Patents

Literature

9572results about How to "High output" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

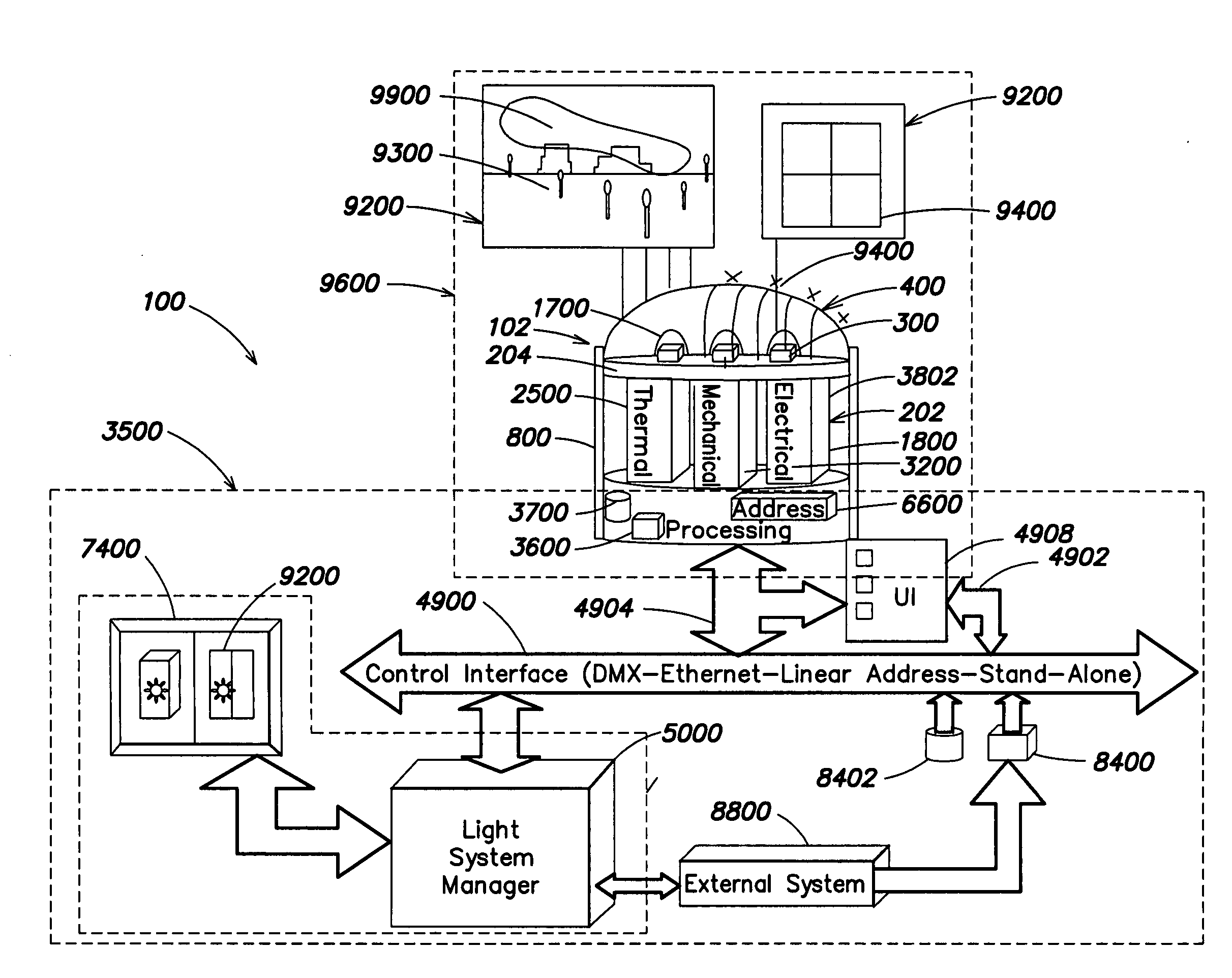

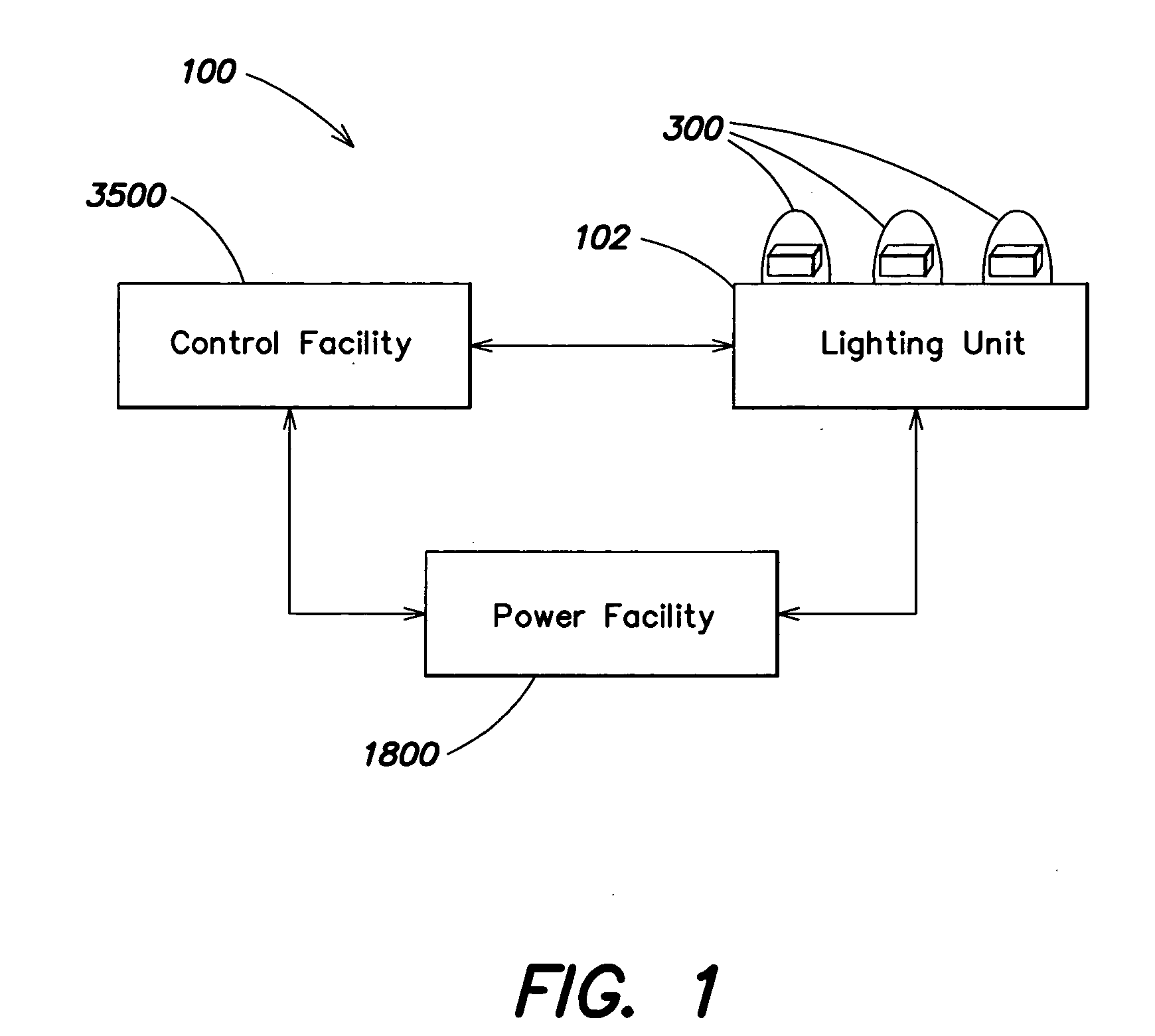

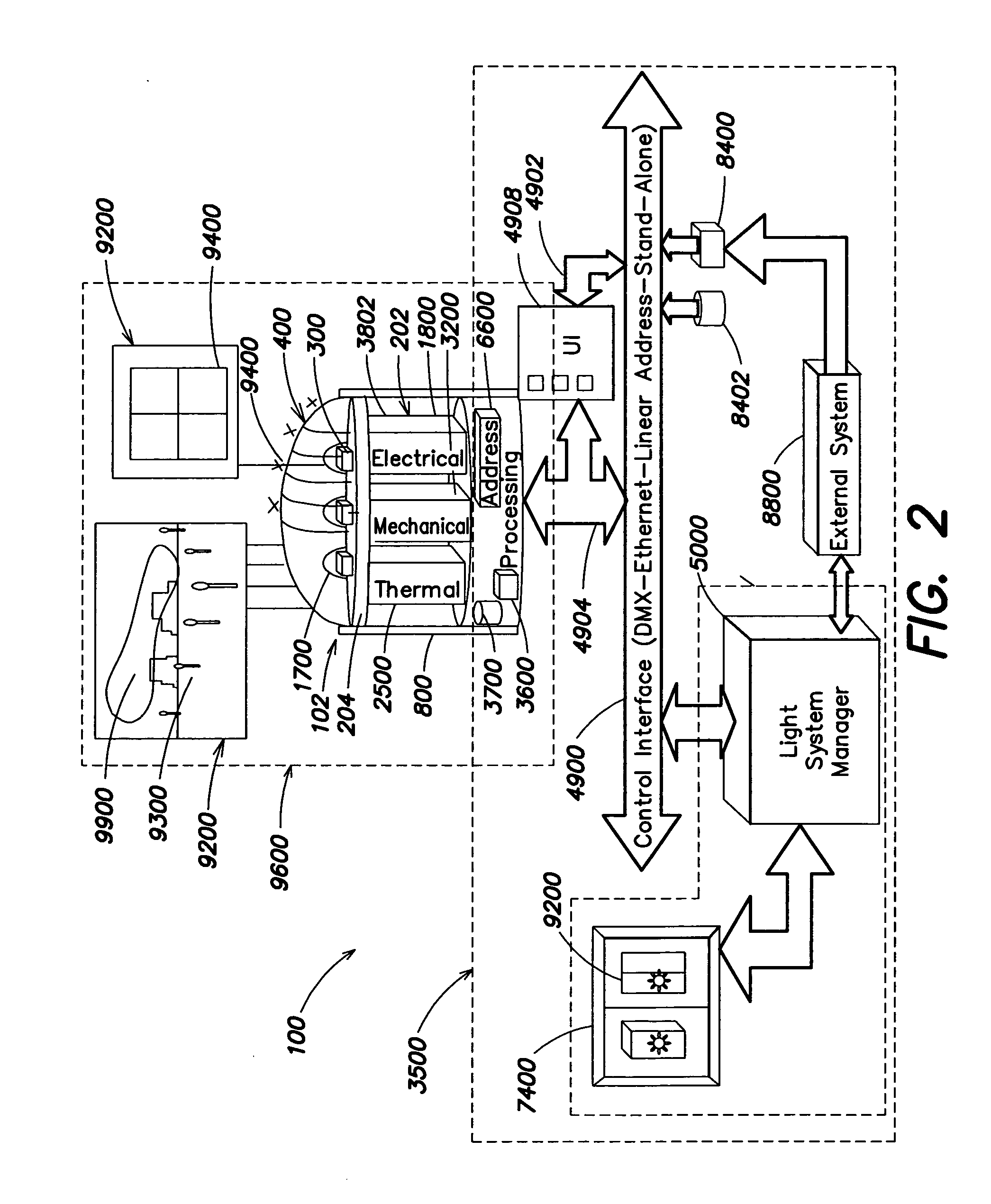

Photography methods and systems

InactiveUS20050174473A1Reduce light outputEasy to customizeLighting applicationsTelevision system detailsEngineeringHue

The embodiments disclosed herein show how such LED methods and systems, especially intelligent LED systems, can be used for photographic and cinematography applications and provide many benefits. Controlled LED illumination allows easy customization of these features to create a particular mood and can be used to create light of desired saturation and hue.

Owner:COLOR KINETICS

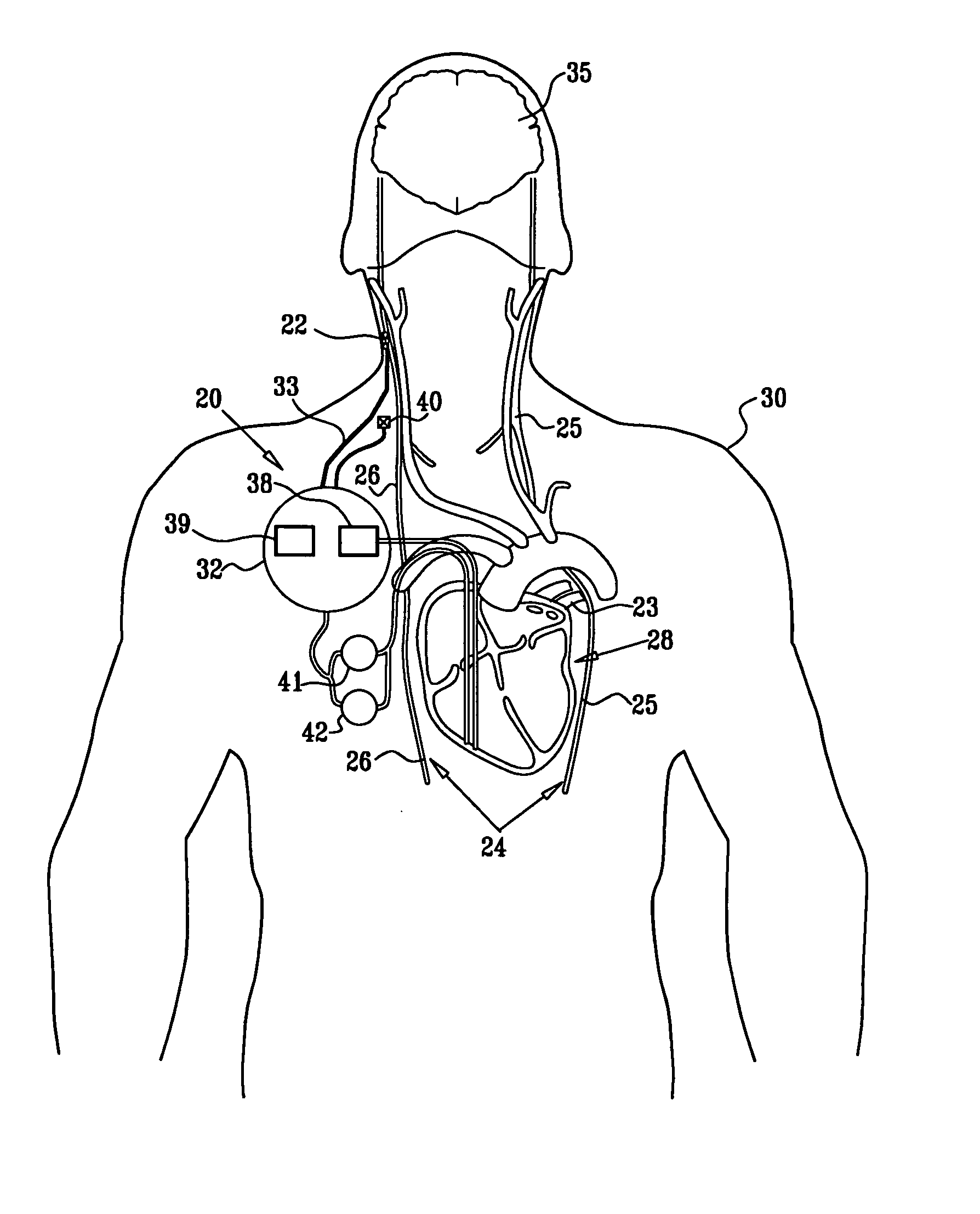

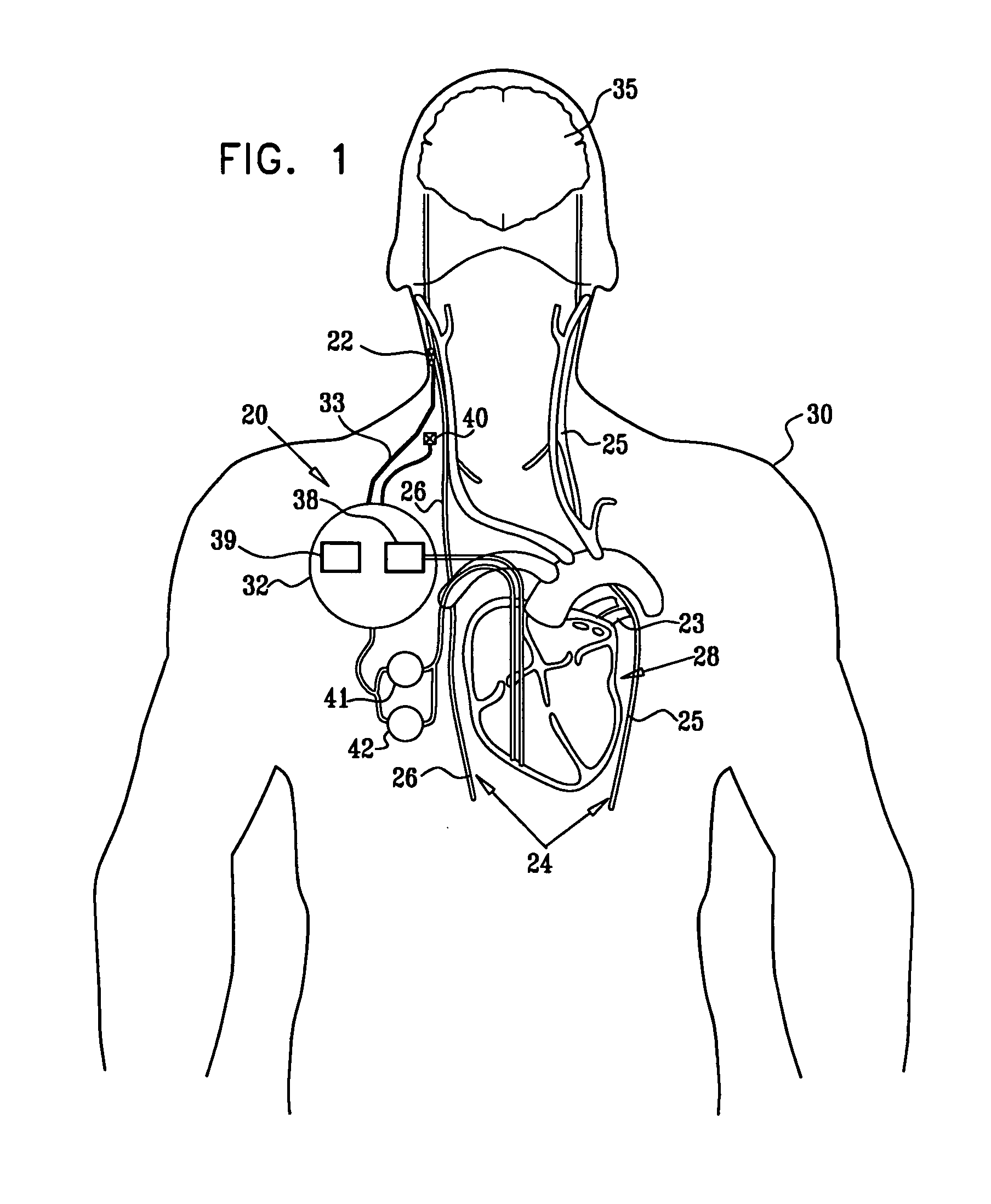

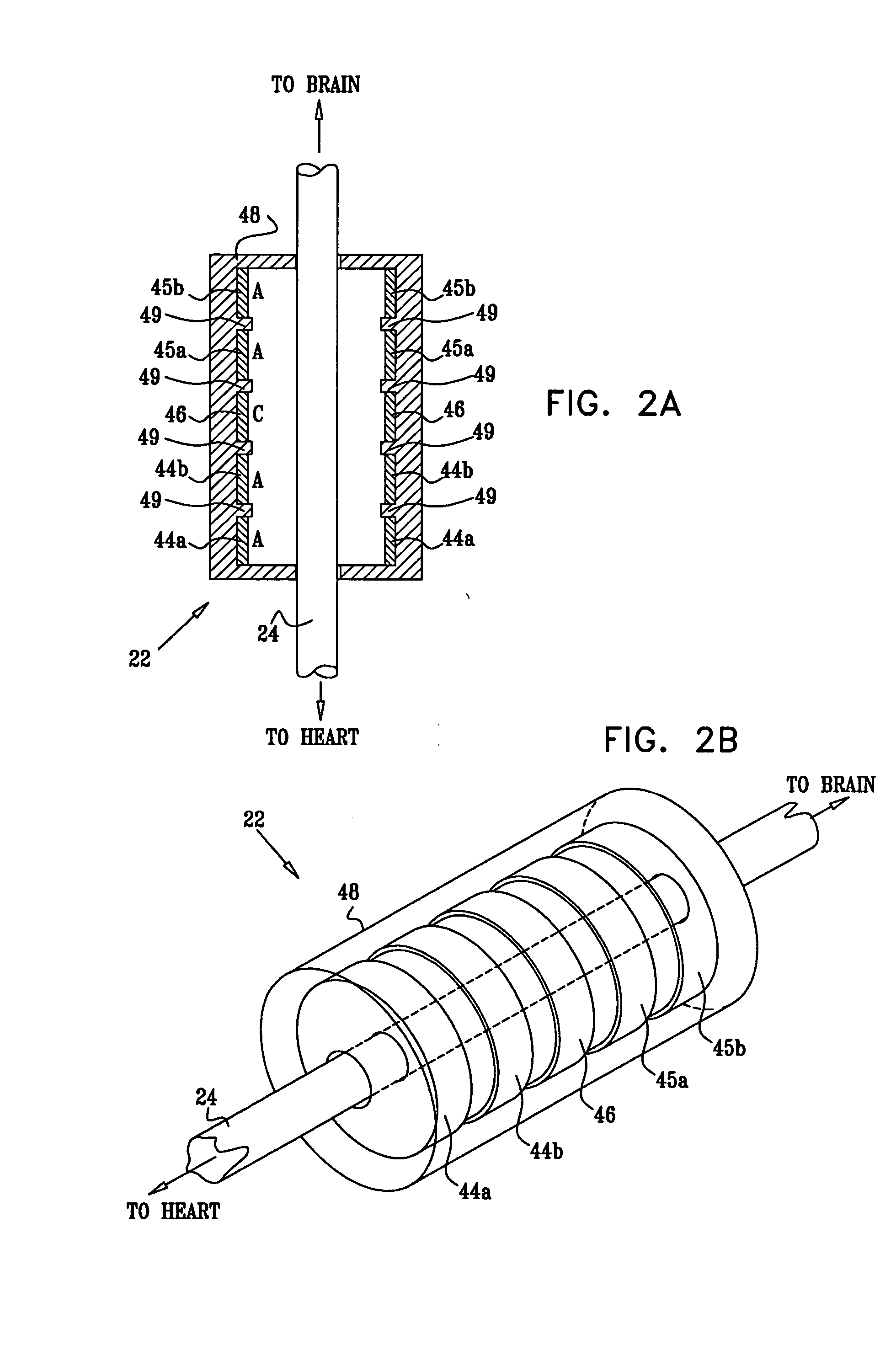

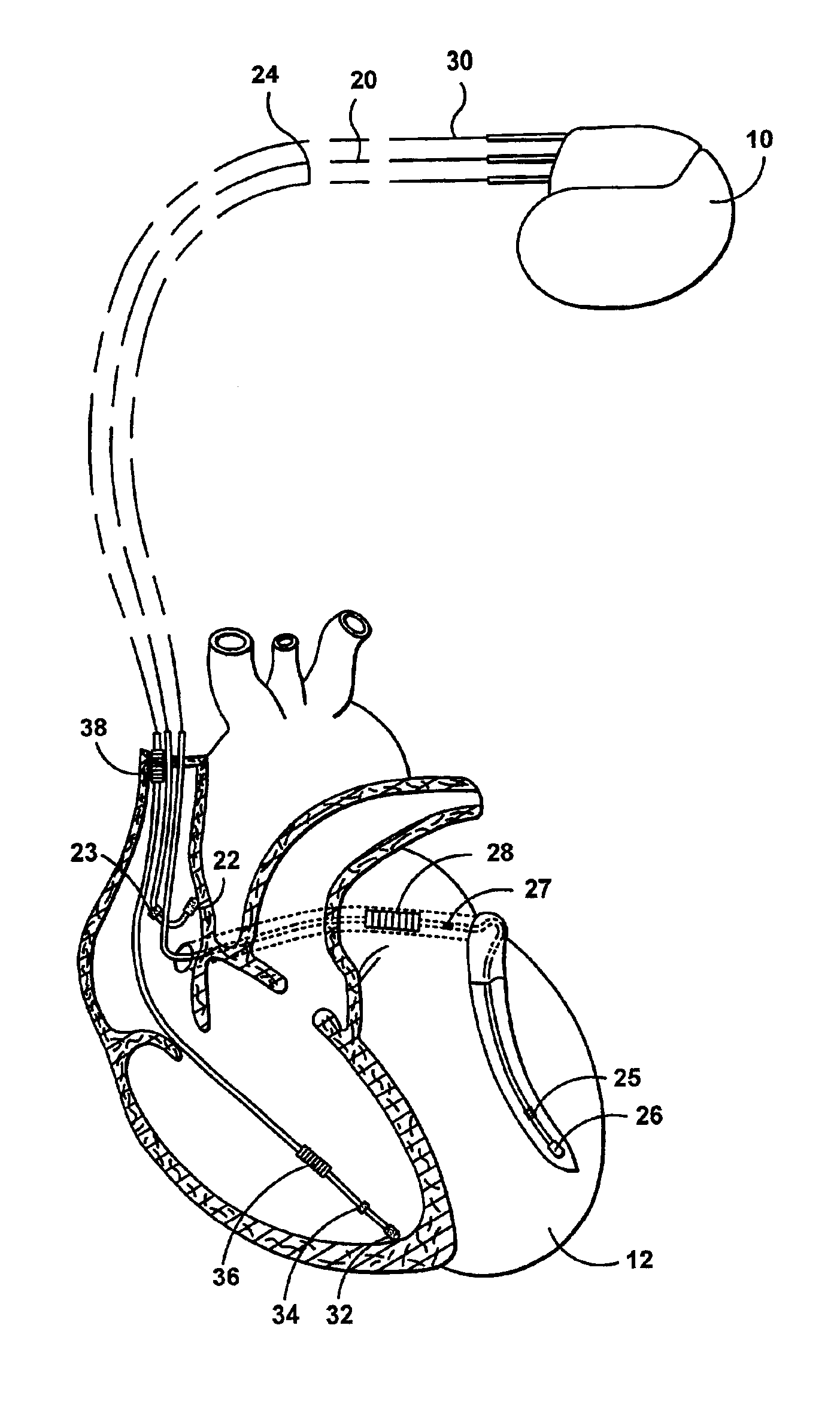

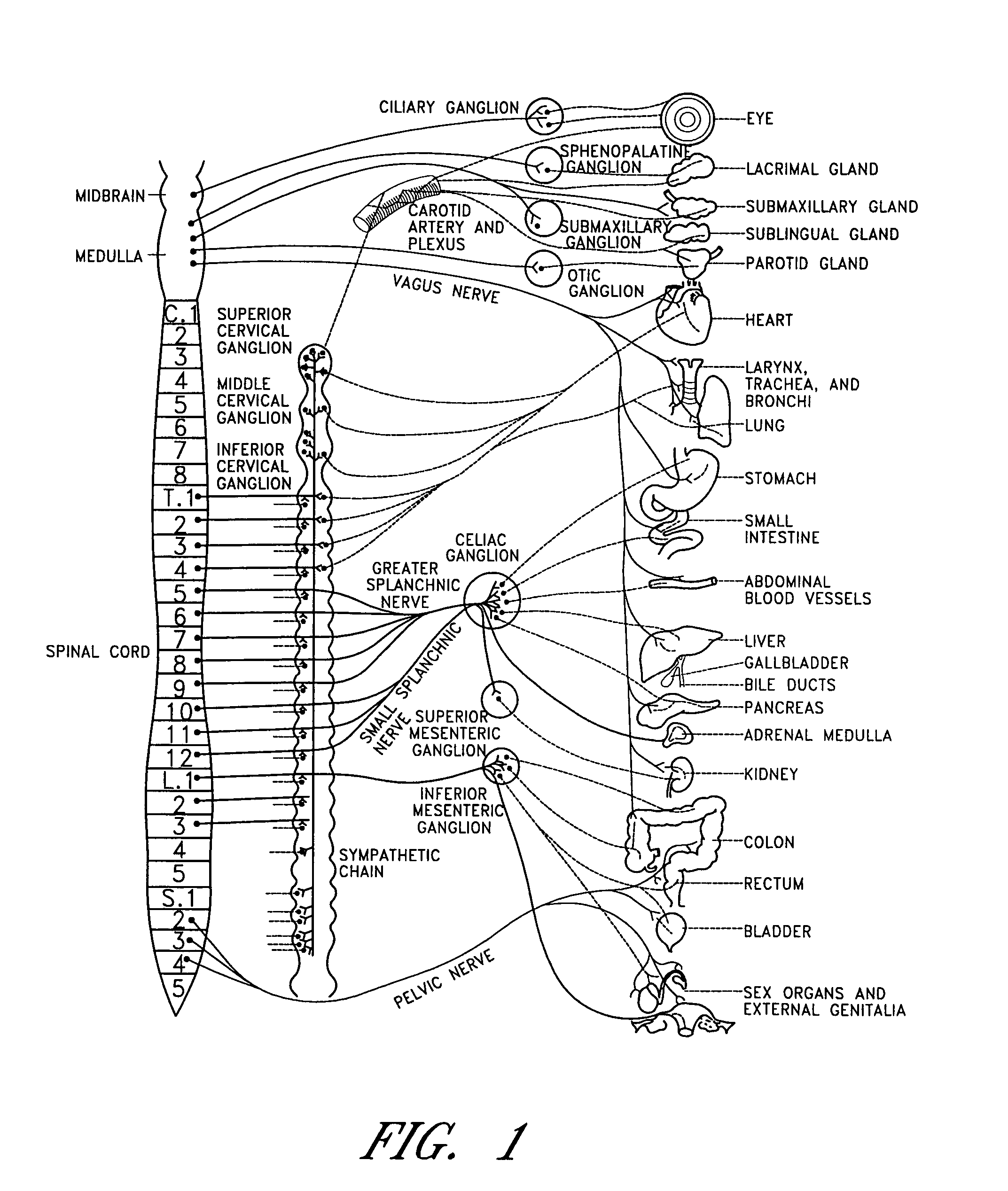

Applications of vagal stimulation

InactiveUS20050065553A1Prevent electrical remodelingEnhancing and sustaining efficacyHeart defibrillatorsHeart stimulatorsEncephalitisAnesthesia

A method is provided for treating a subject, including applying a current to a site of the subject selected from the list consisting of: a vagus nerve of the subject, an epicardial fat pad of the subject, a pulmonary vein of the subject, a carotid artery of the subject, a carotid sinus of the subject, a vena cava vein of the subject, and an internal jugular vein of the subject. The method also includes configuring the current so as to treat a condition of the subject selected from the list consisting of: an autoimmune disease, an autoimmune inflammatory disease, multiple sclerosis, encephalitis, myelitis, immune-mediated neuropathy, myositis, dermatomyositis, polymyositis, inclusion body myositis, inflammatory demyelinating polyradiculoneuropathy, Guillain Barre syndrome, myasthenia gravis, inflammation of the nervous system, inflammatory bowel disease, Crohn's disease, ulcerative colitis, SLE (systemic lupus erythematosus), rheumatoid arthritis, vasculitis, polyarteritis nodosa, Sjogren syndrome, mixed connective tissue disease, glomerulonephritis, thyroid autoimmune disease, sepsis, meningitis, a bacterial infection, a viral infection, a fungal infection, sarcoidosis, hepatitis, and portal vein hypertension.

Owner:MEDTRONIC INC

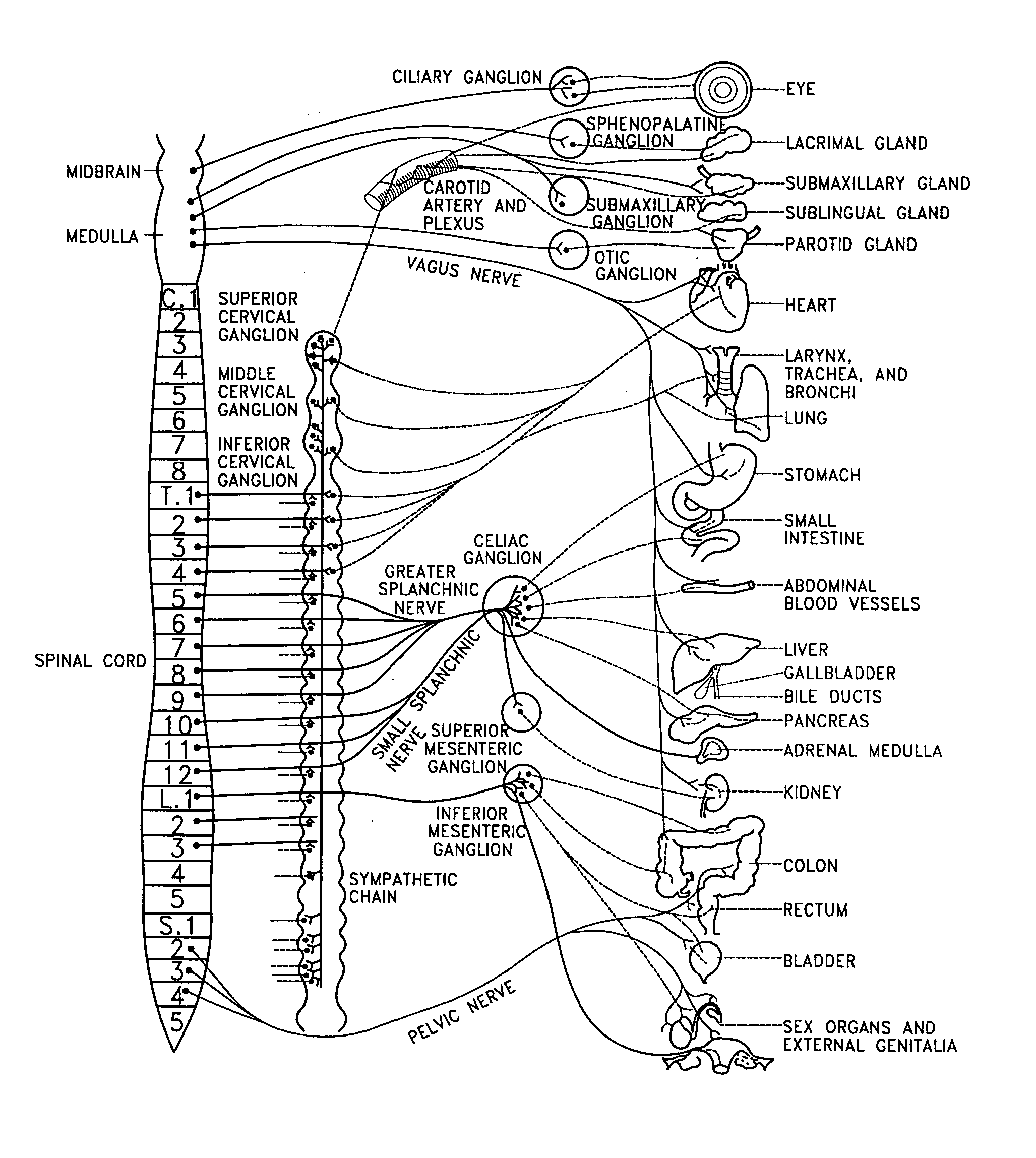

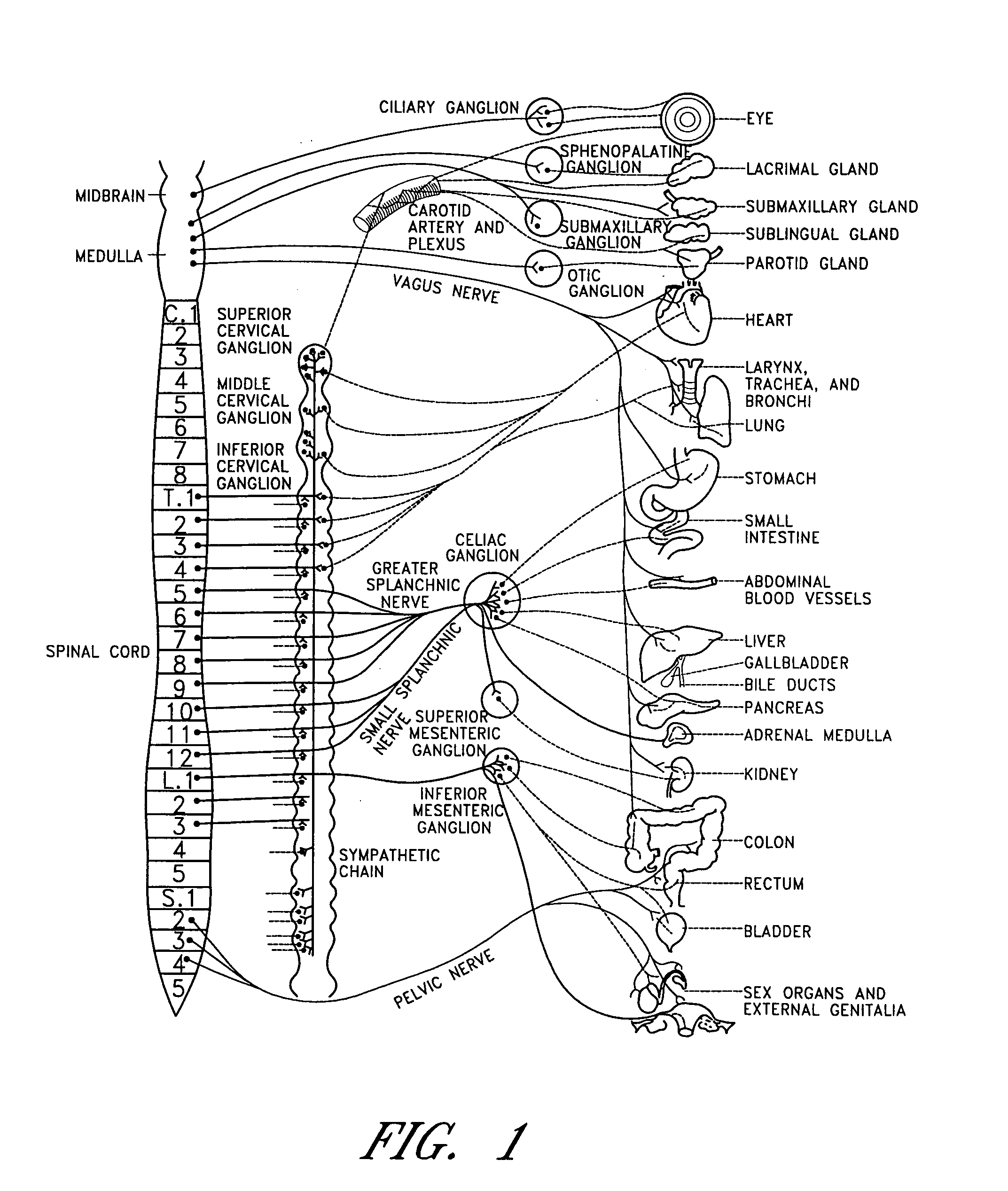

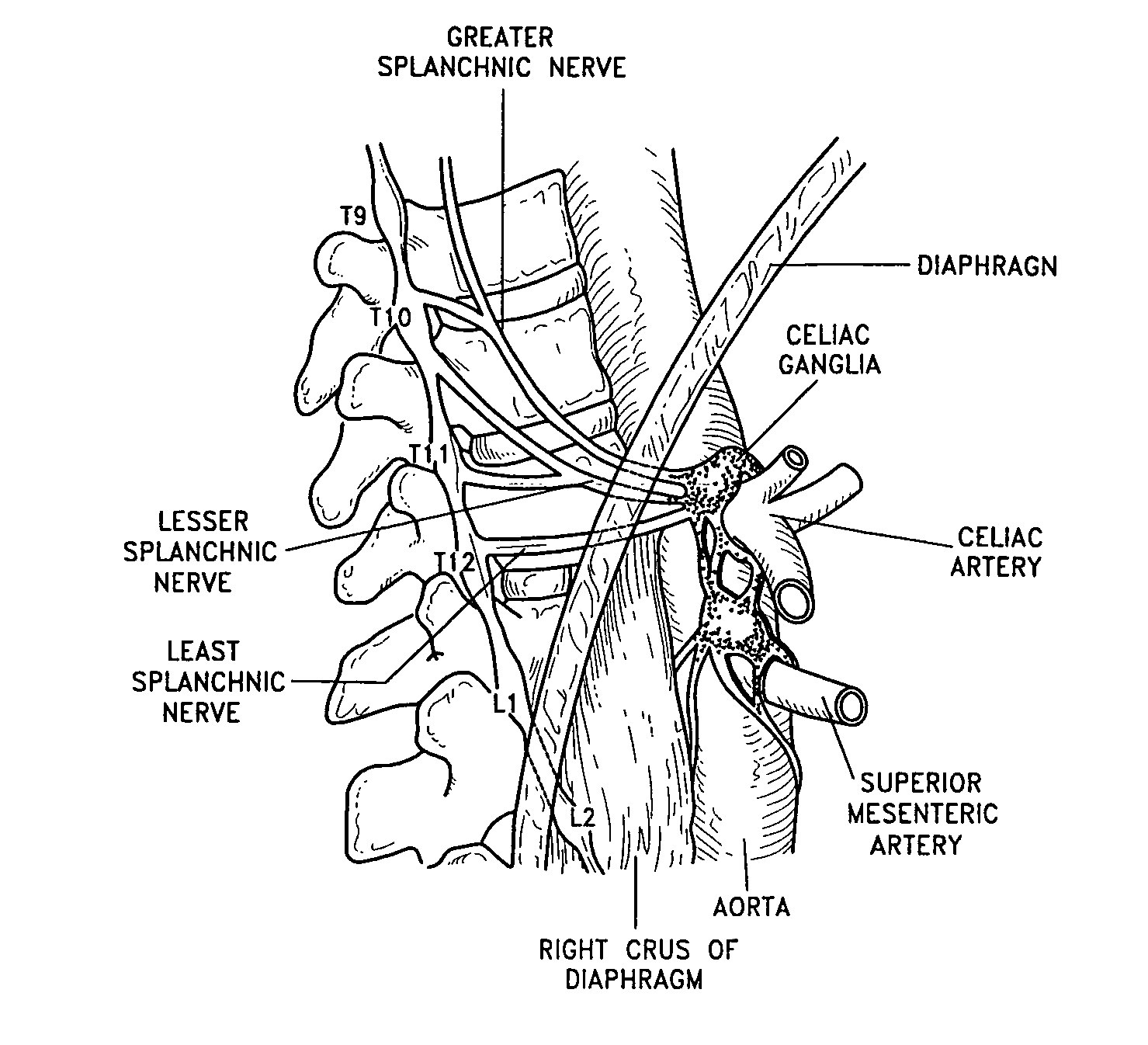

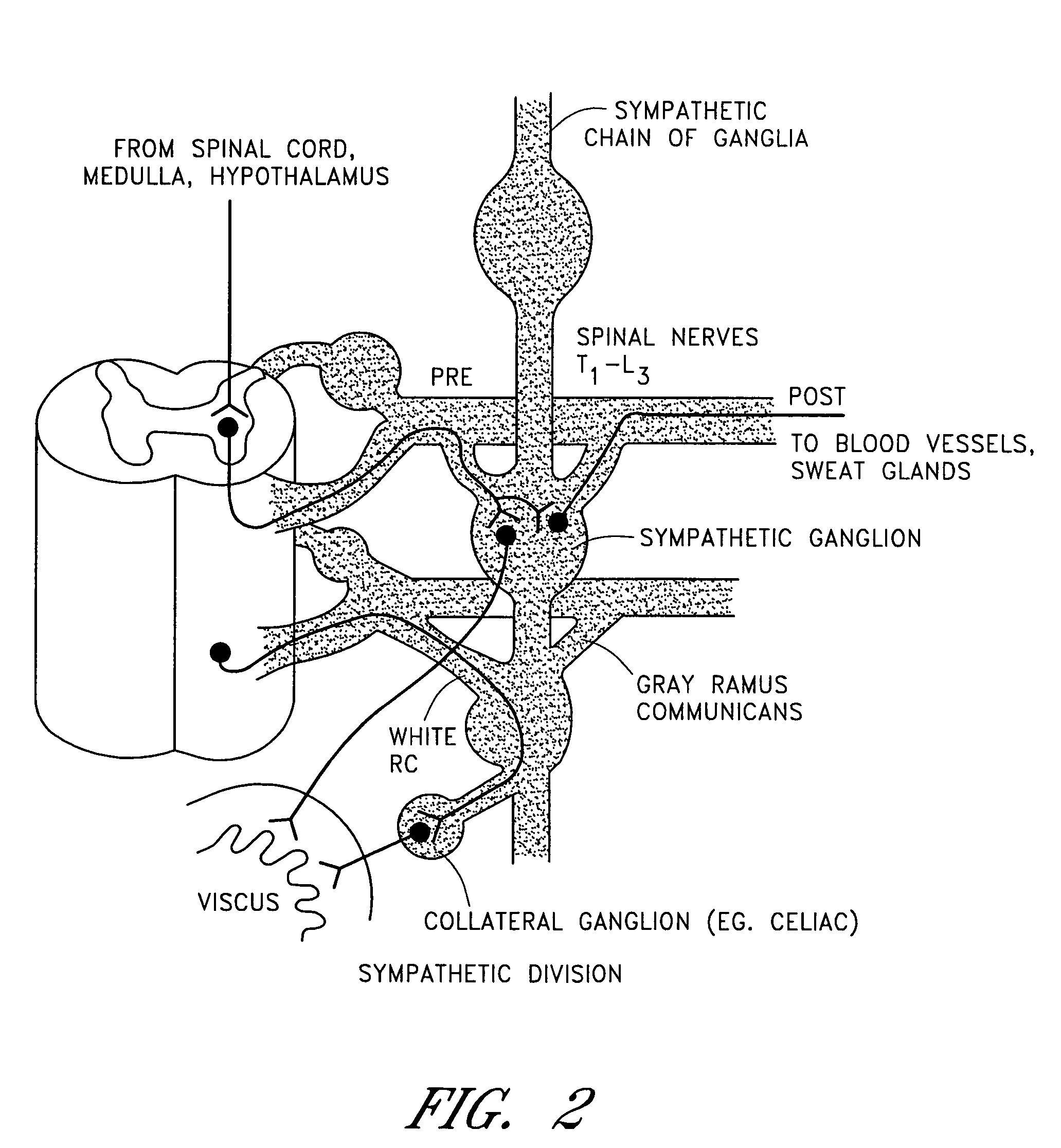

Dynamic nerve stimulation for treatment of disorders

ActiveUS20050065575A1Provide central nervous system satietyIncreased energy expenditureSpinal electrodesDiseasePhysical therapy

A method for the treatment of obesity or other disorders by electrical activation or inhibition of nerves is disclosed. This activation or inhibition can be accomplished by stimulating a nerve using an electrode. Dynamic stimulation through ramped cycling of electrical stimulation, stimulation frequency alteration, and / or duty cycle variance can produce therapeutic benefits.

Owner:ADVANCED NEUROMODULATION SYST INC

Stimulation device for sleep apnea prevention, detection and treatment

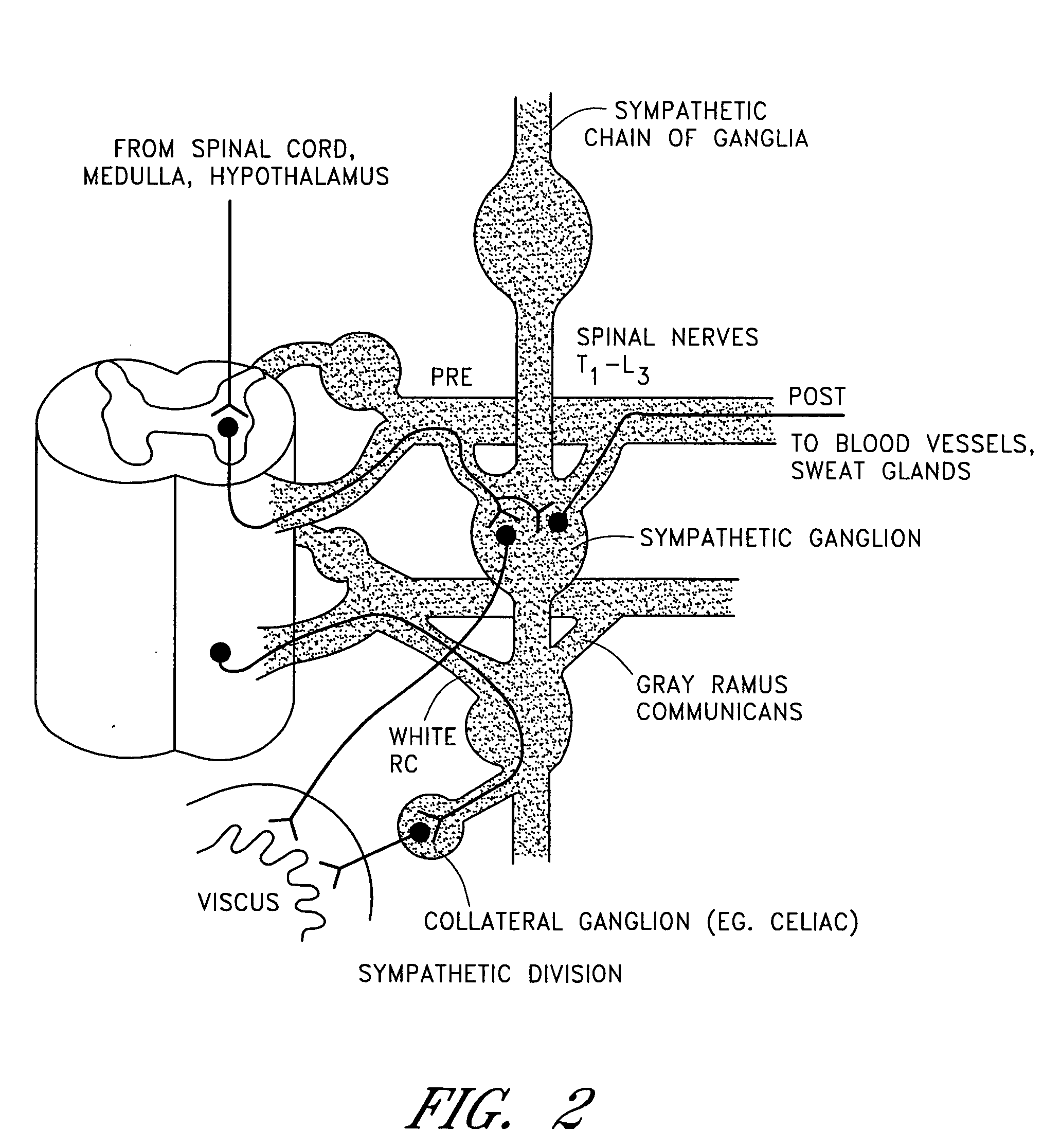

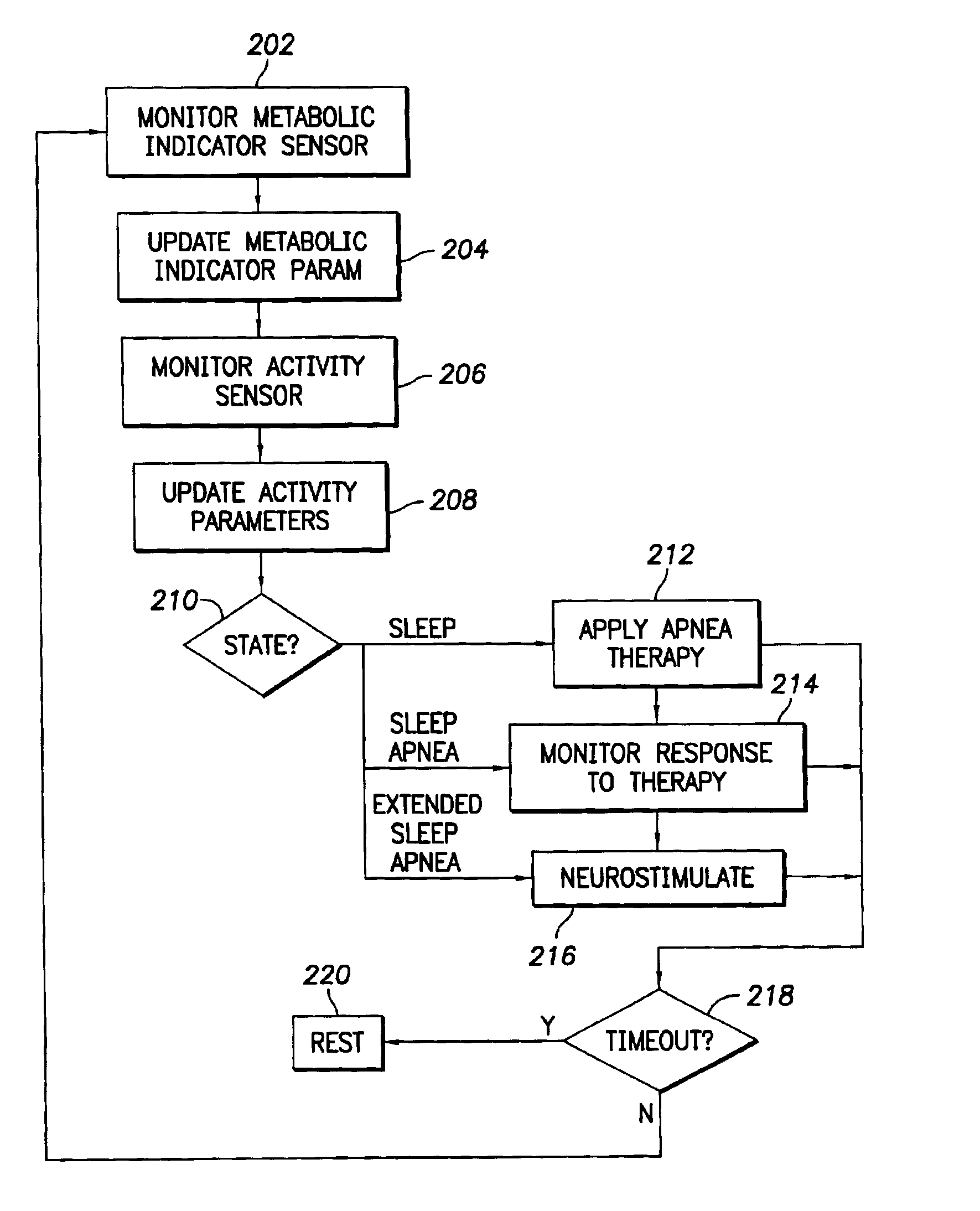

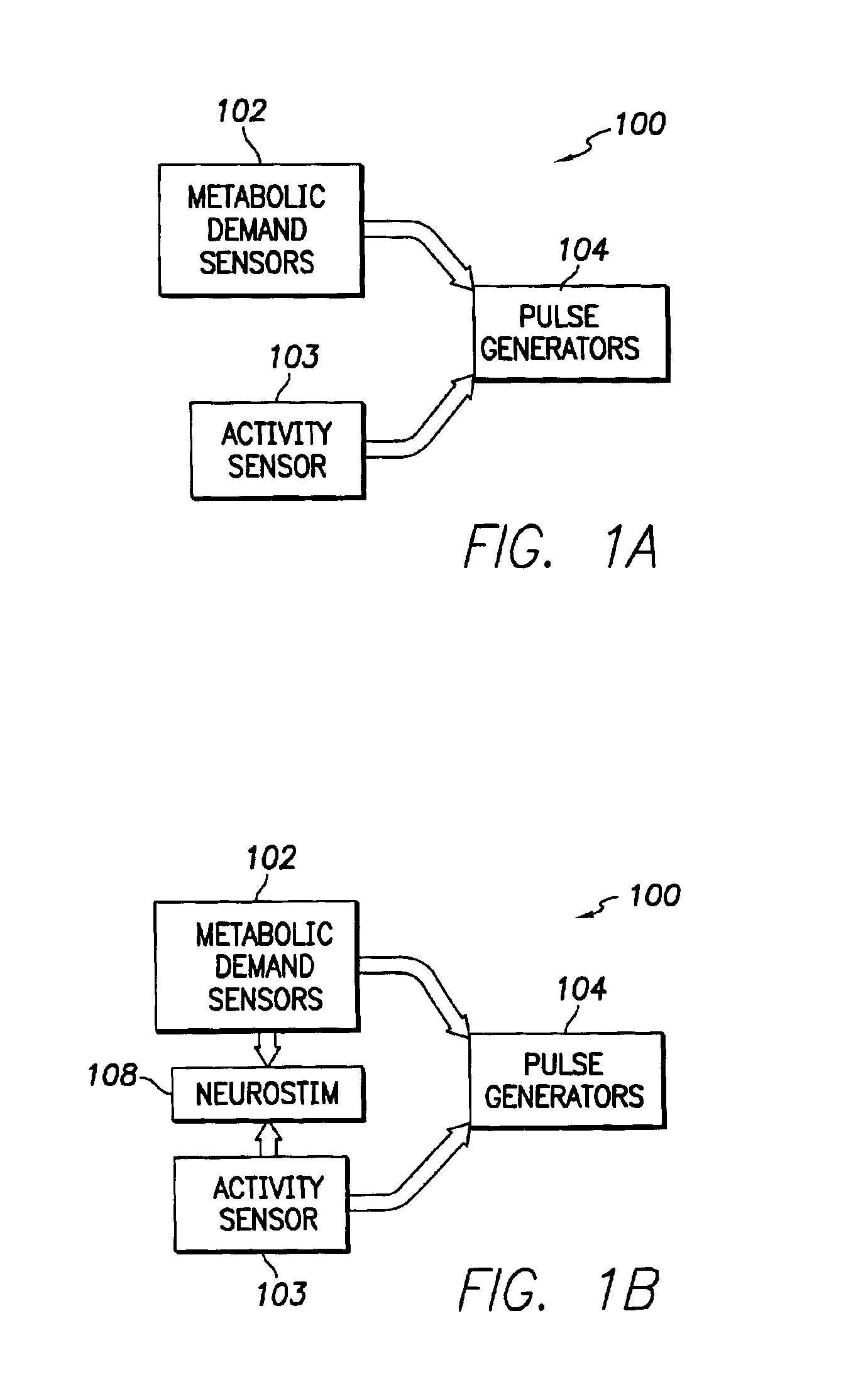

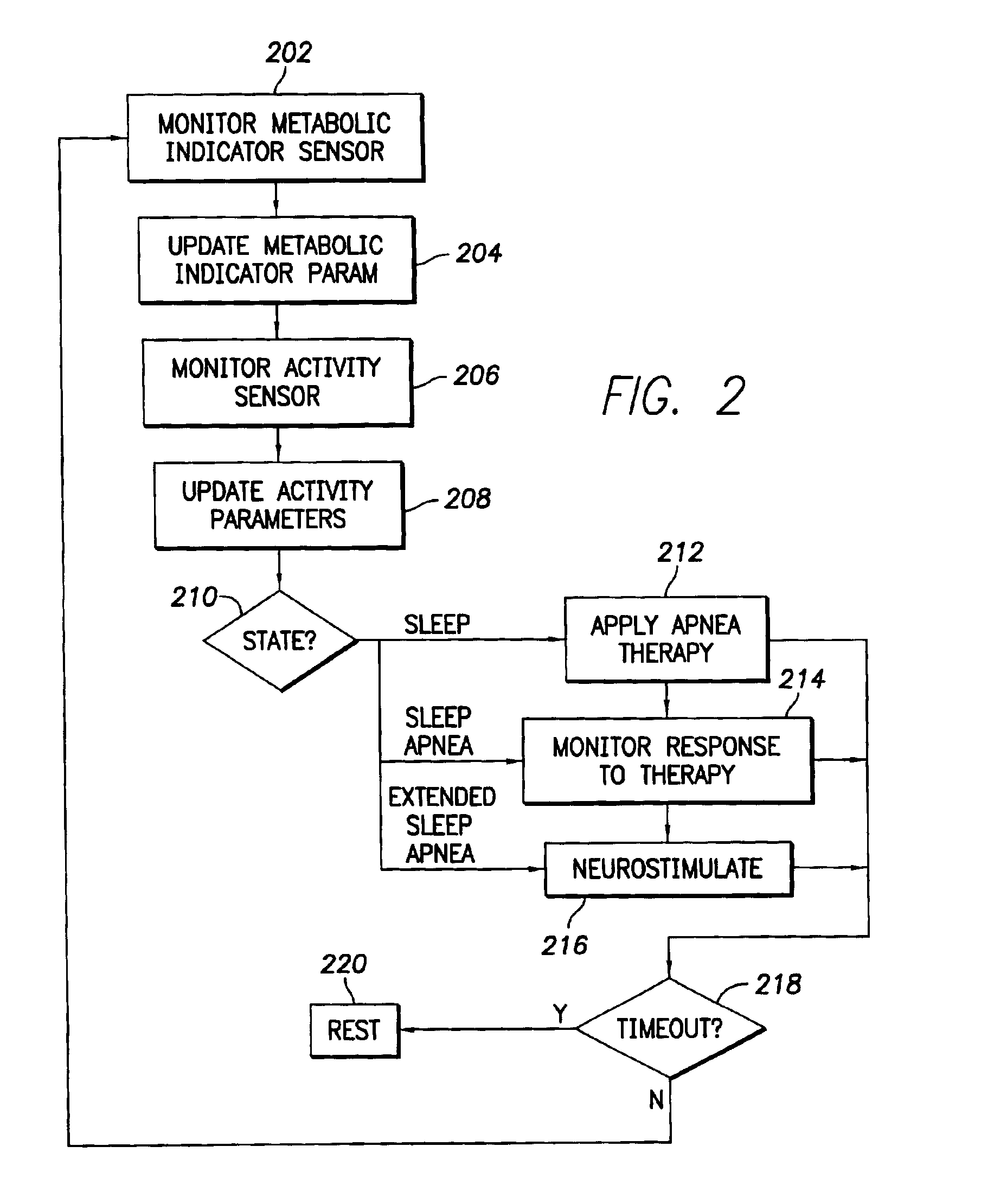

InactiveUS6928324B2Increase oxygen concentrationReduce carbon dioxide concentrationHeart stimulatorsArtificial respirationSleep apneaMetabolic demand

An implantable cardiac stimulation device comprises a metabolic demand sensor, an activity sensor, and one or more pulse generators. The metabolic demand sensor and activity sensor can sense metabolic demand and physical activity parameters, respectively. The pulse generators can generate cardiac pacing pulses with timing based on a comparison of the metabolic demand and physical activity parameters. The timed cardiac pacing pulses can prevent a sleep apnea condition.

Owner:PACESETTER INC

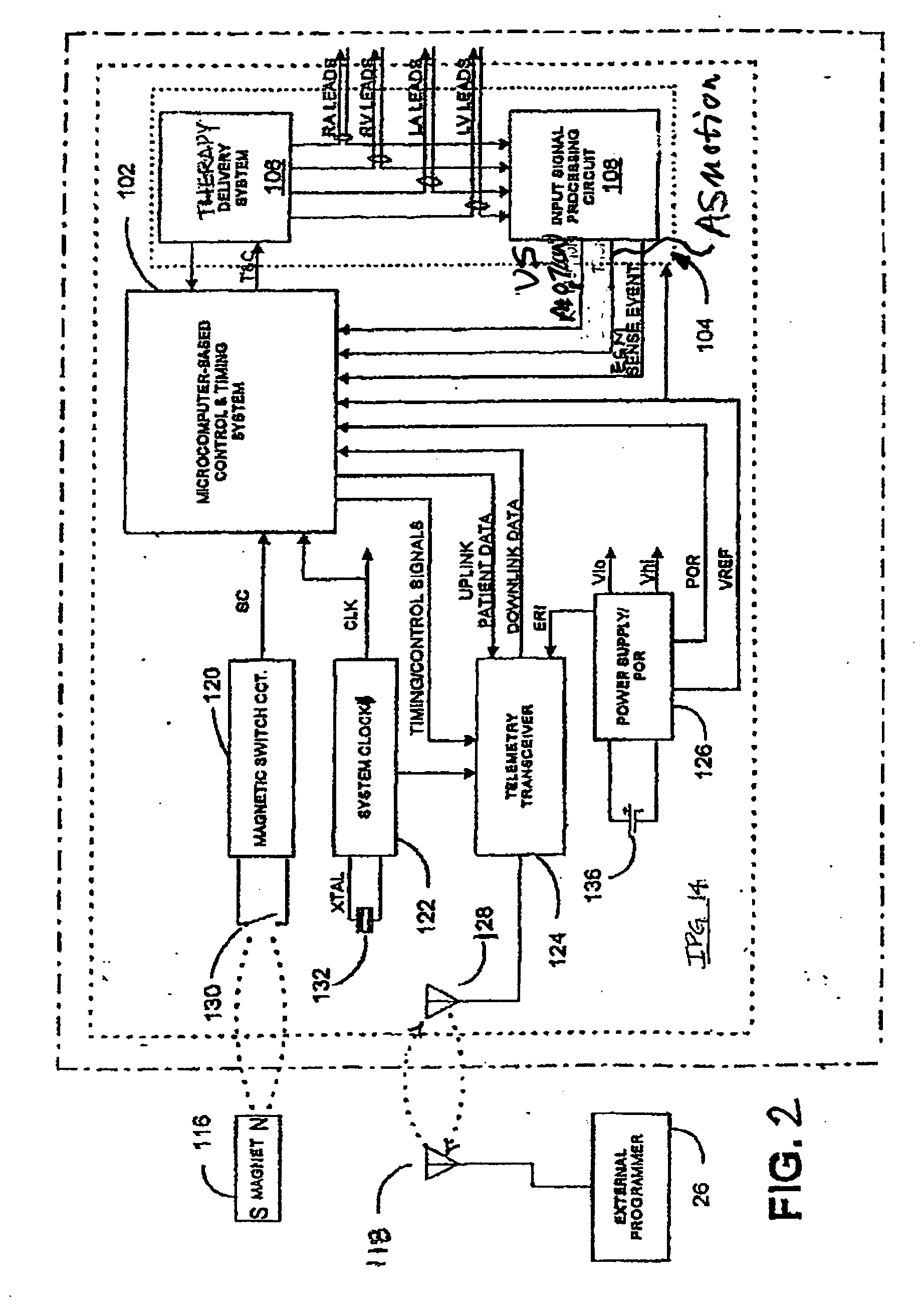

Implantable medical device for treating cardiac mechanical dysfunction by electrical stimulation

InactiveUS20040049235A1Increase the number ofHigh detection specificityHeart defibrillatorsHeart stimulatorsCardiac dysfunctionElectrical stimulations

The above-described methods and apparatus are believed to be of particular benefit for patients suffering heart failure including cardiac dysfunction, chronic HF, and the like and all variants as described herein and including those known to those of skill in the art to which the invention is directed. It will understood that the present invention offers the possibility of monitoring and therapy of a wide variety of acute and chronic cardiac dysfunctions. The current invention provides systems and methods for delivering therapy for cardiac hemodynamic dysfunction.

Owner:MEDTRONIC INC

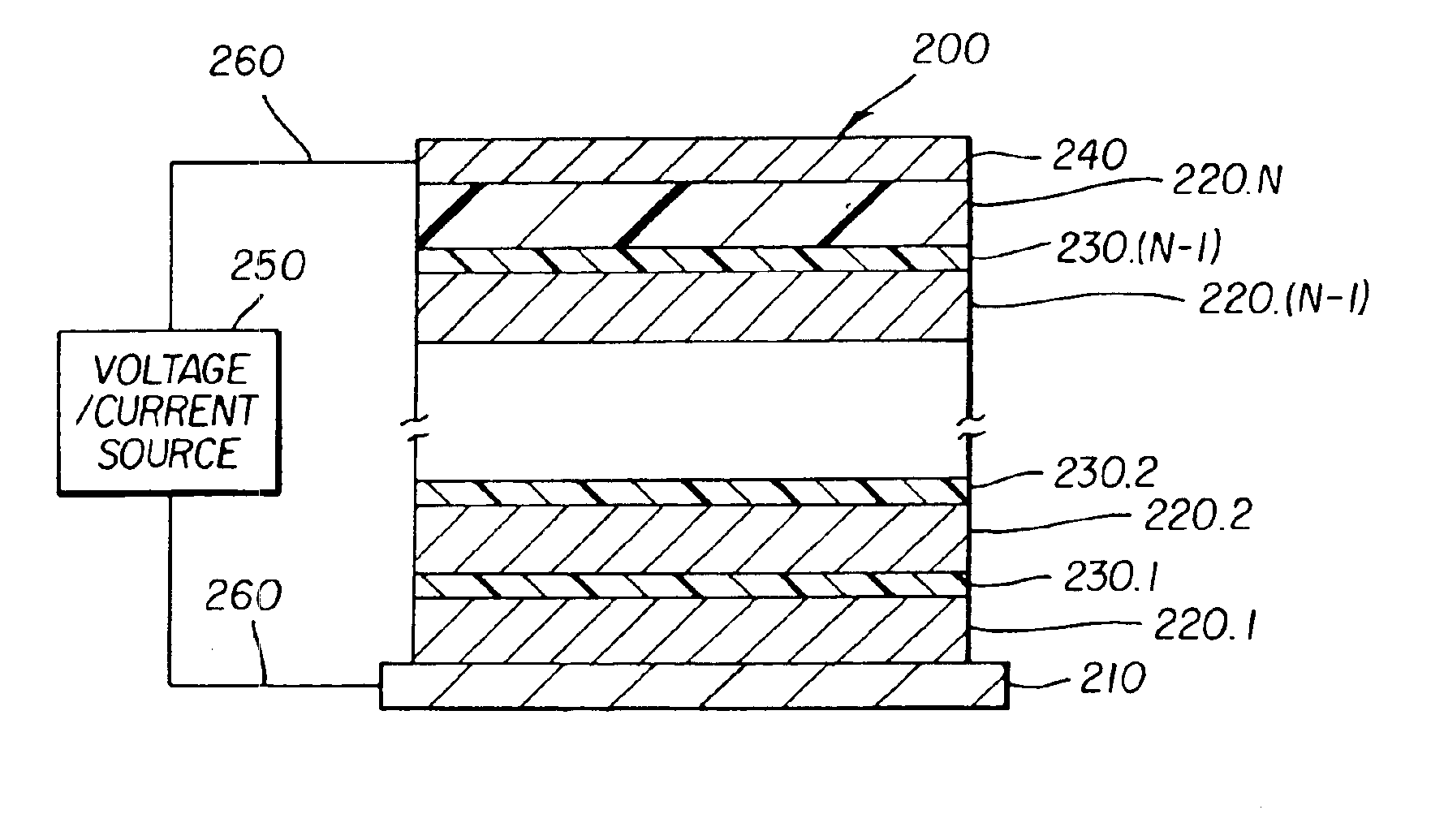

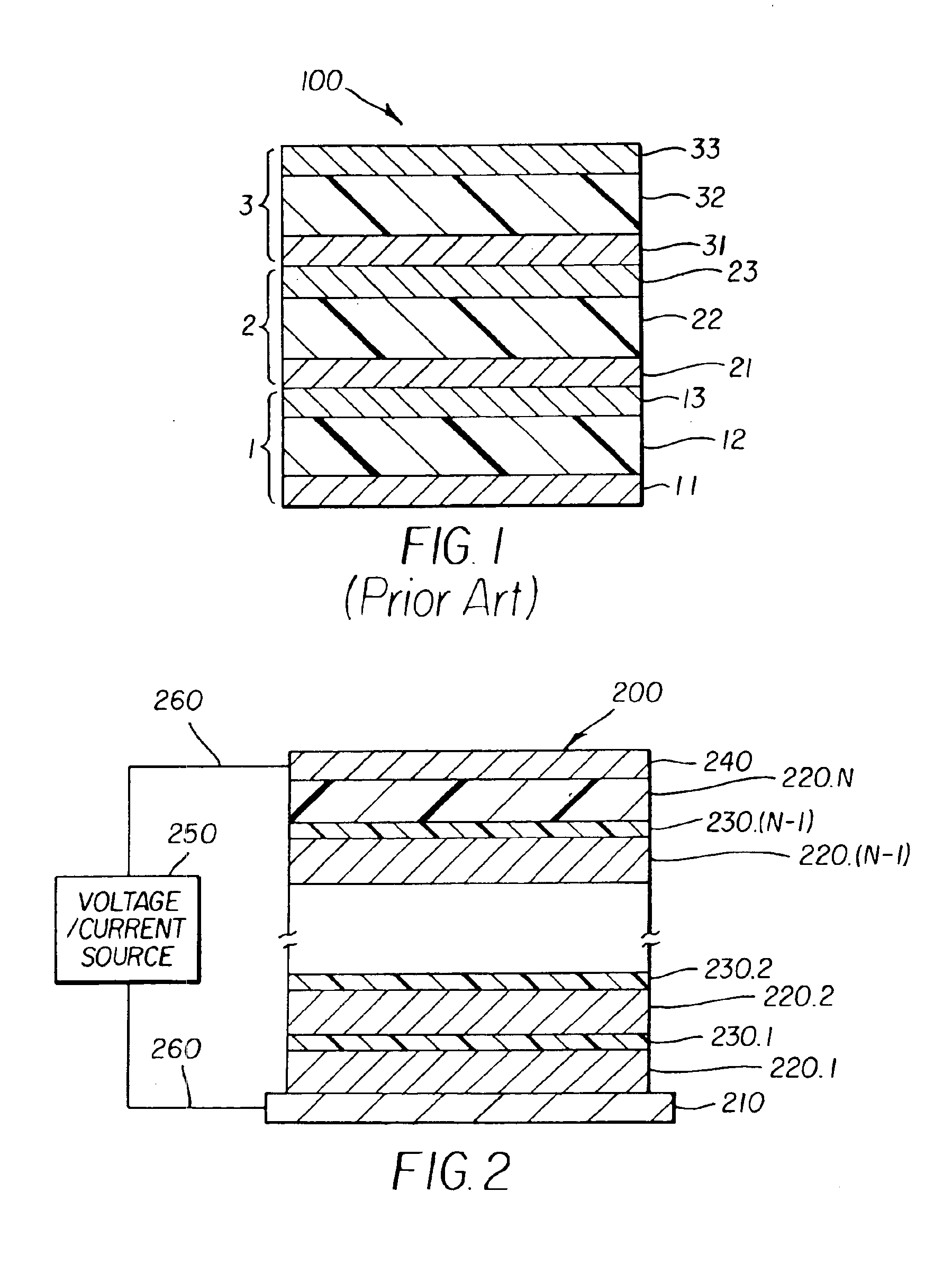

Providing an organic electroluminescent device having stacked electroluminescent units

InactiveUS6872472B2Lowering optical lossesImprove luminous efficiencySolid-state devicesSemiconductor/solid-state device manufacturingOrganic layerElectron transporting layer

A stacked organic electroluminescent device and a method of making such device is disclosed. The device comprises an anode, a cathode, at least two organic electroluminescent units disposed between the anode and the cathode, and a doped organic connector disposed between each adjacent organic electroluminescent unit wherein the organic electroluminescent unit comprises at least one organic hole-transporting layer and one organic electron-transporting layer. The doped organic connector comprises at least one n-type doped organic layer or one p-type doped organic layer, or combinations of layers thereof.

Owner:EASTMAN KODAK CO

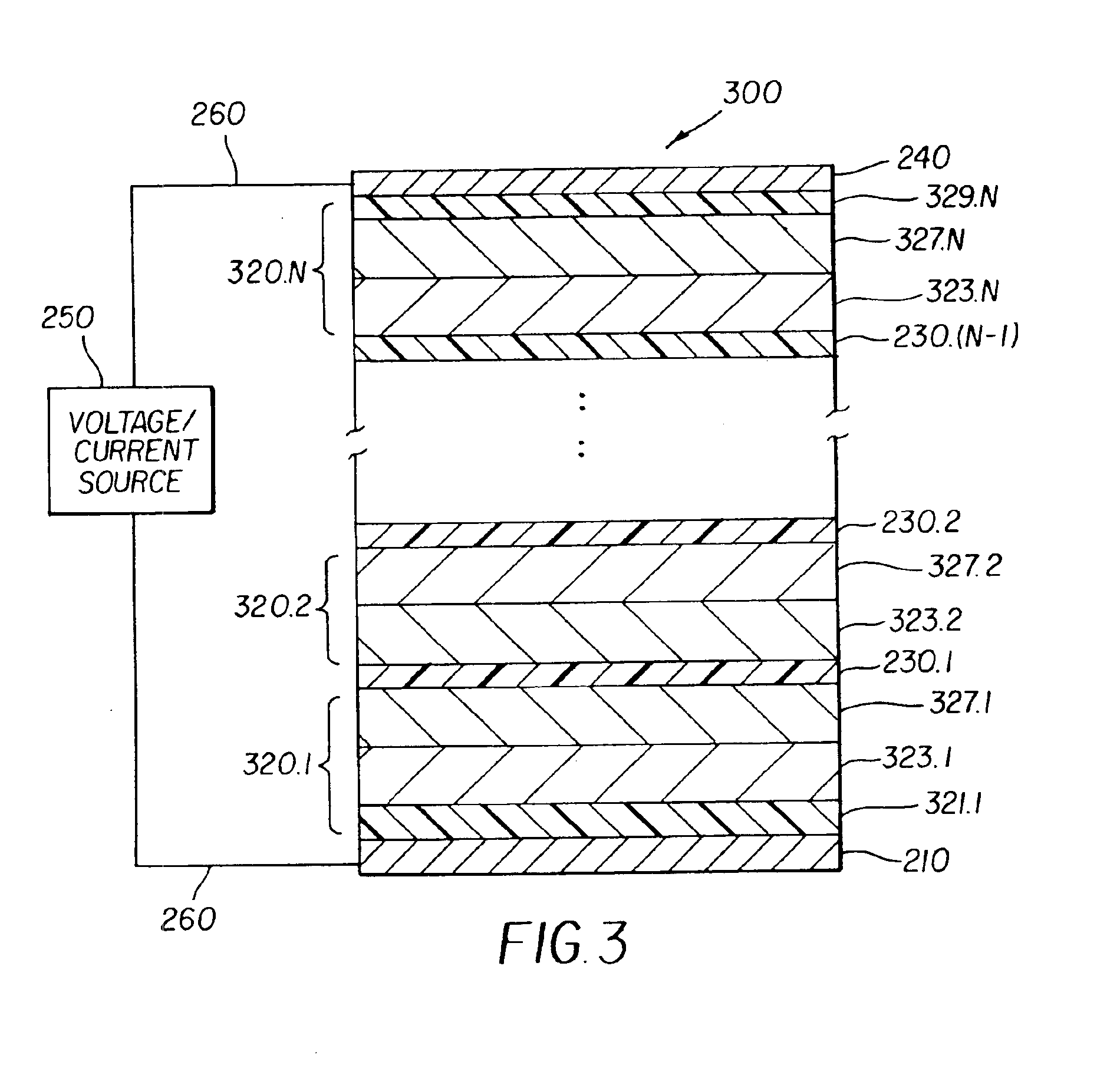

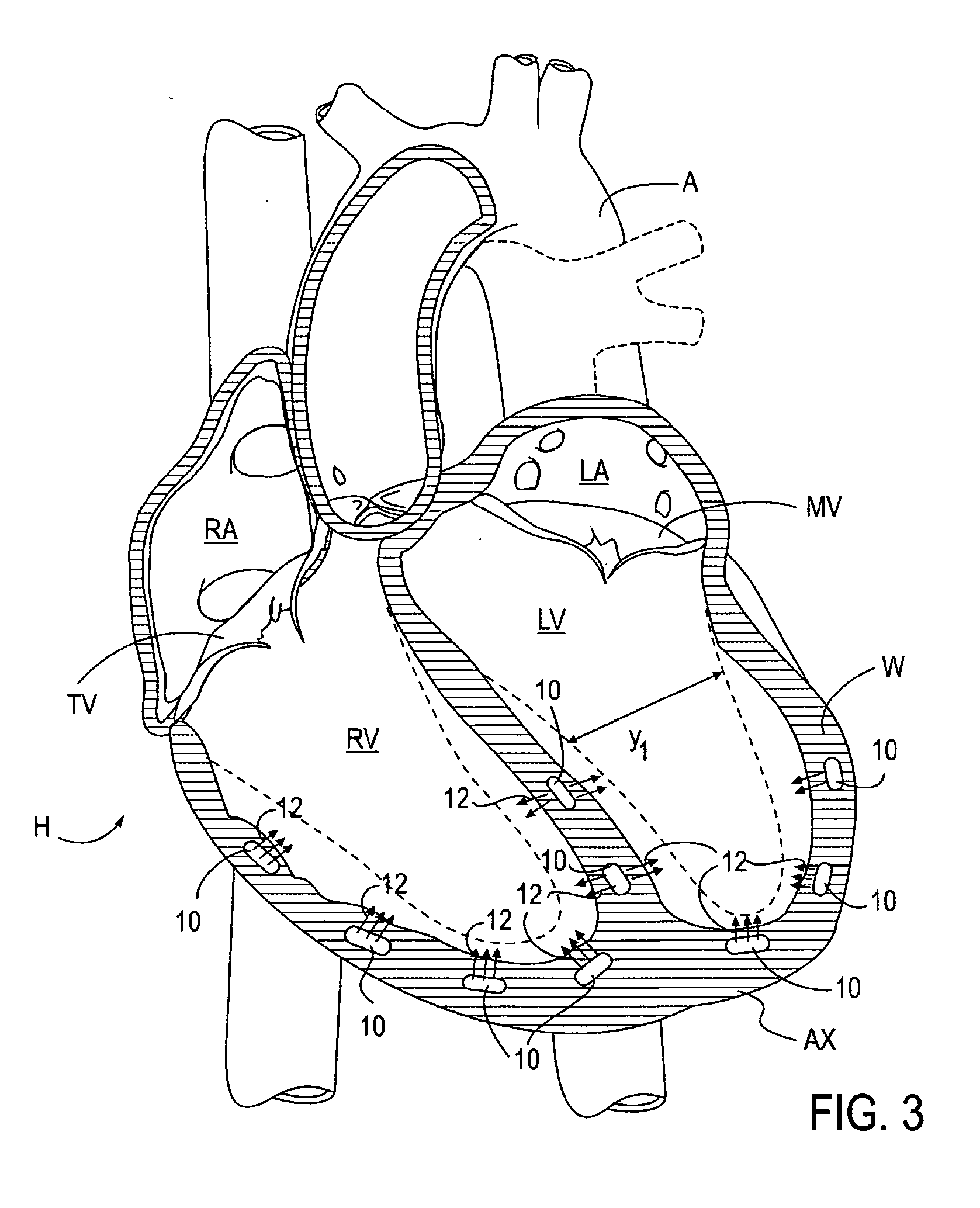

Magnetic devices and methods for reshaping heart anatomy

InactiveUS20060015003A1Improve shrinkageIncreased total stroke volumeElectrotherapyHeart valvesCardiac surfaceHeart Part

Systems, methods and devices are provided for treating heart failure patients suffering from various levels of heart dilation. Heart dilation treated by reshaping the heart anatomy with the use of magnetic forces. Such reshaping changes the geometry of portions of the heart, particularly the right or left ventricles, to increase contractibility of the ventricles thereby increasing the stroke volume which in turn increases the cardiac output of the heart. The magnetic forces are applied with the use of one or more magnetic elements which are implanted within the heart tissue or attached externally and / or internally to a surface of the heart. The various charges of the magnetic forces interact causing the associated heart tissue areas to readjust position, such as to decrease the width of the ventricles. Such repositioning is maintained over time by the force of the magnetic elements, allowing the damaging effects of heart dilation to slow in progression or reverse.

Owner:MICARDIA CORP

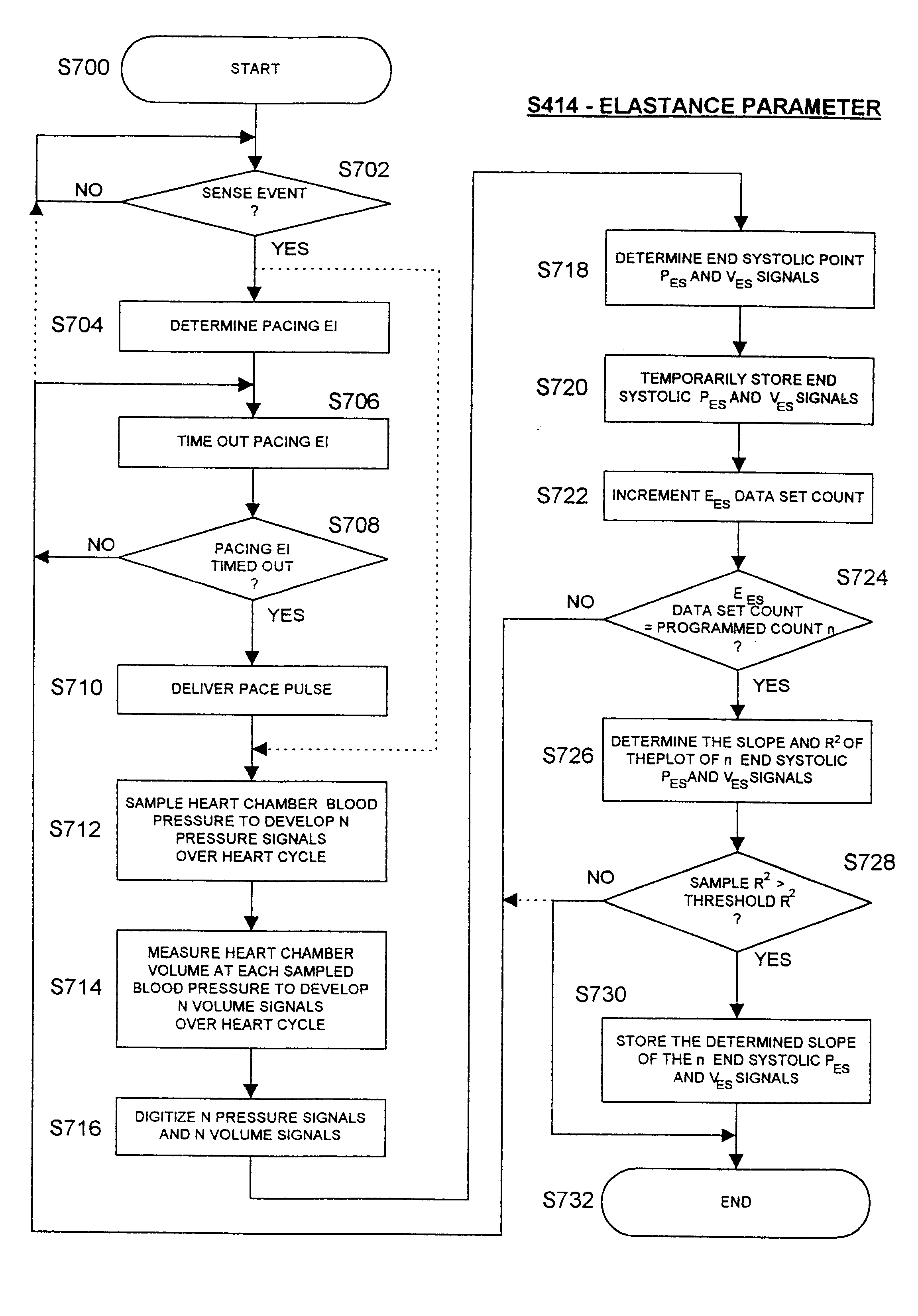

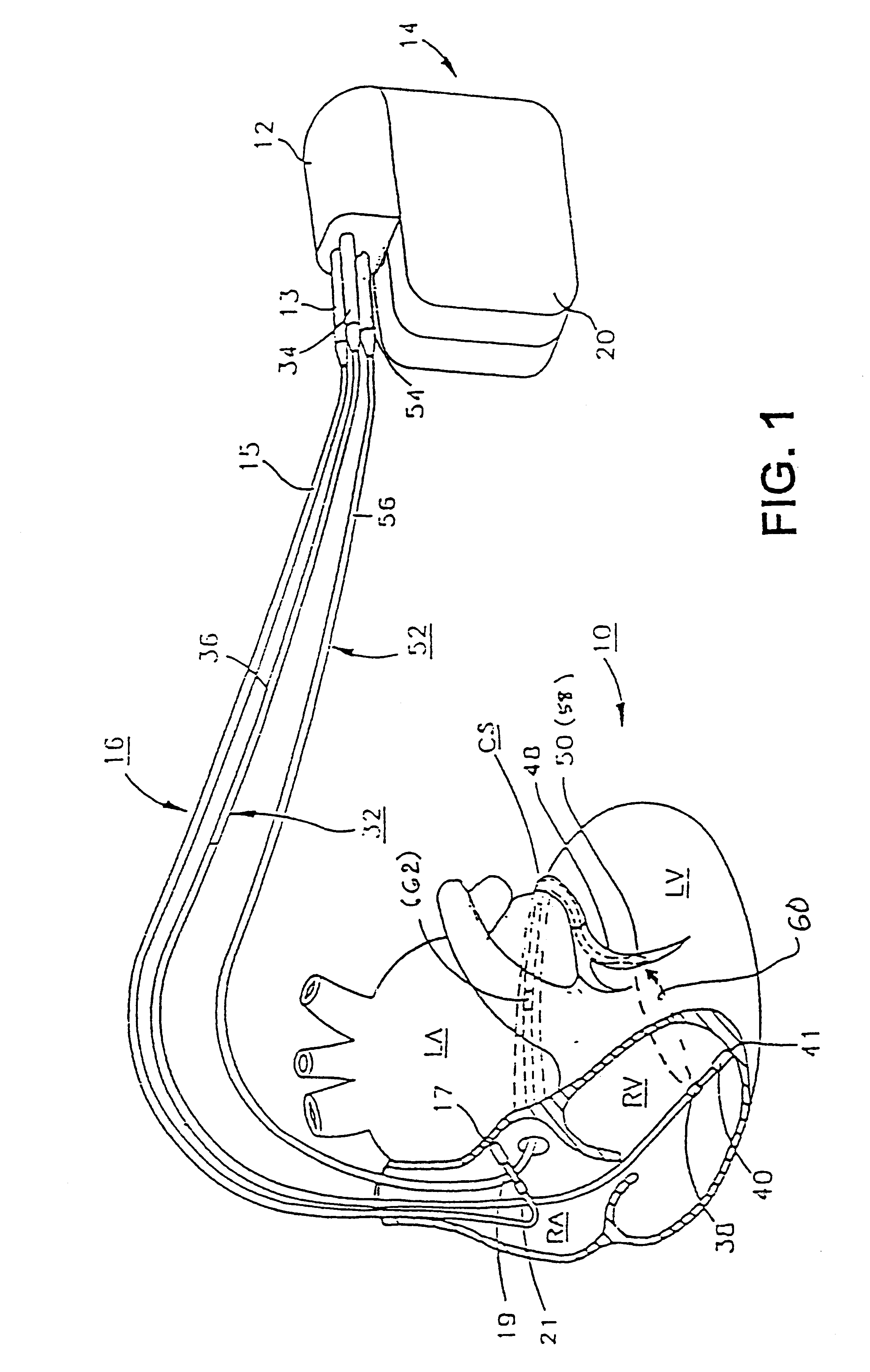

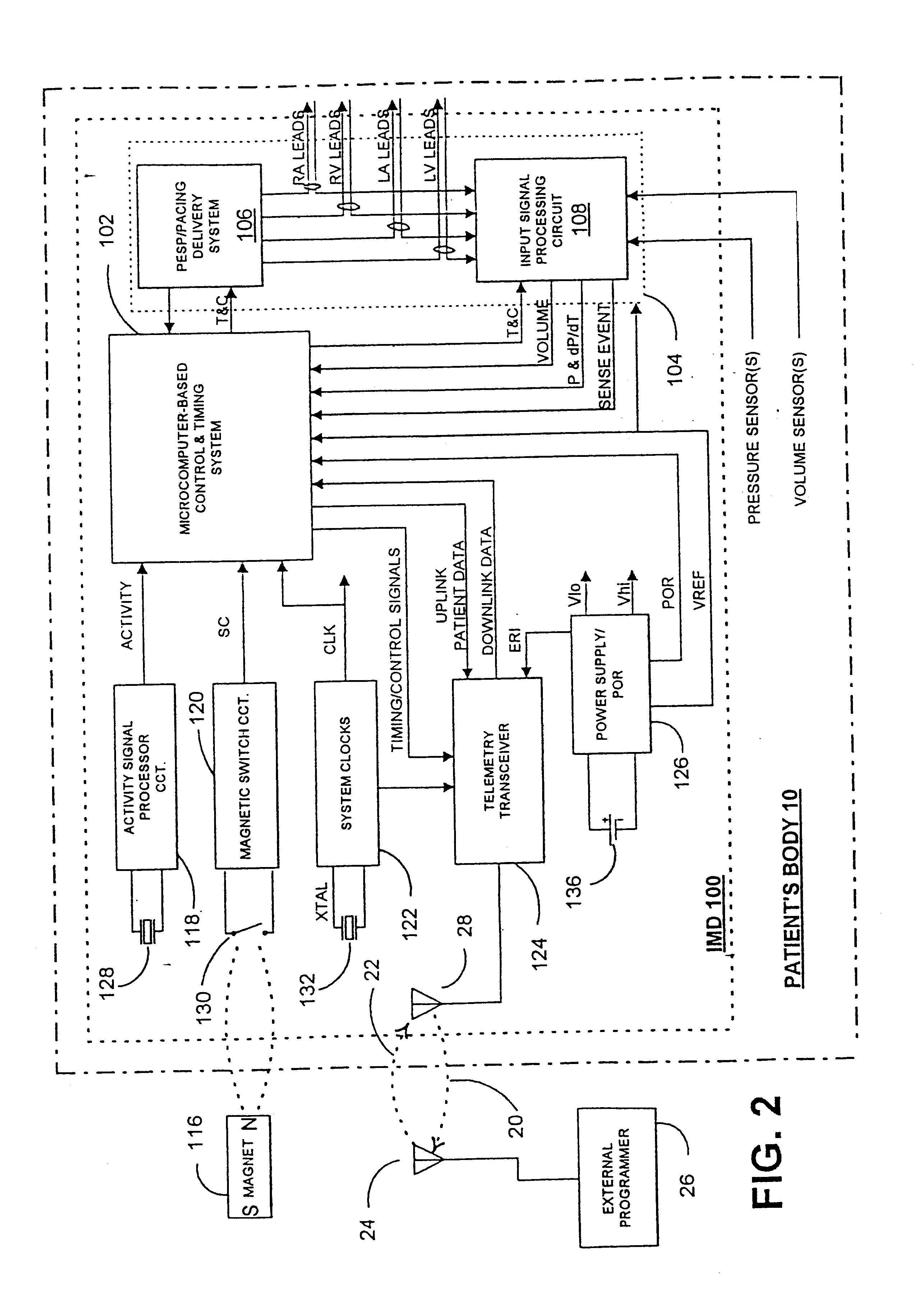

Implantable medical device for treating cardiac mechanical dysfunction by electrical stimulation

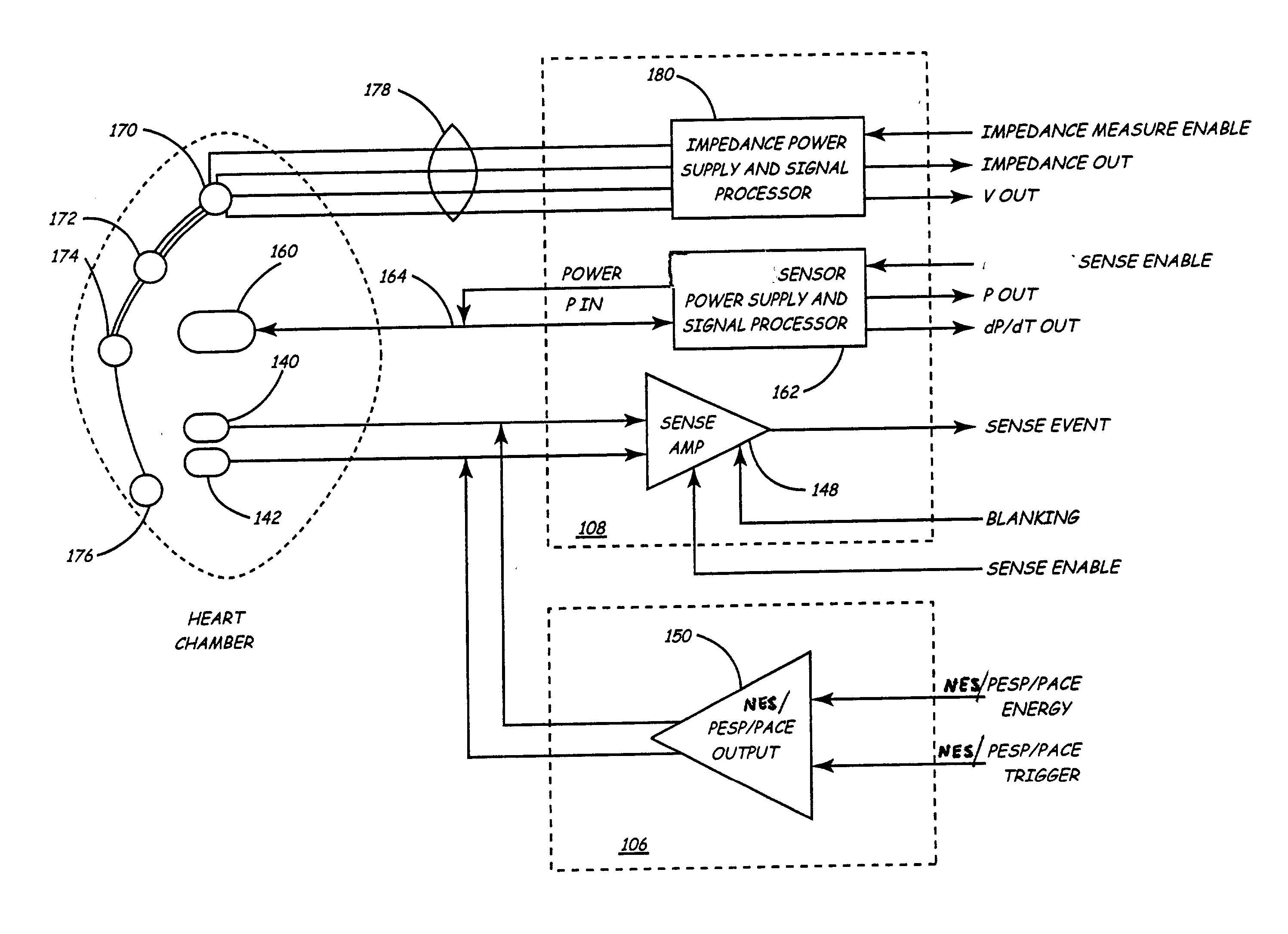

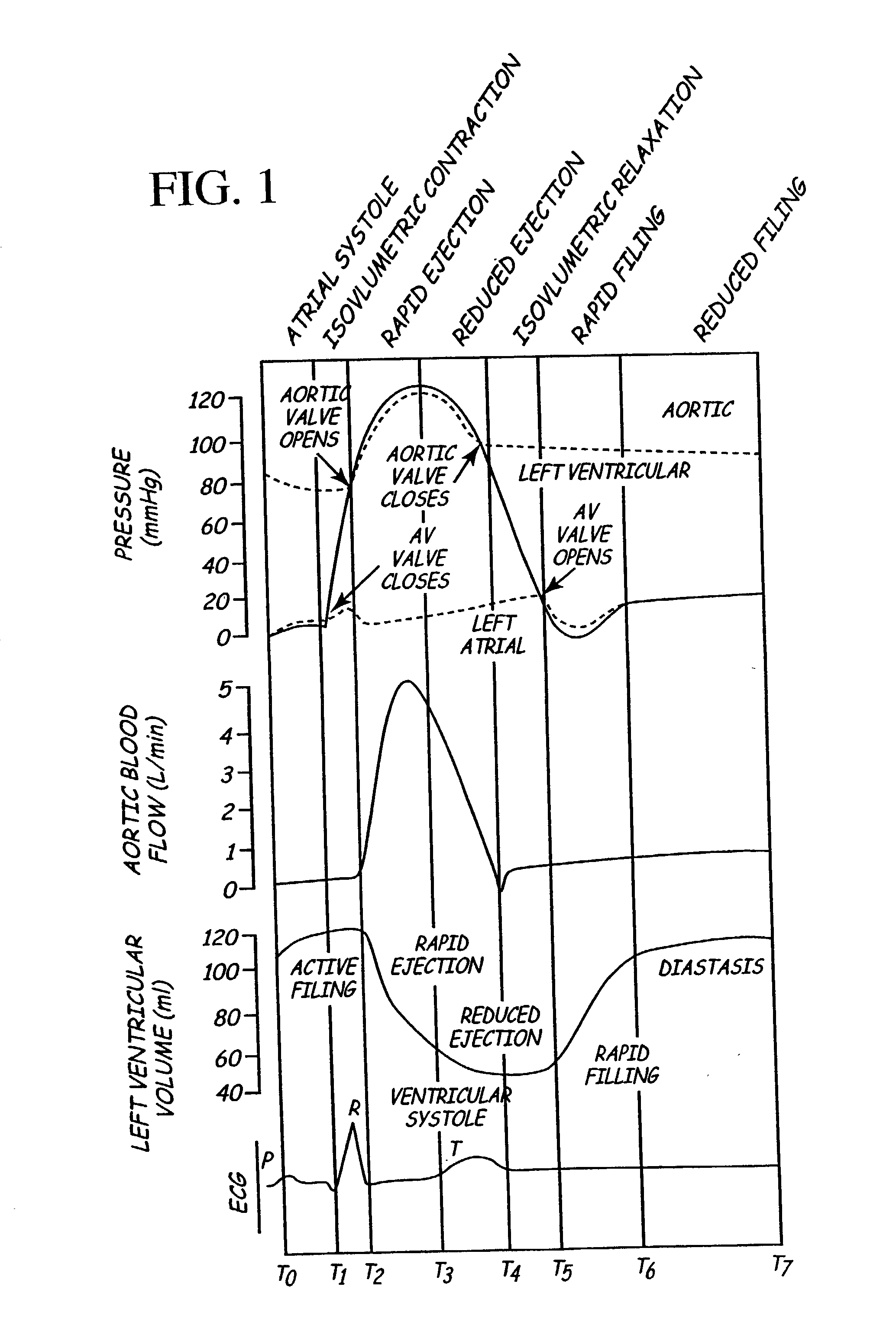

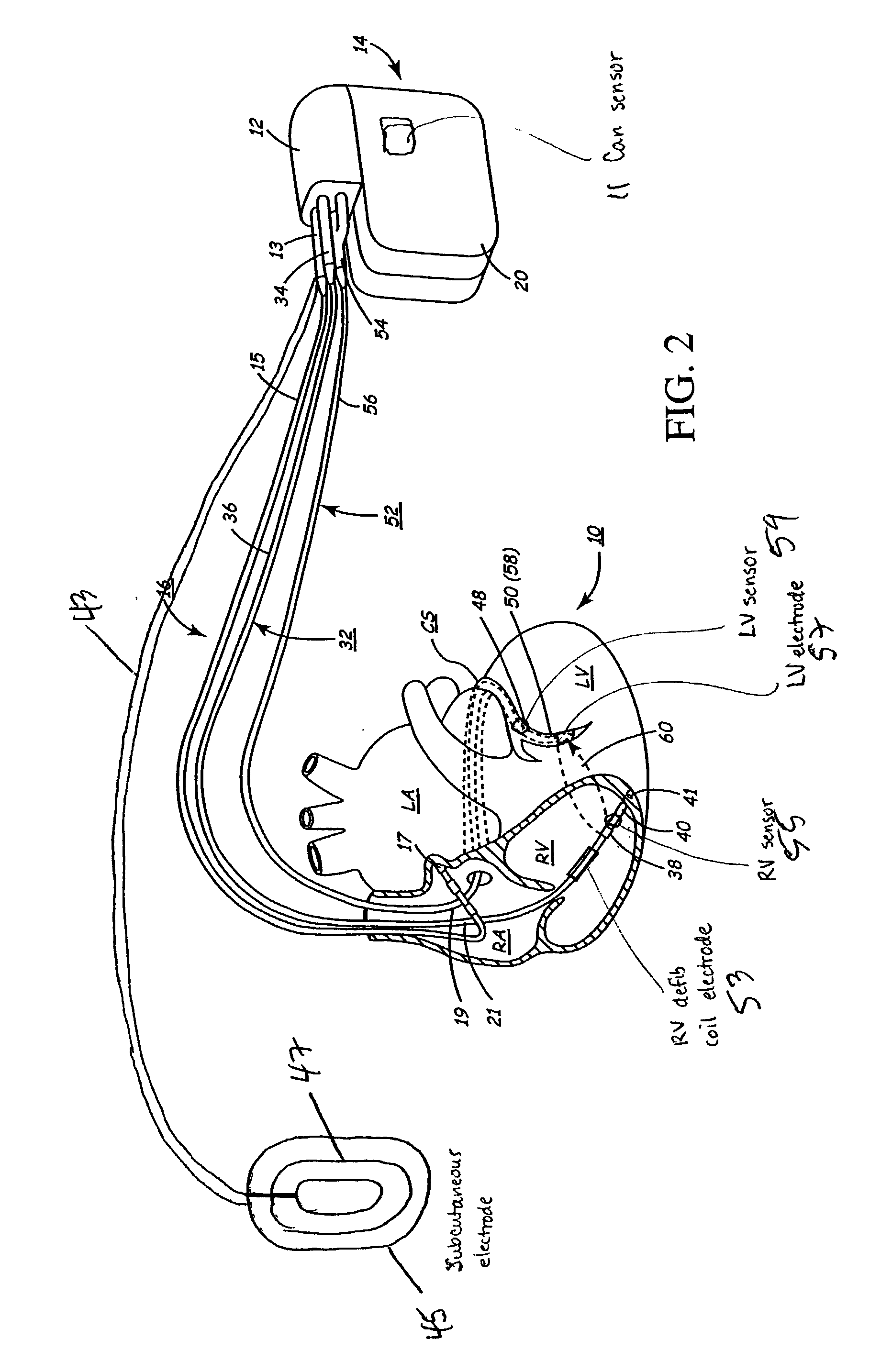

InactiveUS6738667B2Increase contractilityEasy to relaxCatheterHeart stimulatorsCardiac cycleHeart chamber

An implantable stimulator and monitor measures a group of heart failure parameters indicative of the state of heart failure employing EGM signals, measures of blood pressure including absolute pressure P, developed pressure (DP=systolic P-diastolic P), and / or dP / dt, and measures of heart chamber volume (V) over one or more cardiac cycles. These parameters include: (1) relaxation or contraction time constant tau (.tau.); (2) mechanical restitution (MR), i.e., the mechanical response of a heart chamber to premature stimuli applied to the heart chamber; (3) recirculation fraction (RF), i.e., the rate of decay of PESP effects over a series of heart cycles; and (4) end systolic elastance (E.sub.ES), i.e., the ratios of end systolic blood pressure P to volume V. These heart failure parameters are determined periodically regardless of patient posture and activity level. The physician can determine whether a particular therapy is appropriate, prescribe the therapy for a period of time while again accumulating the stored patient data for a later review and assessment to determine whether the applied therapy is beneficial or not, thereby enabling periodic changes in therapy, if appropriate. Drug therapies and electrical stimulation therapies, including PESP stimulation, and pacing therapies including single chamber, dual chamber and multi-chamber (bi-atrial and / or bi-ventricular) pacing can be delivered. In patient's prone to malignant tachyarrhythmias, the assessment of heart failure state can be taken into account in setting parameters of detection or classification of tachyarrhythmias and the therapies that are delivered.

Owner:MEDTRONIC INC

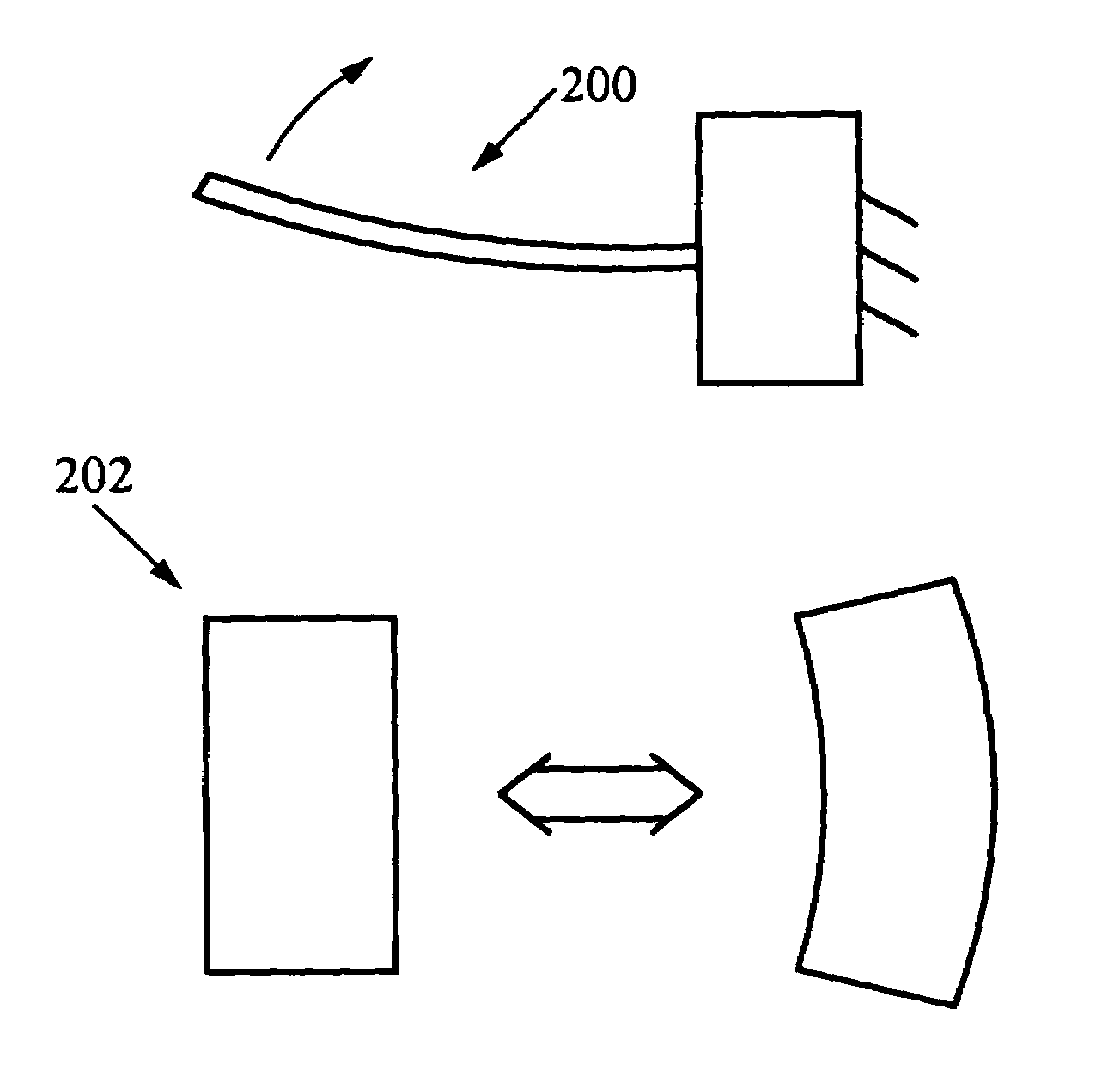

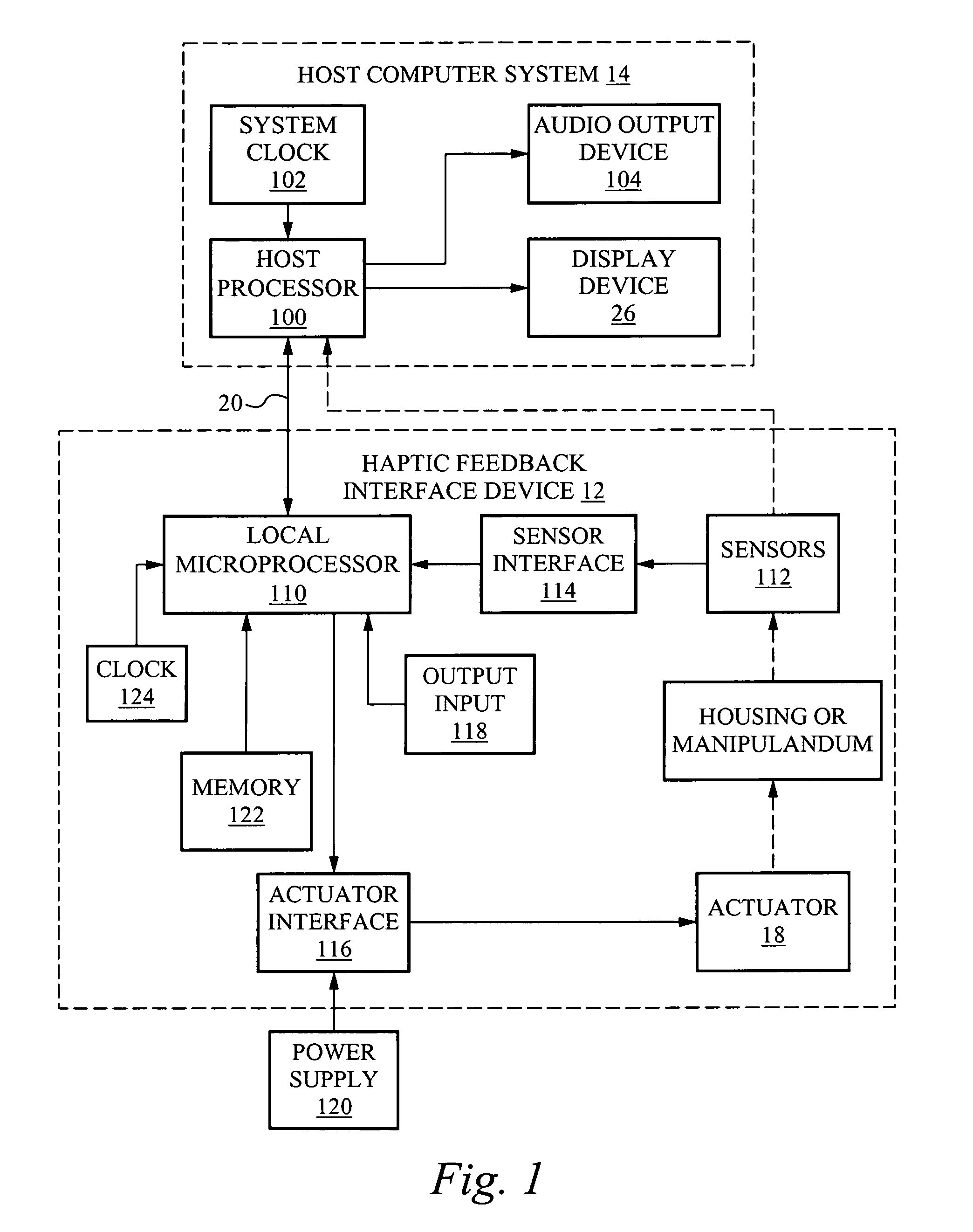

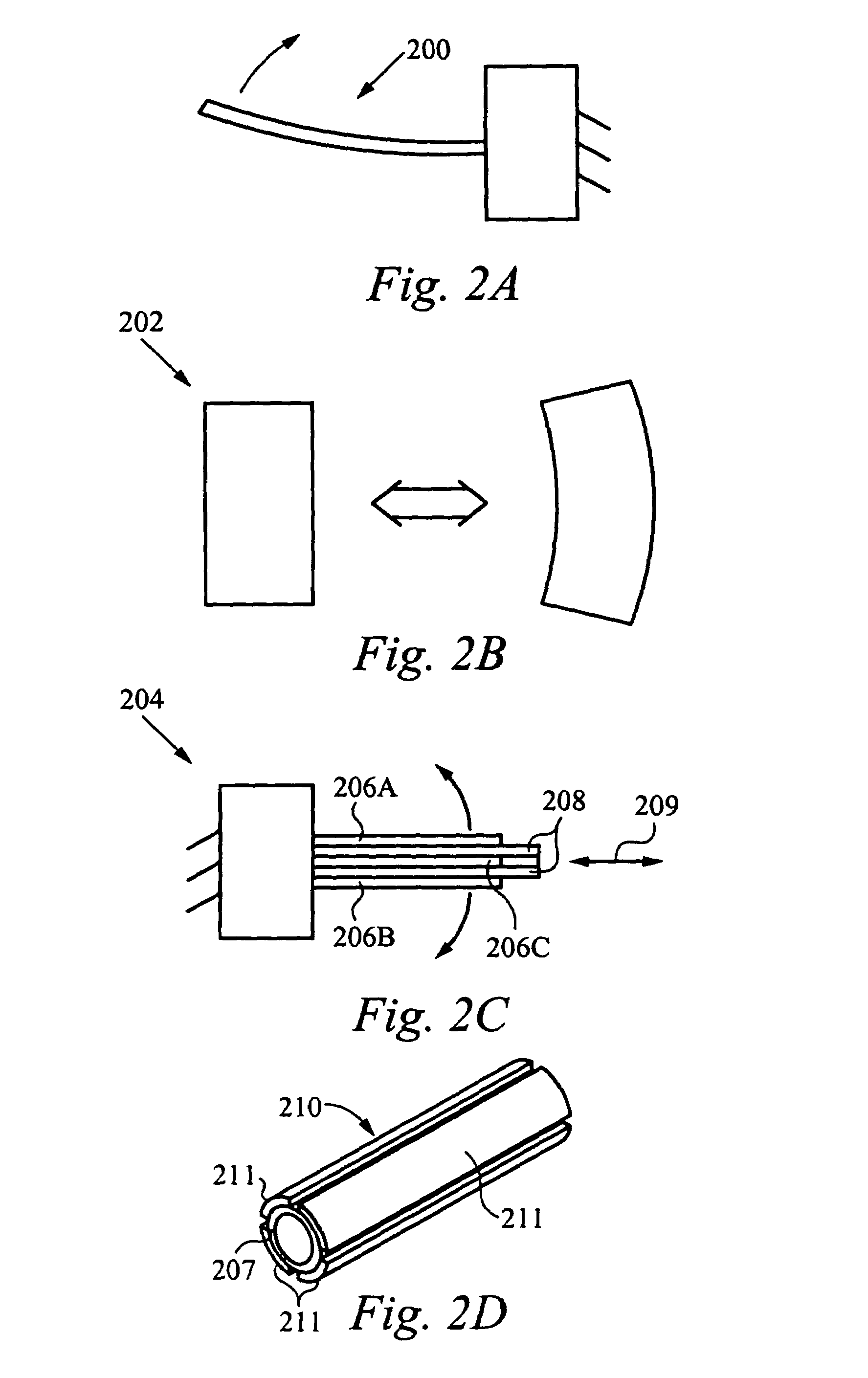

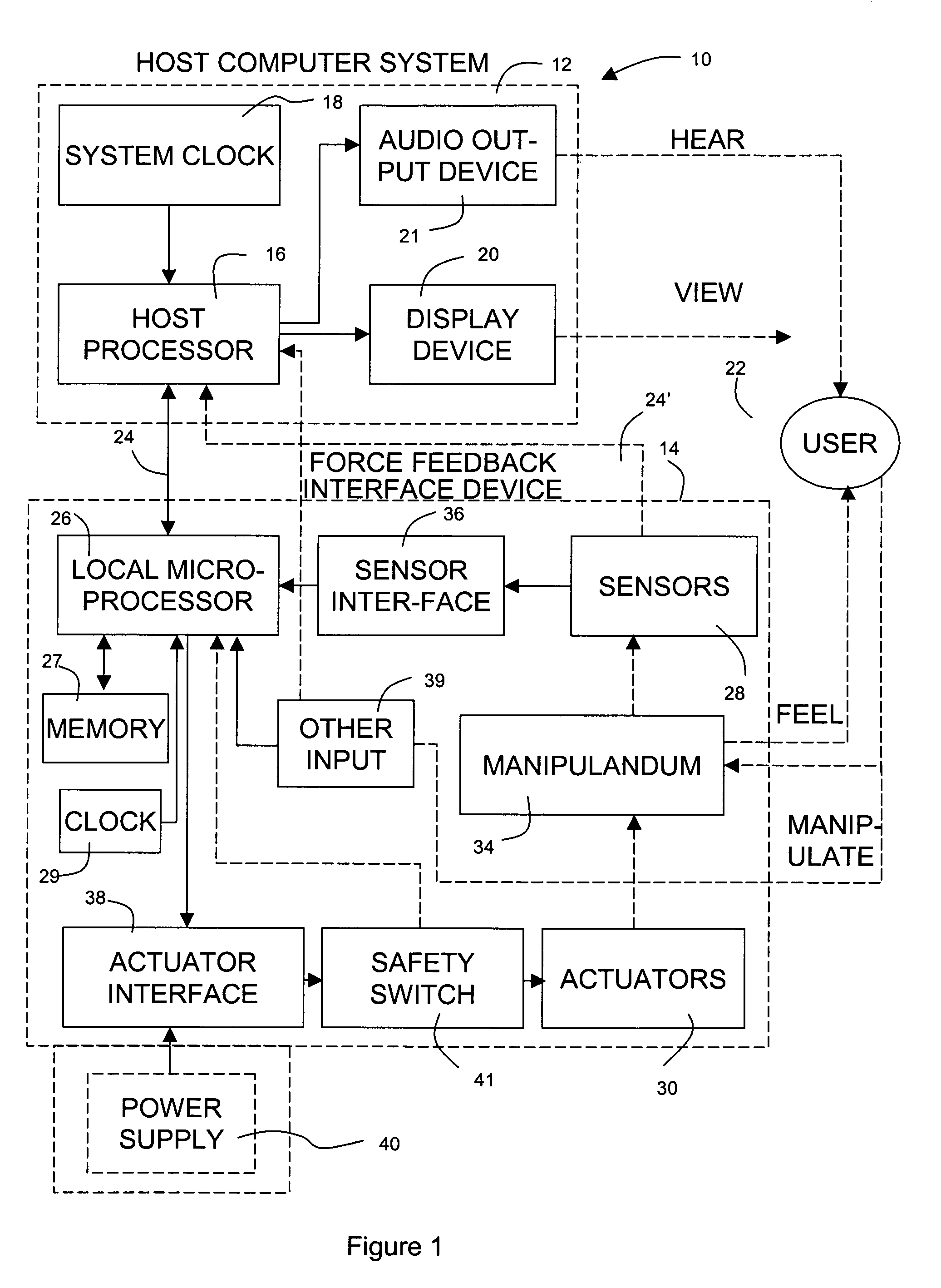

Haptic devices using electroactive polymers

ActiveUS7196688B2Low costEfficiently provideInput/output for user-computer interactionManual control with multiple controlled membersActive polymerHaptic sensing

Haptic feedback interface devices using electroactive polymer (EAP) actuators to provide haptic sensations and / or sensing capabilities. A haptic feedback interface device is in communication with a host computer and includes a sensor device that detects the manipulation of the interface device by the user and an electroactive polymer actuator responsive to input signals and operative to output a force to the user caused by motion of the actuator. The output force provides a haptic sensation to the user. Various embodiments of interface devices employing EAP actuators are described, including embodiments providing direct forces, inertial forces, and braking forces.

Owner:IMMERSION CORPORATION

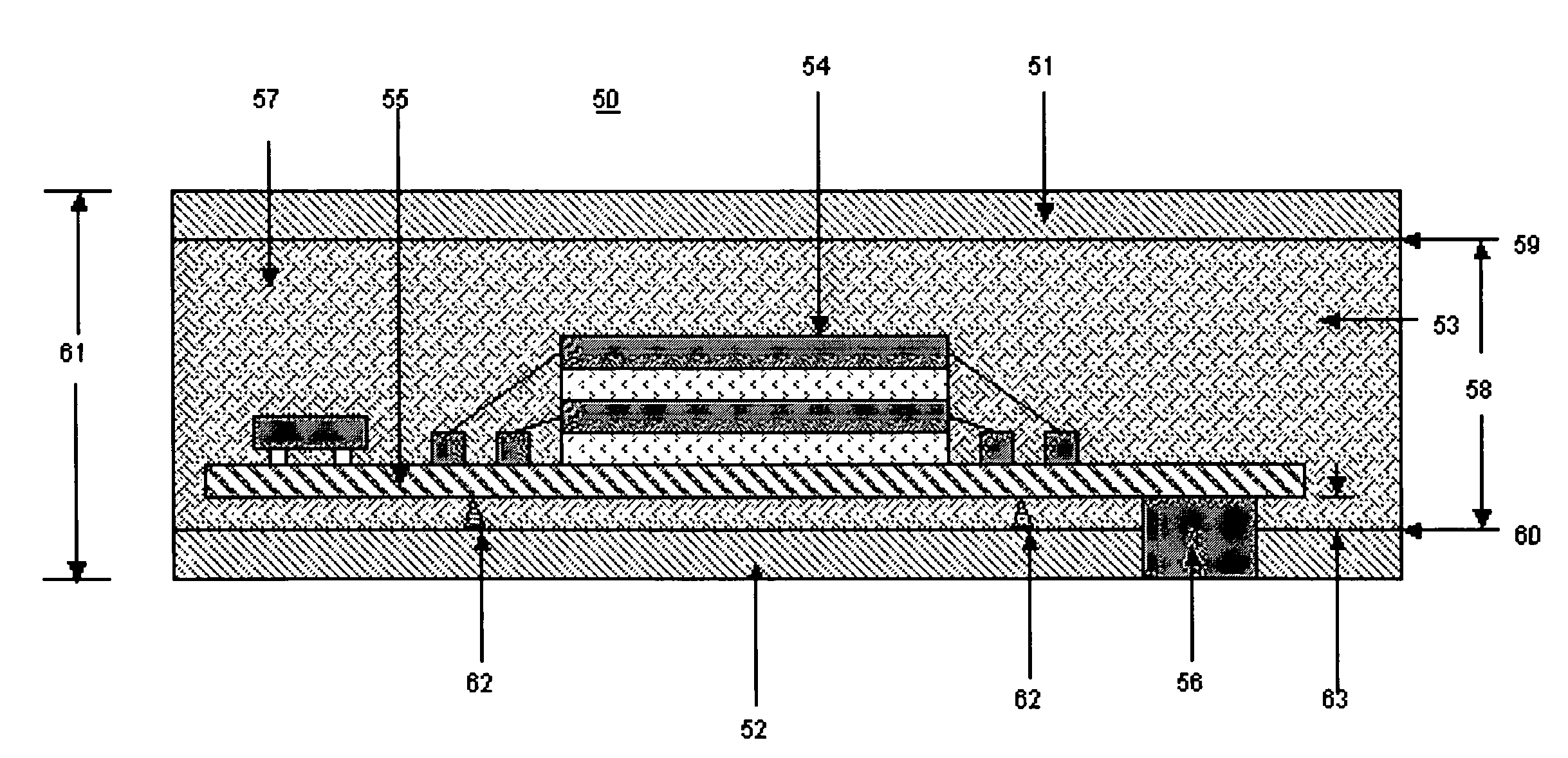

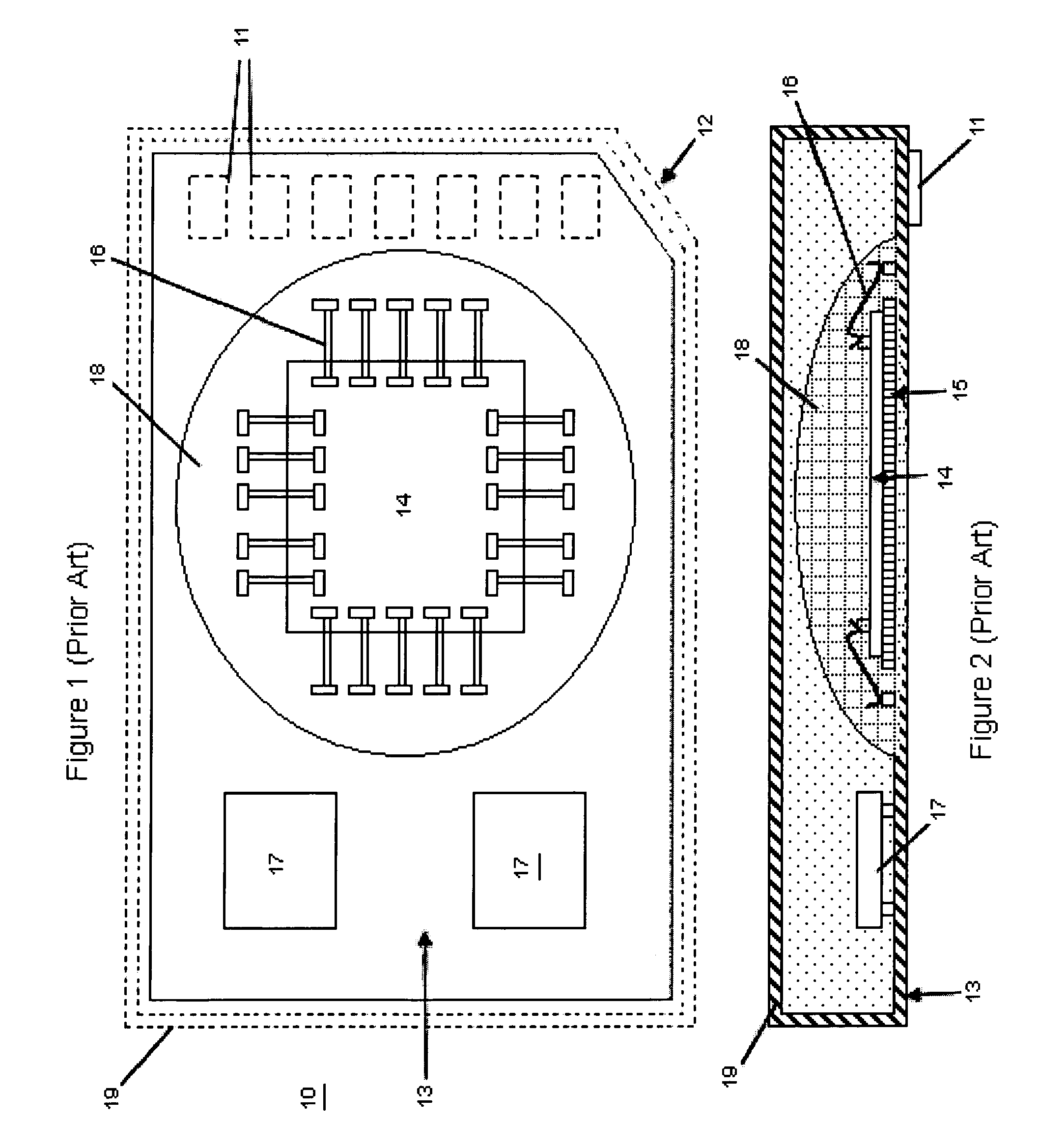

Method for making memory cards and similar devices using isotropic thermoset materials with high quality exterior surfaces

InactiveUS7225537B2Shorten the timeQuality improvementPrinted circuit assemblingLine/current collector detailsEngineeringInjection moulding

Memory Cards containing Integrated Circuits and other electronic components (e.g. resistors) in a variety of form factors having high quality external surfaces of polycarbonate, synthetic paper (e.g. Teslin), or other suitable material (e.g. PVC) can be made through use of injection molded thermoplastic material or thermosetting material that becomes the core layer of said Memory Cards and similar devices. The object of the invention is to provide the following properties to Memory Cards: rapid production cycle, high volume manufacturing throughput, security, electronics protection, better tamper resistance, durability, and highly reliable complex electronics encapsulation, achieved through a process utilizing low temperature and low pressure.

Owner:CARDXX

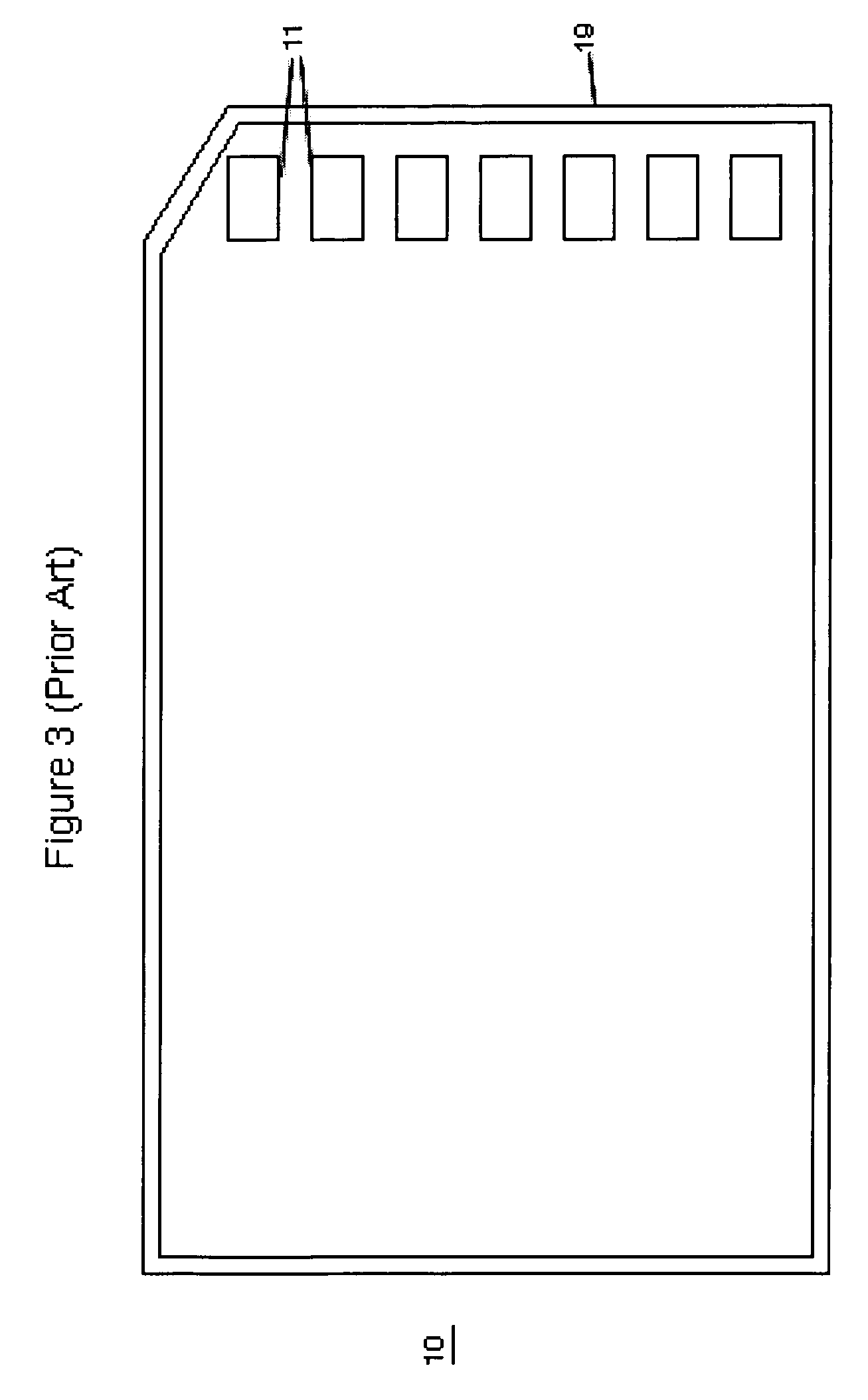

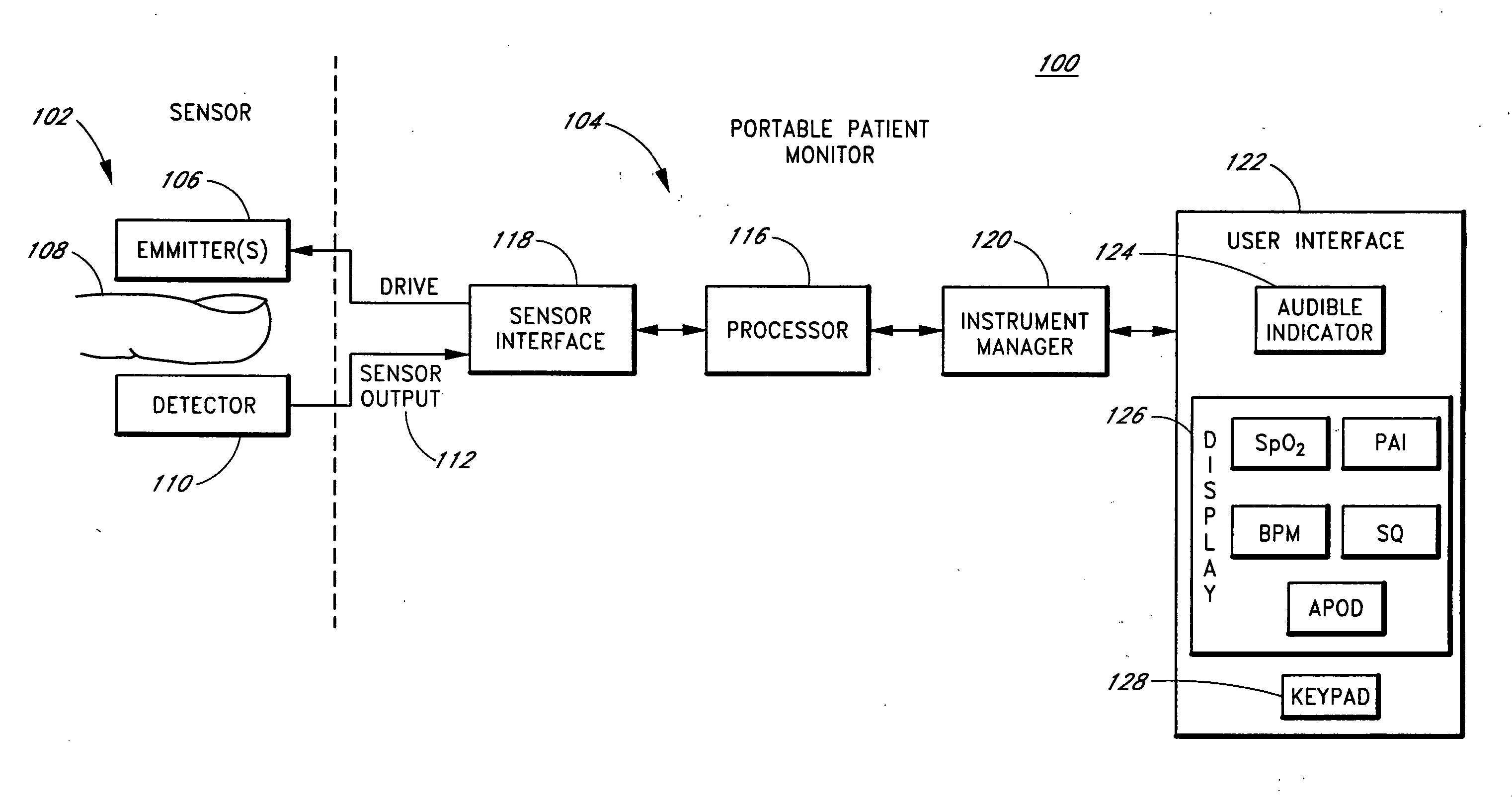

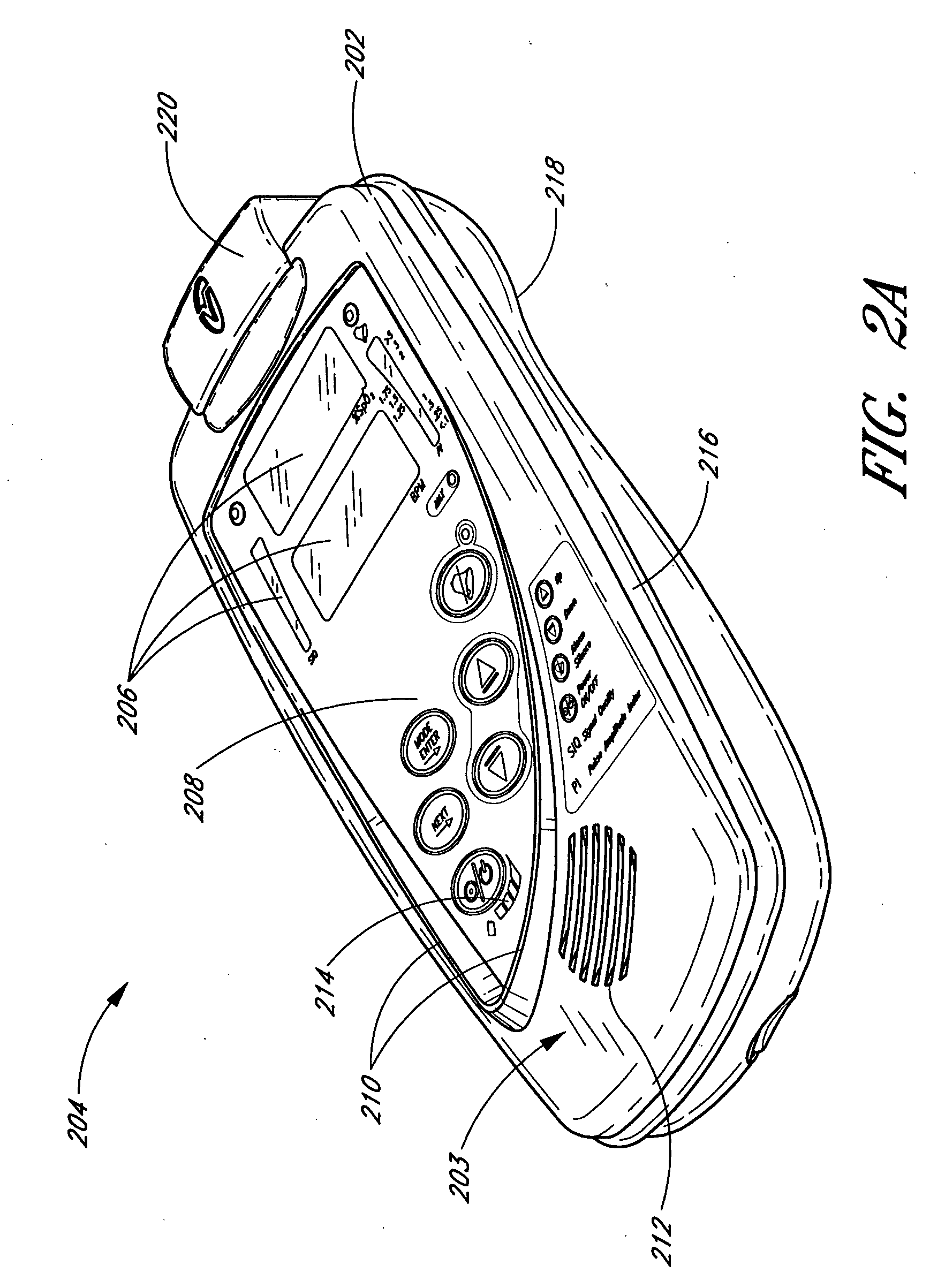

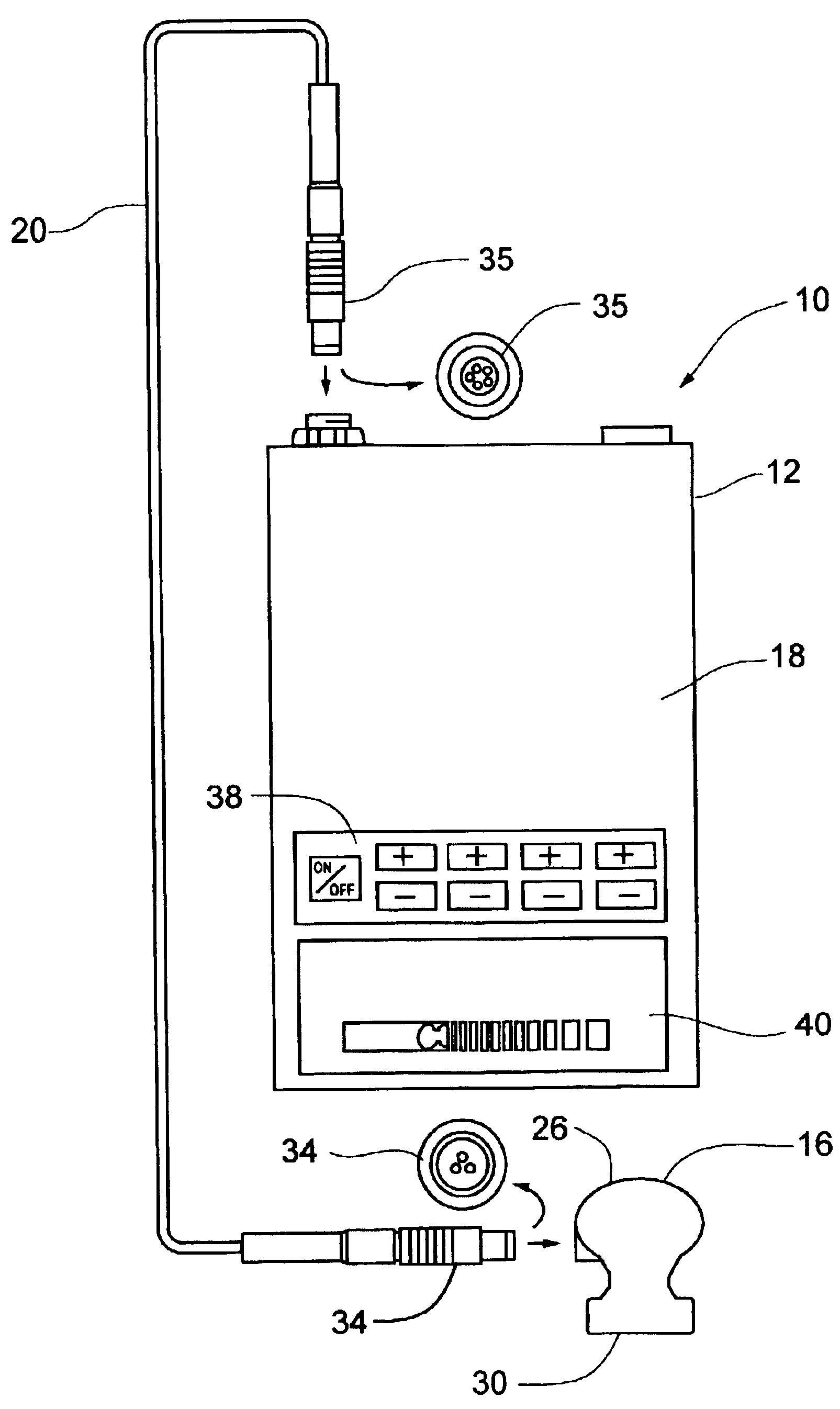

Portable patient monitor

InactiveUS20060189871A1Reduce amountReduce concentrationDiagnostic recording/measuringSensorsEngineeringMarine navigation

Embodiments of the present disclosure includes a portable pulse oximeter, such as a handheld pulse oximeter, that provides a user with intuitive key navigation for device operation, which reduces an amount of visual concentration needed to handle and operate the oximeter. In various embodiments, the portable pulse oximeter includes one or more of user input keys disposed along curve, an alignment edge providing guidance by feel of a user's digits to the input keys, raised convex keys also providing navigation by feel, a protective boot disposed around various portions of the oximeter housing to protect against impacts, a table-top stand, combinations of the same, or the like.

Owner:MASIMO CORP

Method of optimizing cardiac resynchronization therapy using sensor signals of septal wall motion

Owner:MEDTRONIC INC

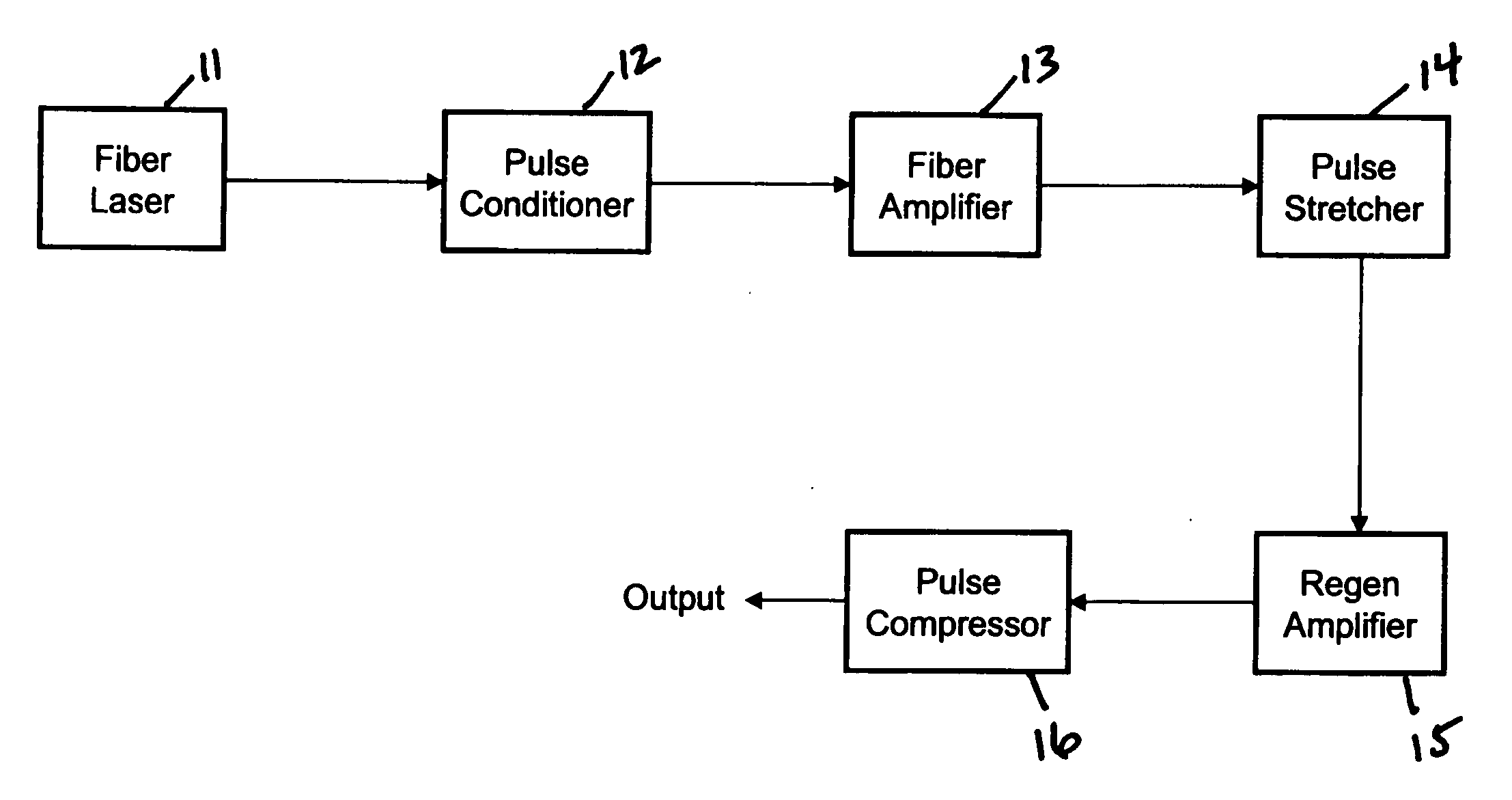

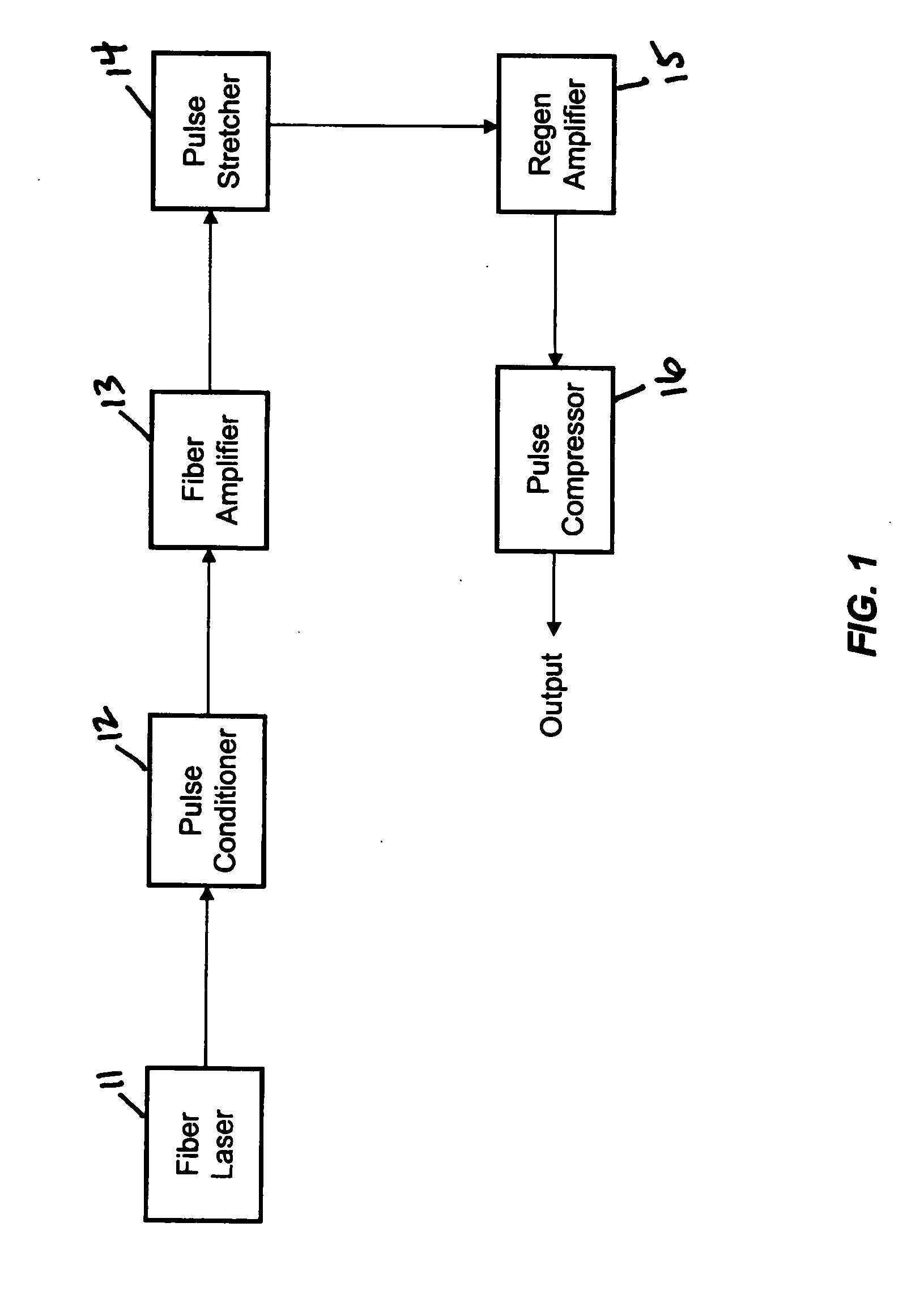

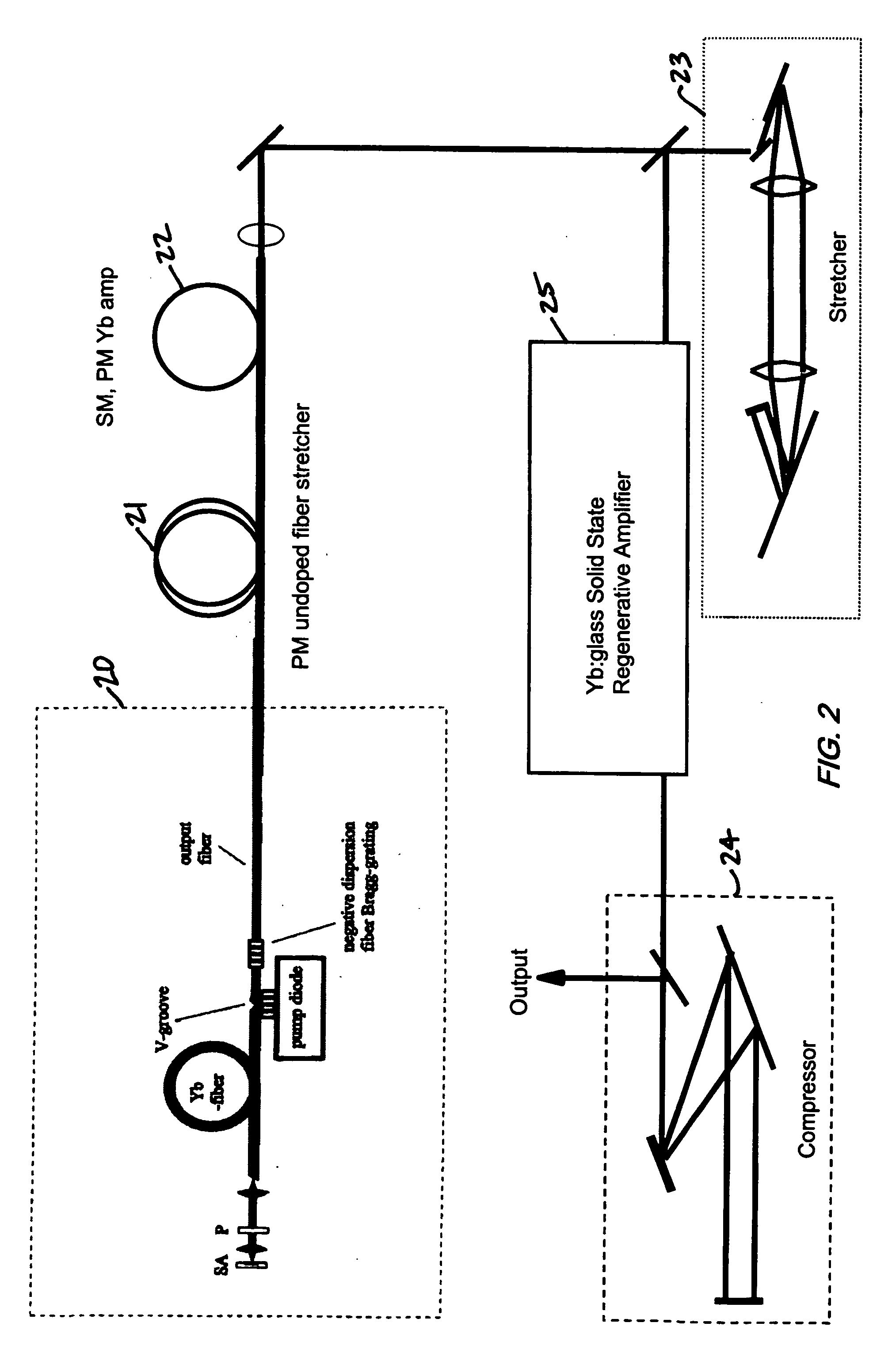

Utilization of Yb: and Nd: mode-locked oscillators in solid-state short pulse laser systems

InactiveUS20050111500A1Increasing pulse energyLow repetition rateCladded optical fibreLaser using scattering effectsSolid-stateUltrasound attenuation

An optimized Yb: doped fiber mode-locked oscillator and fiber amplifier system for seeding Nd: or Yb: doped regenerative amplifiers. The pulses are generated in the Yb: or Nd: doped fiber mode-locked oscillator, and may undergo spectral narrowing or broadening, wavelength converting, temporal pulse compression or stretching, pulse attenuation and / or lowering the repetition rate of the pulse train. The conditioned pulses are subsequently coupled into an Yb: or Nd: fiber amplifier. The amplified pulses are stretched before amplification in the regenerative amplifier that is based on an Nd: or Yb: doped solid-state laser material, and then recompressed for output.

Owner:IMRA AMERICA

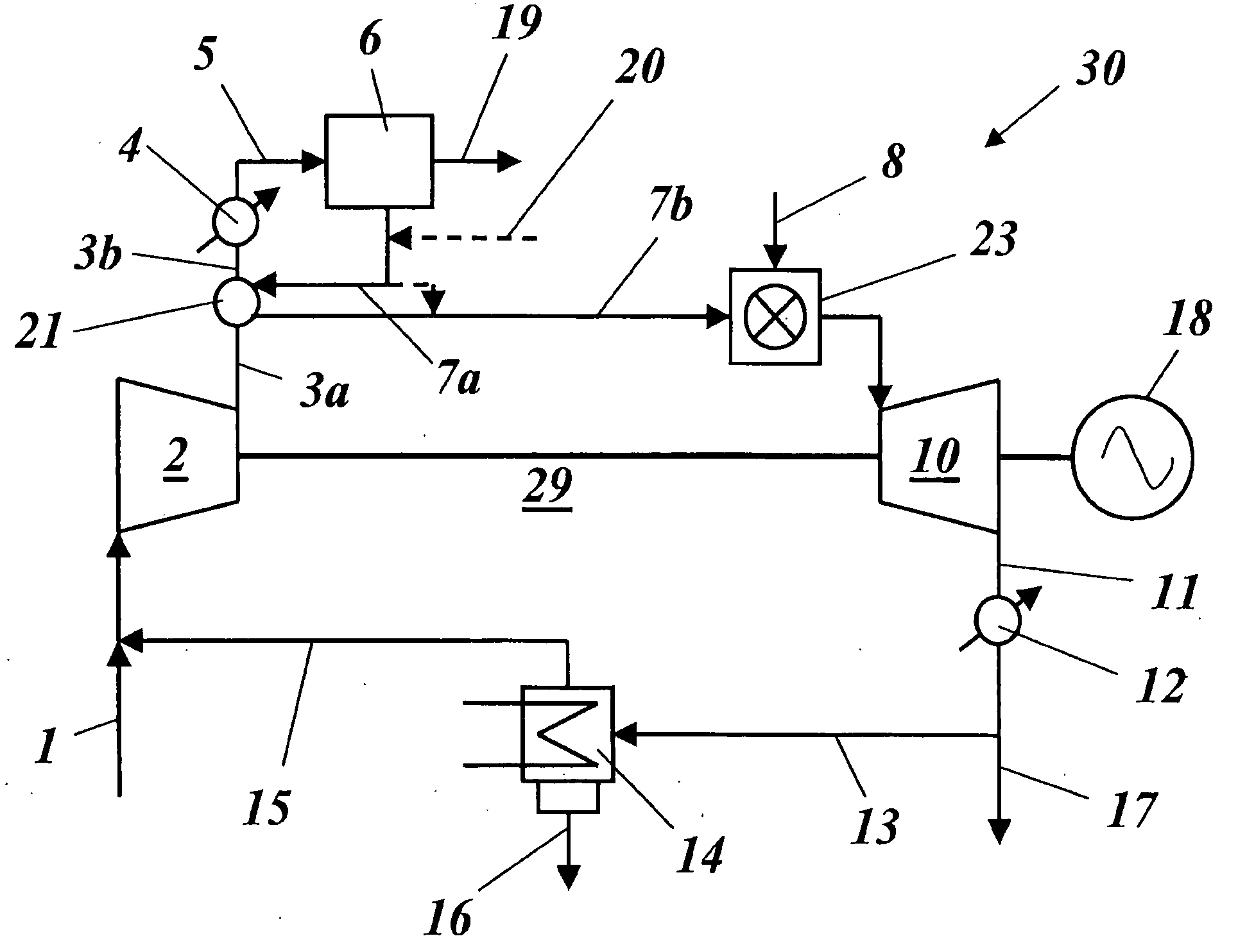

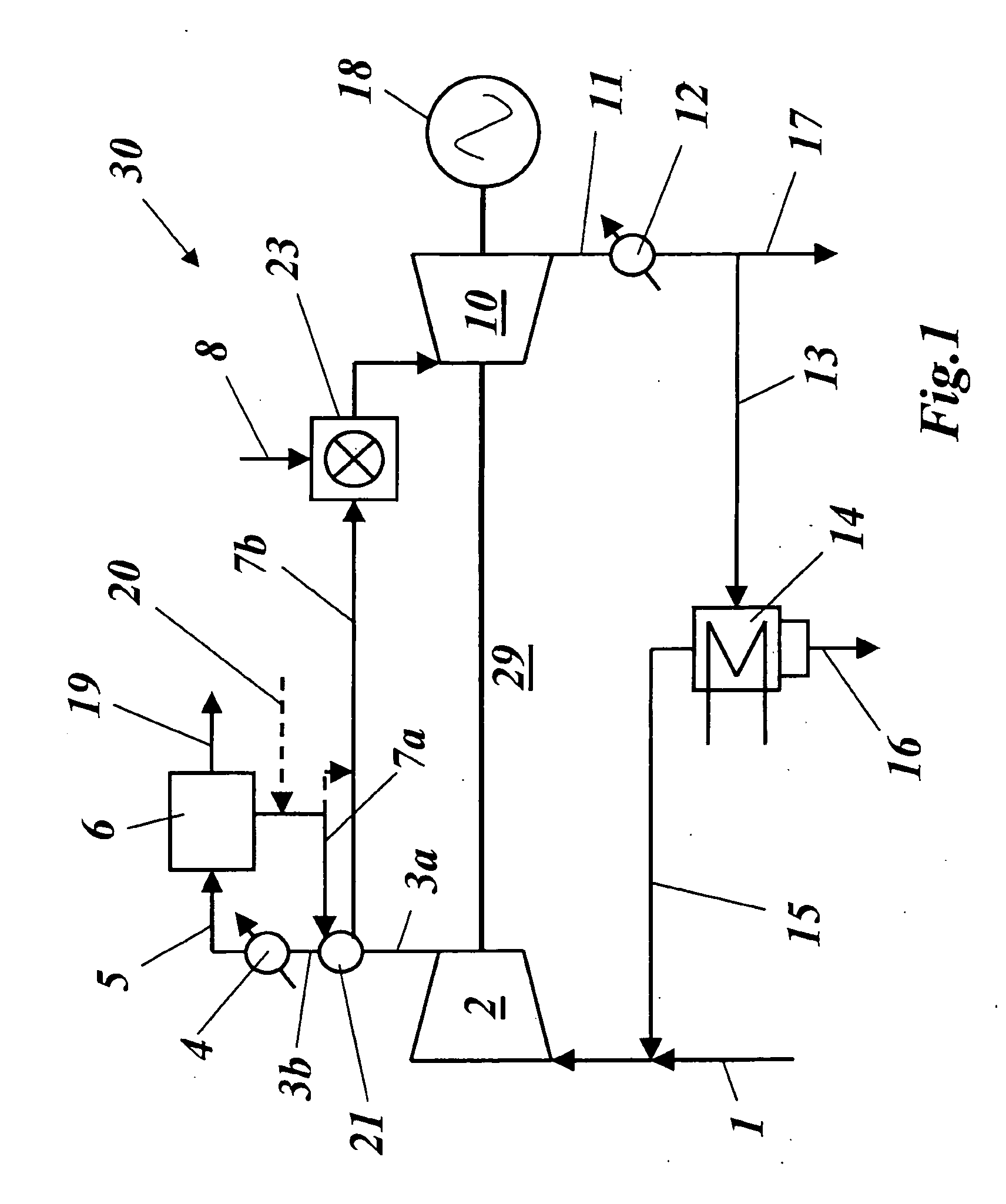

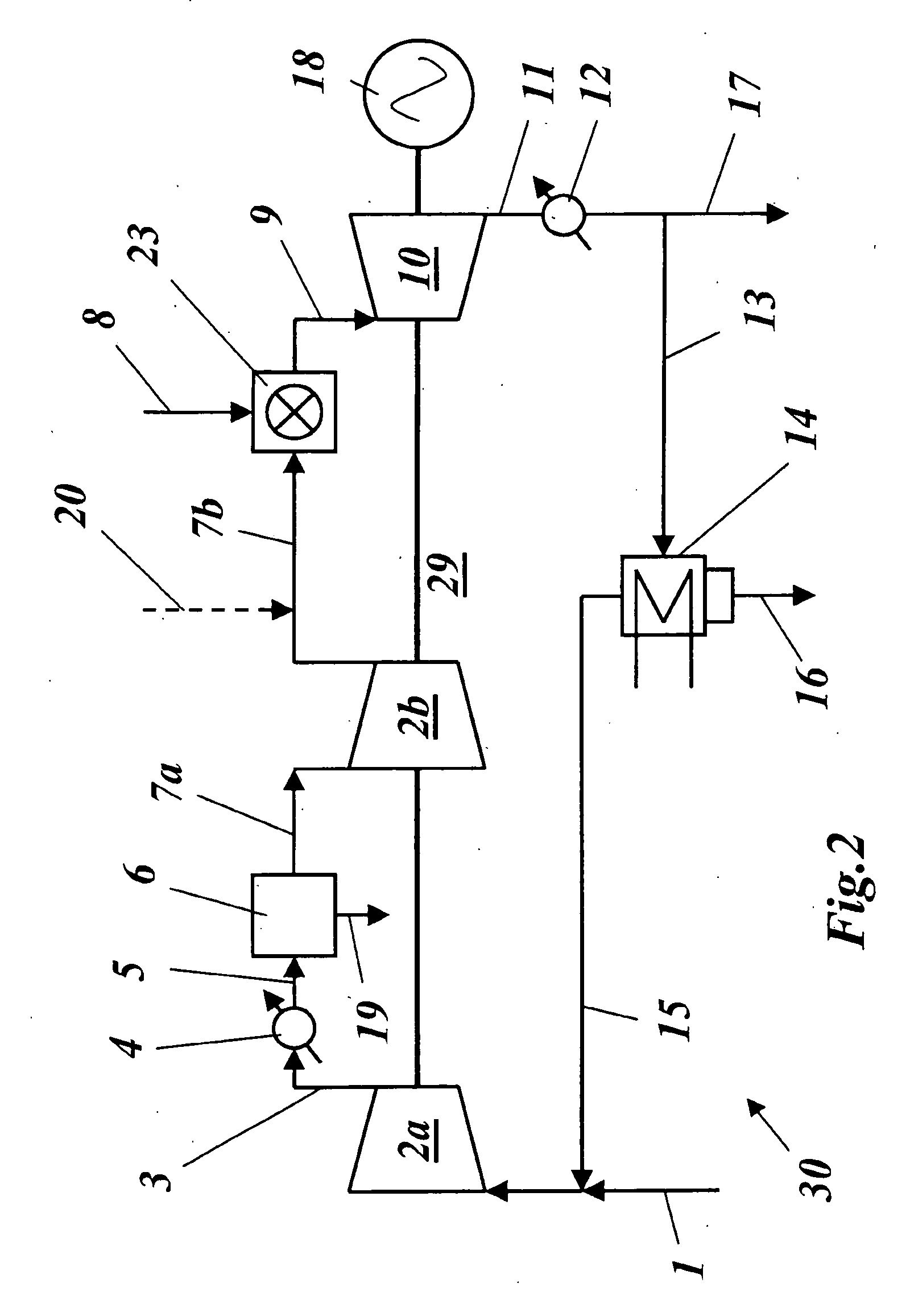

Method of generating energy in a power plant comprising a gas turbine, and power plant for carrying out the method

InactiveUS20050028529A1Small sizeLow costContinuous combustion chamberDispersed particle separationPower stationCombustor

A method of generating energy in a power plant (30) having a gas turbine (29), includes a first step a gas containing air (1) is compressed in a first compressor (2) of the gas turbine (29), a second step the compressed gas (3, 3a, 3b; 5; 7a, 7b) is fed to a combustion process with the addition of fuel (8) in a combustor (23), a third step the hot flue gas (9) from the combustor (23) is expanded in an expander or a turbine (10), driving a generator (18), of the gas turbine (29) while performing work, and a fourth step a partial flow of the expanded flue gas (11) is recirculated to the inlet of the first compressor (2) and admixed with the gas containing air (1). Carbon dioxide (CO2) is separated from the compressed gas (3, 3a, 3b; 5; 7a, 7b) in a CO2 separator (6) before the third step. In such a method, the overall size and energy costs are reduced by virtue of the fact that, to permit increased CO2 concentrations in the CO2 separator (6), not more than about 70% of the carbon dioxide contained in the compressed gas (3, 3a, 3b; 5, 5a, 5b; 7a, 7b) is removed from the compressed gas (3, 3a, 3b; 5, 5a, 5b; 7a, 7b).

Owner:ALSTOM TECH LTD

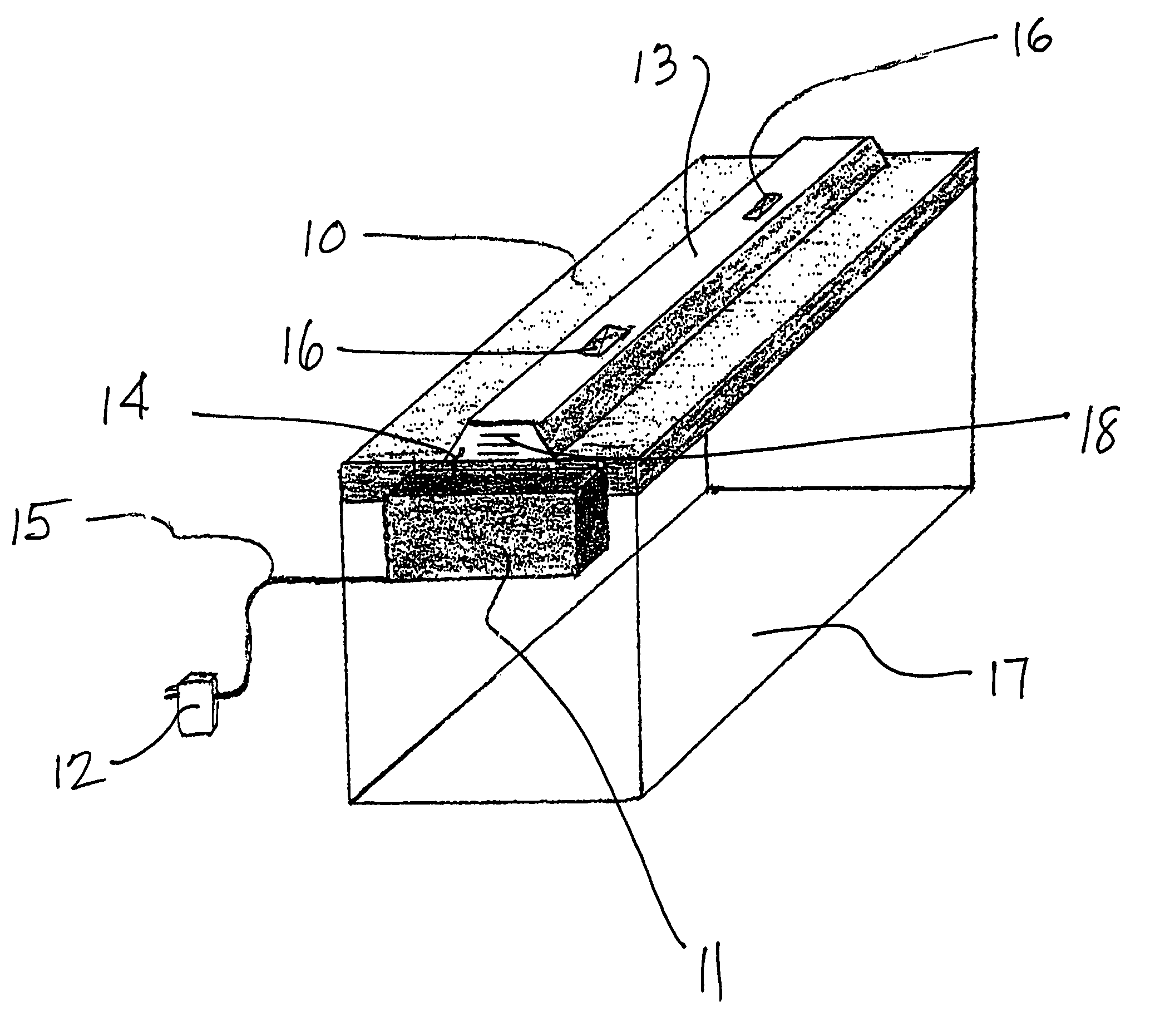

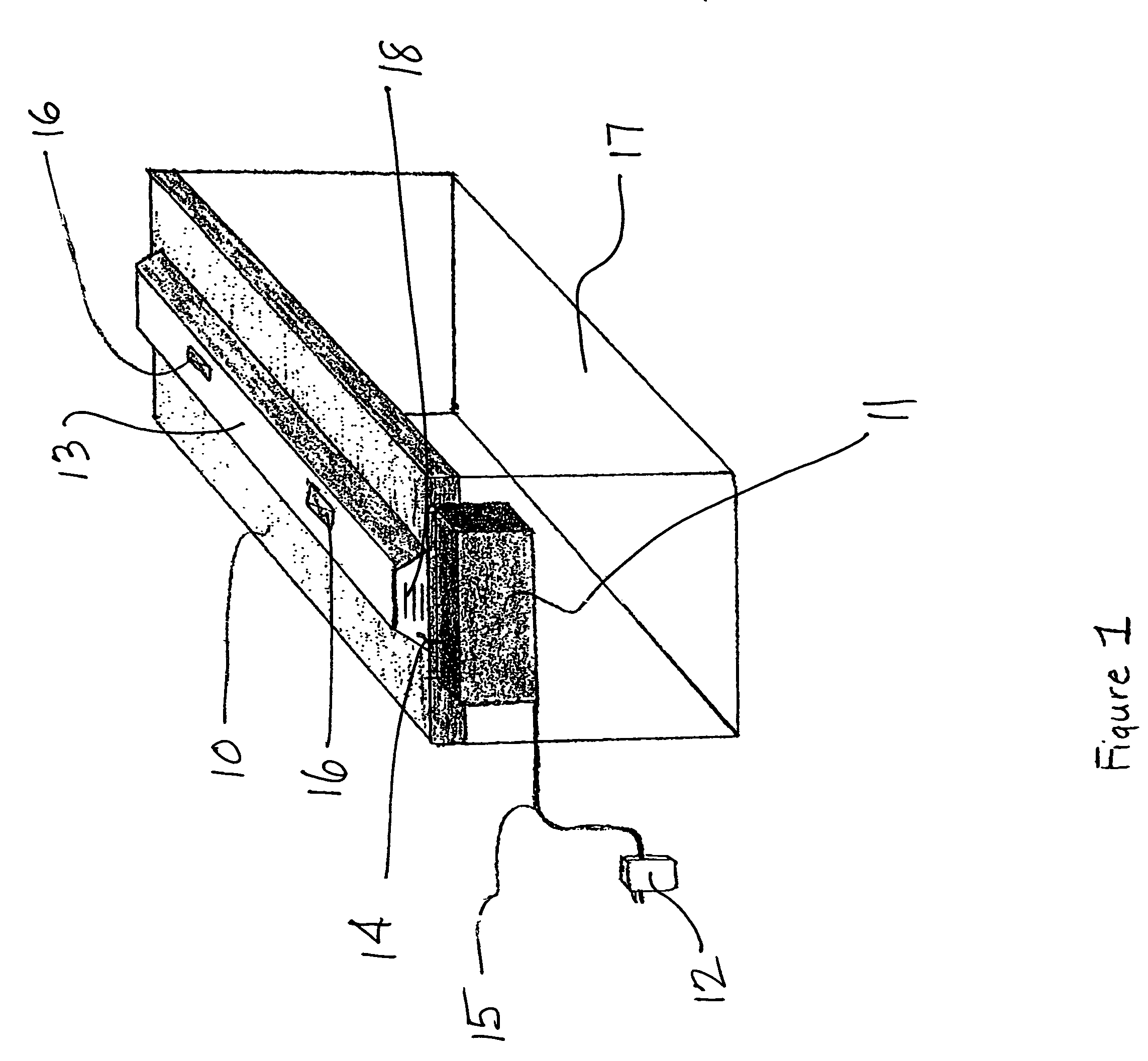

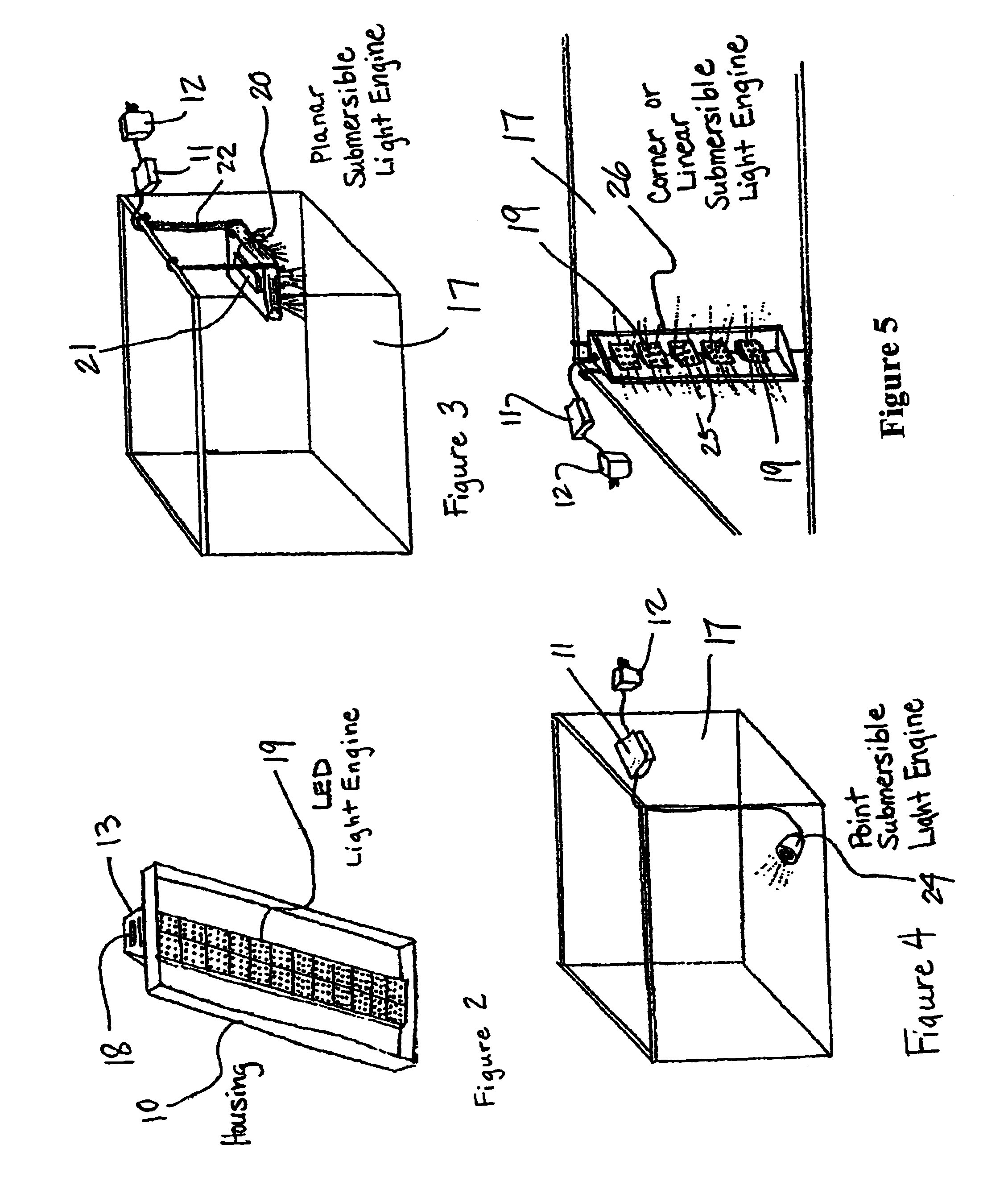

Marine LED lighting system and method

InactiveUS7220018B2High outputIncrease light intensityElectrical apparatusElectric circuit arrangementsMarine habitatsEngineering

A method and apparatus of lighting a marine habitat for growth utilizing an LED light system. The light system includes an LED light source, a power supply for such light source and a controller for controlling the activation status and the intensity of the LED light source.

Owner:ORBITAL TECH

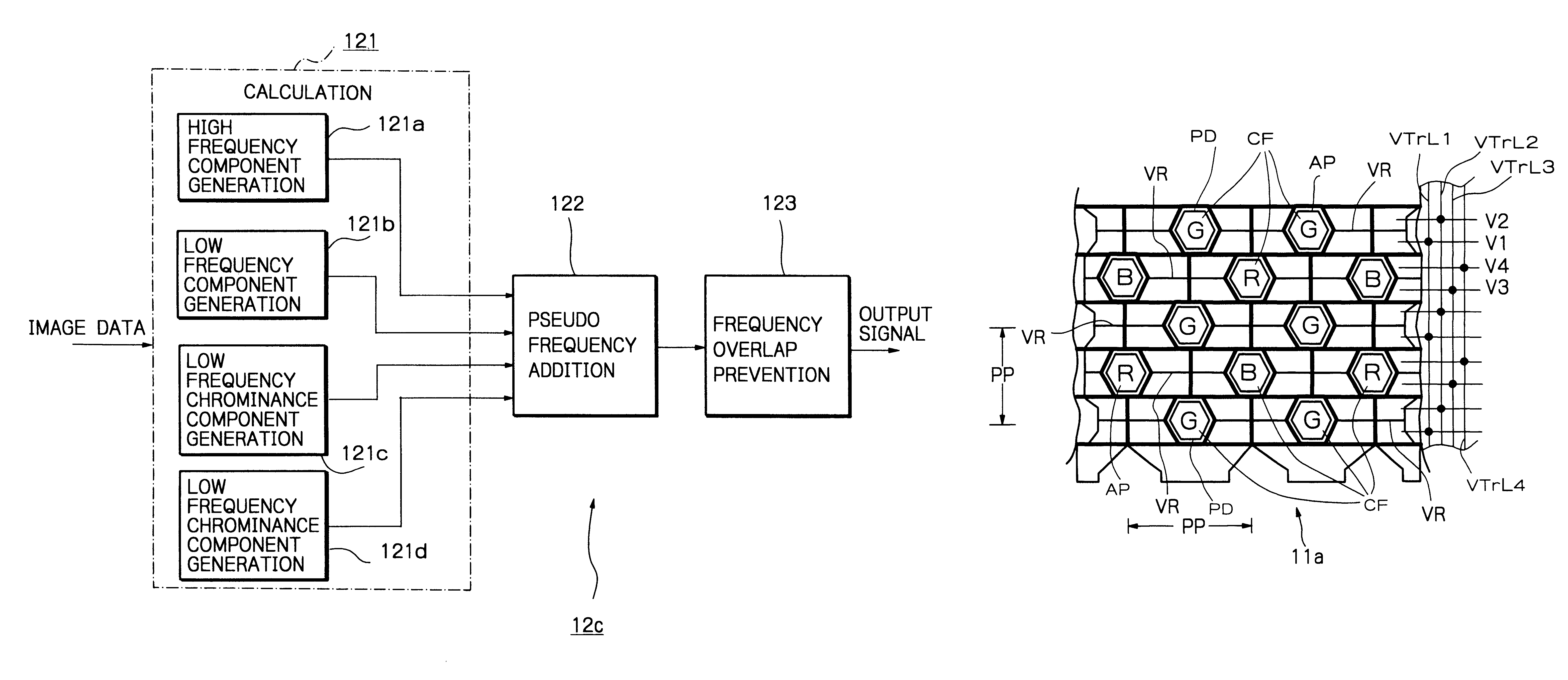

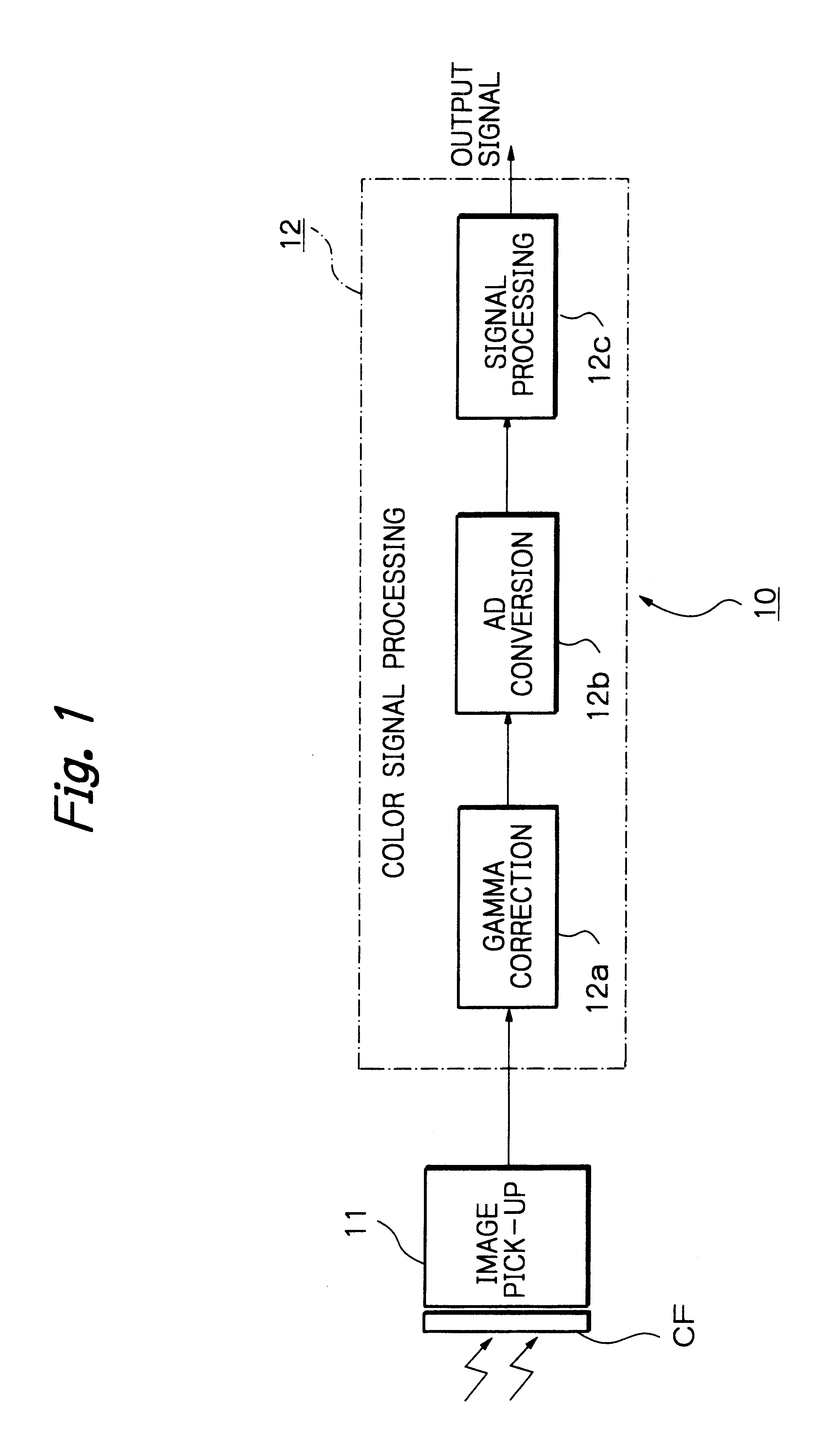

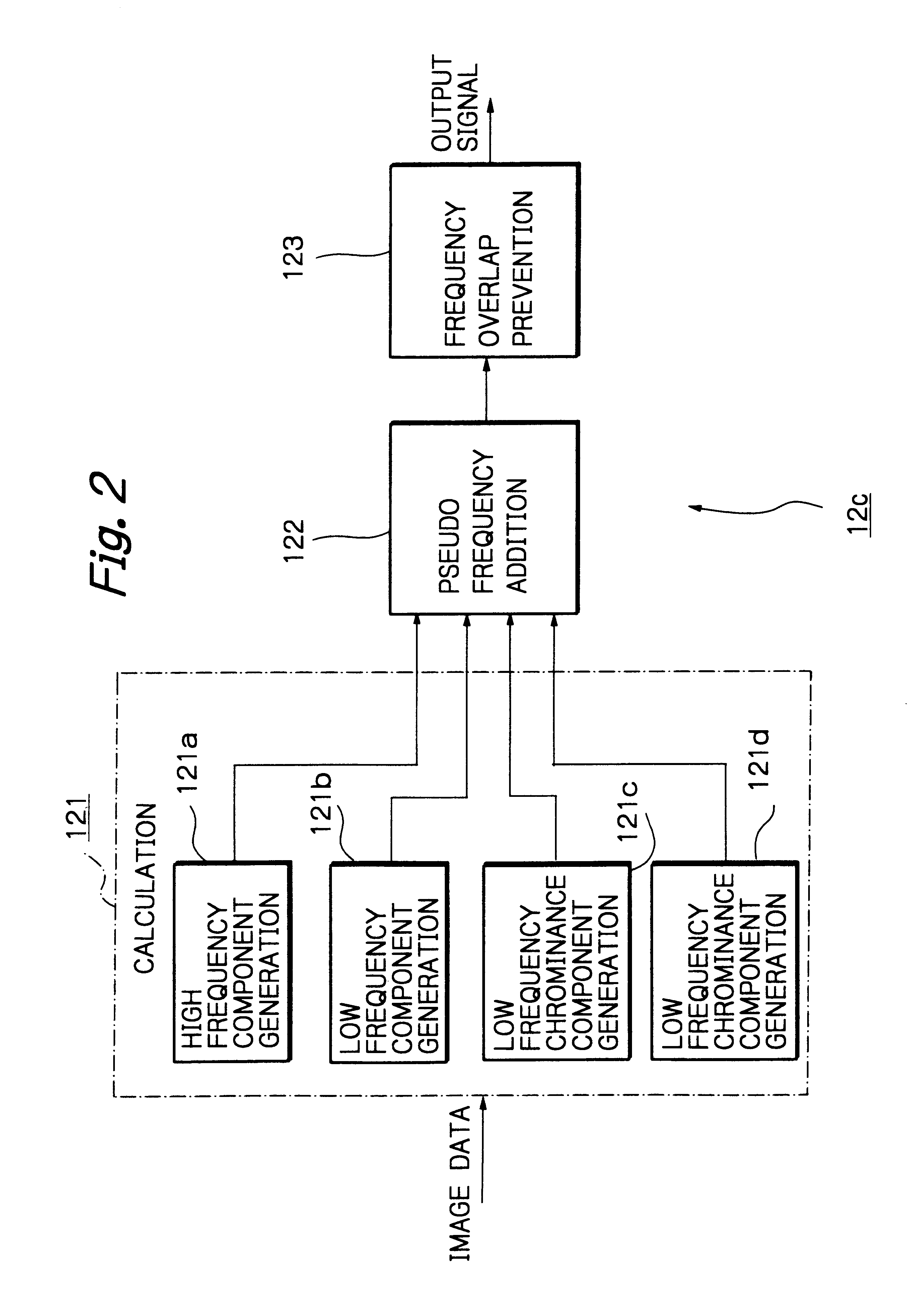

Solid-state imaging apparatus and signal processing method for transforming image signals output from a honeycomb arrangement to high quality video signals

InactiveUS6882364B1High outputWithout delayTelevision system detailsColor signal processing circuitsLow-pass filterFalse color

A solid-state imaging apparatus includes an image pick-up section in which photosensitive devices are arranged in, e.g., a honeycomb G square lattice, RB full-checker pattern due to shifted pixels. Regions void of the photosensitive devices are assumed to be virtual photosensitive devices. A signal processing section generates data for the virtual photosensitive devices by using the data of surrounding photosensitive devices while attaching importance to accurate color reproduction and horizontal and / or vertical resolution. As a result, the number of pixel data are increased in a square lattice arrangement. Therefore, high quality image signals are readily achievable with a smaller number of photosensitive devices than conventional with a conventional apparatus. Interpolation can be executed with the high quality signals to the limit of resolution with an adequate circuit scale. The honeycomb arrangement guarantees the required size of the individual pixel and thereby the sensitivity of the entire apparatus while increasing yield on a production line. False colors particular to a single photosensitive portion can be reduced by, e.g., uniform interpolation. Particularly, when a digital camera is constructed by using an imaging apparatus including optics operable with a silver halide sensitive type of film, false colors can be reduced without resorting to an optical low pass filter.

Owner:FUJIFILM CORP

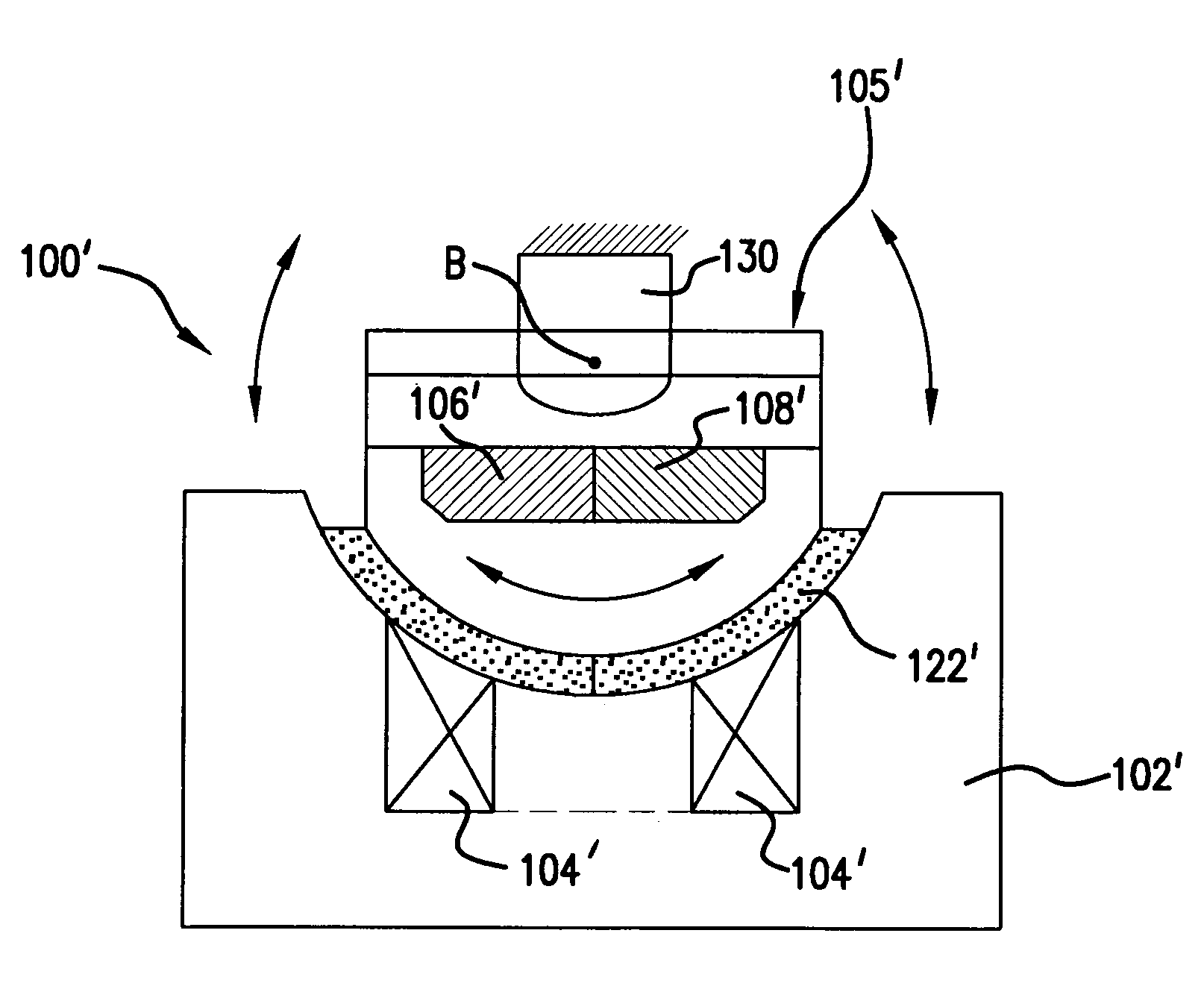

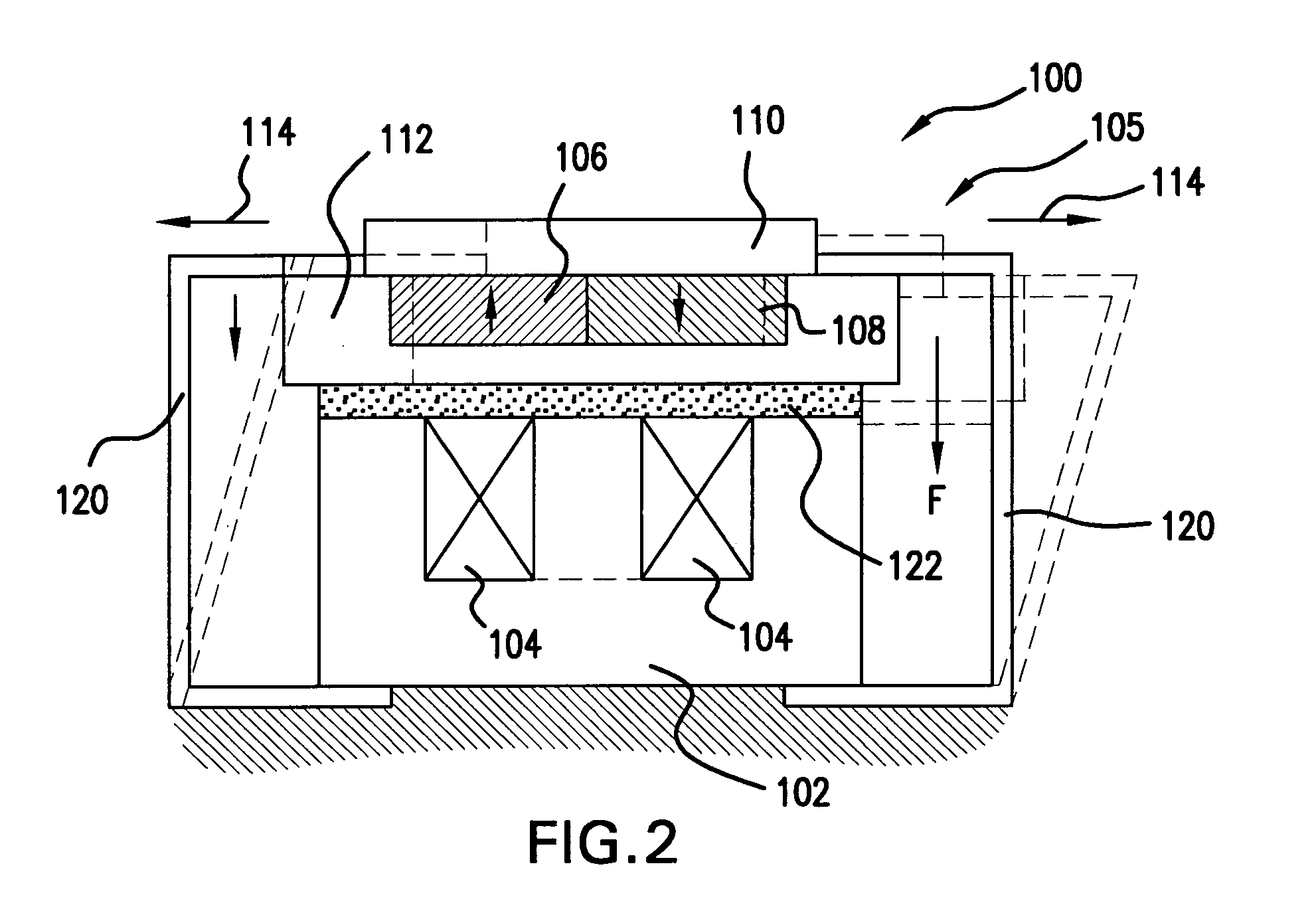

Moving magnet actuator for providing haptic feedback

InactiveUS6982696B1High magnitudeHigh bandwidthInput/output for user-computer interactionManual control with multiple controlled membersCentral projectionSpring force

A moving magnet actuator for providing haptic feedback. The actuator includes a grounded core member, a coil is wrapped around a central projection of the core member, and a magnet head positioned so as to provide a gap between the core member and the magnet head. The magnet head is moved in a degree of freedom based on an electromagnetic force caused by a current flowed through the coil. An elastic material, such as foam, is positioned in the gap between the magnet head and the core member, where the elastic material is compressed and sheared when the magnet head moves and substantially prevents movement of the magnet head past a range limit that is based on the compressibility and shear factor of the material. Flexible members can also be provided between the magnet head and the ground member, where the flexible members flex to allow the magnet head to move, provide a centering spring force to the magnet head, and limit the motion of the magnet head.

Owner:IMMERSION CORPORATION

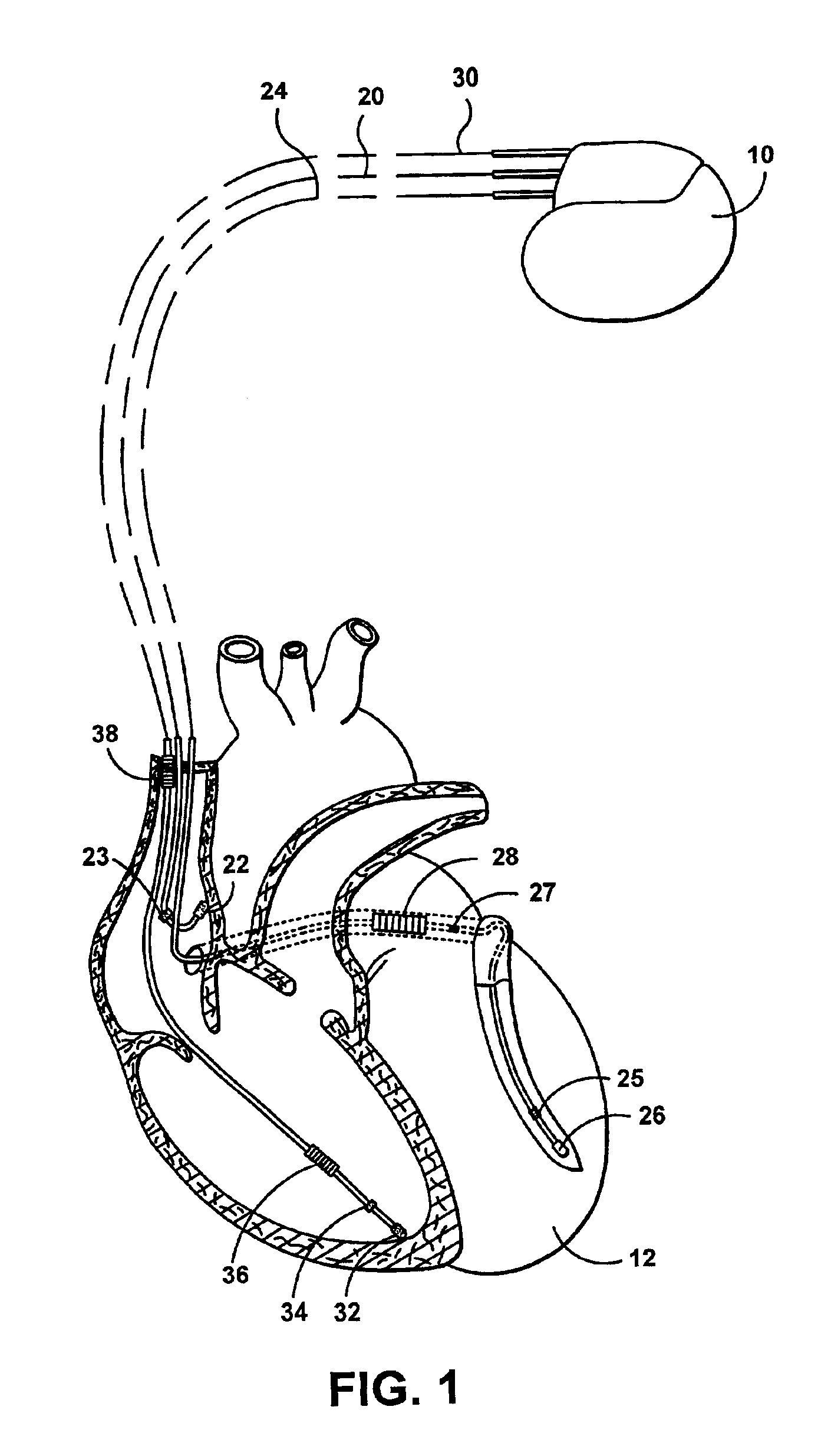

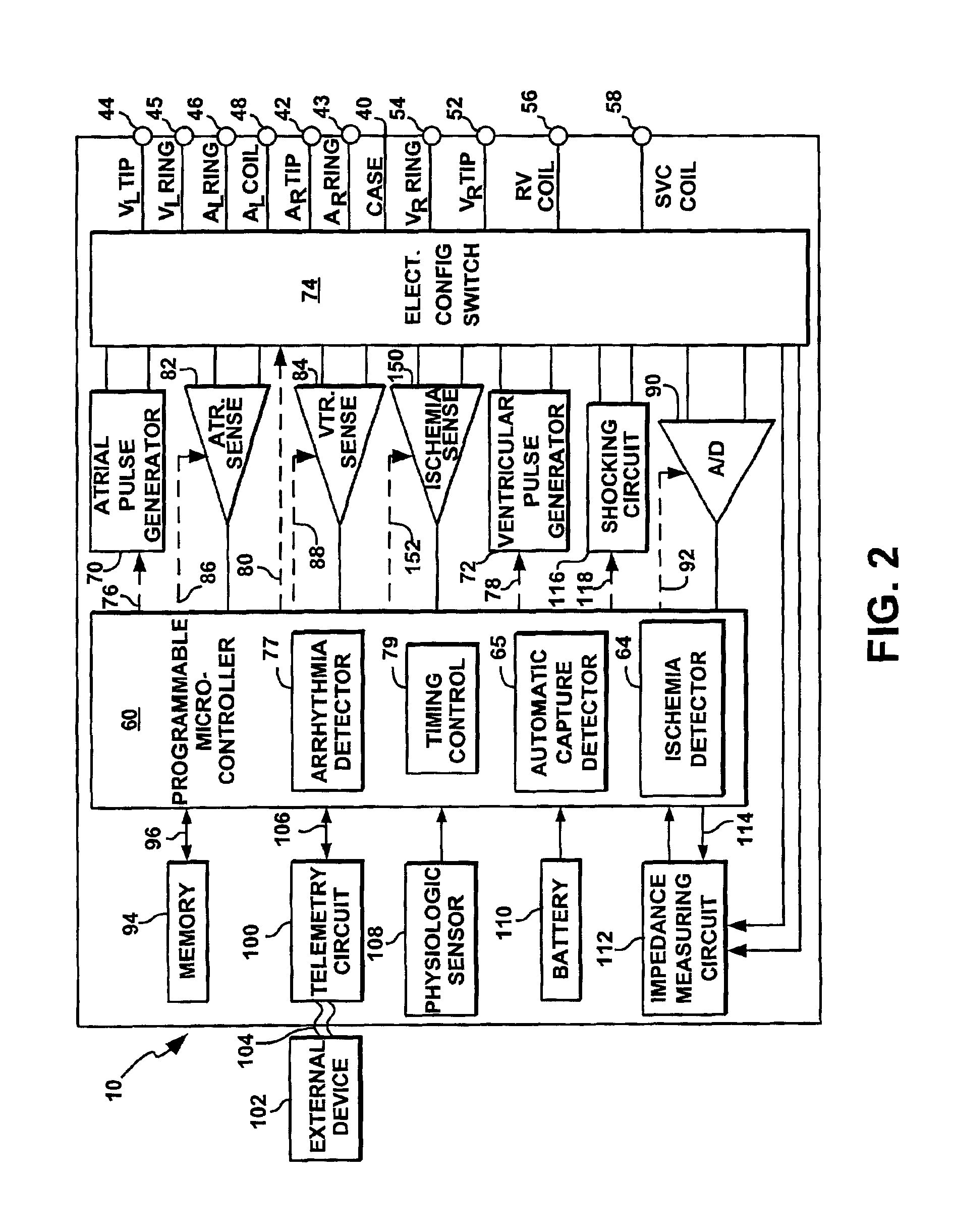

Cardiac stimulation device for optimizing cardiac output with myocardial ischemia protection

InactiveUS6865420B1Reduce demandReduce detectionHeart stimulatorsCardiac muscleIntracardiac Electrogram

A cardiac stimulation device and method detect myocardial ischemia and provide a response for alleviating the ischemia. Myocardial ischemia is detected by identifying changes in the ST-segment of the intracardiac electrogram (EGM) sensed using large sensing electrode surfaces created by electrically coupling one or more cardiac electrodes or by using larger surface area shocking coils. Myocardial ischemia monitoring is performed when stimulation parameters are adjusted for increasing cardiac output, causing an increased metabolic demand to be placed on the myocardium itself. When myocardial ischemia is detected, stimulation parameters are re-adjusted to reduce the demand placed on the myocardium and thereby alleviate the ischemia.

Owner:PACESETTER INC

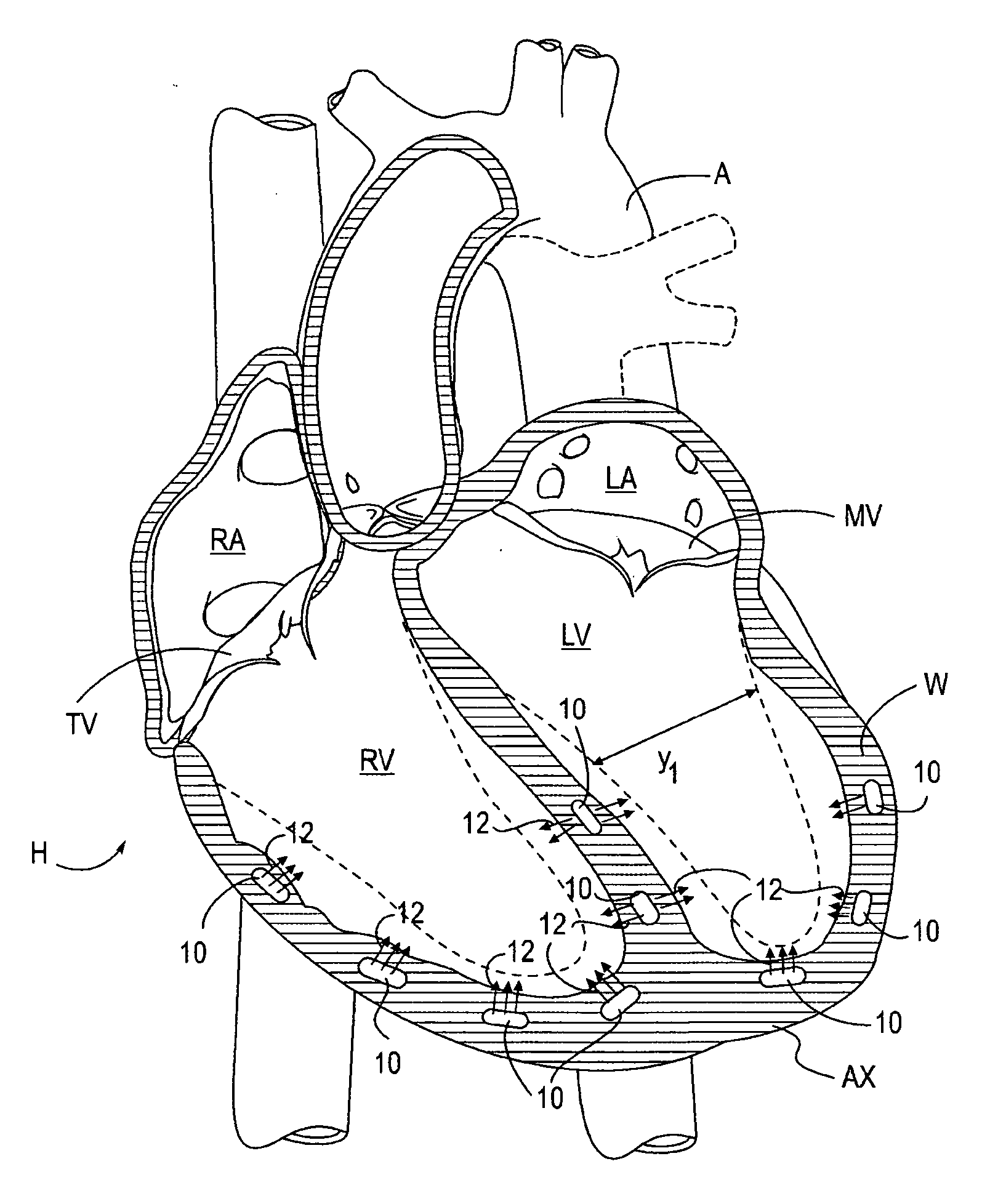

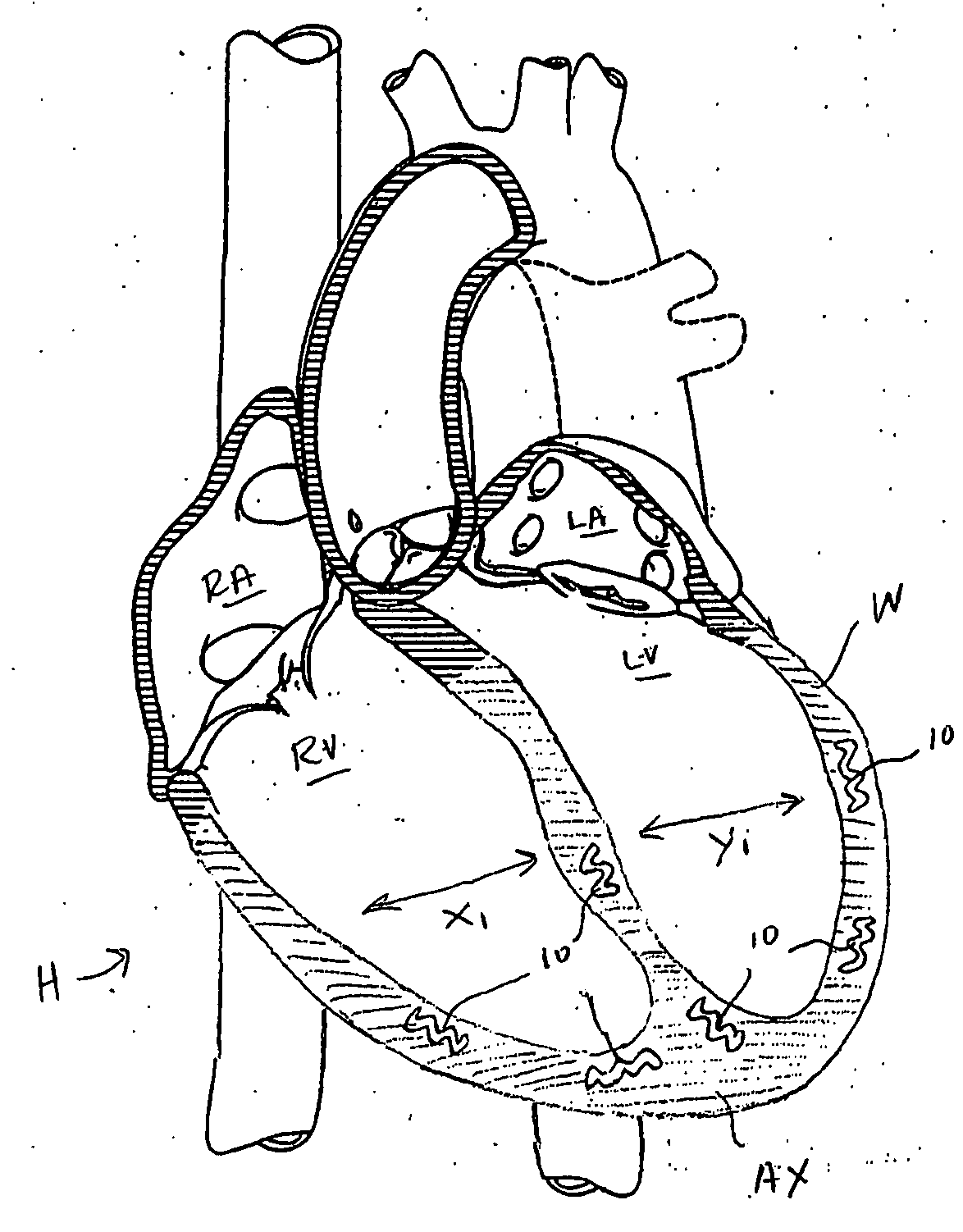

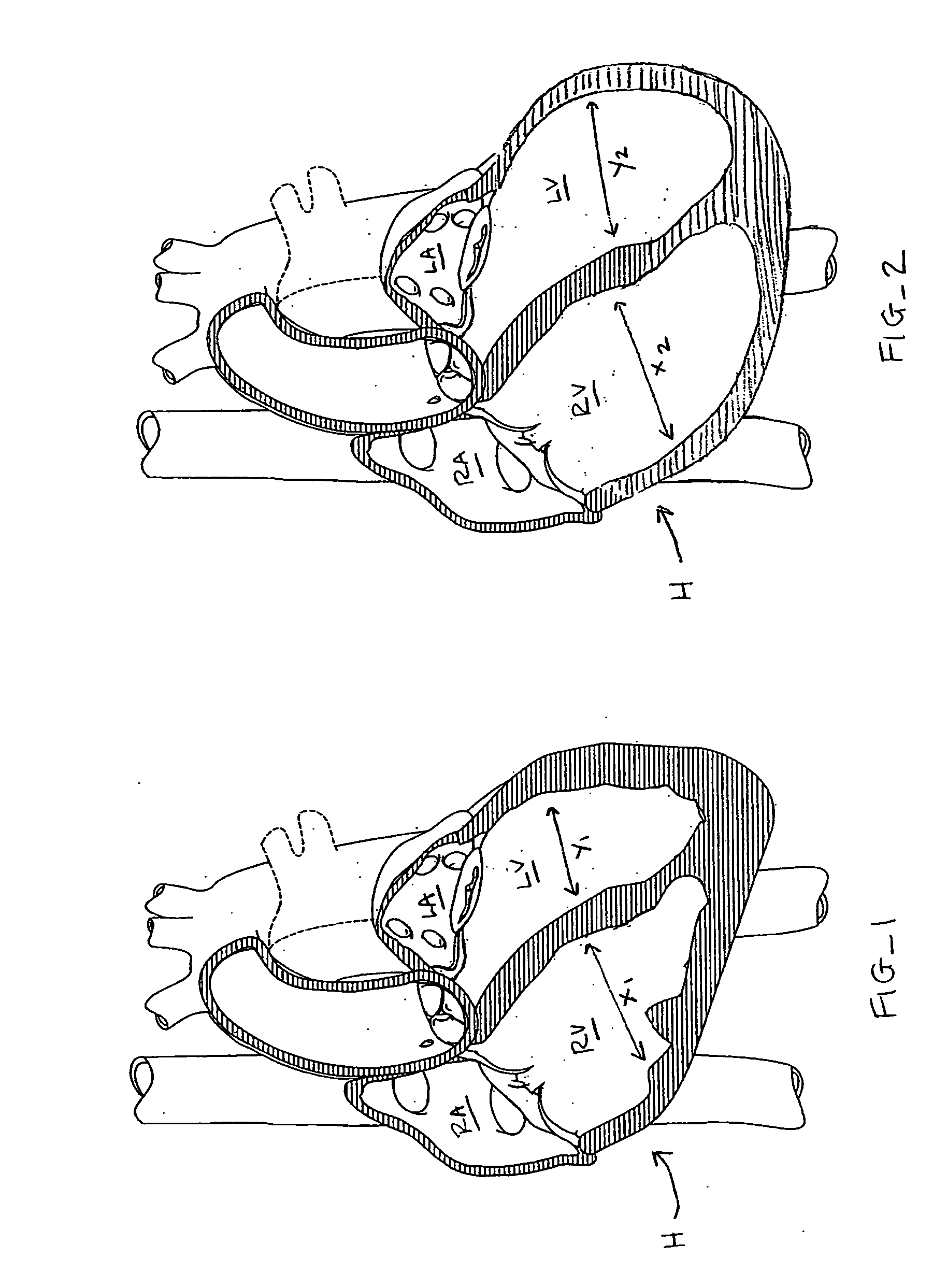

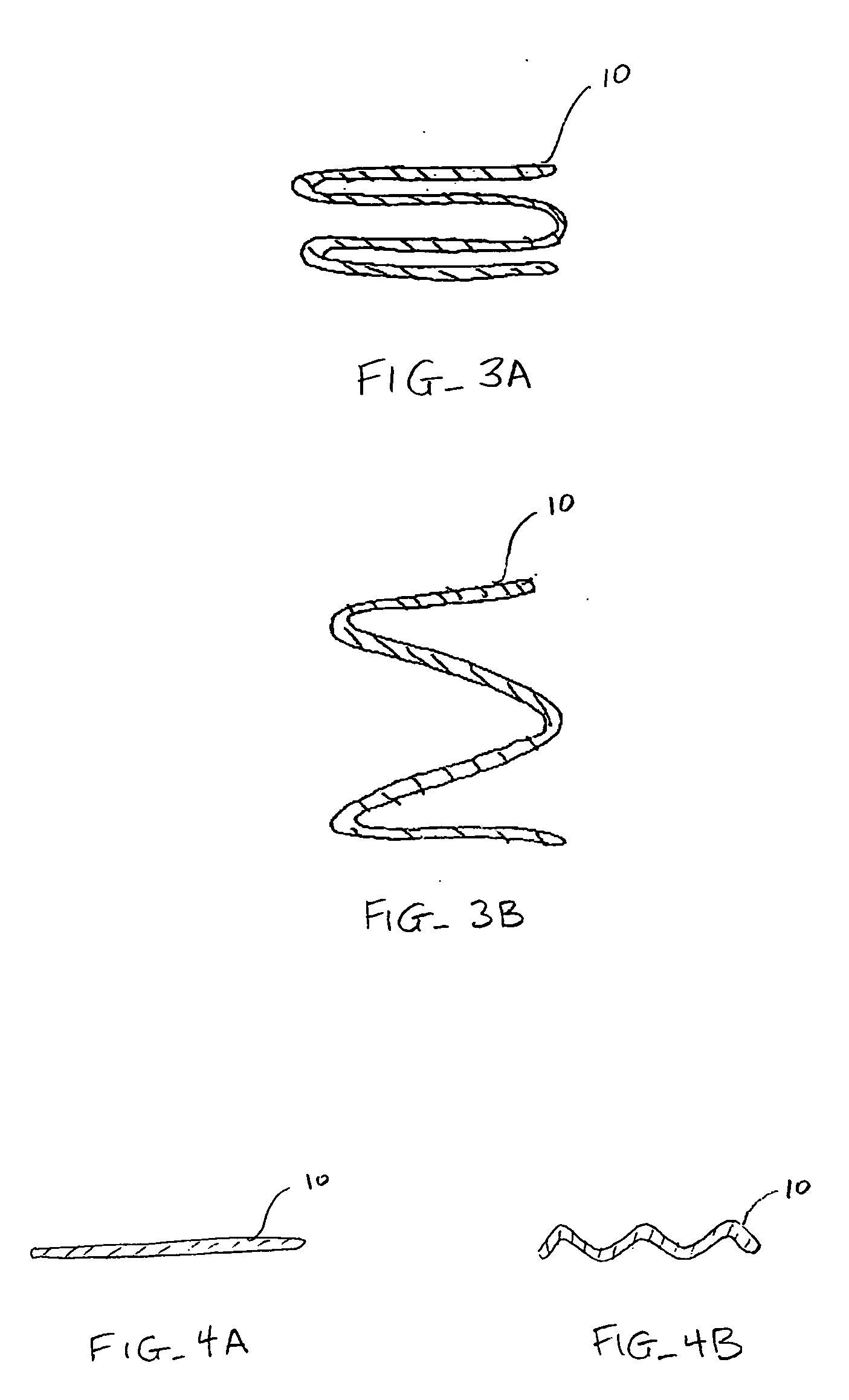

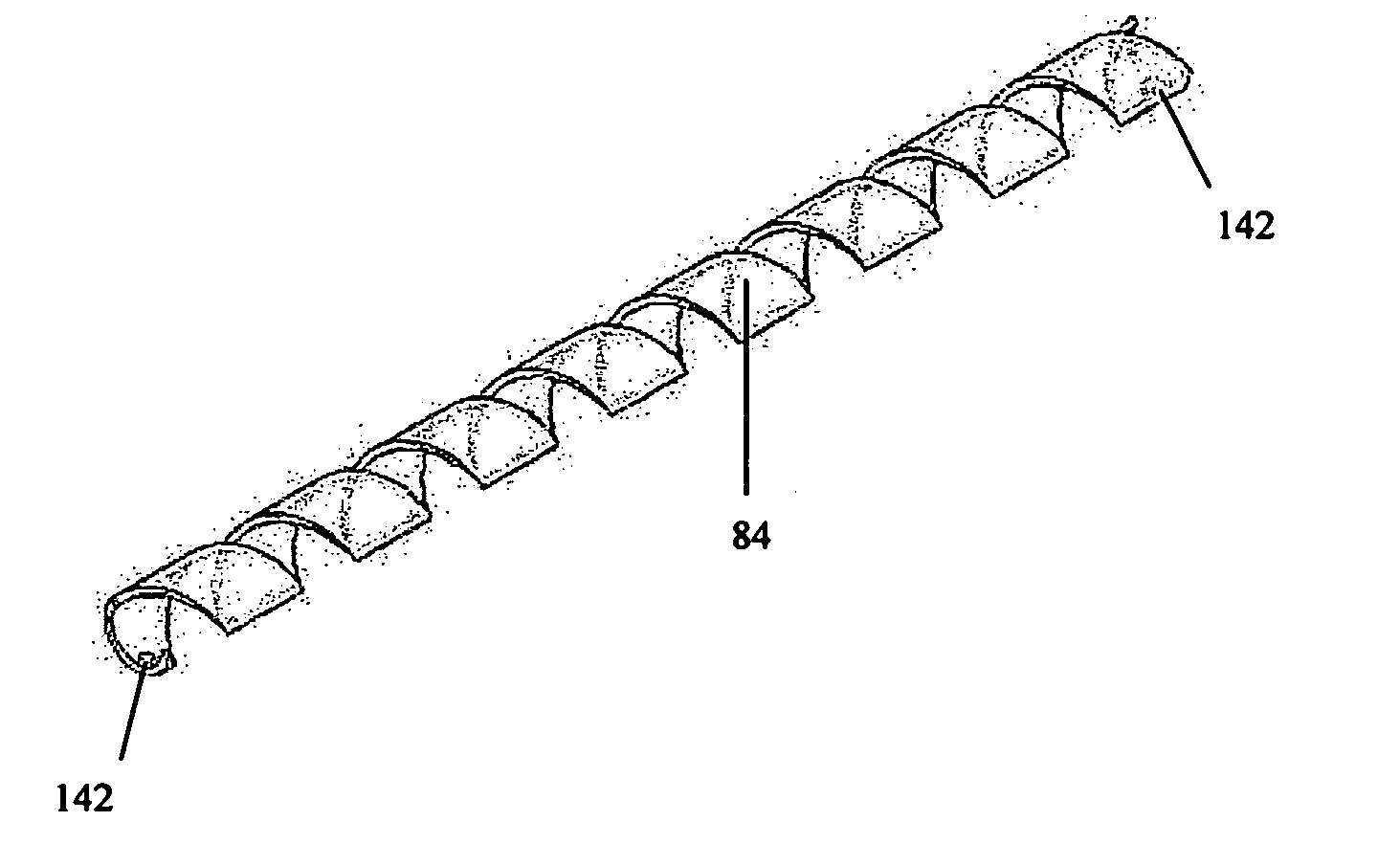

Shape memory devices and methods for reshaping heart anatomy

InactiveUS20060015002A1Improve shrinkageReduce widthSuture equipmentsSurgical needlesCardiac surfaceHeart anatomy

Systems, methods and devices are provided for treating heart failure patients suffering from various levels of heart dilation. Such heart dilation is treated by reshaping the heart anatomy with the use of shape memory elements. Such reshaping changes the geometry of portions of the heart, particularly the right or left ventricles, to increase contractibility of the ventricles thereby increasing the stroke volume which in turn increases the cardiac output of the heart. The shape memory elements have an original shape and at least one memory shape. The elements are implanted within the heart tissue or attached externally and / or internally to a surface of the heart when in the original shape. The elements are then activated to transition from the original shape to one of the at least one memory shapes. Transitioning of the elements cause the associated heart tissue areas to readjust position, such as to decrease the width of the ventricles. Such repositioning is maintained over time by the elements, allowing the damaging effects of heart dilation to slow in progression or reverse.

Owner:MICARDIA CORP

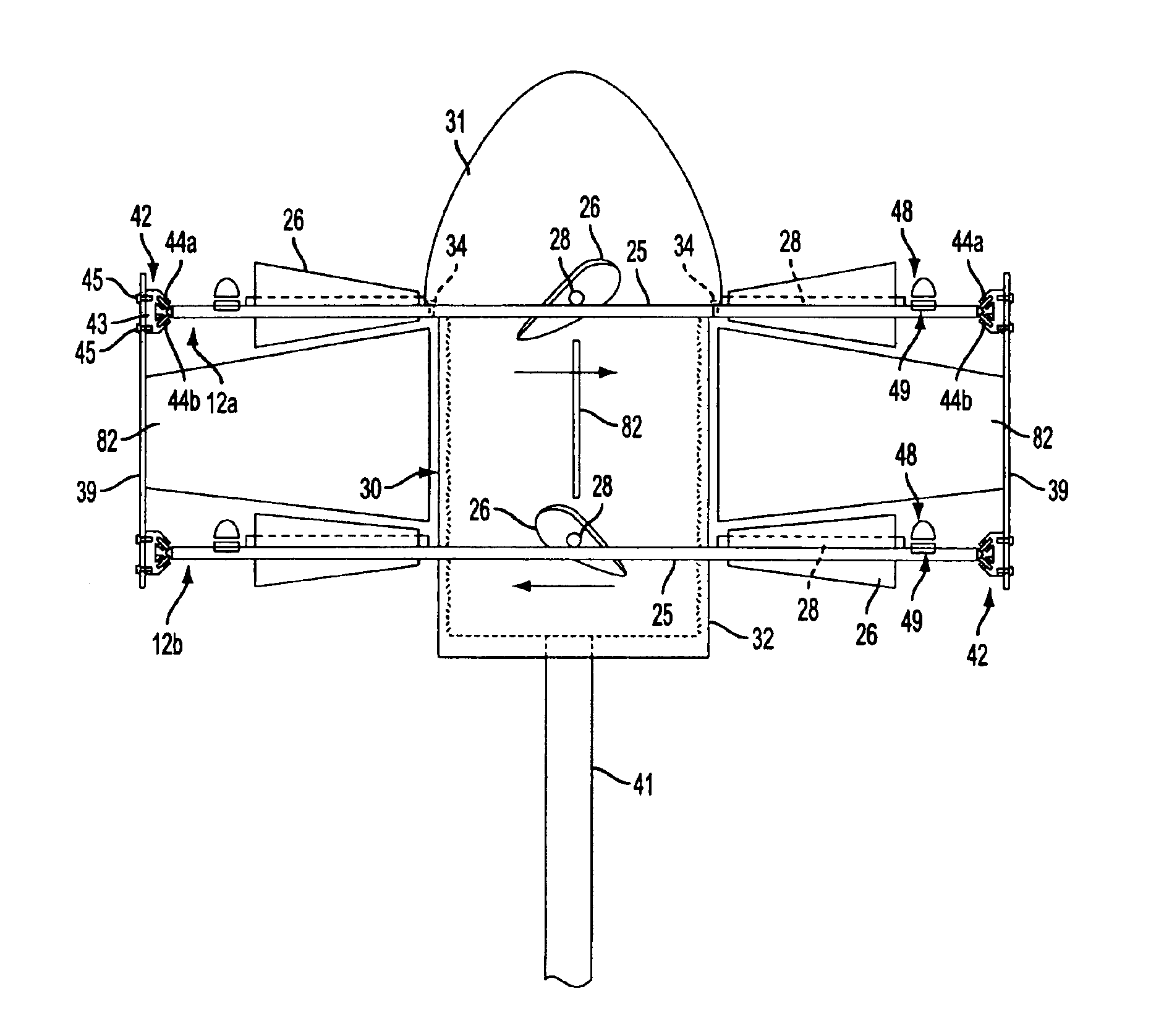

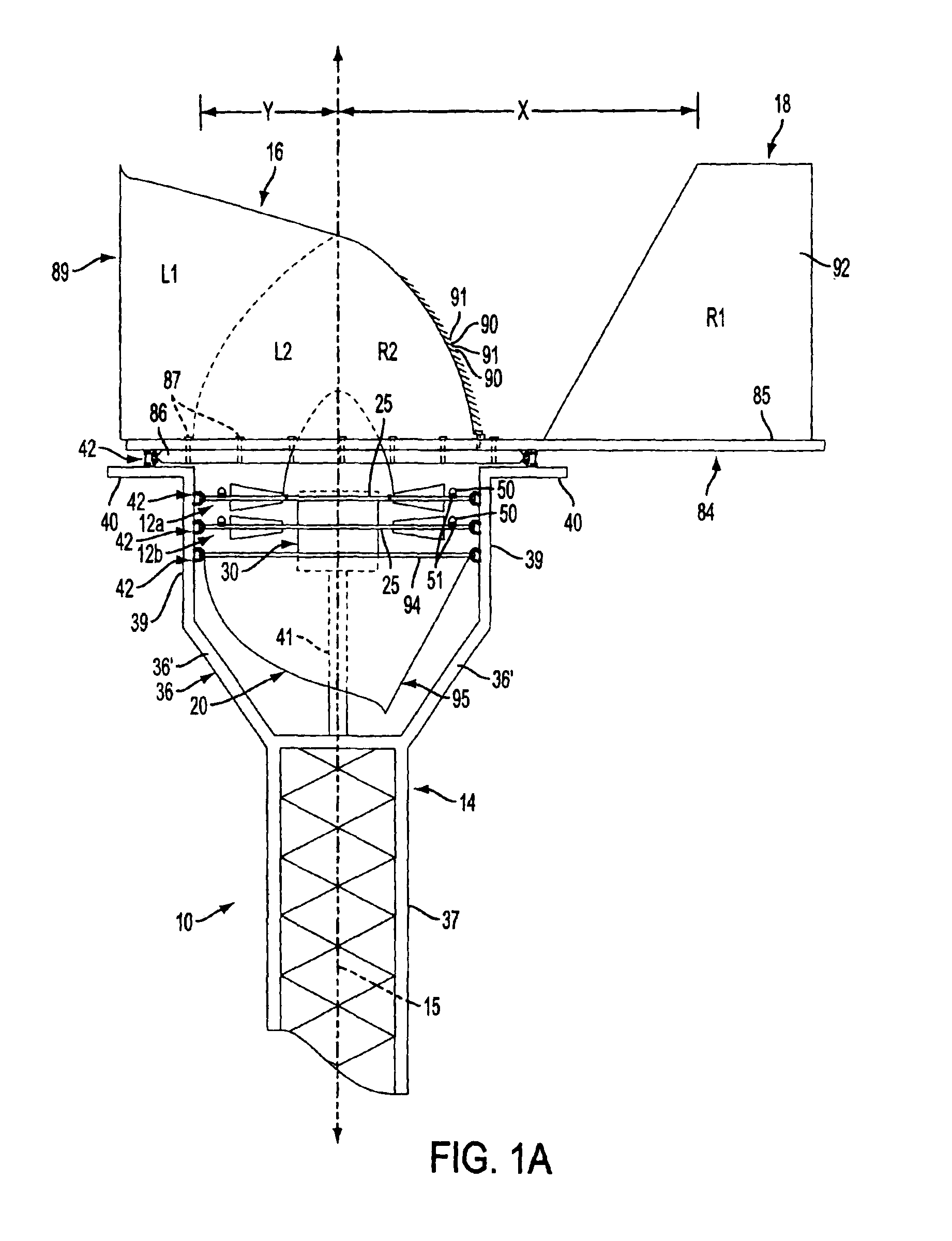

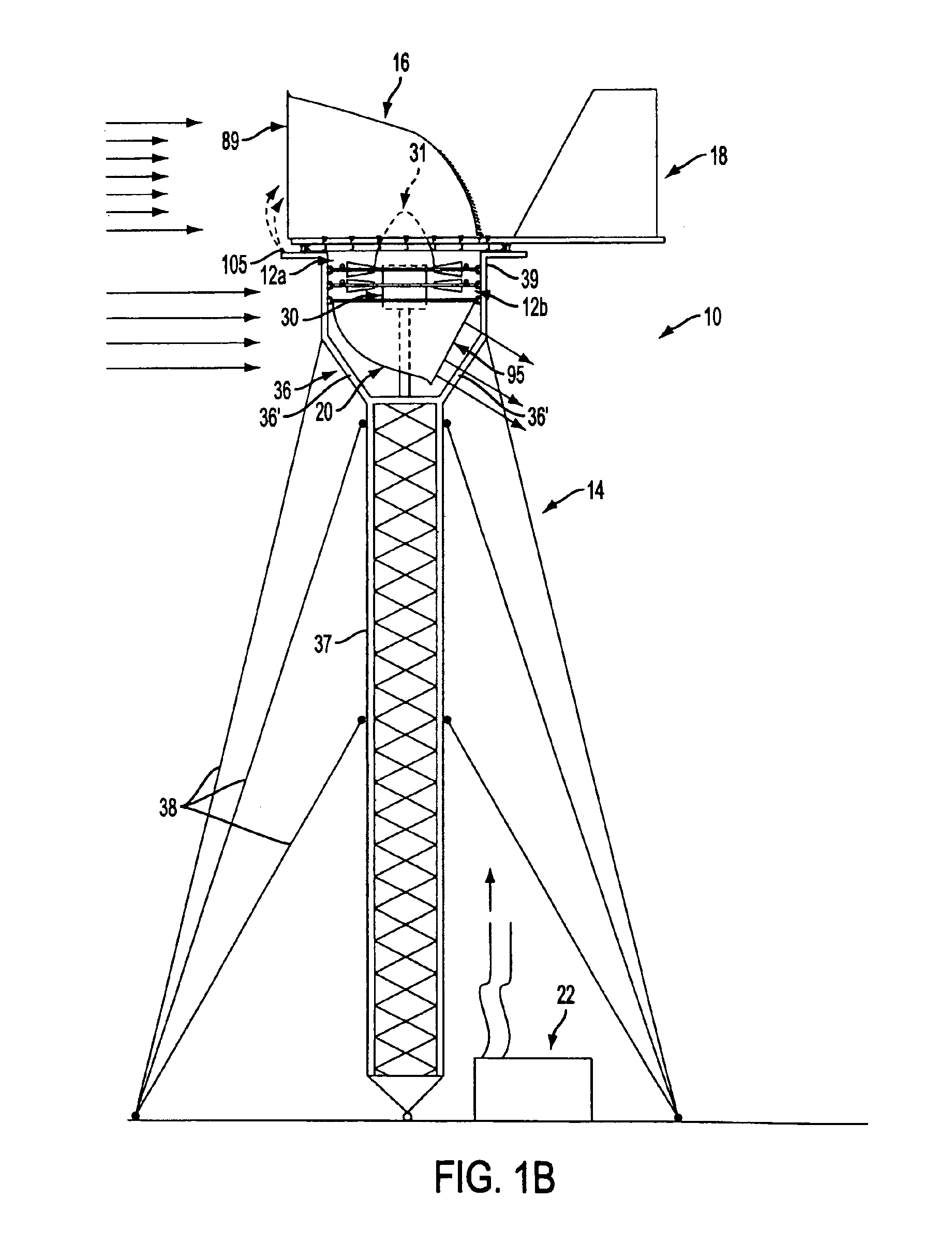

Wind energy conversion system

InactiveUS6952058B2Reduced weight and mass and costAdjustable sizePropellersWind motor supports/mountsWind energy conversionEngineering

A wind energy conversion system includes upper and lower wind turbines having counter-rotating blade assemblies supported for rotation about a vertical rotation axis, with each blade assembly carrying a rotor for rotation past a stator to produce an electrical output. The wind turbines are supported by a tower at an elevated position above the ground. Each wind turbine produces torque, and the wind energy conversion system provides for balancing the torques to avoid a net torque on the tower. Adjustment mechanisms are provided for adjusting blade pitch and for adjusting the size of an air gap between a stator and a rotor that comes into alignment with the stator as the rotor rotates therepast. The wind energy conversion system provides a hood for supplying intake air to a wind turbine and an exhaust plenum for exhausting air from the wind turbine, with the hood and the exhaust plenum being directionally positionable.

Owner:WECS

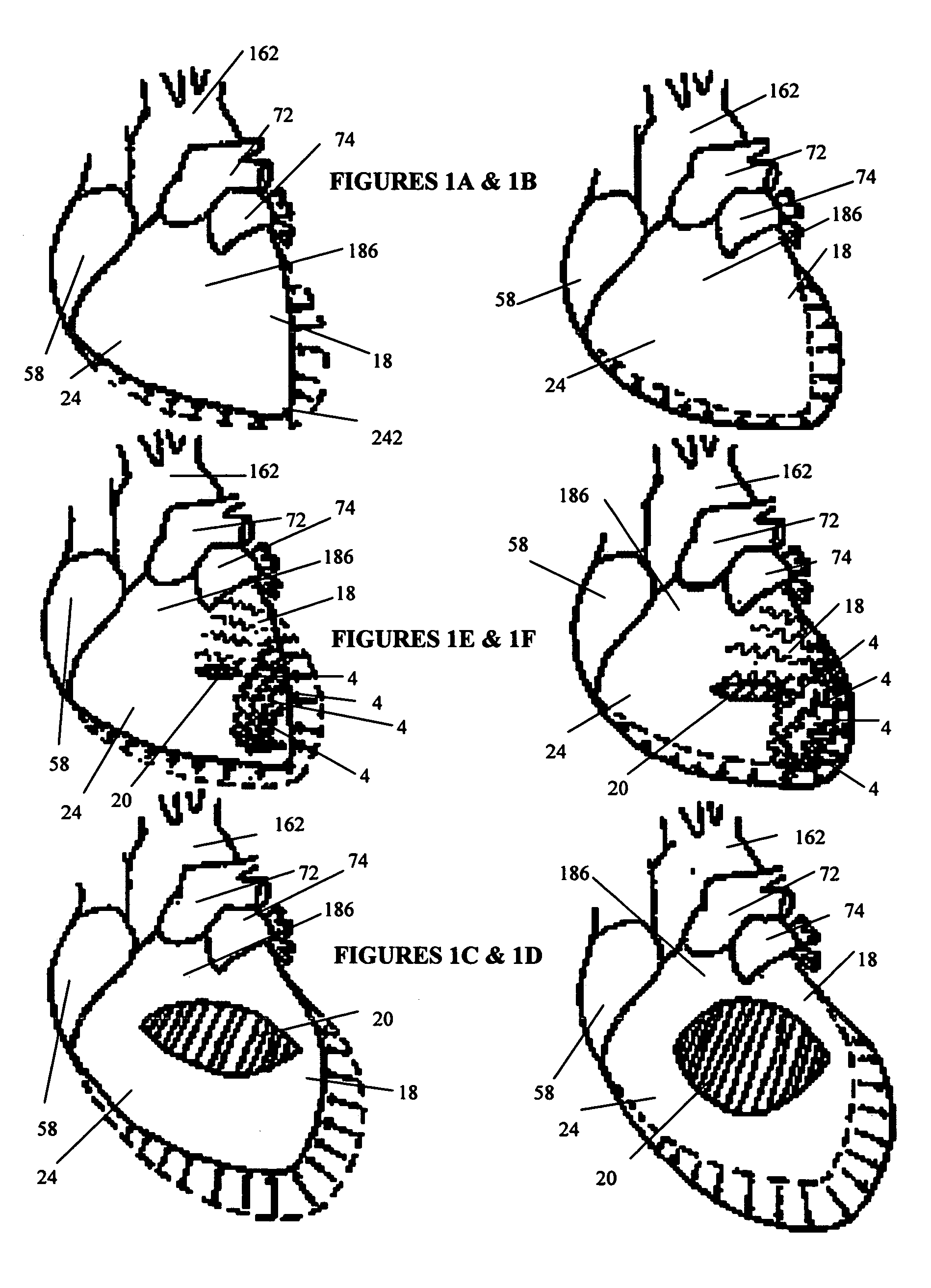

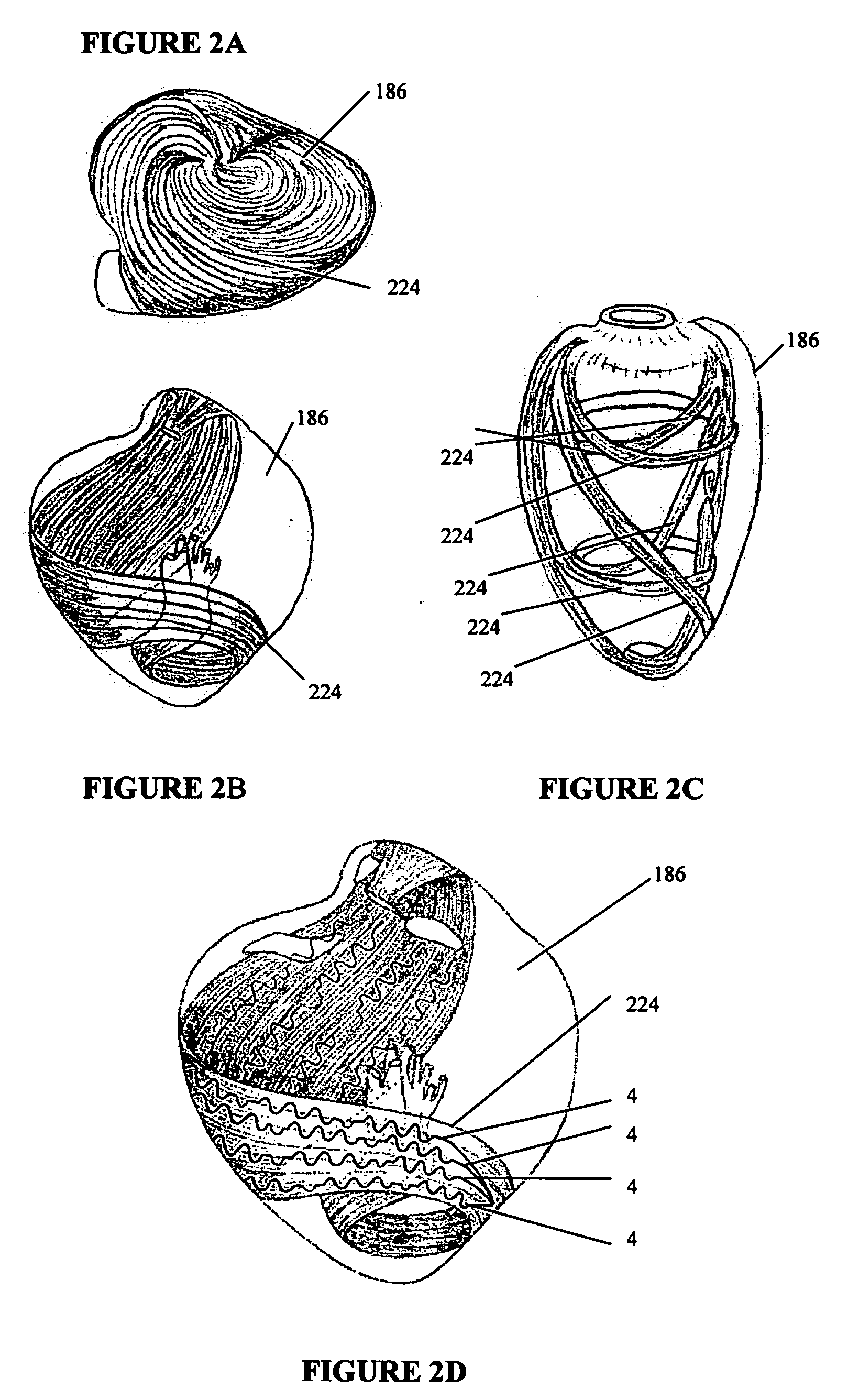

Systems for heart treatment

InactiveUS20050187620A1Reduce stressSufficient exposure and visualizationHeart valvesCongestive heart failure chfTherapeutic treatment

Devices and methods for treating degenerative, congestive heart disease and related dysfunction are described. Passive and active cardiac support structures mitigate changes in ventricular structure (i.e., remodeling) and deterioration of global left ventricular performance related to tissue damage precipitating from ischemia, acute myocardial infarction (AMI) or other abnormalities. Cardiac efficiency is improved by providing reinforcement that restores or maintains an elliptical ventricular shape and mimics the position and positive inotropic effects of helical wound myofibrils to provide active contraction of the ventricle in synchrony with the metabolically required cardiac pace or output. In addition, the cardiac support structures compensate or provide therapeutic treatment for congestive heart failure and / or reverse the remodeling that produces an enlarged heart. The structures may be implanted in target heart regions using less invasive surgical techniques, such as those involving port access or small incisions into the thoracic cavity.

Owner:PAI SURESH +1

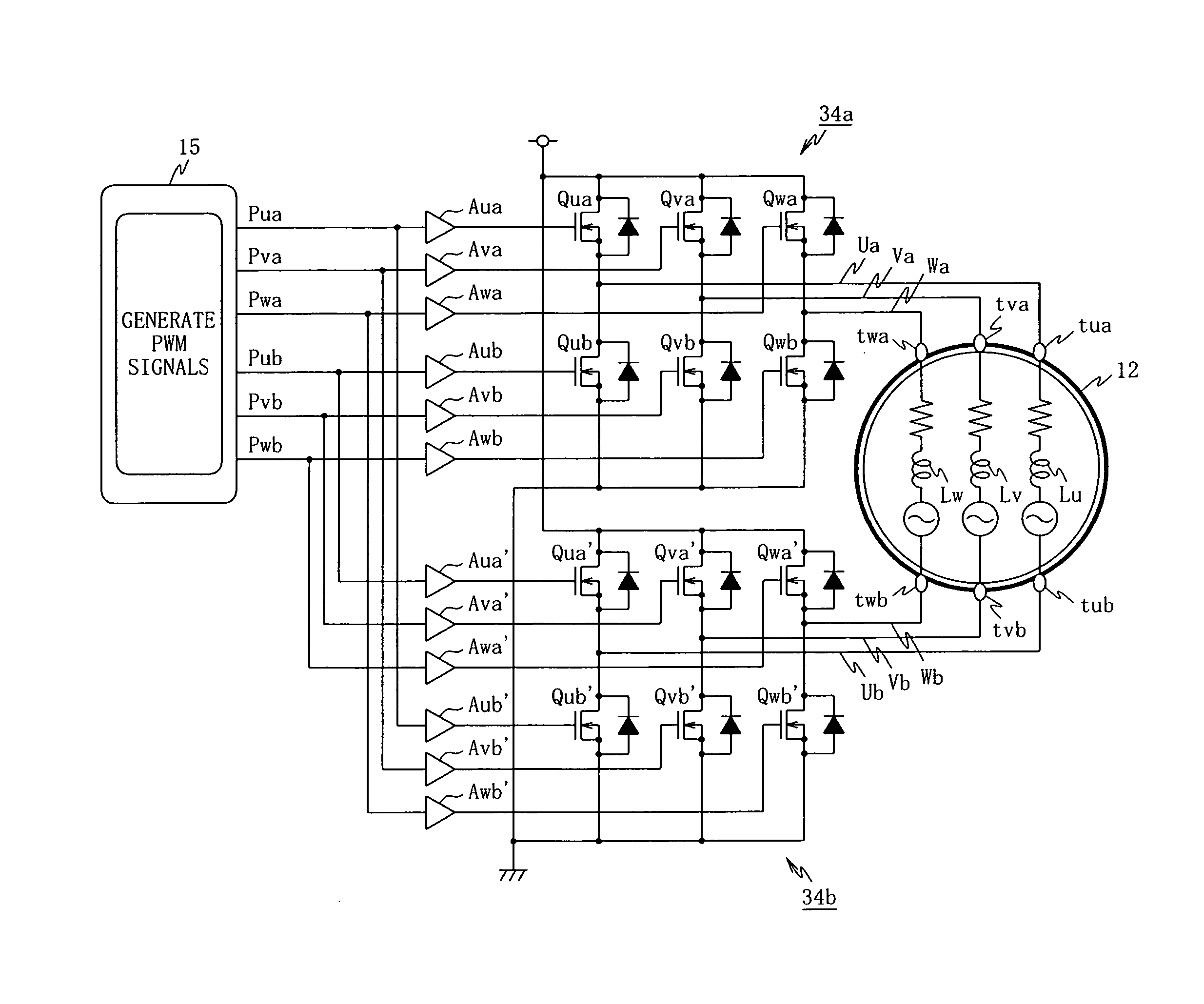

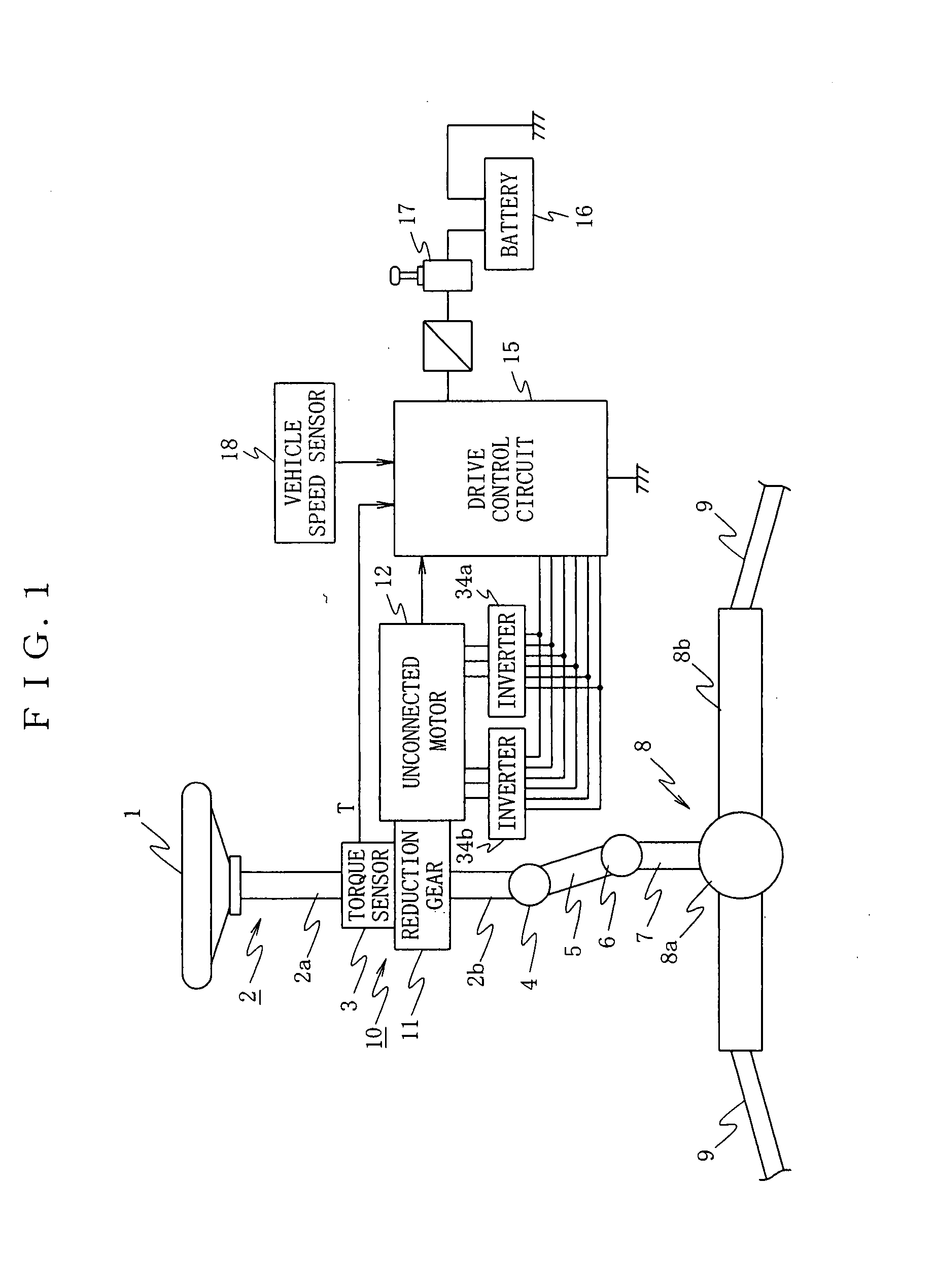

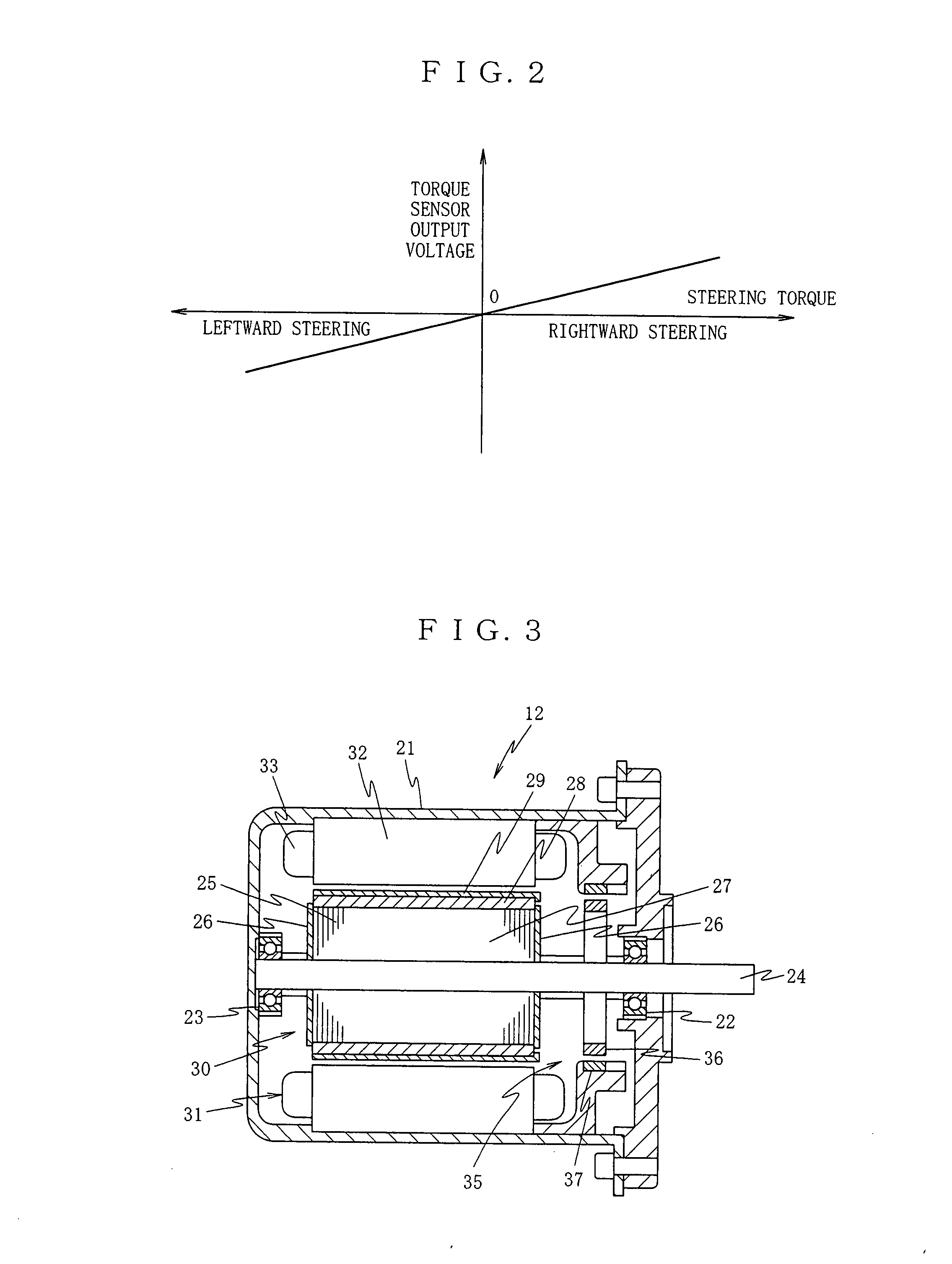

Unconnected Motor, Drive Control Device Thereof, And Electric Power Steering Device Using Drive Control Device Of Unconnected Motor

InactiveUS20080067960A1Constant gainIncreased current consumptionMotor/generator/converter stoppersSynchronous motors startersElectric power steeringControl signal

A drive control device of an unconnected motor capable of resolving power shortage and increasing motor output without using a boost circuit, and an electric power steering device using the unconnected motor. The drive control device comprises an unconnected motor (12) having a rotor in which permanent magnets are allocated and a stator opposing the rotor, in which armature winding Lu to Lw of a plurality (N number) of phases are independently arranged, a pair of inverter circuits (34a, 34b) individually connected to both ends of each armature winding, and a drive control circuit (15) which drives the pair of inverter circuits (34a, 34b) with a predetermined number (e.g. 2N) of PWM drive control signals.

Owner:NSK LTD

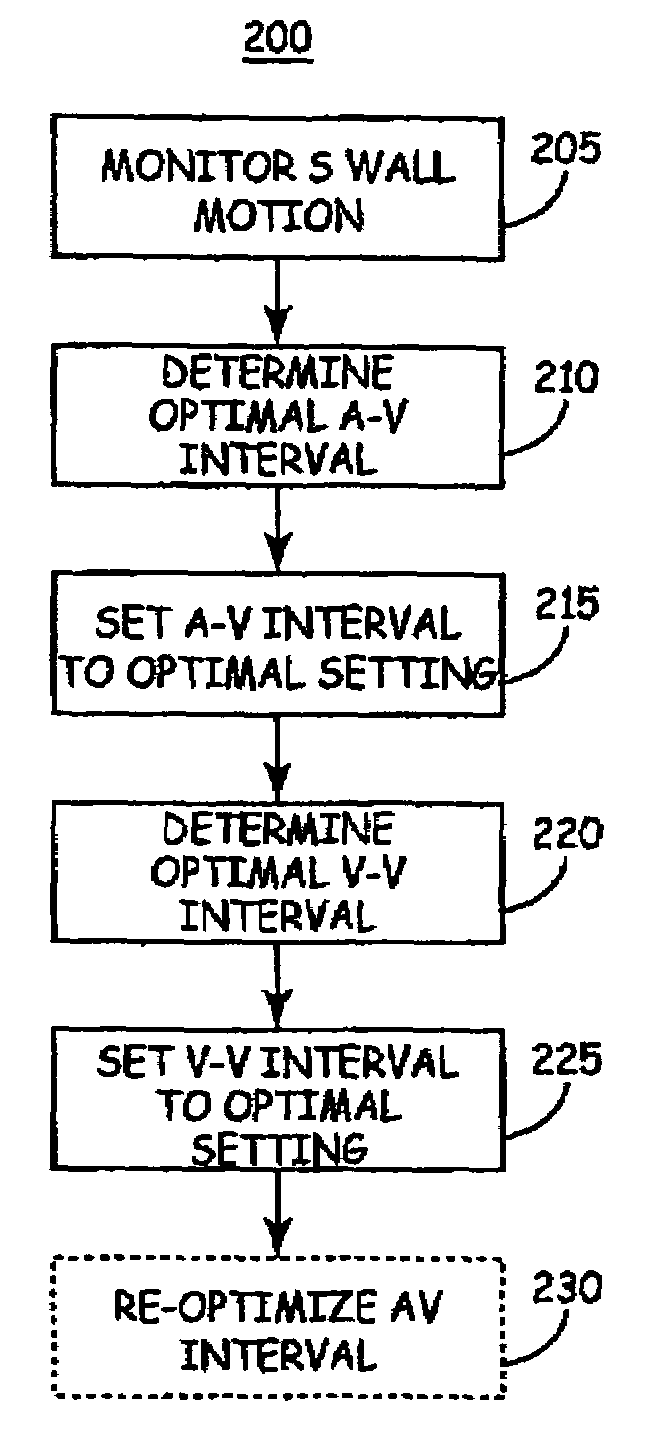

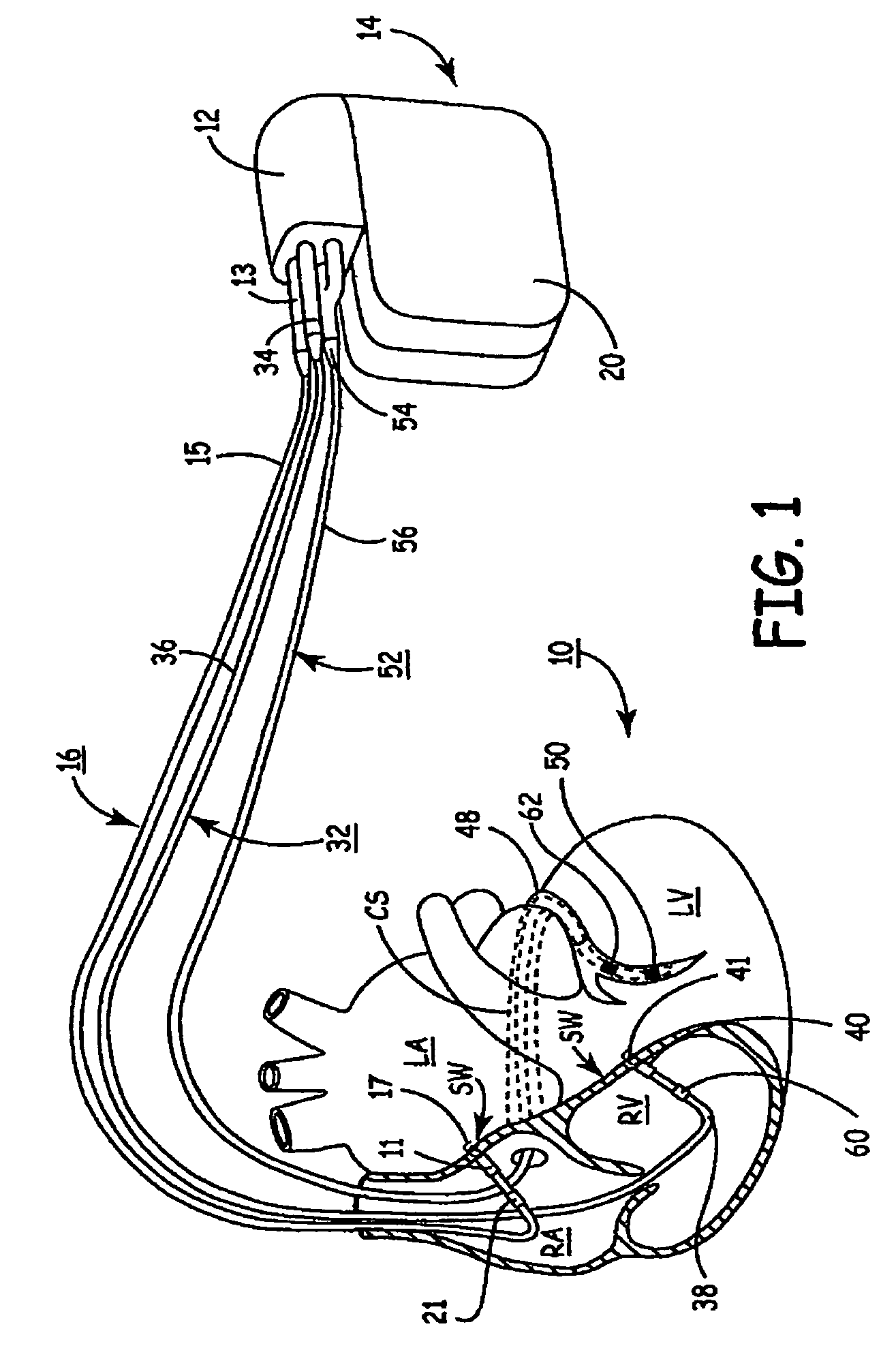

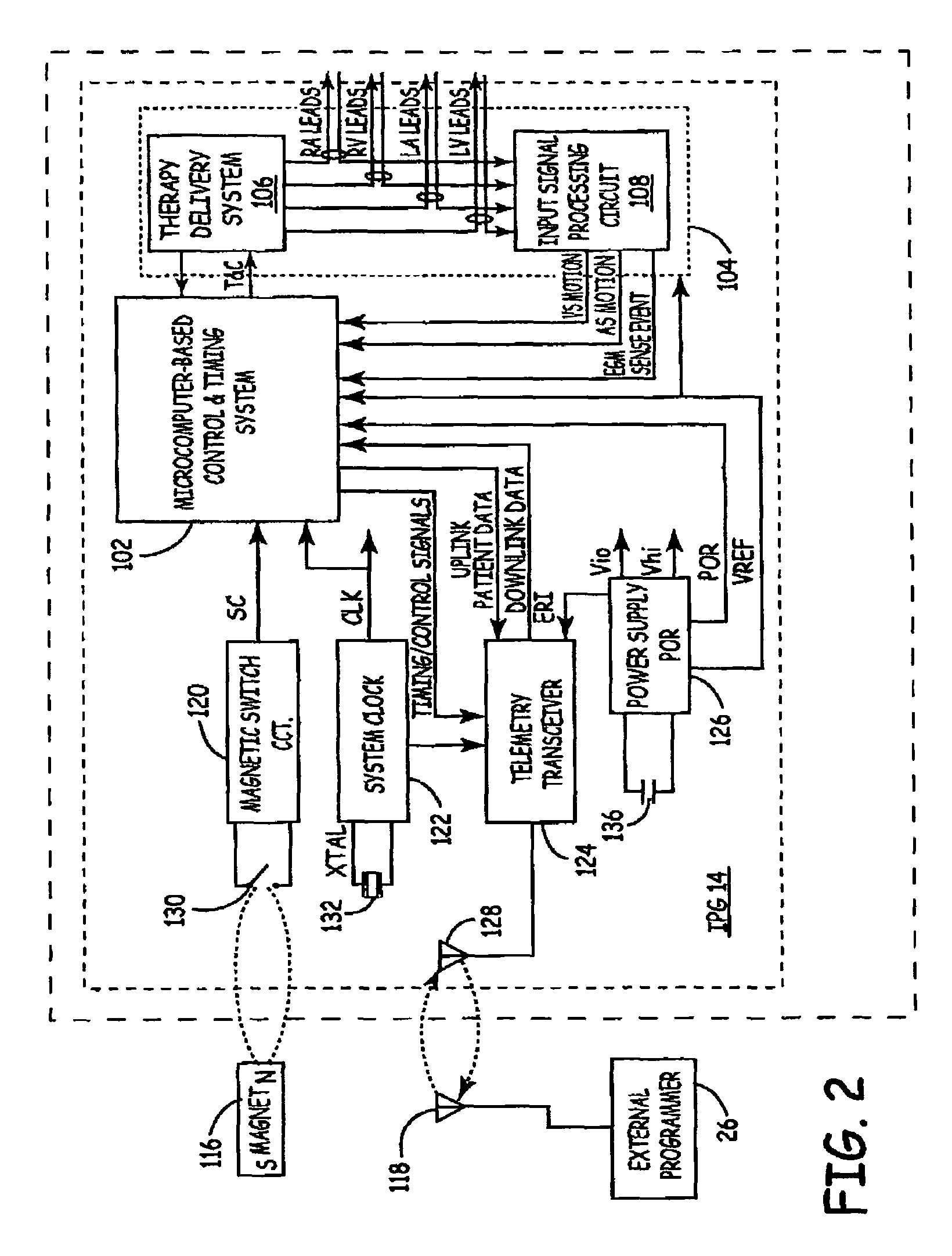

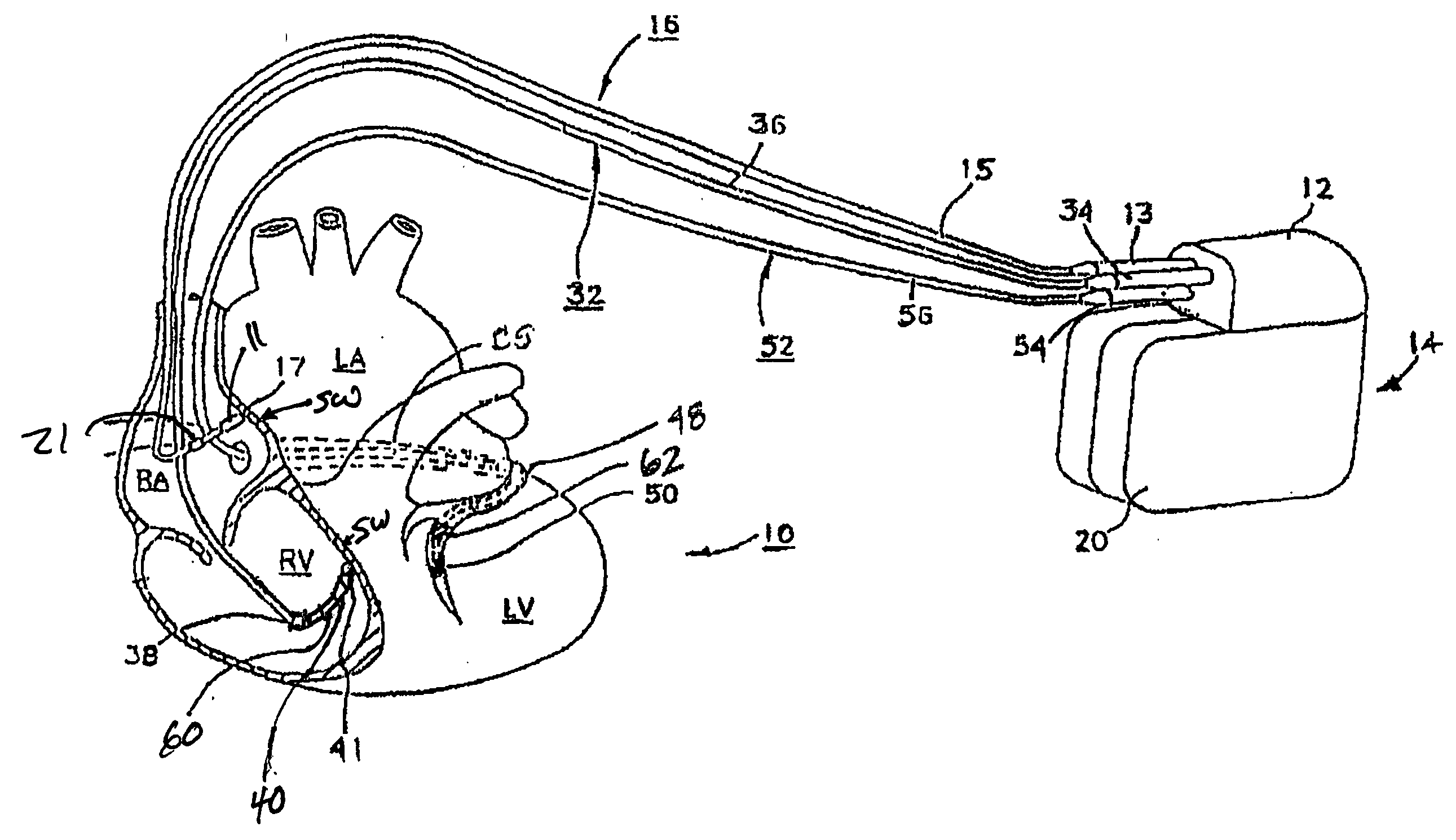

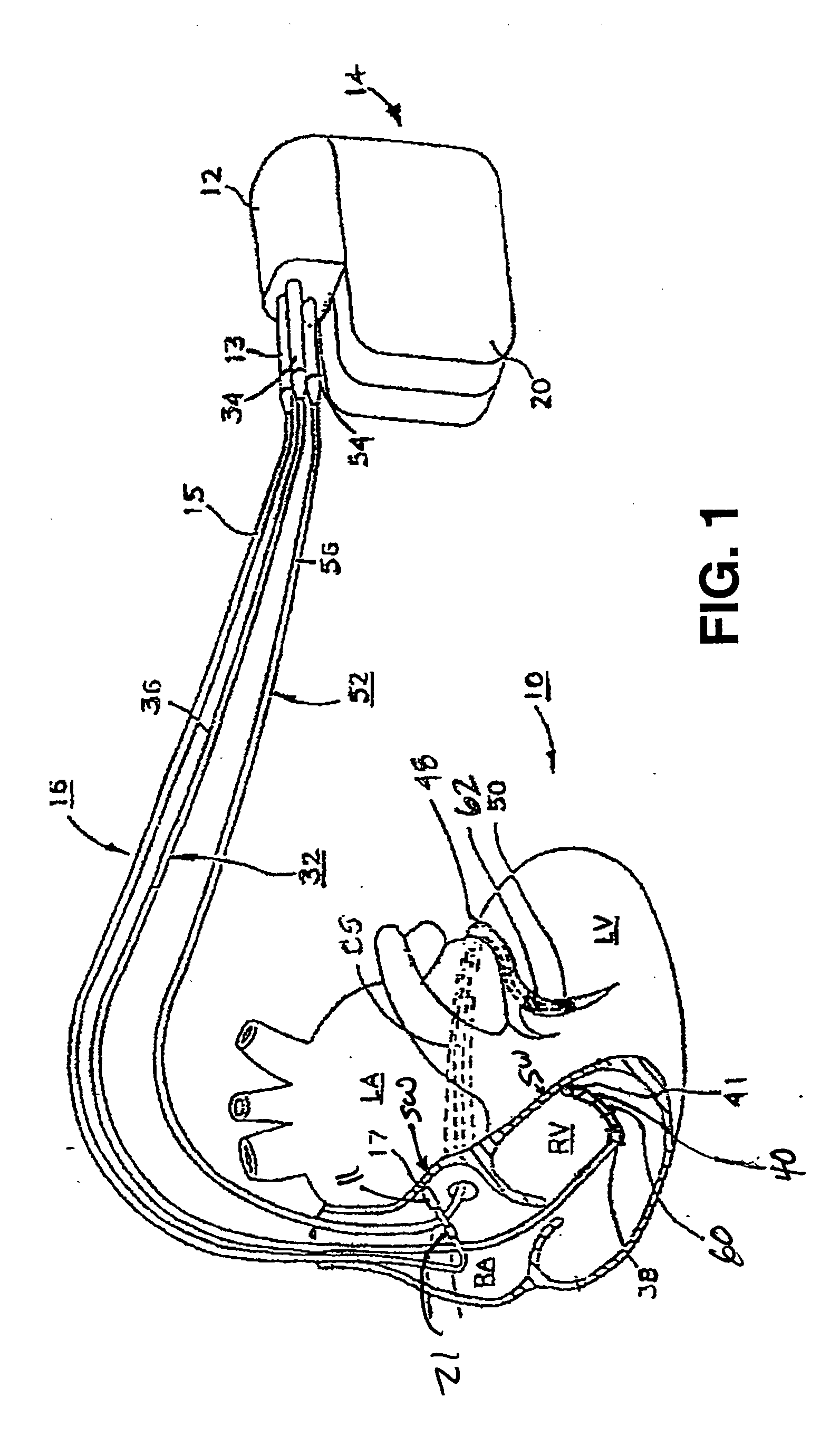

Method of optimizing cardiac resynchronization therapy using sensor signals of septal wall motion

The present invention relates to monitoring septal wall motion of the atrial and / or ventricular chambers of a heart for optimizing cardiac pacing intervals based on signals derived from said wall motion. At least one lead of medical device is equipped with a motion sensor adapted to couple to septal tissue. The device receives and may post-process (e.g., suitably filter, rectify and / or integrate) motion signals to determine acceleration, velocity or displacement. During pacing interval optimization the wall motion is measured for many pacing intervals and the pacing interval setting(s) that produce minimal wall motion are implemented for therapy delivery. In addition, the present invention provides methods for periodically determining whether to cease or resume delivery of a bi-ventricular pacing therapy to a patient that may have experienced beneficial reverse remodeling of the heart.

Owner:MEDTRONIC INC

Dynamic nerve stimulation for treatment of disorders

ActiveUS7689276B2Increased energy expenditureReducing food intakeSpinal electrodesDiseasePhysical therapy

A method for the treatment of obesity or other disorders by electrical activation or inhibition of nerves is disclosed. This activation or inhibition can be accomplished by stimulating a nerve using an electrode. Dynamic stimulation through ramped cycling of electrical stimulation, stimulation frequency alteration, and / or duty cycle variance can produce therapeutic benefits.

Owner:ADVANCED NEUROMODULATION SYST INC

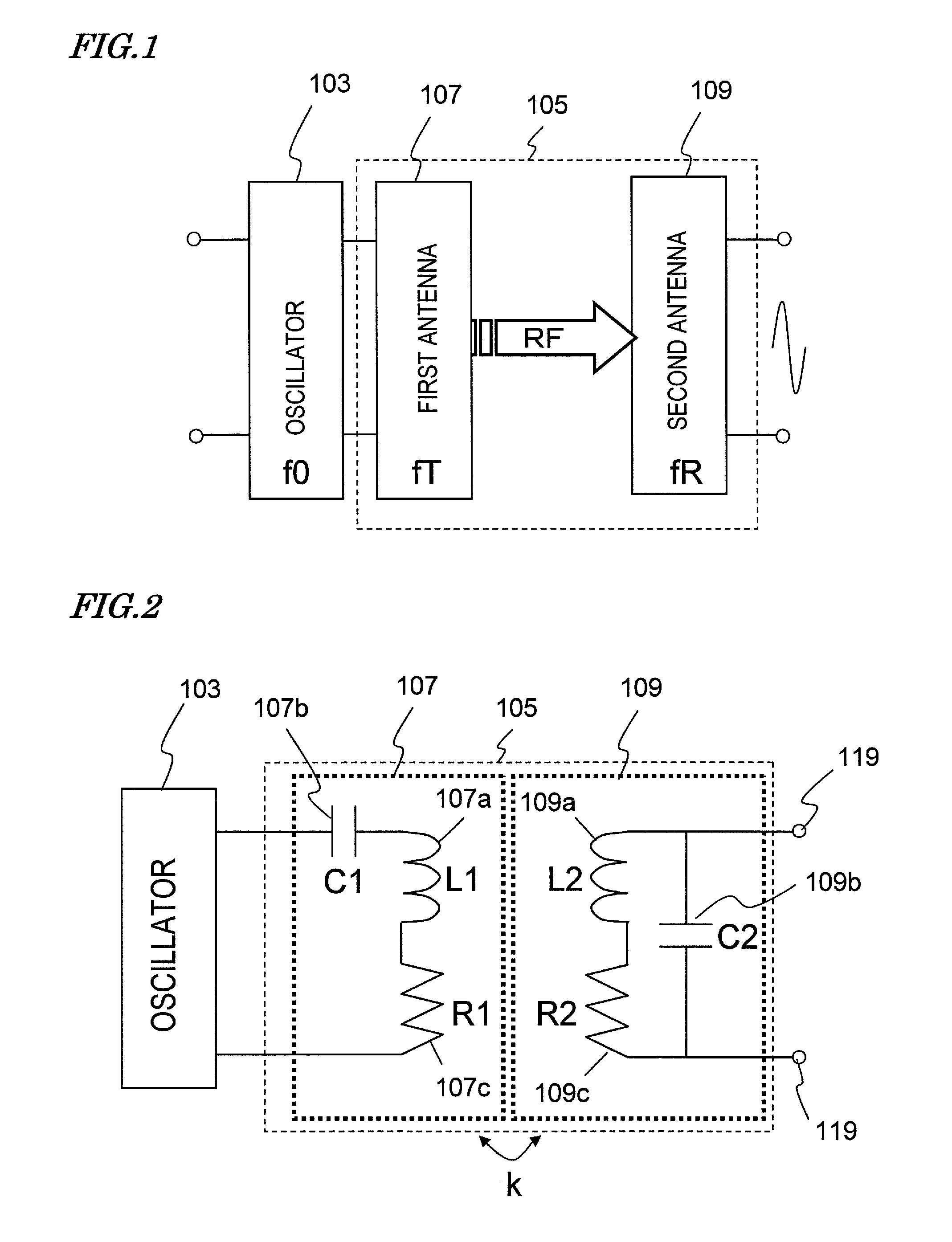

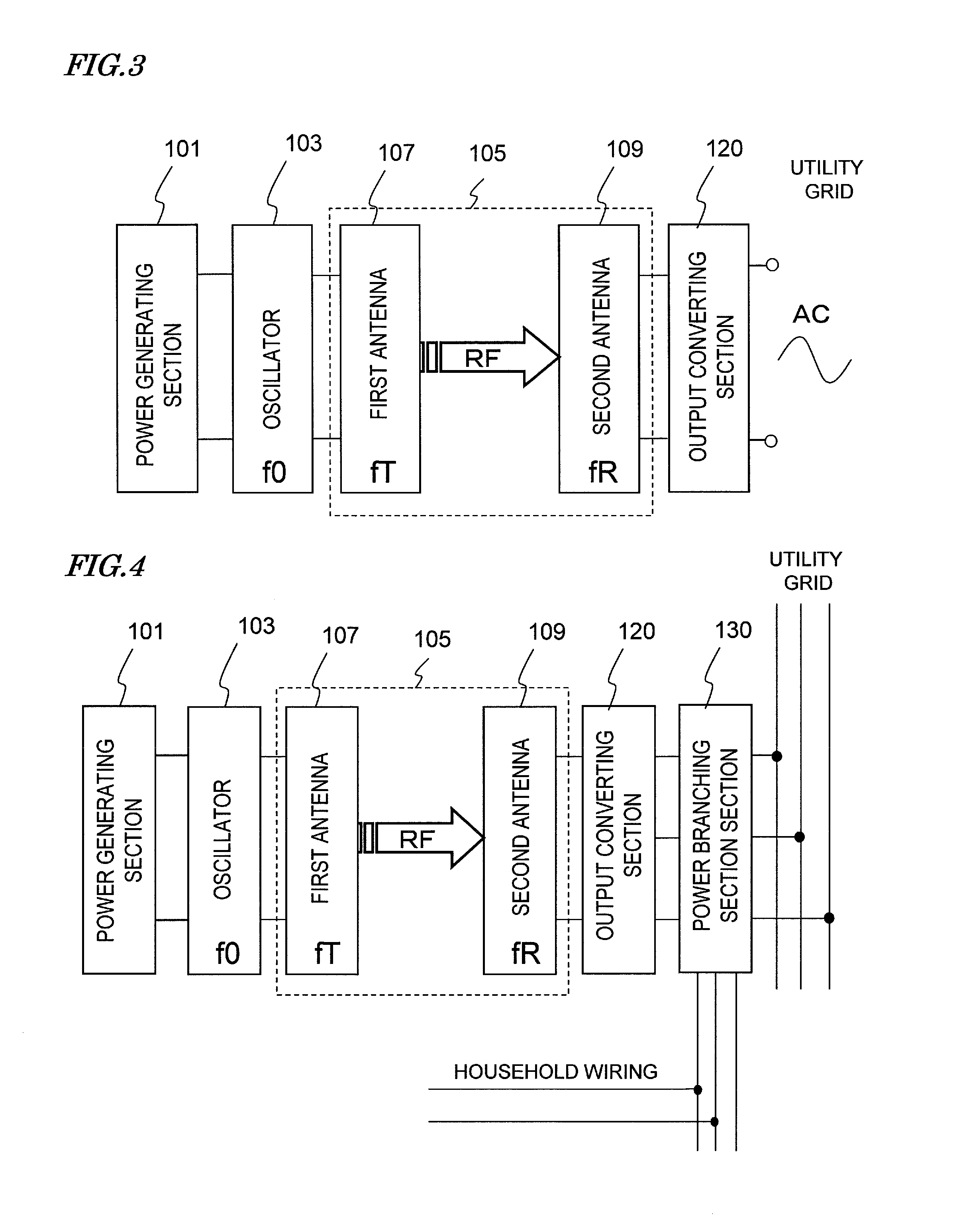

Power generator and power generation system

ActiveUS20120007435A1High voltageLow costDc network circuit arrangementsElectromagnetic wave systemInductorSupply energy

A power generator according to the present invention includes: a power generating section (101) for outputting DC energy; an oscillator (103) for converting the DC energy into RF energy having a frequency f0; a first antenna (107) for transmitting the RF energy; a second antenna, which receives, by coupling a resonant magnetic field, at least a part of the RF energy transmitted by the first antenna (107); and an output converting section (120) for converting the RF energy supplied from the second antenna (109) into AC energy having a lower frequency than the RF energy. If the oscillator (103) has a voltage step-up ratio Voc, the output converting section (120) has a voltage step-up ratio Vtr, the first inductor (107a) of the first antenna (107) has an inductance L1, the second inductor (109a) of the second antenna (109) has an inductance L2, and the first and second antennas (107, 109) have a coupling coefficient k, the power generator satisfies (L2 / L1)≧(k / (Voc×Vtr))2.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

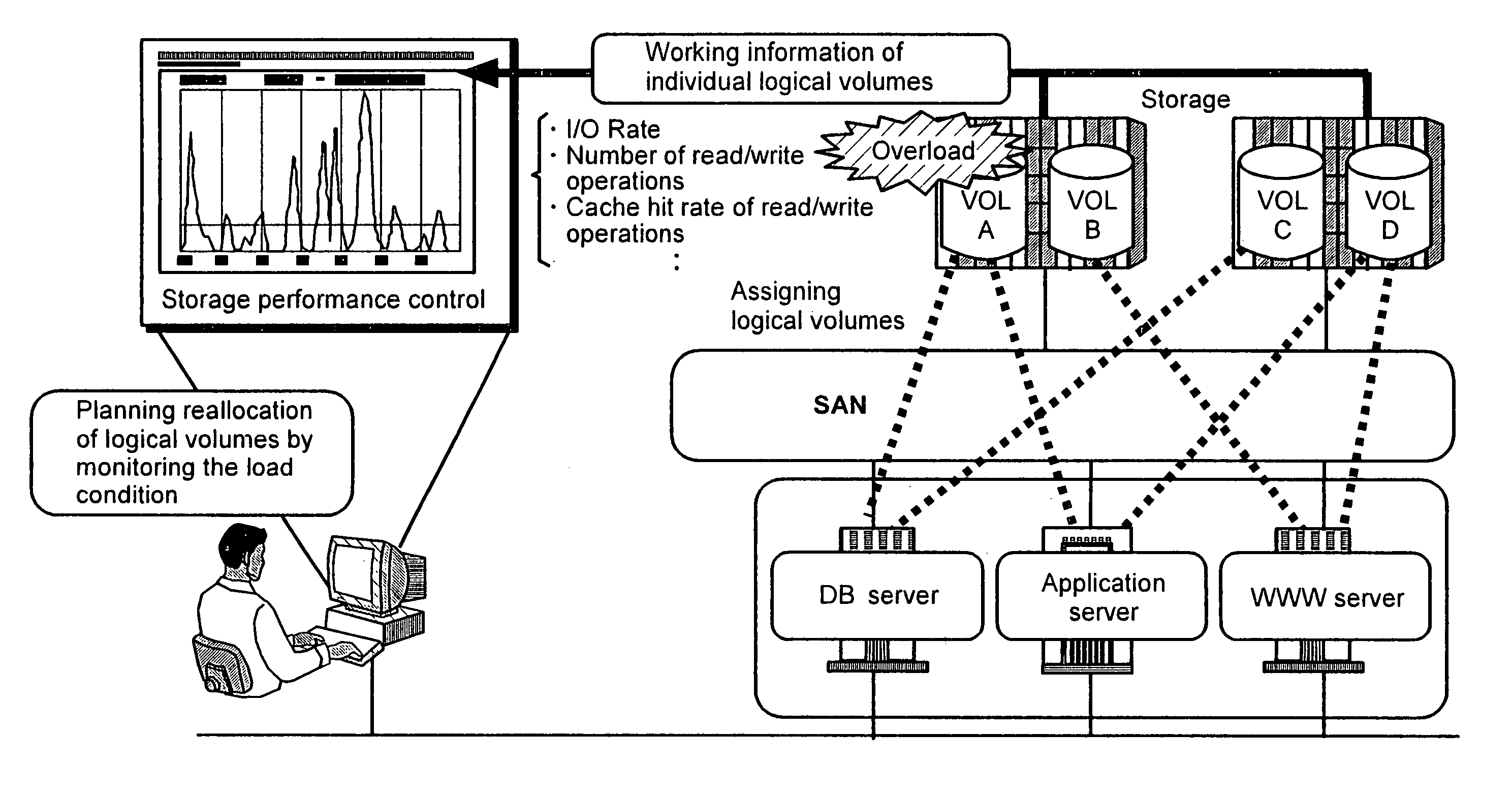

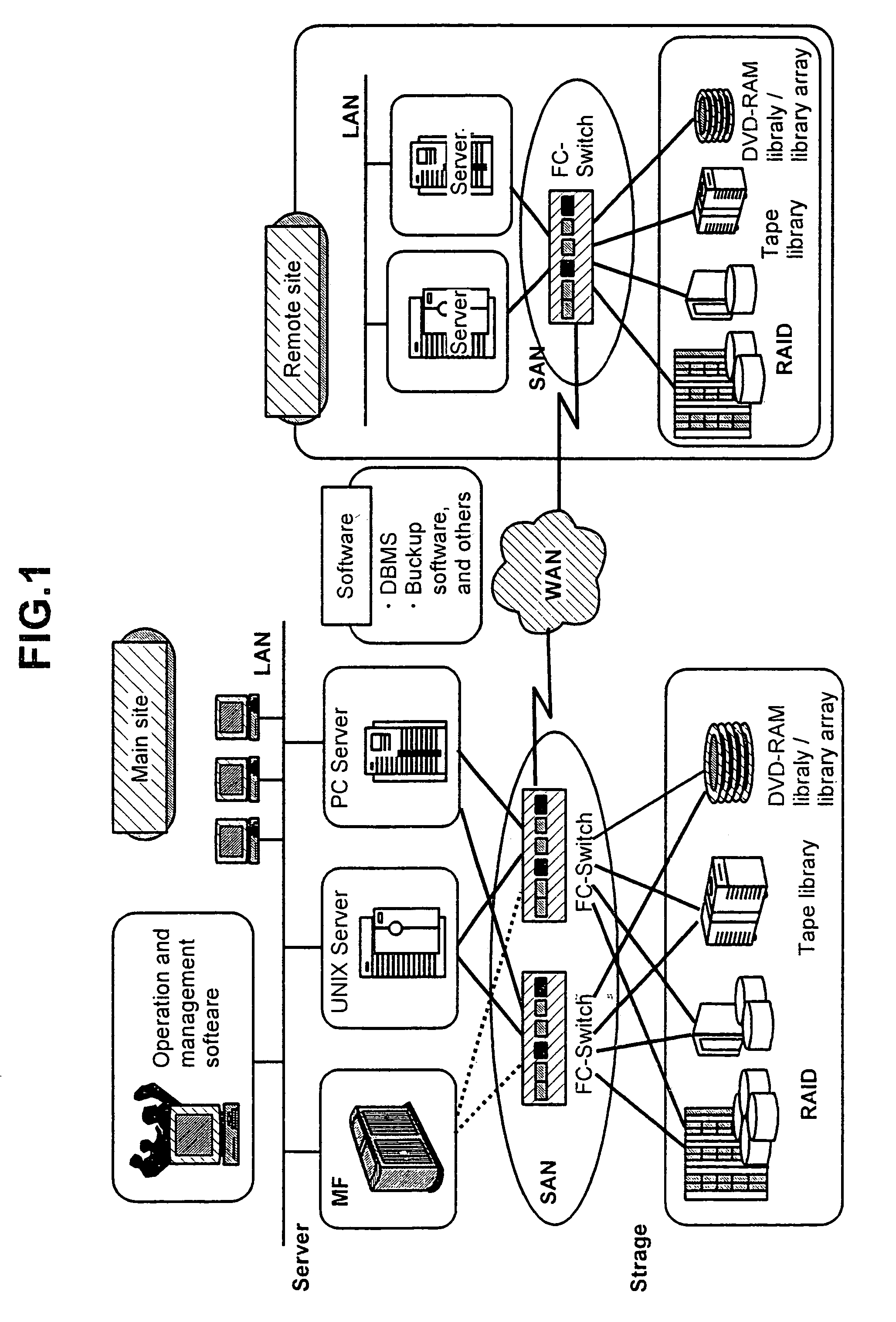

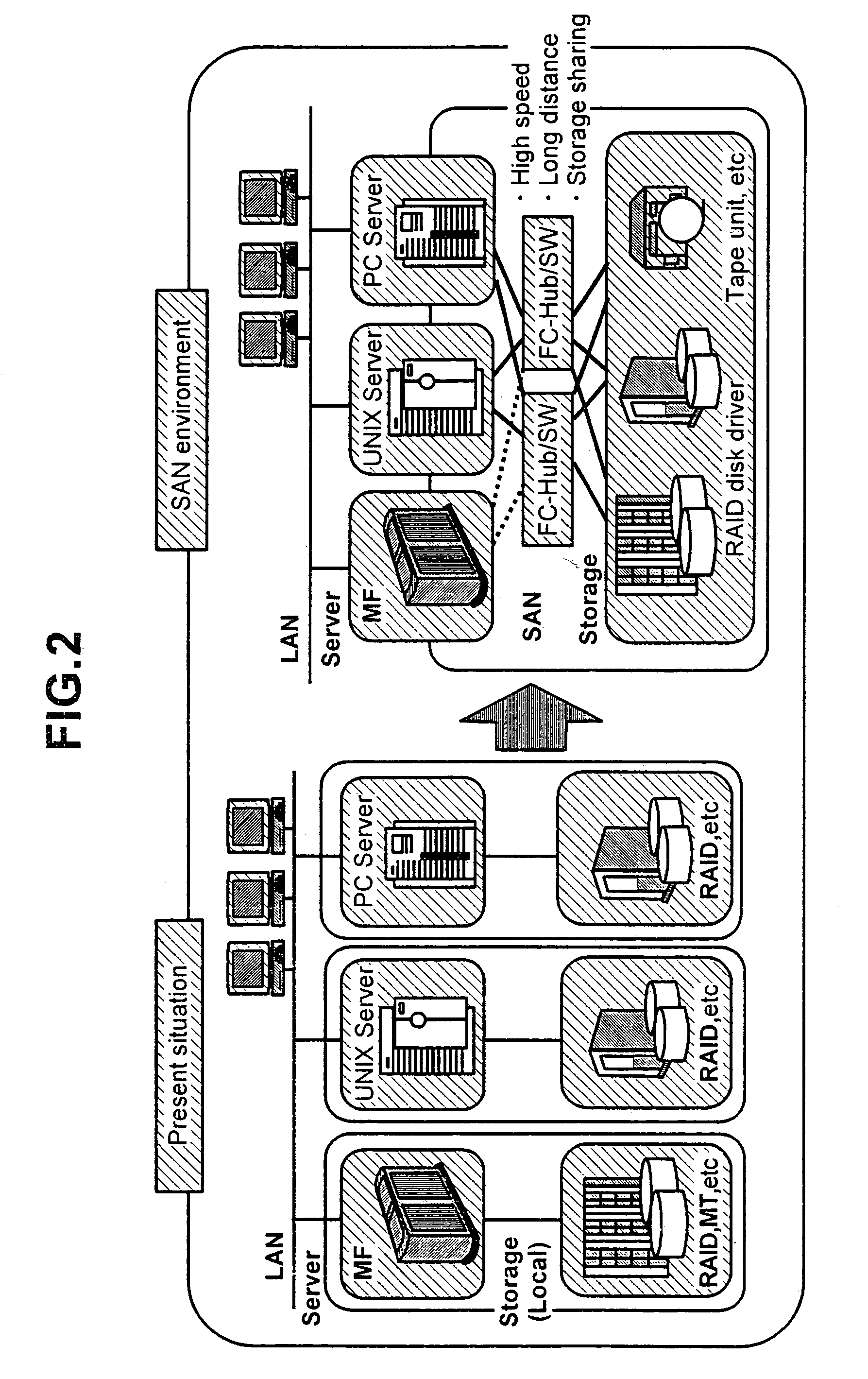

Computer system having a storage area network and method of handling data in the computer system

InactiveUS6950871B1Improve input performanceImprove output performanceDigital computer detailsSpecial data processing applicationsFiberStorage area network

In order to construct an integrated storage system by reinforcing collaboration of components or functions of a storage system in which a storage area network (SAN) is used, in a computer system having multiple client computers, multiple various servers, multiple various storages which keep data, and a local area network (LAN) which connects the computers and the servers, a storage area network (SAN) which lies between the servers and storages forms a switched circuit network which is capable of connecting any server and any storage through fiber channel FC switches. The computer system further includes a terminal which is equipped with operation and management software which performs storage management including management of logical volumes in the various storages, data arrangement, error monitoring, management of setting up the FC switches, and backup for data in the storages.

Owner:HITACHI LTD

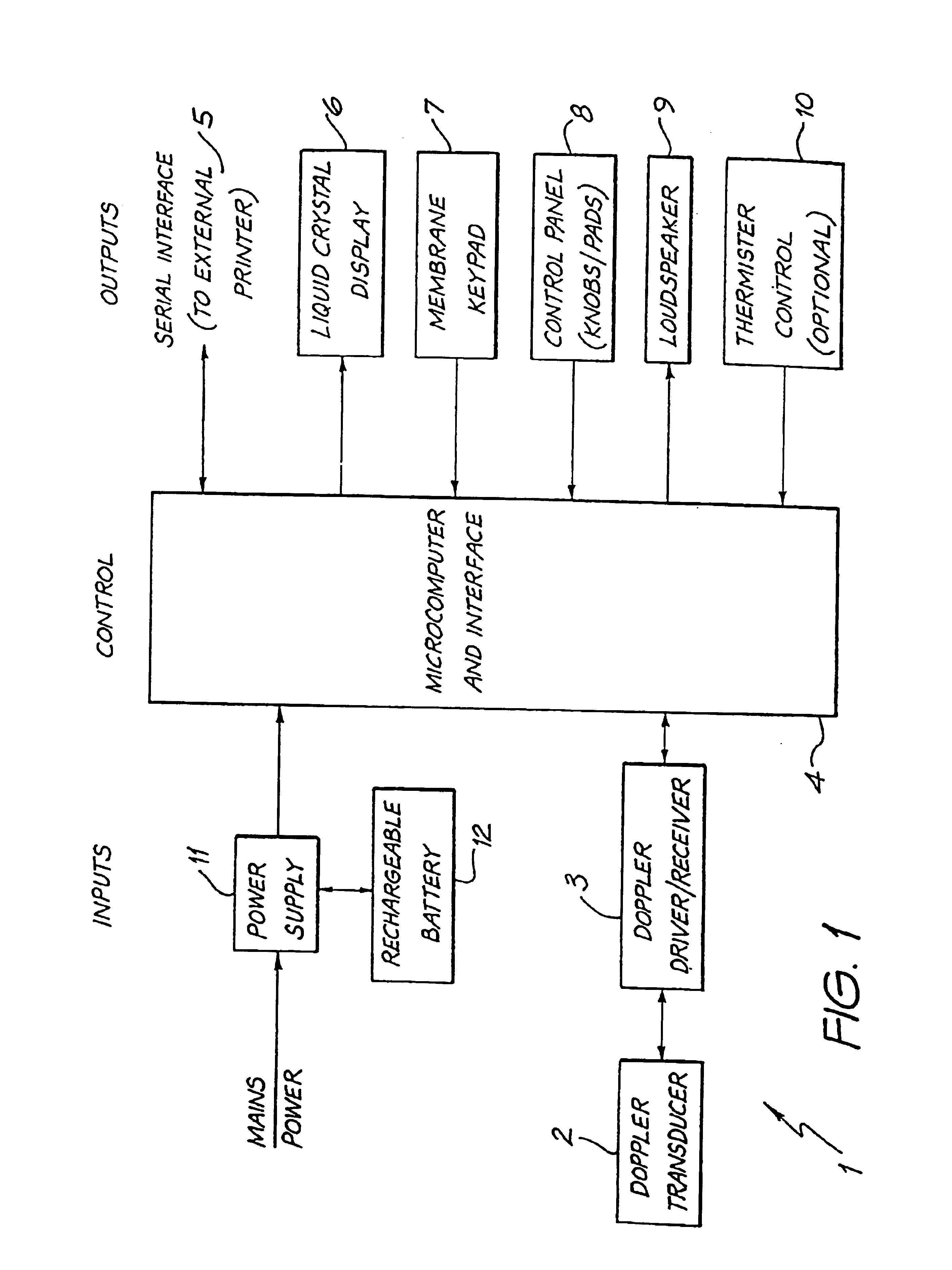

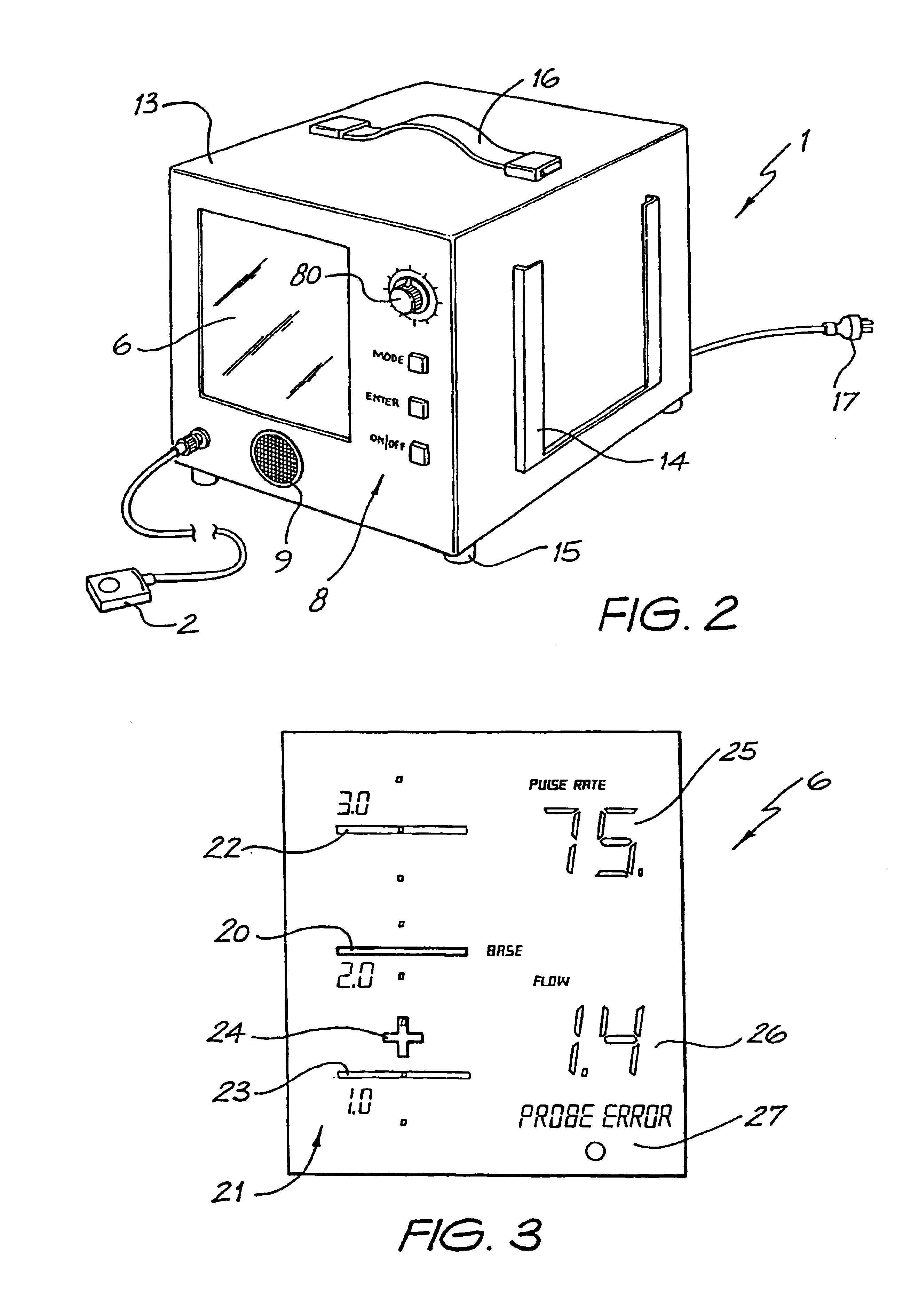

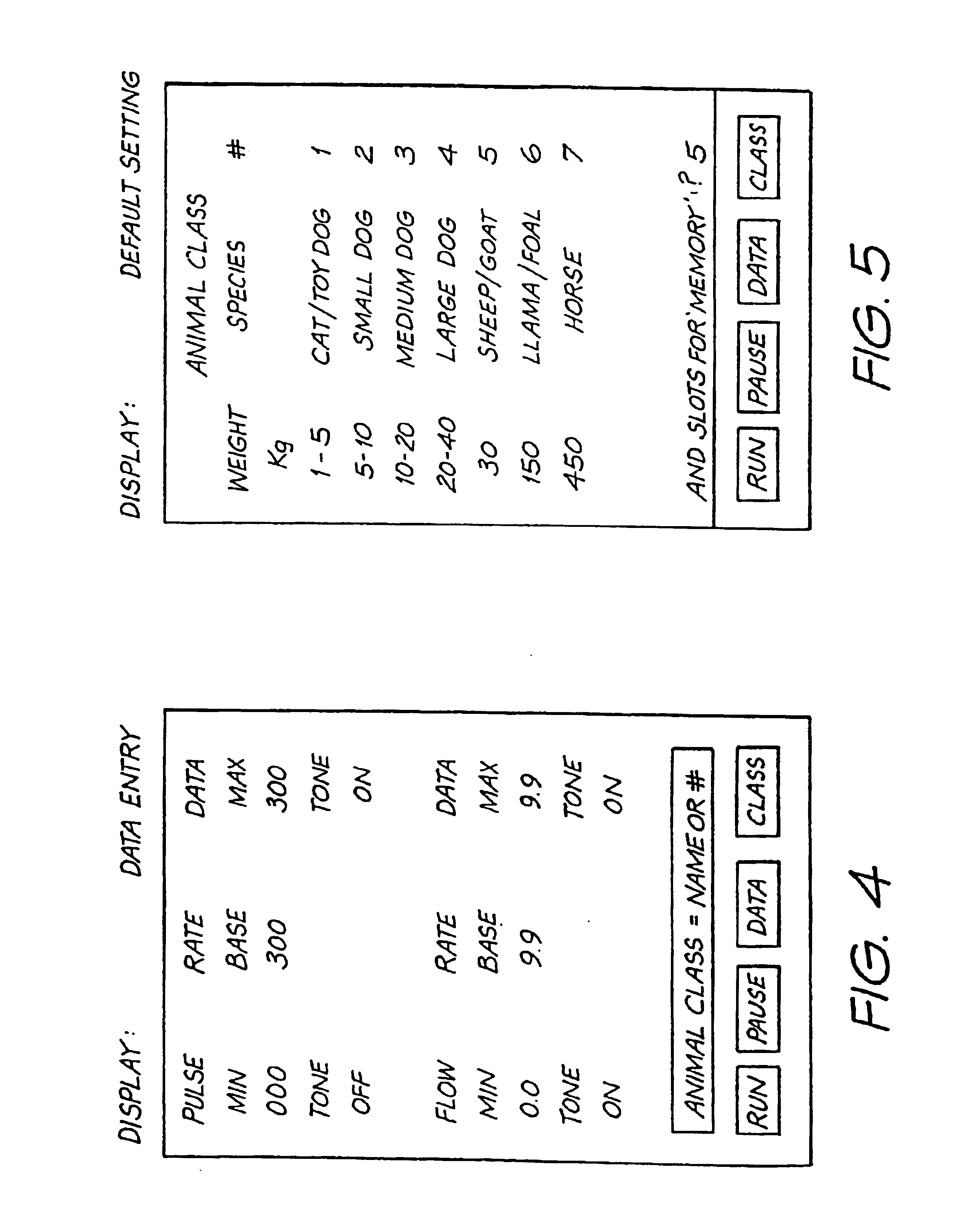

Method and apparatus for monitoring haemodynamic function

InactiveUS6939307B1Accurate indicationAccurate of oxygen deliveryBlood flow measurement devicesCatheterBlood flowBiology

The present invention relates to a method and apparatus for monitoring haemodynamic function in animals and humans during anaesthesia and surgery. During anaesthesia and surgery the subject's haemodynamic, respiratory, neuromuscular and neurological functions are monitored as indicators of the condition of the health of the subject. Commonly, variations in blood pressure are used to imply corresponding variations in cardiac output, i.e. good blood pressure equals good cardiac output. The present invention utilizes a device to monitor changes of blood flow in peripheral blood vessels of the subject as an indicator of cardiac output. This is believed to provide a much more accurate indicator.

Owner:DUNLOP COLIN

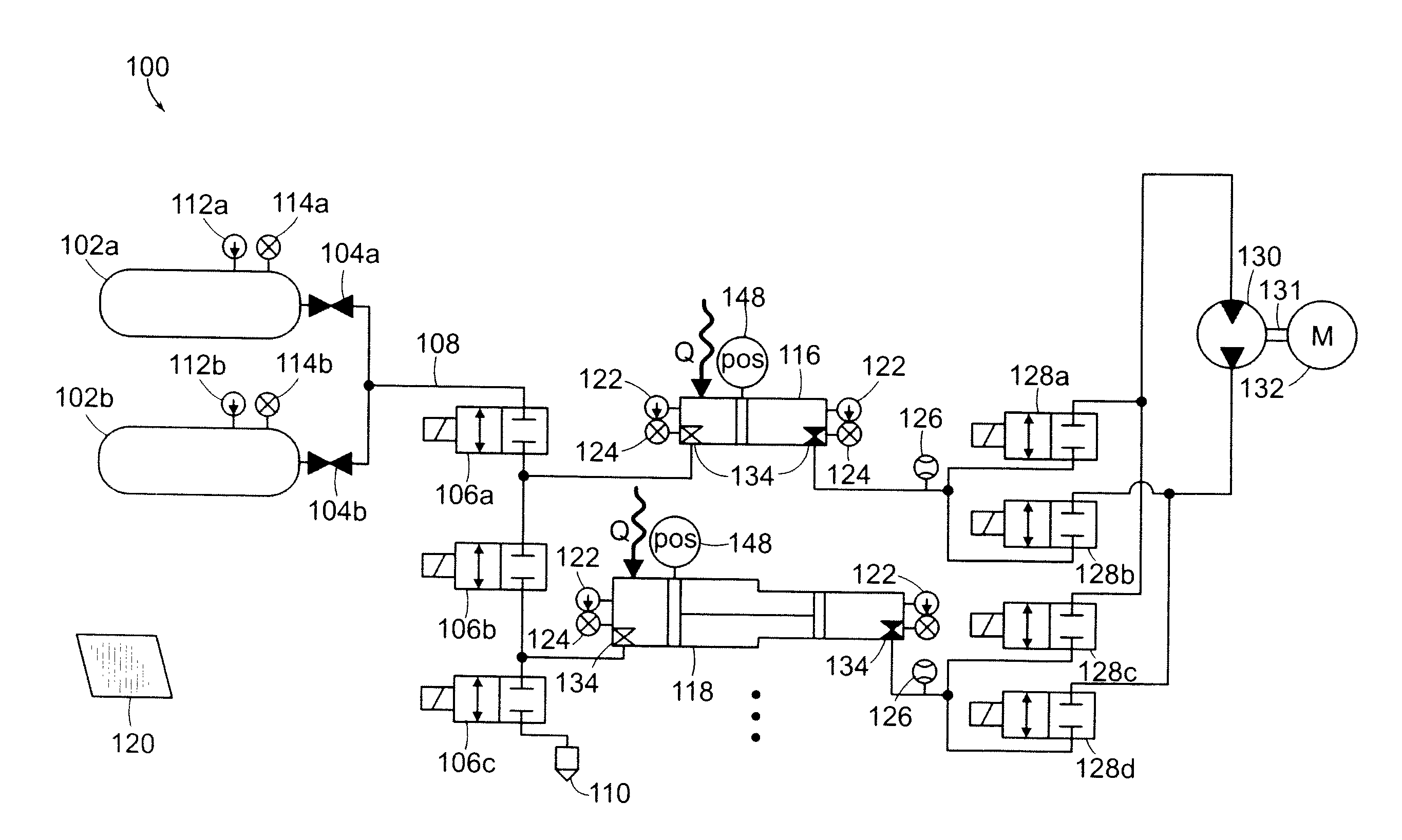

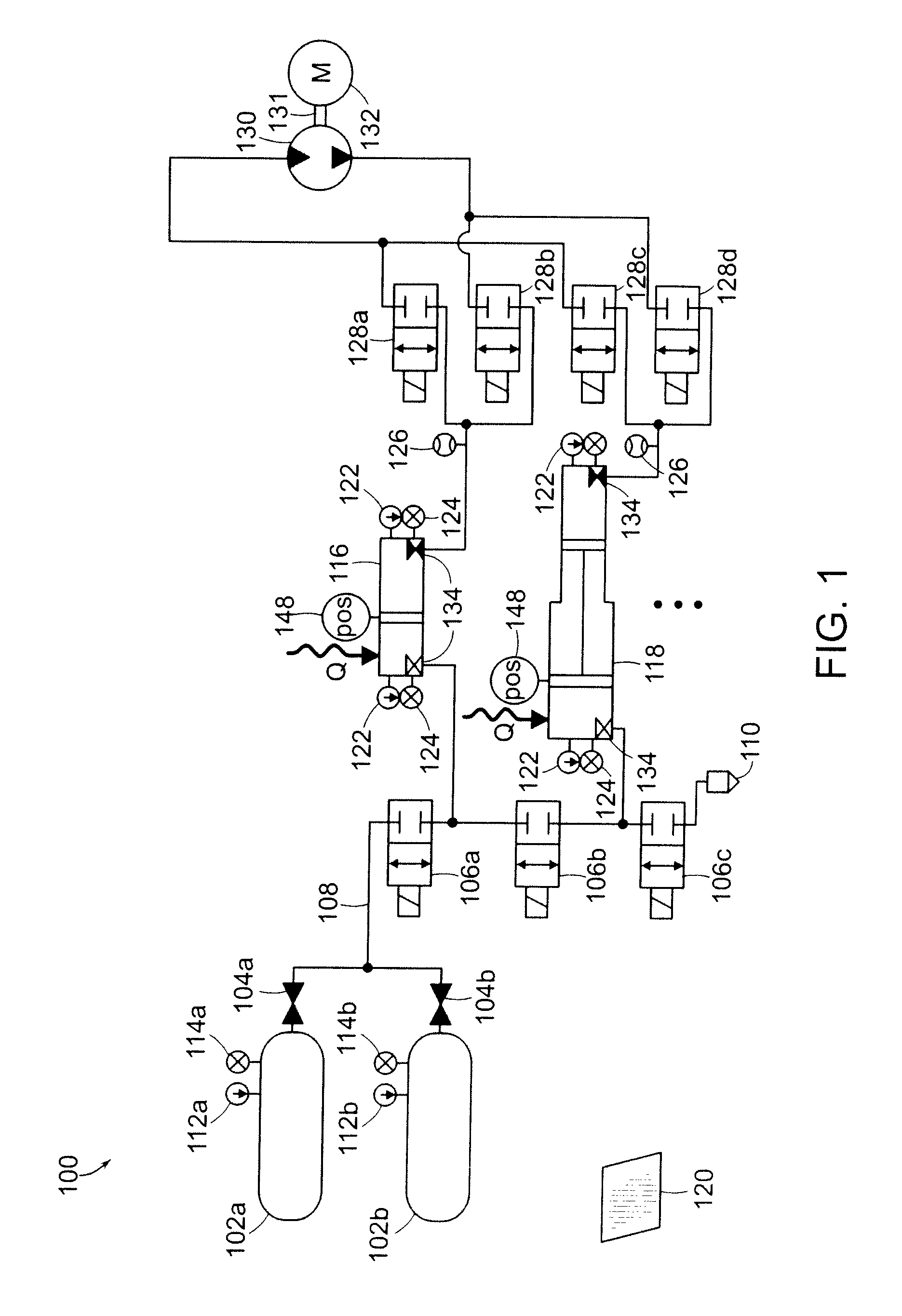

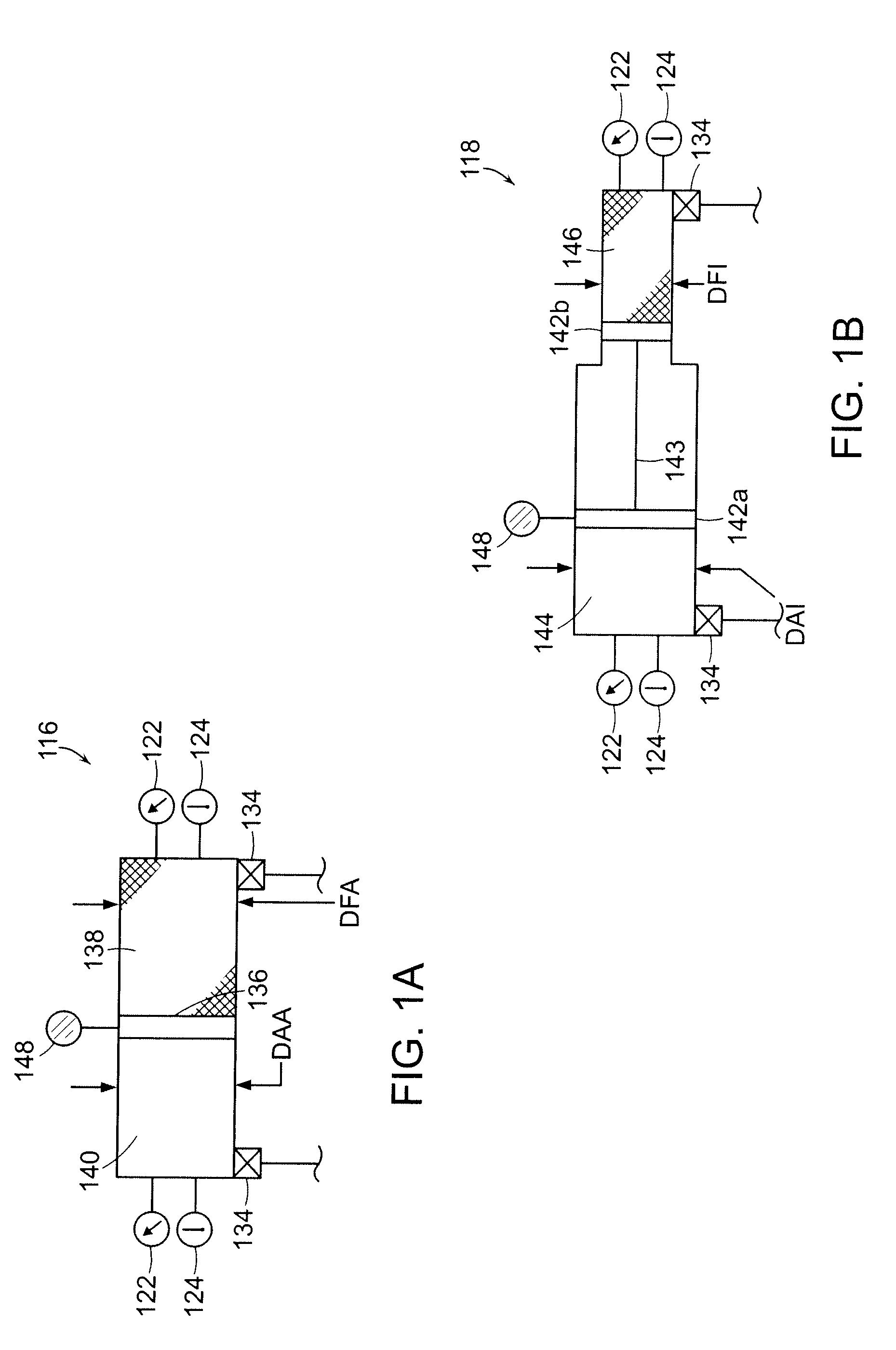

Systems and Methods for Energy Storage and Recovery Using Rapid Isothermal Gas Expansion and Compression

InactiveUS20100089063A1Increase energy densityHigh outputElectrical storage systemInternal combustion piston enginesProduct gasEngineering

The invention relates to systems and methods for rapidly and isothermally expanding and compressing gas in energy storage and recovery systems that use open-air hydraulic-pneumatic cylinder assemblies, such as an accumulator and an intensifier in communication with a high-pressure gas storage reservoir on a gas-side of the circuits and a combination fluid motor / pump, coupled to a combination electric generator / motor on the fluid side of the circuits. The systems use heat transfer subsystems in communication with at least one of the cylinder assemblies or reservoir to thermally condition the gas being expanded or compressed.

Owner:SUSTAINX

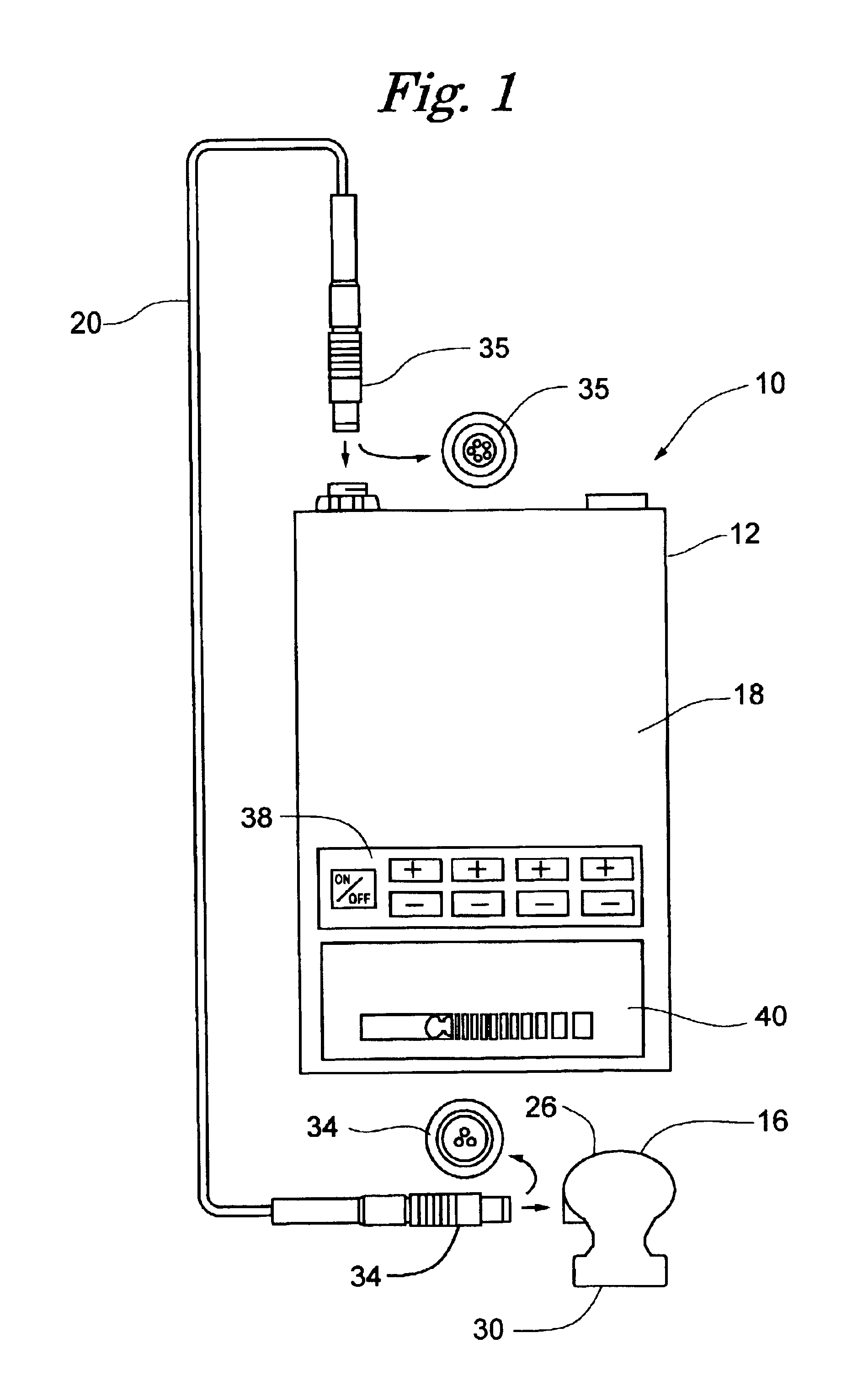

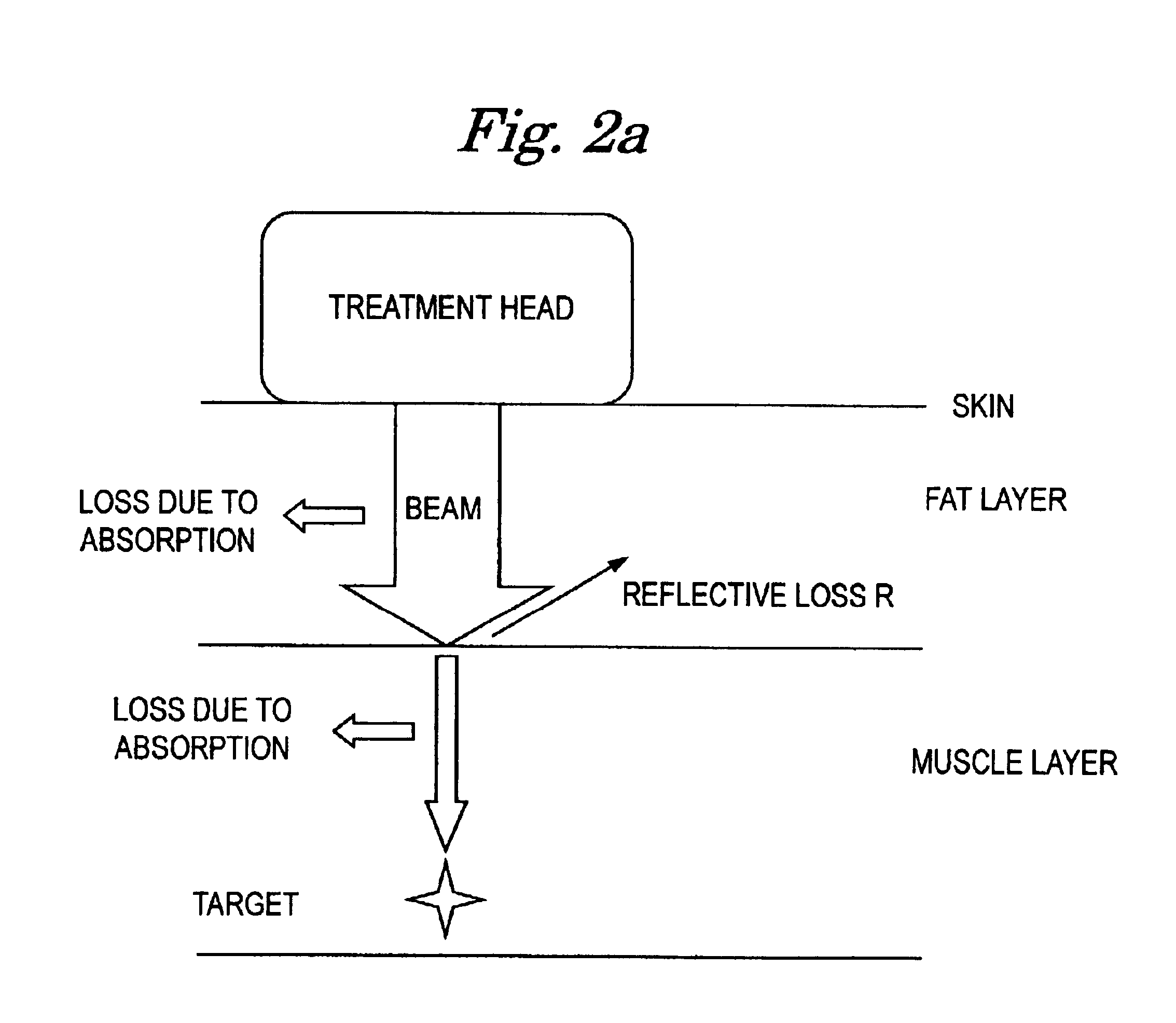

Ultrasound therapeutic device

InactiveUS6860852B2Maintains acoustic powerSafe and effective operationUltrasonic/sonic/infrasonic diagnosticsUltrasound therapyTherapeutic DevicesControl system

The ultrasound therapeutic system of the present invention generally includes a generator unit, at least one transducer treatment head, and a programmable controller. The generator is in operable communication with the at least one transducer treatment head such that electric power outputted from the generator to the head is converted into acoustic power by the head. Re-programmable software at the controller generally controls all features and functions for the system. In particular, the controller calculates an initial optimal treatment dose, maintains effective acoustic power transmitted to the patient through the at least one treatment head, performs calibration procedures for the at least one treatment head, controls outputting for each supported treatment mode, and provides for various other features and functions.

Owner:DJO GLOBAL SWITZERLAND SARL

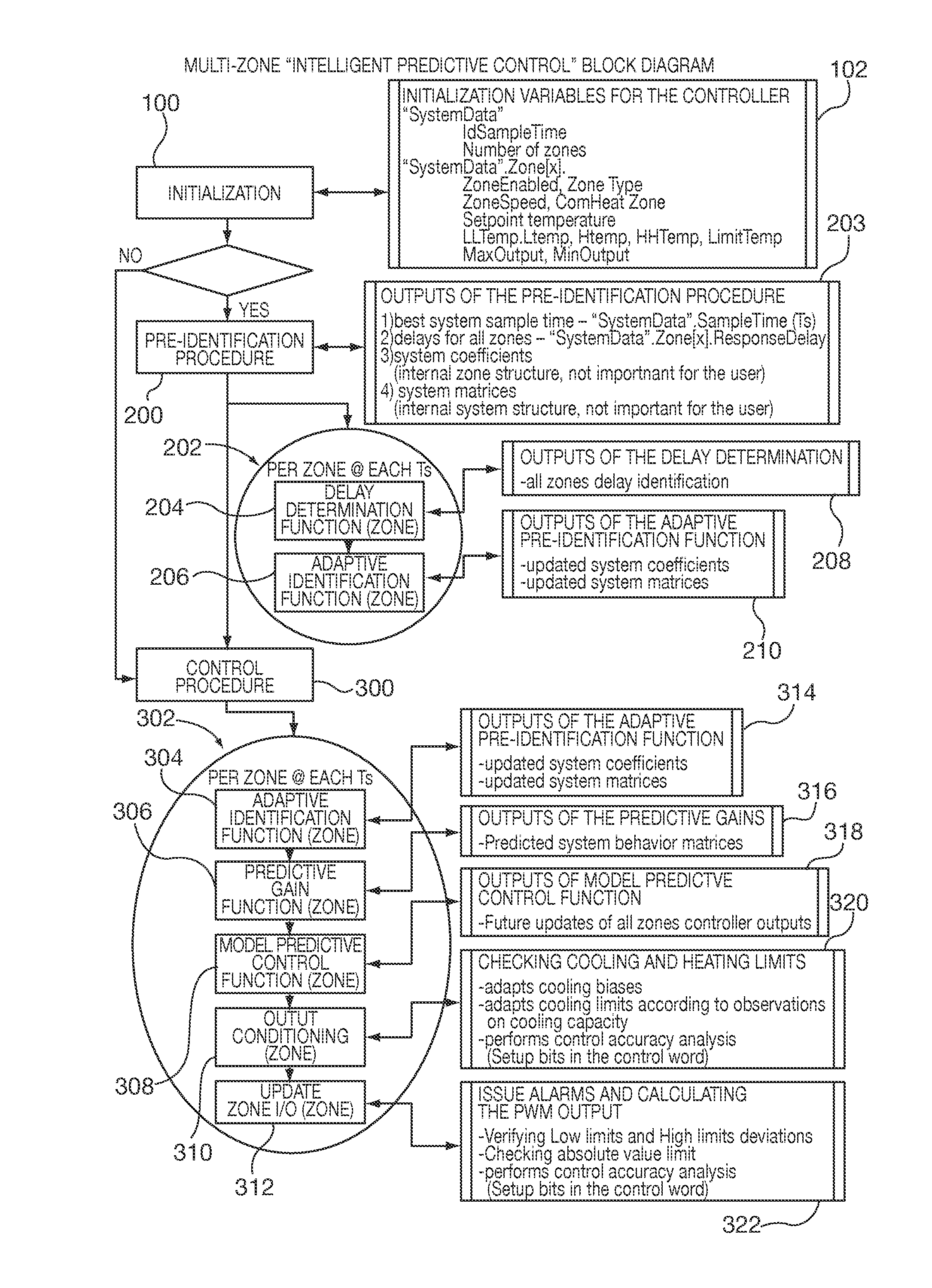

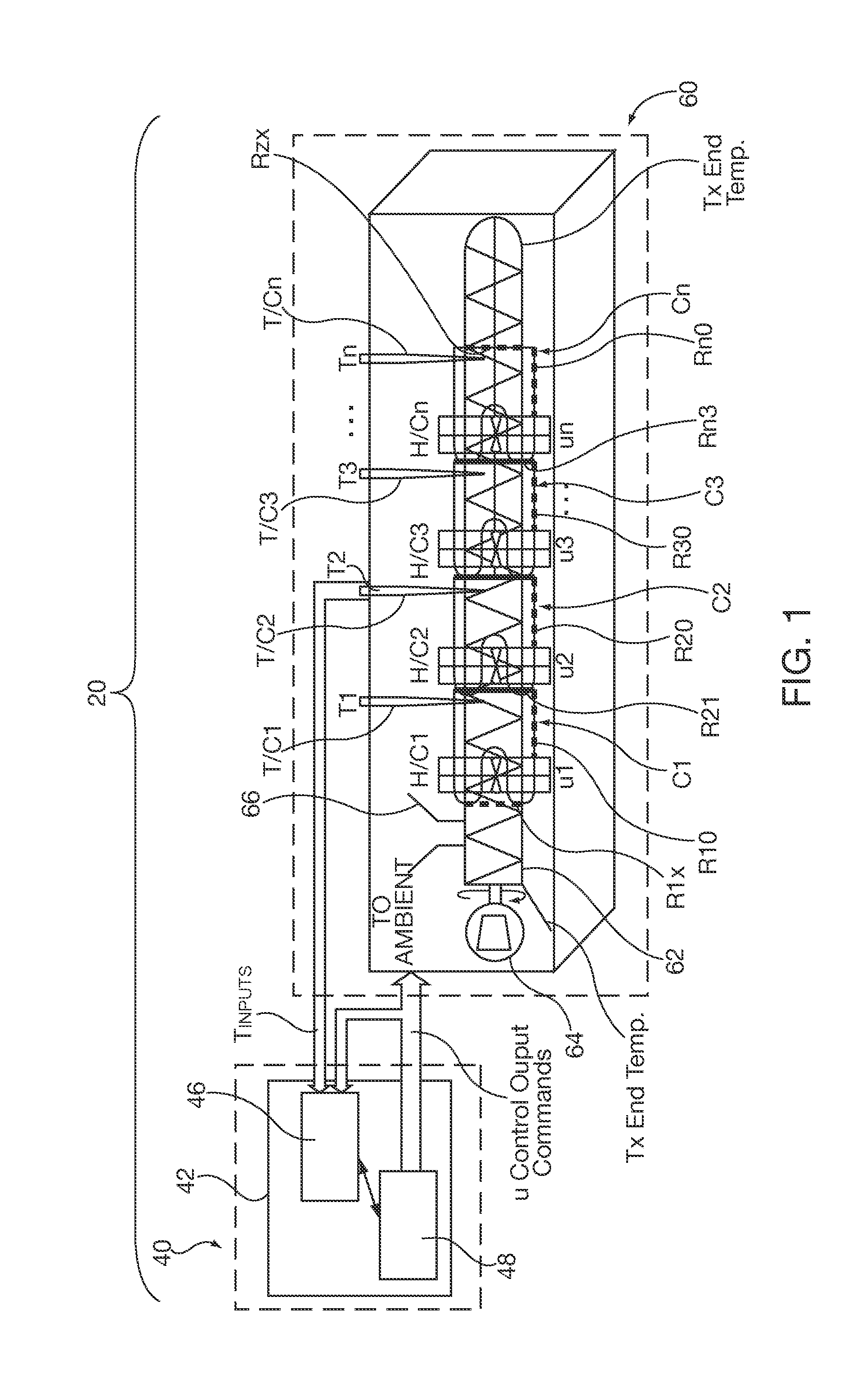

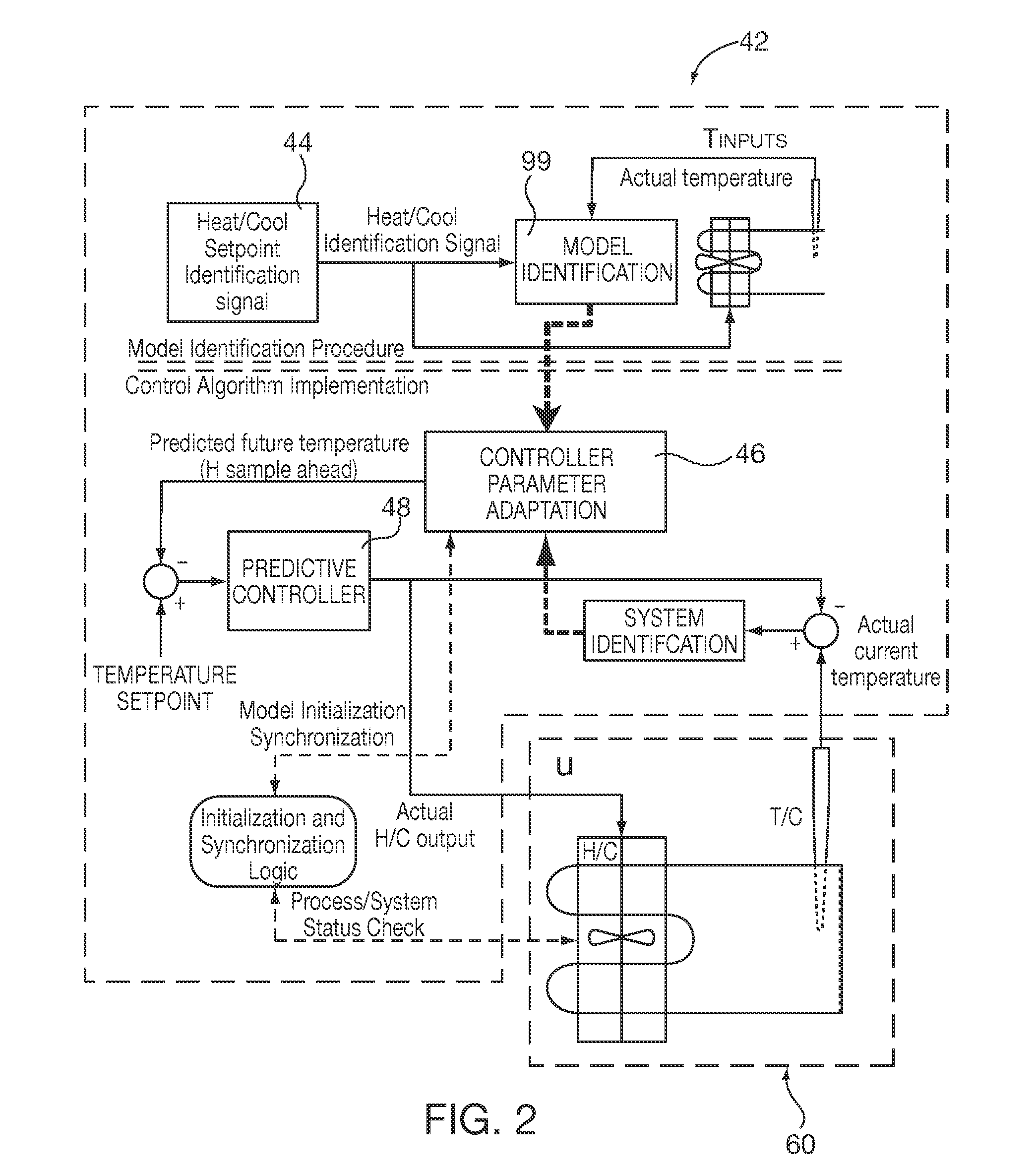

Method and apparatus of a self-configured, model-based adaptive, predictive controller for multi-zone regulation systems

InactiveUS20110022193A1Easy to addPrecise processingSampled-variable control systemsTravelling carriersHorizonPlastic injection molding

A control system simultaneously controls a multi-zone process with a self-adaptive model predictive controller (MPC), such as temperature control within a plastic injection molding system. The controller is initialized with basic system information. A pre-identification procedure determines a suggested system sampling rate, delays or “dead times” for each zone and initial system model matrix coefficients necessary for operation of the control predictions. The recursive least squares based system model update, control variable predictions and calculations of the control horizon values are preferably executed in real time by using matrix calculation basic functions implemented and optimized for being used in a S7 environment by a Siemens PLC. The number of predictions and the horizon of the control steps required to achieve the setpoint are significantly high to achieve smooth and robust control. Several matrix calculations, including an inverse matrix procedure performed at each sample pulse and for each individual zone determine the MPC gain matrices needed to bring the system with minimum control effort and variations to the final setpoint. Corrective signals, based on the predictive model and the minimization criteria explained above, are issued to adjust system heating / cooling outputs at the next sample time occurrence, so as to bring the system to the desired set point. The process is repeated continuously at each sample pulse.

Owner:SIEMENS IND INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com