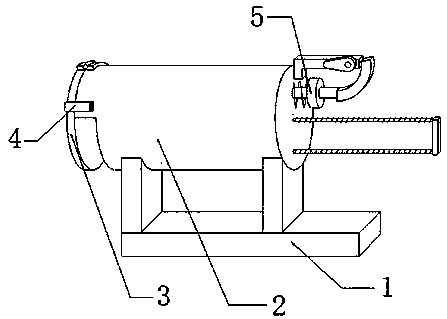

A motor end ring forming and feeding equipment

A technology of end rings and equipment, which is applied in the field of motor end ring forming and feeding equipment, can solve the problems of poor feeding continuity and high labor intensity, and achieve the effects of easy operation, high reliability, and good feeding continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

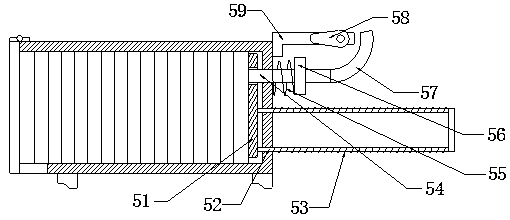

[0020] Specific implementation: during use, the staff moves the motor end ring to the inside of the barrel 2, hangs the motor end ring on the load rod 54, and then pushes the motor end ring to the right, so that the motor end ring pushes the top plate 51 along the The loading rod 54 moves to the right, and the top plate 51 moves to drive the moving rod 52 to move to the right, so that the spring 1 53 is stretched. After the end ring of the motor is placed, the staff rotates the cover plate 3 to the left side of the barrel 2, And rotate the clamping plate 4, so that the left end of the clamping plate 4 rotates to the left side of the cover plate 3, thereby realizing the fixing of the cover plate 3, and then the top plate 51 drives the motor end ring and the cover plate 3 to the right The sides are tightly fitted, and then the staff connects the motor to the external power supply. The motor drives the cam 58 to rotate counterclockwise through the rotating shaft. When the cam 58 r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com