Patents

Literature

2156results about "Manual control with multiple controlled members" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

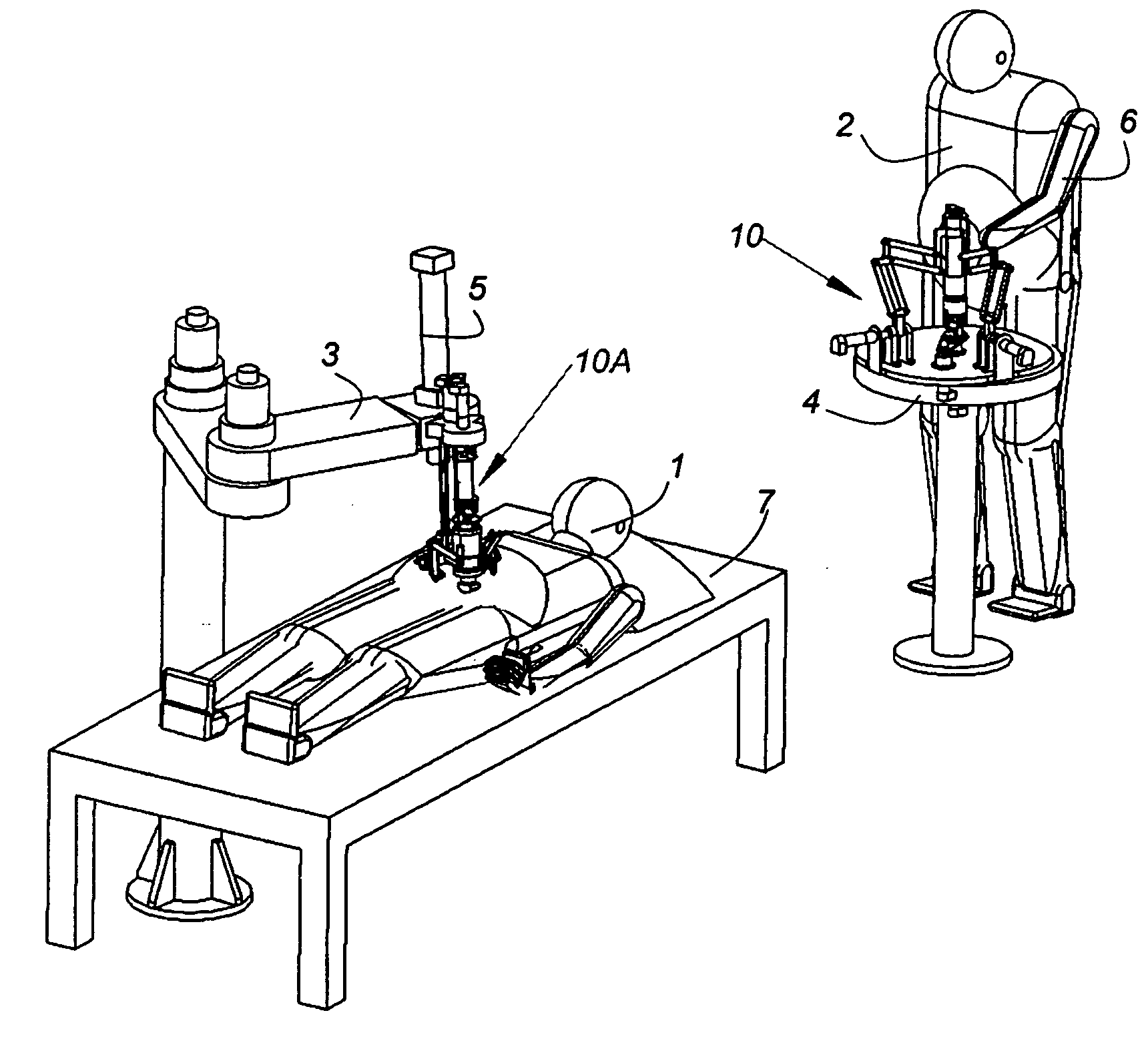

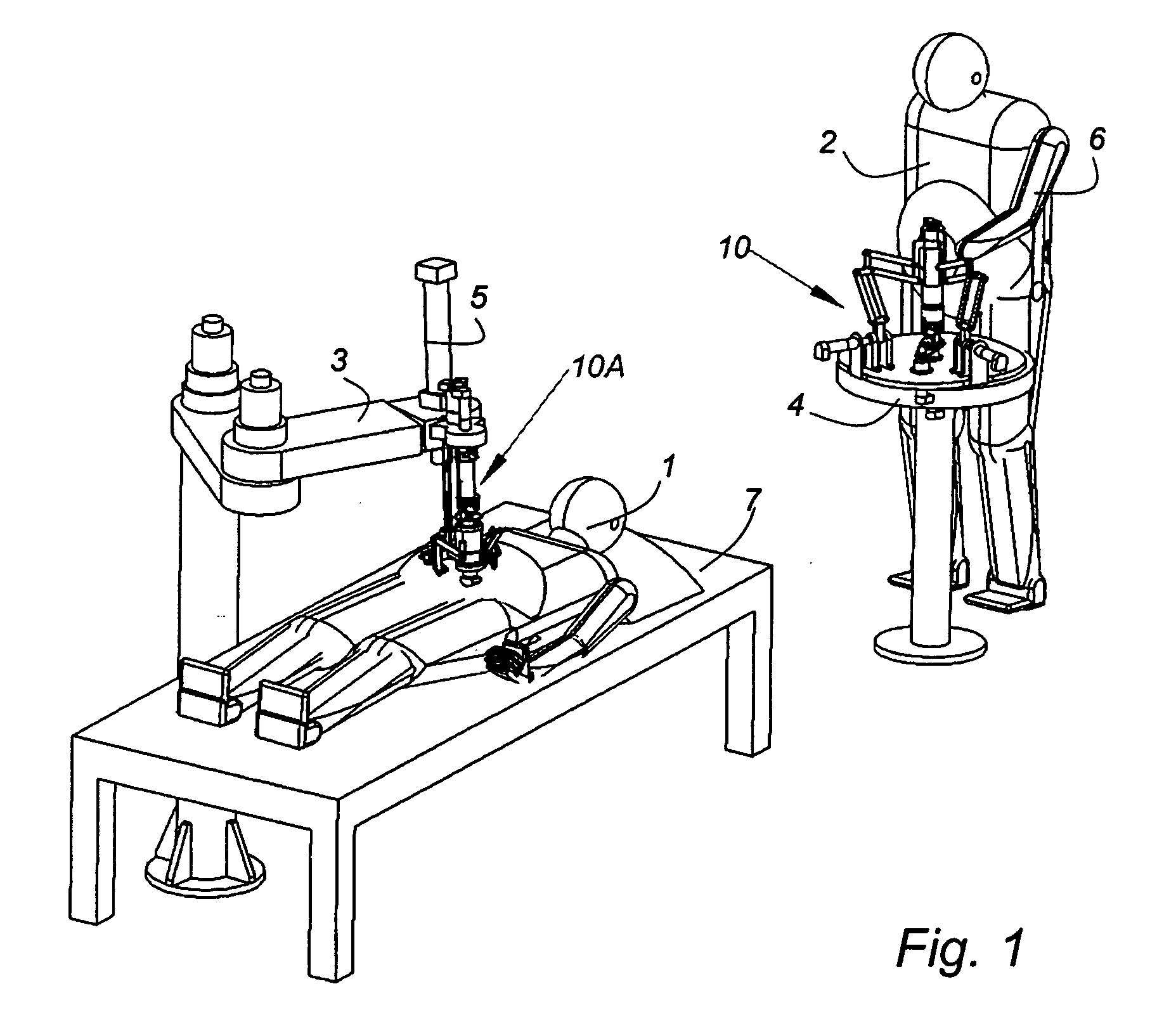

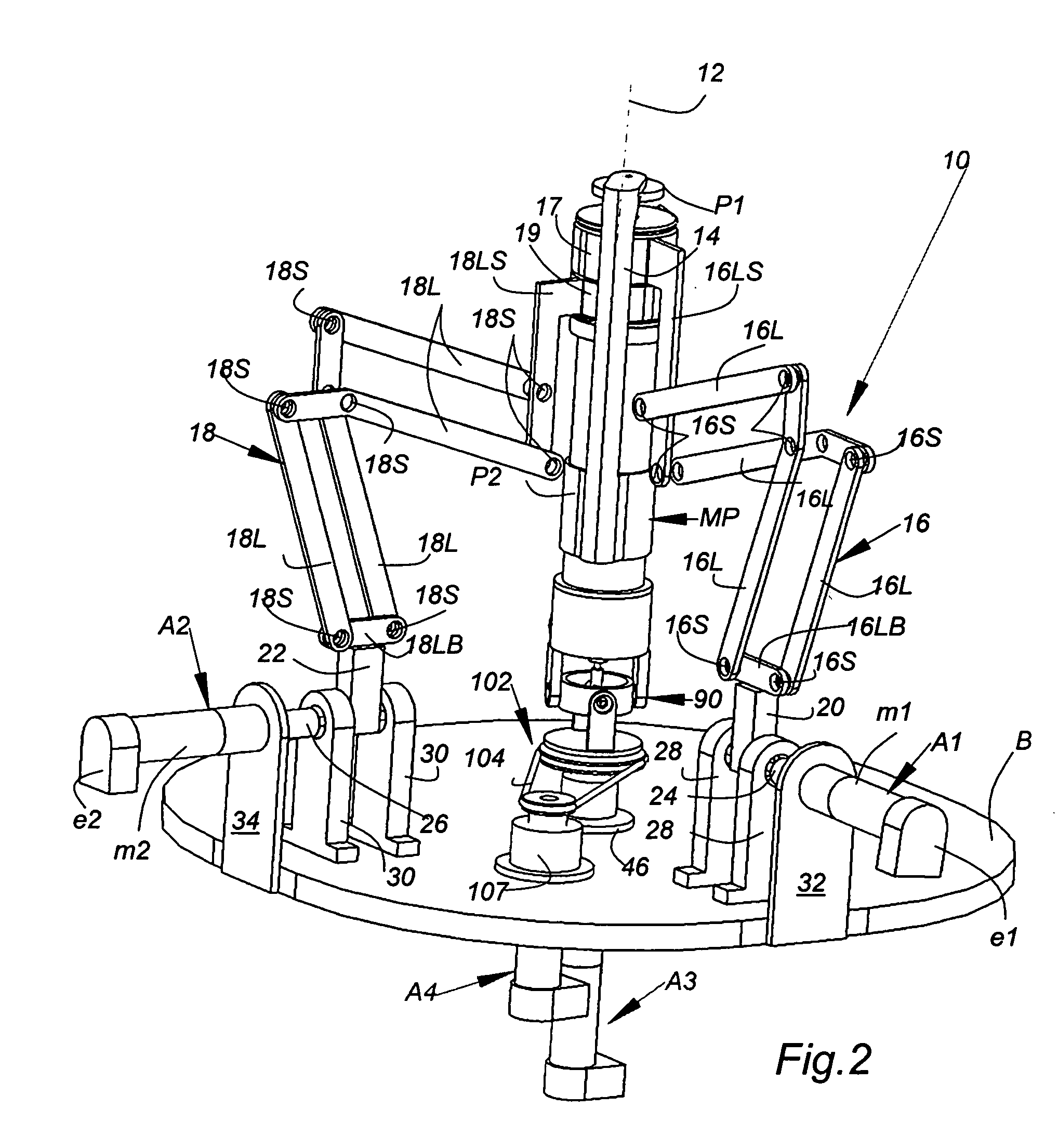

Platform link wrist mechanism

ActiveUS7691098B2Easy to controlSmooth rotationProgramme-controlled manipulatorMechanical apparatusSurgical operationEngineering

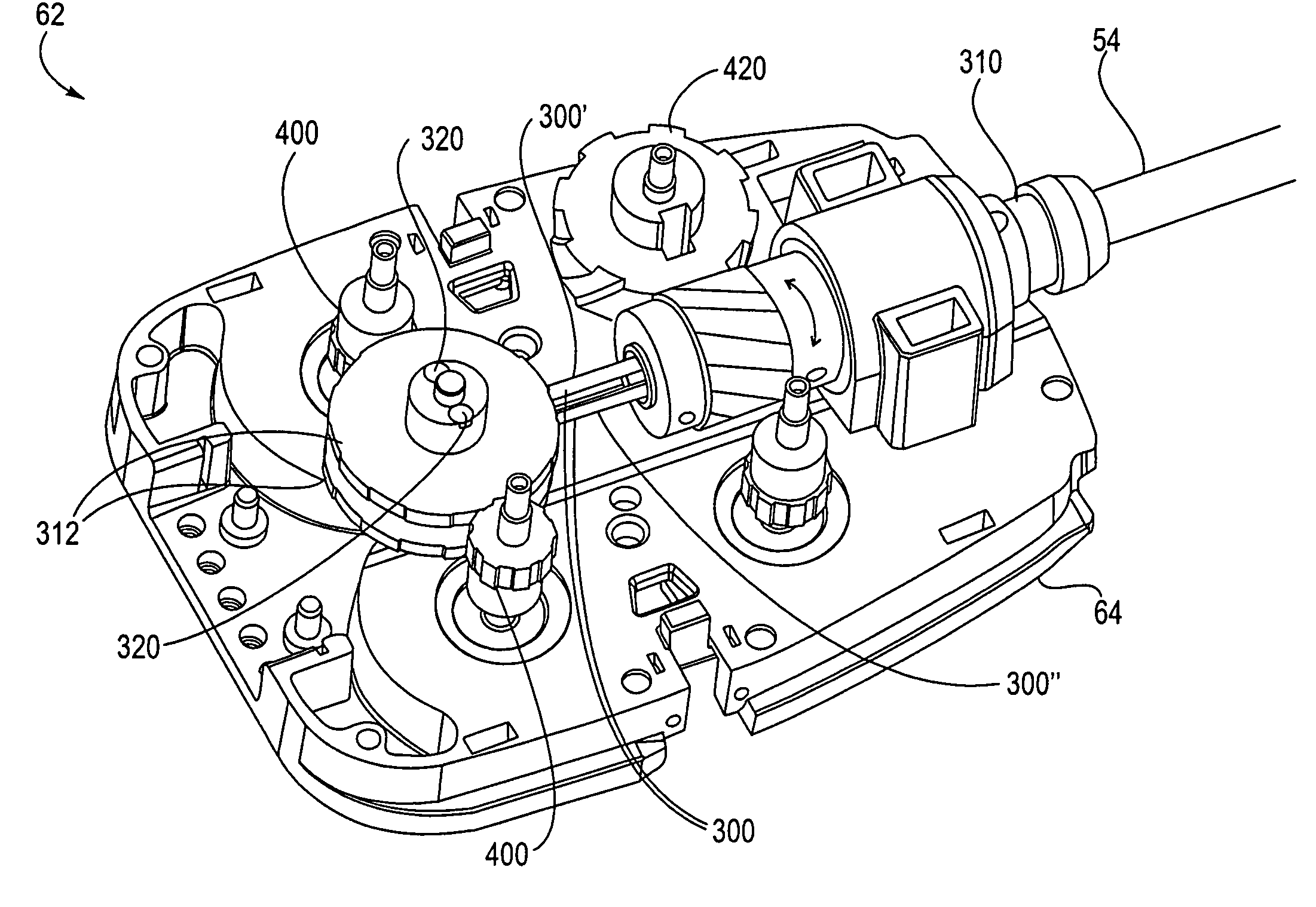

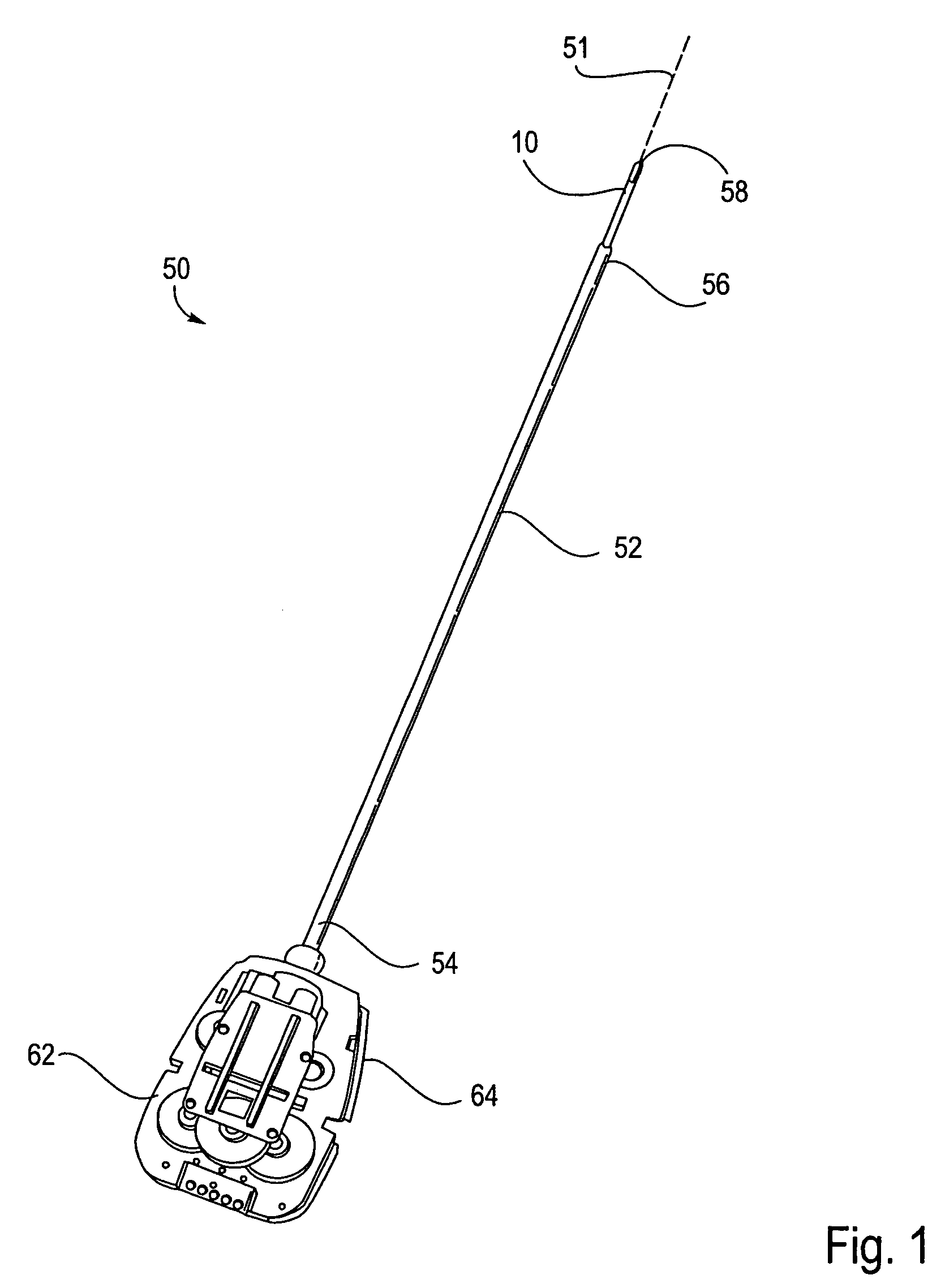

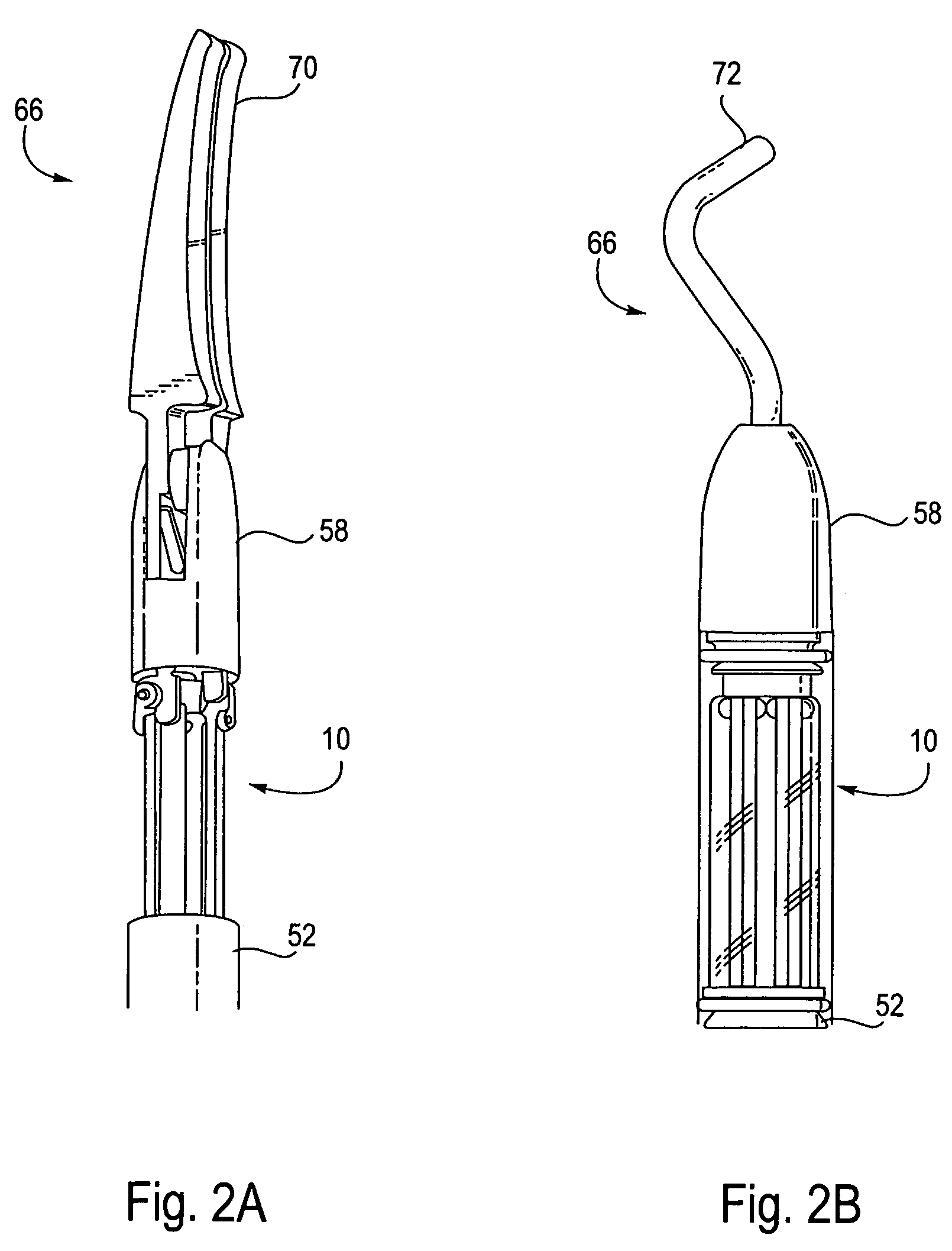

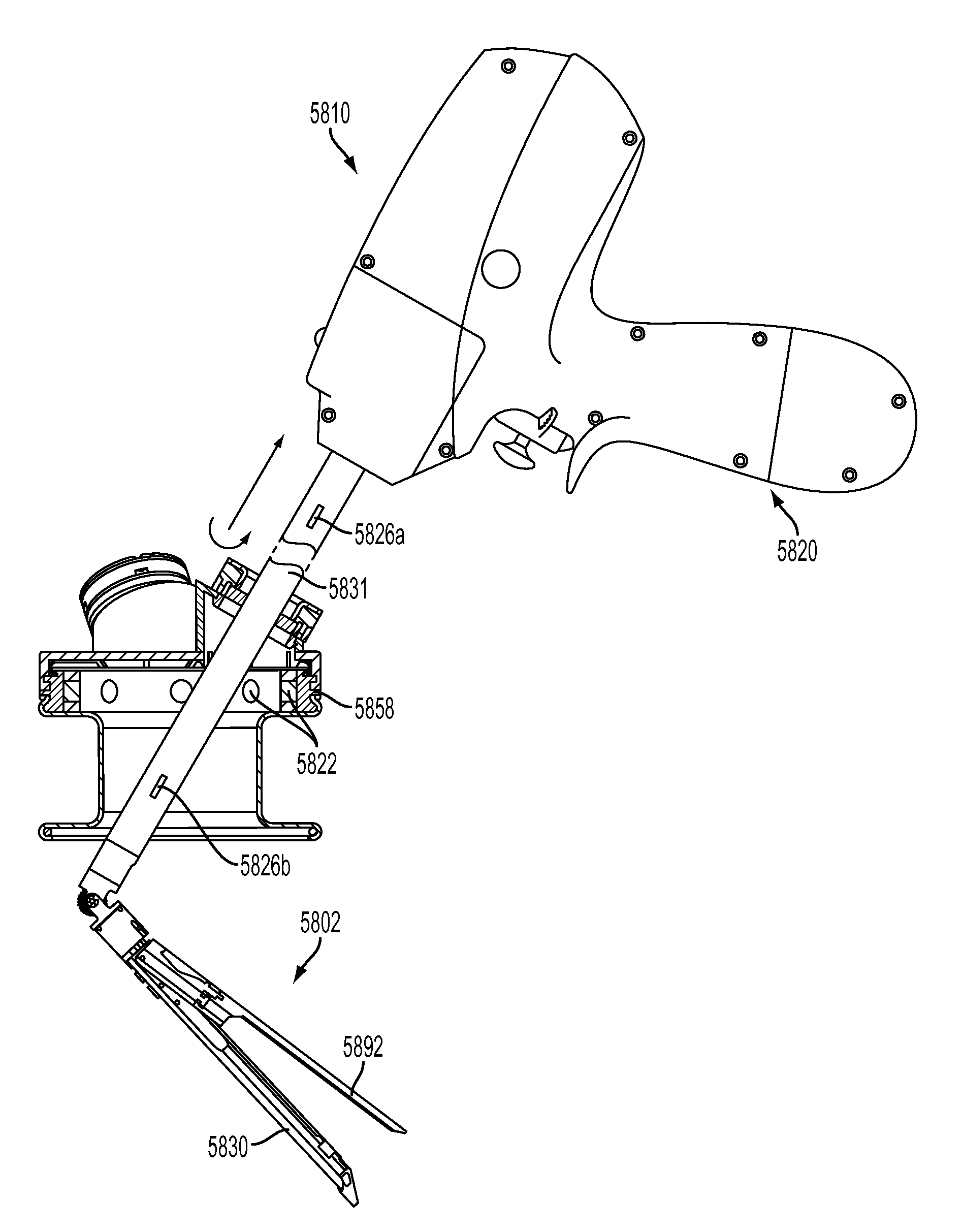

The present invention provides a robotic surgical tool for use in a robotic surgical system to perform a surgical operation. The robotic surgical tool includes a wrist mechanism disposed near the distal end of a shaft which connects with an end effector. The wrist mechanism includes a distal member configured to support the end effector, and a plurality of rods extending generally along an axial direction within the shaft and movable generally along this axial direction to adjust the orientation of the distal member with respect to the shaft. Advancement or retraction of a first rod generally along the axial direction tips the base through a first angle. The addition of a second angle allows the distal member to direct the end effector in essentially a compound angle. The robotic surgical tool may also include provisions for roll movement.

Owner:INTUITIVE SURGICAL OPERATIONS INC

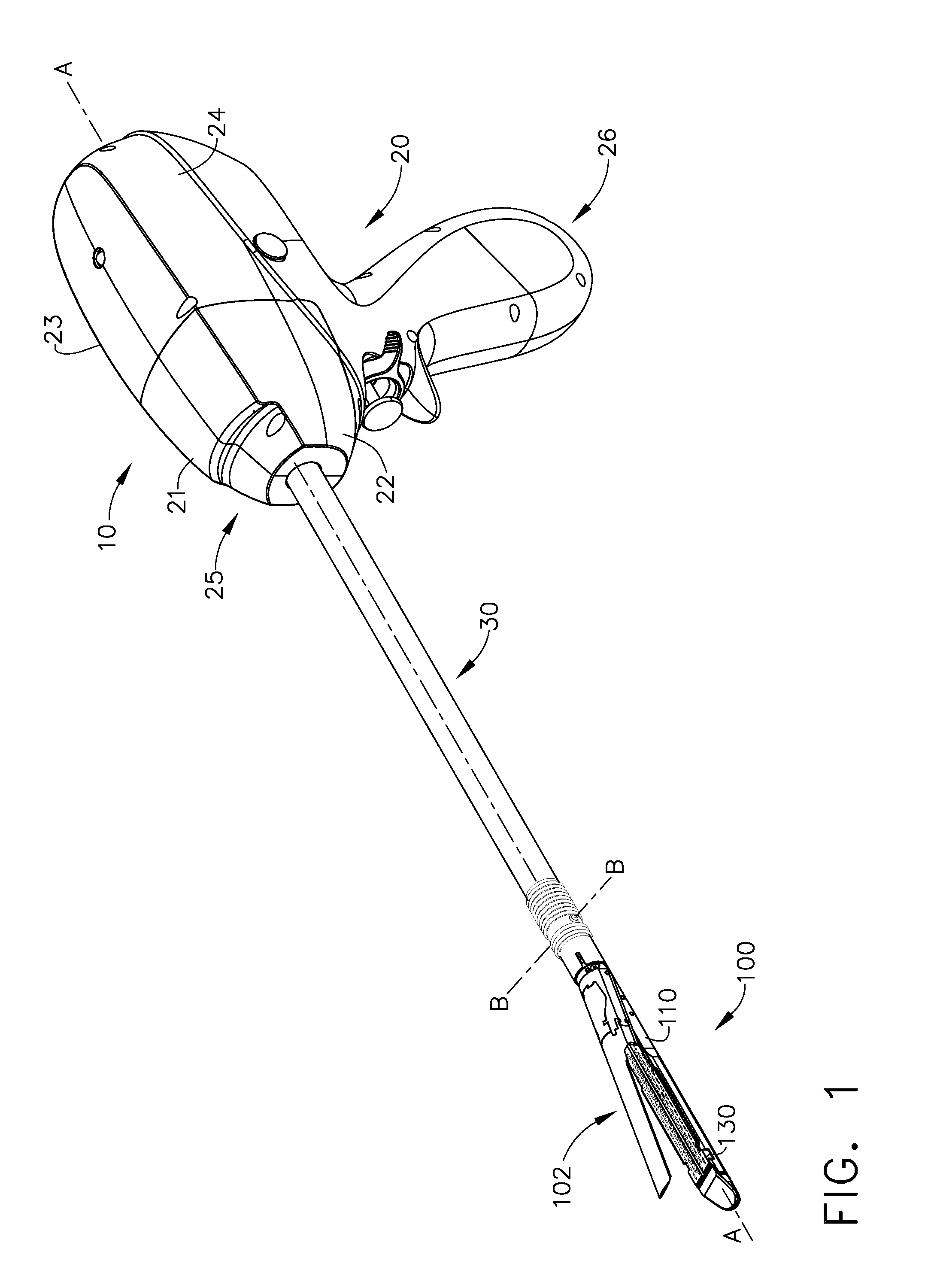

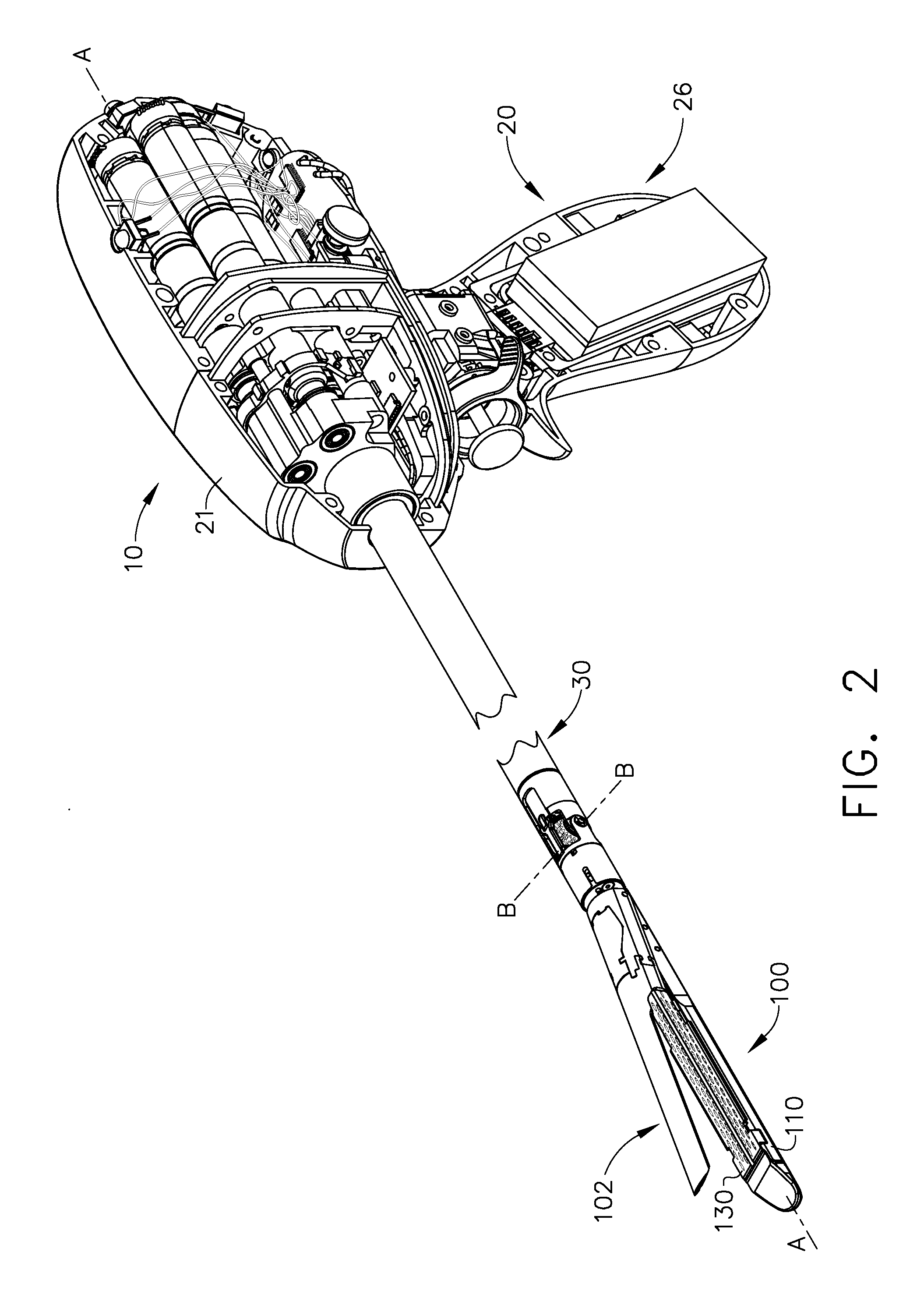

Surgical instrument soft stop

A surgical instrument includes a drive member movable by a drive motor between a home position and an end of stroke. A mechanical stop is disposed at or near the end of stroke and is structured to increase resistance to movement of the drive member from a first position to a second position. A control system detects a current spike associated with the increased resistance and interrupts power to the drive motor.

Owner:CILAG GMBH INT

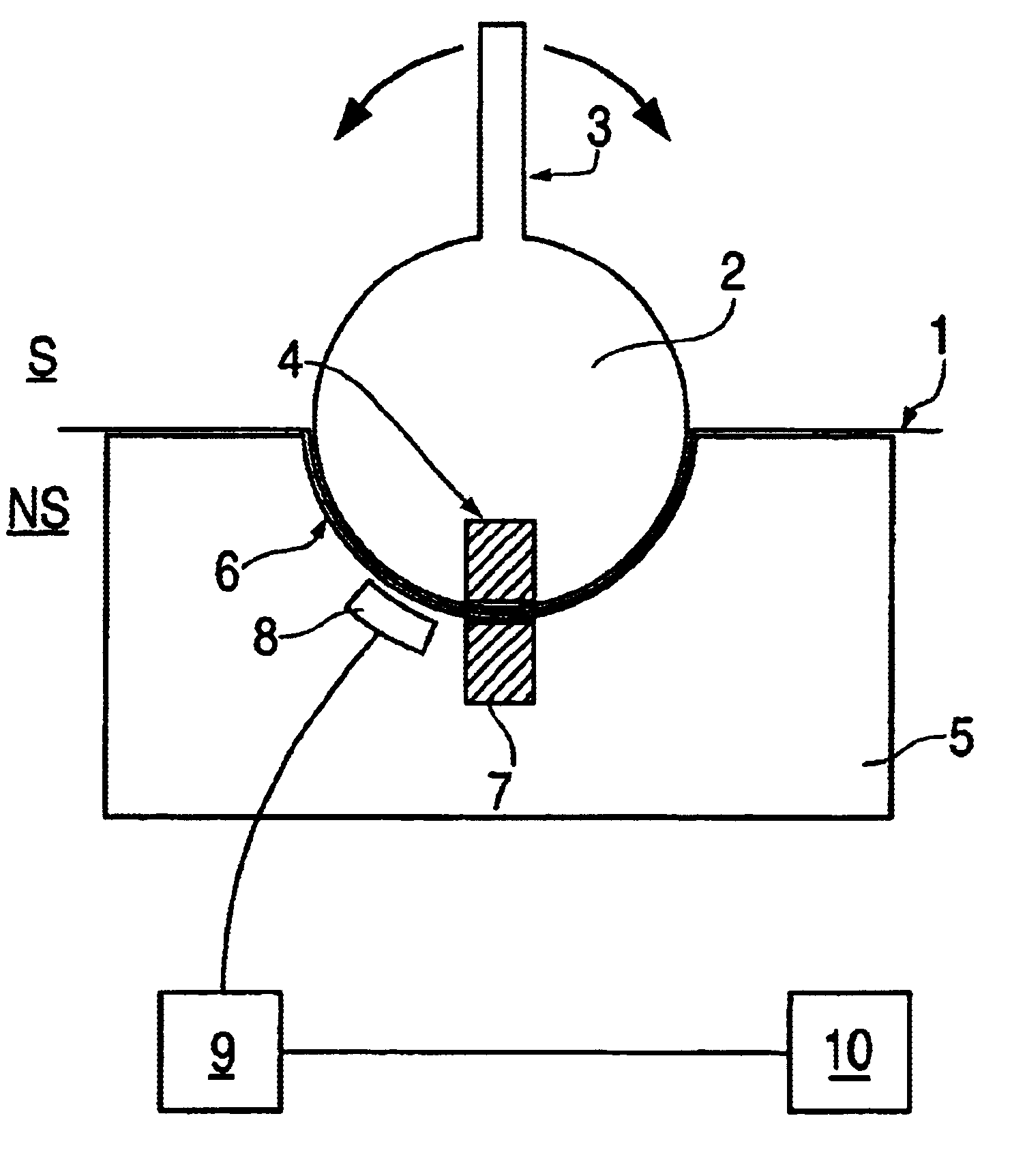

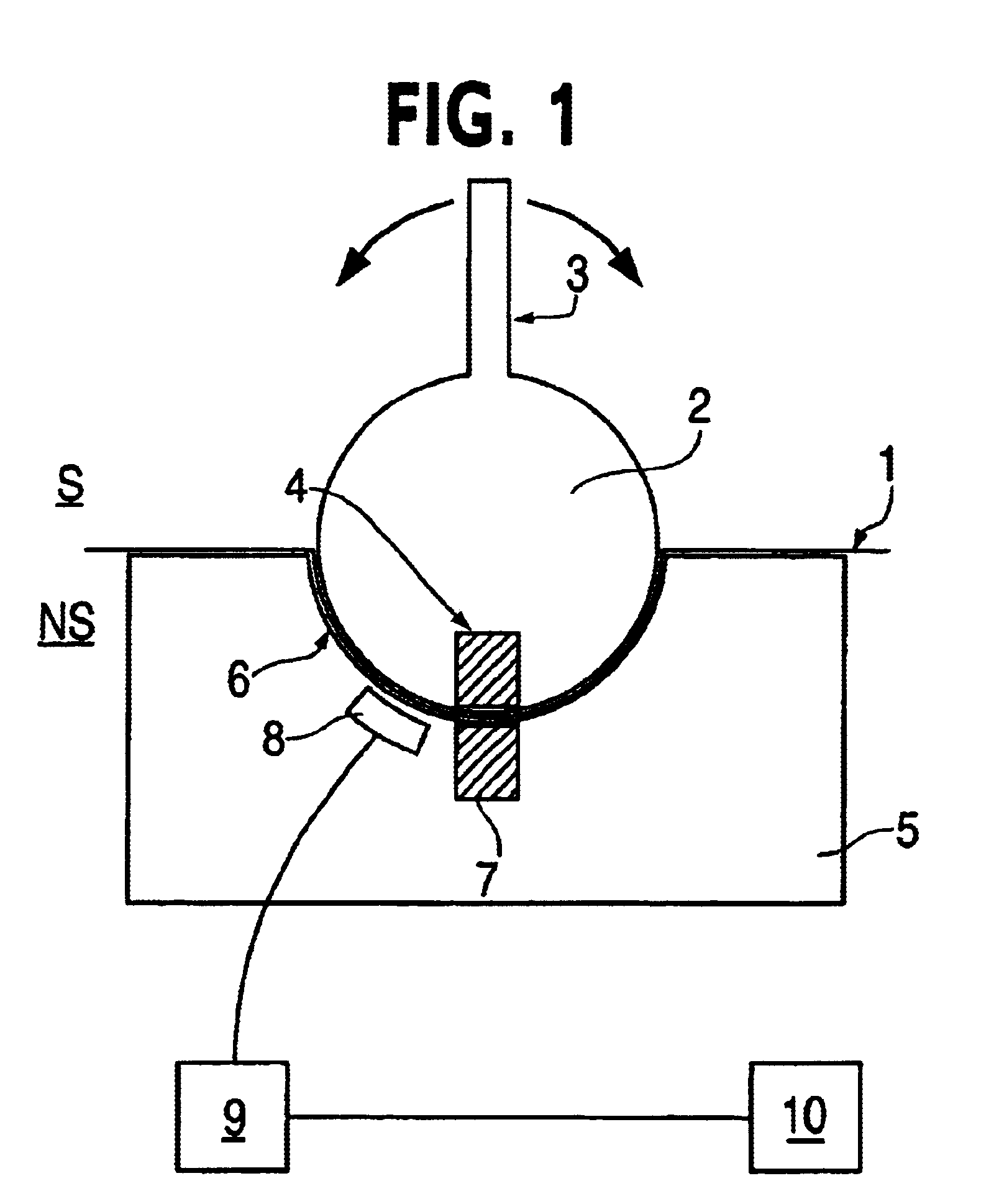

Device for controlling an electric appliance used in the sterile area during medical operations

InactiveUS6755195B1Easy to operateInserting operationManual control with multiple controlled membersDiagnosticsControl signalEngineering

The invention is a device for application in the sterile area for controlling an electric instrument provided in the non-sterile area, with the sterile area being separated from the non-sterile area substantially by a covering. The invention comprises at least one sensor responsive to the magnetic field which is provided in the non-sterile area and a unit generating a magnetic field is provided in the sterile area. The at least one sensor responsive to the magnetic field and the unit generating a magnetic field are separated from each other at least by the covering. The unit generating the magnetic field is disposed relative to the at least one sensor responsive to a magnetic field so that a variation of the magnetic field in space and / or time, which is induced by the unit generating the magnetic field, is detectable by the at least one sensor responsive to the magnetic field and a sensor signal can be generated. A controller unit is provided that generates a control signal for controlling the electric instrument in response to the sensor signal.

Owner:NORBERT LEMKE +1

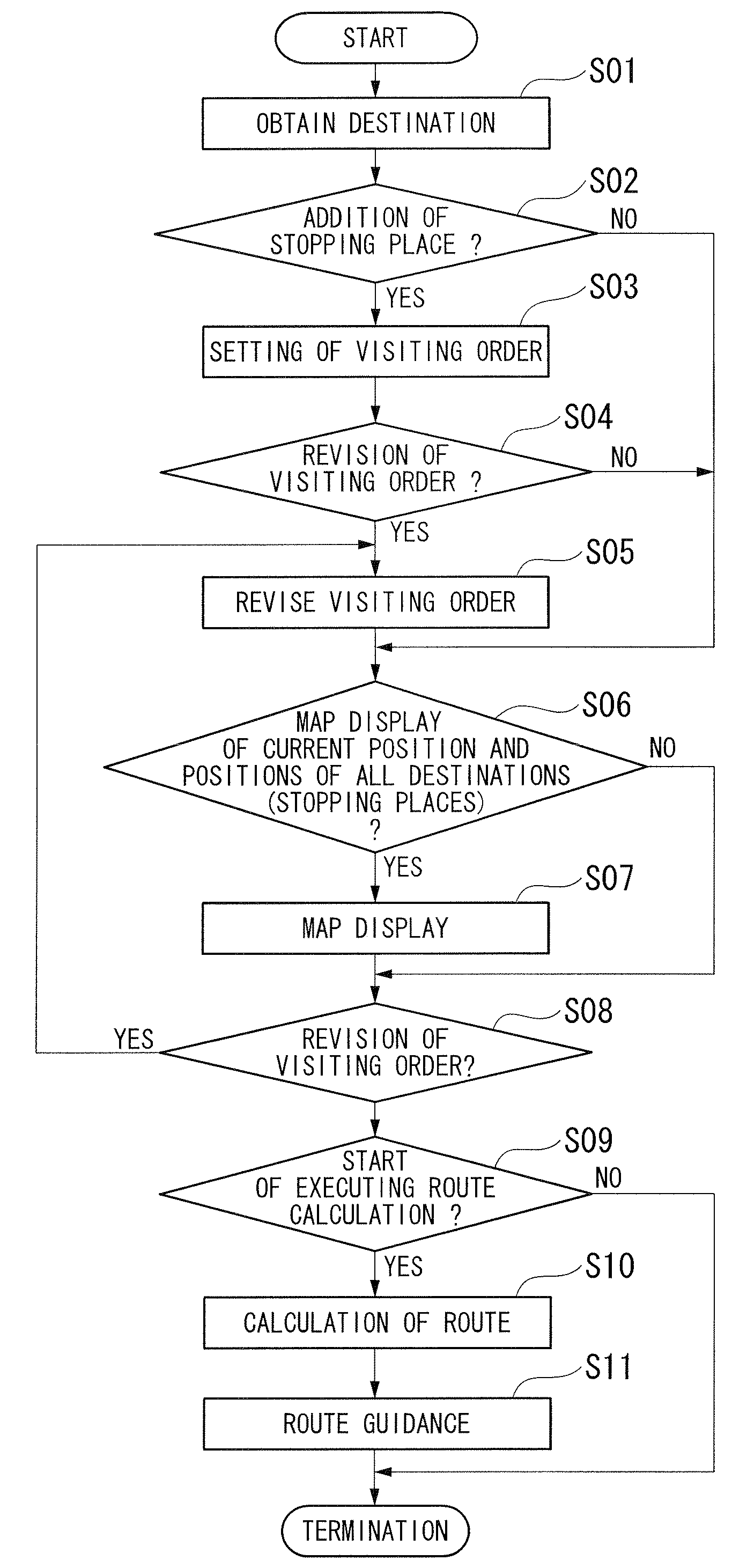

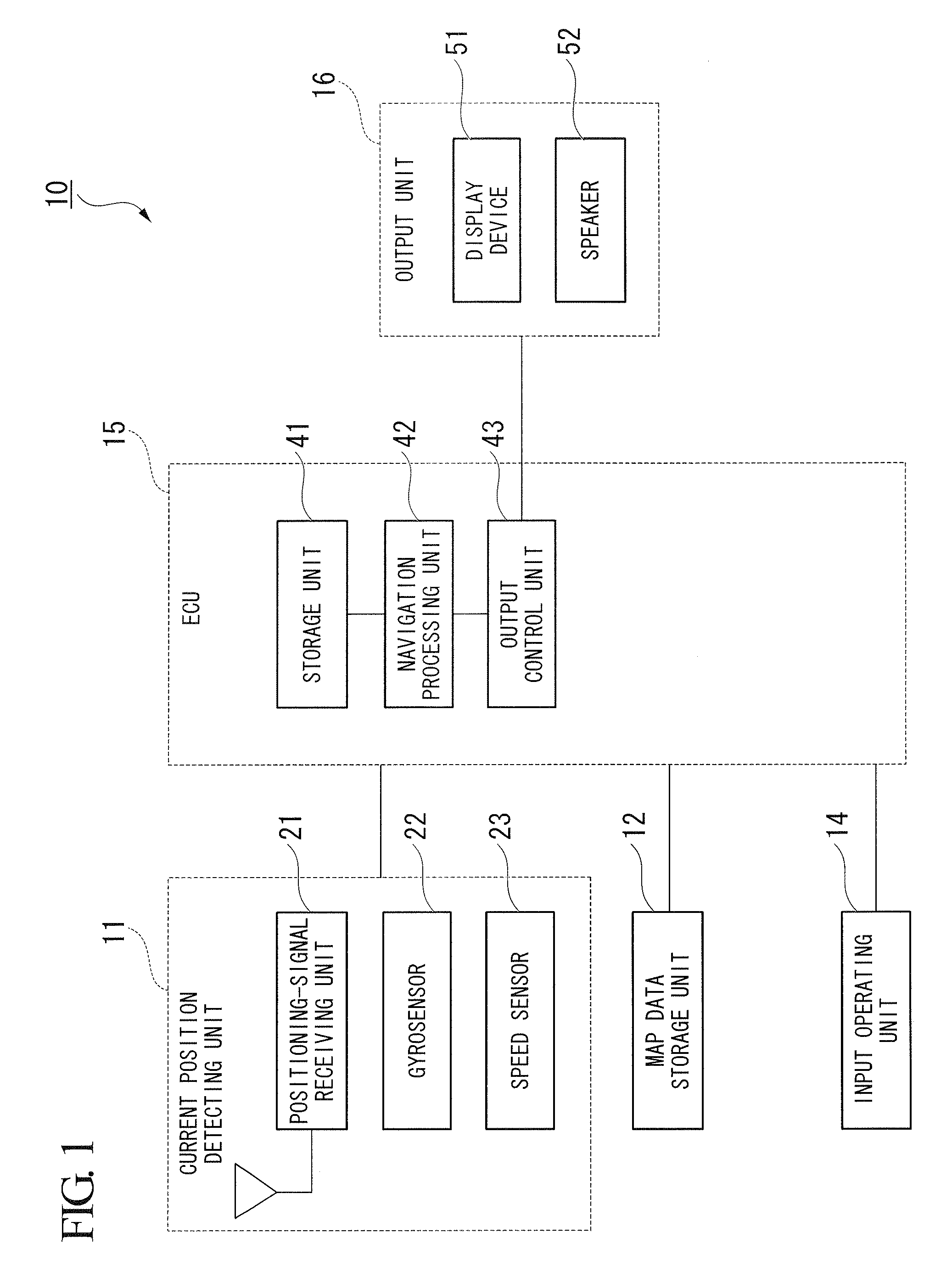

Navigation Apparatus

InactiveUS20090119011A1Improve convenienceEasy to operateManual control with multiple controlled membersInstruments for road network navigationImage storageMarine navigation

A navigation apparatus includes: an input operating unit; a map image storage member; a current position detecting member; a destination determination member; a visiting order determination member which determines a visiting order of each of the plurality of destinations in an revisable manner; a display control member which displays on the display member the map image on which the current position of the user and positions of all of the plurality of destinations are displayed; and a route calculation member which calculates a route from the current position by way of all of the plurality of destinations according to the visiting orders.

Owner:HONDA MOTOR CO LTD

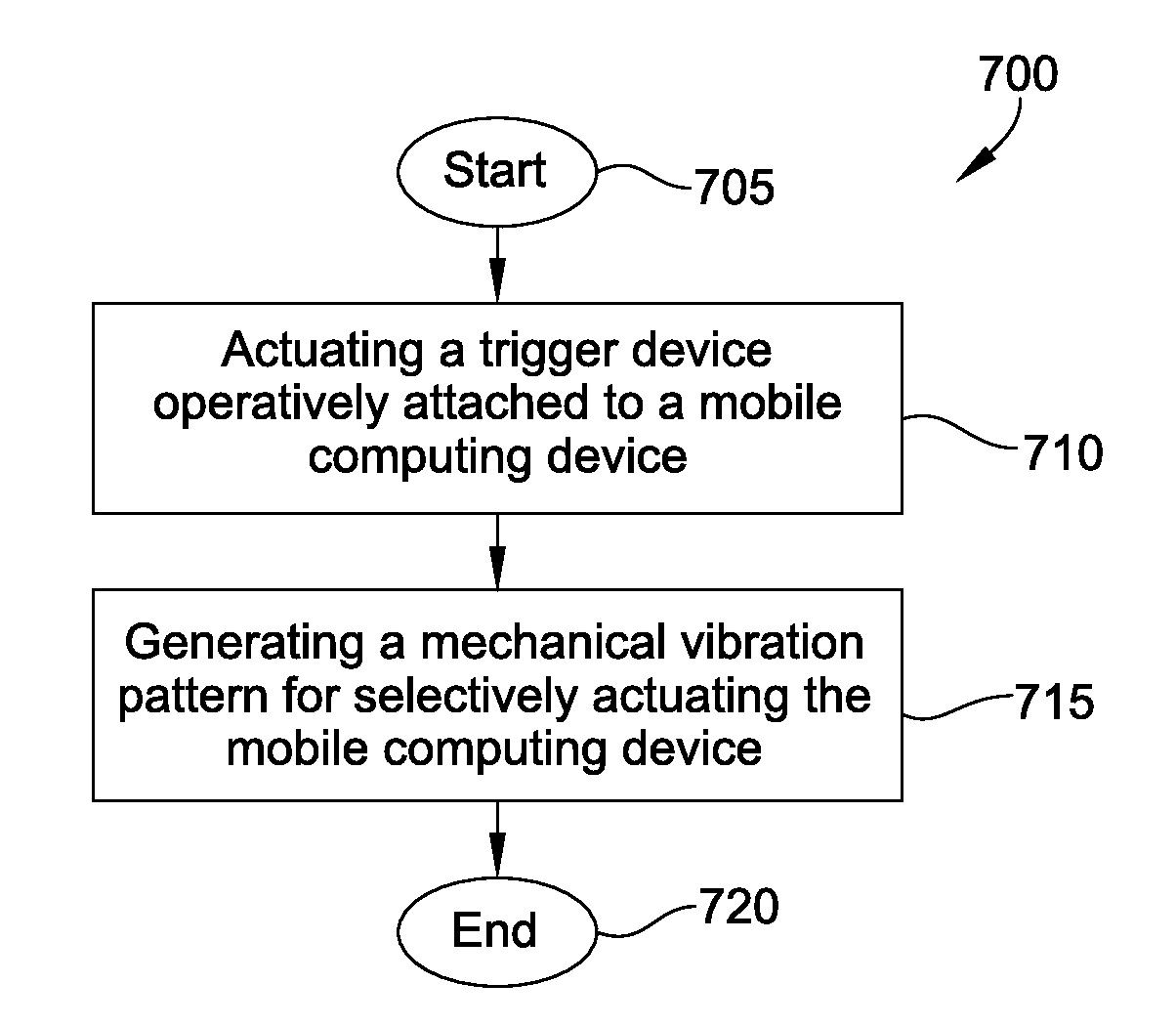

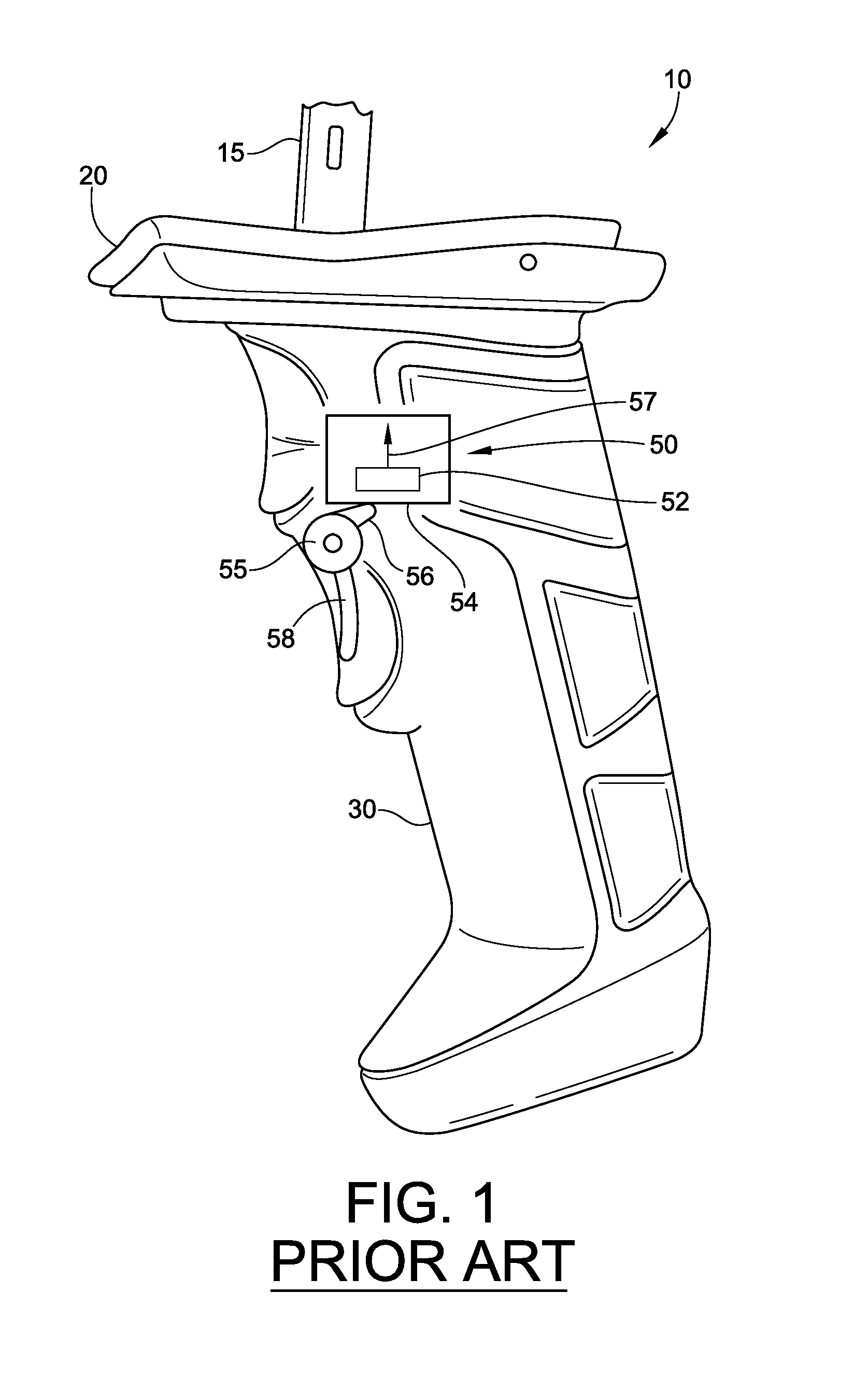

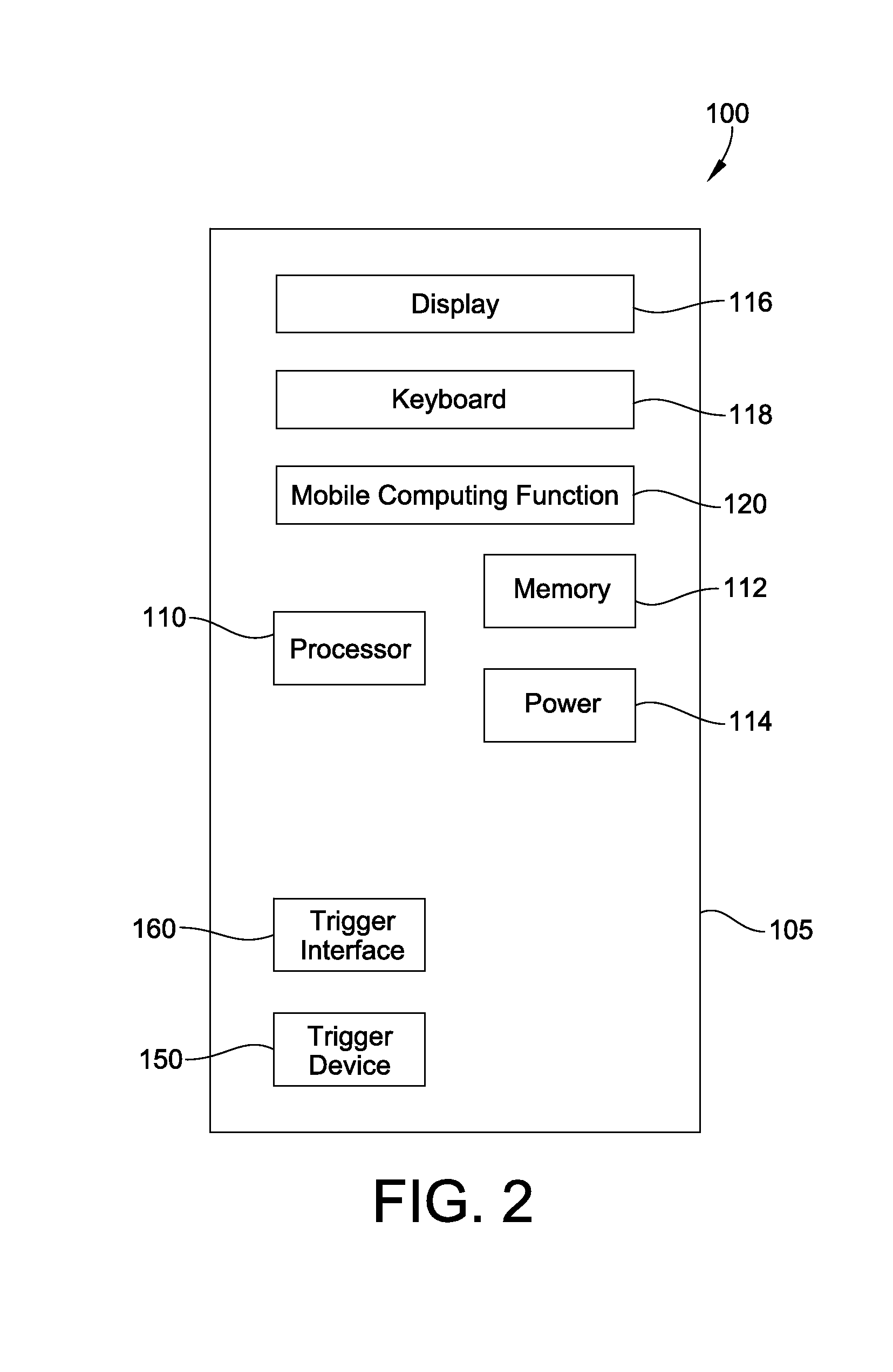

Trigger device for mobile computing device

InactiveUS20140049120A1Controlling membersManual control with multiple controlled membersAccelerometerComputer science

A mobile computing device includes a processor and a trigger device operatively attached to the mobile computing device and configured to generate a mechanical vibration pattern for selectively actuating the mobile computing device. A trigger interface, illustratively an accelerometer, is configured to convert the mechanical vibration pattern into an electrical signal pattern. The processor is configured to actuate a mobile computing function depending on the mechanical vibration pattern generated by the trigger device. A table of properties stored in memory correlates the mechanical vibration generated by the trigger device with a specific mobile computing function. The trigger device may include a plurality of trigger parts; and the mechanical vibration pattern generated by the trigger device may include multiple bits of data generated by the plurality of trigger parts. The mobile computing device may be in a candy bar, clam shell, or other form factor and may include a removable handle.

Owner:INTERMEC IP

Image controller

InactiveUS20060028436A1Easy to controlAdvantage of versatility of complex movementsInput/output for user-computer interactionManual control with multiple controlled membersViewpointsDisplay device

Owner:ANASCAPE

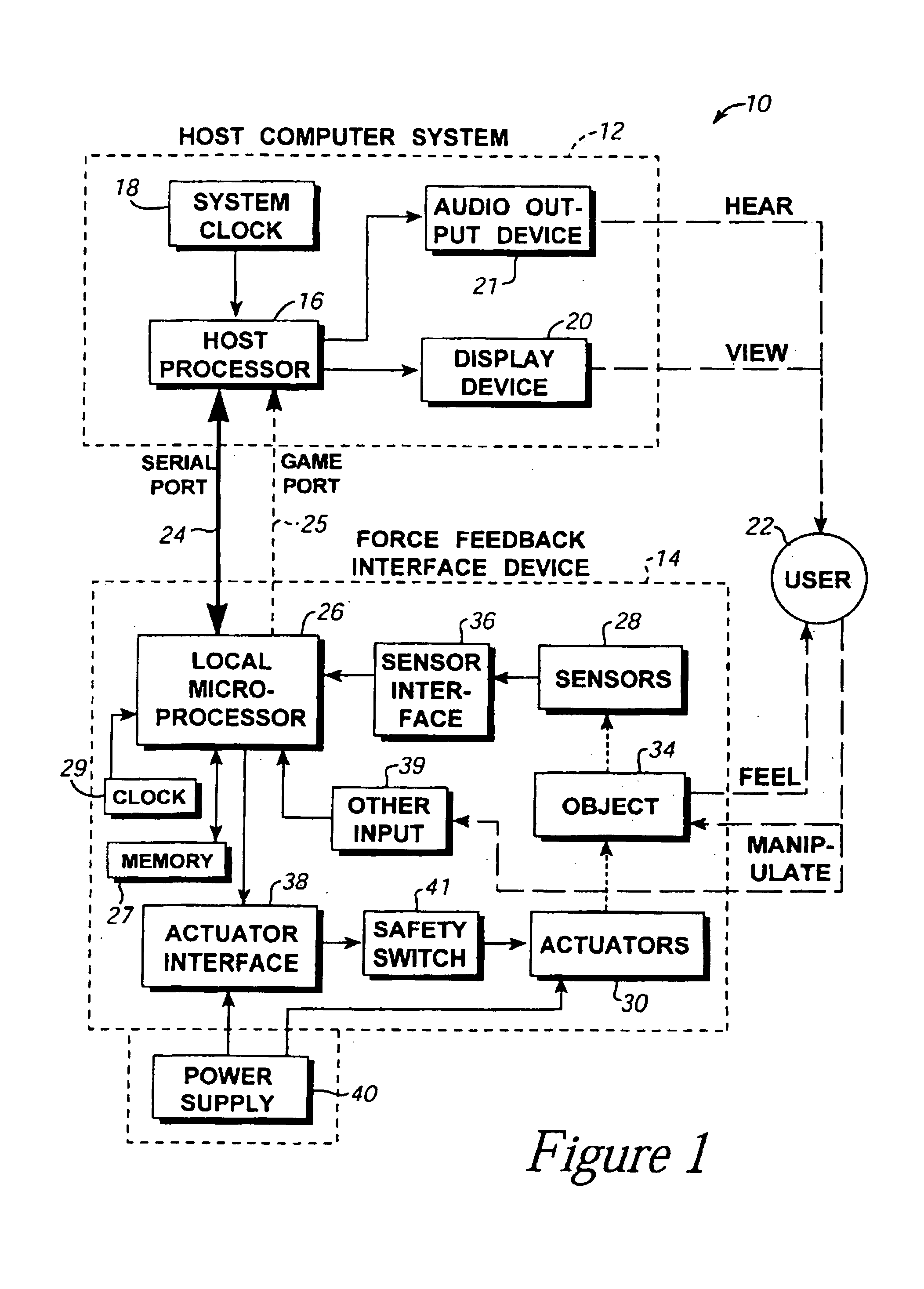

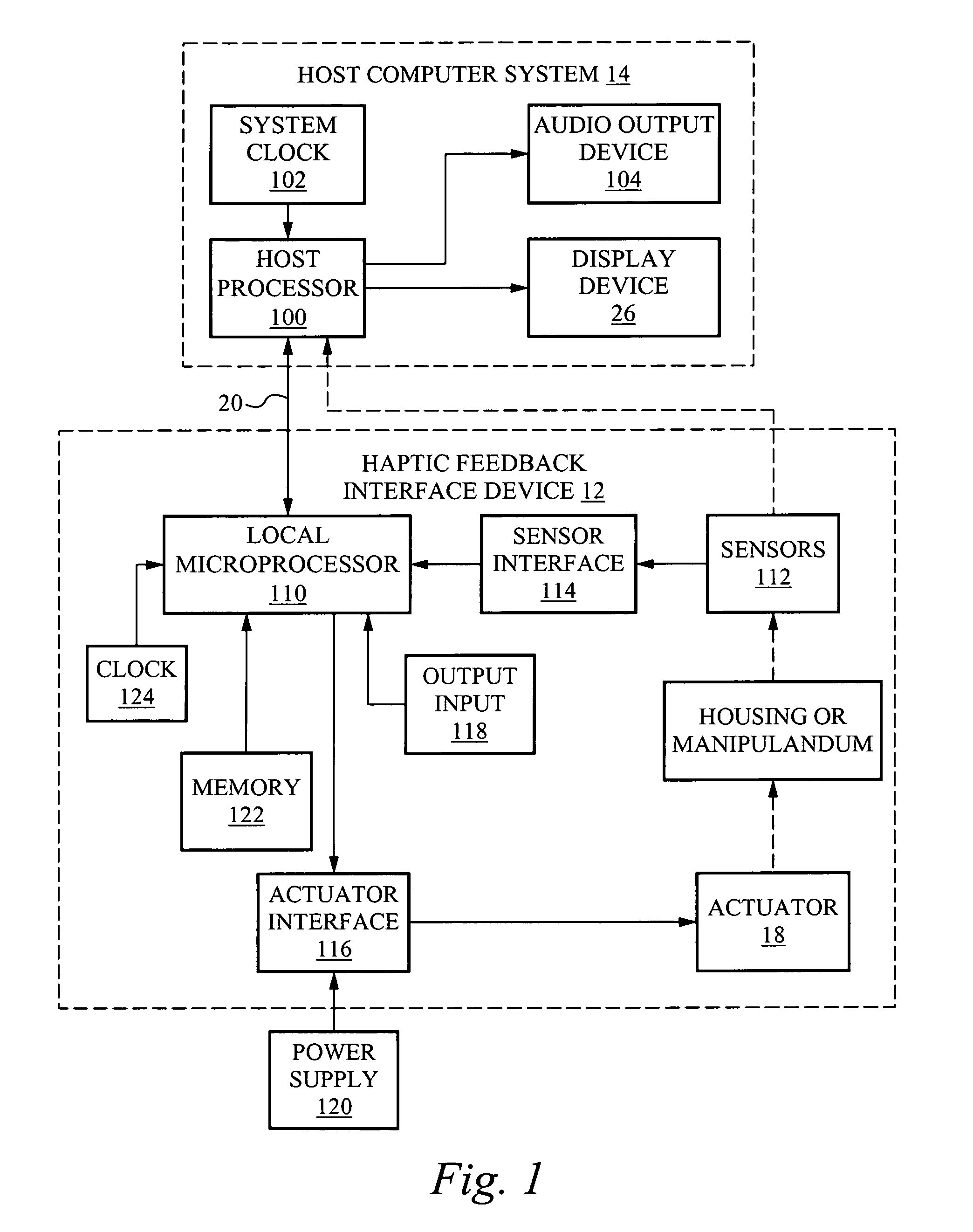

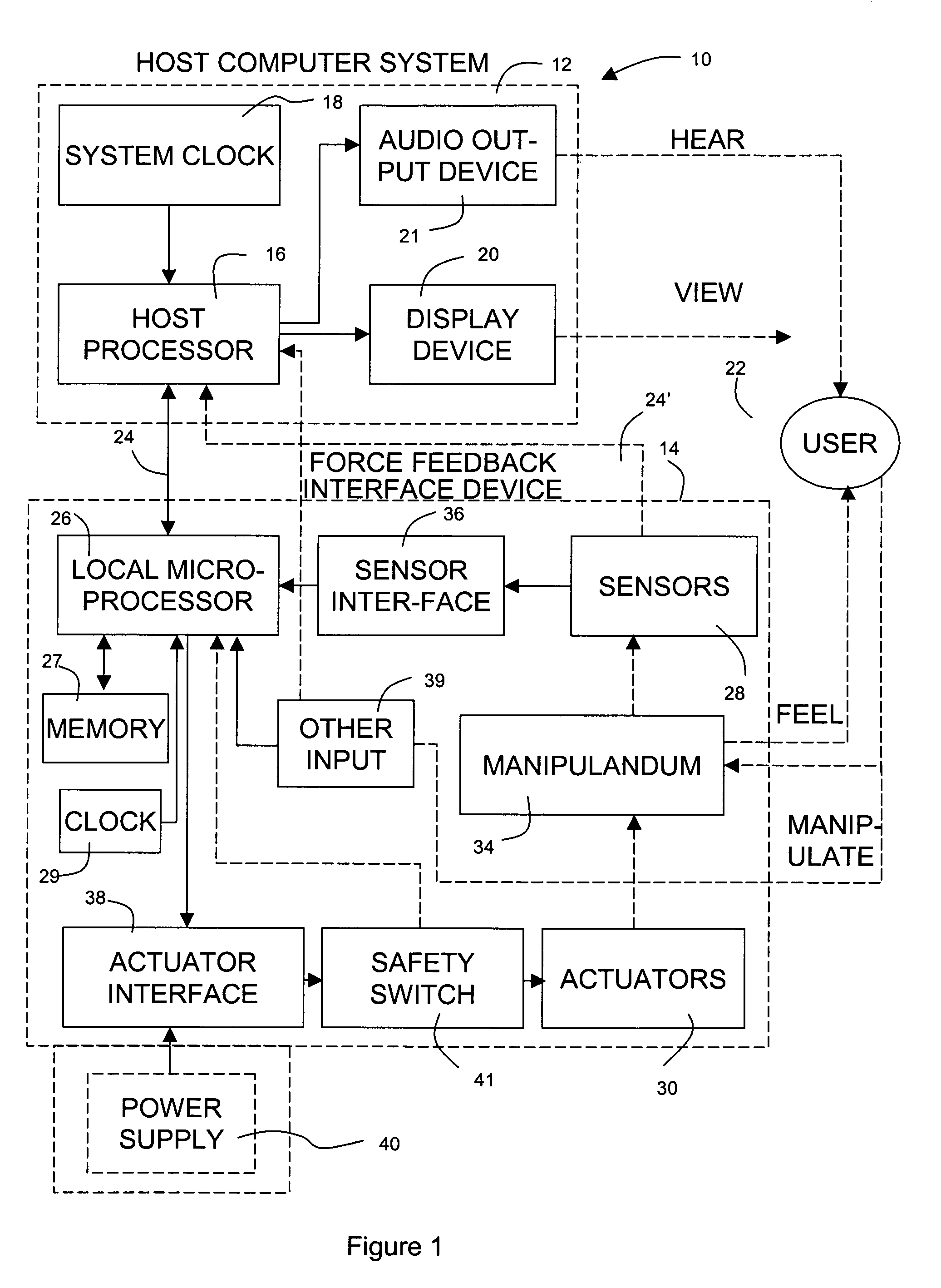

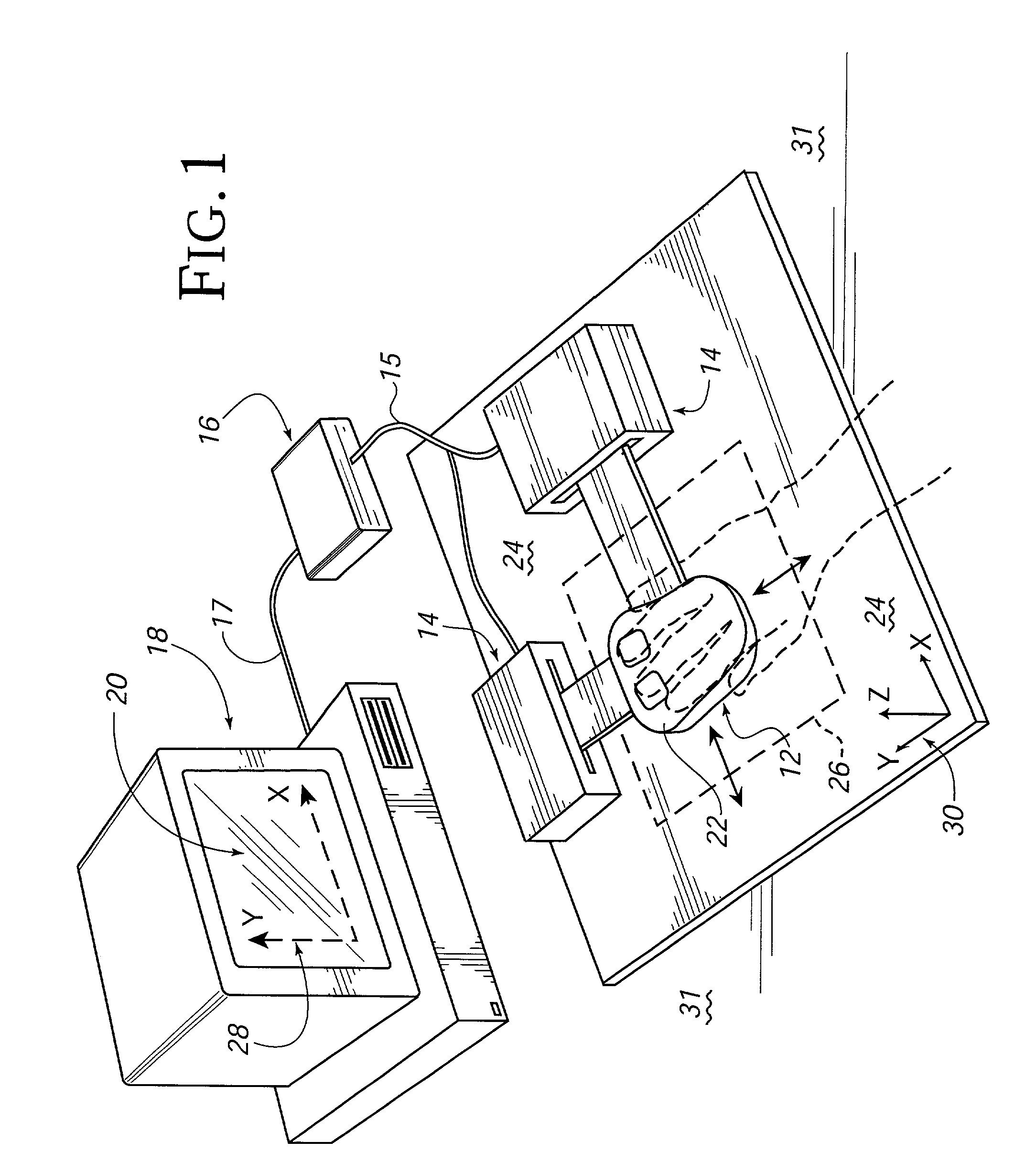

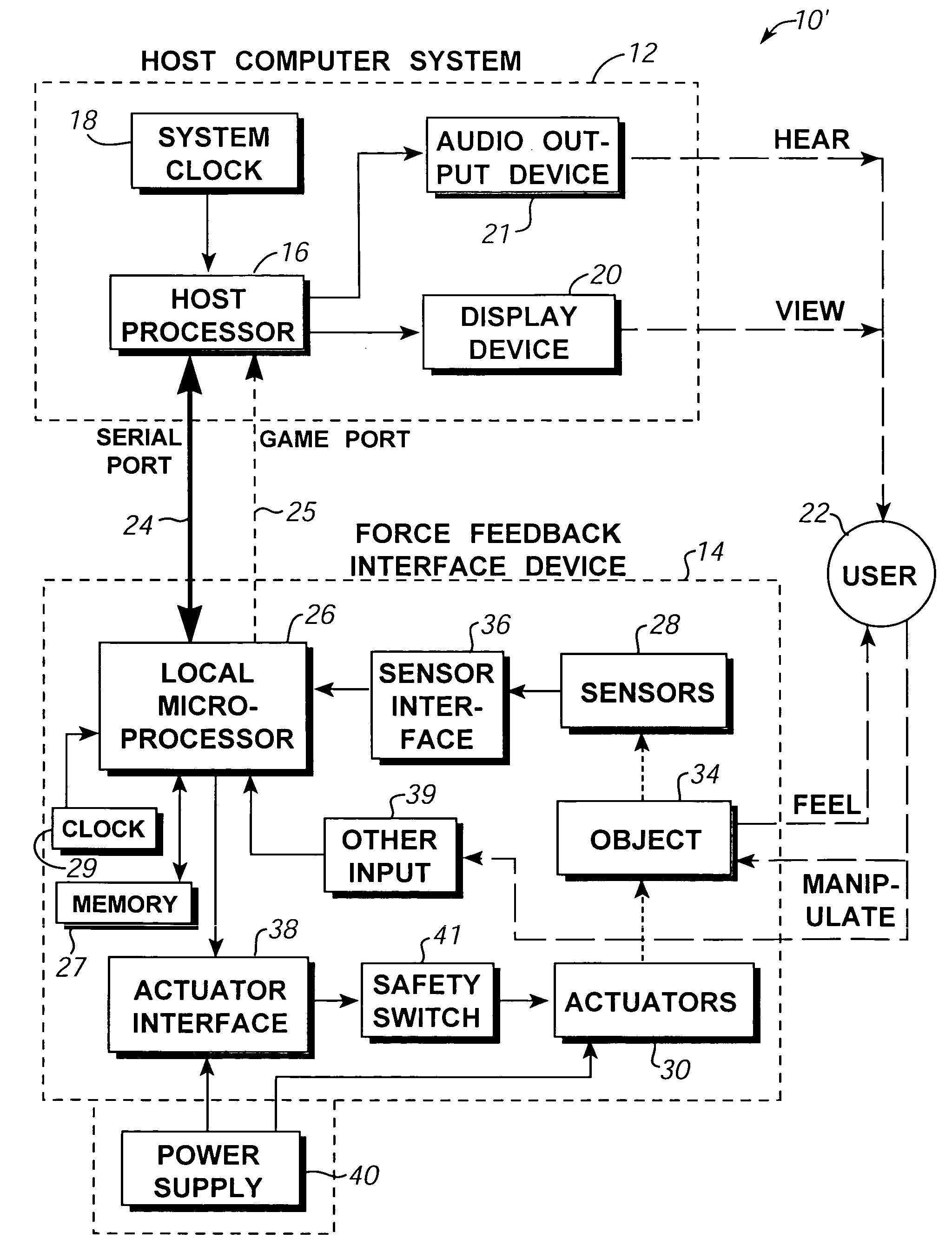

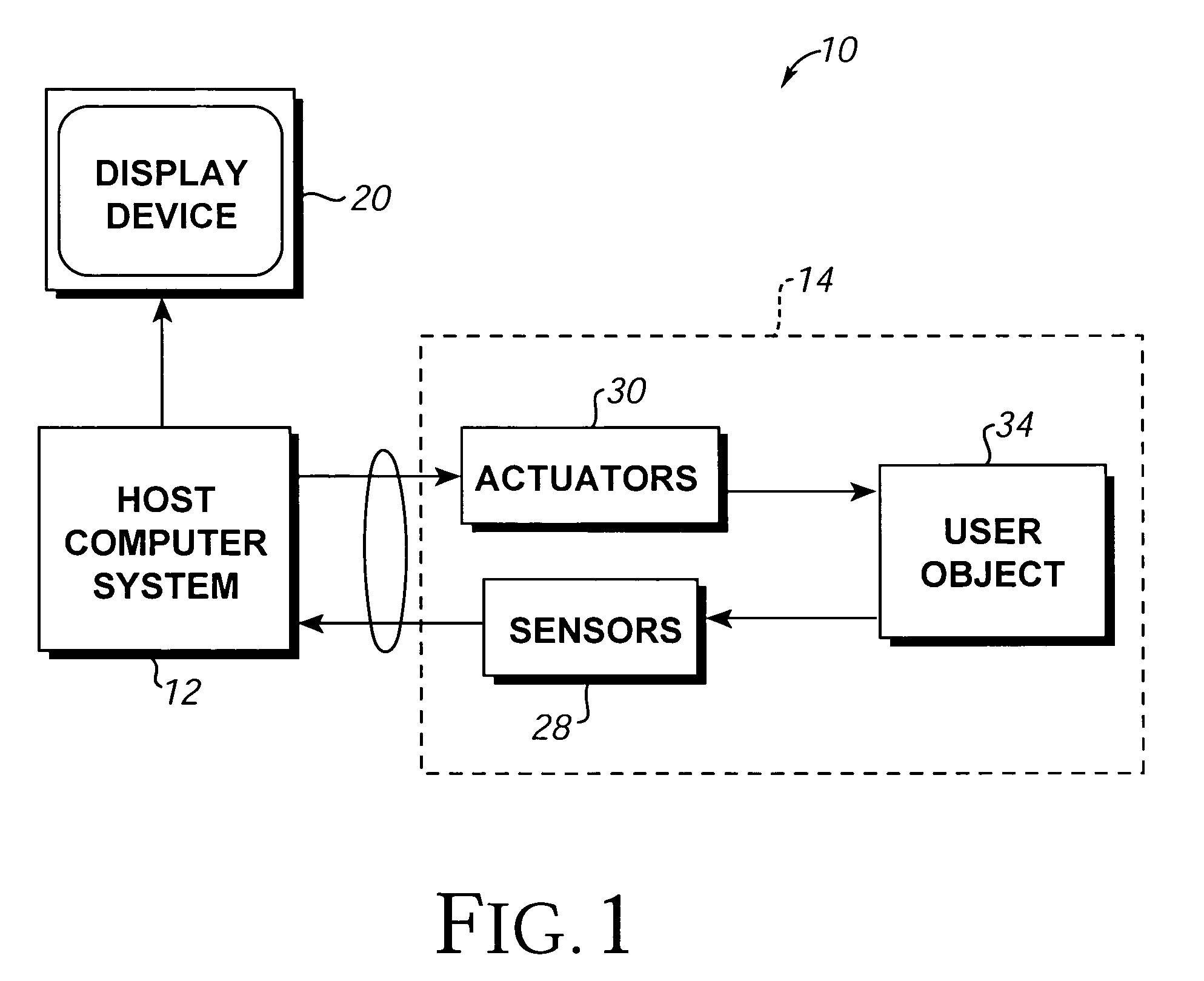

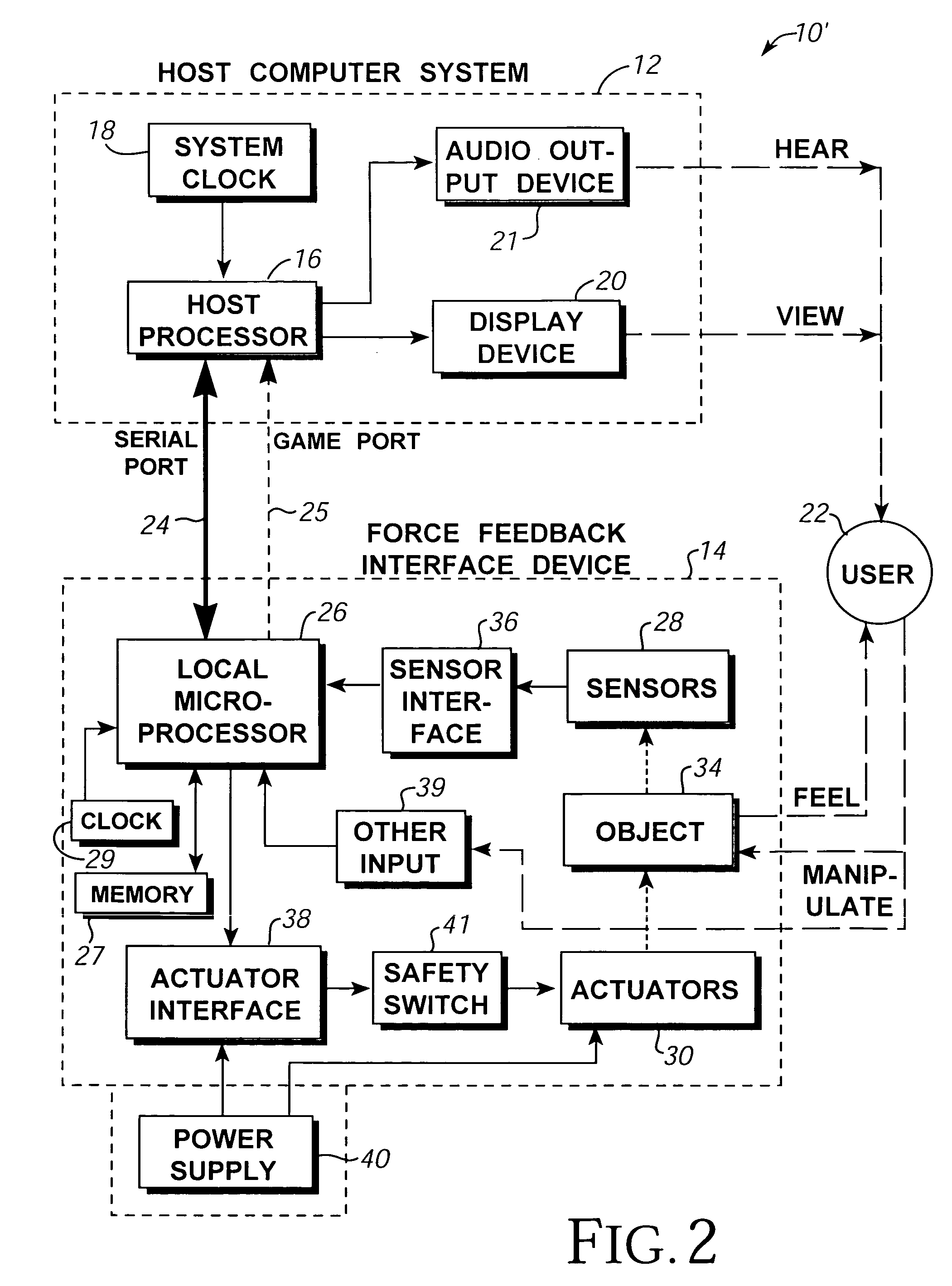

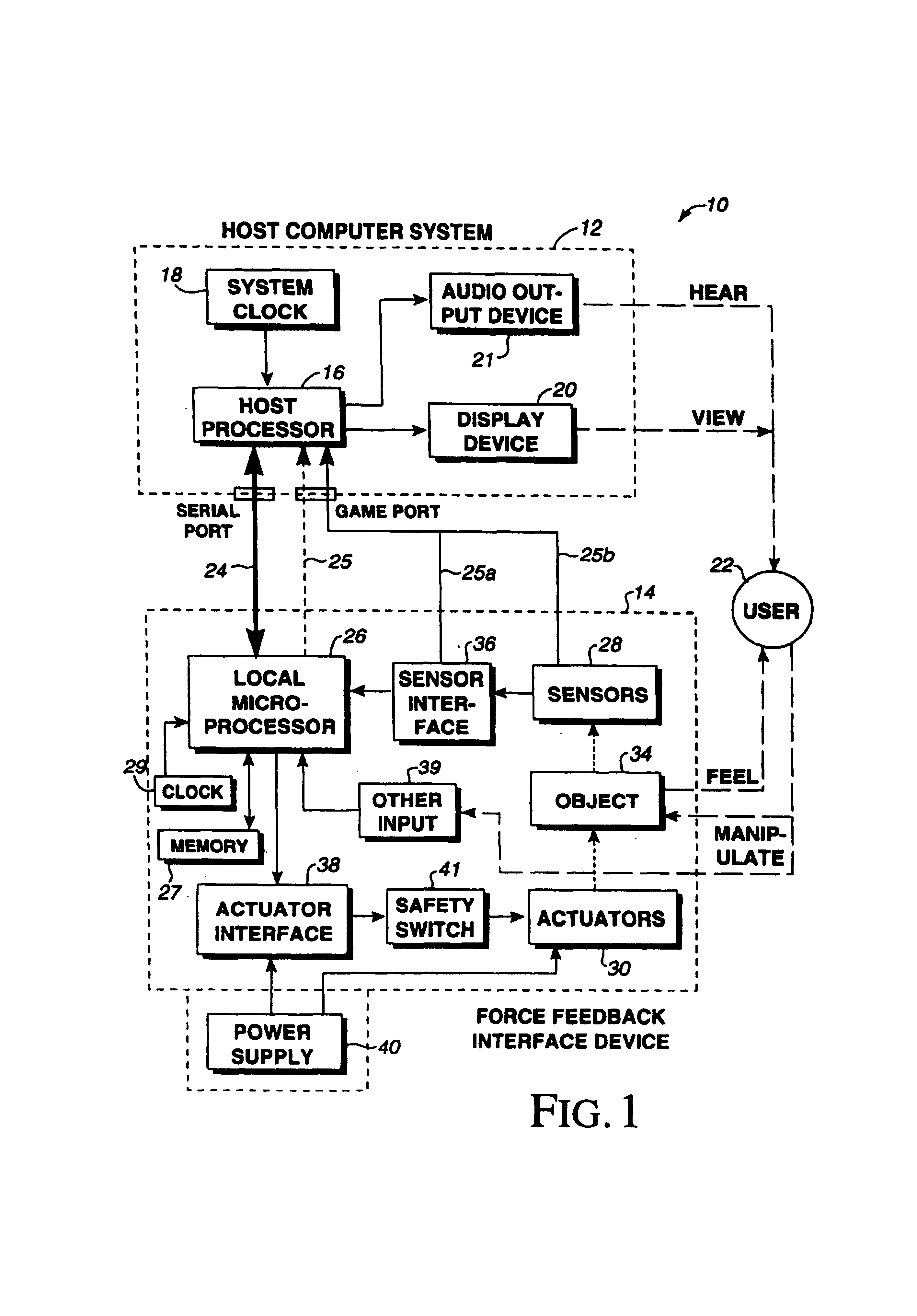

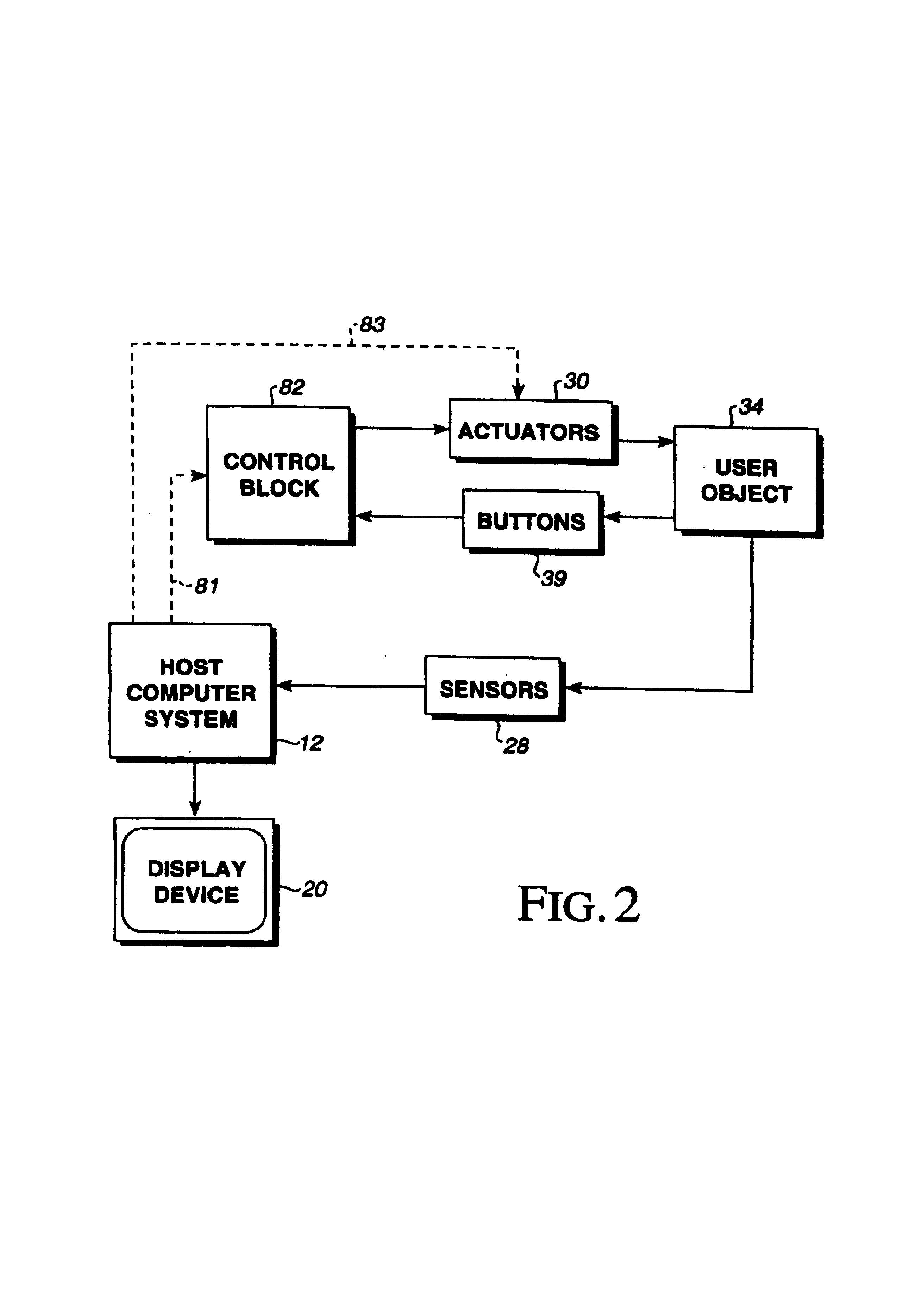

Providing force feedback to a user of an interface device based on interactions of a user-controlled cursor in a graphical user interface

InactiveUS7199790B2Easily moved onto targetFreedom of movementInput/output for user-computer interactionManual control with multiple controlled membersGraphicsJoystick

A method and apparatus for providing force feedback to a user operating a human / computer interface device in conjunction with a graphical user interface (GUI) displayed by a host computer system. A physical object, such as a joystick or a mouse, controls a graphical object, such as a cursor, within the GUI. The GUI allows the user to interface with operating system functions implemented by the computer system. A signal is output from the host computer to the interface device to apply a force sensation to the physical object using one or more actuators. This desired force sensation is associated with at least one of the graphical objects and operating system functions of the graphical user interface and is determined by a location of the cursor in the GUI with respect to targets that are associated with the graphical objects. The graphical objects include icons, windows, pull-down menus and menu items, scroll bars (“sliders”), and buttons. The force sensation assists the user to select a desired operating system function or physically informs the user of the graphical objects encountered by the cursor within the GUI. A microprocessor local to the interface apparatus and separate from the host computer can be used to control forces on the physical object.

Owner:IMMERSION CORPORATION

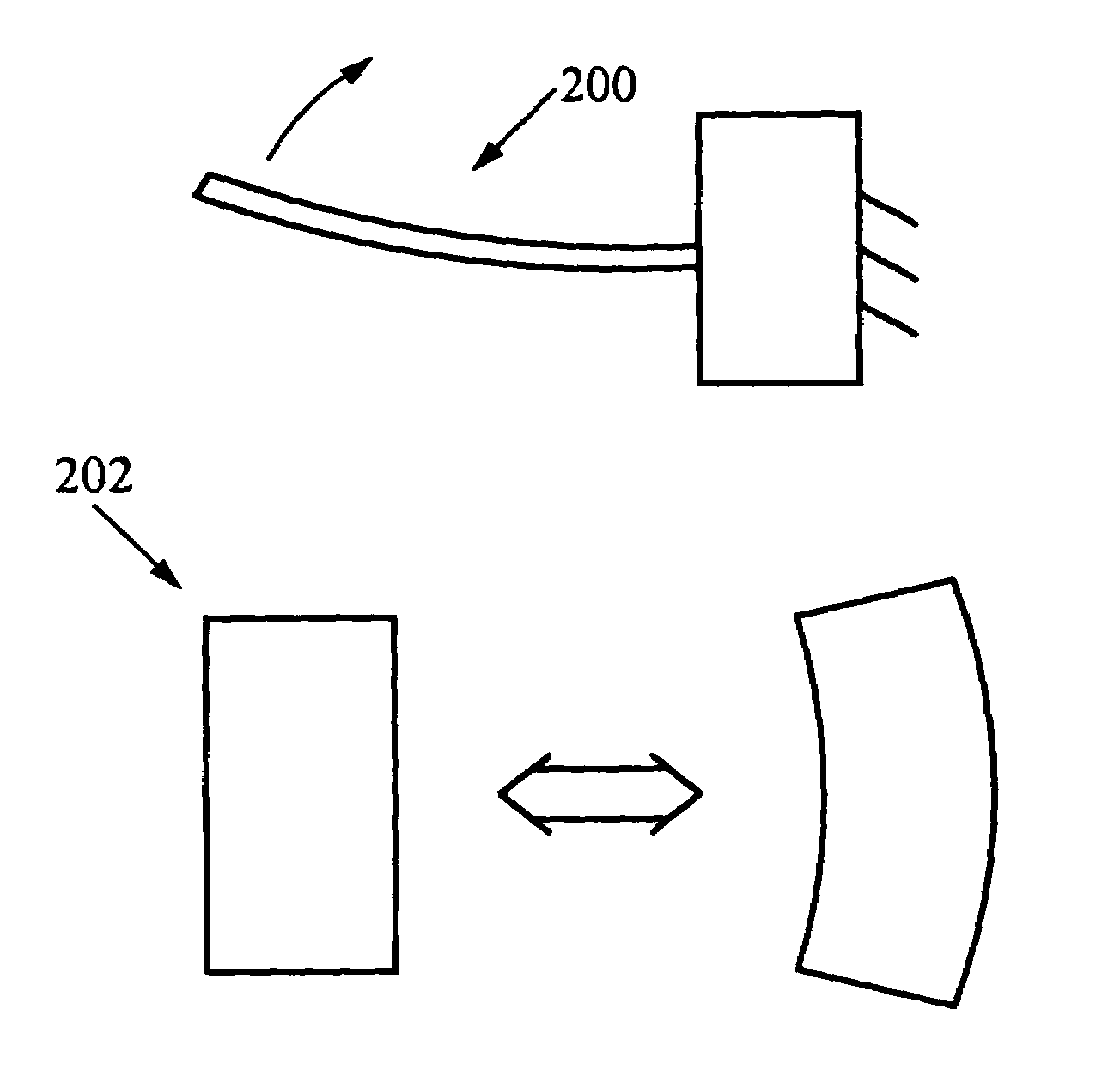

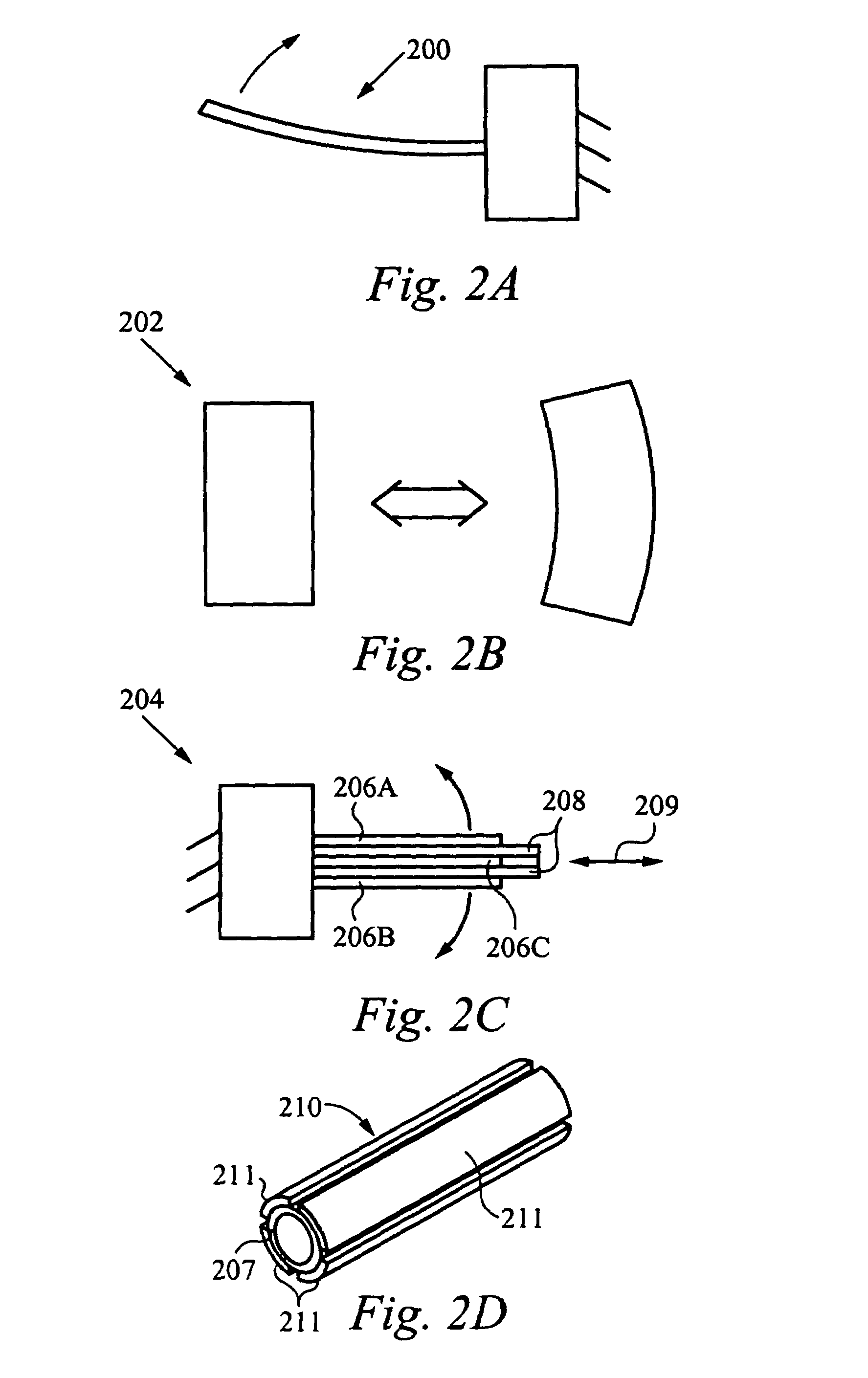

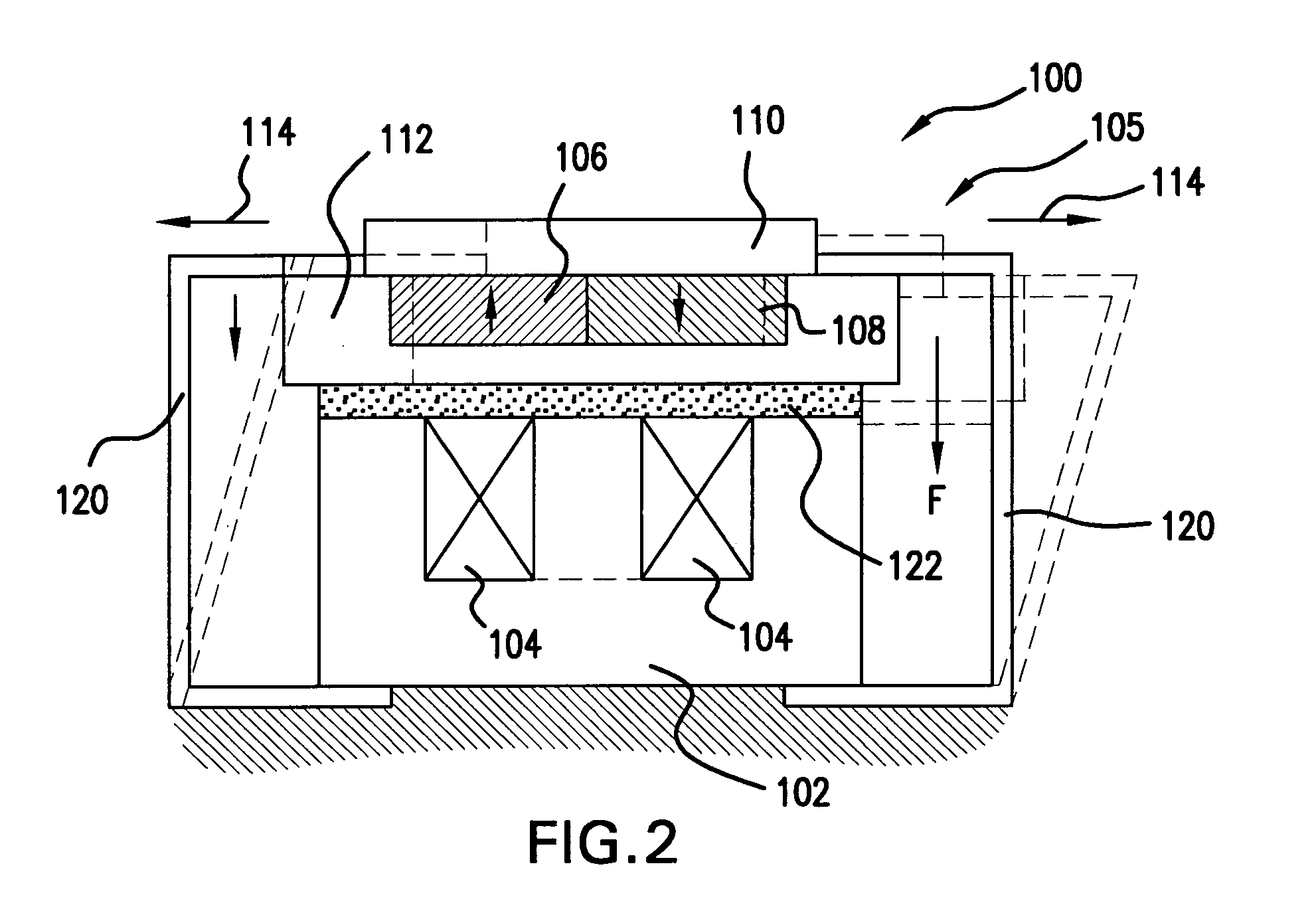

Haptic devices using electroactive polymers

ActiveUS7196688B2Low costEfficiently provideInput/output for user-computer interactionManual control with multiple controlled membersActive polymerHaptic sensing

Haptic feedback interface devices using electroactive polymer (EAP) actuators to provide haptic sensations and / or sensing capabilities. A haptic feedback interface device is in communication with a host computer and includes a sensor device that detects the manipulation of the interface device by the user and an electroactive polymer actuator responsive to input signals and operative to output a force to the user caused by motion of the actuator. The output force provides a haptic sensation to the user. Various embodiments of interface devices employing EAP actuators are described, including embodiments providing direct forces, inertial forces, and braking forces.

Owner:IMMERSION CORPORATION

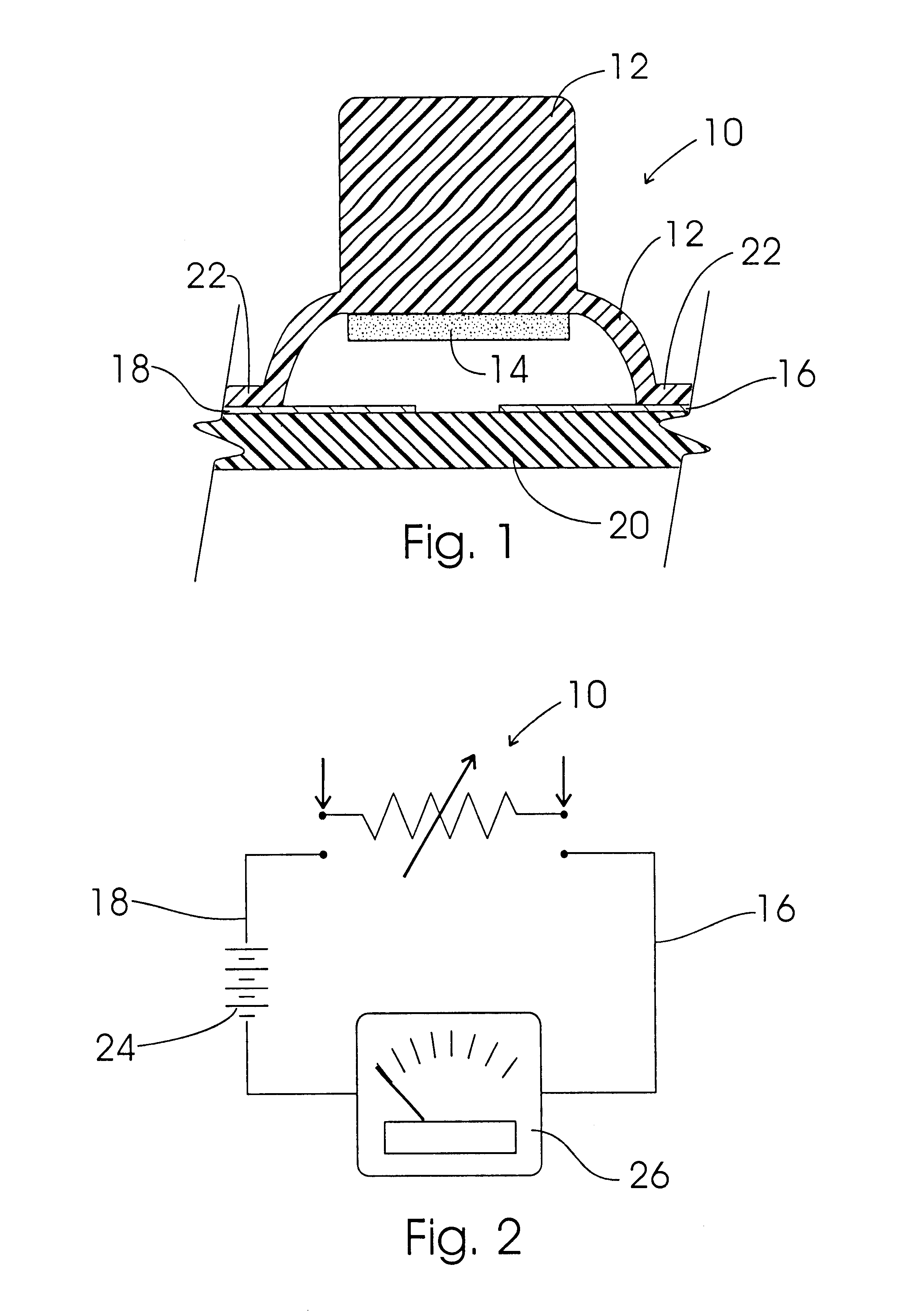

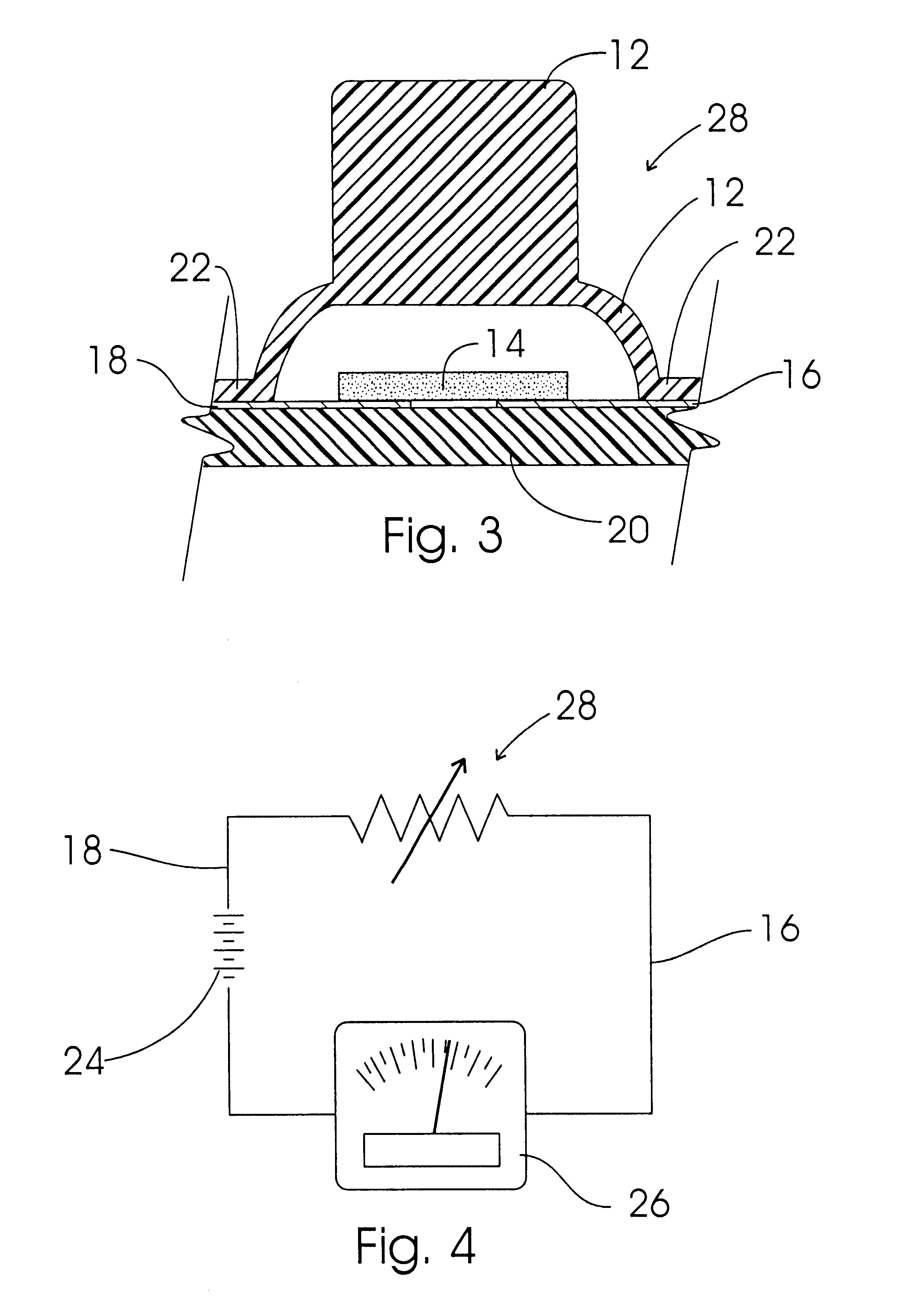

Variable sensor with tactile feedback

InactiveUS6344791B1Input/output for user-computer interactionManual control with multiple controlled membersTouch PerceptionEngineering

Owner:ANASCAPE

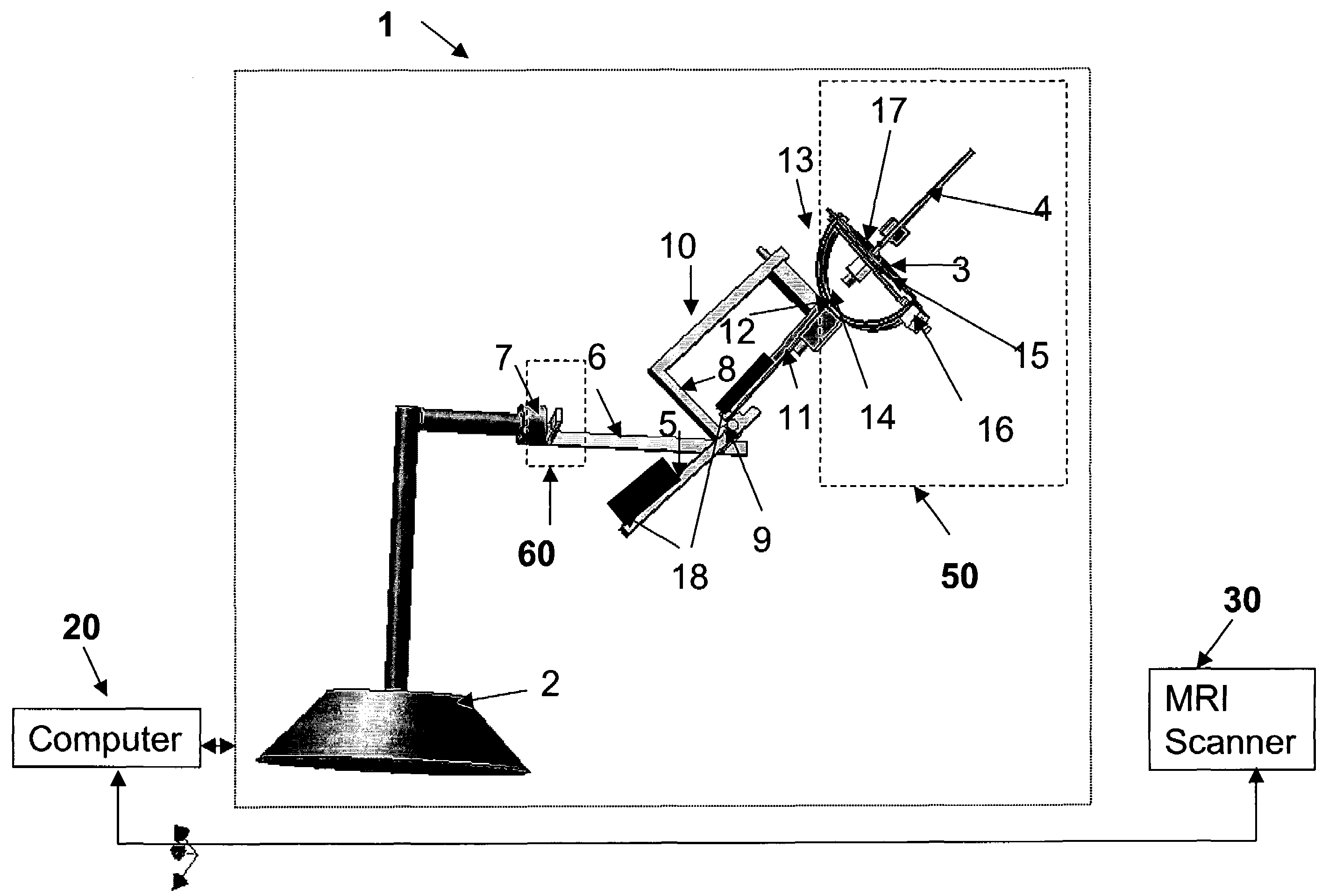

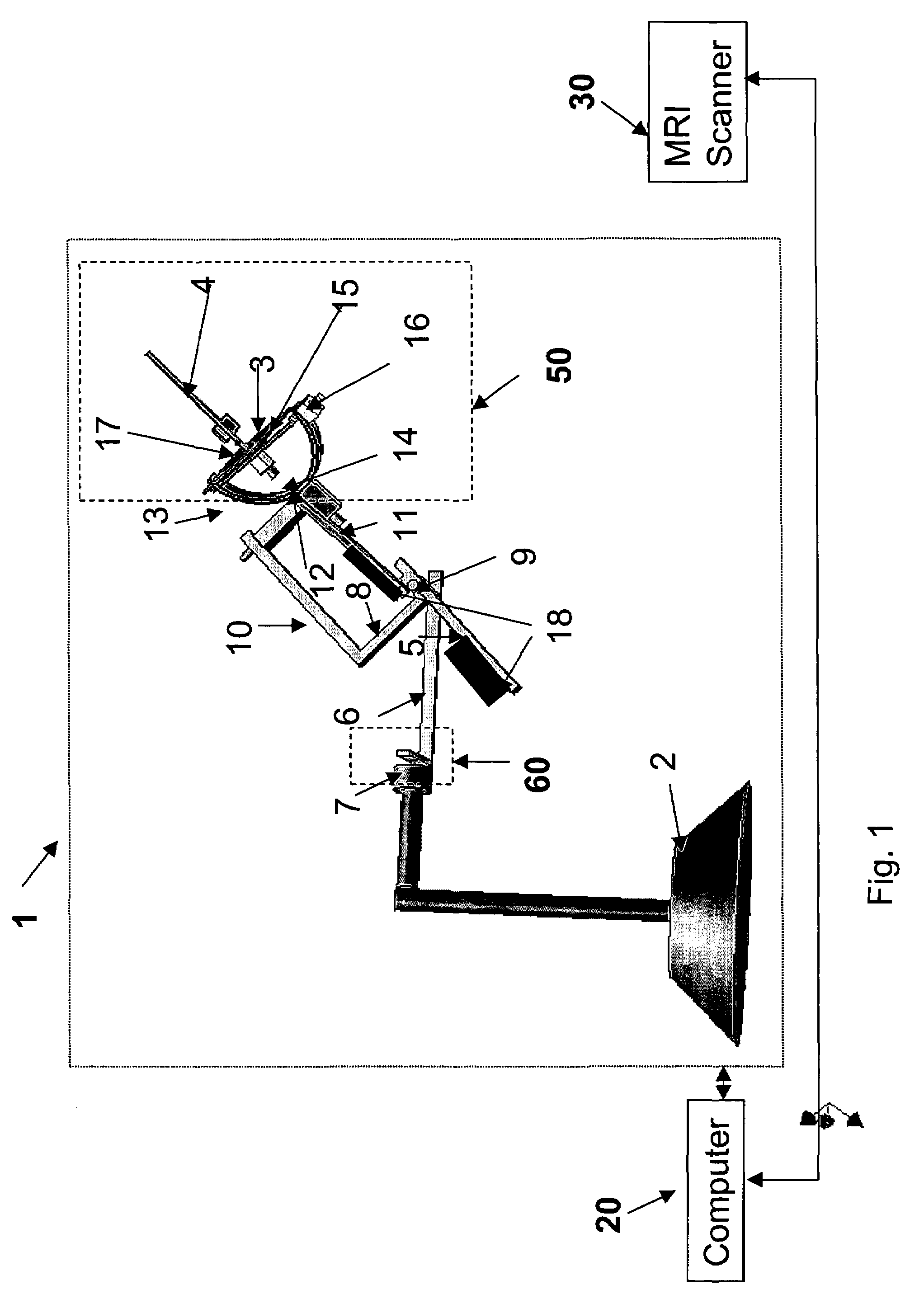

Device and process for manipulating real and virtual objects in three-dimensional space

InactiveUS7466303B2Rapid localizationAccurate detectionManual control with multiple controlled membersSurgeryRest positionThree-dimensional space

Owner:SUNNYBROOK HEALTH SCI CENT

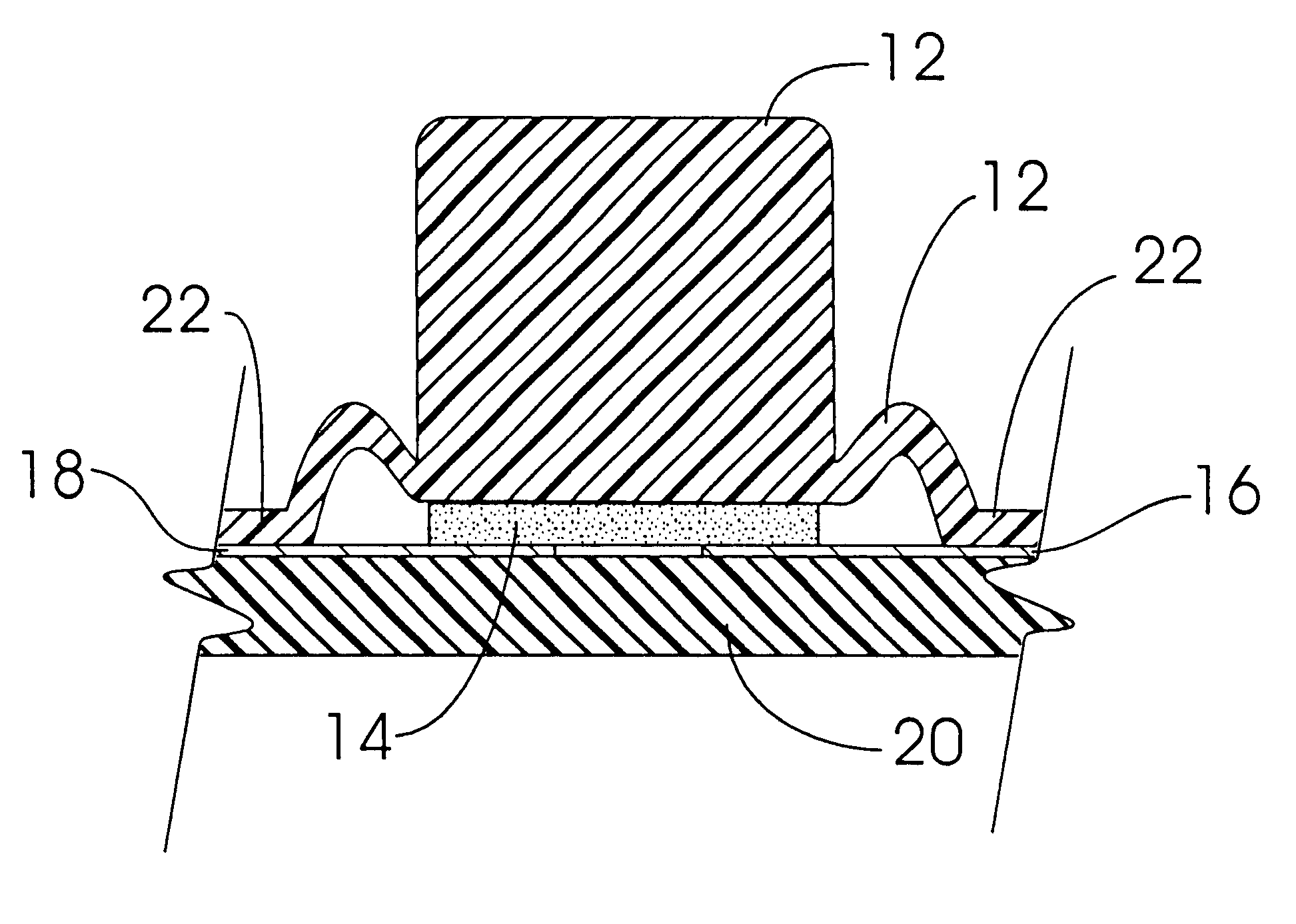

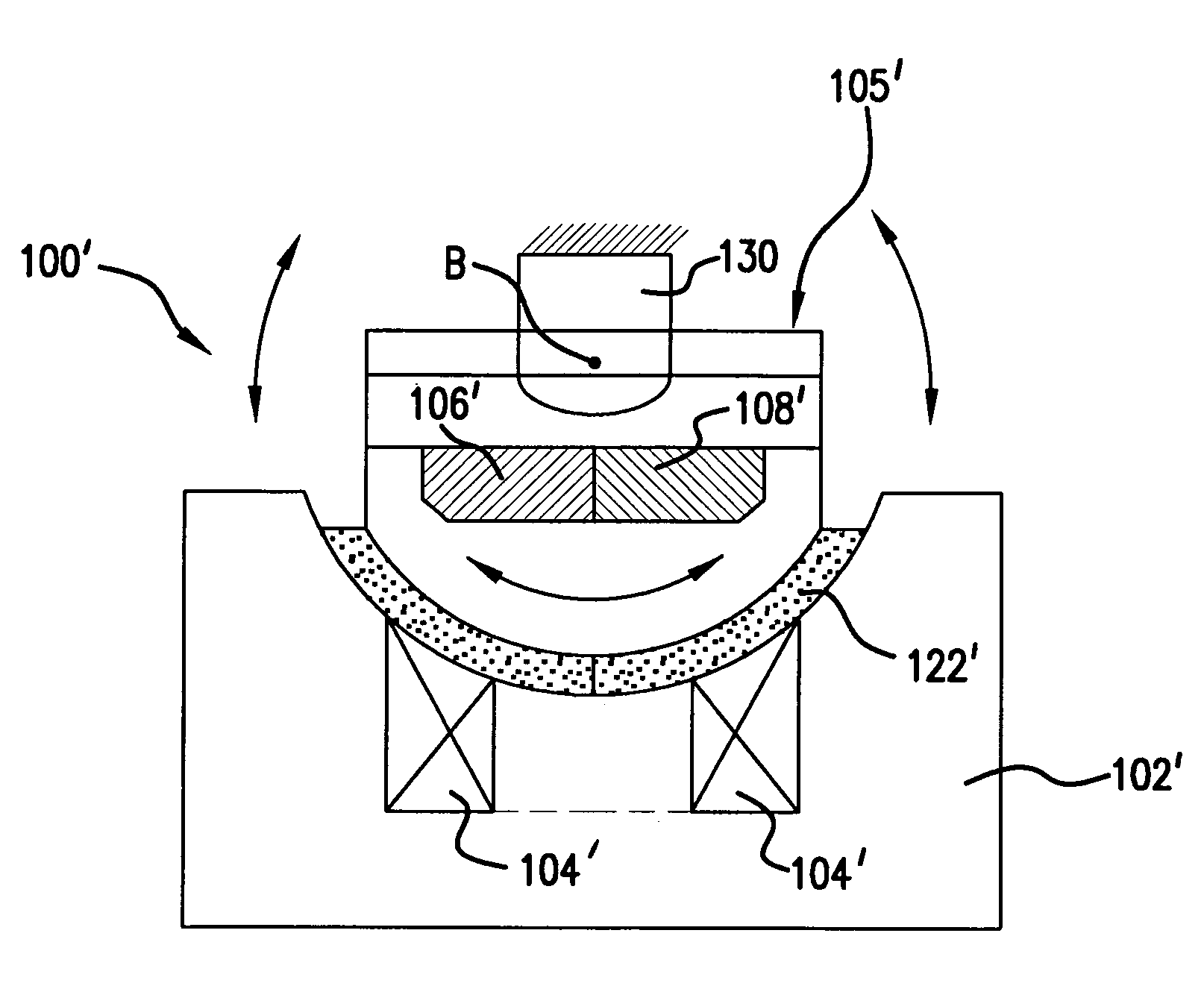

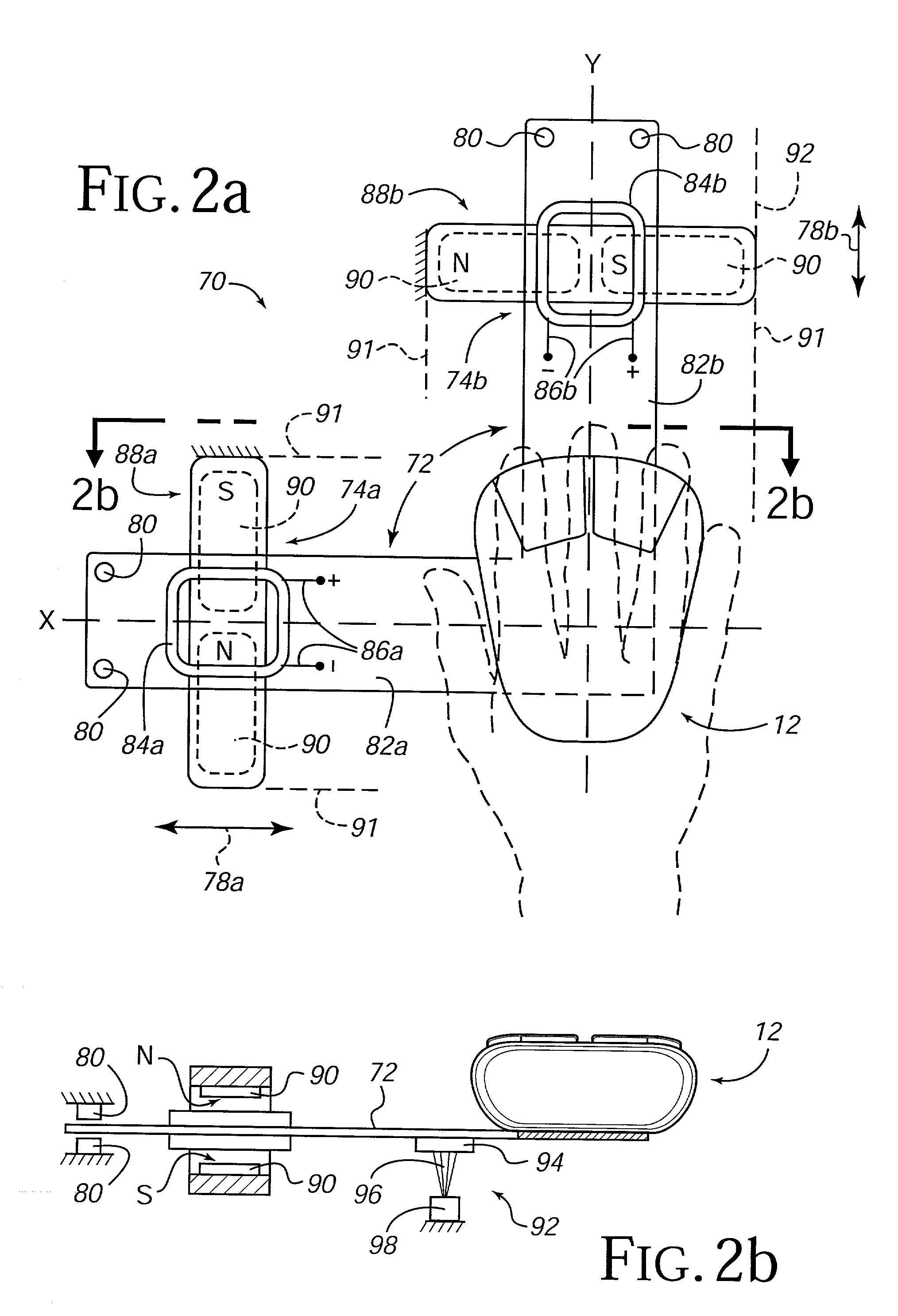

Moving magnet actuator for providing haptic feedback

InactiveUS6982696B1High magnitudeHigh bandwidthInput/output for user-computer interactionManual control with multiple controlled membersCentral projectionSpring force

A moving magnet actuator for providing haptic feedback. The actuator includes a grounded core member, a coil is wrapped around a central projection of the core member, and a magnet head positioned so as to provide a gap between the core member and the magnet head. The magnet head is moved in a degree of freedom based on an electromagnetic force caused by a current flowed through the coil. An elastic material, such as foam, is positioned in the gap between the magnet head and the core member, where the elastic material is compressed and sheared when the magnet head moves and substantially prevents movement of the magnet head past a range limit that is based on the compressibility and shear factor of the material. Flexible members can also be provided between the magnet head and the ground member, where the flexible members flex to allow the magnet head to move, provide a centering spring force to the magnet head, and limit the motion of the magnet head.

Owner:IMMERSION CORPORATION

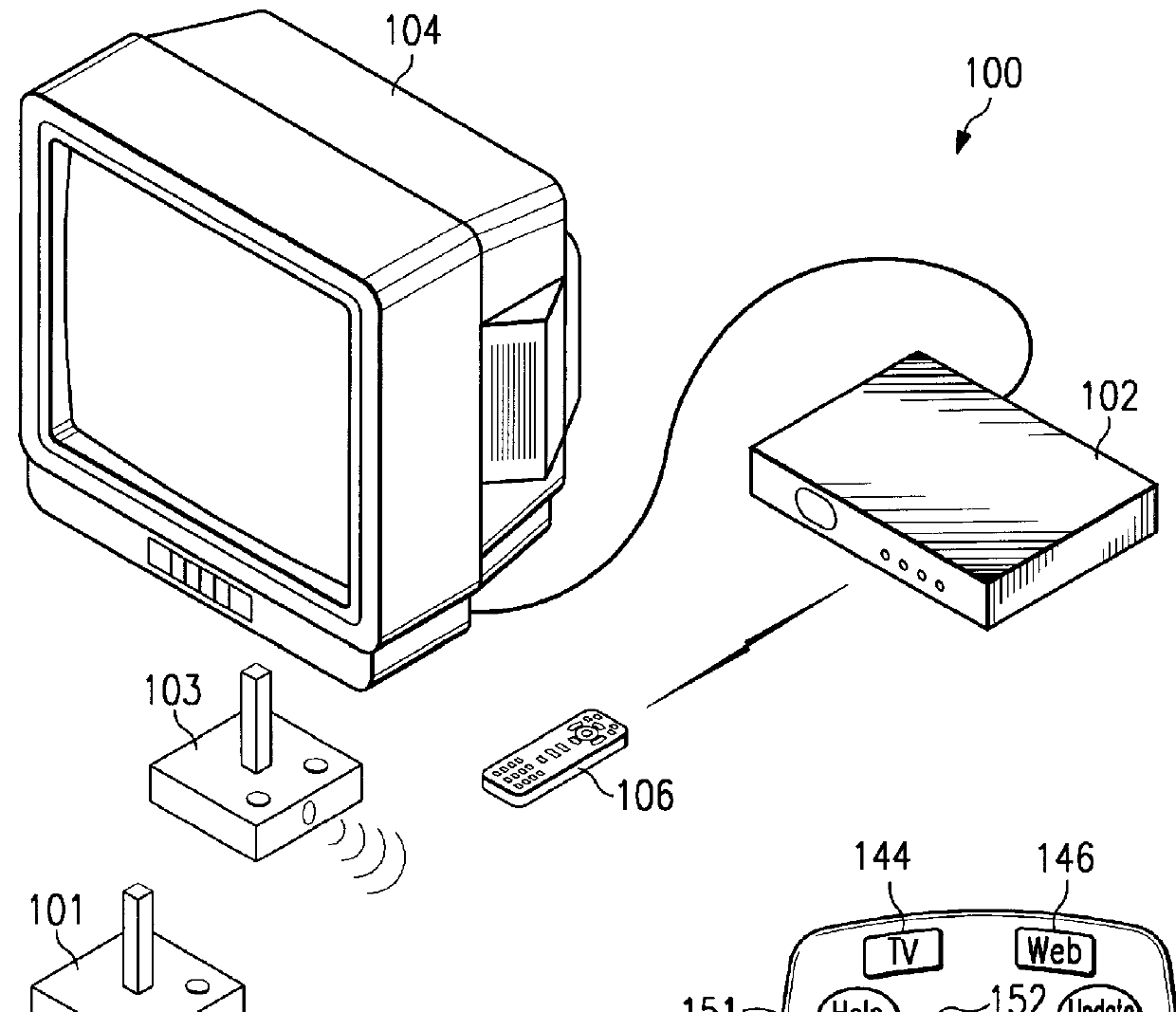

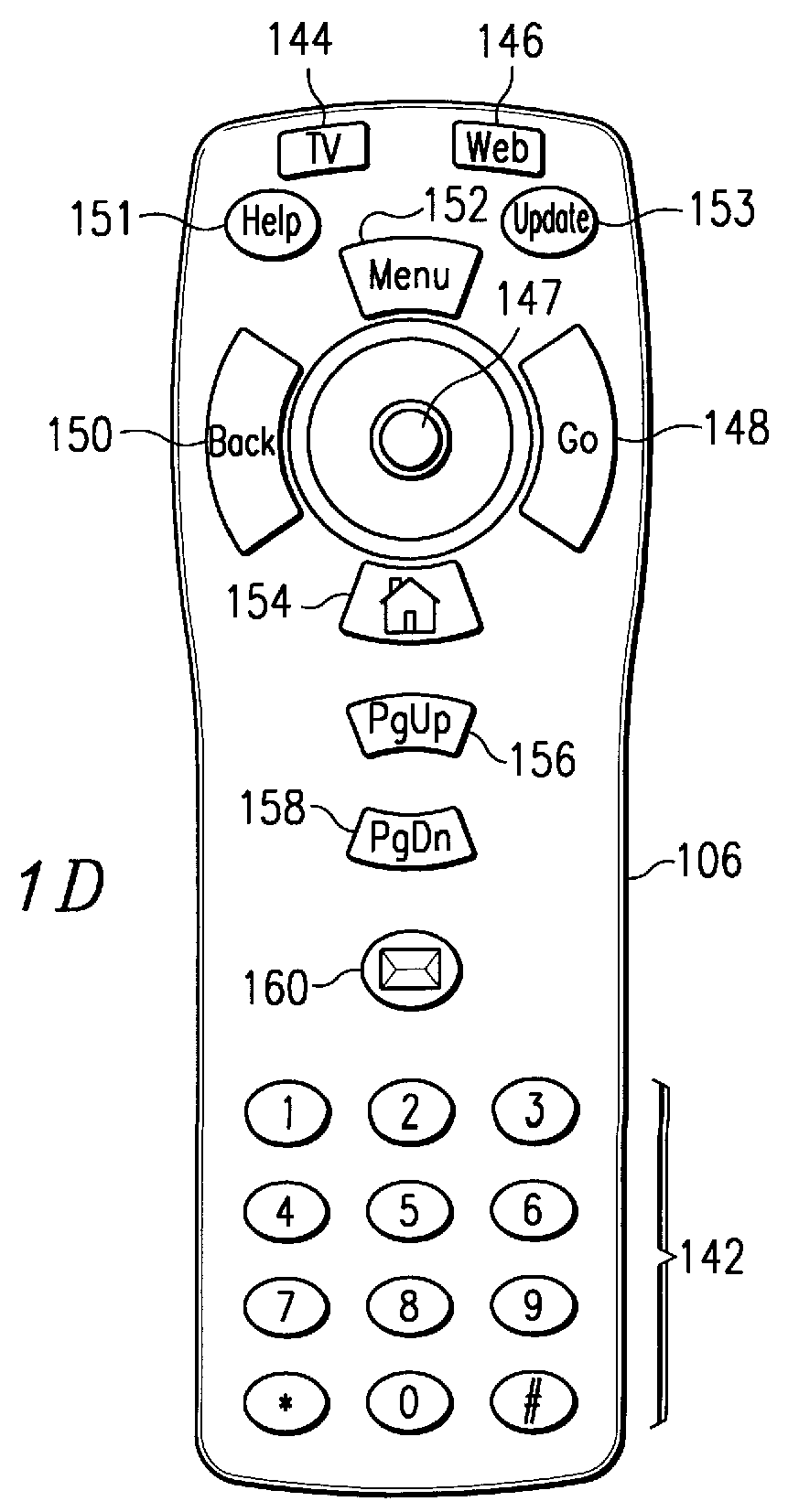

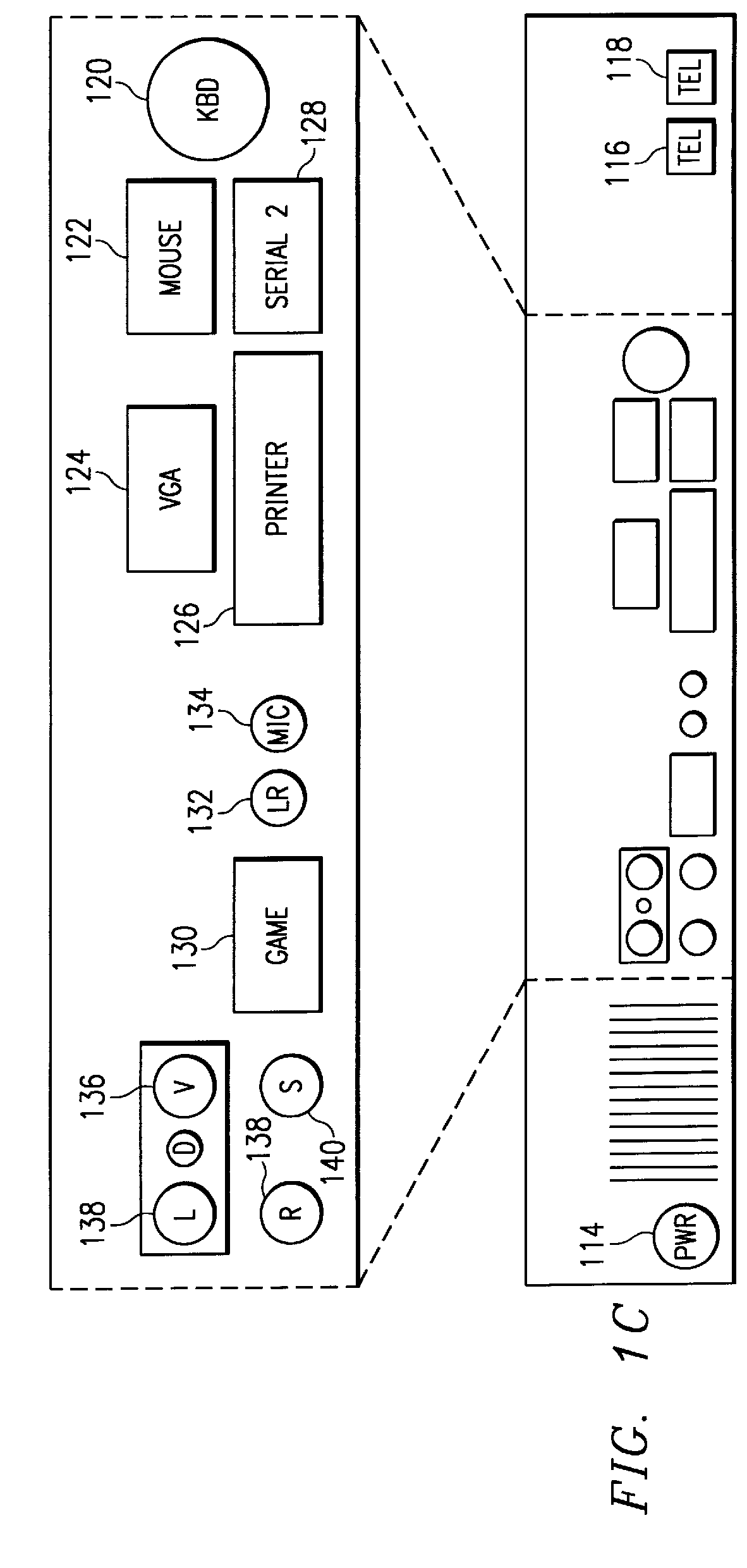

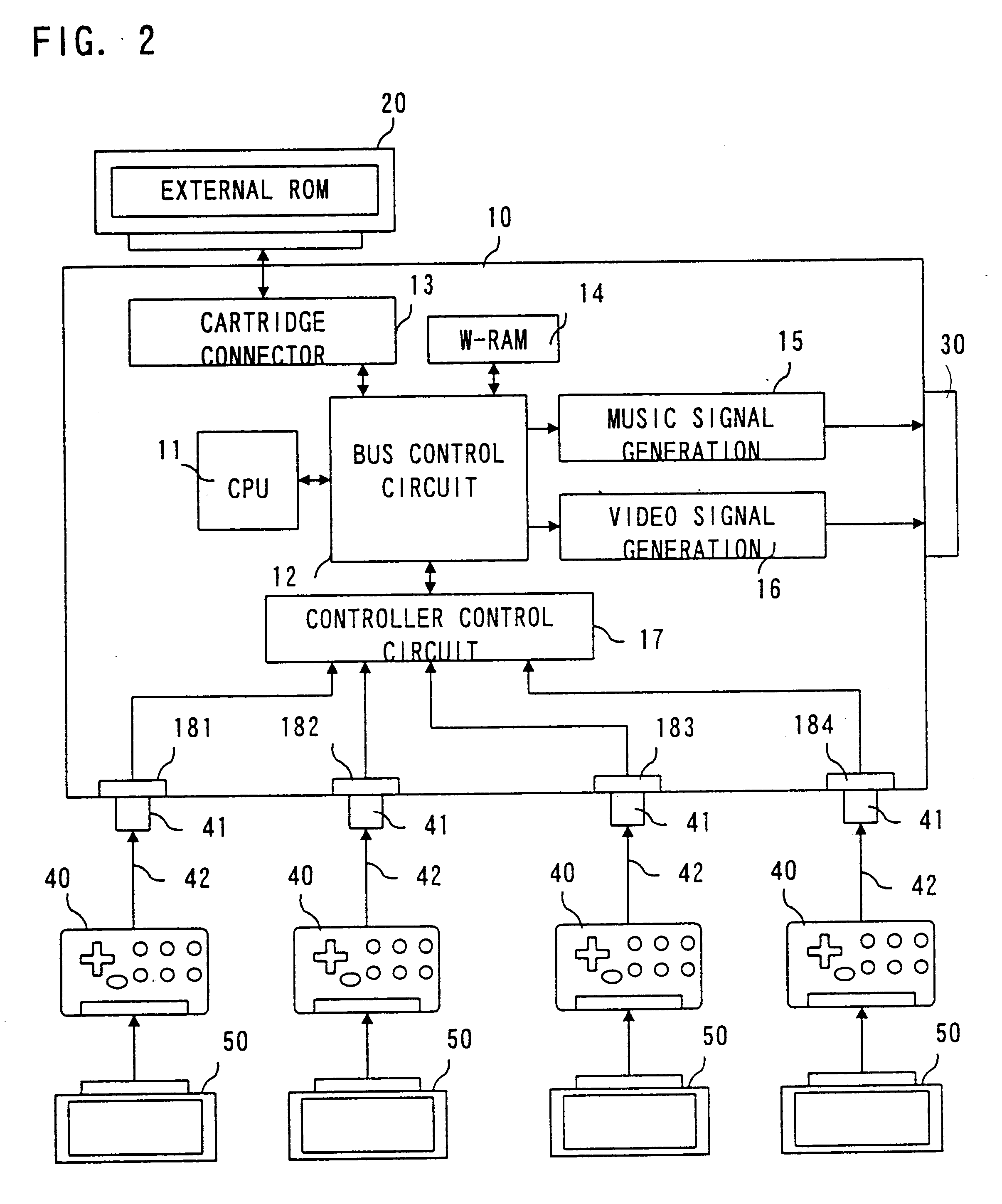

Method and system for simultaneous operation of multiple handheld control devices in a data processing system

InactiveUS6144367AIncrease valueSimple and cost-effectiveTelevision system detailsElectric signal transmission systemsData processing systemControl signal

A method and system for controlling a display of a data processing system uses first and second wireless position control devices, and a control base unit. The first wireless position control device includes an acoustical transducer for transmitting a first ultrasonic carrier signal upon which X-Y position control and / or action control signals generated by the device are imposed. A second wireless position control device includes and acoustical transducer for transmitting a second ultrasonic carrier signal upon which X-Y position control and / or other action control signals generated by the second control device are imposed. The first and second ultrasonic carrier signals have different frequencies. The control base is associated with the data processing system and includes circuitry for receiving and differentiating the first and second ultrasonic carrier signals to generate decoded display control signals. The display control signals are then used to drive the display device. Two users may thus control the display device simultaneously.

Owner:IBM CORP

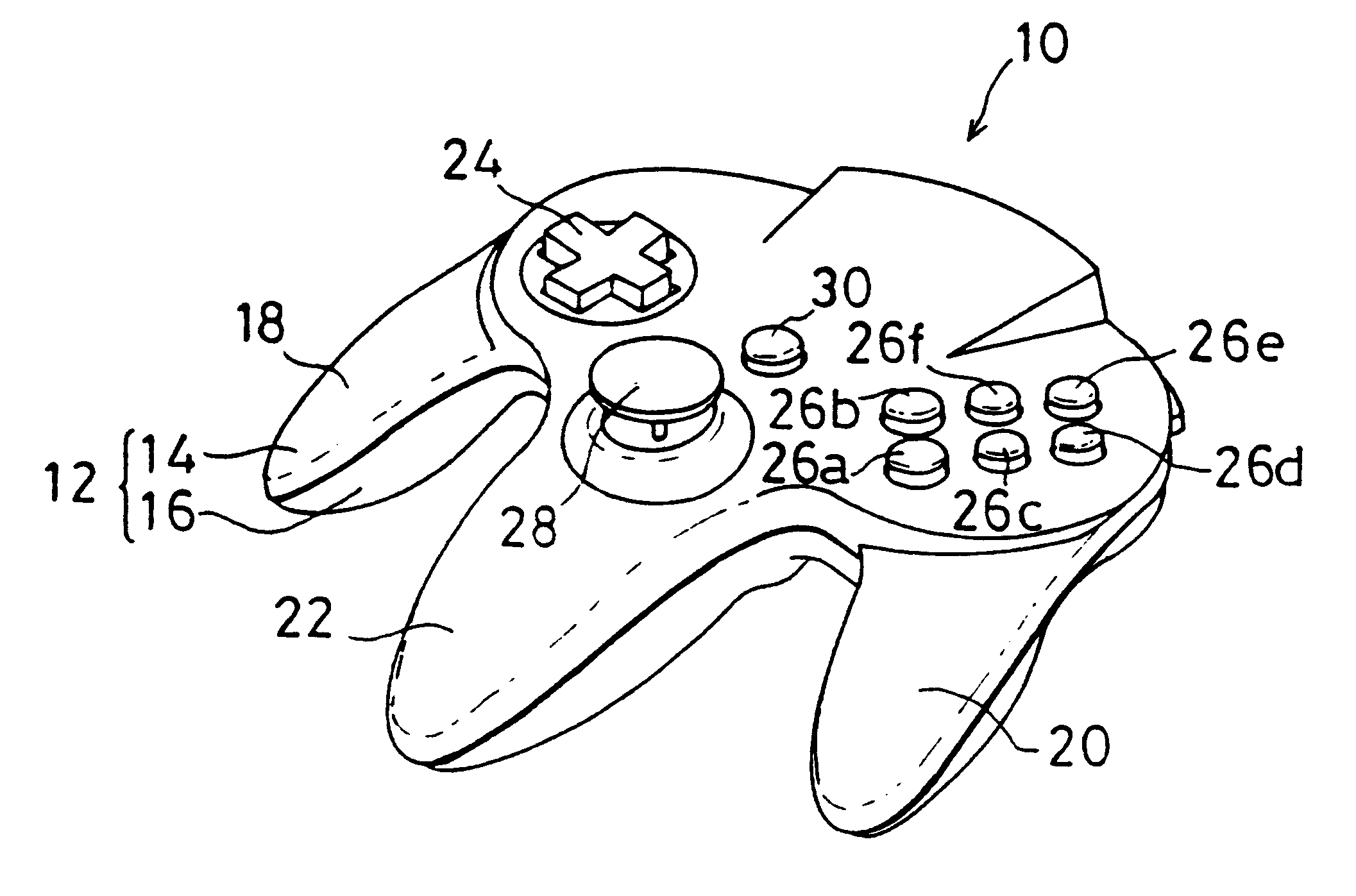

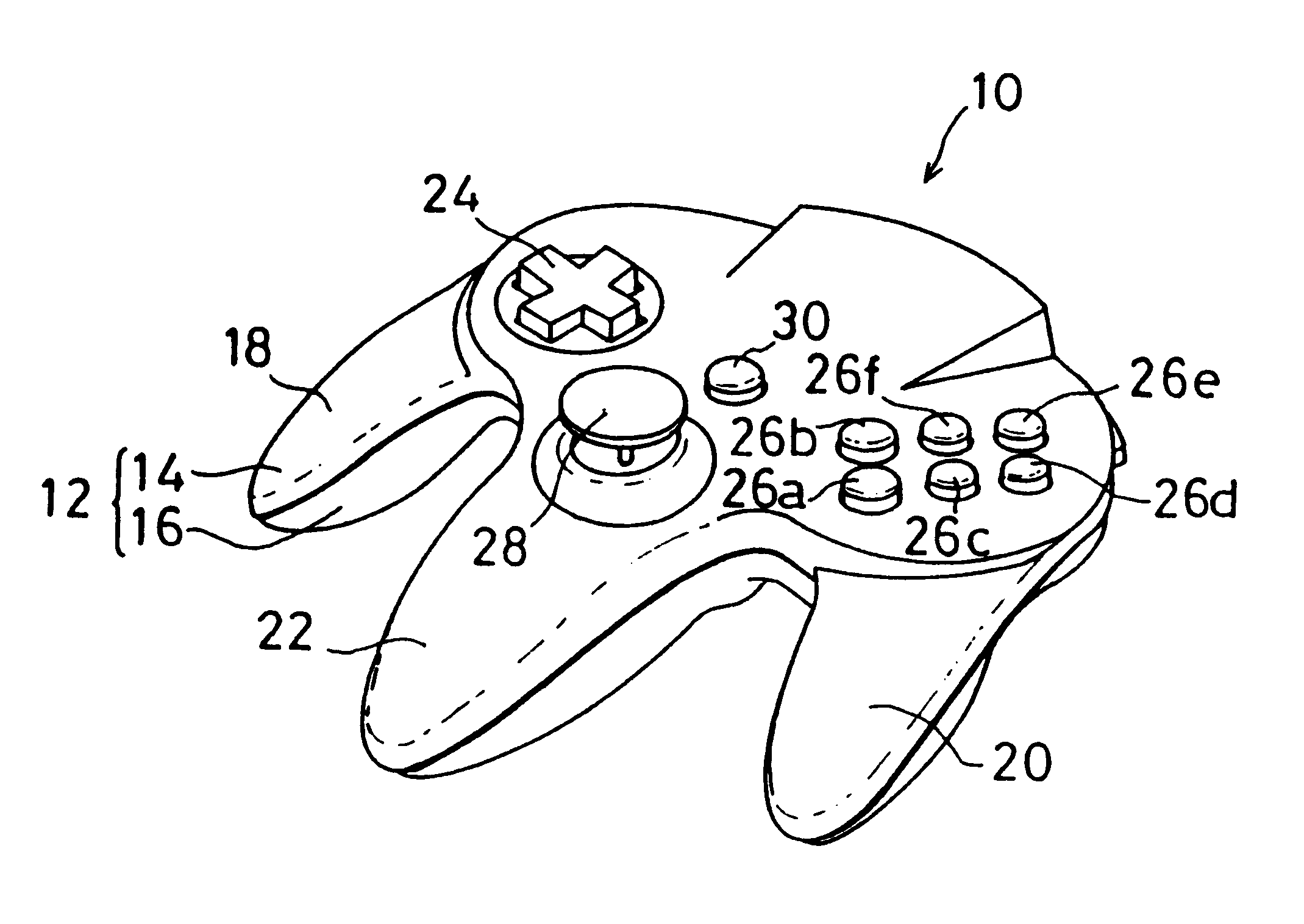

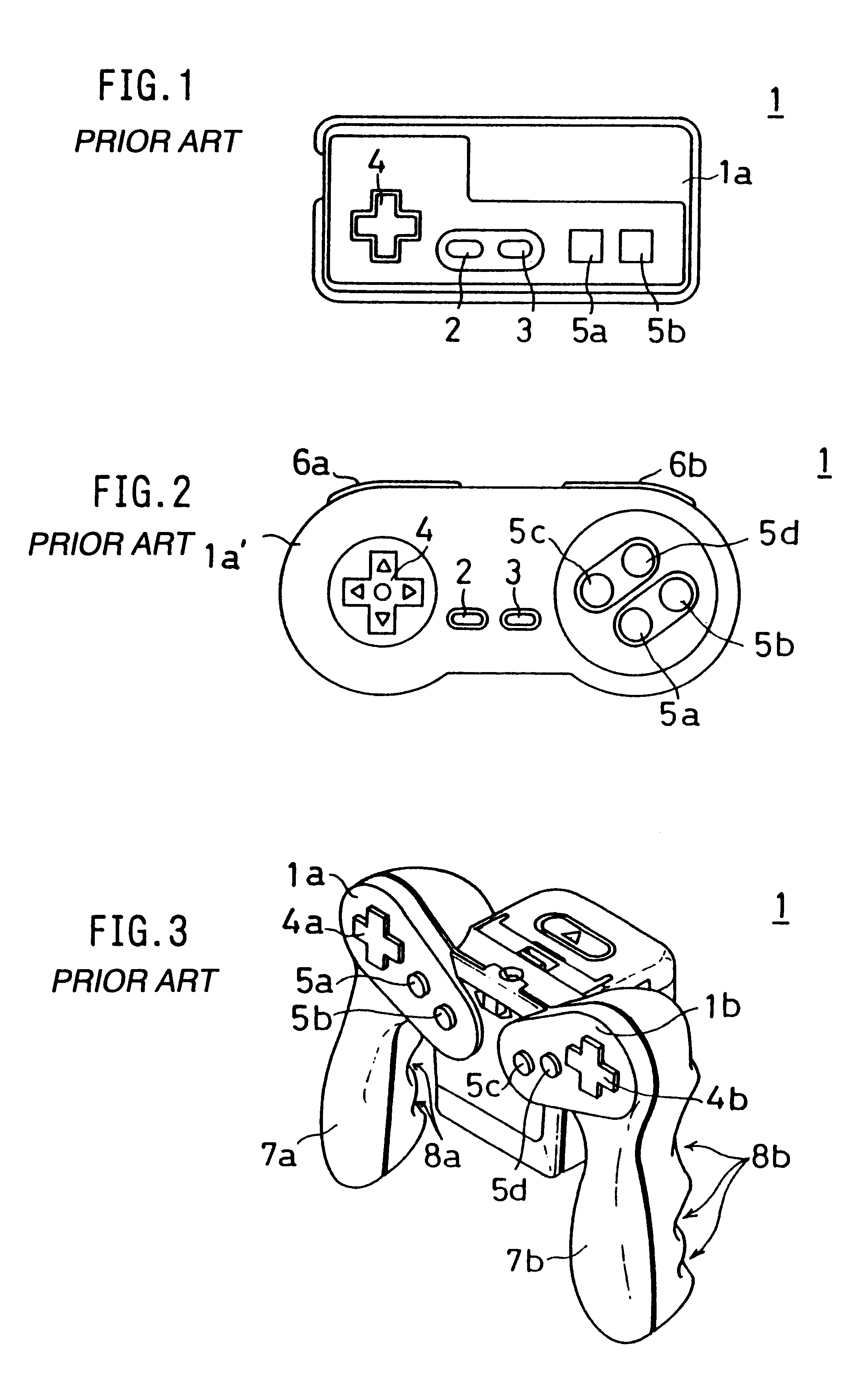

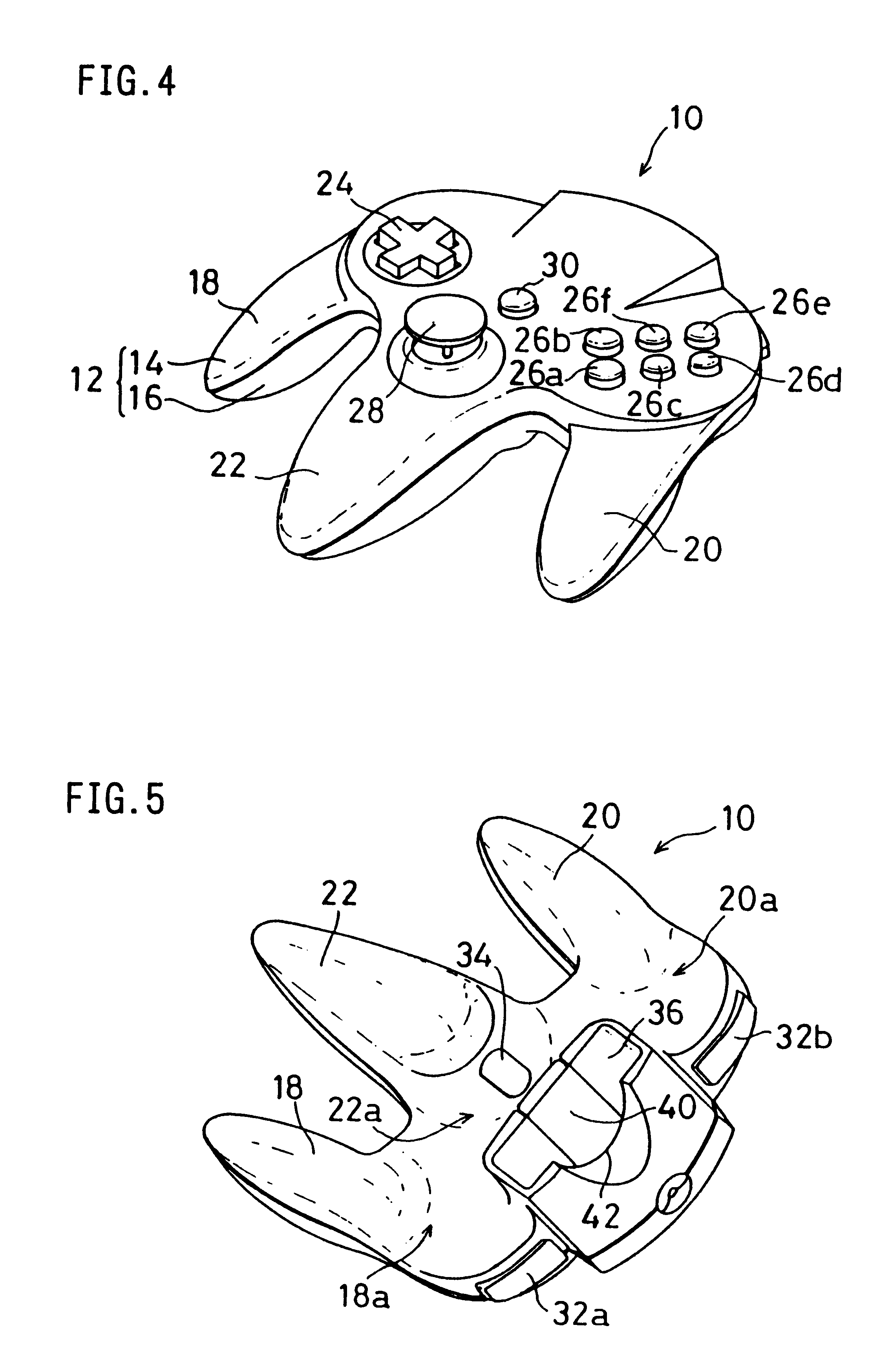

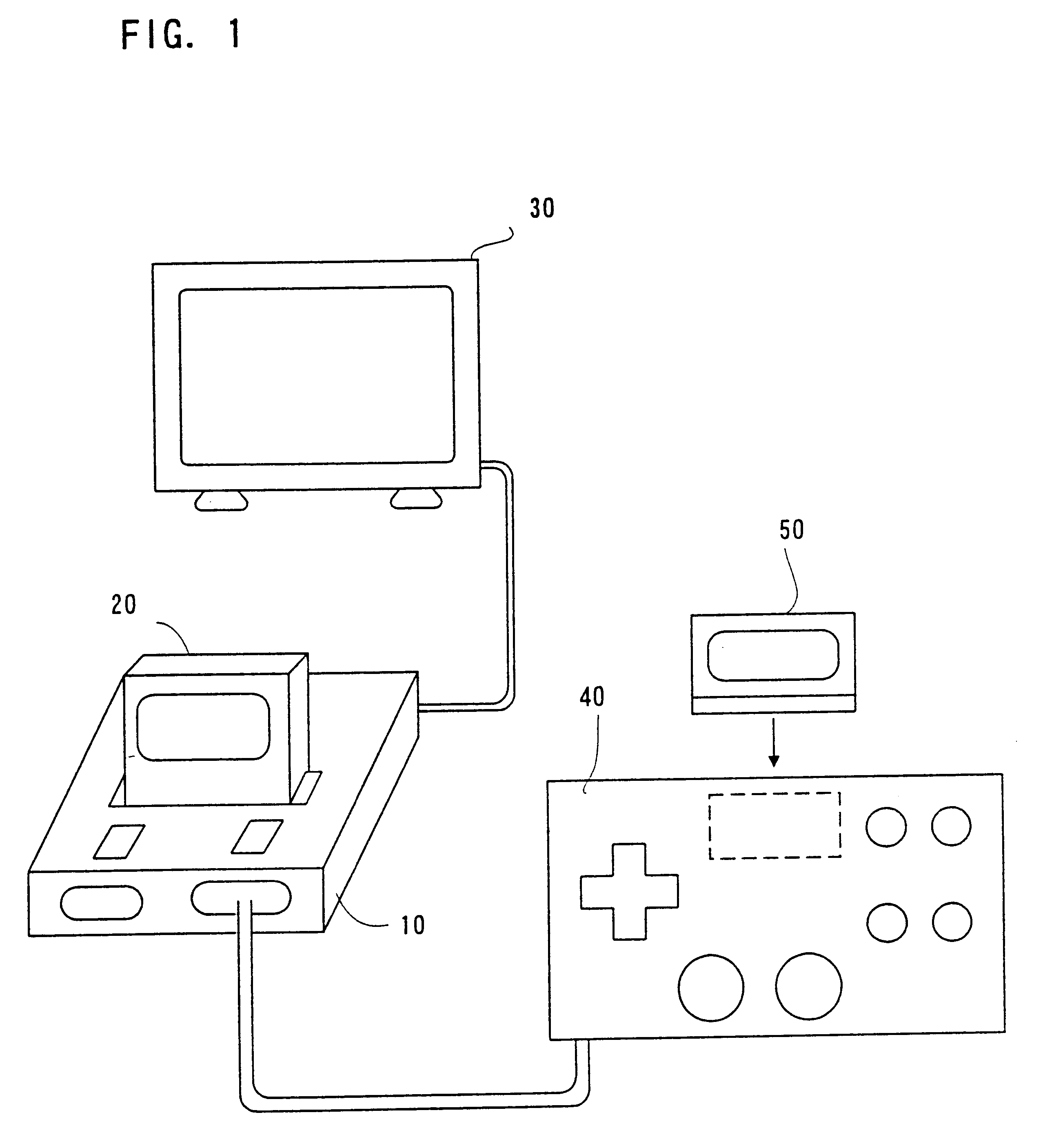

Function expansion device and operating device using the function expansion device

InactiveUS6241611B1Easy to set upStable positionInput/output for user-computer interactionManual control with multiple controlled membersJoystickComputer science

Owner:NINTENDO CO LTD

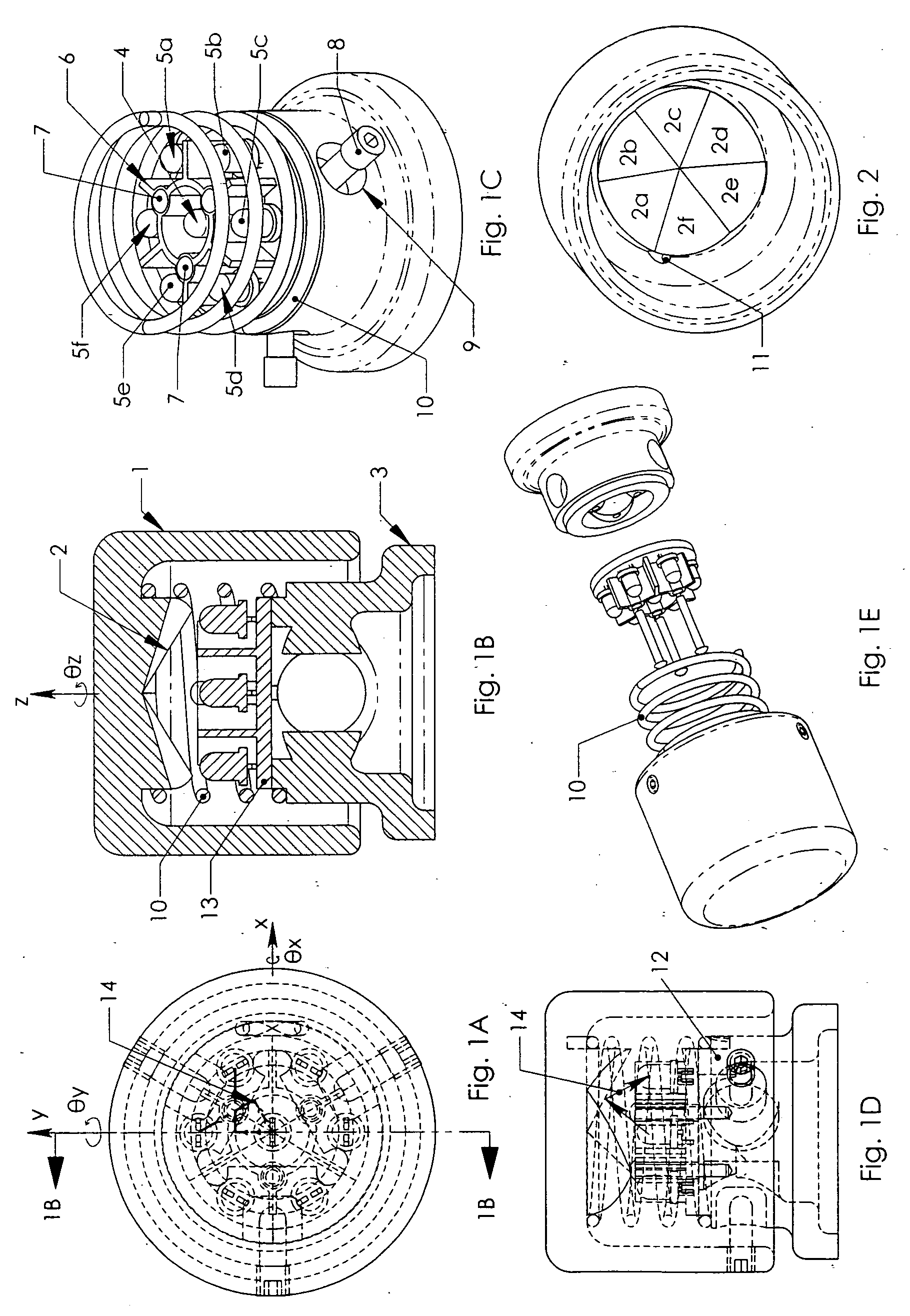

Multi-axis joystick and transducer means therefore

InactiveUS20050162389A1Reduce noiseLow costProgramme controlManual control with multiple controlled membersJoystickTransducer

The invention relates to improved multi-axis joysticks and associated multi-axis optical displacement measurement means. The displacement measuring means may include one or more light emitters and one or more light detectors, preferably mounted in a planar hexagonal array. The relative position of an adjacent movable reflector assembly can be measured in six degrees of freedom by variations in detected light amplitude. Various ergonomic configurations of six axis joystick embodiments which may be facilitated by the compact design of the transducer means are disclosed. Means for dynamically adjusting coordinate transformations for construction machinery control are also disclosed.

Owner:OBERMEYER HENRY K +1

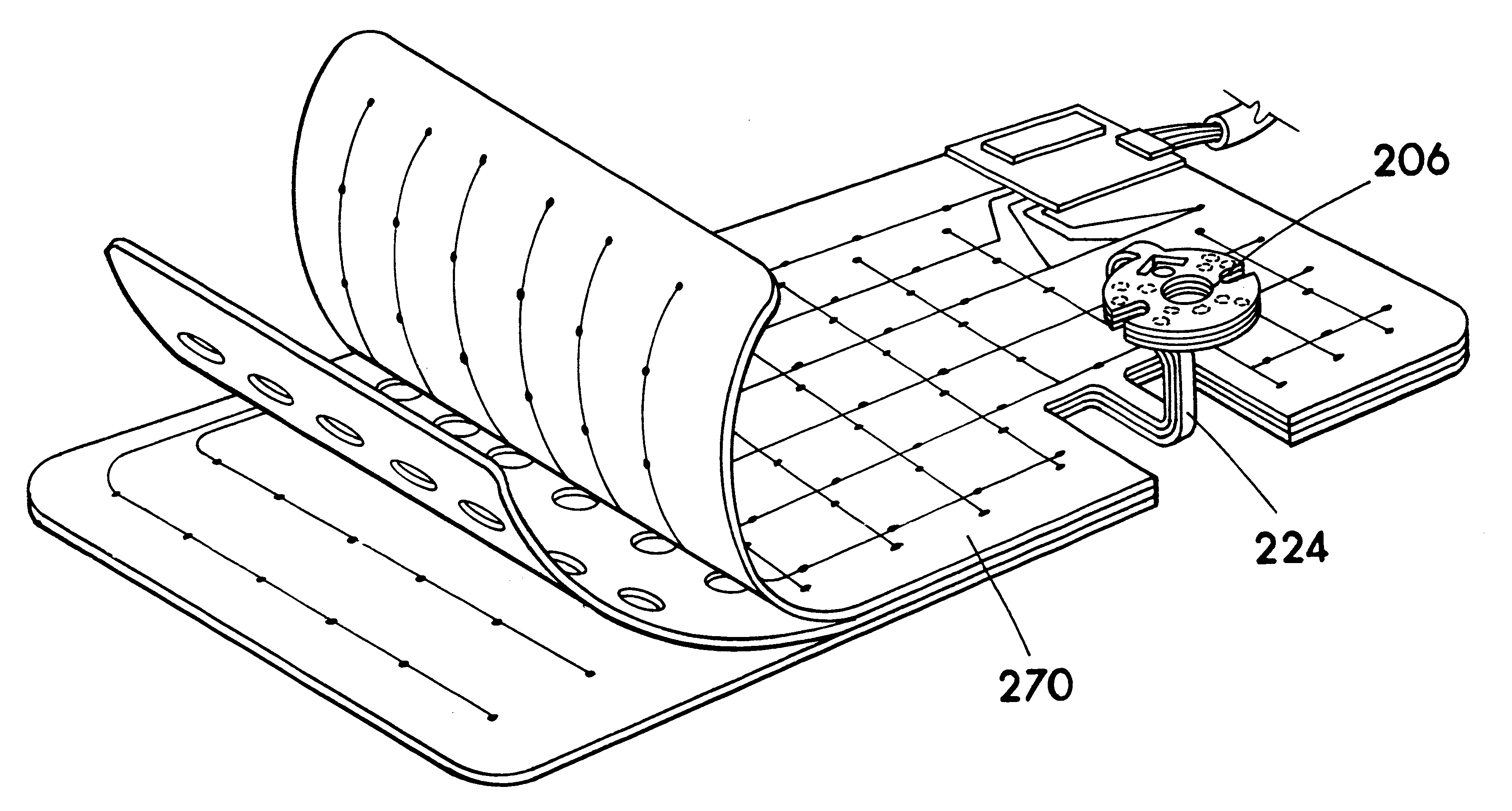

Image controllers with sheet connected sensors

InactiveUS6222525B1Input/output for user-computer interactionManual control with multiple controlled membersJoystickEngineering

A sensor connecting sheet material for inclusion in appropriately structured multiple-axes controllers comprised of a single input member operable in 6 DOF relative to a reference member of the controller. The input member having return-to-center resiliency relative to the reference member on at least the three perpendicular linear axes. The input member can be of a continuously rotatable trackball-type or a limited rotation joystick-type, and the reference member can be a shaft, a base or a housing. The controllers include carriage structuring for influencing sheet connected sensors by hand-applied operation of the input member. The preferred structures provide cooperative interaction with movement or force influenced sensors in primarily a single area. Some, most, or all of the sensors are preferably supported on a generally single plane, such as on a printed flexible membrane sensor sheet or circuit board sheet. In an alternative embodiment, sensors and conductive traces are applied on a generally flat, flexible membrane sensor sheet, which is then bent into a three dimensional configuration which may in some cases reach a widely-spread 3-D constellation of 6 DOF and / or other sensor mountings. The use of sensors connected by a sheet member, whether finally applied in a flat or 3-D configuration, enables efficient circuit and sensor connection and placement during manufacture, resulting in low product costs and high reliability.

Owner:ANASCAPE +1

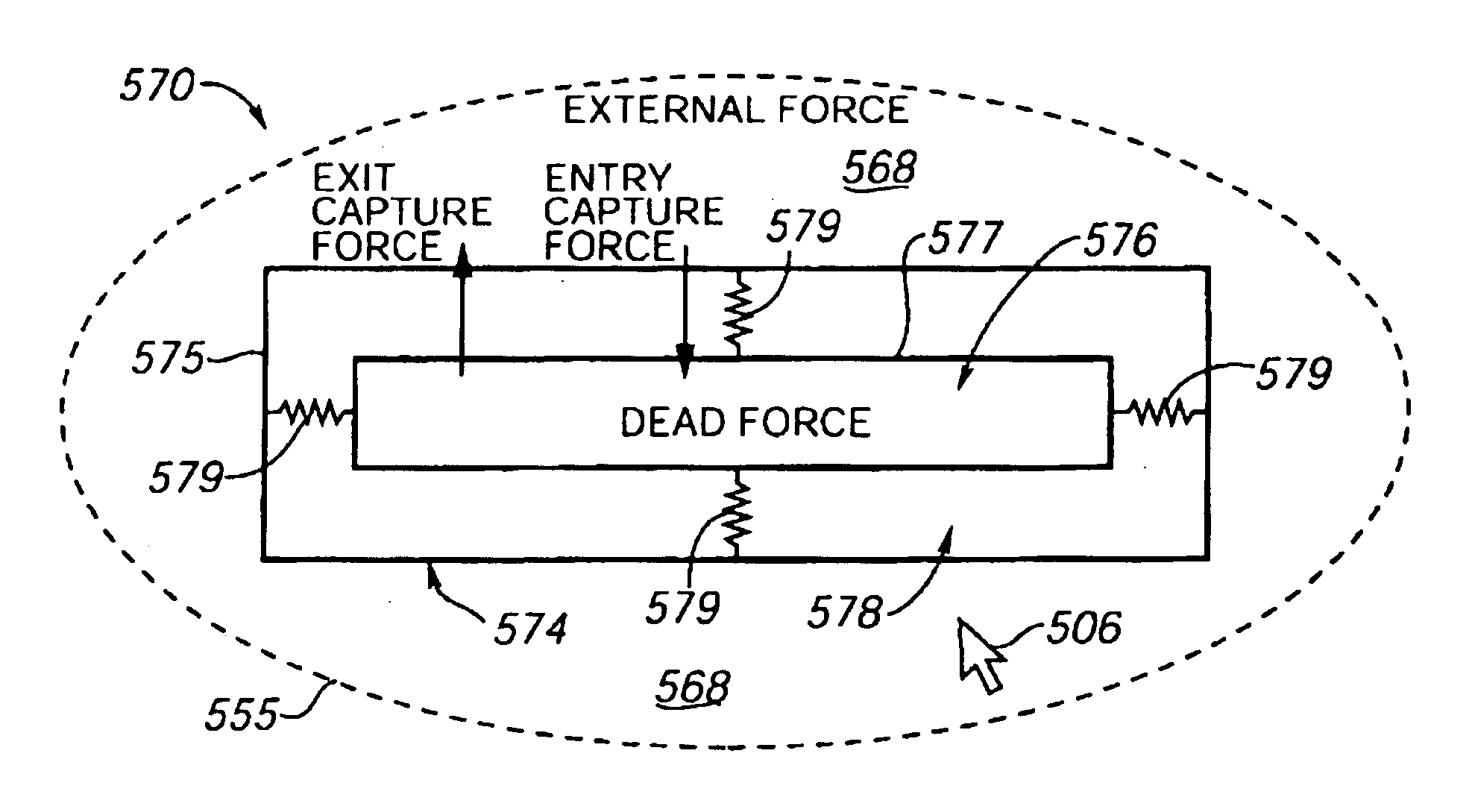

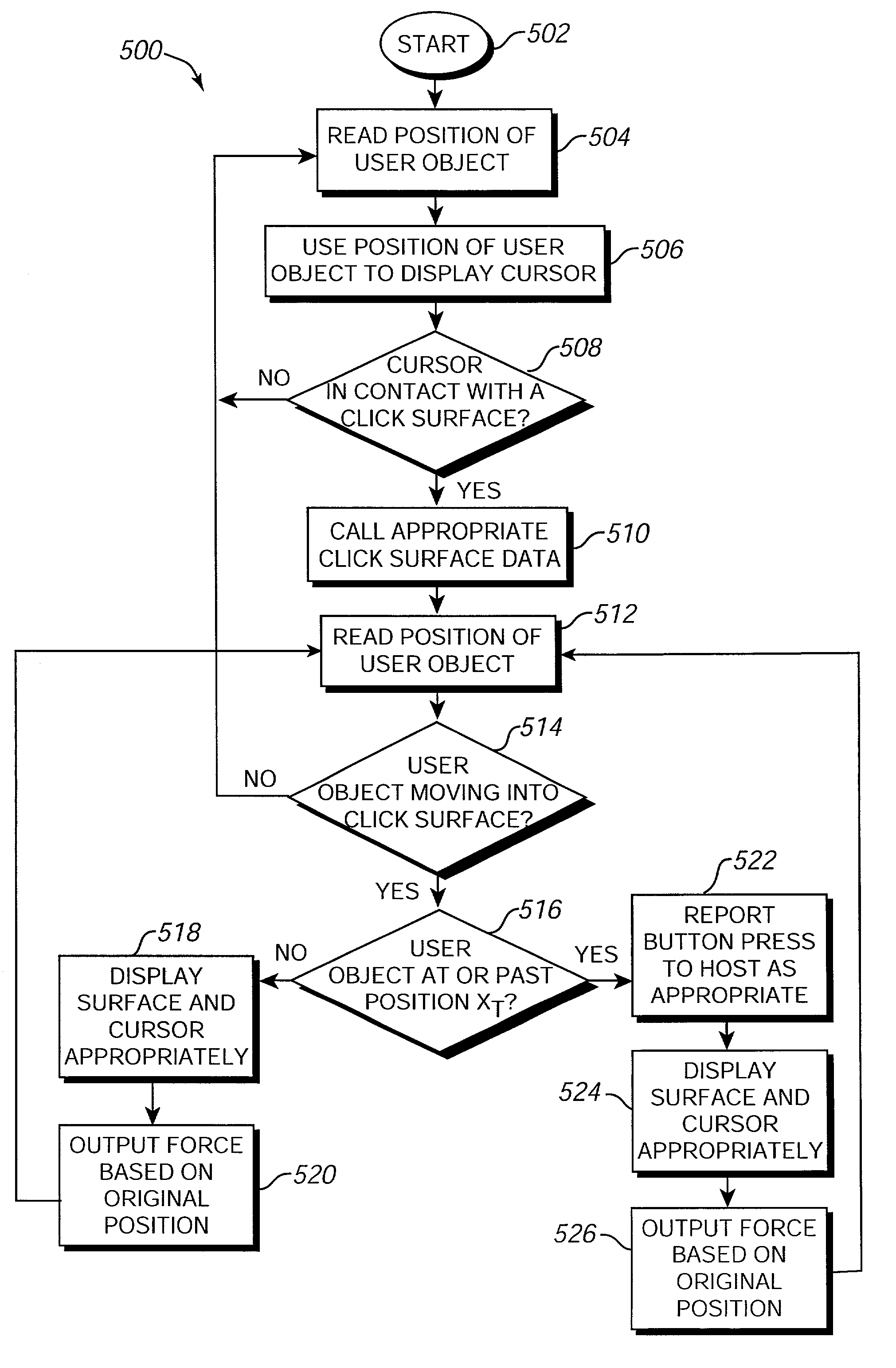

Force feedback applications based on cursor engagement with graphical targets

InactiveUS7131073B2Input/output for user-computer interactionManual control with multiple controlled membersGraphicsGraphical user interface

A method and apparatus for providing a click surface in a graphical environment, such as a graphical user interface, implemented on a host computer for use with a force feedback interface device. A displayed cursor is controlled by a user-moveable user object, such as a mouse, of the interface device. A click surface is displayed with an associated graphical object, such as a graphical button or an edge of a window, icon, or other object. When the click surface is contacted by the cursor, a force is output opposing movement of the user object in a direction into the click surface and into the graphical object. When the user object has moved to or past a trigger position past the contact with the click surface, a command gesture signal is provided to the host computer indicating that the graphical object has been selected as if a physical input device on the user object, such as a button, has been activated by the user. Preferably, the host computer displays the graphical environment including the click surface and cursor, while a microprocessor local to the interface device controls the force output of the click surface in parallel with the host display.

Owner:IMMERSION CORPORATION

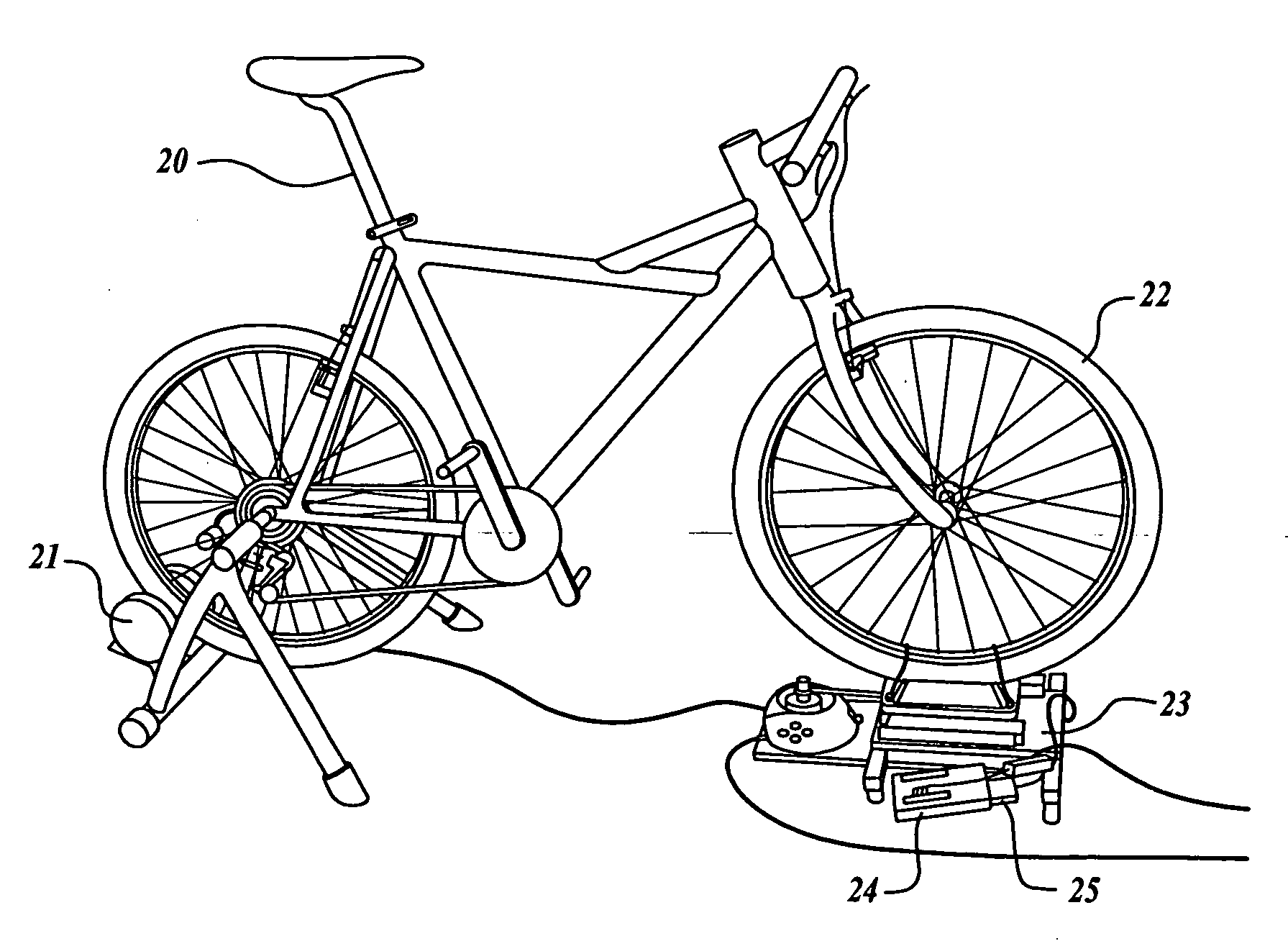

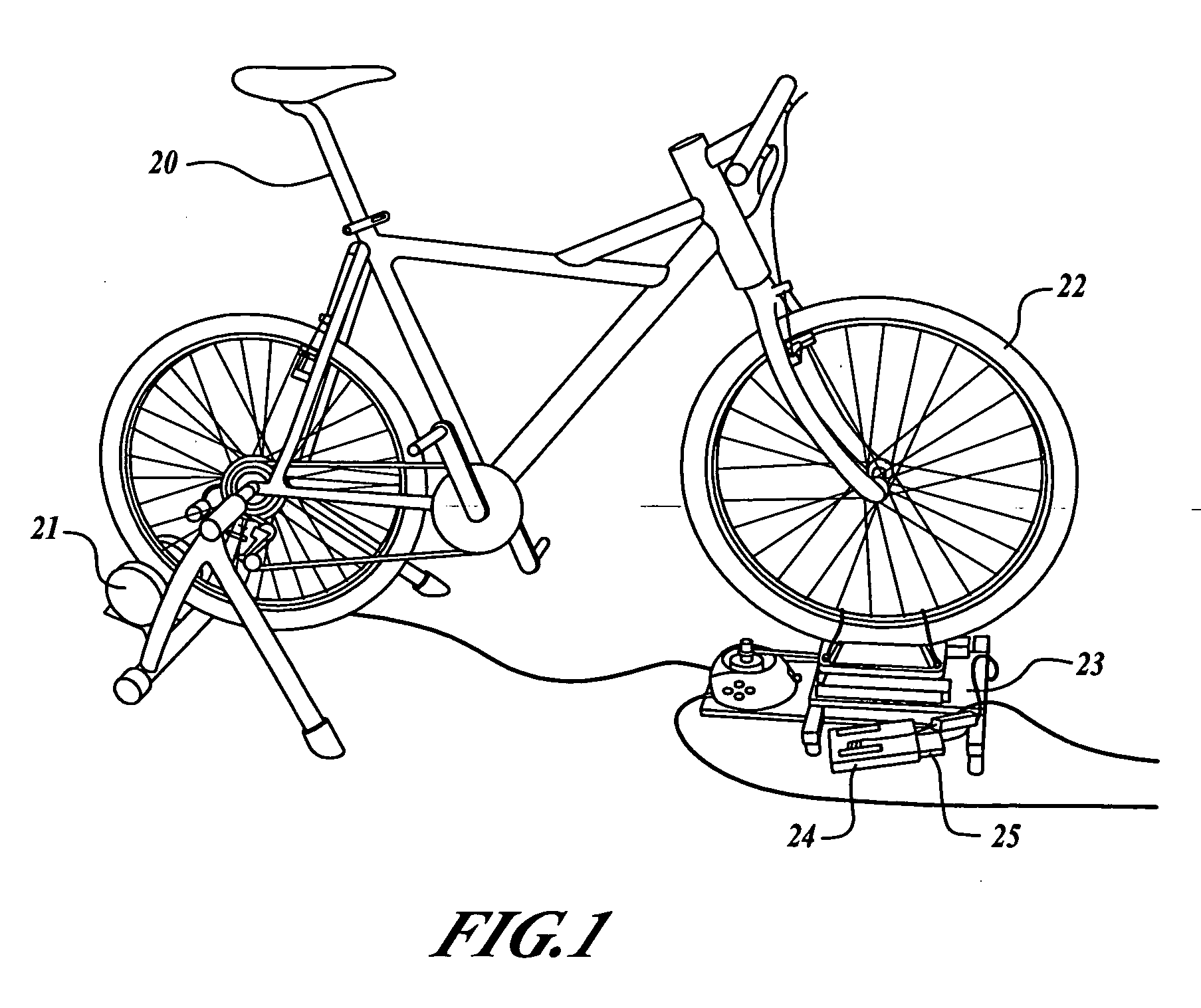

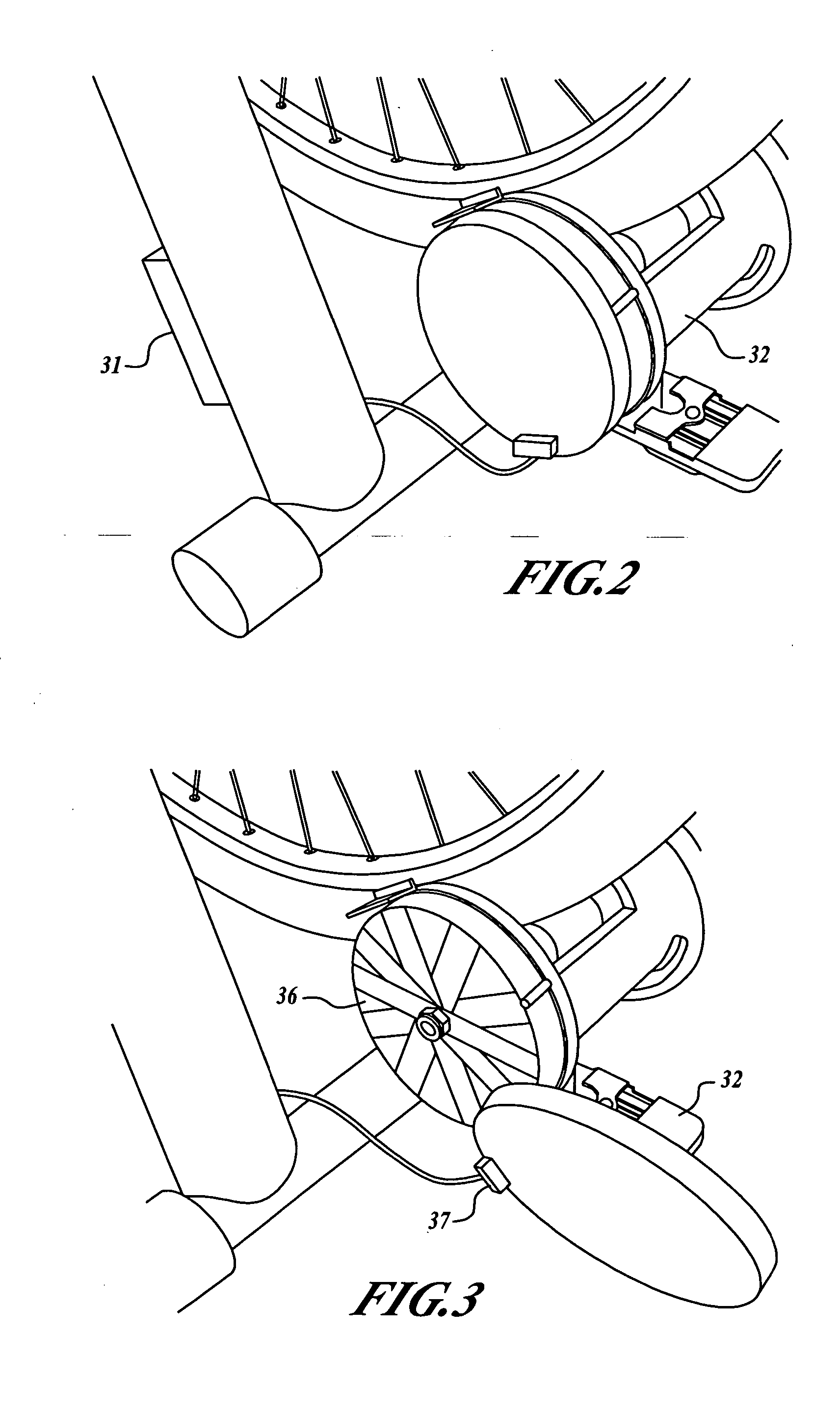

User interactive exercise system

InactiveUS20060229163A1Physical therapies and activitiesManual control with multiple controlled membersInteractive videoGame console

System and method for interactive video game fitness equipment. Fitness hardware (e.g., an exercise bicycle, a stair machine, treadmill, elliptical trainer, rotary climbing wall, or other fitness equipment) interacts with a video game, optionally via various devices, e.g., a PC, gaming console, or other hardware and / or software device or system capable of implementing an interactive application), for an immersive hybrid exercise / game user experience.

Owner:WATERS ROLLAND M

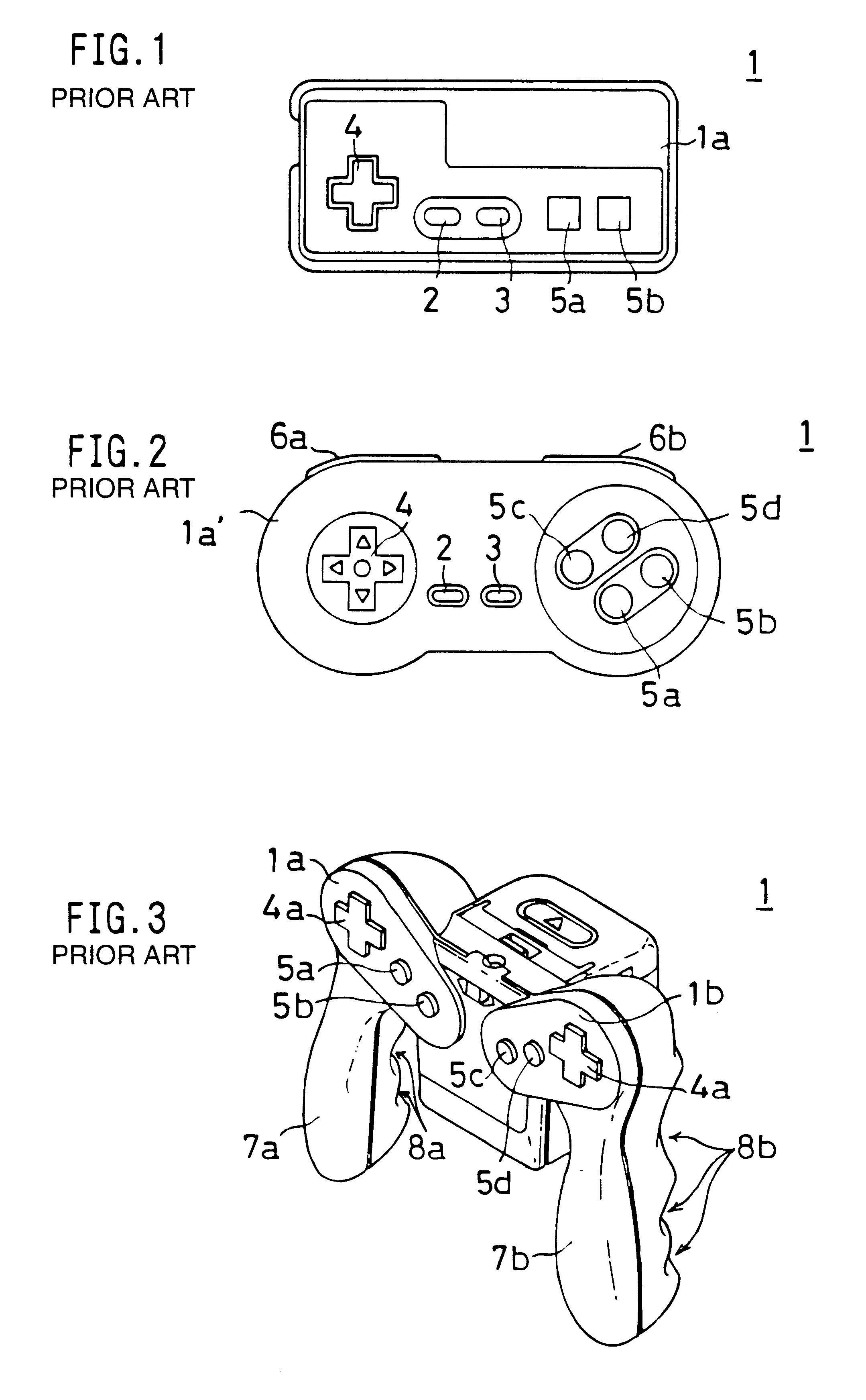

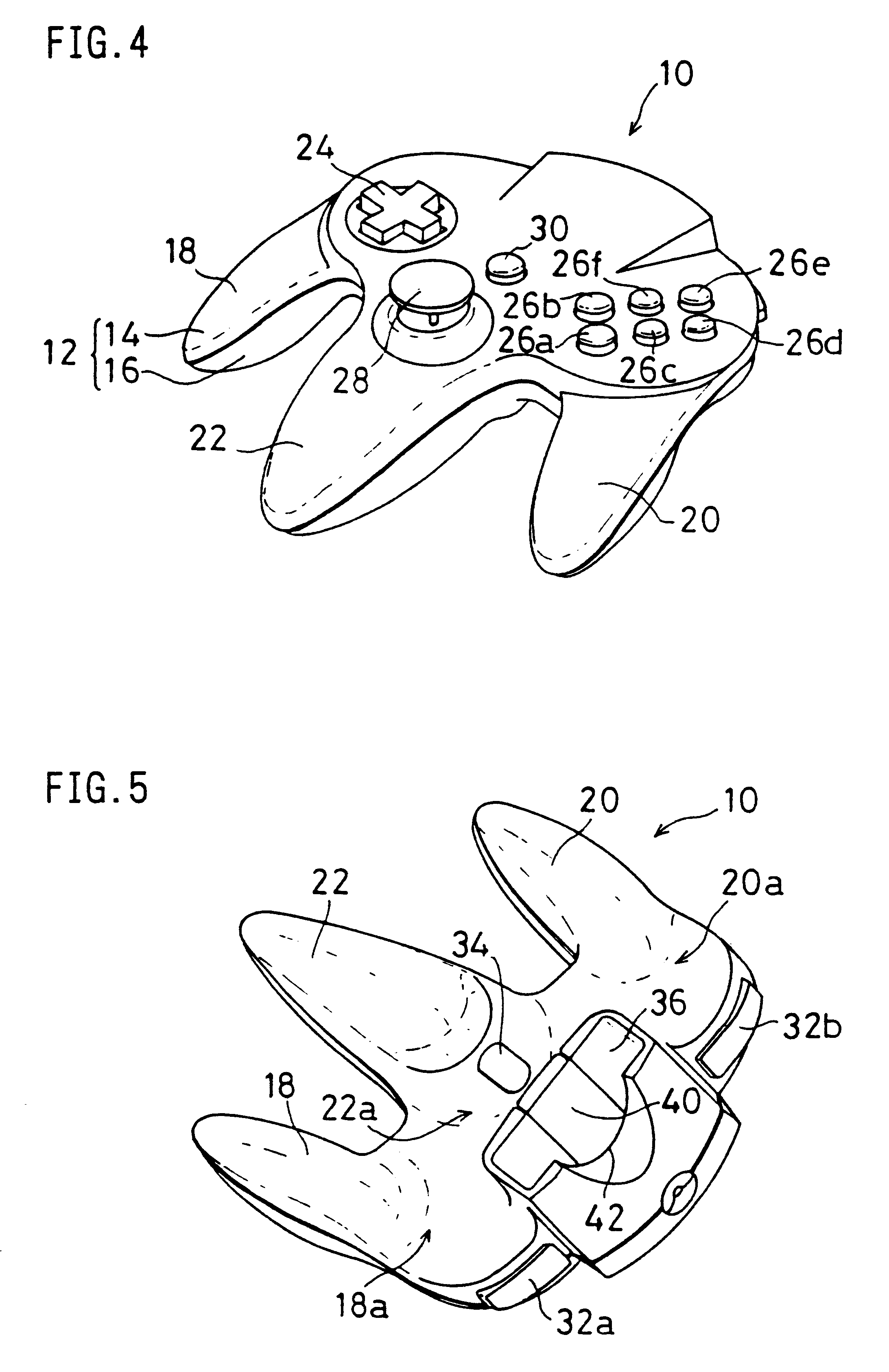

Operating device with analog joystick

InactiveUS6186896B1Easy to set upInput/output for user-computer interactionManual control with multiple controlled membersJoystickEngineering

An operating device is, while in use, connected to an image processor which generates image data of an image to be displayed on a monitor on the basis of a program. The operating device is provided with an analog joystick in addition to a plurality of switches, and outputs operation signals by which the image data can be modified according to an operation by an operator. The analog joystick includes a lever having a tip end which is protruded from a housing and inclined in an arbitrary direction including North, South, East and West. There is provided with a guide ring which includes a guide wall having an octagonal outer edge around the lever, and the guide wall guides the lever to eight corners, that is, upper, lower, left, right, rightupper, right-lower, left-upper and left-lower corners.

Owner:NINTENDO CO LTD

Interactions between simulated objects with force feedback

InactiveUS7158112B2More experienceInput/output for user-computer interactionManual control with multiple controlled membersHuman–computer interactionComputer generation

A method and apparatus for providing force feedback to a user operating a human / computer interface device and interacting with a computer-generated simulation. In one aspect, a computer-implemented method simulates the interaction of simulated objects displayed to a user who controls one of the simulated objects manipulating a physical object of an interface device. The position of the simulated object, as provided within the simulation and as displayed, is mapped to the physical position of the user object. This mapping can be broken under conditions that are effective to provide force feedback to the user which imparts a physical sensation corresponding to the interaction of the simulated objects.

Owner:IMMERSION CORPORATION

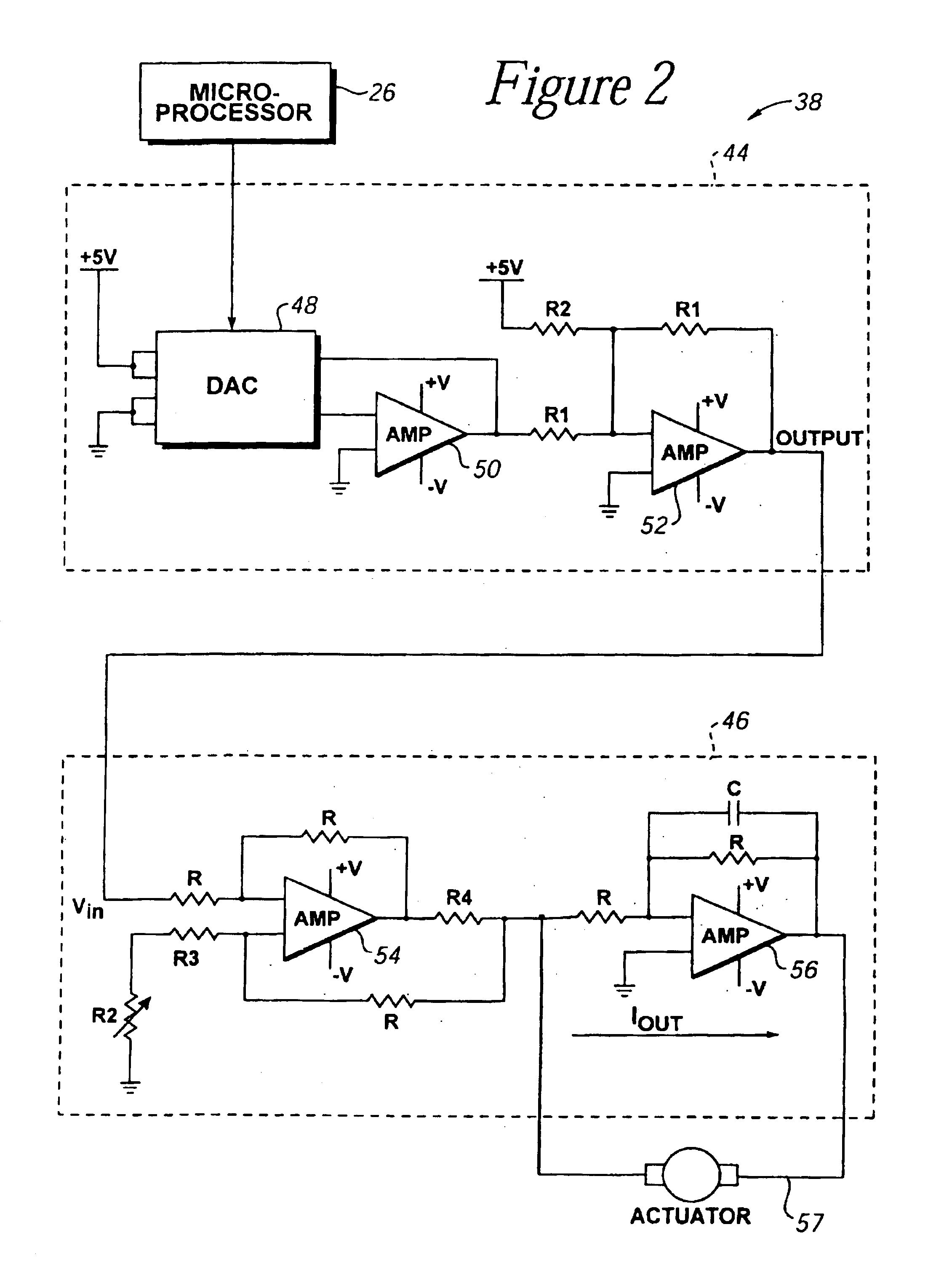

Method for providing high bandwidth force feedback with improved actuator feel

InactiveUS7236157B2Improve realismEliminate the effects ofInput/output for user-computer interactionManual control with multiple controlled membersHigh bandwidthJoystick

A method and apparatus for providing low-cost, realistic force feedback including an improved actuator. The invention provides force sensations to a user and includes an interface device coupled to a host computer and allowing a user to interact with a host application program. A user object, such as a joystick, is moveable by a user in at least one rotary degree of freedom. A sensor reports a locative signal to the host computer to indicate a position of the user object. An actuator outputs forces on the user object in response to signals from the host computer and program. The actuator includes a housing, a set of grounded magnets provided on opposing surfaces of the housing and creating a magnetic field, and a rotor coupled to the user object positioned between the magnets. The rotor rotates about an axis of rotation and includes a shaft and teeth spaced around the shaft. An electric current flows through one or more coils on the teeth to cause the rotor to rotate. The teeth and the magnets are provided in a skewed, helical arrangement relative to each other so that, as the rotor rotates, a first tooth gradually exits the magnetic field as the next consecutive tooth gradually enters the magnetic field, thereby significantly reducing a cogging effect of the rotor when the user object is moved by the user and increasing the fidelity of forces experienced by the user.

Owner:IMMERSION CORPORATION

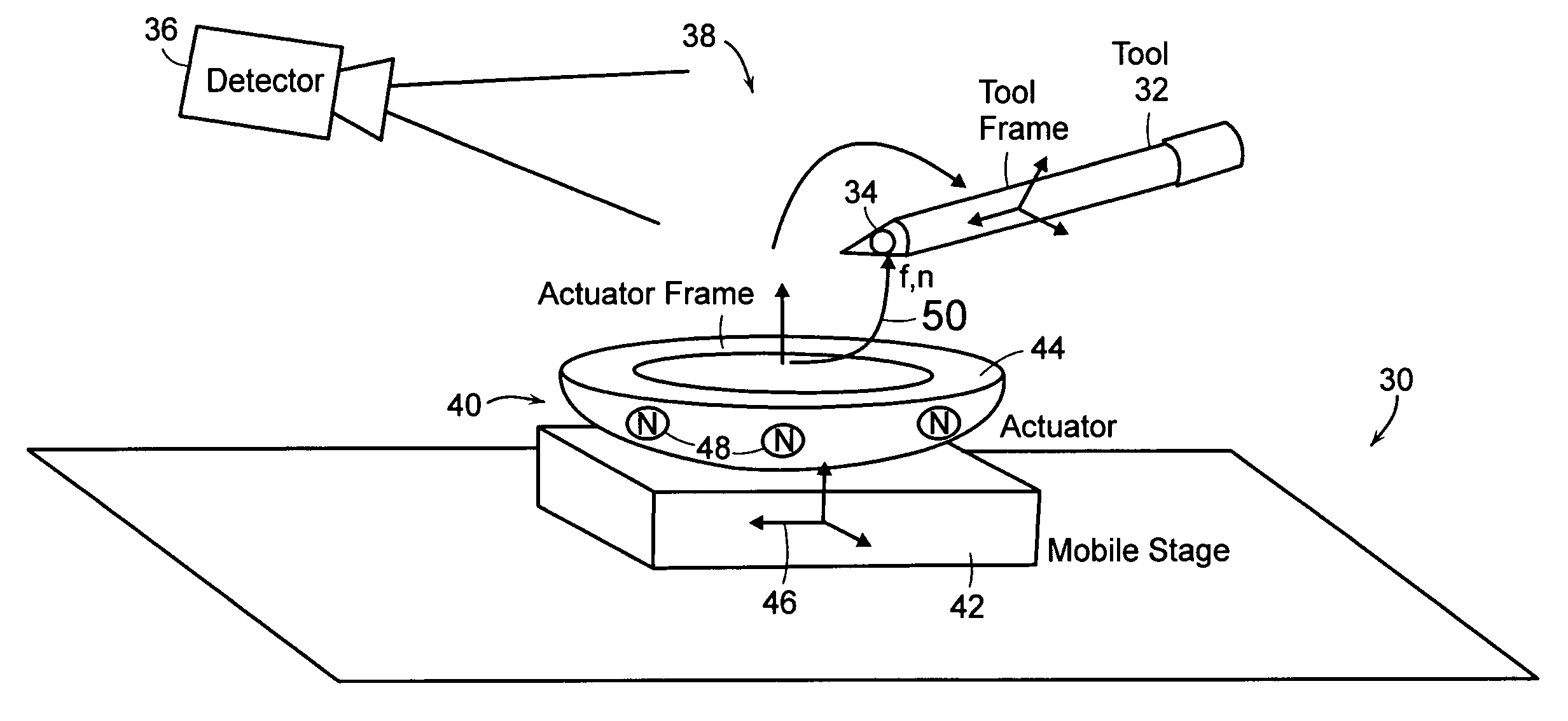

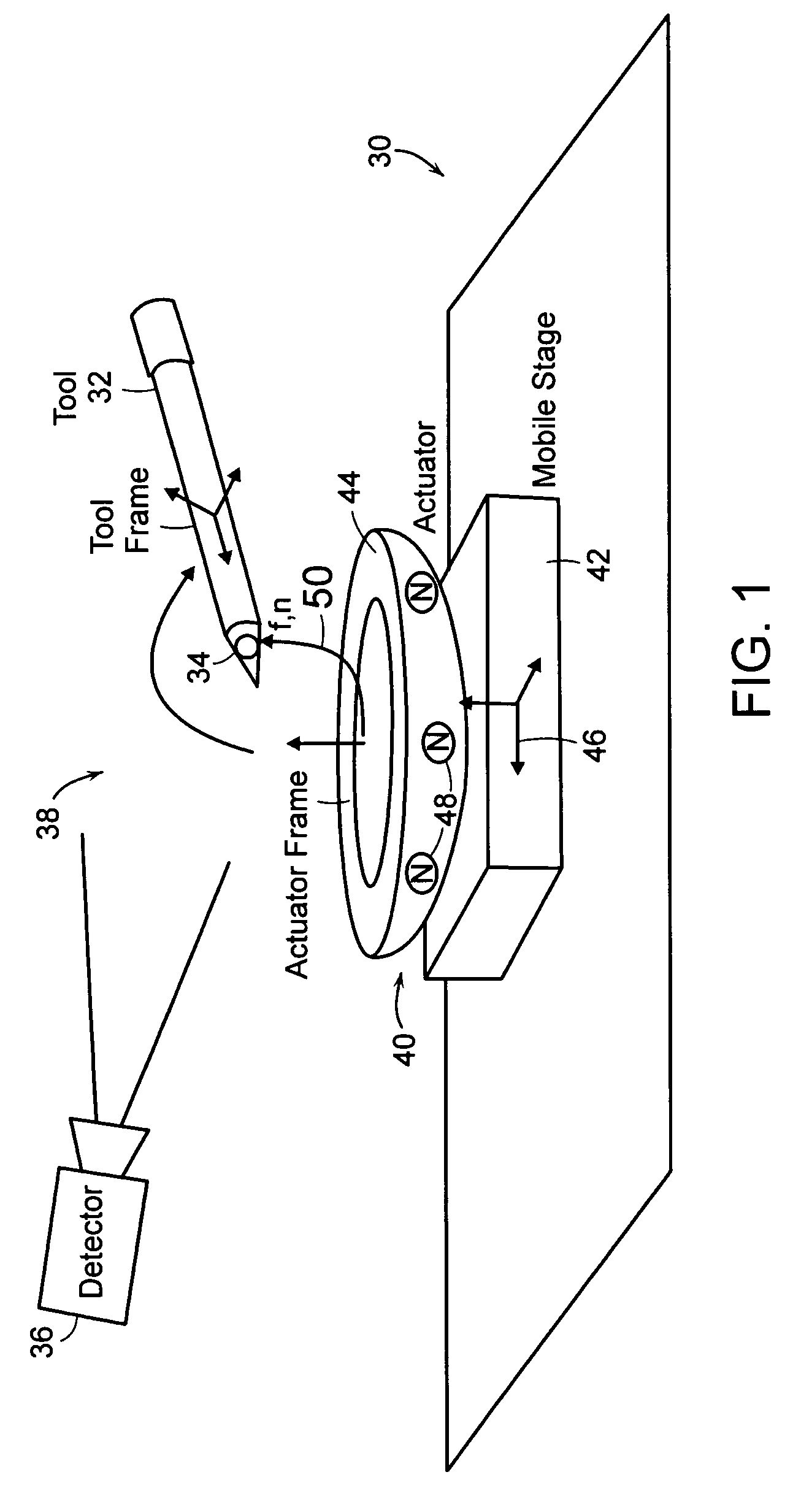

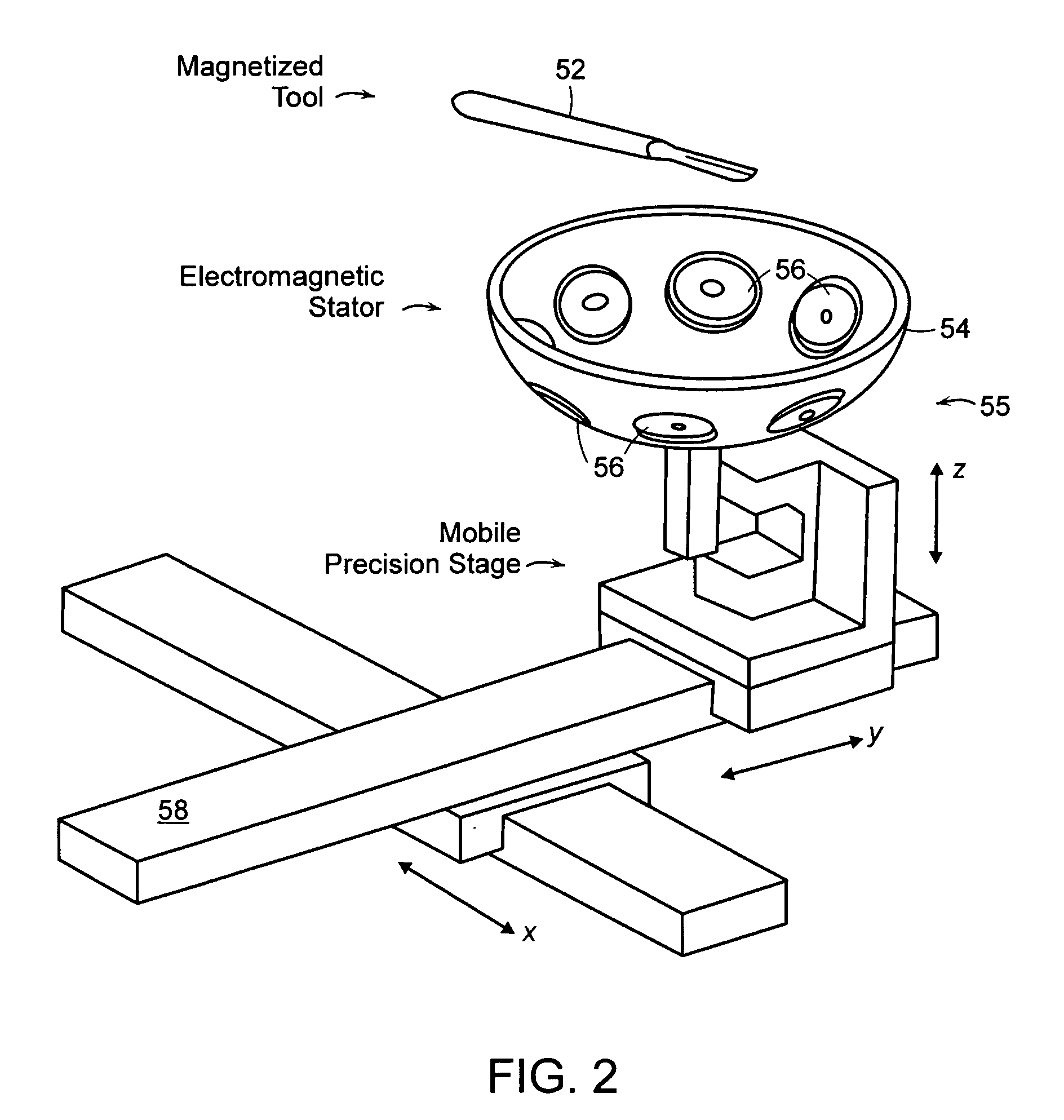

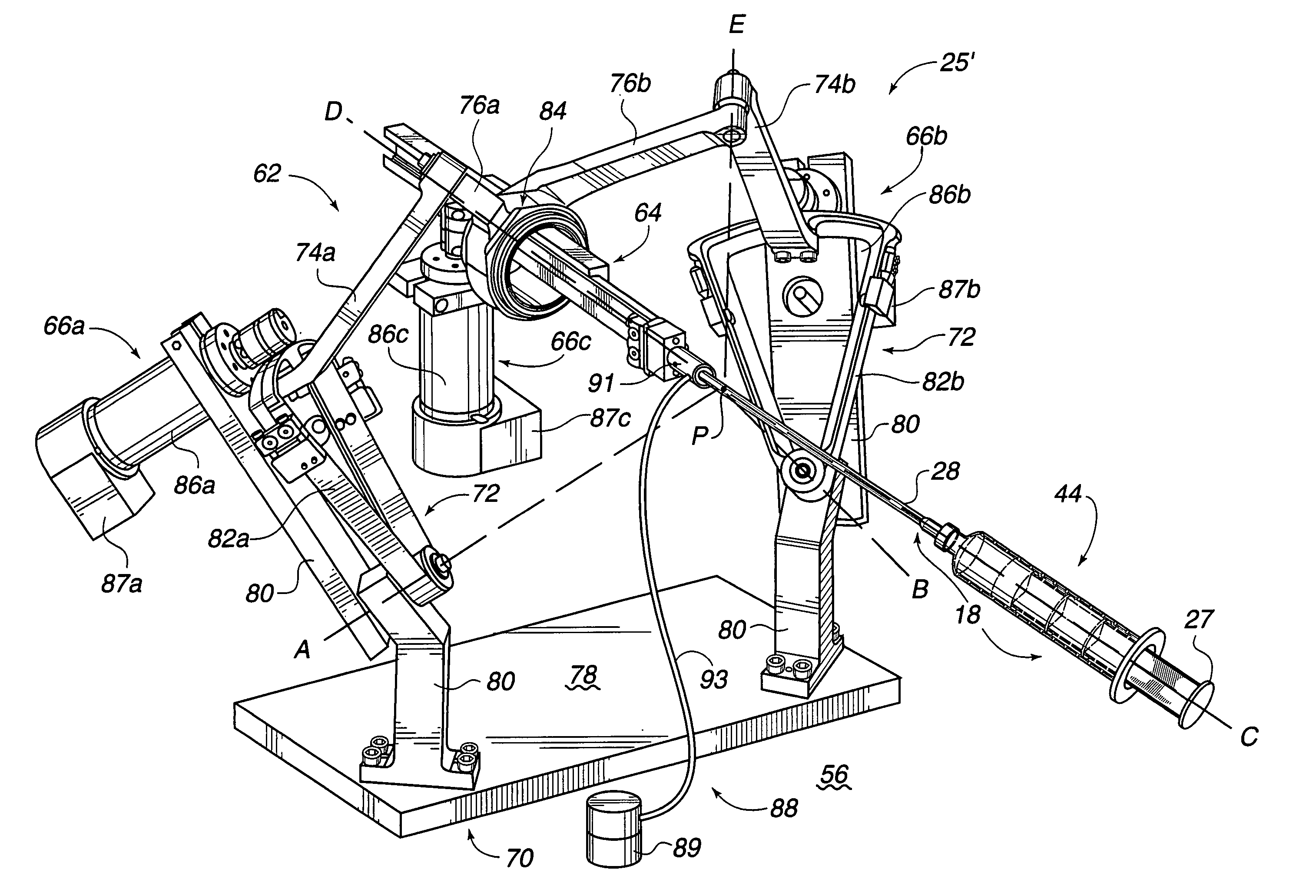

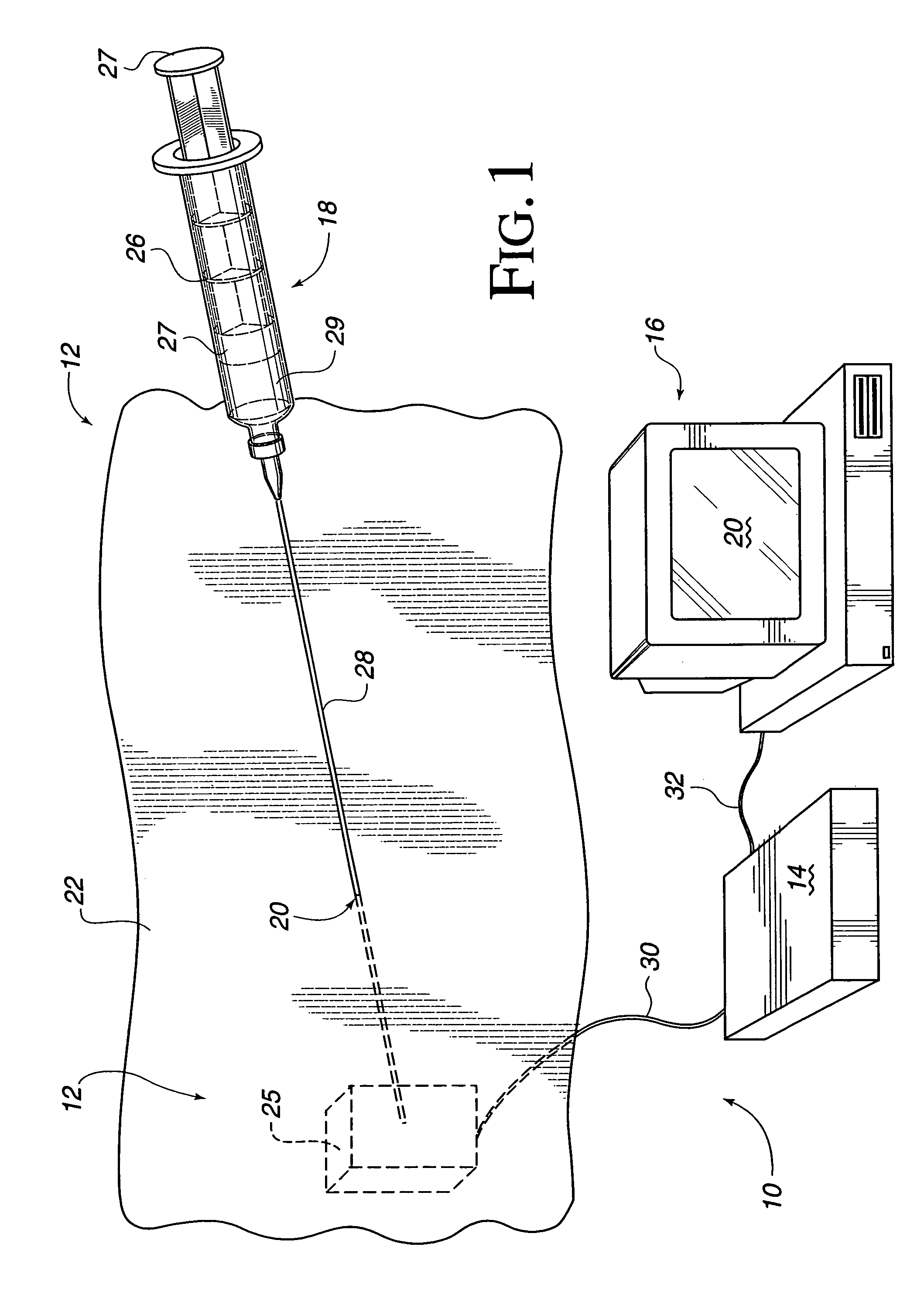

Magnetic haptic feedback systems and methods for virtual reality environments

InactiveUS20060209019A1Improve performanceGreat realismManual control with multiple controlled membersCathode-ray tube indicatorsMagnetic tension forceControl signal

A haptic feedback system comprises a moveable device with at least three degrees of freedom in an operating space. A display device is operative to present a dynamic virtual environment. A controller is operative to generate display signals to the display device for presentation of a dynamic virtual environment corresponding to the operating space, including an icon corresponding to the position of the moveable device in the virtual environment. An actuator of the haptic feedback system comprises a stator having an array of independently controllable electromagnet coils. By selectively energizing at least a subset of the electromagnetic coils, the stator generates a net magnetic force on the moveable device in the operating space. In certain exemplary embodiments the actuator has a controllably moveable stage positioning the stator in response to movement of the moveable device, resulting in a larger operating area. A detector of the system, optionally multiple sensors of different types, is operative to detect at least the position of the moveable device in the operating space and to generate corresponding detection signals to the controller. The controller receives and processes detection signals from the detection sensor and generates corresponding control signals to the actuator to control the net magnetic force on the moveable device.

Owner:ENERGID TECHNOLOGIES

Method and apparatus for providing an interface mechanism for a computer simulation

InactiveUS7249951B2Highly realistic feedbackHighly realistic motionManual control with multiple controlled membersDiagnosticsHigh bandwidthComputerized system

Owner:IMMERSION CORPORATION

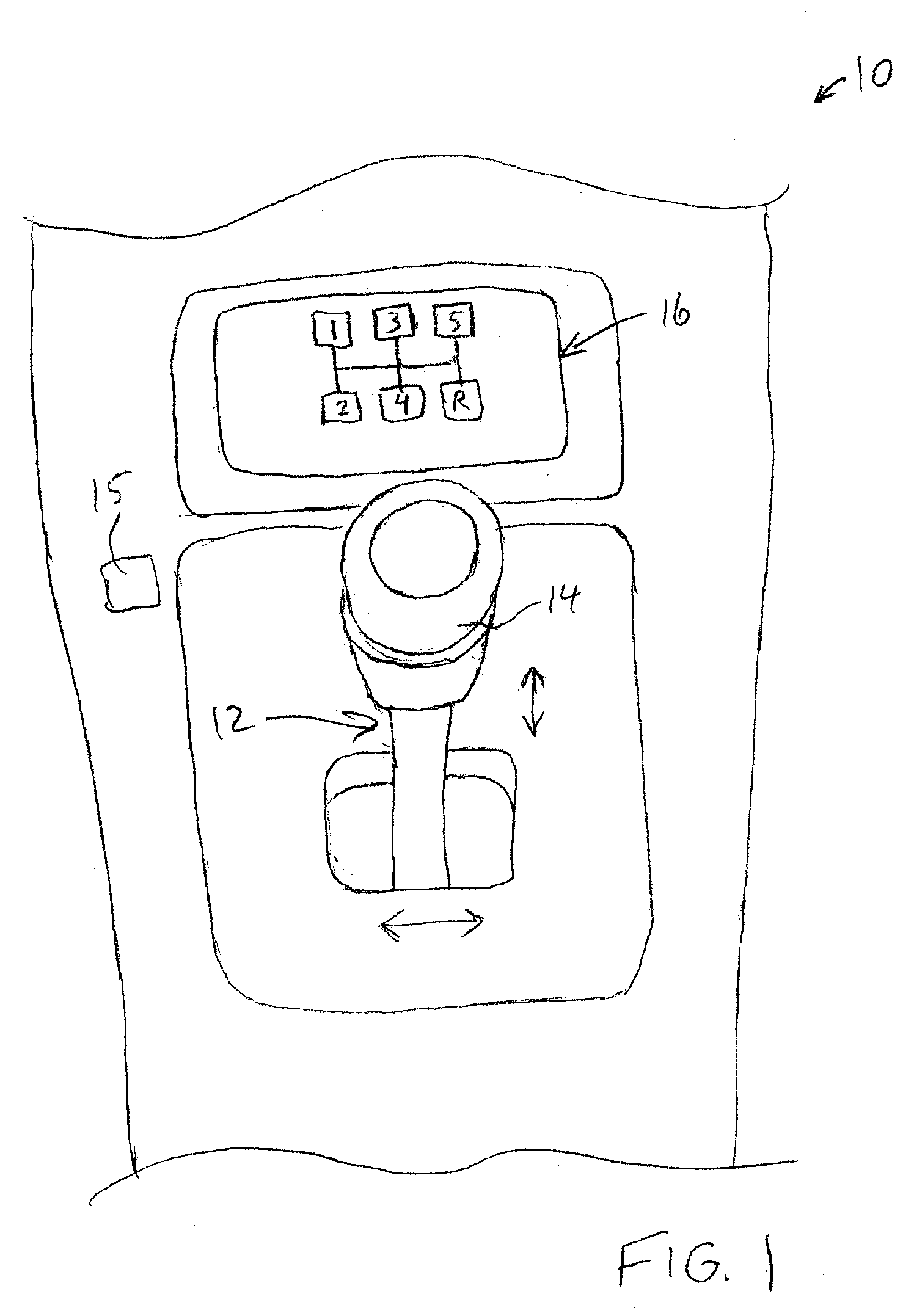

Haptic shifting devices

InactiveUS6904823B2Control operationsControl selectionManual control with multiple controlled membersGearing controlIn vehicleEngineering

A haptic shift device for use in shift-by-wire systems in vehicles. The haptic shift device includes a shift lever manipulatable by a user. At least one sensor detects a position of the shift lever, and a transmission gear of the vehicle is caused to be changed based on the position of the shift lever. At least one electrically-controlled actuator outputs a force on the shift lever. In some embodiments, the shift lever is moveable within a pattern and is blocked from areas outside the boundaries of the pattern. The actuator(s) can be active or passive, and / or a variable mechanical gate can be used to implement the pattern. Provided shifting modes can include automatic, manual, and / or sequential modes. Other shifting modes can also be provided.

Owner:IMMERSION CORPORATION

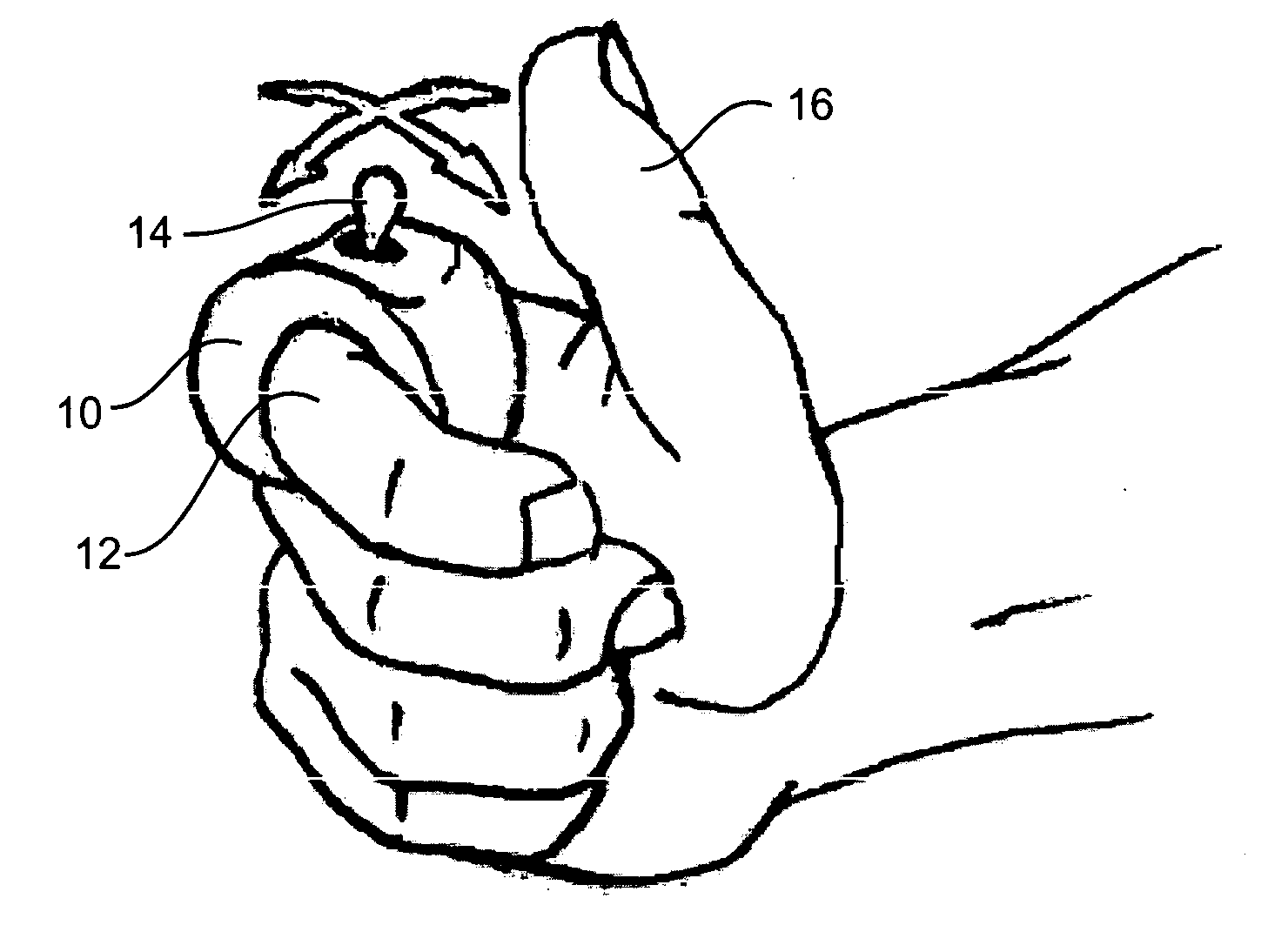

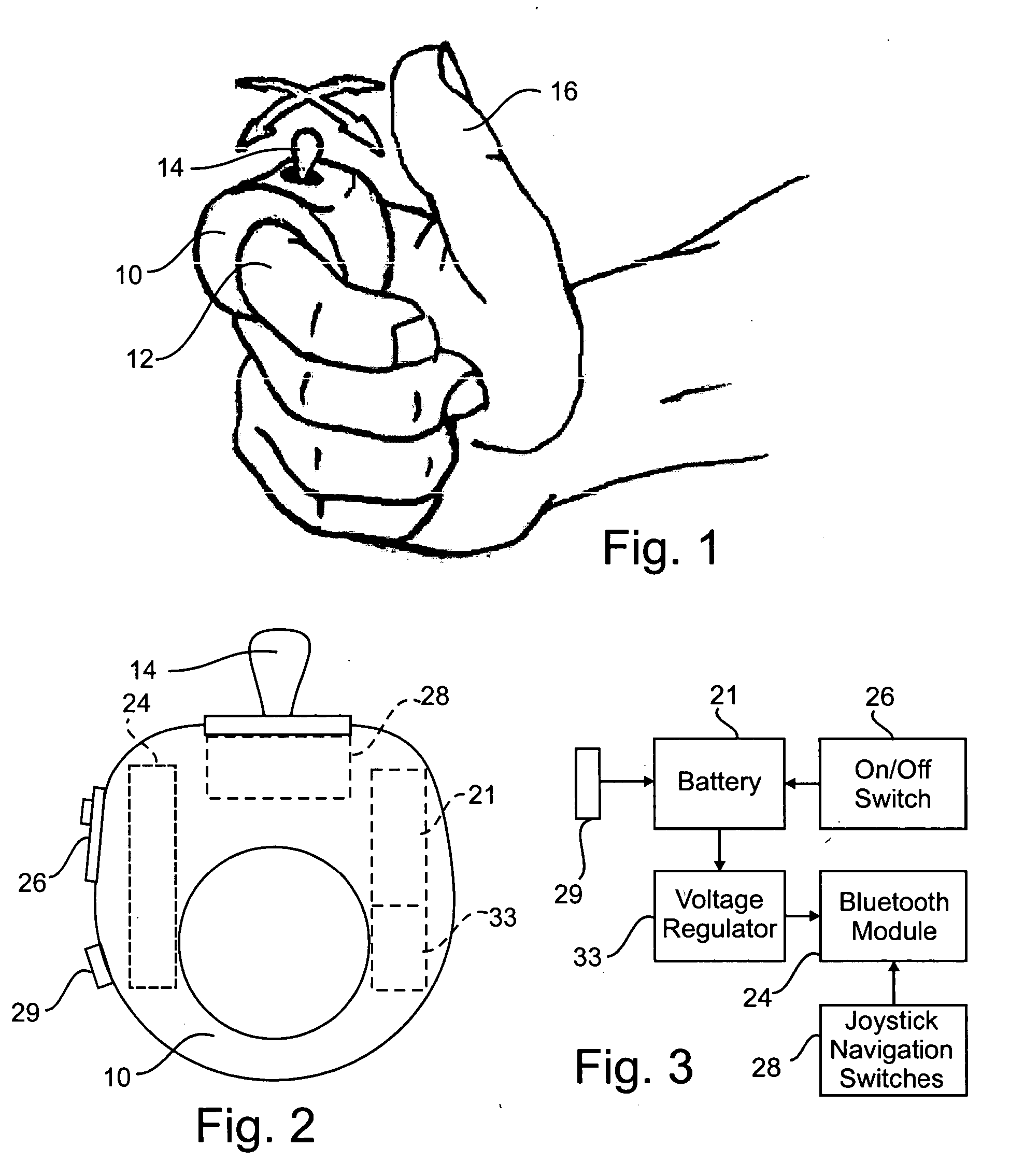

Remote controller ring for user interaction

InactiveUS20060164383A1Minimize disruptionManual control with multiple controlled membersCathode-ray tube indicatorsJoystickControl signal

A hand-worn controller consisting of a housing having a central opening sized to permit the controller to be worn as ring on the index finger of a human hand. A joystick lever projects outwardly from said housing and is positioned to be manipulated by the user's thumb. The joystick operates on or more control devices, such as switches or potentiometers, that produce control signals. A wireless communications device, such as a Bluetooth module, mounted in said housing transmits command signals to a remote utilization device which are indicative of the motion or position of said joystick lever.

Owner:MARSHMAN RES +1

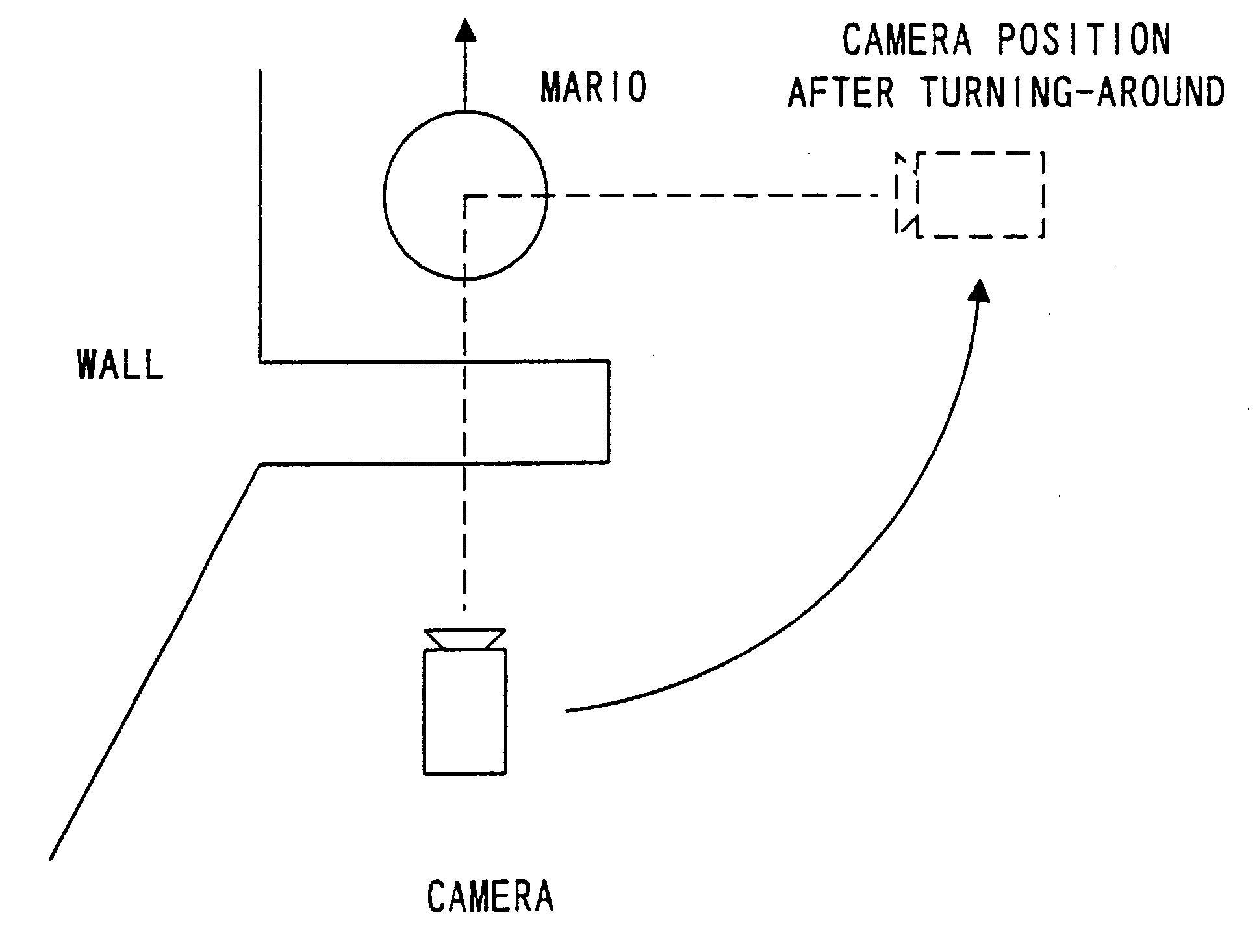

Three-dimensional image processing apparatus

InactiveUS6421056B1Input/output for user-computer interactionImage enhancementImaging processingThree-dimensional space

A three-dimension image processing apparatus includes a CPU. When the CPU detects by collision determination that another object, e.g., a wall, is existent between an operable object and a camera, it calculates such a moving angle of the camera that an eye of the camera to the operable object is not obstructed by the other object. The camera is moved in accordance with the moving angle to a position where the operable object and the other object existing in a photographed three-dimensional space are displayed on a display.

Owner:NINTENDO CO LTD

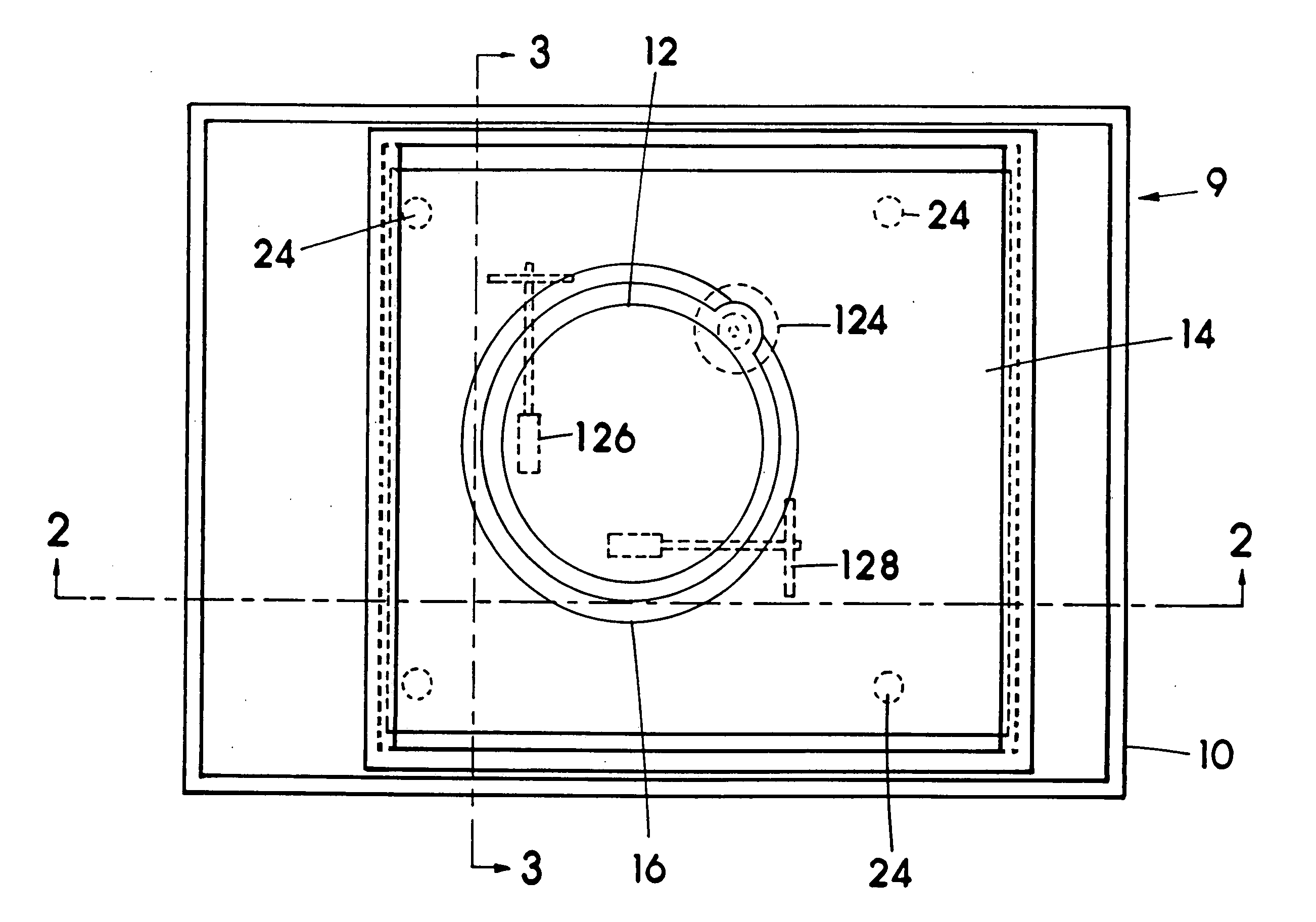

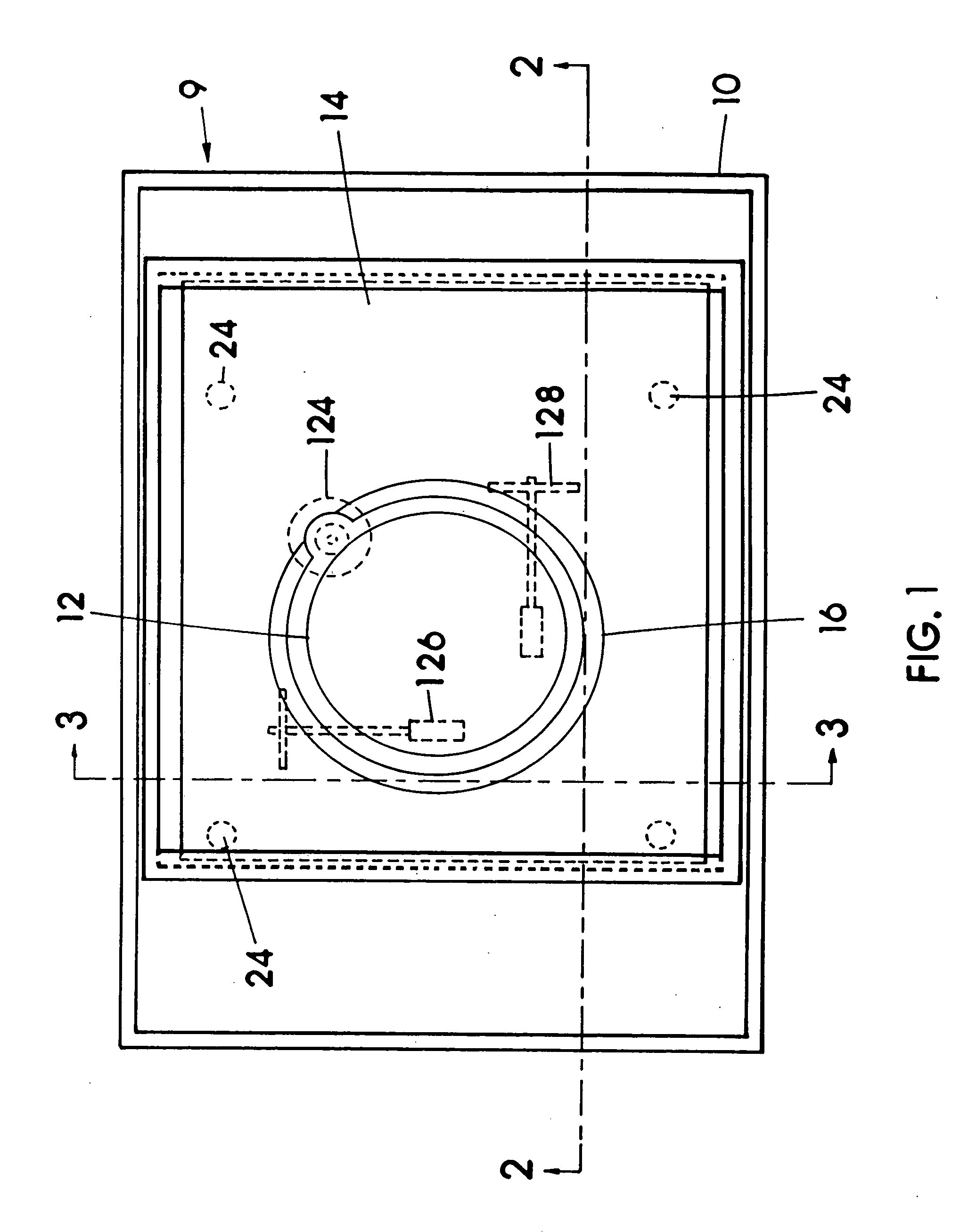

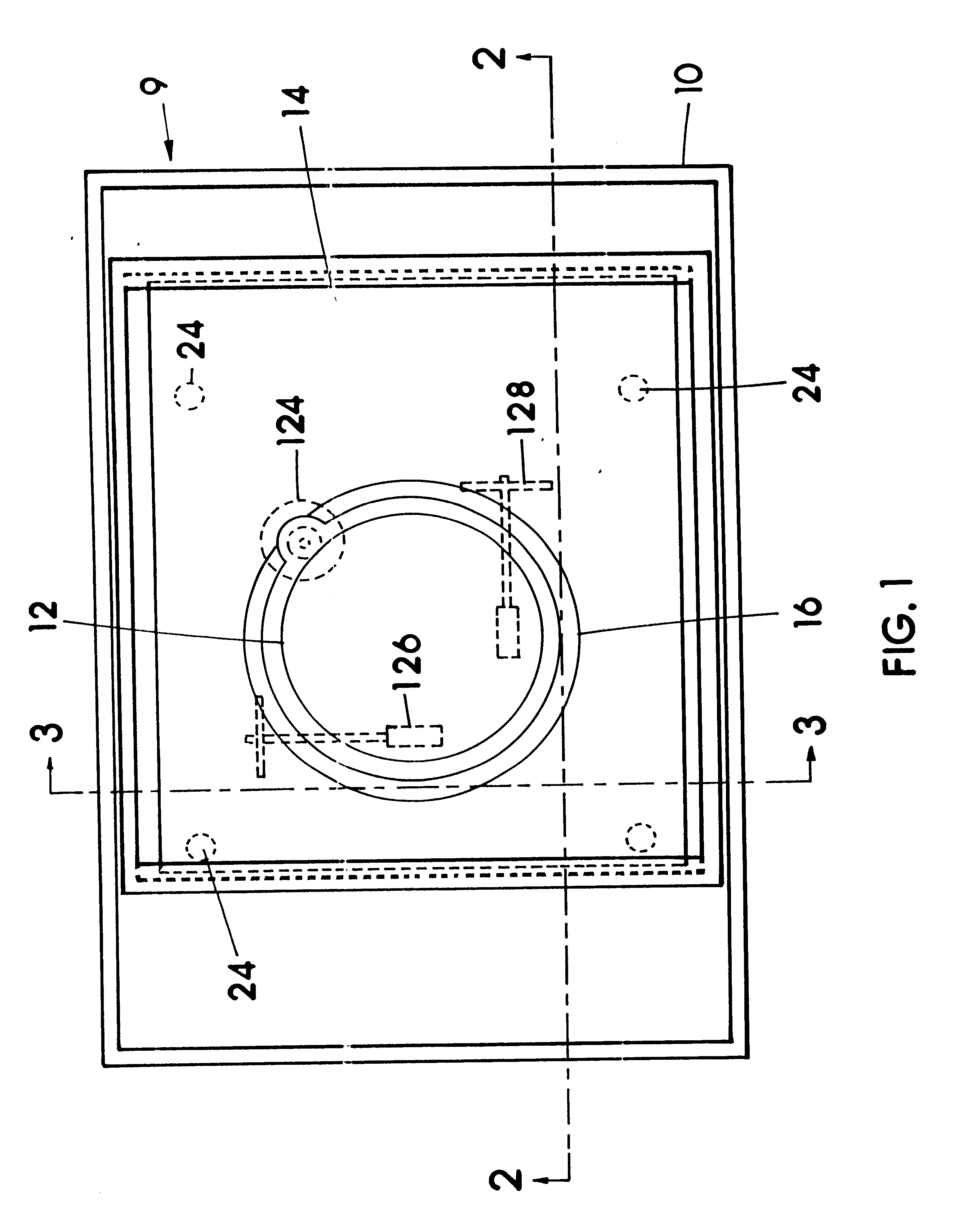

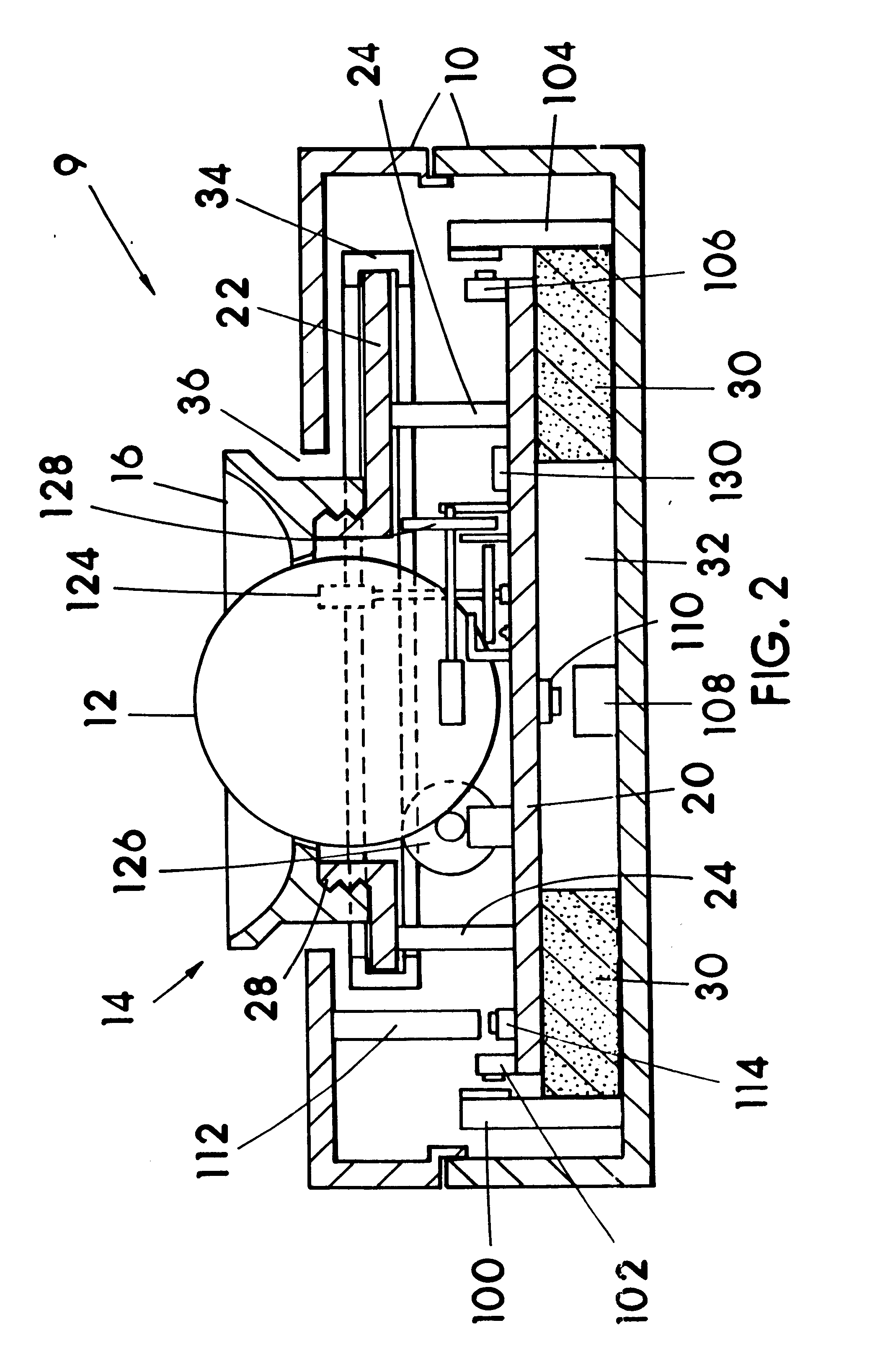

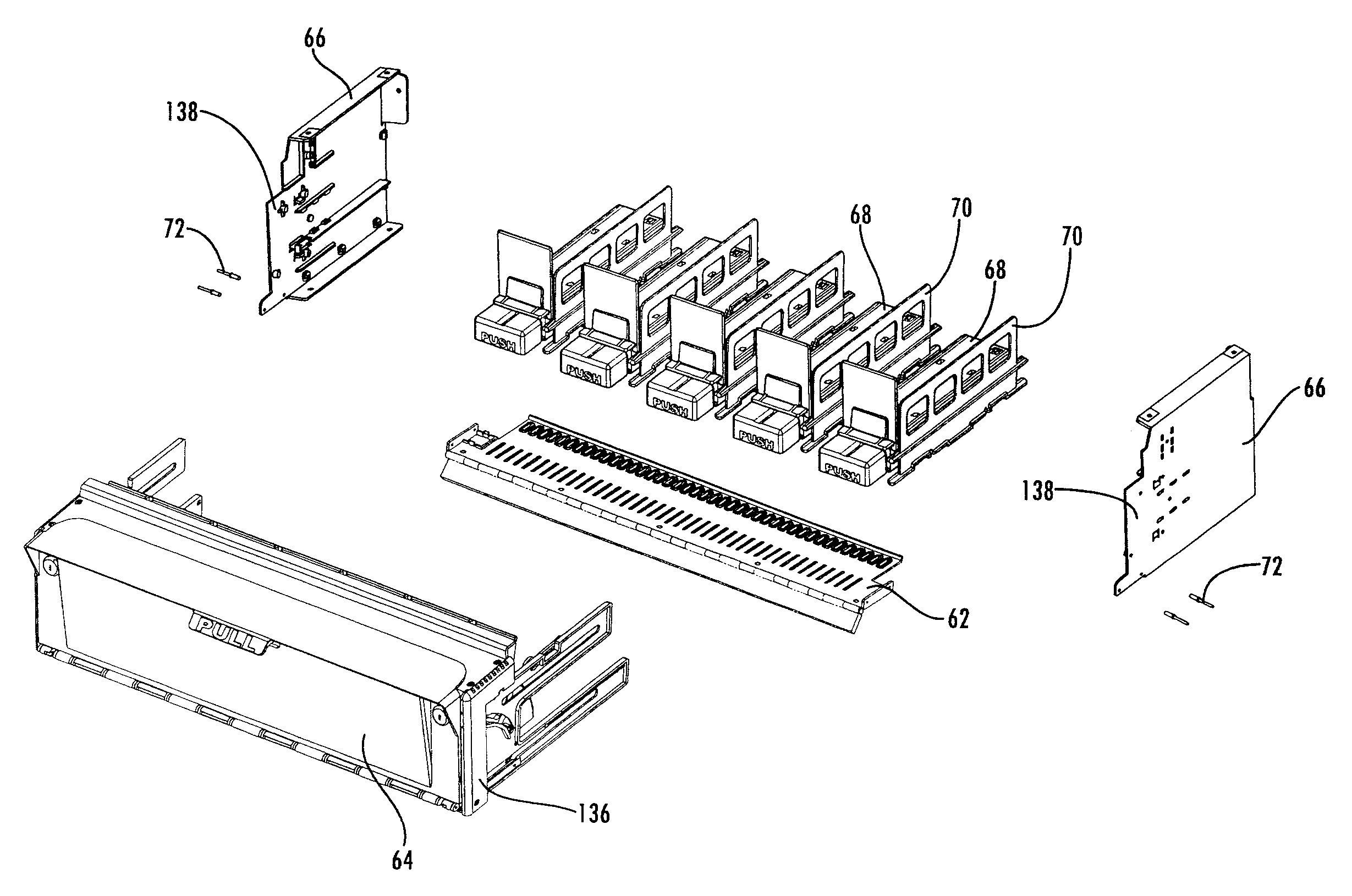

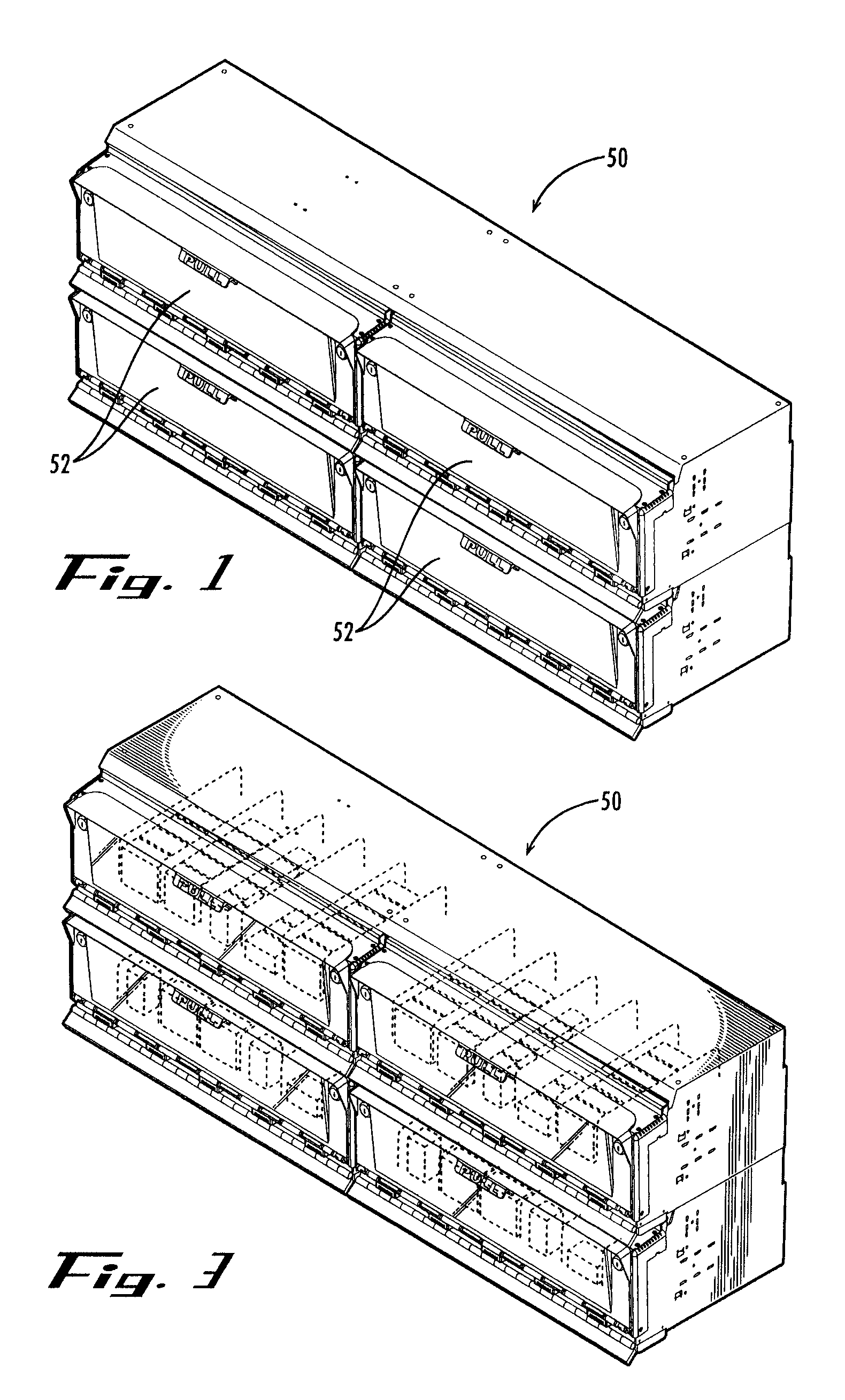

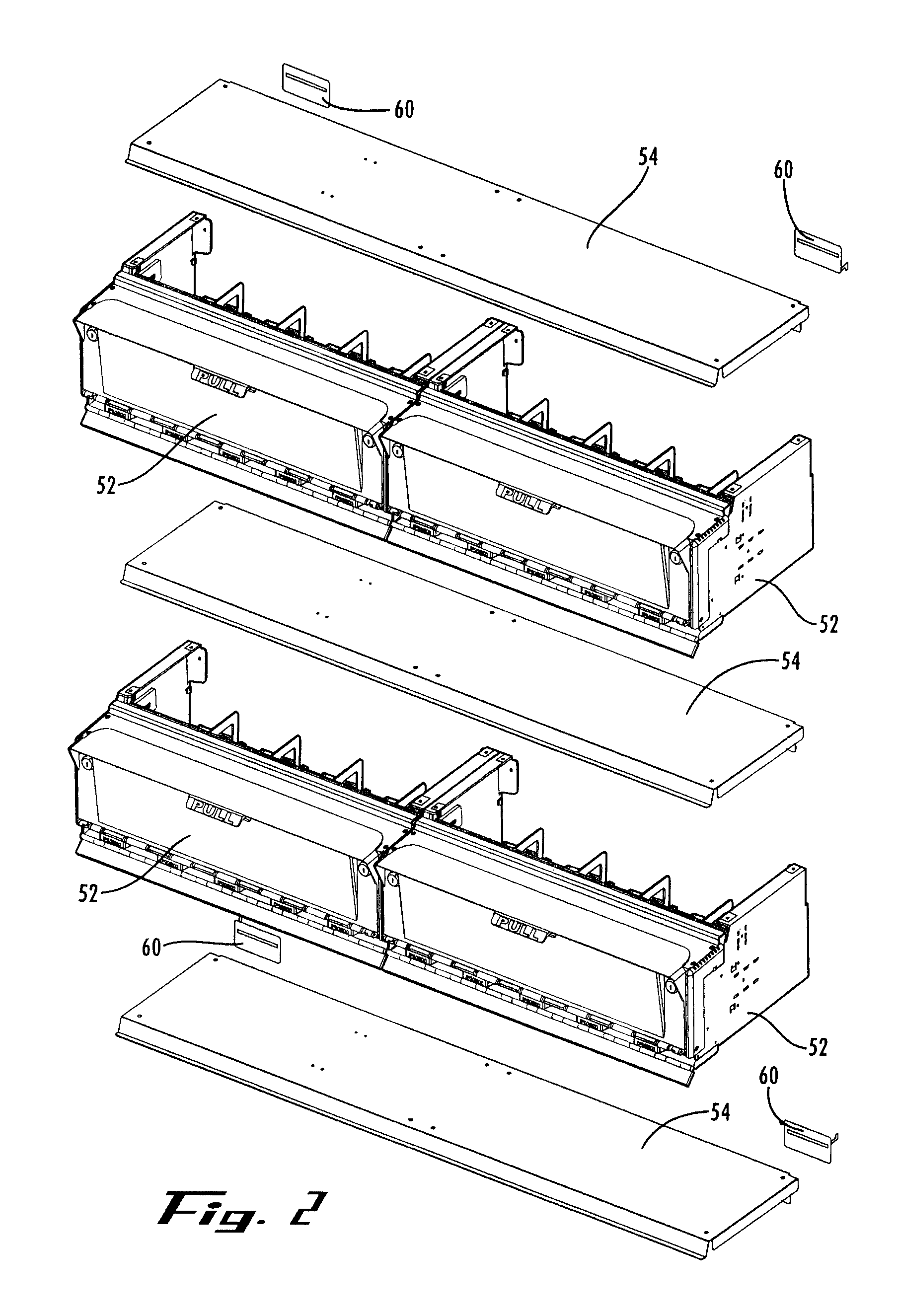

Theft deterrent system

InactiveUS8485391B2Easy to useEasy to adjustMechanical apparatusTobacco pipesTime delaysComputer module

Systems for deterring theft of retail products. Systems of this invention provide theft deterrent dispensing modules for dispensing products and may incorporate theft deterrent measures including mechanical deterrents, time delays and sound. The dispensing modules may include one or more pusher assemblies for dispensing product. Certain systems of this invention may also include a lockout feature, so that only one pusher assembly may be activated to dispense a product at one time.

Owner:WESTROCK SHARED SERVICES LLC

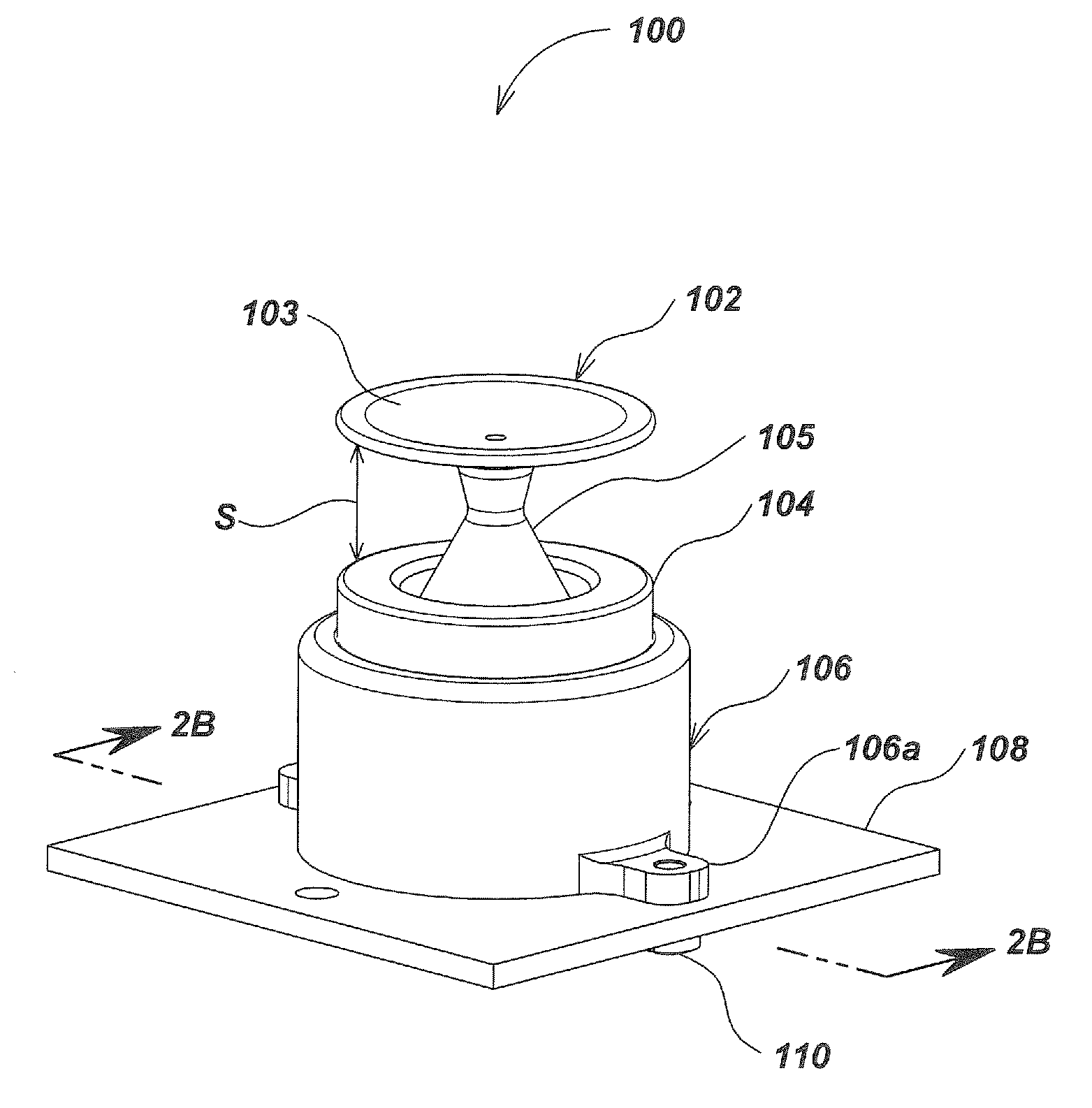

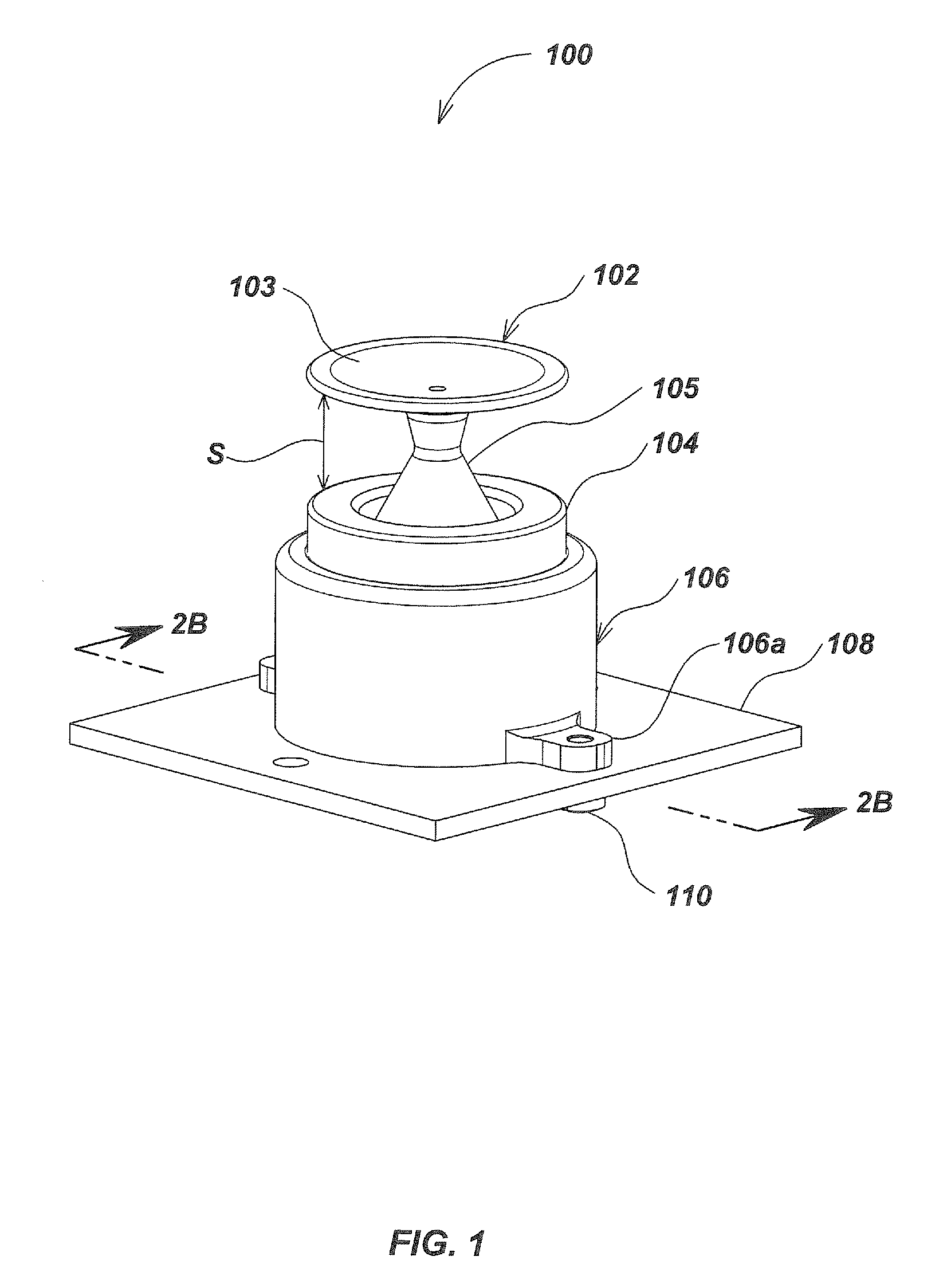

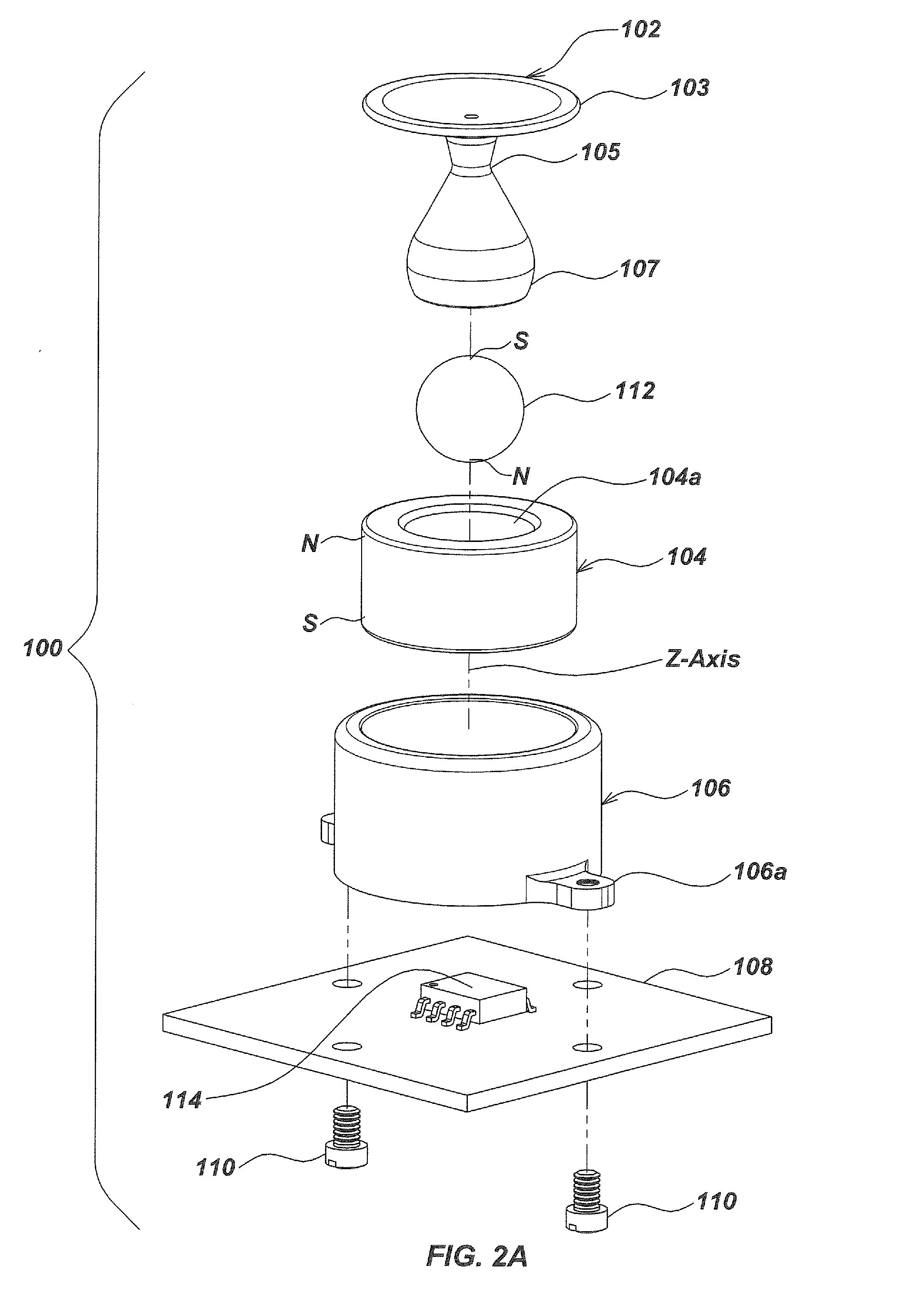

Magnetic Manual User Interface Devices

InactiveUS20100265176A1Manual control with multiple controlled membersLimiting/preventing/returning movement of partsElectrical polarityPersonal computer

Various finger tip controlled manual interface devices that can be used as inputs to personal computers, electromechanical systems and video game consoles utilize concentrically arranged magnets. The polarities of the magnets are oriented to provide restoration forces on a one of the magnets to bias it toward a neutral position. A magnetic sensor including a plurality of sensing elements such as Hall effect devices generates output signals representative of direction and amount of movement of the magnet that is biased to the neutral position.

Owner:SEEKTECH

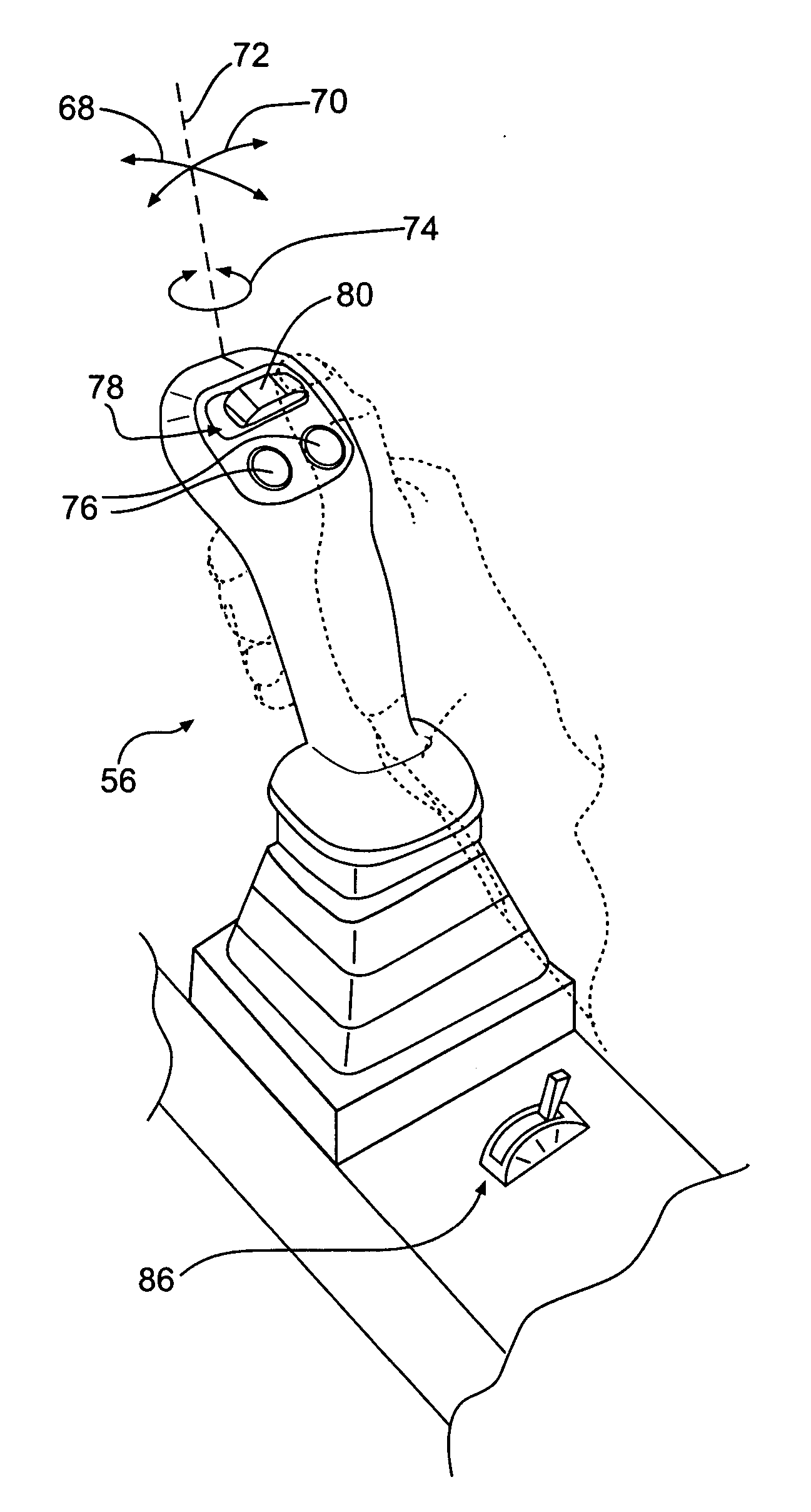

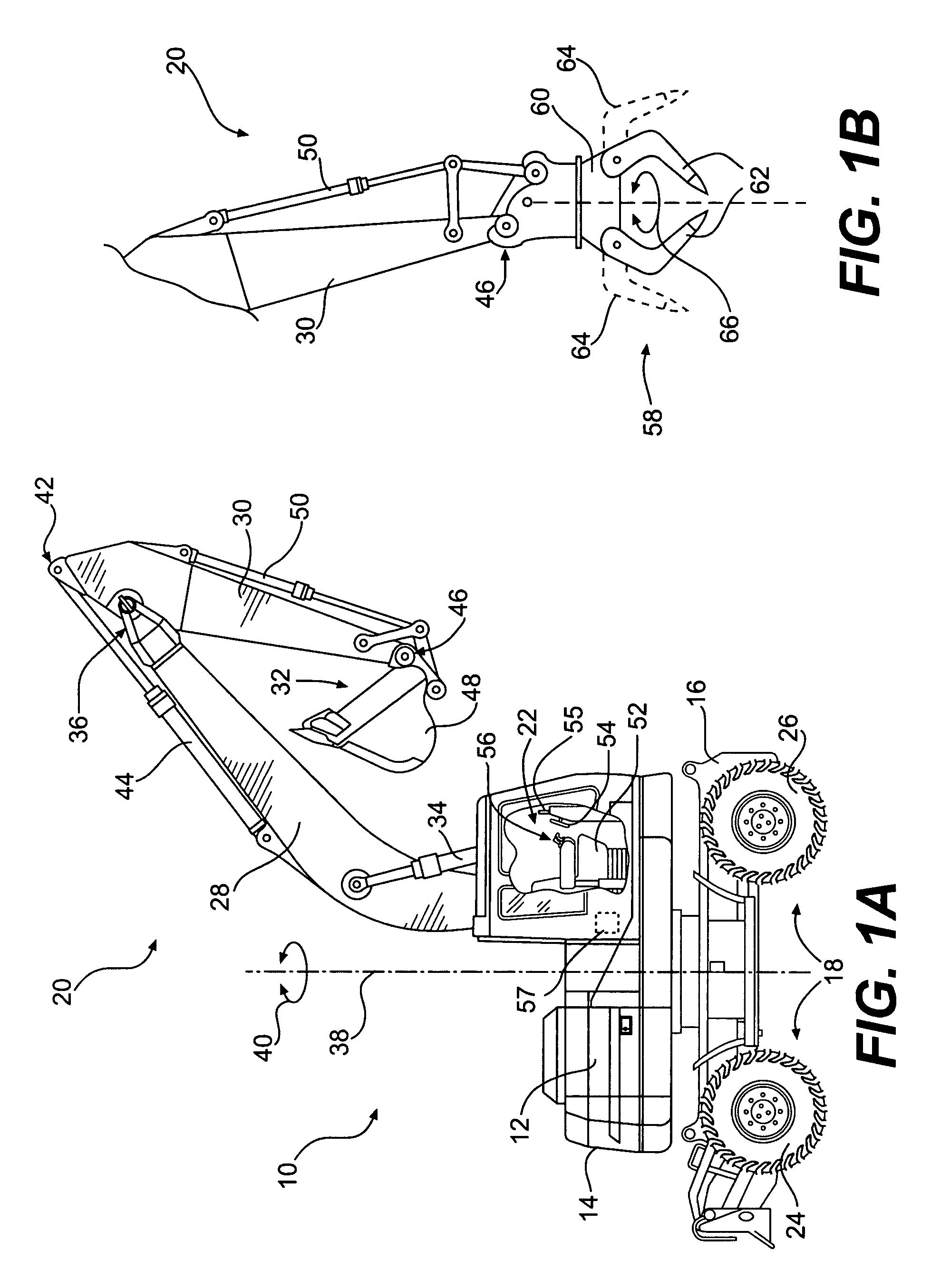

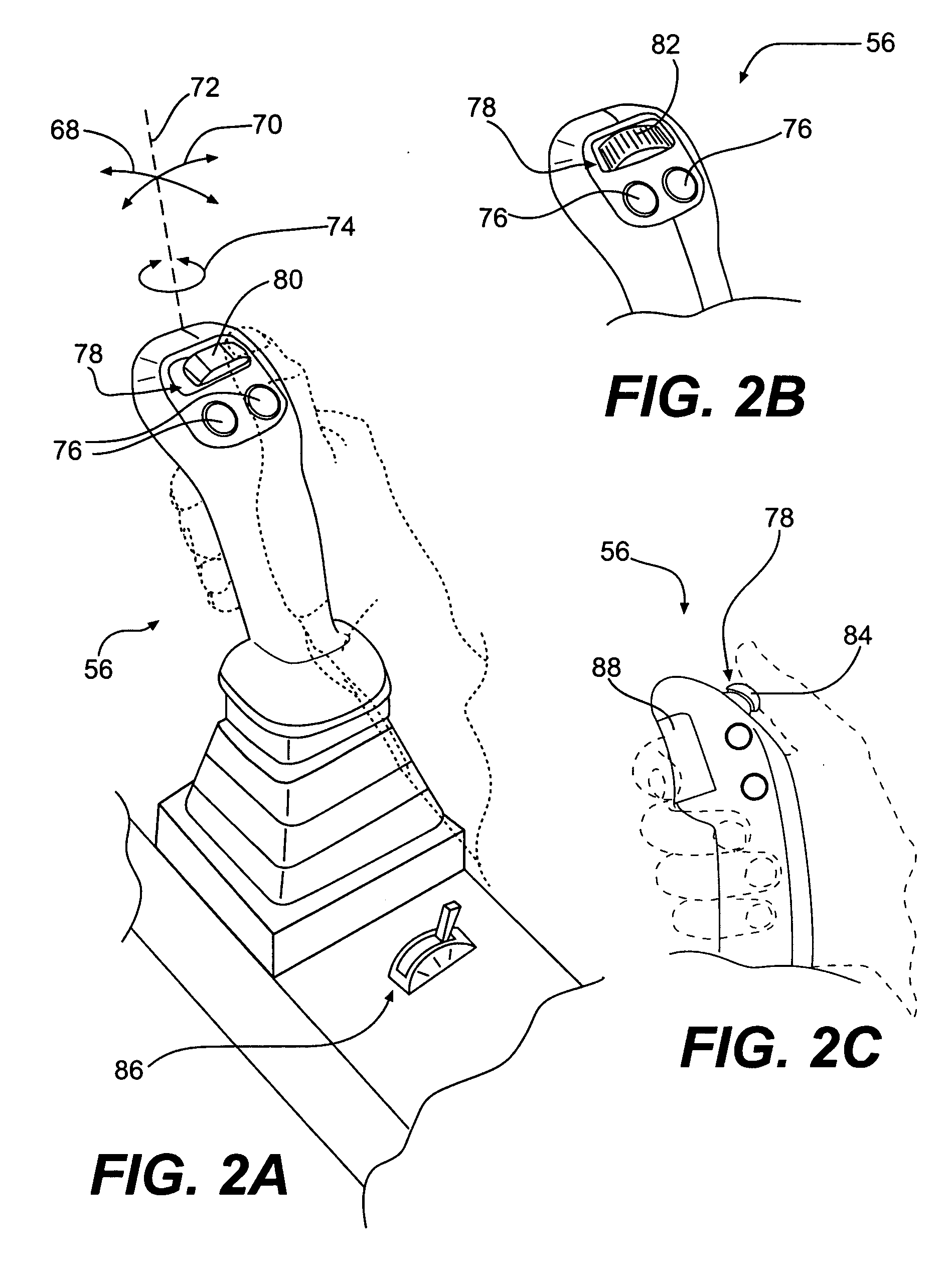

Steering system with joystick mounted controls

InactiveUS20060137931A1Manual control with multiple controlled membersHand leversJoystickEngineering

A steering system is provided for a work machine. The steering system may include at least one hand-operated work implement control device and a steering mechanism configured to control a direction of travel of the work machine. The system may also include a first steering device operatively coupled to the steering mechanism and configured to control at least one component of the steering mechanism based on operator input. The system may further include a second steering device mounted on the work implement control device. The second steering device may be configured to be selectively operatively coupled to the steering mechanism to thereby control a direction of travel of the work machine based on lateral movement of the second steering device relative to the work implement control device.

Owner:CATERPILLAR INC

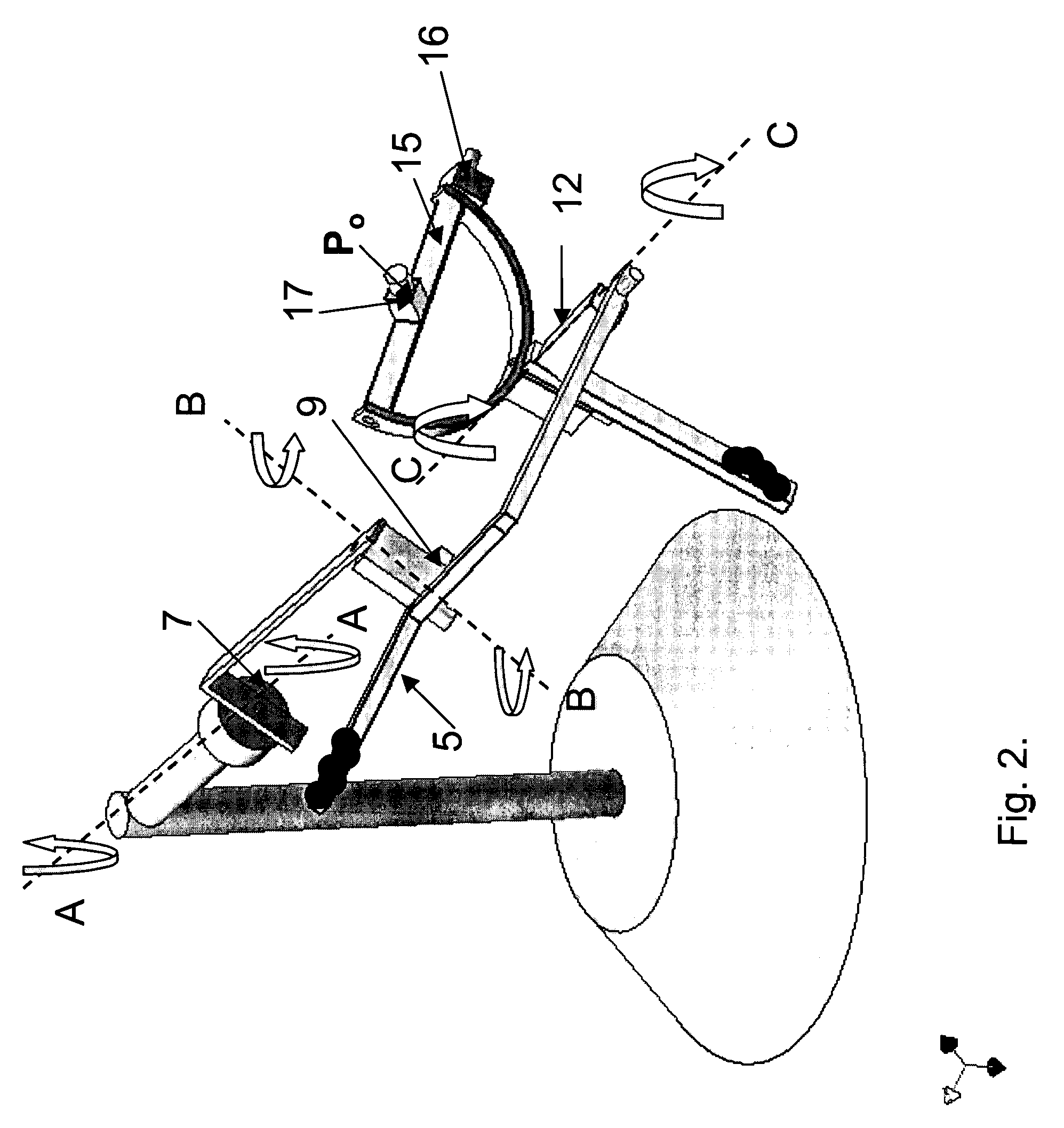

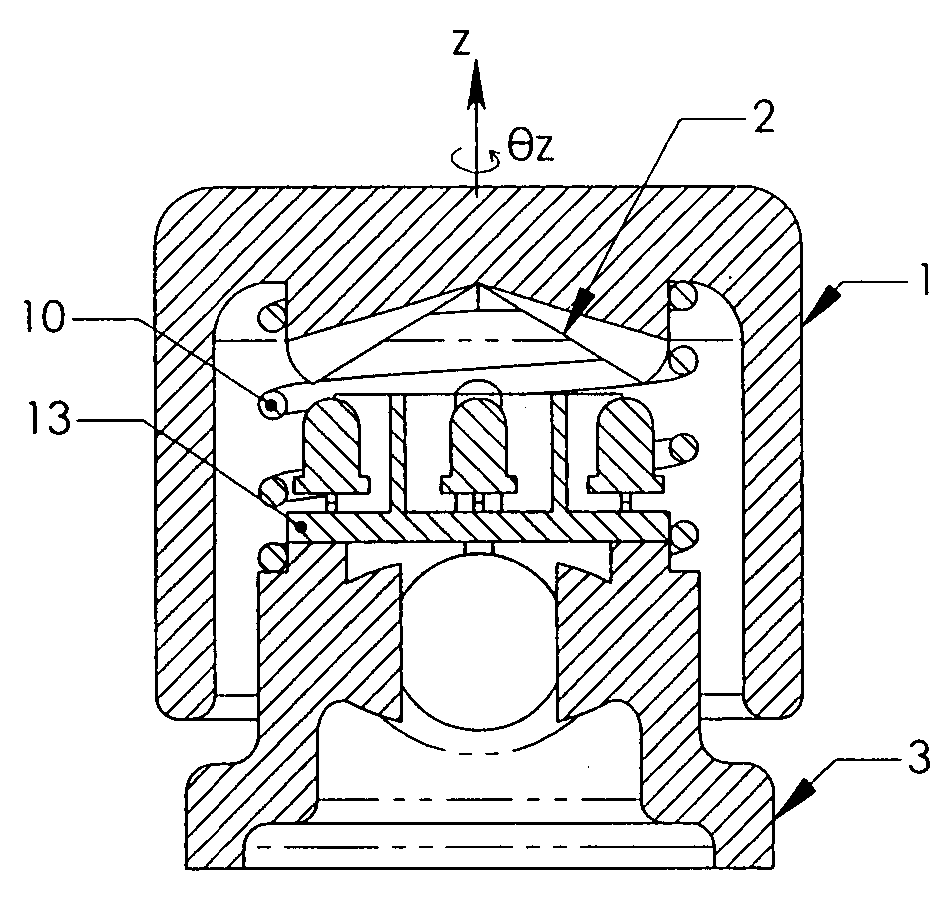

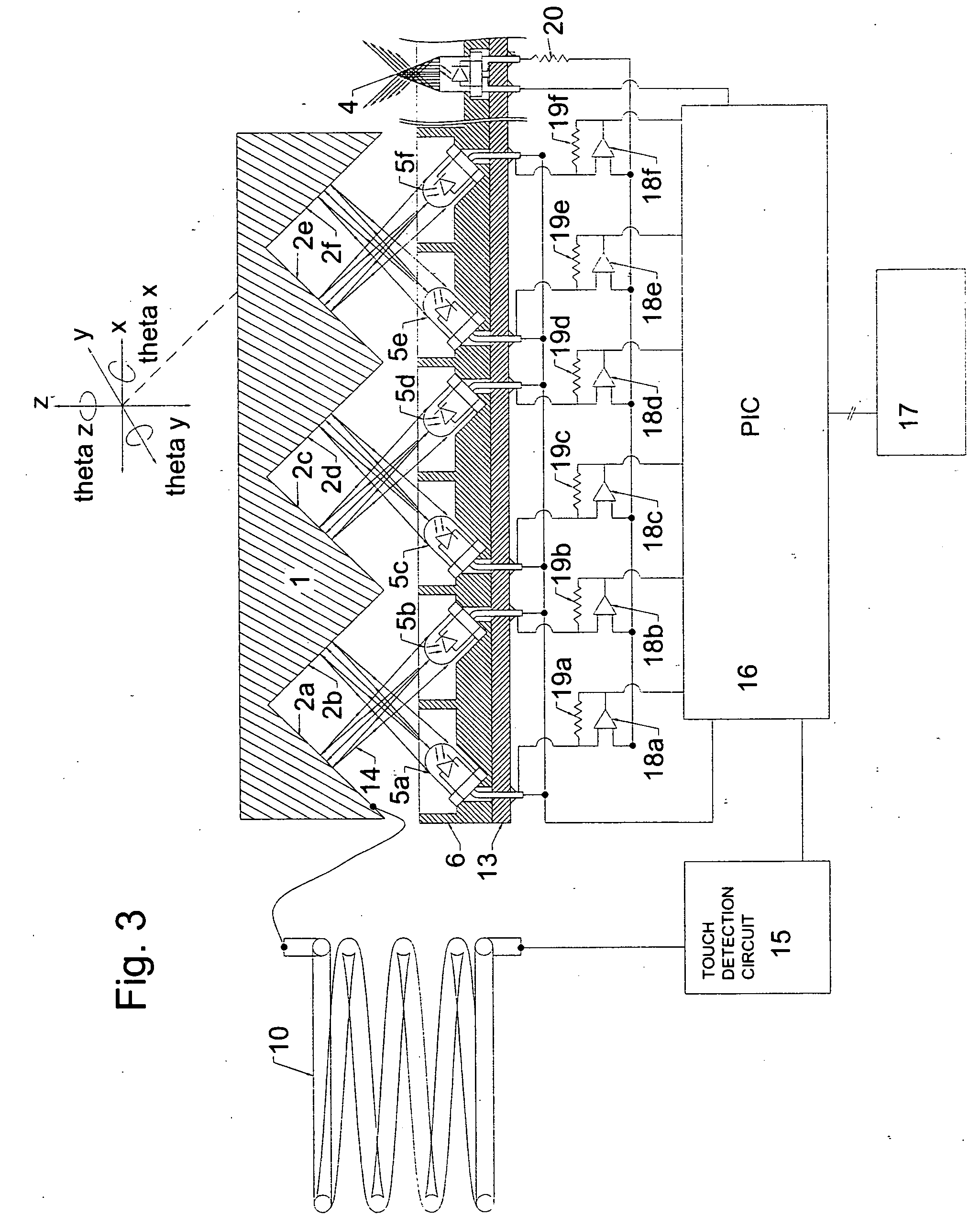

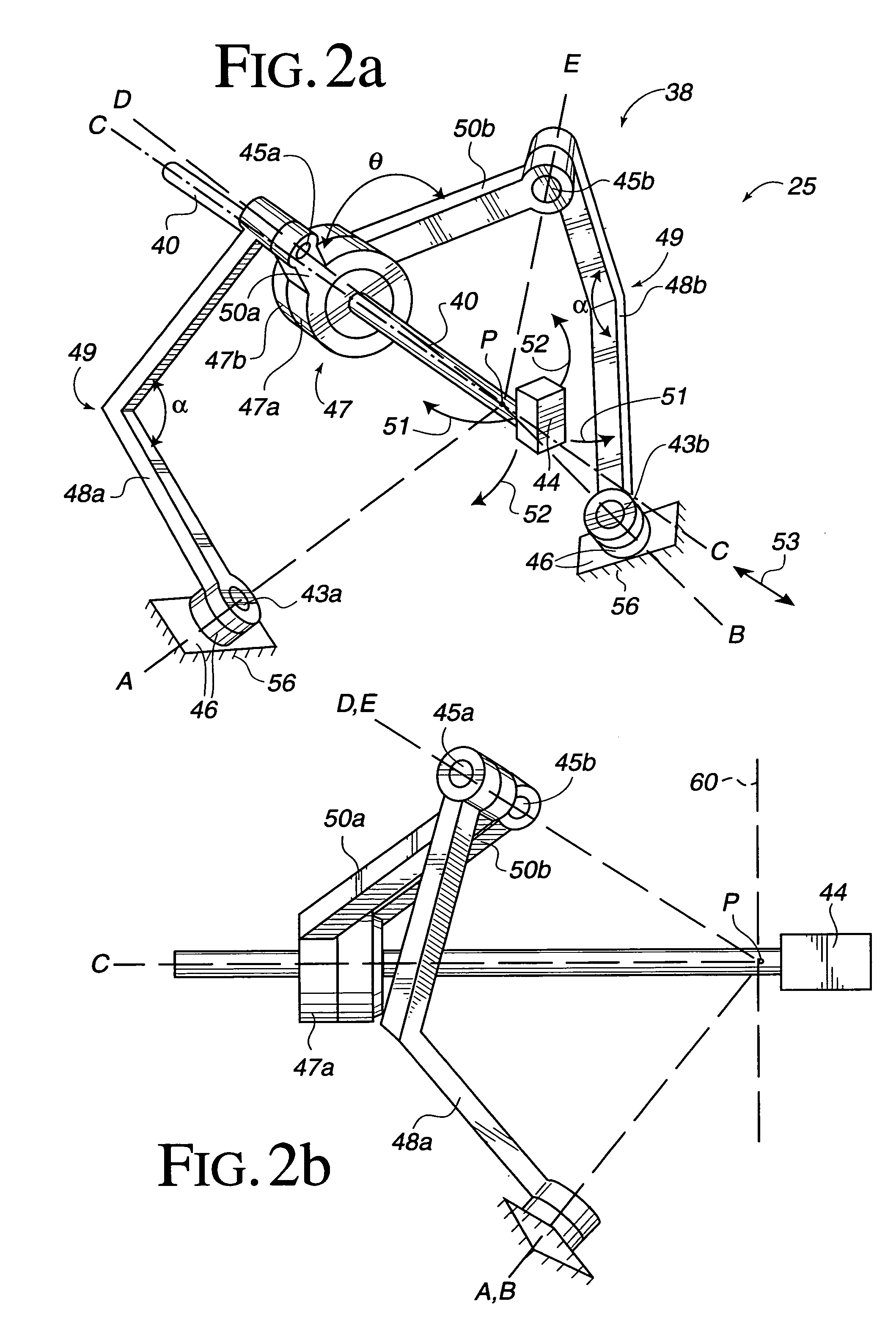

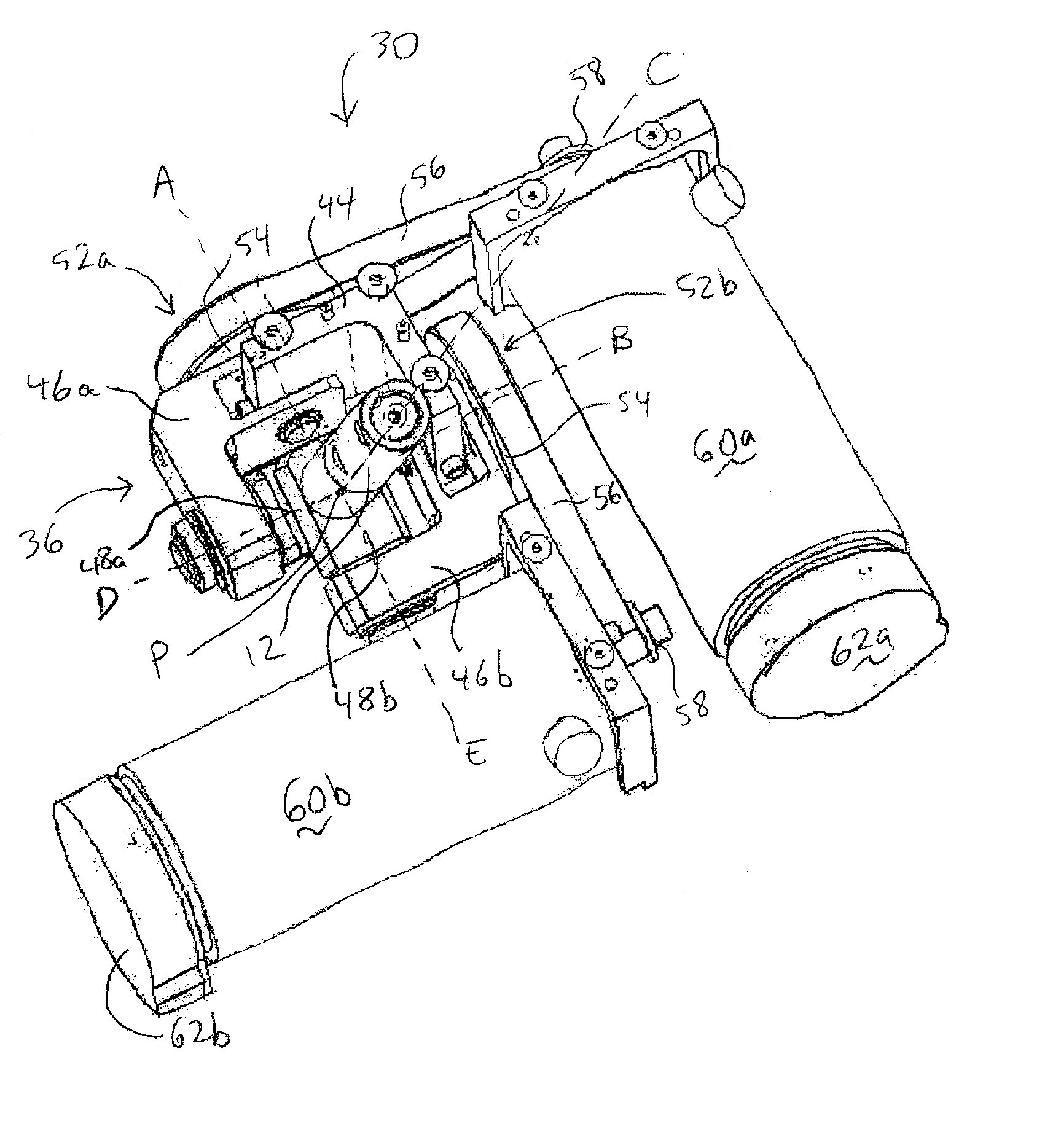

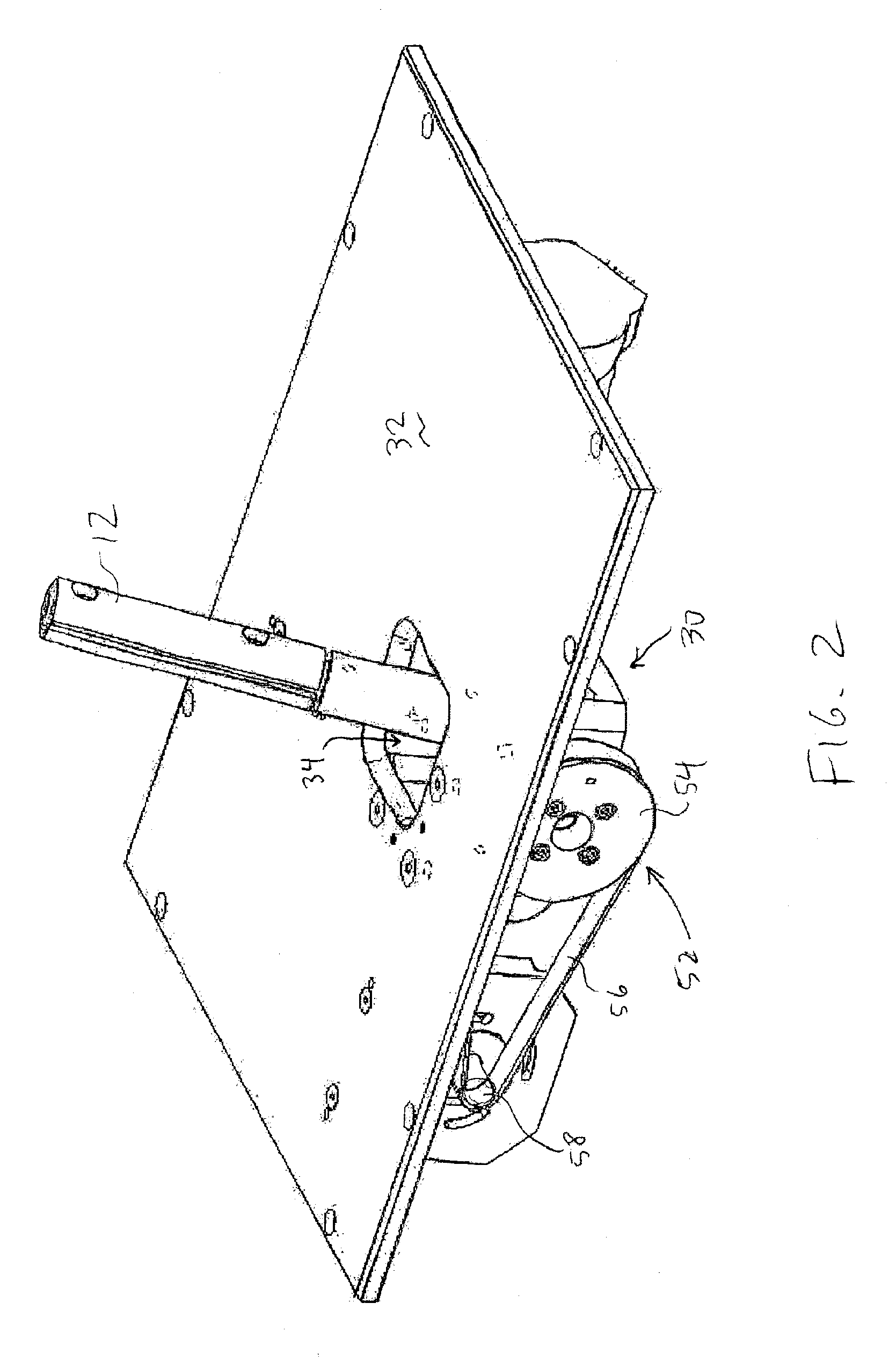

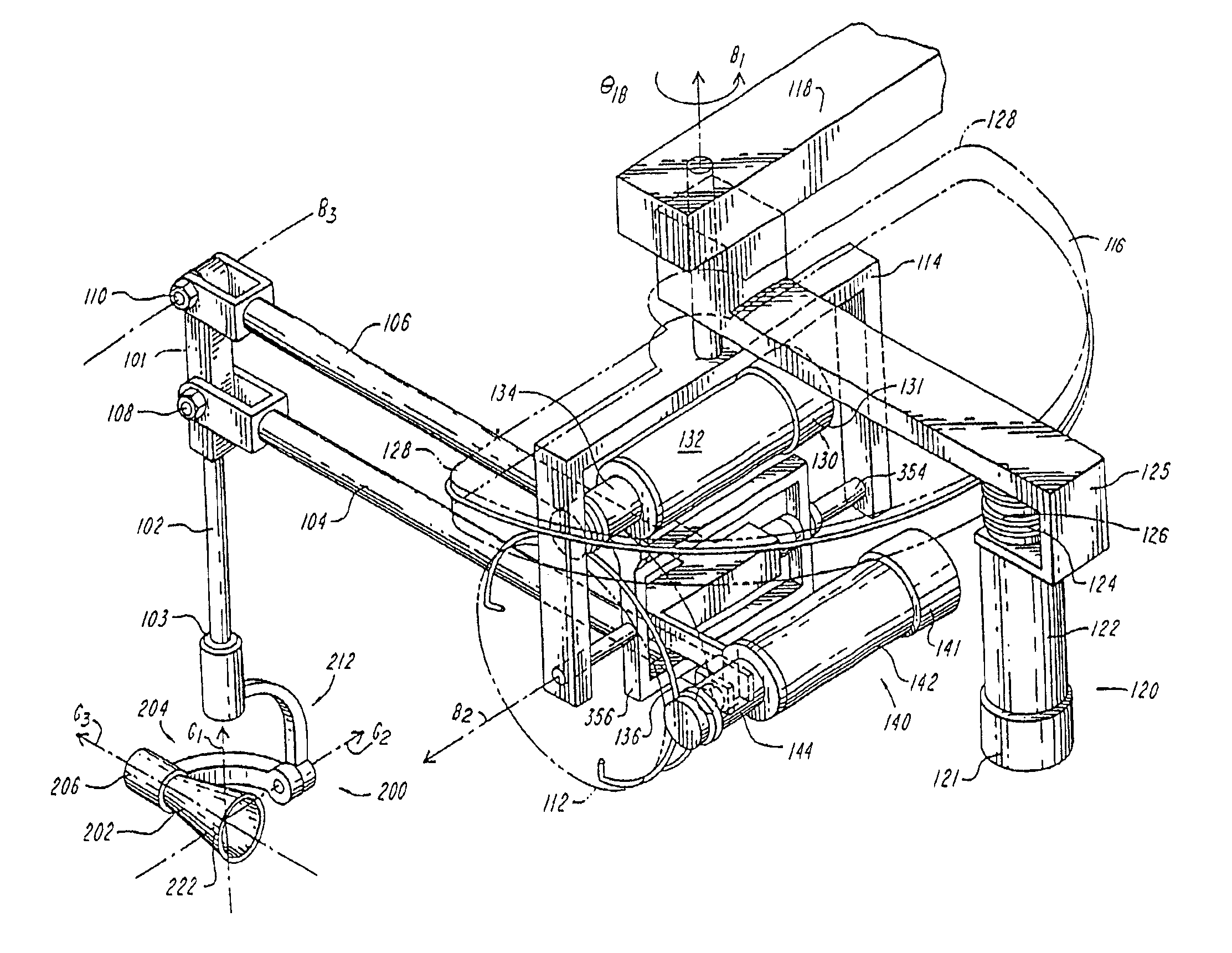

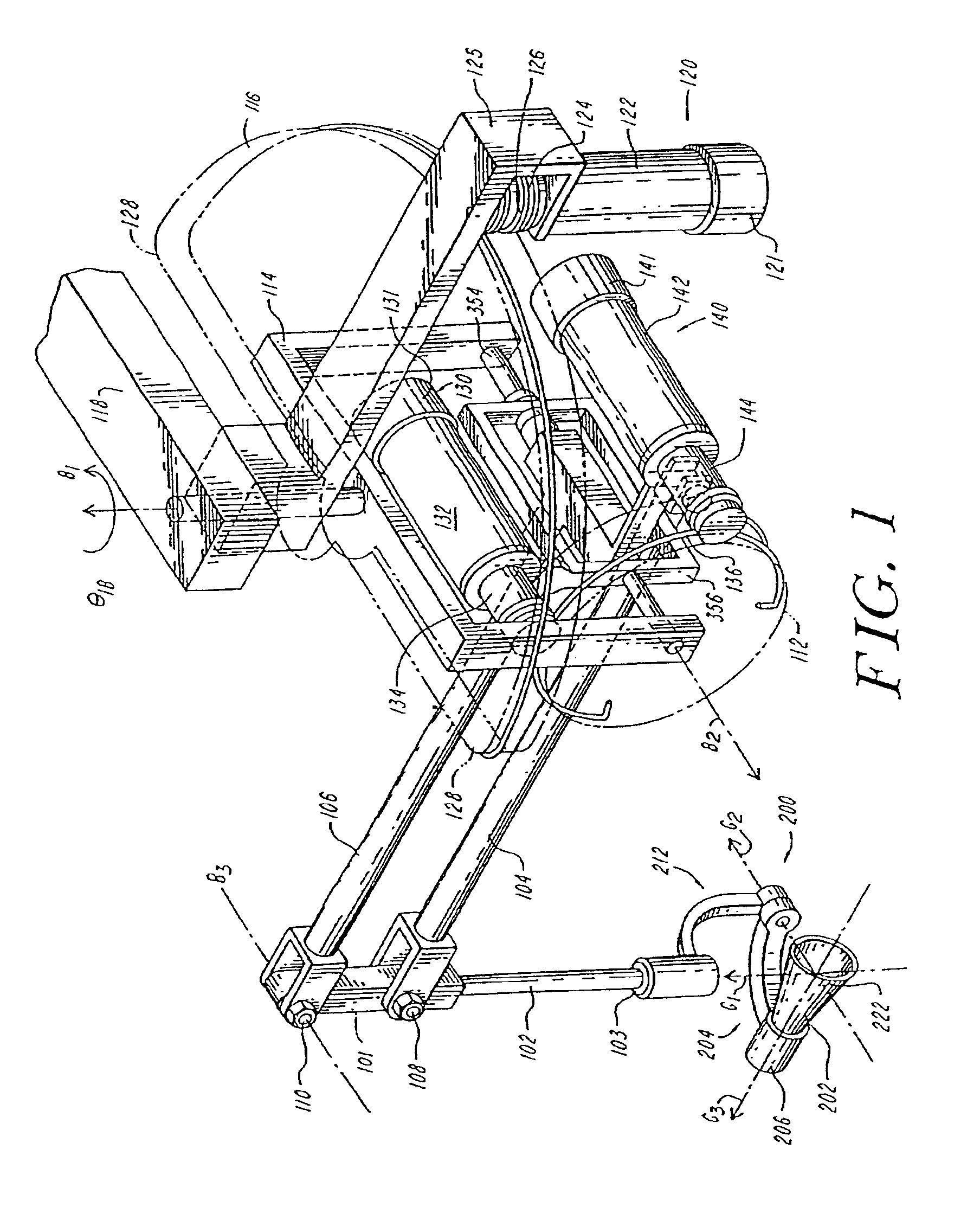

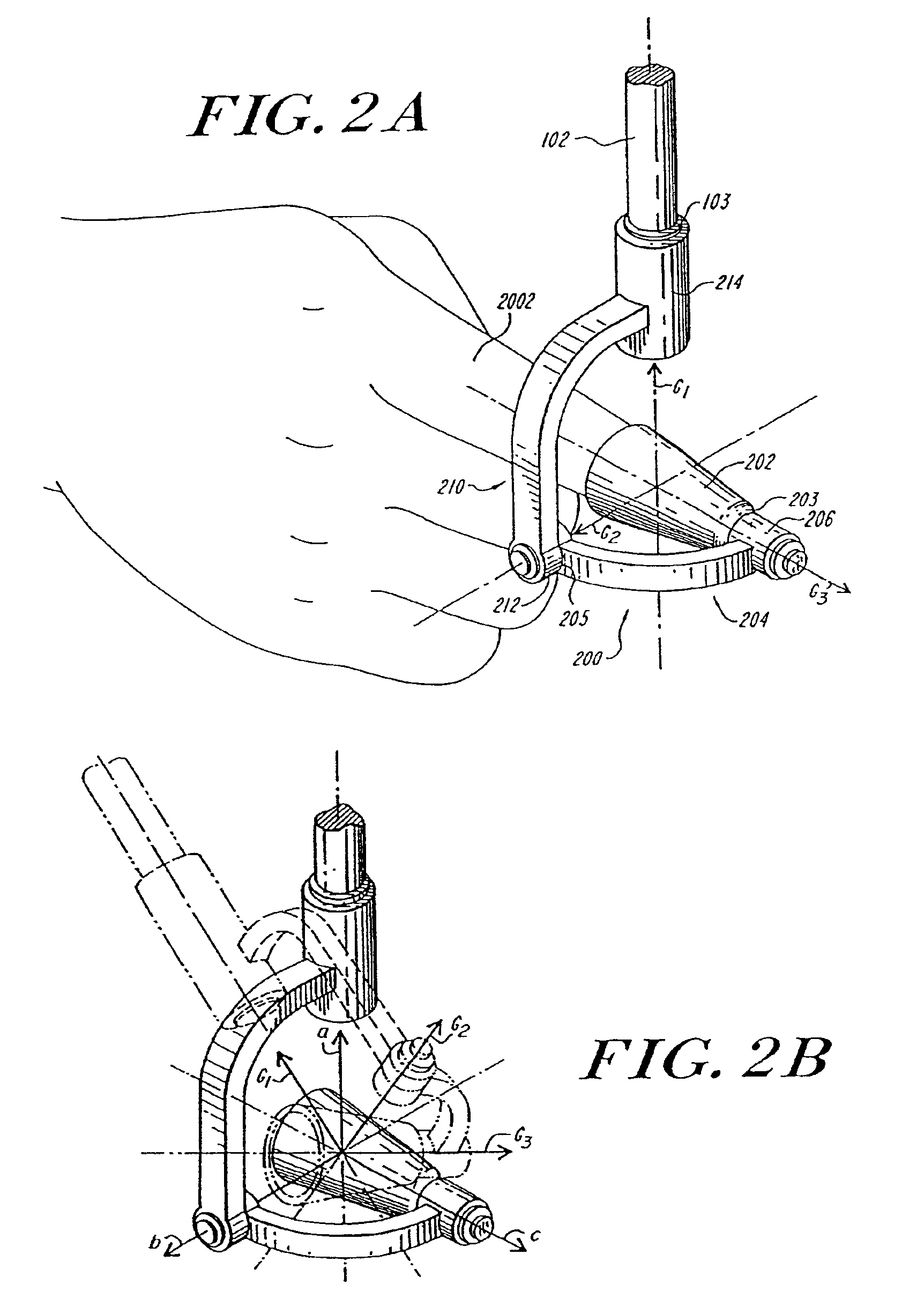

Hand controller and wrist device

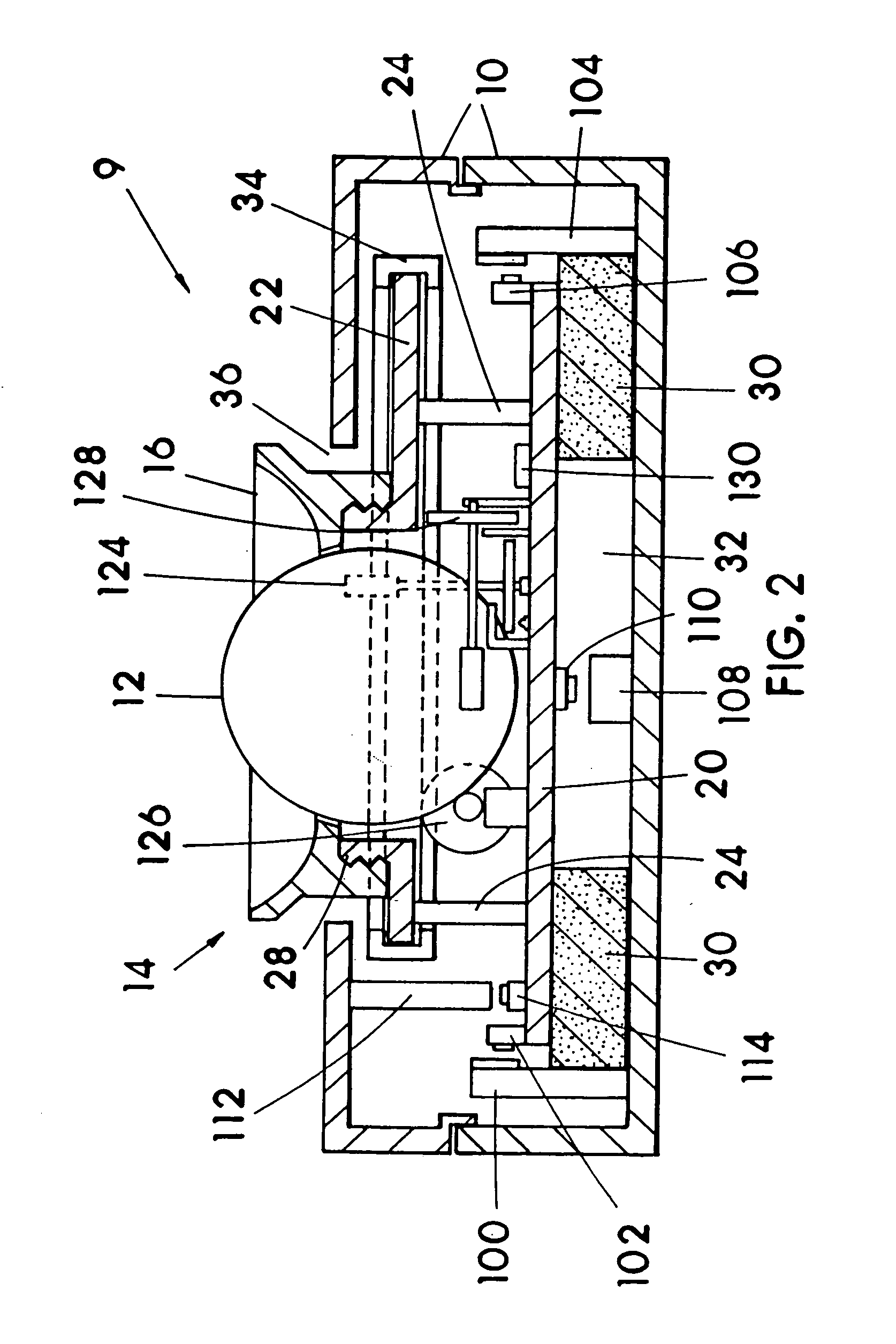

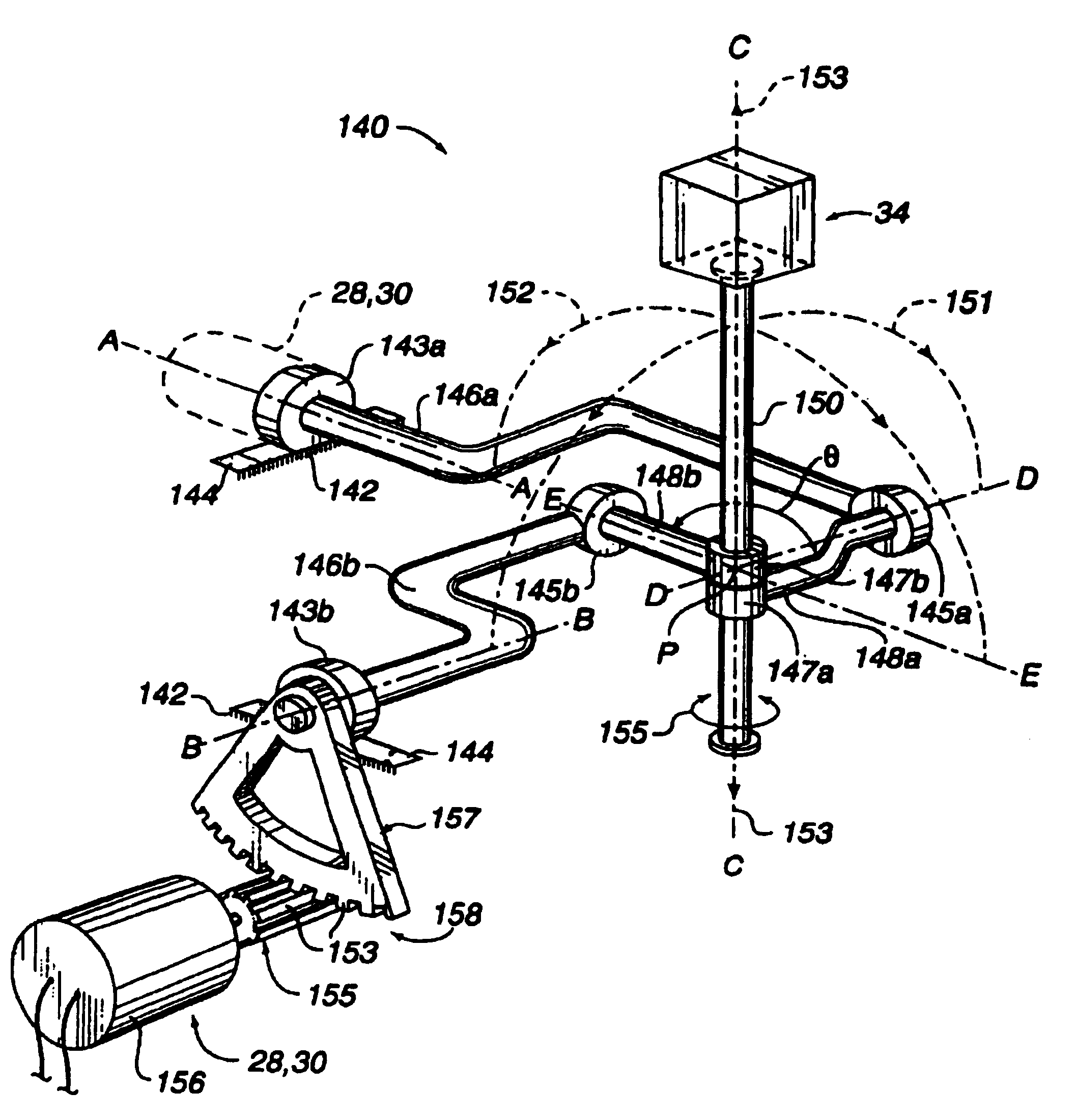

InactiveUS20050183532A1Zero backlashEasy to measureMechanical apparatusJointsWorkspaceSingularity free

A compact four degrees of freedom parallel mechanism suitable for use as a hand control or wrist is provided that has backdrivability, is singularity free and has a large workspace and a large force reflecting capability. The structure is light but rigid, and the electric actuators are all placed on the ground or base and provide independent control of each degree of freedom. Each degree of freedom is connected to an actuator either directly or through a cable drive system. The first two degrees of freedom are created by two identical pantographs pivoted together on pivoted joints to define a hemispherical motion of an object (end point) about a center point (hemisphere center). The third and fourth degrees of freedom represent rotation and sliding motions of the object around and along the radius of the created hemisphere, respectively. The axes of these latter degrees of freedom are concentric, and these axes intersect with the axis of the pantographs pivoted joints at the hemispheric center.

Owner:UNIVERSITY OF MANITOBA

Force reflecting haptic interface

InactiveUS6853965B2Improve realismFacilitate high fidelity positionInput/output for user-computer interactionProgramme-controlled manipulatorTouch PerceptionActuator

The invention is an apparatus for physically exchanging a force with a user in an environment local to the user. A connection element connects to a user's body member and a linkage between the connection element and ground. The linkage includes means for powering at least three independent freedoms of the connection element relative to ground and means for maintaining at least one independent freedom of the connection element relative to ground free of power. Up to three independent freedoms of the connection element may be maintained free of power, and up to five independent freedoms may be powered. Other aspects of the invention include a two actuator counter-balance for controlling a point on a link. The invention also includes apparatus for establishing a virtual, switch, which presents to the user the force and displacement relationship of a spring switch. Another embodiment is a virtual bristled brush, again which presents to the user the force and displacement relationship of such a brush, while also changing the virtual environment to reflect the user's changes in location.

Owner:MASSACHUSETTS INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com