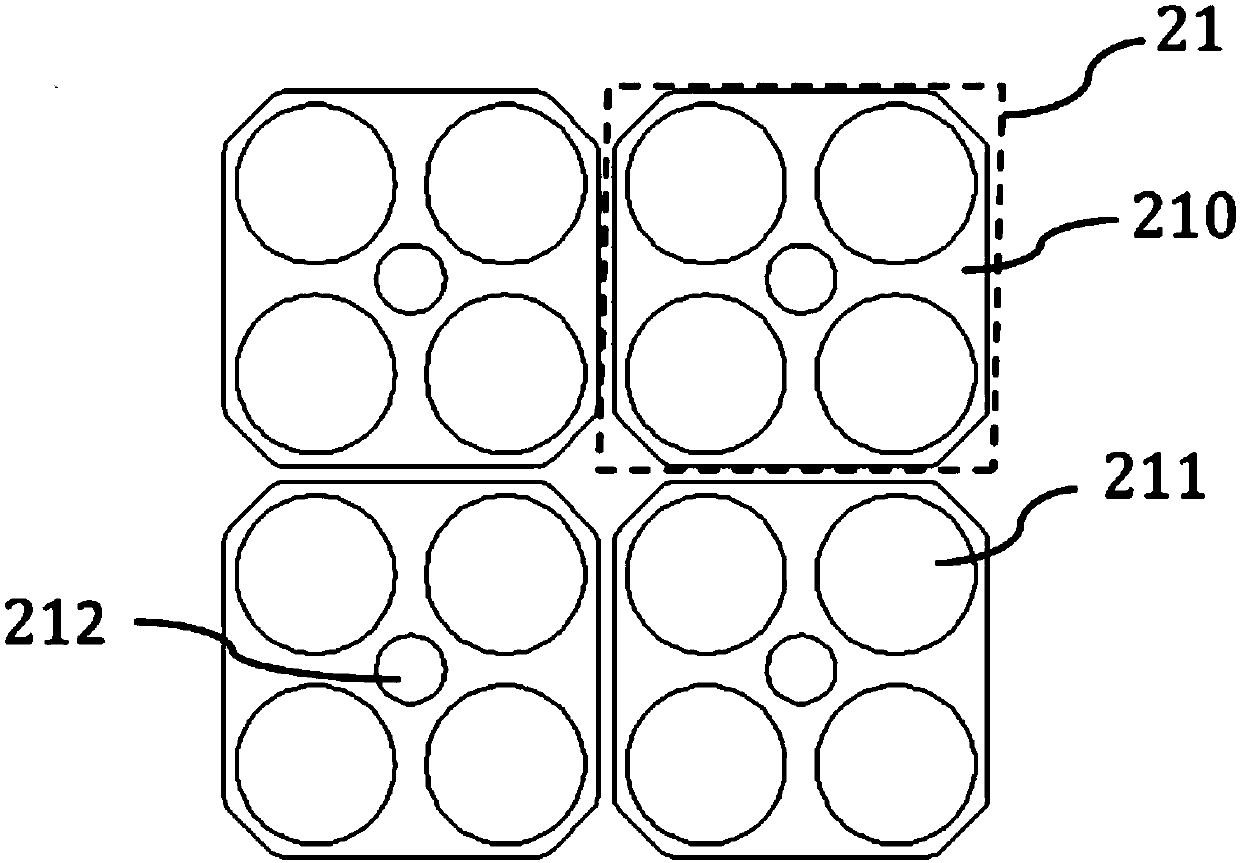

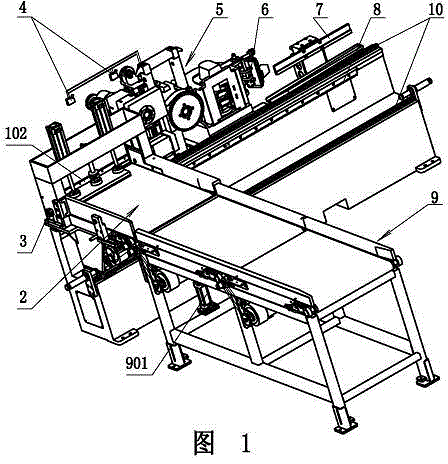

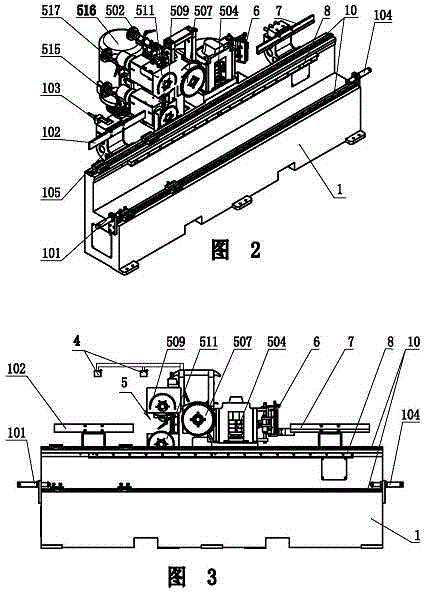

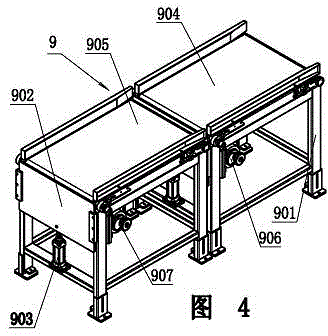

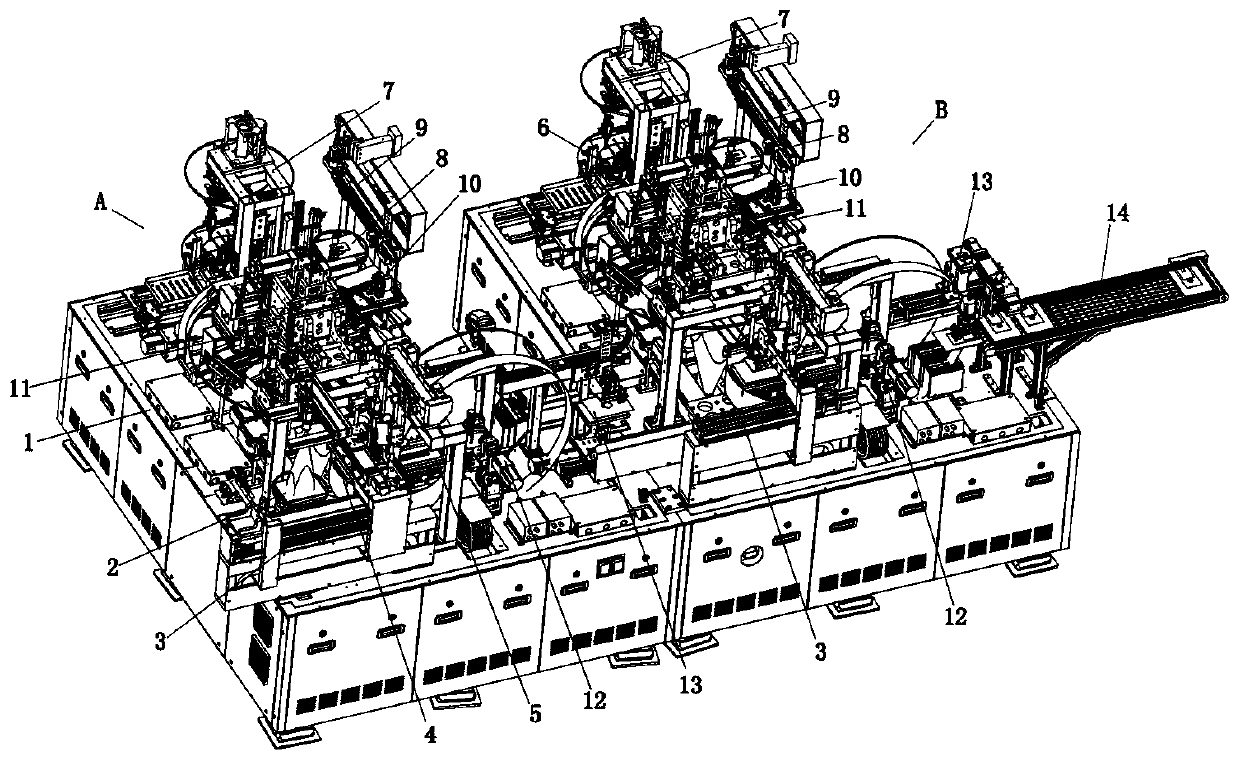

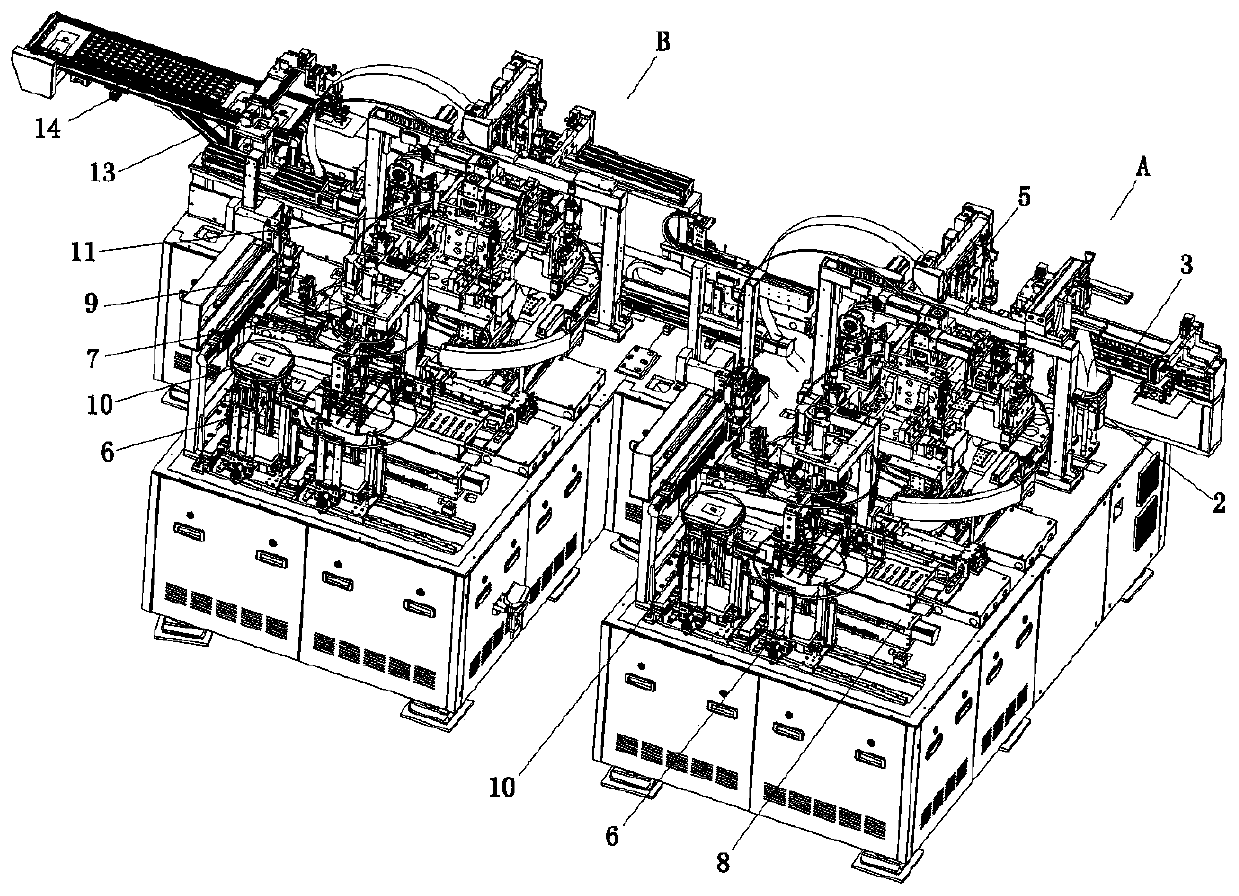

Full-automatic screen double-sided chip mounter and chip mounting technology thereof

PendingCN110174715ARealize automatic and efficient connectionReduce the presence of air bubblesNon-linear opticsOptical elementsEngineeringPolarizer

The invention discloses a full-automatic screen double-sided chip mounter and a chip mounting technology thereof. The full-automatic screen double-sided chip mounter comprises a first mounting part, aturnover mechanism, a second mounting part and a discharging belt which are arranged at intervals in sequence. After one side surface of a to-be-mounted glass sheet is subjected to chip mounting at the first mounting part, the glass sheet is moved to the turnover mechanism; after the glass sheet is turned over by the turnover mechanism, the other side surface of the glass sheet is subjected to chip mounting at the second mounting part; and the glass sheet is exported and discharged through the discharging belt. According to the chip mounter and the chip mounting technology, automatic and efficient connection of double-sided and single-sided mounting devices is effectively realized; automatic mounting of double polarizers is completed; the functions of alternate film tearing, alternating chip mounting, alternate discharging after chip mounting, and the like are realized; the material waiting time of each process gap is effectively utilized; the chip mounting time is shortened; the chipmounting productivity is effectively improved; the polarizers are adhered by adopting a flexible chip mounting adhesive tape; the attachment of the polarizers is completed by single-sided rolling attachment of a rolling attachment assembly; chip mounting air bubbles are effectively reduced; and the chip mounting quality is improved.

Owner:SHENZHEN ETMADE AUTOMATION EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com