Patents

Literature

464 results about "Moving magnet" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

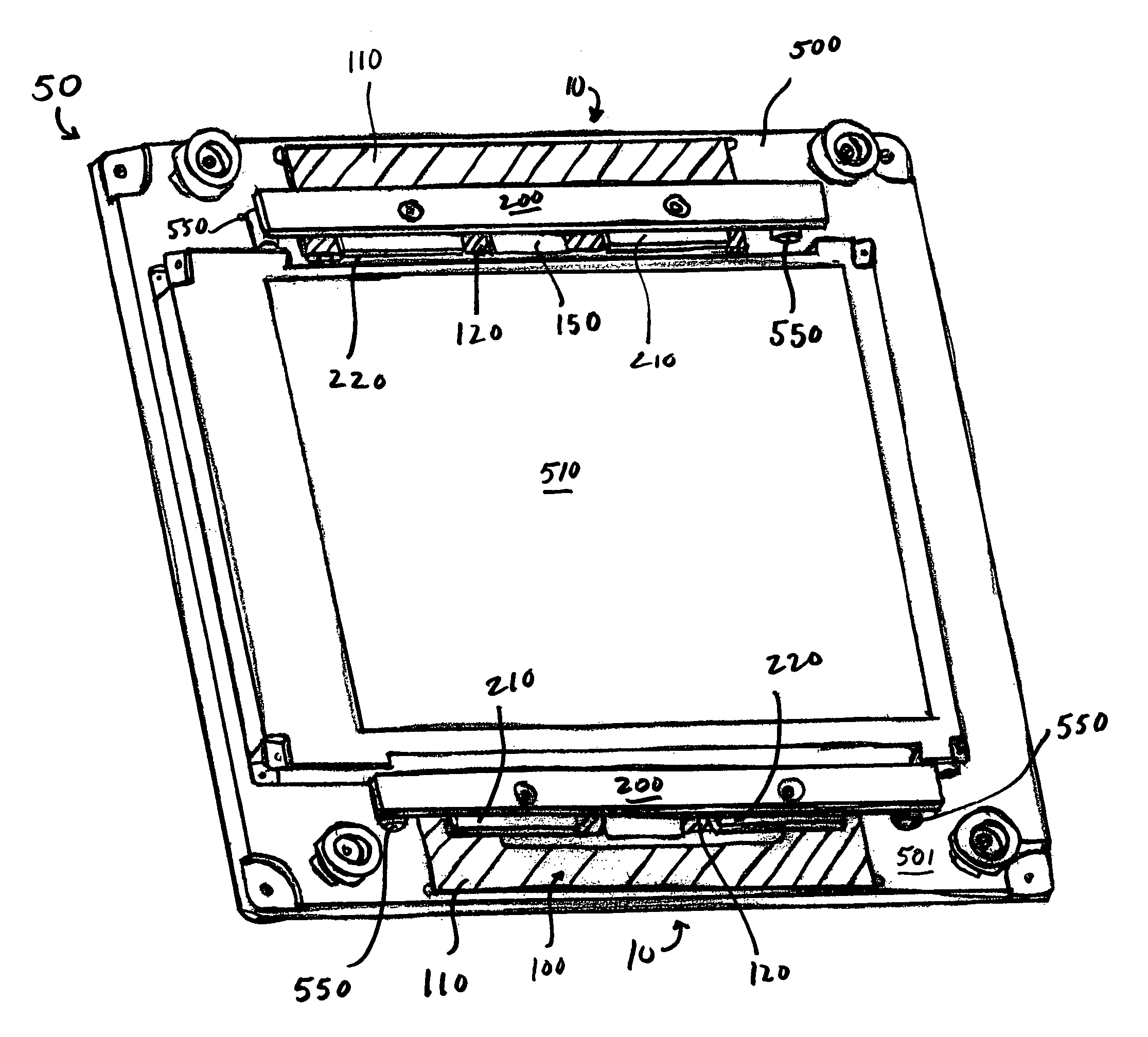

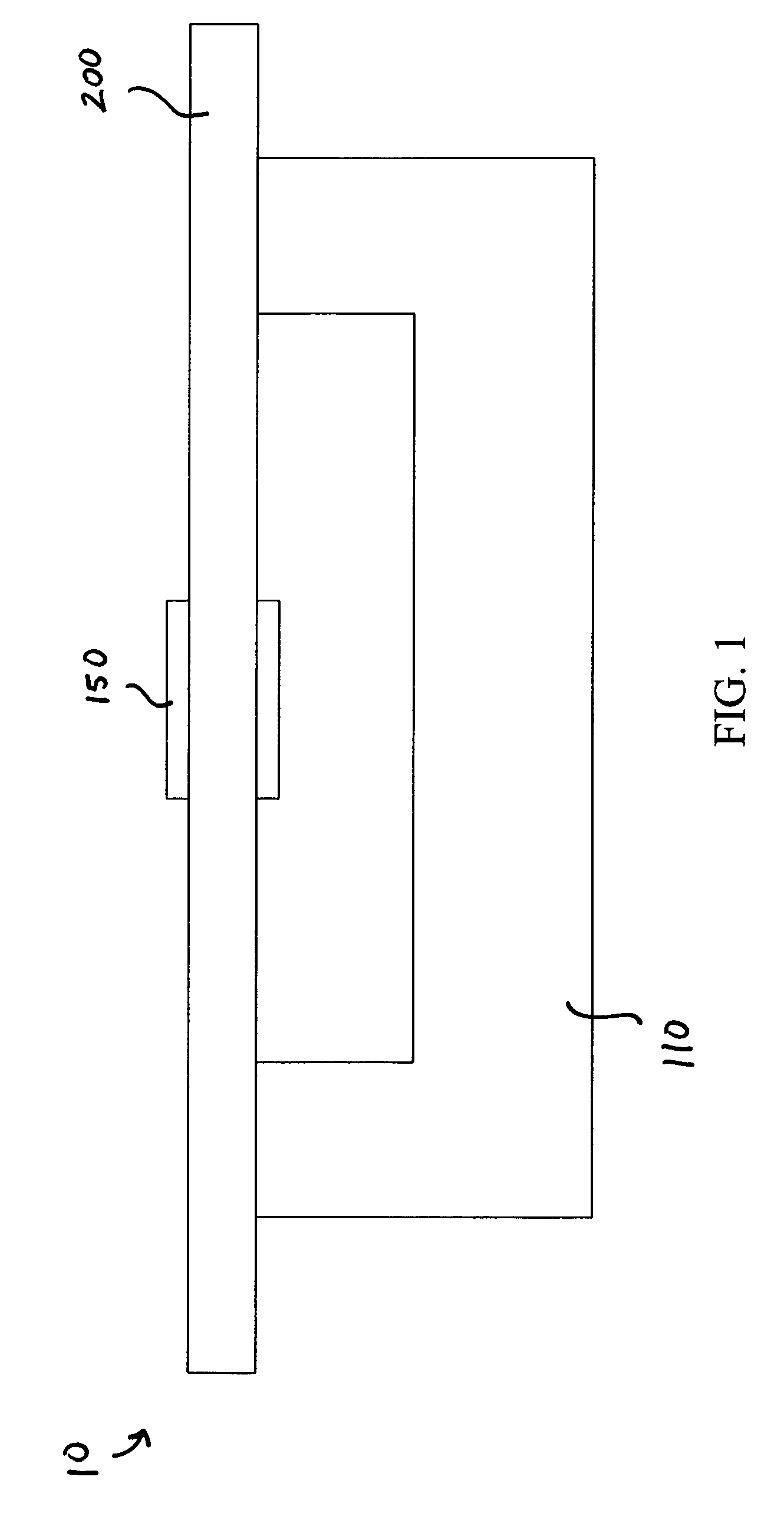

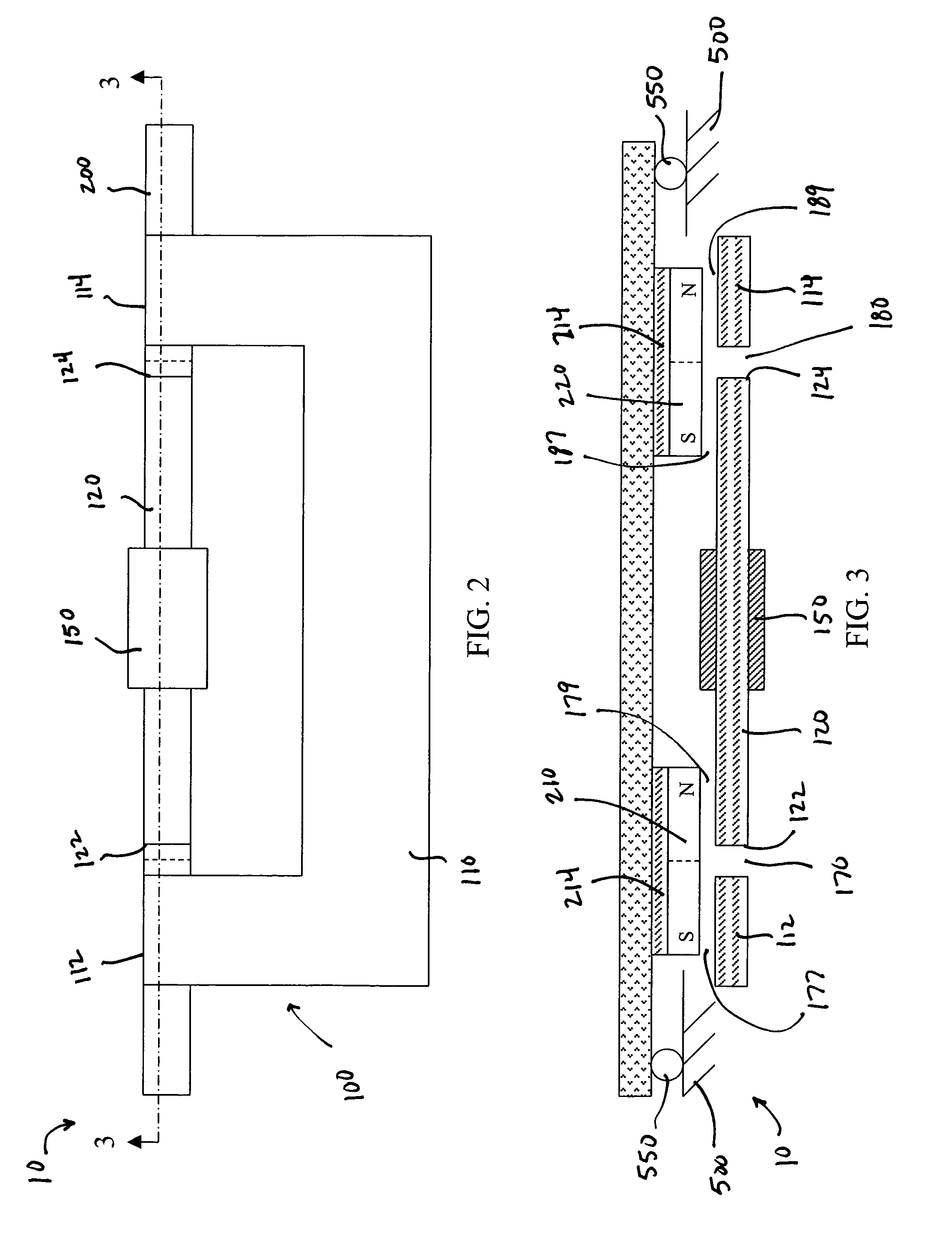

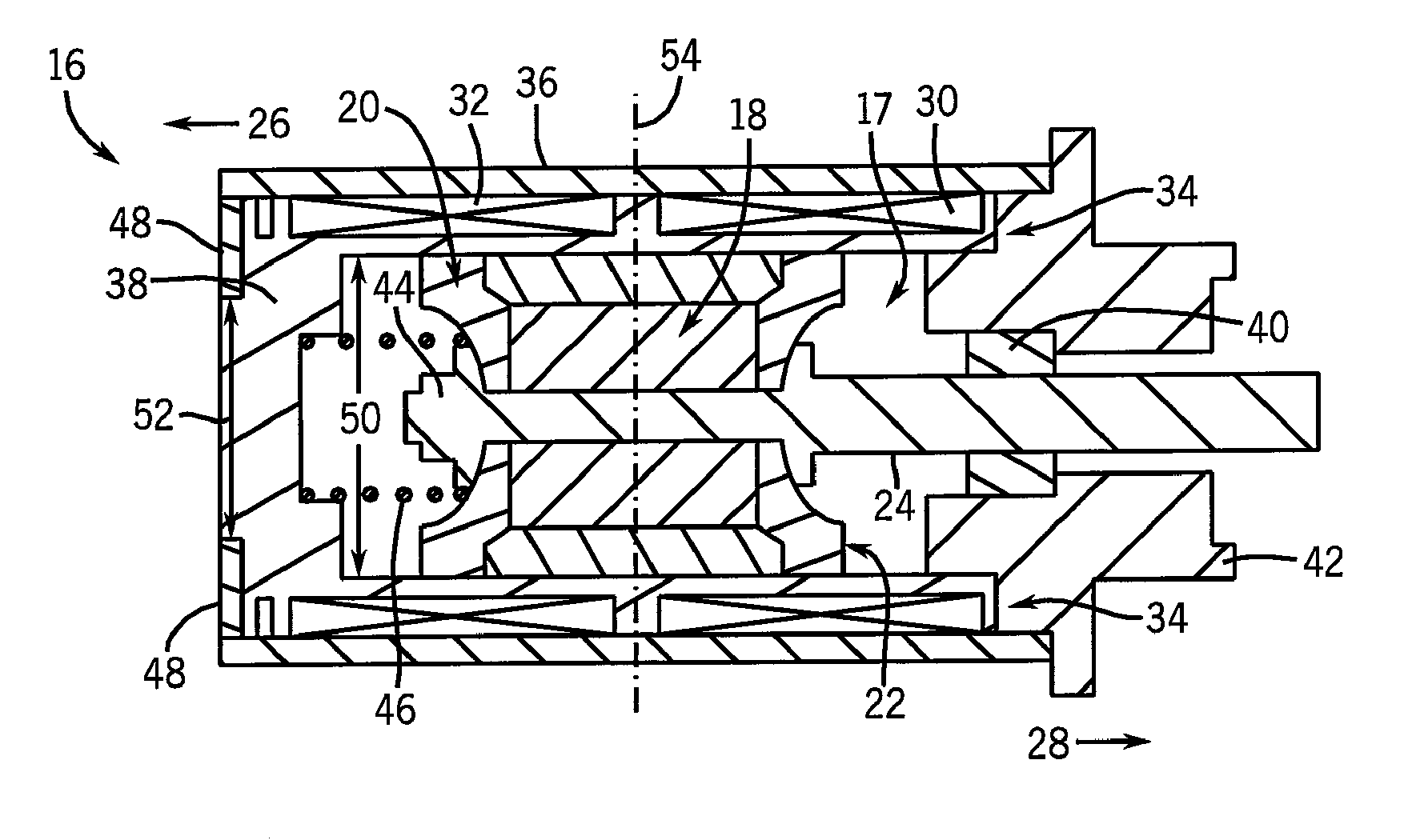

Moving magnet actuator for providing haptic feedback

InactiveUS6982696B1High magnitudeHigh bandwidthInput/output for user-computer interactionManual control with multiple controlled membersCentral projectionSpring force

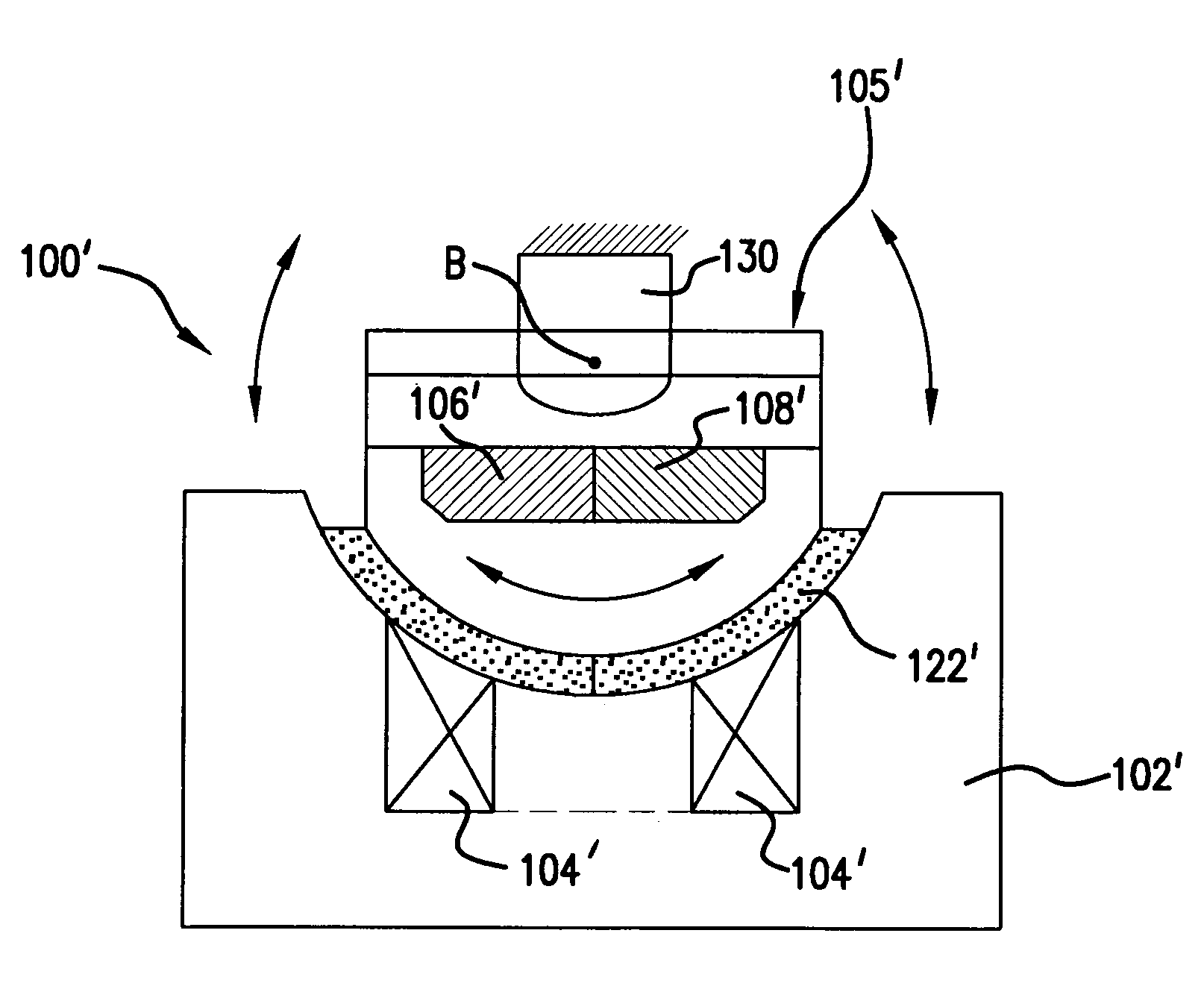

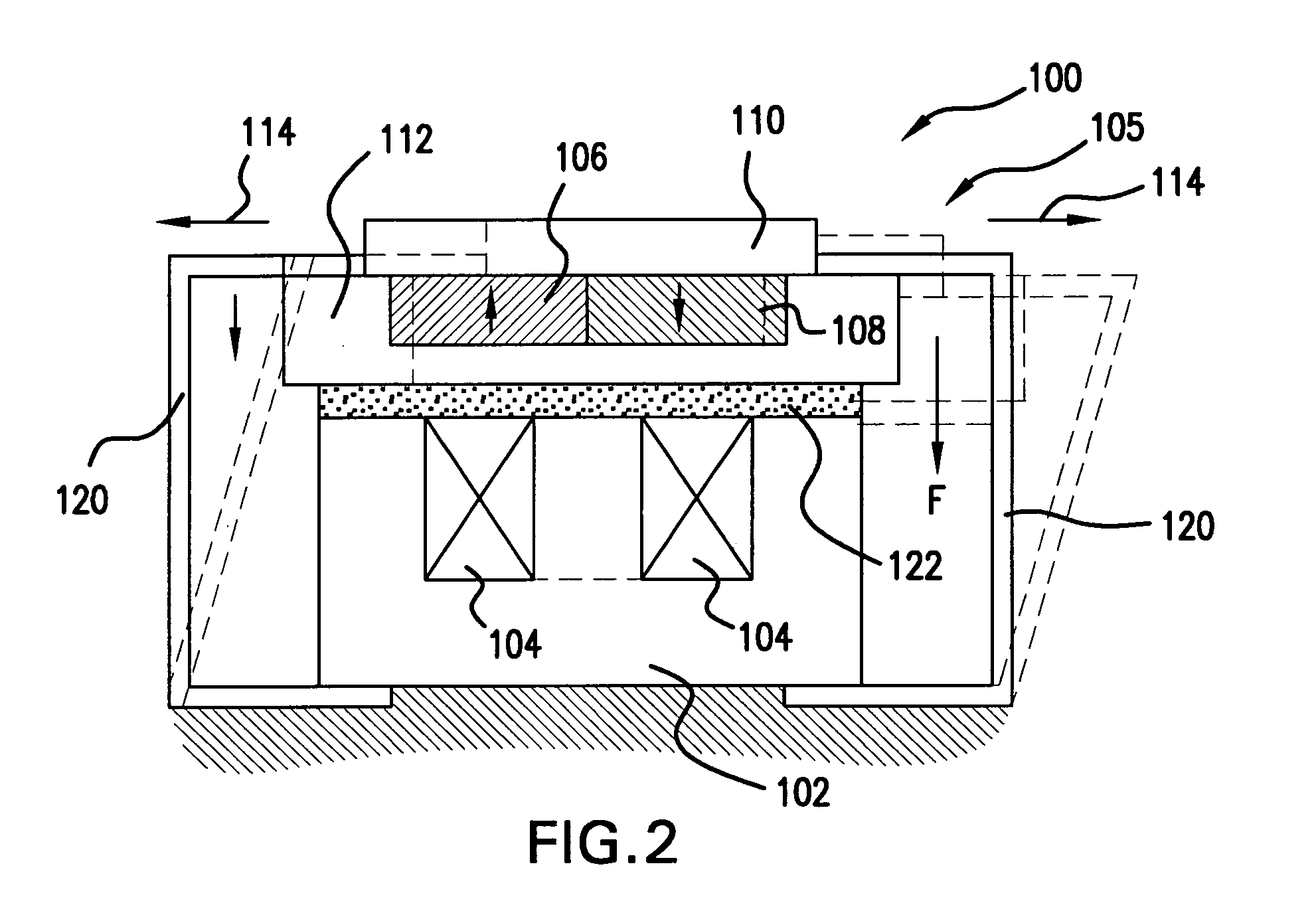

A moving magnet actuator for providing haptic feedback. The actuator includes a grounded core member, a coil is wrapped around a central projection of the core member, and a magnet head positioned so as to provide a gap between the core member and the magnet head. The magnet head is moved in a degree of freedom based on an electromagnetic force caused by a current flowed through the coil. An elastic material, such as foam, is positioned in the gap between the magnet head and the core member, where the elastic material is compressed and sheared when the magnet head moves and substantially prevents movement of the magnet head past a range limit that is based on the compressibility and shear factor of the material. Flexible members can also be provided between the magnet head and the ground member, where the flexible members flex to allow the magnet head to move, provide a centering spring force to the magnet head, and limit the motion of the magnet head.

Owner:IMMERSION CORPORATION

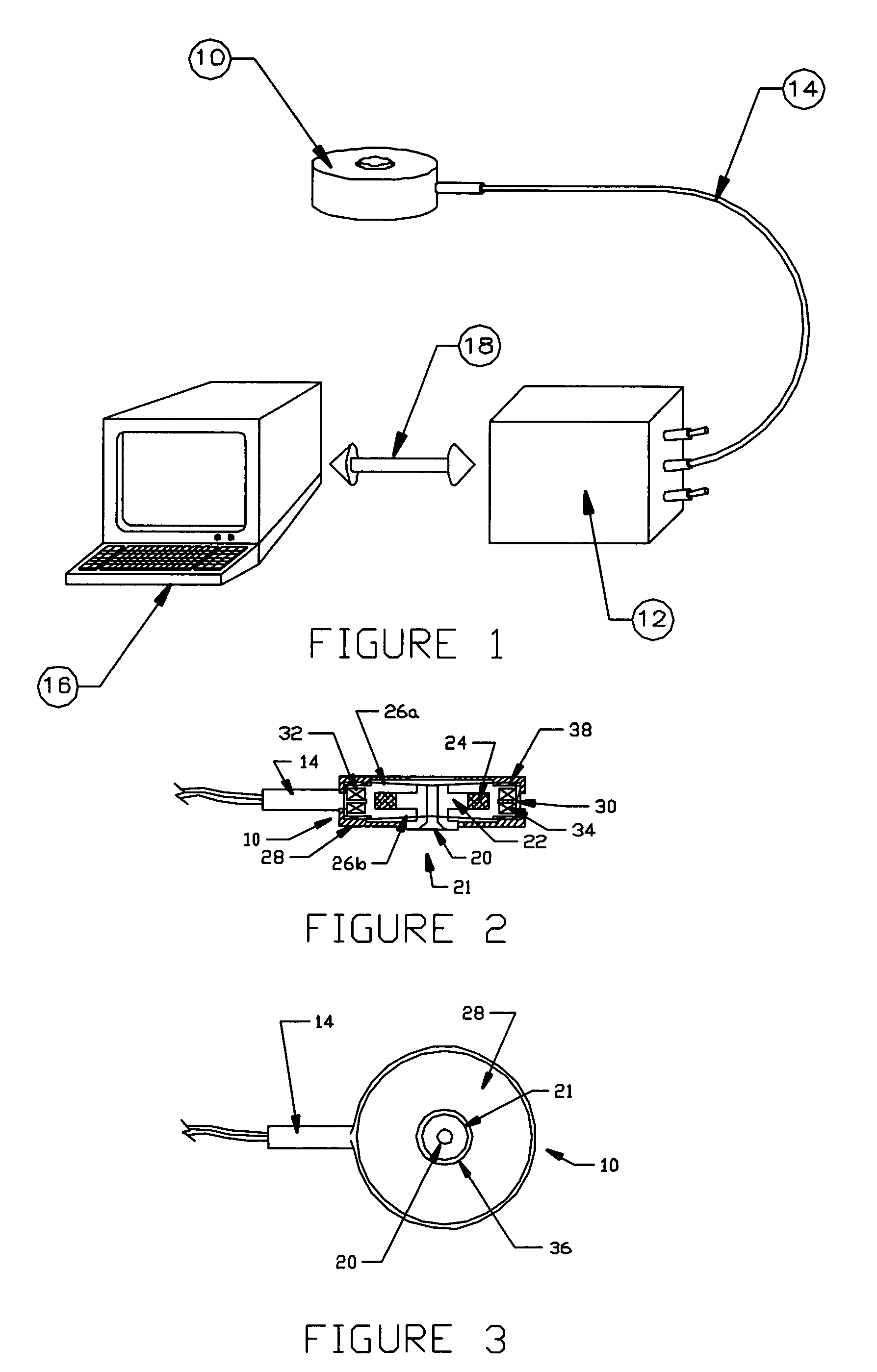

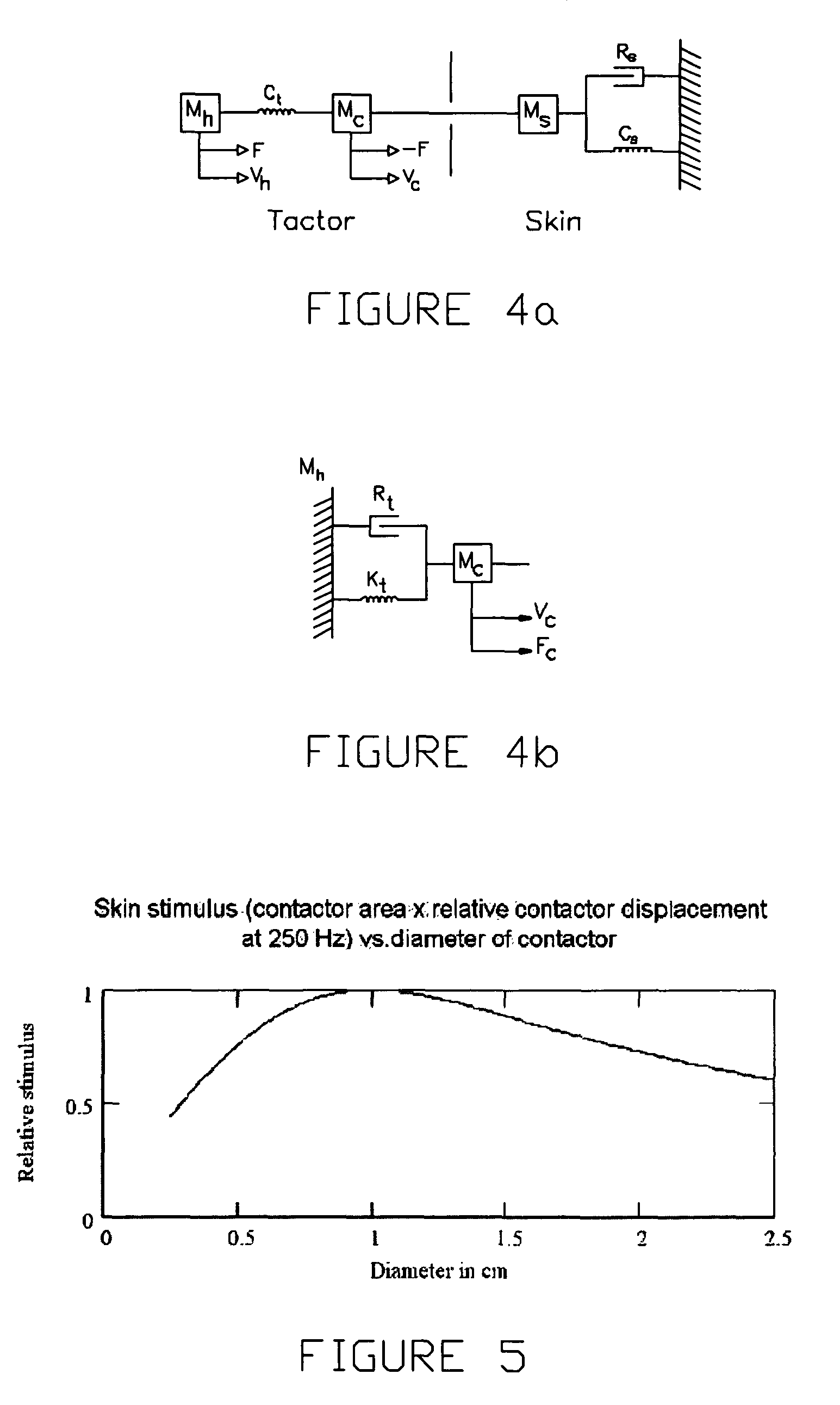

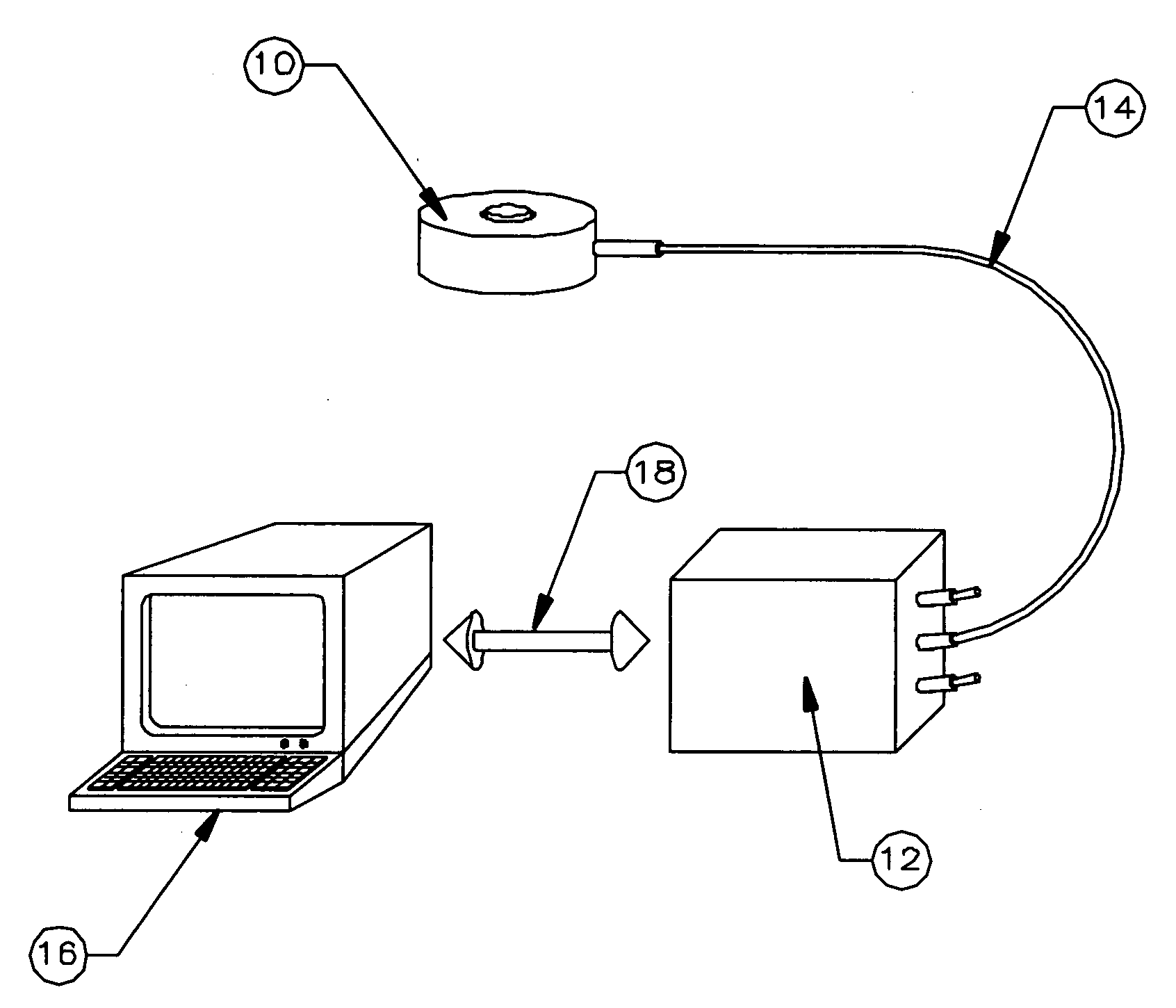

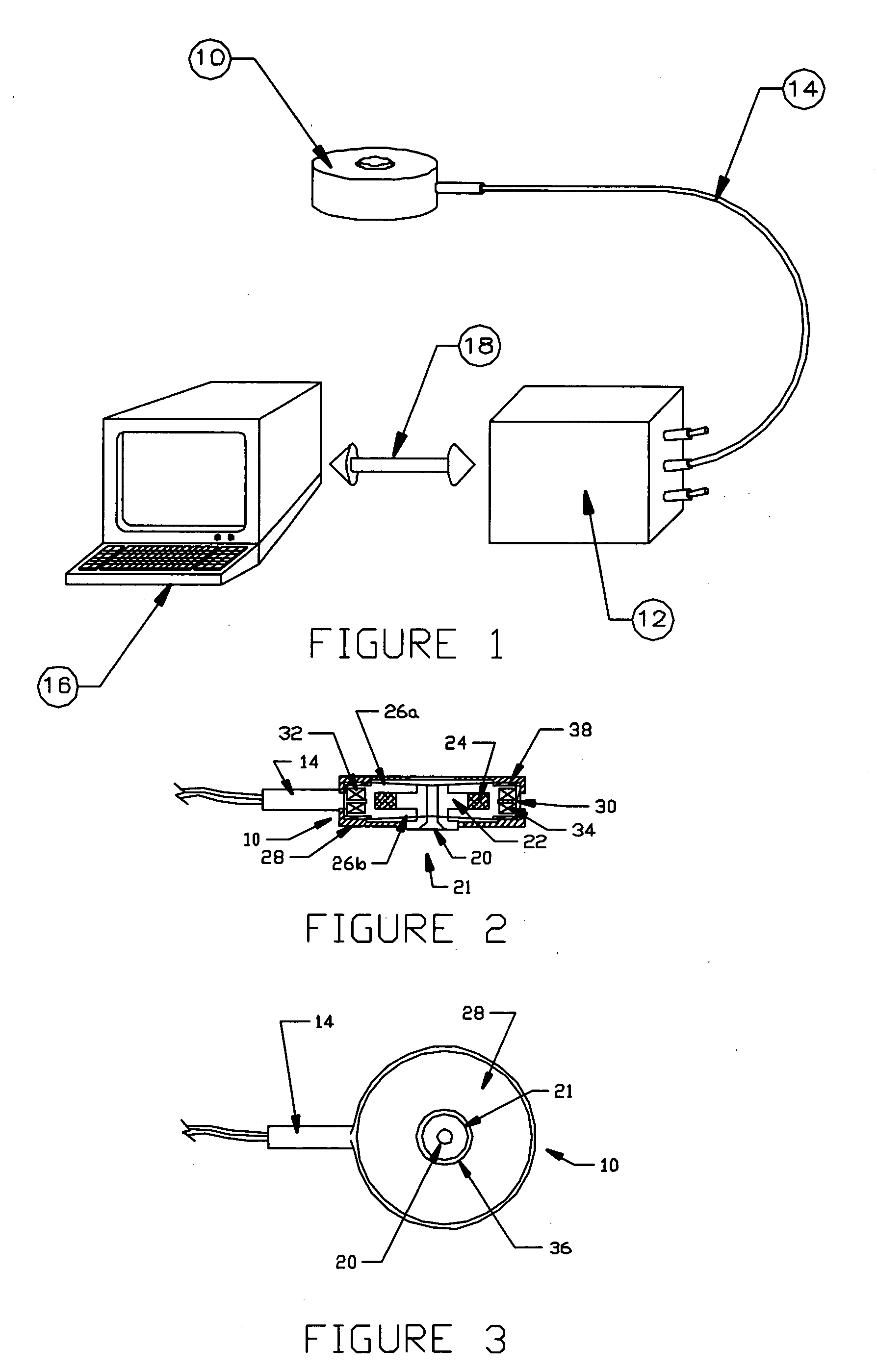

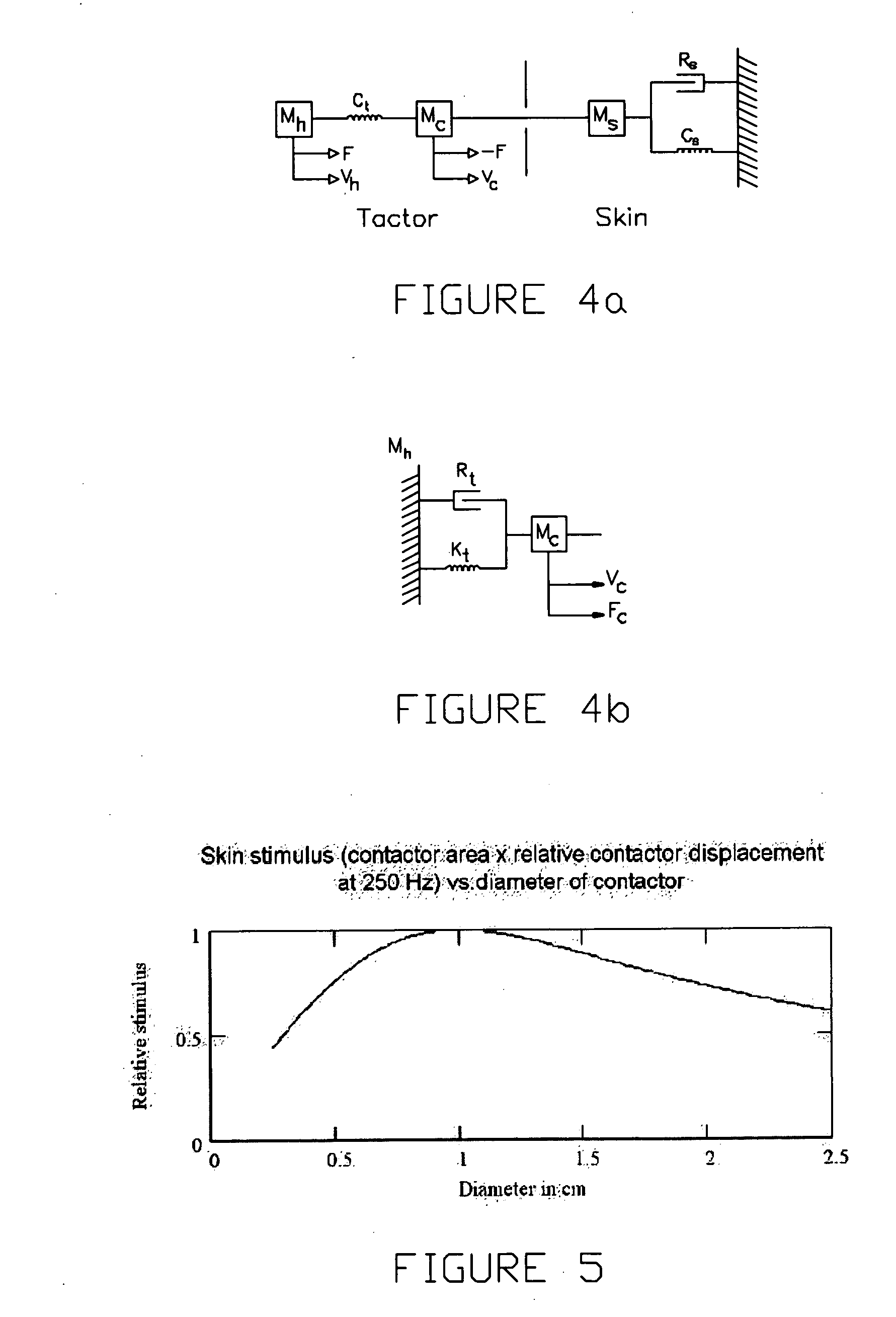

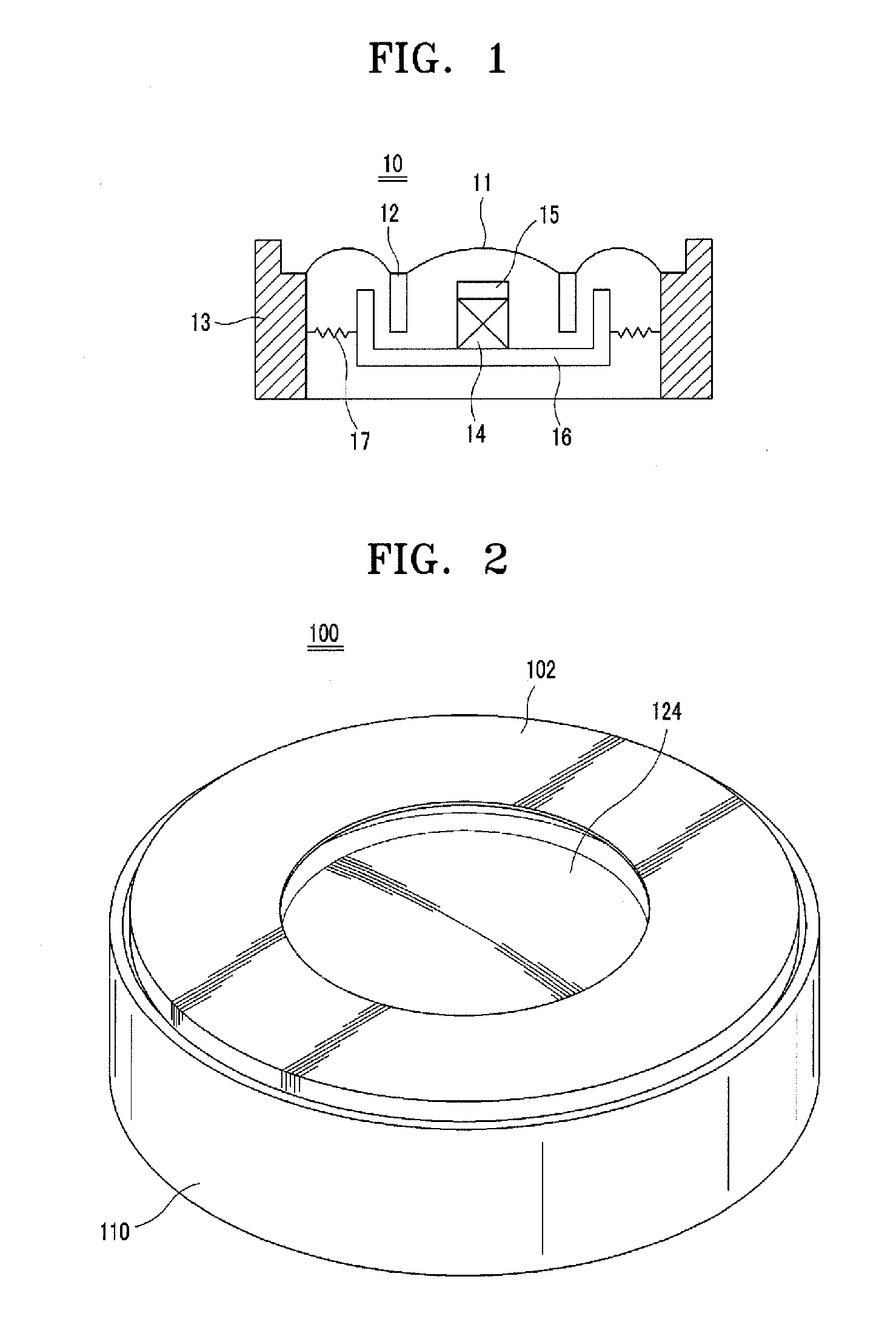

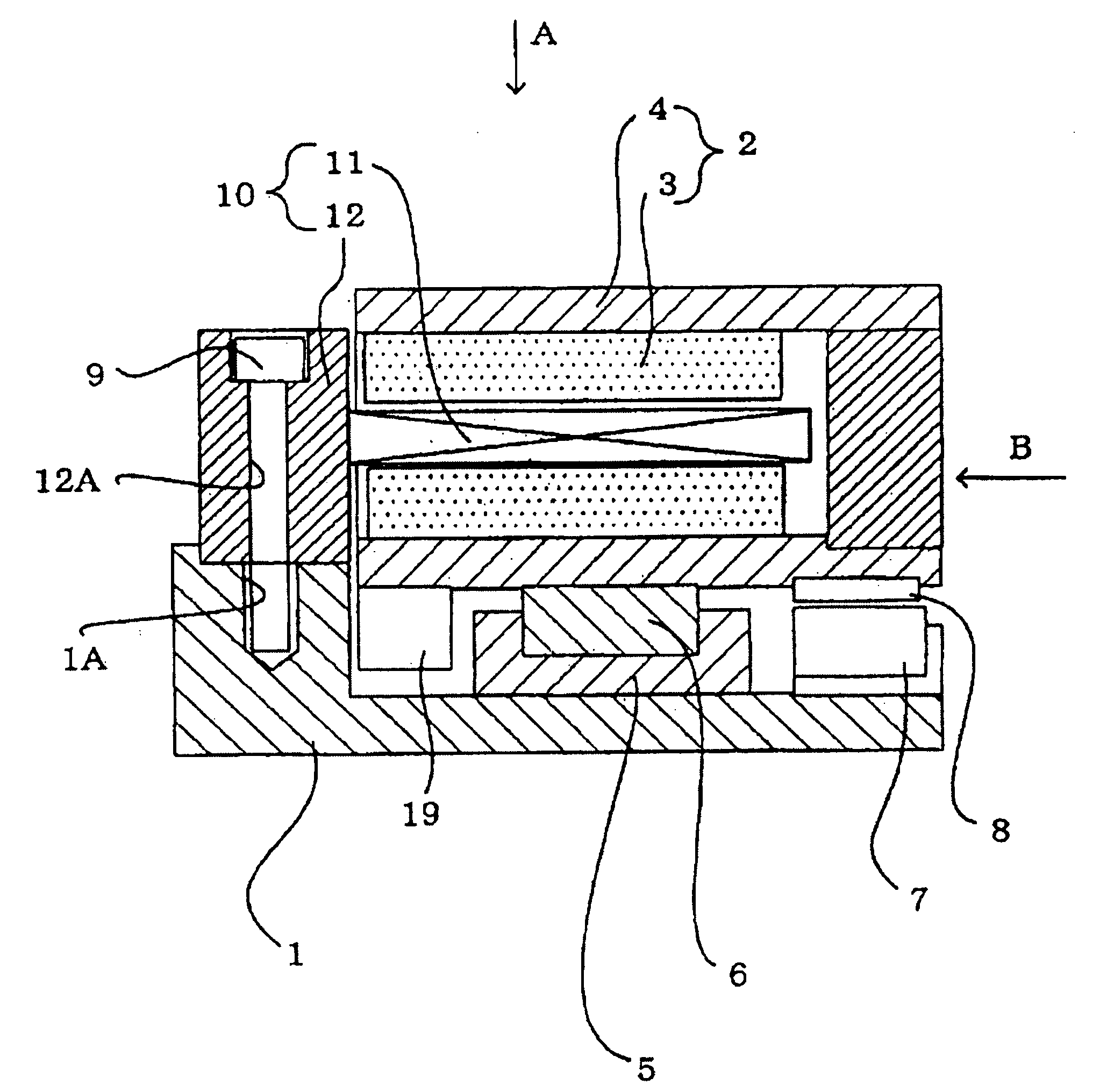

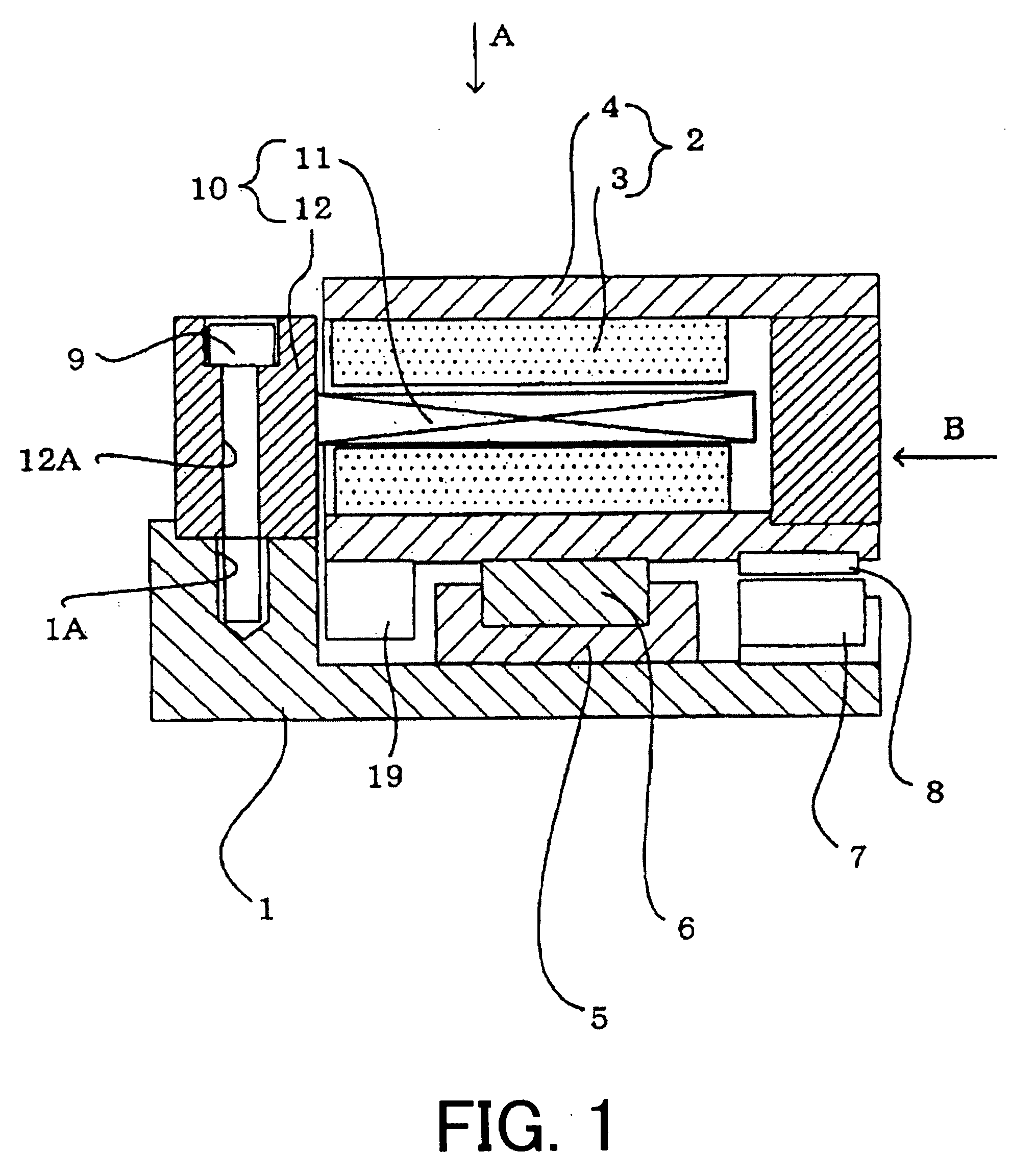

Method and apparatus for generating a vibrational stimulus

ActiveUS7798982B2Easily feltPromote localizationChiropractic devicesVibration massageElectricityTransducer

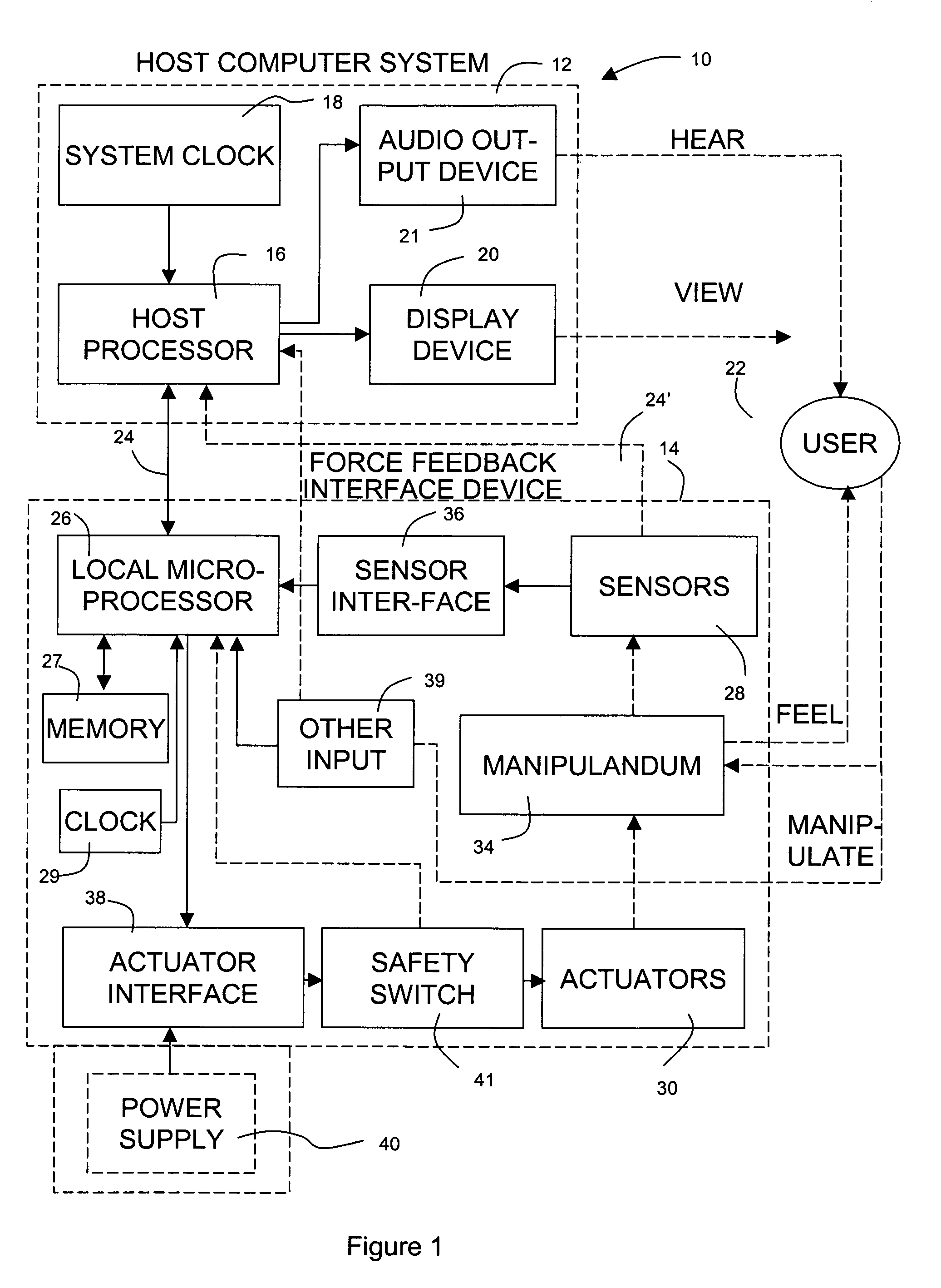

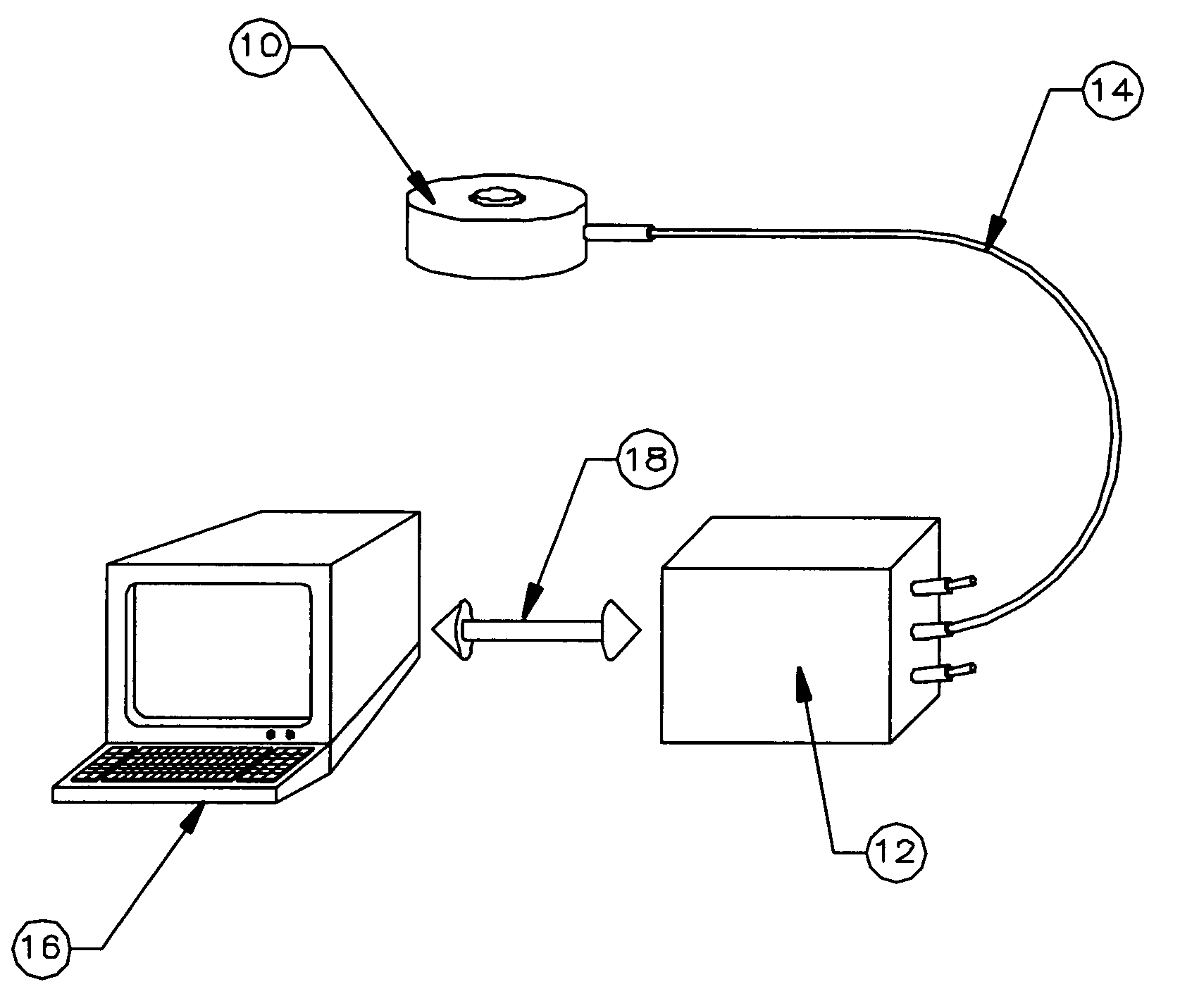

A vibrotactile transducer provides a point-like vibrational stimulus to the body of a user in response to an electrical input. The apparatus includes a housing held in contact with the skin and a moving mechanical contactor protruding through in an opening in said housing and preloaded into skin. The contactor is attached to a torroidal moving magnet assembly suspended by springs in a magnetic circuit assembly consisting of a housing containing a pair of electrical coils. The mass of the magnet / contactor assembly and the compliance of the spring are chosen so that the electromechanical resonance of the motional masses, when loaded by a typical skin site on the human body, are in a frequency band where the human body is most sensitive to vibrational stimuli. By varying the drive signal to the vibrotactile transducer and activating one or more transducer at specific location on the body using an appropriate choice of signal characteristics and / or modulation, different information can be provided to a user in a intuitive, body referenced manner.

Owner:ENG ACOUSTICS

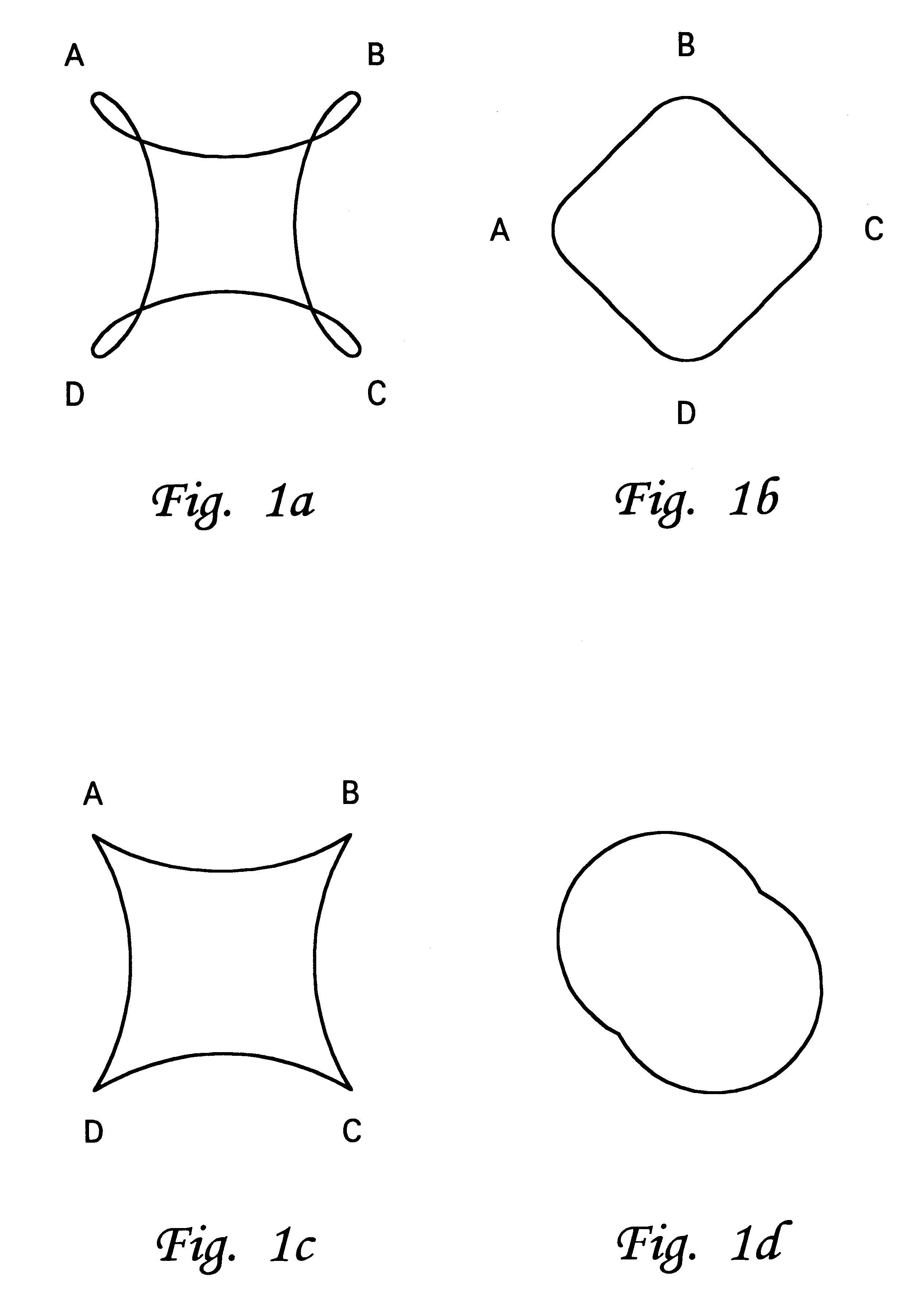

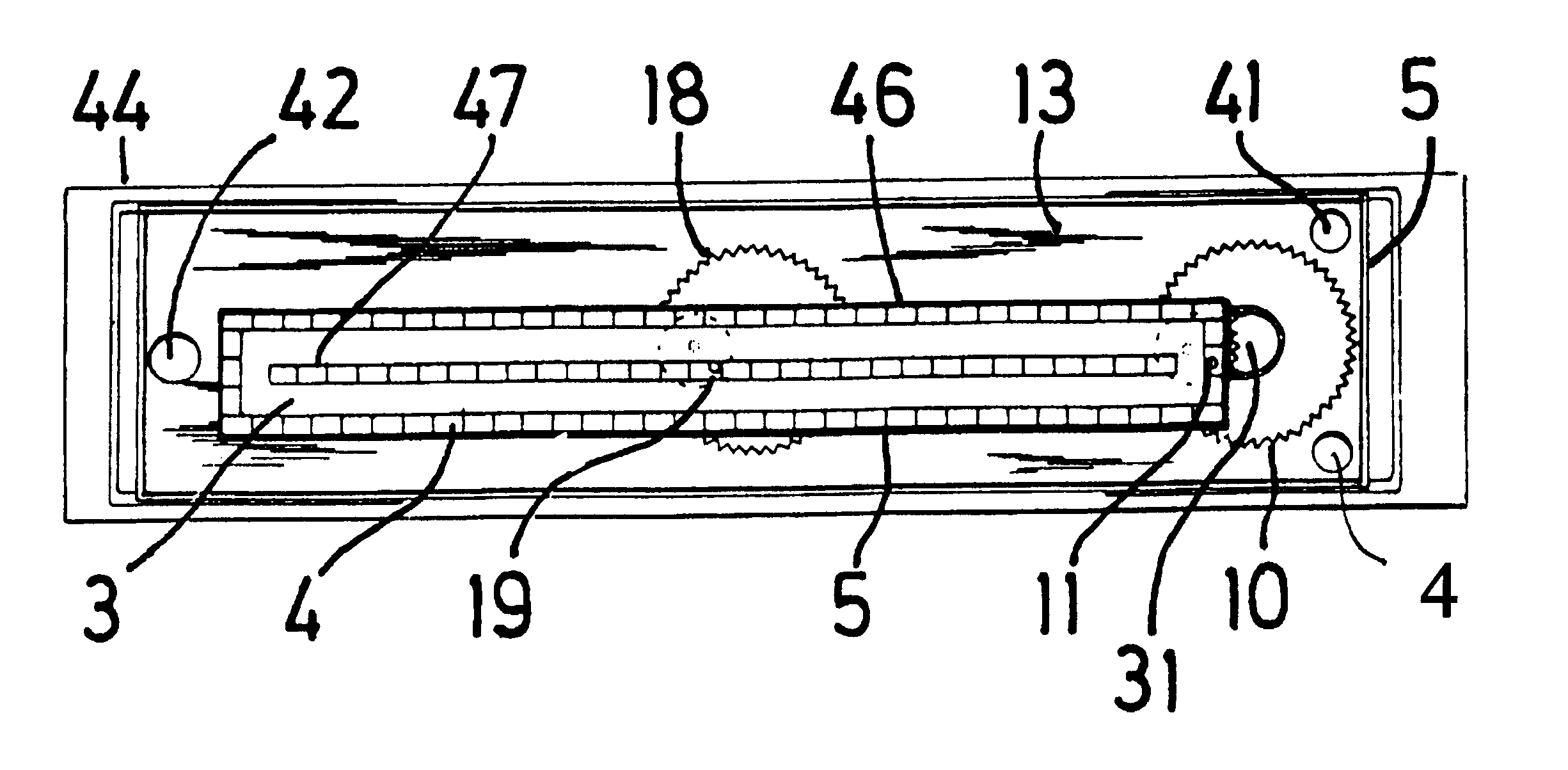

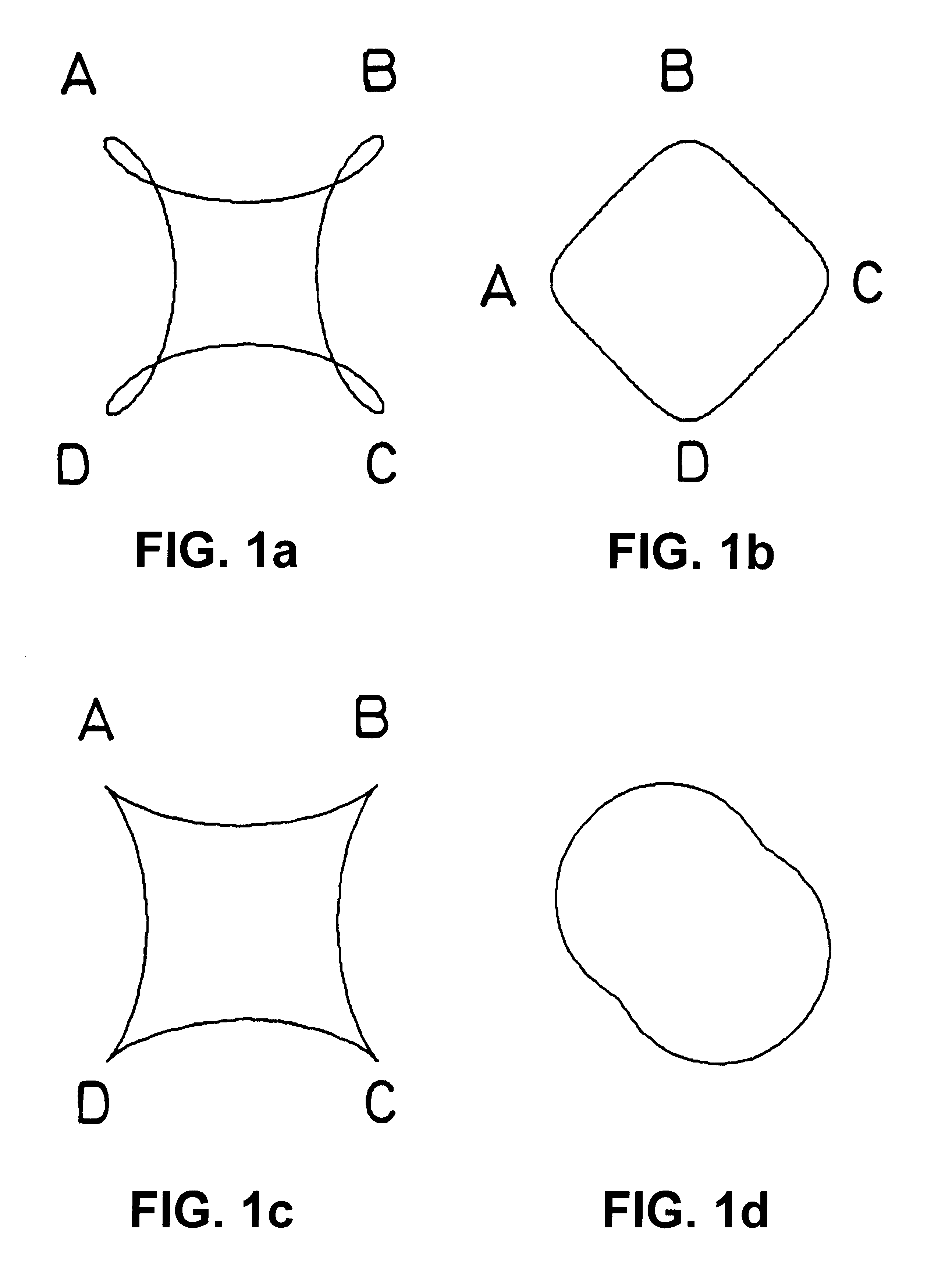

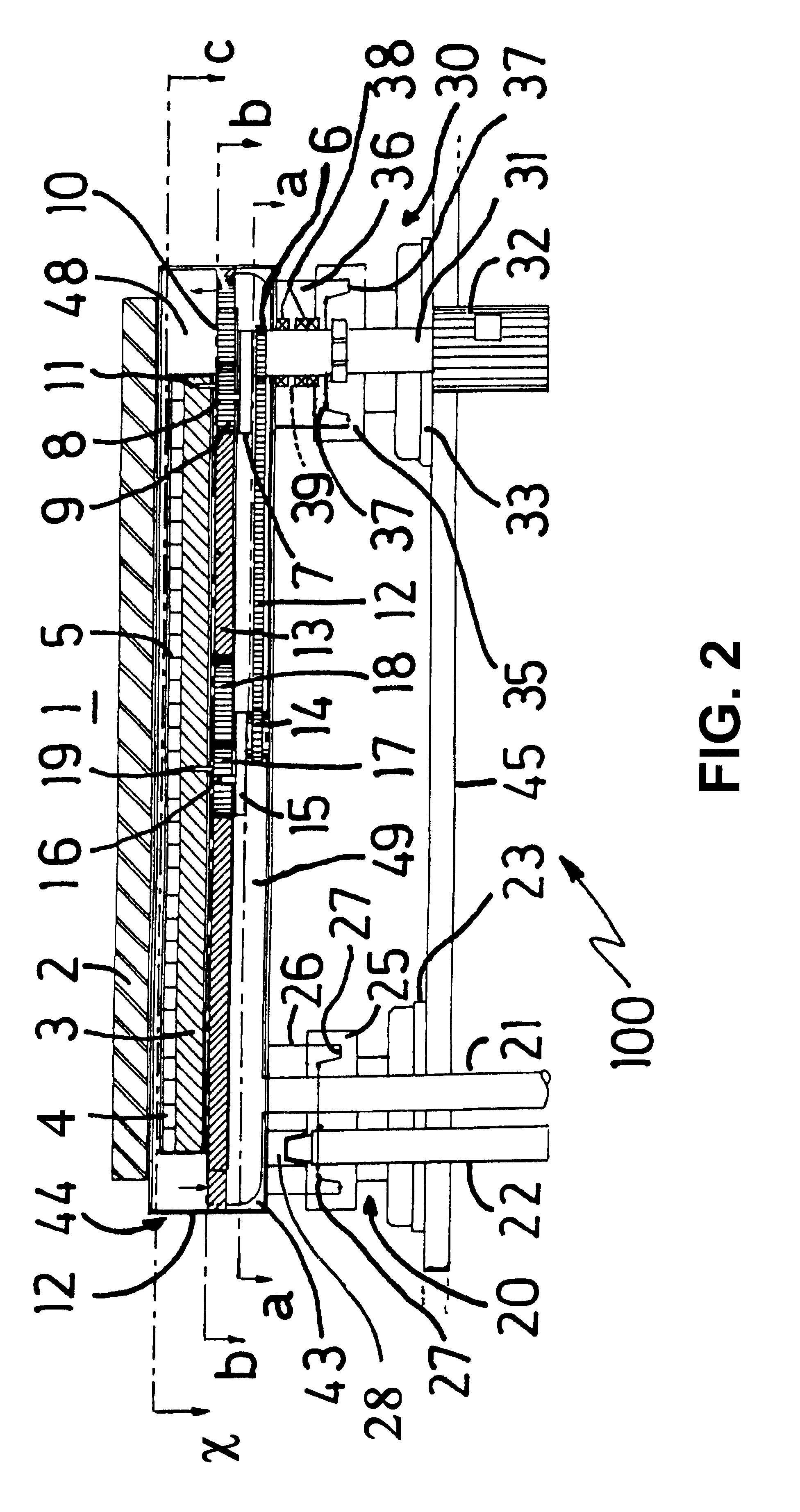

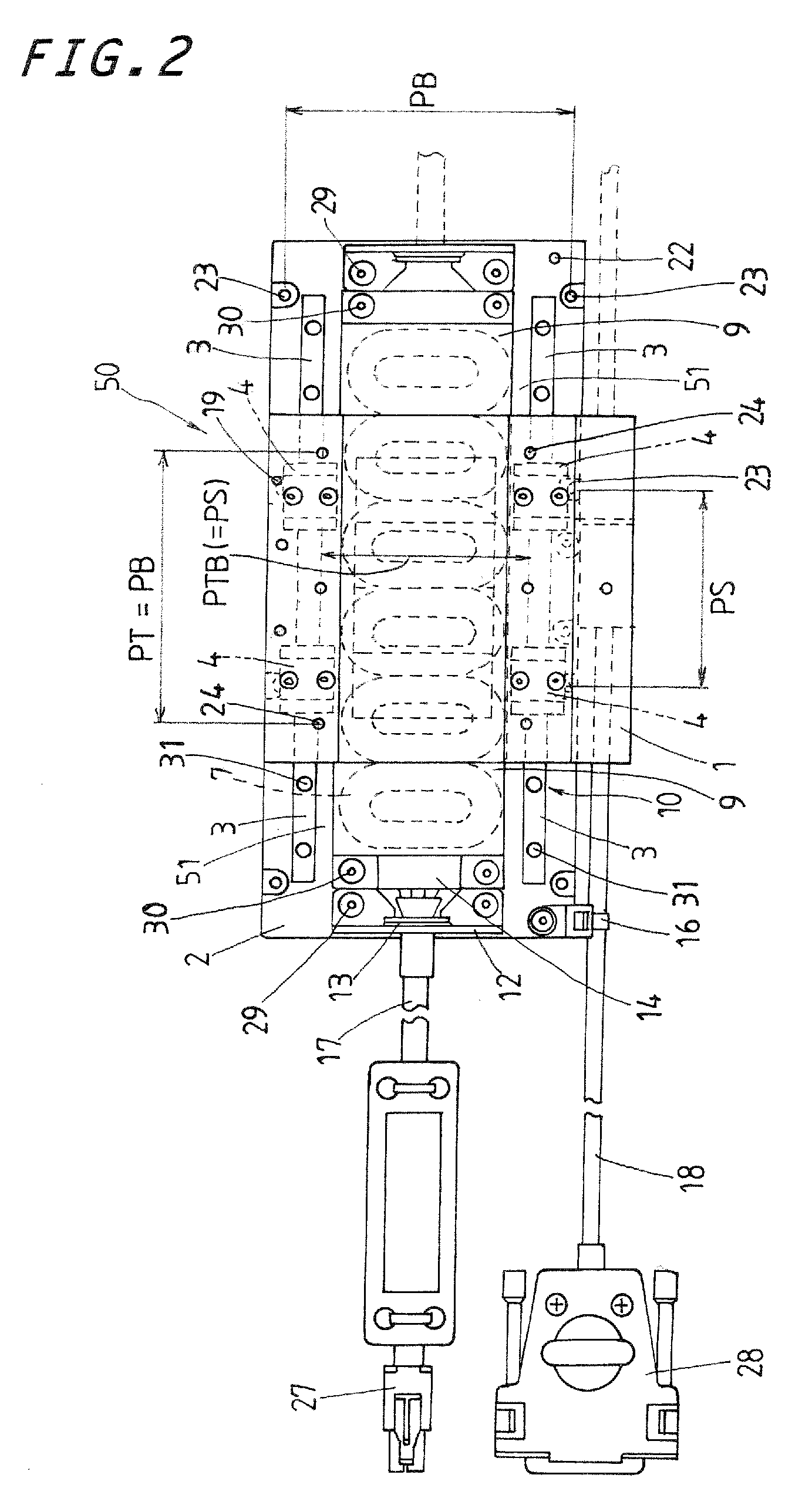

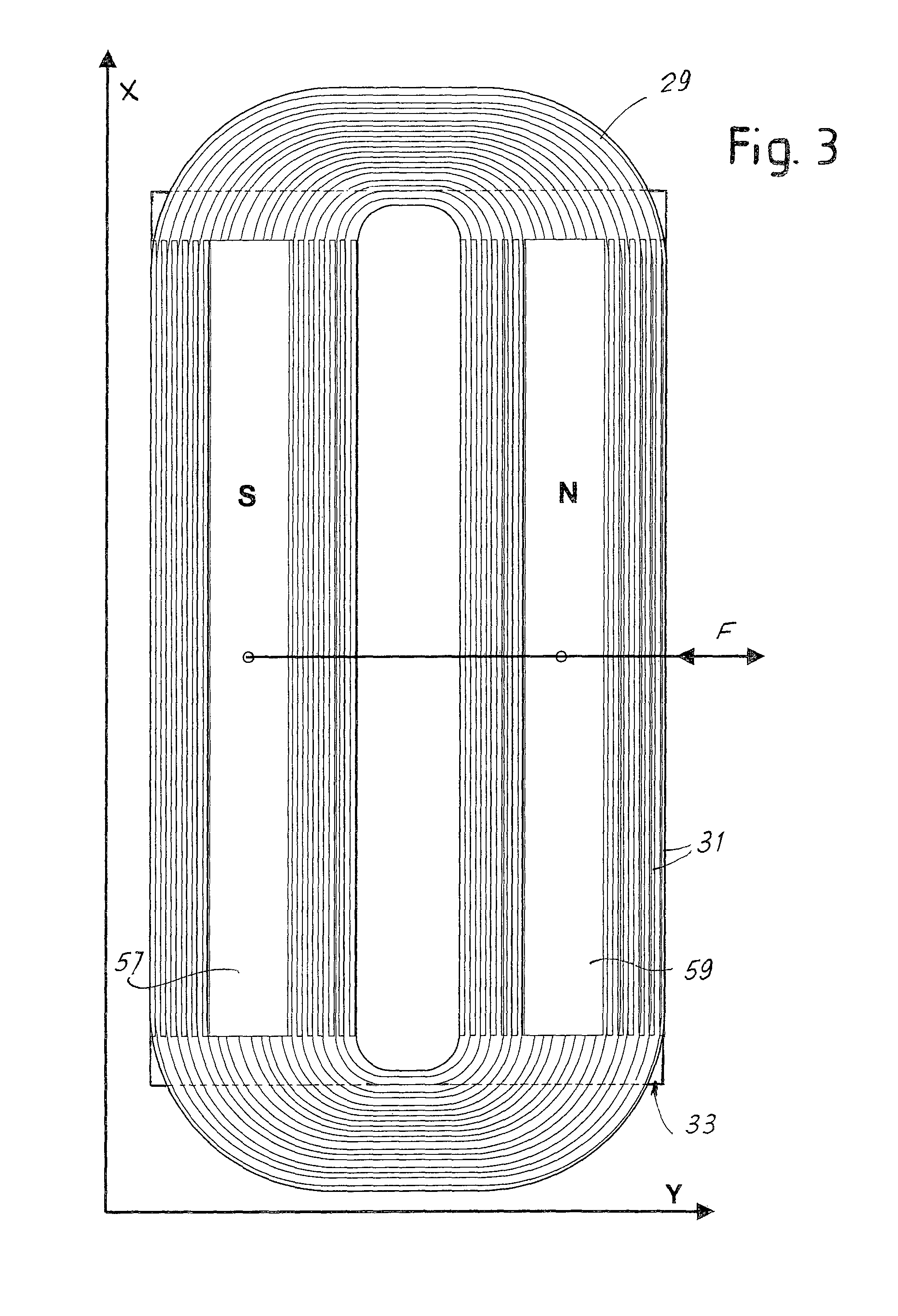

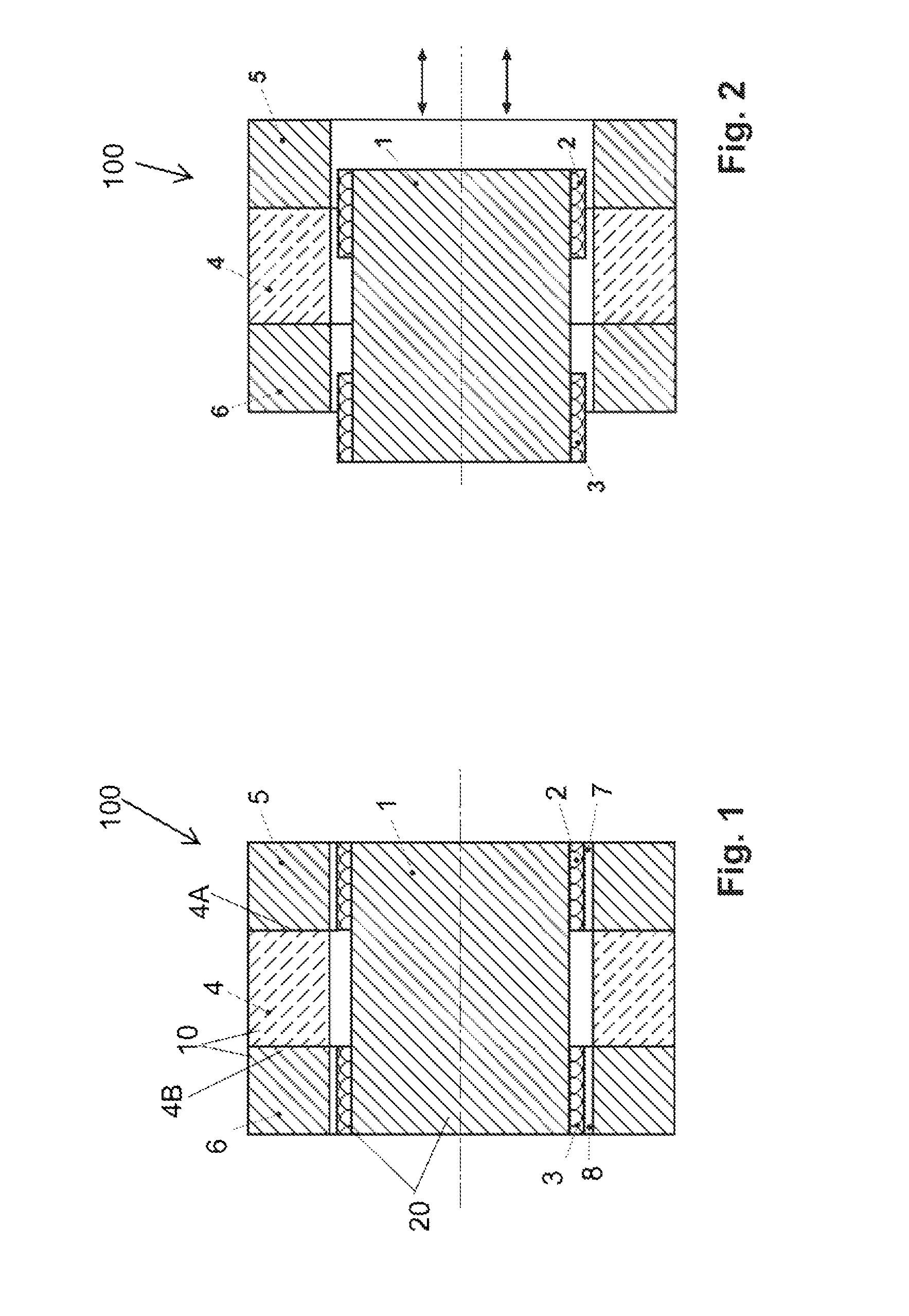

Planar magnetron with moving magnet assembly

InactiveUS6322679B1Simple driving mechanismSimple and efficientCellsElectric discharge tubesClosed loopEngineering

The present invention provides a planar magnetron including a surface for mounting a planar substantially polygonal target (2) having a substantially central target area for sputtering onto a substrate. The magnetron comprises an array of magnets (4) defining a closed loop magnetic field for generating an elongated plasma race-track above the target (2). Means for establishing cyclical, relative, substantially translational movement between the race-track and the target support surface are provided, the substantially translational movement being substantially parallel to this surface and the trace of the substantially translational movement being a two-dimensional figure. The periphery of the race-track lies substantially within said substantially central target area throughout each cycle, the establishing means being adapted to provide a substantially uniform erosion of the target (2) at least within said substantially central target area.

Owner:BEKAERT ADVANCED COATINGS

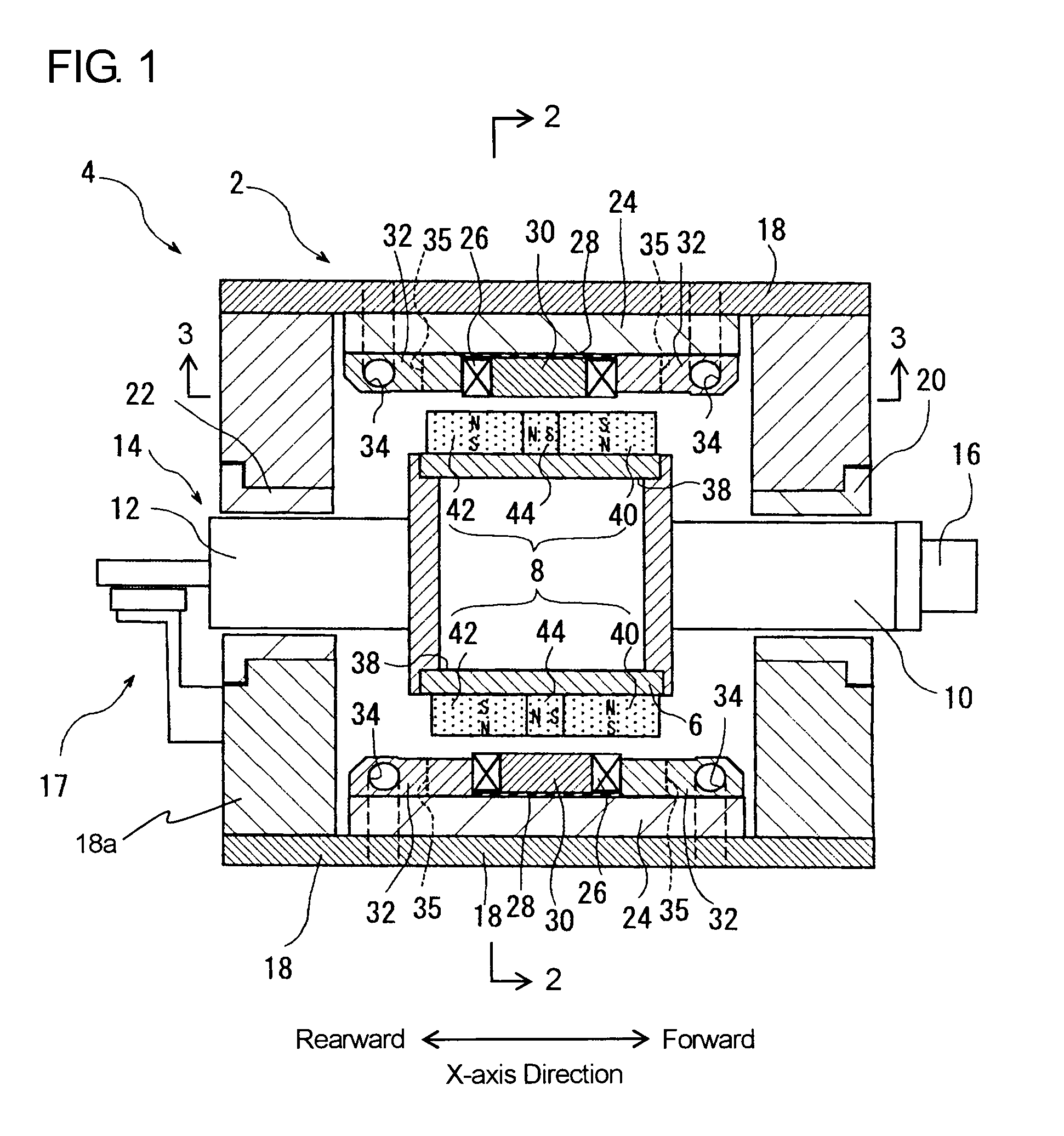

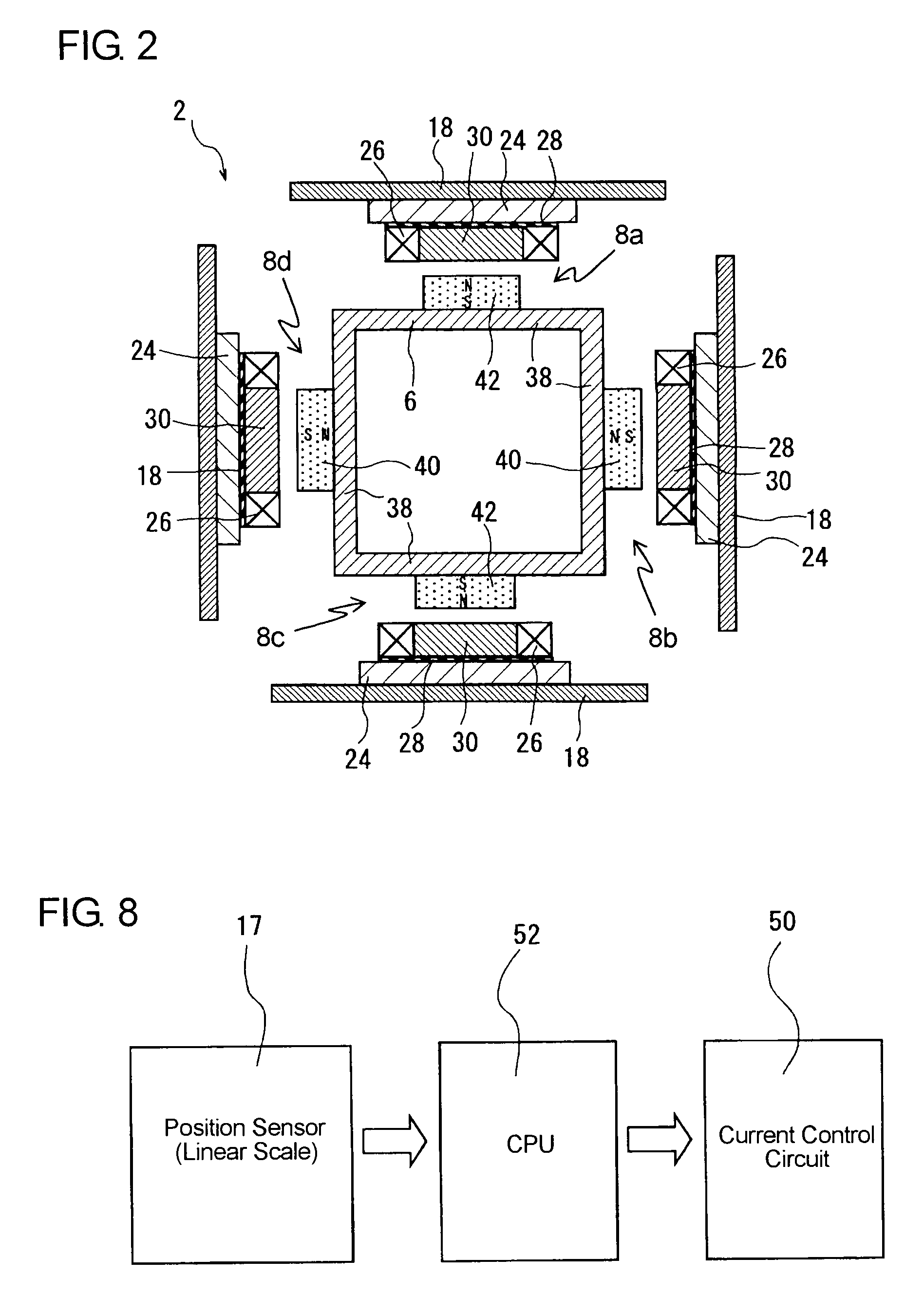

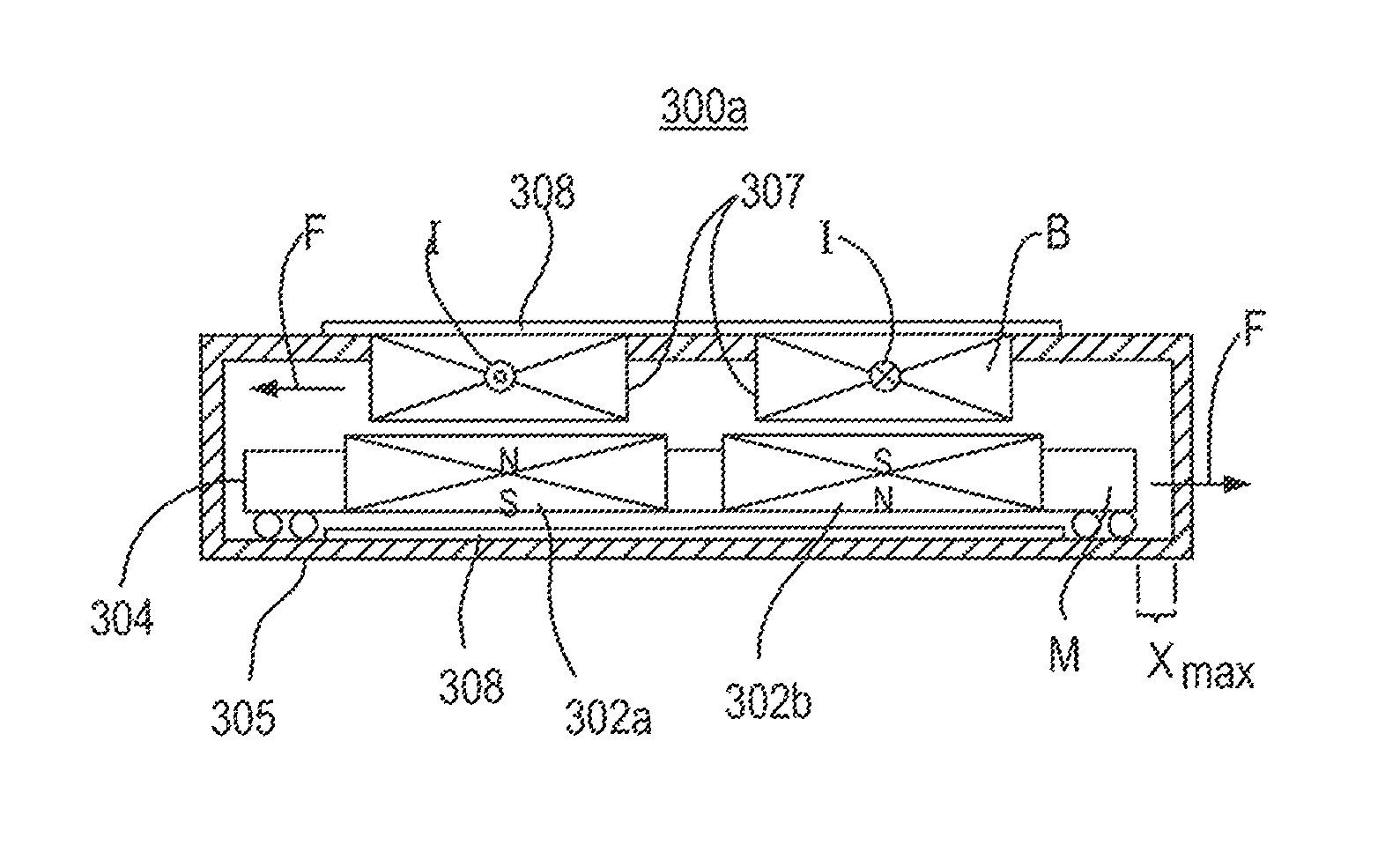

Moving magnet actuator

An apparatus includes an electromagnetically conductive assembly including a first member having a first end and a second end and a second member disposed between the first end and the second end of the first member. The second member and the first end of the first member define a first gap. The second member and the second end of the first member define a second gap. A movable member moves with respect to the conductive member. A first magnet is coupled to the movable member and is disposed a distance from the first gap. A second magnet is coupled to the movable member and is disposed a distance from the second gap.

Owner:IMMERSION CORPORATION

Erosion compensated magnetron with moving magnet assembly

InactiveUS6416639B1Simple profileOptimal utilisationCellsElectric discharge tubesClosed loopRace track

A magnetron including a target (2) for sputtering onto a substrate in described. The magnetron comprises a magnetic field generator (4) for generating a closed loop magnetic field adapted to generate a plasma race-track above the target (2) and a driving device for establishing relative substantially translational movement between the race-track and the target (2) and adapted to influence the magnetic field generated by the magnetic field generator (4) at least during part of the relative substantially translational movement, the distance between any point on the race track and the momentarily closest part of the one or more pieces (50) of ferromagnetic material varying in accordance with the relative substantially translational movement of the race-track and the target (2).

Owner:BEKAERT ADVANCED COATINGS

Method and apparatus for generating a vibrational stimulus

ActiveUS20060015045A1Easily be located against bodyEasily feltChiropractic devicesVibration massageElectricityTactile transducer

A vibrotactile transducer provides a point-like vibrational stimulus to the body of a user in response to an electrical input. The apparatus includes a housing held in contact with the skin and a moving mechanical contactor protruding through in an opening in said housing and preloaded into skin. The contactor is attached to a torroidal moving magnet assembly suspended by springs in a magnetic circuit assembly consisting of a housing containing a pair of electrical coils. The mass of the magnet / contactor assembly and the compliance of the spring are chosen so that the electromechanical resonance of the motional masses, when loaded by a typical skin site on the human body, are in a frequency band where the human body is most sensitive to vibrational stimuli. By varying the drive signal to the vibrotactile transducer and activating one or more transducer at specific location on the body using an appropriate choice of signal characteristics and / or modulation, different information can be provided to a user in a intuitive, body referenced manner.

Owner:ENG ACOUSTICS

Moving-magnet type linear motor

InactiveUS7732951B2Light weightImprove responsivenessMagnetic circuitCooling/ventillation arrangementElectric machineEngineering

A moving-magnet type linear motor is provided with cooling blocks which are attached to each of stator bases alongside a coreless coil and which allow coolant to flow therethrough for cooling the coreless coil. Each of the cooling blocks has in a base end portion thereof a fluid passage for flowing coolant and at an extreme end portion thereof a plurality of sheet-like protrusions like fins which are arranged alongside a part of the circumferential surface of the coreless coil with a clearance between each protrusion and the next thereto. Each cooling block is thermally closely jointed with the coreless coil at the extreme ends of the sheet-like protrusions.

Owner:JTEKT CORP

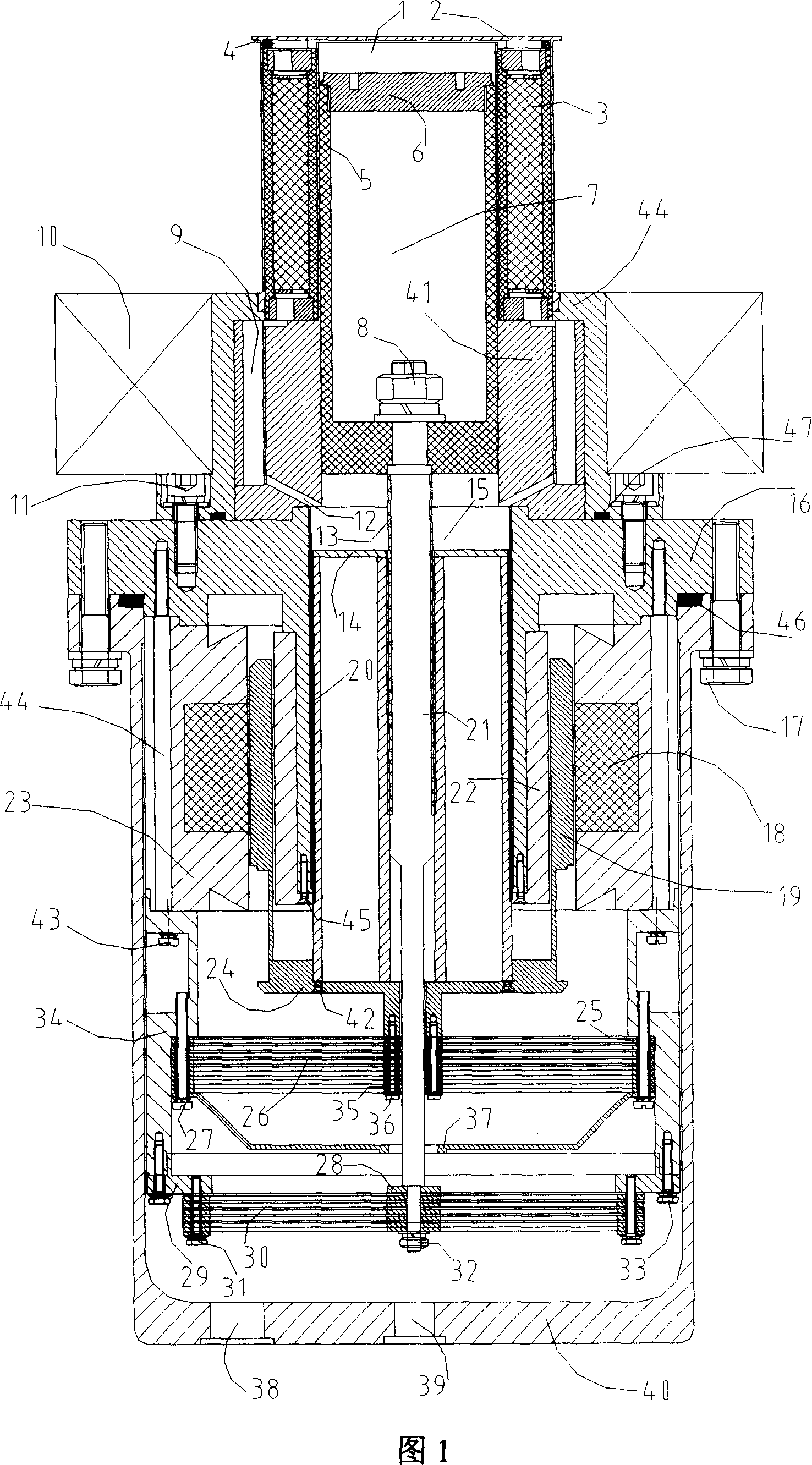

Stirling refrigerating machine being as cold source of low temperature refrigerator

InactiveCN1959298ACompact structureImprove cooling efficiencyCompression machinesGas cycle refrigeration machinesEngineeringDrive motor

A Stirling refrigerator used as refrigeration source of low temperature freezer is prepared as arranging compression cavity and expansion cavity coaxially, using plate spring to support expansion piston and compression piston, applying seal structure at gap between piston and air cylinder, using a moving-magnet linear motor as driving motor of compression, setting no motor on expansion machine, applying pneumatic driving on expansion piston, using linear cut red copper ring as heat radiator, building in red copper ring in heat exchanger setting cold storage to be ring structure and arranging hole on wall of expansion cylinder to let He enter to compression cavity.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

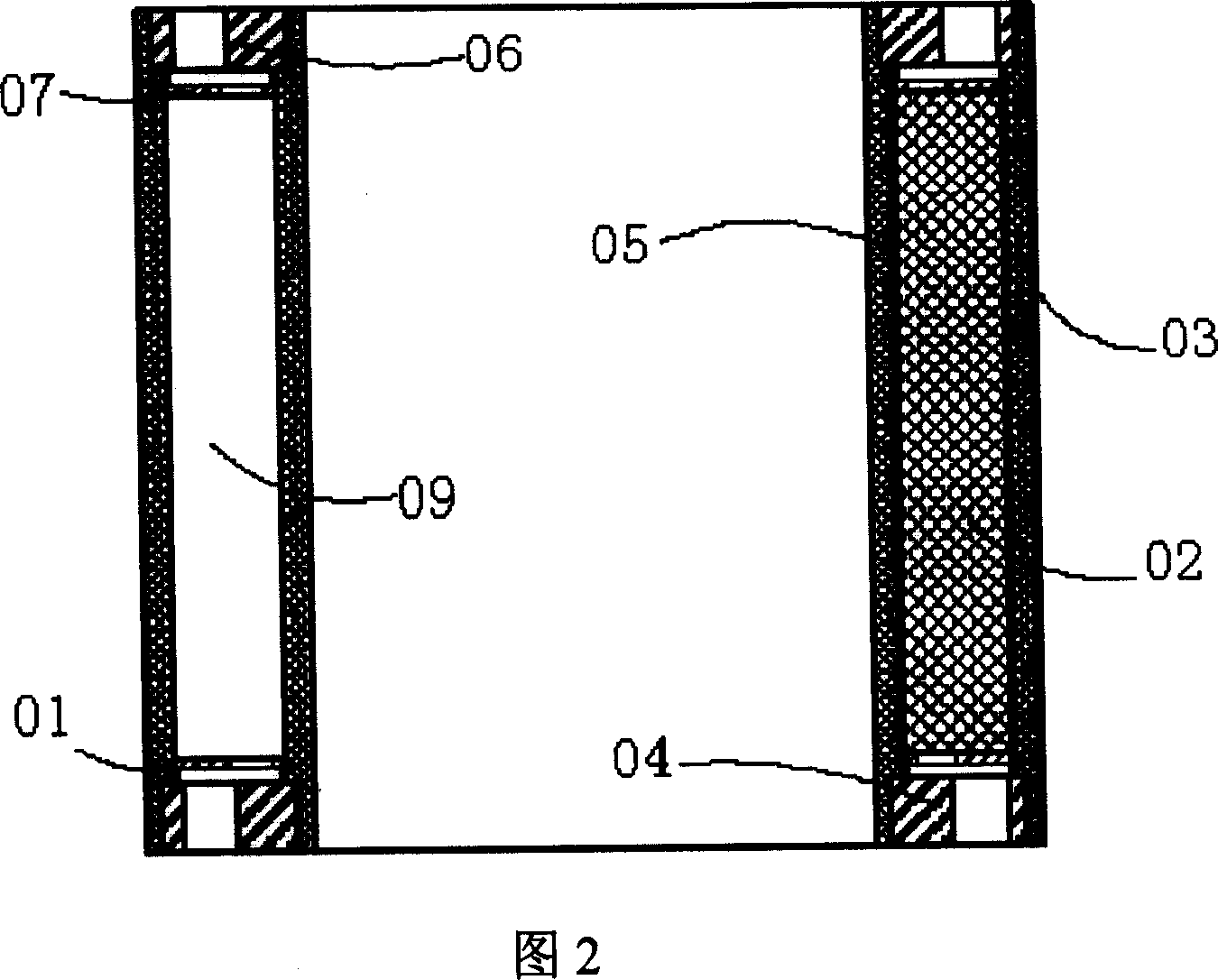

Moving-magnetic linear compressor

InactiveCN1773112AReduced risk of demagnetizationReduce frictionPiston pumpsPositive-displacement liquid enginesMagnetic tension forceExhaust valve

The present invention relates to a moving-magnet straight-line compressor. It includes a linear motor component, it mainly has inner and outer magnetic yokes with concentric combined structure, moving-magnet coil, permanent magnet and motor runner bracket, the permanent magnet is positioned on the motor rotor bracket and placed in the magnetic field formed from inner and outer magnetic yokes; a compressor component, it mainly has machine seat, cylinder, exhaust valve and suction valve which are positioned on the machine seat and piston connected with motor runner; and a machine shell which is seal-connected with machine seat. It is characterized by that it also includes a suspension component, it mainly has a spring support frame, flexible springs, inner and outer washers and collision-prevention mechanism, etc.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI +1

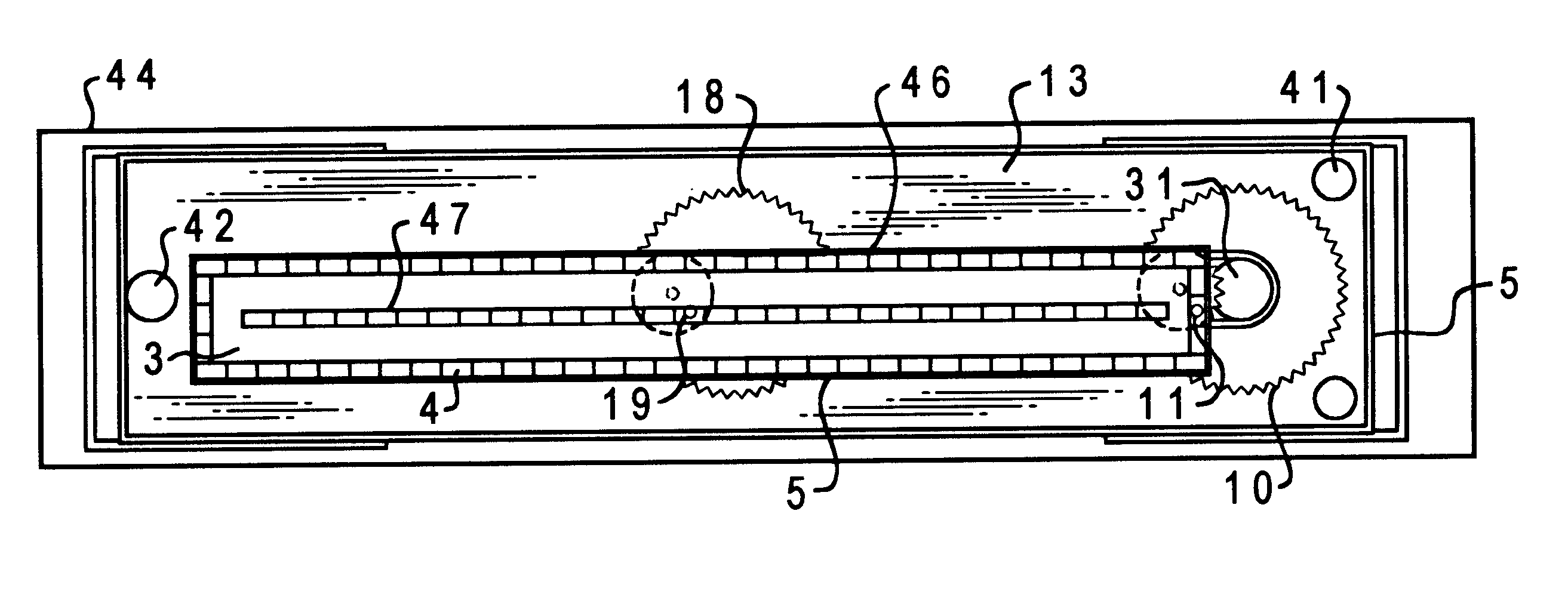

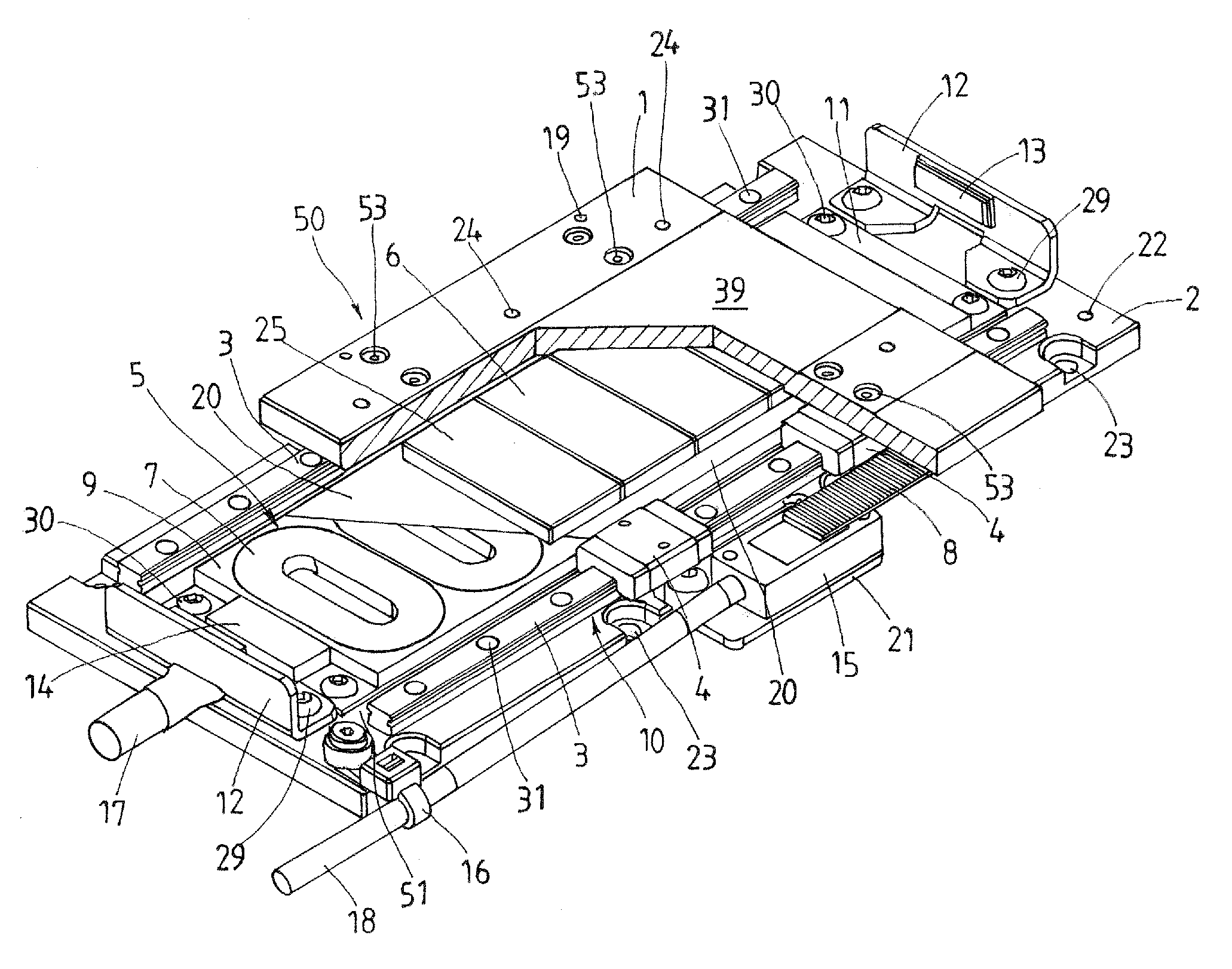

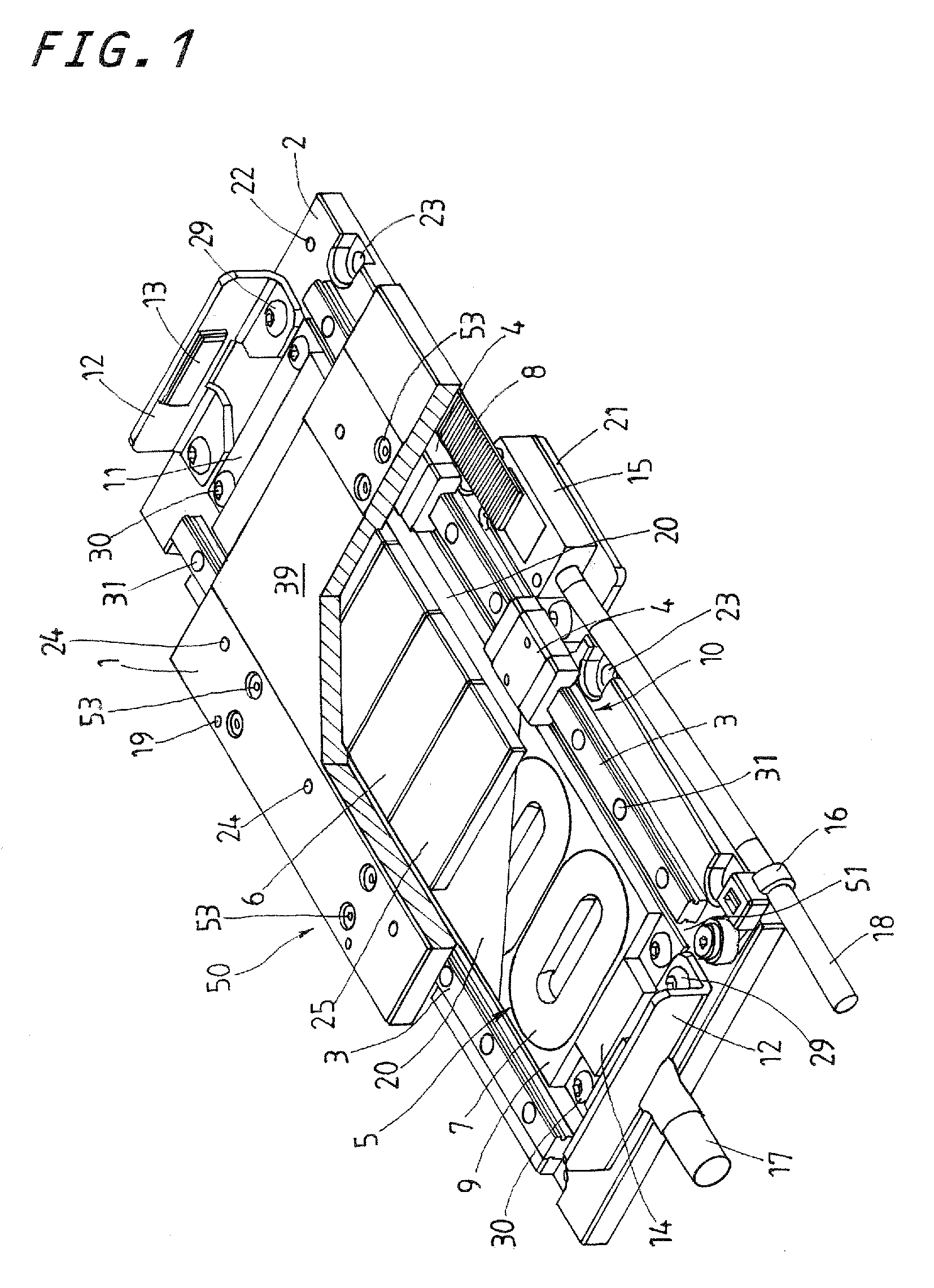

Sliding device with onboard moving-magnet linear motor

ActiveUS20070257564A1Improve performanceLose weightMechanical energy handlingPropulsion systemsEngineeringLinear motor

A sliding device with onboard moving-magnet linear motor is envisaged making the reciprocating stroke of a table longer, and enhancing the propulsion, high velocity and response of the table even with small in dimension, compact in construction and better in production efficiency. With the sliding device, a bed serves as a coil yoke while a table is as a magnet yoke. An armature assembly is composed of armature windings, a board on which the armature windings lie in juxtaposition, a wiring lying on the board and making connections with a power line to supply electric power to the armature windings, a protective sheet covering an overall surface of the armature windings and moldings of adhesive material to get the armature windings and connections of a power line with wiring closely adhering to the board.

Owner:NIPPON THOMPSON +1

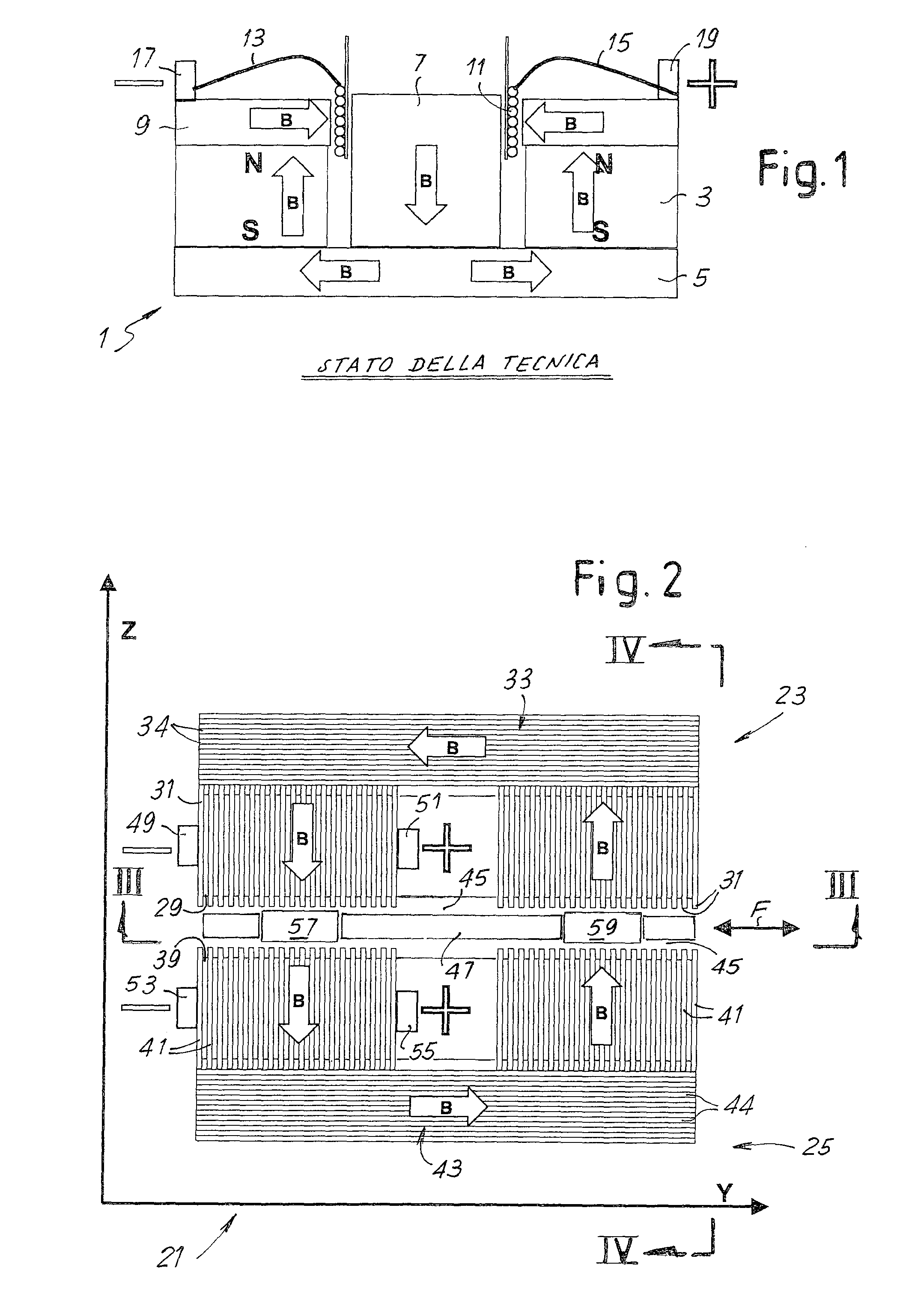

Electromechanical conversion system with moving magnets; acoustic diffuser comprising said system and a moving member that generates sound waves

The invention relates to an electromechanical conversion system comprising: a fixed supporting structure, a movable element with respect to the fixed structure; at least one excitation coil; and at least one permanent magnet for generating an excitation magnetic field. The permanent magnet is integral with the movable element and the coil is integral with the fixed supporting structure. Moreover, a ferromagnetic circuit is provided fixed with respect to the structure and cooperating with the permanent magnet.

Owner:LASTRUCCI CLAUDIO

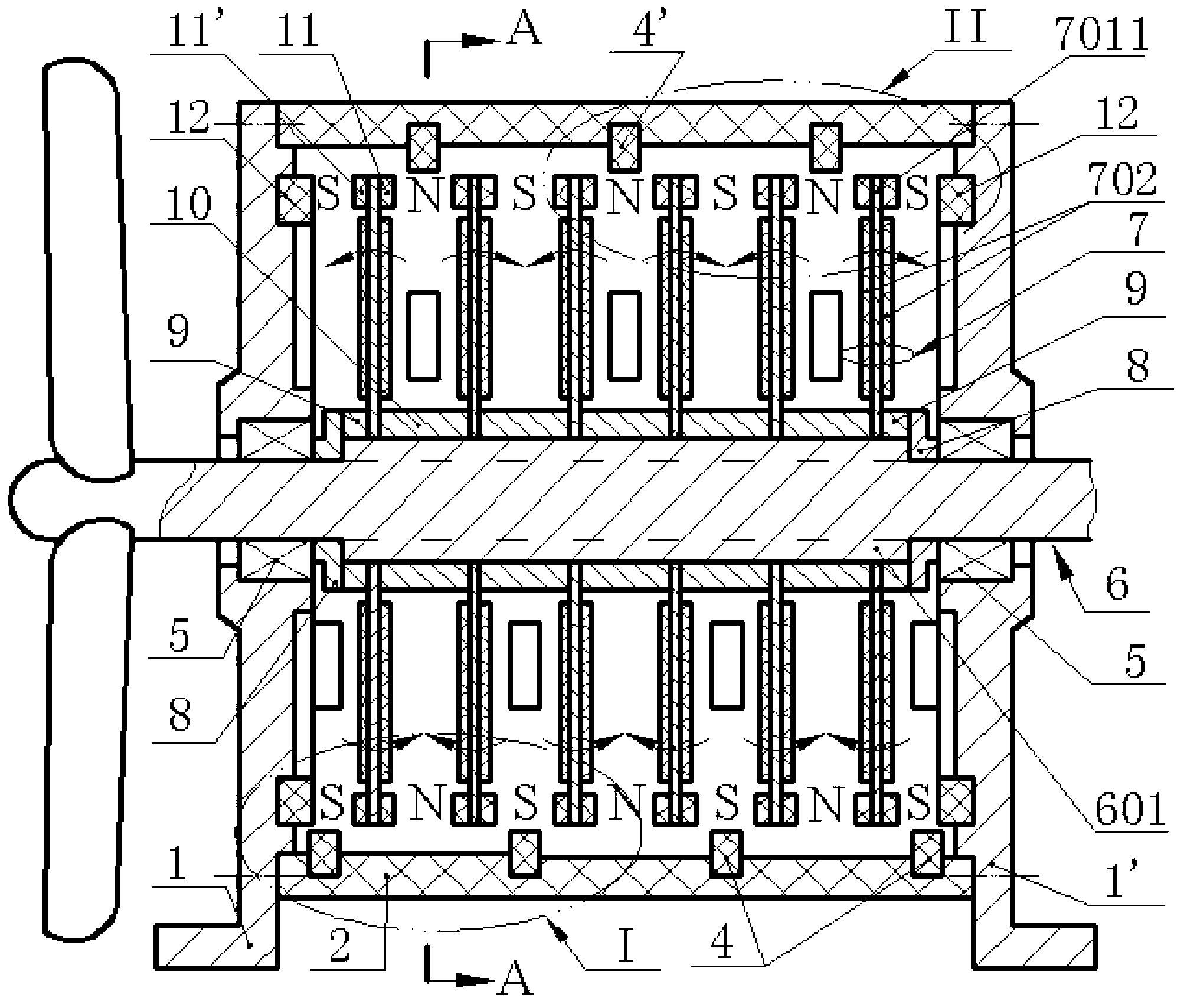

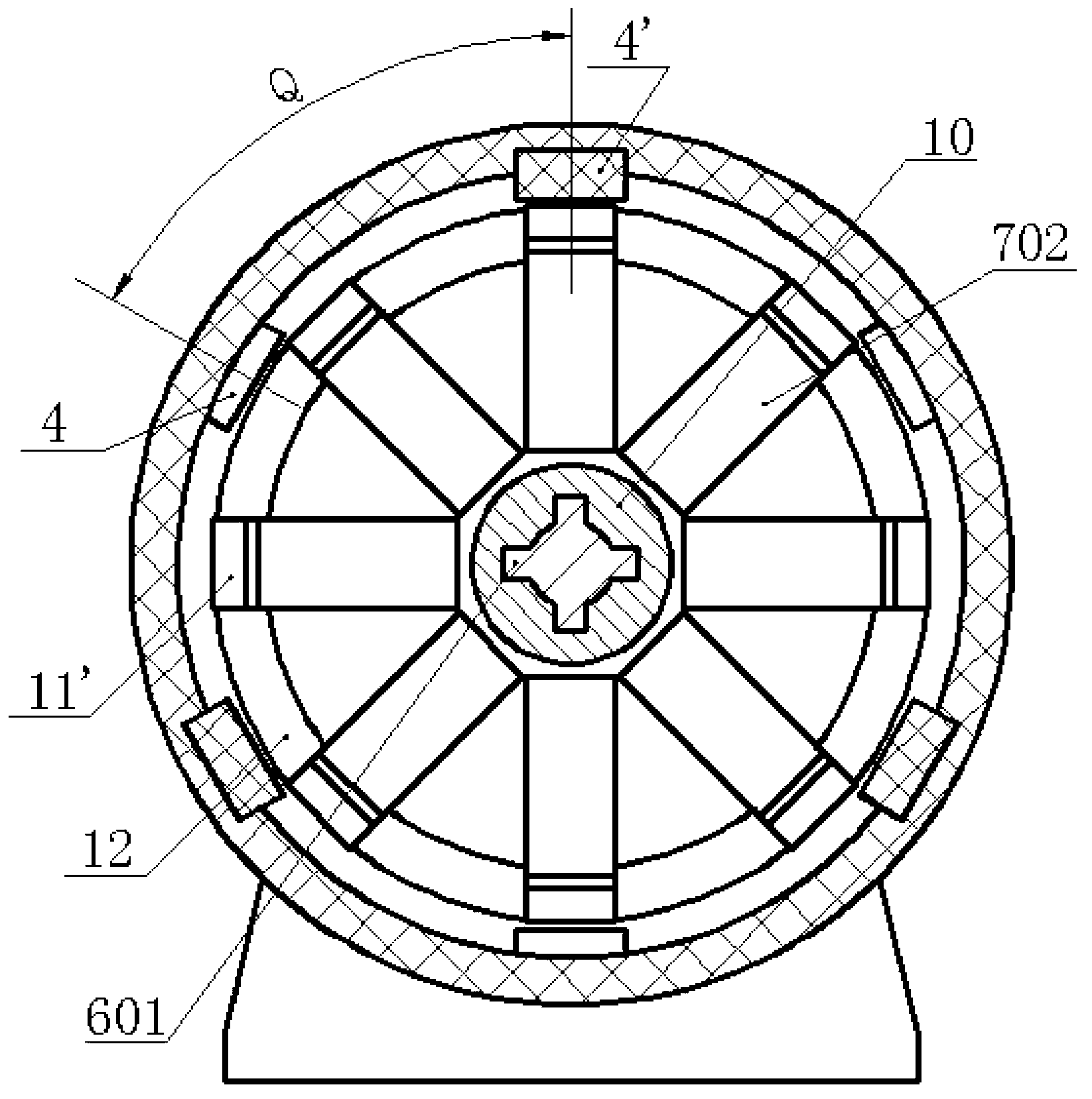

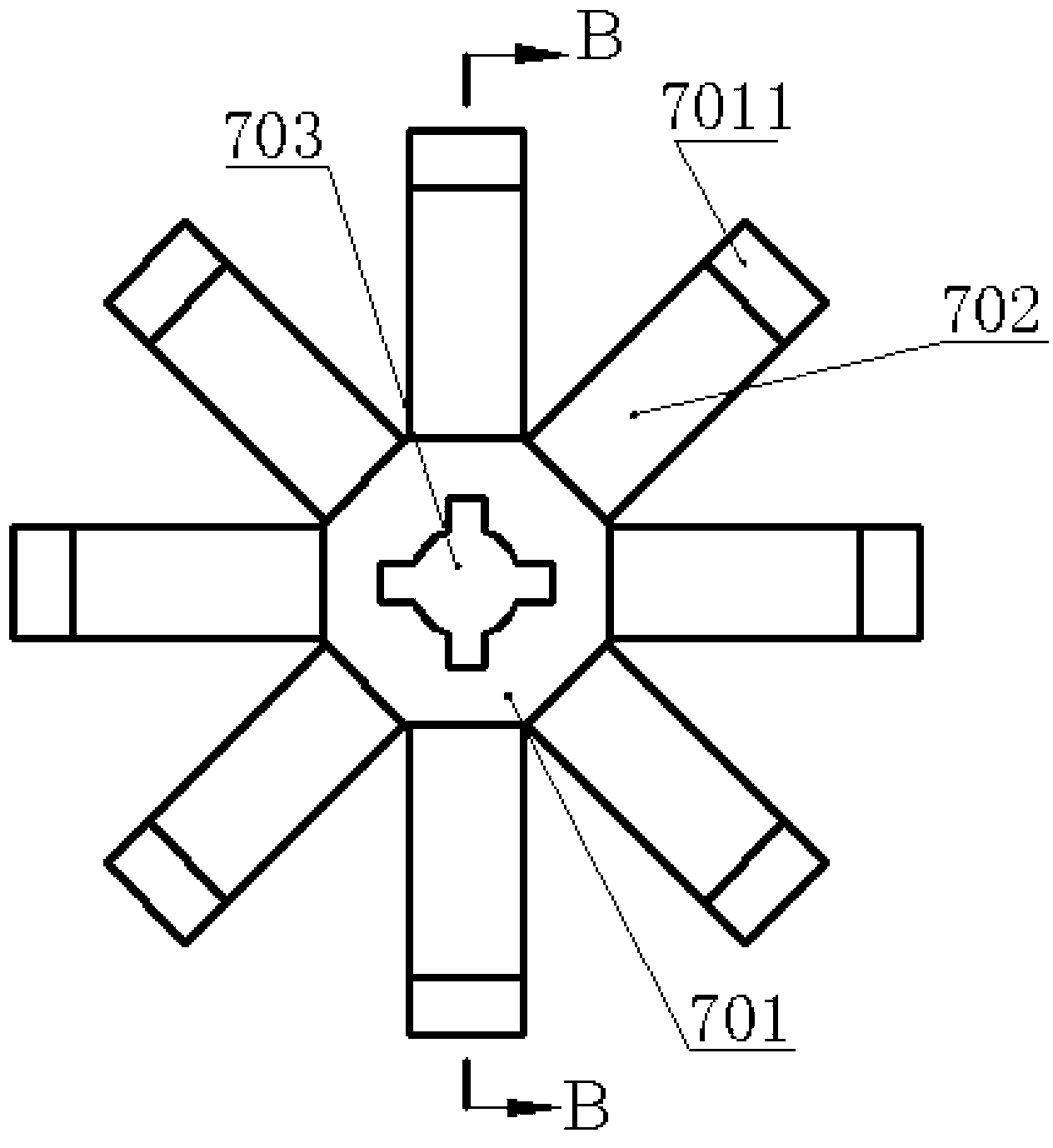

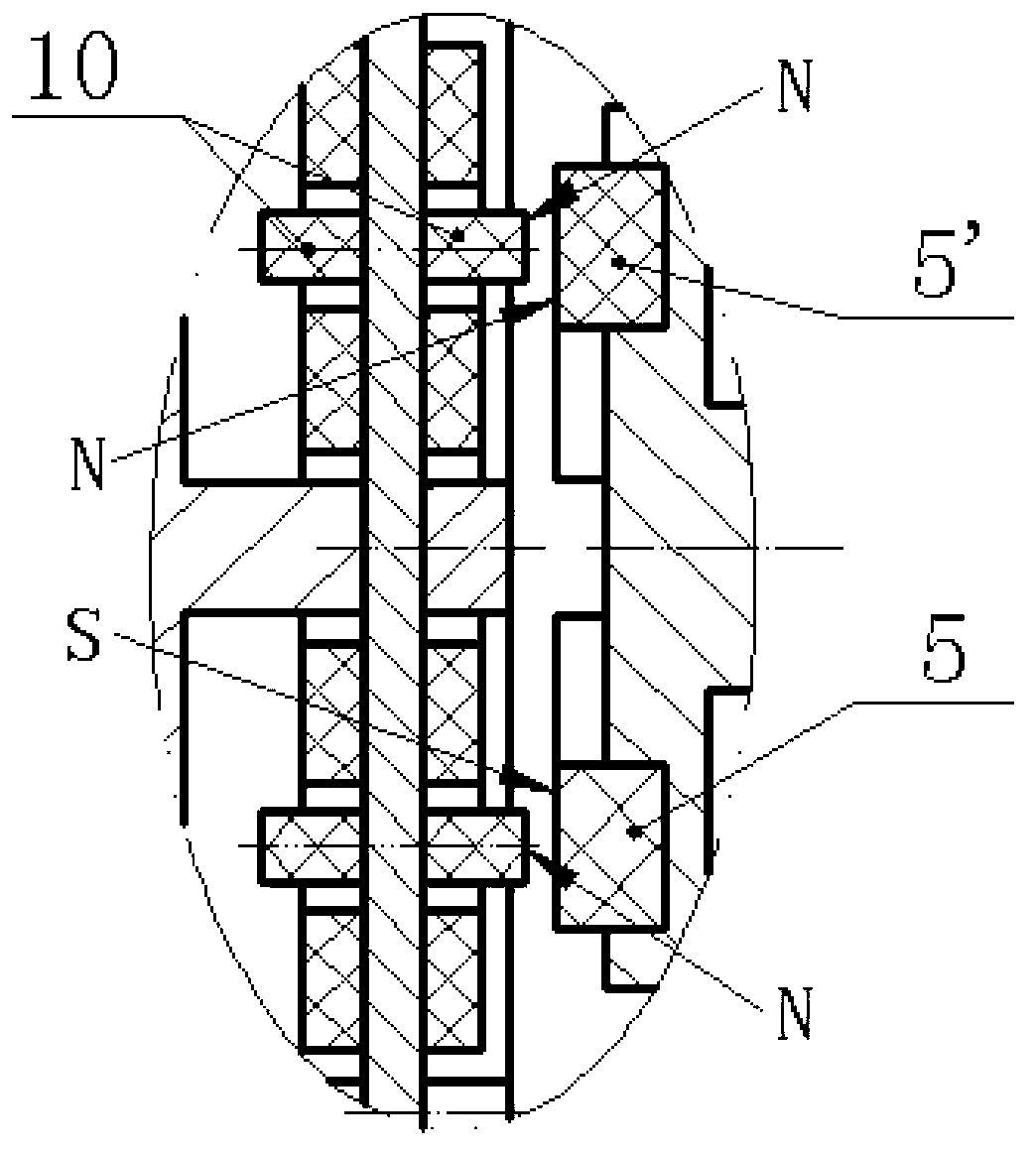

Bi-directionally magnetically coupled and axially excited and limited rotating-shaft piezoelectric generator

InactiveCN102801358AImprove reliabilityStrong speed adaptabilityPiezoelectric/electrostriction/magnetostriction machinesMagnetic tension forceElectricity

The invention relates to a bi-directionally magnetically coupled and axially excited and limited rotating-shaft piezoelectric generator and belongs to the field of piezoelectric generation. A cylinder is fixed between two bearing blocks by a bolt; multiple groups of static magnets I and static magnets II are alternately embedded on different cross sections of the internal wall of the cylinder; both the two bearing blocks are embedded with a bearing and a magnetic ring; a main shaft is arranged on the bearing block by the bearing; the spline of the main shaft is sleeved with multiple groups of piezoelectric transducers; and a pair of moving magnets are arranged at the free end of each of the piezoelectric transducers by bolts, and the opposite magnetic poles of the moving magnets are opposite. The piezoelectric generator has the advantages of no contact impact and noise, high reliability, convenience for providing electricity to a monitoring system rotating along with a rotating shaft, and capability of generating power at a constant or high speed.

Owner:ZHEJIANG NORMAL UNIVERSITY

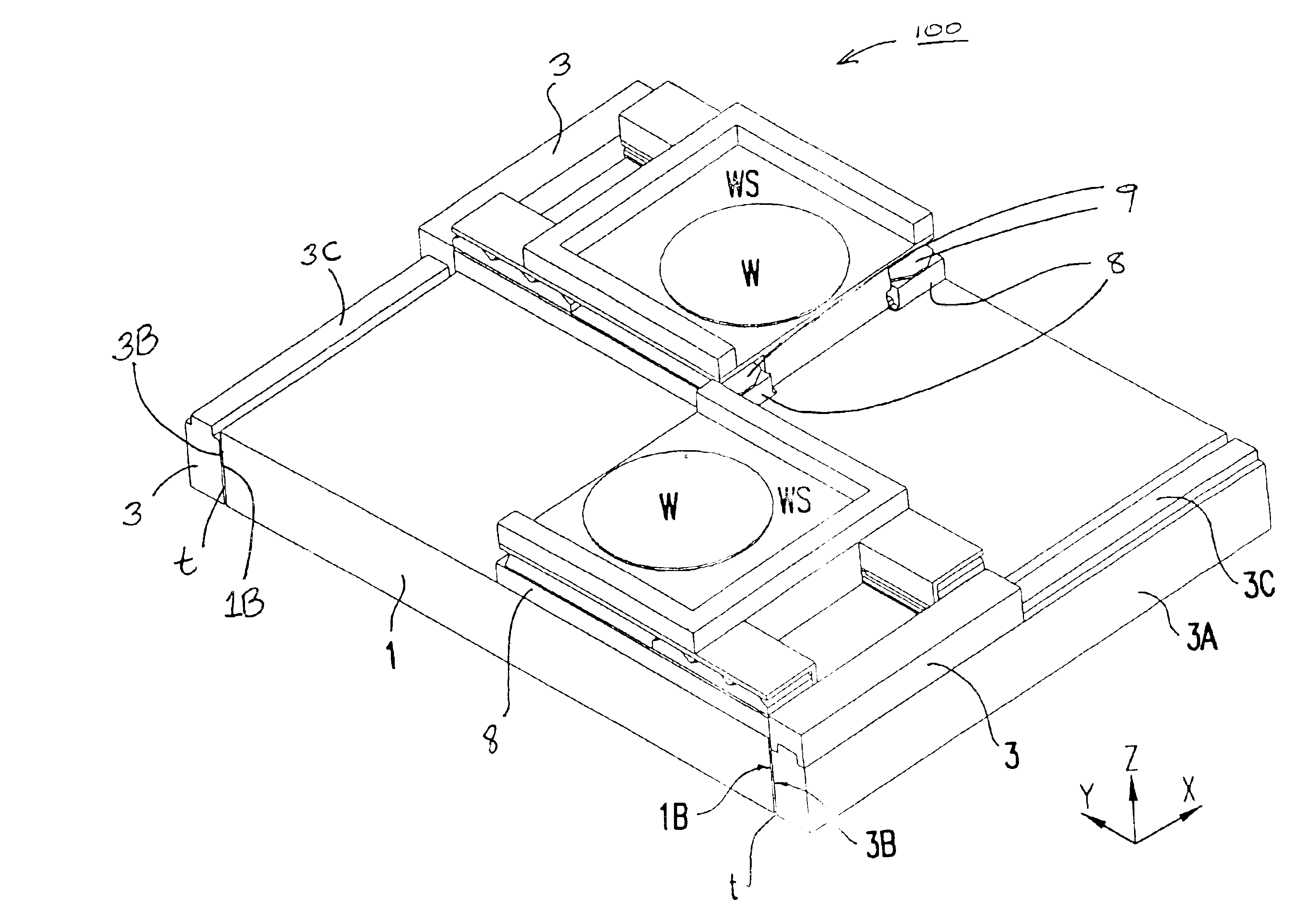

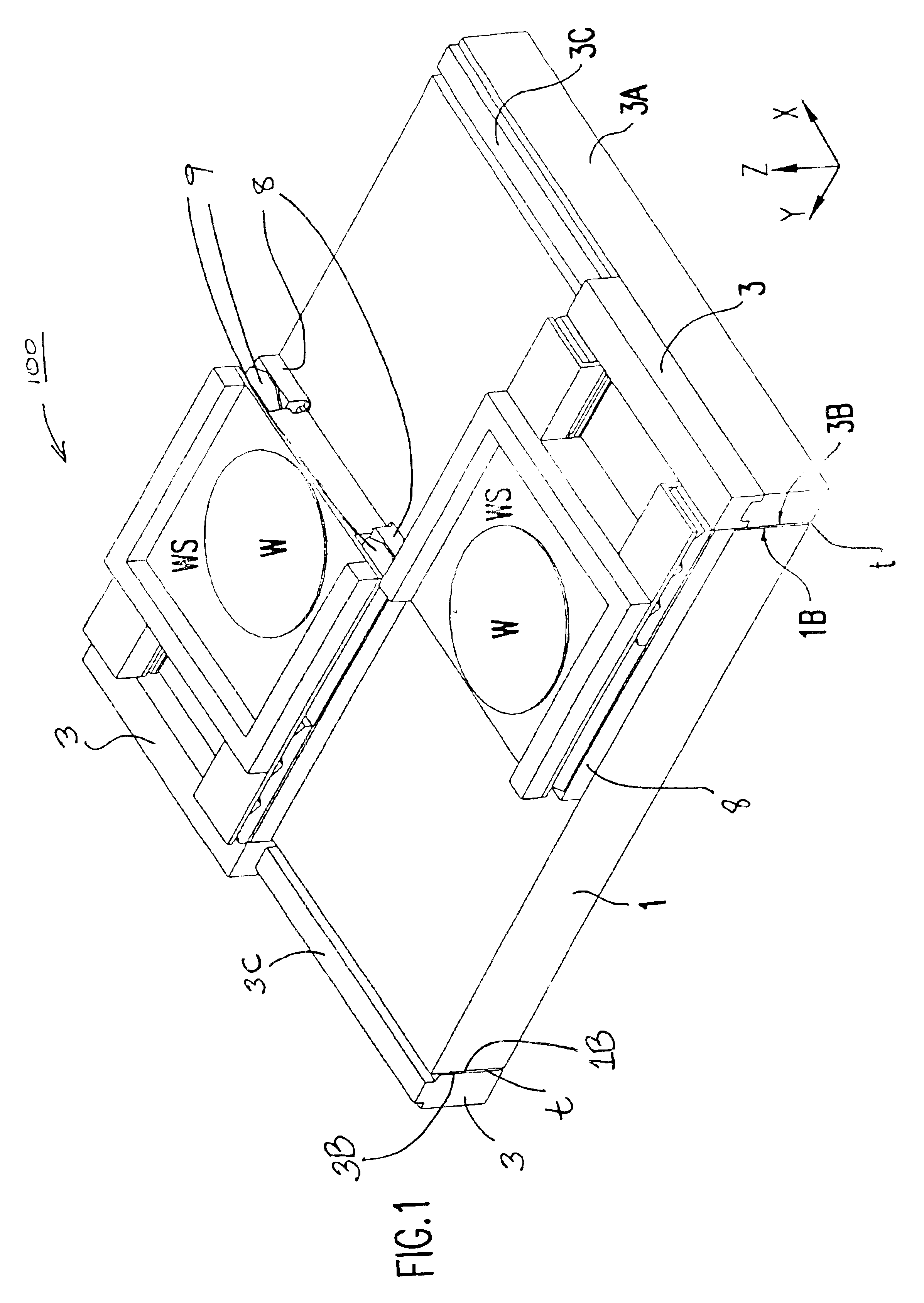

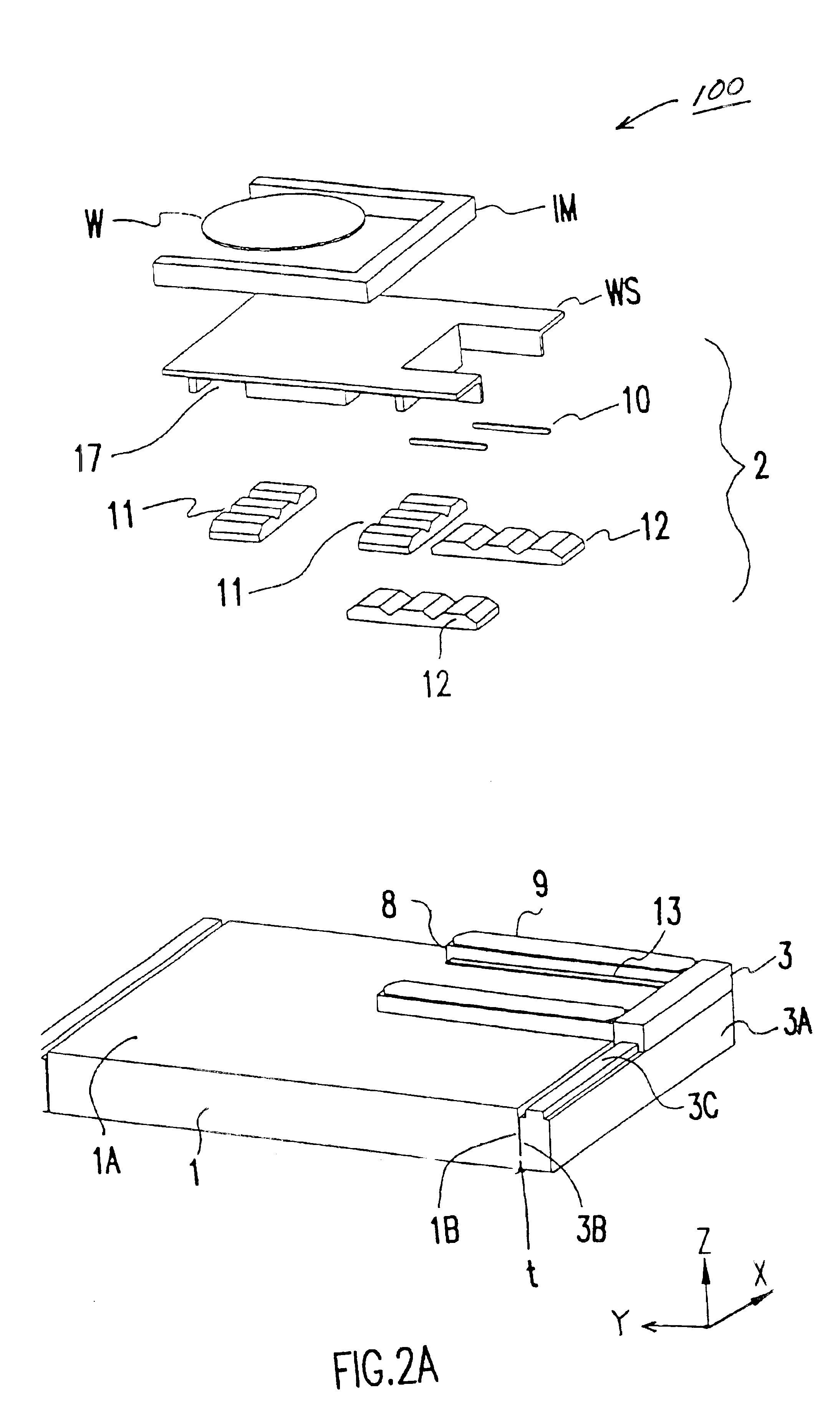

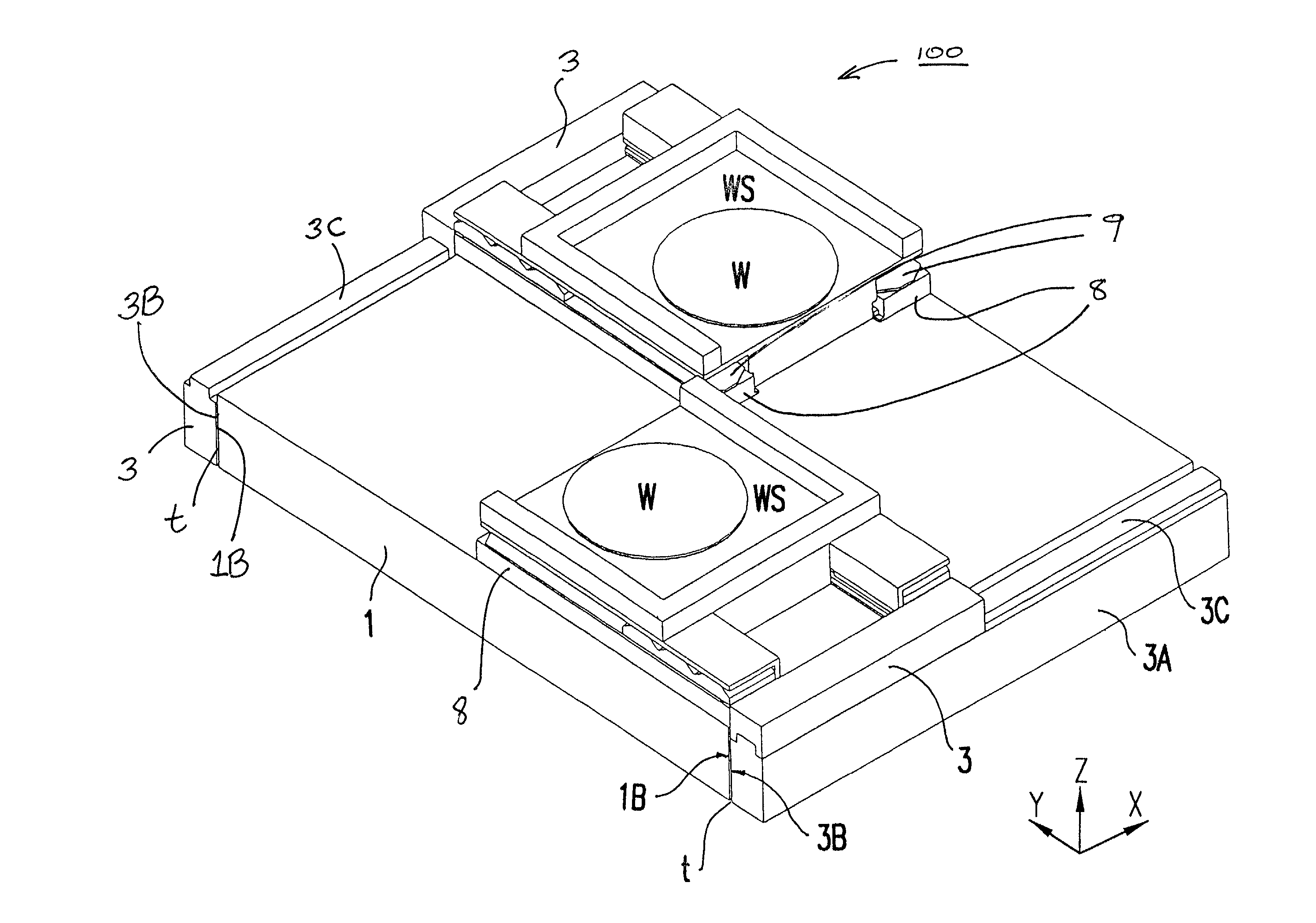

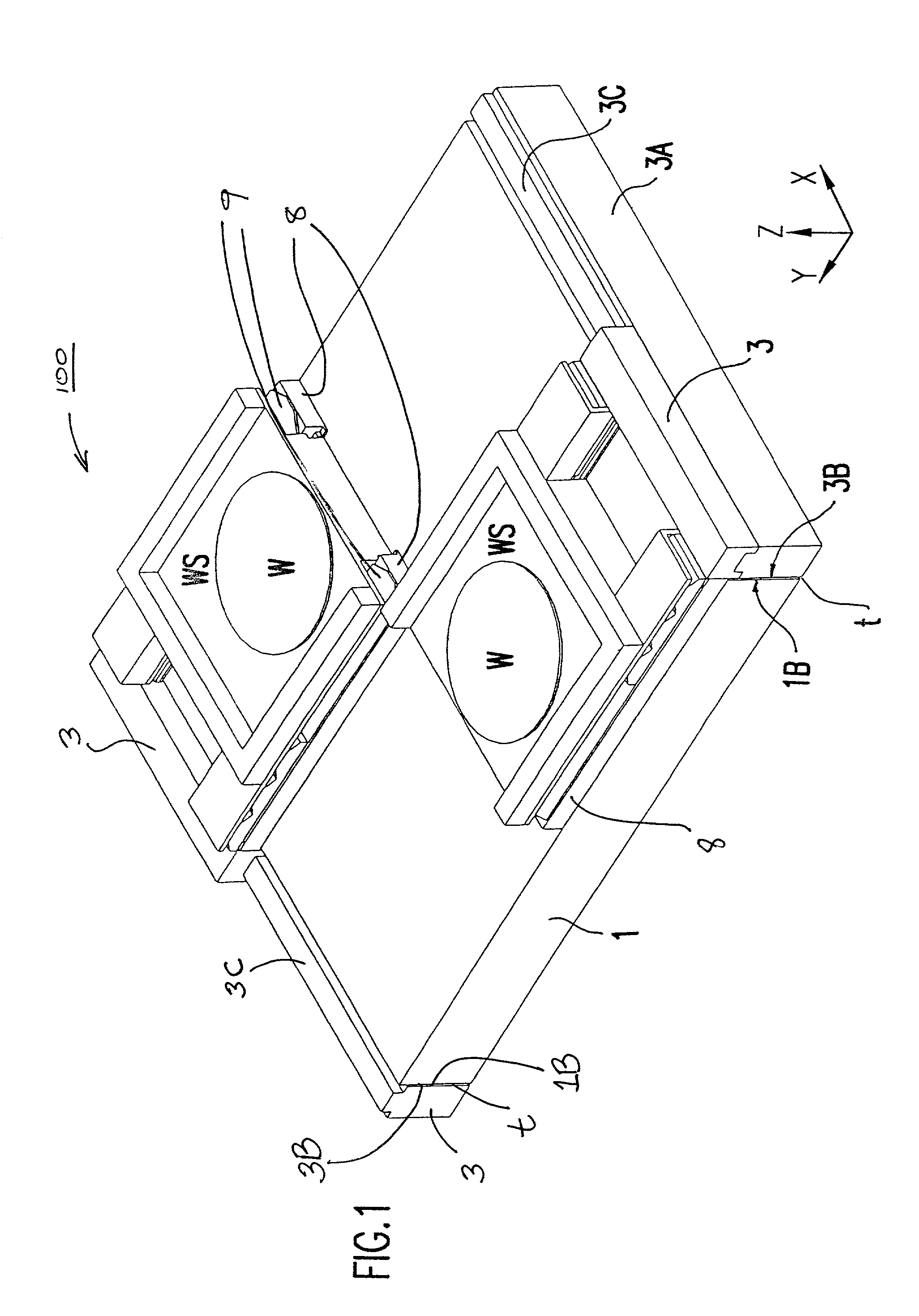

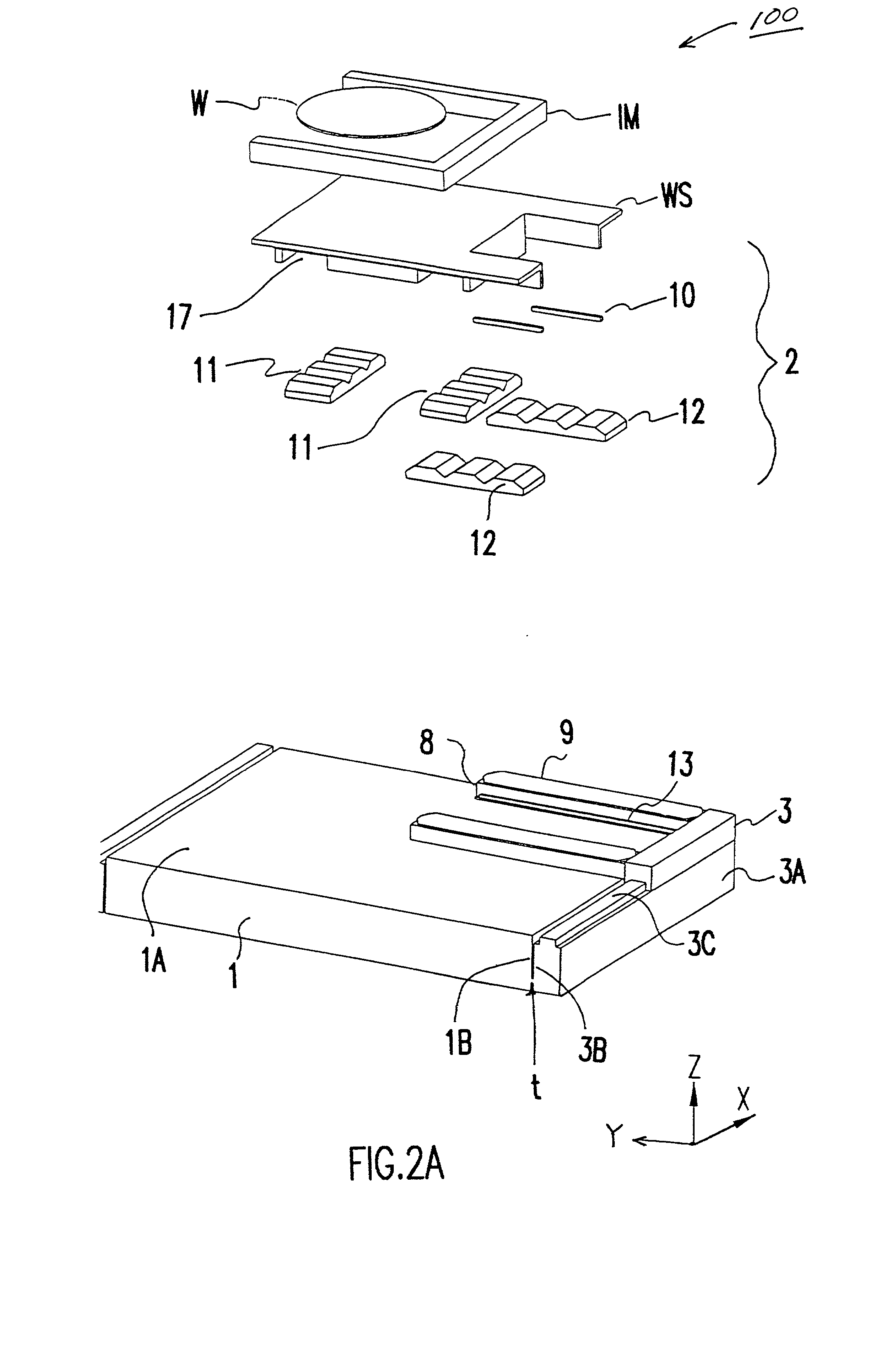

Following stage planar motor

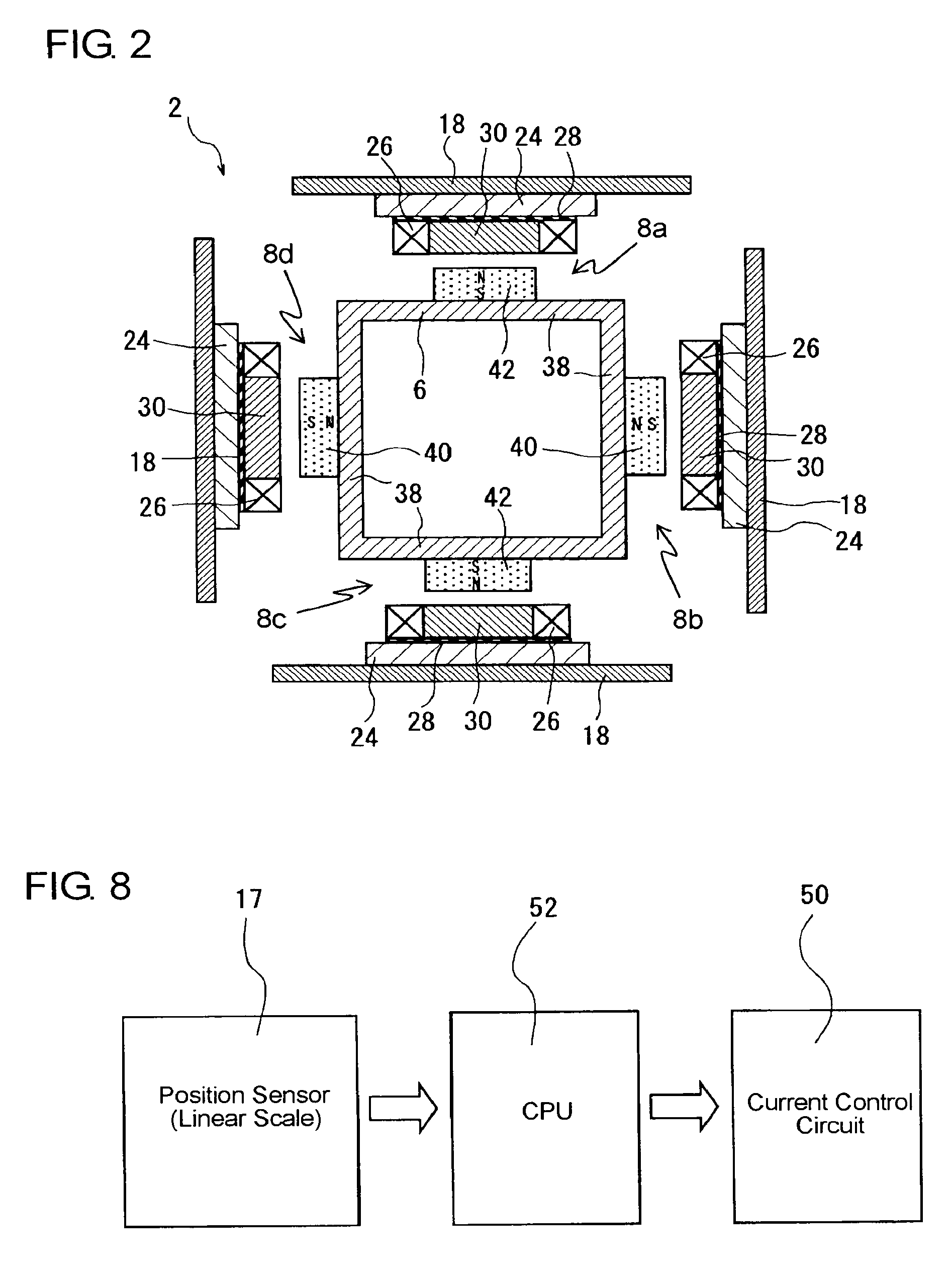

InactiveUS6927505B2Large range of motionFunction increaseMagnetic circuitSemiconductor/solid-state device manufacturingCoil arrayPlanar motor

In electric motor assemblies, separating the x and y coils may achieve significant advantages. An advantageous design includes pairs of interacting magnet array / coil arrays. Separated coil arrays are provided, with a coil array on an arm connected to a following stage, and another coil array on a stage base (the stage being one to which is attached magnet arrays). Positioning devices, moving magnet motor assemblies, moving coil motor assemblies, and methods of driving a stage are provided. By differential driving and creation of torques about the x and y axes, a stage may be driven in six independent degrees of freedom.

Owner:NIKON CORP

Following stage planar motor

InactiveUS20030111912A1Magnetic circuitSemiconductor/solid-state device manufacturingCoil arrayDegrees of freedom

In electric motor assemblies, separating the x and y coils may achieve significant advantages. An advantageous design includes pairs of interacting magnet array / coil arrays. Separated coil arrays are provided, with a coil array on an arm connected to a following stage, and another coil array on a stage base (the stage being one to which is attached magnet arrays). Positioning devices, moving magnet motor assemblies, moving coil motor assemblies, and methods of driving a stage are provided. By differential driving and creation of torques about the x and y axes, a stage may be driven in six independent degrees of freedom.

Owner:NIKON CORP

Piezoelectric power-generation device for supplying power for rail vehicle bearing monitoring system

InactiveCN102801357AStrong speed adaptabilityImprove reliabilityPiezoelectric/electrostriction/magnetostriction machinesMagnetic tension forceElectricity

The invention relates to a piezoelectric power-generation device for supplying power for a rail vehicle bearing monitoring system, and belongs to the technical field of rail transportation monitoring and piezoelectric power-generation. A wheel shaft is arranged on a frame by a bearing; moving magnets with opposite pole configuration directions are embedded on the end faces of a T-shaped chock block; a bearing cap is arranged on the frame by a bolt, a piezoelectric transducer is arranged in the internal part of the bearing cap in a pressure-connecting manner by a circular separation blade and an annular separation blade, and the piezoelectric transducer is formed by bonding a metal substrate and a piezoelectric crystal plate; a static magnet is arranged on the metal substrate of the piezoelectric transducer by a bolt; and a sensing monitoring system on the frame is connected with the piezoelectric transducer by a wire. The piezoelectric generating device has the advantages that the generating device is integrated inside the bearing cap and is excited in a non-contact way by the rotating wheel shaft and magnetic coupling, has no contact impact and noise, and is capable of generating electricity at a constant or high speed.

Owner:ZHEJIANG NORMAL UNIVERSITY

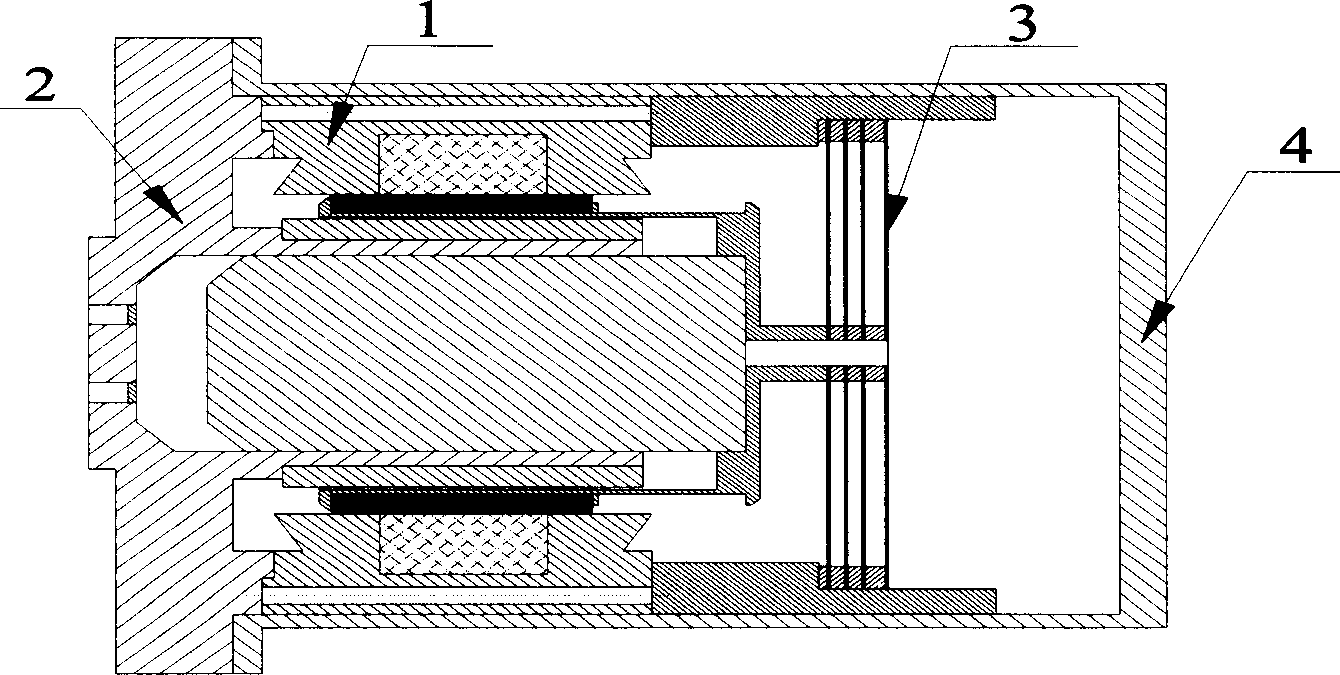

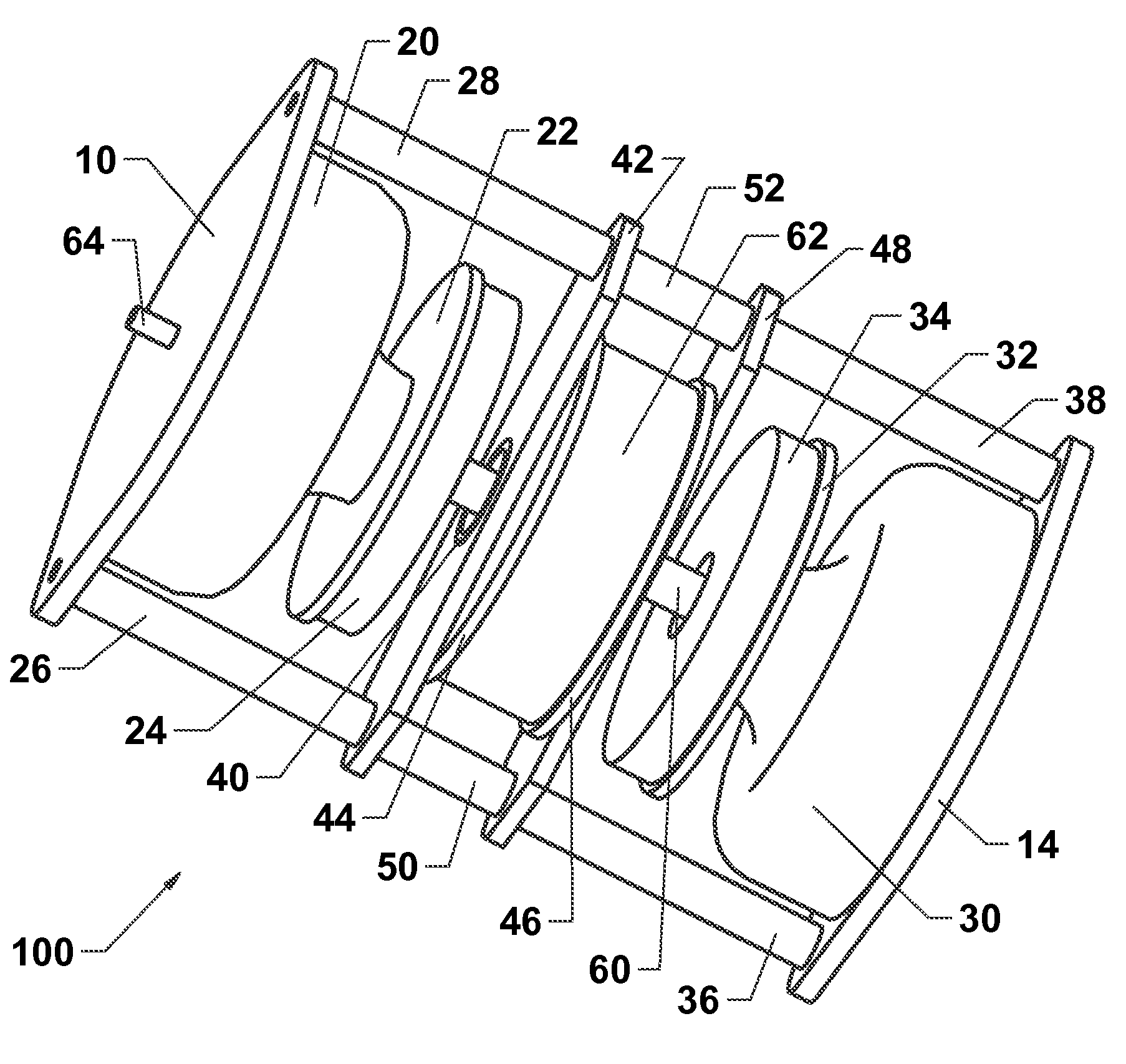

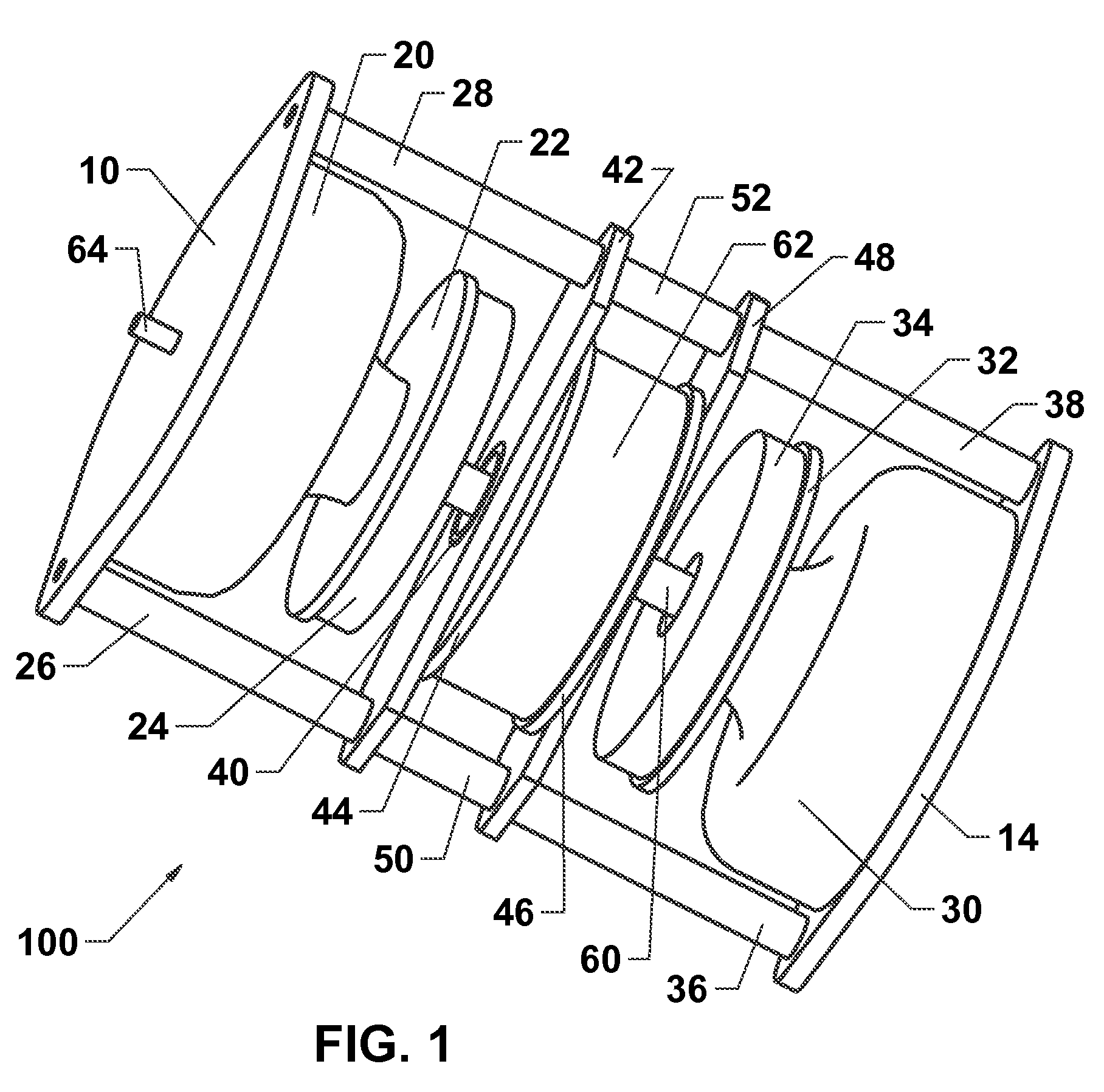

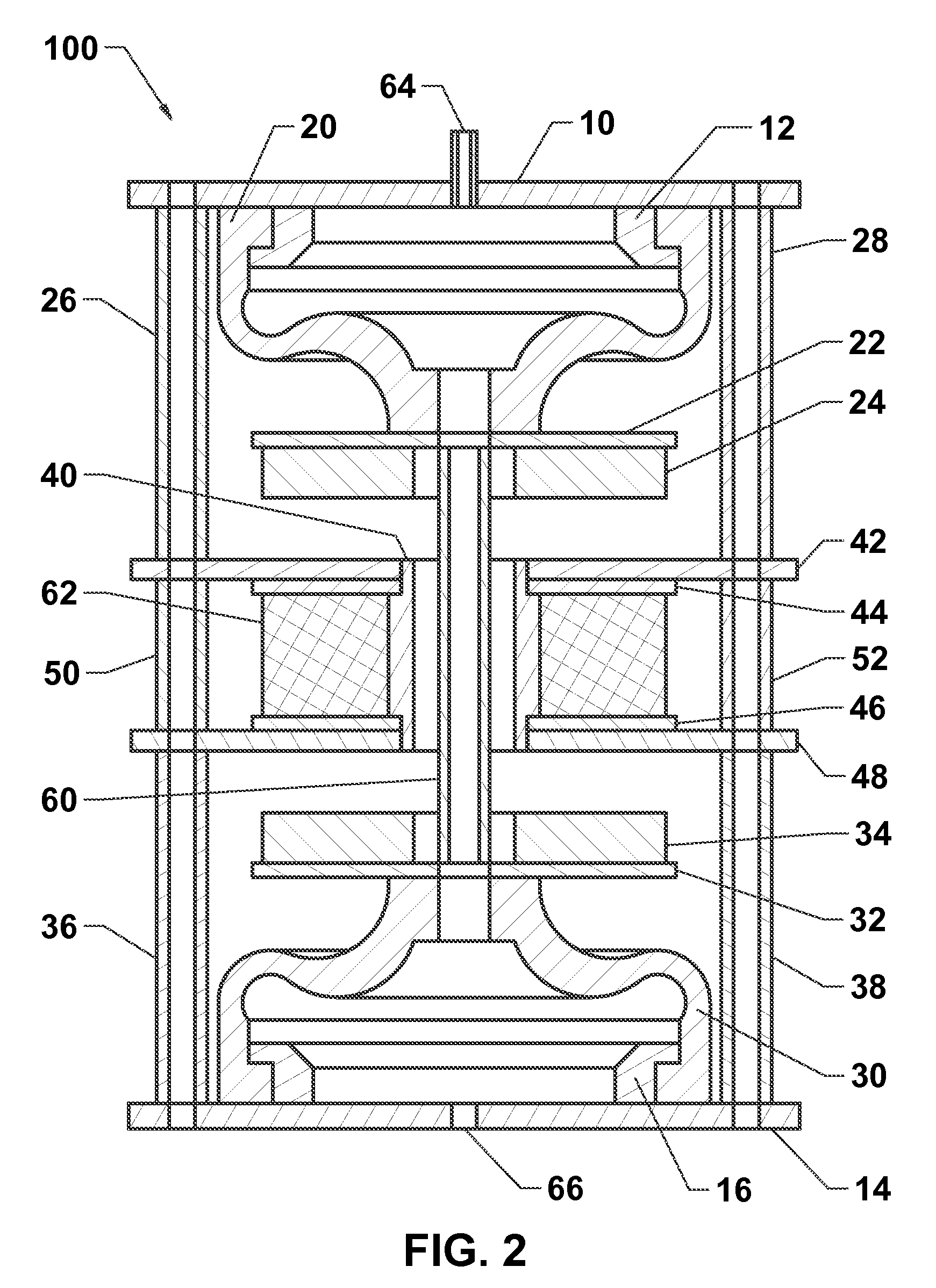

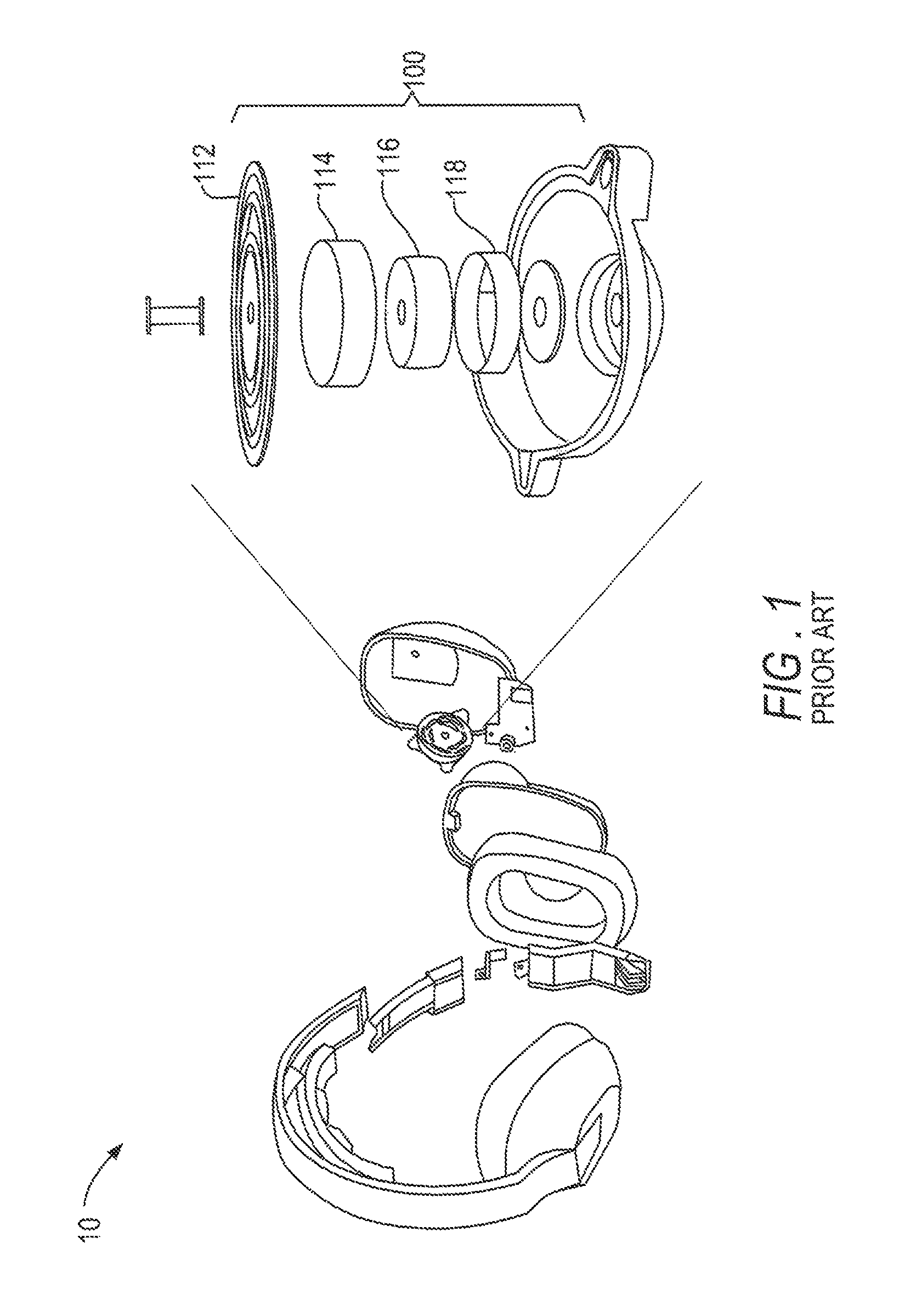

Ear Canal Pressurization Device

ActiveUS20090012420A1Minimization requirementsEasy to implementEar treatmentPneumatic massageBobbinMagnetic poles

An ear canal pressurization device optimized for aural acoustic immittance testing is disclosed. The preferred embodiment of the device is comprised of a rigid mounting framework which holds in position, axially aligned, a first flexible chamber assembly, a centrally disposed forcer assembly, and a second flexible chamber assembly. The forcer assembly comprises a ferromagnetic bobbin and coil that provides electromotive force for a moving magnet linear motor. The motor is comprised of a rigid chamber link, which passes through the hollow core of the bobbin, with a ferromagnetic keeper washer and axially aligned rare earth ring magnet at either end, with like magnetic poles facing each other. The motor is elastically suspended between the first and second flexible chambers. Current flow through the coil of the forcer assembly provides motive force for the motor via attraction or repulsion of the motor magnets and movement of the motor increases the volume of the first flexible chamber while decreasing the volume of the second flexible chamber, or vice versa. The internal volume of the first flexible chamber is coupled via an air line to an ear canal and through a controlled valve to a small vent, and the internal volume of the second flexible chamber is vented to ambient air pressure. Changes in volume of the first flexible chamber, due to motor movement, produce changes in ear canal pressure re Boyle's law. The vent may be opened to allow ear canal pressure to gently equalize to ambient air pressure or to generate ear canal pressure sweeps free of pressure baseline offset. The vent may be closed to set a static ear canal pressure or to generate ear canal pressure sweeps with an incidental baseline offset. The vent may be controlled to generate ear canal pressure sweeps with an intended baseline offset. The device produces ear canal pressure proportional to drive voltage, so any desired pressure versus time function can be generated by applying a coil driving voltage with the appropriate amplitude versus time function. The device operates quietly to avoid interference with aural acoustic immittance measurement, and should have a long and maintenance free life span.

Owner:MICRO AUDIOMETRICS CORP

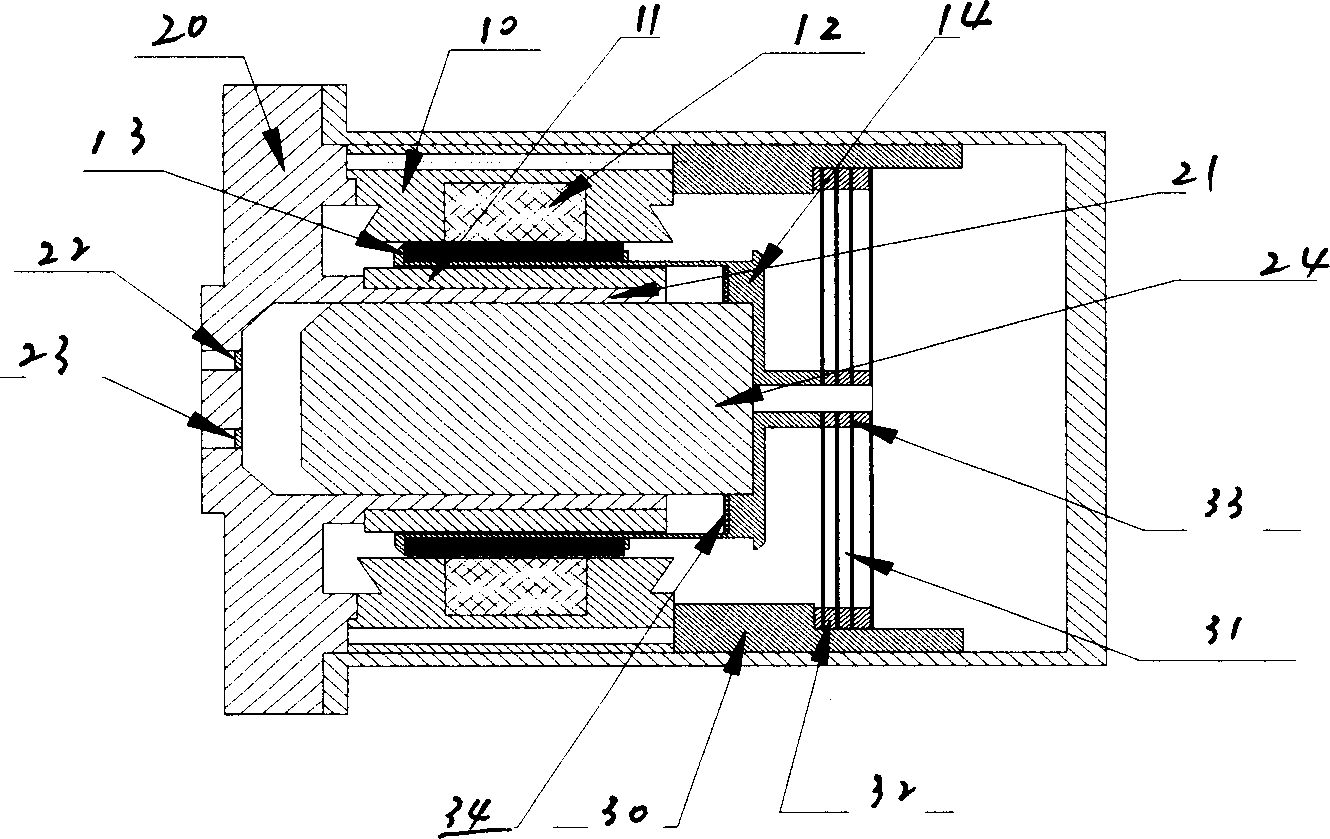

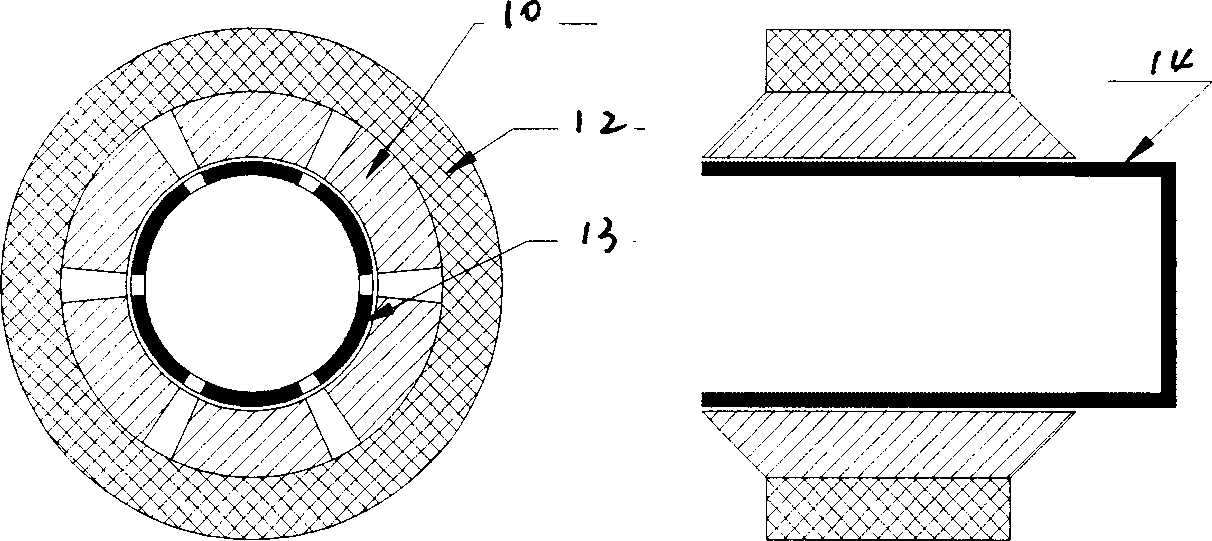

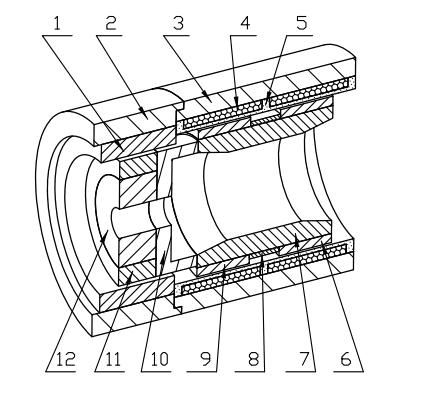

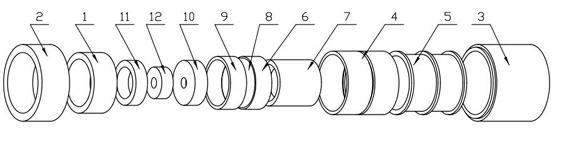

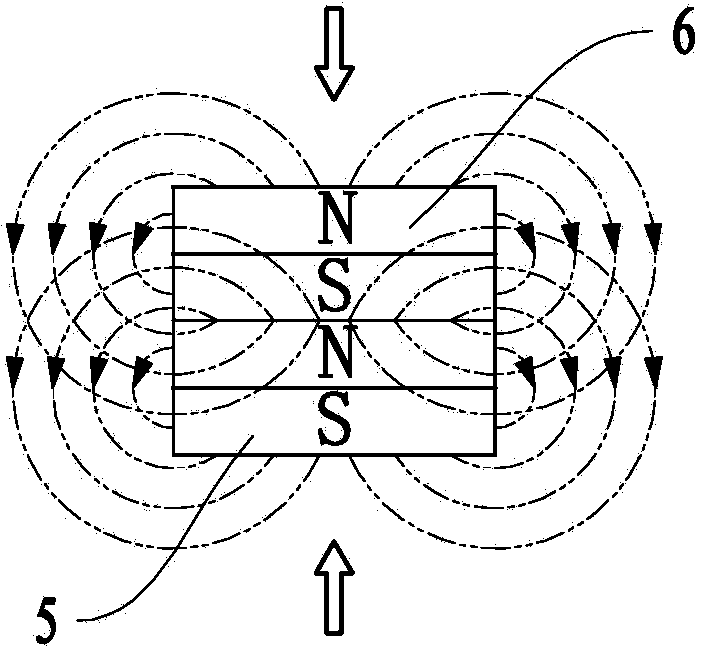

Moving magnet type linear rotation two-degree-of-freedom motor

The invention relates to a moving magnet type linear rotation two-degree-of-freedom motor. The moving magnet type linear rotation two-degree-of-freedom motor comprises a rotor and a stator. The stator comprises a circular front magnet yoke, a back magnet yoke, a winding support, a front winding and a back winding, wherein one end of the front magnet yoke is connected with one end of the back magnet yoke; the front winding is sleeved on the inner side of the front magnet yoke; and the back winding is sleeved between the outer side of the winding support and the inner side of the back magnet yoke. The rotor comprises a permanent magnet, an iron core, an inner magnet yoke, a magnet isolating seat and a positioning ring, wherein the permanent magnet comprises a front magnet ring, a middle magnet ring and a back magnet ring; and the front magnet ring is sleeved between the inner side of the front winding and the outer side of the iron core. The invention has the advantages that: the rotor can be driven to do rotary motion by the front winding and also can be driven to do linear motion by the back winding, and the two-degree-of-freedom composite motion of the rotary motion and the linear motion can be output by one motor.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL +1

Electrodynamic linear oscillating motor

InactiveUS8624448B2Improve power densityReduce weightMotor/generator/converter stoppersDC motor speed/torque controlMobile vehicleElectric machine

The invention is an electrodynamic linear oscillating motor, which has high power densities in the magnet gap, a high efficiency, and magnetically restores the oscillating system to a center position. The linear oscillating motor has a stator system, which has at least one magnet, and an oscillating system, which is movably mounted in the magnetic field of the stator. The oscillating system has at least one core made of a soft magnetic material, and at least one driving coil. The electrodynamic linear motor combines the advantages of the known moving coil and moving magnet linear motor, achieving electrodynamic conversion levels of up to 99%. The motor is suited as a drive for refrigerating and air conditioning systems having low power and also for pumping and injection systems, and, reversing the electrodynamic principle, as a generator, such as for shock absorber systems in a motor vehicle.

Owner:INST FUER LUFT & KAELTETECHNIK GEMEINNUETZIGE GMBH

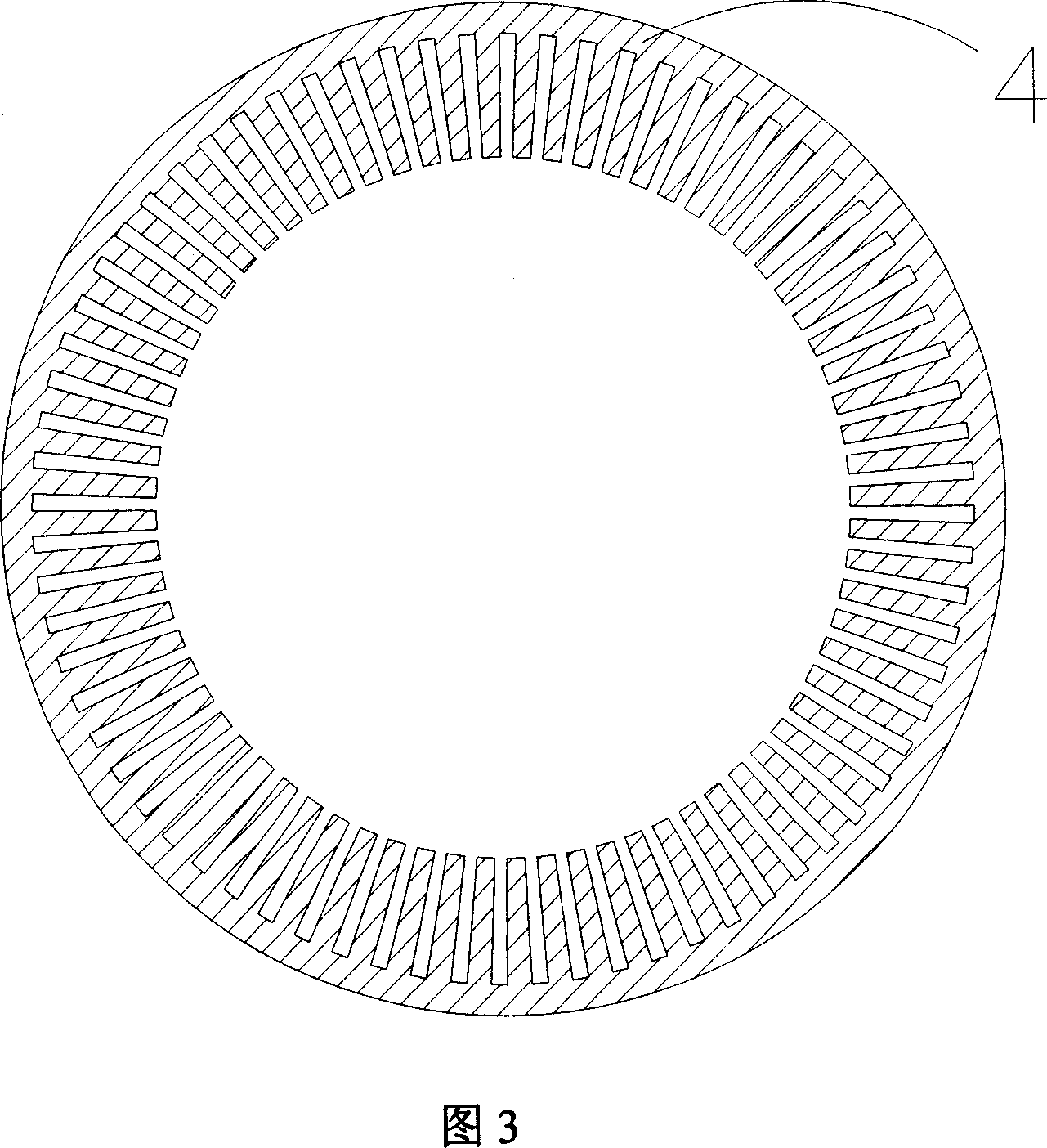

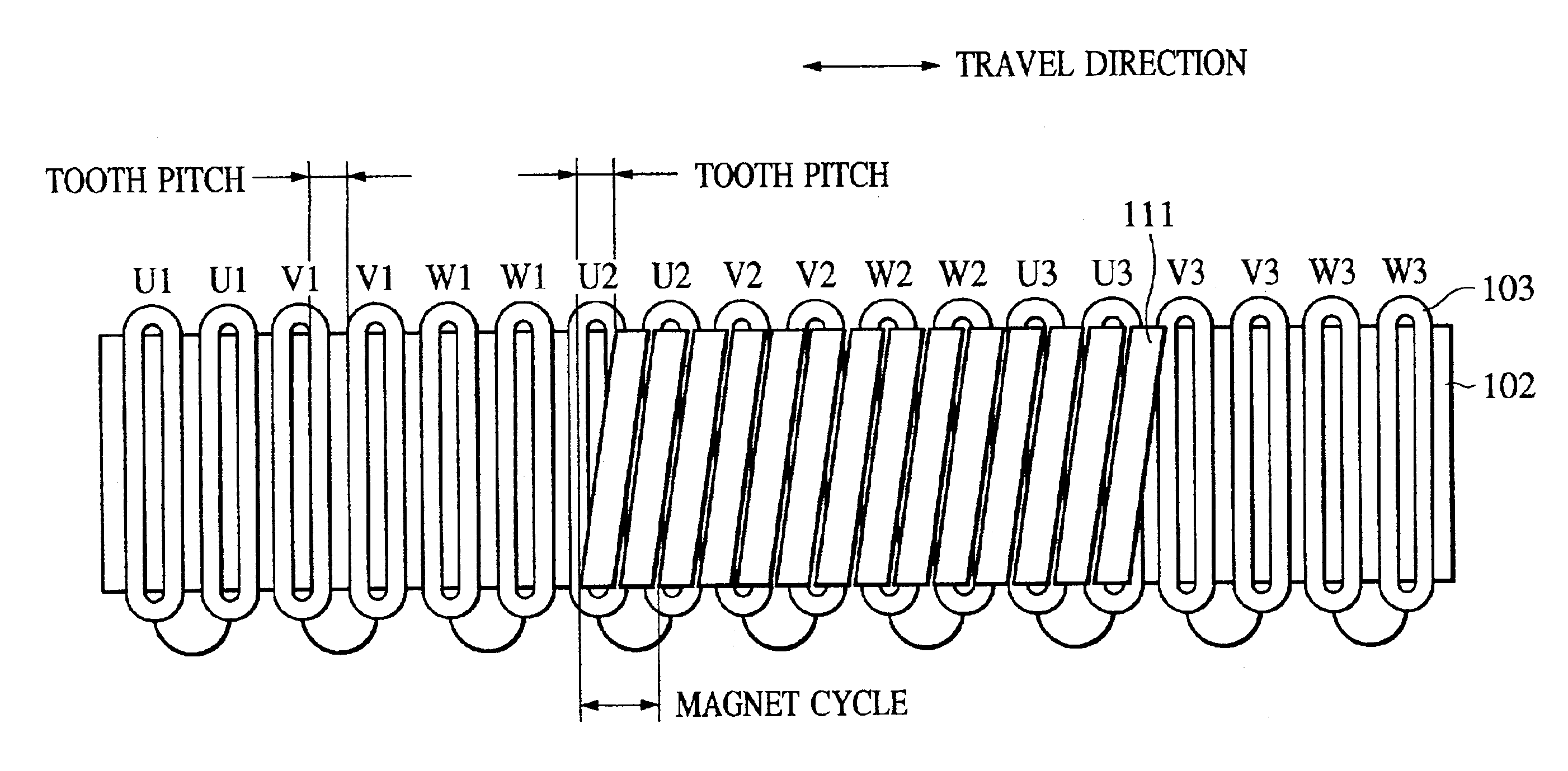

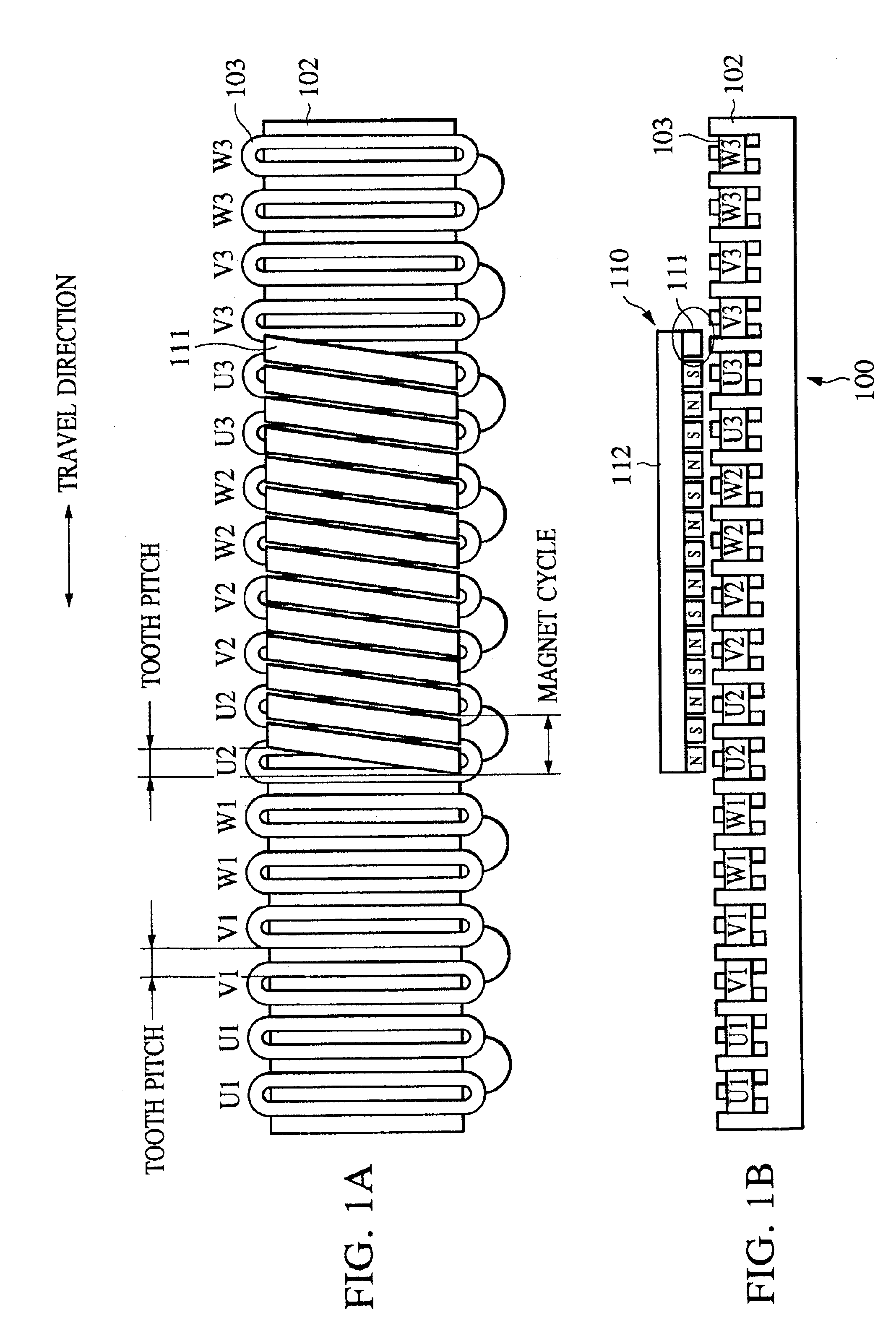

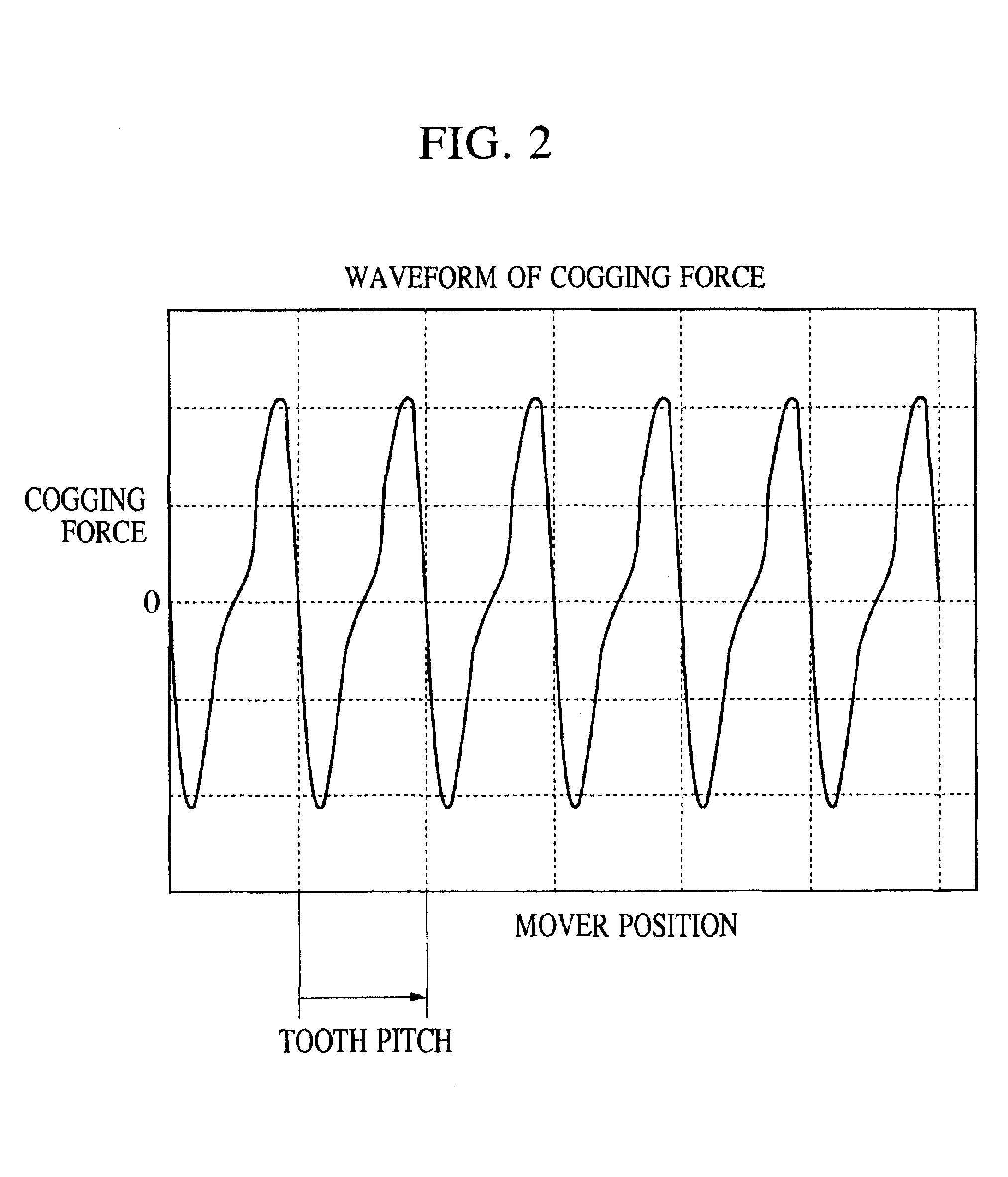

Moving-magnet linear motor, aligner and apparatus provided therewith, and method for manufacturing devices using the same

InactiveUS6791214B2Semiconductor/solid-state device manufacturingPhotomechanical exposure apparatusEngineeringLinear motor

A moving-magnet, linear motor which substantially produces no cogging force is provided. The moving-magnet, linear motor has a mover and a stator. The mover has a plurality of permanent magnets orderly disposed along the traveling direction of the mover. The stator has a toothed iron-core having a plurality of teeth and a plurality of coils wound around the teeth thereof. The permanent magnets are disposed such that the two longitudinal ends of each permanent magnet are skewed with respect to each other by a tooth pitch of the toothed iron-core.

Owner:CANON KK

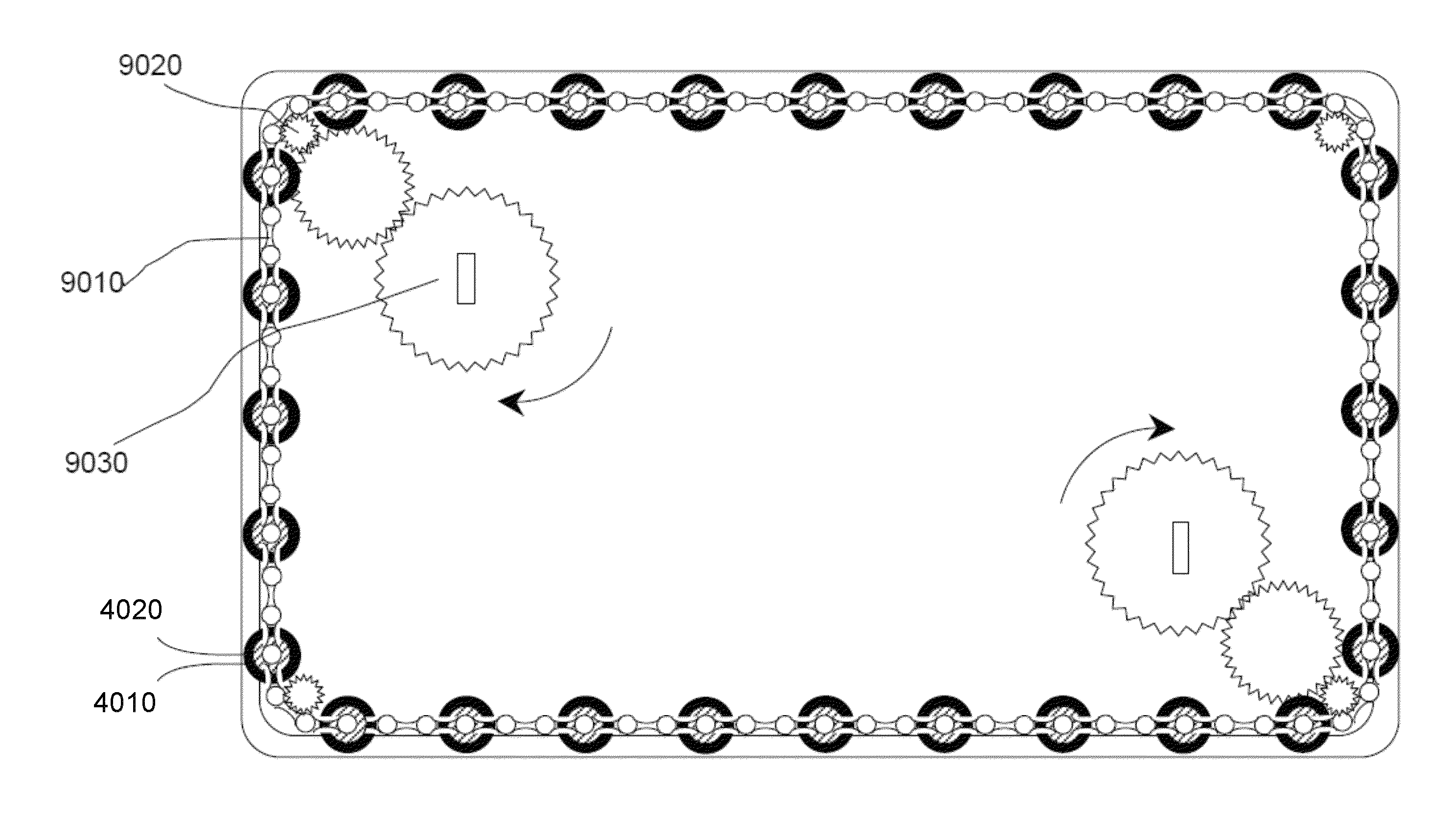

Substrate container sealing via movable magnets

ActiveUS20090272743A1Small pressure differentialImprove protectionBuilding locksAnti-theft devicesEngineeringMoving magnet

A system of moving magnets for sealing a container may include a plurality of moveable magnets disposed near a perimeter of a container door and a rotatable linkage hub positioned within the perimeter of the container door. In addition, the system may include a plurality of control linkages connecting each of the plurality of moveable magnets to the linkage hub so that rotating the linkage hub causes the control linkages to move the moveable magnets between a sealed position and an open position. Alternatively, the moveable magnets may be connected to each other by a magnet positioning mechanism to physically move the magnets along a path near the perimeter. A plurality of static magnets may be disposed near an opening sized to receive the container door and positioned to form a magnetic seal with the moveable magnets when the moveable magnets are positioned at the sealed position.

Owner:BOOKS AUTOMATION US LLC

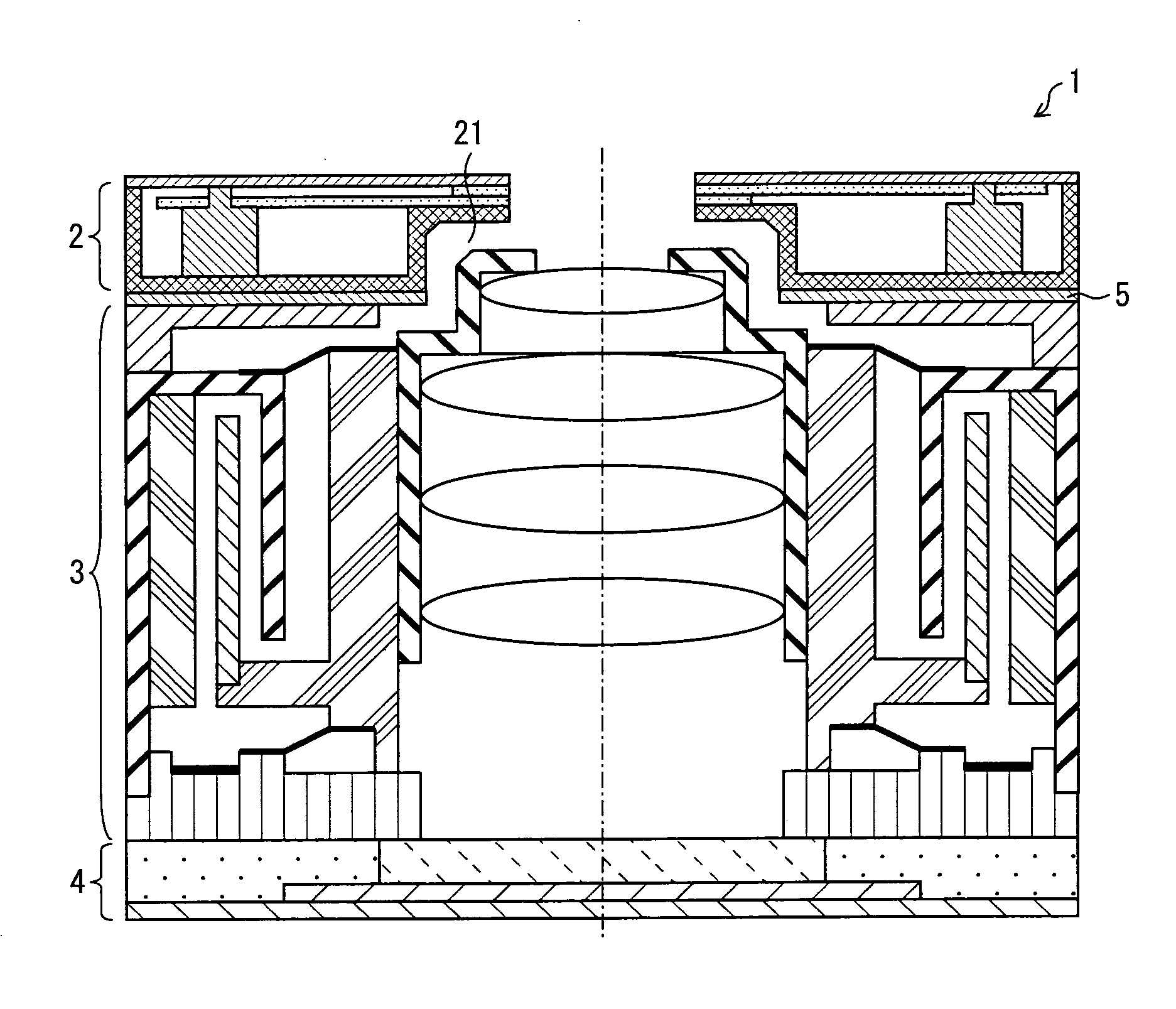

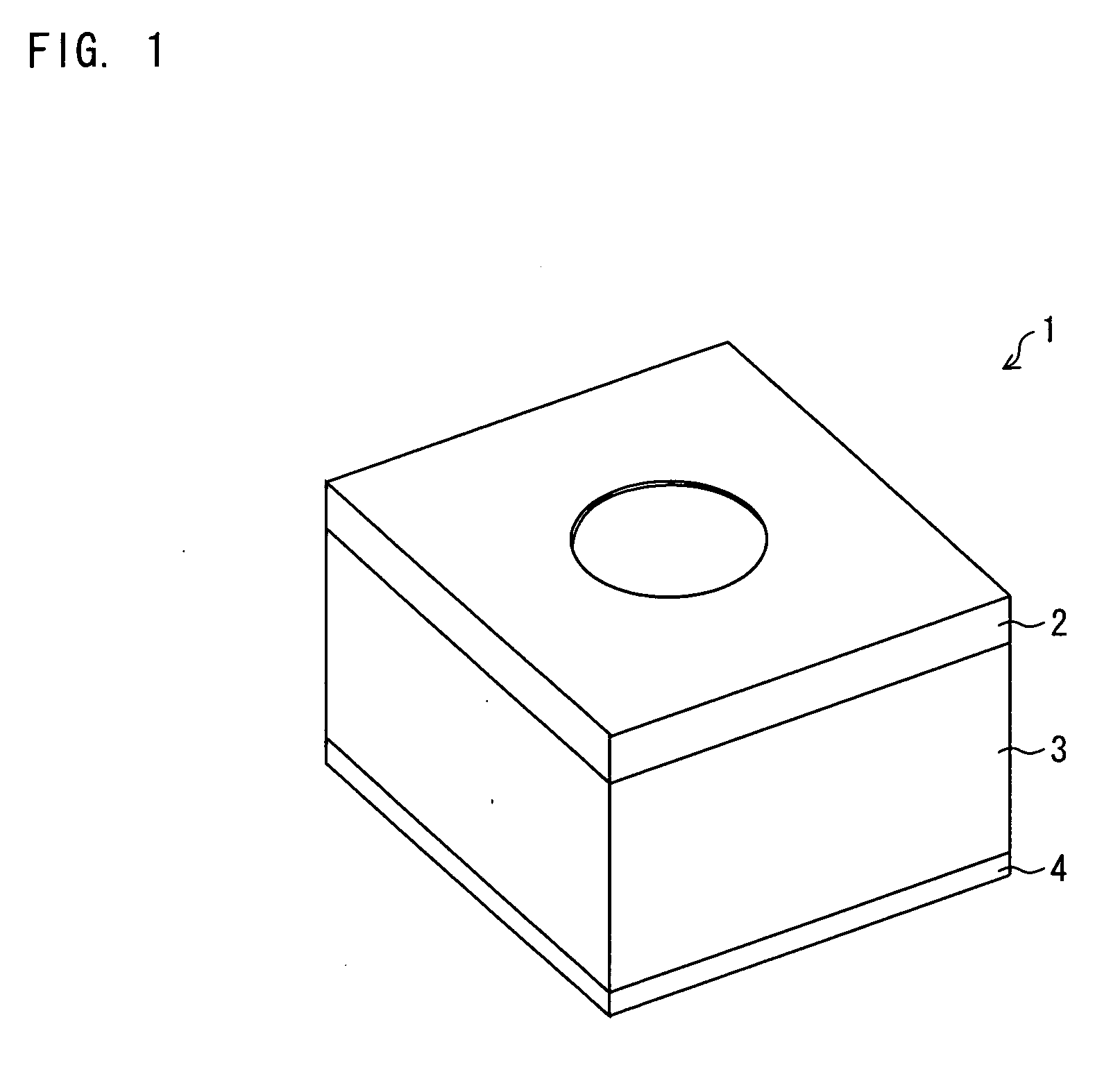

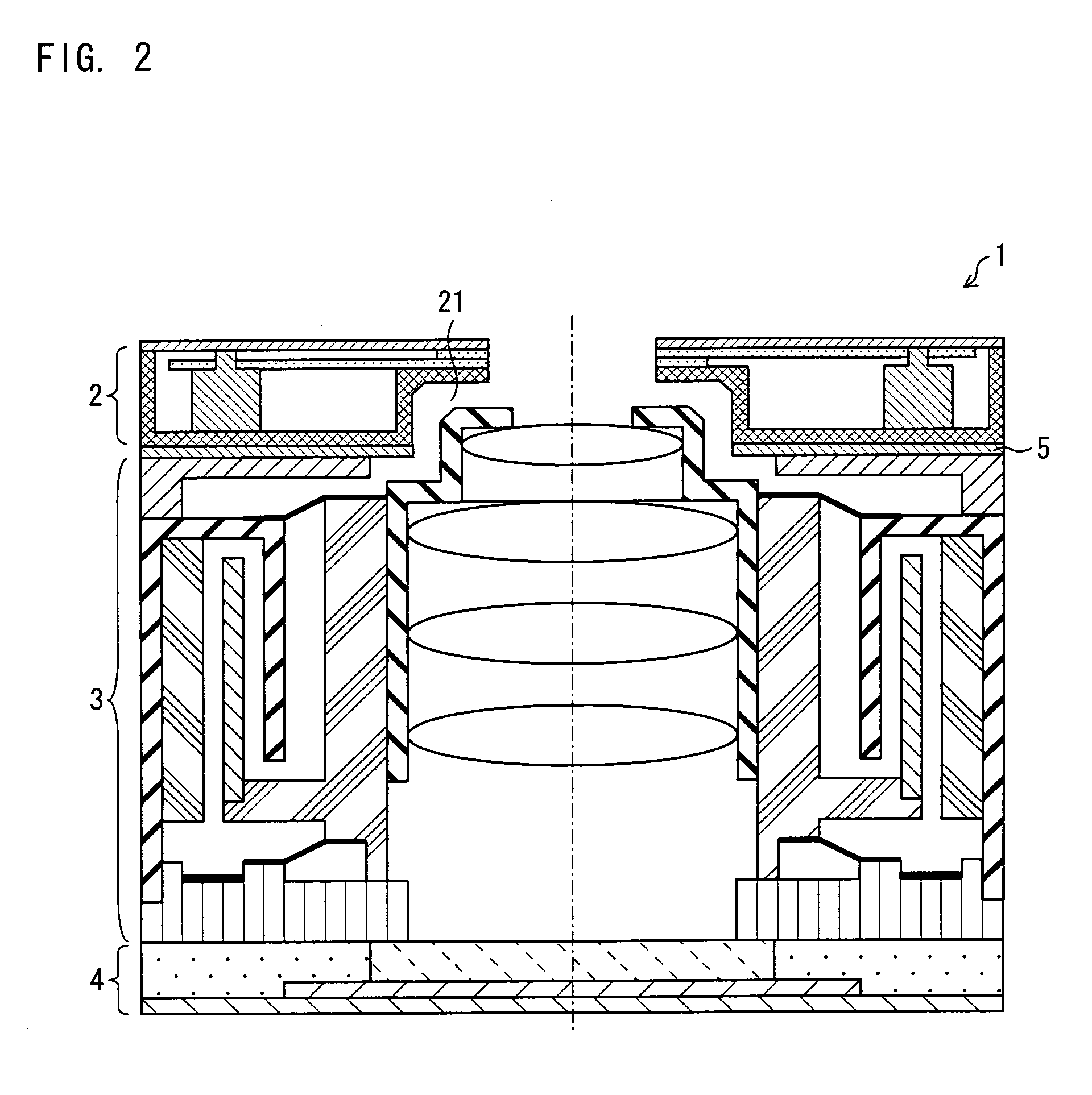

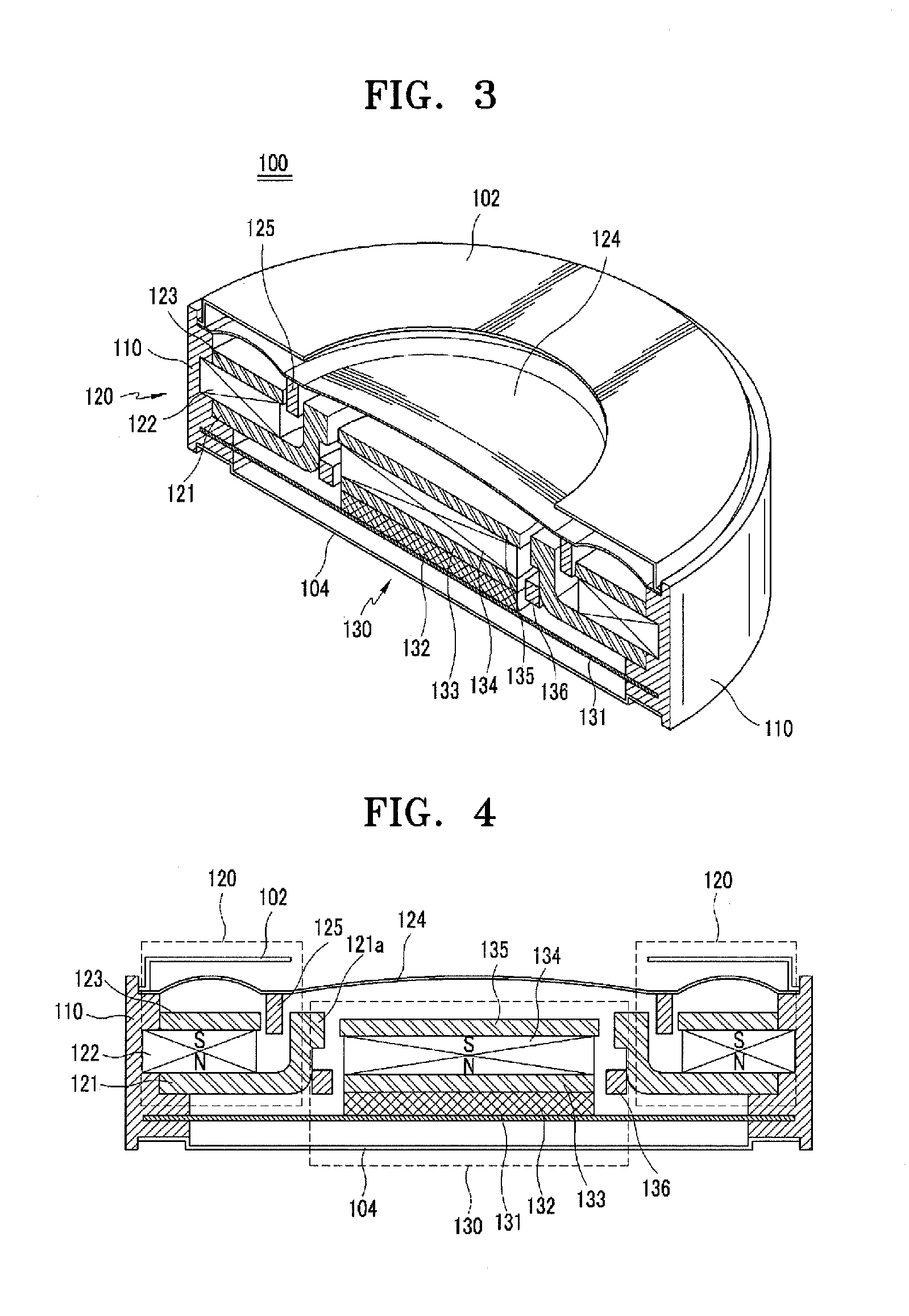

Camera module and electronic device including the same

InactiveUS20100053412A1Avoid it happening againQuick closeTelevision system detailsColor signal processing circuitsCamera lensClassical mechanics

A camera module 1 of the present invention includes a moving magnet type mechanical shutter 2 and a lens unit 3 (lens drive section) for driving a lens by electromagnetic force. A magnetic field for driving the lens is set so that a light path is closed by a shutter fin while a magnetic field leaked from the lens unit 3 is acting on a drive mechanism of the mechanical shutter 2. With the configuration, the leak magnetic field leaked from the lens unit 3 causes the light path to be closed at a faster speed by the shutter fin of the mechanical shutter 2. Accordingly, generation of a smear can be prevented by the camera module including the lens drive section and the moving magnet type mechanical shutter, which are driven by the electromagnetic force.

Owner:SHARP KK

Multifunctional micro-speaker

InactiveUS20110255715A1Reproduction distortionAvoid changeTransducer detailsLoudspeakersEngineeringLoudspeaker

An integrated multifunctional micro speaker including a speaker frame having an upper portion (an outer portion) that is configured by a moving voice coil type speaker and a lower portion (an inner portion) that is configured by a moving magnet and weight type vibrator supported by a suspension, thereby reproducing a sound and a vibration. The multifunctional micro speaker includes a cylindrical speaker frame; a yoke having an end fixed to the cylindrical speaker frame; a speaker magnet fixed onto the yoke; a speaker plate fixed onto the speaker magnet; a diaphragm having an outer circumferential surface supported against the cylindrical speaker frame; a voice coil that is attached to the diaphragm so as to be disposed in a space formed between the speaker plate and the yoke; a suspension fixed to a lower portion of the speaker frame; a cylindrical weight attached to a central portion of the suspension; a lower plate attached onto the cylindrical weight and having the same shape as the cylindrical weight; a vibrator magnet attached onto the lower plate and having the same shape as the lower plate; an upper plate attached onto the vibrator magnet and having the same shape as the vibrator magnet; and a vibrator coil attached to the yoke.

Owner:BSE CO LTD

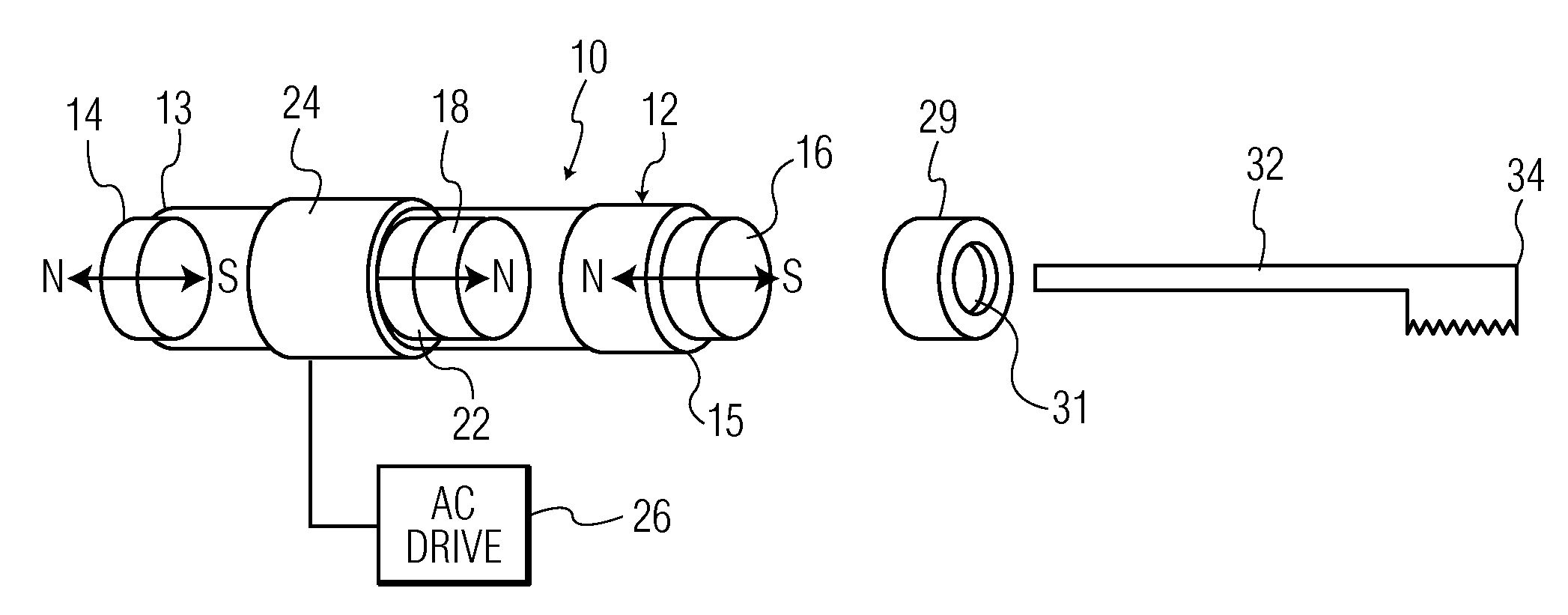

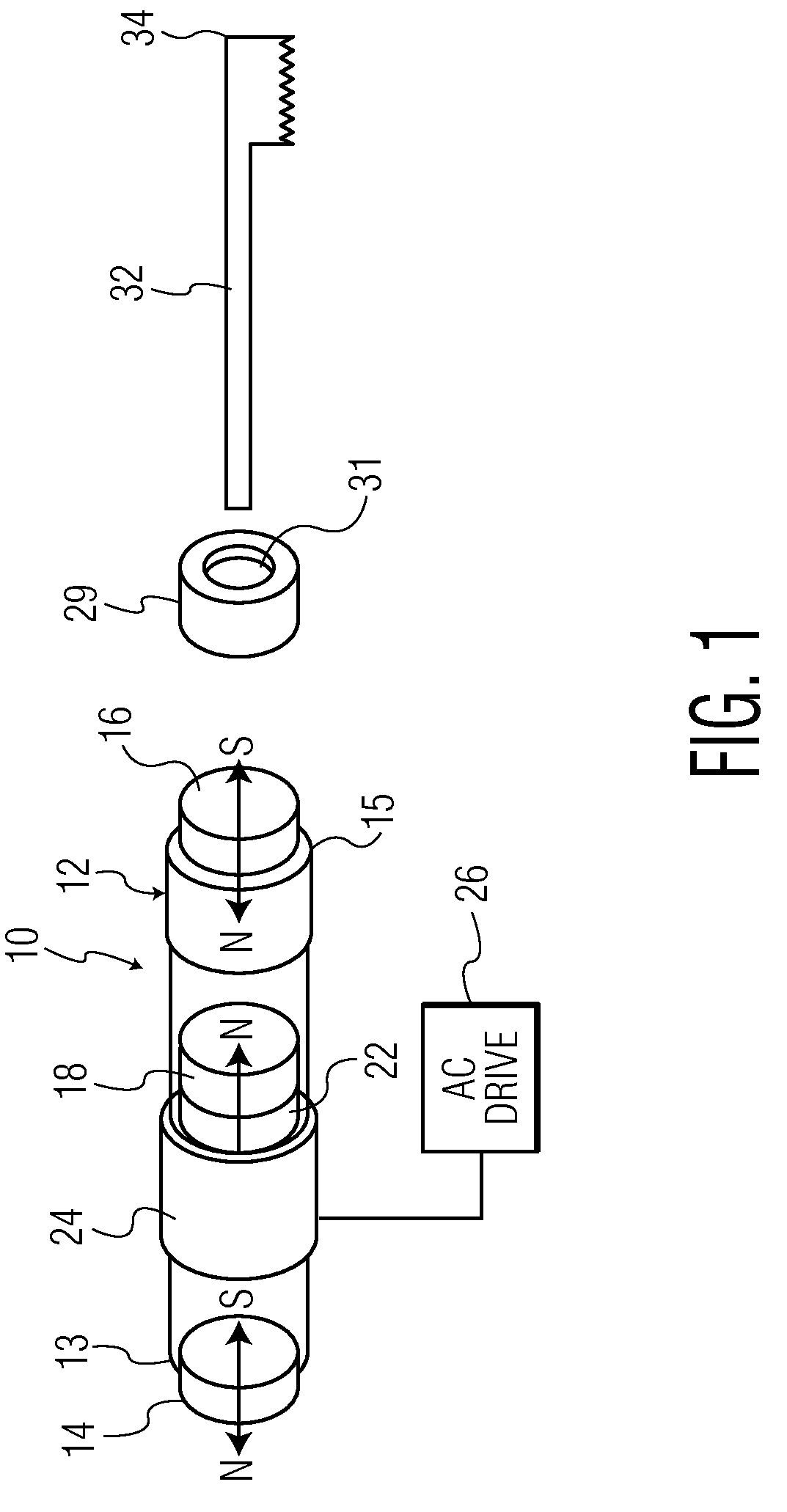

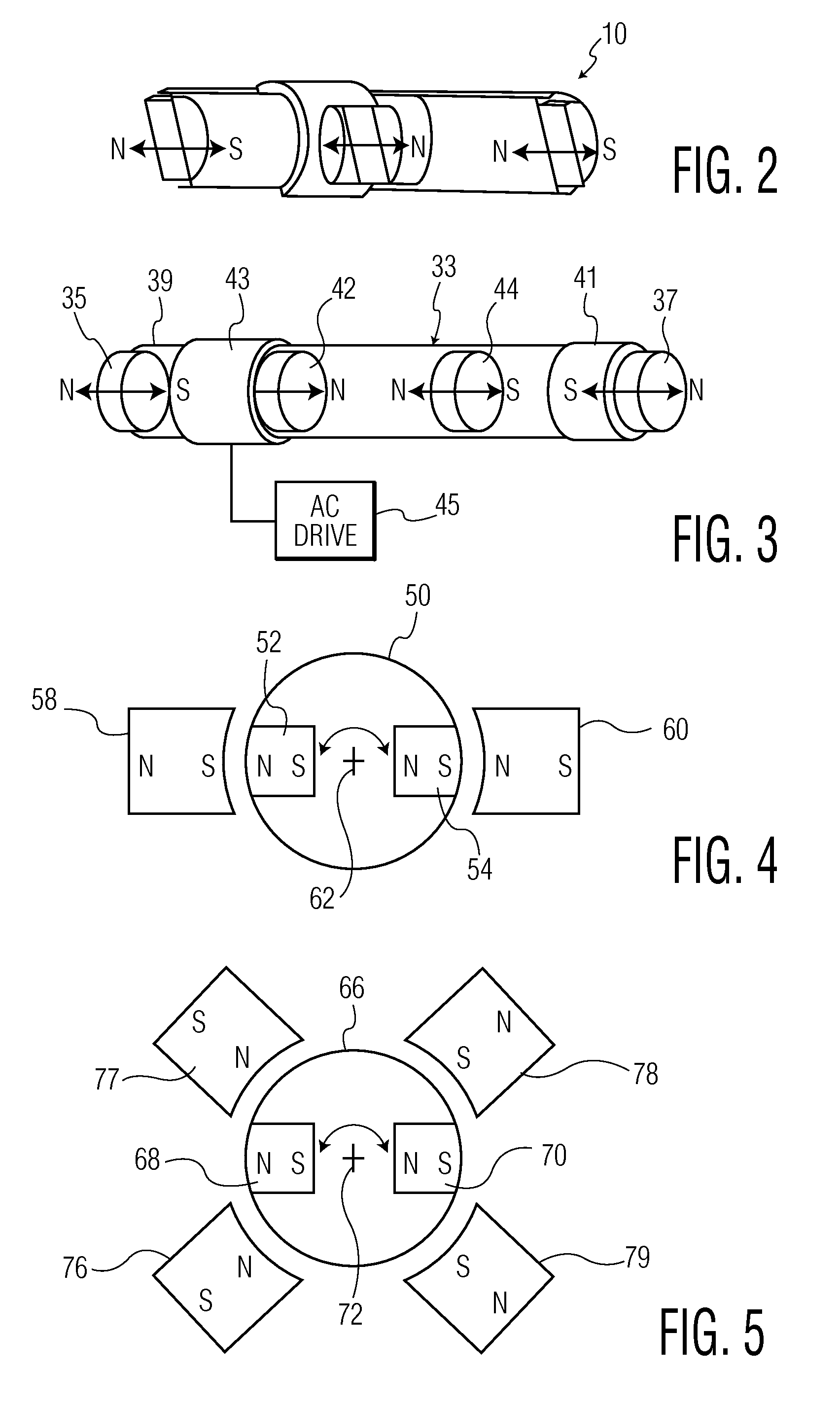

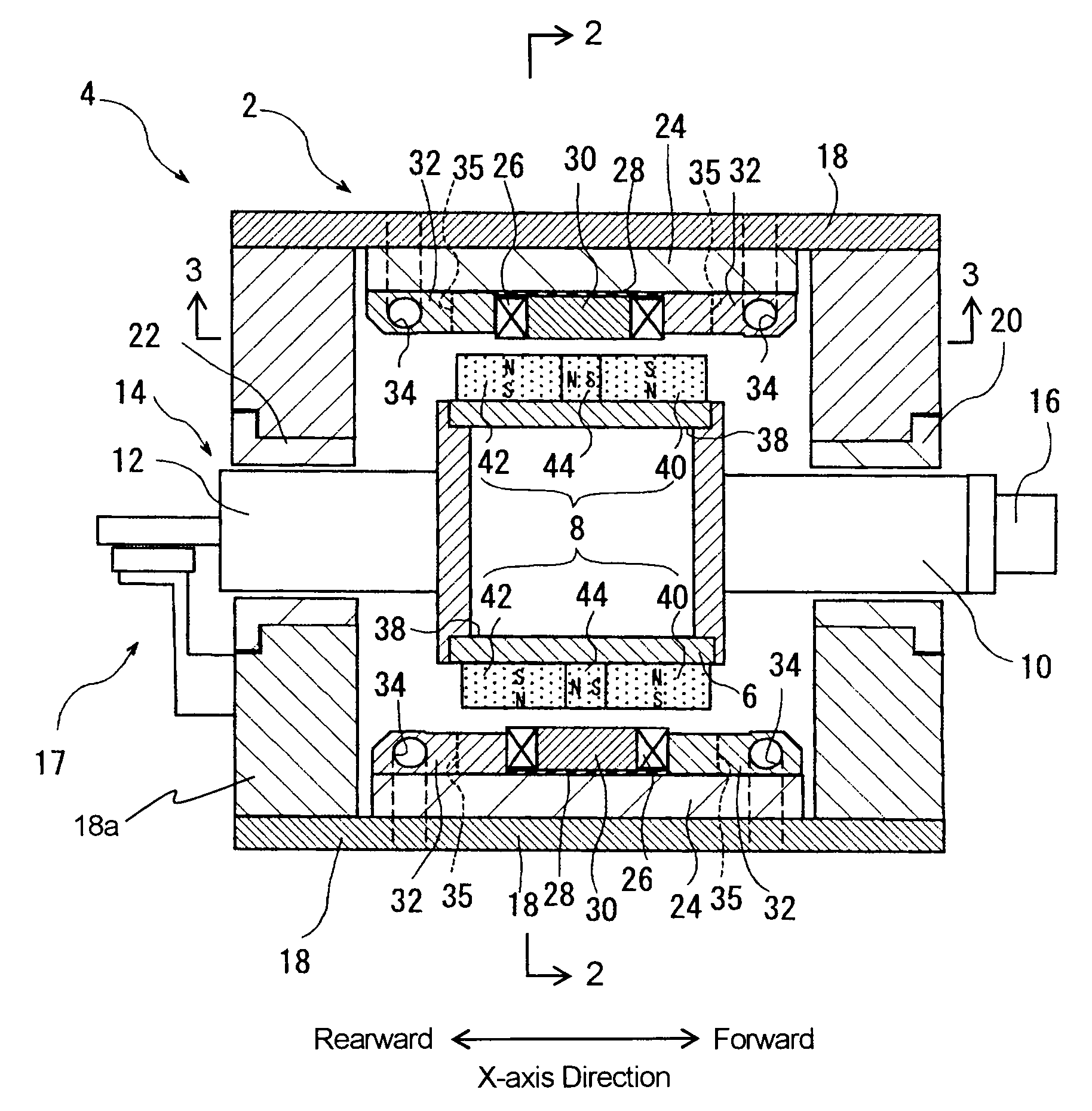

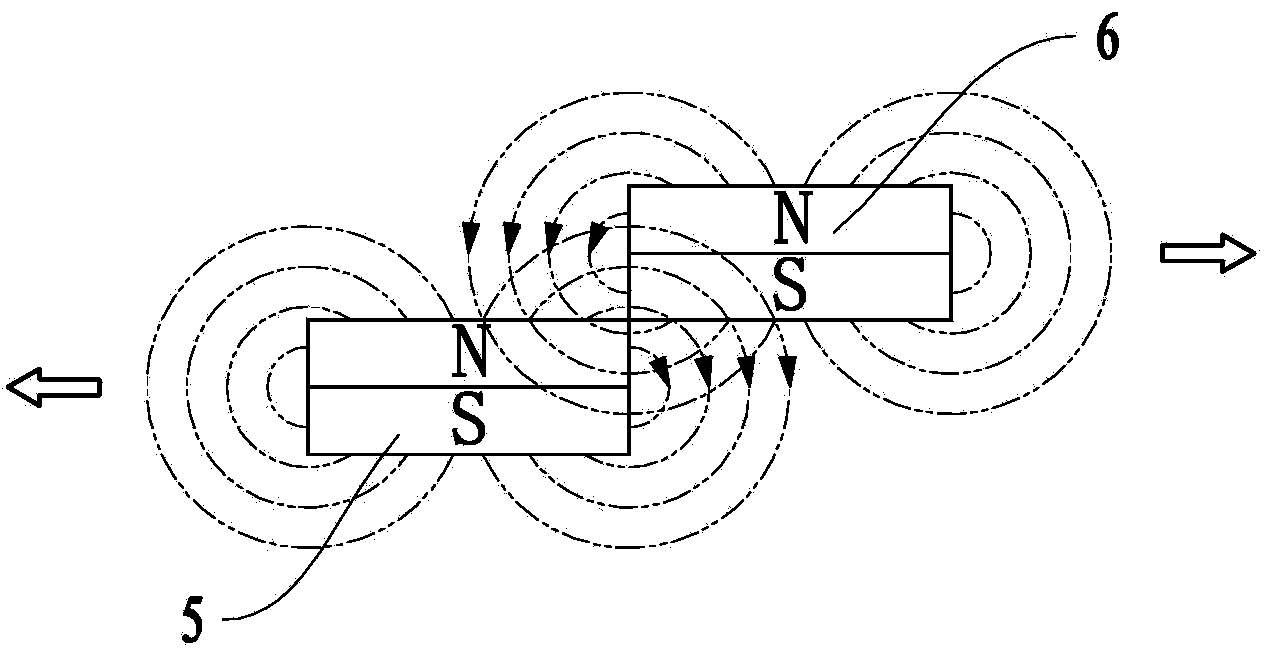

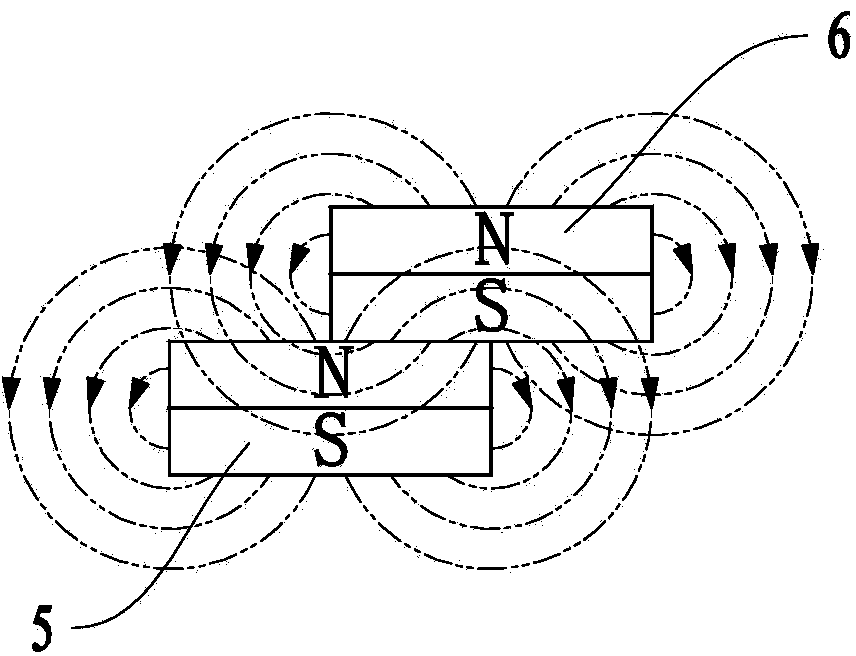

Magnetic spring system for use in a resonant motor

A magnetic spring arrangement for a resonant motor, comprising: a housing (12), magnets (14, 16) fixed in position at opposing ends (13, 15) of the housing, a magnet (18) positioned within the housing for movement toward and away from the fixed magnets in a reciprocal oscillating motion with a driving action produced by a stator coil (24) and an AC drive signal (26), wherein an applicator member (32) is attachable to the moving magnet for corresponding movement of a workpiece portion (34) of the applicator member.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

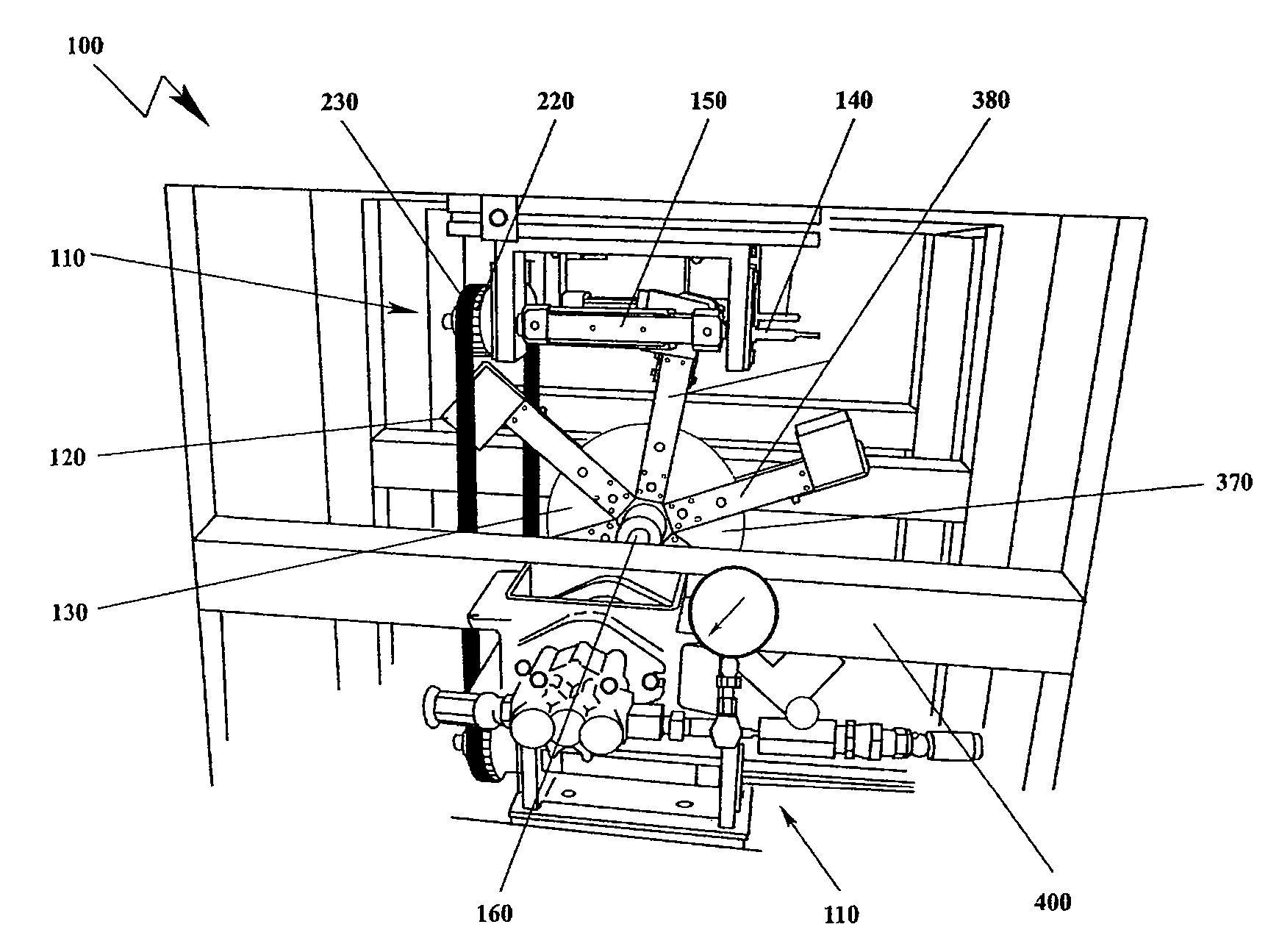

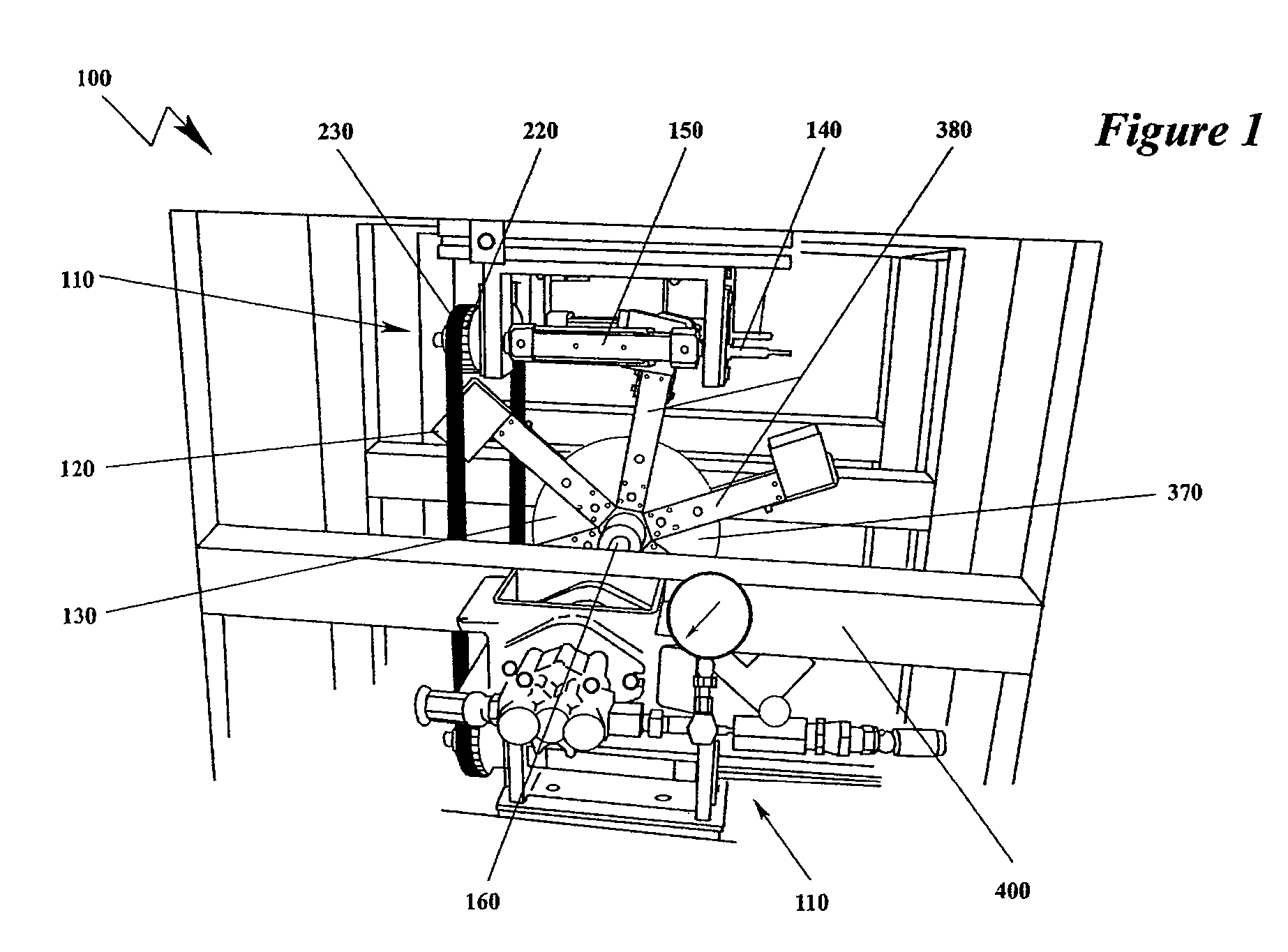

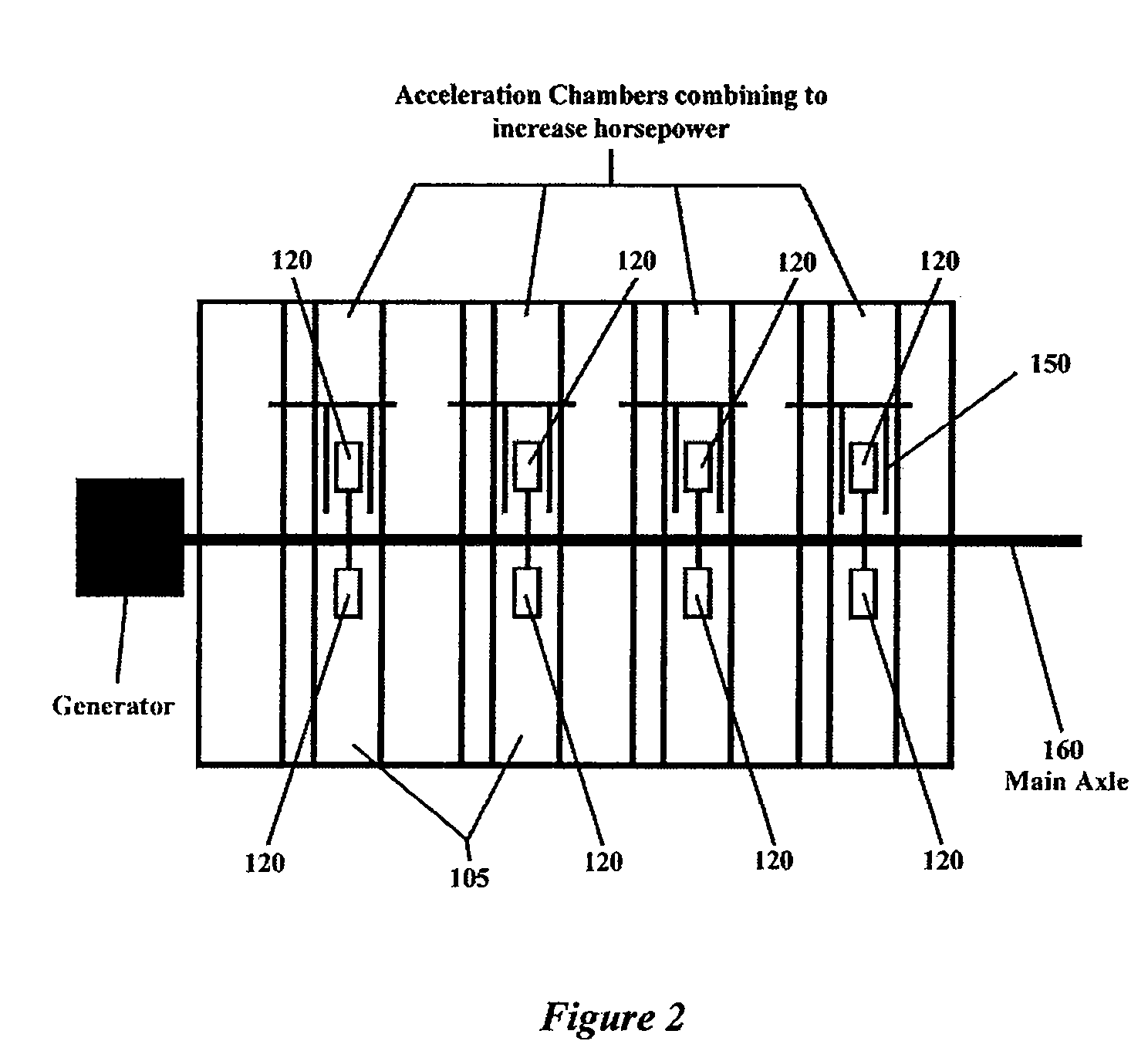

Magnetic propulsion motor

InactiveUS7385325B2Minimizes repelling forceDynamo-electric brakes/clutchesSynchronous machinesEngineeringElectric motor

The present invention relates to a magnetic propulsion motor comprising a magnetic drive assembly comprising a drive magnet, a rotating hub, and a motion magnet attached to the rotating hub to rotate the motion magnet proximate to the magnetic drive assembly. A driving force is applied to the magnetic drive assembly, which causes the drive magnet to rotate to a position proximal to the motion magnet when the motion magnet is in a position proximate to the magnetic drive assembly. This arrangement exerts a repelling force on the motion magnet from the drive magnet as the motion magnet rotates away from the magnetic drive assembly. The rotation of the drive magnet also rotates the drive magnet to a position distal to the motion magnet as the motion magnet approaches the position proximate to the magnet drive assembly thereby minimizes the repelling force exerted on the motion magnet from the drive magnet as the motion magnet rotates towards the magnetic drive assembly.

Owner:FUTURE FORCE LLC

Moving-magnet type linear motor

InactiveUS20080218004A1Improve production efficiencyLow costMagnetic circuitCooling/ventillation arrangementLinear motorCoolant

A moving-magnet type linear motor is provided with cooling blocks which are attached to each of stator bases alongside a coreless coil and which allow coolant to flow therethrough for cooling the coreless coil. Each of the cooling blocks has in a base end portion thereof a fluid passage for flowing coolant and at an extreme end portion thereof a plurality of sheet-like protrusions like fins which are arranged alongside a part of the circumferential surface of the coreless coil with a clearance between each protrusion and the next thereto. Each cooling block is thermally closely jointed with the coreless coil at the extreme ends of the sheet-like protrusions.

Owner:JTEKT CORP

Staged magnet positioning device and camera provided with same

ActiveCN103557421AIncrease the number ofExtended service lifeTelevision system detailsColor television detailsEngineeringMoving magnet

The invention relates to the technical field of positioning devices, and provides a staged magnet positioning device and a camera provided with the same. The staged magnet positioning device comprises a base and a rotating part, the rotating part and the base are rotatably arranged together through rotating shafts on two sides of the rotating part, at least one positioning magnet is fixedly arranged on one side wall of the base, and at least one moving magnet is correspondingly and fixedly arranged on the rotating part and is parallel to the positioning magnets. The staged magnet positioning device can effectively achieve angle adjusting and positioning functions for electronic products in a mounting structure, and is simple in structure and assembly, easy to machine, wear-free and long in service life. The camera provided with the staged magnet positioning device has the angle adjusting and positioning functions, and privacy of users can be protected by adjusting the angle of the camera.

Owner:GOERTEK OPTICAL TECH CO LTD

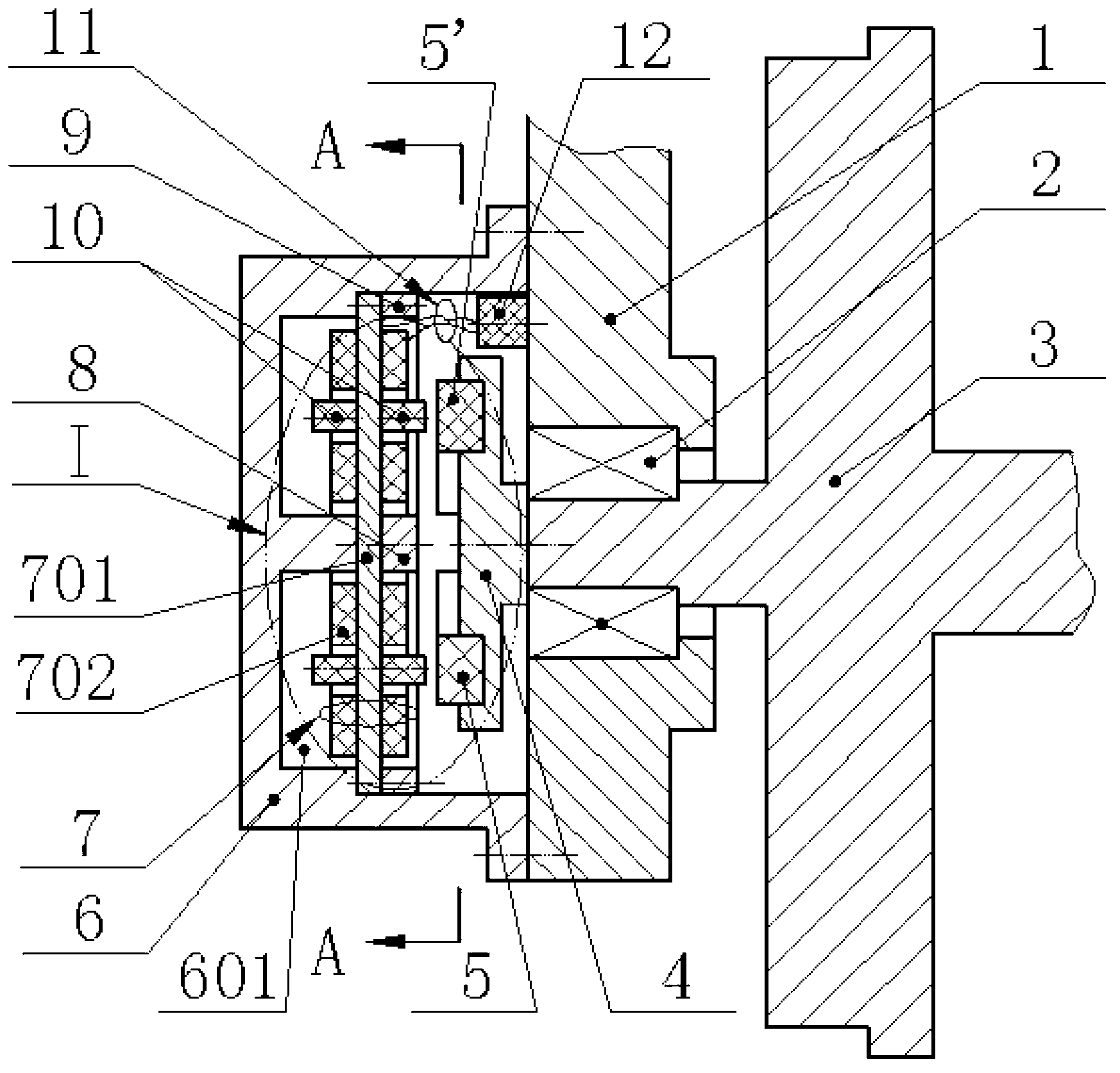

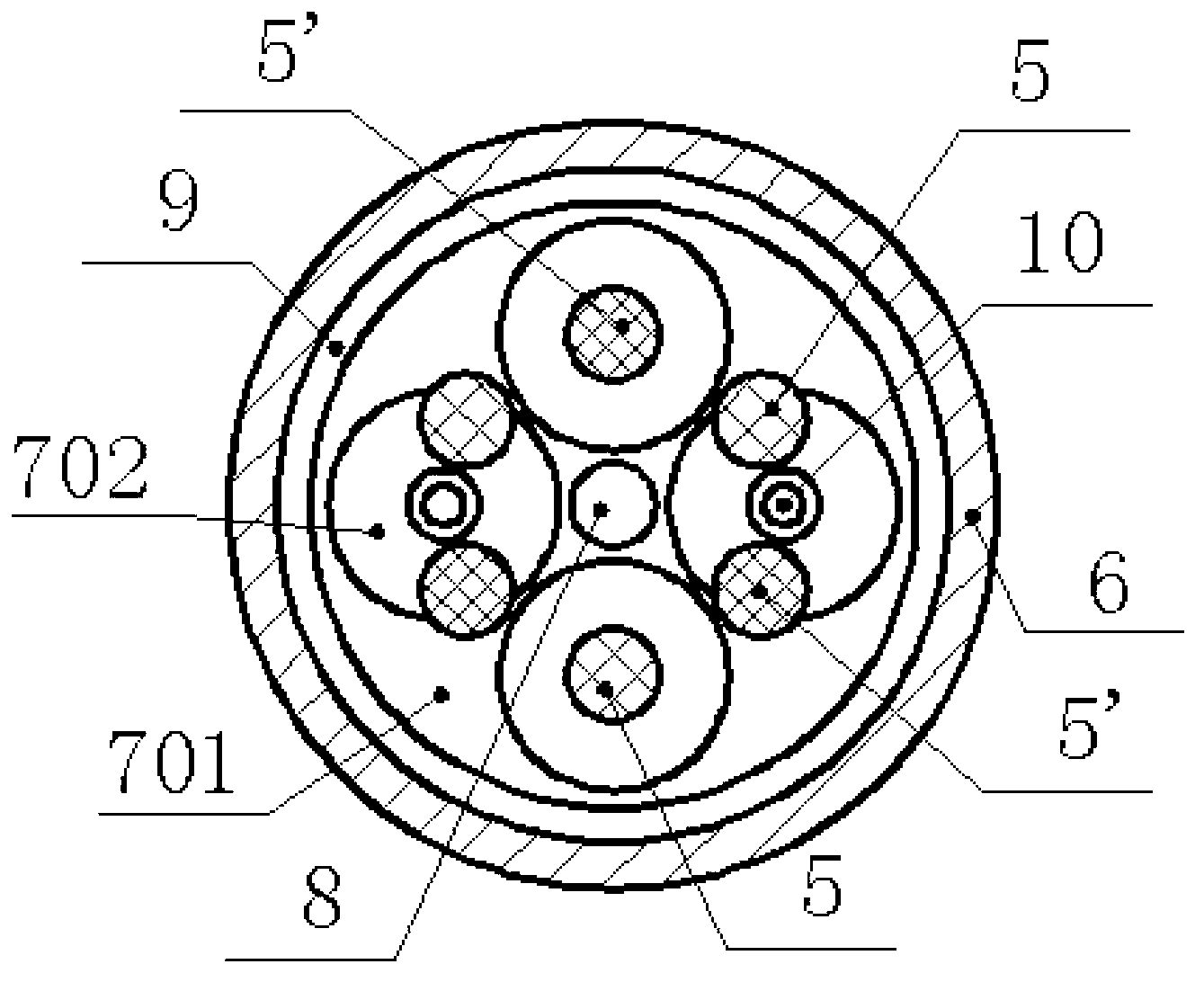

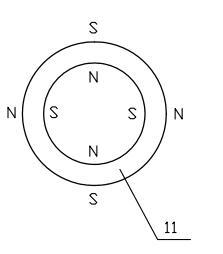

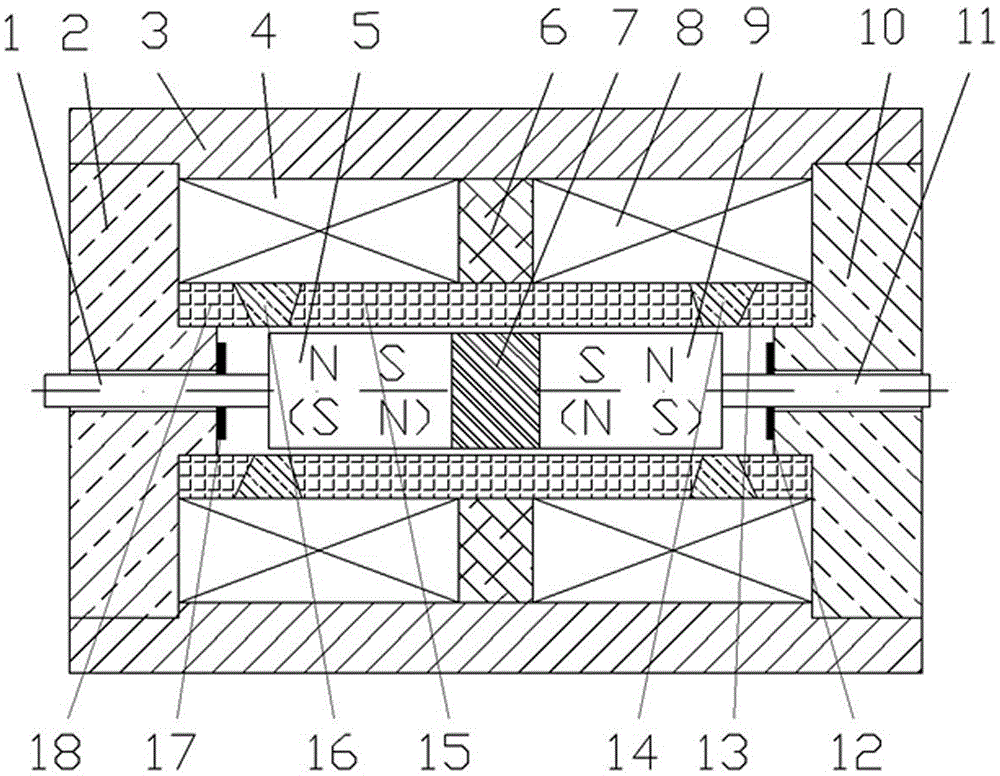

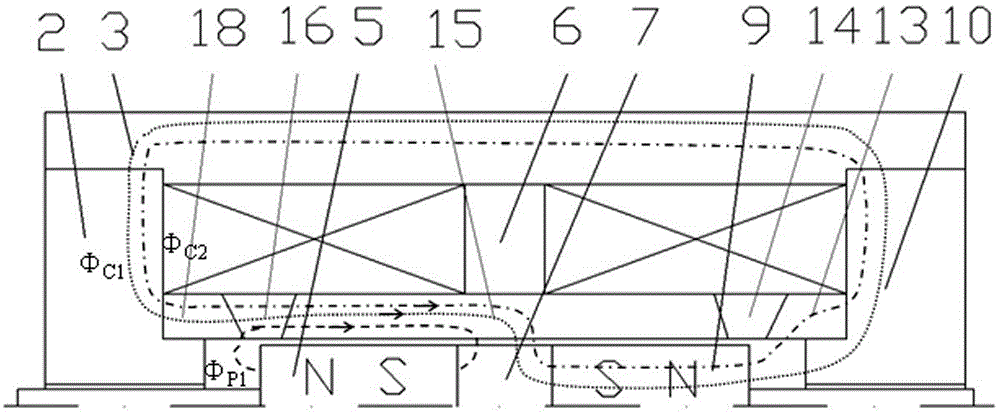

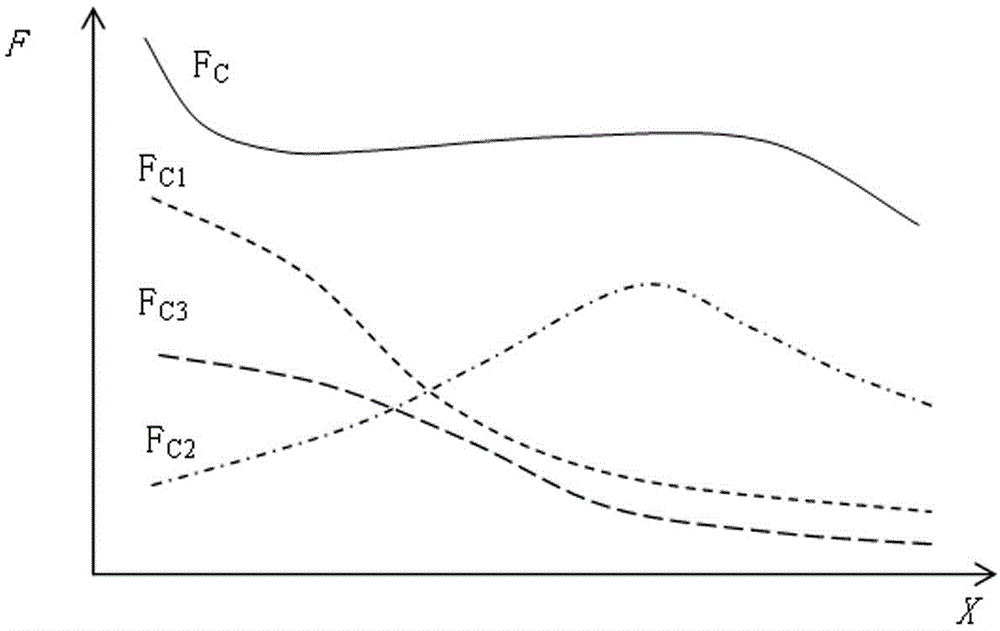

High-pressure-resistant moving-magnet type bidirectional proportional electromagnet

InactiveCN103606431AHigh outputNo zero dead zoneElectromagnets with armaturesEngineeringNon magnetic

The invention provides a high-pressure-resistant moving-magnet type bidirectional proportional electromagnet which comprises push rods, yokes, a shell, control coils, a first permanent magnet, a magnetic conduction ring, an armature, a second permanent magnet, limiting plates, guide sleeves and non-magnetic rings. Flanges of the yokes are matched with inner holes of the guide sleeves, and the three guide sleeves are magnetic conductors, are separated from one another by the non-magnetic rings made of non-magnetic-conduction materials and then are integrated with one another by means of welding. Compared with the prior art, the high-pressure-resistant moving-magnet type bidirectional proportional electromagnet has the advantages that the permanent magnets are used as main moving components, so that the shortcoming of constraints due to magnetic saturation and the like can be overcome, and outputted force of a system can be greatly increased; the outputted force or displacement can be bidirectionally and continuously controlled, and zero positions and dead zones can be prevented; the high-pressure-resistant moving-magnet type bidirectional proportional electromagnet is high-oil-pressure-resistant and can be used as a wet electro-mechanical converter; the high-pressure-resistant moving-magnet type bidirectional proportional electromagnet is simple in structure and low in manufacturing cost.

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

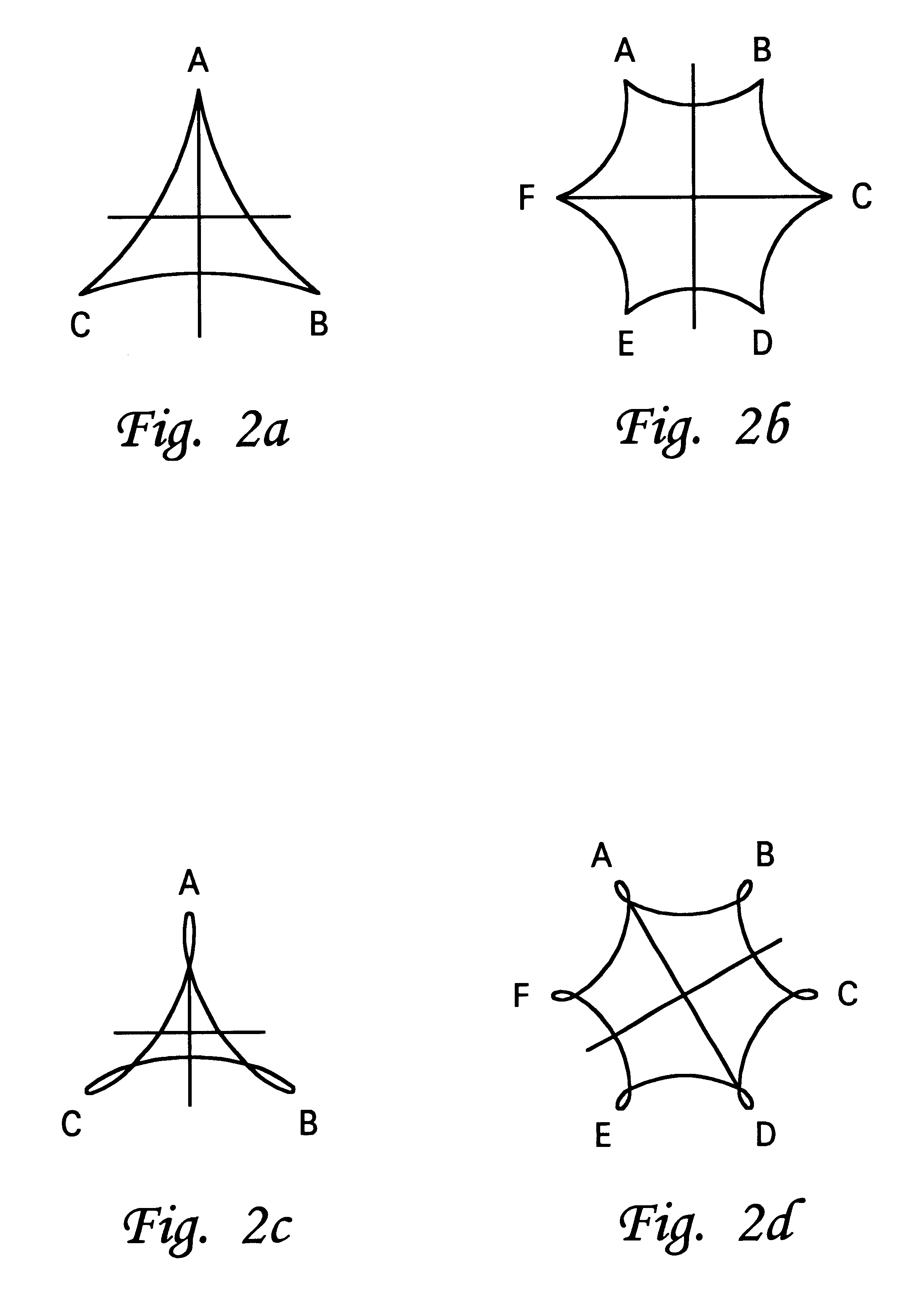

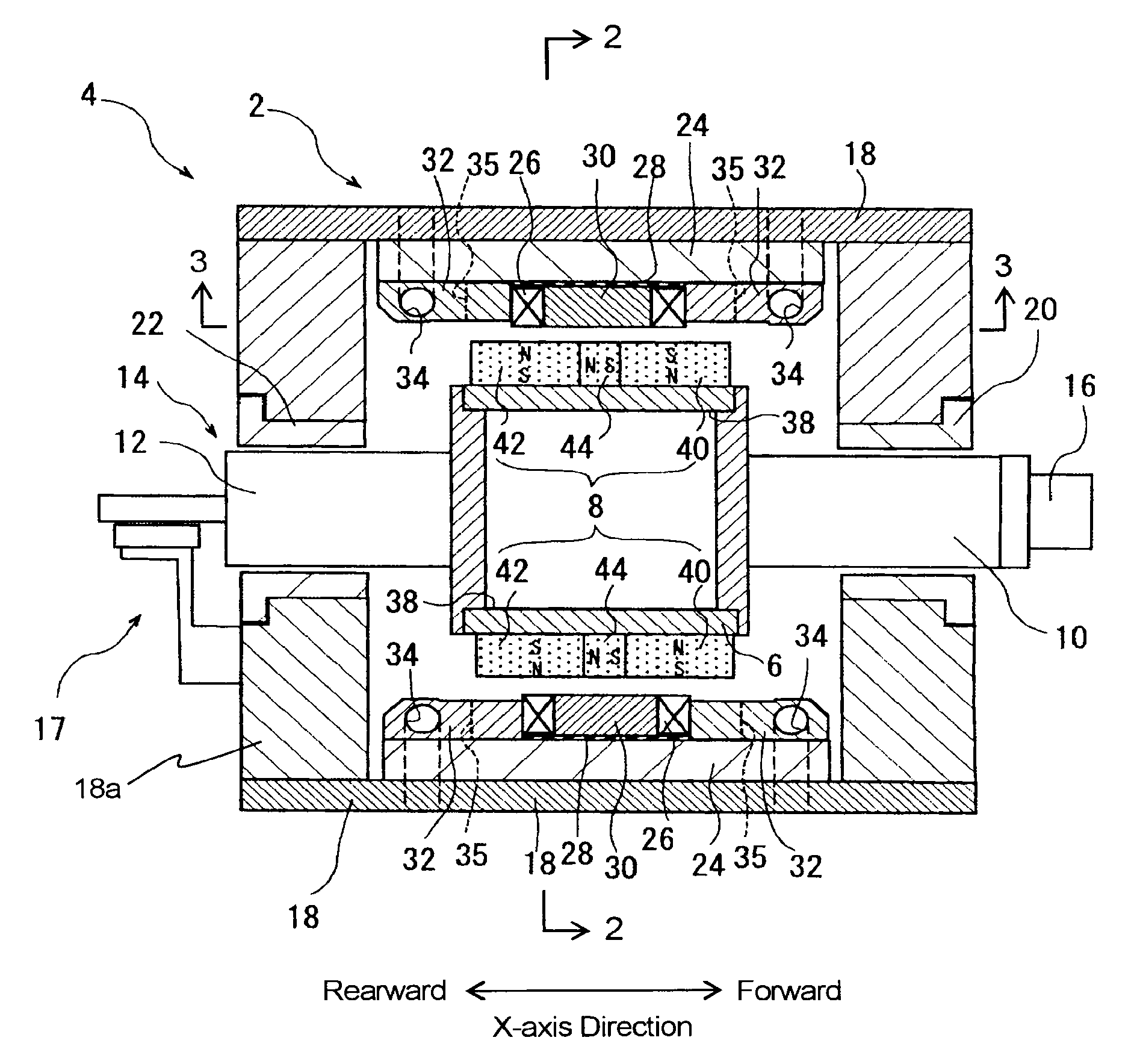

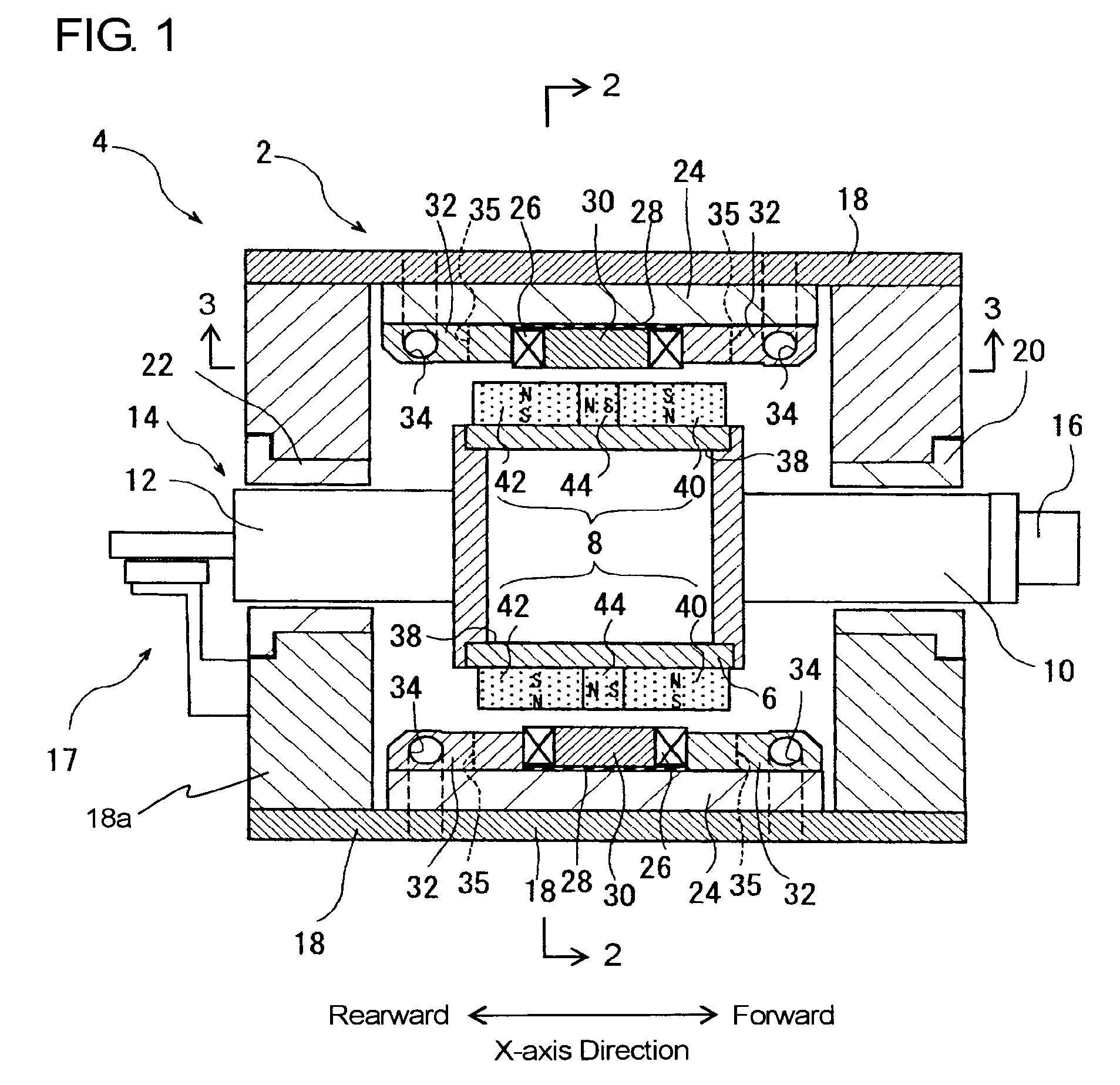

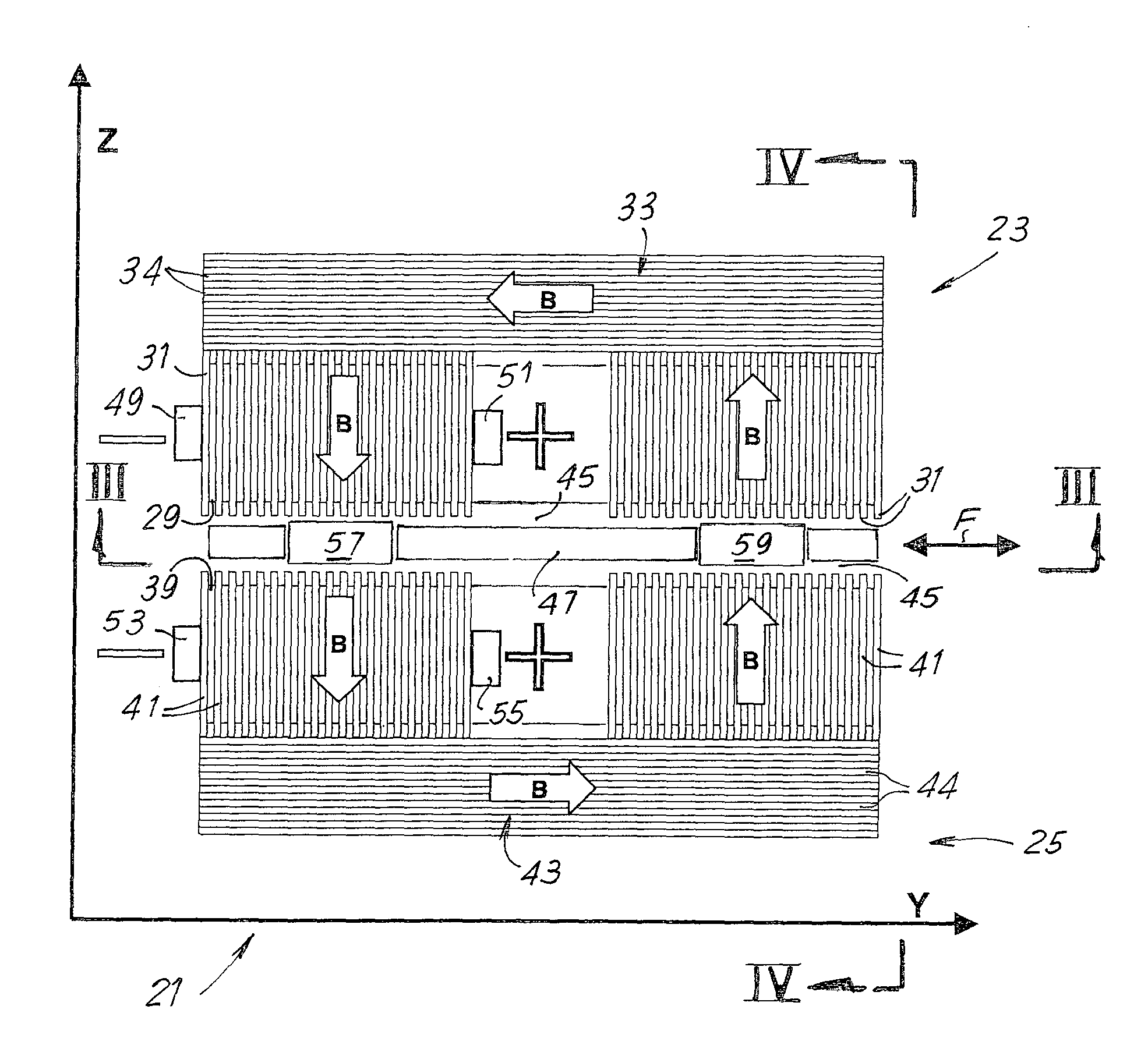

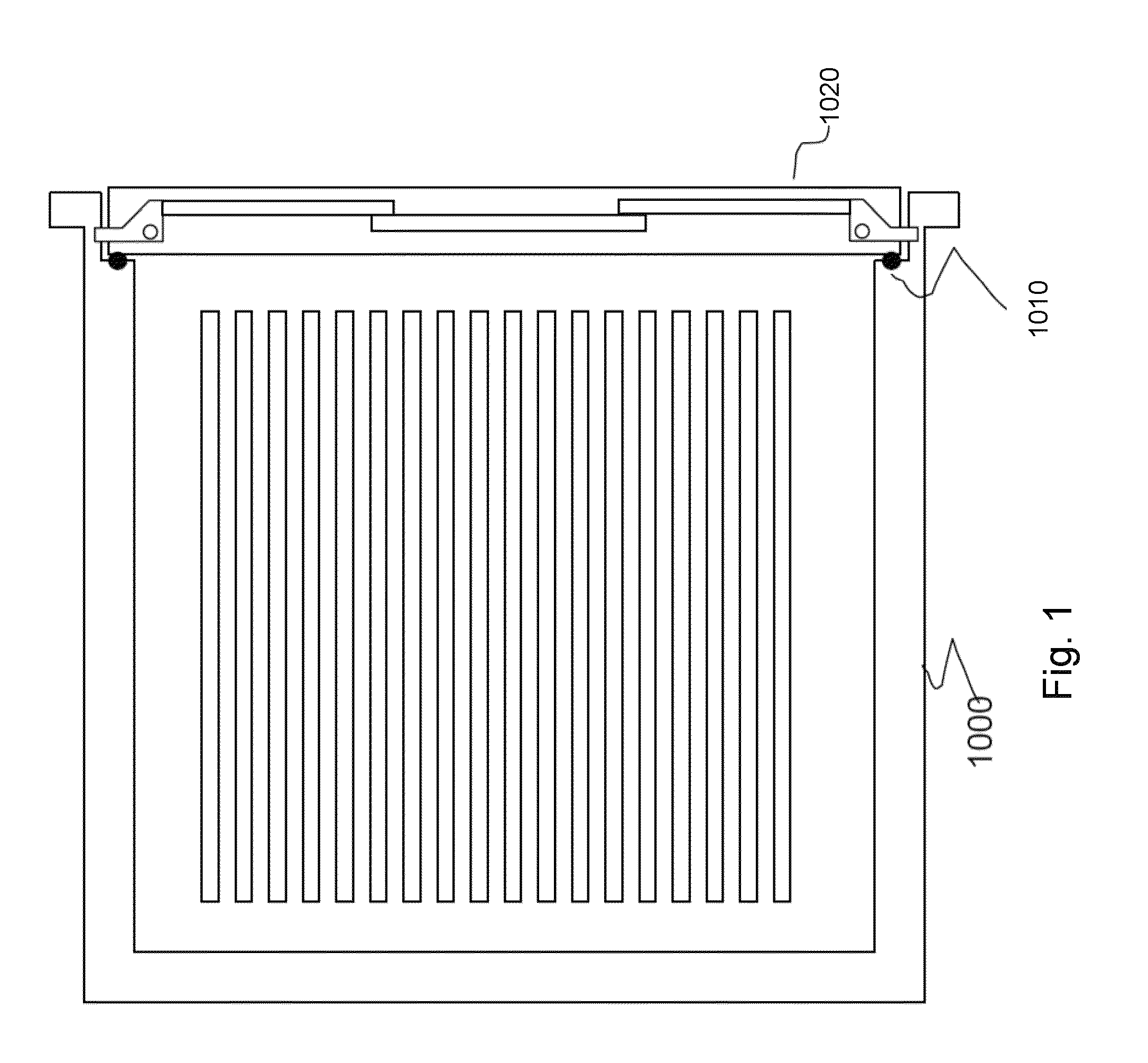

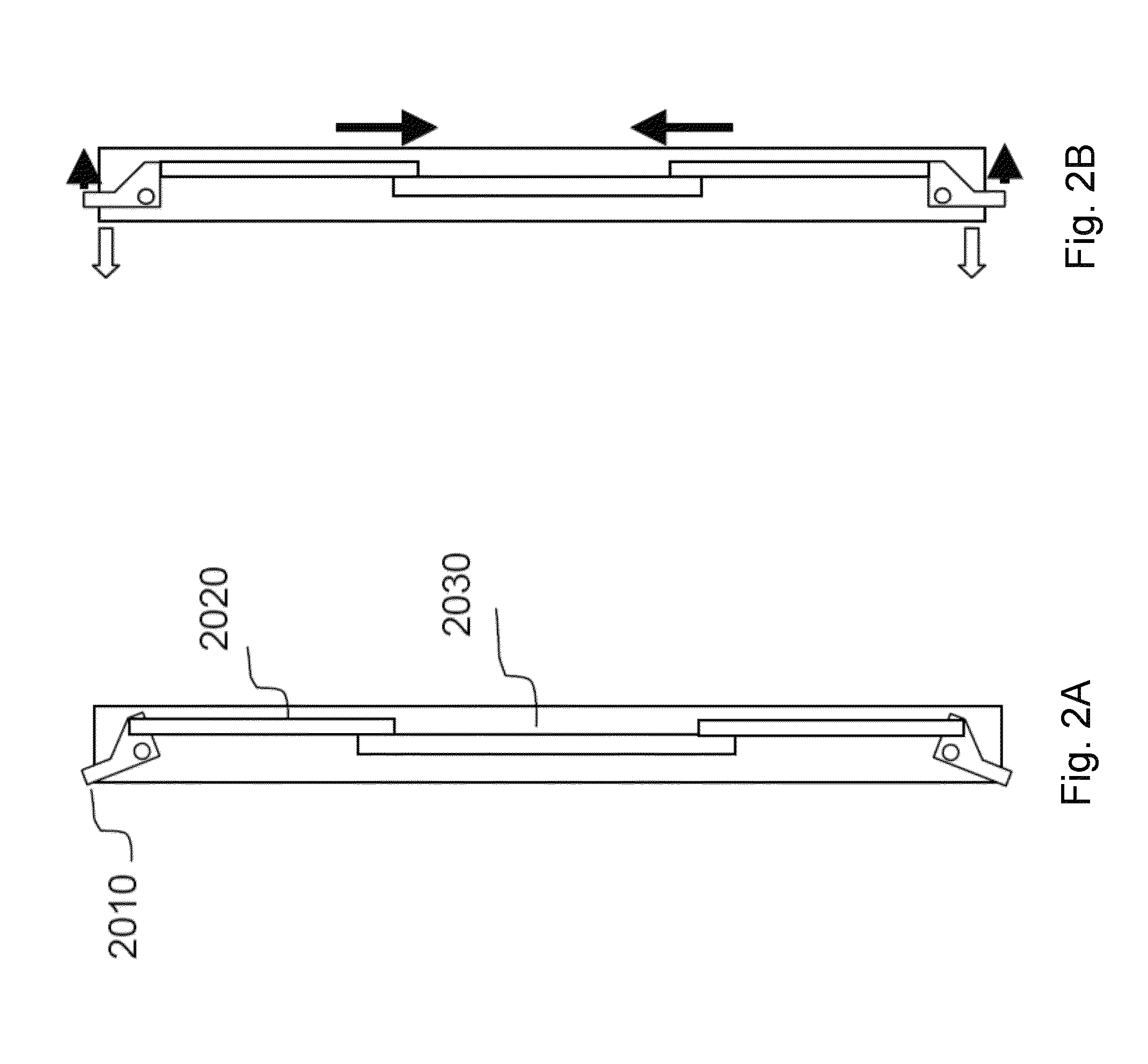

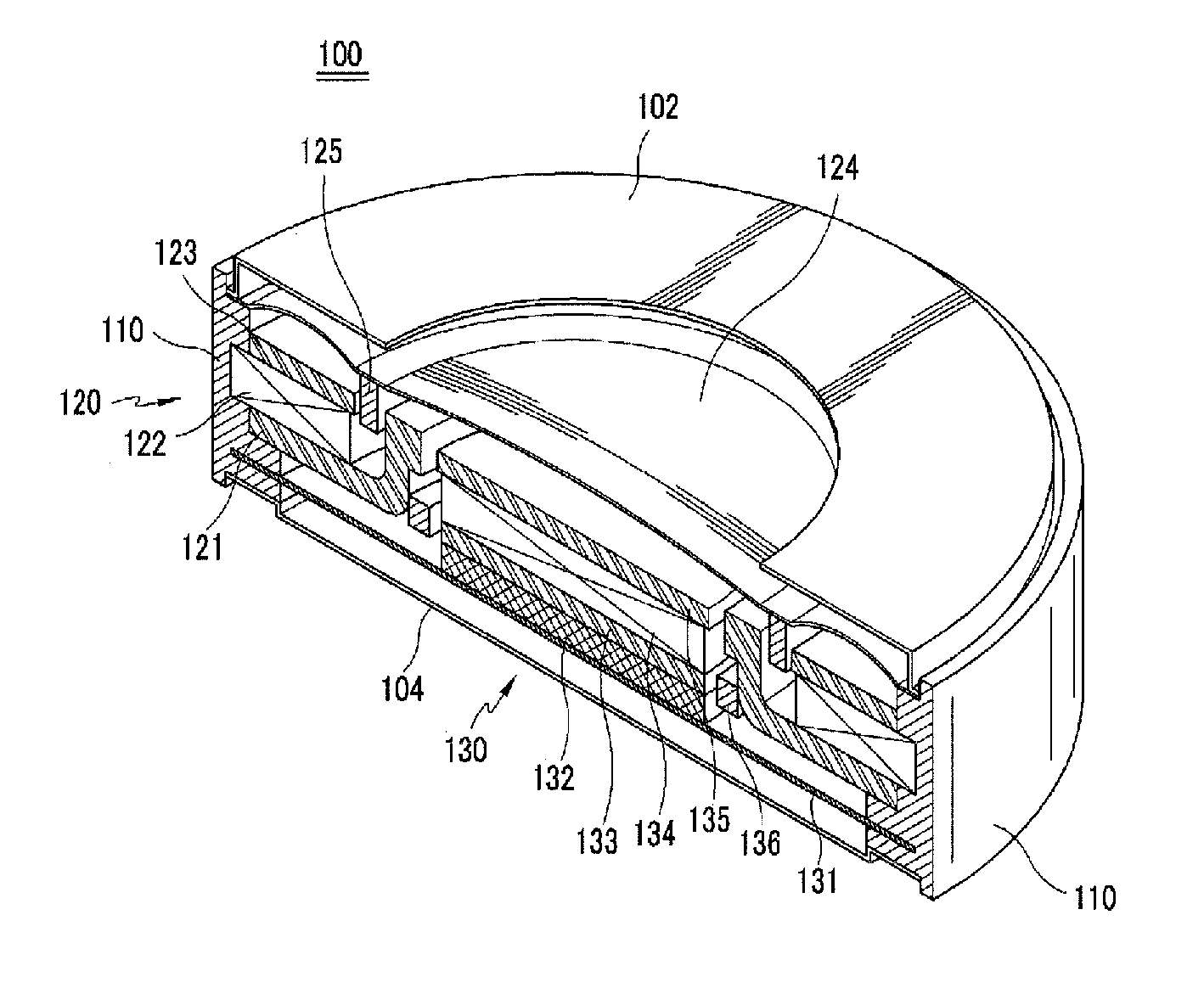

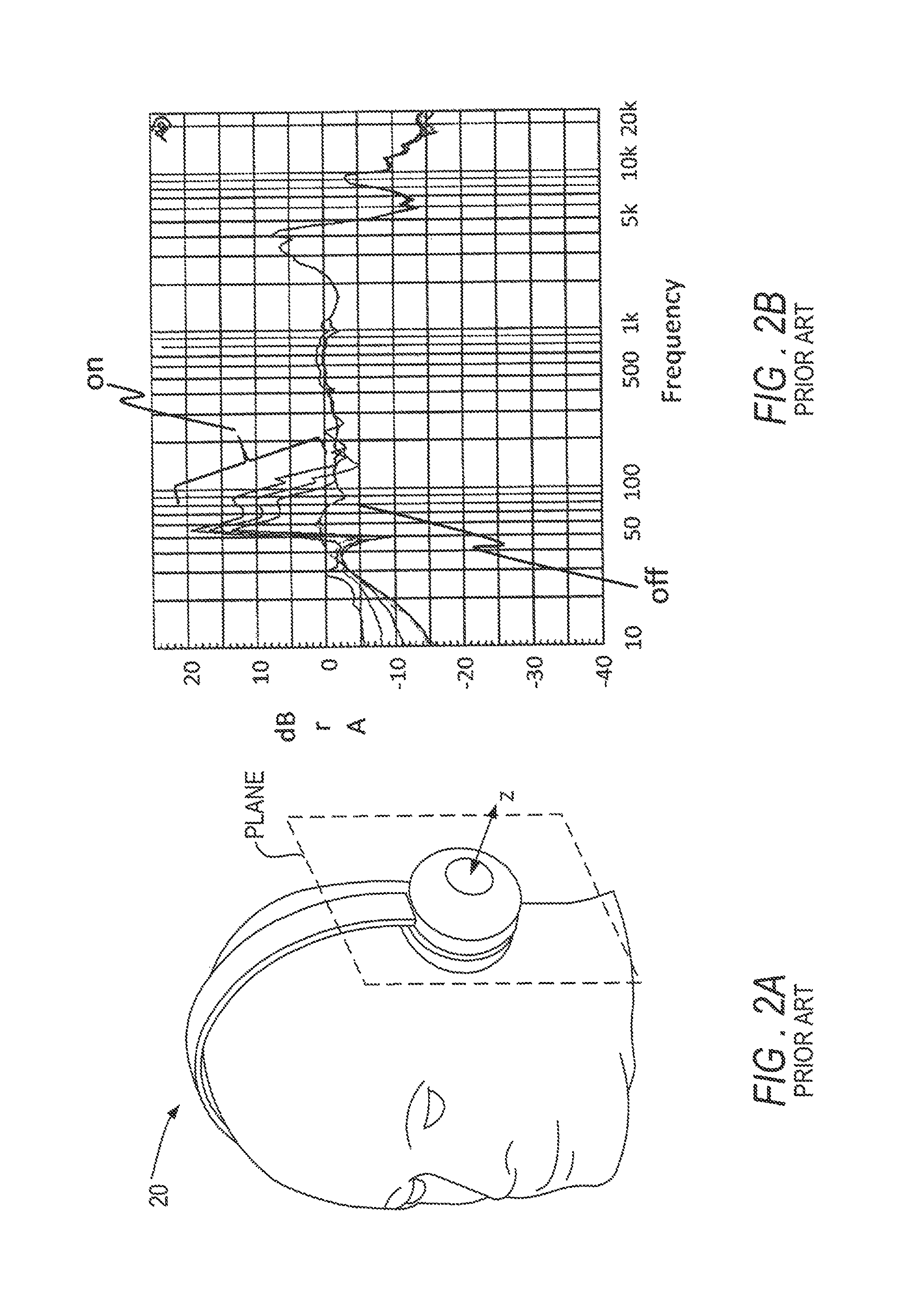

Systems and methods for generating damped electromagnetically actuated planar motion for audio-frequency vibrations

ActiveUS9430921B2Unwanted distortionProduce unwantedElectrotherapyEar treatmentElectricityElectrical recording

A vibration module for applying vibrational tractions to a wearer's skin is presented. Use of the vibration module in headphones is illustrated for providing tactile sensations of low frequency for music, for massage, and for electrical recording and stimulation of the wearer. Damped, planar, electromagnetically-actuated vibration modules of the moving magnet type are presented in theory and reduced to practice, and shown to provide a substantially uniform frequency response over the range 40-200 Hz with a minimum of unwanted audio.

Owner:TACTION TECH

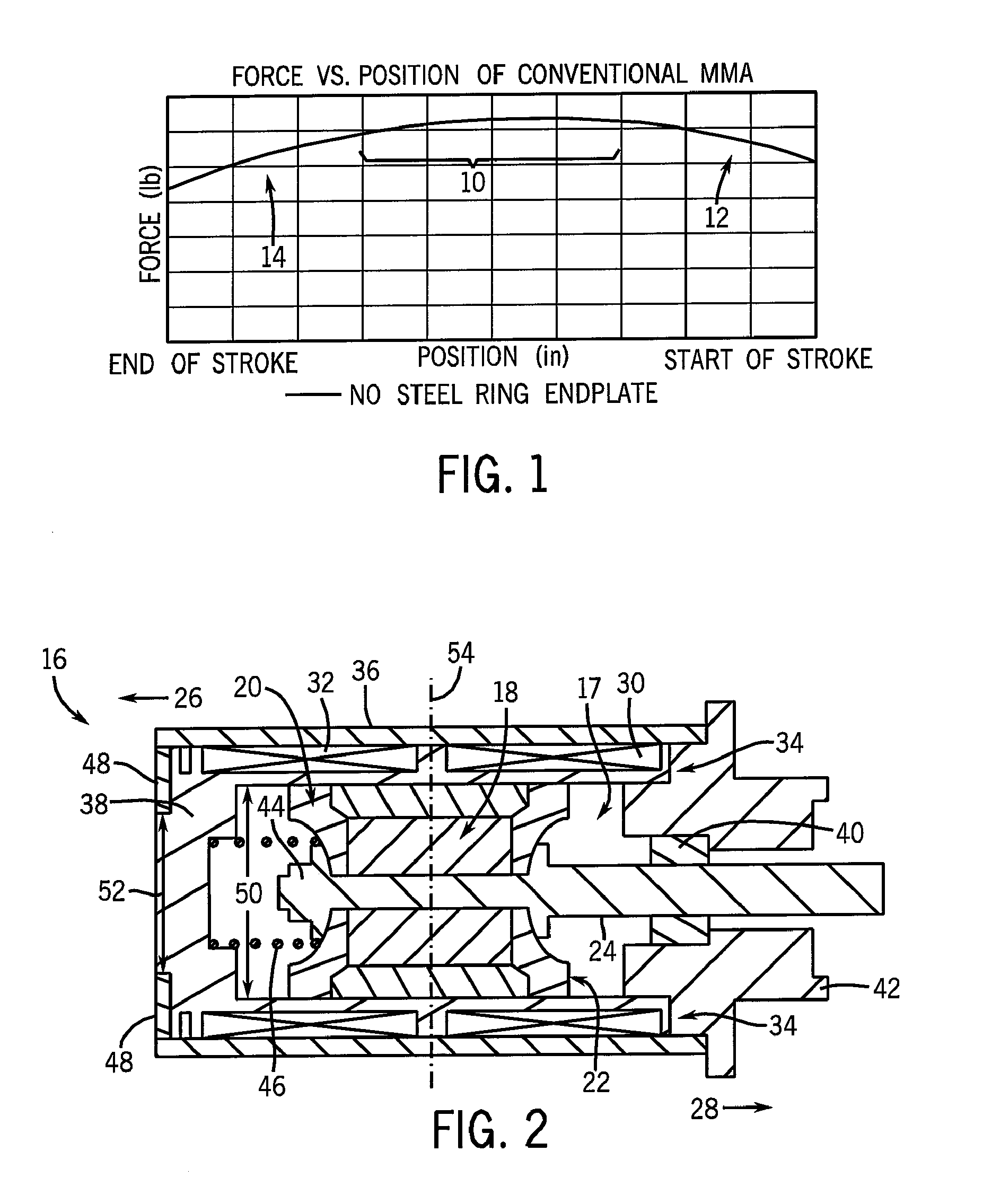

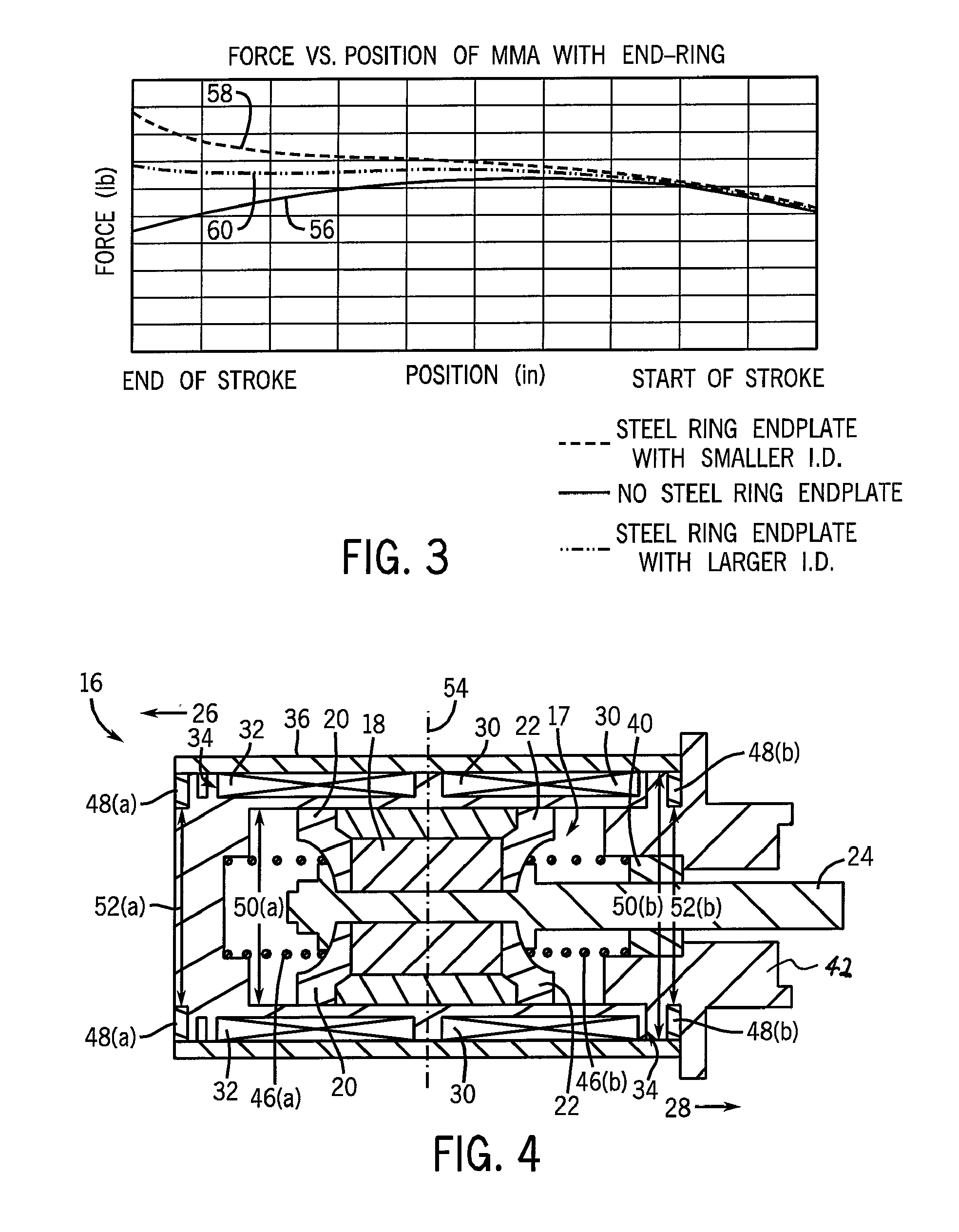

Moving Magnet Actuator with Counter-Cogging End-Ring and Asymmetrical Armature Stroke

A moving magnet actuator (MMA) includes a magnetically conductive end-ring that is spaced from a magnet pole piece. The end-ring is constructed and spaced to provide a desired counter or anti-cogging force when the MMA is in a powered state. The MMA is also constructed such that a central portion of its armature stroke is axially displaced from a radial centerline of the magnetically conductive conduit enclosing the MMA components.

Owner:WOODWARD GOVERNOR CO

Moving magnet type linear magnet

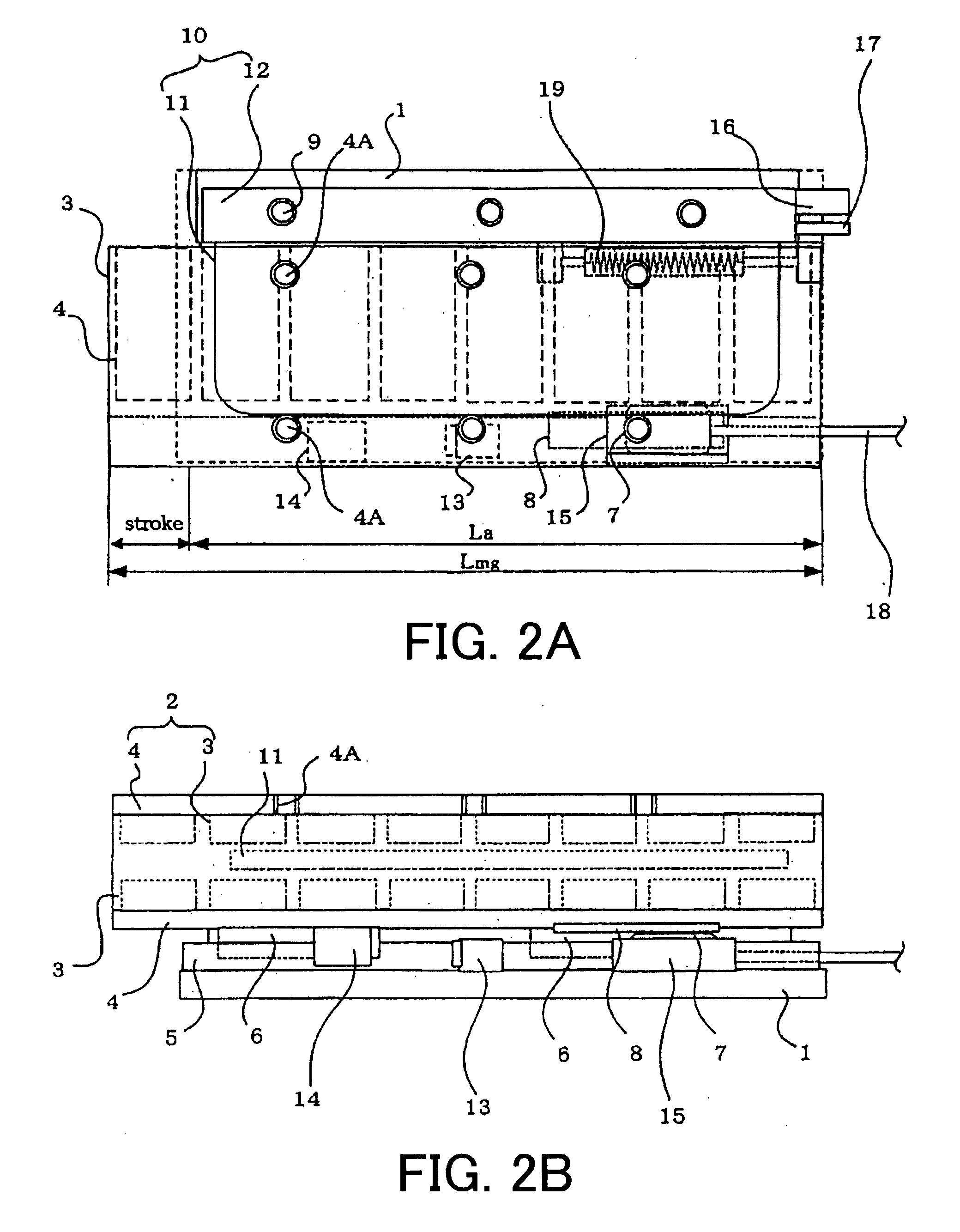

InactiveUS20070096567A1Reduce viscous frictionReduce frictionMechanical energy handlingPropulsion systemsSuction forceElectrical polarity

In some embodiments, a moving magnet type linear slider capable of eliminating a magnet suction force caused by a linear motor to minimize the linear guide friction is provided. The field of the linear motor includes magnet track having a horizontally arranged generally U-shaped magnetic yoke and plural pairs of field permanent magnets arranged on inner opposed surfaces of the magnetic yoke with polarities arranged alternately in a longitudinal direction of the magnetic yoke, each pair of the filed permanent magnets being arranged with opposite polarities faced with each other. The armature of the linear motor includes an armature holder mounted on the side portion of the fixed base in a vertically extended manner, and a planar coreless armature holder horizontally held by the armature holder. The stroke direction length Lmg of the magnet track is set to be longer than the stroke direction length La of the armature. Furthermore, a gravity compensation spring for compensating the weight of the movable unit is provided at the bottom portion of the magnet track so as to face the fixed base.

Owner:YASKAWA DENKI KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com