Automatic feed and discharge system of press robot

A technology of automatic loading and unloading and automatic blanking, which is applied to metal processing equipment, feeding devices, manufacturing tools, etc., can solve problems such as hidden safety hazards, low work efficiency, and labor costs accounting for costs, so as to improve accuracy, process Fast and accurate, the effect of uniform processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

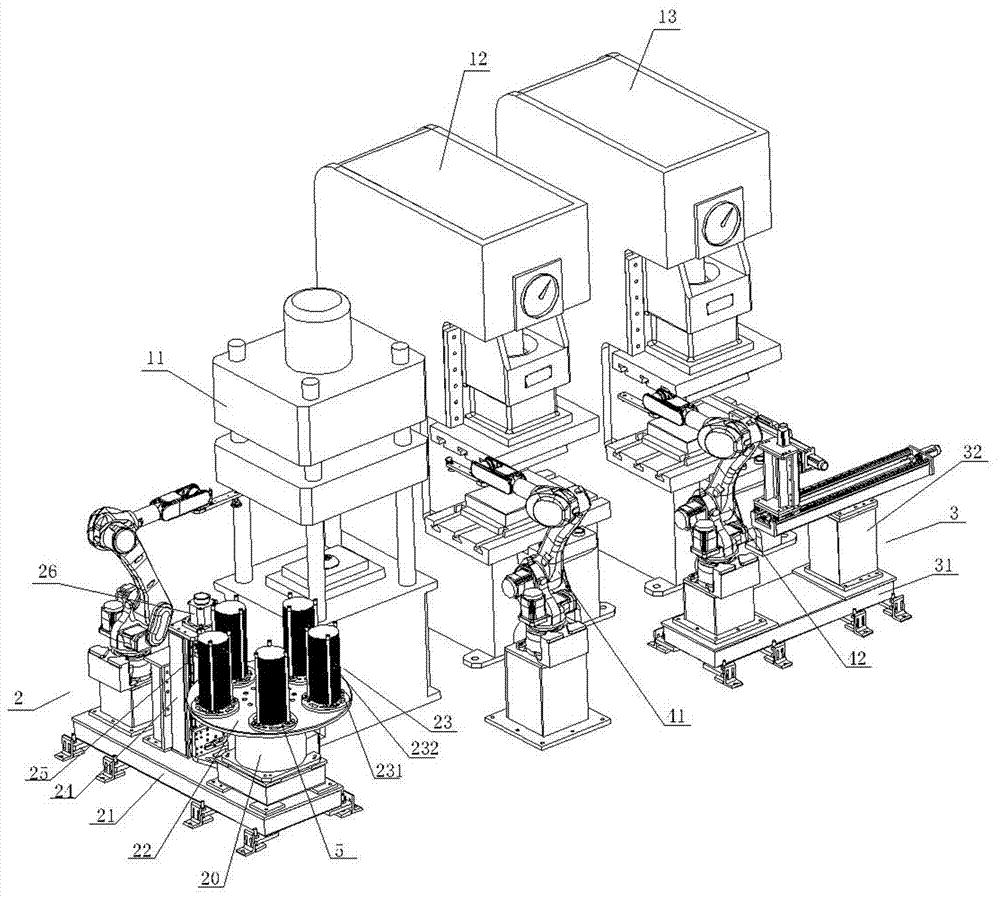

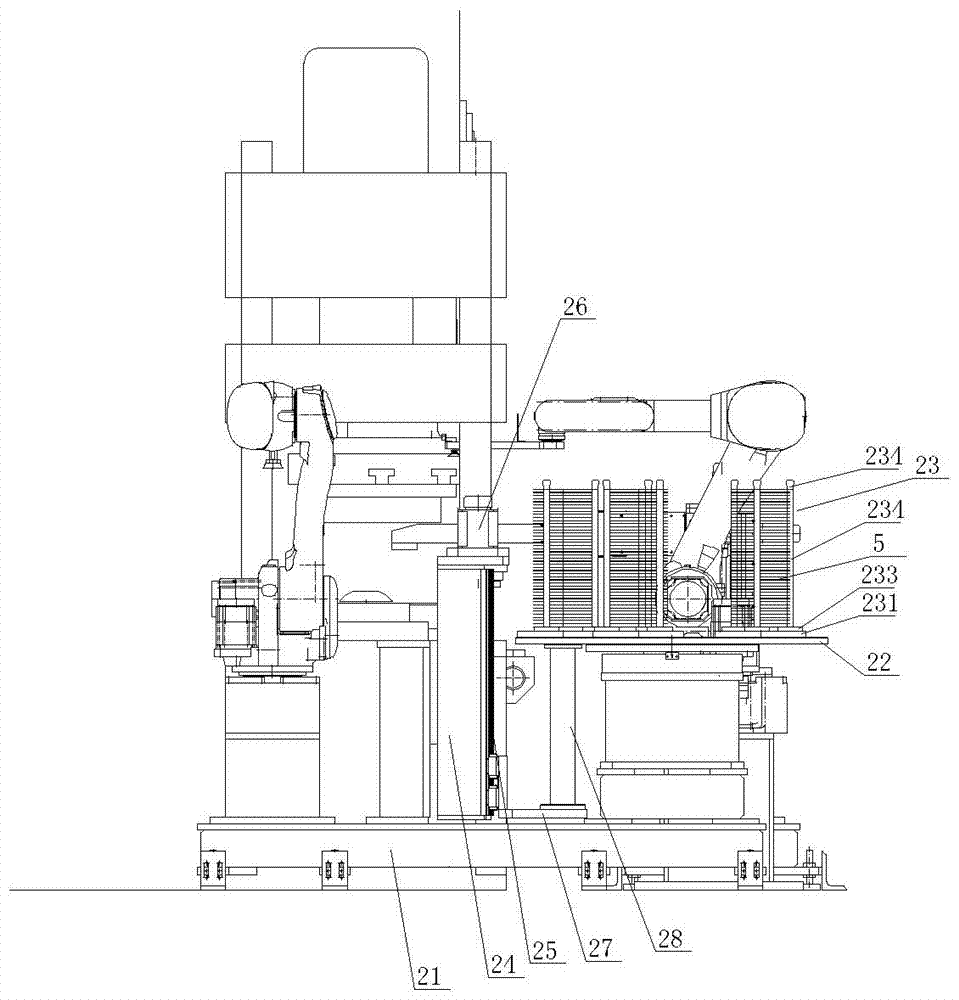

[0029] Such as Figure 1-6 As shown, the present invention is an automatic loading and unloading system for a punching robot, comprising at least one punching machine, an automatic feeding device 2, an automatic feeding device 3 and a computer automatic control system, and the automatic feeding device 2 includes a rotary feeding mechanism and a feeding manipulator device, the computer automatic control system includes an integrated chip, a numerical control circuit, a display screen and a control panel; Stamping and automatic blanking.

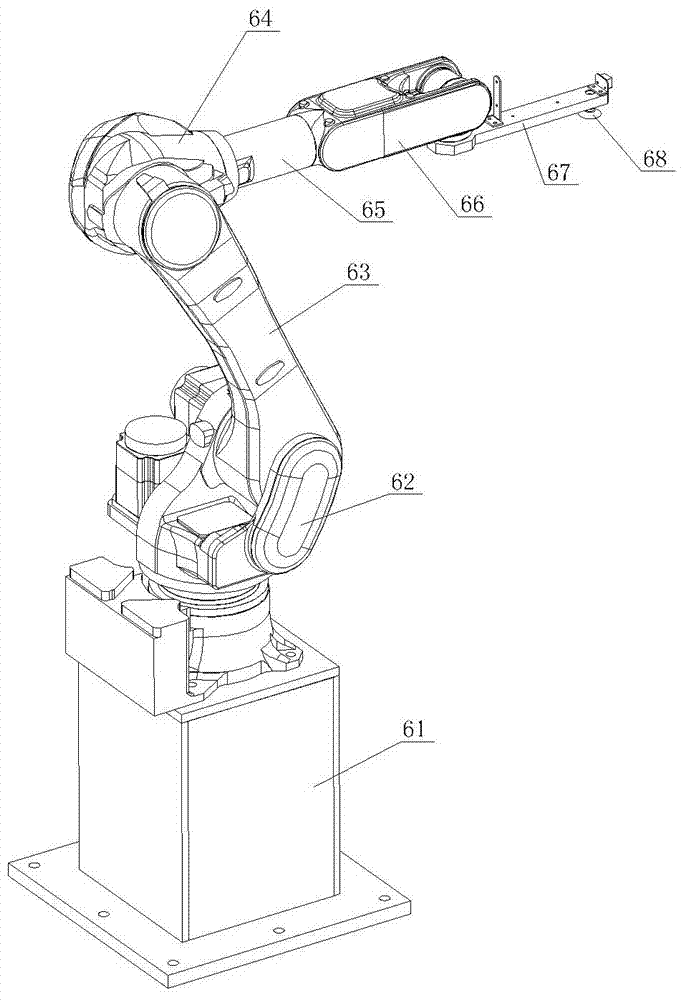

[0030] Such as figure 1 , 2 As shown, the punching machine includes a stretching hydraulic press 11, a punching punching machine 12 and a forming punching machine 13, and the feeding manipulator device includes a feeding manipulator device 40 arranged between the rotary feeding mechanism and the stretching hydraulic press 11, and is arranged on the stretching punching machine. The first material transfer robot device 41 between the machine ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com