Feeding system for building contour forming

A feeding system and building technology, which is applied in building construction, building material processing, construction, etc., can solve the problems of reducing operating efficiency, clogging feeding pipes, and reducing feeding efficiency, so as to reduce clogging of feeding pipes The probability of reducing the probability of clogging and the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

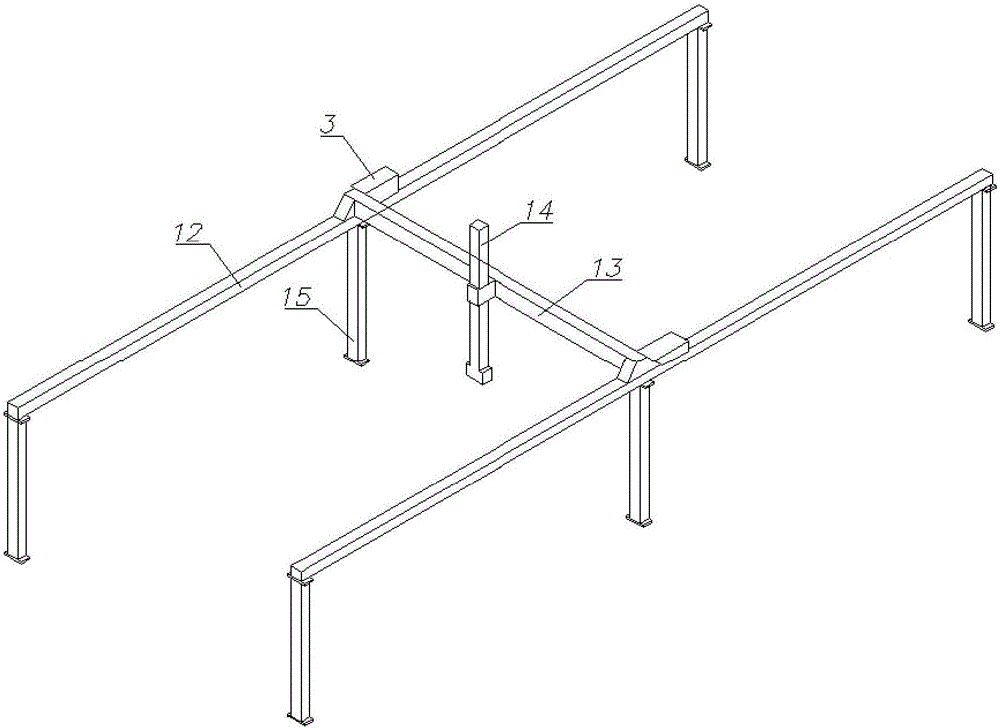

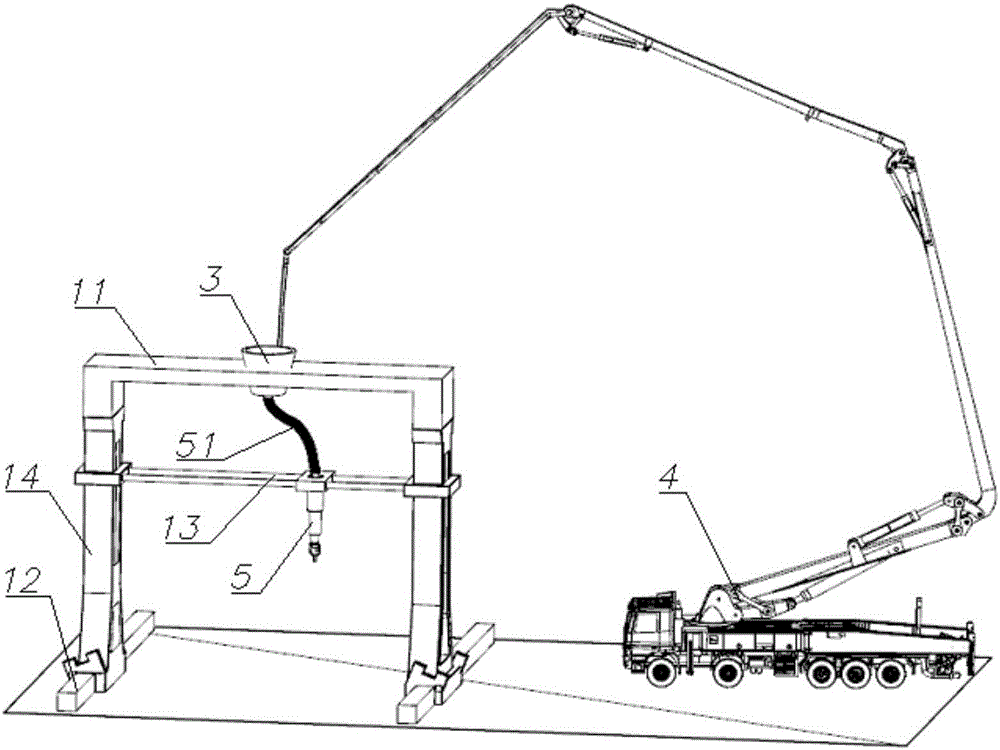

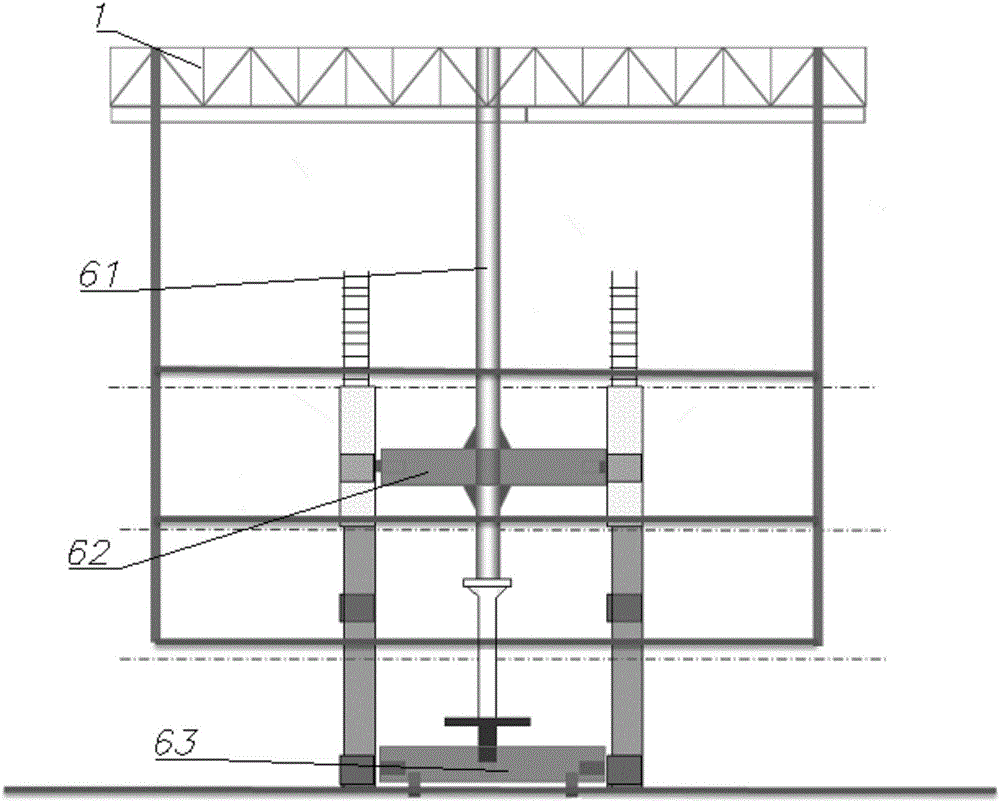

[0030] combine figure 2 Another embodiment of the present invention is shown, the mobile support platform 1 includes an X-guiding rail 12 arranged on the ground, a Z-guiding rail 14 is arranged on the X-guiding rail 12, and a Y-guiding rail 13 is arranged on the Z-guiding rail 14 Above, the Z-guiding rail 14 is set vertically perpendicular to the X-guiding rail 12, and can move along the X-guiding rail 12 in the X-axis direction, and the two ends of the Y-guiding rail 13 are arranged on the Z-guiding rail 14 and can extend in the Z-axis direction To move, the 3D building printing nozzle 5 is set on the Y-guiding rail 13 and can move horizontally along the Y-guiding rail 13. A supporting beam 11 is arranged above the Y-guiding rail 13, and the intermediate silo 3 is fixedly arranged on the supporting beam 11. and connected to the 3D building printing nozzle 5 through the feed pipe 51 , and the two ends of the support beam 11 are connected to the Z guide rail 14 . By setting t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com